Cutting device for synthetic leather processing

A cutting device, a technology for synthetic leather, applied in cleaning methods and utensils, removing smoke and dust, textiles and papermaking, etc., can solve the problems of poor work hygiene, affecting the health of workers, low work efficiency, etc. Easy-to-destroy, fast-cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

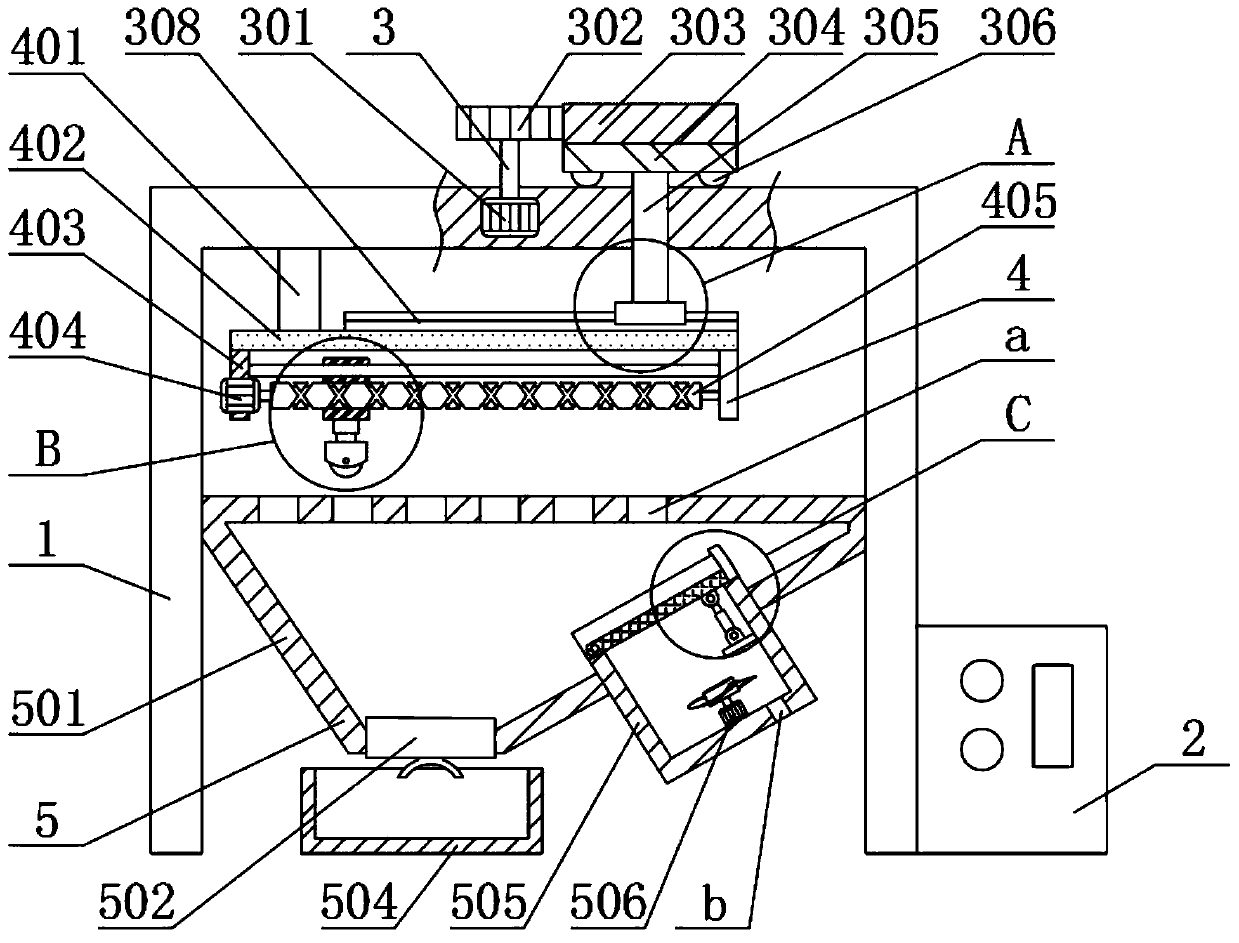

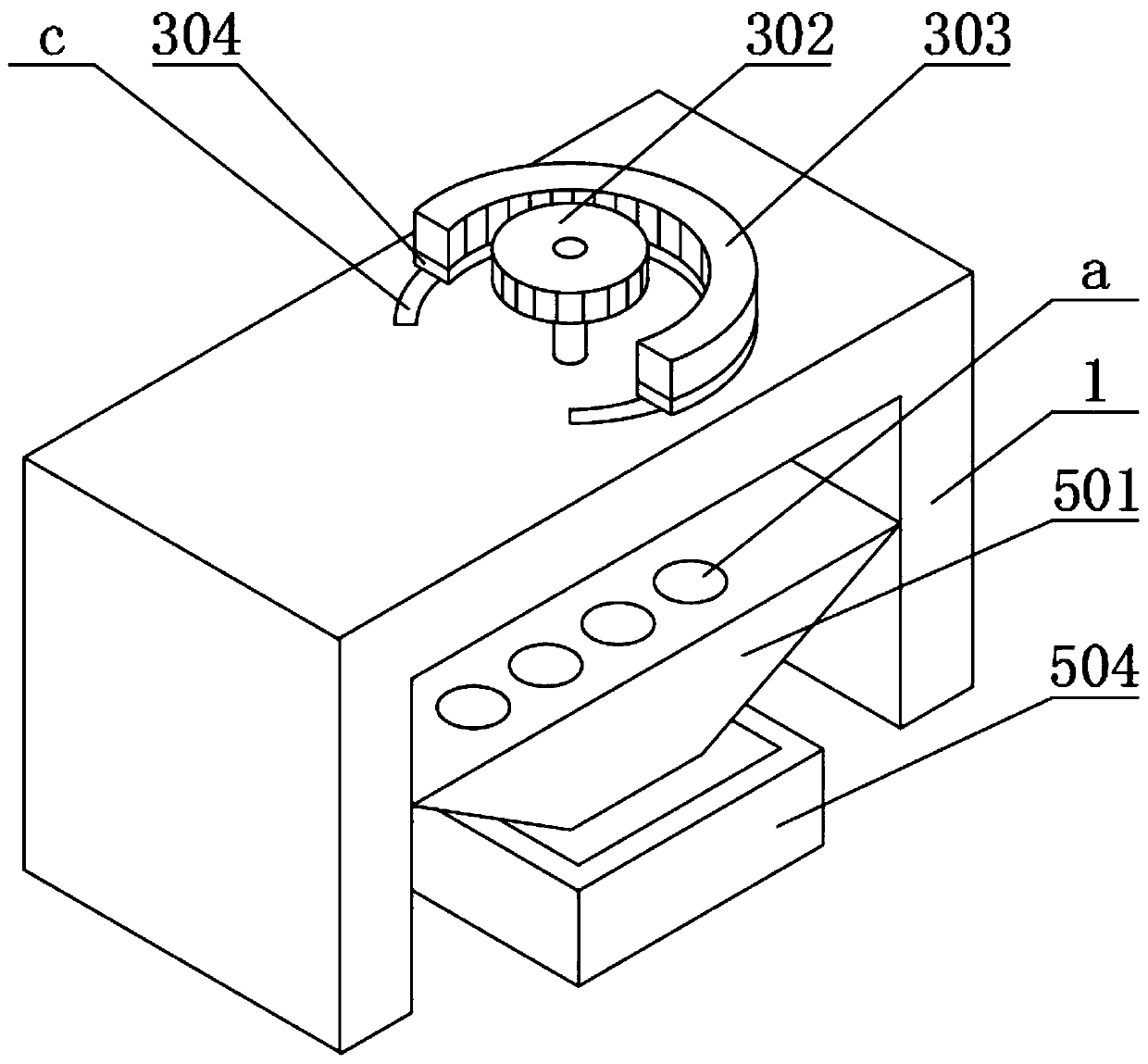

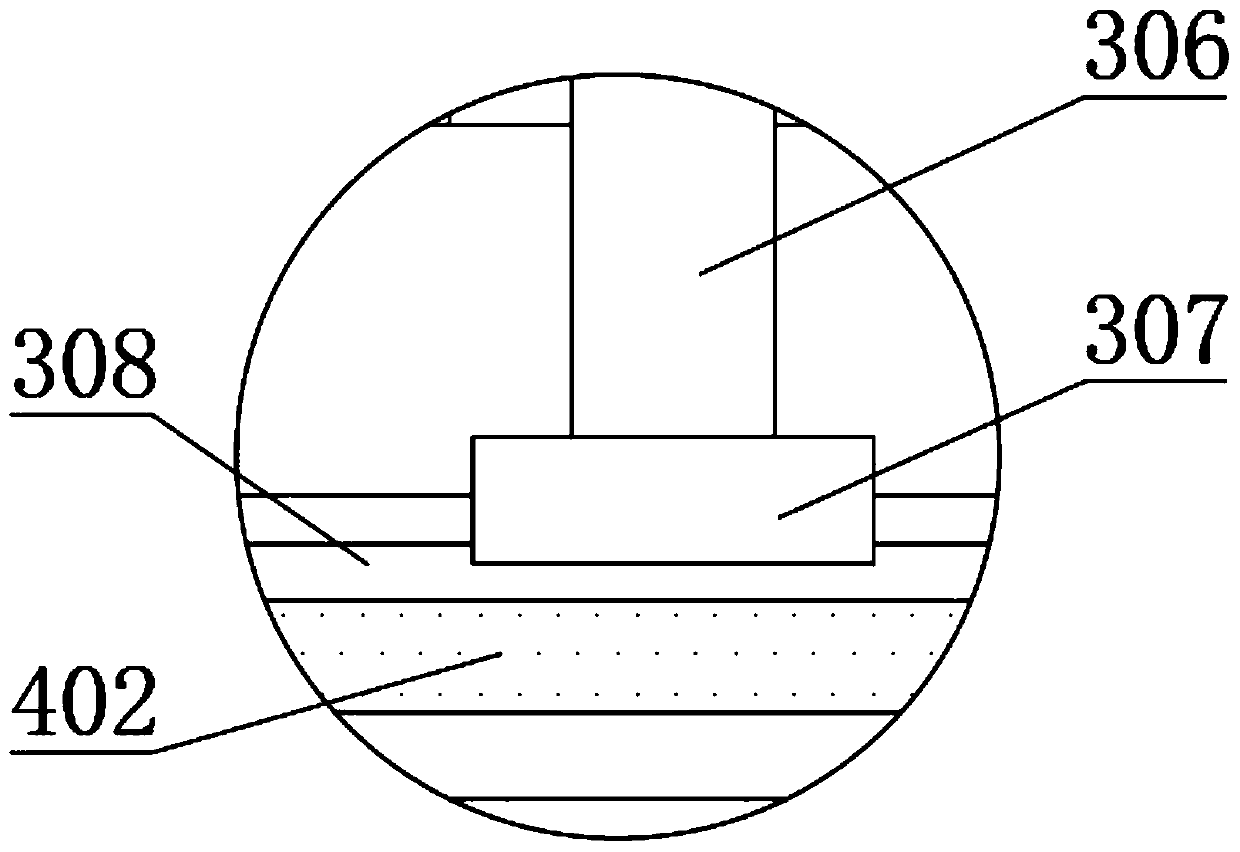

[0025] see Figure 1-5 , the present invention provides a kind of technical scheme:

[0026]A cutting device for processing synthetic leather, comprising a fixing frame 1, a general control cabinet 2, an adjusting device 3, a cutting device 4 and a collecting device 5, one end face of the fixing frame 1 is fixedly connected with an adjusting