Warm-mixed auxiliary agent for asphalt mixture and preparation method thereof

A warm-mix asphalt and mixture technology, applied in the field of material science and engineering, can solve problems such as unstable road performance, achieve the effects of reducing exhaust gas emissions and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

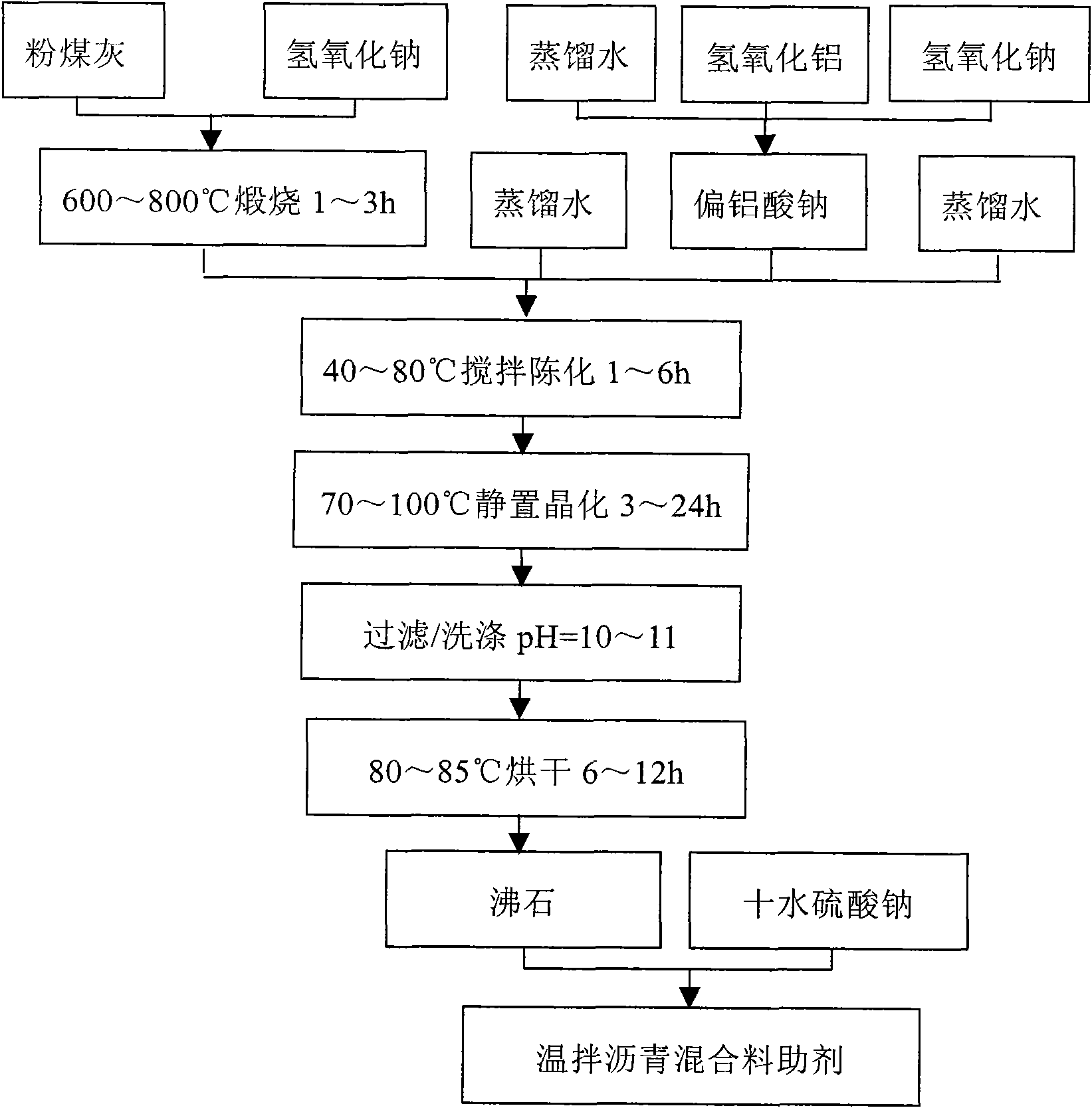

Method used

Image

Examples

Embodiment 1

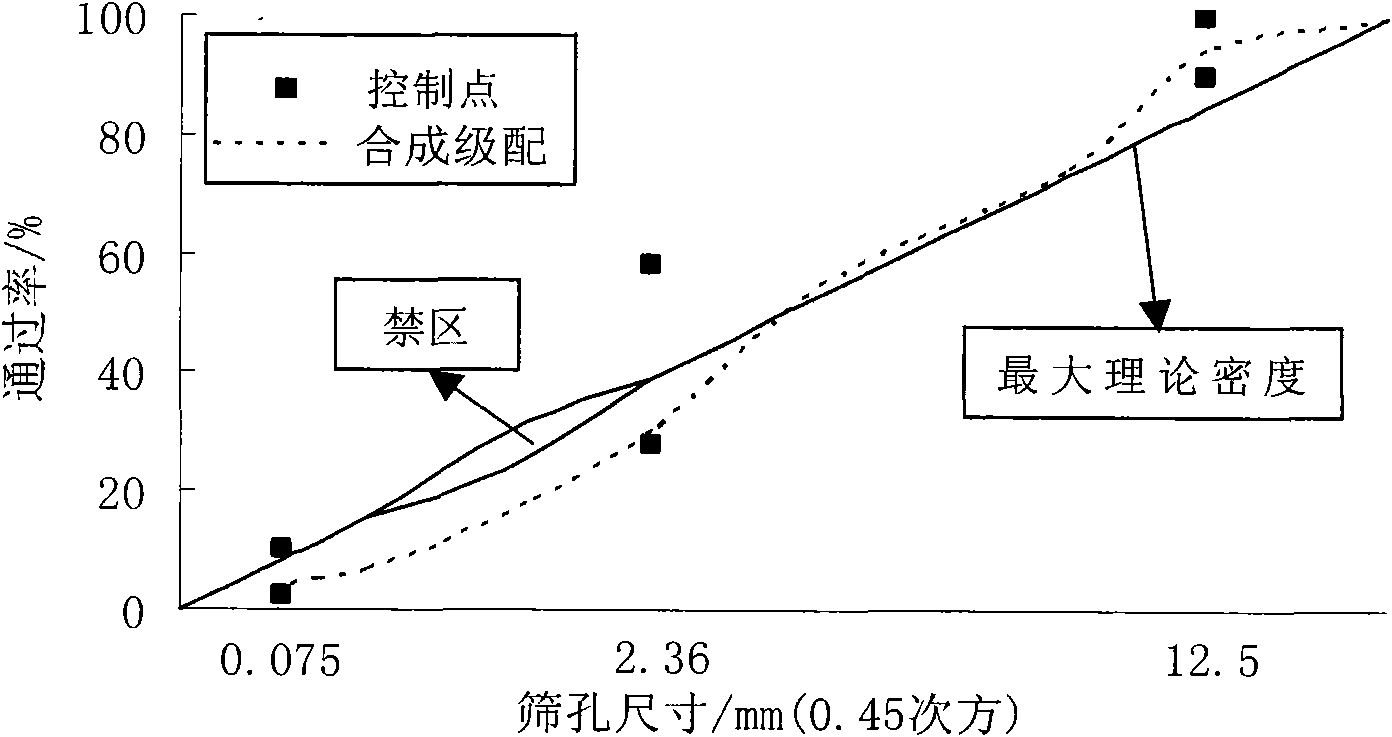

[0032] Superpave gradation design method is used for gradation design. Taking Superpave12.5 as an example, the gyratory compactor is used for forming. The forming pressure of the gyratory compactor is 600KPa, and the design rotation times are N-Initial=9, N-Design=125 and N-Max=205 (the addition amount of warm mix asphalt mixture additive is 0.4% of the total mass of asphalt mixture):

[0033] 1. Asphalt: SBS modified asphalt provided by Hubei Ezhou Keshi Asphalt Material Co., Ltd. is used, and its quality requirements meet the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0034] 2. Warm mix asphalt additives:

[0035] The warm mix asphalt additive is composed of synthetic zeolite and sodium sulfate decahydrate, the ratio is 96:4, the water release amount of the mixture is 13.6% when dried at 125°C for 2 hours, and the water release amount is 21.5% after continuous drying at 200°C for 2 hours .

[0036] The technical indicators of sy...

Embodiment 2

[0046] Take densely graded asphalt concrete mixture AC-13 as an example (the addition amount of warm mix asphalt mixture additive is 0.5% of the total mass of asphalt mixture):

