Patents

Literature

224results about How to "Increase cooling intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium-raising cooling agent, method for preparing same and use method

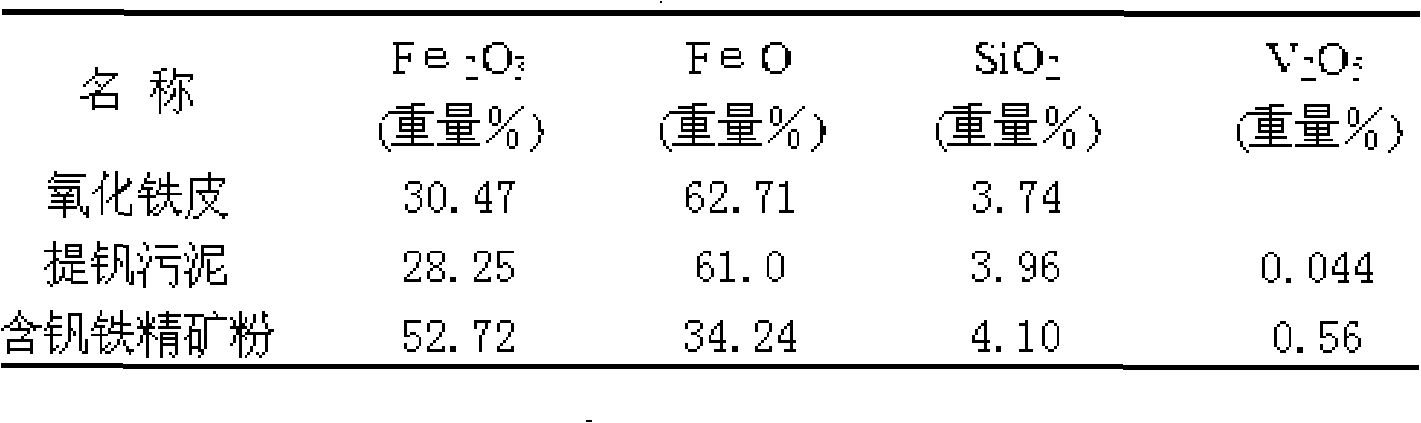

The invention relates to a vanadium extraction coolant and a preparation method and a use method thereof which belong to the field of metallurgy. The invention provides a novel vanadium extraction coolant and overcomes the defects of complex use of the existing coolant and the large operation difficulty of the existing vanadium extraction technique. The vanadium extraction coolant comprises 80 to 95 percent of the oxides of iron, 3 to 6 percent of SiO2, 0.1 to 0.6 percent of V2O5, 1 to 3 percent of MgCl2 and the rest is less inevitable unpurified elements; the total amount is 100 percent. The vanadium extraction coolant of the invention is collocated and pressed by adopting iron concentrate powder containing vanadium and ferric oxide (or vanadium extraction mud) with a bonding agent which not only has a simple preparation method, but also has high cooling intensity; besides, the using method is simple during the process of using the vanadium extraction; the vanadium extraction technique is more smooth; the quality of the vanadium slag and the quality of gun iron are more stable; the invention fully recycles the most resources of iron and vanadium in the coolant simultaneously when achieving the goals of ''removing vanadium and preserving carbon''.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

