Patents

Literature

499results about How to "Avoid chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

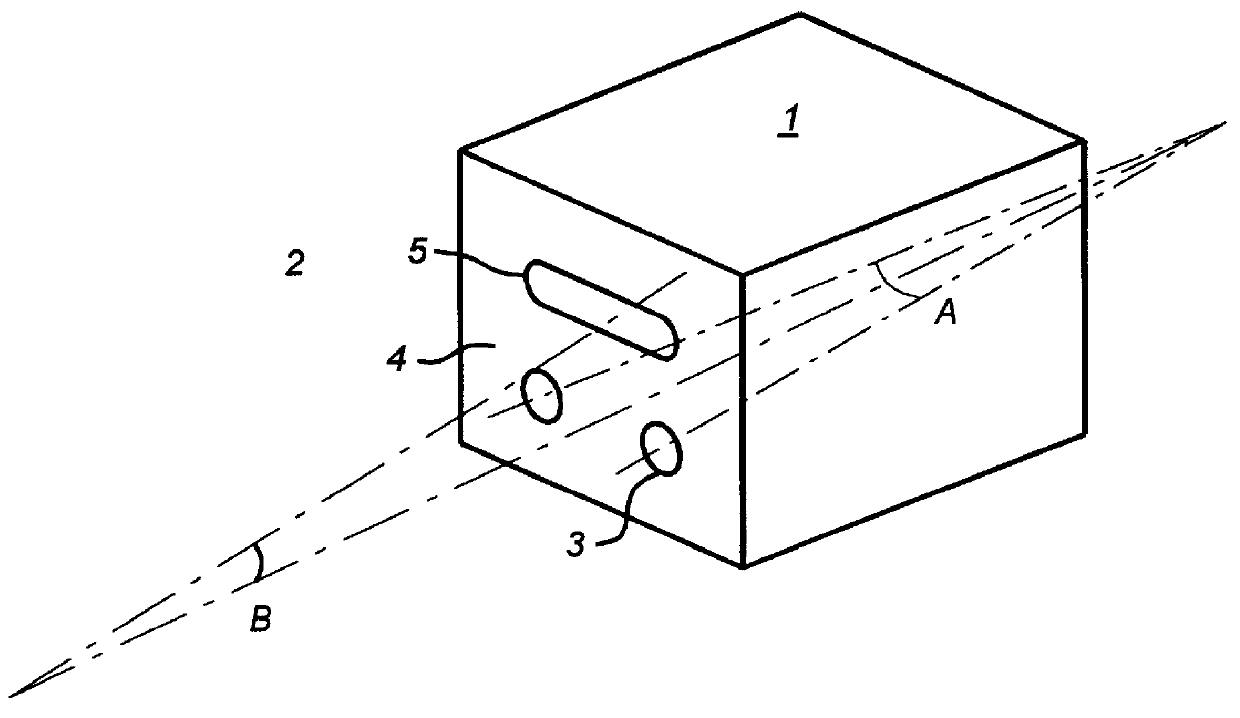

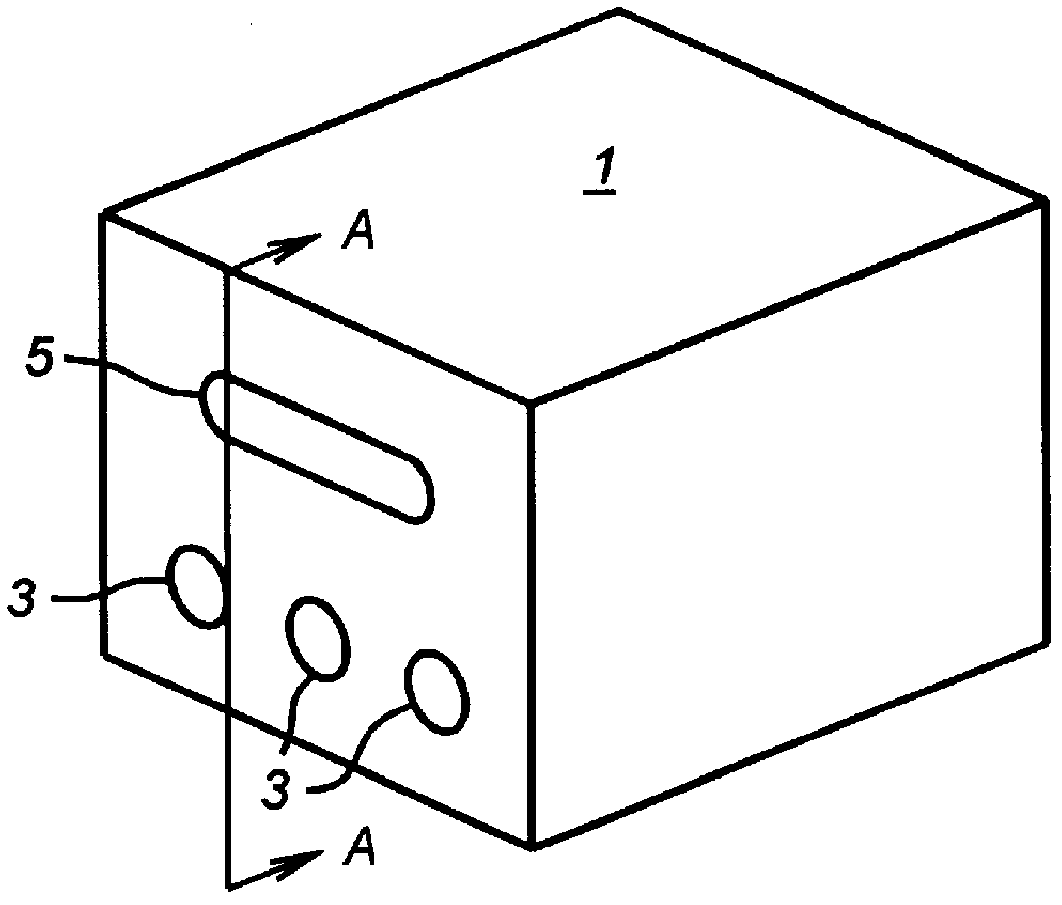

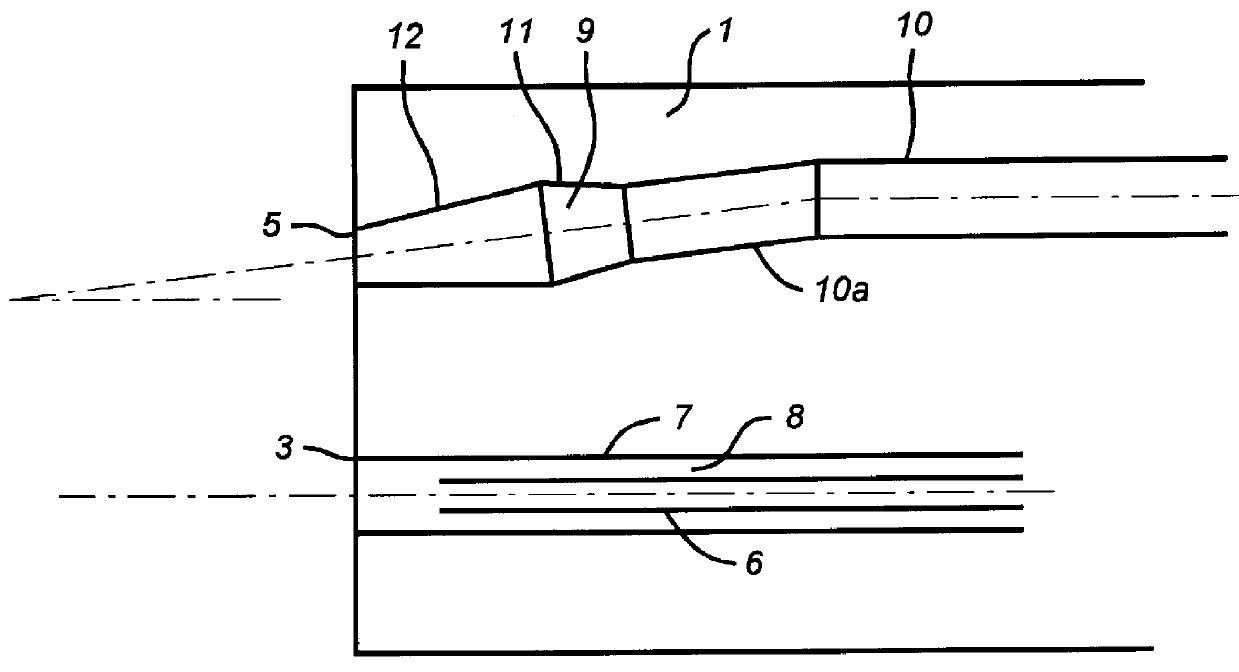

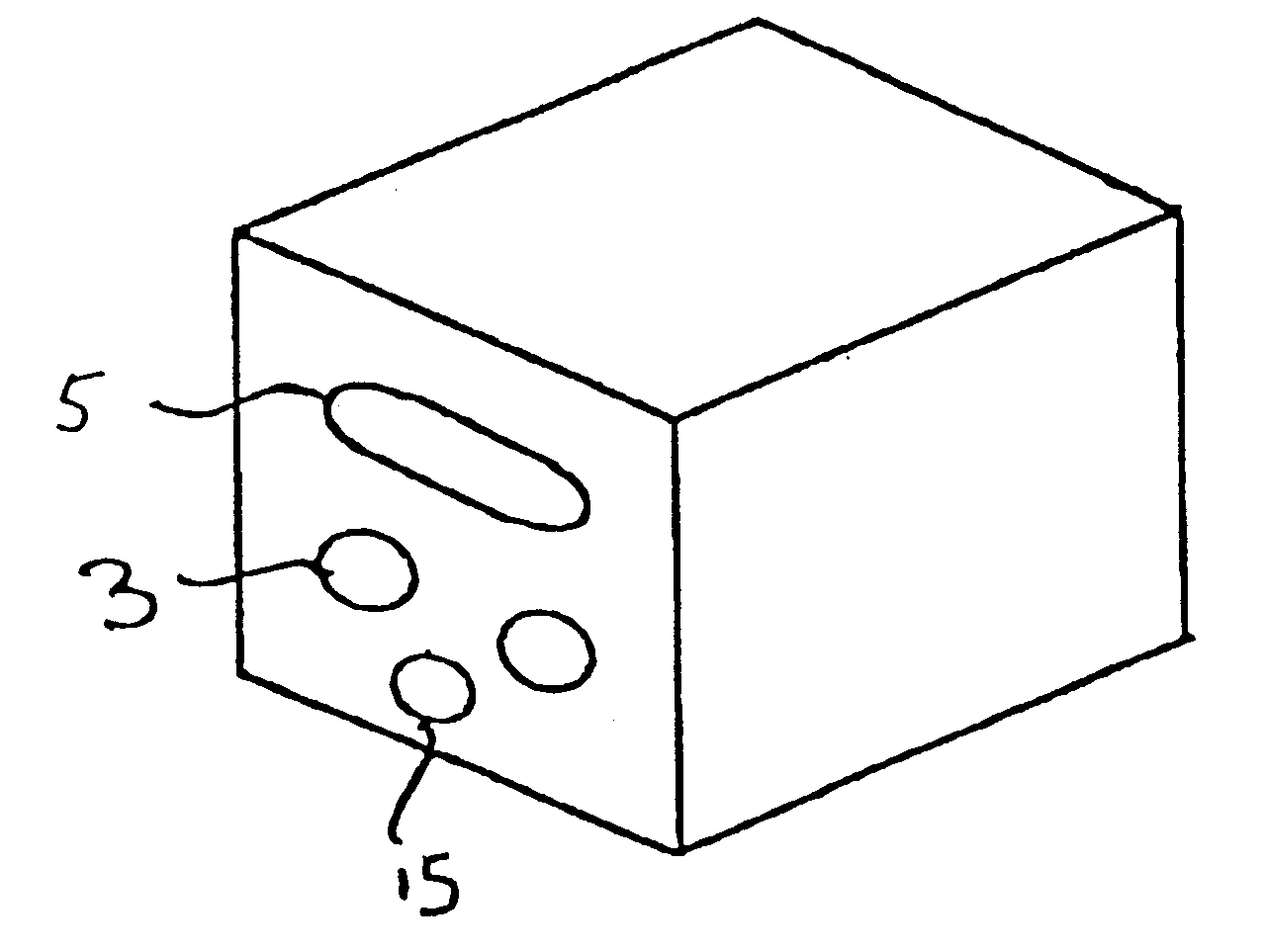

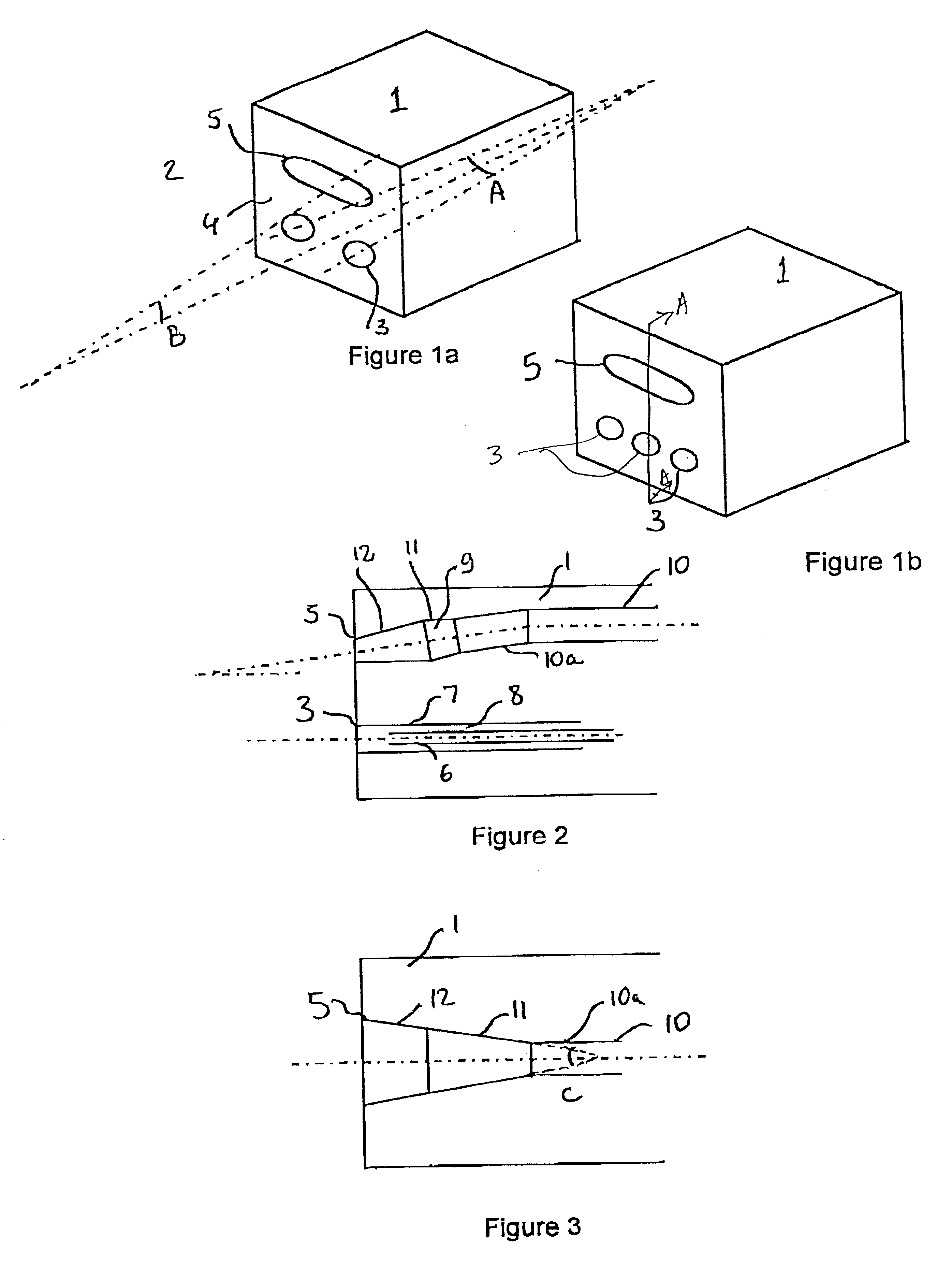

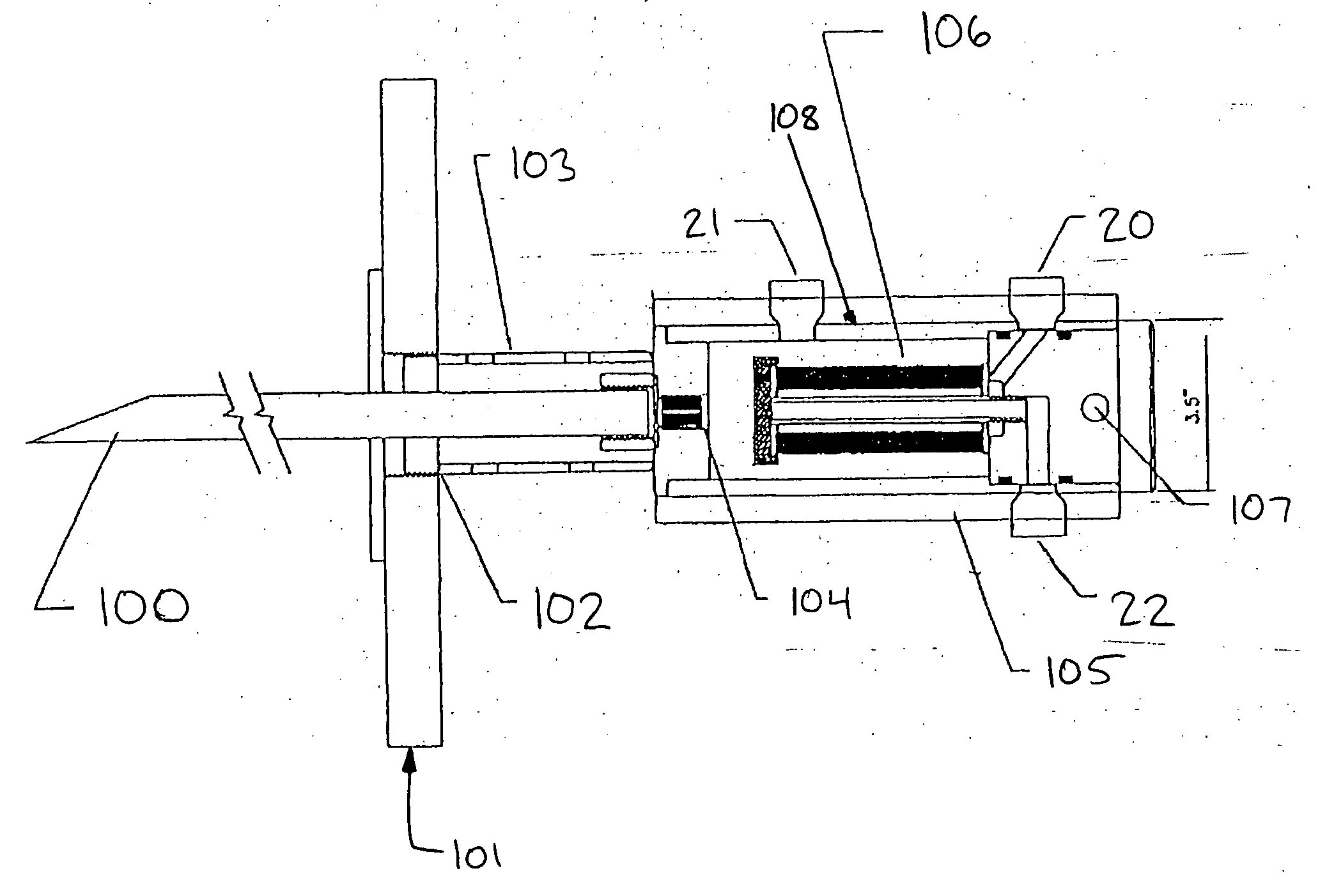

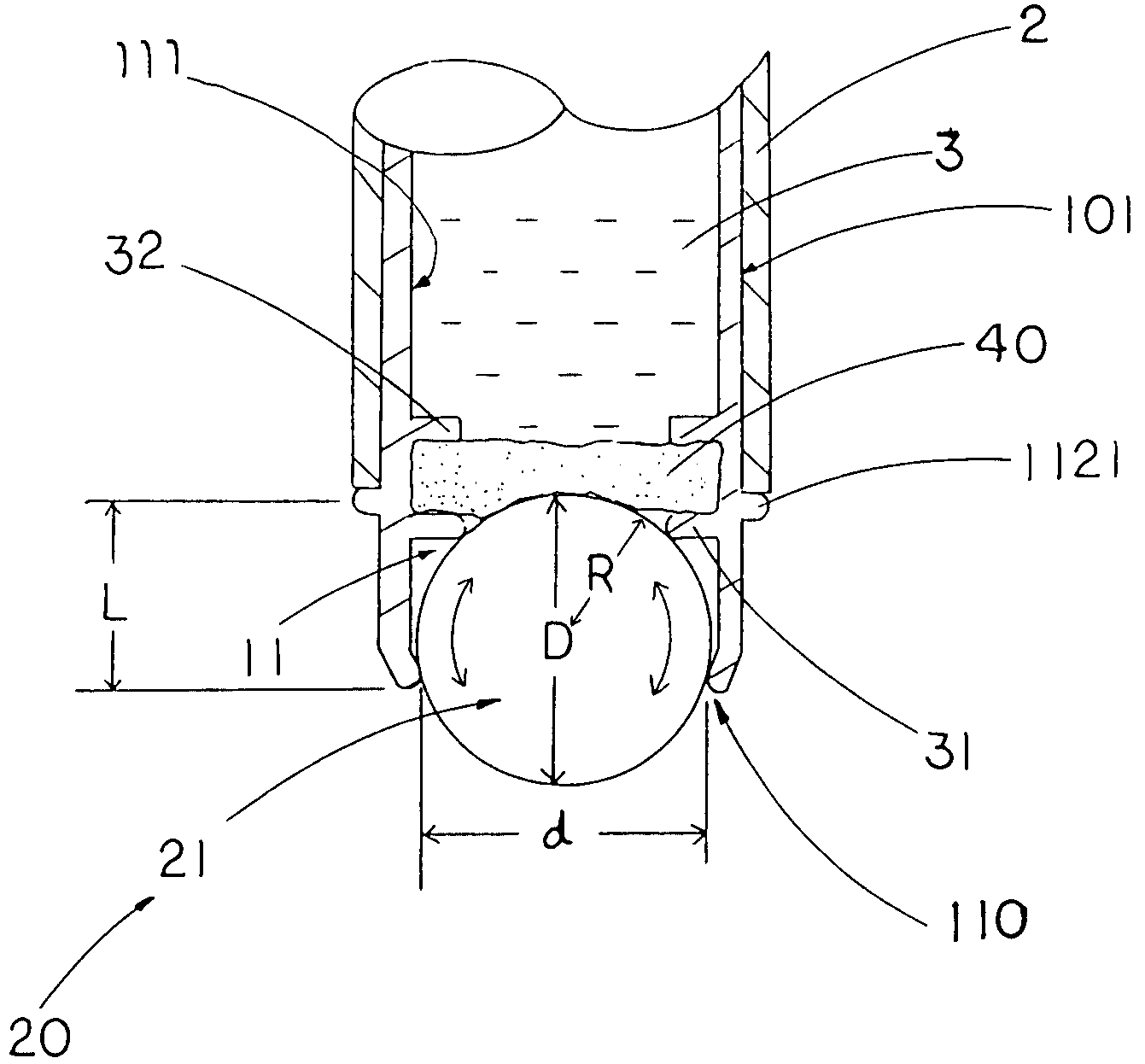

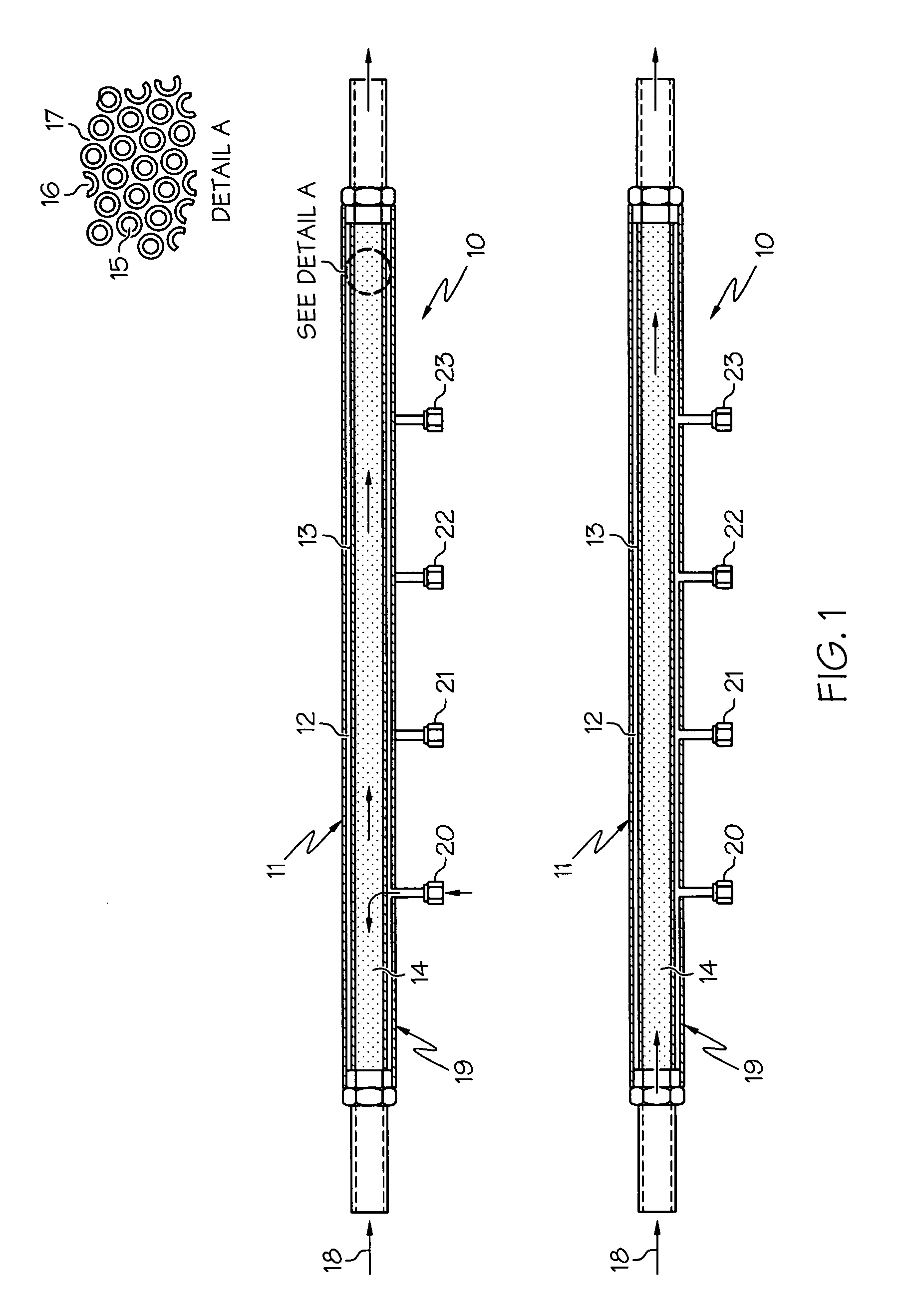

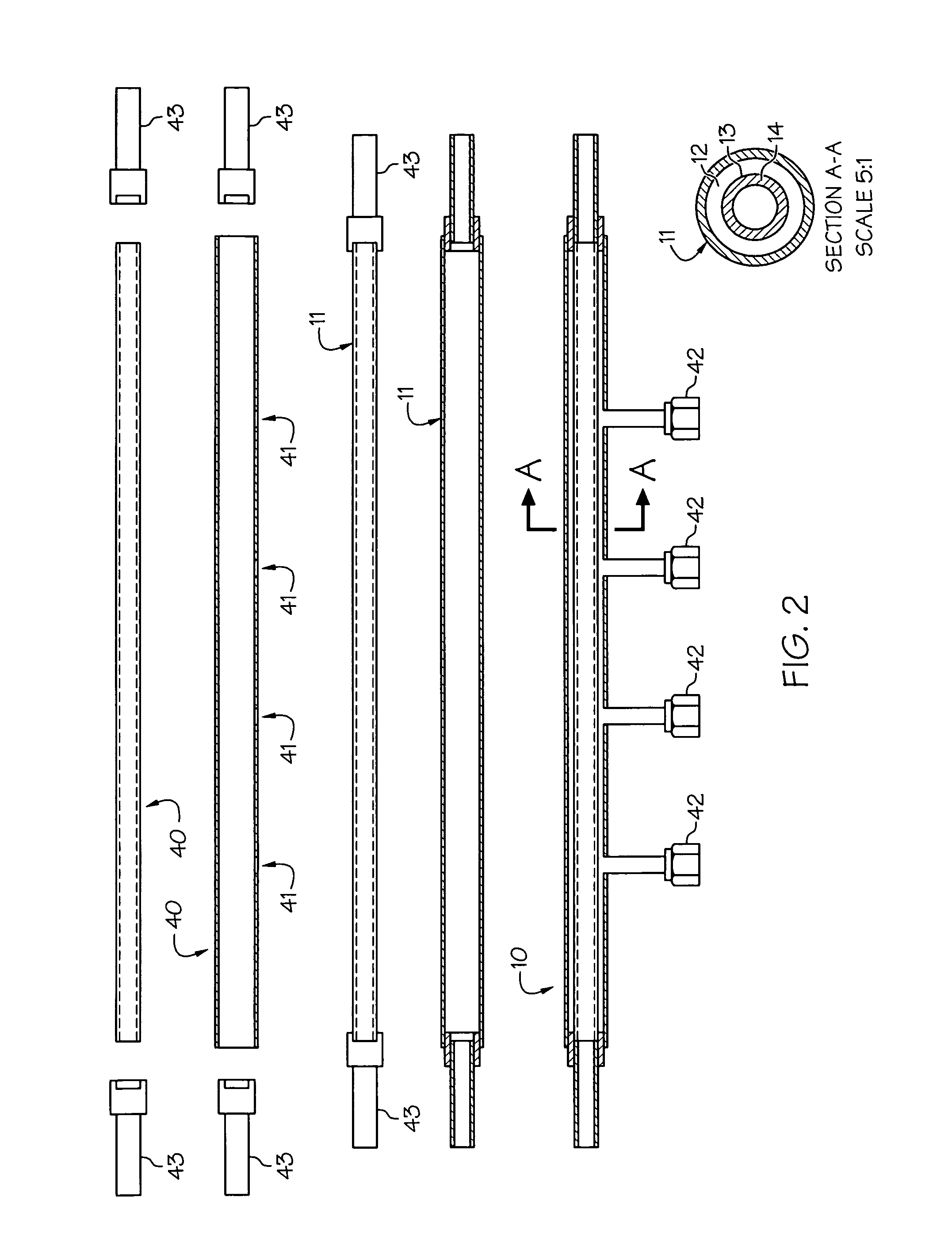

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6074197AReduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

