Patents

Literature

326 results about "Ceramic bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

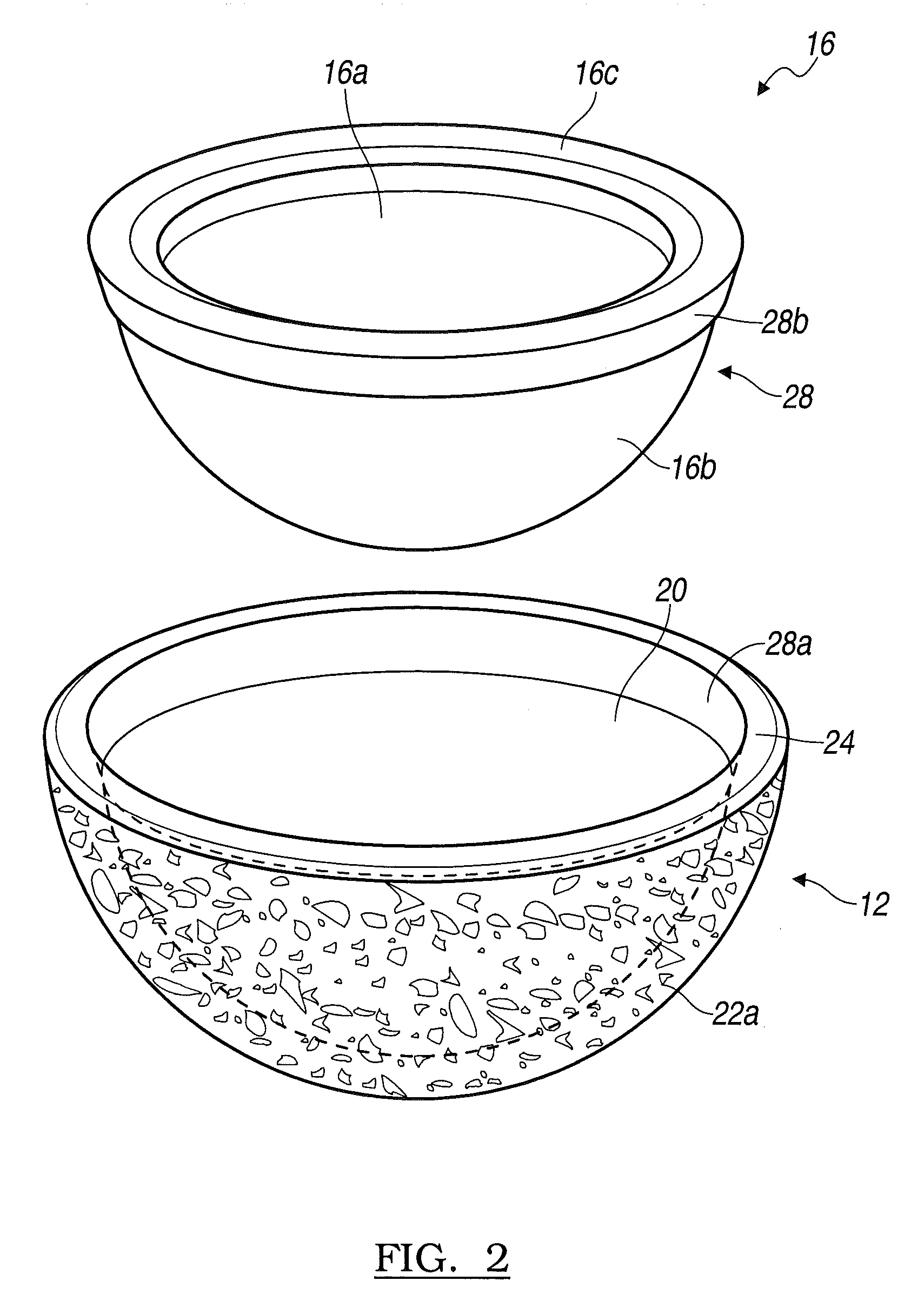

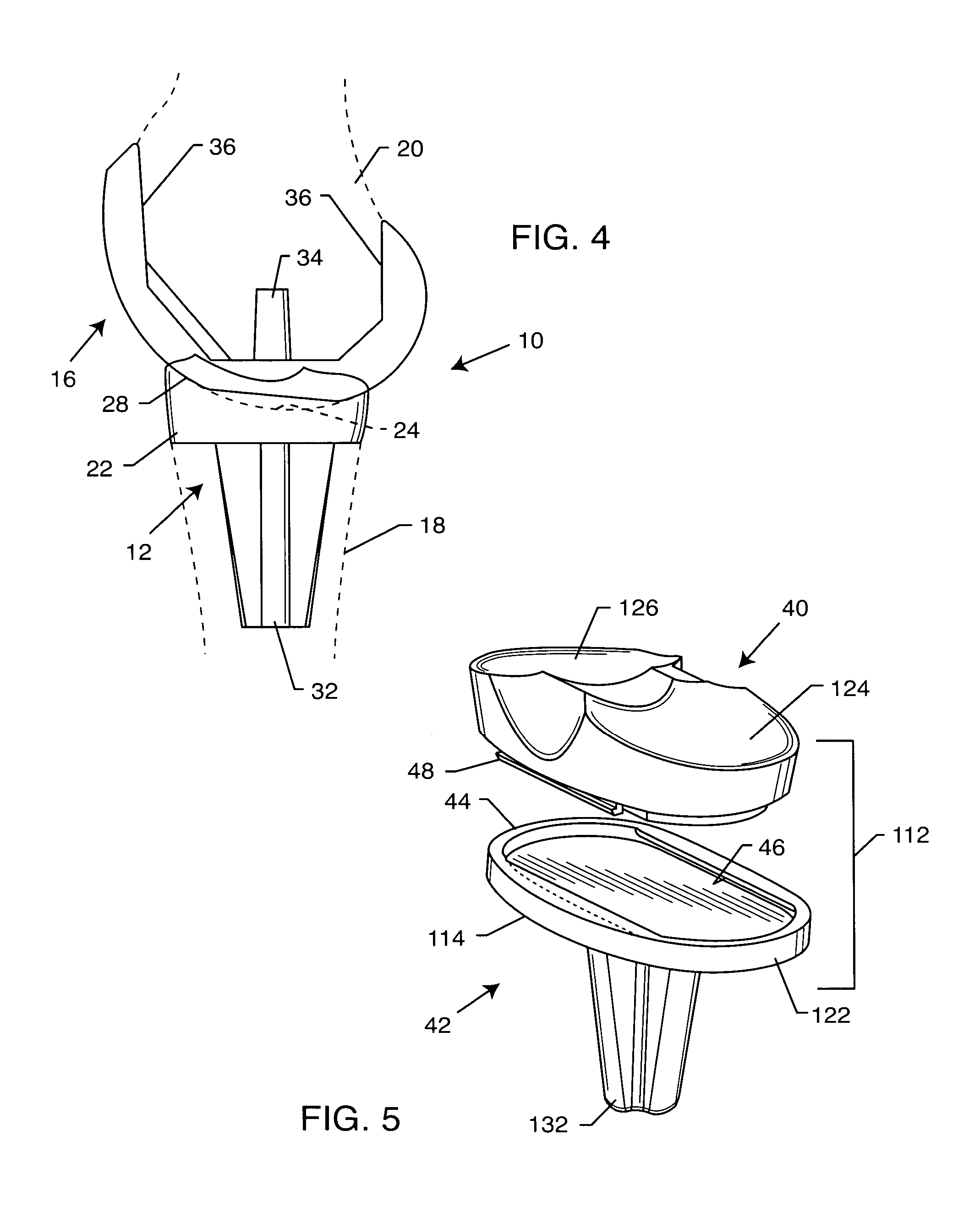

Knee prosthesis with ceramic tibial component

InactiveUS20060052875A1Reduce wearHigh strengthHeart valvesJoint implantsArticular surfacesTibial bone

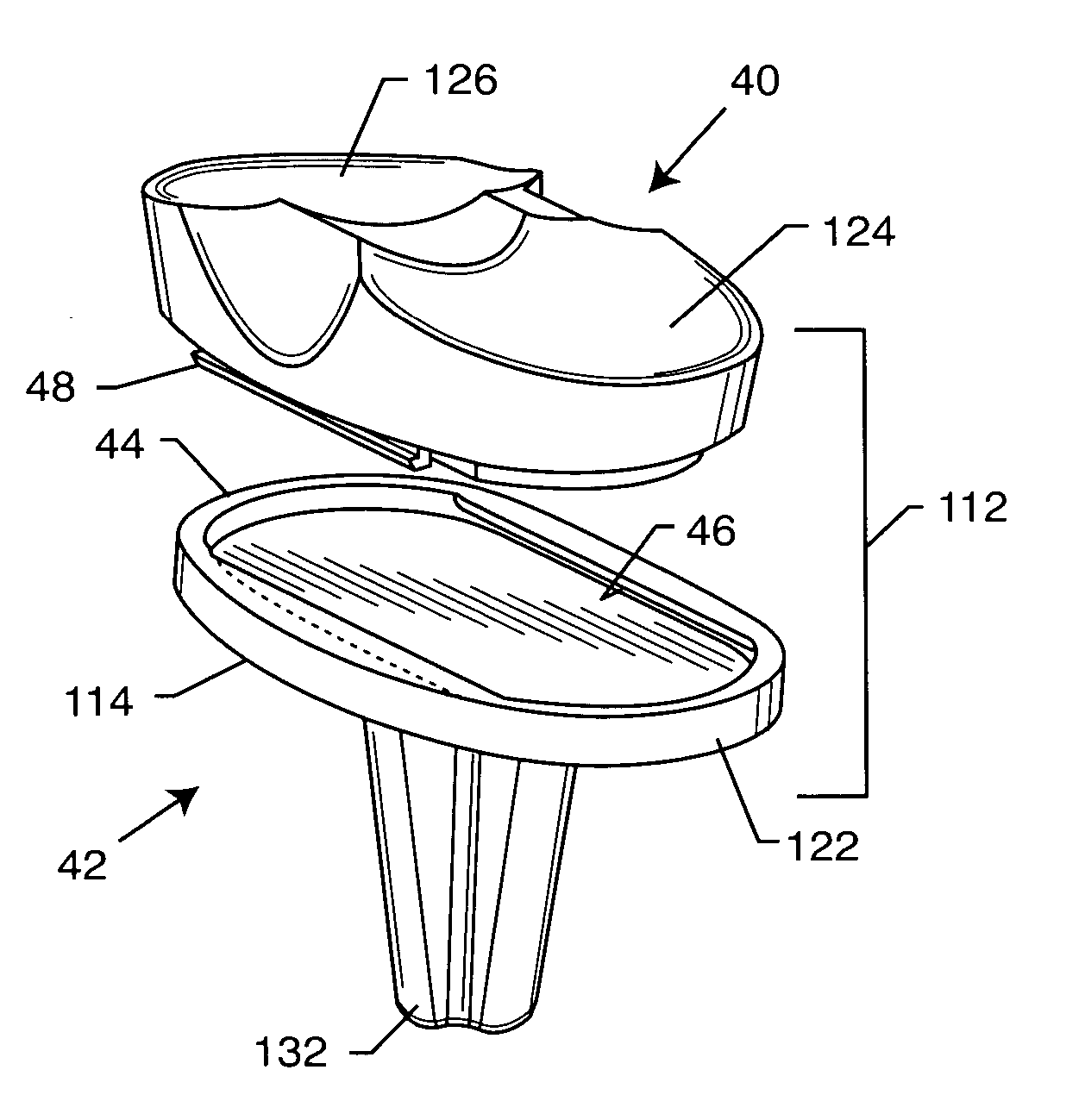

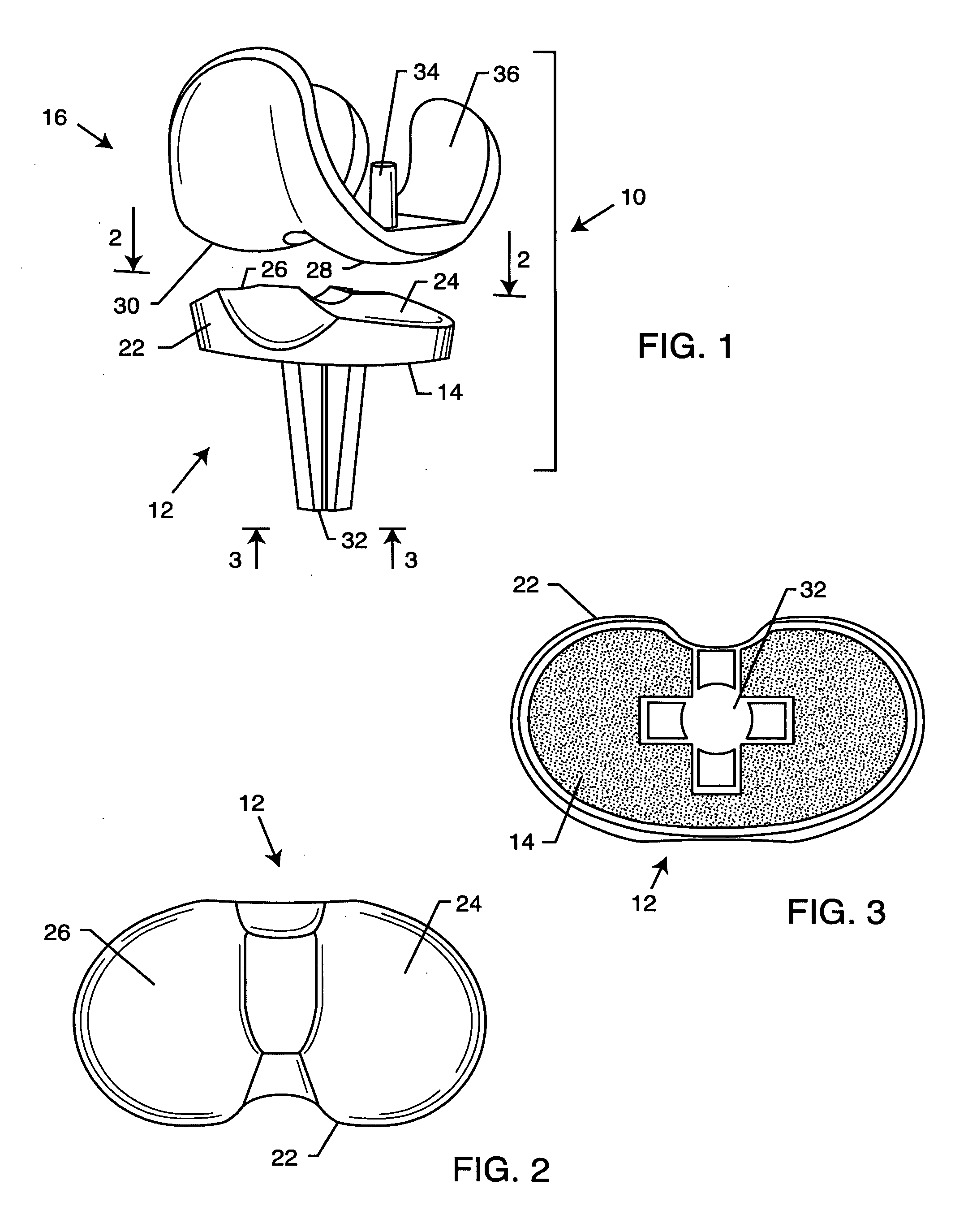

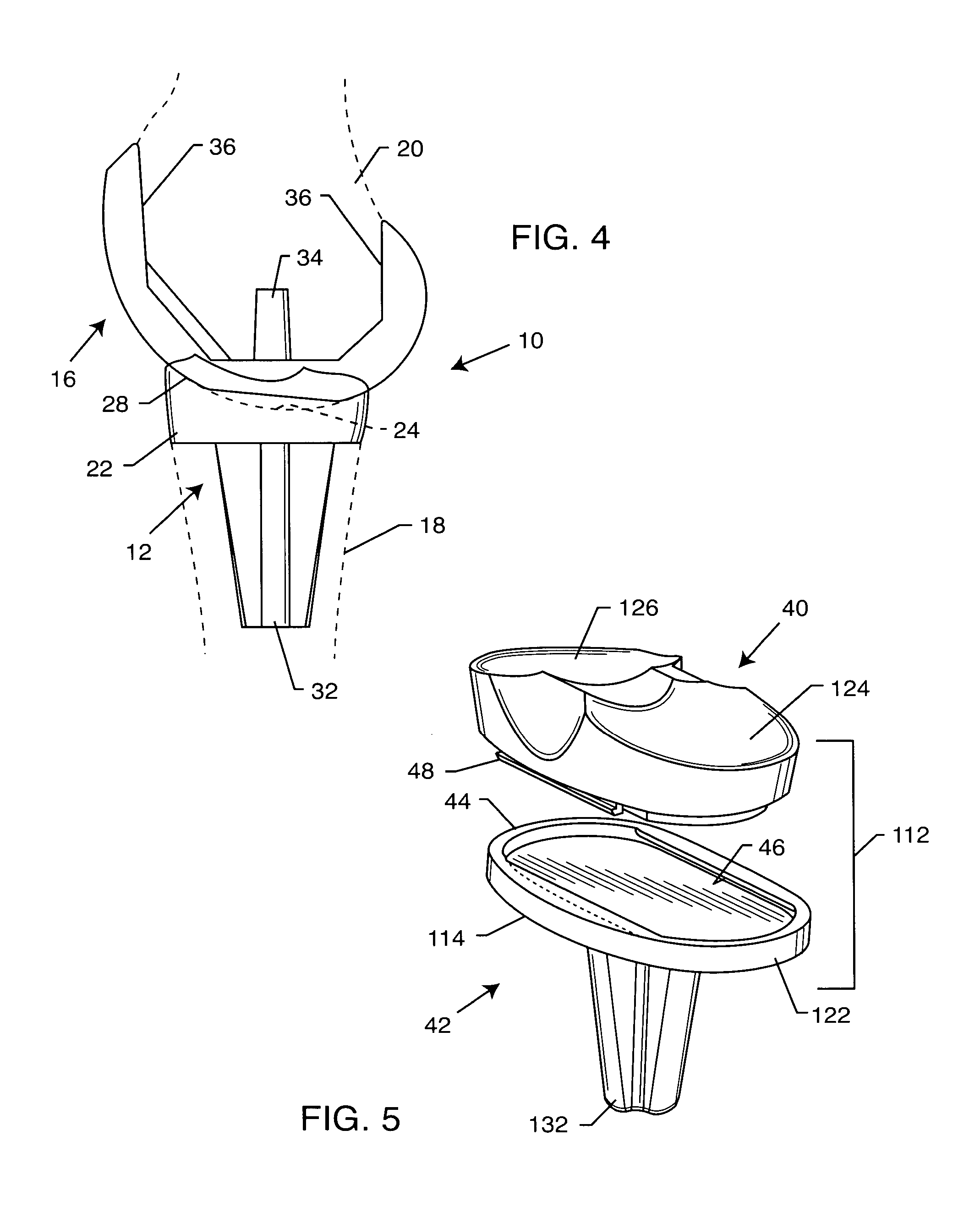

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

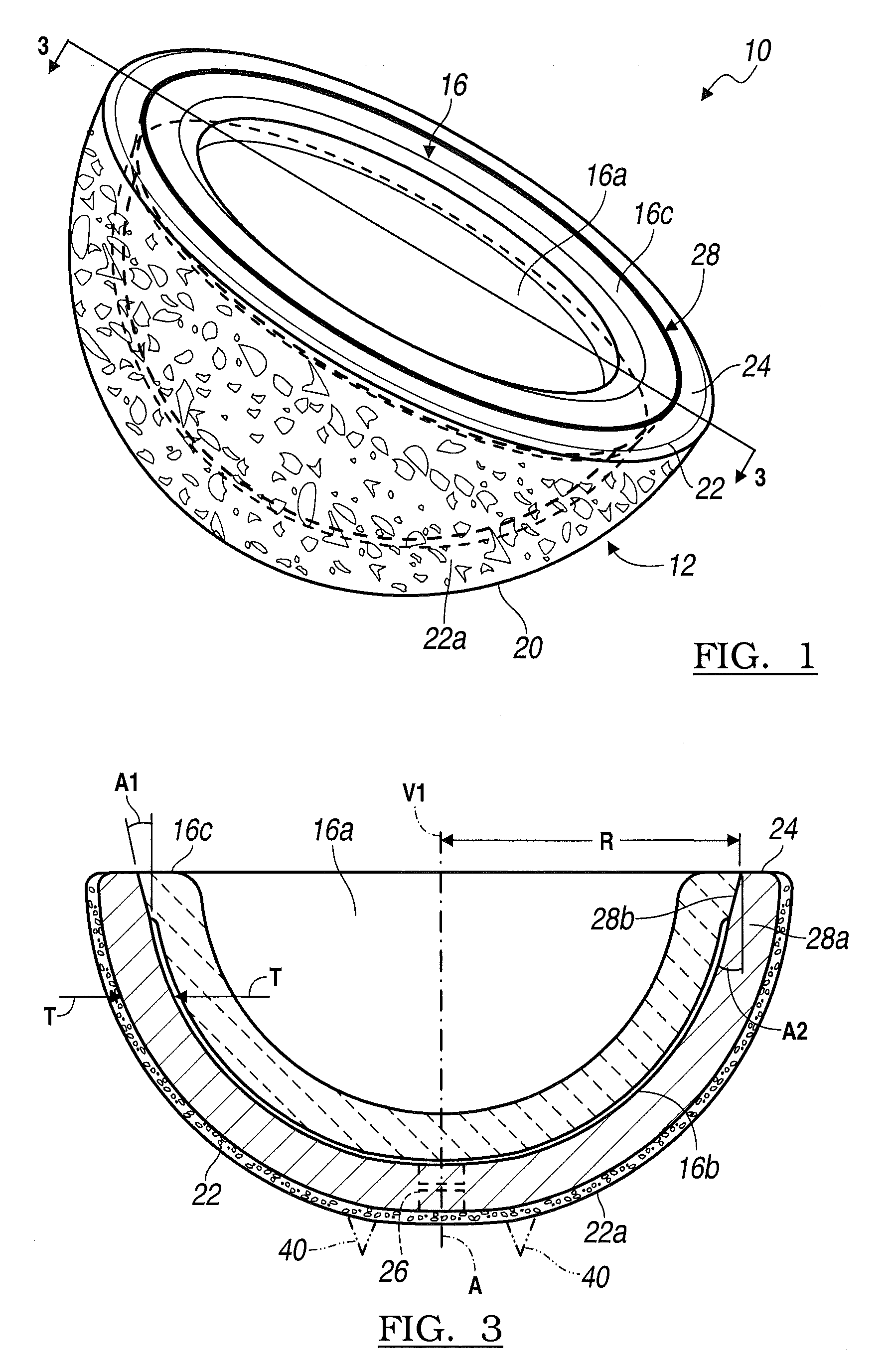

System and Method for Acetabular Cup

An acetabular implant assembly for replacing a portion of the anatomy is provided. The acetabular implant assembly can include a fiber-reinforced polymeric cup having an exterior surface that engages the anatomy and an interior surface. The acetabular implant assembly can also include a metal or ceramic bearing liner, which can be coupled to the interior surface of the with an acetabular implant assembly cup via a taper lock connection. The metal or ceramic bearing liner can have an interior bearing surface. The acetabular implant assembly can include a metal articulating member, which can be movable within the interior bearing surface to replace the articulating portion of the anatomy.

Owner:BIOMET MFG CORP

Knee prosthesis with ceramic tibial component

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

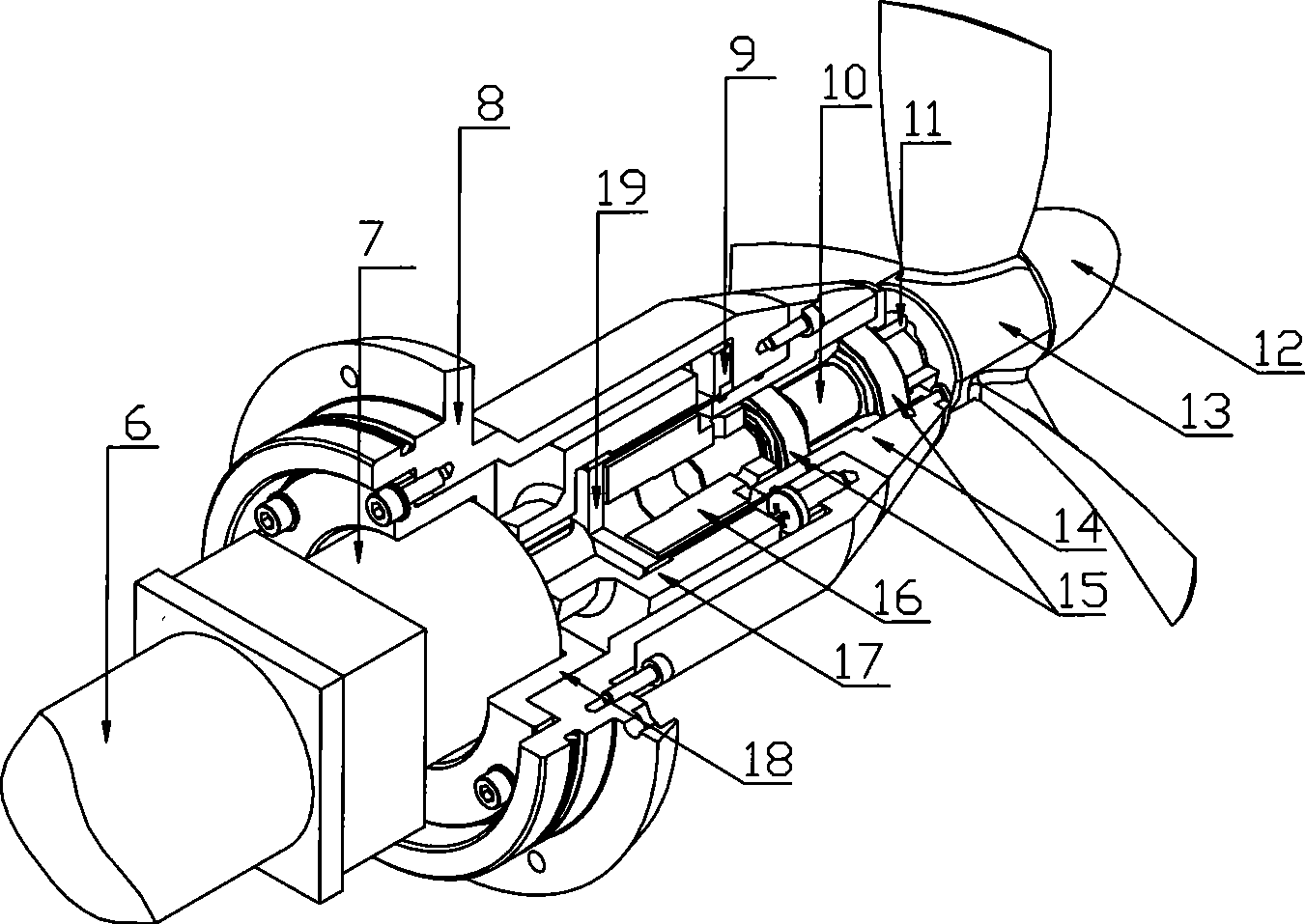

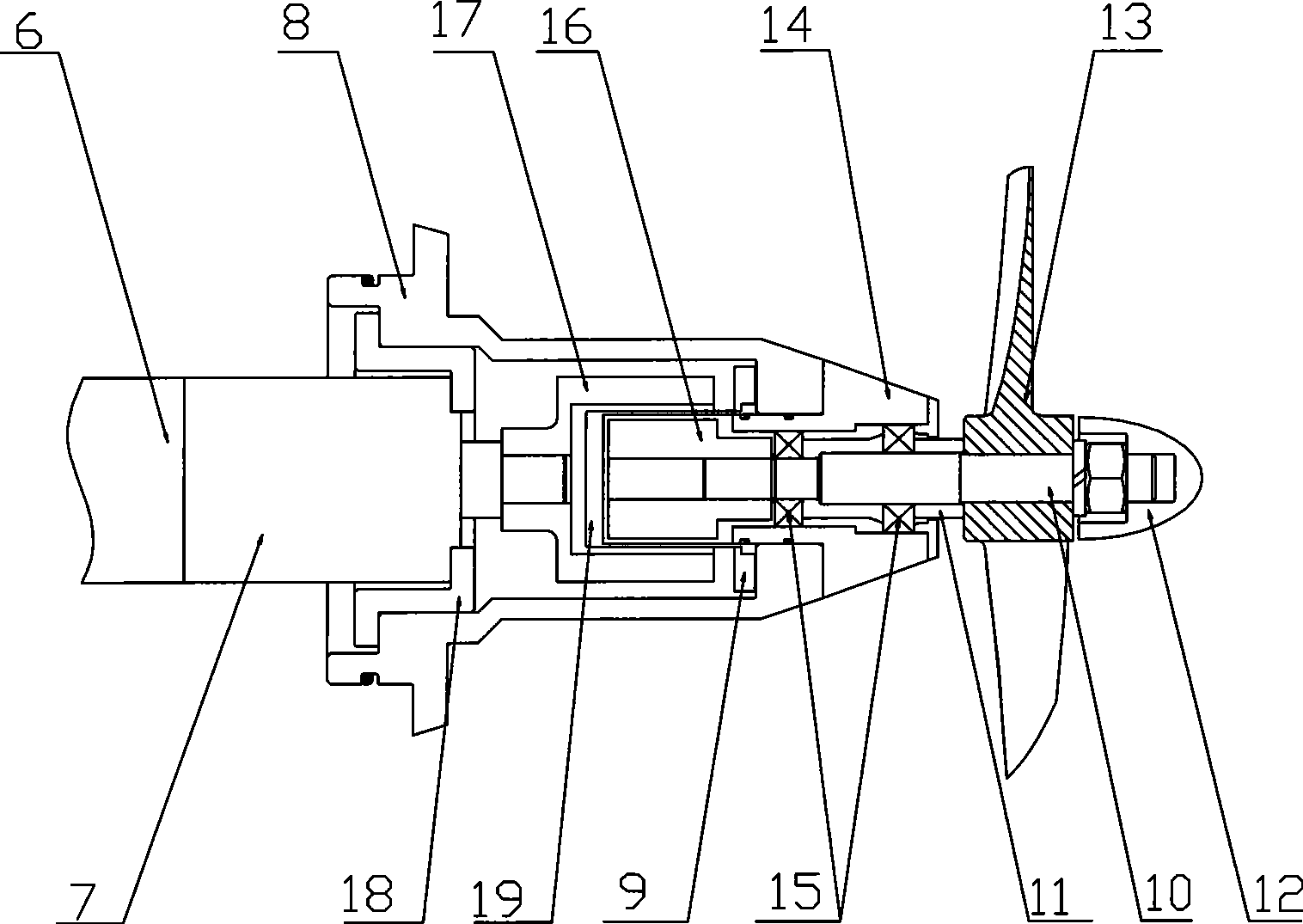

Underwater screw propulsion die and underwater navigation device containing the same

InactiveCN101508335AAchieve absolute sealingOvercoming frictional resistanceUnderwater vesselsUnderwater equipmentAqueous corrosionUnderwater navigation

The invention discloses an underwater screw propeller propelling module, which comprises a servo motor and a speed reducer connected with a tail cone, wherein the speed reducer is fixedly connected with the inside of the tail cone and is connected with a driven shaft passing through a bearing support through a shaft coupling, and the driven shaft is provided with a screw propeller; the shaft coupling is a magnetic shaft coupling consisting of an inner hub, an outer hub sleeved outside the inner hub, a stainless steel isolation cover arranged between the inner hub and the outer hub, and a clamp ring fixedly connected with the stainless steel isolation cover; and the outer hub is arranged on an output shaft of the speed reducer, the inner hub is arranged on the driven shaft, and the clamp ring is fixedly arranged in the tail cone. The invention also discloses an underwater vehicle comprising the underwater screw propeller propelling module. The underwater screw propeller propelling module adopts a magnetic coupling technique to realize power transmission, adopts the isolation cover to isolate water from a sealed cabin, adopts a corrosion resistant material and a ceramic bearing to solve the problem of aqueous corrosion resistance, adopts the modularization design to make the structure compact and easy to replace, dismount and mount, and achieves the absolute sealing between a pressure resistant cabin of the underwater vehicle and the external sea water.

