High-speed electric main shaft for mixed use of outer ring of steel bearing and inner ring of ceramic bearing

A high-speed electric spindle and bearing outer ring technology, applied in the field of mechanical components, can solve the problems affecting the performance of the electric spindle and the difficulty in guaranteeing machining accuracy, and achieve the effects of eliminating heat treatment, improving service life, and reducing moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the drawings.

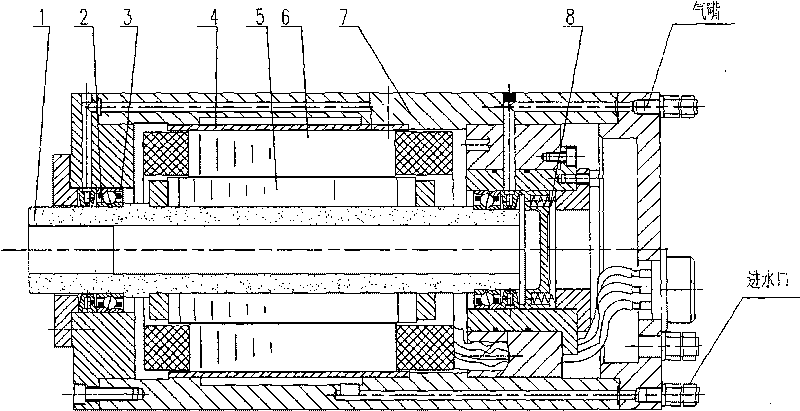

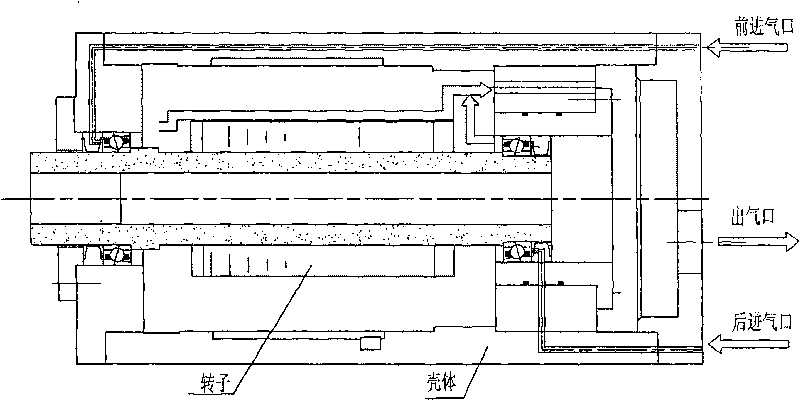

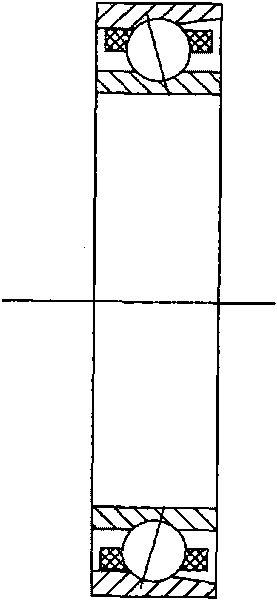

[0019] The electric spindle structure mainly includes a shell, a ceramic spindle, a ceramic bearing inner ring, a ceramic ball, a steel bearing outer ring, a stator, a rotor, a cooling device, a lubricating device and a bearing pre-tensioning device. The inner and outer rings of the electric spindle bearing are made of different materials. The inner ring is made of ceramic material, which ensures the large rigidity and low moment of inertia of the rotating parts of the electric spindle. The outer ring adopts steel material, which reduces the processing difficulty and plays a certain role in damping vibration. At the same time, the lubrication of the front and rear bearings adopts an oil mist lubrication method with two inlets and one outlet, and the oil mist is forced to pass through the surface of the rotor to realize the cooling of the rotor. The electric spindle bearing adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com