Patents

Literature

92 results about "Technical specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

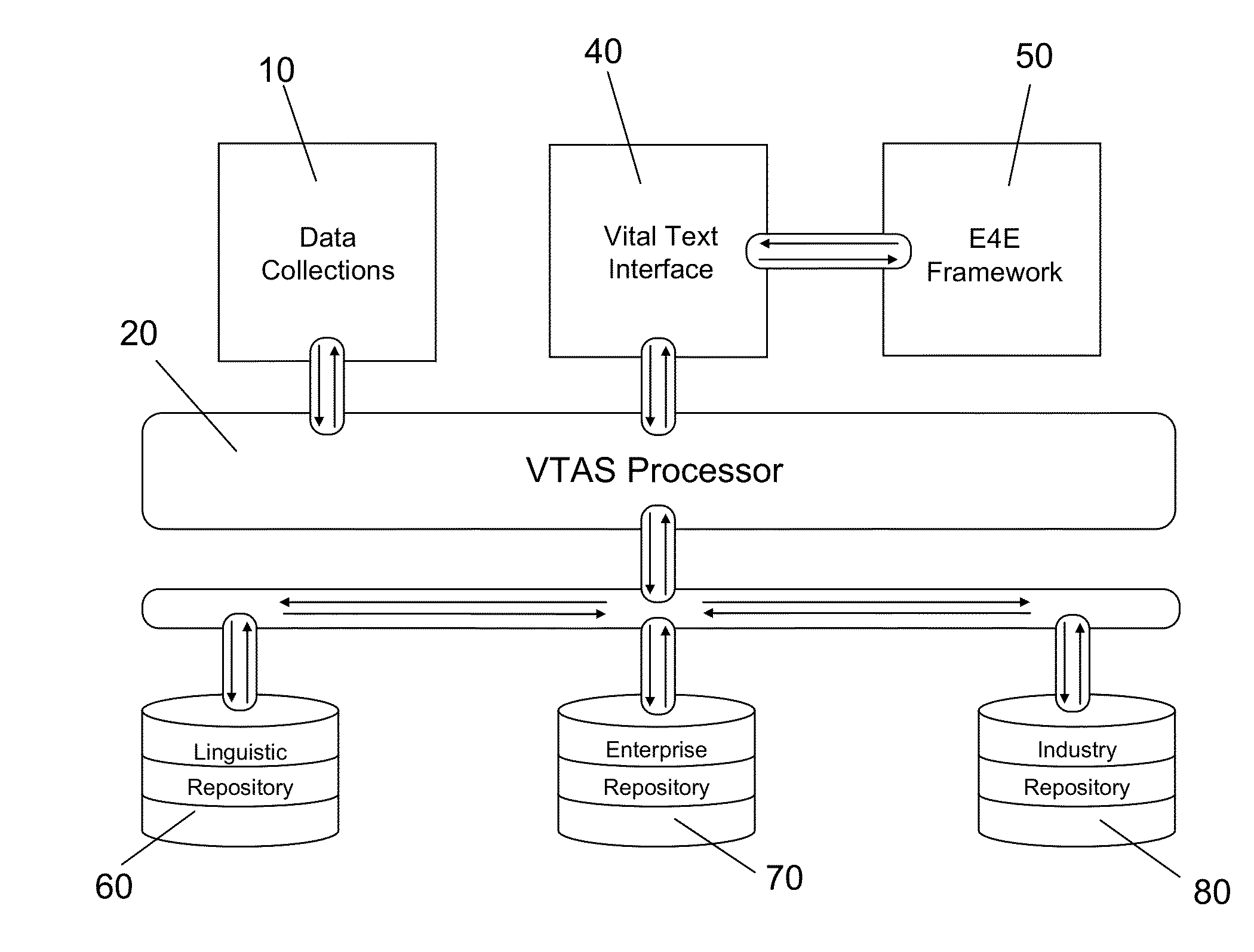

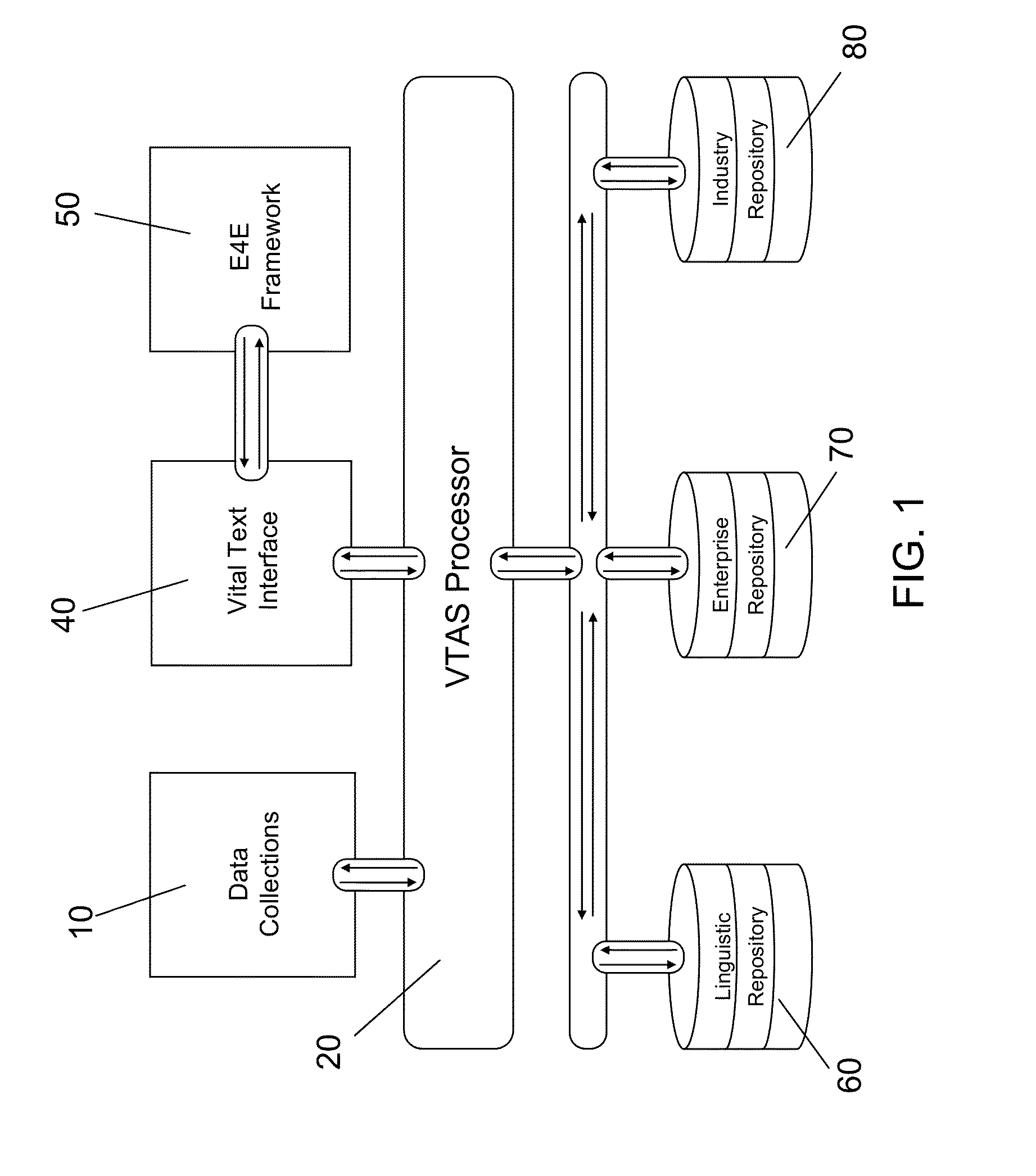

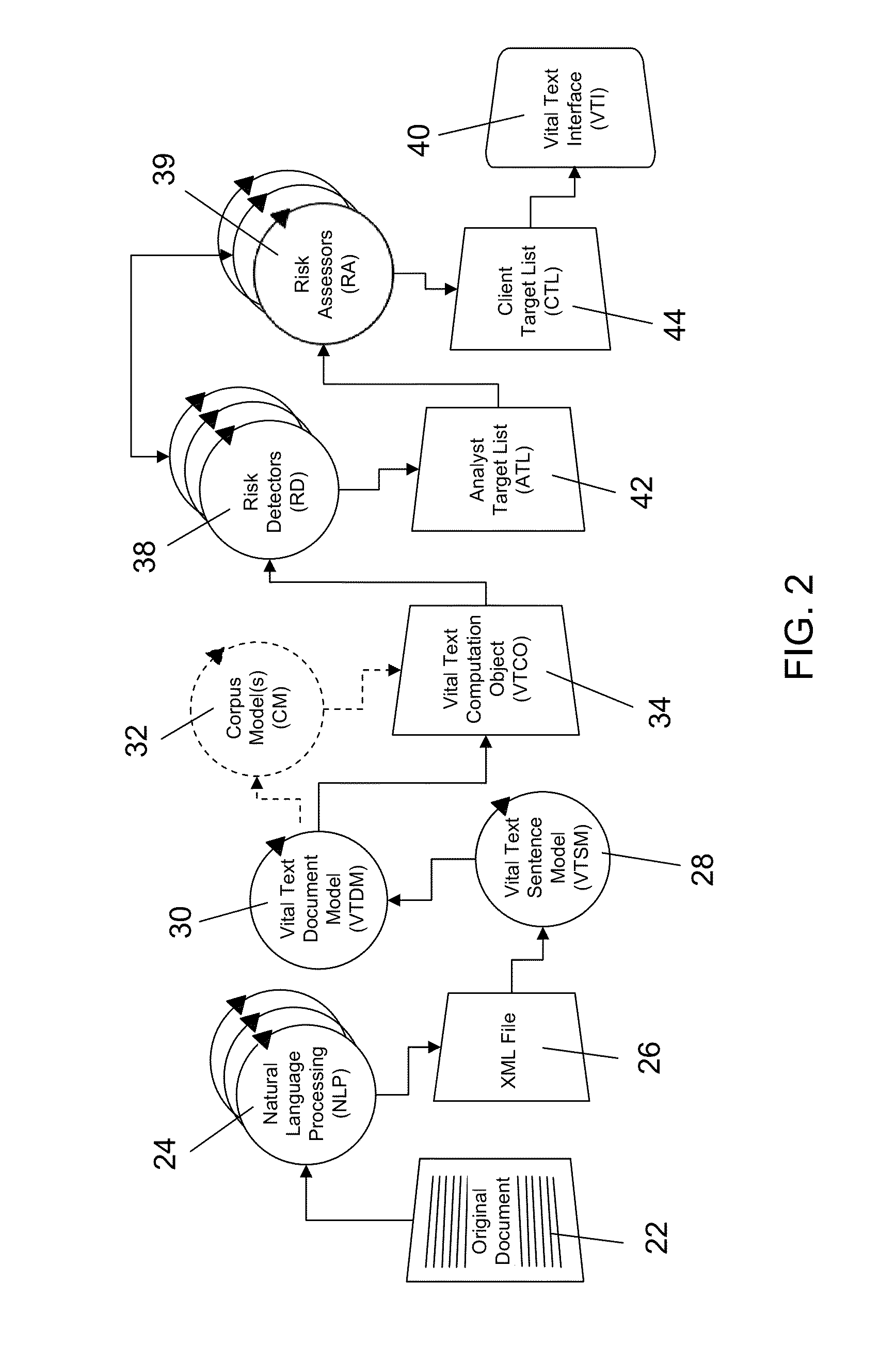

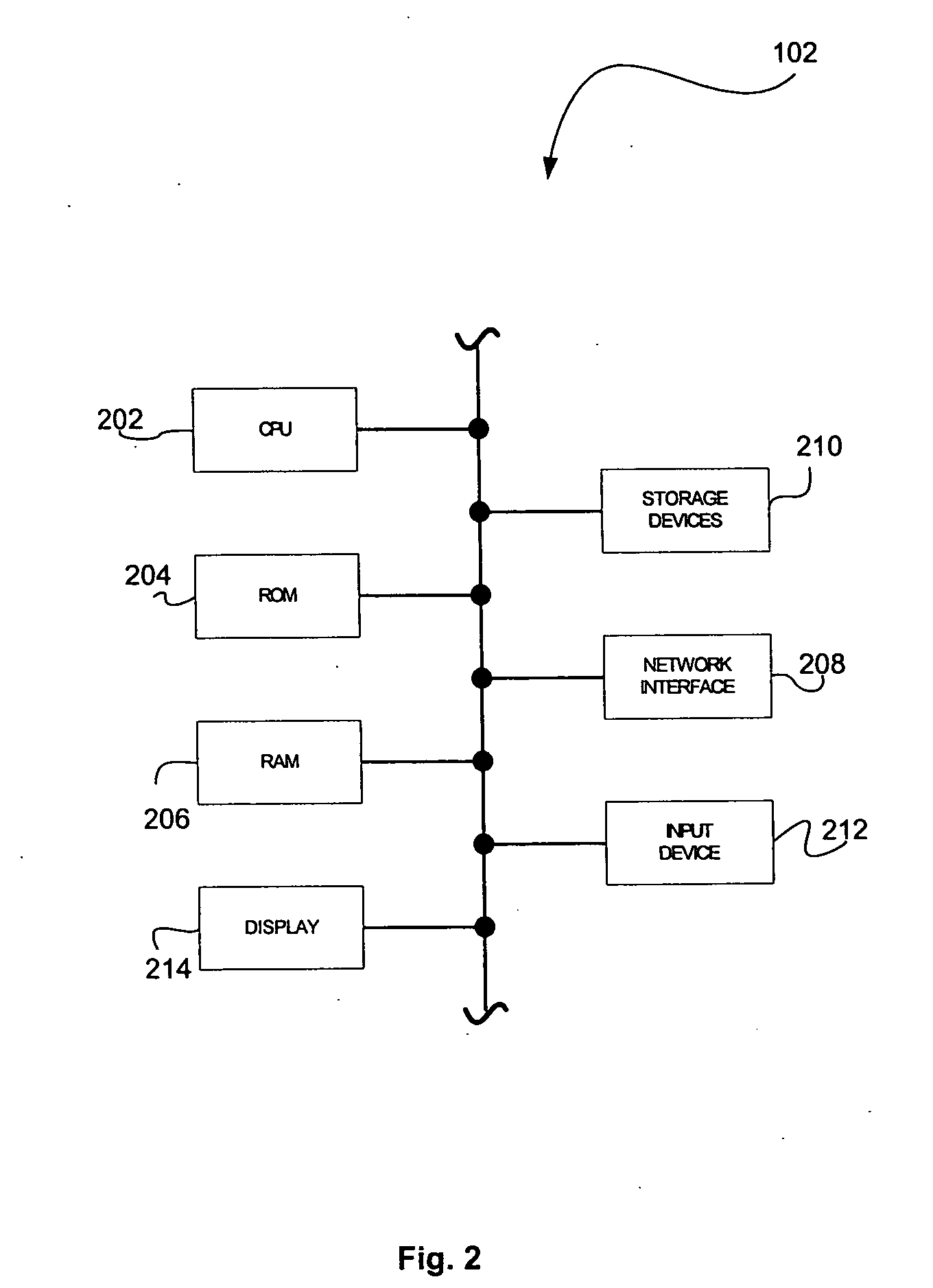

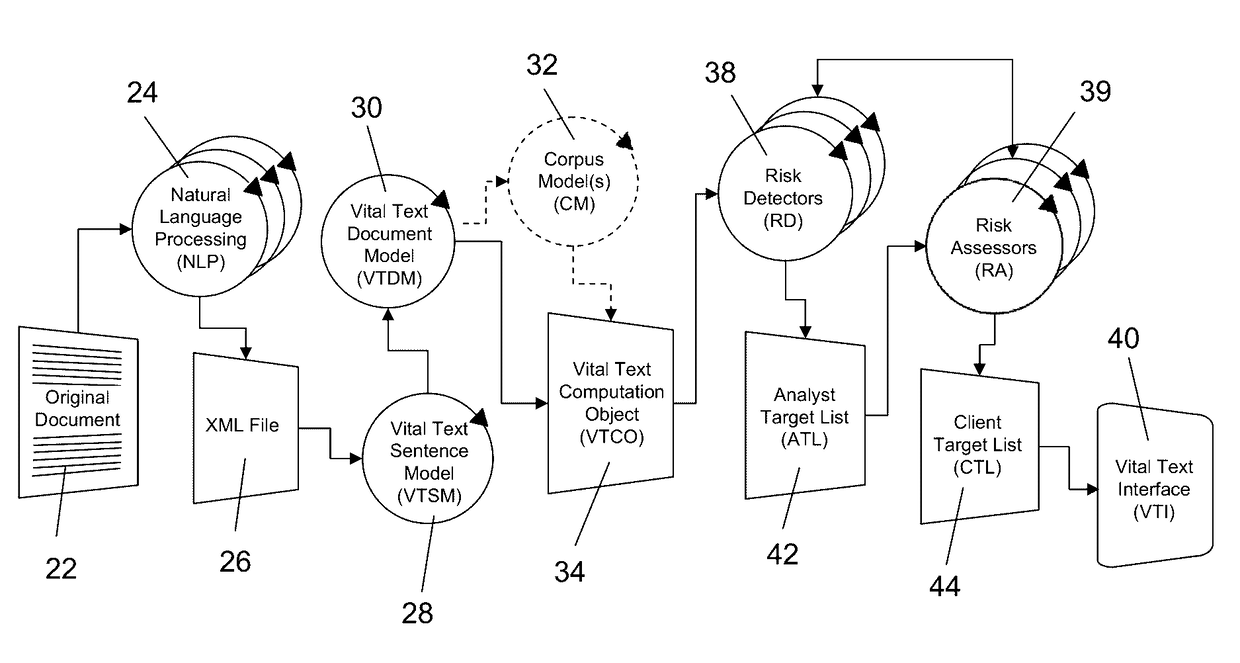

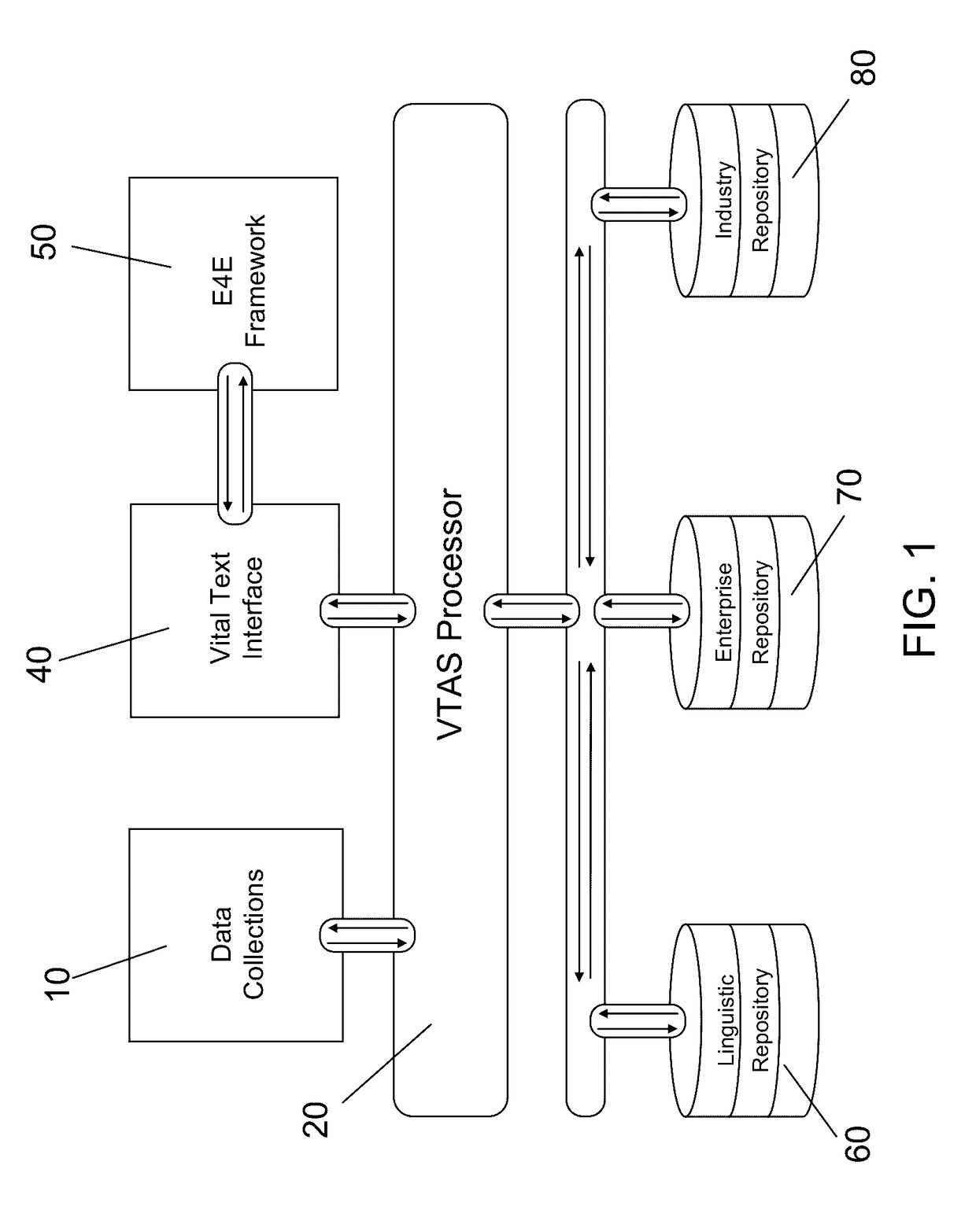

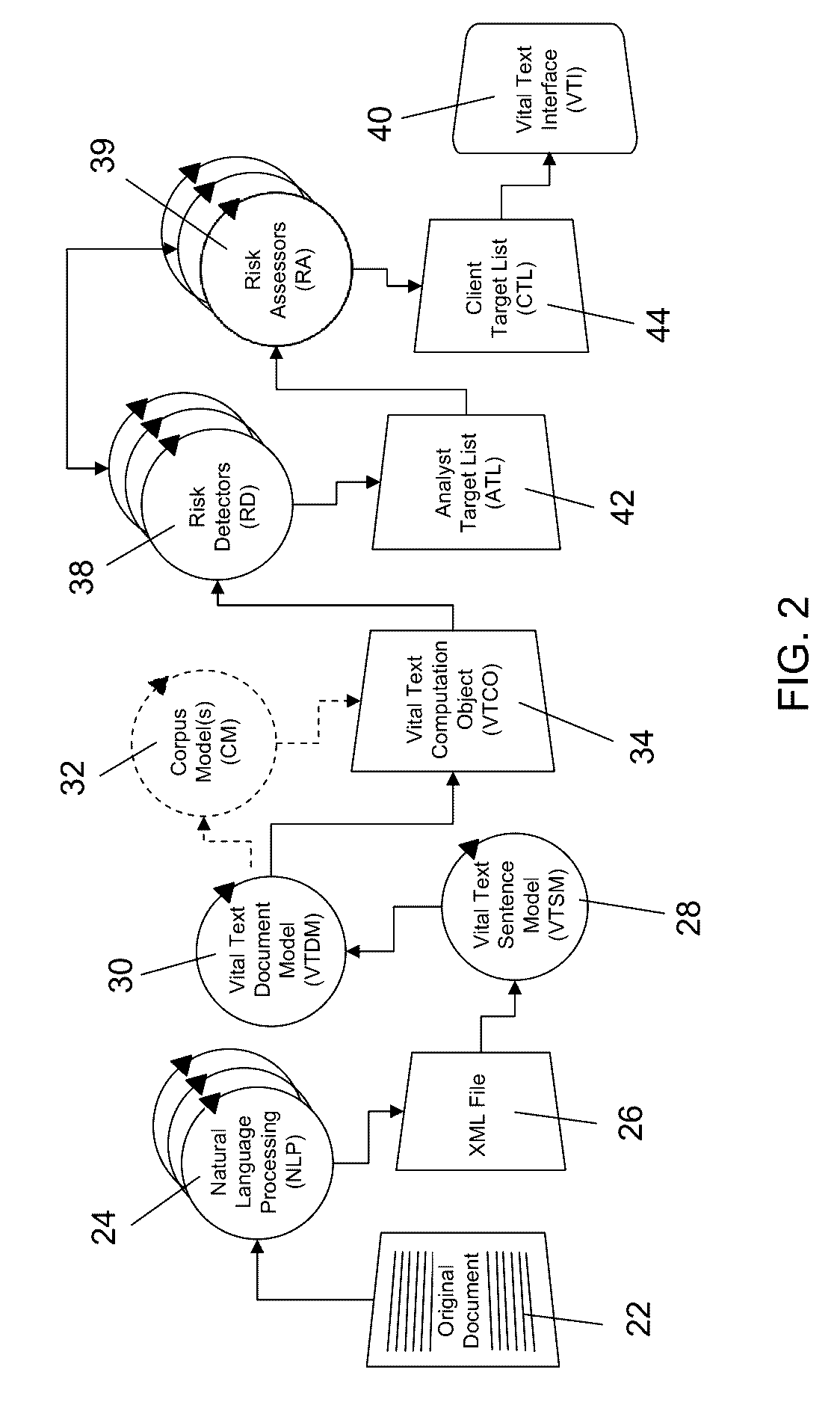

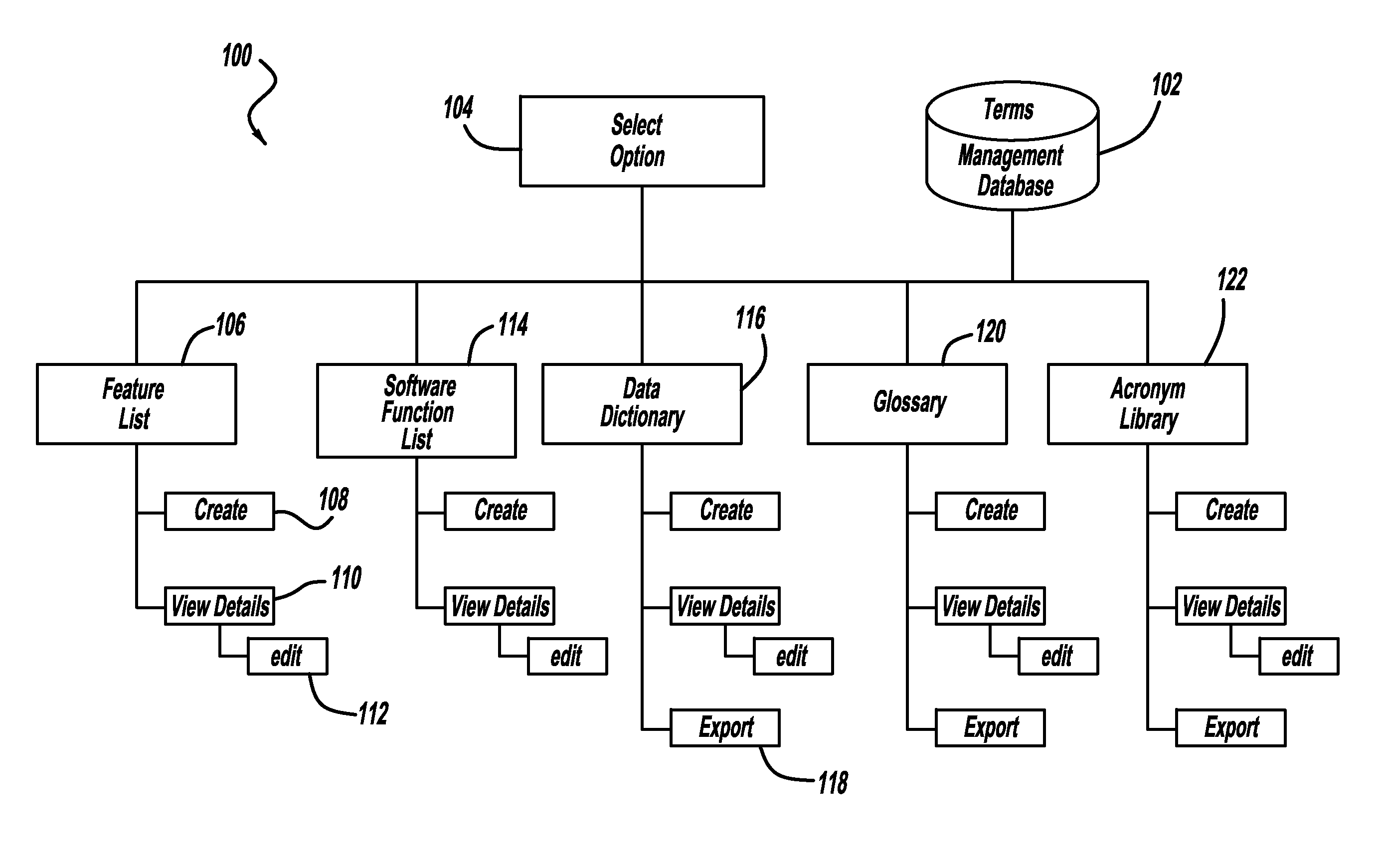

Vital text analytics system for the enhancement of requirements engineering documents and other documents

ActiveUS20140172417A1Improve efficiencyReduce defectsSemantic analysisSpecial data processing applicationsDocumentation procedureTechnical specifications

A Vital Text Analytics System (VTAS), incorporating a repository of enterprise terms or concepts, is one that improves the readability and fidelity of technical specifications, instructions, training manuals requirements engineering documents and other related engineering documents, typically from a single organization or workgroup. The system stresses ontological analysis of a corpus of related documents, and applies a suite of computational tools that supports the identification and assessment of risk in evaluating the content of the documents, as well as providing statistical measures reflecting the frequency and severity of document features that threaten comprehension.

Owner:CLOUD 9 LLC DBA VITAL TEXT SYST

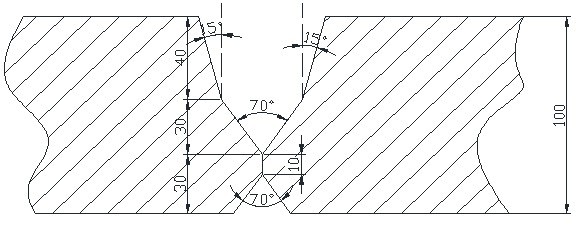

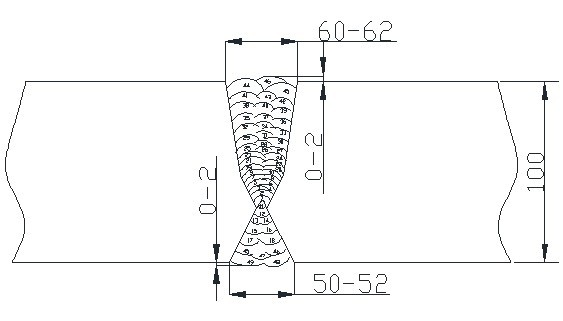

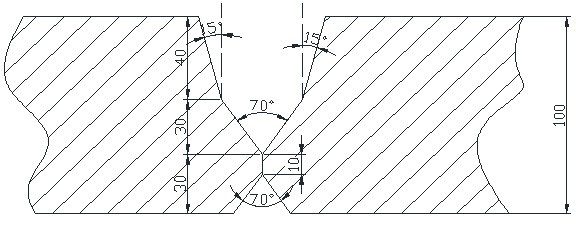

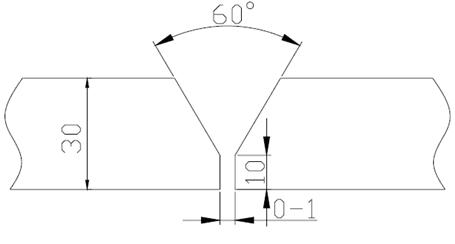

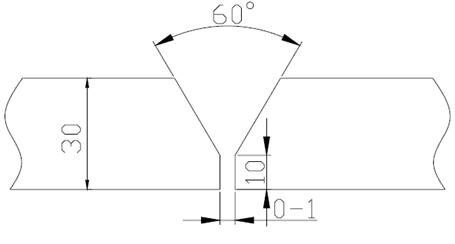

Downward and butt welding process for high strength steel for ship structure

ActiveCN102009256AShorten the construction periodImprove labor efficiencyArc welding apparatusCold treatmentButt welding

The invention in particular relates to a welding process for super thick high strength steel plates for ships and provides a downward and butt welding process aiming at downward and butt welding of EH36Z 100mm-thick high strength steel plates for a ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding, the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials is saved, the production cost is reduced, the ship building period is shortened, large scale practical application of the steel to the engineering is successfully implemented for the first time and the gap in the technical specifications in welding of the EH36Z 100mm-thick high strength steel for thick plates for the ship structure at home is filled in.

Owner:WUCHANG SHIPBUILDING IND

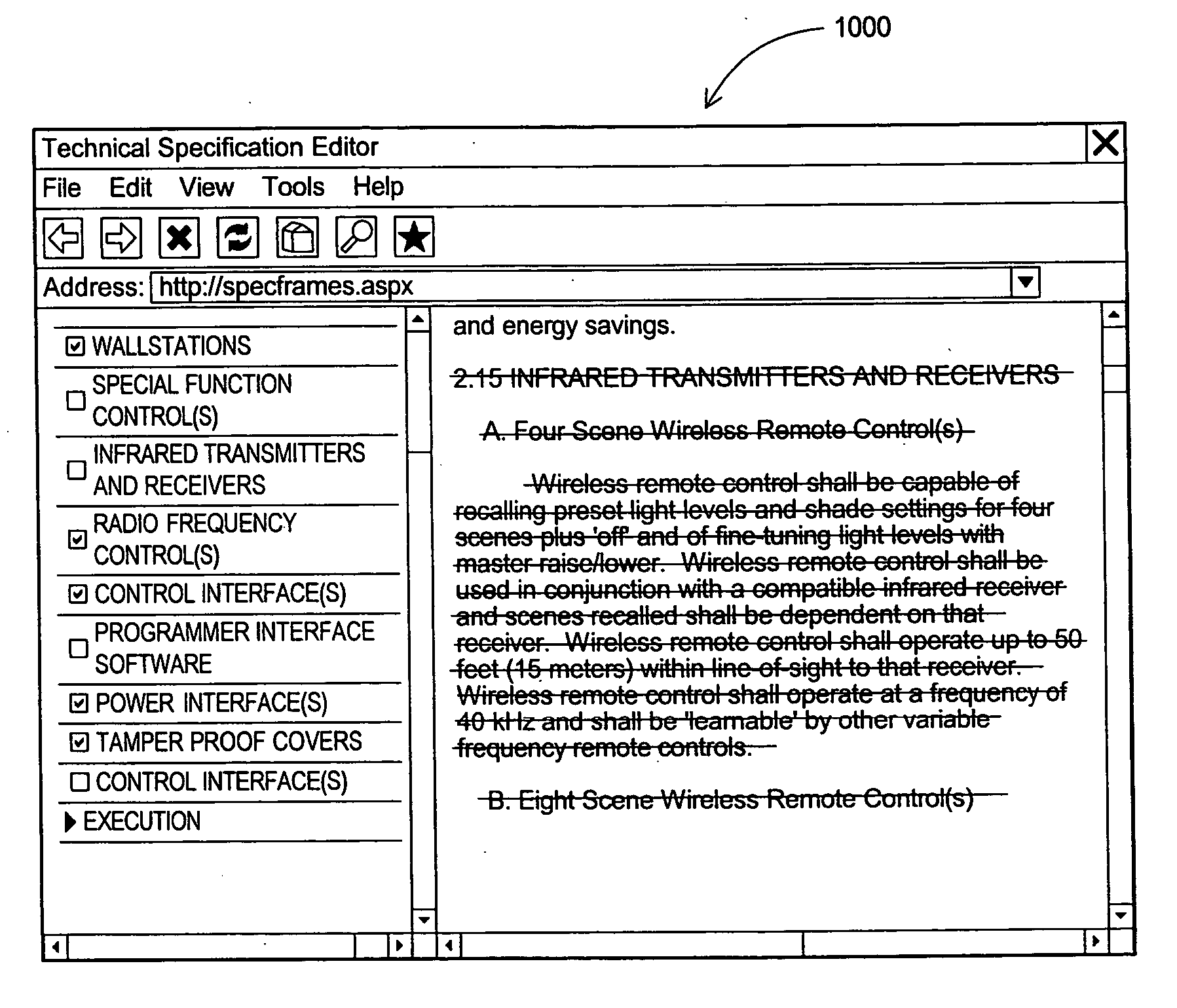