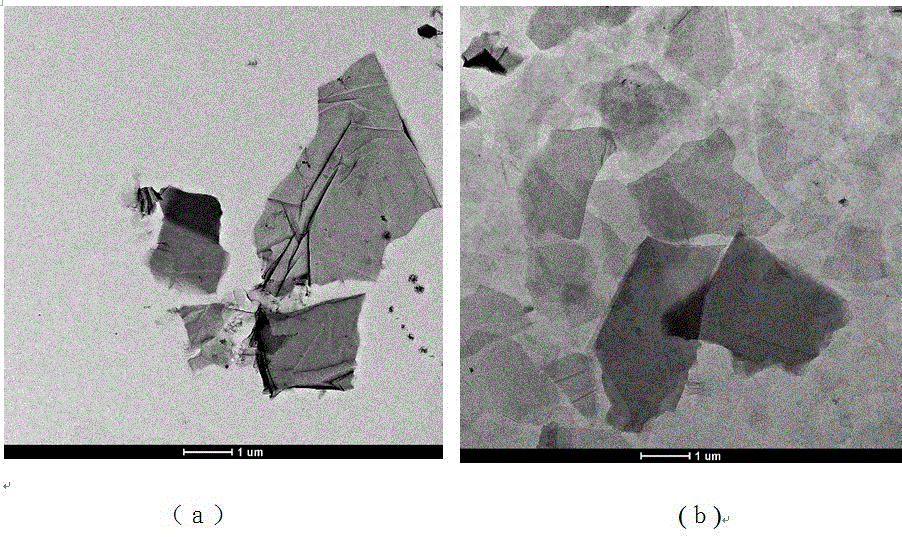

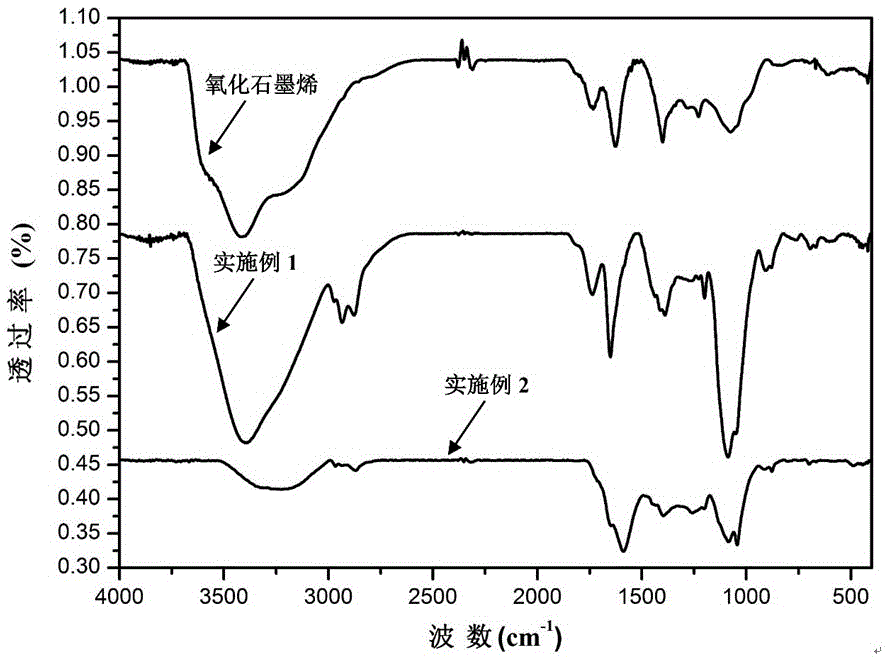

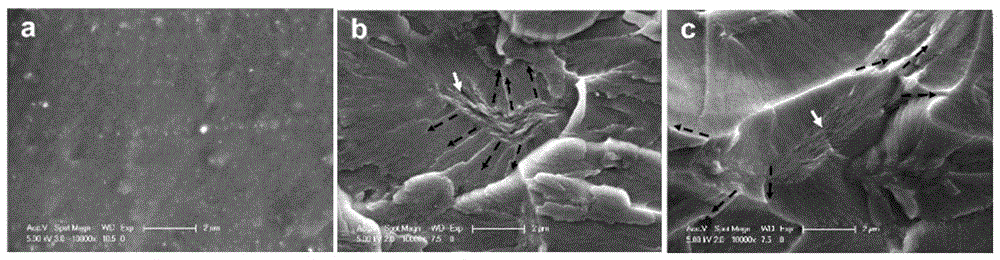

Graphene/polysiloxane composite coating material and preparation method thereof

ActiveCN106752926AImprove scratch resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyResin-Based Composite

The invention provides a graphene / polysiloxane composite coating material and a preparation method thereof. The method comprises the following steps: modifying the graphene surface with active groups by a chemical modification technique to obtain modified graphene, mixing the modified graphene with a silane compound, a dispersion medium, a non-essential comonomer and a non-essential accelerator, and carrying out hydrolytic condensation or hydrolytic condensation-free radical polymerization to generate a graphene / polysiloxane composite resin in situ; and mixing the resin with a non-essential blend resin, a non-essential curing agent, a non-essential solvent, a non-essential pigment and filler and a non-essential aid, and carrying out physical blending, amino epoxy addition reaction, Michael addition reaction and the like to form a film, thereby obtaining the graphene / polysiloxane composite coating material. The uniformly dispersed graphene lamellae and polysiloxane have strong interface effects, also have the gas / liquid barrier and heat shielding effects, and endow the coating with excellent corrosion resistance, flame retardancy and the like, thereby greatly enhancing the mechanical properties, corrosion resistance, scratch resistance, wear resistance and the like of the coating.

Owner:FUDAN UNIV

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6331107B1Reduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC

Filter for determination of mercury in exhaust gases

InactiveUS20050084976A1Improve accuracyPreventing catalyzed oxidationComponent separationWithdrawing sample devicesFlue gasExhaust fumes

An apparatus, process, coating, and filter for the accurate measurement of total mercury concentration in flue gas. In a preferred aspect, the concentrations of both elemental and oxidized mercury are preserved by the apparatus for analysis. Accordingly, embodiments of the present apparatus and process can be used to determine regulatory compliance or for process control measurement.

Owner:PERMA PURE LLC

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

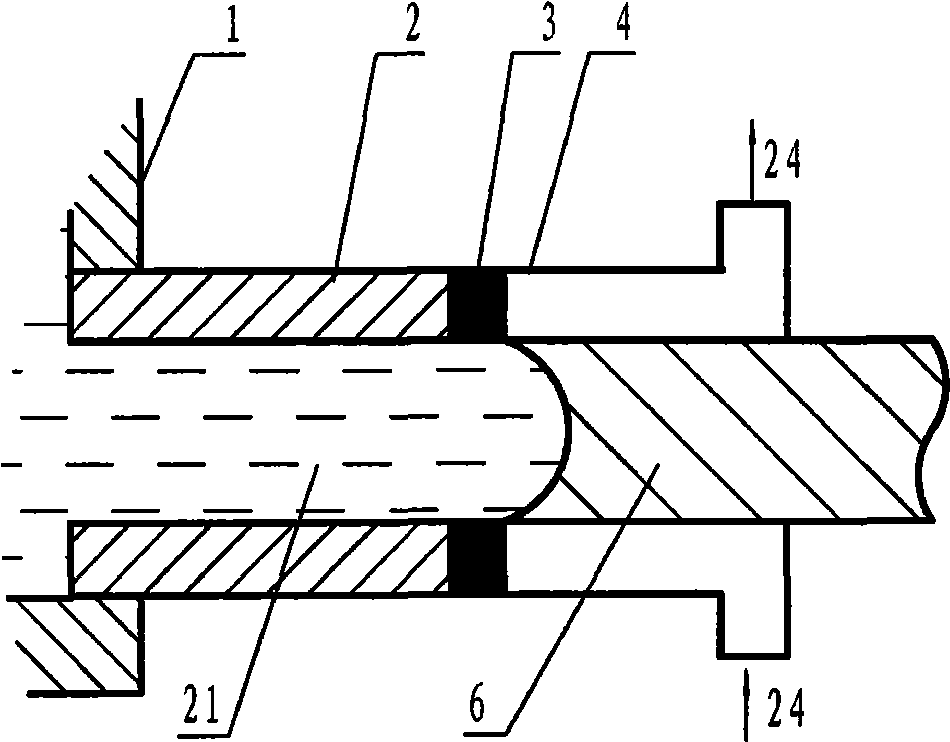

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

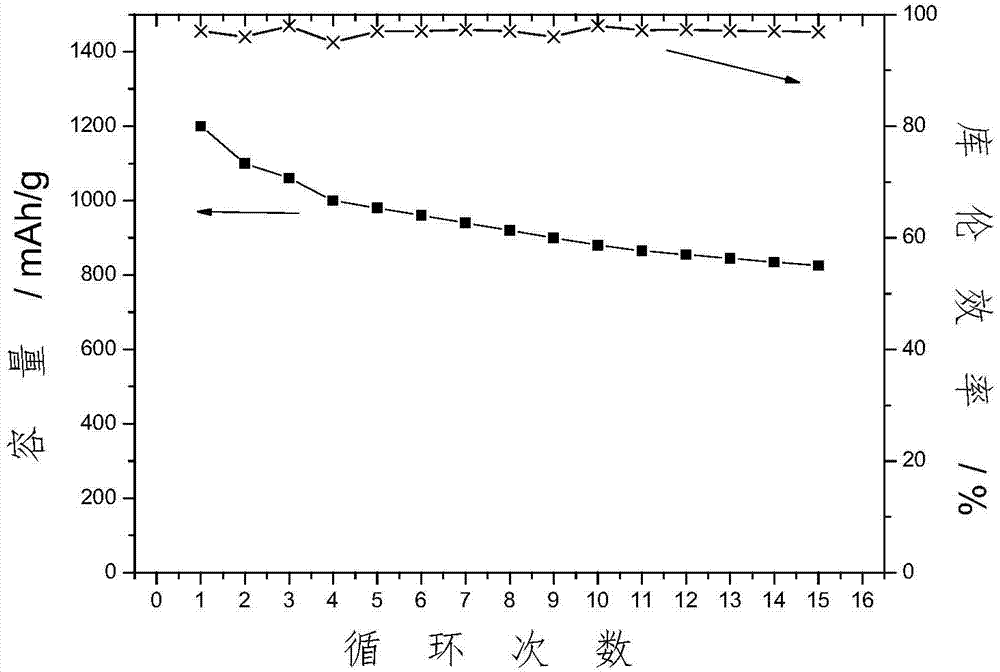

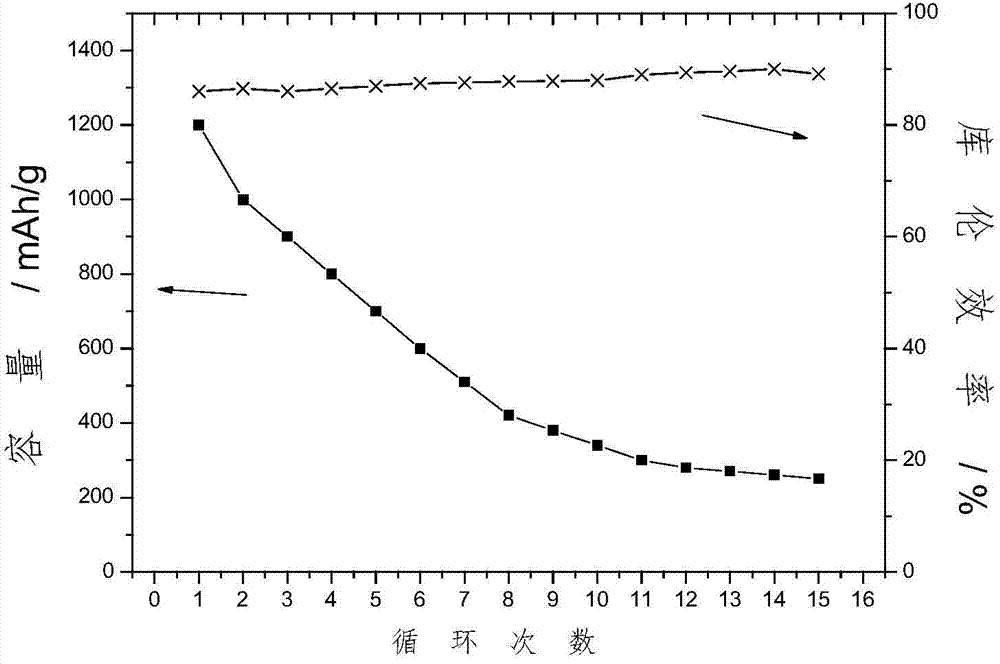

Method for protecting negative electrode of lithium sulfur battery

InactiveCN104716381ADoes not affect the assembly processPracticalFinal product manufactureLi-accumulatorsBorideLithium metal

The invention discloses a method for protecting the negative electrode of a lithium sulfur battery. A lithium sulfur battery negative electrode protection additive layer is adhered to the surface of the anode of the lithium sulfur battery. An additive component forming the protection additive layer can be an inorganic compound or an organic compound; the inorganic compound is one or above two of metal oxides, nonmetal oxides, sulfides, phosphides, nitrides, borides and fluorides; and the organic compound is one or above two of ionic liquid molecules, amino acids, polycation electrolytes, polyanion electrolytes, cationic surfactants, polyoxyether and polythioether. The morphology of the liquid metal protection layer is dynamically changing, and does not physically shed or crack due to continuous dissolution and deposition of the lithium metal in order to effectively protect the negative electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

