High-boron high-speed steel composite roller and manufacturing method thereof

A high-speed steel, high-boron technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of high brittleness and poor use safety, and achieve high production efficiency, less processing, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

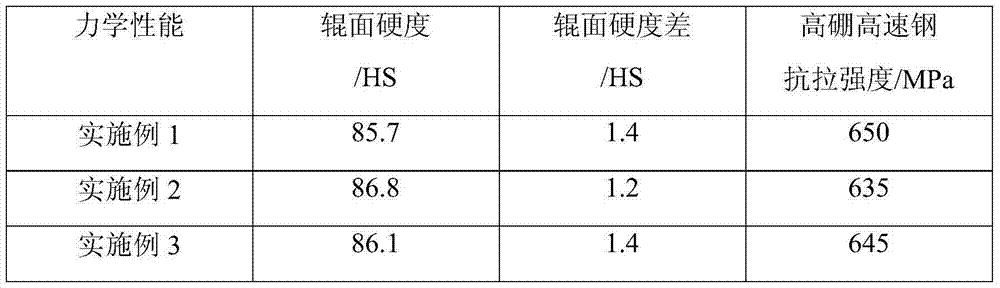

Embodiment 1

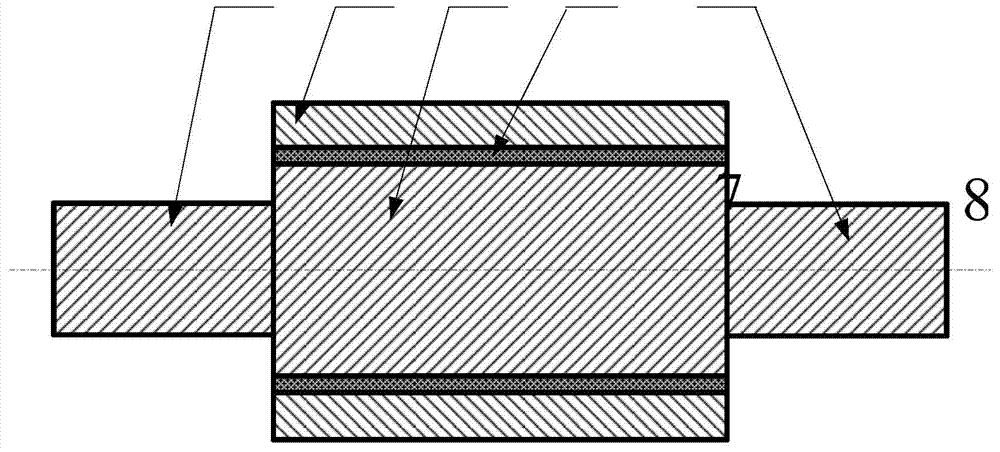

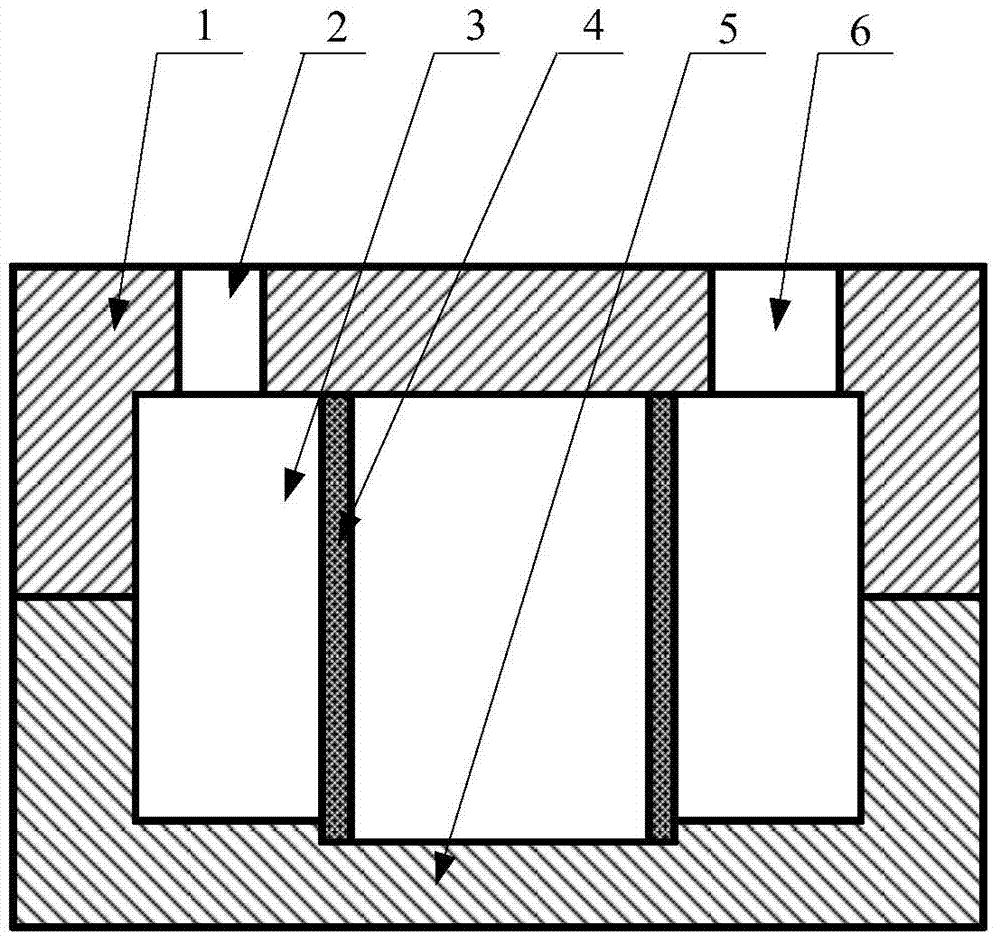

[0027] The high-boron high-speed steel compound roll is combined by the roller shaft 7 and the high-boron high-speed steel compound roll sleeve through hot fitting. The roll body size of the combined roll is The high-boron high-speed steel combination roll and its preparation method are as follows:

[0028] ① Melt the outer wear-resistant high-boron high-speed steel molten steel of the high-boron high-speed steel composite roller sleeve in a 500-kg medium-frequency induction furnace first. The chemical composition and mass fraction of the high-boron high-speed steel molten steel are: 1.25%C, 1.59%B, 5.53%Cr, 1.47%W, 2.56%Mo, 0.35%V, 1.19%Ni, 0.33%Si, 0.54%Mn, 0.036%S, 0.040%P, the balance is Fe and unavoidable impurities.

[0029] ②When the temperature of the above-mentioned high-boron high-speed steel molten steel reaches 1581°C, the molten steel is discharged into the ladle, and then the diameter is added to the ladle. The alloy wire, the chemical composition and mass fr...

Embodiment 2

[0033] The high-boron high-speed steel compound roll is combined by the roller shaft 7 and the high-boron high-speed steel compound roll sleeve through hot fitting. The roll body size of the combined roll is The high-boron high-speed steel combination roll and its preparation method are as follows:

[0034] ① Melt the outer wear-resistant high-boron high-speed steel molten steel of the high-boron high-speed steel composite roller sleeve in a 500-kg medium-frequency induction furnace first. The chemical composition and mass fraction of the high-boron high-speed steel molten steel are: 1.78%C, 1.25%B, 7.94%Cr, 1.02%W, 3.00%Mo, 0.58%V, 0.65%Ni, 0.87%Si, 0.32%Mn, 0.037%S, 0.043%P, the balance is Fe and unavoidable impurities.

[0035] ②When the temperature of the above-mentioned high-boron high-speed steel molten steel reaches 1598°C, the molten steel is discharged into the ladle, and then the diameter is added into the ladle. The alloy wire, the chemical composition and mass ...

Embodiment 3

[0039] The high-boron high-speed steel compound roll is combined by the roller shaft 7 and the high-boron high-speed steel compound roll sleeve through hot fitting. The roll body size of the combined roll is The high-boron high-speed steel combination roll and its preparation method are as follows:

[0040] ① Melt the outer wear-resistant high-boron high-speed steel molten steel of the high-boron high-speed steel composite roller sleeve in a 500-kg medium-frequency induction furnace first. The chemical composition and mass fraction of the high-boron high-speed steel molten steel are: 1.55%C, 1.39%B, 6.70%Cr, 1.38%W, 2.66%Mo, 0.40%V, 0.91%Ni, 0.68%Si, 0.43%Mn, 0.035%S, 0.039%P, the balance is Fe and unavoidable impurities.

[0041] ②When the temperature of the above-mentioned high-boron high-speed steel molten steel reaches 1593°C, the molten steel is discharged into the ladle, and then the diameter is added to the ladle. The alloy wire, the chemical composition and mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com