Patents

Literature

780 results about "Vapor liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquid or solid does not have to boil to release a vapor. Vapor is responsible for the familiar processes of cloud formation and condensation. It is commonly employed to carry out the physical processes of distillation and headspace extraction from a liquid sample prior to gas chromatography.

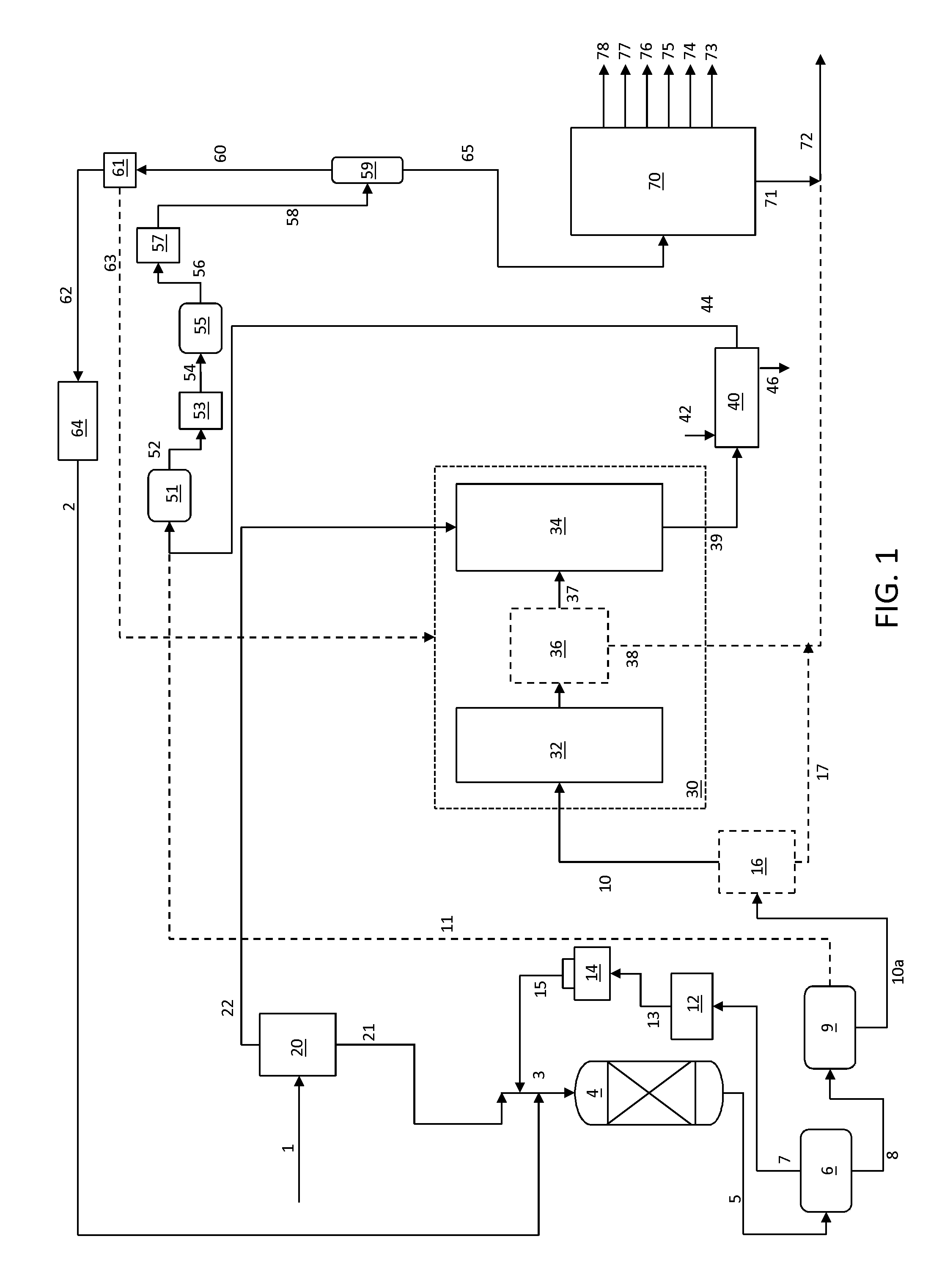

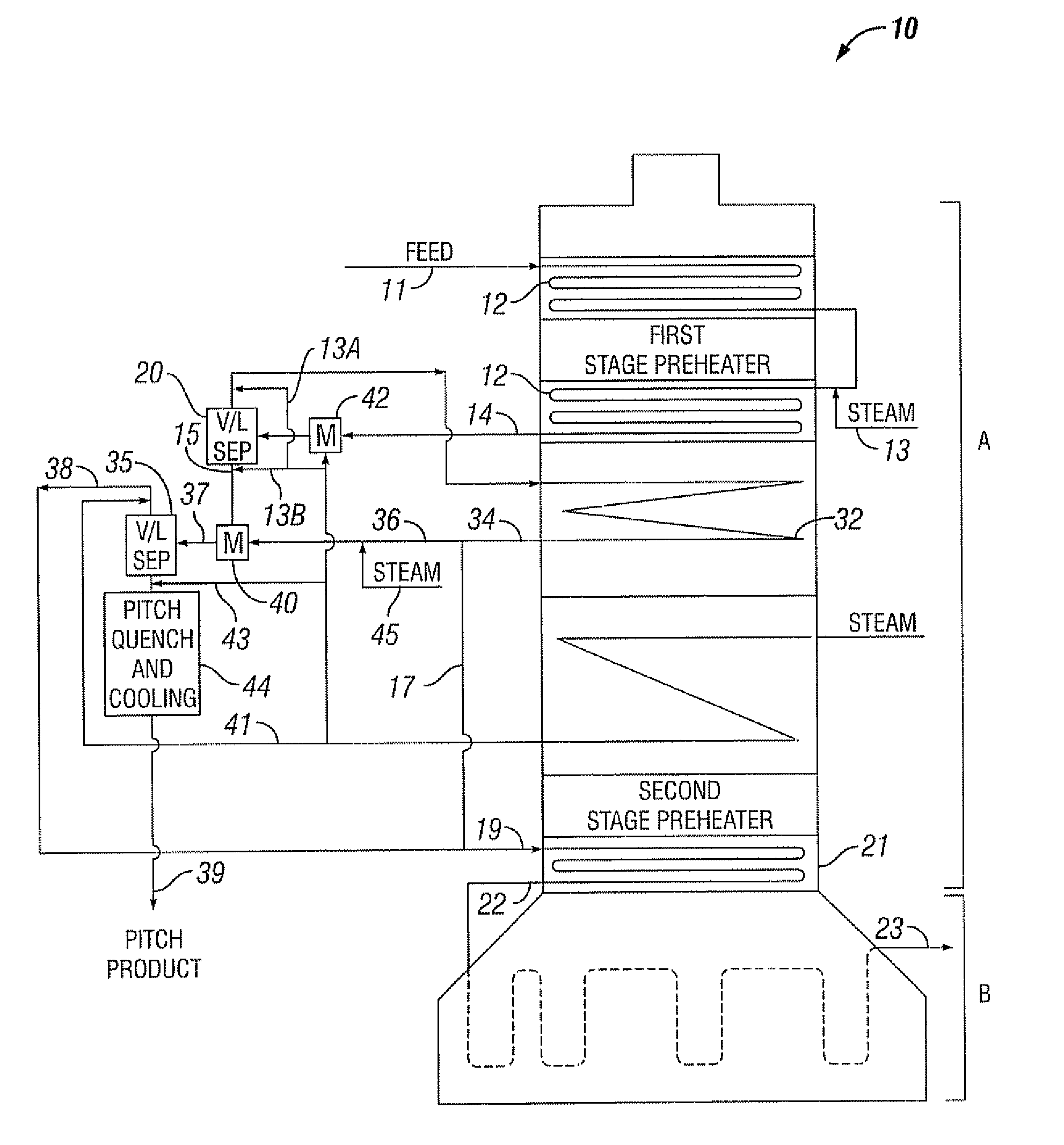

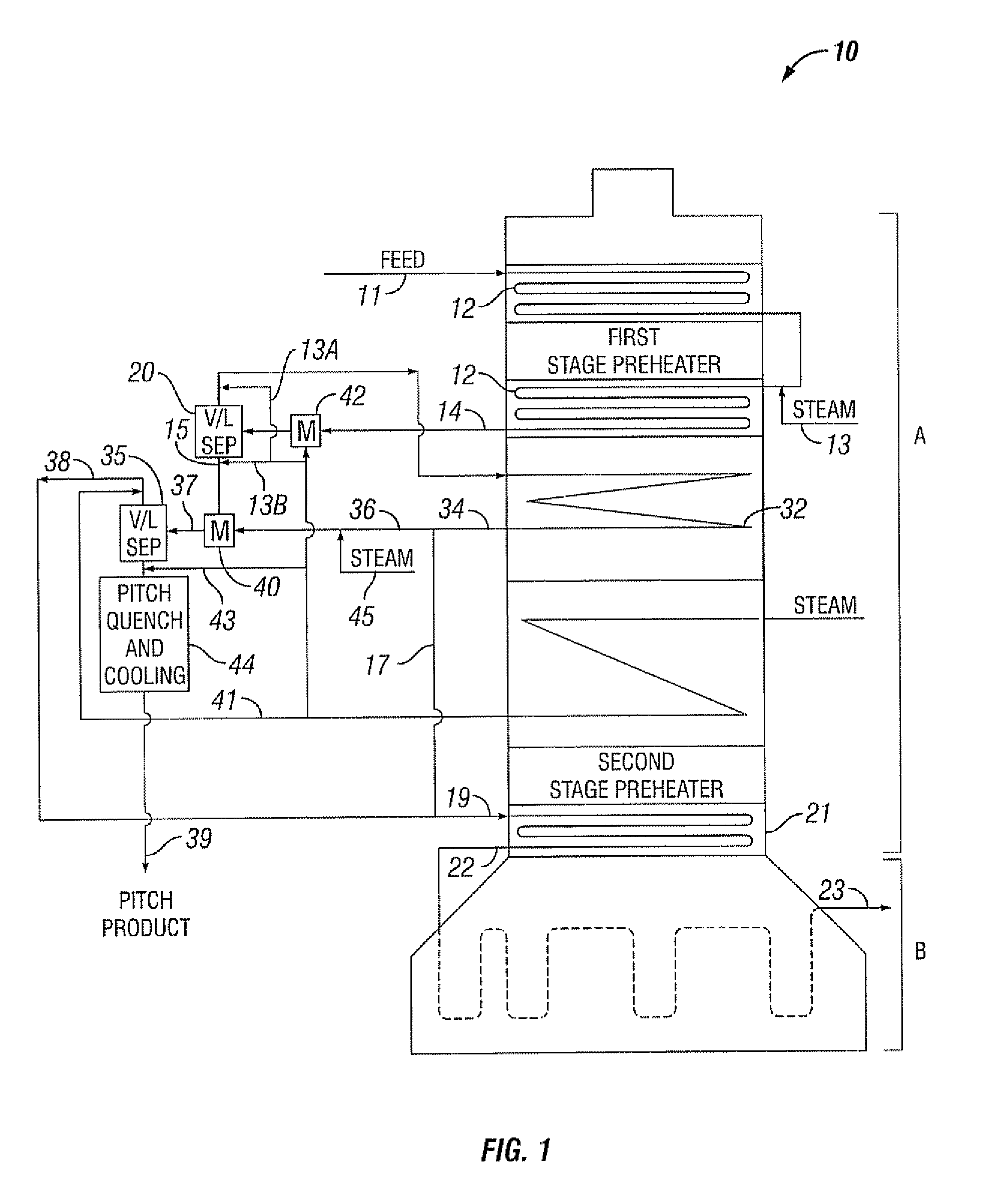

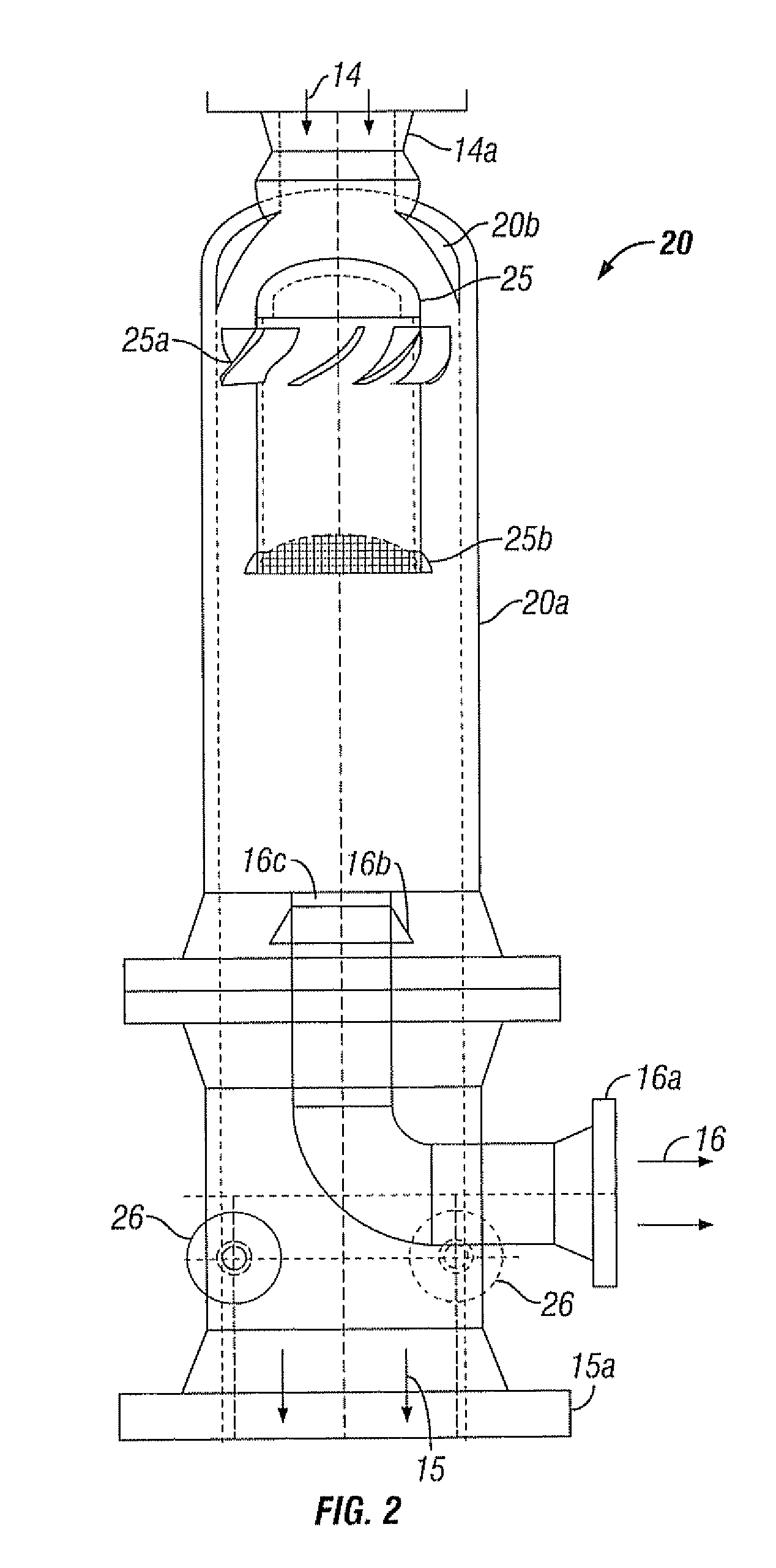

Low Grade Heat Recovery from Process Streams for Power Generation

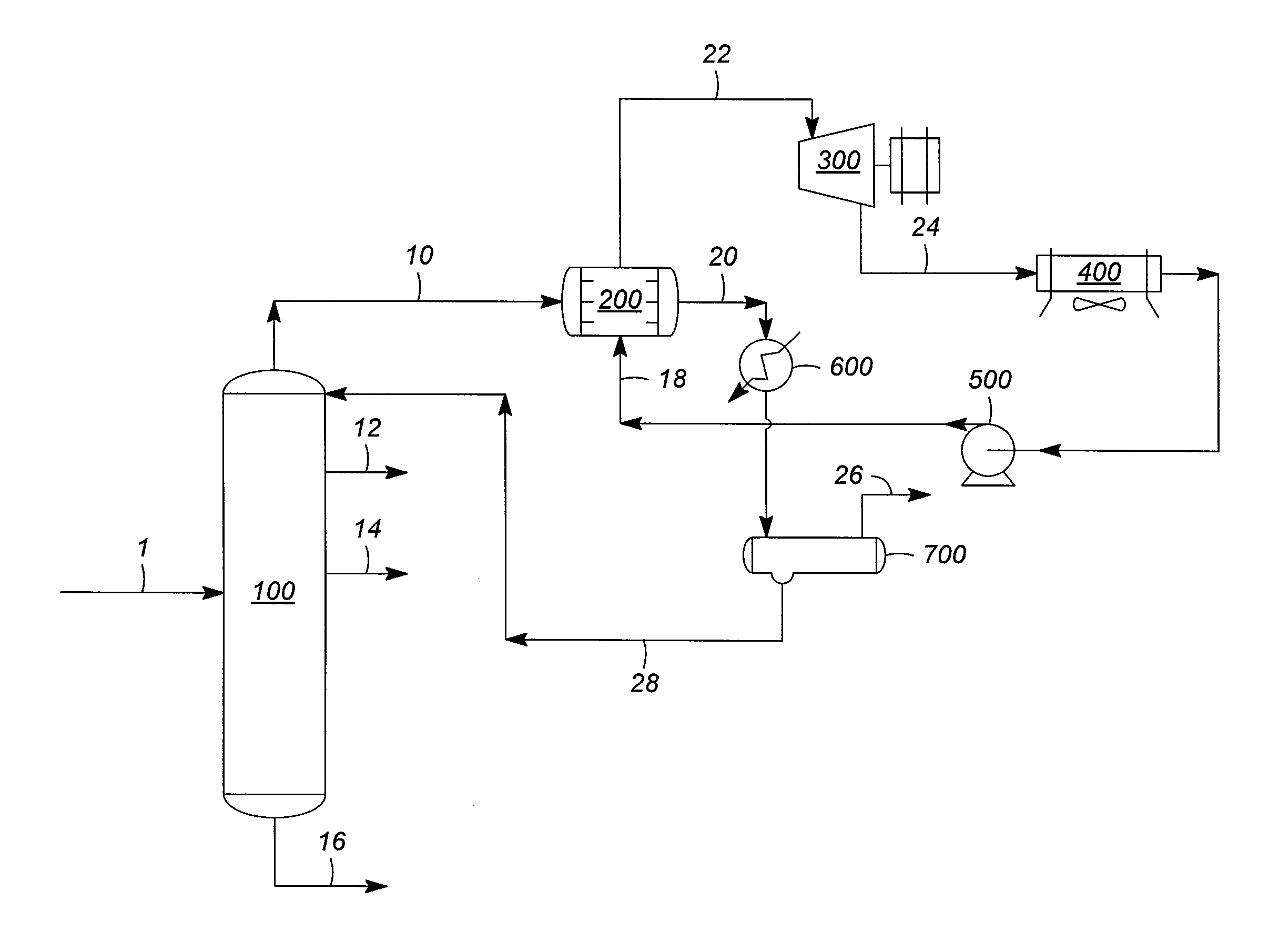

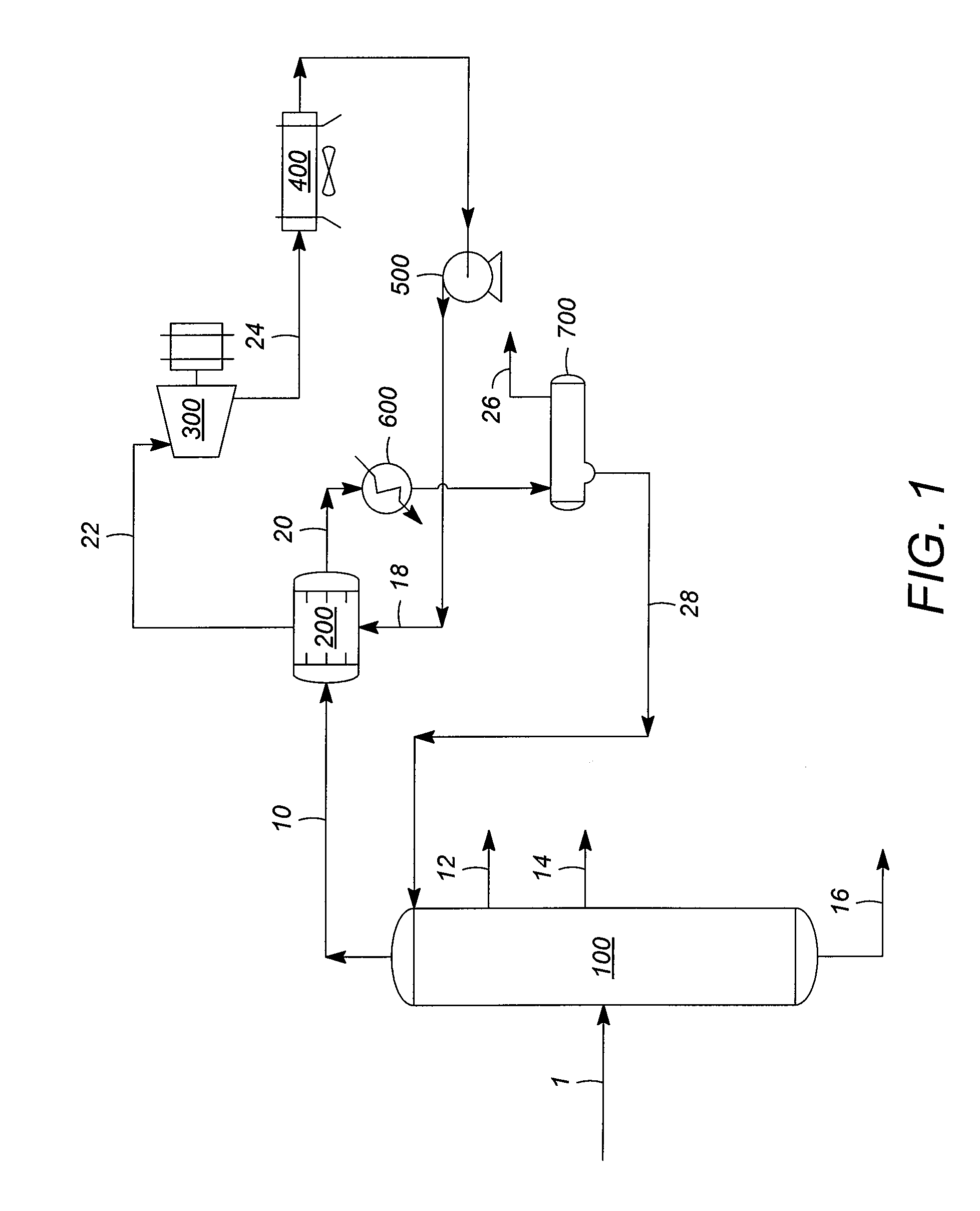

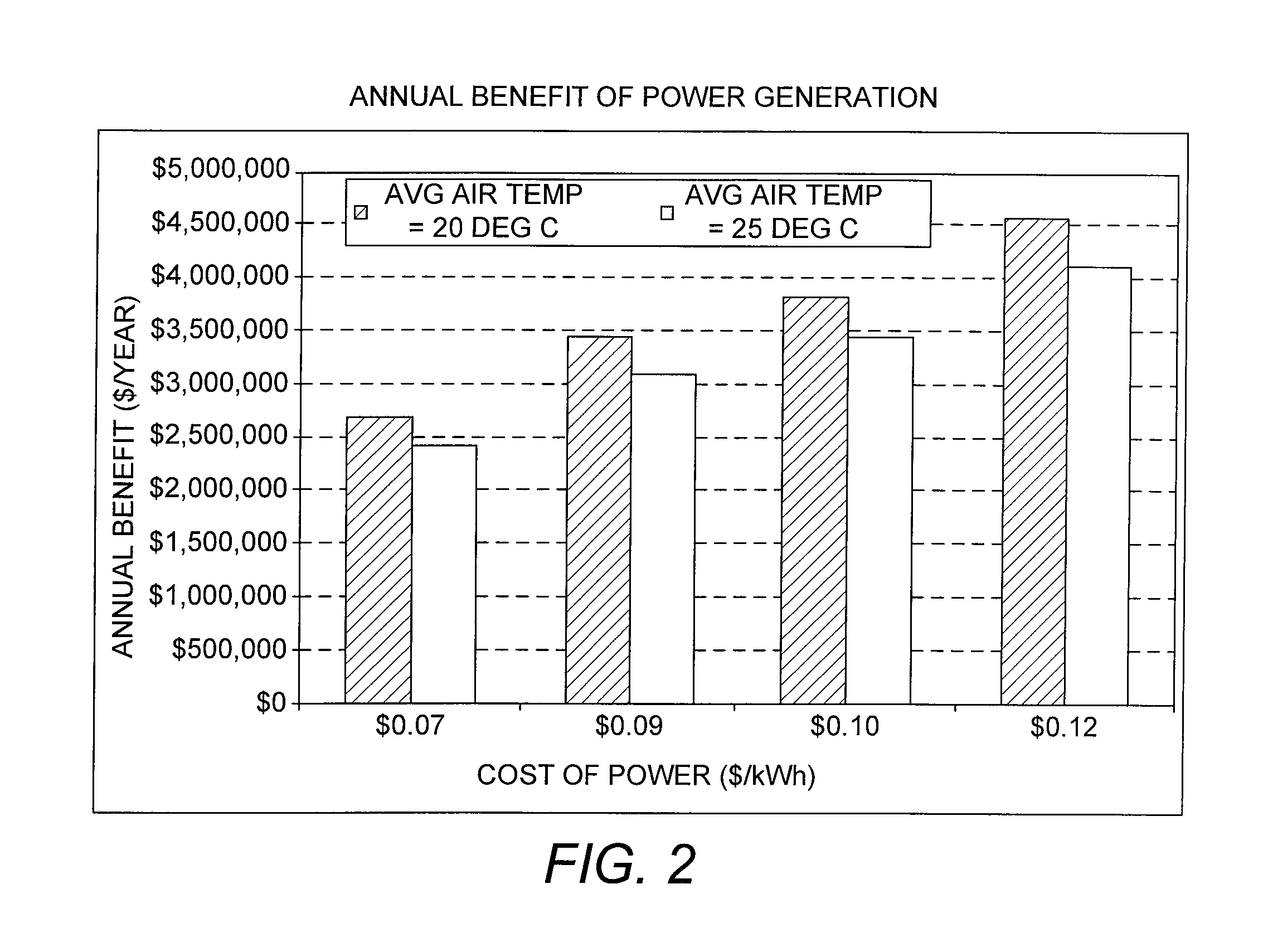

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

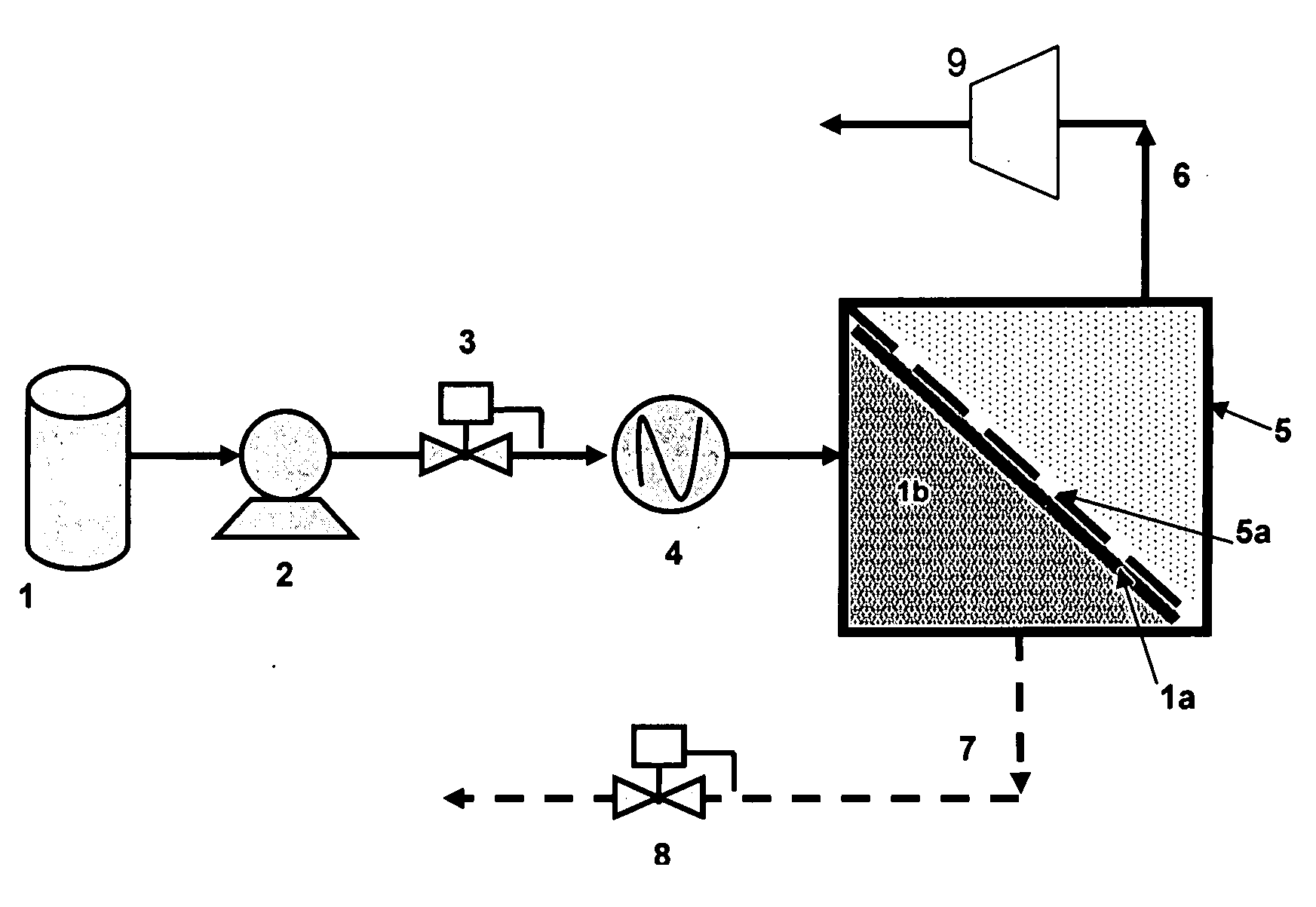

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

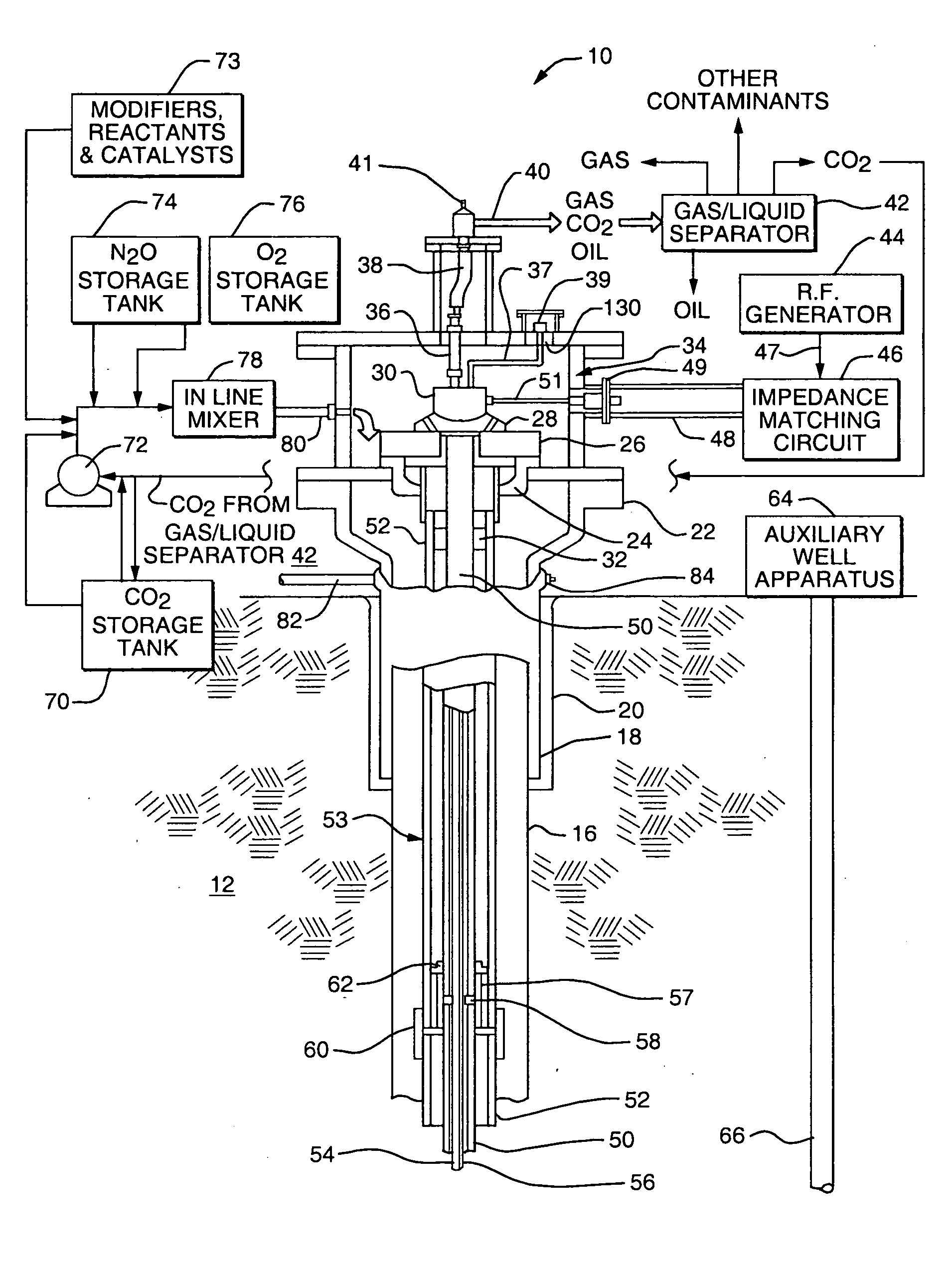

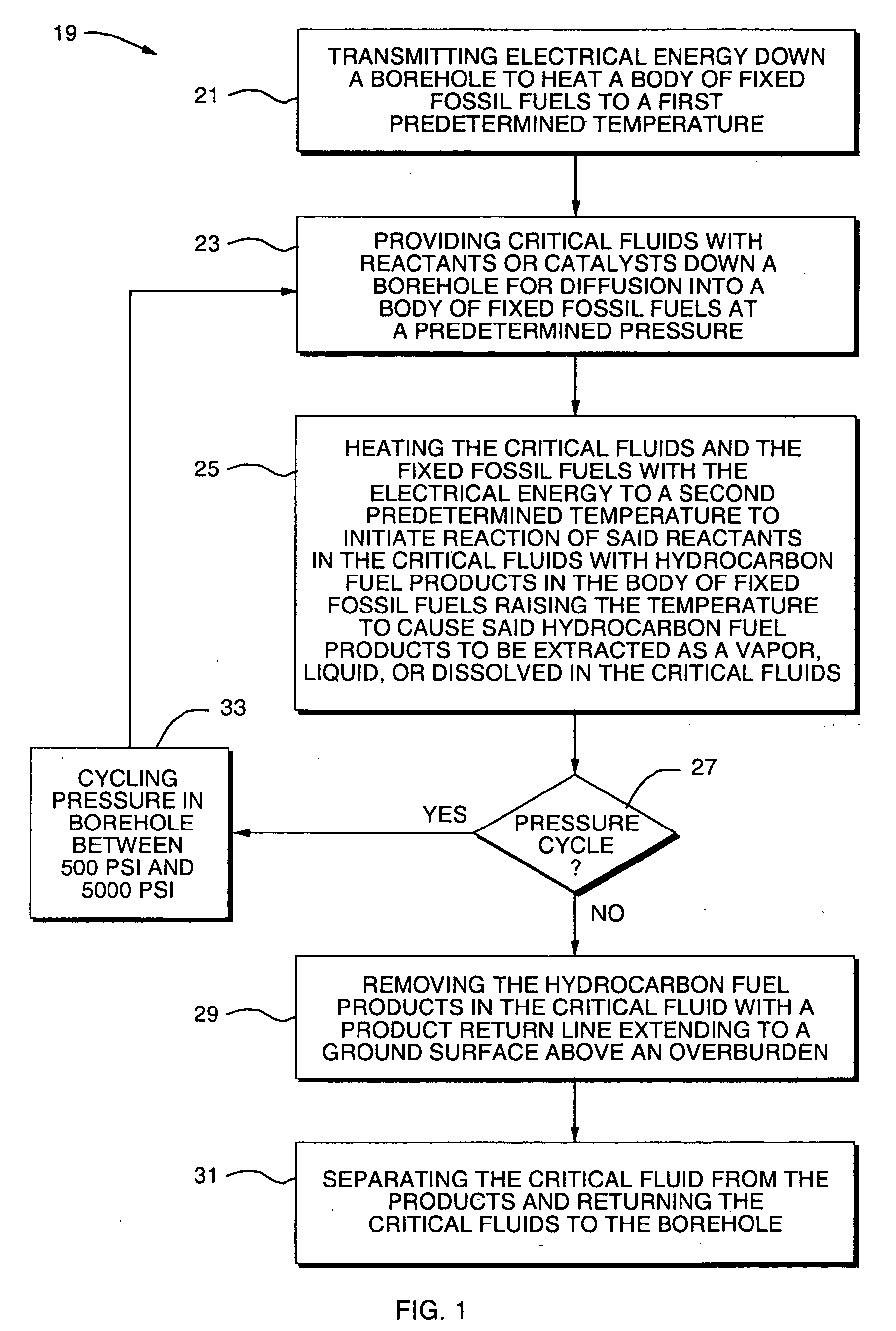

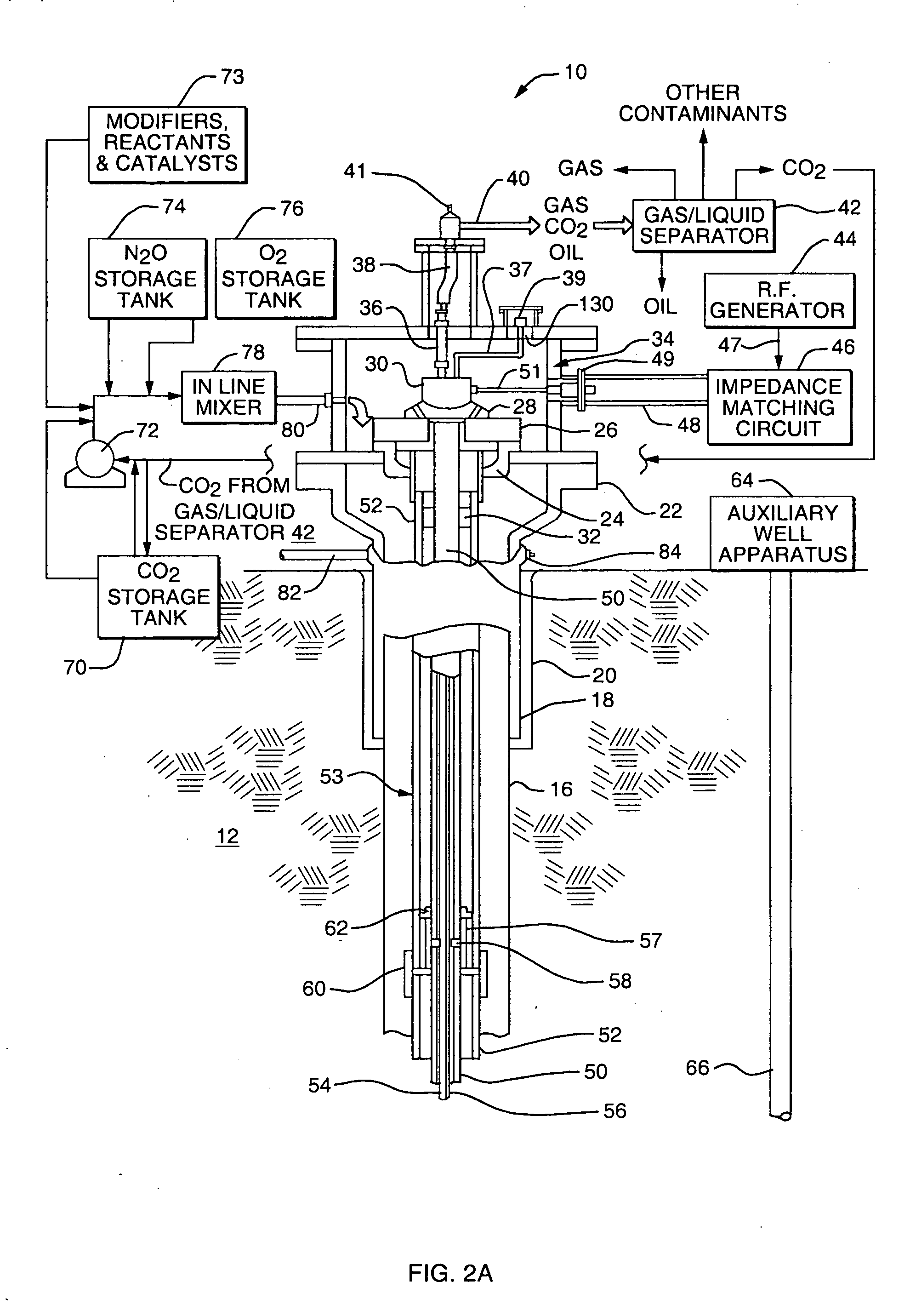

Method for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

ActiveUS20070137858A1Efficient heatingValid conversionSurveyHollow article cleaningVapor liquidHydrocotyle bowlesioides

