Patents

Literature

52333results about How to "High hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite proppant, composite filtration media and methods for making and using same

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

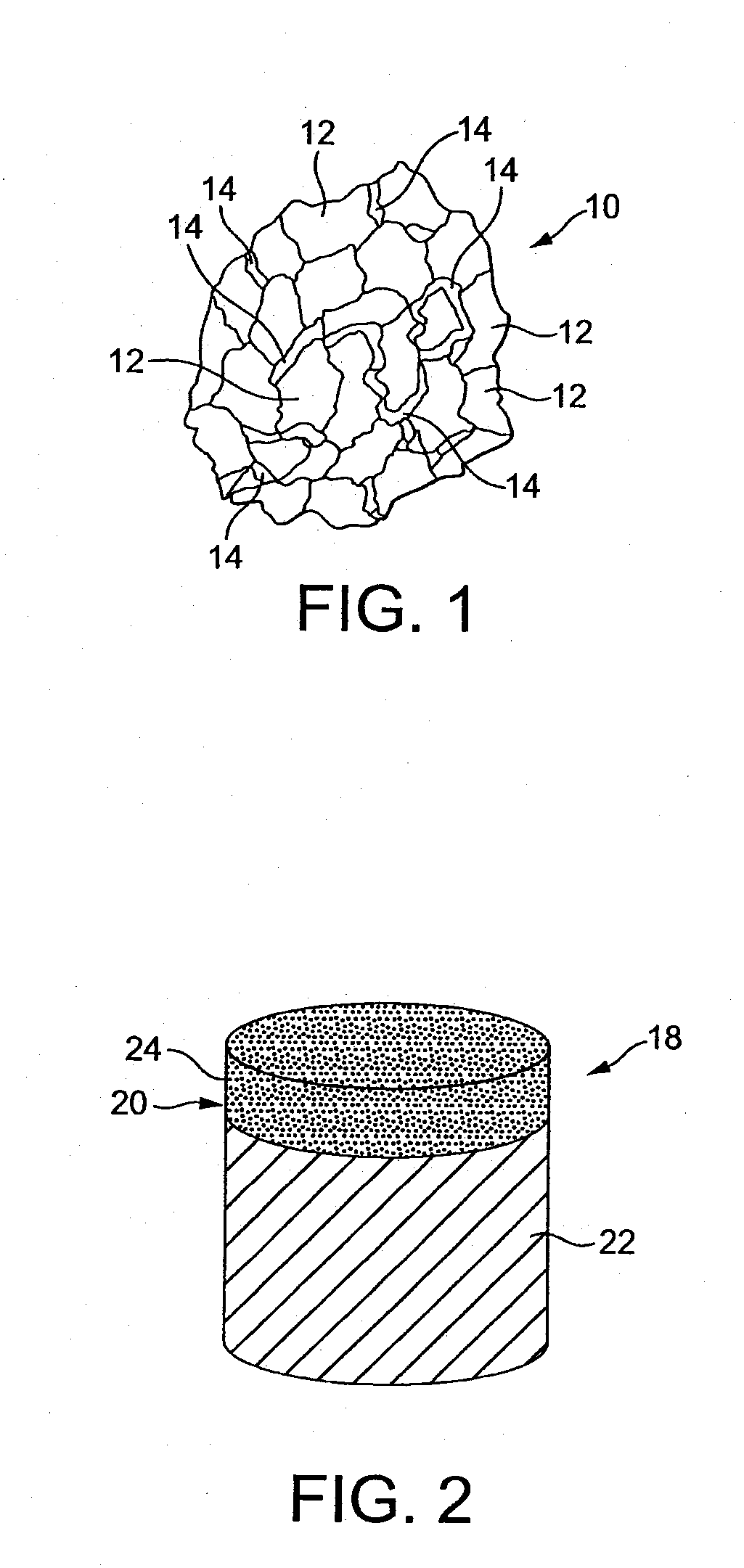

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

Plasma curing process for porous low-k materials

InactiveUS6913796B2Improving elastic modulusImproving material hardnessSilicaLayered productsHardnessMaterials science

Low dielectric constant porous materials with improved elastic modulus and hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material to produce a plasma cured porous dielectric material. Plasma curing of the porous dielectric material yields a material with improved modulus and hardness. The improvement in elastic modulus is typically greater than or about 50%, more typically greater than or about 100%, and more typically greater than or about 200%. The improvement in hardness is typically greater than or about 50%. The plasma cured porous dielectric material can optionally be post-plasma treated. The post-plasma treatment of the plasma cured porous dielectric material reduces the dielectric constant of the material while maintaining an improved elastic modulus and hardness as compared to the plasma cured porous dielectric material. The post-plasma treated, plasma cured porous dielectric material has a dielectric constant between about 1.1 and about 3.5 and an improved elastic modulus and hardness.

Owner:DOW CORNING CORP

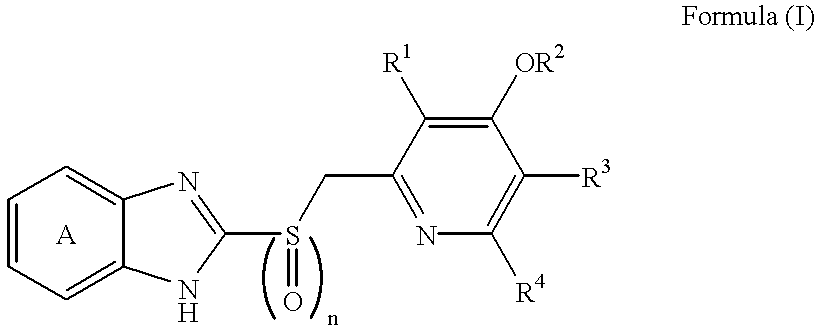

Orally disintegrable tablets

InactiveUS6328994B1Sufficient oral disintegrabilityHigh strengthOrganic active ingredientsPowder deliveryDiseaseOrally disintegrating tablet

An orally disintegrable tablet, of the present invention, which comprises (i) fine granules having an average particle diameter of 400 mum or less, which fine granules comprise a composition coated by an enteric coating layer, said composition having 10 weight % or more of an acid-labile physiologically active substance and (ii) an additive, has superior disintegrability or dissolution in the oral cavity so that it can be used for treatment or prevention of various diseases, as an orally disintegrable tablet capable of being administered to the aged or children and easily administered without water. Also, because the tablet of the present invention contains fine granules having the average particle diameter such that it will not impart roughness in mouth, it can be administered easily without discomfort at the administration.

Owner:TAKEDA PHARMA CO LTD

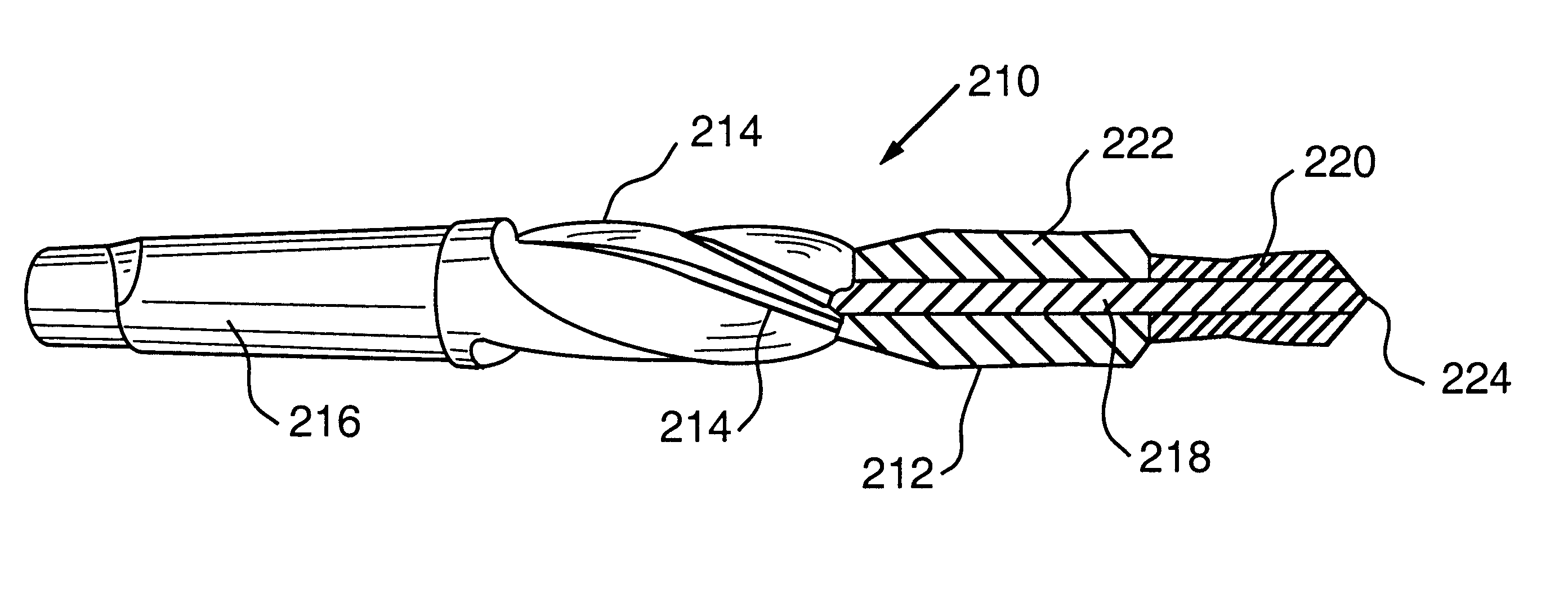

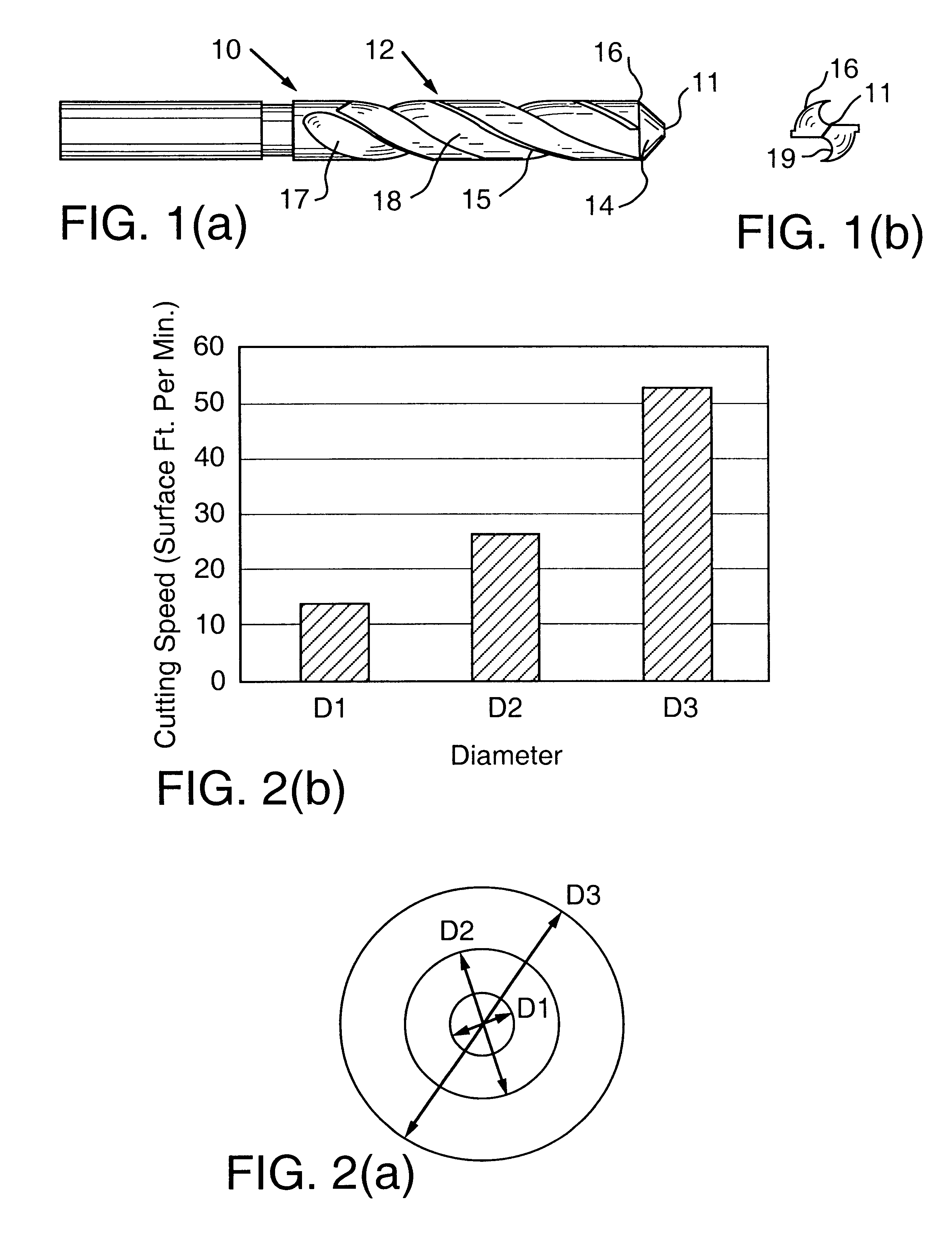

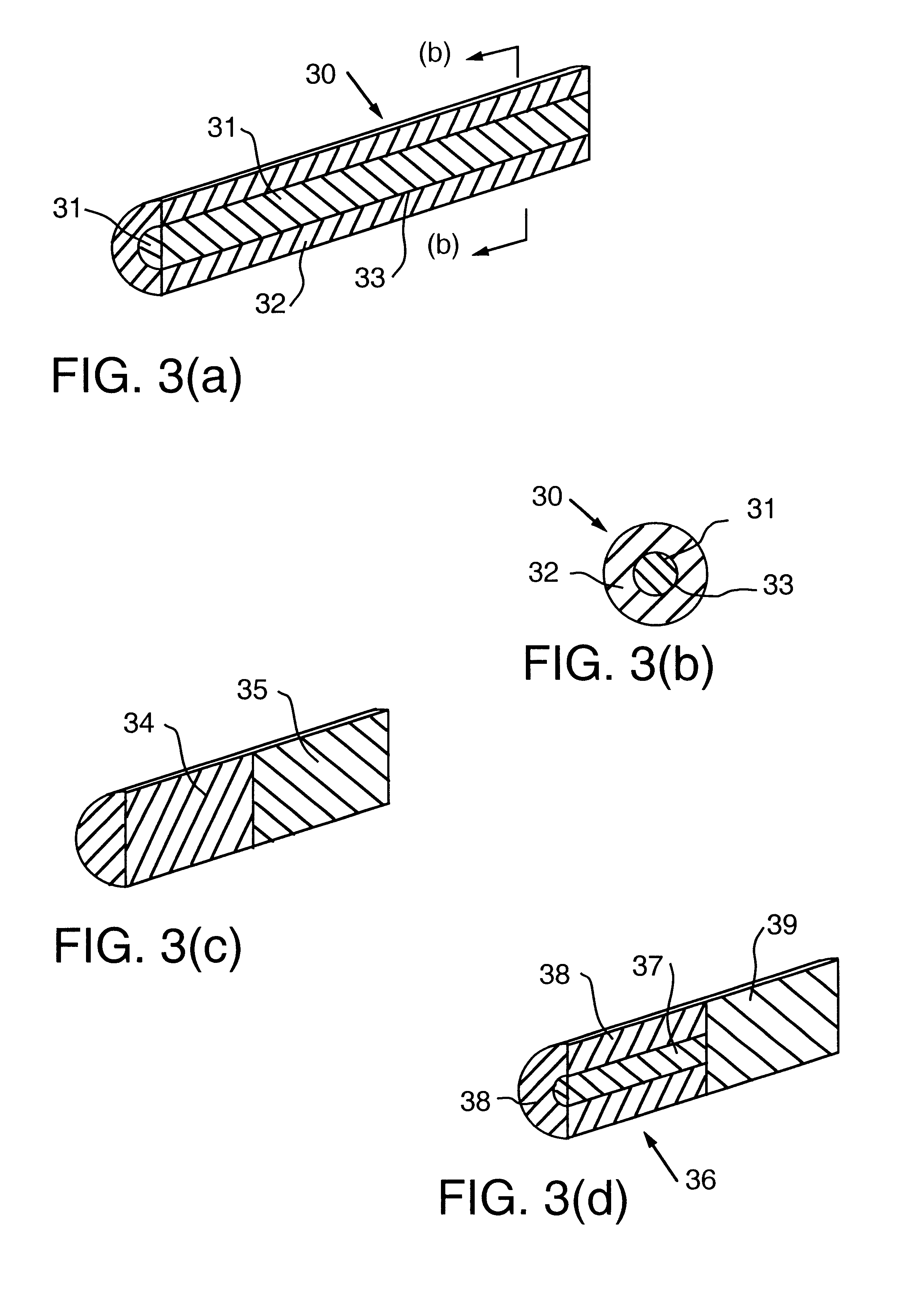

Composite rotary tool and tool fabrication method

InactiveUS6511265B1High cutting speedIncrease in costWood turning toolsTransportation and packagingThermal conductivityElastic modulus

A composite rotary tool includes at least first and second regions comprising first and second materials, respectively. The first and second regions are autogenously bonded and differ with respect to at least one characteristic such as, for example, modulus of elasticity, hardness, wear resistance, fracture toughness, tensile strength, corrosion resistance, coefficient of thermal expansion, or coefficient of thermal conductivity. A method for producing the composite rotary tool includes placing a first metallurgical powder into a first region of a void of a mold, and placing a second metallurgical powder into a second region of the void. The first metallurgical powder differs from the second metallurgical powder, and at least a portion of the first metallurgical is brought into contact with the second metallurgical powder. The mold is compressed to consolidate the first and second metallurgical powders to form a compact, and the compact subsequently is sintered.

Owner:KENNAMETAL INC

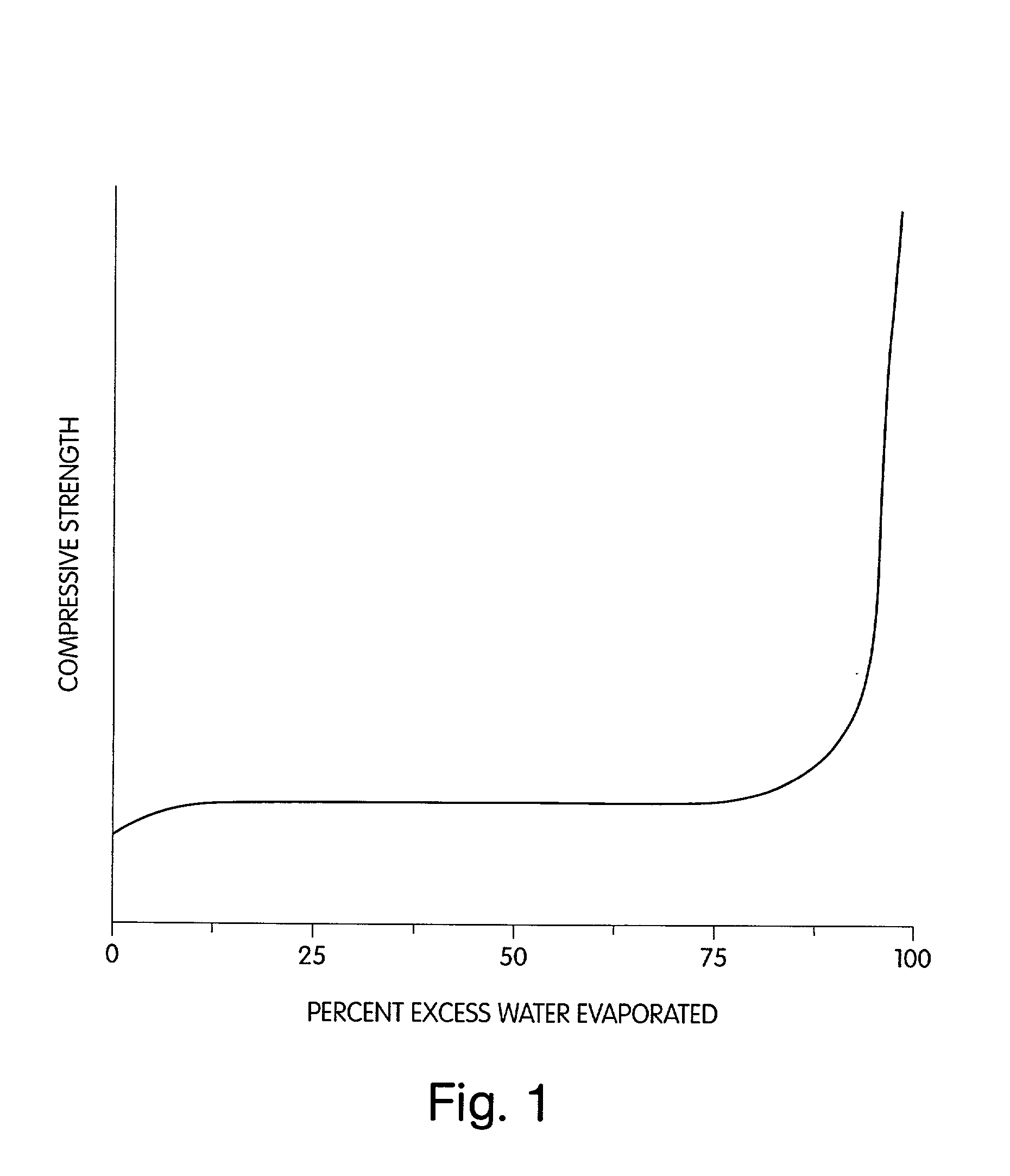

Dosage form exhibiting rapid disperse properties, methods of use and process for the manufacture of same

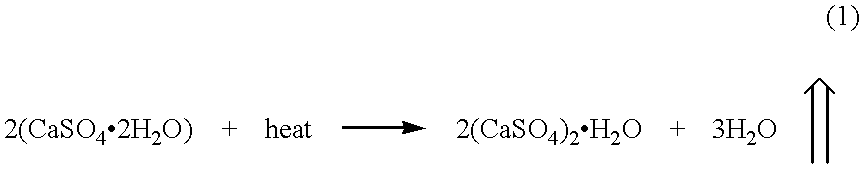

InactiveUS6471992B1Disperse fastHigh hardnessPowder deliveryAdditive manufacturing apparatusThree dimensional shapeBULK ACTIVE INGREDIENT

A rapidly dispersing dosage form is described, which releases its active ingredients within a period of less than about ninety seconds. These dosage forms exhibit a three-dimensional shape that is retained for adequate storage but is readily dispersed in the presence of excess moisture. Also disclosed are methods of administration of a medicament and a process for the preparation of rapidly dispersing dosage forms.