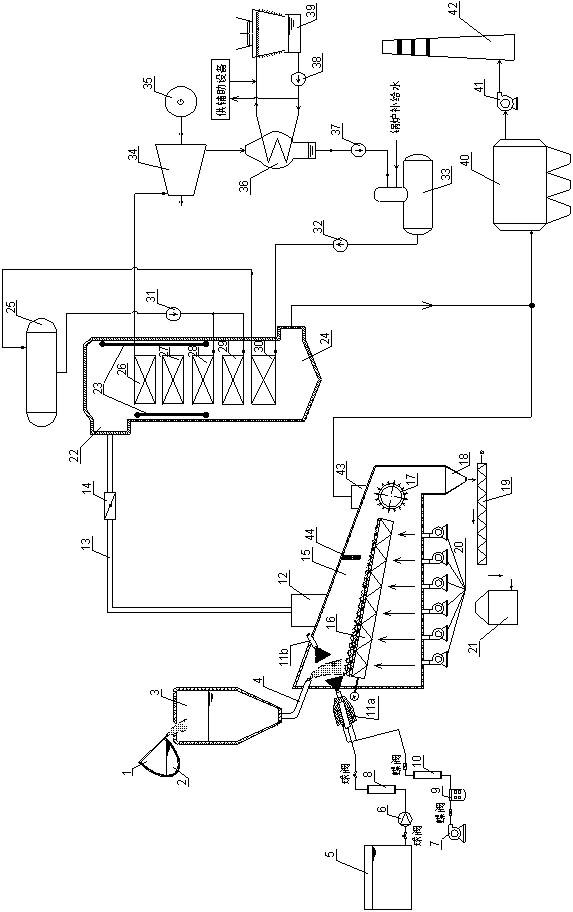

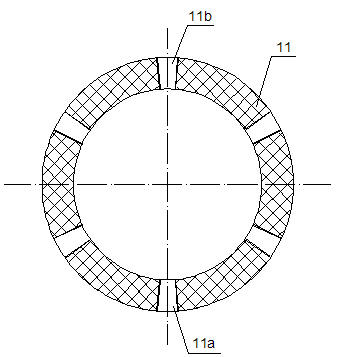

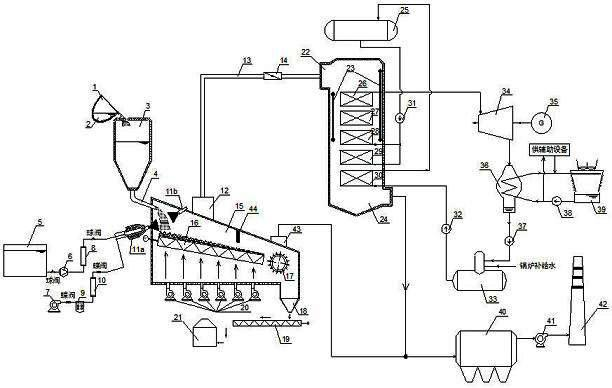

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

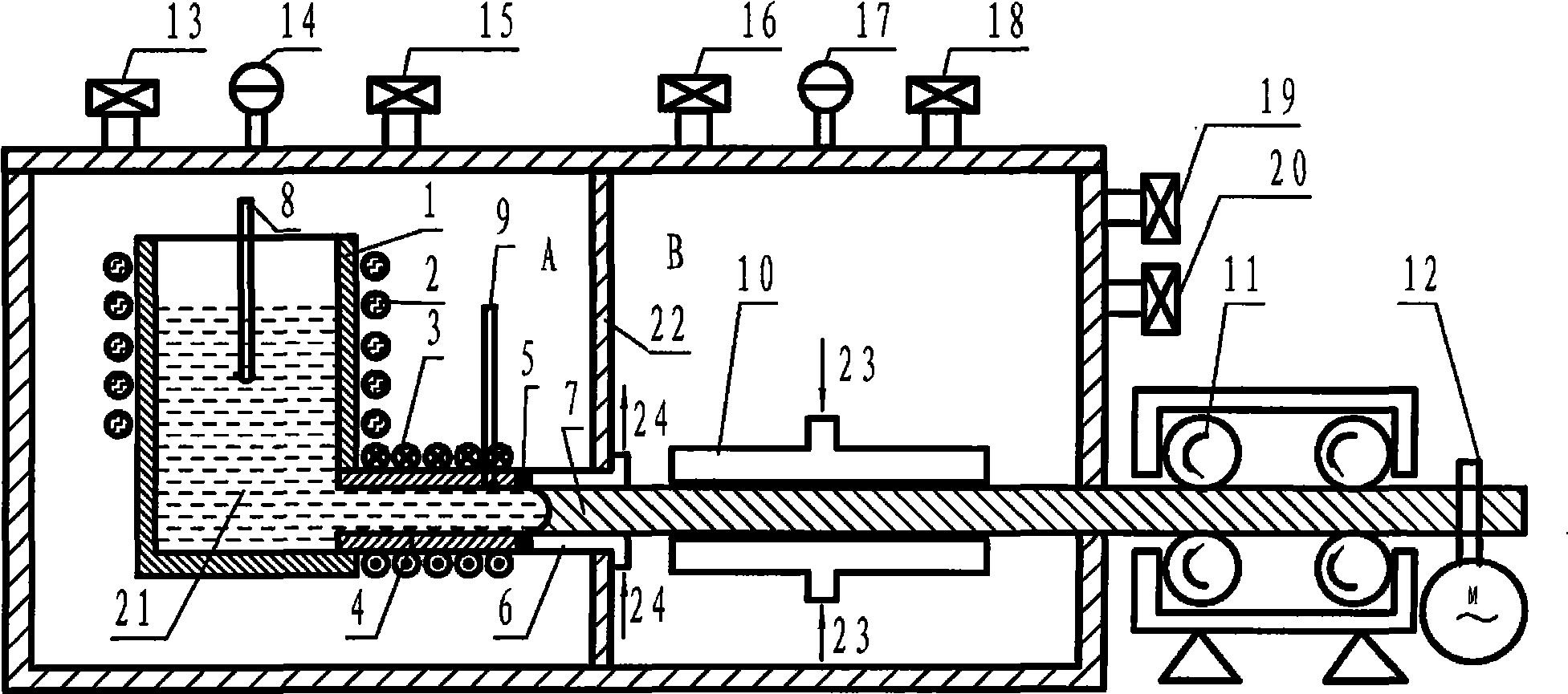

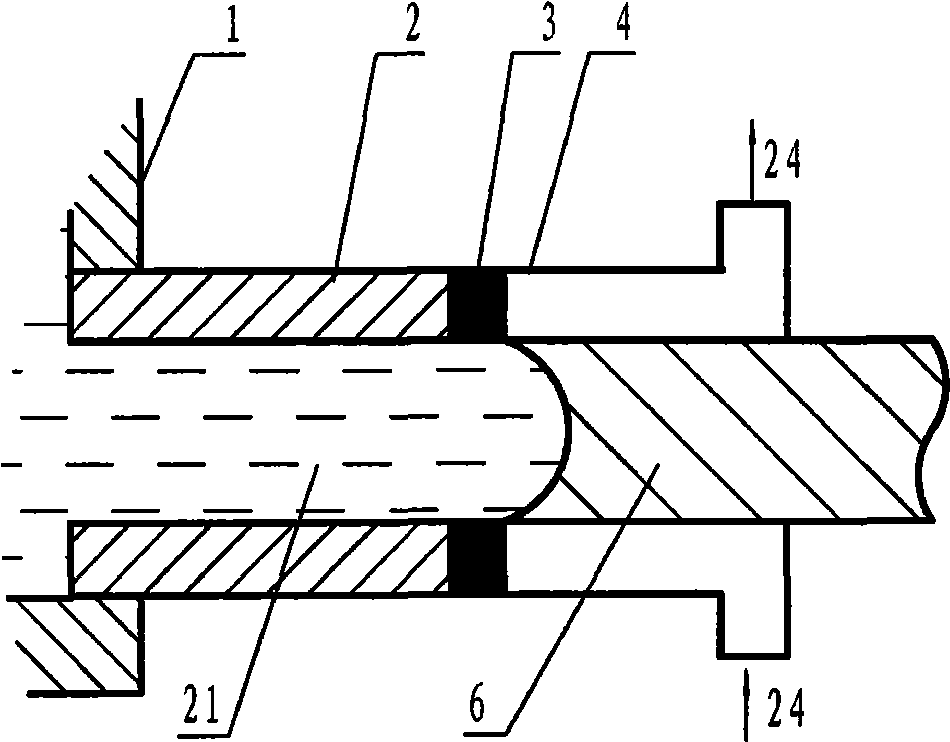

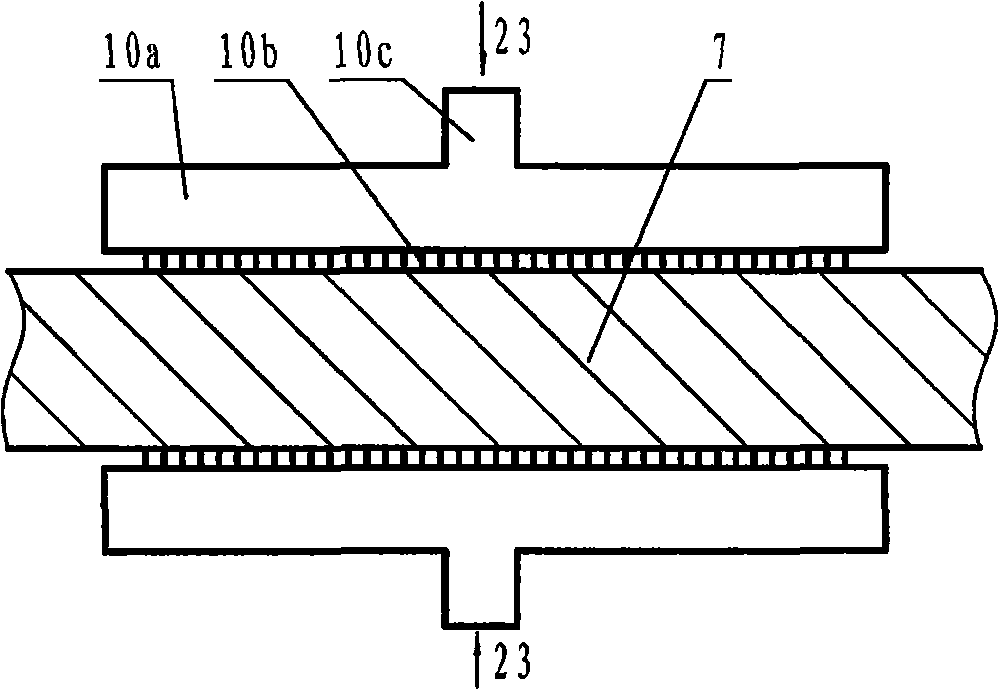

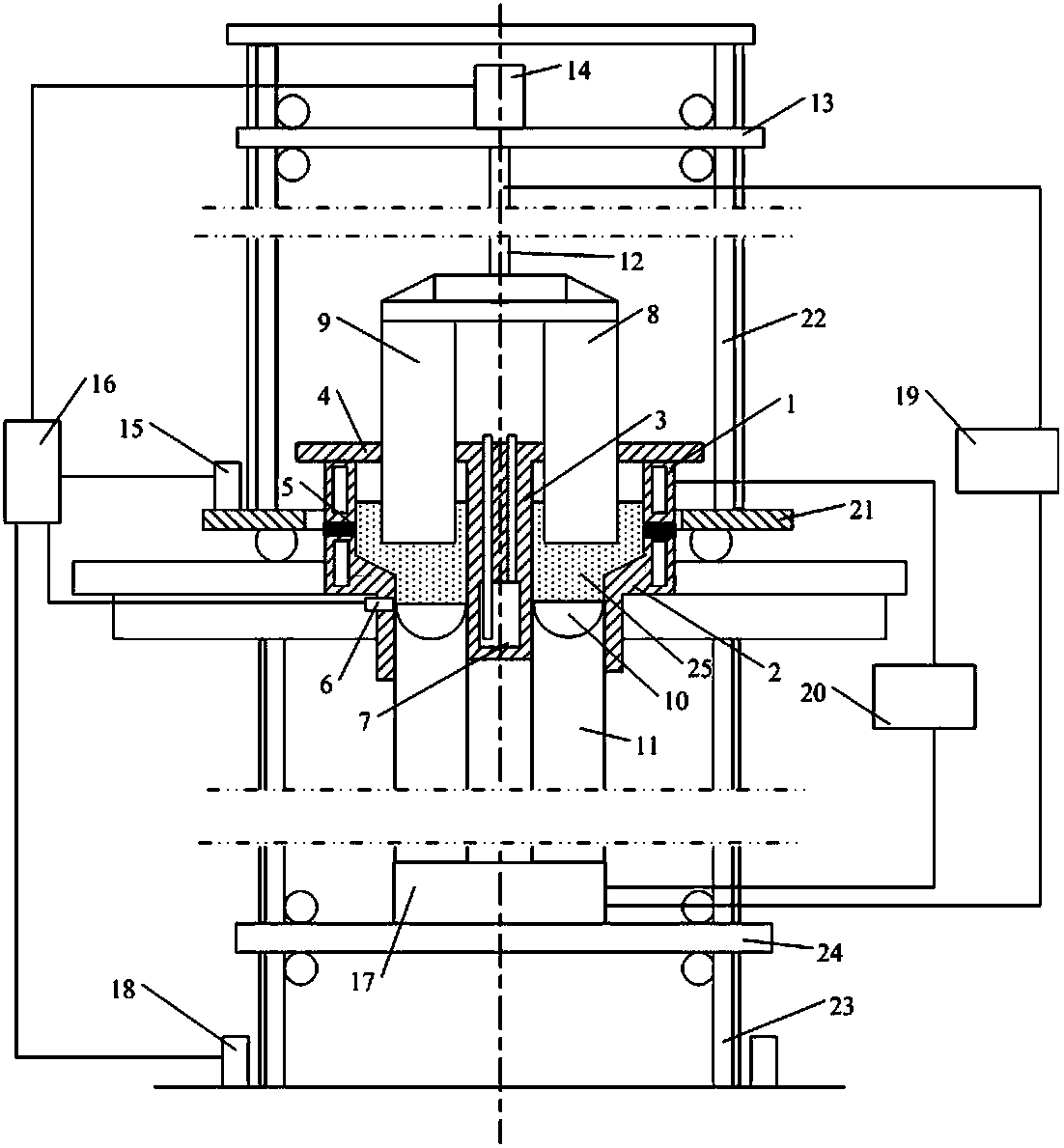

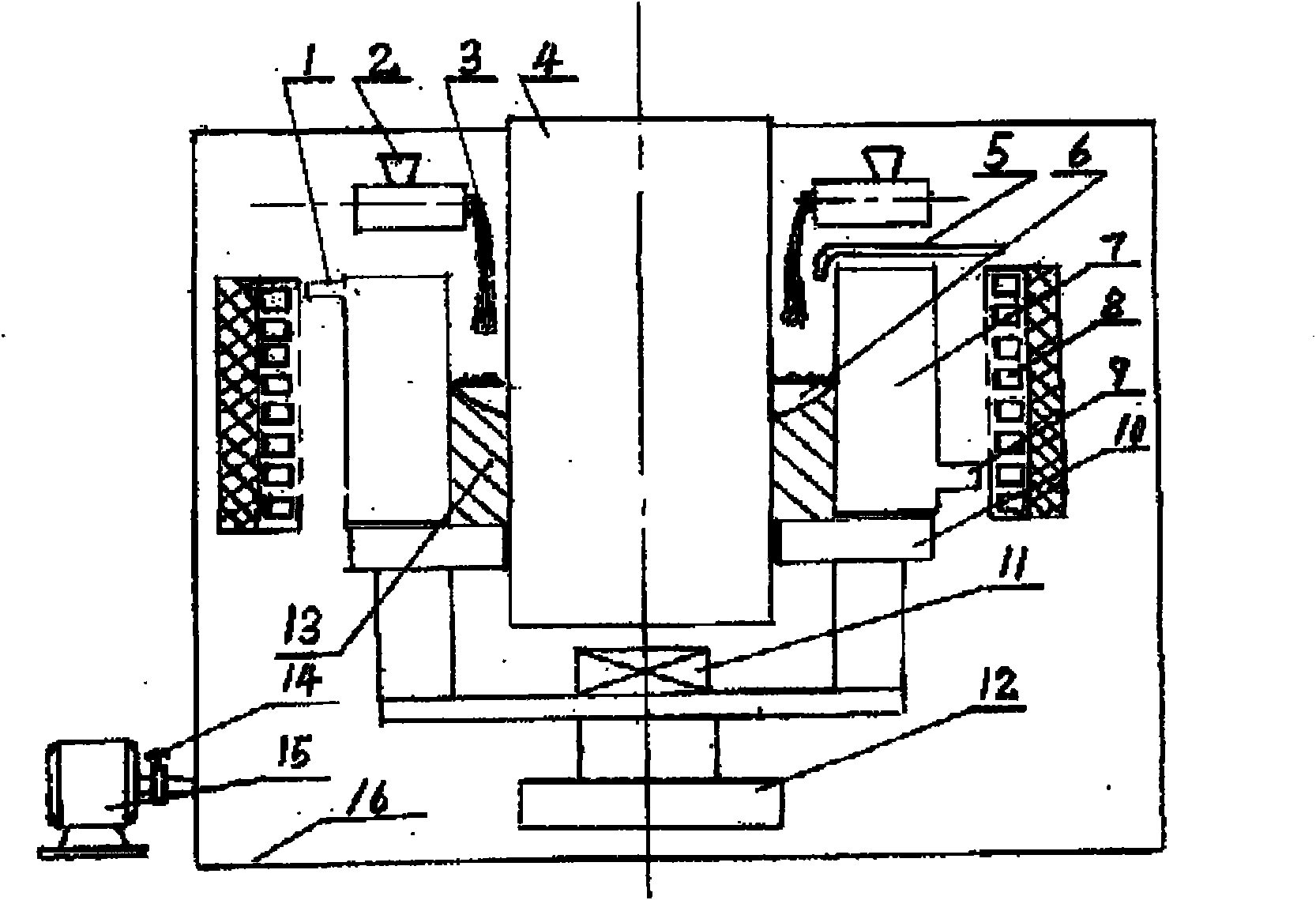

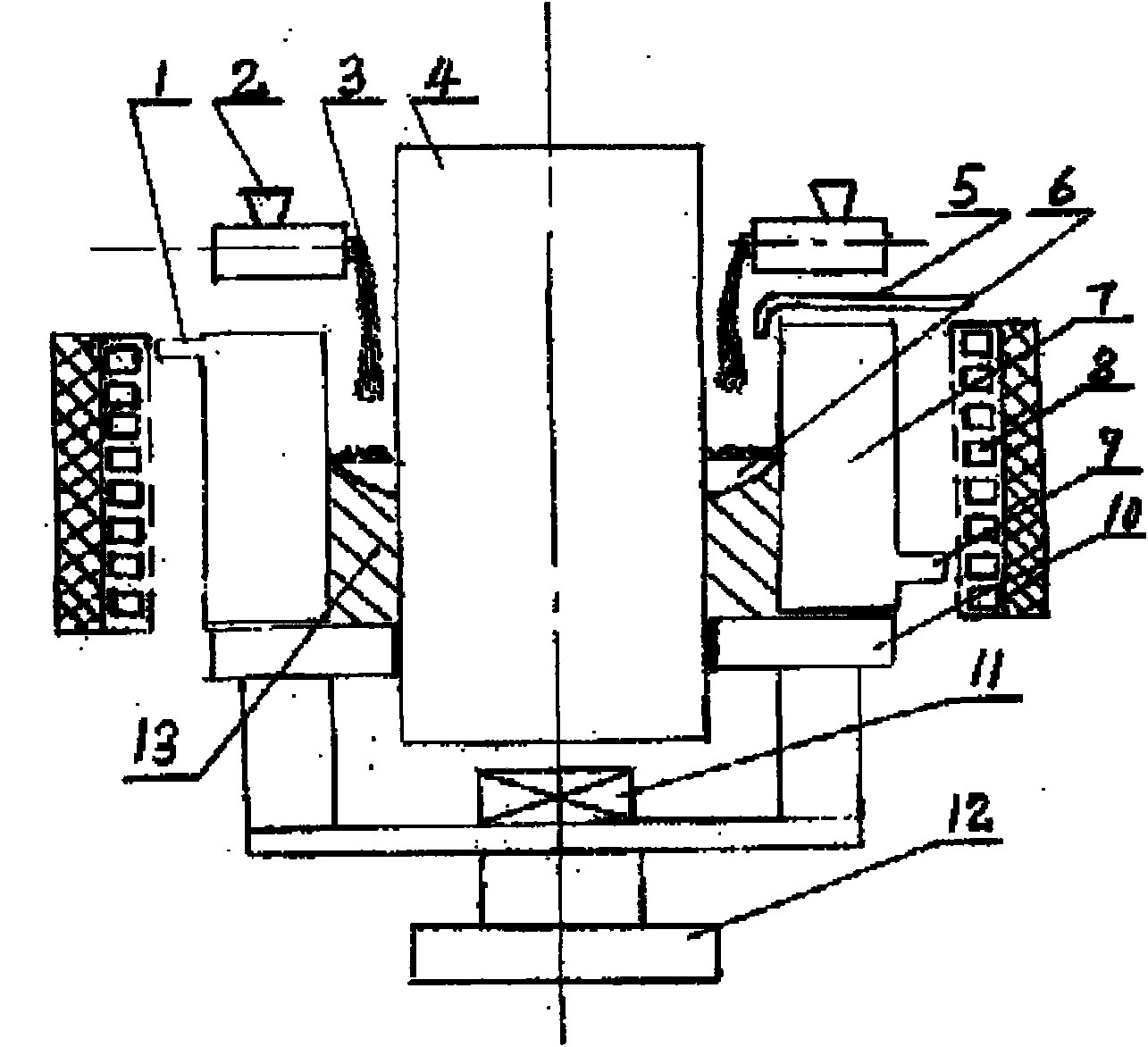

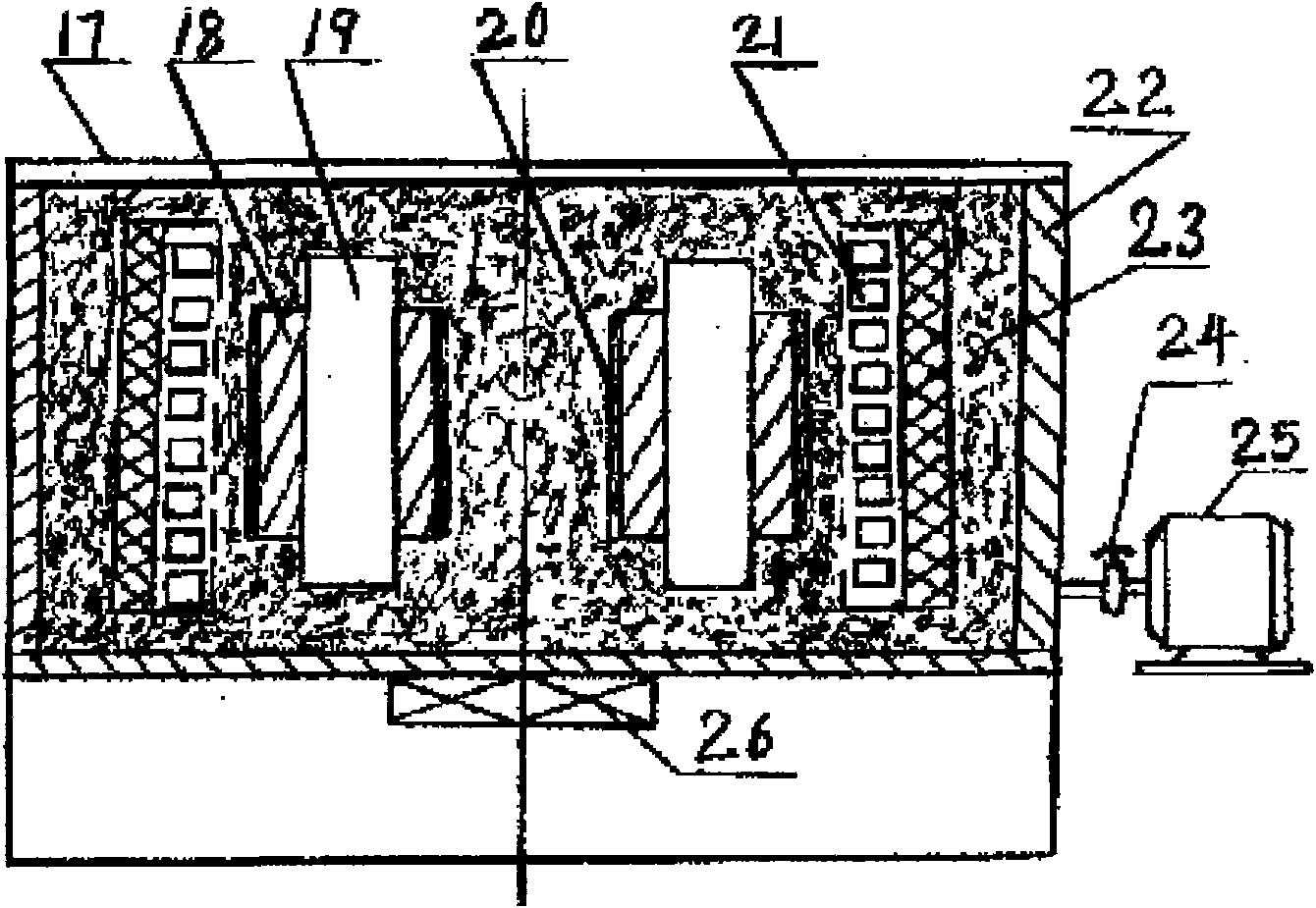

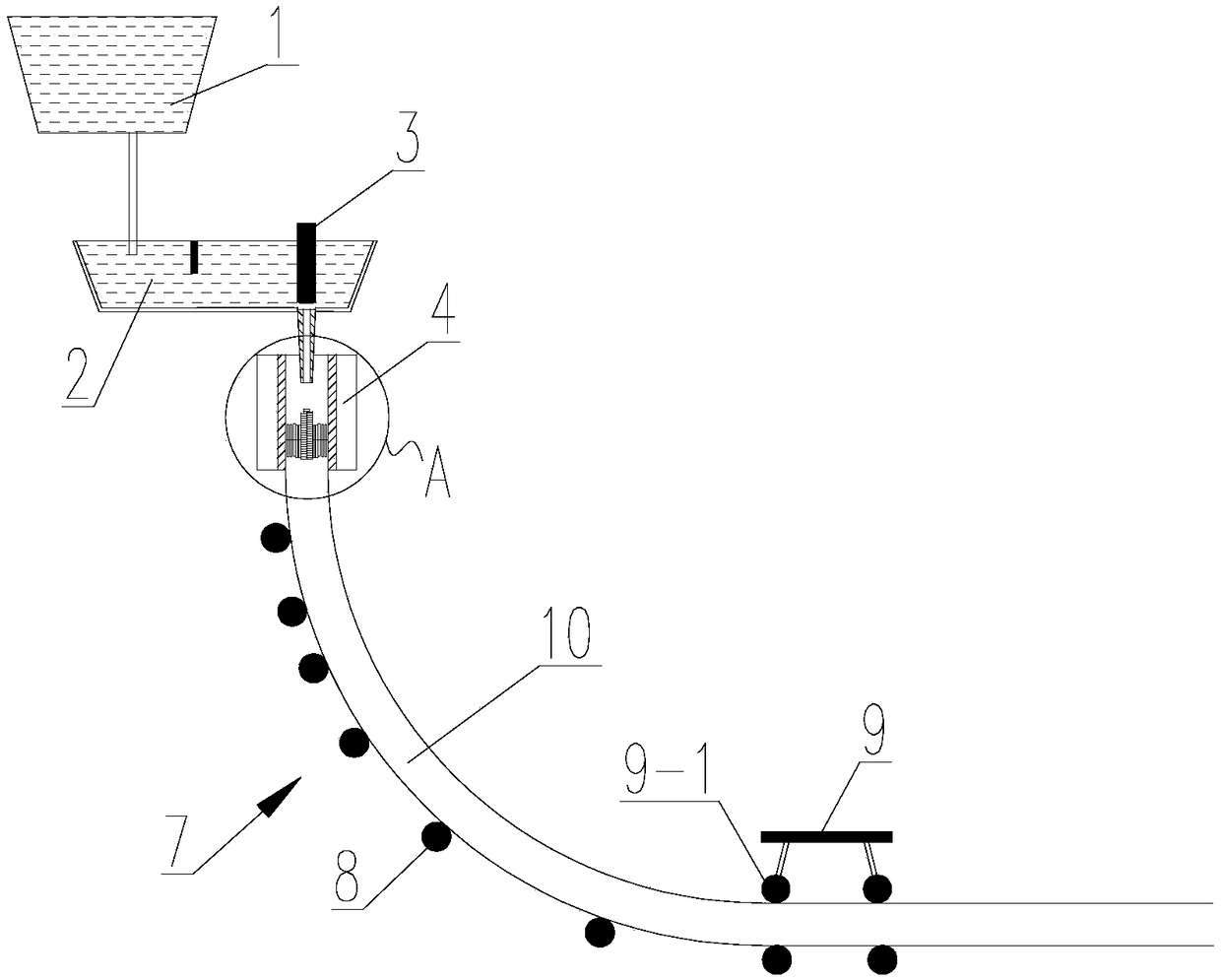

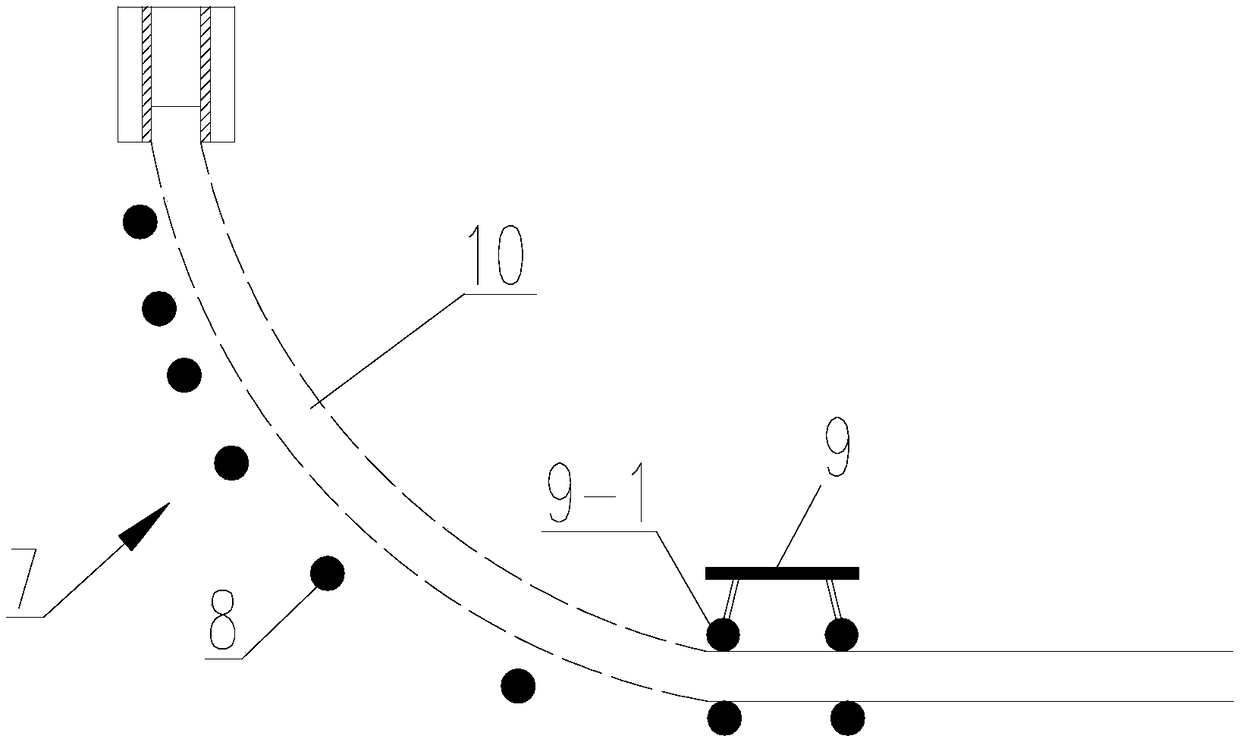

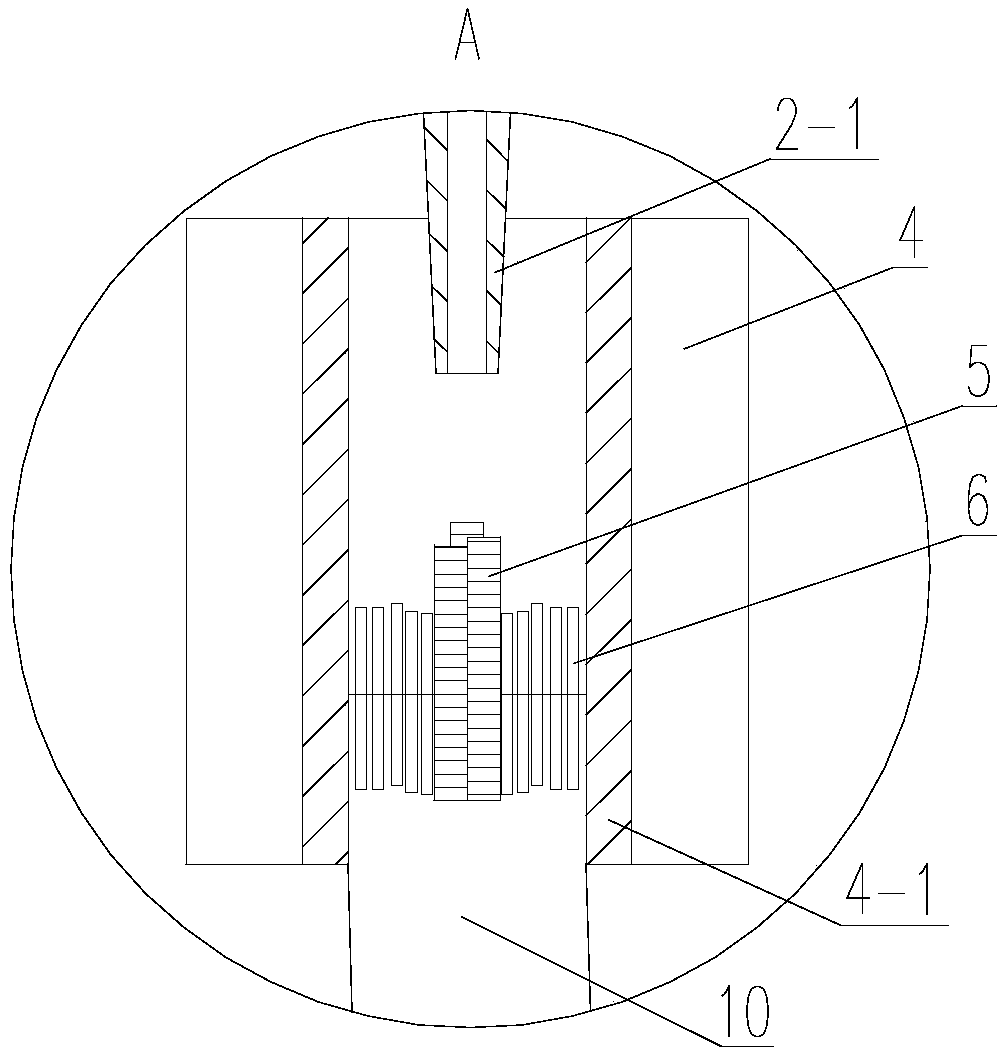

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624AShort production cycleLow costFurnace typesHeat treatment furnacesSteel platesQuenching

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperature reduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

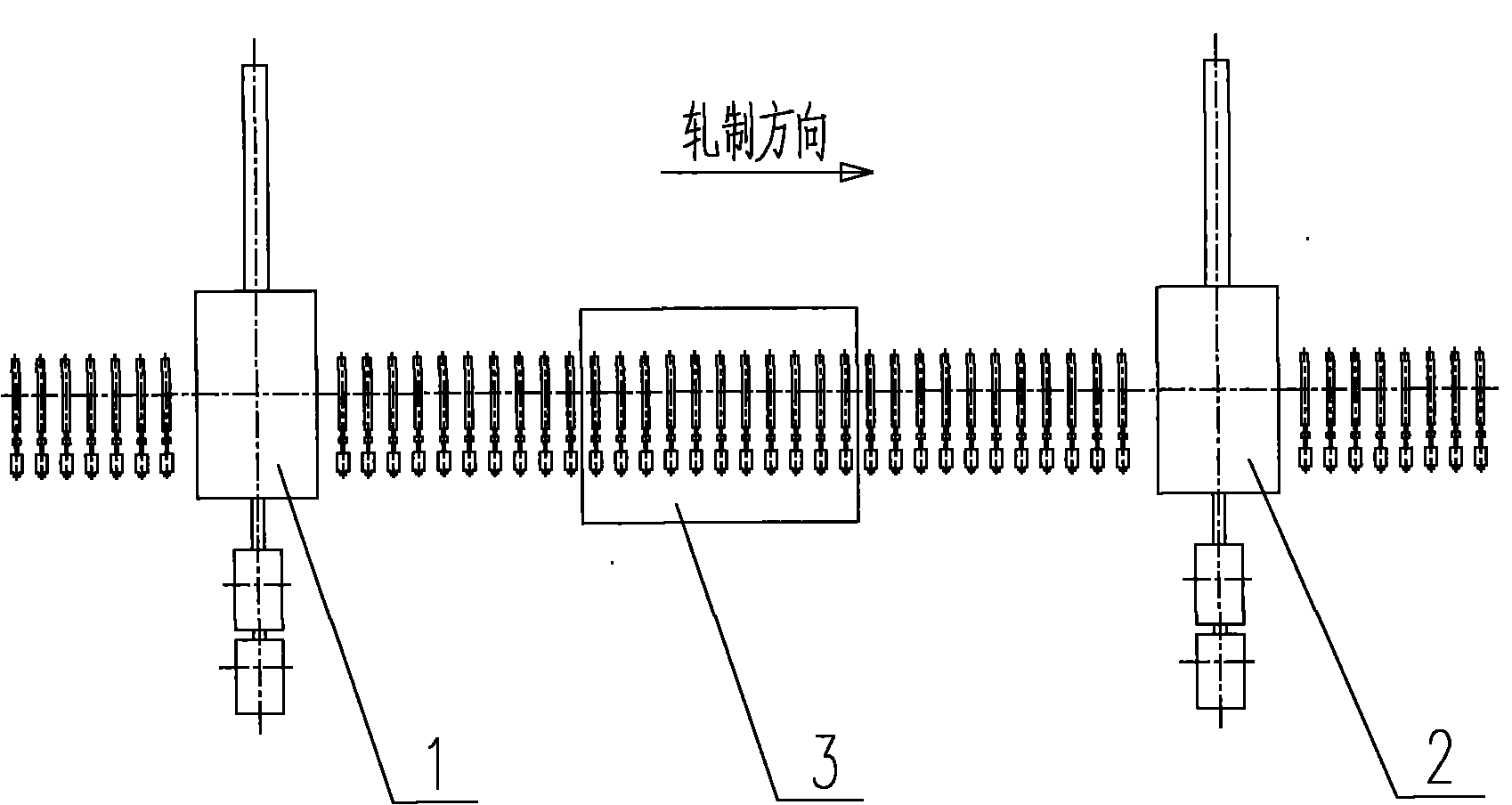

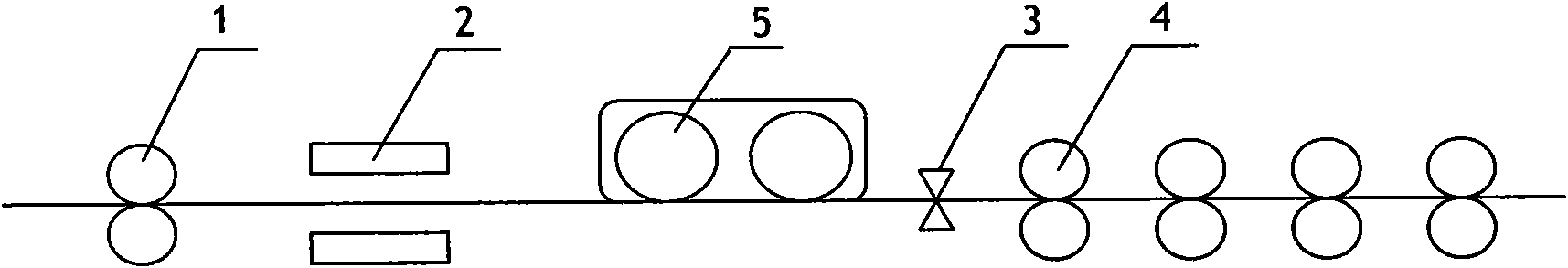

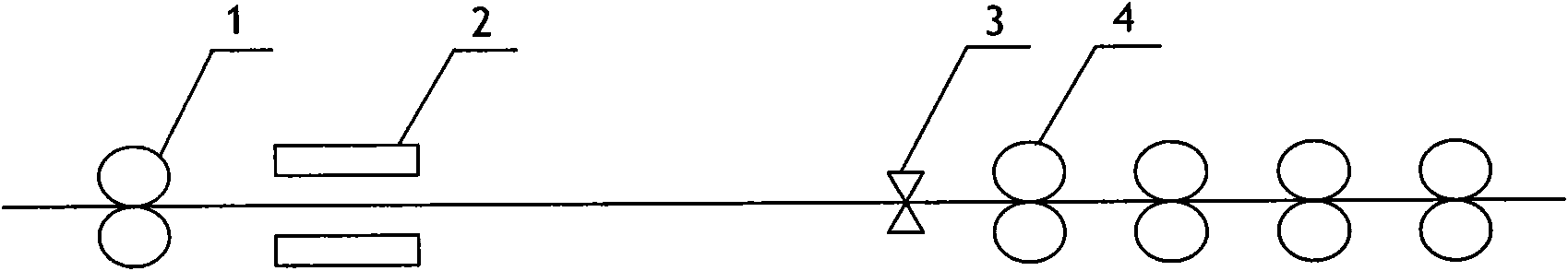

Cooling method of heavy and medium plate controlled rolling intermediate blank

InactiveCN101829688ALess investmentImprove applicabilityTemperature control deviceWater qualityWater cycling

The invention belongs to a producing and cooling technique of rolled steel, relating to a cooling method of a heavy and medium plate controlled rolling intermediate blank, which can be realized by both a single-stand heavy and medium plate roll and a double-stand heavy and medium plate roll. The cooling method comprises the following steps of: transmitting a roughly rolled intermediate blank with the thickness range of 30-110 mm in an austenite recrystallization zone into an intermediate controlled cooling zone from a transmission roller way for rapidly cooling to 800-950 DEG C, and then transmitting the intermediate blank into the roll for rolling in a non- recrystallization zone after short-time air cooling and temperature evening. In the intermediate cooling process, an upper collecting pipe and a lower collecting pipe with high density or ultra-high density are adopted to impact, jet and cool the intermediate blank, and specific technological parameters are accurately controlled by a computer. Water is cooling water for the roll with the pressure of 0.3-1.0 MPa in a common water circulating system for workshops. The intermediate cooling holding time is 30-70% shorter than that of the conventional process so that the production efficiency is improved, and due to austenite grain refinement after intermediate controlled cooling, the mechanical properties of a steel plate can be improved.

