Patents

Literature

213results about How to "Adjust the rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stepless speed changer

InactiveCN1940348AReduce defectsQuality improvementGearing detailsFriction gearingsRotational axisControl theory

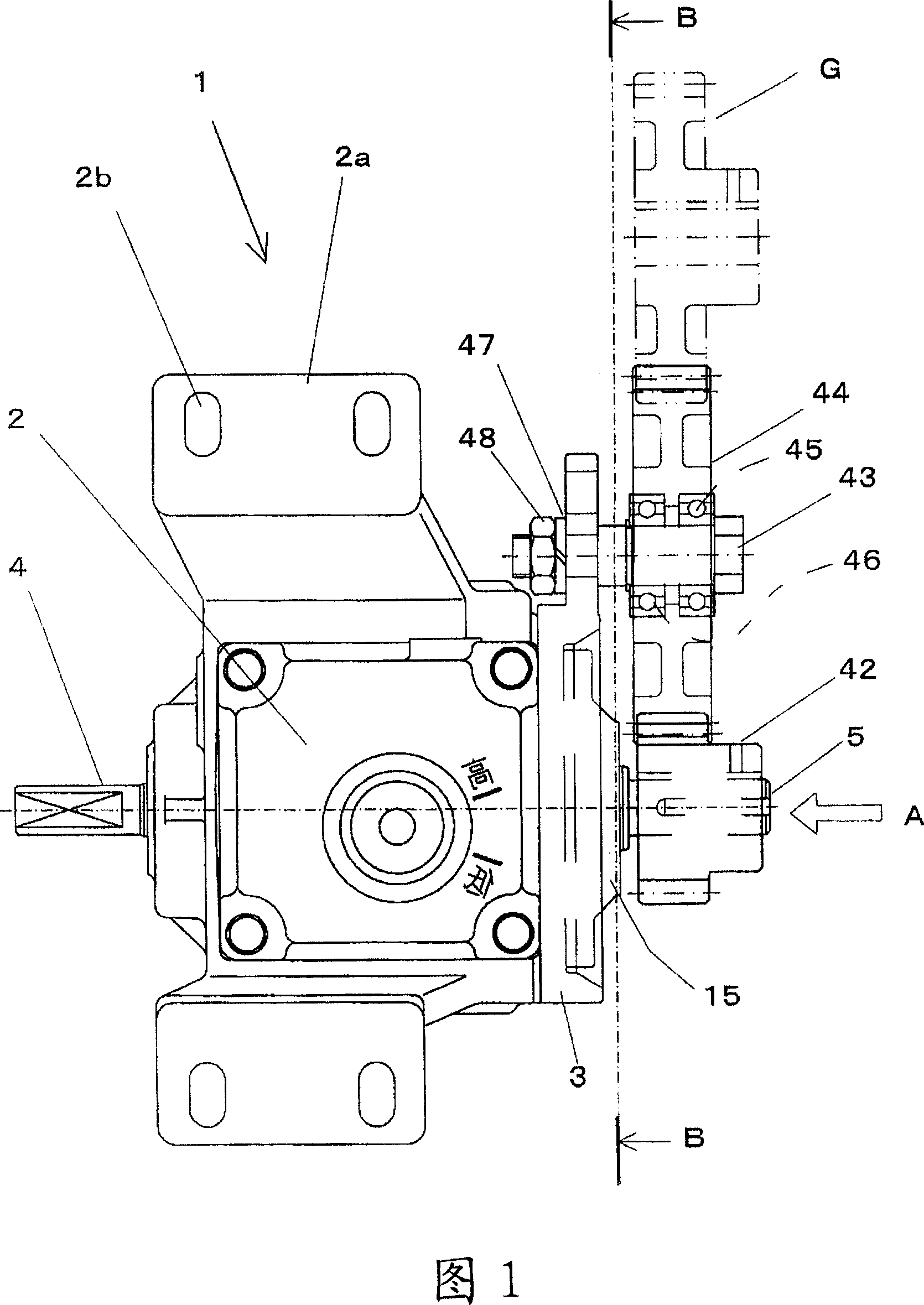

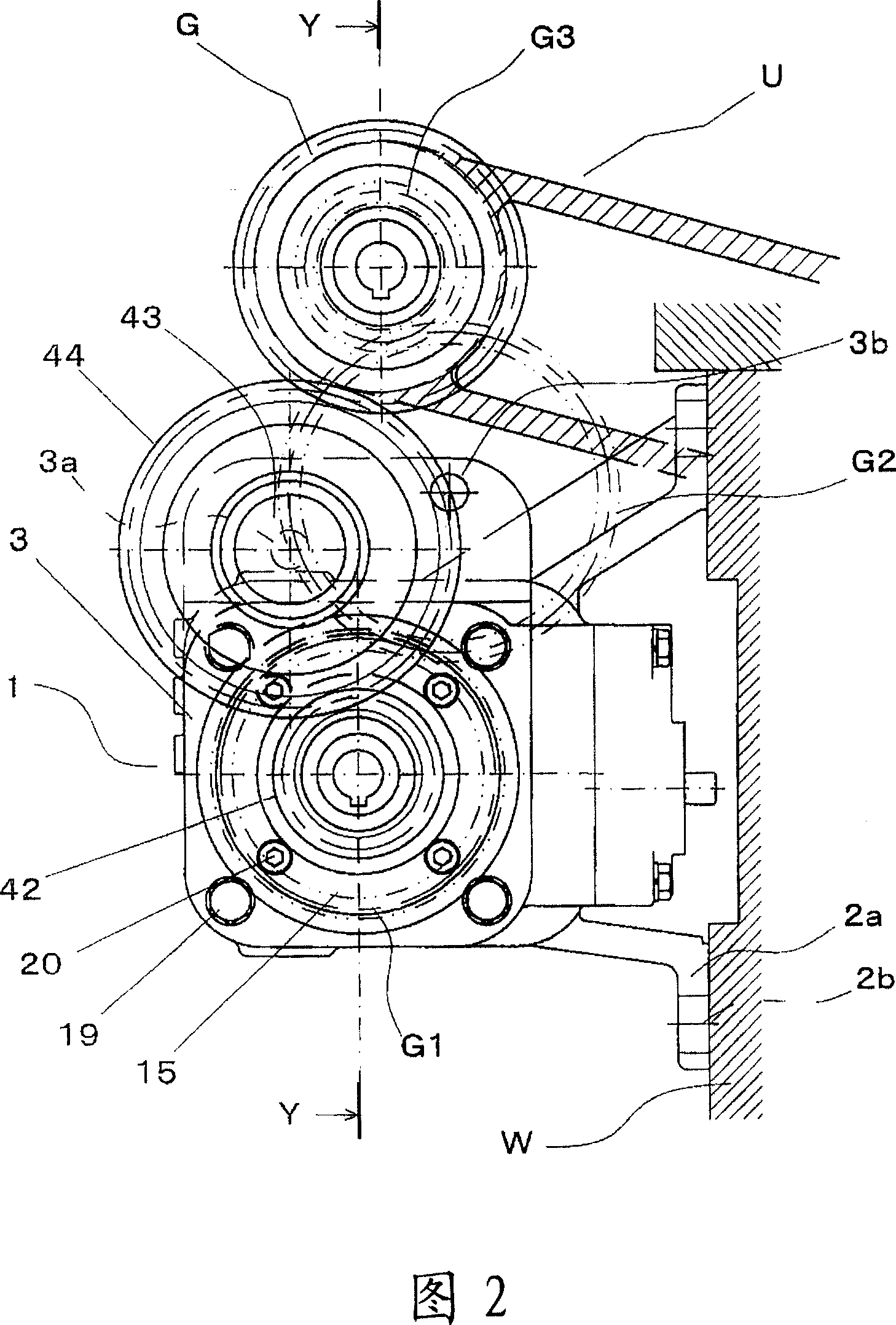

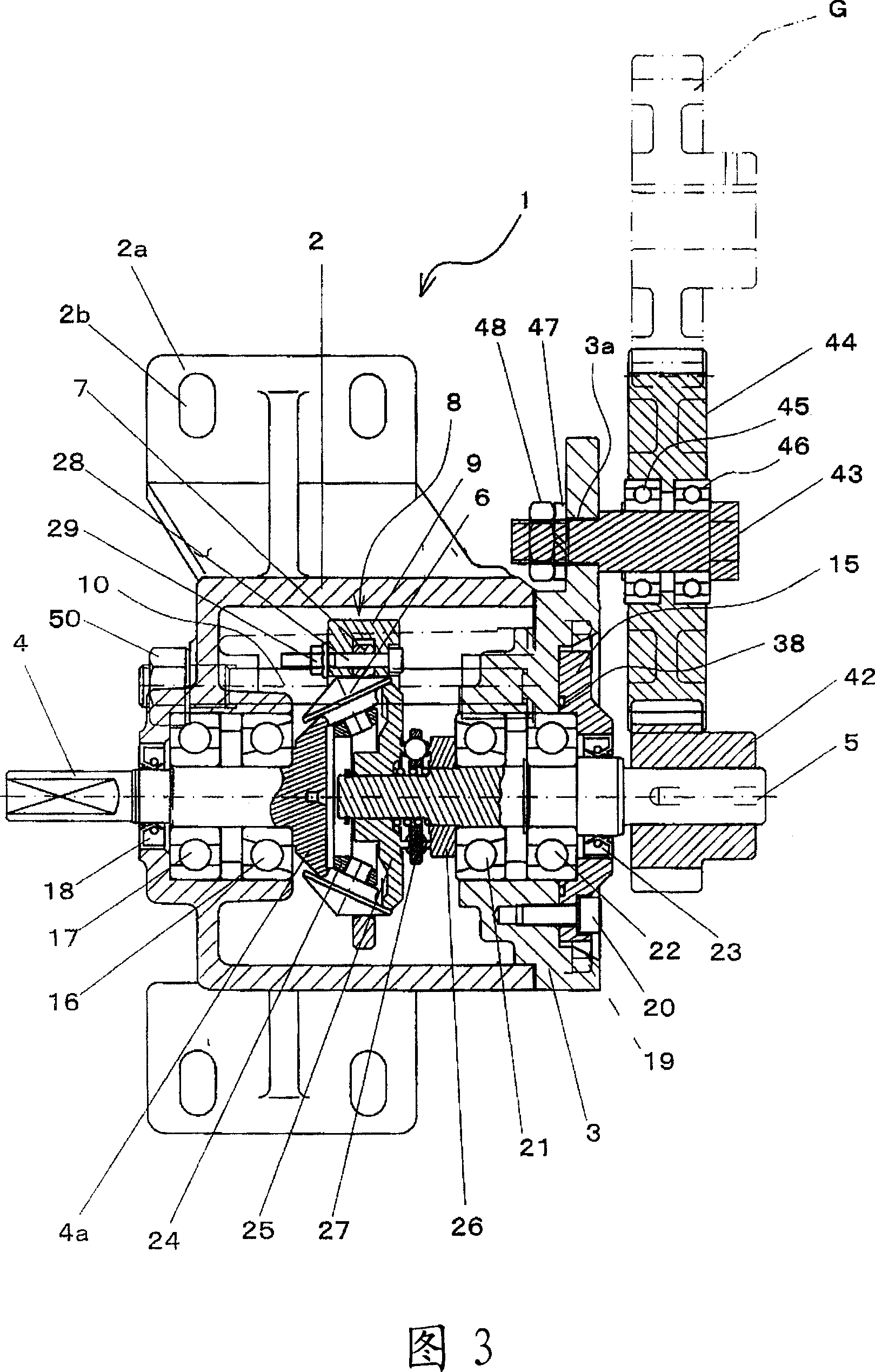

The present invention provides a gearless drive mechanism, facilitating the connection between an output shaft of a continuously variable transmission and a rotating shaft of a driven body, and transmitting the rotating speed of the output shaft to the rotating shaft of the driven body with good accuracy. The gearless drive mechanism includes: an input shaft 4 rotating on receiving the driving force; an output shaft 5, one end of which is connected to the input shaft through a variable speed mechanism, the other end being projected from a casing; a first gear 42 disposed outside the casing 3 to be spline-coupled to the projecting part of the output shaft 5 and rotated in a body with the output shaft 5; and a second gear 44 rotatablely supported on the casing 3 through a support shaft 43 to mesh with the first gear 42.

Owner:NIDEC SHIMPO CORP

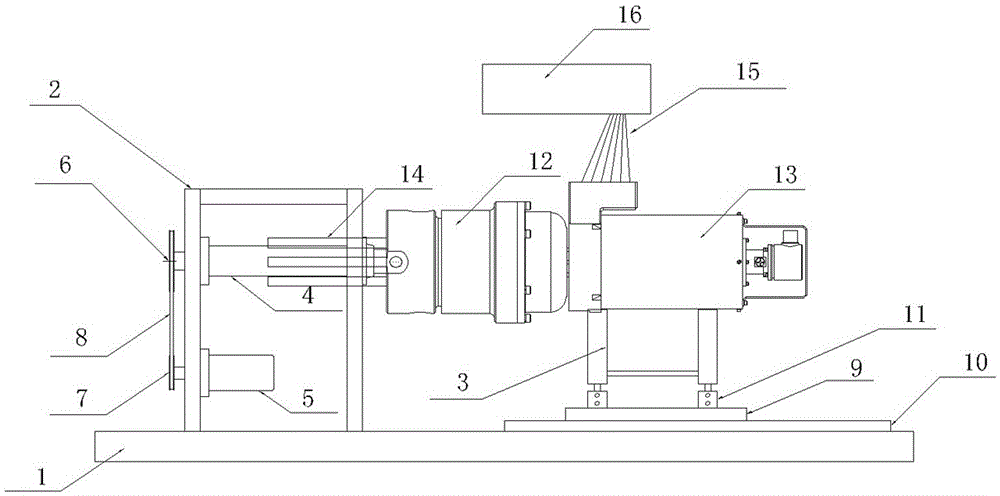

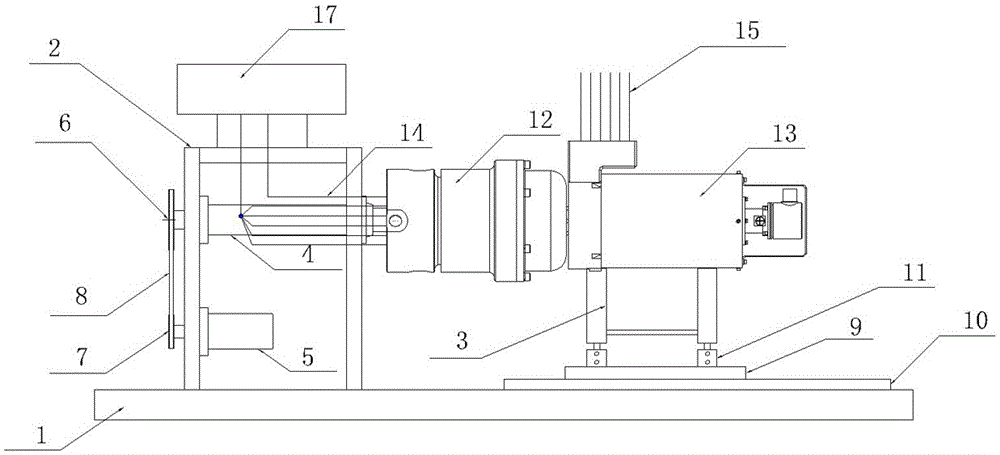

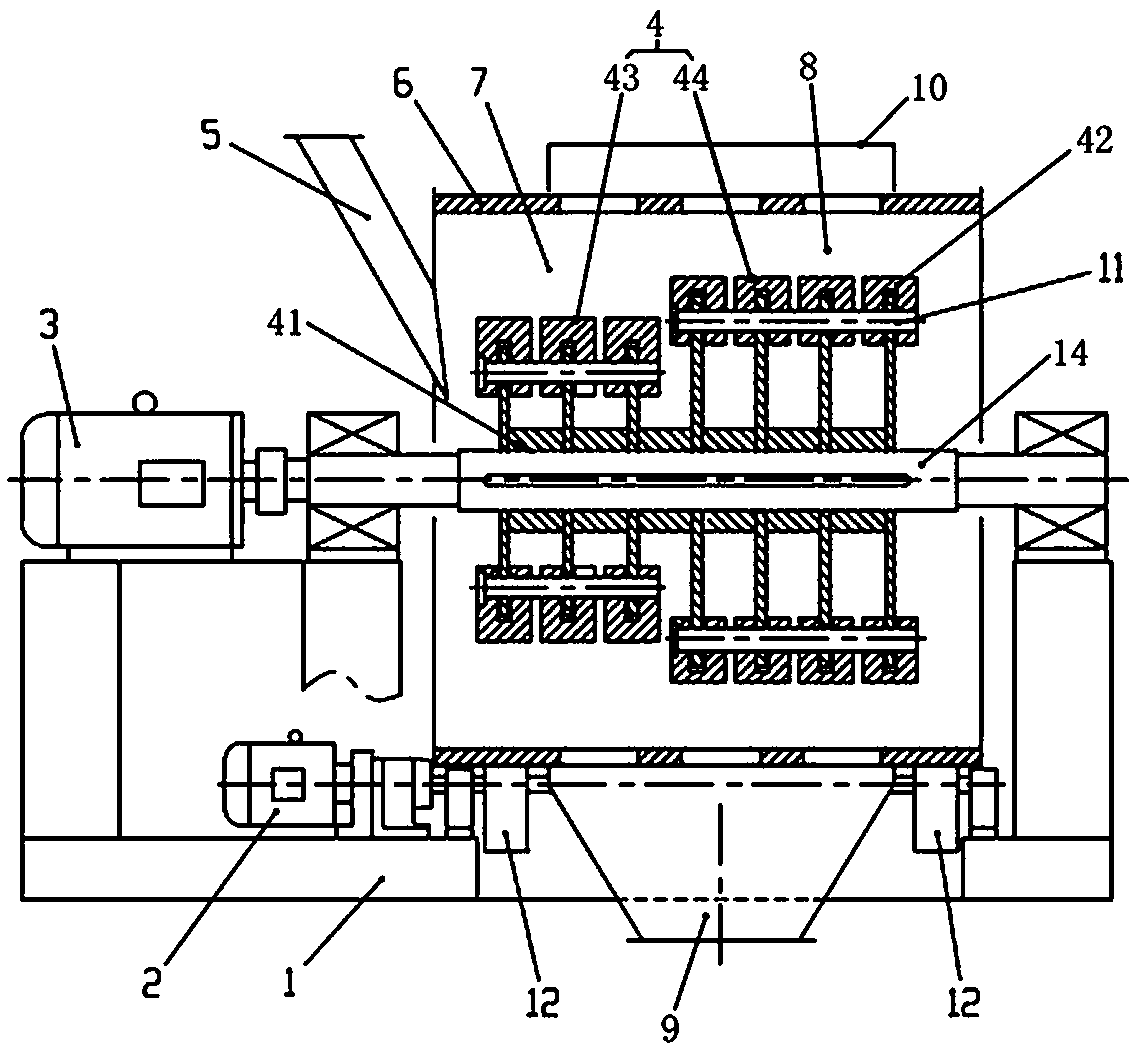

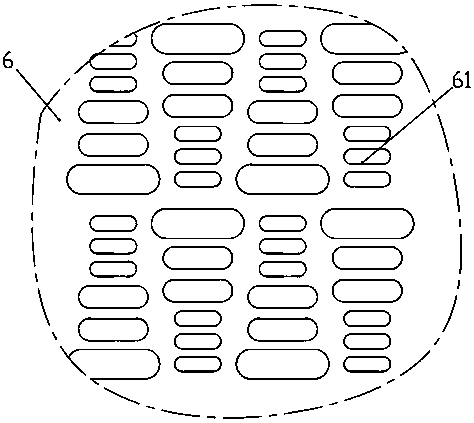

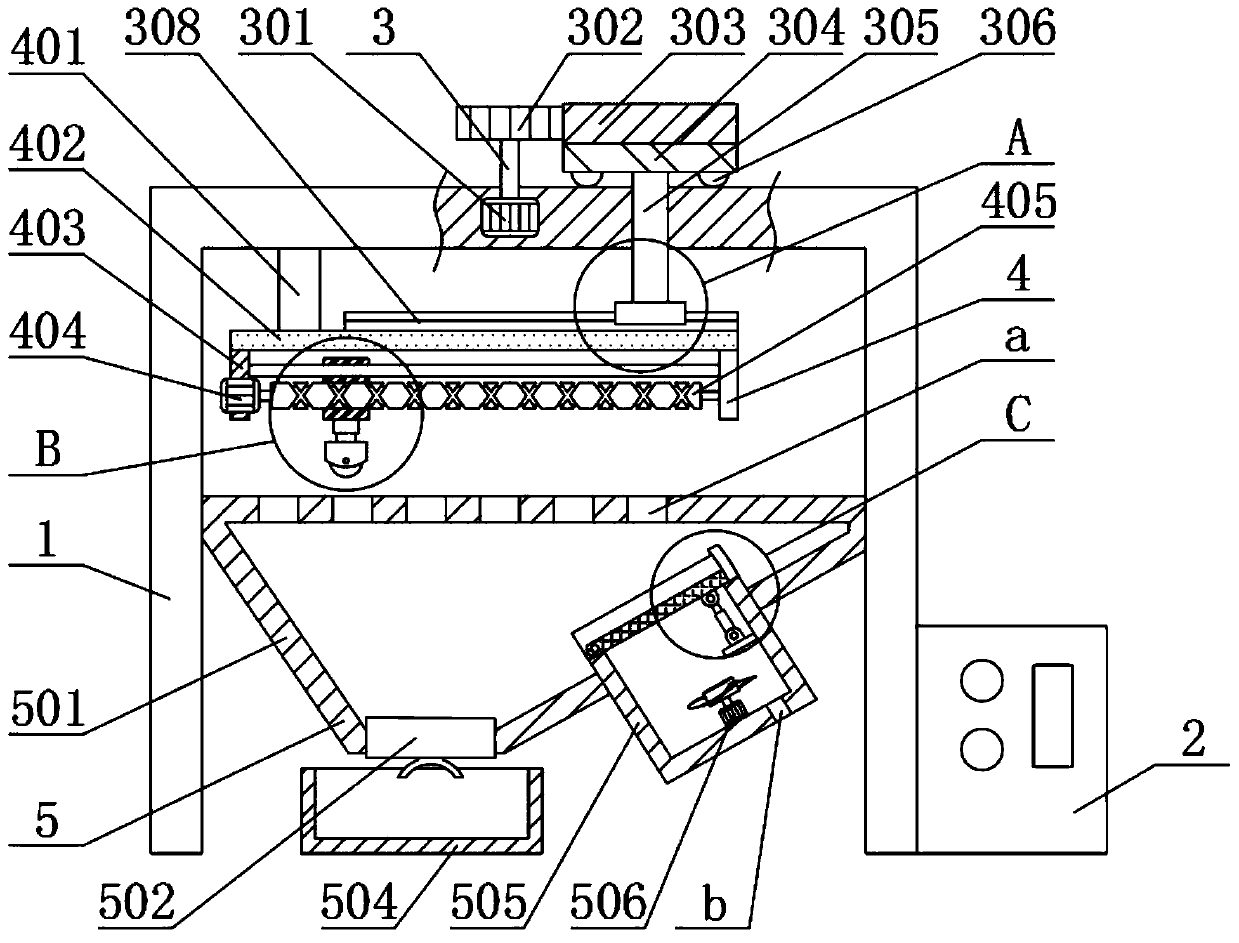

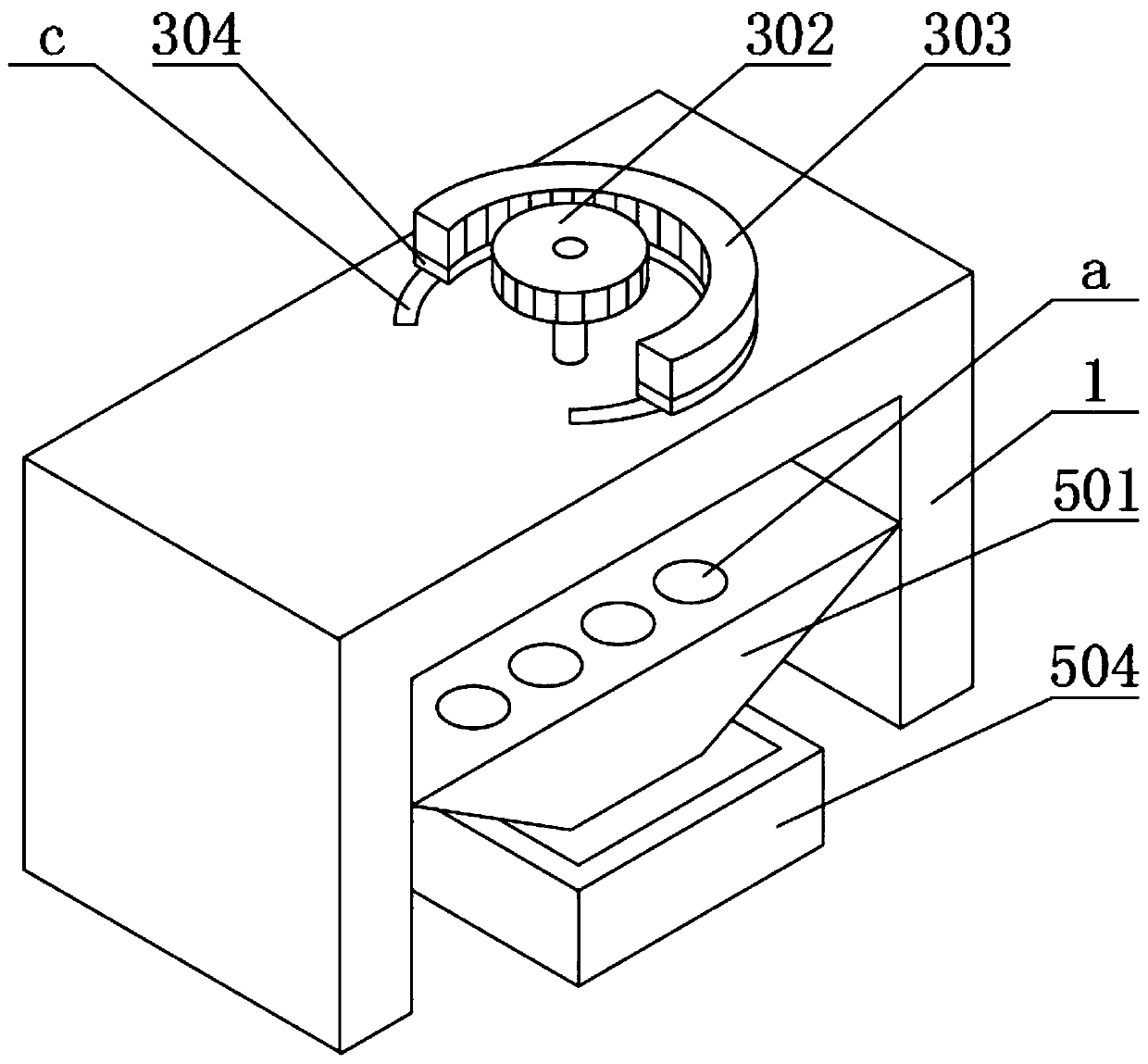

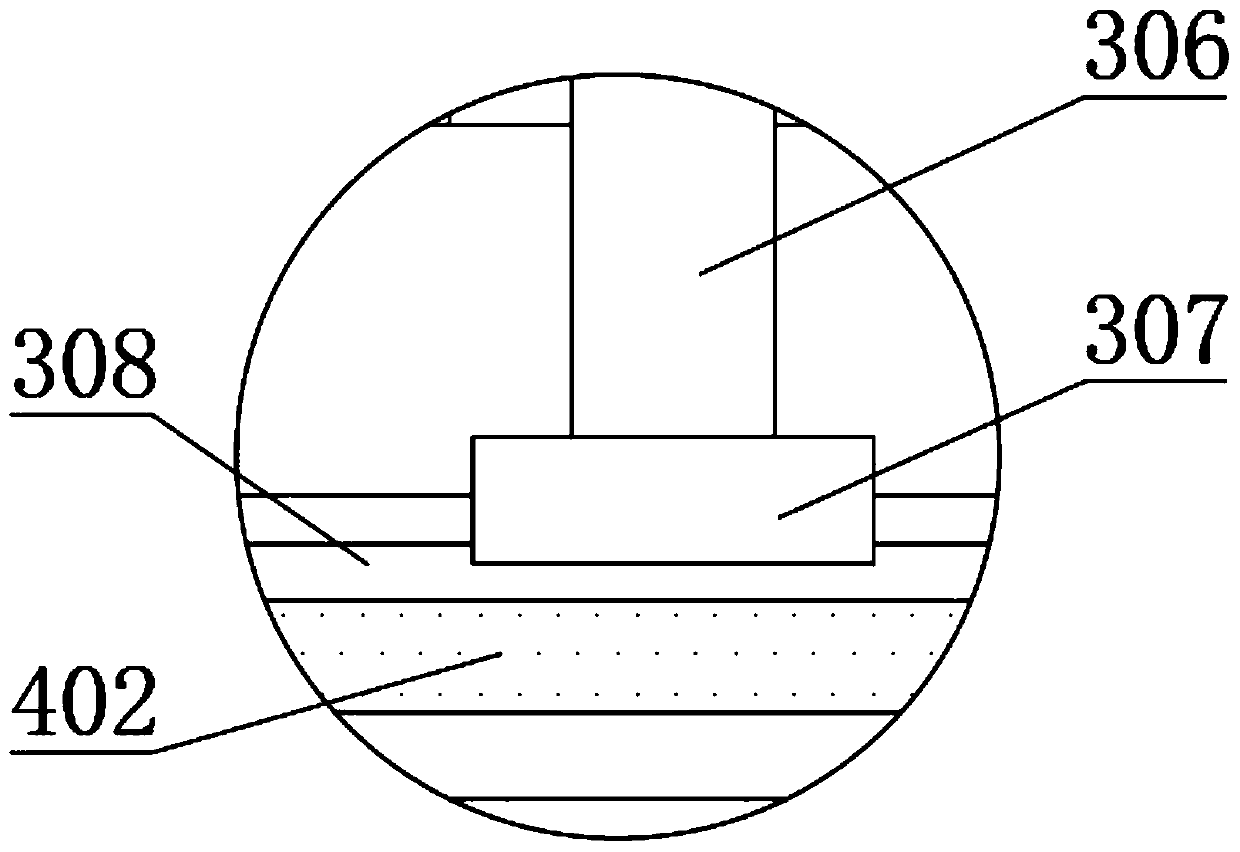

Wind-power slip ring detection system capable of simulating real working state

InactiveCN105137189AImplement automatic detectionImprove qualityTesting dielectric strengthResistance/reactance/impedenceDynamic resistanceInsulation resistance

The invention discloses a wind-power slip ring detection system capable of simulating a real working state, comprising a working table, brackets and a support; the support is provided with a rotation shaft driving a rotor to rotate and a driving motor driving a rotation shaft; the system also comprises a low resistance tester for testing multi-path dynamic resistance of the power-wind slip ring, an insulation resistance tester for testing insulation resistance of the power-wind slip ring, and a voltage resistance tester for testing the voltage resistance capability of the power-wind slip. The invention designs a working table capable of bearing the product weight, adopts the rotation shaft to rotate the rotor to perform 360-degree rotation, and is provided with the brackets in cooperation with the stator of the product. As a result, when the rotor is rotating, the stator maintains a relatively fixed state. The invention can simulates the real working state of the wind-power slip ring, realizes the automatic detection of the product dynamic resistance, product insulation resistance and product voltage resistance capability, and improves the product quality and detection efficiency.