Owner:MASSACHUSETTS INST OF TECH +2

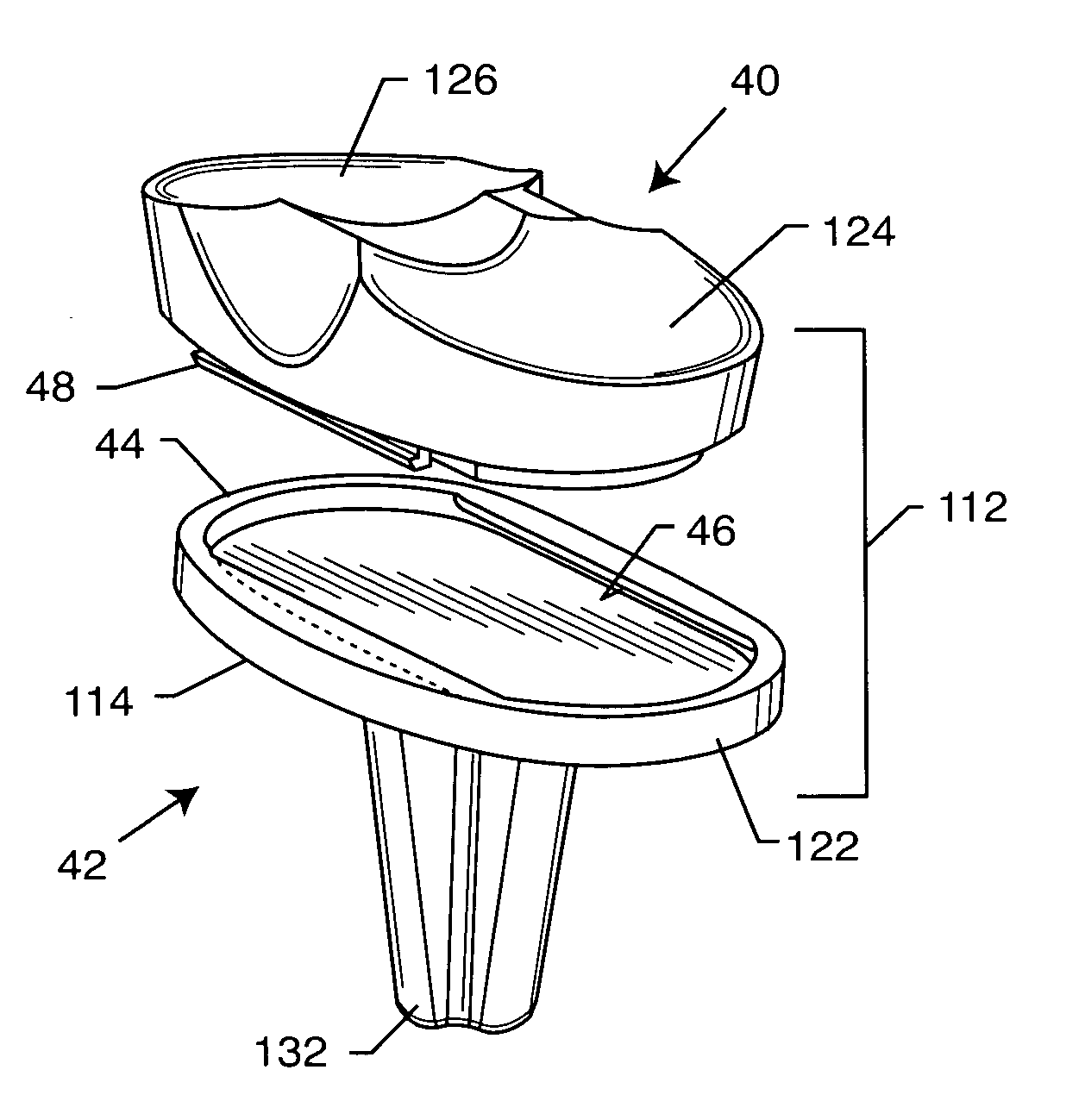

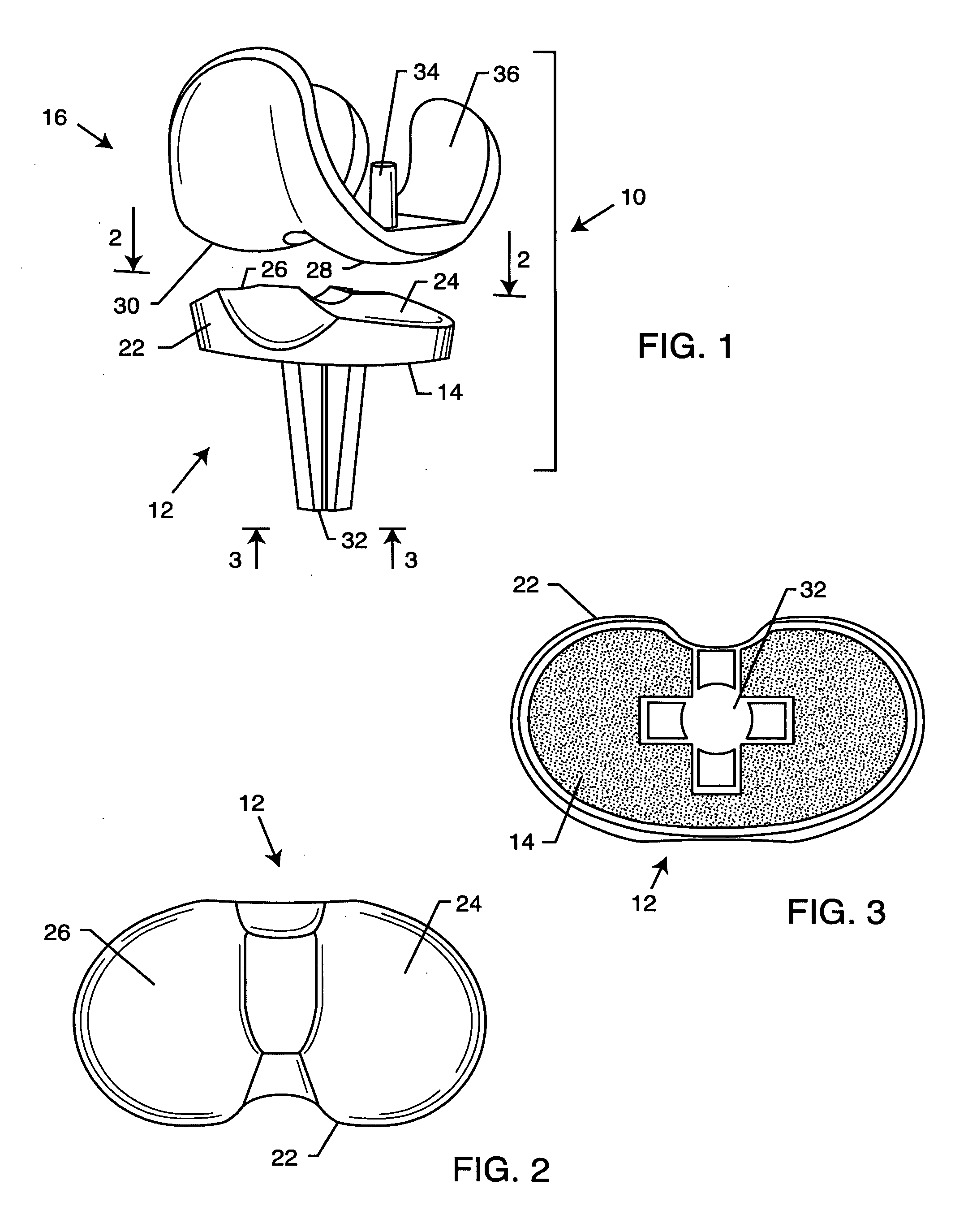

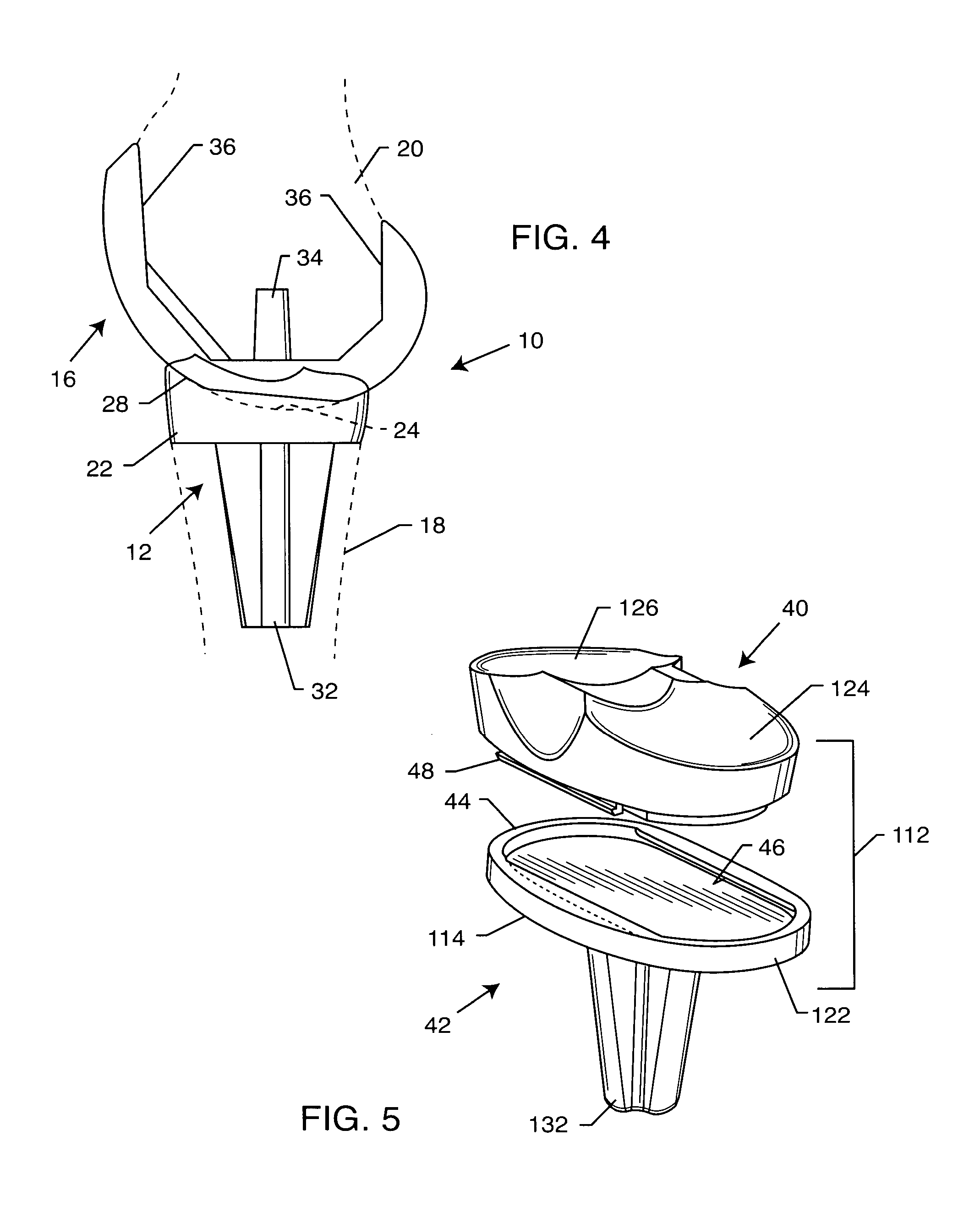

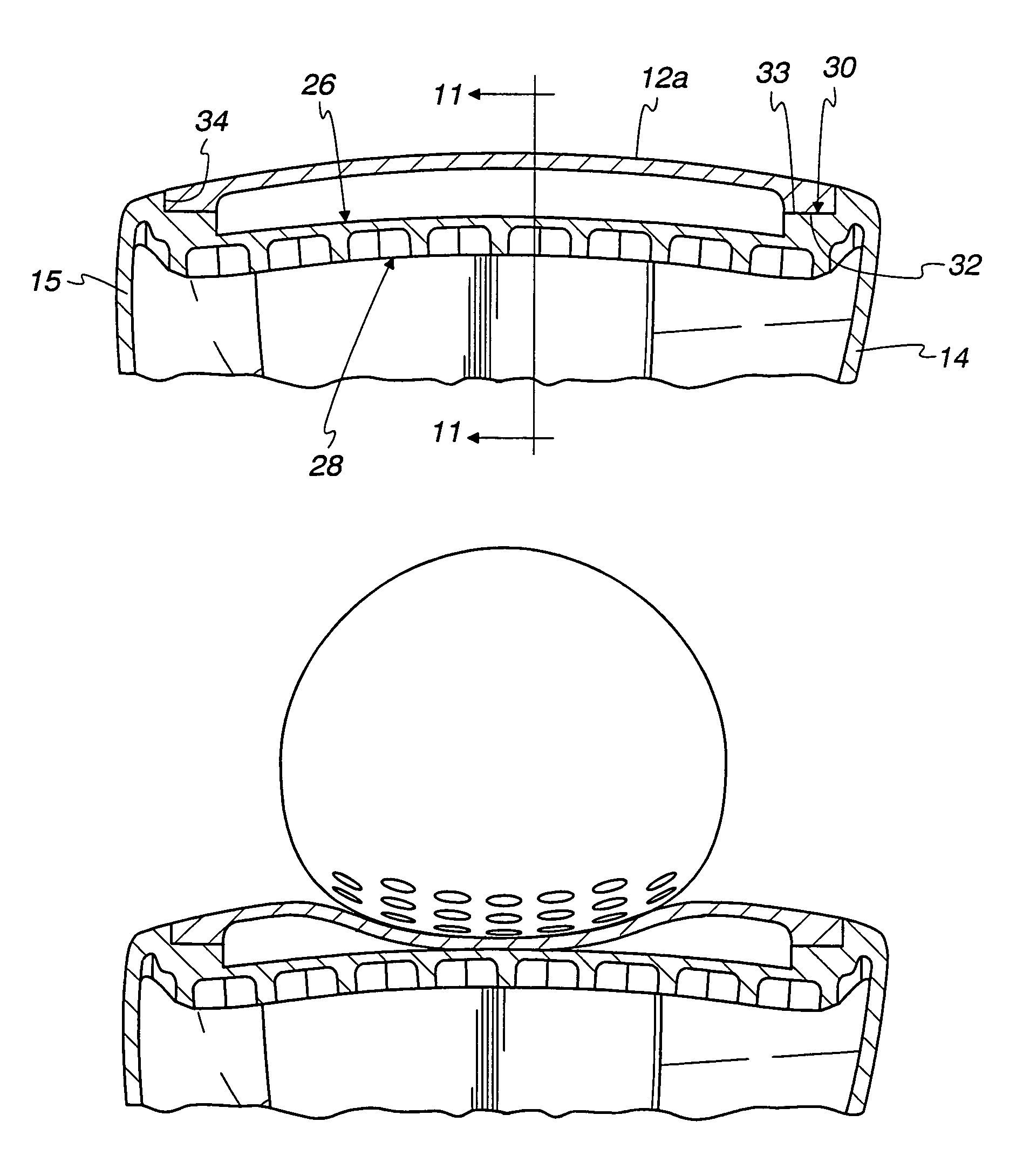

Knee prosthesis with ceramic tibial component

InactiveUS20060052875A1Reduce wearHigh strengthHeart valvesJoint implantsArticular surfacesTibial bone

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

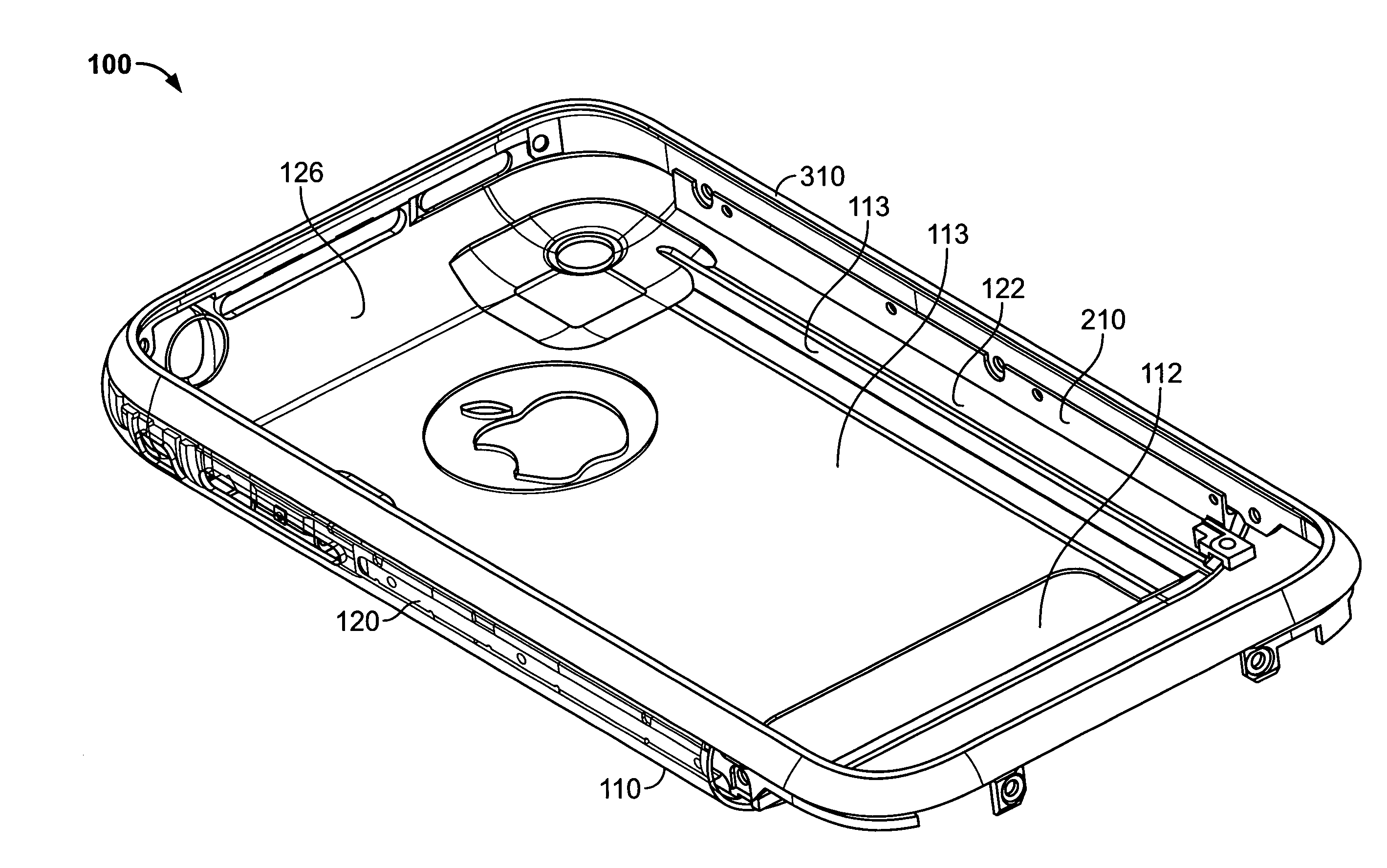

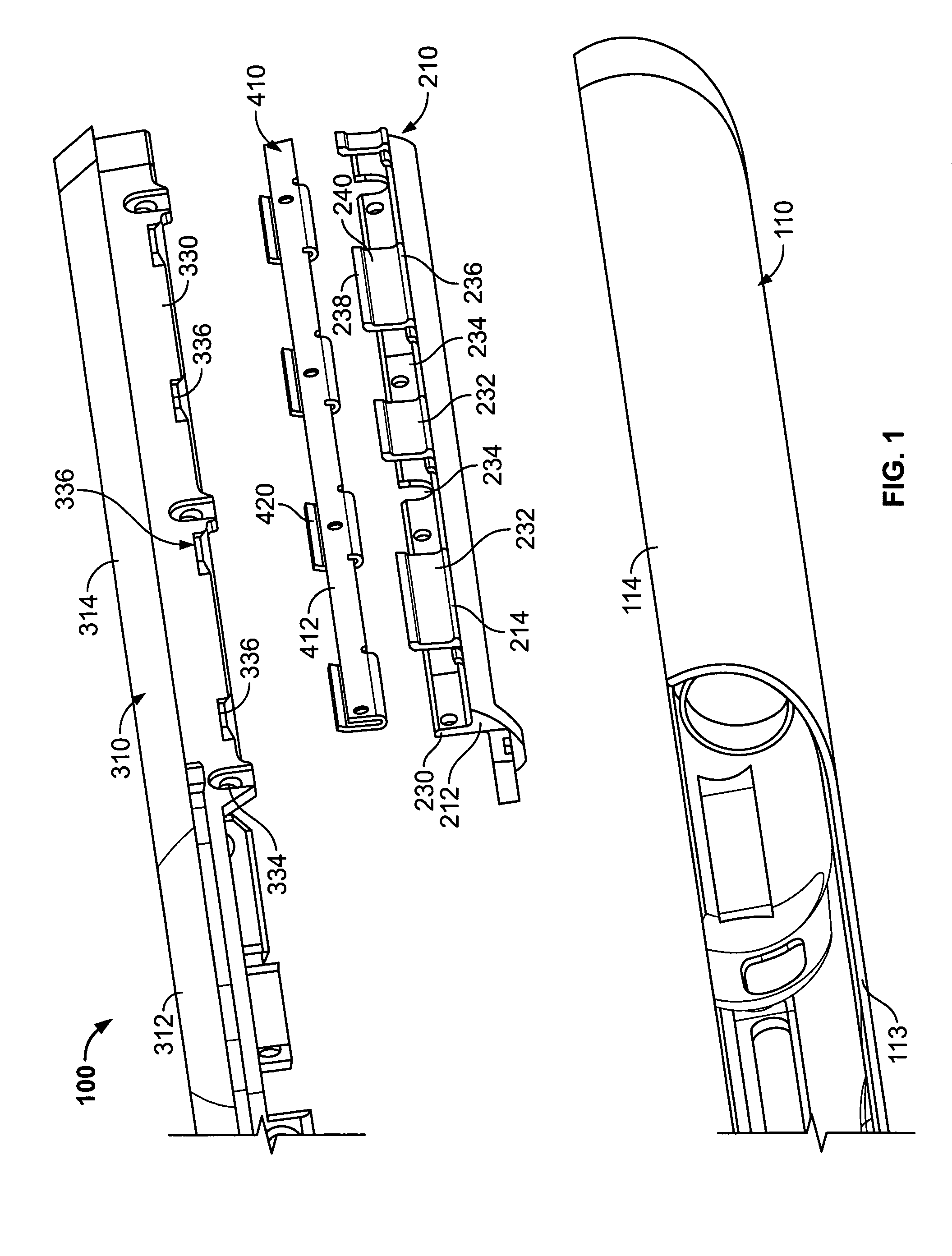

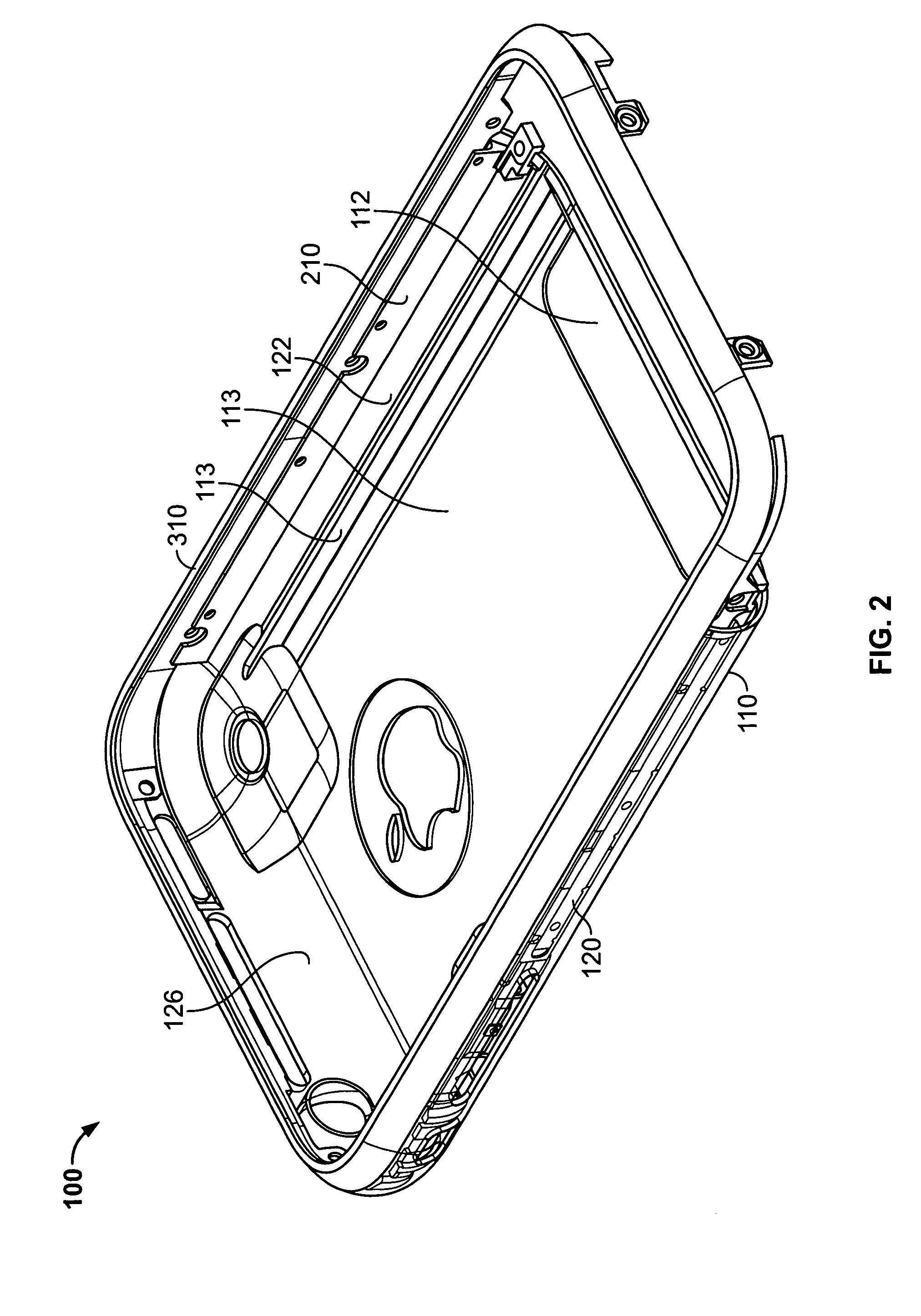

Cold worked metal housing for a portable electronic device

ActiveUS7688574B2High hardnessDesired impact and scratch resistant propertyClosed casingsDigital data processing detailsEngineeringMachining

A cold worked stainless steel bezel for a portable electronic device is provided. The bezel is secured flush to a housing to form part of the case of the portable electronic device. A brace that includes a slot for receiving a wall extending from the bezel is fixed to the housing. When the bezel engages the housing, the wall of the bezel is inserted in the slot of the brace and releasably held by a spring that engages both the brace and the wall. The bezel can be released by disengaging the spring, (e.g., using a special tool or a magnetic field). Because the bezel is manufactured from cold worked stainless steel, it is hard and resistant to impacts. Cold worked steel also facilitates manufacturing within design constraints and tolerances, and requires very little machining after manufacturing to comply with those constraints. The portable electronic device may include a personal media device, a mobile telephone, or any other suitable device or combination thereof.

Owner:APPLE INC

Thermally stable ultra-hard polycrystalline materials and compacts

InactiveUS20070187155A1Improved property of thermal stability , wear resistance and hardnessFacilitate attachmentDrill bitsConstructionsBoron nitrideSingle element

Thermally stable ultra-hard polycrystalline materials and compacts comprise an ultra-hard polycrystalline body that wholly or partially comprises one or more thermally stable ultra-hard polycrystalline region. A substrate can be attached to the body. The thermally stable ultra-hard polycrystalline region can be positioned along all or a portion of an outside surface of the body, or can be positioned beneath a body surface. The thermally stable ultra-hard polycrystalline region can be provided in the form of a single element or in the form of a number of elements. The thermally stable ultra-hard polycrystalline region can be formed from precursor material, such as diamond and / or cubic boron nitride, with an alkali metal catalyst material. The mixture can be sintered by high pressure / high temperature process.