Owner:UNIV OF SCI & TECH BEIJING

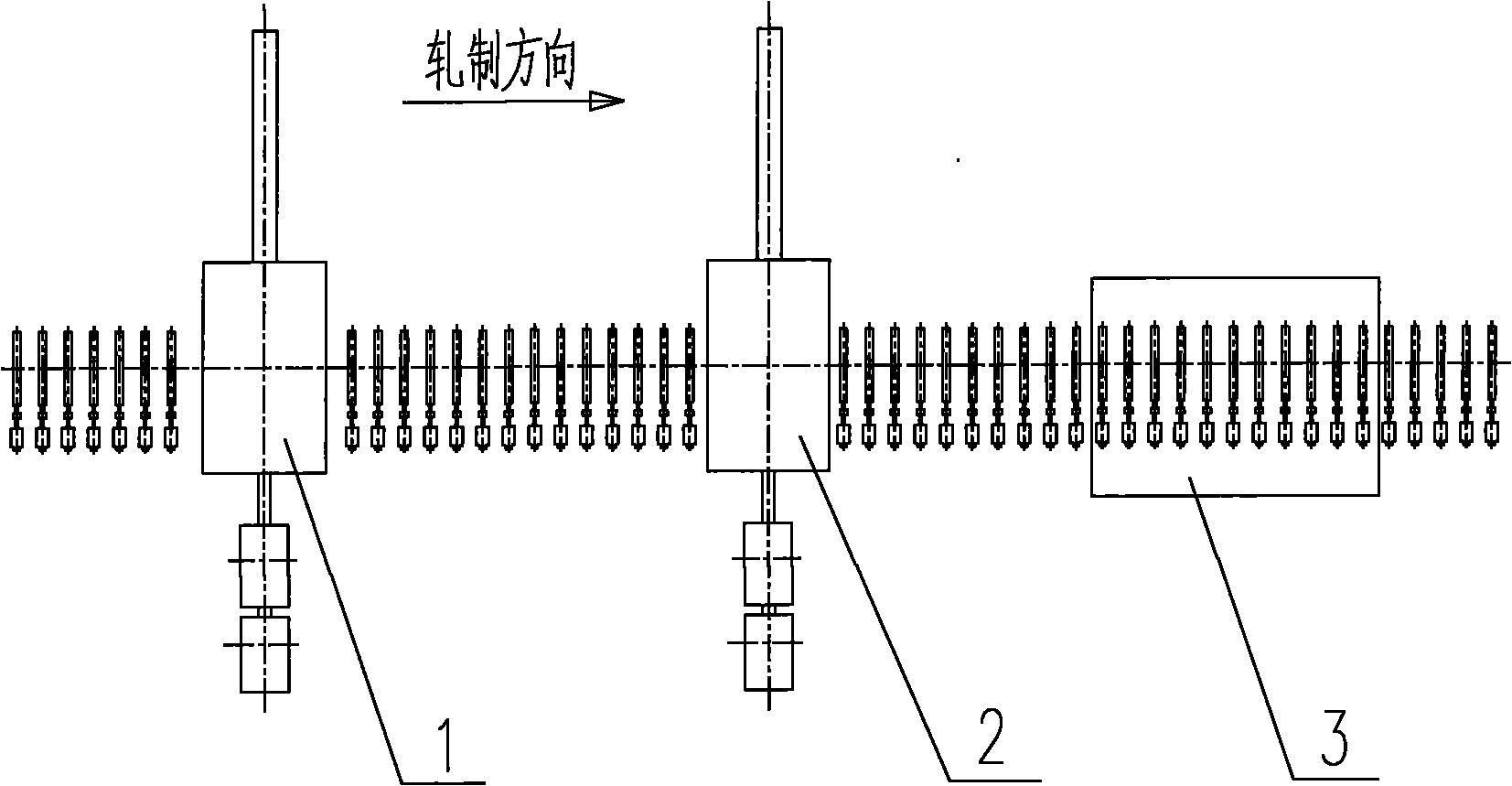

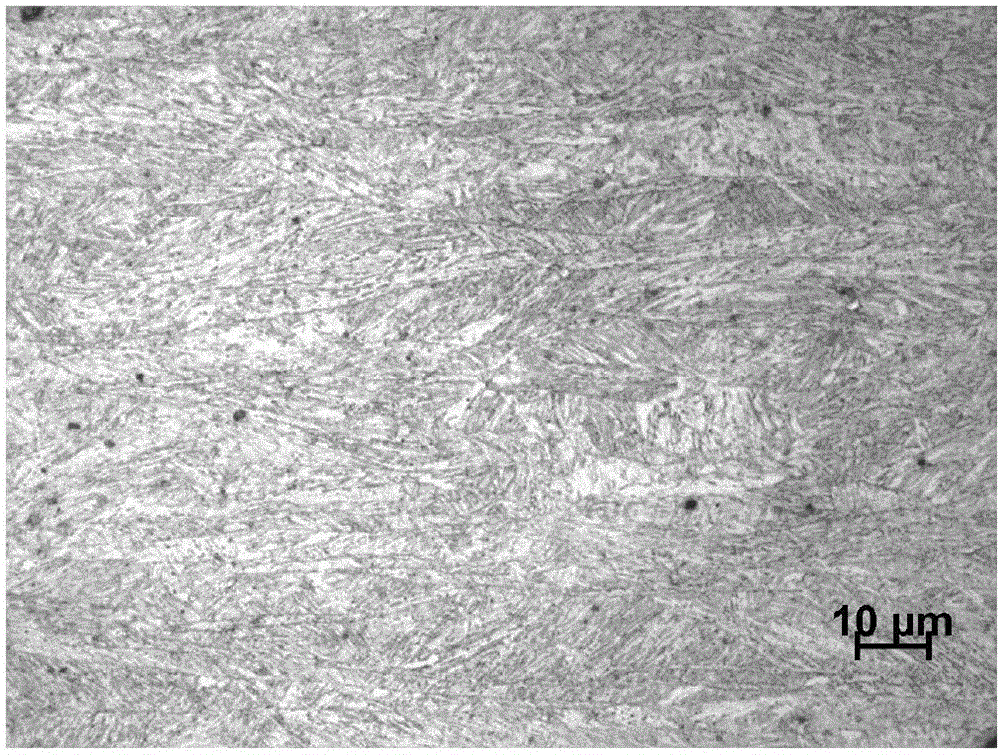

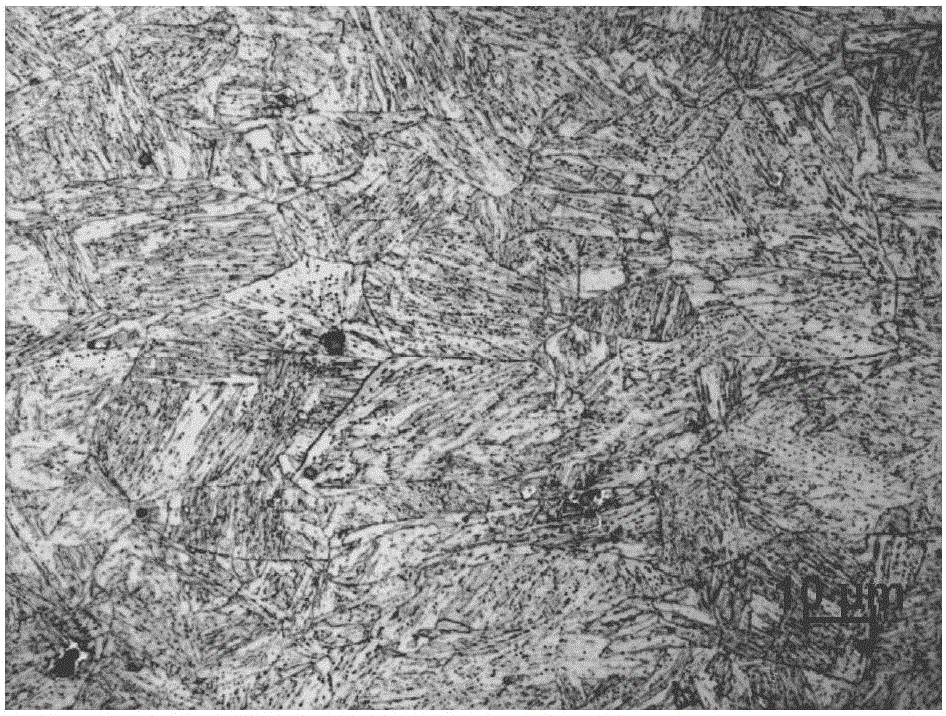

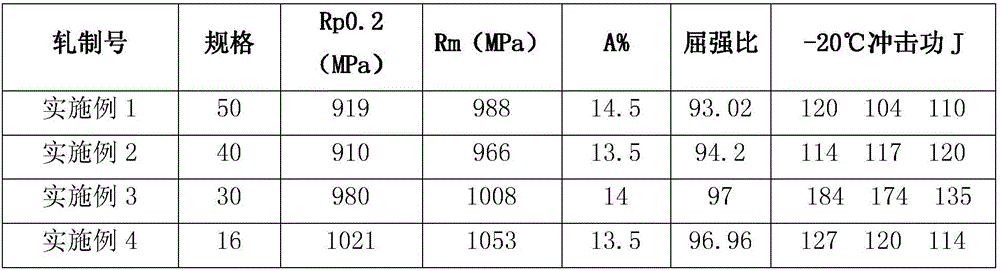

Method for producing Q890 high-strength steel intermediate-thickness plate through online quenching

The invention provides a method for producing a Q890 high-strength steel intermediate-thickness plate through online quenching. The method comprises the steps that rolling is carried out, wherein the heating temperature of a heating furnace is 1180+ / -30 DEG C, the total heating time is 1.0-1.2 hour, two-stage rolling is adopted, rough rolling and scale removing are conducted for two passes, finish rolling and scale removing are conducted for two passes, the temperature at the beginning of the rough rolling is 1050-1150 DEG C, the thickness of an intermediate slab is larger than or equal to 80 mm, the temperature at the beginning of the second-stage rolling is lower than or equal to 860 DEG C, and the finishing rolling temperature is lower than or equal to 830 DEG C; cooling is conducted, wherein water cooling online quenching is adopted, the temperature of the intermediate slab is 780+ / -10 DEG C when entering water, the self-tempering temperature is lower than or equal to 250 DEG C, and the cooling speed is higher than 15 DEG C per second; and heat treatment is conducted, wherein the tempering temperature is 500+ / -10 DEG C, the heating rate is 1.8+ / -0.2 min / mm, the heat preservation time is 20-30 min, the temperature is lowered to the indoor temperature through air cooling, and then a double-phase structure of a lath martensite and a lath bainite is obtained. Online quenching shortens the technological process and reduces cost.

Owner:NANJING IRON & STEEL CO LTD

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

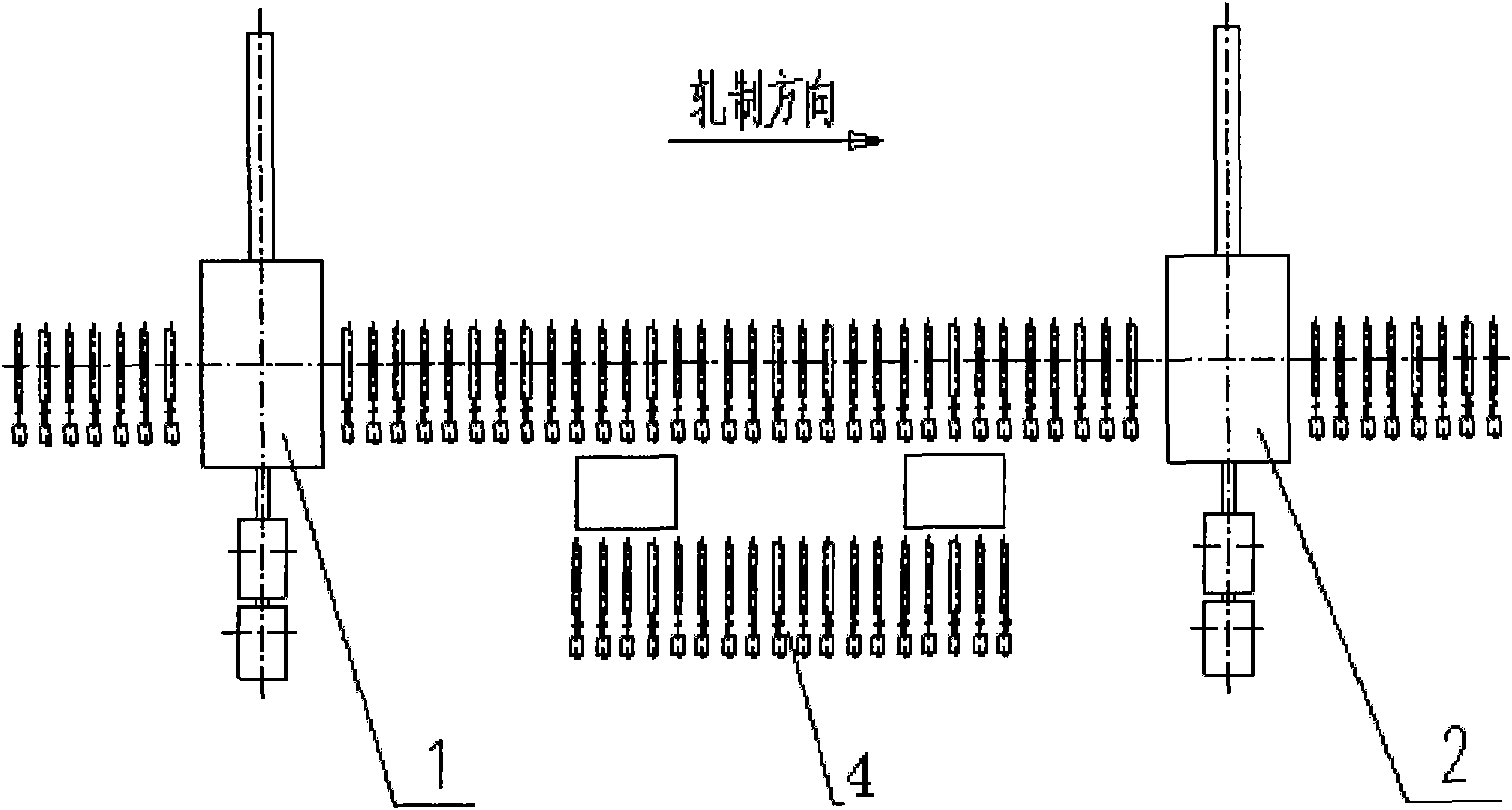

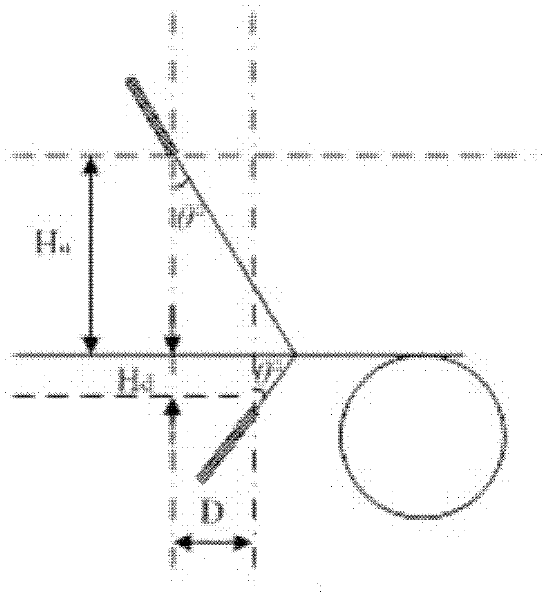

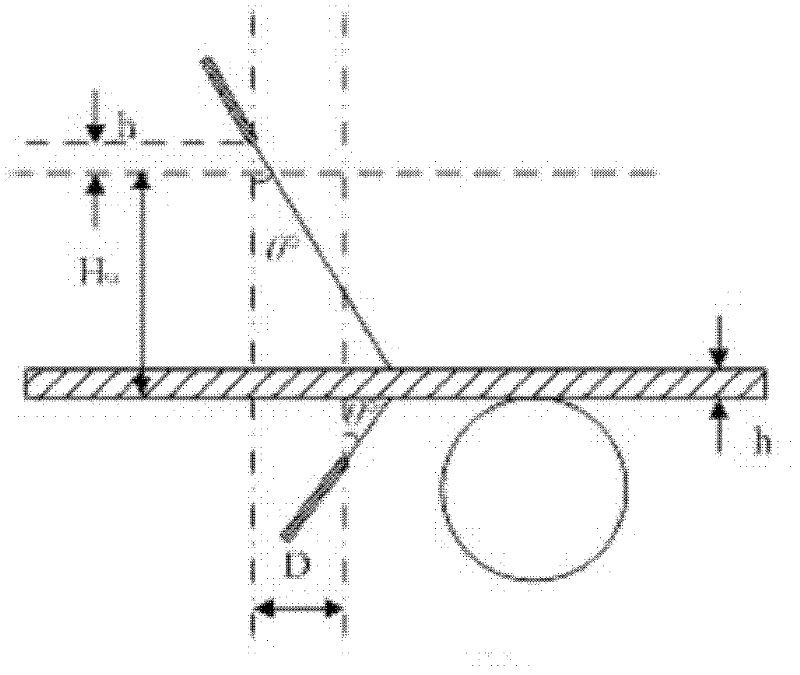

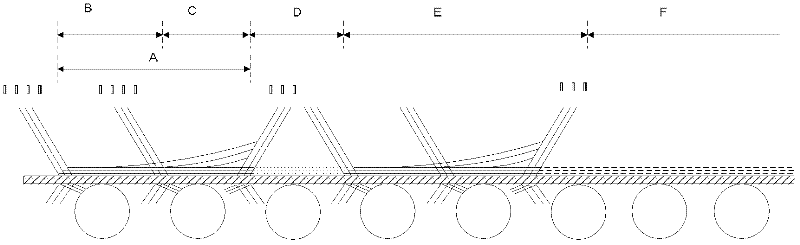

Method for improving ultra-fast cooling uniformity of medium and heavy plate after rolling

ActiveCN102371283AIncrease cooling intensityImprove cooling uniformityTemperature control deviceWork treatment devicesJet flowWater discharge

The invention relates to a method for improving the ultra-fast cooling uniformity of a medium and heavy plate after rolling, the position of a jet flow header can be reasonably adjusted, and the method is characterized in that, 1) the position of an upper header is set as follows: an ultra-fast cooling upper header framework is adjusted up and down in the vertical direction, and the conditions ofthe formula: Hu*tg(theta)=Hd*tg(theta)+D are met; 2) the setting of a soft water seal of a washing water region on the upper surface of a steel plate meets the conditions of the formula: 1 / 2*the sum of flow rates of all forward headers in the region<water amount of the soft water seal<2*the sum of the flow rates of all the forward headers in the region; 3) the flow rate of a lower header is increased to compensate the heat exchange capacity of the lower surface, and the optimal ratio of water supply to water discharge is set to be between 1: 1.1 and 1: 2.5; 4) the measure of clearing residualcooling water on the upper surface is taken, side spraying devices are arranged on the two sides of an ultra-fast cooling roller table, a middle spraying device is arranged on the upper header framework and strong blowing devices are arranged at the two ends of the ultra-fast cooling device; and 5) the head and tail shading control of the speed of the roller table is performed as follows: an ultra-fast cooling control system is used for transformation control of the speed of the roller table of a steel plate head and a tail part low-temperature region according to a speed curve. By adopting the method, the cooling uniformity of a steel plate of the medium and heavy plate after rolling under ultra-fast cooling condition can be realized.

Owner:NORTHEASTERN UNIV

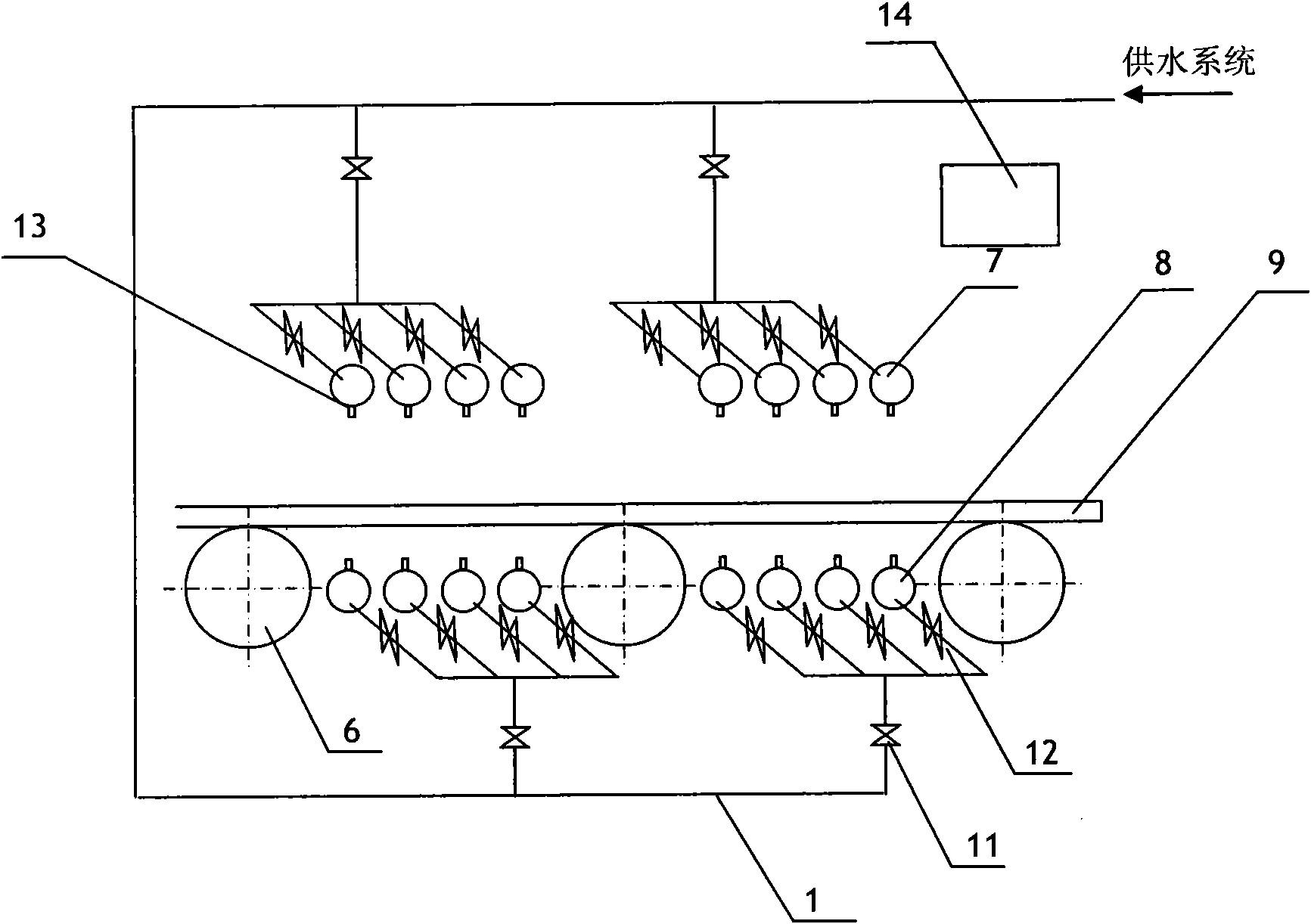

Device and method for cooling intermediate rolled blank of hot rolled strip

ActiveCN101972782ALess prone to overcoolingCool evenlyTemperature control deviceWork treatment devicesPipe waterWater quality

The invention provides a device and method for cooling an intermediate rolled blank of a hot rolled strip. The device comprises an upper collecting pipe arranged above roller beds and a lower collecting pipe arranged between the roller beds, wherein the upper collecting pipe and the lower collecting pipe are both provided with nozzles and opening and closing control valves and are connected with a workshop circulating water system through collecting pipe water supply pipelines; and the collecting pipe water supply pipelines are provided with flow control valves. The opening and closing control valves and the flow control valves are controlled by a programmable controller. A plurality of groups of cooling collecting pipes which can be independently controlled to open and close and has smaller flow are arranged between every two roller beds, the intermediate blank is cooled by adopting water jet, and the cooling speed is correspondingly dynamically controlled according to the transmission speed of the intermediate blank. The invention has the advantages of relatively simple structure of the device, low requirement for water quality, good flow stability and high production efficiency, and is convenient to maintain and free of limit of speed raising of a roughing mill and deceleration of throwing steel; rolling mill cooling water is adopted and a single water supply and drainage system is not needed; and grains of the intermediate blank are remarkably refined, and the mechanical property of a steel plate is improved.

