Liquid separating air condenser

A technology for air condensers and condensers, which is applied in steam/steam condensers, evaporators/condensers, refrigerators, etc., and can solve problems such as high manufacturing and operating costs, decreased utilization of fins, and poor condensation effects , to reduce production and operating costs, facilitate overall layout, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

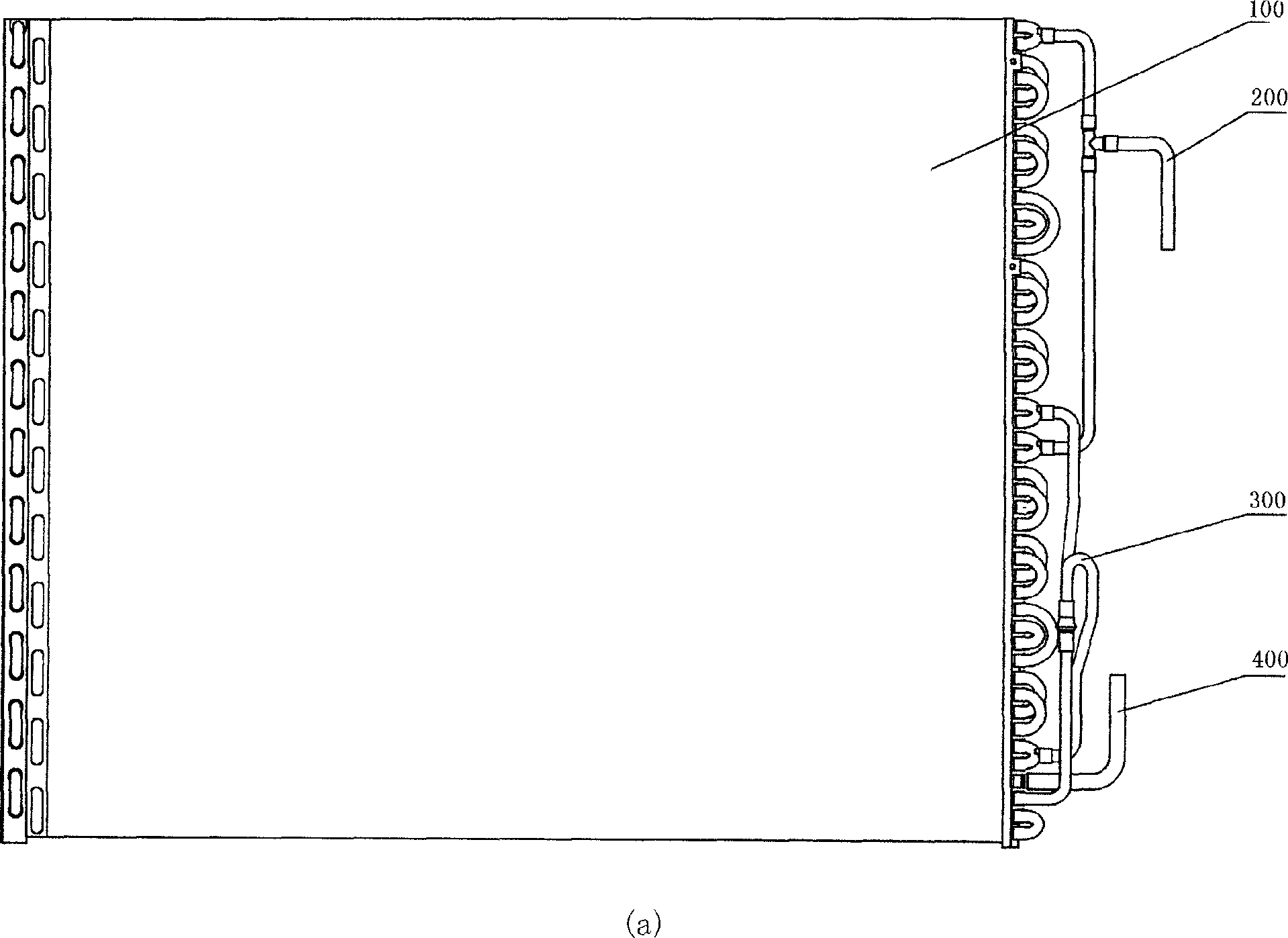

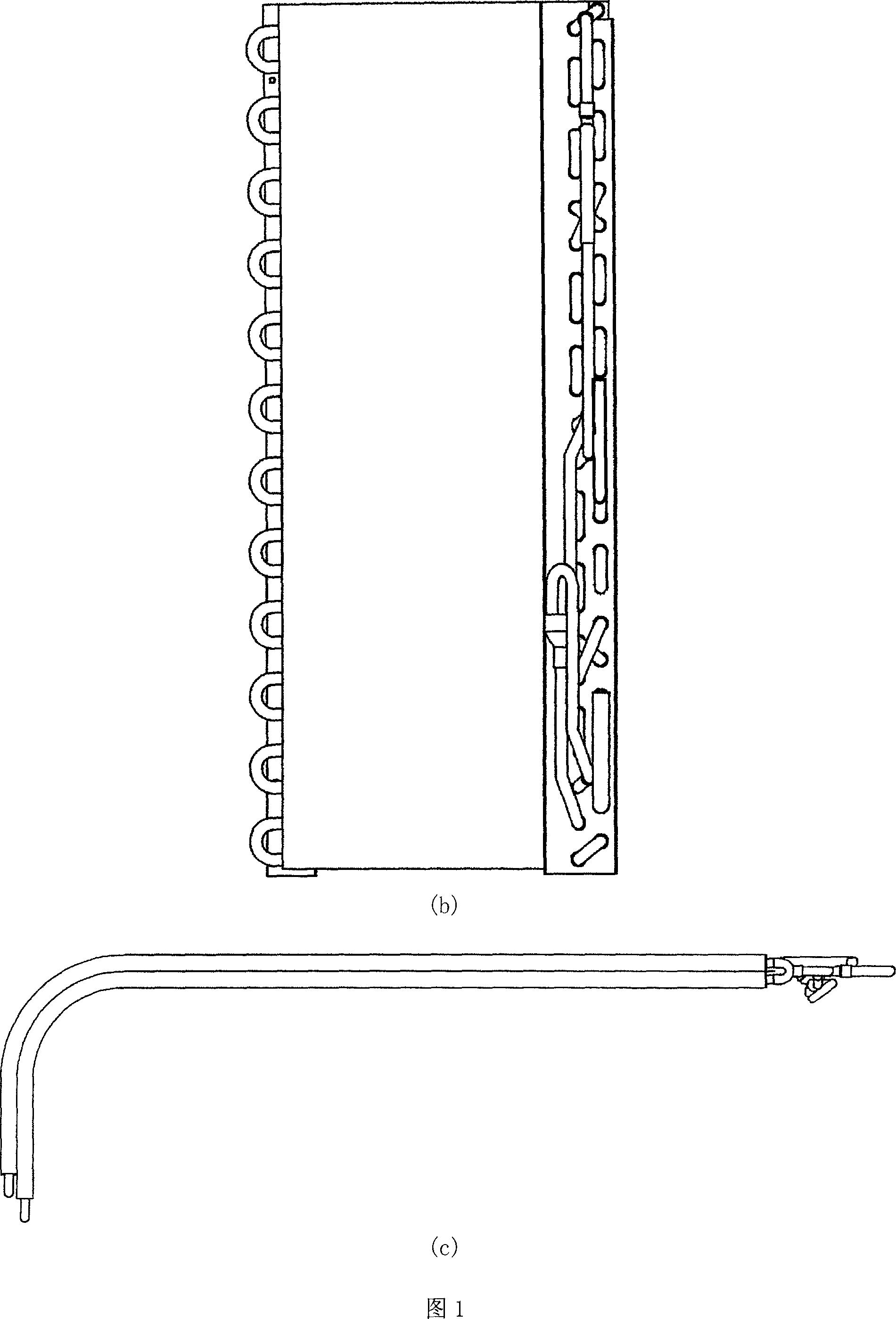