Owner:TIANJIN UNIV

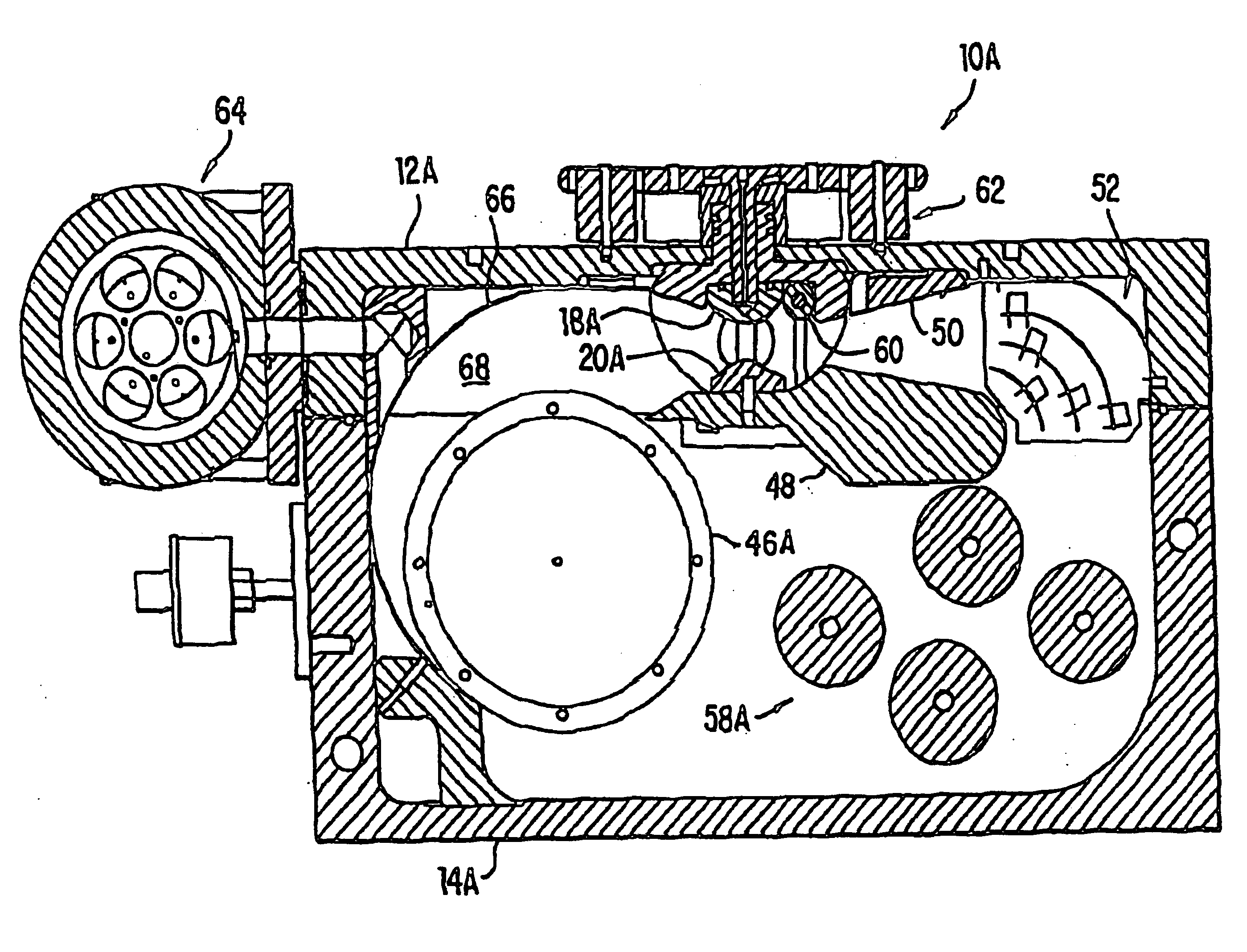

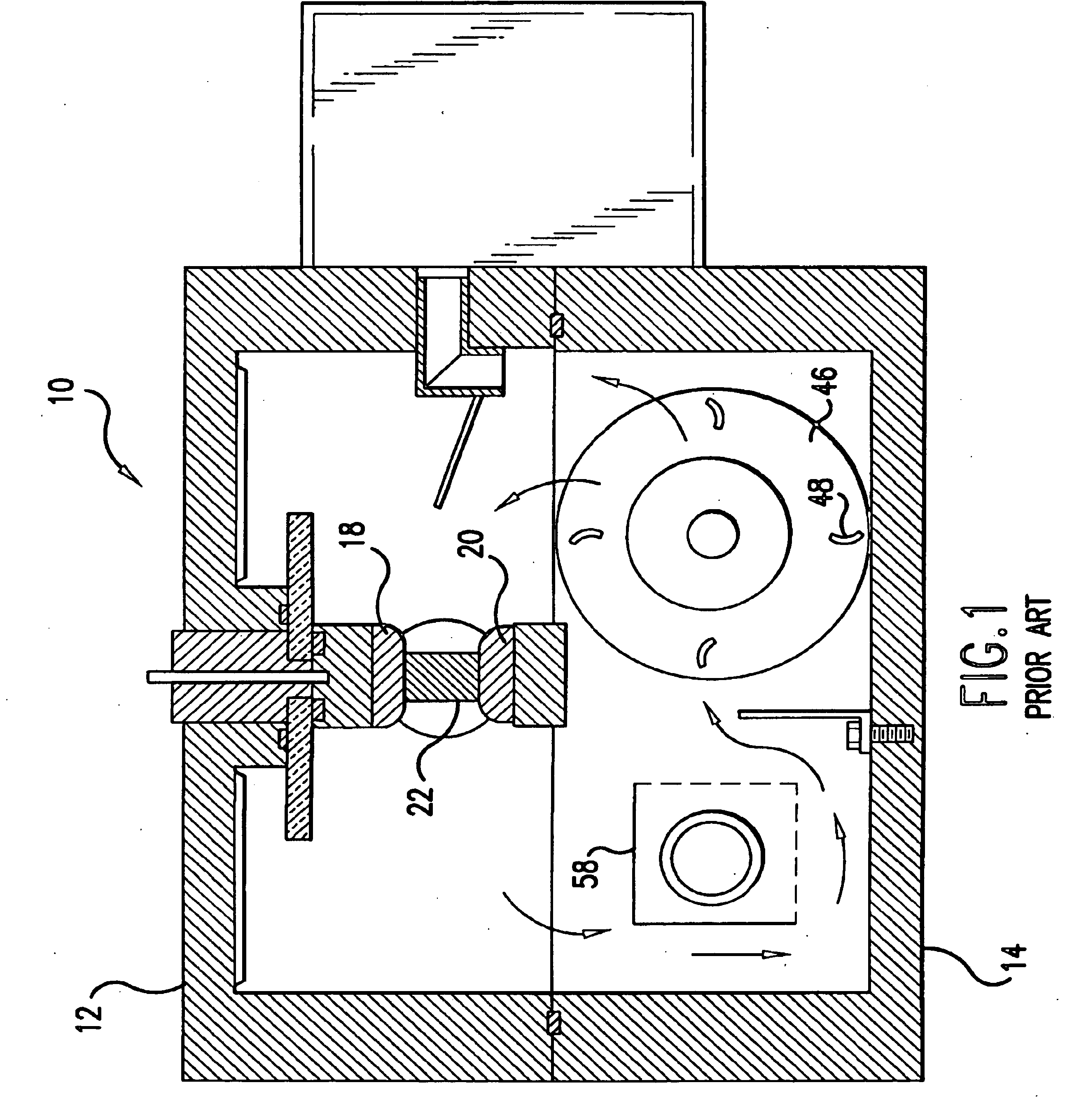

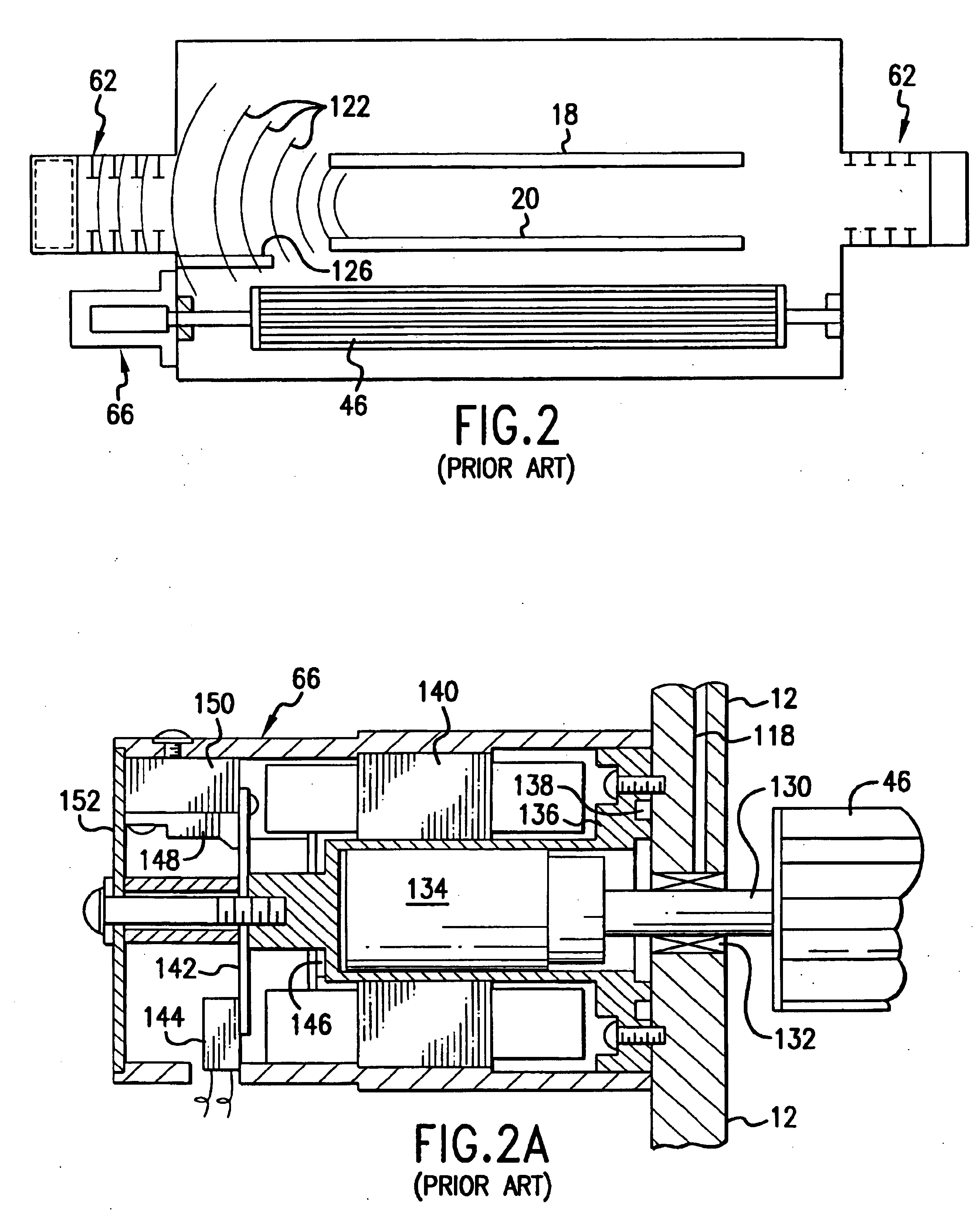

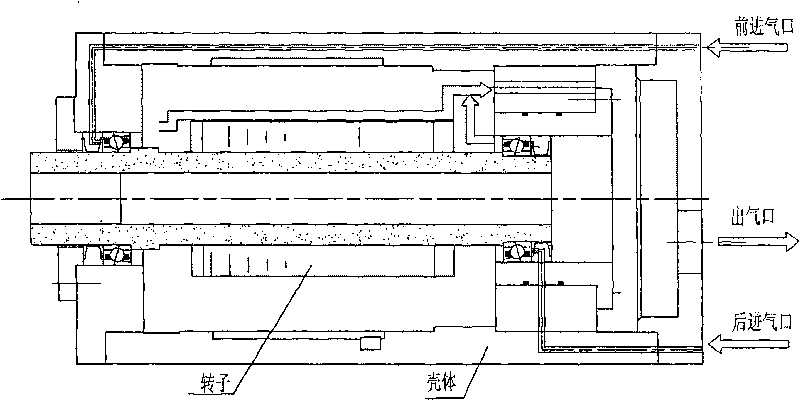

Six to ten KHz, or greater gas discharge laser system

InactiveUS6914919B2Reliable long-term operationSpeed up the gas flowOptical resonator shape and constructionLaser arrangementsMagnetic bearingSystems design

The present invention provides gas discharge laser systems capable of reliable long-term operation in a production line capacity at repetition rates in the range of 6,000 to 10,0000 pulses power second. Preferred embodiments are configured as KrF, ArF and F2 lasers used for light sources for integrated circuit lithography. Improvements include a modified high voltage power supply capable for charging an initial capacitor of a magnetic compression pulse power system to precise target voltages 6,000 to 10,0000 times per second and a feedback control for monitoring pulse energy and determining the target voltages on a pulse-by-pulse basis. Several techniques are disclosed for removing discharge created debris from the discharge region between the laser electrodes during the intervals between discharges. In one embodiment the width of the discharge region is reduced from about 3 mm to about 1 mm so that a gas circulation system designed for 4,000 Hz operation could be utilized for 10,000 Hz operation. In other embodiments the gas flow between the electrodes is increased sufficiently to permit 10,000 Hz operation with a discharge region width of 3 mm. To provide these substantial increased gas flow rates, Applicants have disclosed preferred embodiments utilize tangential forms of the prior art but with improved and more powerful motors and novel bearing designs. New bearing designs include both ceramic bearings and magnetic bearings. In other embodiments, some or all of the gas circulation power is provided with a blower located outside the laser chamber. The outside blower can be located in the laser cabinet or in separate location.

Owner:CYMER INC

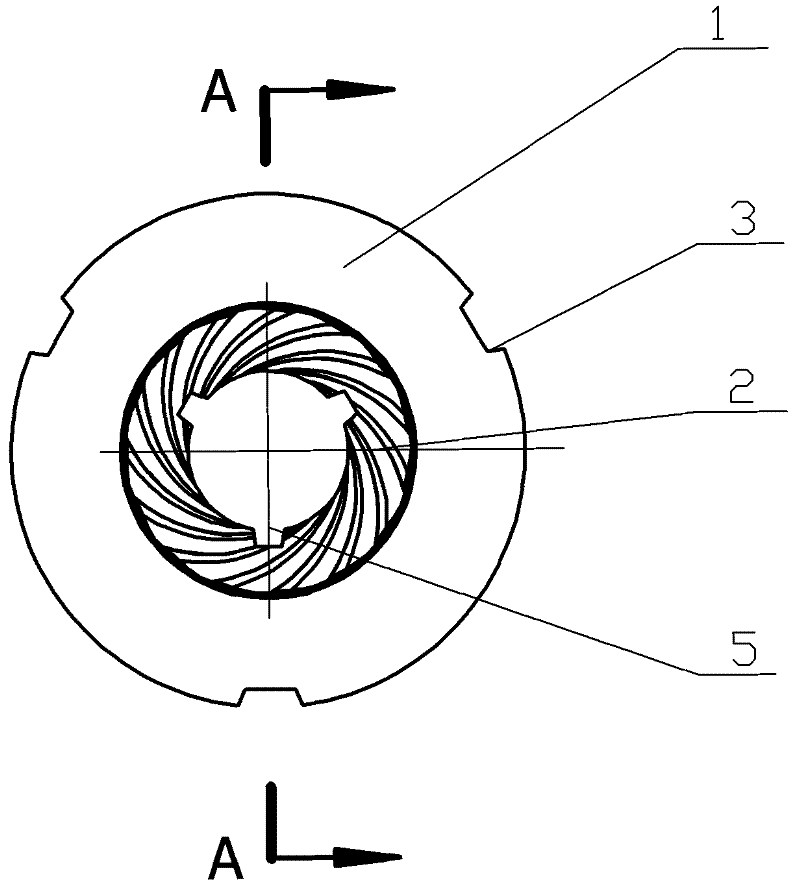

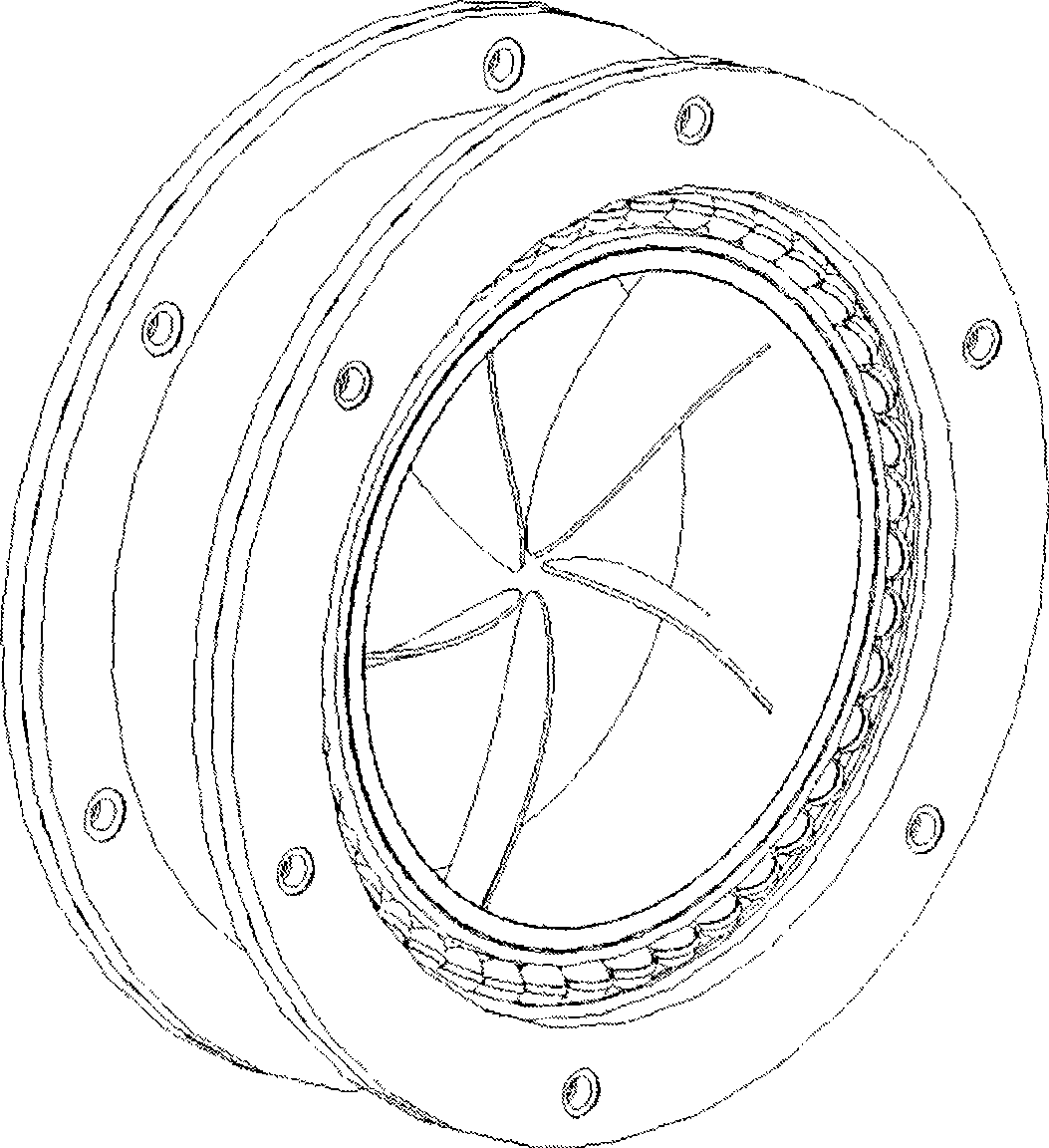

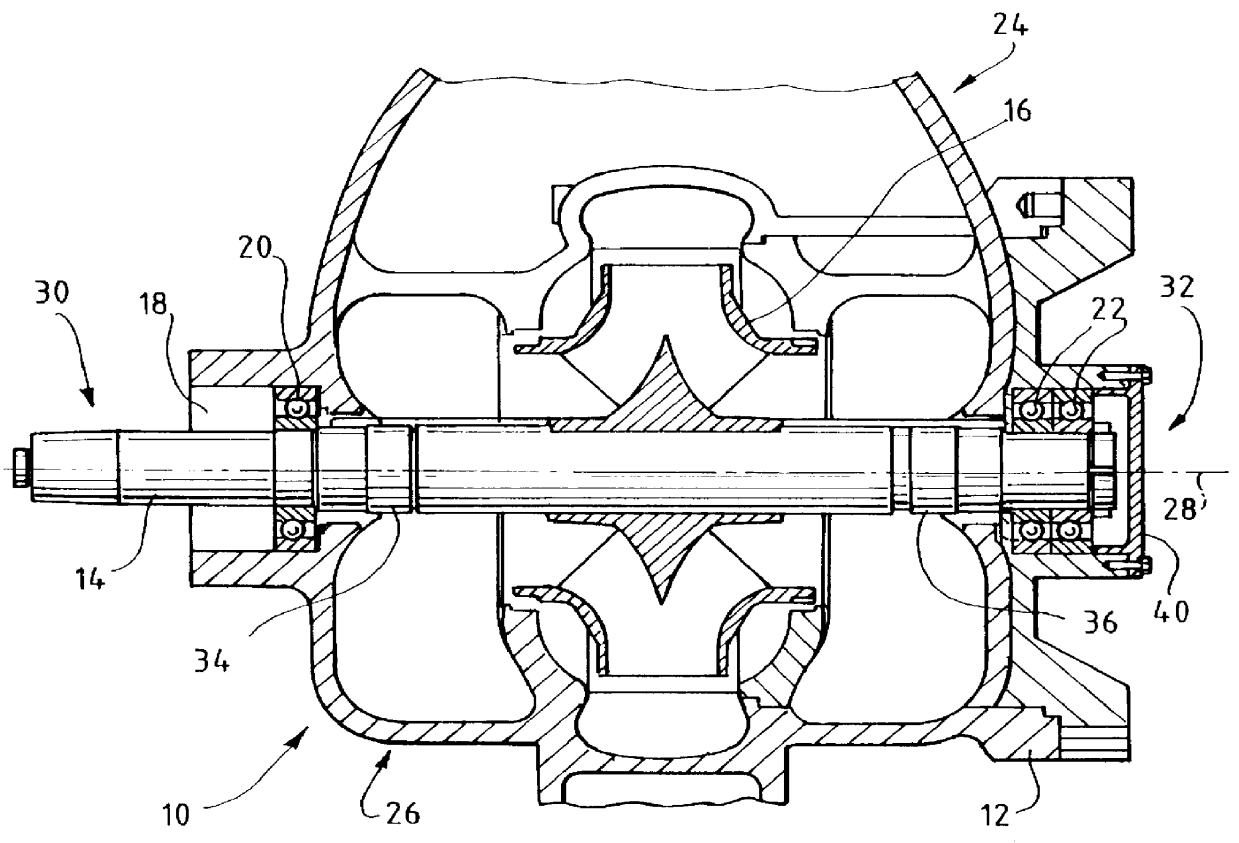

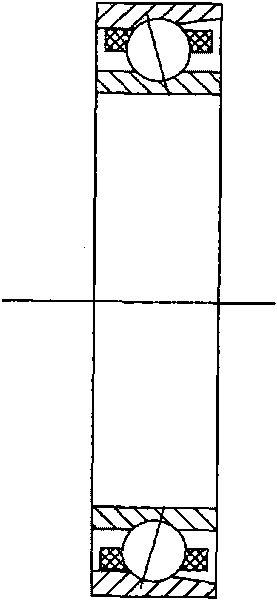

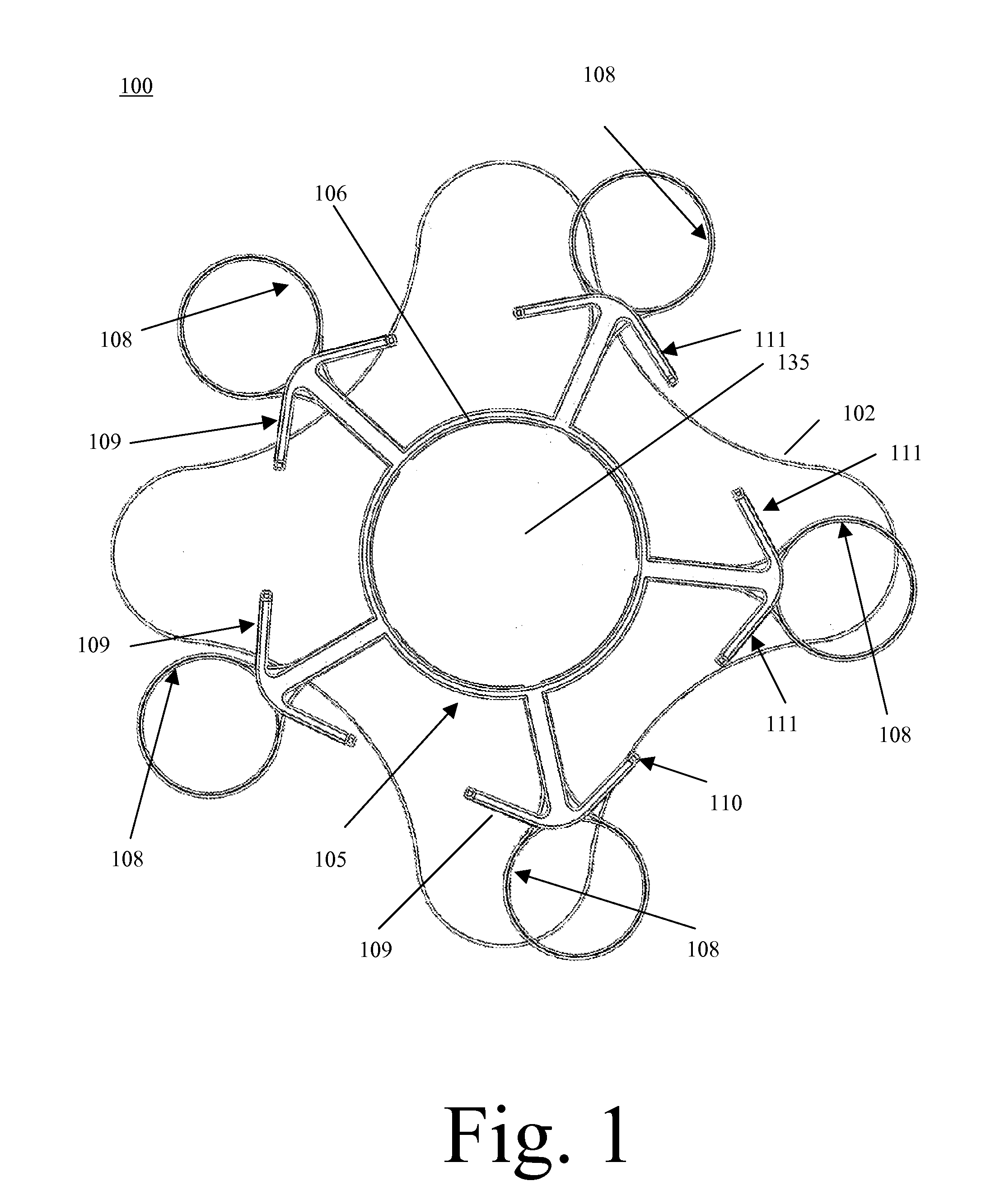

Dynamic pressure gas radial ceramic bearing

ActiveCN102242762ASimple structureEasy to installBearing componentsSliding contact bearingsCarbideDynamic pressure

The invention discloses a dynamic pressure gas radial ceramic bearing, which comprises a ceramic bearing outer sleeve and a ceramic bearing inner sleeve, wherein the ceramic bearing inner sleeve is positioned in the ceramic bearing outer sleeve, the external circle of the ceramic bearing outer sleeve is provided with uniformly distributed grooves and uniformly distributed concave holes, the external circle and two ends of the ceramic bearing inner sleeve are provided with groove-type patterns with regular shape, and the internal circle of the ceramic bearing inner sleeve is provided with uniformly distributed grooves. Because a carbide ceramic-based composite material is used as the manufacturing material of the bearing, the bearing has the characteristics of simple structure, conveniencefor installation, economical efficiency, low cost, strong practicability, easiness in industrialized implementation and the like; because the groove-type patterns with regular shape are machined at the external circle and two ends of the ceramic bearing inner sleeve, the dynamic pressure gas continuously generated under the drive of a high-speed rotating shaft can be well kept in a fit clearance of the internal circle of the ceramic bearing outer sleeve and the external circle of the ceramic bearing inner sleeve, and an air film required for supporting the bearing function of the high-speed rotating shaft is formed to realize certain stability and loading capacity.