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

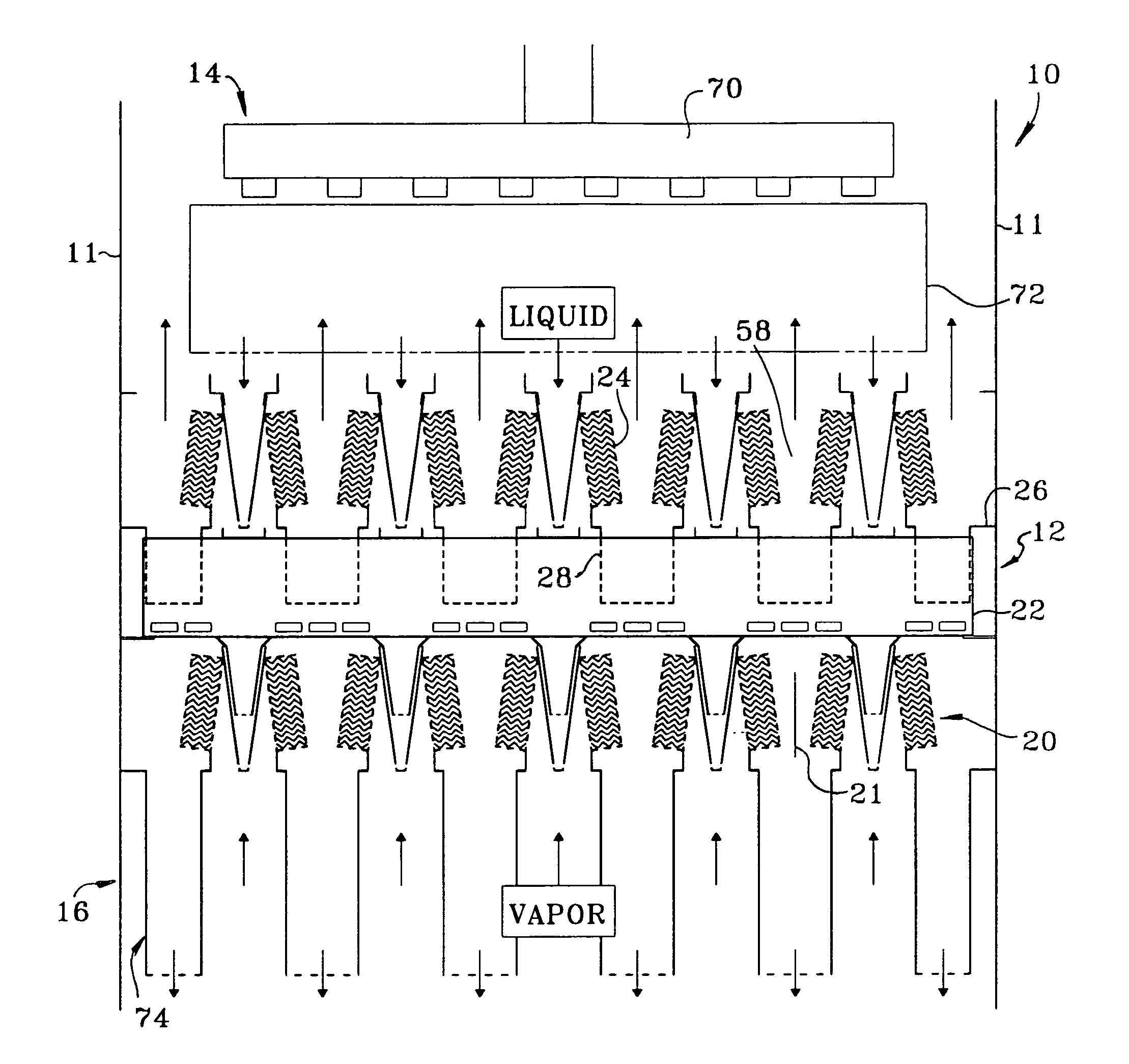

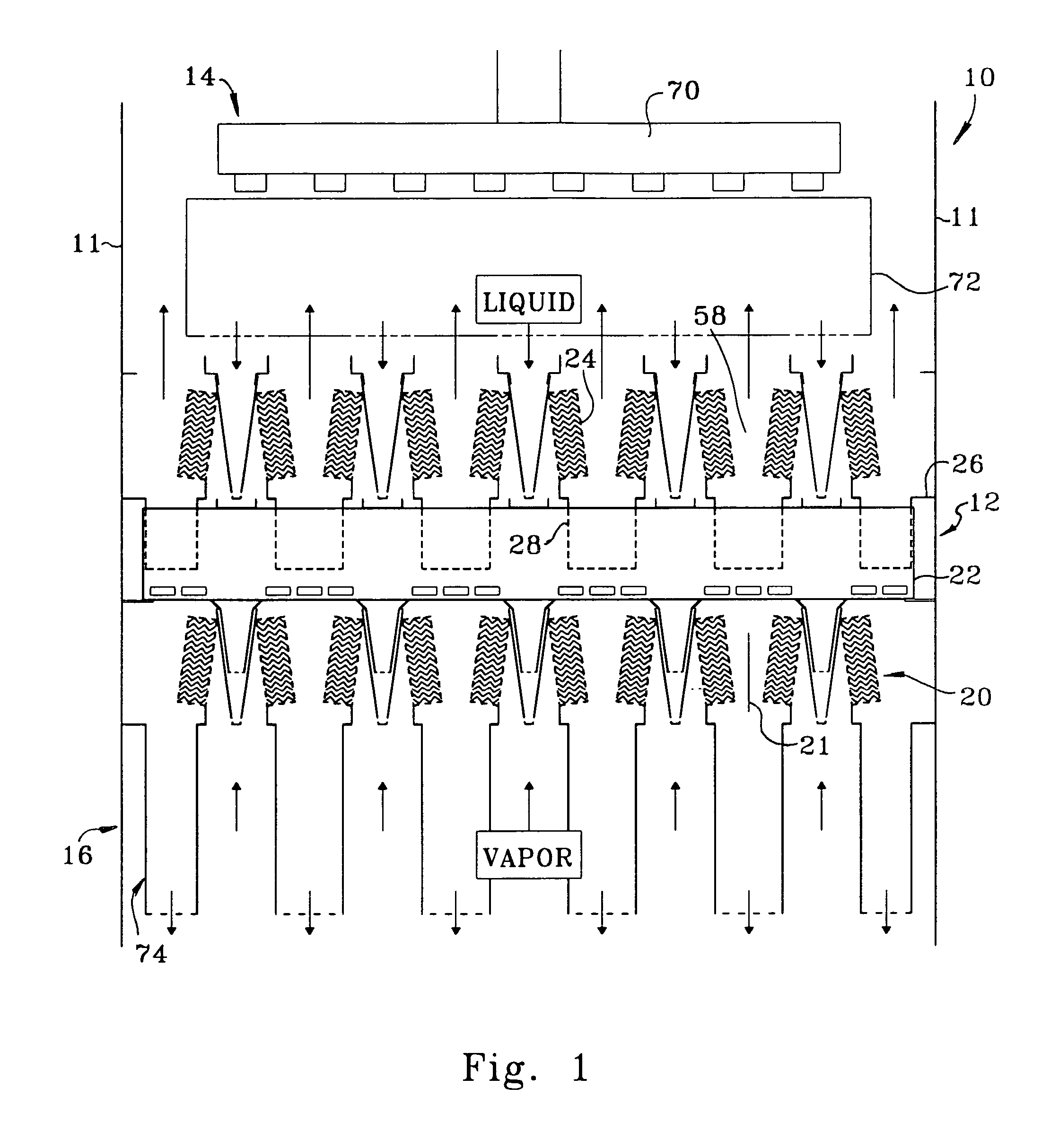

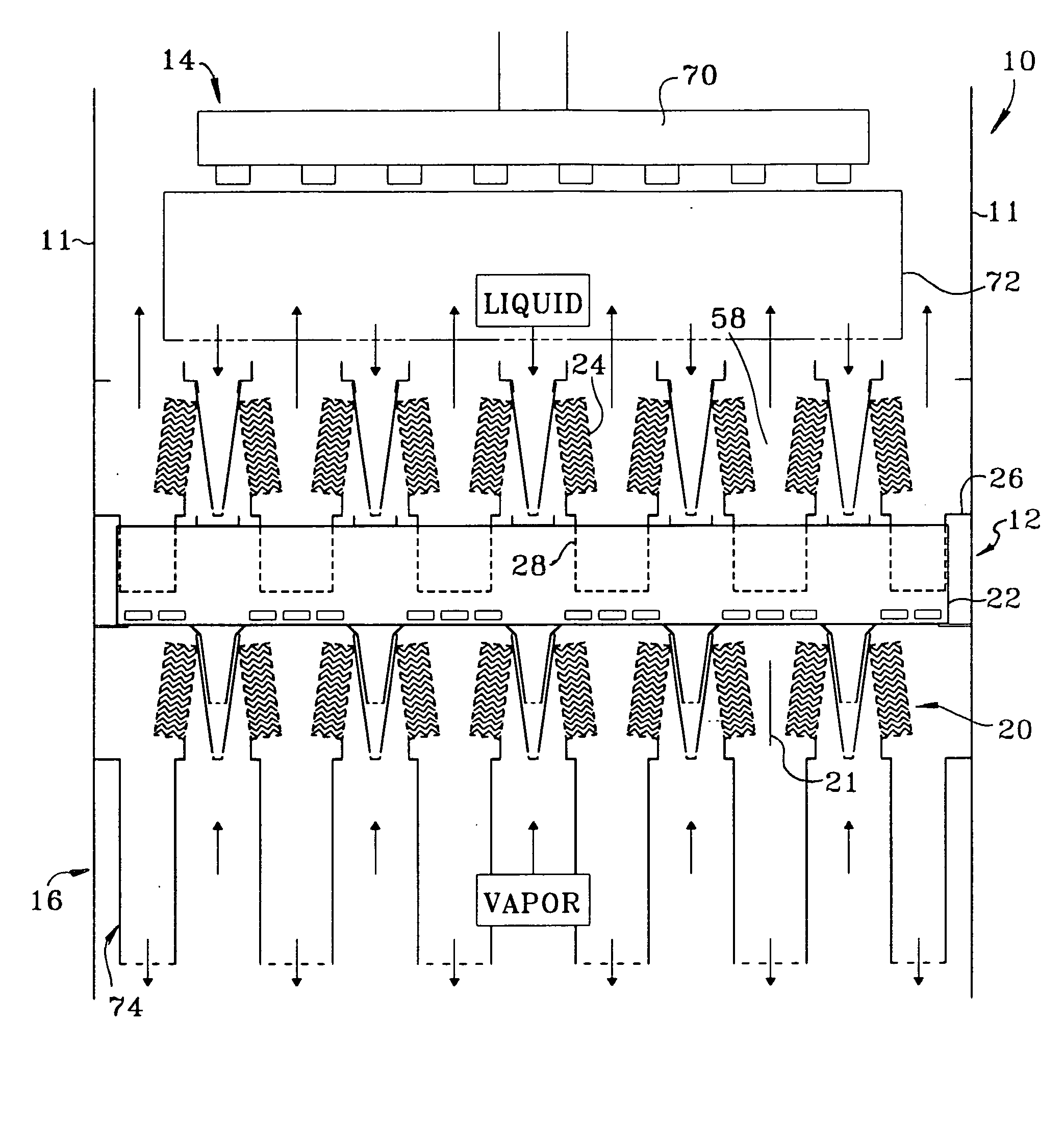

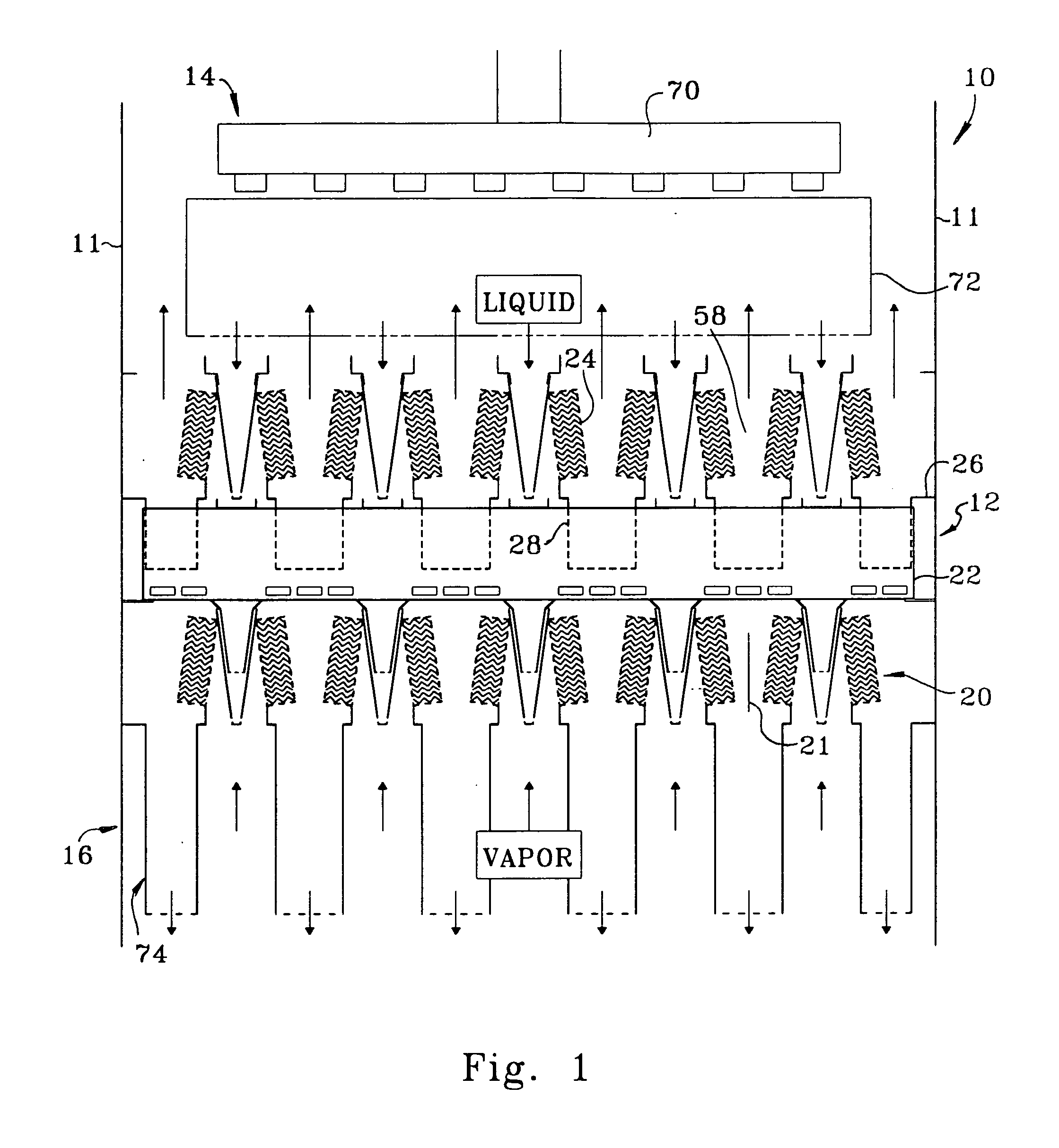

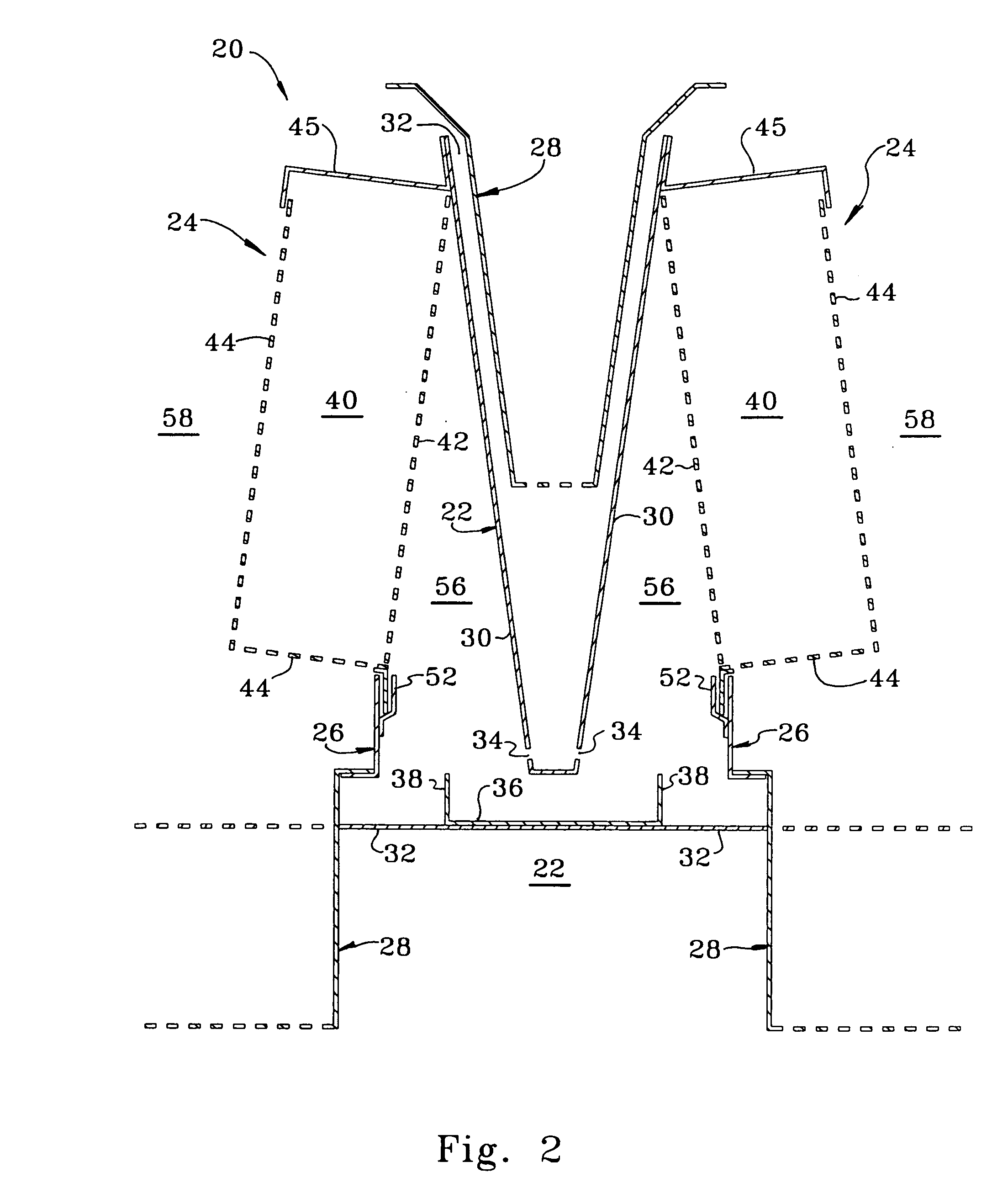

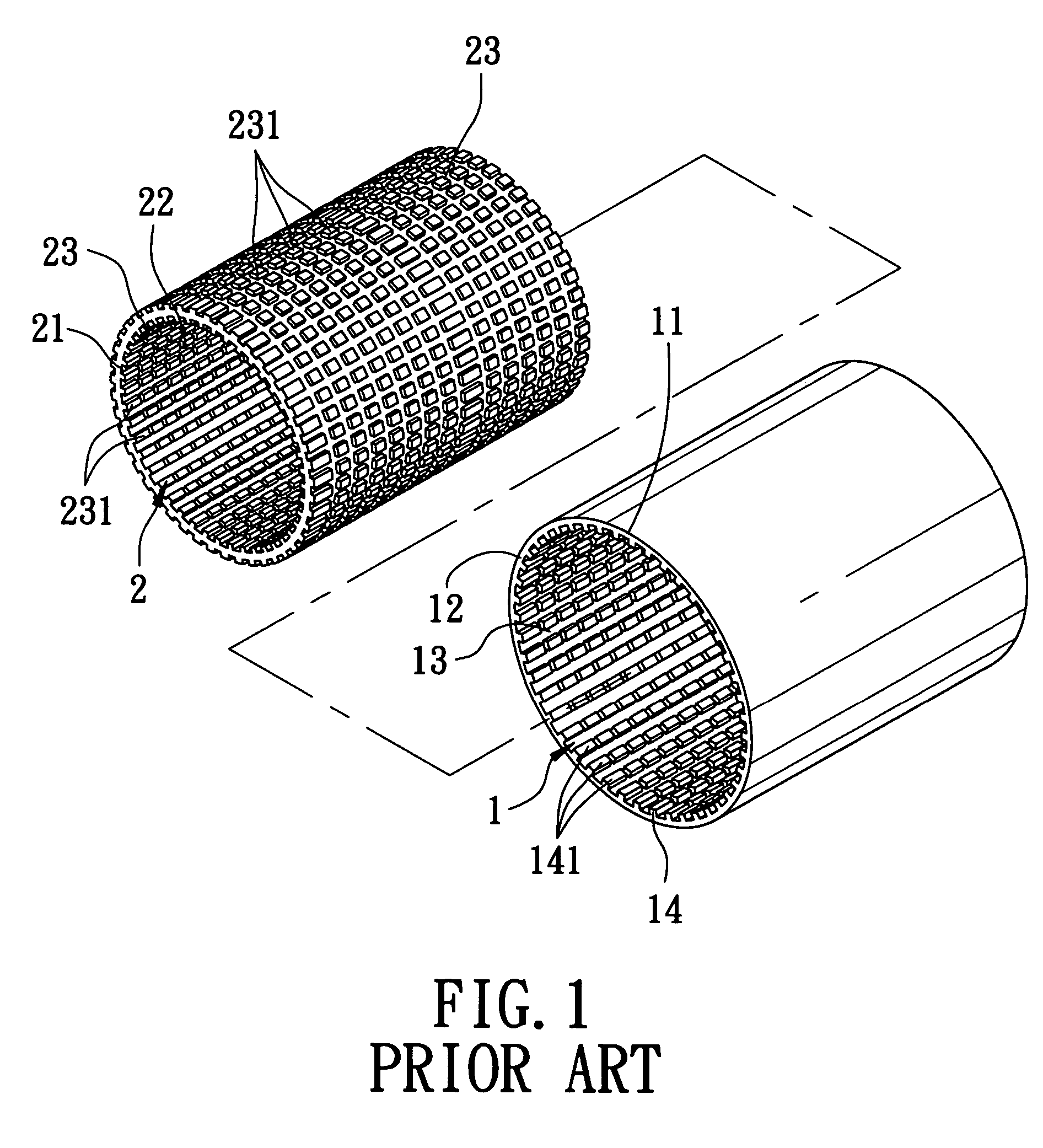

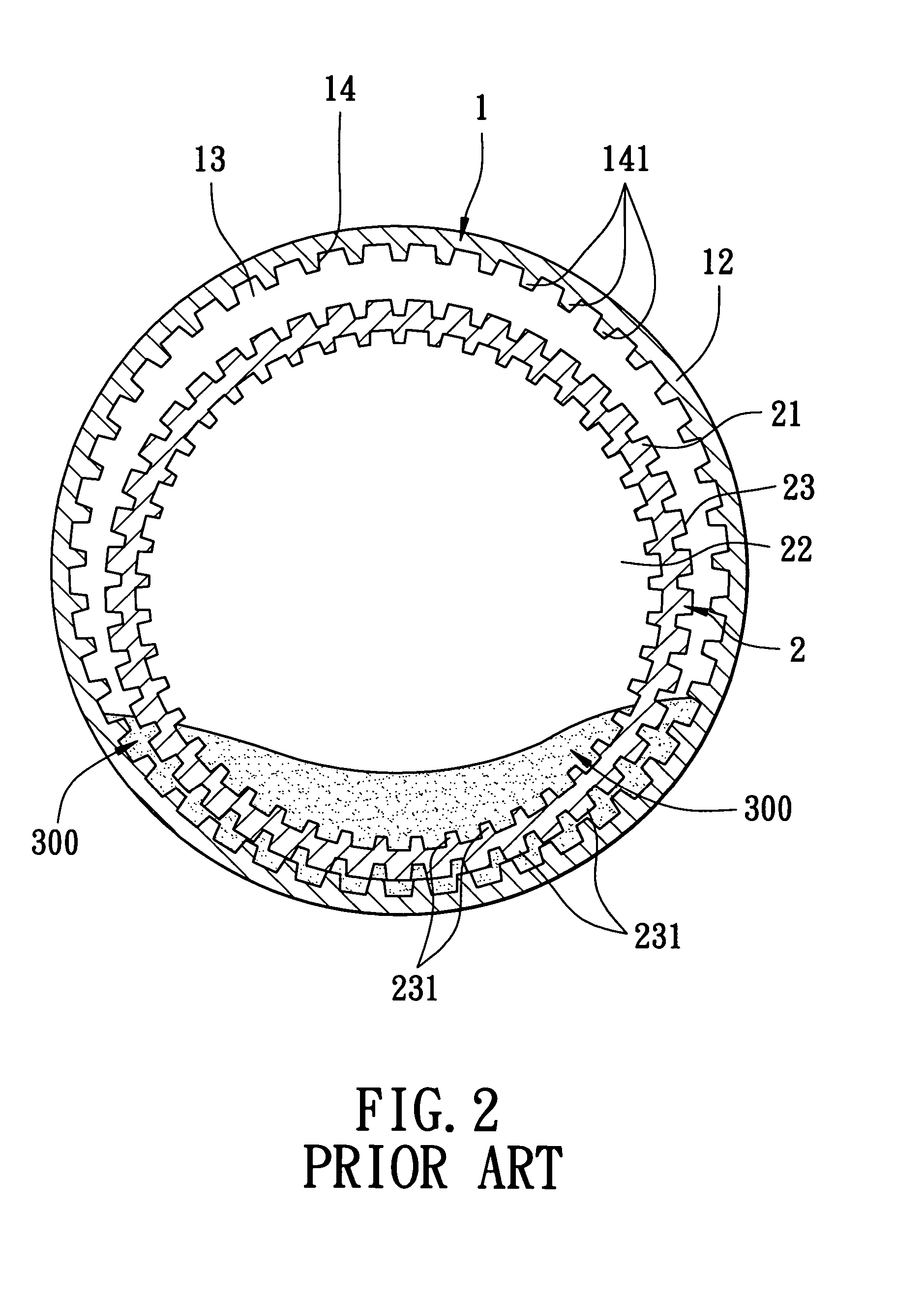

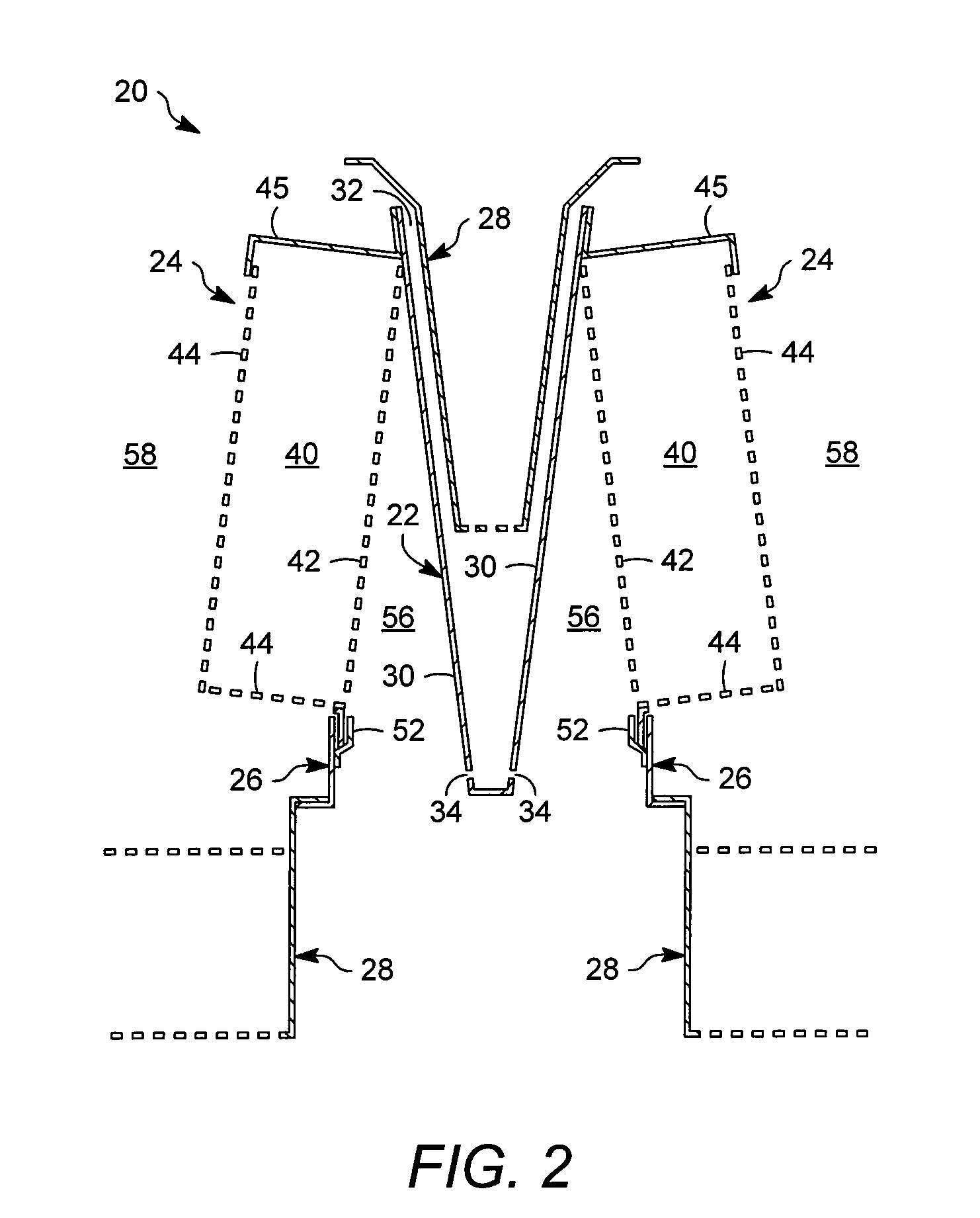

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

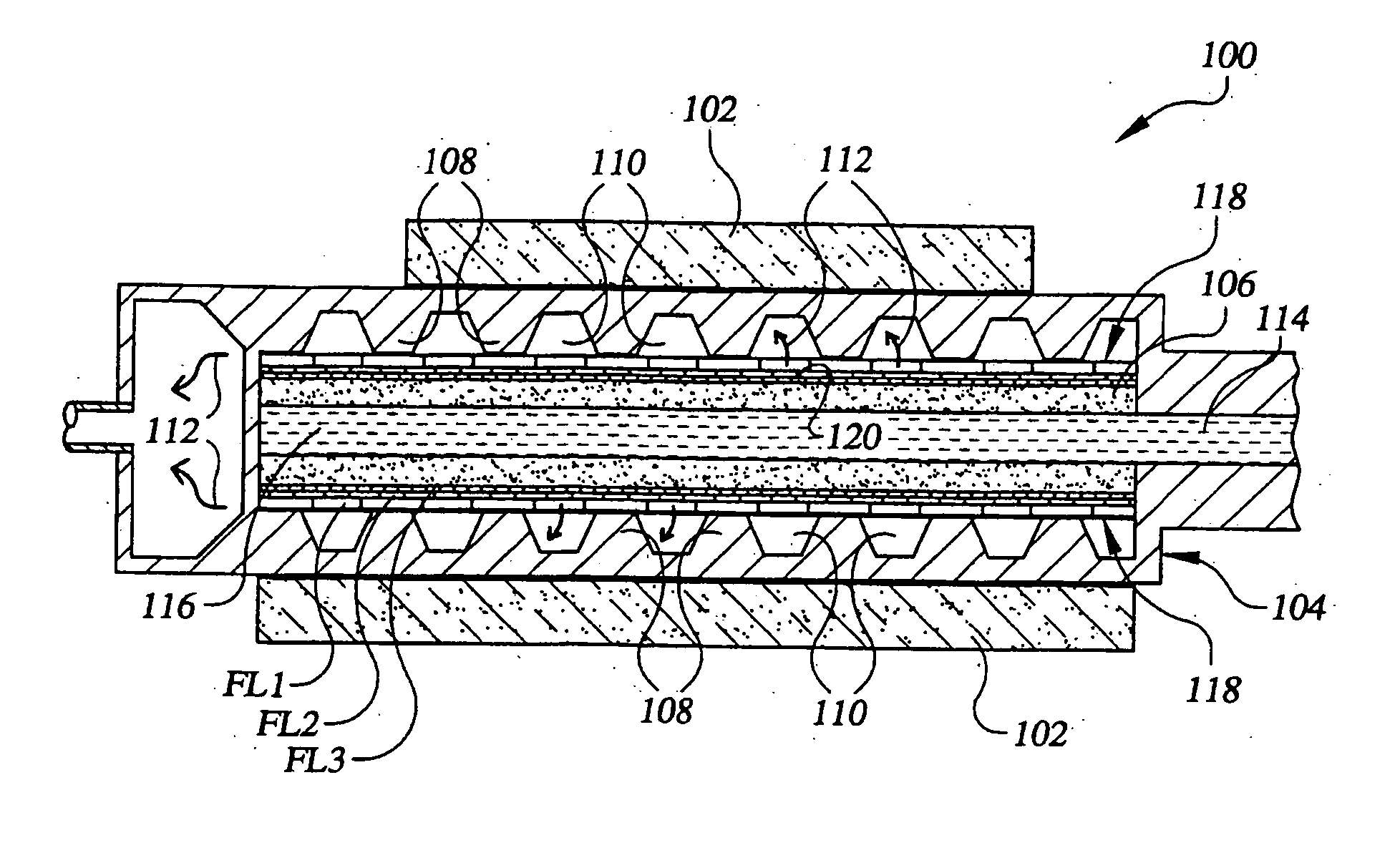

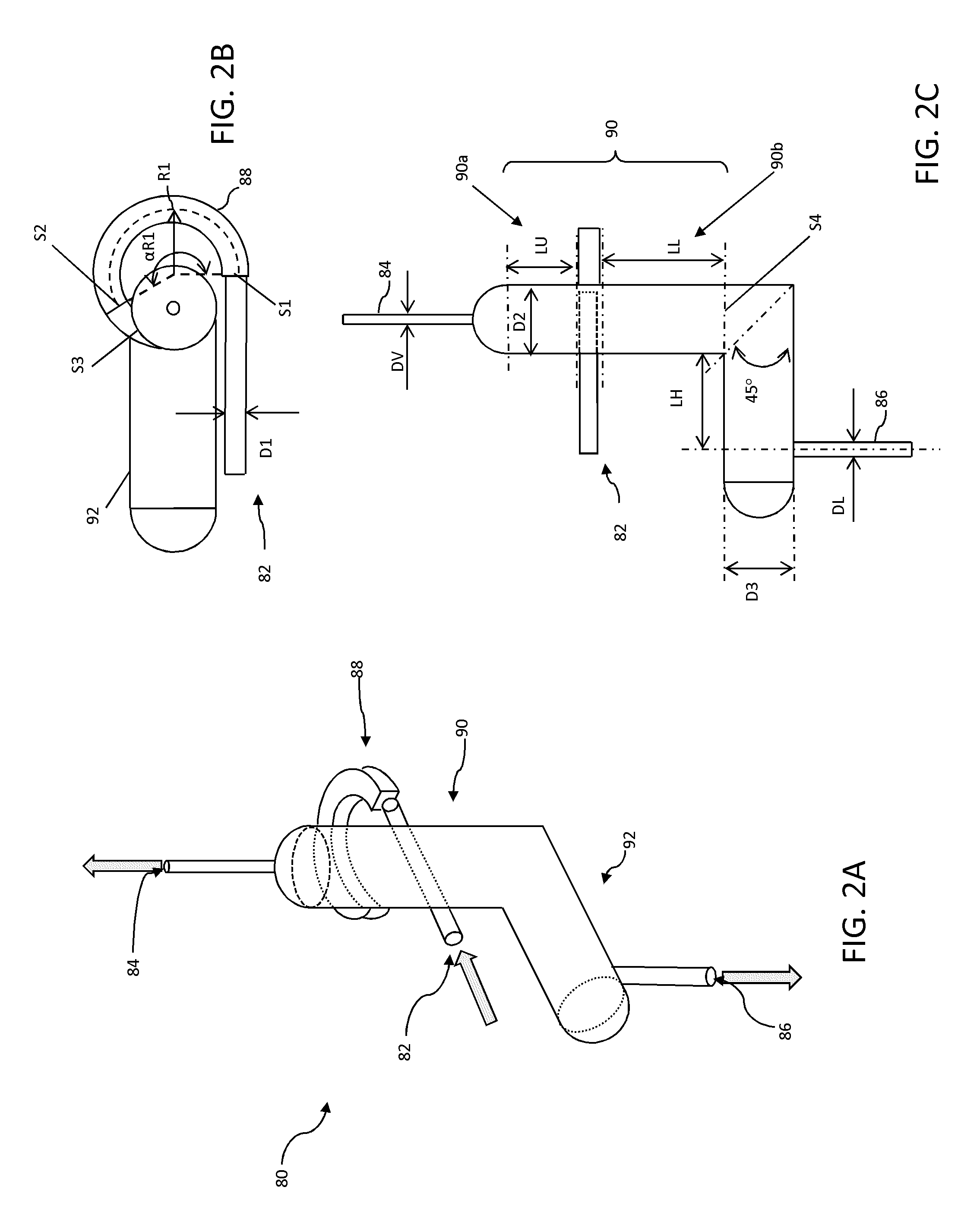

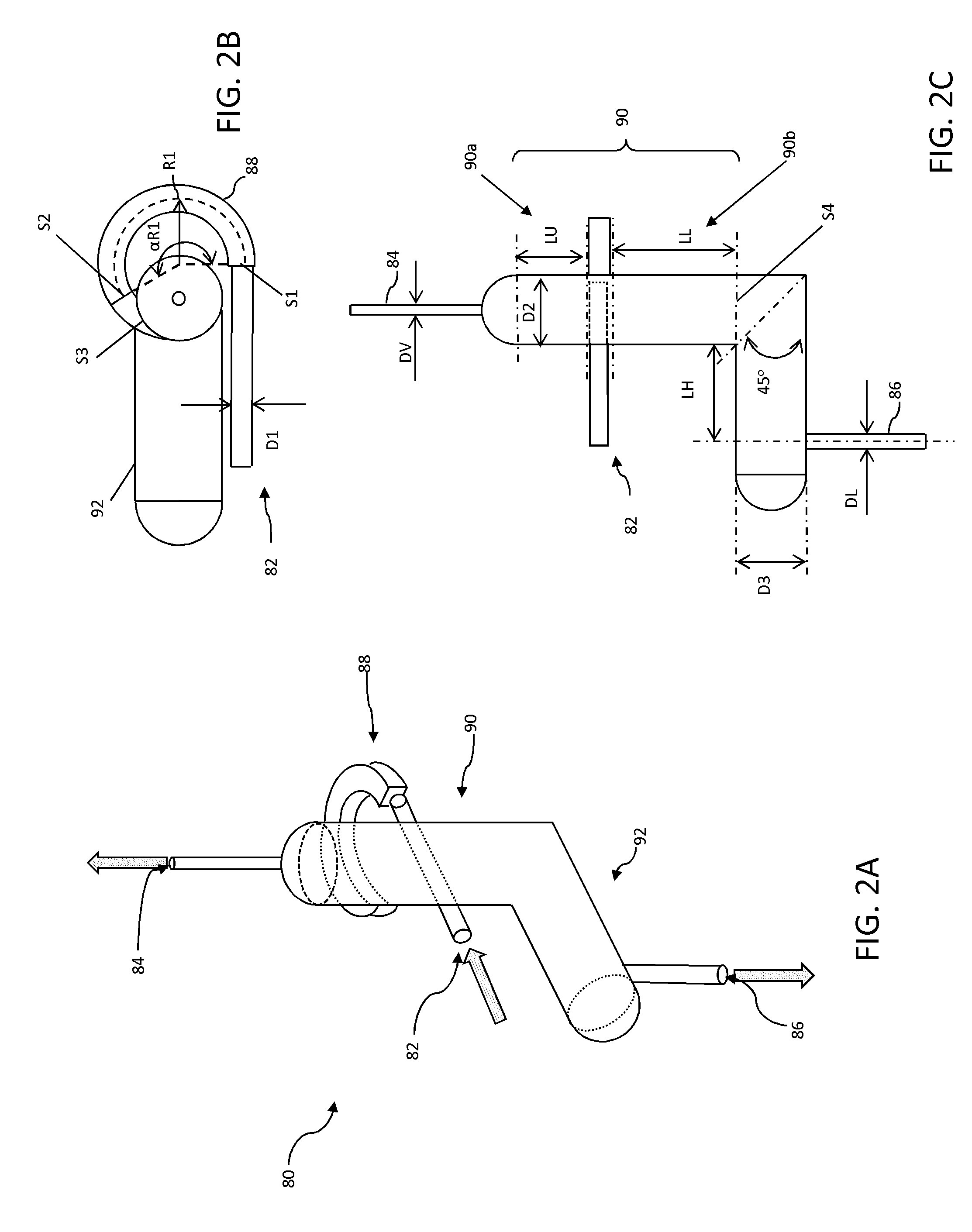

Capillary condenser/evaporator

ActiveUS20050230085A1Increase the cross-sectional areaReduce the cross-sectional areaIndirect heat exchangersCapillary condensationVapor liquid