Owner:SMITH INT INC

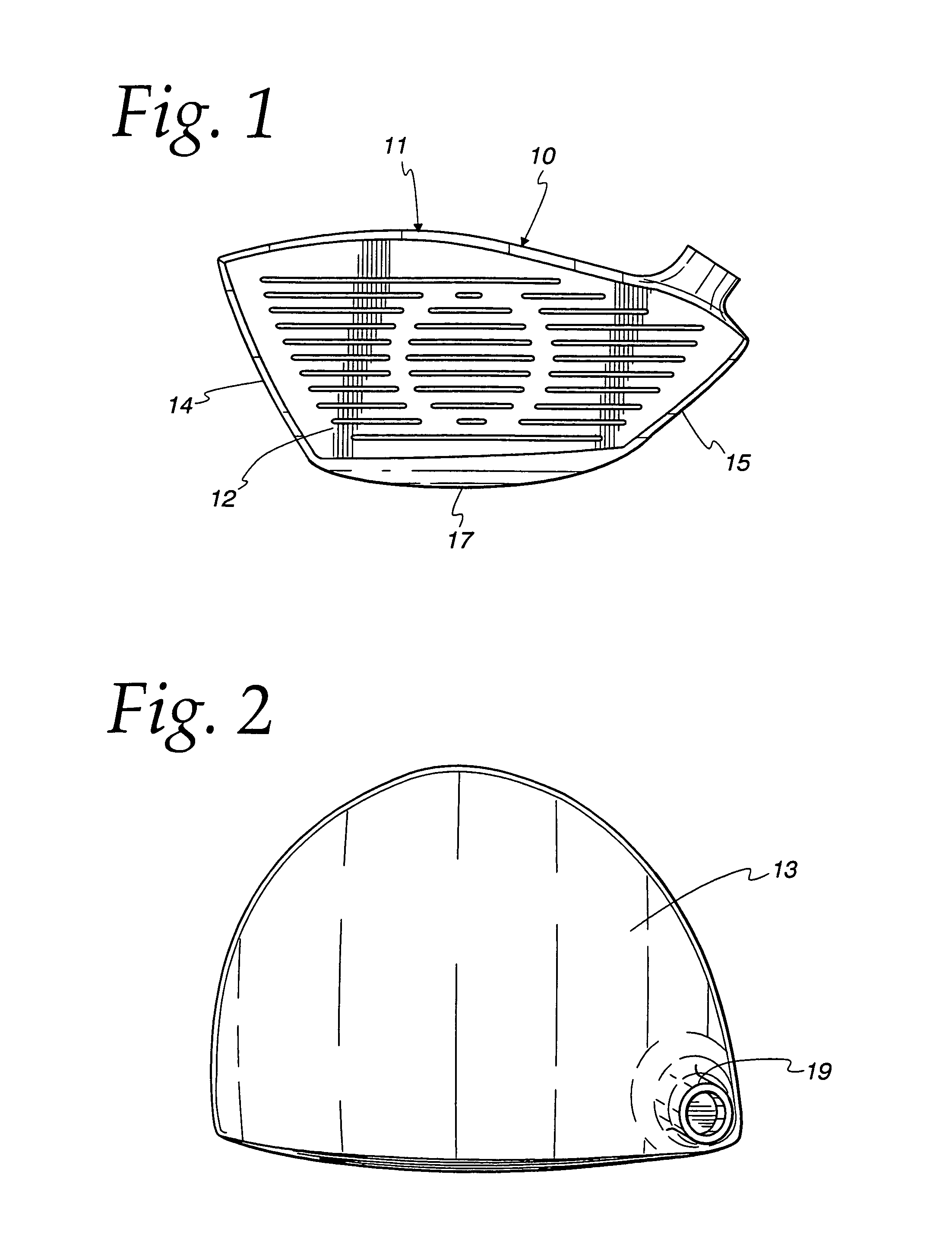

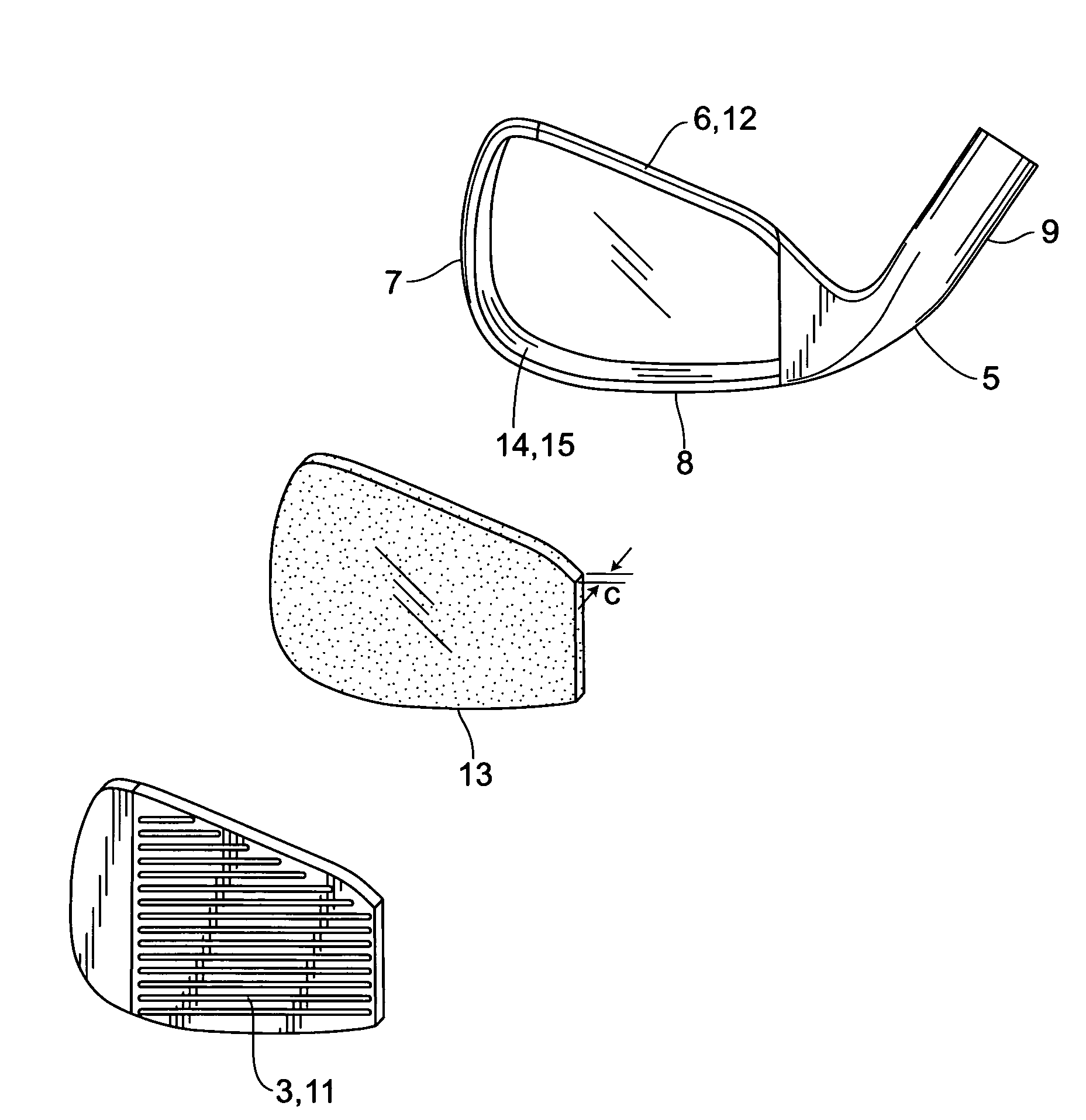

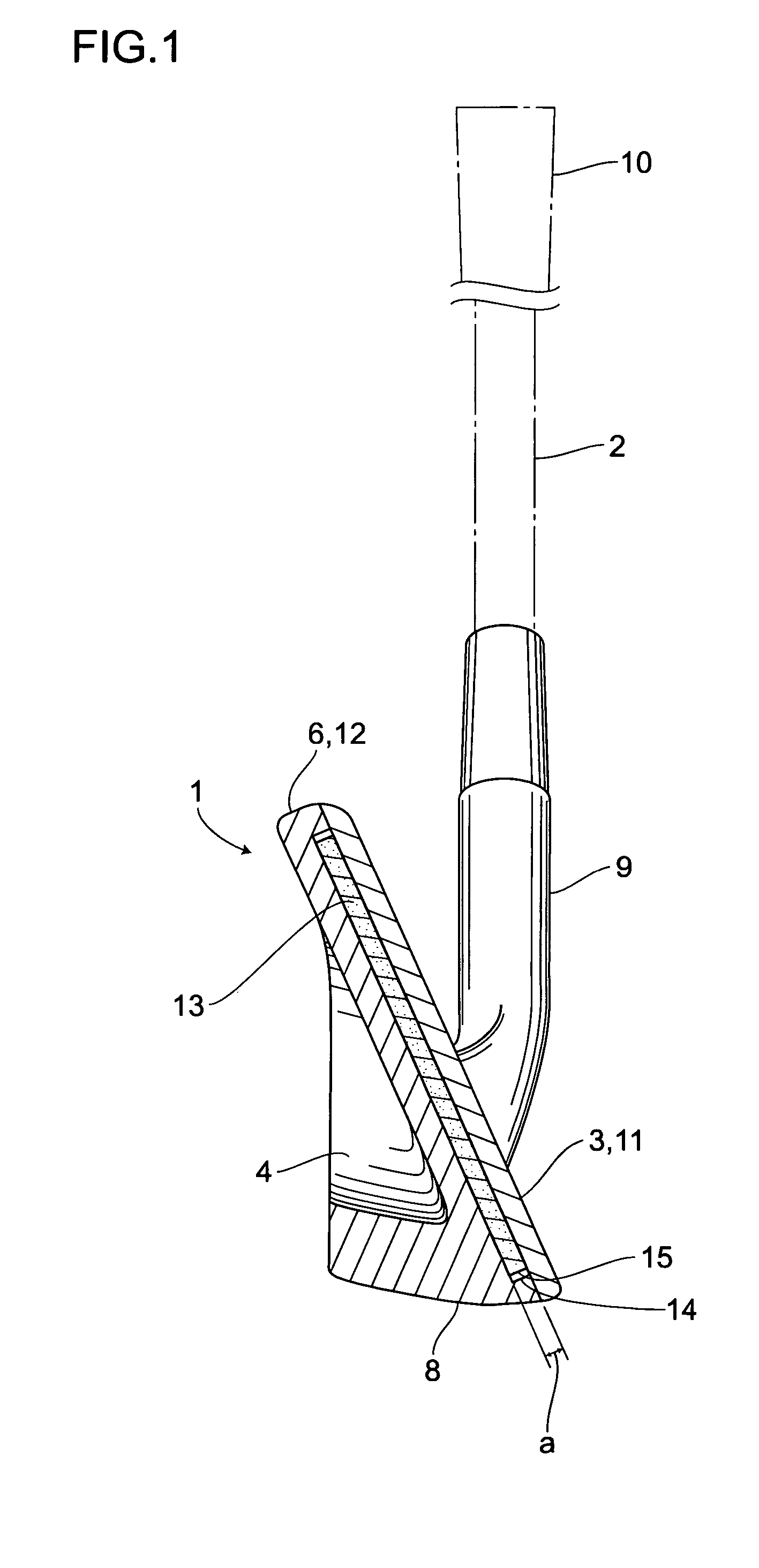

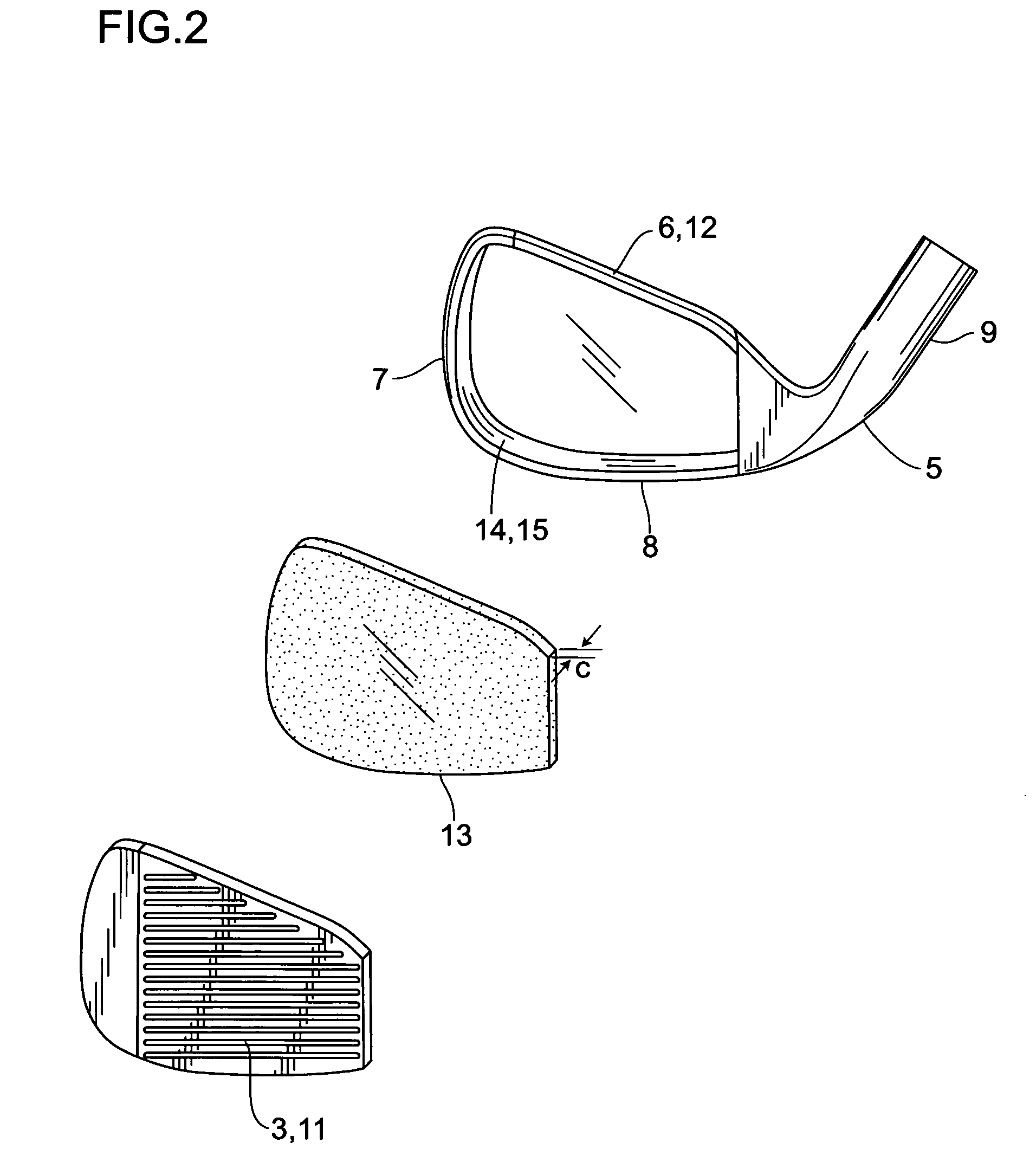

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

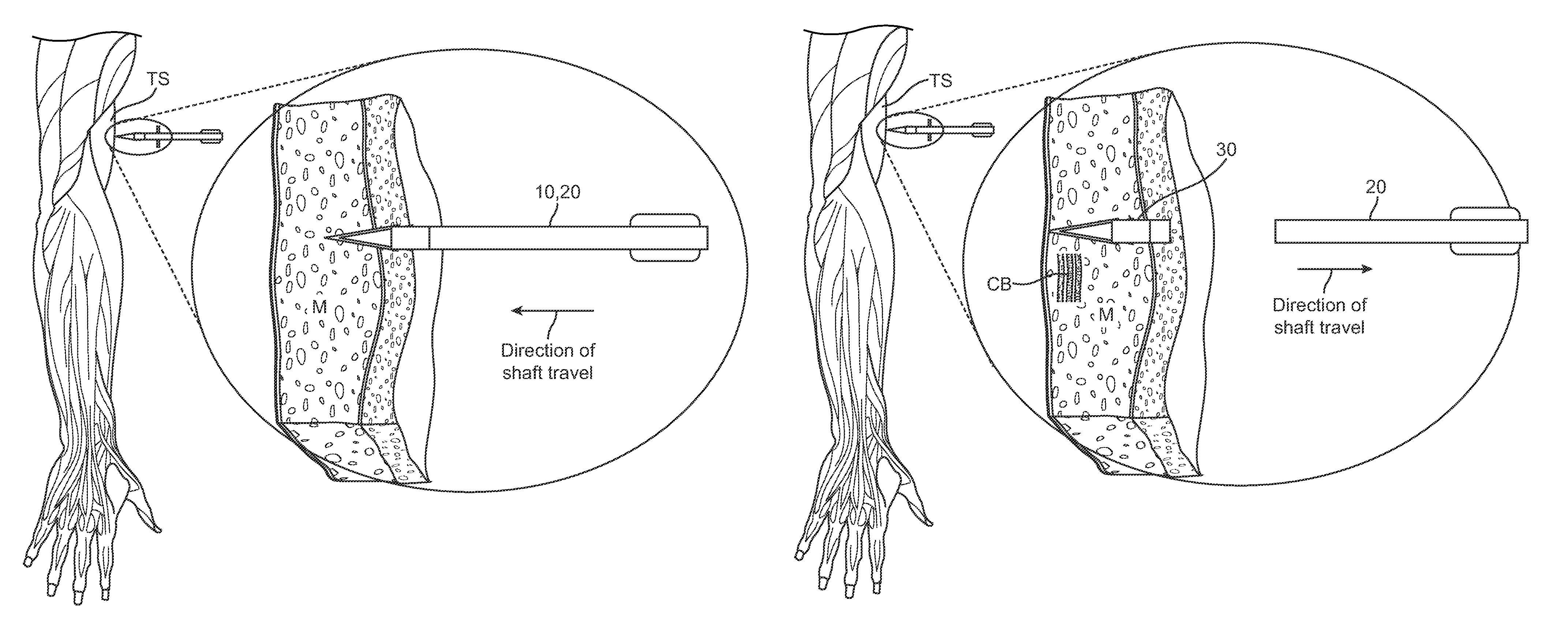

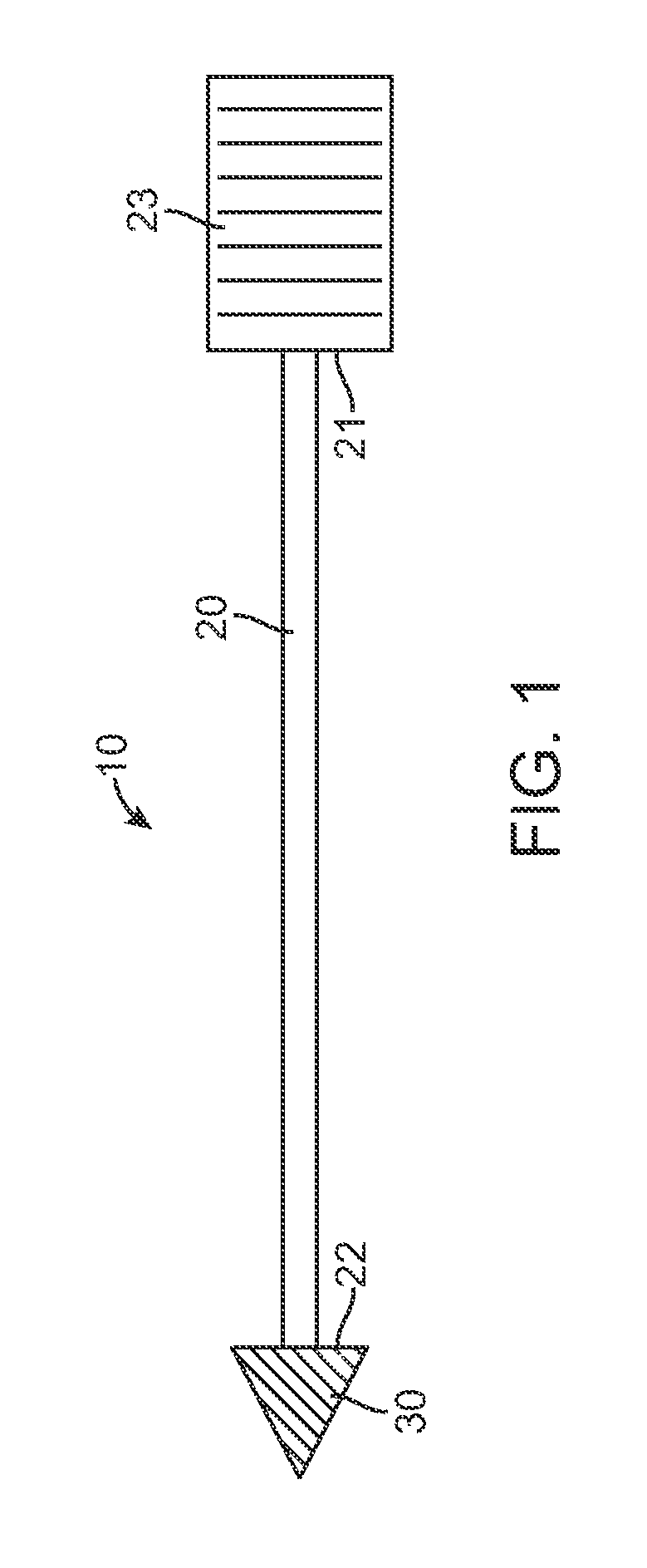

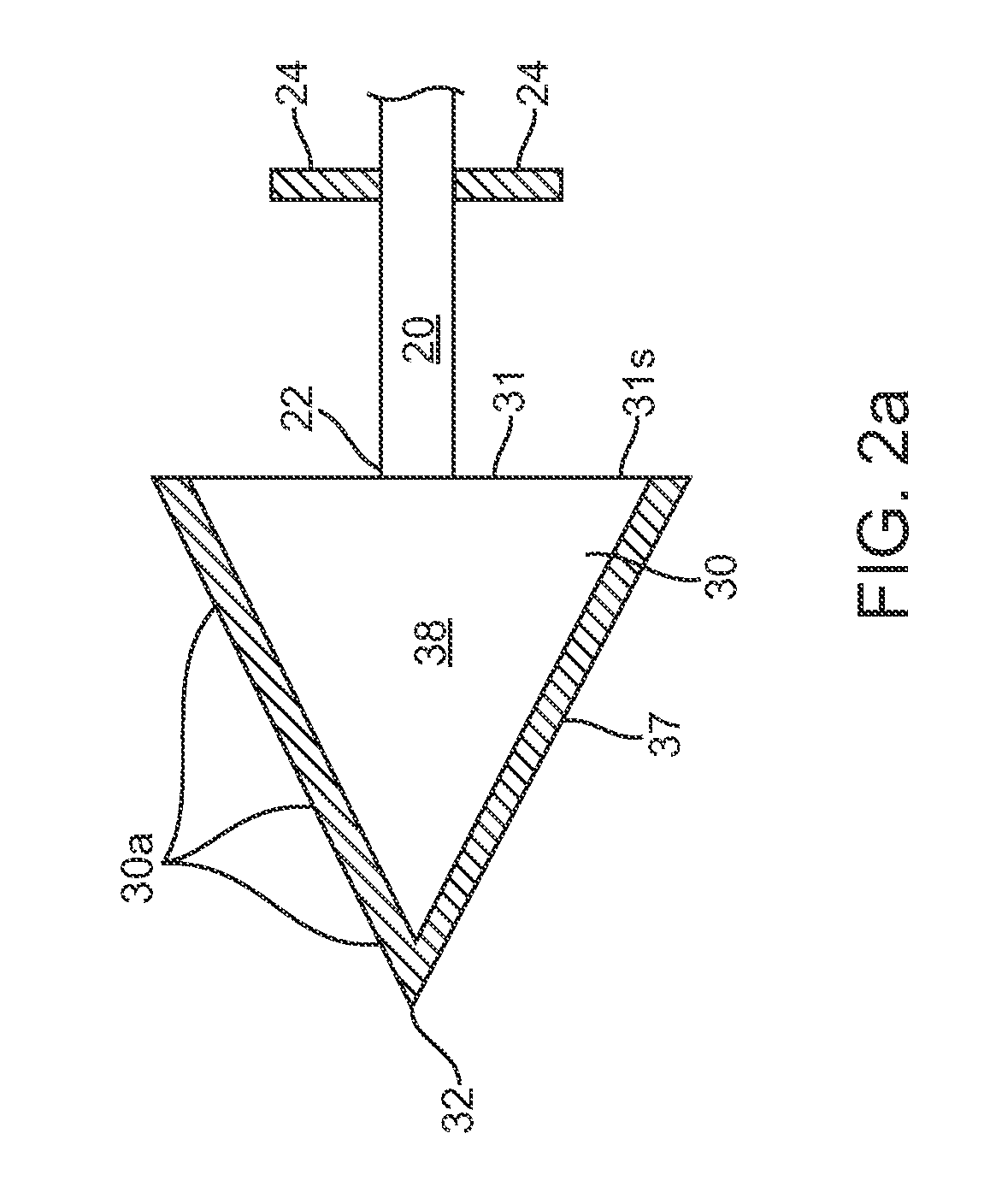

Skin penetrating device and method for subcutaneous solid drug delivery

ActiveUS8353863B2Easy to keepHigh hardnessMedical devicesIntravenous devicesTherapeutic effectBody tissue

Embodiments described herein provide a skin penetrating device and method for the subcutaneous delivery of therapeutic agents in solid form. One embodiment provides such a device comprising an elongated shaft having proximal and distal ends and a skin penetrating element detachably coupled to the shaft. At least a portion of the penetrating element is fabricated from a solid form therapeutic agent composition that dissolves in body tissue and is absorbed into the blood stream so as to produce a therapeutic effect. The penetrating element has shape for penetrating and lodging beneath the skin when inserted through the skin by force applied from the shaft. The penetrating element is configured to detach from the shaft when the shaft is pulled away from the skin so as to leave the element in place beneath the skin where it is absorbed by body tissue and the therapeutic agent is released.

