Patents

Literature

7691 results about "Petrochemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petrochemicals (also known as petroleum distillates) are chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources such as corn, palm fruit or sugar cane.

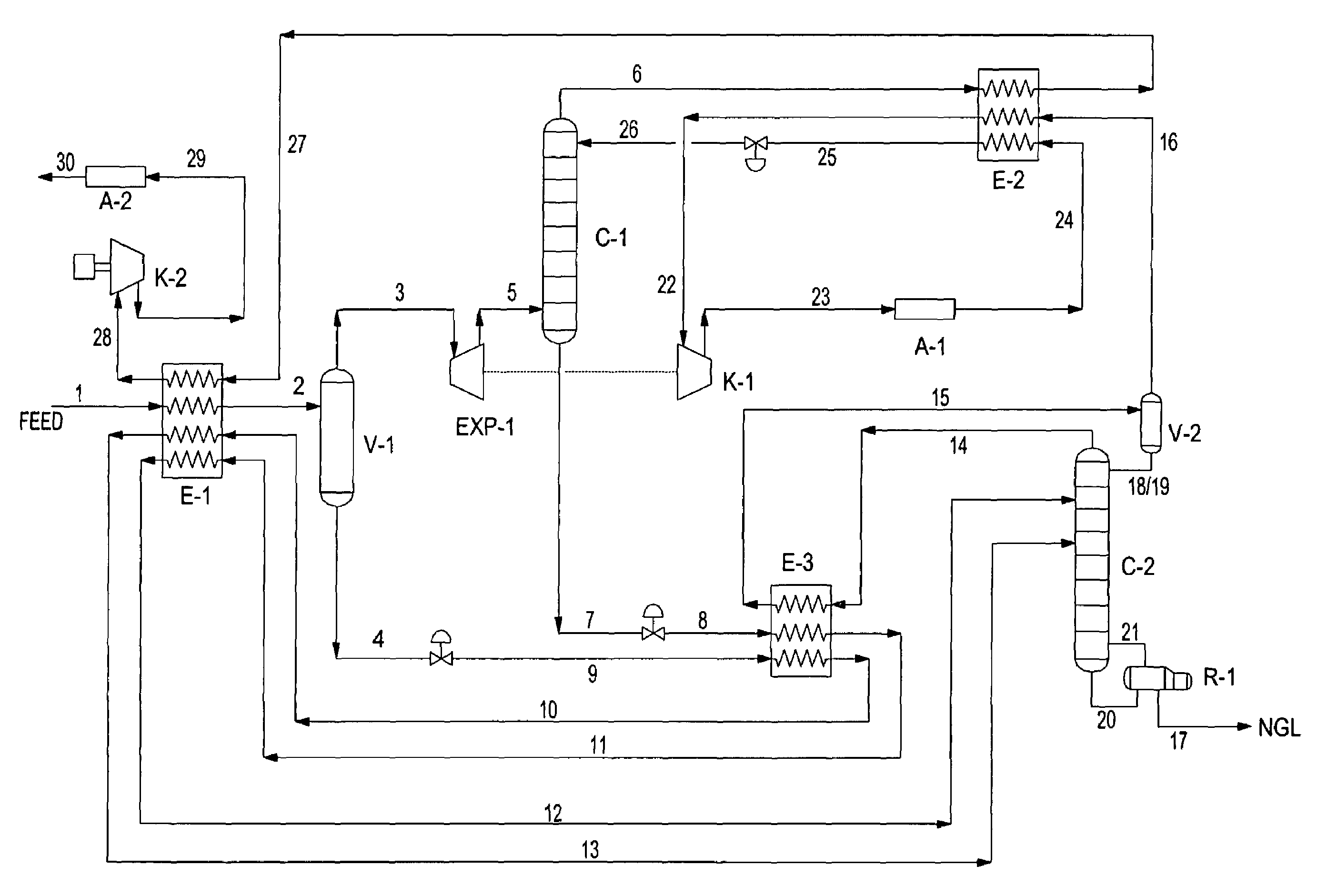

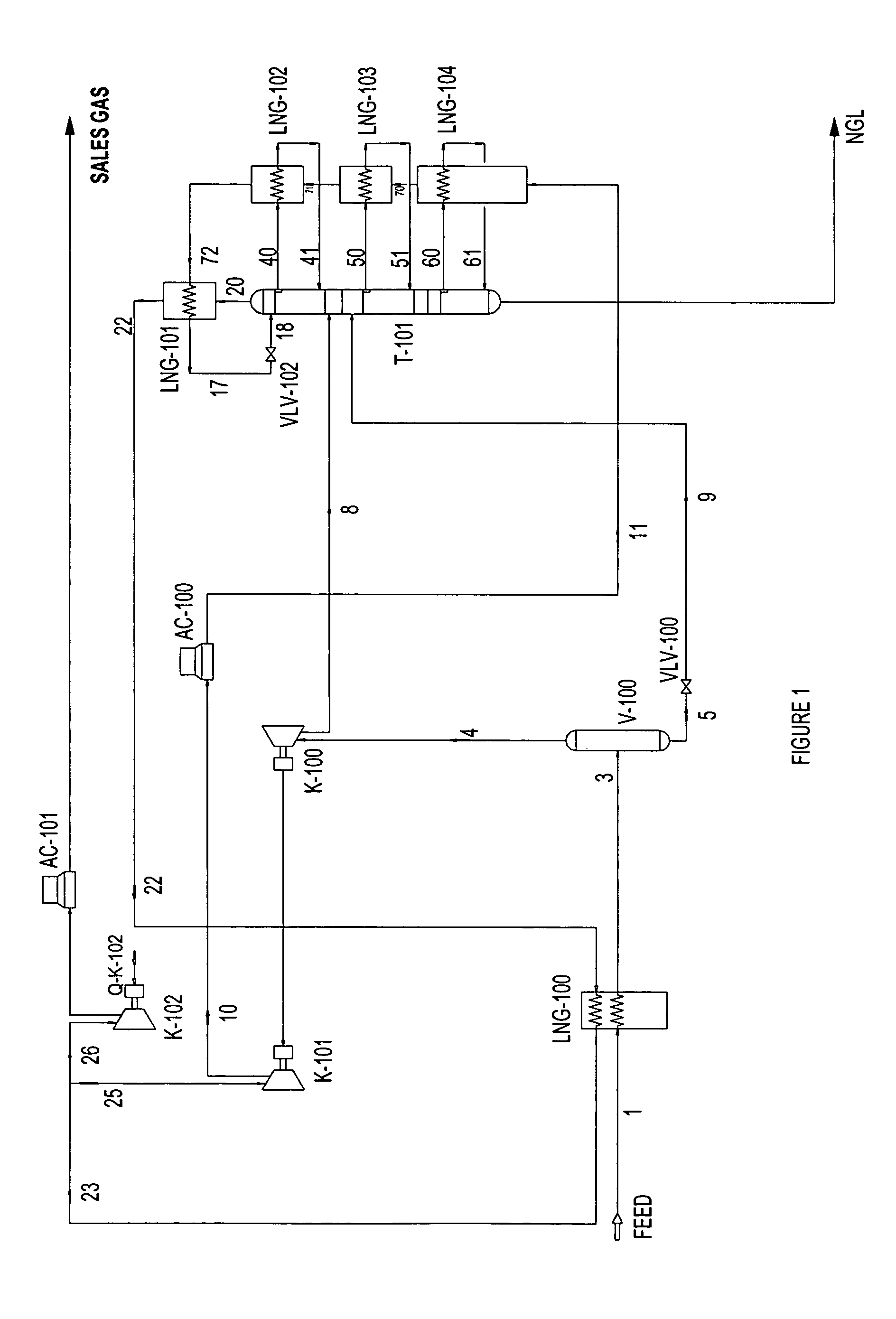

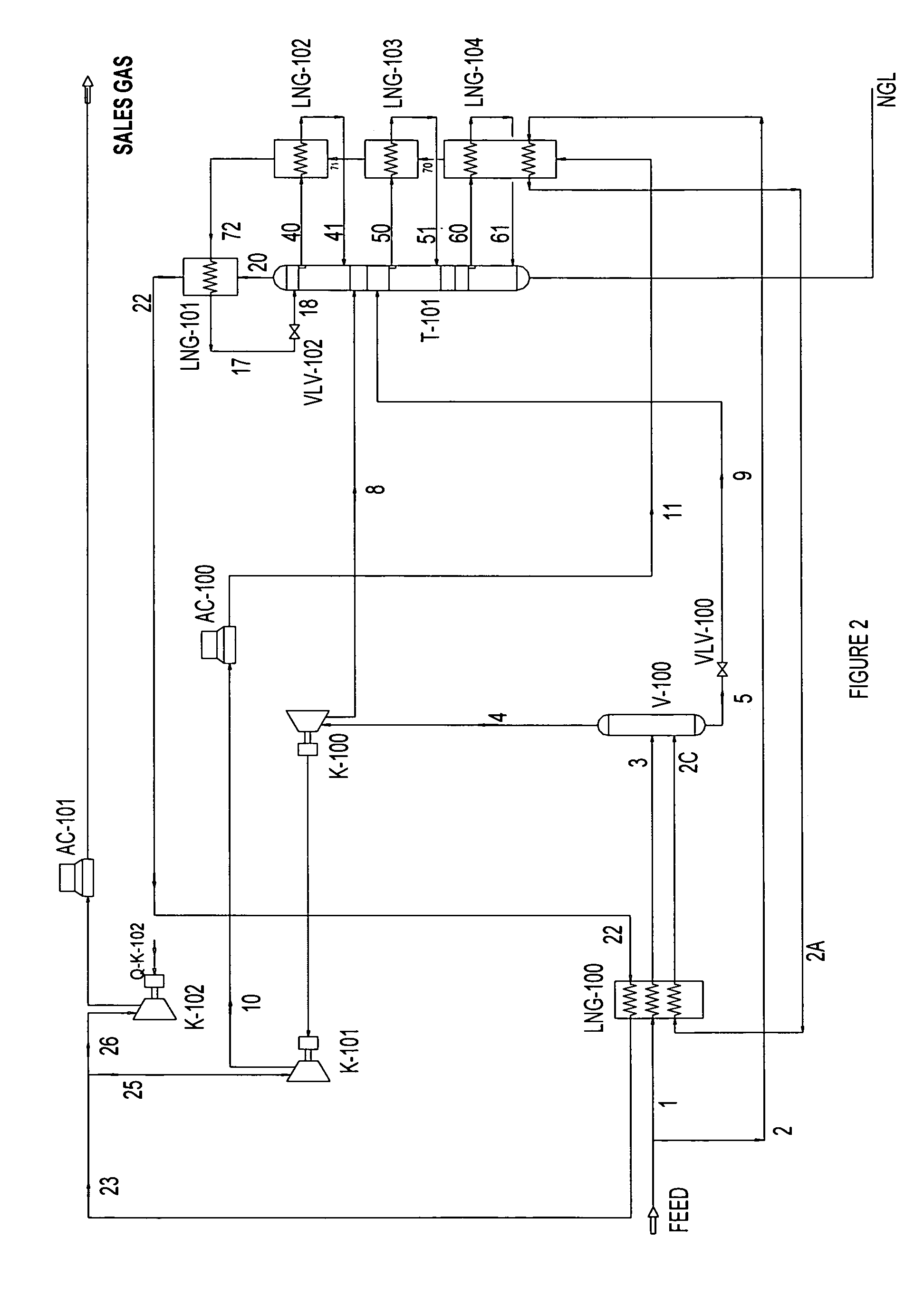

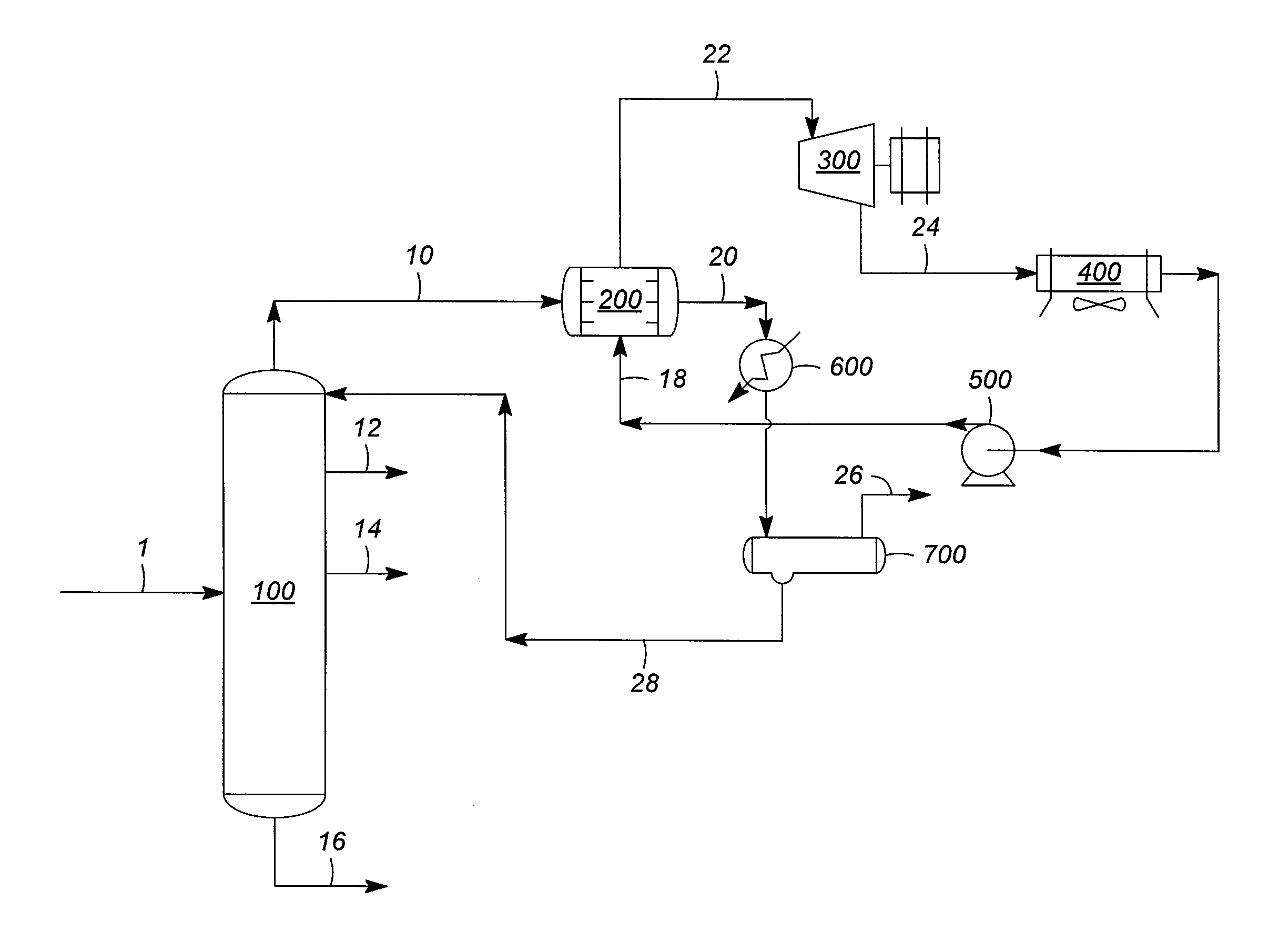

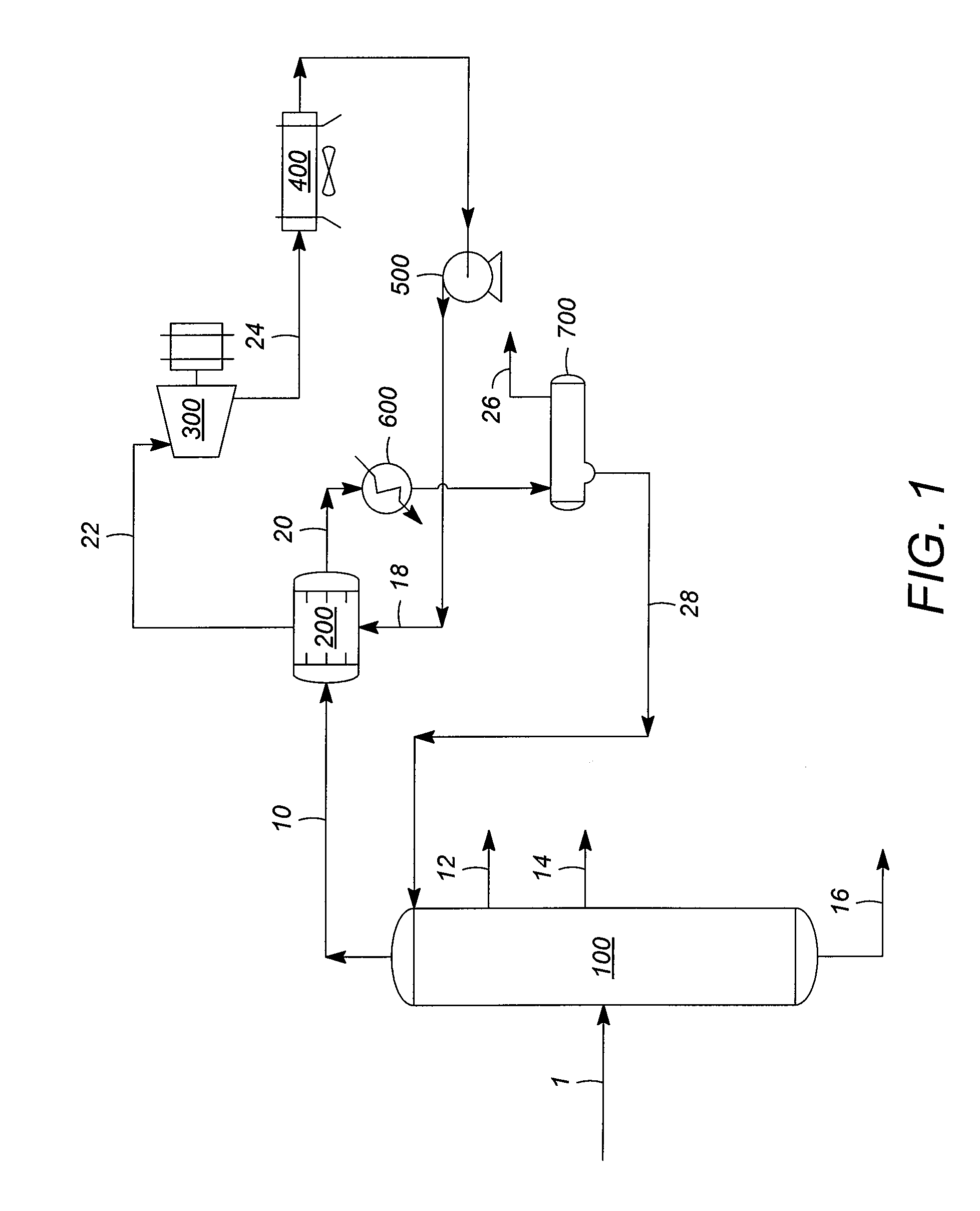

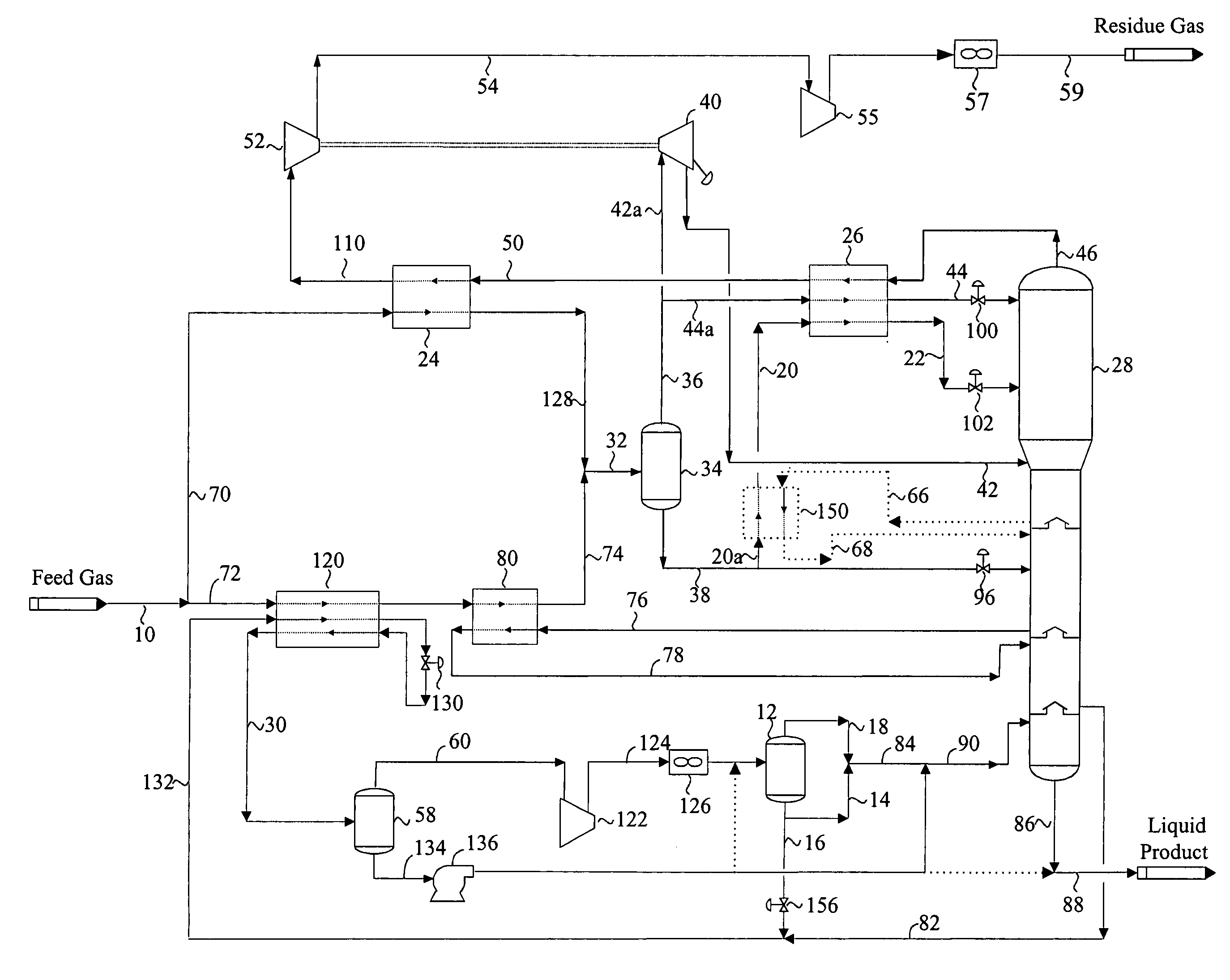

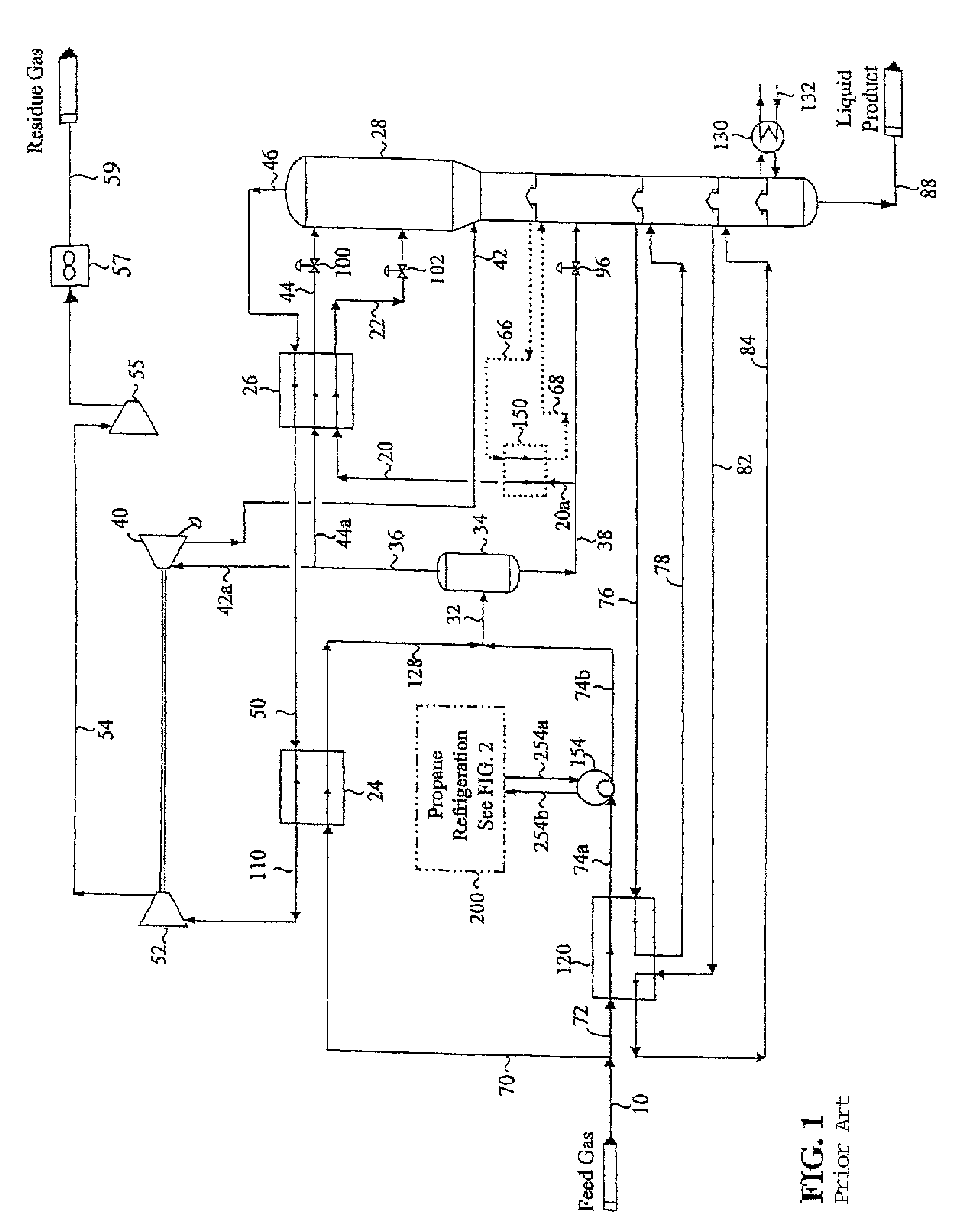

Ethane plus and HHH process for NGL recovery

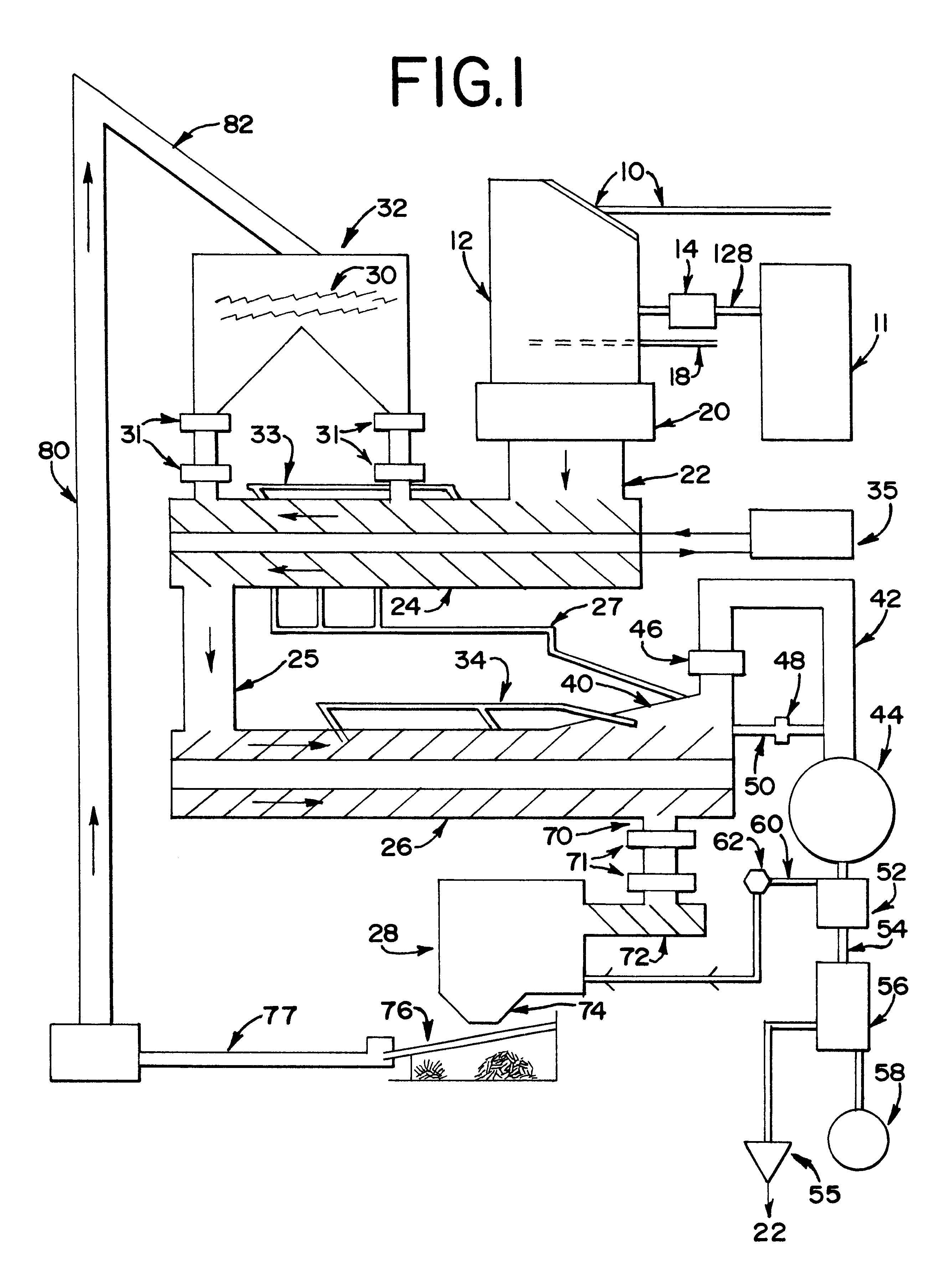

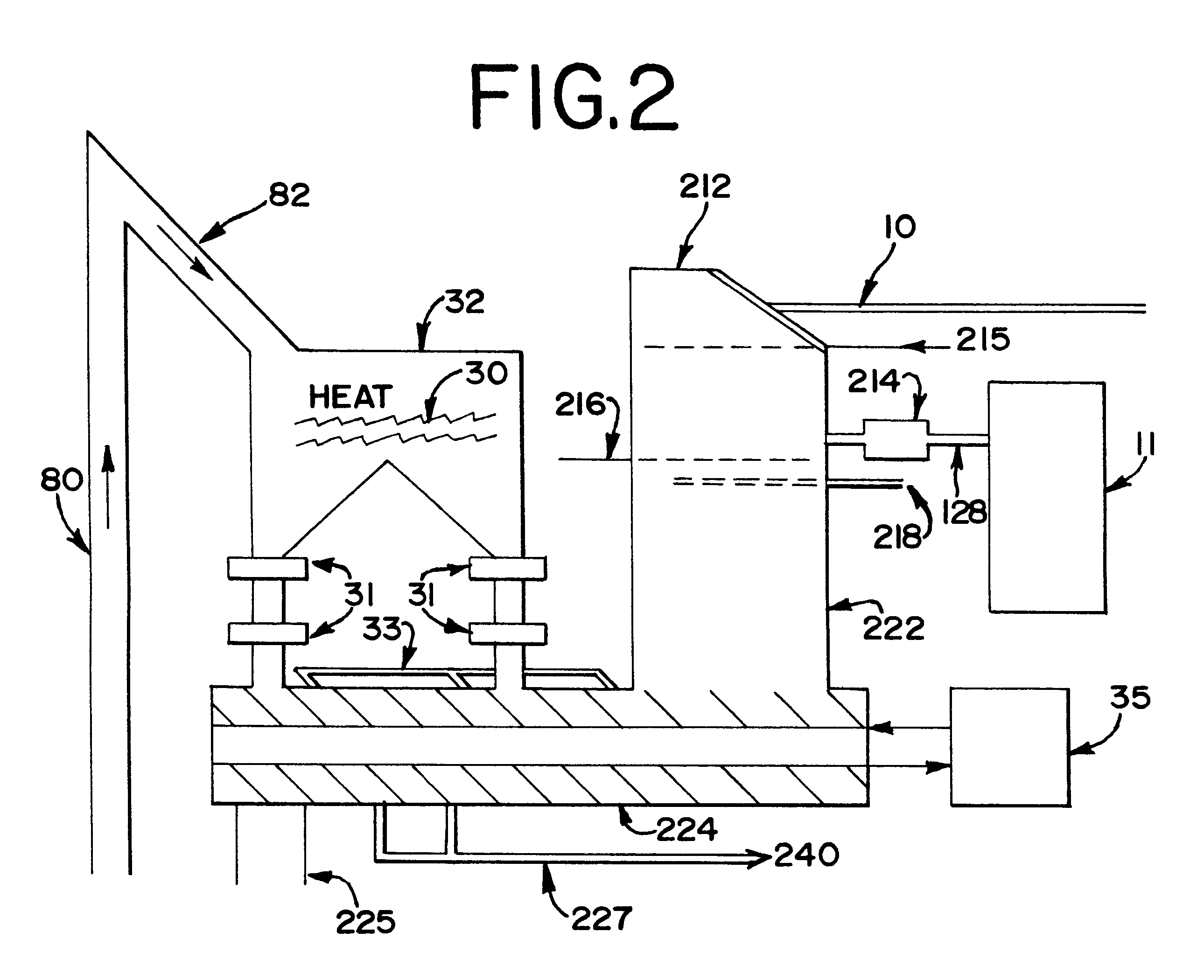

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

Cellular plastic material

An improved cellular plastic material comprises a urethane foam that is the reaction product of soy oil, an isocyanate, and a cross linker. The soy oil replaces the polyol typically generally required in the production of urethanes. Because the replaced polyol is a petrochemical, use of a renewable and environmentally friendly material such as soy oil is most advantageous. Further, plastic materials of many final qualities may be formed using a single vegetable oil. In addition to cellular foams, solid plastic elastomers may be formed.