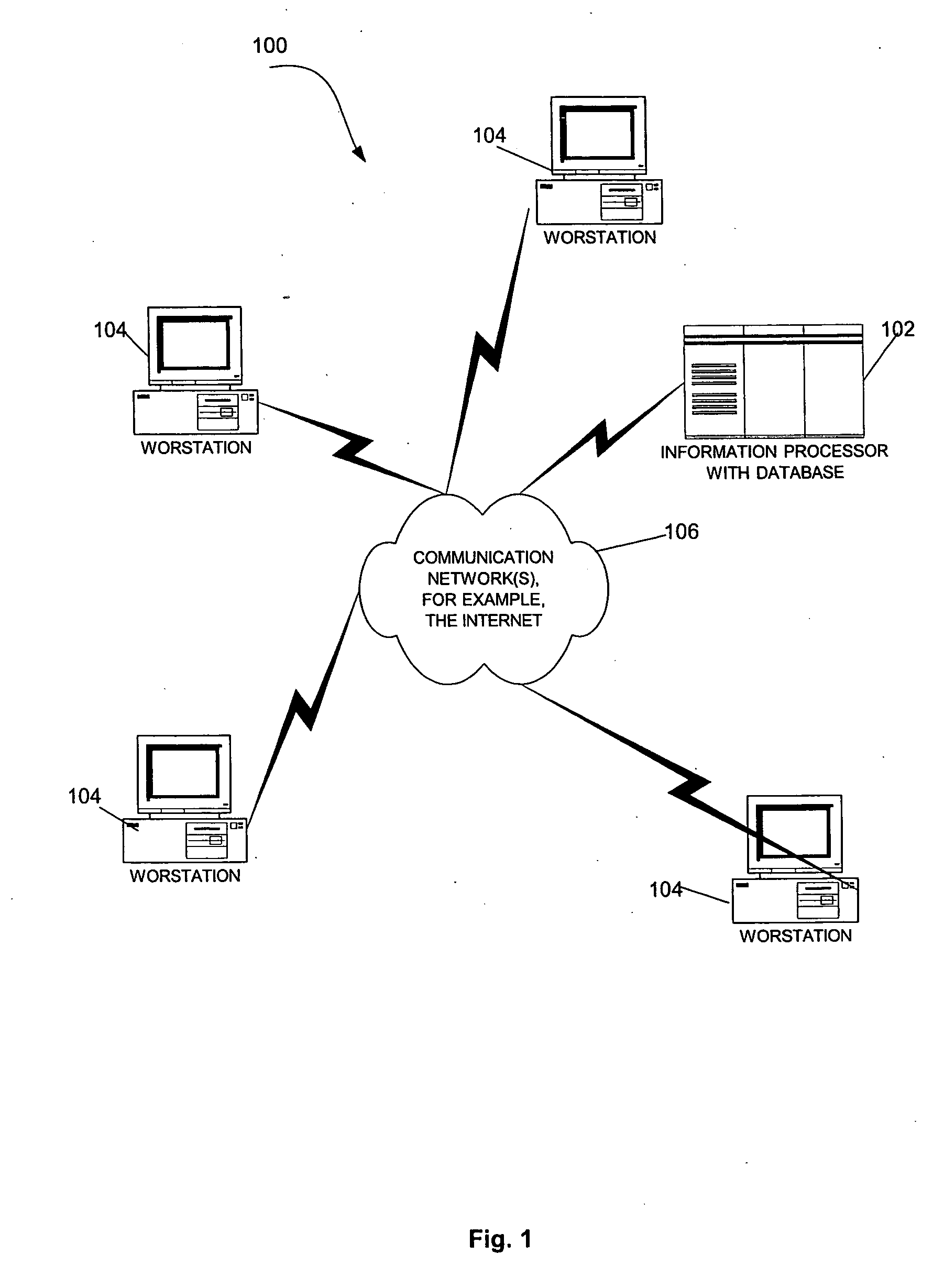

Technical specification editor

InactiveUS20060069986A1Improve efficiencyNatural language data processingProgram controlTechnical specificationsReference database

The production of formal technical specification documents using a web-based interface is disclosed. The interface is used to identify one or more products, for example, lighting control systems that will be used in a construction. After receiving a selection of one or more products, a database is referenced to automatically retrieve text for the technical specification document that corresponds with the product(s), and a fully formatted technical specification document is generated for a user. Any portion of the technical specification document may be altered by the user via the user interface. Any technical specification document that is generated in accordance with the present invention can be stored to be used in the future as a template for new technical specification documents.

Owner:LUTRON TECH CO LLC

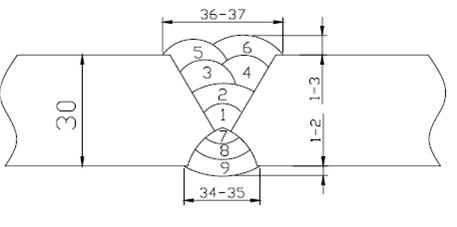

Downward and butt welding process for high strength steel for ship structure

ActiveCN102009255AIncrease productivityReduce energy consumptionArc welding apparatusThick plateSheet steel

The invention in particular relates to a downward and butt welding process for high strength steel for a ship structure and provides a downward and butt welding process aiming at EH36 30mm-thick high strength steel plates for the ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials are saved, the production cost is reduced, the ship building period is shortened and the gap in the technical specifications in downward and butt welding of the EH36 30mm-thick high strength steelfor the ship structure at home is filled in.

Owner:WUCHANG SHIPBUILDING IND

Seed reproduction and high-yield cultivation technical specification of onion

InactiveCN101675724AThe cultivation method is simpleCultivation method scienceHarvestersFertilising methodsTechnical specificationsReproduction

The invention discloses a seed reproduction and high-yield cultivation technical specification of onion, which aims at providing the seed reproduction and high-yield cultivation technical specification of the onion against the problem that the prior seed reproduction of the onion is lack of the quipped cultivation technical measures, so that the seed production is low and unstable. The seed reproduction according to the specification has the advantages of simple and scientific cultivation method, high seed production, labor-saving property, low cost, stable seed nature and high purity.

