Method for catalytic oxidation NO with ZSM-5 type molecular sieve as catalyst

A catalytic oxidation, ZSM-5 technology, applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of high active temperature and poor water vapor resistance, and achieve simple operation, low cost, and reduced consumption and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

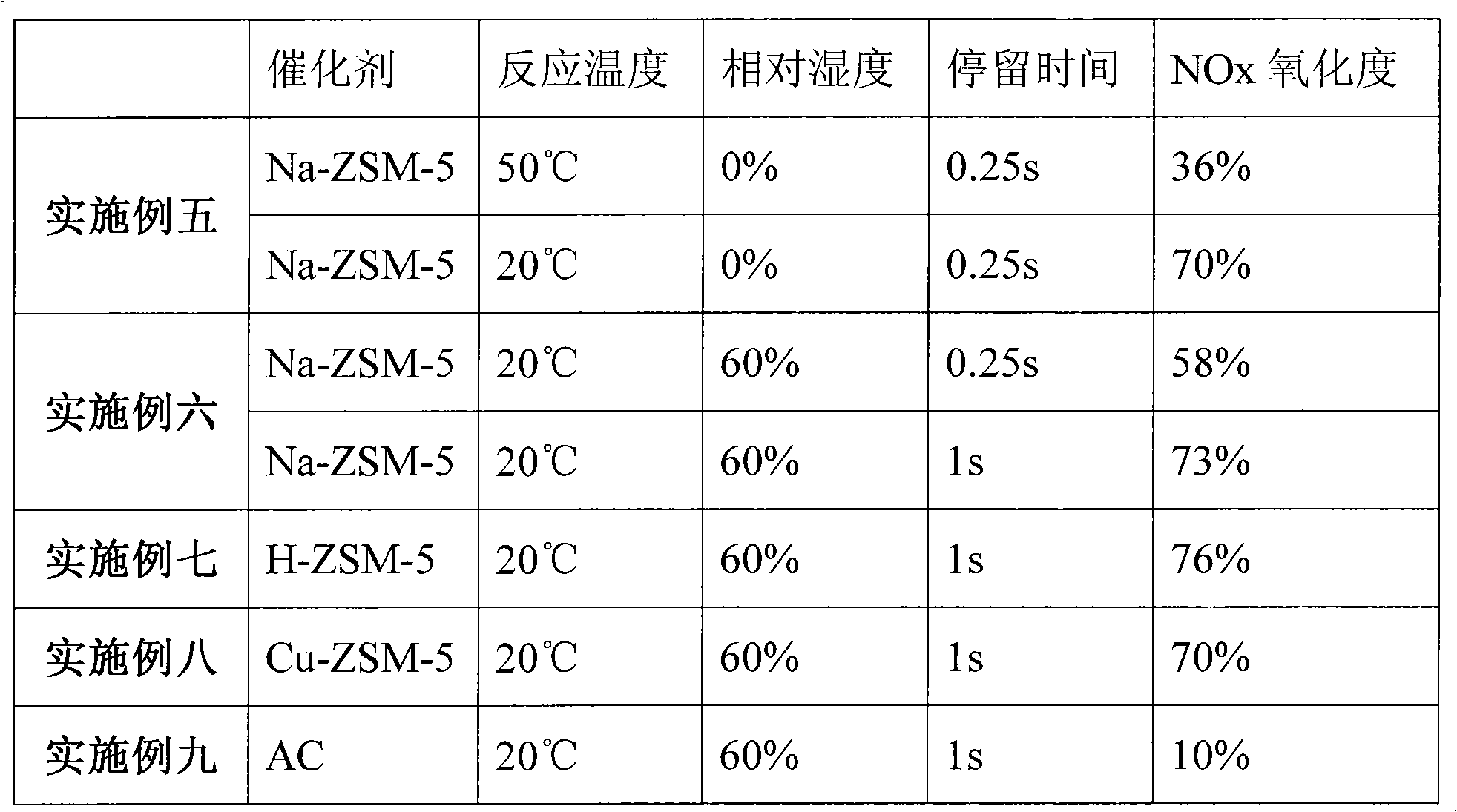

Examples

Embodiment 1

[0030] Na-ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =300), into powder, its specific surface area is 300m 2 / g, the single crystal grain size is 1μm~3μm, and the pore size is 0.56nm. Dry at 110°C for 2 hours, calcined at 500°C for 3 hours, tablet, crush and sieve the powdered Na-ZSM-5 to obtain 0.6mm-0.9mm particles, which is the catalyst used in this experiment.

Embodiment 2

[0032] Take the H-ZSM-5 type molecular sieve (SiO 2 / Al 2 o 3 =300), into powder, its physical properties are the same as the molecular sieve in Example 1. The specific implementation method is also the same as above, and the particles of 0.6mm to 0.9mm are obtained for subsequent use.

Embodiment 3

[0034] Take 40g of Na-ZSM-5 raw powder from Shanghai Zhuoyue Chemical Co., Ltd. and mix it with 0.8mol / L and 300ml copper nitrate solution, reflux and stir at 80°C for 8 hours to carry out ion exchange reaction, and after the reaction, use a centrifuge to separate and wash until There is no metal ion in the lotion, and then dried at 110°C overnight, roasted at 550°C for 2 hours, pressed into tablets, crushed, and sieved to obtain 0.6mm-0.9mm particles for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com