Owner:INCUBE LABS

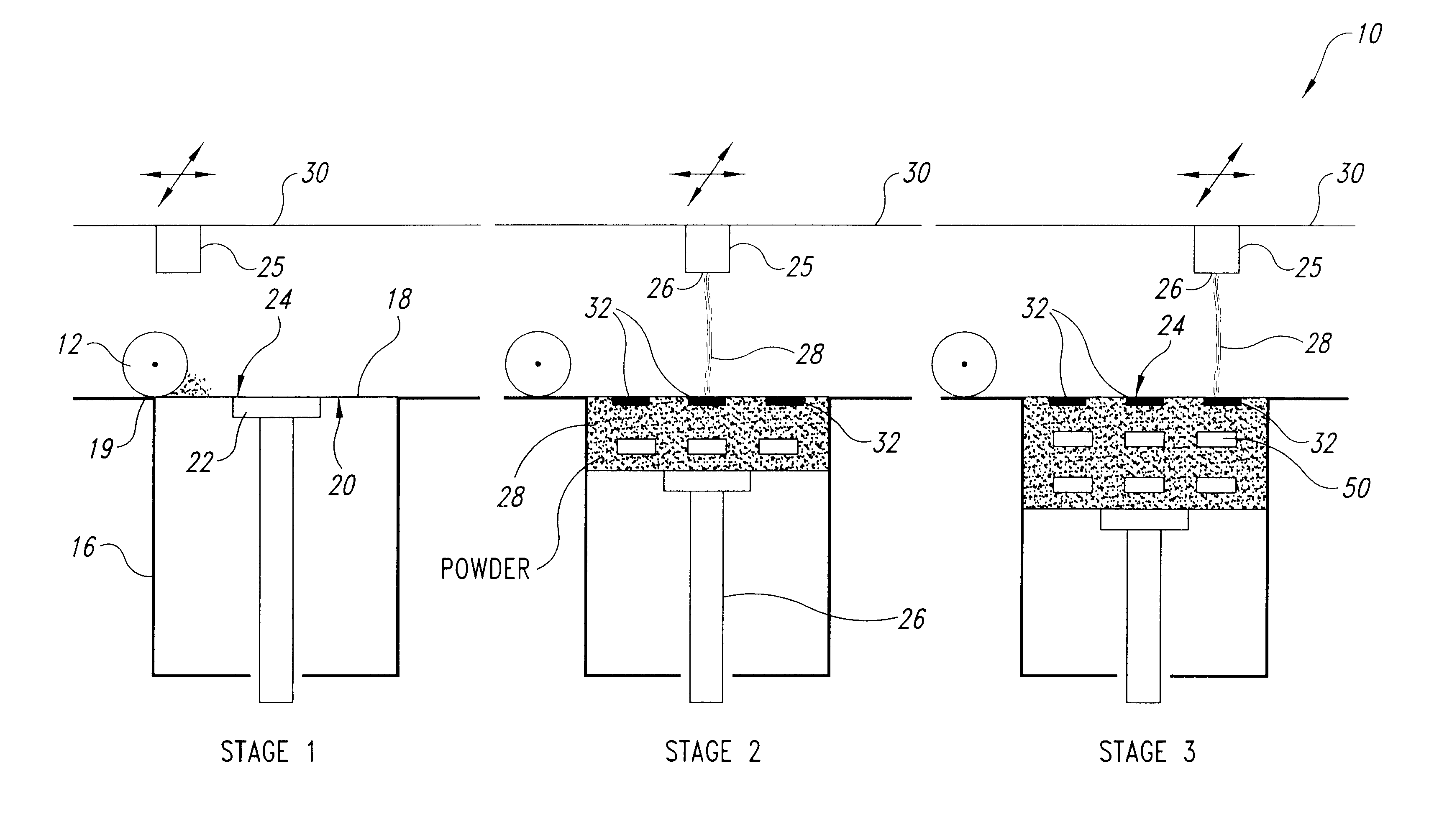

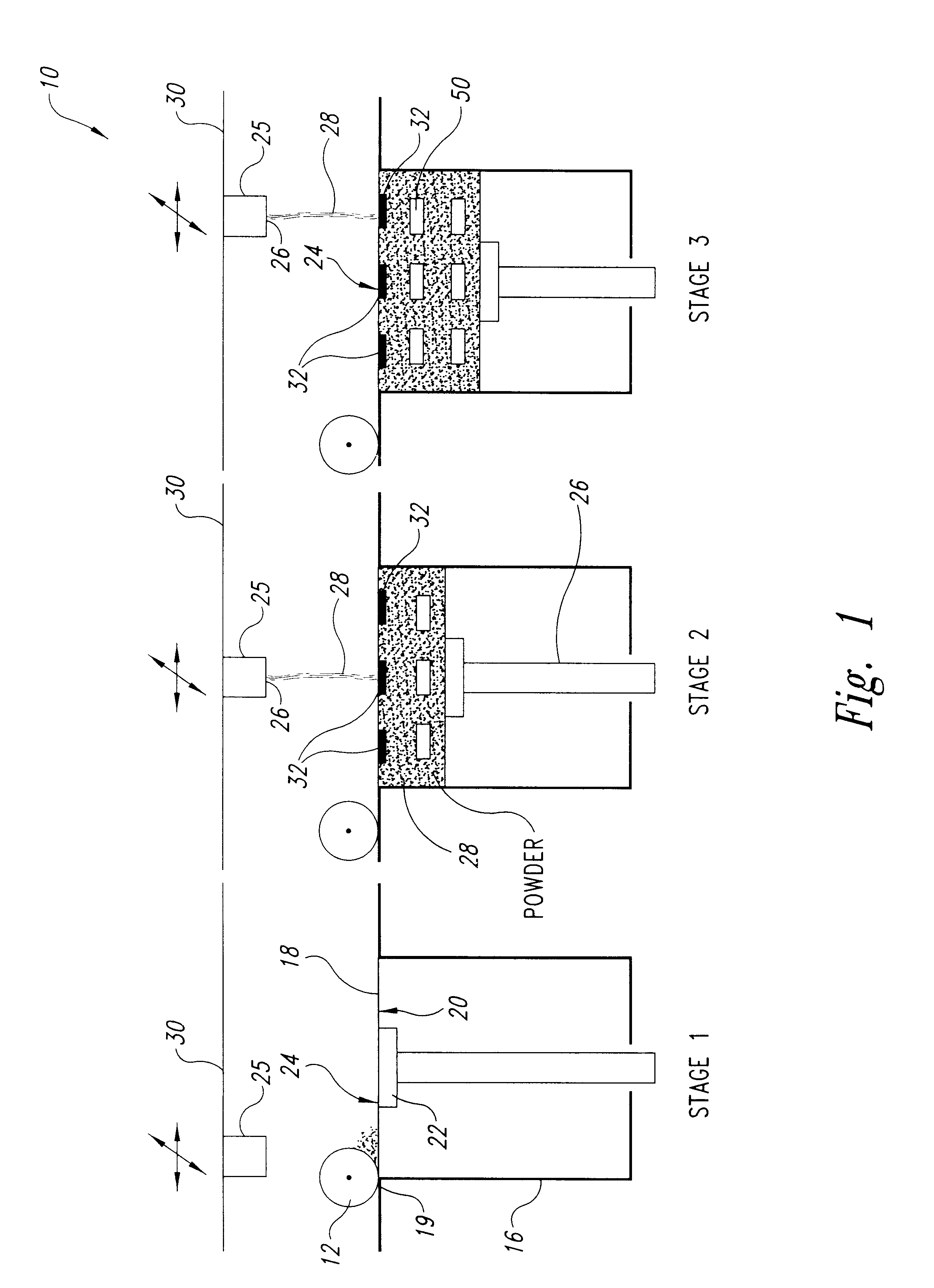

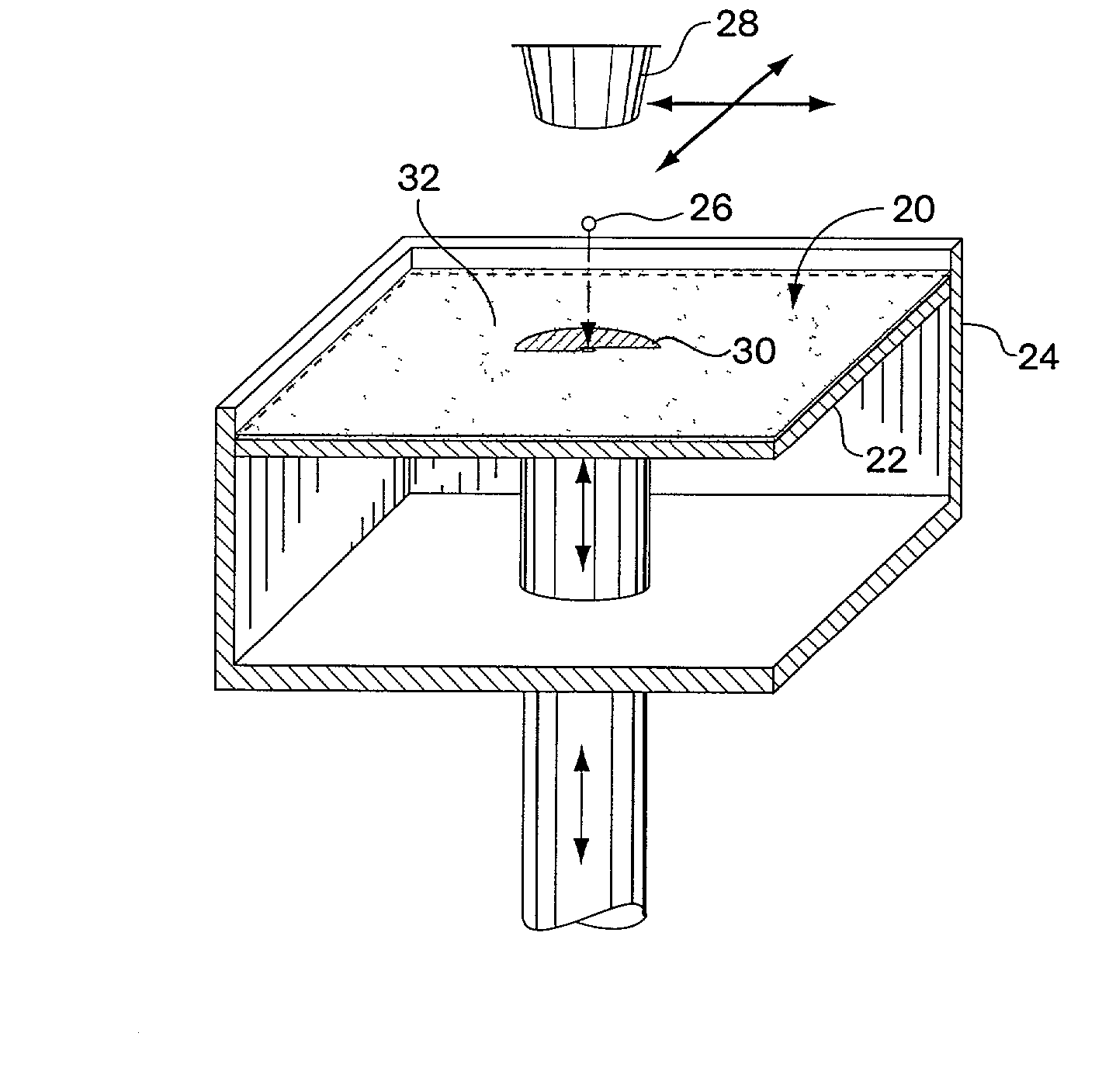

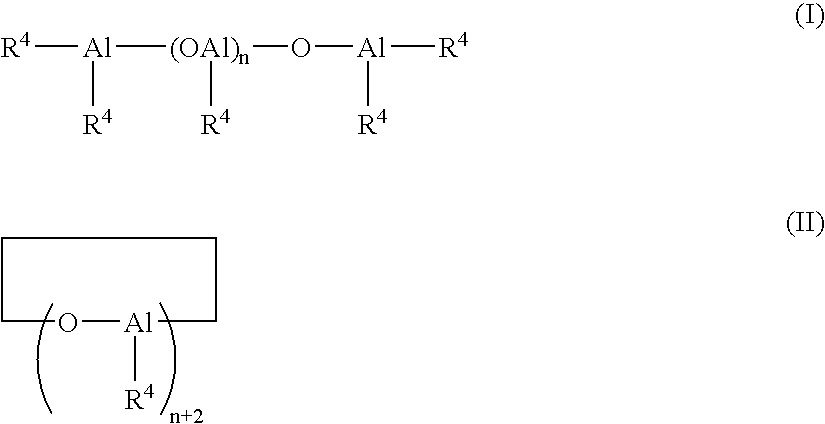

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

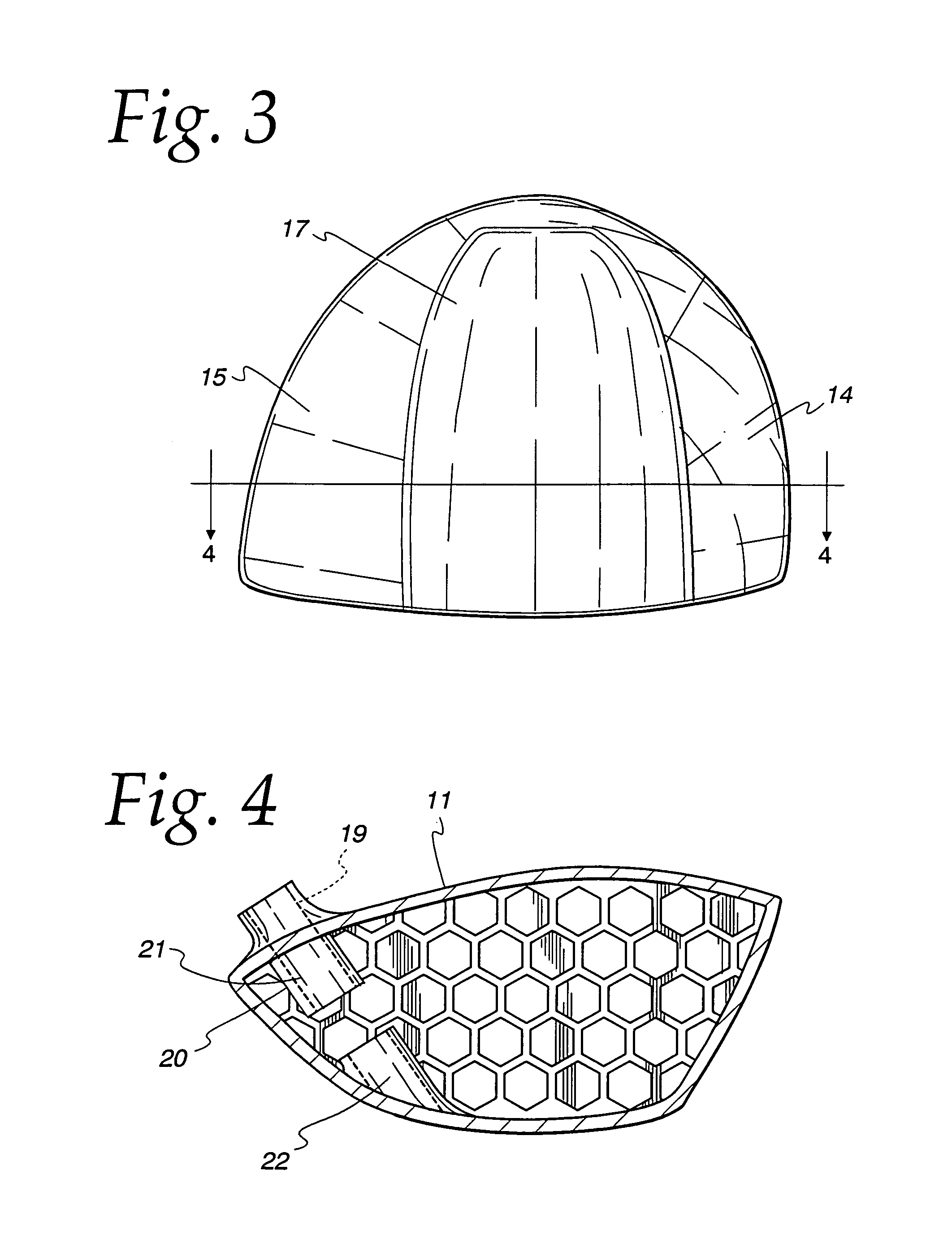

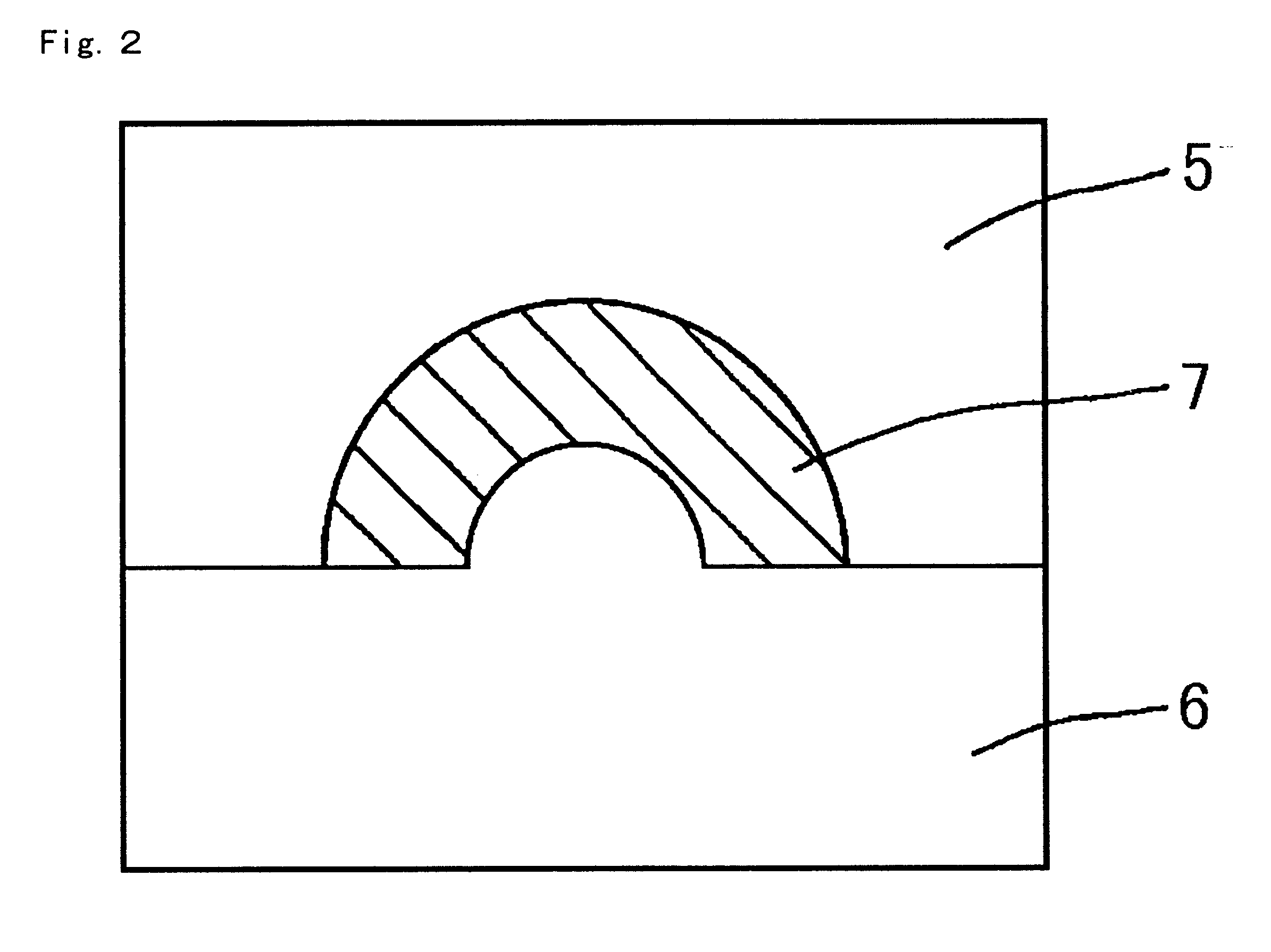

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

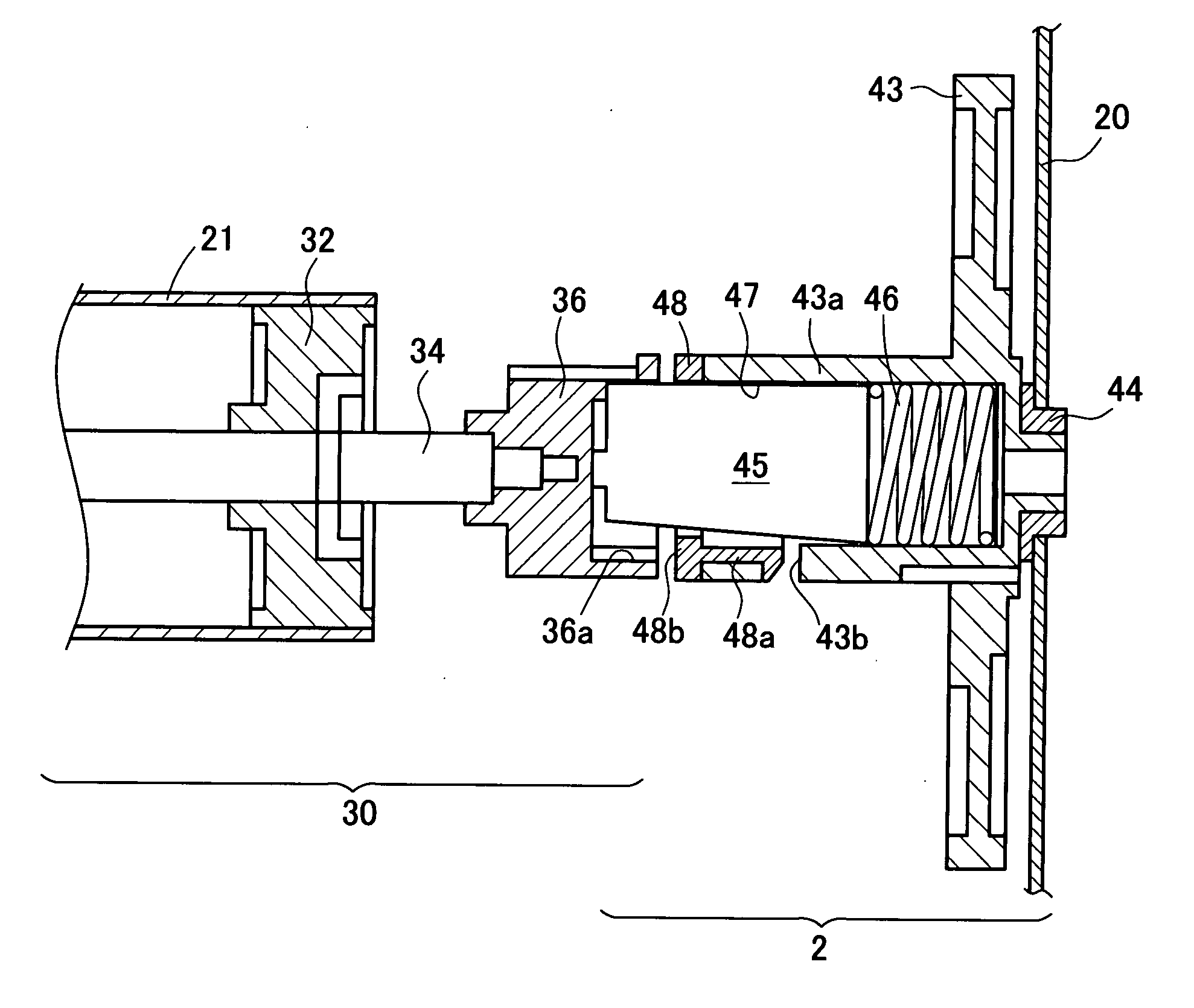

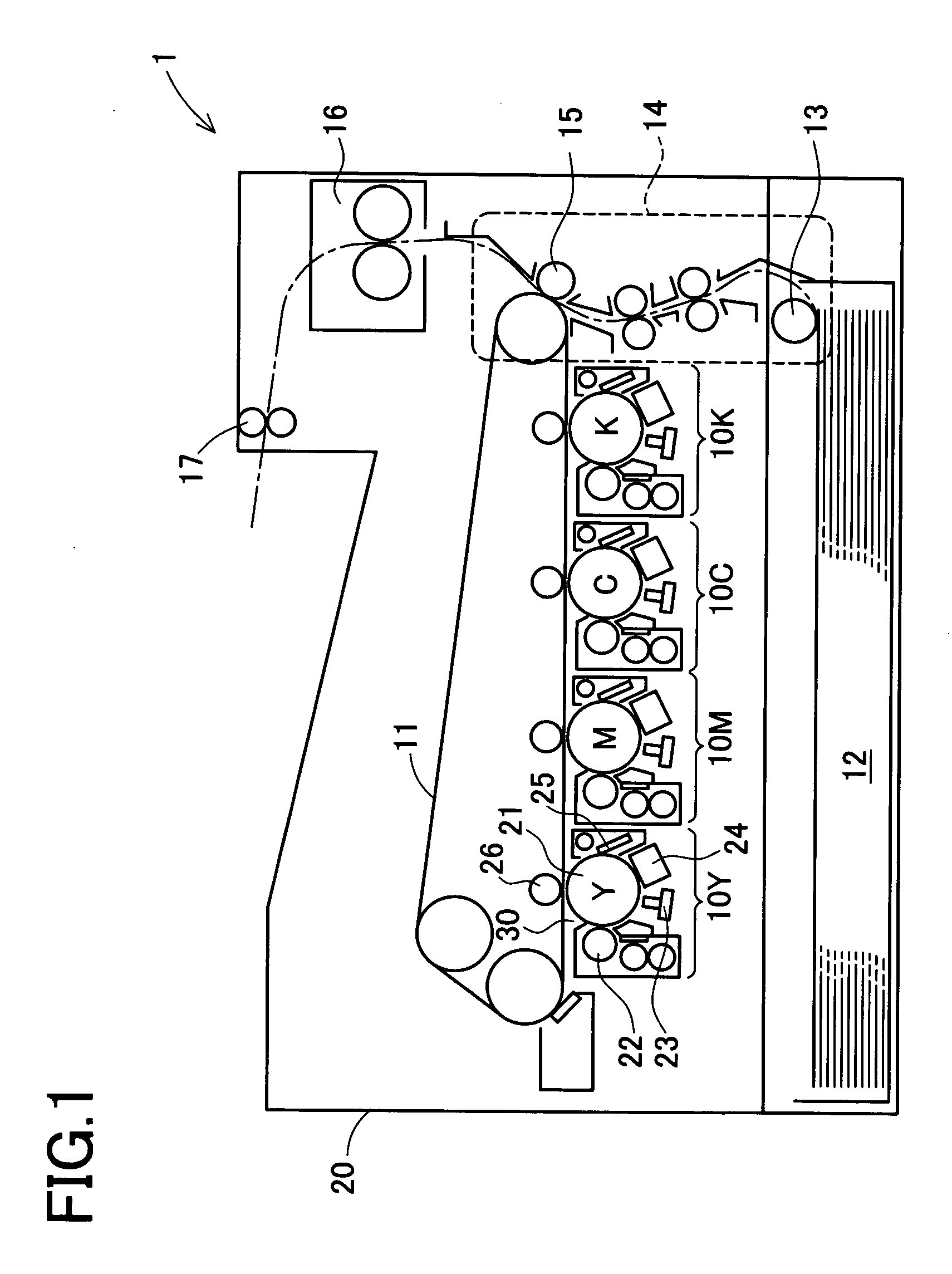

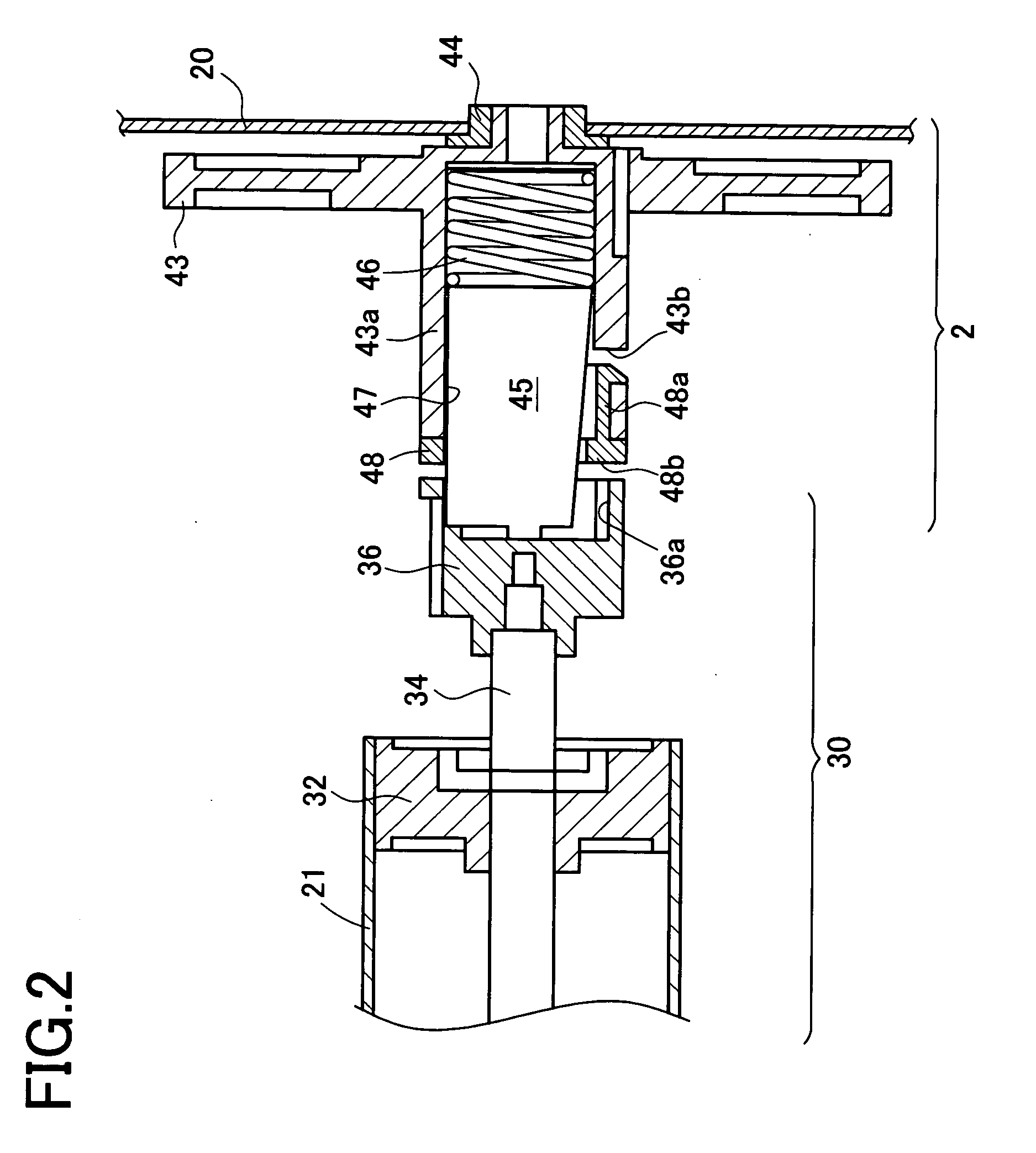

Image forming apparatus

ActiveUS20050191092A1Securing rotation transmission accuracyHigh strengthElectrographic process apparatusEngineeringMechanical engineering

It is intended to provide an image forming apparatus capable of securing rotation transmission accuracy among input / output axes without giving stress to a holding portion despite shaft misalignment and without using material of high strength. A color printer 1 comprises a main body 2 and an image forming unit 30 removable from the main body 2. The main body 2 includes a gear 43 for receiving rotary driving force to the image forming unit 30 and a joint 45 and the image forming unit 30 has a coupling 36 for receiving rotary driving force from the main body 2. Furthermore, a joint holder section 43a for the gear 43 and the coupling 36 has a contact hole 47, and contact hole 36a, respectively and both ends of the joint 45 are inserted in those holes. The contact holes 47 and 36a are in not-twisted triangle pole shape and the joint 45 is in twisted triangle pole shape.