Owner:尹永良

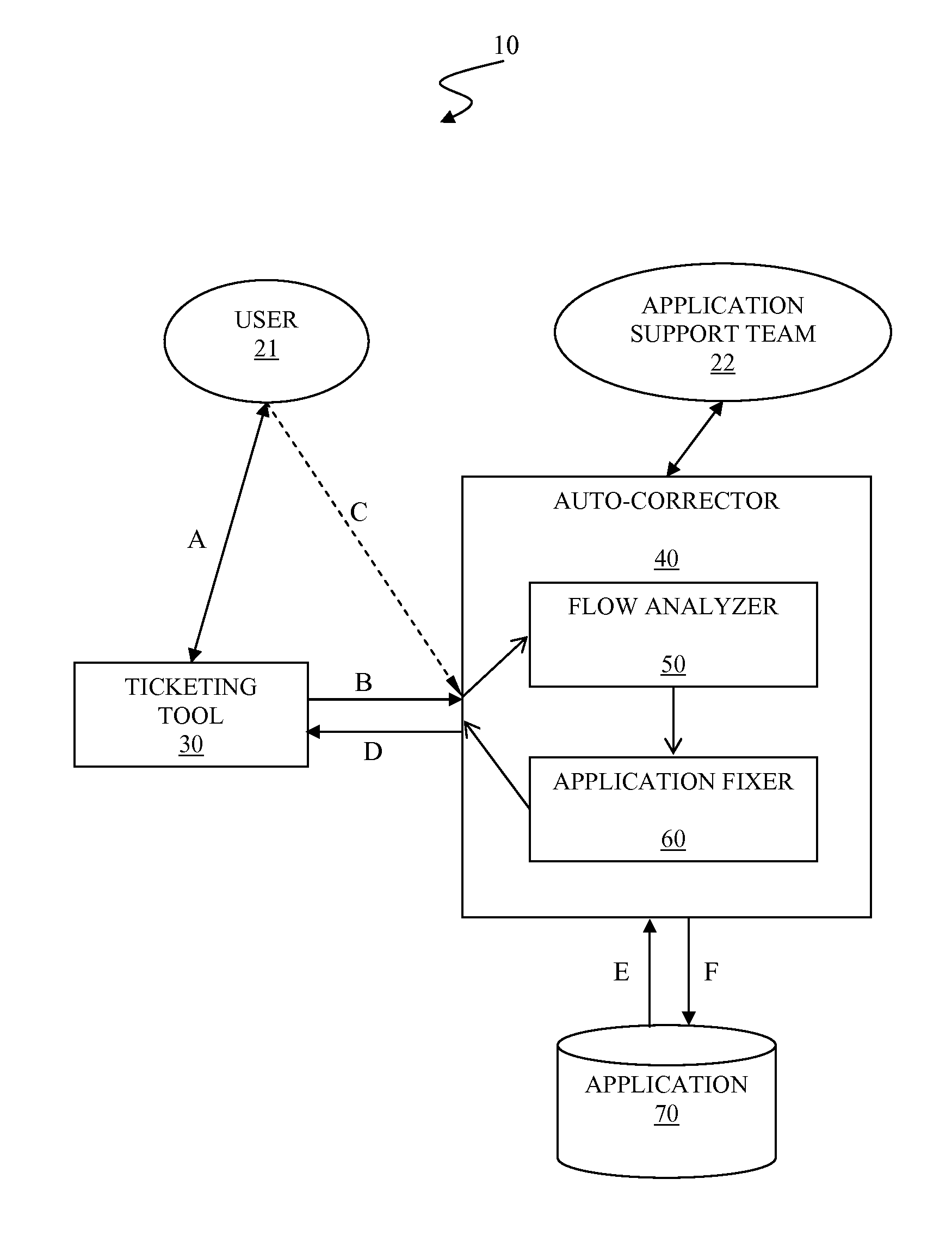

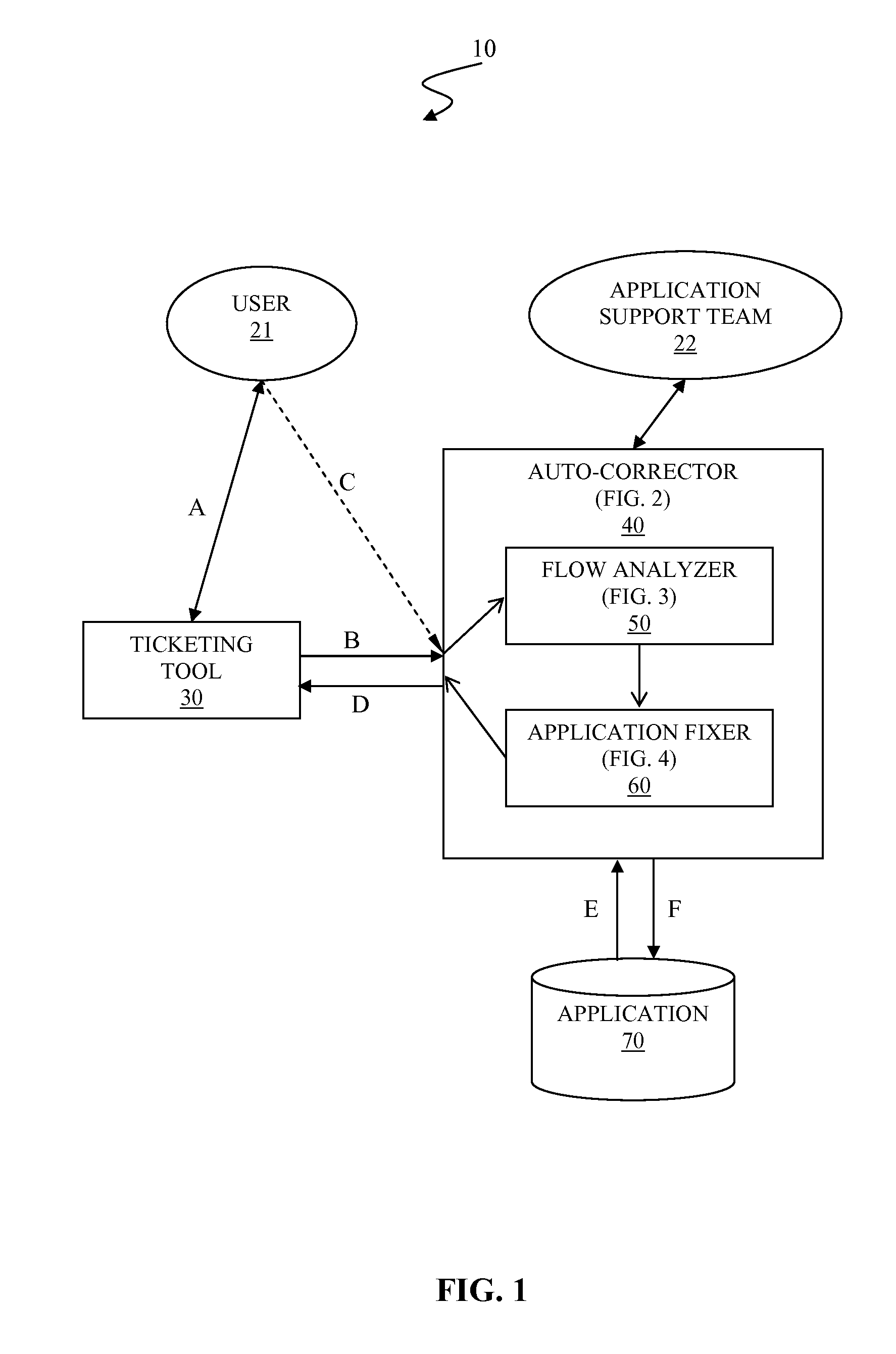

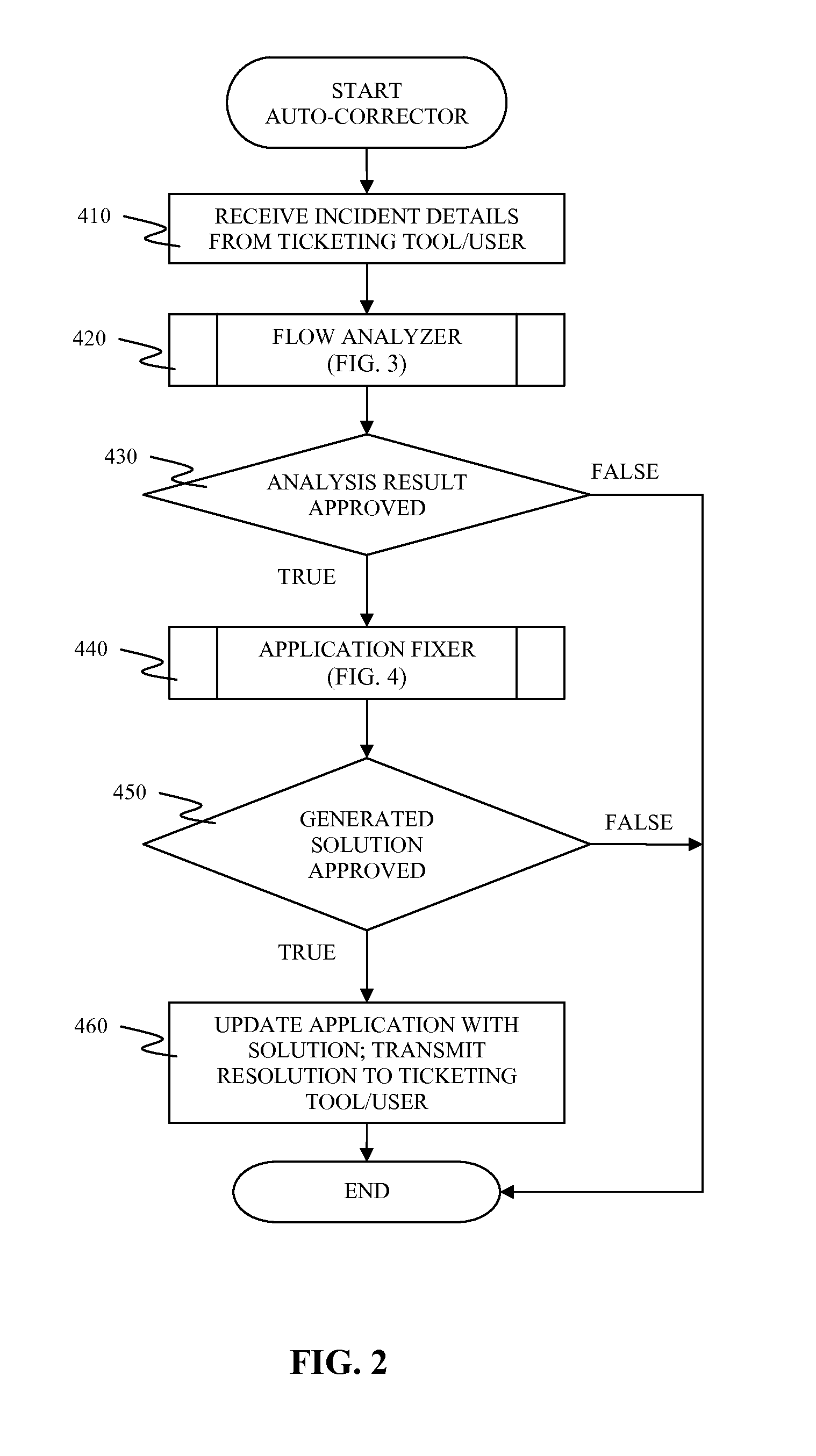

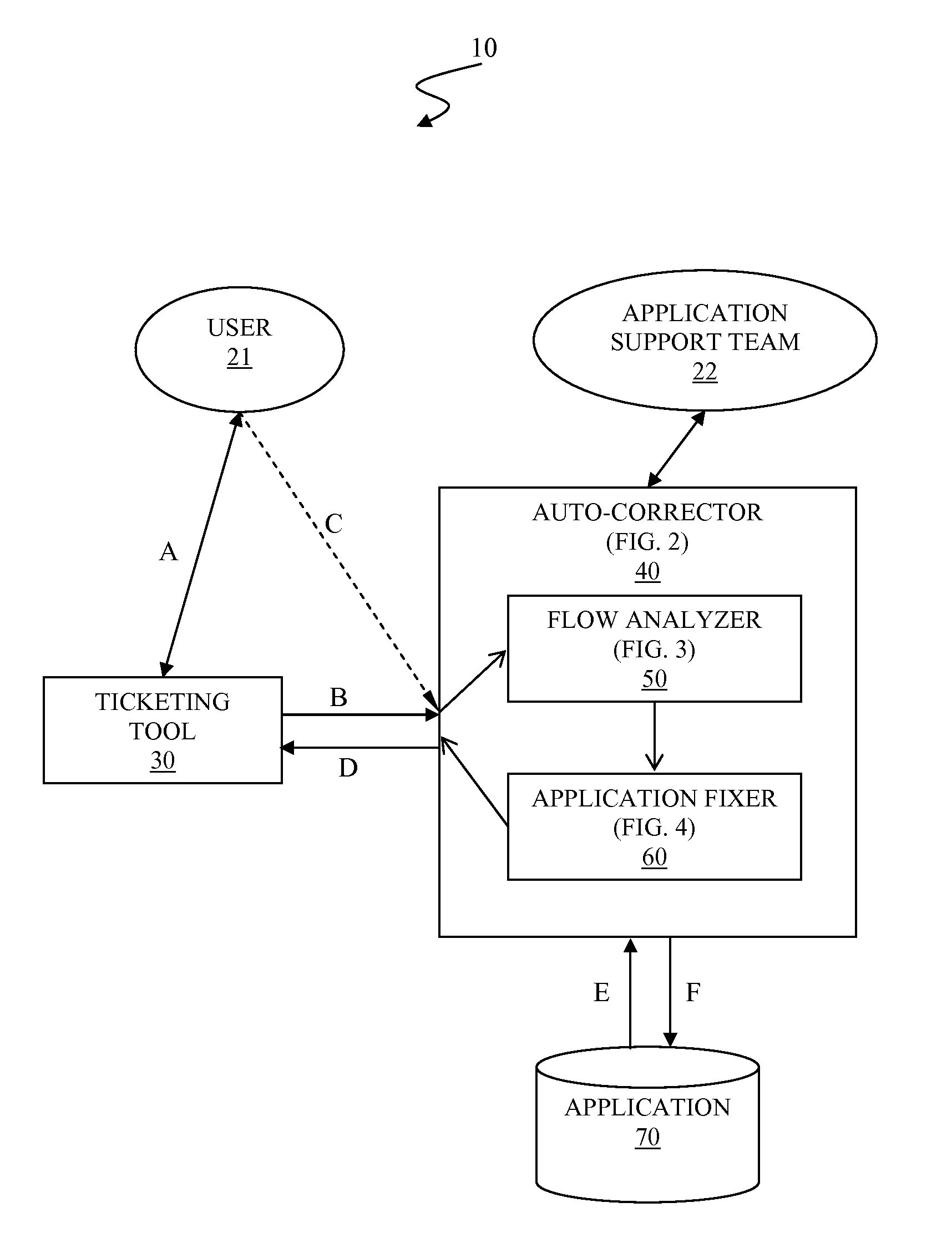

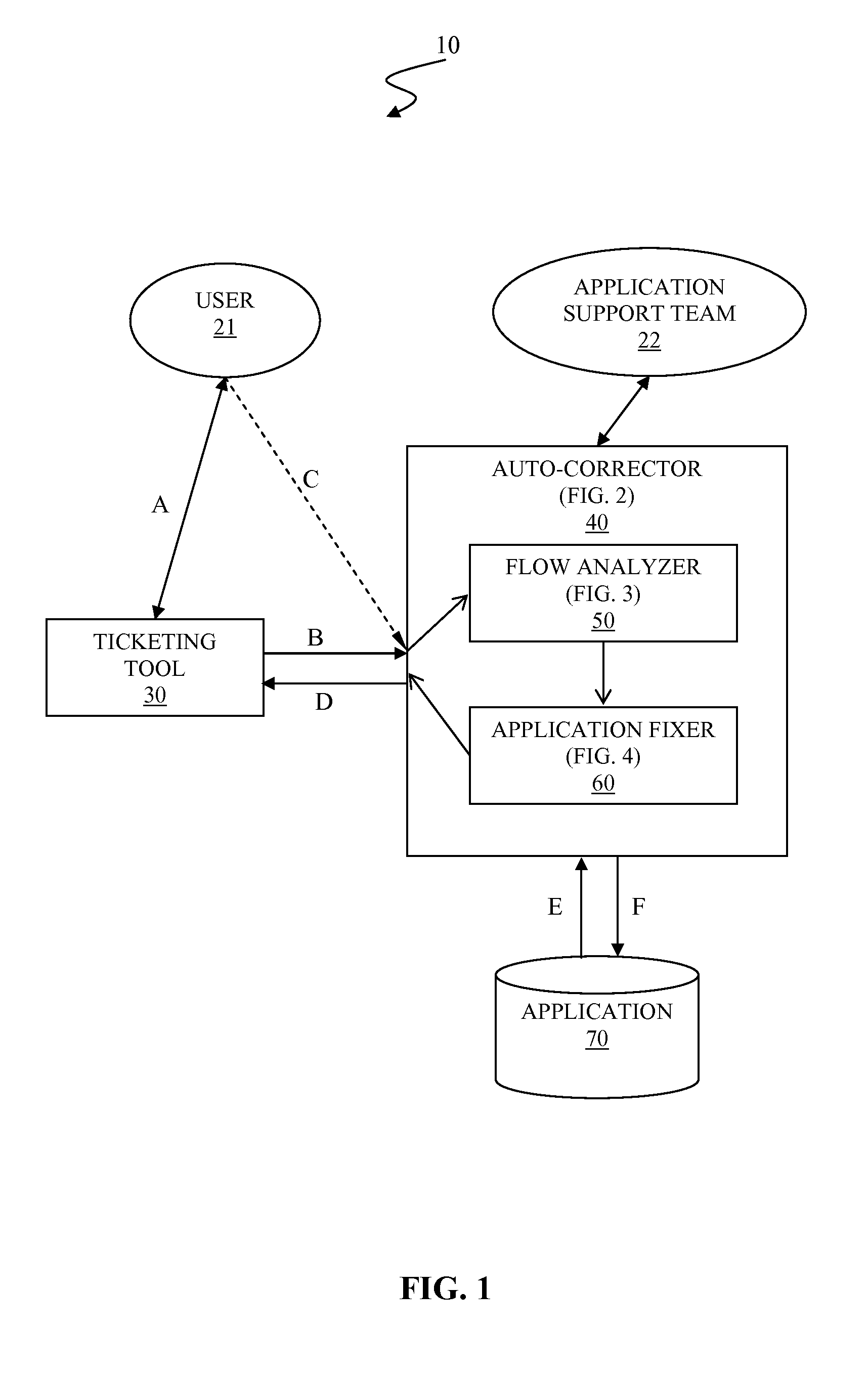

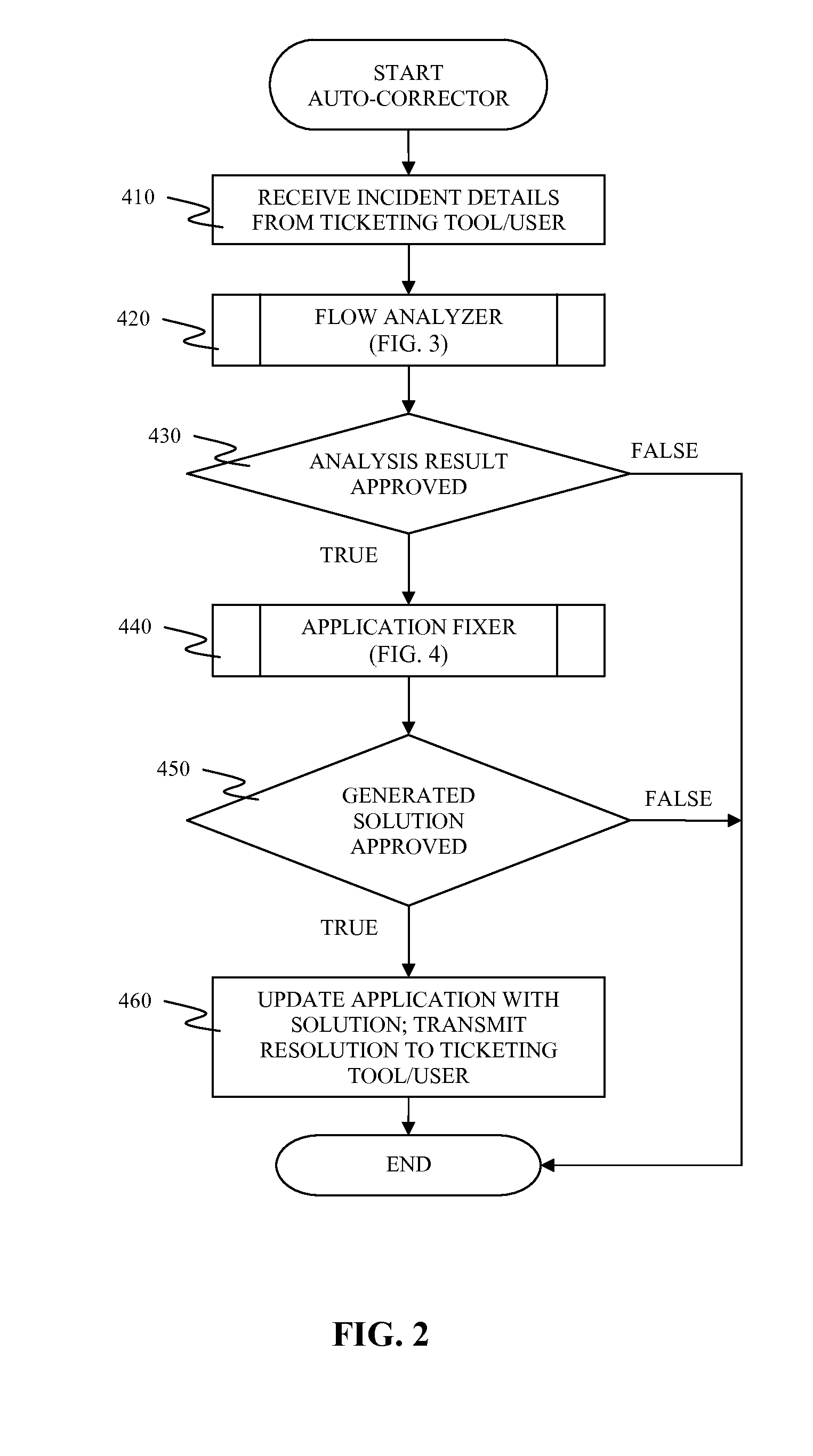

Automatic correction of application based on runtime behavior

InactiveUS8448139B2Software testing/debuggingSpecific program execution arrangementsTechnical specificationsData stream

A system and associated method for automatically correcting an application based on runtime behavior of the application. An incident indicates a performance of the application in which a problem object produces an outcome that had not been expected by a user or by a ticketing tool. An incident flow for the problem object is automatically analyzed. Actual run of the application renders a forward data flow and at least one backward data flow is simulated from an expected outcome of the problem object. The forward data flow and the backward data flow(s) are compared to create a candidate fault list for the problem object. A technical specification to correct the candidate fault list and a solution to replace the application are subsequently devised.