Owner:罗立峰

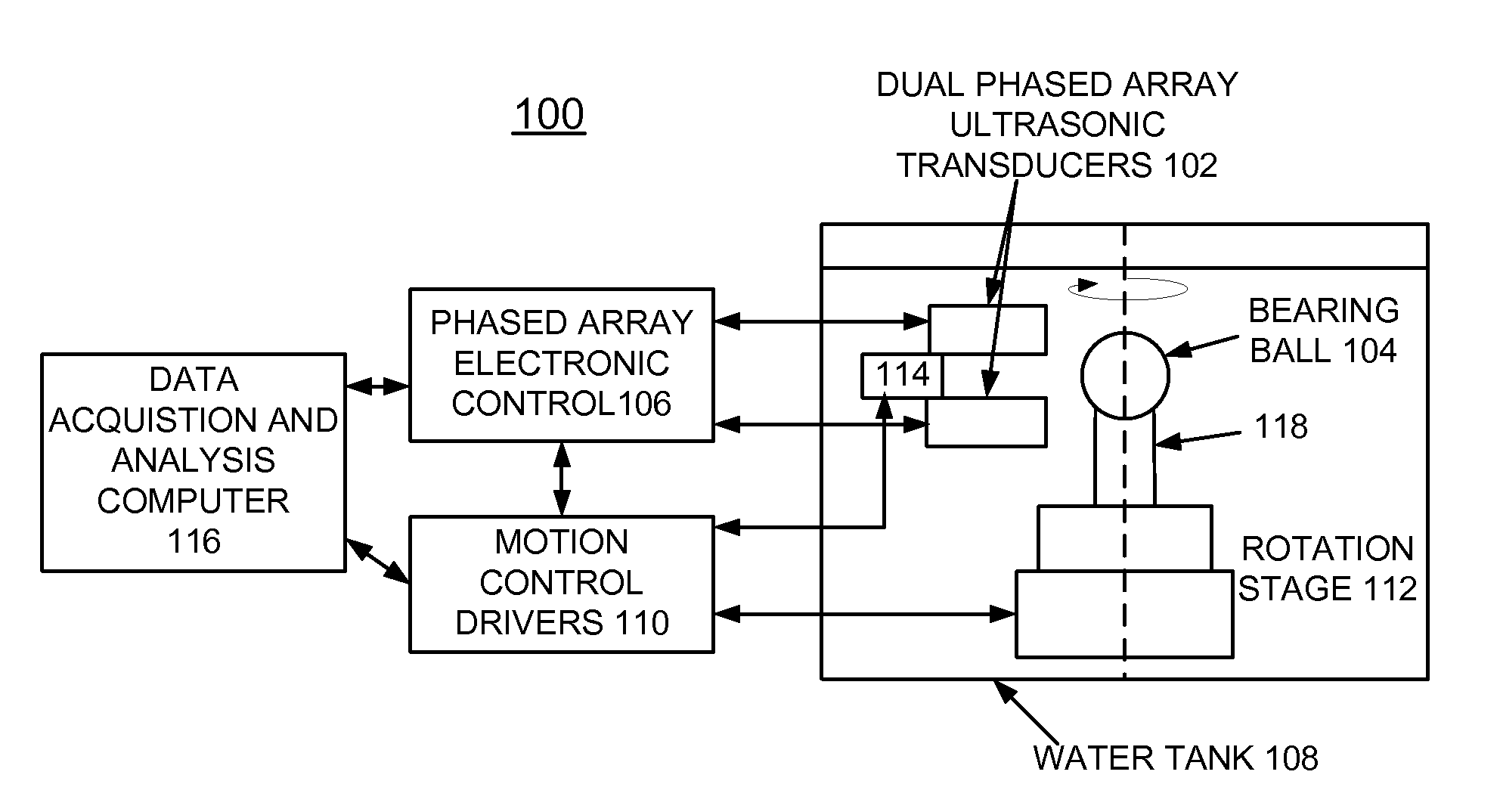

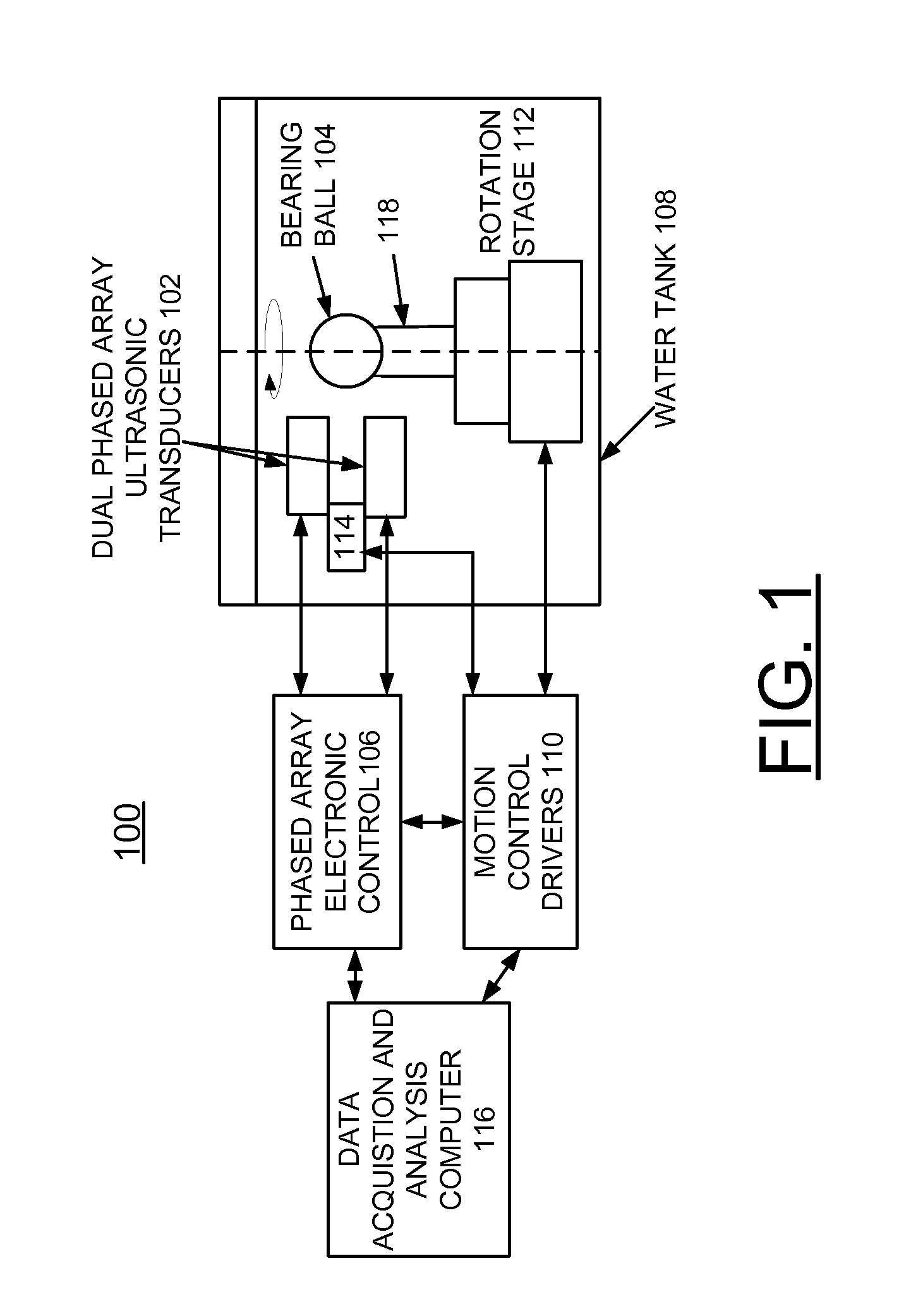

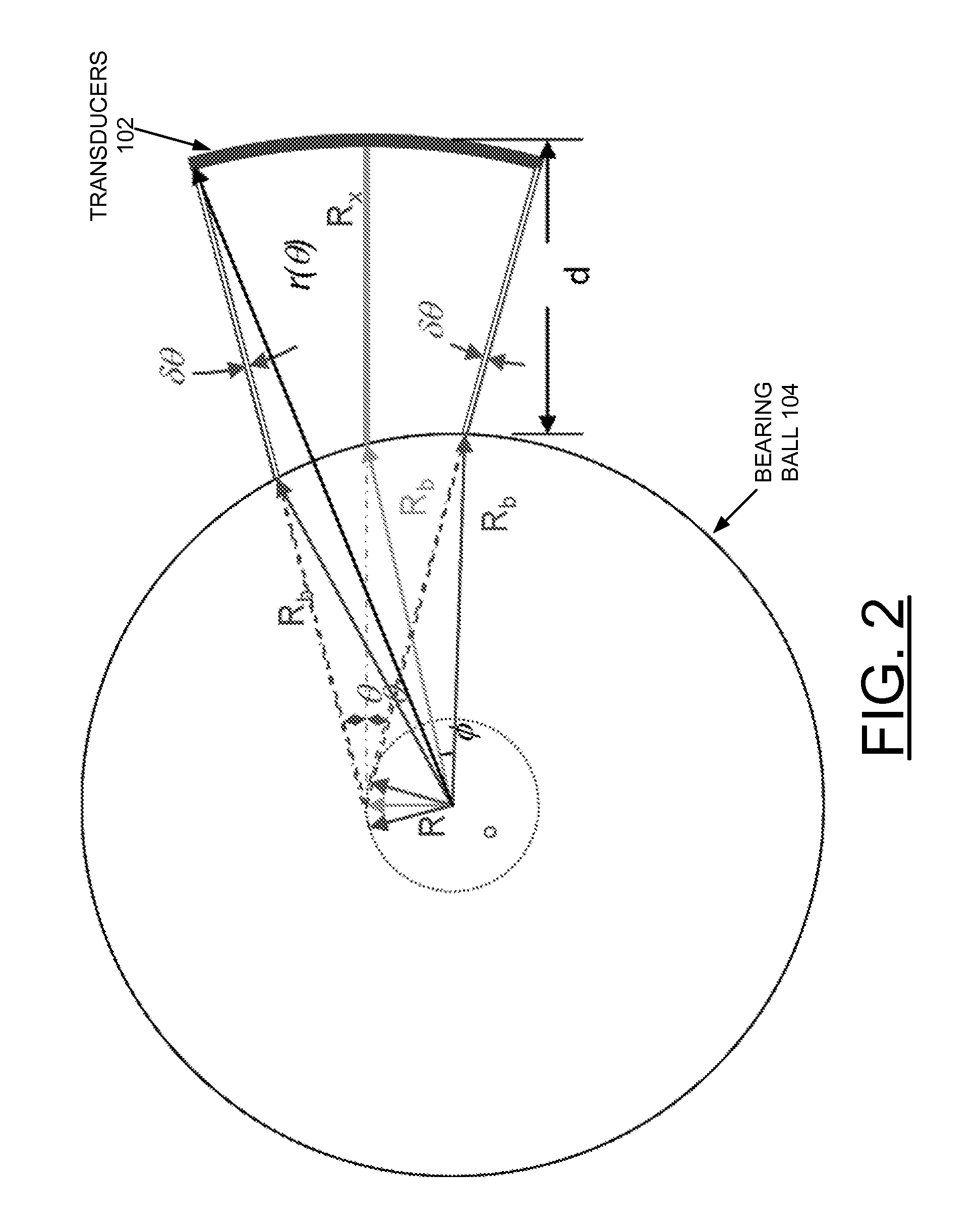

Method and apparatus for ultrasound phased array testing of bearing balls

InactiveUS20090019937A1Rapid and low-cost detectionRapid surfaceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSonification

Owner:UCHICAGO ARGONNE LLC

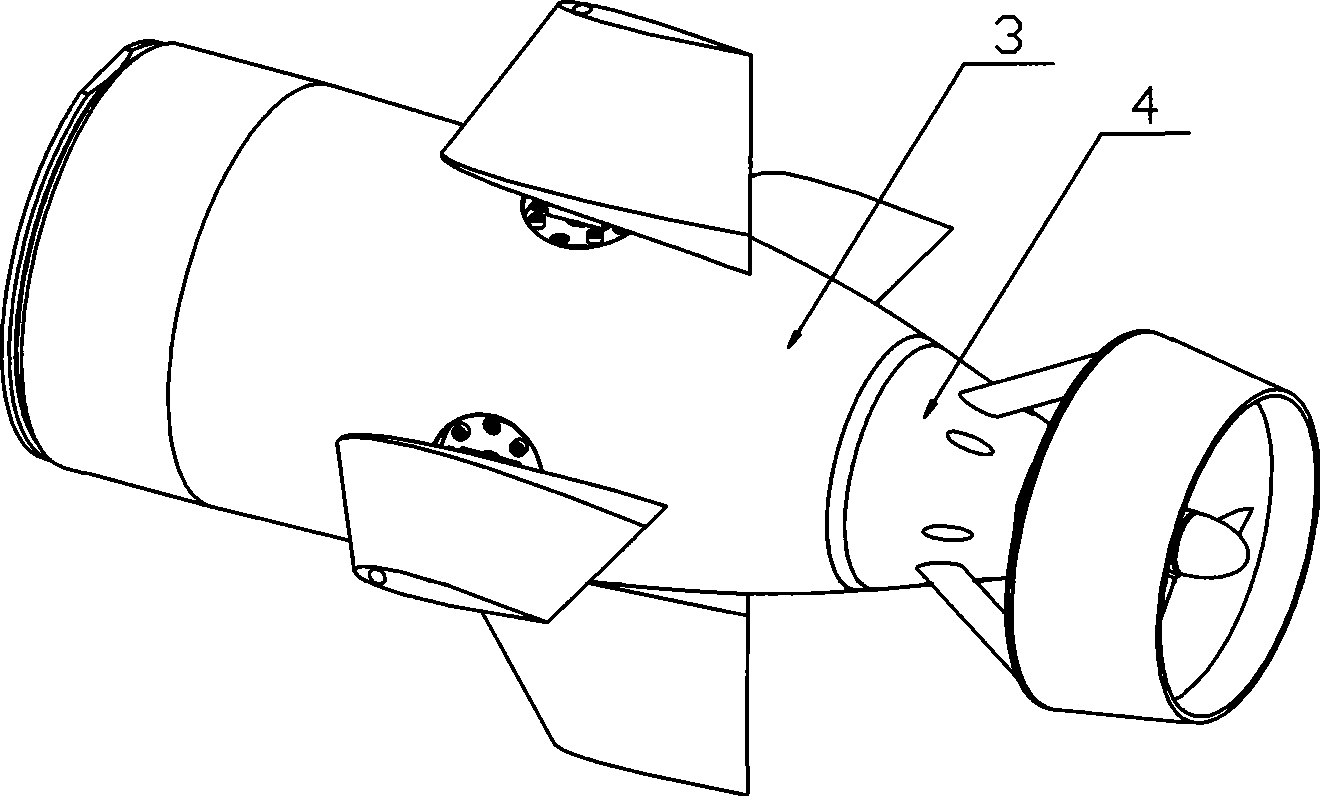

Underwater hollow hub-free propeller

InactiveCN101546939AWork lessIncrease the number of polesRotary propellersMechanical energy handlingUnderwaterPropeller

The invention provides an underwater hollow hub-free propeller, which comprises a motor shell, a stator coil, a stator silicon-steel sheet, a rotor permanent magnet, a rotor, a screw propeller and a ceramic bearing. The stator coil is wound on the stator silicon-steel sheet, the stator coil wound on the stator silicon-steel sheet is arranged at the center of the motor shell, the rotor has a hollow annular structure, split poles of the rotor permanent magnet are fixed on the rotor to form a hollow structural rotor, the screw propeller is fixed inside the hollow rotor, and the screw propeller, the rotor and the rotor permanent magnet form a whole; and the rotor is fixed in the motor shell through the ceramic bearing. When blades rotate, induced resistance and cavity bubble phenomenon are not generated so as to greatly improve the efficiency of the screw propeller. Moreover, because the diameter of a motor is enlarged, the pole number of the motor is increased and the torque of the motor is improved, the underwater hollow hub-free propeller is particularly suitable for working in an environment with large water depth and large density; and because the motor and the screw propeller of the underwater propeller have an integral hollow structure, the underwater hollow hub-free propeller can be easily arranged on a ship hull.

Owner:HARBIN ENG UNIV

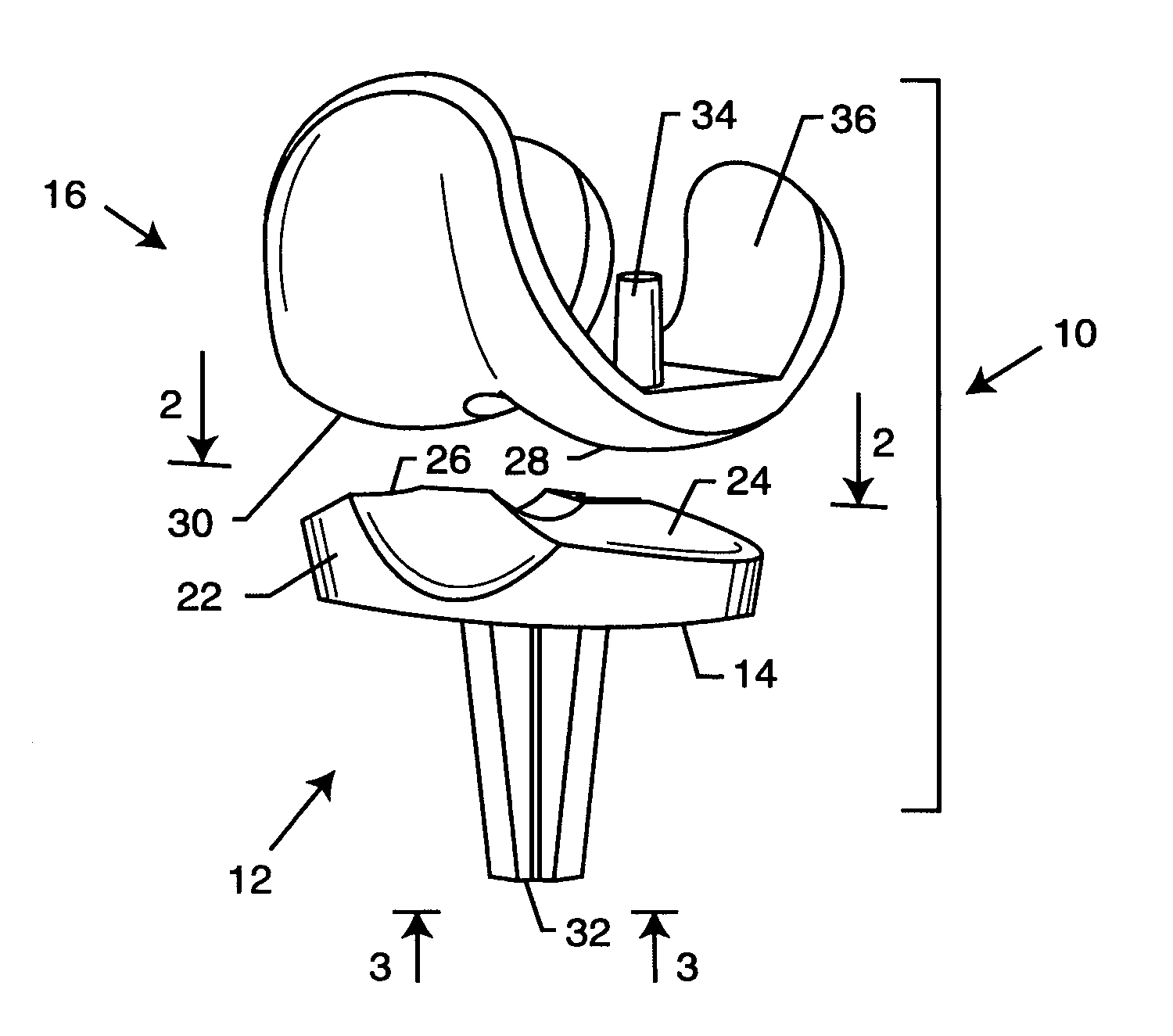

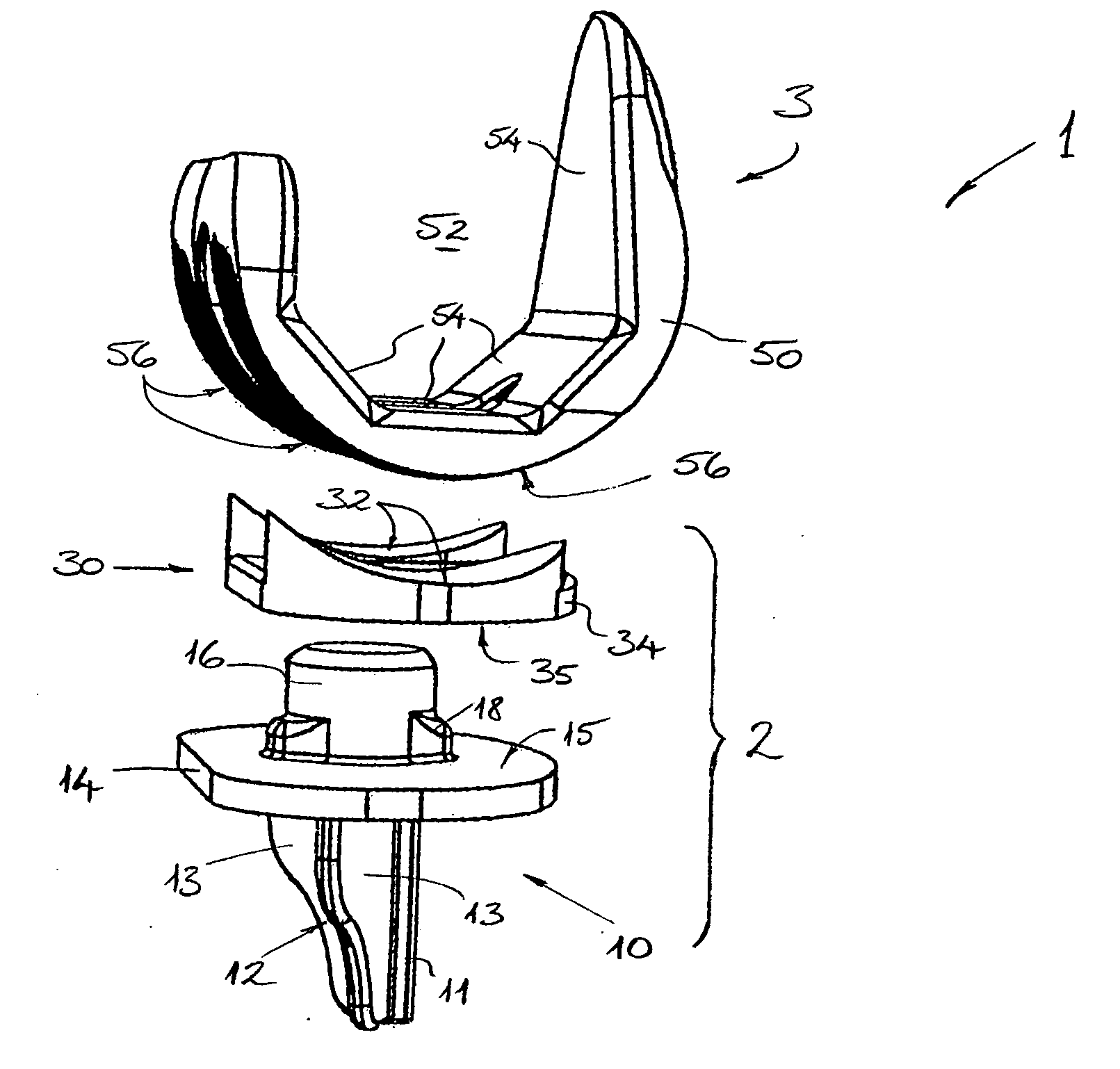

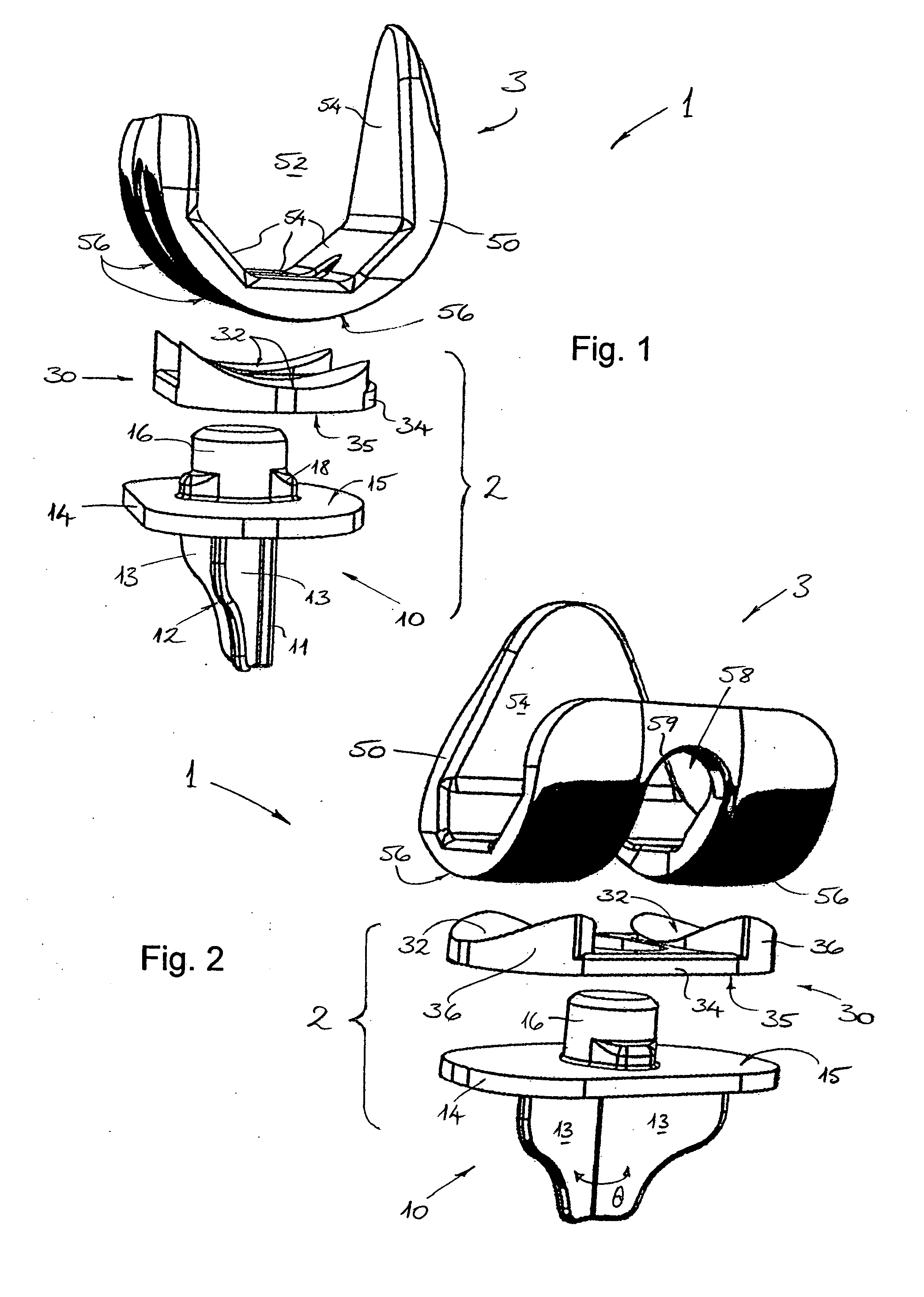

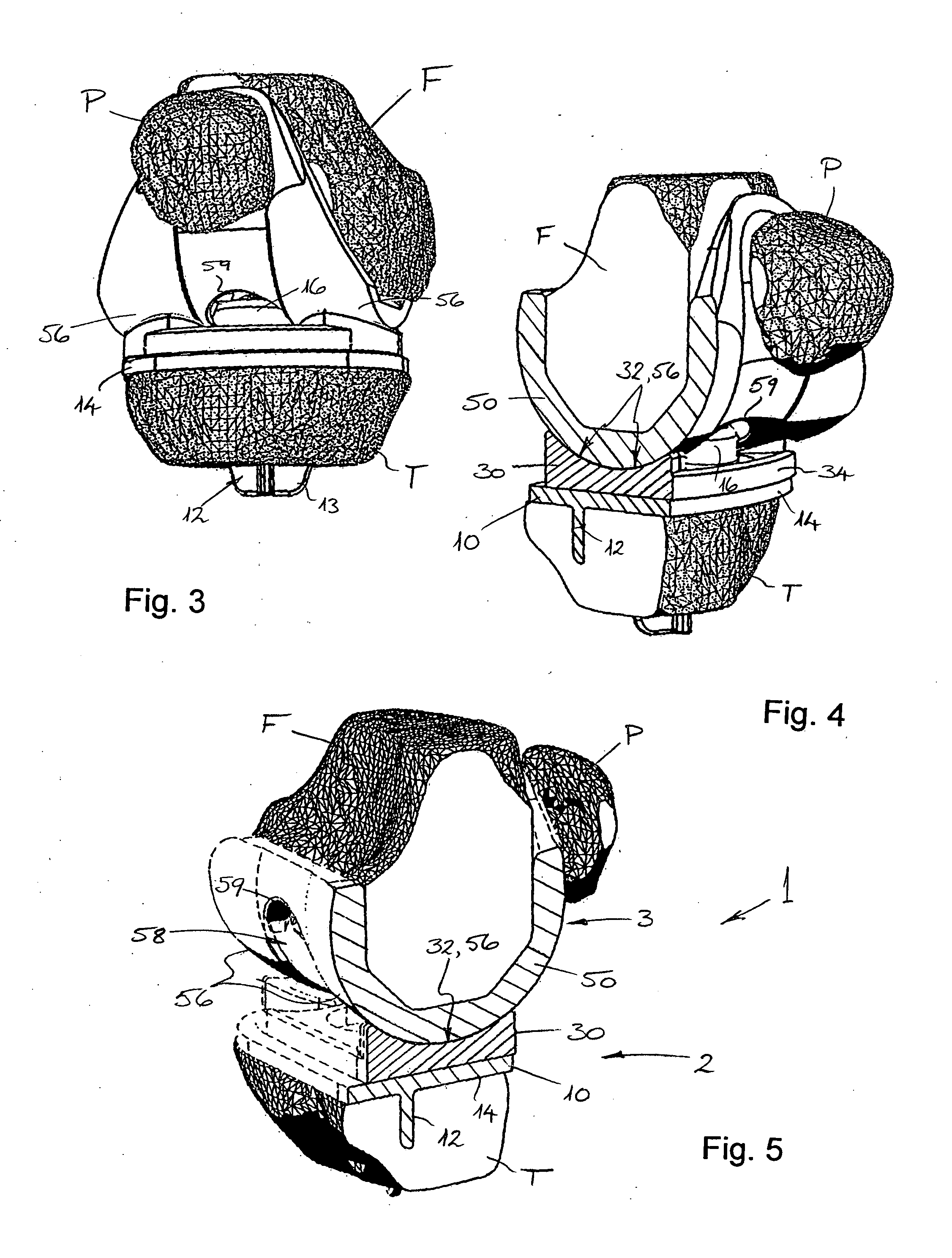

Knee joint prosthesis and related method

ActiveUS20120136452A1High degree of conformityGood tribologyPolishing machinesJoint implantsArticular surfacesRange of motion

The present invention relates to a knee joint prosthesis having a tibial component and a femoral component. The tibial component includes a fixation portion fixed to an upper end of a prepared tibia and a ceramic bearing portion presenting articulation surface(s). The femoral component is fixed to a lower end of a prepared femur and comprises a ceramic body portion presenting articulation surface(s). The respective articulation surfaces of the tibial and femoral components are configured for essentially congruent engagement over a full range of movement of the prosthesis, and the bearing portion of the tibial component is adapted for movement relative to the fixation portion. Also disclosed is an apparatus and a method for finishing articulation surfaces of ceramic components of a knee joint prosthesis, including the steps of combining the ceramic bearing portion and the ceramic body portion, and imparting relative movement to the bearing portion and / or the body portion.

