Photovoltaic cleaning robot

A cleaning robot and cleaning mechanism technology, applied in the field of robots, can solve the problems of high water consumption, unsatisfactory, high price, etc., and achieve the effect of reducing the use cost of the product, expanding the applicable occasions, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

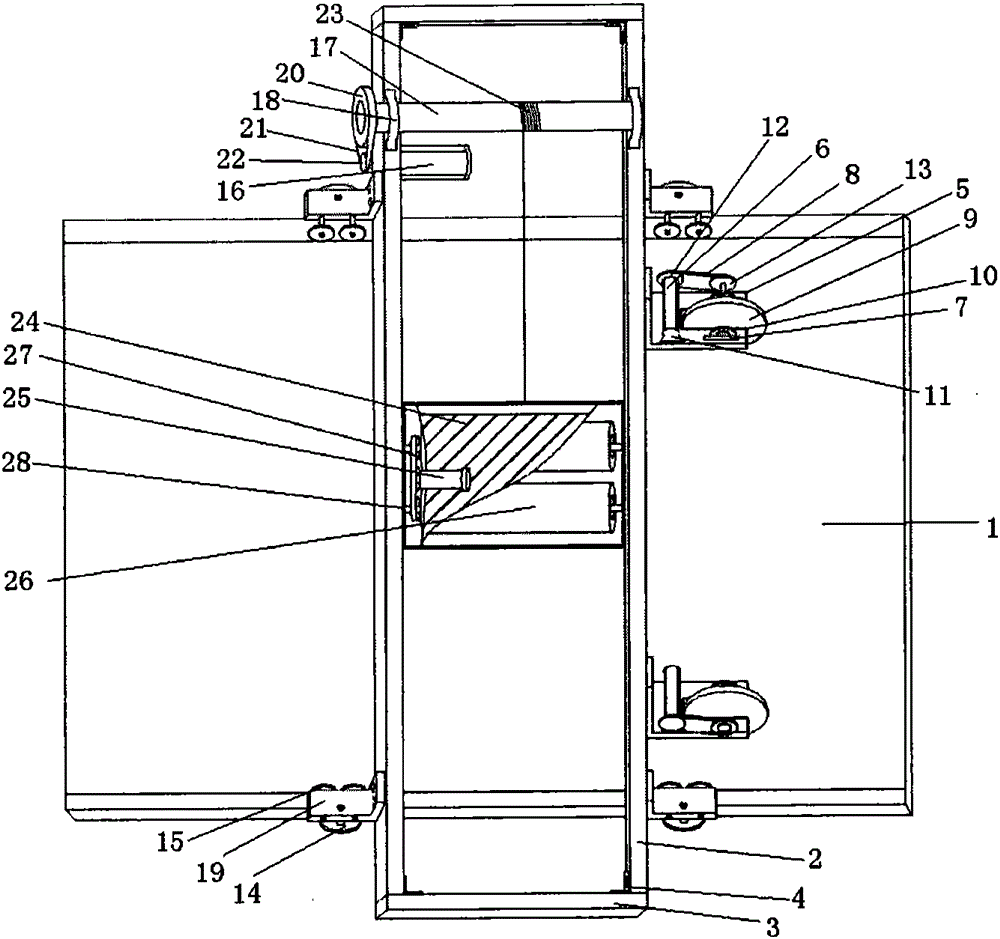

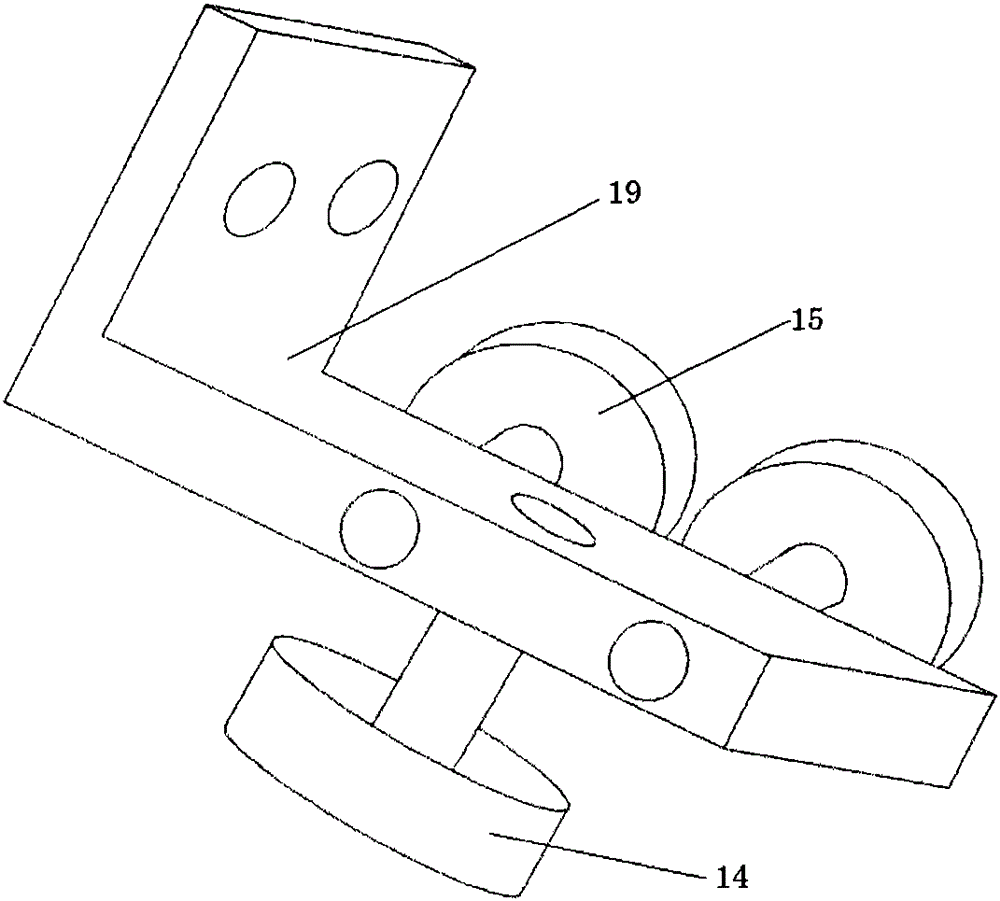

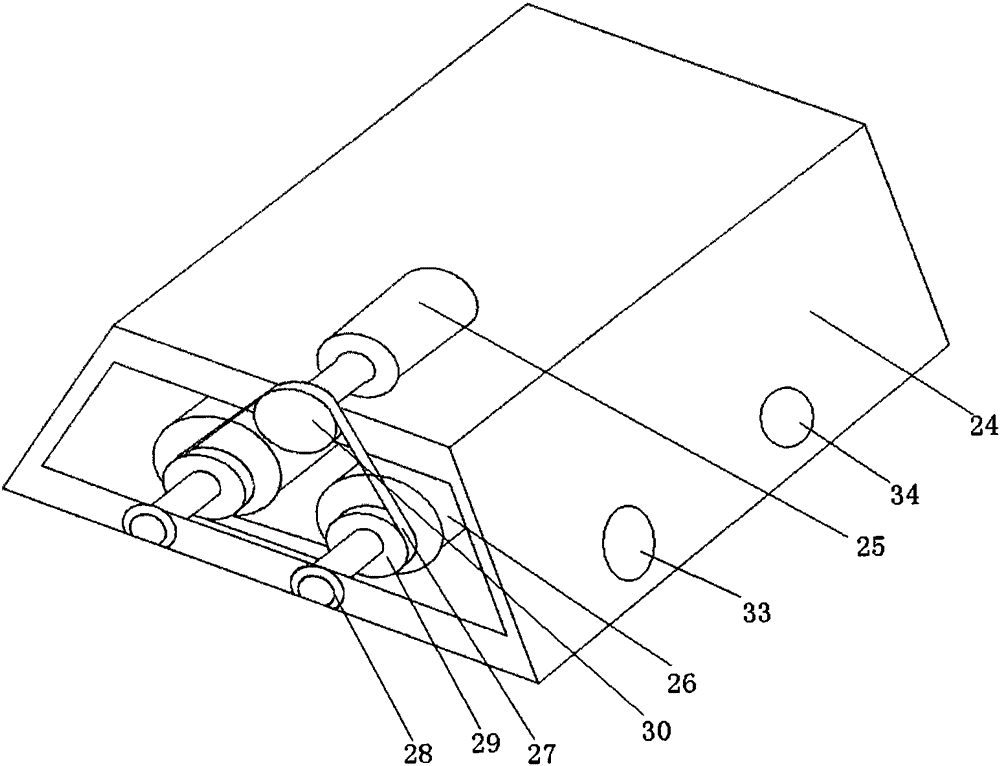

[0027] The photovoltaic cleaning robot cleans the dust accumulated on the photovoltaic module 1, so as to improve the power generation efficiency of the photovoltaic power station. The above-mentioned robot includes a mobile platform mechanism, a driving mechanism, a traveling mechanism, a cable receiving mechanism, and a cleaning mechanism. Photovoltaic module 1 is generally installed on an incline, and is composed of a row of battery panel arrays, and the mobile platform mechanism is connected to the photovoltaic module, such as figure 1 As shown, the mobile platform mechanism is a rectangular frame structure, which is composed of two relatively parallel long brackets 2 and a horizontal bracket 3. The two horizontal brackets 3 are respectively located at the two ends of the two long brackets 2, and the inner sides of the right angle formed between them are A connecting piece 4 is provided, and the connecting piece 4 is fixed on the inside of the long bracket and the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com