Owner:URETHANE SOY SYST +1

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

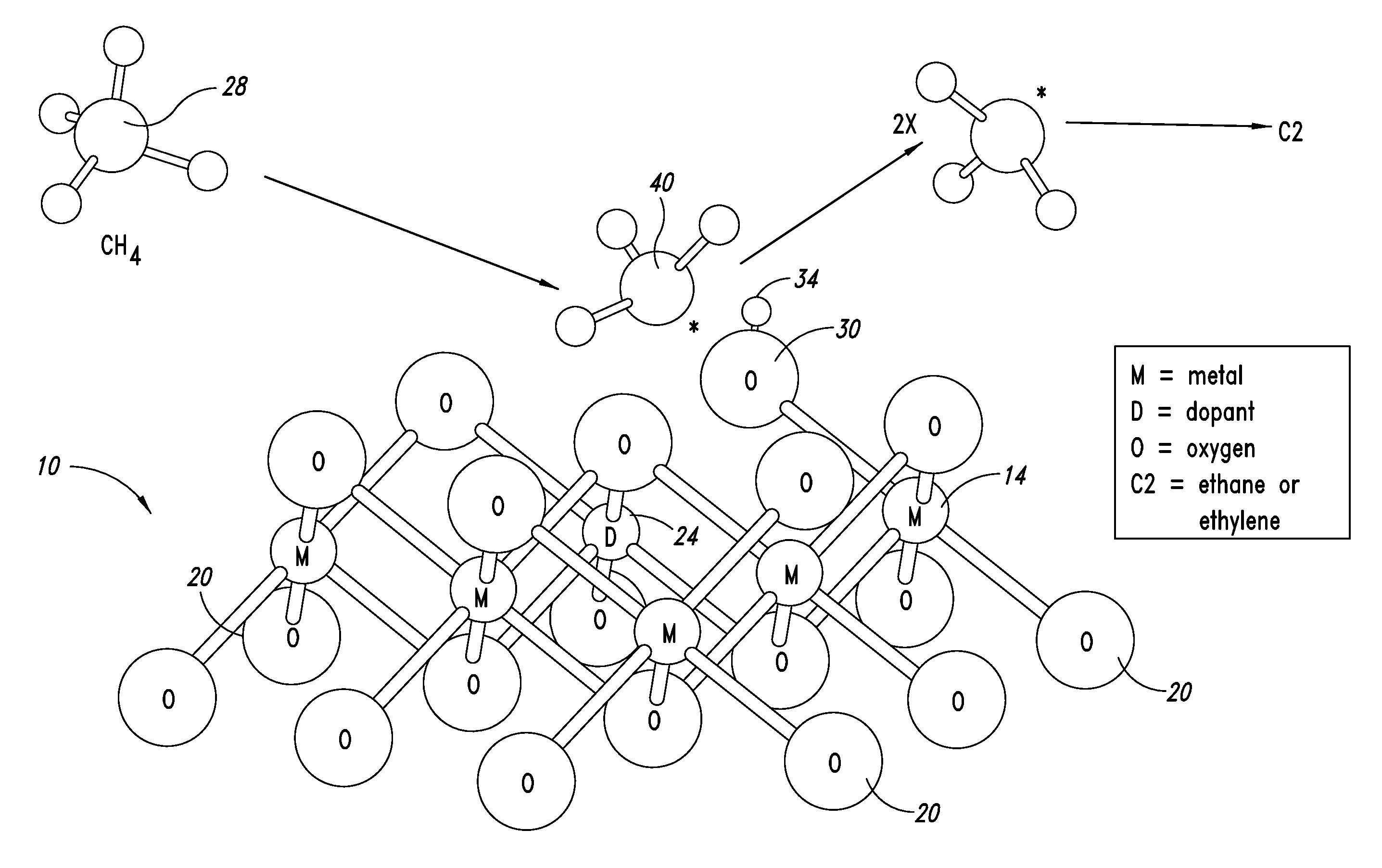

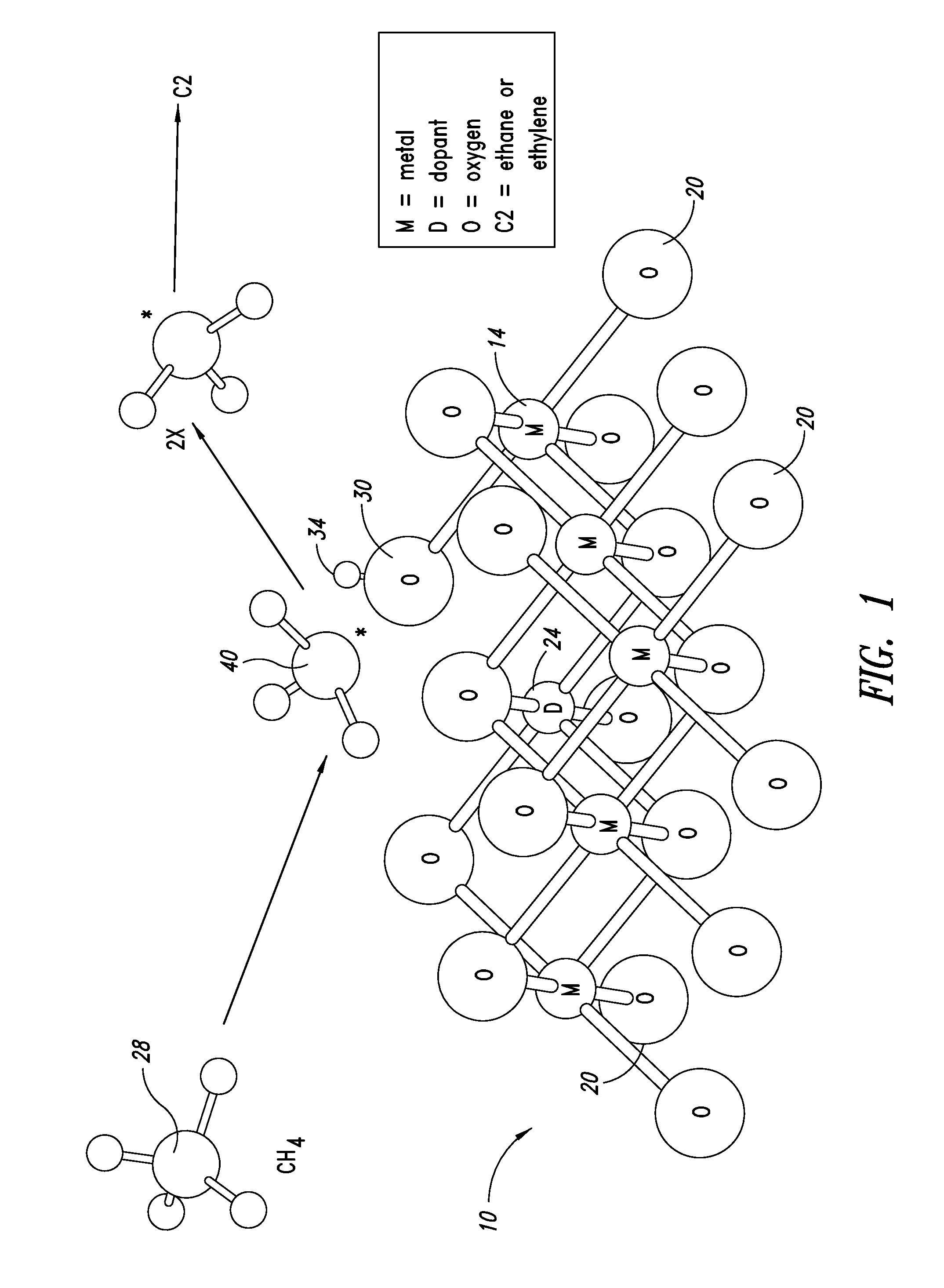

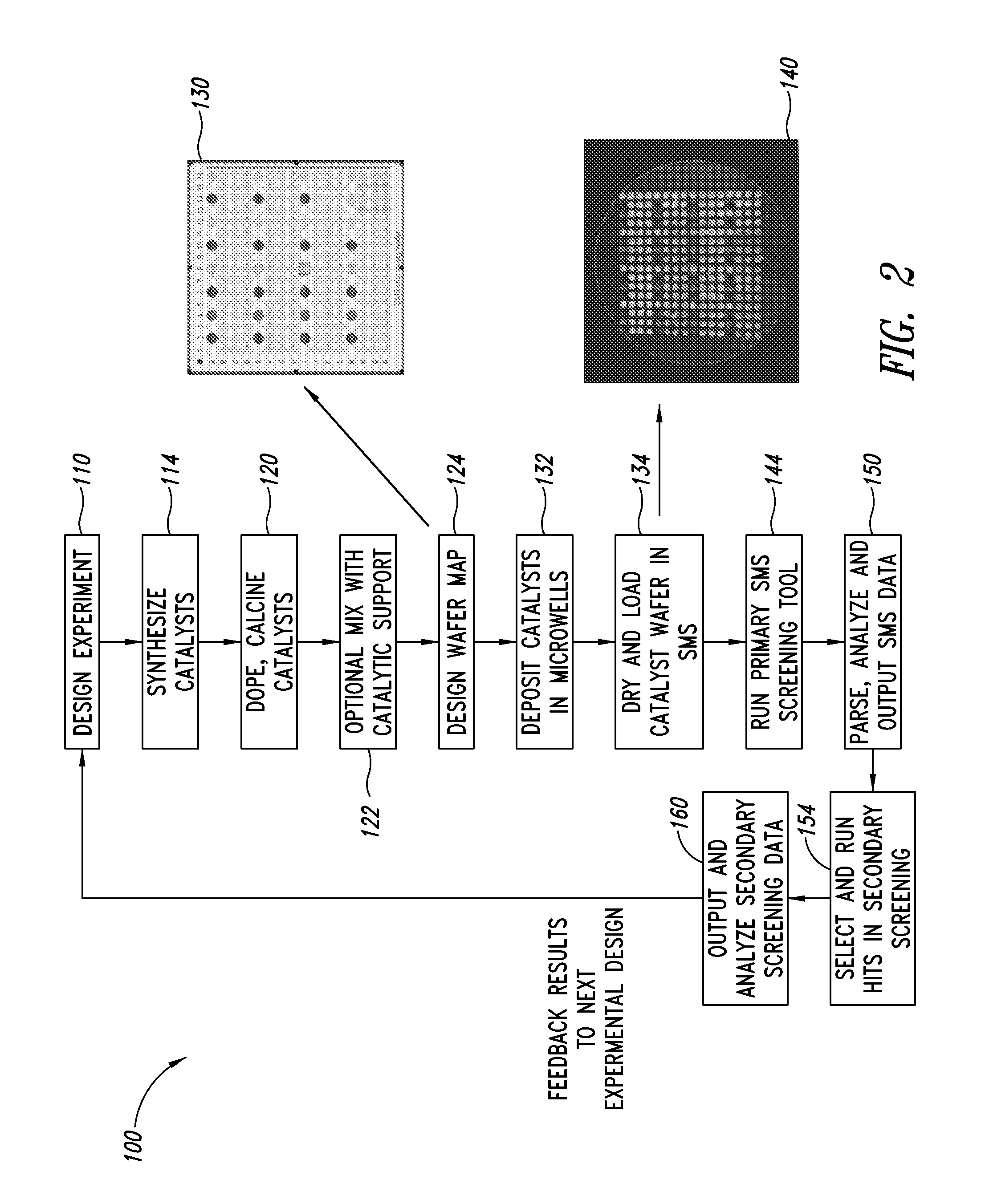

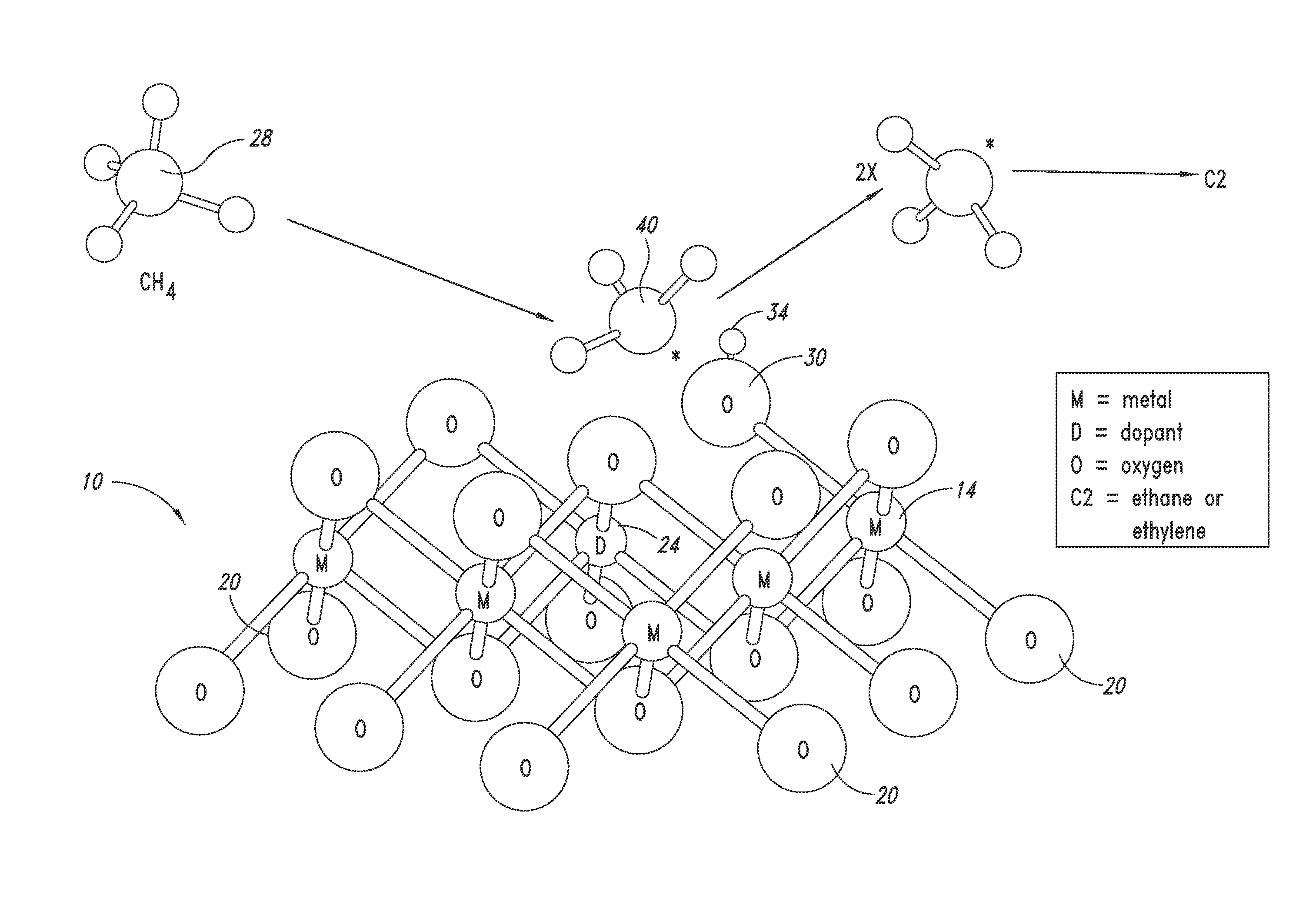

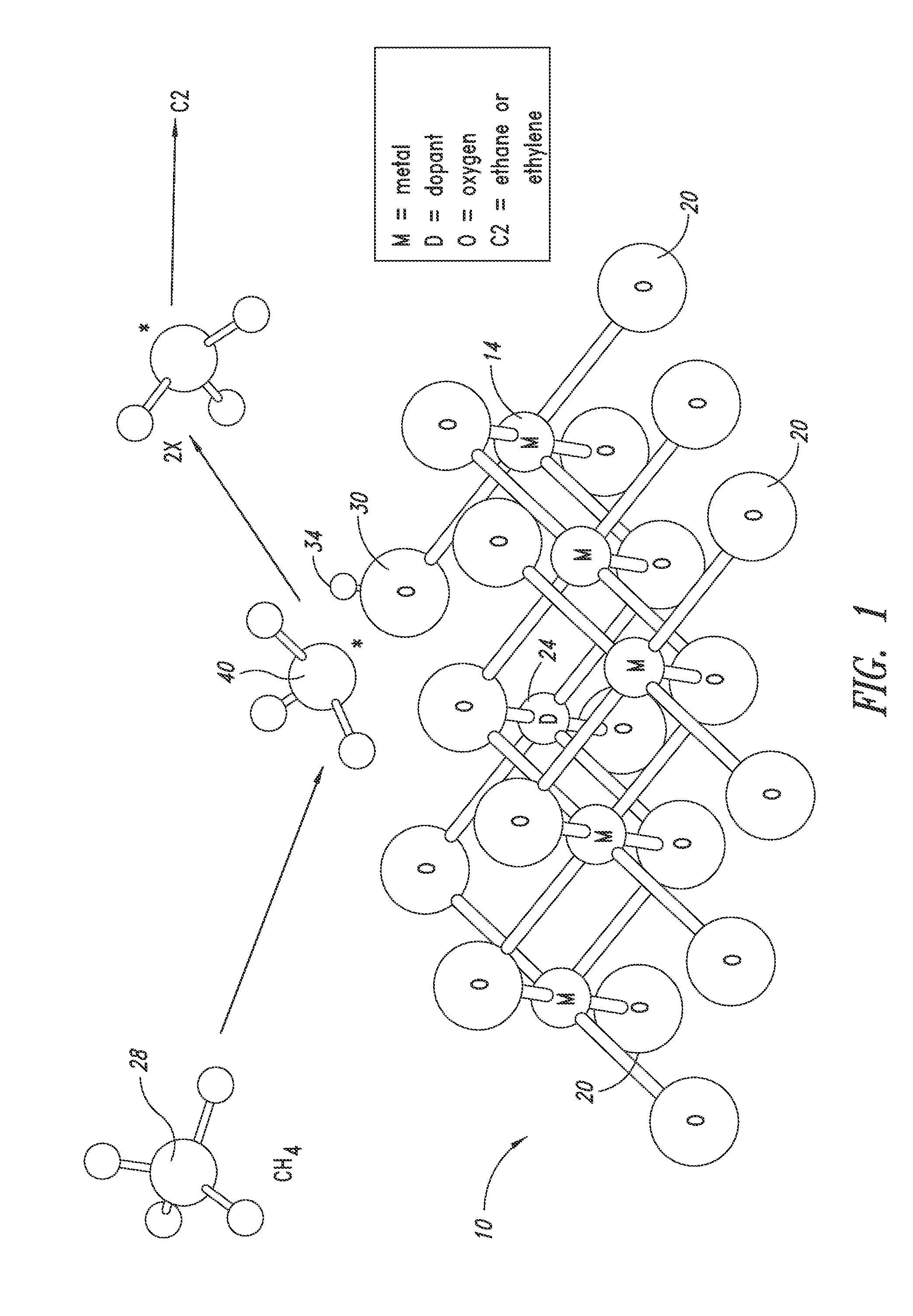

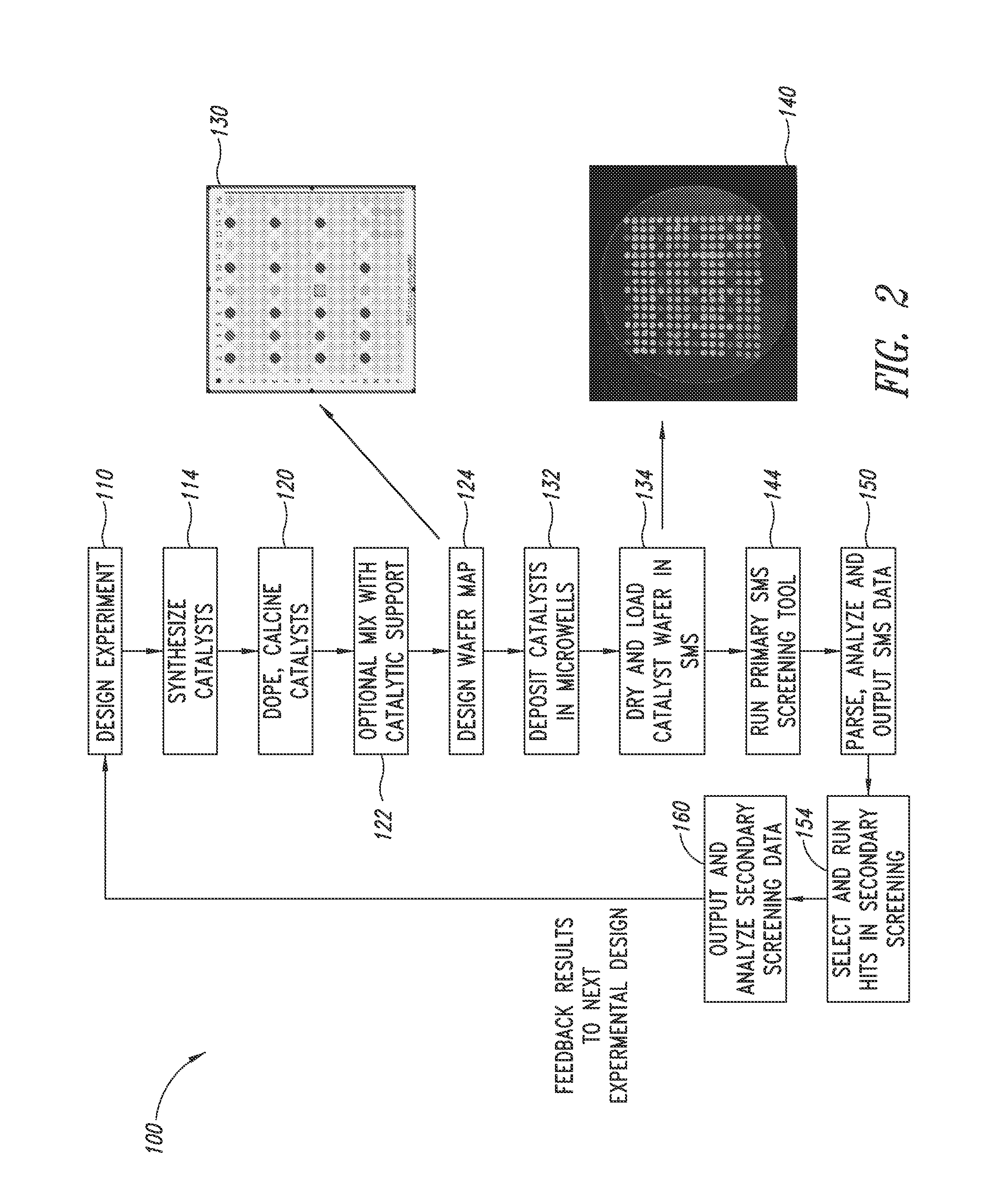