Owner:AESCULAP AG

Method for processing ceramic bearing ball

ActiveCN101486145AReduce processing costsShorten the processing cycleLapping machinesOther manufacturing equipments/toolsBoron carbideZirconia ceramic

The invention provides a superfine processing method for silicon nitride ceramic bearing balls. The superfine processing method takes boron carbide, silicon carbide, tungsten carbide, corundum, chrome corundum, zirconia corundum, diamond micro powder, diamond ointment and the like as grinding materials, chrome oxide, cobalt oxide, ferric oxide and cerium oxide as grinding aids, and kerosene, gasoline, alcohol and the like as grinding media, and utilizes a vertical bearing ball grinder to release the processing pressure so as to realize low-stress precision processing of bearing balls. The technology is suitable for the silicon nitride ceramic bearing balls, alumina ceramic balls, zirconia ceramic balls, boron carbide ceramic balls and silicon carbide ceramic balls with a diameter between 0.5 and 50.4 millimeters, and obviously shortens the processing period and the processing stress so as to effectively improve the service life of the ceramic balls.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

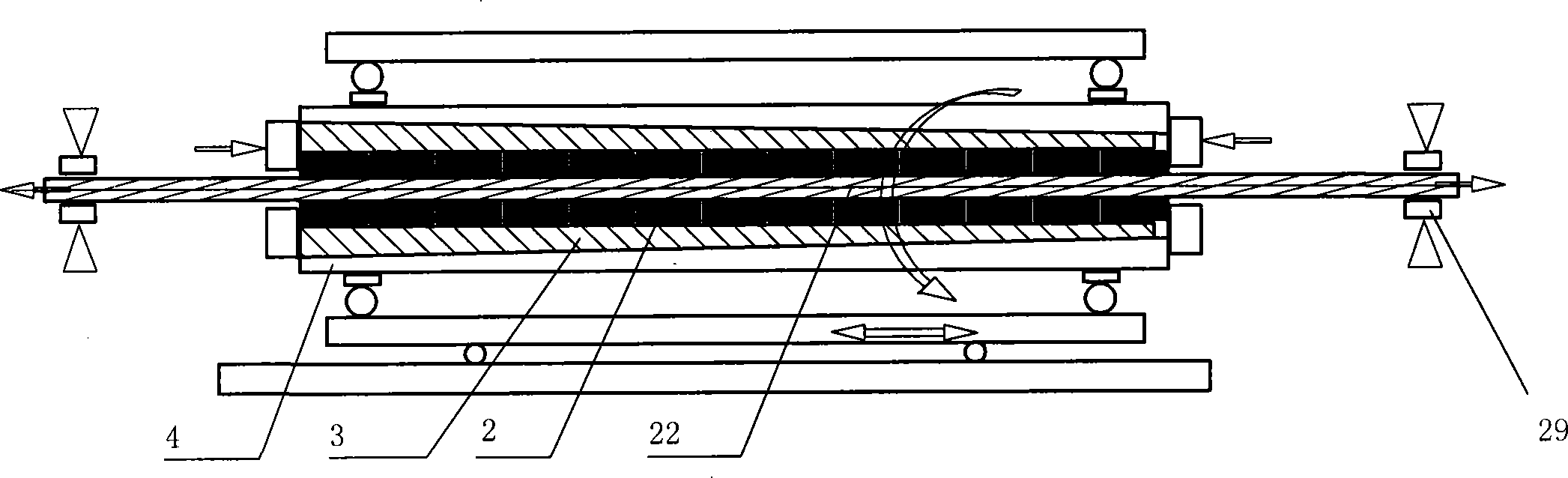

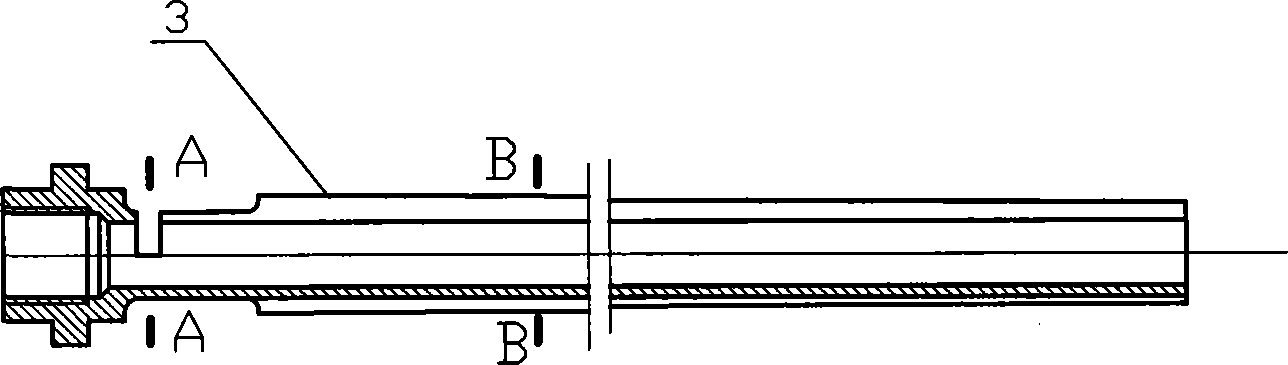

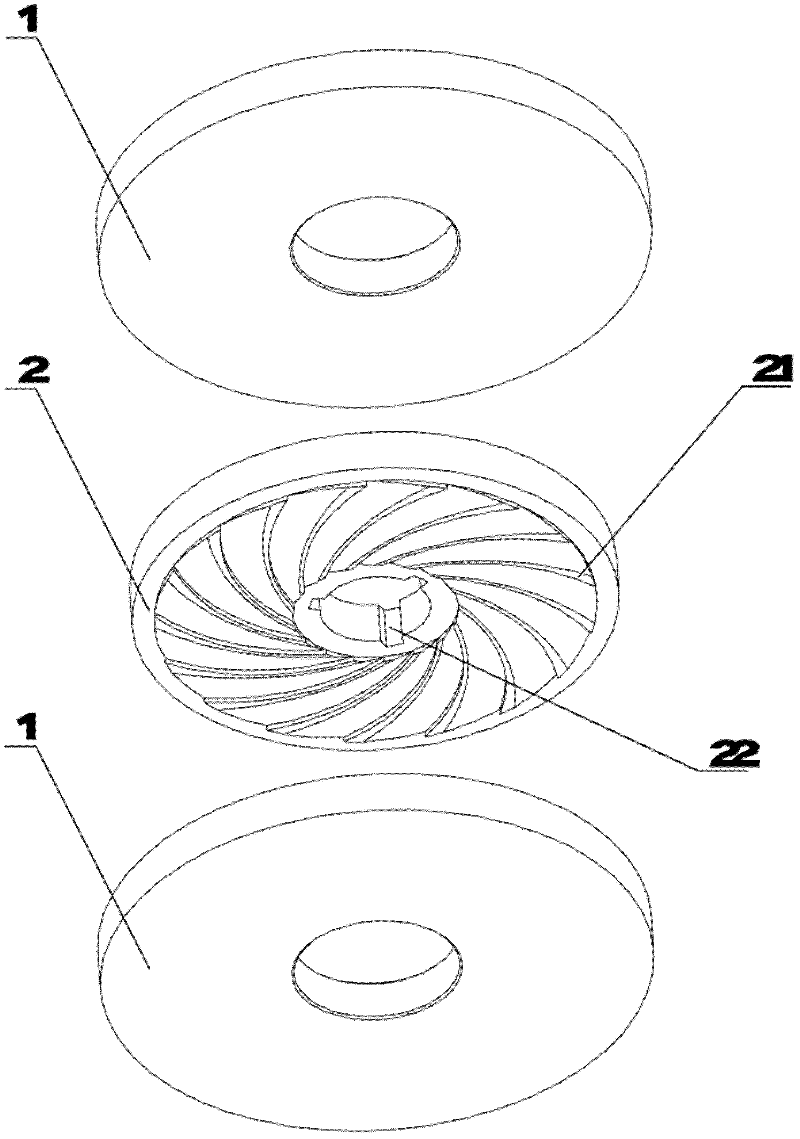

Miniature ceramic bearing hole abrading machine

InactiveCN101249622AImprove grinding precisionReduce labor intensityRevolution surface grinding machinesReciprocating motionEngineering

The invention discloses an inner-hole grinding machine with micro-ceramic bearing. A centering sleeve (3), which has an external surface with a taper and a shrinkable inner-hole diameter, is arranged in a rotary shaft(4) with an internal cone. A workpiece (2) can be mounted in the inner hole of the centering sleeve. A clamping device which clamps the centering sleeve (3) and the workpiece in the rotary shaft (4) is arranged on the two ends of the rotary shaft. An grinding steel wire rope (22) axially passes through the centering sleeve (3) and the inner hole of the workpiece (2), and the two ends of the grinding steel wire rope are fixed on a tension and clamping mechanism (29). The rotary shaft (4) is arranged on a rotary support which allows the rotary shaft to rotate around the axis line of the rotary shaft under high speed. The rotary support is arranged on a linear supporting seat which allows the rotary support to move back and forth along the axial line of the rotary shaft. The relative friction motion combined by reciprocating and rotating is produced between the wall of the inner hole of the workpiece and the convex site of the grinding steel wire rope, so the grinding of the inner hole of the ceramic bearing is achieved. Through controlling the parameters such as grinding time, tension force of grinding steel wire rope, the grinding machine can ensure that the grinding precision of the inner hole of the ceramics bearing is increased by one order of magnitude as compared with traditional grinding, and the efficiency is increased by 10 times.

Owner:CENT SOUTH UNIV

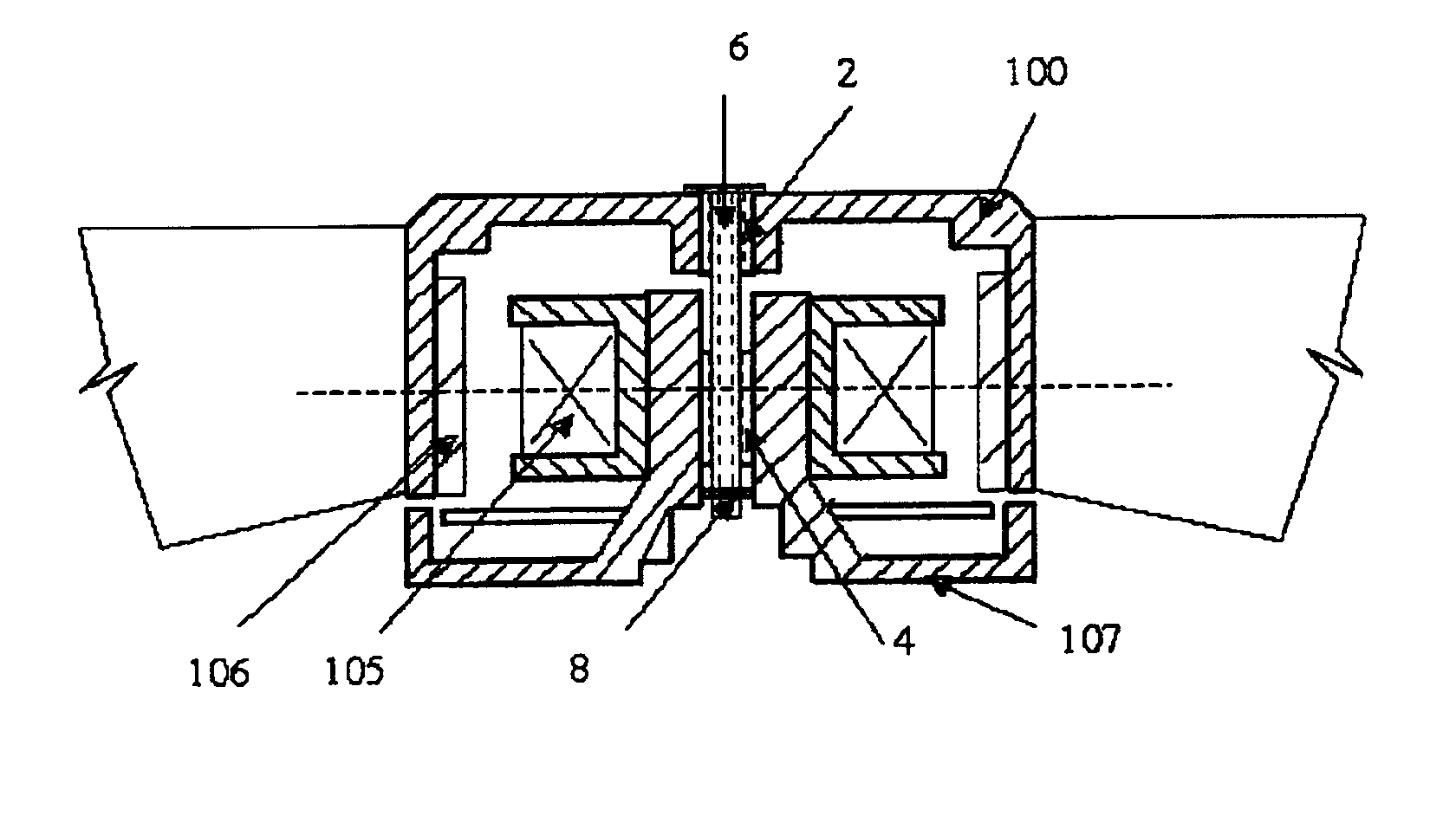

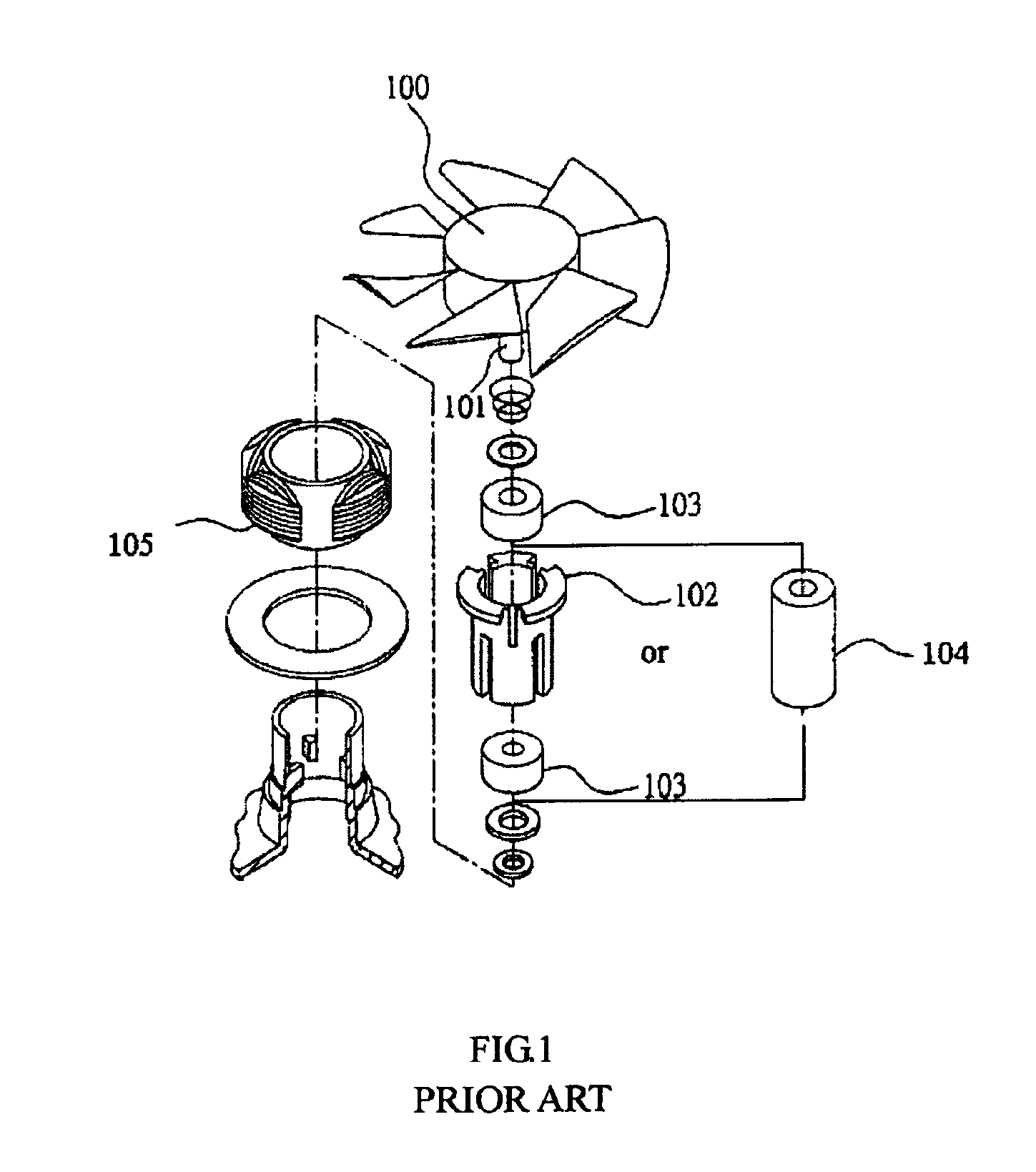

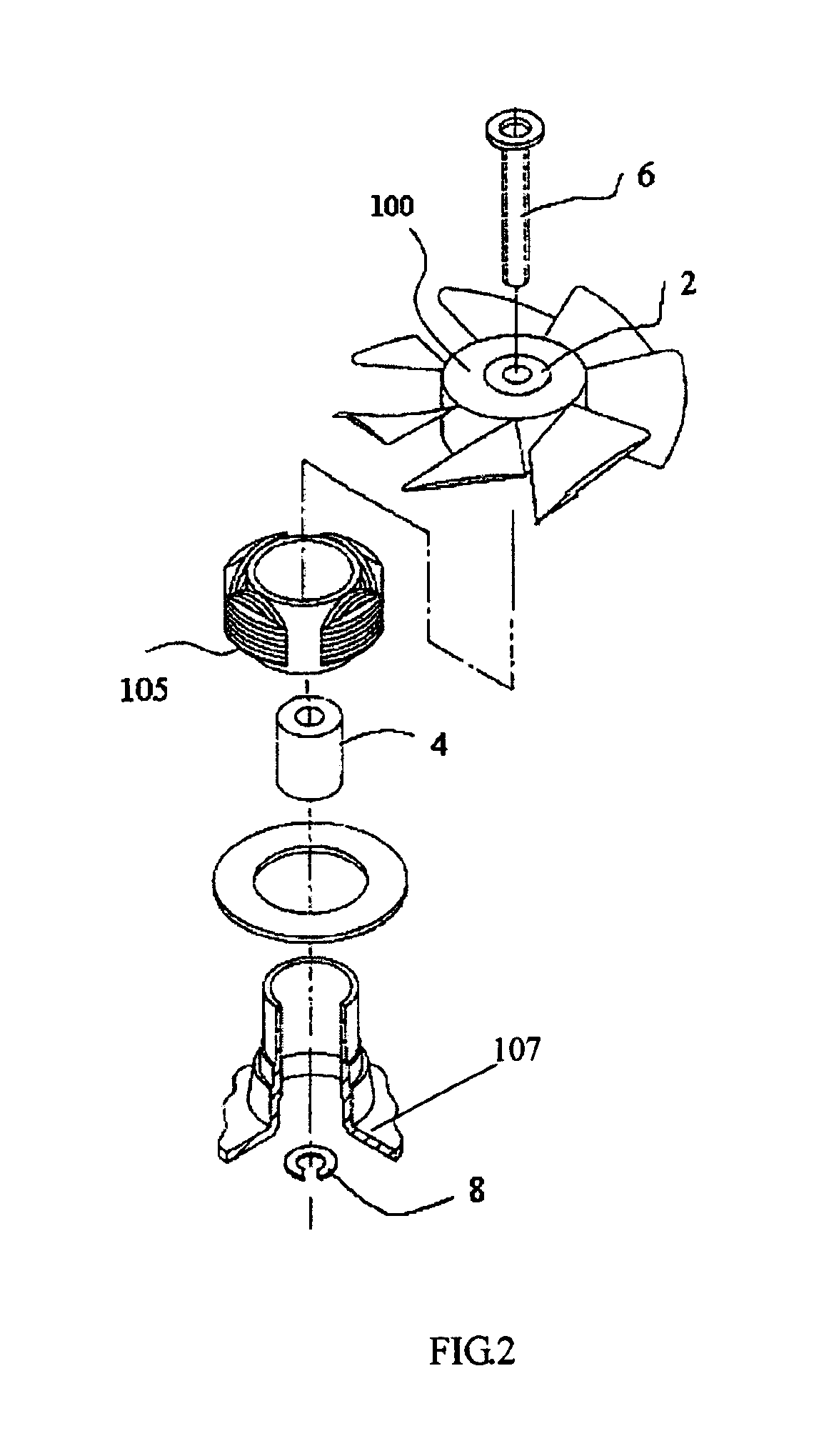

Rotation support of heat-dissipation fan

InactiveUS6893230B2Reduce frictionHigh speed rotationPropellersPump componentsFriction reductionFree rotation

An improved structure for rotational support for a heat-dissipation fan is disclosed, comprising a hollow ceramic bearing passing through and concentric with the fan rotor and rotating with said rotor, a hollow ceramic support bearing fixedly mounted to the base of the fan, and a hollow or solid ceramic axle tube passing through the inside of said bearing and rotating freely to reduce friction and allow high-speed rotation. The exterior surface of said bearing is ground or otherwise formed to provide better connection with the rotor, while the interior of the bearing and exterior of the axle tube are further processed to reduce contact area therebetween to reduce rotation friction. This improved structure has achieved reduced friction, reduced noise, reduced power consumption, longer life and higher rotational speed.

Owner:SUNG KUAN KUAN +1

Lubricated ceramic/hybrid anti-friction bearing centrifugal pump

A pump assembly for conventionally driven centrifugal pumps having a rolling element comprised of product lubricated ceramic or hybrid anti-friction bearings. The ceramic bearings are comprised of ceramic balls and ceramic races, whereas the hybrid bearings are comprised of ceramic balls with races made of another material. The ability of these bearings to perform well with poor lubrication allows the fluid that is being pumped to be used to lubricate and cool the bearings. An alternate embodiment comprises a double suction pump with the same durability and cost saving advantages.

Owner:GOULDS PUMPS

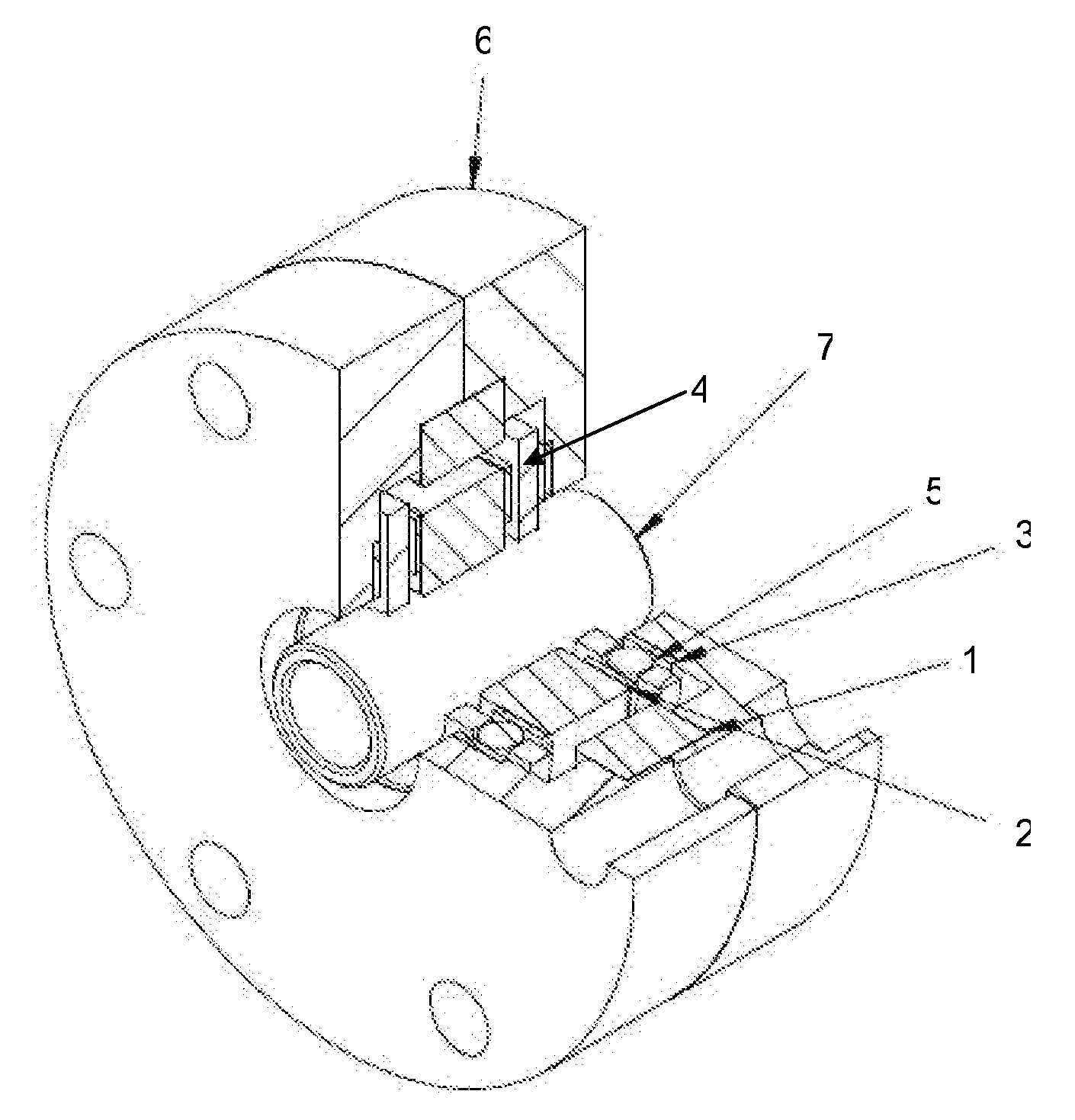

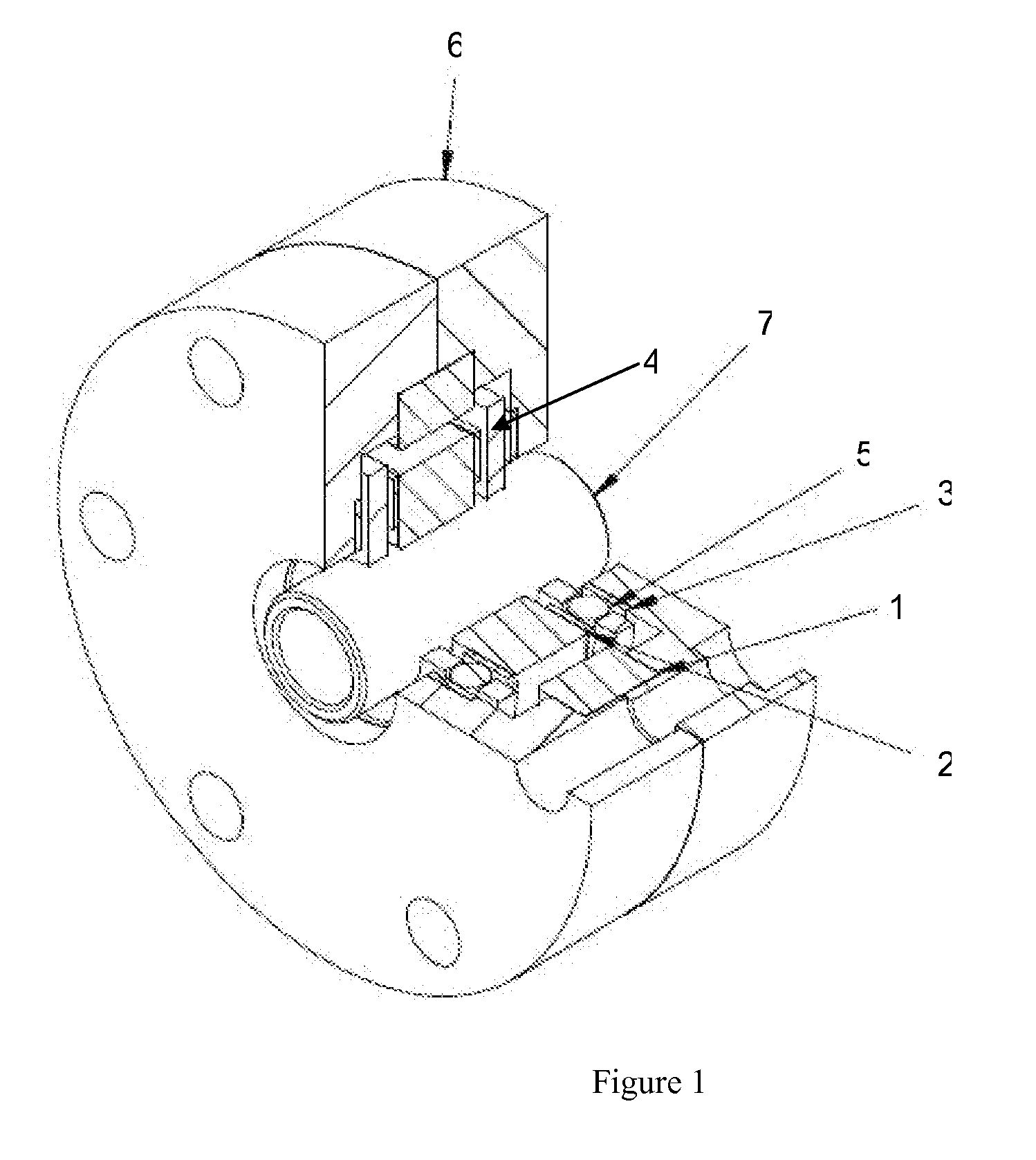

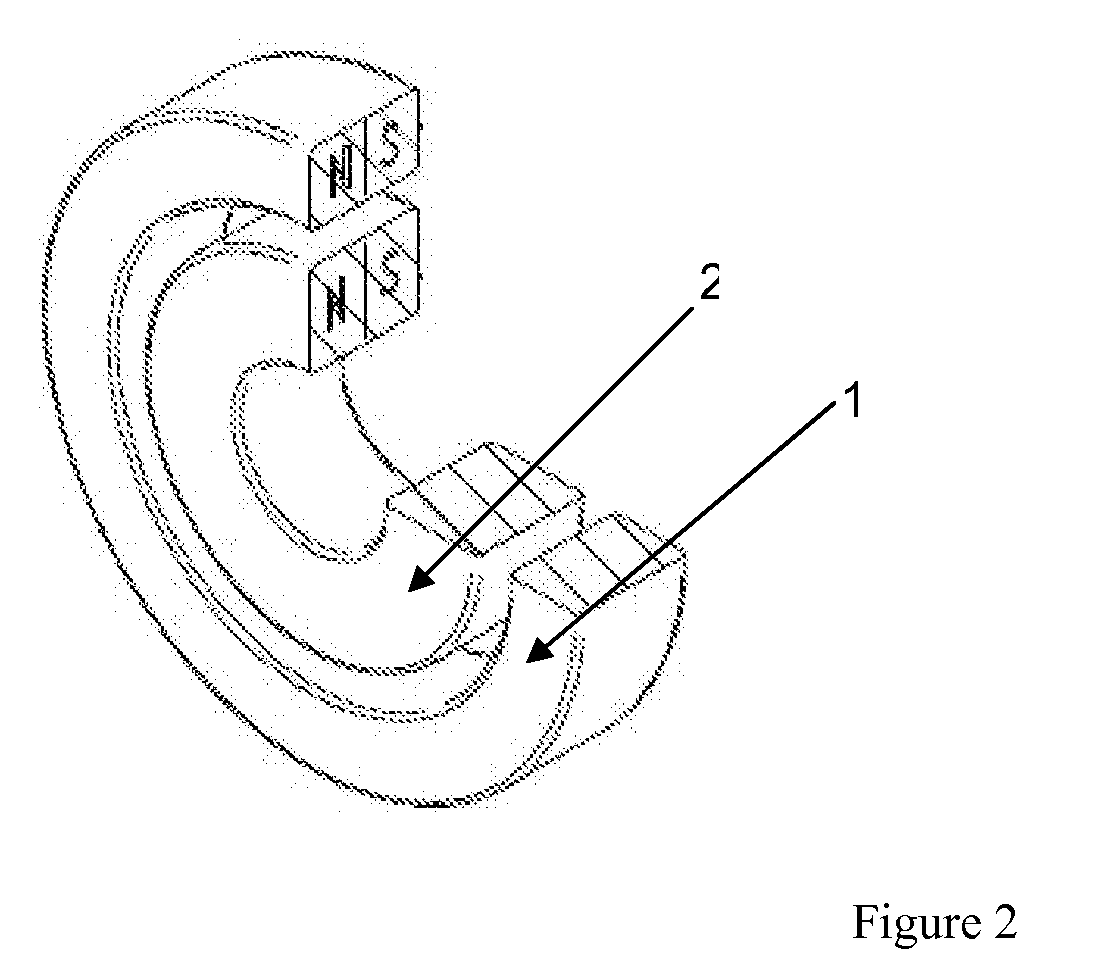

Passive magnetic bearing

InactiveUS20110001379A1MiniaturizationIncrease resistanceBall bearingsMechanical energy handlingMagnetic bearingEngineering

A passive magnetic bearing which has an exceptionally low friction couple. Radial and axial restraint is achieved through magnetic and mechanical means. The embodiment of the passive magnetic bearing has two axially magnetized rings, which each exhibit at least one pair of north and south poles. The magnetized rings are positioned in a manner where the poles are in a repulsive magnetic interaction such that the plane of symmetry which separates the like poles lies perpendicular to the axis of the rotation of a shaft and this radially constrains the movement of the shaft. Axial rigidity is added to the system by the use of ceramic bearings and related axial retaining mechanisms on one of the ring magnets thus maintaining the magnetic bearing in an otherwise unstable axial plane.