A heat transfer device is disclosed for transferring heat to or from a fluid that is undergoing a phase change. The heat transfer device includes a liquid-vapor manifold in fluid communication with a capillary structure thermally connected to a heat transfer interface, all of which are disposed in a housing to contain the vapor. The liquid-vapor manifold transports liquid in a first direction and conducts vapor in a second, opposite direction. The manifold provides a distributed supply of fluid (vapor or liquid) over the surface of the capillary structure. In one embodiment, the manifold has a fractal structure including one or more layers, each layer having one or more conduits for transporting liquid and one or more openings for conducting vapor. Adjacent layers have an increasing number of openings with decreasing area, and an increasing number of conduits with decreasing cross-sectional area, moving in a direction toward the capillary structure.

Owner:MIKROS MFG

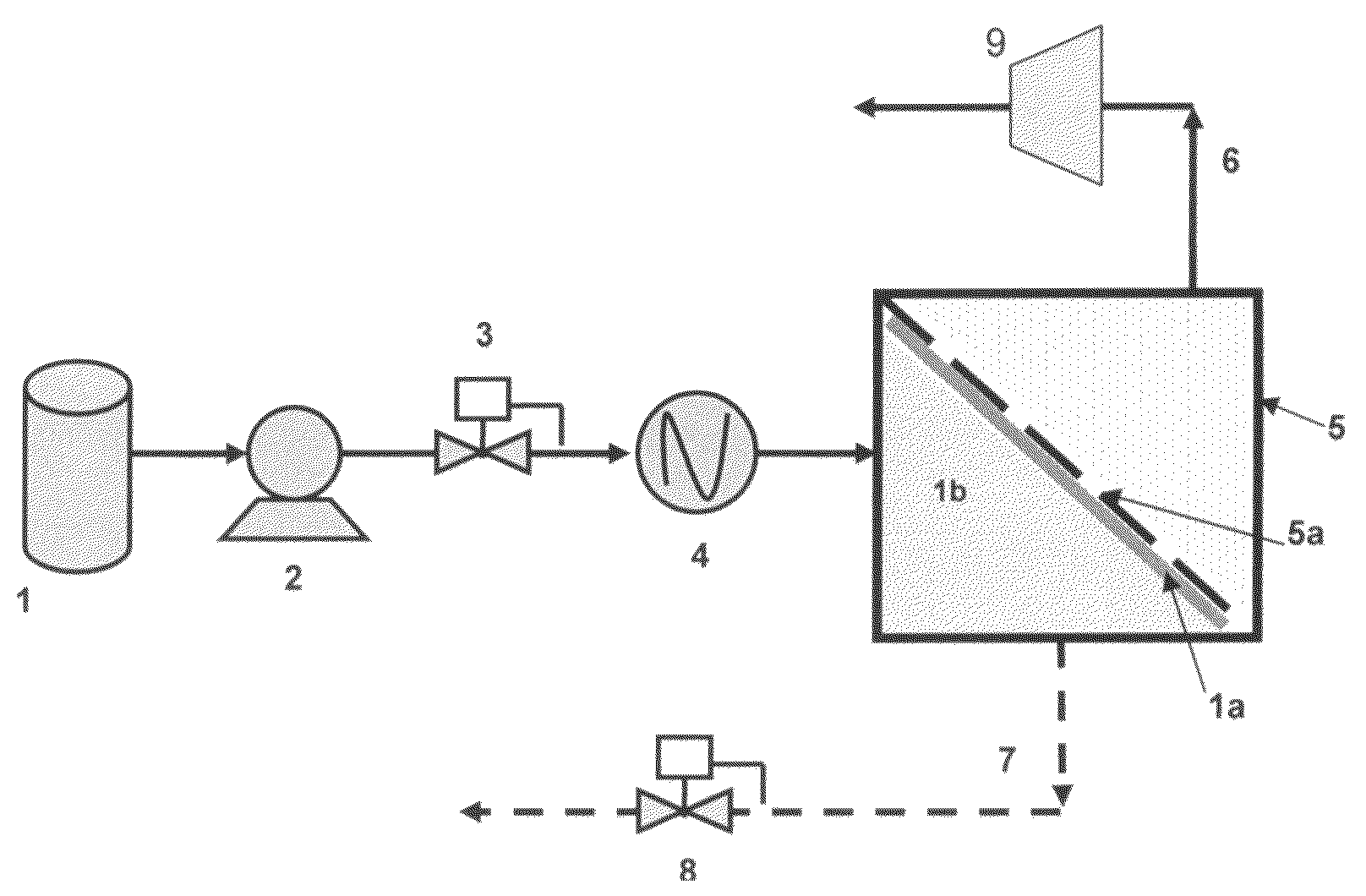

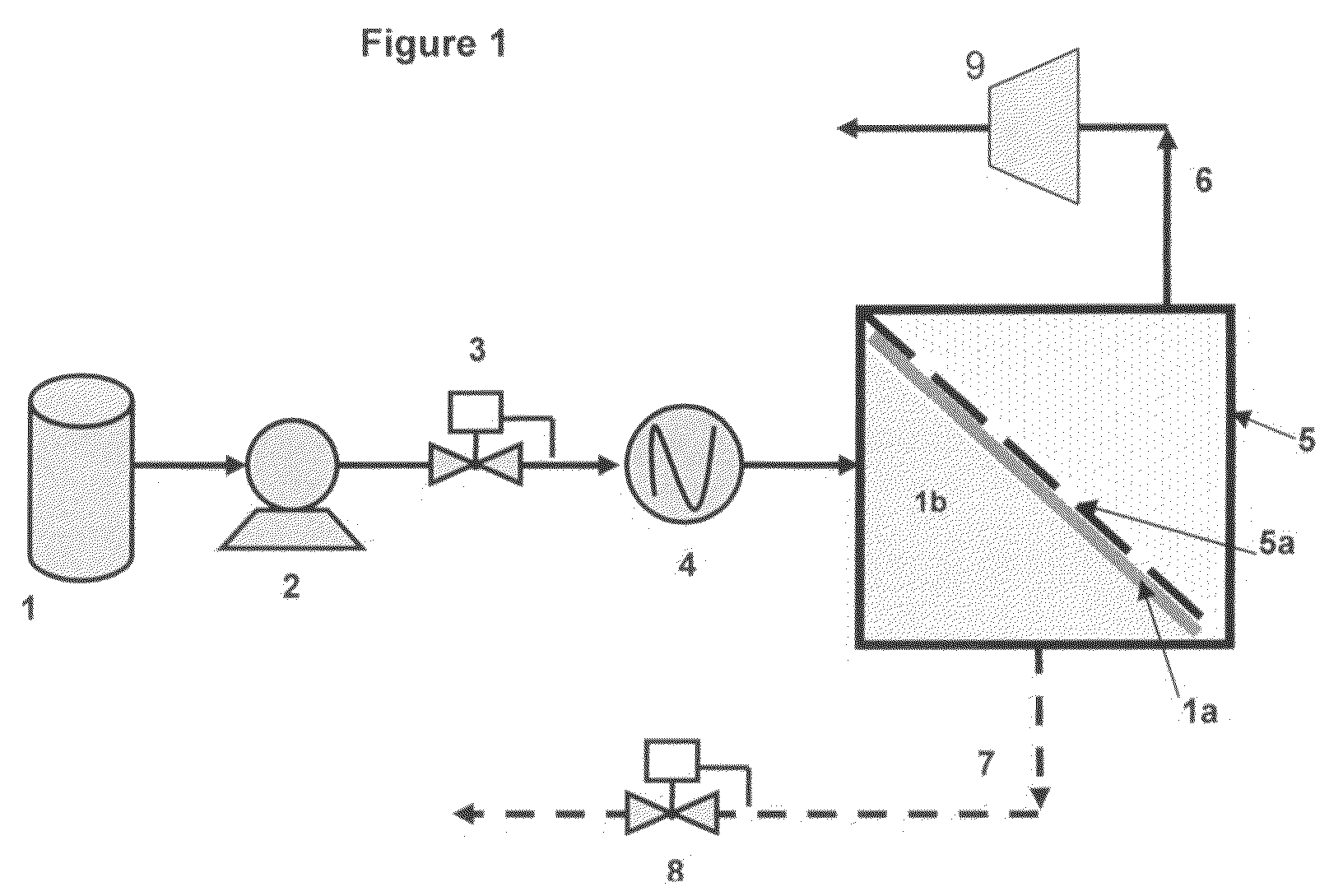

Membrane separation process using mixed vapor-liquid feed

ActiveUS20080011680A1Reduce the impactEfficient executionMembranesSemi-permeable membranesVapor liquidChemical physics

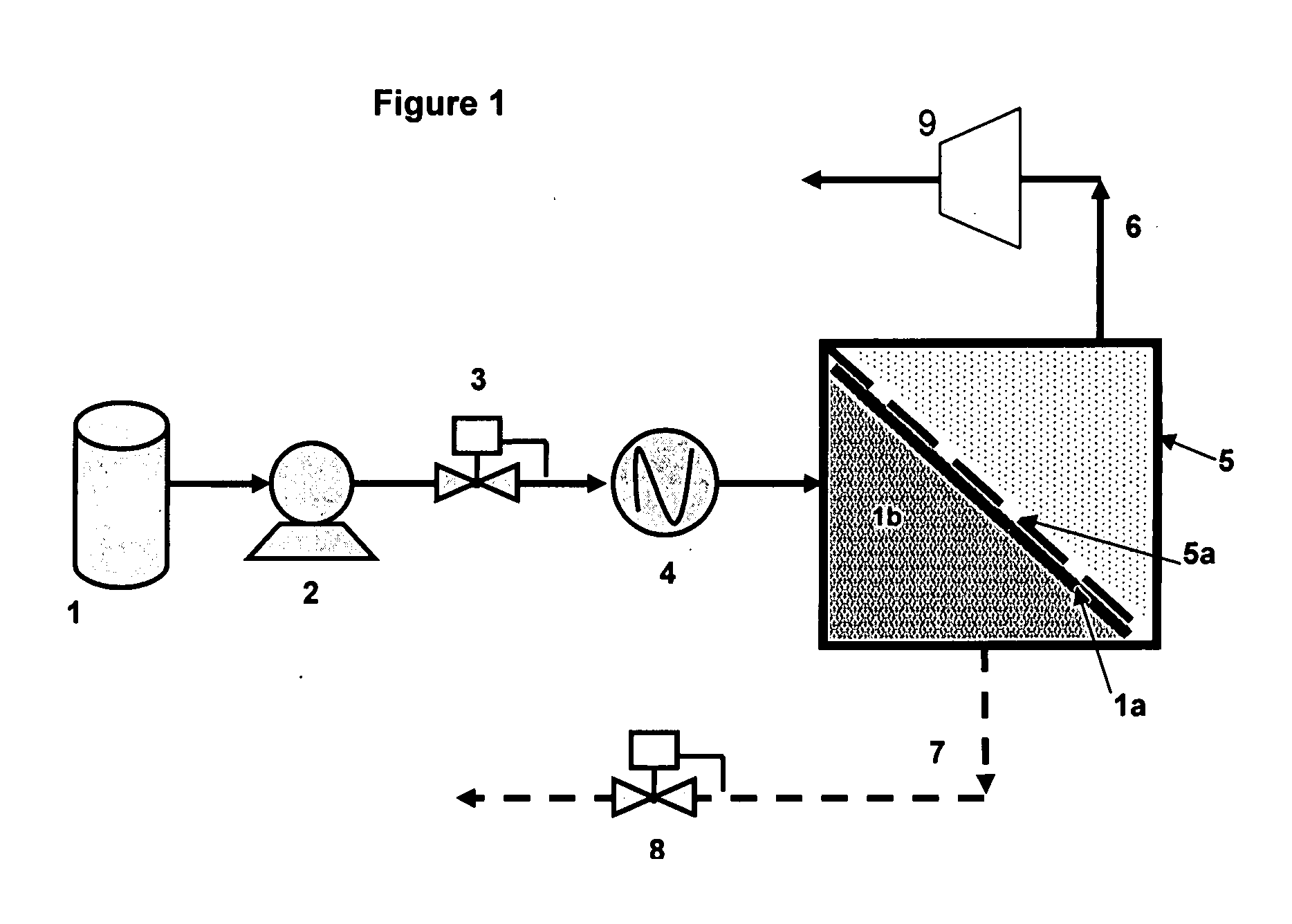

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

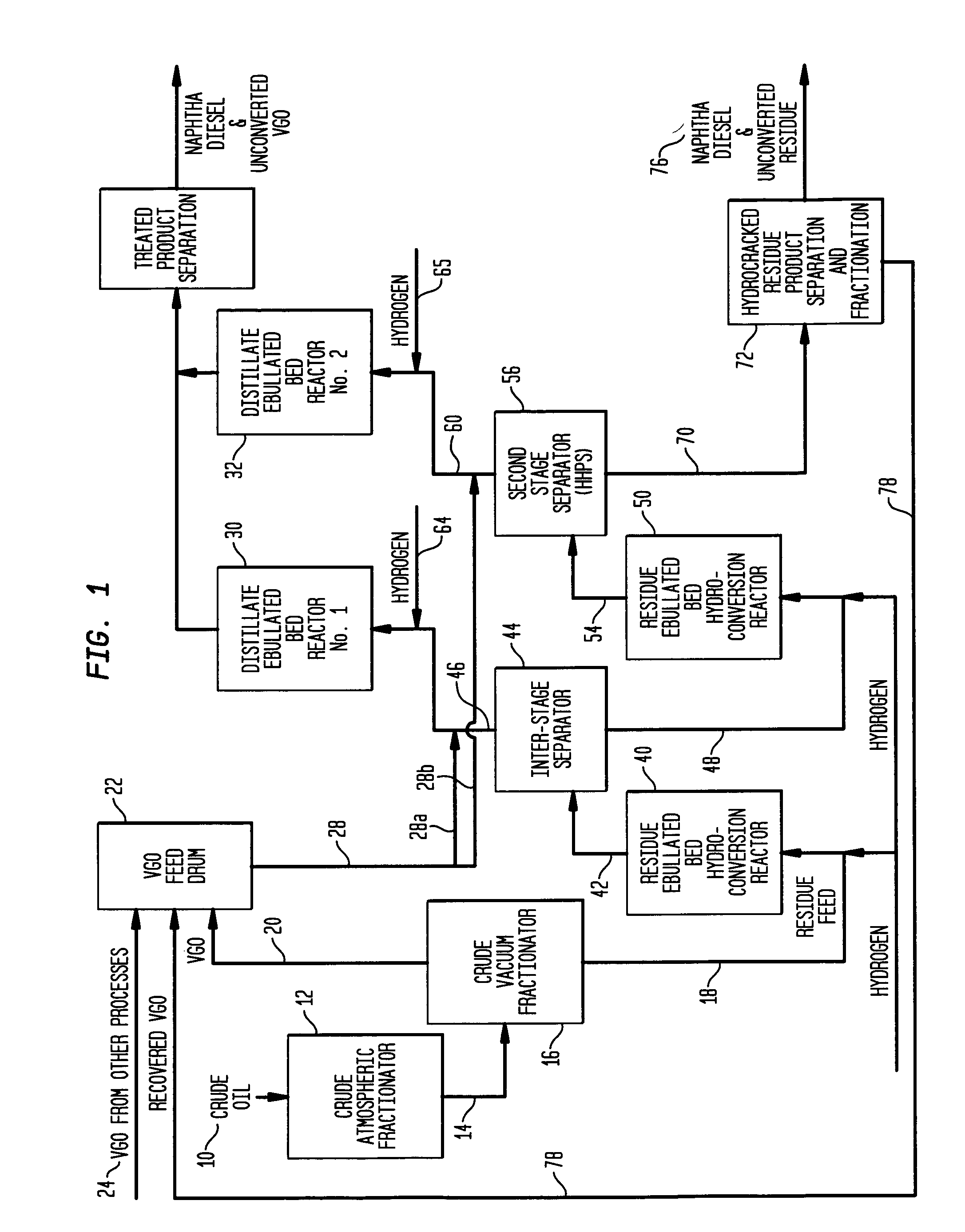

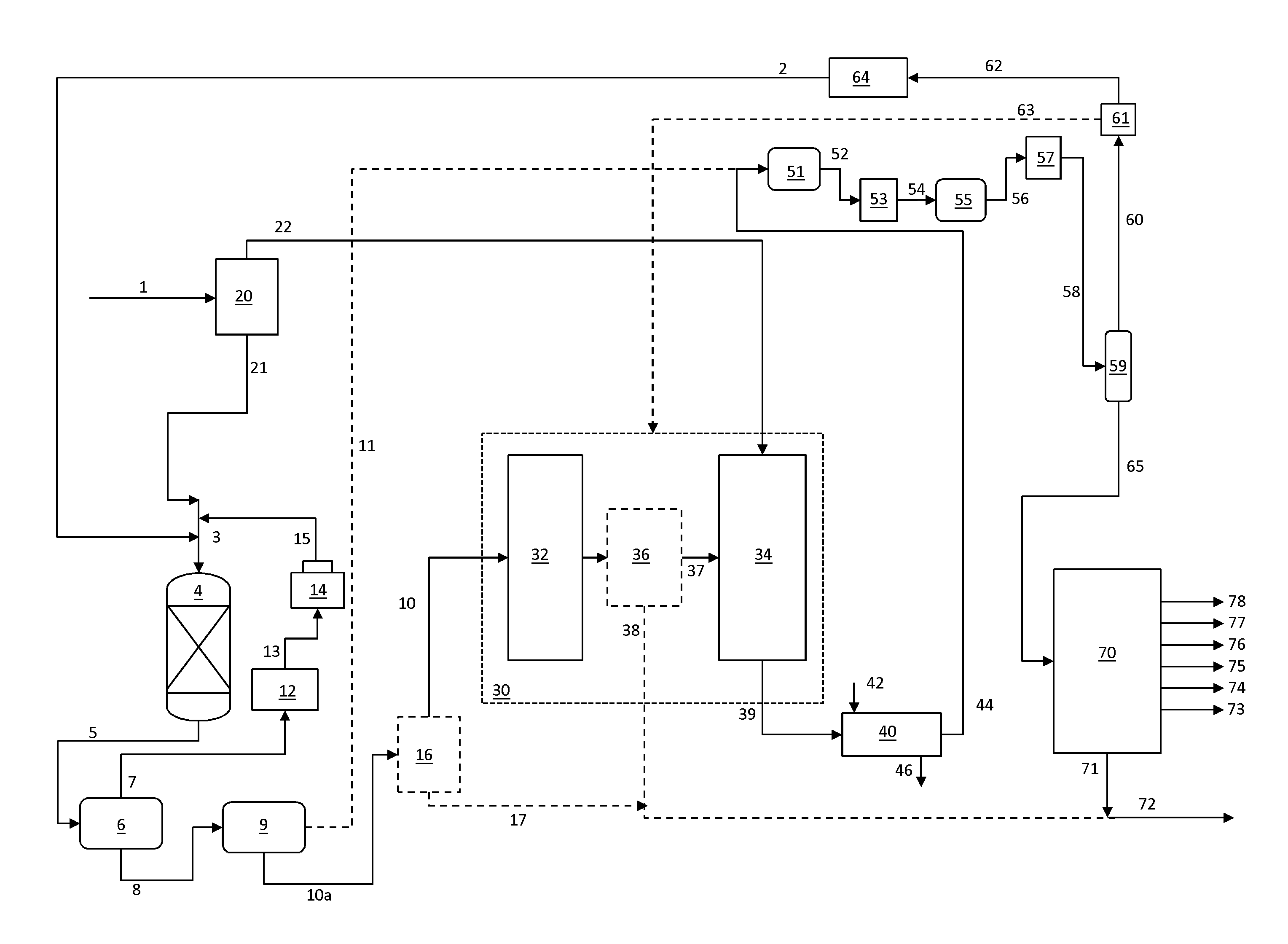

Process for multistage residue hydroconversion integrated with straight-run and conversion gasoils hydroconversion steps

InactiveUS7938952B2Improve throughputMitigate issueTreatment with plural serial cracking stages onlyMolecular sieve catalystsVapor liquidLiquid product

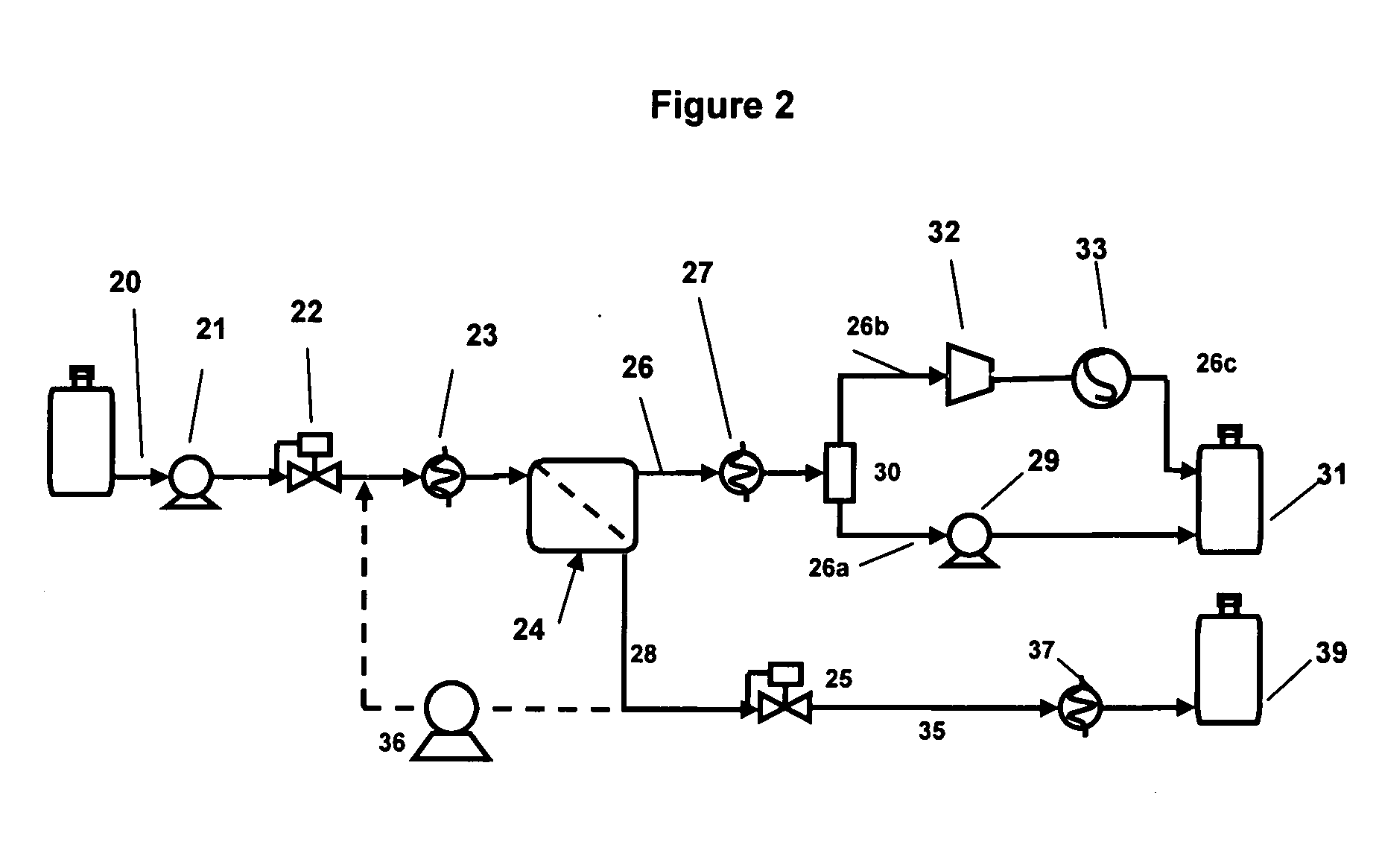

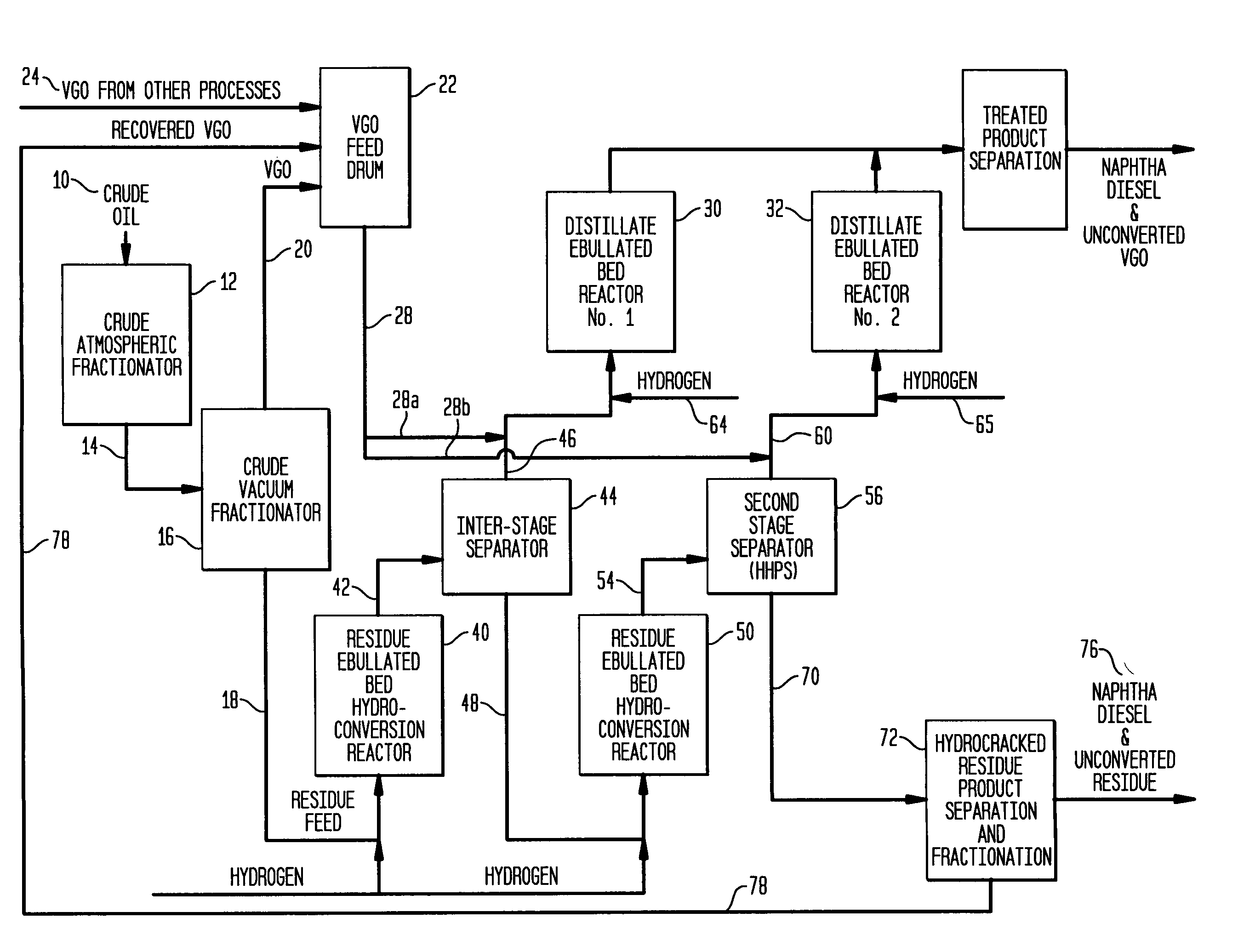

This invention relates to a novel integrated hydroconversion process for converting heavy atmospheric or vacuum residue feeds and also converting and reducing impurities in the vacuum gas oil liquid product. This is accomplished by utilizing two residue hydroconversion reaction stages, two vapor-liquid separators, and at least two additional distillate ebullated-bed hydrocracking / hydrotreating reaction stages to provide a high conversion rate of the residue feedstocks.

Owner:INST FR DU PETROLE

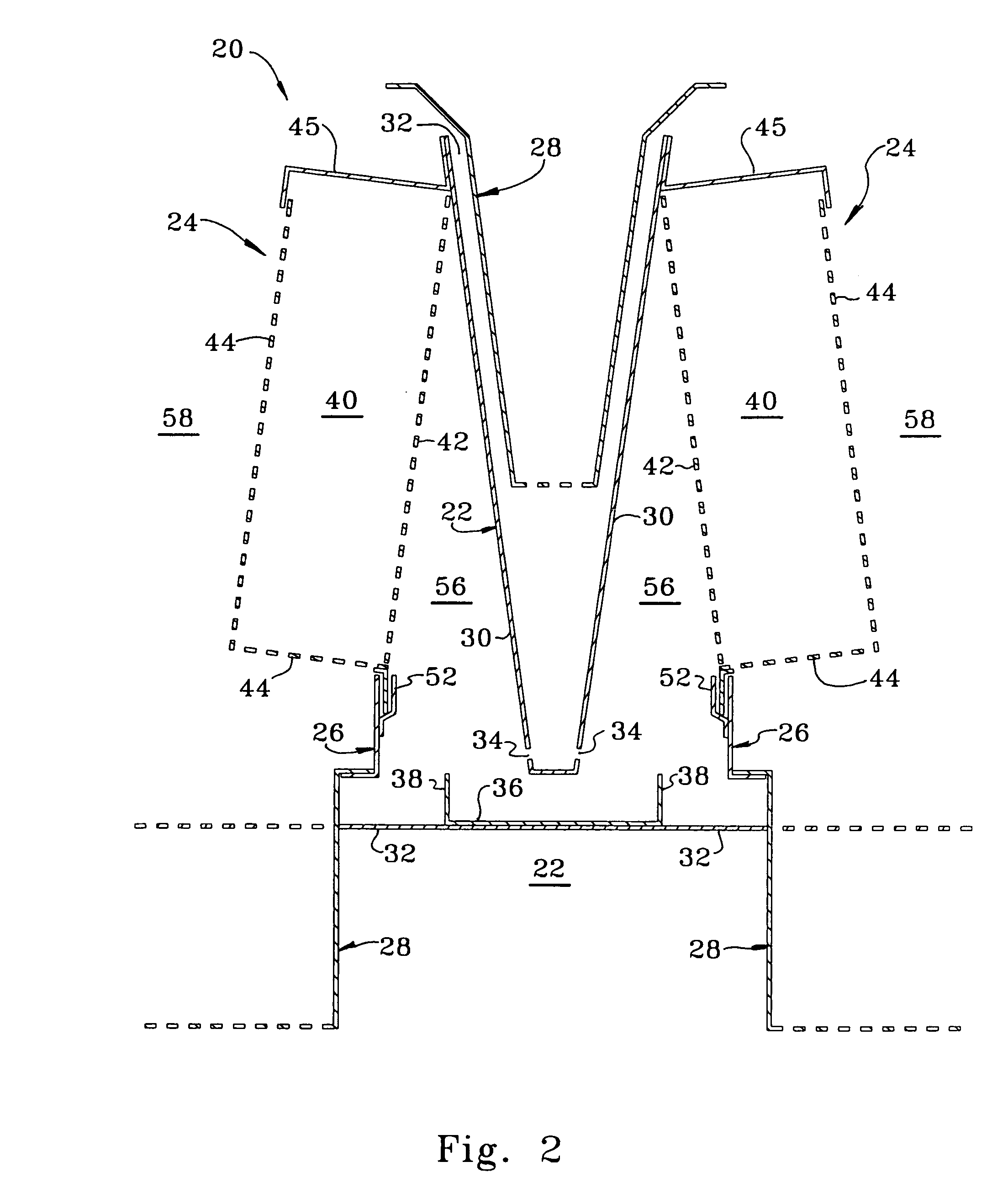

Co-current vapor-liquid contacting apparatus

ActiveUS20070137482A1Easily redistributedIncrease capacityCombination devicesTransportation and packagingVapor liquidFractionating column

The invention is a high capacity and high efficiency co-current vapor-liquid contacting apparatus for use in distillation columns and other vapor-liquid contacting processes. The apparatus is characterized by an arrangement of modules in horizontal stages rather than tray-like construction. The modules define a co-current contacting volume and in an exemplary configuration the modules include a liquid distributor, a demister, a receiving pan and a duct. The modules of one stage are rotated to be non-parallel with respect to the modules of an inferior stage, a superior stage, or both. Variations relate to the design of the individual elements such as the demister, liquid distributor, ducts, and contacting volumes, and the overall arrangement of the apparatus.