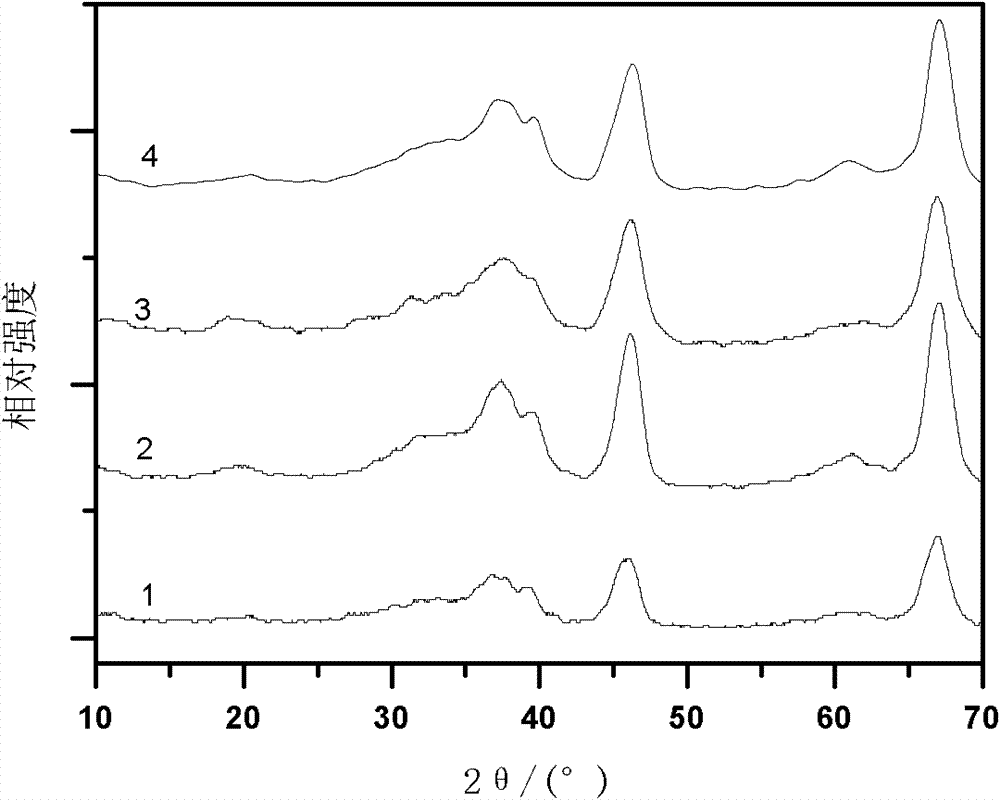

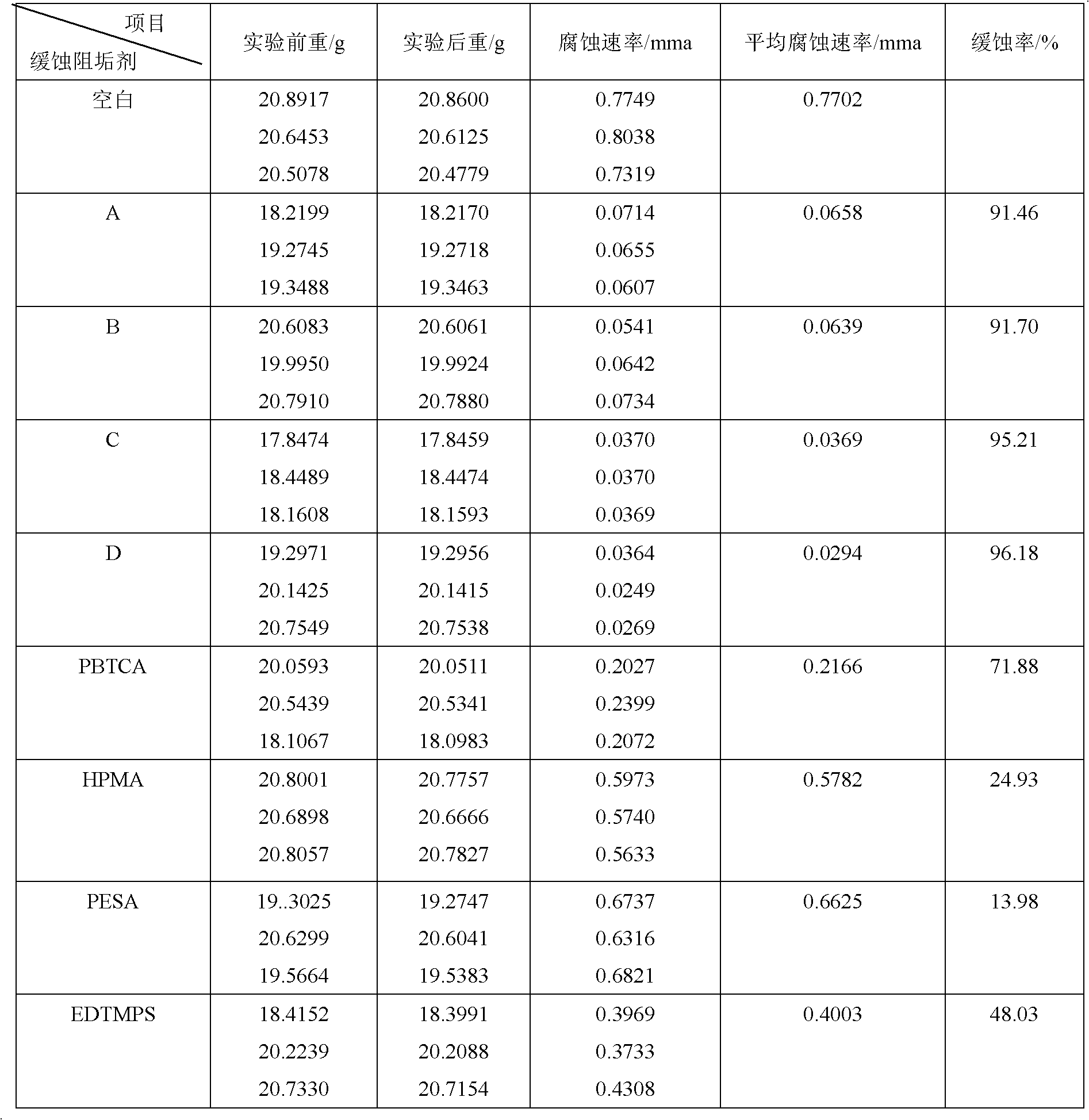

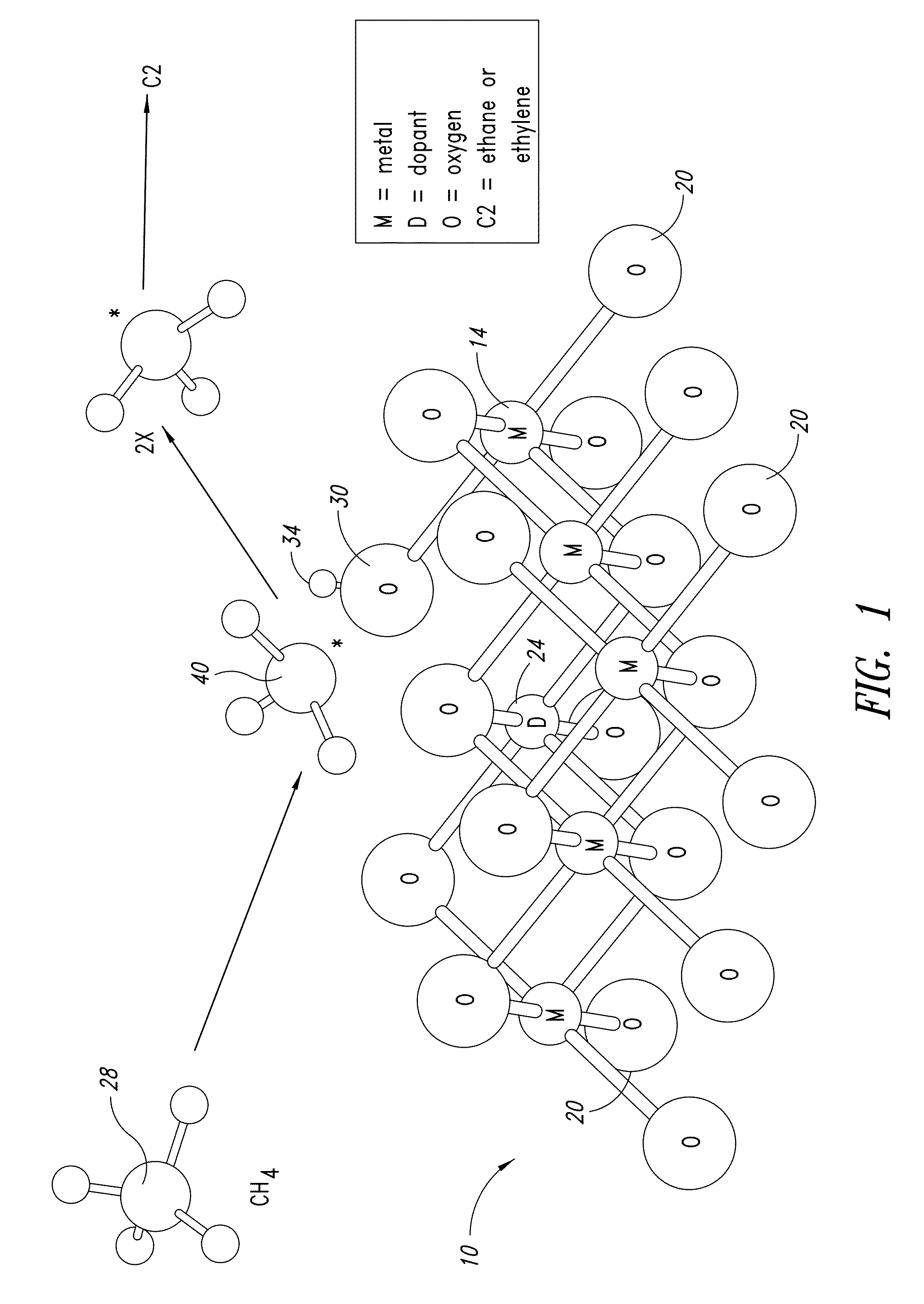

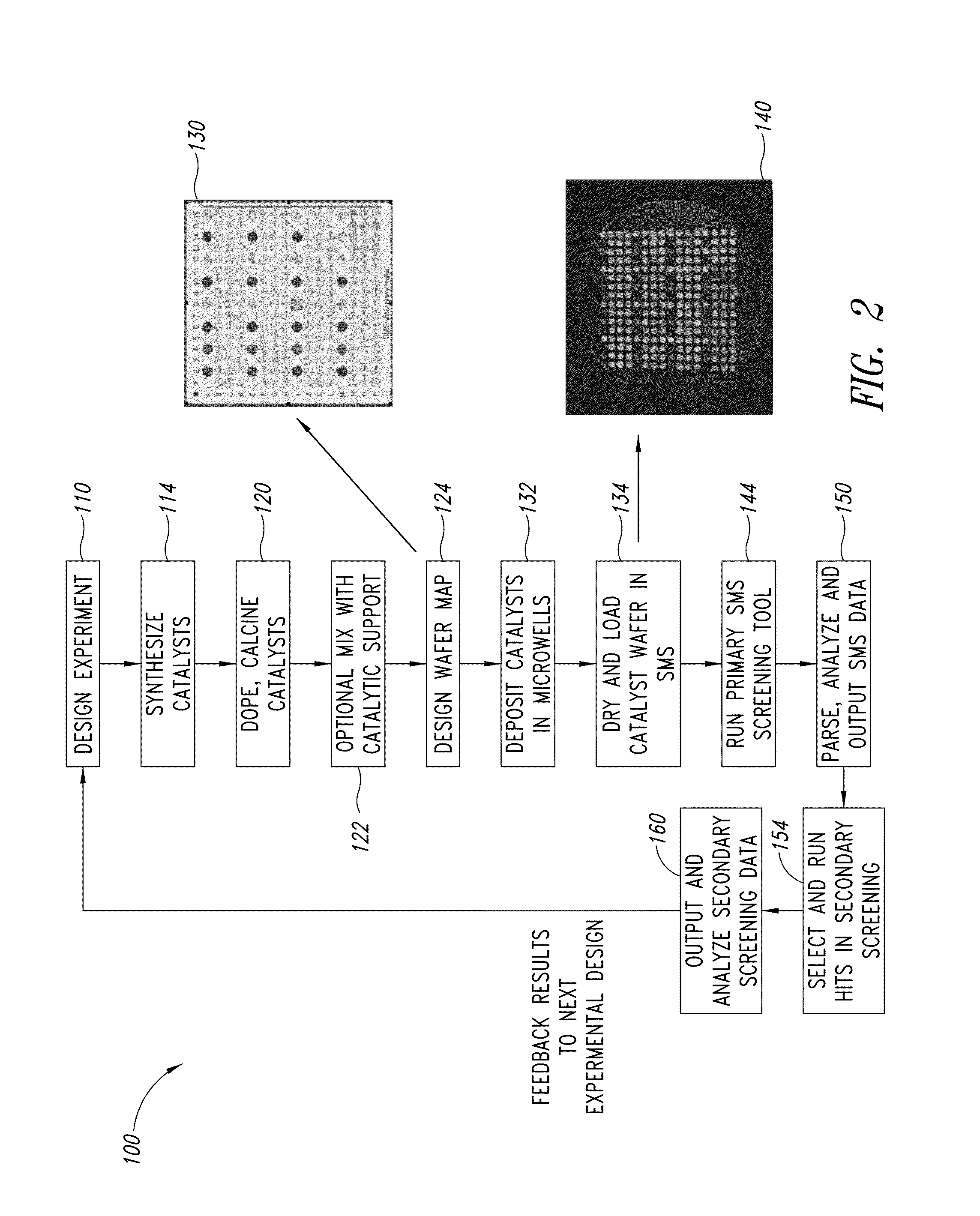

Catalysts for petrochemical catalysis

ActiveUS20130023709A1Sequential/parallel process reactionsManganese oxides/hydroxidesDopantPetrochemical