Owner:杭州全盛机电科技有限公司

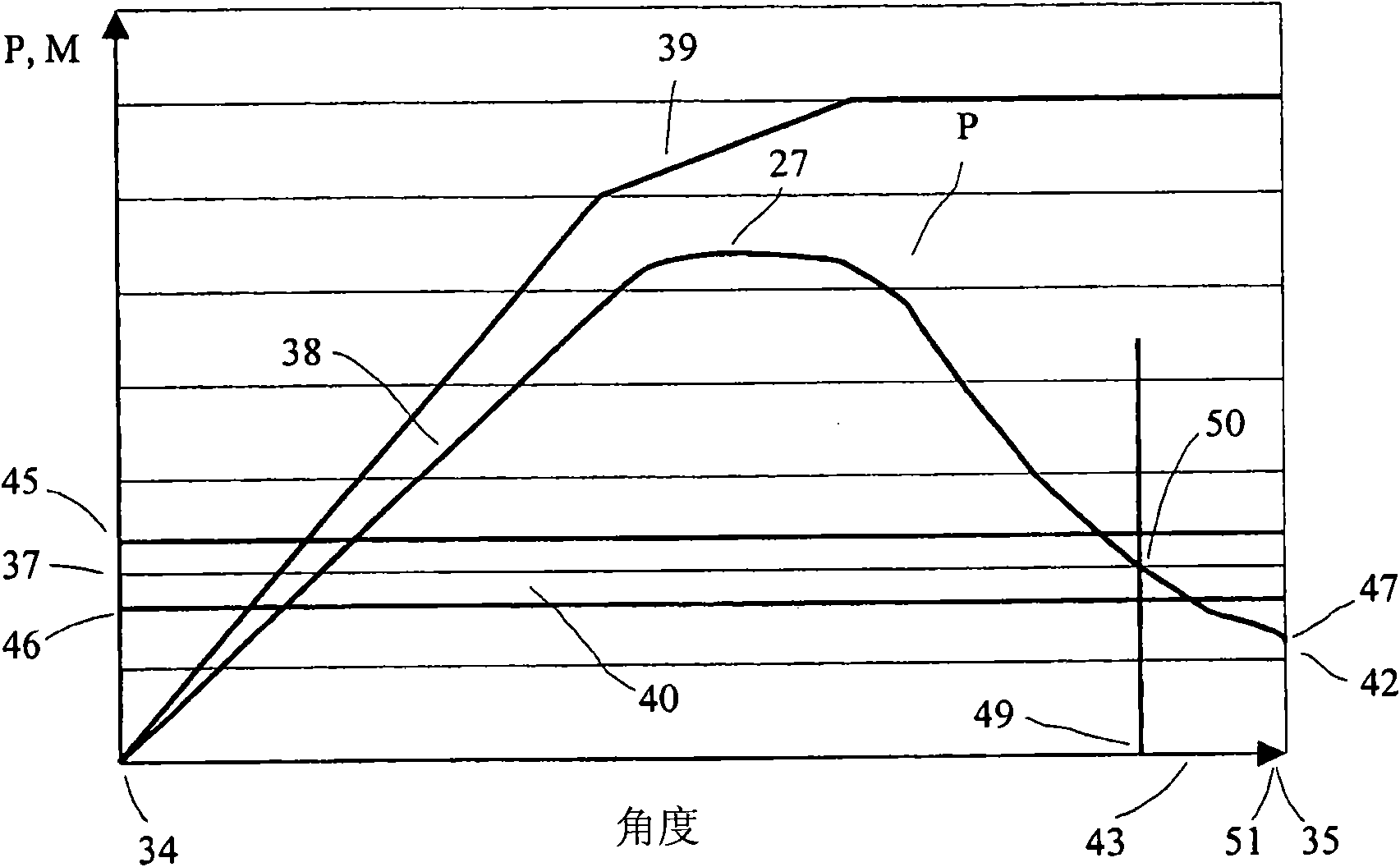

Method and filling system for filling bags

ActiveCN102046471AWaiting Time OptimizationReduce waiting timeSolid materialEngineeringPressure sensor

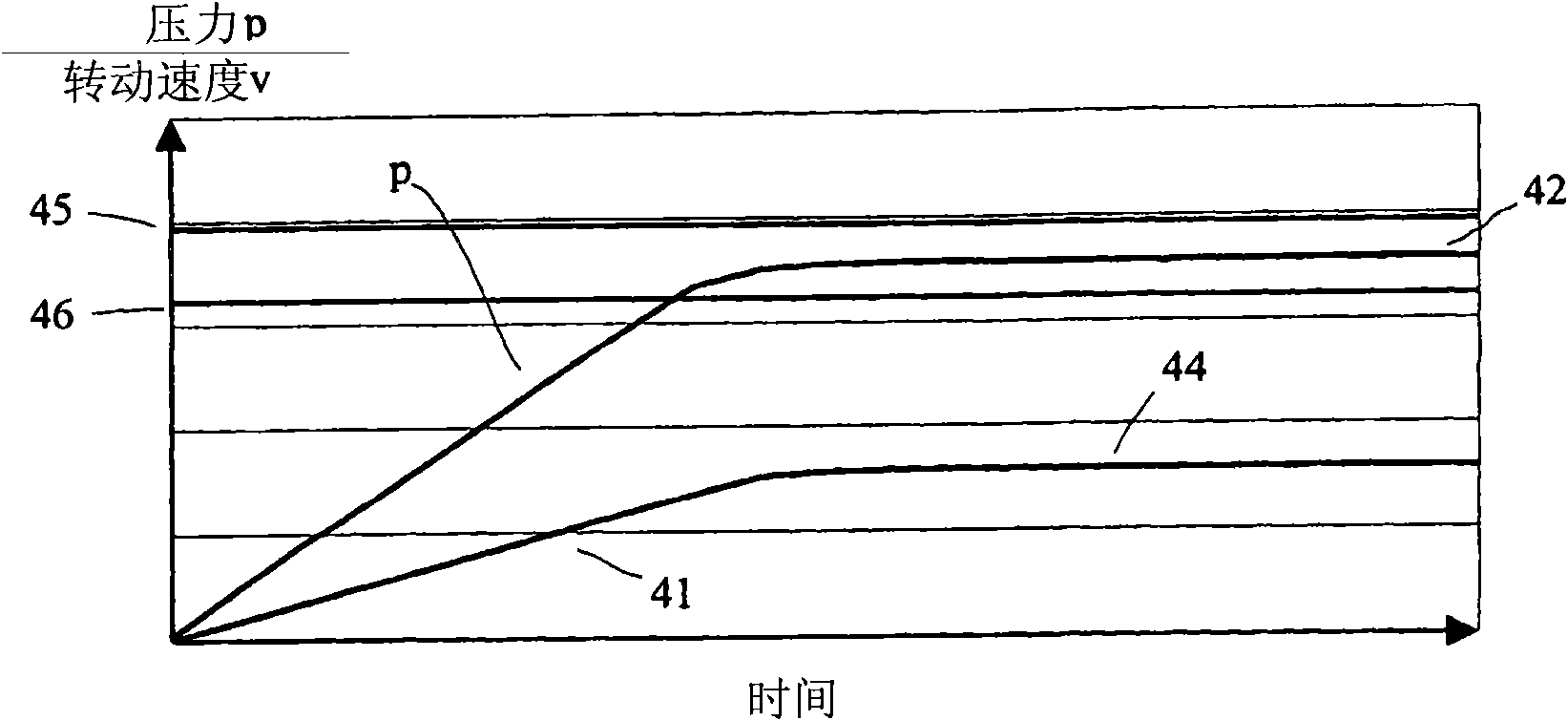

The invention relates to a filling system for filling valve bags, and to a method for operating a filling system, which comprises at least one rotating packing machine having a drive for rotating the packing machine, and a plurality of filling nozzles, which are distributed across the periphery of the rotating packing machine. The filling nozzles are provided for receiving the valve bags and can be fixed to the filling nozzles at an opening, and they may be filled with a pourable material through the filling nozzles. The valve bags are placed onto the filling nozzles at a defined insertion position and are automatically released at a defined release position. The invention provides a controller in order to control the filling process. A pressure sensor (10) is associated with at least one filling nozzle in order to determine a degree of the filling pressure of the valve bag disposed at the filling nozzle. The controller determines a representative characteristic pressure value for the filling pressure present at a predetermined position (51) in front of the release position by means of a pressure sensor, and adjusts a rotational speed of the packing machine to the speed of the drive by way of a control unit.

Owner:HAVER & BOECKER

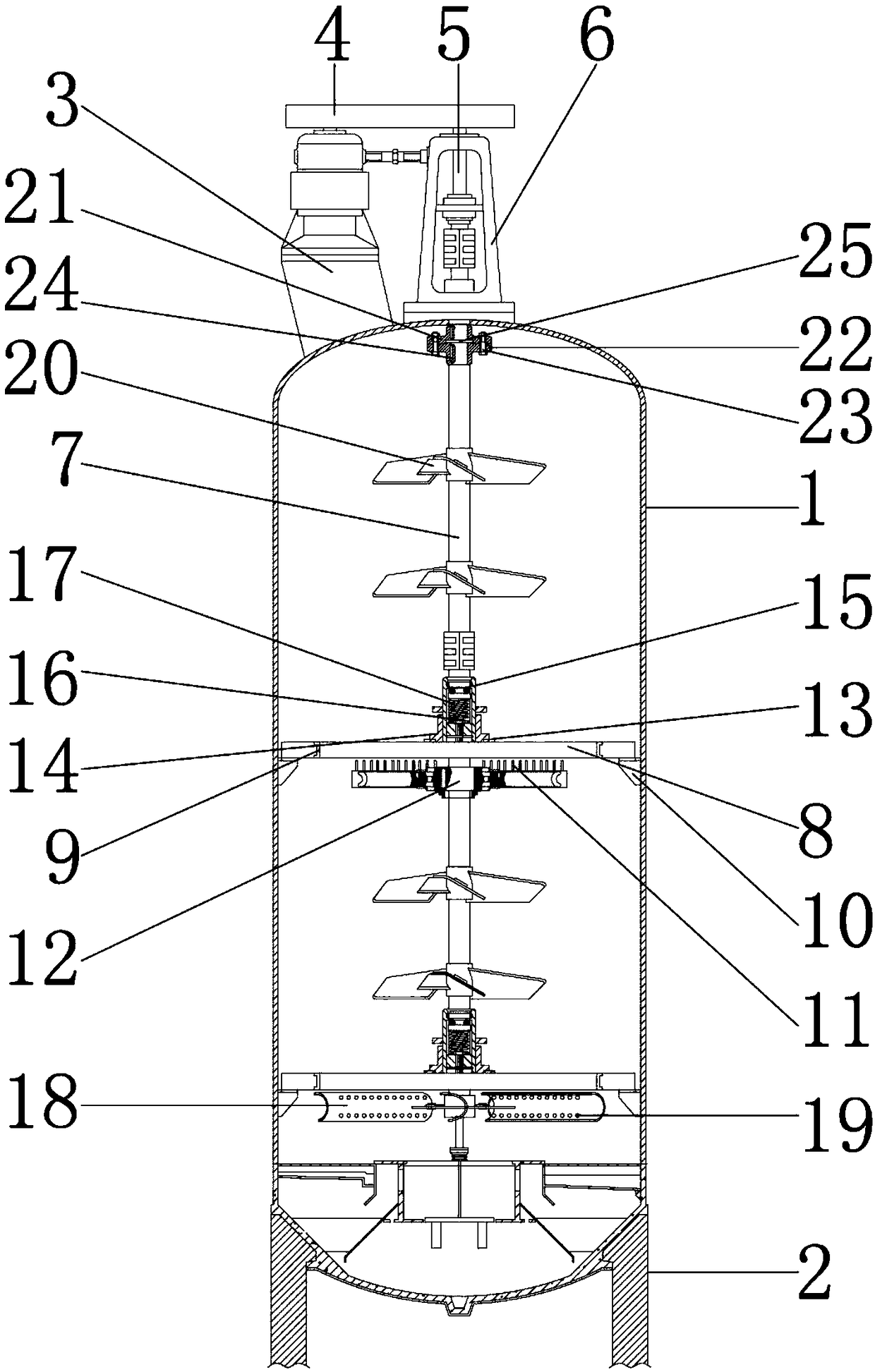

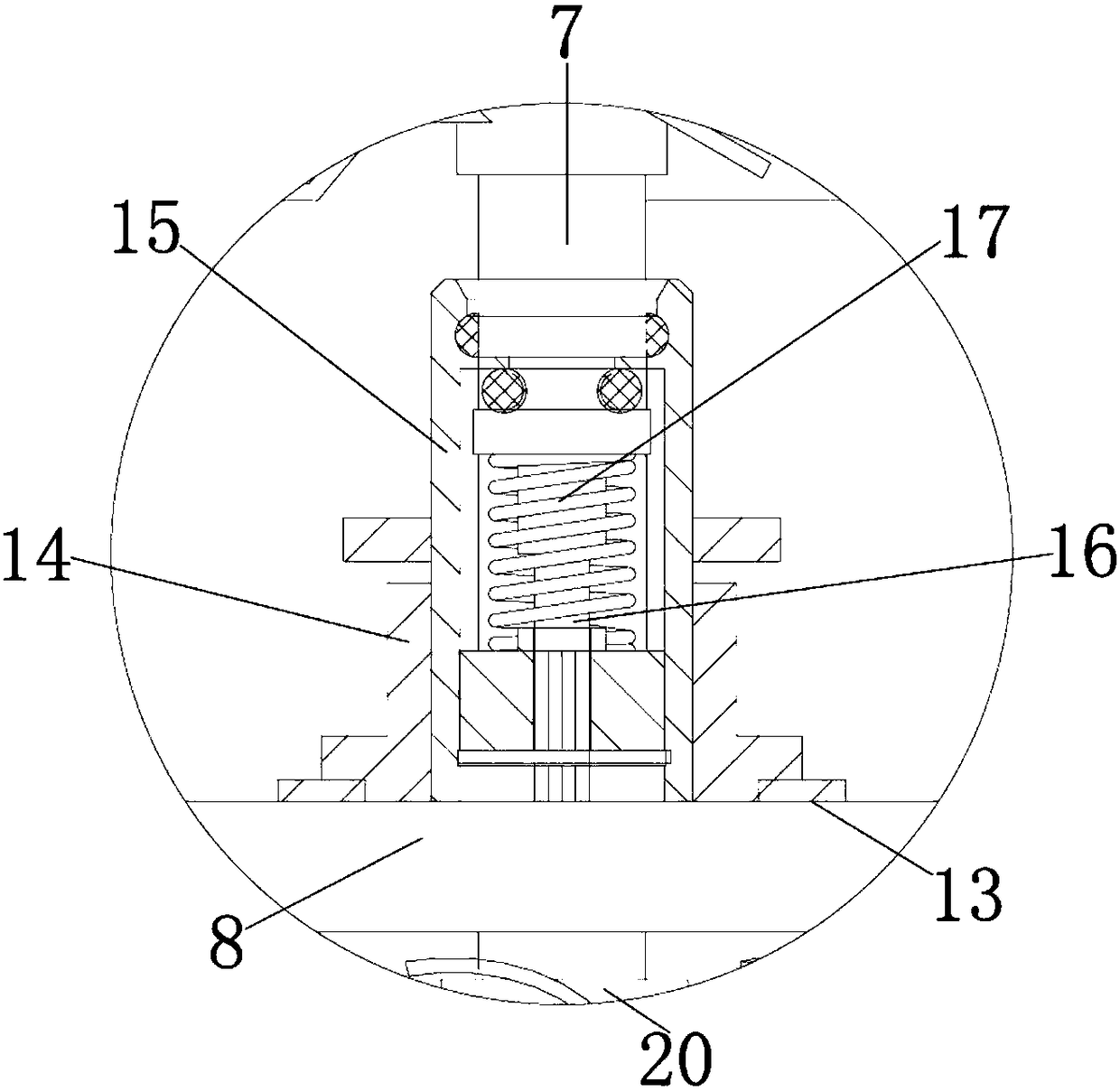

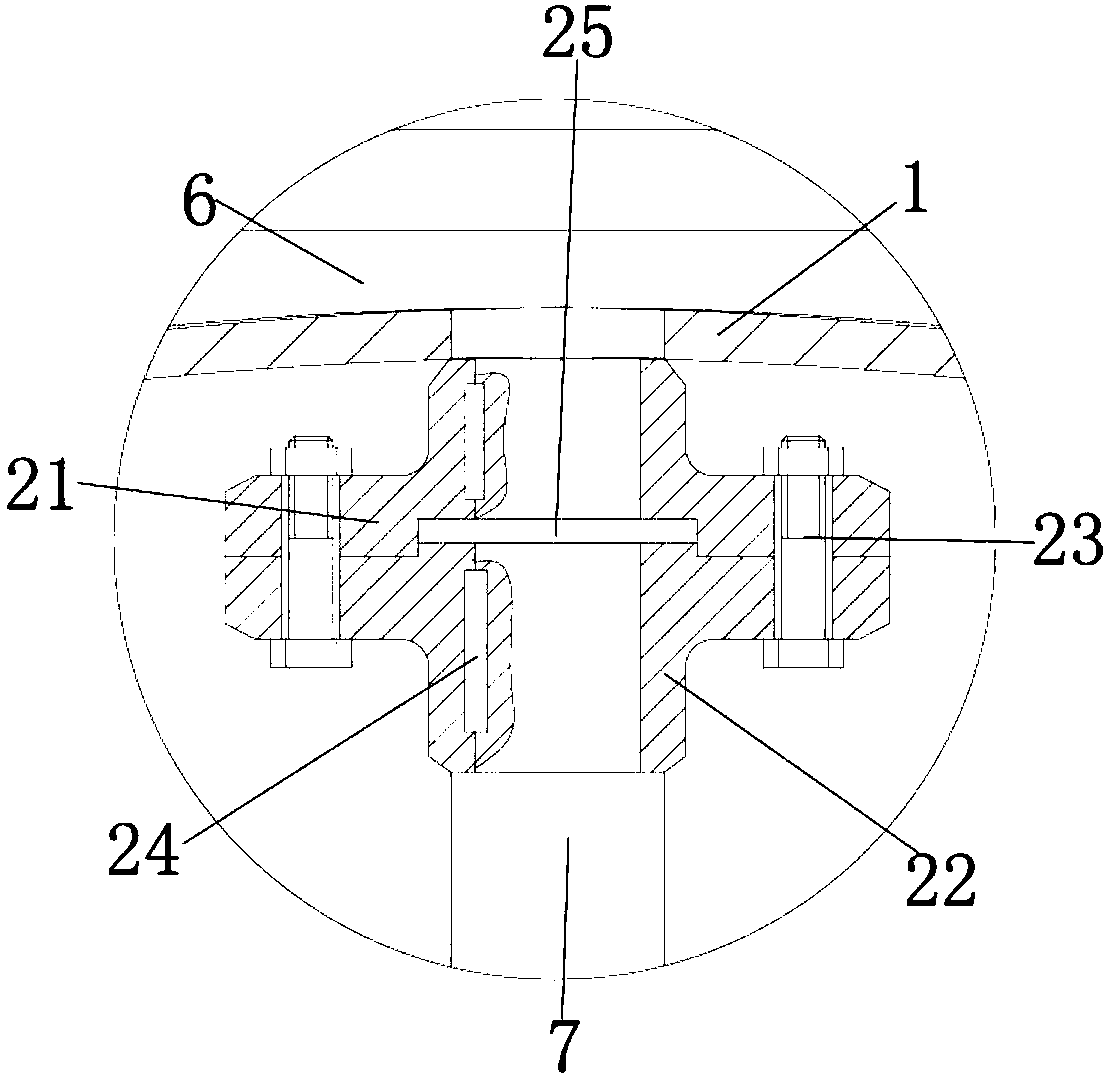

Biological pharmacy extraction liquid filtering device capable of easily realizing full stirring and grinding

PendingCN108355385AFirmly connectedImprove work efficiency and service lifeRotary stirring mixersTransportation and packagingLeather beltSurface mounting

The invention discloses a biological pharmacy extraction liquid filtering device capable of easily realizing full stirring and grinding. The filtering device comprises a tank body, wherein the lower surface of the tank body is provided with support legs; the upper surfaces of the support legs are connected with the lower surface of the tank body; the top end of the outer wall of the tank body is provided with a motor; the lower surface of the motor is connected with the upper surface of the tank body; the outer wall of the motor is provided with a belt; the inner wall of the belt is movably connected with the outer wall of the motor; the top end of the outer wall of the tank body is provided with a machine frame. The biological pharmacy extraction liquid filtering device capable of easilyrealizing full stirring and grinding has the advantages that through the matching of the motor, a rotating rod and a rotating shaft, under the driving of the belt, the motor is an alternating currentservo motor; the product quality of the biological pharmacy extraction liquid filtering device capable of easily realizing full stirring and grinding is improved; the procurement cost of users is reduced; the resource waste of the biological pharmacy extraction liquid filtering device capable of easily realizing full stirring and grinding is avoided; the biological pharmacy extraction liquid filtering device is suitable for being popularized and used.

Owner:浙江两山信息科技有限公司

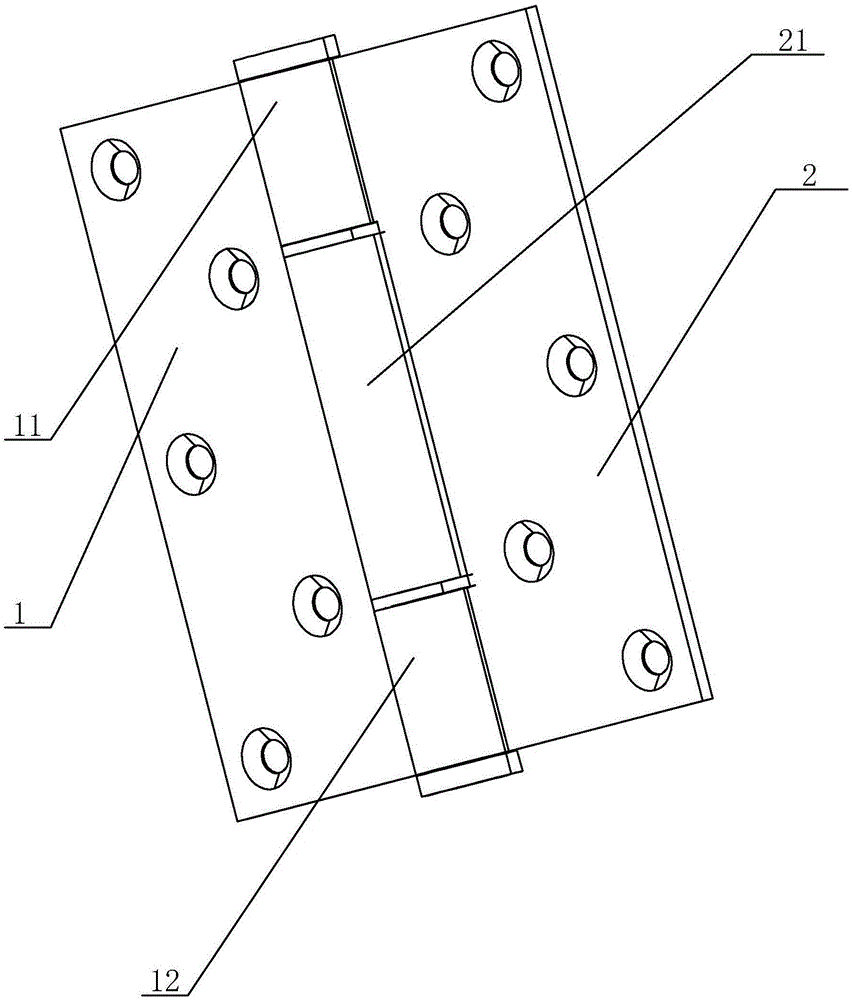

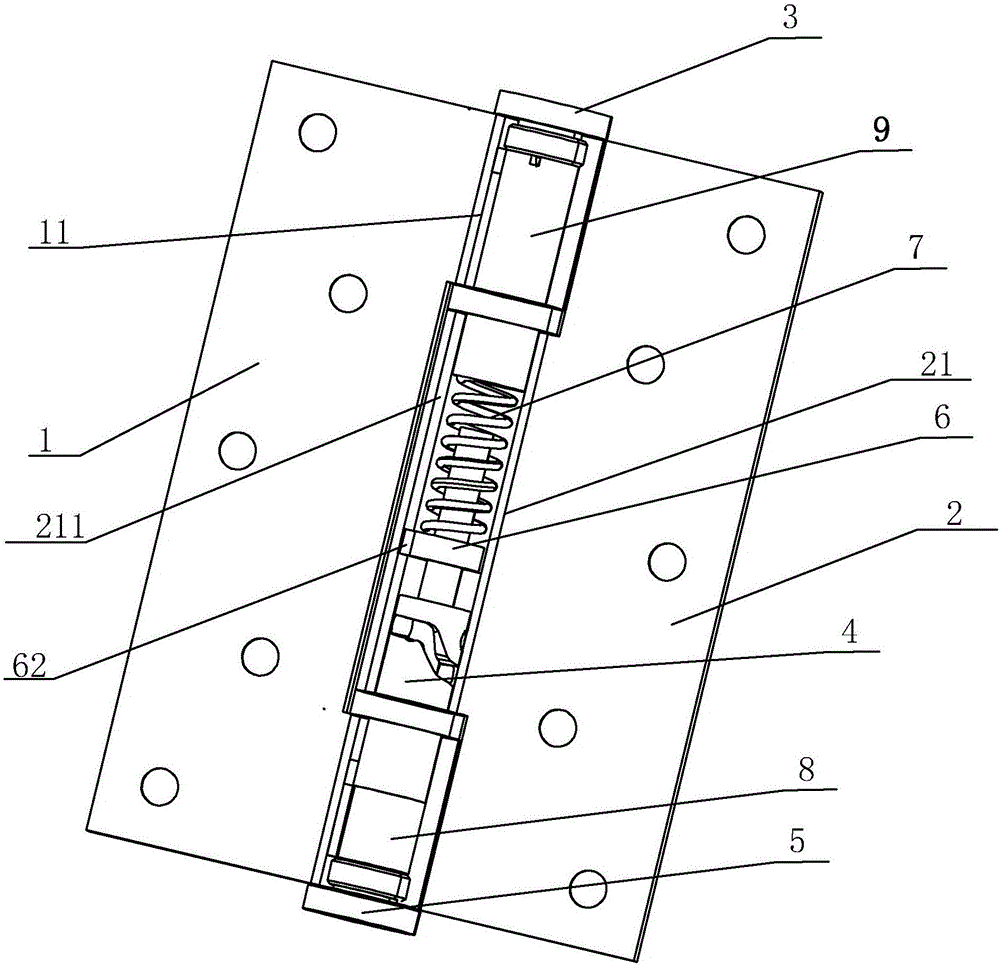

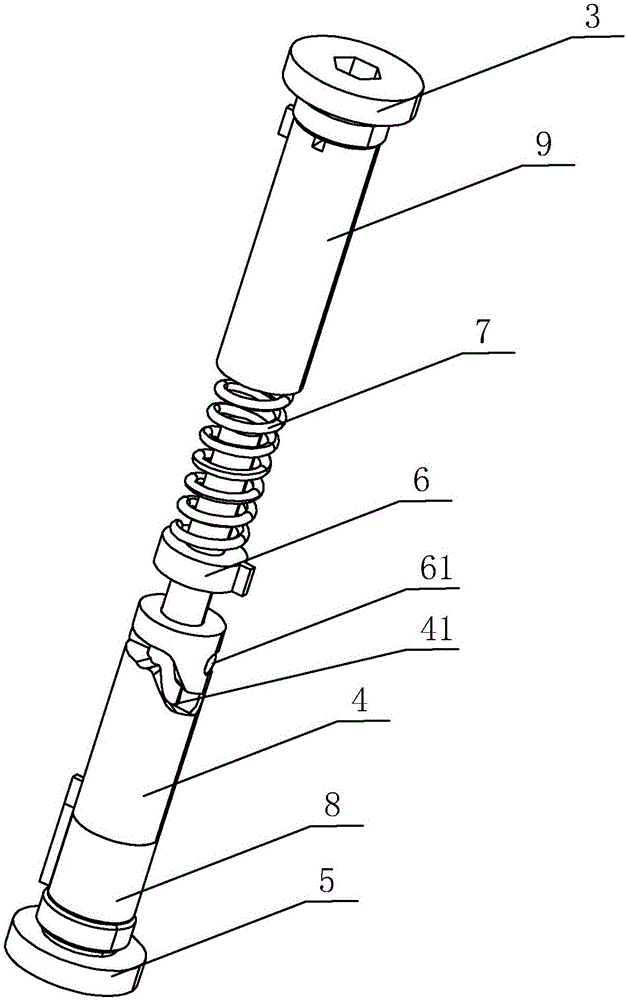

Screw type buffer hinge

ActiveCN106761082AGuarantee the size of the rotation forceAvoid collisionBuilding braking devicesPin hingesEngineeringMechanical engineering

The invention discloses a screw type buffer hinge. Upper and lower portions of one side of a left hinge piece are provided with an upper sleeve and a lower sleeve. One side of a right hinge piece is provided with a middle sleeve. An upper end cover is disposed in the upper sleeve. A fixing sleeve, a damper and a lower end cover are disposed in the lower sleeve. A side wall of one end portion of the fixing sleeve is provided with a rotating chute. A screw member is disposed in the middle sleeve. One end portion of the screw member is fixedly sleeved with a spring. One end of the spring extends towards the inside of the upper sleeve and is fixed in the upper sleeve. The other end portion of the screw member is provided with a rotating pin cooperated with the rotating chute. When the rotating pin moves in the rotating chute, the screw member is driven to move in the middle sleeve up and down, and the screw member drives the right hinge piece to rotate relative to the left hinge piece, so that a door is closed. The door can be closed without being powerfully pushed by a user, collision between the door and a doorframe can be effectively prevented, and compared with a hydraulic hinge, the screw type buffer hinge has the advantages that the screw type buffer hinge is simple in structure and long in service lifetime, and oil leakage can be prevented.