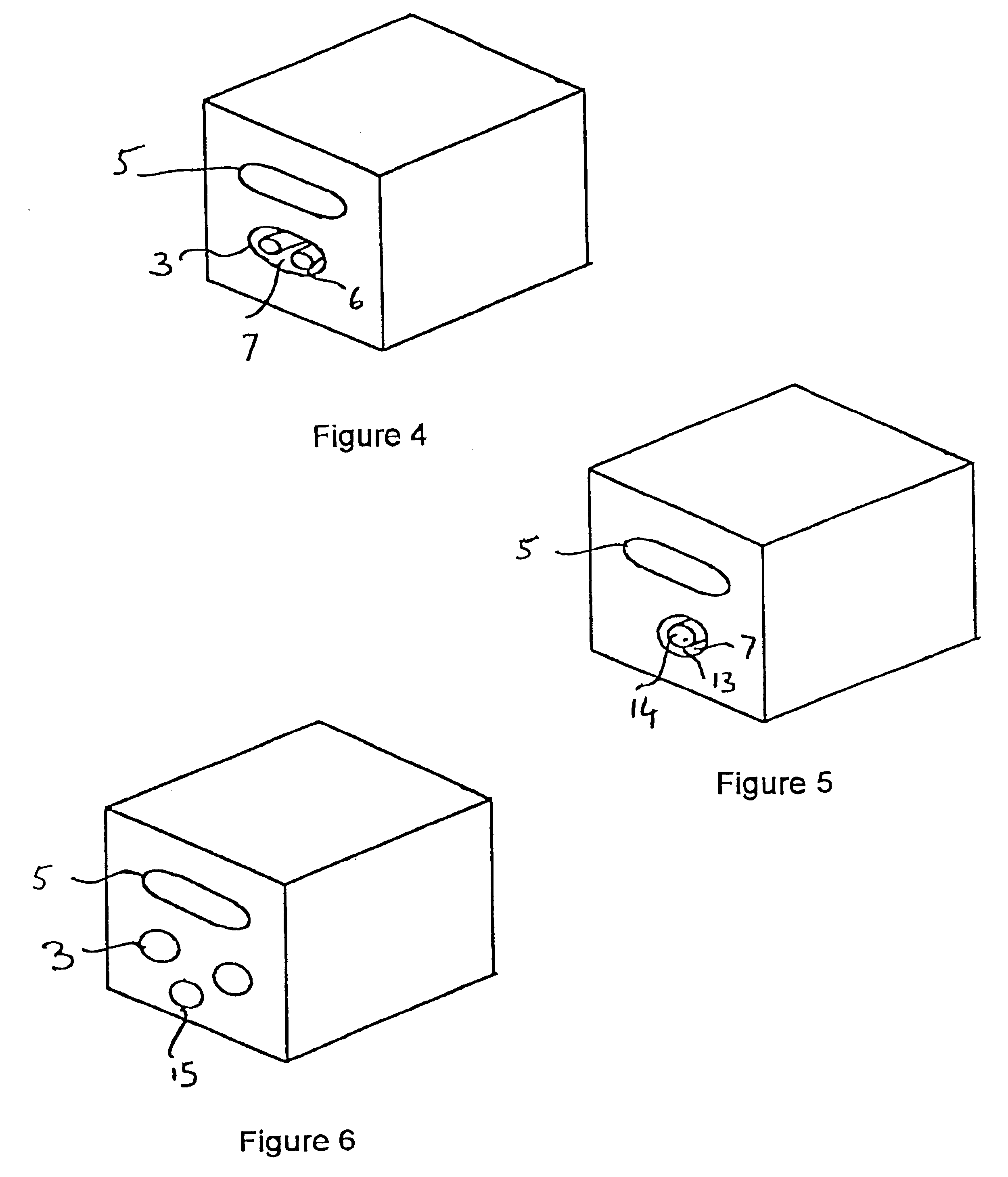

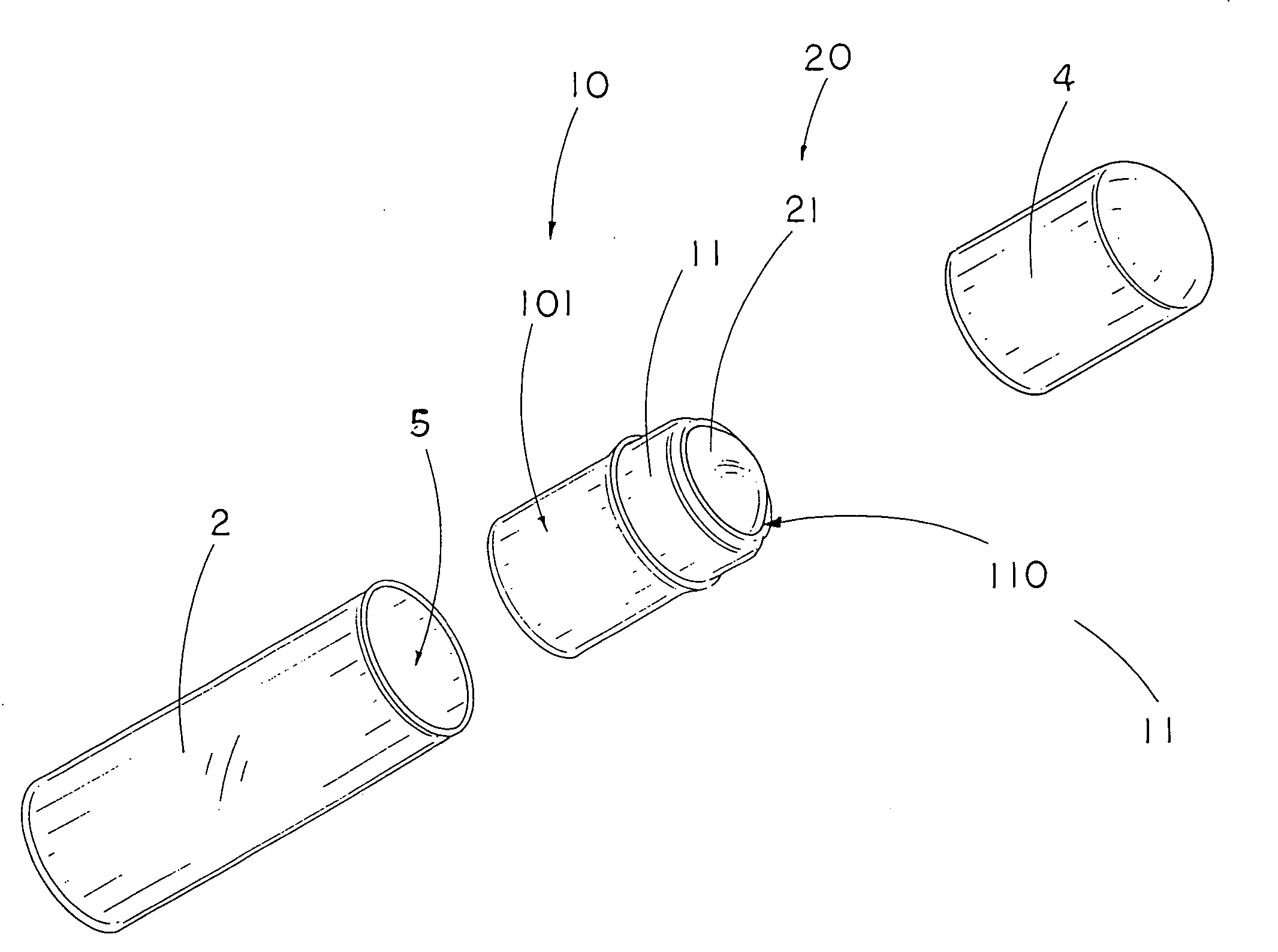

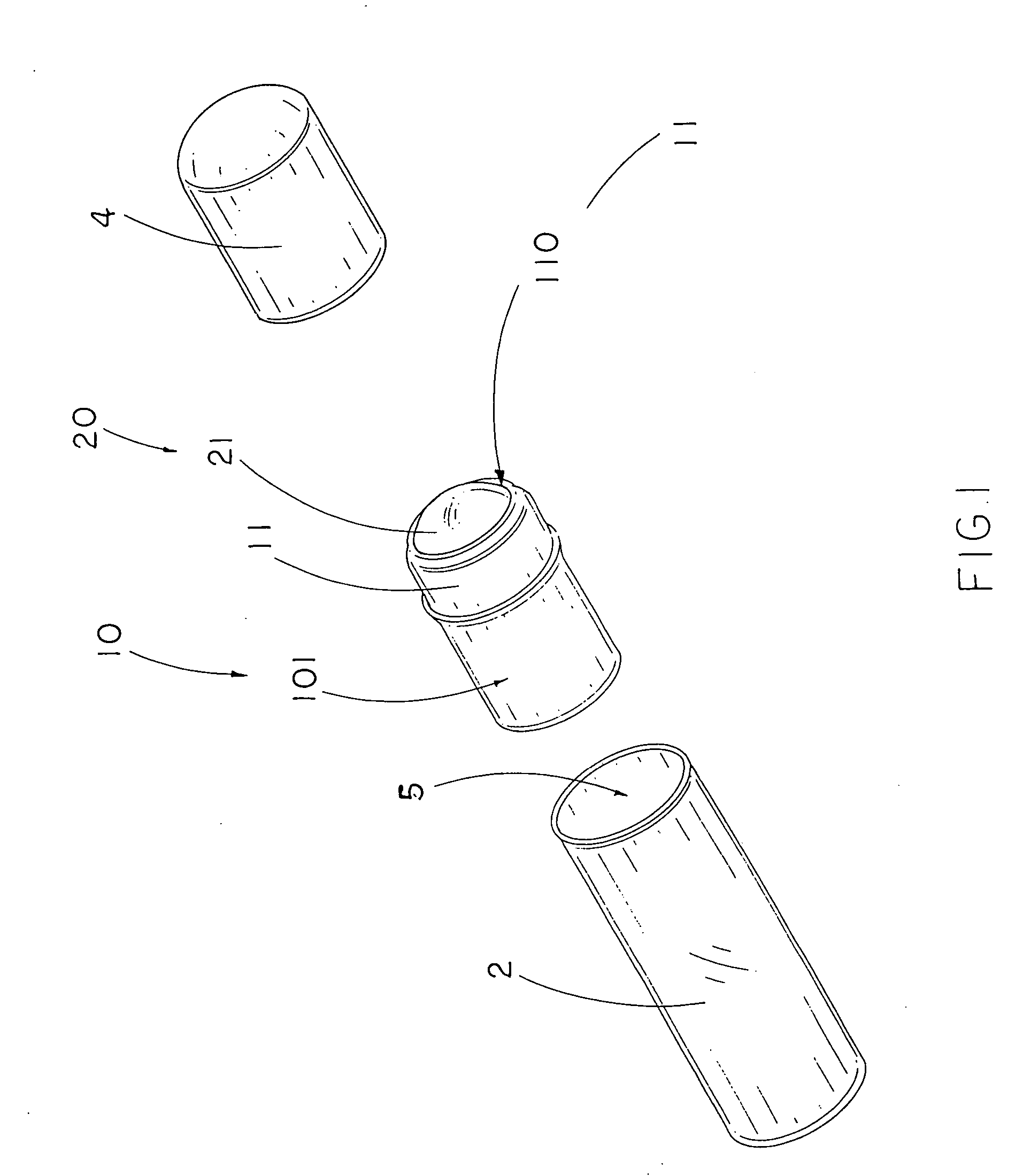

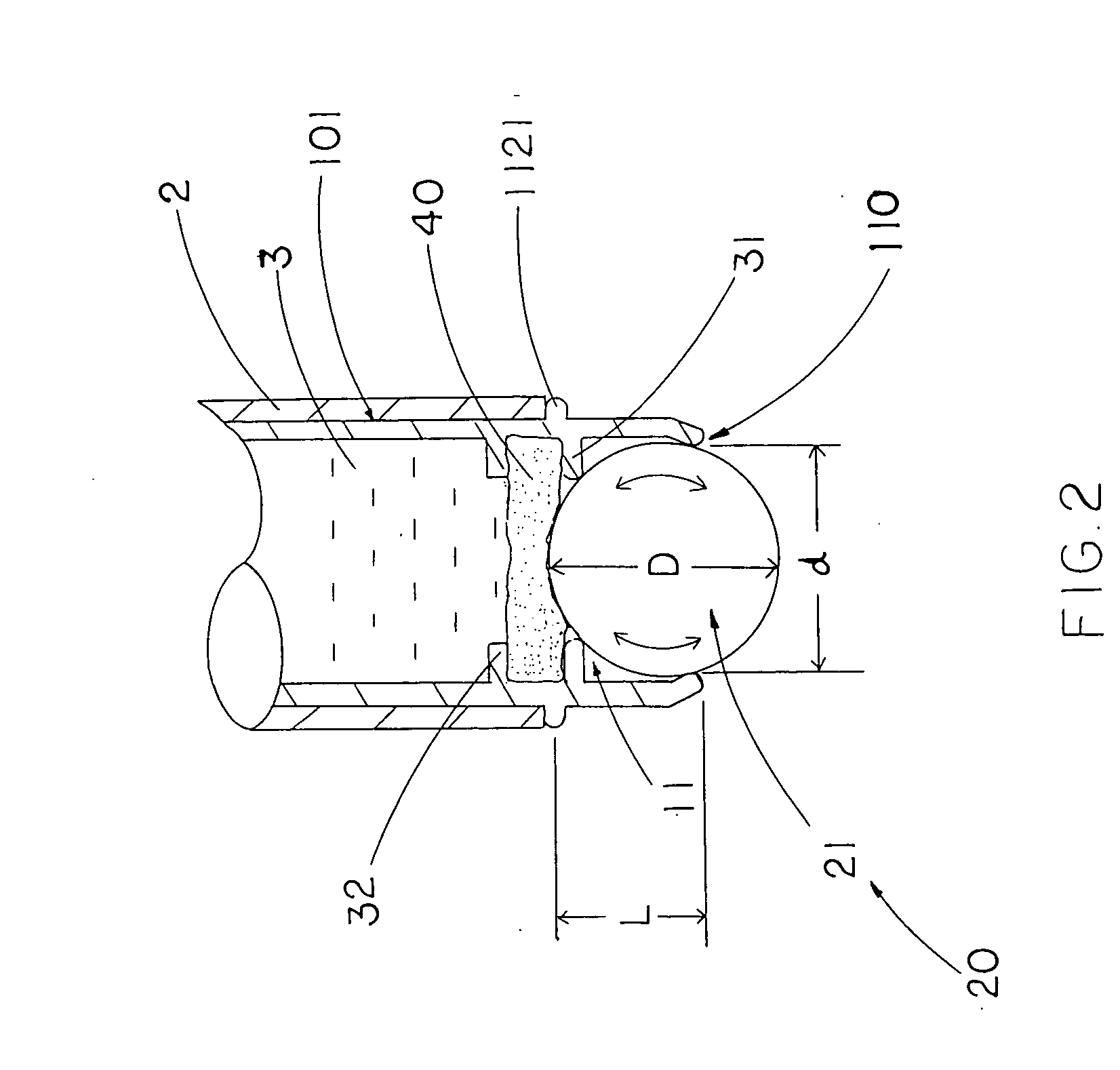

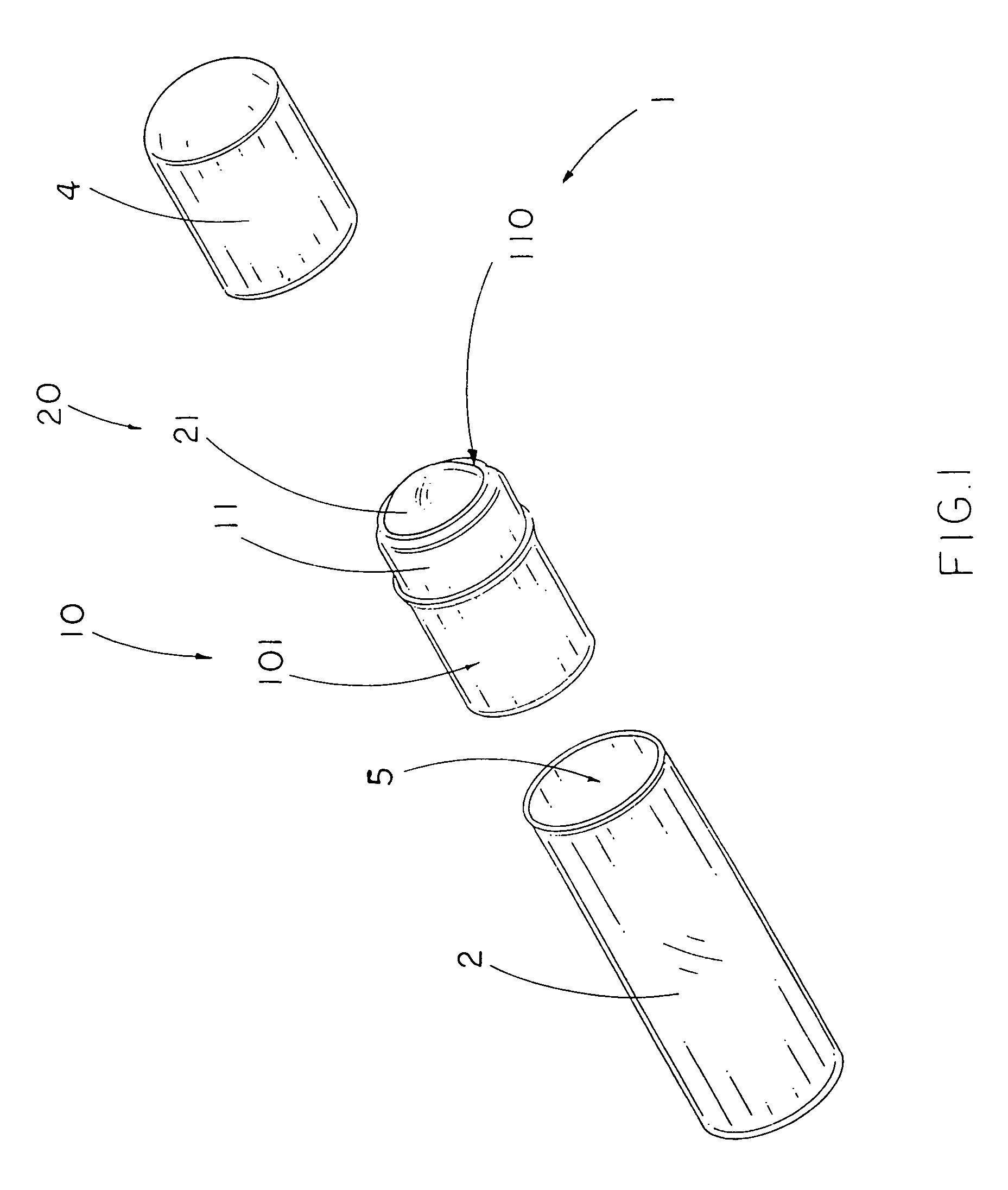

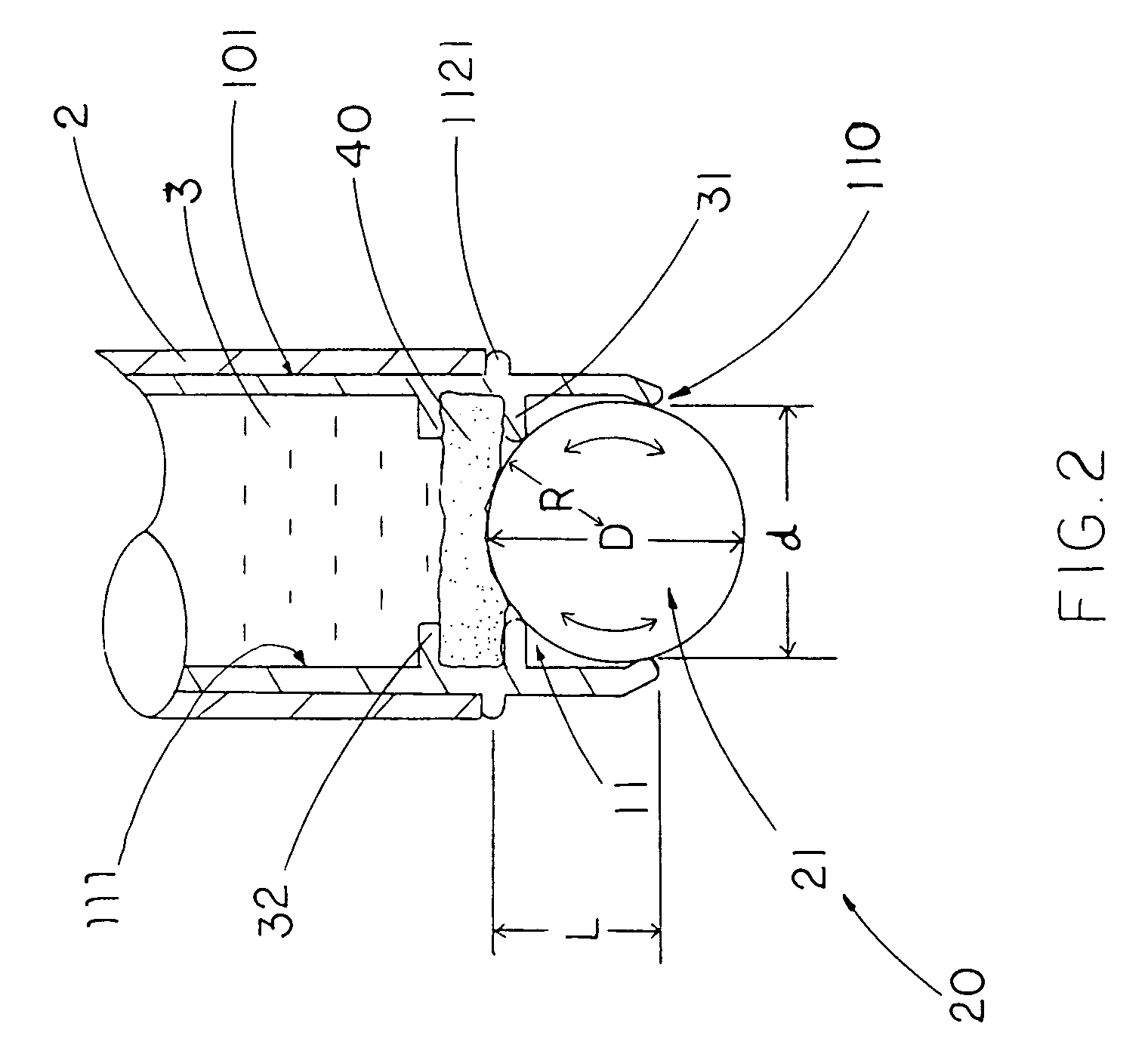

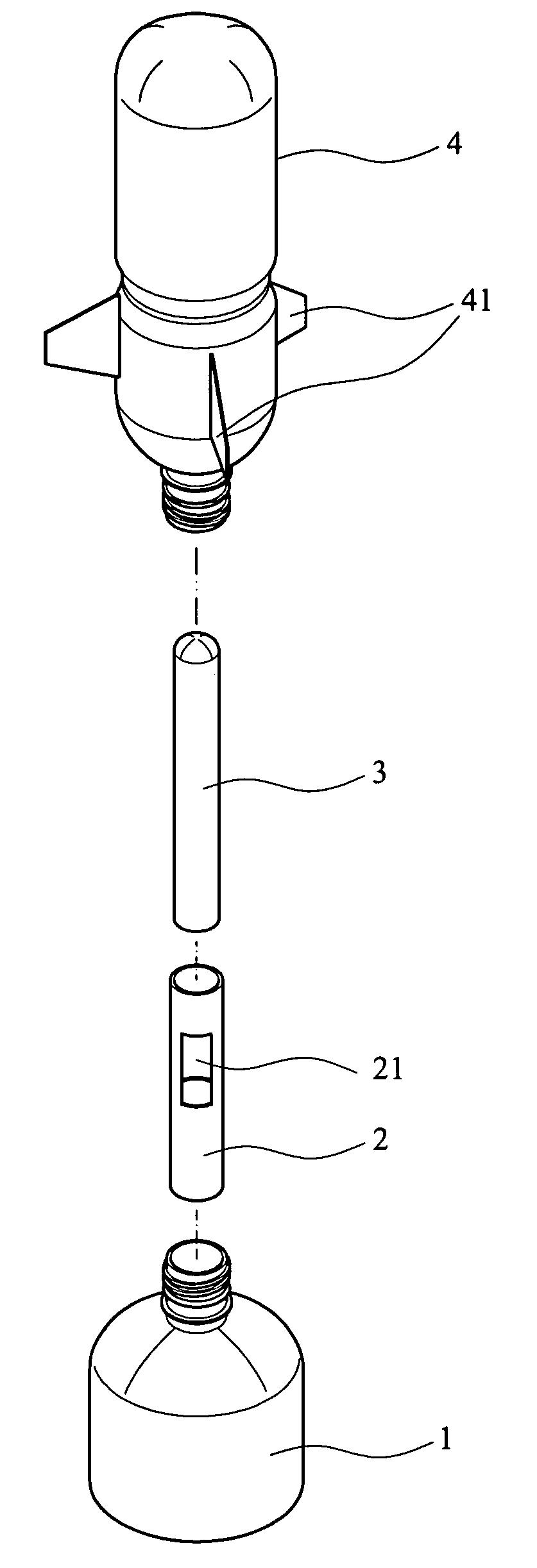

Dispenser head for fluid container

InactiveUS20060222445A1Reduce manufacturing costLow costPropelling pencilsBall-point pensEngineeringMechanical engineering

Owner:CHUANG KAIWIN

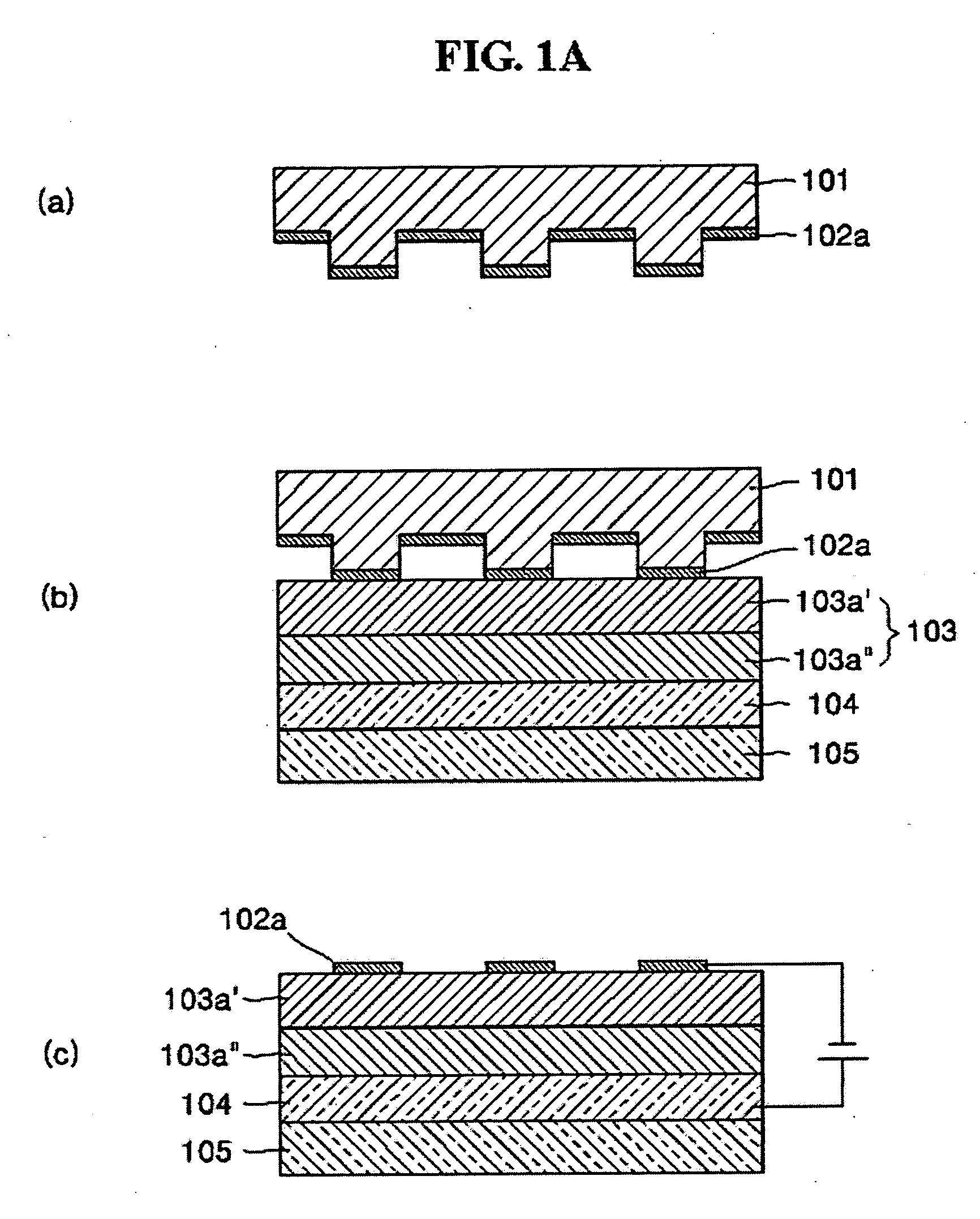

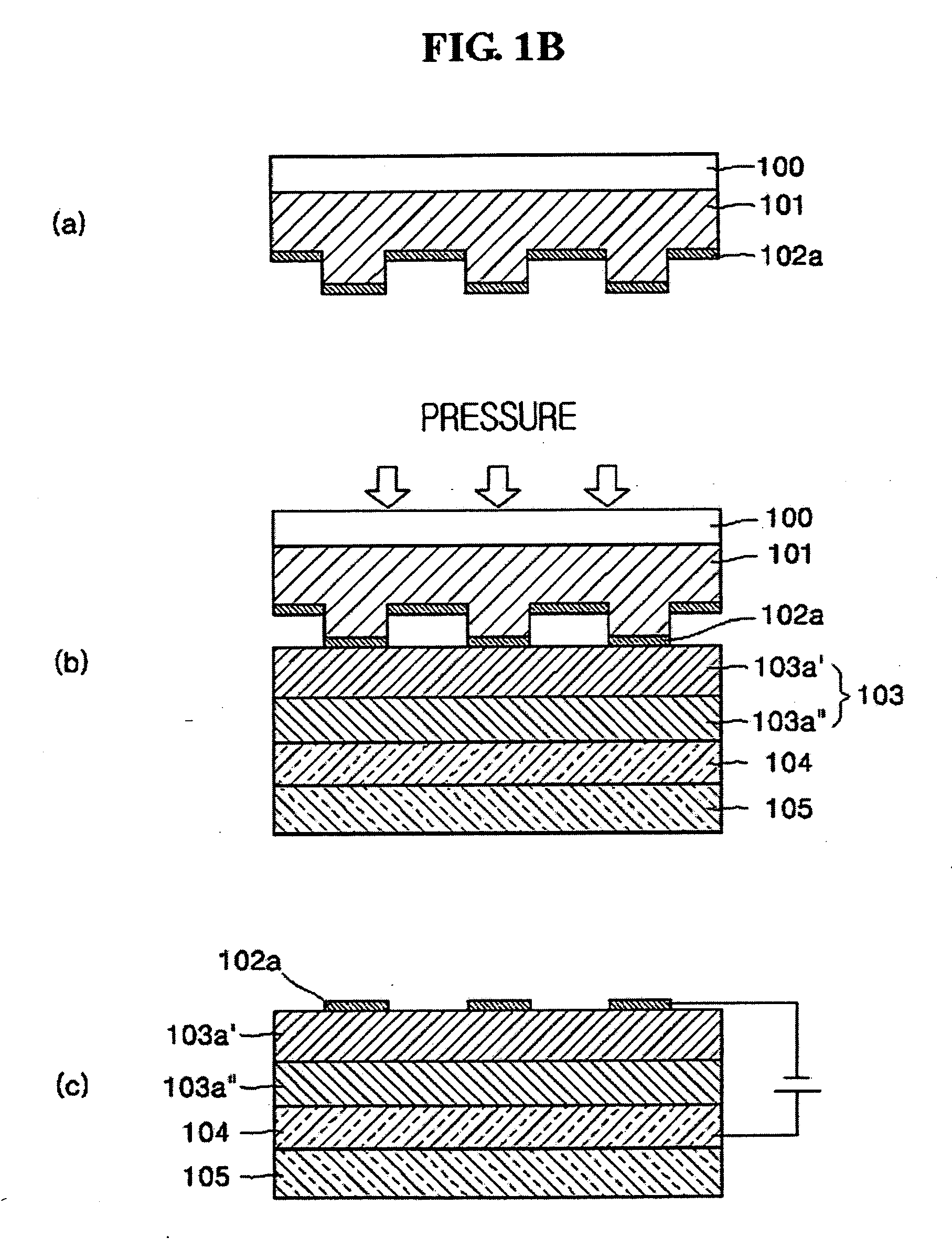

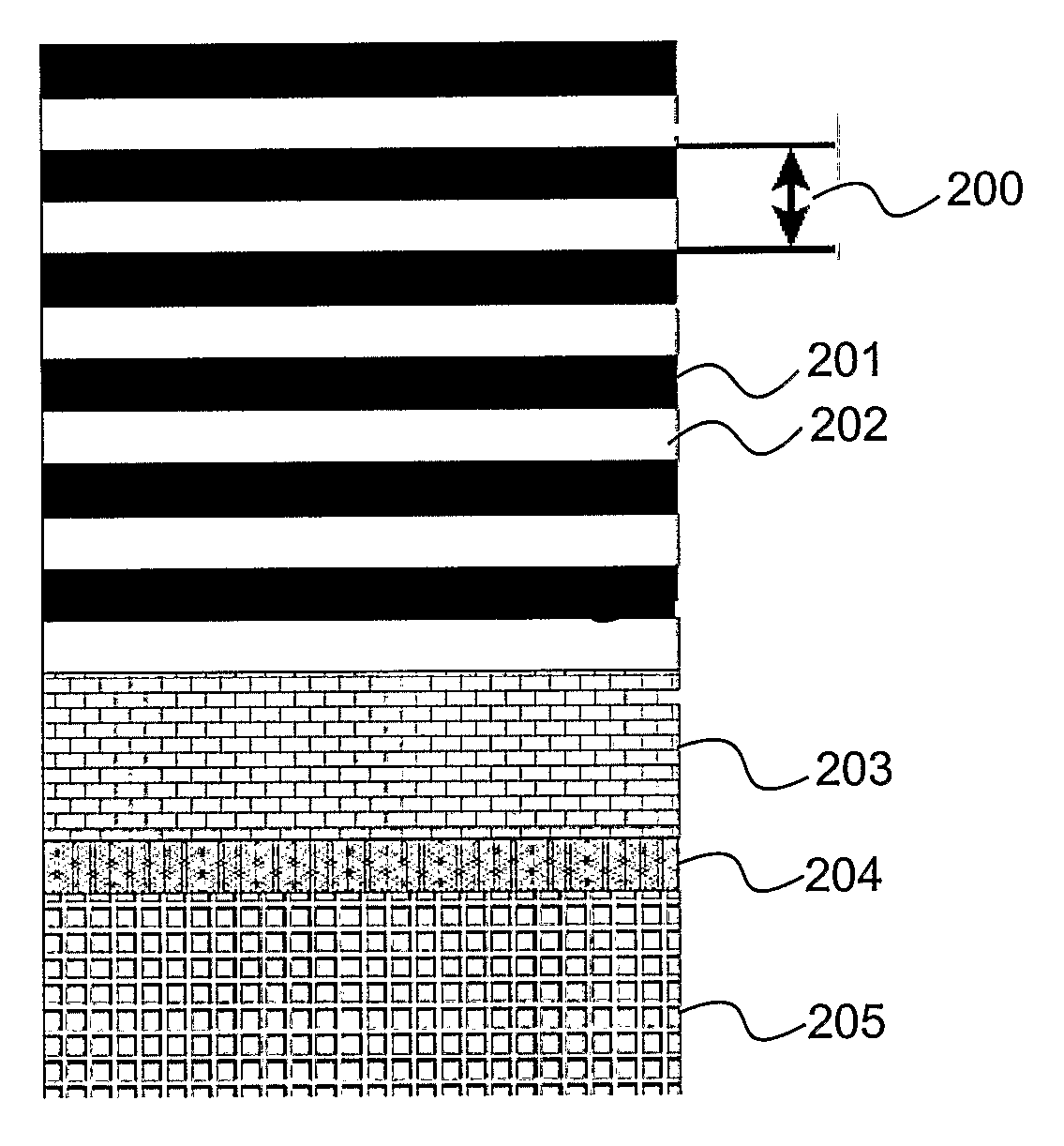

Donor film and methods for fabricating patterned organic electroluminescent devices using the same

InactiveUS20060188697A1Improve transmission efficiencyEasy and efficient to manufactureLayered productsDecorative surface effectsPhotothermal conversionOrganic electroluminescence

A donor film has a soft polymer film and a transfer layer to be transferred which is formed on the soft polymer film. When fabricating a patterned organic electroluminescent device using the donor film for thin film transfer, the transfer layer is transferred even with a small amount of energy due to good adhesion between the transfer layer of the donor film and an acceptor film, and multiple layers, such as organic small molecular and polymer layers in addition to a metal layer, may be simultaneously transferred, while eliminating a need of a photothermal conversion layer.

Owner:SAMSUNG DISPLAY CO LTD

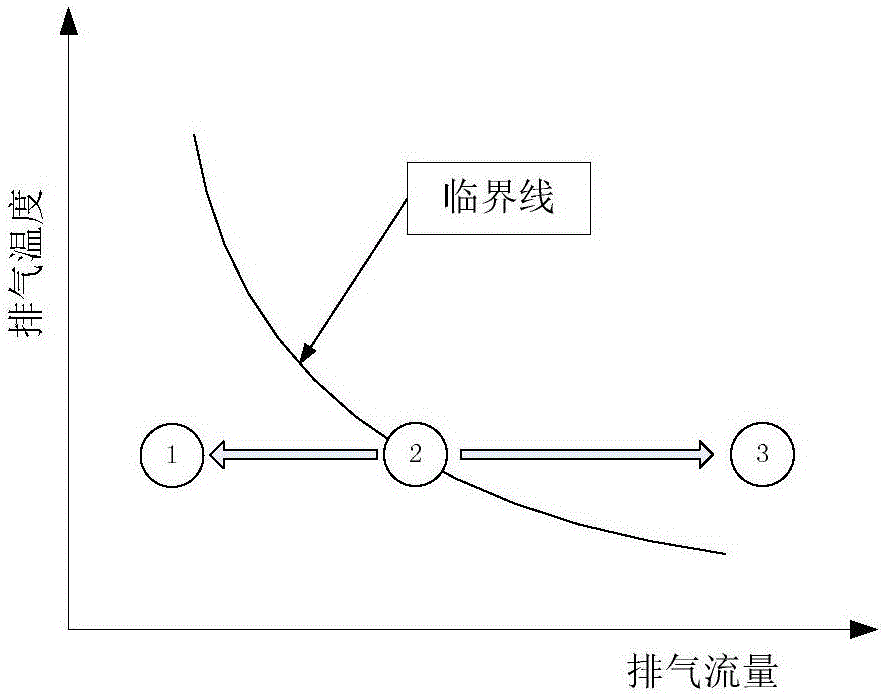

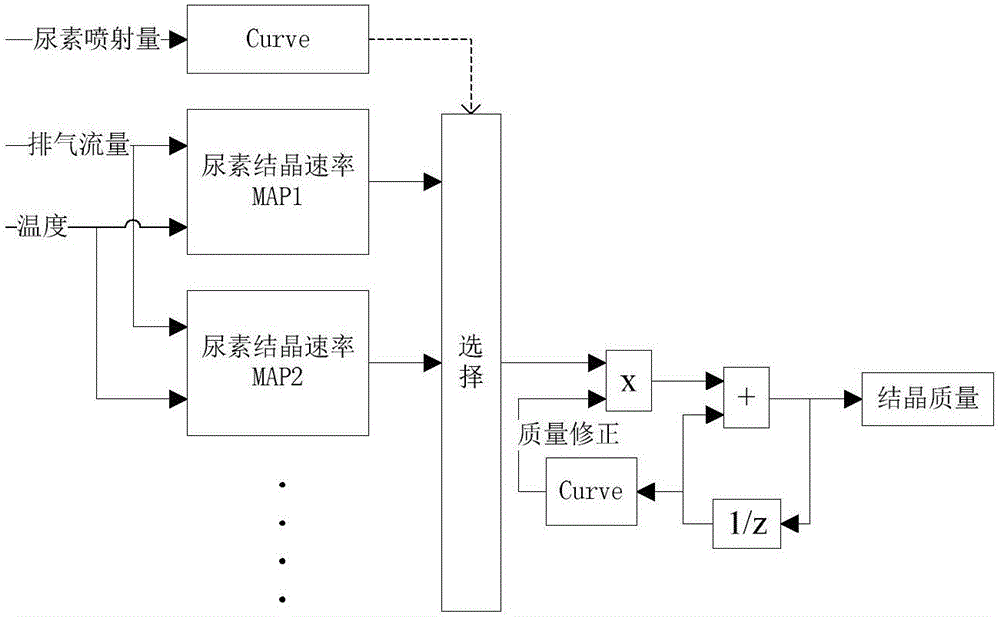

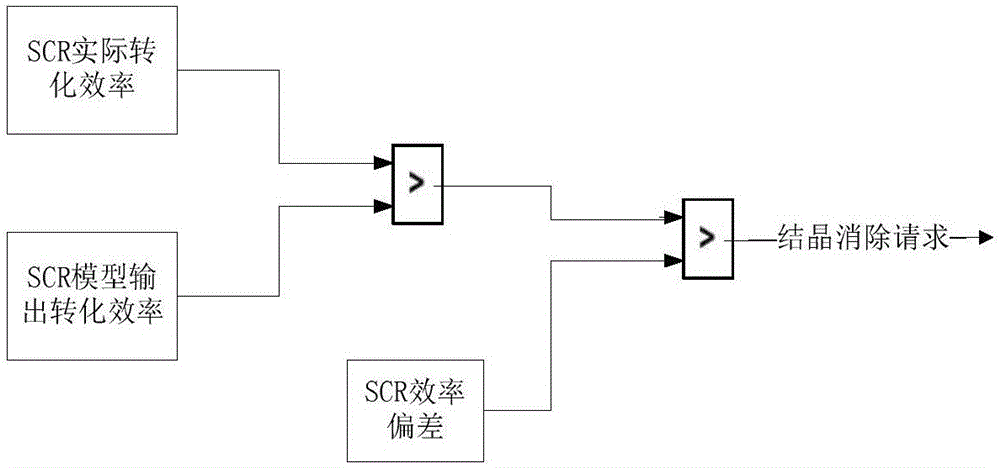

Urea crystallization amount estimation, crystalline state judging and crystal eliminating method

ActiveCN106837498AImprove conversion efficiencyAvoid corrosion riskInternal combustion piston enginesExhaust apparatusCrystallizationUrea

The invention provides a urea crystallization amount estimation, crystalline state judging and crystal eliminating method. Based on the engine running working conditions, influences of the urea crystallization speed and the SCR conversion efficiency on urea crystallization are estimated under the current working condition. When the urea crystallization amount is too much, the engine running state is adjusted, crystals are removed in time, and the stone forming phenomenon is prevented.