Owner:INT BUSINESS MASCH CORP

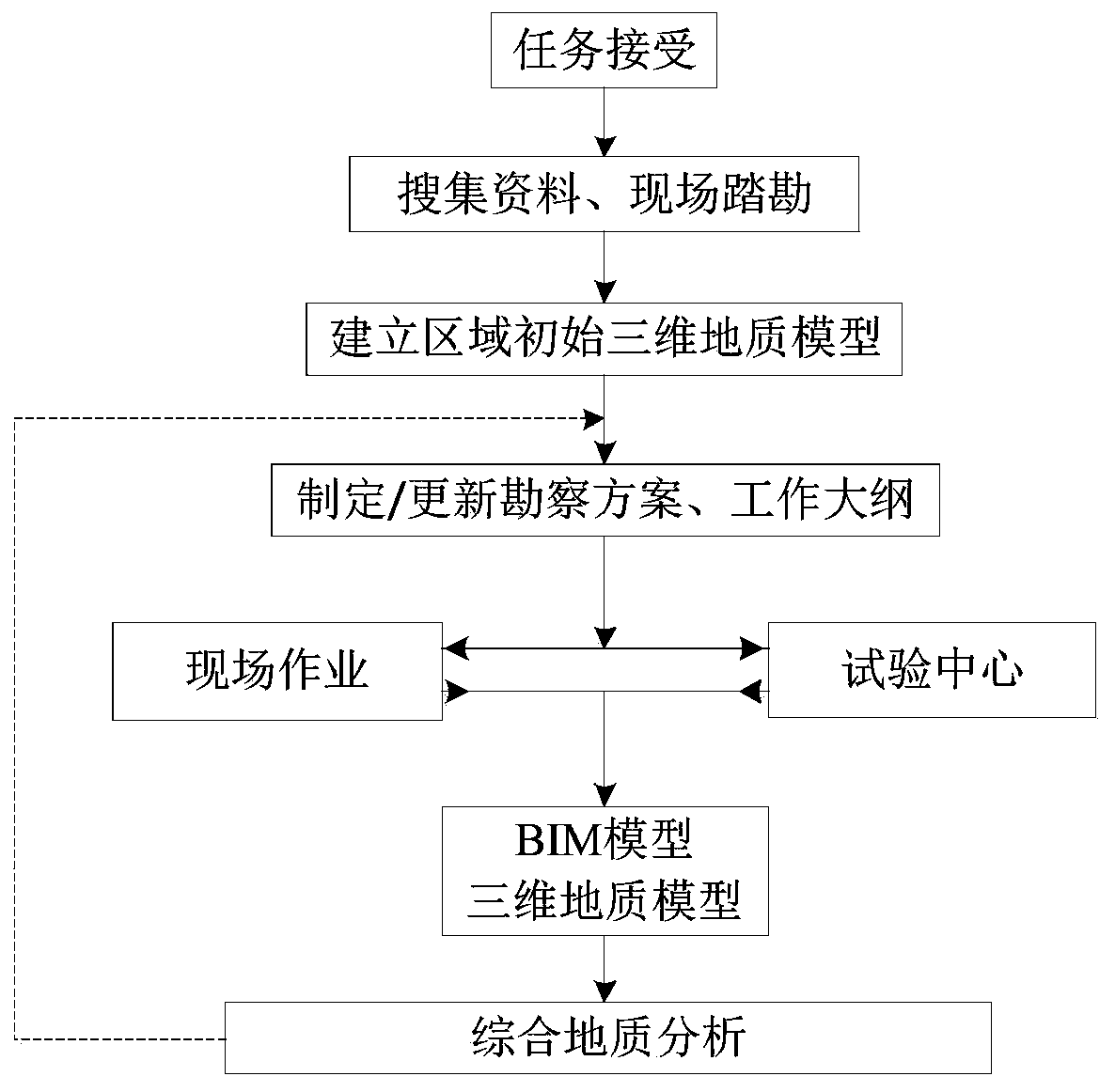

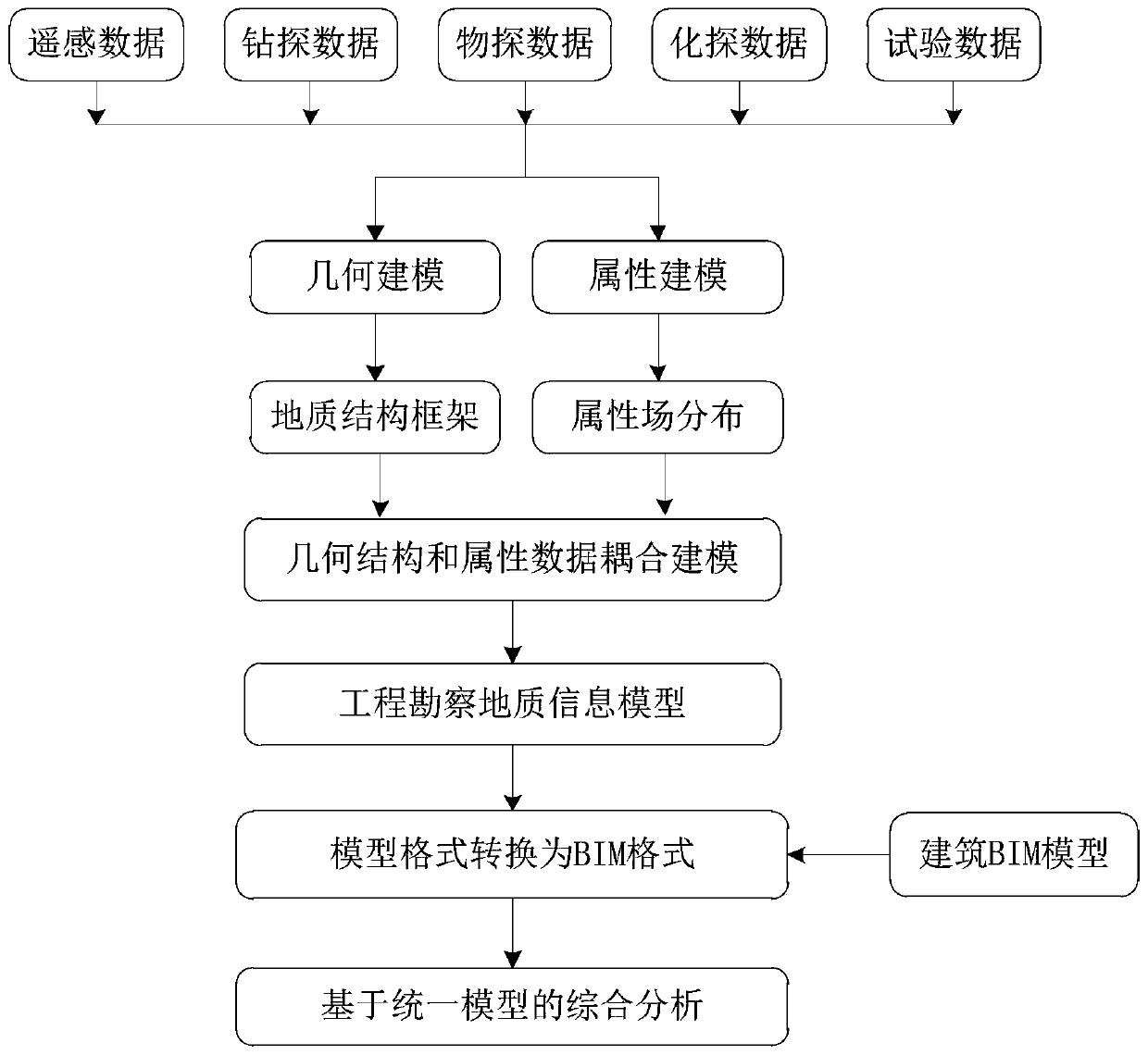

A dynamic optimization method for a geotechnical engineering investigation scheme

InactiveCN109933867AHigh feasibilityImprove usabilitySpecial data processing applicationsTechnical specificationsUsability

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

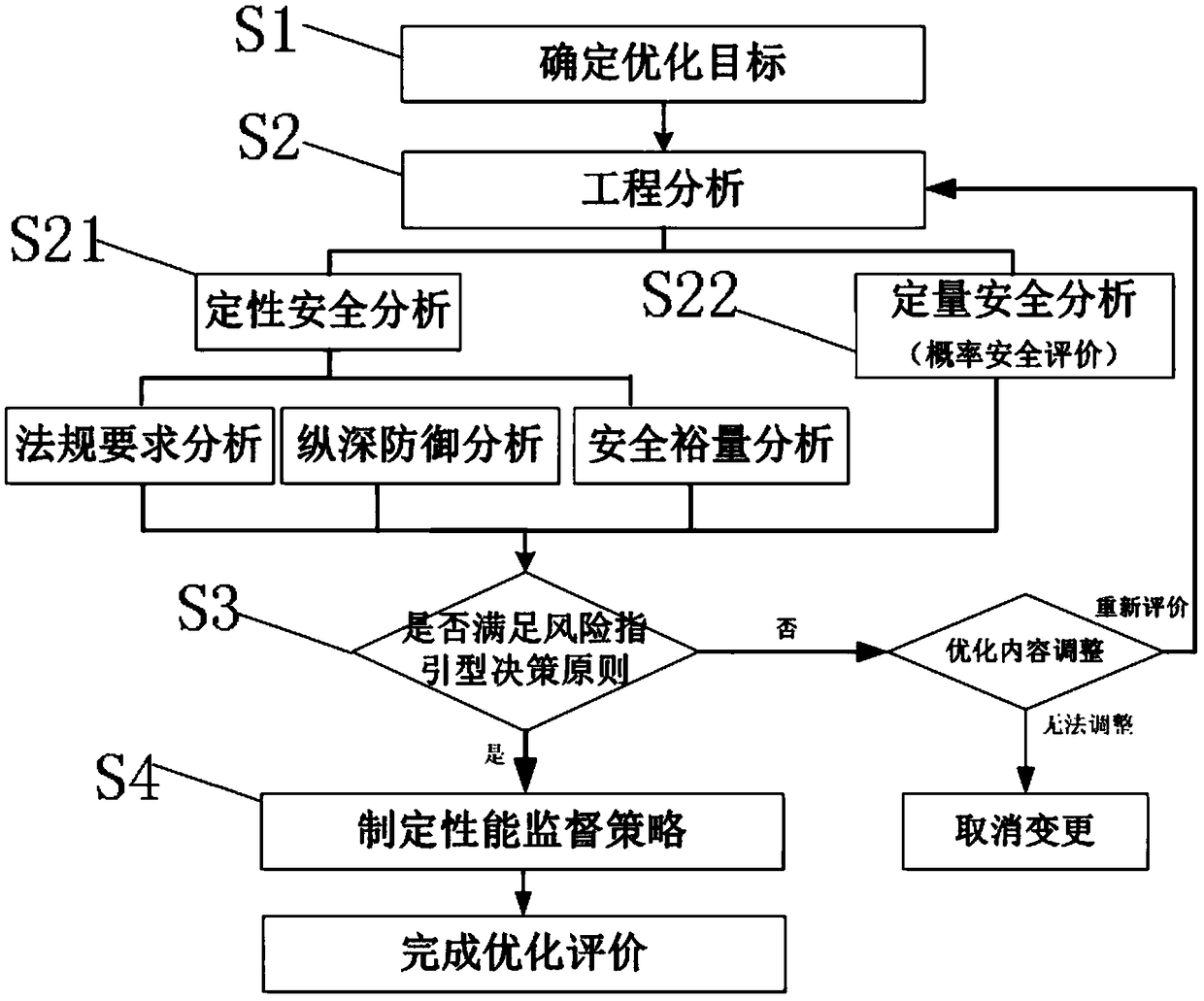

Risk-guided analysis method for optimization of technical specifications of nuclear power plants

InactiveCN109064035AProcess improvement and clarityOptimize risk assessmentResourcesNuclear powerEngineering

The invention provides a risk-guiding analysis method for optimizing technical specifications of a nuclear power plant, comprising the following steps: S1, determining an optimization objective: determining an optimization objective according to the actual situation of the nuclear power plant; S2, engineering analysis, specifically including step qualitative safety analysis and quantitative safetyanalysis; S21, qualitative safety analysis: evaluate and analyze the compliance of the regulation requirements, the compliance of the defense in depth and the compliance of the safety margin for theoptimization objective formulated in S1 step; S22, quantitative safety analysis is probabilistic safety assessment: evaluating the influence of optimization on the safety of nuclear power plant and the influence of optimization on the PSA model of the power plant, obtaining quantitative evaluation results, and comprehensively judging whether the optimization of the technical specifications of thenuclear power plant is acceptable or not; S3, risk-guiding decision-making principle judgment; S4, formulating a performance monitoring strategy; The invention establishes a set of risk evaluation system and a performance tracking strategy to ensure that the risk-guided decision principle is met optimally.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Vital text analytics system for the enhancement of requirements engineering documents and other documents

ActiveUS9678949B2Reduce defectsAccelerated trainingSemantic analysisSpecial data processing applicationsTechnical specificationsDocumentation procedure

A Vital Text Analytics System (VTAS), incorporating a repository of enterprise terms or concepts, is one that improves the readability and fidelity of technical specifications, instructions, training manuals requirements engineering documents and other related engineering documents, typically from a single organization or workgroup. The system stresses ontological analysis of a corpus of related documents, and applies a suite of computational tools that supports the identification and assessment of risk in evaluating the content of the documents, as well as providing statistical measures reflecting the frequency and severity of document features that threaten comprehension.

Owner:CLOUD 9 LLC DBA VITAL TEXT SYST

High-dense emulsified asphalt and preparation method thereof

InactiveCN101139465ASimple production processShort manufacturing timeBuilding insulationsHigh concentrationTechnical specifications

An emulsified asphalt of high concentration is provided, which is an emulsified asphalt in concentration by weight 63-80% and comprising 63.0%-80.0% asphalt, 1.0-3.0% emulsifier and some water in proper proportion. The preparing method is: heating the asphalt to 110-130 DEG C, adding the emulsifier into water of 60-70 DEG C, mixing and melting into an emulsifier water solution, adding the emulsifier water solution into a gel mill, adding 75-85% of the total asphalt into the gel mill, emulsifying about 1-2 minutes to produce emulsion, adding the emulsion and the rest asphalt into a hi-speed shearing machine, and shearing 2-3 minutes to produce the emulsified asphalt of high concentration. The tests on the emulsified asphalt of high concentration and the diluted emulsified asphalt according to the Experimental Rules for Asphalt and Asphalt Mixture of Road Engineering issued by the Ministry of Transportation prove that all the indicators meet the Implementation Manual for the Technical Specifications for Asphalt Pavement Construction of Roads issued by the Ministry of Transportation. The invention can be spread and used in the building of asphalt road and maintenance of asphalt pavement.

Owner:徐培华

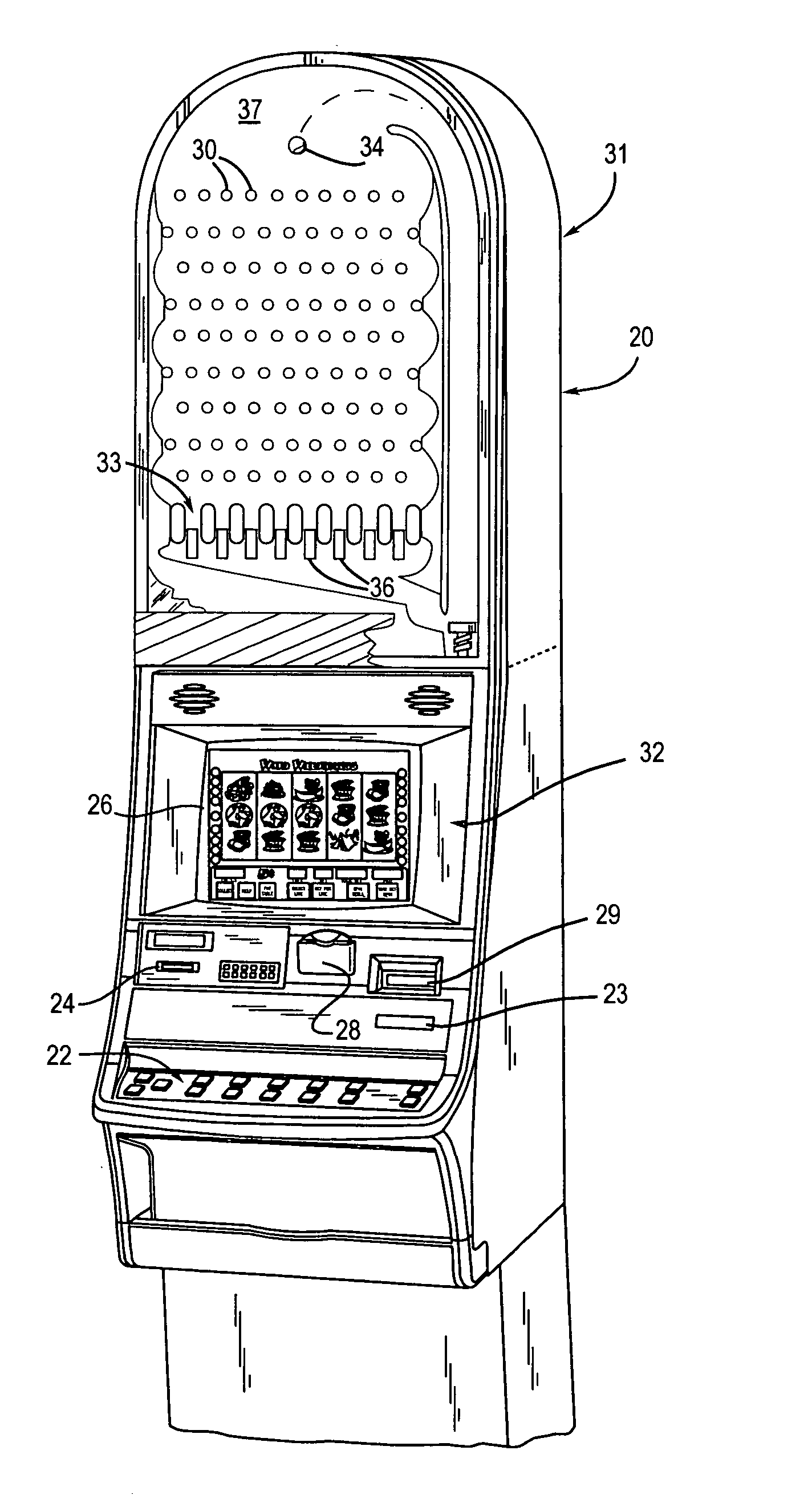

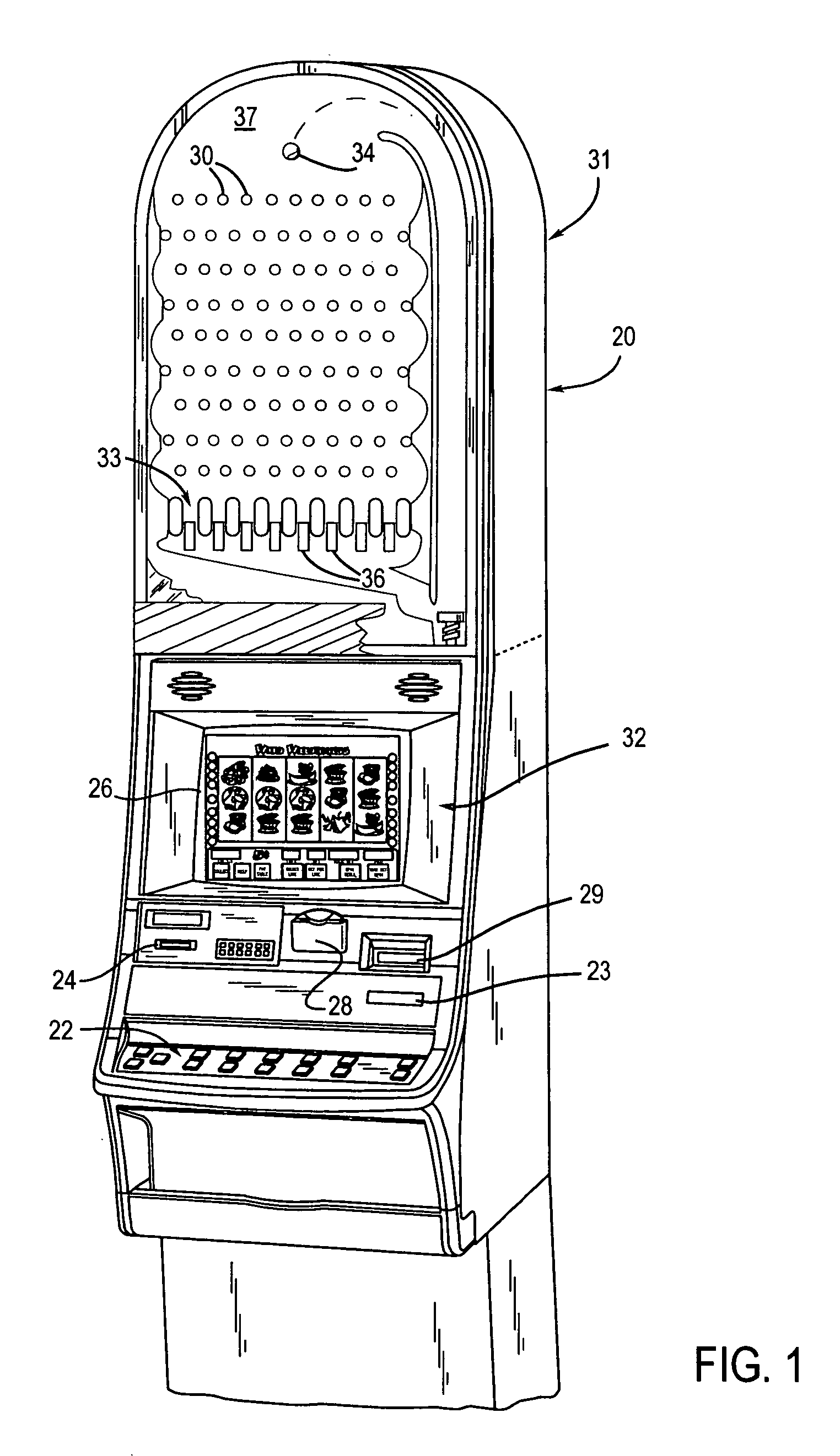

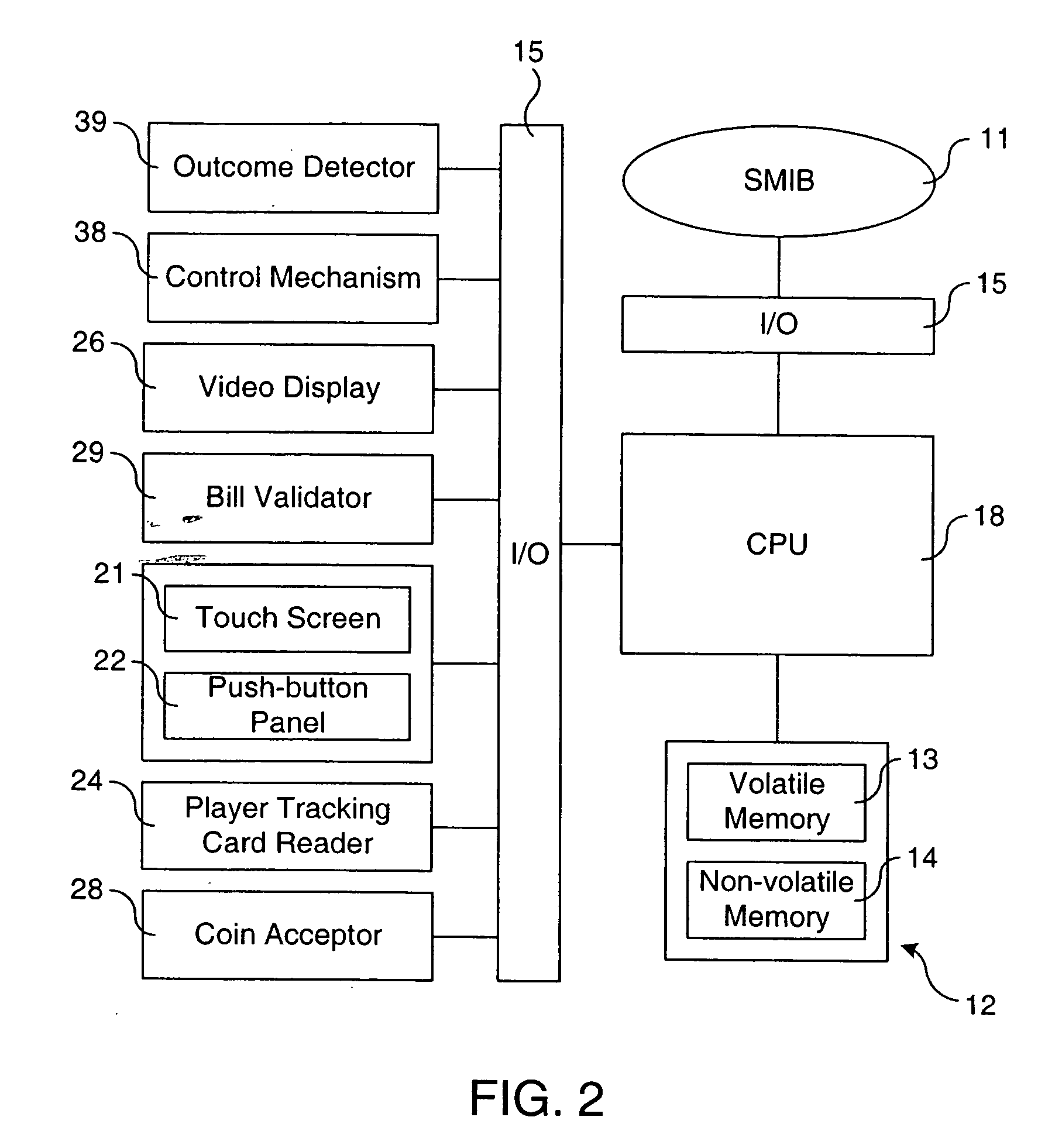

Gaming machine with a feedback control loop to ensure random selections

InactiveUS20050250581A1Eliminate inherent biasCard gamesApparatus for meter-controlled dispensingTechnical specificationsEngineering

The invention relates generally to wagering games and, more particularly, to a gaming machine which determines game outcomes with a mechanical selector mechanism. Wagering games with game outcomes produced by a mechanical mechanism have not been widely accepted. Mechanical gaming machines are susceptible to bias from both inherent manufacturing defects and wear related degradation. Because gaming machines must meet regulatory required payback percentages, deviation from random operation may jeopardize the gaming machine's license. To overcome bias that may cause operation of the gaming machine outside its regulatory approved technical specifications, a feedback control loop can be implemented in the gaming machine to detect and correct bias as it occurs.

