#110 road petroleum asphalt and preparation method thereof

A technology of road petroleum asphalt and wax oil, which is applied to building components, building insulation materials, buildings, etc., and can solve the problems of some indicators not up to standard and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

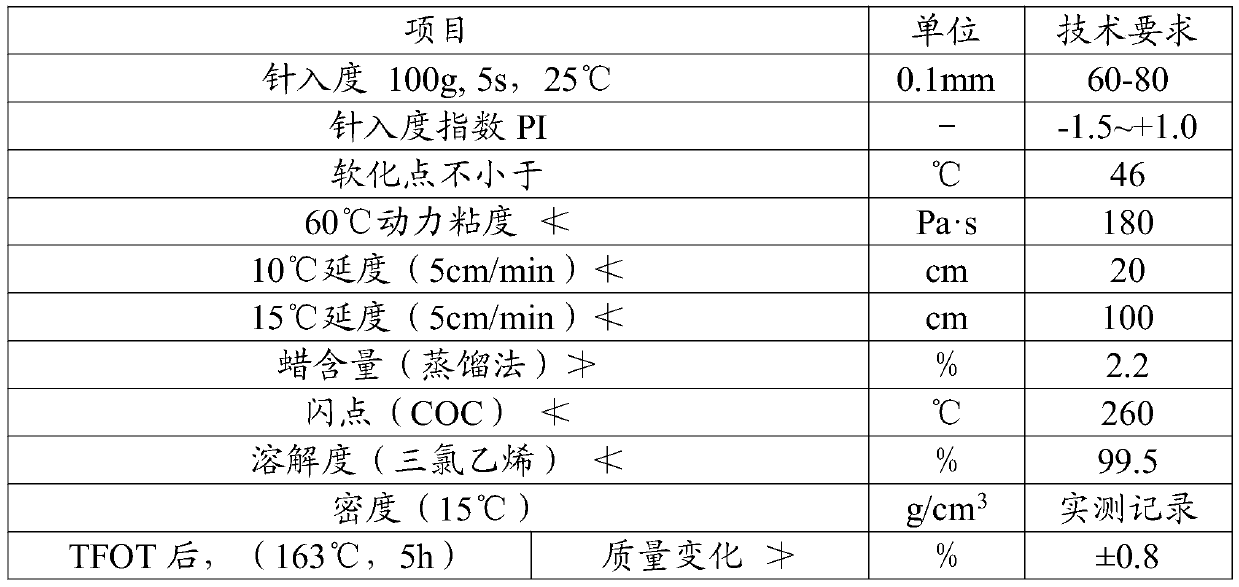

[0039] The present invention also provides a kind of preparation method of No. 110 road petroleum asphalt, comprises the following steps:

[0040]100 parts by weight of No. 70 road petroleum asphalt, 1 to 12 parts by weight of minus three line wax oil and 0.2 to 1 weight part of polyphosphoric acid are mixed to obtain No. 110 road petroleum asphalt.

[0041] In the preparation method provided by the present invention, the No. 110 road petroleum asphalt provided by the present invention can be obtained by directly mixing the above-mentioned raw materials in proportion. Wherein, the mixing temperature is preferably 80-180°C, specifically 80°C, 85°C, 90°C, 95°C, 100°C, 105°C, 110°C, 115°C, 120°C, 125°C, 130°C, 135°C, 138°C, 140°C, 145°C, 150°C, 155°C, 160°C, 165°C, 170°C, 175°C or 180°C; the stirring speed of the mixing is preferably 60 to 1000 rpm, which can be specified 60 rpm, 100 rpm, 200 rpm, 300 rpm, 400 rpm, 500 rpm, 600 rpm, 700 rpm, 800 rpm, 900 rpm or 1000 rpm; the mi...