device 3, and the adjusting device The bottom end of 3 is fixedly connected with a cutting device 4, the lower side of the cutting device 4 is provided with a collecting device 5, and the collecting device 5 is fixedly connected with the fixing frame 1, and the rear side of the right end of the fixing frame 1 is fixedly connected with a general control Cabinet 2, the adjusting device 3 includes a first motor 301, a gear 302, a gear ring 303, a sliding ring 304, a connecting shaft 305, a ball 306, a first sliding block 307, a sliding rail 308 and a chute c, the fixing frame A first motor 301 is fixedly connected to the inner side of the to...

Embodiment 2

[0030] see Figure 1-5 , the present invention provides a kind of technical scheme:

[0031] A cutting device for processing synthetic leather, comprising a fixing frame 1, a general control cabinet 2, an adjusting device 3, a cutting device 4 and a collecting device 5, one end face of the fixing frame 1 is fixedly connected with an adjusting device 3, and the adjusting device The bottom end of 3 is fixedly connected with a cutting device 4, the lower side of the cutting device 4 is provided with a collecting device 5, and the collecting device 5 is fixedly connected with the fixing frame 1, and the rear side of the right end of the fixing frame 1 is fixedly connected with a general control Cabinet 2, the adjusting device 3 includes a first motor 301, a gear 302, a gear ring 303, a sliding ring 304, a connecting shaft 305, a ball 306, a first sliding block 307, a sliding rail 308 and a chute c, the fixing frame A first motor 301 is fixedly connected to the inner side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com