Low Grade Heat Recovery from Process Streams for Power Generation

a technology of process streams and heat recovery, applied in the direction of water feed control, steam engine plants, lighting and heating apparatus, etc., can solve the problems of insufficient value of residual heat in overhead streams, rejection of significant heat content of such low grade heat sources, etc., to achieve greater efficiencies and economies of scale, and improve flexibility in design and plot space planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

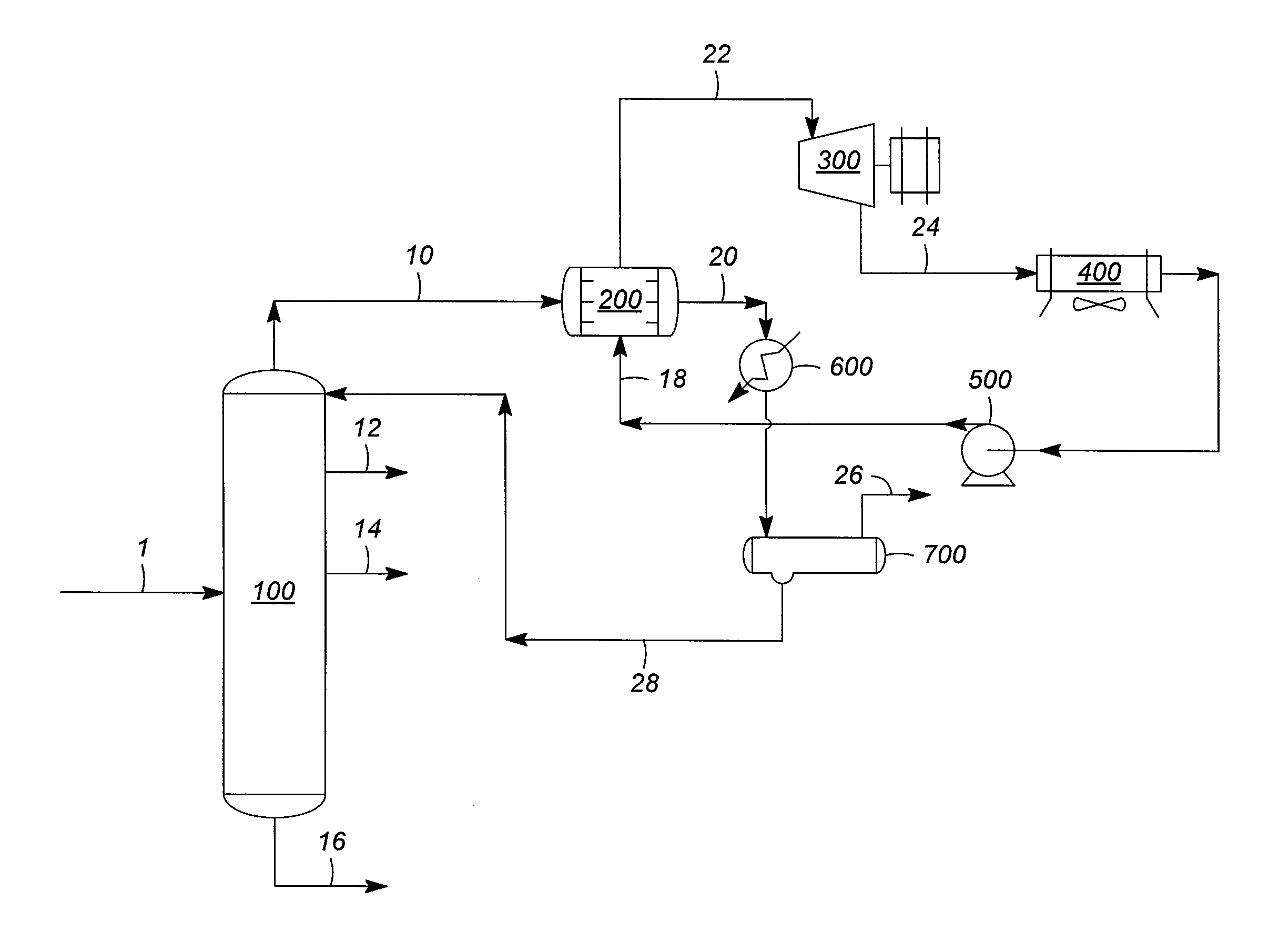