Owner:STEORN

Optical fibre rotary collector

InactiveCN101013186AIncrease freedomRealize two-way transmissionCoupling light guidesFiberGear drive

The invention relates to a fiber rotary connector, which combines optical system and mechanical system to complete optical signal transmission in the relative movement state. Collimator combines the prism to form the fiber rotary connector optical system, and mechanical system uses the planetary gear drive mechanism. The fiber exhaled light passes through the collimator to collimate to big light spot parallel rays, and when the parallel rays rotating with velocity v, the prism rotating with velocity v / 2 with the same direction, so the exhaled light and the incident light have the same position. The program features v / 2 velocity, and the same direction rotation, so the mechanical system totally uses 8 precision gears, 4 ceramic bearings, 6 double-sealed bearings, and the 8 gears have both rotation and revolution, considering two center round space as multiple planetary transmission loads; the incident parallel rays passes through the optical system, and with the prism all-reflection to form the corresponding exhaled parallel rays. The program can be very convenient to achieve space free rotation, optical signal two-way transmission.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

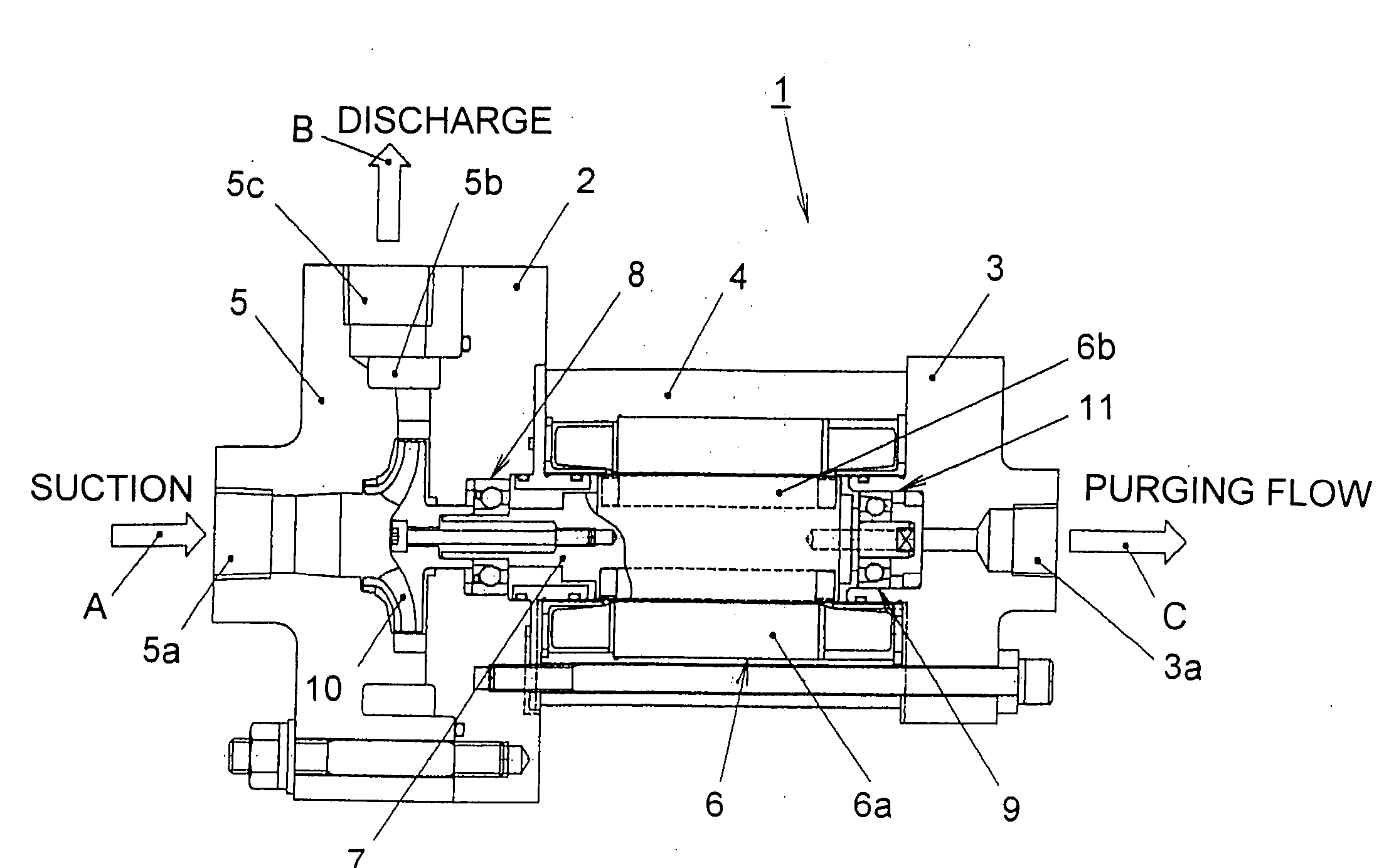

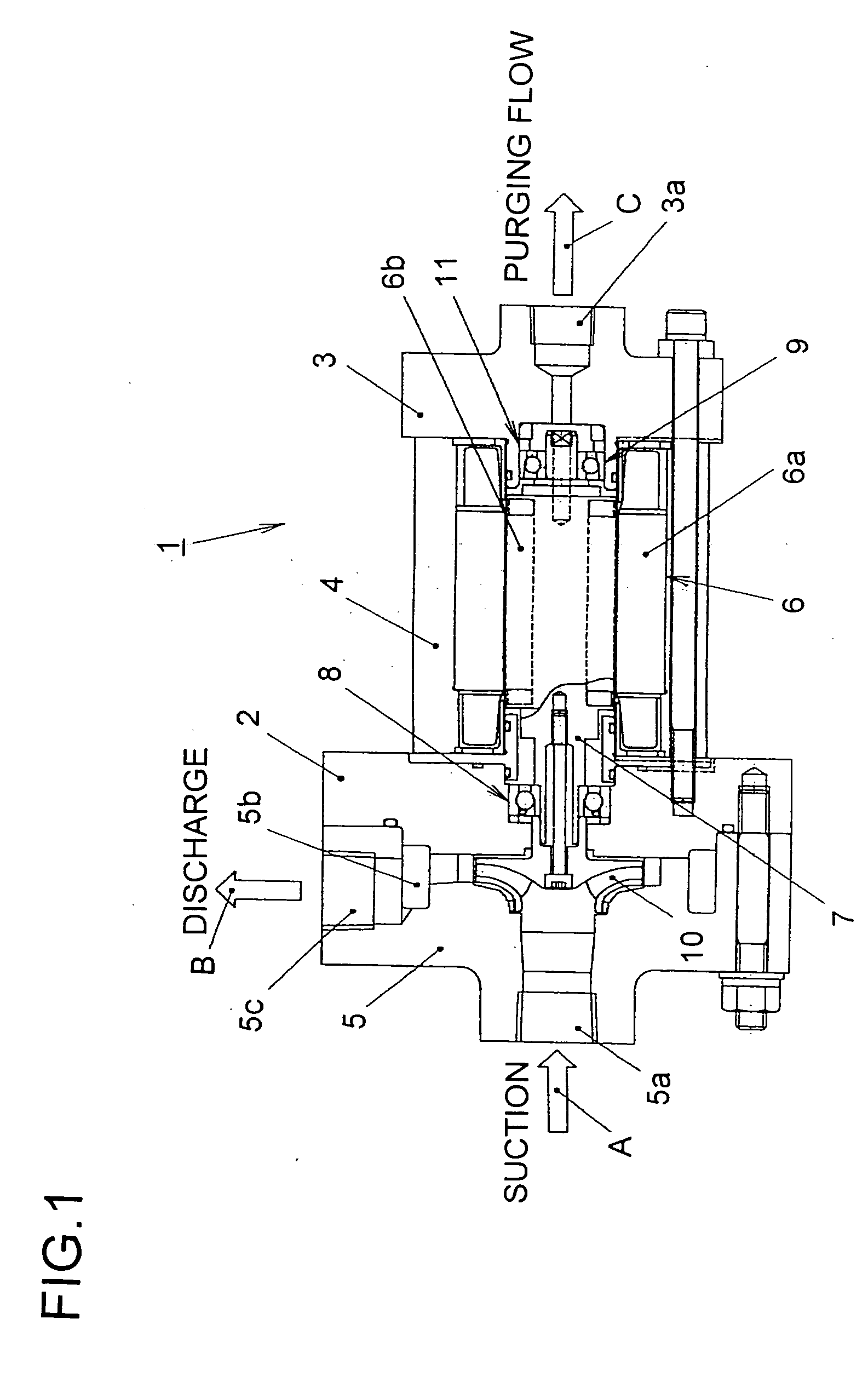

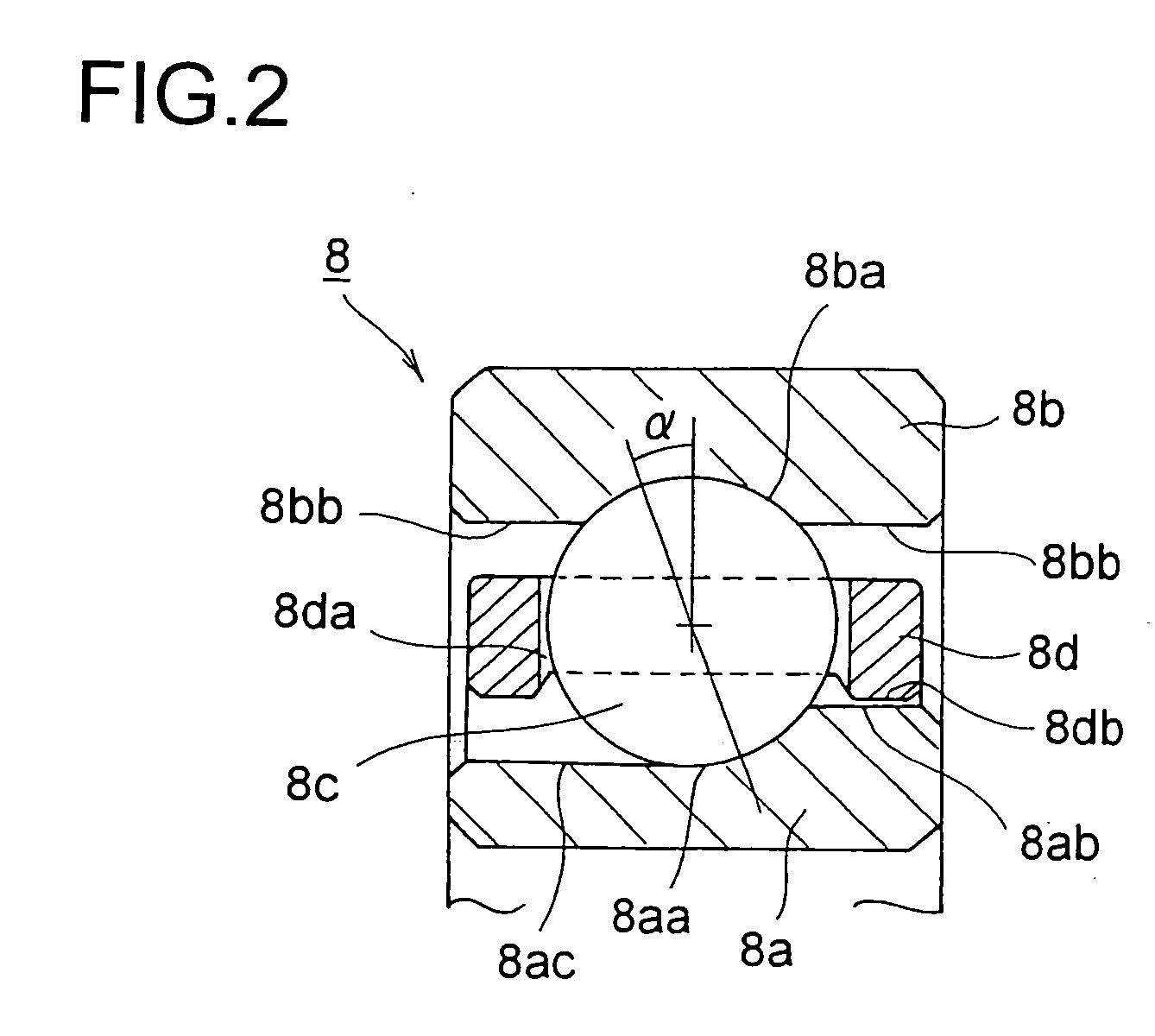

Pump

ActiveUS20060239845A1Reliably securedImprove corrosion resistancePositive displacement pump componentsShaftsBall bearingMechanical engineering

A pump for carrying supercritical CO2 fluid or liquid CO2 capable of securing reliability by optimizing a bearing part. An angular ball bearing (8) comprises an inner ring (8a), an outer ring (8b), balls (8c) held therebetween, and a cage (8d) holding the balls (8c). Both the balls and the inner and outer rings are formed of a ceramic to form a totally ceramic bearing. Also, the cage (8d) is guided by the outer ring or the inner ring. Specifically, for example, when the cage is guided by the inner ring, the inner peripheral surface (8db) of the cage (8d) opposed to the outermost peripheral surface (8ab) of the inner ring (8a) is guided by the outermost peripheral surface (8ab) of the inner ring (8a).

