Device and method for producing tooth-like profiled sections on workpieces

A technology for forming parts and workpieces, applied in gears, applications, household appliances, etc., can solve the problems of high production costs, high transformation costs, and cannot be reduced, and achieve the effects of low inertia moment, high productivity, low equipment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

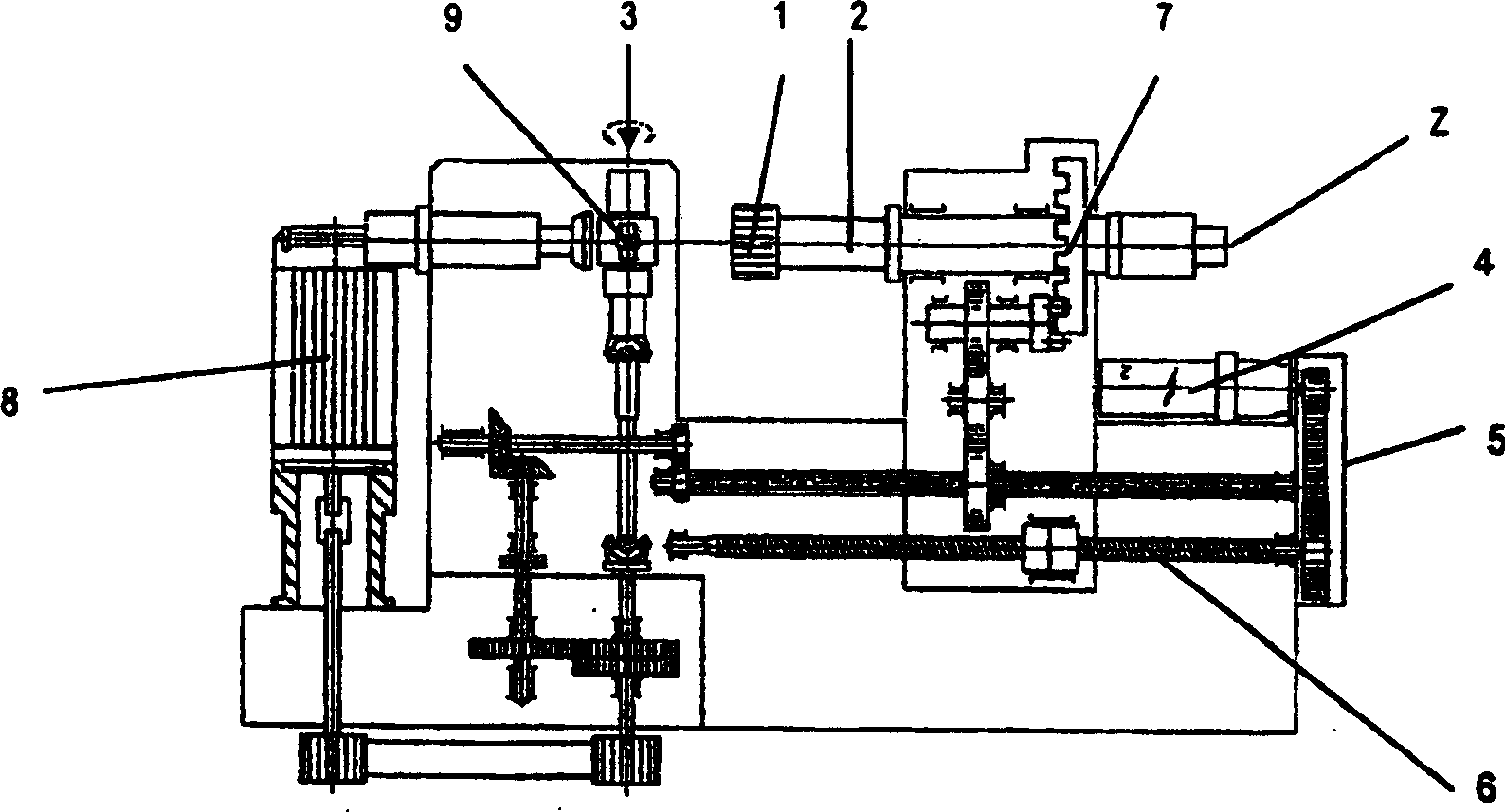

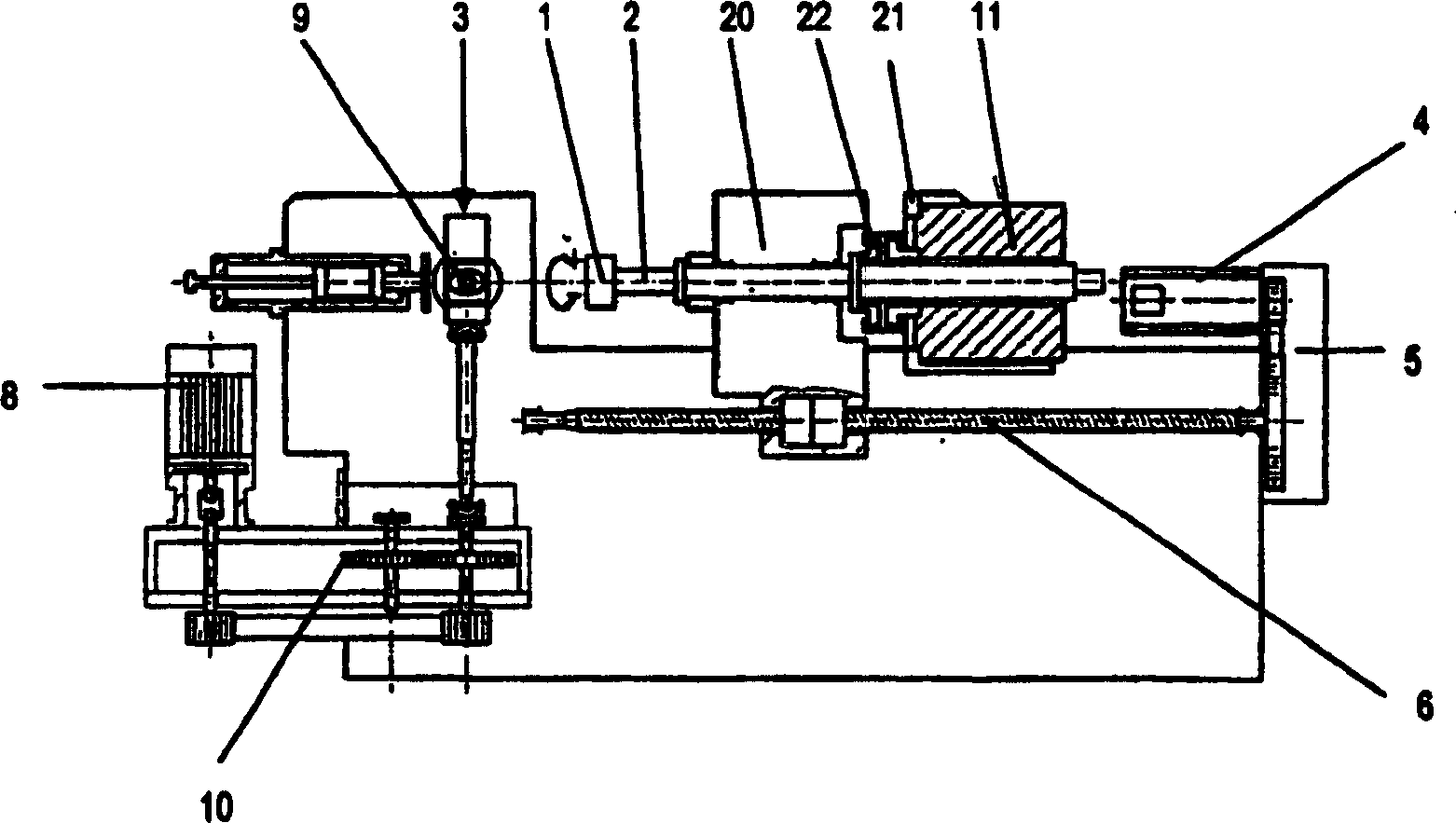

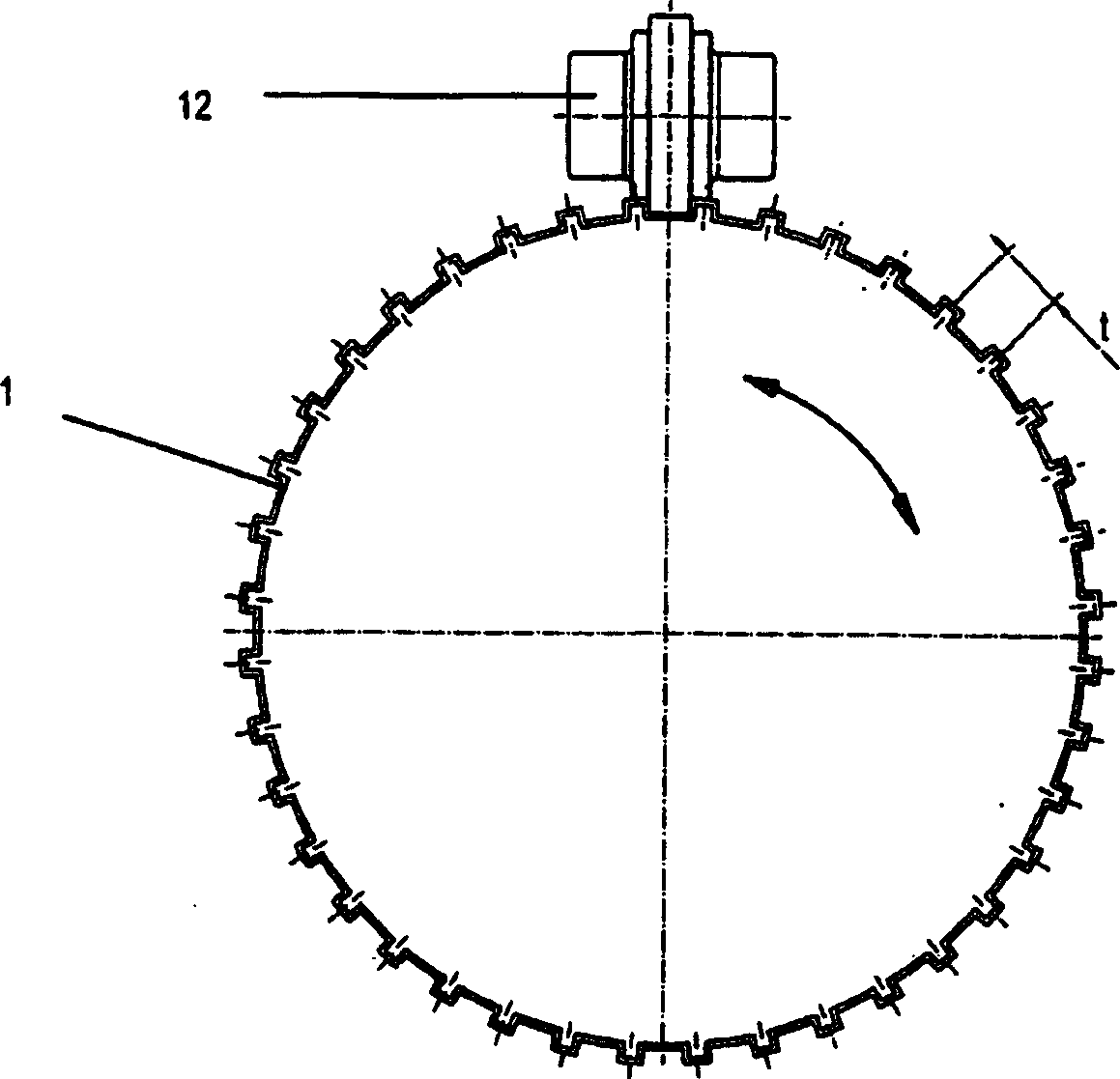

[0025] figure 1 A longitudinal section through a conventional punching and rolling mill for machining cylindrical workpieces 1 is shown.

[0026] The workpiece 1 is mounted on a workpiece holder 2 which can be advanced along its axis z in the machining area 3 . This feed takes place, for example, via its own drive 4 , which drives the spindle 6 via a transmission 5 .

[0027] A forming tool 9 driven by a drive 8 is mechanically connected directly to the workpiece holder 2 via a transmission 7 of the Malformed gear type. The intermittent rotation of the workpiece holder 2 about the axis z is thus directly coupled or synchronized with the movement of the forming tool 9 according to the transmission ratio and the configuration of the transmission 7 of the Martensitic intermittent transmission type. Due to this configuration, a certain profile can now be produced on the surface of the workpiece 1 by means of the forming tool 9 .

[0028] With this construction, it is now possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com