Owner:BALLY GAMING INC

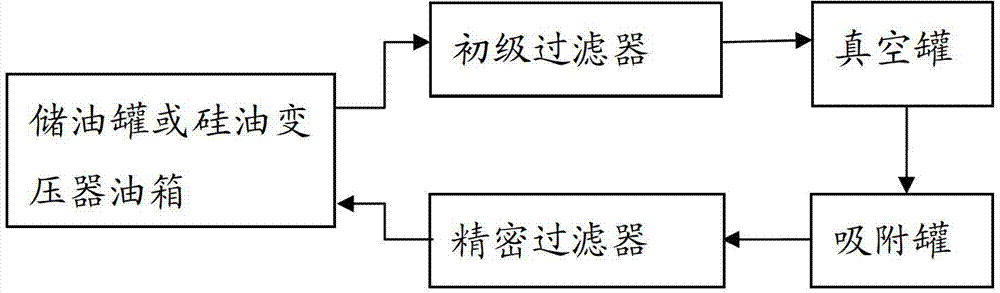

Transformer oil and preparation method thereof

The invention provides synthetic transformer oil and a preparation method thereof. Dimethyl silicone oil is used as base oil, the purity of the dimethyl silicone oil is improved by post-treatment processes such as molecular distillation, precision filtration and adsorption, and the physical, chemical and electrical properties of the dimethyl silicone oil are improved, so that the dimethyl silicone oil can meet the requirements of international standards on the technical specifications of the silicone oil transformer oil.

Owner:CHINA PETROLEUM & CHEM CORP

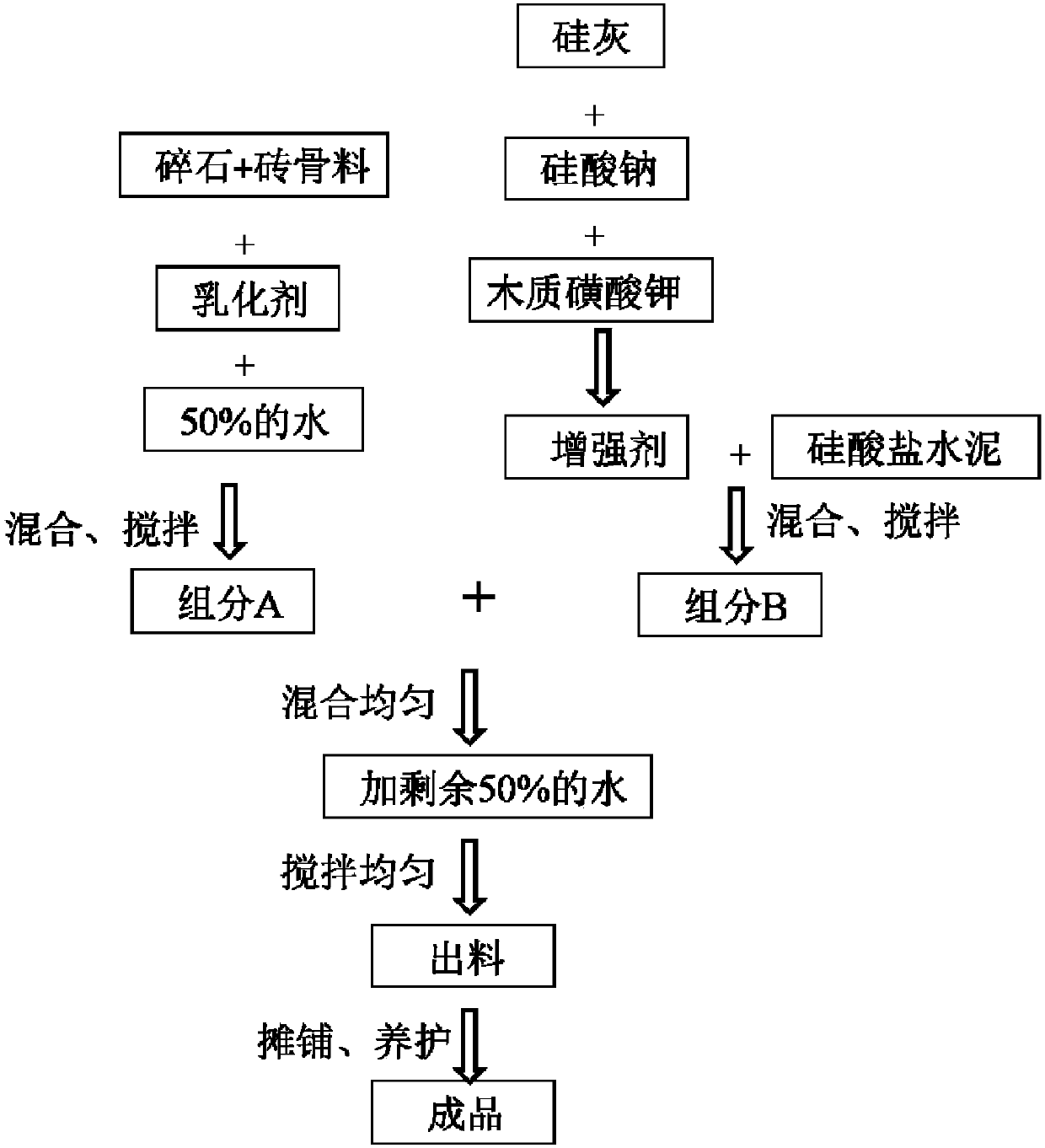

Concrete with high strength and high permeable rate and preparation method of concrete

ActiveCN107673699AHigh compressive strengthGood water permeabilityCeramicwareBrickTechnical specifications

The invention discloses concrete with high strength and high permeable rate and a preparation method of the concrete. The concrete is prepared by mixing gravels with brick aggregate, and taking a mixture as coarse aggregate; mixing silica fume, potassium lignosulfonate and sodium silicate, taking a mixture as a fortifier and then adding cement, an emulsifier and water. The permeation coefficient of the concrete obtained by the preparation method disclosed by the invention reaches 0.82 mm / s, so the concrete belongs to an efficient permeable pavement material with superior permeability; in addition, the compressive strength reaches 35.6MPa which is in line with standards of GJJ / T135-2009 Technical Specification of Permeable Cement Concrete Pavement; an internal exposure index (IRa) is 0.10,an external exposure index (Ir) is 0.17; besides, the concrete is in line with A type decoration materials.

Owner:安徽诺威新型建材有限公司

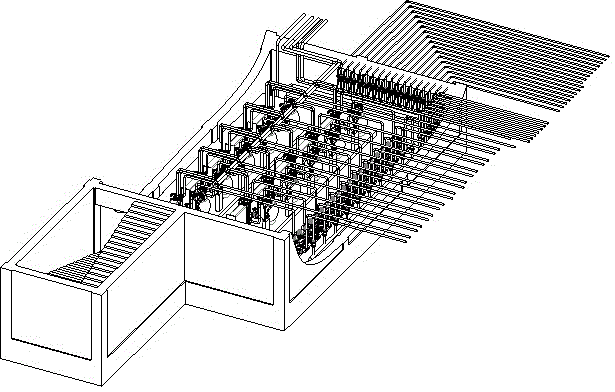

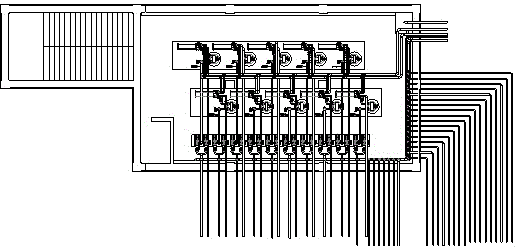

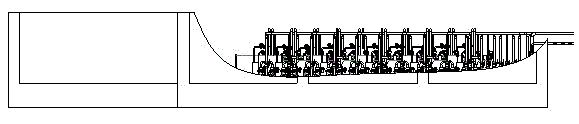

Integrated pipeline distribution modeling method of pipeline

ActiveCN105260491AImprove construction periodQuality improvementSpecial data processing applicationsTechnical specificationsSelf-Examination

The invention discloses an integrated pipeline distribution modeling method of a pipeline. The integrated pipeline distribution modeling method uses SolidWorks mechanical design software and is characterized by comprising the following steps: a) collating an electronic edition construction drawing; b) carrying out unified labeling and basic modeling; c) when the professional drawing is revised and optimized by each specialty, making pipeline schematic movement directions and dimensions in an original drawing clear; d) after each electromechanical installation specialty revises the drawing, carrying out self-examination on a finished first draft from the aspects of the requirements of a professional technical specification, a design idea, an executing unit and a supervisor; e) before an integrated plane graph is drawn, determining an elevation and a plane position; and f) checking the dimensions of the girders, the plates and the columns of each professional electromechanical installation drawing and architectural structure drawing. The integrated pipeline distribution modeling method has the advantages that large pipelines which occupy top space and include ventilation air conditioner air hoses, air conditioner water pipes and the like in a building can be reasonably distributed, the requirements of aspects including construction periods, quality, cost, impressions and the like are improved, and various requirements of interested parties including the executing unit, the supervisor, design parties and the like can be reasonably coordinated and met to a largest extent.

Owner:MCC5 GROUP CORP SHANGHAI

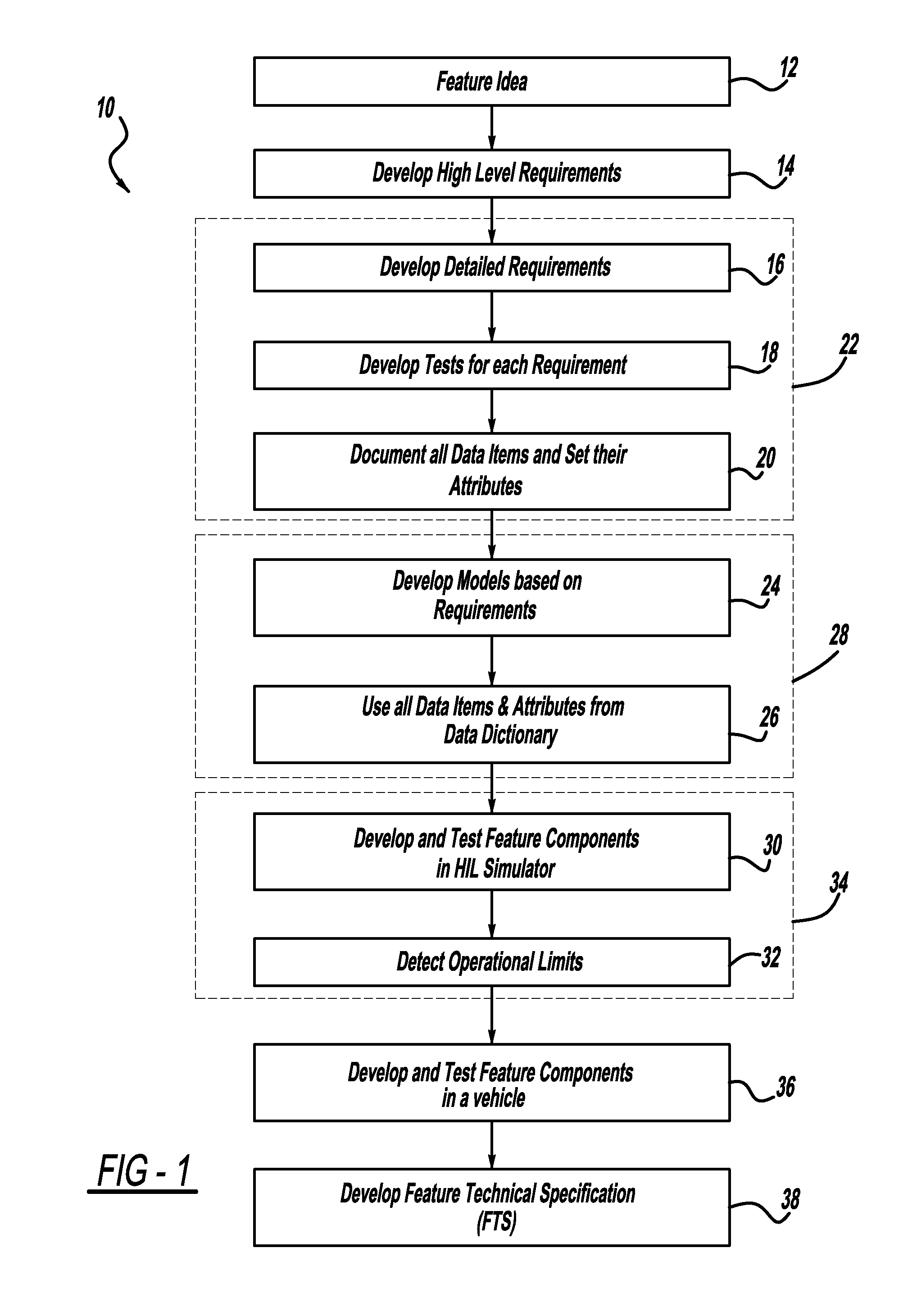

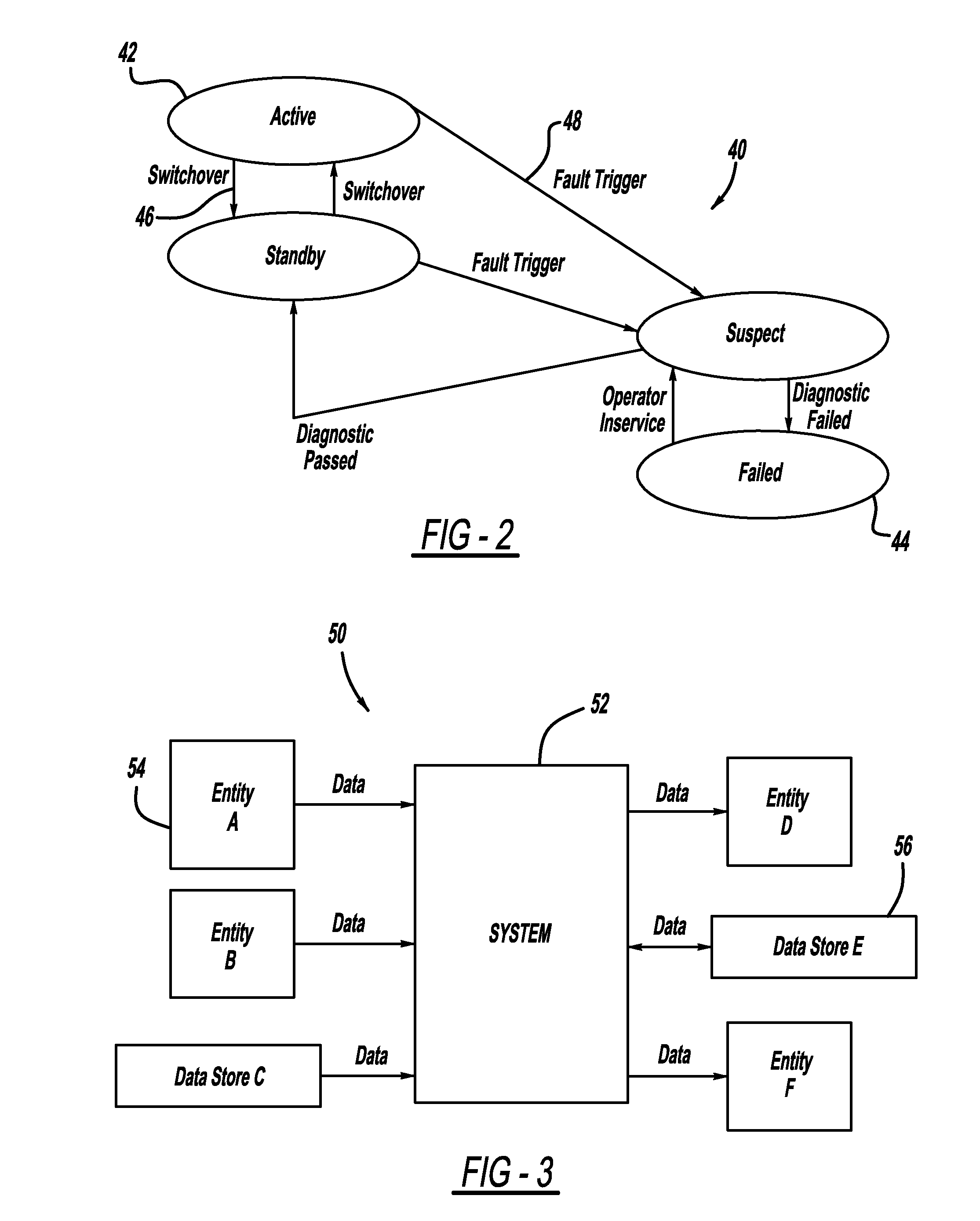

Requirements driven feature development process

InactiveUS8433550B2Geometric CADComputation using non-denominational number representationSoftware development processDocumentation procedure

Owner:GM GLOBAL TECH OPERATIONS LLC

Nitrided silicon-manganese-iron alloy

The invention relates to a silicon nitride ferromanganese alloy used for steel-making alloying that is made up from Mn 30-80%, Si 10-60%, N 8-35%, the rest is iron and ineluctable impurity. The alloy could take place of ferroniobium, ferrovanadium to take steel-making micro-alloying to enhance the strength of the steel material. The invention could ensure the steel material meet the request of technical specification.

