Patents

Literature

4923 results about "Butterfly valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

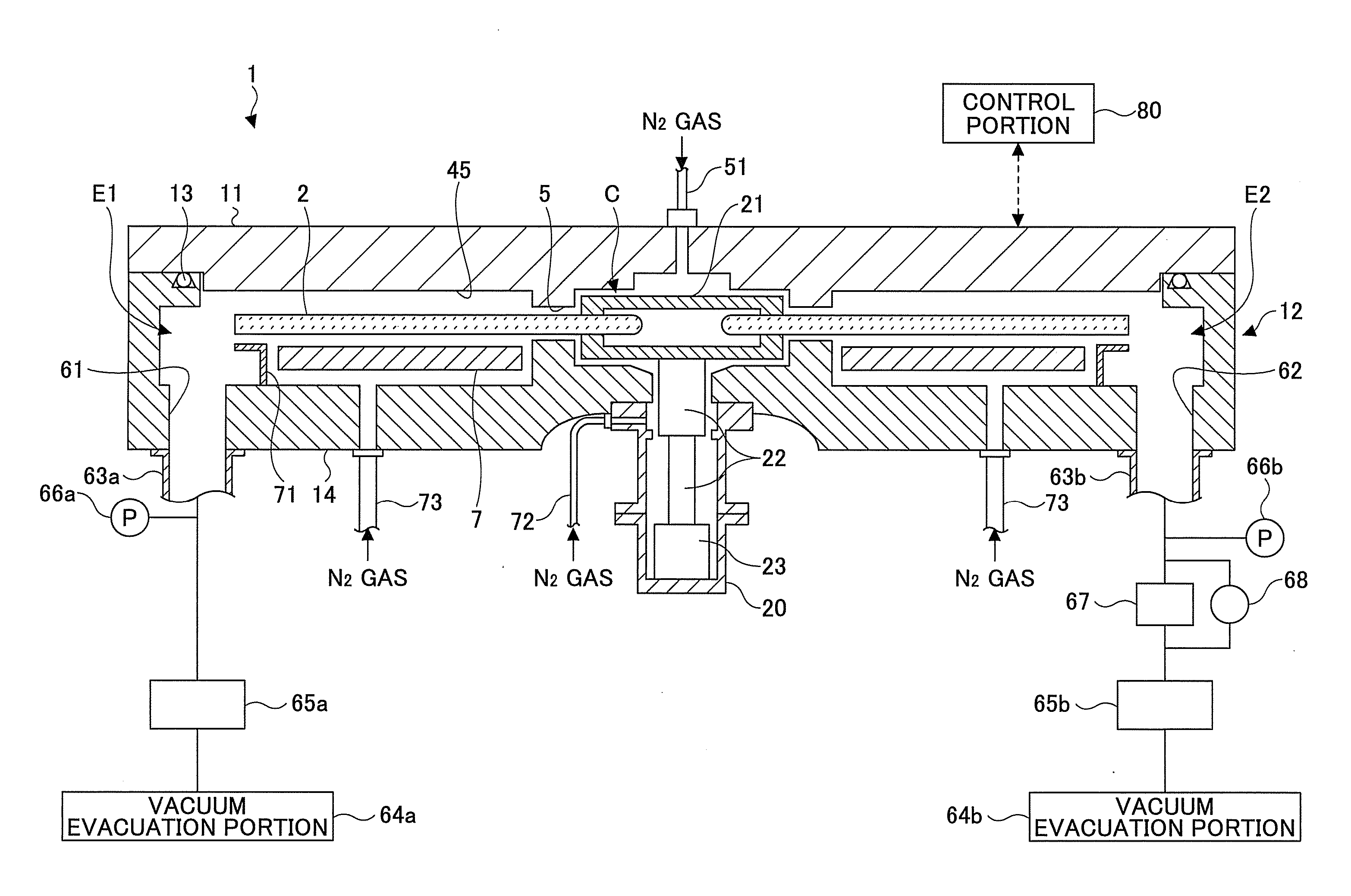

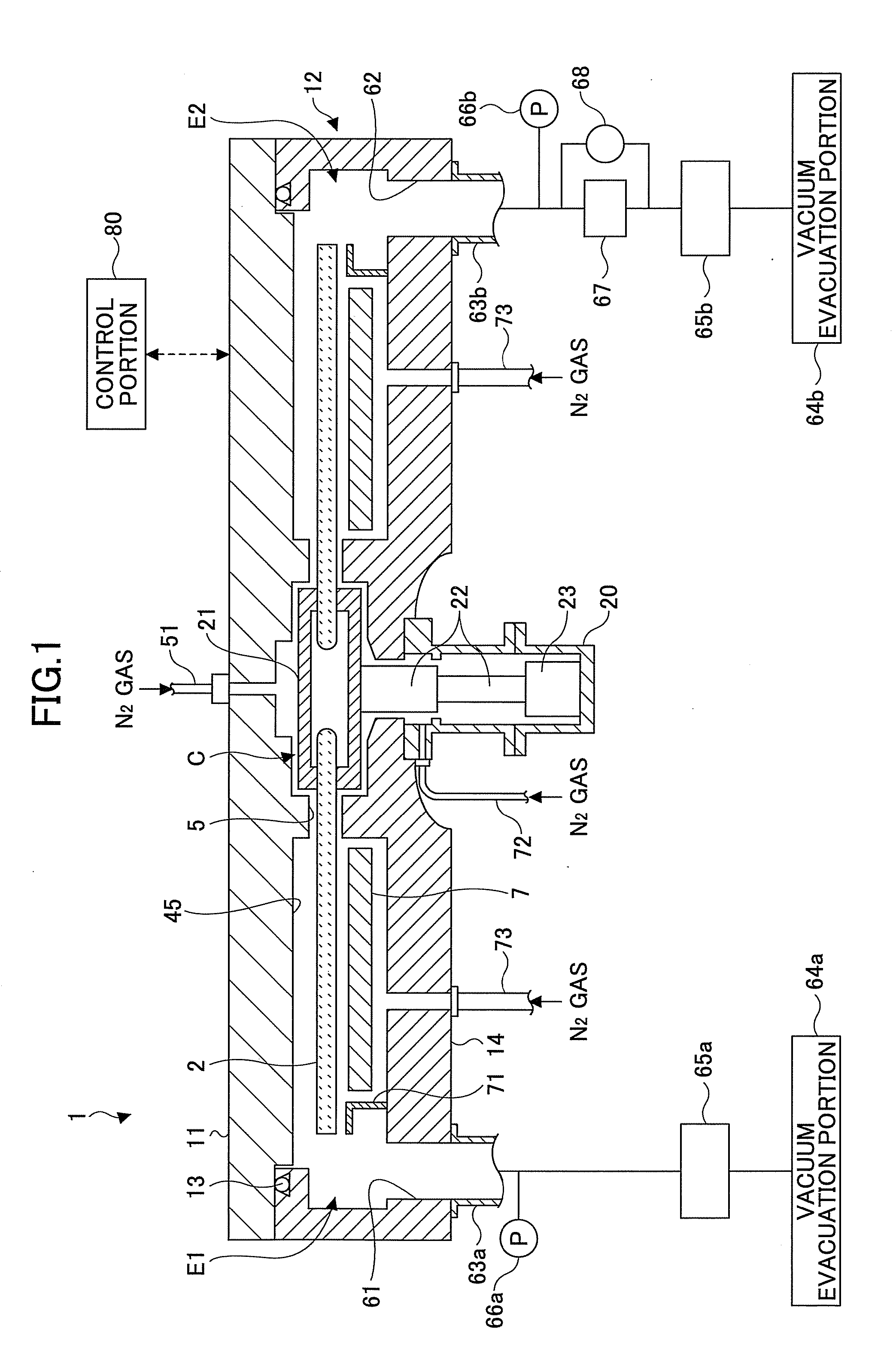

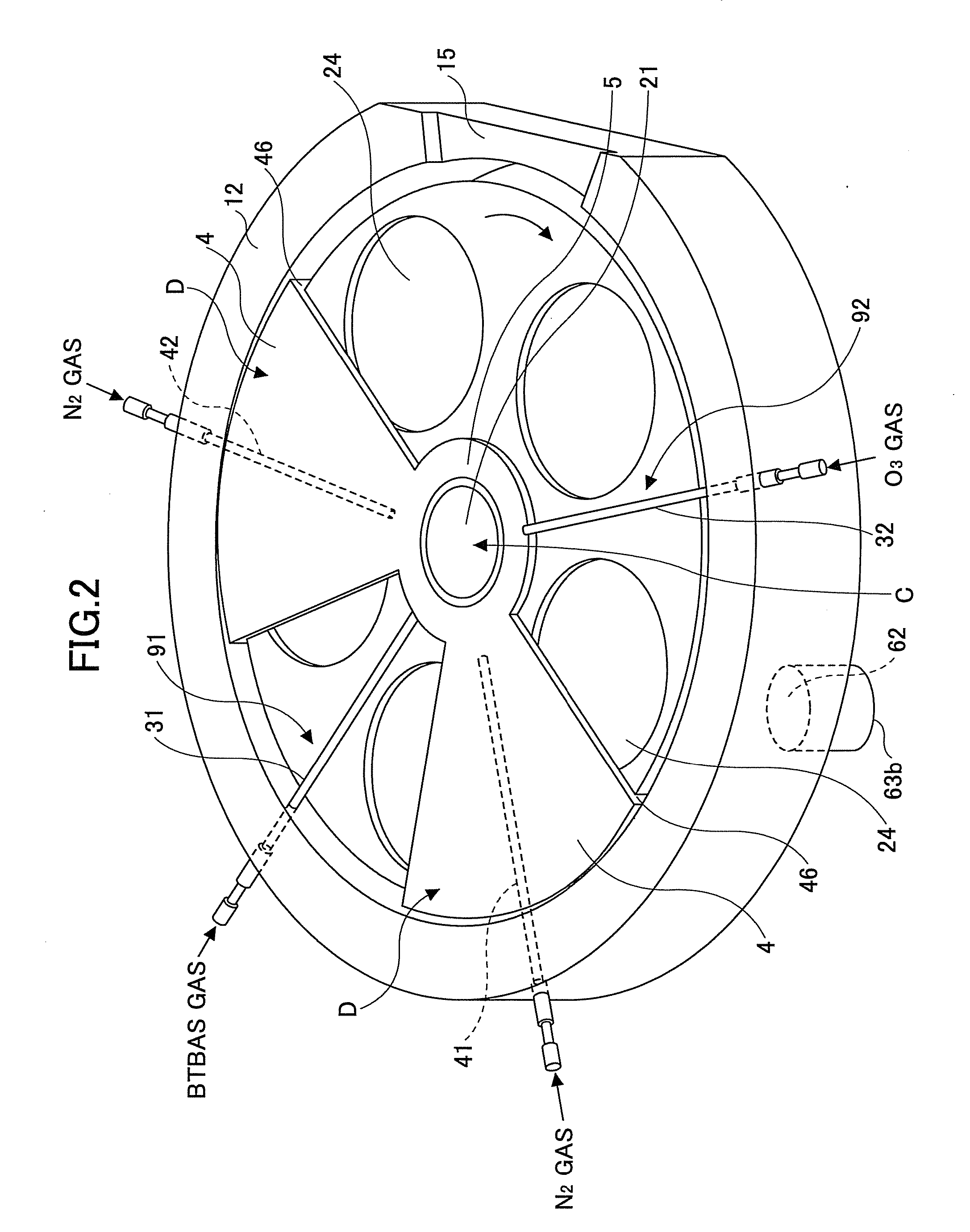

Substrate process apparatus, substrate process method, and computer readable storage medium

ActiveUS20110100489A1Servomotor componentsSemiconductor/solid-state device manufacturingDifferential pressureEngineering

A vacuum chamber is evacuated through a first evacuation passage provided with a first valve and a second evacuation passage provided with a second valve. An opening degree of the first valve is adjusted so that a pressure in the vacuum chamber becomes substantially equal to a process pressure P; an opening degree of a butterfly valve further provided in the second evacuation passage is adjusted to substantially equal to a set value determined by a table in order to set flow rates of gases to be evacuated through the first evacuation passage and the second evacuation passage to be substantially equal to corresponding set values determined by the recipe; and an opening degree of the second valve is adjusted so that a measurement value of a differential pressure gauge further provided in the second evacuation passage becomes substantially equal to a differential pressure written in the table.