Owner:WEICHAI POWER CO LTD

Dispenser head for fluid container

InactiveUS7293930B2Reduce manufacturing costLow costBall-point pensPackaging toiletriesEngineeringMechanical engineering

Owner:CHUANG KAIWIN

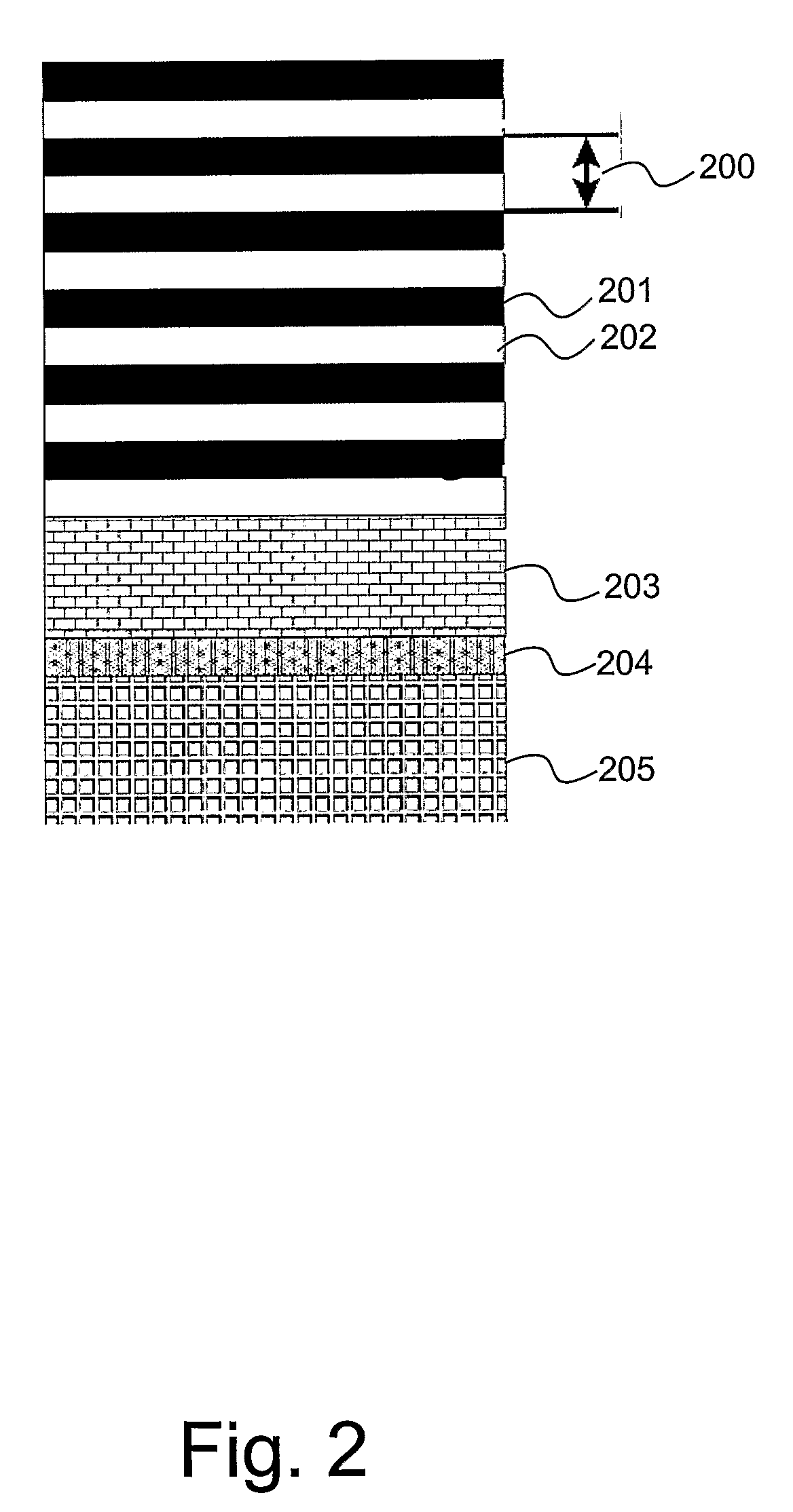

Pvd Coated Substrate

InactiveUS20080260478A1High hardnessReduce coefficient of frictionPigmenting treatmentVacuum evaporation coatingMetal alloyHardness

A PVD coating is disclosed, and in particular a nanoscale multilayer superlattice PVD coating comprising high hardness, a low friction coefficient and increased chemical inertness. The multilayer coating comprises a repeating bilayer represented by (VxMe(i-x))CyN(i-y) / (MezV(1-z))CyN(i-y) where 0.1≦x≦0.9; 0.01<y<0.99 and 0.1≦z≦0.9 and Me is a substantially pure metal or a metal alloy. The composition of the coating through the layers alternates from layer to layer according to a V-rich layer and a Me-rich layer modulated sequence. Vanadium is incorporated within the layer composition and has been found to act as a lubricating agent during sliding wear. Carbon, also incorporated within the coating, serves to further stabilise the friction coefficient thereby increasing the chemical inertness between cutting tool and workpiece material.

Owner:SHEFFIELD HALLAM UNIVERSITY

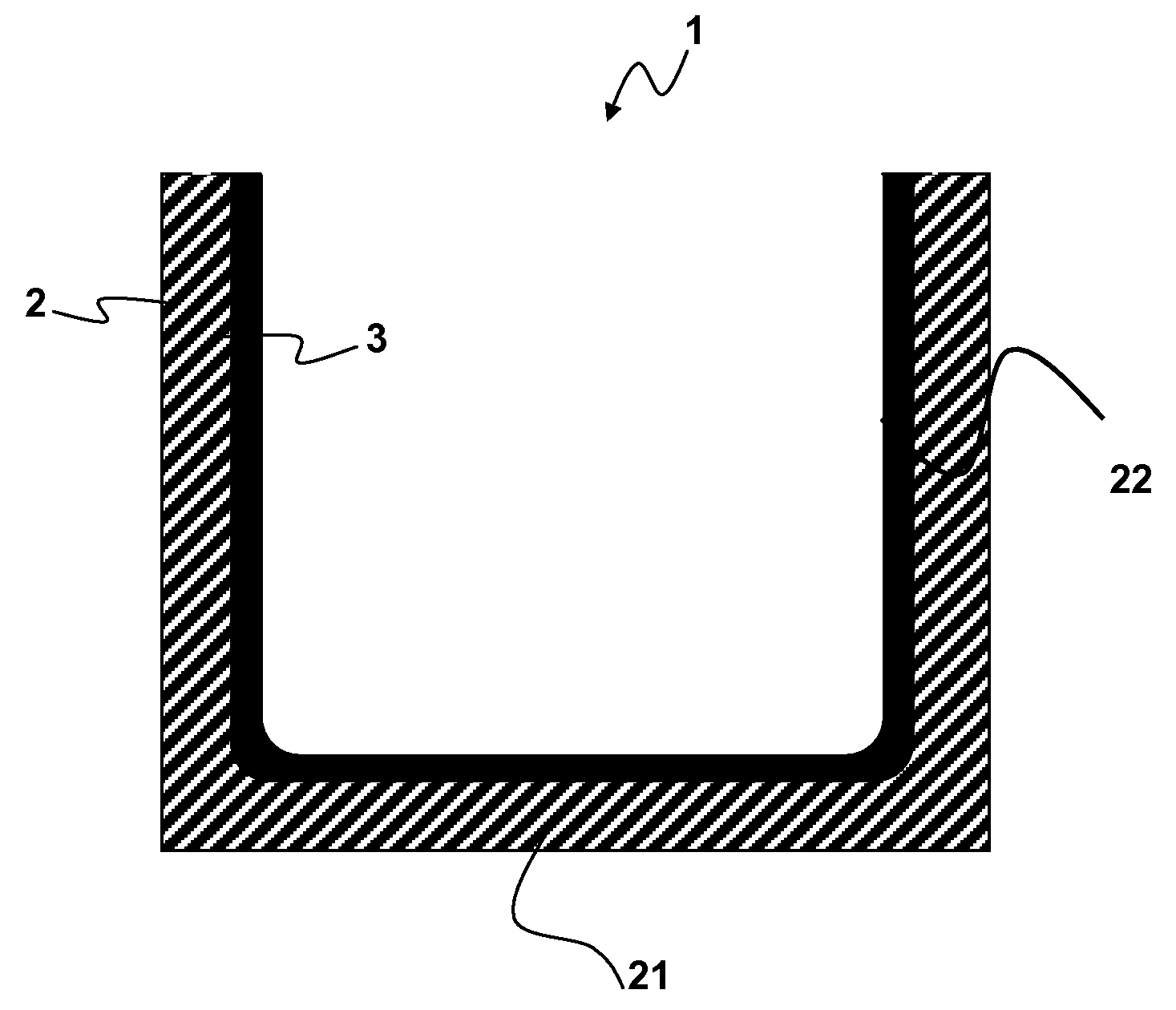

Crucible for the Crystallization of Silicon and Process for Making the Same

InactiveUS20080260608A1Reduce the temperatureImprove responsePolycrystalline material growthLiquid surface applicatorsCrucibleIngot

A protective coating is prepared for, and applied to, crucibles used in the handling of molten materials that are solidified in the crucible and then removed as ingots. Crucibles containing this protective coating may be used for the solidification of silicon. The coating has a specified oxygen content and contains a mineral binder and silicon nitride or silicon oxynitride.

Owner:VESUVIUS USA CORP

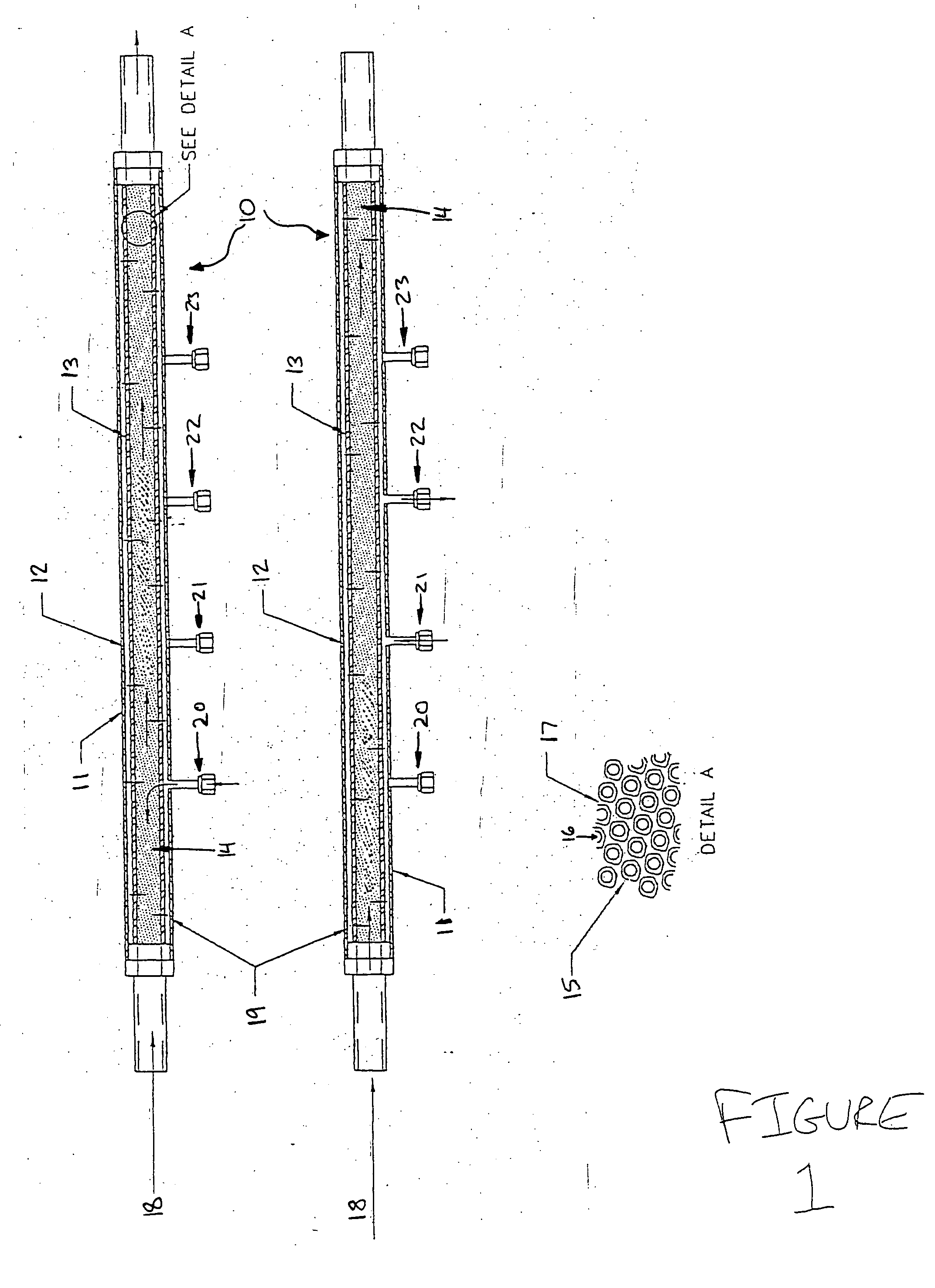

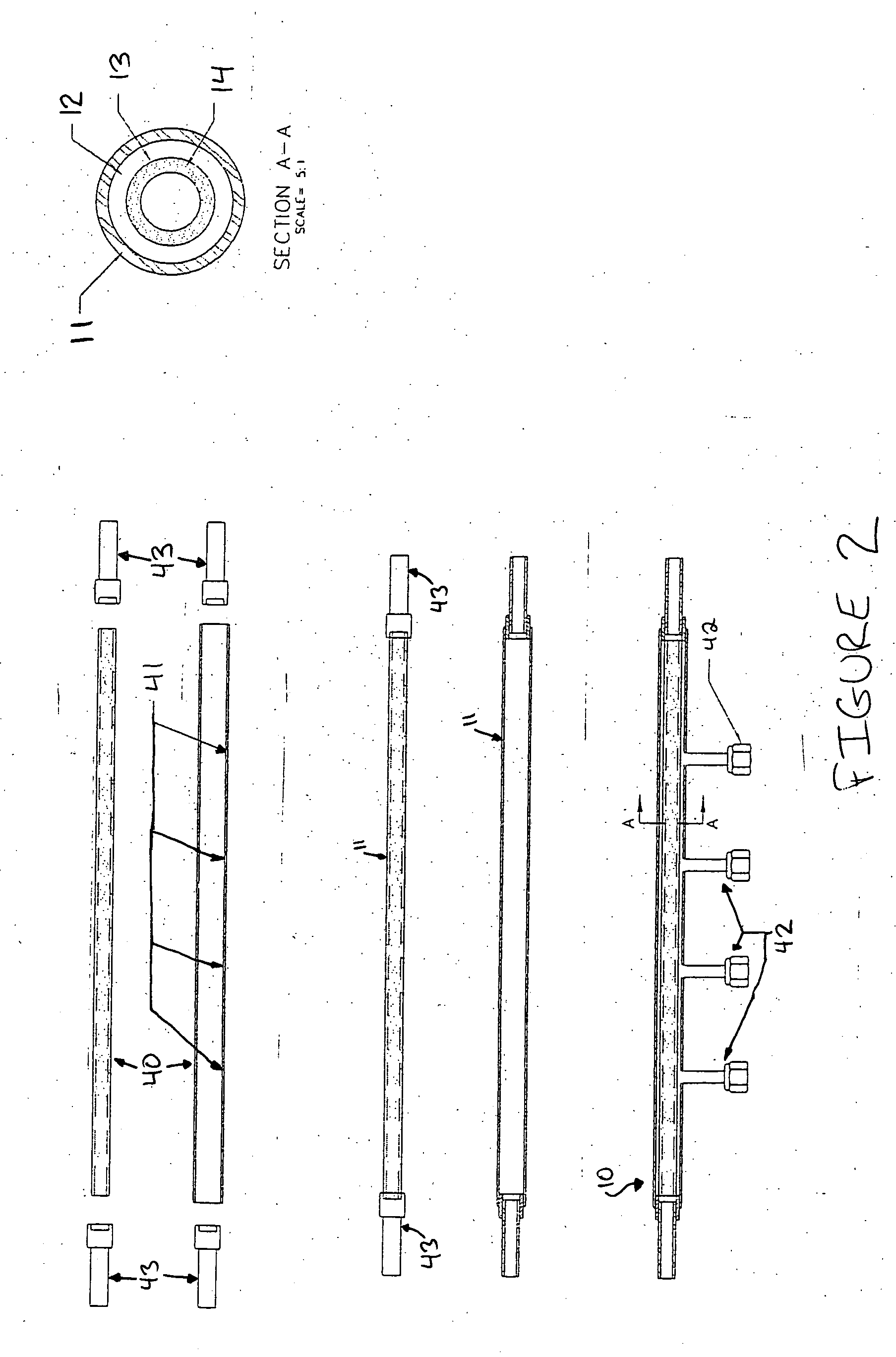

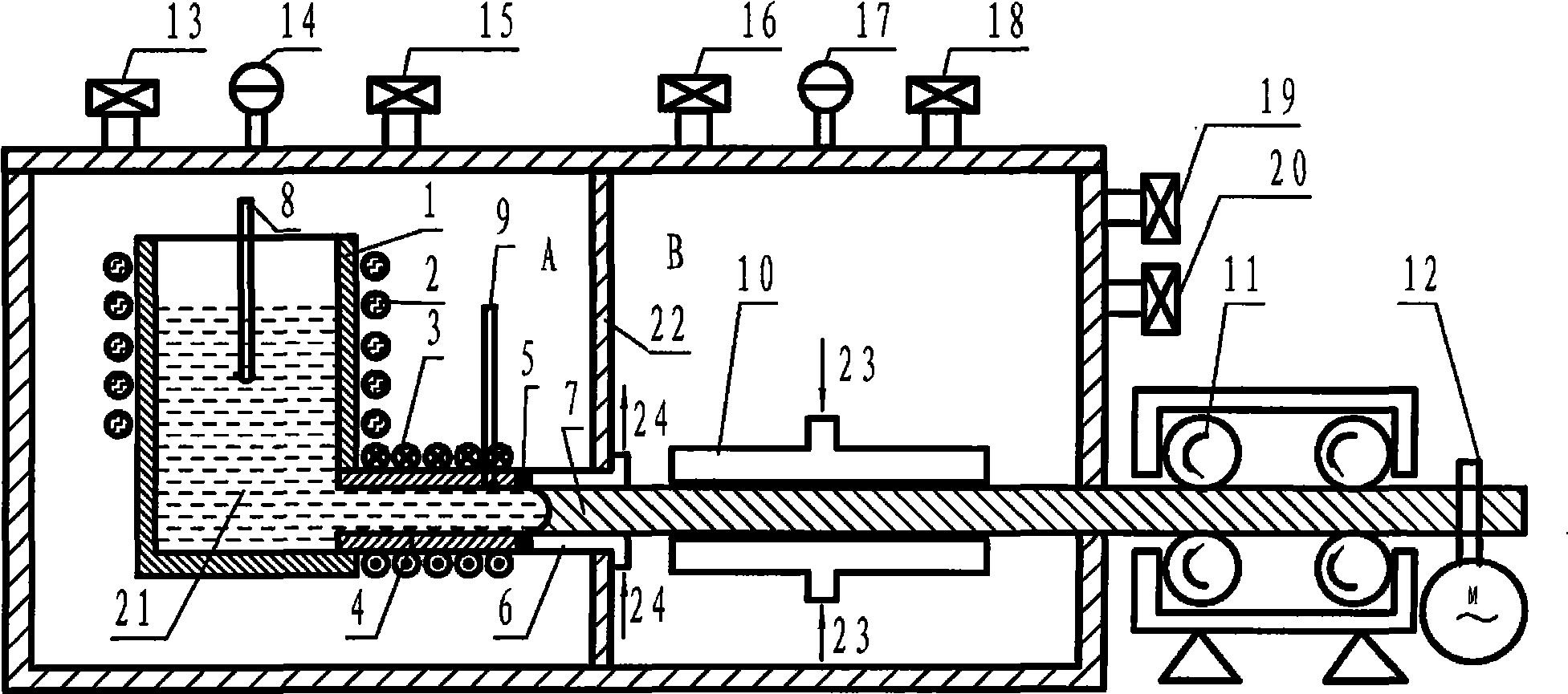

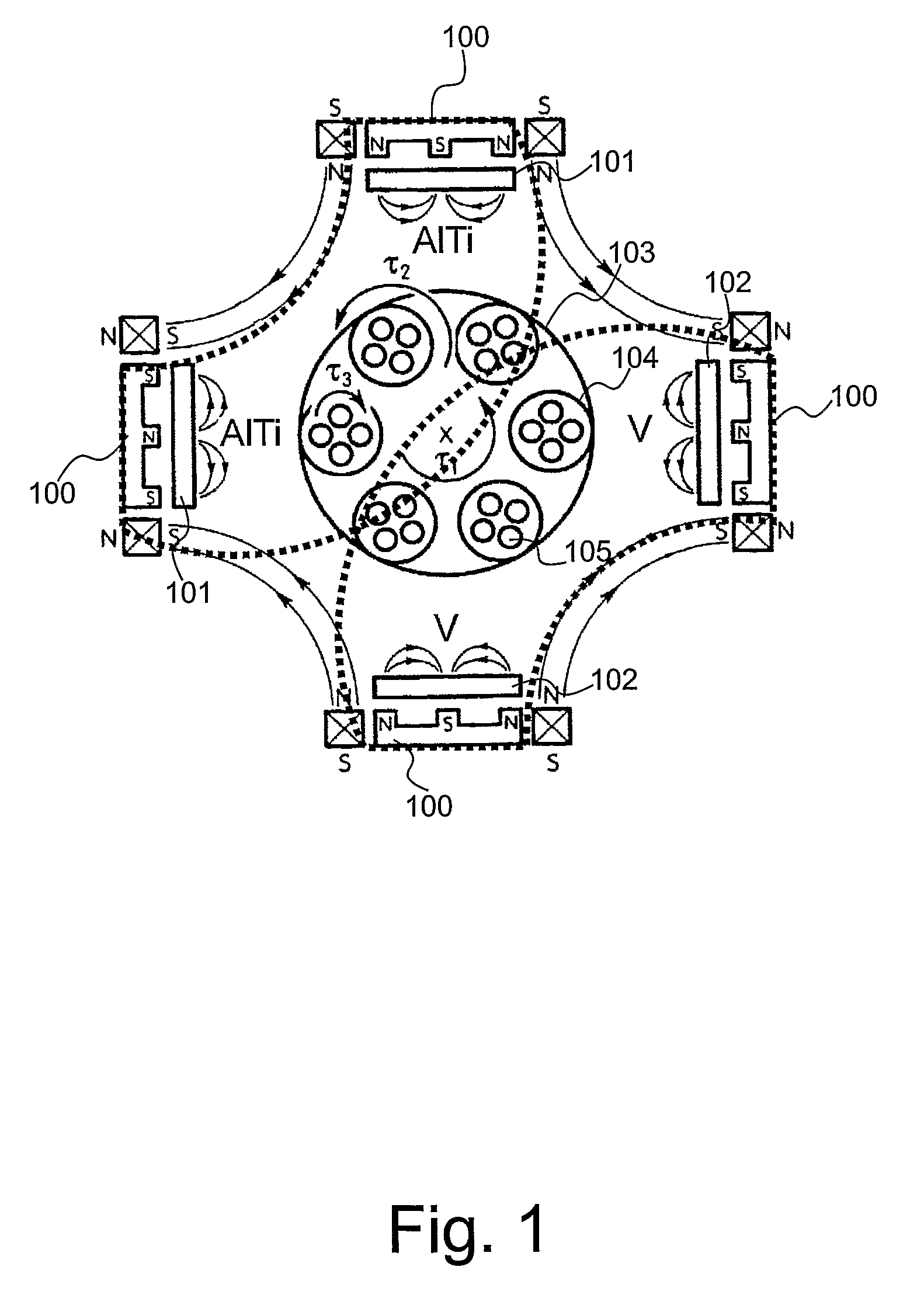

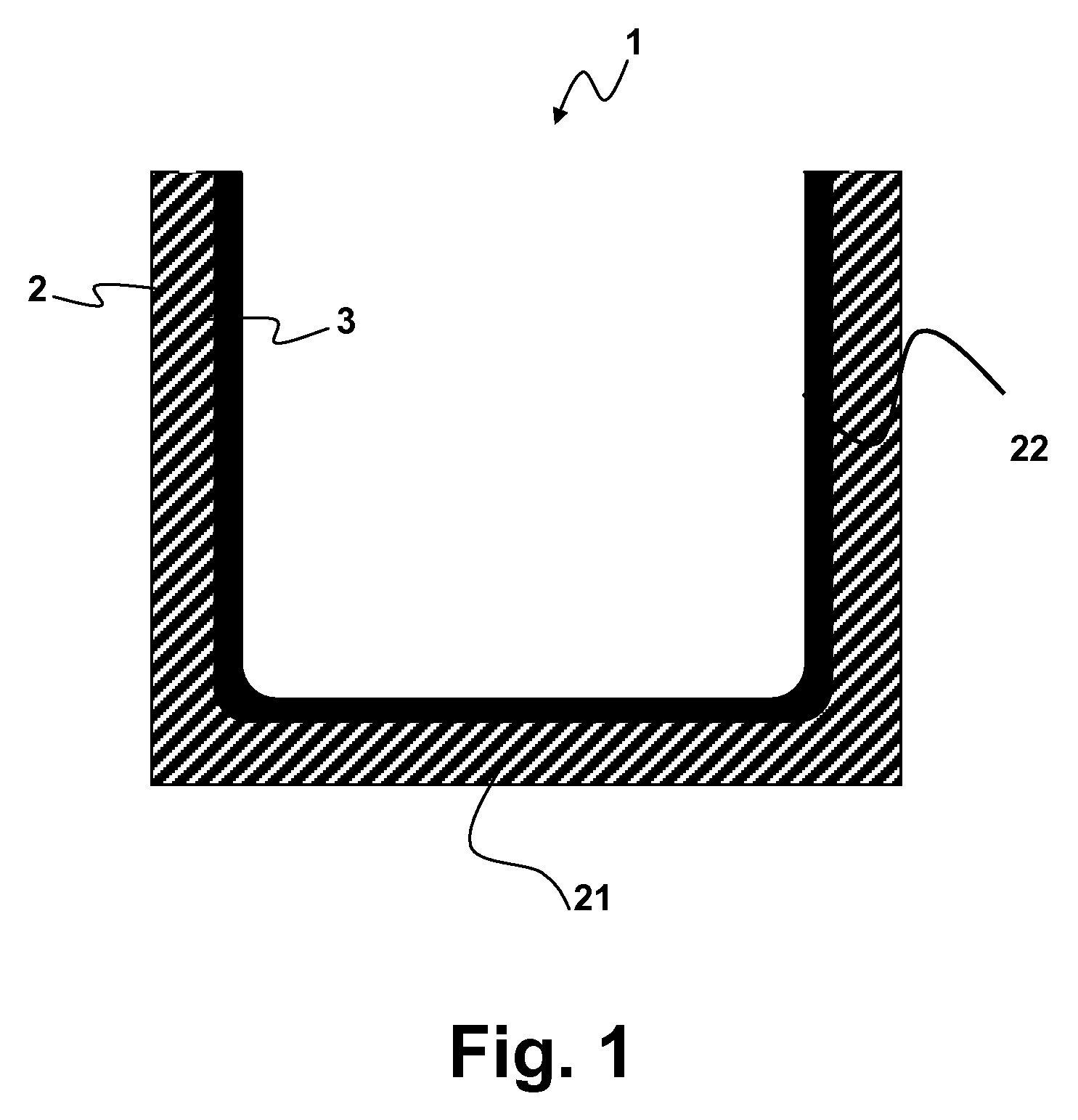

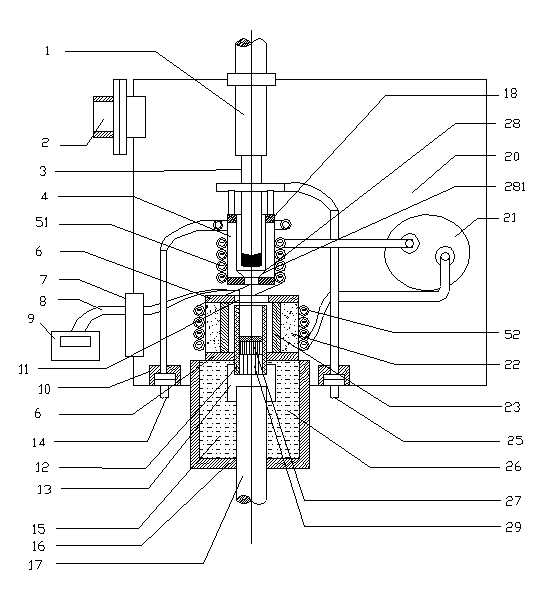

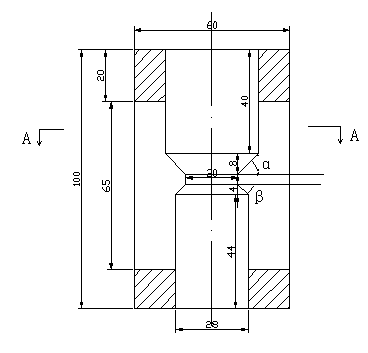

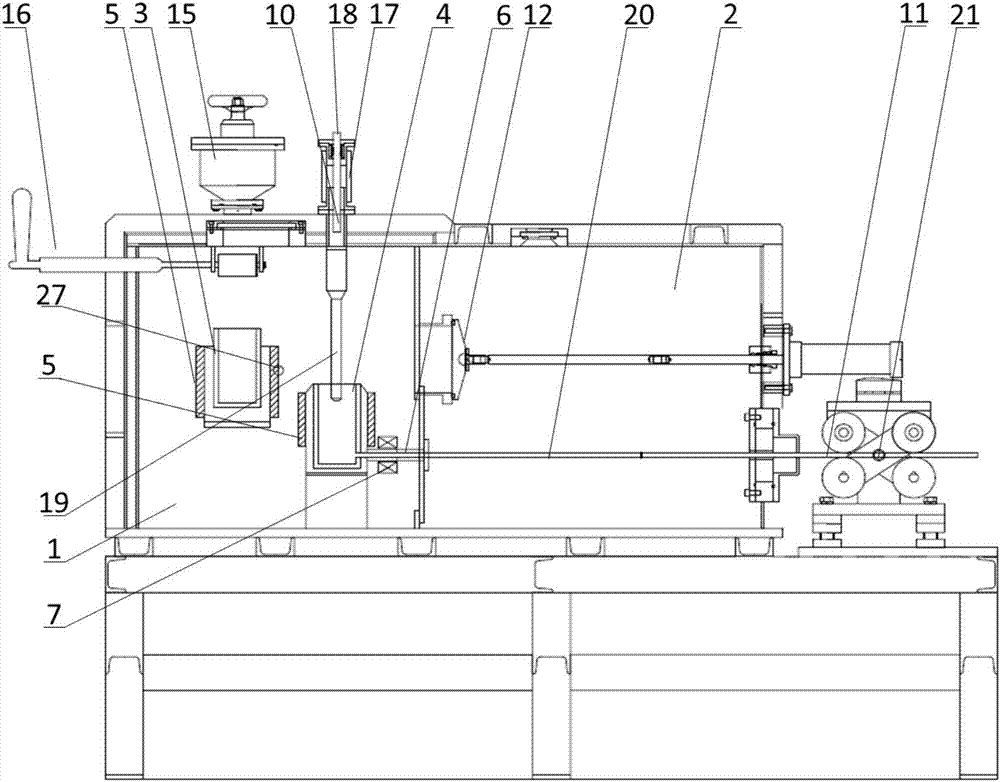

Continuous suspension type directional solidification casting device of cold crucible

ActiveCN102935506AAvoid chemical reactionsImprove directional solidification processing efficiencyChemical reactionAlternating current

The invention provides a continuous suspension type directional solidification casting device of a cold crucible. Heat-resisting lightweight titanium-aluminum alloy vanes are badly needed in transportation and energy industries, and a traditional directional solidification device causes severe impurity pollution and damages plasticity and toughness of the vanes. The directional solidification casting device aims at improving the efficiency of the directional solidification device of the cold crucible and overcomes the shortcoming that the existing casting device cannot be used for casting vanes with complex shape. A trapezoid boss is annularly arranged on the inner wall of the water cooling copper crucible, an induction coil is wound around the outer portion of the crucible, the boss is placed in the coil, an excited alternating current magnetic field is diffused inwards through crucible gaps to generate a hot area to achieve suspension rod liquid feeding of material rods. The device further comprises a drawing-pulling rod in a crystallizer, a mould casing with cross section being vane-shaped is fixed on the upper end face of the drawing-pulling rod, and the mould casing is heated by an outer induction graphite sleeve. The continuous suspension type directional solidification casting device achieves suspension melting liquid feeding, sequential filling and directional solidification of metal liquid, avoids chemical reaction of a titanium-aluminum alloy melt body and the mould casing and improves directional solidification processing efficiency of titanium-aluminum alloy.