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

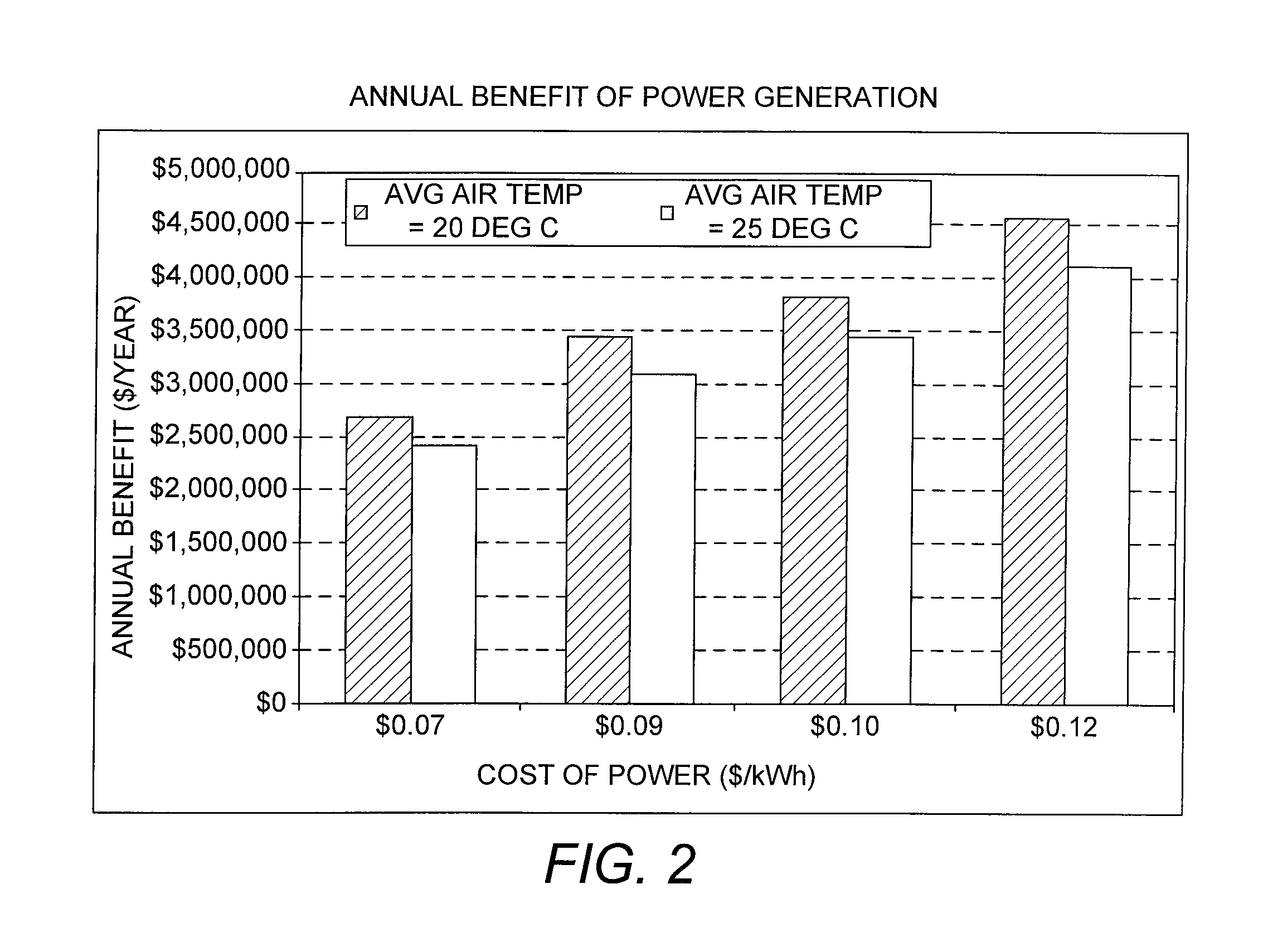

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

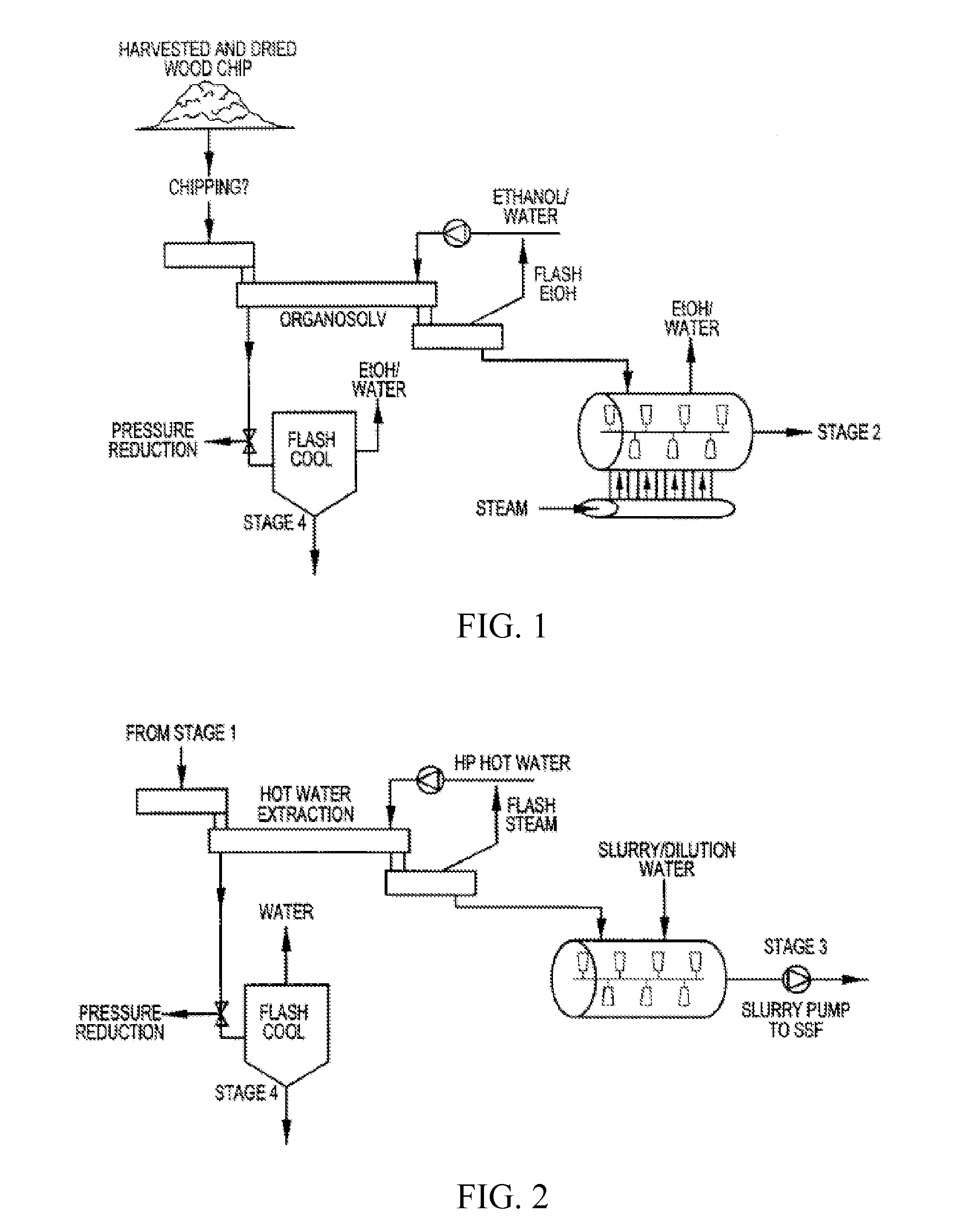

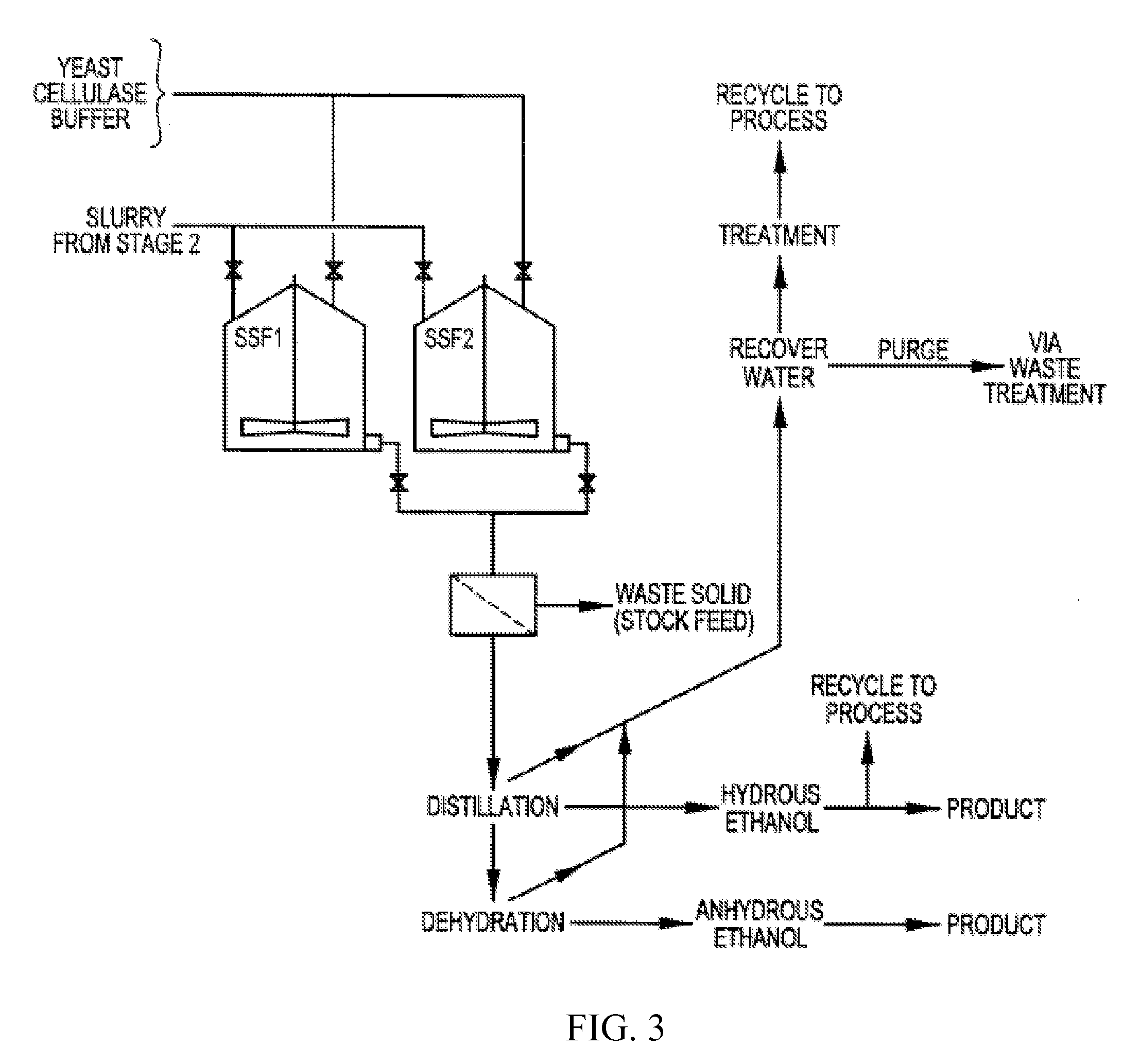

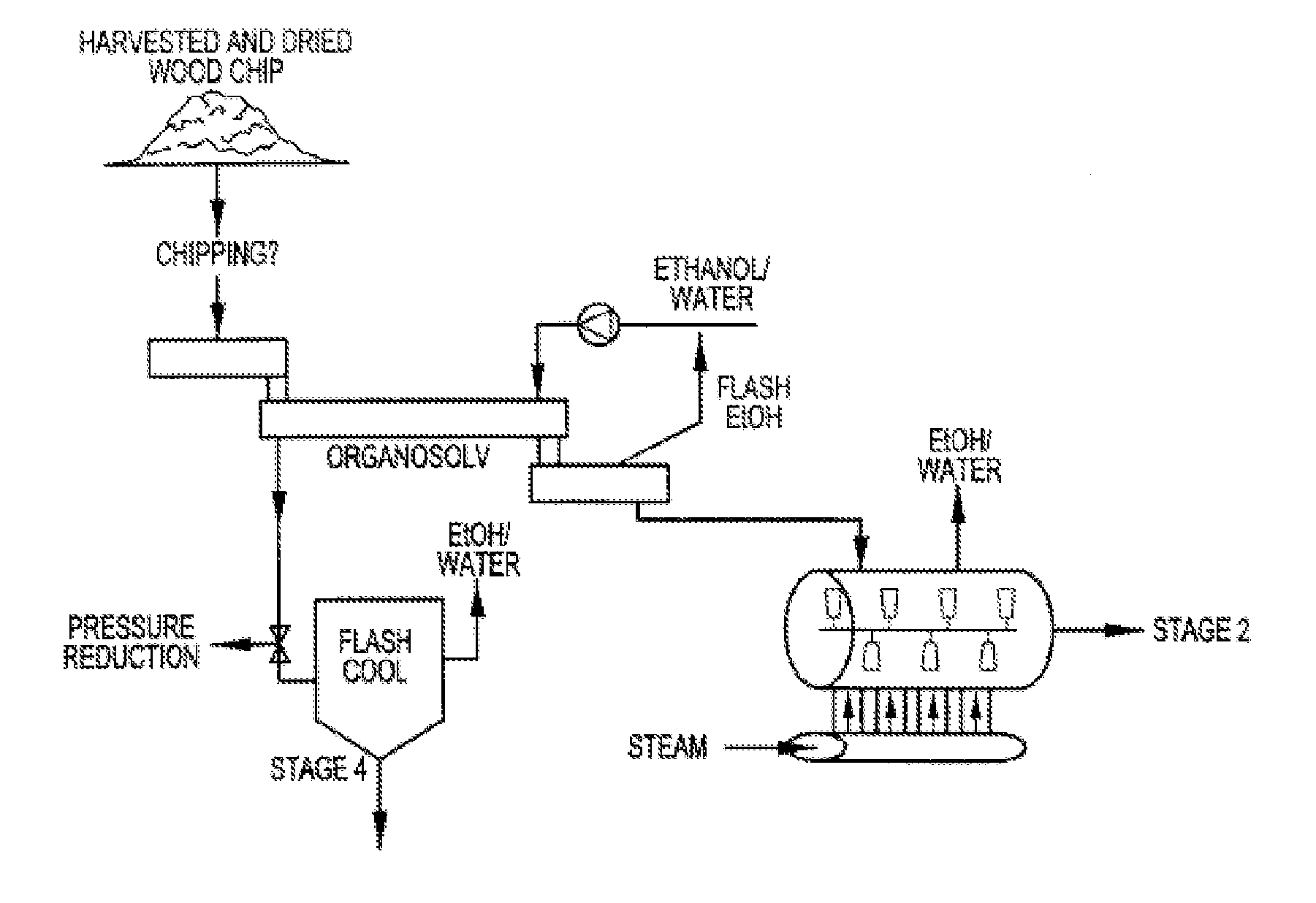

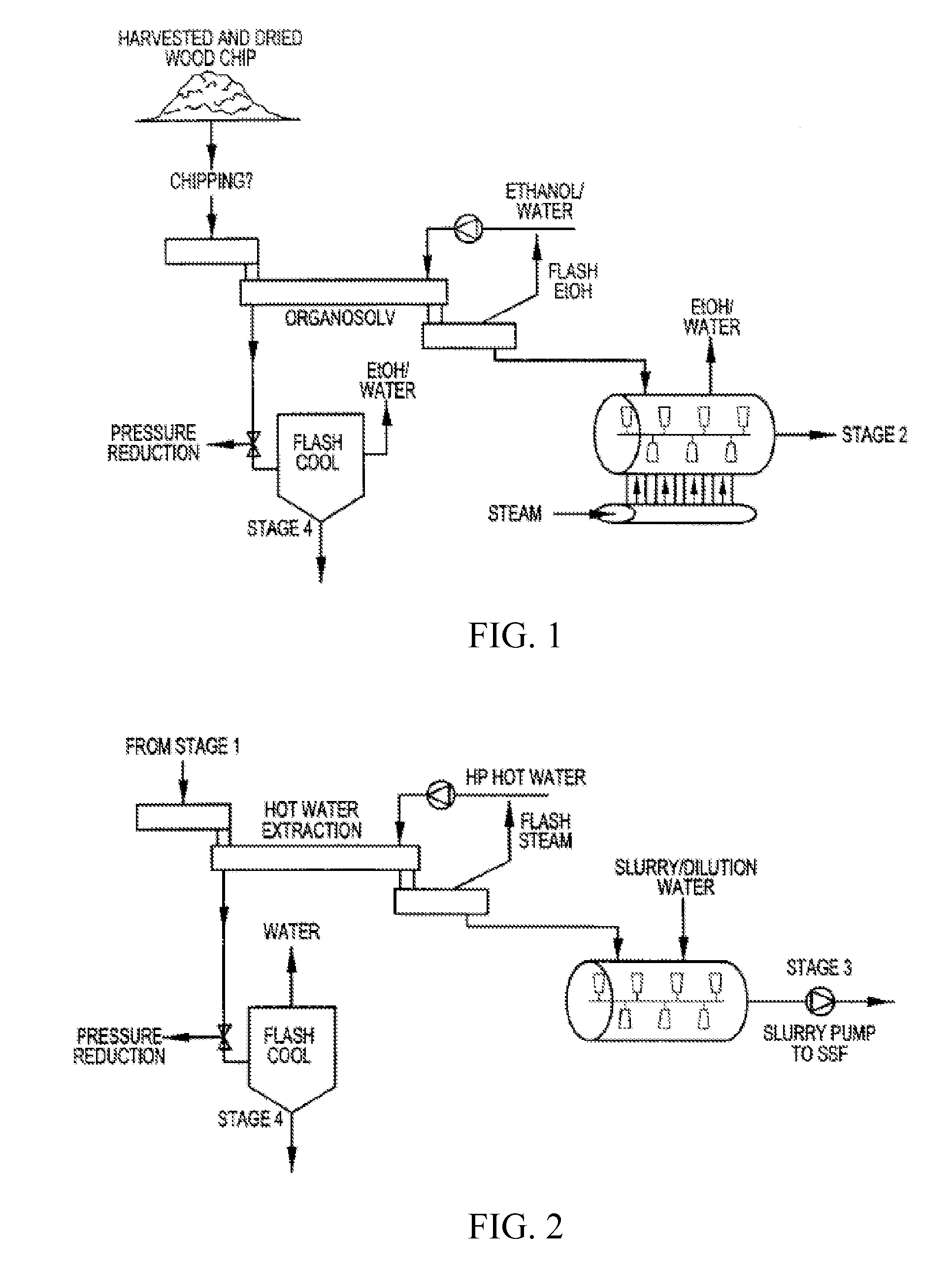

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

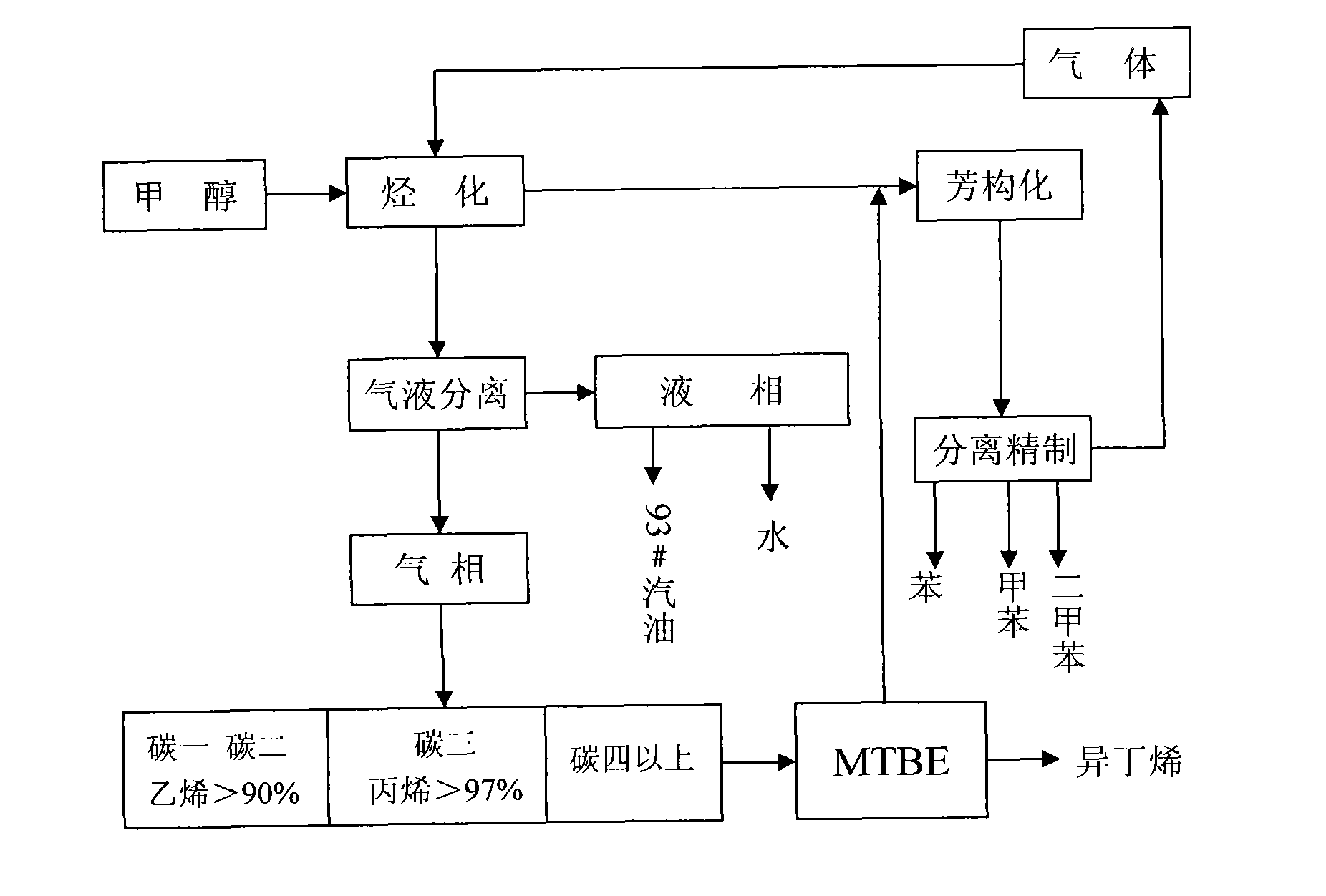

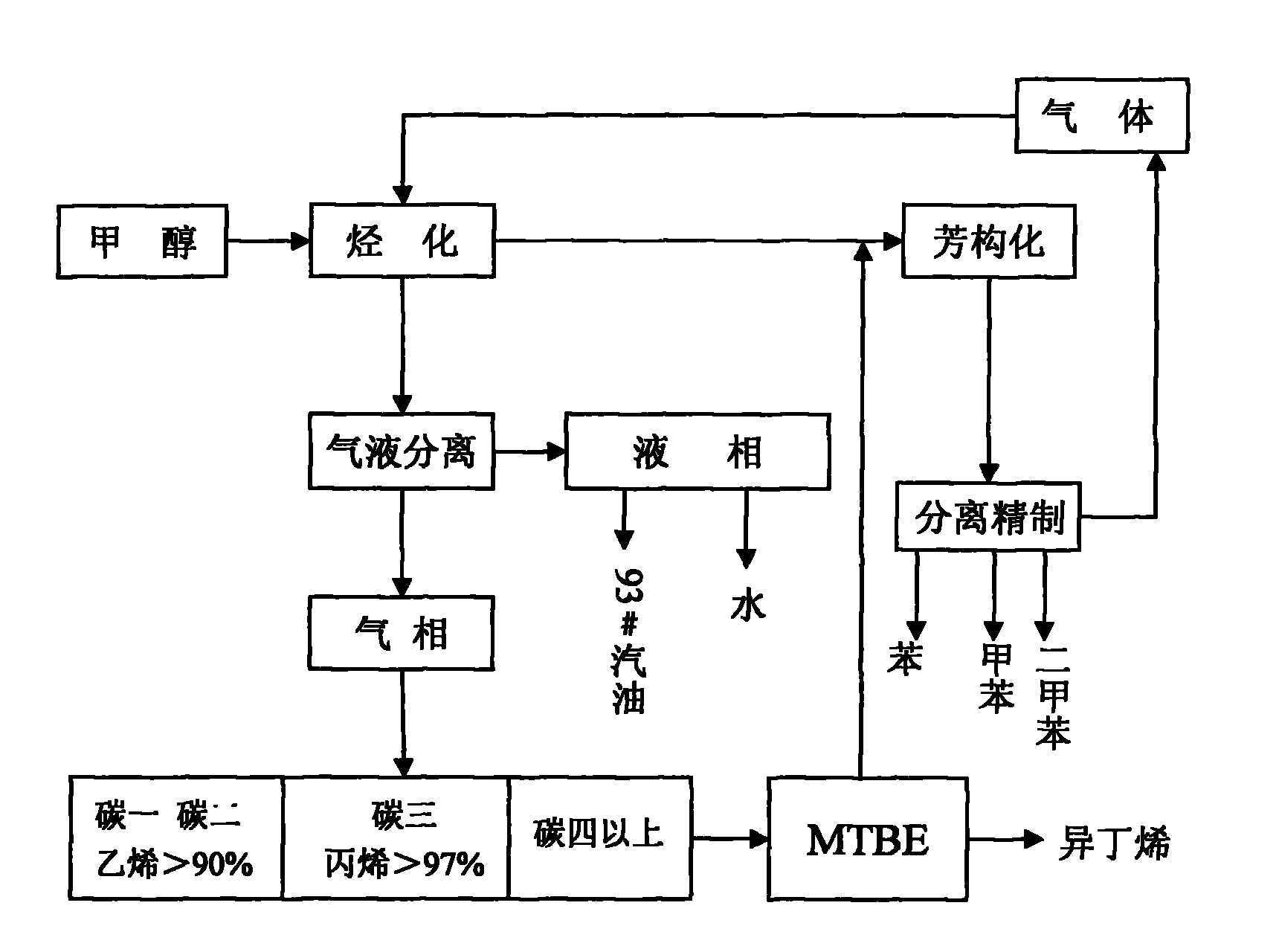

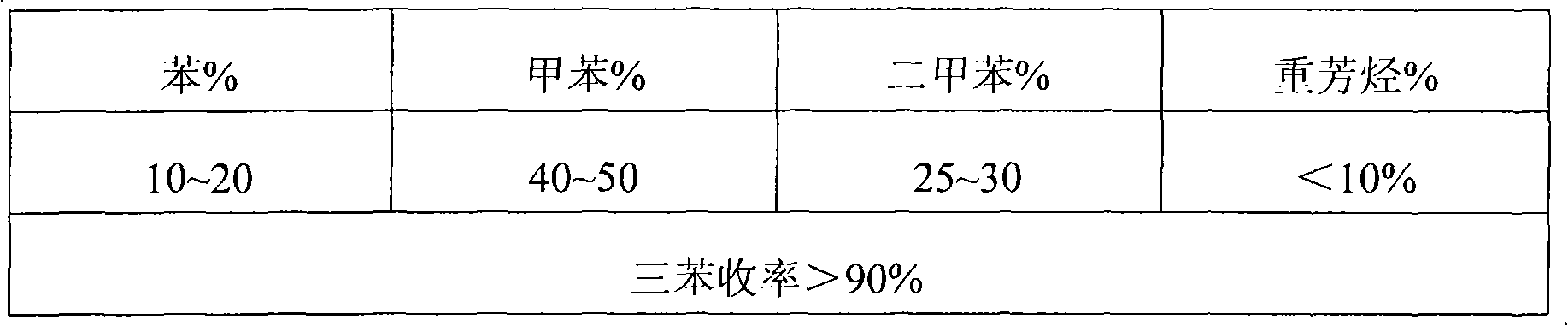

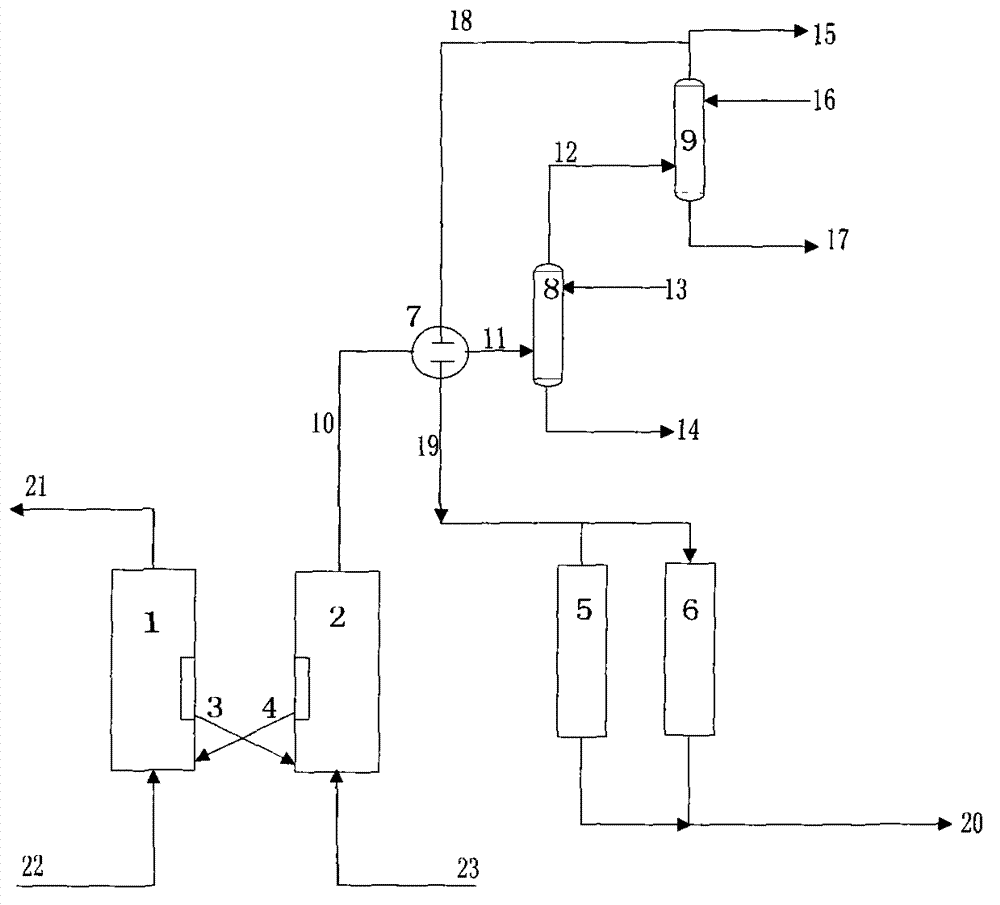

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090069550A1Great potentialTotal calories lowLignin derivativesPulp by-products recoveryFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

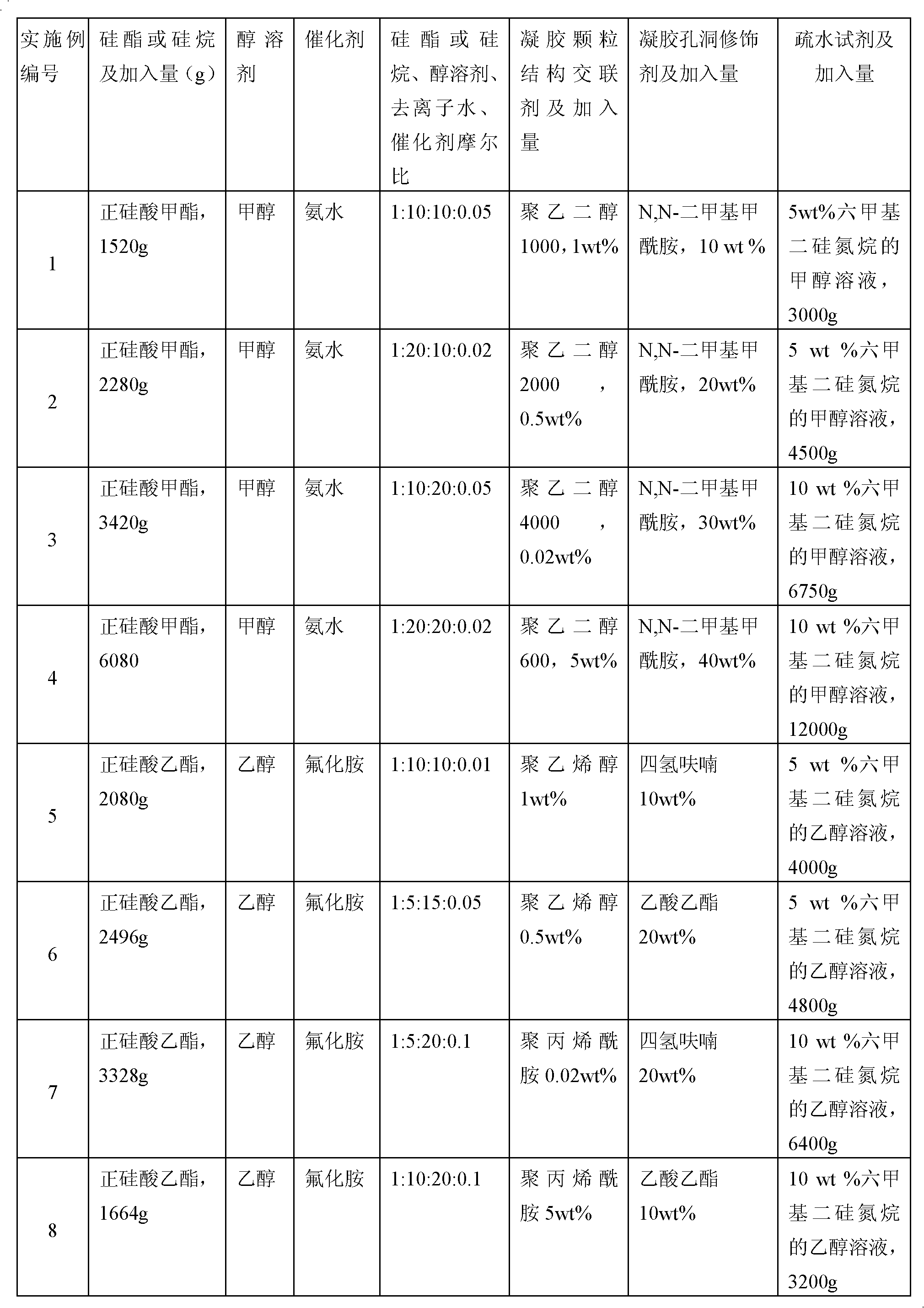

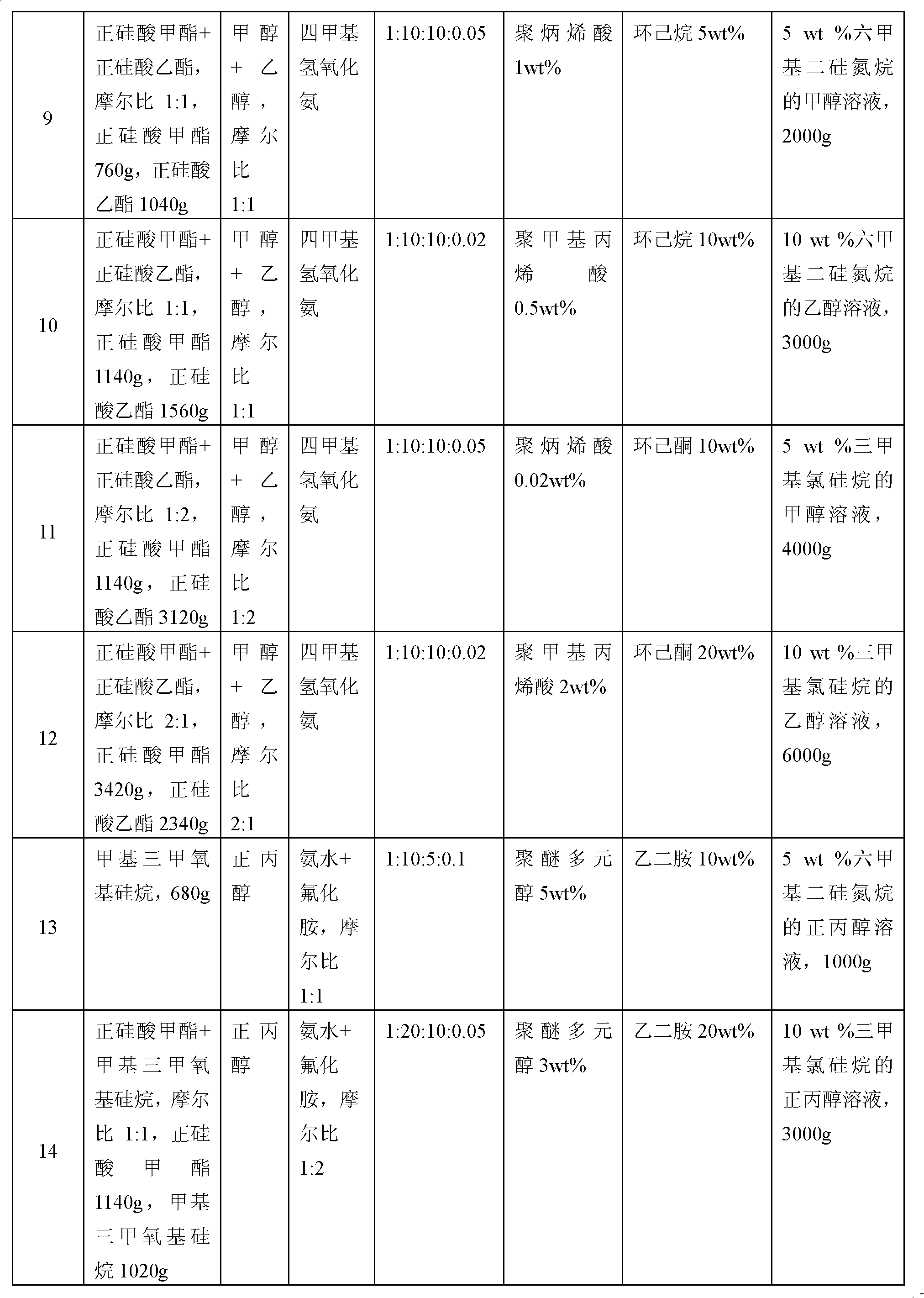

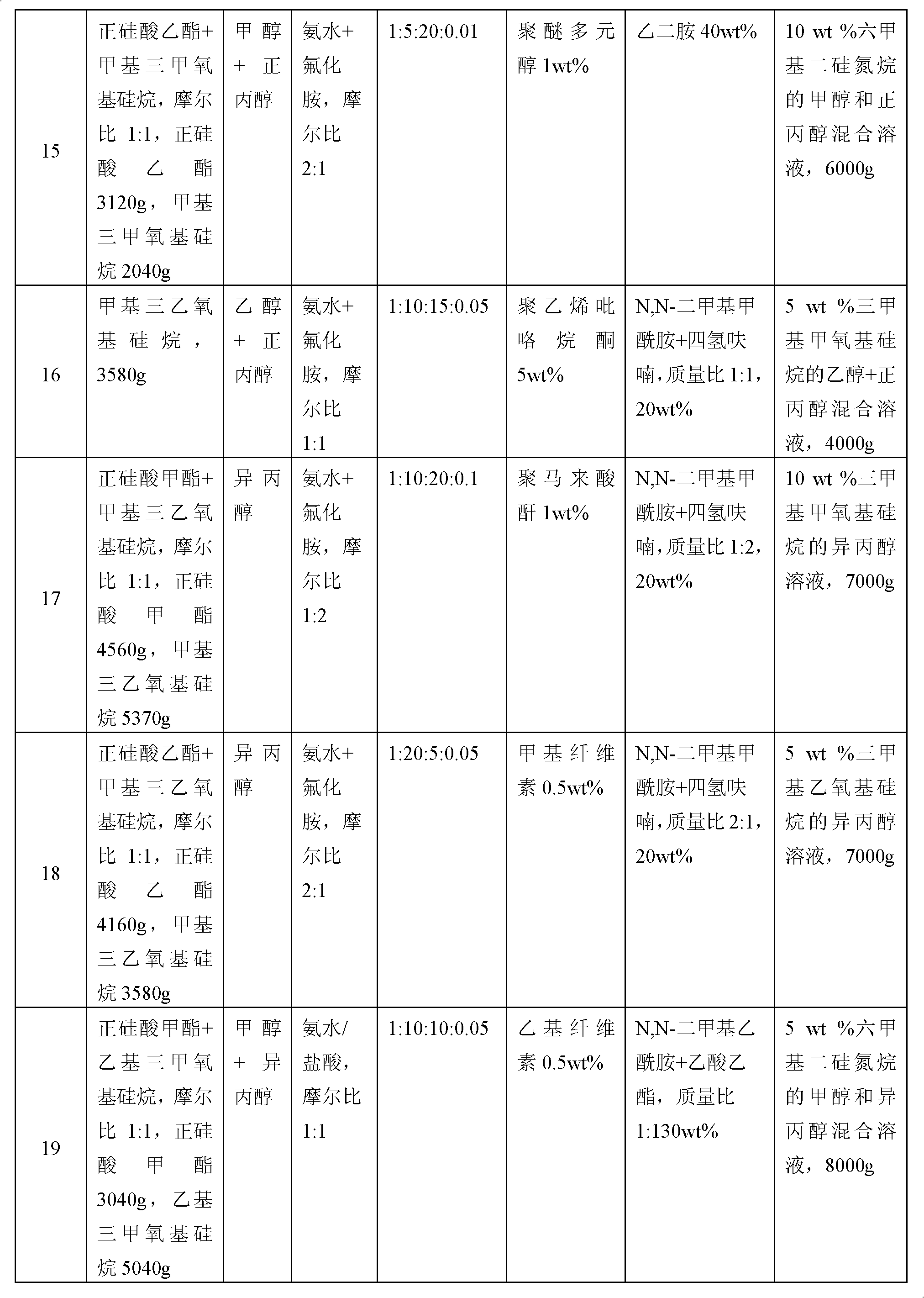

Silica aerogel material and preparation method thereof

The invention provides a novel silica aerogel material which is diaphanous, adiabatic, heat-retaining and noise-proof and a preparation method of the silica aerogel material. The silica aerogel material has the advantages of being high in tenacity strength, high in transparency, flawless, light in mass, low in density, especially big in block and the like. The silica aerogel material besides can be used in the field of energy saving buildings such as glass curtain walls, doors and windows which are heat-retaining, adiabatic and noise-proof, can be further used in the fields such as aerospace, petroleum and petrochemical, new energy resources, ships and refrigeration, and has good application prospect.