Owner:温州瓯海利尔达五金制品有限公司

Hammer type dynamically and cyclically screening-crushing machine

The invention discloses a hammer type dynamically and cyclically screening-crushing machine, belonging to the field of material crushing equipment. The hammer type dynamically and cyclically screening-crushing machine comprises a rotatable hammer type rotor group, a feeding port, a discharging port, and a rotatable screening roller, wherein the inner wall of the screening roller is fixedly provided with a lifting plate used for pushing up a material; the hammer type rotor group is arranged in the screening roller along an axial direction; the feeding port communicates with the interior of thescreening roller; and the discharging port communicates with the outer wall of the screening roller. According to the invention, a material is dynamically and cyclically crushed in the screening roller and is discharged only when the granularity of the material is qualified, and cyclic crushing realizes crushing of the material multiple times, so high material crushing efficiency of machine is guaranteed; and a conveying speed can be artificially controlled, and material output and output granule distribution are also completely artificially controlled and are large in adjustment range. Compared with the prior art, the hammer type dynamically and cyclically screening-crushing machine of the invention has the advantages that discharge granularity is no longer determined by a gap between a hammer head and a sieve plate, so the problem that the hammer head and the sieve plate are prone to wearing and are frequently replaced is overcome.

Owner:成都万基电力设备制造有限公司

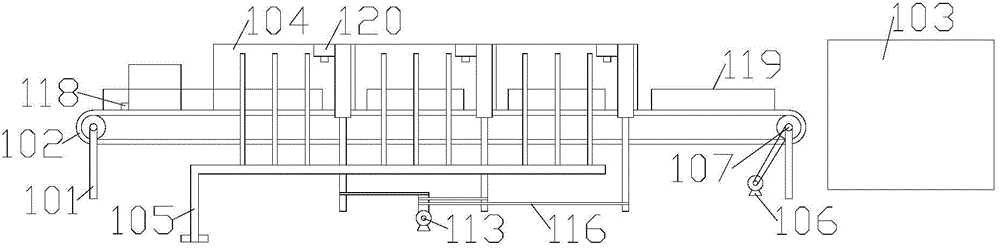

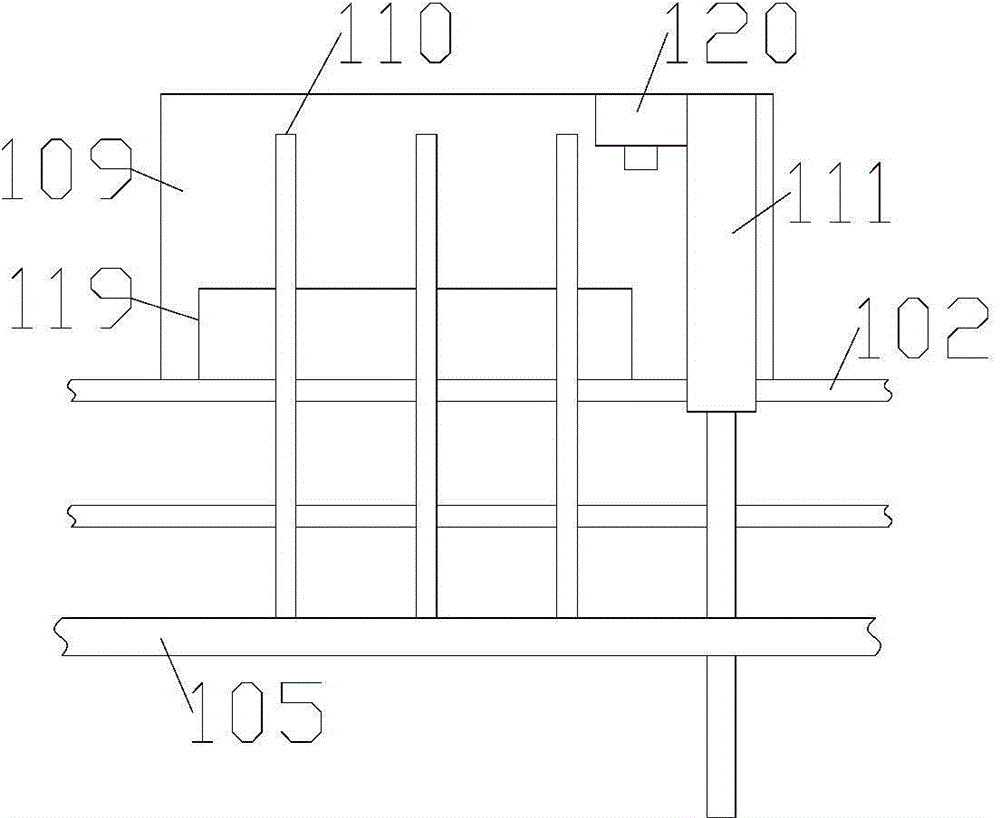

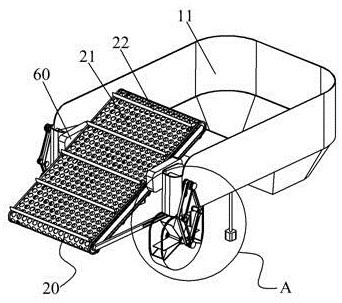

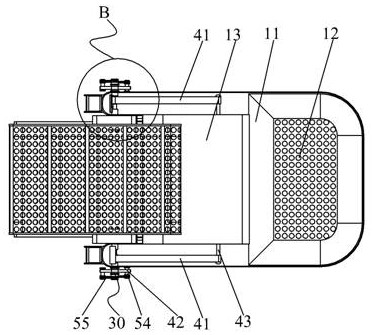

Seedling-raising plate cleaning device

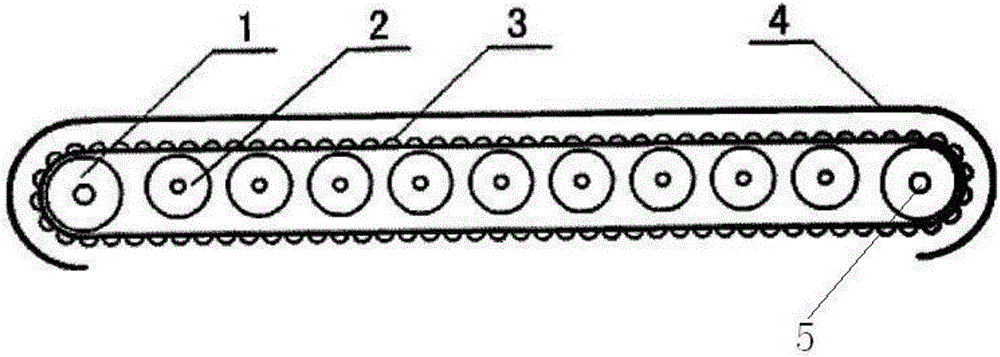

InactiveCN104646357AFully cleanedEasy to cleanCleaning using toolsCleaning using liquidsUltimate tensile strengthWater spray

The invention provides a seedling-raising plate cleaning device, and belongs to the field of cleaning machinery. The seedling-raising plate cleaning device comprises a rack, a conveyer belt and a plurality of cleaning units; a water inlet pipe is arranged on the rack; transmission wheels driven by a first motor are arranged on two ends of the inner side of the conveyer belt; the transmission wheels are arranged rotatably on the rack; a plurality of first slots for blocking the seedling-raising plates are arranged at intervals on the outer surface of the conveyer belt, the seedling-raising plates are embedded in the first slots; the larger side of each seedling-raising plate is parallel to the heading direction of the conveyer belt; the conveyer belt penetrates through the cleaning units; each cleaning unit comprises a box body, at least two water spray pipes and at least two vertically arranged brush rods. The seedling-raising plates are driven to move forwards by the conveyer belt and cleaned by the cleaning units, the cleaning of the seedling-raising plates is realized by arranging and taking the seedling-raising plates by manpower, the cleaning process is realized by machines, the manpower cleaning is not required, so the labor intensity of workers is reduced and the cleaning efficiency is improved.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

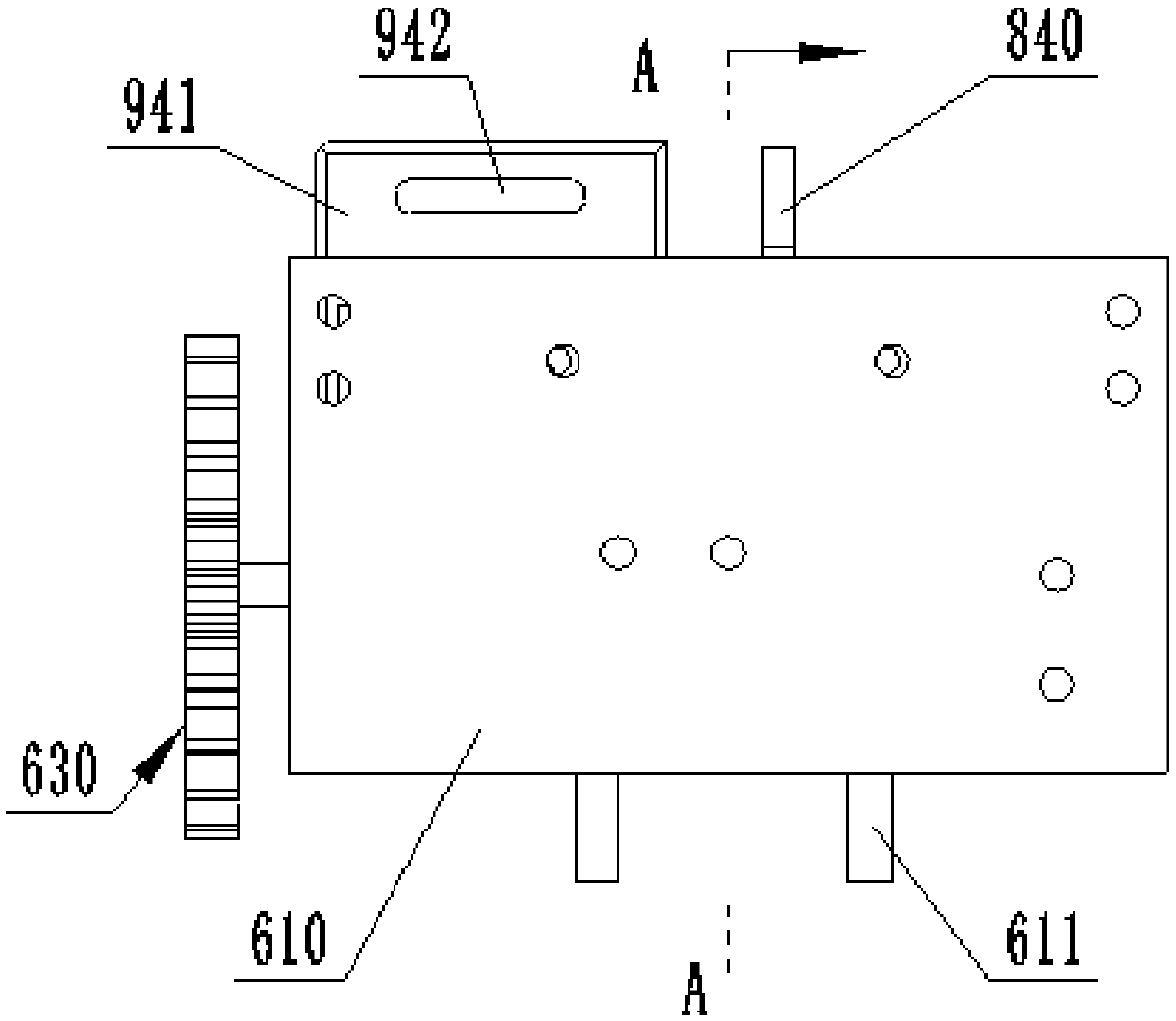

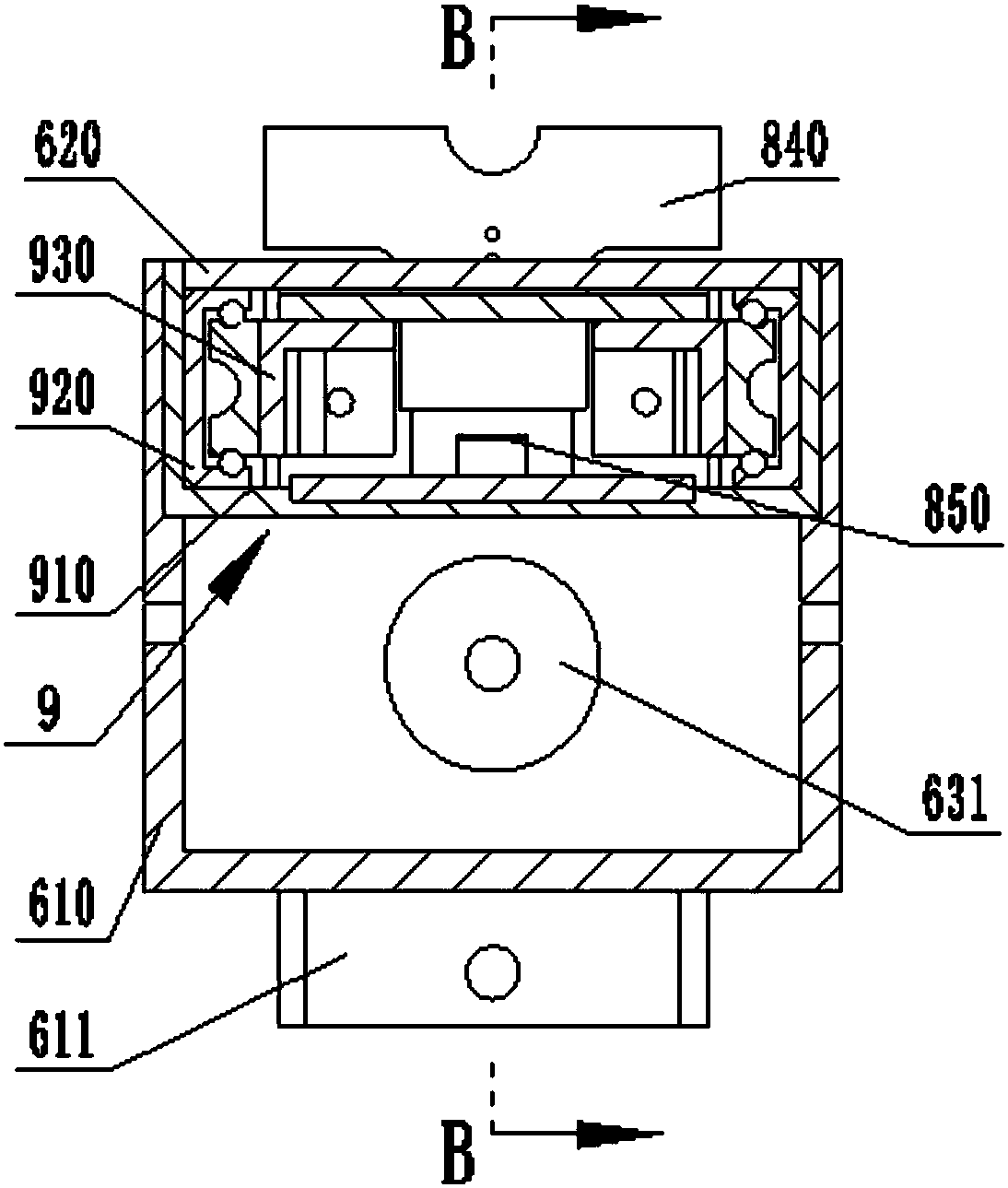

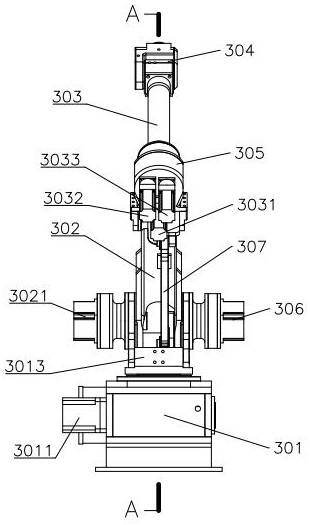

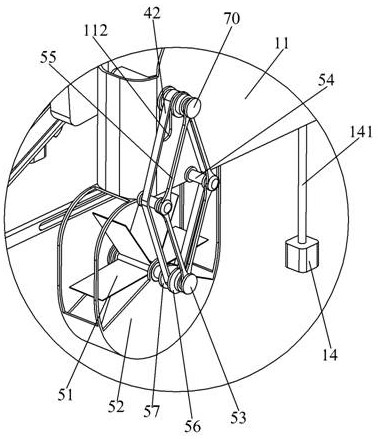

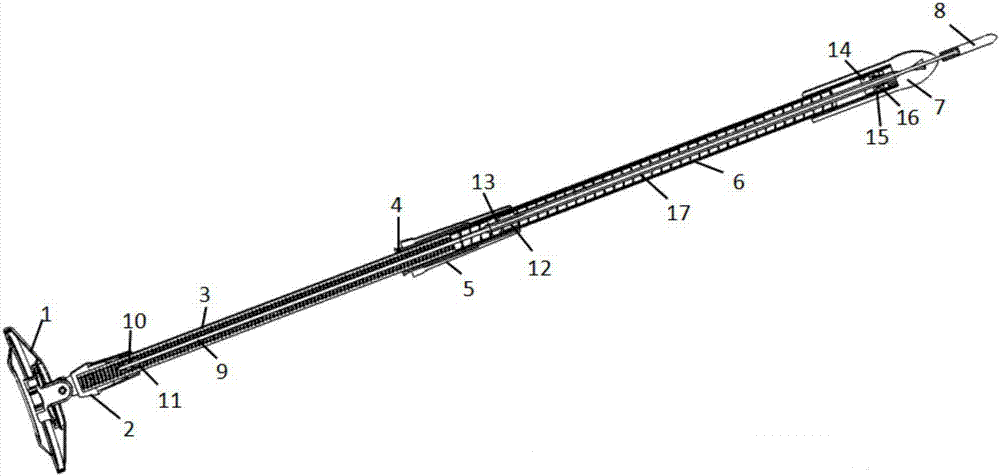

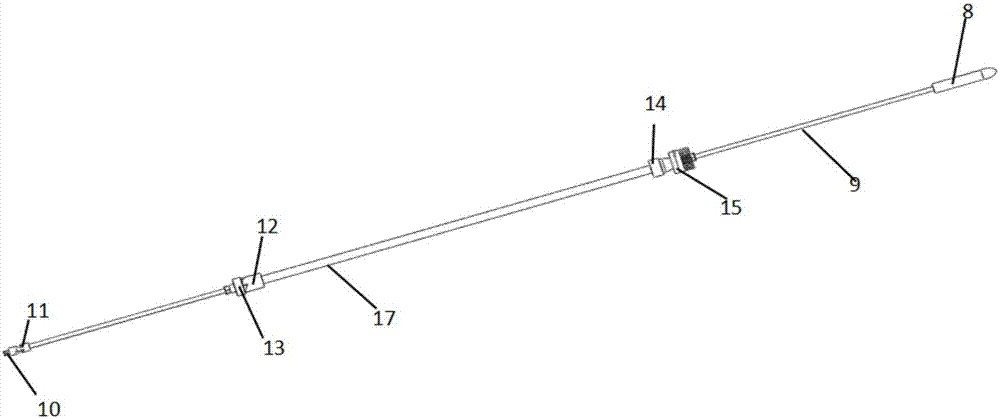

Guide wire controller and operation method thereof

PendingCN107753107ASimple clamping structureSimple combinationGuide wiresSurgical manipulatorsSurgical robotModular design

The invention discloses a guidewire controller in a slave device of an interventional surgery robot and a method for using the same, belonging to the technical field of minimally invasive blood vessel interventional surgery. The guide wire controller includes a guide wire controller base, a guide wire clamping device and a clamping switching mechanism installed on the guide wire controller base; the guide wire clamping device is used to clamp the guide wire, and the clamping switch The mechanism is used to drive the guide wire clamping device to loosen the clamp on the guide wire; the guide wire lock adopts a special cone surface and cone hole structure to realize the clamping of the guide wire. The pedestal is mounted on a height-adjustable base that also includes a guidewire torsion device and a force-measuring assembly. The present invention has a simple overall structure, adopts a modular structure design, is easy to disassemble and assemble, has a compact structure, is light in weight overall, and has low manufacturing cost.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

Multifunctional table capable of doing revolution and autorotation

The invention provides a multifunctional table capable of doing revolution and autorotation. The multifunctional table mainly comprises a table plate, a base, a revolution device and an autorotation device, and is characterized in that dinner plates on the table can do regular slow autorotation during the revolution. The revolution of the diner dishes on the multifunctional table is realized through the revolution device; the autorotation of the diner dishes on the multifunctional table is realized through the autorotation device; the power driving and the flat panel television hiding can be realized through an H-shaped rotating support frame; through a servo motor, an ascending and descending gear and a rack, the ascending or the descending of a flat panel television is realized; and through a rotating frame A and a rotating gear A with the same tooth number, the slow regular autorotation of the diner dishes can be realized.

Owner:UNIV OF JINAN

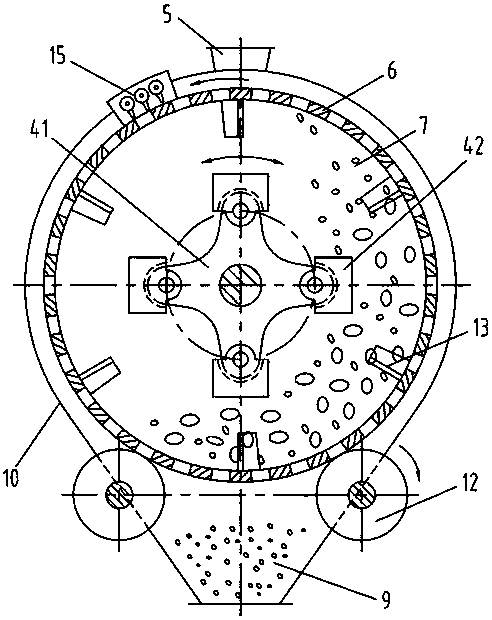

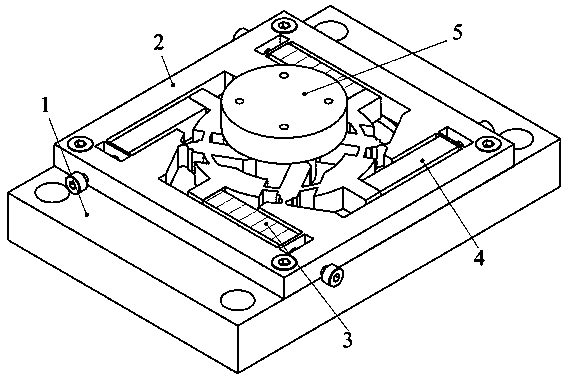

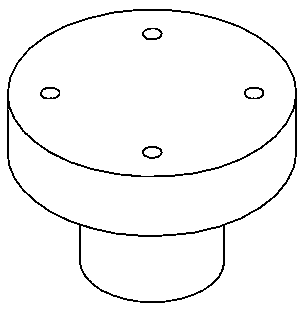

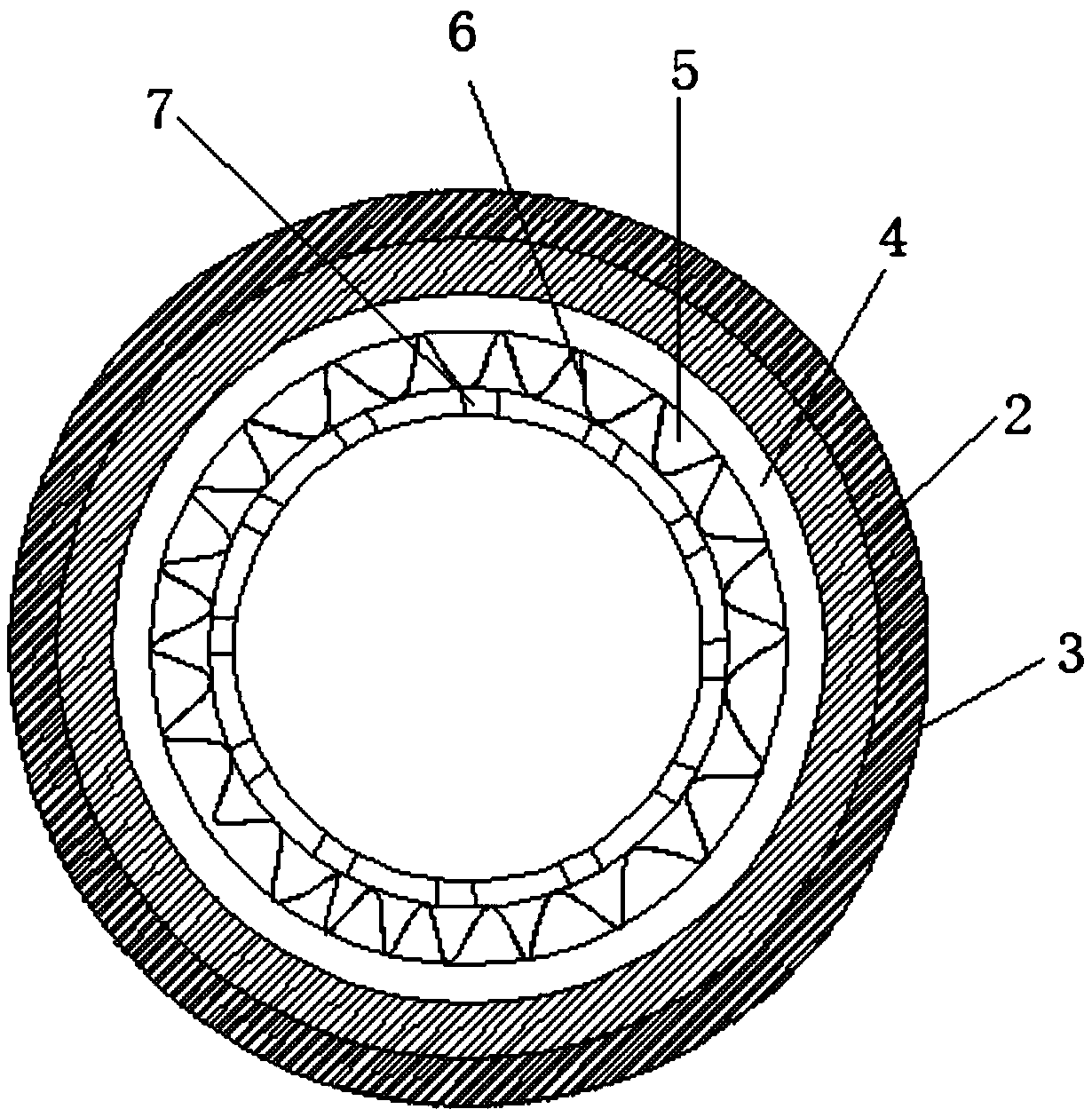

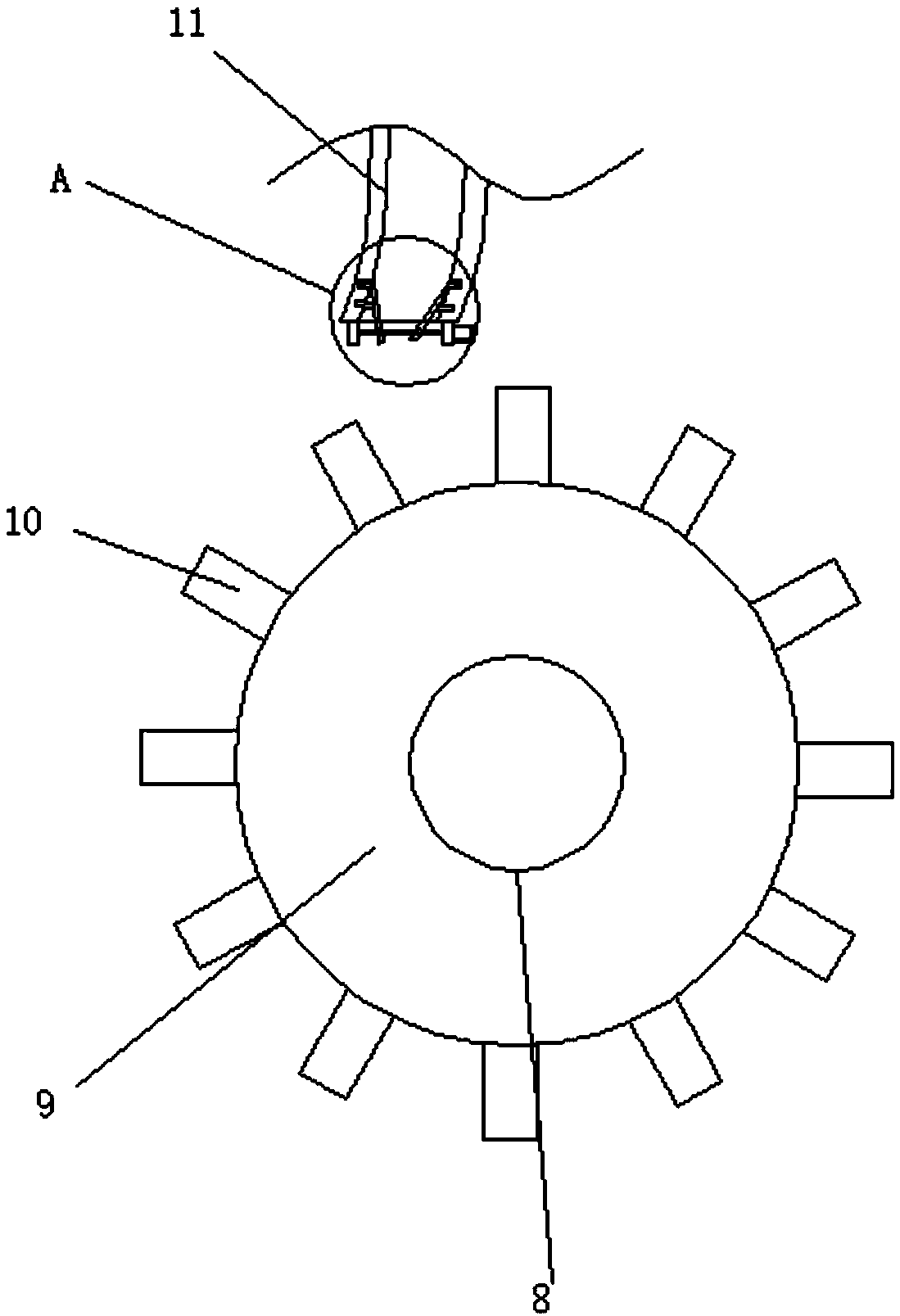

Piezoelectric driver for improving performance based on four-foot coupling motion mode and control method

ActiveCN110460264AStable continuous rotary motionImprove angular resolutionPiezoelectric/electrostriction/magnetostriction machinesLow noiseMicron scale

The invention relates to a piezoelectric driver for improving the performance based on a four-foot coupling motion mode and a control method, and belongs to the field of precision machinery. The piezoelectric driver comprises a base, a flexible mechanism, a piezoelectric element, a pre-tightening cushion block and a rotor, wherein the flexible mechanism is matched with the piezoelectric element togenerate micron-scale motion to drive the rotor to rotate through the driving feet which are rotationally and symmetrically distributed; the piezoelectric element converts electric energy into kinetic energy based on an inverse piezoelectric effect and drives the flexible mechanism to act; the pre-tightening cushion block is used for matching with a pre-tightening screw to adjust the friction force between the driving feet and the rotor; and the rotor serves as an output terminal of the driving device. The piezoelectric driver has the advantage of high rotation angle resolution, stable motion, quick response, high rotation speed and the like, and has the characteristics of no electromagnetic interference, compact structure, light weight, simple processing, simple and convenient assembly,low cost, low power consumption and low noise. The piezoelectric driver is wide in application range and has good application prospect in the fields of precision instruments, precision optics, aerospace, micromanipulation and the like.