Owner:MITSUBISHI HEAVY IND LTD

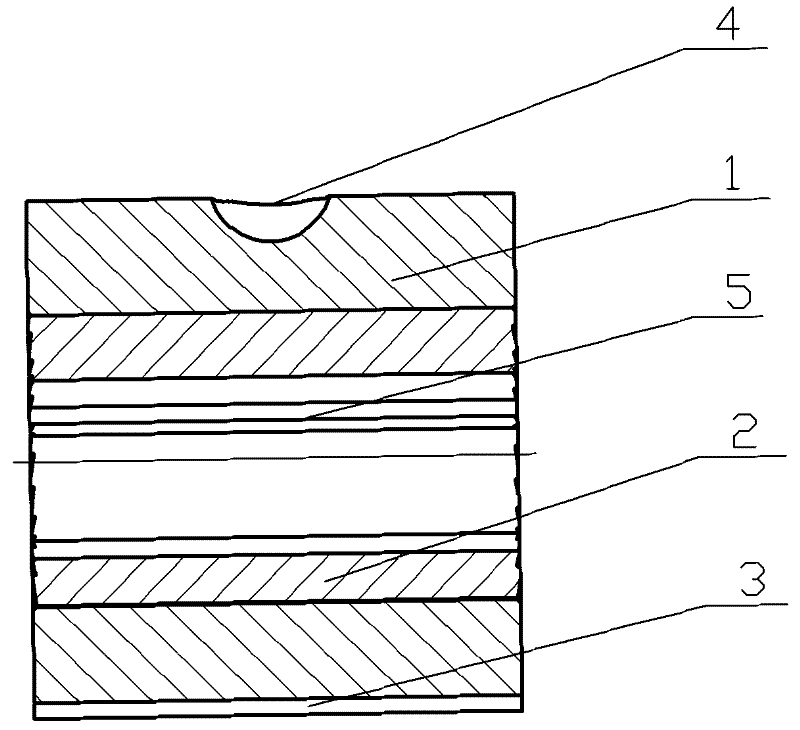

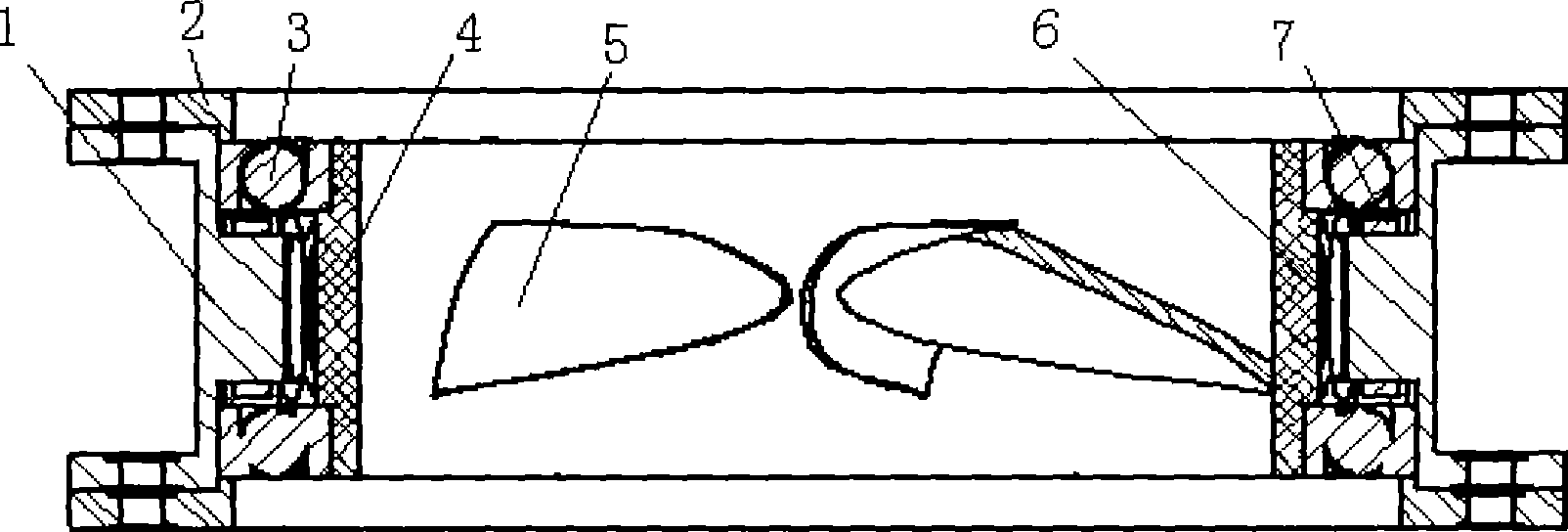

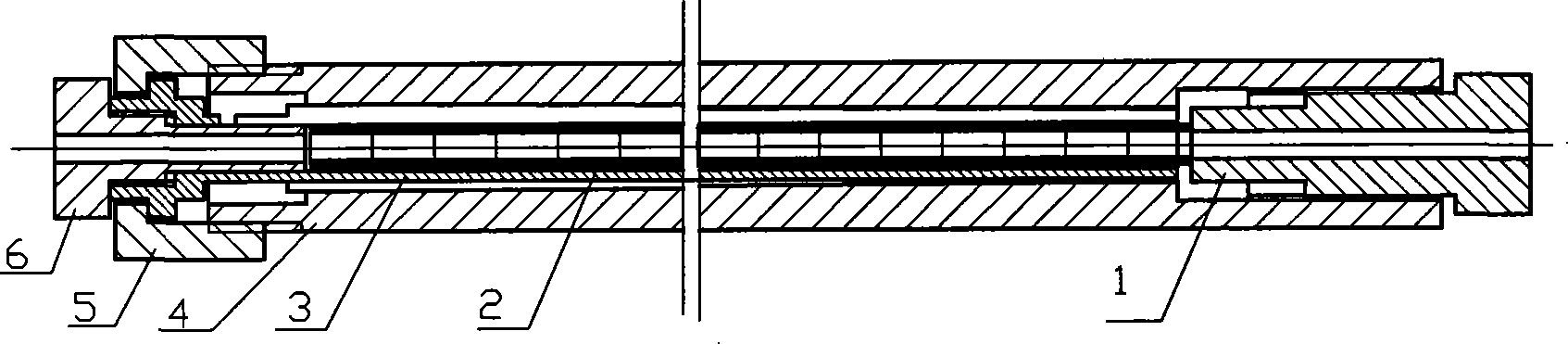

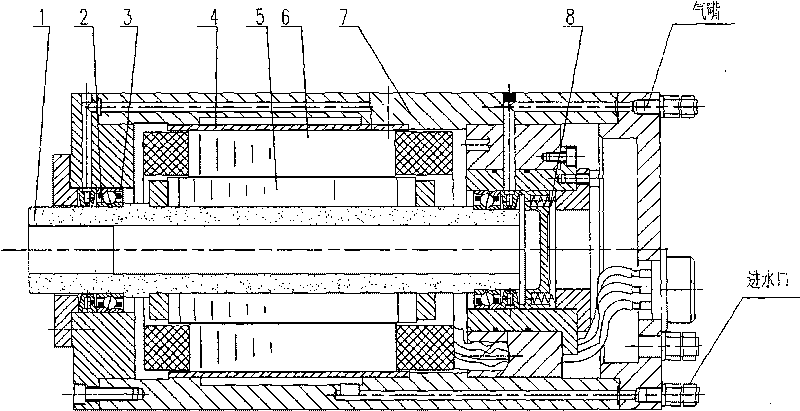

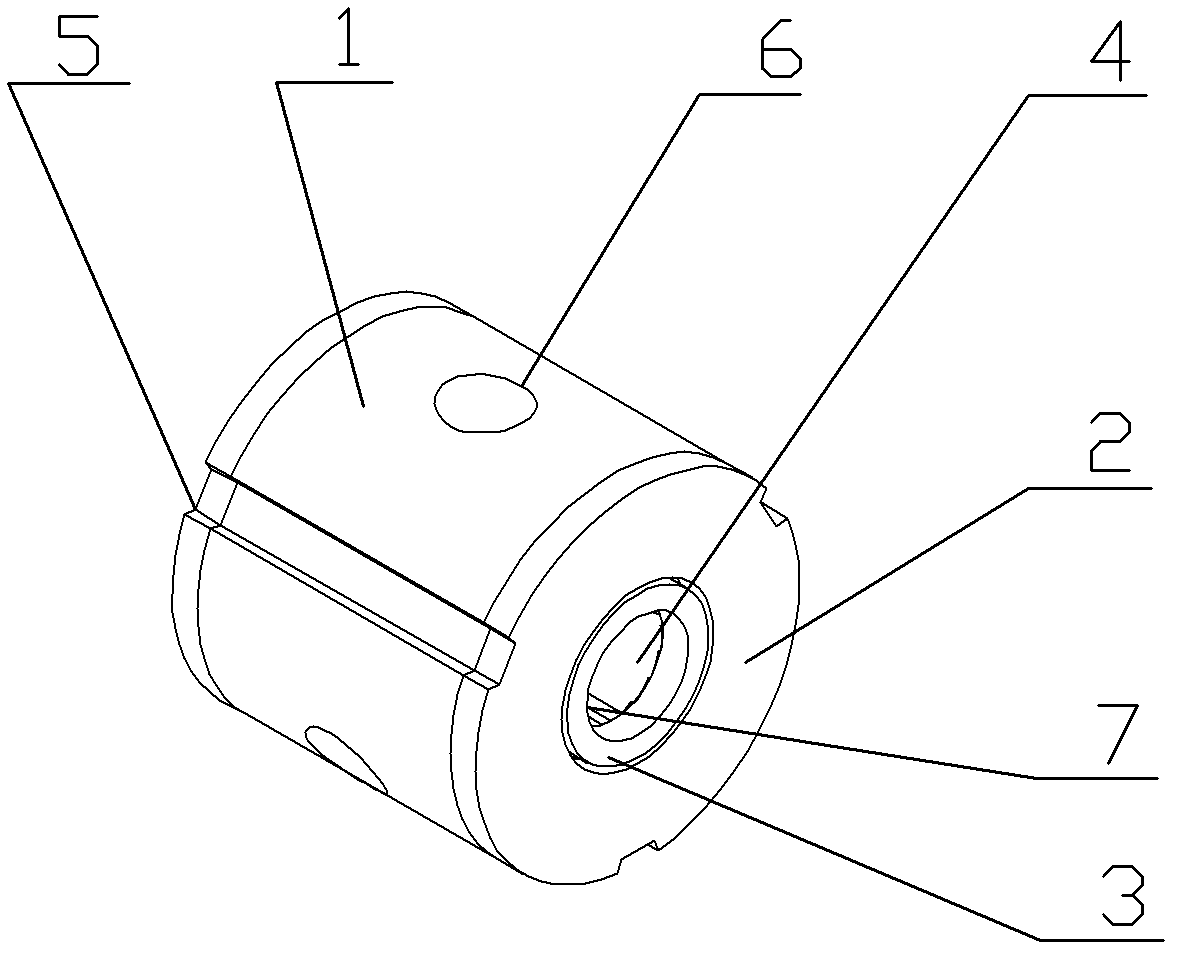

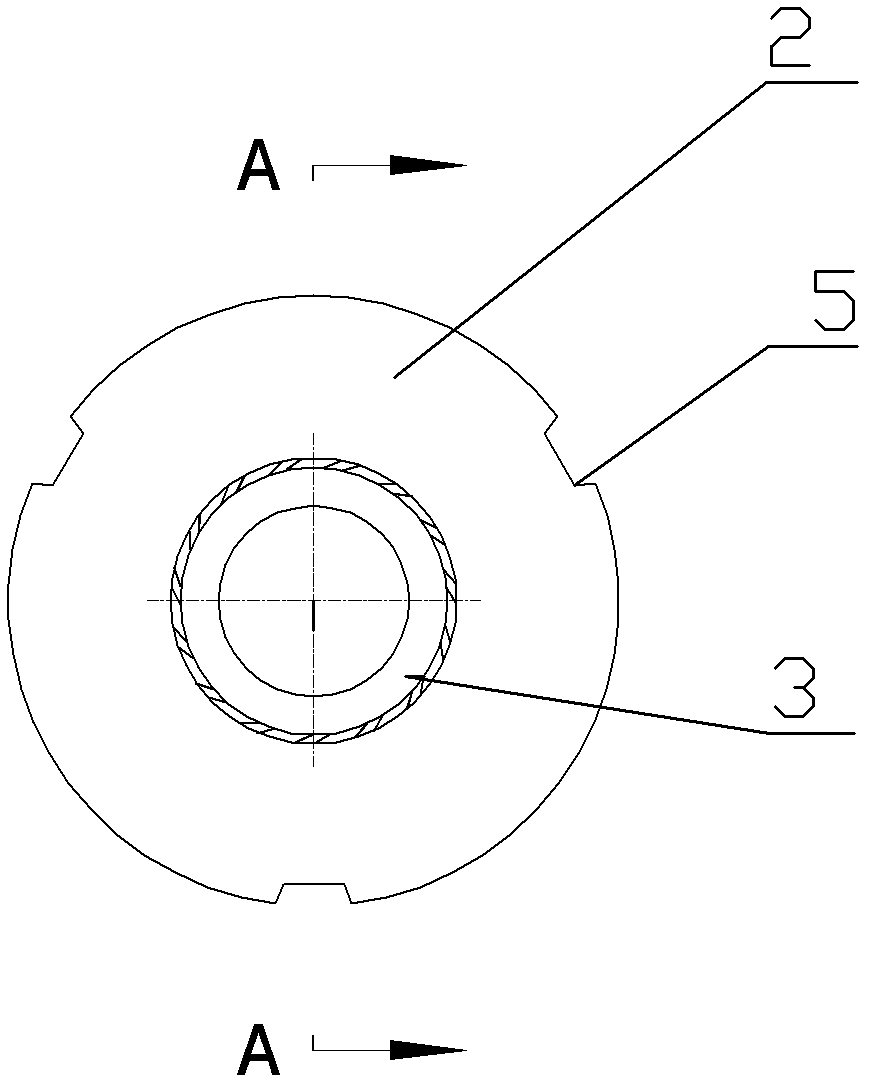

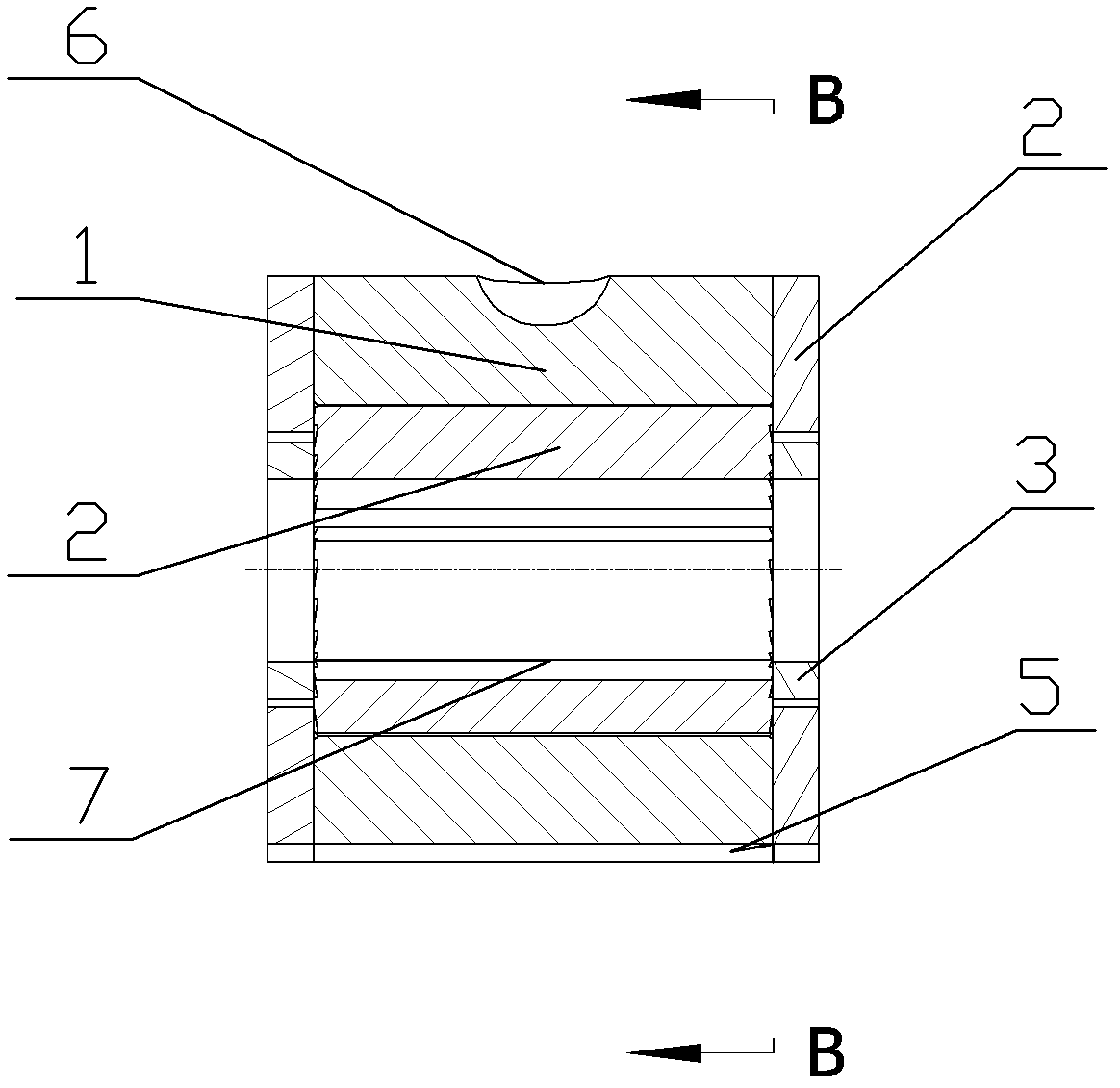

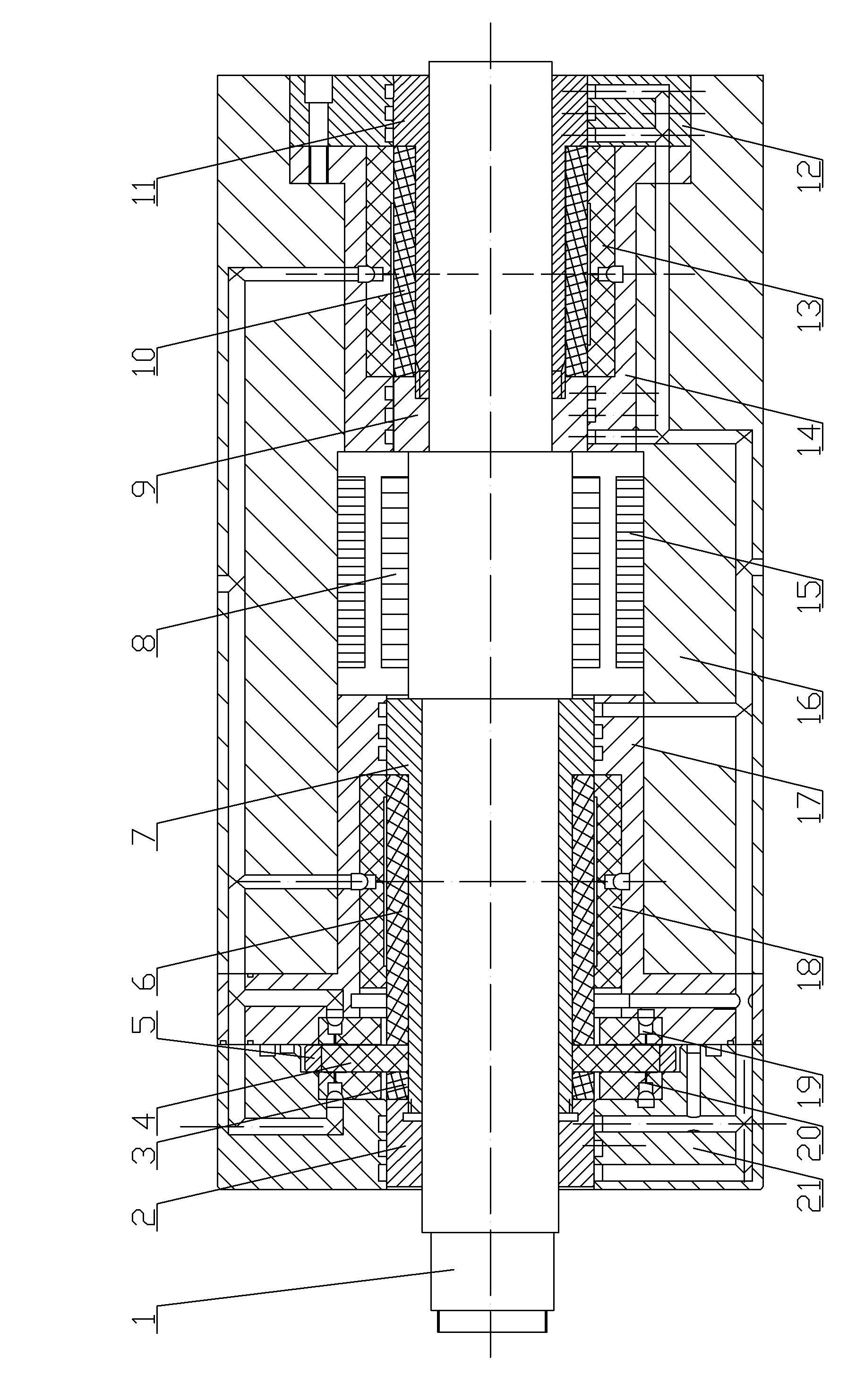

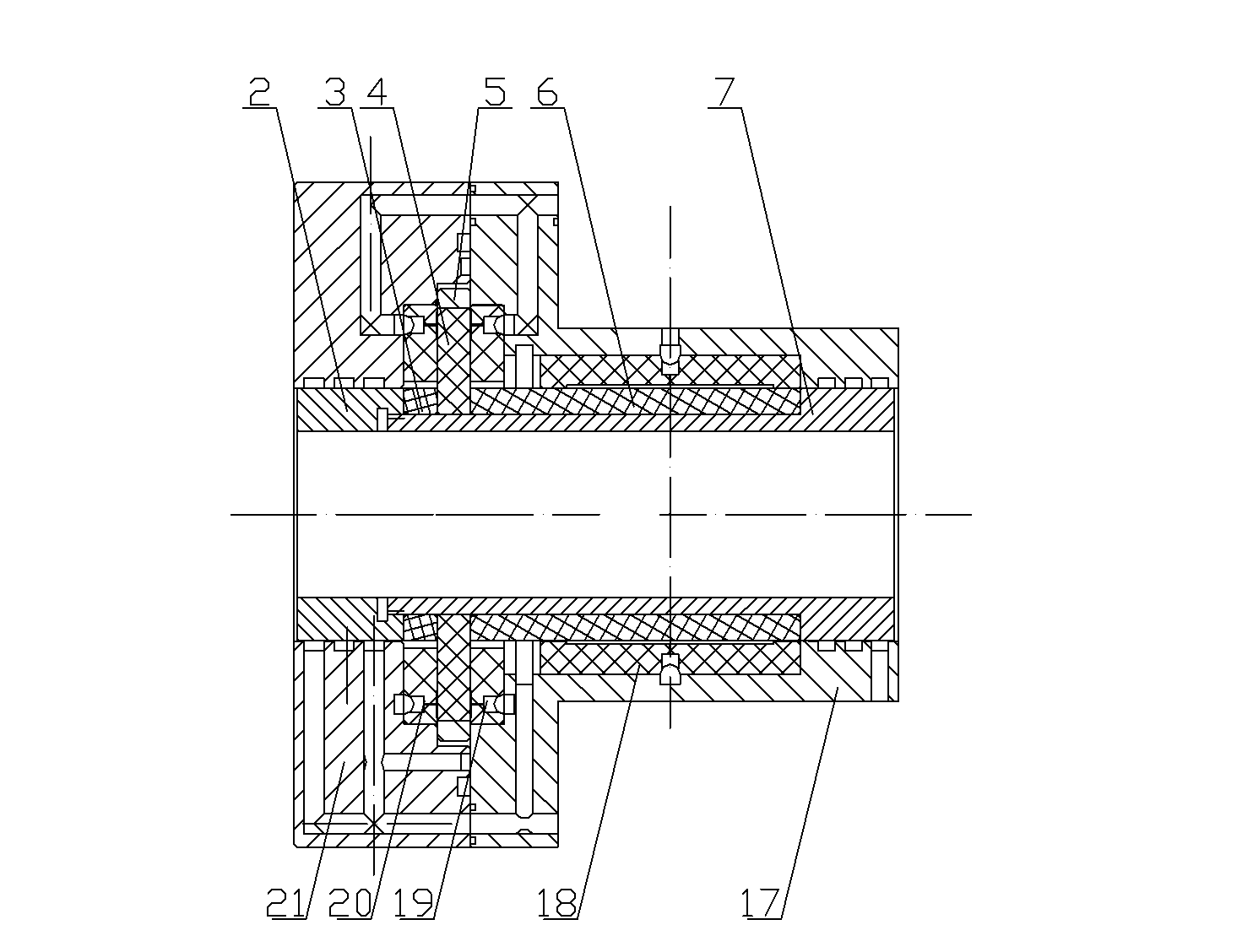

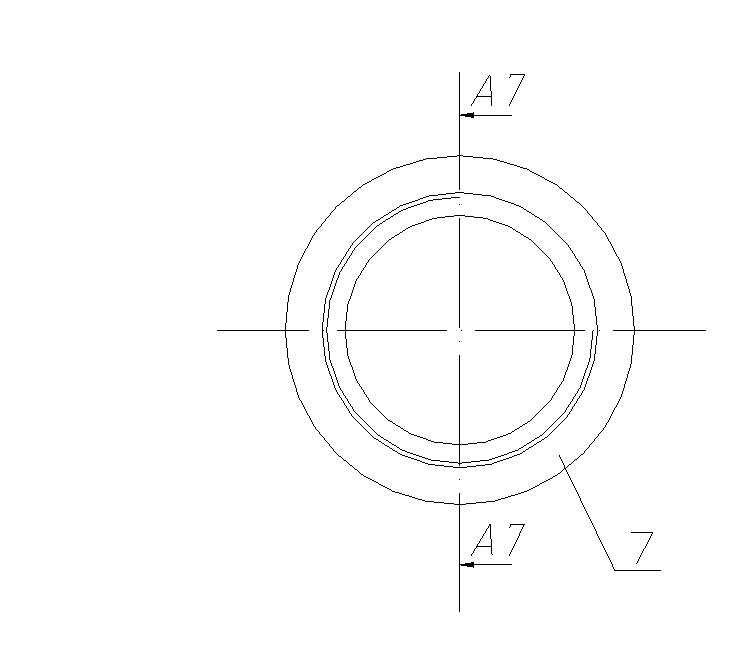

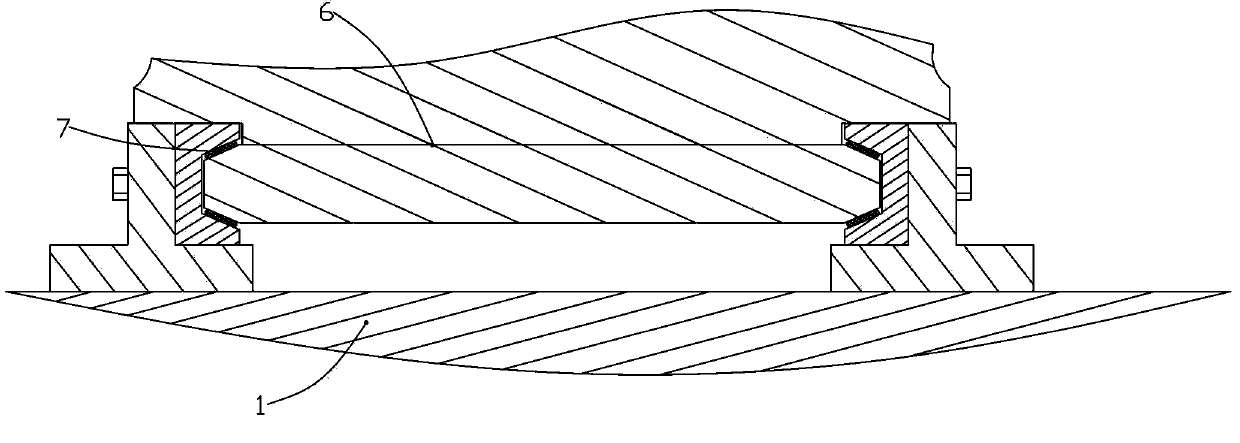

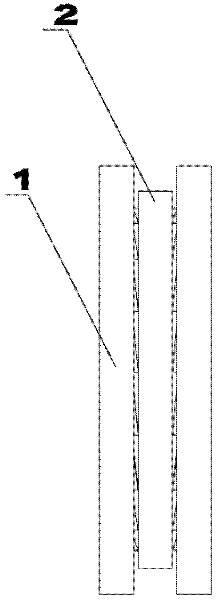

High-speed electric main shaft for mixed use of outer ring of steel bearing and inner ring of ceramic bearing

InactiveCN101697435AReduce moment of inertiaIncrease stiffnessMechanical energy handlingMaintainance and safety accessoriesElectricityMechanical components

The invention provides a high-speed electric main shaft for mixed use of an outer ring of a steel bearing and an inner ring of a ceramic bearing, and relates to a mechanical component. The high-speed electric main shaft comprises an electric main shaft shell (7), a ceramic rotating shaft of the electric main shaft (1), a bearing inner ring (2) of a mixed material bearing device, a bearing outer ring (3), a motor stator (6), a rotor (5), a cooling device (4), a bearing preloading device (8) and a lubricating device, wherein the bearing inner ring (2) of the bearing device and a bearing ball are made of a ceramic material, a bearing retainer is made of a resin material, and the bearing outer ring (3) is made of a steel material; and the bearings adopt an assembly mode. The invention provides the high-speed electric main shaft for mixed use of the steel bearing outer ring, the ceramic rotating shaft, the ceramic bearing inner ring and the ceramic ball. Zirconium oxide and hot pressed silicon nitride are adopted as materials of the main shaft, the bearing inner ring and the bearing ball so as to reduce the weight of the rotating part of the main shaft, and improve the rotating speed. The bearing outer ring is made of the steel material to reduce the manufacture strength and improve the vibration resistance effect.

Owner:SHENYANG JIANZHU UNIVERSITY

Self-sealing hydrodynamic gas radial ceramic bearings

InactiveCN102278366ASimple structureEasy to installBearing componentsSliding contact bearingsRegular patternForming gas

The invention discloses a self-sealing dynamic pressure gas radial ceramic bearing, which comprises a ceramic bearing outer sleeve, a ceramic bearing inner sleeve, a large sealing stop ring and a small sealing stop ring. Grooves and evenly distributed concave holes, the outer circle and both ends of the ceramic bearing inner sleeve have regular-shaped groove patterns, and the inner circle has evenly distributed grooves, and the ceramic bearing inner sleeve is located in the ceramic bearing outer sleeve , the large sealing stop ring is arranged at both ends of the ceramic bearing outer sleeve, and the small sealing stop ring is arranged at both ends of the ceramic bearing inner sleeve. The dynamic pressure gas radial ceramic bearing of the present invention is equipped with large sealing stop rings at both ends of the ceramic bearing outer sleeve, small sealing stop rings at both ends of the ceramic bearing inner sleeve, and processed at both ends of the ceramic bearing inner sleeve. With regular-shaped groove patterns, driven by the high-speed rotary shaft, the continuously generated dynamic pressure gas can be better kept in the matching gap between the two ends of the inner sleeve of the ceramic bearing and the large sealing stop ring and the small sealing stop ring. The air film required for the sealing function is formed to play a self-sealing role, thereby ensuring that the bearing has good stability and load capacity.

Owner:罗立峰

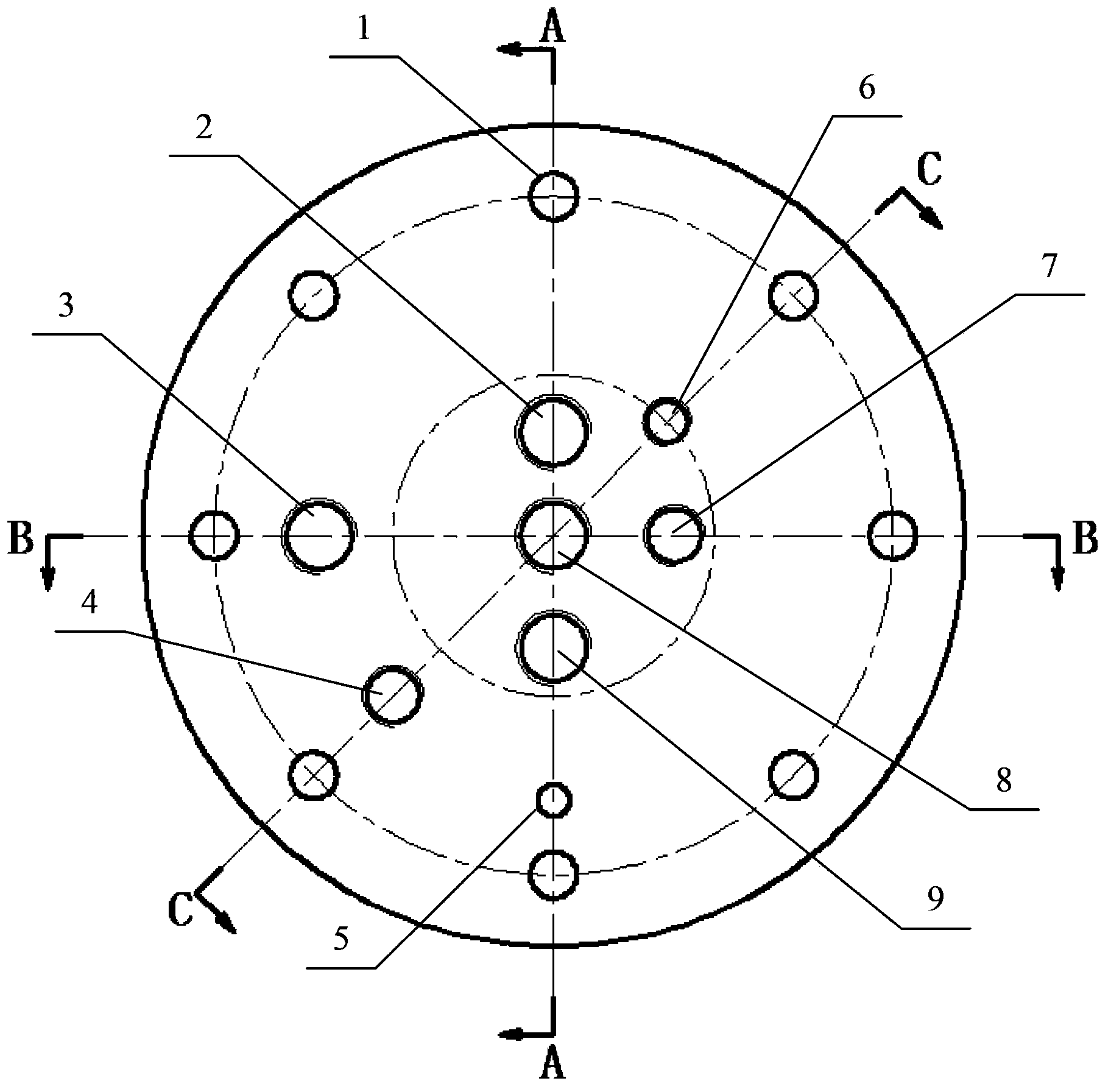

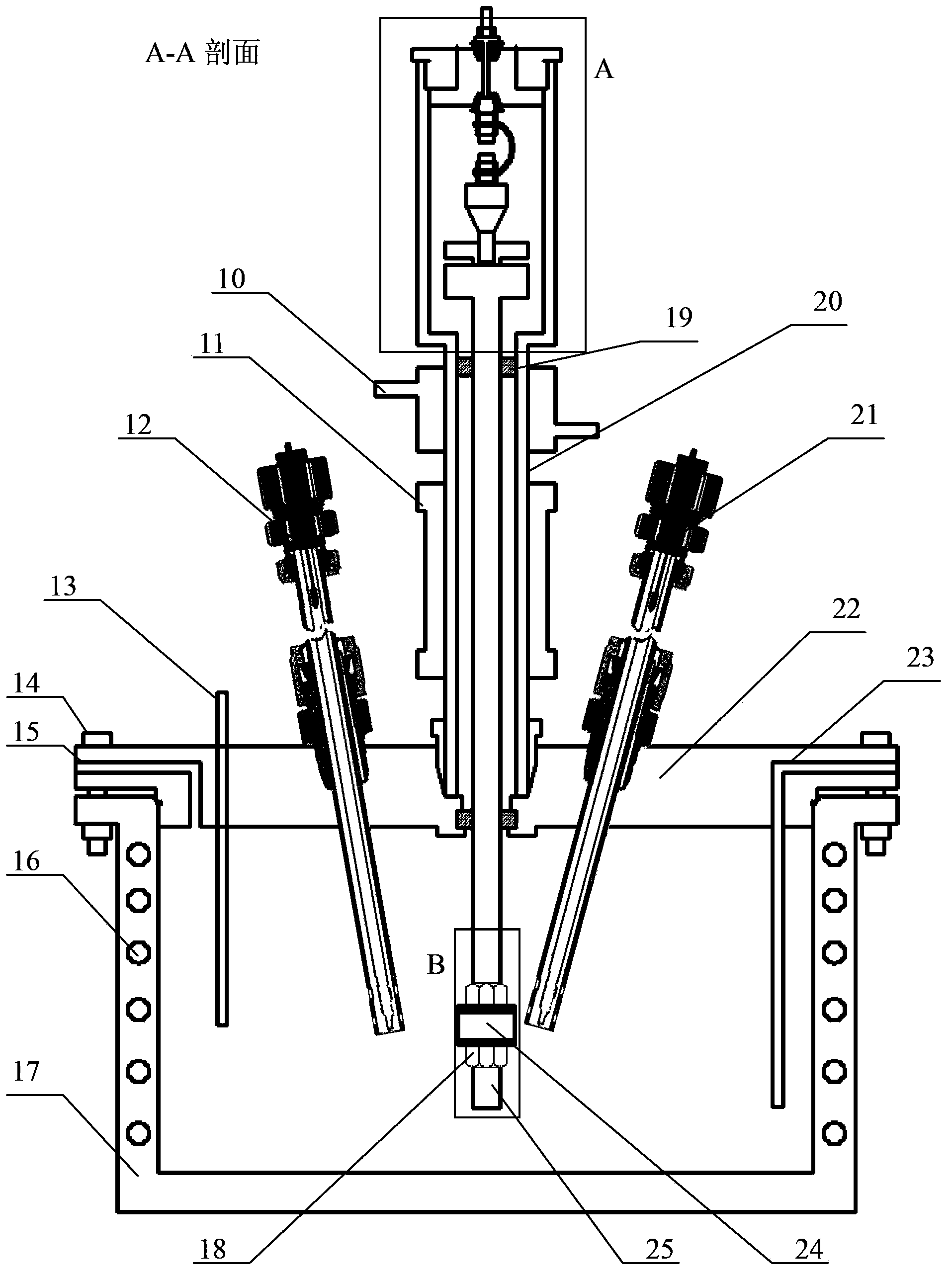

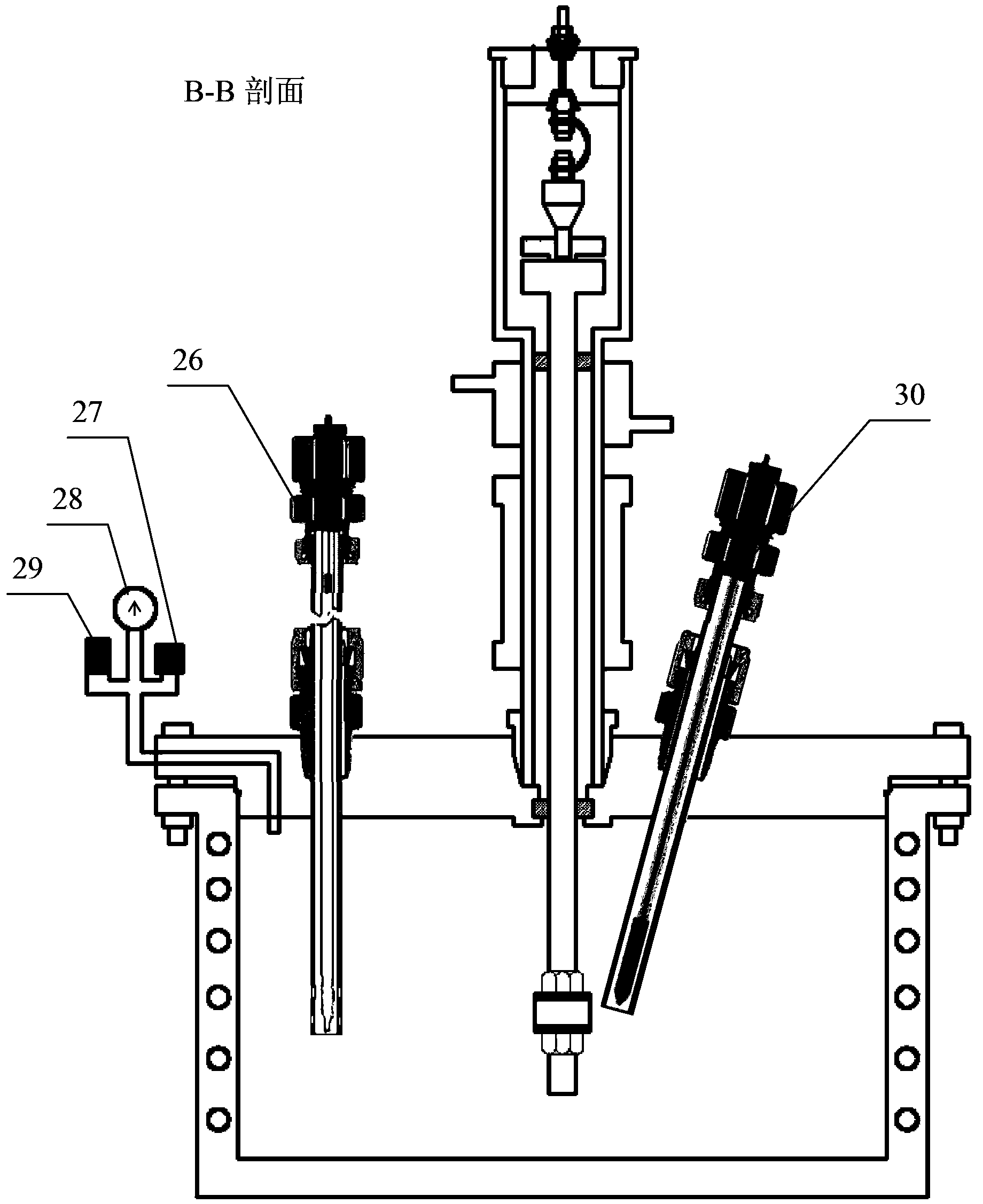

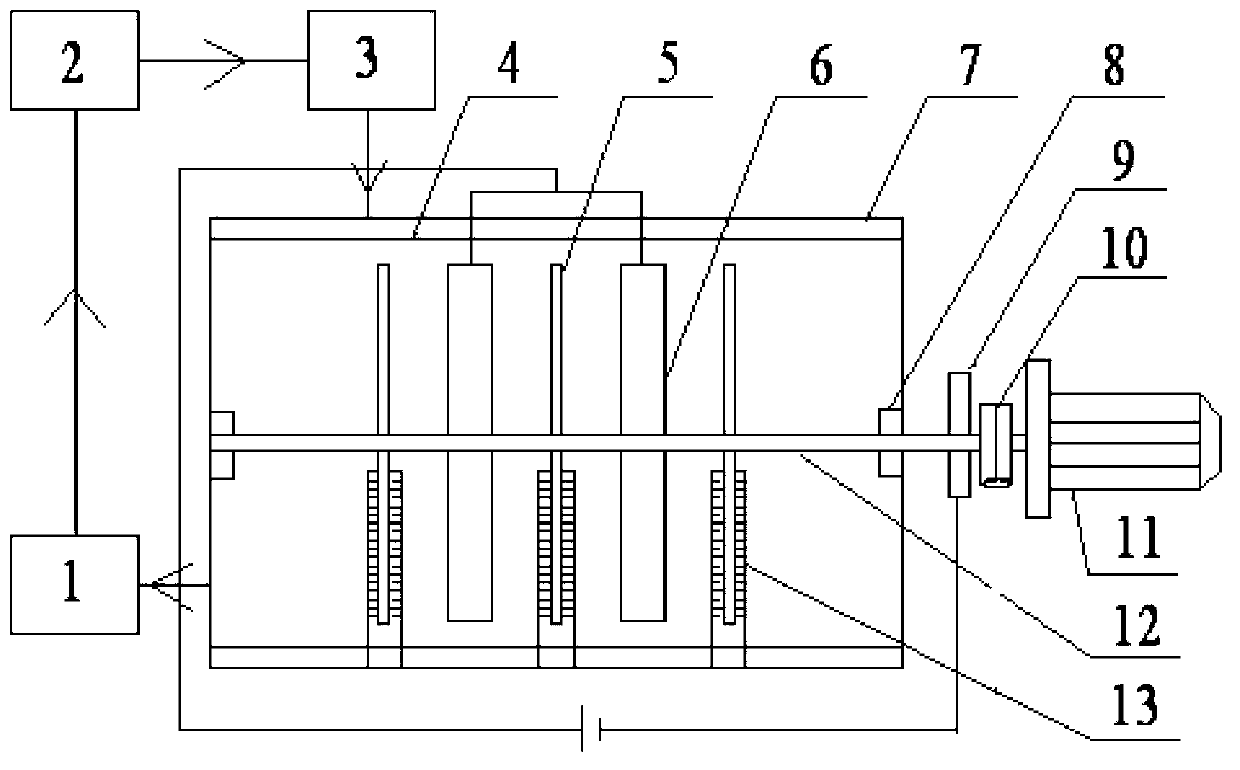

High temperature and high pressure dynamic electrochemical test and pH in situ monitoring experimental device

InactiveCN103411879AEliminate the effects of resistance changesIncrease speedWeather/light/corrosion resistanceInsulation systemHigh pressure

The invention relates to a high temperature and high pressure dynamic electrochemical test and pH in situ monitoring experimental device. The device includes a high temperature and high pressure reaction kettle, a rotation system, a heating insulation system, an external air supply system, a three-electrode system, a first pH composite electrode system, a second pH composite electrode system, a signal transduction pathway, a control box, an external electrochemical workstation, an external pH instrument and a computer. The device utilizes the high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetoelectric insulation, oil-free self-lubricating, high rotation speed, high strength and other characteristics of a ceramic bearing, can be used in a severe corrosion environment, and also improves the rotation speed and concentricity precision of a rotary working electrode. A collector ring is employed to realize connection of a moving lead and a static lead. The electrochemical signal of a working electrode under a high temperature and high pressure dynamic state can be tested. A high temperature and high pressure pH composite electrode system is employed to realize in situ continuous monitoring and record the pH change of a solution in the vicinity of the rotary working electrode and a bulk solution. The device can be used for high temperature and high pressure dynamic corrosion behavior and mechanism study.