Owner:海鹰空天材料研究院(苏州)有限责任公司

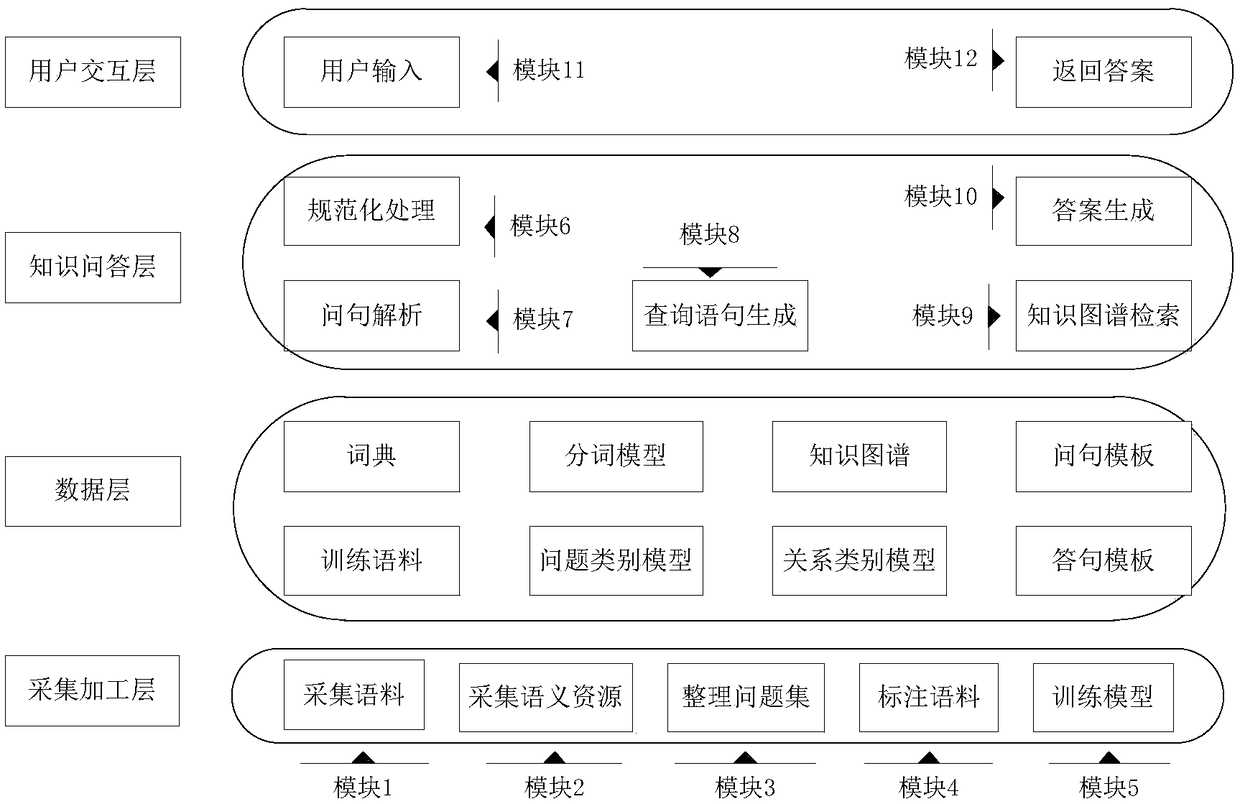

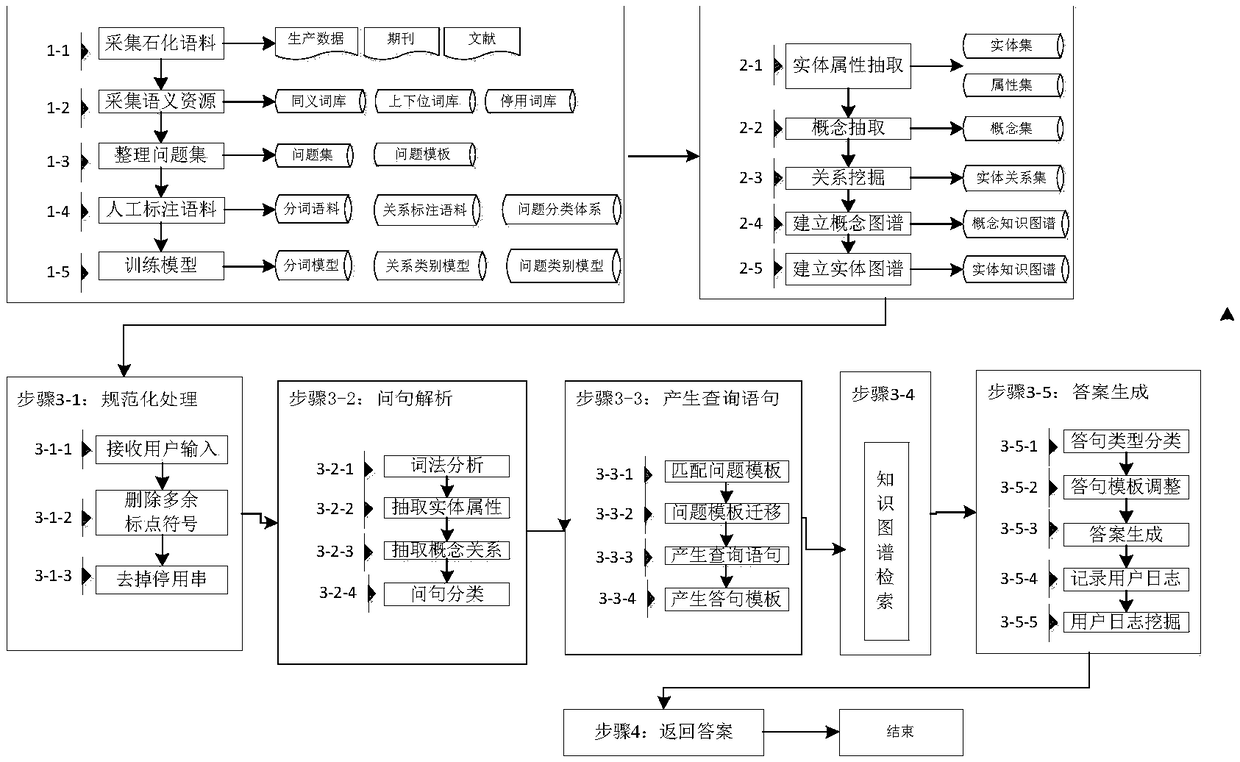

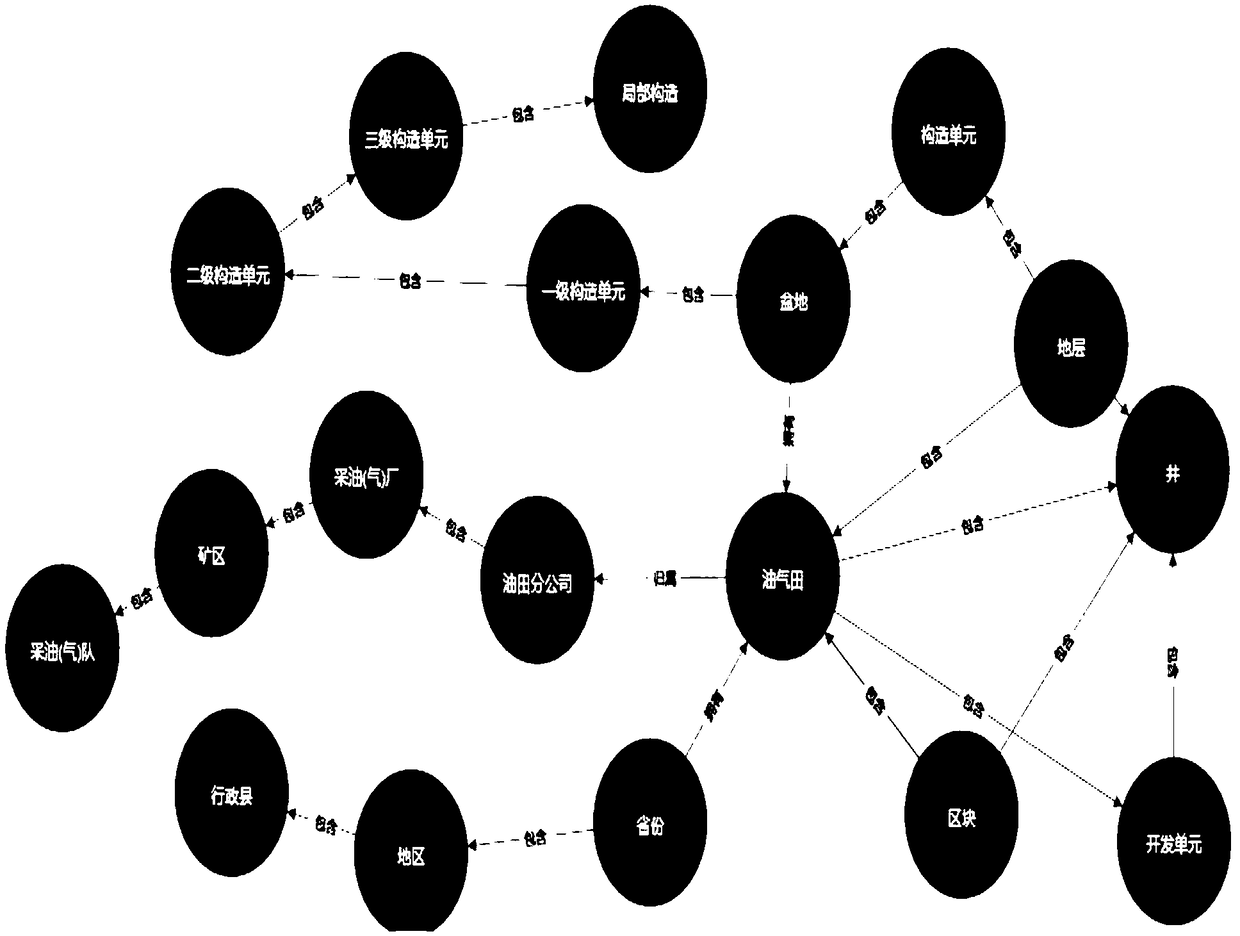

Method for answering questions in petrochemical field based on knowledge map

ActiveCN109492077AImprove experienceHelp work efficiencyDigital data information retrievalSpecial data processing applicationsPetrochemicalQuery statement

The invention discloses a method for answering questions in the petrochemical field based on a knowledge map, which comprises the following steps: constructing conceptual knowledge map and entity knowledge map; receiving the question input by user, segmenting the question, extracting entity, attribute, relation and restriction condition, abstracting the entity into concept, matching the question template and transforming it into structured query statement; query conceptual knowledge map and entity knowledge map, generate answers, match answers to answer sentences template, and transform them into natural language answers. The invention also discloses a petrochemical field question answering system based on knowledge map. The invention can store and express the knowledge in the petrochemical field in the form of knowledge map, establish the connection between the business requirement and the development and production data, provide convenience for the user to obtain the professional knowledge in the form of natural language interactive question answering, improve the user experience, and help to provide the work efficiency of the user.

