Patents

Literature

8440results about How to "Improve heat transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

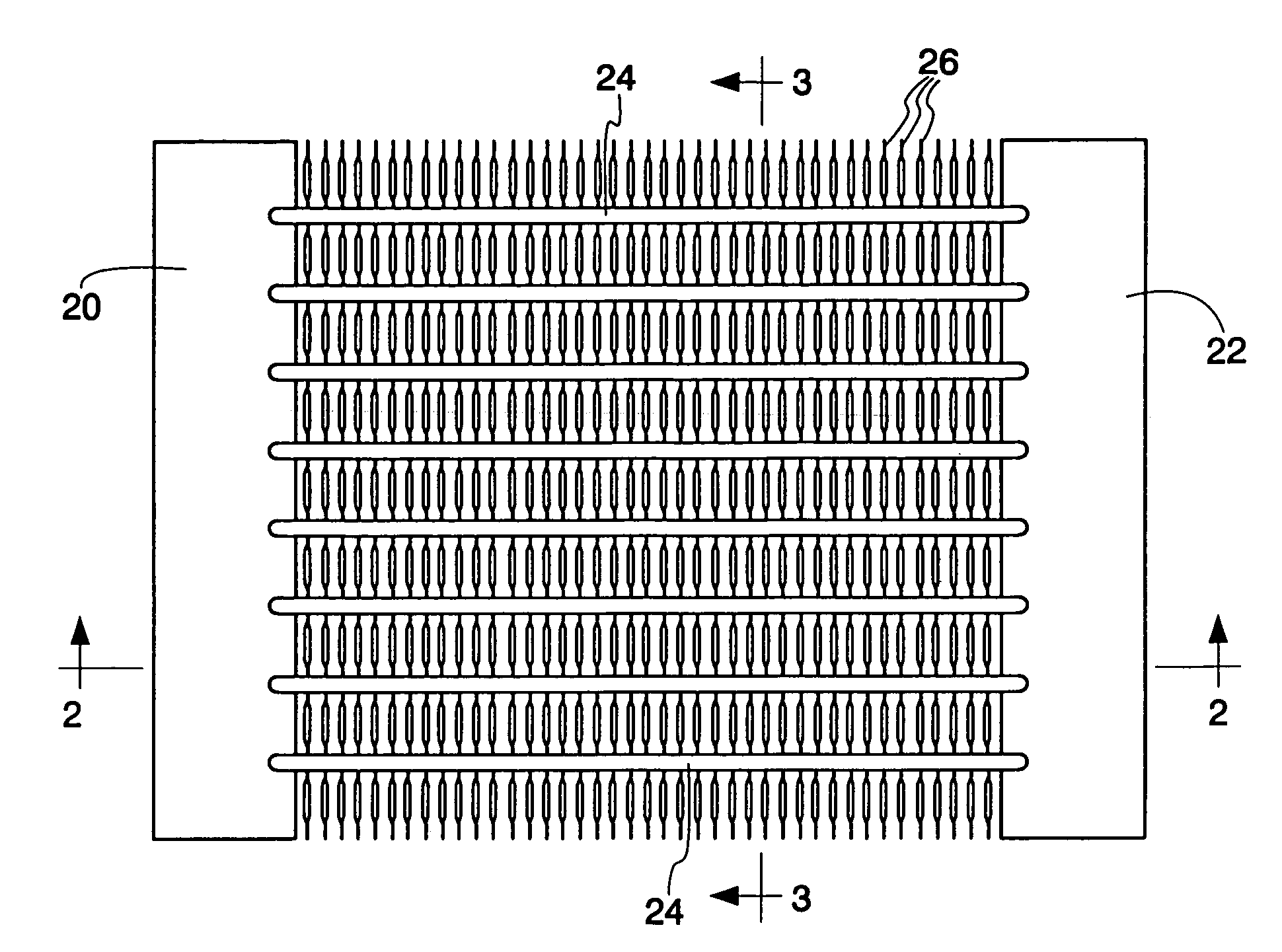

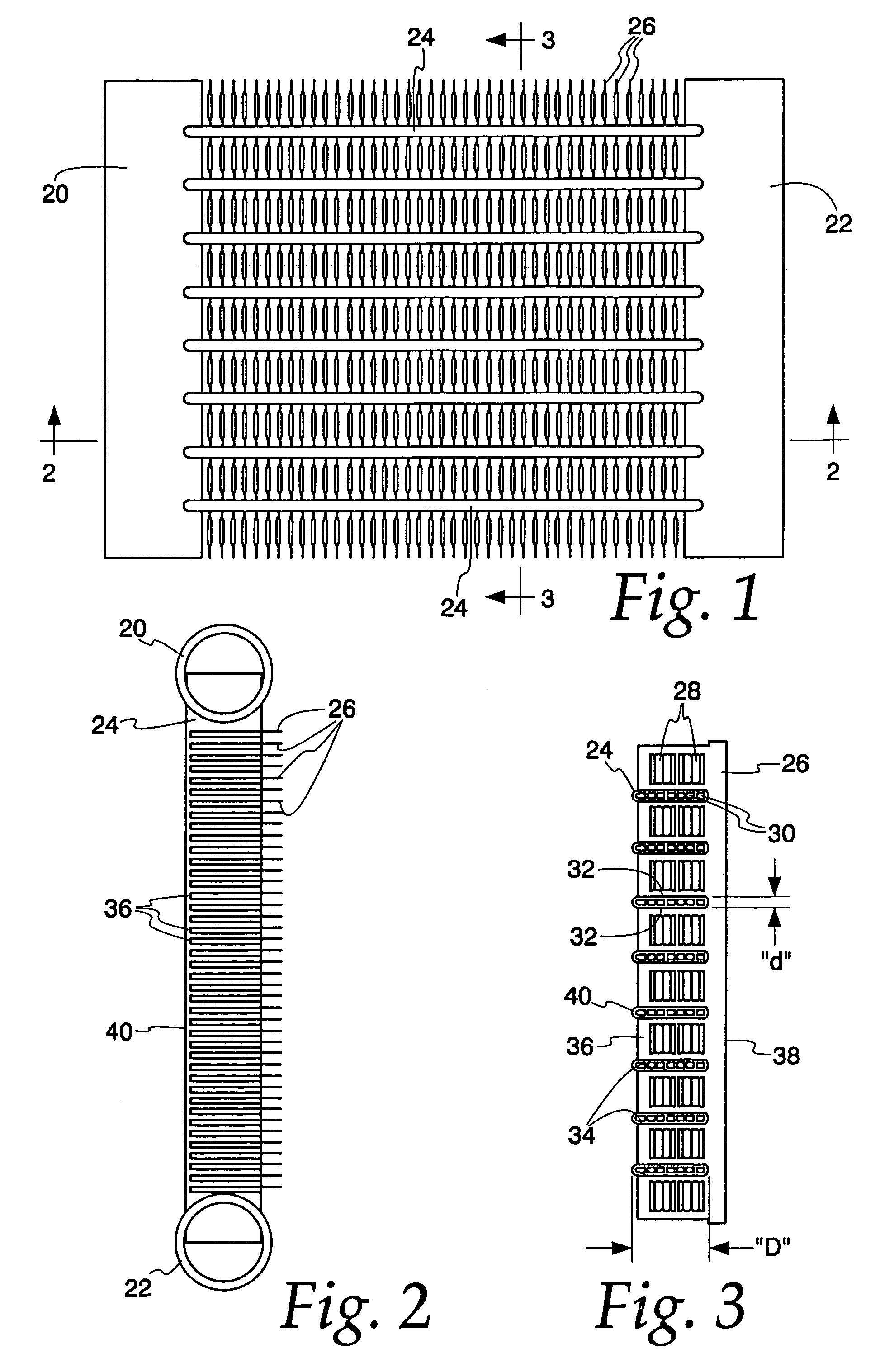

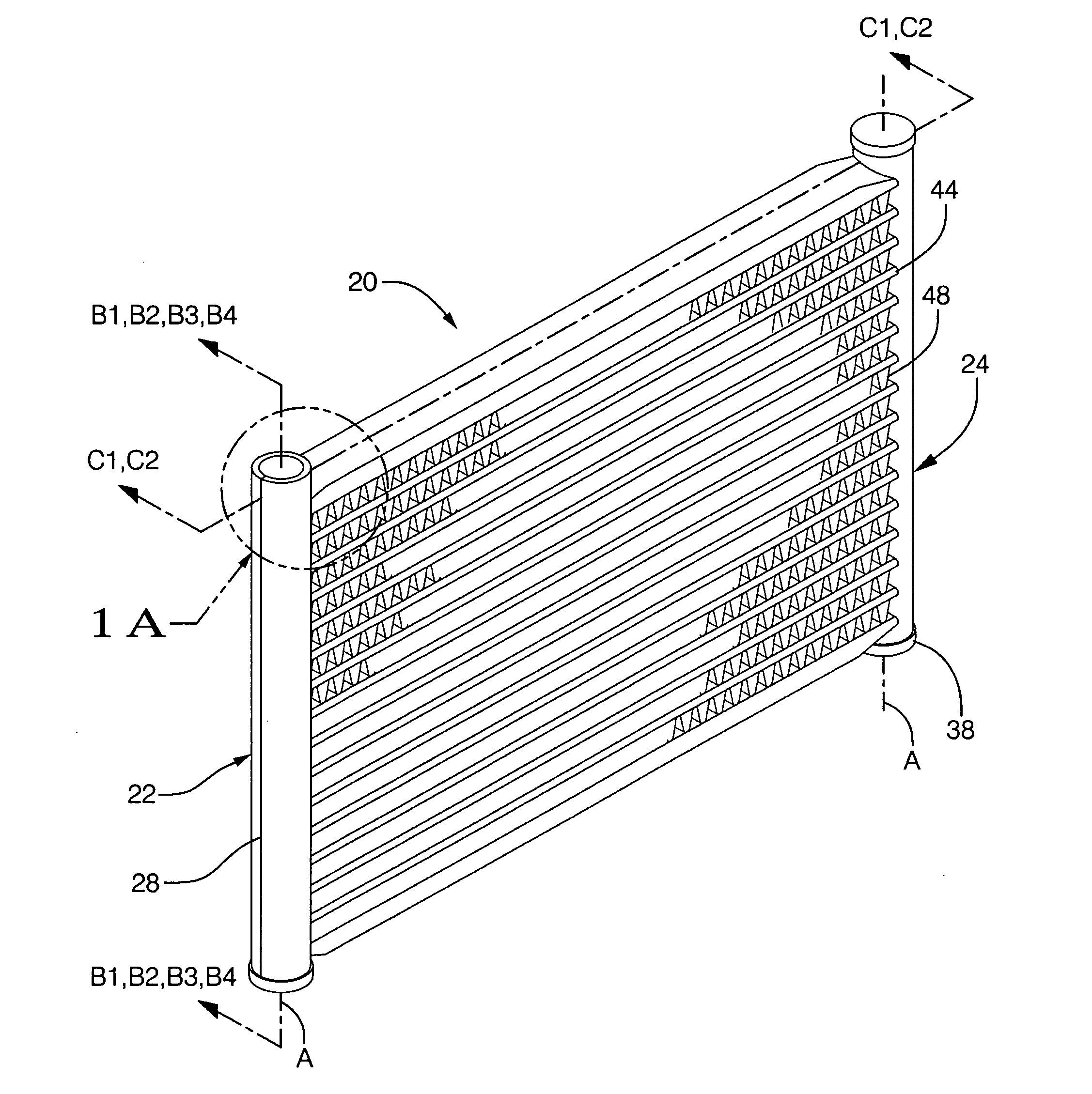

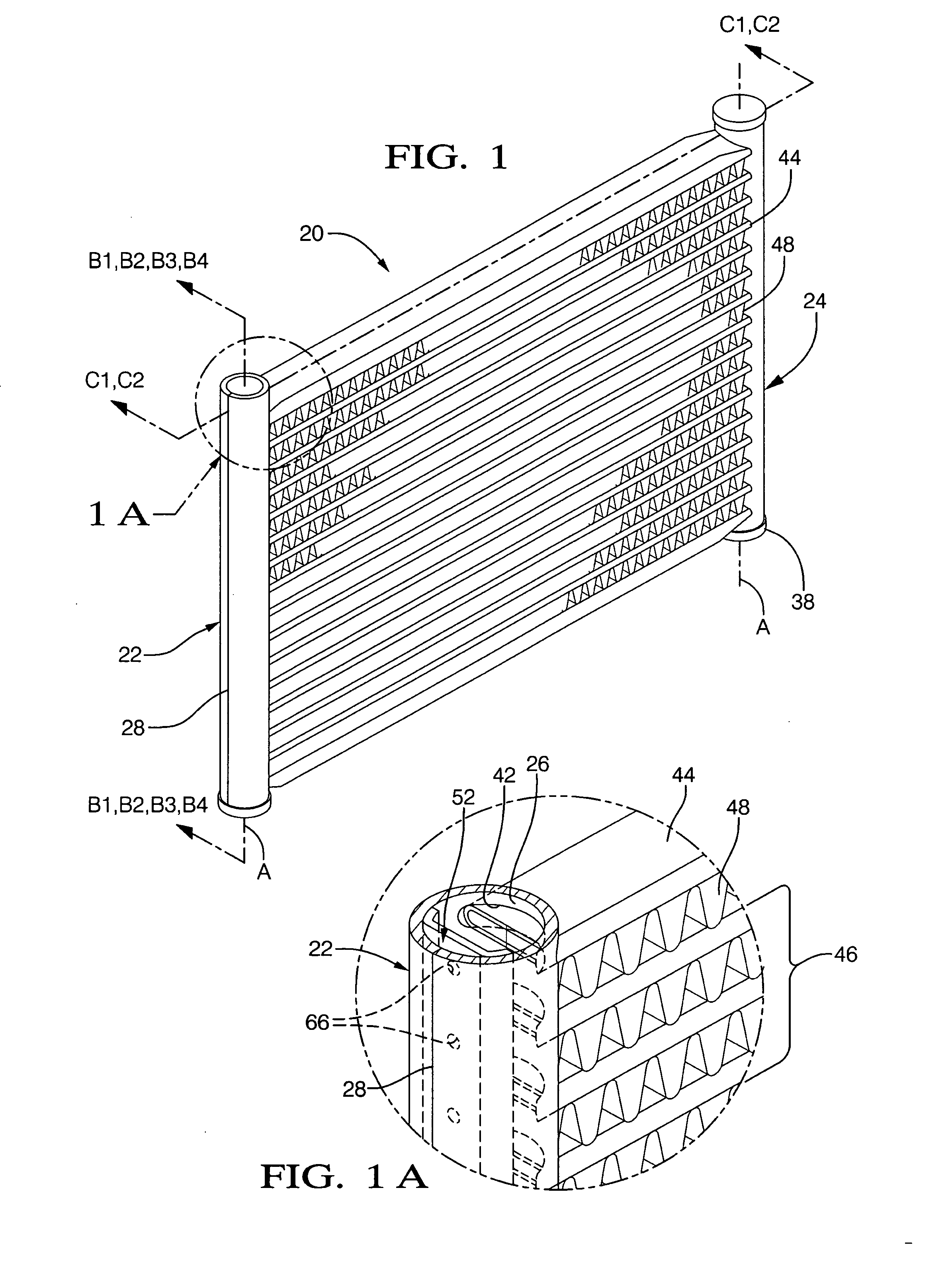

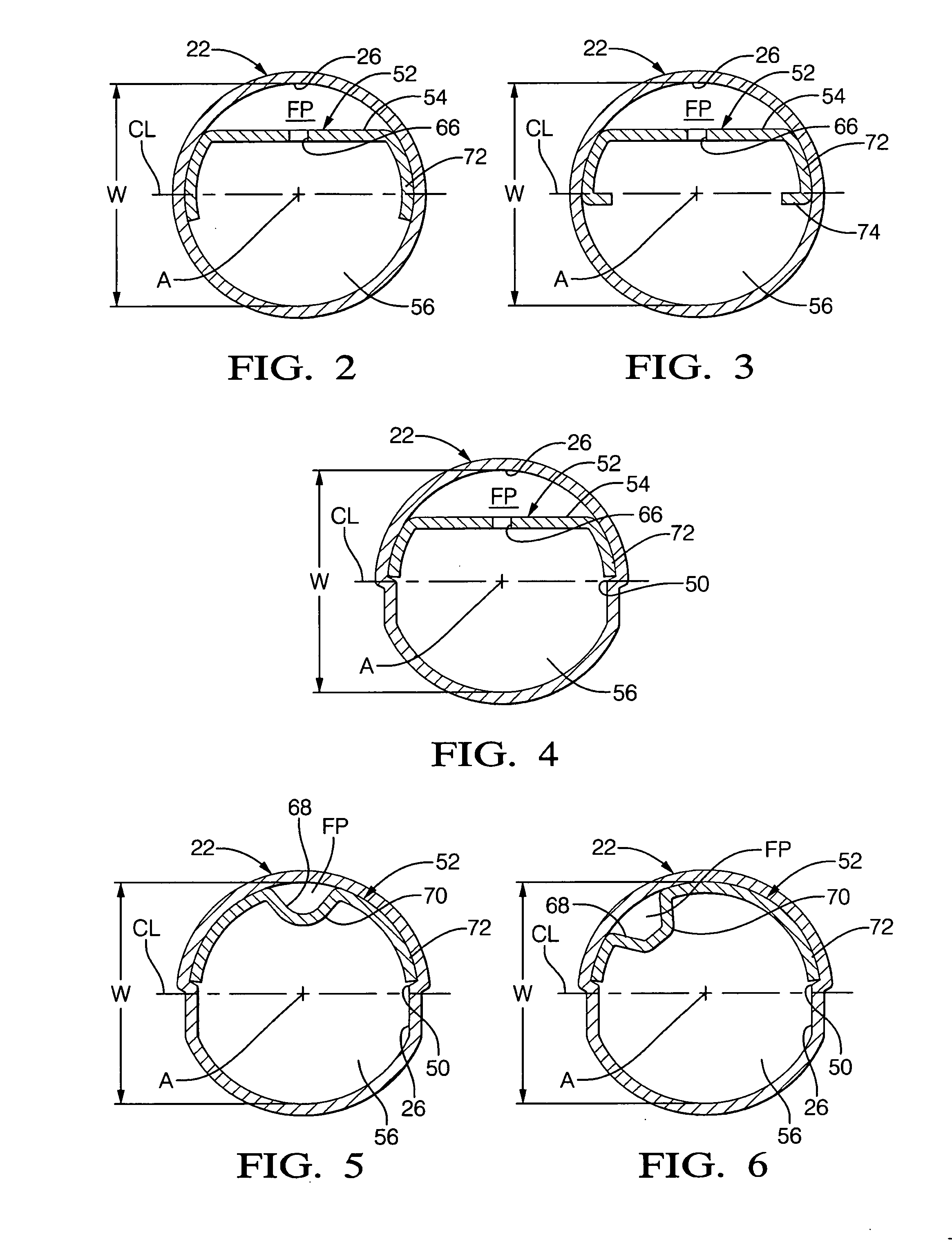

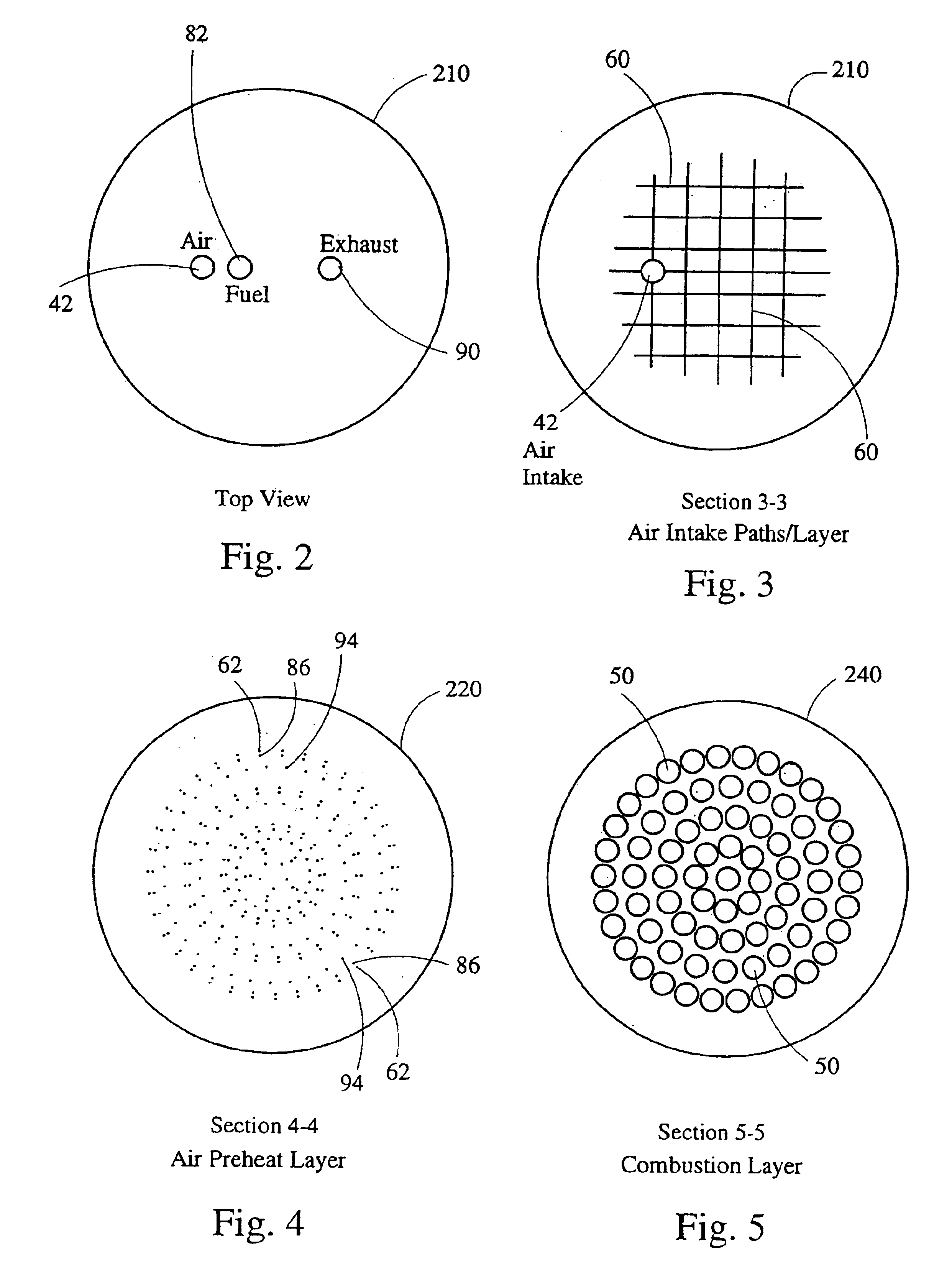

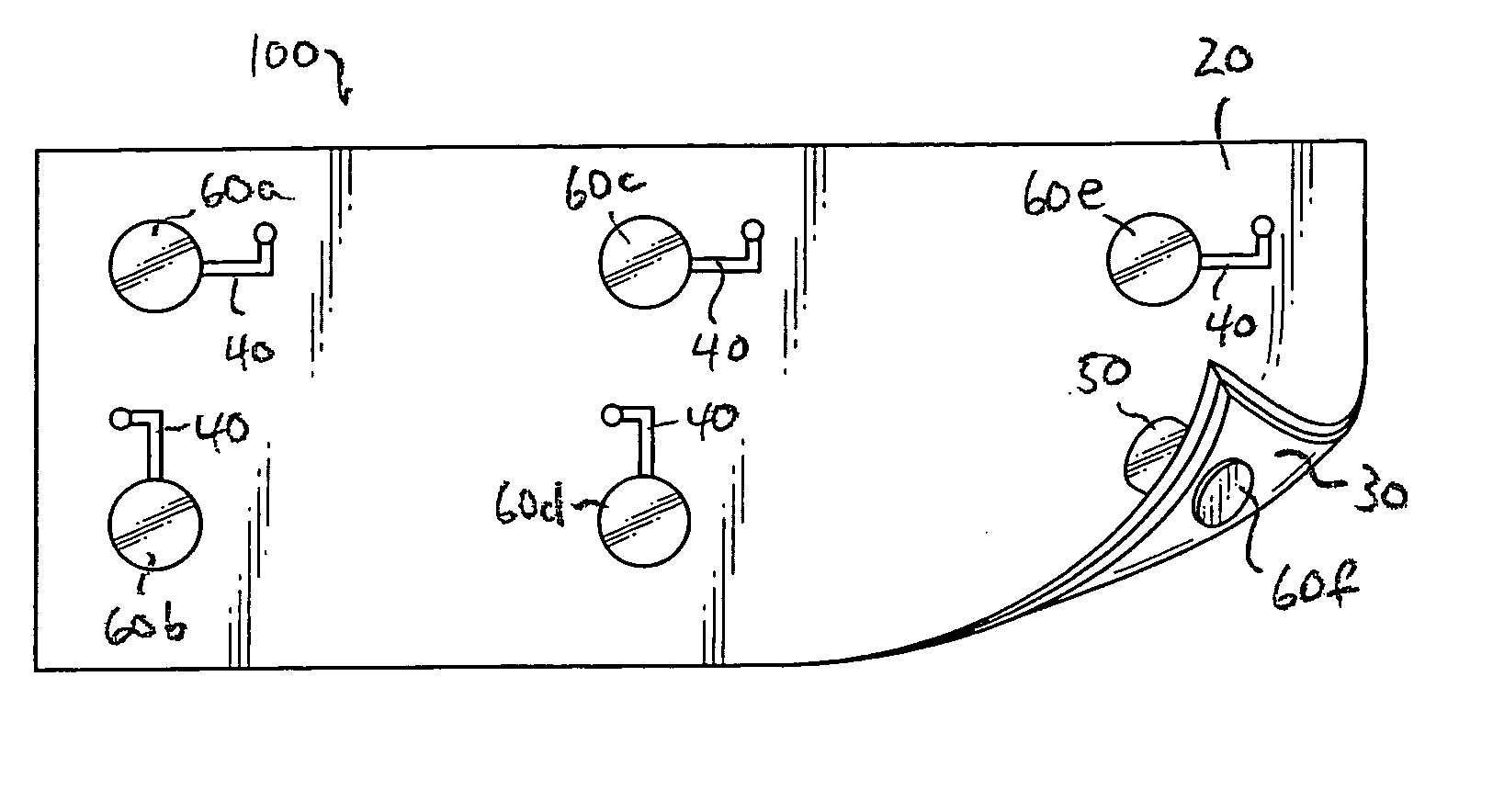

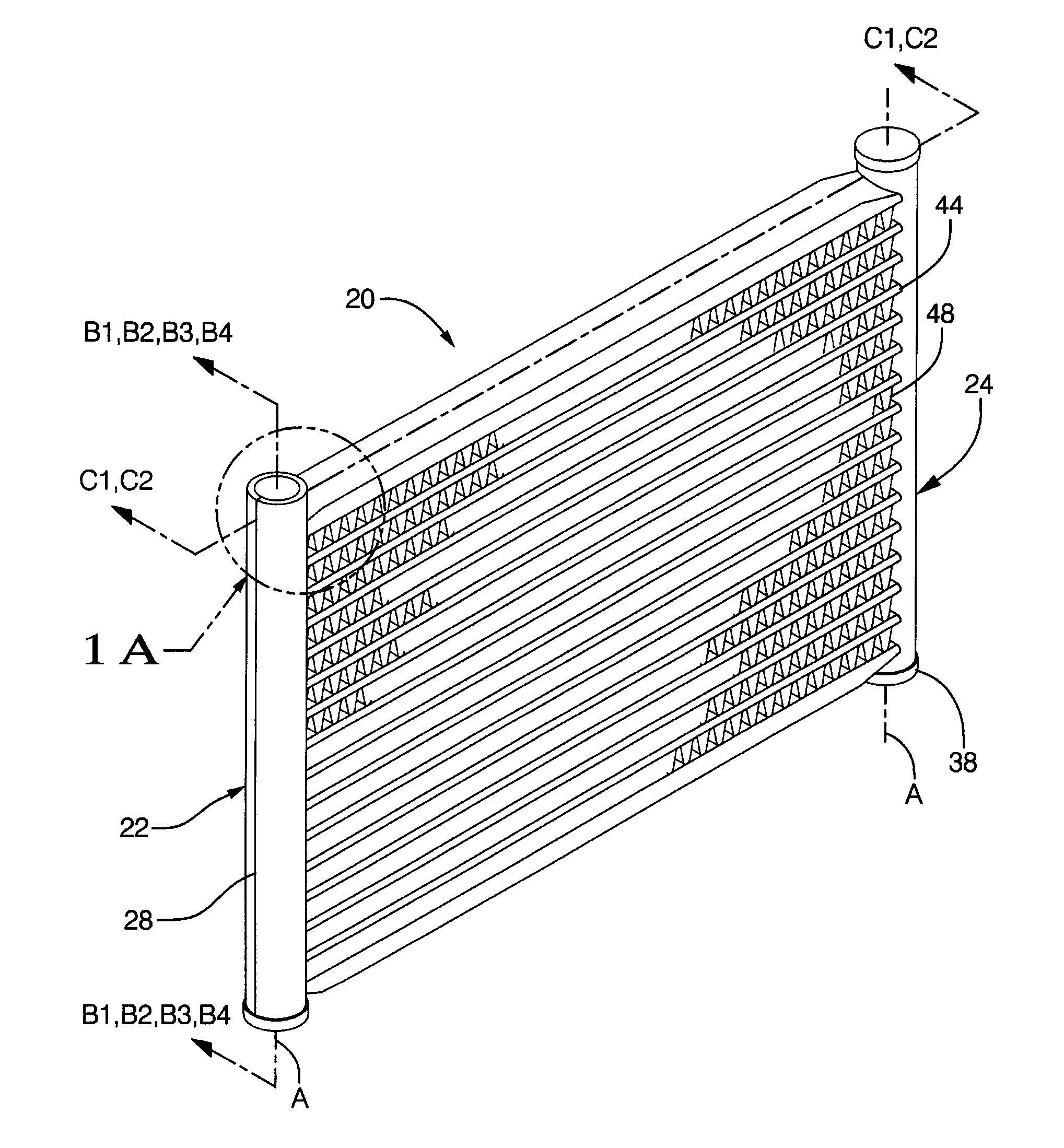

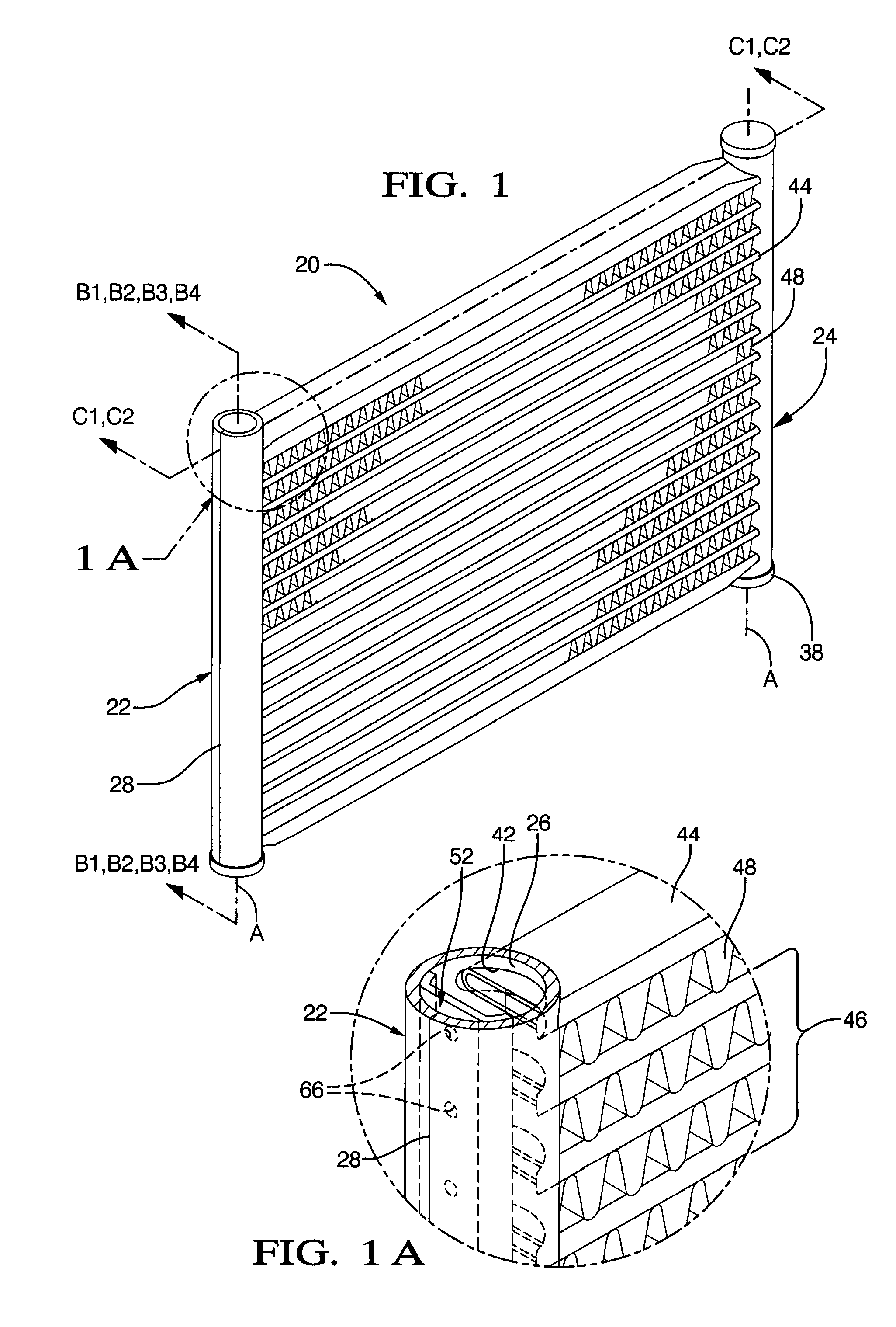

Heat exchanger

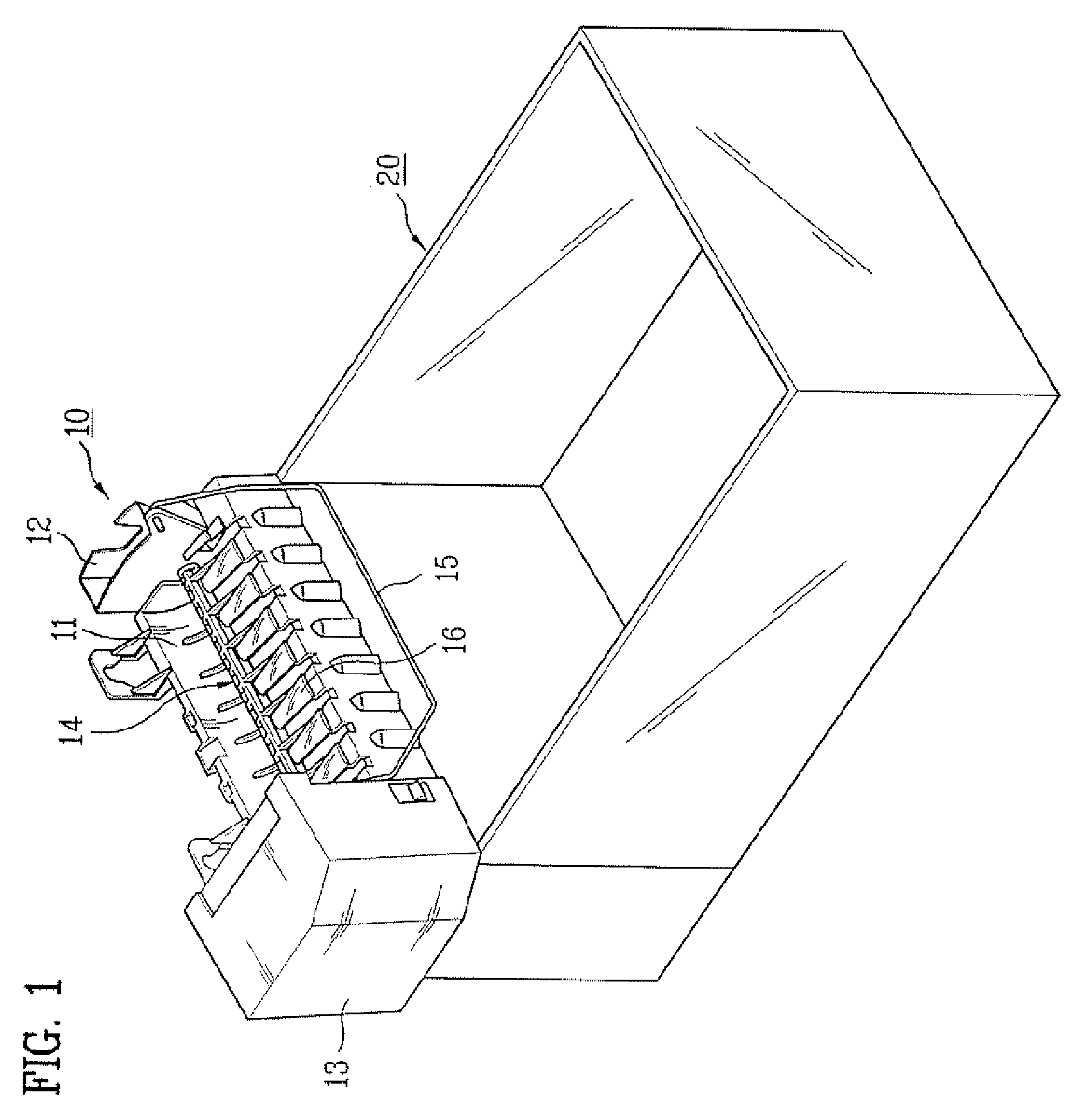

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

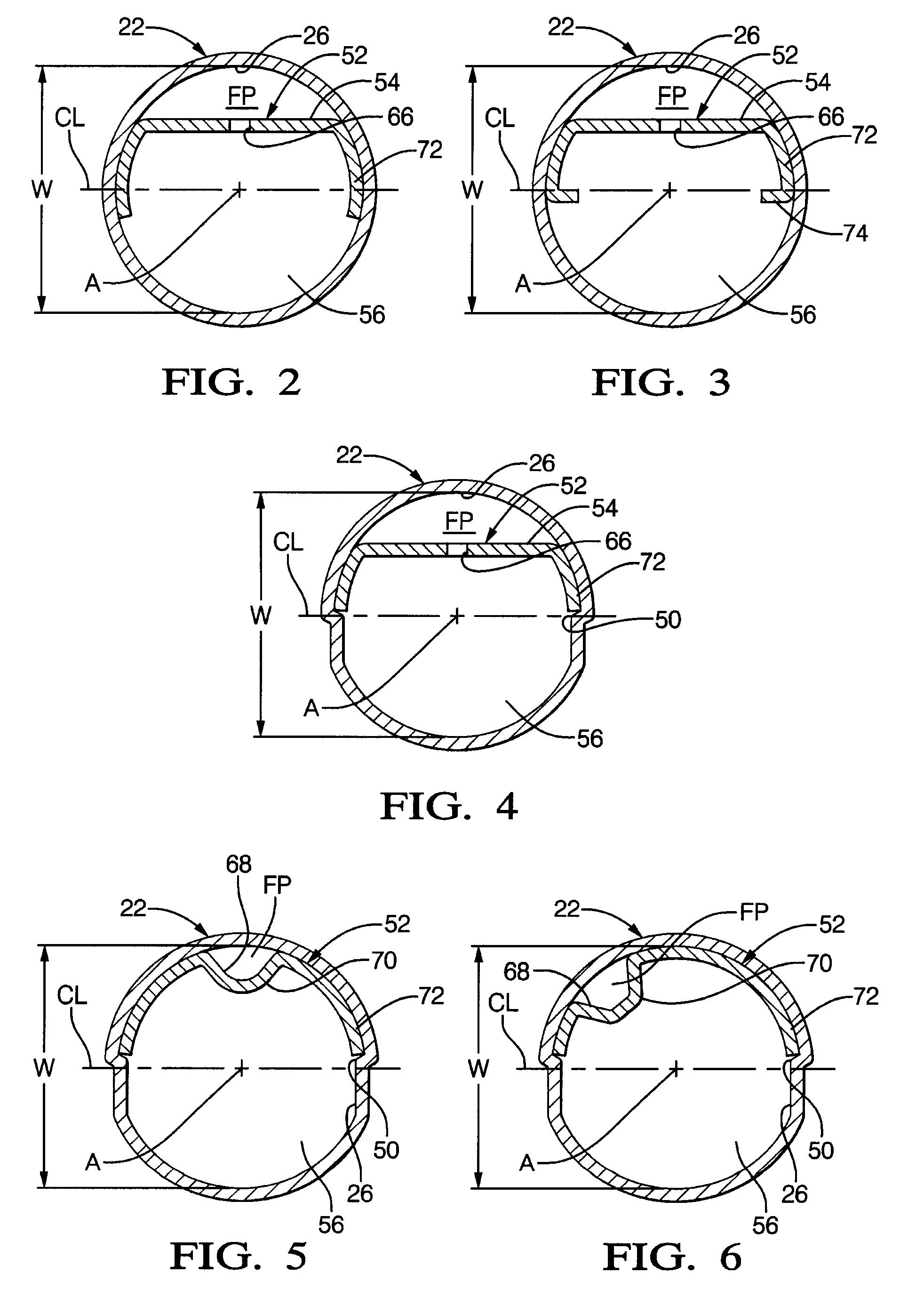

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

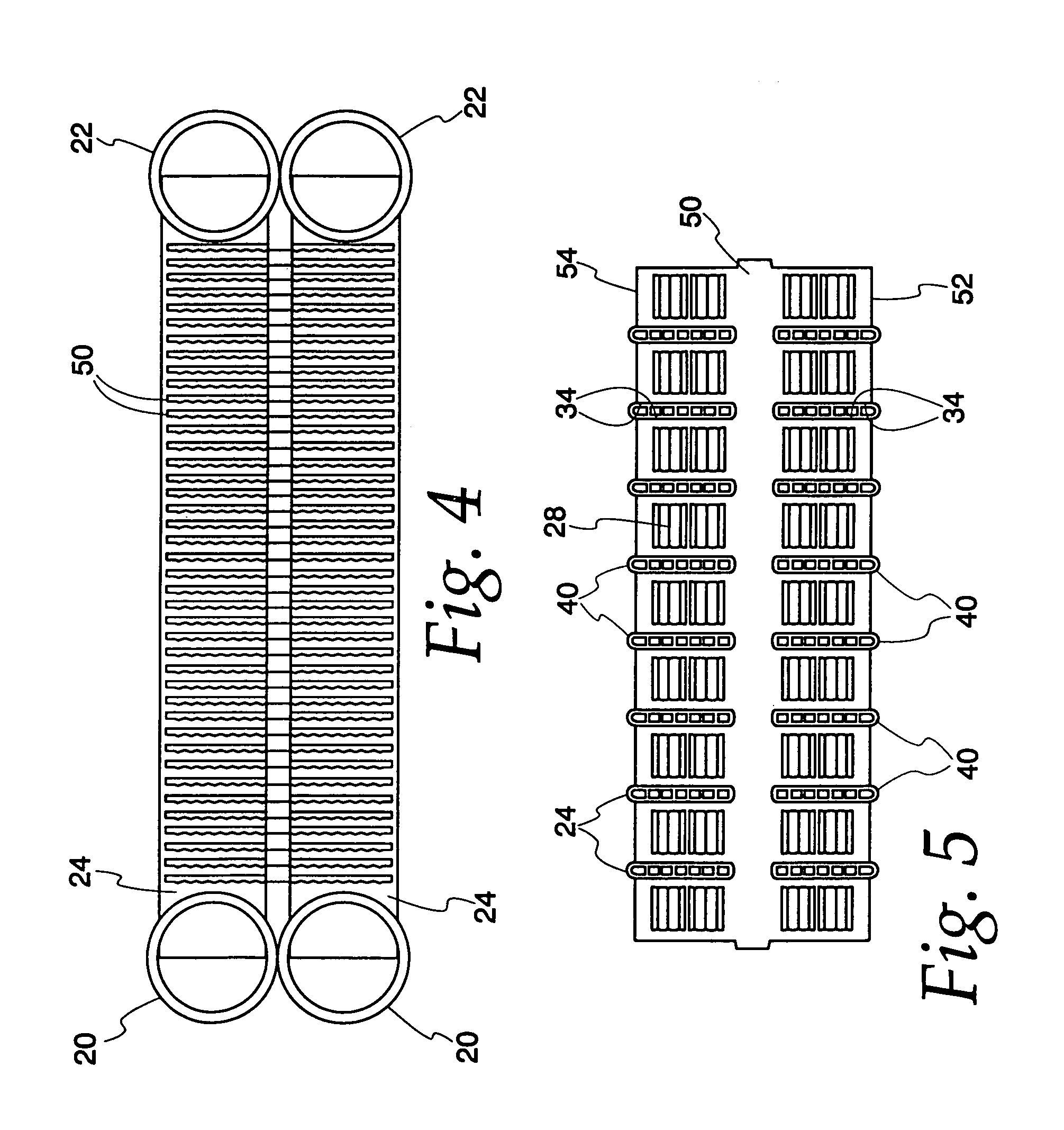

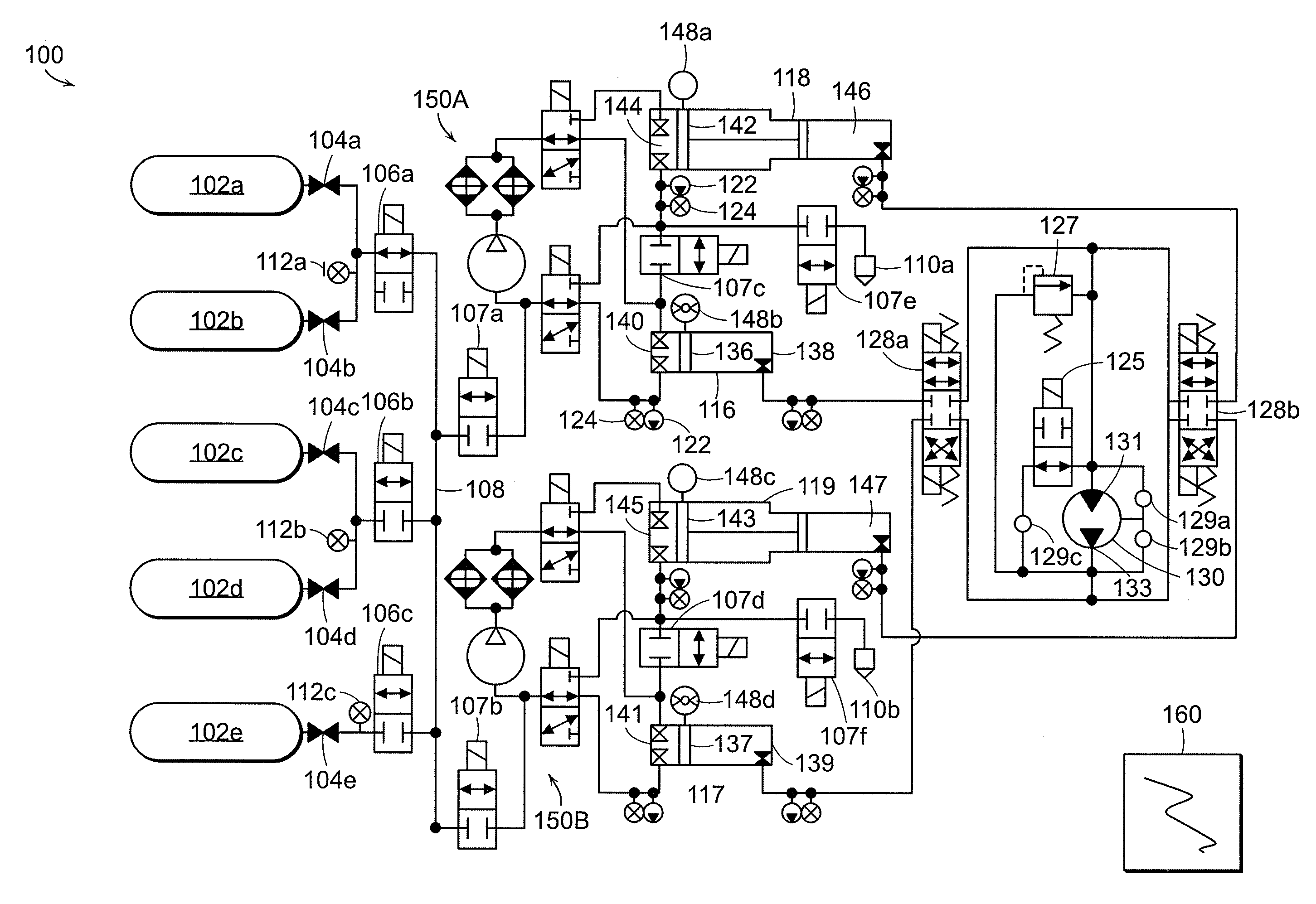