Owner:CHANGZHOU MAOSHENGTE ALLOY PROD

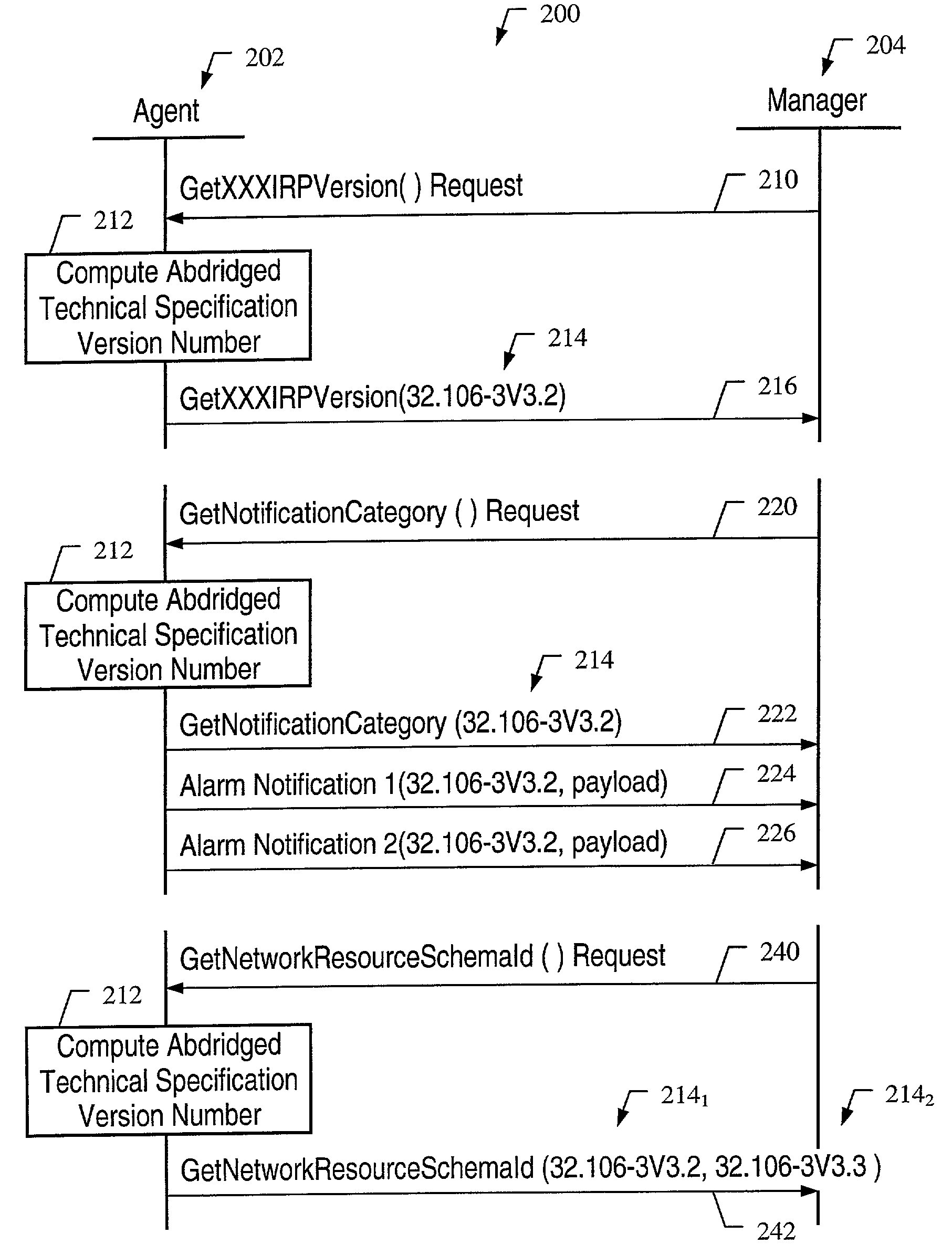

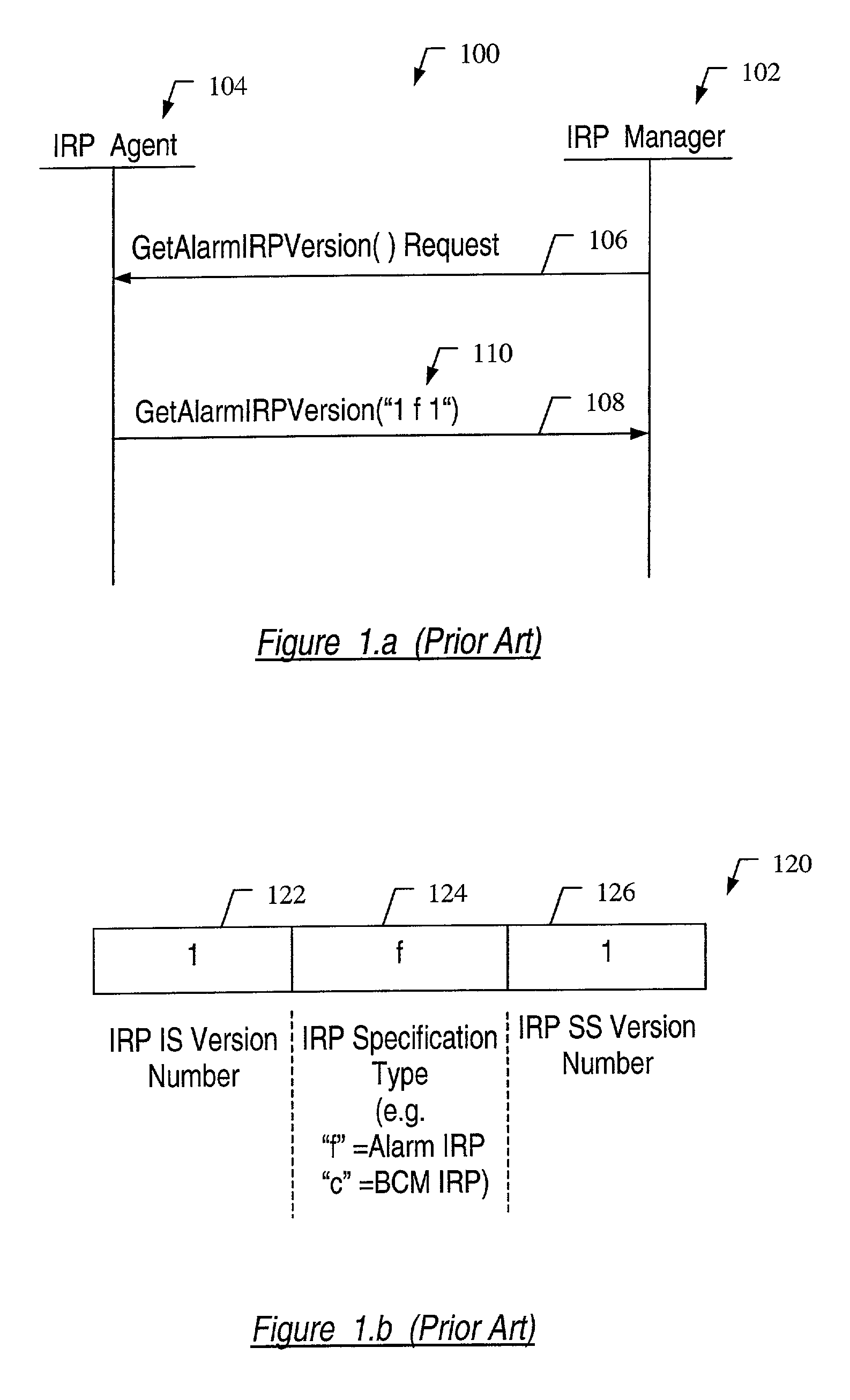

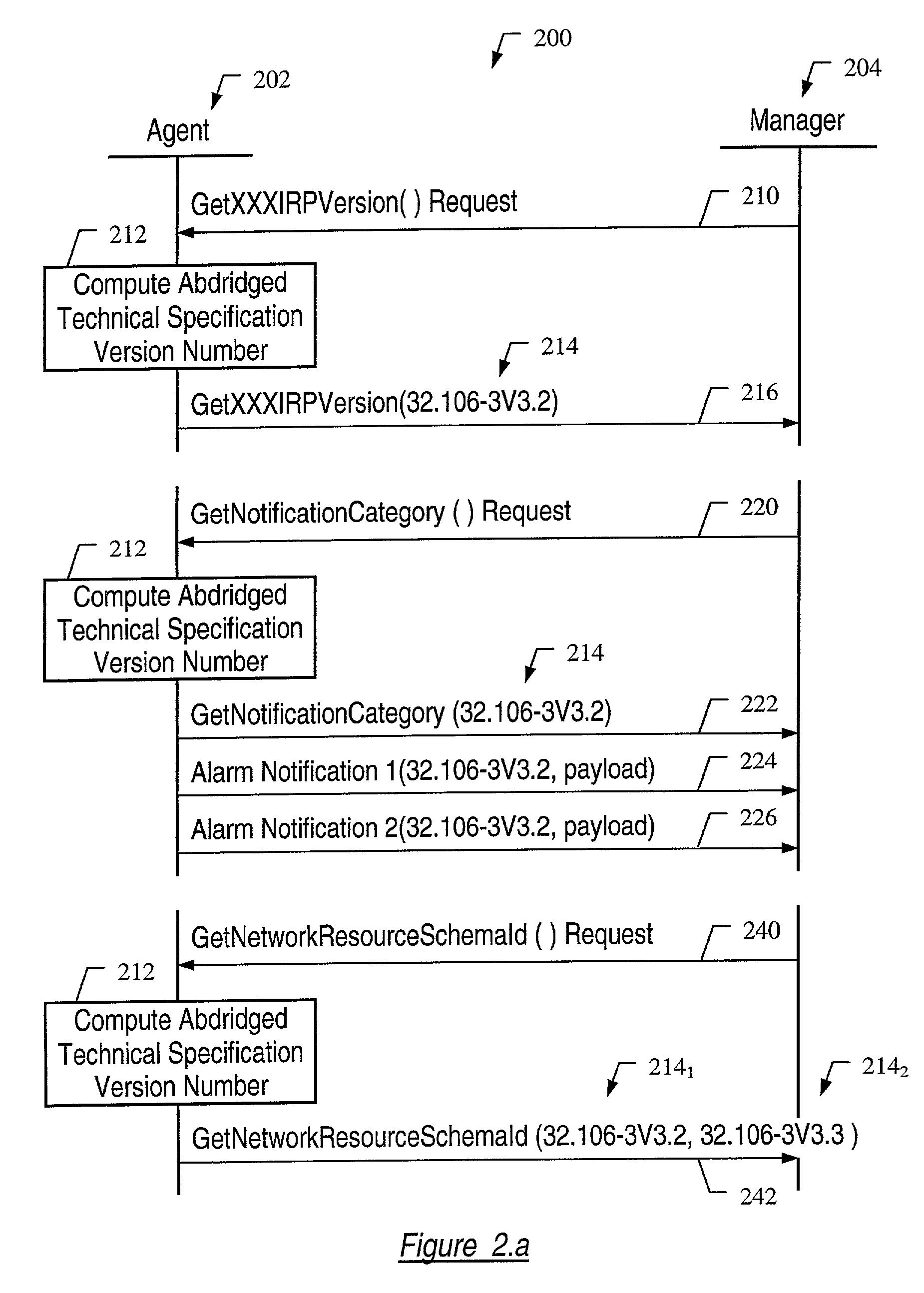

Method, system and agent for third generation partnership project (3GPP) technical specification (TS) document number exchange

A method, system and agent for exchanging the Third Generation Partnership Project (3GPP) Technical Specification document number a first node uses, with a second node of the network, so that subsequent communications can be properly carried between the nodes. The first node may be an agent and the second node may be a manager of a management system. The manager sends a GetXXXIRPVersion request message, a GetNotificationCategories request message, or a GetNetworkResourceSchemeId request message, to which the agent responds with an abridged version of the 3GPP TS document number the agent uses in this type of communications, so that the manager is informed of the protocol employed by the agent and can expect communications of the type indicated by the agent.

Owner:TELEFON AB LM ERICSSON (PUBL)

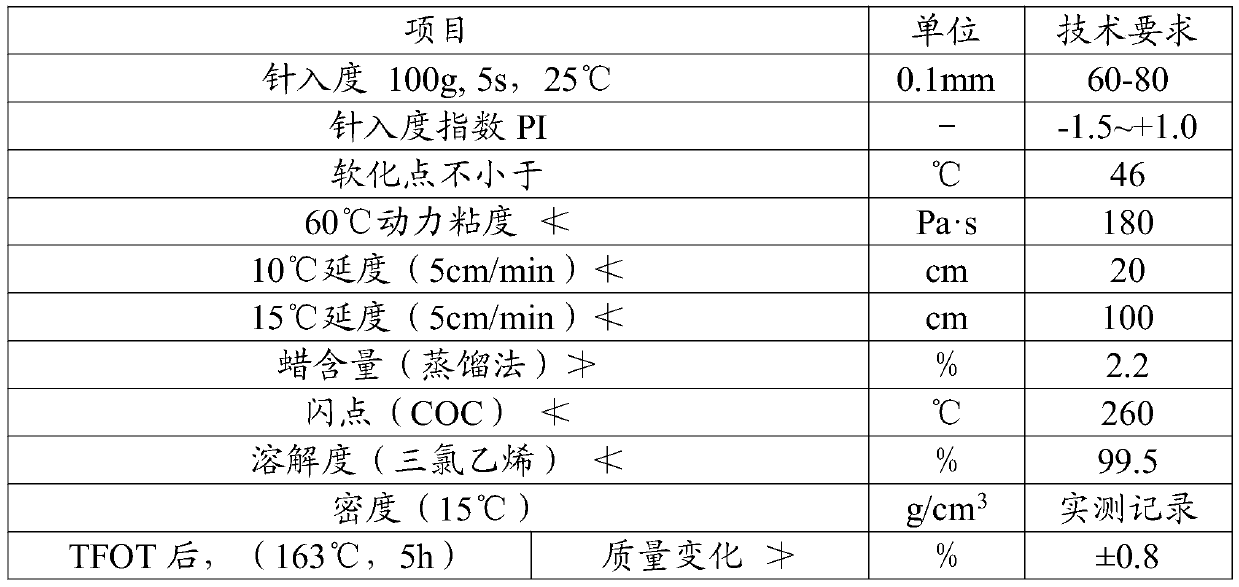

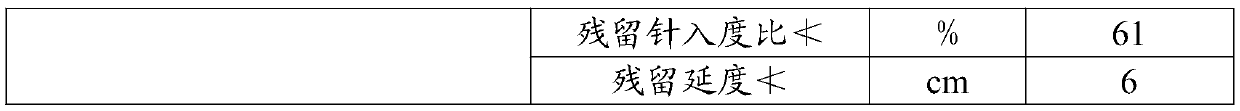

#110 road petroleum asphalt and preparation method thereof

InactiveCN110484009ASolve the costSolve the problem that some indicators are not up to standardBuilding insulationsWaxTechnical specifications

The invention relates to the field of petrochemical engineering, in particular to #110 road petroleum asphalt and a preparation method thereof. The #110 road petroleum asphalt comprises the followingcomponents in parts by weight: 100 parts of #70 road petroleum asphalt; 1-12 parts of vacuum third-line wax oil; and 0.2 to 1 part of polyphosphoric acid. The #110 road petroleum asphalt meeting the index requirements is obtained by taking the #70 road petroleum asphalt as a main raw material and adding a proper amount of the vacuum third-line wax oil and the polyphosphoric acid as additives, andthe problems of high costs and substandard partial indexes in straight-run production of a small amount of #110 road petroleum asphalt are solved. Experimental results show that the #110 road petroleum asphalt provided by the invention meets the technical index requirements of #110 road petroleum asphalt in Technical Specifications for Construction of Highway Asphalt Pavements JTG F04-2004 of Ministry of Communications, and the key technical indexes are superior to those of straight-run #110 road petroleum asphalt.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

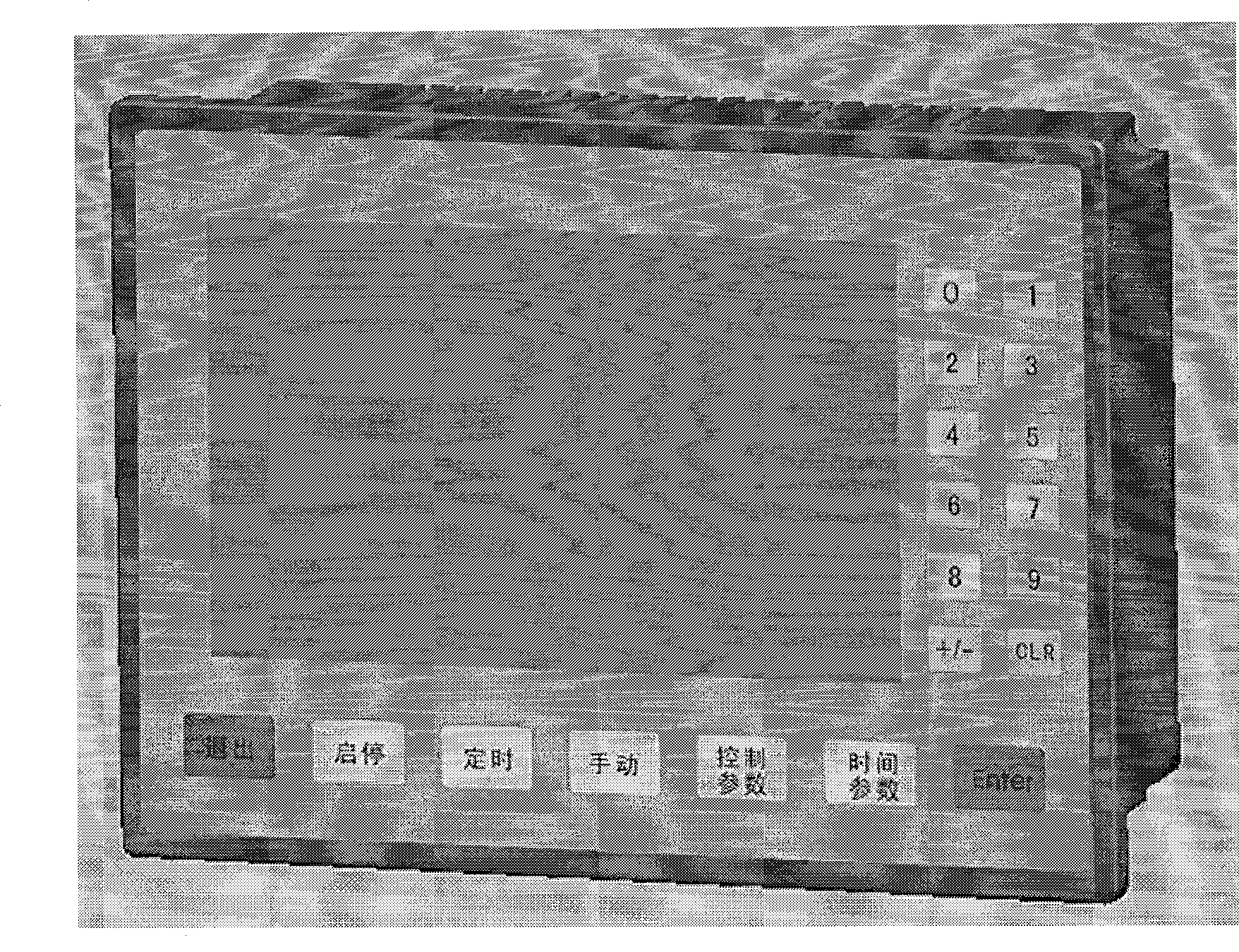

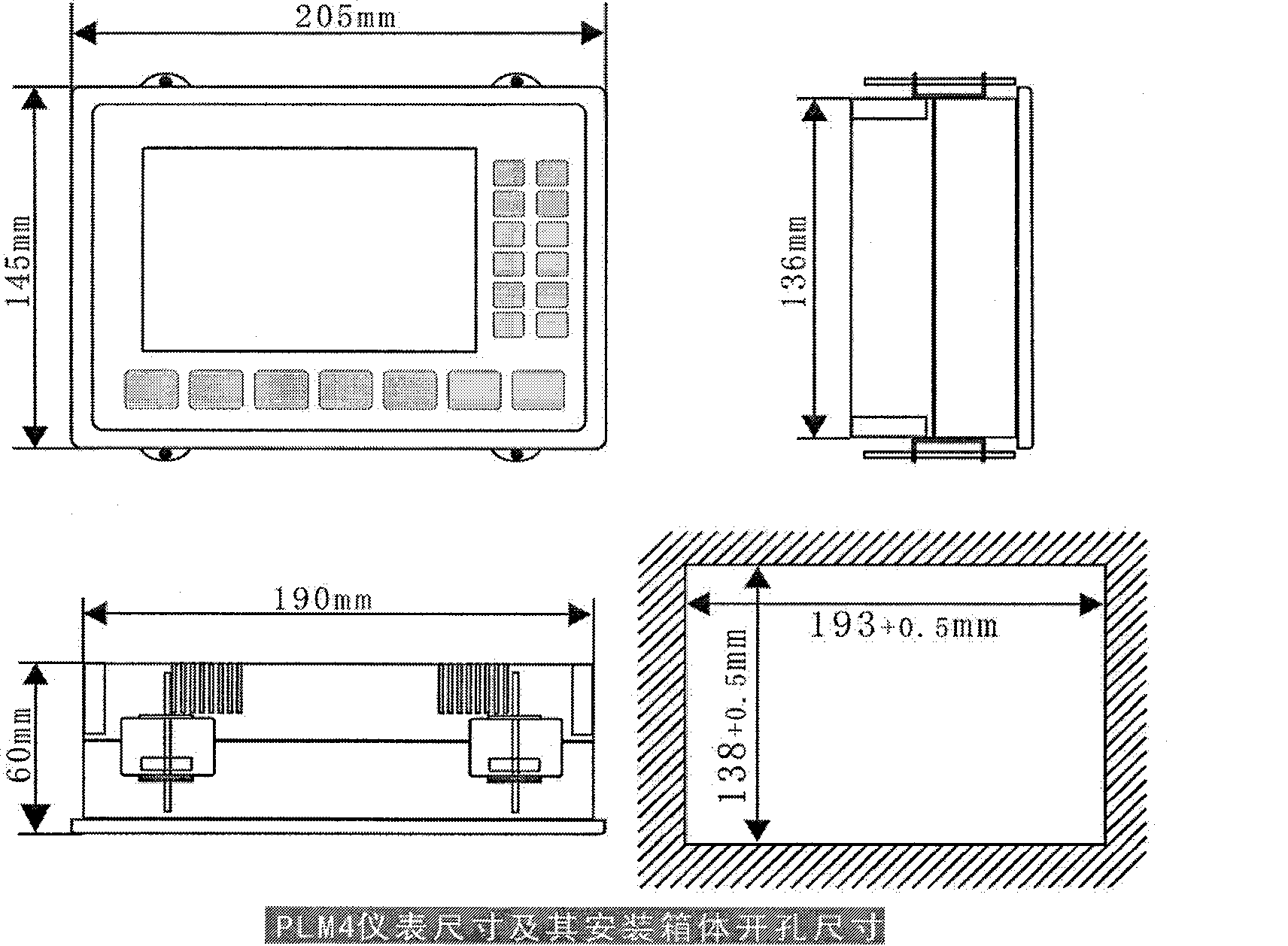

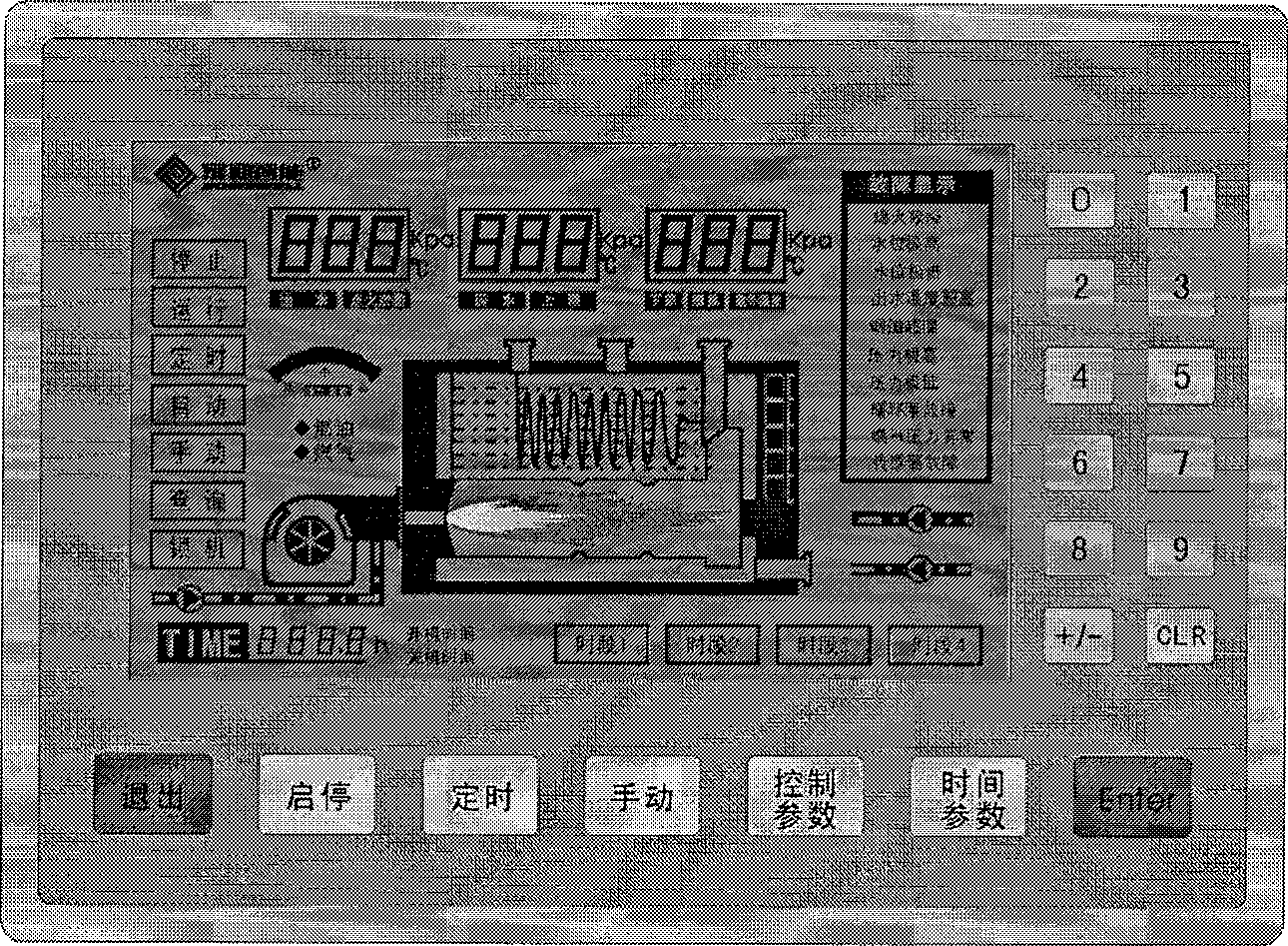

Intelligent control instrument of boiler

InactiveCN101470419AEasy to replaceAvoid getting out of controlFluid heatersElectric testing/monitoringCore productTechnical specifications

A PLM fourth-generation intelligent boiler control instrument (PLM4 intelligent boiler control instrument) resolves the problem that the intelligent boiler control products with non-standard design are incapable of realizing mass production for industrial boiler intelligent controllers. In addition, with years of experiences in developing and producing intelligent boiler control instruments, by standardizing thousands of common solutions for boiler intelligent control, and based on control characteristics of various industrial boilers below 25T / H and intelligent control technical specifications of the industrial boilers, a novel standardized industrial boiler intelligent control core product adaptable to mass production is developed by our company, which simplifies and popularizes complicated production of industrial boiler intelligent control products. Any boiler controller manufacturer utilizing the PLM fourth-generation intelligent boiler control instrument as the industrial boiler intelligent control core can avoid the completed development of intelligent control products, can conveniently produce industrial boiler intelligent control cabinets, and greatly reduces cost and increases reliability of the products through mass and automatic production.