Owner:HARBIN INST OF TECH

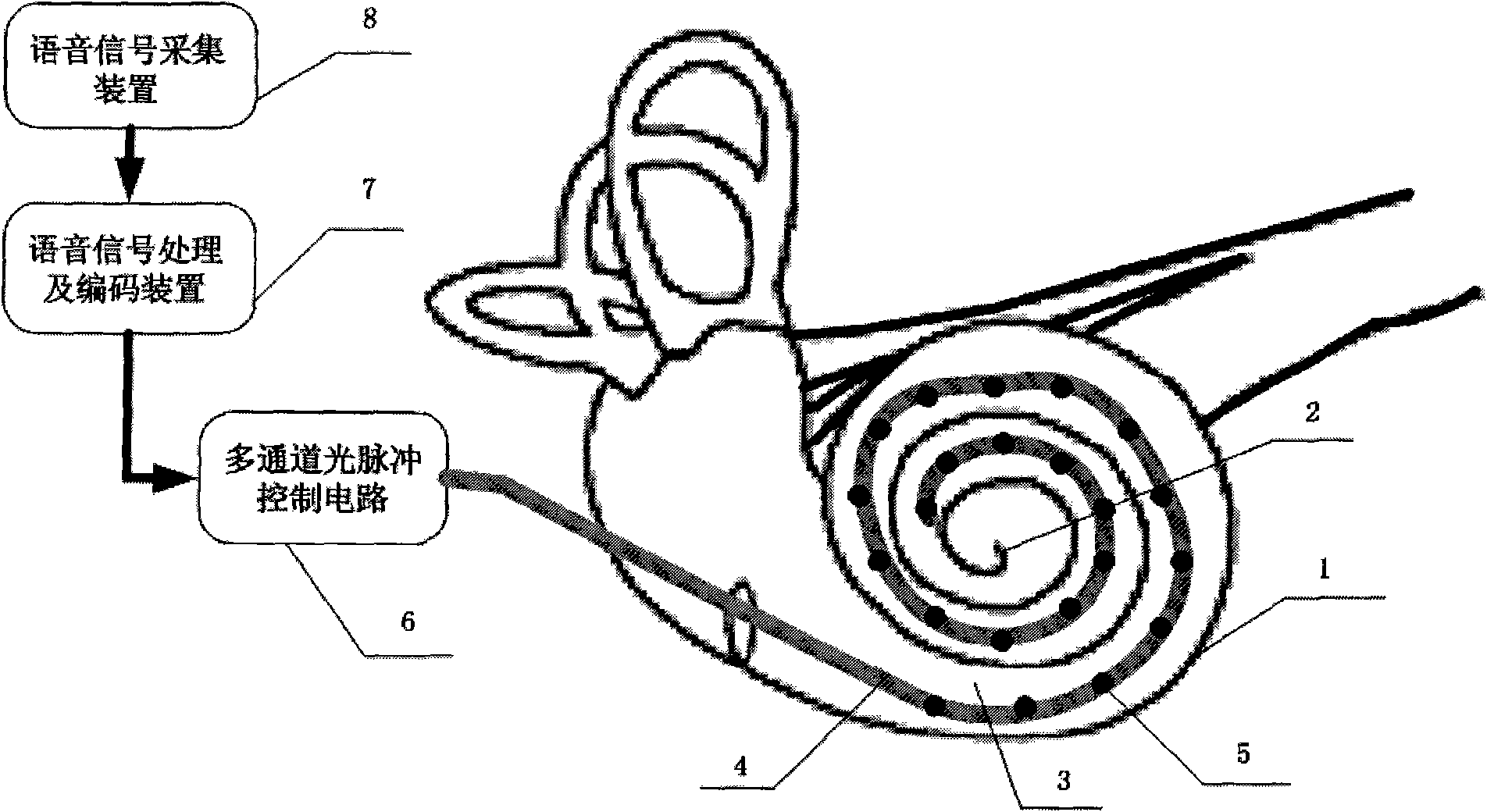

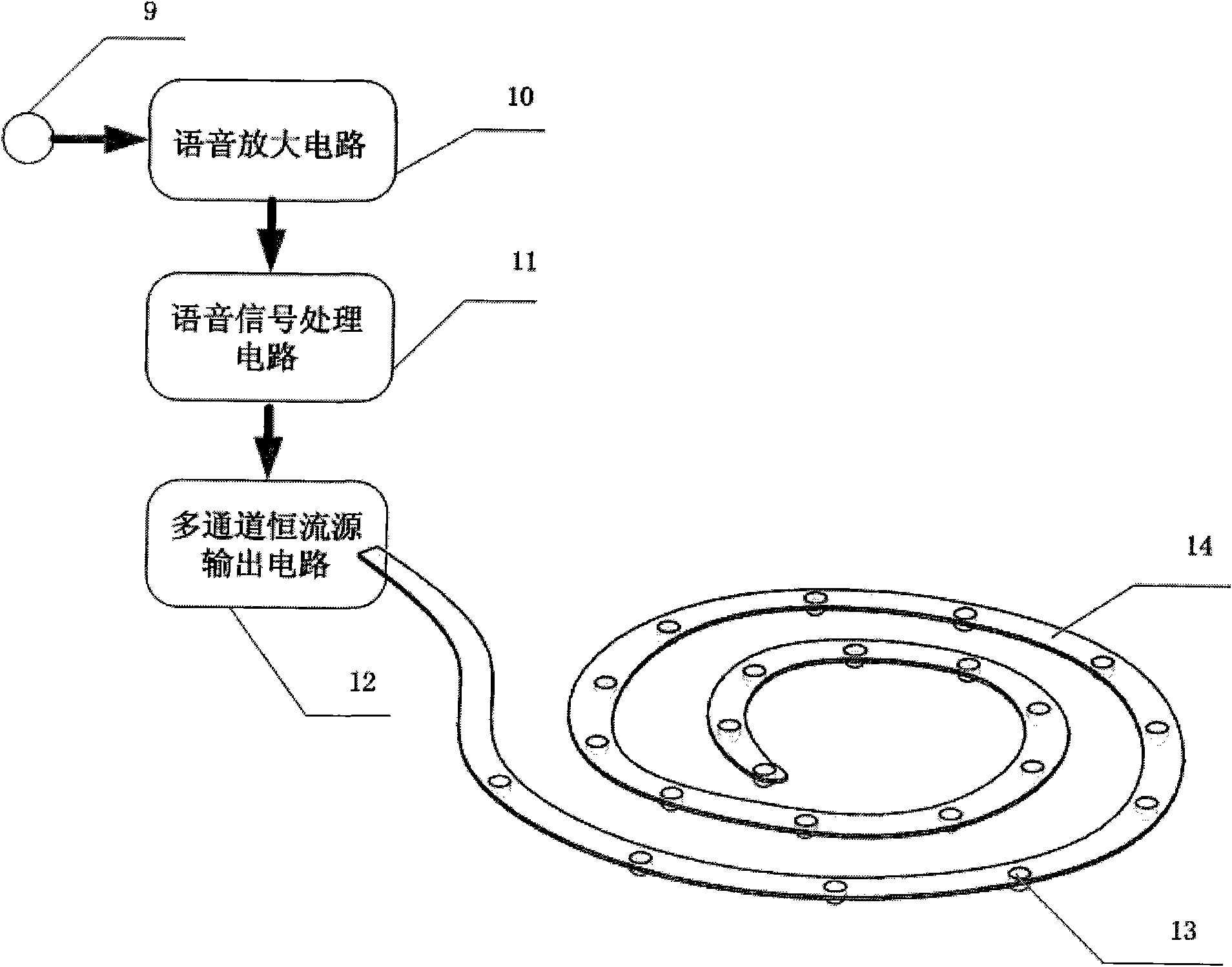

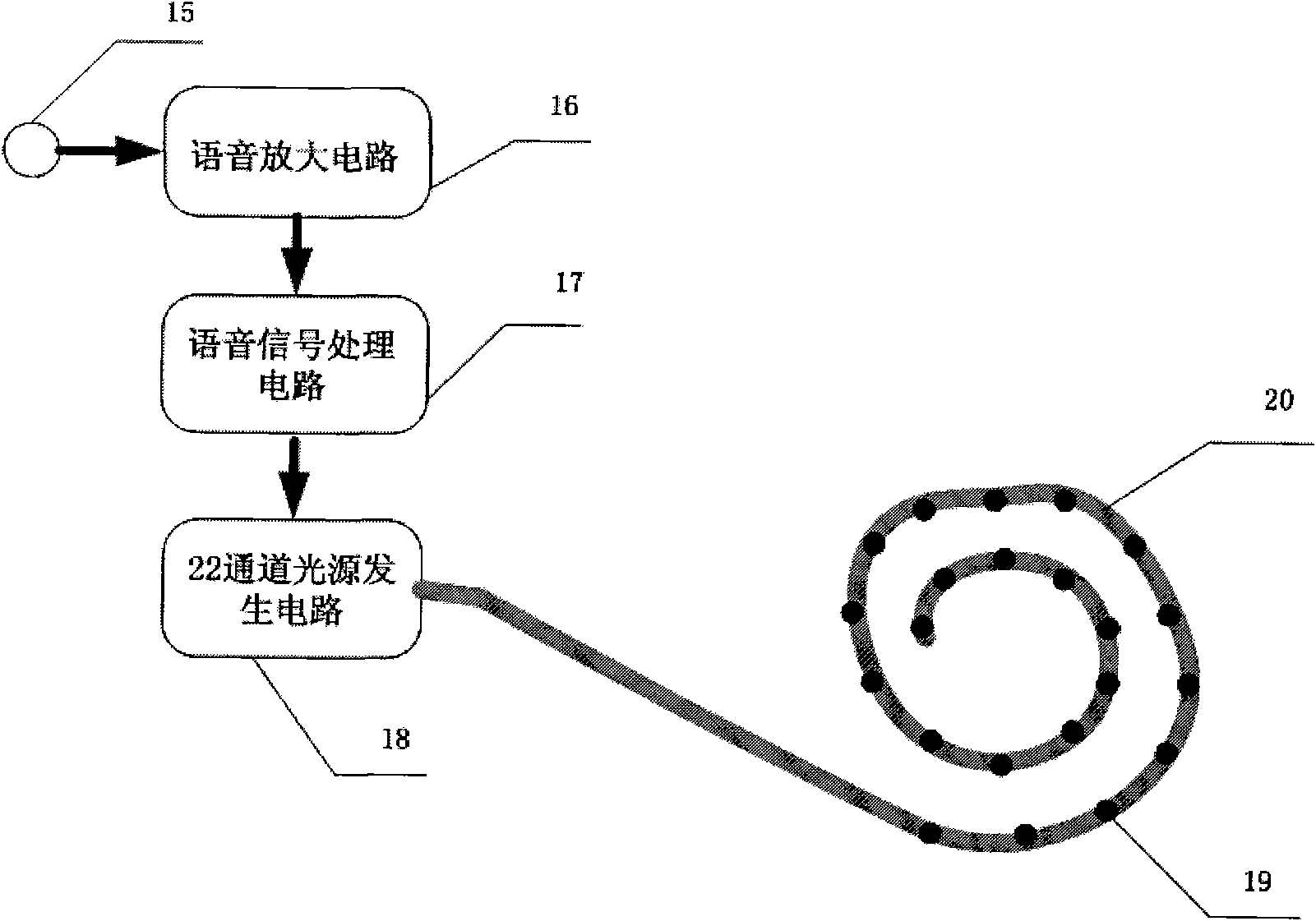

Multi-channel light stimulation-based cochlear implant device

InactiveCN101926693AImprove spatial resolutionRealize contactless stimulationProsthesisHearing perceptionLIGHT STIMULATION

The invention relates to a multi-channel light stimulation-based cochlear implant device. The device comprises a multi-channel light stimulation device, a multi-channel light pulse control circuit, a voice signal acquisition deice and a voice signal processing and encoding device, wherein the device acquires a voice signal and encodes the voice signal into a light stimulation signal; and the light stimulation signal stimulates cochlear auditory nerve through a cochlea-implanted multi-channel light pulse output port to cause nerve impulse so as to form hearing in a central nervous system. The multi-channel light stimulation-based cochlear implant solves the problem of compatibility of a stimulating electrode and biological tissue in the electronic cochlear implant and also solves the problem of mutual interference between stimulating channels caused by current diffusion in the tissue.

Owner:CHONGQING UNIV

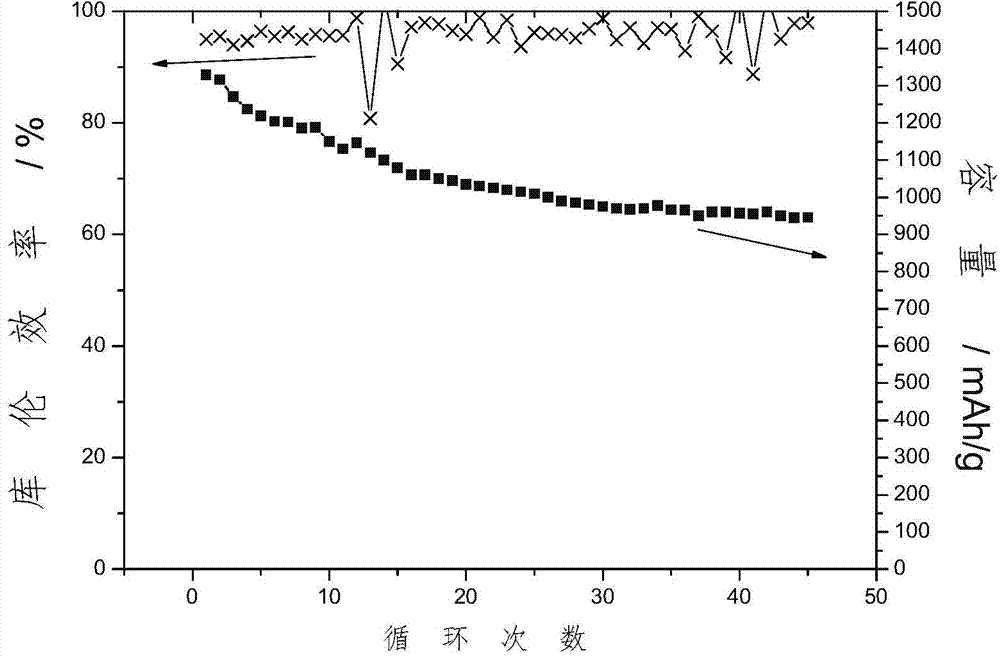

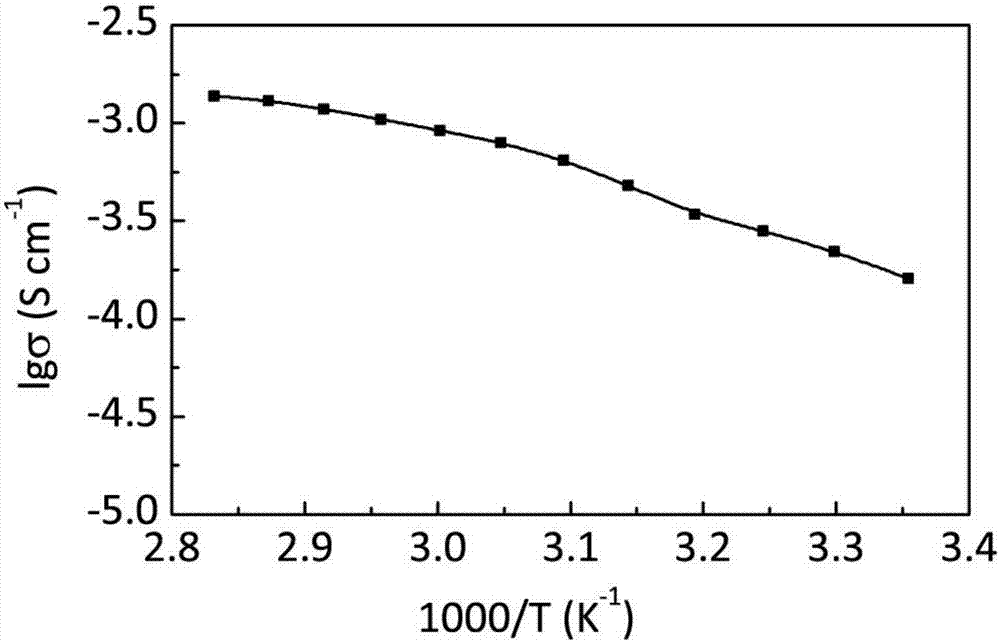

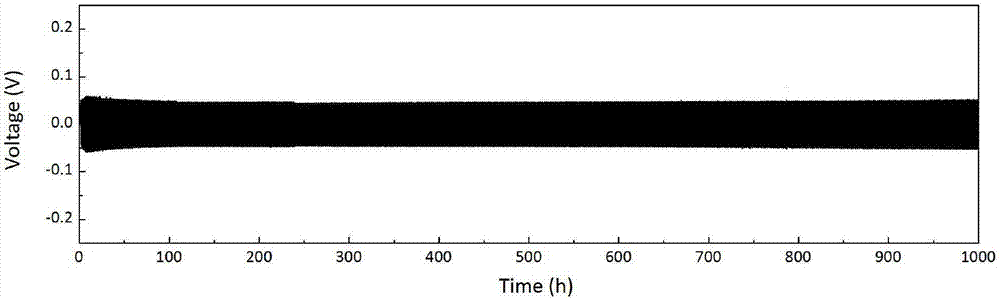

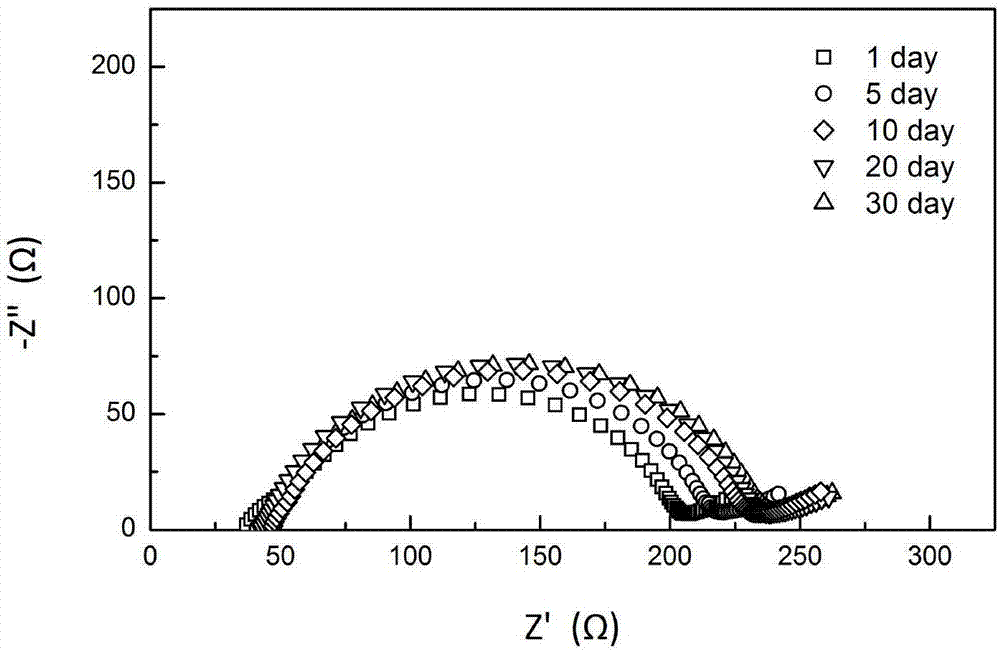

Composite solid electrolyte and preparation method thereof

ActiveCN107195962AInhibition of crystallinityImprove athletic abilityLi-accumulatorsMetallic lithiumSolid-state battery

The invention provides a composite solid electrolyte, and can solve the problem that the interface of inorganic solid electrolyte and metallic lithium in a solid battery is unstable and low in contact. The composite solid electrolyte is an inorganic oxide electrolyte plate modified with a mixture electrolyte layer used for a surface, and the mixture electrolyte layer is a mixture of a polymer matrix, an alkali metal salt and a sulfide. The invention also provides a preparation method of the composite solid electrolyte, the composite solid electrolyte stable for the metallic lithium can be obtained, and the production cost is reduced.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

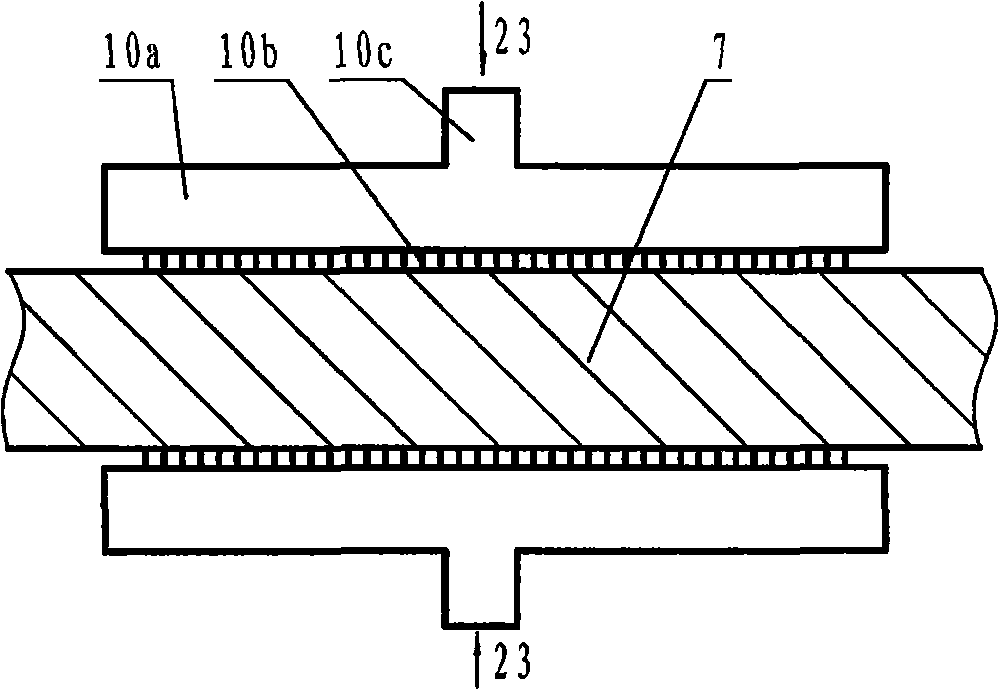

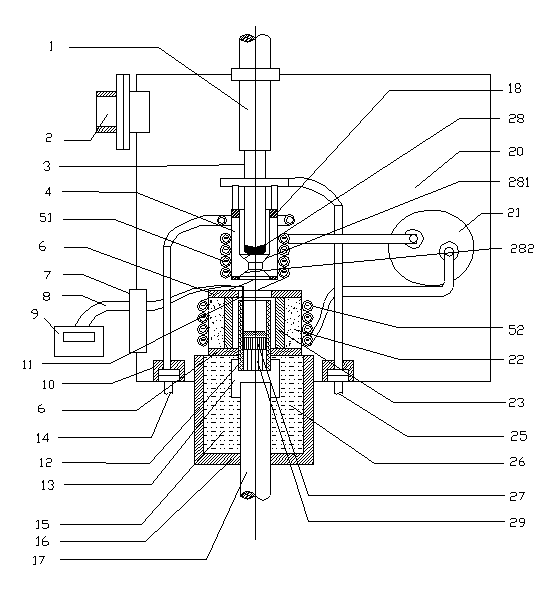

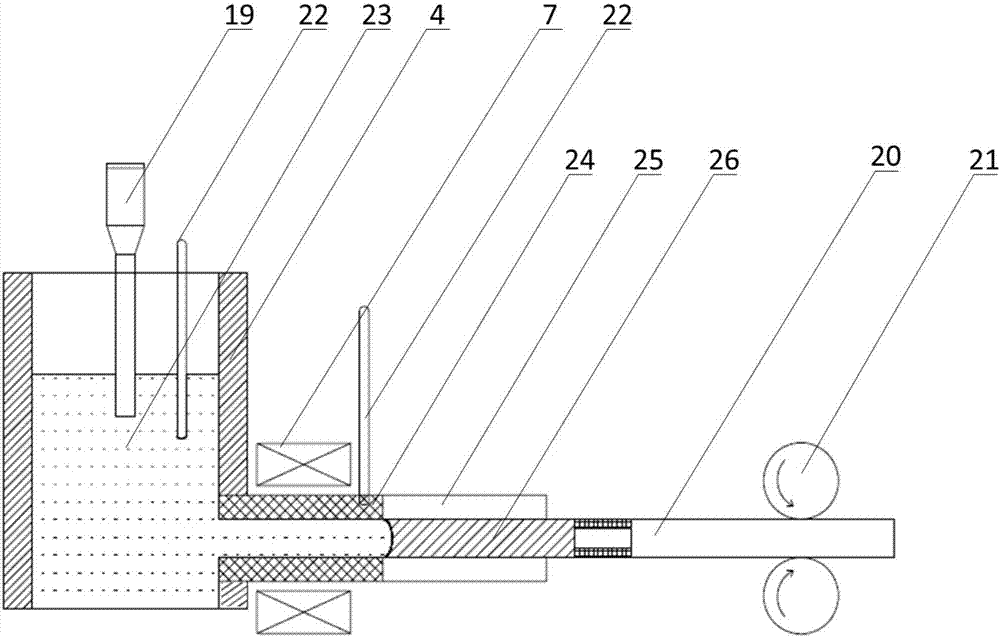

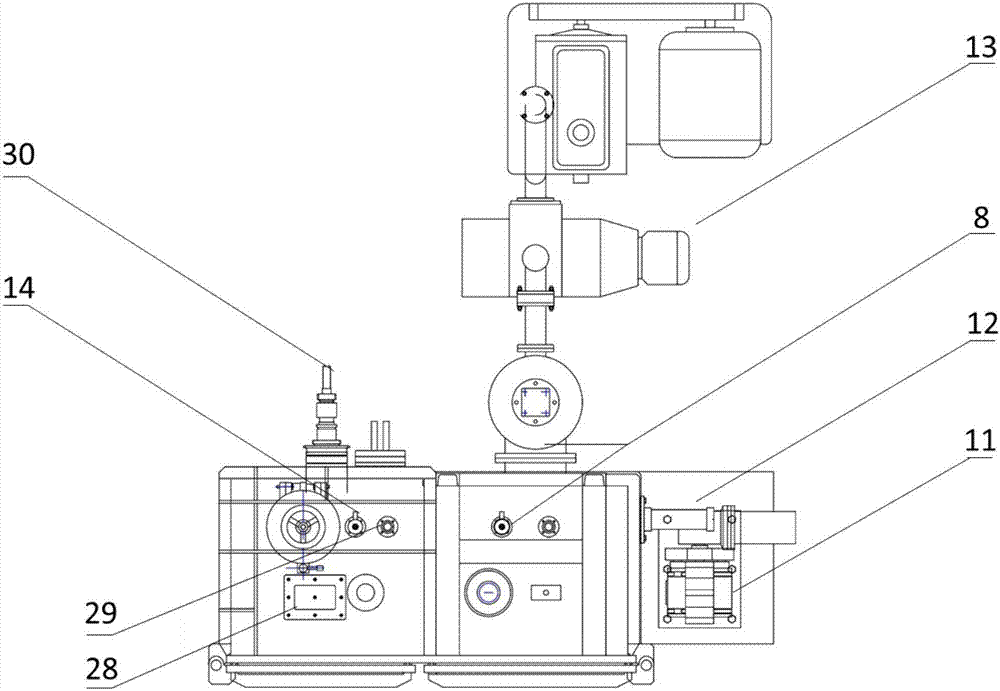

Integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on vacuum condition

The invention provides an integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition and belongs to the field of metal casting. The integrated device comprises a first vacuum chamber, a second vacuum chamber, a vacuum control system, a material supplementing device, an ultrasonic treatment device and a throwing device. According to the integrated device and technology for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition, the device can be widely applied to horizontal continuous casting of a high-temperature alloy, a titanium alloy, a magnesium alloy, a rare earth metal, multi-component amorphous alloy, high-entropy alloy and other active alloys, smelting, pouring and continuous forming under electromagnetic and ultrasonic coupled fields of the alloys can be all completed in the vacuum state, and the obtained horizontal continuous casting alloy workpiece has the effects of being smooth and clean in surface, uniform in component and dense in structure.