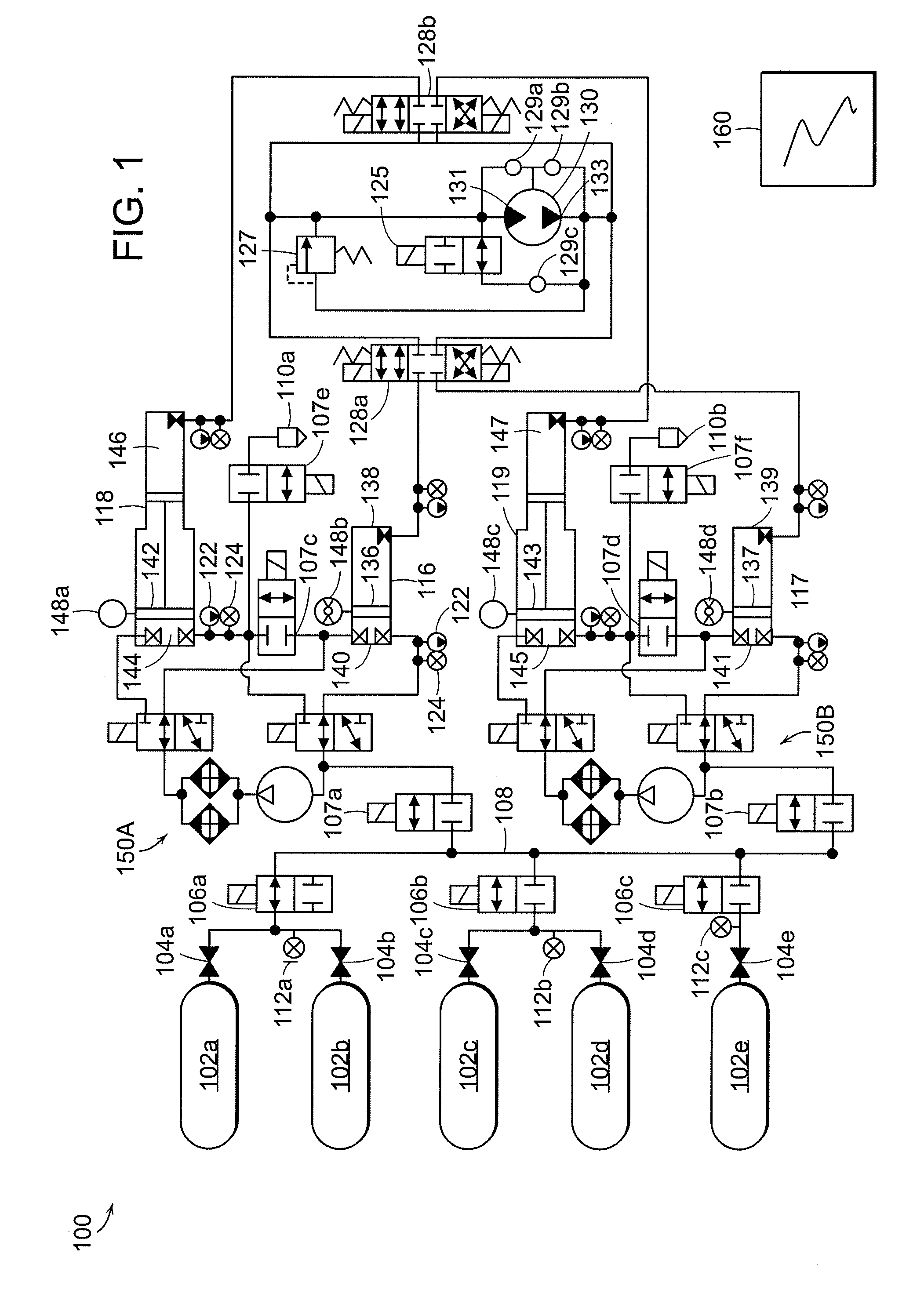

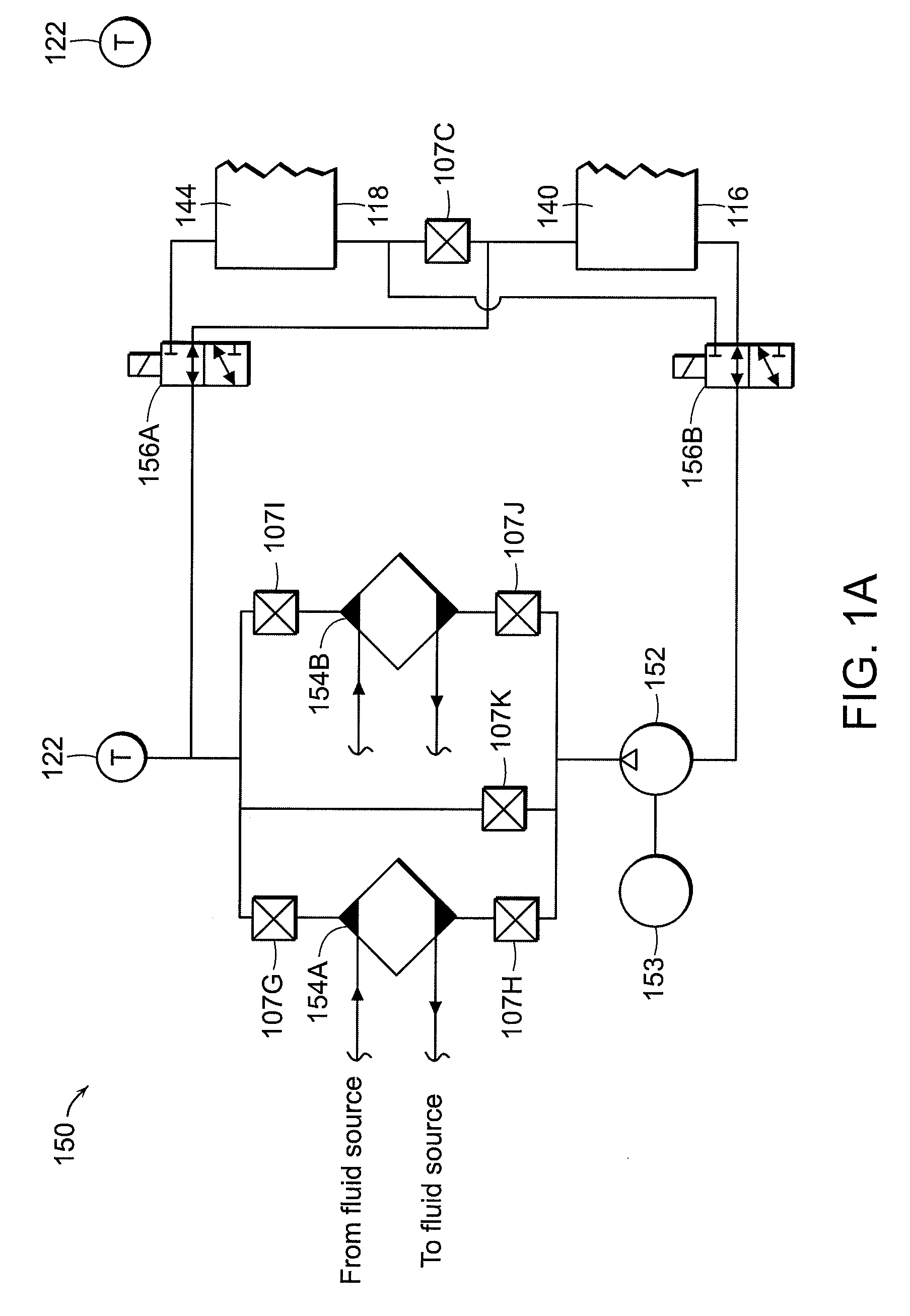

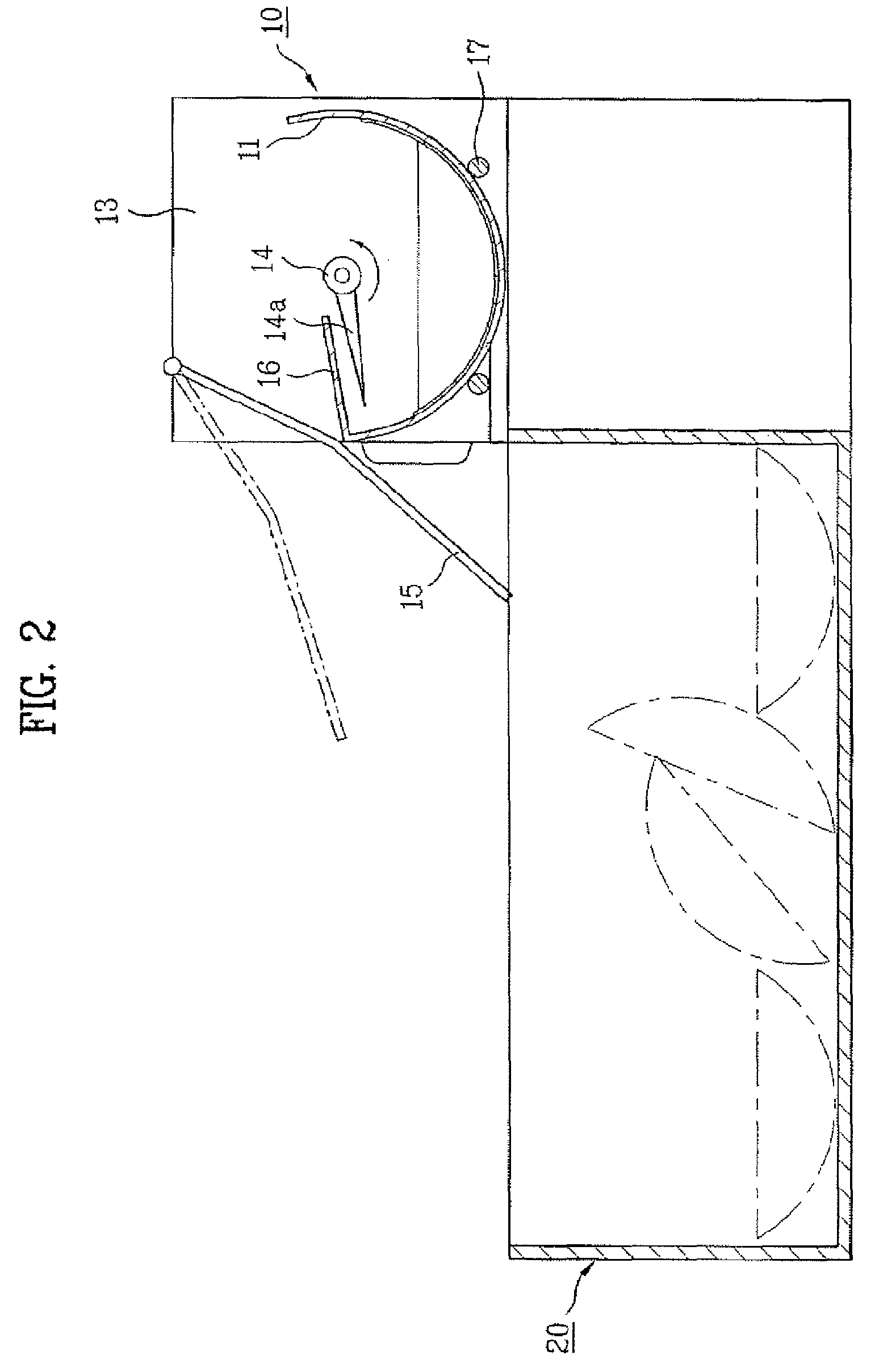

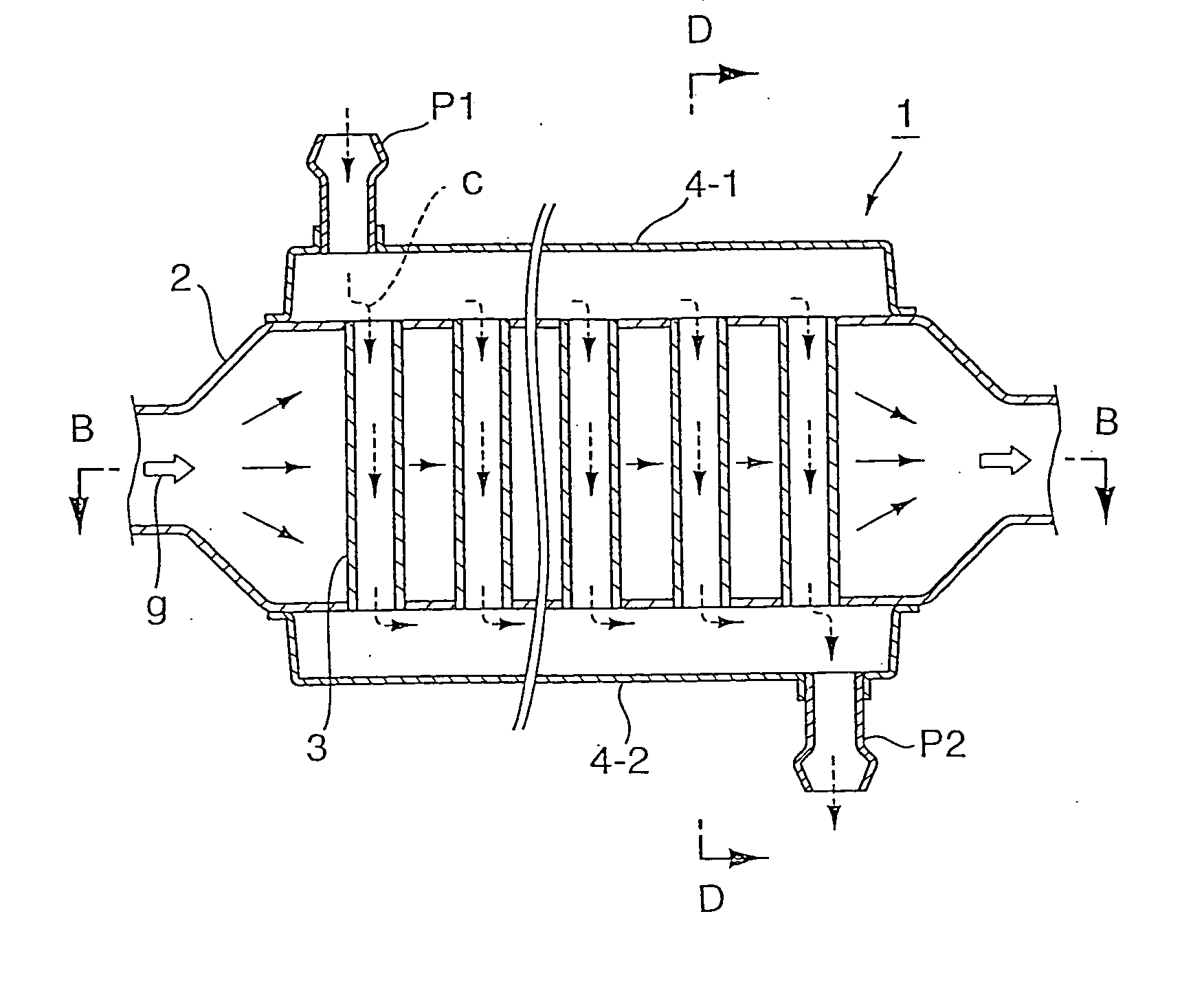

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

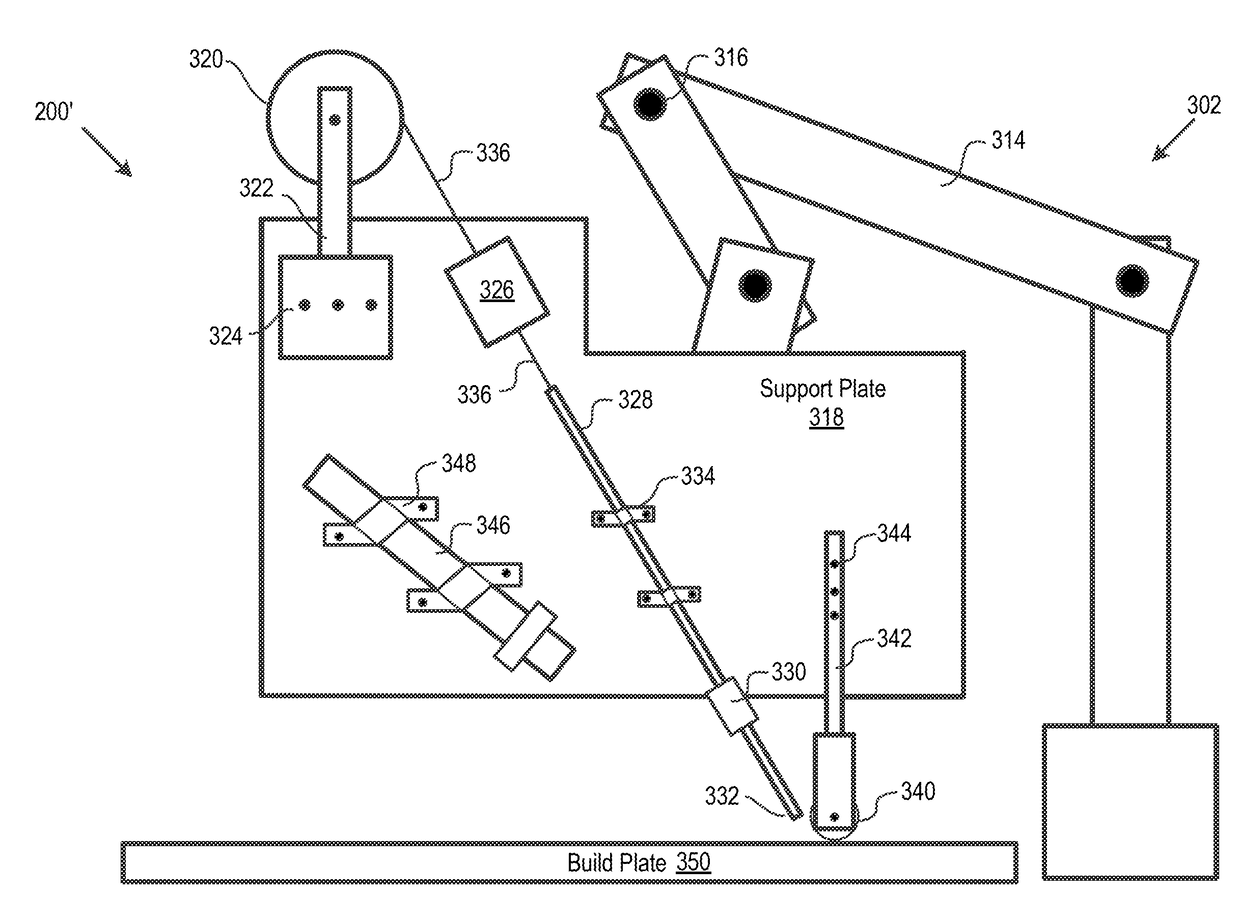

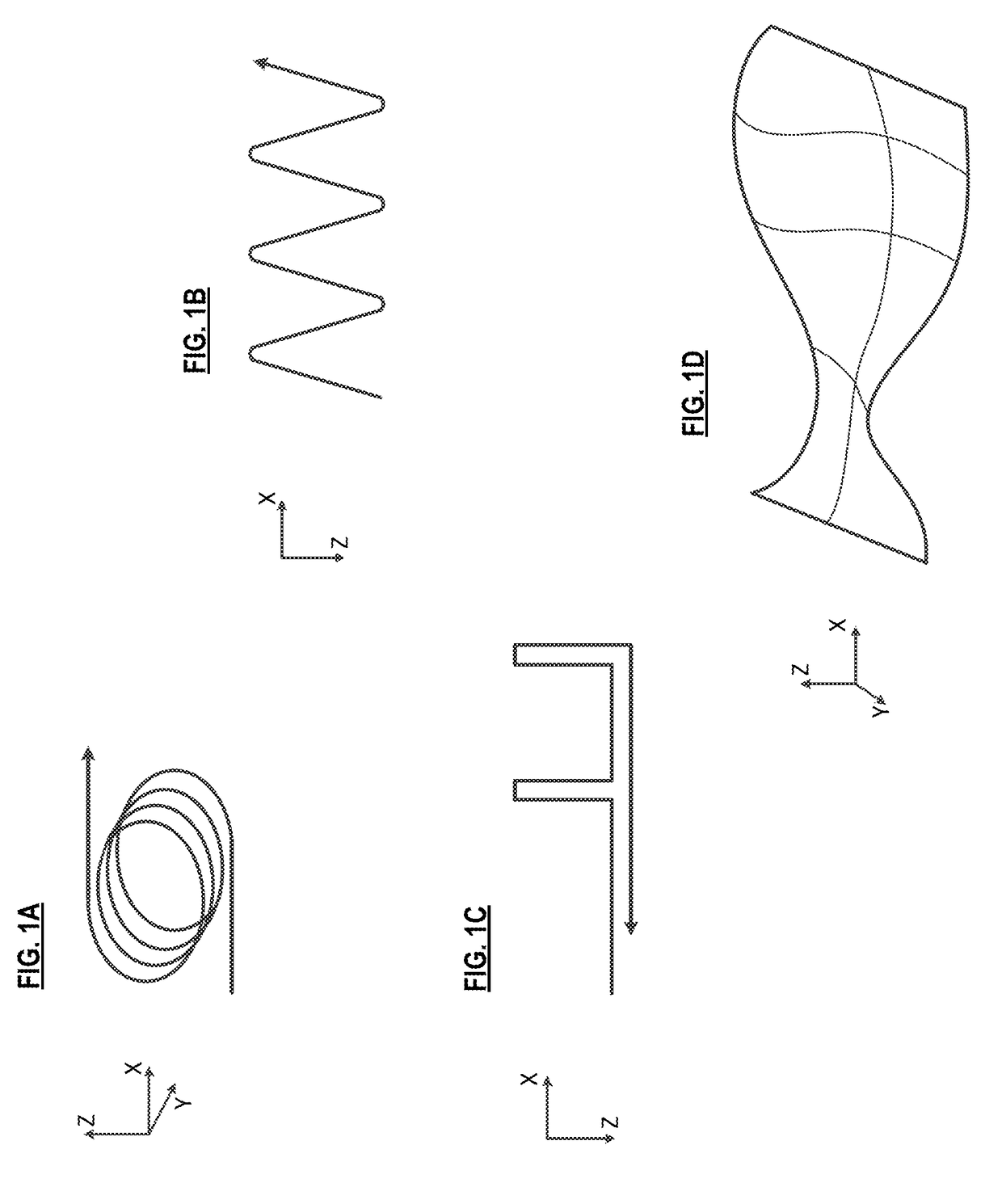

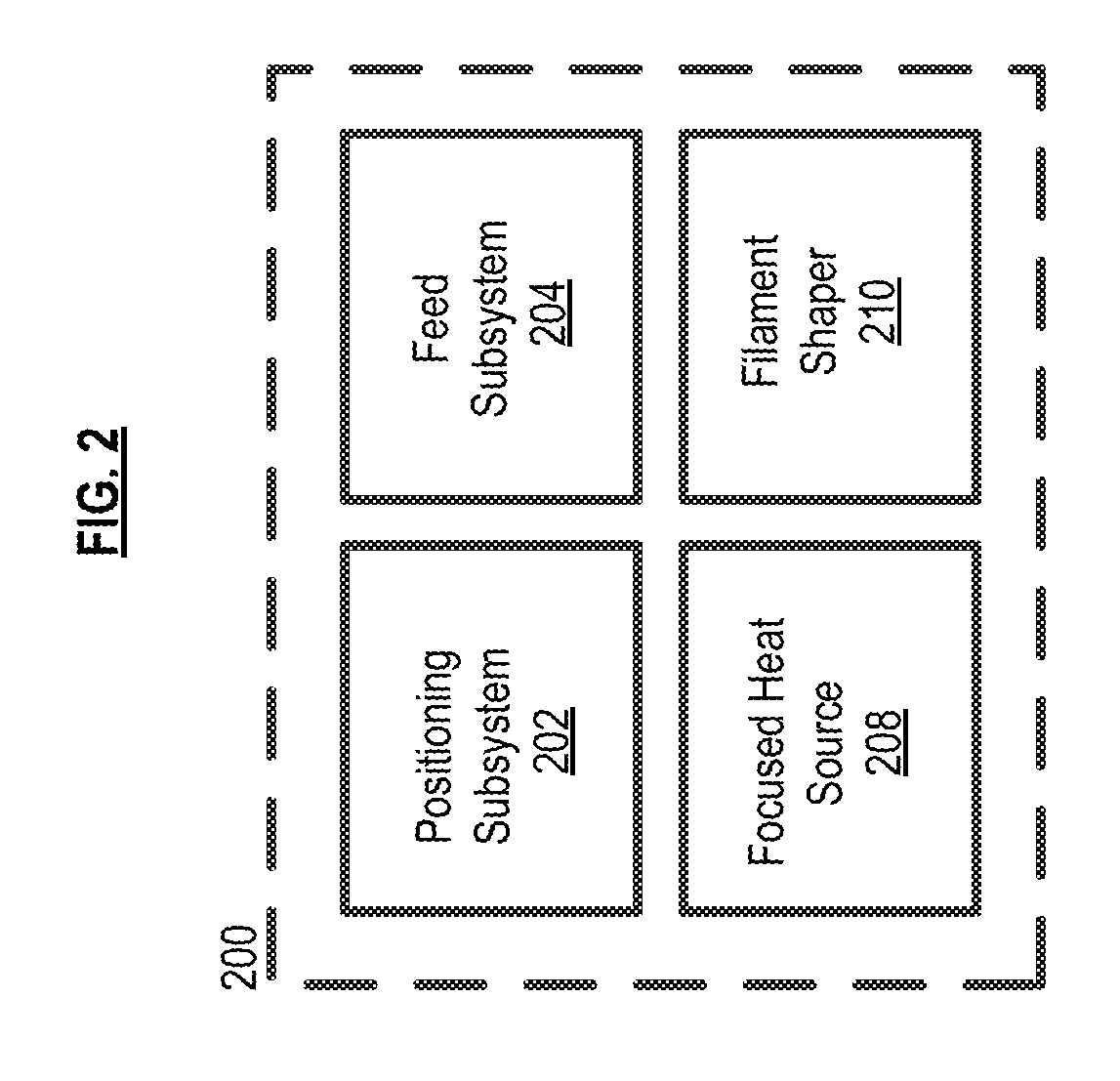

Method and Apparatus for Additive Manufacturing Using Filament Shaping

ActiveUS20170274585A1StrengthImprove heat transfer effectAdditive manufacturing apparatus3D object support structuresFibrous compositesMaterials science

A method and apparatus for additive manufacturing wherein a fiber composite filament having an arbitrarily shaped cross section is softened and then flattened to tape-like form factor for incorporation into a part that is being additively manufactured.