Owner:JILIN UNIV

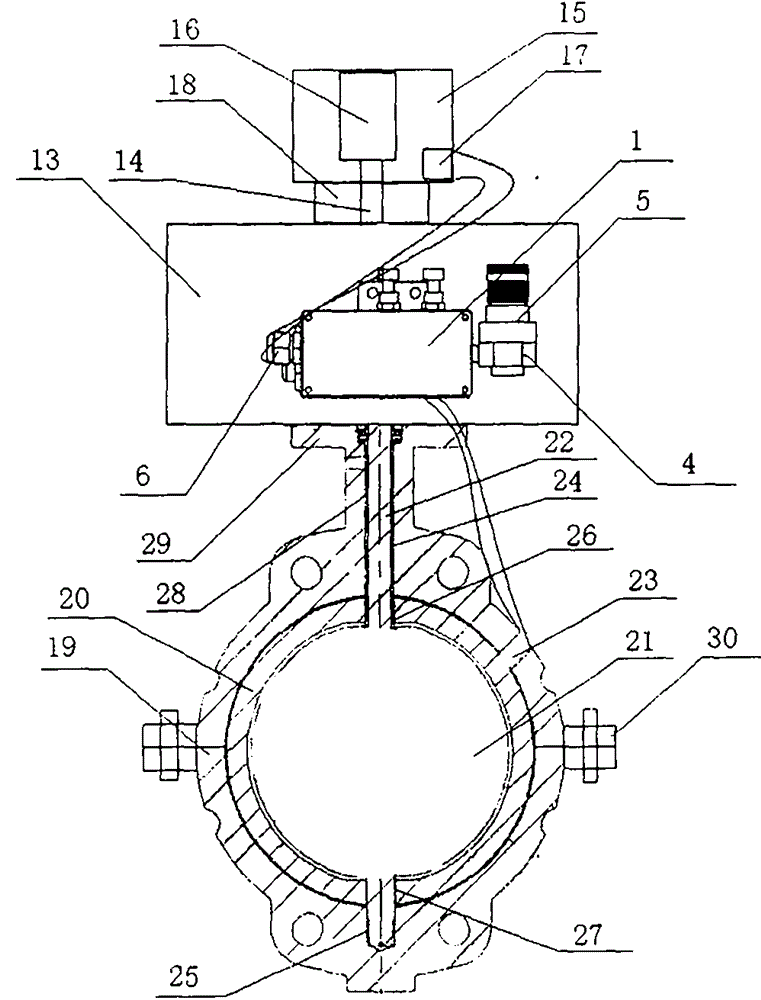

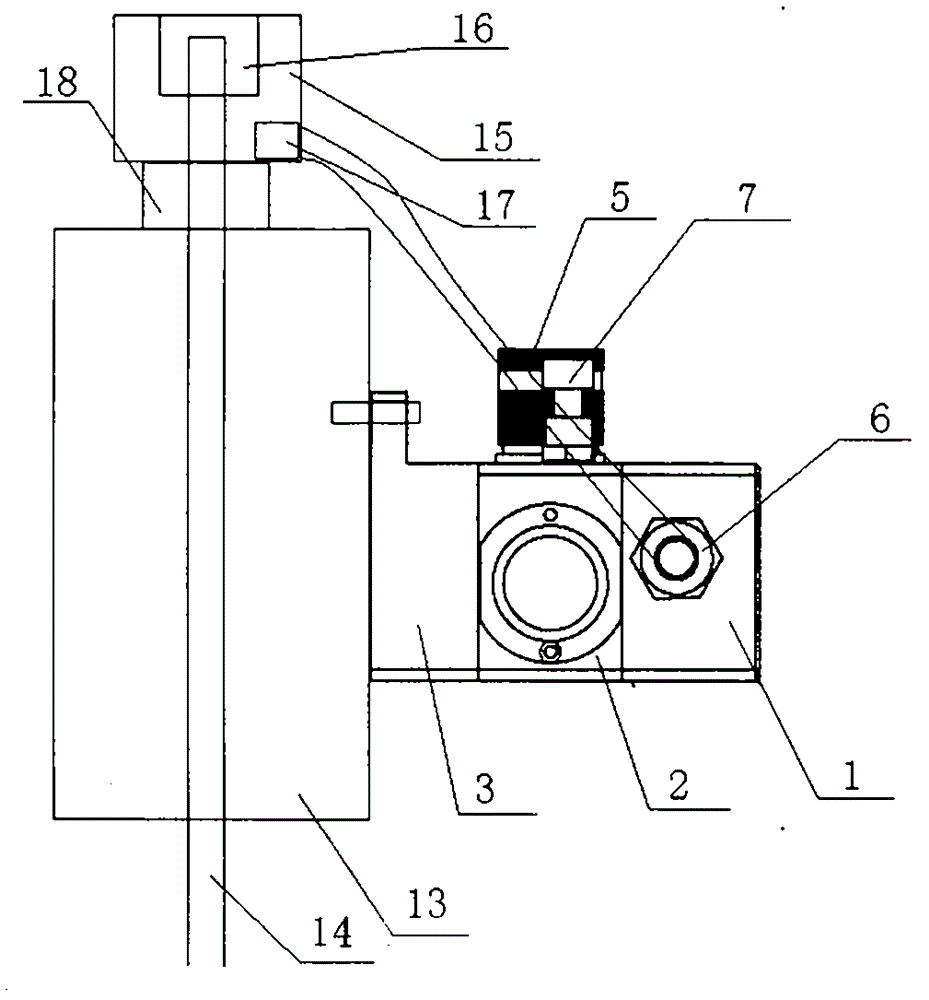

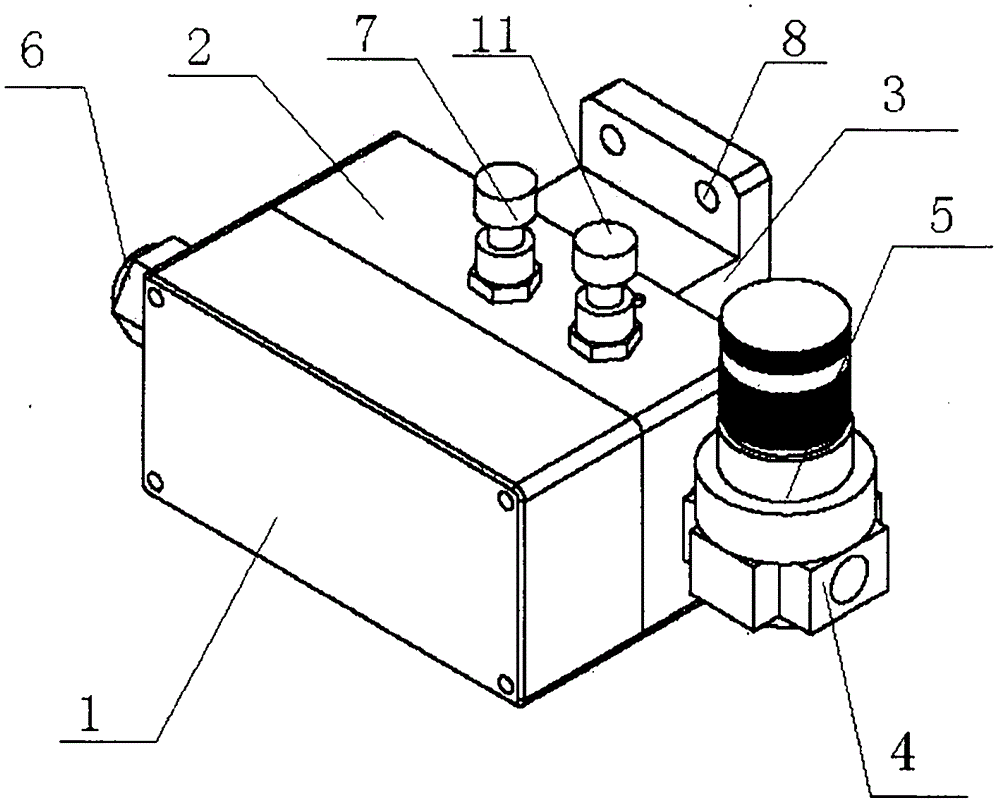

Novel pneumatic butterfly valve

InactiveCN104696534AReduce wearGuaranteed tightnessOperating means/releasing devices for valvesLift valveSolenoid valveEngineering

The invention discloses a novel pneumatic butterfly valve. The pneumatic butterfly valve comprises a butterfly valve body, a pneumatic actuator and a controller, wherein the butterfly valve body comprises a valve chamber, an elastic valve seat, a valve disc and a valve rod; the controller comprises a casing, an air source connector, air outlets and a solenoid valve, the air outlets comprise a first air outlet connected with the pneumatic actuator and a second air outlet connected with the elastic valve seat, the air source connector is connected with the solenoid valve, and the solenoid valve is connected with the first air outlet and the second air outlet respectively; an air inlet for inflating the elastic valve seat is arranged on the valve chamber and communicated with the second air outlet through an air pipe. The pneumatic butterfly valve is simple in structure, reasonable in arrangement, convenient to mount and dismount and attractive in appearance; meanwhile, an action air path of the pneumatic actuator and an inflation air path of the elastic valve seat can be controlled, so that abrasion during opening and closing of the valve disc and the valve seat can be reduced, and the sealing performance during closing of the valve disc and the valve seat can also be guaranteed.

Owner:HANGZHOU SAIMIKE VALVE MFG

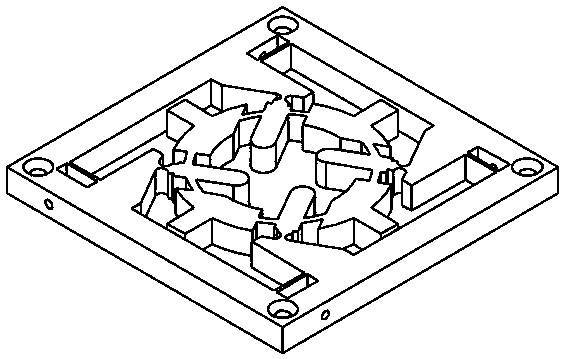

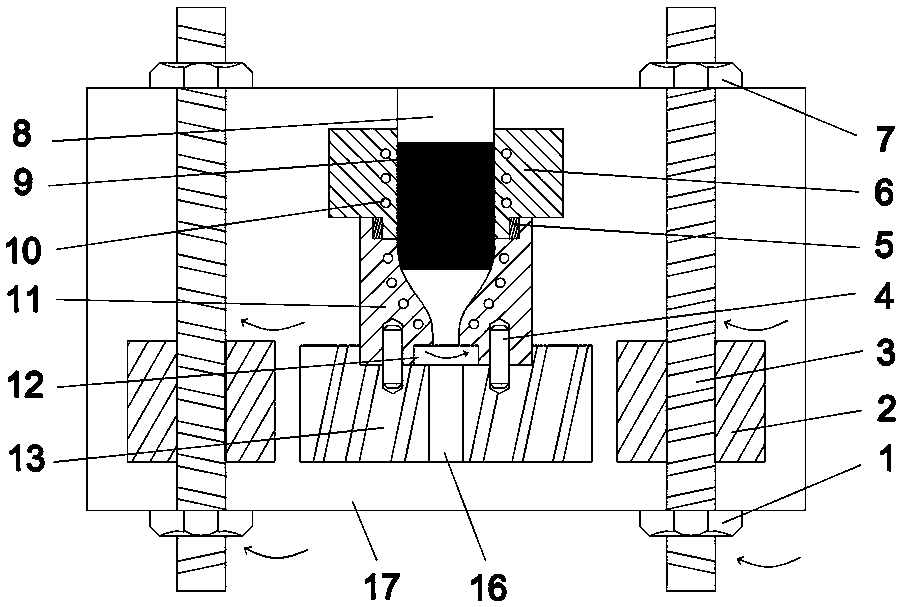

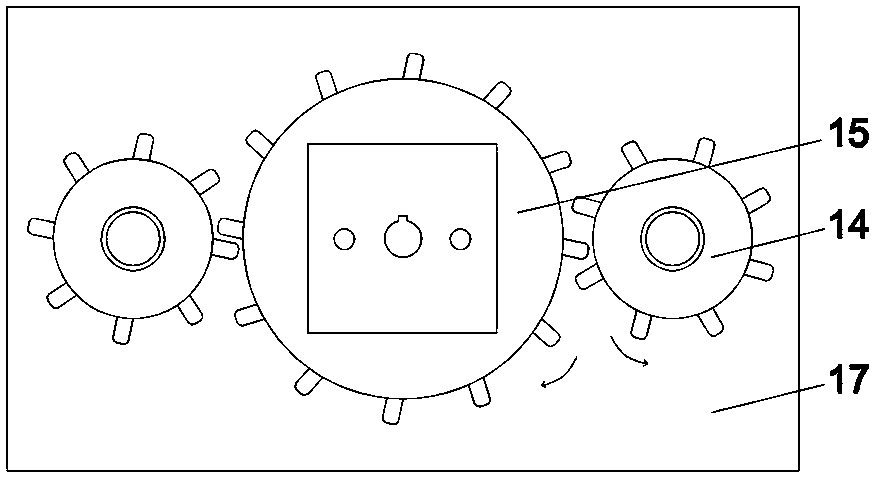

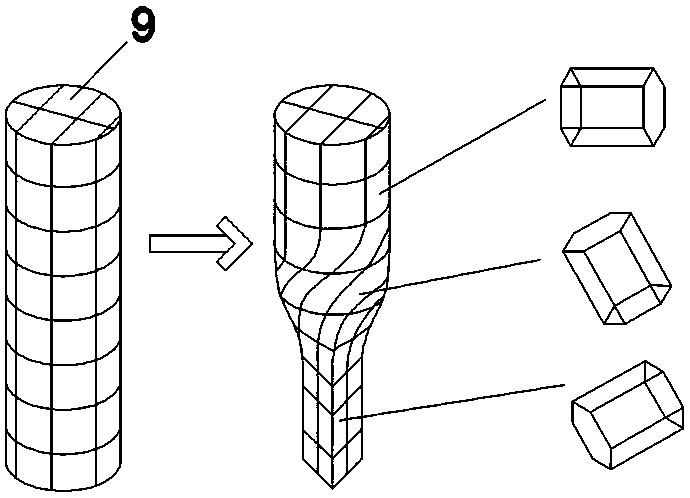

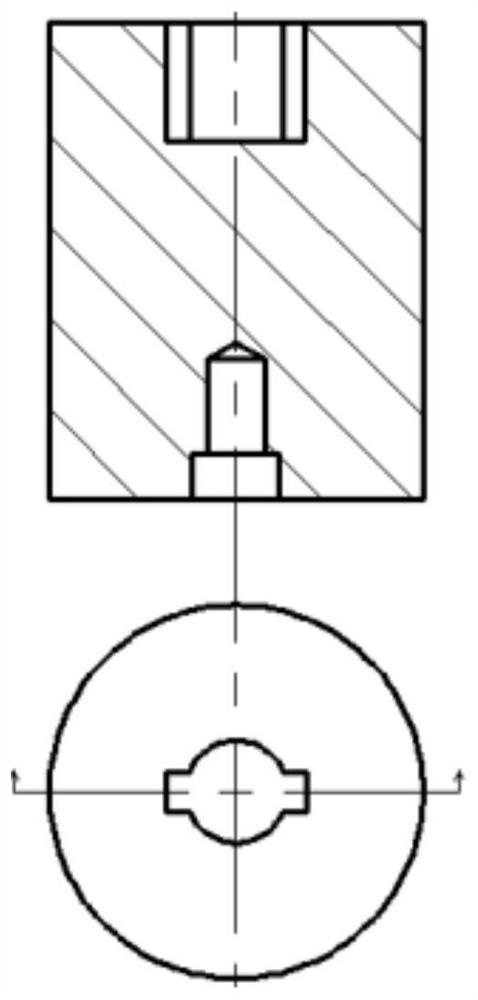

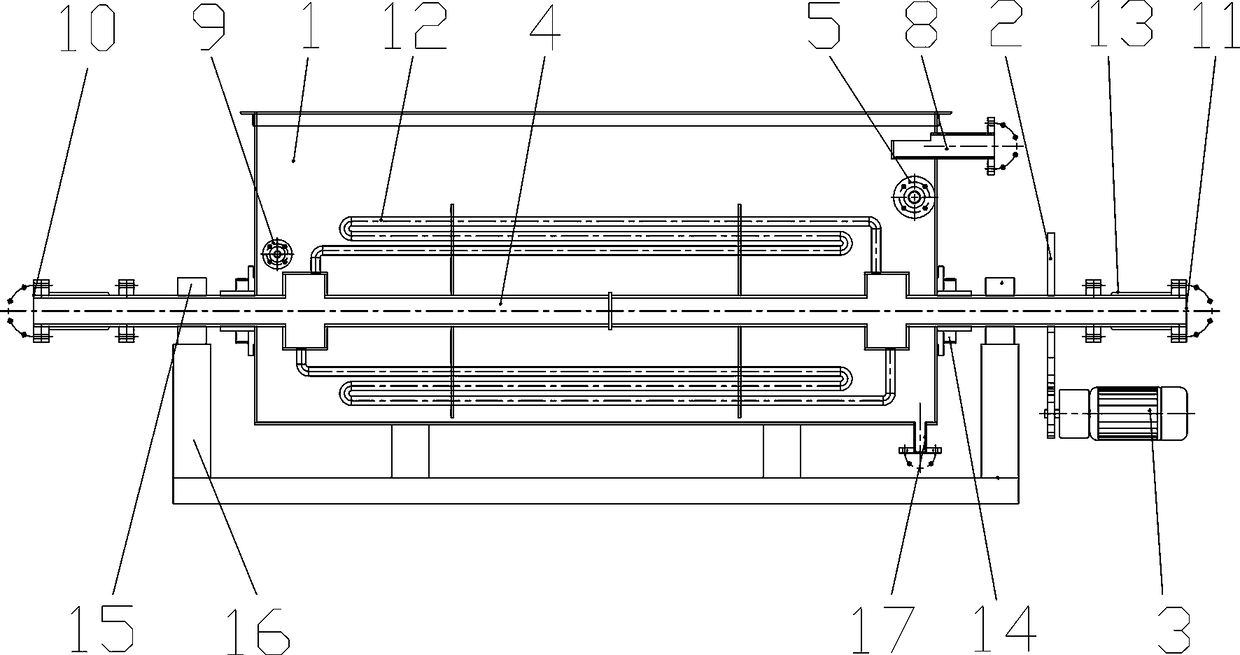

Screw-driven synchronous extruding and twisting composite device for fine-grain magnesium alloy and processing method

ActiveCN110560500AImprove mechanical propertiesGuaranteed deformation uniformityExtrusion diesExtrusion cleaning devicesFine grainSevere plastic deformation

The invention discloses a screw-driven synchronous extruding and twisting composite device for a fine-grain magnesium alloy and a processing method, and relates to the technical field of magnesium alloy application. The device comprises a base and a magnesium alloy blank, wherein a concave extrusion die is arranged at the upper end of the middle part of the inner side of the base, and the lower end of the concave extrusion die is in rotating connection with a variable-section concave extruding and twisting die through a roller bearing; the magnesium alloy blank is arranged in the concave extrusion die and the variable-section concave extruding die; a convex extrusion die is glidingly connected with the upper end of the inner side of the concave extrusion die and is positioned right above the magnesium alloy blank; a discharging port is formed in the middle part of the lower end of the inner side of the variable-section concave extruding and twisting die; and a synchronous twisting device is fixedly connected to the bottom part of the variable-section concave extruding and twisting die. According to the device, a severe plastic deformation process in which extruding and twisting aresynchronously carried out is achieved, and thus the deformation uniformity of the magnesium alloy blank is ensured in the process of fully refining grains.

Owner:TAIYUAN UNIV OF TECH

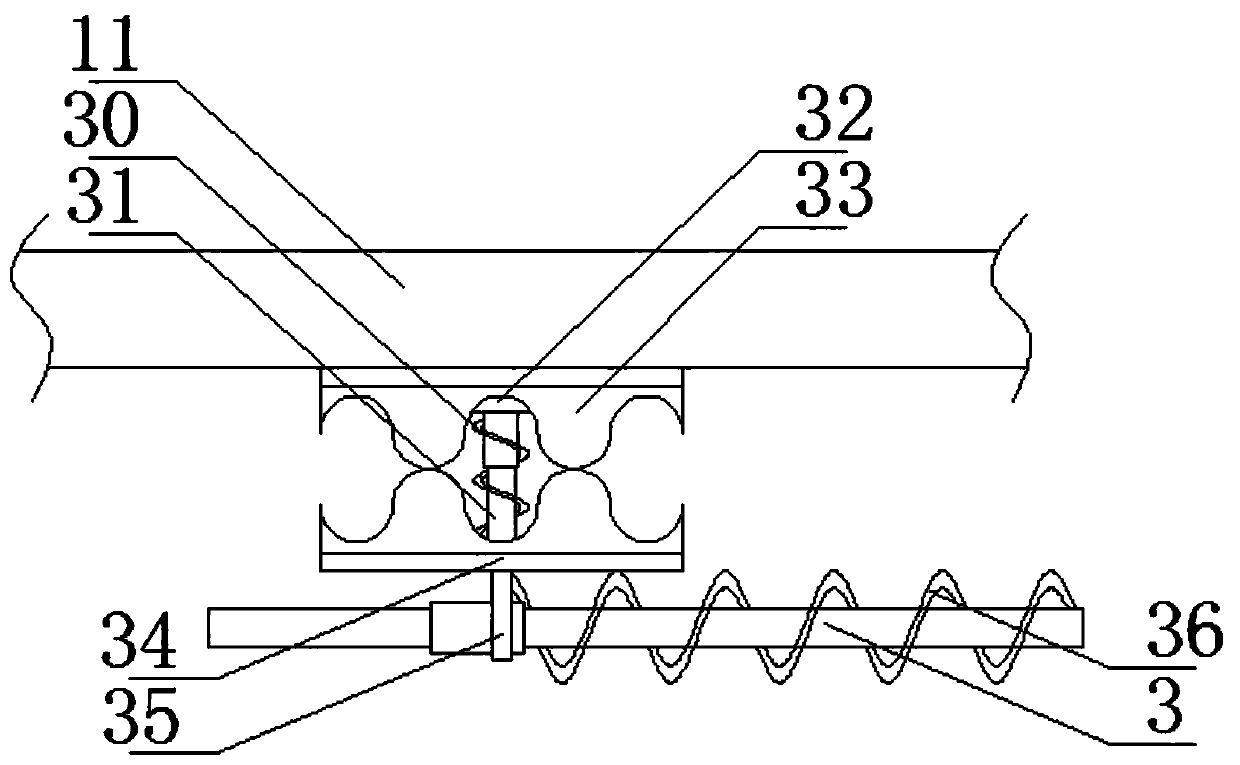

Roller brush cleaning device

InactiveCN107335640AAdjust the rotation speedCleaning using toolsCleaning using liquidsLinear motionReciprocating motion

The invention relates to a glass substrate roller brush cleaning device in the field of displayer manufacturing. The device comprises a guide rail, a screw lead, a cleaning part and a spraying nozzle. A to-be-cleaned roller brush rotates at the fixed position, the guide rail and the screw lead are both parallel to the axis of the roller brush, the cleaning part is limited by the guide rail to do linear motion along the roller brush, the screw lead provides power required for the reciprocating motion of the cleaning part, the spraying nozzle sprays a cleaning fluid to the to-be-cleaned roller brush, and the cleaning part makes contact with the rotating roller brush and does reciprocating motion along the axis of the roller brush, so that the cleaning of the roller brush is completed. The cleaned roller brush can be repeatedly used for cleaning glass substrates.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Novel vertical type sampling tool for geological prospecting

InactiveCN108663231AImprove work efficiencyExtended service lifeWithdrawing sample devicesInstabilityGeological exploration

The invention discloses a novel vertical type sampling tool for geological prospecting. The novel vertical type sampling tool comprises a base and is characterized in that a short rod is mounted on the inner wall of the base, the outer wall of the short rod is movably connected with the inner wall of the base, a first compression spring sleeves the outer wall of the short rod, the inner wall of the compression spring is movably connected with the outer wall of the short rod, a retaining plate is mounted on the outer wall of the base, the inner wall of the retaining plate is movably connected with the outer wall of the base, and the inner wall of the retaining plate is connected with the outer wall of the short rod. The novel vertical type sampling tool has the advantages that by the coordination of the short rod, the first compression spring and the retaining plate and by the aid of an alternating-current servo motor, the connecting part instability of the holding rod, connected with aconnecting rod, a rod sleeve and a spring, of a traditional sampling device is overcome, the purchasing cost of a user is saved, the resource waste of the novel vertical type sampling tool is avoided, and the novel vertical type sampling tool is suitable for being popularized and used.