Owner:UNIV OF SCI & TECH BEIJING

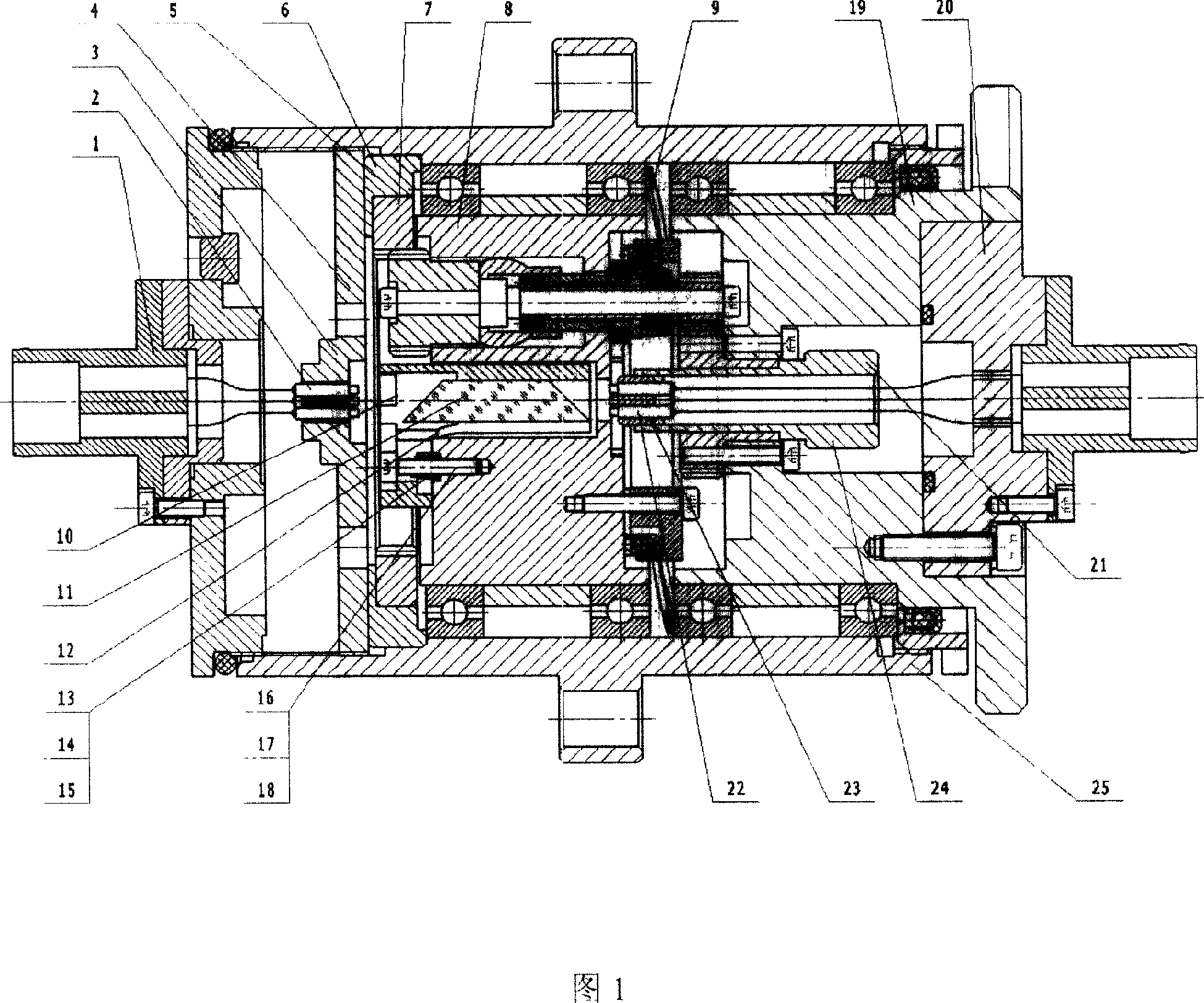

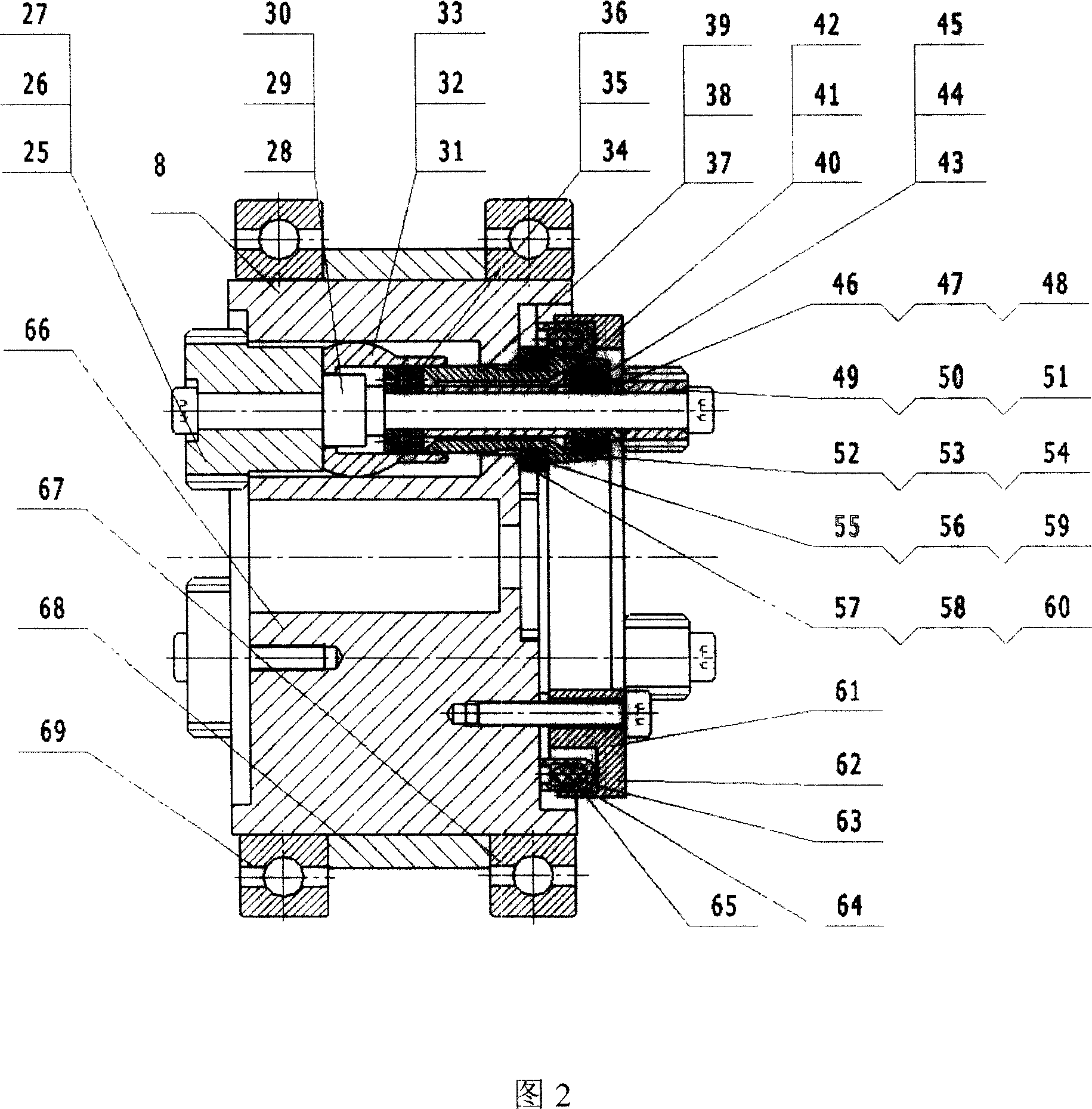

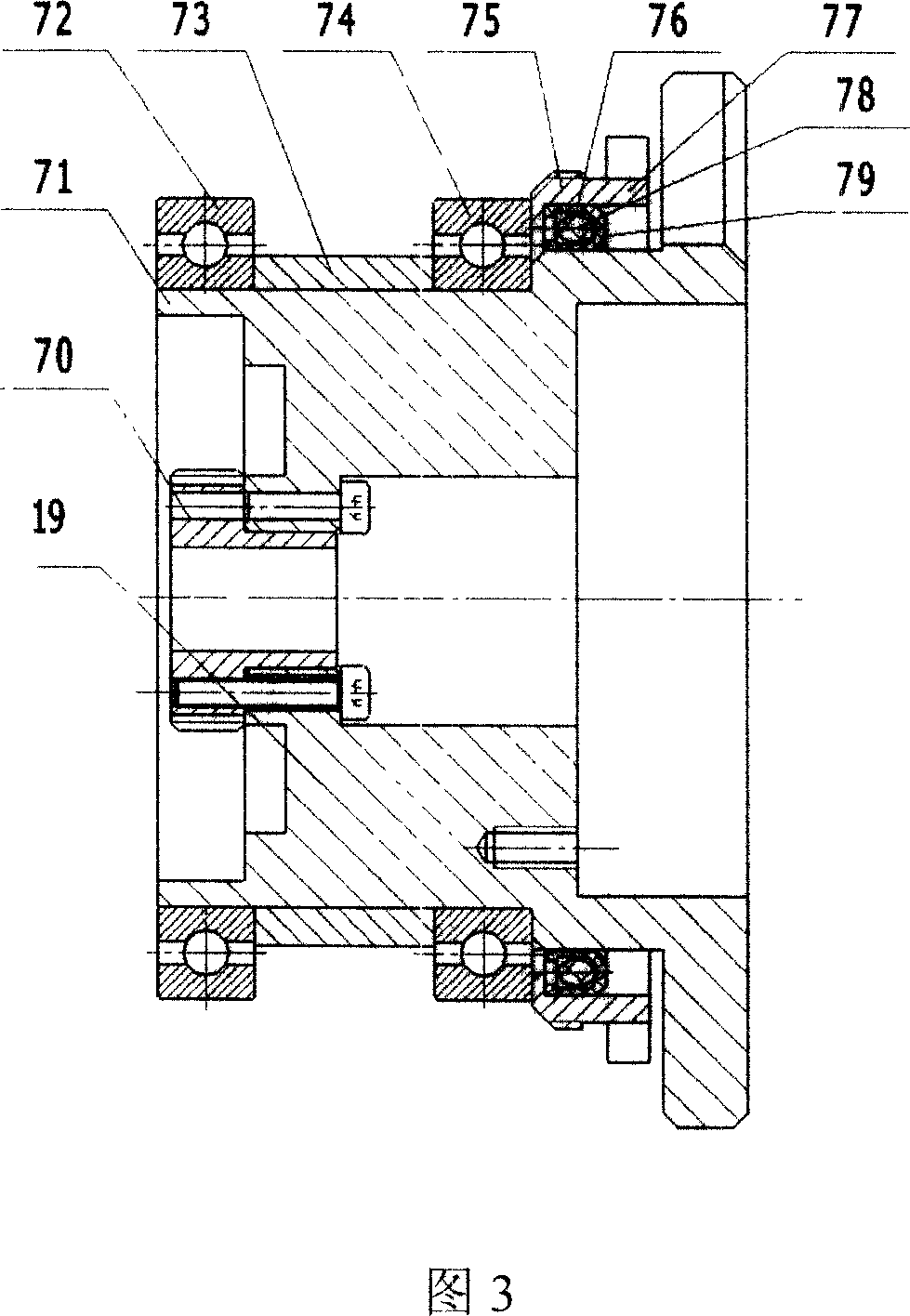

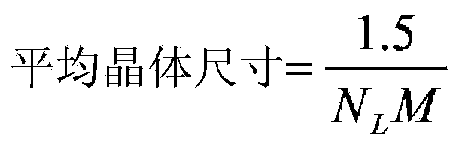

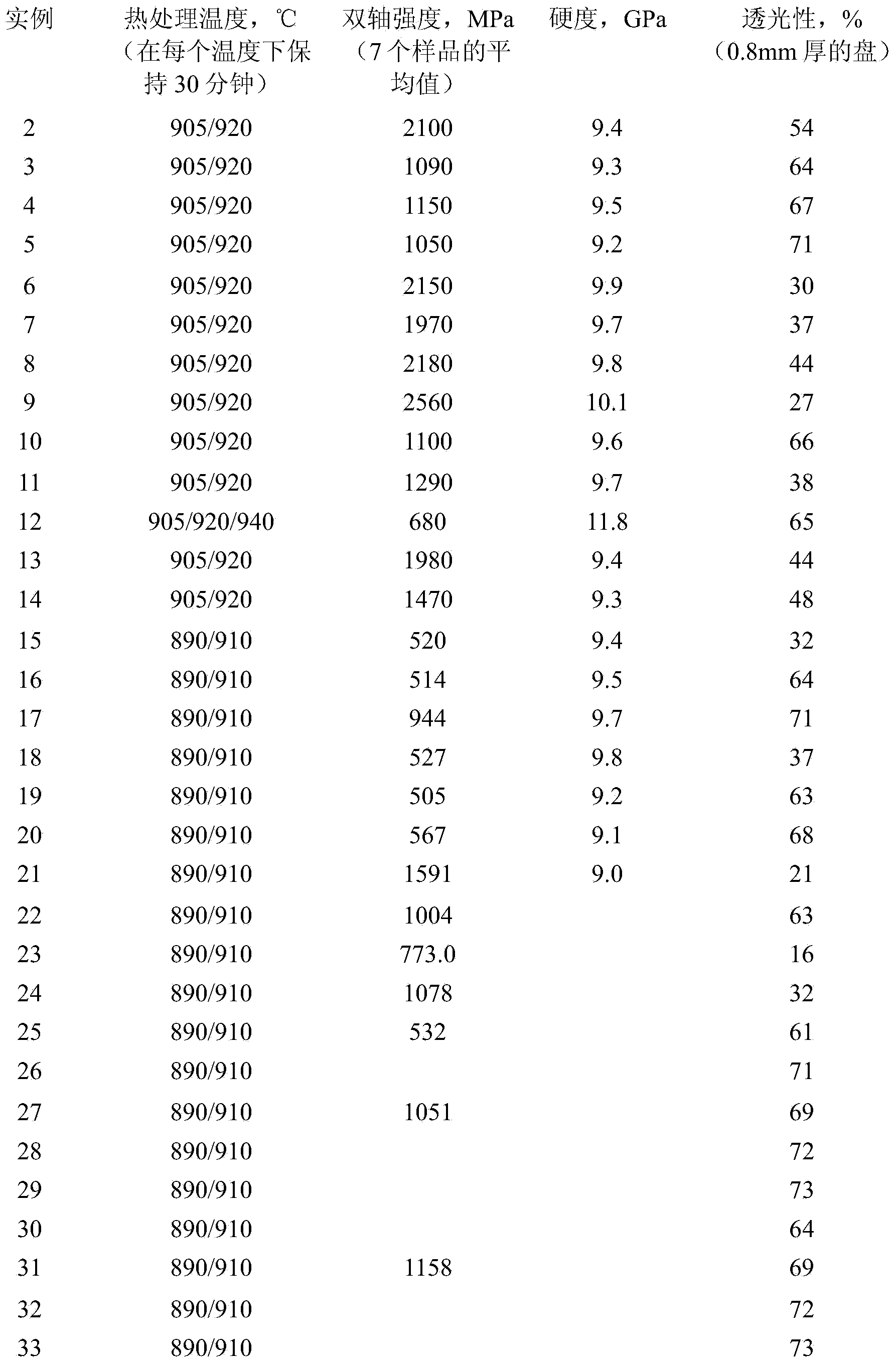

A precision dynamic and static pressure ceramic spindle device

InactiveCN102266951AIncrease speedIncreased operating lifeMaintainance and safety accessoriesThrust bearingEngineering

The invention discloses a precise type dynamic and static pressure ceramic main shaft device. A front radial-bidirectional thrust bearing is mounted at the front end of a main shaft, and a back radial bearing is mounted at the back end of the main shaft. The front radial-bidirectional thrust bearing comprises a front main shaft lining. A front ceramic right shaft sleeve, a thrust ceramic shaft sleeve, a front ceramic left shaft sleeve and a front shaft sleeve end cover are assembled at the external part of the front main shaft lining. A thrust shaft sleeve lining is assembled at the externalpart of the thrust ceramic shaft sleeve. A radial ceramic bearing bush, a left thrust ceramic bearing brush, a right thrust ceramic bearing brush, a front bearing brush lining and a front bearing brush end cover are mounted on a stand. The back radial bearing comprises a back main shaft lining. A back ceramic shaft sleeve and a back shaft sleeve end cover are assembled on the back main shaft lining. A back bearing brush end cover, a back ceramic bearing brush and a back bearing brush lining are mounted on the stand. The edge of a ceramic part can be protected by the precise type dynamic and static pressure ceramic main shaft device, so that the impact resistance is enhanced; the strength of a radial-thrust combined bearing is enhanced; the processibility of the ceramic part is enhanced, and the finished product ratio is increased; and the sealing property of the main shaft is enhanced.

Owner:TIANJIN UNIV

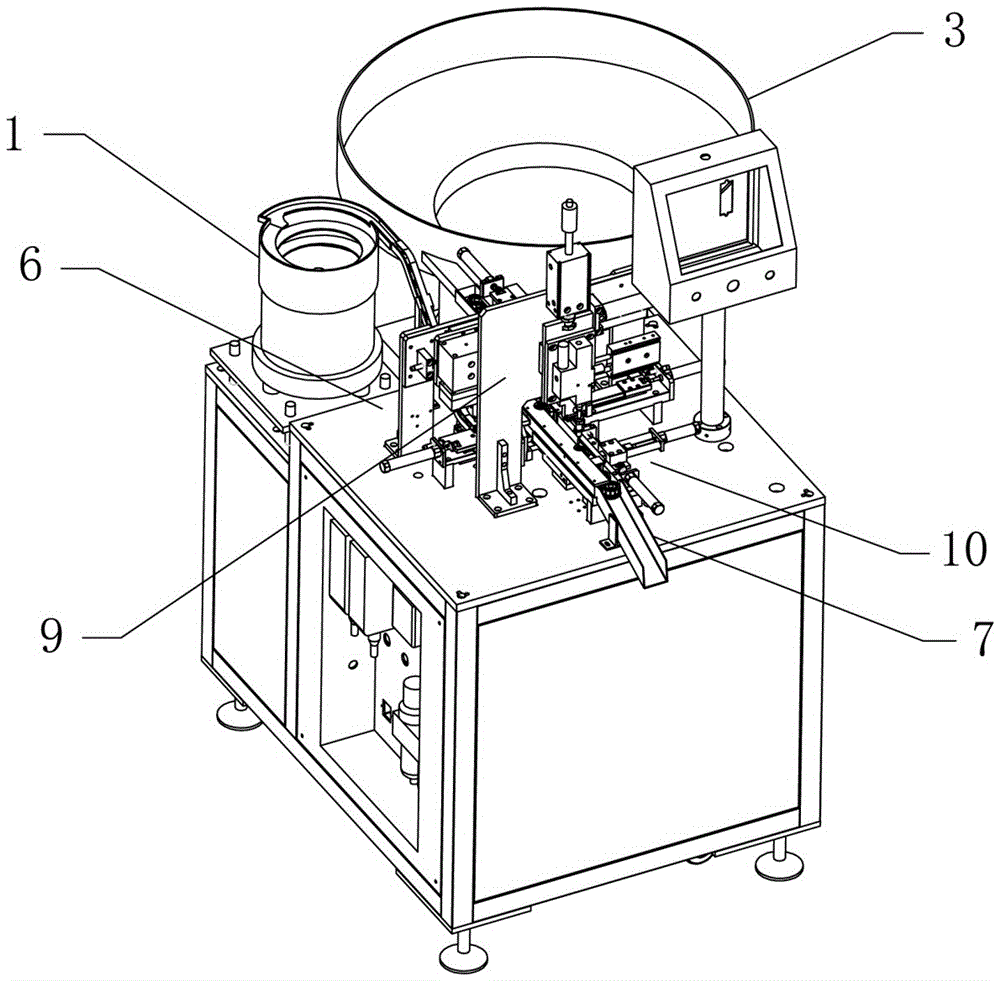

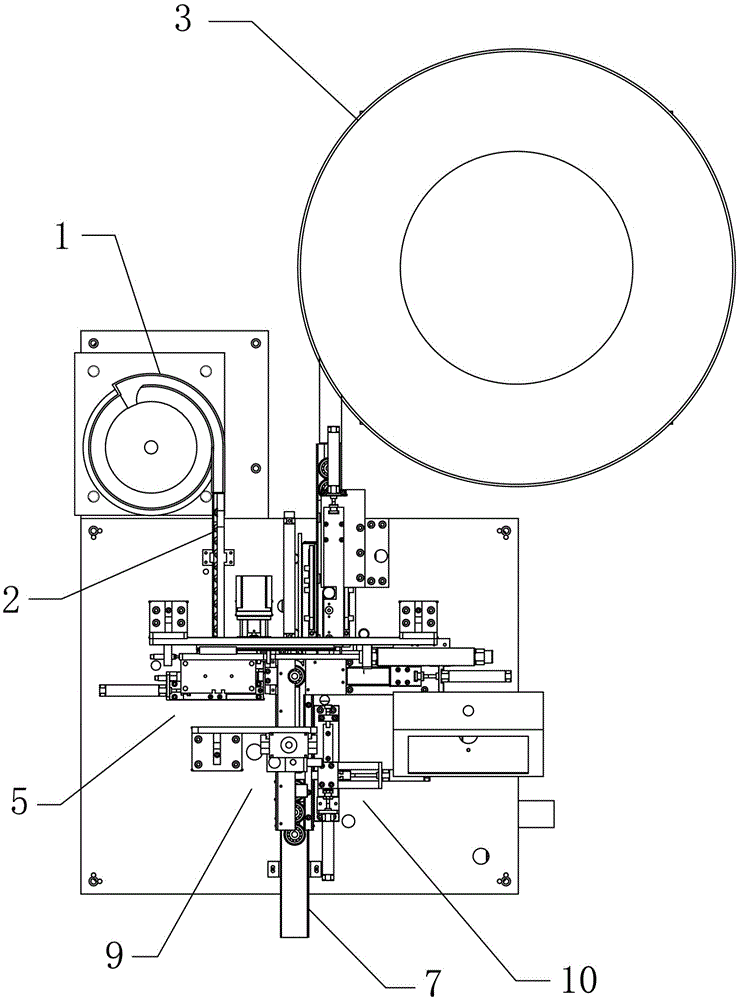

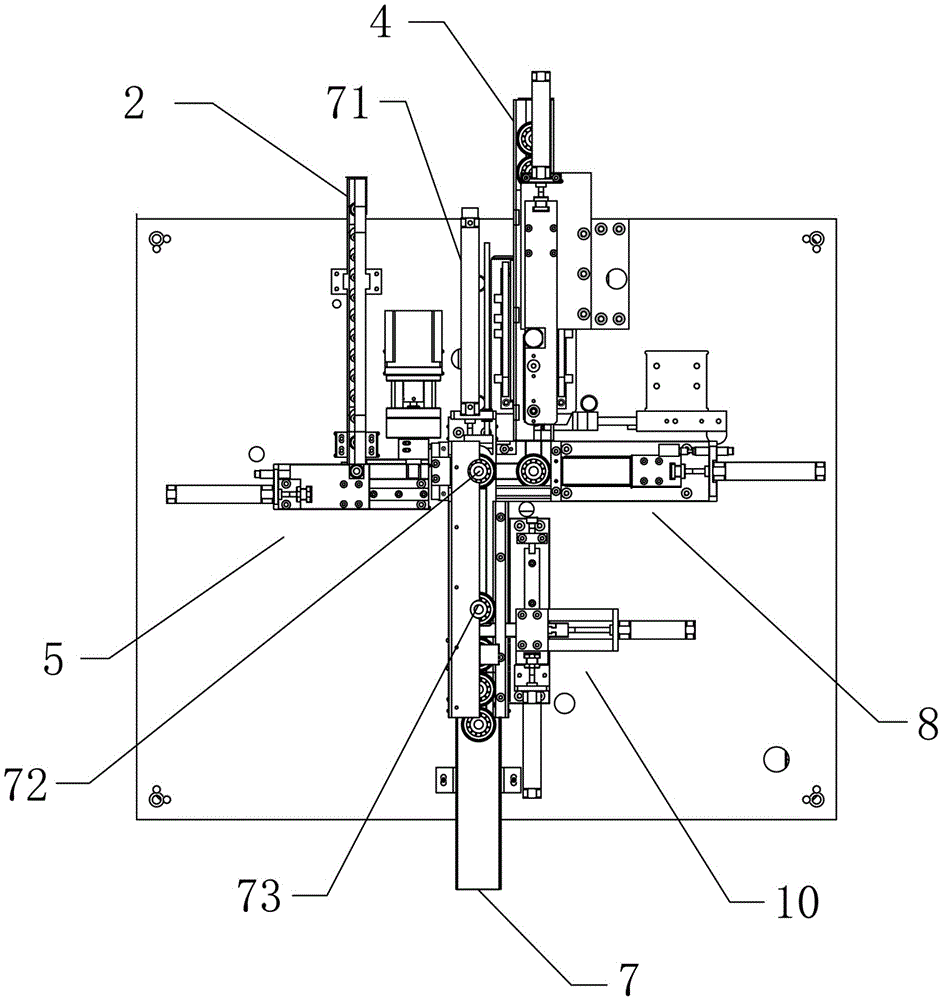

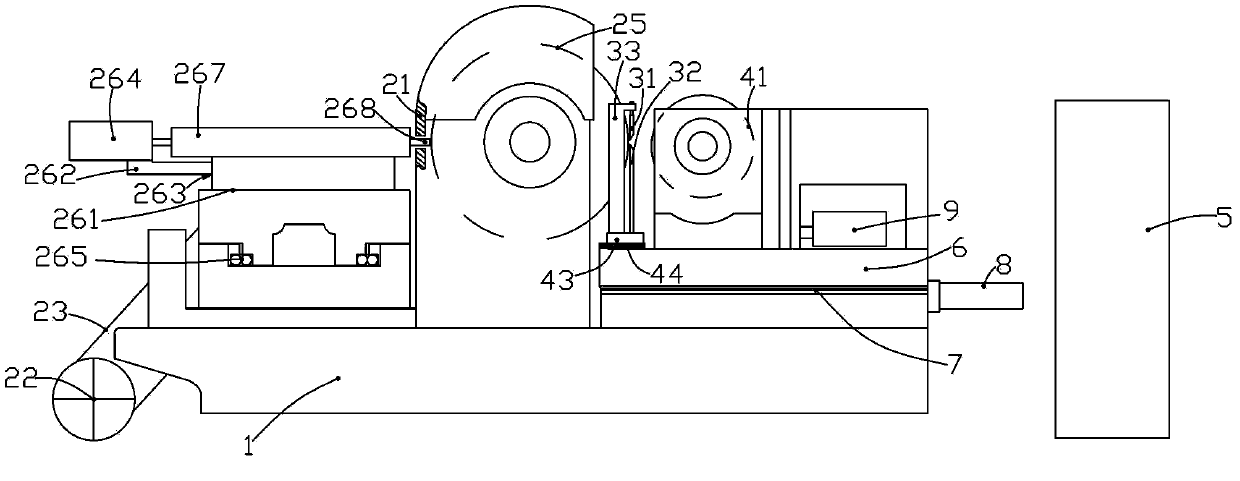

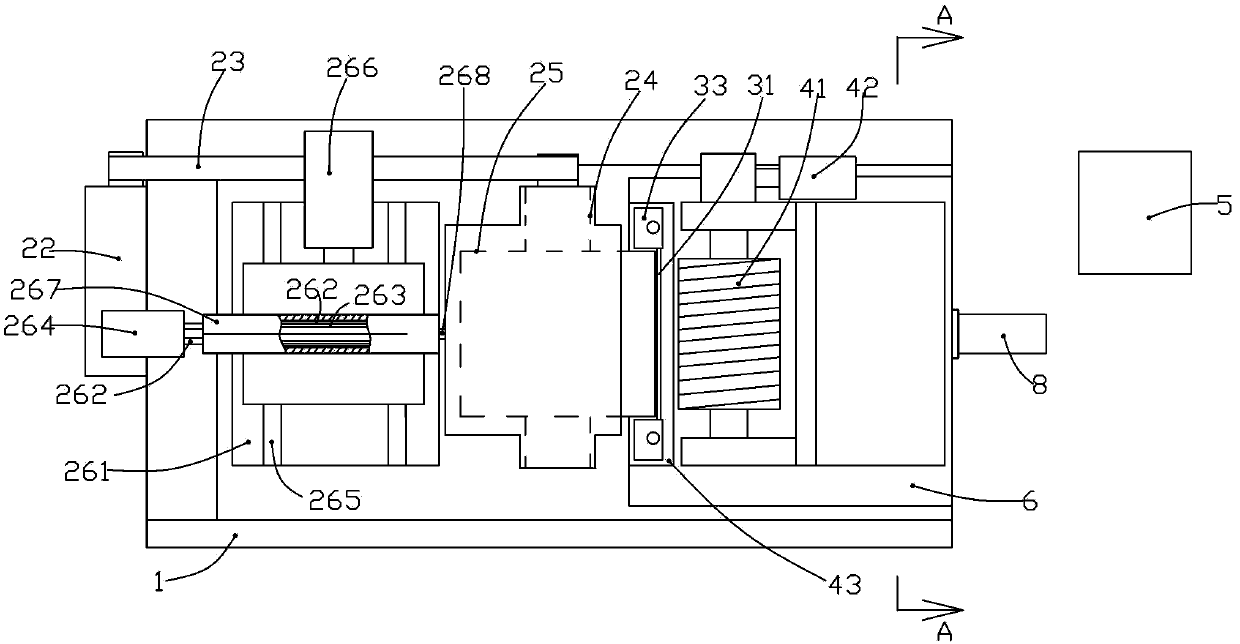

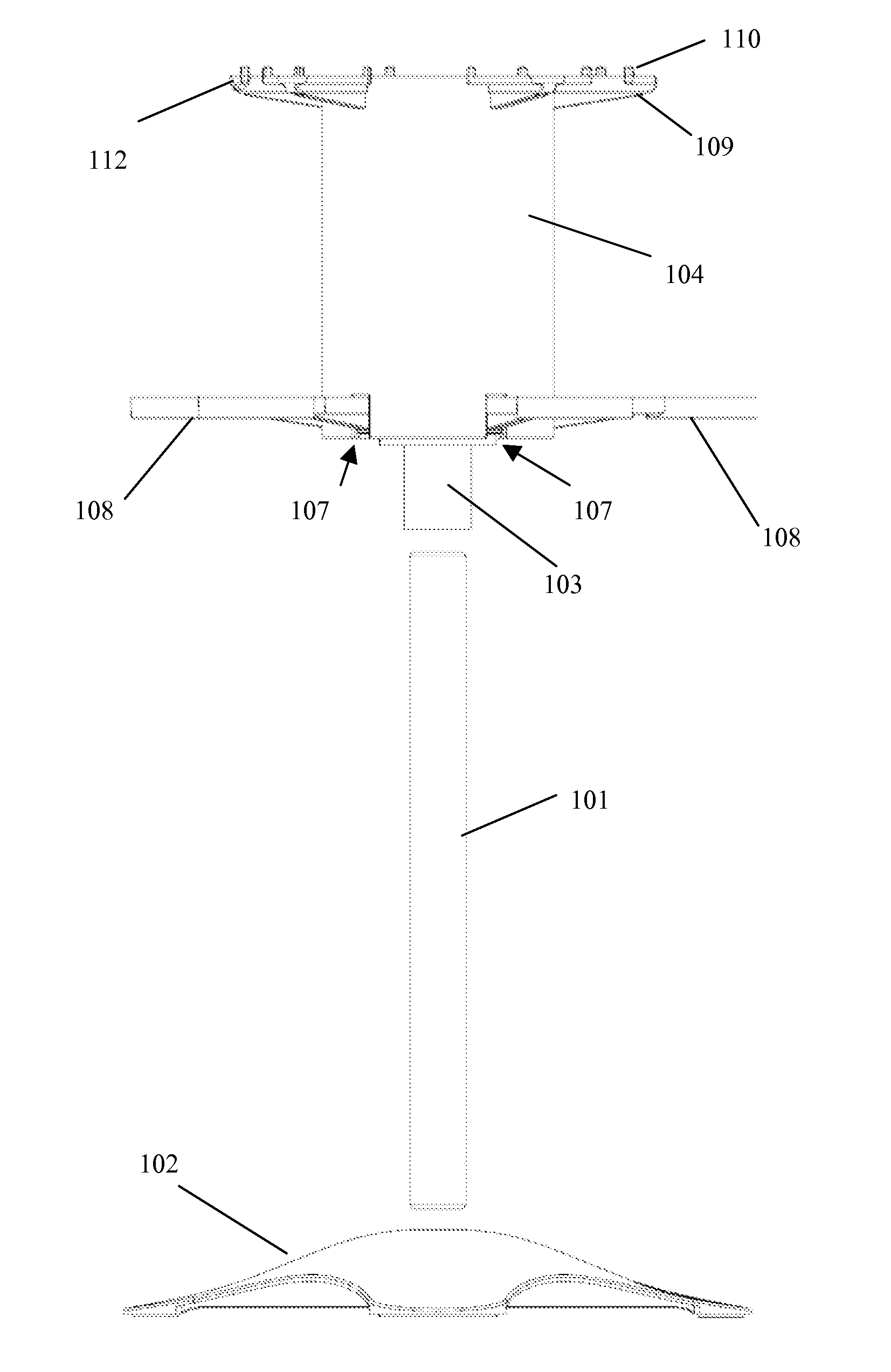

Numerical control automated assembly equipment for ceramic bearing

ActiveCN105540202ARealize automatic assemblyHigh degree of automationConveyorsControl devices for conveyorsNumerical controlEngineering

The invention discloses numerical control automated assembly equipment for a ceramic bearing. The equipment comprises a bearing feeding device for inputting the bearing, bearing conveying guide rails for guiding the bearing, a shaft sleeve feeding device for inputting a shaft sleeve, shaft sleeve conveying guide rails for guiding the shaft sleeve, a bearing turnover mechanism for turning the bearing to the front side, an assembly mechanism for sleeving the bearing with the shaft sleeve to form an assembly as well as assembly conveying guide rails for guiding the assembly.

Owner:佛山市东丽塑胶有限公司

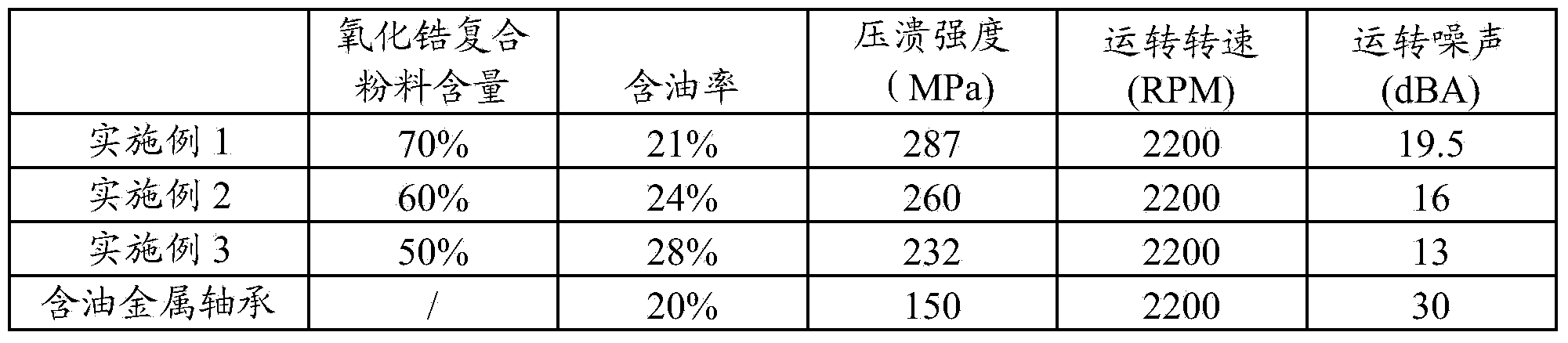

Multihole ceramic bearing and manufacturing method thereof

ActiveCN104355673AImprove mechanical propertiesSolve the problem of low temperature agingCeramicwareAdhesiveComposite ceramic

The invention provides a manufacturing method of a multihole ceramic bearing. The manufacturing method comprises the steps of fully and uniformly mixing an enhanced type zirconium oxide composite ceramic powder material, a pore forming material and an adhesive to obtain mixed slurry; molding powder obtained by drying the mixed slurry by a die to obtain a green blank; sintering the green blank to obtain a bearing blank body; performing vacuum oil soaking treatment on the bearing blank body. According to the preparation method disclosed by the invention, the bearing is manufactured by the enhanced type zirconium oxide composite ceramic powder material; by the technically enhanced partially stabilized zirconium oxide, the phase change toughening action is enhanced, and the mechanical property of ceramic is improved; the problem of low-temperature aging of existing partially stabilized zirconium oxide is solved.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Method for preparing copper or nickel powder and electrolysis device based on same

The invention discloses a method for preparing copper or nickel powder and an electrolysis device based on the same, so as to achieve continuous large-scale production. The method comprises the steps of: preparing electrolyte; clearing metal particles or turning scraps to be powdered to obtain a metal raw material; putting the metal raw material as a sacrificial anode into an electrolysis basket for electrolysis; continuously sending a suspension solution of the metal powder and the electrolyte out to filter and separate the metal powder; cleaning the filtered metal powder with deionized water; vacuum drying the metal powder; mechanically grinding the dried metal powder; and examining a finished product. The electrolysis device comprises an electrolysis tank, a cathode assembly plate, a conductive spindle, a ceramic bearing, a collector, an insulating coupling, a speed reduction motor, the anode basket, a bracket, a scraping brush, a separation tank, an acid-resistant pump and an overhead tank. The device has a compact structure, and the effective cathode area is enlarged by more than five times compared with the roller type electrolysis tank with the equal capacity, so that the working efficiency is greatly improved, and the labor intensity is reduced.

Owner:辽宁索研科技有限公司

Centerless grinding machine for conical rollers

ActiveCN103394978ANot easy to wearImprove grinding accuracyGrinding carriagesRevolution surface grinding machinesElectrical controlEngineering

A centerless grinding machine for conical rollers comprises a grinding wheel mechanism, a composite base, a guide plate and guide frame mechanism and a guide wheel mechanism. The grinding wheel mechanism is fixed onto a machine body, the composite base matches with the machine body through a MV guide rail, and the guide plate and guide frame mechanism is arranged on the composite base by a cross roller guide rail through a guide plate and guide frame base. The cross roller guide rail is also adopted on a sliding rail in a grinding wheel dressing part of the grinding wheel mechanism, a grinding wheel spindle adopts a double-support ceramic bearing bush, and the end portion of a grinding wheel dressing pen is provided with a King Kong pen point. The grinding wheel dressing part, the composite base and the guide plate and guide frame base are driven by servo motors, and each servo motor and driving motor are under servo control through a electrical control cabinet. The centerless grinding machine is high in degree of automation, fine in accuracy and consistency of grinding machining, convenient to adjust, mount and maintain, high in grinding efficiency, and lower in equipment failure rate, maintenance load, and maintenance cost.