Owner:AREVO INC

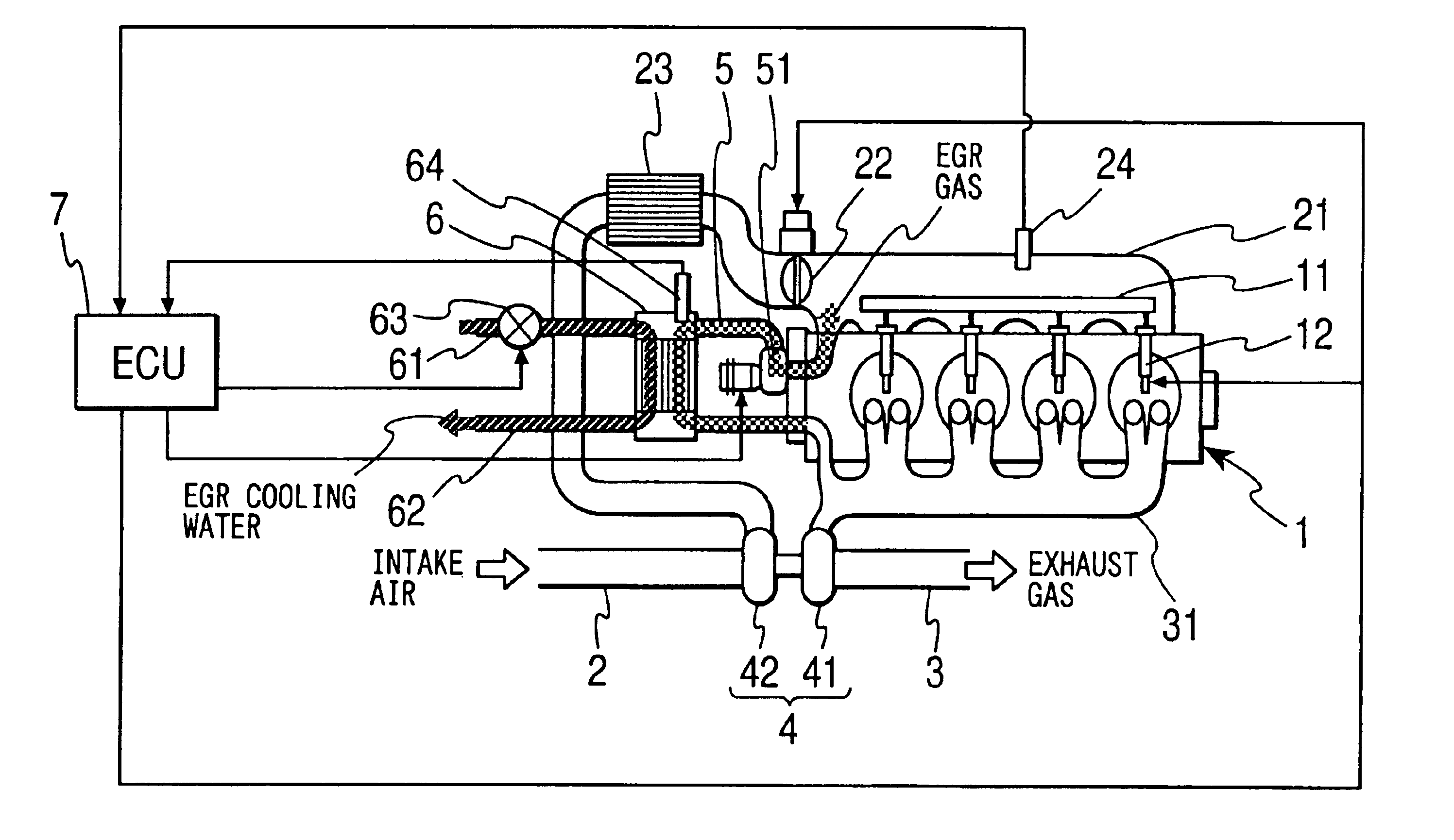

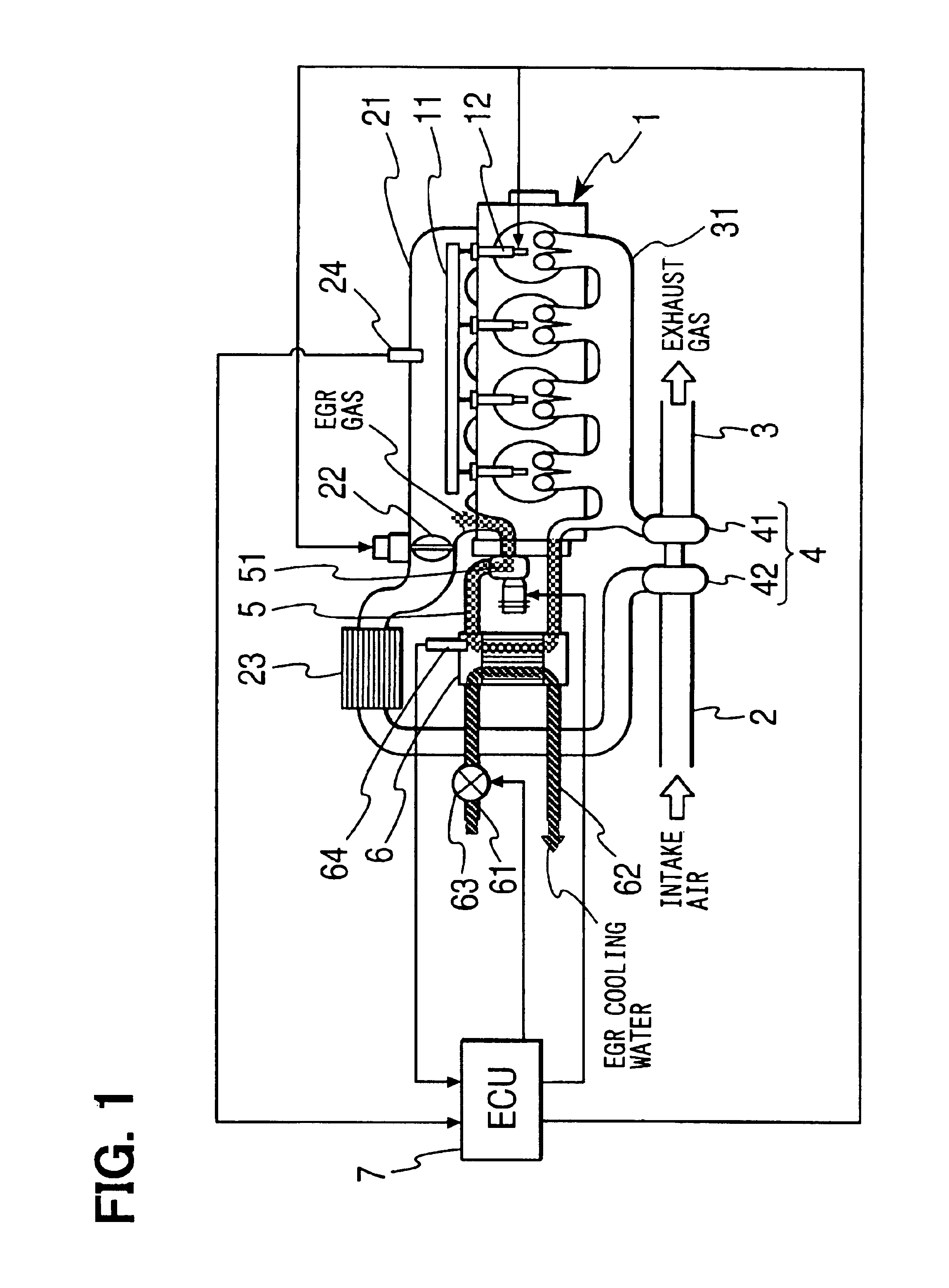

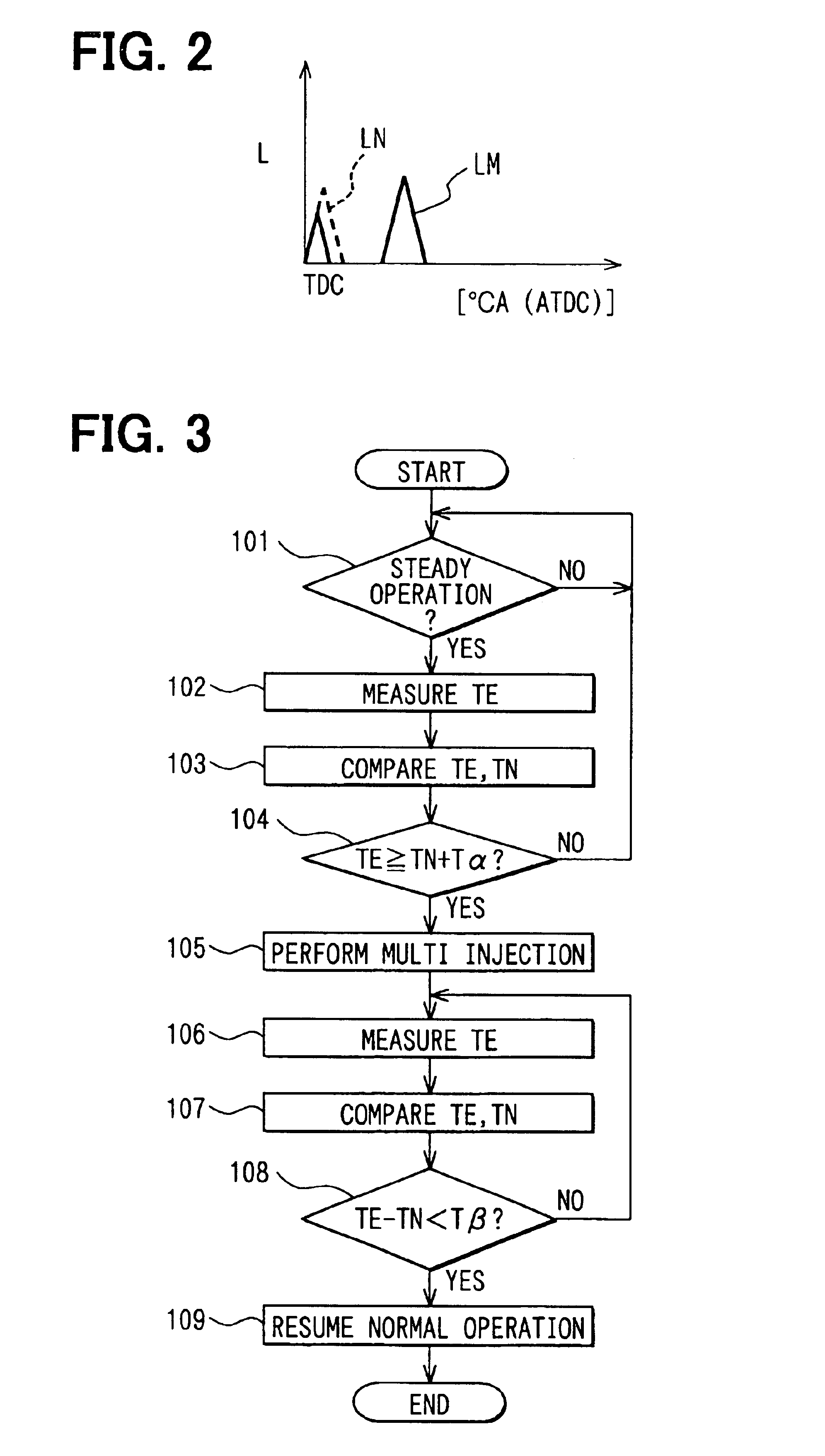

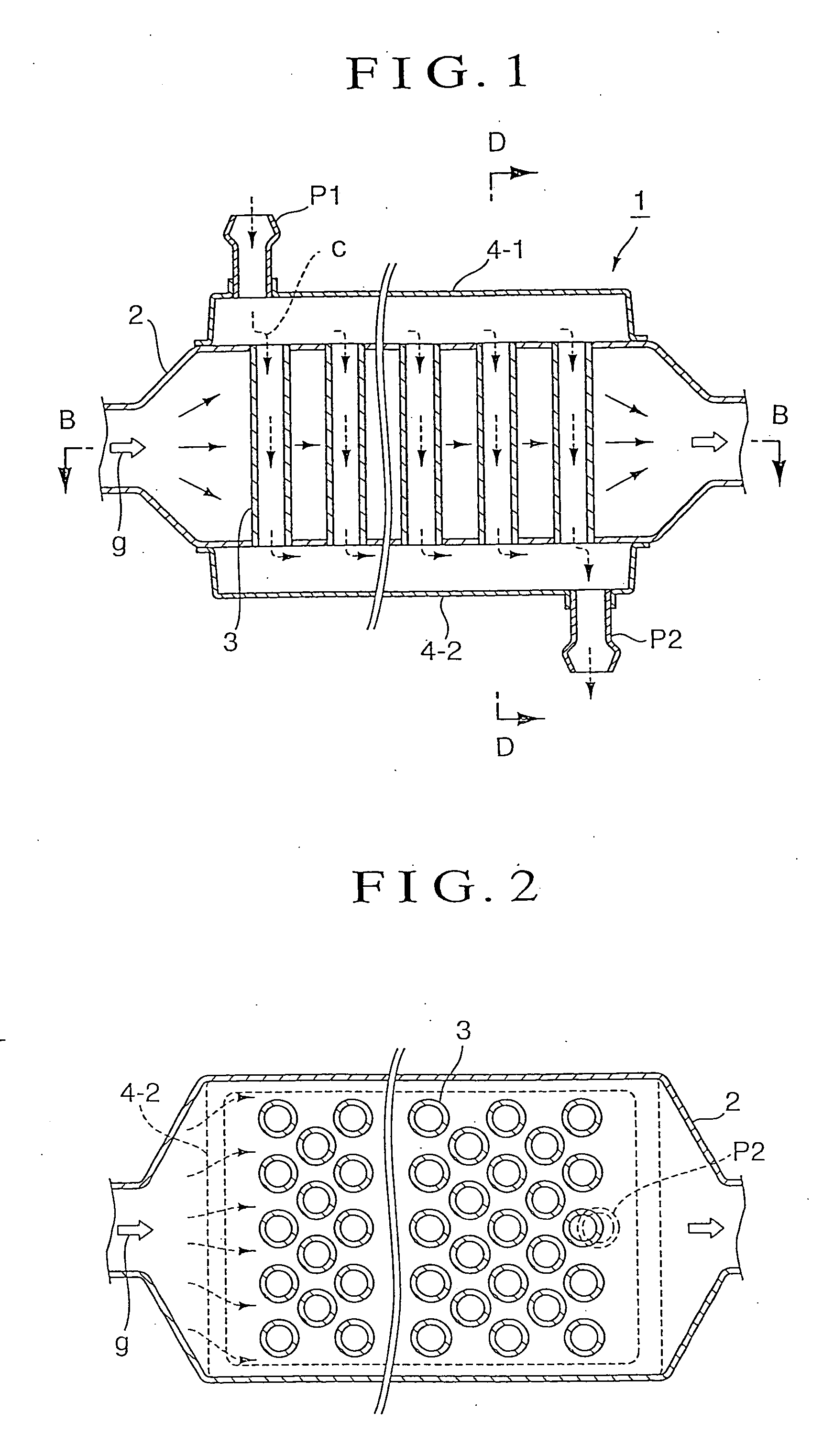

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

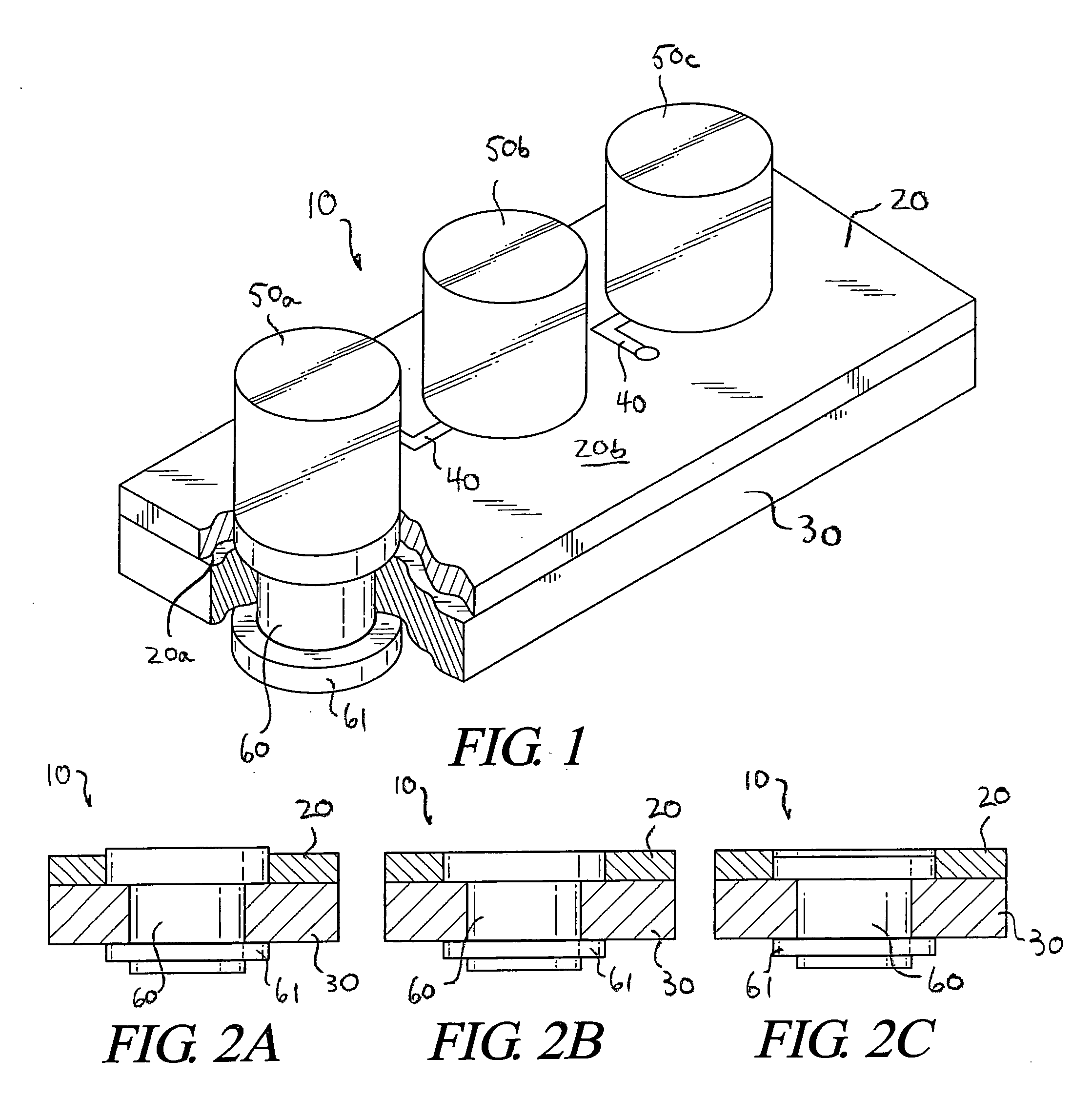

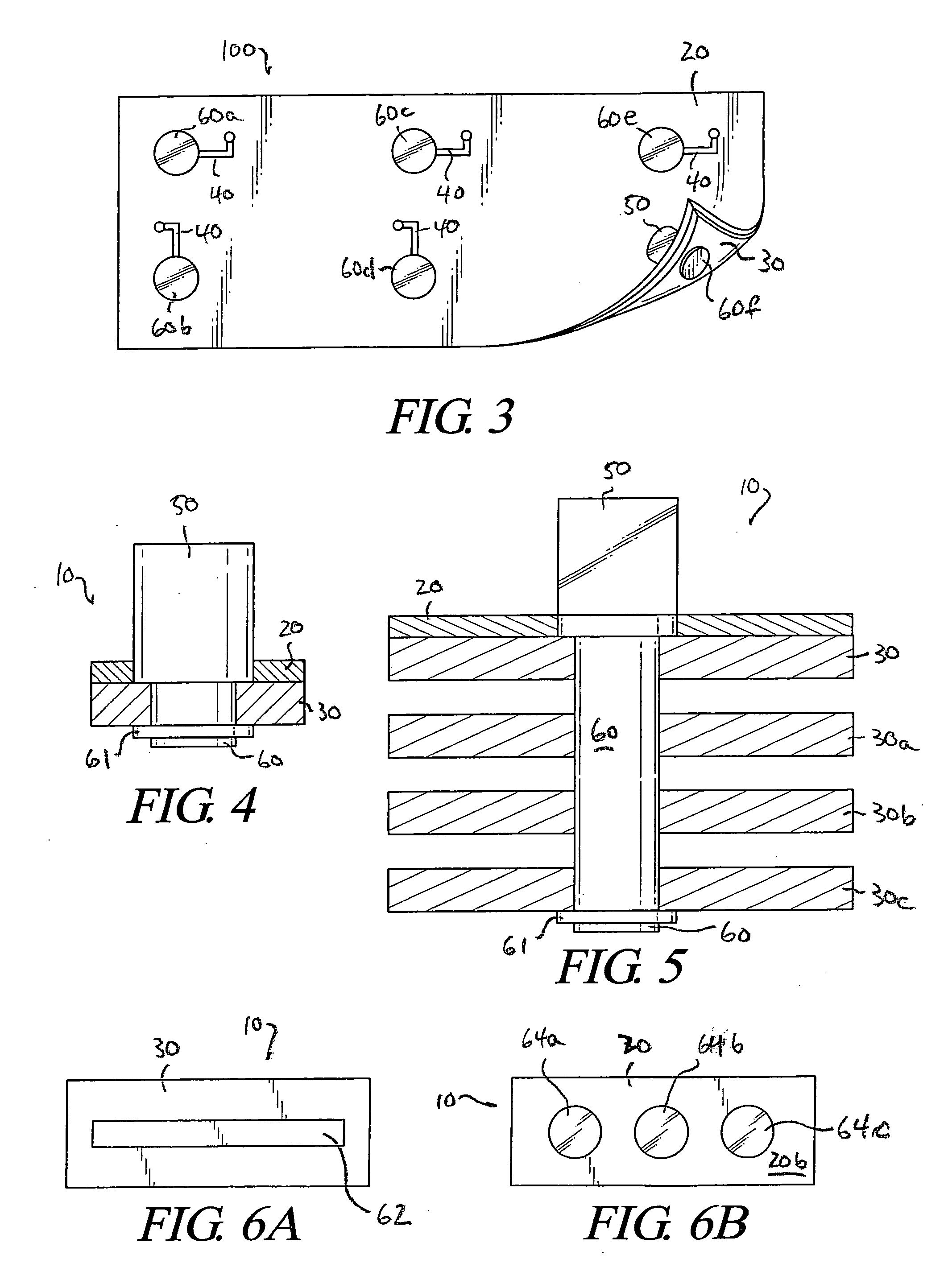

Heat exchanger assembly

InactiveUS20080023185A1Avoid separationImprove heat transfer effectStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

A heat exchanger assembly includes a first single-piece manifold and a second single-piece manifold spaced from and parallel to the first single-piece manifold. Each of the first and second single-piece manifolds has a tubular wall defining a flow path. A plurality of flow tubes extend in parallel between the first and second single-piece manifolds and are in fluid communication with the flow paths. An insert having a distribution surface is slidably disposed in the flow path of the first single-piece manifold to establish a distribution chamber within the first single-piece manifold. A series of orifices defined in the distribution surface of the insert are in fluid communication with the flow path and the distribution chamber for uniformly distributing a heat exchange fluid between the flow path and the flow tubes.

Owner:DELPHI TECH INC

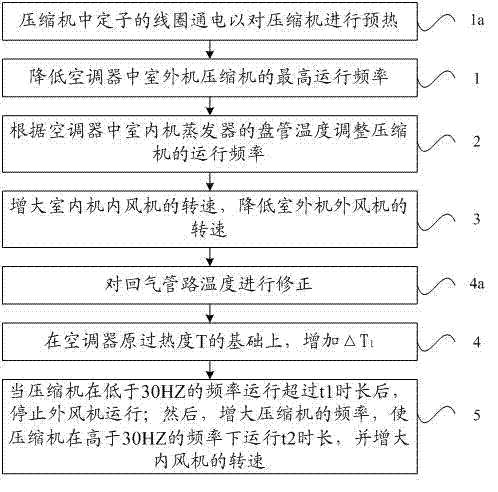

Refrigeration method of low temperature environment air conditioner

ActiveCN103115417AAchieve normal coolingAvoid frequent downtimeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringRefrigeration

The invention provides a refrigeration method of a low temperature environment air conditioner. When the air conditioner operates to refrigerate, the refrigeration method comprises the following steps of: step 1, reducing the topmost operating frequency of an outer door machine compressor in the air conditioner; step 2, adjusting the operating frequency of the compressor according to the temperature of a coil of an indoor machine evaporator in the air conditioner; and step 3, increasing the rotation speed of an inner fan of an indoor machine, and reducing the rotation speed of an outer door of an outdoor machine. The topmost operating frequency of the compressor is reduced, the compressor is frequently lifted frequency because of high frequency under the low temperature environment to be avoided, the frequency of the compressor is adjusted according to the temperature of the coil, and an evaporator is iced so that the compressor is stopped to be avoided; and the wind speed of the inner fan is increased, the evaporator and indoor heat transfer quantity is improved, the wind speed of the outer fan is reduced, the heat transfer quantity of a condenser is reduced, the air conditioner can normally refrigerate under the low temperature environment to be realized, and the refrigerating effect is optimized.

Owner:QINGDAO HAIER JIAOZHOU AIR CONDITIONER

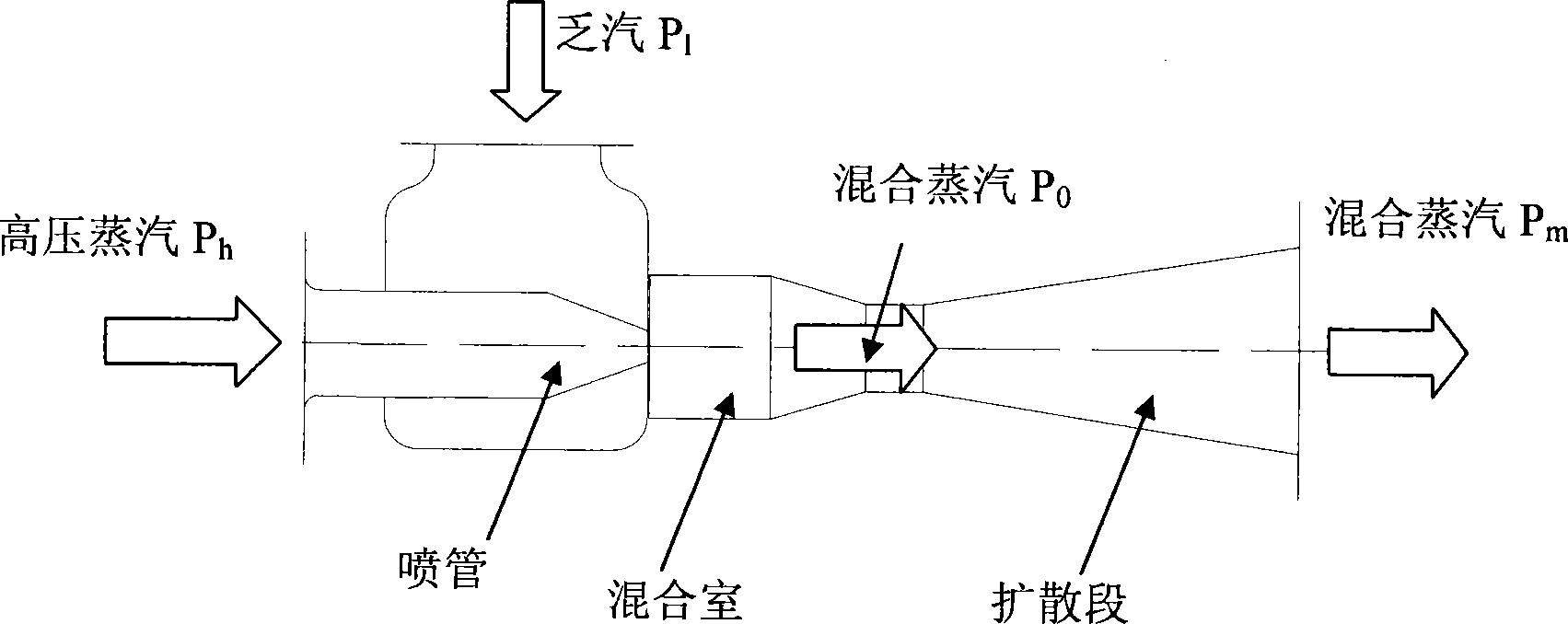

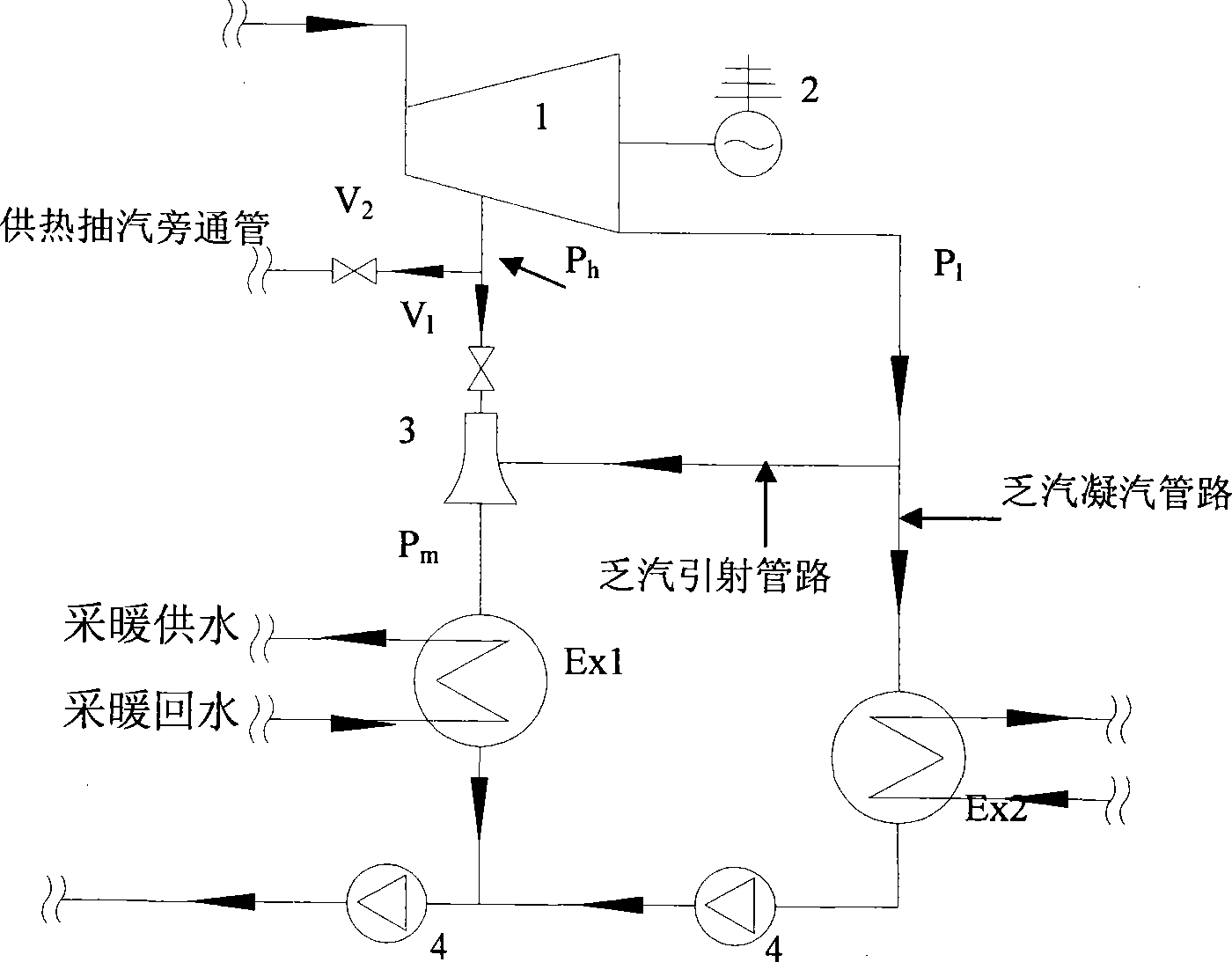

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

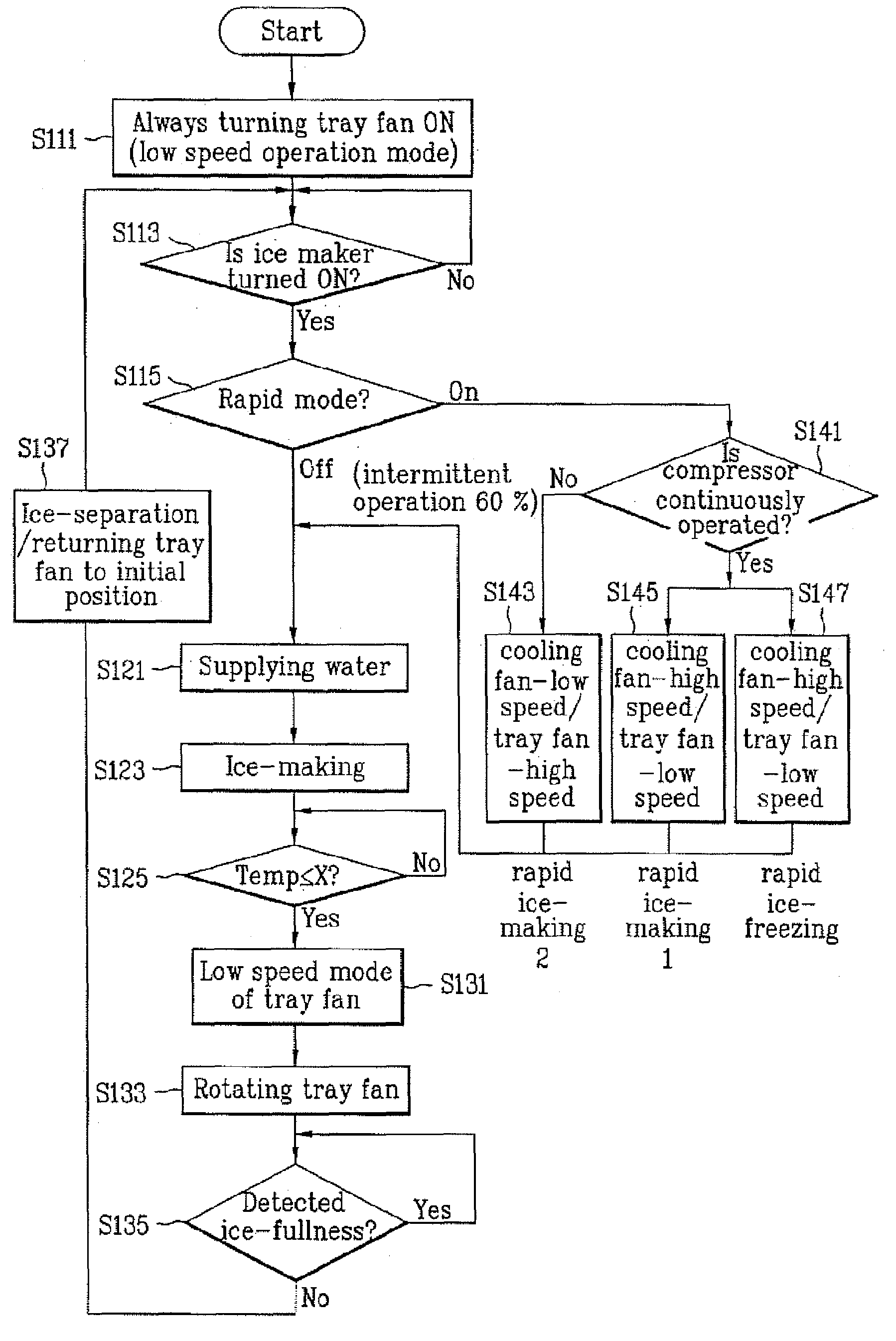

Control method of refrigerator

ActiveUS20070137241A1Simple structureProduce significantLighting and heating apparatusIce productionEngineeringRefrigerated temperature