Owner:广西珠委南宁勘测设计院有限公司

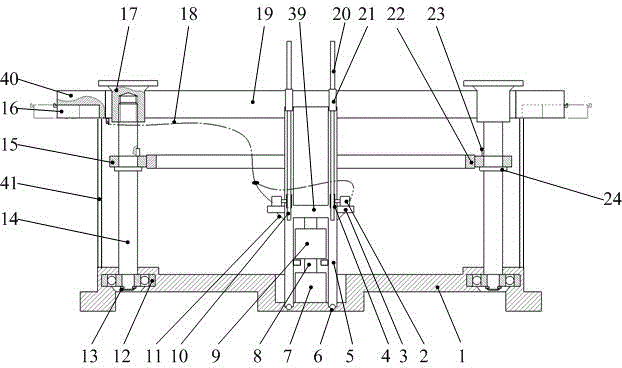

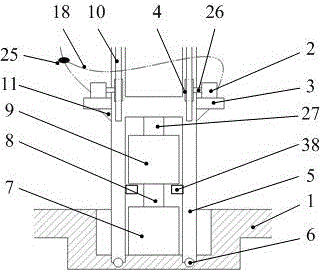

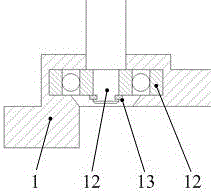

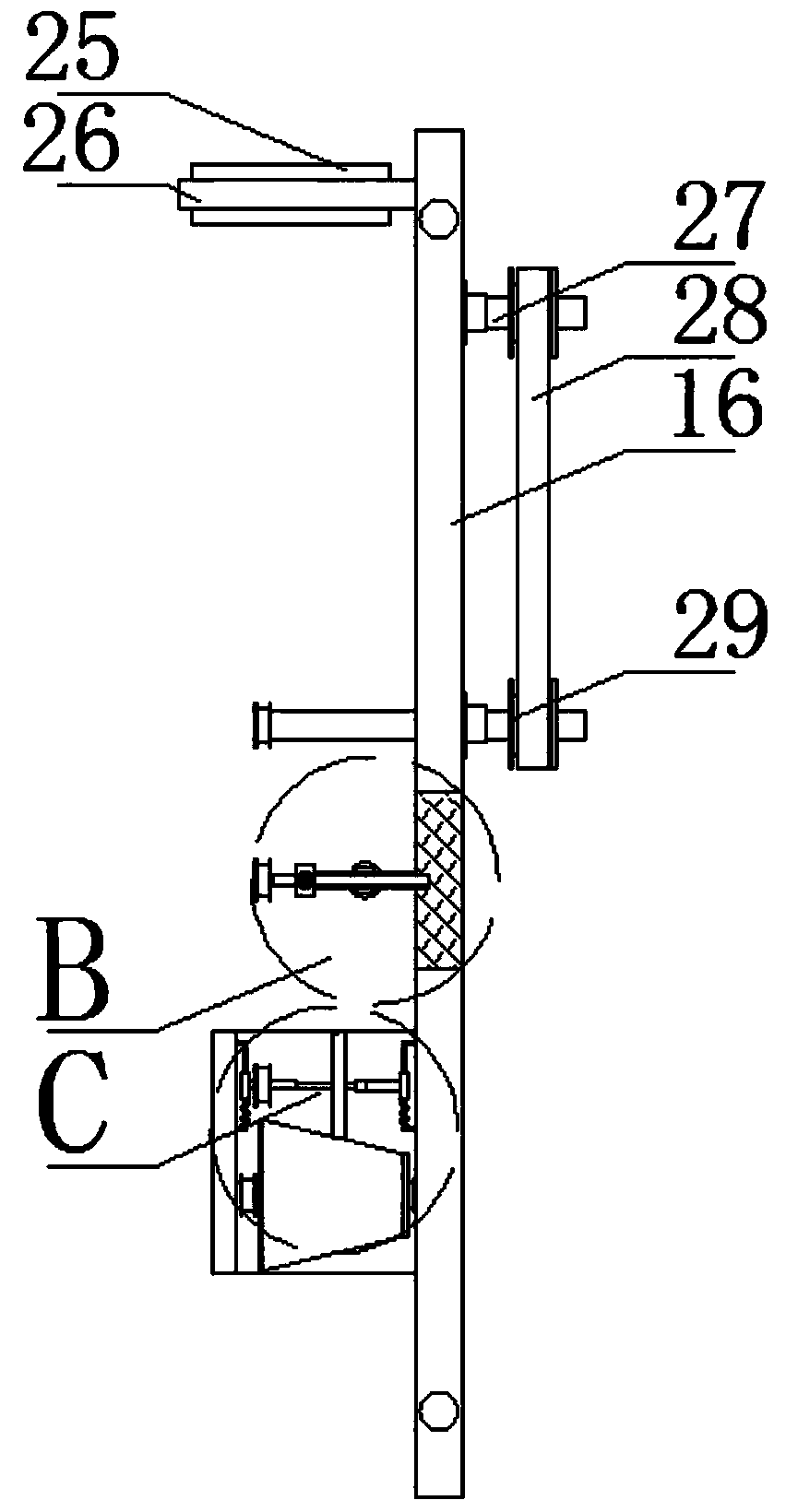

Overturning method for mechanically clamping long steel structural parts

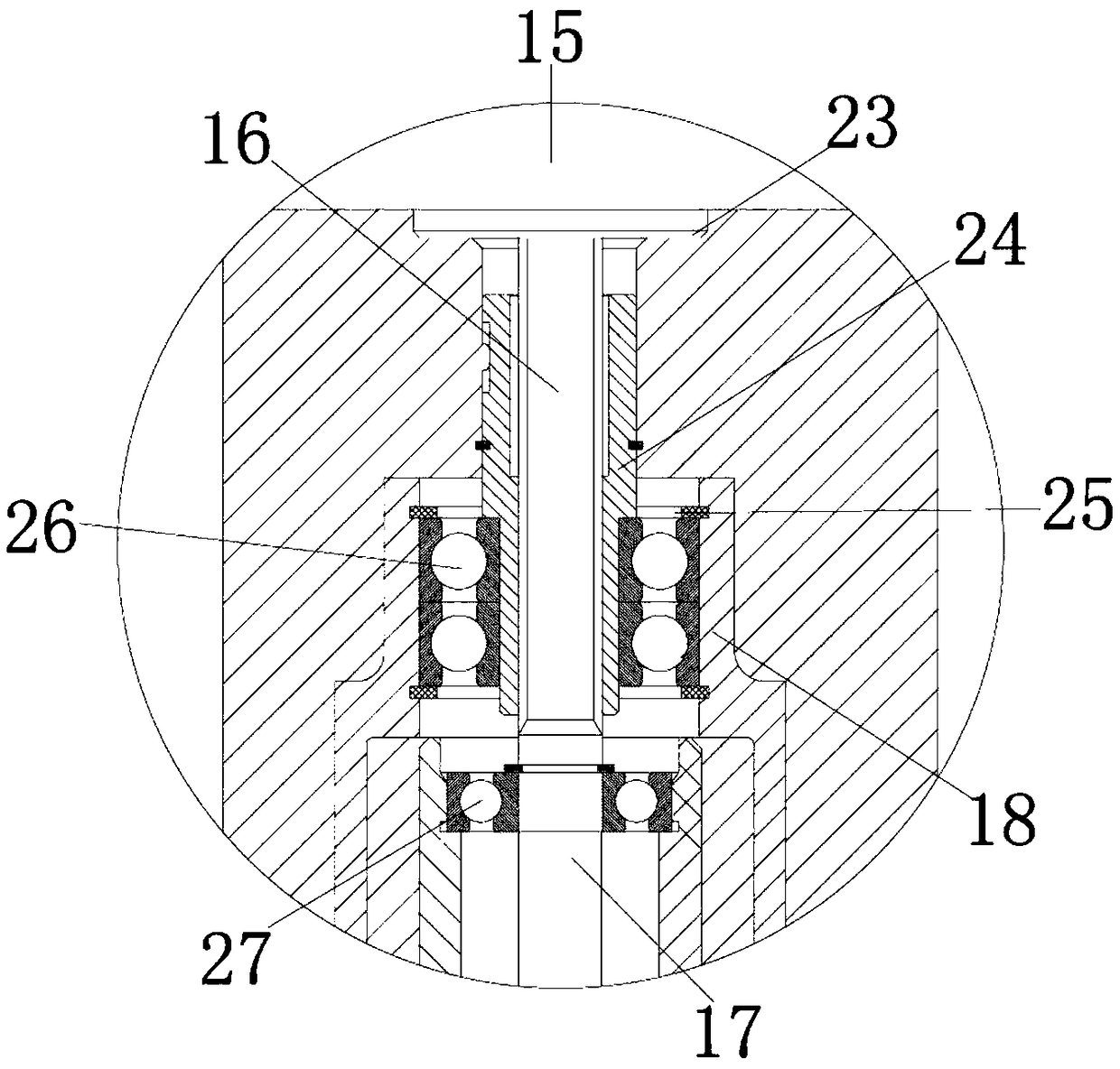

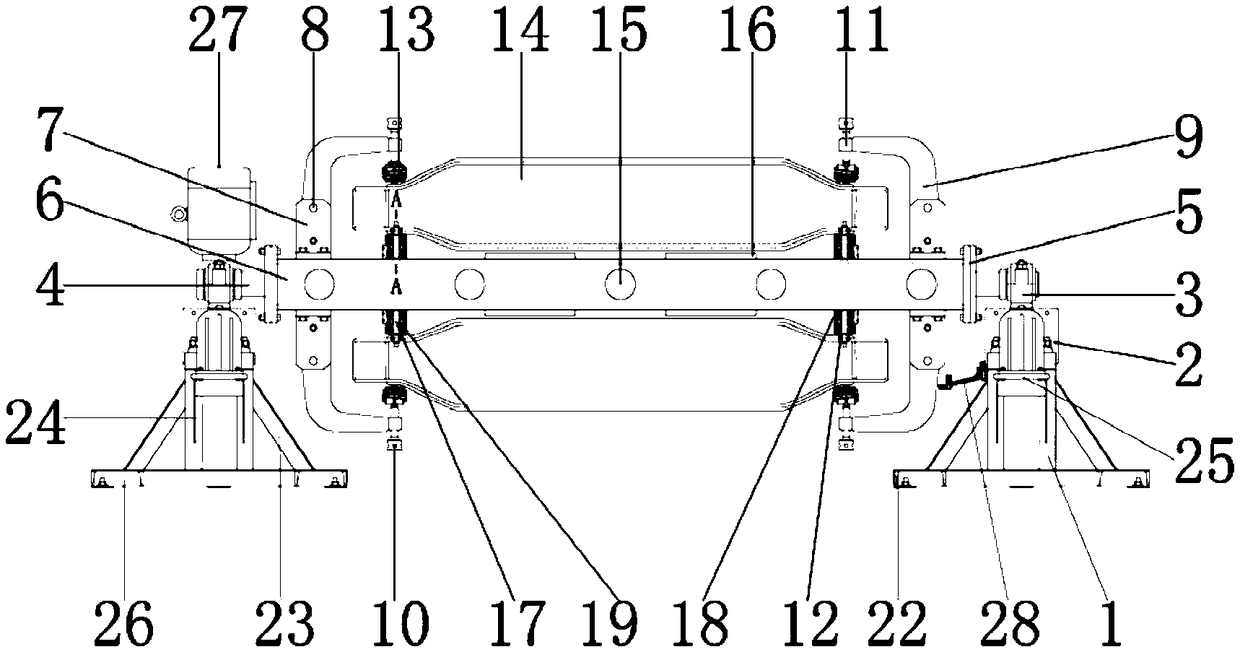

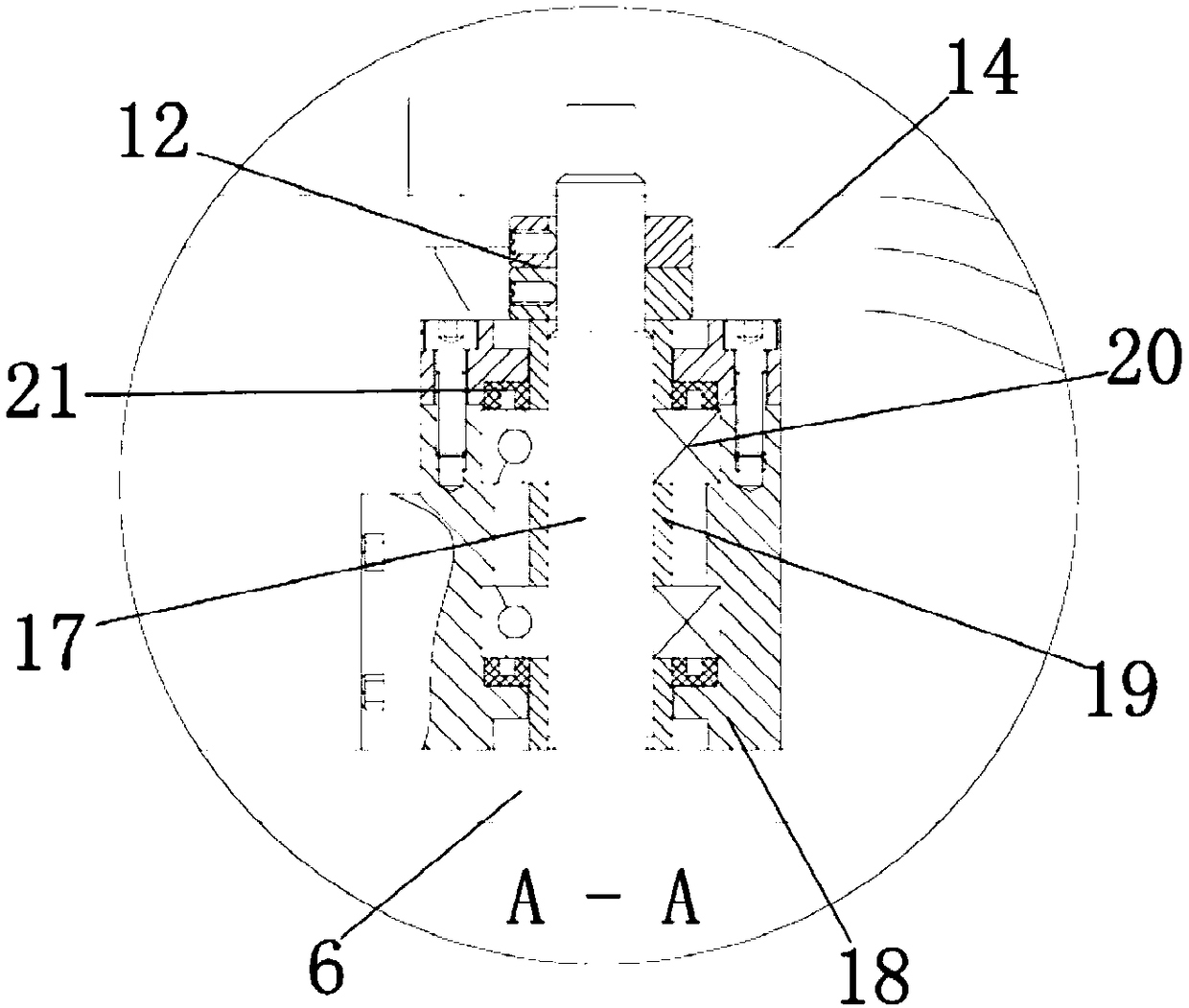

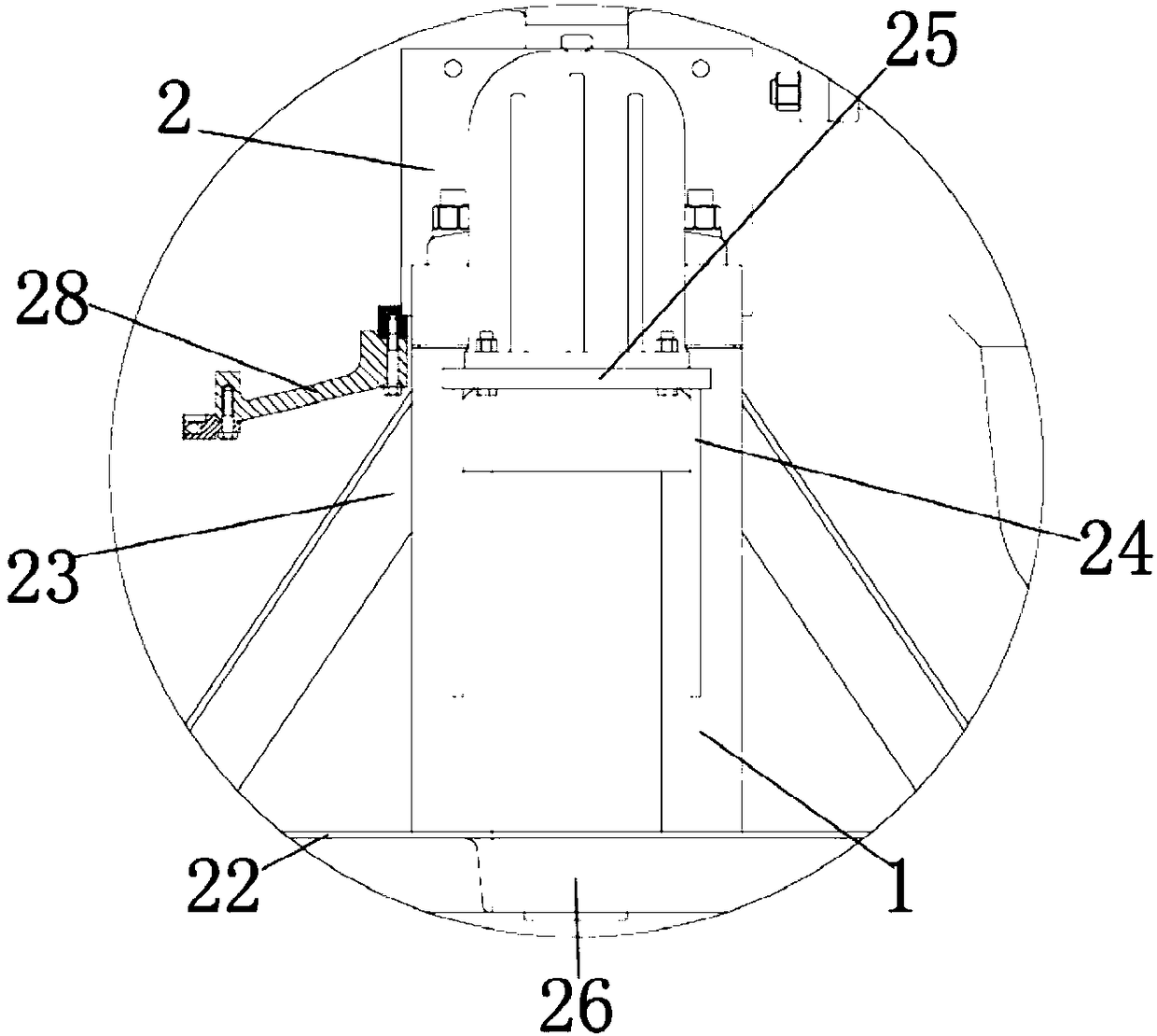

InactiveCN109048182AAdjust the rotation speedPrevent fallingWelding/cutting auxillary devicesAuxillary welding devicesMachine partsEngineering

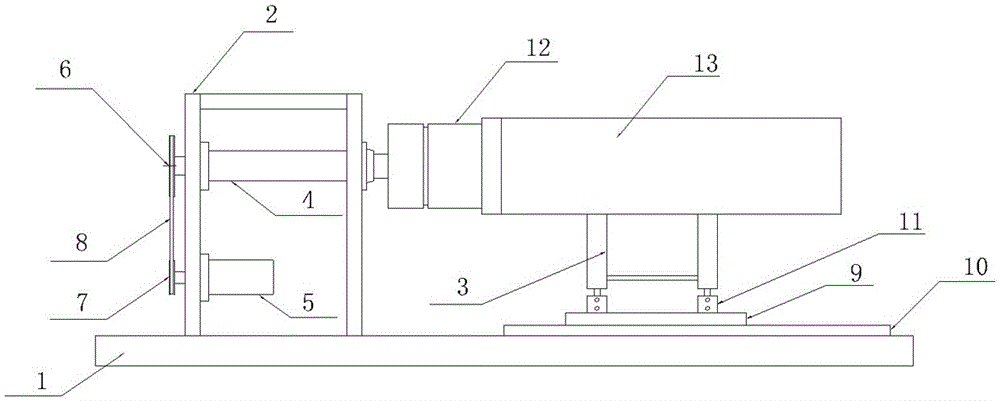

The invention discloses an overturning method for mechanically clamping long steel structural parts. A motor 27 is connected with a rotating wheel 3; a rotating shaft 4 is connected with the rotatingwheel 3; a rotating rod 6 is connected with the rotating shaft 4 by using a connecting flange 5, so that an external power supply of a motor 27 is electrified; the motor 27 is started to work; the motor 27 drives the rotating wheel 3 to rotate; the rotating wheel 3 drives the rotating shaft 4 to rotate during rotating; the rotating shaft 4 drives the connecting flange 5 to rotate during rotating;the connecting flange 5 is connected with the rotating rod 6; the connecting flange 5 drives the rotating rod 6 to rotate during rotating; the rotating wheel 3 is fixed on a bracket 2; the bracket 2 is supported by using support legs 1 to reach a certain height from the ground, so that machined parts 14 are conveniently driven to overturn by the motor 27; ejector bases 7 are mounted on two sides of the outer wall of the rotating rod 6; pin shafts 8 are mounted in the ejector bases 7; crankshafts 9 are mounted in the ejector bases 7; the crankshafts 9 can be driven by the pin shafts 8 to incline; the machined parts 14 are fixed; and stoppers 13 are mounted on the crankshafts 9. Therefore, the assembly work of an overturning device for mechanically clamping the long steel structural parts.

Owner:陈海锋

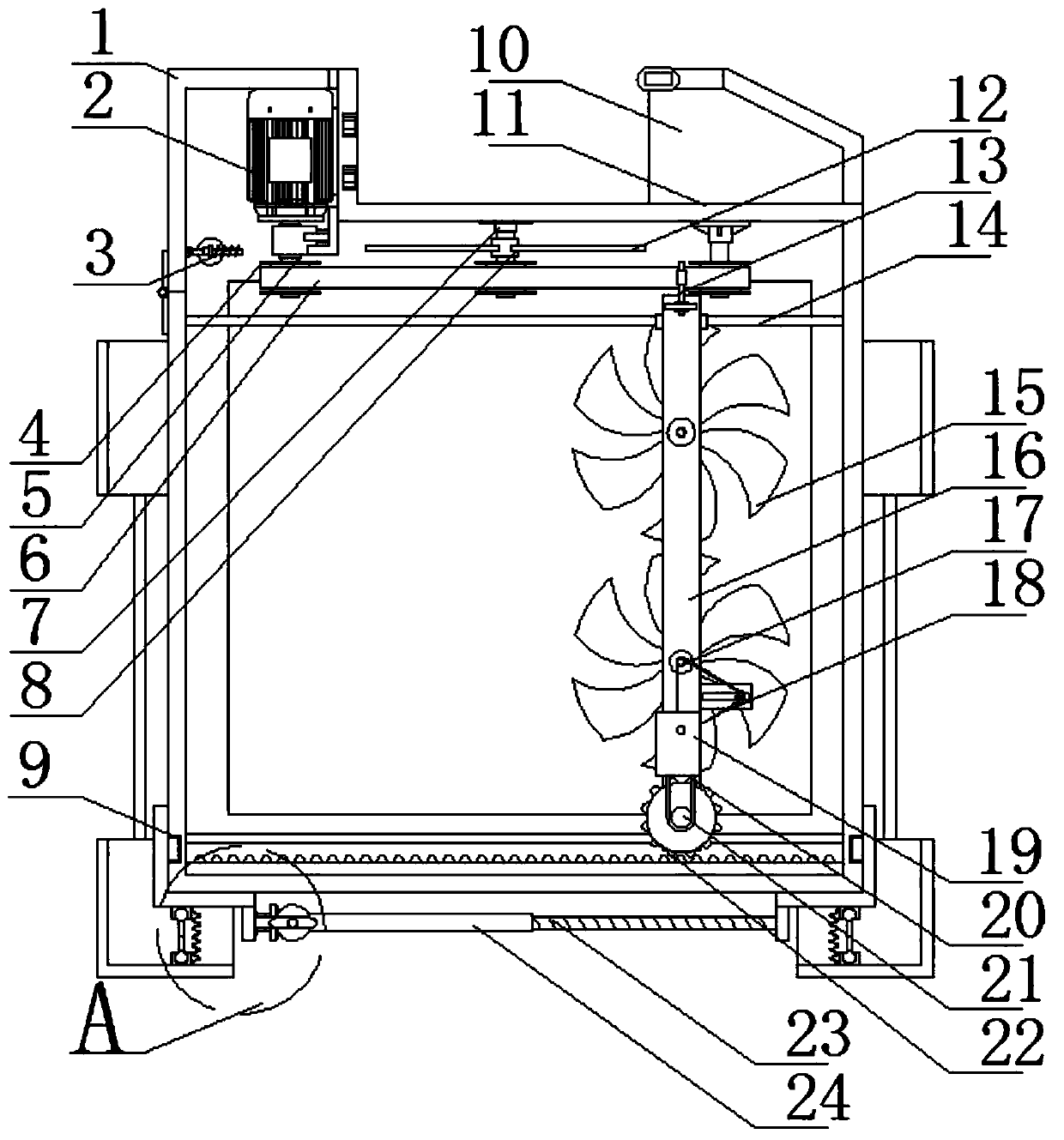

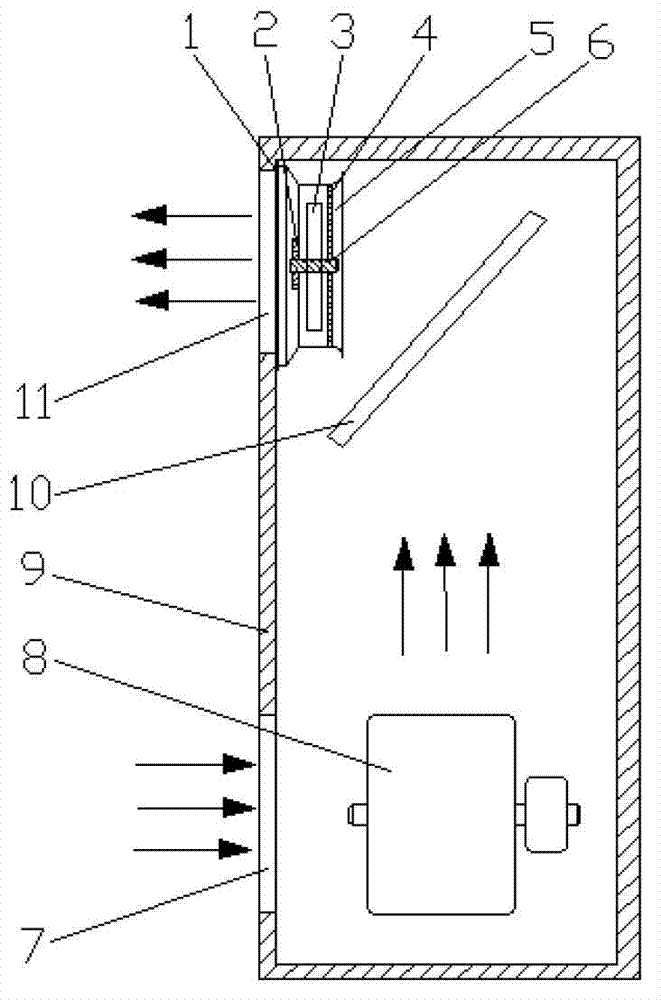

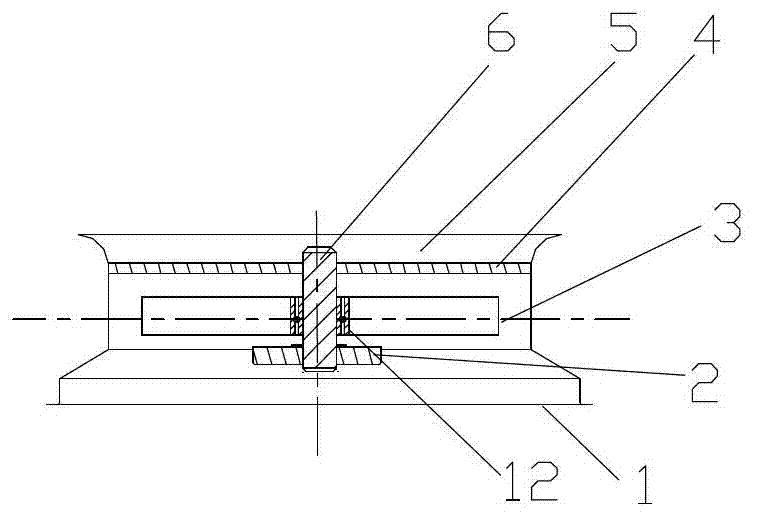

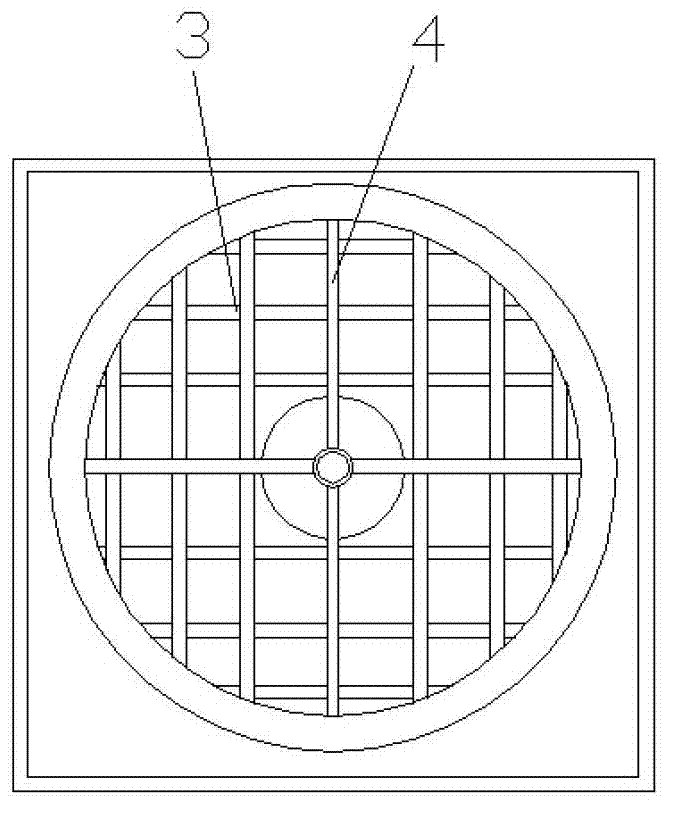

Computer case which can efficiently dissipate heat and is excellent in protection performance

InactiveCN111338436AEasy to fixConducive to revealDigital processing power distributionAutomatic controlReciprocating motion

The invention discloses a computer case which can efficiently dissipate heat and is excellent in protection performance. First openings are formed in the two sides of the machine box, a second openingis formed in the other side of the machine box, a power mechanism is arranged on one side of the top in the machine box, a first synchronous belt is arranged on the power mechanism, a reciprocating transmission mechanism is arranged on the first synchronous belt, and a vertical plate is arranged on the reciprocating transmission mechanism. According to the invention, the fan blades can do reciprocating motion during rotation; efficient flow of air is facilitated, the quality of air entering the case can be ensured; therefore, efficient and high-quality heat dissipation can be carried out in the case; and the rotating speed of the fan blades can be automatically controlled, adjustment can be conveniently conducted according to the use condition of equipment, the heat dissipation quality isbetter guaranteed, the temperature in the case is effectively reduced, protection can be effectively conducted, external collision can be effectively resisted, the stability of the case is guaranteed, and the service life of internal parts of the case can be prolonged.