Owner:临清市宏森轴承有限公司

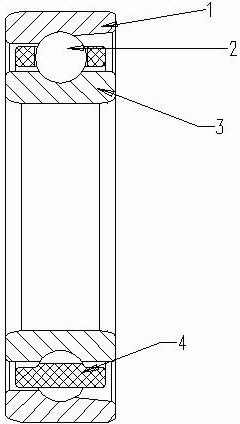

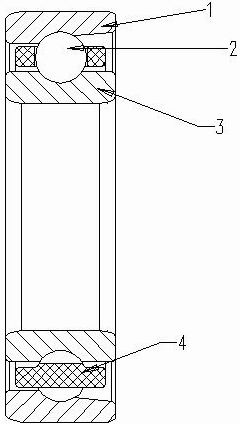

Precise ceramic bearing and machining process thereof

InactiveCN102635635AExtended service lifeReduce coefficient of frictionBearing componentsBall bearingVolumetric Mass Density

The invention relates to a ceramic ball bearing, particularly relates to a precise ceramic bearing and a machining process thereof and belongs to the field of bearings and machining thereof. According to the precise ceramic bearing and the machining process thereof, a rolling body utilizes a silicon nitride ceramic material, the density is reduced, the centrifugal force is reduced by more than 40%, the limited rotating speed is improved by more than 30% and the service life of the bearing is prolonged by more than 50%. Meanwhile, the silicon nitride ceramic material has the advantages of small friction coefficient, strong self-lubricating capability, wear resistance, high-temperature resistance and the like. Furthermore, a sleeve ring machining process adopts cold rolling and the effect of the cold rolling procedure reduces a lathing procedure, shortens the production cycle, improves the production efficiency and reduces the consumption of raw materials. If the precise ceramic bearing is manufactured by a common cutting machining process, the utilization rate of materials is commonly 40-50%, but if the precise ceramic bearing is manufactured by a cold rolling method, the material utilization rate can reach 70-80%.

Owner:李东炬

Utensil Storage Stand

InactiveUS20100237030A1Compact storagePromote densificationKitchen equipmentShow shelvesBall bearingEngineering

A utensil storage stand, which comprises a base, a column extending away from the base, a distal end on the column, and utensil engaging means rotatably mounted on the column. The utensil engaging means is rotatably mounted on the distal end of the column by a ball bearing arrangement comprising plastic races cooperating with plastic or ceramic bearings interposed between the races. The utensil engagement means comprises a first set of radially extending spokes with enlarged perforations through the spokes and a second set of radially extending spokes providing utensil support hooks extending from the spokes. The utensil engagement means is rotatably mounted with respect to column having an axis substantially perpendicular to the plane of the base. The open body of the utensil engagement means creates a canister for the purpose of containing small kitchen items with the disc top acting as the floor or bottom of the canister.

Owner:CASS DAVID LEE +1

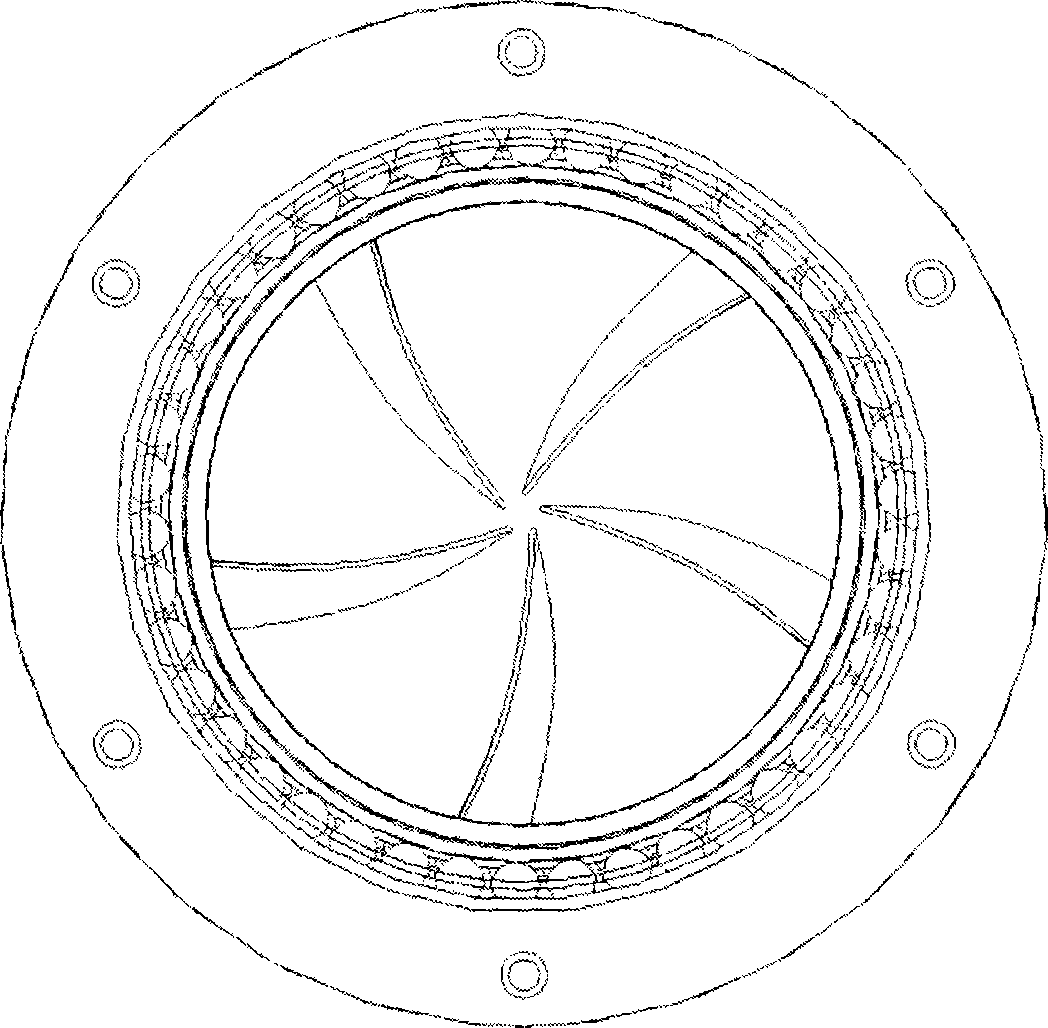

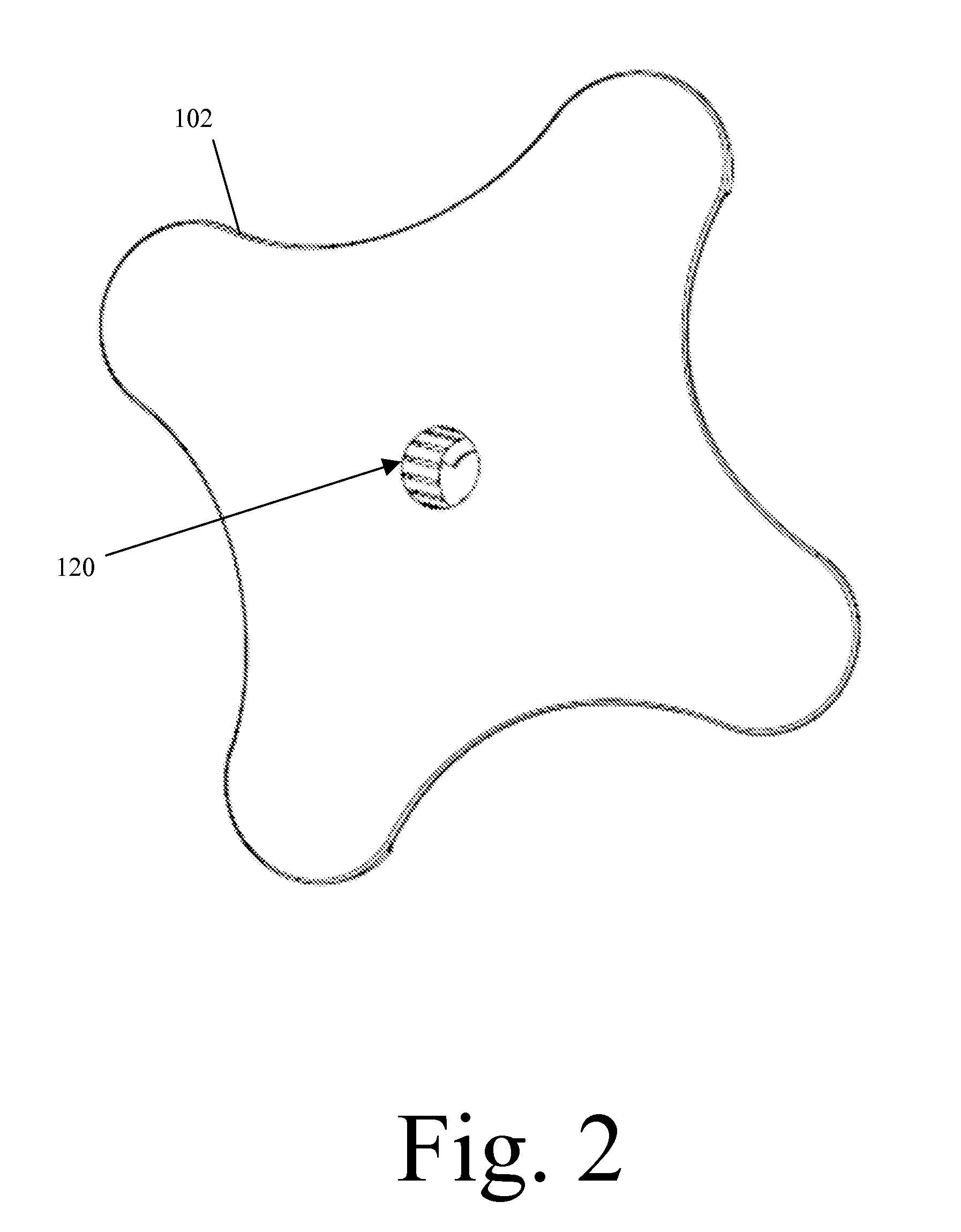

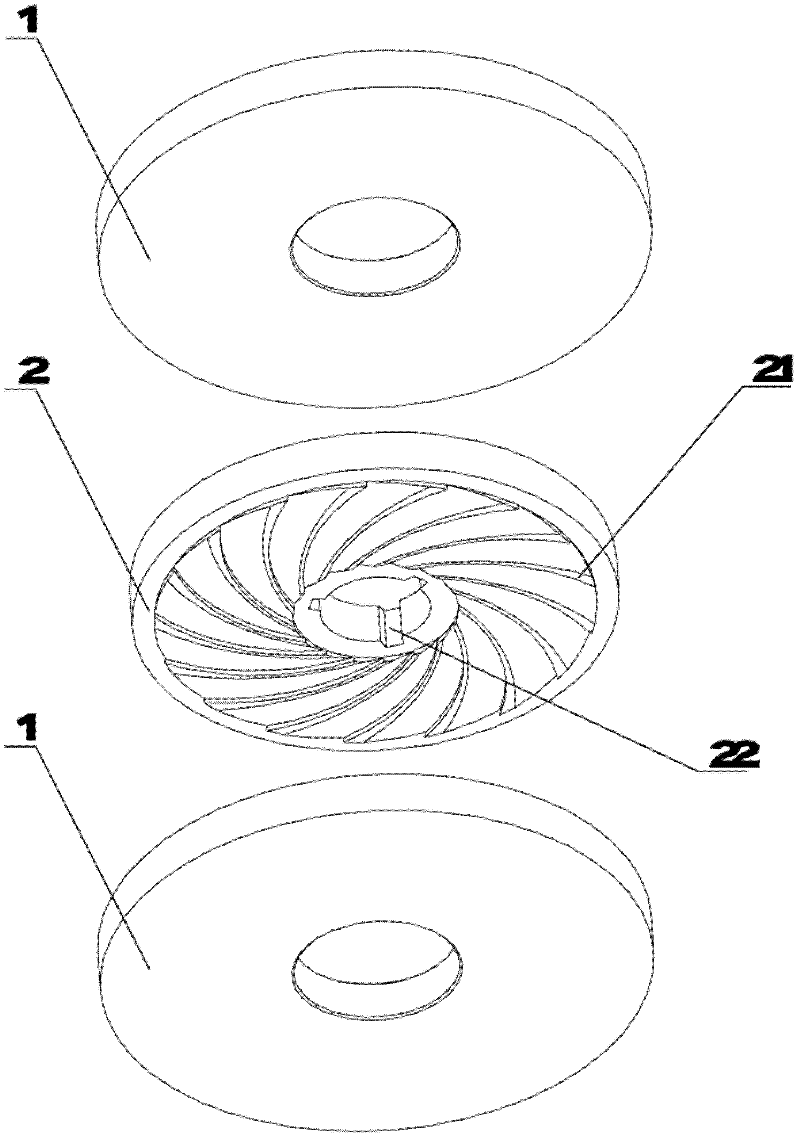

Dynamic pressure gas thrust ceramic bearing

ActiveCN102261374ASimple structureEasy to installBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a dynamic pressure gas thrust ceramic bearing, which comprises two outer discs and an inner disc in clearance fit, wherein the inner disc is clamped between the two outer discs. Two ends of the outer discs are provided with high-precision planes, and two ends of the inner disc are provided with groove-type patterns. The groove-type patterns are uniformly distributed in an impeller type so as to form a wedge-shaped space between the outer discs and the inner disc. Each groove is formed by extending an inner circle of the inner disc to an outer circle. The groove-type patterns at both ends of the inner disc are arranged symmetrically. The dynamic pressure gas thrust ceramic bearing is fixedly arranged on a high-speed rotating shaft through the inner disc, the two outer discs are fixedly arranged on a bearing seat, and the continuously generated dynamic pressure gas can be well kept in the fit clearance of the outer discs and the inner disc under the drive of the high-speed rotating shaft to form an air film required for supporting the axial positioning, namely thrust function of the high-speed rotating shaft, so that the functions of the dynamic pressure gas thrust ceramic bearing with certain stability and load capability are realized.

Owner:罗立峰

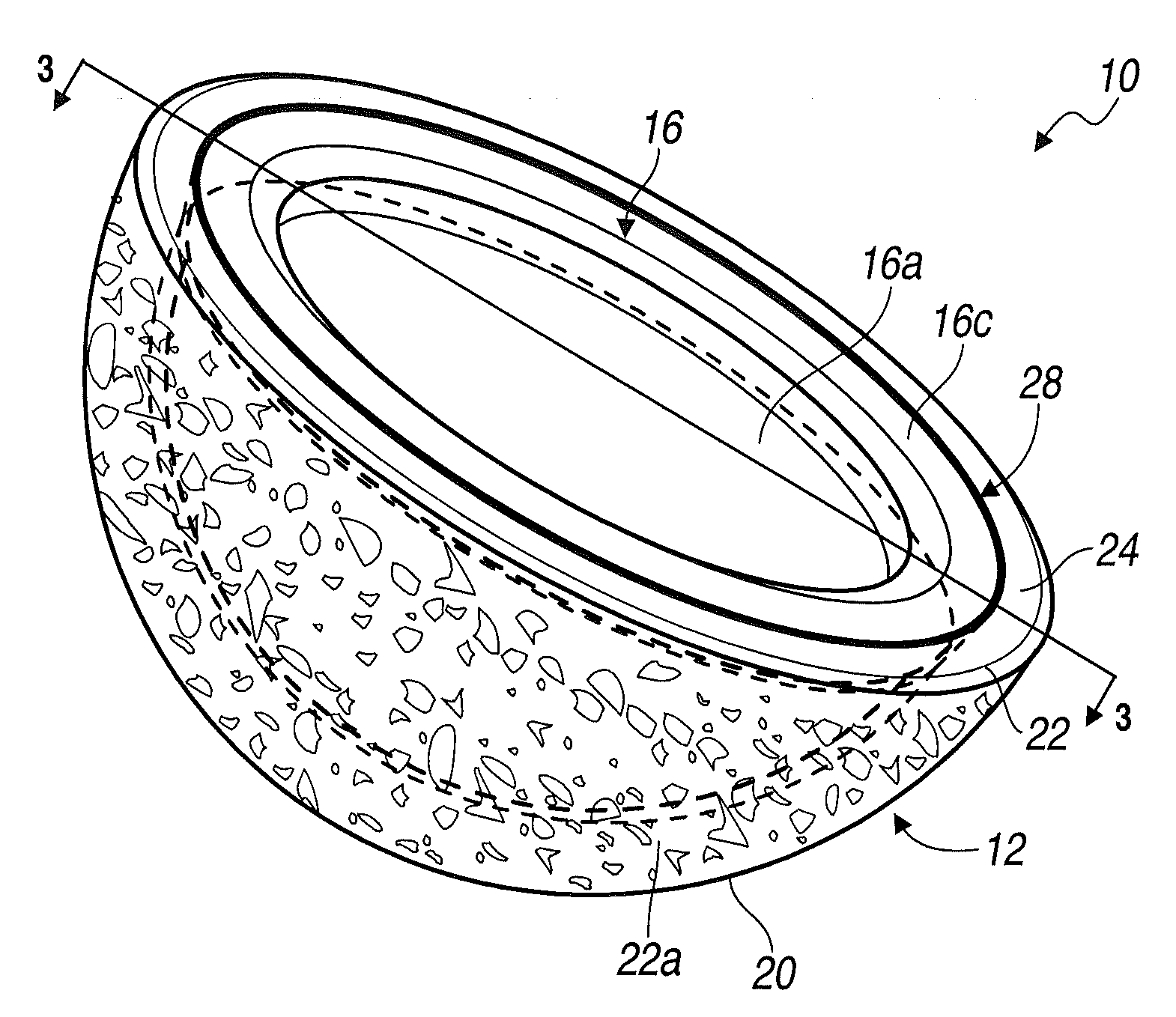

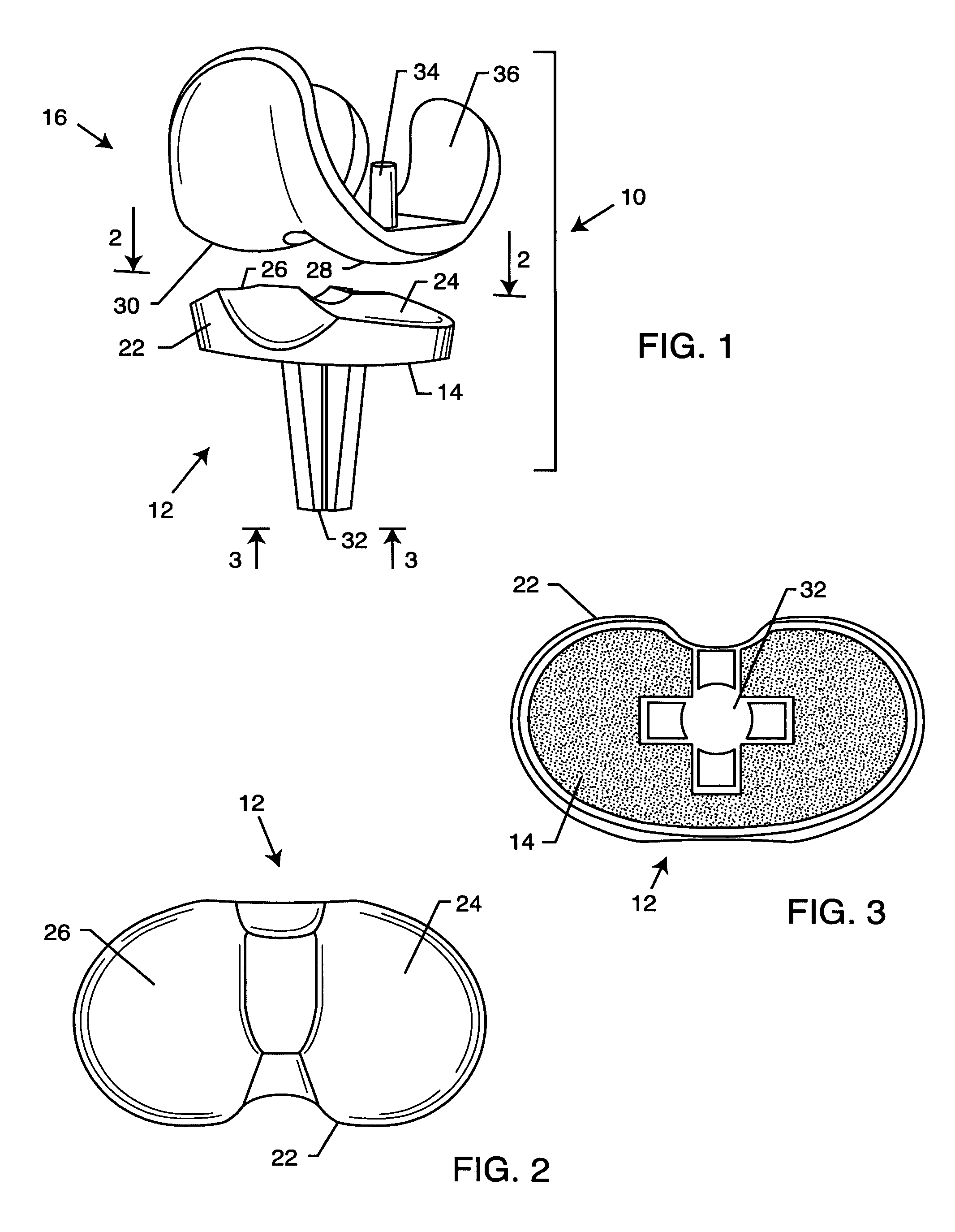

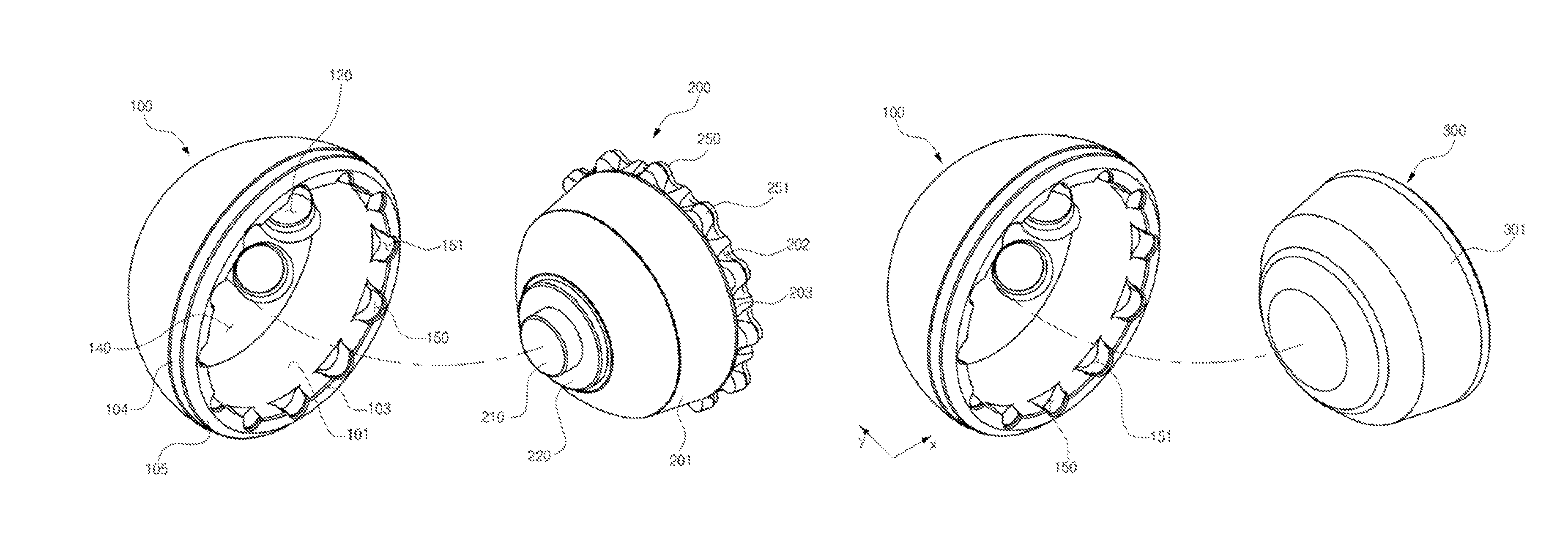

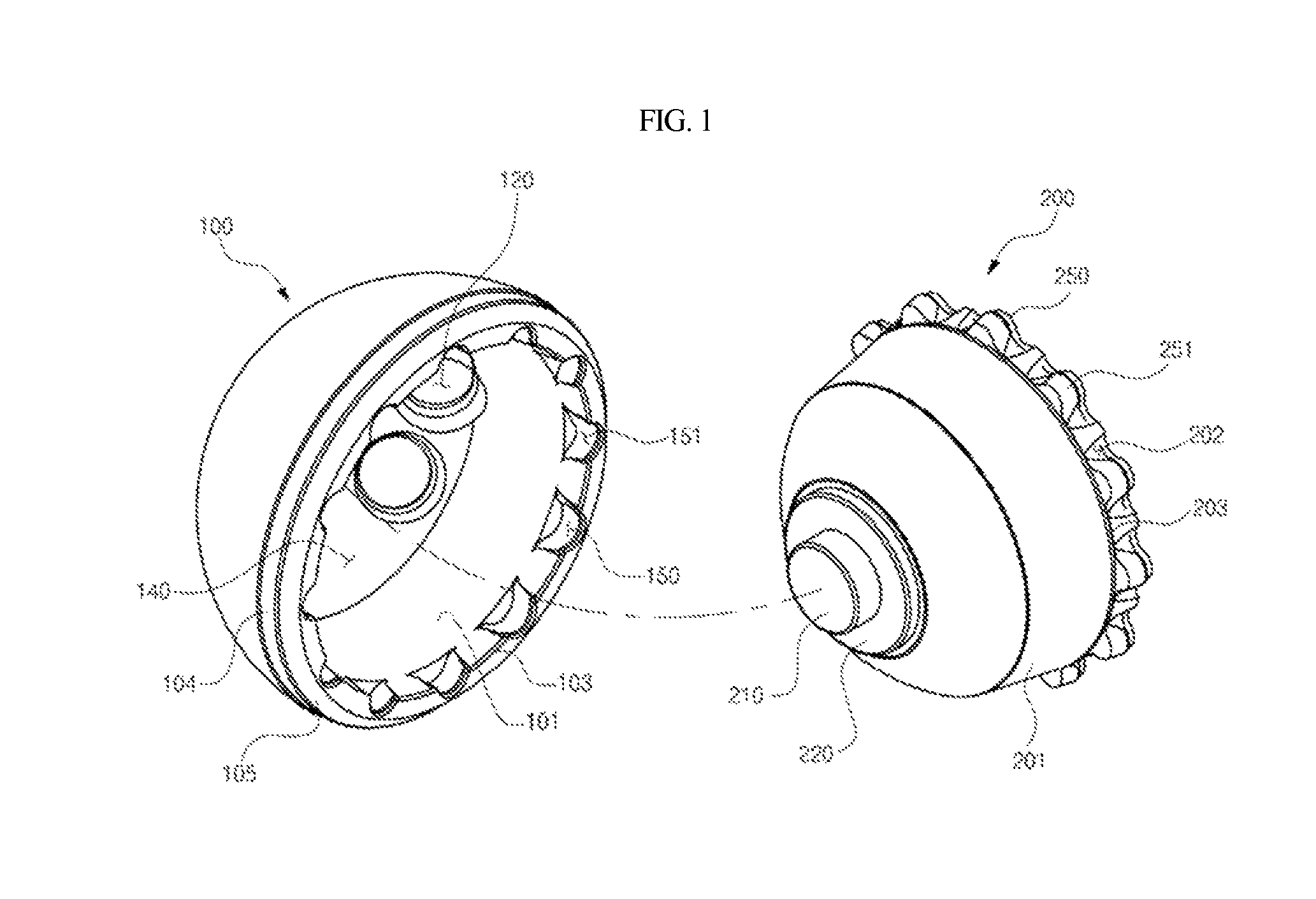

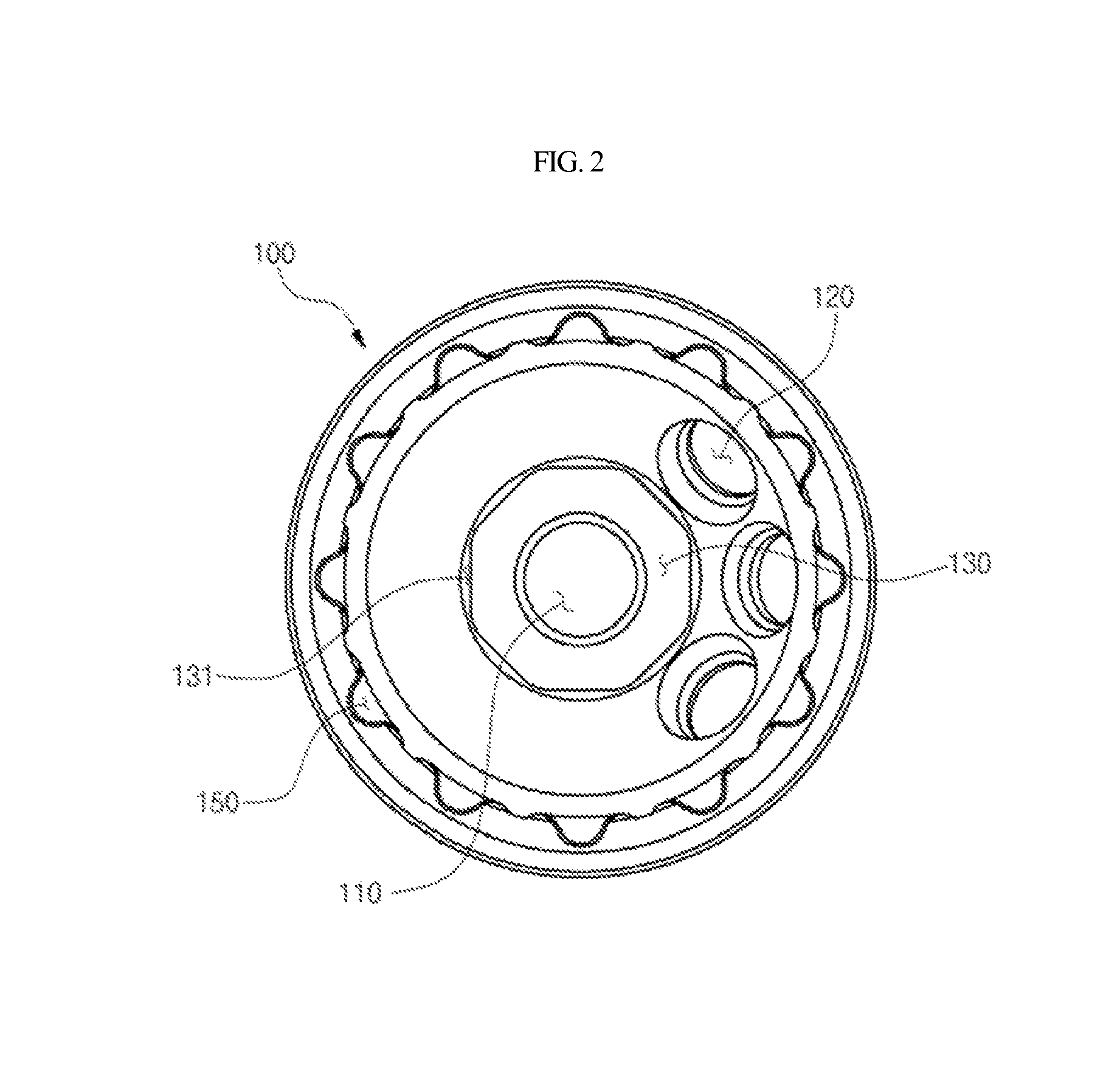

Acetabular cup for an artificial hip joint and bearing, and acetabular cup assembly

ActiveUS9144497B2High strengthPrevent protrudingJoint implantsAcetabular cupsArtificial hip jointsBiomedical engineering

An acetabular cup assembly for an artificial hip joint includes an acetabular cup including a seating recess, a female taper formed on an inner wall, protrusion recesses formed to communicate with the seating recess and insertion recesses each positioned inside a corresponding one of the protrusion recesses; and a bearing including a male taper on an outer circumference thereof, protrusions inserted into the protrusion recesses, and insertion protruding portions each formed on a corresponding one of the protrusions, the insertion protruding portions being inserted into the insertion recesses. A polyethylene bearing can be firmly fixed to the acetabular cup. When a ceramic bearing made is inserted into the acetabular cup, the area where the bearing adjoins the acetabular cup is increased, thereby preventing the ceramic bearing from being broken. Since no groove is formed along the entire circumference of the acetabular cup, the strength is increased.

Owner:CORENTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com