Owner:YALE UNIV +1

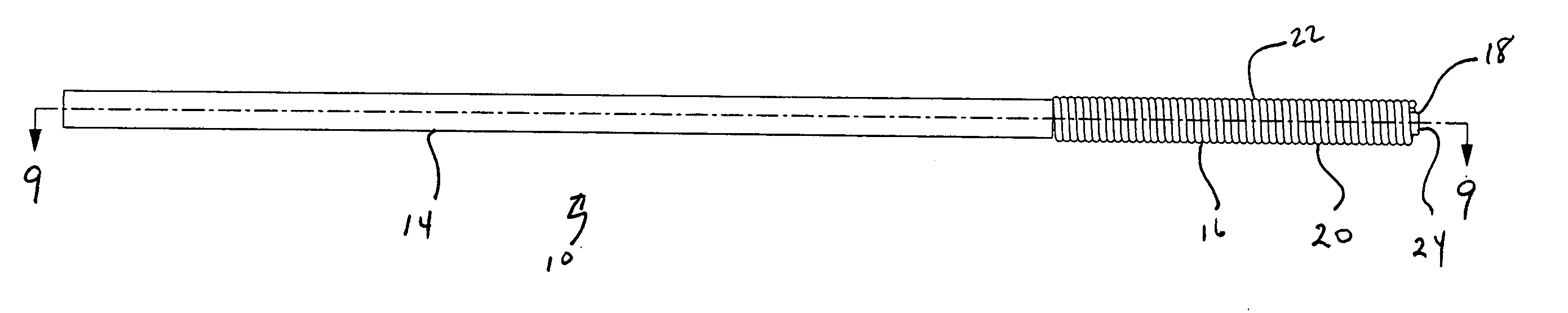

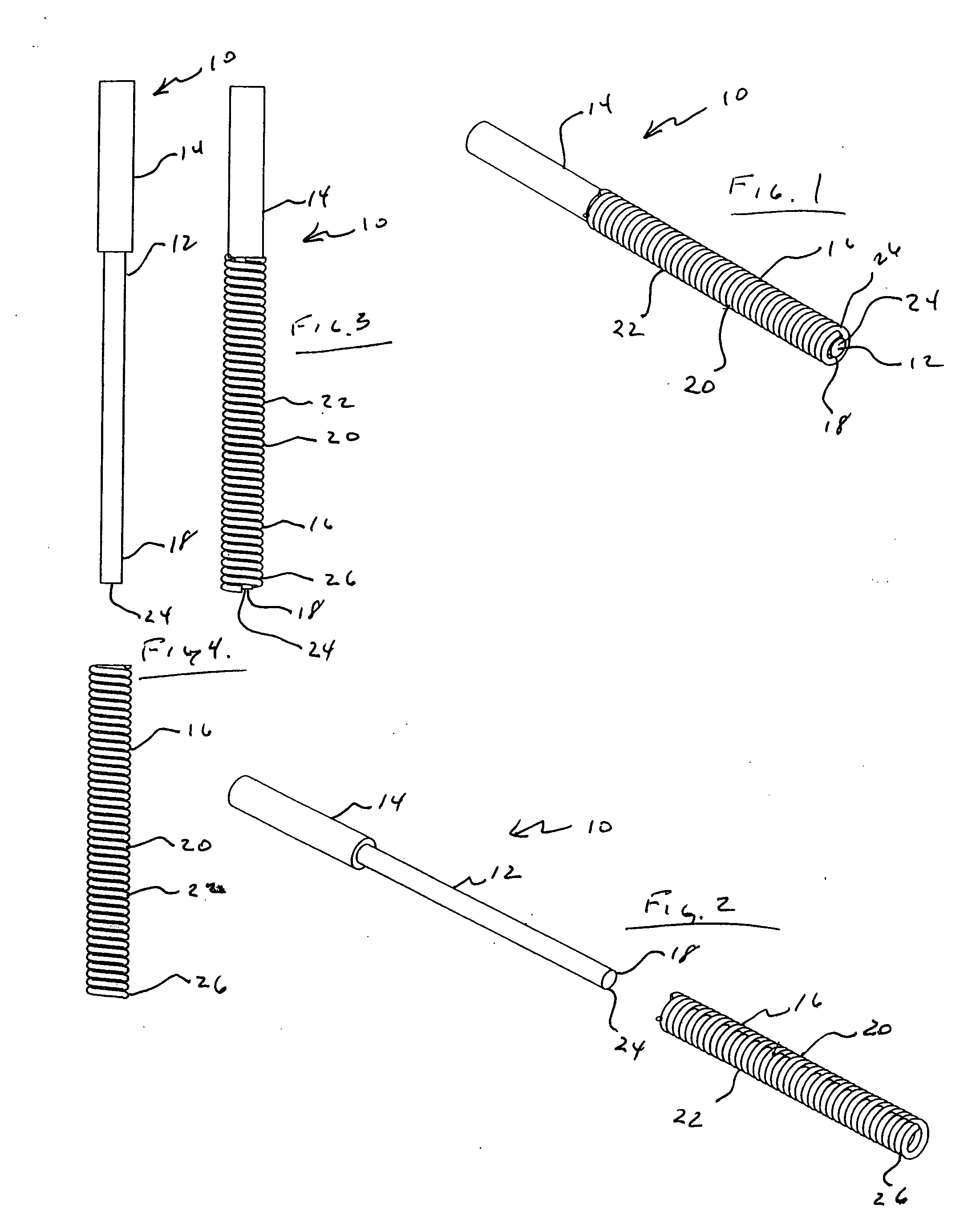

Laser fiber for endovenous therapy having a shielded distal tip

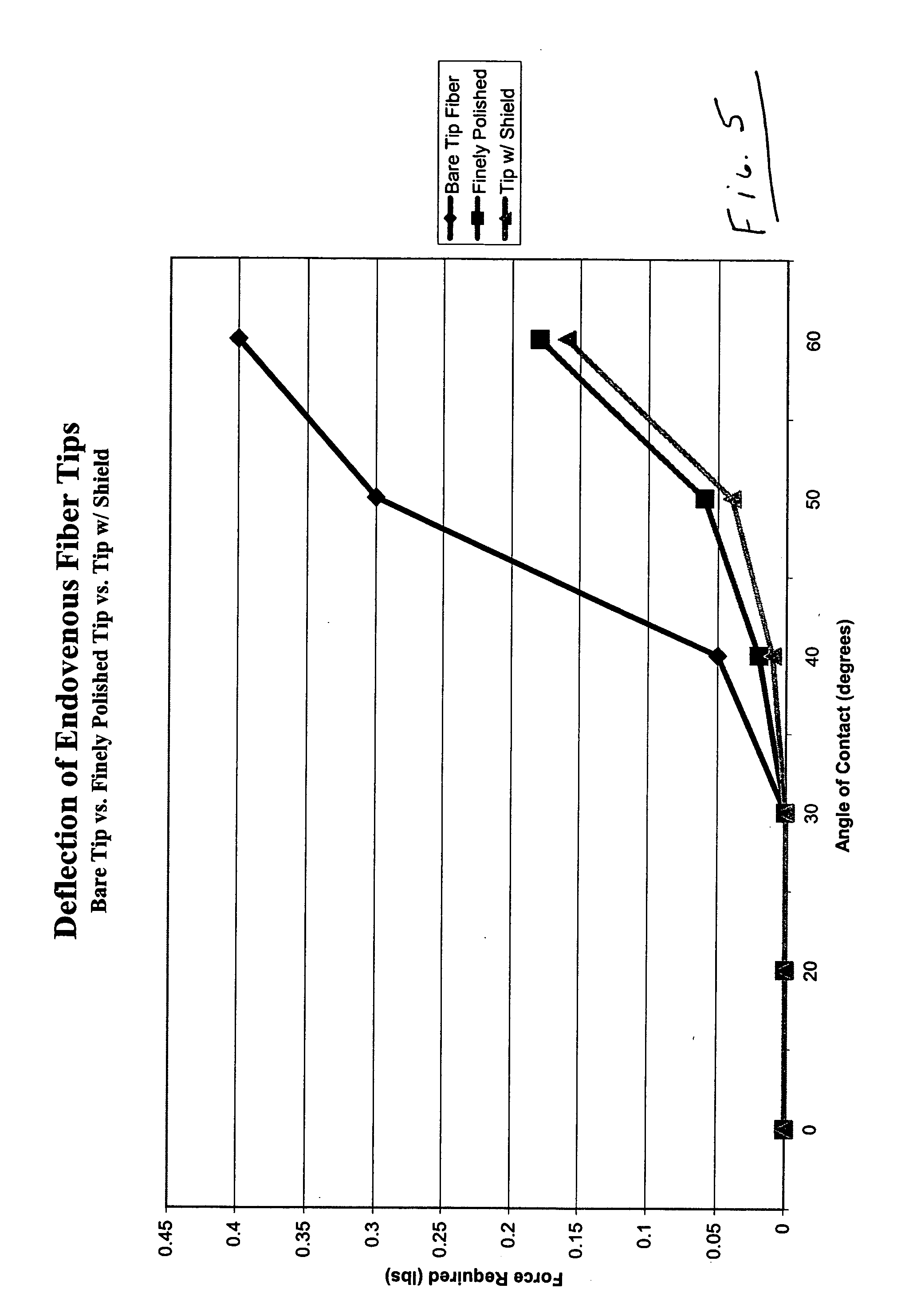

InactiveUS20070179486A1Increase awarenessReduce riskDiagnosticsSurgical instrument detailsVeinThermal break

An endovenous laser fiber optic member for endovenous laser therapy of peripheral veins of the body including a heat resistant insulative tip shield covering the distal end of the laser fiber optic. The tip shield may have echogenic qualities to increase ultrasound reflectivity. The tip shield also improves deflectability of the distal end and acts as a thermal break.

Owner:VASCULAR SOLUTIONS

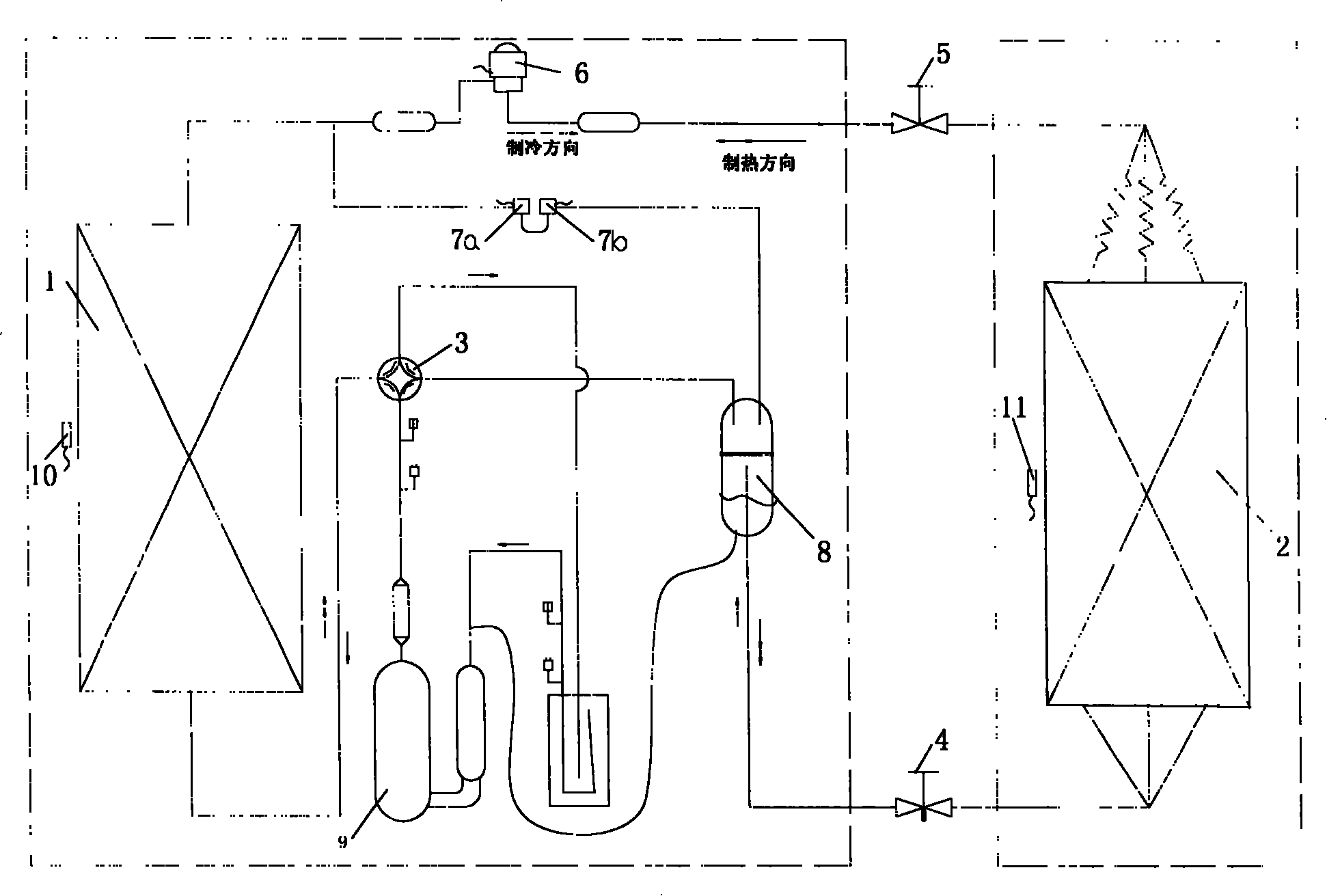

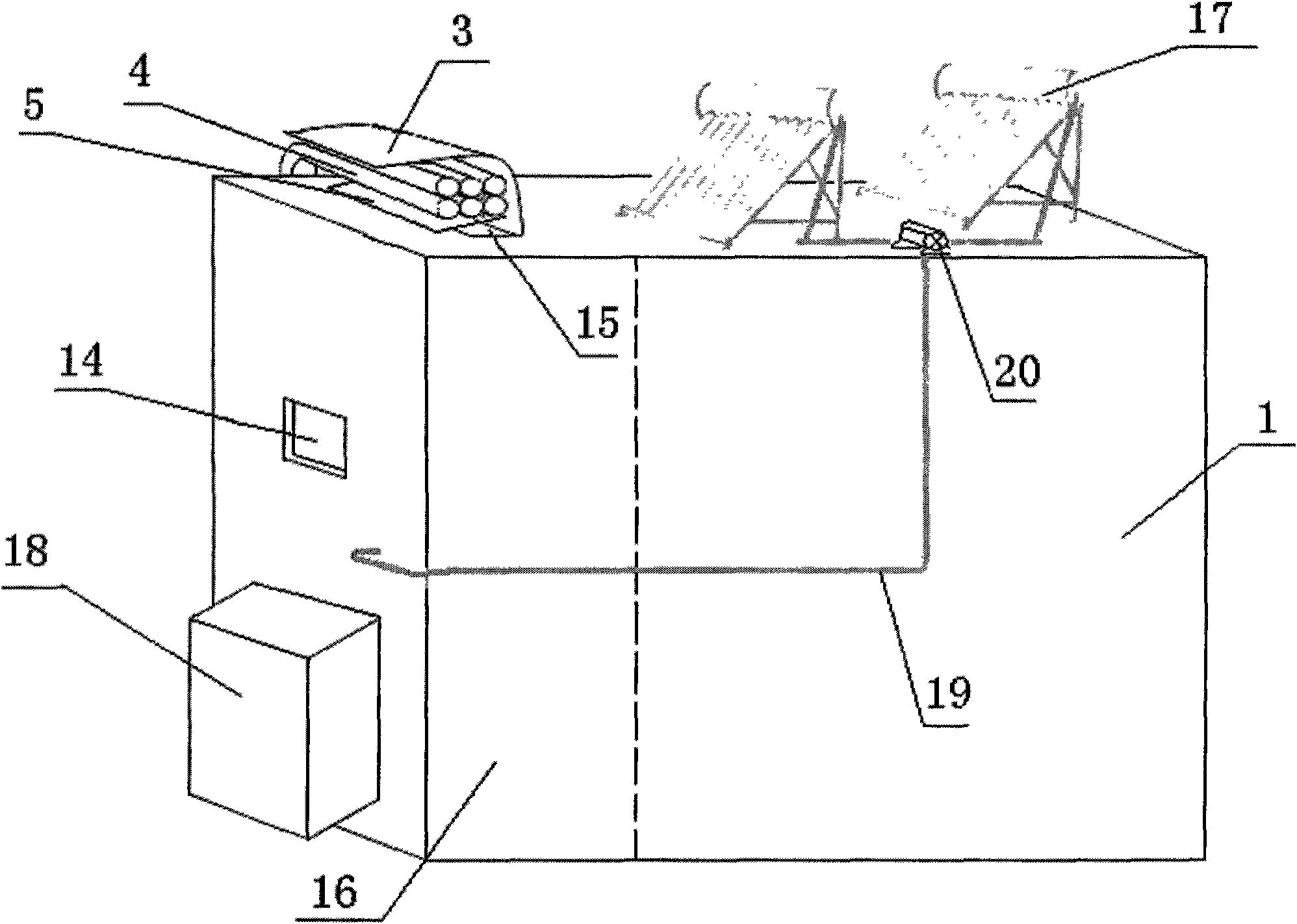

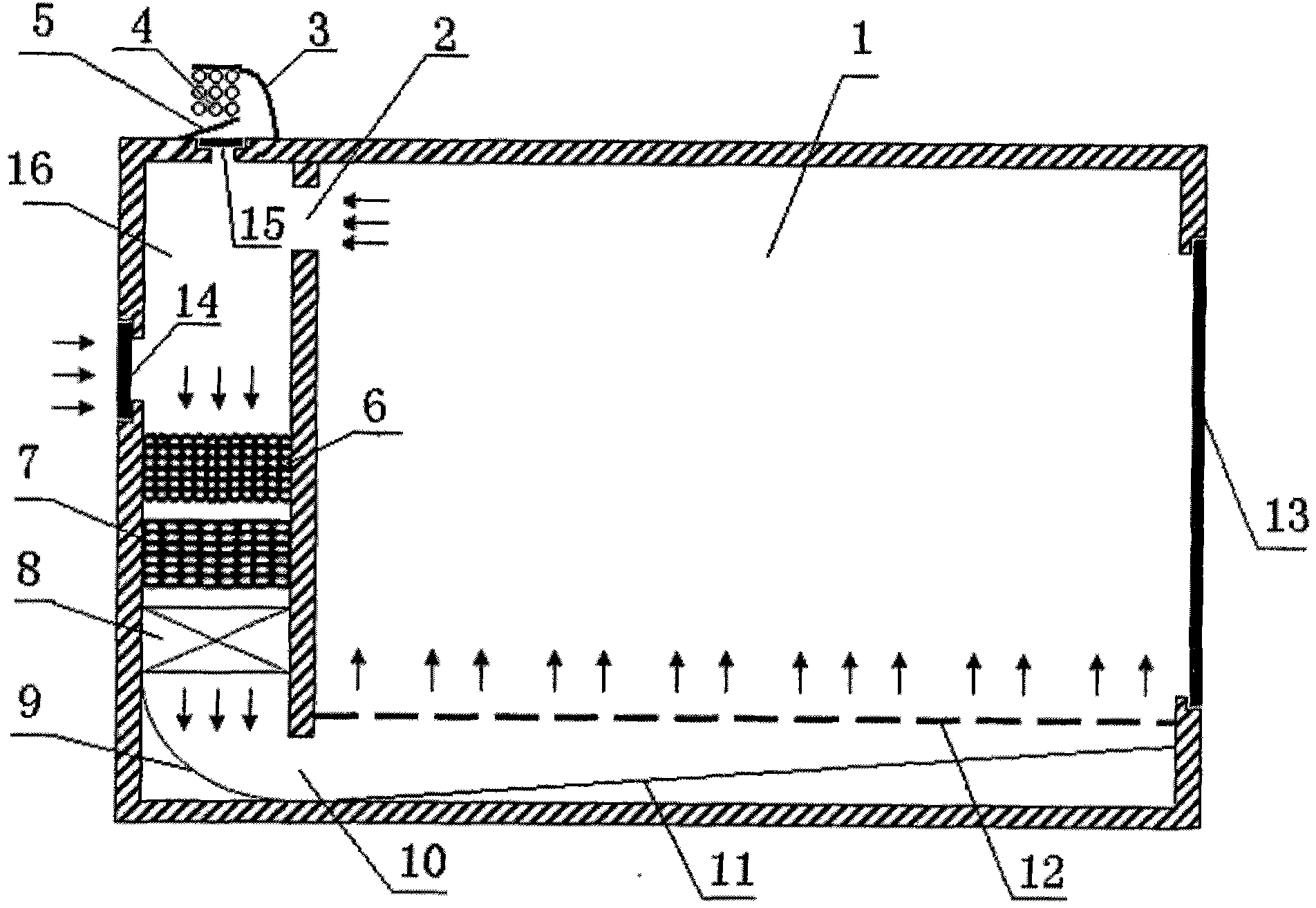

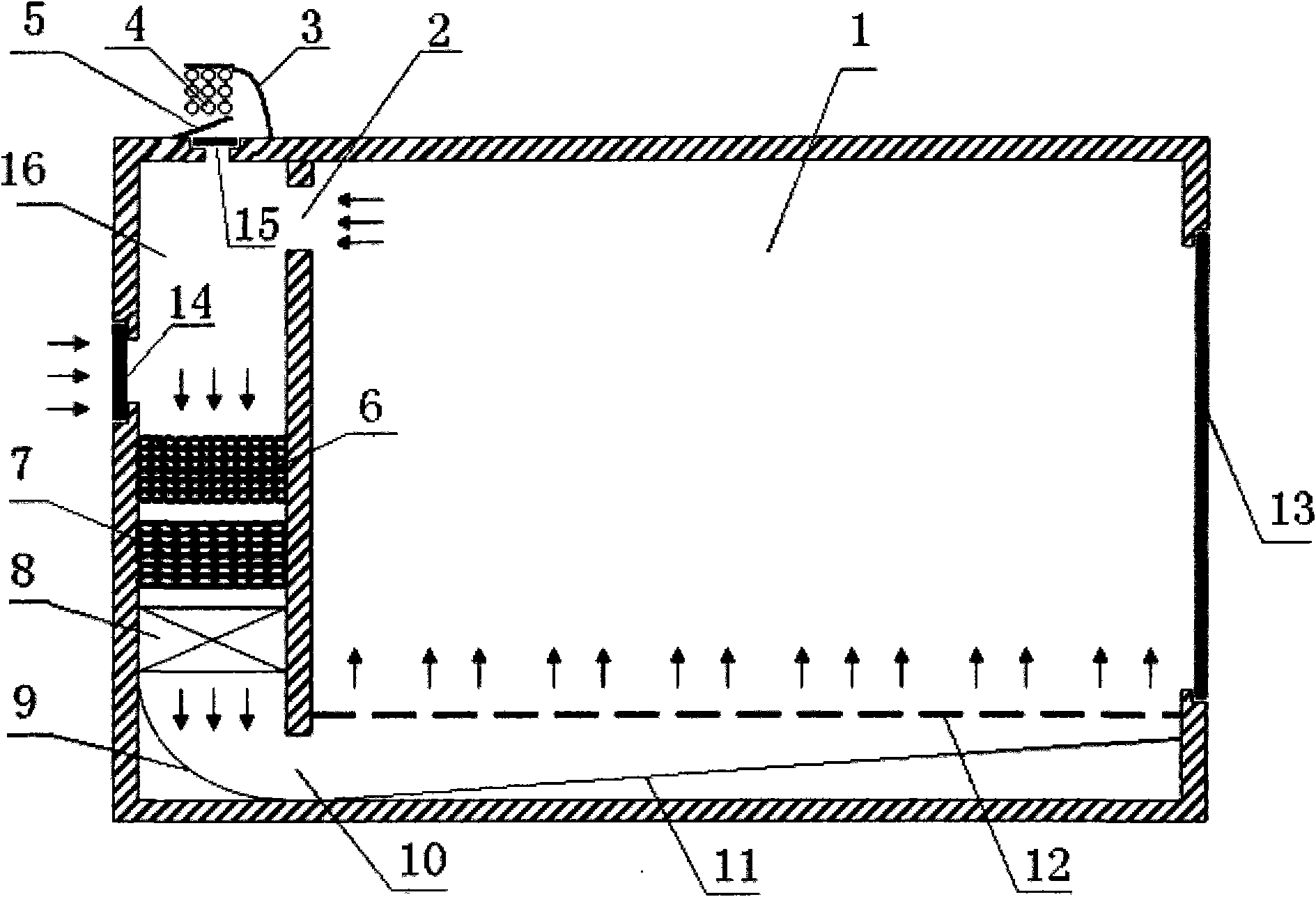

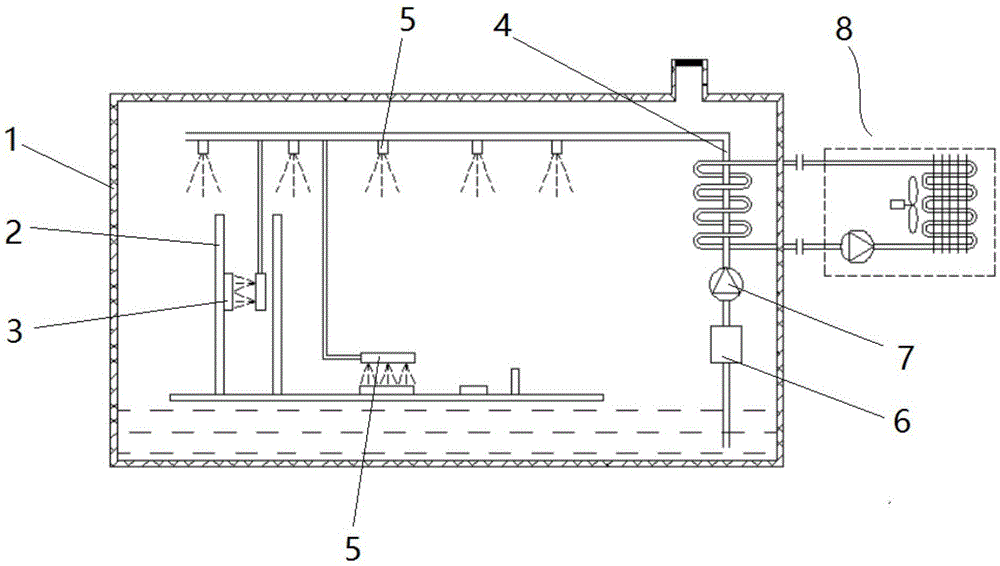

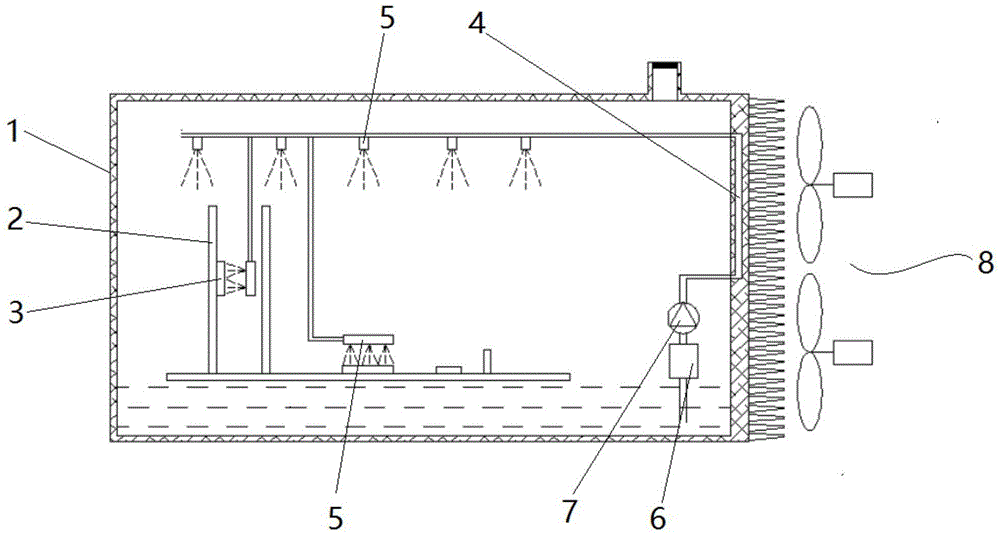

Heat pipe composite air conditioning unit for machine room and control method of heat pipe composite air conditioning unit

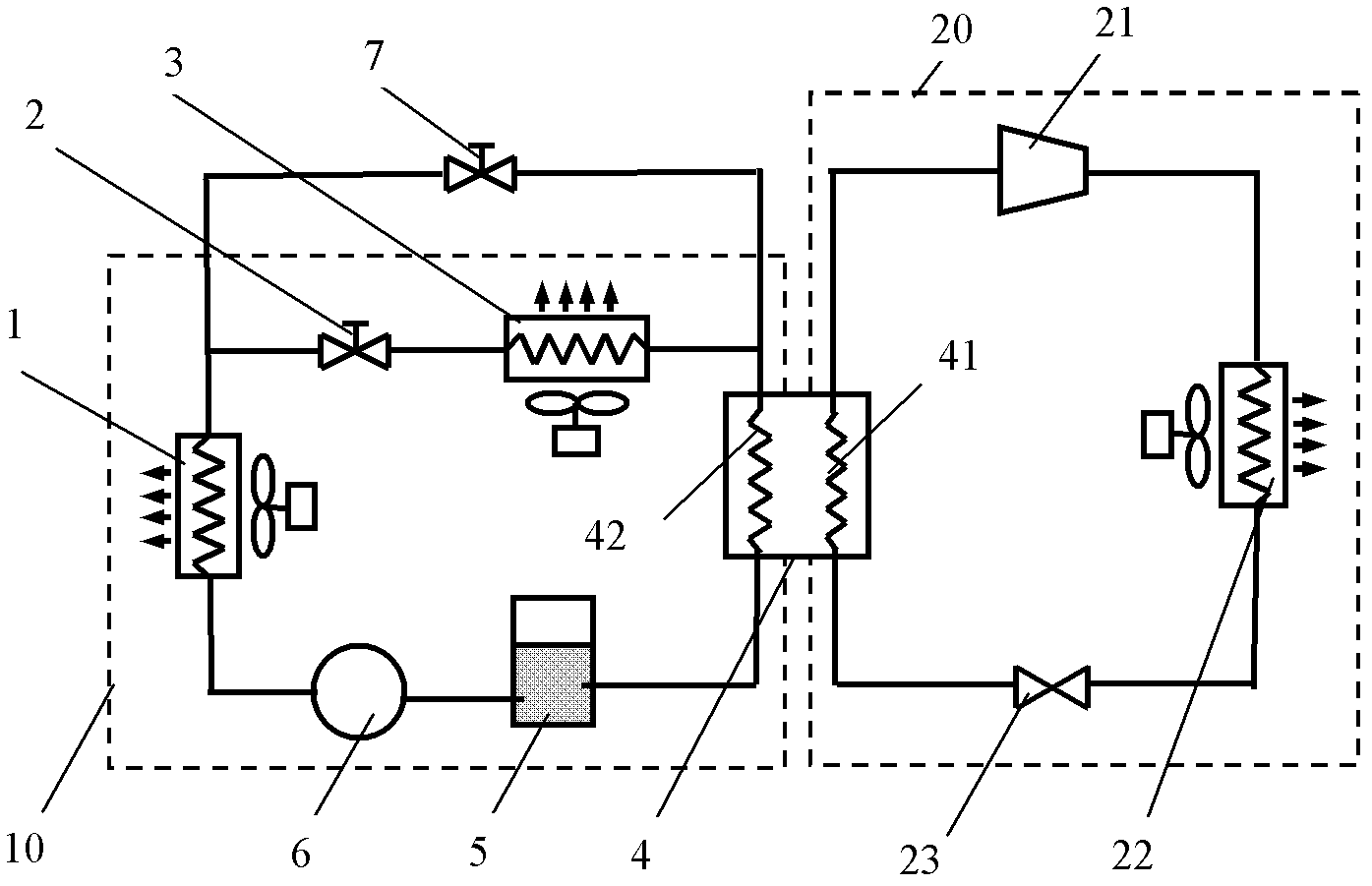

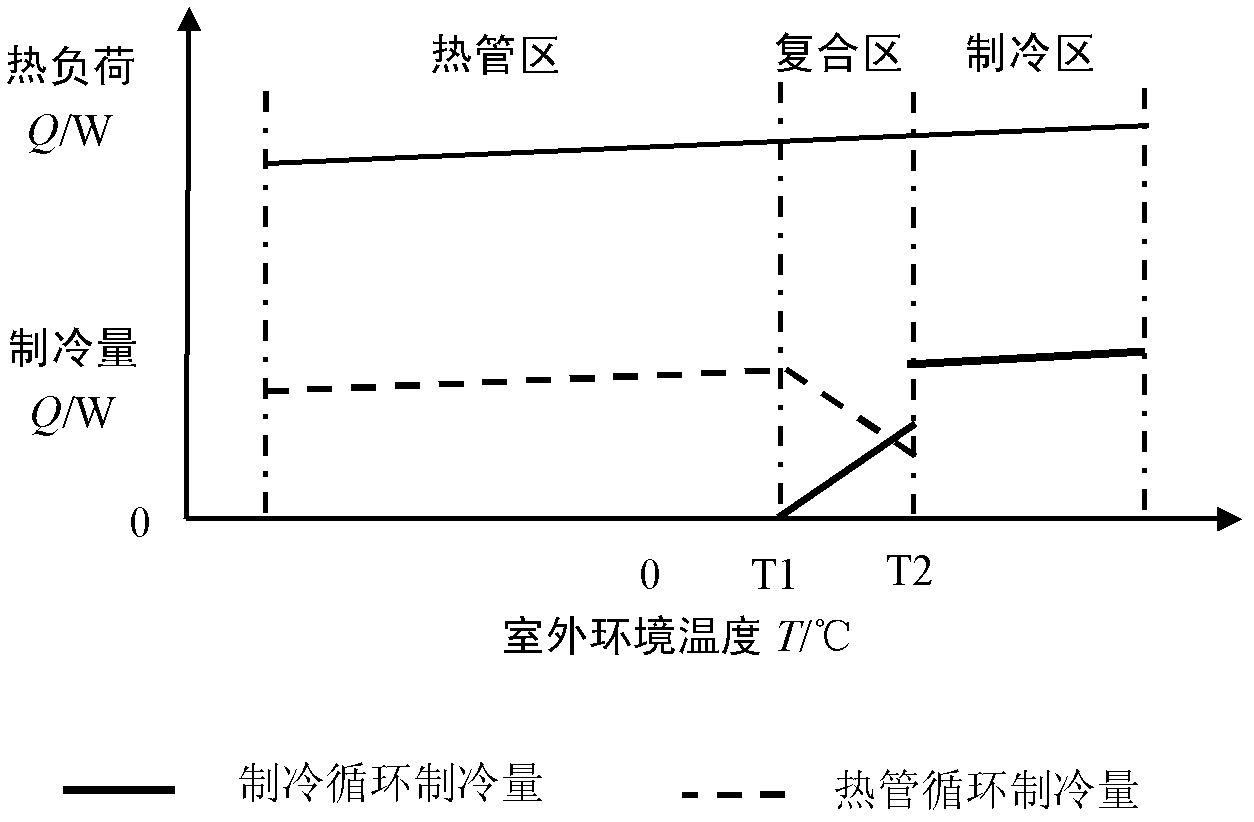

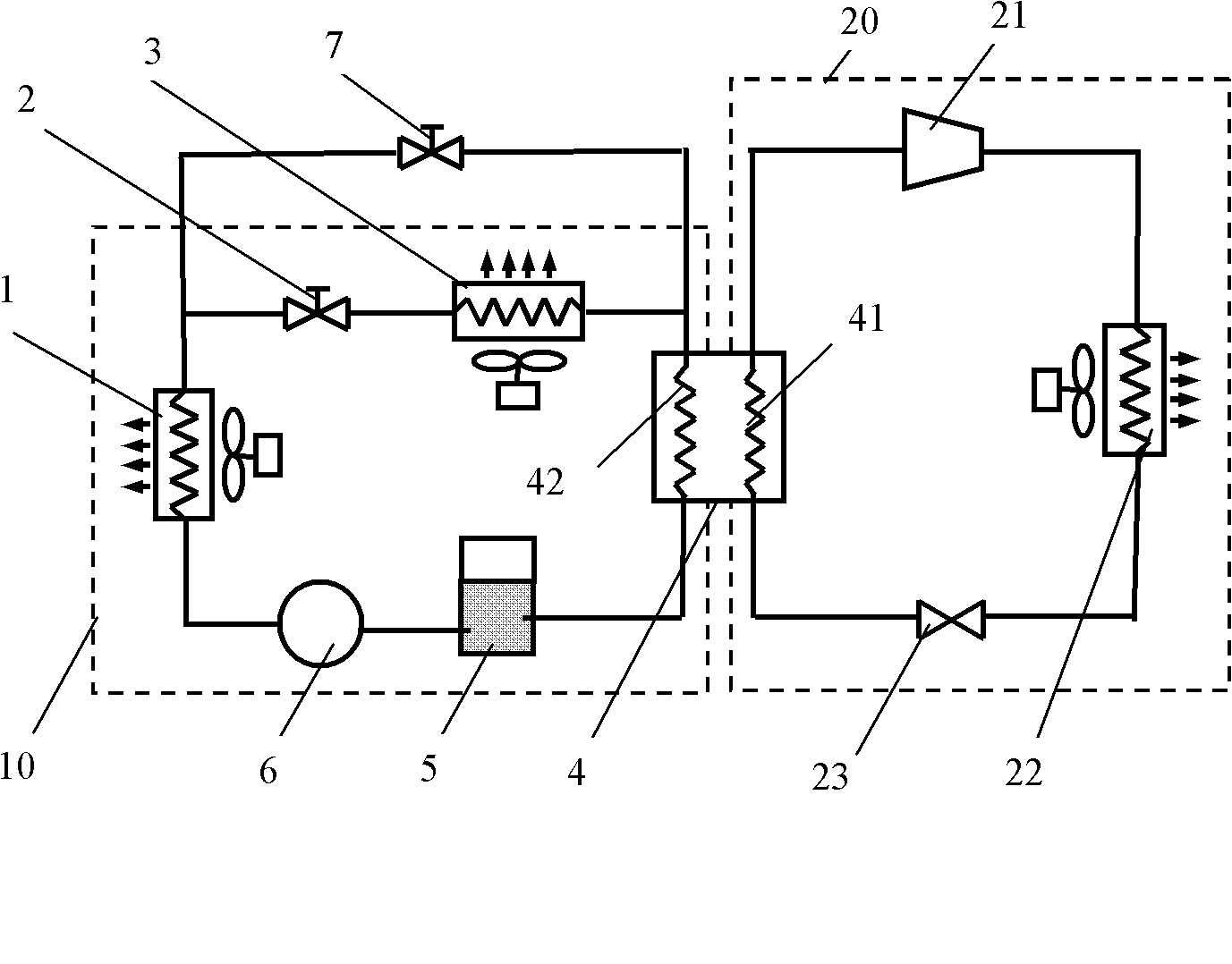

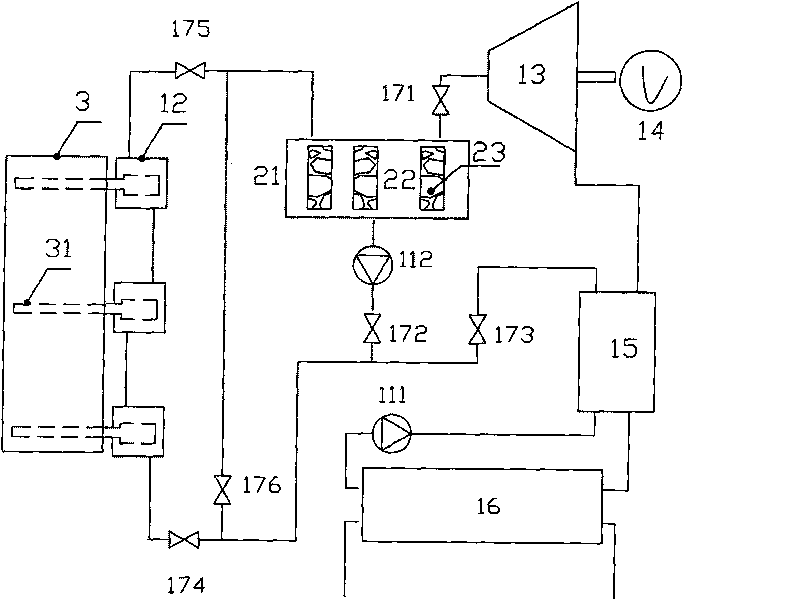

InactiveCN102538100ACompact structurePrevent intrusionSpace heating and ventilation safety systemsLighting and heating apparatusEvaporationEngineering