Owner:KONICA MINOLTA INC

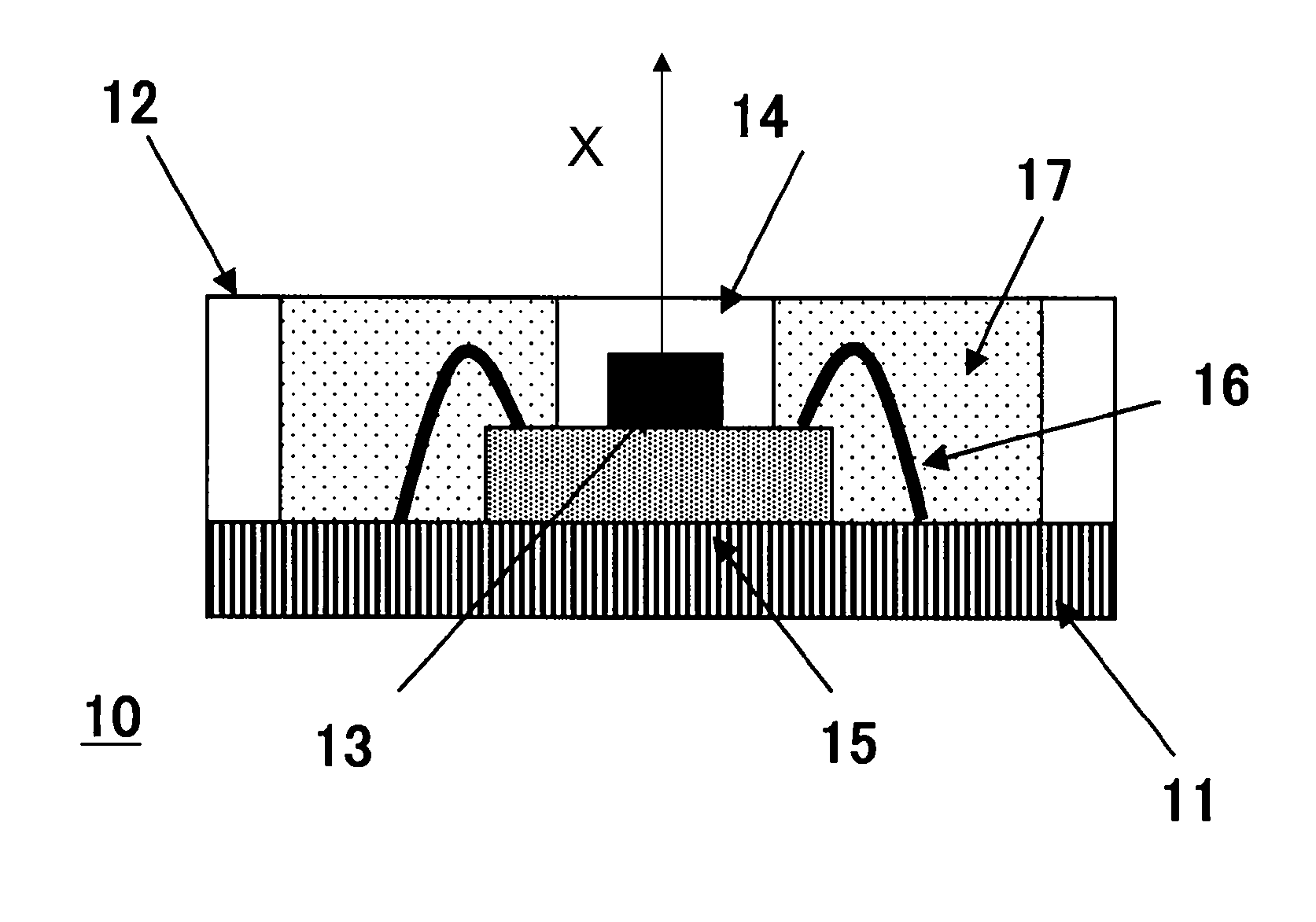

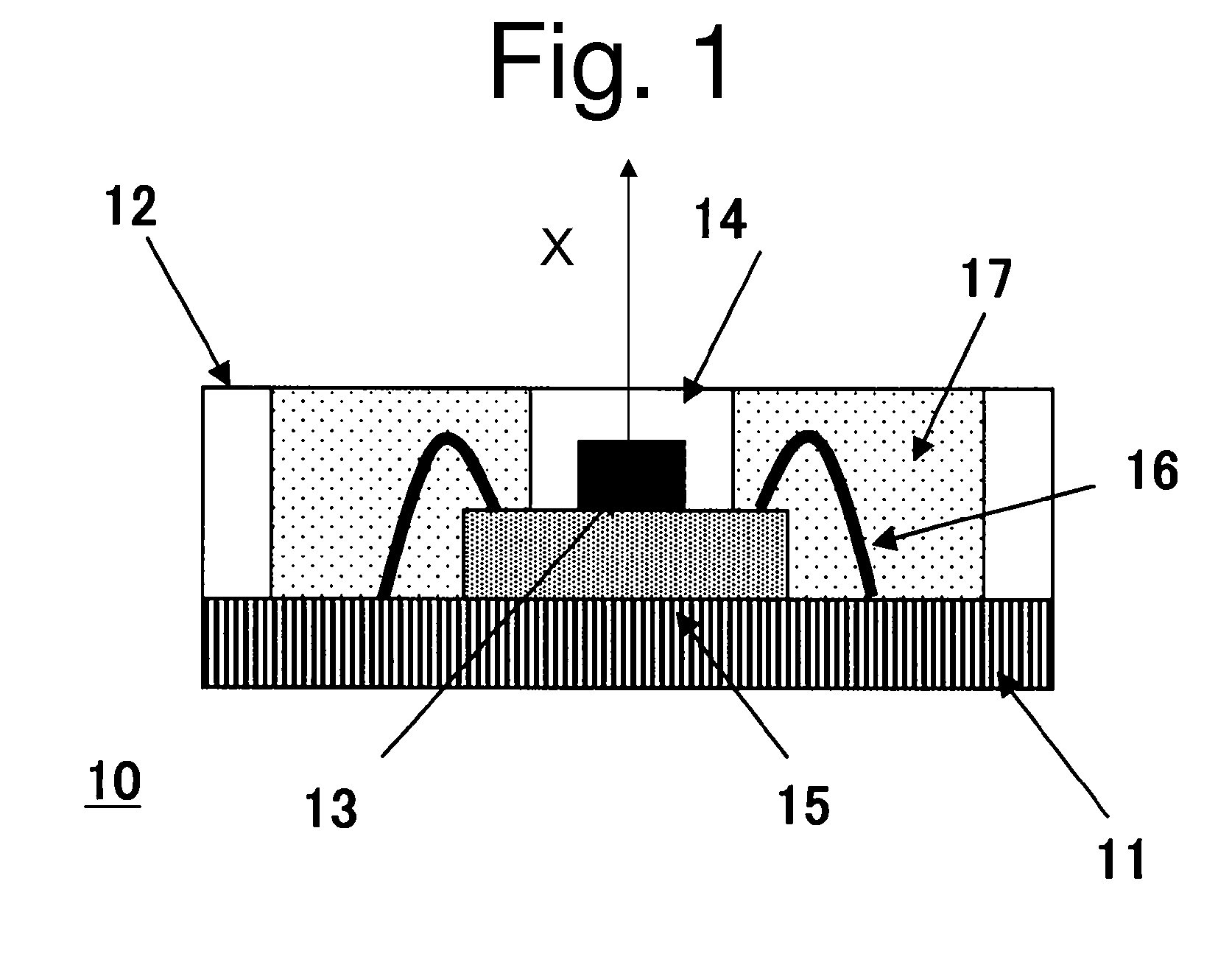

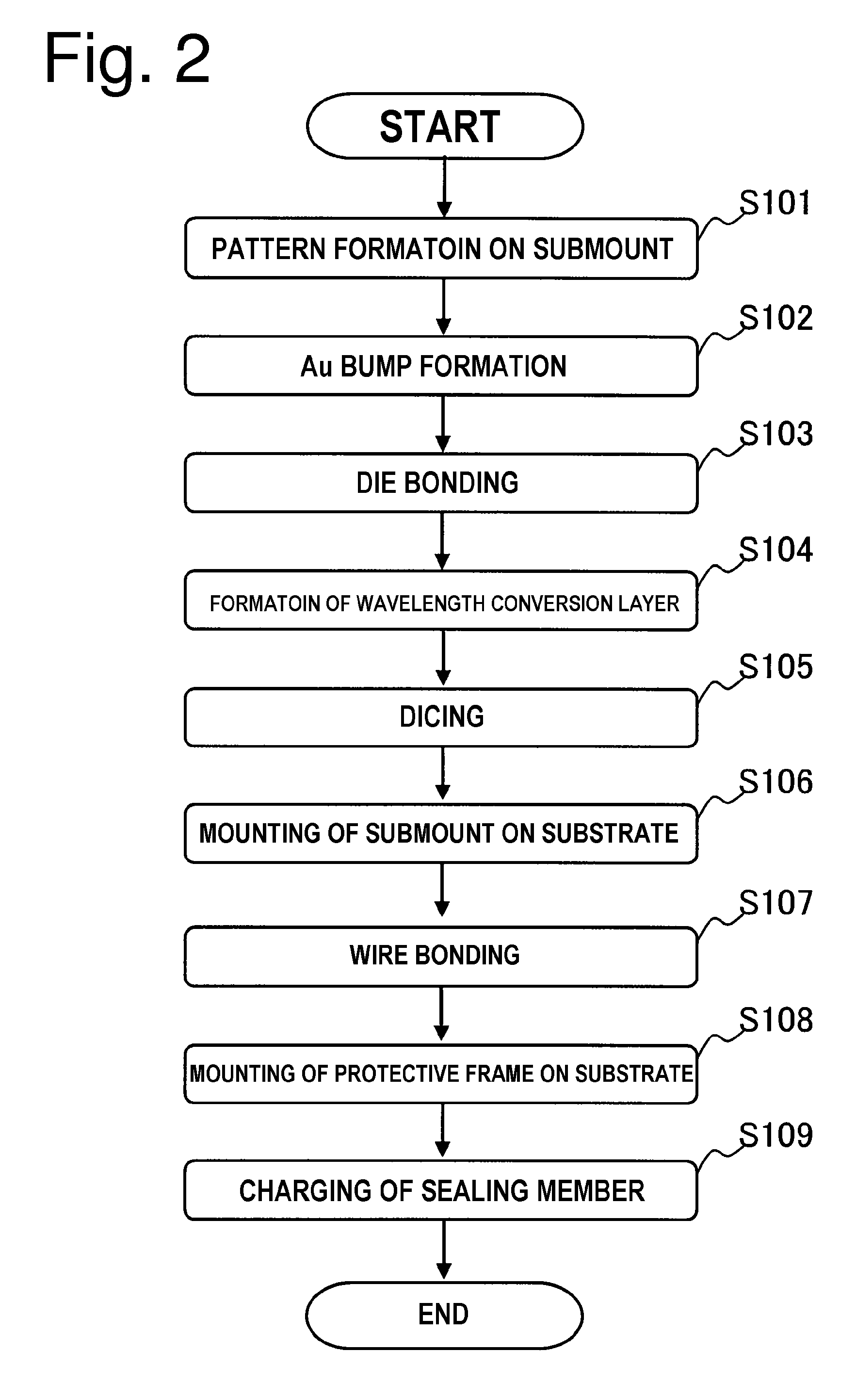

Semiconductor light emitting device and method for producing the same

InactiveUS20100140648A1Increase brightnessInhibitionSemiconductor/solid-state device testing/measurementSolid-state devicesHigh luminanceLuminous flux

A semiconductor light emitting device can be configured to maintain high luminance and to suppress the possibility of the occurrence of wire breakage with high quality and reliability. A method for producing such a semiconductor light emitting device with a high process yield is also disclosed. The semiconductor light emitting device can include a sealing member into which a reflective filler can be mixed in such an amount (concentration) range that luminous flux with a predetermined amount can be maintained and the possibility of the occurrence of wire breakage can be lowered. Various sealing members containing a reflective filler with a plurality of concentrations within this range can be prepared in advance. By taking advantage of the phenomenon where chromaticity shifts depending on the concentration of the reflective filler, a semiconductor light emitting device with less chromaticity variation can be produced utilizing a sealing member with a particular concentration in accordance with the chromaticity of a particular semiconductor light emitting element that is used and which may be varied during fabrication.

Owner:STANLEY ELECTRIC CO LTD

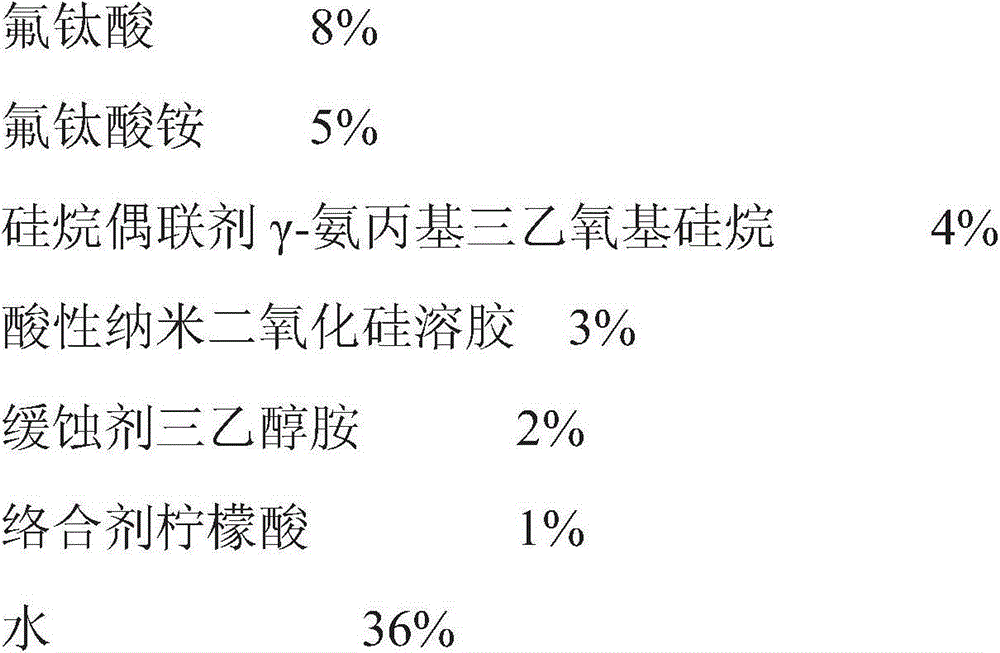

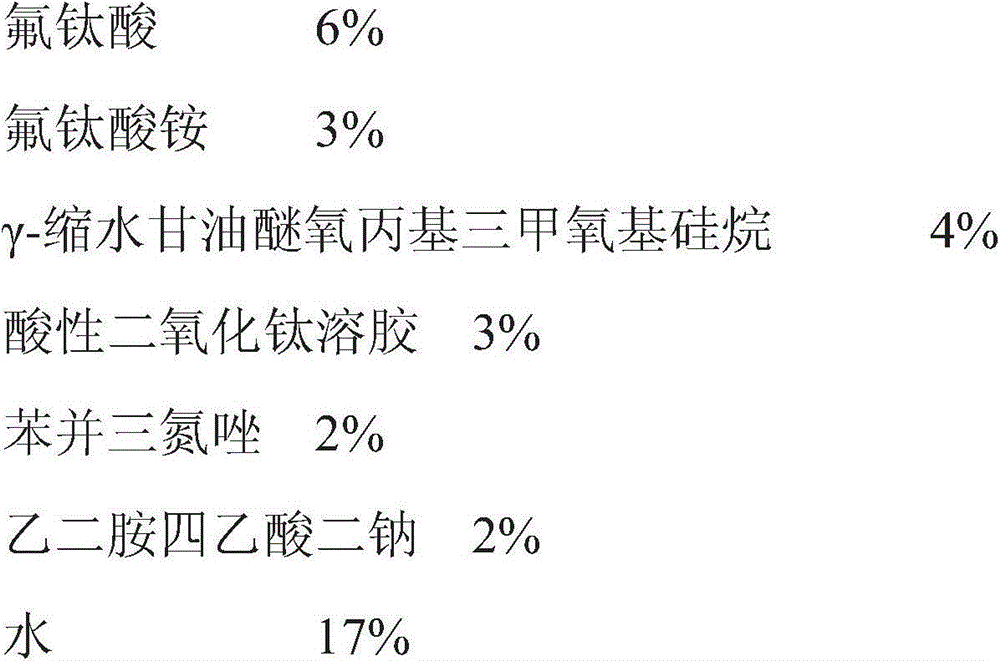

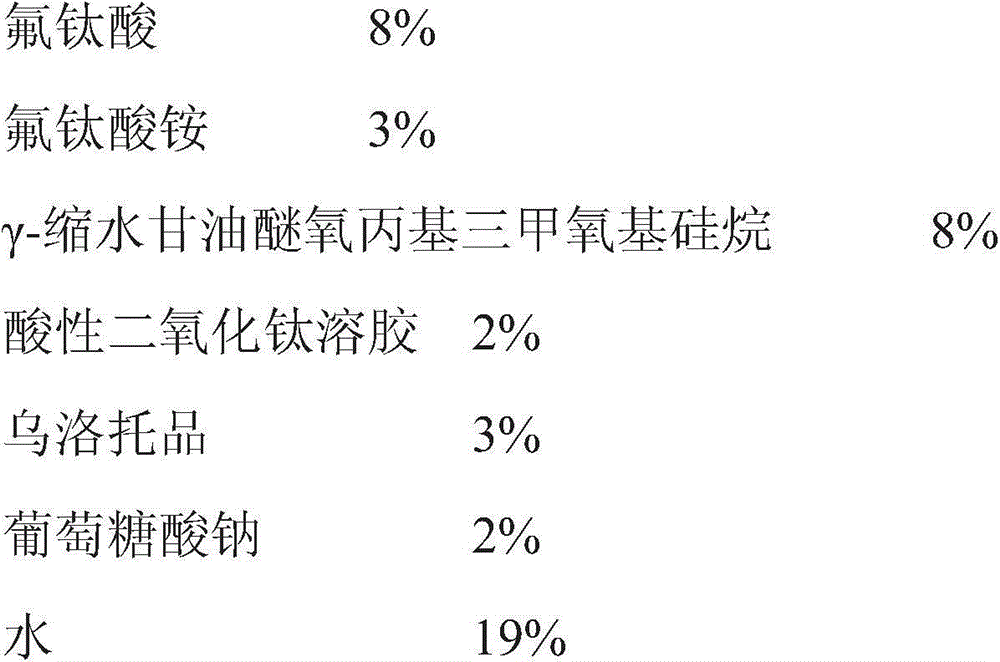

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Nanocomposite ceramics and process for making the same

InactiveUS20070049484A1High hardnessImprove fracture toughnessMaterial nanotechnologyNanometreMaterials science

A nanocomposite ceramic composition and method for making the same, the composition comprising a uniform dispersion of nanosize ceramic particles composed of at least one ceramic phase, interspersed and bound throughout a tough zirconia matrix phase.

Owner:RUTGERS THE STATE UNIV

Golf club

A recess portion is formed on a front side of a head body, and a gel is placed in the recess portion. A face member is fixed on the head body so as to seal the gel in the recess portion. Thus, the gel can be certainly provided on the rearward of the face, whereby a hitting force (striking force) can be improved, while a sound generated when hitting a golf ball can be reduced. The sealed gel sticks to the recess portion without forming any space in a condition that it is pressed therein. Thus, the sound generated when hitting a golf ball can be made uniform, ensuring the transmission of a force for hitting a golf ball.