Owner:北京智通云联科技有限公司

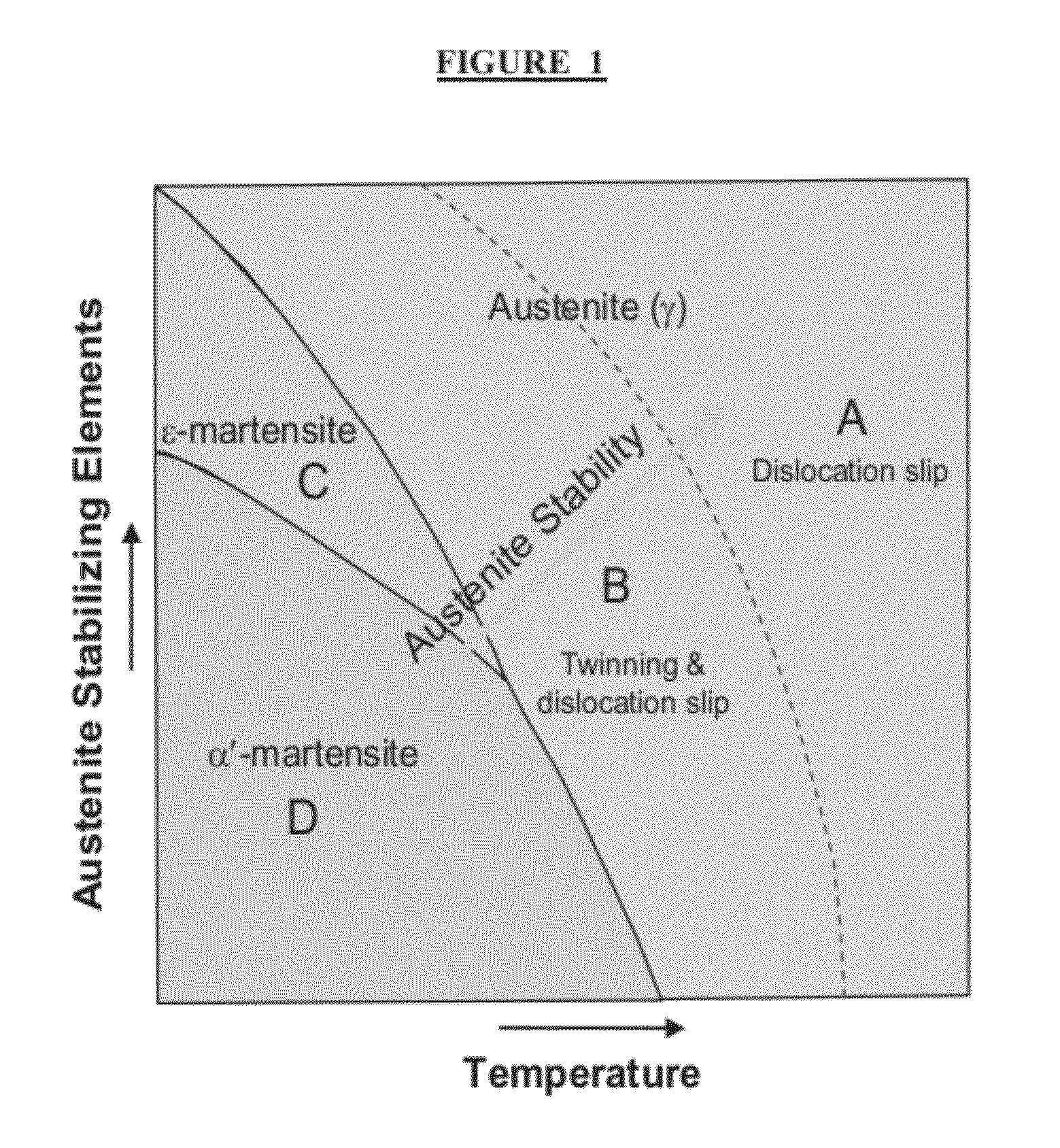

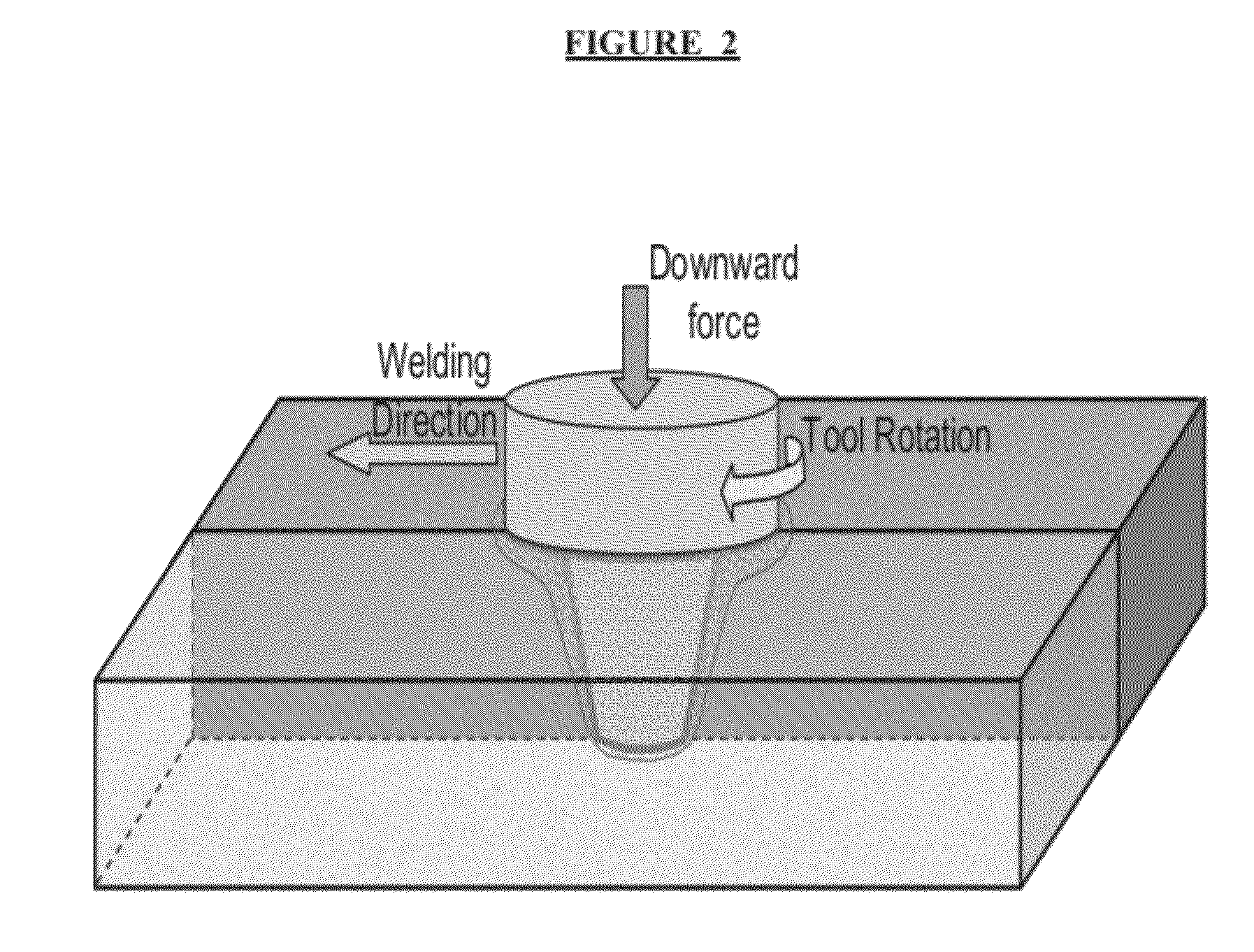

High manganese containing steels for oil, gas and petrochemical applications

Provided are high manganese containing ferrous based components and their use in oil, gas and / or petrochemical applications. In one form, the components include 5 to 40 wt % manganese, 0.01 to 3.0 wt % carbon and the balance iron. The components may optionally include one or more alloying elements chosen from chromium, nickel, cobalt, molybdenum, niobium, copper, titanium, vanadium, nitrogen, boron and combinations thereof.

Owner:EXXON RES & ENG CO

Multifunctional methanol processing method and apparatus

InactiveCN102775261AFlexible planningShort processHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionGasolinePetrochemical

Owner:李小燕

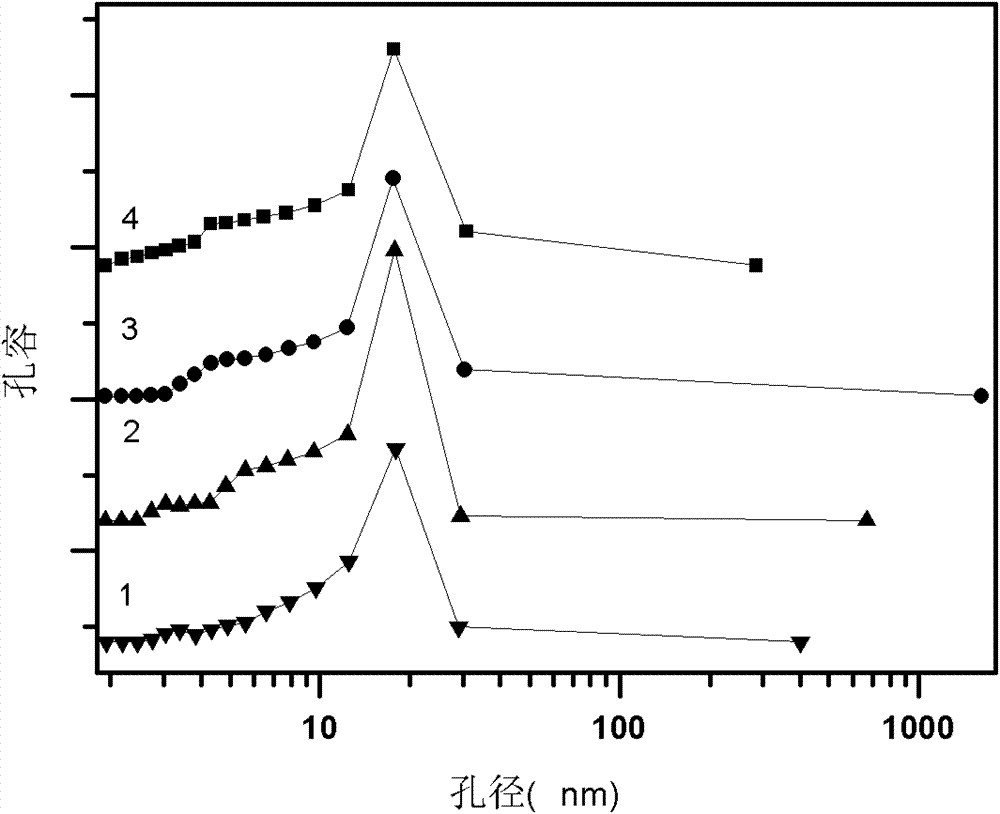

Mesoporous spherical alumina prepared by guiding of template and preparation method thereof

The invention provides mesoporous spherical alumina and a method for preparing the mesoporous spherical alumina by guiding of a template. By the adoption of an oil column forming method, the template with a guiding function is added into aluminum sol during the aluminum sol preparation process; and during the forming and aging processes of the aluminum sol, due to the existence of the template with the guiding function, a large number of meso-structures are prepared in alumina balls. The mesoporous spherical alumina has the following characteristics of: its specific surface is 150-300 m<2> / g; particle diameter is 0.1-5 mm; pore volume is 0.7-1.5 ml / g; holes, hole diameter of which is 2-40 nm, are greater than 97%; bulk density is 0.30-0.80g / cm<3>; and crushing strength is 70-250 N / granule. The mesoporous spherical alumina can be used as a catalyst or a catalyst carrier in the petrochemical industry and the industry of fine chemicals.

Owner:BEIJING UNIV OF CHEM TECH

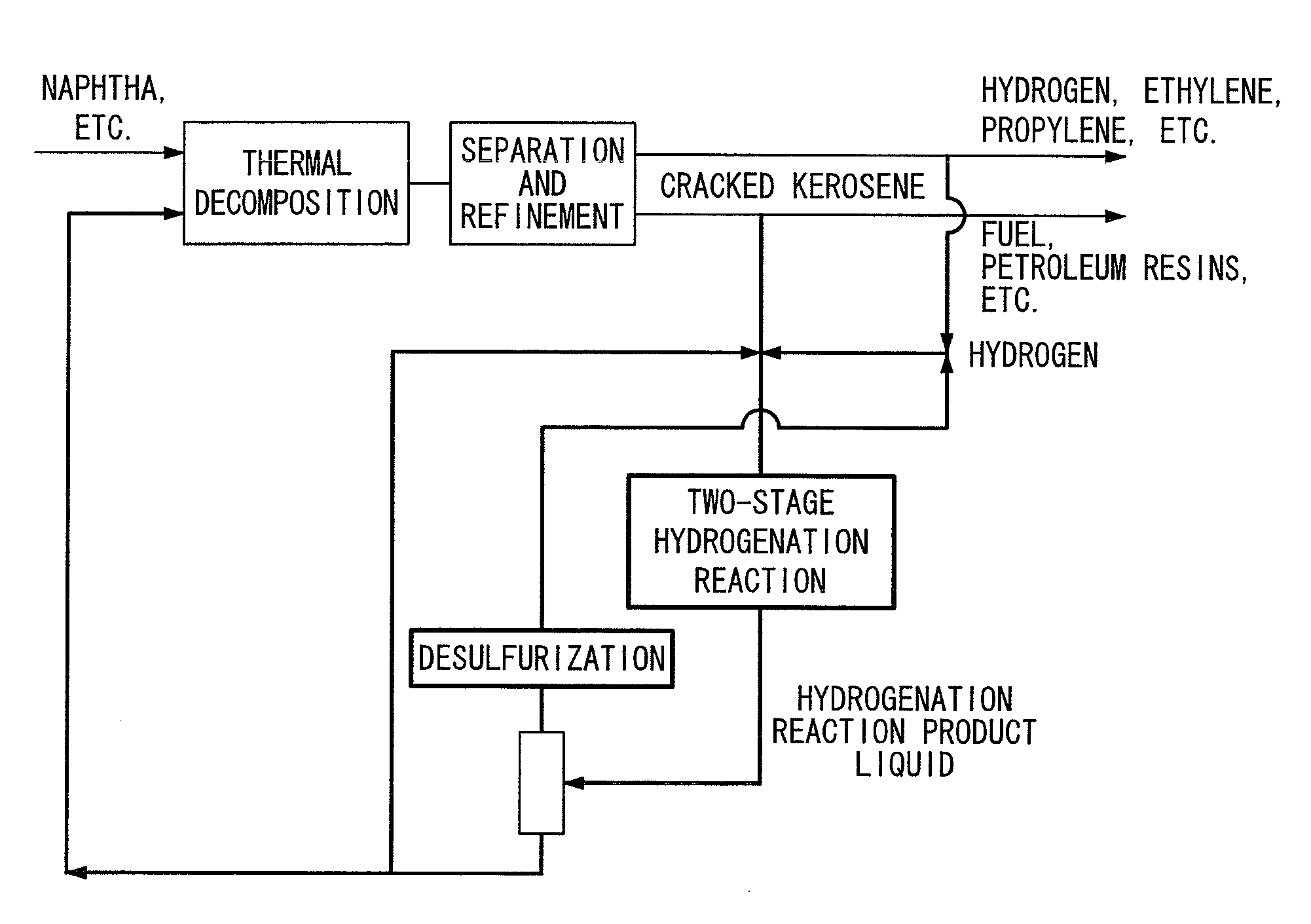

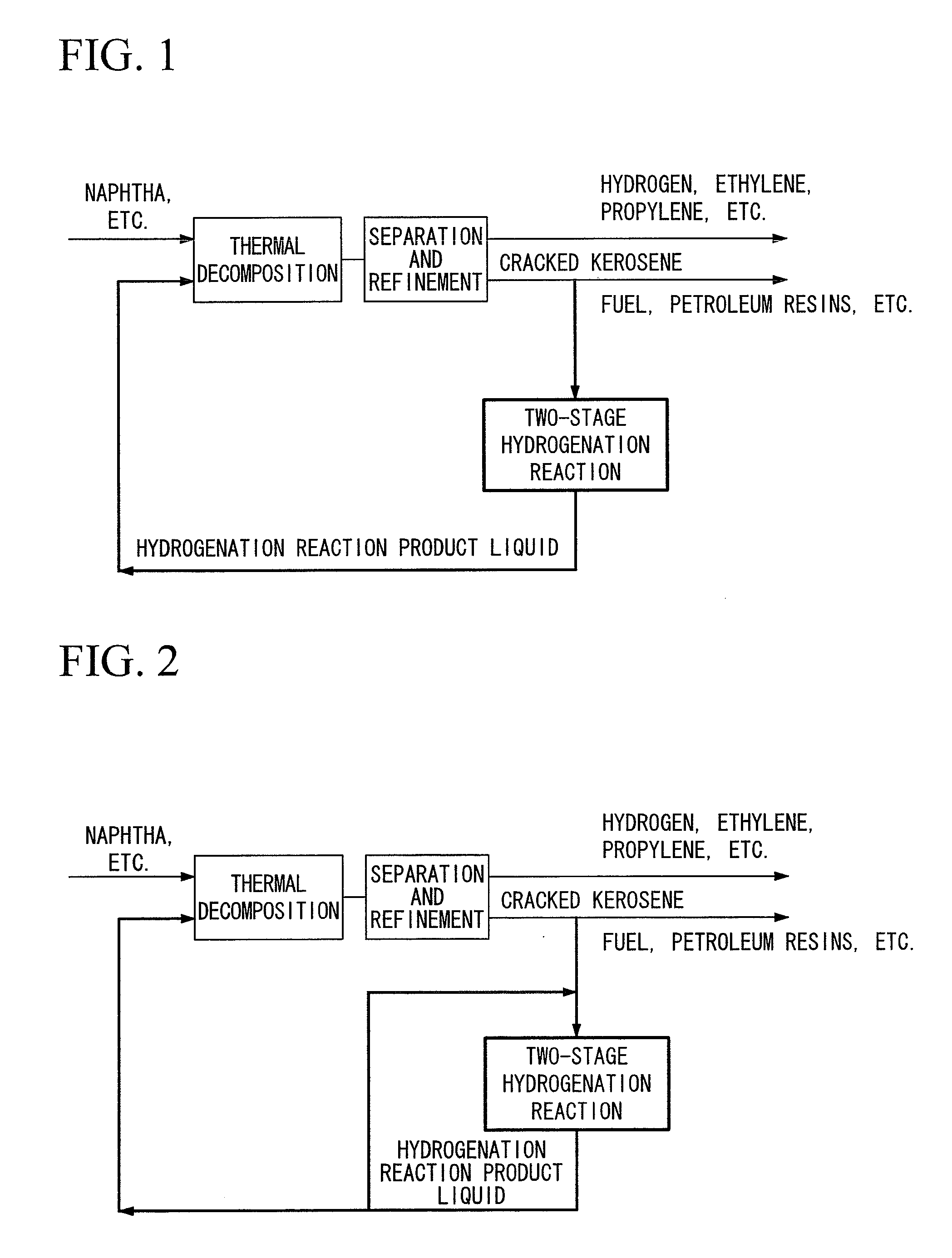

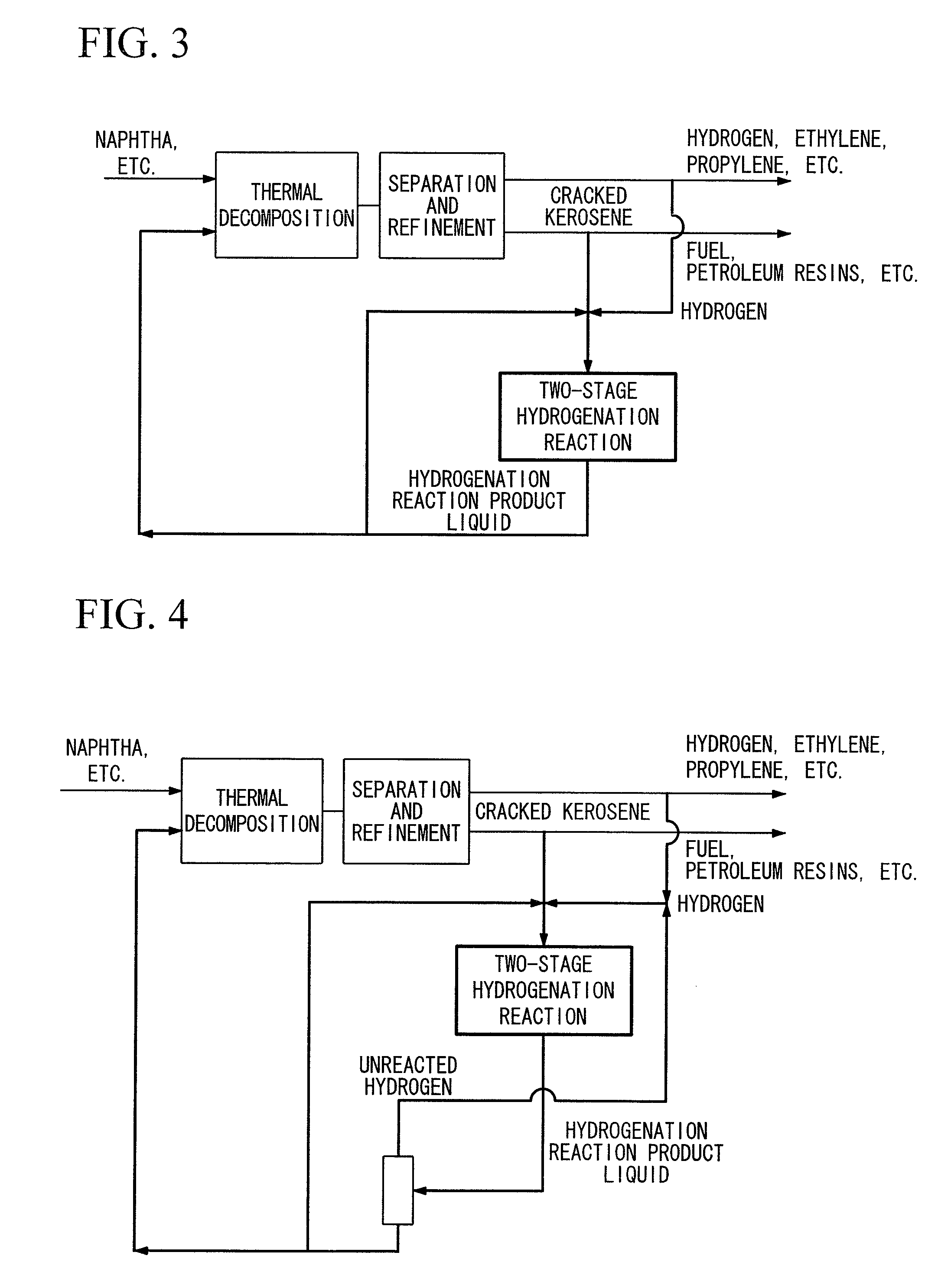

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

Method for separating hydrocarbon-containing gas mixtures using hydrocarbon-resistant membranes

A method of separating or concentrating hydrocarbon-containing gas mixtures such as hydrogen from hydrocarbons, carbon dioxide from hydrocarbons, nitrogen from hydrocarbons, and hydrocarbons from one another using a selectively permeable membrane. The method is well suited to separate hydrocarbon-containing mixtures such as those generated by petroleum refining industries, petrochemical industries, natural gas processing, and the like. The membranes exhibit extremely good resistance to plasticization by hydrocarbon components in the gas mixture under practical industrial process conditions.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Catalyst for C4 liquefied petroleum gas aromatization and its preparing method

InactiveCN1586721ALess modification stepsLow costMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFixed bed

The present invention belongs to the field of catalyst preparation in petrochemical technology, and especially one kind of catalyst for the aromatization of liquefied C4 petroleum gas in fixed bed reactor and its preparation process. Technologically, the catalyst features that its mother substance is high-silicon zeolite with crystal granulation of 10-500 nm and the zeolite is alumina formed and prepared into the hydrogen type catalyst via conventional process, and the hydrogen type catalyst is vapor treated to regulate the acidity and acid treated to expand the pores and restore the pore passage. The catalyst is used in the aromatization of liquefied C4 petroleum gas, and has low reaction temperature, high olefin converting rate and high carbon deposition resistance.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Oleochemical Plasticizers with Thermal and Ultraviolet Radiation Stabilizing Activity for PVC Molding Resins and Process for Obtaining Thereof

The present invention is related with bioplasticizers or primary oleochemical plasticizers and the improved process for obtaining thereof. It refers primarily to epoxydized oleochemical plasticizers produced from vegetable oils, as substitute of traditional petrochemical plasticizers. The process starts with the epoxydized product of natural oils, such as sunflower, linseed, Jatropha curcas, soybean, etc., which are transesterified with an alcohol such as ethylic or methylic, in the presence of a catalyst such as sodium methoxide or sodium hydroxide in order to produce an alkylic esters mixture of the fatty acids that were present in the oil or oil mixture used as raw material in the epoxydized oil production. When the plasticizer obtained by the process already mentioned is used for the formulation of moldable poly(vinyl chloride), PVC, resins; the resulting plastic films get adequate hardness, static and dynamic thermal stability, and plasticizer extractability by solvents, such as n-hexane, gasoline and oil. Besides, when the PVC resin is formulated with a phthalic or terephthalic plasticizers mixture and the bioplasticizer, the bioplasticizer presents a full range solubility and or compatibility with the remainder of the resin compounds. The oxyrane chemical ring of the bioplasticizer is an excellent chemical neutralizer of the HCL that might be formed from the PVC, due to the action or interference of thermal or UV radiation.