Owner:HANGZHOU HOMEWELL INTELLIGENCE CONTROL

Cotton bamboo fiber blending broad width woven fabric and production method thereof

ActiveCN106939464AHigh surface glossRetain AntibacterialLiquid/gas/vapor open-width material treatmentTextile storage in superimposed formFiberTechnical specifications

The invention discloses a cotton bamboo fiber blending broad width woven fabric and a production method thereof. The production technical flow process sequentially comprises the steps of blank cloth turning and stitching, singeing, amylase desizing, boiling-off, oxygen bleaching, pre-tentering, half mercerizing, dyeing, tentering, formaldehyde-free anti-shrinkage sorting, pre-shrinking, calendering and the like. The cotton bamboo fiber blending broad width woven fabric has the advantages that the surface glossiness is high; the warp and weft water washing dimension change rate is -3.0 percent to +1.0 percent; the fastness to soaping is greater than or equal to 4 stage; the fracture strength is greater than or equal to 280 N. The production method of a product has the advantages that the operation is easy; the environment-friendly effect is achieved; the product safety can reach requirements of GB18401 National Textile Product Basic Safety Technical Specification class A: baby and infant products.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Intelligent networked fitness equipment

The invention provides intelligent networked fitness equipment. Various sensors are applied, and interaction between a user of the fitness equipment and a large-scale data center network can be realized; technical specifications are improved, reasonable exercising plan is made by combining personal corporeity, and the purposes of enhancing corporeity and shaping healthily can be achieved.

Owner:丁兴民

Method for repairing an oil or gas pipeline

InactiveUS20050065660A1Low costShorten the timeSampled-variable control systemsPipe elementsTechnical specificationsQuality assurance

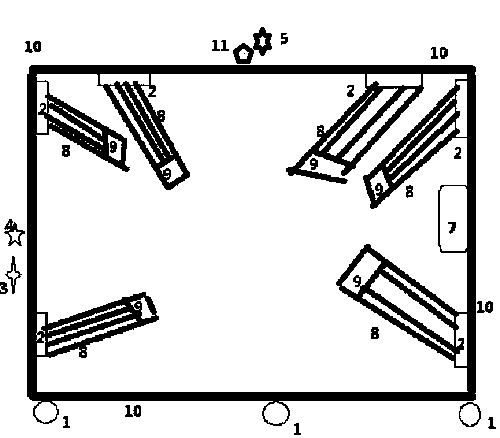

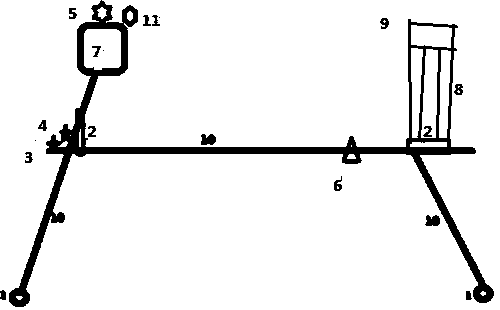

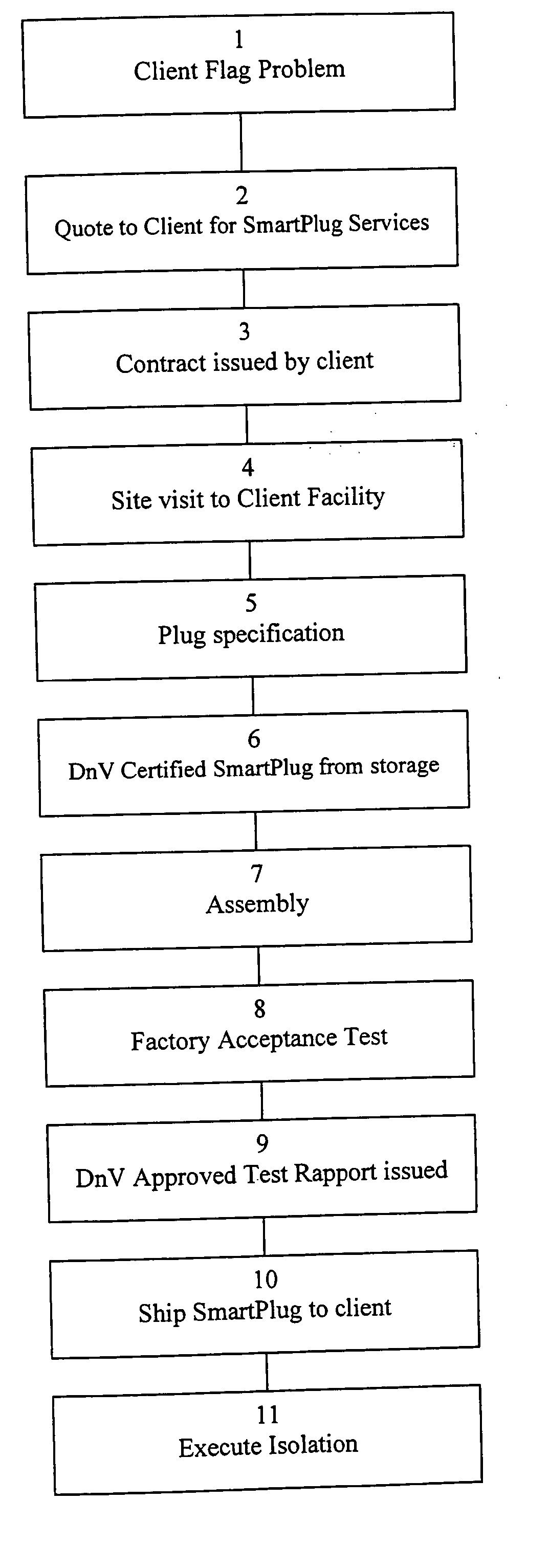

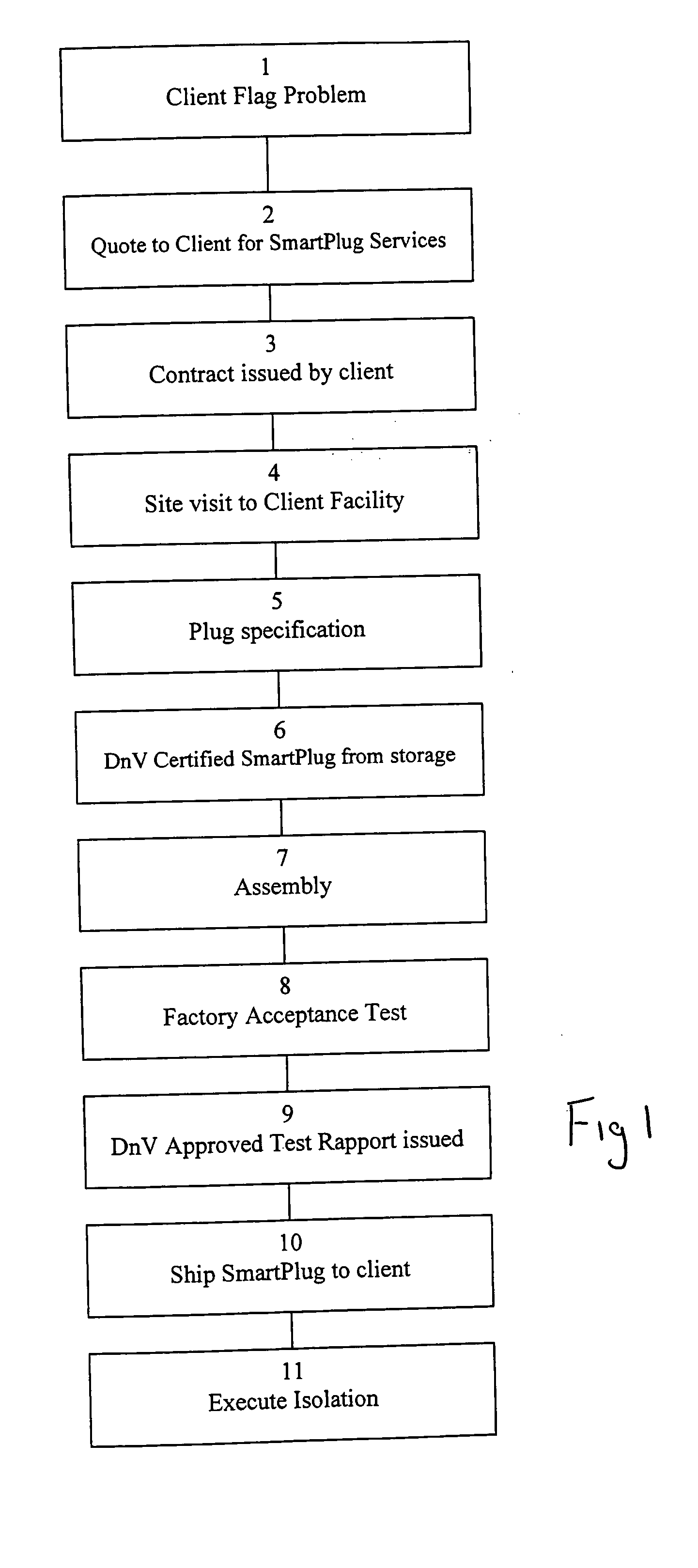

A method for repairing an oil or gas pipeline without disclosing sensitive technical information to the customer, comprising the steps of providing pre-certified plugs of standard sizes that are pre-manufactured and stored in a storage facility. When a request for a repair operation is received, a plan for executing a repair is formulated and executed by representatives of the plug manufacturer using the pre-manufactured plugs. In order to satisfy the customer's concerns for safety and effectiveness, the technical details of the plan, as well as the actual devices to be utilized in the repair, are examined and certified by an independent Quality Assurance body. However, neither the technical details of the repair plan, nor the technical specifications of the plugs themselves, are transmitted to the customer.

Owner:TDW OFF SHORE SERVICE CO LTD

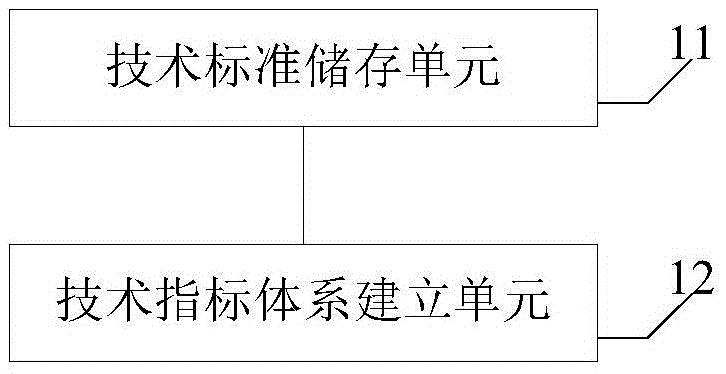

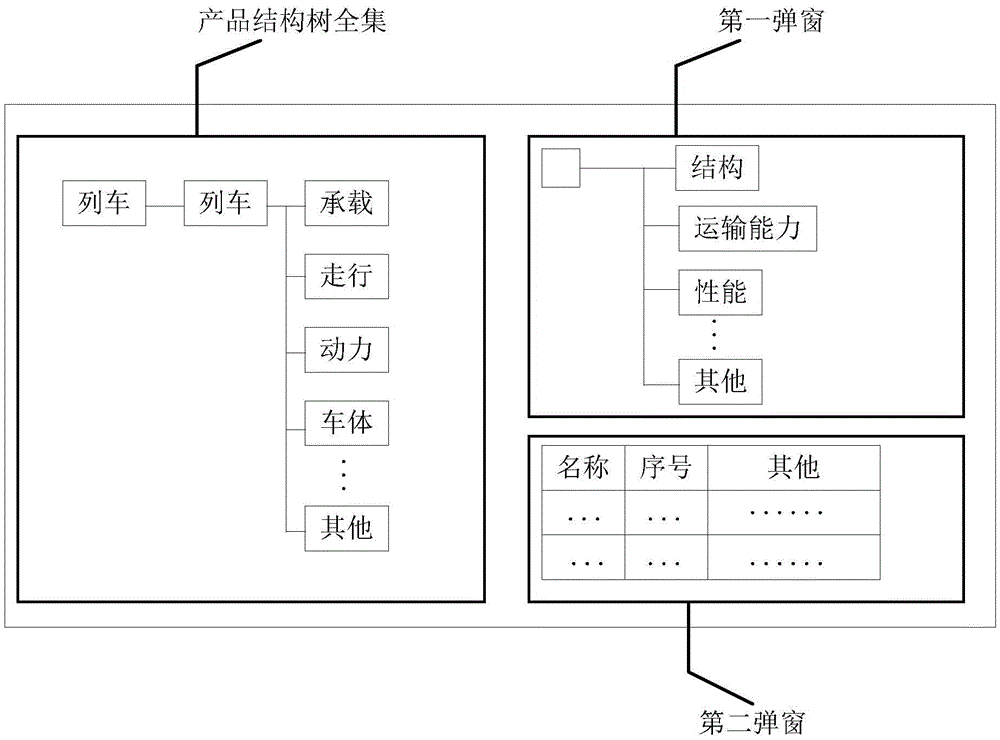

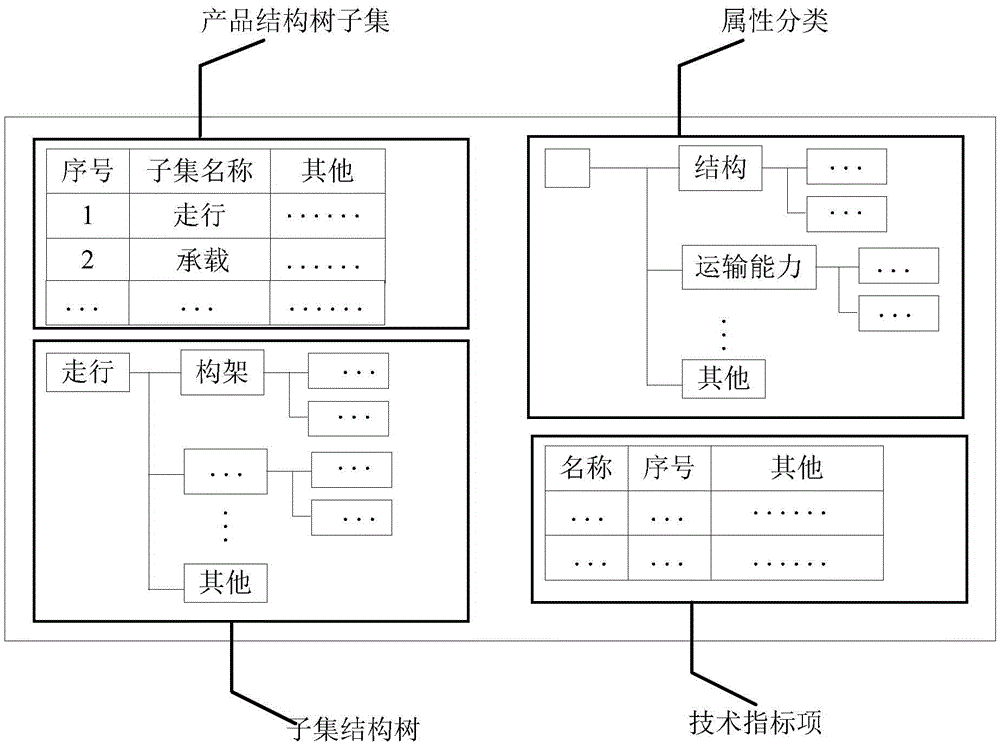

Design method and system for high-speed train technical specification system

InactiveCN105468813AEasy accessAccurately obtainedGeometric CADSpecial data processing applicationsTechnical specificationsTechnical standard

The present invention provides a design method and system for a high-speed train technical specification system. The system comprises: a standard storage unit, which is used for providing a user with a technical standard information input interface, receiving technical standard information input by the user, and storing the technical standard information into a database; and a technical specification system establishing unit, which is used for displaying a product structure tree to the user in a way of a layered structure, and, according to technical standard information selected by the user in accordance with a node of the product structure tree, associating technical specifications on each layer according to the layered structure to establish a technical specification system. The method and system provide a fast and convenient design platform for designers, and help designers to fast query technical standards and design the technical specification system layer by layer, according to the layered structure, in the system.

Owner:CRRC QINGDAO SIFANG CO LTD +1

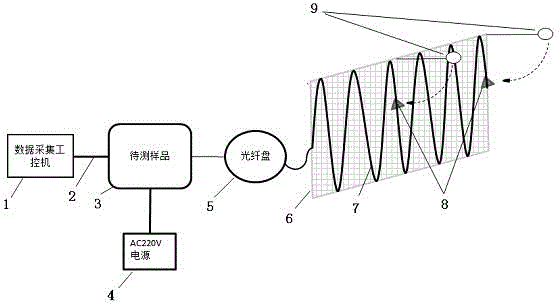

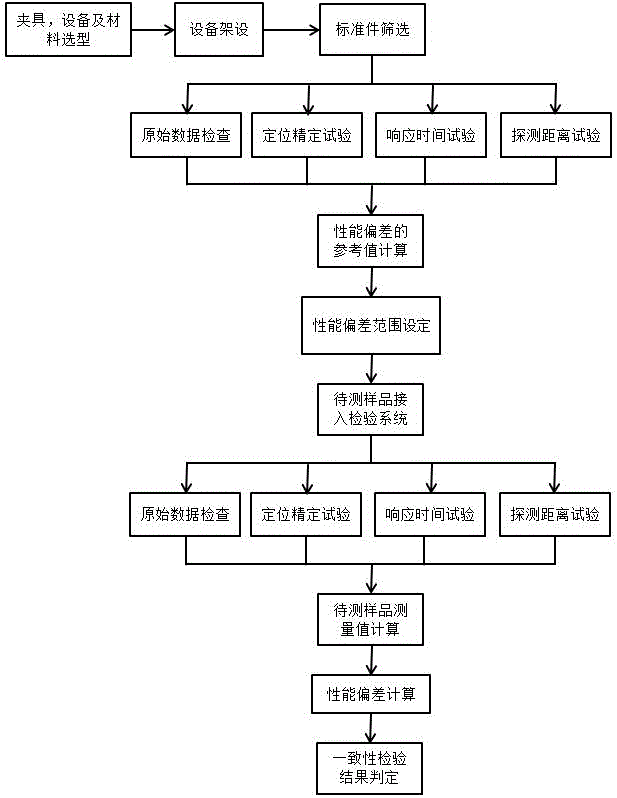

Optical fiber sensing system consistency test method

ActiveCN104596563AMeet specification requirementsMeet the standardsInstrumentsConsistency testTechnical specifications

Owner:BANDWEAVER TECH CO LTD

Automatic correction of application based on runtime behavior

InactiveUS20140289563A1Precise applicationSoftware maintainance/managementSoftware testing/debuggingData streamTechnical specifications

A method and associated system for automatically correcting an application based on runtime behavior of the application. An incident indicates a performance of the application in which a problem object produces an outcome that had not been expected by a user or by a ticketing tool. An incident flow for the problem object is automatically analyzed. Actual run of the application renders a forward data flow and at least one backward data flow is simulated from an expected outcome of the problem object. The forward data flow and the backward data flow(s) are compared to create a candidate fault list for the problem object. A technical specification to correct the candidate fault list and a solution to replace the application are subsequently devised.

Owner:IBM CORP

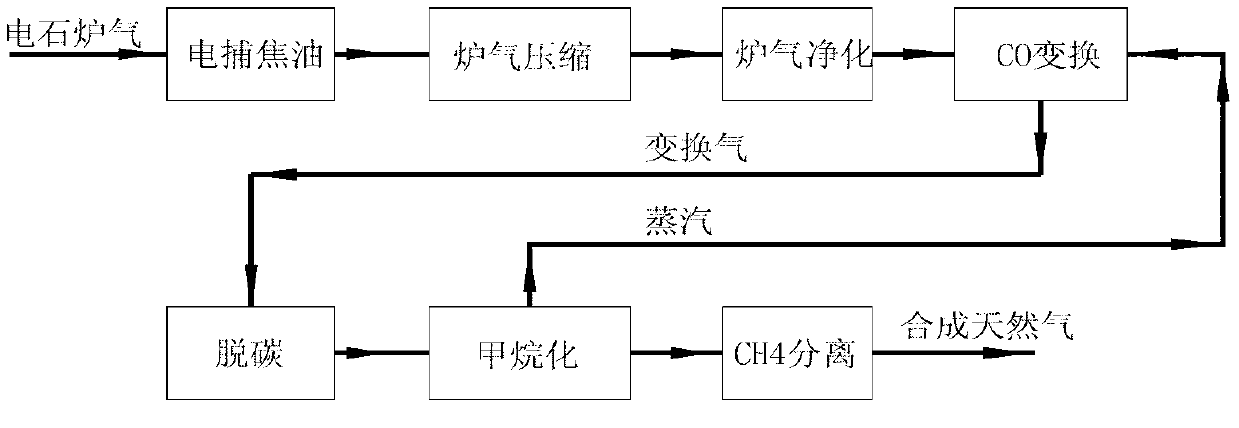

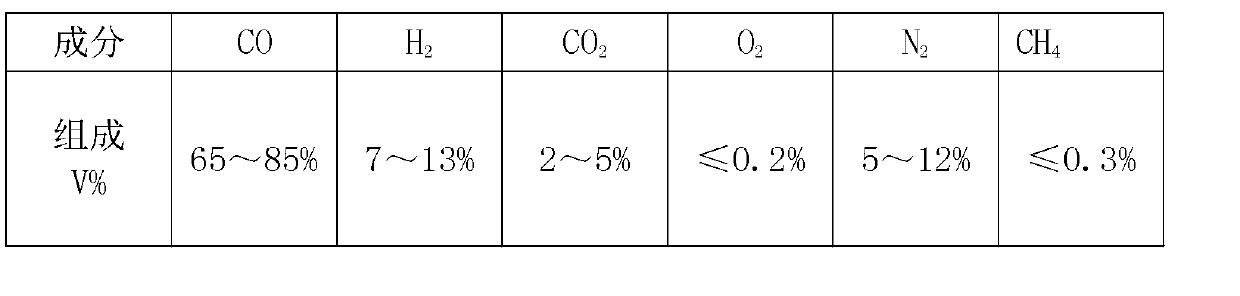

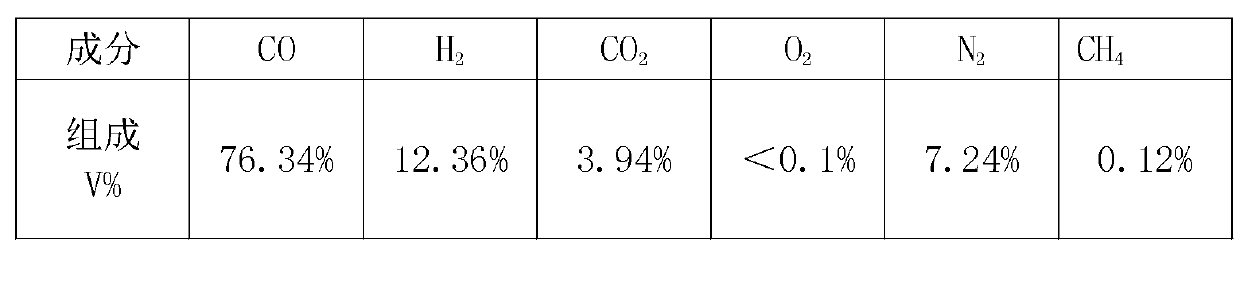

Process for synthesizing natural gas employing methanation of calcium carbide furnace gas

InactiveCN103343025AReduce energy consumptionReasonable process designGaseous fuelsElectricityTechnical specifications

The invention provides a process for synthesizing natural gas employing methanation of calcium carbide furnace gas, and belongs to the technical field of new energy utilization. Specifically, the calcium carbide furnace gas coming from an upstream gas holder is subjected to steps of electrically precipitating tar, boosting by a compressor, purifying, CO transforming, decarburization, entering into one or more methanation reactors and separating natural gas, and thus the natural gas, which is accord with the standard of technical specification (first class) in natural gas GB (GB17820-2012), is prepared. The objective of high-efficiency integrative utilization of the calcium carbide furnace gas is realized, and the method is a new approach for producing natural gas.