[0047] 1. Asphalt: No. 90 road petroleum asphalt provided by Liaoning Panjin North Asphalt Co., Ltd. is used, and its quality requirements meet the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0048] 2. Warm mix asphalt additives:

[0049] The warm-mix asphalt additive is composed of synthetic zeolite and sodium sulfate decahydrate, and its mass ratio is 95:5. The water release amount of the mixture is 13.8% when it is dried at 125°C for 2 hours, and the water release amount is 19.7% when it is continuously dried at 200°C for 2 hours. %.

[0050] The technical indicators of synthetic zeolite are: yellow-white powder, SiO 2 The content is 30.6%, Al 2 o 3 The content is 29.2%, Na 2 The content of O is 16.1%, the amount of crystallization water released a...

Embodiment 3

[0058] Take graded asphalt concrete mixture AC-20 as an example (the addition amount of warm mix asphalt mixture additive is 0.3% of the total mass of asphalt mixture):

[0059] 1. Asphalt: No. 70 road petroleum asphalt provided by Hubei Ezhou Keshi Asphalt Material Co., Ltd. is used, and its quality requirements meet the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0060] 2. Warm mix asphalt additives:

[0061] The warm-mix asphalt additive is composed of synthetic zeolite and sodium sulfate decahydrate, and its mass ratio is 94:6. The water release amount of the mixture is 13.0% when it is dried at 125°C for 2 hours, and the water release amount is 18.7% when it is continuously dried at 200°C for 2 hours. %.

[0062] The technical indicators of synthetic zeolite are: yellow-white powder, SiO 2 The content is 26.28%, Al 2 o 3 The content is 28.32%, Na 2 The content of O is 17.36%, the amount of crystallization water released a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com