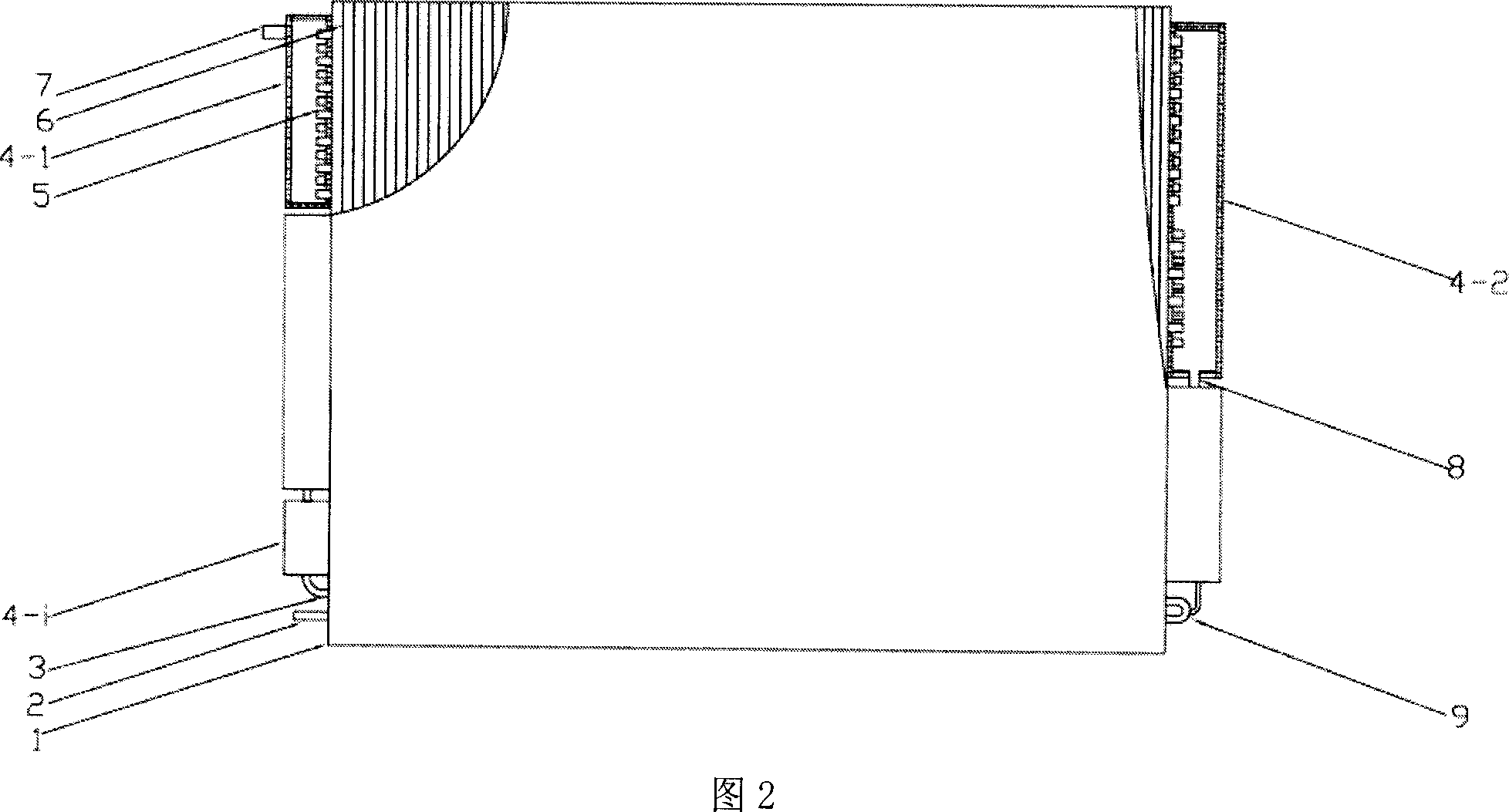

[0025] Fig. 2 is the front view of the present invention (horizontal tube type). Among them, 1 shell, 2 condensate outlet, 3 one-way pipe, 4-j cascade box j, 4-i last cascade box, 5 heat exchange tubes, 6 fins (fins), 7 steam inlet, 8 drain pipes, 9 tee pipes. A liquid separation type air condenser, comprising a steam inlet 7, a heat exchange tube 5, fins 6, a j-th cascade box 4-j, a drain pipe 8, a tee pipe 9, a condensate outlet 2, and a one-way exchange The heat pipe 3 and the shell 1; the jth cascade box (4-j) is installed at both ends of the heat exchange tube (5); the steam inlet (7) is connected to the first cascade box, and the first cascade box passes through a set of heat exchange The tube (5) communicates with the second cascade box; the second cascade box communicates with the next-level header through another set of heat exchange tubes (5); ...; until the last-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com