Owner:UNIV OF SCI & TECH BEIJING

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

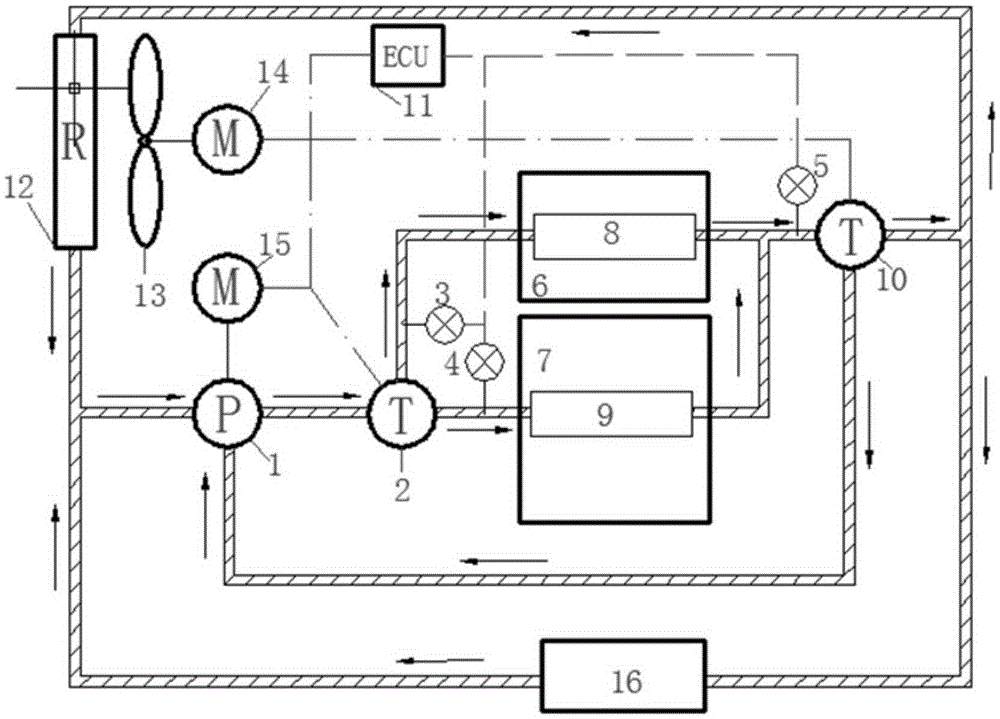

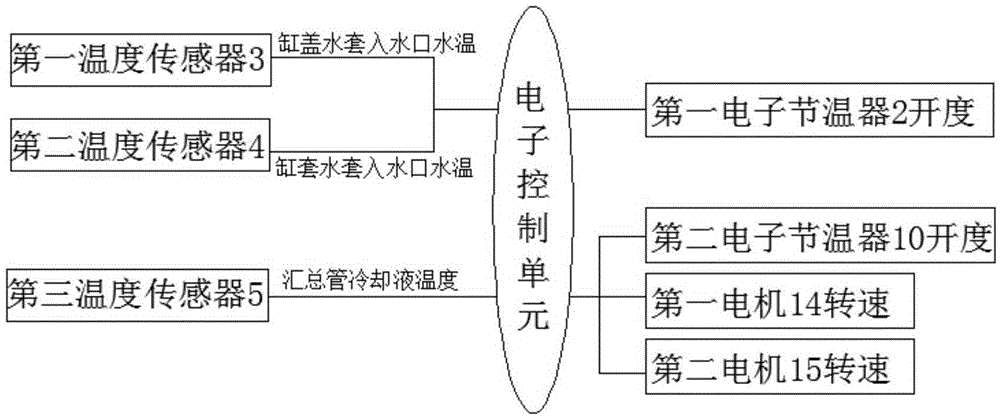

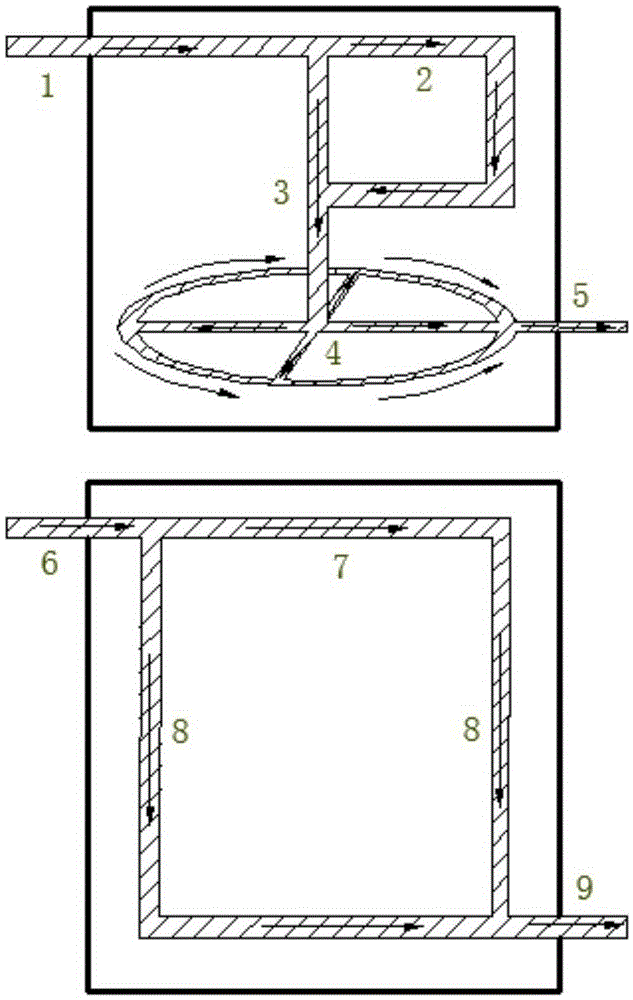

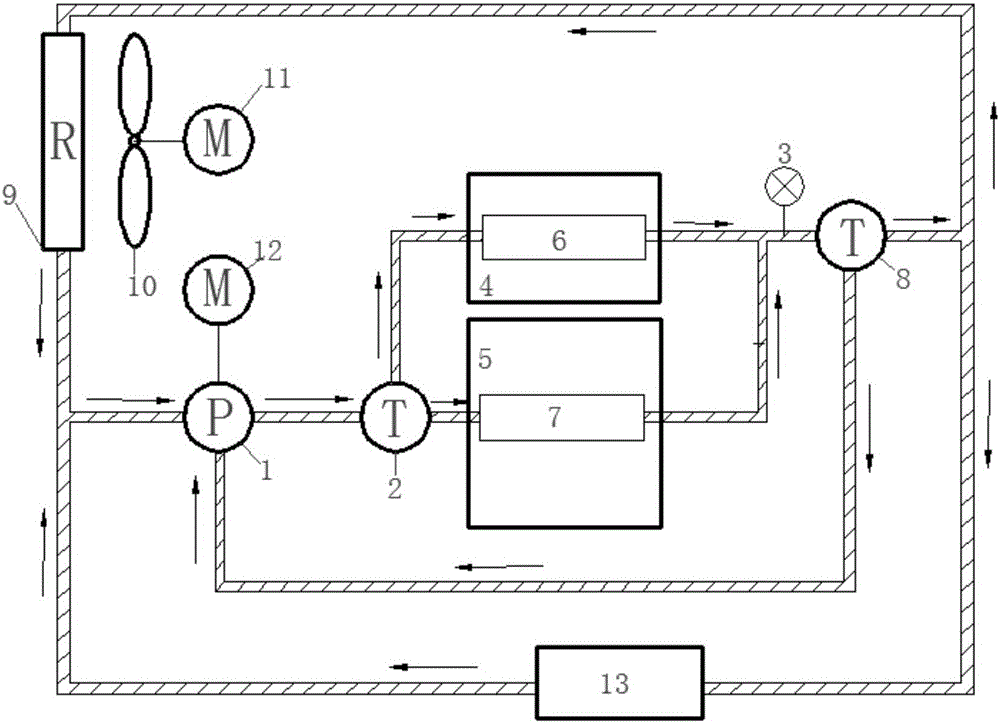

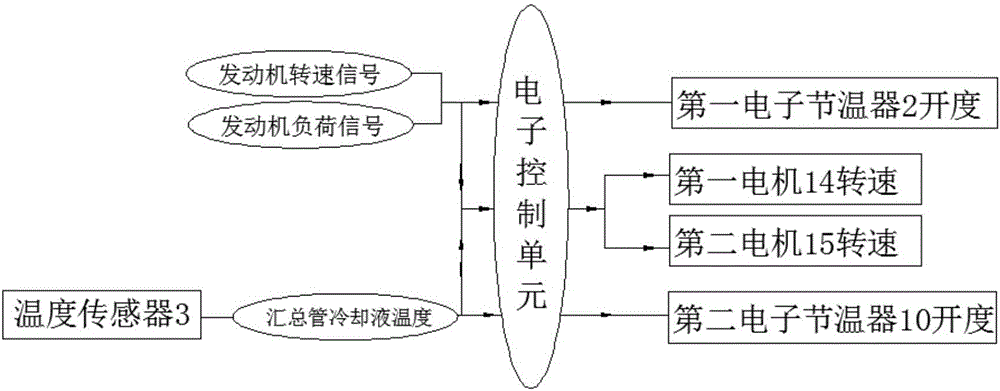

Intelligent cooling system based on split cooling and reverse cooling for engine, and control method

ActiveCN105422247AImprove fuel economyImprove economyLiquid coolingCoolant flow controlExpansion tankLiquid temperature

The invention discloses an intelligent cooling system based on split cooling and reverse cooling for an engine, and a control method. The cooling system comprises a cylinder cover water jacket, a body water jacket, an electronically-controlled water pump, electronic thermostats, an electronically-controlled fan, a heat dissipater, an expansion water tank, temperature sensors, motors and an electronic control unit. During a working process of the system, the electronically-controlled water pump pumps a cooling liquid in the engine, the first electronic thermostat controls the cooling liquid to enter the cylinder cover water jacket and the body water jacket according to cooling liquid temperature signals of a cylinder cover and a body respectively, flow from top down, and flow out after the cooling the cylinder cover and the body; and the second electronic thermostat distributes the flow rate of the cooling liquid entering large circulation and small circulation according to a cooling liquid temperature of a main tube, and the cooling liquid is circulated and then pumped in the engine to cool. The cooling system disclosed by the invention is capable of accurately distributing the flow rate of the cooling liquid in the cylinder body and the body of the engine, reducing the phenomenon of non-uniform cooling, and shortening the warm-up time of the engine; and the heat states of heated components are optimized through the reverse cooling.

Owner:ZHEJIANG UNIV

High-temperature furnace roller for CSP (Compact Strip Production) heating furnace

InactiveCN102618716ASimple structureEasy to makeCharge manipulationFurnace typesHeating furnacePipe support

The invention discloses a high-temperature furnace roller for a CSP (Compact Strip Production) heating furnace. The high-temperature furnace roller comprises a tubular roller body steel shaft, wherein the outer wall of the roller body steel shaft is provided with roller rings at intervals; the outer wall of the roller body steel shaft between adjacent roller rings is provided with a heat-insulating lining; a water-cooling pipe is arranged in the roller body steel shaft; one end of the water-cooling pipe is provided with a water-cooling pipe supporting clamp seat; a roller body end head baffleplate which is hermetically connected with the inner wall of the roller body steel shaft is arranged outside the end part of the water-cooling pipe supporting clamp seat; a first cavity is formed between the roller body steel shaft and the water-cooling pipe; the pipe wall of the water-cooling pipe close to the water-cooling pipe supporting clamp seat is provided with water outlet through holes which are uniformly distributed along circumference; and the water outlet through holes are communicated with a water inlet end in the water-cooling pipe and the first cavity to form a closed water path. The high-temperature furnace roller has the advantages of simple structure, convenience and quickness in manufacturing, convenience in use and maintenance, low cost, application temperature reaching up to 1,300 DEG C and suitability for being widely applied to the technical field of thermal equipment of industrial furnaces.

Owner:武汉钢铁有限公司

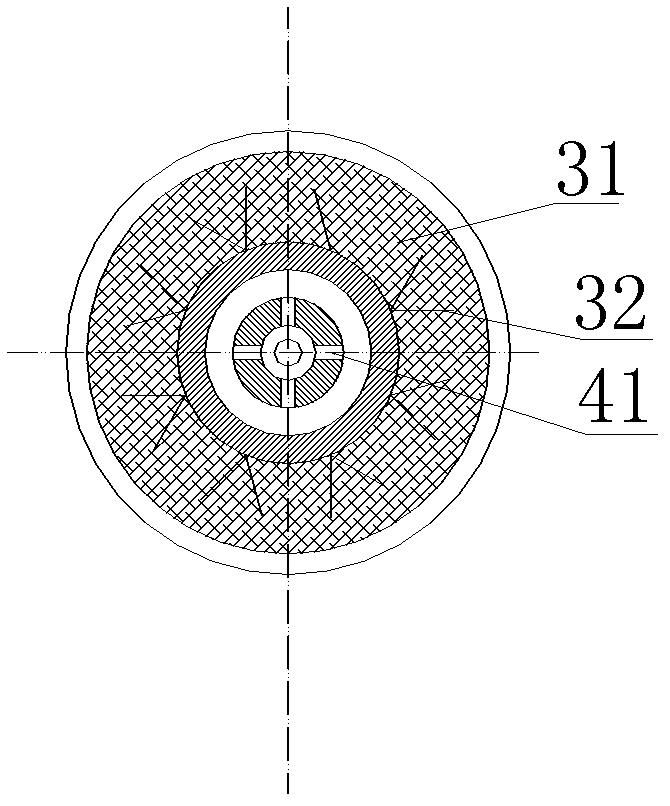

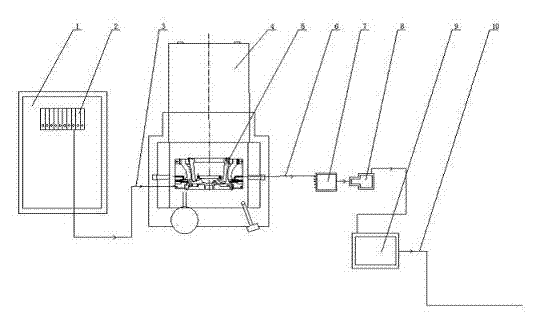

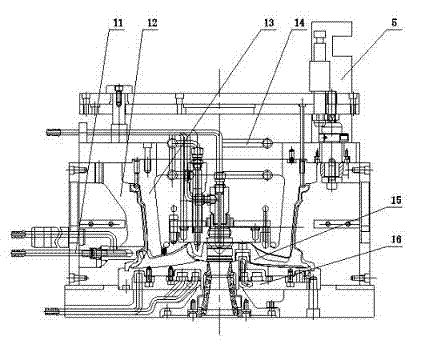

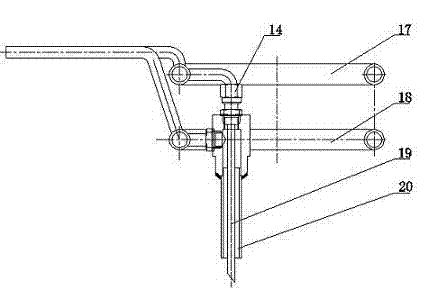

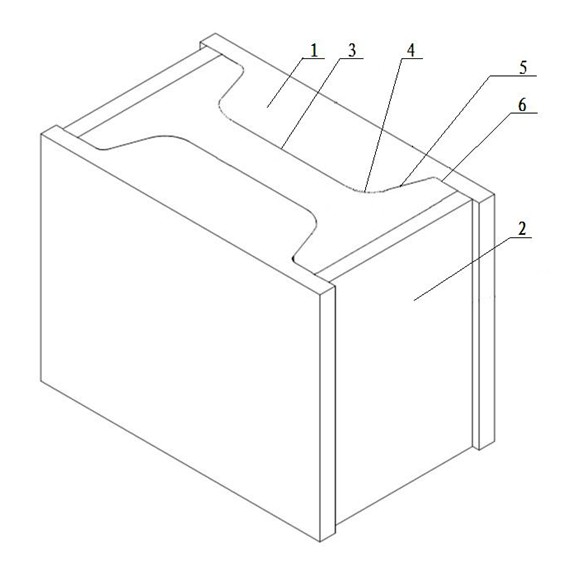

Automobile wheel hub low-pressure casting vacuum water cooling mold system

The invention relates to an automobile wheel hub low-pressure casting vacuum water cooling mold system. A low-pressure casting mold comprises an upper die, a lower die and four side molds; the upper die, the lower die and the four side molds are combined to form into a casting chamber of a wheel hub to be cast; a cooling system comprises a water flow control cabinet, a water storage tank, a water storage buffer and a vacuum pump; the water flow control cabinet is communicated with a low-pressure casting machine platform through an input water pipe; the low-pressure casting machine platform is communicated with the water storage tank through an output water pipe; the water storage tank is connected with a water return pipe; cooling devices which are connected with the input water pipe and the output water pipe respectively are arranged inside empty chambers of the upper die, the lower die and the four side molds. The automobile wheel hub low-pressure casting vacuum water cooling mold system has the advantages of being scientific in design, reasonable in structure, convenient to operate, environment-friendly, high in cooling intensity and good in cooling effect, effectively improving the production efficiency, enabling the cooling devices in the mold to be uniformly arranged and the water flow speed to be adjustable, significantly reducing the production cost, improving the working environment and reducing the labor intensity of operating personnel.

Owner:TIANJIN LIZHONG GRP CO LTD

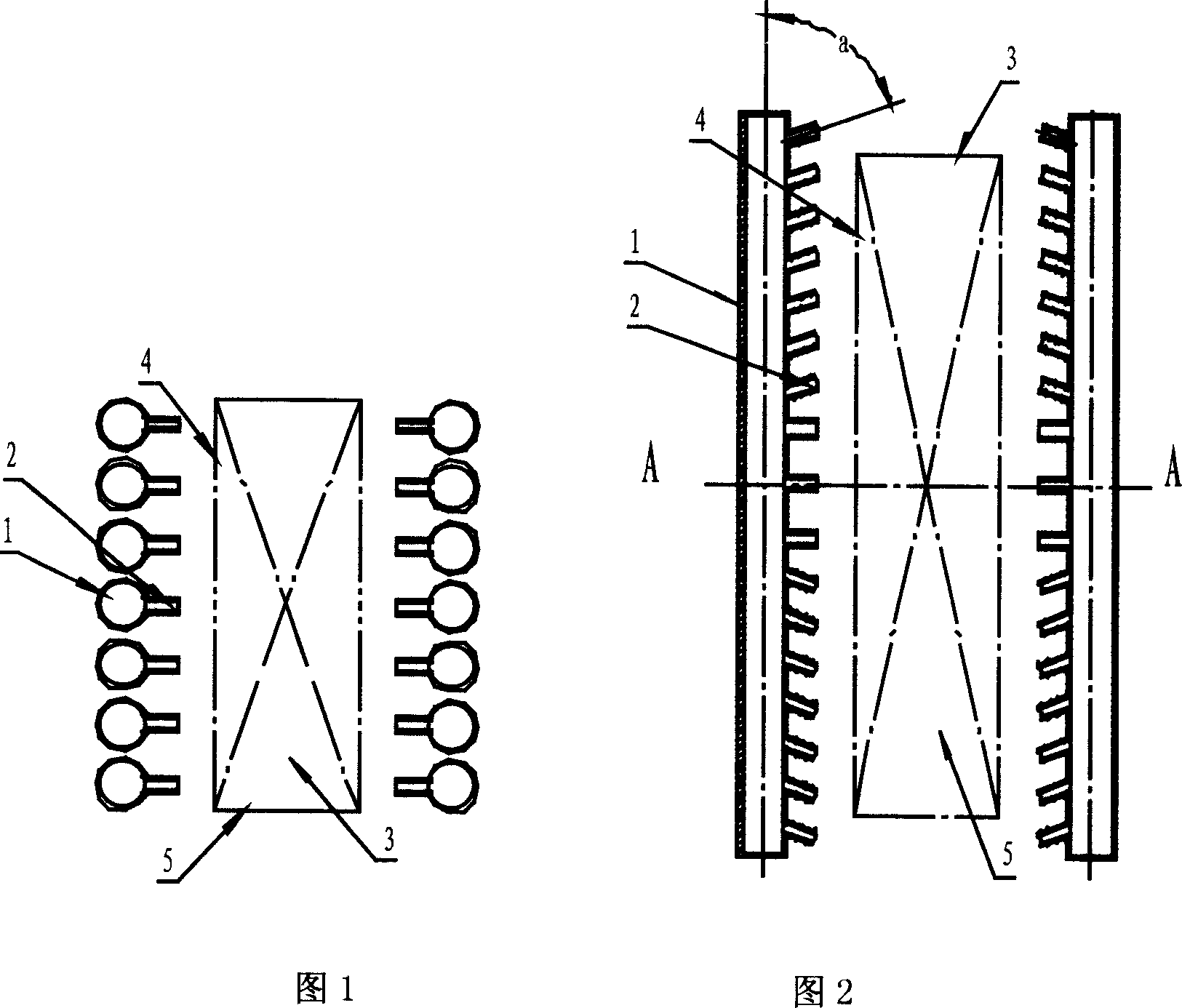

Method for preventing end-face spray quenching cracking of quenching piece by changing spray angle

InactiveCN101012491AReduce cooling intensityIncrease cooling intensityFurnace typesHeat treatment process controlDielectricQuenching

The invention discloses an end-face spray quenching crack-preventing method of quenching piece through changing spraying angle in the heat disposal domain of metal material, which is characterized by the following: placing quenching piece in the quenching equipment with pipe; making quenching piece with lateral and end faces; setting lateral face as rapid freezing face only; paralleling lateral face and pipe; setting the end face of quenching piece perpendicular to pipe; flowing quenching dielectric through pipe; displaying angle a (0-90 deg) for pipe and lateral face of quenching piece; fitting for cooling lateral face of quenching piece; avoiding crack effectively.