Owner:UOP LLC

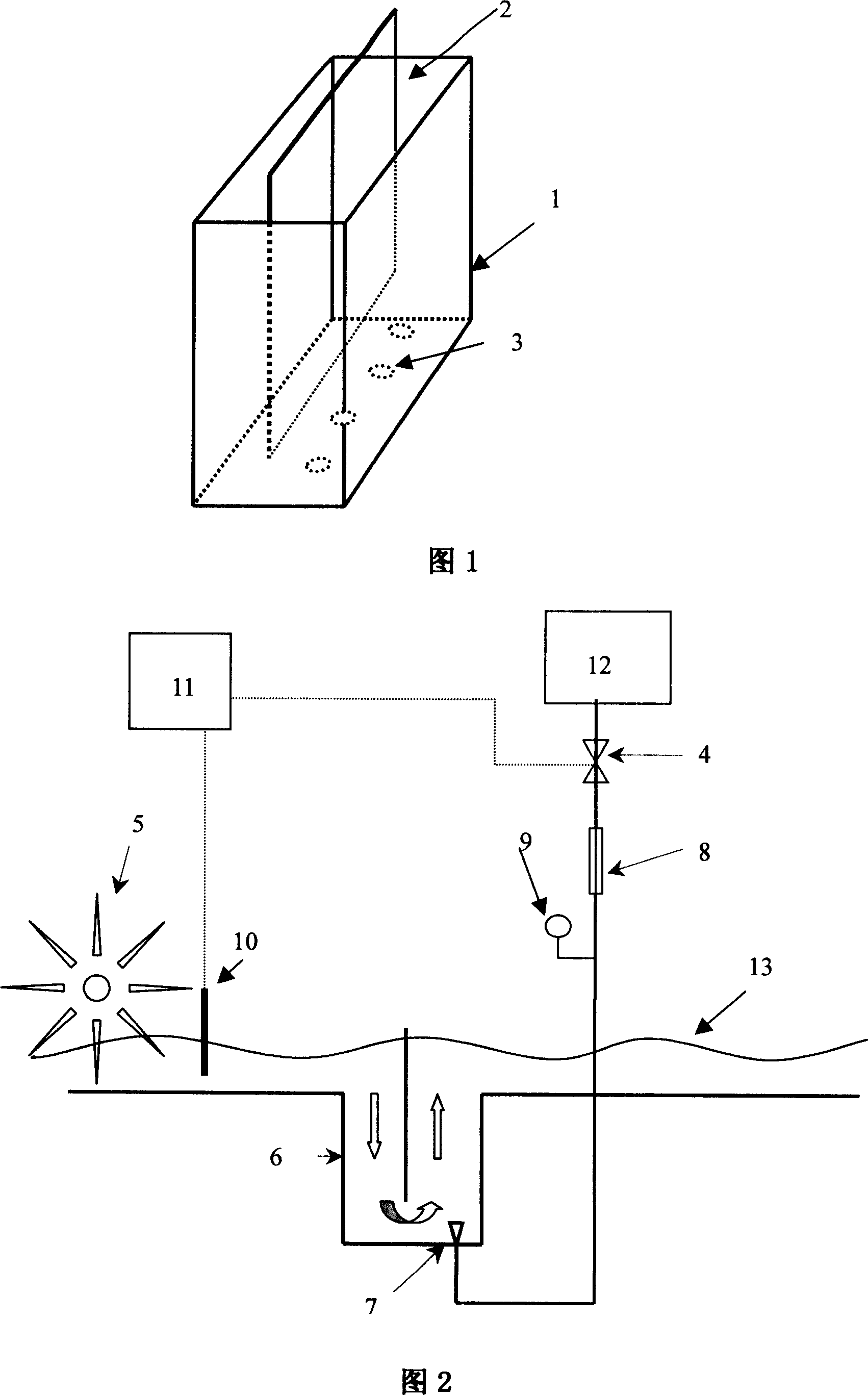

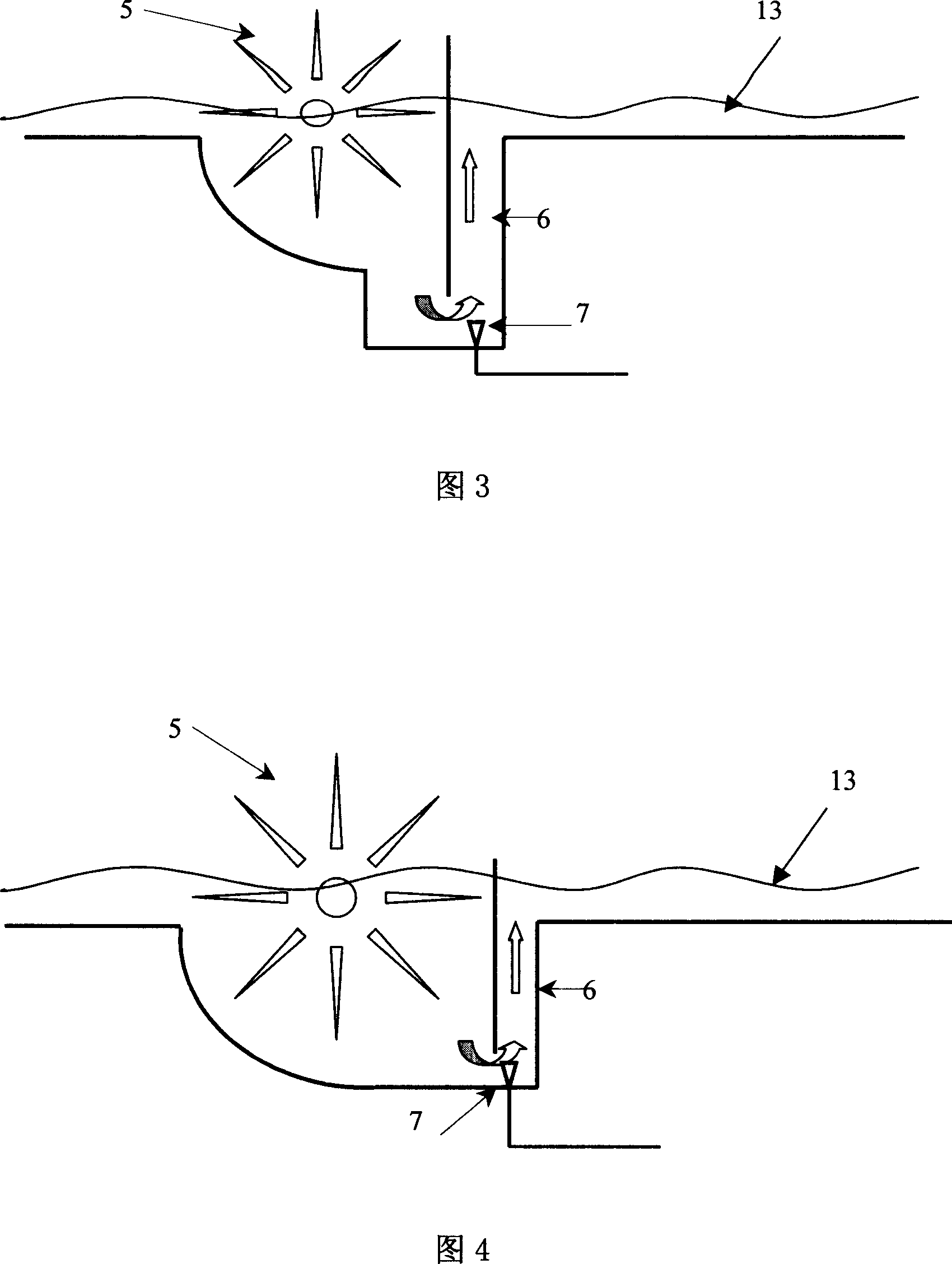

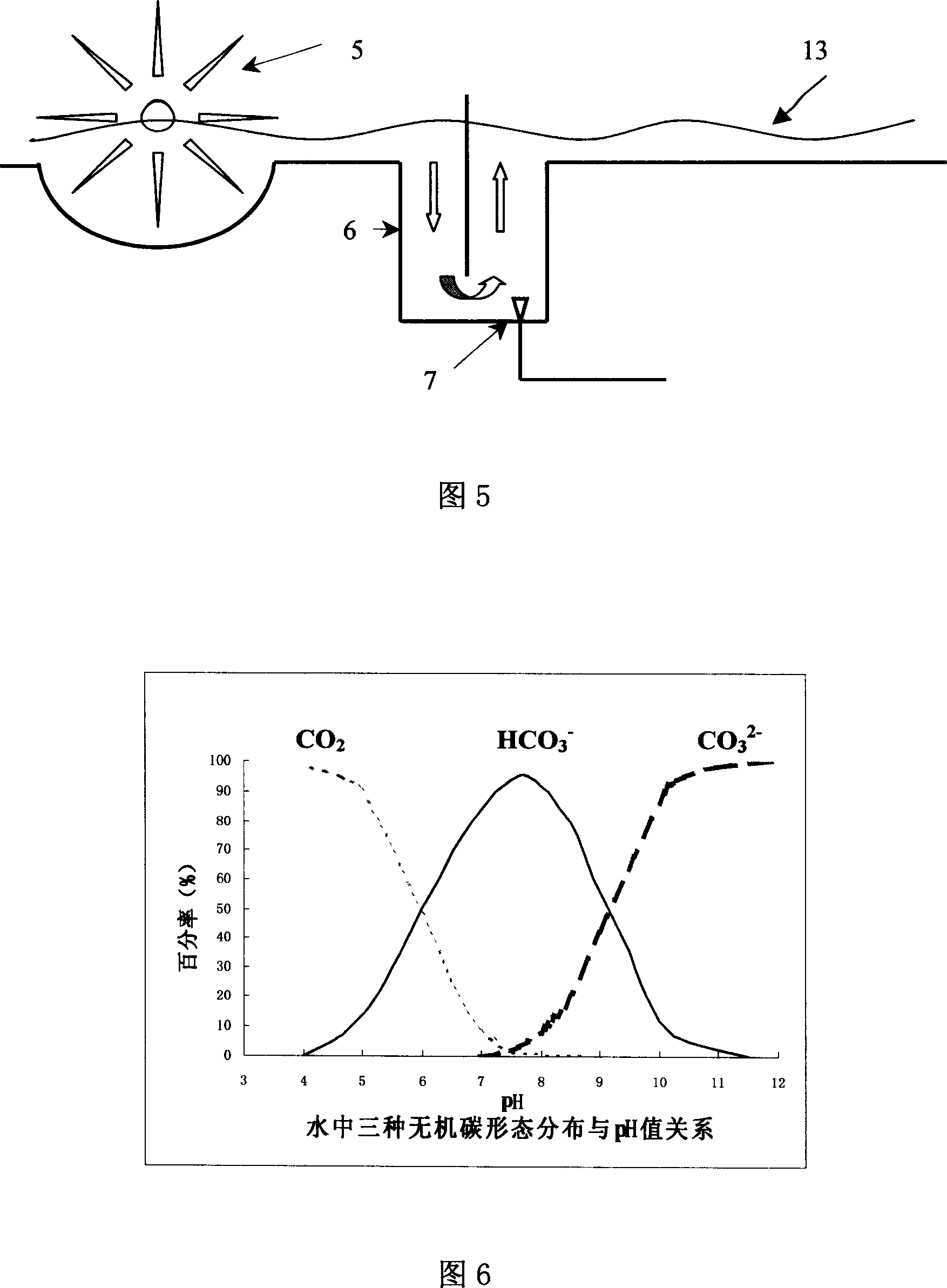

Carbon compensator for large-scale culturing micro-algae, its utilization and use

InactiveCN1982432AIncrease profitReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsVapor liquidContact time

A carbon supplementing apparatus for supplying carbon dioxide efficiently in micro-algae culturing tank, its usage and use are disclosed. A vertical baffle plate is installed above in the container with 10-50 cm gap, gas distributor is arrange at bottom of tank, the apparatus is built-in the bottom of tank, whose upper edge is aligned with the tank bottom, baffler plate is above culturing level of tank so as to pass culturing fluid to the apparatus with agitator driven. It has longer vapor-liquid contact time, more vapor-liquid contact area and higher carbon dioxide efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

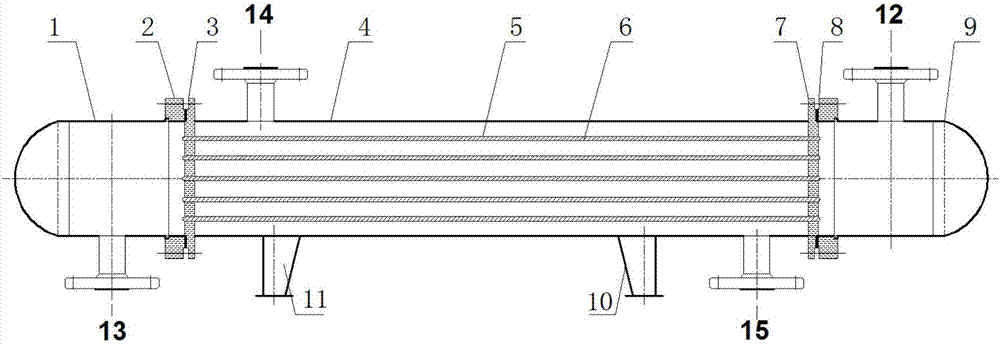

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

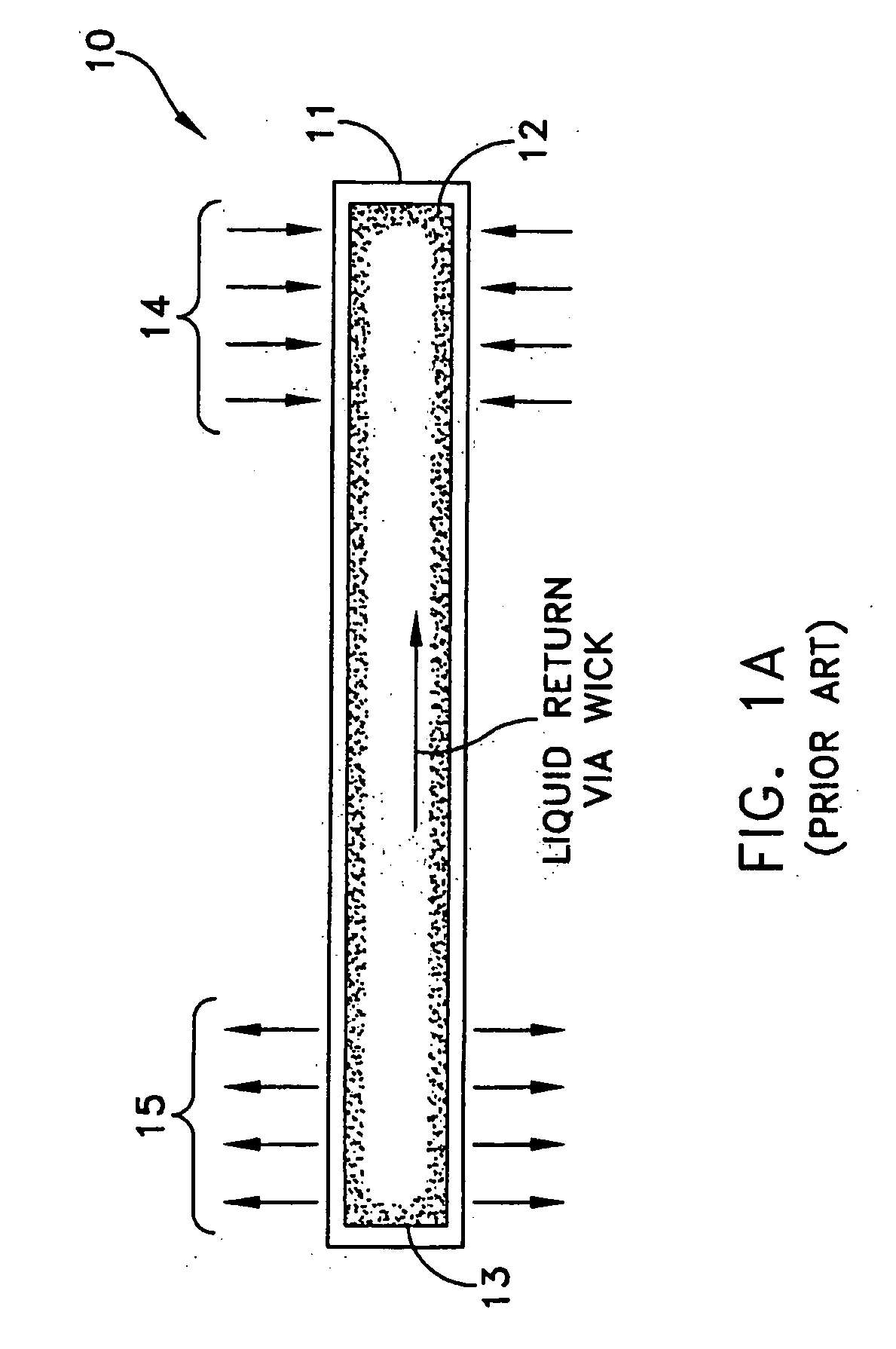

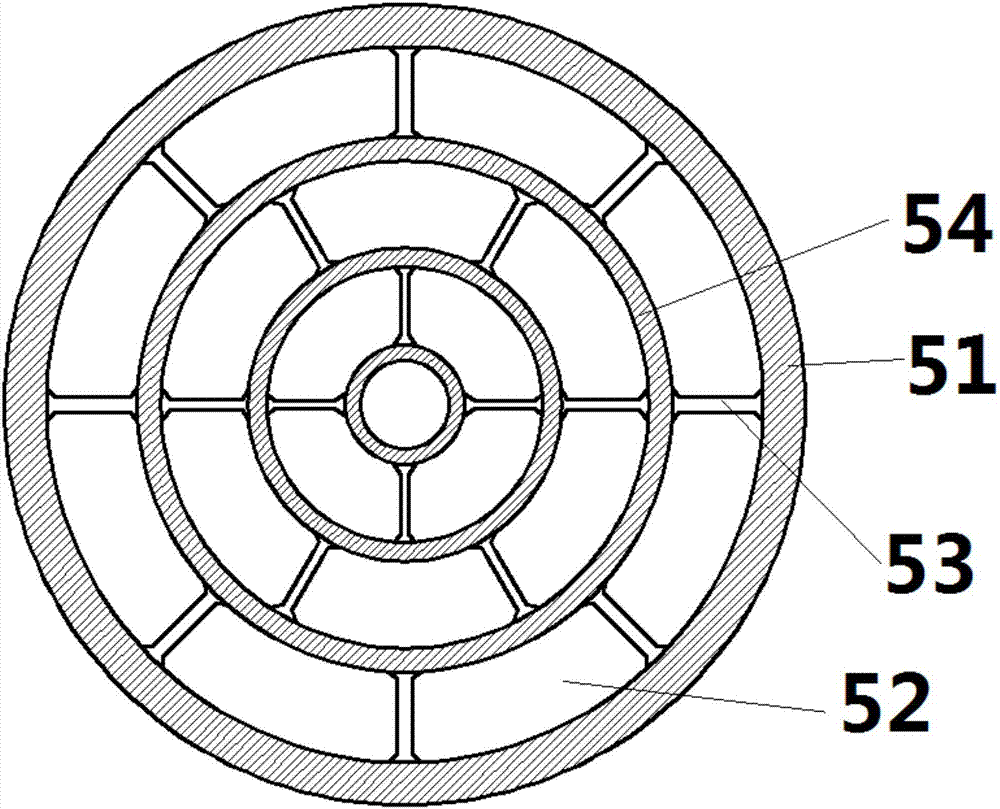

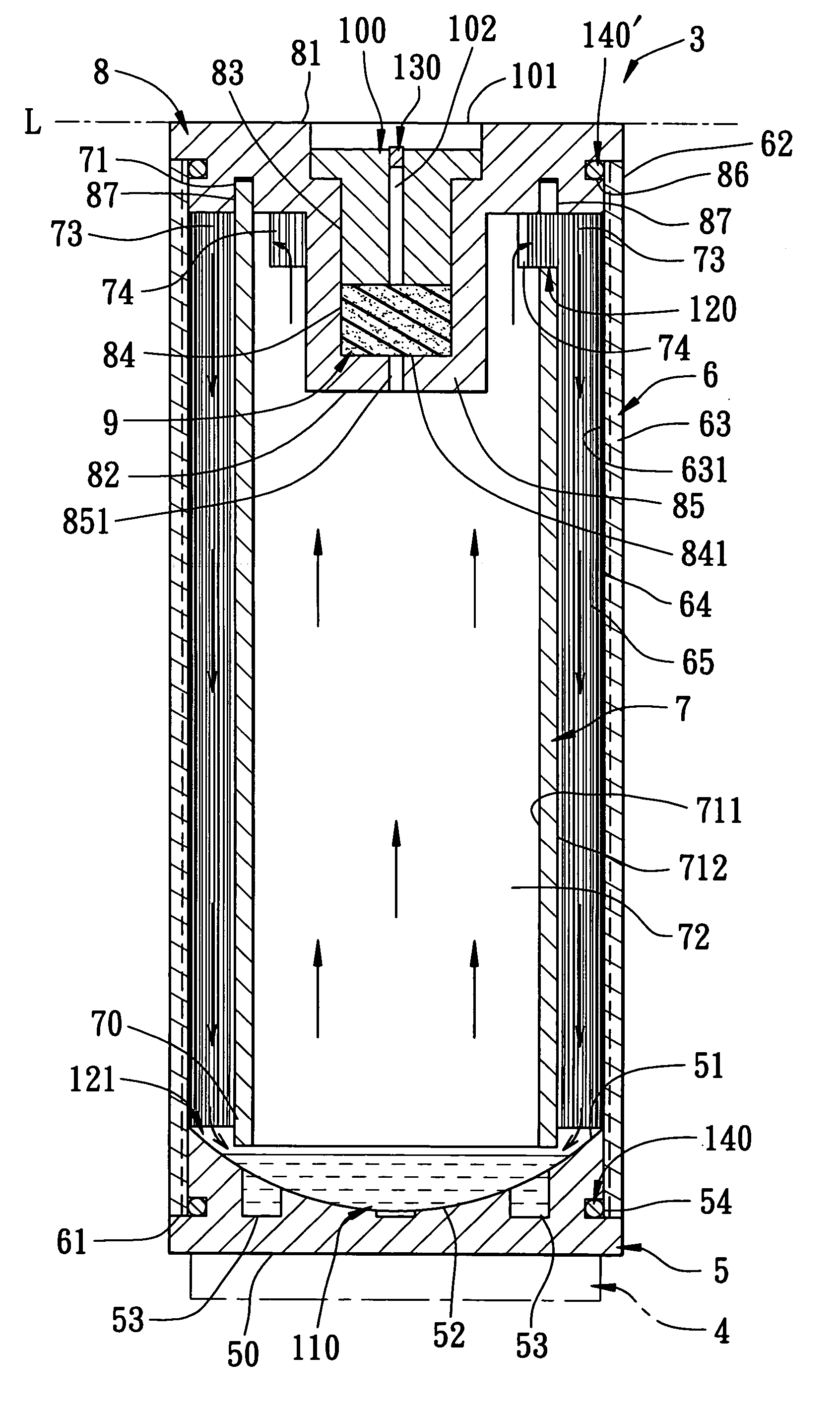

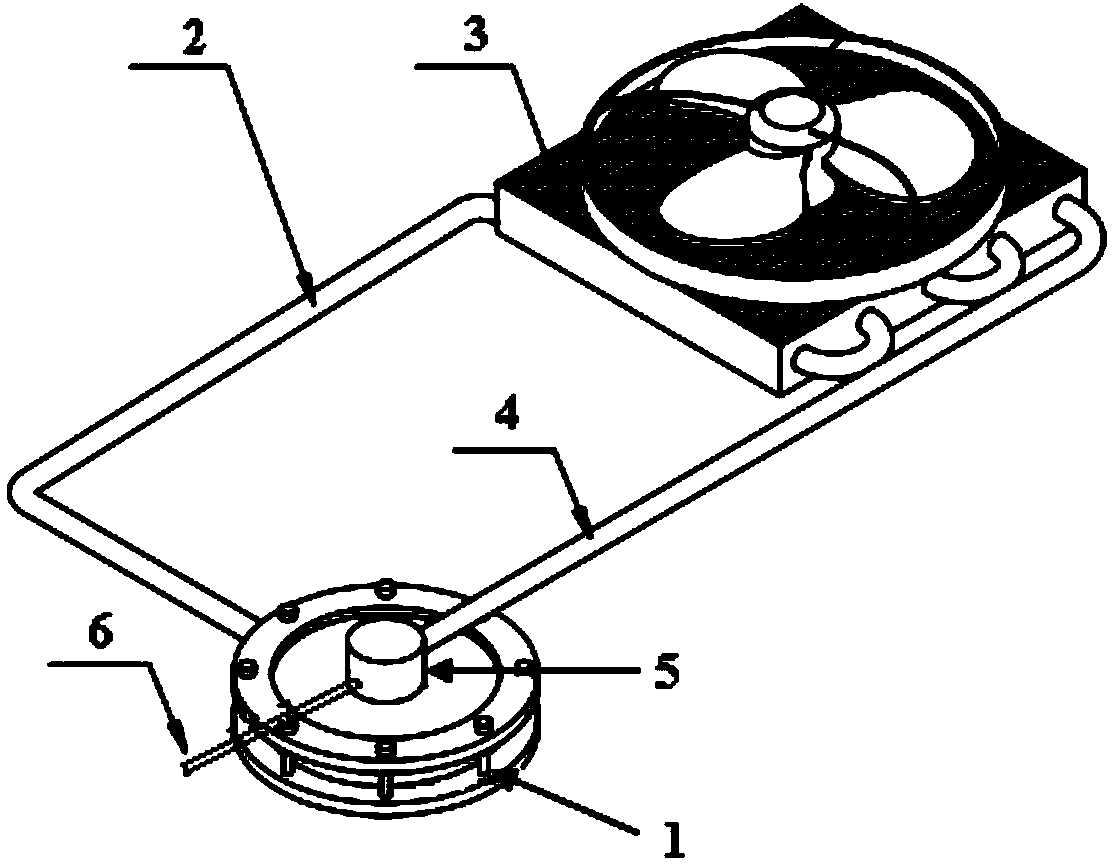

Vapor-liquid separating type heat pipe device

InactiveUS7051794B2Heat dissipation fastDissipate quicklySemiconductor/solid-state device detailsSolid-state devicesVapor liquidEngineering

A vapor-liquid separating type heat pipe device includes a heat sink member mountable on a heat source, tubular outer and inner bodies, a heat transfer fluid, a top vapor passage, and a bottom liquid passage. The outer body has an outer peripheral wall defining an inner chamber. The inner body is disposed in the inner chamber, and has an inner peripheral wall defining thereinside an evaporating space and cooperating with the outer peripheral wall to define a condensing space therebetween. The fluid is introduced into the inner chamber. The vapor passage is provided between and is in fluid communication with the evaporating and condensing spaces. The liquid passage is provided between and is in fluid communication with the condensing space and the heat sink member. The vapor and liquid passages are located proximate to the top and bottom ends of the inner and outer bodies, respectively.

Owner:LUO CHIN KUANG

Integrated hydrotreating and steam pyrolysis process including hydrogen redistribution for direct processing of a crude oil

ActiveUS9279088B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyVapor liquidSteam pyrolysis

Owner:SAUDI ARABIAN OIL CO

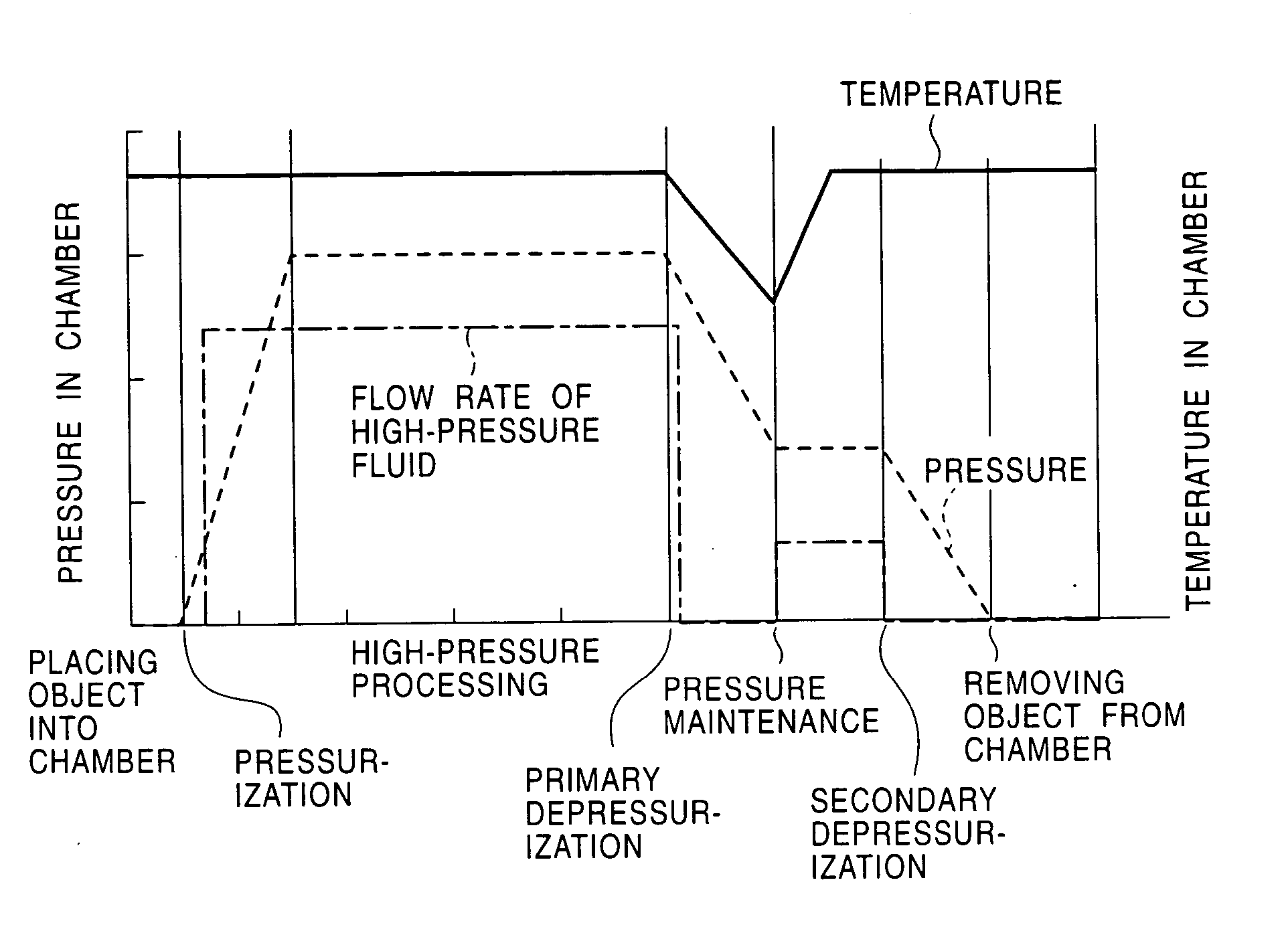

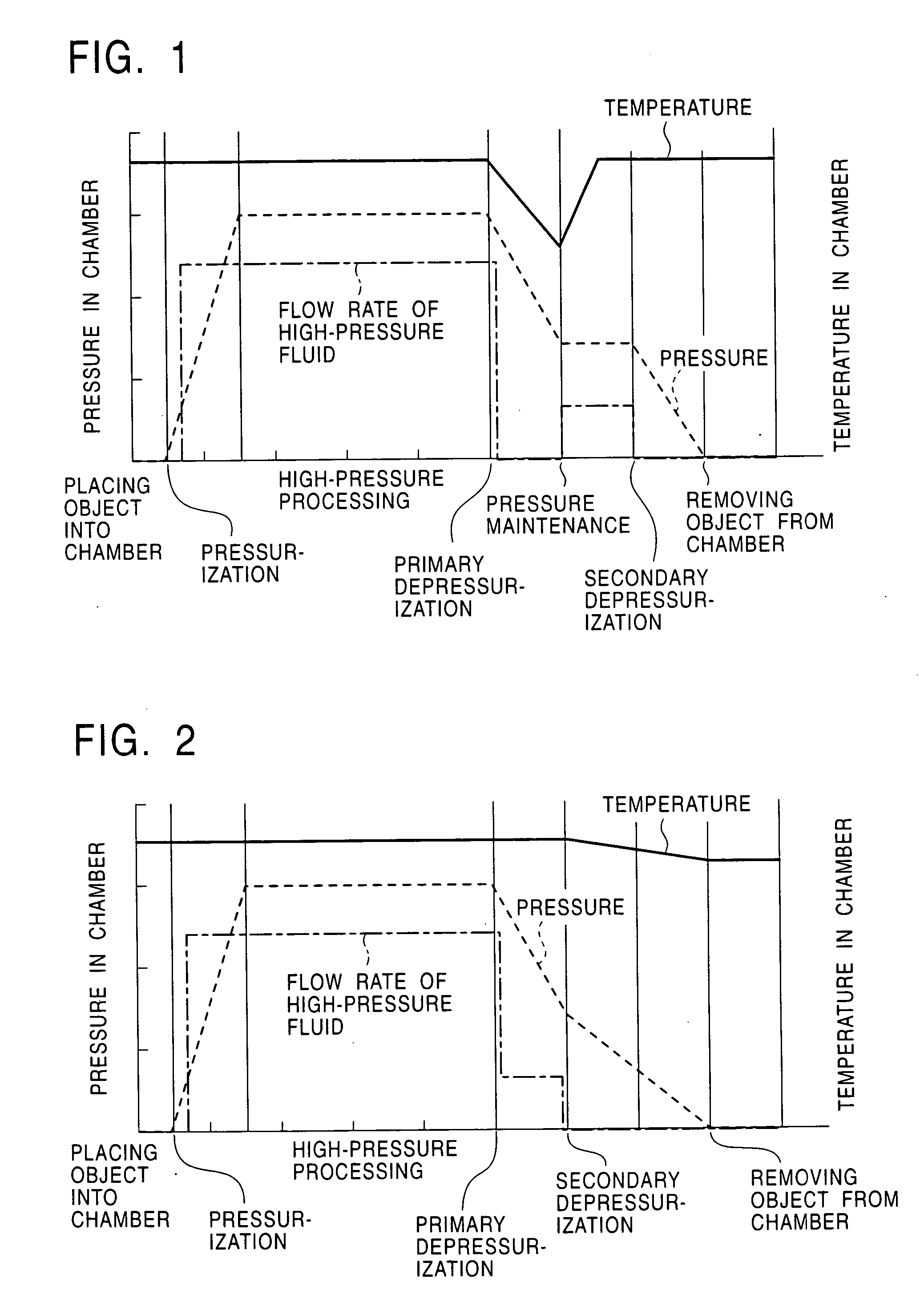

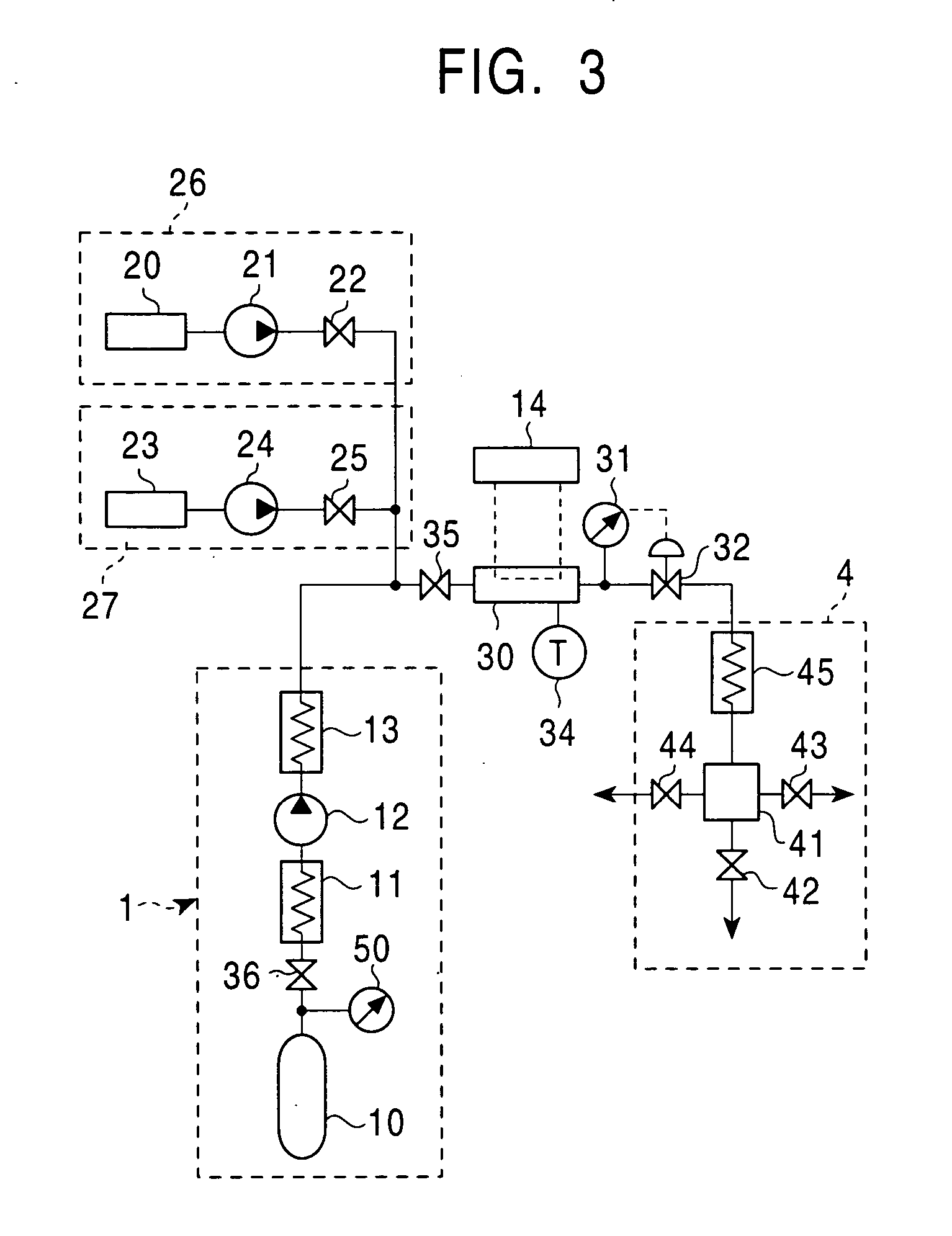

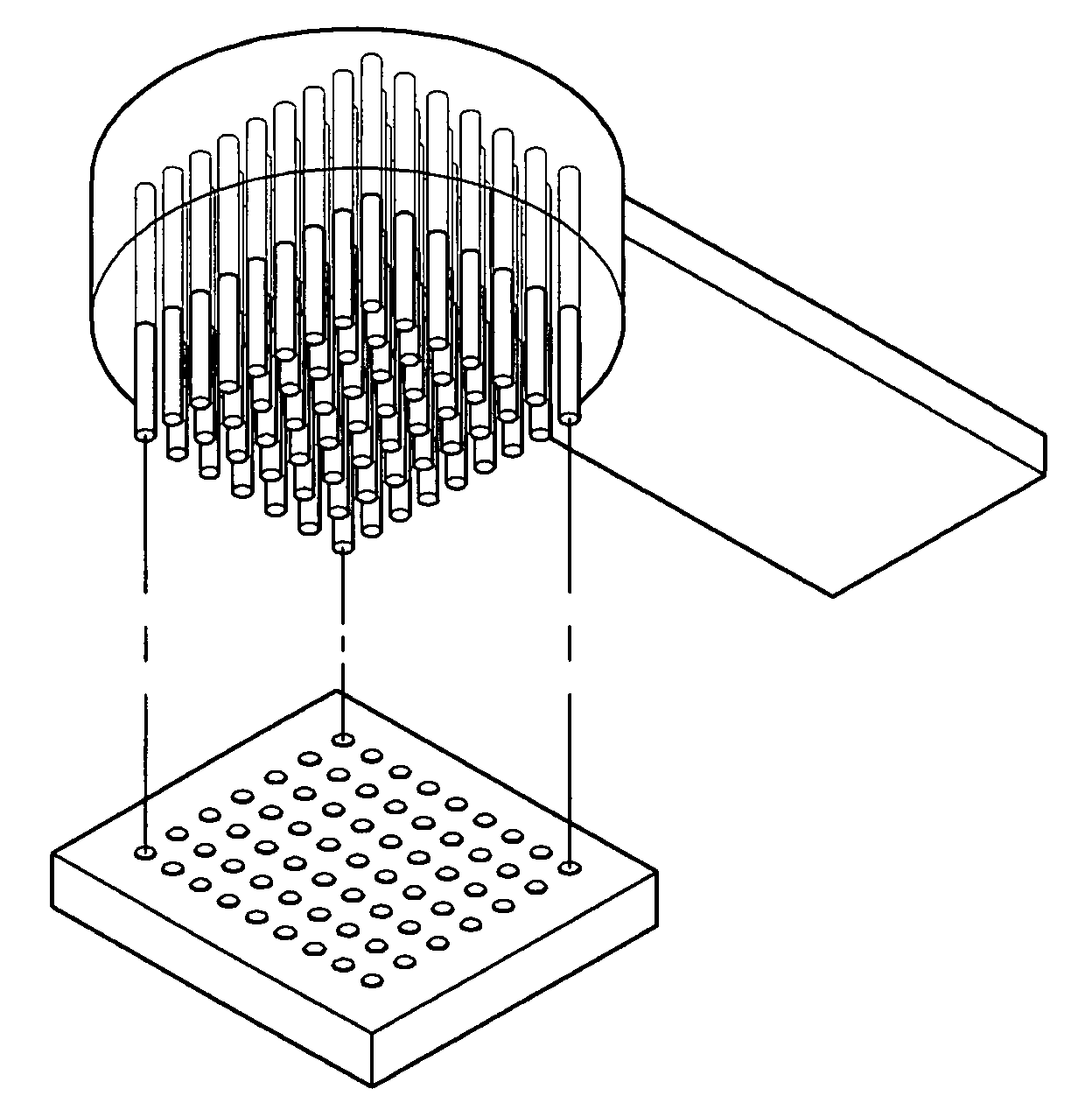

Method for high-pressure processing

InactiveUS20050051194A1Improve production yieldReduce pressureMilk treatmentSemiconductor/solid-state device manufacturingVapor liquidEngineering

An object is subjected to high-pressure processing by bringing at least a high-pressure fluid into contact with the object under pressure in a high-pressure processing chamber, and then the high-pressure processing chamber is depressurized while the temperature in the chamber is controlled to be maintained above a temperature achieved by an adiabatic expansion, the adiabatic expansion starting from the pressure and temperature at the end of the high-pressure processing step. To control in such a way, the temperature in the high-pressure processing chamber is controlled so as to suppress or recover a temperature descent caused by an adiabatic expansion during the depressurizing step. This solves a problem in which the temperature is decreased to the vapor-liquid phase coexistence region or a region in which a solid is deposited.