Owner:ENDO MFG COMPANY

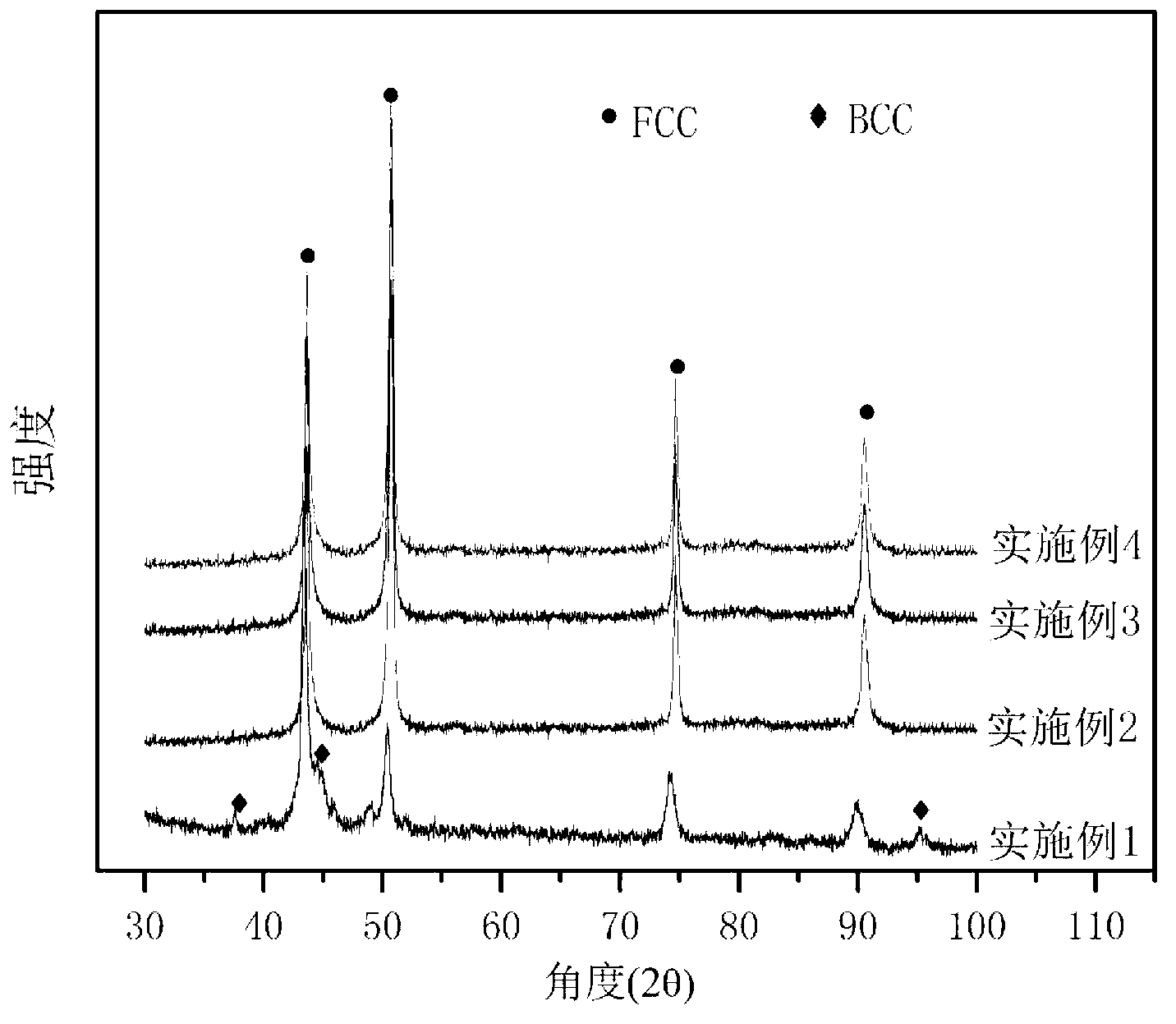

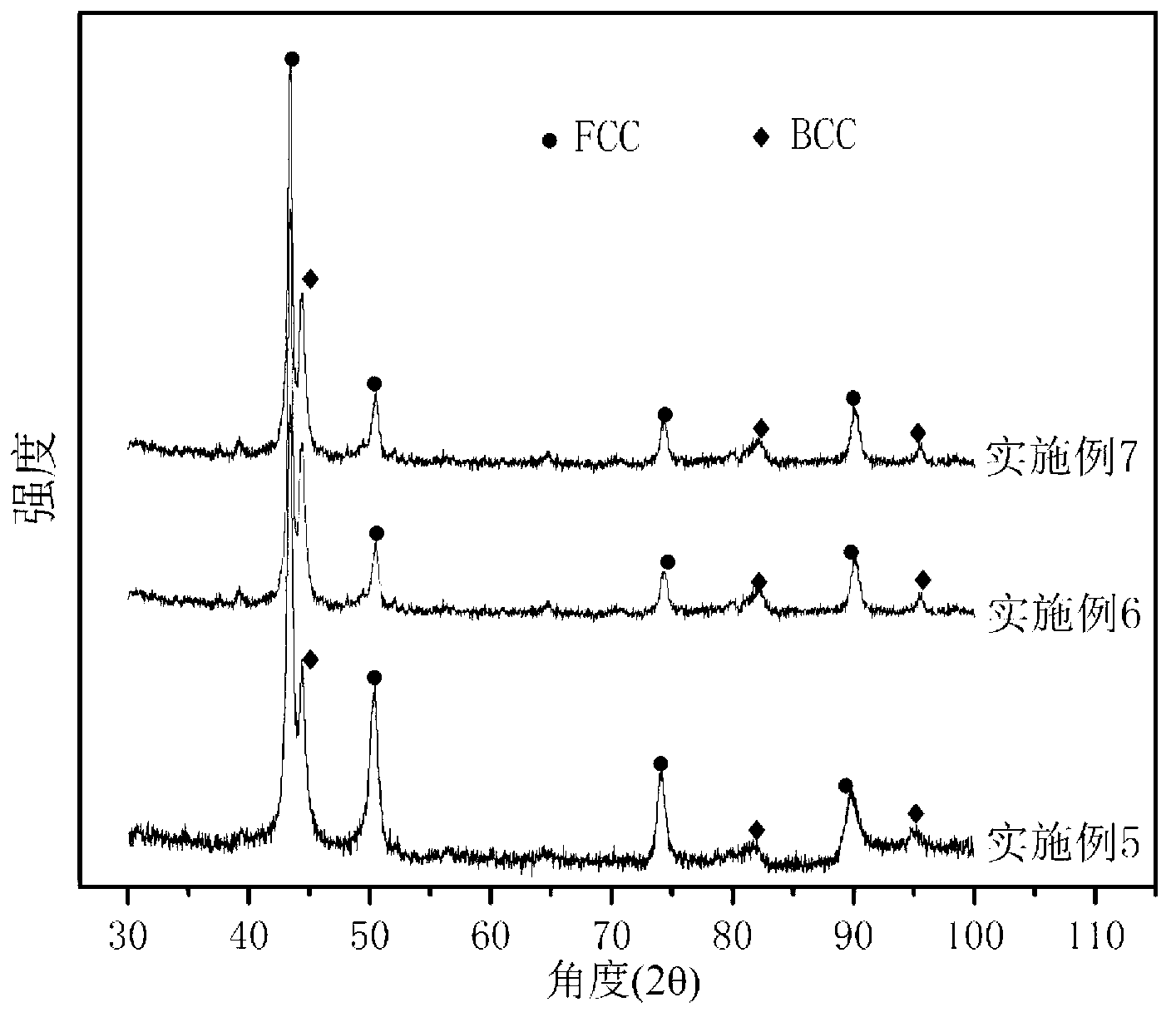

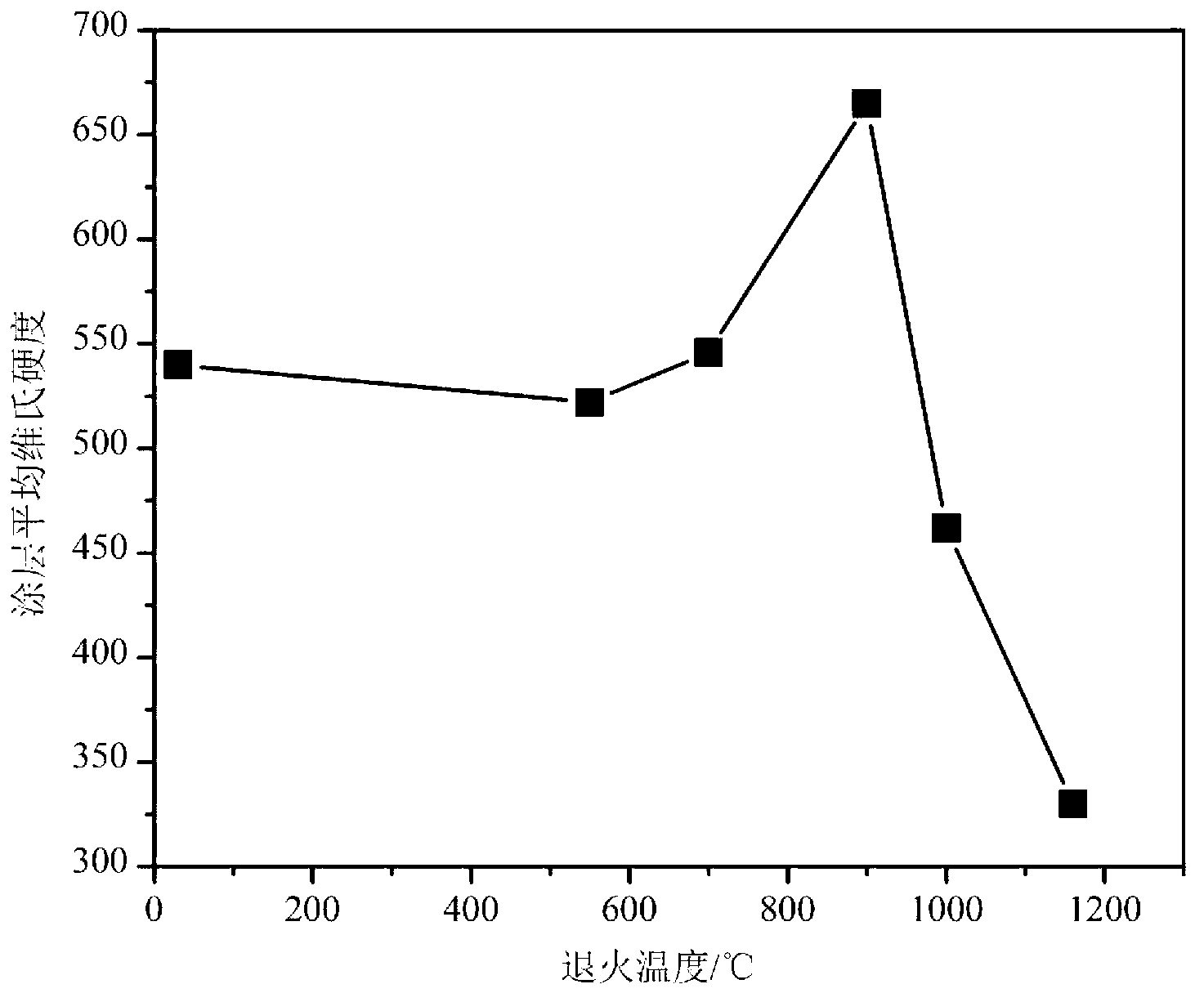

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

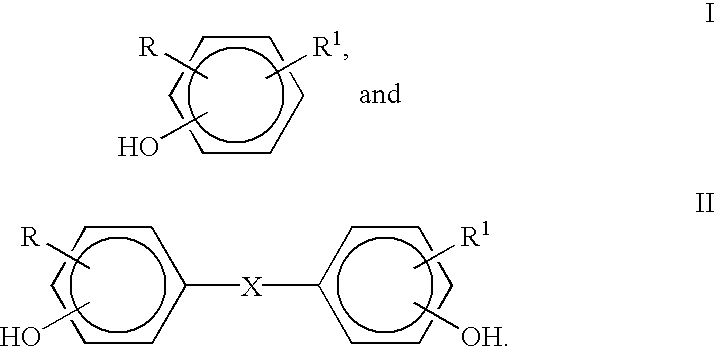

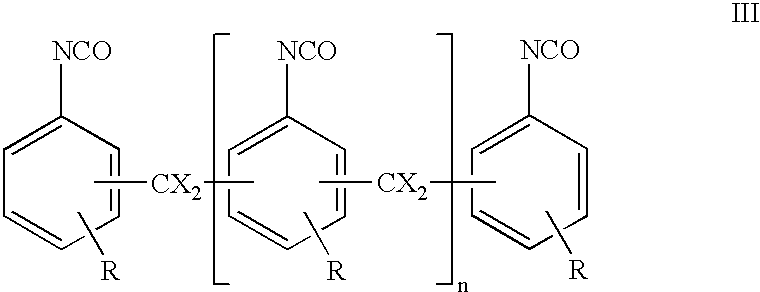

Crosslinkable rubber compositions and use thereof

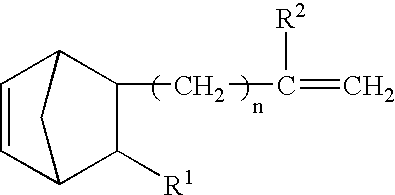

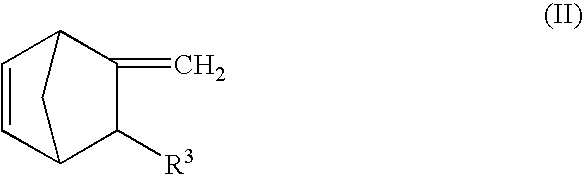

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

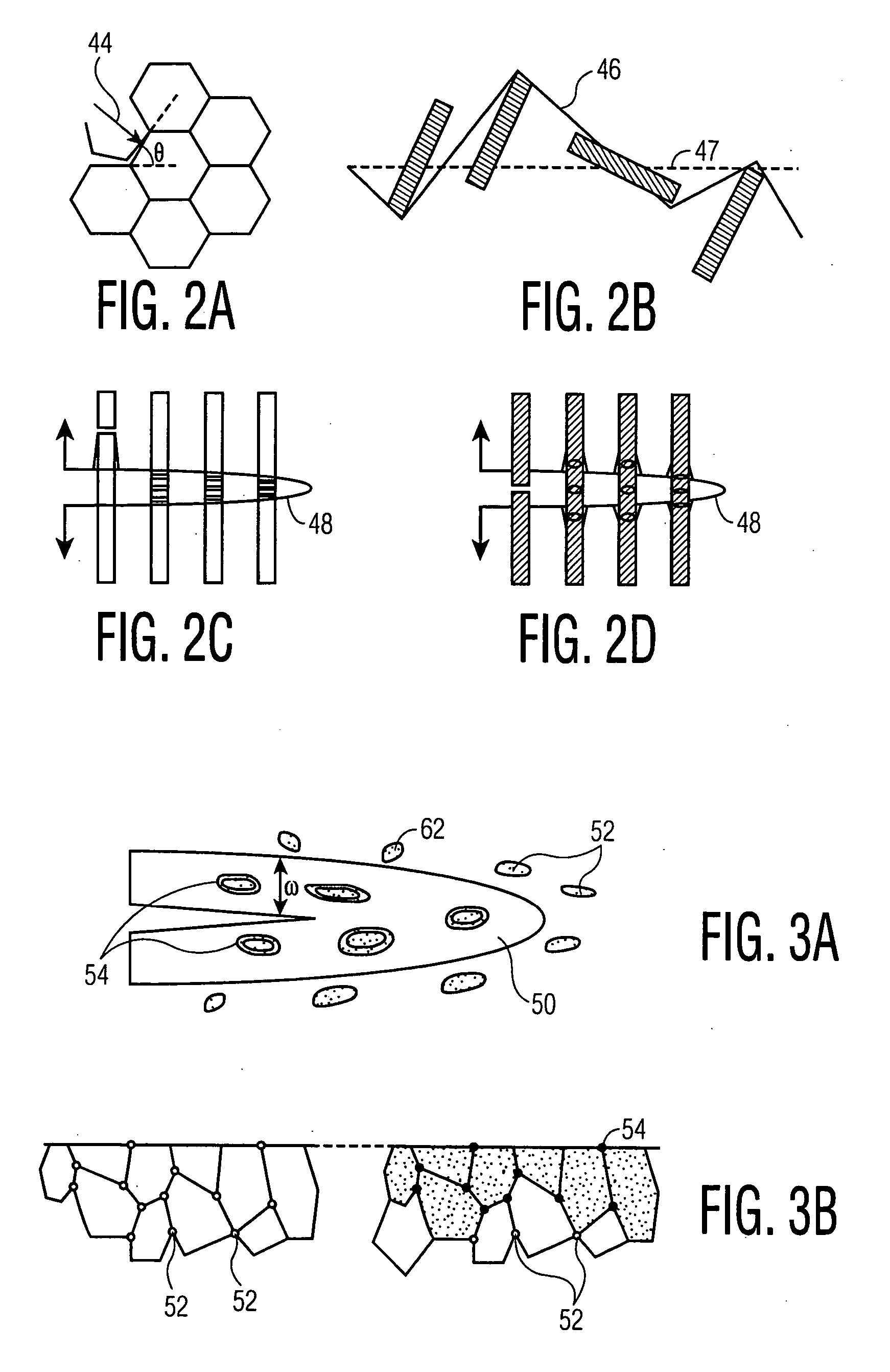

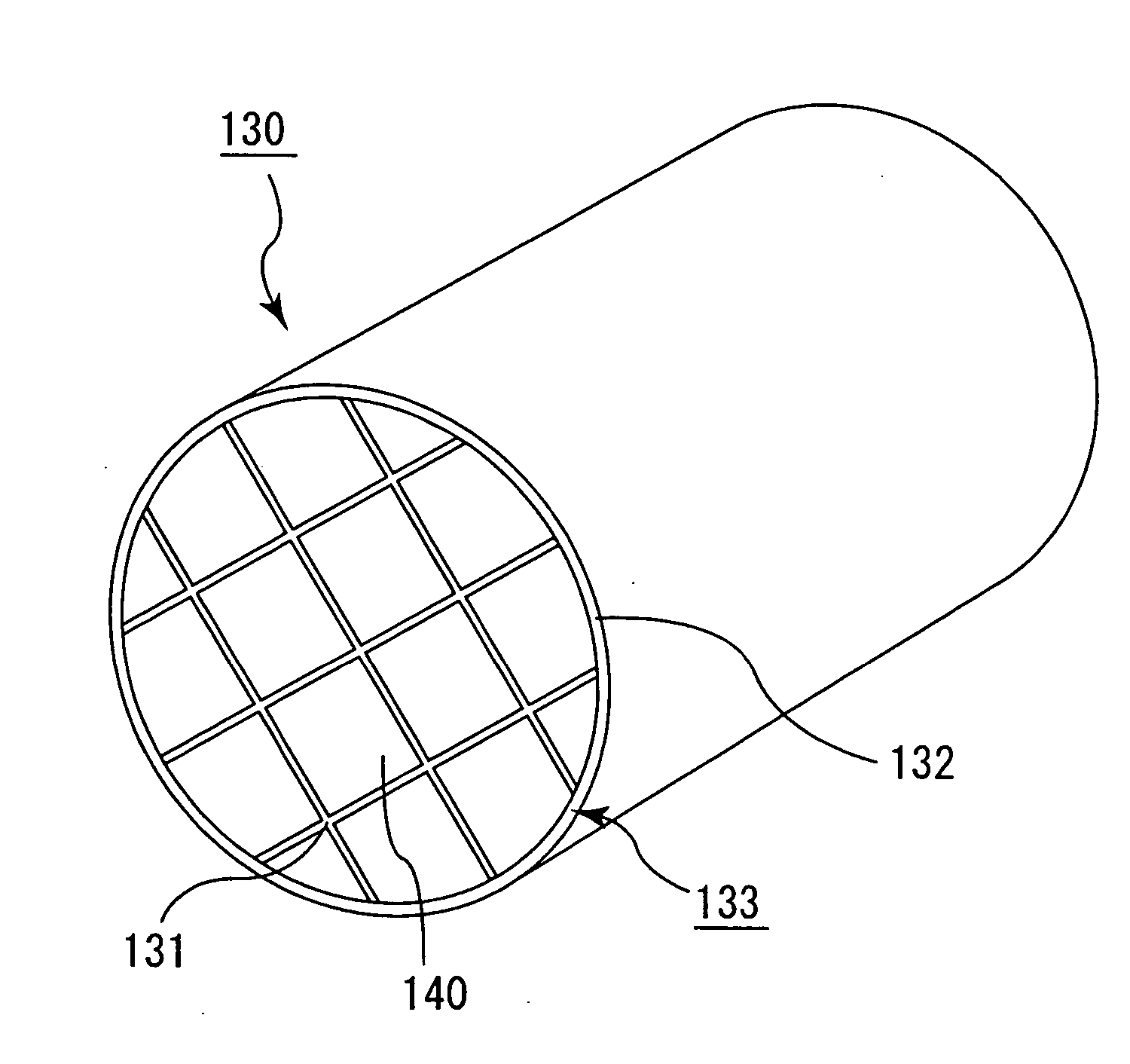

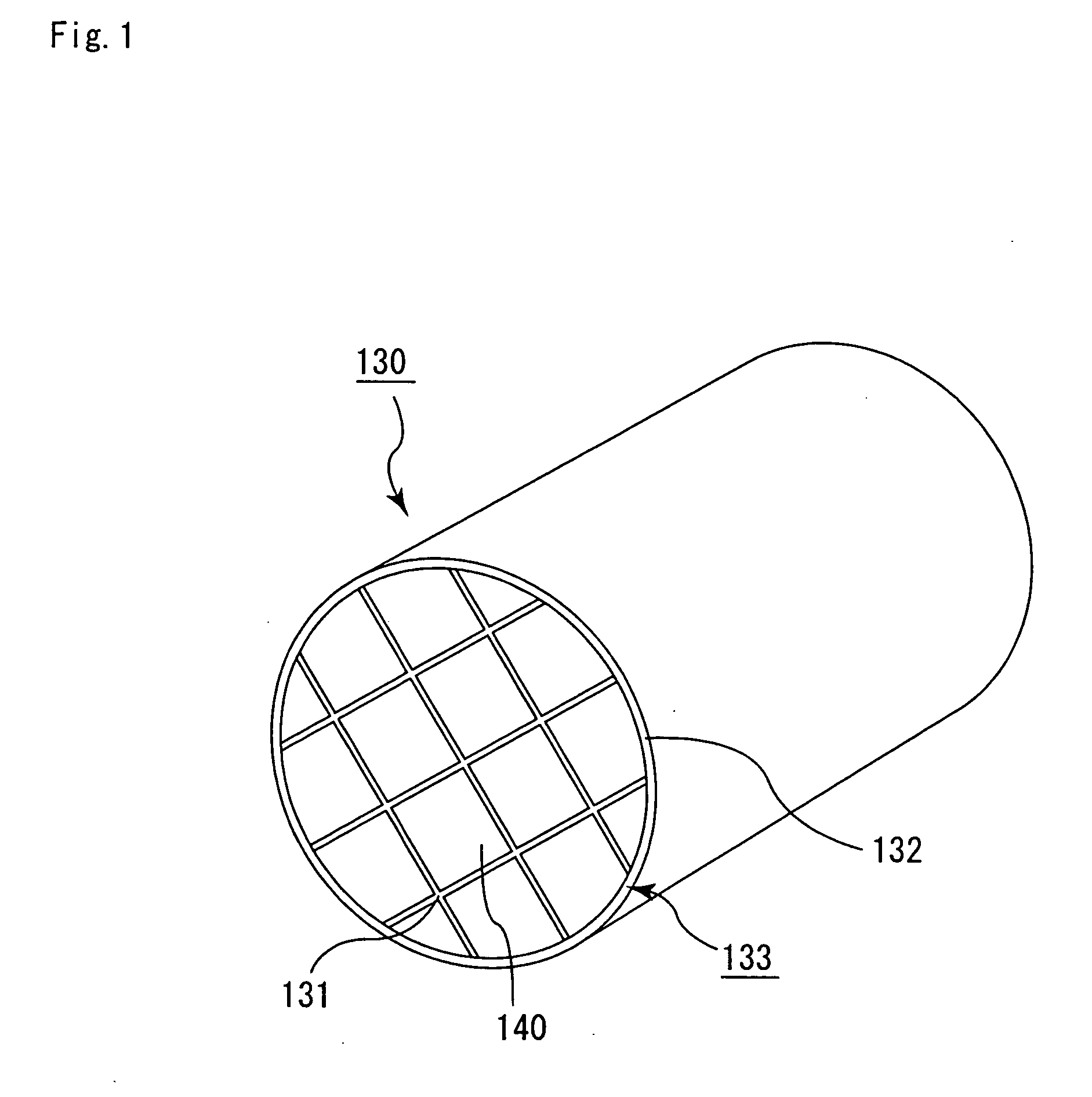

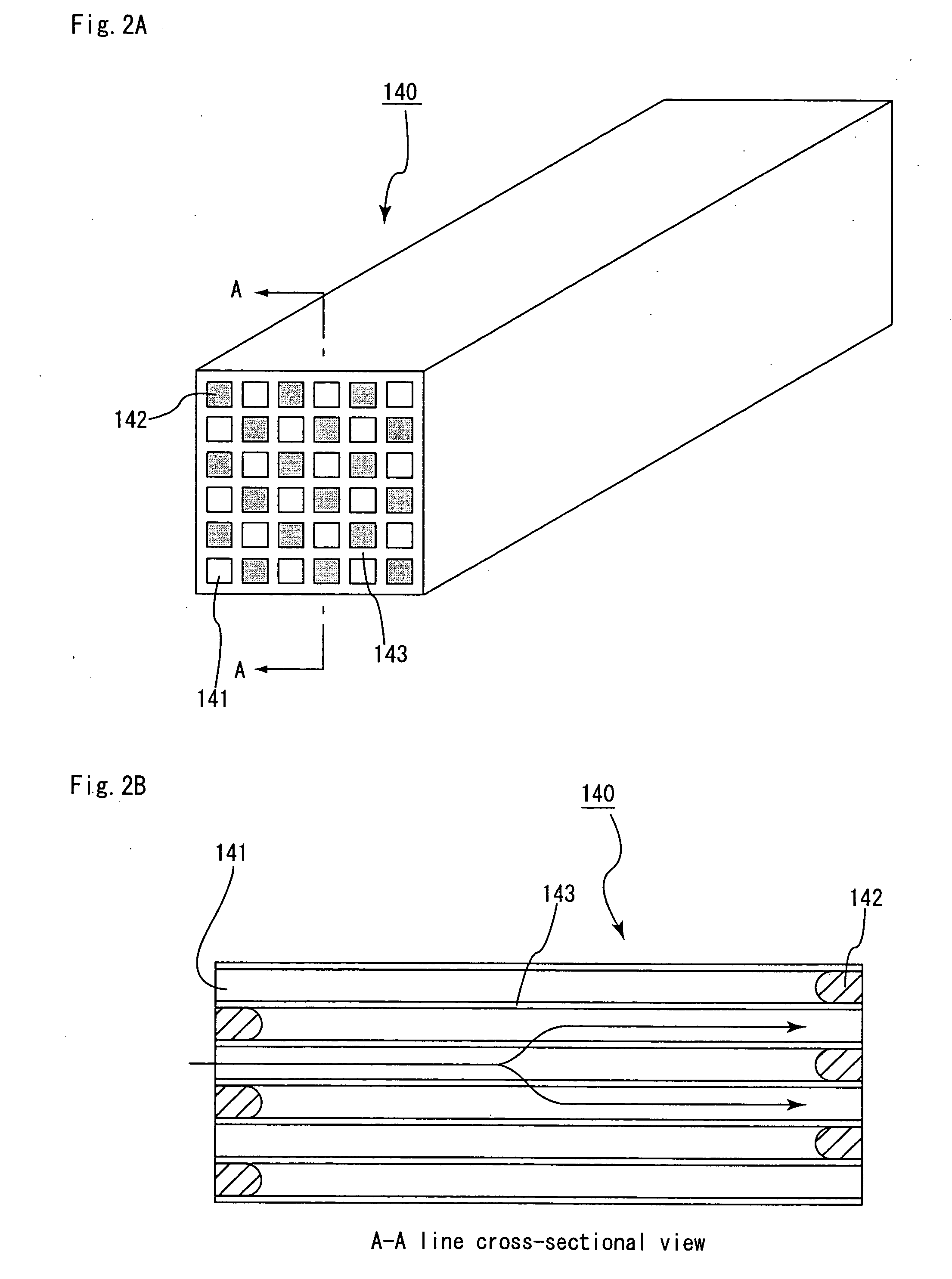

Method for mixing powder, agitation apparatus, and method for manufacturing honeycomb structured body

InactiveUS20070187651A1High hardnessRotary stirring mixersTransportation and packagingHardnessHoneycomb structure

A method for mixing powder according to the present invention is a method for mixing powder by conducting mixing and transporting of at least one kind of powder, comprising: charging said at least one kind of powder into an agitation apparatus; and translating said at least one kind of powder while mixing the powder by rotating an agitation shaft of said agitation apparatus, said agitation apparatus comprising: a screw comprised of the agitation shaft and an agitating blade, said screw configured to rotate along with the said agitation shaft as the center; and, a casing surrounding said screw, wherein either the entire body of said agitating blade is formed of a high hardness member, or, a high hardness coat layer is formed onto at least a portion of said agitating blade.

Owner:IBIDEN CO LTD

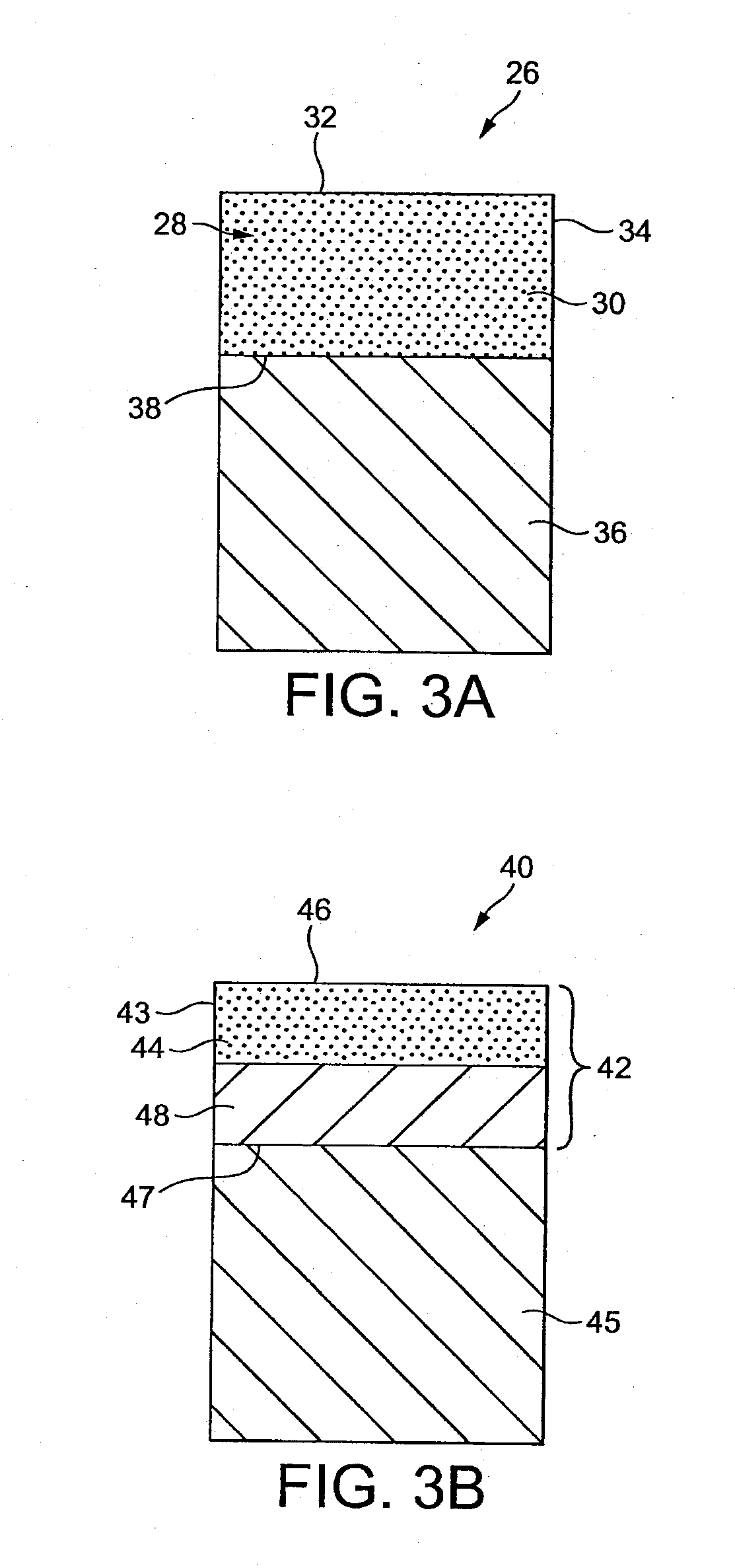

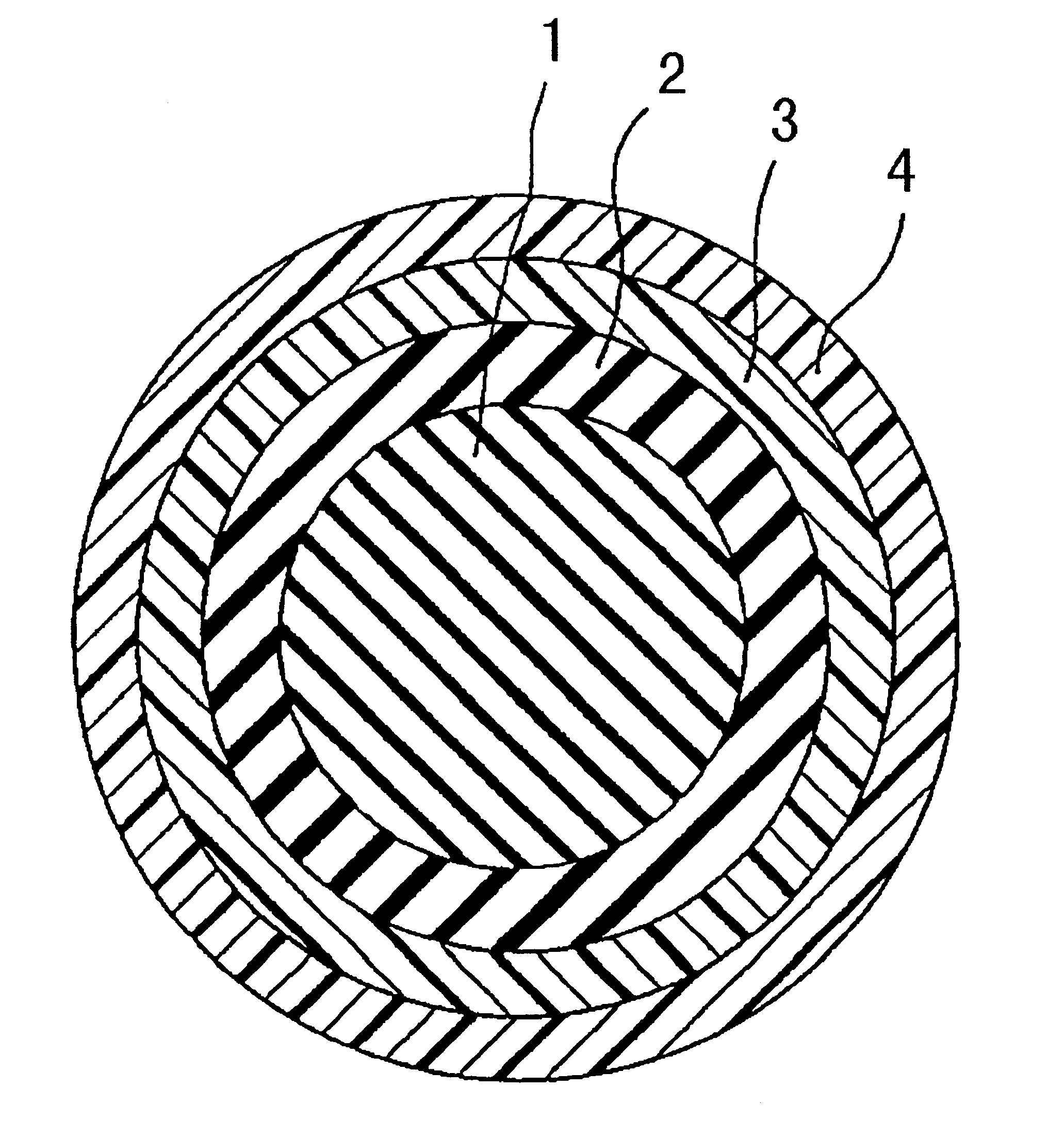

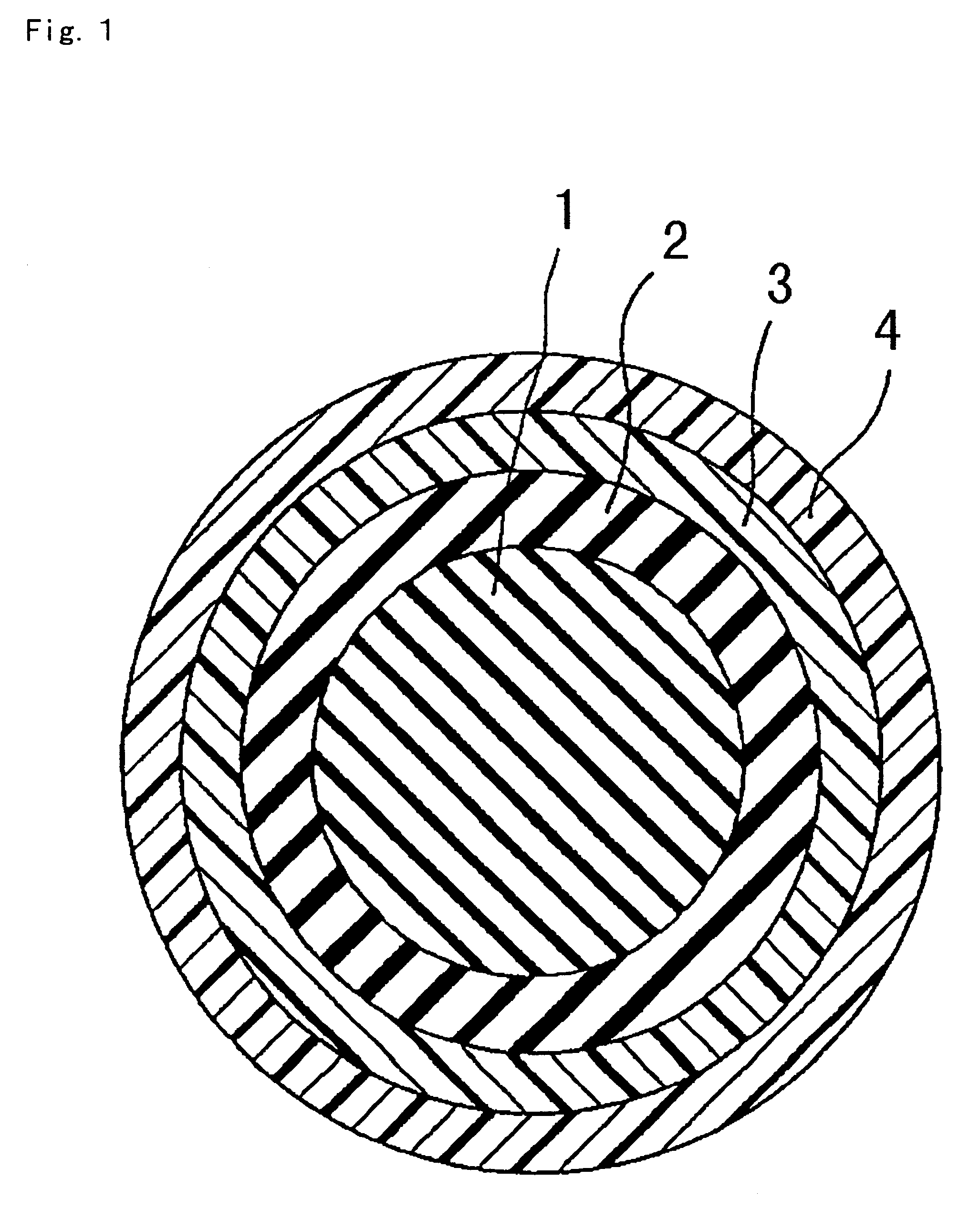

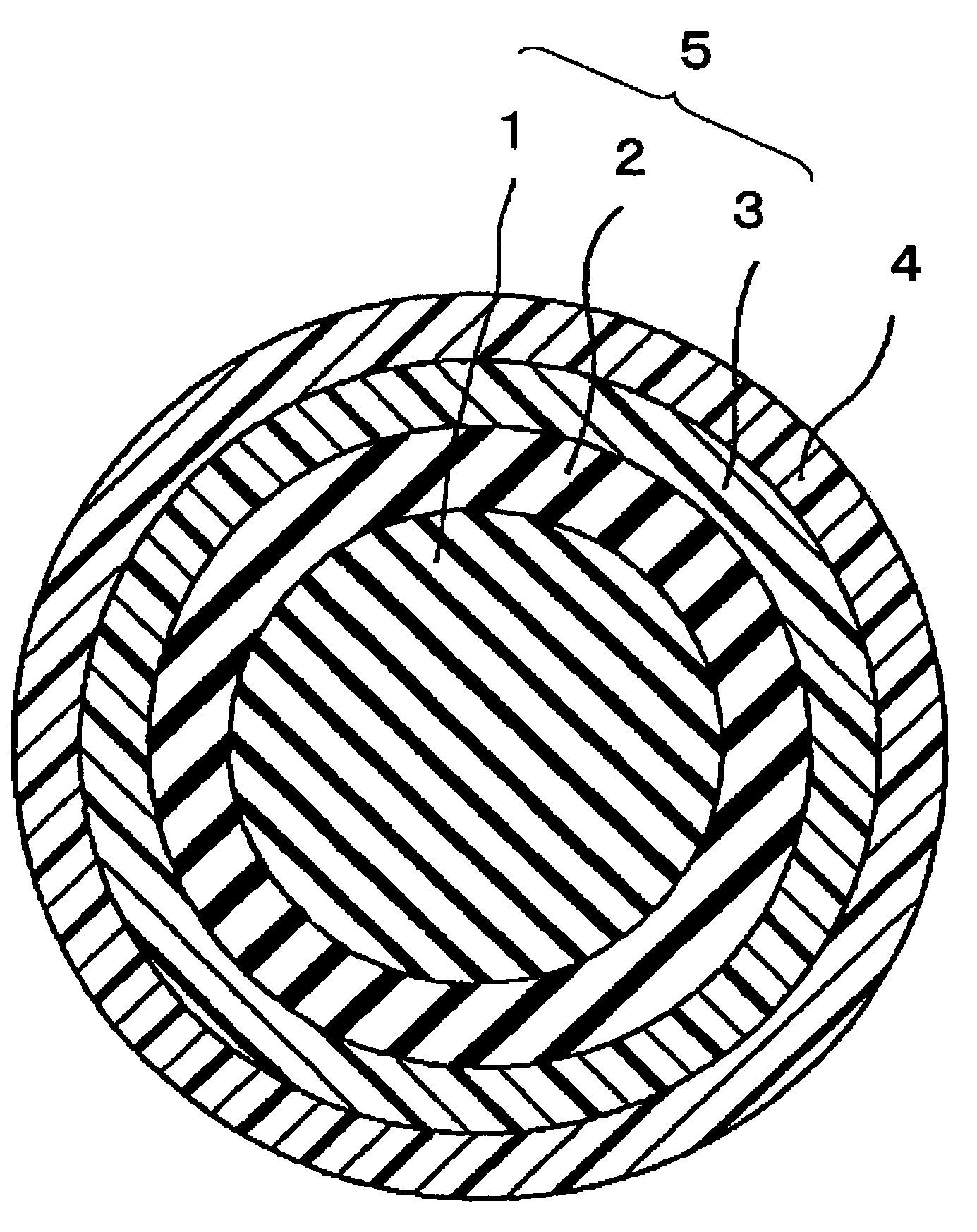

Four-piece solid golf ball

The present invention provides a four-piece solid golf ball having excellent flight performance and good shot feel at the time of hitting. The present invention relates to a four-piece solid golf ball comprising a core, an intermediate layer formed on the core, an outer layer formed on the intermediate layer and a cover covering the outer layer, wherein the core has a surface hardness in JIS-C hardness of 67 to 85, a JIS-C hardness of the intermediate layer is higher than the surface hardness of the core, and a JIS-C hardness of the outer layer is higher than the hardness of the intermediate layer.