Owner:SHANGHAI JIAO TONG UNIV

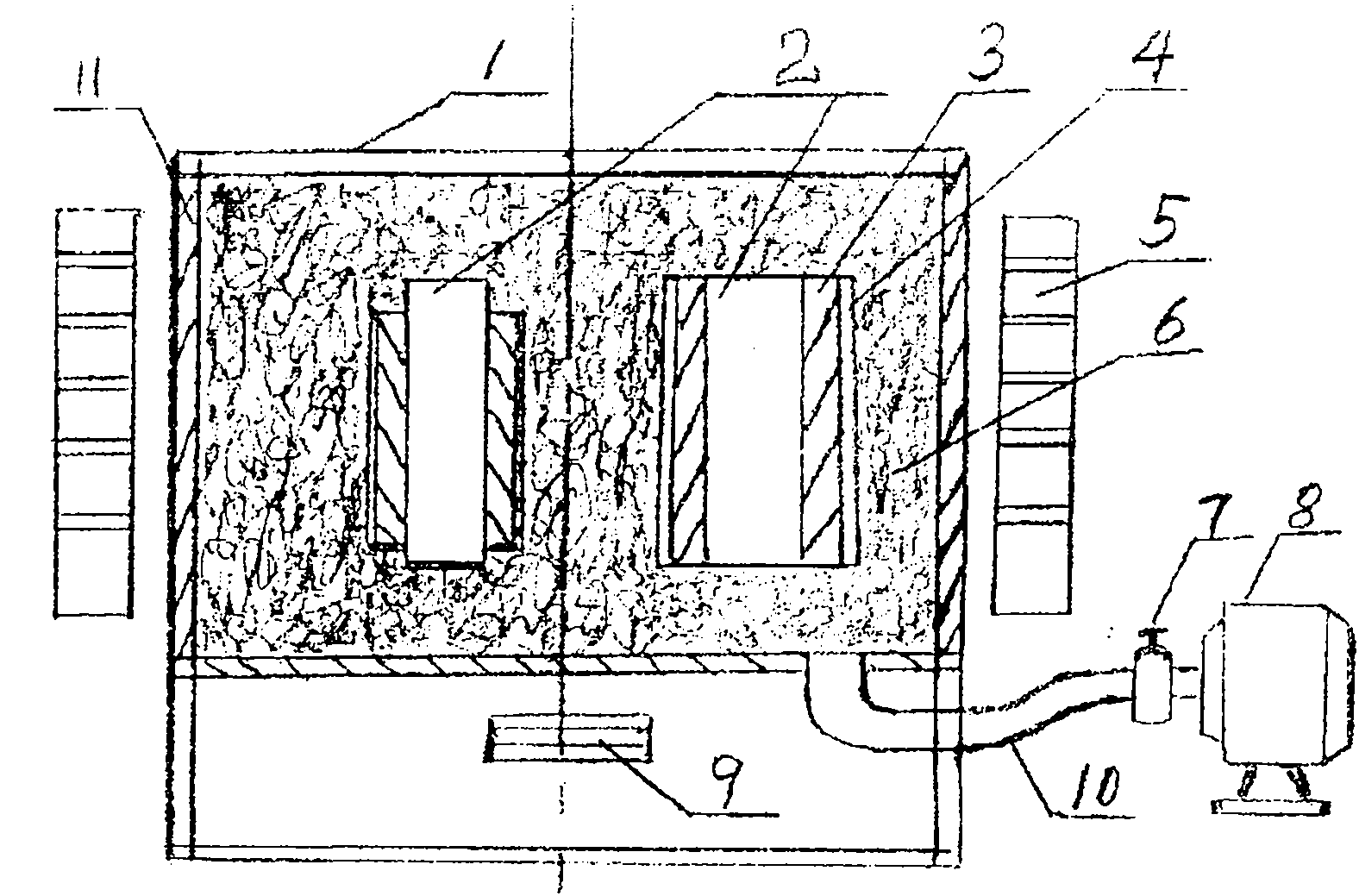

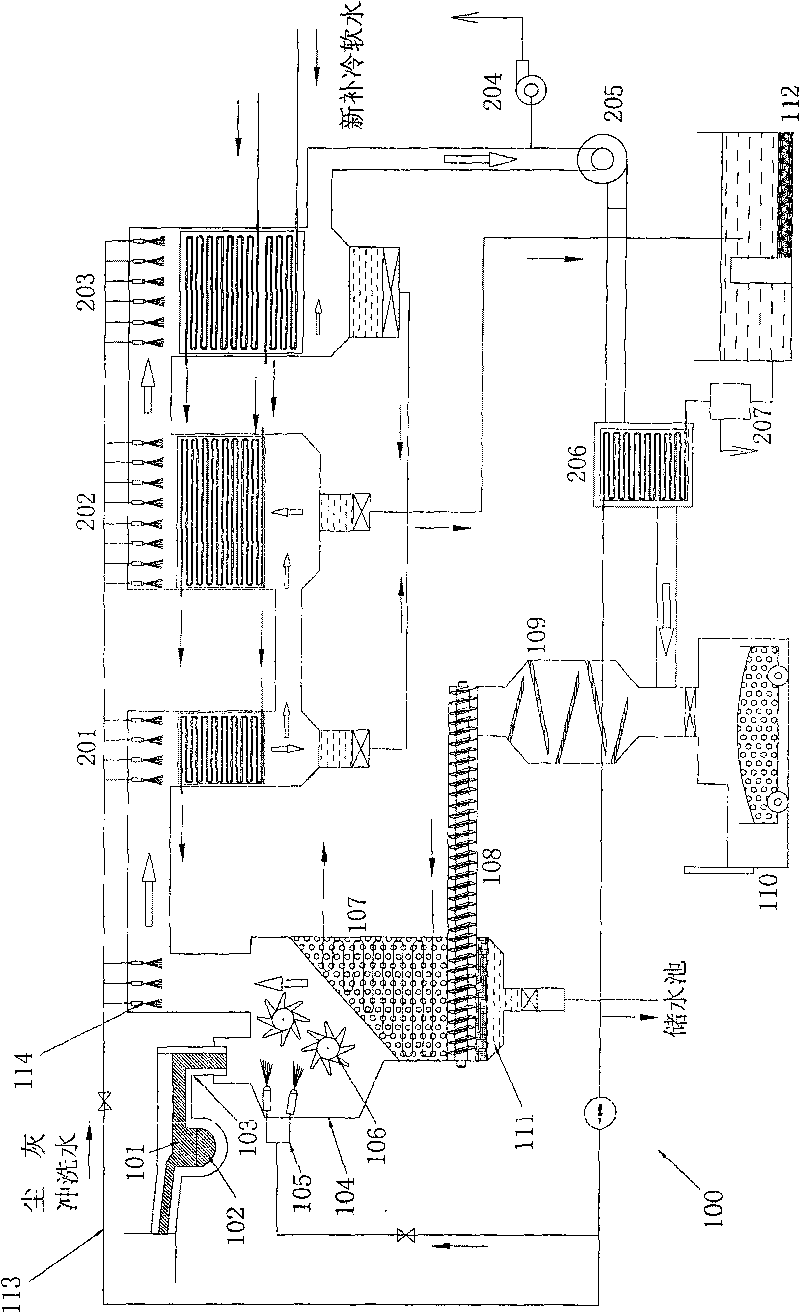

Half-wet method slag processing system and method

InactiveCN101709338AIncrease cooling intensityUniform cooling inside and outsideRecycling and recovery technologiesSlagWater resources

The invention discloses half-wet method slag processing system and method, wherein the half-wet method slag processing system comprises a slag storage bin, a high-pressure atomizing nozzle and a crushing device with high-speed revolution, wherein the upper part of the slag storage bin is provided with a high-temperature liquid slag inlet which is connected with a slag outlet of a blast furnace; the high-pressure atomizing nozzle and the crushing device are arranged in the slag storage bin and positioned below the high-temperature liquid slag inlet; the high-pressure atomizing nozzle sprays high-pressure aerial fog towards the crushing device to impact and cool the liquid slag of the blast furnace; and the crushing device is used to further mechanically crush and cool the slag and process the slag into materials for preparing cement. The invention overcomes the defects of the high use level and the waste of water resources, difficult heat energy recovery and the high cost of the reprocessing of slag secondary products in the traditional slag processing method.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

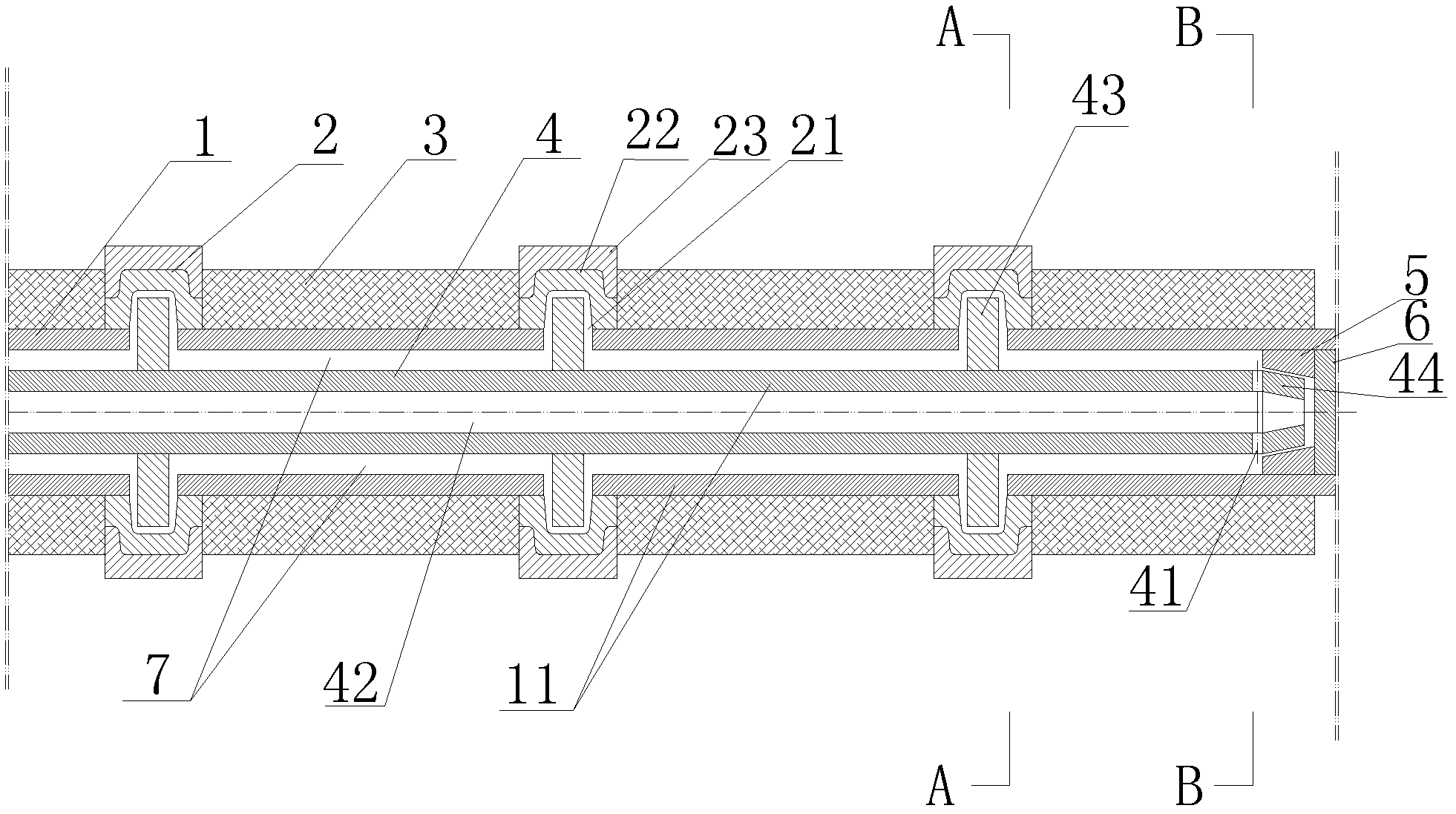

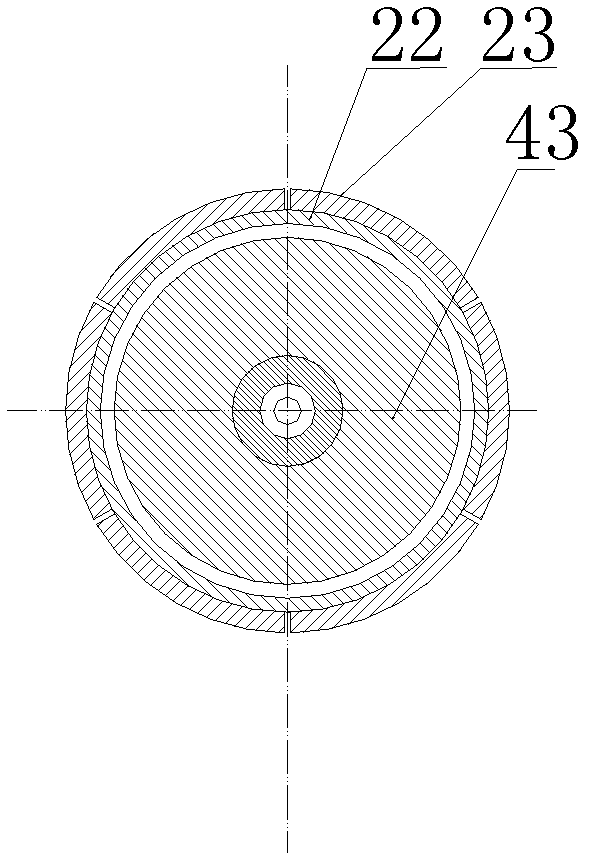

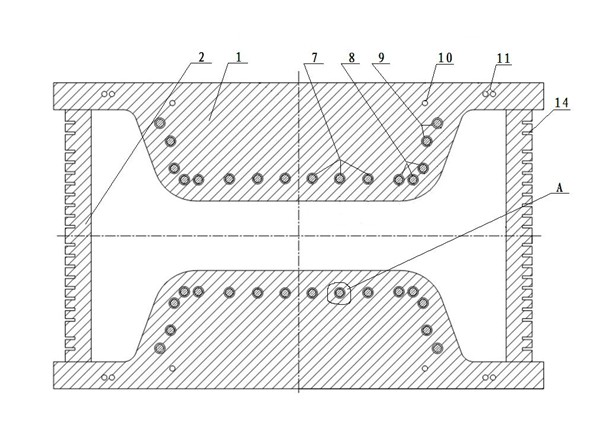

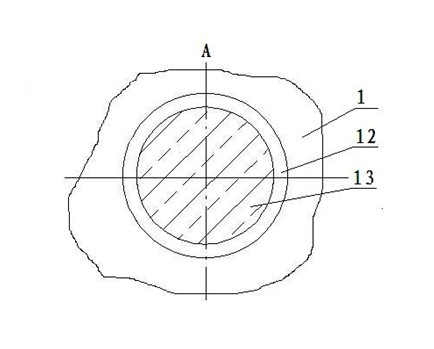

Water cooling channel for large beam blank continuous casting crystallizer

The invention belongs to a cooling casting blank or casting mould device and relates to a water cooling channel for a large beam blank continuous casting crystallizer,,and particularly to a copper plate cooling device for a beam blank continuous casting crystallizer. The copper plate cooling channel is characterized in that: a web water gap, a R angle water gap, a bevel water gap, a flange inner angle water hole and a flange top water hole are formed on a broadside copper plate according to the characteristics of the copper plate shape and heat face heat flux; the water gaps without corners are distributed uniformly, and the water gaps at R angle are dense, and few water holes are arranged at concave corners; and a cooling water tank is arranged outside a narrow side copper plate. The copper plate cooling channel has the advantages that cooling water channels are arranged in areas, the number of cooling water channels is reduced, water gap diameter is reduced, and processing quantity is reduced; the water gaps are arranged reasonably, temperature peak value at the R angle is eliminated, the temperature gradient is reduced, the cooling strength of the flange top is weakened, the overall temperature of the copper plate tends to be uniform, the working environment of the copper plate and blank heat transmission condition are improved, the cooling effect is good, and water is saved; deformation and abrasion of the copper plate are reduced, and service life is prolonged; the surface quality of blanks is remarkably improved, the cogging yield is improved, and continuous casting production can be performed smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

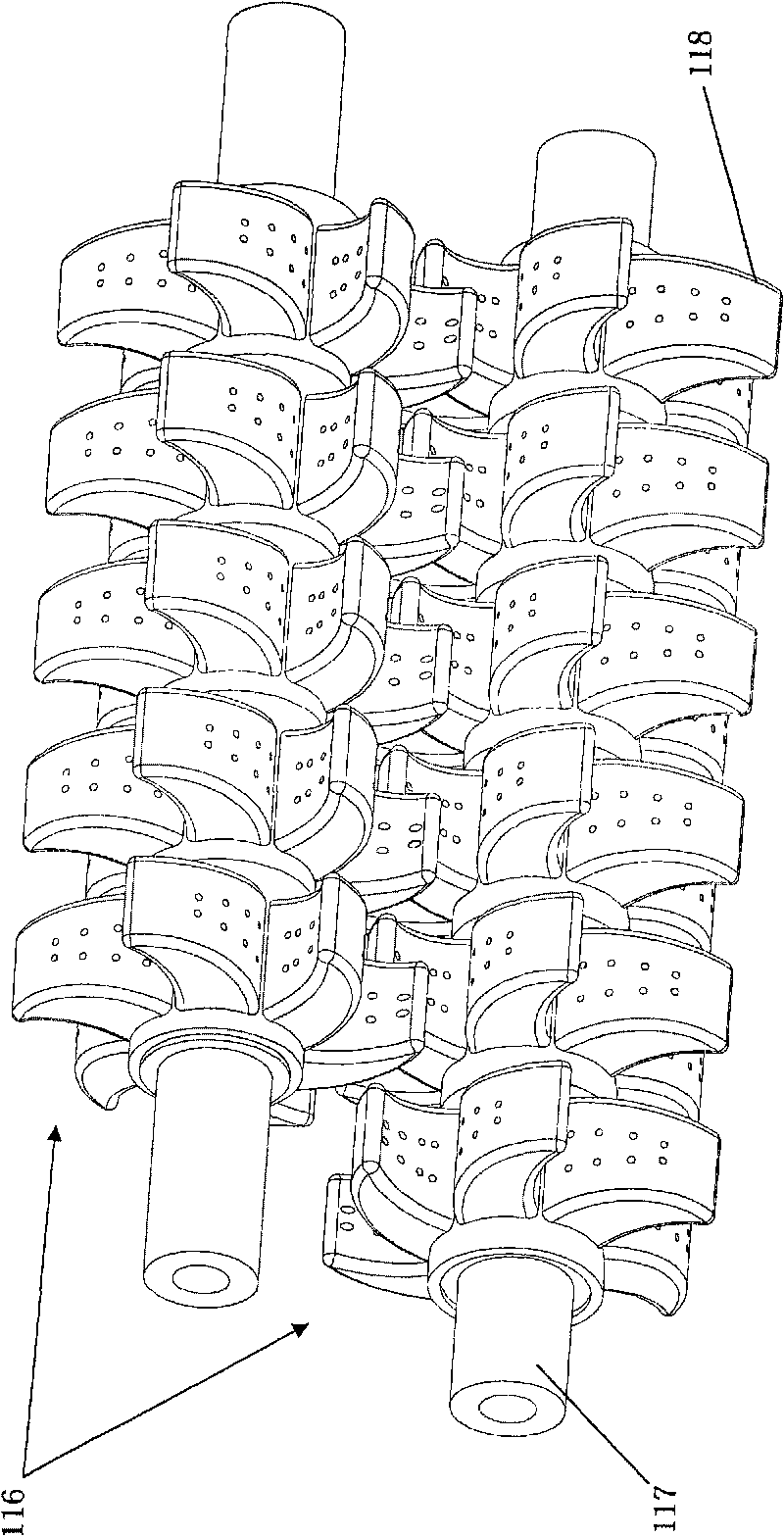

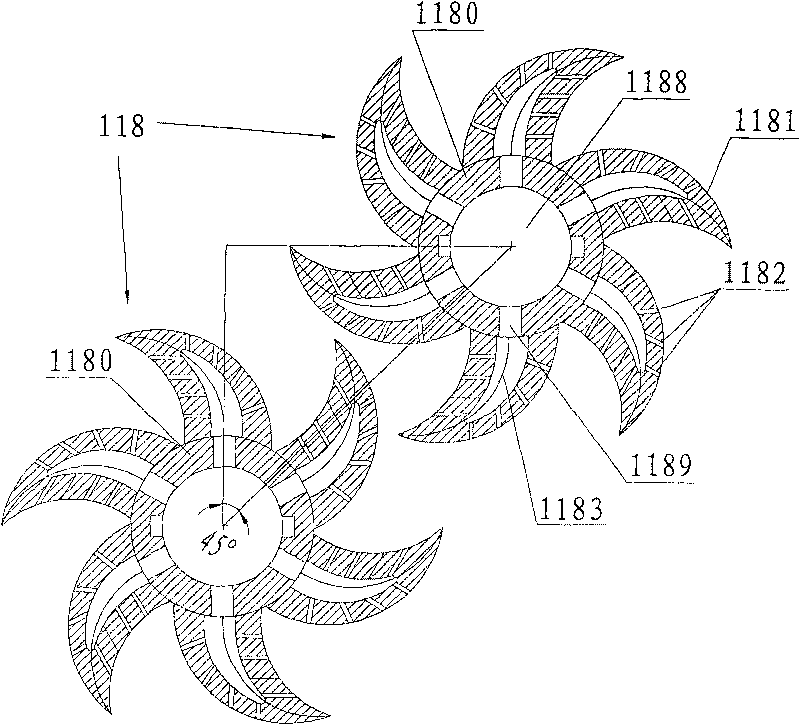

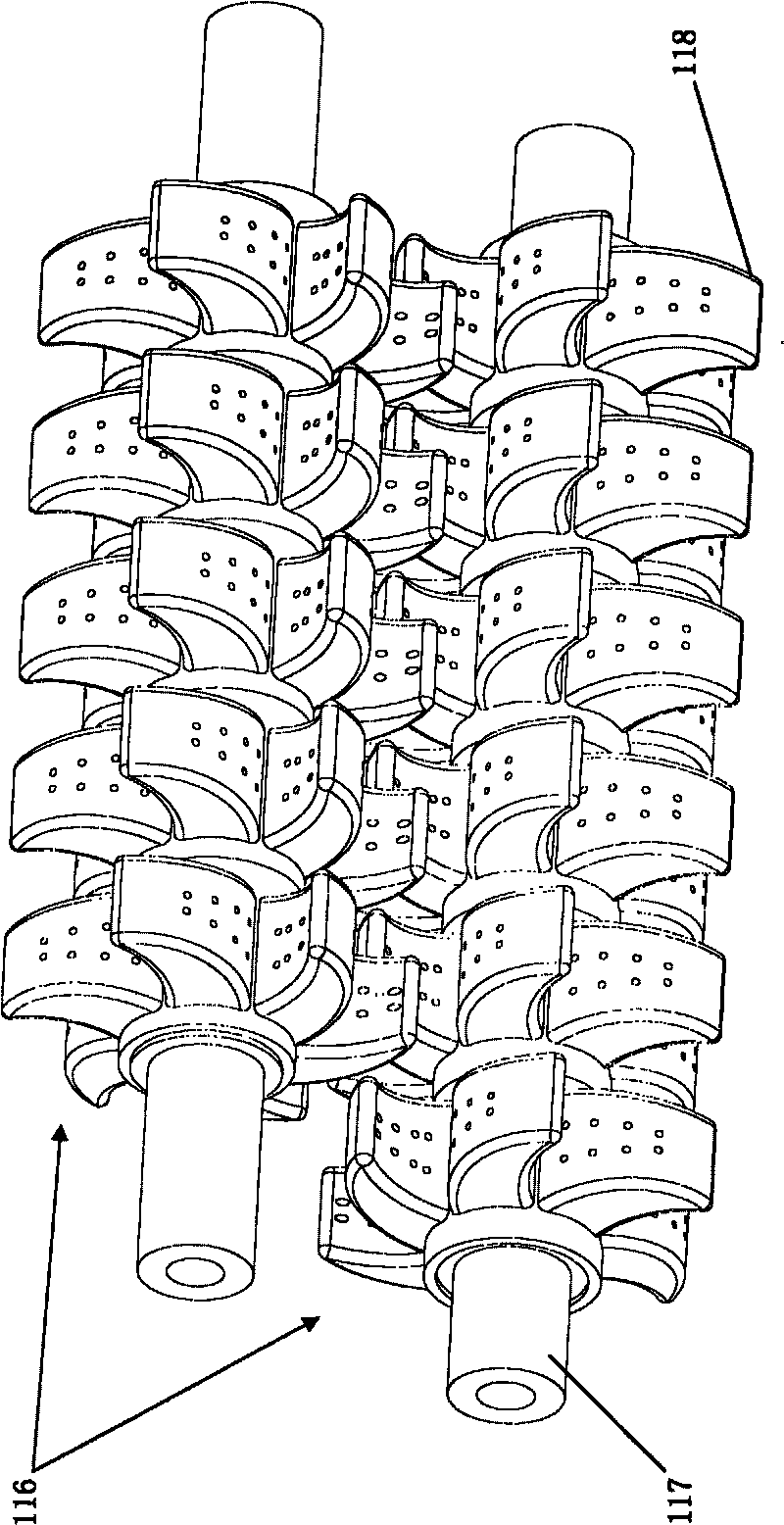

Furnace slag crushing device, crushing method and semi-wet method furnace slag processing system

ActiveCN101716542AReduce the temperatureAvoid stickingRecycling and recovery technologiesGrain treatmentsMechanical crushingSlag

The invention discloses a furnace slag crushing device, a crushing method and a semi-wet method furnace slag processing system. The crushing device comprises two crushing wheel groups which are arranged in a rotating way, are meshed with each other in a non-contact-type reversing way and have water spraying structure. By utilizing a water spraying mechanism to spray high pressure water out from a tooth surface to crush and cool furnace slag, thus preventing the furnace slag grains from being adhered again; the invention adopts the conception that a small quantity of water which is taken as cooling medium is combined with the mechanical crushing so as to improve the quality of byproducts of the furnace slag and the heat exchange efficiency.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