Owner:长沙凯泽工程设计有限公司

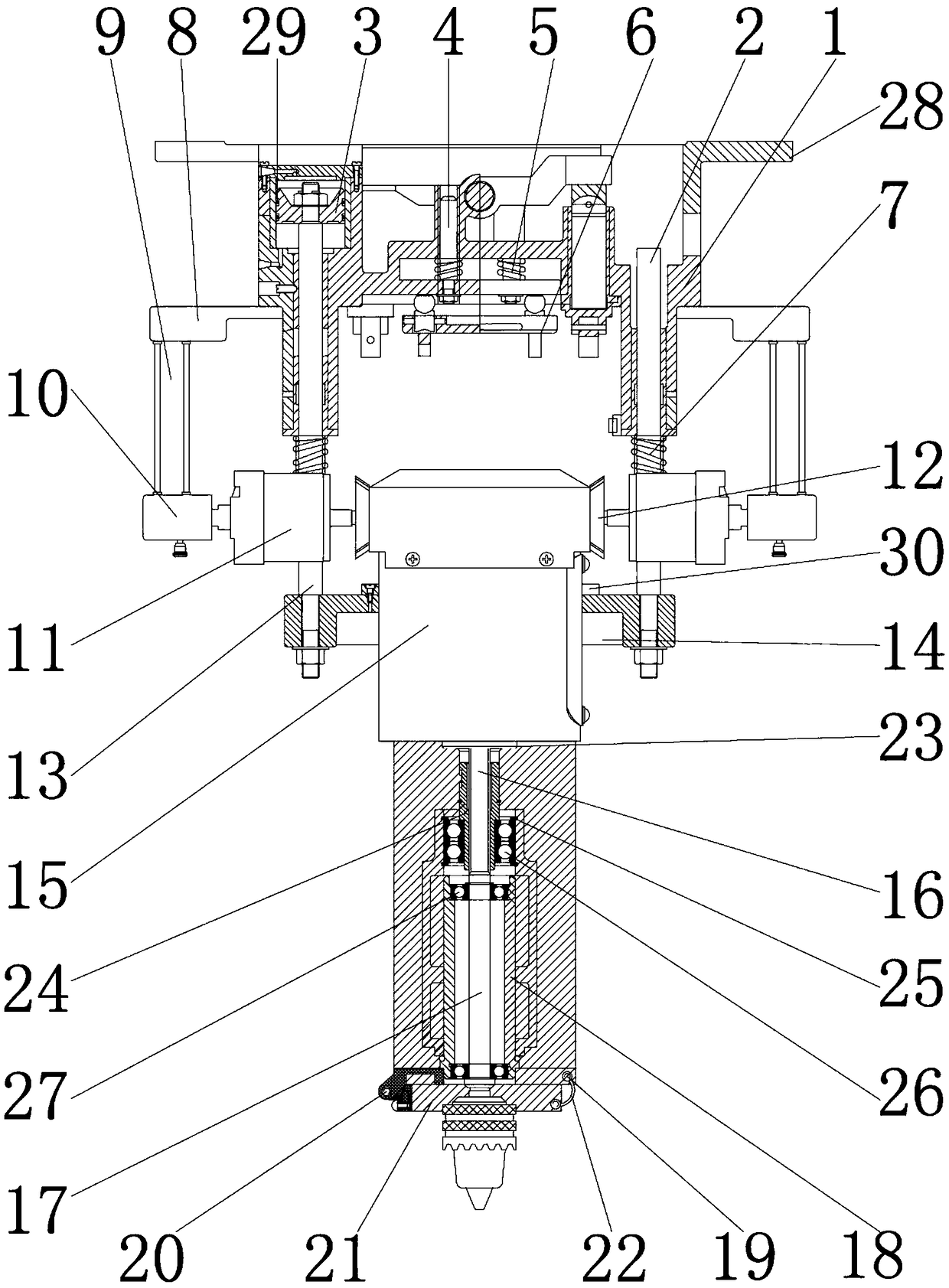

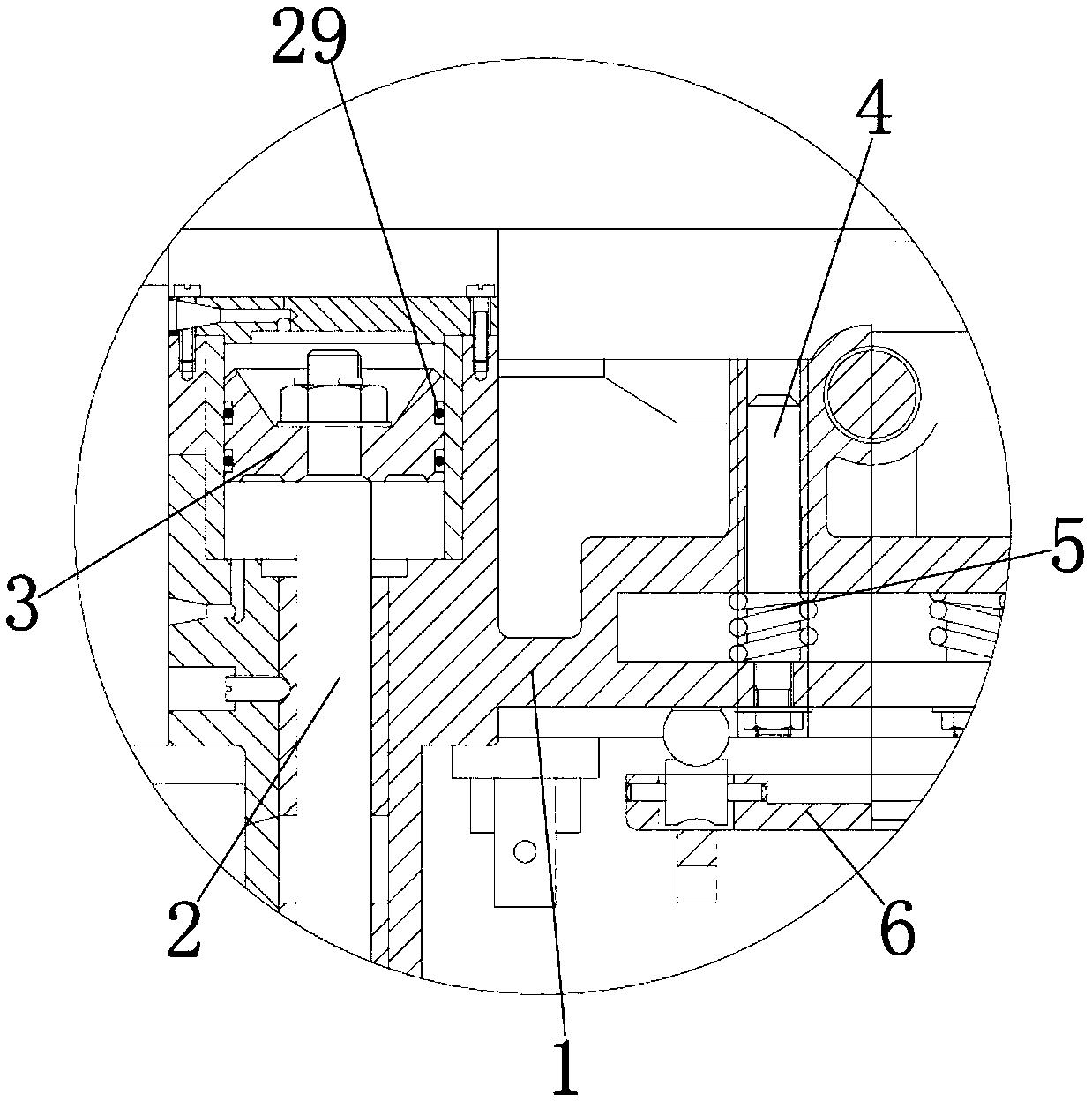

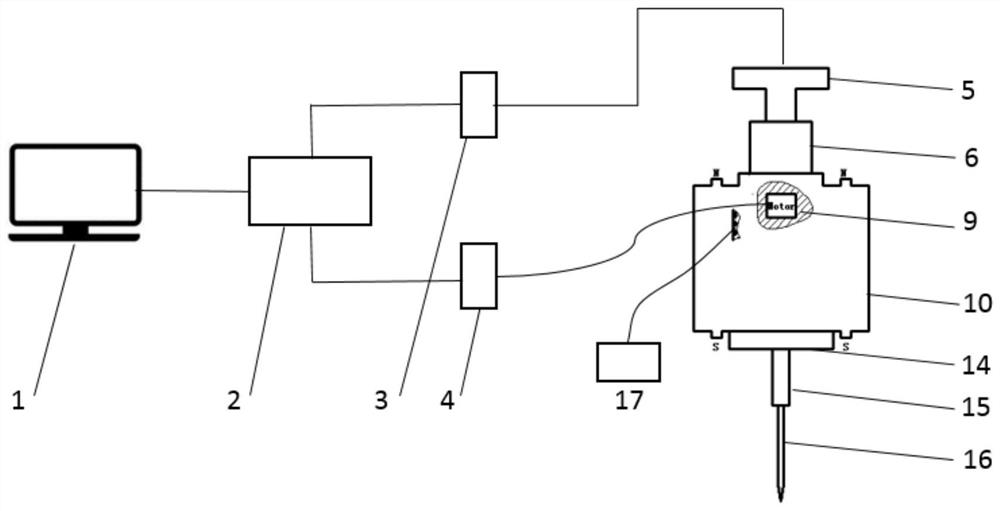

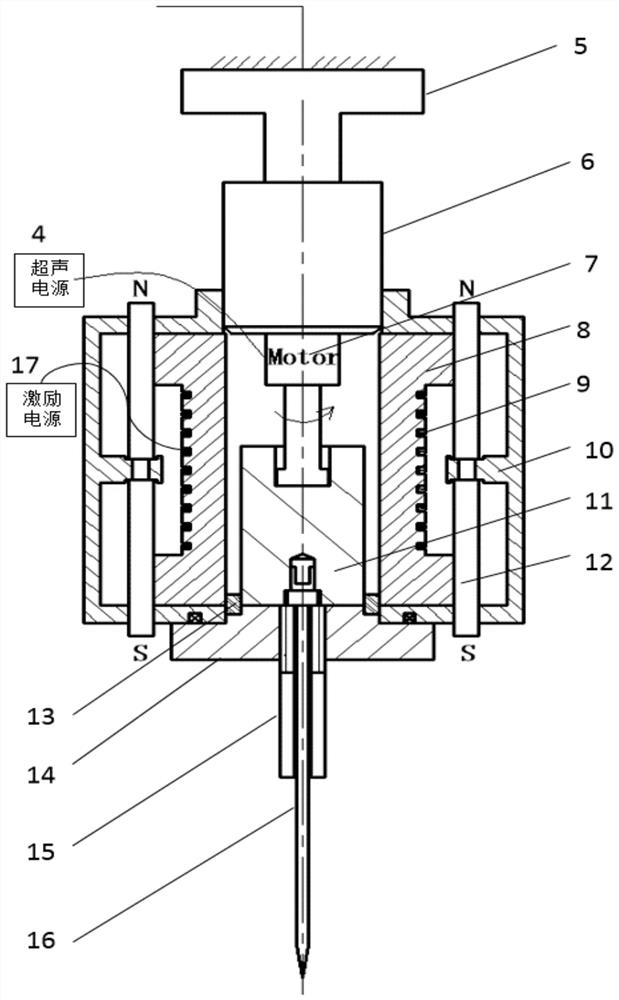

Ultrasonic multi-mode acupuncture device and method

ActiveCN111789761AResolve swingGood guiding mechanismAcupunctureDevices for locating reflex pointsAcupuncture needlesElectric machinery

The invention discloses an ultrasonic multi-mode acupuncture device and method. The ultrasonic multi-mode acupuncture device comprises a supporting shaft, a motor and an acupuncture needle. The motoris arranged at the lower end of the supporting shaft; the acupuncture needle is connected to the output end of the motor through a vibration tool head; the motor can vertically move up and down alongwith the supporting shaft, and meanwhile the acupuncture needle arranged at the output end is driven to rotate when the motor rotates; the motor is driven by an ultrasonic power supply; the device realizes automatic needle application by controlling the motor; by mechanically assembling and disassembling a permanent magnet in the ultrasonic multi-mode device and applying matched coil exciting current, the ultrasonic mode conversion of the acupuncture needle is realized by changing the relative position of a magnetic field, and meanwhile, the acupuncture needle is prevented from swinging or bending under the guide of a guide sleeve, so that the needle applying efficiency and precision and the ultrasonic treatment gain are obviously improved, and relatively high use values are realized.

Owner:JIANGSU UNIV

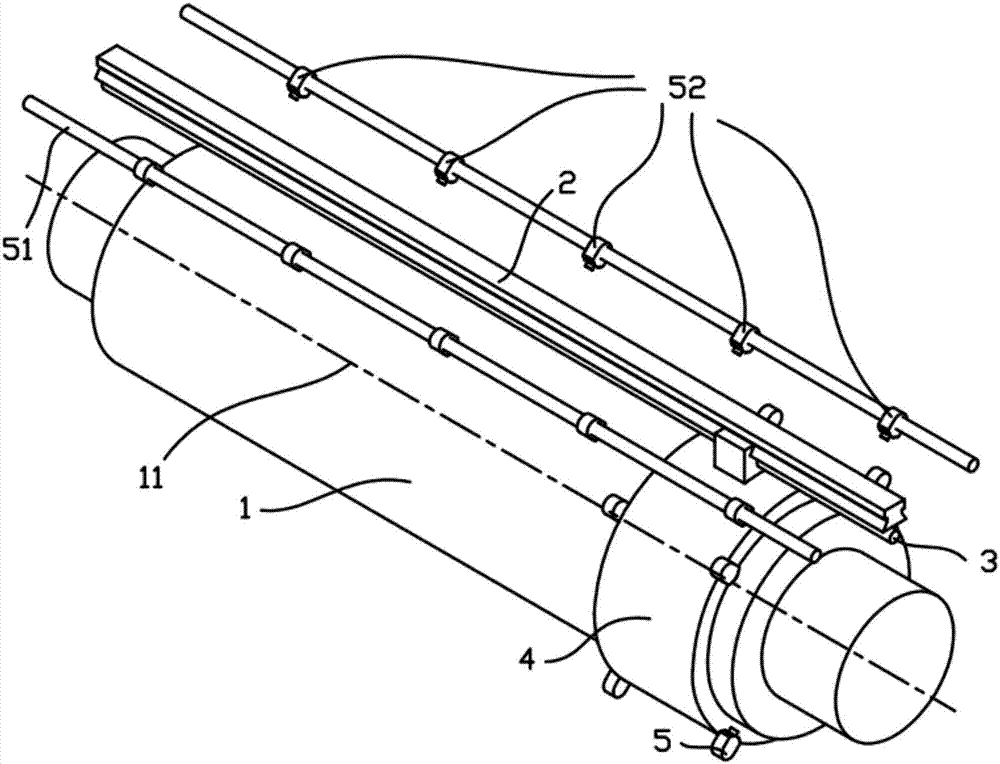

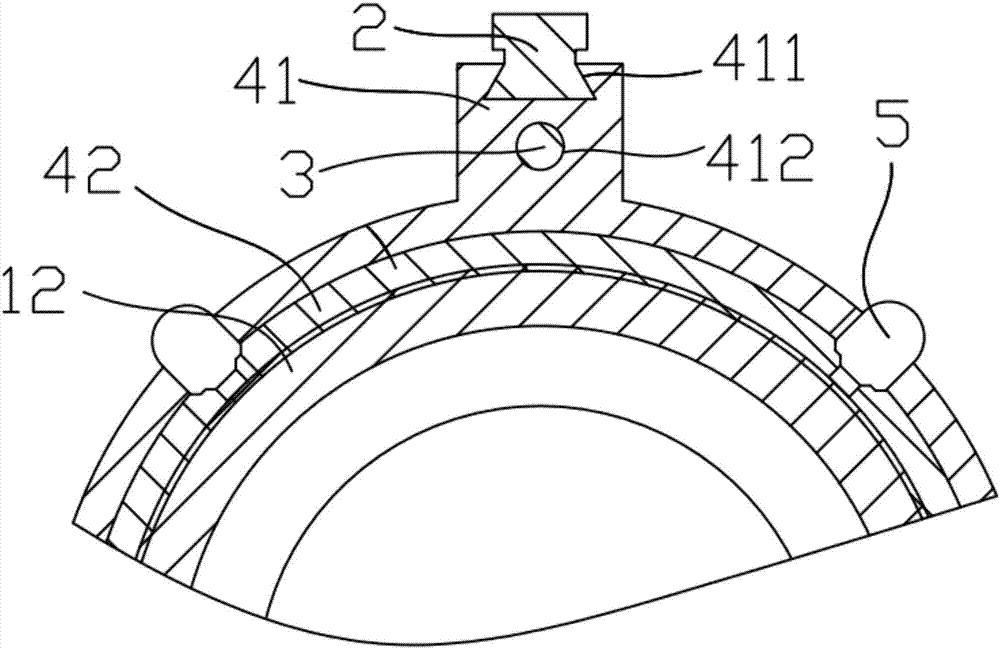

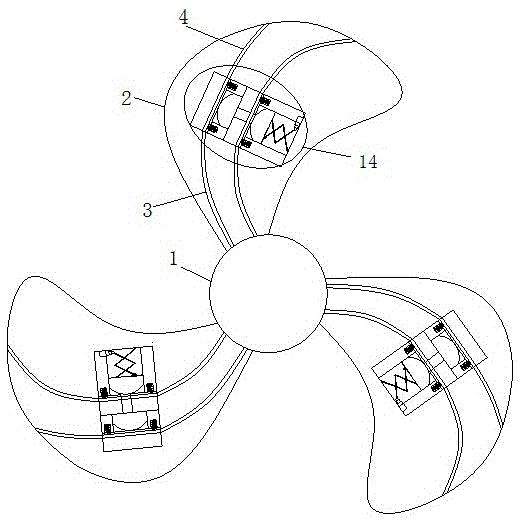

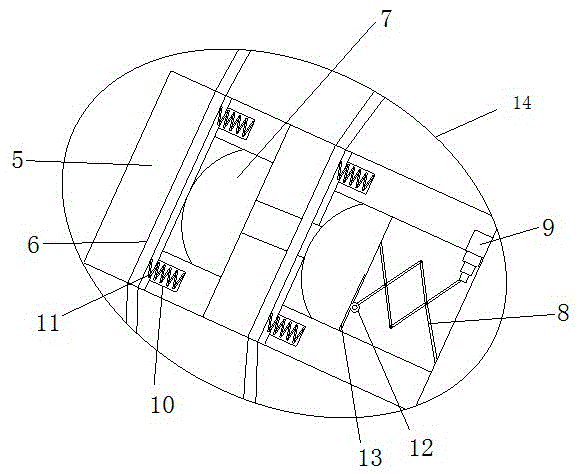

Adjustable nozzle propeller of ship

The invention discloses an adjustable nozzle propeller of a ship. The adjustable nozzle propeller comprises a shaft sleeve, wherein paddles are arranged on the shaft sleeve in a circumferential direction, curve-shaped water inlets and curve-shaped water outlets are respectively formed in inner chambers of the paddles, the water inlets communicate with the shaft sleeve, T-shaped slots are formed in the middle parts of the inner chambers of the paddles, the water inlets and the water outlets are connected through spiral hoses, and the spiral hoses are positioned in the inner chambers of the T-shaped slots, curve-shaped blocks are arranged on the lower sides of the T-shaped slots, shears-fork type expansion brackets are arranged on the lower sides of the curve-shaped blocks, grooves are formed in two sides of the T-shaped slots, springs are arranged in the inner chambers of the grooves, and the upper ends of the springs are connected with the spiral hoses. The adjustable nozzle propeller disclosed by the invention adopts the manner of adjusting the angle of the curve-shaped spray waterway to adjust the size of the deviating force from the circumferential direction of the propeller, so that the adjustment the rotating speed of the propeller can be realized; according to navigation requirements of the ships, the navigational speed can be adjusted, and the adjustable nozzle propeller is energy-saving, environmentally-friendly, and suitable for general popularization

Owner:JIANGSU HUIZHI INTPROP SERVICES CO LTD

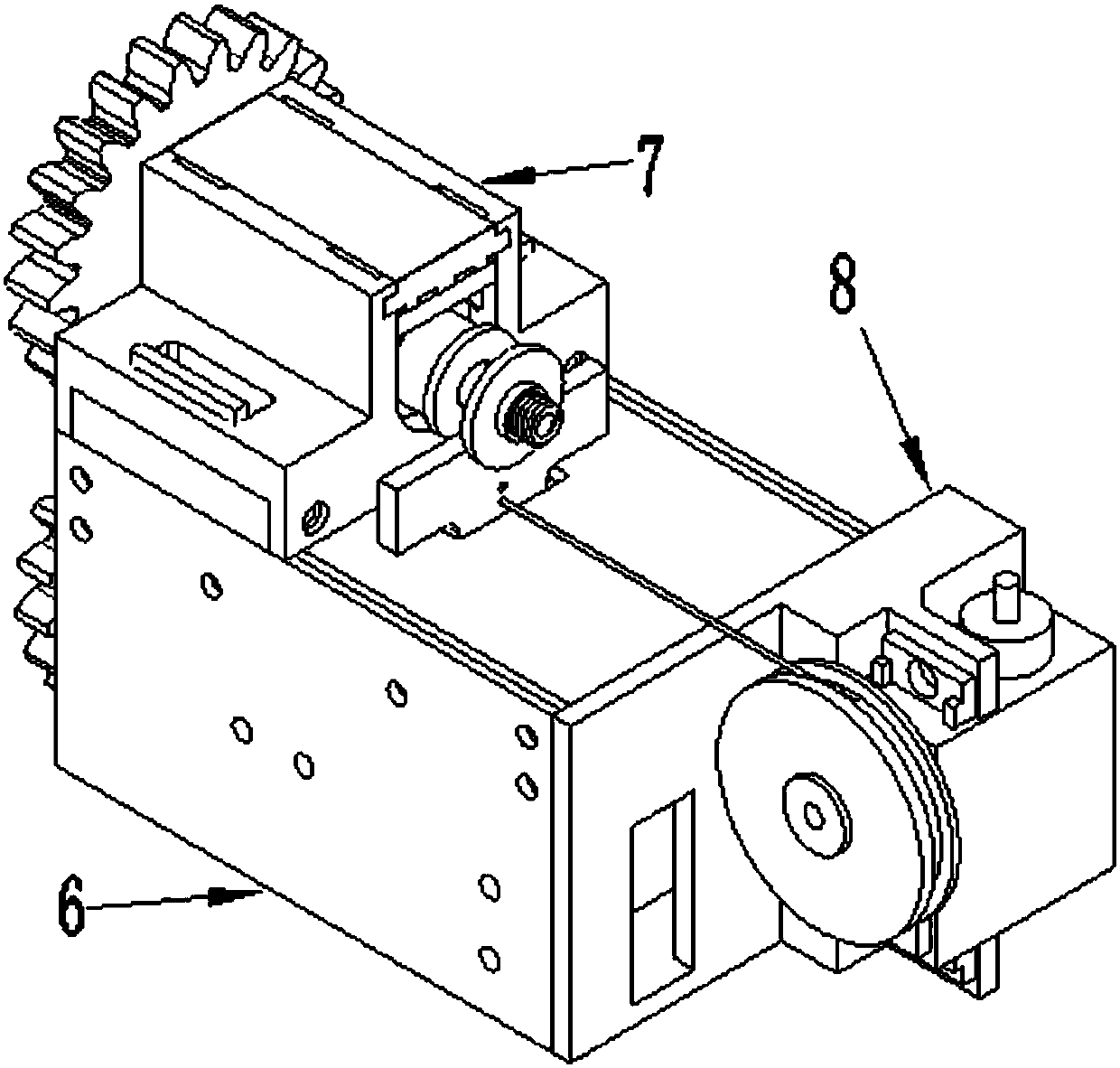

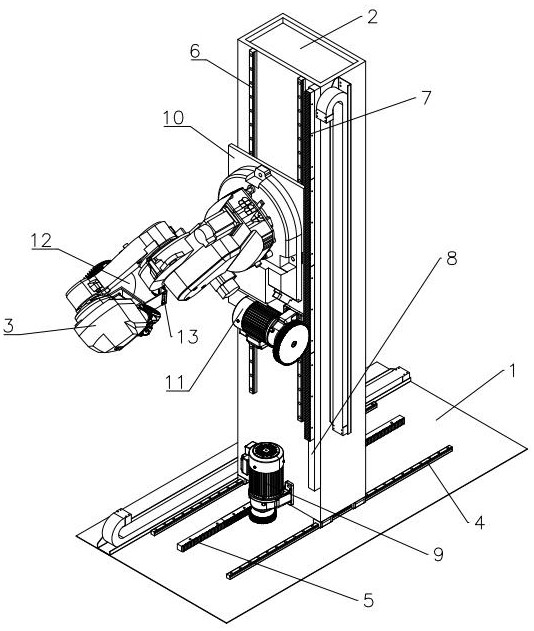

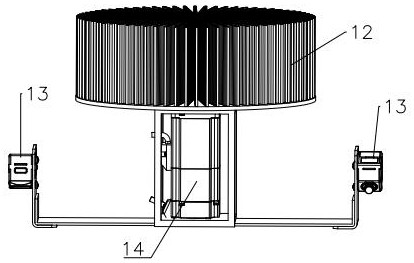

Car washing robot based on manipulator

PendingCN112025721AAdjust the rotation speedAdjust Wiping EfficiencyProgramme-controlled manipulatorCleaning apparatus for vehicle exteriorsLaser rangingRobot hand

The invention relates to the technical field of mechanical equipment, and particularly provides a car washing robot based on a manipulator. The car washing robot comprises a supporting stand column and a six-axis manipulator, a front-back moving sliding rail and a front-back moving rack are arranged on the lower part of the supporting stand column, and an up-down moving sliding rail, an up-down moving rack, a rack base plate and a front-back servo motor are mounted on the supporting stand column. A manipulator mounting plate and an up-down servo motor are mounted at the bottom of the six-axismanipulator, a brush and a laser ranging sensor are mounted at the head of the six-axis manipulator, the supporting stand column is slidably mounted on the front-back moving sliding rail, and the manipulator mounting plate is slidably mounted on the up-down moving sliding rail. The front-back servo motor and the up-down servo motor are combined with gears and the racks, so that the manipulator moves at any point in the length and height directions of a car body, car washing is more thorough, and the laser ranging sensor can judge the distance between the manipulator brush and the car body; andthe rotating speed of the brush can be changed according to requirements to adjust the rotating speed and the wiping efficiency of the brush.