Owner:RESINAS & MATERIALES

Upgradation of undesirable olefinic liquid hydrocarbon streams

InactiveUS6153089ASufficient flexibilitySlowly variedCatalytic crackingCatalytic naphtha reformingPetrochemicalLarge pore

A process for converting undesirable olefinic hydrocarbon streams to hydrogen and petrochemical feedstock e.g. light olefins in C2-C4 range and aromatics especially toluene and xylenes, which comprises simultaneous cracking and reforming at olefin rich hydrocarbons using a catalyst consisting of dehydrogenating metal components, shape selective zeolite components and large pore acidic components in different proportions in a circulating fluidized bed reactor-regenerator system having reactor temperature within 450-750 DEG C. and WHSV of 0.1-60 hour-1.

Owner:INDIAN OIL CORPORATION

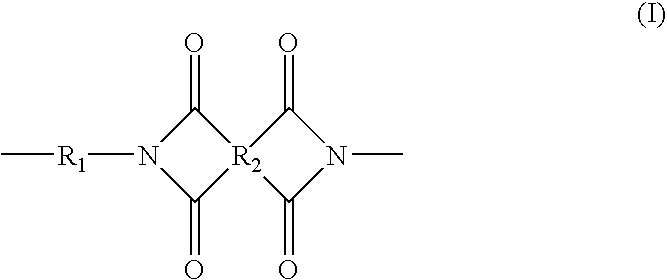

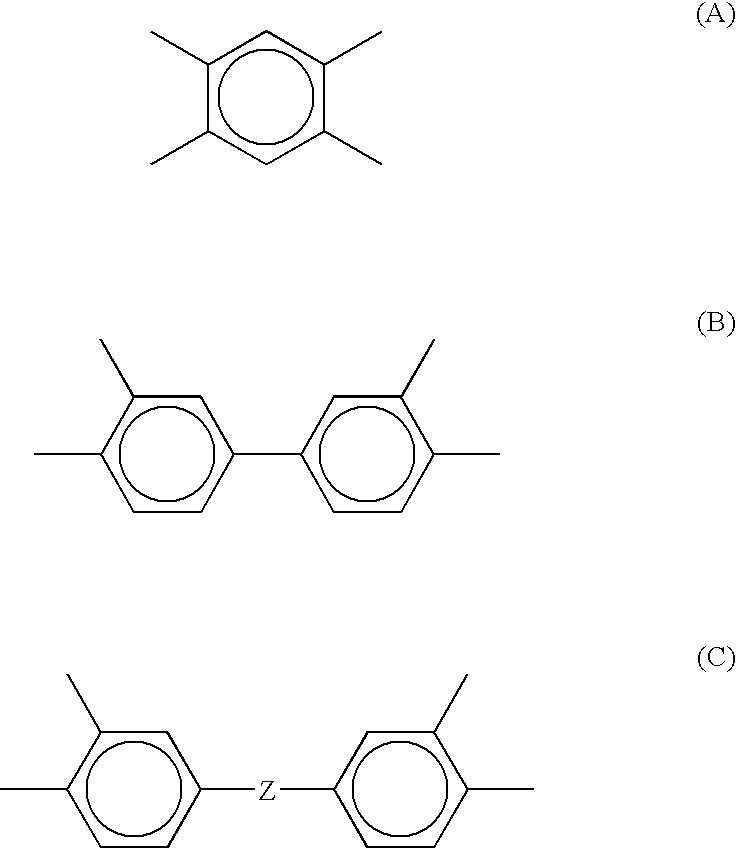

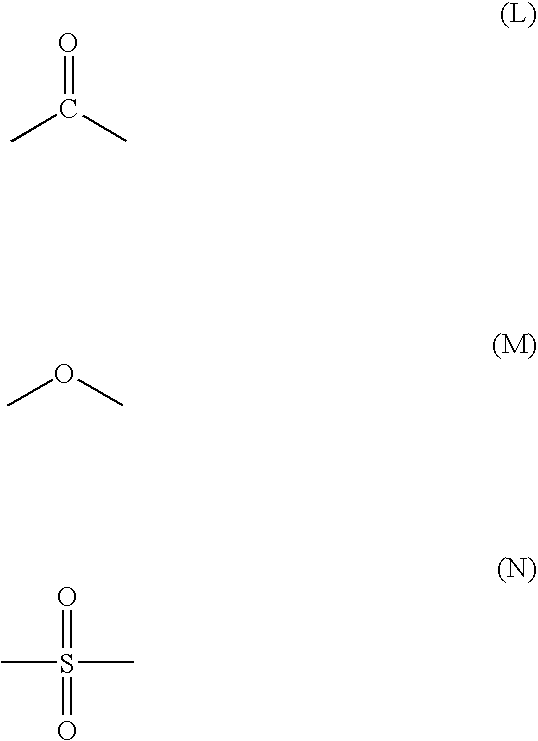

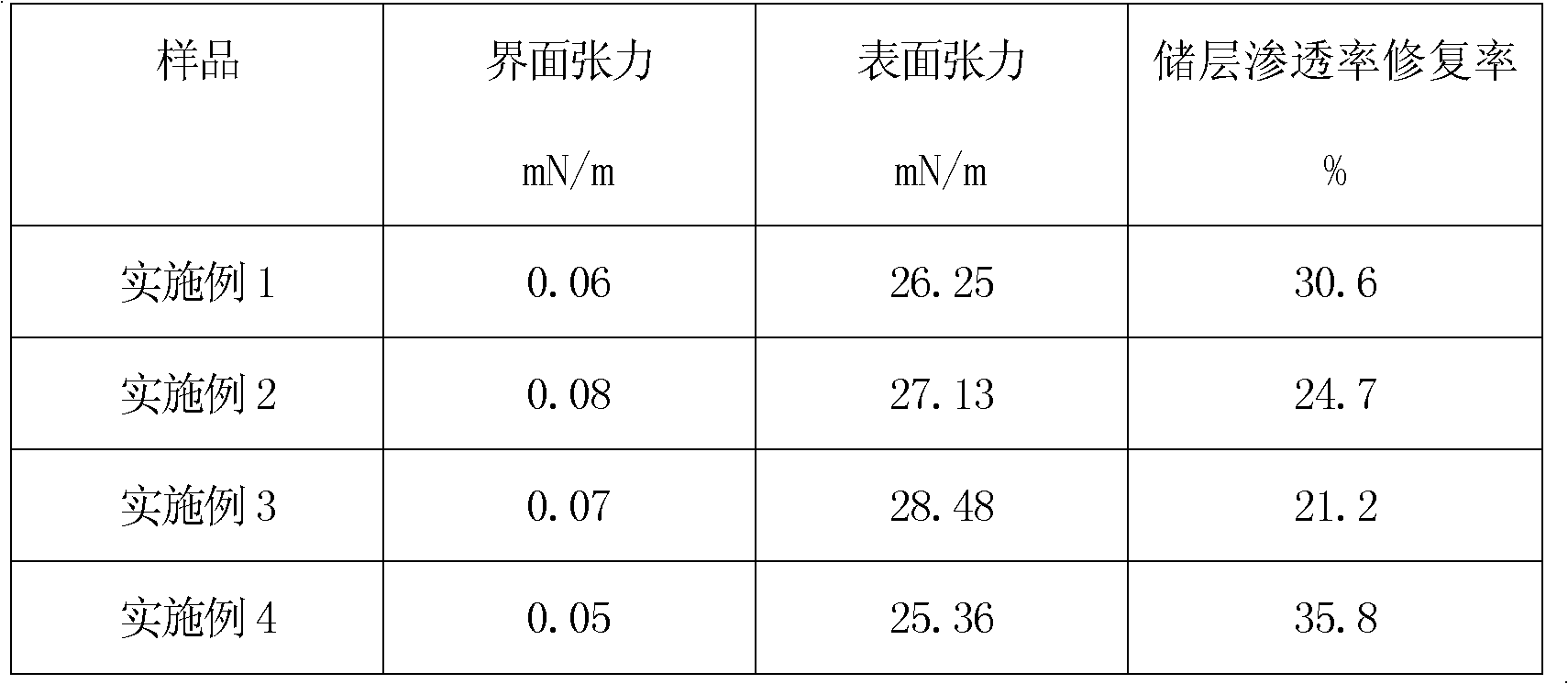

Microemulsion-type fracture acidizing cleanup additive, and preparation method and application thereof

InactiveCN102127414APerformance is not affectedGood compatibilityDrilling compositionType fracturePetrochemical

The invention relates to a microemulsion-type fracture acidizing cleanup additive, and a preparation method and application thereof, belonging to the technical field of petrochemical industry. The microemulsion-type fracture acidizing cleanup additive is prepared from the following components in percentage by weight:5-10% of surfactant, 2-8% of cosurfactant, 35-45% of oil phase, 35-45% of water phase and 3-10% of inorganic electrolyte. The microemulsion-type fracture acidizing cleanup additive provided by the invention has a function of restoring reservoir permeability; and compared with the existing cleanup additive system, the microemulsion-type fracture acidizing cleanup additive provided by the invention can reduce the degree of reservoir damage, which is caused by incompatibility of water locks, residues and formation fluids in the wellbore area of an oil well in the fracture acidizing process of an oil and gas well, by more than 50%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of oil well

InactiveCN102250604AAchieve slow releaseAchieve long-term effectiveDrilling compositionBorehole/well accessoriesPetrochemicalComponents of crude oil

The invention relates to the technical field of petrochemical engineering, in particular to a controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of an oil well. The invention discloses a solid controlled releasing microcapsule for scale and corrosion prevention in the production process of crude oil and wax prevention or viscosity reduction in the production process of the crude oil as well as a preparation method thereof. Filler comprising an inorganic framework and agent components is arranged in a macromolecule composite membrane. The controlled releasing microcapsule has a stable structure comprising an inside inorganic framework support and an outer-layer macromolecular composite membrane wrapping film, can be used for realizing the slow release of the agent and achieving the aim of maintaining the agent effective for a long term as well as the functions of corrosion inhibition and dispersion. With proper volume and density, the controlled releasing microcapsule can be prevented from being taken away by an extraction solution and can be added through a sleeve; and the controlled releasing microcapsule is simple in process and is strong in maneuverability. According to the controlled releasing microcapsule, volatile matters and harmful components which do harm to the human health are avoided; various components can be basically and slowly dissolved; the labor intensity of workers is reduced; and one-time agent addition can ensure stable operation for 30-90 days.

Owner:门正国

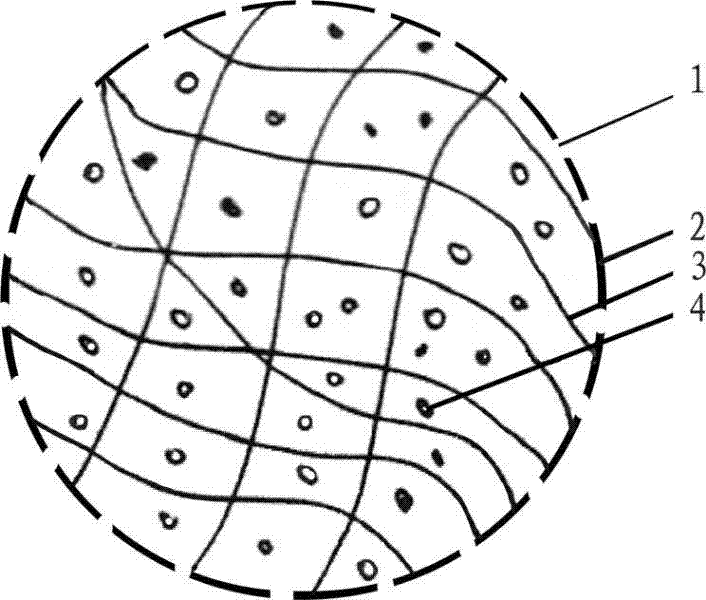

Corrosion and scale inhibitor for cooling water in petrochemical industry

ActiveCN102603086AStrong targetingLow phosphine contentScale removal and water softeningChemical industryPetrochemical

The invention belongs to the technical field of chemical industry, and relates to a cooling water corrosion inhibitor, in particular to an efficient composite corrosion and scale inhibitor which can remarkably reduce corrosion and scaling phenomena of the cooling water of a petrochemical system. The corrosion and scale inhibitor is prepared by evenly mixing organic phosphine carboxylic acid corrosion inhibitor, organic multi-element phosphine acid corrosion and scale inhibitor, polymer scale inhibitor, metal ion succimer, surface active agent, zinc salt, functionality additive and water. The corrosion and scale inhibitor prepared from the components has low phosphine content and excellent corrosion and scale inhibition performance, can prolong the service life of devices, improve the repeated utilization rate of cooling water and reduce the water resource consumption.

Owner:山东京博众诚清洁能源有限公司

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

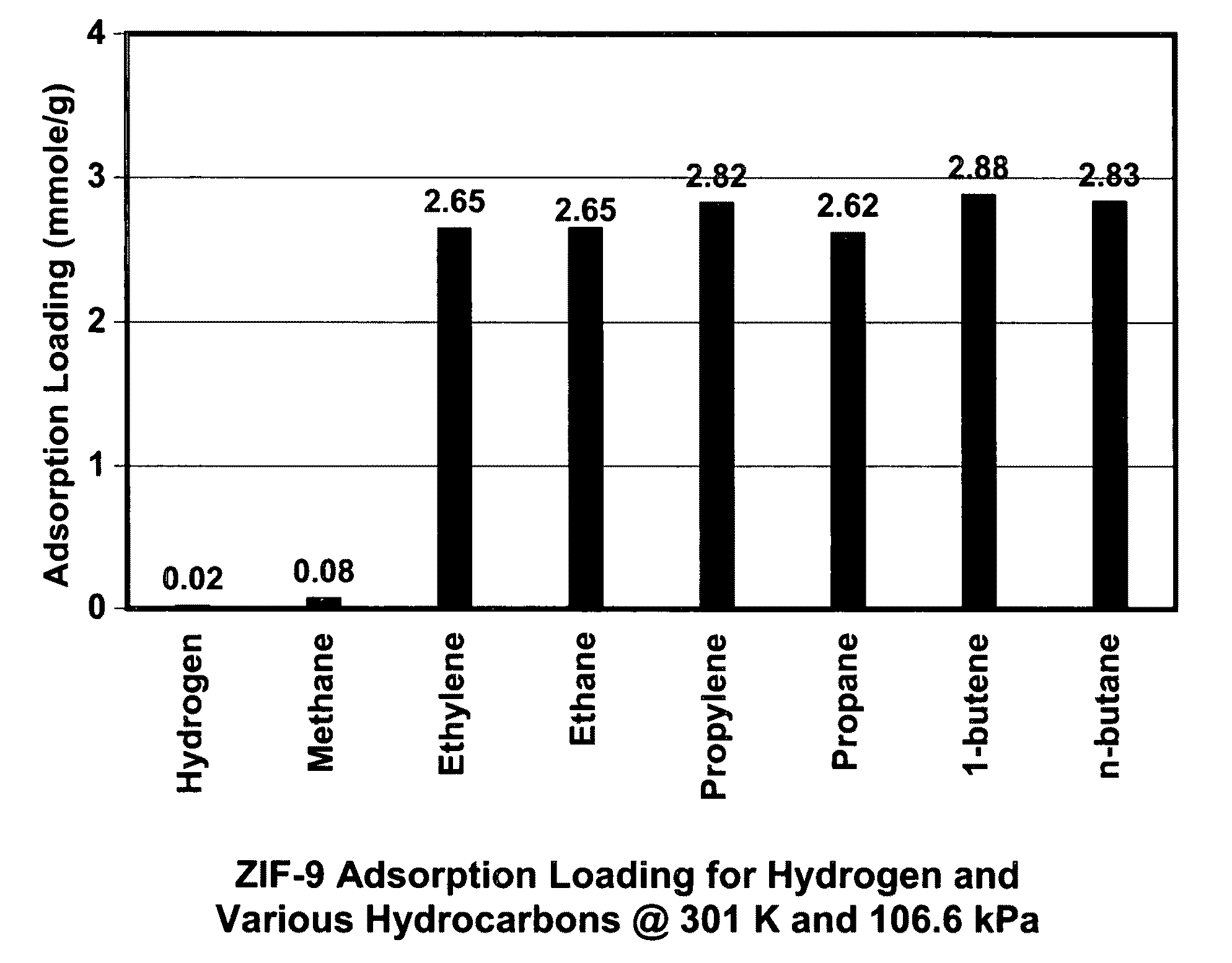

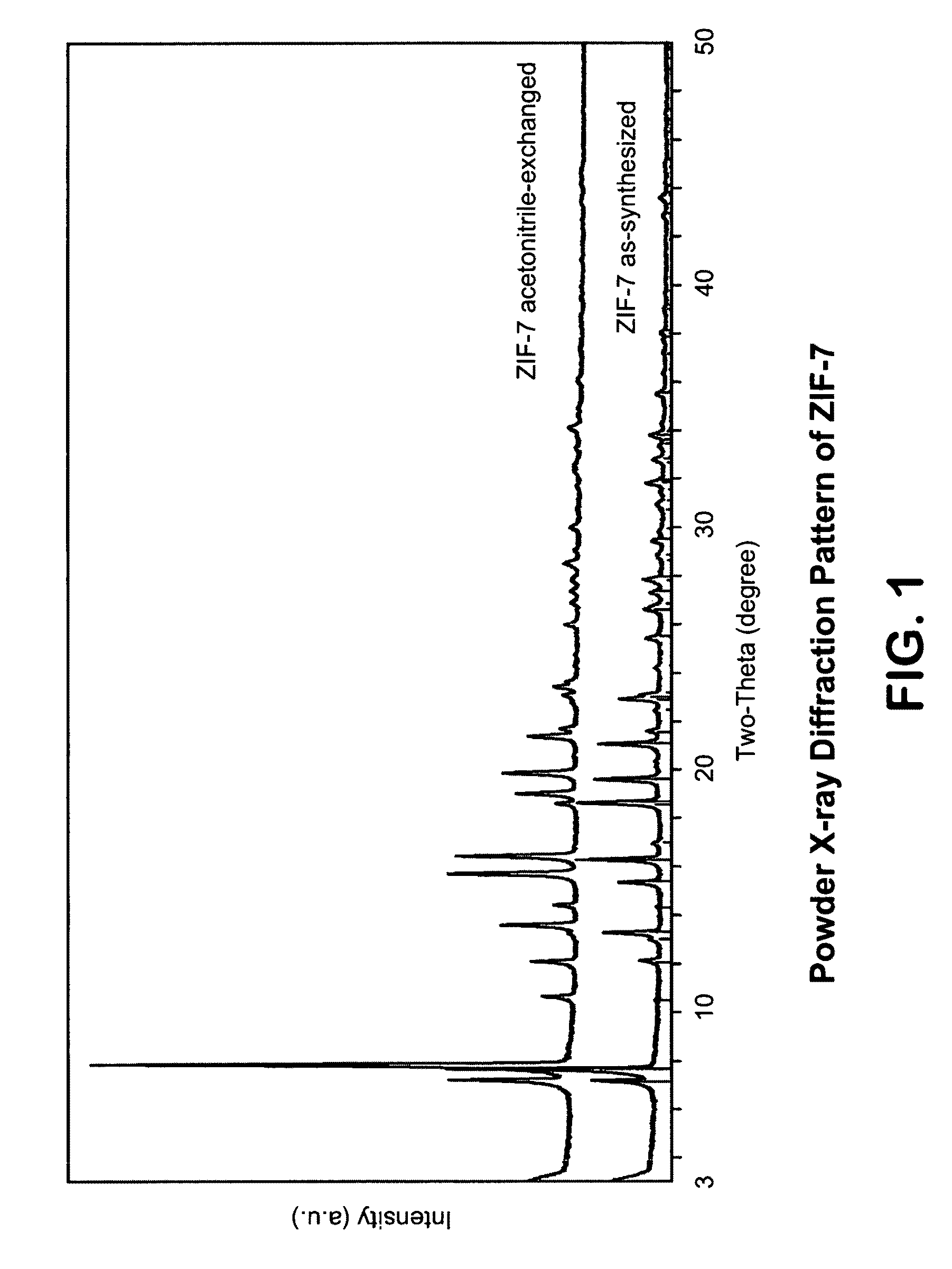

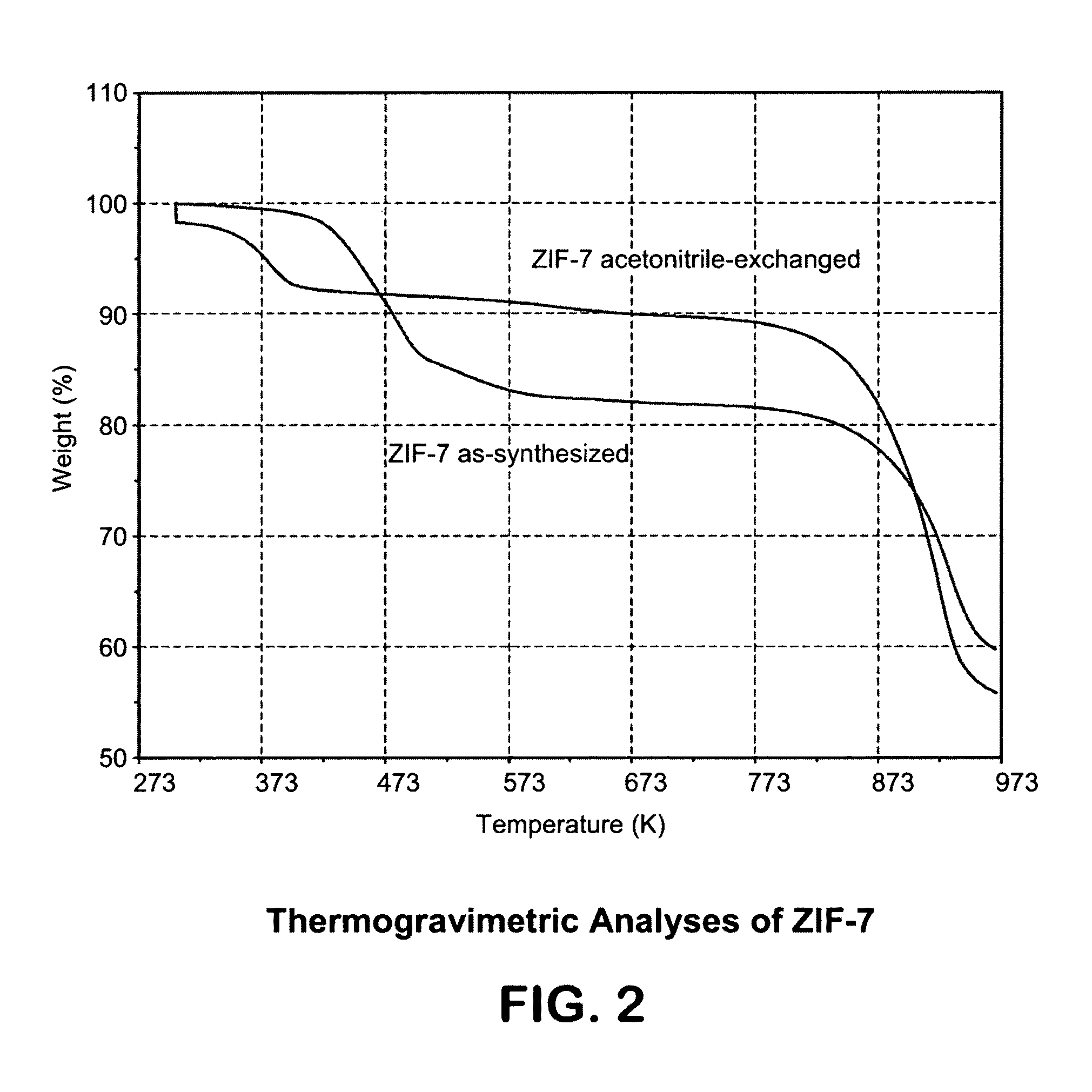

Separation of hydrogen from hydrocarbons utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of hydrogen (“H2”) hydrocarbons in streams containing both hydrogen and hydrocarbons (e.g. methane, ethylene, ethane, propylene, propane, etc.) utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in either a pressure swing adsorption process, a temperature swing adsorption process, or a membrane separations process to separate hydrogen from hydrocarbons present in hydrogen production streams or petrochemical / petroleum refining product streams and intermediate streams.