Owner:KOBE STEEL LTD

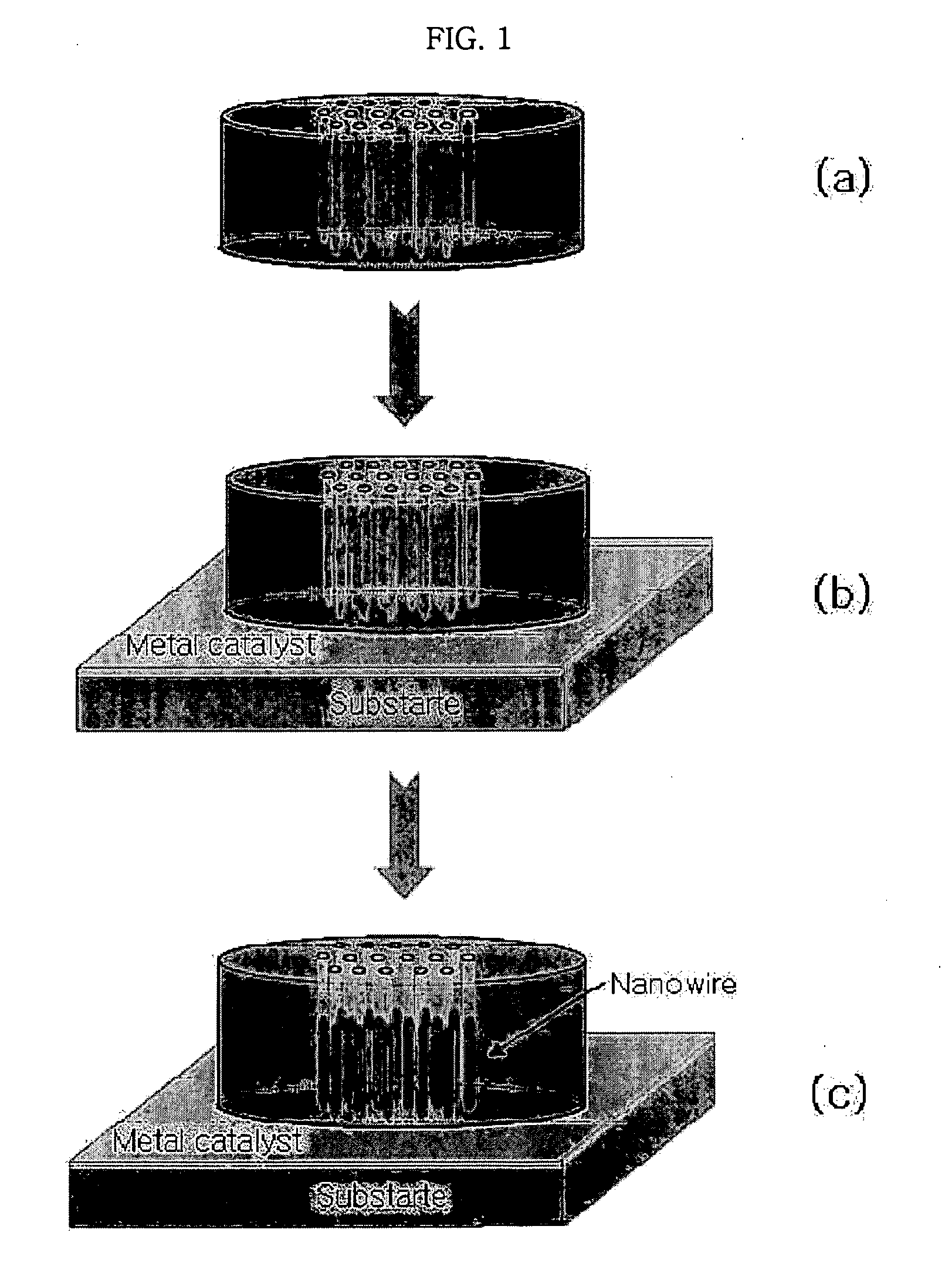

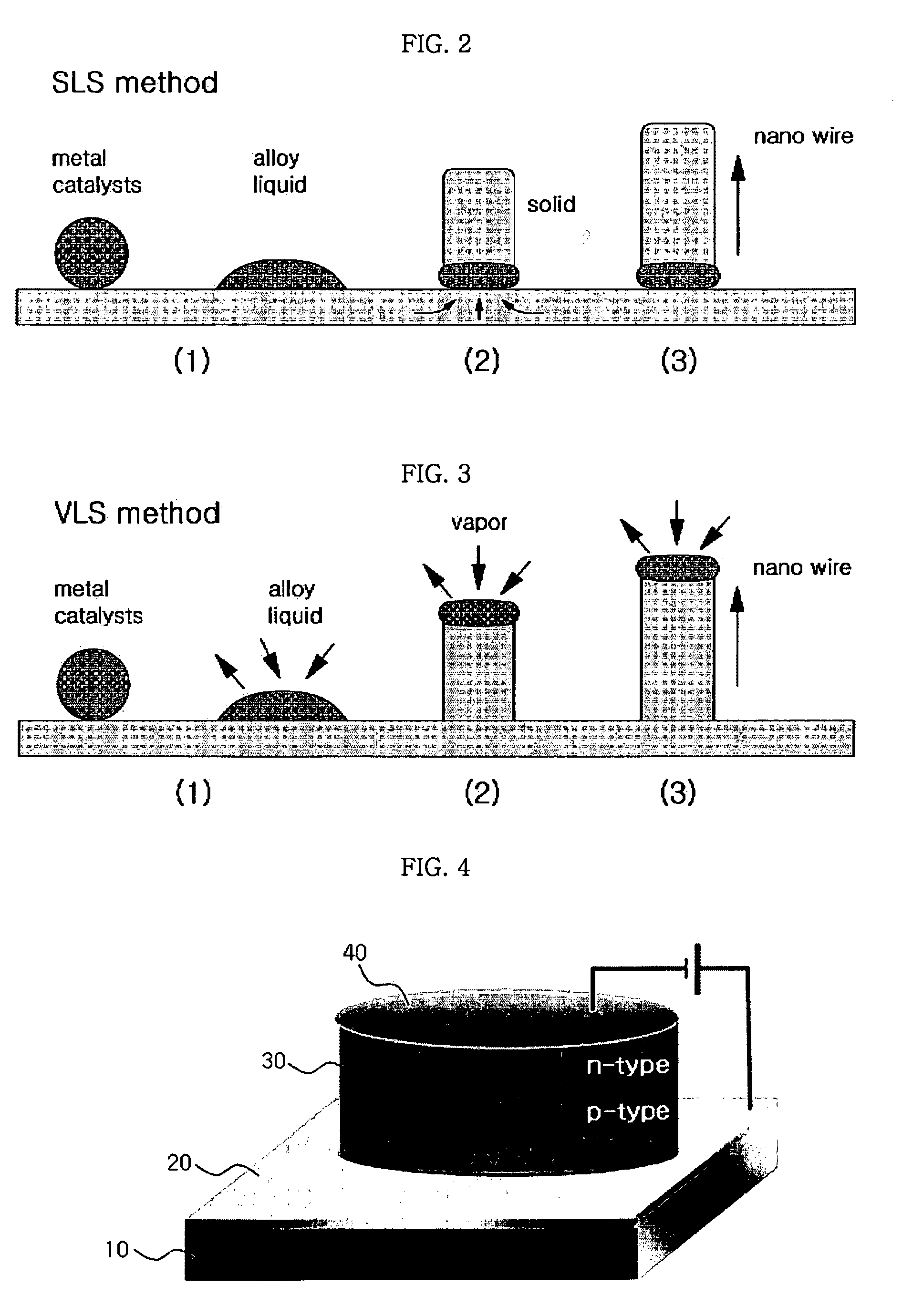

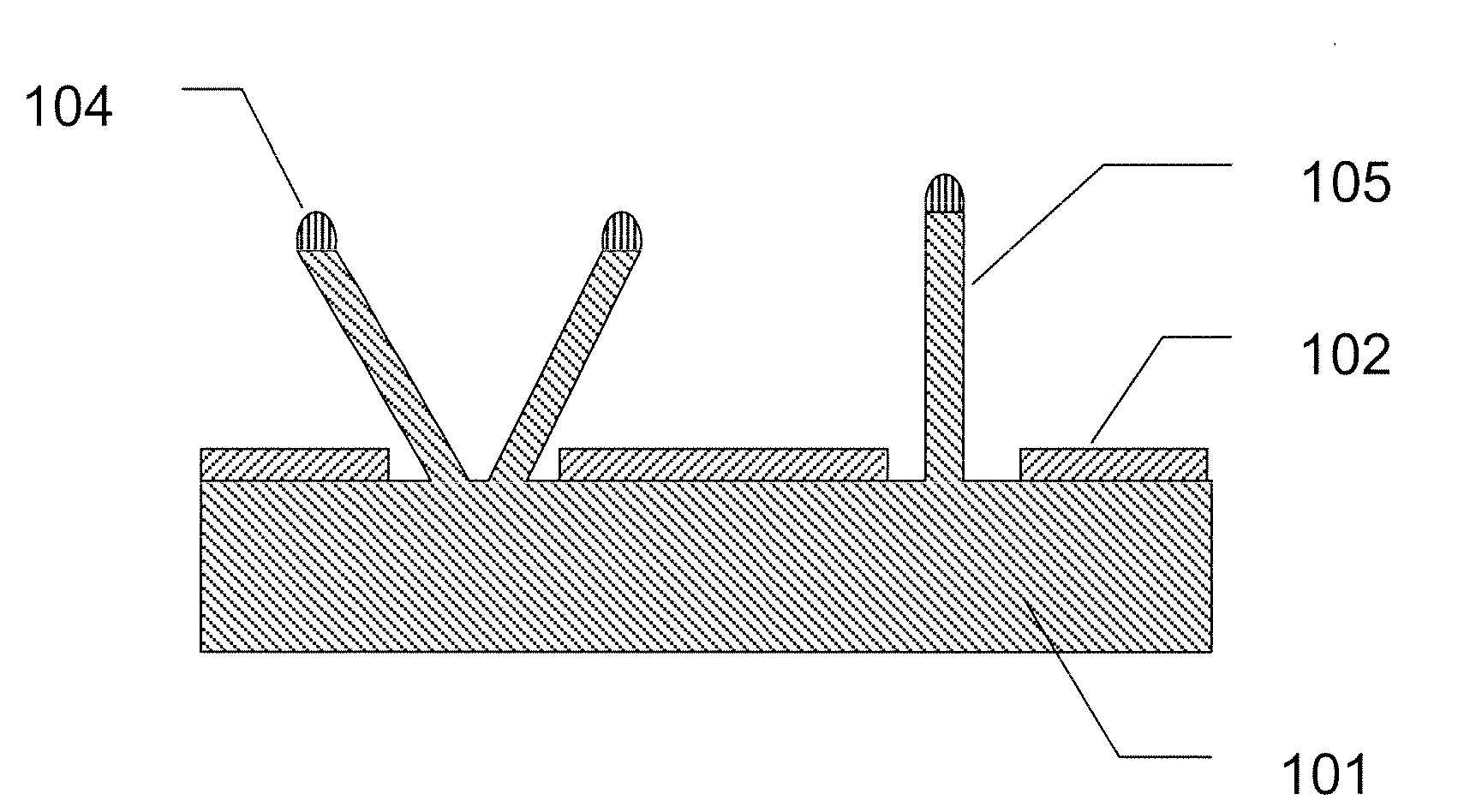

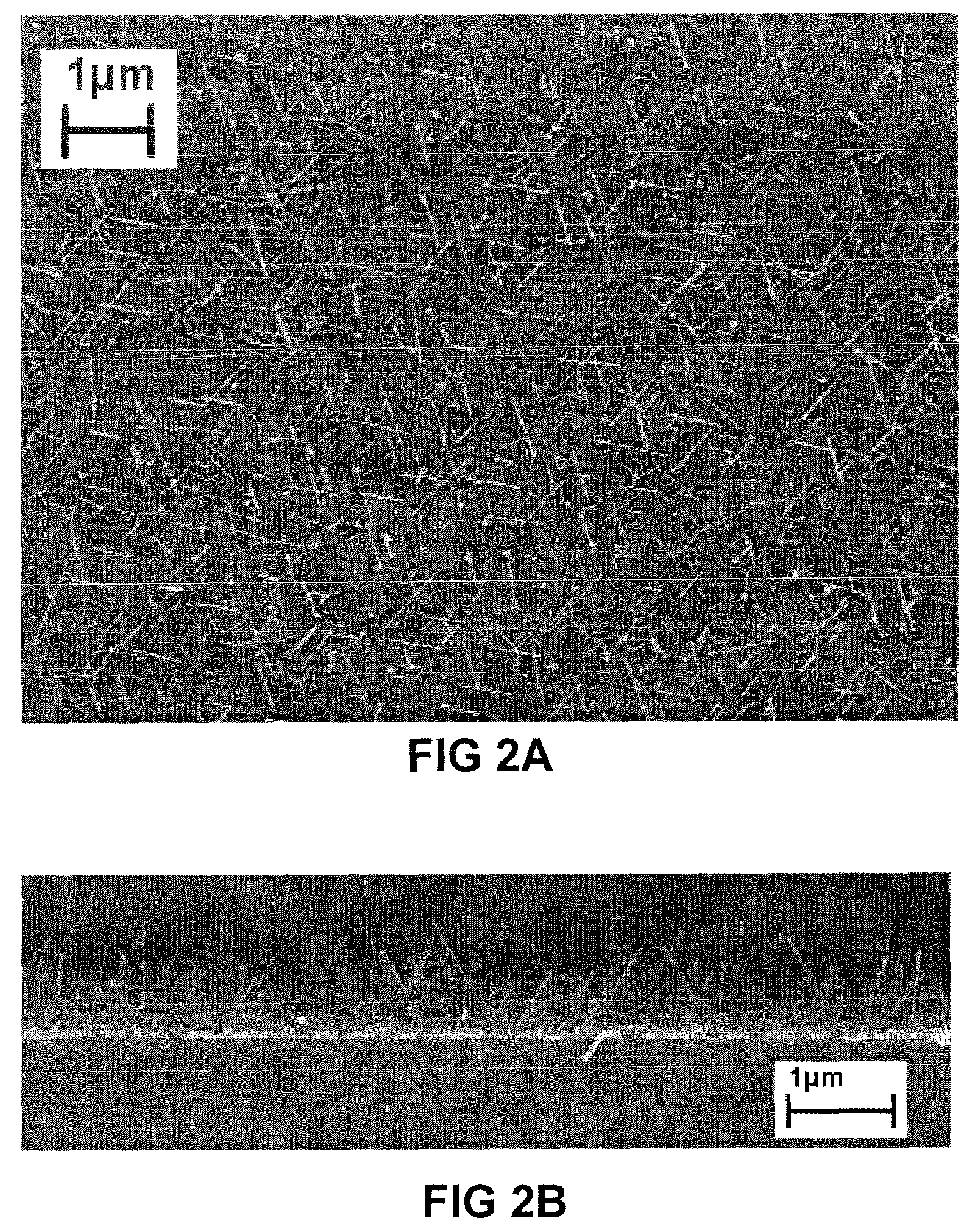

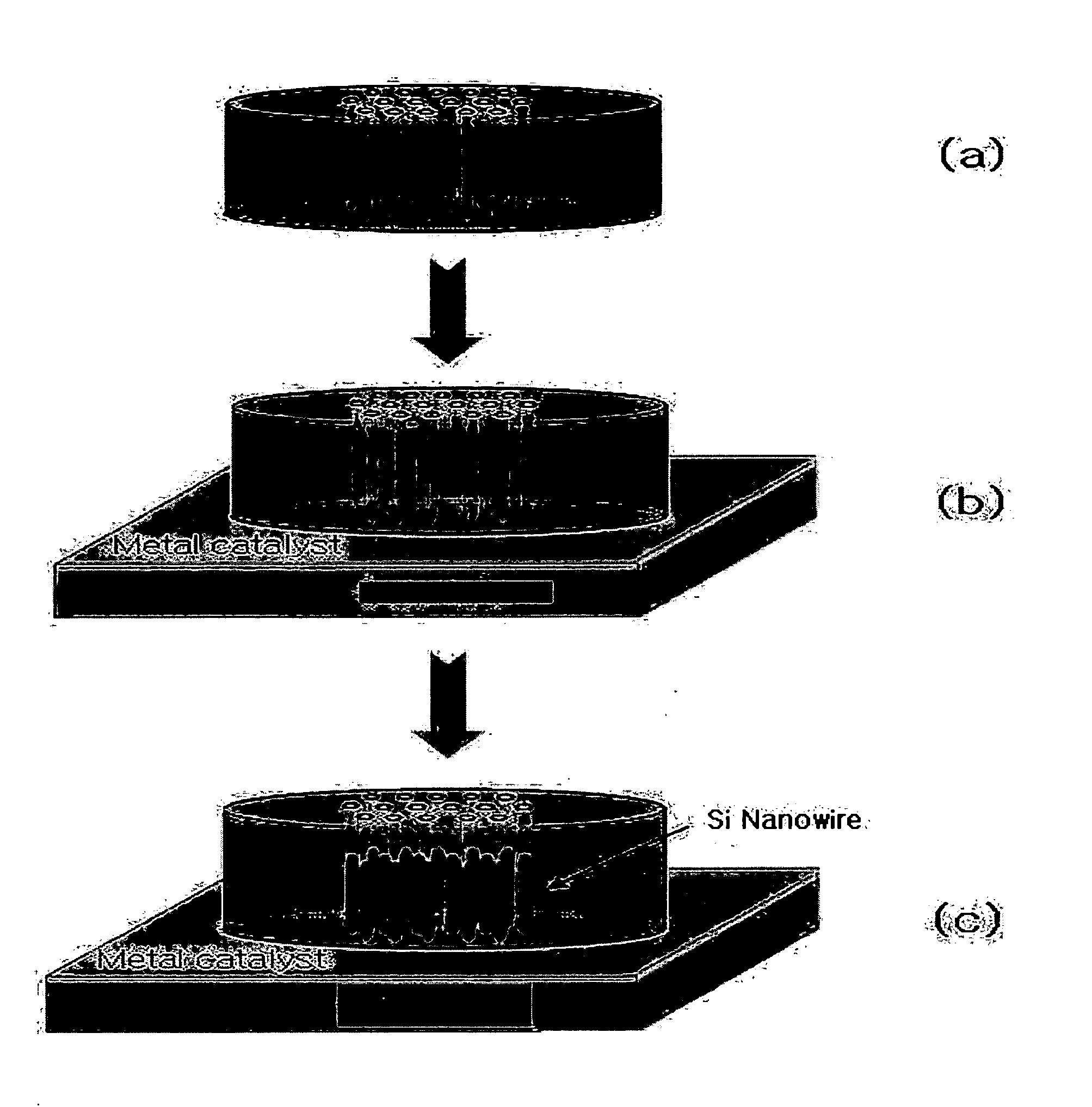

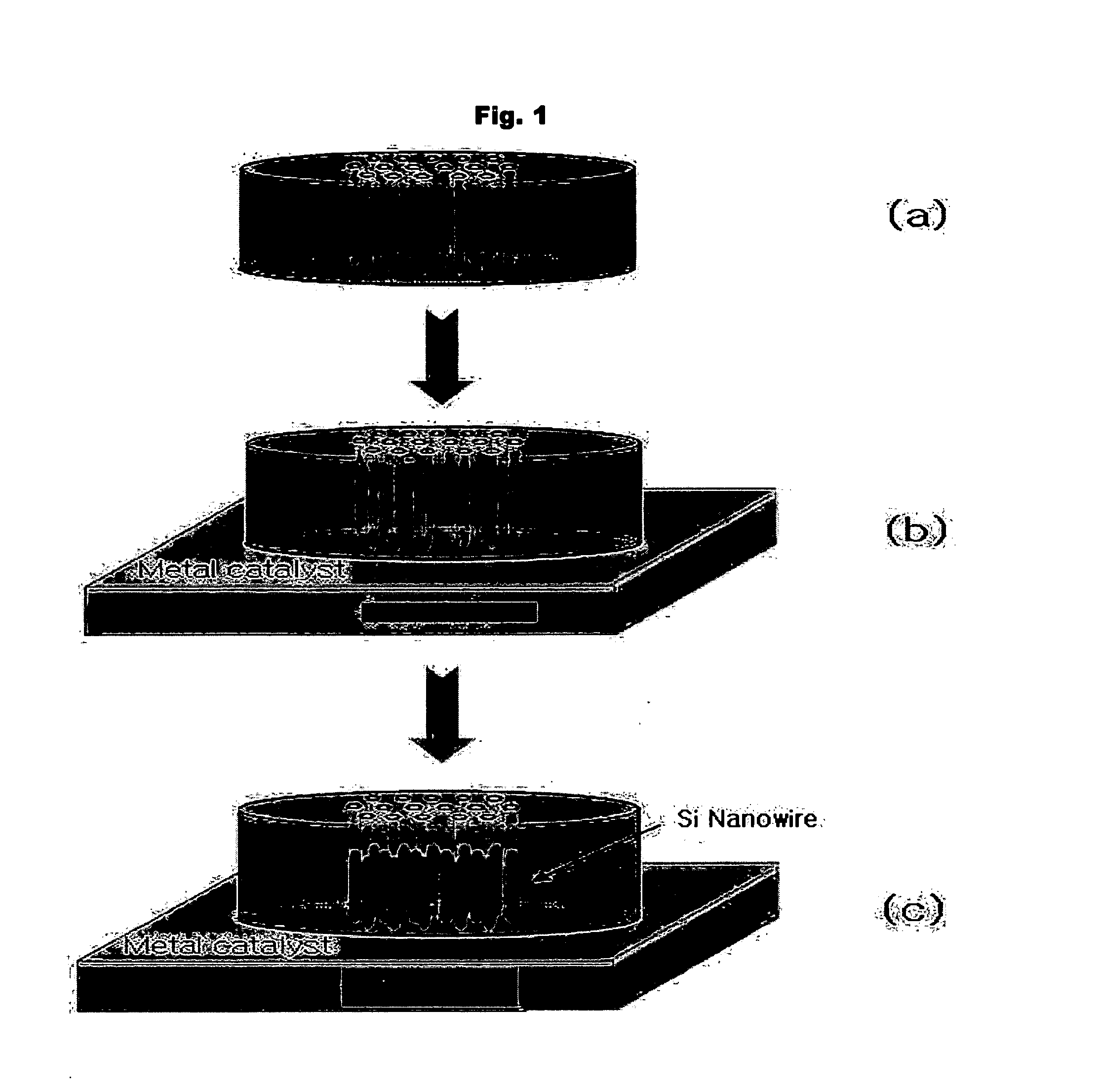

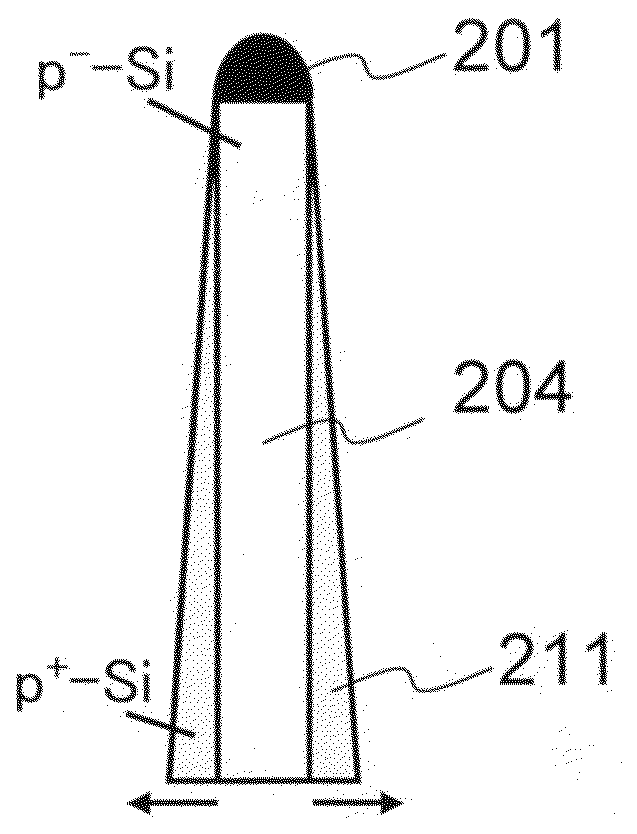

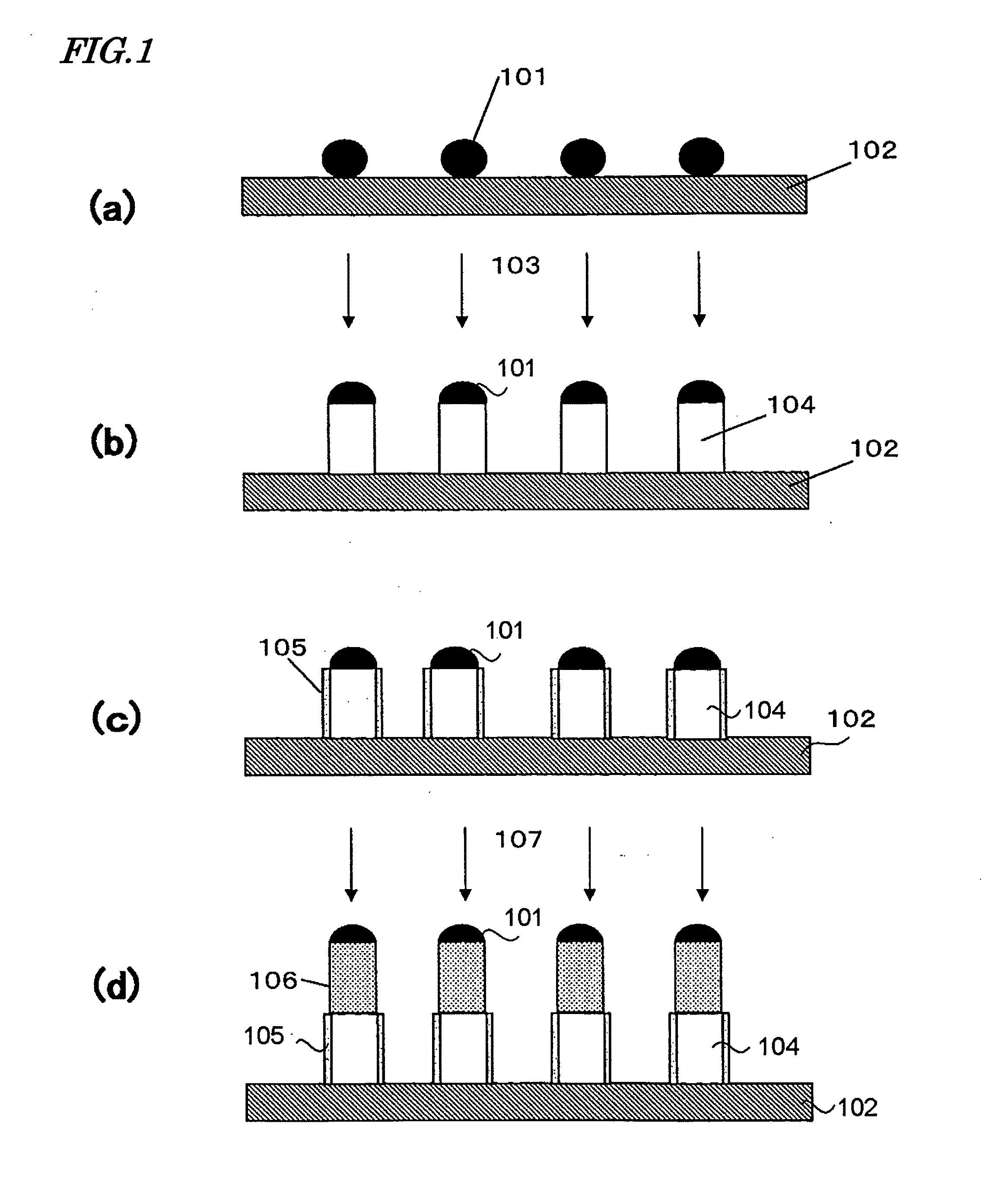

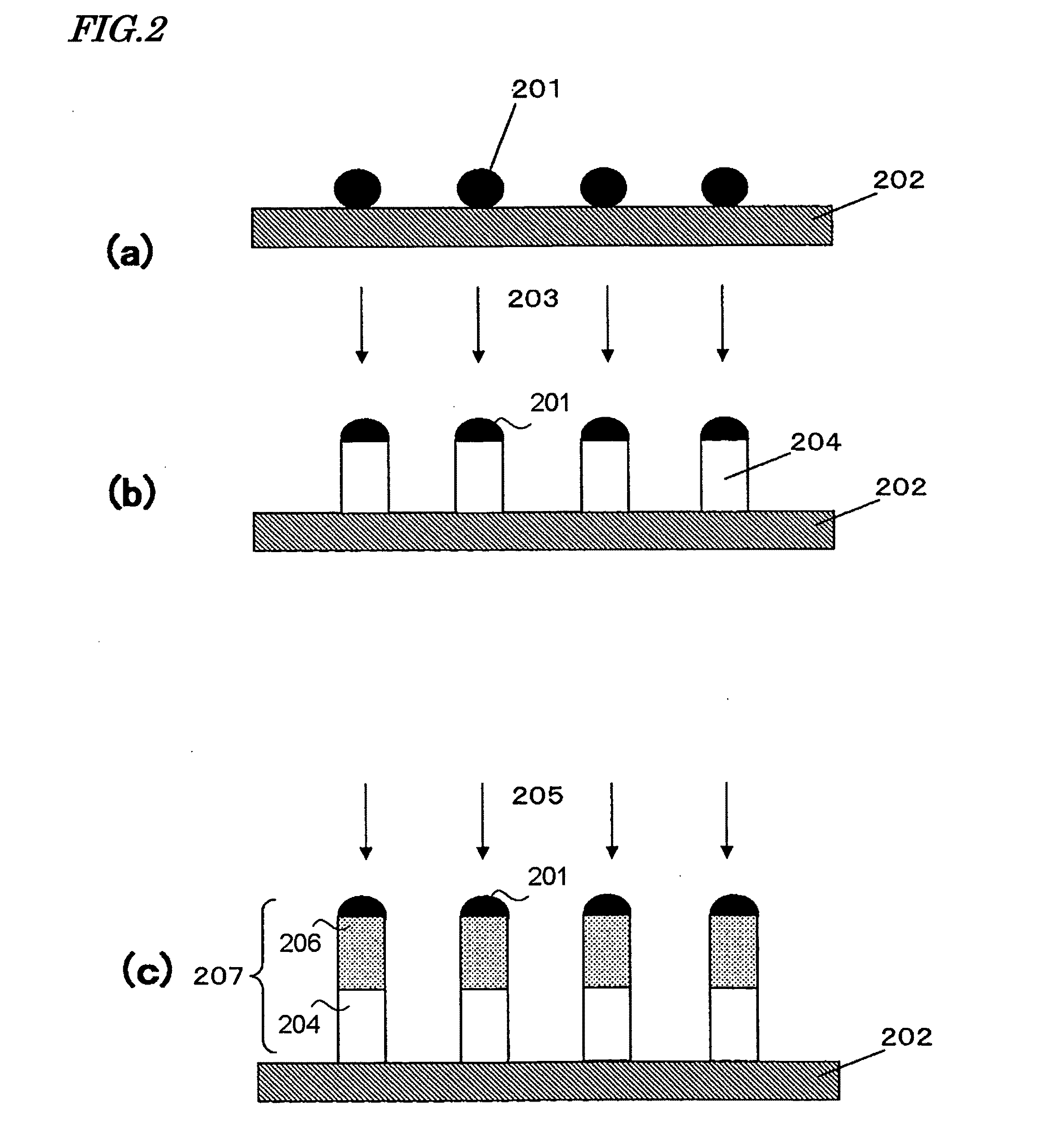

Method for producing nanowires using porous glass template, and multi-probe, field emission tip and devices employing the nanowires

InactiveUS20090045720A1Easy to controlMaterial nanotechnologyDischarge tube luminescnet screensVapor liquidNanowire

Disclosed herein is a method for producing nanowires, which features the use of a porous glass template in combination with a solid-liquid-solid or vapor-liquid-solid process for growing nanowires which are highly straight and have nanoparticles precisely arranged therein. The nanowires can be grown into composite structures of superlattices and hybrids by modulating the composition of the materials provided thereto. Also disclosed is the use of the nanowires in multi-probes, field emission tips, and devices.

Owner:SAMSUNG ELECTRONICS CO LTD

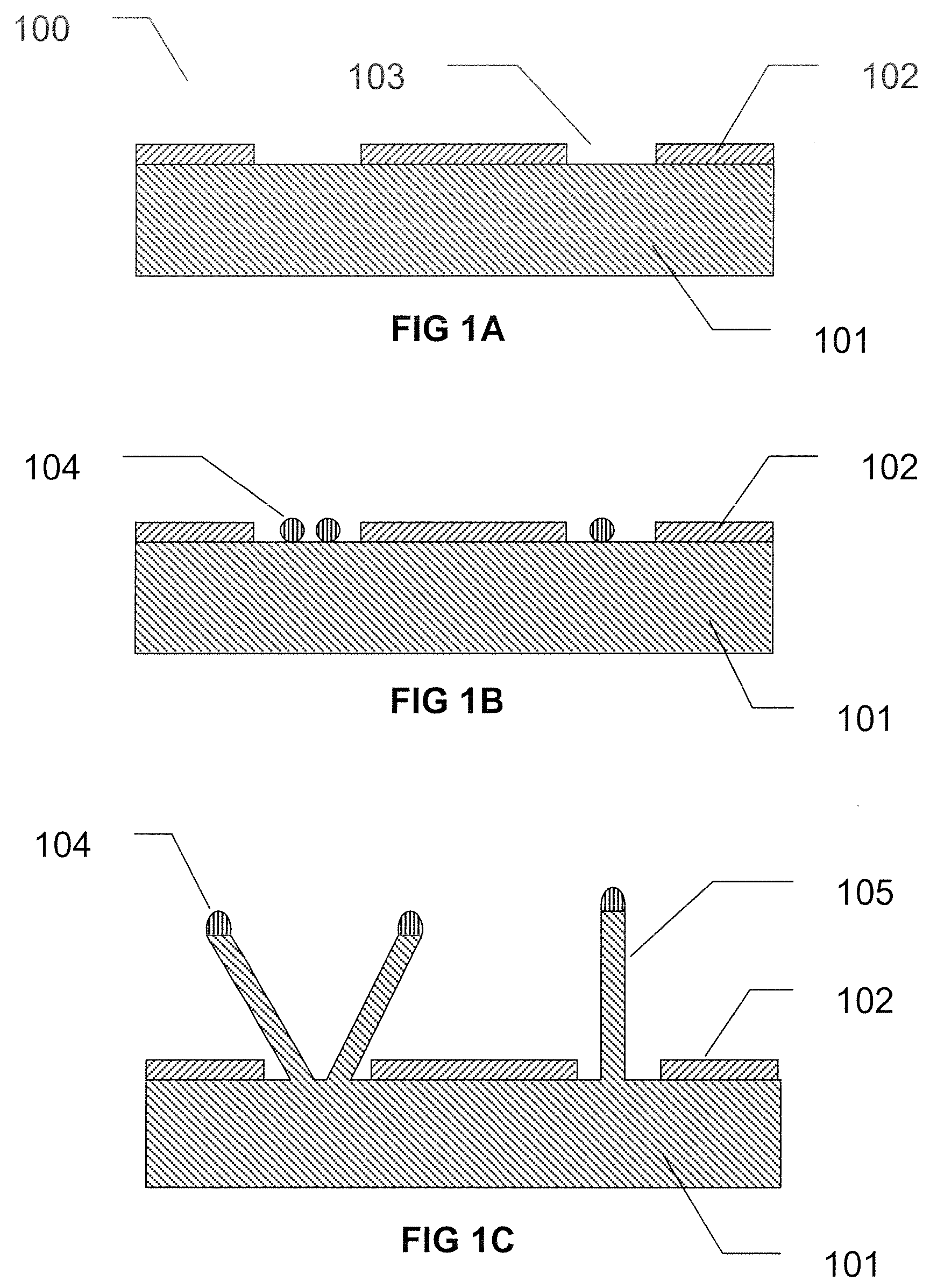

Self-aligned epitaxial growth of semiconductor nanowires

Disclosed herein is a method of forming a nanostructure having nanowires by forming a mask with at least one opening on a surface of a substrate, to expose a portion of the surface of the substrate; depositing particles of a metal capable of catalyzing semiconductor nanowire growth on the exposed surface of the substrate by electroplating or electroless plating; and growing nanowires on the plated substrate with a precursor gas by a vapor-liquid-solid (VLS) process. Also disclosed is a nanostructure including nanowires prepared by the above method.