Owner:TOKYO ELECTRON LTD

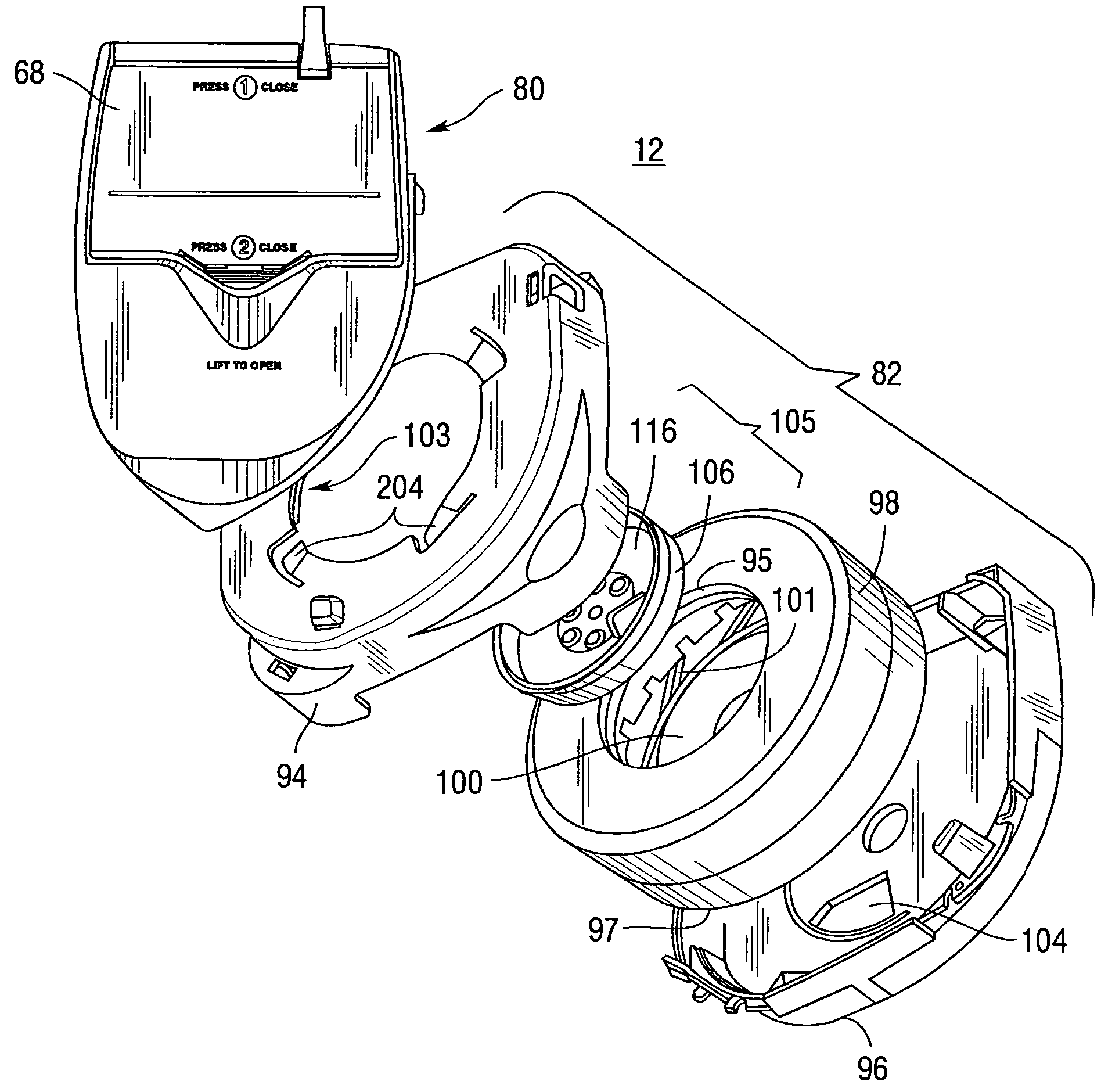

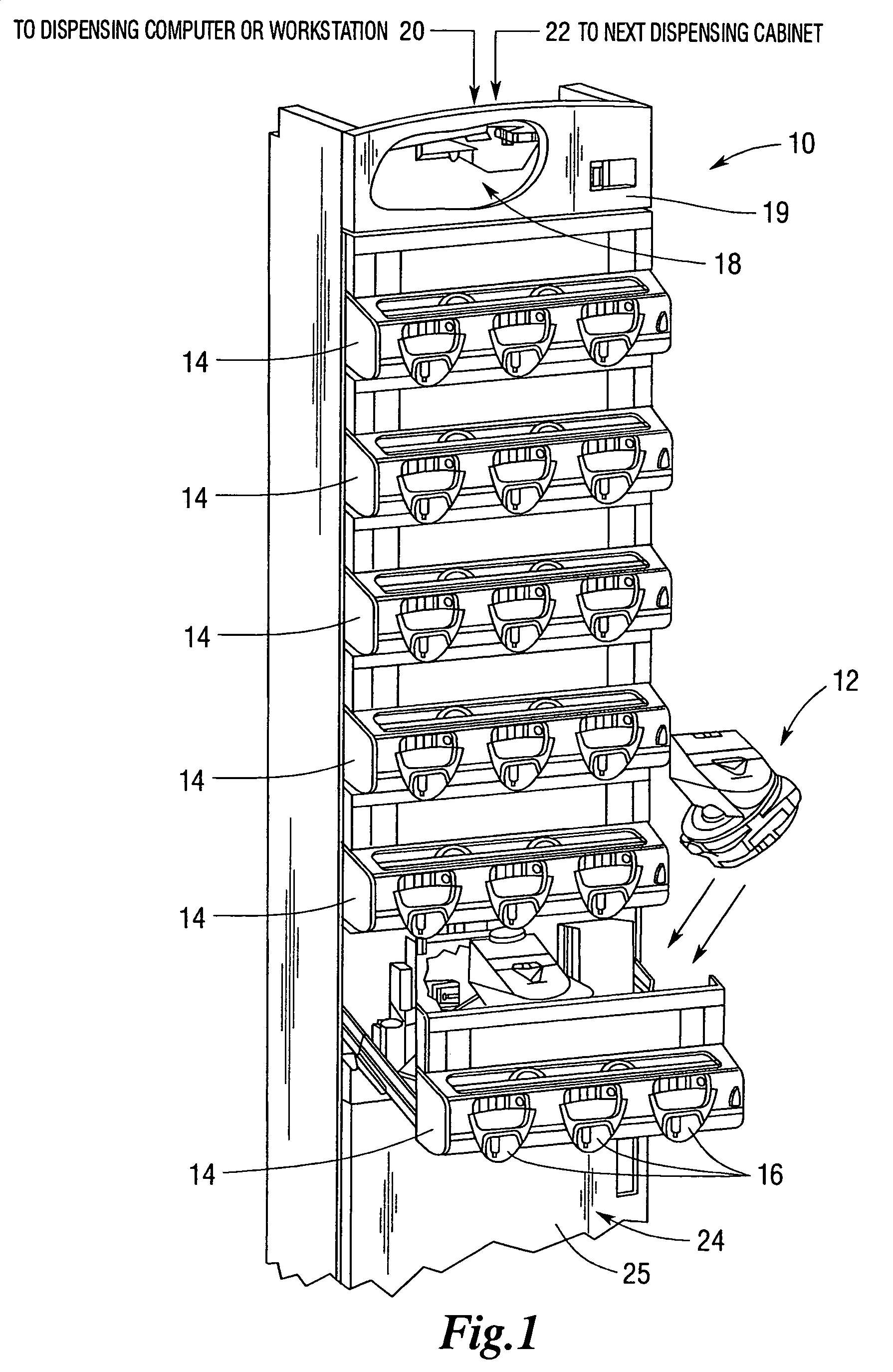

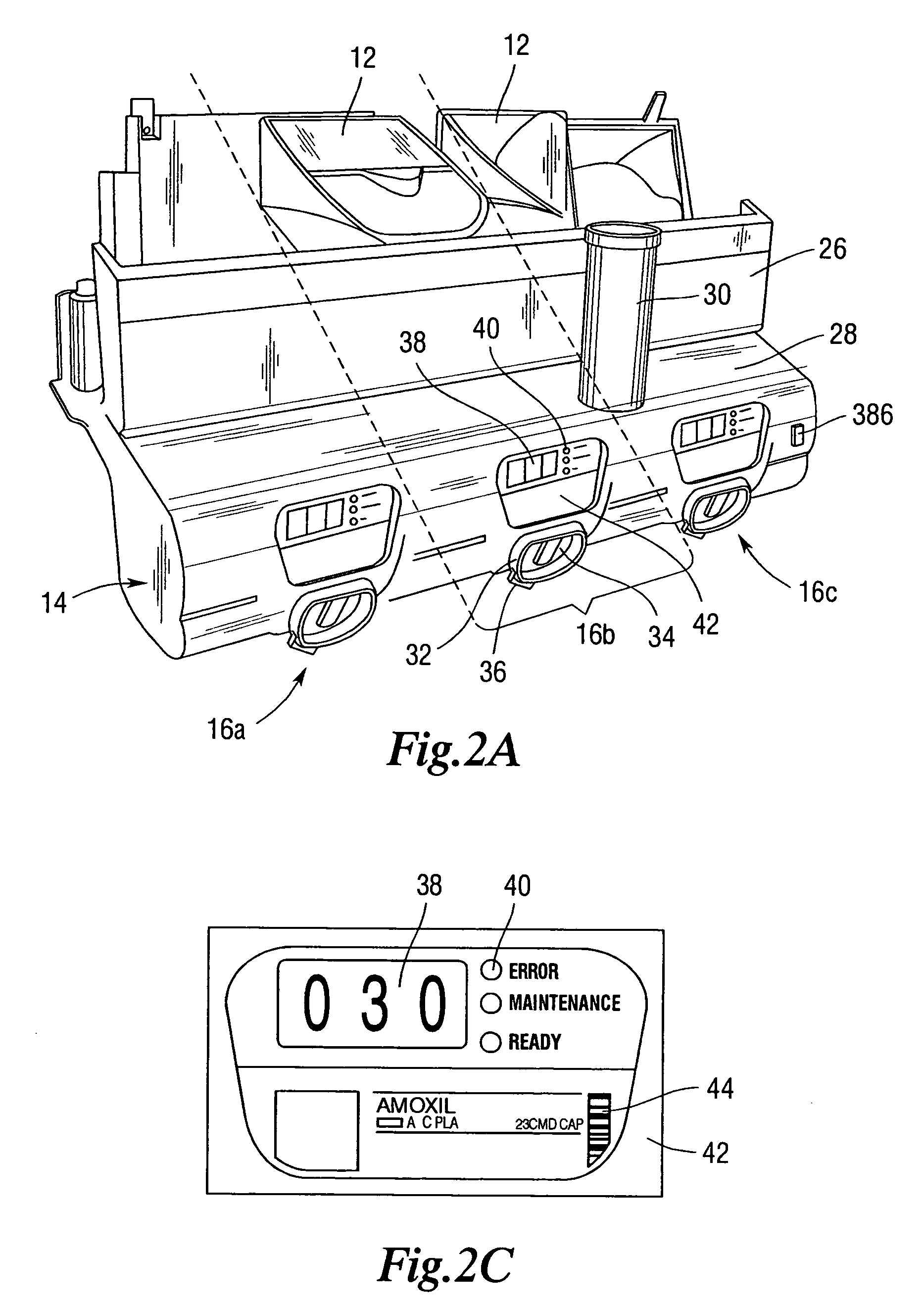

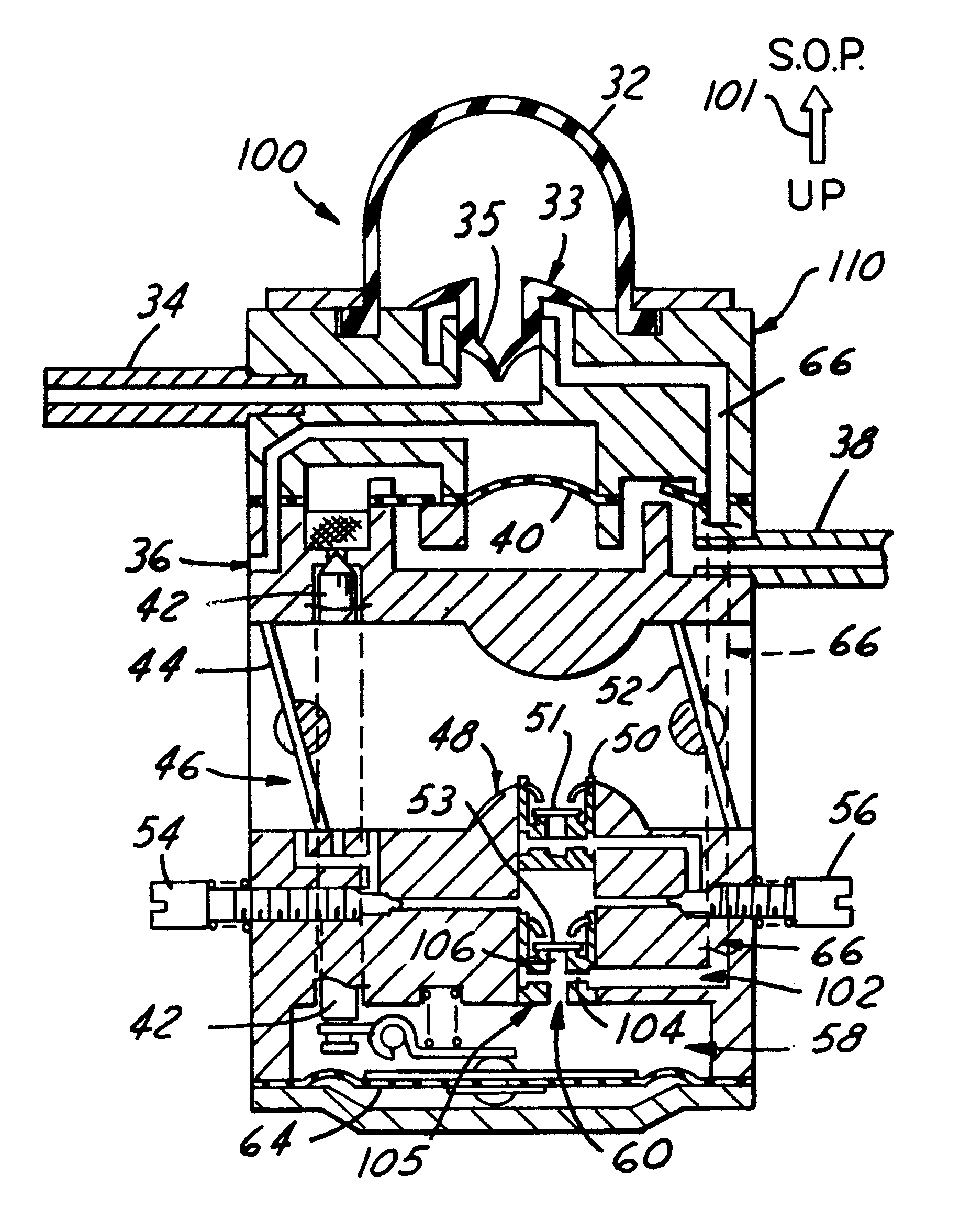

Dispensing device having a storage chamber, dispensing chamber and a feed regulator there between

A drug dispensing device is comprised of an upper hopper having an upper opening for receiving a medicament and a lower opening. A lid covers the upper opening. A lower hopper having an upper opening and a lower opening in a bottom portion thereof is provided. The upper hopper defines a bulk storage chamber and the lower hopper defines a dispensing chamber. A rotatable dispensing disc is positioned in a lower portion of the dispensing chamber for dispensing medicament from the drug dispensing device through the lower opening in the lower hopper. A regulator is situated between the bulk storage chamber and the dispensing chamber for controlling the rate at which medicament moves from the storage chamber to the dispensing chamber. The regulator may take a variety of forms. In one embodiment, the regulator includes a valve for controlling the flow of medicament from the storage chamber to the dispensing chamber. The valve may include a member responsive to the volume of medicament in the dispensing chamber for controlling the position of the valve. The valve and member may include a trap door valve and a float, a butterfly valve and a rotatable arm, a guillotine valve and a movable arm, and a conical plunger and a wing extending from the base of the plunger. In another embodiment, the regulator may include a rotatable member having an opening therein. The rotatable member may include a cylindrical wall having an opening in a portion thereof, a plate having an opening therein, a cup shaped member defining an opening and a pair of rotatable members which together define at least one opening therein. The regulator may be configured such that the rate at which medicament moves from the storage chamber to the dispensing chamber is never zero. Further, agitating members may be provided which extend toward the upper hopper. Methods of operation are also disclosed.