Owner:DALIAN UNIV OF TECH

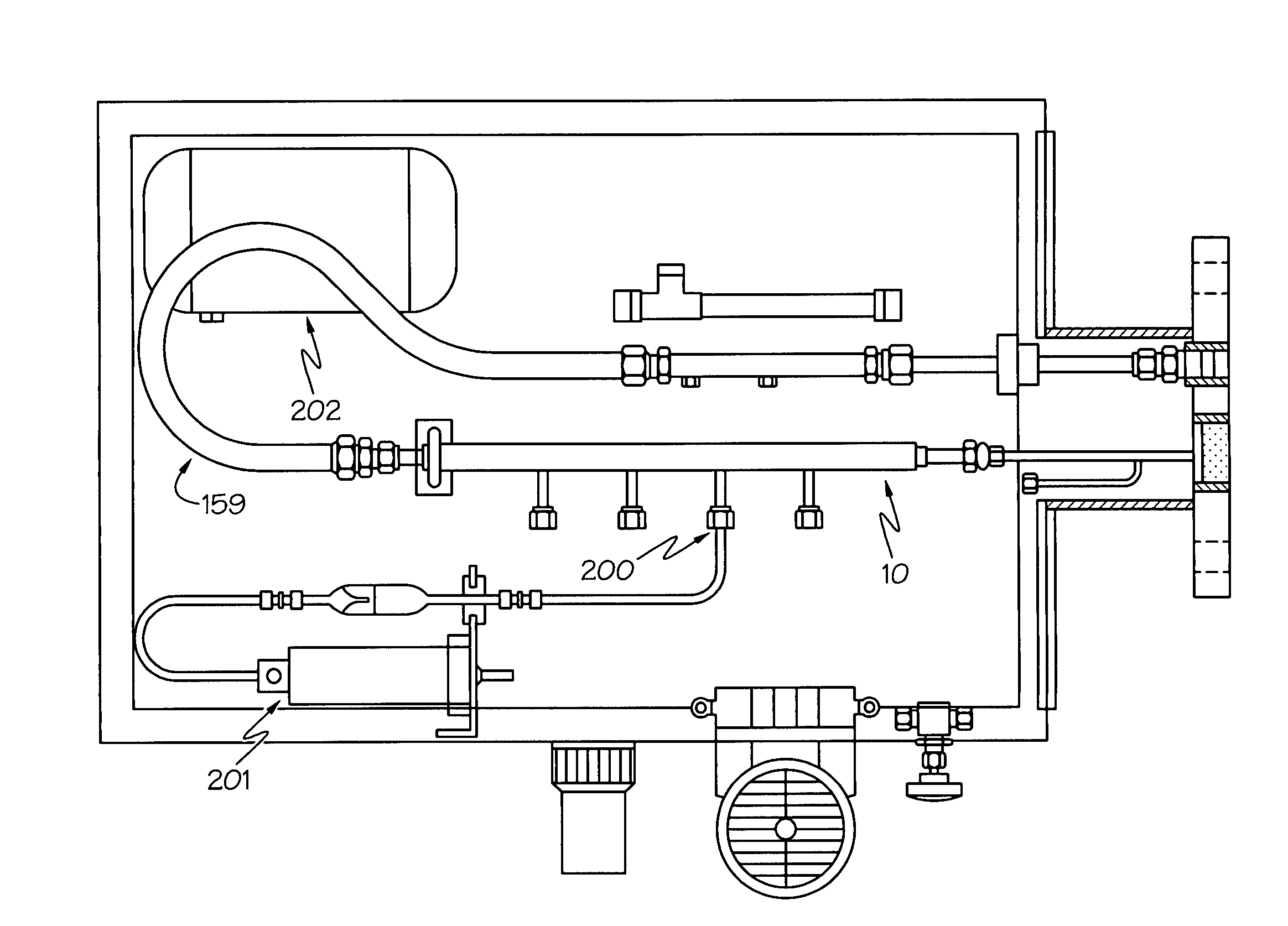

Filter for determination of mercury in exhaust gases

InactiveUS7368289B2Improve accuracyPreventing catalyzed oxidationComponent separationWithdrawing sample devicesFlue gasExhaust fumes

An apparatus, process, coating, and filter for the accurate measurement of total mercury concentration in flue gas. In a preferred aspect, the concentrations of both elemental and oxidized mercury are preserved by the apparatus for analysis. Accordingly, embodiments of the present apparatus and process can be used to determine regulatory compliance or for process control measurement.

Owner:PERMA PURE LLC

Preparation method for microsphere open-top bait for high-economic fish

InactiveCN1989833AStable traitsAvoid chemical reactionsClimate change adaptationAnimal feeding stuffChemistryAmount of substance

The invention belongs to a preparation method of high economic fish micro-spheres opening bait, specifically it uses sodium alginate and starch as micro-spheres binding material and embeds bait nutritional component through air and mist means. It protects vitamins, proteins, inorganic salts and other material components away the influence and interreaction of heat, moisture, oxygen, ultraviolet rays and metallic ion during the process of processing, storing, transporting and feeding. It controls the particle diameter of opening bait using micro-spheres particle diameter to fitting the first ingress of fish fry. It could reduce loss rate of bait nutrient components in water, maintain water clean, improve survival rate of economic fish seedlings and reduce the production costs of artificial breading.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Pharmaceutical formulations of statins and omega-3 fatty acids for encapsulation

PendingUS20130115281A1Avoid chemical reactionsMaintain chemical stabilityBiocideMetabolism disorderOmegaFatty acid

A multi phase soft gelatin dosage form comprising at least one preformed solid dosage form comprising a statin compound and at least one liquid fill phase comprising Omega-3 fatty acids. The multi phase soft gelatin dosage forms of the present invention are especially useful to combine at least one solid dosage form and at least one liquid phase for single ingestion. The solid phase, liquid phase or coatings may further comprise active pharmaceutical ingredients, nutraceuticals, nutritional supplements, or therapeutic substances, functional excipients or combinations thereof.

Owner:CATALENT ONTARIO LTD

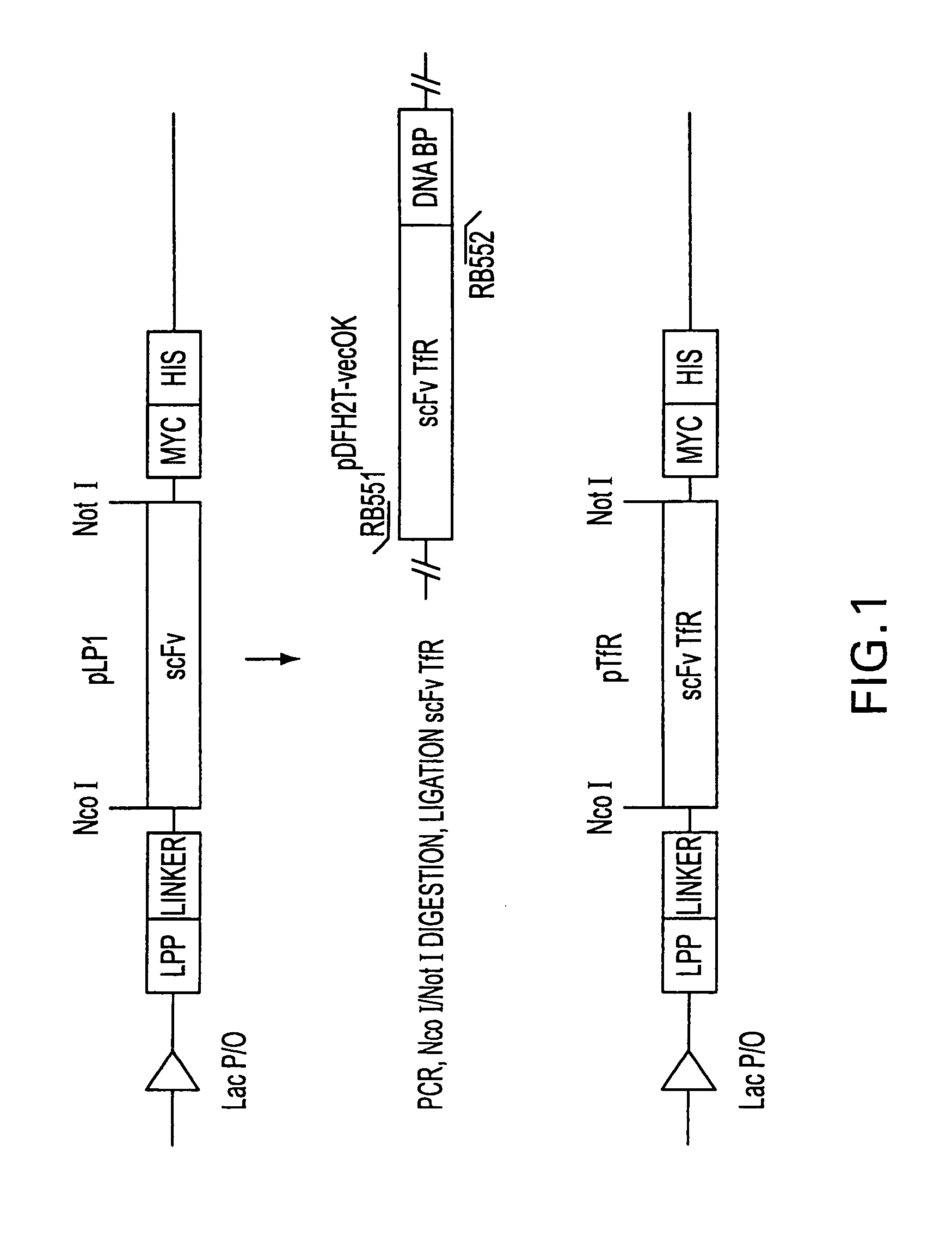

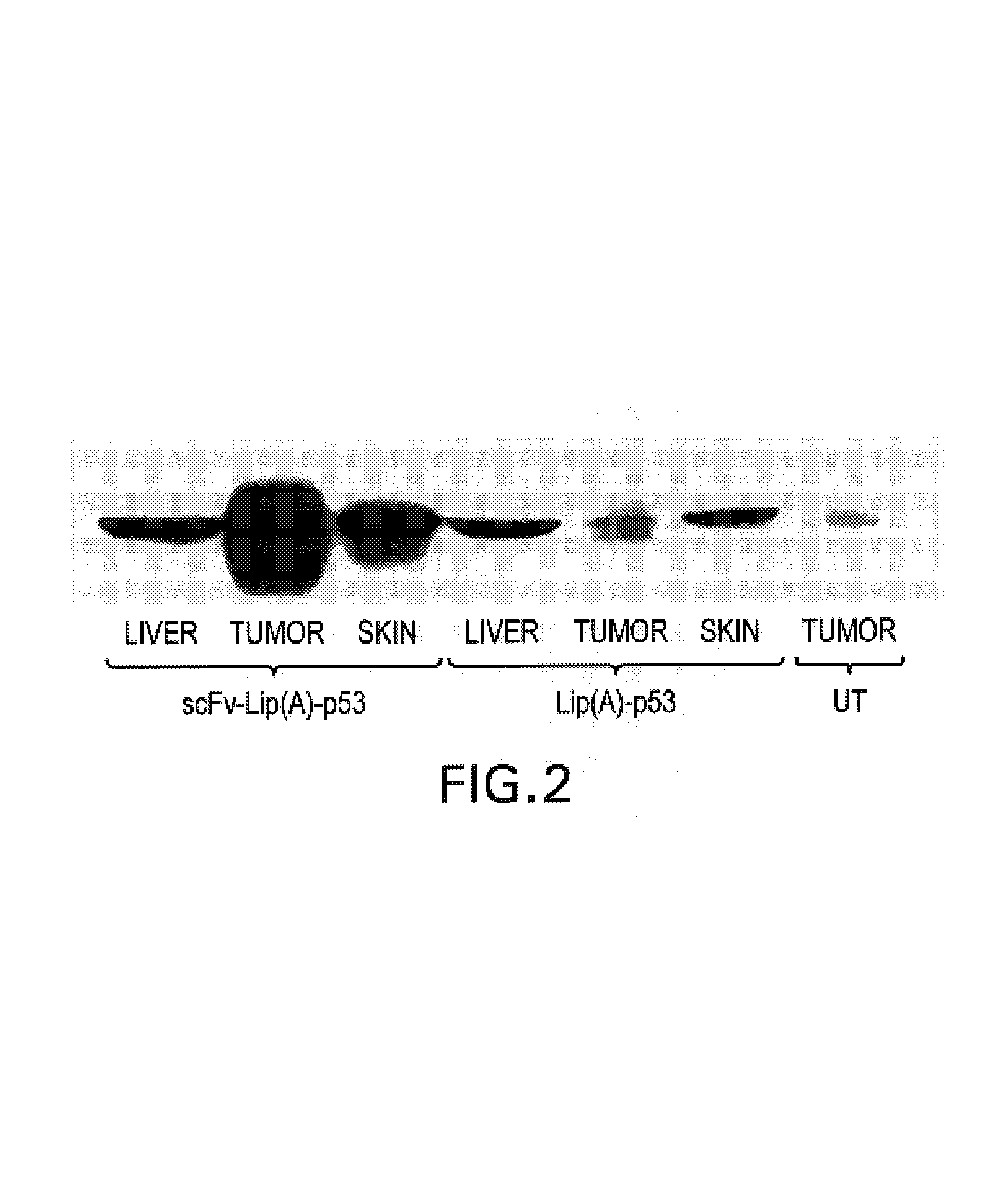

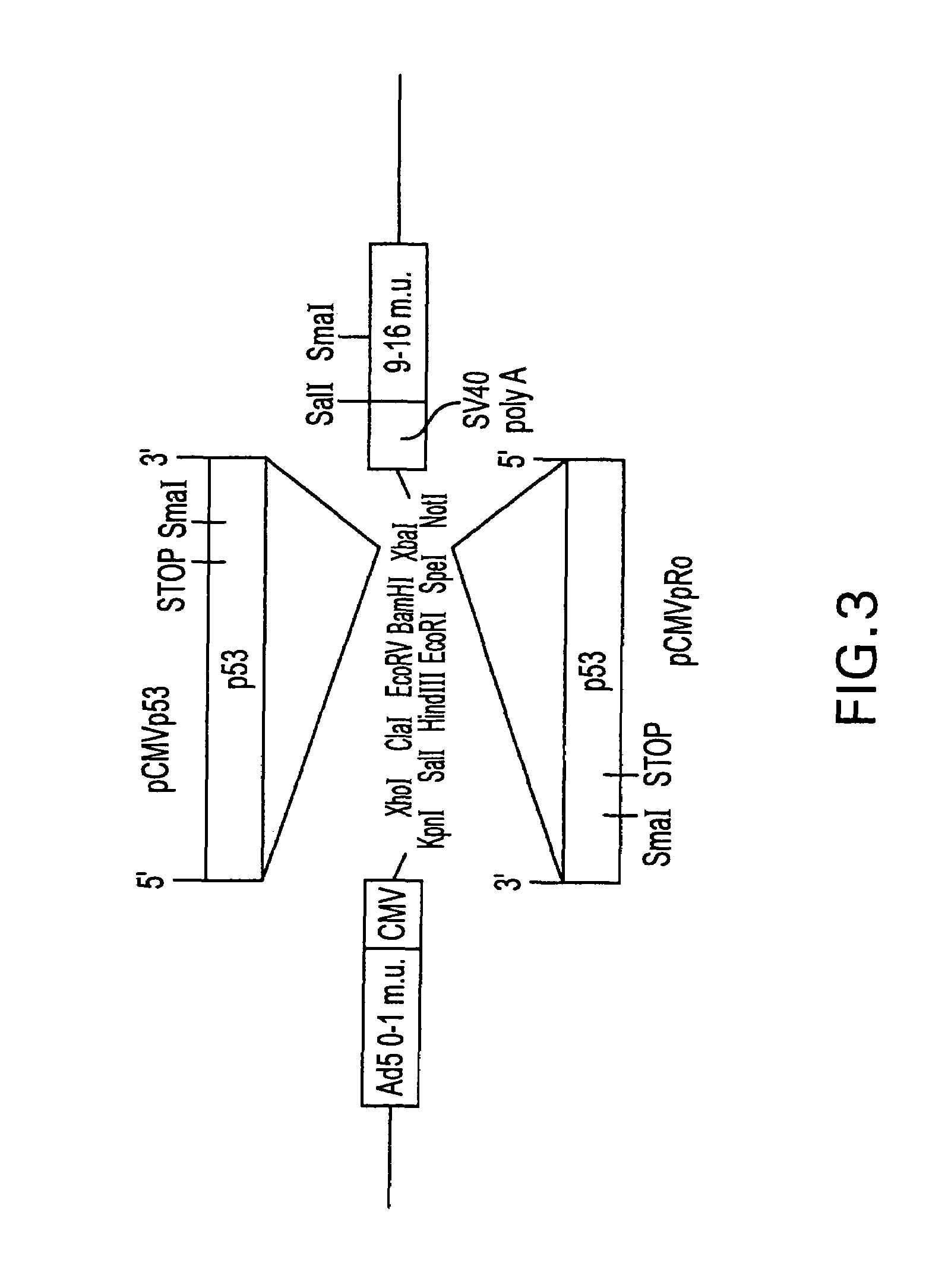

Antibody fragment-targeted immunoliposomes for systemic gene delivery

InactiveUS7479276B1Improve the level ofEfficient transfectionVectorsAntibody ingredientsGene deliveryAntiendomysial antibodies

Nucleic acid-immunoliposome compositions useful as therapeutic agents are disclosed. These compositions preferably comprise (i) cationic liposomes, (ii) a single chain antibody fragment which binds to a transferrin receptor, and (iii) a nucleic acid encoding a wild type p53. These compositions target cells which express transferrin receptors, e.g., cancer cells. These compositions can be used therapeutically to treat persons or animals who have cancer, e.g., head and neck cancer, breast cancer or prostate cancer.

Owner:SYNERGENE THERAPEUTICS +1

acidified straw

ActiveCN104128354BIntrinsic Quality GuaranteeAvoid chemical reactionsSolid waste disposalChemical reactionAdditive ingredient

The invention discloses an acidified straw. The main point of the technical scheme is that the acidified straw ingredients are composed of straw, attapulgite clay, magnesium oxide, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methyl Composed of cellulose and sodium carbonate. The acidified straw ingredients are input into a mill for grinding, and the powder after grinding is the acidified straw. The production method of the acidified straw can avoid the chemical reaction between sulfuric acid and instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; the straw is a new product that has been carbonized after being acidified and roasted. The utilization rate of the straw can be improved, not only can bring good economic benefits, environmental benefits and social benefits, but also can realize turning waste into wealth. It has the characteristics of good adsorption, thixotropy, thermal stability, plasticity, cohesiveness and high dry compressive strength. The acidified straw is suitable for the production of environmental protection materials, garden materials, building materials and foaming agent products.