Owner:EXXON RES & ENG CO

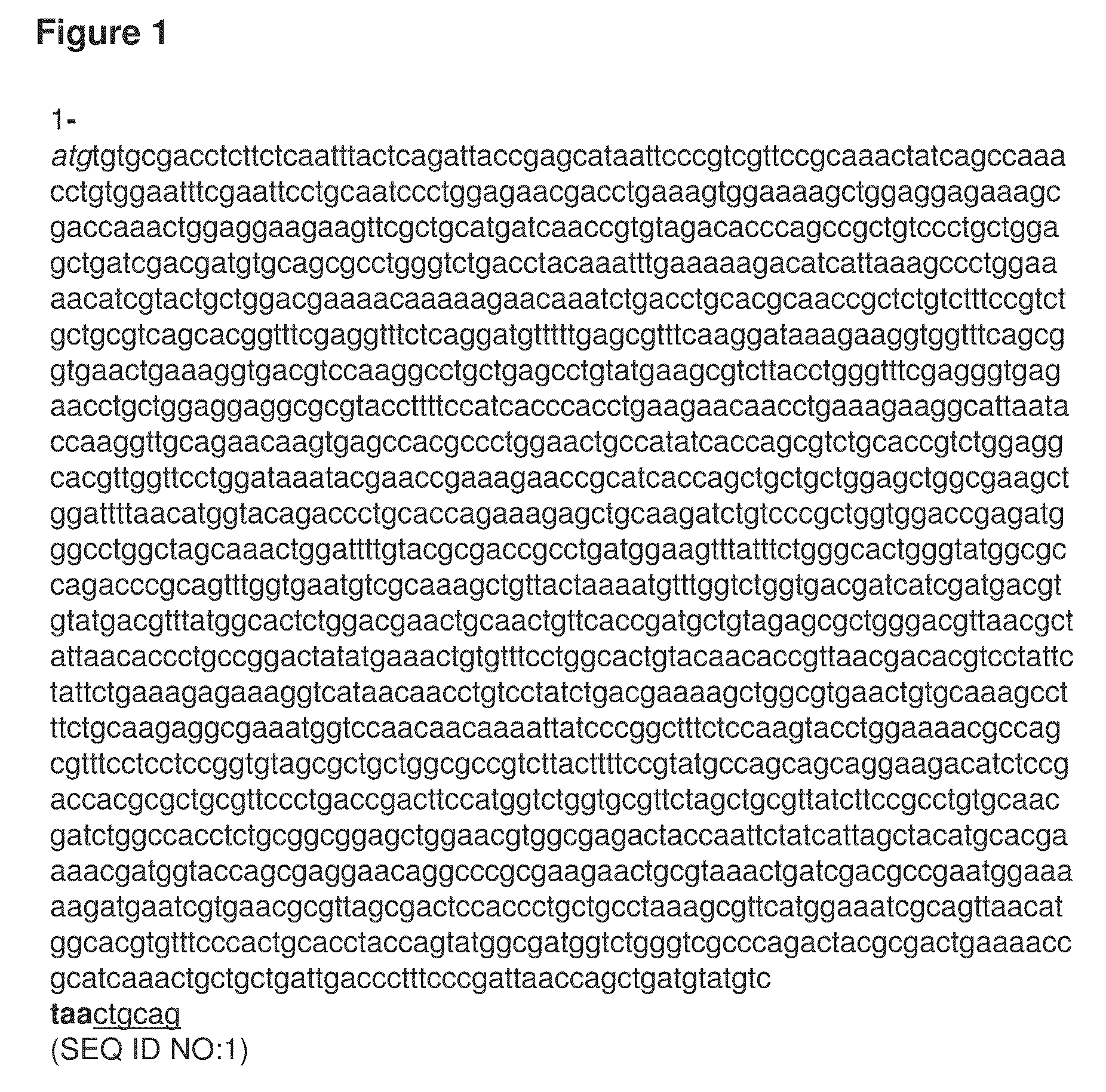

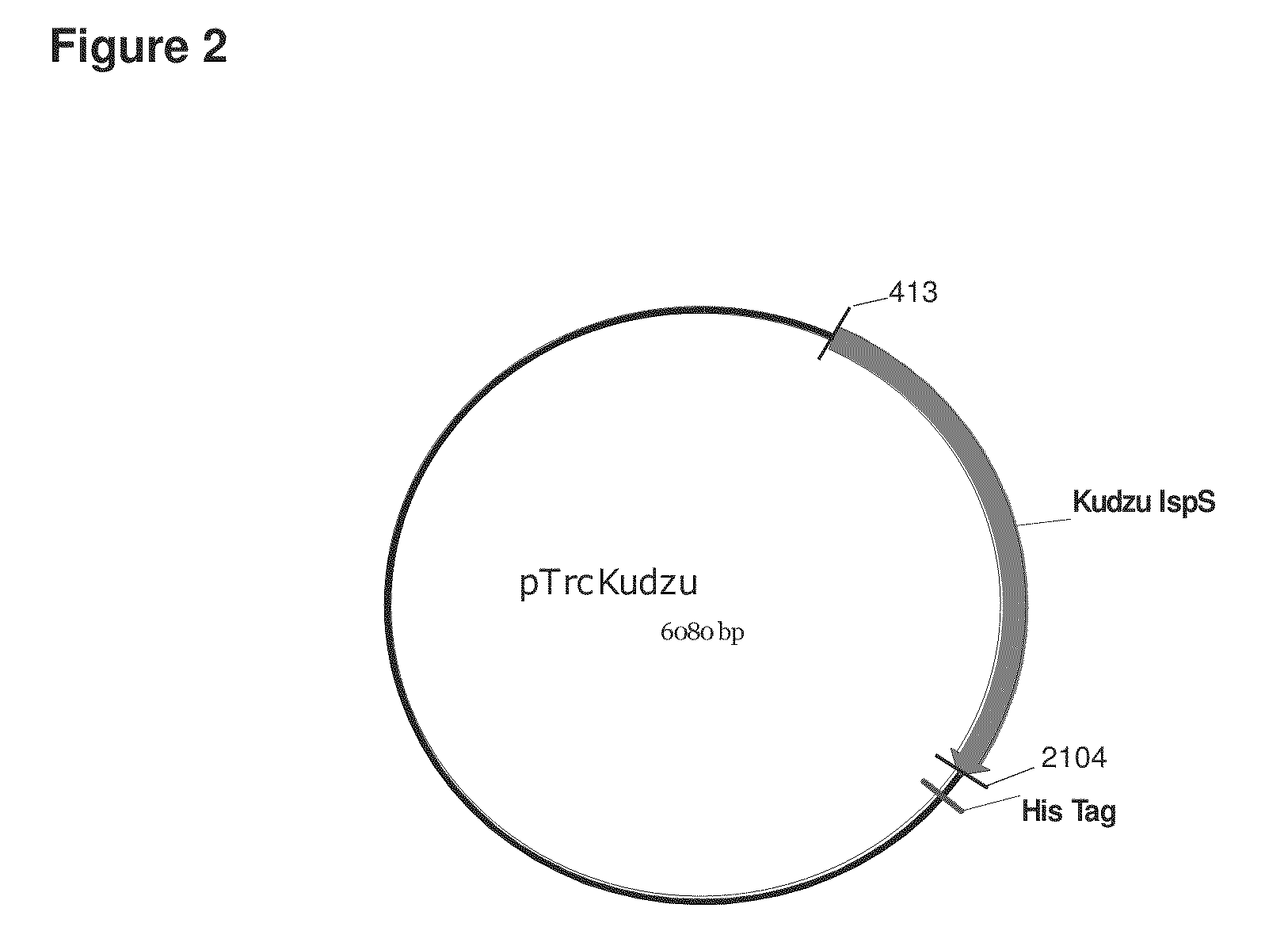

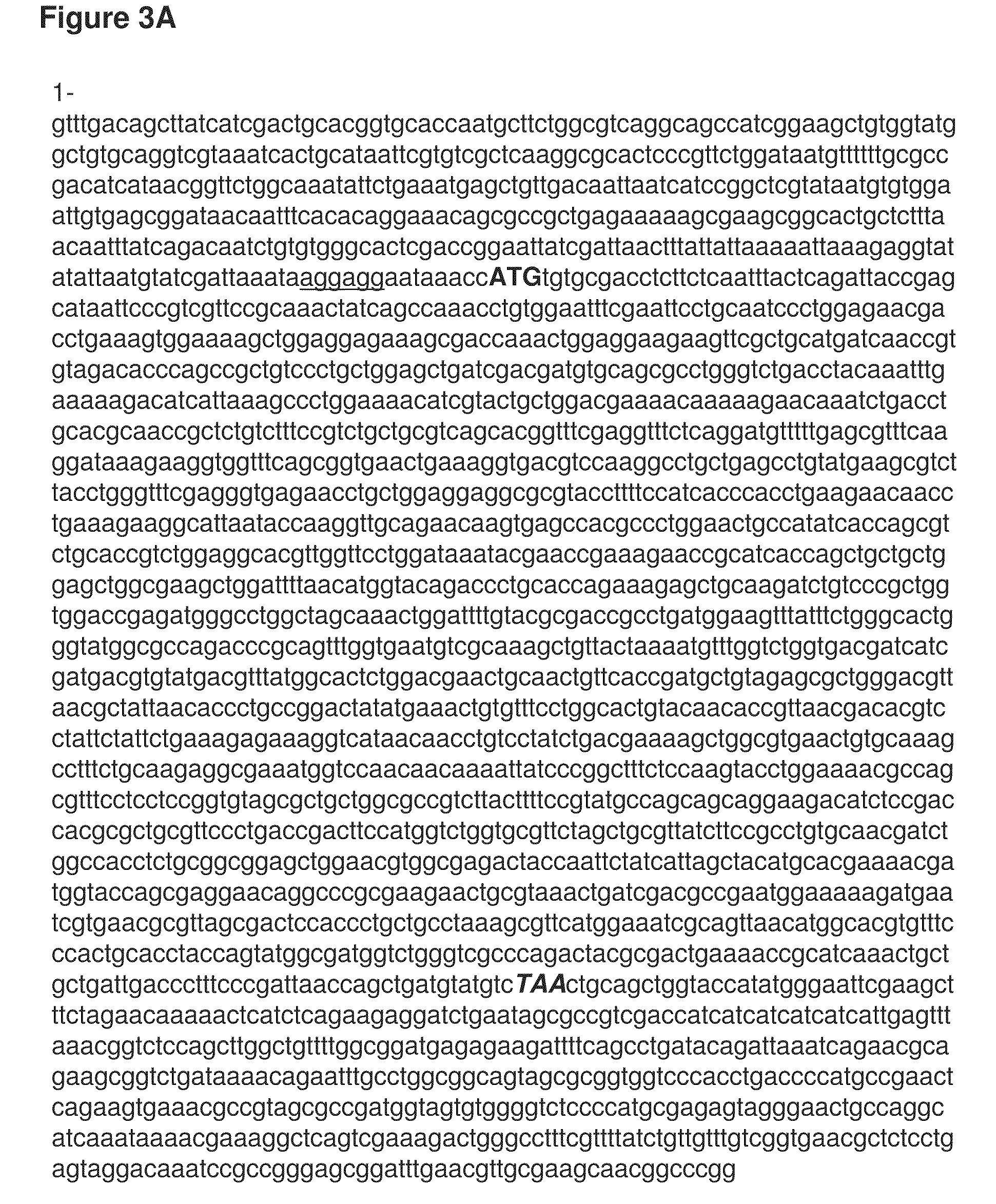

Conversion of prenyl derivatives to isoprene

InactiveUS20100113846A1HydrolasesHydrocarbon from oxygen organic compoundsPetrochemicalCultured cell

The present invention provides methods for producing derivatives from cultured cells. In addition, the present invention provides methods for conversion of prenyl deerivatives, obtained from biological or petrochemical sources, to isoprene by employing chemical or biological catalysts. The present invention also provides compositions that include the cultured cells or isoprene or prenyl derivatives produced there from.

Owner:THE GOODYEAR TIRE & RUBBER CO

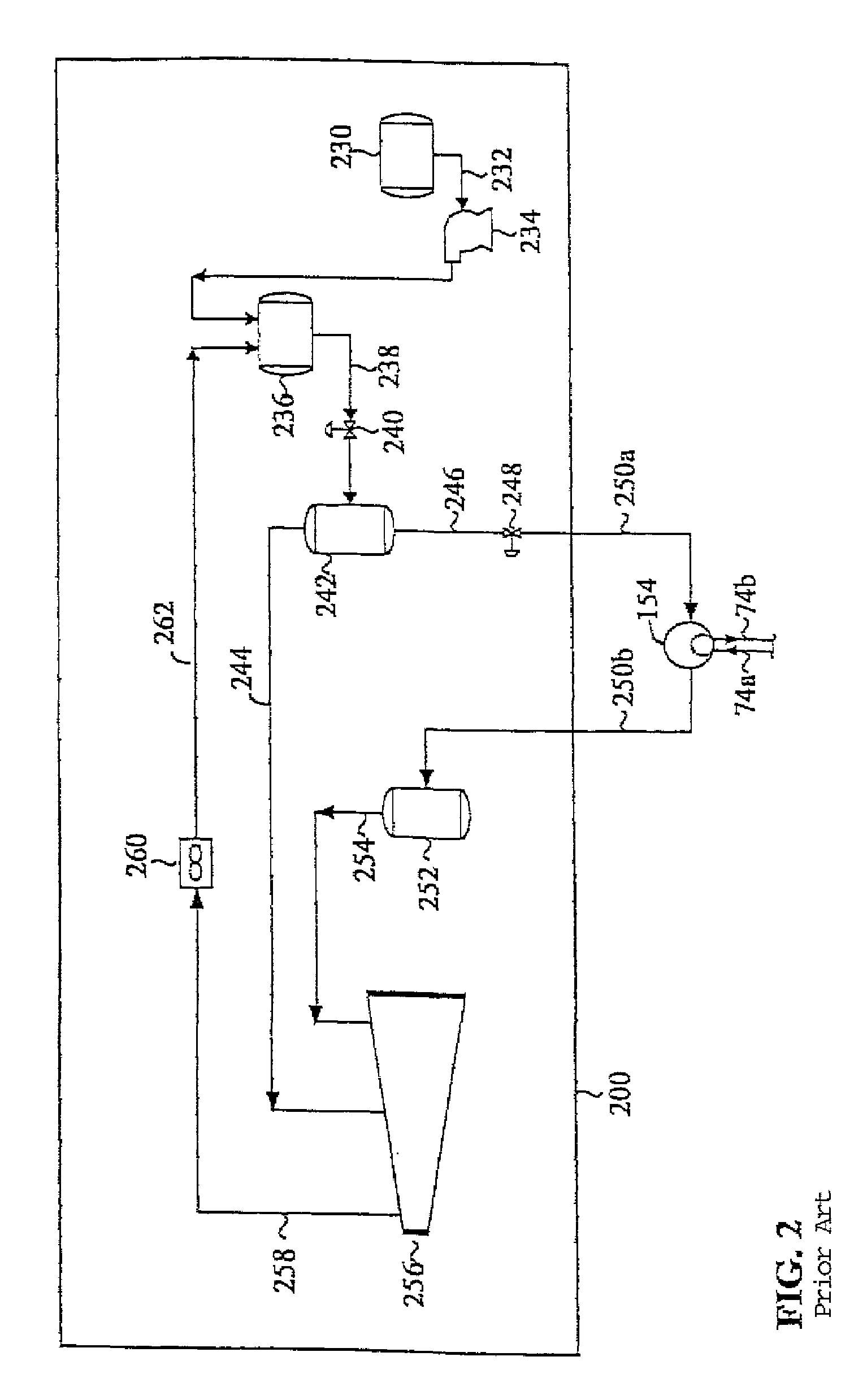

Internal refrigeration for enhanced NGL recovery

InactiveUS7257966B2Improve efficiency and economyEasy to separateSolidificationLiquefactionFractionating columnPetrochemical

The present invention is directed to methods for improving the efficiency of processes for the recovery of natural gas liquids from a gas feed, e.g., raw natural gas or a refinery or petrochemical plant gas stream. These methods may be employed with most, if not all, conventional separation methods using distillation towers, e.g., a demethanizer and / or deethanizer column. The methods of the present invention involve installing an internal refrigeration system consisting of an open cycle refrigerant withdrawn from a distillation column and a closed cycle refrigerant derived from the open cycle refrigeration system. A separator is installed downstream of the recycle compressor discharge cooler in the open cycle refrigeration scheme. At least a portion of liquid withdrawn from this separator is used as a closed cycle refrigerant by indirect heat exchange with the inlet gas or other process streams. Thus a closed refrigeration cycle enhances the performance of the open refrigeration cycle.

Owner:IPSI

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

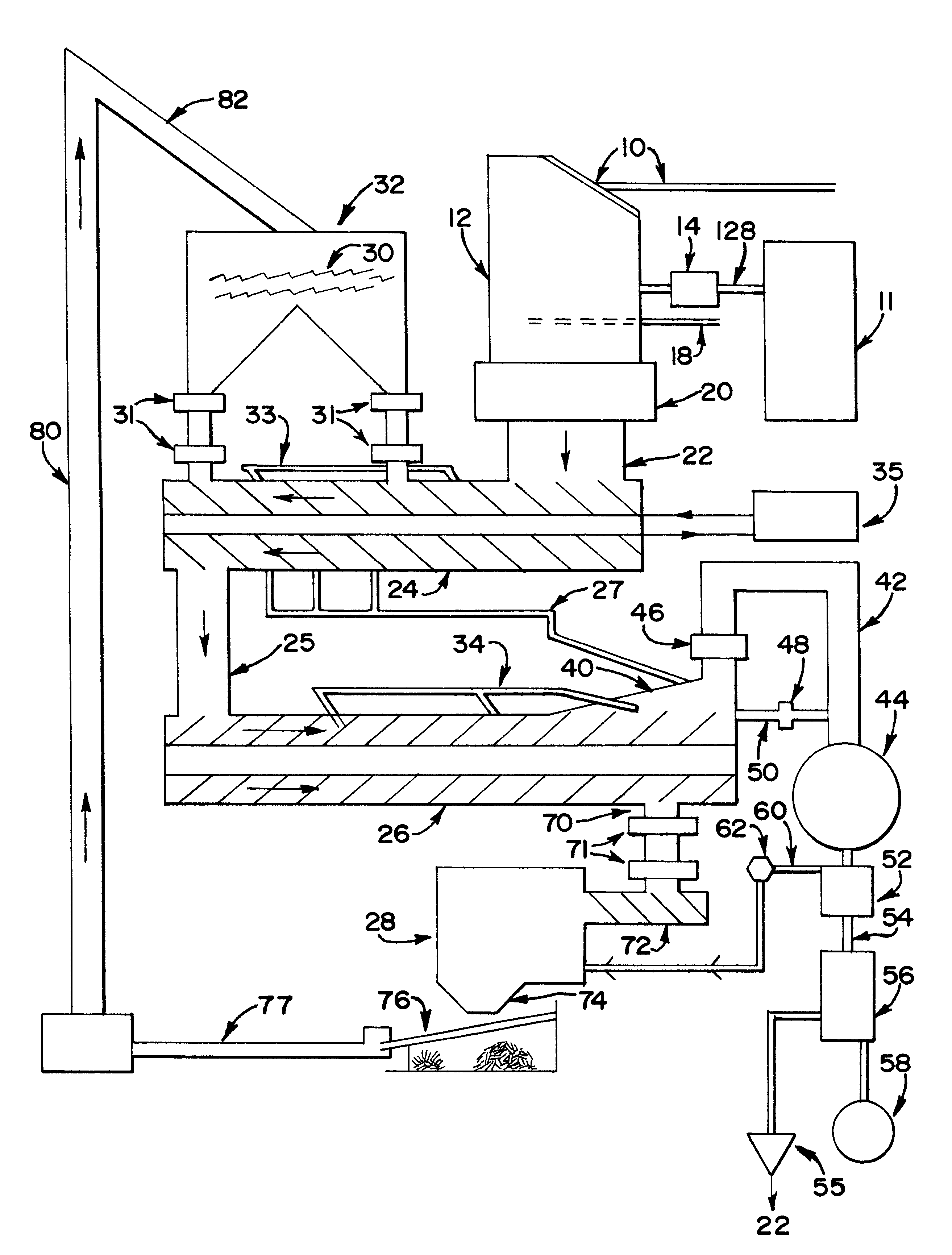

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

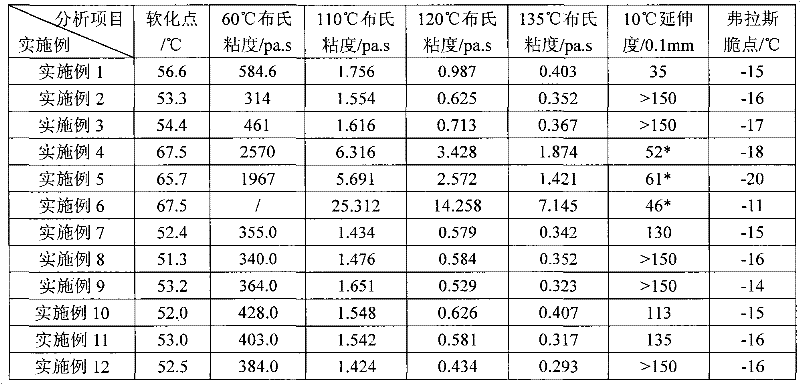

Warm mixed asphalt cement and preparation method thereof

ActiveCN102532920AWith viscosity reducing effectHas a lubricating effectIn situ pavingsClimate change adaptationEnvironmental resistanceChemical industry

Owner:PETROCHINA CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com