Owner:PARATA SYST

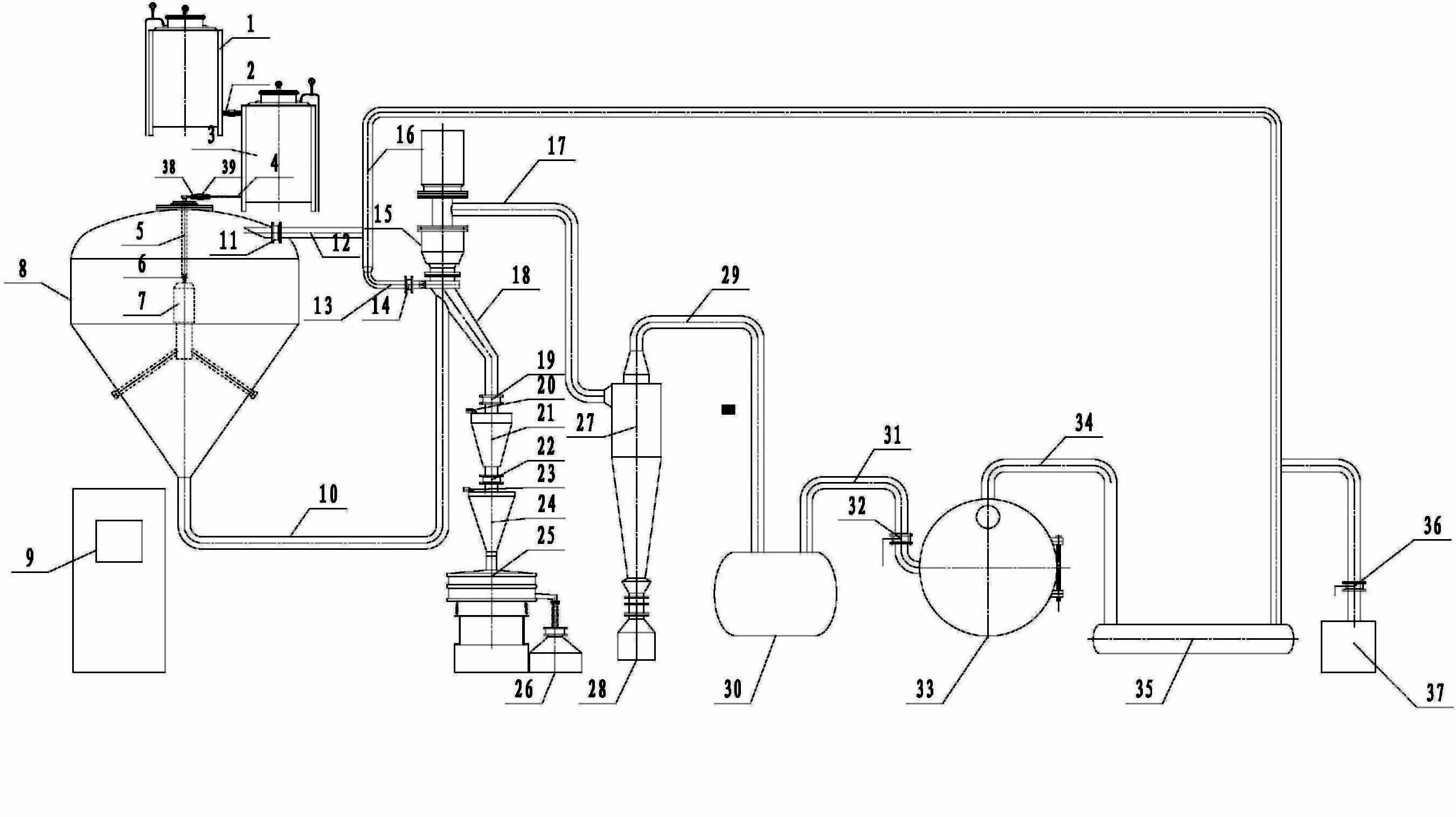

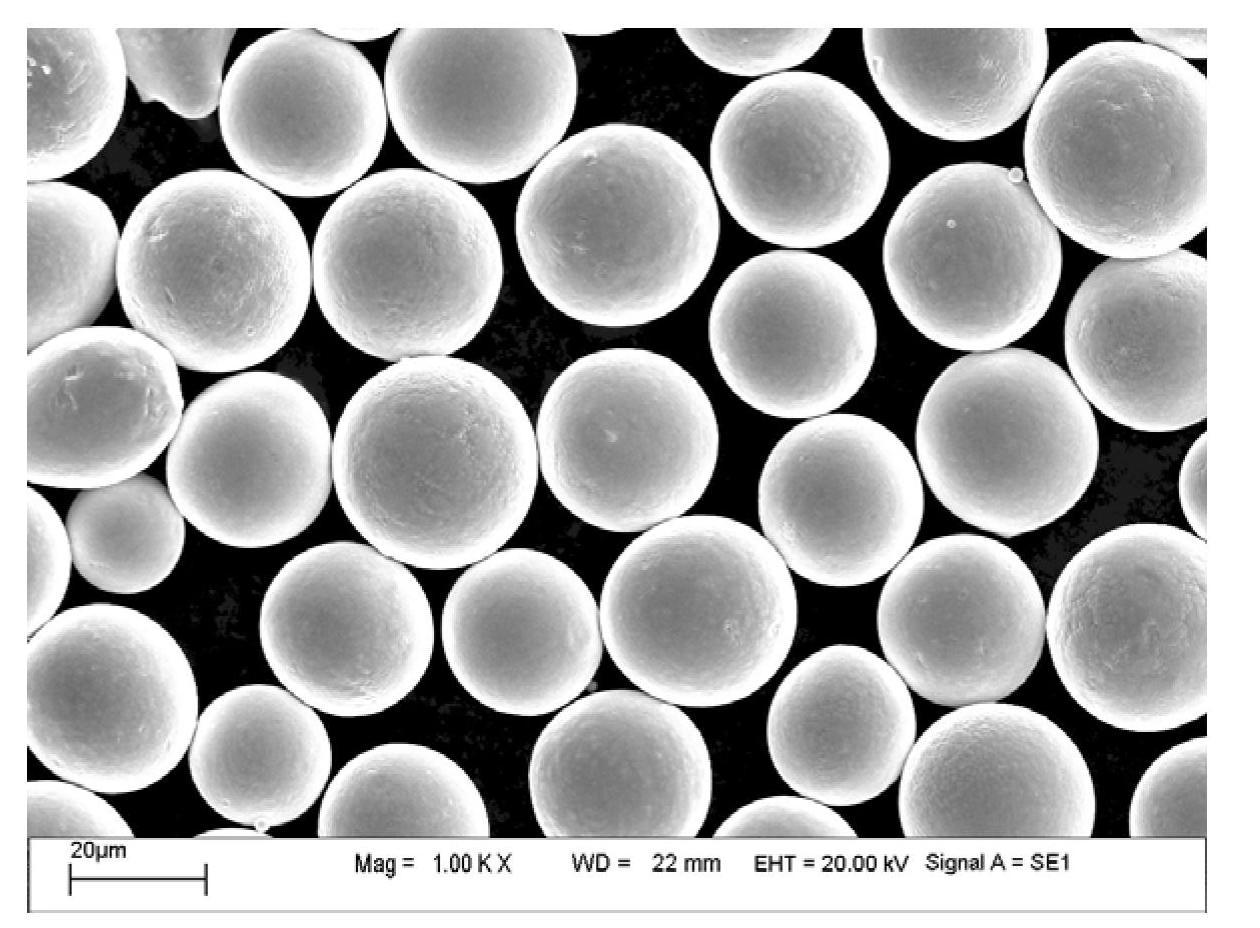

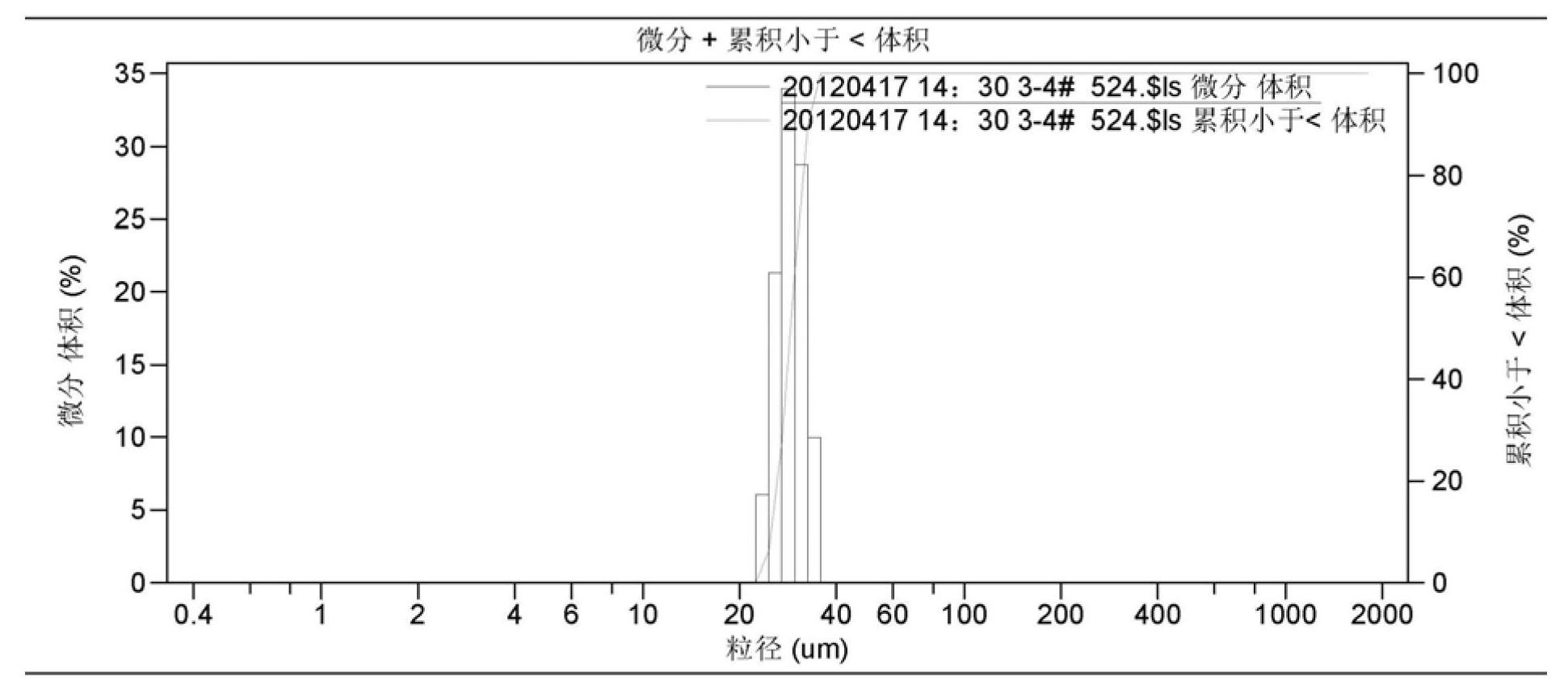

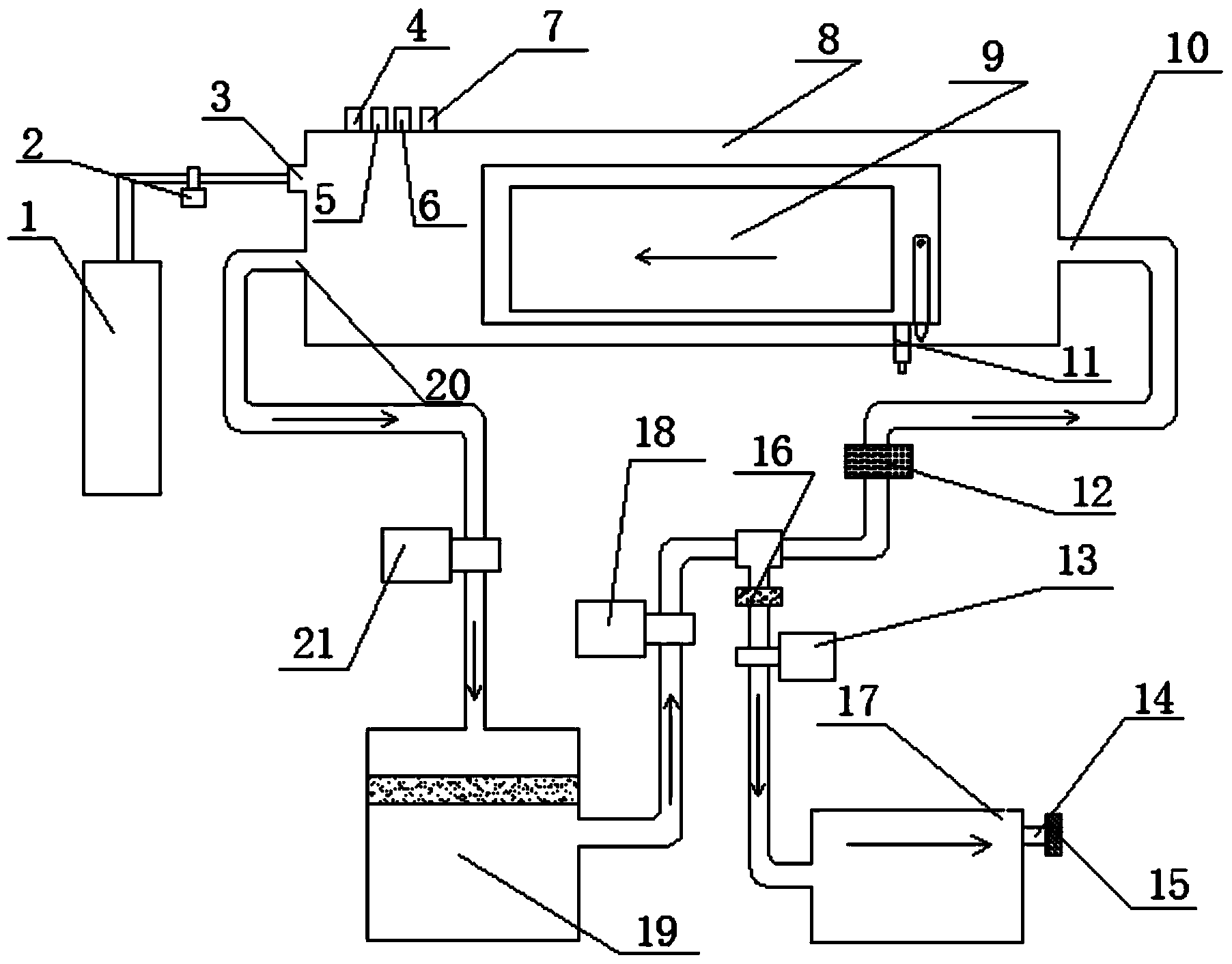

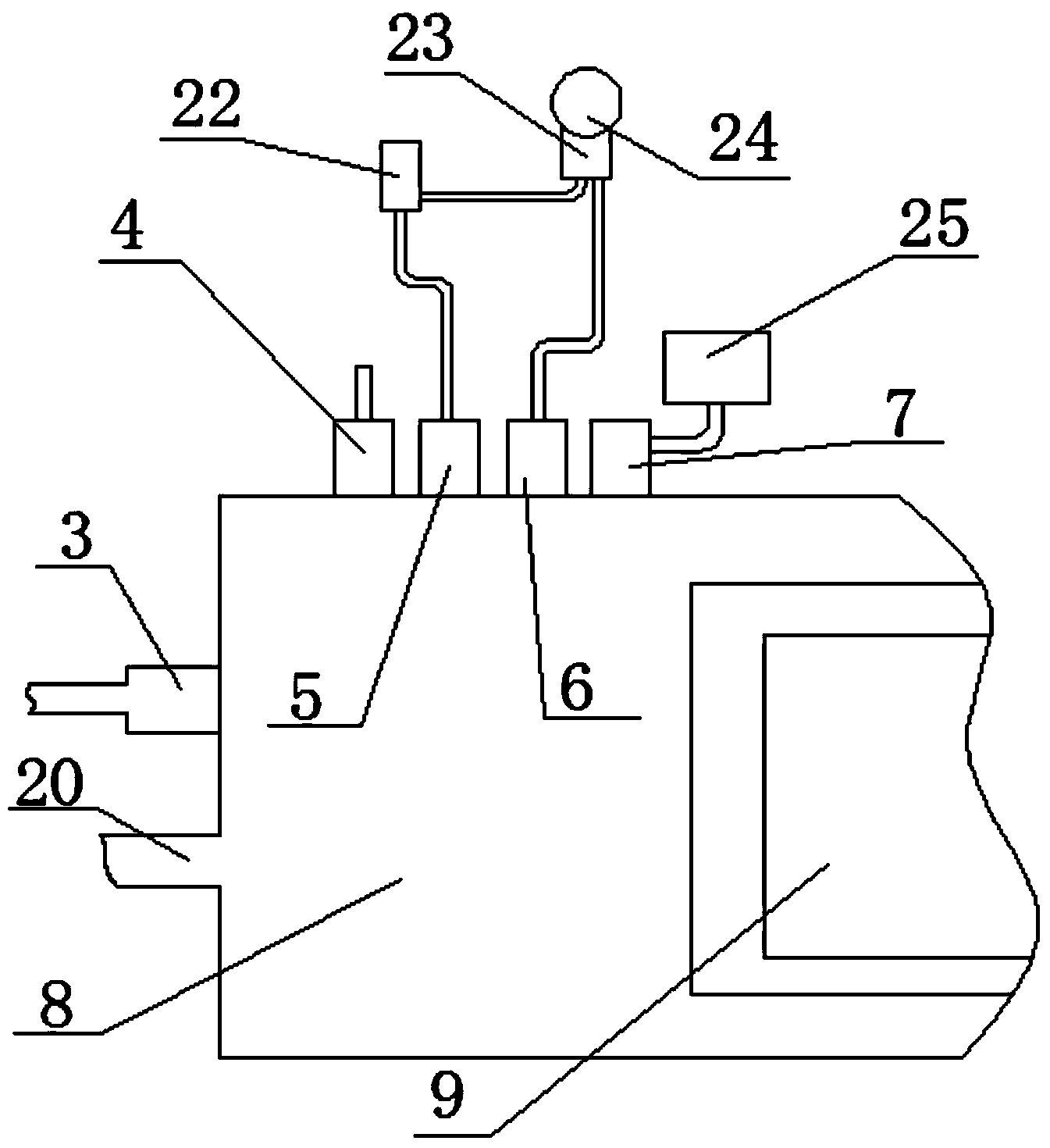

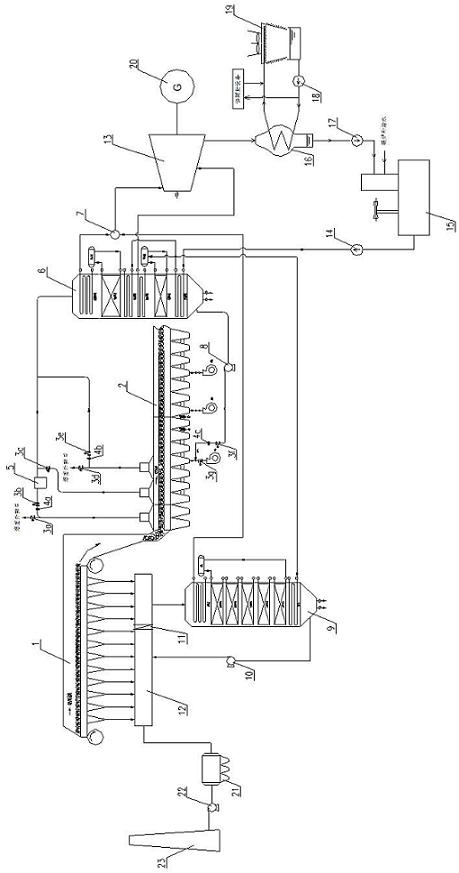

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

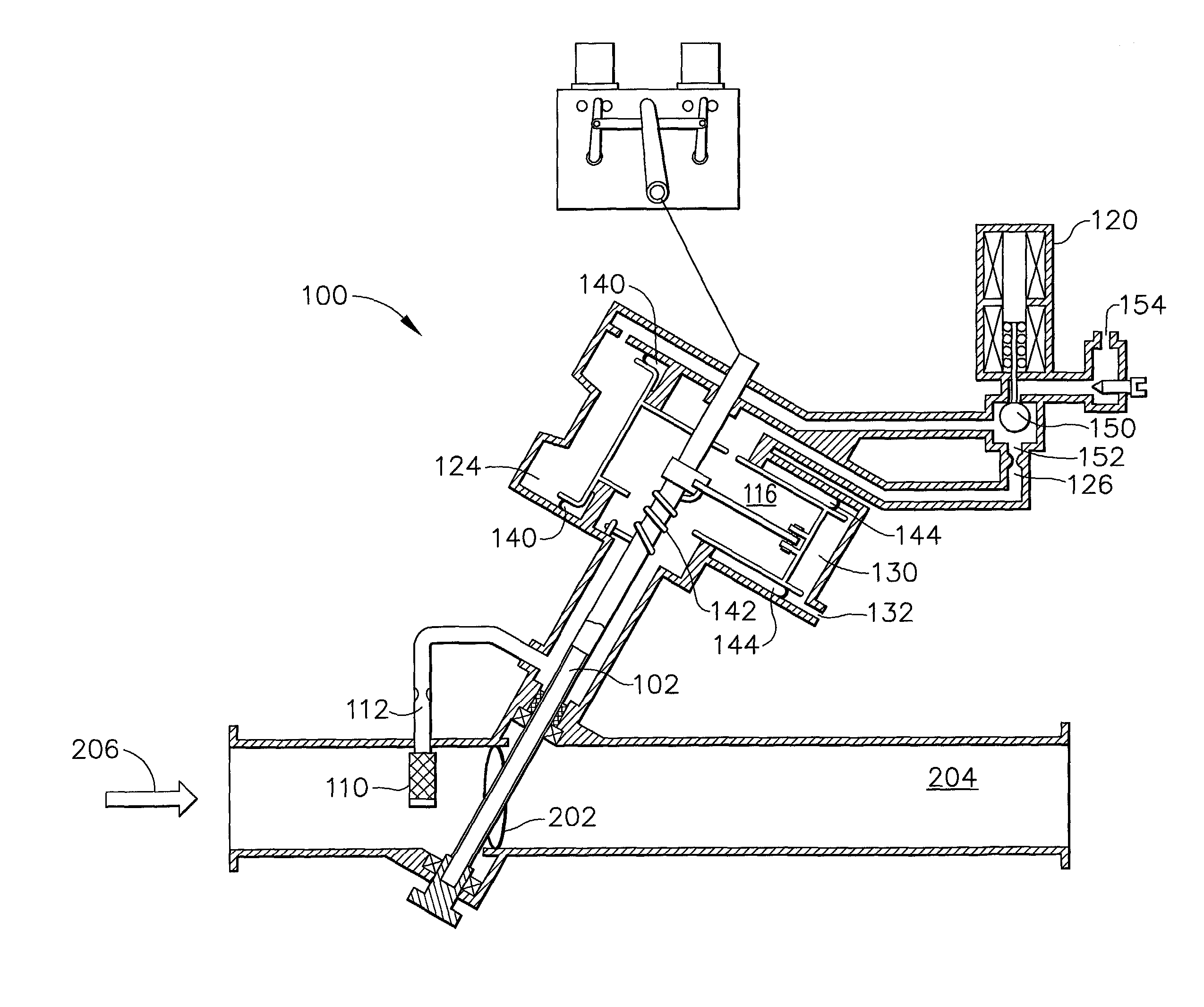

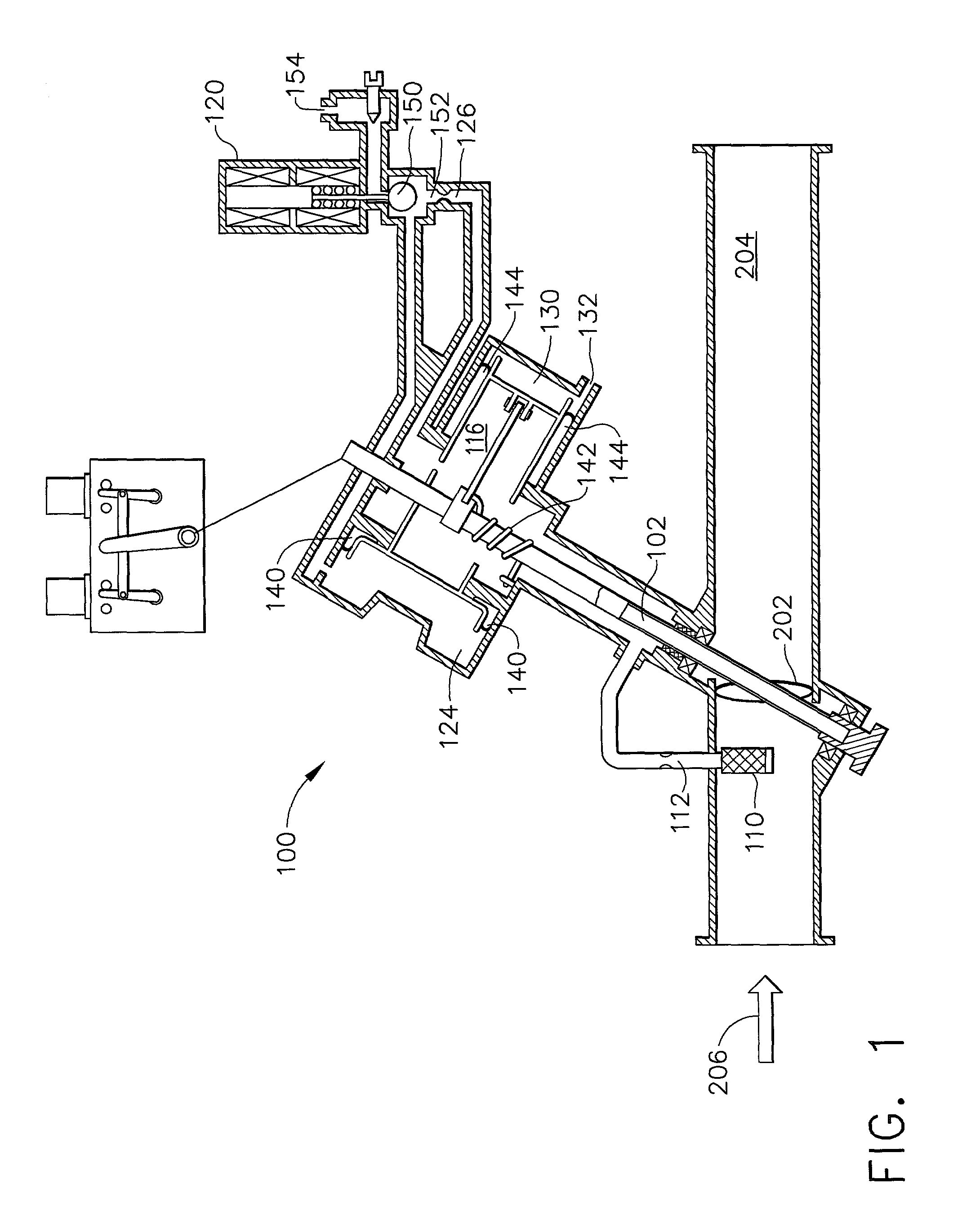

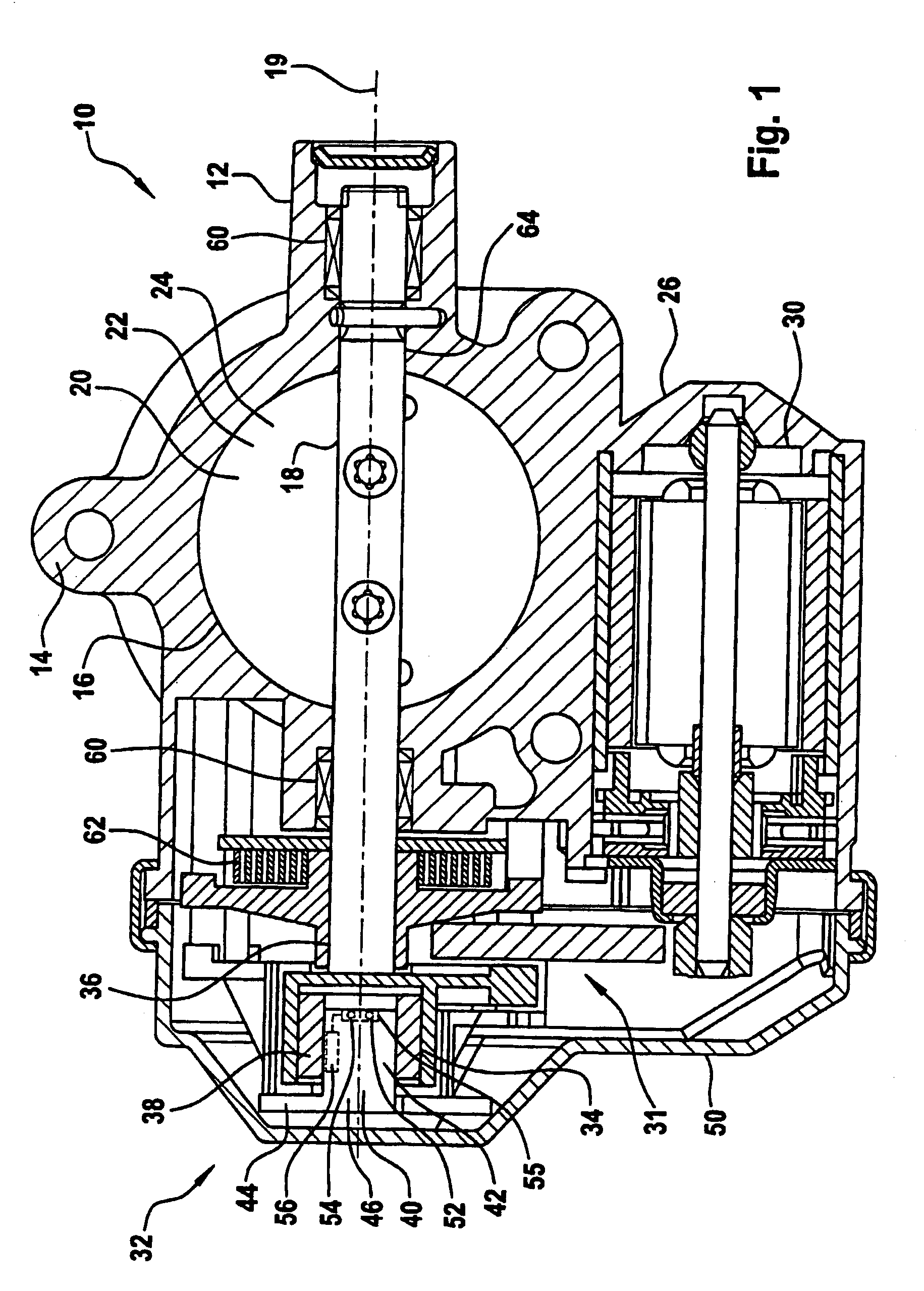

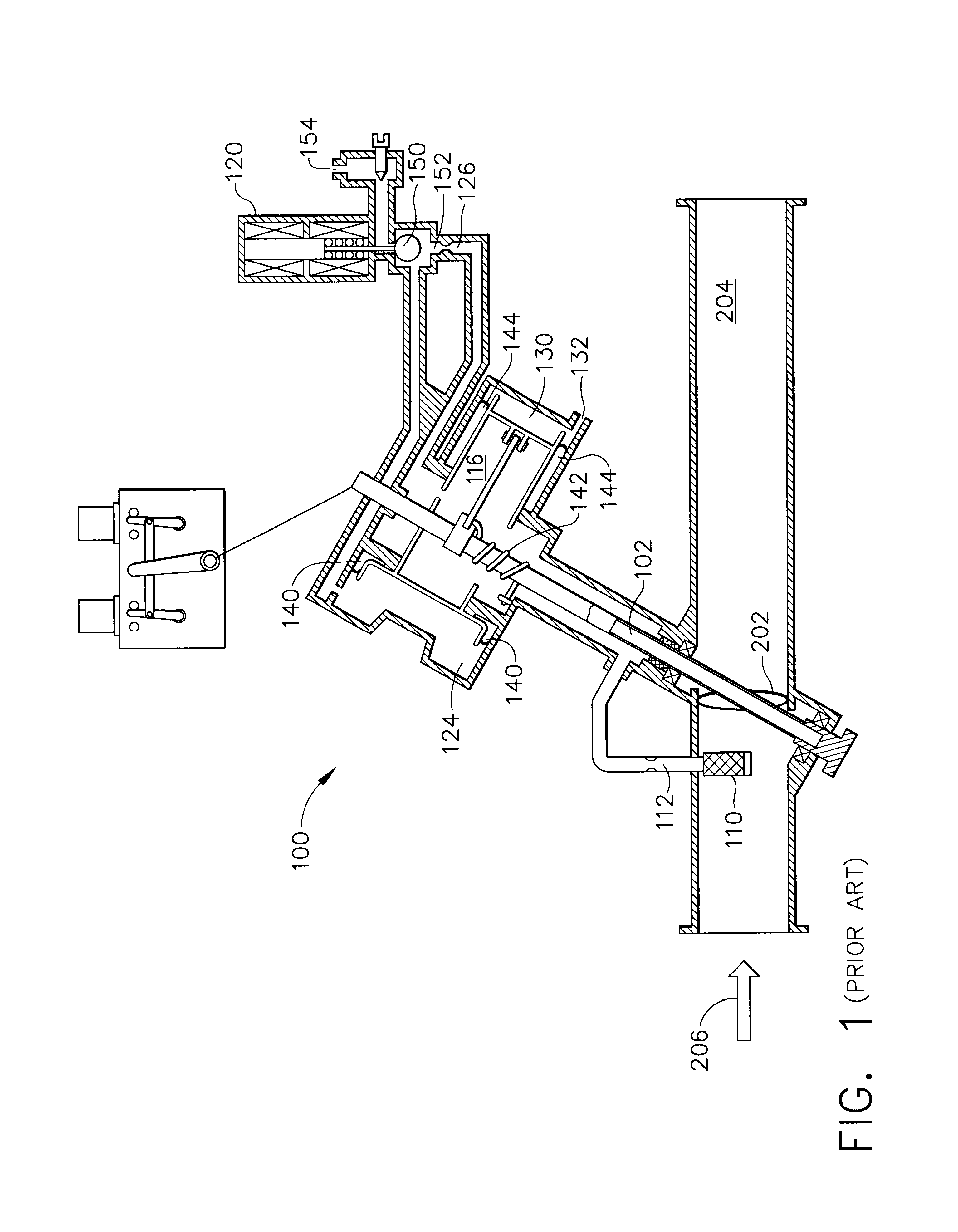

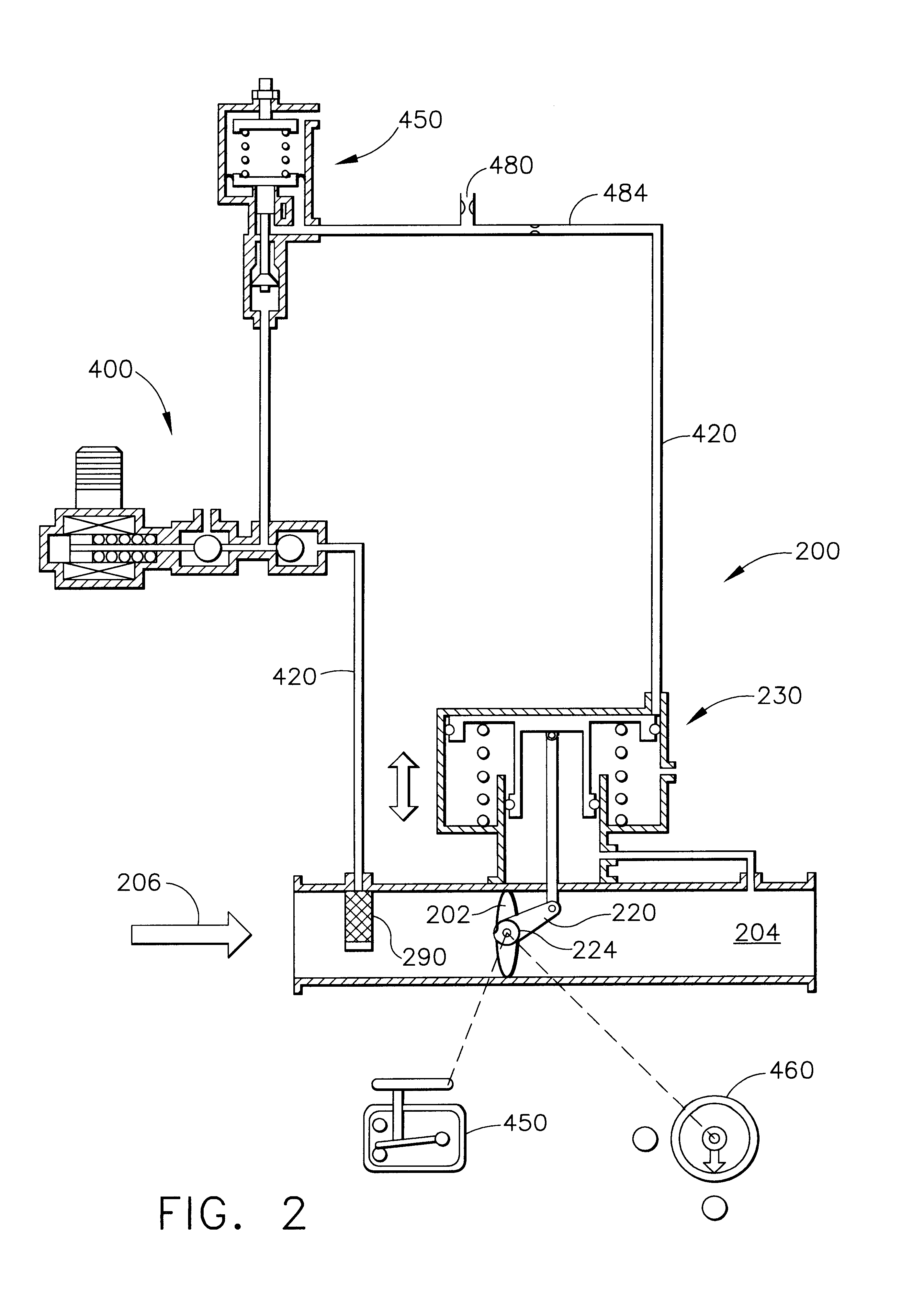