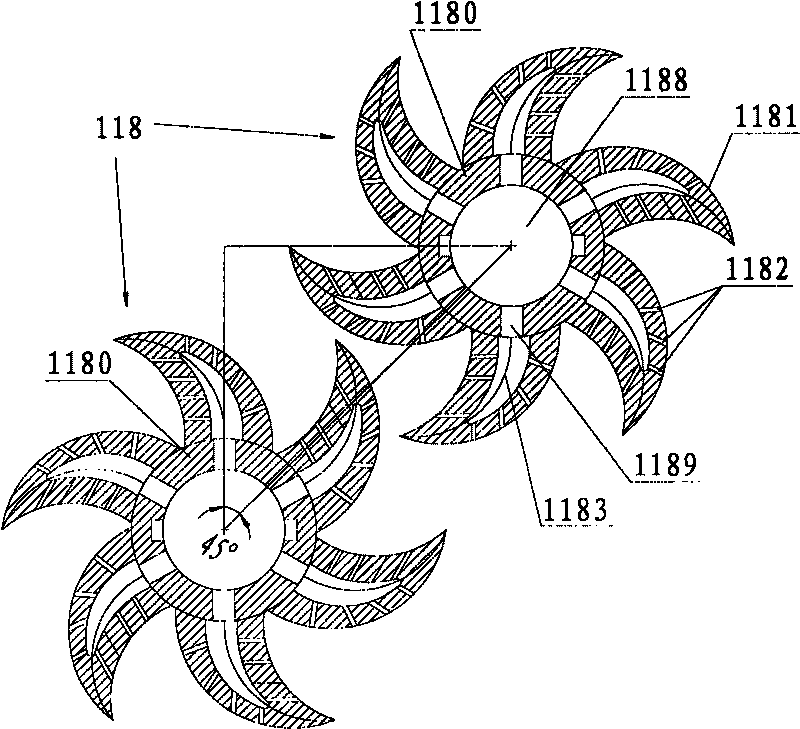

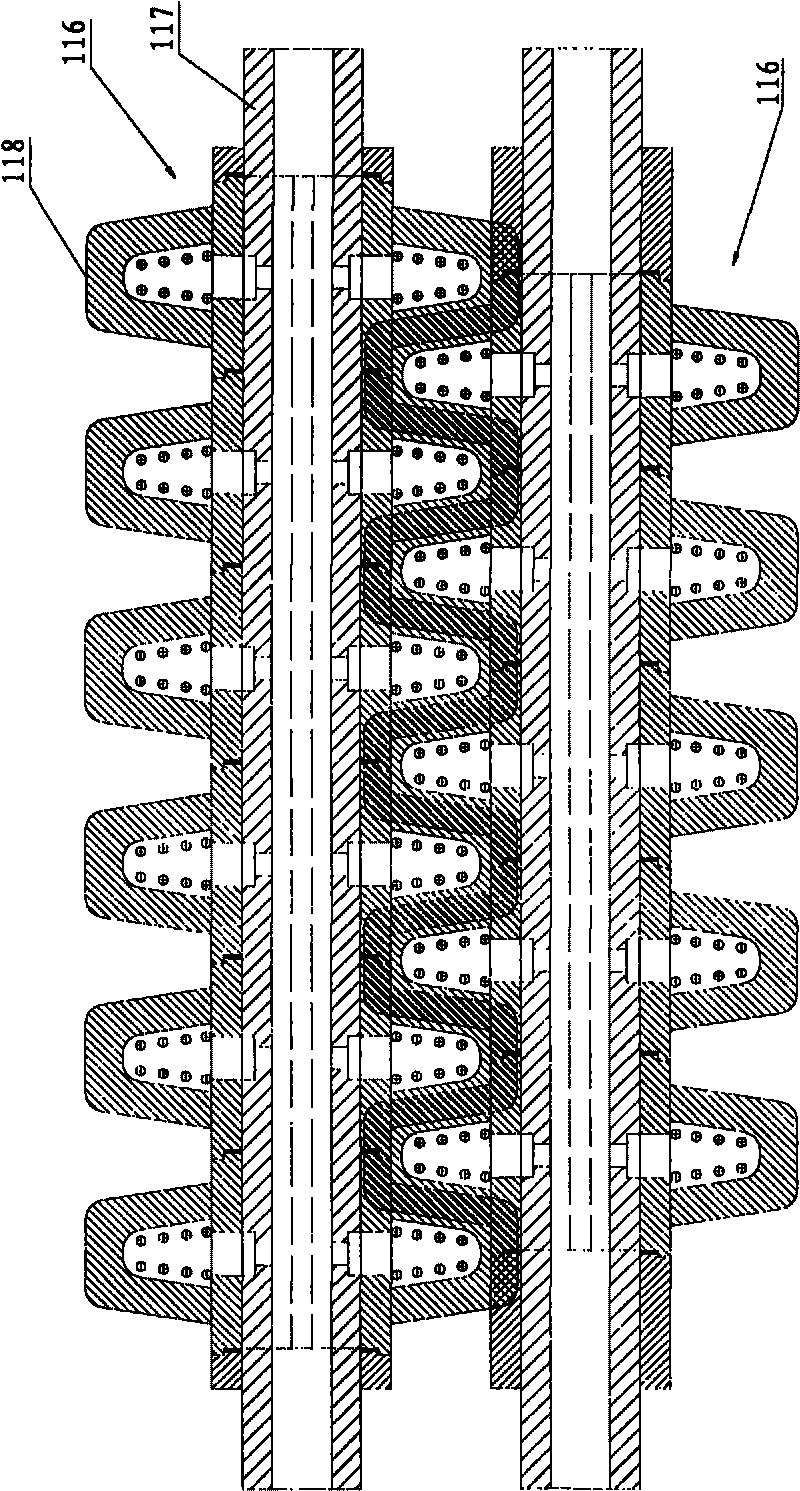

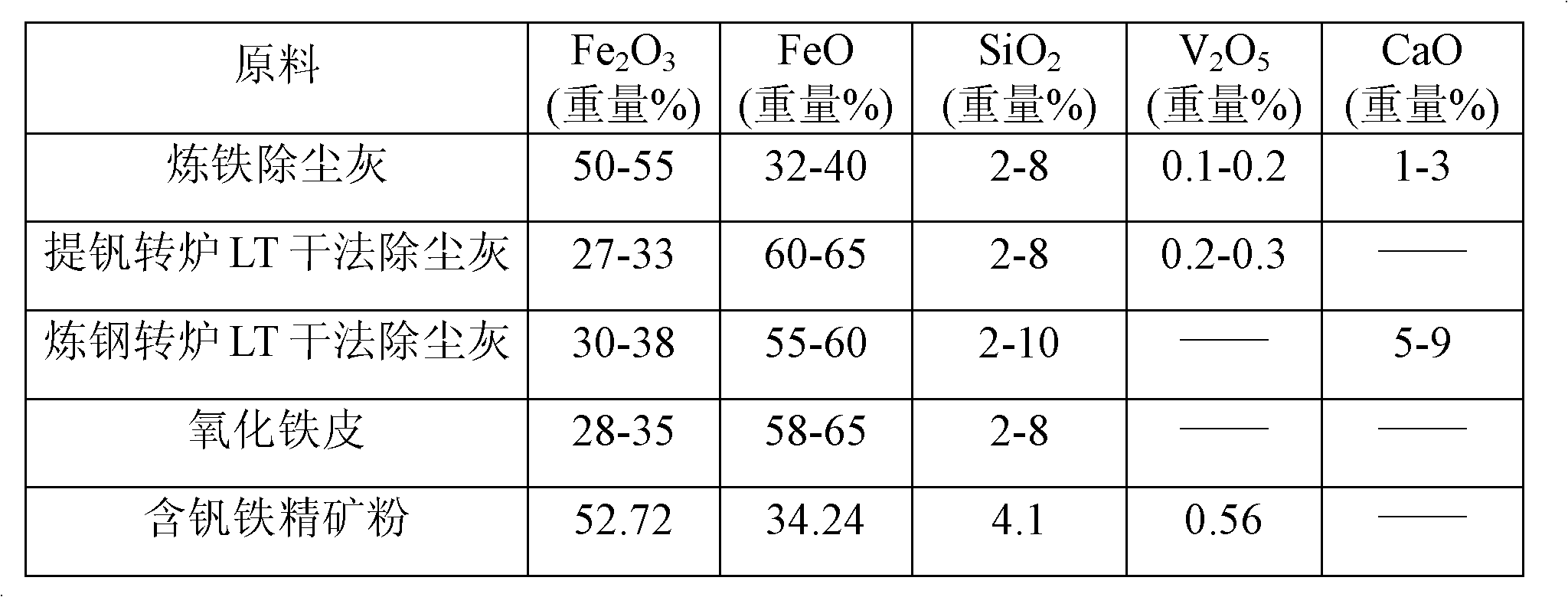

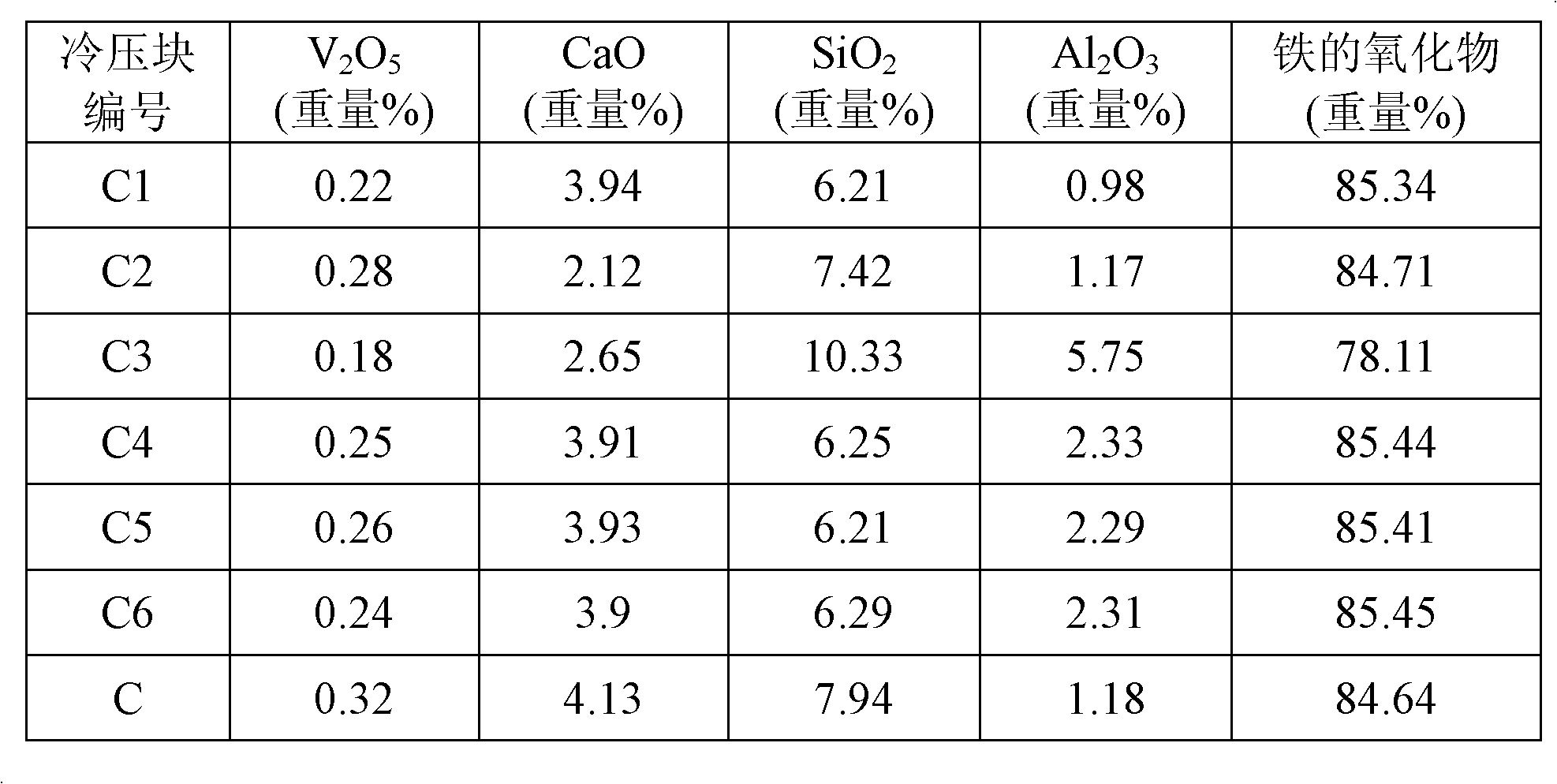

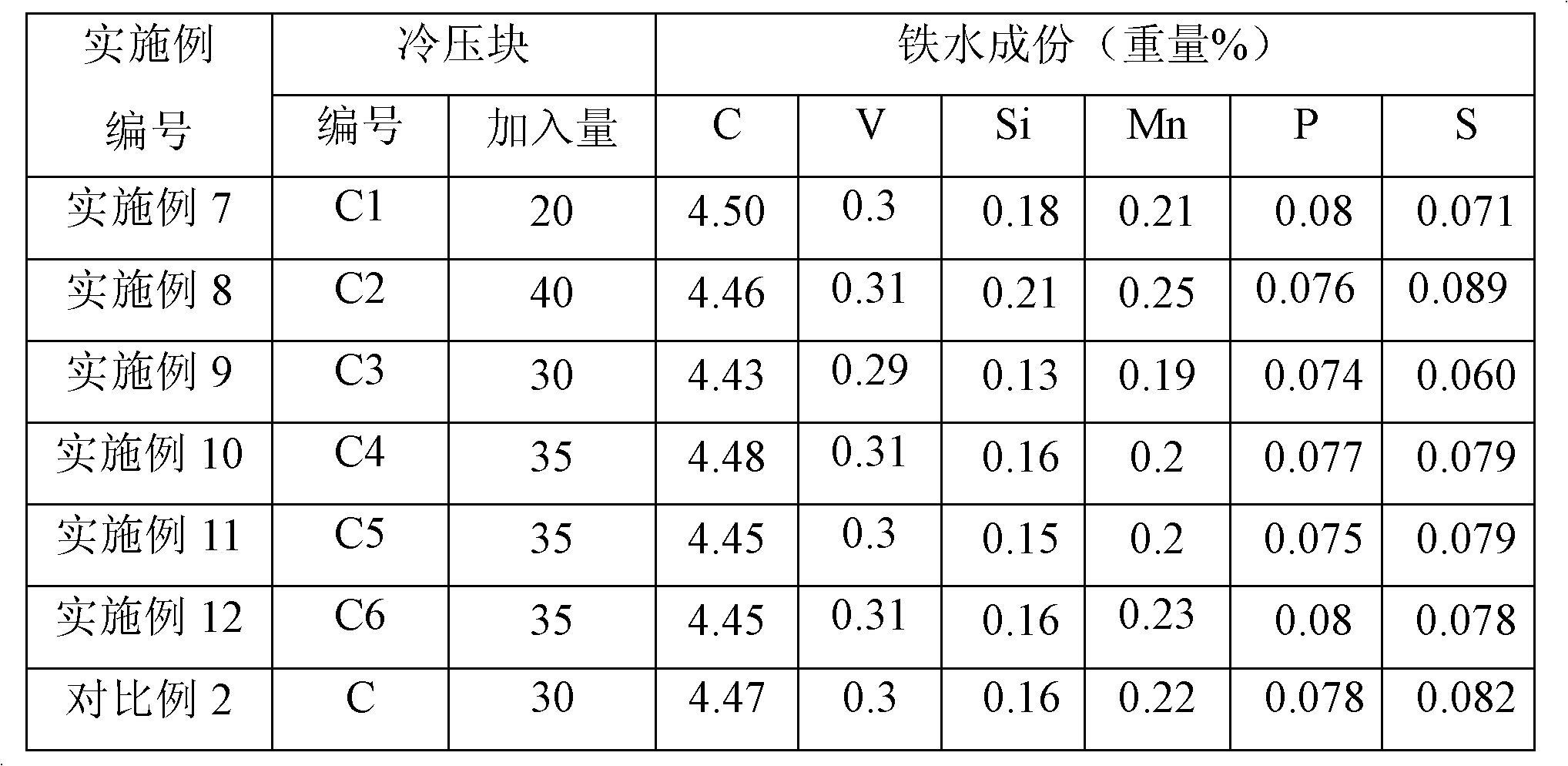

Vanadium extraction cold pressing block and preparation method and applications thereof and vanadium extraction method

ActiveCN103103310AHigh mechanical strengthIncrease cooling intensityManufacturing convertersProcess efficiency improvementIron industryUltimate tensile strength

The invention discloses a vanadium extraction cold pressing block and a preparation method and applications thereof and a vanadium extraction method. The vanadium extraction cold pressing block is prepared by effectively adopting a dry-method for dust removal, so that not only can the difficulties of dust removal and scale recycling in steel industry be effectively solved, but also the vanadium extraction cold pressing block with high mechanical strength and cooling strength is prepared under the condition of not adding ferro-vanadiumconcentrate fines-containing raw materials, and the cost for extracting vanadium can be lowered to certain extent. The cold pressing block has the advantages of being higher in mechanical strength and cold pressing strength and less in dust, the mechanical strength of each block is 750-1500N, the cooling strength of the cold pressing block is 2.5-4.5 DEG C.kg / t molten iron. The cold pressing block is used for vanadium extracting technique, the oxidation ratio of the vanadium can be achieved by more than 86%, and the utilization efficiency of the vanadium resources can be improved effectively.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

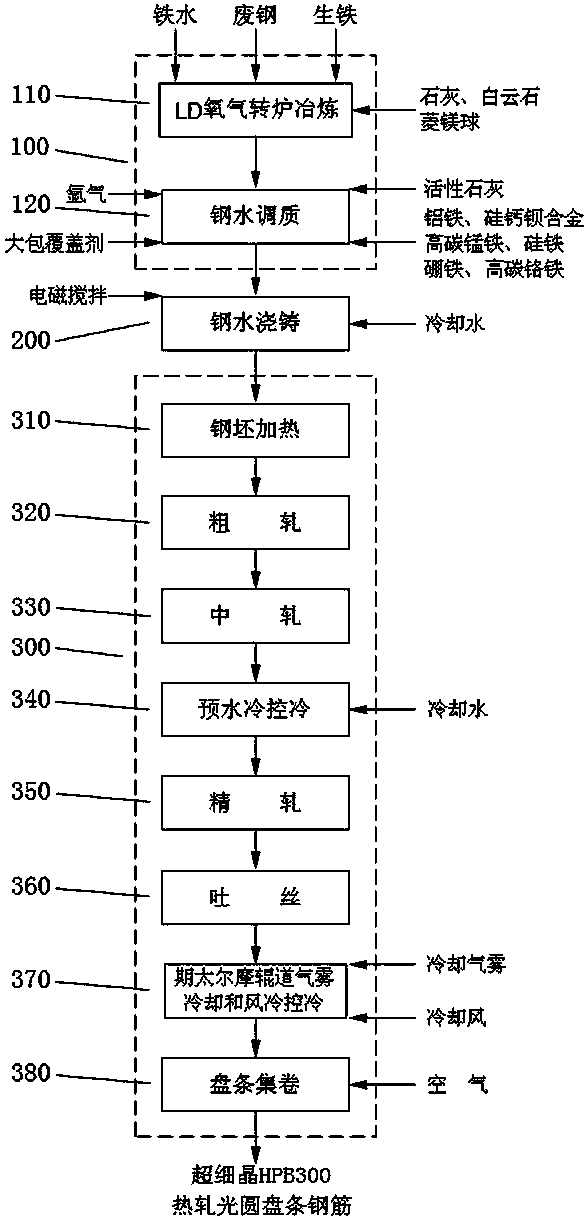

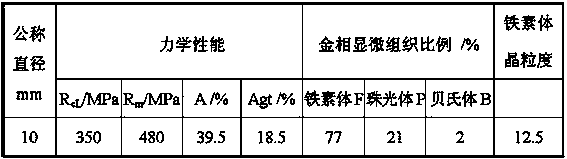

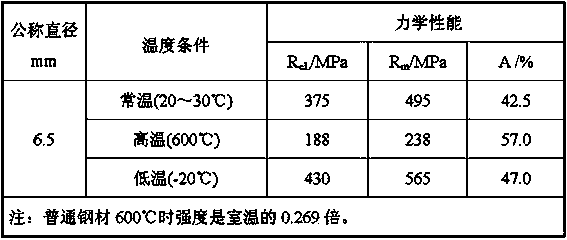

Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

The invention discloses an ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and a preparation method thereof. The ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar comprises the following components in percentage by weight: 0.15-0.18% of C, 0.10-0.16% of Si, 0.16-0.28% of Mn, 0.080-0.120% of Cr, 0.0010-0.0020% of B, less than 0.030% of S, less than 0.045% of P and the balance of Fe. The reinforcing steel bar is prepared from molten iron, steel scrap and pig iron through steps of molten steel smelting, molten steel pouring and billet controlled rolling and controlled cooling. According to the reinforcing steel bar, a small amount of ferromanganese, ferroboron and high carbon ferro-chrome alloy into the steel-making step, so that the alloying cost is remarkably lowered. By adopting low-temperature controlled rolling before spinning and a stelmor roller aerial fog cooling process after spinning, the reinforcing steel bar has the advantages of low cost, good toughness, excellent high- and low-temperature performance, low stress time-validity and the like.

Owner:WUKUN STEEL

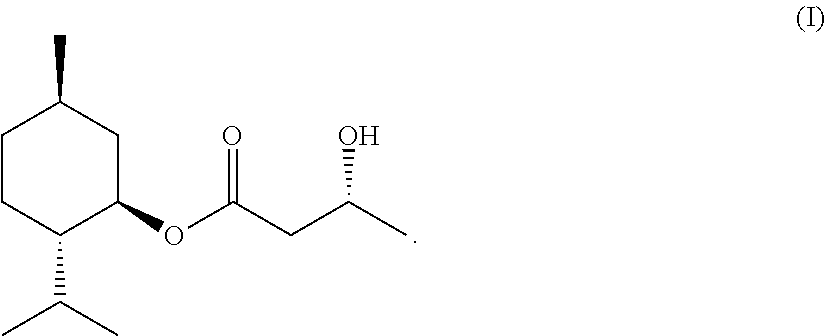

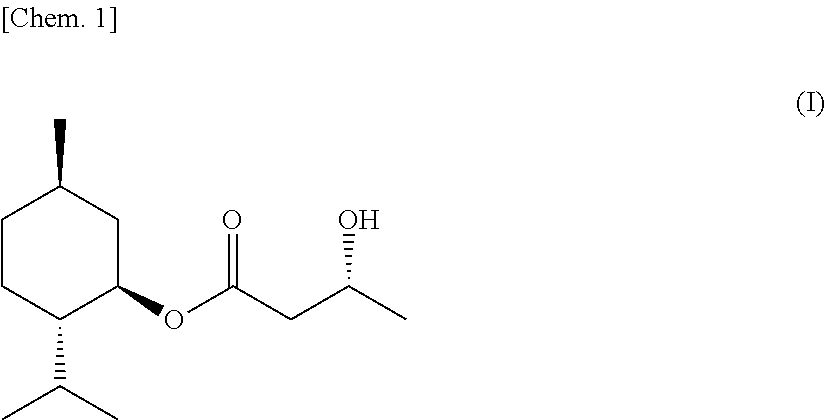

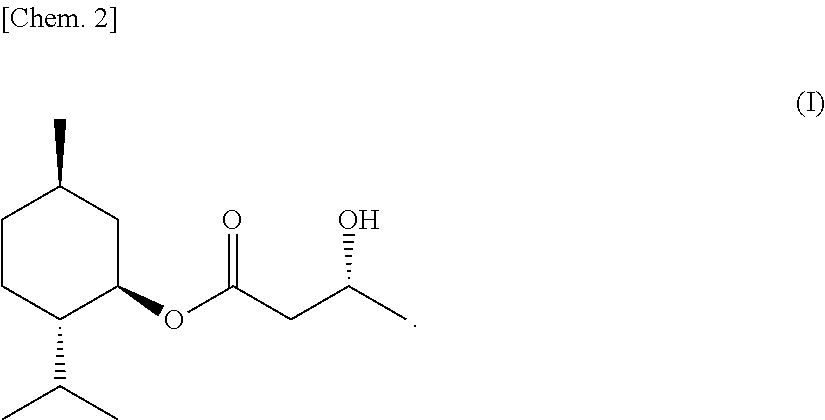

(3R)-L-menthyl 3-hydroxybutyrate, process for producing the same, and sensate composition comprising the same

InactiveUS8476472B2Increase cooling intensityBiocideCosmetic preparationsHydroxybutyratesFood science

Owner:TAKASAGO INTERNATIONAL CORPORATION

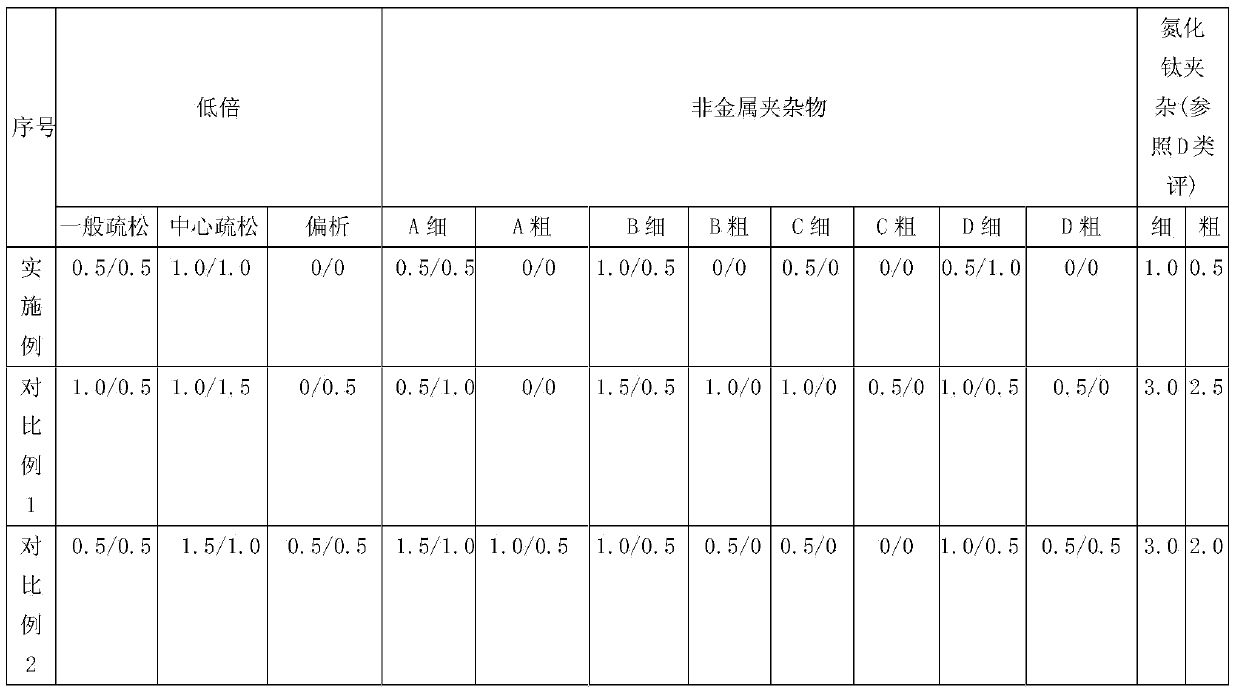

Control method for titanium nitride inclusion of gear steel bar material

InactiveCN104212934AReduce precipitationIncrease cooling intensityManufacturing convertersTitanium nitrideMolten steel

The invention discloses a control method for a titanium nitride inclusion of a gear steel bar material. The control method adopts a production process of converter smelting-LF refining-RH refining-rectangular blank continuous casting, and comprises the following specific operation steps: (1) converter smelting: molten iron and waste steel are added in a converter; and the weight ratio of the molten iron to the waste steel is greater than 15: 1; (2) LF refining: the LF refining is performed for the molten steel to prevent the molten steel from being contacted with air; (3) RH vacuum refining: the vacuum degassing treatment is performed for the molten steel; the treatment time is kept not lower than 15 minutes under high vacuum degree not higher than 66.7 Pa; and an titanium-iron alloy is added in the period; and (4) continuous casting: after the RH refining is finished, the molten steel ladle is continuously cast; and in the continuous casting process, a crystallizer electromagnetic mixing technology with low superheat degree not higher than 35 DEG C, constant temperature and constant casting speed is adopted, and the argon sealing is performed. Thereby, the separated concentration product of titanium nitride is controlled.