Owner:SUMITOMO RUBBER IND LTD

Multi-piece solid golf ball

The present invention provides a four-piece solid golf ball having excellent flight performance and good shot feel at the time of hitting. The present invention relates to a four-piece solid golf ball comprising a core, an intermediate layer formed on the core, an outer layer formed on the intermediate layer and a cover covering the outer layer, wherein the core has a surface hardness in JIS-C hardness of 67 to 85, a JIS-C hardness of the intermediate layer is higher than the surface hardness of the core, and a JIS-C hardness of the outer layer is higher than the hardness of the intermediate layer.

Owner:SUMITOMO RUBBER IND LTD

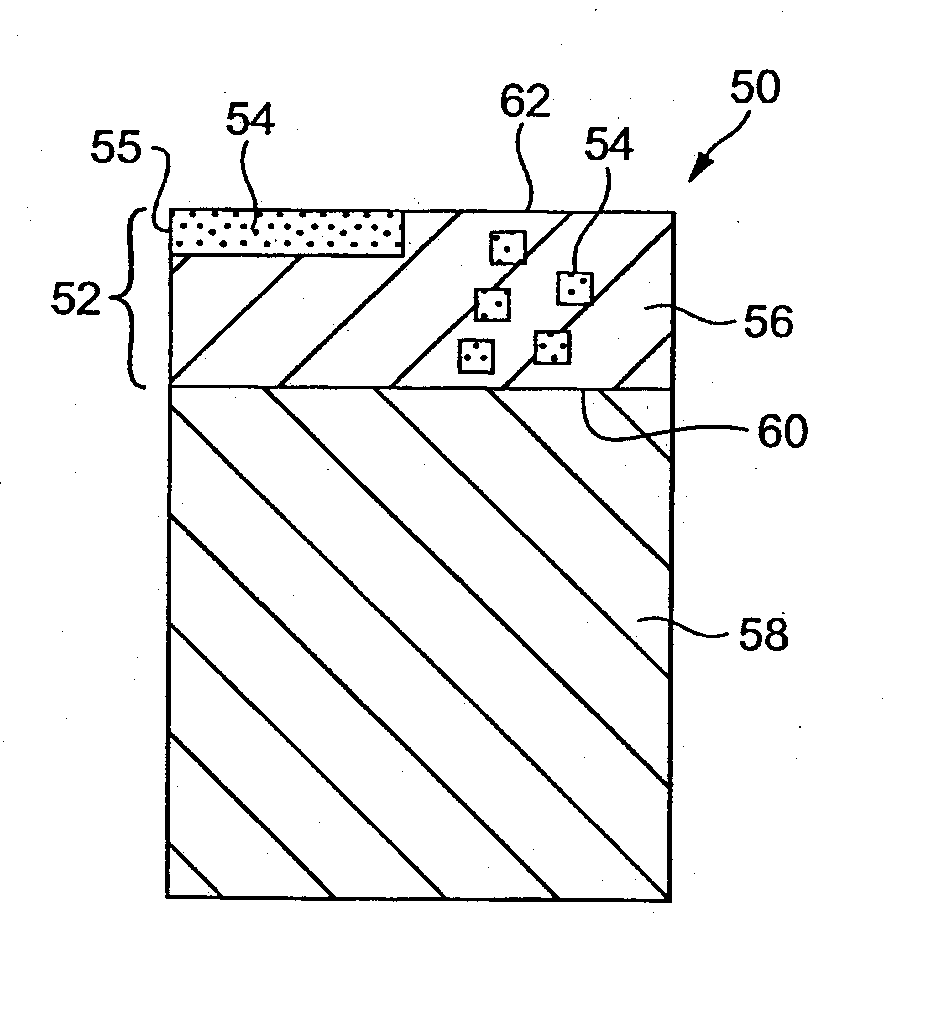

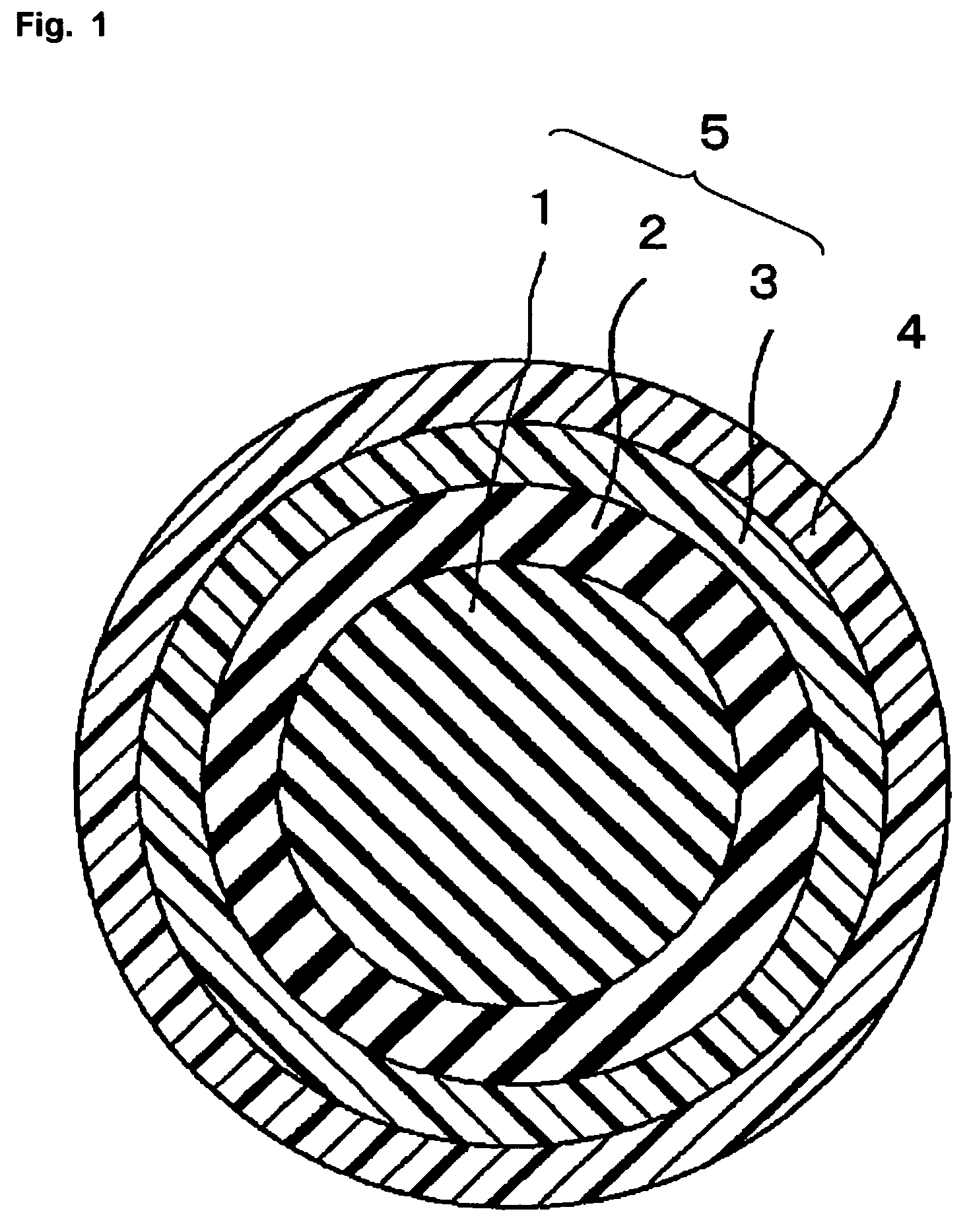

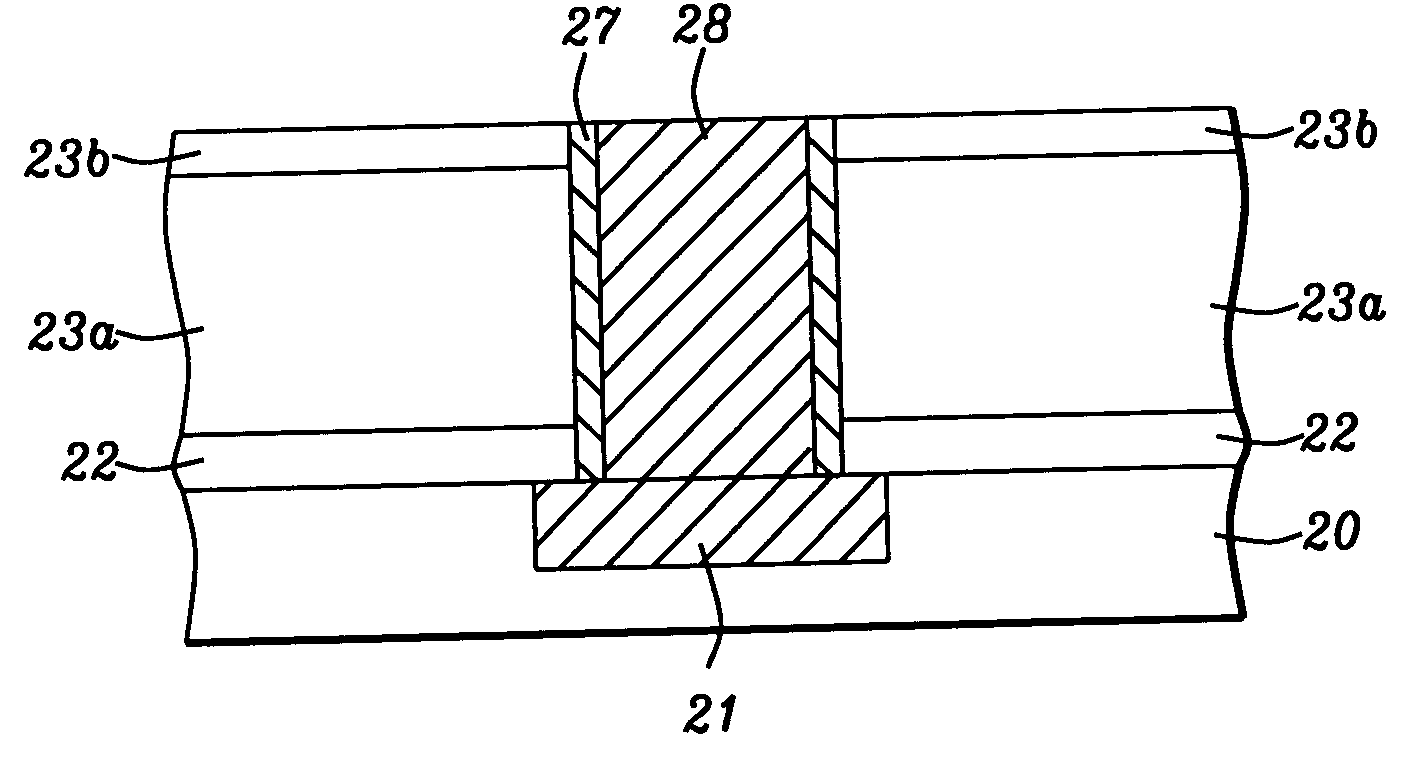

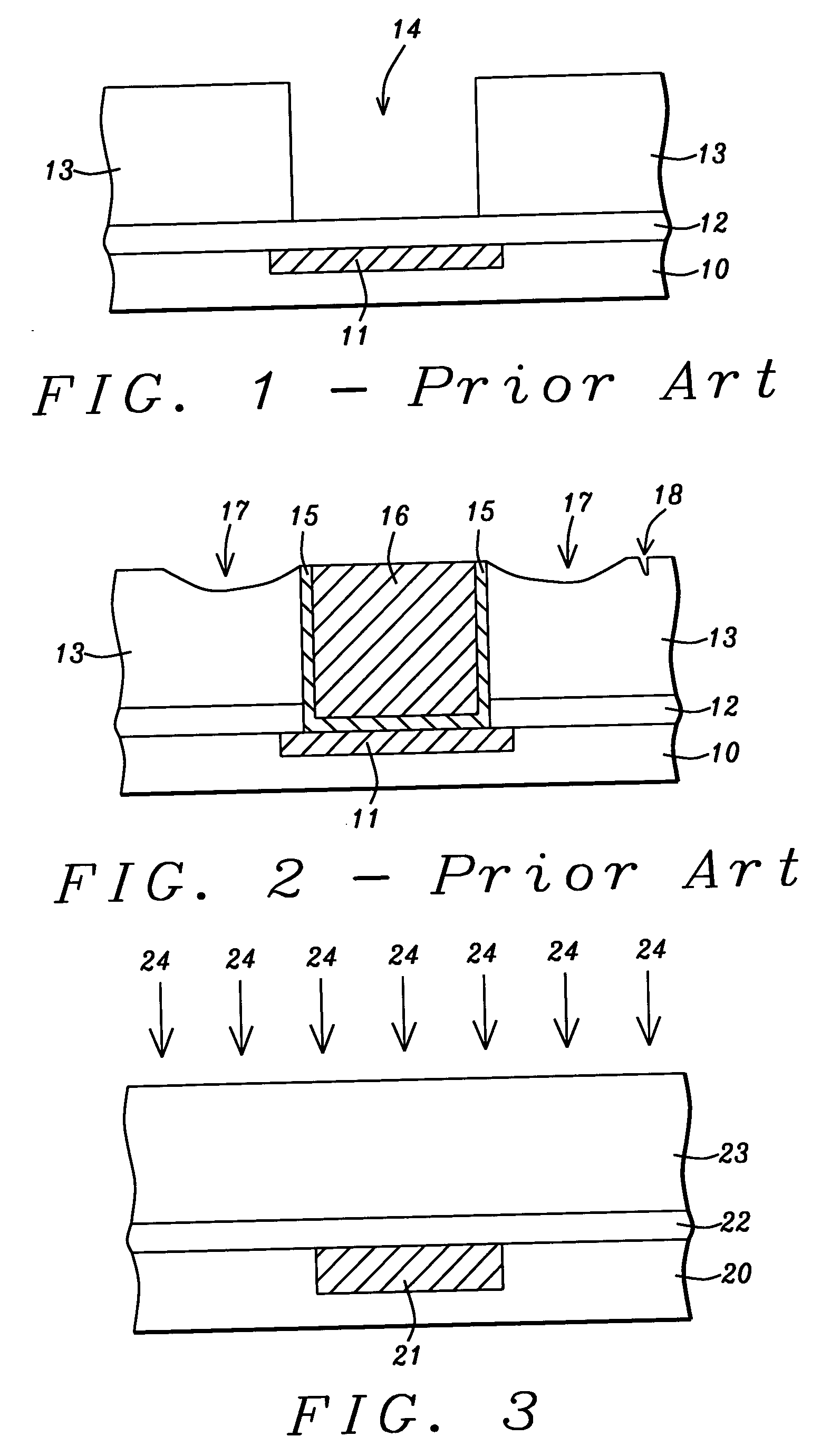

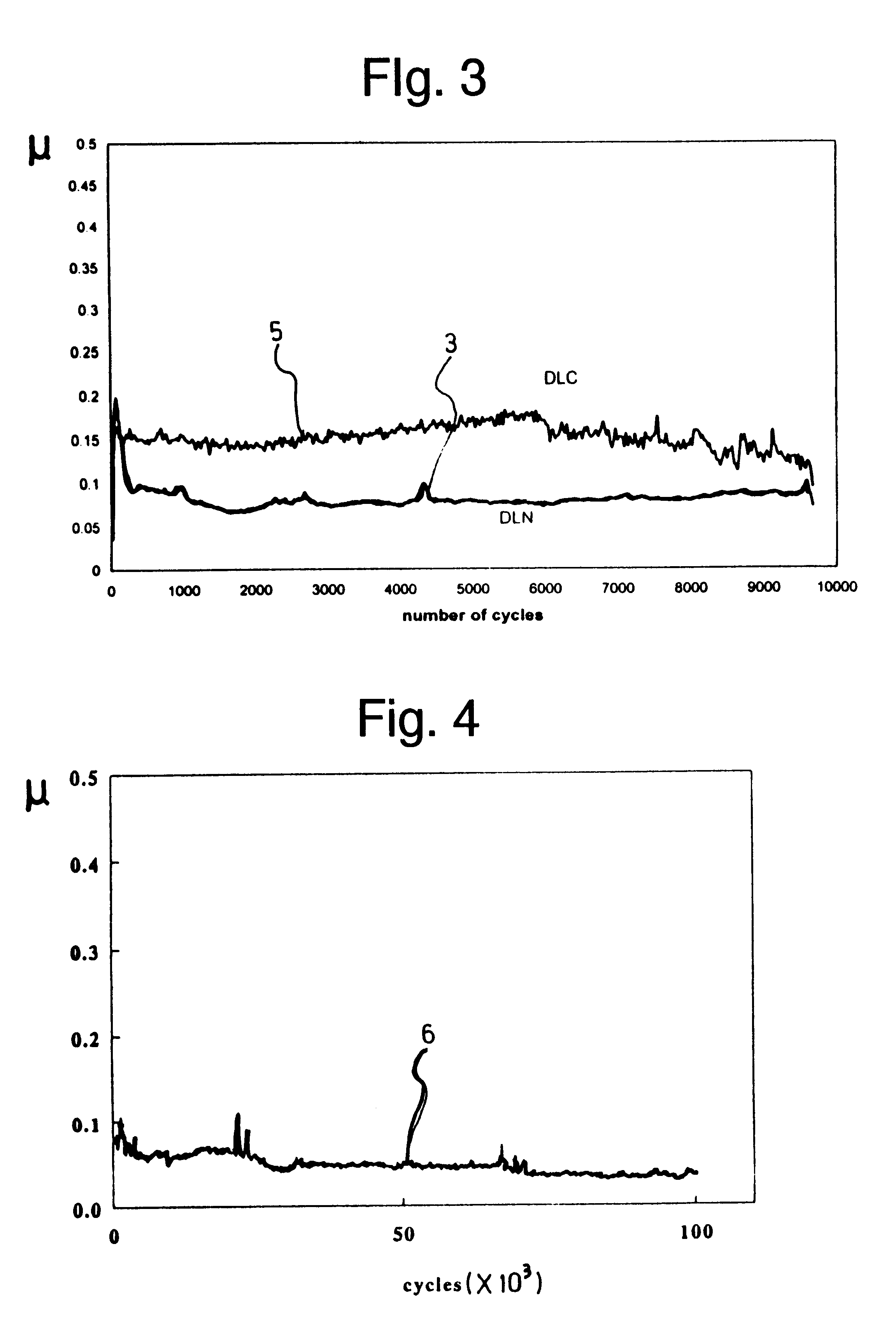

Two step post-deposition treatment of ILD layer for a lower dielectric constant and improved mechanical properties

InactiveUS20050064698A1Increase resistanceImprove the immunityDecorative surface effectsSemiconductor/solid-state device detailsMoistureMechanical property

A method of lowering the dielectric constant of an organosilicon low k dielectric layer while improving the hardness and thermal stability is provided. A deposited layer of carbon doped oxide, HSQ, or MSQ is cured and treated with a He plasma which improves hardness for a subsequent CMP step and lowers the dielectric constant. There is no loss of H2O or CH4 during the He treatment. The low k dielectric layer is then treated with a H2 plasma which converts some of the Si—O and Si—CH3 bonds near the surface to Si—H bonds, thereby further lowering the dielectric constant and increasing thermal stability that improves breakdown resistance. Moisture uptake is also reduced. The method is especially useful for interconnect schemes with deep sub-micron ground rules. Surprisingly, the k value obtained from two different plasma treatments is lower than when two He treatments or two H2 treatment are performed.

Owner:TAIWAN SEMICON MASNUFACTURING

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

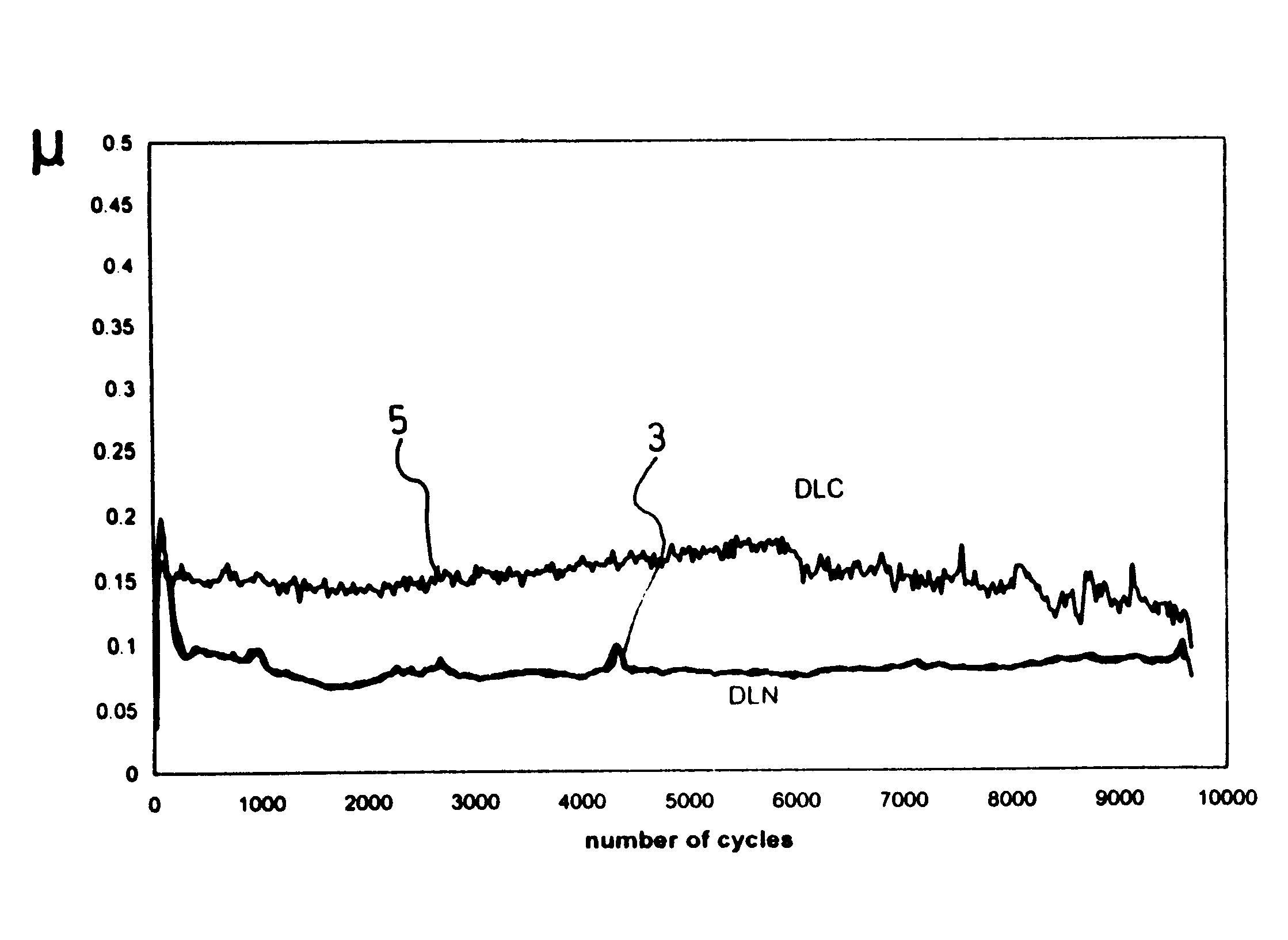

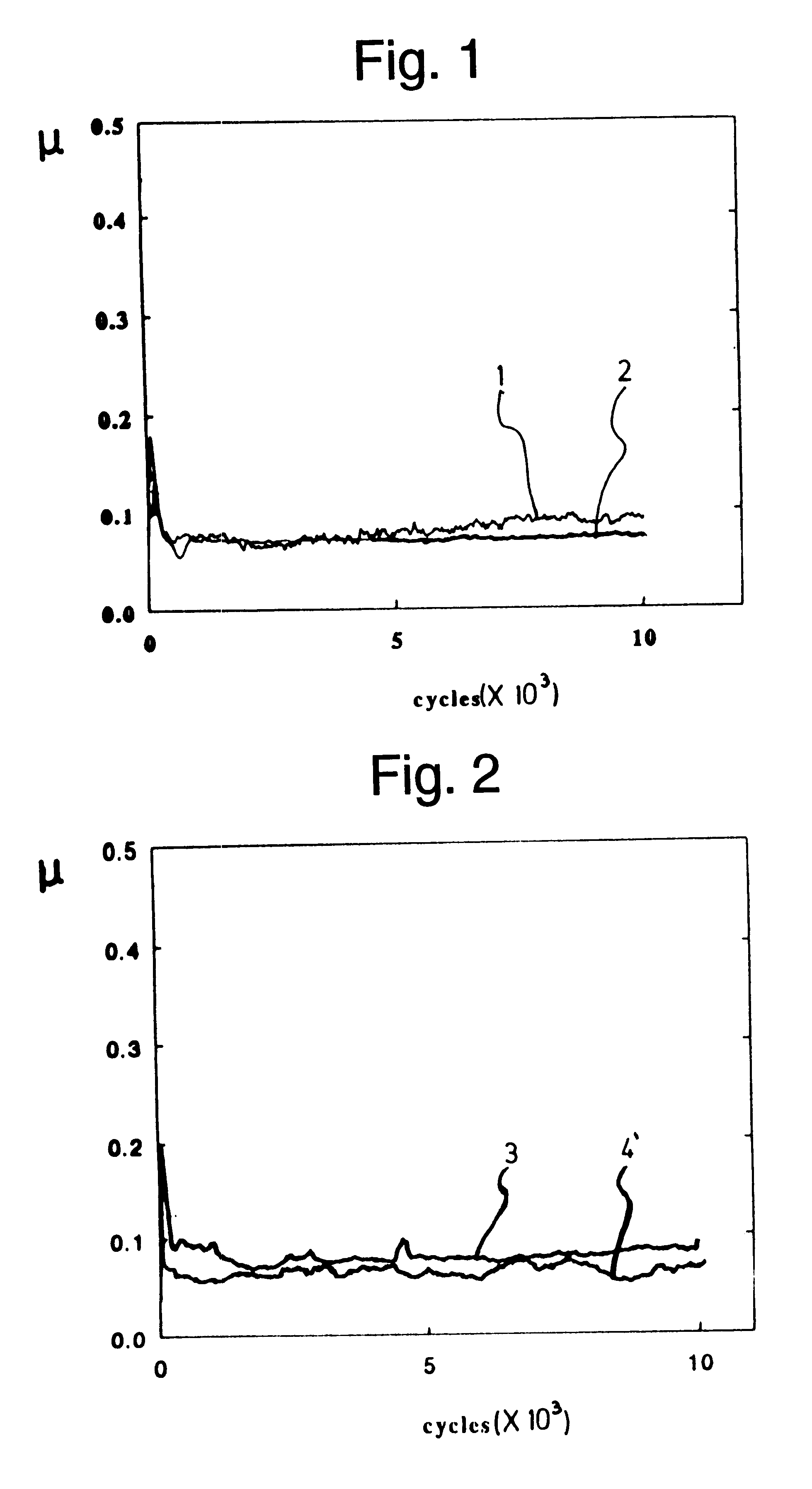

Diamond-like nanocomposite compositions

InactiveUS6200675B1Simple compositionHigh hardnessLayered productsVacuum evaporation coatingVacuum chamberRelative humidity

The invention relates to an improved diamond-like nanocomposite composition comprising networks of a-C:H and a-Si:O wherein the H-concentration is between 40% and 80% of the C-concentration and having a coefficient of friction against steel which is smaller than 0.1 in air with a relative humidity up to 90%, or in water. The invention relates also to a process for depositing the composition on a substrate in a vacuum chamber. The composition comprises preferably 30 to 70 at % of C, 20 to 40 at % of H, 5 to 15 at % of Si and 5 to 15 at % of O and can be doped with transition metals.