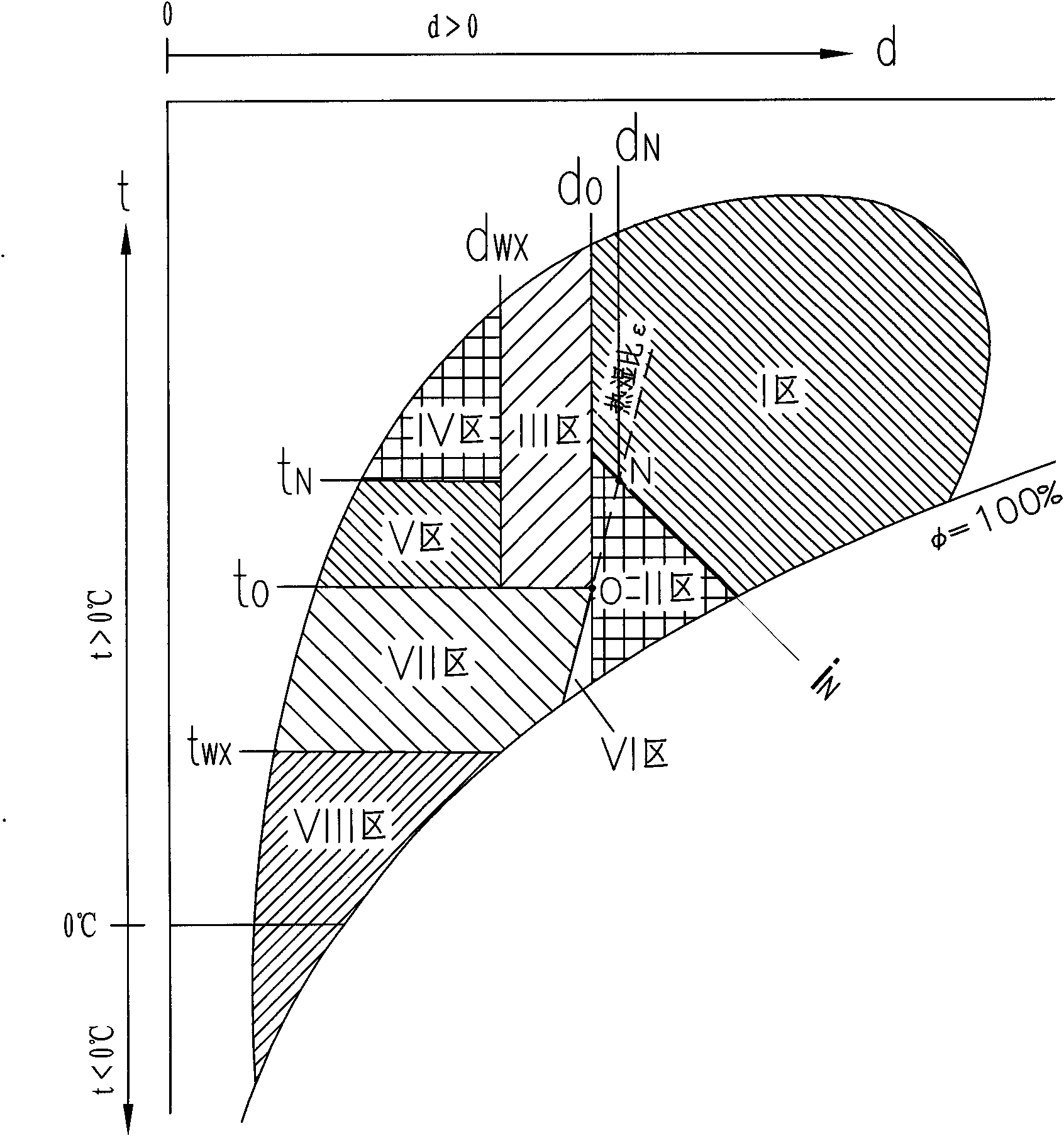

The invention discloses a heat pipe composite air conditioning unit for a machine room and a control method of the heat pipe composite air conditioning unit. The heat pipe composite air conditioning unit is characterized in that a heat pipe module and a refrigerating module are combined to form a cold source system in the air conditioning unit, the refrigerating module consists of a compression unit, a condenser, a throttling mechanism, an evaporation channel of an evaporation condenser and the like which form a first working medium circulating loop, the heat pipe module consists of an indoor heat exchanger, a main electromagnetic valve, an air-cooling heat exchanger, a condensation channel of the evaporation condenser, a liquid storage device, a liquid pump and the like which form a second working medium main loop, a bypass branch is arranged between an outlet of the indoor heat exchanger and an inlet of the condensation channel of the evaporation condenser, and a bypass electromagnetic valve is disposed in the bypass branch. A wide annular temperature zone is divided into three functional zones including a refrigerating zone, a composite zone and a heat pipe zone, and working modes of running refrigerating circulation, composite circulation and heat pipe circulation are correspondingly switched and run by the cold source system according to the different functional zones. By the aid of the heat pipe composite air conditioning unit and the control method thereof, utilization of outdoor natural cold sources can be maximized, and low-cost running and energy conservation can be realized.

Owner:HEFEI UNIV OF TECH

Evaporator

InactiveUS20050172664A1Good conditionReduce total pressure lossEvaporators/condensersStationary conduit assembliesEngineeringEvaporator

The present invention relates to an evaporator for an air conditioner of a vehicle, and the major object of the present invention is to provide the evaporator which is capable of decreasing the whole dimension of an evaporator and enhancing a heat exchange performance. To achieve the above objects, an evaporator includes an upper and lower header units comprising a tank member, a partition member, a header plate, an intermediate baffle, a finishing baffle; and a plurality of tubes comprising a front tube portion, a rear tube portion, a connection tube portion; and a wrinkle fin.

Owner:MODINE KOREA

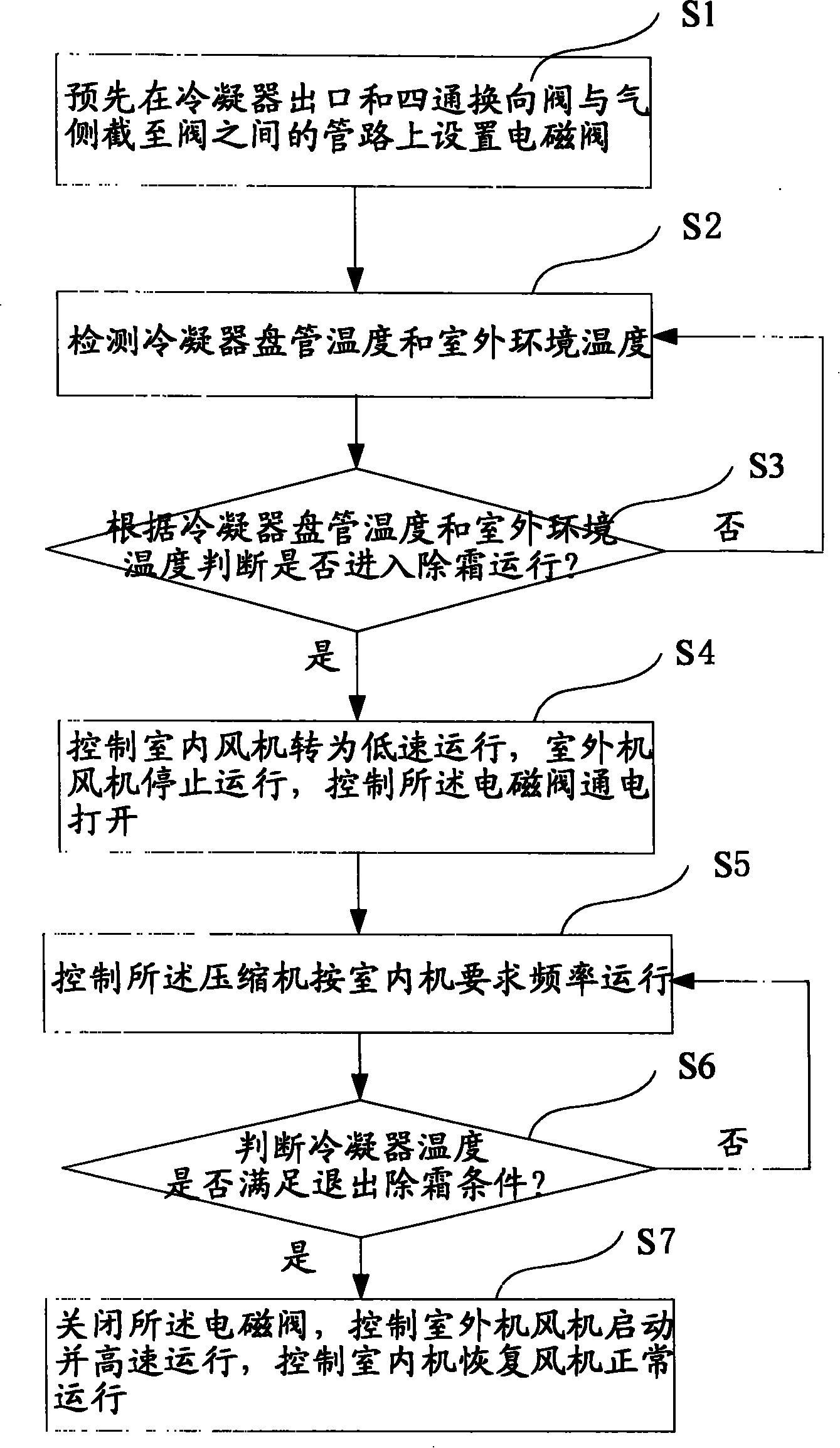

Air-conditioner defrosting method

InactiveCN101187517AGuaranteed to workImprove heat transfer effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsLow speedMagnetic valve

The invention discloses a method for air conditioner defrosting, which comprises the following steps, namely magnetic valves are provisionally arranged on an outlet of a condensator and a pipe line between a four-way change-over valve and a gas side cutoff valve, the temperature of a coil pipe of the condensator and the temperature of outdoor environment are detected, a defrost operation is judged to be operated or not according to the temperature of the coil pipe of the condensator and the outdoor environment, when in defrosting operation, an indoor draught fan is controlled to operate in a lower speed, and an outdoor draught fan is stopped operating, the magnetic valve is energized to open, the compressor is controlled to operate according to a required frequency of an indoor set, and then the temperature of the condensator is judged to detect whether the temperature is satisfied for the condition of defrosting withdrawal. The magnetic valve is closed after defrosting is existed, and the outdoor draught fun is controlled to start and operate in high speed, and the indoor draught fan is controlled to recover to a normal operation. The invention provides a method for air conditioner defrosting, which solves the problem that a current air condition needs to be transferred to a refrigerating condition in the process of defrosting, and refrigerating effect of the air conditioner is not good.

Owner:HAIER GRP CORP +1

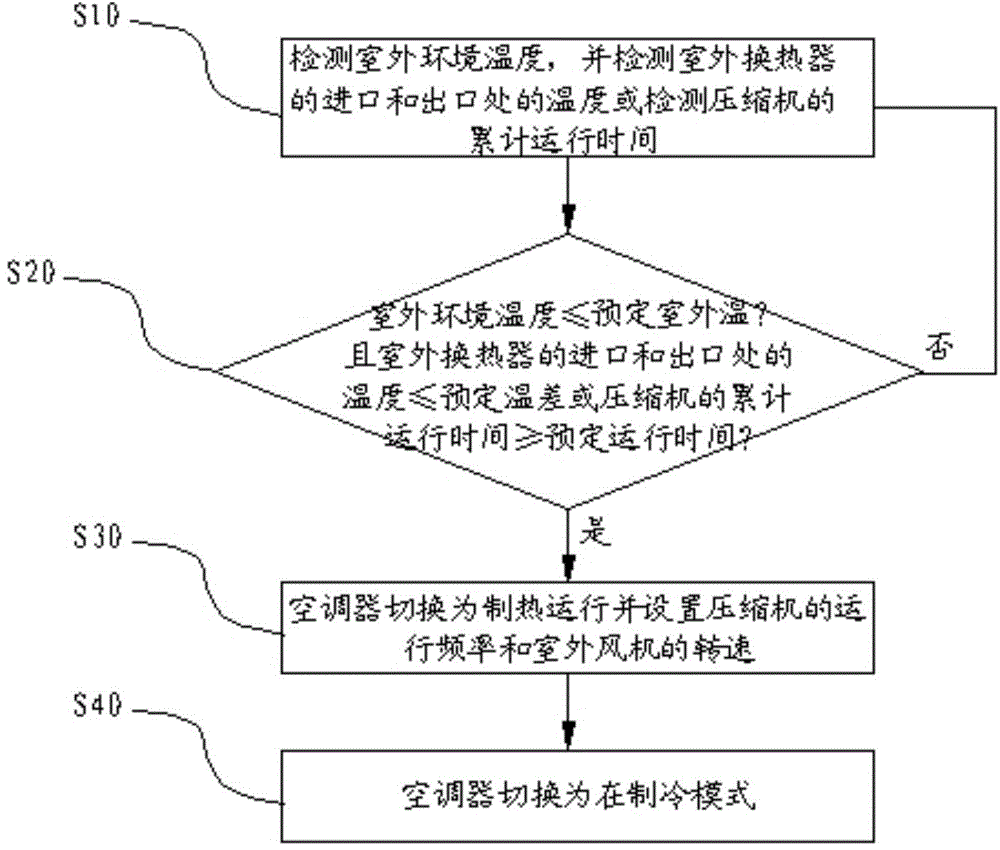

Self-cleaning control method for air conditioners

ActiveCN104949261AImprove heat transfer effectReduce dust accumulationMechanical apparatusSpace heating and ventilation safety systemsFrostTemperature difference

The invention discloses a self-cleaning control method for air conditioners. The self-cleaning control method includes enabling the air conditioners to detect outdoor environmental temperatures, detecting the temperatures of inlets and outlets of outdoor heat exchangers or detecting the cumulative run time of compressors; enabling the air conditioners to carry out heating running to allow frost to condense on the outdoor heat exchangers when the outdoor environmental temperatures are lower than or equal to preset outdoor temperatures and temperature difference between the inlets and the outlets of the outdoor heat exchangers is lower than or equal to preset temperature difference or the cumulative run time of the compressors is longer than or equal to preset run time; switching the air conditioners into a refrigerating mode. The self-cleaning control method for the air conditioners has the advantages that the air conditioners carry out heating running to allow the frost to condense on the outdoor heat exchangers and then are switched into the refrigerating mode to defrost the outdoor heat exchangers, accordingly, dust accumulated on the outdoor heat exchangers can be cleaned by condensed water generated after the outdoor heat exchangers are defrosted and can be effectively reduced, heat exchange effects of the air conditioners can be effectively improved, and energy consumption can be reduced.

Owner:MIDEA GRP CO LTD

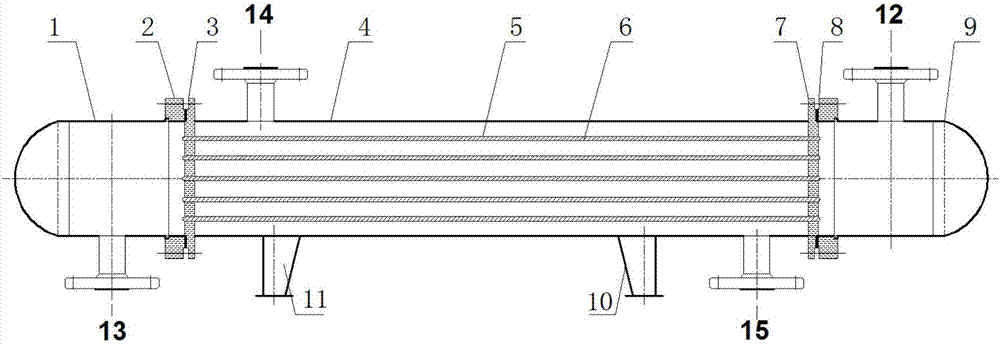

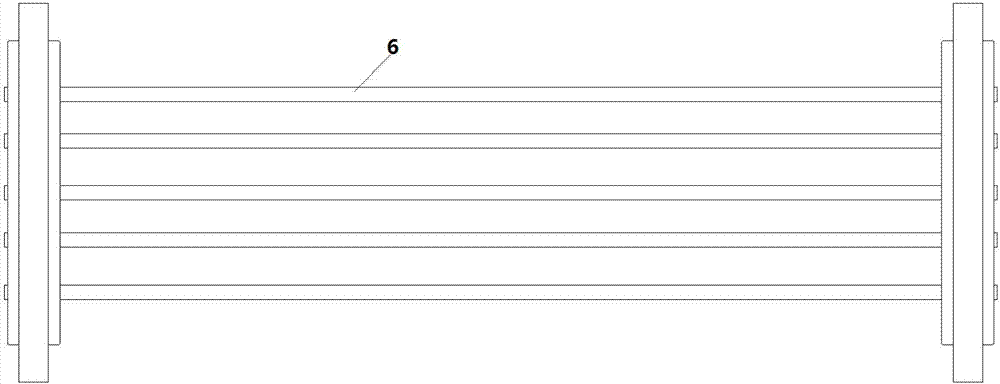

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

Hot air drying system heated by double energy sources

InactiveCN101936644AIncrease the heat exchange areaReduce deliveryTobacco preparationDrying solid materials with heatPlate heat exchangerBusiness efficiency

The invention discloses a hot air drying system heated by double energy sources, which comprises a heating chamber with a fresh air opening, a drying chamber, a solar heating device, an air source heat pump and a condenser fan of the air source heat pump, wherein the upper part of the heating chamber or the drying chamber is provided with a dehumidifying opening; a condenser and the condenser fan of the air source heat pump are arranged in the heating chamber; a hot water heat exchanger of the solar heating device is arranged at the front end of an air inlet of the condenser in the heating chamber; the condenser fan supplies air in an induced draft way; the ratio of the heat exchange area of the condenser to the input power of a compressor is 5.3 to 11 m<2> / kw; the ratio of the heat exchange area of the hot water heat exchanger to the input power of the compressor is not less than 1.5 m<2> / kw; and the total pressure of the condenser fan is 100 to 400 Pa. The hot air drying system heated by the double energy sources makes full use of solar energy as a hot air heat source for drying, solves the problems of the independent use of the solar energy, achieves high energy efficiency ratio by adopting the air heat pump as the hot air heat source, is energy-saving, environmentally-friendly and low in running cost, and manifests the advantages of the combined use of the air source and the solar energy in oven-drying.

Owner:湖南省浏阳市择明热工器材有限公司

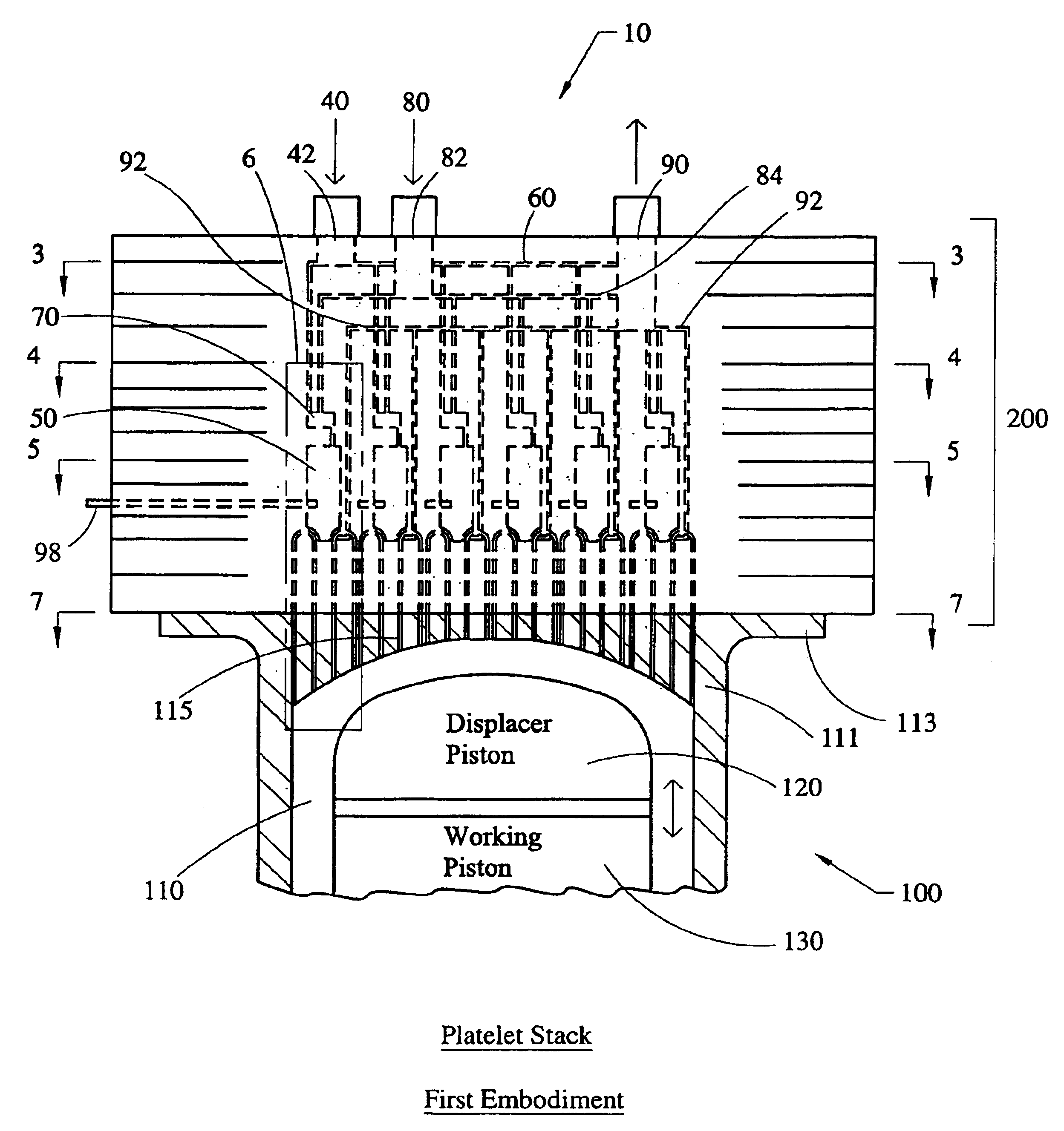

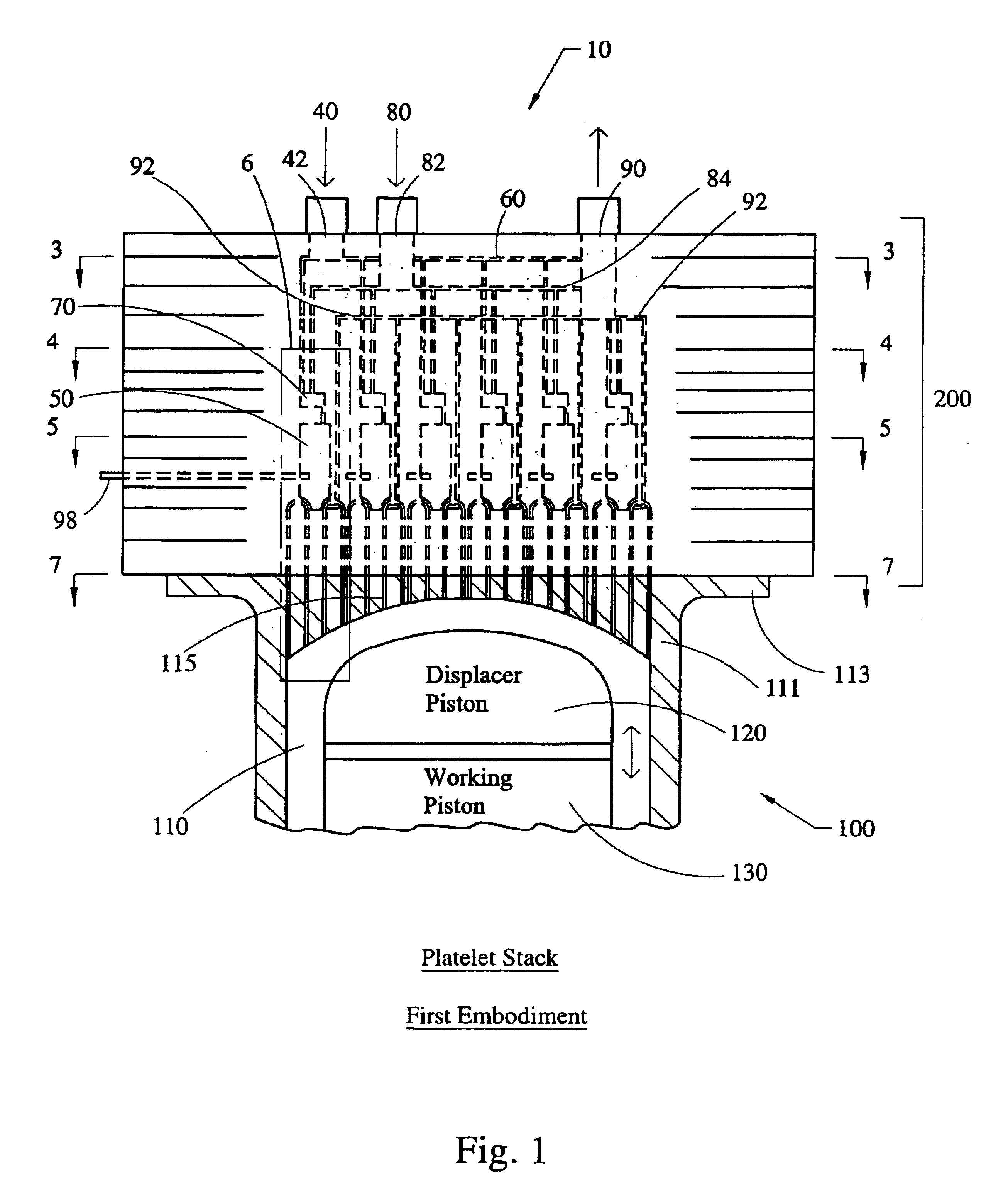

Stirling engine having platelet heat exchanging elements

InactiveUS6931848B2Guaranteed uptimeEfficient heat transferSolar heating energySolar heat devicesEngineeringStaged combustion

The present invention provides heat exchanging elements for use in Stirling engines. According to the present invention, the heat exchanging elements are made from muliple platelets that are stacked and joined together. The use of platelets to make heat exchanging elements permits Stirling engines to run more effiecient because the heat transfer and combustion processes are improved. In one embodiment, multi-stage combustion can be introduced with platlets, along with the flexibility to use different types of fuels. In another embodiment, a single component constructed from platelets can provide the heat transfer rquirements betweeen the combustion gas / working gas, working gas in the regenerator and the working gas / coolant fluid of a Stirling engine. In another embodiment, the platelet heat exchanging element can recieve solar energy to heat the Stirling engine's working gas. Also, this invention provides a heat exchanging method that allows for multiple fluids to flow in opposing or same direction.

Owner:DISENCO +1

Heat spreaders with vias

InactiveUS20070102142A1Improve heat transfer performanceLow costSemiconductor/solid-state device detailsPrinted circuit aspectsGraphiteHeat spreader

Constructions for and methods of manufacturing graphite heat spreaders having thermal vias placed therethrough are provided. Thermal vias having one or two flanges are disclosed, as are flush thermal vias. Graphite heat spreaders having surface layers covering the graphite material are provided. Graphite heat spreaders having a layer of cladding for increased structural integrity are provided. Also disclosed are methods of co-forging a graphite heat spreader element with a metal thermal via in place therein.