Owner:지앙수위에다인베스트먼트컴퍼니리미티드

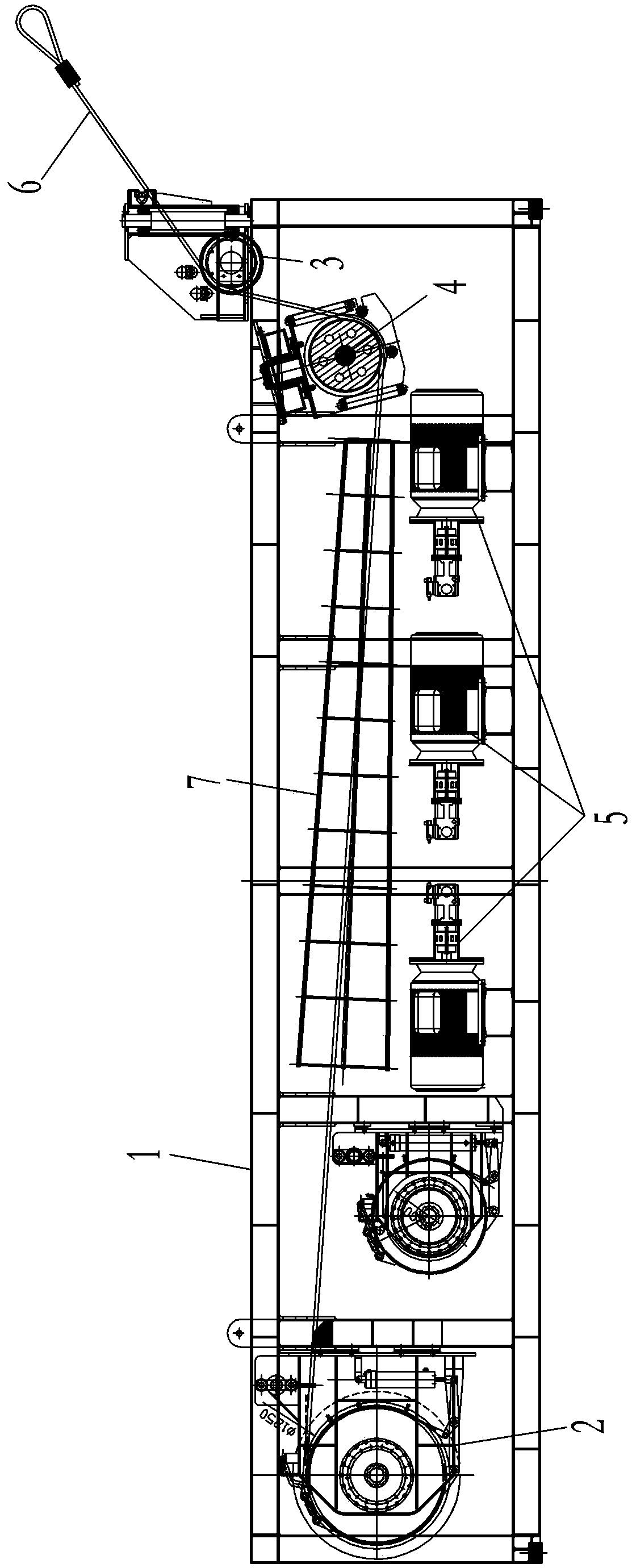

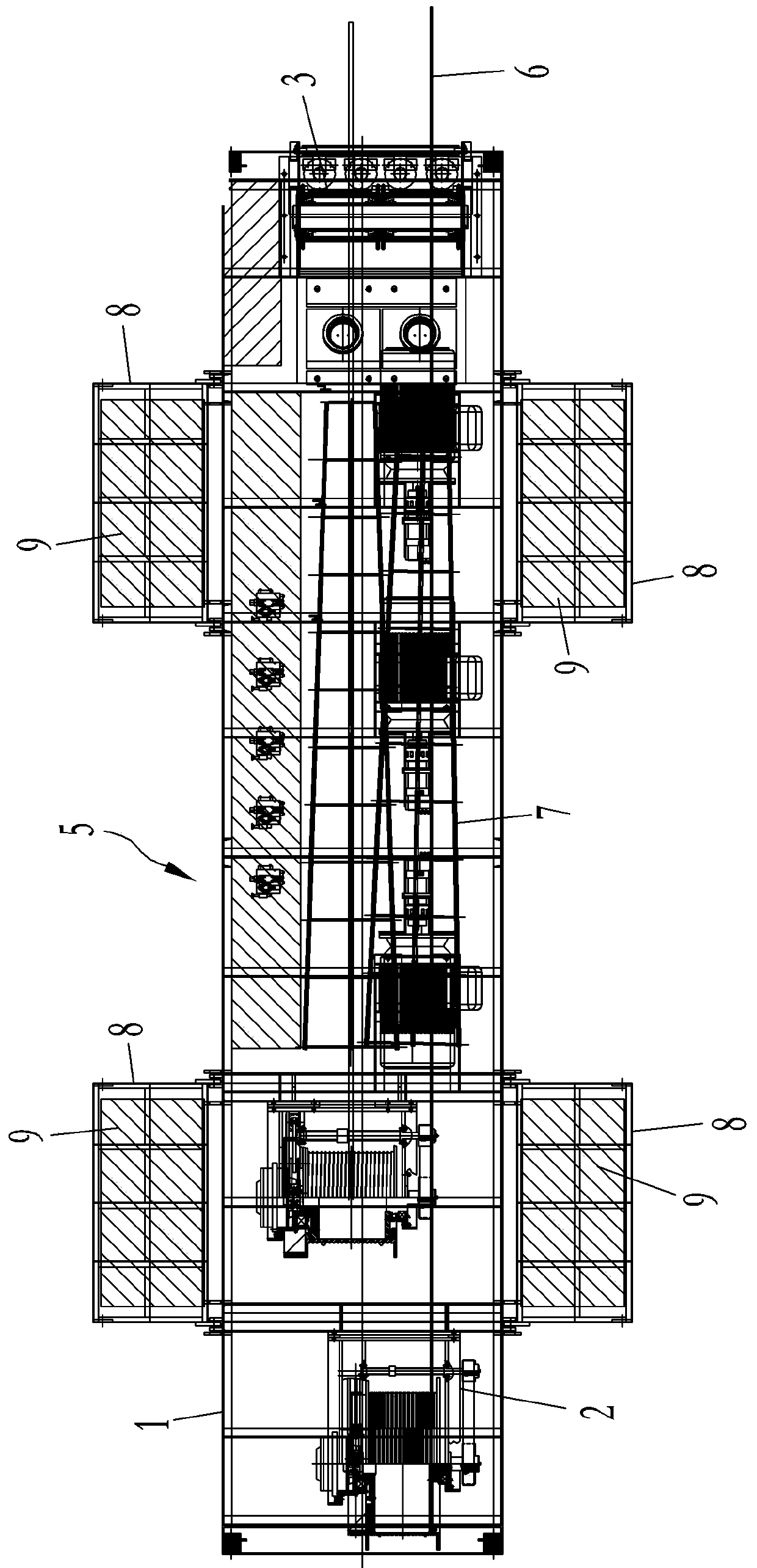

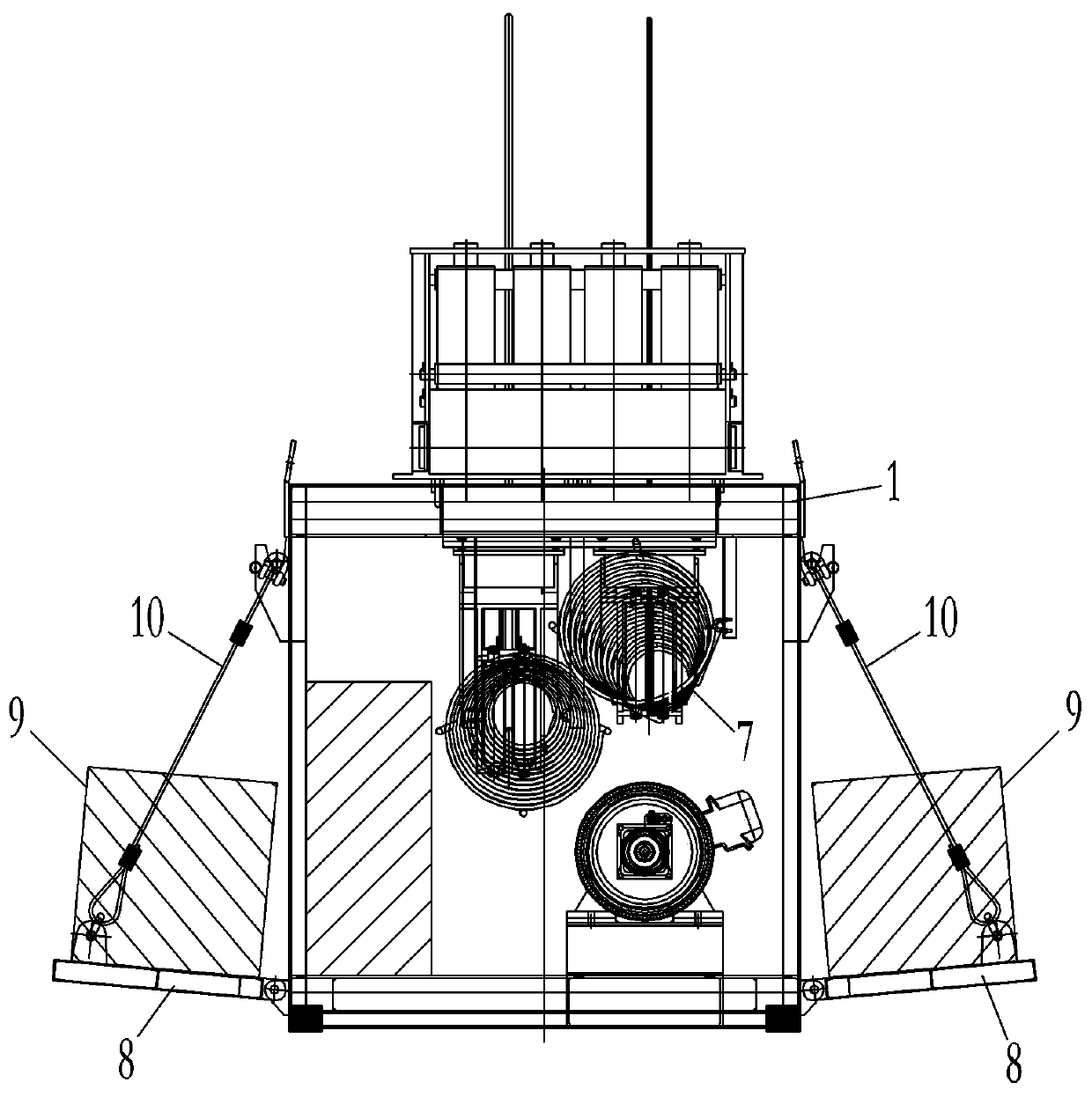

Sea state simulation device for ship

The invention discloses a sea state simulation device for a ship. After a steel wire rope is connected with a steel cable on the ship on water, a hydraulic system drives a main winch to rapidly, forward and reversely rotate, so that the steel wire rope can be rapidly taken up and paid off, the ship is rapidly pulled and loosened to swing by the steel wire rope, specific sea states can be simulated by repeating the process, the rotating speed of the main winch is adjusted by controlling hydraulic pressure of the hydraulic system, and the swing amplitude and the swing frequency of the ship can be adjusted, so that the sea states at different levels are simulated. Running conditions of devices on the ship can be detected in sea state simulation, sea state level standards suitable for navigation of the ship are judged, and safety of the ship devices and ship navigation are ensured.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

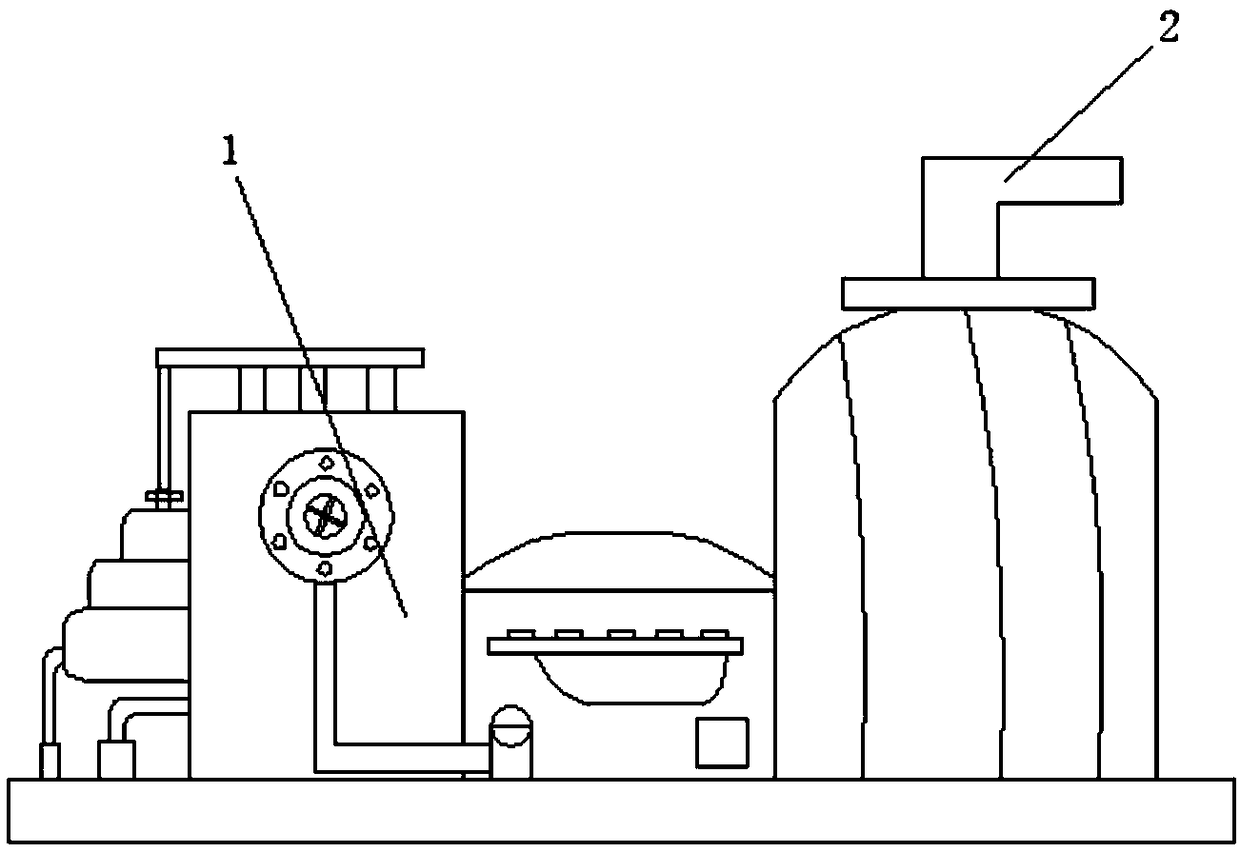

High back pressure steam turbine unit

ActiveCN109209525AImprove conversion efficiencyReduce heat dissipationMachines/enginesEngine componentsImpellerAirflow

The invention discloses a high back pressure steam turbine unit, comprising a unit body. The unit body comprises an inlet duct and an impulse mechanism. The outside of the inlet duct is provided witha heat preservation mechanism, and the heat preservation mechanism comprises a joint mounted on the outer side wall of the inlet duct. The inner sleeve of the inlet pipe is fixed with an annular plate, the inner part of the annular plate is provided with a cavity, and the inner side of the cavity is connected with a heating wire, and the inner side wall of the annular plate is provided with an exhaust port along the axial array direction thereof. The exhaust port communicates with the interior of the cavity. The impulse mechanism includes a rotating shaft, an impeller, a moving blade and a nozzle. The outer side wall of the rotating shaft is fixed with an impeller. The outer sidewall of the impeller is fixed with a plurality of symmetrically disposed moving blades along the axial array direction. The steam turbine unit can adjust the spray outlet diameter of the nozzle, thereby adjusting the speed at which the steam flow is ejected from the nozzle to adjust the rotation speed of the impeller, and improving the conversion efficiency. Moreover, the steam turbine unit can achieve the heat preservation heating of the inlet duct to reduce the heat dissipation of steam.

Owner:府谷科创源能源科技股份有限公司

Treadmill

InactiveCN106075810APromote blood circulationAchieve massageDevices for pressing relfex pointsBathing devicesPhysical medicine and rehabilitationDrive wheel

The invention relates to fitness equipment, in particular to a treadmill which comprises a driving wheel, a driven wheel, a massage running belt and a machine body protecting plate, wherein semispherical massage blocks are arranged on the surface of the massage running belt; a steam device is arranged on the driving wheel. By adopting the treadmill, feet can be massaged while a person runs on the treadmill to build up the body, and moreover, the whole body can have medicinal bath, so that not only can the body be built, but also blood circulation of the body can be improved, chronic diseases can be treated, and meanwhile a very good prevention function on various infectious diseases can be achieved.

Owner:HEZE HENGTAI FITNESS EQUIP MFG

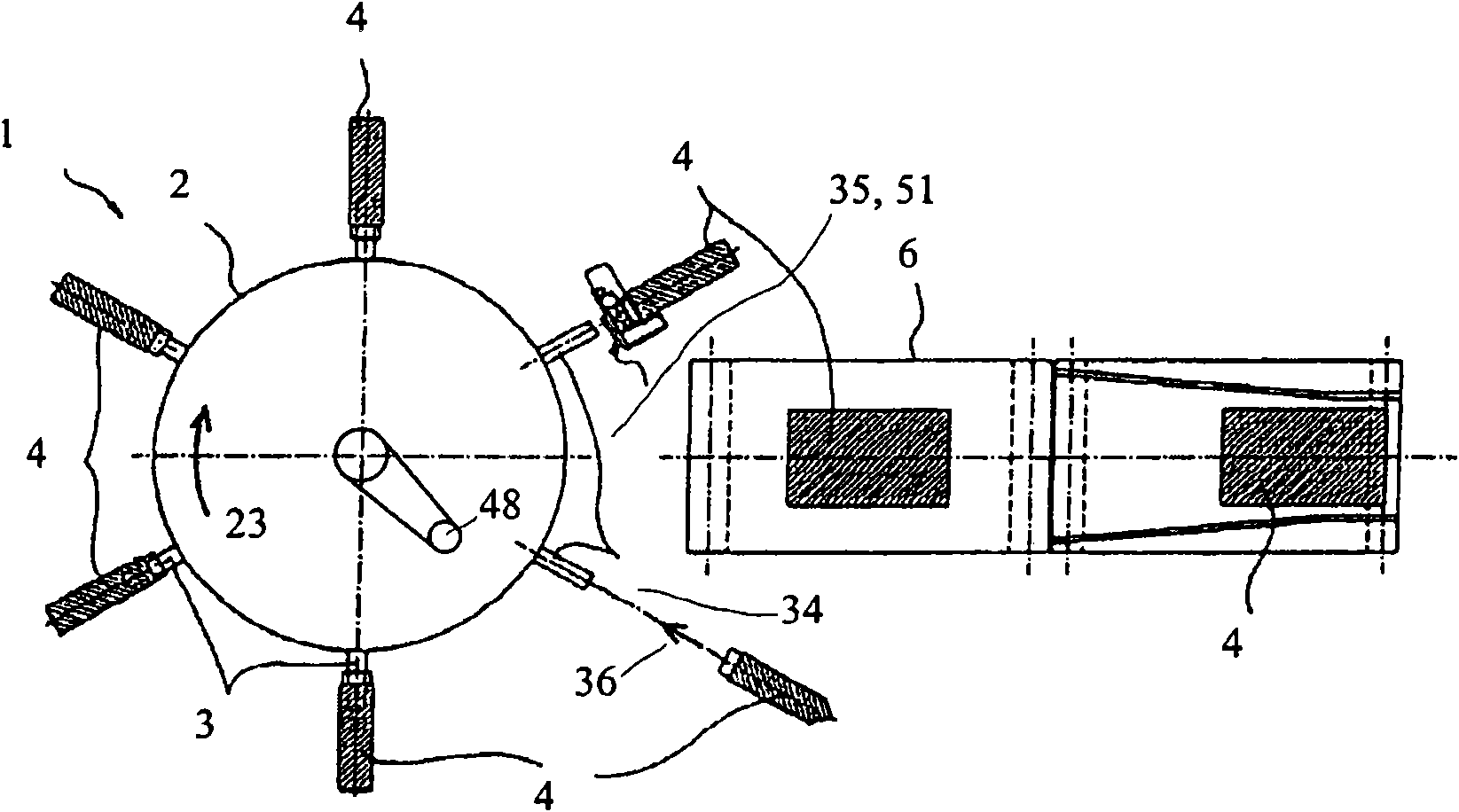

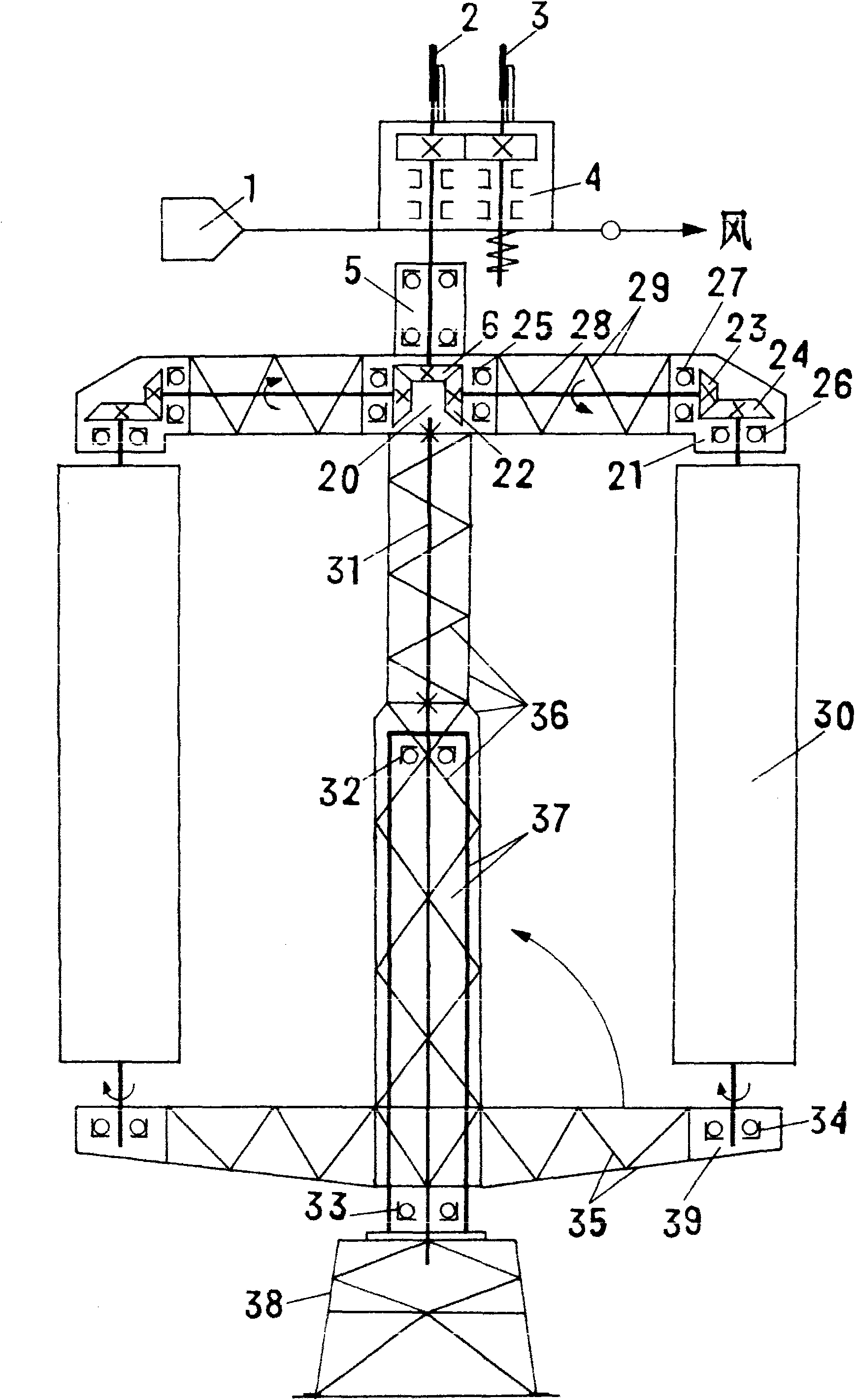

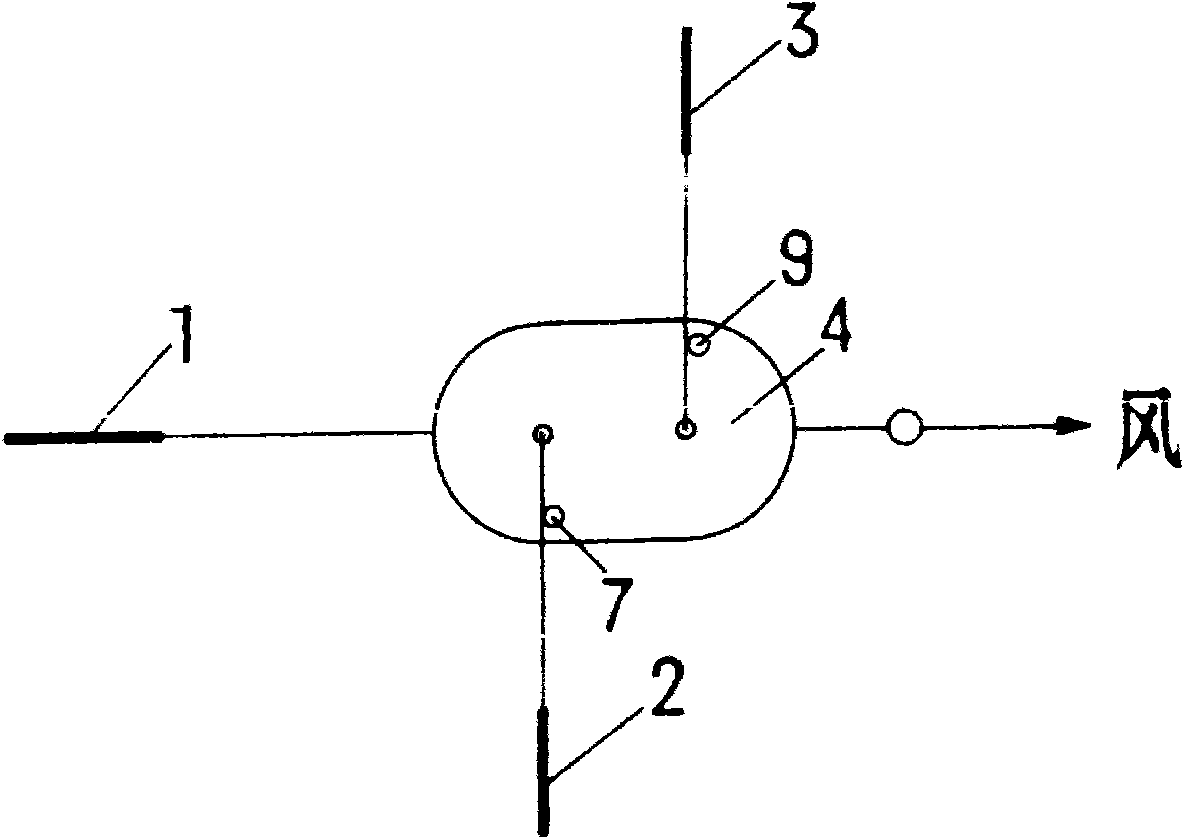

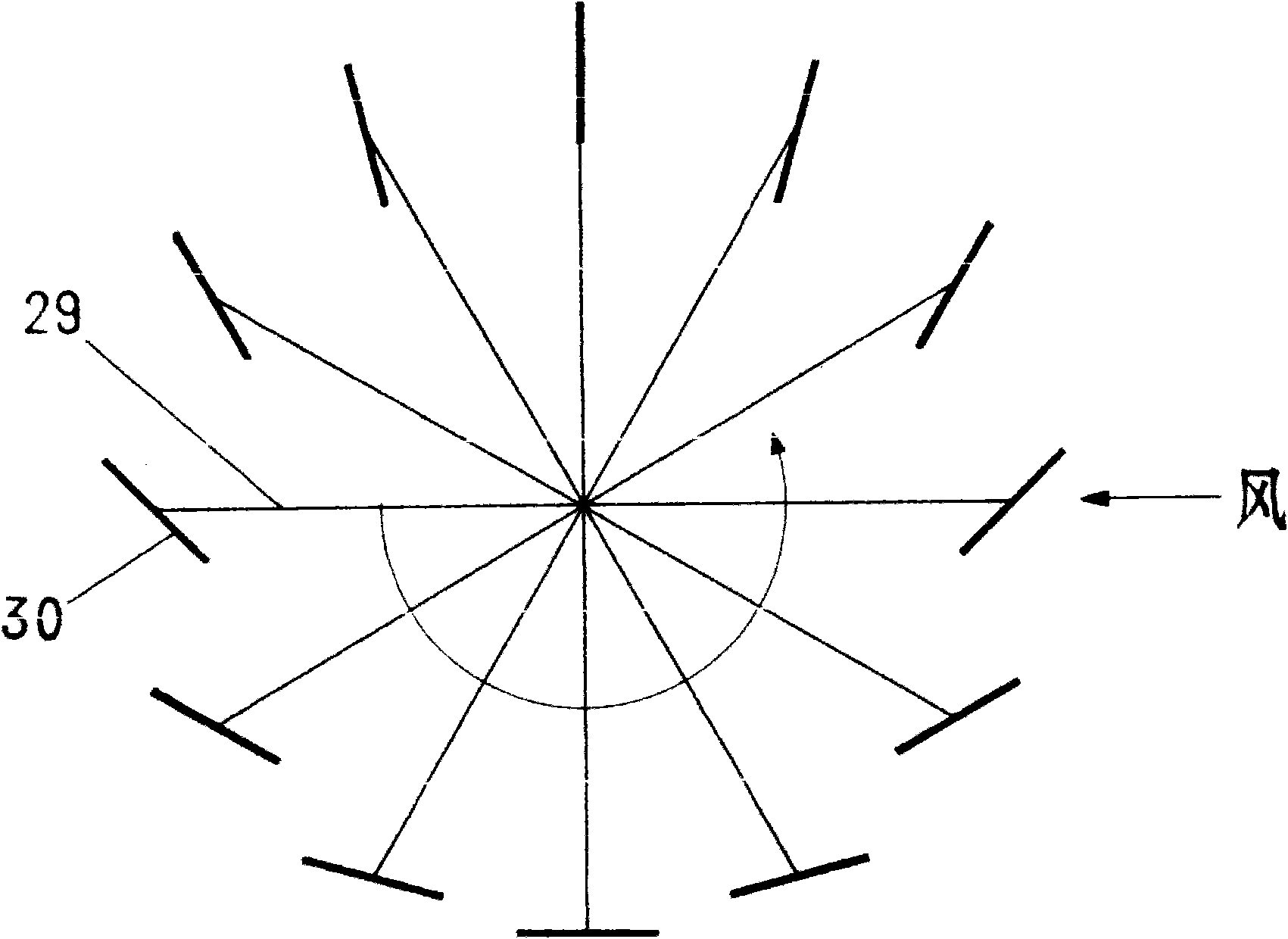

Vertical axis wind turbine with blade angle varying along with wind direction and wind velocity

InactiveCN101956653AReduce manufacturing costReduce power generation costsWind motor controlRenewable energy generationDrive shaftControl system

The invention relates to a vertical axis wind turbine with a blade angle varying along with wind direction and wind velocity, which comprises a control system, a planetary gearbox, a fixed axis gearbox, a transmission shaft, a main support, an upper cantilever beam, a lower cantilever beam, a bearing pedestal, a bearing, blades, a vertical axis, a tower and the like, wherein the vertical axis is connected with the tower through the bearing and the bearing pedestal; the main support is sleeved outside the vertical axis and the bearing pedestal, so that the middle part of the main support is connected with the middle part of the vertical axis, and the top end of the main support and the head of the vertical axis are connected with the bottom of the planetary gearbox; the control system is connected with the top of the planetary gearbox through the bearing pedestal; the root part and the end part of the upper cantilever beam are respectively connected with the side face of the planetary gearbox and the side face of the fixed axis gearbox, and the root part and the end part of the lower cantilever beam are respectively connected with the lower end of the main support and the bearing pedestal; both ends of the transmission shaft are respectively connected with the planetary gearbox and the fixed axis gearbox; and the blades are respectively connected with the fixed axis gearbox and the bearing pedestal so that output power maintains near the rated power value.

Owner:孙世杰

Cutting device for synthetic leather processing

InactiveCN110004697AAffect healthAvoid affecting the working environmentSevering textilesDirt cleaningFixed frameEngineering

The invention relates to the technical field of synthetic leather processing, in particular to a cutting device for synthetic leather processing. The cutting device comprises a fixing frame, a mastercontrol cabinet, an adjusting device, a cutting device and a collecting device. The adjusting device is fixedly connected to an end face of the fixing frame, the cutting device is fixedly connected tothe bottom end of the adjusting device, and the collecting device is arranged on the lower side of the cutting device and fixedly connected with the fixing frame. By arrangement of a gear, a gear ring, a slide ring, a connecting shaft, balls, a slide rail and the like, the position of a cutter can be adjusted according to requirements in practical operation; when cut synthetic leather is still, the cutter can be adjusted in the middle of the fixing frame to realize cutting of the synthetic leather; when the cut synthetic leather is in a production moving process, the rotating speed and position of the cutter can be adjusted according to the moving speed of the synthetic leather, and accordingly vertical cutting of the synthetic leather by the cutter is guaranteed.

Owner:福建省三源兴纺织科技有限公司

Air conditioner with air guiding impeller

InactiveCN102767894AReduce power consumptionNo power consumptionAir-flow control membersImpellerEngineering

The invention discloses an air conditioner with an air guiding impeller. The air conditioner comprises an indoor machine and an outdoor machine or comprises an indoor machine and outdoor machine integrated whole air conditioner. An air supply port is arranged on a front panel of the indoor machine, an air guiding impeller assembly is arranged on the air supply port or on the inner side of the air supply port and comprises the air guiding impeller, an air guiding frame, an air distribution fixing frame, an air guiding shaft and an air guiding bearing, wherein the air distribution fixing frame is fixed in the air guiding frame, the air guiding bearing is installed in a central hole of the air guiding impeller, and the air guiding shaft is used for connecting the air guiding bearing, the air guiding impeller and the air distribution fixing frame. The air conditioner with the air guiding impeller is energy-saving and efficient, and air guiding blades are not easily damaged.