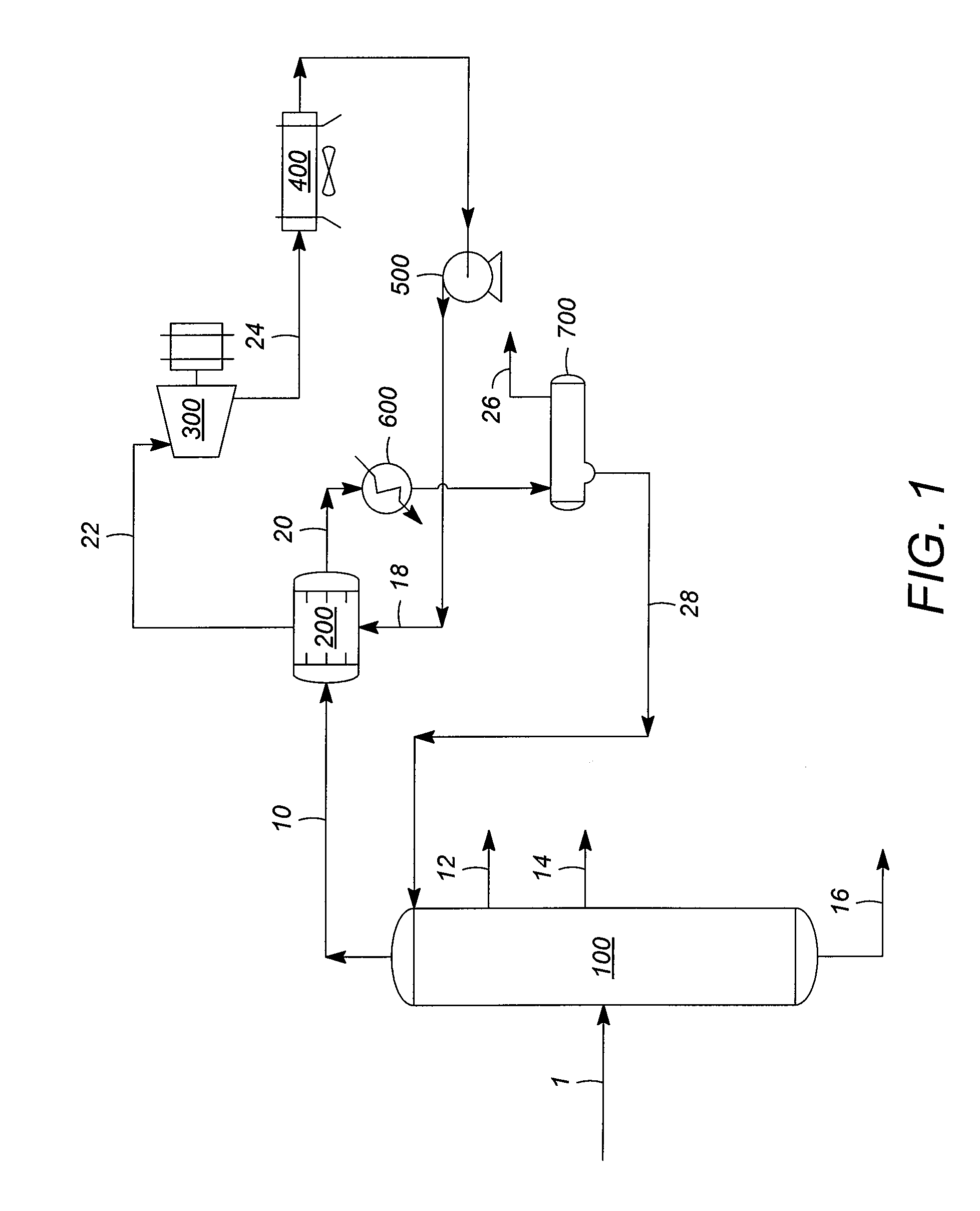

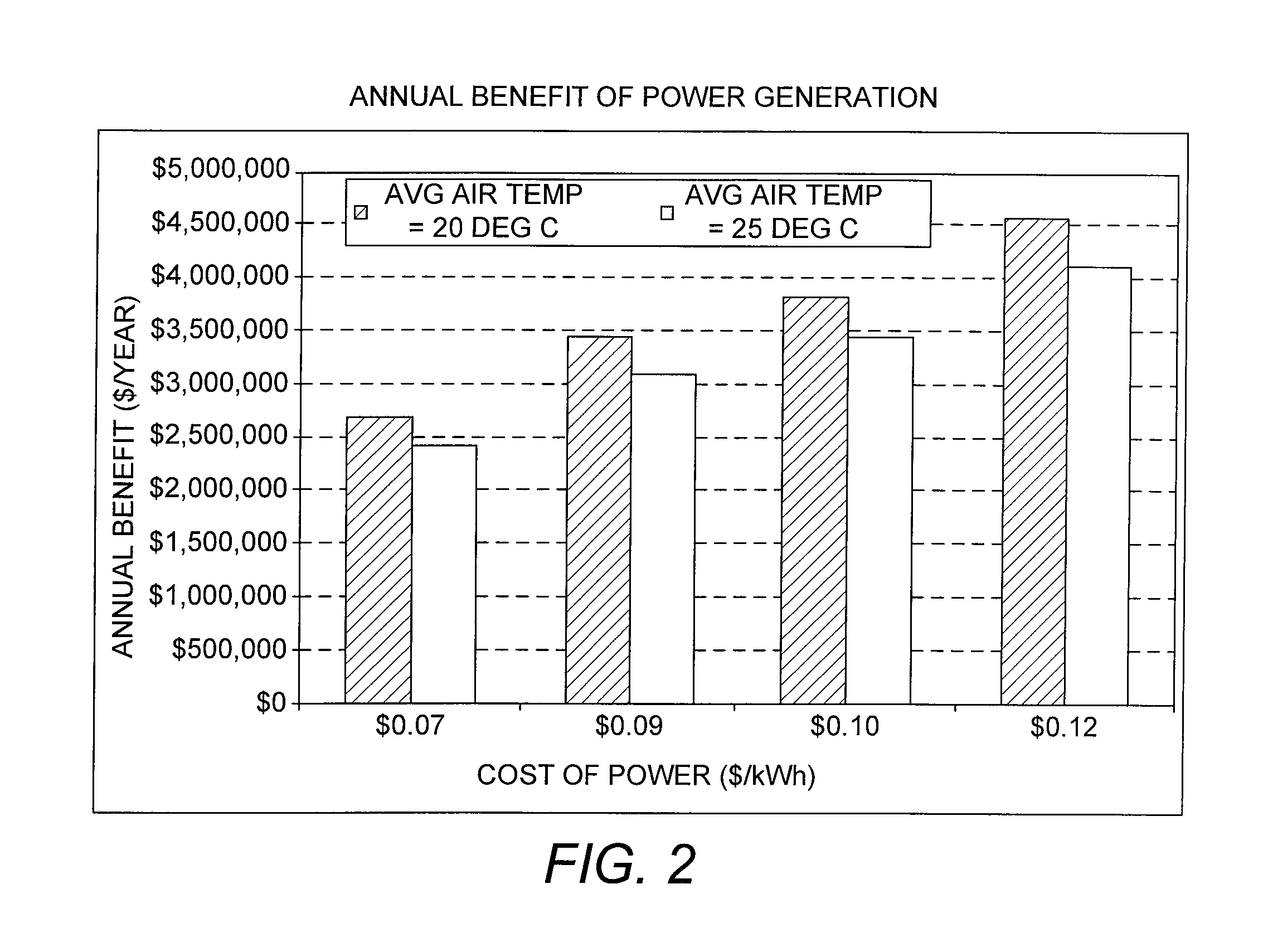

[0046]The economics of generating electricity were investigated, using an Organic Rankine Cycle (ORC) and a low grade heat source from a commercial refining process stream. In particular, this stream was the main fractionation column overhead product of a hydrocracking process, exiting the column at a temperature of 126° C. (259° F.). Normally, this stream is cooled using an air cooled exchanger to reject 231 GJ / hr (55.1 Gcal / hr) of low grade heat and achieve a cooler outlet temperature of 91° C. (196° F.).

[0047]Using Unisim® Design Suite R390 (Honeywell International, Inc., Morristown, N.J.) an ORC process was simulated, in which the overhead product was exchanged against the organic fluid 1,1,1,3,3-pentafluoropropane (HFC-245fa) for evaporation of this fluid and utilization of the evaporated fluid in a turbine and generator to obtain electricity. The condensation of this fluid in an air condenser downstream of the turbine and pumping of the condensed fluid back to the evaporator w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com