Owner:NEOGRAF SOLUTIONS LLC

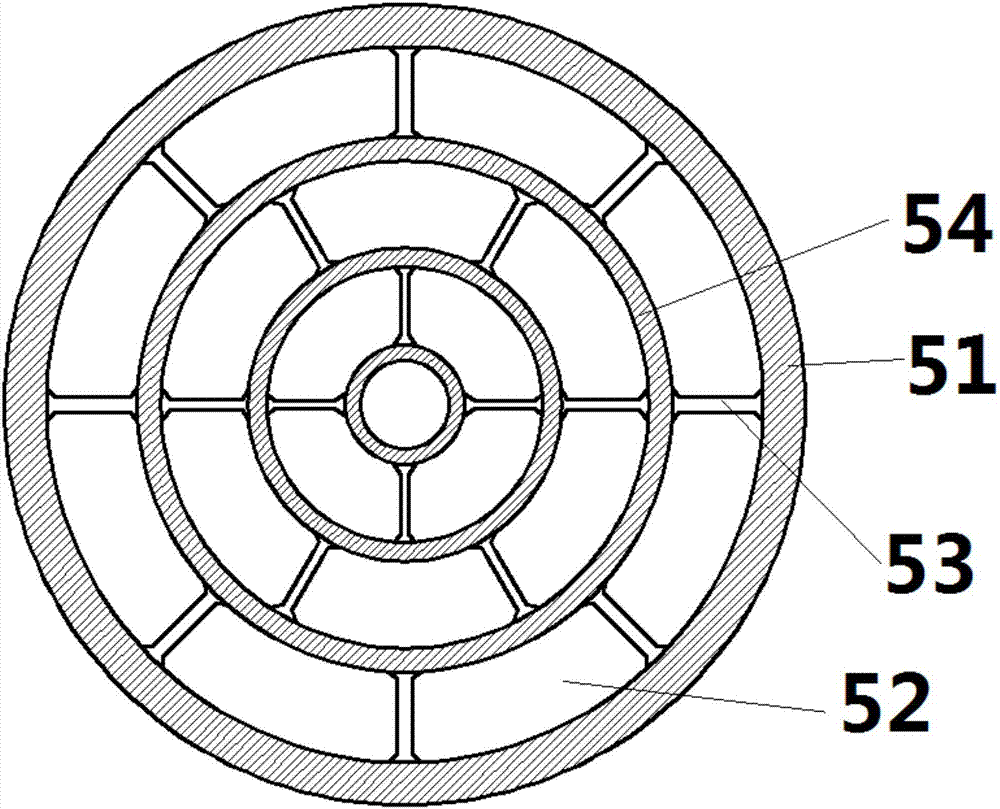

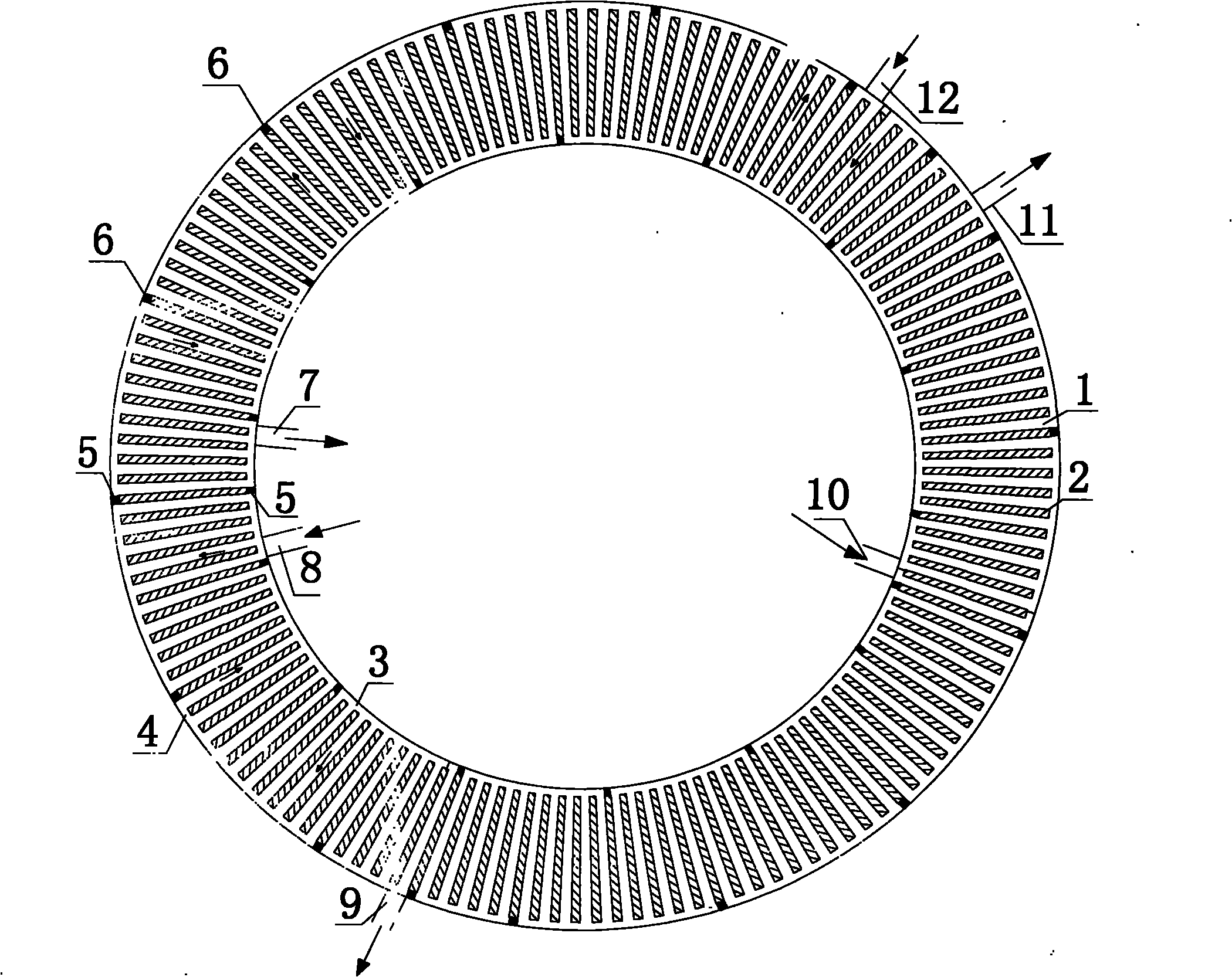

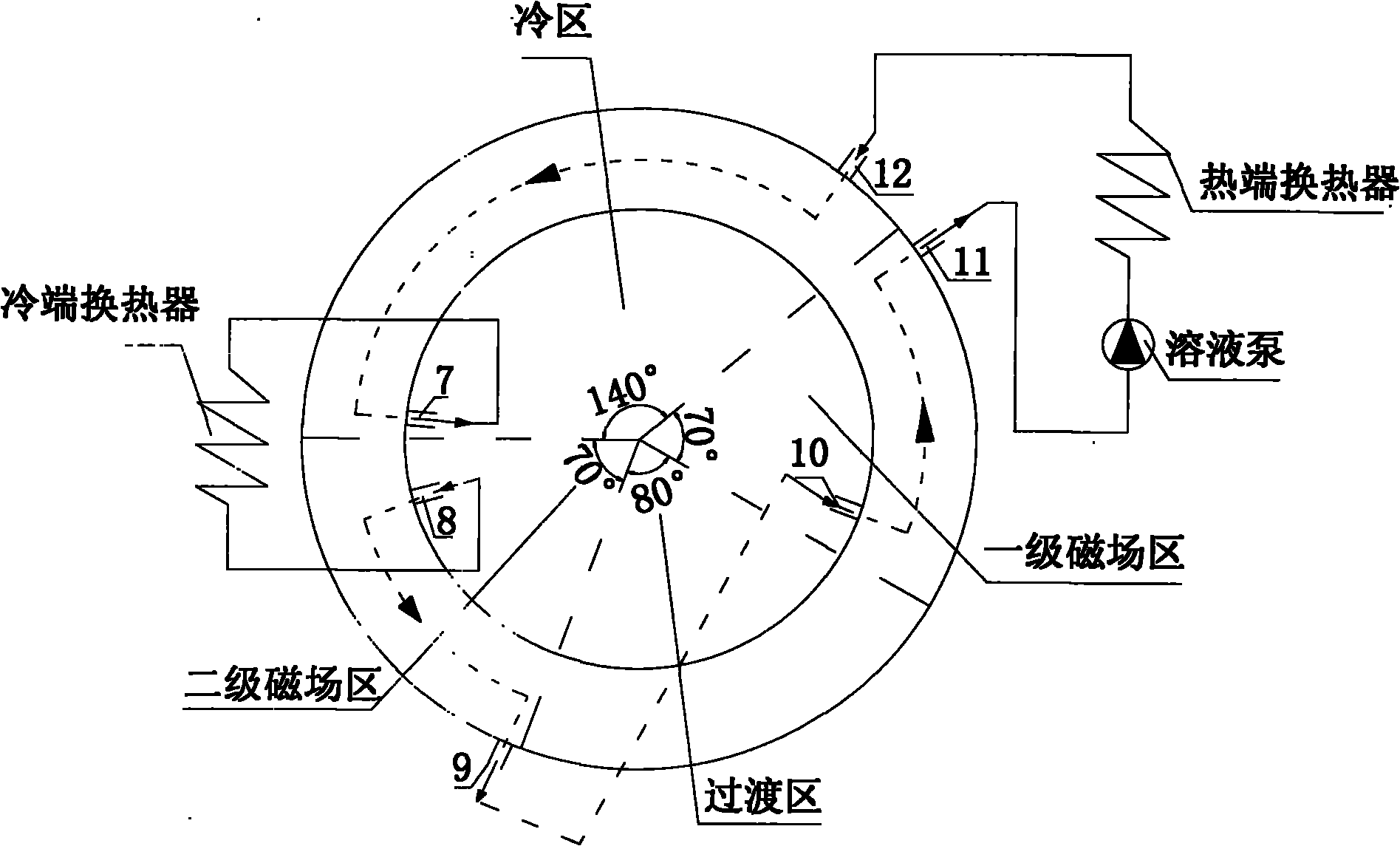

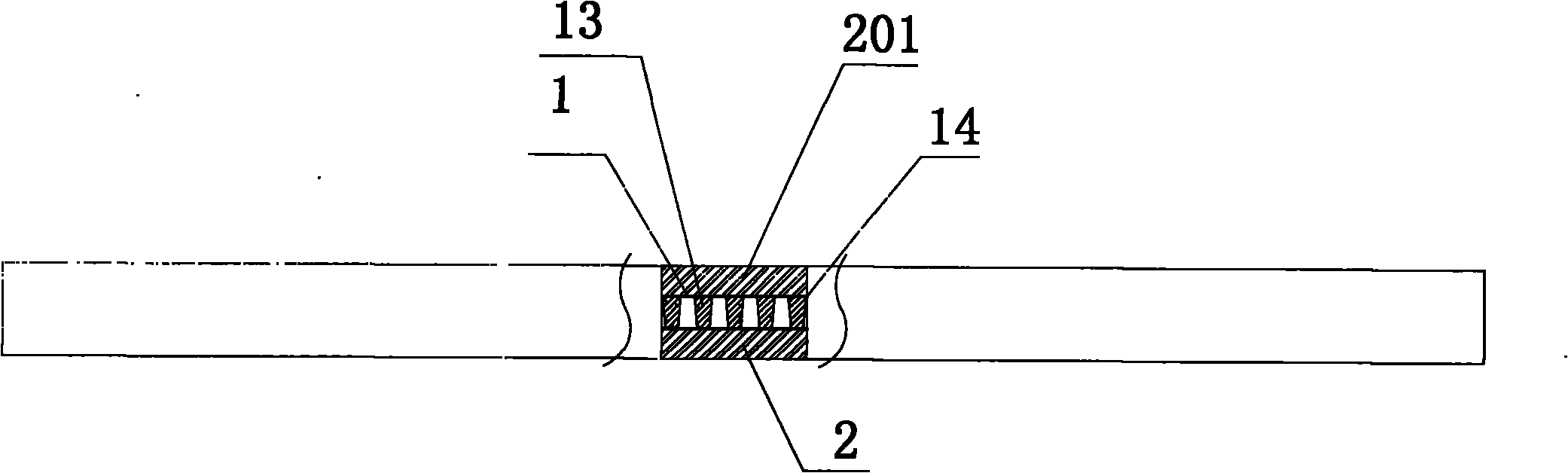

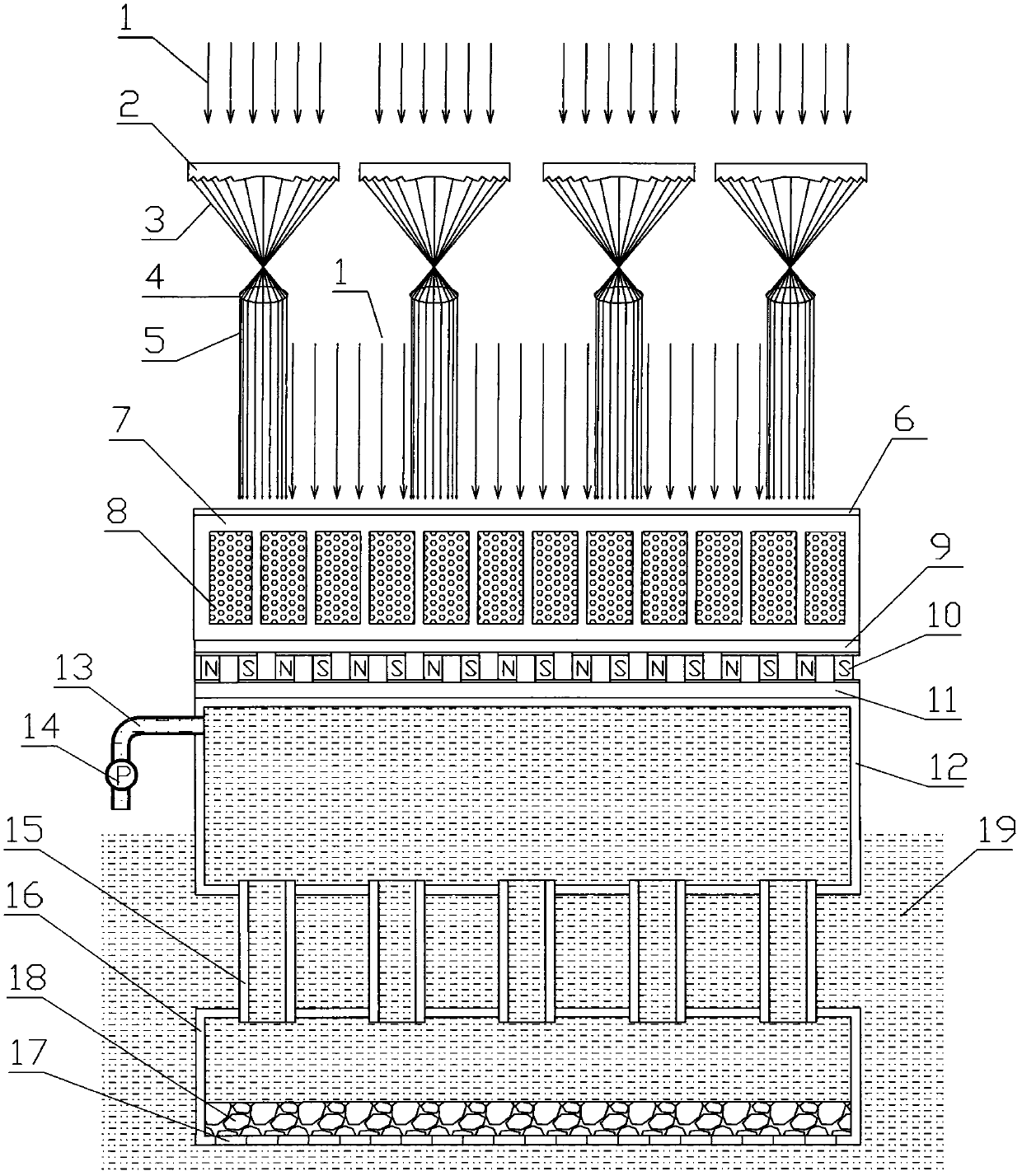

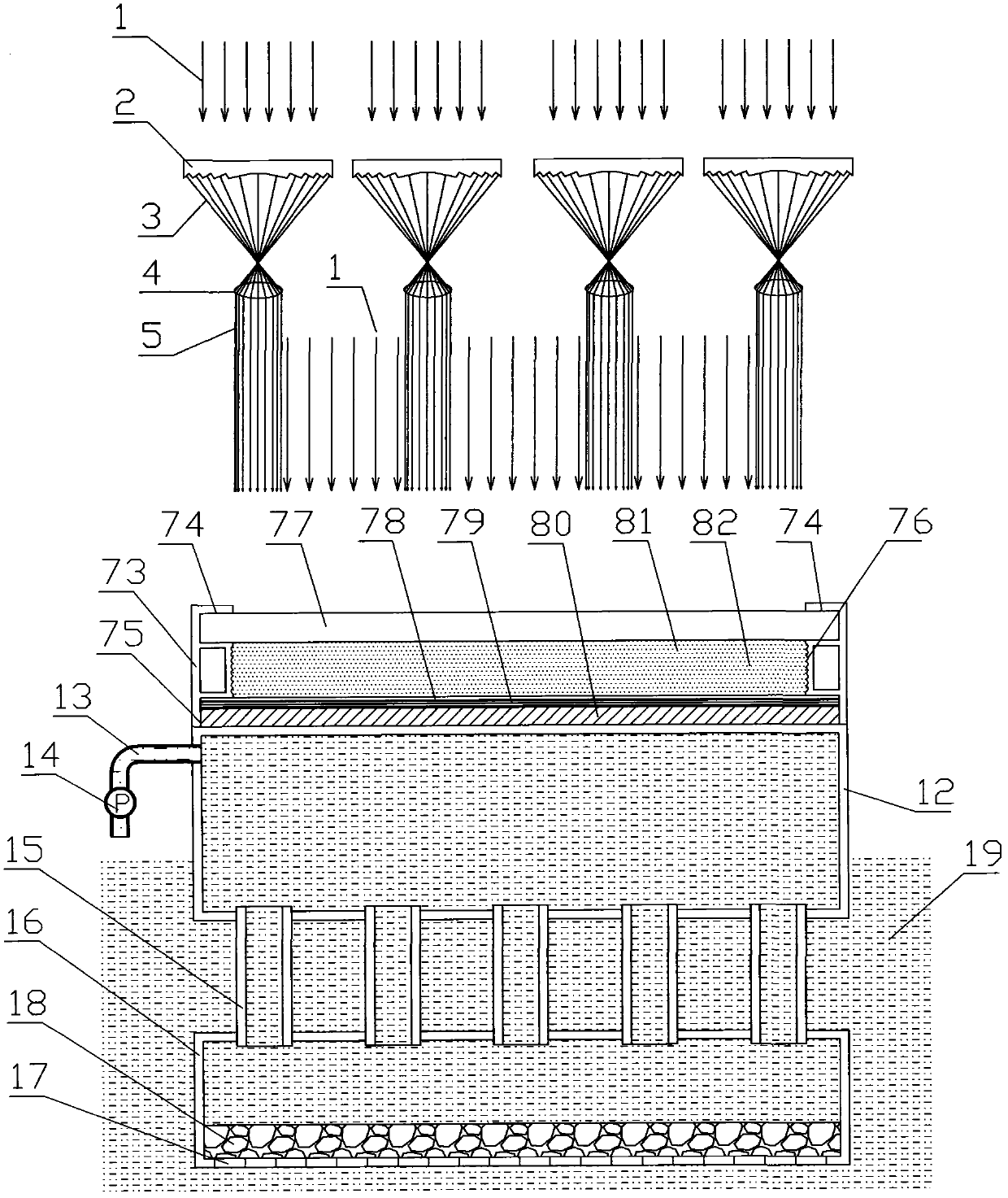

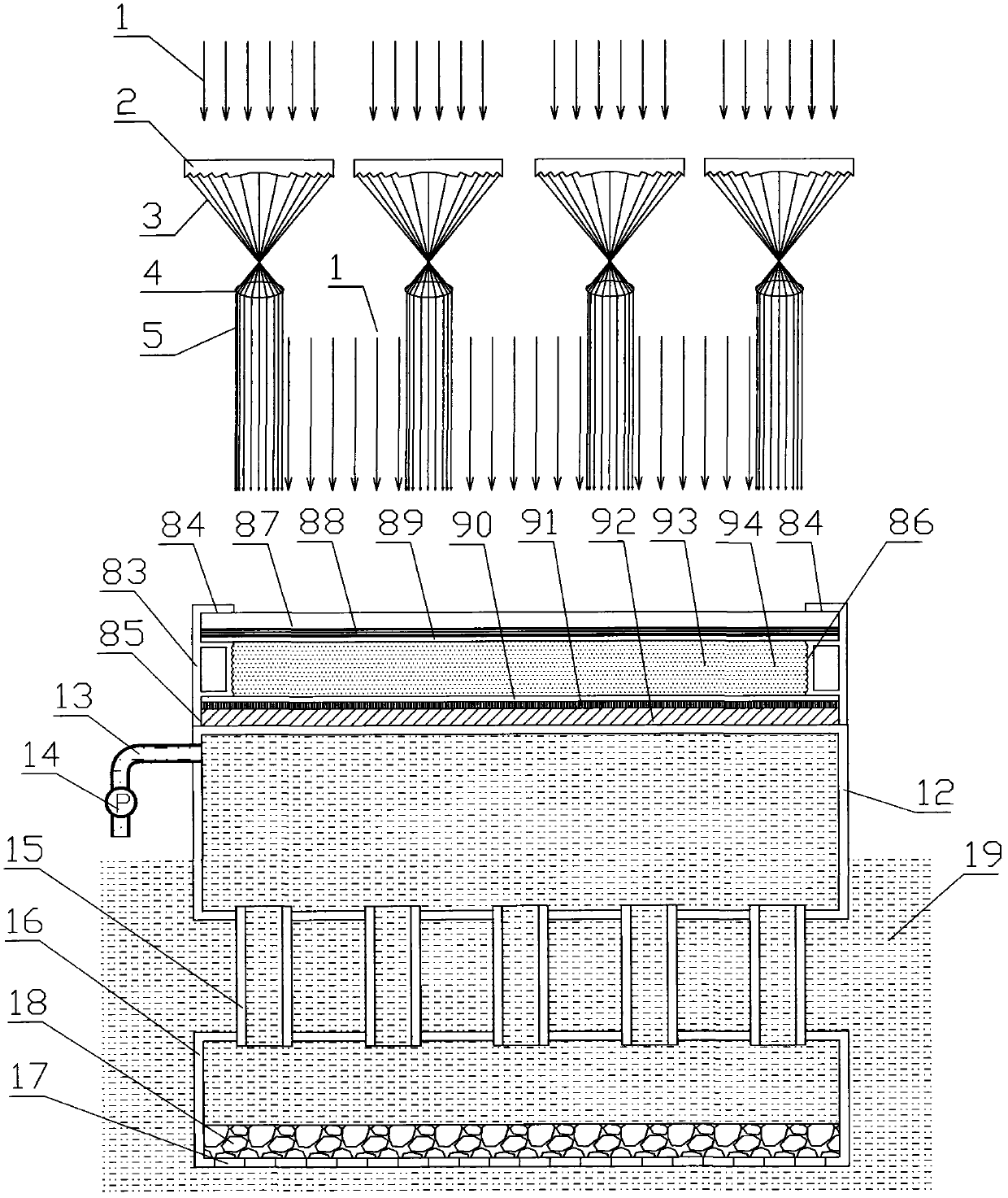

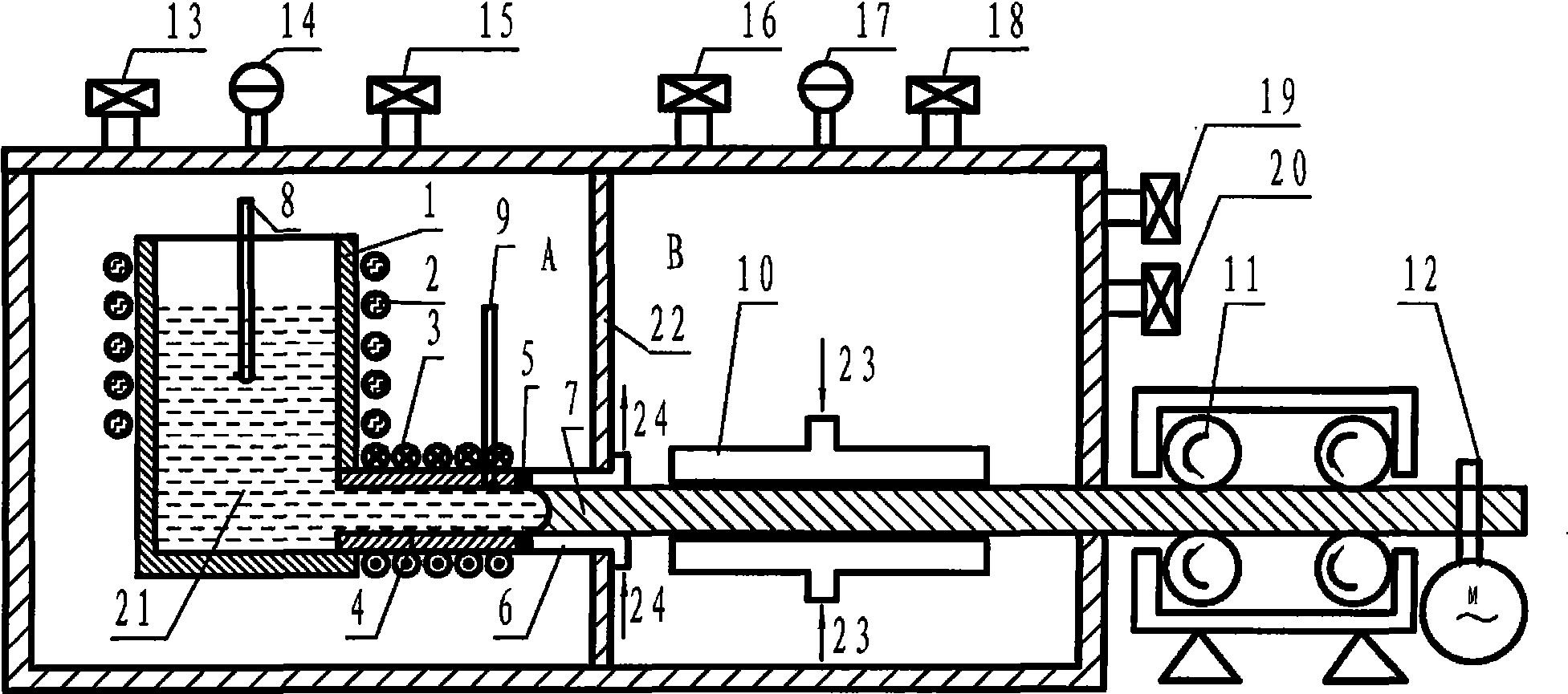

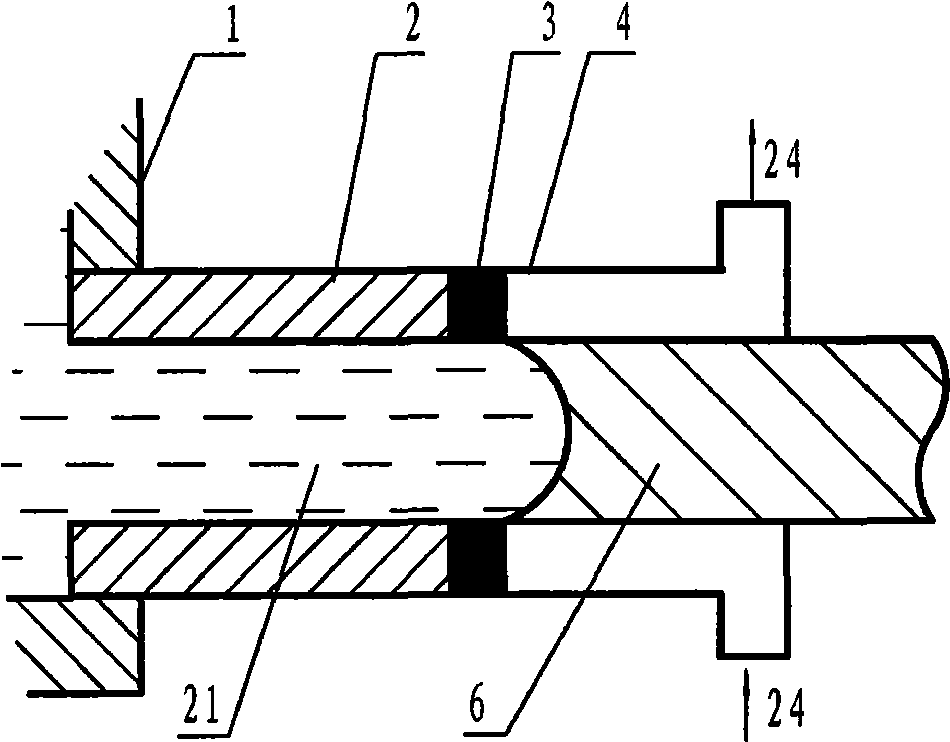

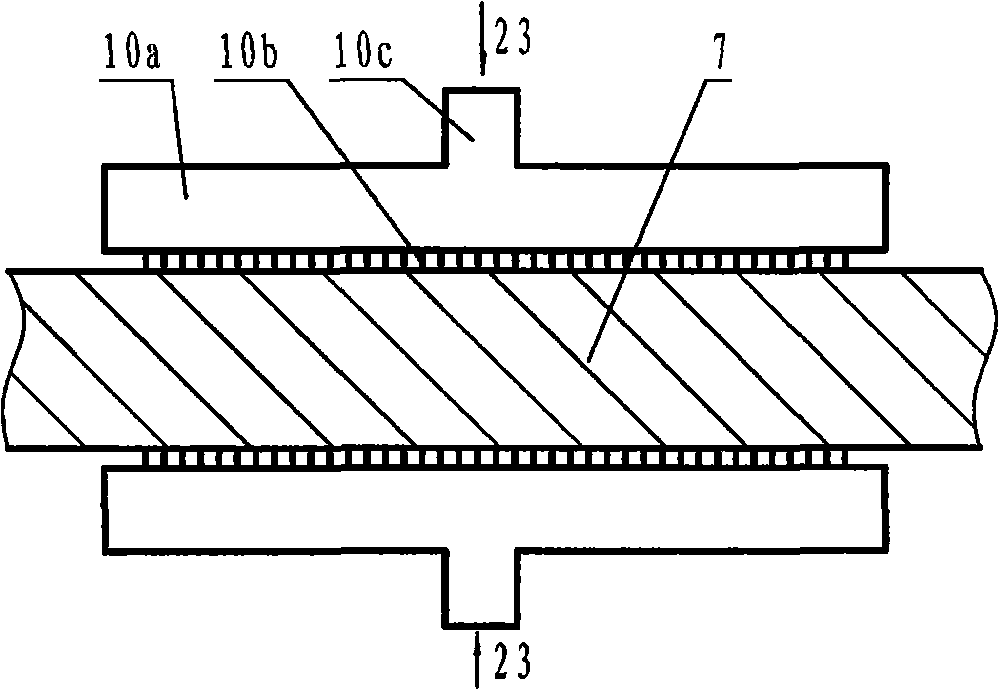

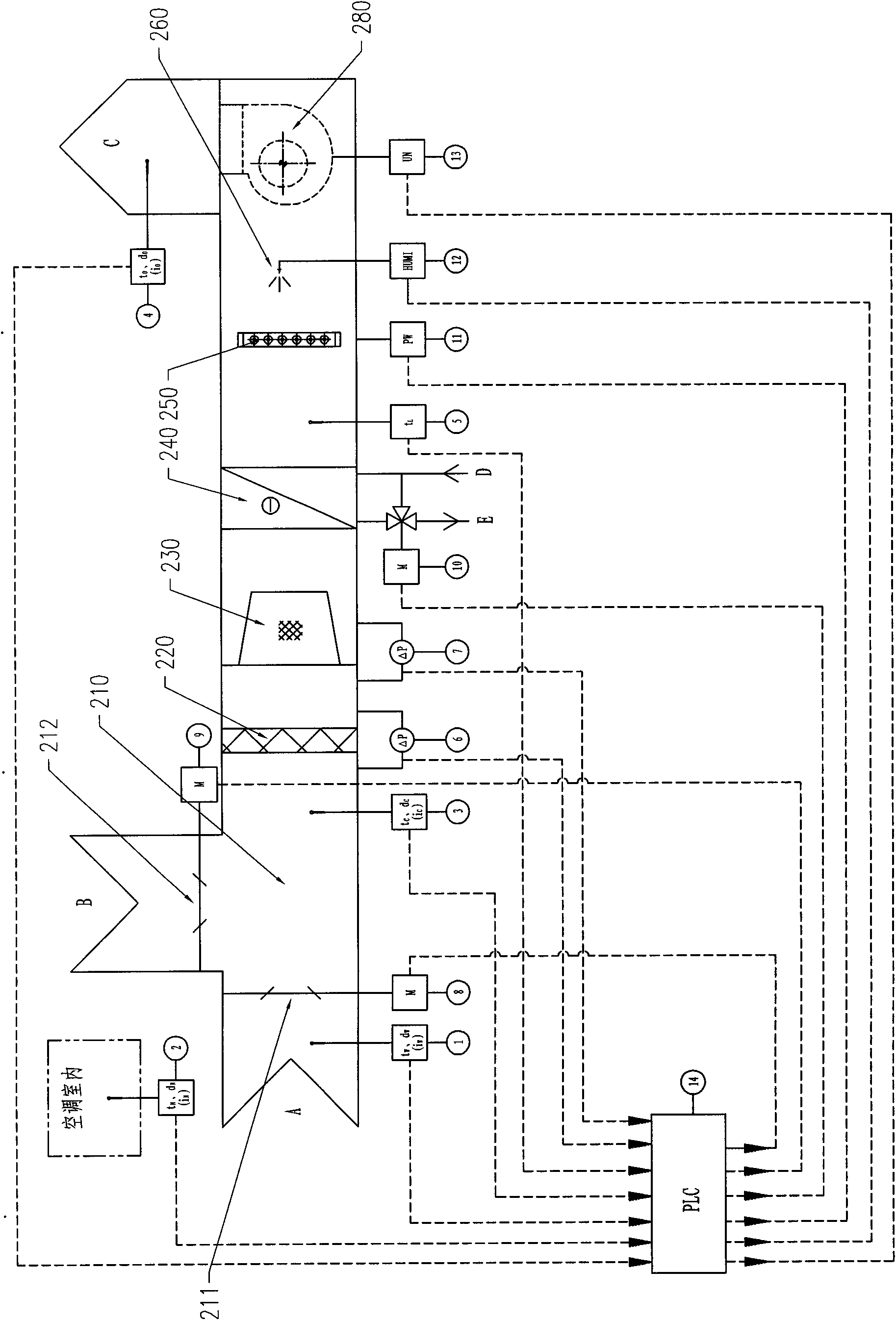

Microchannel enhanced heat exchange system of rotary room-temperature magnetic refrigerator and heat transfer method thereof

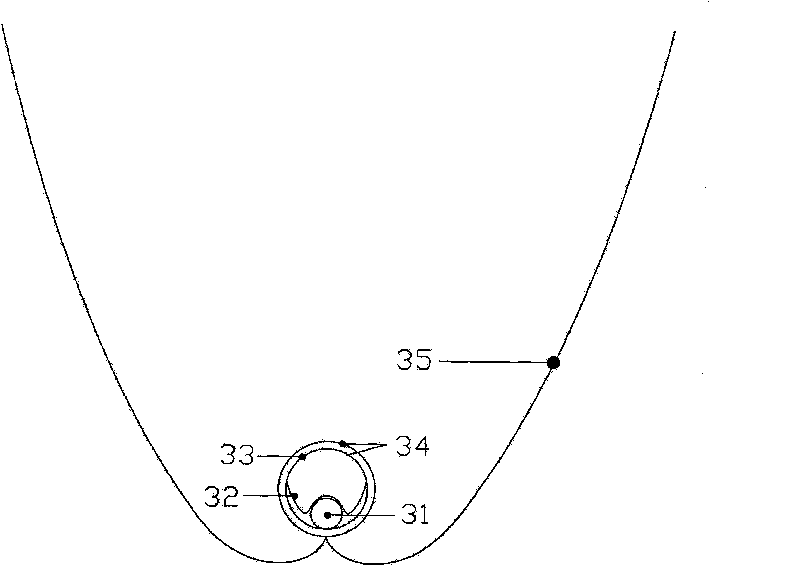

InactiveCN101788207AAchieve refrigerationGuaranteed safe operationEnergy efficient heating/coolingMachines using electric/magnetic effectsRoom temperatureEngineering

The invention discloses a microchannel enhanced heat exchange system of a rotary room-temperature magnetic refrigerator and a heat transfer method thereof. The system comprises a refrigerant disc, a cold end heat exchanger, a hot end heat exchanger and a solution pump, wherein the cold end heat exchanger and the hot end heat exchanger are connected with the refrigerant disc. the refrigerant disc comprises a refrigerant bed, an inner circle collecting tank, an outer circle collecting tank, four pairs of interzone adiabatic baffles and a plurality of intra-zone adiabatic baffles; the refrigerant bed comprises a plurality of trapezoidal microchannel flat tubes, an upper magnetic refrigerant plate and a lower magnetic refrigerant plate; the trapezoidal microchannel flat tubes, the upper magnetic refrigerant plate and the lower magnetic refrigerant plate are arranged between the inner circle collecting tank and the outer circle collecting tank; and the trapezoidal microchannel flat tubes are arranged between the upper magnetic refrigerant plate and the lower magnetic refrigerant plate. The heat transfer method is characterized in that the heat transfer fluid experiences a cycle of adiabatic excitation and demagnetization after passing through the different zones of the microchannel enhanced heat exchange system; and the rotary magnetic refrigerator recirculates the processes to realize refrigeration. In the invention, the characteristic that the microchannel can effectively enhance heat exchange due to scale effect is adopted and the microchannel is applied to the refrigerant bed, thus improving the efficiency of the refrigerating system and reducing corrosion of the heat transfer fluid to the magnetic refrigerant.

Owner:SOUTH CHINA UNIV OF TECH

Solar thermoelectric power generation system

InactiveCN103259458AImprove heat transfer effectStrong complementarityFrom solar energyMachines/enginesLight energyPhotothermal conversion

A solar thermoelectric power generation system comprises a solar thermoelectric power generation system body, a concentrated solar device, a metal photothermal conversion device, a water circulating cooling system and a solar heat absorption coating. Sunlight and concentrated sunlight can irradiate on the metal photothermal conversion device which is coated by the solar heat absorption coating, the solar heat absorption coating converts light energy into heat energy, and then the heat energy is transmitted to the metal photothermal conversion device, the metal photothermal conversion device transmits the heat energy to a hot end of a thermoelectric power generation device, a cold end of the thermoelectric power generation device is cooled by the seawater or river water or lake water or pond water or underground water circulating cooling system, and the solar thermoelectric power generation system body which is composed of the hot end of the thermoelectric power generation device and the cold end of the thermoelectric power generation device can convert heat into electrical energy.

Owner:王广武

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

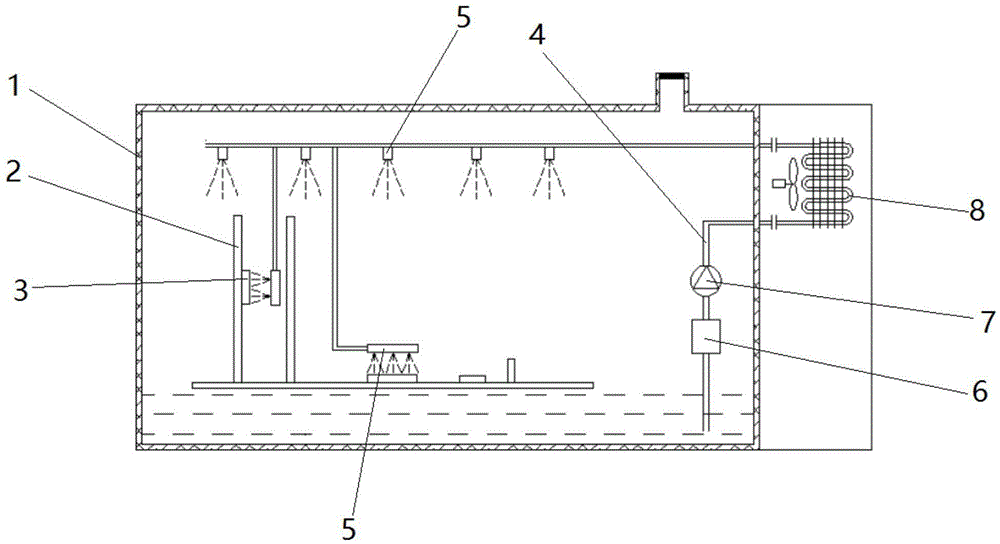

Integrated liquid-cooling heat dissipation case

ActiveCN105658037AImprove heat transfer effectImprove cooling efficiencyCooling/ventilation/heating modificationsCooling fluidCoolant pump

The invention relates to the field of liquid cooling, and provides an integrated liquid-cooling heat dissipation case. The integrated liquid-cooling heat dissipation case comprises a case body, a circuit board and a liquid-cooling heat dissipation system. A closed space composed of a plurality of wall boards is formed in the case body. The circuit board is arranged in the case body, and one or more heat emission devices are arranged on the circuit board. A liquid storage groove is formed in the bottom of the case body and used for storing cooling liquid. The liquid-cooling heat dissipation system comprises a pipeline, a heat dissipation mechanism, a pumping mechanism and a spraying mechanism. The pumping mechanism is used for pumping the cooling liquid in the liquid storage groove into the pipeline, the spraying mechanism is connected to one end of the pipeline and used for spraying the cooling liquid into the case body or directly spraying the cooling liquid to the heat emission devices, and the heat dissipation mechanism is arranged at the position, in front of the spraying mechanism, of the pipeline and used for transferring heat of the cooling liquid to the outside of the case body. By the adoption of the integrated structural design, the integrated liquid-cooling heat dissipation case can be used in hostile environments and is convenient to carry, reasonable in design, light in weight, high in heat exchange capability and low in cost.