Owner:GLOBALFOUNDRIES INC

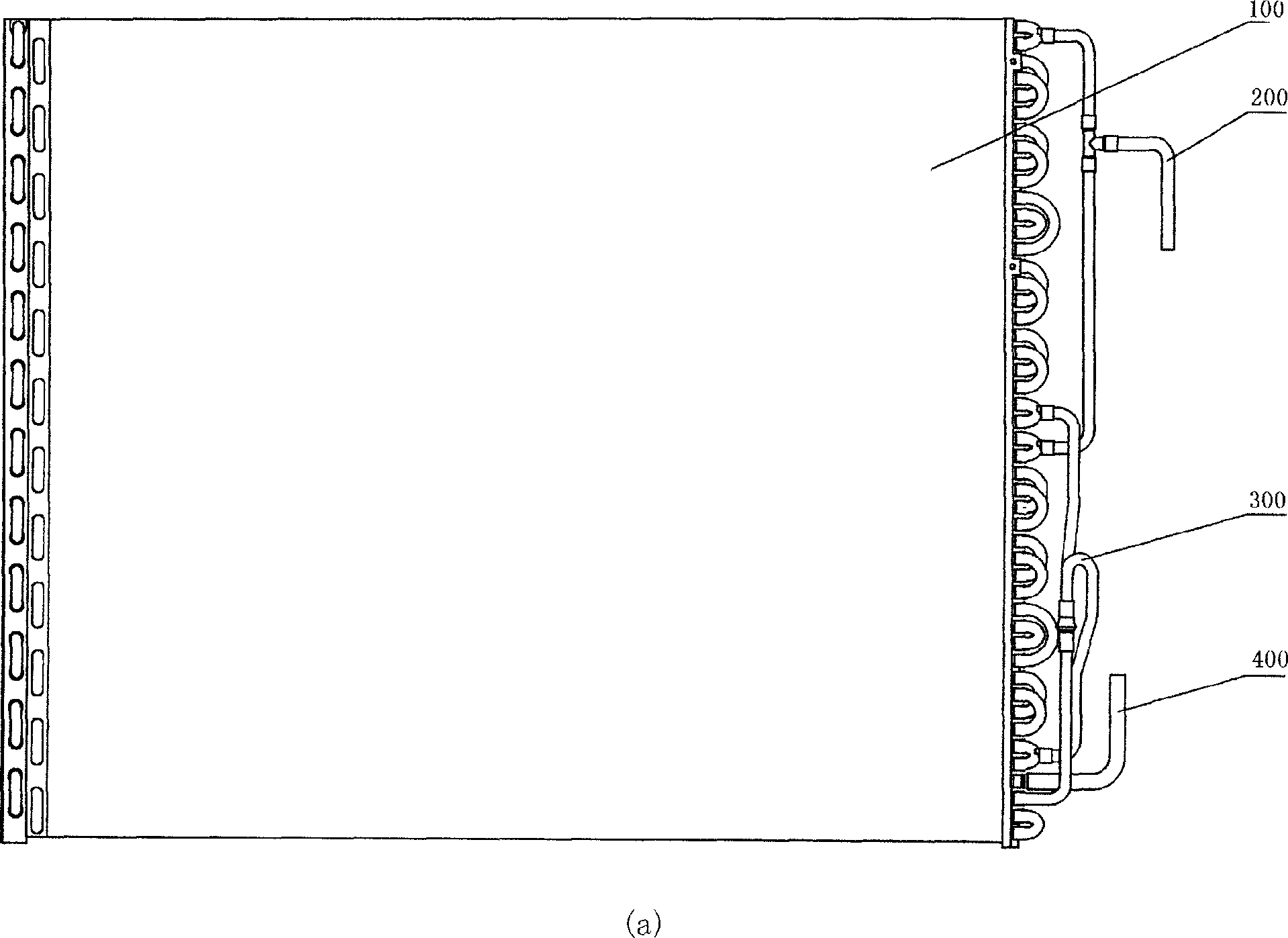

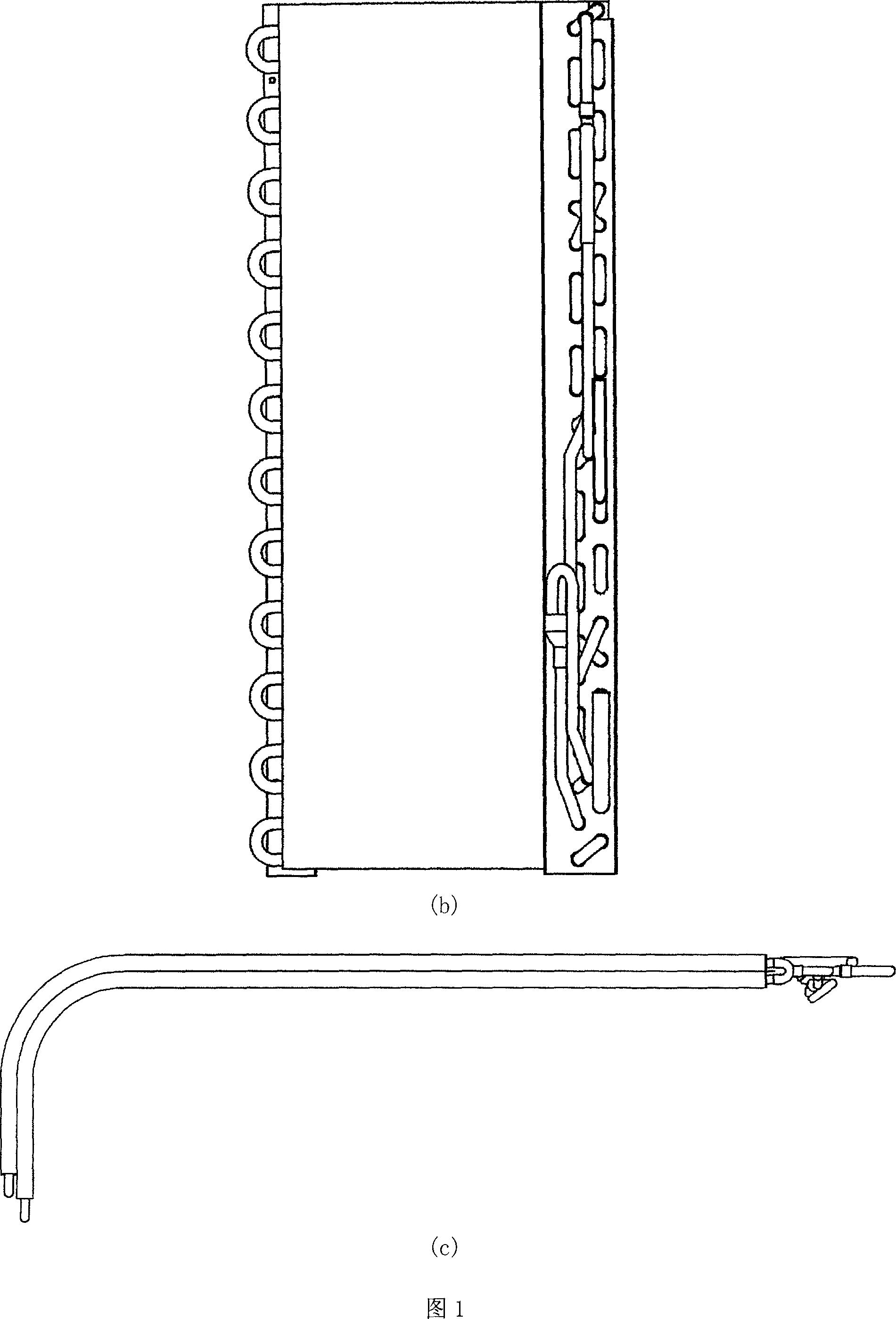

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

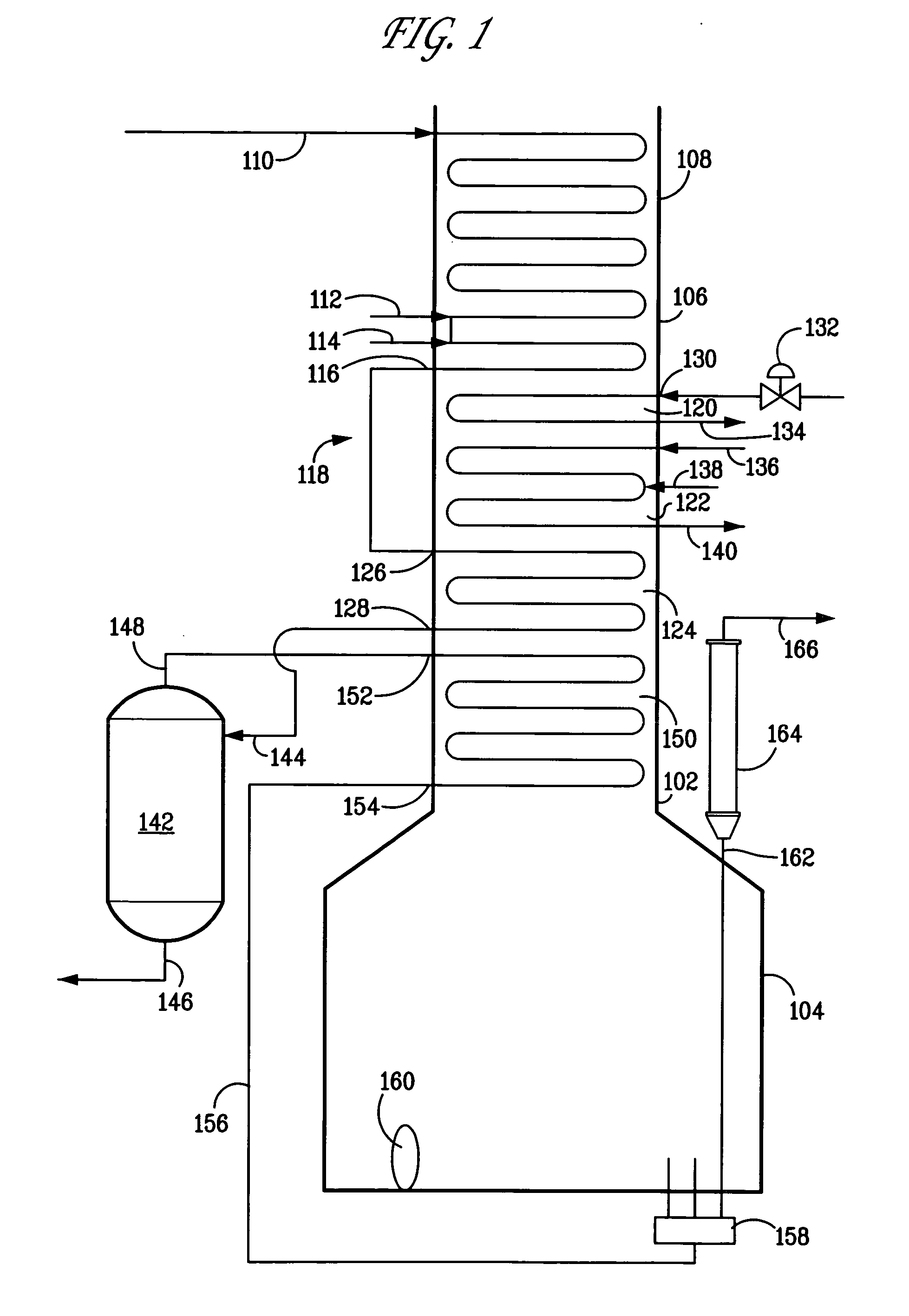

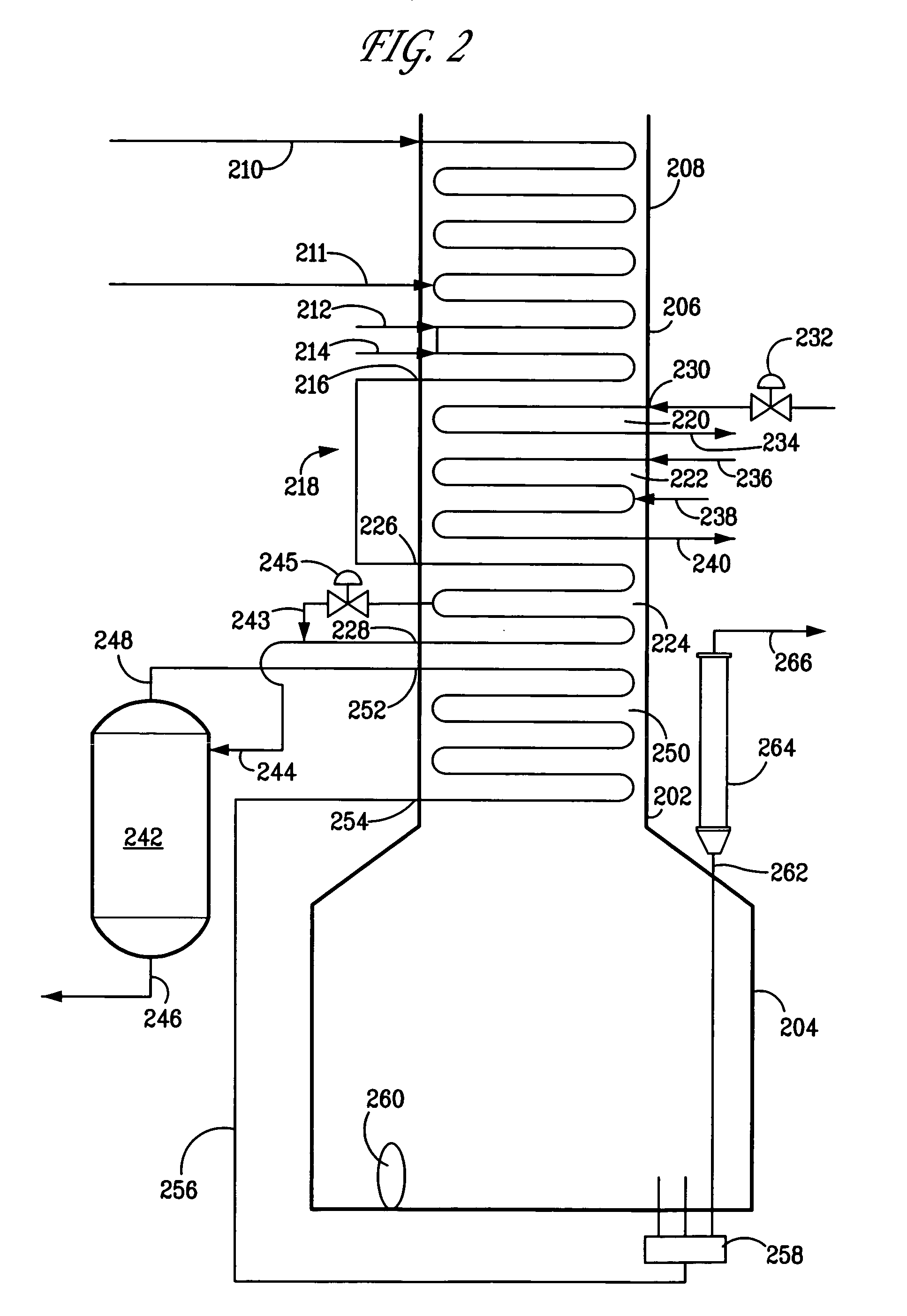

Apparatus and process for controlling temperature of heated feed directed to a flash drum whose overhead provides feed for cracking

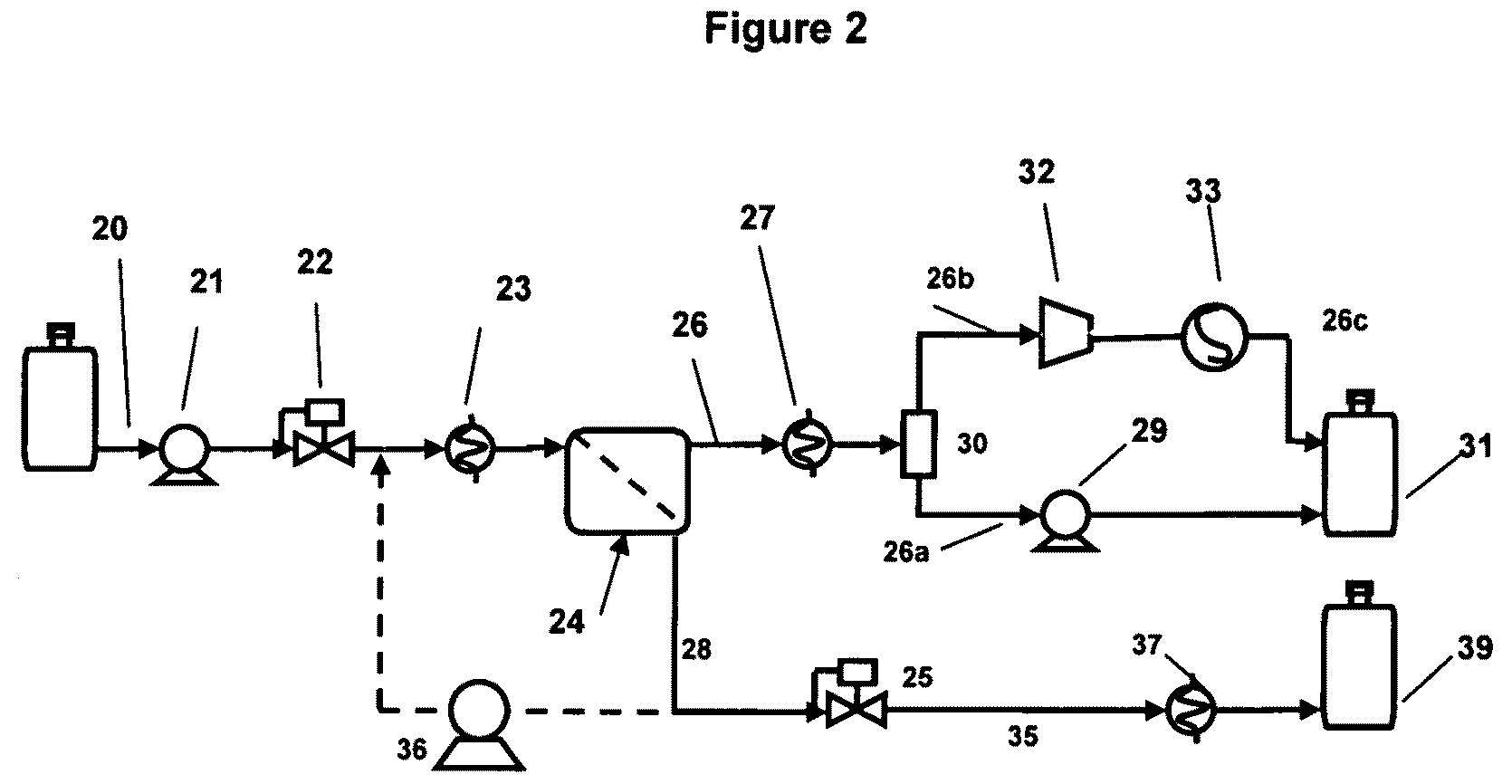

InactiveUS20050261536A1Great heat contentThermal non-catalytic crackingHydrocarbon oil cracking processVapor liquidTemperature control

An apparatus and process are provided for cracking hydrocarbonaceous feed, wherein the temperature of heated effluent directed to a vapor / liquid separator, e.g., flash drum, whose overhead is subsequently cracked, can be controlled within a range sufficient so the heated effluent is partially liquid, say, from about 260 to about 540° C. (500 to 1000° F.). This permits processing of a variety of feeds containing resid with greatly differing volatilities, e.g., atmospheric resid and crude at higher temperature and dirty liquid condensates, at lower temperatures. The temperature can be lowered as needed by: i) providing one or more additional downstream feed inlets to a convection section, ii) increasing the ratio of water / steam mixture added to the hydrocarbonaceous feed, iii) using a high pressure boiler feed water economizer to remove heat, iv) heating high pressure steam to remove heat, v) bypassing an intermediate portion of the convection section used, e.g., preheat rows of tube banks, and / or vi) reducing excess oxygen content of the flue gas providing convection heat.

Owner:EXXONMOBIL CHEM PAT INC

Method of manufacturing silicon nanowires using porous glass template and device comprising silicon nanowires formed by the same

InactiveUS20070232028A1Increasing structural efficiency of structureMaterial nanotechnologyPolycrystalline material growthVapor liquidPhotovoltaic detectors

A method of manufacturing silicon nanowires is characterized in that silicon nanowires are formed and grown through a solid-liquid-solid process or a vapor-liquid-solid process using a porous glass template having nanopores doped with erbium or an erbium precursor. In addition, a device including silicon nanowires formed using the above exemplary method according to the present invention can be effectively applied to various devices, for example, electronic devices such as field effect transistors, sensors, photodetectors, light emitting diodes, laser diodes, etc.

Owner:SAMSUNG ELECTRONICS CO LTD

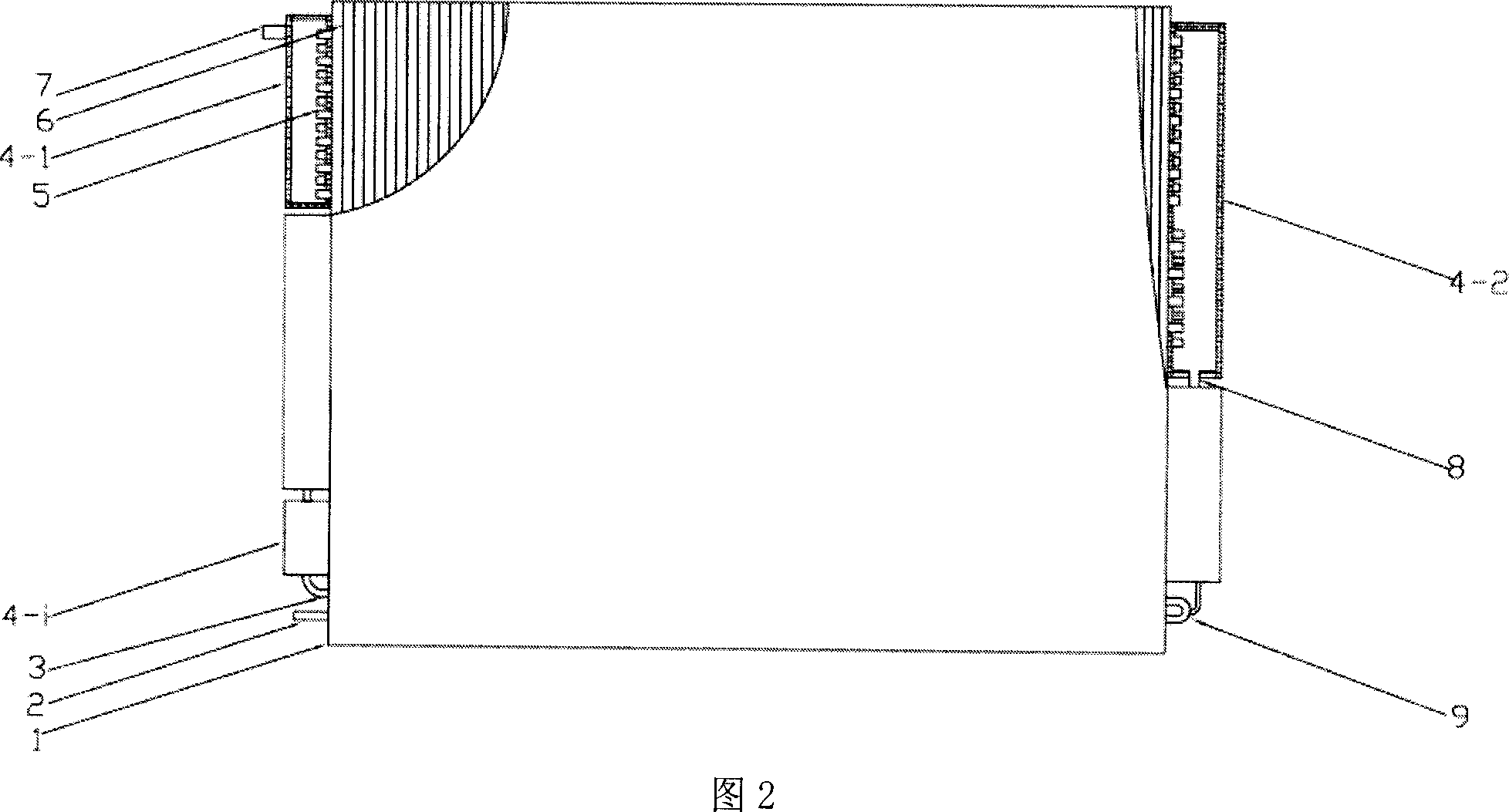

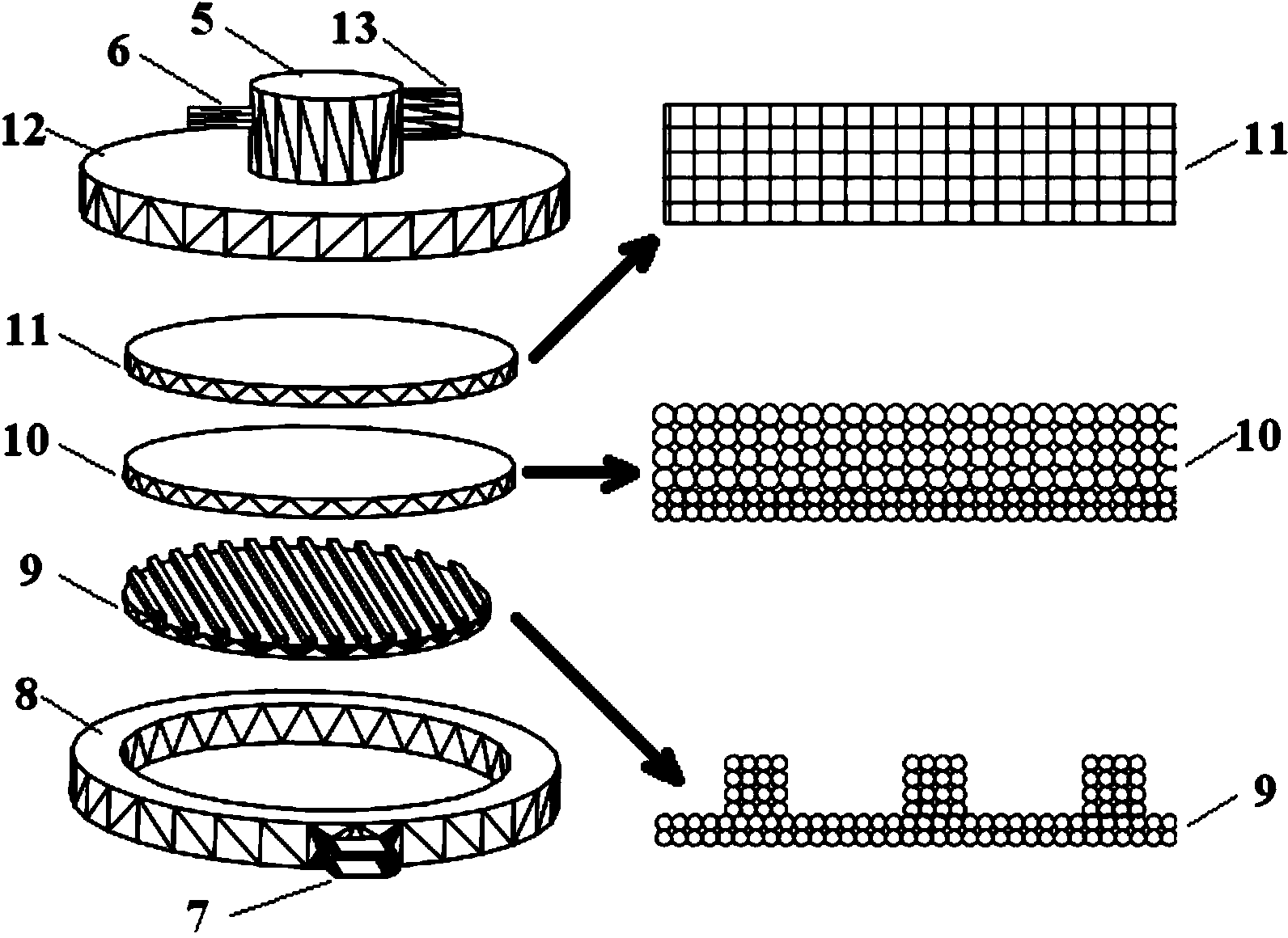

Multi-scale capillary core flat plate loop heat pipe type heat-dissipation device

InactiveCN103629963ASolve flow resistanceSolve the paradoxical relationship between capillary suctionSemiconductor/solid-state device detailsSolid-state devicesVapor liquidSuction force

The invention relates to a multi-scale capillary core flat plate loop heat pipe type heat-dissipation device, and belongs to the technical field of phase transition heat dissipation. The heat-dissipation device comprises an evaporating part, a condensing part, a compensating cavity, a gas phase pipeline and a liquid phase pipeline, wherein the gas phase pipeline is connected with the evaporating part and the condensing part, and the liquid phase pipeline is connected with the condensing part and the compensating cavity; a base plate of the evaporating part is in a flat plate shape, metal powder is sintered to form two layers of multi-scale capillary cores at the upper surface of the base plate, and a steam channel is constructed between the two layers of capillary cores; a layer of water absorption cotton tightly covers a second layer of capillary cores and is taken as a third layer of capillary cores, and the three layers of capillary cores form a multi-scale structure. By utilizing the multiple layers of multi-scale capillary cores and the constructed steam channel, the problem of the contradictoriness between the vapor-liquid flow resistance and the capillary suction force is solved, the starting temperature of a loop heat pipe is lowered, the high heating flux bearing capacity of the heat-dissipation device is improved, and the instability in heat transfer is reduced; the multi-scale capillary core flat plate loop heat pipe type heat-dissipation device has the advantages of high cooling capacity, large heat flux bearing capacity, low starting temperature, small temperature fluctuation, good antigravity performance and long transmission distance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

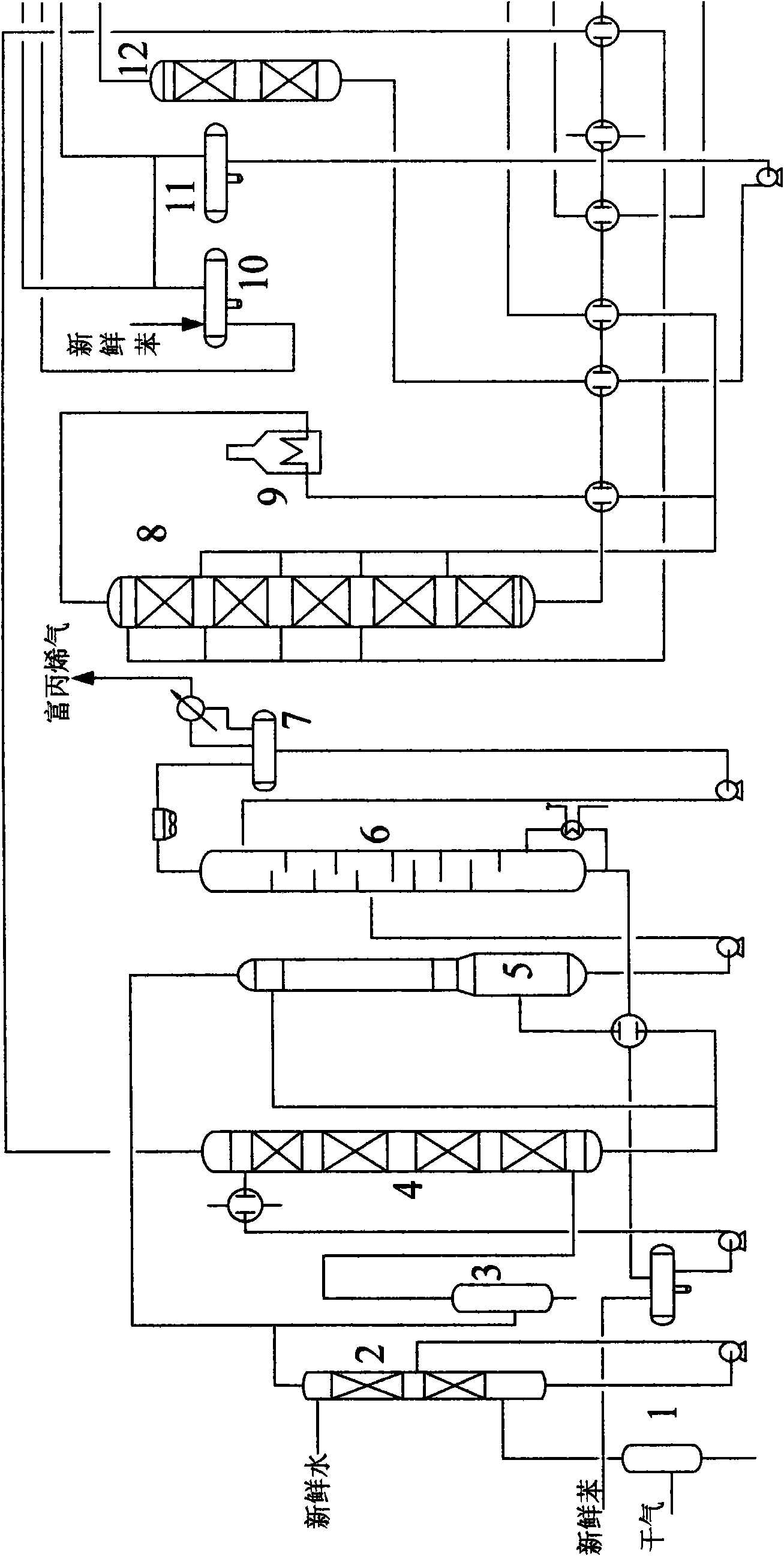

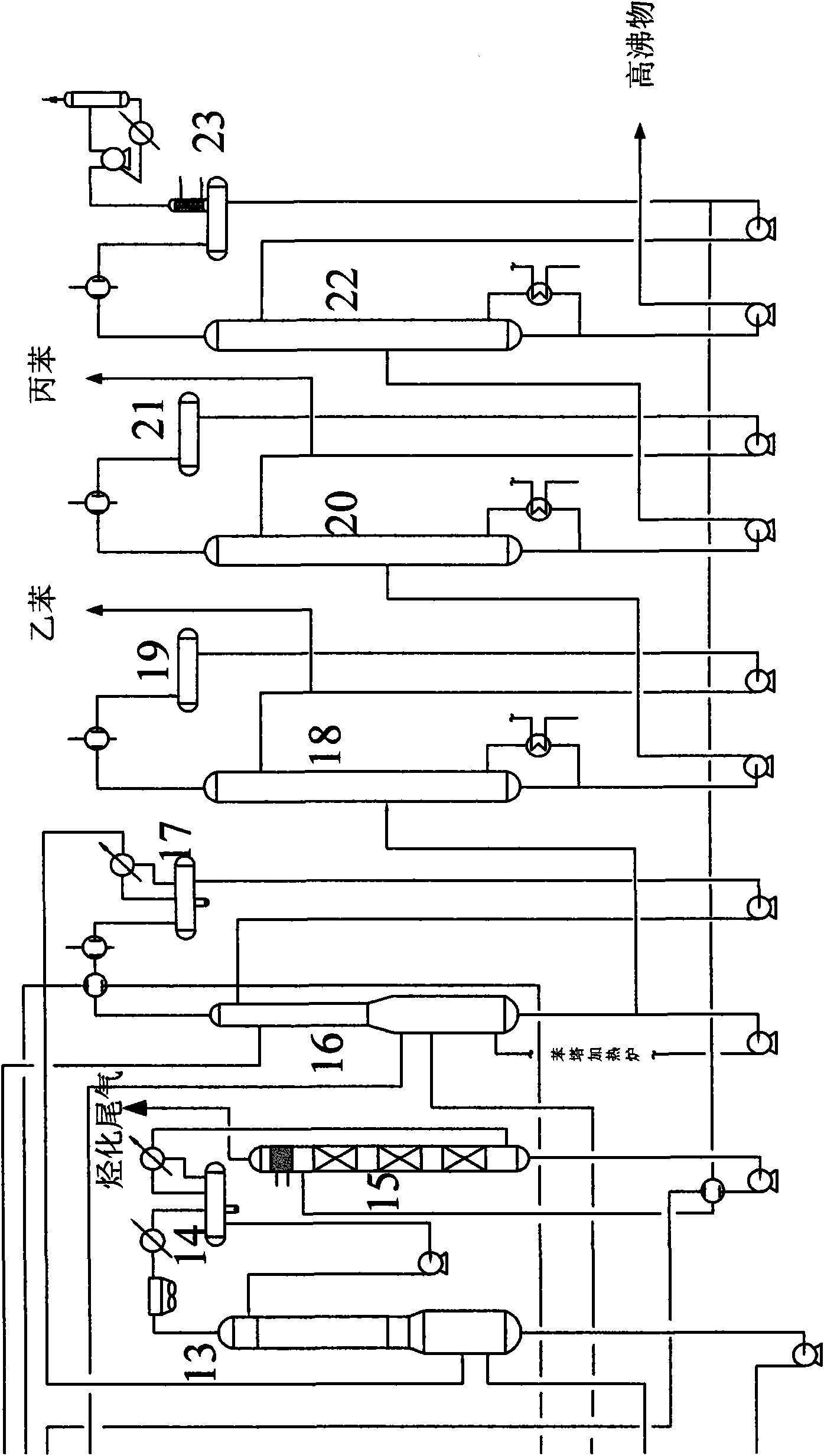

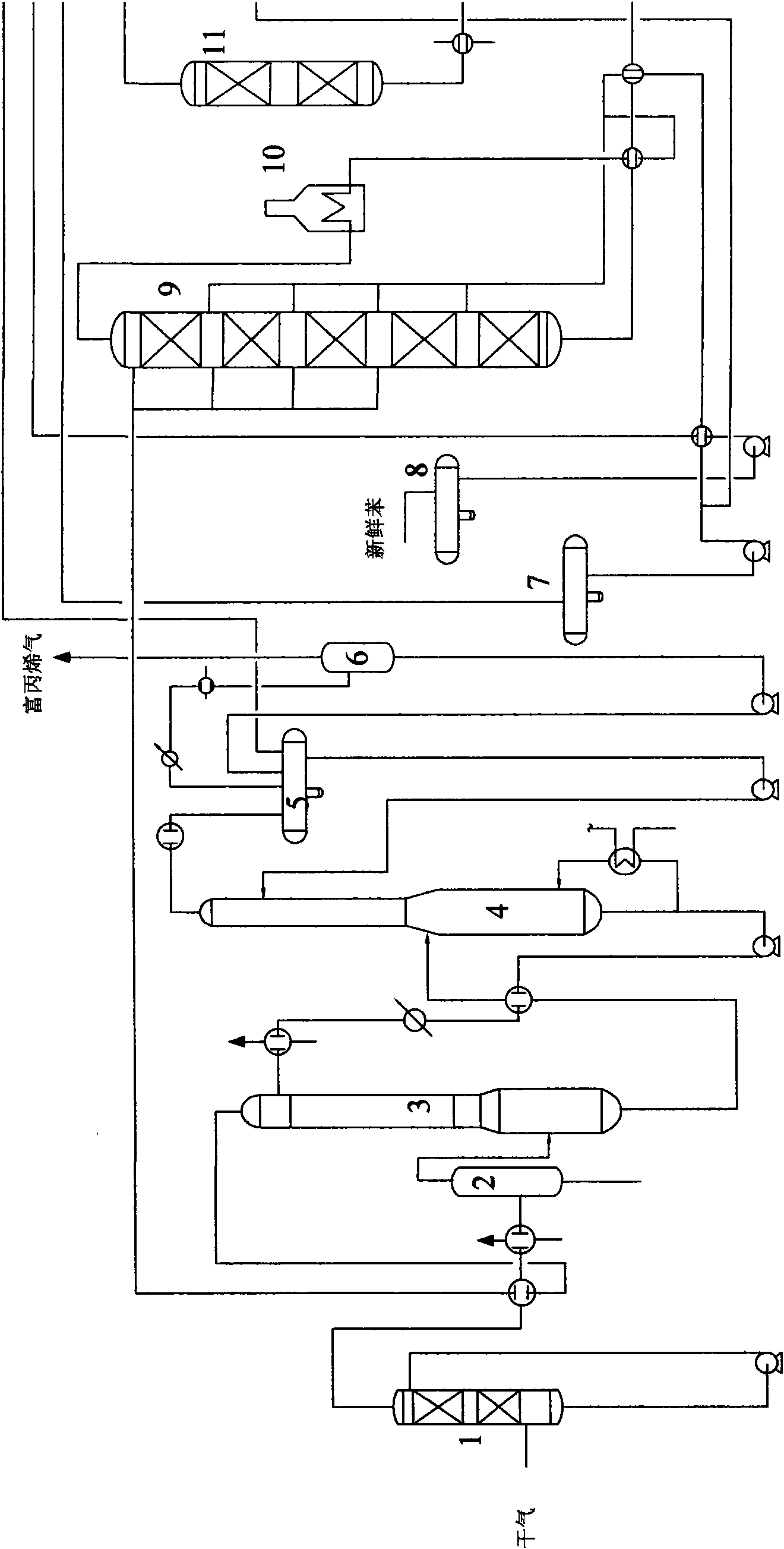

Method for preparing ethylbenzene by reaction of dilute ethylene and benzene

ActiveCN101768043AReduce temperature riseEfficient use ofHydrocarbonsBulk chemical productionVapor liquidLiquid product

The invention discloses a method for preparing ethylbenzene by reaction of dilute ethylene and benzene, which uses the dilute ethylene in dry gas of oil refinery as raw material, water washing and selective removal of propylene are conducted for the dry gas before the dry gas enters an alkylation reactor in sections, alkylation reaction of the dilute ethylene in dry gas and the benzene proceeds under the circumstances that zeolite catalyst exists, the dry gas and / or low-temperature gas-phase benzene are utilized for taking heat during the alkylation reaction, and the reaction temperature rising is reduced; after the vapor-liquid separation of the alkylation reaction product, tail gas is discharged from the device through low-temperature absorption, and cycle benzene, ethylbenzene, propyl benzene, diethylbenzene and heavy component are sequentially separated from the liquid product through a separation system; the diethylbenzene and the benzene are mixed and enter an anti-alkylation reactor and anti-alkylation reaction proceeds on molecular sieve catalyst for further converting to the ethylbenzene. The invention effectively reduces the benzene consumption and the energy consumption during the course of preparing ethylbenzene by dilute ethylene, the ethylene conversion rate is more than or equal to 99%, the total selectivity of generating ethylbenzene is more than or equal to 99%, the recovery rate of benzene carried by the tail gas is more than or equal to 99.5%, and the xylene content in the ethylbenzene is less than 800 ppm.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Semiconductor nanowire and its manufacturing method

ActiveUS20100133509A1Easy to carryControl shapeMaterial nanotechnologyPolycrystalline material growthVapor liquidNanowire

A method for fabricating a semiconductor nanowire that has first and second regions is provided. A catalyst particle is put on a substrate. A first source gas is introduced, thereby growing the first region from the catalyst particle via a vapor-liquid-solid phase growth. A protective coating is formed on a sidewall of the first region, and a second source gas is introduced to grow the second region extending from the first region via the liquid-solid-phase growth.