Owner:江苏世澳非金属应用科技有限公司

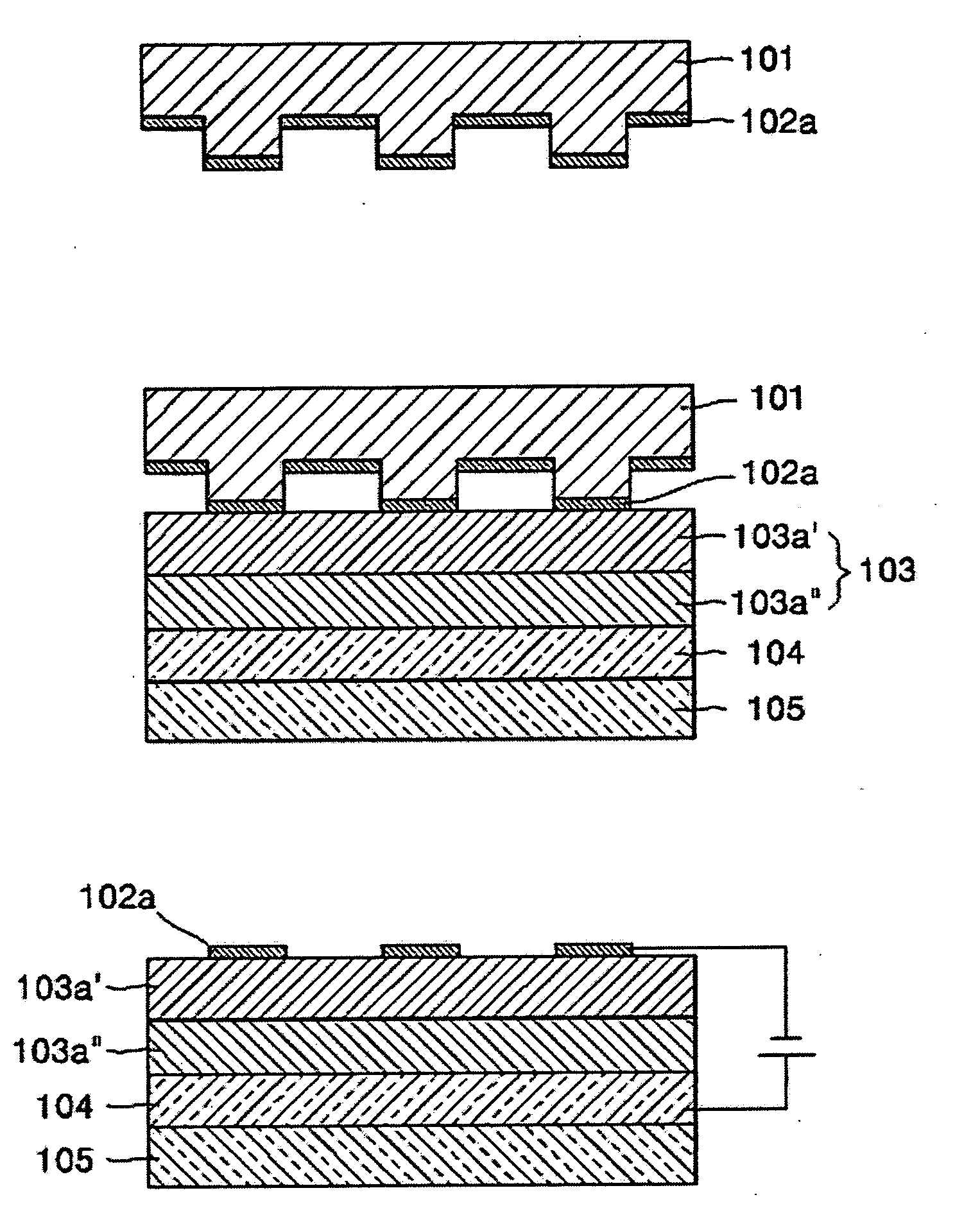

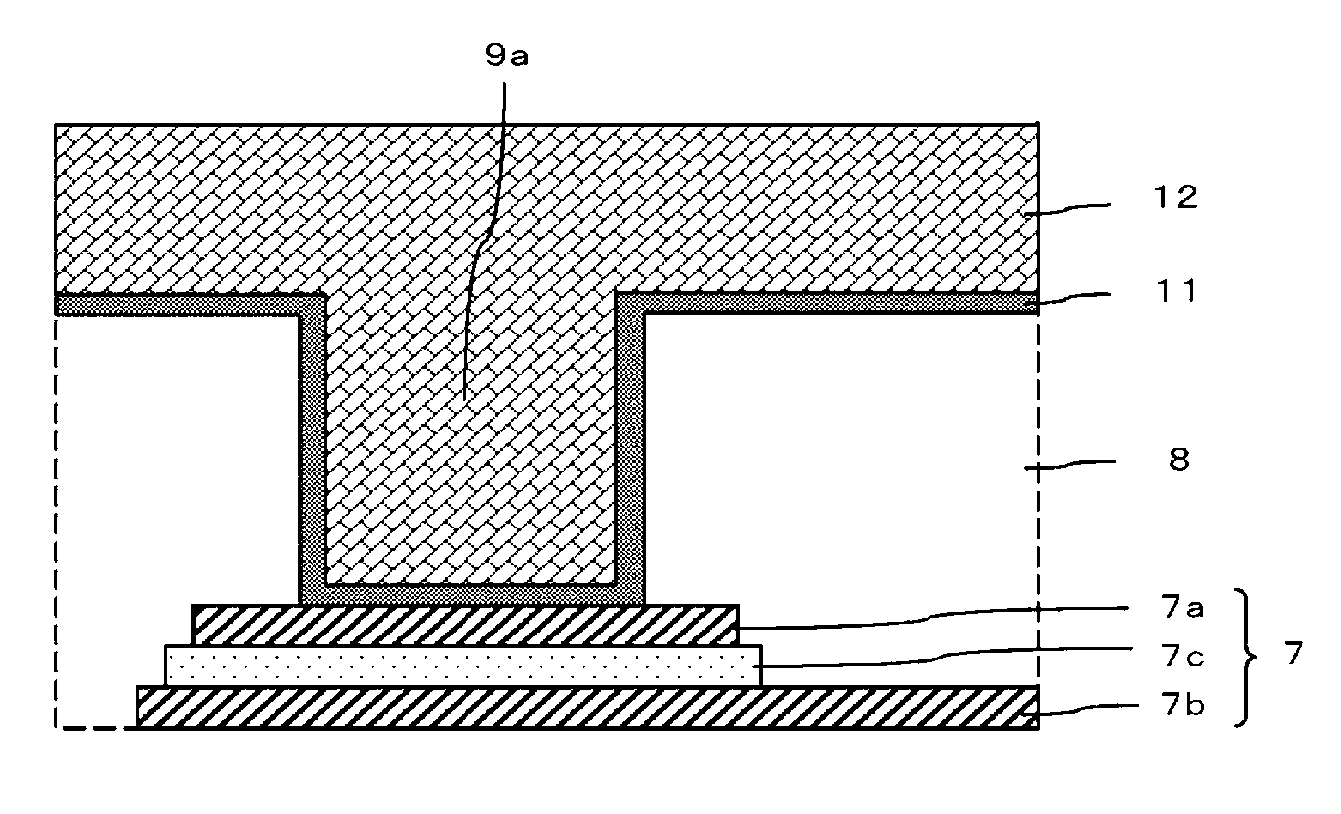

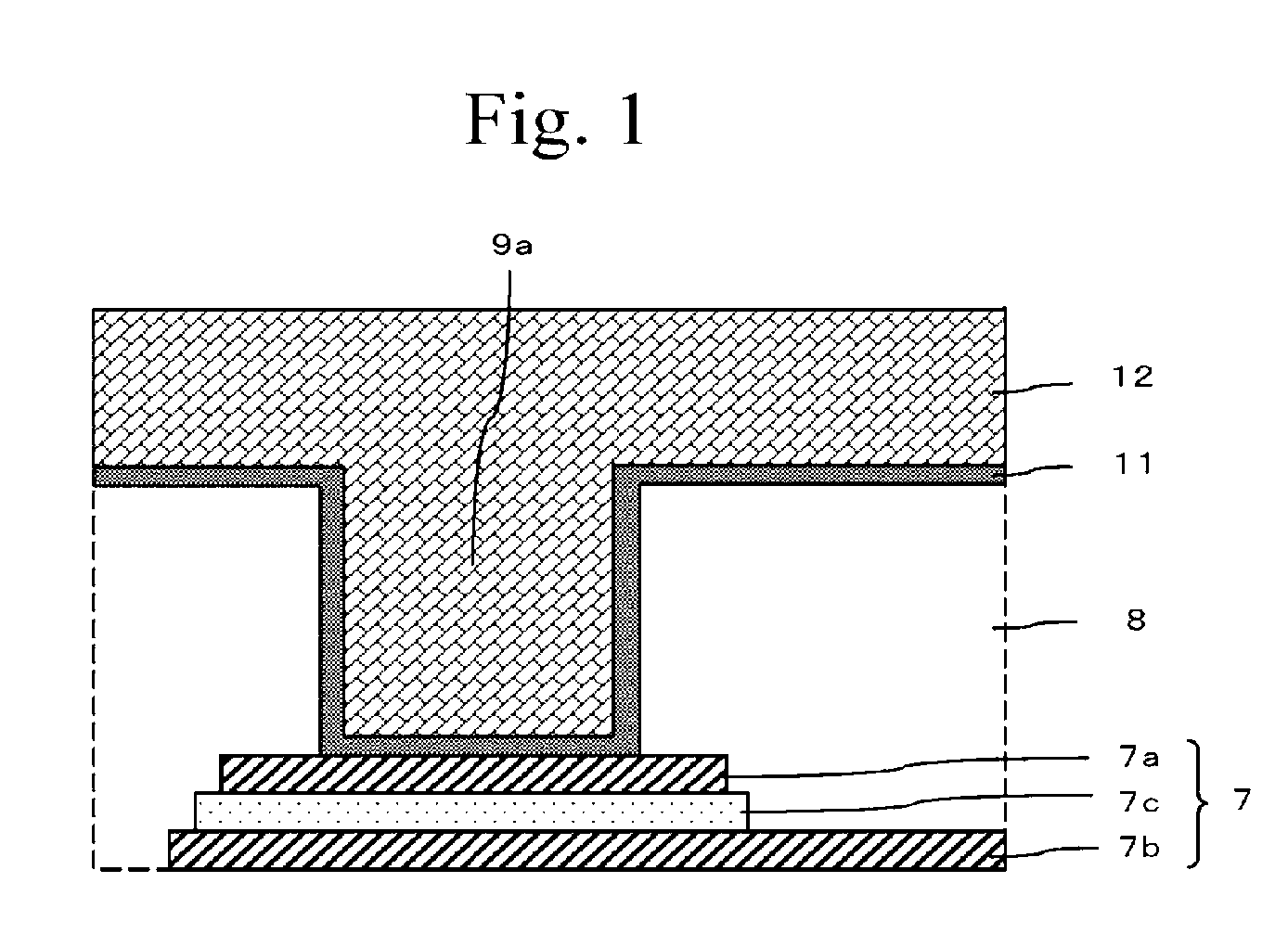

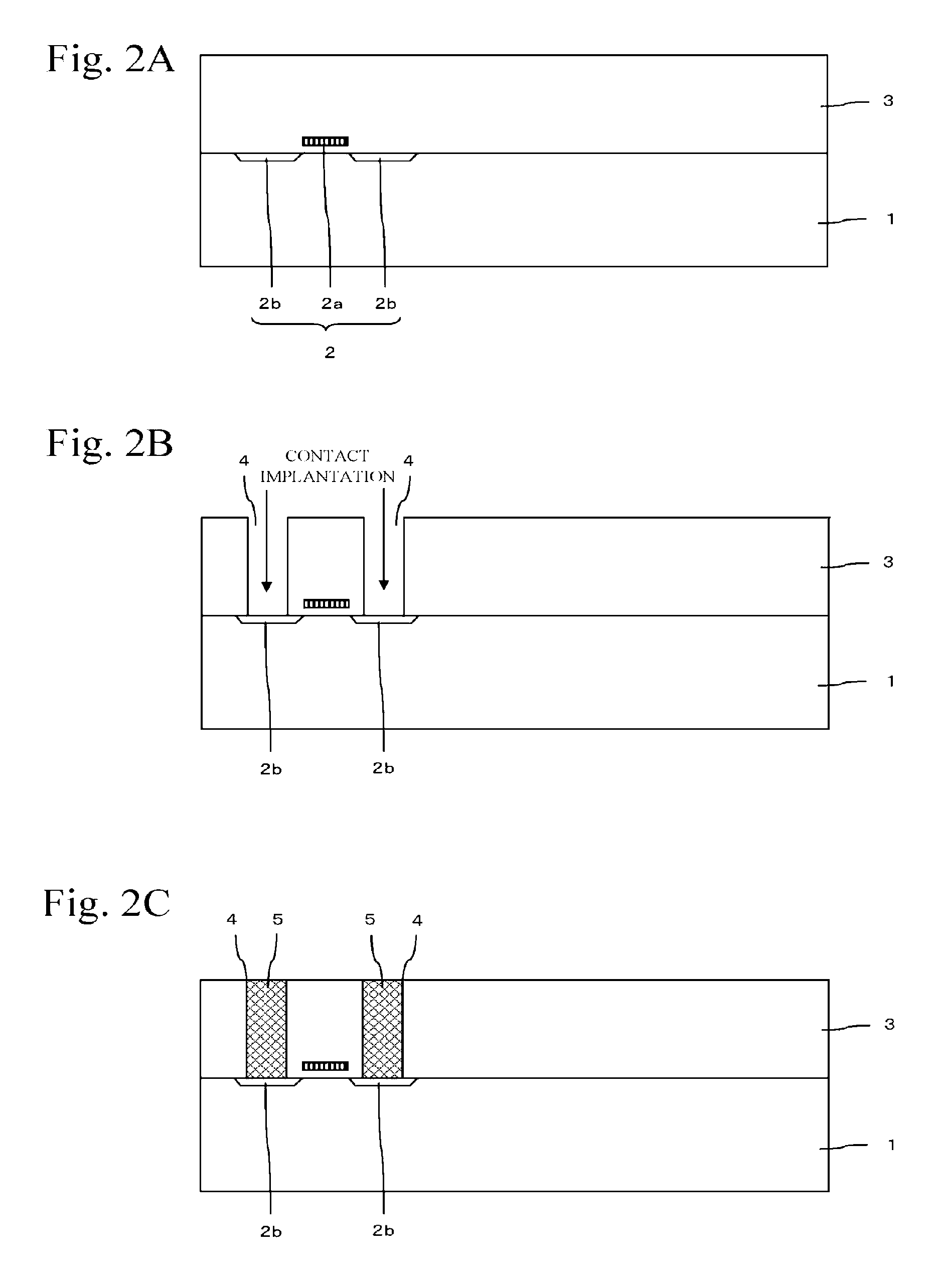

Semiconductor device

InactiveUS20060220083A1Prevents thickness of deviceAvoid chemical reactionsSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceDevice material

A semiconductor device includes a semiconductor substrate, a first electrode that is formed over said semiconductor substrate, a capacitive insulating film that is formed on the first electrode and is made of a metal oxide ferroelectric, a second electrode that is formed on the capacitive insulating film, an insulating film that has a first opening exposing a portion of an upper side of the second electrode and is formed so that it covers the first electrode, the capacitive insulating film, and the second electrode, a first barrier film having an amorphous structure which is formed inside the first opening and on the insulating film, and a wiring film that is formed over the first barrier film.

Owner:LAPIS SEMICON CO LTD

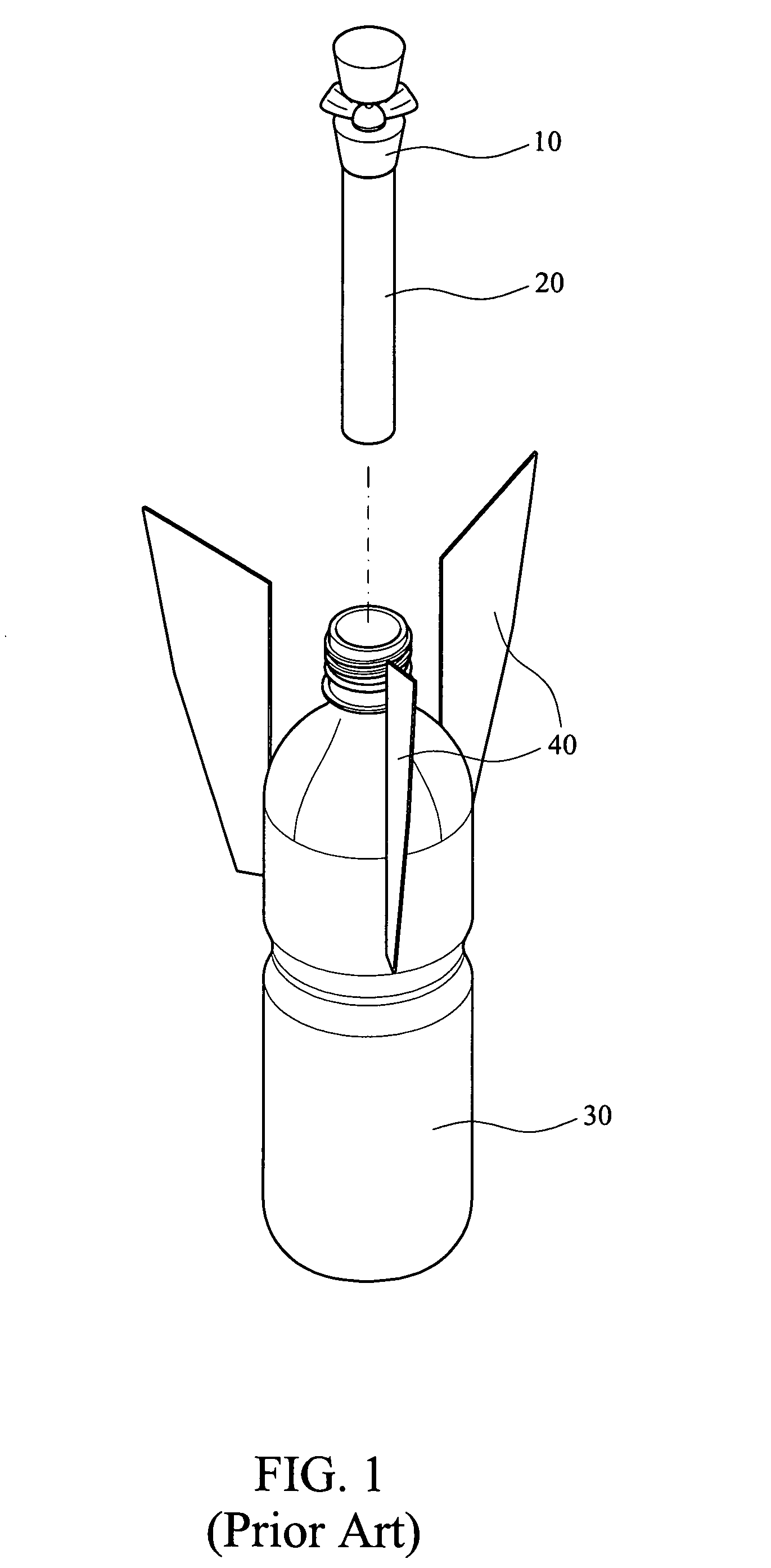

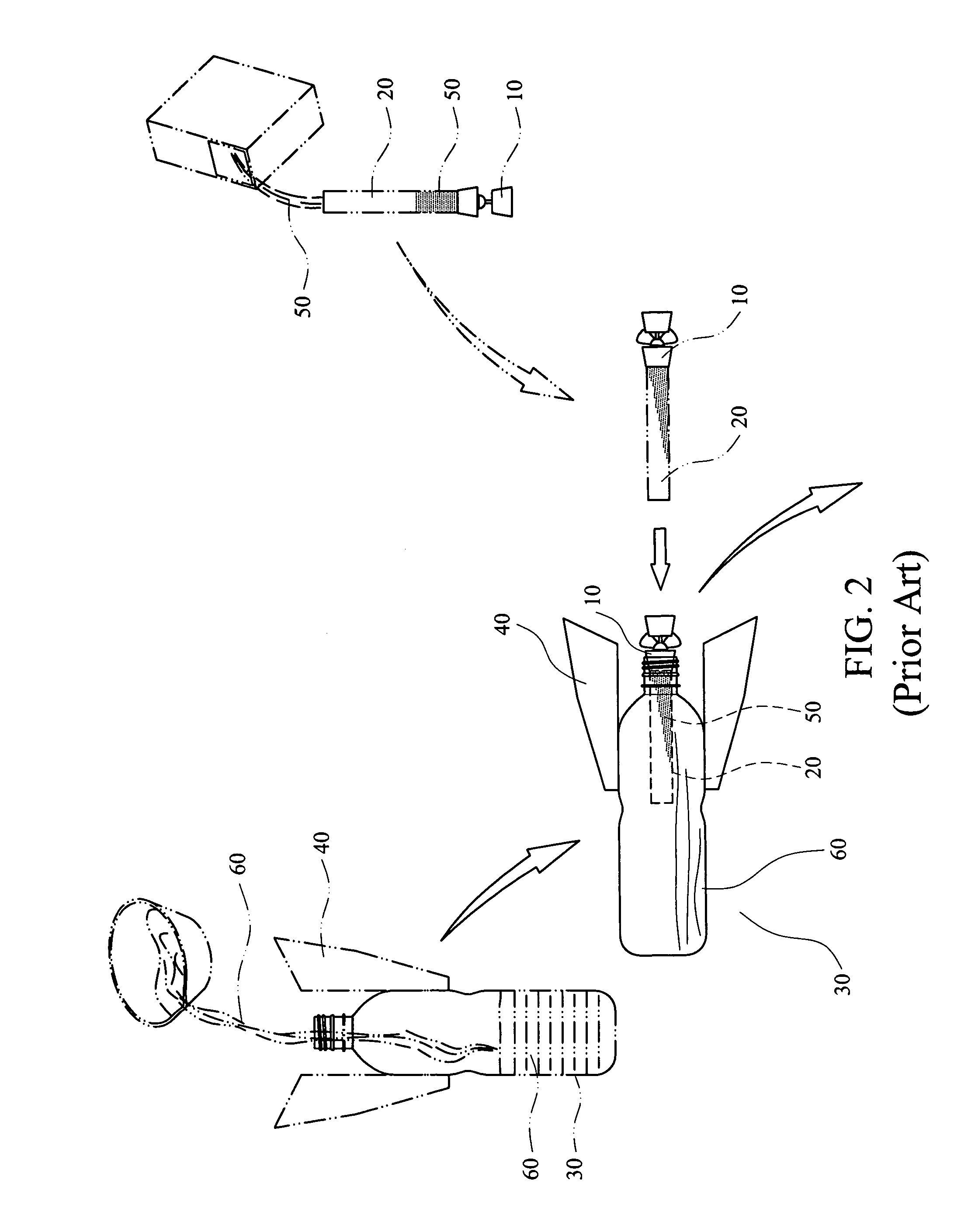

Pressure-actuated toy rocket system

InactiveUS6957526B1Improve economic efficiencyPleasing to eyeCompressed gas gunsToy aircraftsDetonatorRocket

A pressure-actuated rocket system comprises a bottom base, a detonator and a rocket body. A top base is placed on a top surface of the bottom base. At least one through hole is located on a side of the top base and extended to an opening of the top surface. The hollow detonator has a closed and an opened ends. The rocket body is a bottle with fins. After soda powder is placed inside the detonator and vinegar is filled into the rocket body, the bottom base, the detonator and the rocket body are held inclined. The openings are aimed at the inclined bottom base in turn, the pressure-actuated rocket system is then turned upside down. Soda powder subsequently falls and reacts with vinegar, and gas is generated. A pressure accumulates inside the rocket body until it is high enough to shoot the rocket body up.

Owner:LIN CHITSAN

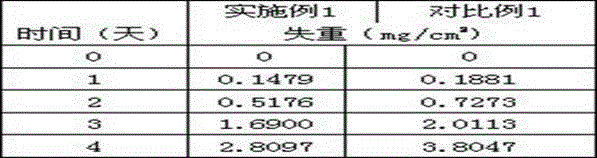

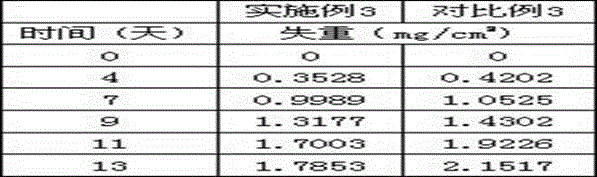

Manufacturing method for improving magnetic performance of sintered neodymium-iron-boron magnet

InactiveCN104143403ANitrogen content decreasedThe total amount is stableInorganic material magnetismInductances/transformers/magnets manufactureHafniumNitrogen gas

A high-magnetism sintered neodymium-iron-boron magnet is characterized by comprising, by weight, 27-31% of rare earth elements, 0.9-1.2% of boron, 0-3.0% of cobalt, 0-2% of adding elements and the balance iron, the rare earth elements comprise two or more of neodymium, praseodymium, dysprosium, terbium and holmium, and the adding elements comprise two or more of aluminum, copper, gallium, niobium, zirconium, titanium and hafnium. A manufacturing method includes the working procedures of batching, smelting, hydrogen breaking, pulverizing, forming and sintering, and argon protection is selected for replacing nitrogen protection in the working procedures from smelting to sintering, so that the content of nitrogen in the sintered neodymium-iron-boron magnet is reduced substantially, the total quantity of the rare earth elements in the magnet is relatively stable, the coercivity of the magnet is improved, and the magnetic performance is kept well. A magnet crystal boundary structure change caused by the nitrogen does not exist in the production process, and the corrosion-resistant capacity of the sintered magnet is improved.

Owner:NINGBO KETIAN MAGNET +1

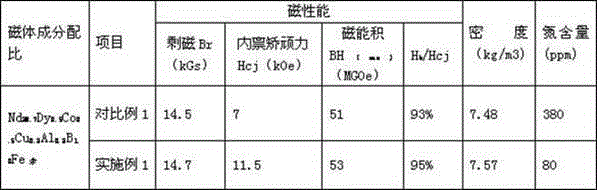

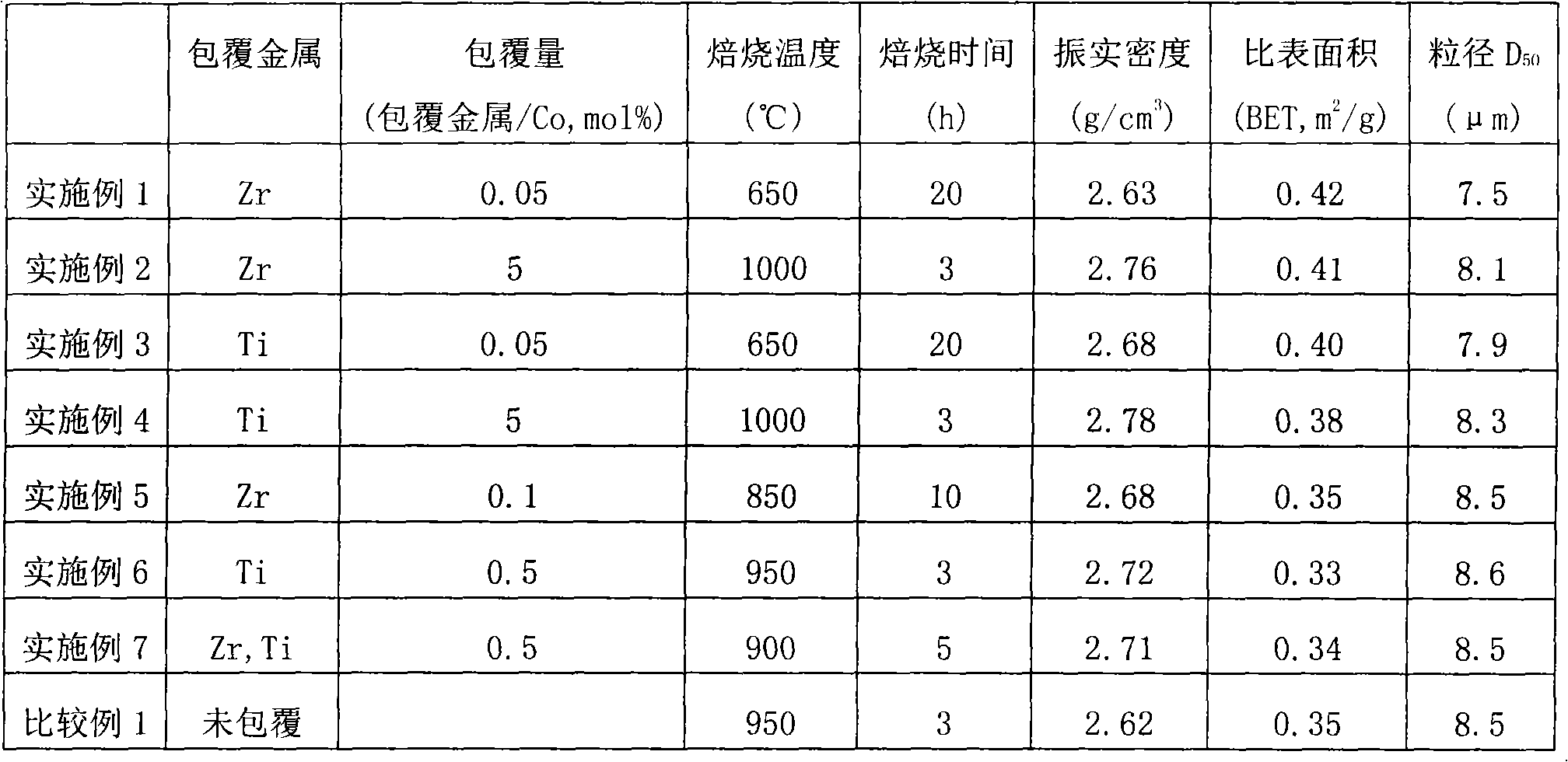

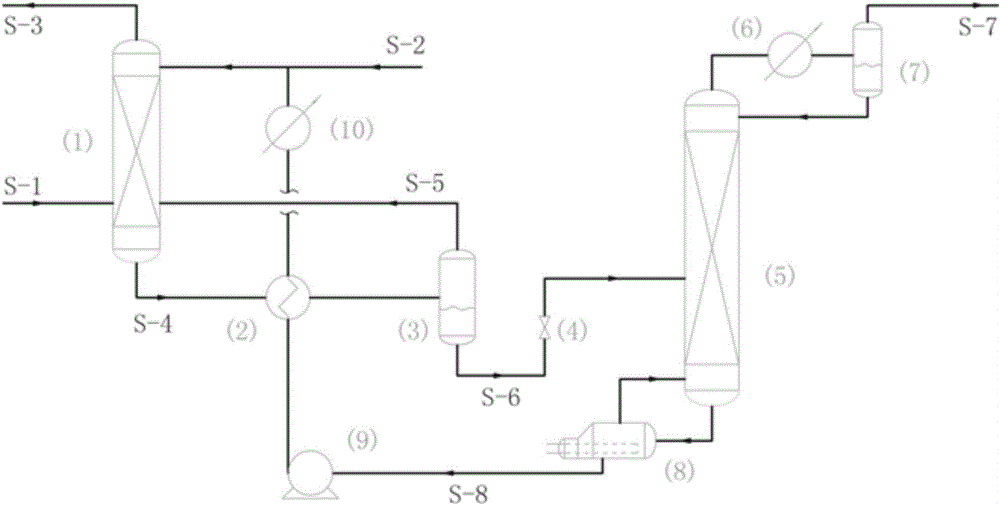

Lithium cobaltate composite oxide coated by hydrolytic precipitation-roasting method and manufacturing method thereof

InactiveCN101872859AImprove cycle stabilityImprove anti-overcharge performanceElectrode manufacturing processesActive material electrodesLithium-ion batteryAqueous solution

The invention provides a lithium cobaltate composite oxide coated by a hydrolytic precipitation-roasting method. When being used as an anode material of a lithium ion battery, the lithium cobaltate composite oxide can enable the performance of the lithium ion battery, especially cycle performance and overcharge resistance to be excellent. The invention is characterized in that a manufacturing method comprises the following steps: adjusting the pH value of a water solution containing metallic ions to be coated by using a liquid phase hydrolytic precipitation method to obtain a coating precursor; roasting at high temperature; and using metal oxides (the metal is at least one of Ti or Zr) to coat the particle surface of lithium cobaltate which is represented by the general formula of Li1+xCoO2-a (x is greater than or equal to -0.1 and less than or equal to 0.1, and a is greater than or equal to -0.1 and less than or equal to 0.1).

Owner:北京圣比和科技有限公司

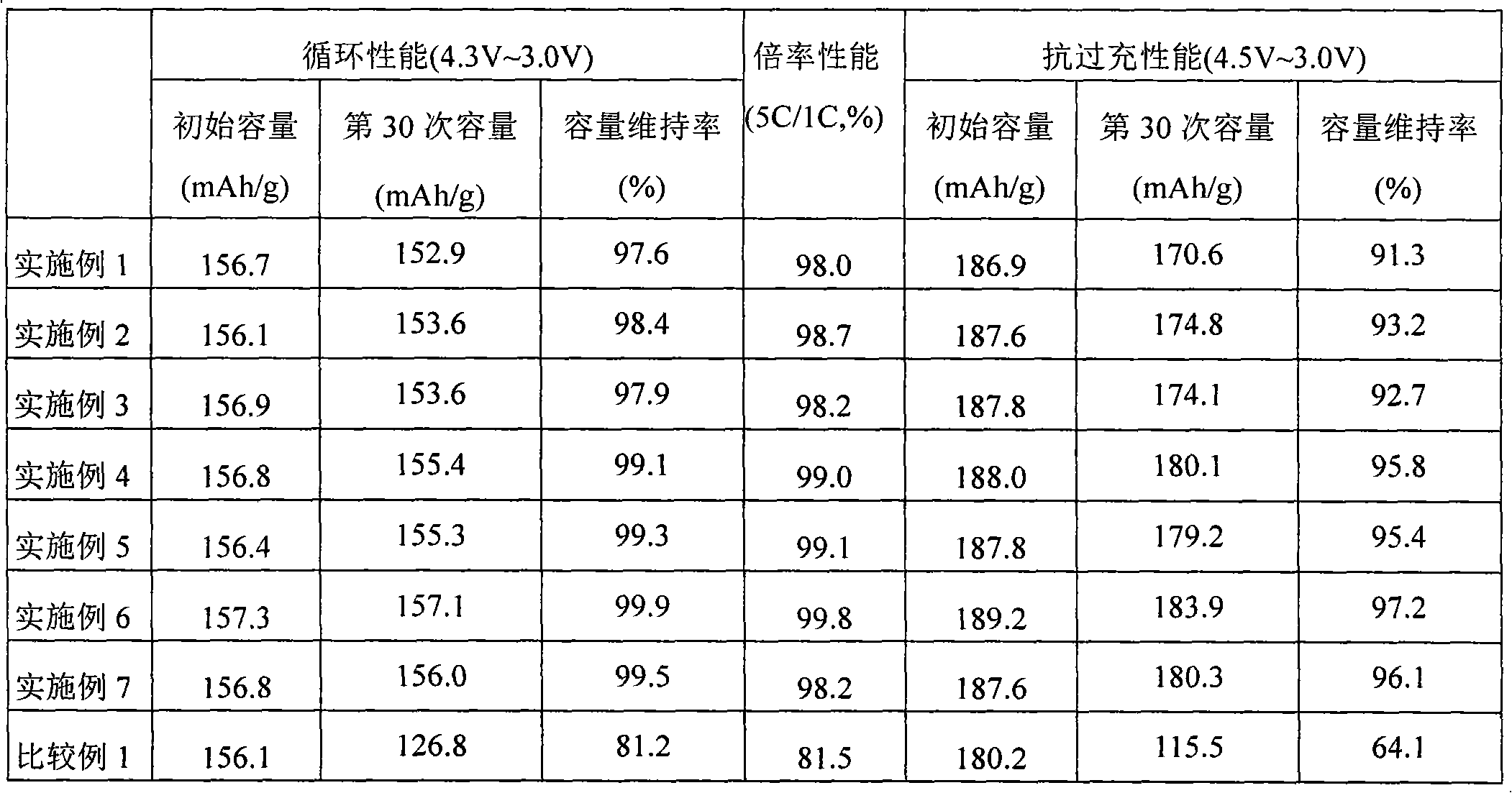

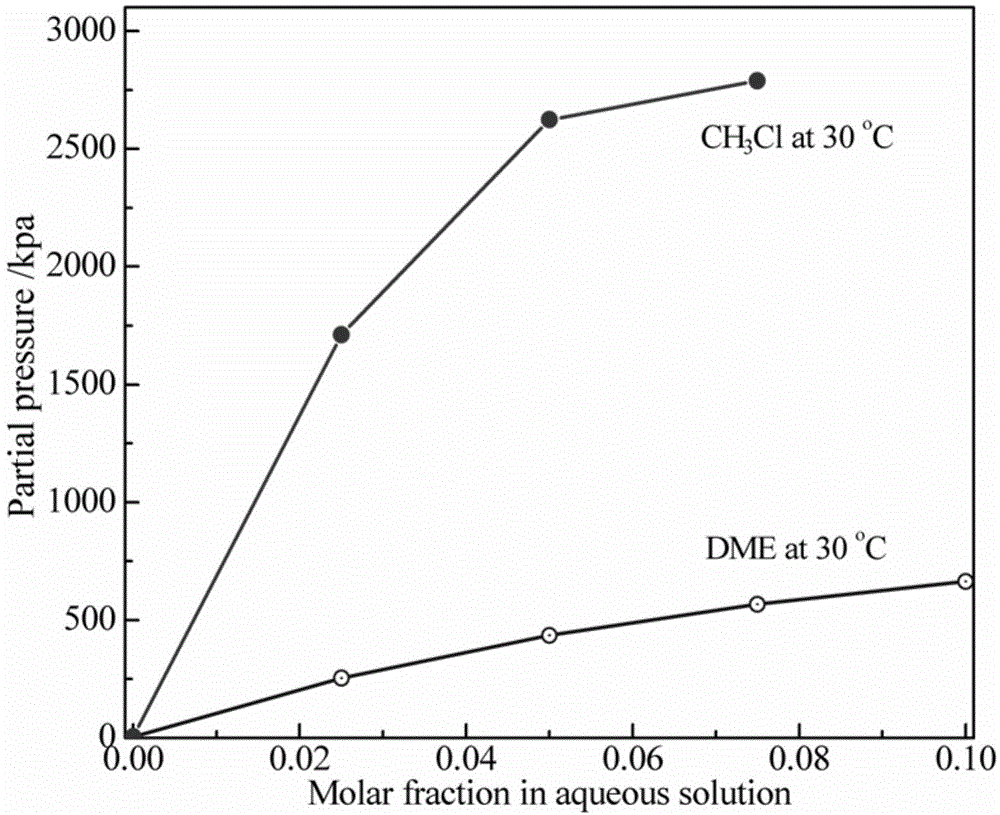

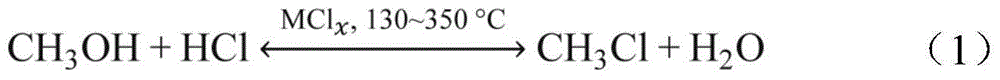

Separation process of removing dimethyl ether impurities in chloromethane through water absorption

InactiveCN104926595ASafe removalAchieve recyclingEther separation/purificationHalogenated hydrocarbon separation/purificationSolubilityChemical reaction

The invention provides a separation method and process of removing dimethyl ether impurities in chloromethane by using water as an absorbent, and belongs to the field of gas separation and purification. Based on the chemical theory that hydrogen bonds are formed by polar gas molecules and water, a significant difference of water solubility properties between chloromethane and dimethyl ether is used, water is used as an absorbent or a mixture of water and another material is used as an absorbent to replace traditional concentrated sulfuric acid, and a joint process formed by combining absorption and rectification is used, so as to separate a mixture of chloromethane and dimethyl ether safely and efficiently in low cost. By using the separation method and process, in which water is used as the absorbent, to treat a passivated tail gas produced by a dehydration apparatus, the removal rate of dimethyl ether is greater than 99%, the concentration of purified chloromethane can reach 99 mol%, and the recovery rate of the chloromethane can be kept at about 98%. Furthermore, because a chemical reaction is avoided, separated dimethyl ether from which chloromethane is removed through hydrolysis can be used as a byproduct, thus increasing the economic benefit.