Owner:沈珂

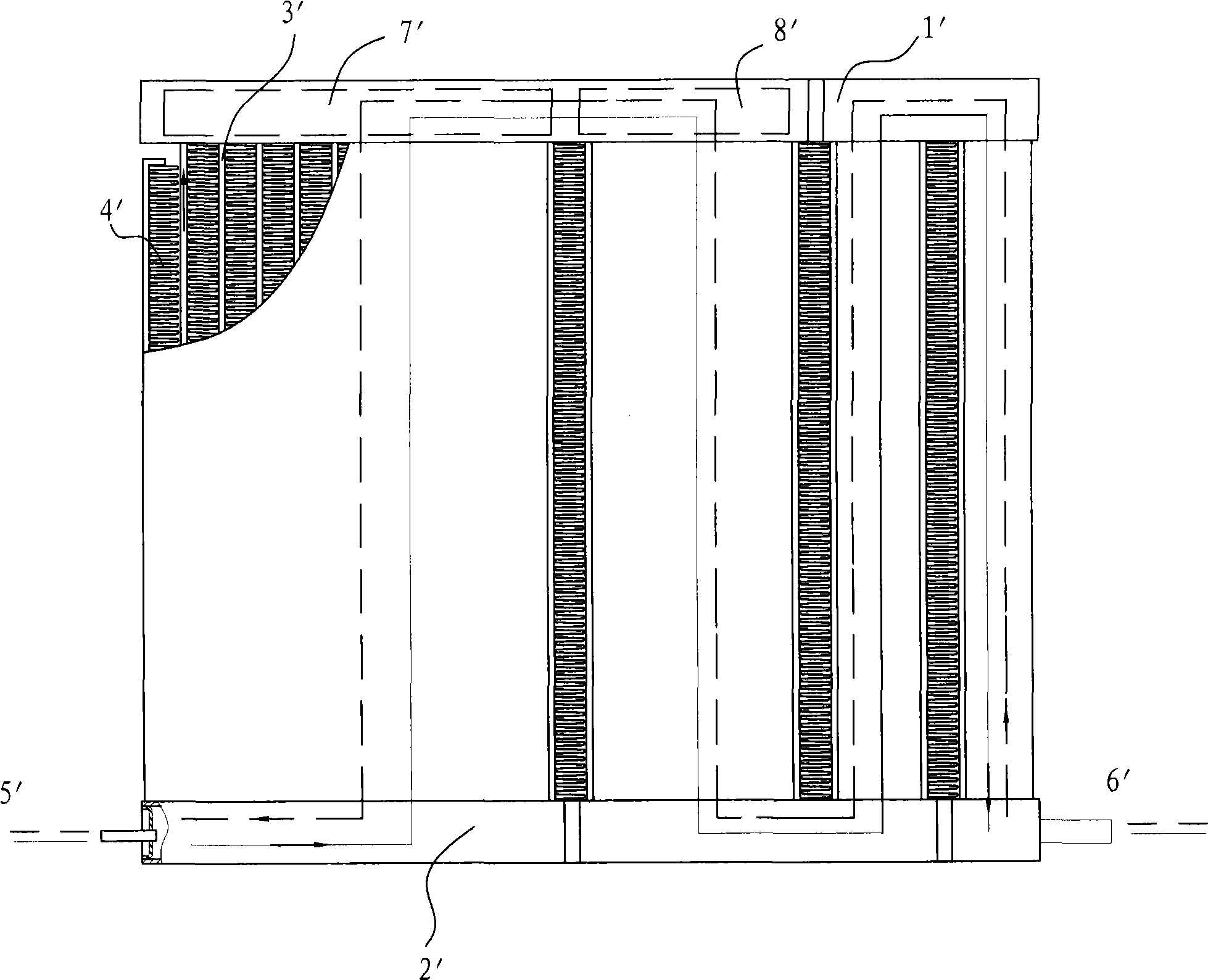

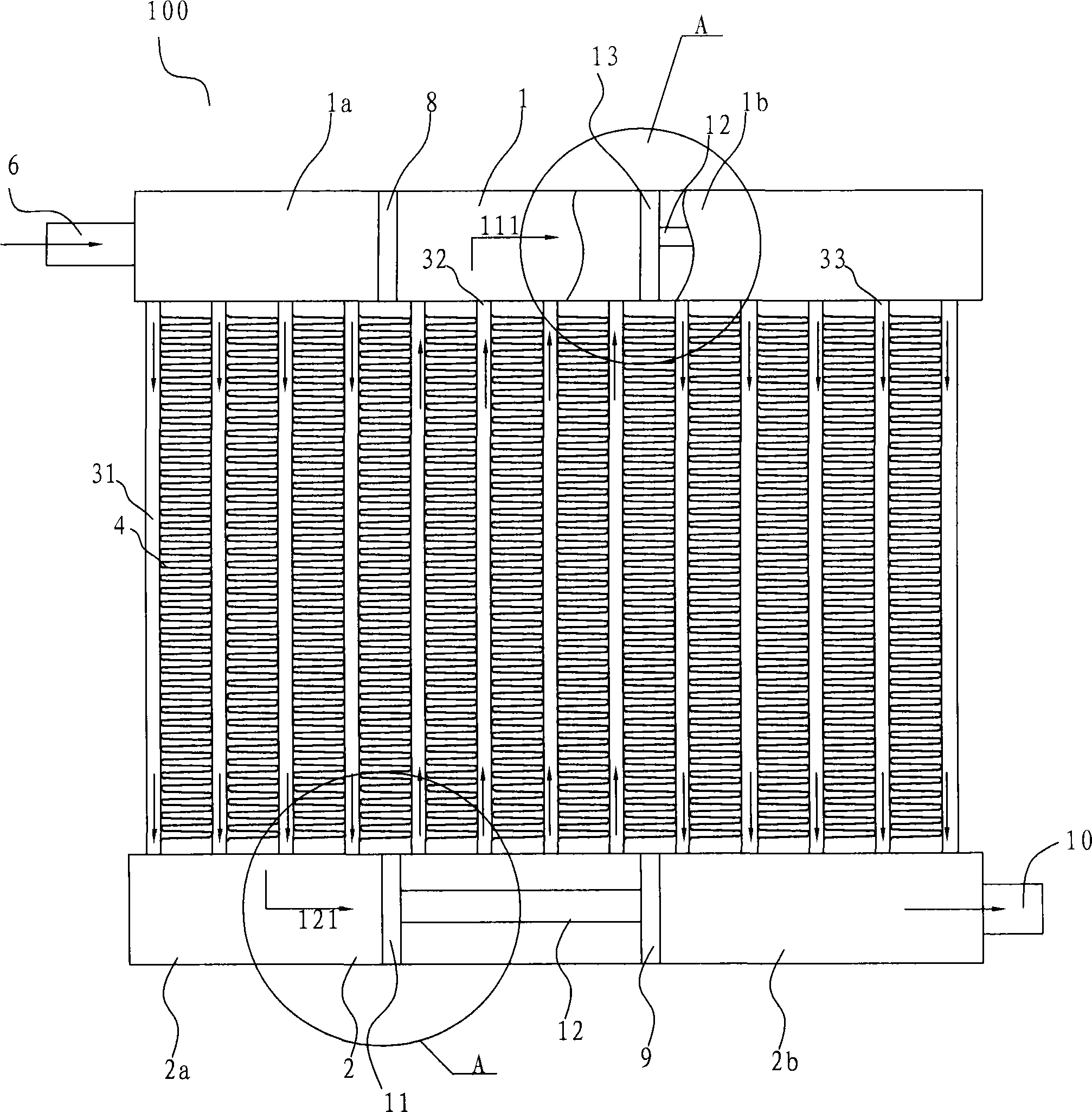

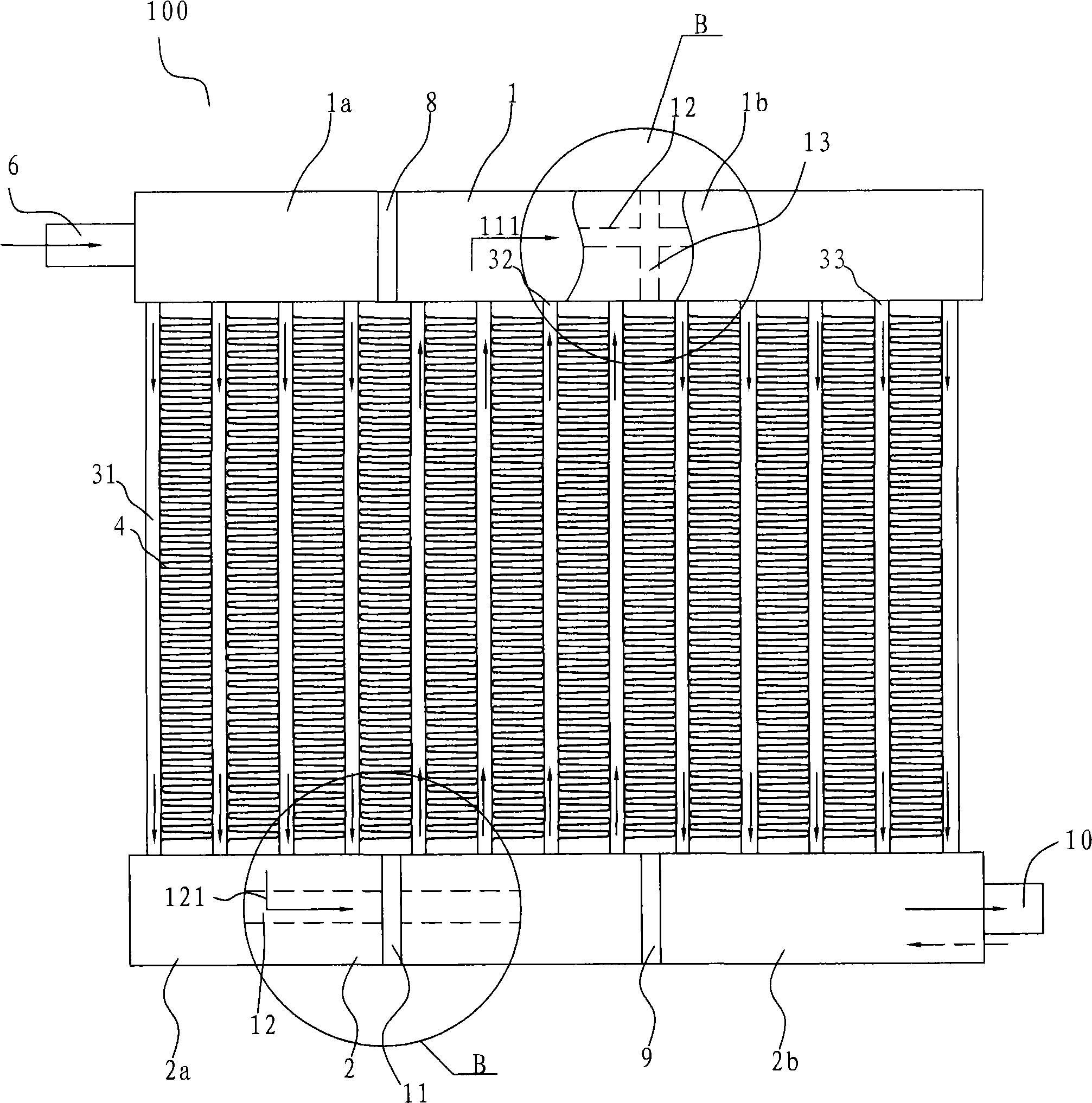

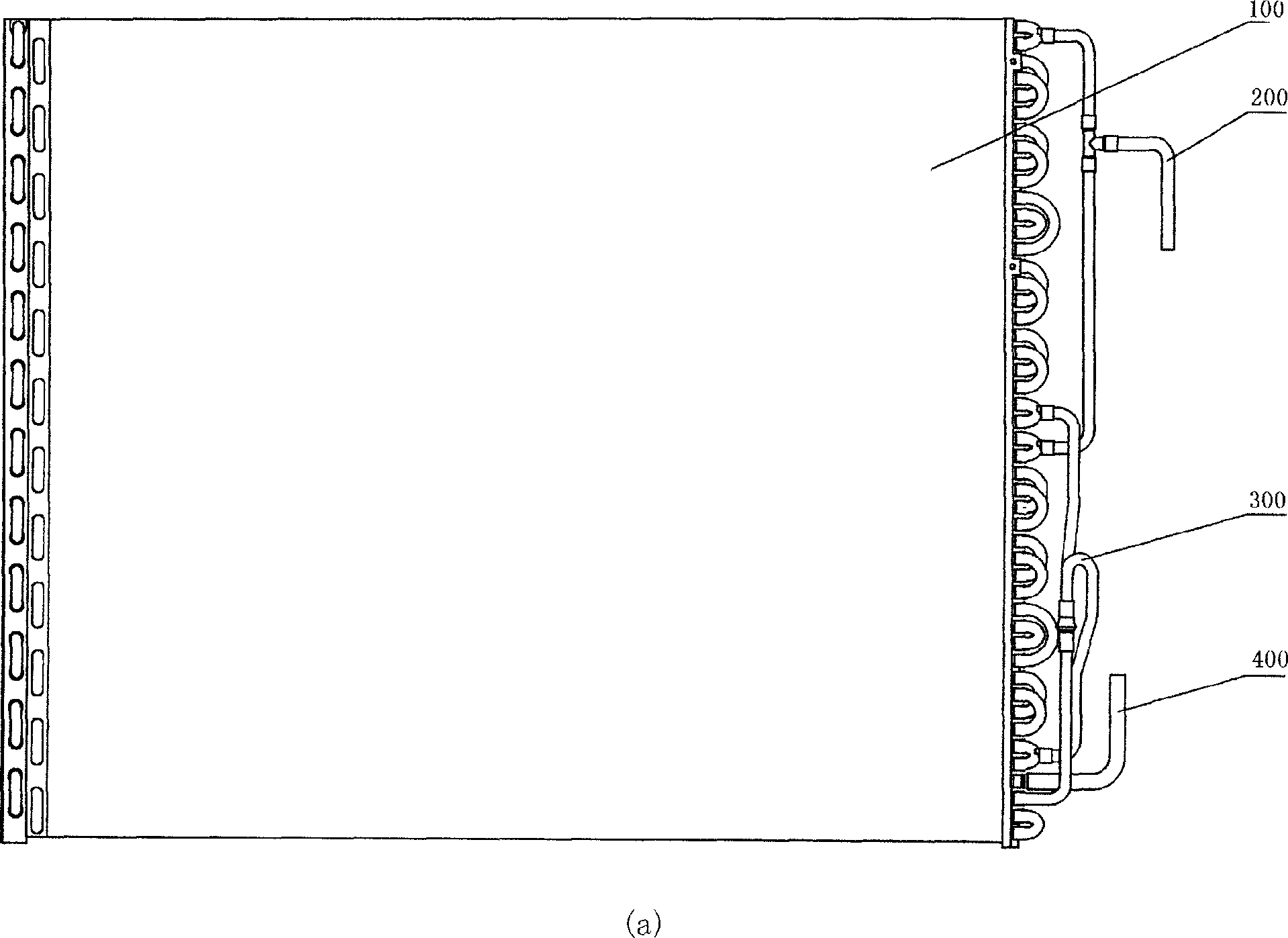

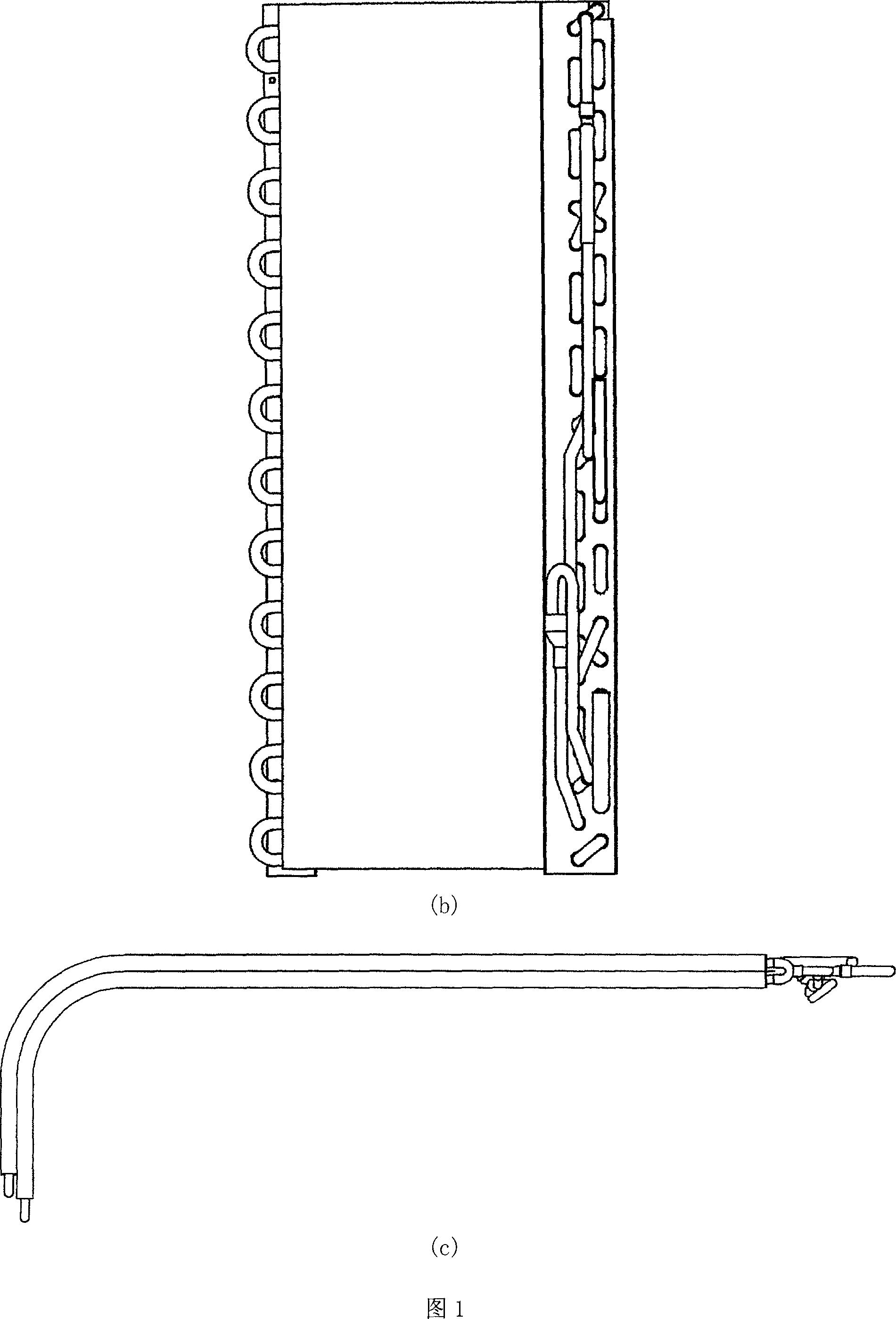

Microchannel heat exchanger and heat exchanging system

ActiveCN101520282AImprove heat transfer effectReduce gas-liquid stratificationEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

The invention provides a microchannel heat exchanger which comprises a first collecting tube, a second collecting tube, flat tubes and fins. The fins are respectively arranged between adjacent flat tubes; the inside of the first collecting tube and / or the second tube are / is divided into a plurality of chambers by at least one partition member to form a plurality of flow passages in the microchannel heat exchanger; two adjacent flow passages are communicated with each other through one of connection flow passages in the first collecting tube and / or the second collecting tube; and at least one connection passage is internally provided with a second partition member and a distributor which communicates both sides of the second partition member so as to distribute the fluid at one side of the second partition member to the other side of the second partition member. The microchannel heat exchanger can reduce gas-liquid stratification of refrigerant and improve the heat exchanging performance of refrigerant. In addition, the invention also provides the heat exchanging system using the microchannel heat exchanger.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

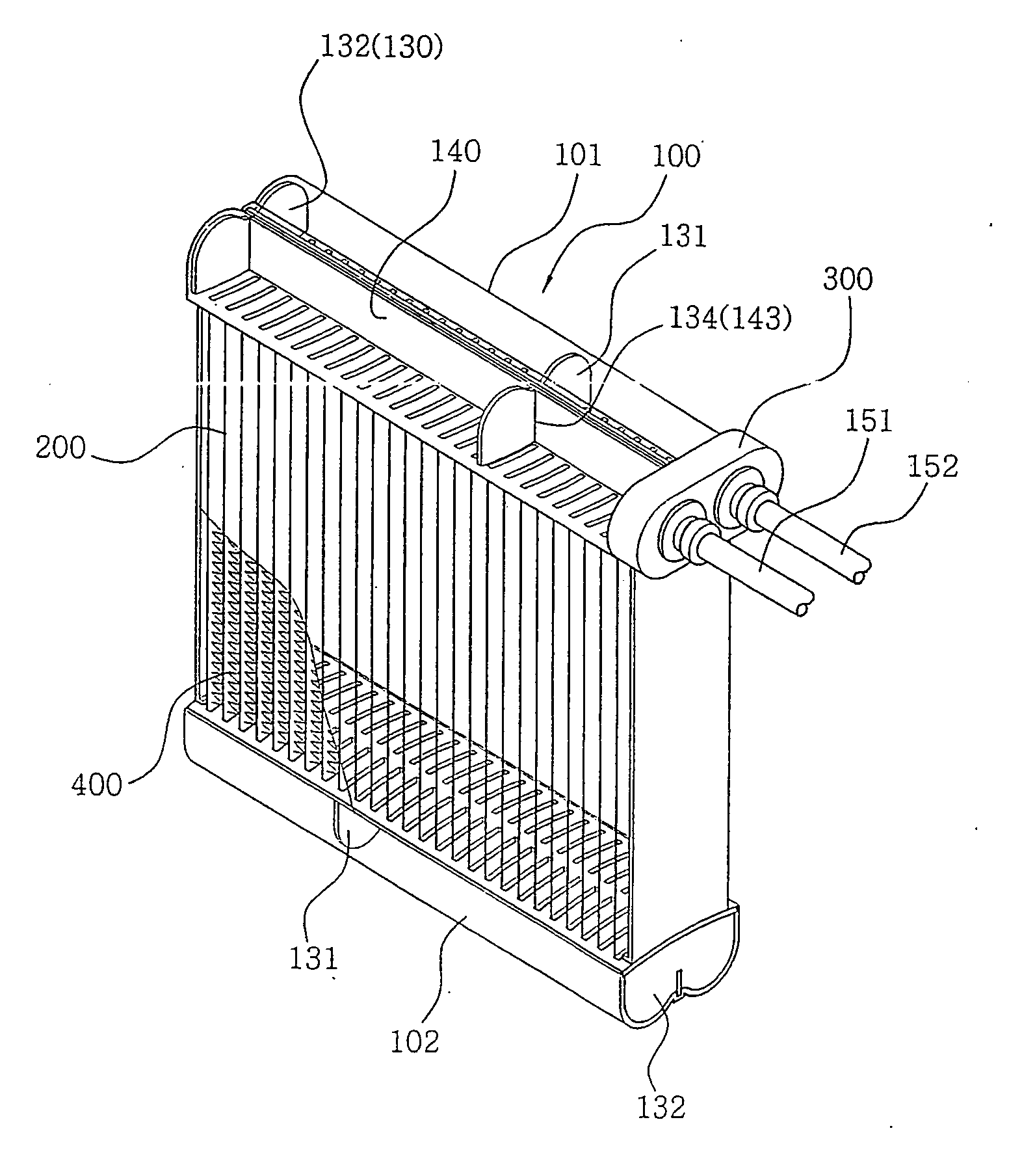

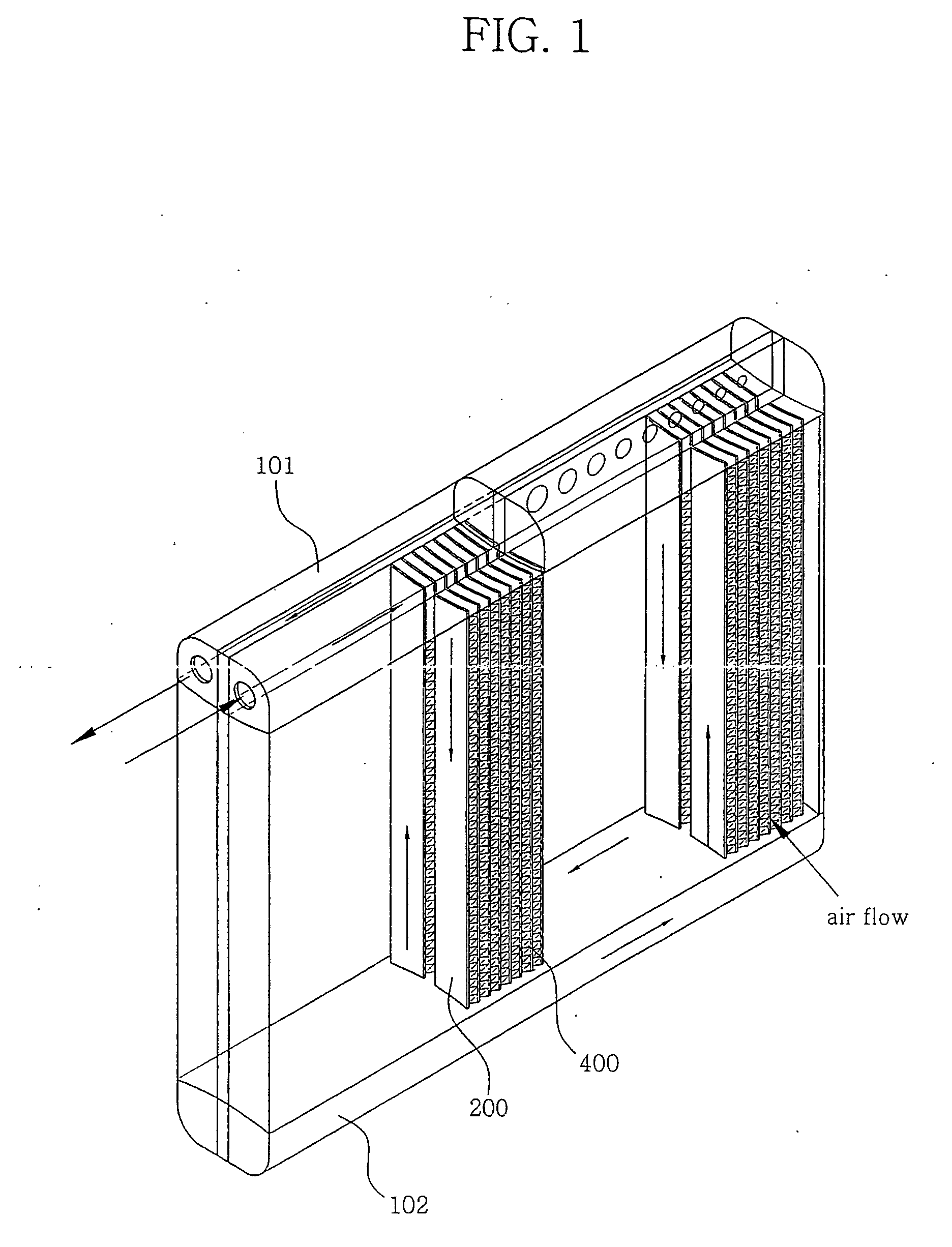

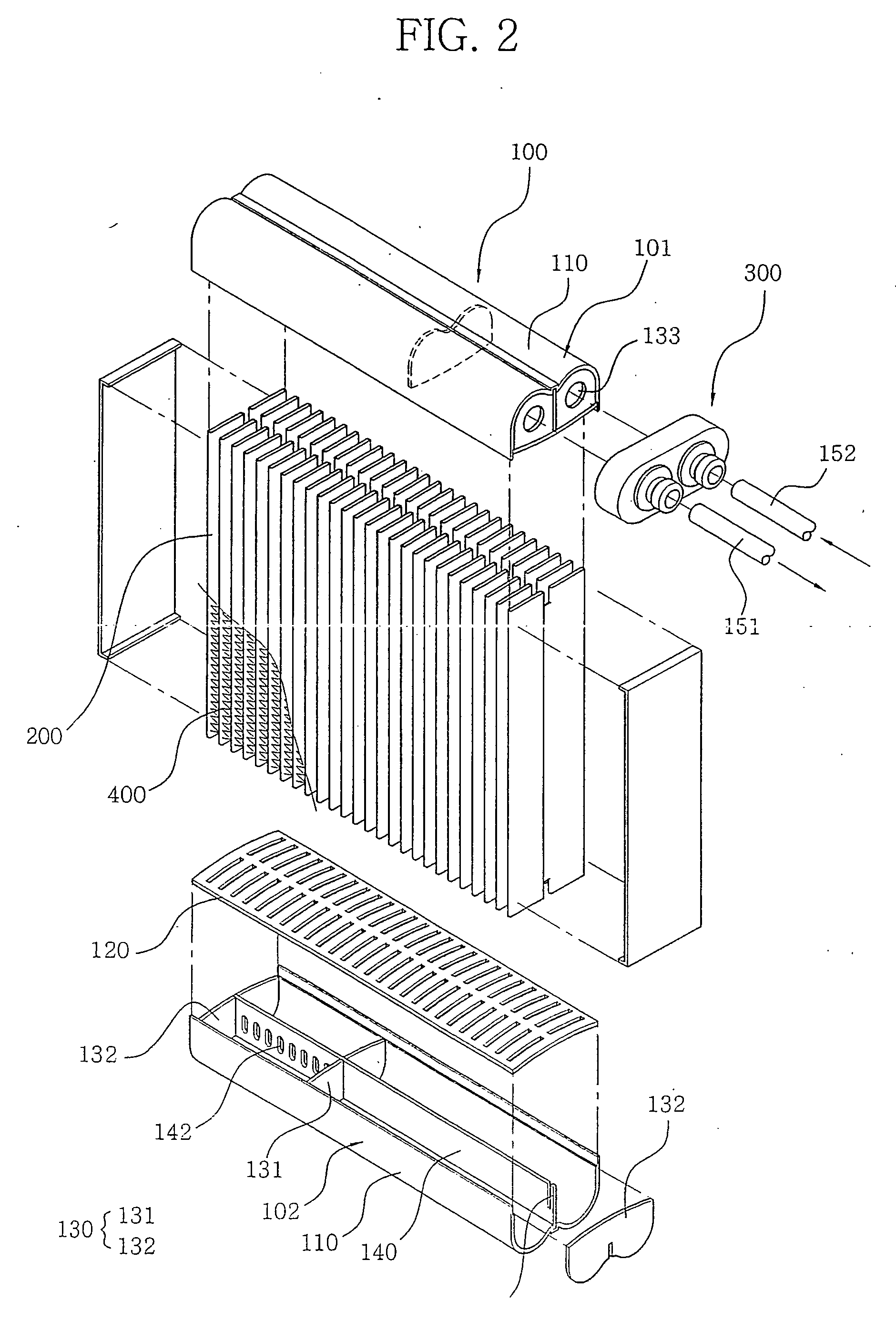

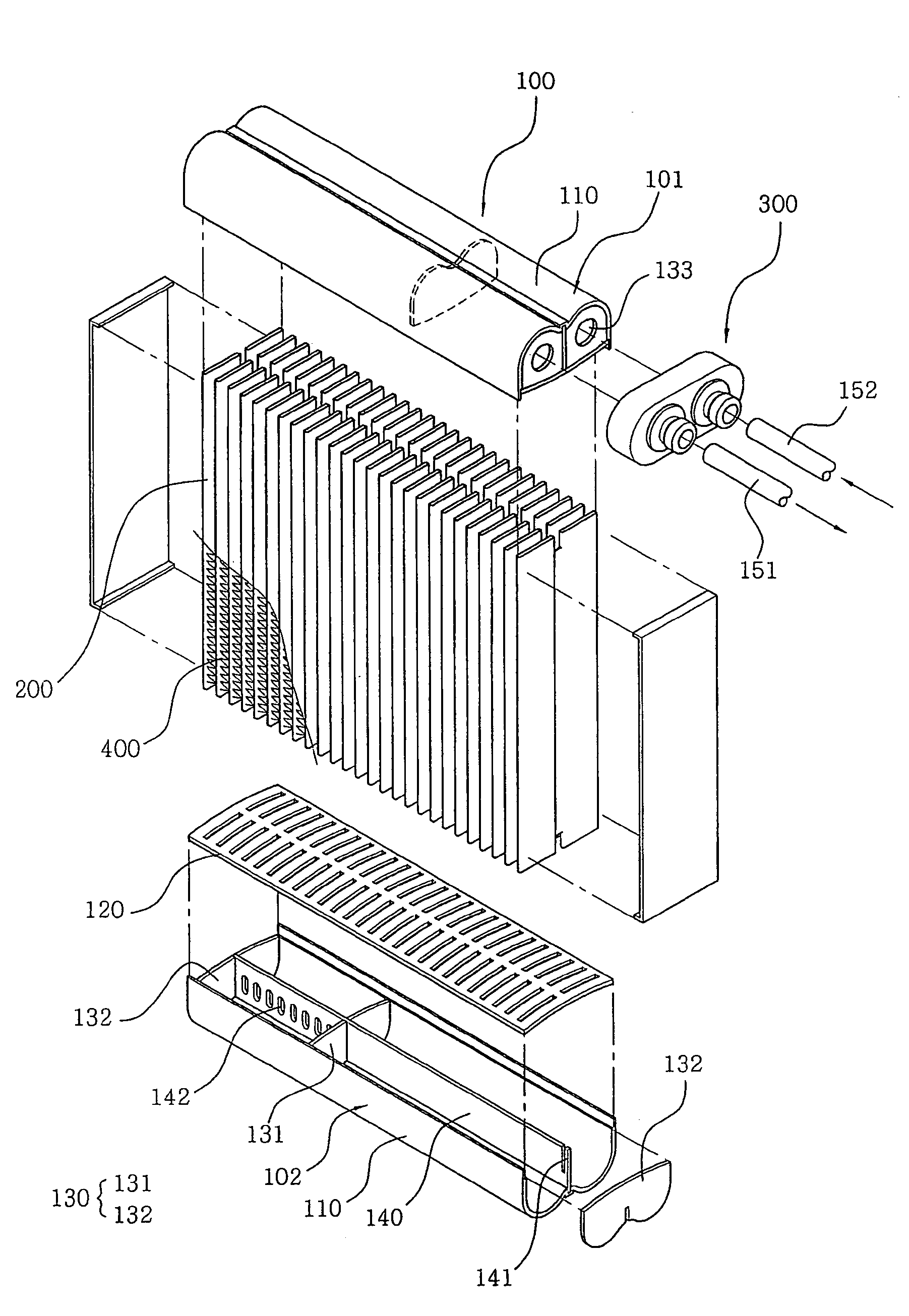

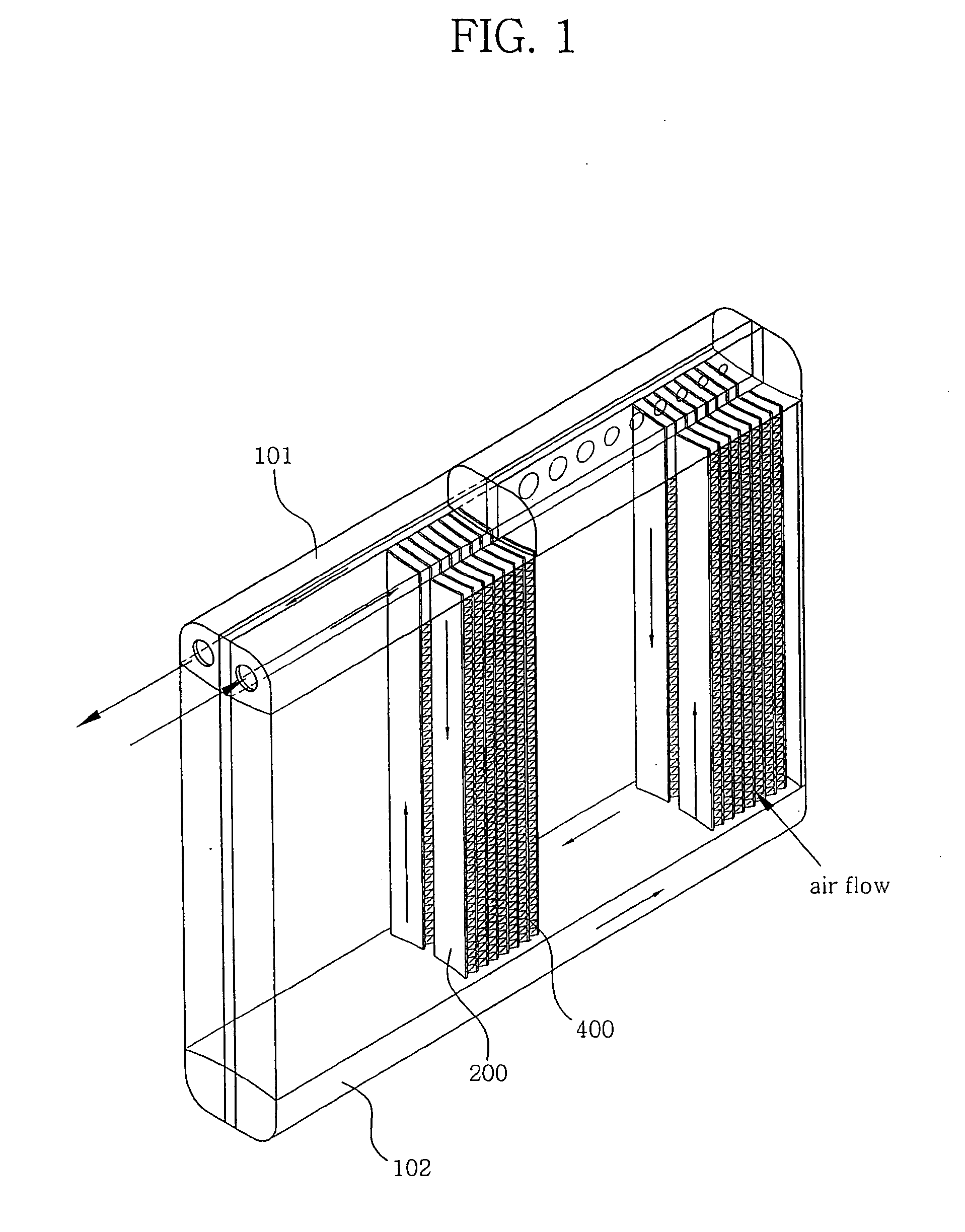

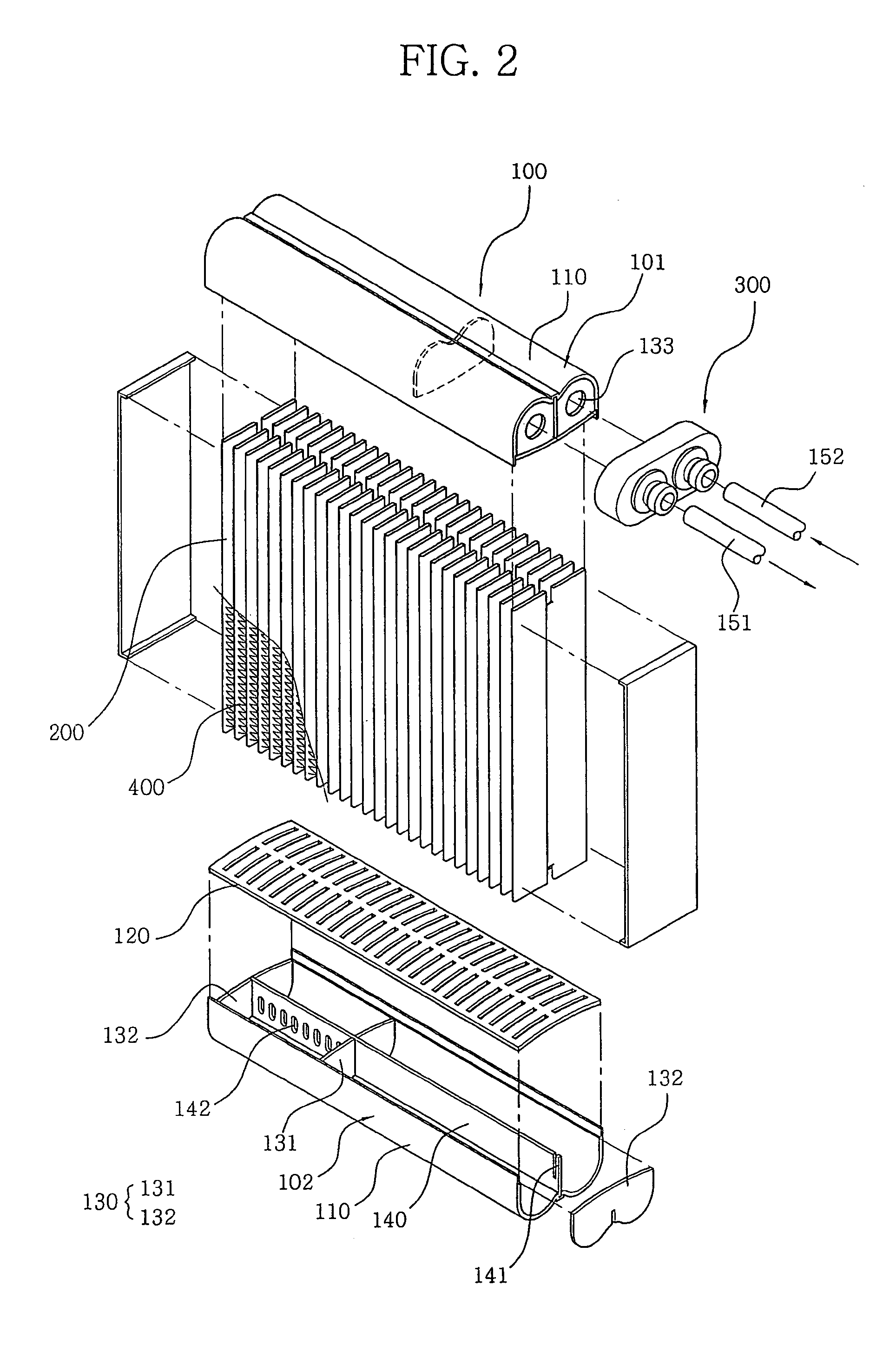

Evaporator

InactiveUS7222501B2Reduced dimensionImprove heat transfer effectEvaporators/condensersStationary conduit assembliesEngineeringEvaporator