Owner:EAST CHINA ENG SCI & TECH

Finishing agent for restoring pH value of fabrics as well as preparation method and application thereof

InactiveCN101781844AQuality is not affectedEase of industrial productionFibre treatmentTechnical specificationsPotassium

The invention discloses a finishing agent for restoring the pH value of fabrics, which comprises the following raw materials in percentage by weight: 0.5-12 percent of potassium hydrogen phthalate, 2-30 percent of potassium chloride, 0.5-8 percent of surfactant and the balance of water. By using the finishing agent, the fabrics with the pH value exceeding 7.5 can be restored to have the pH value in range of 4.0-7.5 through simple padding and drying without influencing other qualities of the fabrics, thereby the requirements on the safety technical specification and export can be met. The invention also discloses a preparation method and application of the finishing agent, and has the advantages of simple operation and suitability for industrial production.

Owner:ZHEJIANG SCI-TECH UNIV

Web front-end code conversion method

ActiveCN113553064AIncreased chance of reusabilityVersatilityBinary to binaryDecompilation/disassemblyTechnical specificationsEngineering

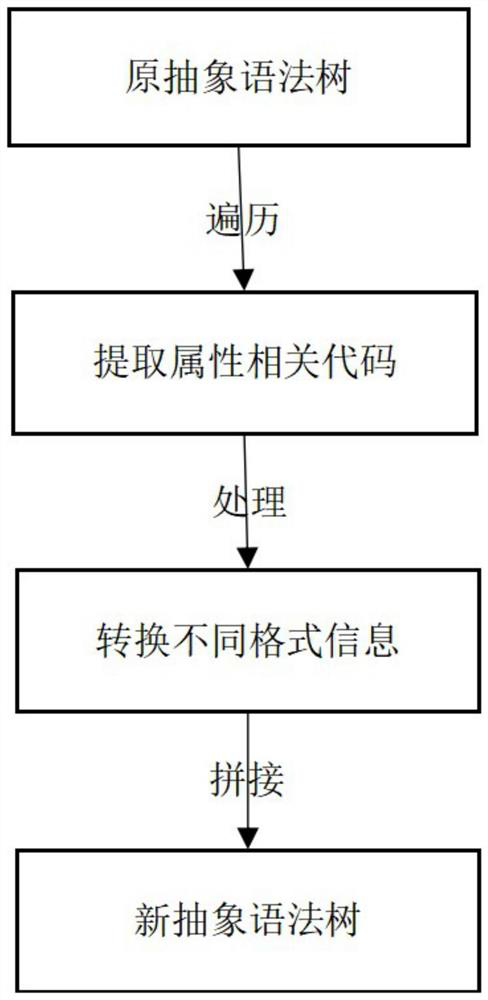

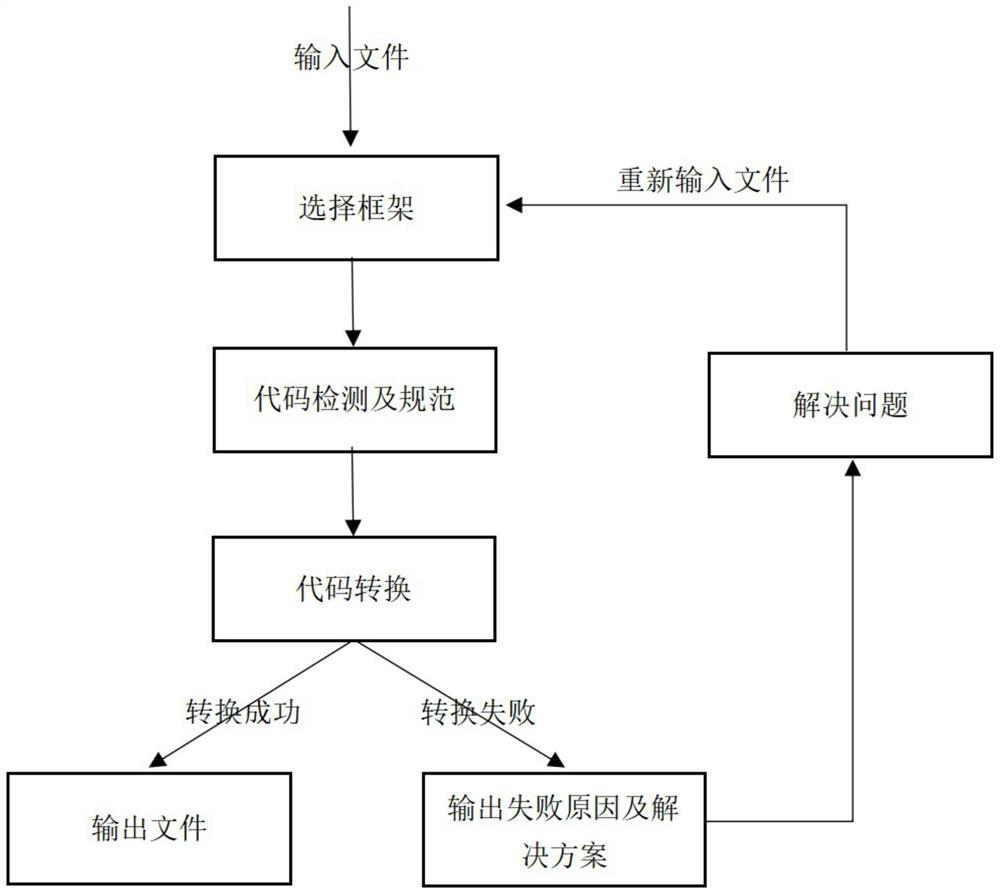

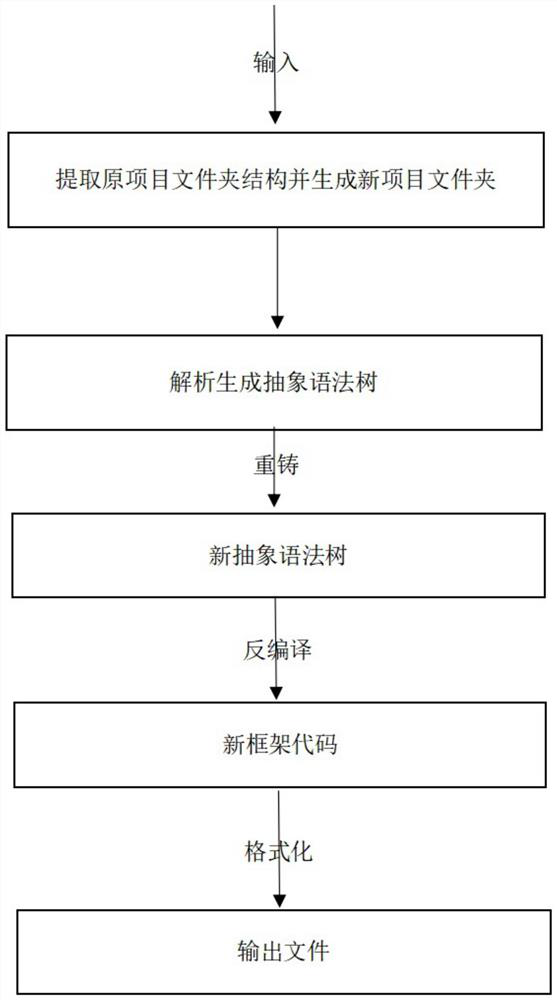

The invention relates to a web front-end code conversion method, and belongs to the technical field of computer networks. According to the method, the new software front-end framework can be quickly reconstructed according to the original software front-end framework, after the front-end file needing to be converted is submitted, the framework needing to be converted is selected from the convertible new frameworks according to the old framework, and the new front-end file can be obtained after conversion succeeds. The method relates to the conversion among various frames, so that the multiplexing probability of the existing system and the existing function is greatly improved; the abnormal record can summarize various conditions that front-end codes are not standard, and reference is provided for front-end technical specifications; a new standard front-end code can be obtained through code conversion, whether an original code is standard or not can be detected, and reference is provided for optimization of the original code.

Owner:BEIJING INST OF COMP TECH & APPL

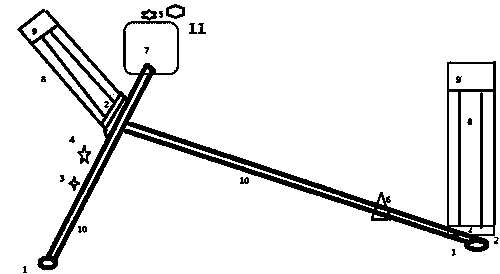

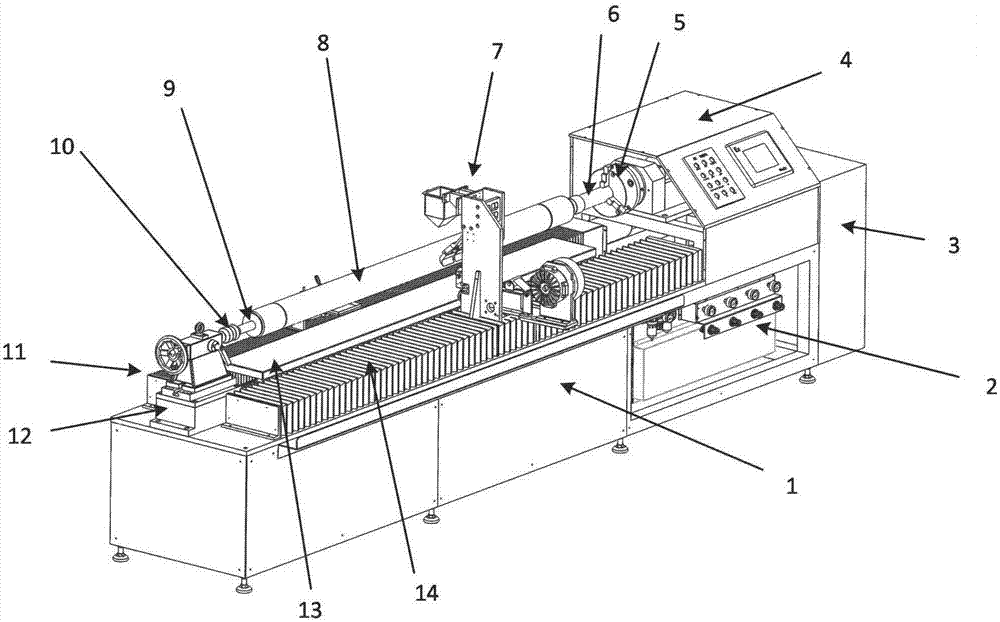

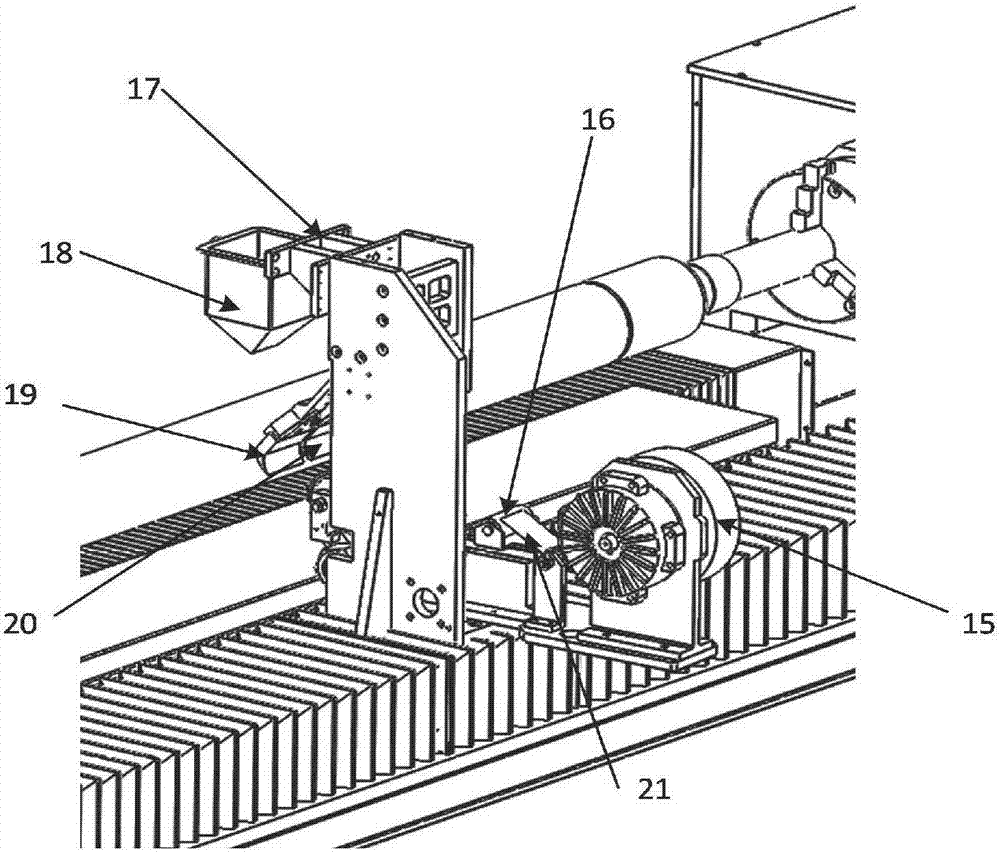

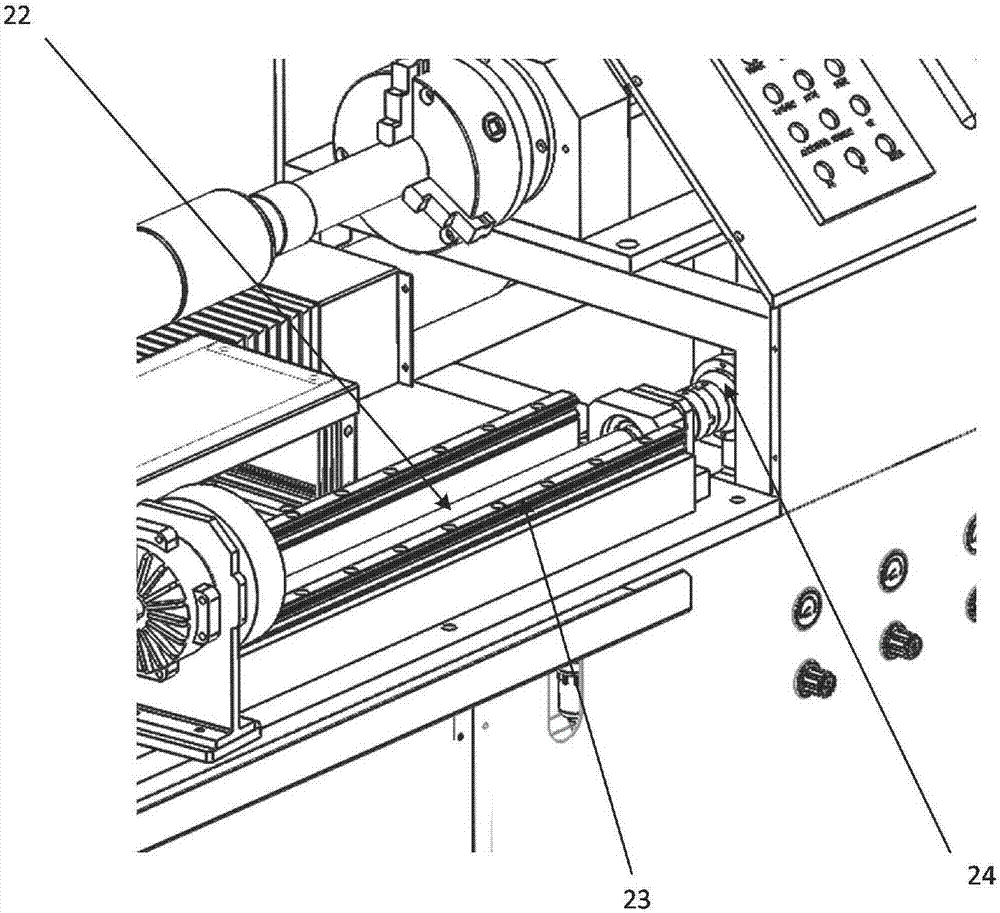

Automatic side face winding and coating device of large slenderness ratio propellant

ActiveCN106986733AReduce the ratioFully automatedExplosive working-up apparatusEngineeringConductor Coil

The invention relates to an automatic side face winding and coating device of large slenderness ratio propellant, and belongs to the field of mechanical electronic automation. In order to solve the problems of massive labor operation, interrupted production, big labor intensity, and low instinct safety level during the side winding and coating processes in the prior art, the invention designs an automatic side face winding and coating device of a horizontal single station; the device is mainly composed of a frame, an anti-explosion power distribution box, a spindle box, an air control system, a three-jaw chuck, a tail bed, an adjusting plate, a winding machine, a glue pushing head, and others. Through theoretical and experimental verification, the device can realize automatic glue coating, winding, tension control, gluing continuity, and automatic operation on the basis of ensuring the safety and product quality. The production process can realize man-machine isolation. After winding and coating, the drug pillar quality can meet the quality index requirement of technical specification, realize the continuity, automation, and man-machine isolation of the side face winding and coating process, improve the production efficiency, instinct safety and product quality.

Owner:CHINA WUZHOU ENG GRP +1

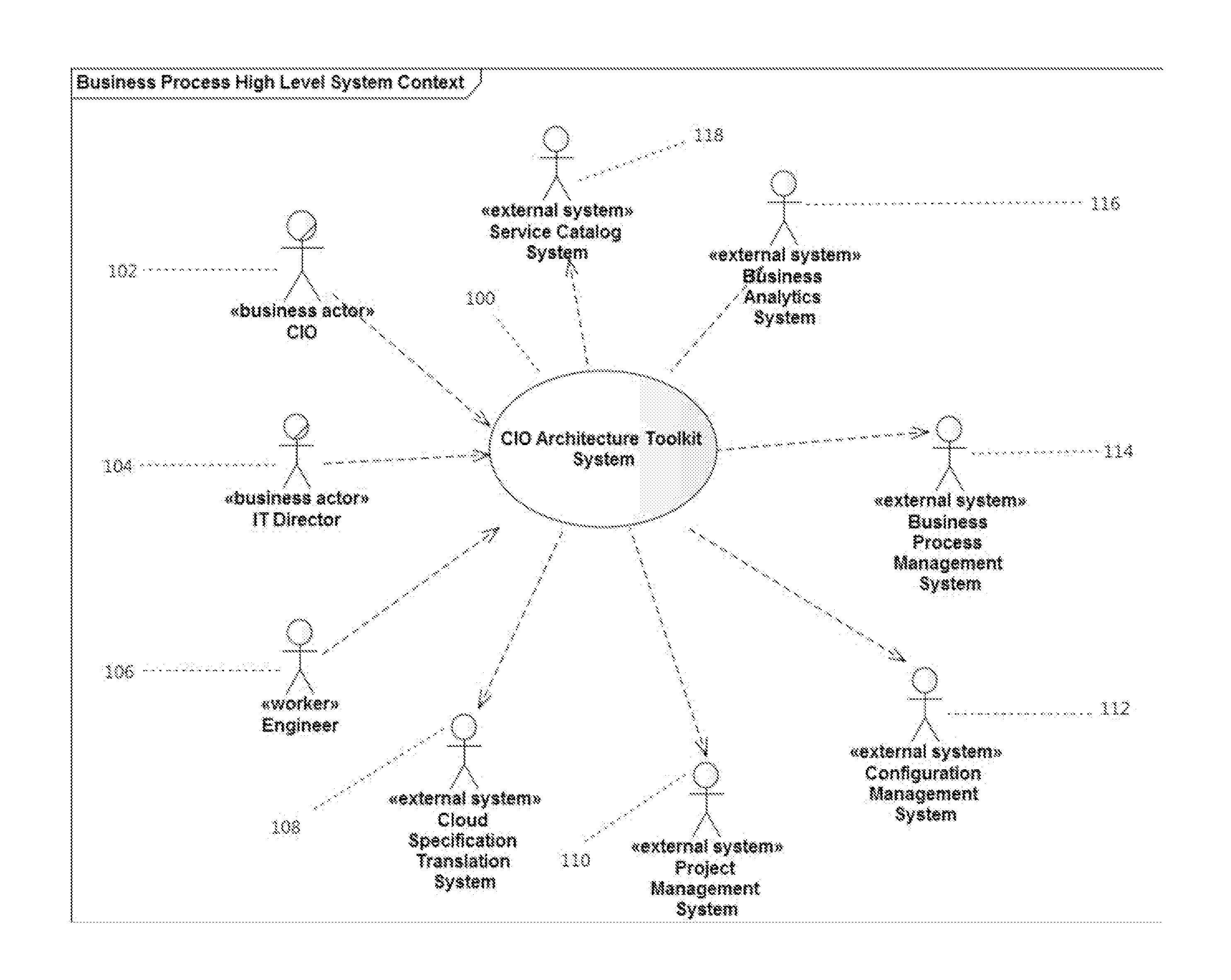

Method of generating a computer architecture representation in a reusable syntax and grammar

InactiveUS20140282363A1Easy to processQuick buildNatural language data processingProgramming languages/paradigmsProgramming languageTechnical specifications

Techniques and a system for creating a vendor independent computer language and compiling the language into an architecture specification language allowing for taking a source data stream (file, wsdl, xml) and passing thru a language parser, populating a storage medium with a plurality of technical inputs and vendor technical specifications for generic technologies and probable technologies required for desired architectures generated by the language parser, and optimizing the inputs and creating relationships between technologies and groups of technologies and storing results in said storage medium.

Owner:ARGANTEAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com