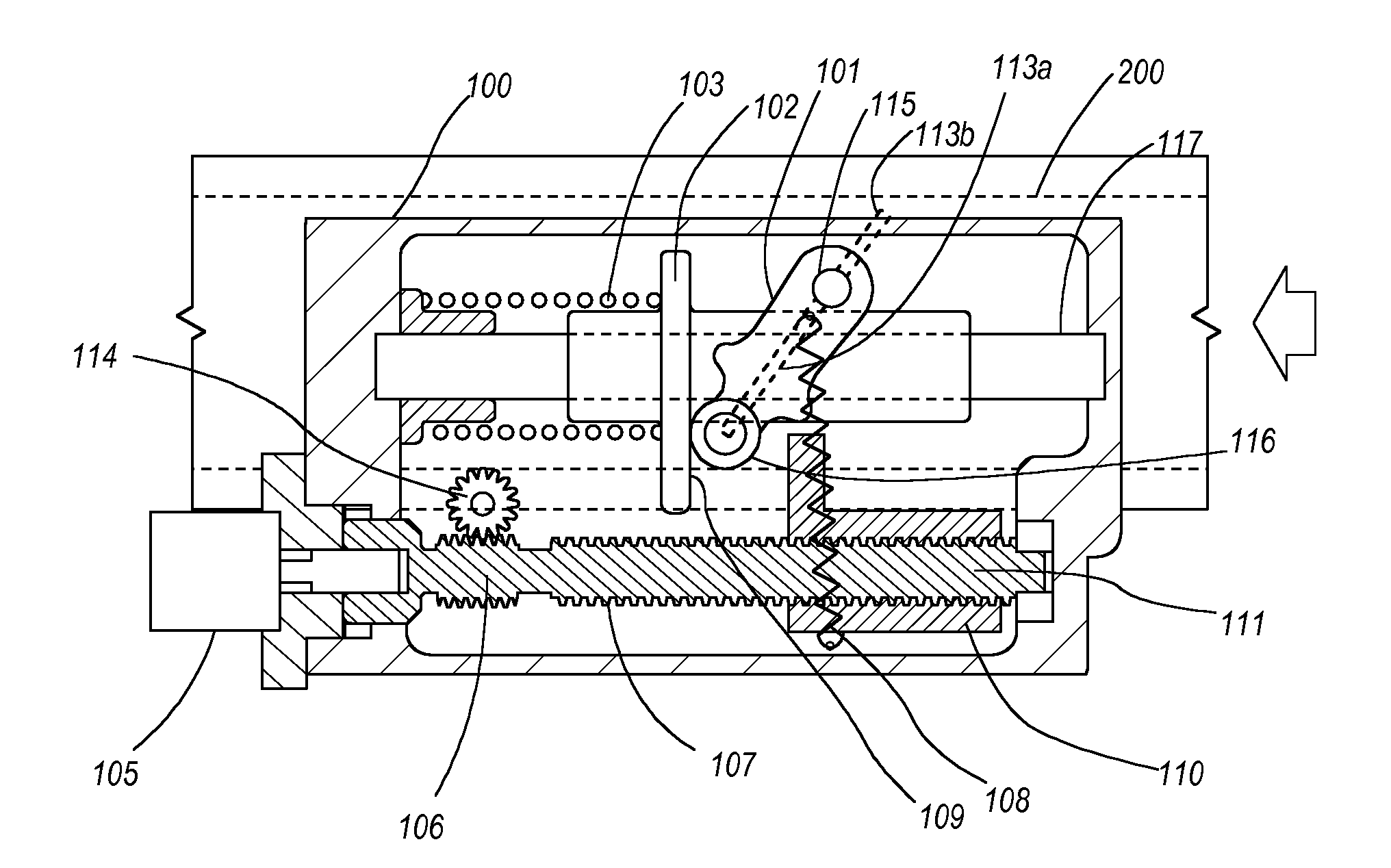

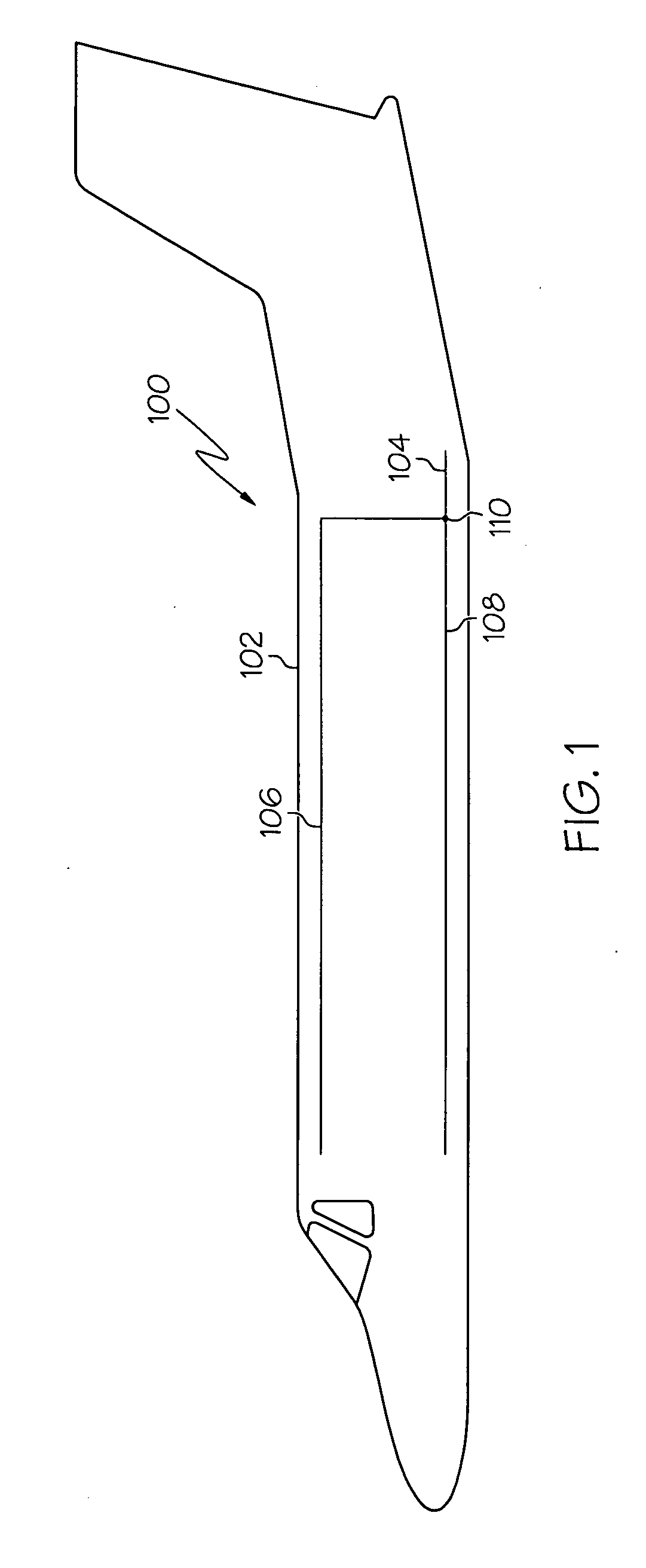

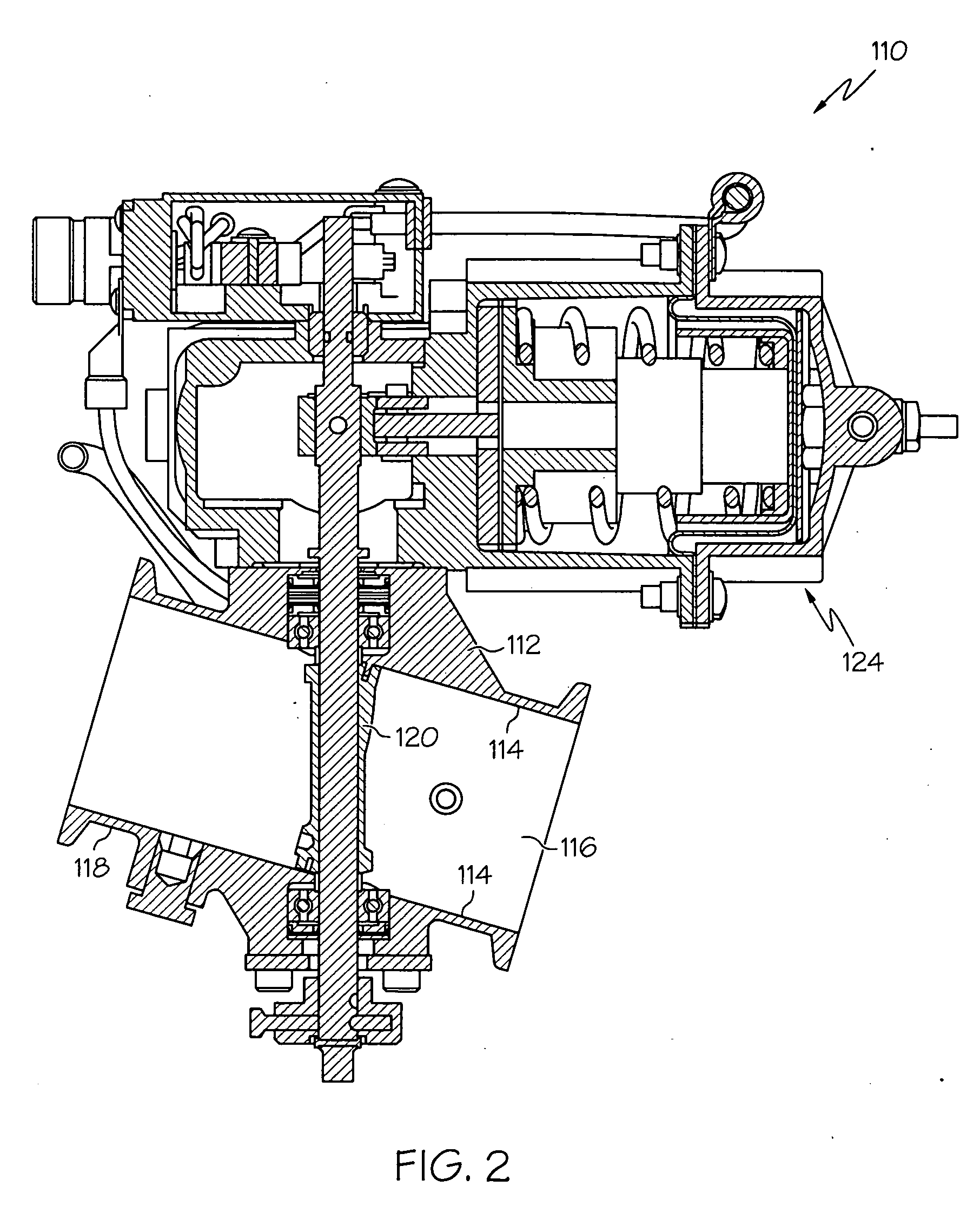

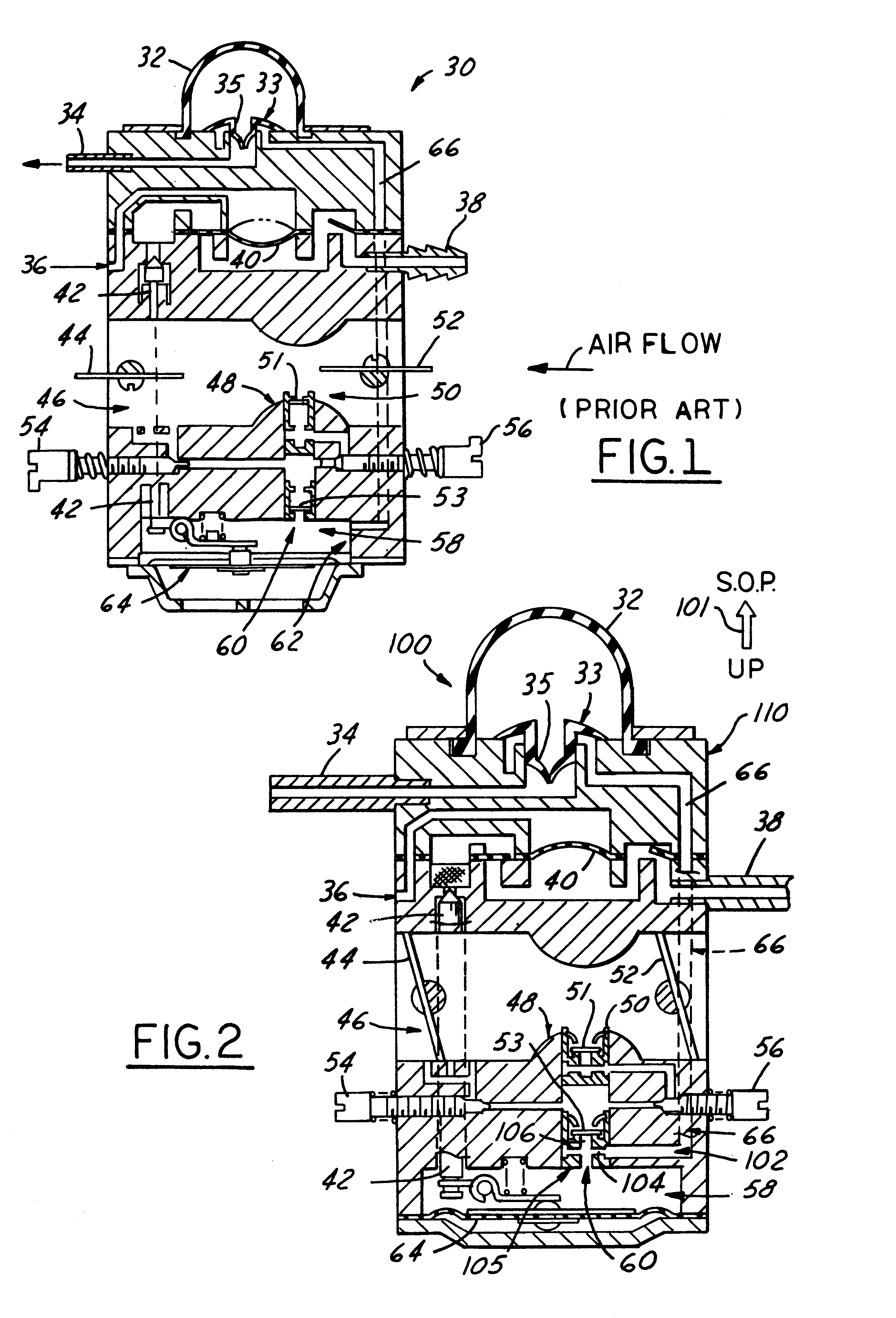

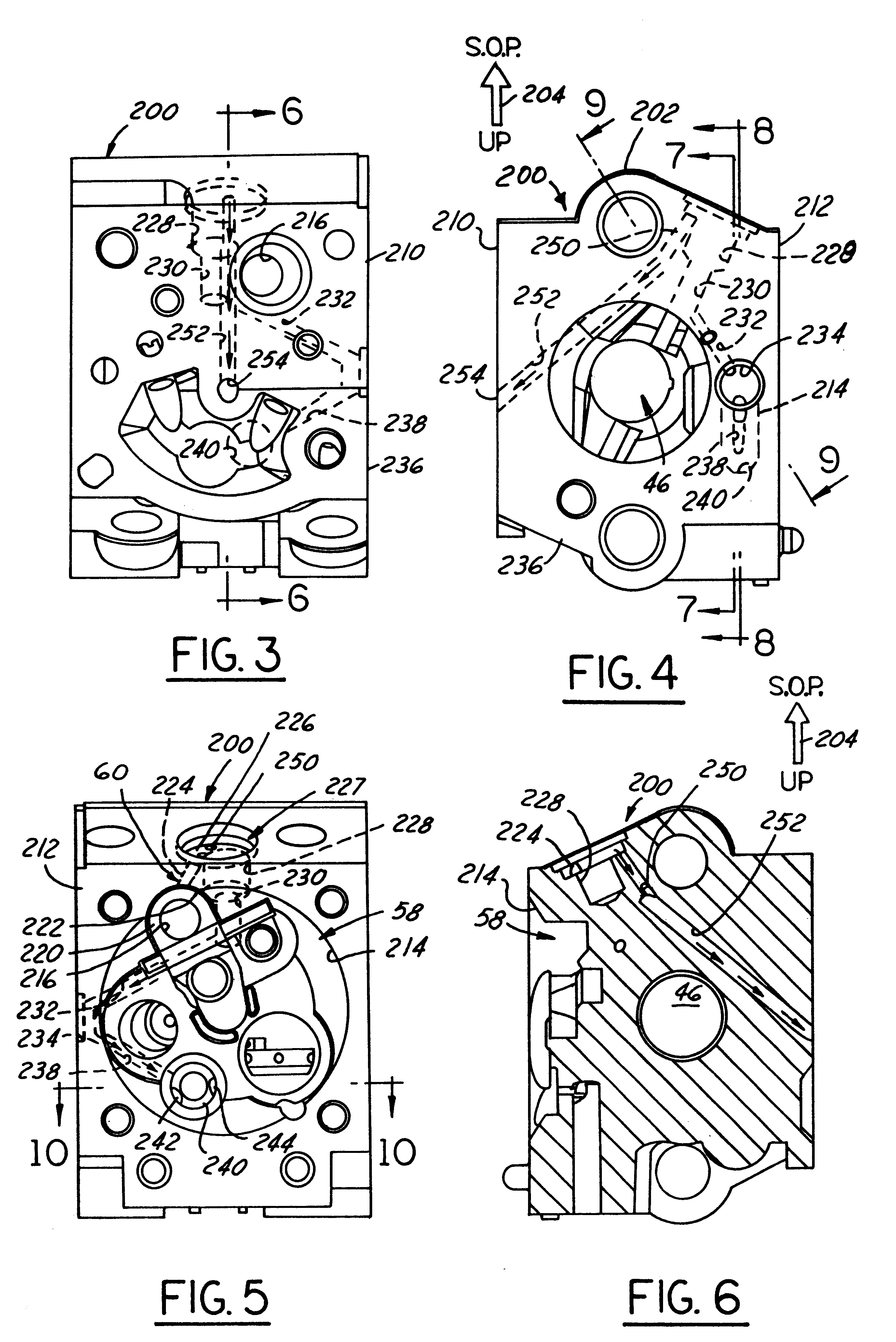

Micro volume actuator for an air turbine starter

InactiveUS20030145603A1Operating means/releasing devices for valvesEngine manufactureButterfly valveActuator

An air turbine starter system and air turbine starter valve that has a microvolume actuator to prevent the connected butterfly valve from opening too quickly. Air turbine starter valves can in some circumstances freeze shut, but may be opened by normal actuator operation. Such operation may open the valve too quickly due to stored potential energy. A sharp pressure transient may be inflicted upon the connected air turbine starter which can cause damage. The microvolume actuator air turbine starter system set forth herein allows generation of sufficient force to break ice and move the valve while minimizing stored potential energy that could open the valve too quickly.