The present invention relates to an evaporator for an air conditioner of a vehicle, and the major object of the present invention is to provide the evaporator which is capable of decreasing the whole dimension of an evaporator and enhancing a heat exchange performance. To achieve the above objects, an evaporator includes an upper and lower header units comprising a tank member, a partition member, a header plate, an intermediate baffle, a finishing baffle; and a plurality of tubes comprising a front tube portion, a rear tube portion, a connection tube portion; and a wrinkle fin.

Owner:MODINE KOREA

Gas cooling device

InactiveUS20050098307A1Easy to manufactureLow costAir-treating devicesNon-fuel substance addition to fuelProduct gasEngineering

A gas cooling device capable of efficiently cooling a gas such as an EGR gas, etc. is provided. A multiplicity of cooling pipes perpendicularly intersecting a gas flow direction in a gas pipe for a gas such as an EGR gas, etc. are provided to extend through an outer peripheral wall of the gas pipe, a cooling jacket is provided on an outer surface of the gas pipe on both sides of a group of the cooling medium pipes in an axial direction, or on the entire outer surface of the gas pipe, and the gas in the gas pipe is cooled by a cooling medium flowing through the cooling pipes.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

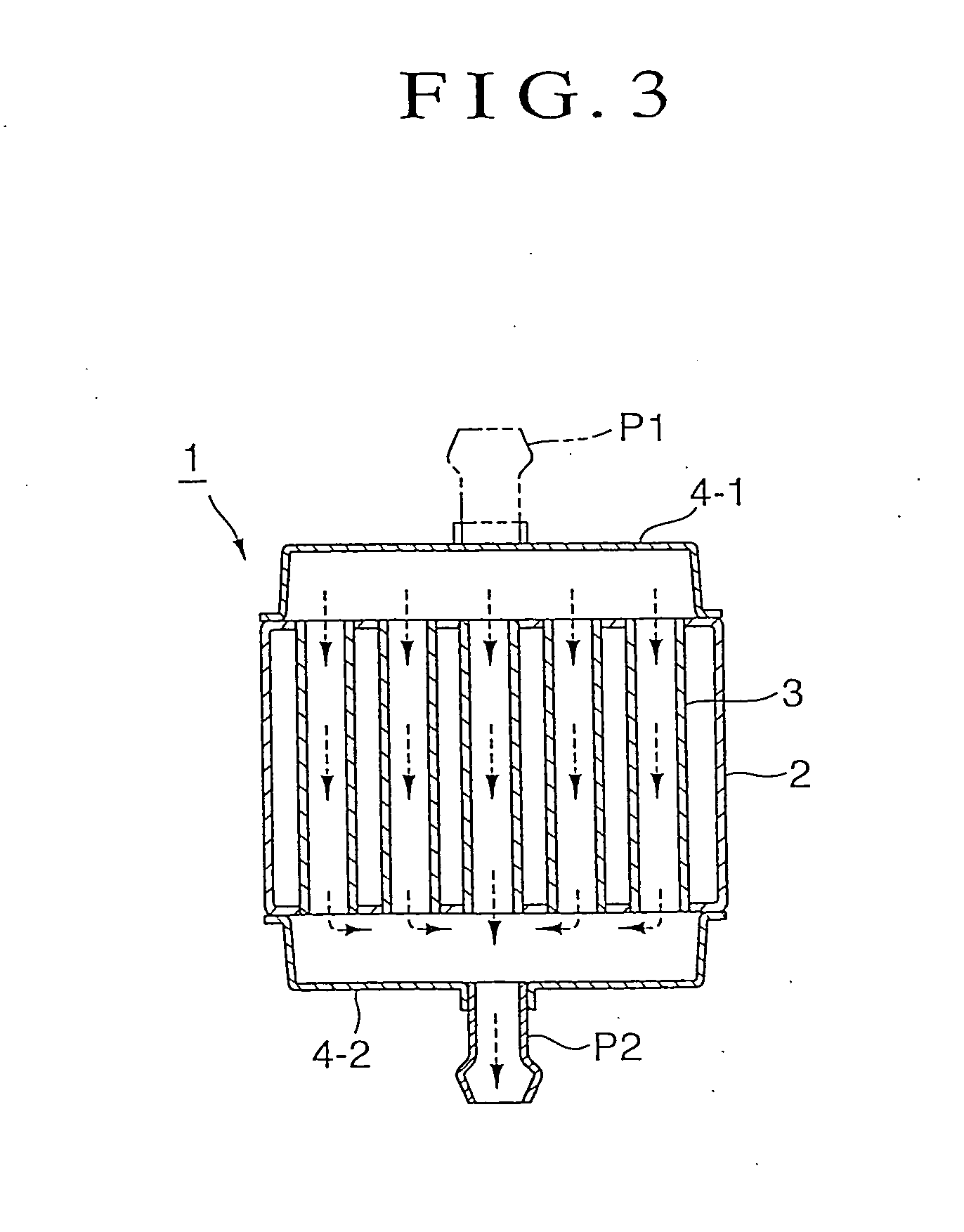

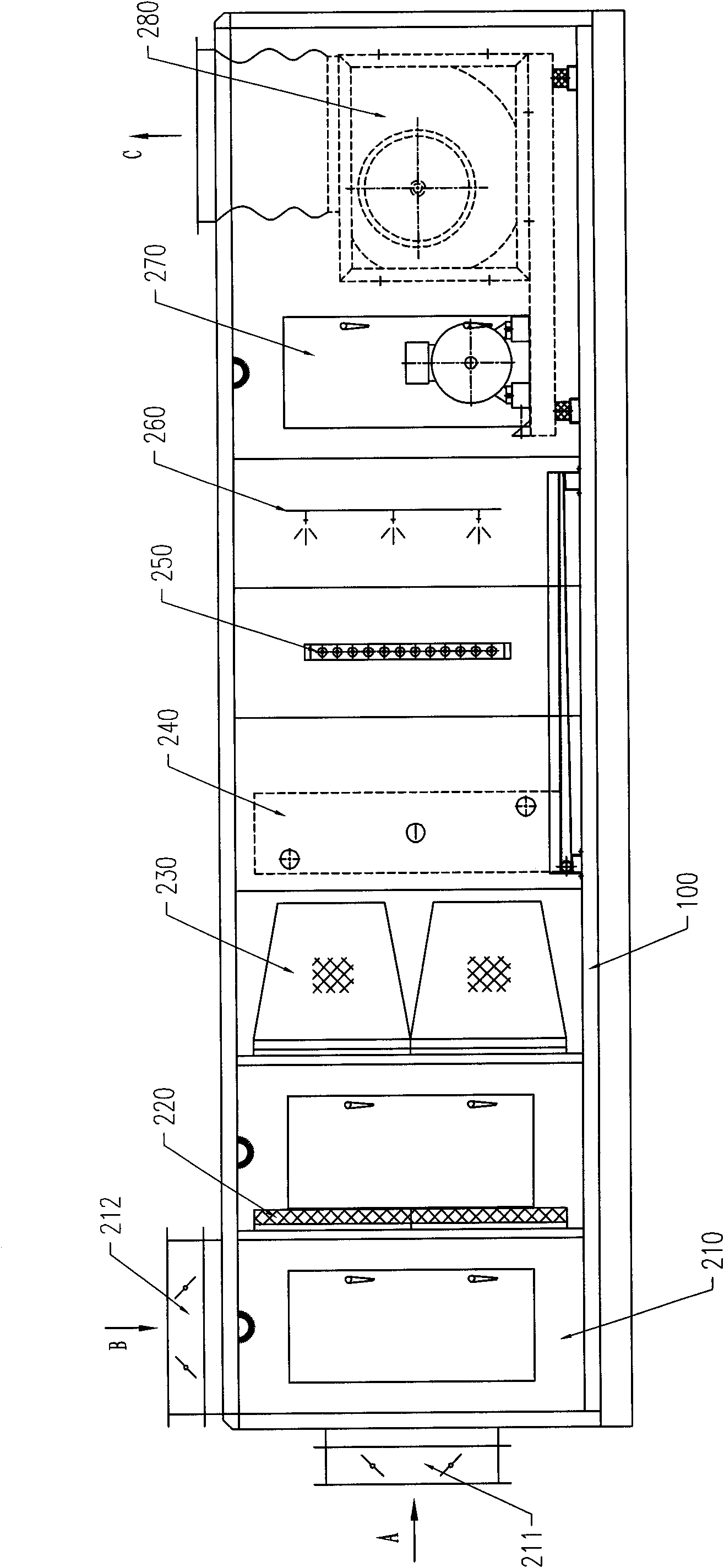

Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

ActiveCN101782263AReduce resistanceFully contactedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemNuclear power

The invention relates to a multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with a thermometal compound box body structure special for nuclear power stations. The air conditioning unit comprises a control system and a box body structure, wherein a primary-efficiency filter, a medium-efficiency filter, a surface cooler, a heater, a humidifier and a blow-off device are sequentially arranged in the box body; the front side of the primary-efficiency filter is provided with a fresh air and return air mixing section, and inlets of fresh air and return air are respectively provided with a fresh air proportioning valve and a return air proportioning valve; the control system adopts a programmable logic controller (PLC) and adopts air conditioning multi-operating mode zone control to realize the energy-saving operation of the unit; the surface cooler adopts a large temperature difference cold water heat exchanging technology and can save the investment and operation expenses of a water system; and the box body adopts a double-layer compound structure and an anti-shock device to meet the special requirements on the nuclear power stations. The invention has the characteristics of high efficiency, energy saving, good tightness, strong anti-shock capacity, safety, reliability, long service life, and the like.

Owner:广东吉荣核电设备暖通技术有限公司

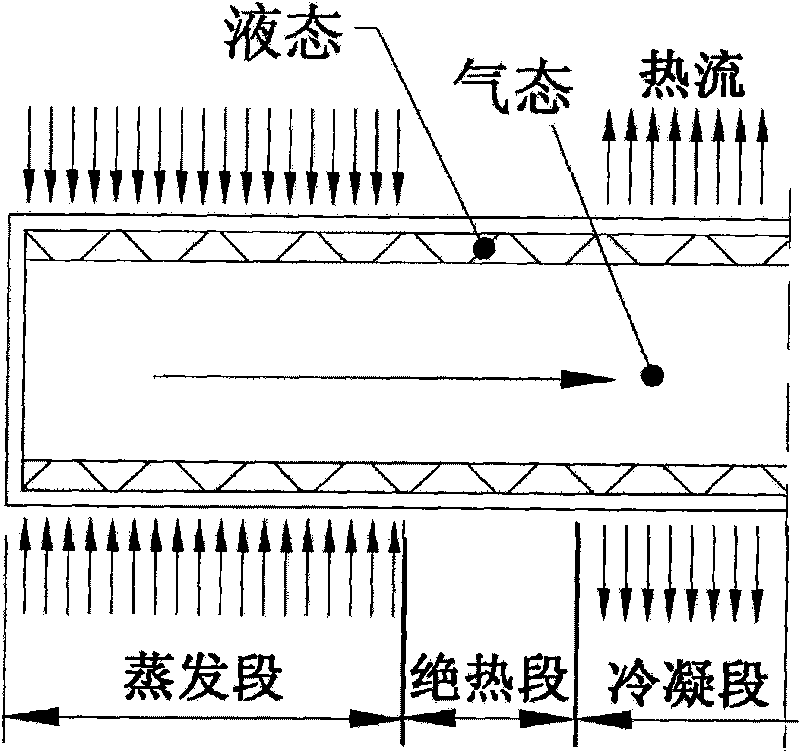

Heat pipe type solar energy ORC (organic Rankine cycle) low-temperature thermal power generating system

InactiveCN101761461AReduce loopGuaranteed heat exchange effectSolar heating energySteam generation heating methodsOrganic Rankine cycleCollector device

The invention relates to a heat pipe type solar energy ORC (organic Rankine cyle) low-temperature thermal power generating system which comprises an ORC power generating system, a heat storage system and a heat pipe collector system. The power generating system comprises working medium evaporation sleeves, a turbine, a power generator, a heat regenerator, a condenser and the like. The heat pipe collector system is composed of more than three heat pipe collector modules; each module includes a heat pipe, a vacuum pipe and a CPC (composite parabolic) reflector; the condensing section of the heat pipe is embedded in the working medium evaporation sleeves, and the evaporating section of the heat pipe is arranged at the bottom part in the CPC reflector; and the more than three working medium evaporation sleeves are connected in series. In the invention, the heat pipe, the CPC reflector and an ORC are combined to form the heat pipe type solar energy low-temperature thermal power generating system based on the ORC. Compared with the traditional solar energy low-temperature thermal power generating system, the invention not only has high heat efficiency and strong pressure bearing capacity, but also innovatively utilizes the phase inversion heat exchanging principle of the heat pipe to reduce a heat conduction oil loop and realizes the high-efficiency heat exchanging between an organic working medium and the heat collector.

Owner:UNIV OF SCI & TECH OF CHINA

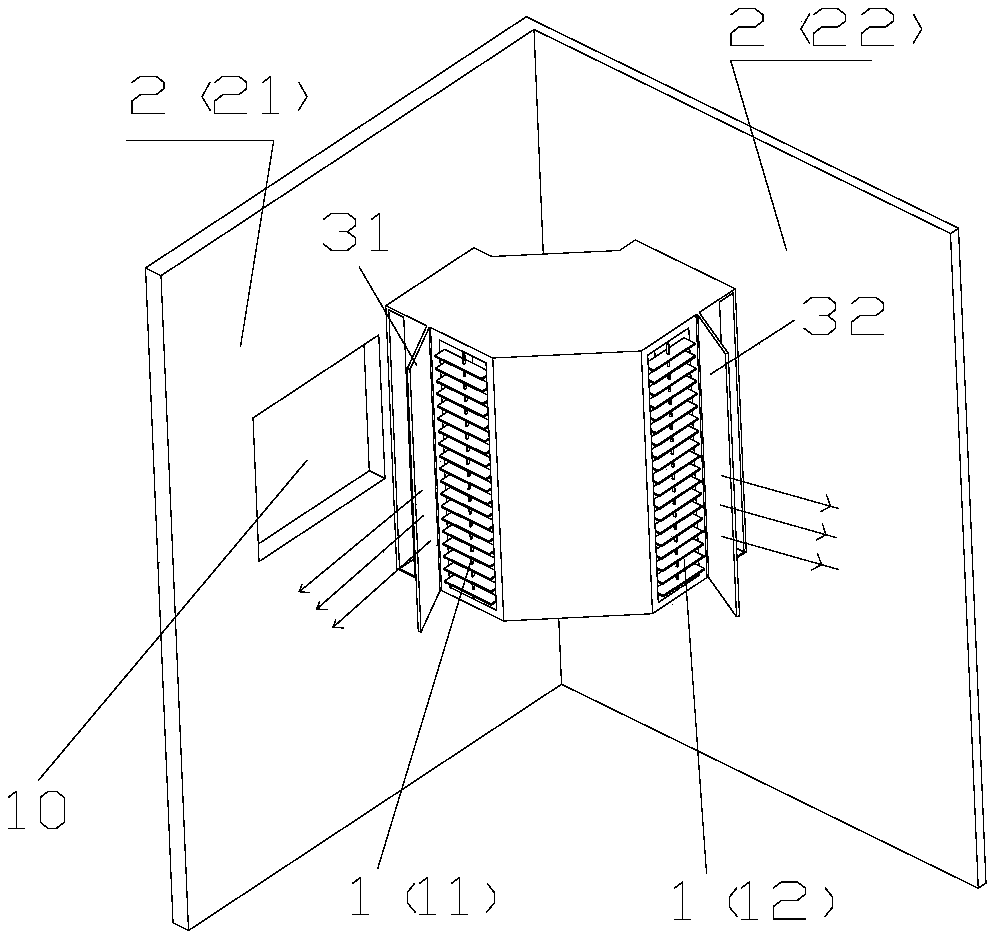

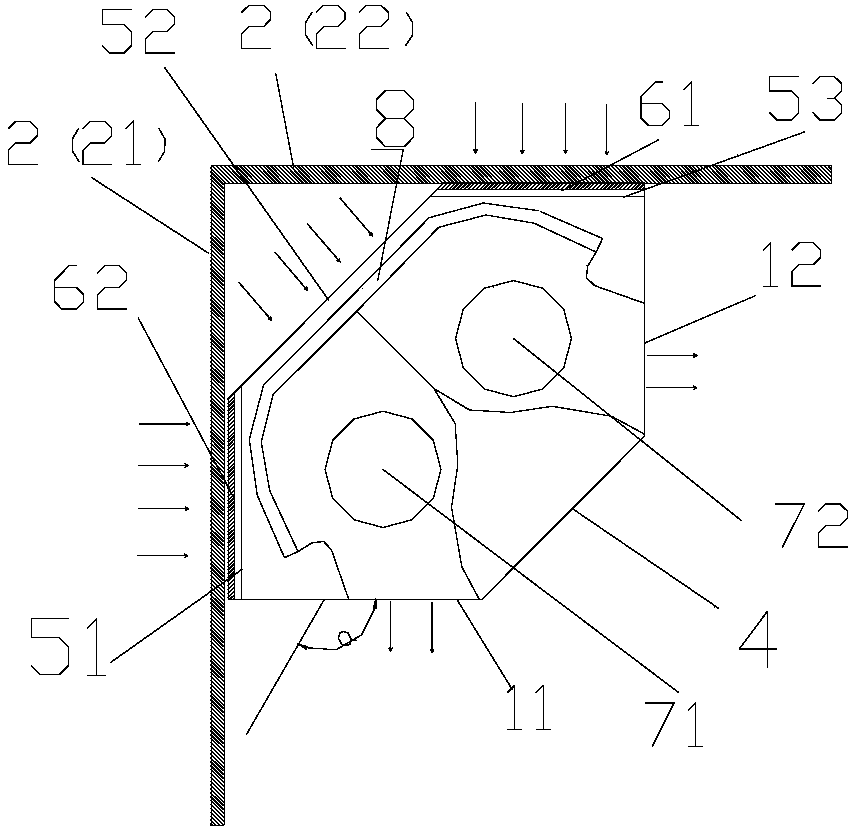

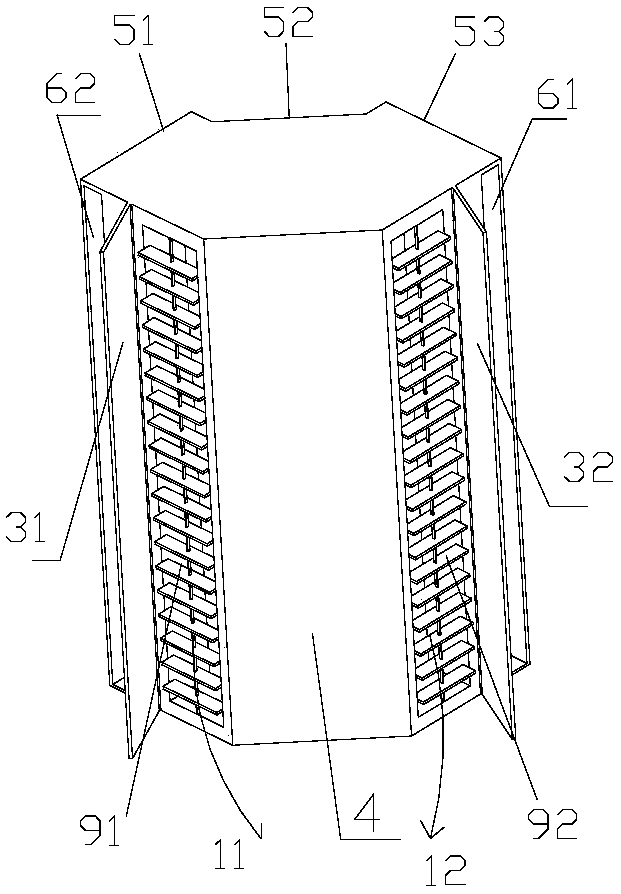

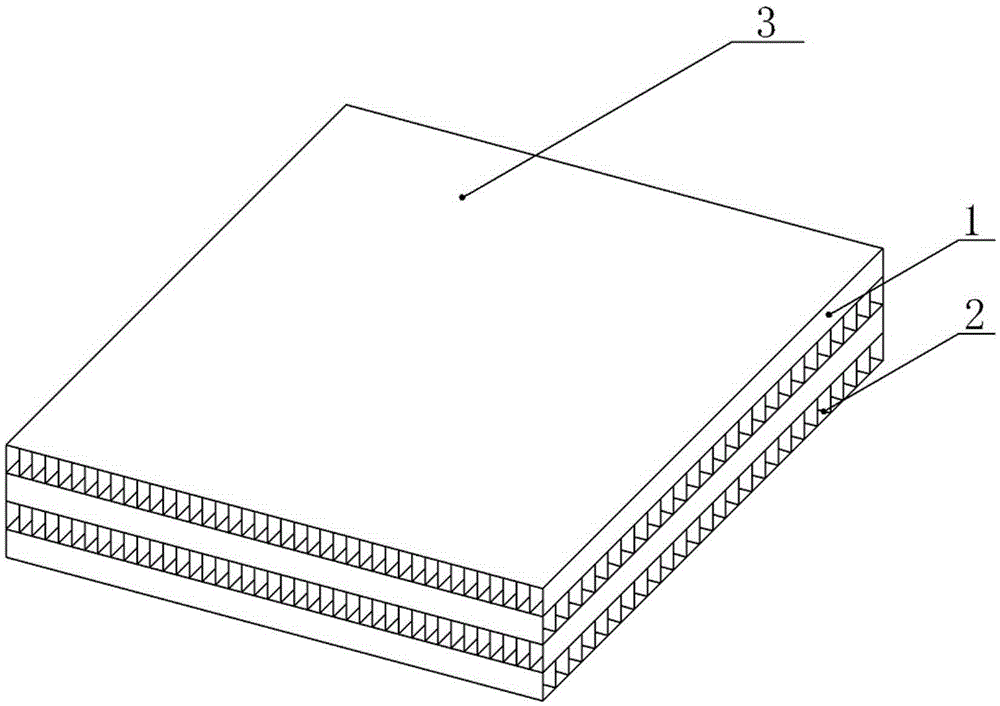

Vertical air conditioner indoor unit and air conditioner

PendingCN108413499AFacilitates the formation of the Coanda effectImprove comfortLighting and heating apparatusHeating and ventilation casings/coversSystemic circulationWaste management

The invention provides a vertical air conditioner indoor unit and an air conditioner. The vertical air conditioner indoor unit (1) is installed at the position of an indoor wall corner (2) and comprises a first air outlet (11) and a second air outlet (12), the first air outlet (11) can conduct air outlet in the direction of a first wall face (21) of the wall corner (2), and the second air outlet (12) can conduct air outlet in the direction of a second wall face (22) of the wall corner (2). By means of the vertical air conditioner indoor unit and the air conditioner, airflow sent from the leftand right air outlets can flow along the wall, the air conditioner is prevented from blowing a person directly, the left and right air outlets achieve air supply along the wall, surrounding airflow can be achieved, the airflow achieves systemic circulation indoors, the coanda effect of the airflow is conveniently formed, even temperature distribution caused by uneven indoor airflow is prevented, the indoor temperature distribution is even, and the comfort of the user is improved.

Owner:GREE ELECTRIC APPLIANCES INC

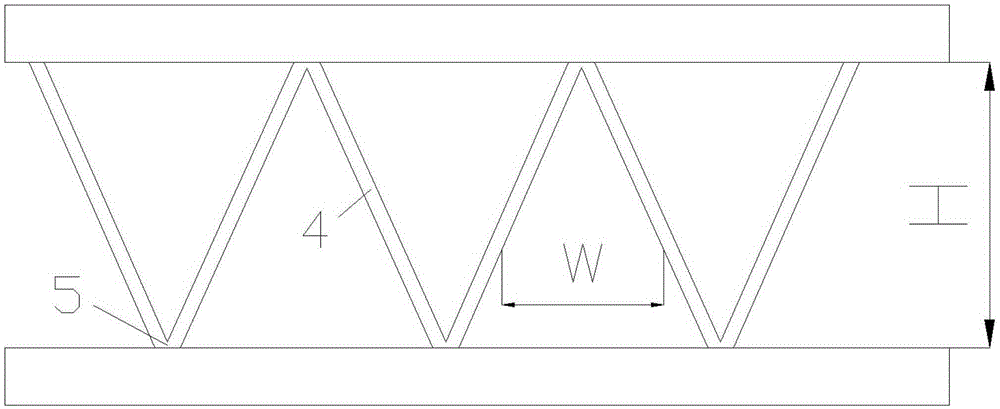

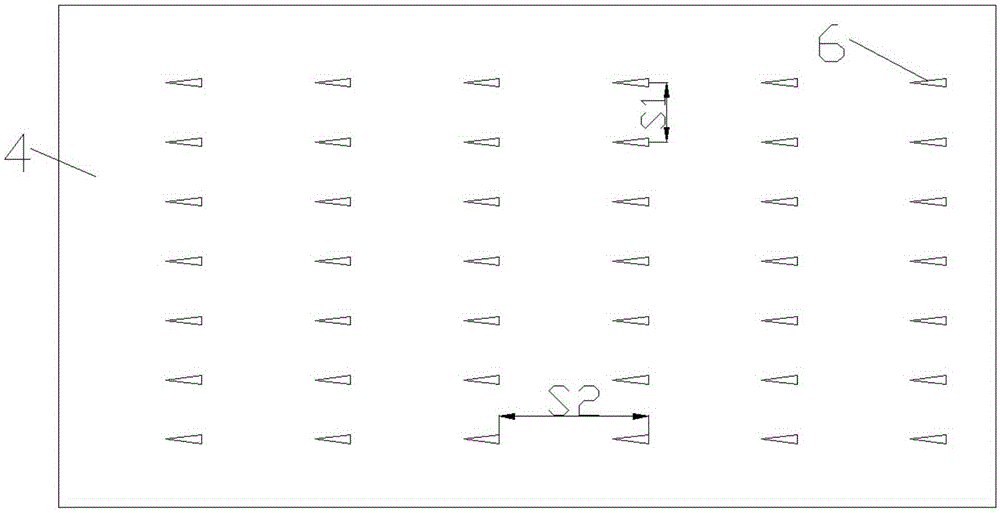

Triangular convex-stab-shaped plate-fin heat exchanger used for condensation of non-azeotropic multi-component mixture

ActiveCN105258535AOvercoming the problem of low heat transfer efficiencyImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesBoiling pointParallel plate

The invention provides a triangular convex-stab-shaped plate-fine heat exchanger used for condensation of a non-azeotropic multi-component mixture. The plate-fin heat exchanger comprises parallel plates; fins are arranged between the plates; the fins comprise inclined parts inclining towards the plates; convex stabs are machined on the inclined parts in a stamping mode, so that fluid on the two sides of the inclined part circulates through holes formed in the inclined parts in a stamping mode, and the convex stabs extend outwards in the flowing direction of the mixture from the inclined parts. The novel triangular convex-stab-shaped plate-fine heat exchanger is suitable for being used in condensation of the non-azeotropic multi-component mixture, so that condensation of the non-azeotropic multi-component mixed medium is achieved, the heat exchange efficiency is improved, and the fluid flowing resistance is reduced.

Owner:SHANDONG UNIV

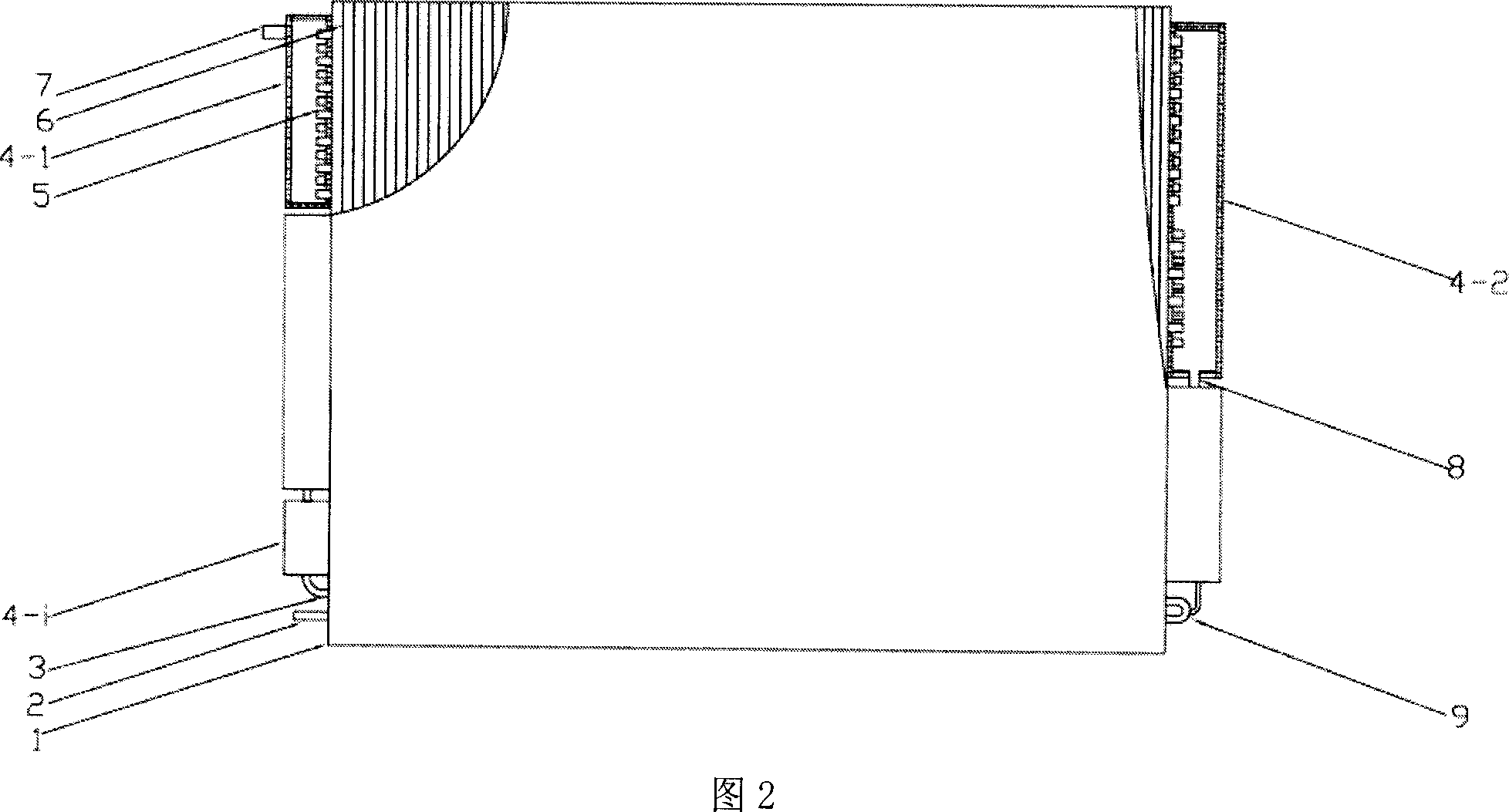

Heat exchanger assembly

InactiveUS20090120627A1Improve heat transfer effectCost-effective and flexible and efficientStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

A heat exchanger assembly includes a first single-piece manifold and a second single-piece manifold spaced from and parallel to the first single-piece manifold. Each of the first and second single-piece manifolds has a tubular wall defining a flow path. A plurality of flow tubes extend in parallel between the first and second single-piece manifolds and are in fluid communication with the flow paths. An insert having a distribution surface is slidably disposed in the flow path of the first single-piece manifold to establish a distribution chamber within the first single-piece manifold. A series of orifices defined in the distribution surface of the insert are in fluid communication with the flow path and the distribution chamber for uniformly distributing a heat exchange fluid between the flow path and the flow tubes.

Owner:MAHLE INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com