Owner:SGIS SONGSHAN CO LTD

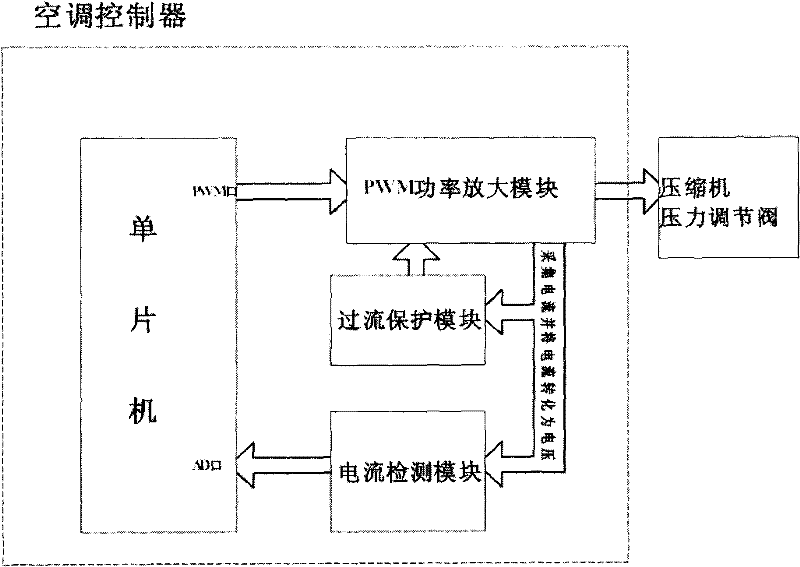

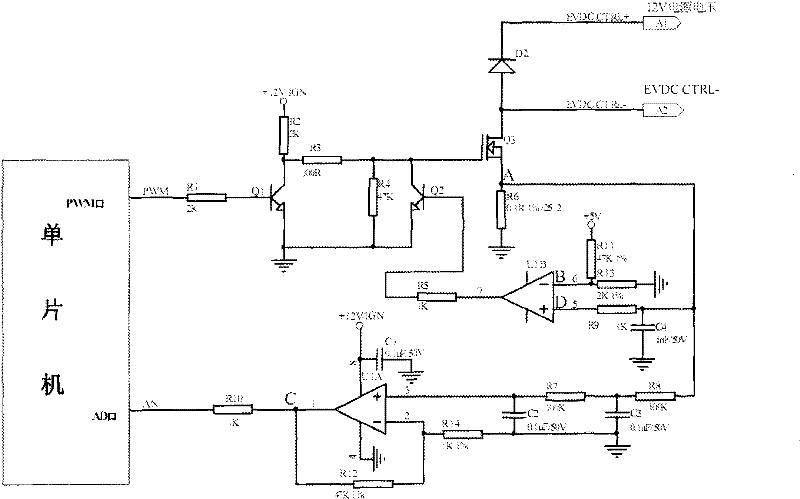

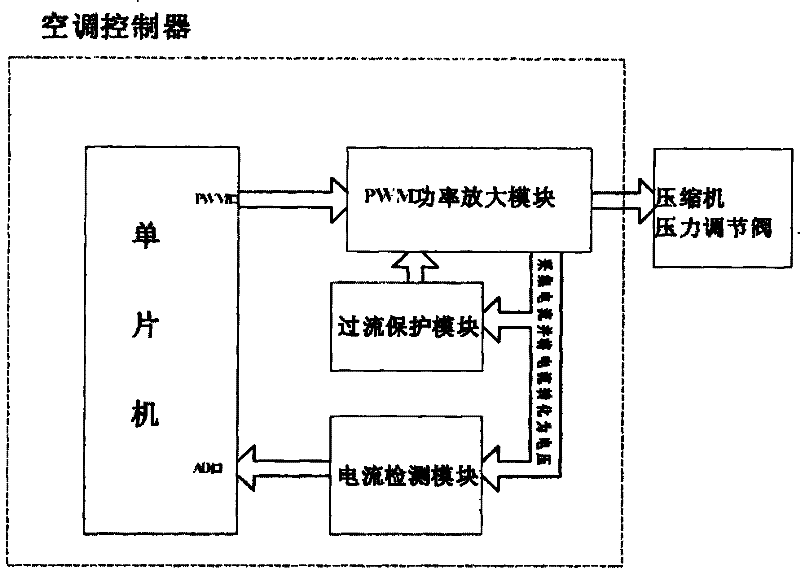

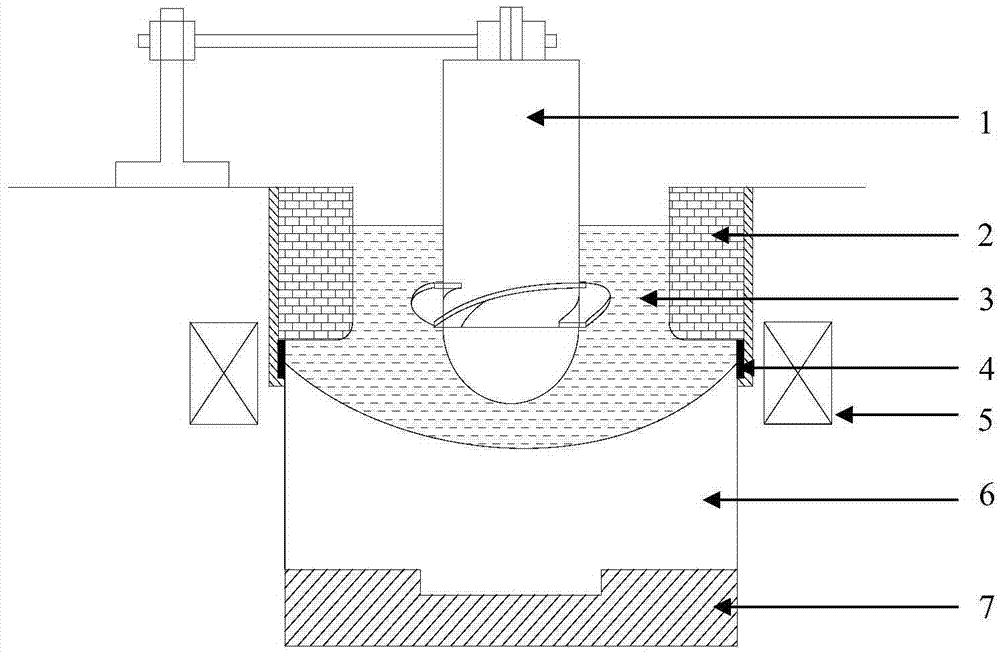

Externally controlled variable displacement compressor air conditioner controller

InactiveCN102287890AReduce the compression ratioReduced cooling intensitySpace heating and ventilation safety systemsLighting and heating apparatusMicrocontrollerAir conditioning

An externally controlled variable-displacement compressor air-conditioning system, which includes an air-conditioning controller, which also includes a pressure regulating valve that controls the compression ratio of the compressor according to the change signal of the pressure in the air-conditioning pipeline; The control module of the pressure regulating valve of the displacement compressor, the control module includes a single-chip microcomputer, a pulse width modulation power amplification module, an overcurrent protection module that can realize overcurrent protection, and a current detection module that can detect the output current. Beneficial effects: the air conditioning system using the variable displacement compressor can automatically adjust the power output according to the set temperature, saving a lot of energy.

Owner:SHANGHAI FENGTIAN ELECTRONICS

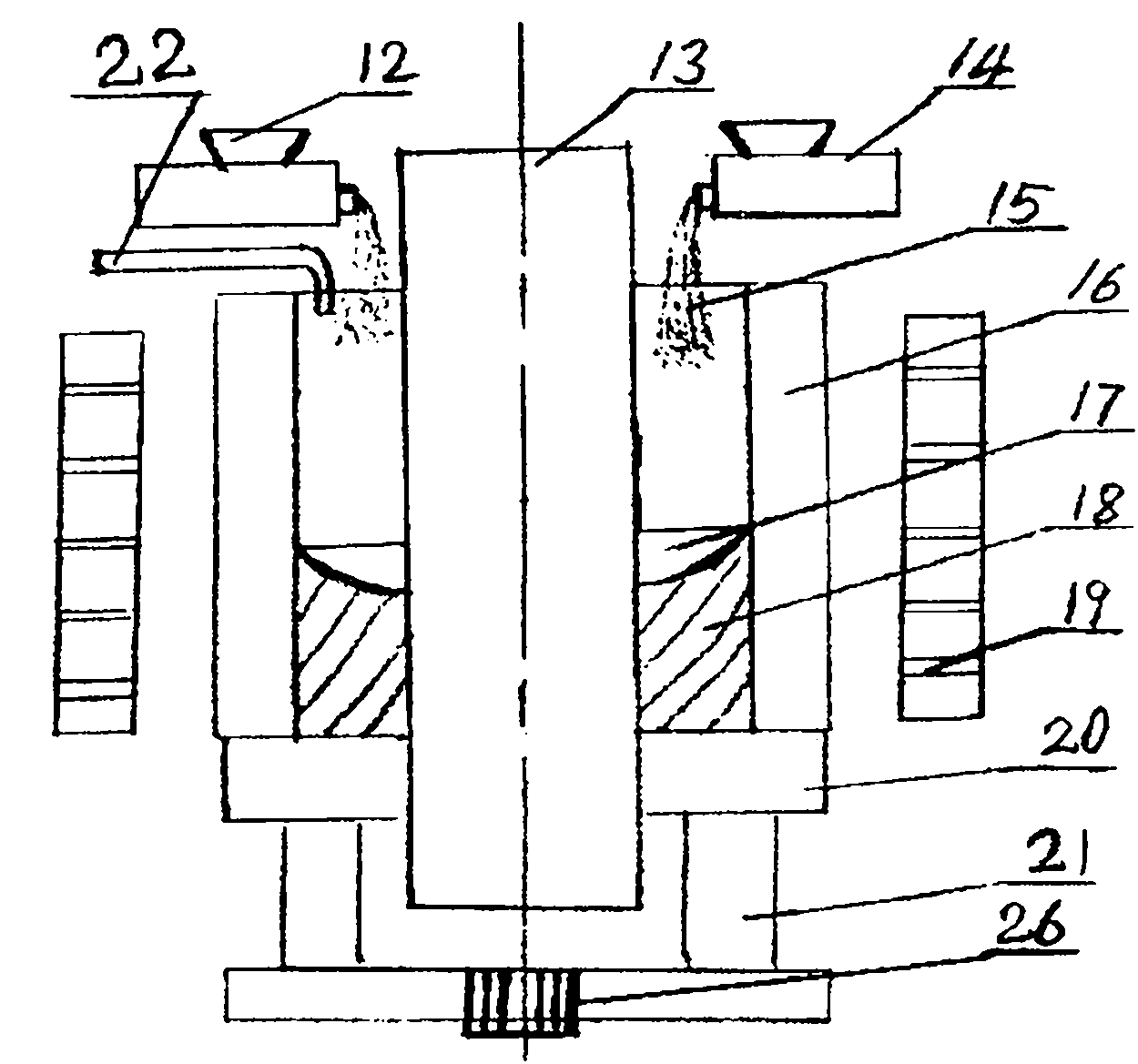

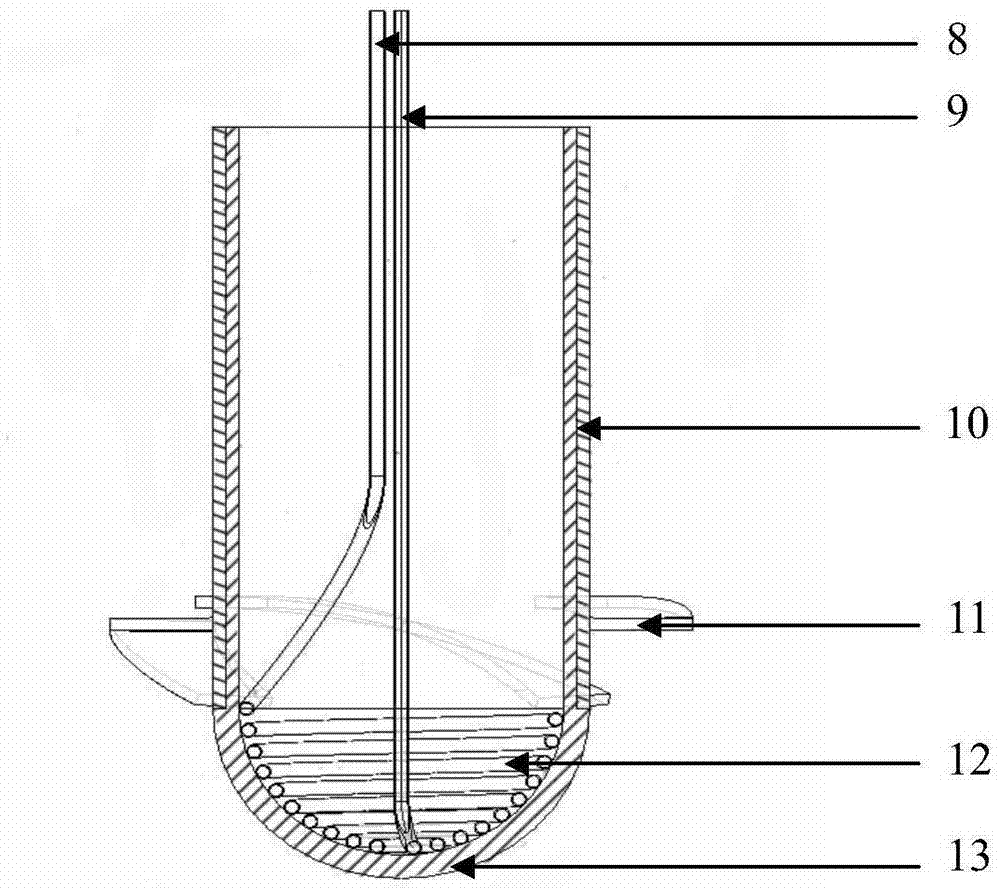

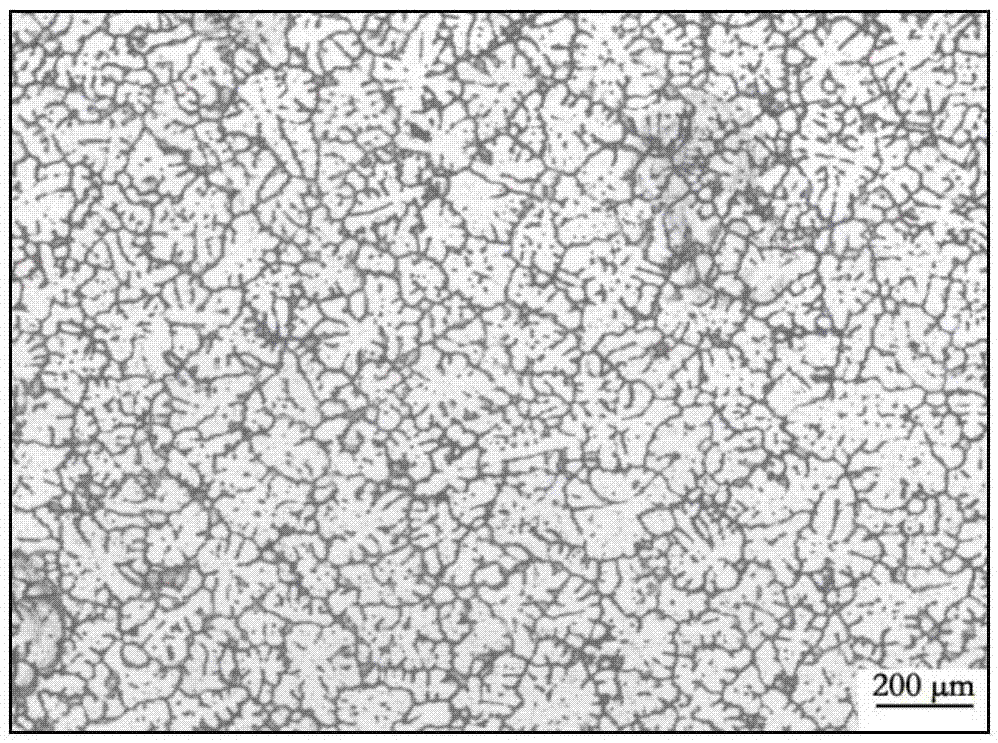

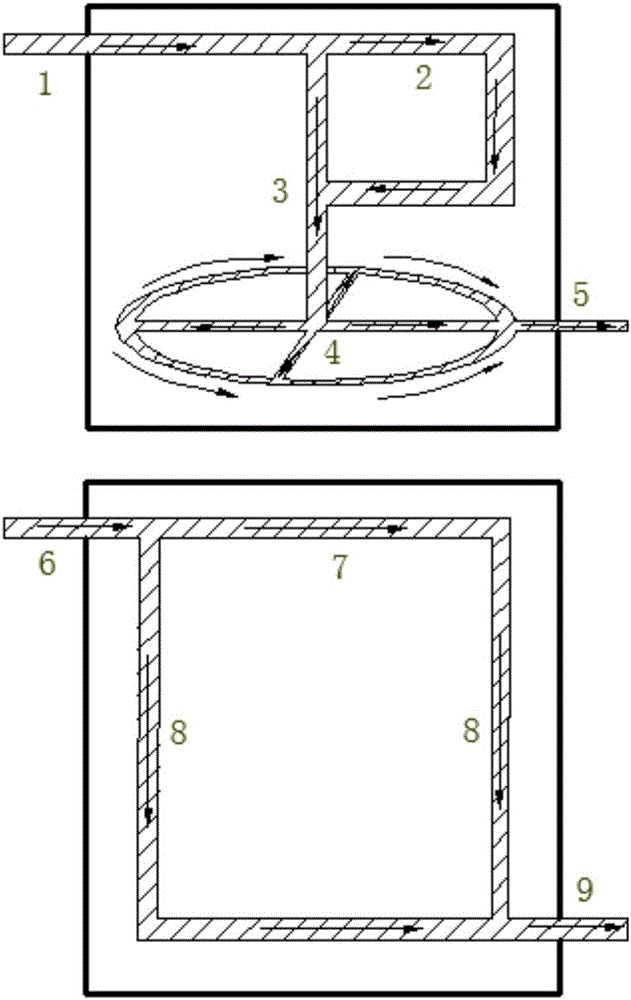

Manufacture device and method for large-size fine-grain homogeneous aluminum alloy cast ingot

The invention relates to a manufacture device and method for a large-size fine-grain homogeneous aluminum alloy cast ingot, belonging to the field of metal material machinery. The device mainly comprises a uniform cooler, a thermal ejector, an electromagnetic stirrer, a crystallizer and a dummy ingot, wherein the thermal ejector is arranged above the crystallizer; the electromagnetic stirrer is arranged on the periphery of the thermal ejector and the crystallizer; the dummy ingot is arranged below the crystallizer; the uniform cooler is arranged in the crystallizer; and the uniform cooler consists of an inner pipe and an outer pipe. According to the manufacture device and method, through special coupling treatment of uniform cooling in the crystallizer and electromagnetic stirring outside the crystallizer is applied to an alloy melt, so that effective control on uniformity of a temperature field and a component field of the large-size alloy melt is realized, and the large-size aluminum alloy cast ingot with uniform and fine structure and uniform components is manufactured. The manufacture device is simple in structure, feasible in method, obvious in effect, high in production efficiency and easy for combination with large-scale industrial production, and has a wide industrial application prospect in the fields of aerospace, rail transportation and manufacture of ships and the like.