Owner:HONEYWELL INT INC

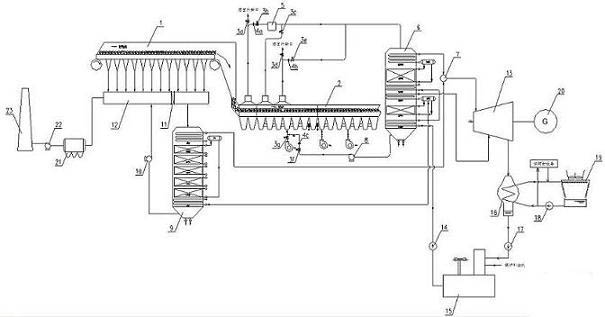

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

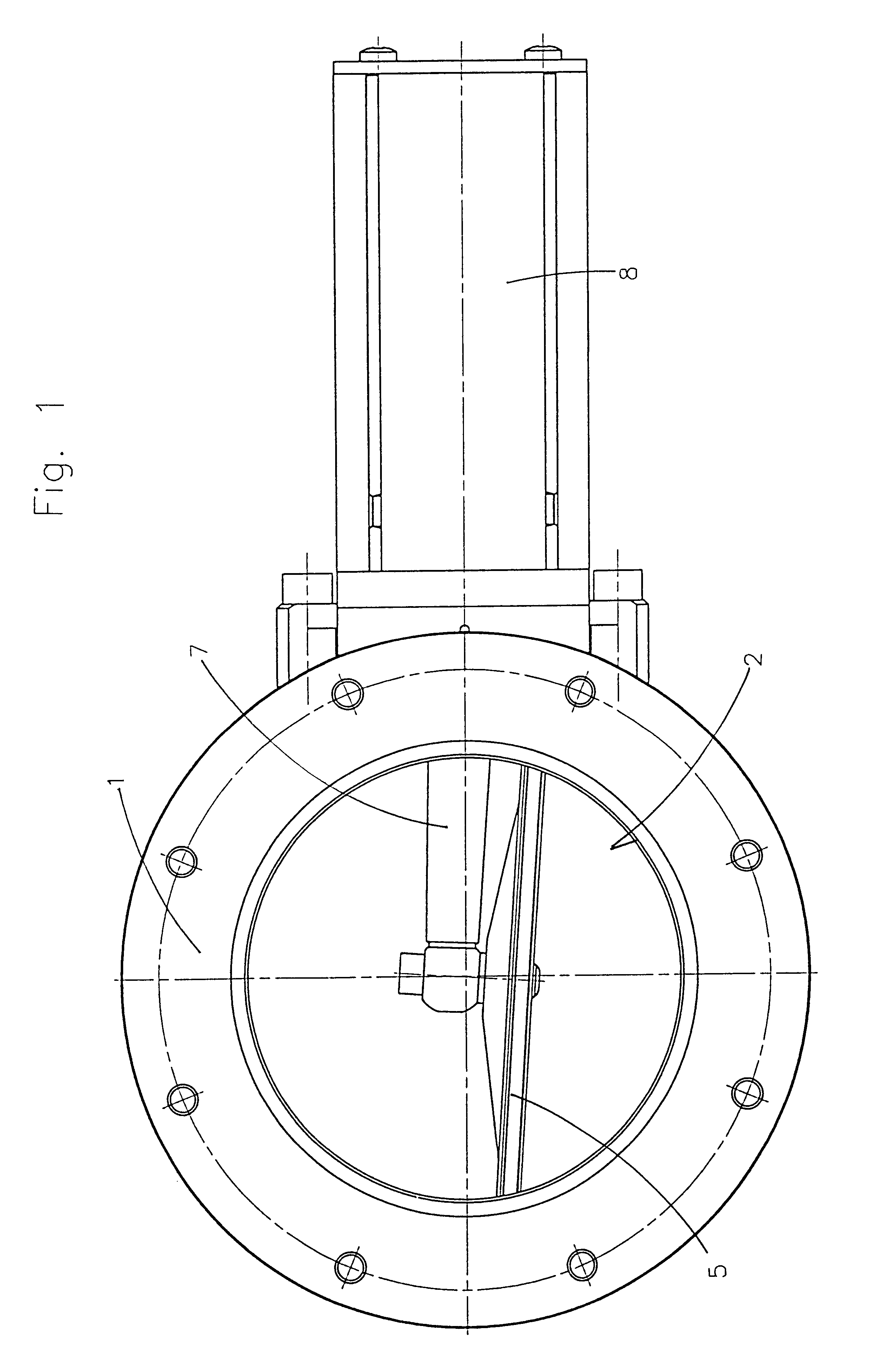

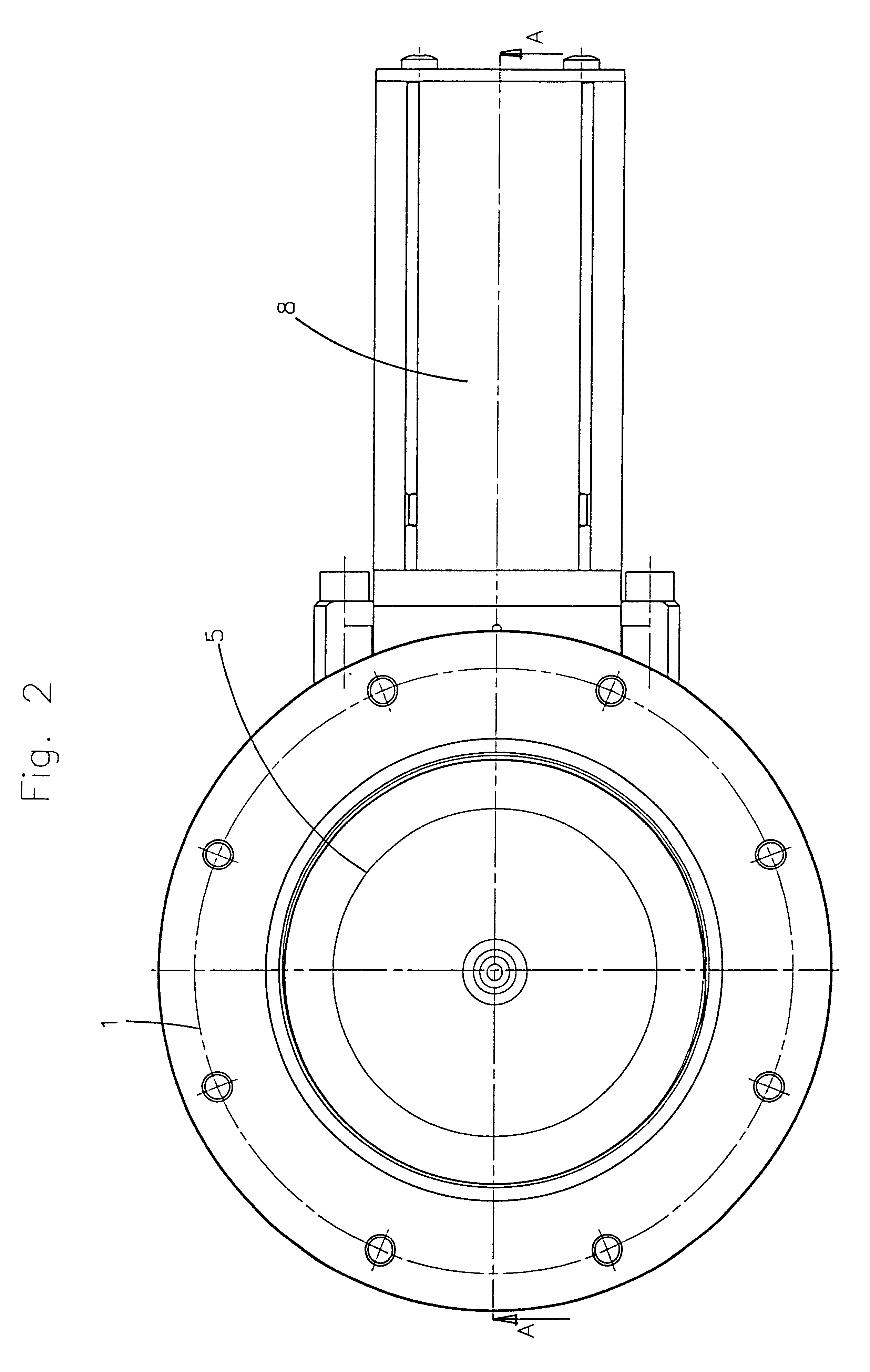

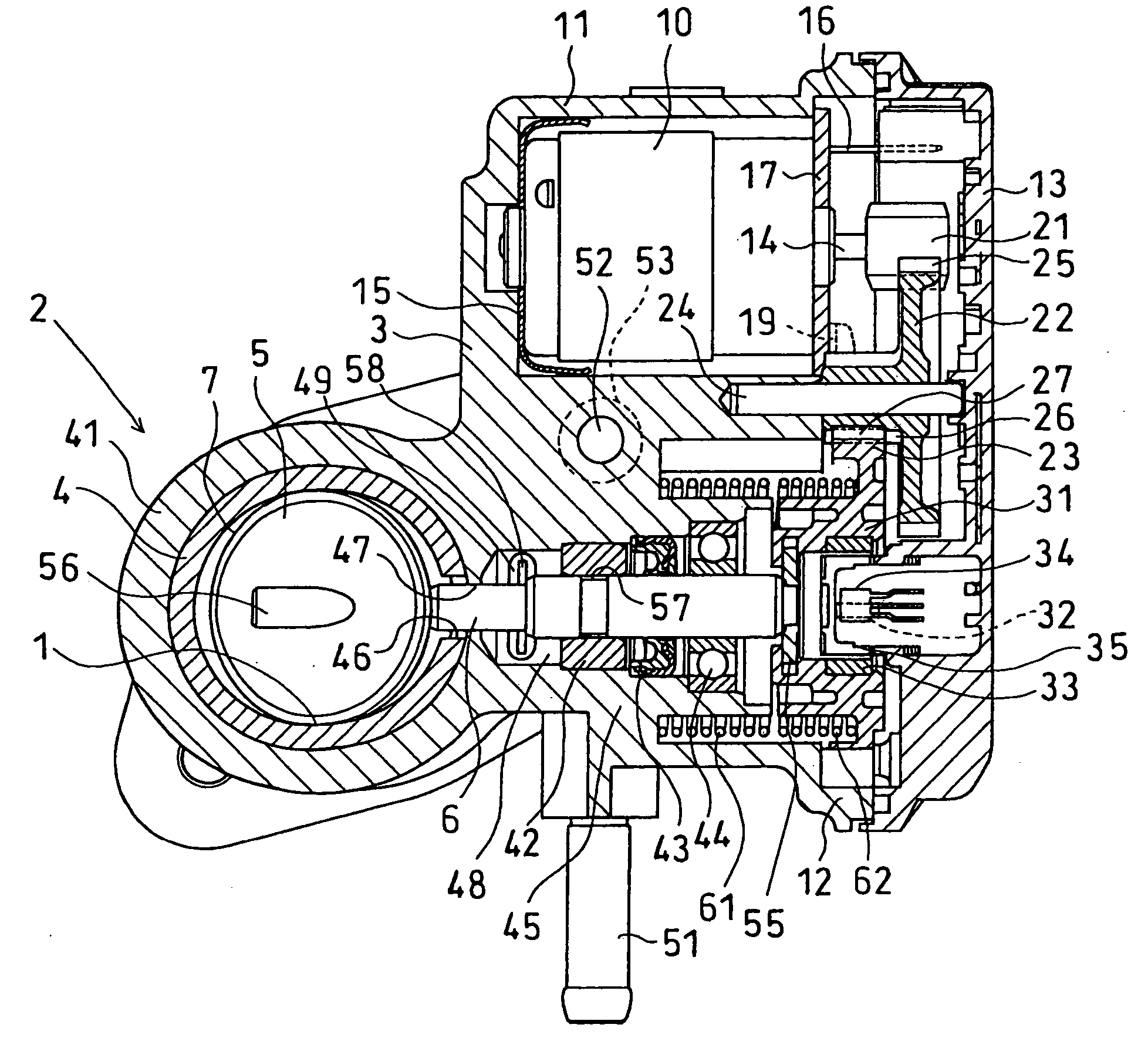

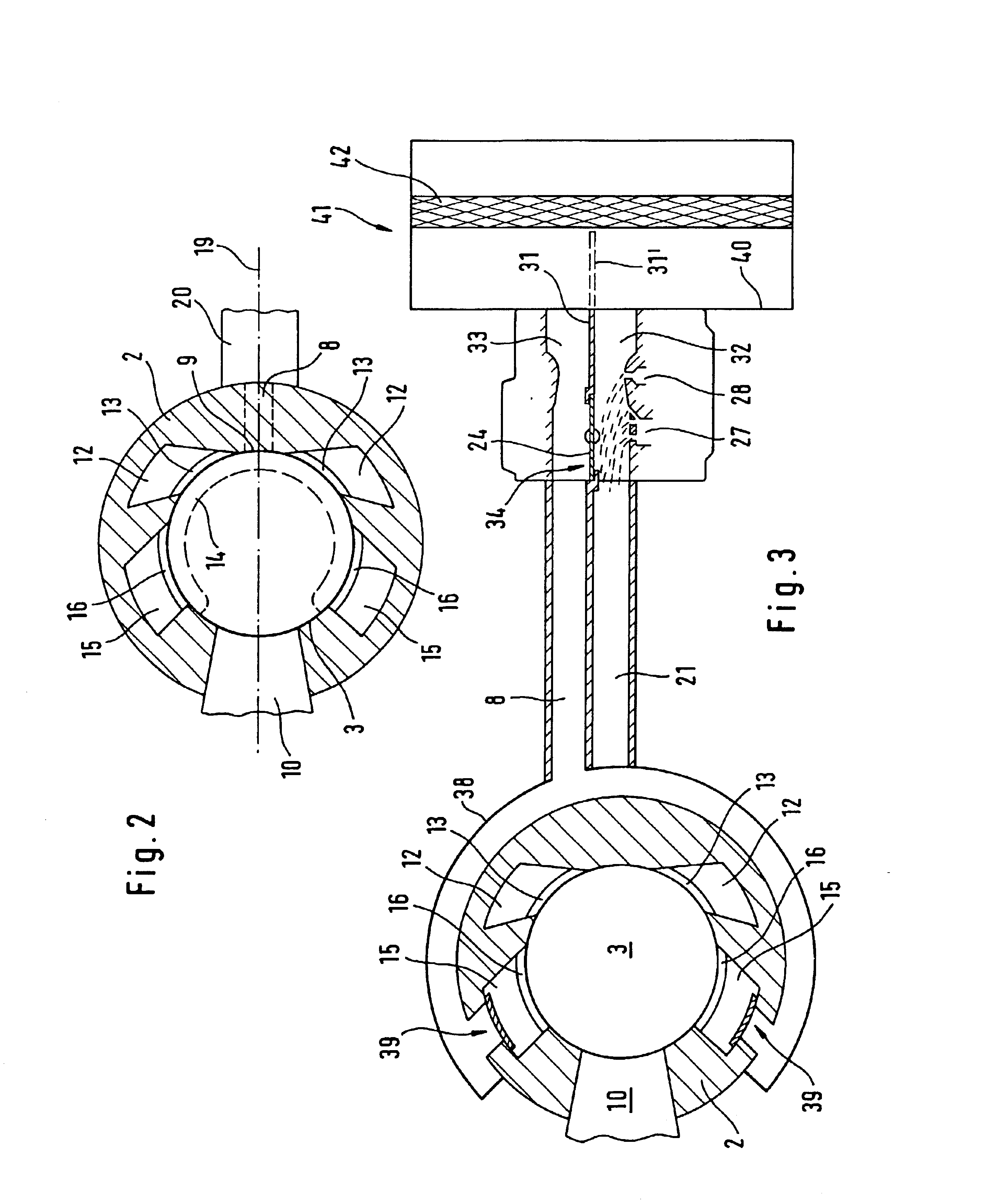

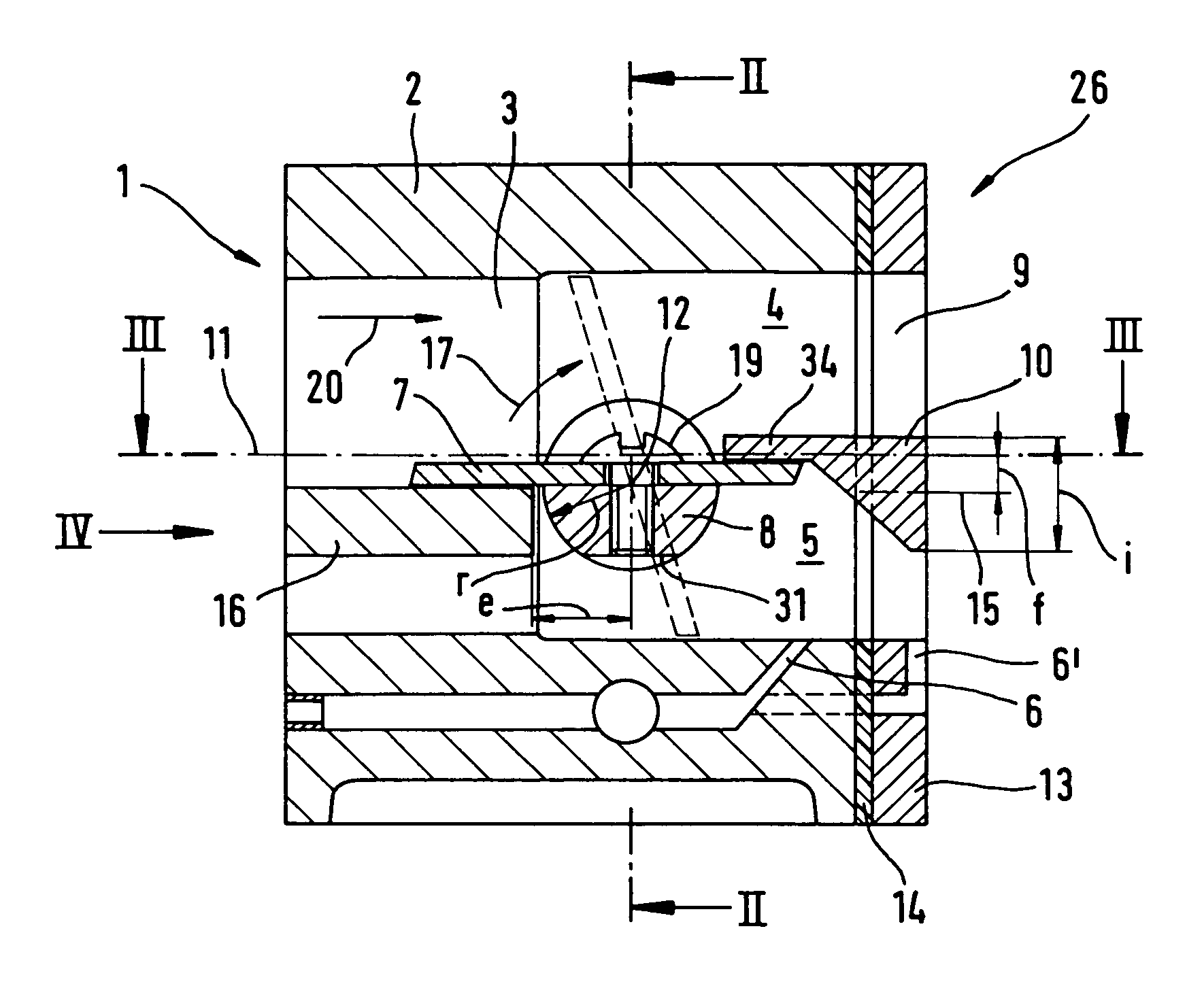

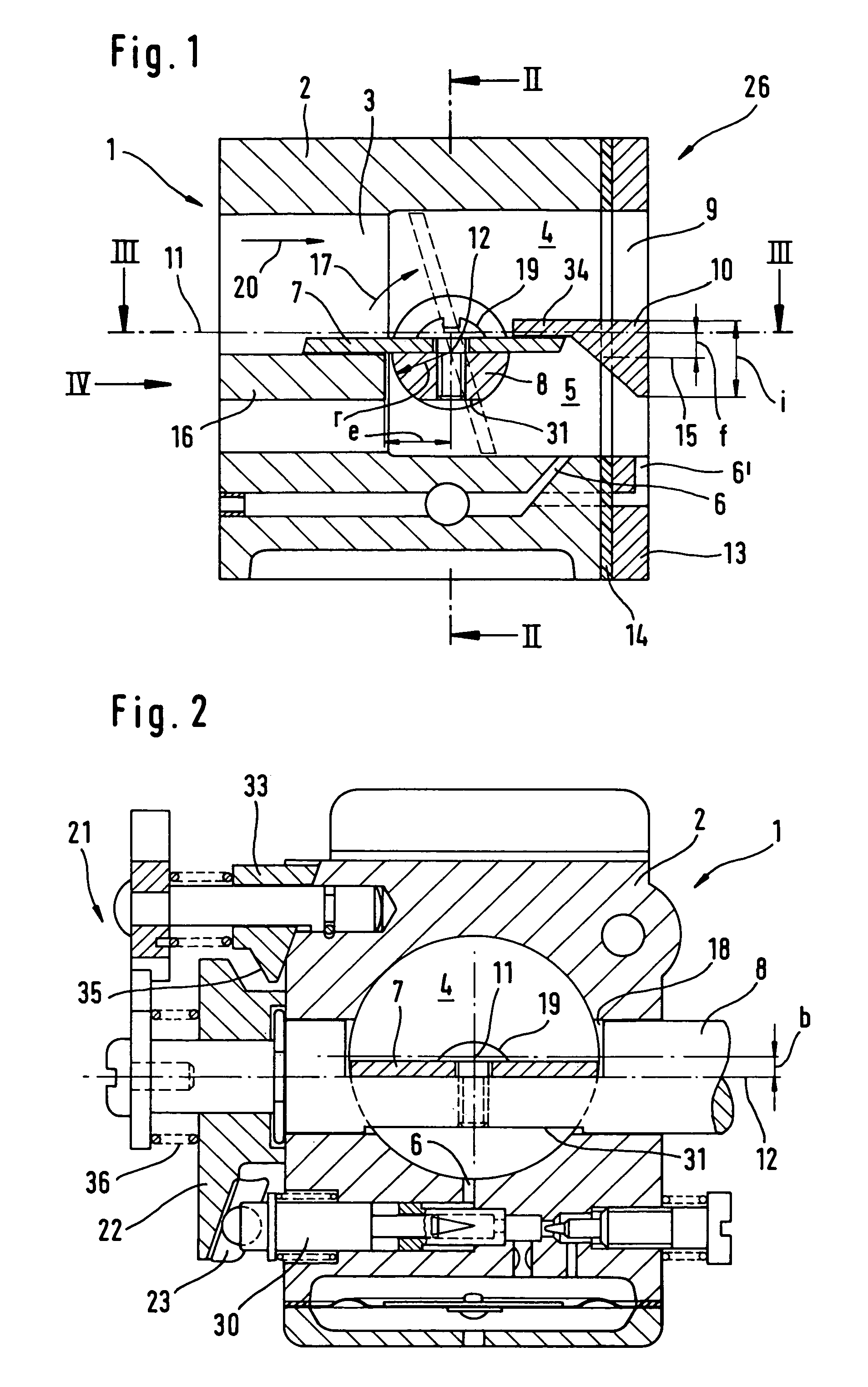

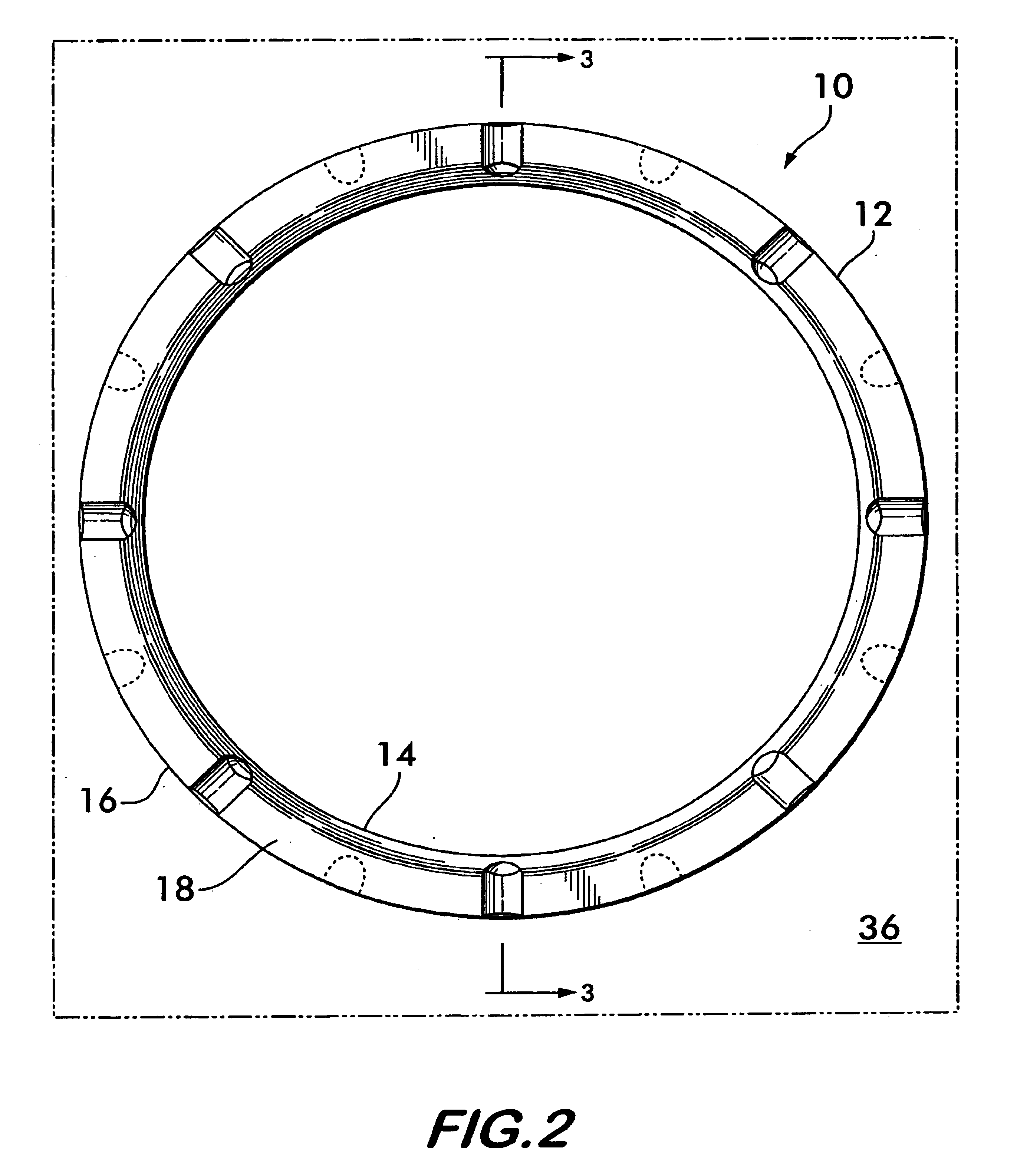

Butterfly valve

InactiveUS6494434B1Less prone to failureSolution to short lifeOperating means/releasing devices for valvesGearingEngineeringButterfly valve

A butterfly valve comprises a valve housing with a valve opening and a valve seat, this valve housing enclosing a vacuum area of the valve; a valve plate which is mounted at a valve rod guided through the valve housing and which is pressed against the valve seat in a closed position of the valve, tilted relative to the valve seat in a partially open position of the valve through tilting of the valve rod about a tilting axis, and tilted and rotated relative to the valve in a completely open position of the valve by subsequent rotation of the valve rod about its longitudinal axis; wherein the valve rod has portions extending on both sides of the tilting axis, the portion located on one side of the tilting axis acting centrally at the valve plate and the portion located on the other side of the tilting axis being connected, via a link guide which is located outside the vacuum area and which has a link with a part extending at an inclination to the longitudinal axis of the valve rod and a helical surface-shaped part and a journal which is guided in the link, to an actuating member which is mounted so as to be displaceable in axial direction of the valve rod.