Embodiment 1

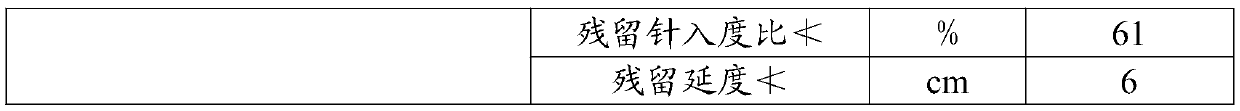

[0051] Take a certain quality of Haiyun No. 70 road petroleum asphalt, and conduct a blending experiment with the mass ratio of Haiyun No. 70 road petroleum asphalt: polyphosphoric acid: minus three-line wax oil at a ratio of 100: 0.3: 5.5. The order of reagent addition is first Add polyphosphoric acid to the asphalt, stir for 1 hour, add the minus three line wax oil and continue to stir for 1 hour, the stirring temperature is 138 ℃, and the rotation speed is 400 rpm. In this way, No. 110 road petroleum asphalt is obtained. The test results are shown in the table 2 shows:

[0052] The technical index of No. 110 road petroleum asphalt that table 2 embodiment 1 produces

[0053]

[0054] It can be seen that the indicators of No. 110 road petroleum asphalt prepared in Example 1 all meet the technical index requirements of No. 110 road petroleum asphalt.

Embodiment 2

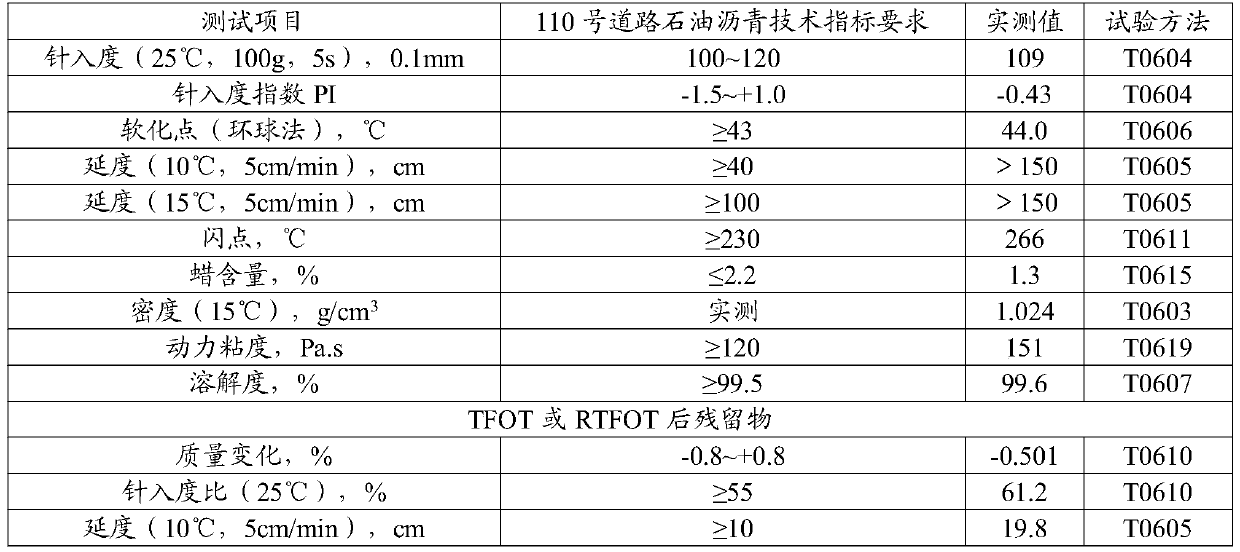

[0056] Take a certain quality of Haiyun No. 70 road petroleum asphalt, and conduct a blending experiment with the mass ratio of Haiyun No. 70 road petroleum asphalt: polyphosphoric acid: minus three-line wax oil at a ratio of 100: 0.5: 5.5. The order of adding reagents is first Add minus three line wax oil to the asphalt, stir for 1 hour, add minus three line wax oil and continue stirring for 1.0 hour, the stirring temperature is 138°C, and the rotation speed is 400 rpm. In this way, No. 110 road petroleum asphalt is obtained. The test results are as follows Table 3 shows:

[0057] The technical index of No. 110 road petroleum asphalt that table 3 embodiment 2 produces

[0058]

[0059] It can be seen that the indicators of No. 110 road petroleum asphalt prepared in Example 2 all meet the technical index requirements of No. 110 road petroleum asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com