Owner:JOLED INC

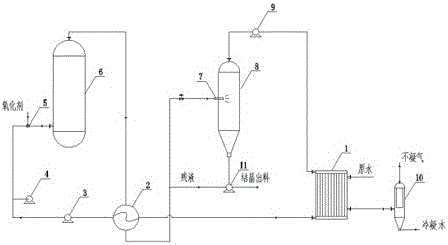

Method and device for treating high-salt refractory organic wastewater

PendingCN106495386AHigh thermal efficiencyReduce energy consumptionWater contaminantsMultistage water/sewage treatmentHigh concentrationVapor liquid

The invention discloses a method and a device for treating high-salt refractory organic wastewater, and particularly relates to a method and a device for treating high-concentration refractory COD and high-salt industrial wastewater by coupling the catalytic wet oxidation and MVR evaporation and concentration crystallization technology. The device comprises a vapor-liquid heat exchanger, a liquid-liquid exchanger, a booster pump (or a circulating pump), a compression fan, an oxidant dosing device, a wet catalytic oxidation reactor (WAO), an evaporator, a vapor compressor and a vapor-water separator. Raw water is subjected to air catalytic wet oxidation in the WAO reactor after two-stage preheating through the vapor-liquid heat exchanger and the liquid-liquid exchanger; the oxidized wastewater is evaporated and concentrated by an evaporator to obtain crystalline salt and the distilled water. The method and the device provided by the invention combine advantages of a wet oxidation technology and an MVR technology, effectively degrade organic matters, improve biodegradability of wastewater, and realize effective utilization of heat energy generated by WAO oxidation reaction and secondary vapor of the evaporator.

Owner:HUNAN PINGAN ENVIRONMENT PROTECTION

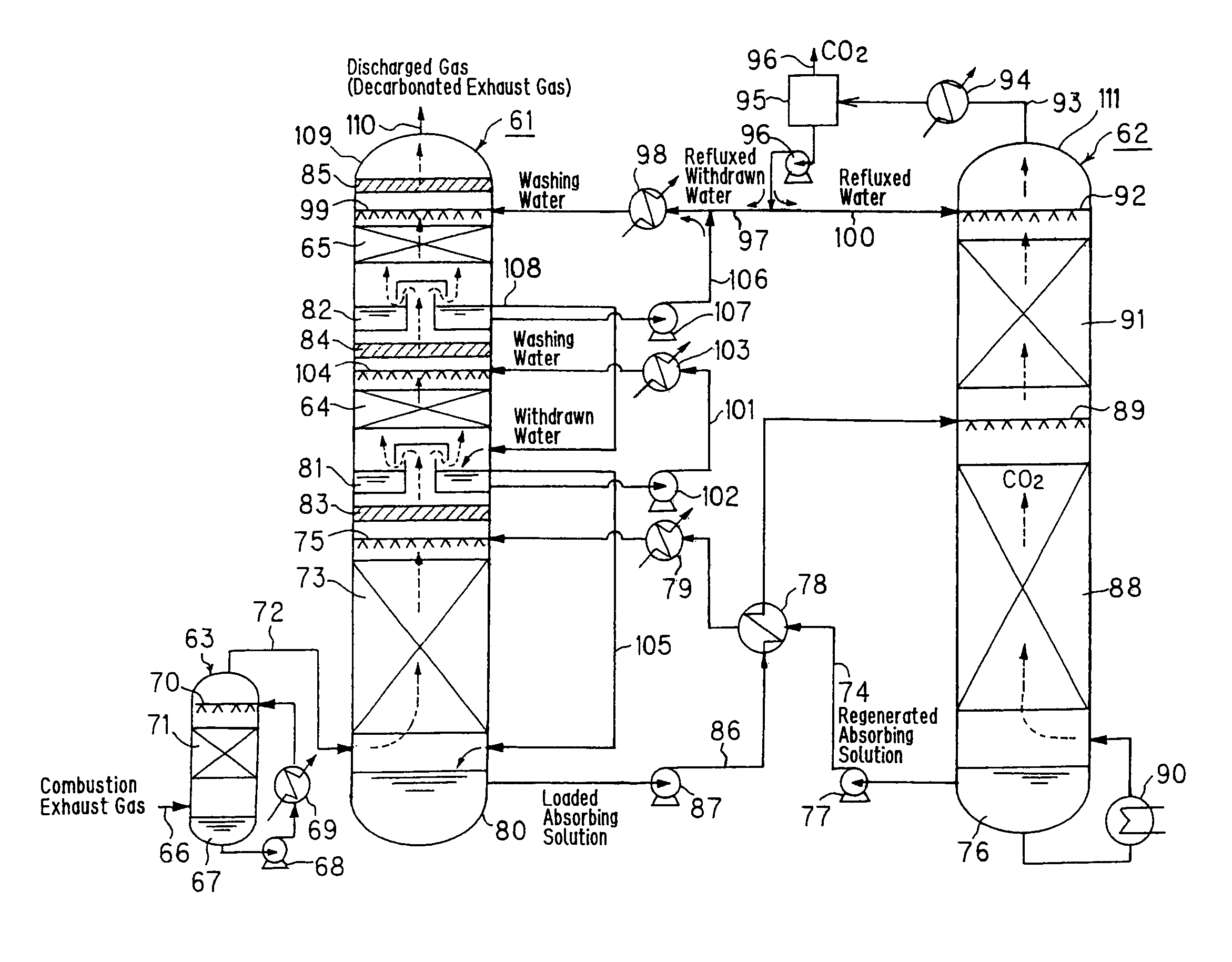

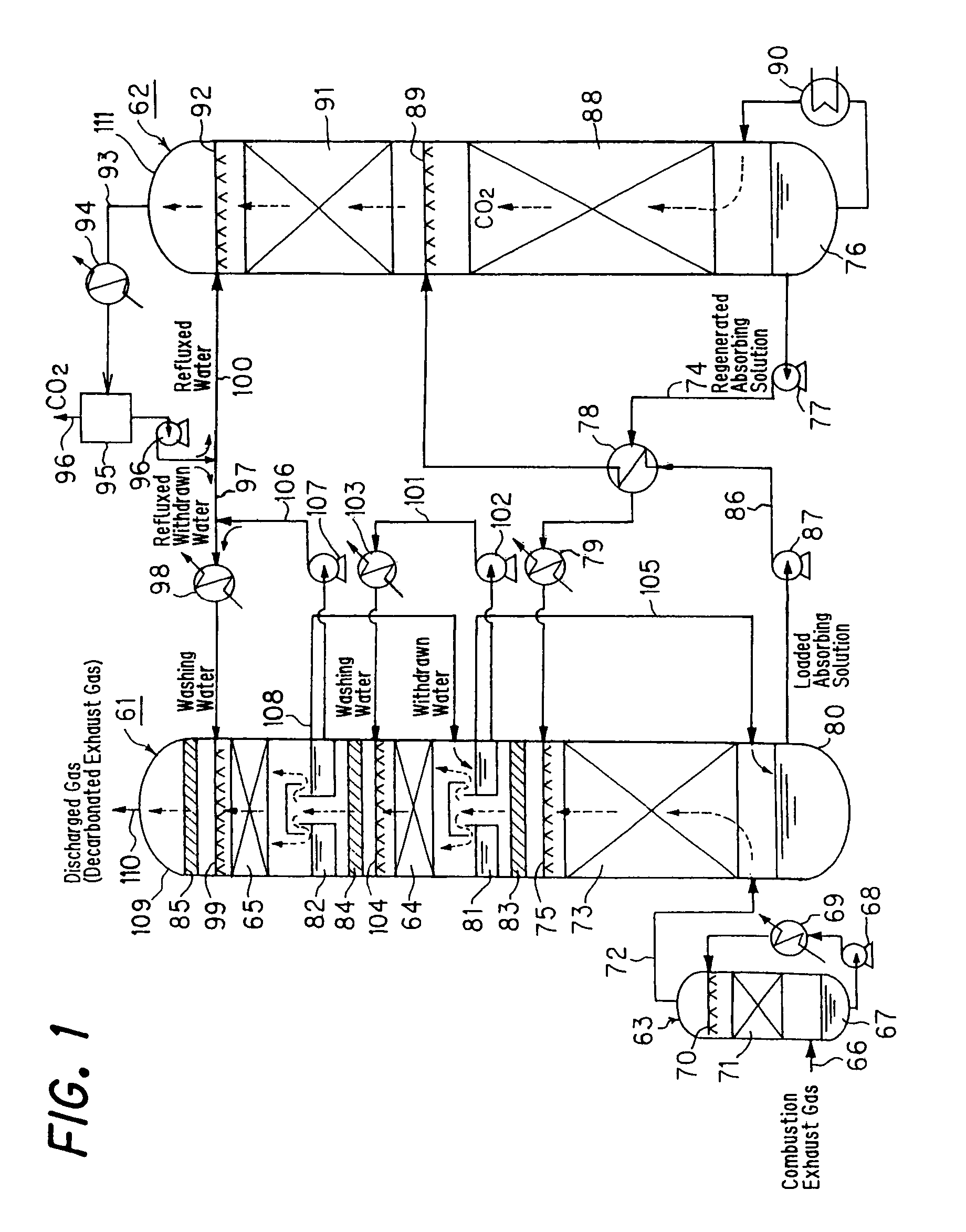

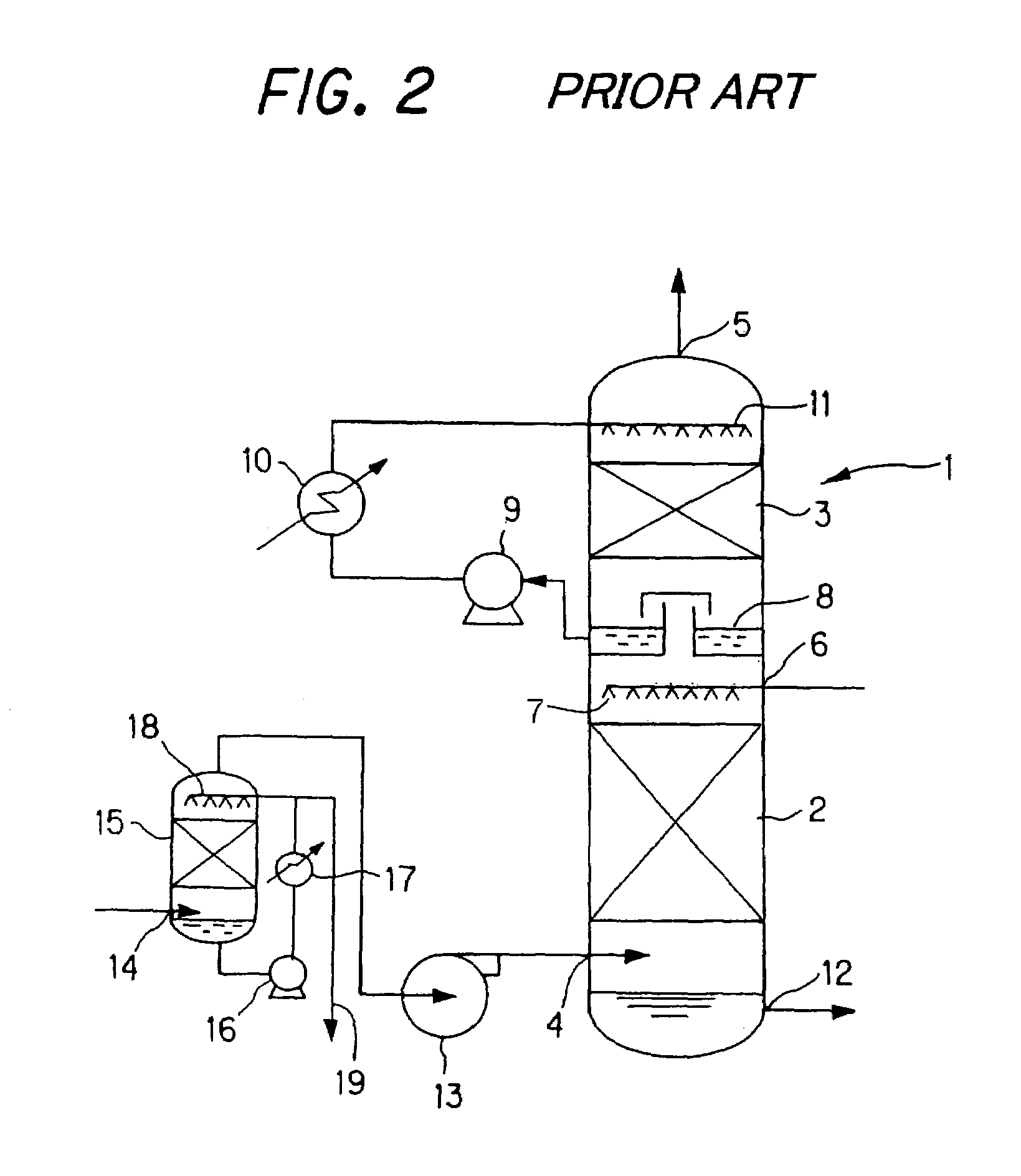

Amine recovery apparatus and decarbonation apparatus having same

InactiveUS7316737B2High ability to recover amine compoundReduce operating costsCombination devicesOrganic compound preparationVapor liquidCo2 absorption

An amine recovery apparatus includes a carbon dioxide absorption section and plural water washing sections. The carbon dioxide absorption section brings the exhaust gas into vapor-liquid contact with an absorbing solution containing an amine compound and produces decarbonated exhaust gas. The water washing sections bring the decarbonated exhaust gas into vapor-liquid contact with washing water and sequentially recover the amine compound accompanying the decarbonated exhaust gas, while the decarbonated exhaust gas passes through the water washing sections in sequence from inlet portions to outlet portions thereof, respectively. The water washing sections have plural liquid reservoirs provided at the inlet portions of the water washing sections, respectively, and the liquid reservoirs reserve the washing water which is transported to the outlet portions of the water washing sections and supplied to the water washing sections, respectively.

Owner:MITSUBISHI HEAVY IND ENG LTD

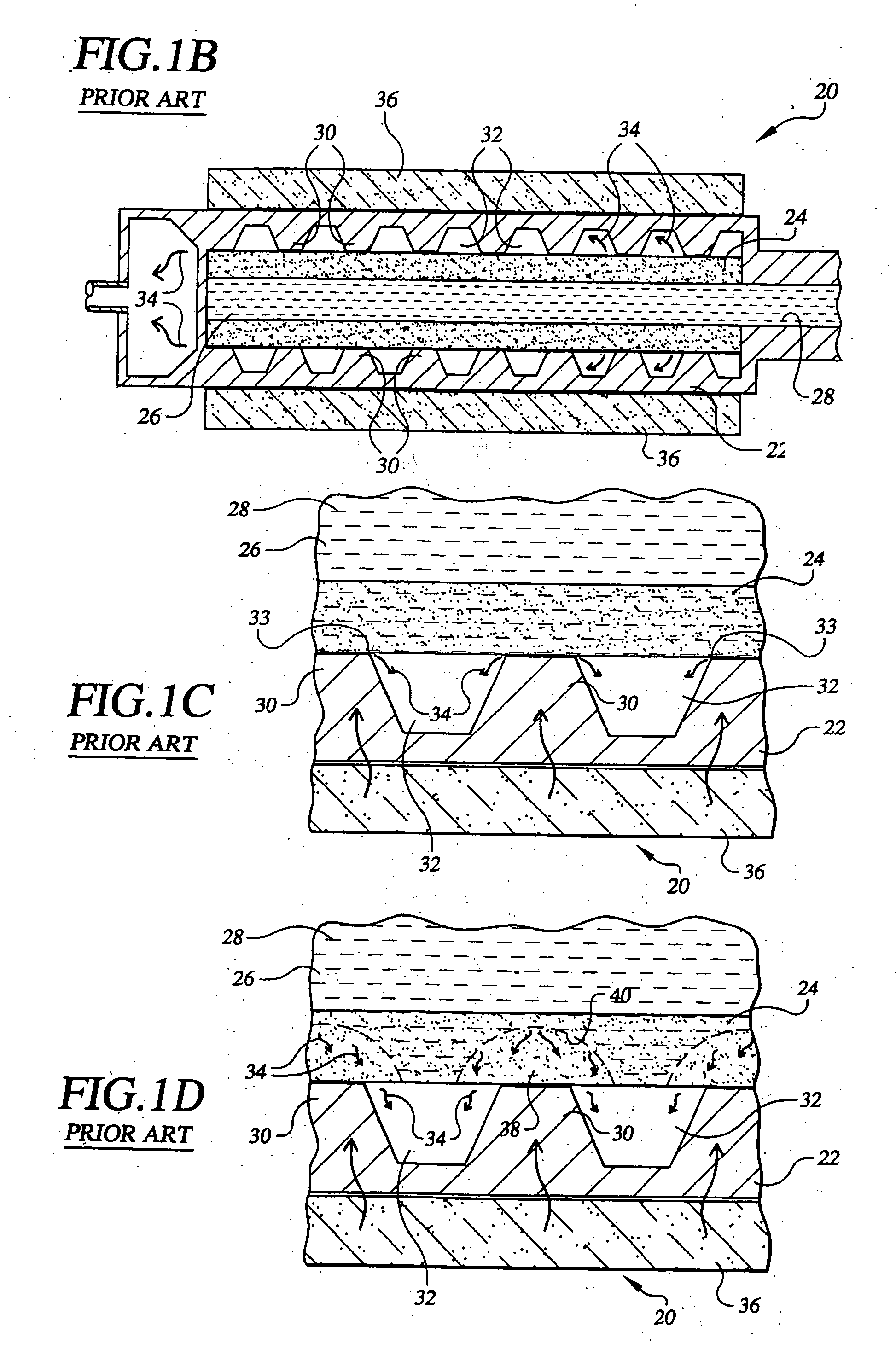

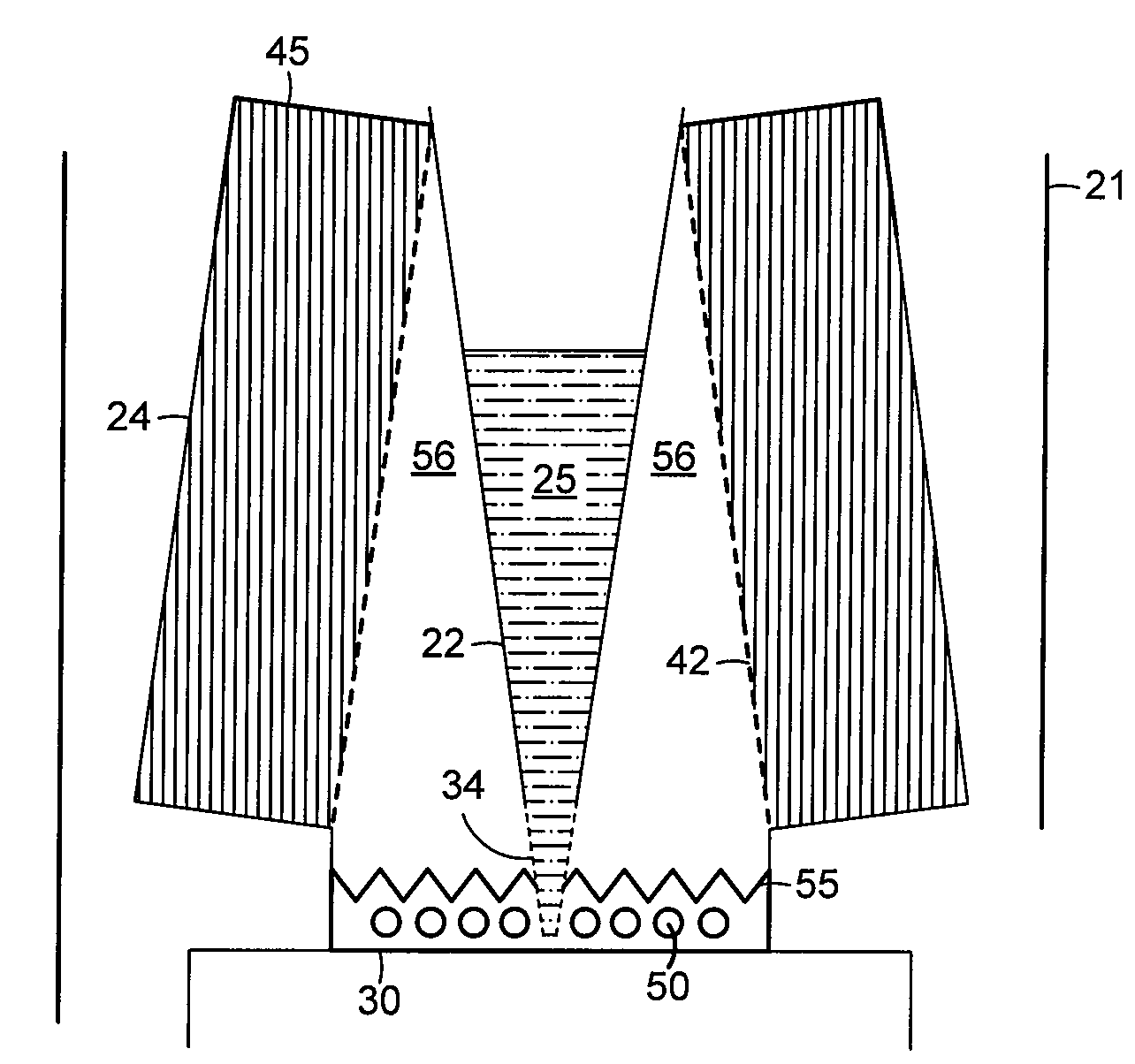

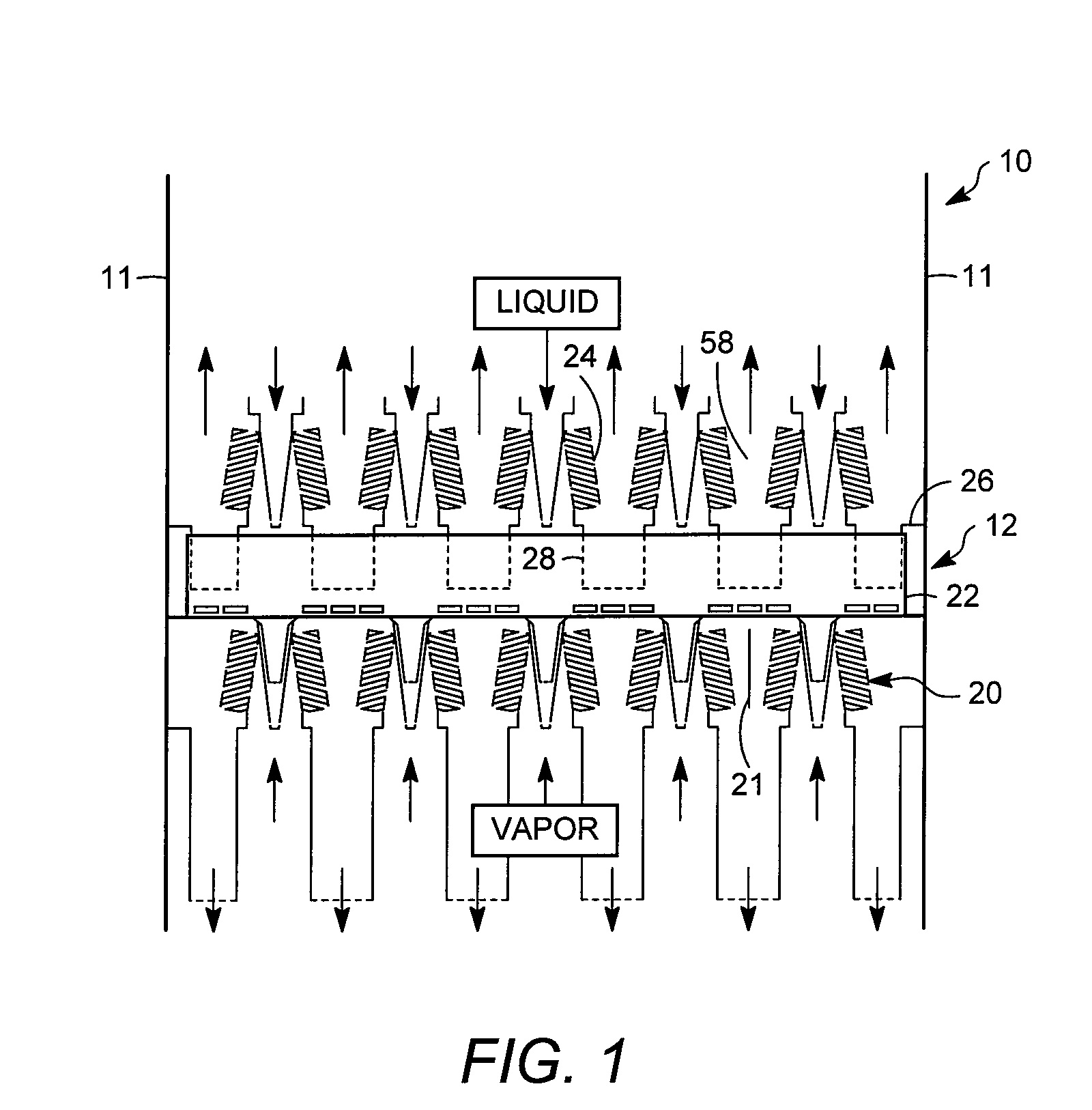

Vapor-liquid contacting in co-current contacting apparatuses

InactiveUS20100162891A1Reducing liquid handling capabilityLarge capacityCarburetting airLiquid degasificationVapor liquidEngineering

Improved contacting modules and apparatuses containing the modules, for carrying out vapor-liquid contacting, are described. In representative contacting modules, liquid (and possibly vapor) are discharged into co-current flow channels in a non-uniform manner (e.g., from only one side of the channels). Particular contacting modules comprise at least one liquid downcomer and a demister, wherein the liquid downcomer and an inlet surface of the demister define a co-current flow channel and wherein liquid is discharged from an outlet of the downcomer. The use of one or more added liquid distribution devices to more uniformly distribute the discharged liquid improves vapor-liquid contacting efficiency in the co-current flow channel and consequently vapor-liquid mass transfer and approach to equilibrium for the contacting stage.

Owner:UOP LLC

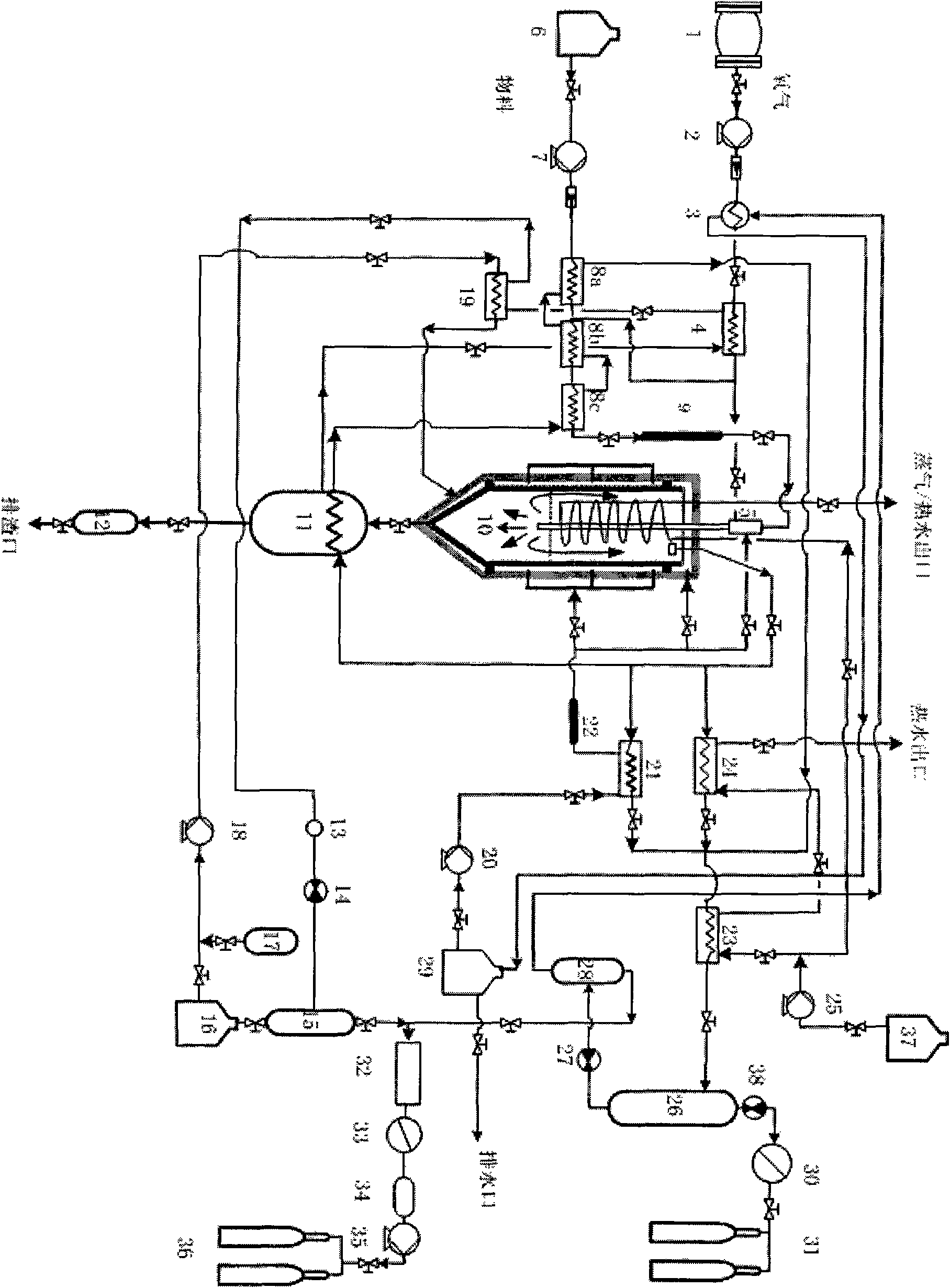

Method for recovery and cascade utilization of waste heat of supercritical water treatment system of waste organic substances

InactiveCN101570375AReasonable distributionReasonable useSolid waste disposalMultistage water/sewage treatmentVapor liquidWater treatment system

The invention belongs to the field of supercritical water treatment, and discloses a method for recovery and cascade utilization of waste heat of a supercritical water treatment system of waste organic substances. The method comprises the following steps that: for fluid overflowing out of the reaction outlet end of a reactor, one part of the fluid flows through a heating coil pipe in a desalting and deslagging device first, and then flows through a heat exchanger group to preheat materials after strong brine in the desalting and deslagging device is heated; another part of the fluid is used for preheating a first path of evaporation wall water; then two parts of the fluids are mixed together, and after vapor-liquid separation, the liquid flows through a hot bath type liquid oxygen vaporizer to vaporize liquid oxygen, and finally flows back into a first liquid collection box; and the fluid overflowing out of the upper outlet end of the desalting and deslagging device flows through a first heat exchanger to preheat oxygen first and then preheat a second path of the evaporation wall water, and after the vapor-liquid separation, the liquid flows back into a second liquid collection box. Thus, the sufficient recovery and the cascade utilization of the waste heat are achieved.