Owner:SULZER METAPLAS

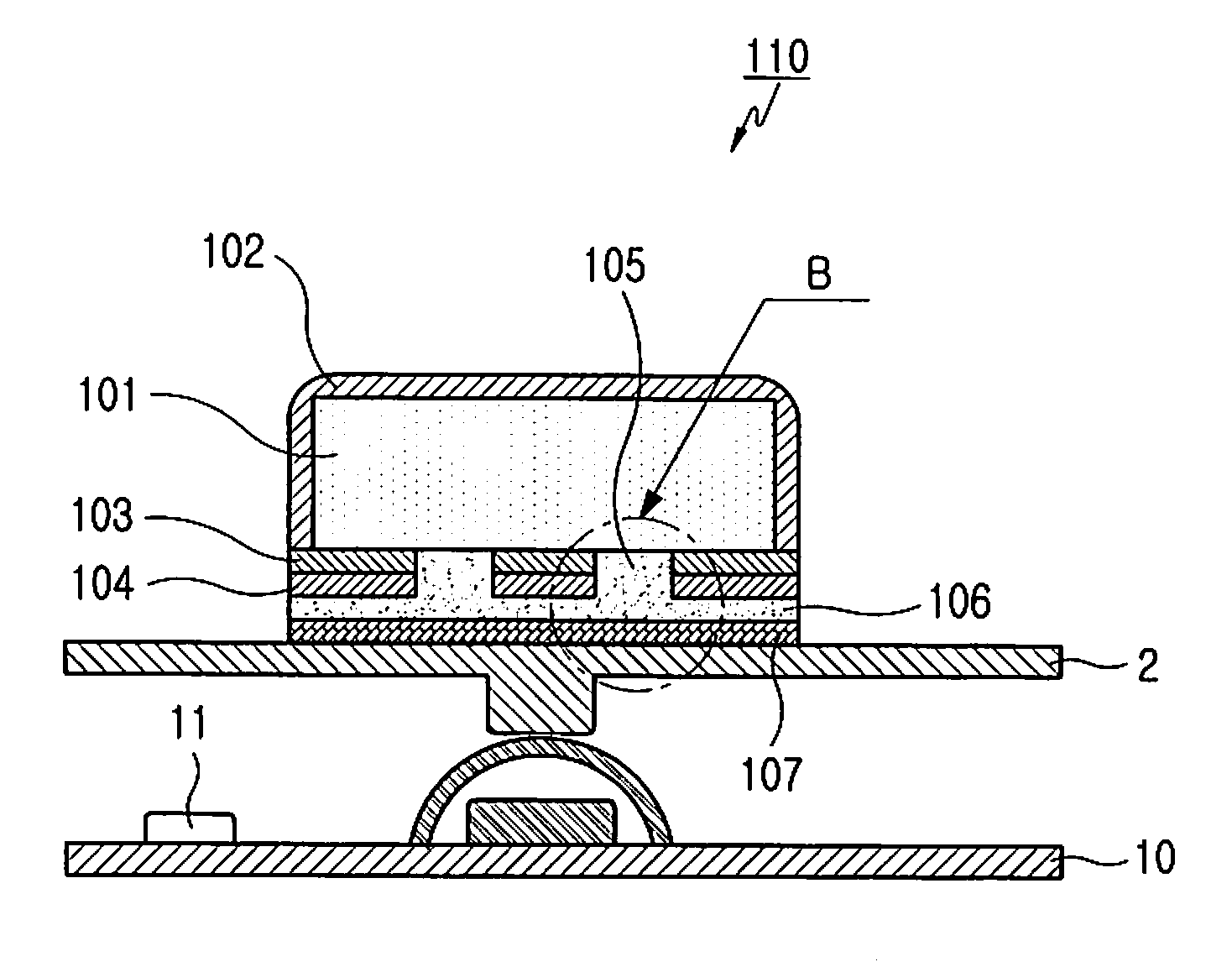

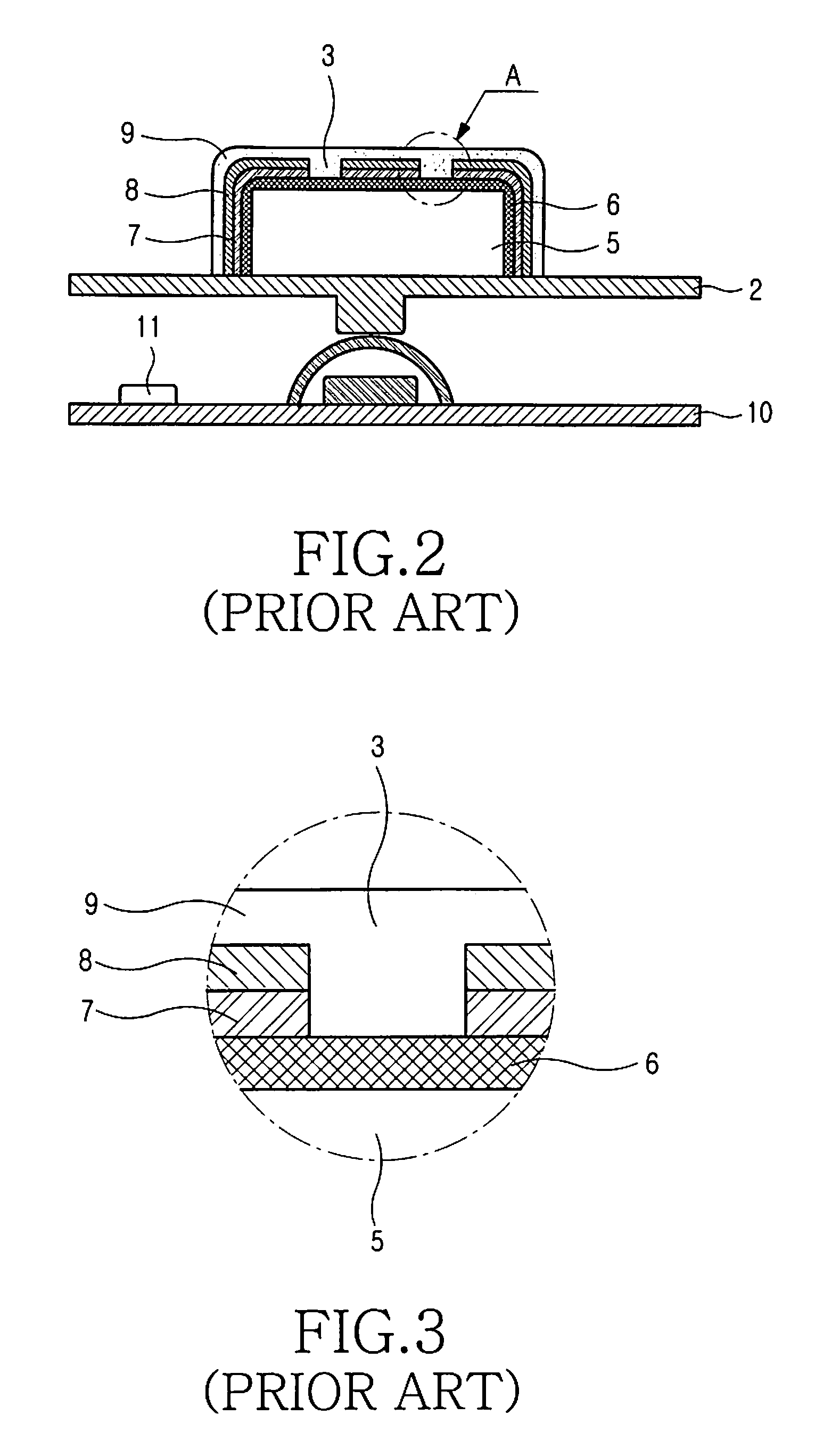

Manufacturing method of keypad for mobile phone and keypad manufactured thereby

ActiveUS7414213B2Increase resistanceHigh hardnessInput/output for user-computer interactionEmergency actuatorsLaser processingLacquer

Disclosed is a manufacturing method of a keypad for a mobile phone and the keypad manufactured thereby, in which a vacuum deposition layer and a cellophane paper are attached to a lower surface of a key in the keypad. The keypad for a mobile phone includes a plurality of keys, each key includes a key body of a transparent resin material and a high-hardness transparent coating layer coated onto a surface of the key body in order to increase hardness, and each key comprises a key background color paint layer for color presentation, coated onto a lower surface of the key body; an opaque paint layer coated onto a lower surface of the key background color paint layer; a transparent marking portion formed by performing a laser processing according to a shape of a numeral, a character, or a symbol with respect to the lower surface of the key body so as to remove the color paint layer and the opaque paint layer; a metallic vacuum deposition layer formed on the lower surface of the key body and a lower surface of the opaque paint layer; and a transparent color-printed layer or a cellophane paper attached to a lower surface of the metallic vacuum deposition layer so as to present various colors.

Owner:ROVI GUIDES INC

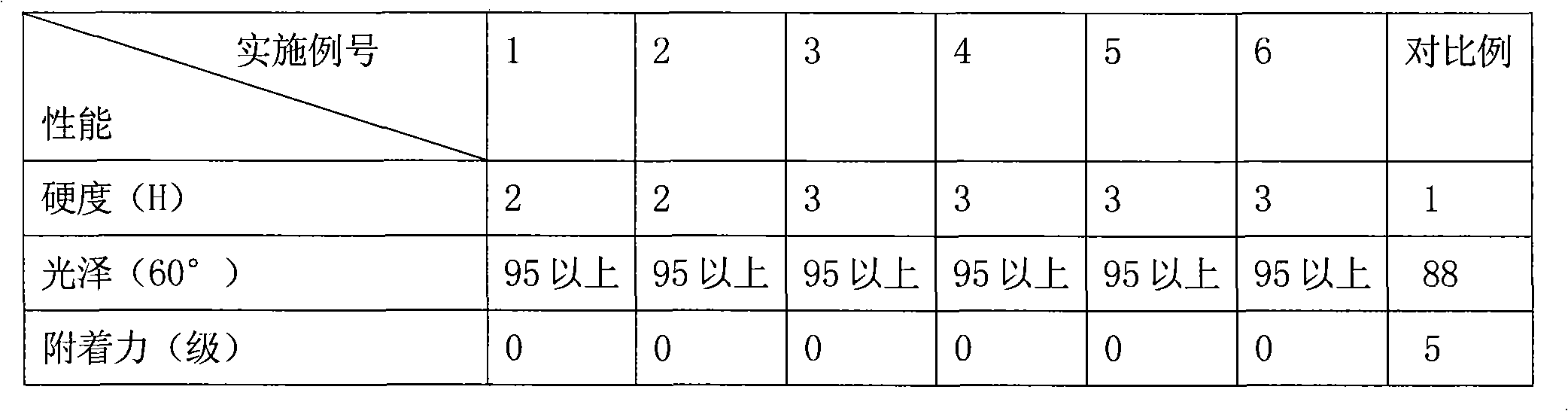

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

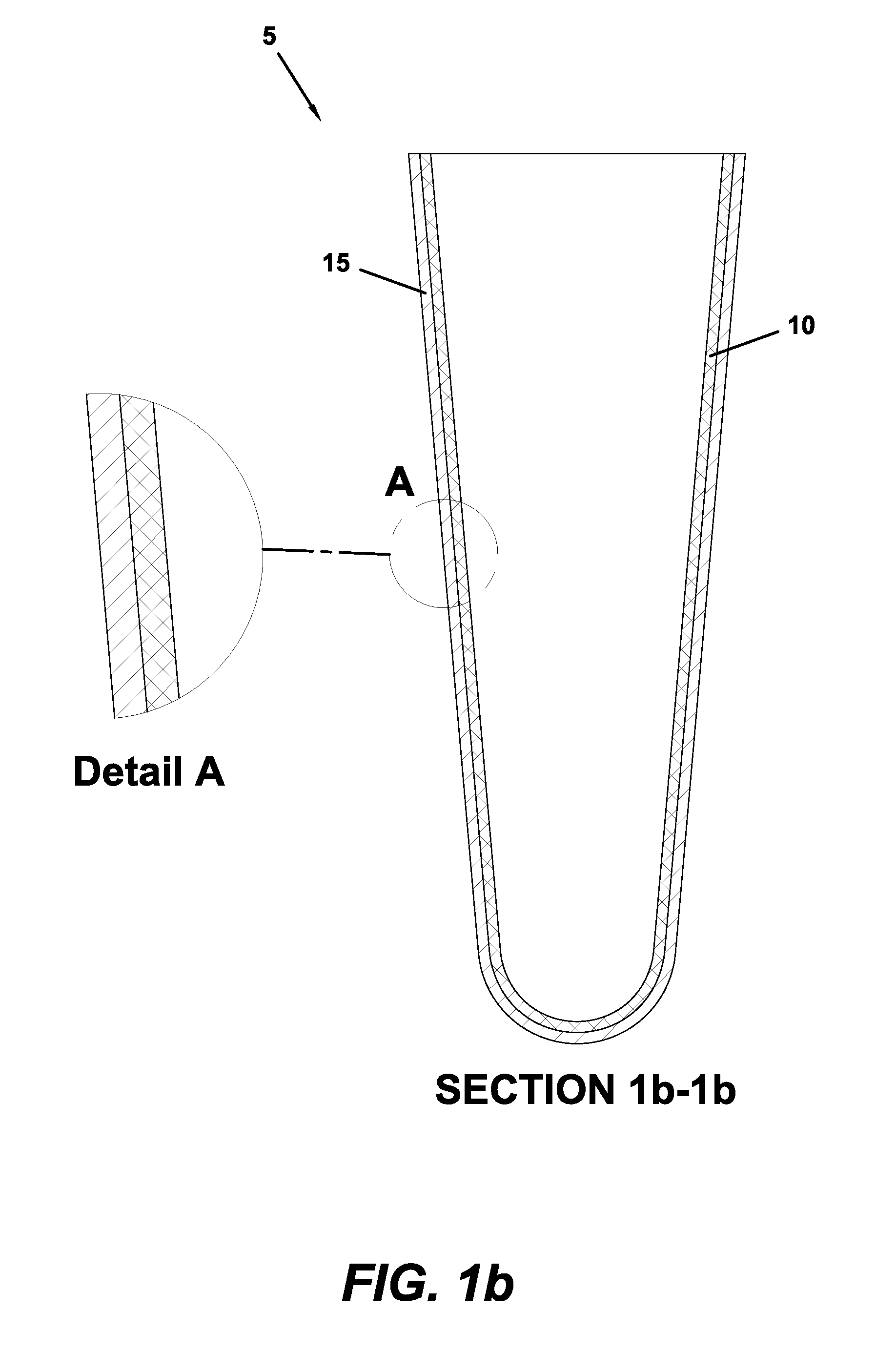

Multi-layer polymeric prosthetic liner

Owner:THE OHIO WILLOW WOOD CO INC

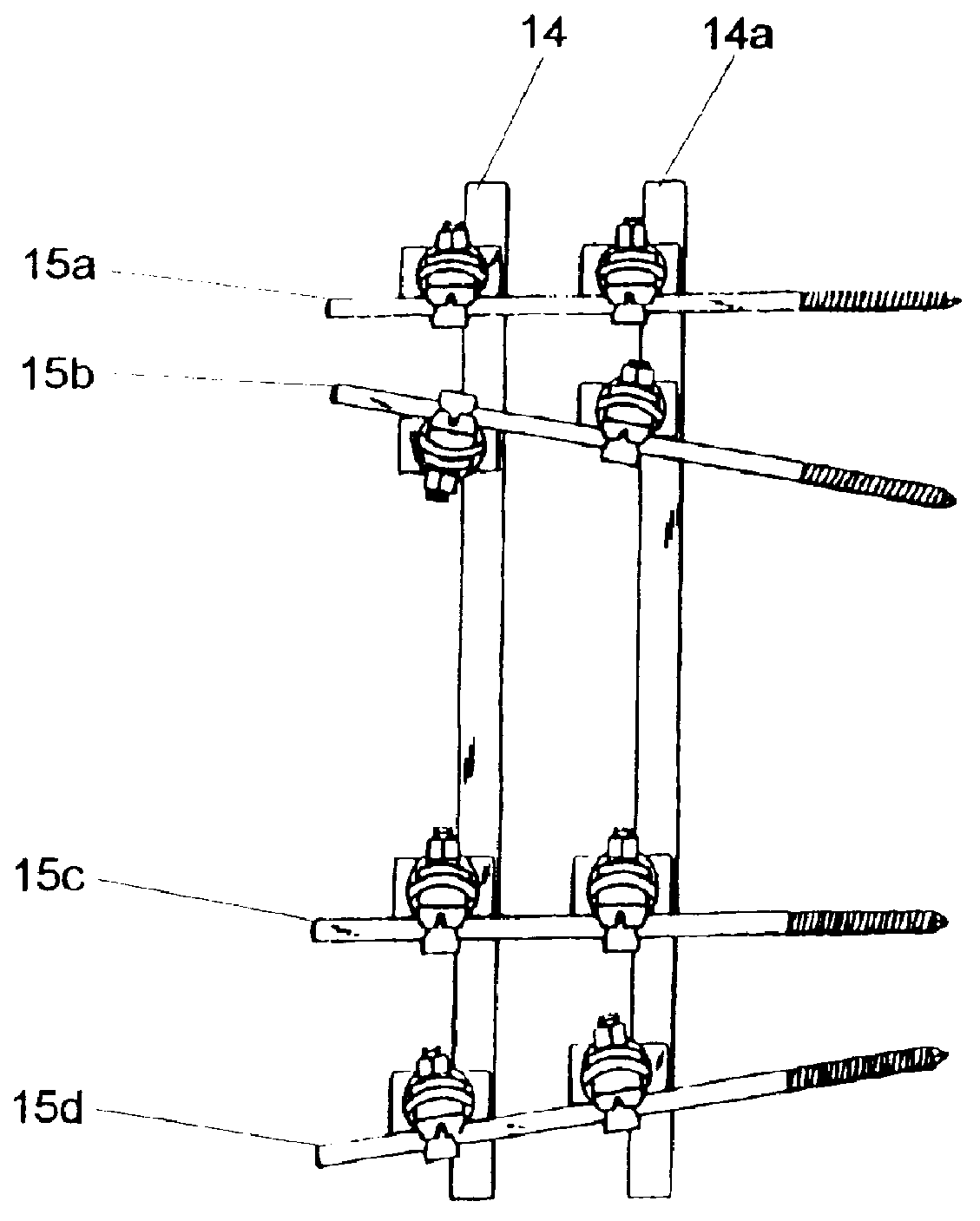

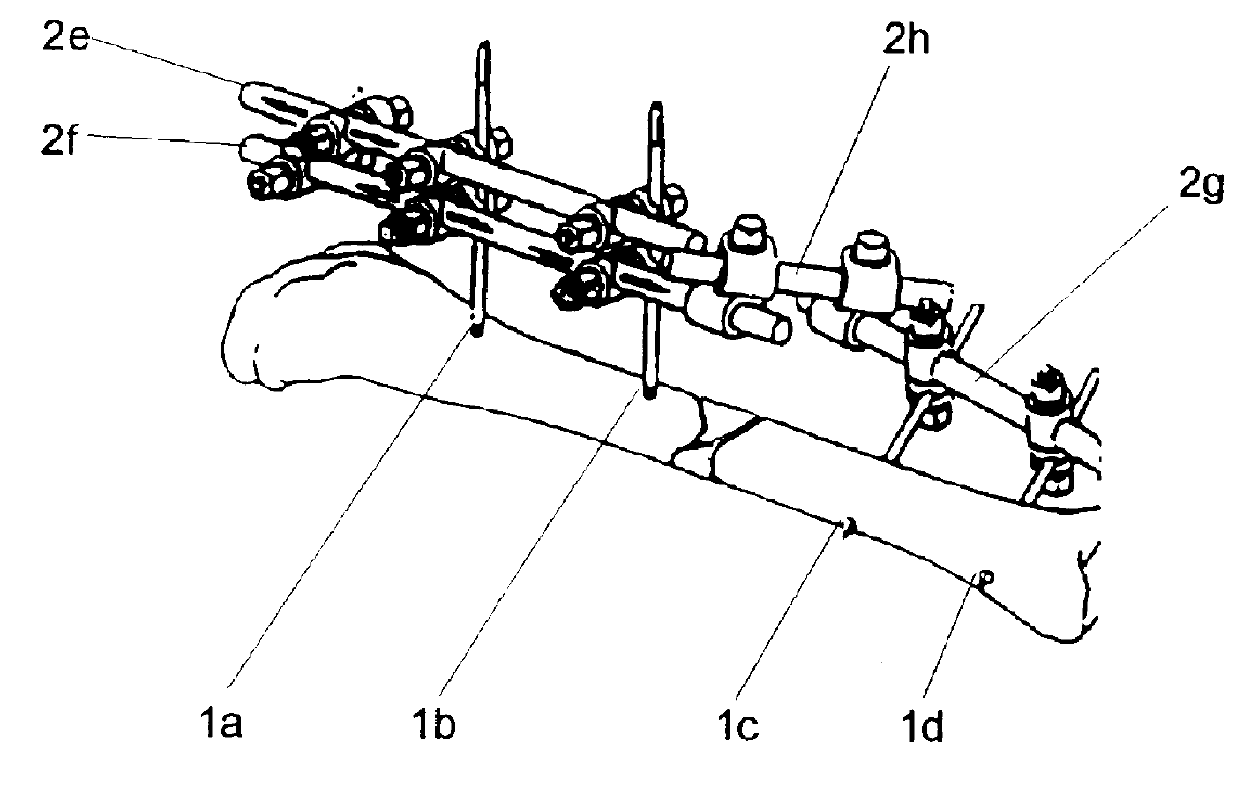

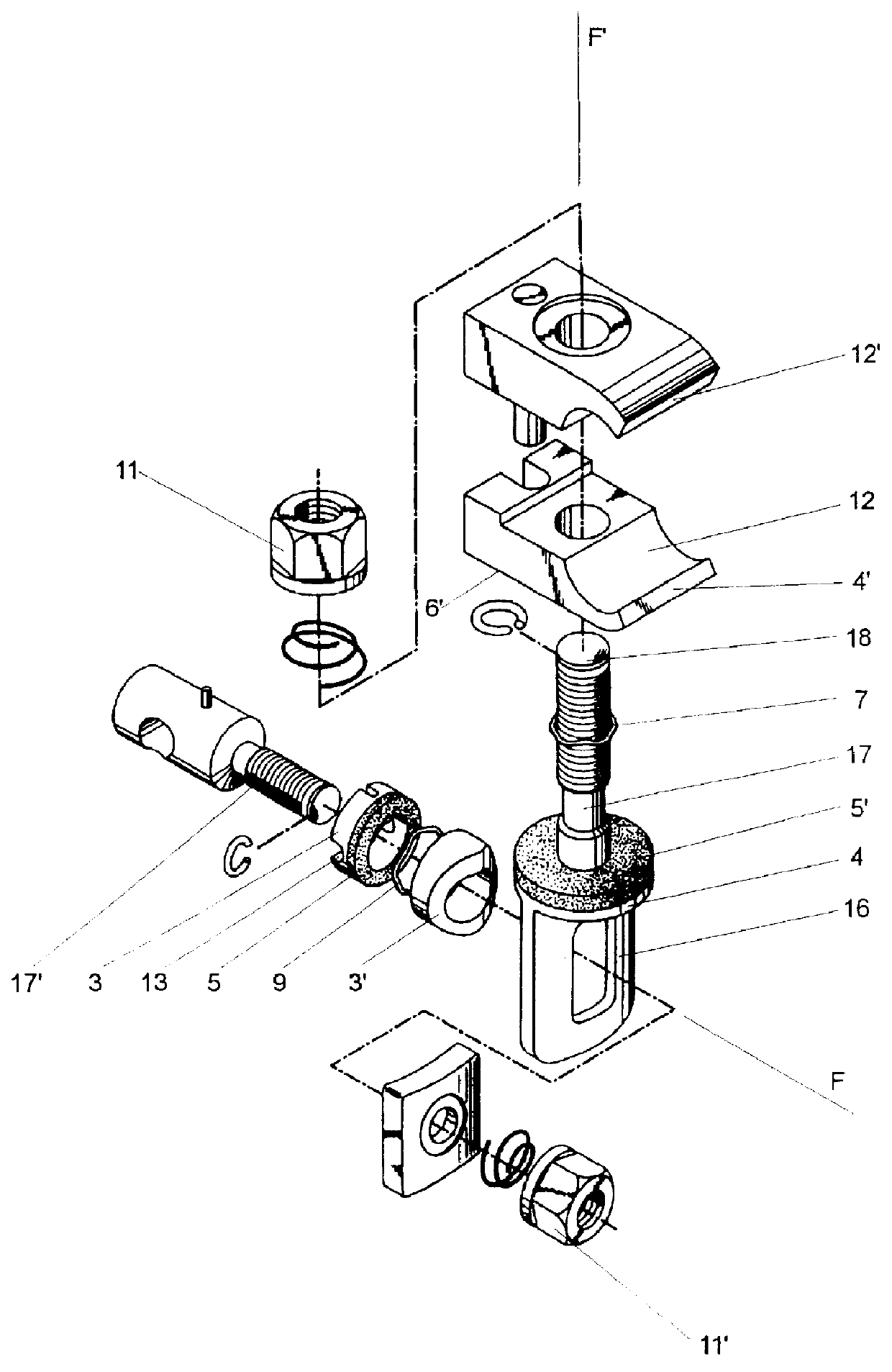

Clamping connection for medical equipment and apparatus

InactiveUS6022348AMinimal motionEasy to disassembleSuture equipmentsLigamentsExternal fixatorCoupling

The invention relates to a coupling of two sides of a synergetically cooperating fixation system in medical equipment and apparatus, illustrated by way of example of an external fixator with rod-like guide elements, wherein a point-precise and internally tension-free clamping connection is formed by in each case two planar parallel disposed faces. The complementary, uncoated coupling surface is shape-matchingly impressed "de novo" and "uniquely" during each coupling closure by a static press-on force based on a diamond, plastic grain layer of a chaotic profile solidly attached to one of the faces, such that a clamping connection with the multilatent force-form match closure is furnished.

Owner:SPITZER DANIEL

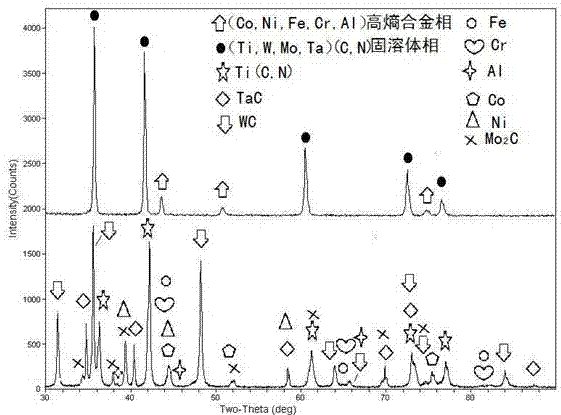

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com