Owner:SHUNDE POLYTECHNIC

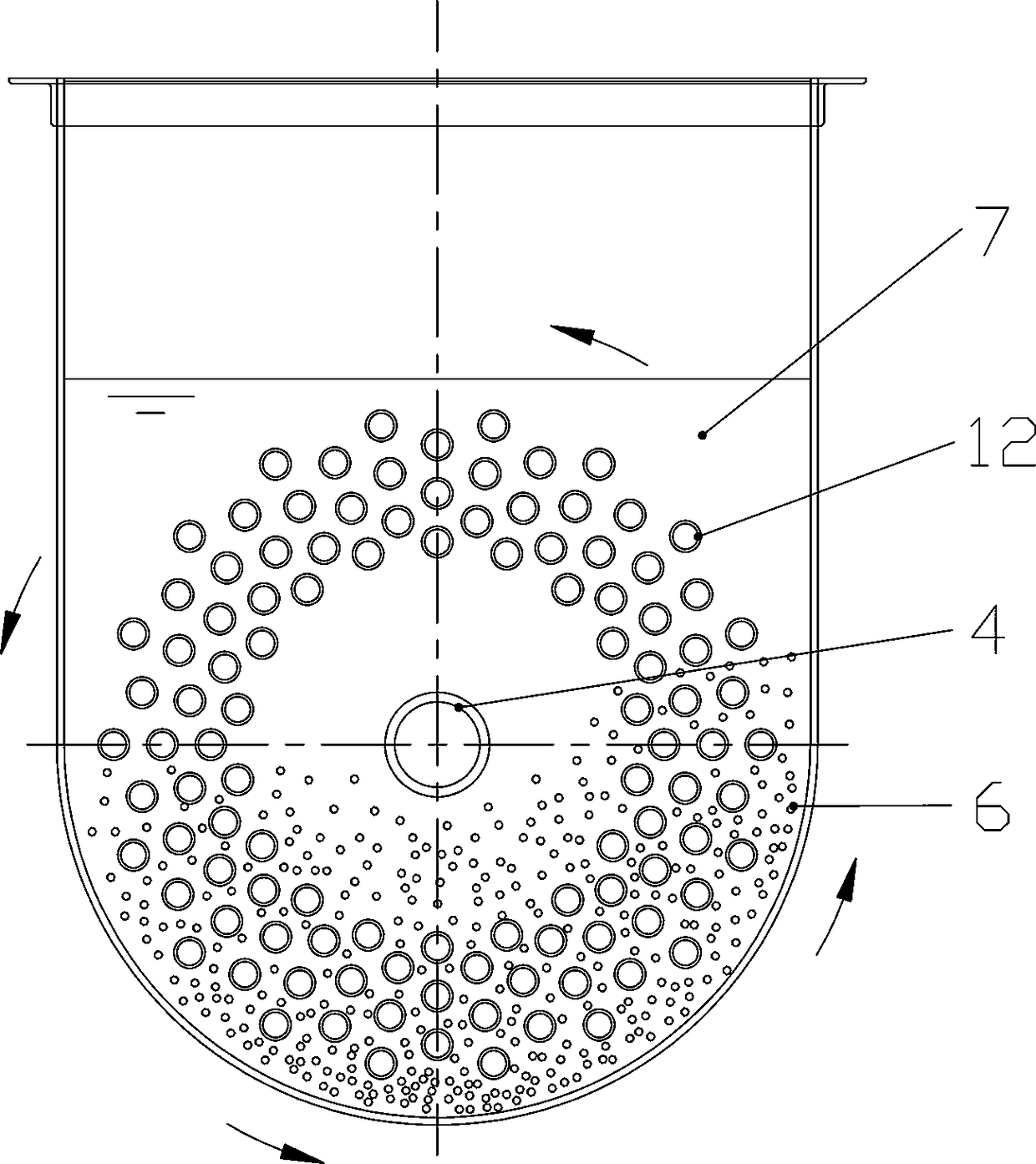

Self-descaling evaporator and running method thereof

PendingCN109399745ASolve easy foulingSolve the blockageWater/sewage treatment by heatingEngineeringDrive motor

The invention discloses a self-descaling evaporator. The self-descaling evaporator comprises an evaporator shell, a transmission device and a driving motor, wherein the evaporator shell is internallyprovided with a rotating inner tube, the rotating inner tube divides the evaporator shell into an inner part of the tube and an outer part of the tube, the outer side of the tube of the evaporator shell is provided with a working medium inlet, a working medium containing descaling particles is added into the evaporator shell from the working medium inlet, the outer side of the tube of the evaporator shell is further provided with a steam outlet and a working medium outlet, one end of the rotating inner tube is provided with a rotating inlet, the other end of the rotating inner tube is providedwith a rotating outlet, the steam in the evaporator shell enters the rotating inner tube from the rotating inlet via a pipeline through the steam outlet and is discharged from the rotating outlet after heat transfer, and a concentrated solution is discharged from the working medium outlet. The self-descaling evaporator has the advantages that the descaling particles are added, so that a heating tube rubs with the descaling particles, the problems of easy scale formation, blockage and sealing off of a heat exchanger are solved, and the effect of descaling is achieved; the driving motor can perform forward and backward switching, thereby capable of preventing scale formation on the reverse side of the heating tube during single-side rotation.

Owner:GUANGDONG CODE OF ENVIRONMENTAL PROTECTION ENG CO LTD

Intelligent sewage treatment device

The invention relates to the technical field of sewage treatment, and particularly relates to an intelligent sewage treatment device. The intelligent sewage treatment device comprises a cleaning module, two input shafts and a sewage collecting bin, wherein the cleaning module comprises a frame and a conveying belt; the sewage collecting bin is mounted on the frame through the input shafts; a power module and an impeller assembly are arranged on the sewage collecting bin; the power module is connected with the input shafts; the input shafts are connected with the conveying belt; and the input shafts are connected with the impeller assembly through a speed change mechanism. When the cleaning module rotates and drives a rotating column to rotate, the rotating column drives a main movable wheel of a driving wheel to move inwards so as to be away from a main fixed wheel, the transmission ratio is increased to reduce the rotating speed of the impeller assembly, thus, the intelligent sewage treatment device can dynamically match advancing and cleaning power of a garbage truck according to resistance generated by floating garbage in front, when the garbage in front is much, the power distributed to advancing by the power module is reduced, the power distributed to cleaning is increased, the cleaning effect is ensured, and the cleaning efficiency is improved.

Owner:启东市新港阀门仪表成套有限公司

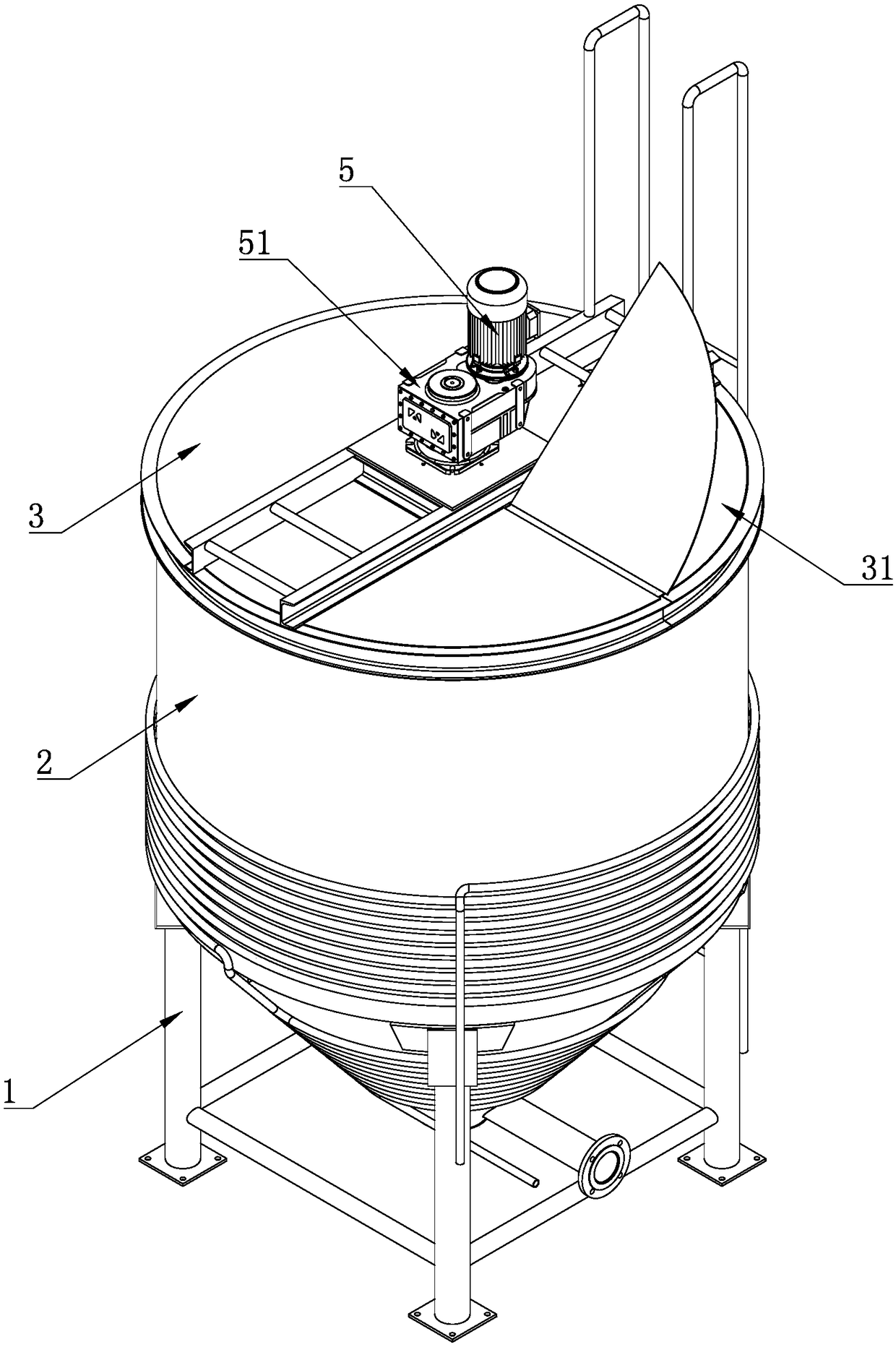

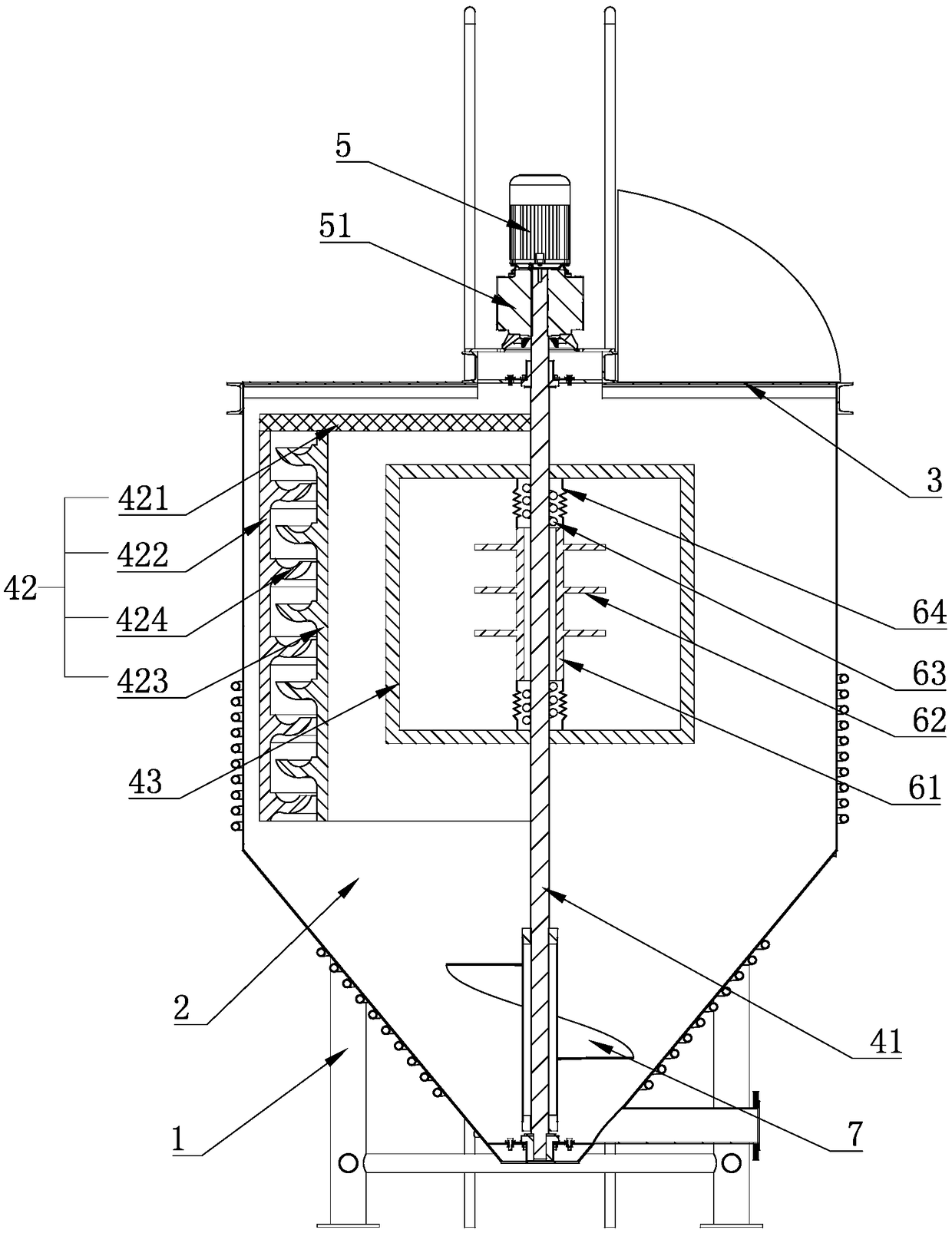

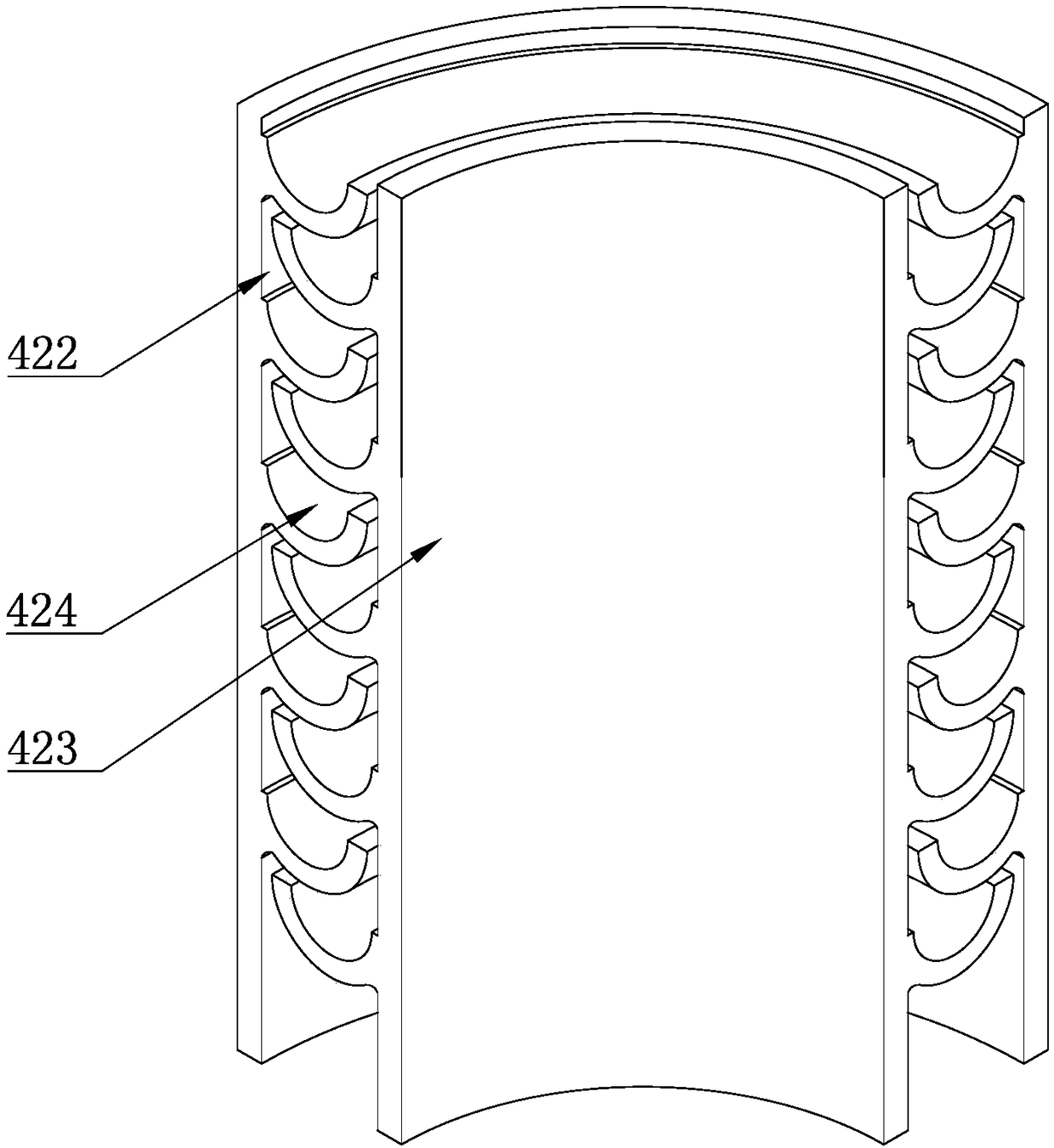

Mortar stirring machine

PendingCN108890891AEven mortarGood mixing effectCement mixing apparatusSolid waste managementEngineering

The invention discloses a mortar stirring machine. The machine comprises a supporting frame, a barrel body, a barrel cover, a stirring assembly and a driving device used for driving the stirring assembly, the barrel body is located on the supporting frame, the barrel cover is connected with the barrel body and is provided with a feeding port, the stirring assembly is connected with the barrel cover and extends into the barrel body, the stirring assembly comprises a rotary shaft which is connected with the driving device, a grounding member which is connected with the rotary shaft and a stirring rod which is located on the inner side of the grounding member, the stirring rod is U-shaped, the two ends of the stirring rod are connected with the rotary shaft, the grounding member is arranged close to the inner wall of the barrel body, the grounding member comprises a sector connecting plate, a first arc-shaped plate and a second arc-shaped plate which are connected below the connecting plate, and stirring blades are arranged on the opposite side walls of the first and second arc-shaped plates. By the combination of the grounding member and the stirring rod, the failure of stirring mortars close to the inner wall of the barrel body is prevented, mortars everywhere in the barrel body can be uniformly stirred and grounded by the stirring assembly, and the obtained mortars are more uniform.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

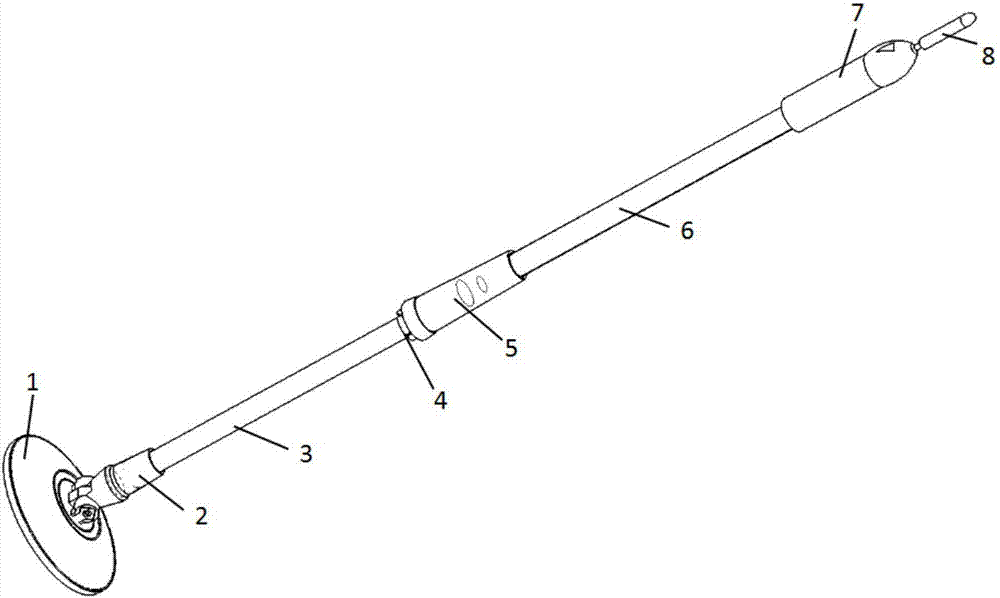

Labor-saving rotating mop with speed regulating function

ActiveCN106963308AAdjust the rotation speedSimple structureCarpet cleanersFloor cleanersEngineeringScrew thread

The invention relates to a labor-saving rotating mop with a speed regulating function. The labor-saving rotating mop with the speed regulating function is composed of a mop disc, a rotating rod, an outer sleeve, a middle rod, an inner rod, an inner rod movable buckle, an inner rod fixed buckle, a middle rod fixed buckle and a middle rod movable buckle. The interior of the rotating rod is divided into two sections of internal threads with different screw pitches and diameters, the upper-section thread of the rotating rod is an internal thread with the large screw pitch and the large diameter, the lower-section thread of the rotating rod is an internal thread with the small screw pitch and the small diameter, the inner rod movable buckle is engaged with the lower section of the rotating rod, and the middle rod movable buckle is engaged with the upper section of the rotating rod. When the middle rod is pressed downwards, the middle rod drives the rotating rod and the mop disc to slowly rotate through the cooperation of the middle rod fixed buckle and the middle rod movable buckle, and when the inner rod is pressed downwards, the inner rod drives the rotating rod and the mop disc to rapidly rotate through the cooperation of the inner rod movable buckle and the inner rod fixed buckle. Compared with the prior art, the labor-saving rotating mop is simple in structure, easy to control and easy to spin-dry and spin-wet, labor is saved, and cleaning is complete.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

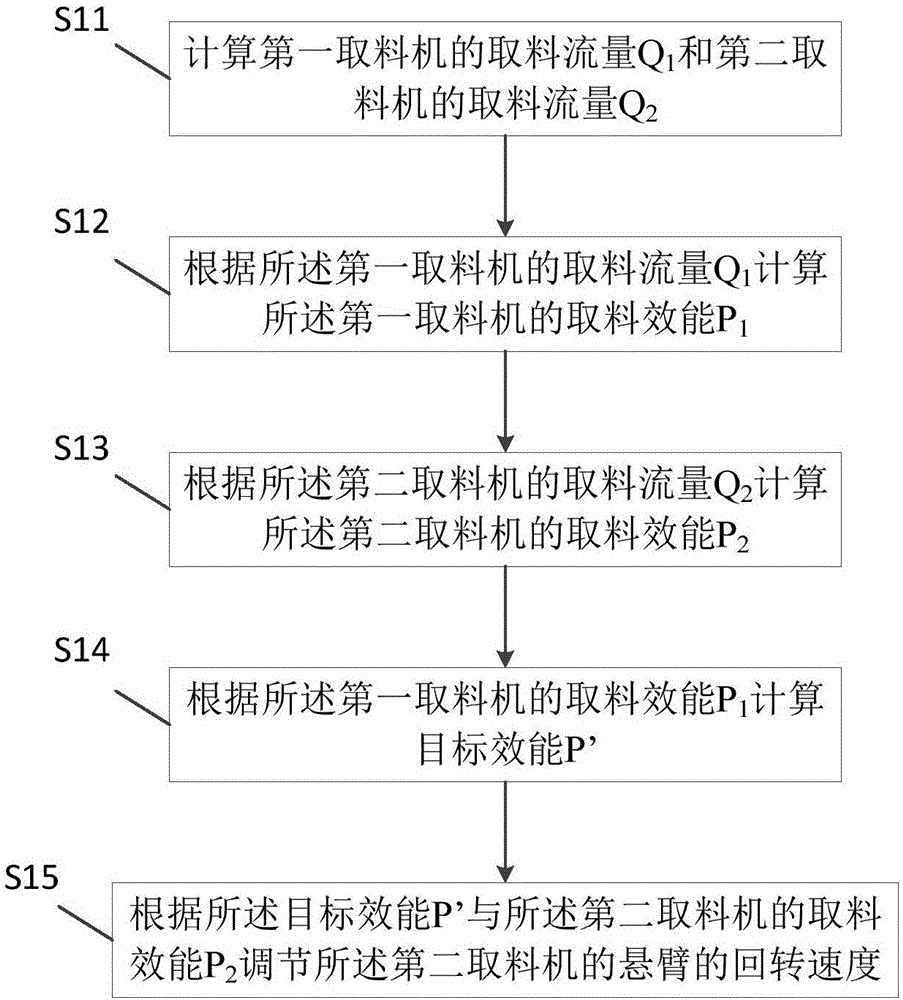

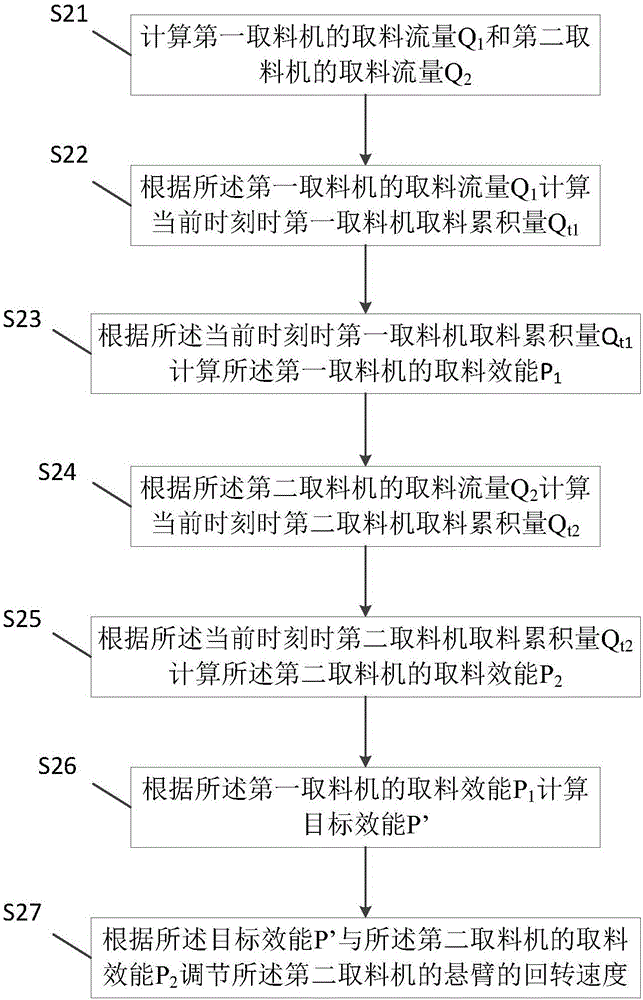

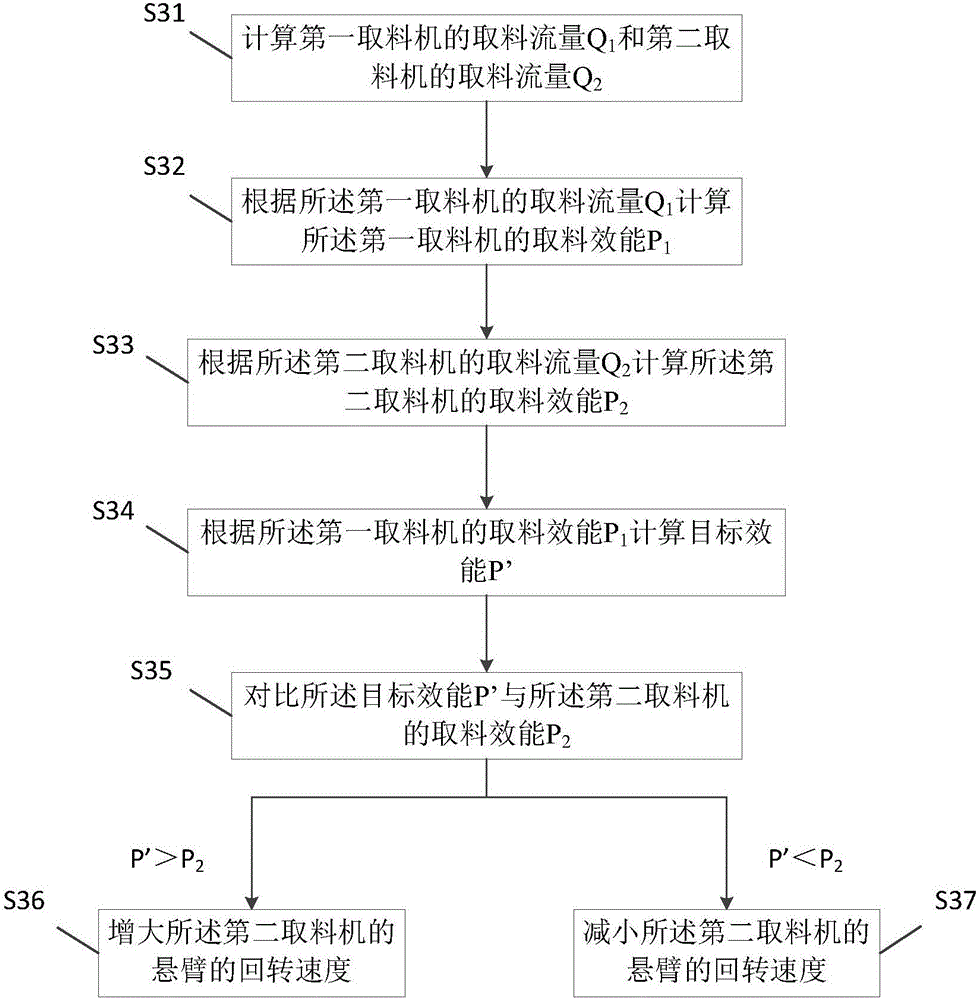

Taking system coal blending control method

ActiveCN106743722AAdjust the rotation speedImprove work efficiencyConveyorsLoading/unloadingCantileverIndustrial engineering

The invention relates to material transportation, and discloses a taking system coal blending control method. A taking system comprises a first taking machine and a second taking machine; the control method comprises the steps that taking flow Q1 of the first taking machine and taking flow Q2 of the second taking machine are calculated; the taking efficiency P1 of the first taking machine is calculated according to the taking flow Q1 of the first taking machine, and the taking efficiency P2 of the second taking machine is calculated according to the taking flow Q2 of the second taking machine; the target efficiency P' is calculated according to the taking efficiency P1 of the first taking machine; and the rotation speed of a cantilever is adjusted according to the target efficiency P' of the first taking machine and the taking efficiency P2 of the second taking machine. By means of the taking system coal blending control method, on the premise that halting motion is avoided, the coal blending proportion is strictly controlled, and the operation efficiency is improved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com