Owner:XI AN JIAOTONG UNIV +1

Membrane separation process using mixed vapor-liquid feed

ActiveUS7803275B2Reduce penetrationEfficient executionSemi-permeable membranesMembranesVapor liquidChemical physics

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

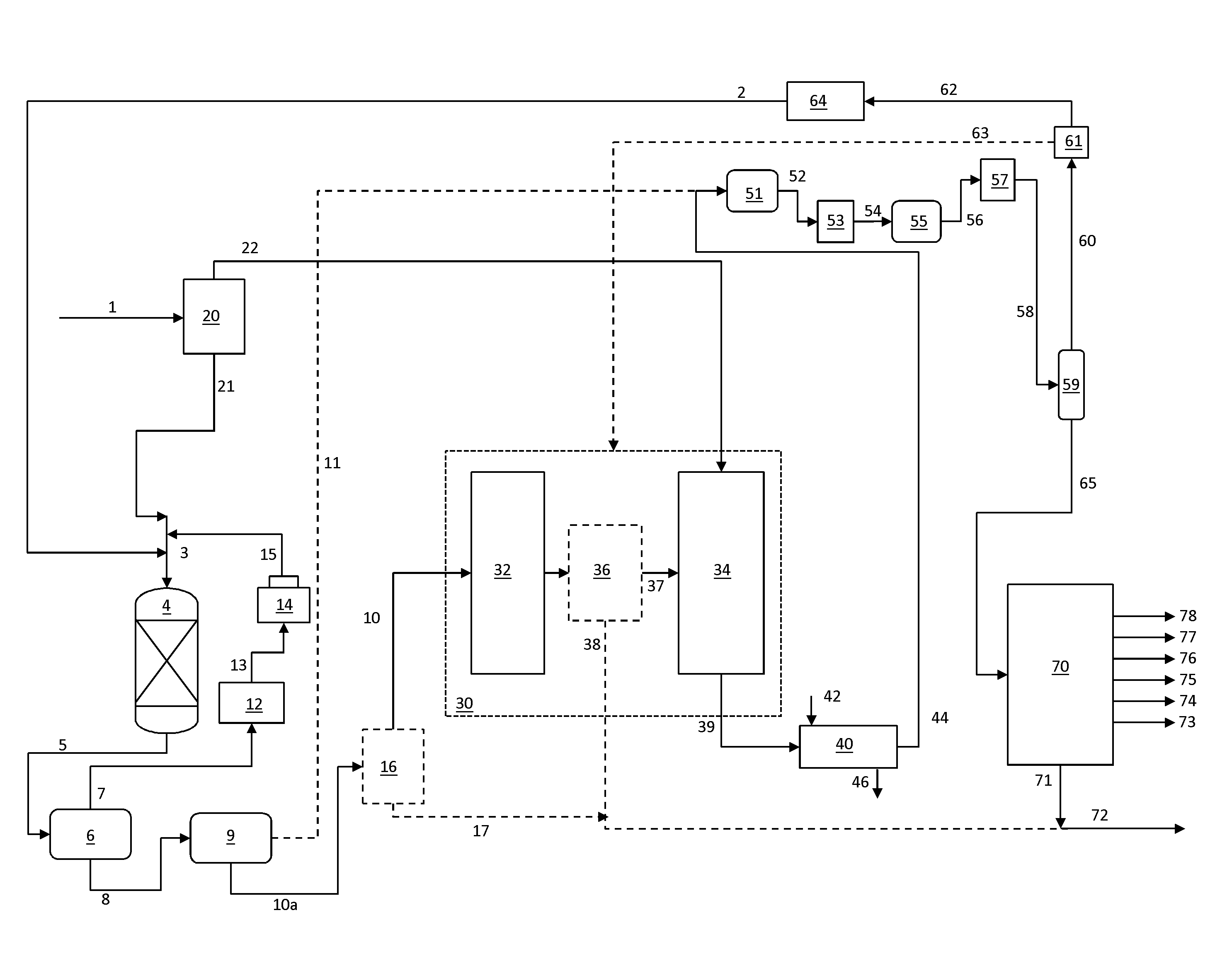

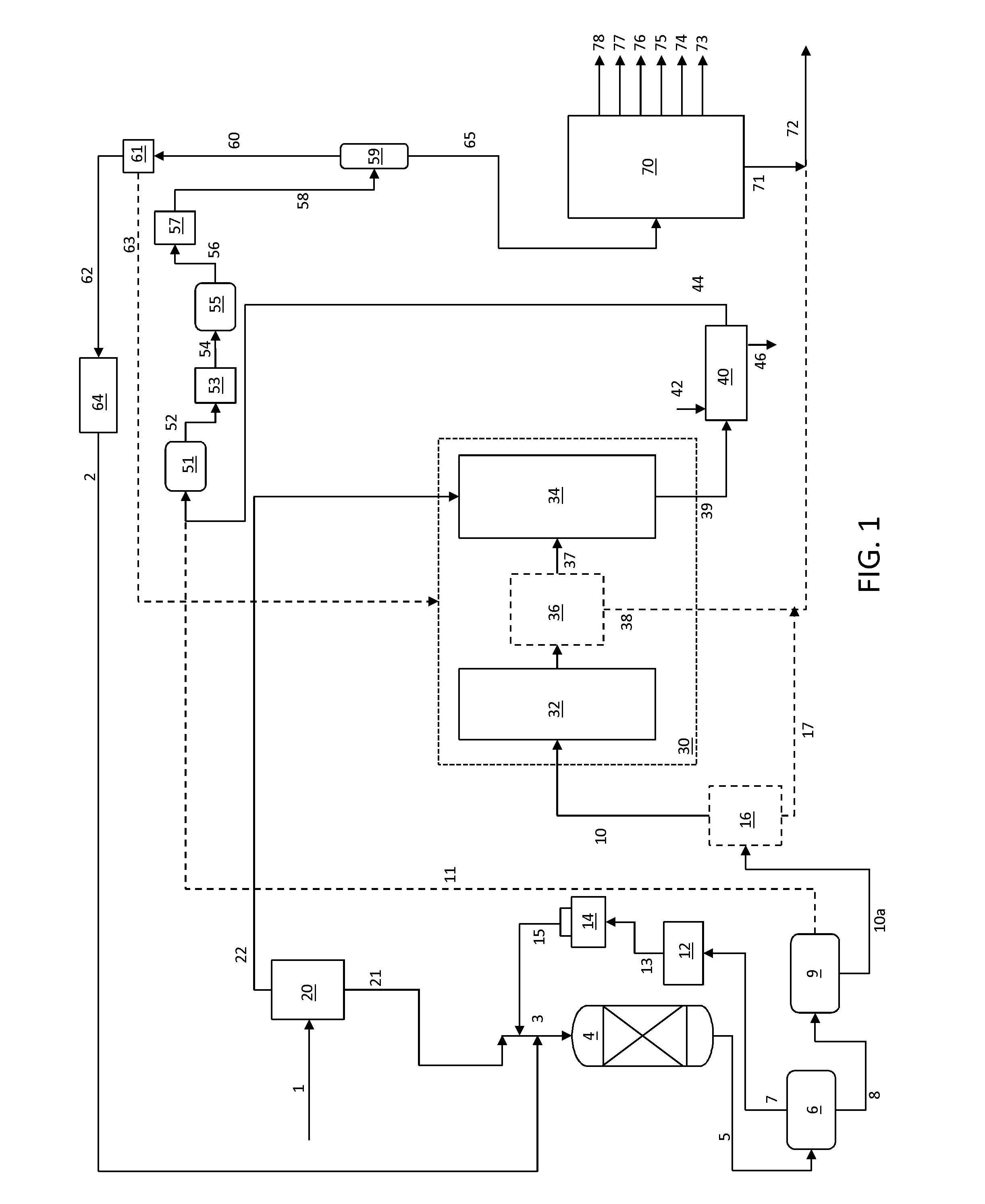

Integrated hydrotreating and steam pyrolysis process including hydrogen redistribution for direct processing of a crude oil

ActiveUS20130228495A1Reduce pollutant contentIncreased paraffinicityThermal non-catalytic crackingTreatment with plural serial cracking stages onlyVapor liquidSteam pyrolysis

Steam pyrolysis and hydroprocessing are integrated including hydrogen redistribution to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. A feed is initially split into a light portion and a heavy portion, and the heavy portion is hydroprocessed. A hydroprocessed effluent is charged, along with steam, to a convection section of a steam pyrolysis zone. The mixture is heated and passed to a vapor-liquid separation section. A residual portion is removed and light components are charged to a pyrolysis section of the steam pyrolysis zone. A mixed product stream is recovered from the steam pyrolysis zone and it is separated into product including olefins and aromatics.

Owner:SAUDI ARABIAN OIL CO

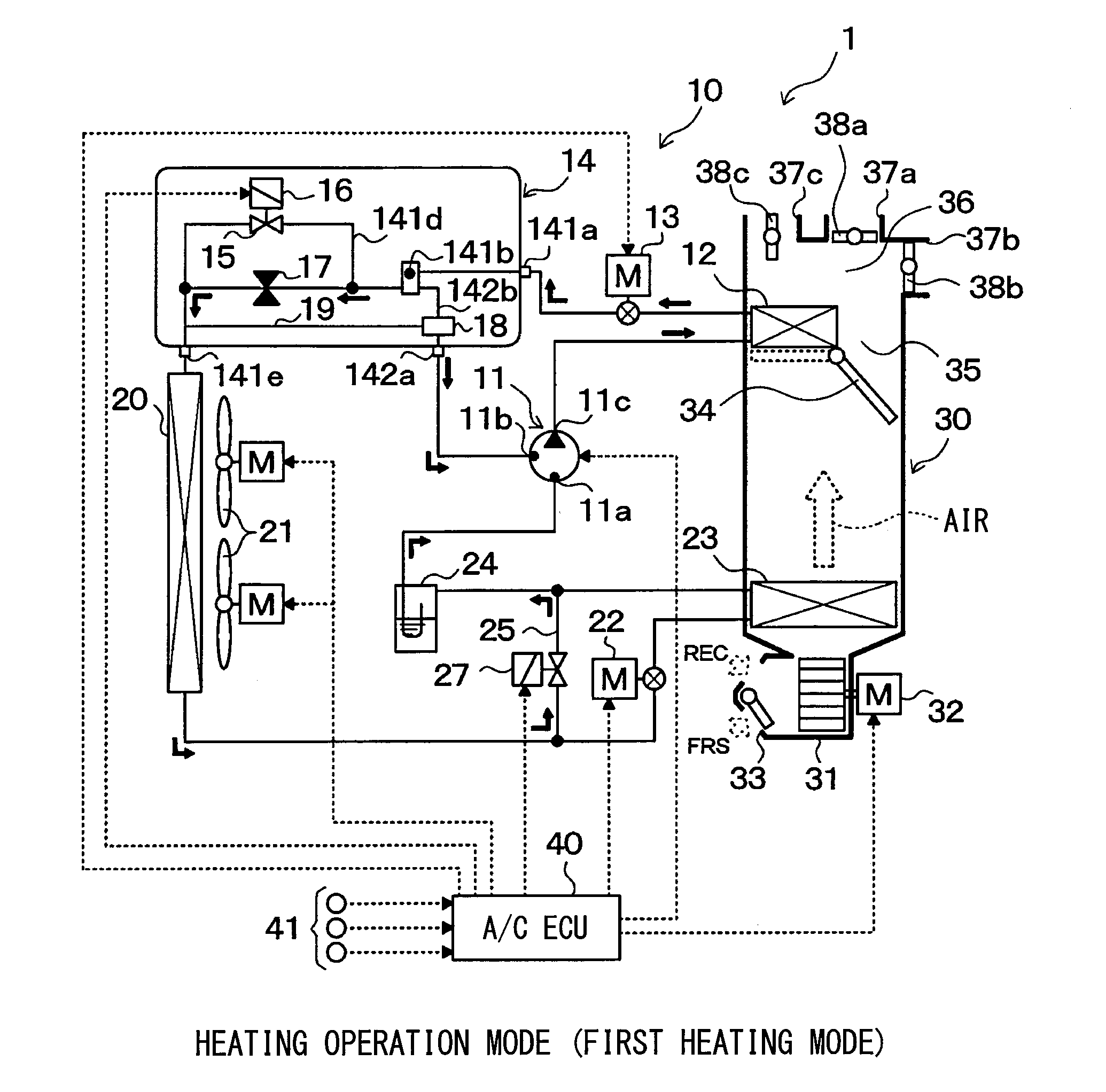

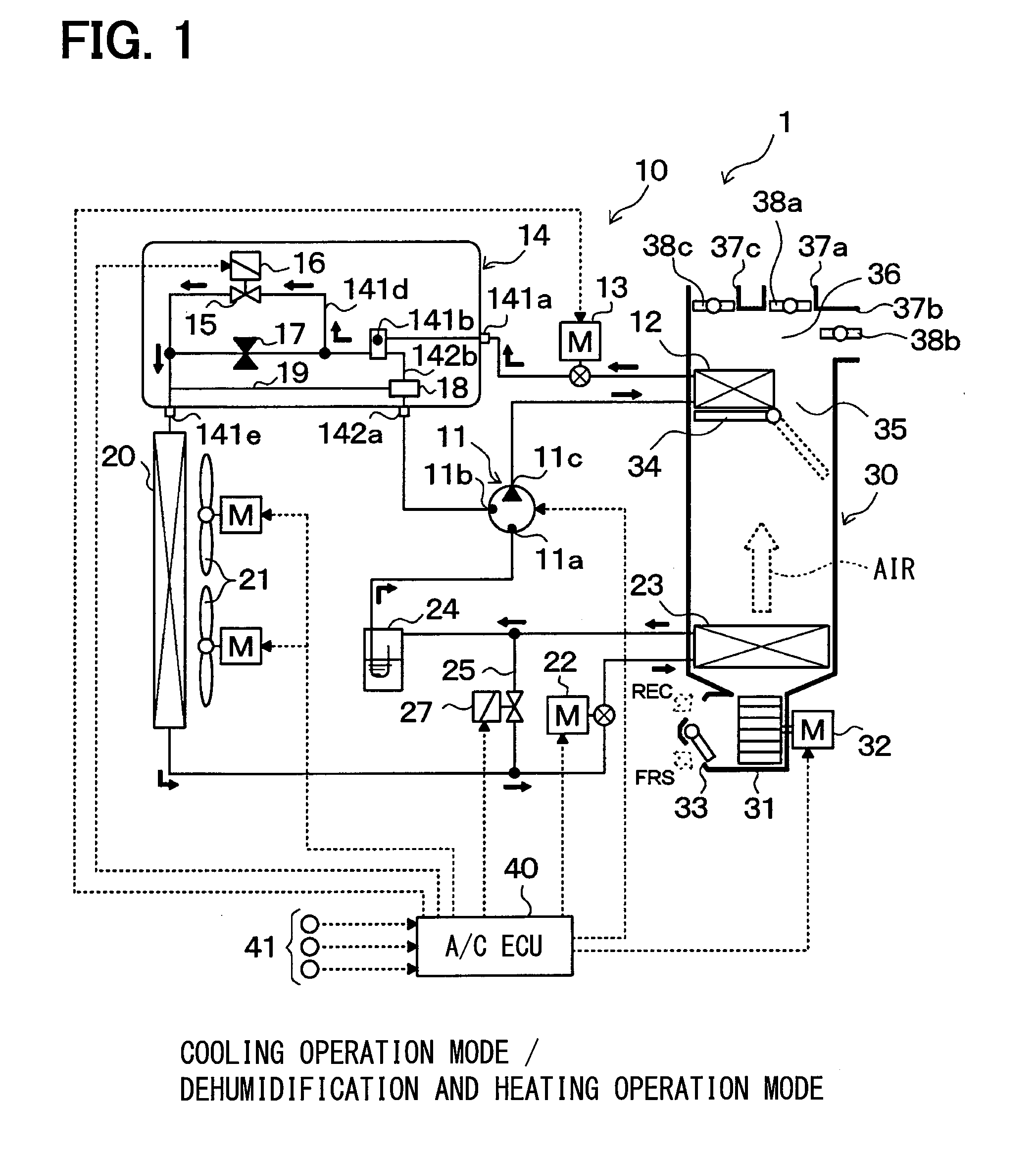

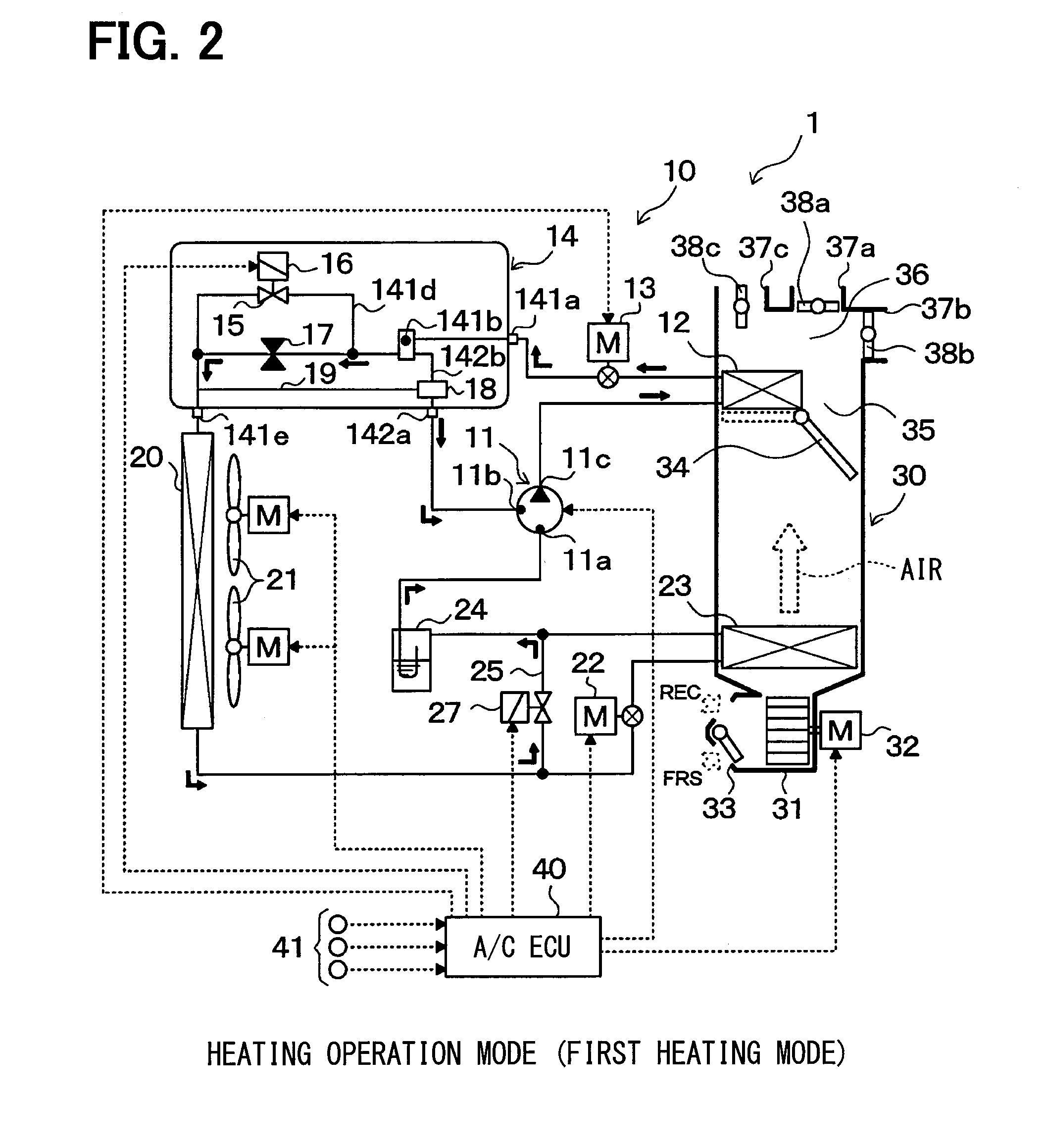

Integration valve and heat pump cycle

ActiveUS20140238067A1Simple configurationImprove installabilityMechanical apparatusHeat pumpsVapor liquidDifferential pressure

In an integration valve, a body, in which a vapor-liquid separating space is provided, includes a fixed throttle decompressing liquid-phase refrigerant, a liquid-phase refrigerant side valve body member opening or closing a liquid-phase refrigerant passage, and a vapor-phase refrigerant side valve body member opening or closing a vapor-phase refrigerant passage. Further, the vapor-phase refrigerant side valve body member is configured by a differential pressure regulating valve operated based on a pressure difference between a refrigerant pressure at a side of the vapor-phase refrigerant passage and a refrigerant pressure at a side of the liquid-phase refrigerant passage. The vapor-phase refrigerant side valve body member is movable when the liquid-phase refrigerant side valve body member is moved by a solenoid. Therefore, a cycle configuration of a heat pump cycle configuring a gas injection cycle can be simplified.

Owner:DENSO CORP

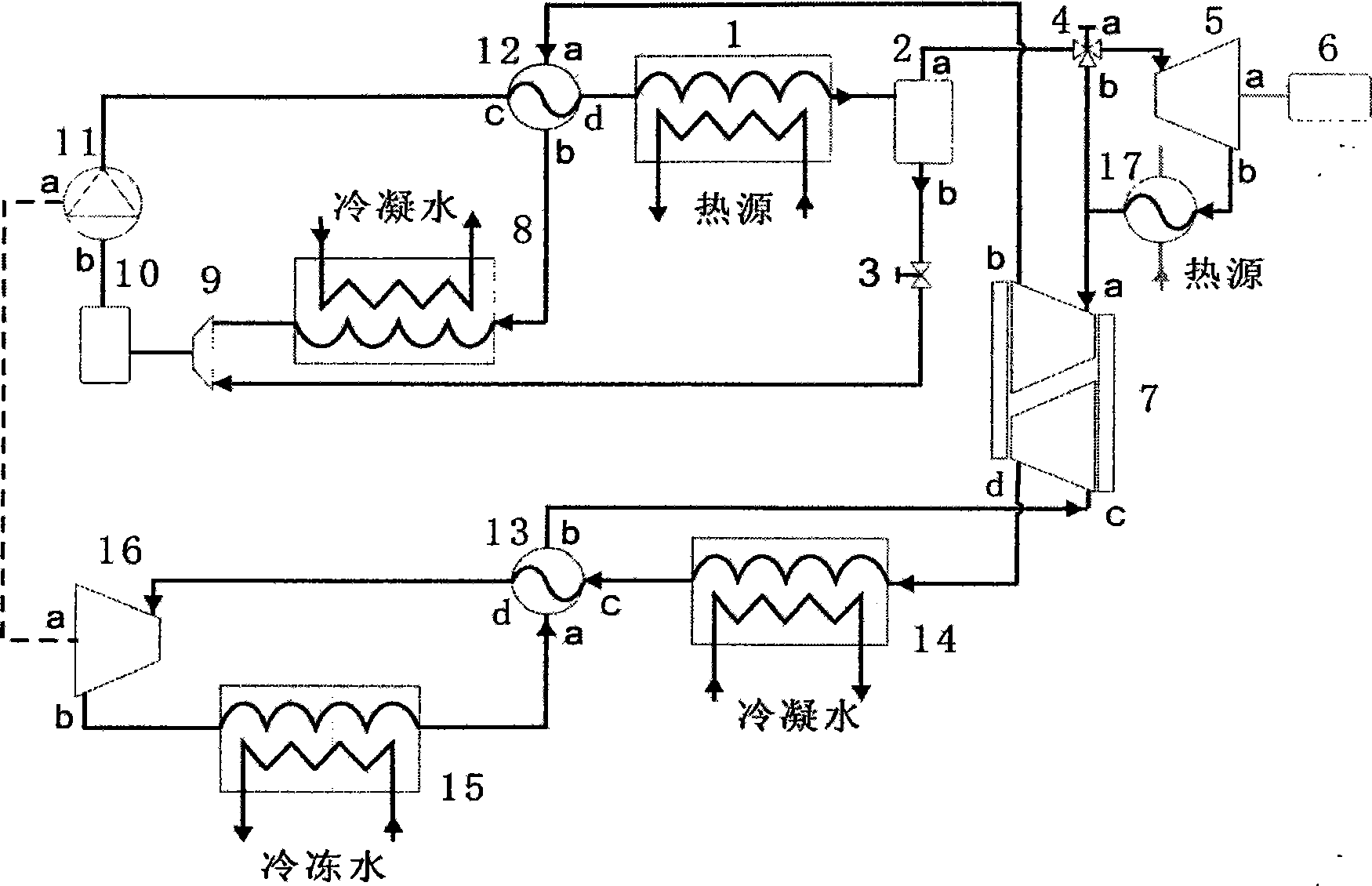

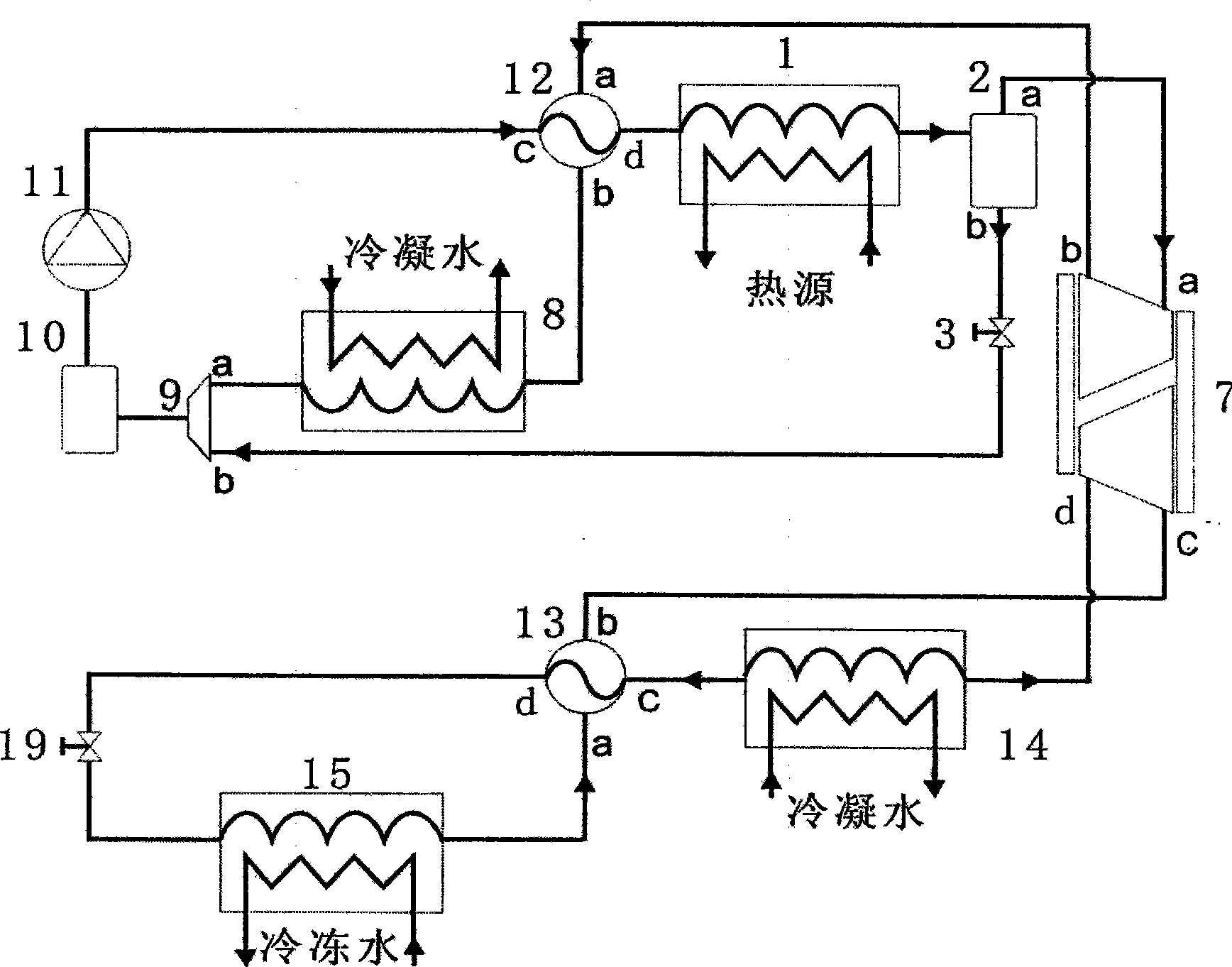

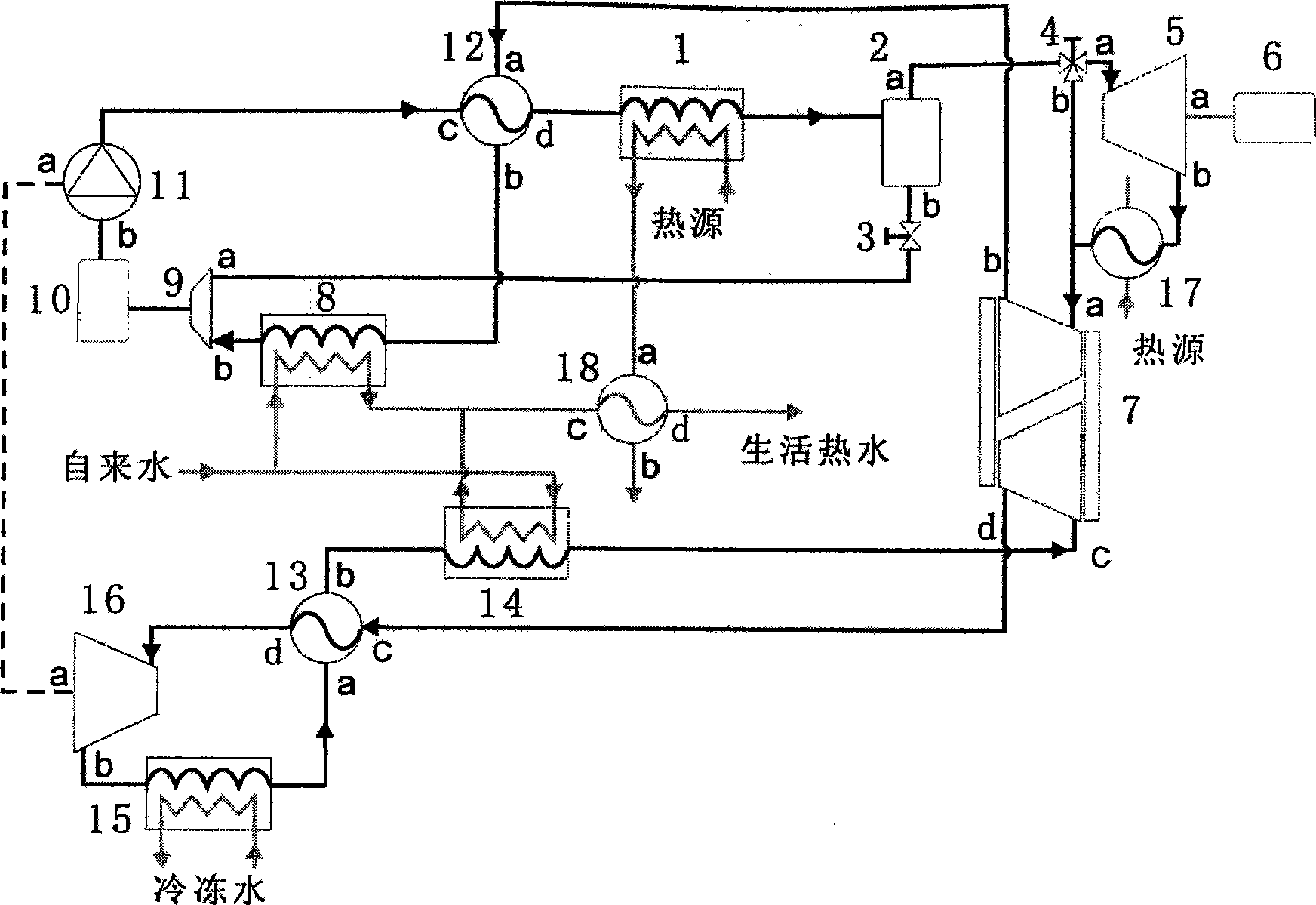

Heat-driven refrigeration and power generation integration apparatus

InactiveCN101458000AWorking fluid selection is not limitedOptimizationCompression machines with non-reversible cycleSteam engine plantsVapor liquidThermal energy

The invention provides a device integrating functions of heat-driven refrigeration and power generation which comprises a heat energy engine and a refrigerator. The heat energy engine comprises a circulating pump, a steam generator, a vapor liquid separator, a two-way valve, a three-way valve, a turbine, a generator, a pressure exchanger, a first vapor-liquid heat exchanger, a first condenser, a unit with two mixing canterns, a reservoir and a reheater. The heat energy engine utilizes heat energy to generate high pressure vapor to drive the compression refrigeration and promote the turbine and the generator to generate power. The refrigerator comprises an evaporator, a second vapor-liquid heat exchanger, a pressure exchanger, a second condenser and an expander. The shaft power output of the expander of the refrigerator is used for driving the circulating pump. Working media of the heat energy engine and the refrigerator can be the same or not. Non-azeotropic working media can be adopted for improving the efficiency. The heat driven-refrigeration and power generation integrated device can use a low grade heat source and can be regulated into individual cold supplying system, a cooling and power combined system or an electricity heat and chilled water congenerating system. The heat driven-refrigeration and power generation integrated device has the advantages of high efficiency, small investment, short installation period, low maintaining fee, etc.

Owner:SOUTHEAST UNIV

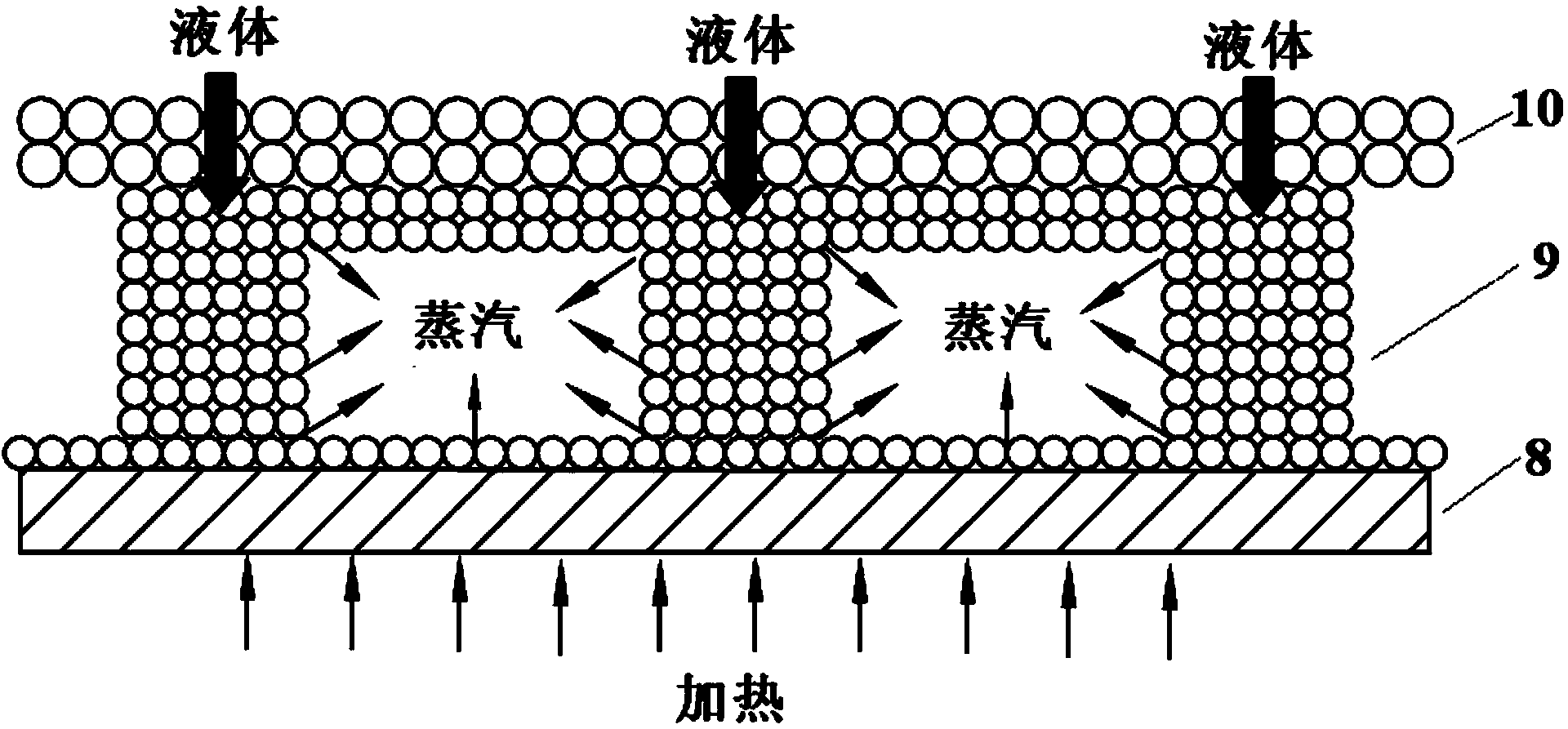

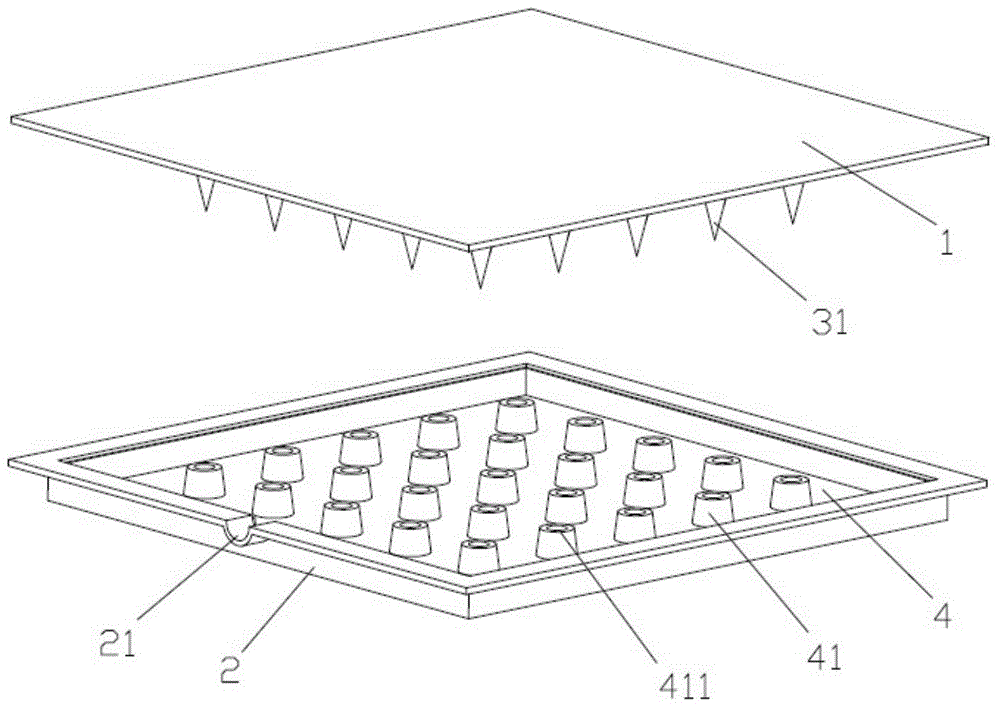

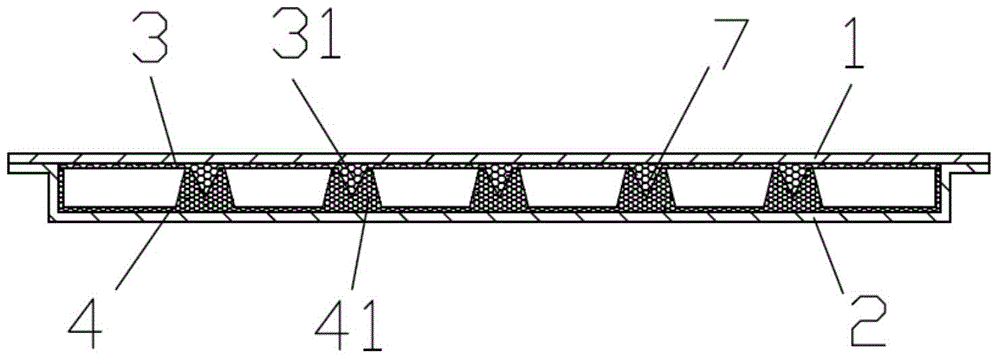

Panel heat pipe with embedded porous wick and manufacturing method thereof

InactiveCN104534906ARaise the capillary limitShorten return pathIndirect heat exchangersVapor liquidCapillary pressure

The invention provides a panel heat pipe with an embedded porous wick and a manufacturing method thereof. The panel heat pipe comprises an upper metal cover plate, a lower metal cover plate, and a closed cavity is formed between the upper metal cover plate and the lower metal cover plate in a welded and sealed mode. The cavity is filled with liquid working media. The inner surface of the cavity is divided into an evaporation face and a condensation face. The condensation face and the evaporation face are paved with a thin-layer porous wick structure formed by sintering metal powder particles. Sintering porous columns with inner grooves which are distributed in an array mode are machined on the evaporation face. Porous protrusions matched with the inner grooves are machined in the condensation face. The sintering porous columns and the porous protrusions are in close fit to form an embedded porous structure column. A working medium backflow channel is formed in the embedded porous structure column. According to the panel heat pipe, the capillary pressure is improved, the working medium backflow speed is remarkably increased, vapor-liquid two-phase separation is achieved, and the heat transfer performance is greatly improved; meanwhile, the embedded wick plays a supporting column role, and panel heat pipe inward sinking or crack deformation or other problems are effectively avoided.

Owner:XIAMEN UNIV

Process for producing lower olefins from heavy hydrocarbon feedstock utilizing two vapor/liquid separators

ActiveUS20070232845A1Reduce the amount requiredCheap and more energy efficientThermal non-catalytic crackingLiquid degasificationVapor liquidHydrocarbon

A process for making lower olefins from a heavy hydrocarbon feed by use of a combination of two vapor-liquid separation devices, and, then, pyrolytically cracking the light fraction of the heavy hydrocarbon feed to thereby produce a lower olefin product.

Owner:SHELL USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com