Owner:DALIAN UNIV OF TECH

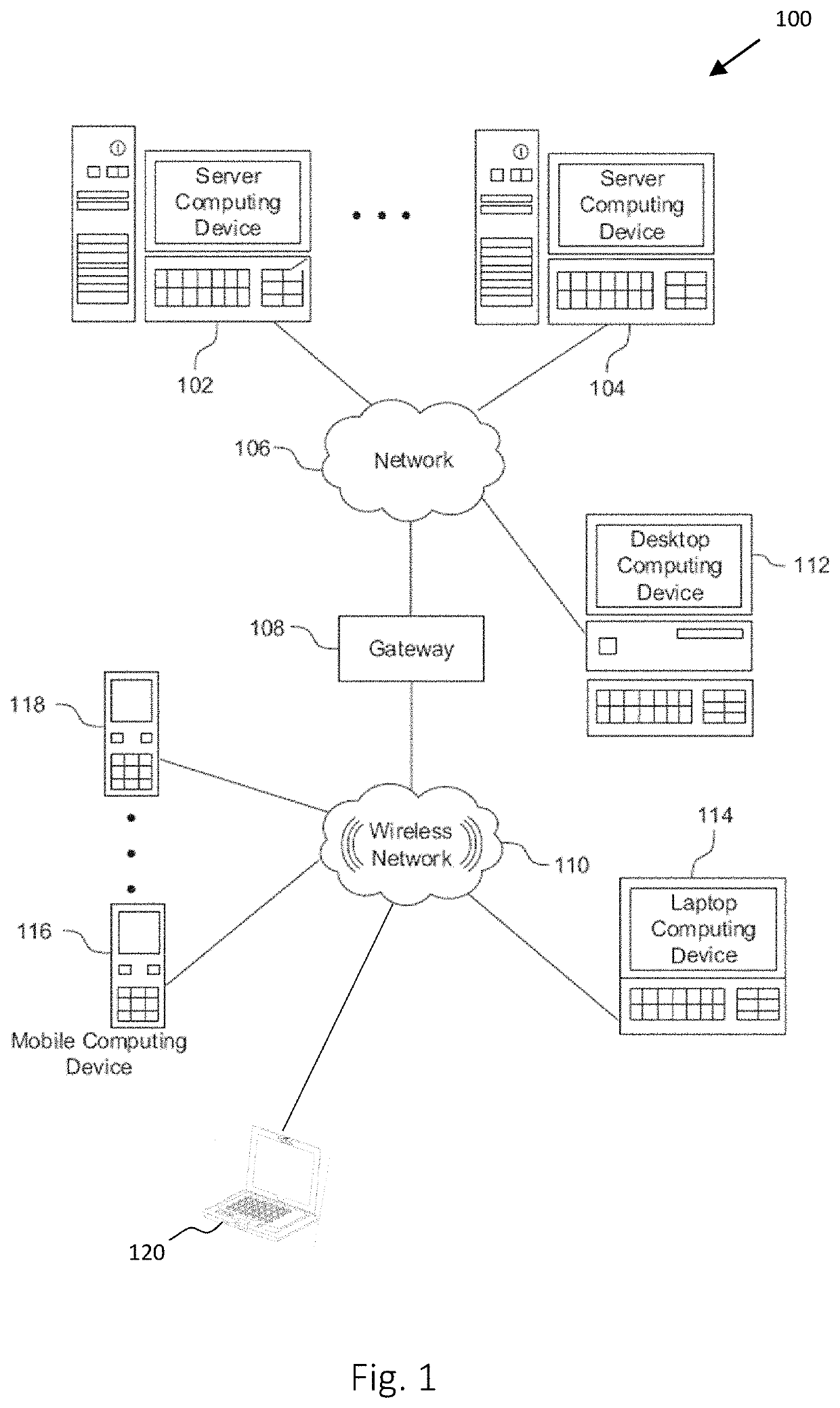

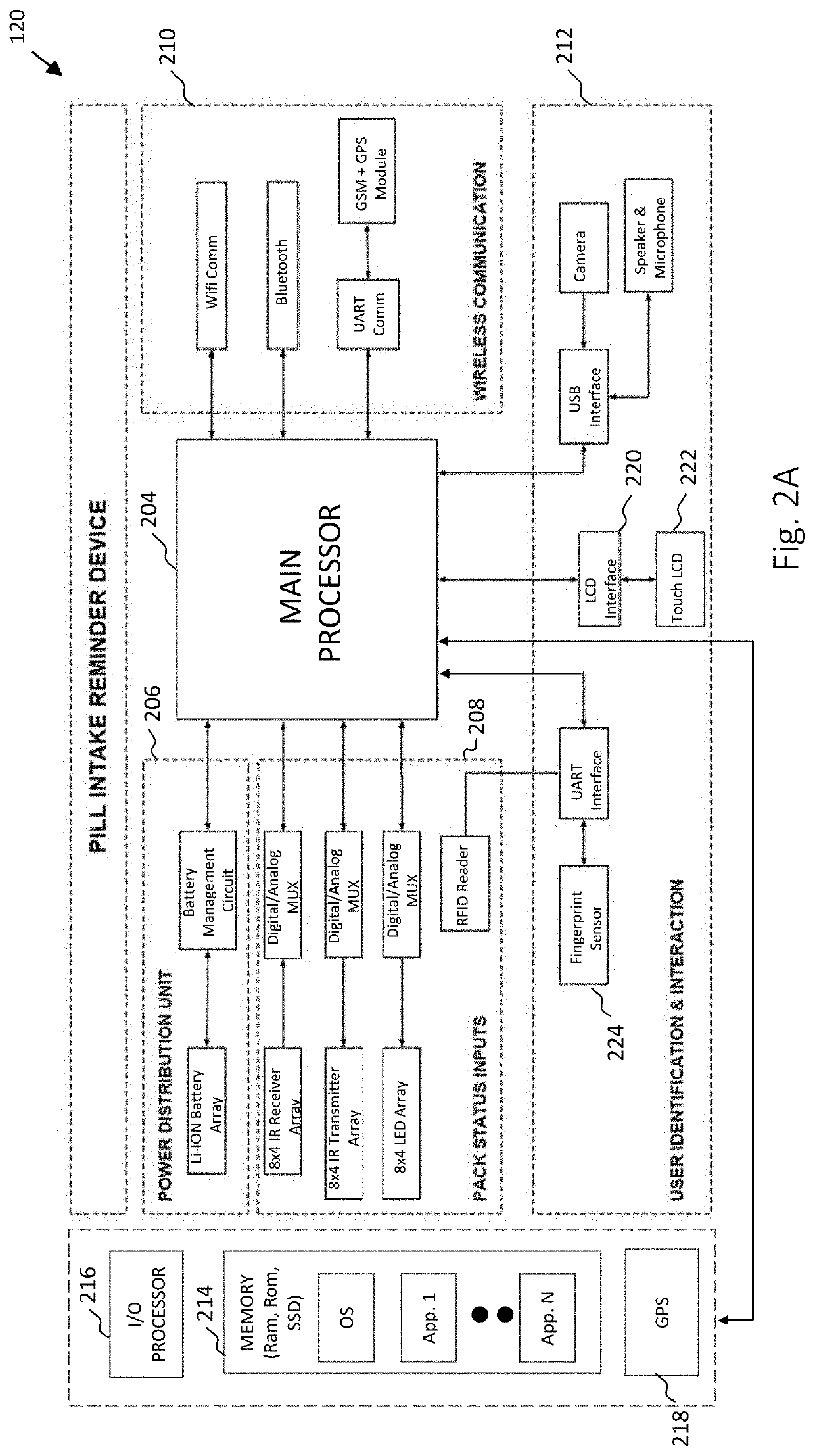

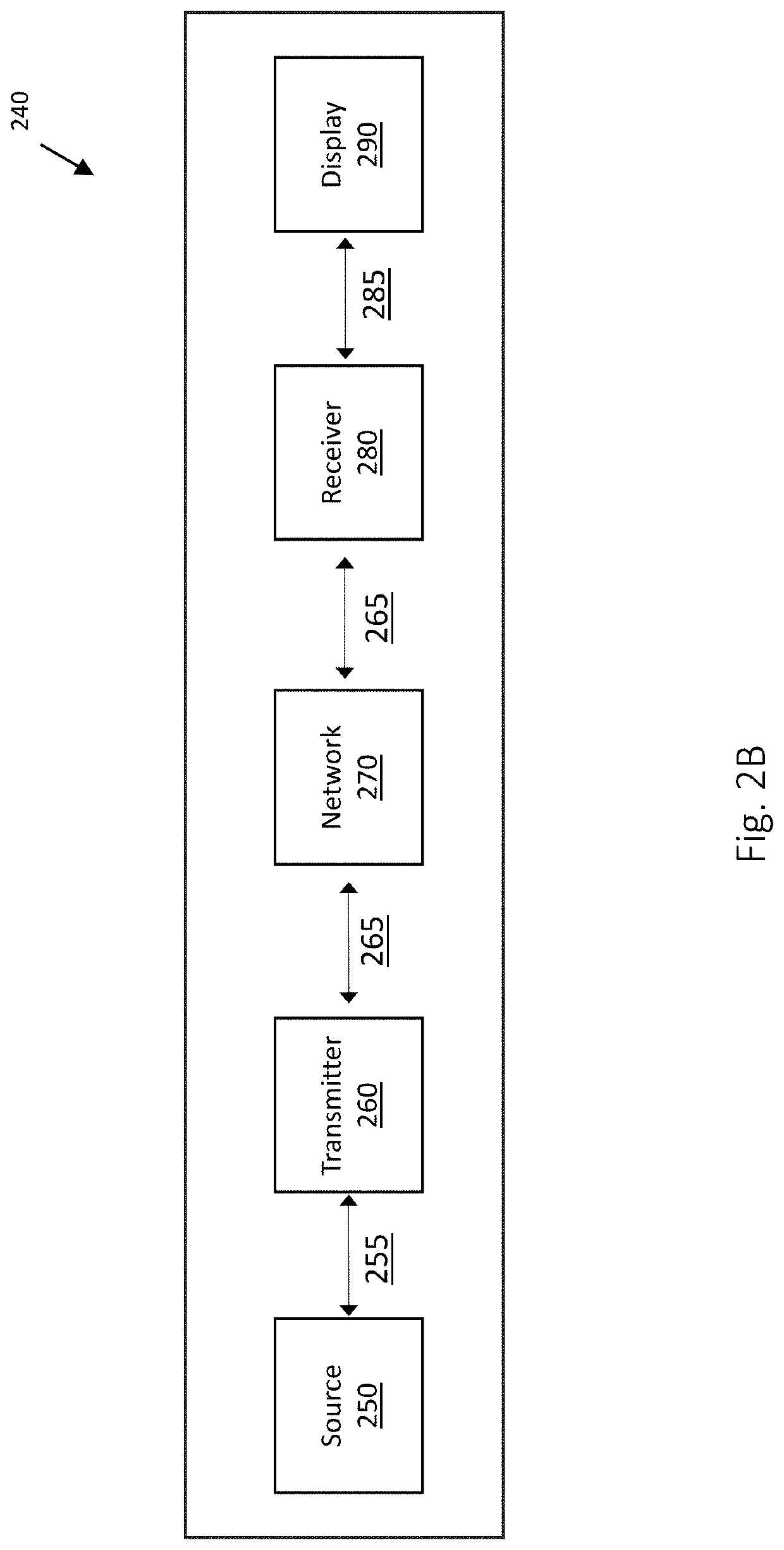

System and method for storing medication and alerting users and caregivers for timely intake

ActiveUS20200085694A1Avoid chemical reactionsDrug and medicationsPharmaceutical containersComputer hardwarePill count

A computerized pill intake reminder device is disclosed. The computerized pill intake reminder device is used for storing pills, detecting the number of pills in each pouch of the blister pack, inventory management, reminding users to take their medication on time, alerting by providing an audible or a visual alarm if the medications are not taken on time and as a secondary mechanism alerting their caregiver if the user has not responded to the alert and taken the medication on time.The device includes a top housing and a bottom housing that can be rotated about each other to form a closed and sealed module. It also includes a processor that is communicatively coupled through an electronic circuit to a plurality of electronic components housed within the pill intake reminder device. These include a speaker, microphone, infrared sensors, cameras, LED lights, microphone, RFID scanner, non-volatile memory, transmitter, and a receiver. The LED lights can be programmed with various colors.The speaker is used to sound an audible alarm play an audible message at a specific time to remind the user to take their medication or provide an alert if the time has passed. The device also includes a pill storage module that has an upper and a lower packing plate. The space in between the plates is where the blister pack is inserted.The device includes a pill detection module. This module includes an infrared sensor (IR) and a camera. In operation, the processor causes the infrared sensor to detect the presence of a pill inside the pouch of the pill / blister pack and the processor causes the camera to quantify the number of pills in the pouch. The pill detection is performed by using a combination of IR Sensors, photodiodes, and a light emitting mechanism. A light beam, or an array of light beams, are passed from one side of the pouch to another and the light that passes through is read by the IR sensors and used for determining whether the pouch includes pills.The device includes a guidance system to guide the user of the pill intake reminder device to a specific pouch of the pill / blister pack for retrieving pills stored in that pouch. It does so by illuminating a light emitting diode (LED) on or around a specific pouch from which medication / pills are to be retrieved by the user. It operates by obtaining the hours of administration (HOA) schedule for the patient and then locating a pouch of the pill / blister pack that correlates with the HOA schedule. Once located, the pouch is illuminated for guidance.The device includes a display that can be used for providing visual alerts, videos, or recorded messages for instructing the user for taking the pills.The device uses a transmitter to send alerts to mobile phone for reminding the user to take the medication as well as sending an alert for missing or noncompliance.The radio frequency identification (RFID) reader is used to verify that a correct pill / blister pack, the one that is associated with the user / patient is being inserted into the device. The verifying process includes scanning an RFID tag located on the blister pack and matching it to patient information.The device also performs periodic inventory of the pills in the blister pack. This includes using an infrared sensor housed within the electronic module to determine the presence of one or more pills in the pouch and using a camera housed underneath the pouch to image and count the number of pills that are in the pouch. The inventory serves as an error check to ensure that the right number of pills from the right pouch were taken by the user at their HOA. The pill inventory system also is used to re-order more medication, if allowed by the prescription, when it detects that it is time to replenish them.

Owner:PATEL MITESHKUMAR ISHWARBHAI +1

Hydrolysis-resistant glass, a method of making said glass and uses of same

InactiveUS20060264313A1High crystallization stabilityStable and resistant to reactionGlass furnace apparatusGlass drawing apparatusTitanium dioxideOxide

The glass for a fluorescent light with a high hydrolytic resistance, which has composition, in % by weight based on oxide content of: SiO2, 63-75; B2O3, 15-18; Al2O3, 2.5-4.5; Na2O, 0-10; K2O, 0-10; ΣNa2O+K2O, 2-10; MgO, 0-8; CaO, 0-10; SrO, 0-10; BaO, 0-10; ZnO, 0-5; ΣMgO+CaO+SrO+BaO+ZnO, 0-10; ZrO2, 0-3; CeO2, 0-10; Fe2O3, 0-1; WO3, 0-3; Bi2O3, 0-5; MoO3, 0-3; TiO2, 0-10; ΣHf+Ta+W+Re+Os+Ir+Pt+La+Pr+Nd+Sm+Eu+Gd+Tb+Dy+Ho+Er+Tm+Yb+Lu in oxidic form, 0 to 5% by weight, as well as one or more conventional refining agents. The glass is characterized in that it contains no lithium and has a weight ratio of Na2O to K2O of less than one.

Owner:SCHOTT AG

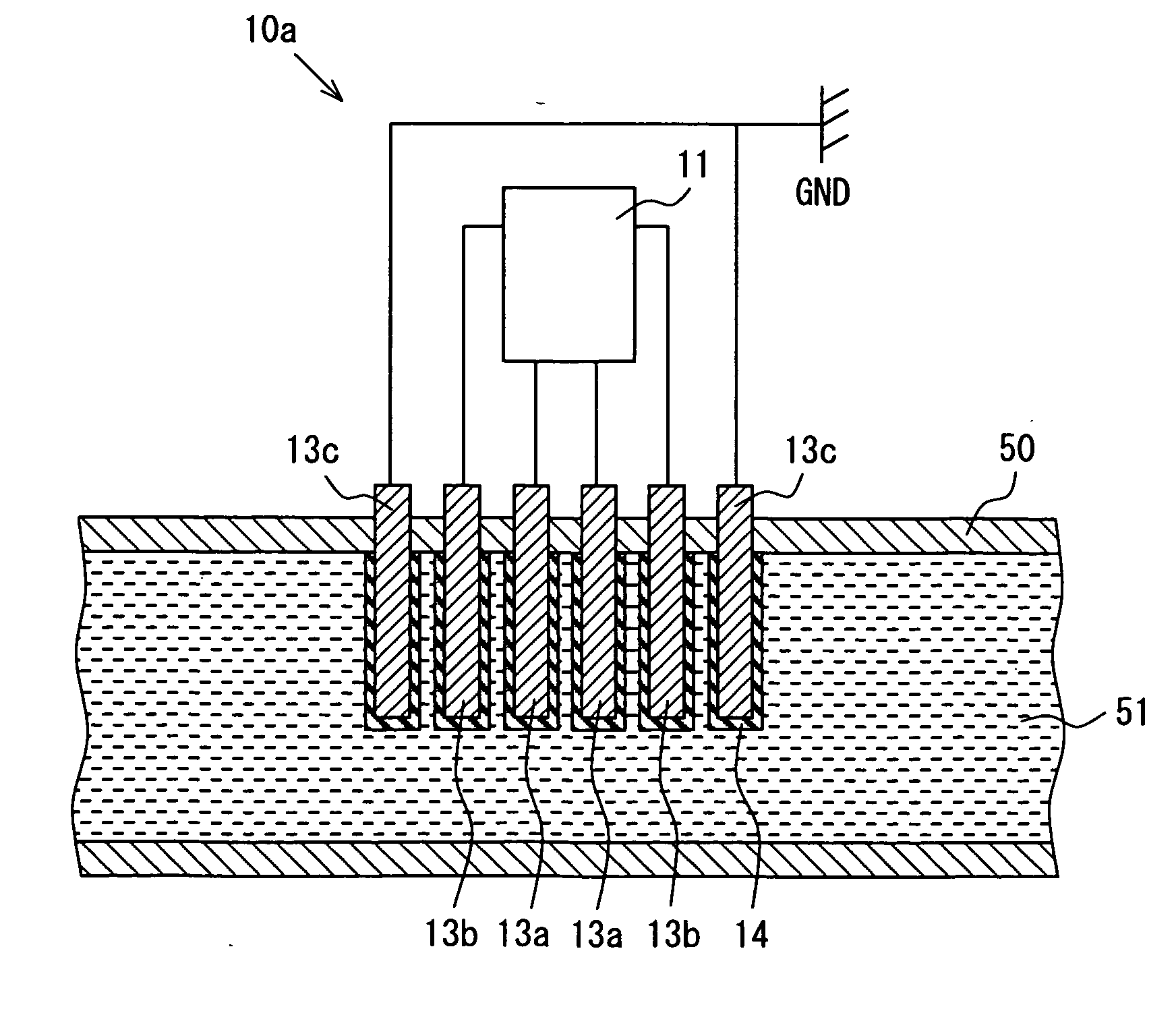

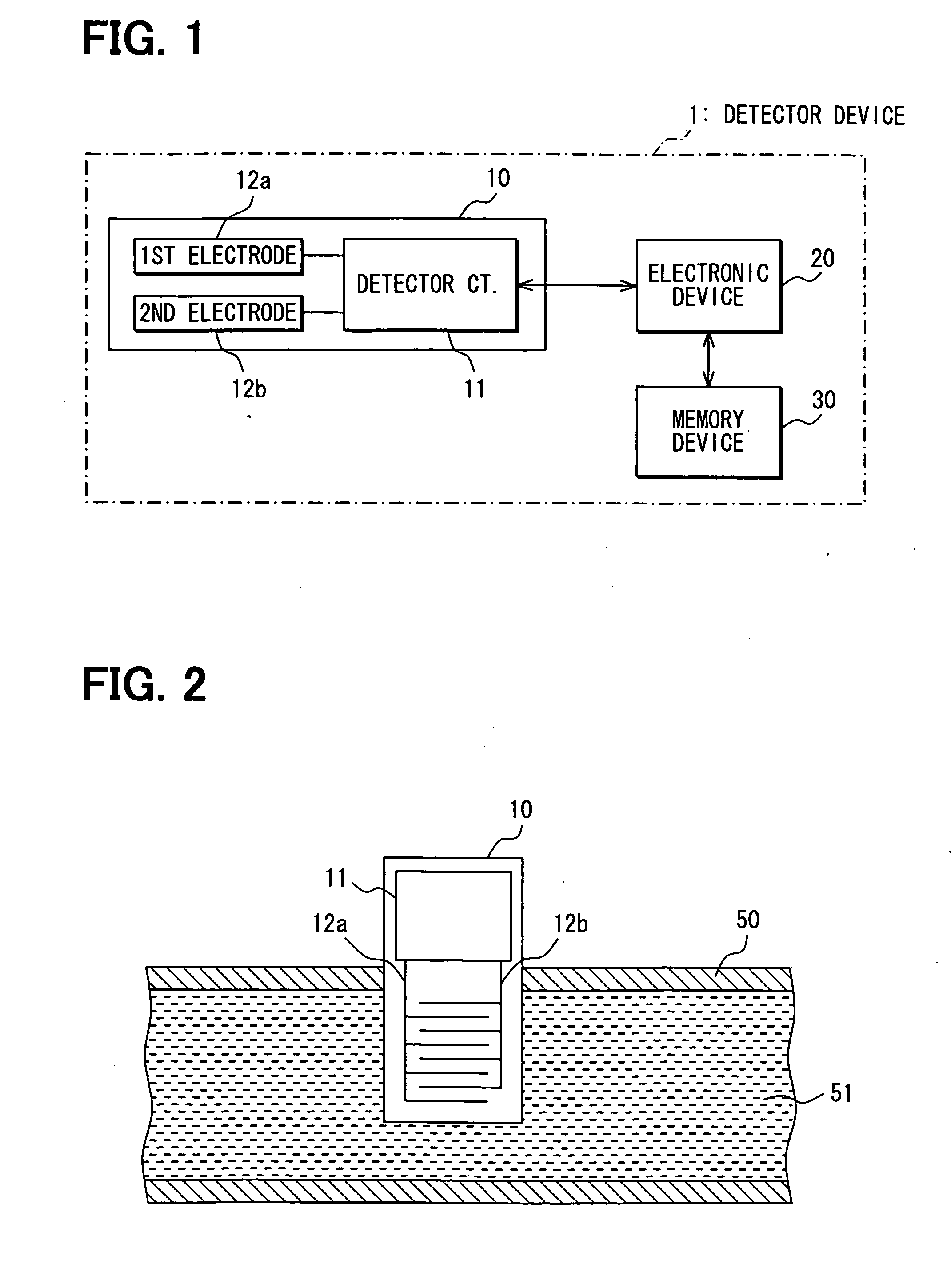

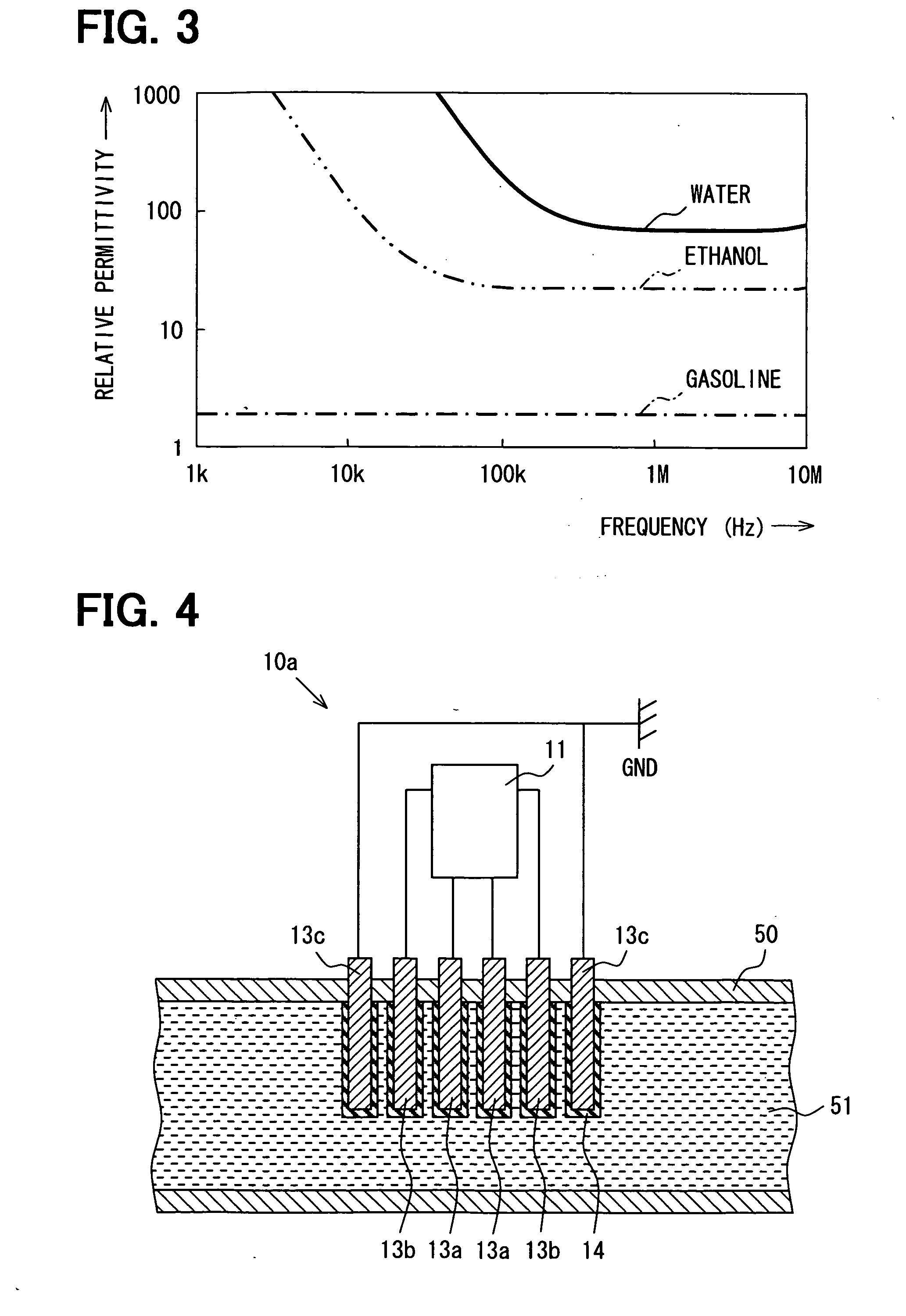

Detector device for detecting component density contained in mixture fuel

InactiveUS20090157345A1Density is accurateAvoid chemical reactionsMaterial analysis by electric/magnetic meansDigital computer detailsGasolineEngineering

A detector device of the present invention detects densities of components, such as gasoline and ethanol, contained in mixture fuel even when some water is included in the mixture fuel. The detector device includes a sensor having a pair or electrodes, an electronic device for calculating the densities and a memory device for storing permittivities of pure components including water measured beforehand. Alternating current having two different frequencies f1, f2 is applied to the pair of electrodes immersed in the mixture fuel to detect the permittivities of the mixture fuel under f1 and f2. The two frequencies, f1 and f2, are so chosen that the premittivities of gasoline and ethanol show no change between f1 and f2, while the permittivitiy of water shows a substantial difference between f1 and f2. The electronic device calculates the densities of the components based on permittivities of the mixture fuel detected by the sensor and those of components stored in the memory device.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com