Owner:有研金属复材技术有限公司

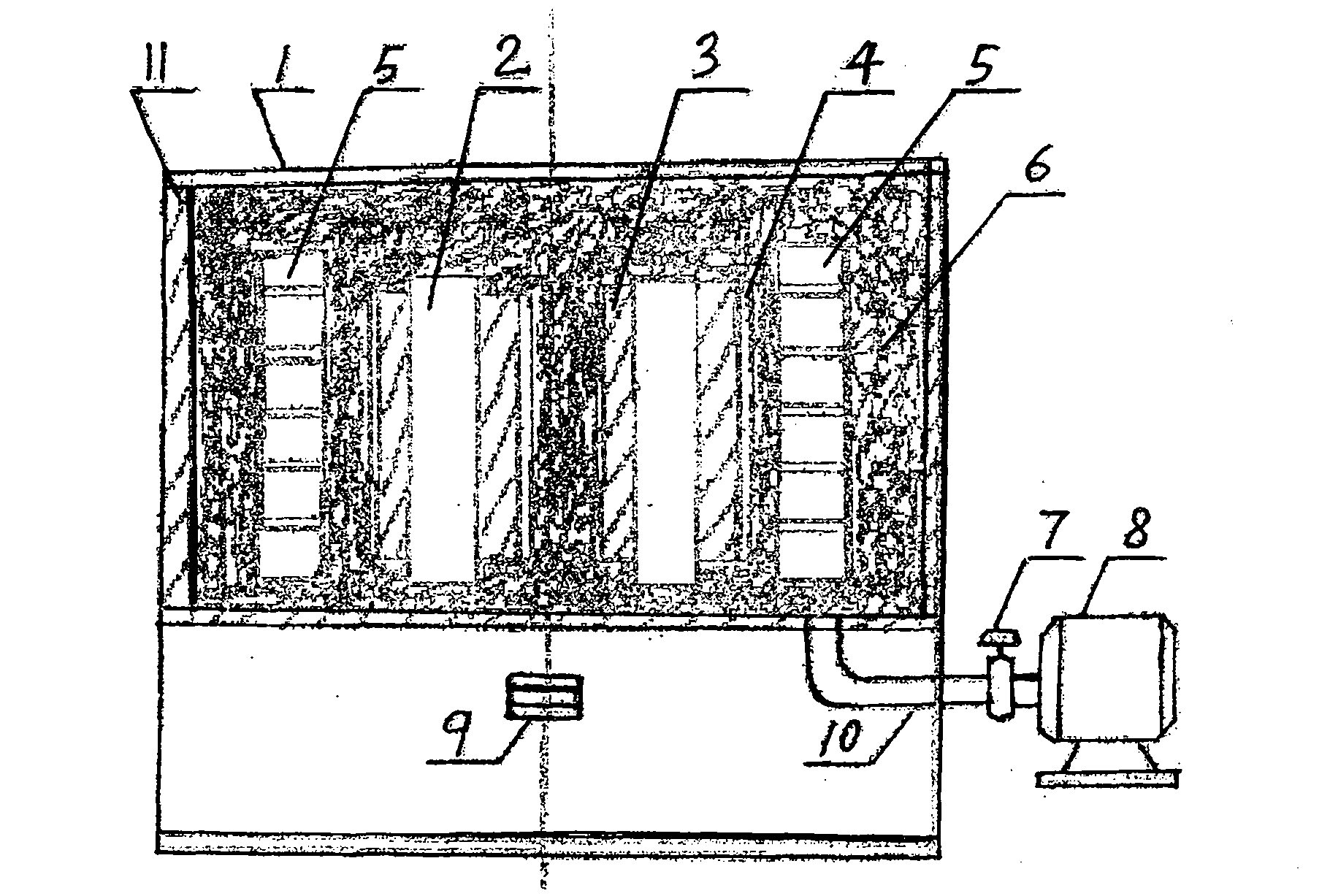

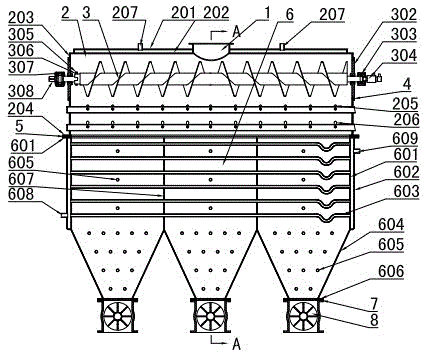

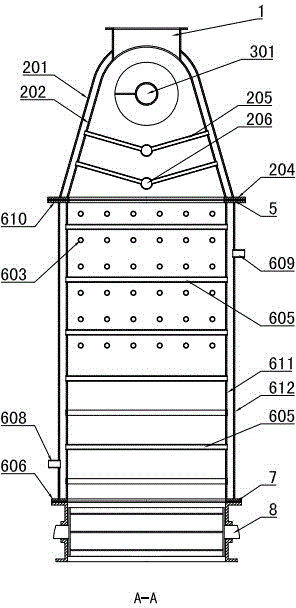

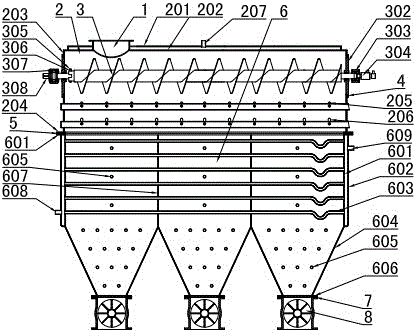

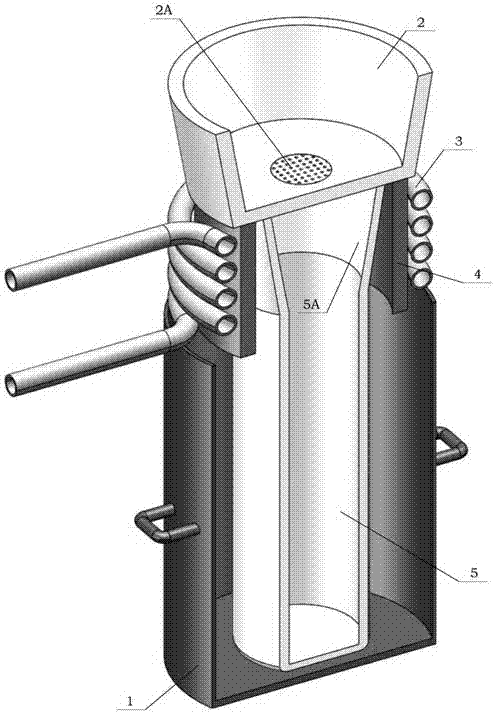

Large box type high-temperature material heat exchanger

ActiveCN104697371ALarge flow cross-sectional areaLarge cooling capacityMoving conduit heat exchangersImpellerEngineering

The invention provides a large box type high-temperature material heat exchanger, and belongs to the field of high-temperature solid material cooling equipment. The large box type high-temperature material heat exchanger is characterized by sequentially comprising a water cooling box cover (2), a heat exchanging box (6) and necking-down type hoppers from top to bottom, wherein a water cooling jacket is arranged on a wall of the water cooling box cover (2); end water cavities and / or side water cavities are formed in the wall of the heat exchanging box (6) and the walls of the necking-down hoppers; a plurality of heat exchanging pipelines are respectively arranged in the water cooling box cover (2), the heat exchanging box (6) and cavities of the necking-down type hoppers; a feeding opening (1) is formed in the upper portion of the water cooling box cover (2); a water cooling spiral distributor (3) which can convey and cool down materials is arranged in the water cooling box cover (2); the necking-down type hoppers are arranged side by side; and an impeller discharging valve (8) is arranged at an outlet of the bottom of each necking-down type hopper. The large box type high-temperature material heat exchanger is large in material cooling amount, low in energy consumption and long in service life; and abrasion of heat exchanging components is small.

Owner:SHANDONG UNIV OF TECH

Furnace-protecting anhydrous stemming

InactiveCN102320852AAvoid breakingAvoid accidents such as running a big streamWear resistantTemperature resistance

The invention provides furnace-protecting anhydrous stemming which comprises the following raw material chemical components by weight: 15-25% of corundum powder; 15-20% of coke powder; 15-20% of clay powder; 9-14% of silicon carbide powder; 2-4% of asphalt powder; 15-25% of anthracene oil; and 9-11% of titanium dioxide powder. The stemming of the invention has the characteristics of high strength, low shrinkage, and good caking property, has stable high temperature resistance, can be sintered rapidly, can prolong tapping time and ensure tapping smoothness, provides an iron notch drilling-trhough rate of above 95%, avoids the iron-leaking phenomenon and accidents of iron notch fracture and channel enlargement due to a shallow iron notch, increases the smelting intensity, reduces production cost, and ensures the safe running of blast furnace production. Especially, a titanium sediment wear-resistant protection layer with a small thermal conductivity coefficient and good corrosion resistance is formed, which has the effect of protecting the hearth and the furnace wall near the iron notch, and thus prolongs the service life of the blast furnace hearth and the furnace wall.

Owner:ANSTEEL INDAL TIEYUAN REFRACTORY MATERIALS

Method for increasing fast replacement success rate by decreasing drawing speed through continuous casting machine

The invention relates to the technical field of steelmaking, in particular to a method for increasing the fast replacement success rate by decreasing the drawing speed through a continuous casting machine. According to the method for increasing the fast replacement success rate by decreasing the drawing speed through the continuous casting machine, the drawing speed is decreased when a tundish isreplaced, the time of passing of a casting blank through a secondary cooling chamber is prolonged, and thus the cooling strength of the casting blank is improved; the temperature of the casting blankis lower before the fast replacement drawing speed returns to zero, in this way, the relative deformation quantity of the casting blank staying in the secondary cooling chamber is smaller in the period that the fast replacement drawing speed returns to zero and casting is started again, it is ensured that when a new tundish starts to be cast, the casting blank can be normally drawn out of a crystallizer under the current pressure of straightening rollers, straightening cracks are avoided, the success rate of fast replacement and casting starting is increased, the quality of the casting blank is guaranteed, and operation is easy; and in addition, when casting is started again, connecting rods are utilized as a connector, after high-temperature molten steel flowing into a copper pipe in thecrystallizer makes contact with the connecting rods, heat of the molten steel is absorbed, the molten steel is solidified while the connecting rods are smelted, thus the connecting effect is achieved,the breed-out situation is avoided, and successful casting starting is guaranteed.

Owner:ZENITH STEEL GROUP CORP

Novel engine intelligent cooling system and control method based on split cooling and reversed cooling

ActiveCN105697120AImprove fuel economyImprove economyLiquid coolingCoolant flow controlExpansion tankHeating time

The invention discloses a novel engine intelligent cooling system and control method based on engine split cooling and reversed cooling. The cooling system comprises a cylinder cover water sleeve, an engine body water sleeve, an electronic control water pump, electronic thermostats, an electronic control fan, a radiator, an expansion tank, a temperature sensor, a motor and an electronic control unit. In the working process of the system, cooling liquid is pumped into an engine water sleeve through the electronic control water pump, the first electronic thermostat controls the cooling liquid to enter the cylinder cover water sleeve and the engine body water sleeve according to the rotating speed and load signals of an engine, and the cooling liquid flows from top to bottom and passes through a cooling cylinder cover and an engine body to flow out; and the second electronic thermostat distributes the flow of the cooling liquid entering large circulation and small circulation according to the temperature of the cooling liquid of a header pipe, and the cooling liquid is circulated to be pumped into the engine body of the engine to be cooled. By means of the novel engine intelligent cooling system and control method, the flow of the cooling liquid of the cylinder cover and the engine body of the engine can be accurately distributed, uneven cooling is reduced, and the heating time of the engine is shortened; and meanwhile, the heat state of heated components is optimized through reversed cooling.

Owner:ZHEJIANG UNIV

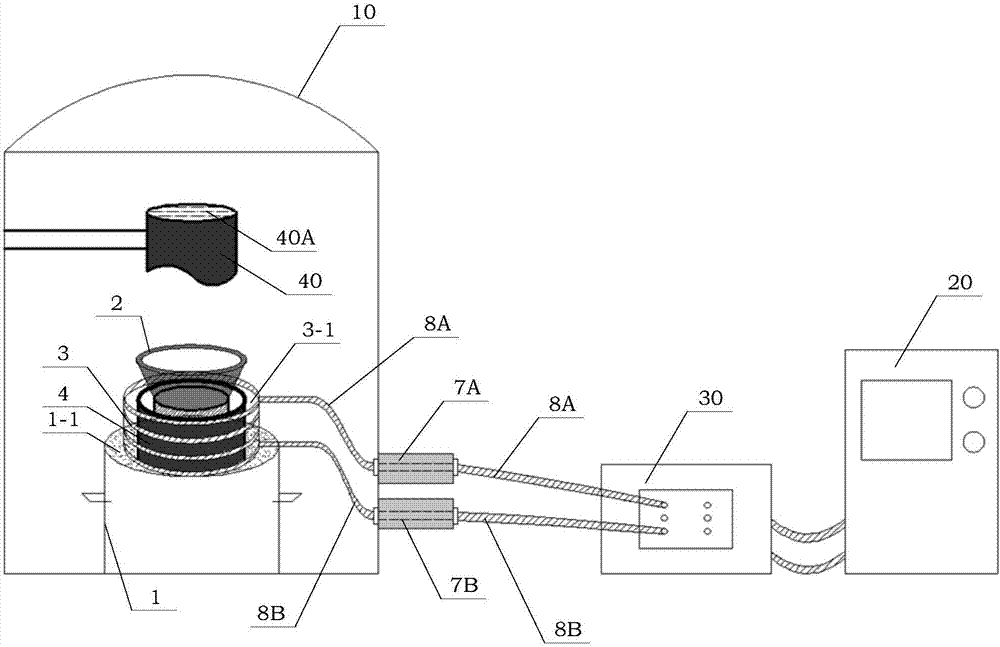

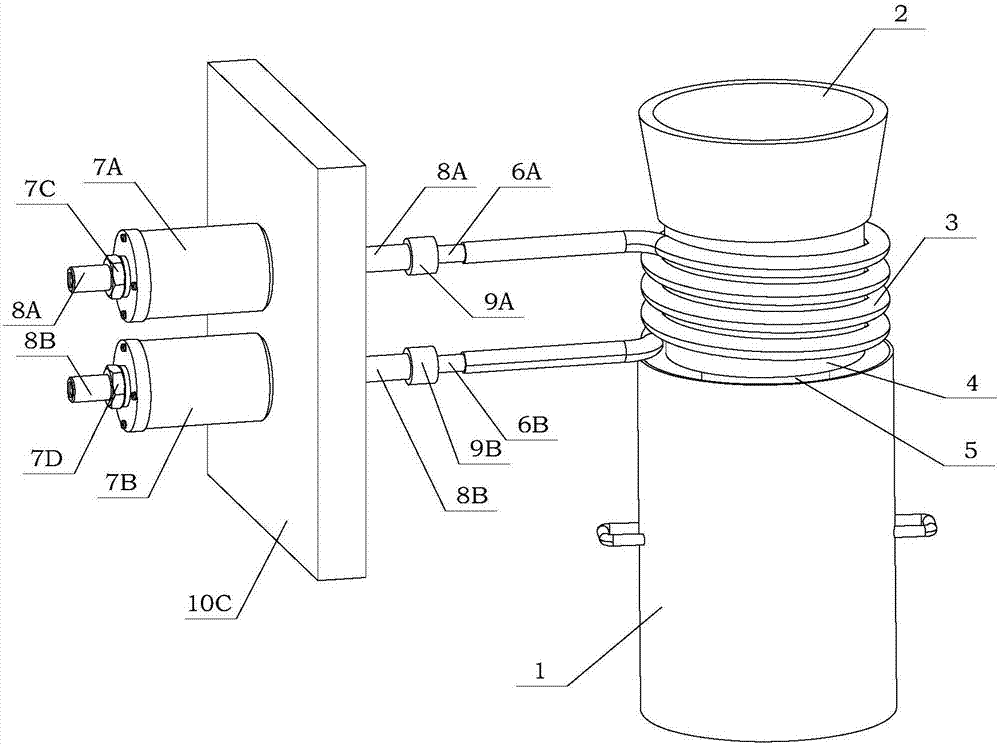

Sequential solidification technology device and method used in vacuum smelting equipment

The invention discloses a sequential solidification technology device and method used in vacuum smelting equipment. An induction heating coil is placed in a dead head section of an ingot die, and the feeding capacity of metal liquid in a dead head is enhanced through an induction heating method; a bottom cooling device with the cooling area smaller than the area of the cross section, at the bottom position of the ingot die, of a casting is arranged at the bottom of an ingot die base, the solid-liquid interface angle is reduced, and the metal liquid in the ingot die after pouring can be sequentially solidified from bottom to top. The solidification process control method is applicable to production of metal bar castings in the vacuum smelting equipment. Through the sequential solidification technology device and method, macroshrinkage and shrinkage porosity in alloy bar castings can be eliminated, the casting quality and the technology yield are improved, and the production efficiency is greatly improved.

Owner:BEIHANG UNIV

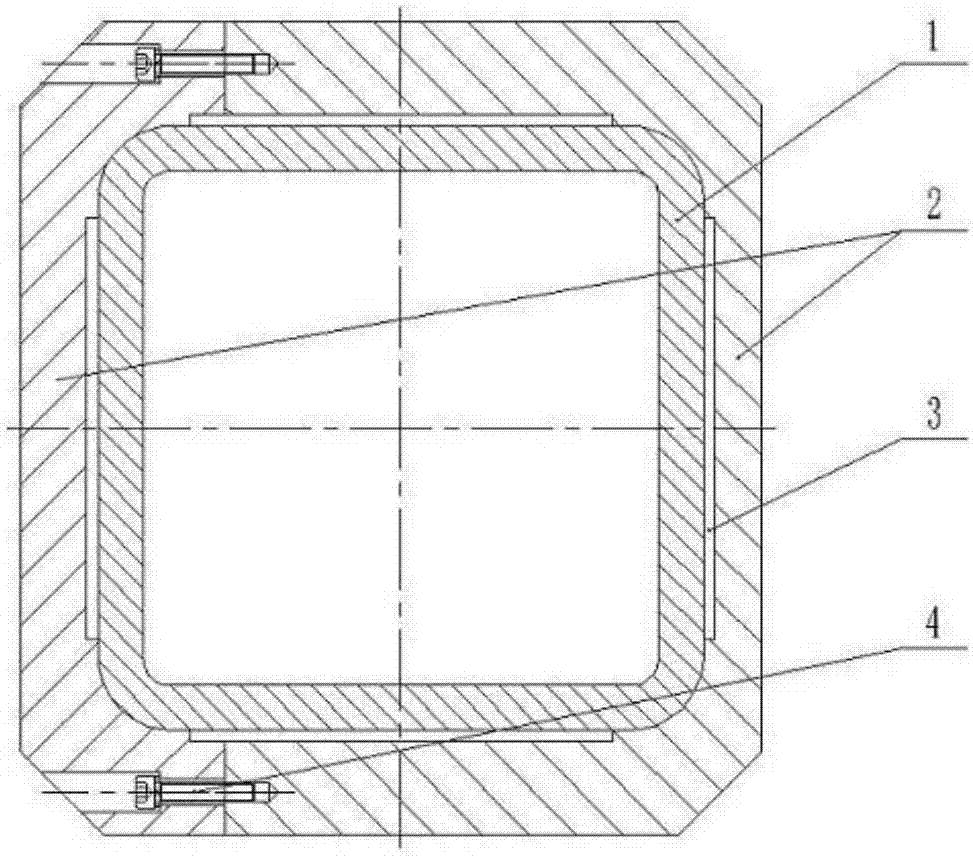

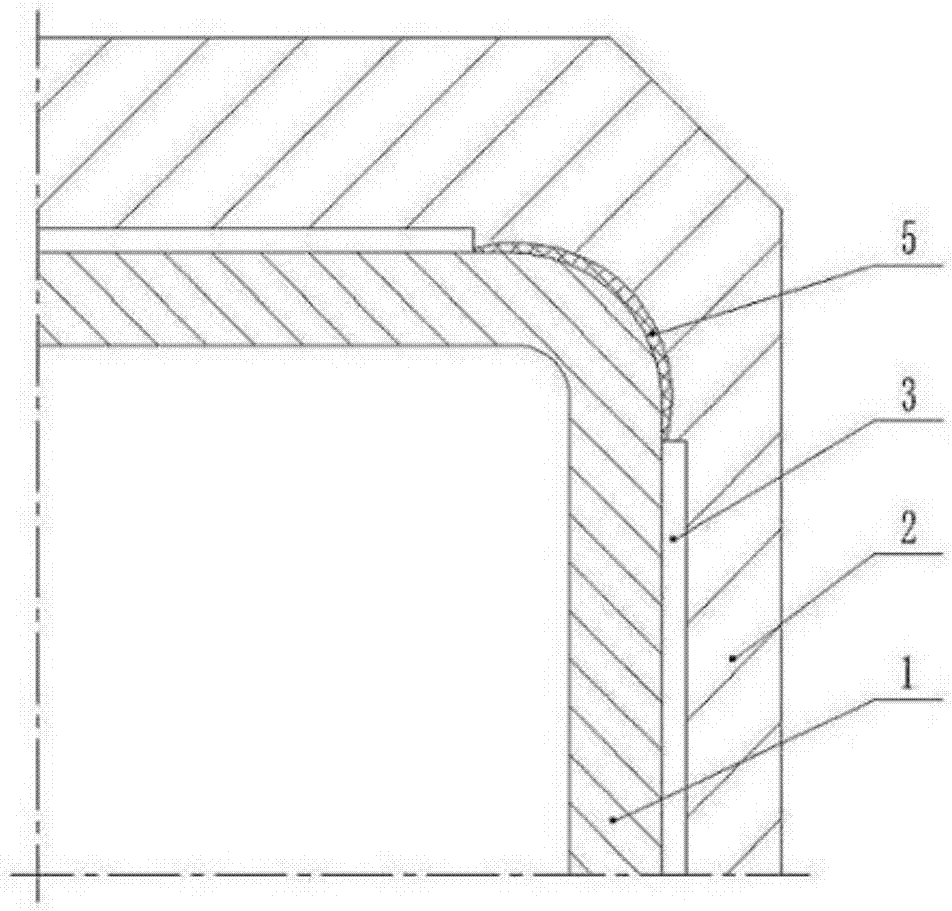

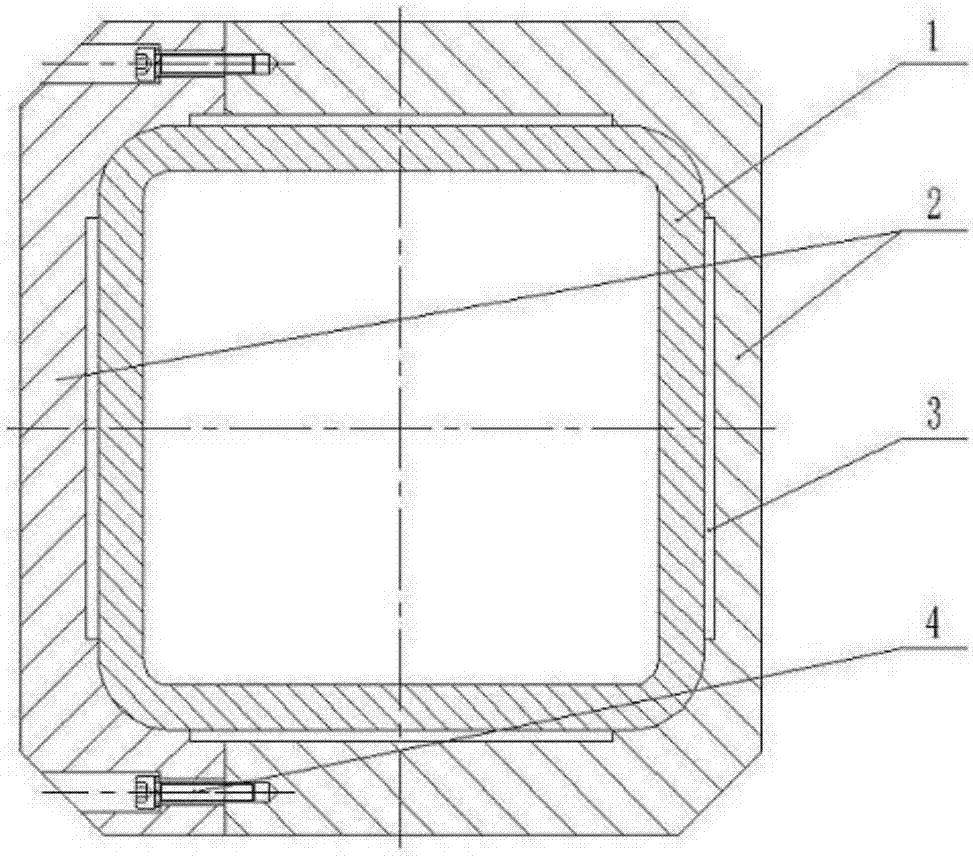

Uniform cooling crystallizer

The invention discloses a uniform cooling crystallizer. A flow-guiding water jacket of the crystallizer is in contact with and is supported by four corners of a crystallizer copper tube. The flow-guiding water jacket is directly supported by the four corners of the crystallizer copper tube, so that the accuracy of a crystallizer water seam is greatly improved; meanwhile, the flow-guiding water jacket is in contact with the four corners of the crystallizer copper tube, so that cooling of the corners of the crystallizer copper tube is weakened and the cooling strength of the corners and the surface of the crystallizer copper tube are uniformized. The uniform cooling crystallizer is simple in structure and vivid in effect, achieves simultaneous solidification in the circumferential directionof the crystallizer when continuous casting molten steel is initially set, and reduces the tendencies of corner cracking and collapse of a casting blank.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com