Owner:VAT HLDG AG

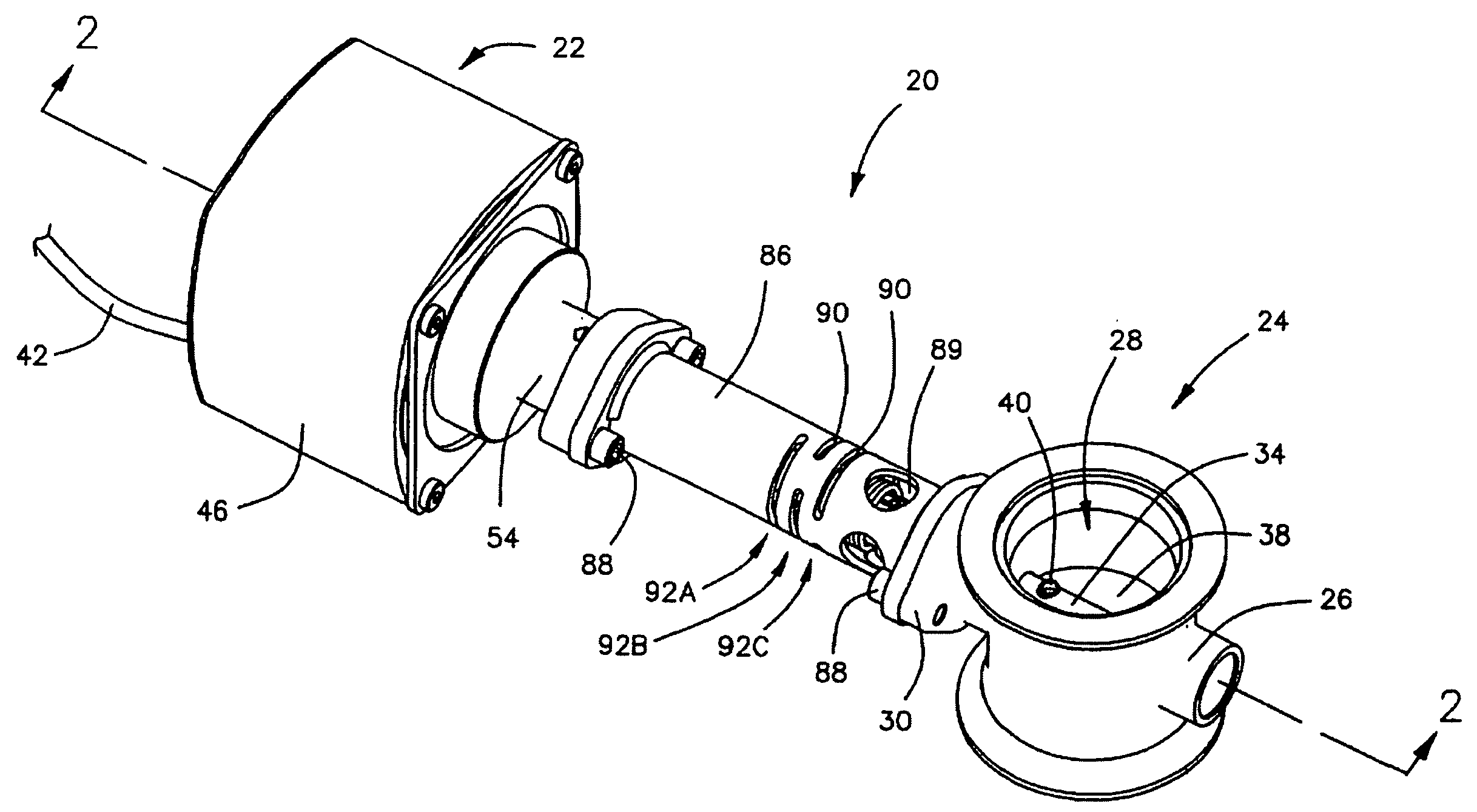

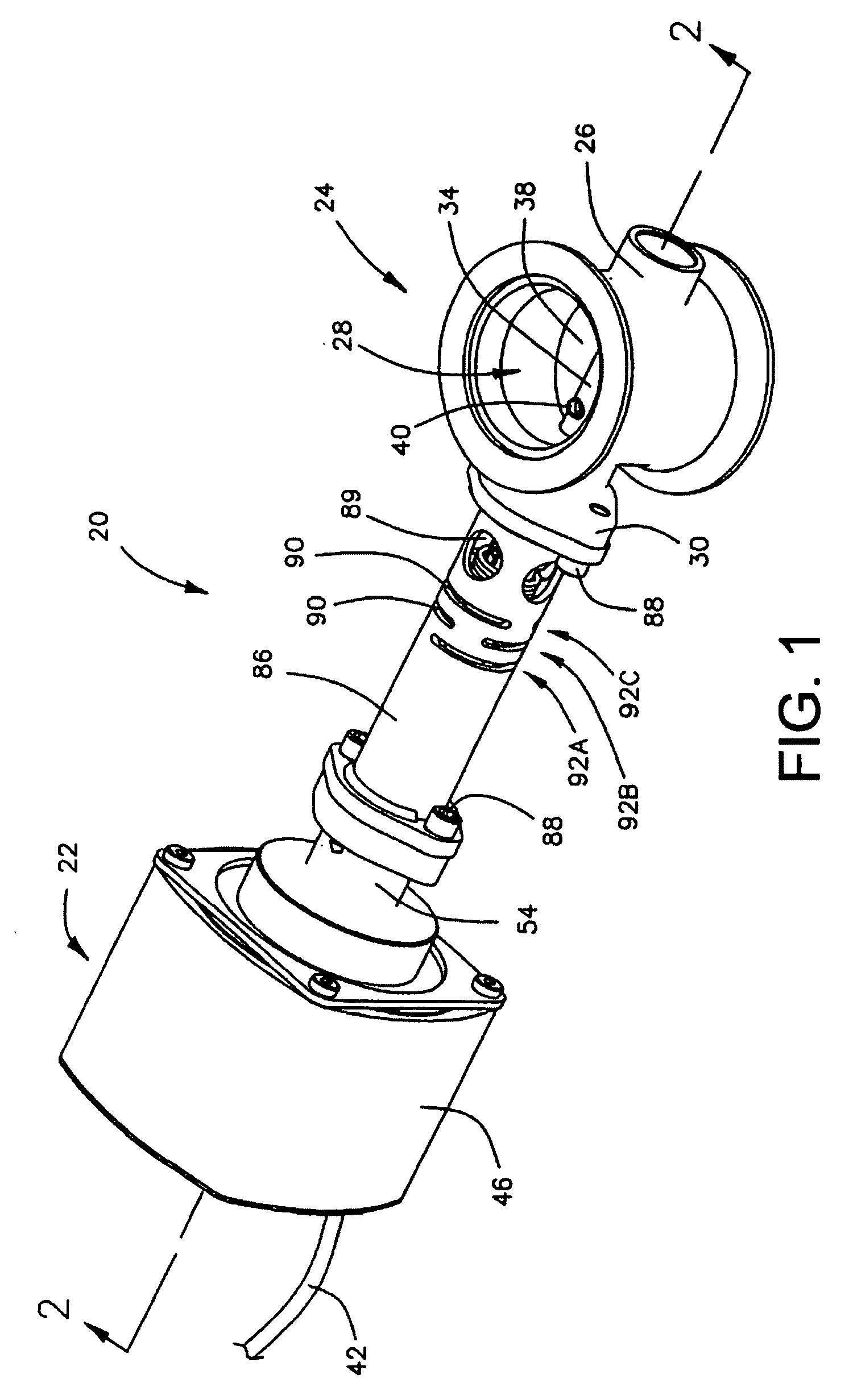

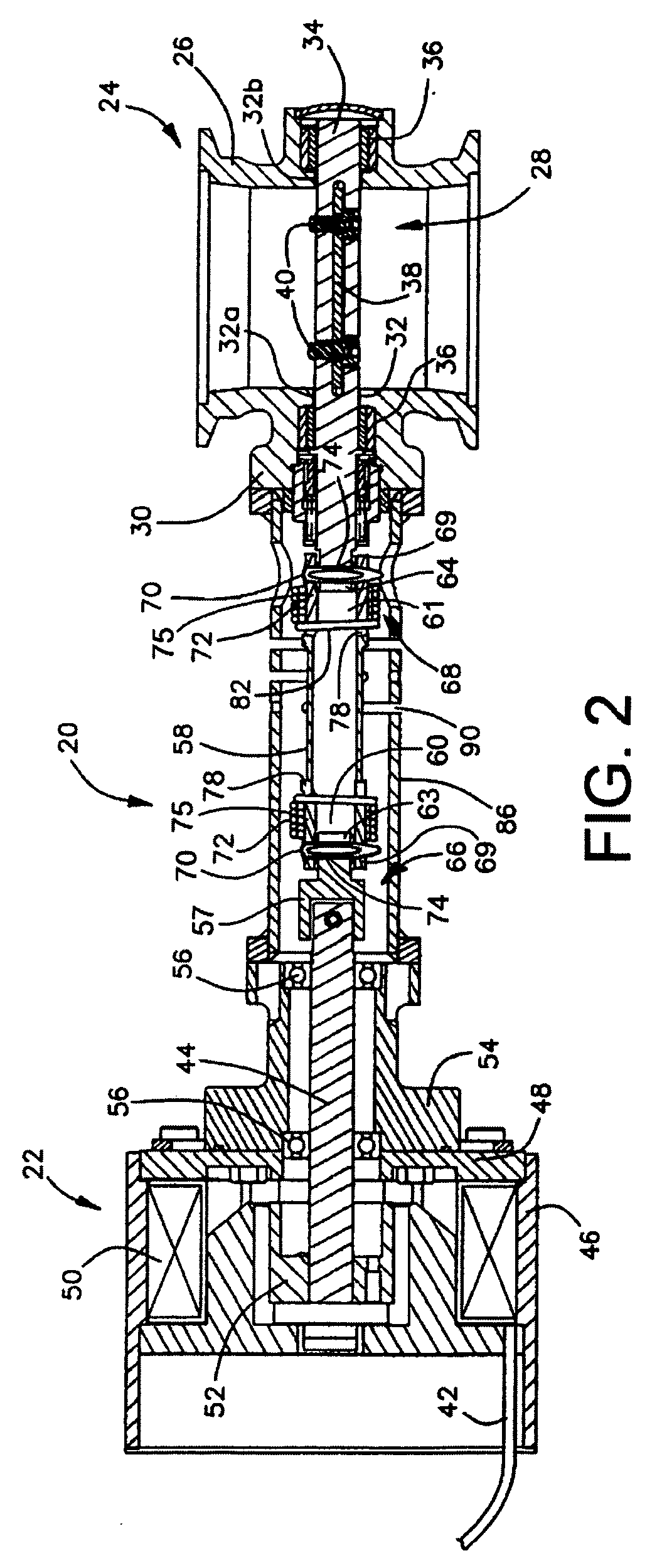

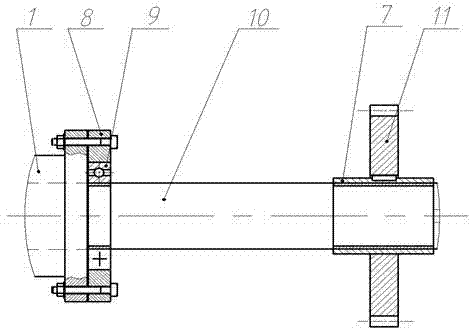

Tortionally Stiff, Thermally Isolating Shaft Coupling with Multiple Degrees of Freedom to Accommodate Misalignment

ActiveUS20090293654A1Easy to controlPrevent heat transferClutchesOperating means/releasing devices for valvesHysteresisCoupling

A coupling arrangement coupling and thermally isolating a continuously variable electrical actuator rotationally coupled to and from a butterfly valve is provided. The valve may be used to modulate high temperature exhaust gas flow through an engine turbocharger. The actuator provides a continuously variable control of the valve. The coupling arrangement provides a thermal block to reduce heat transfer and vibration insulation between the actuator and the valve. The coupling arrangement generally includes a coupling shaft rotationally coupled at opposite ends to the input and output shafts by torsion spring mechanisms. The torsion spring mechanisms include yokes rotationally locking the coupling shaft to the input and output shafts. The torsion spring mechanisms allow a limited range of axial and pivotal translation between the coupling shaft and the input and output shafts and are preloaded to prevent rotational hysteresis in the valve.

Owner:WOODWARD GOVERNOR CO

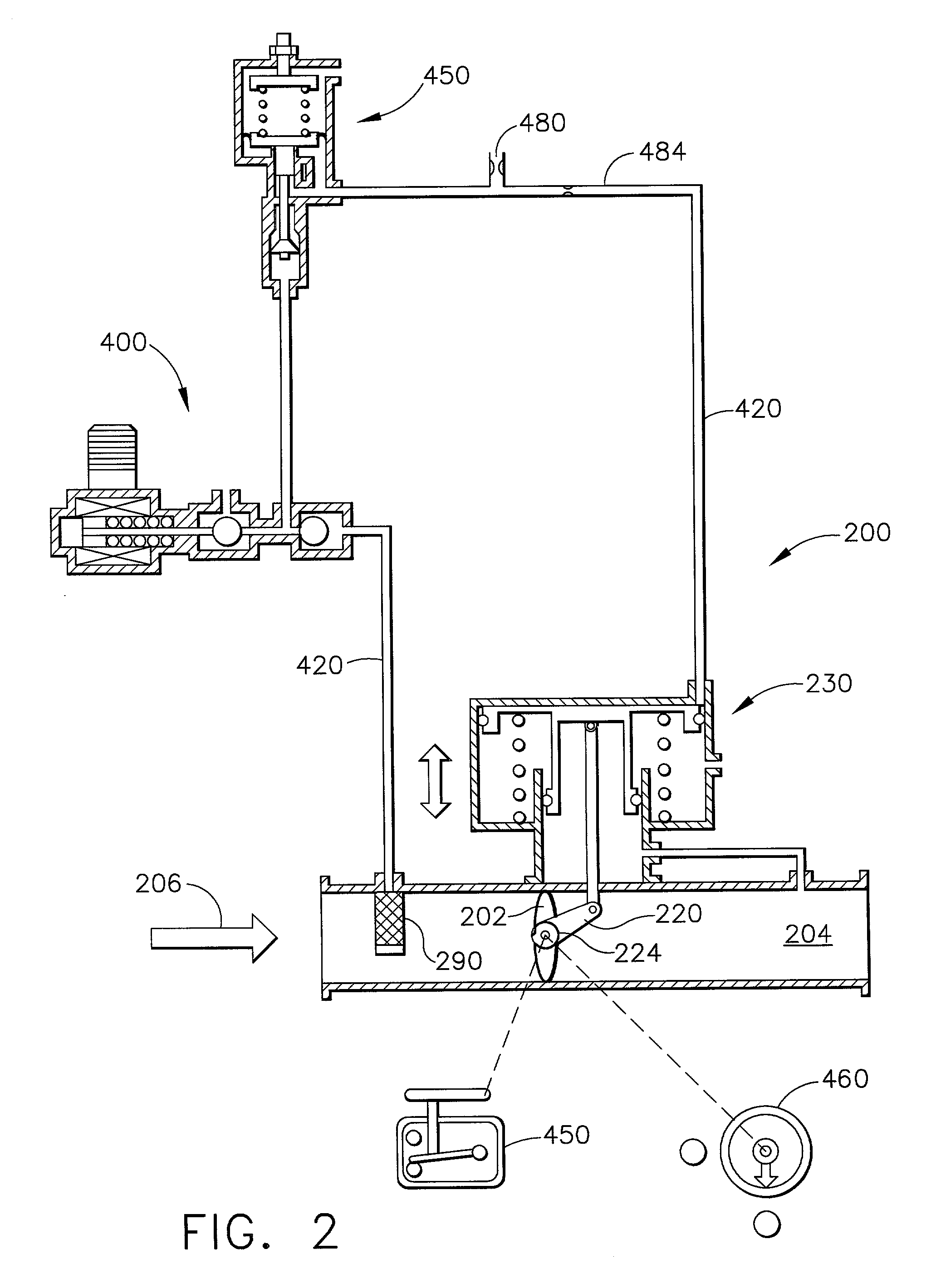

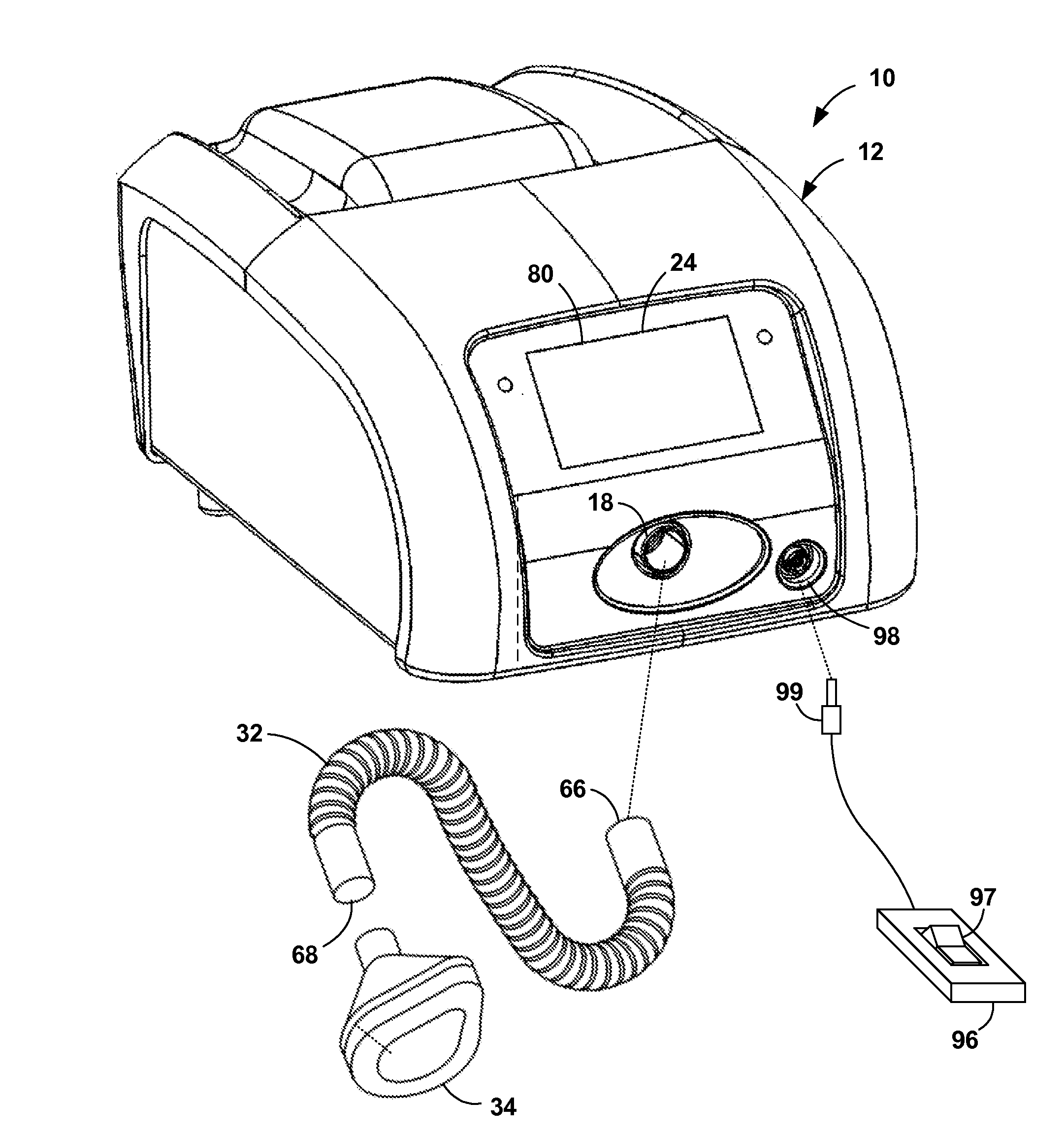

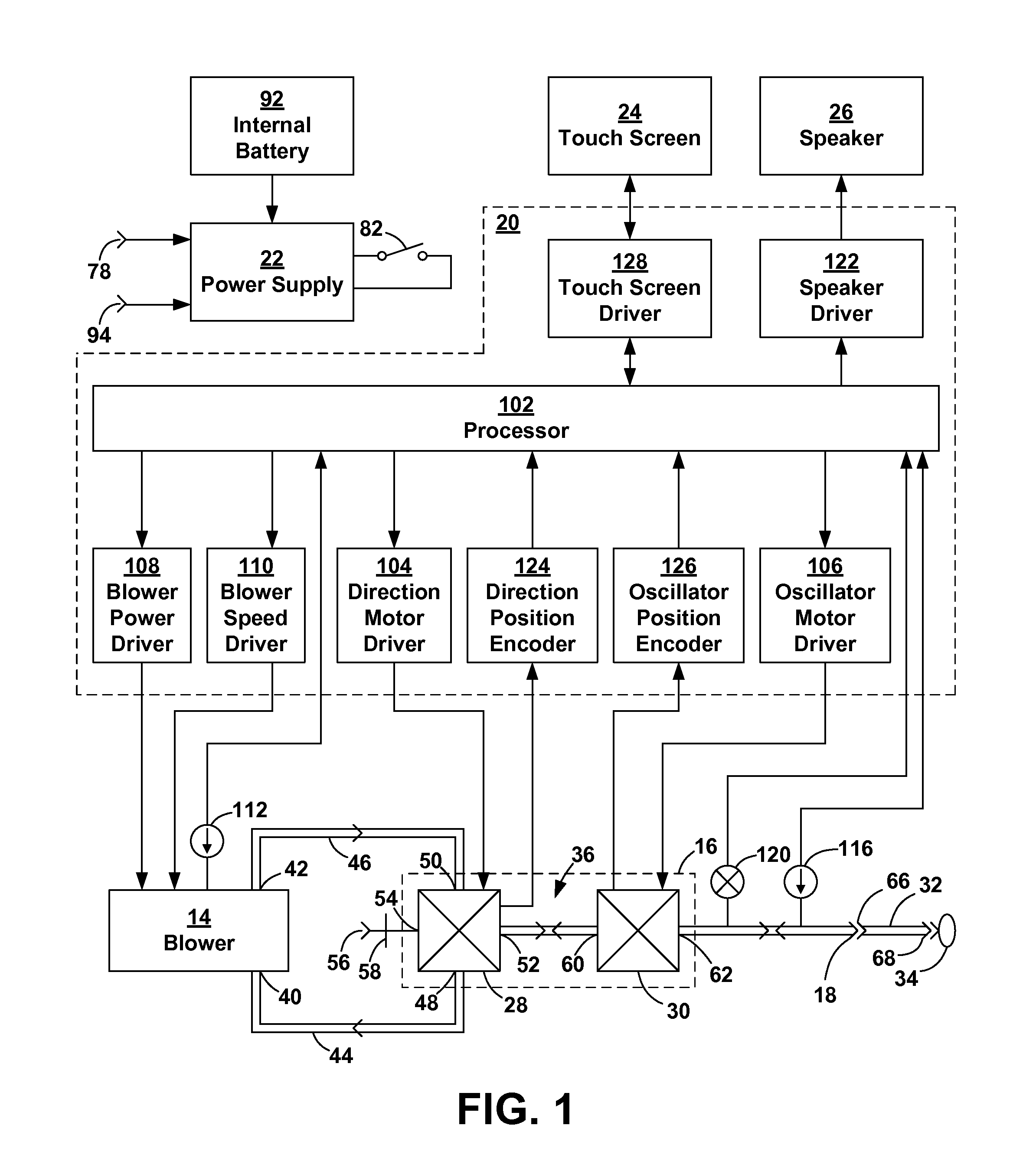

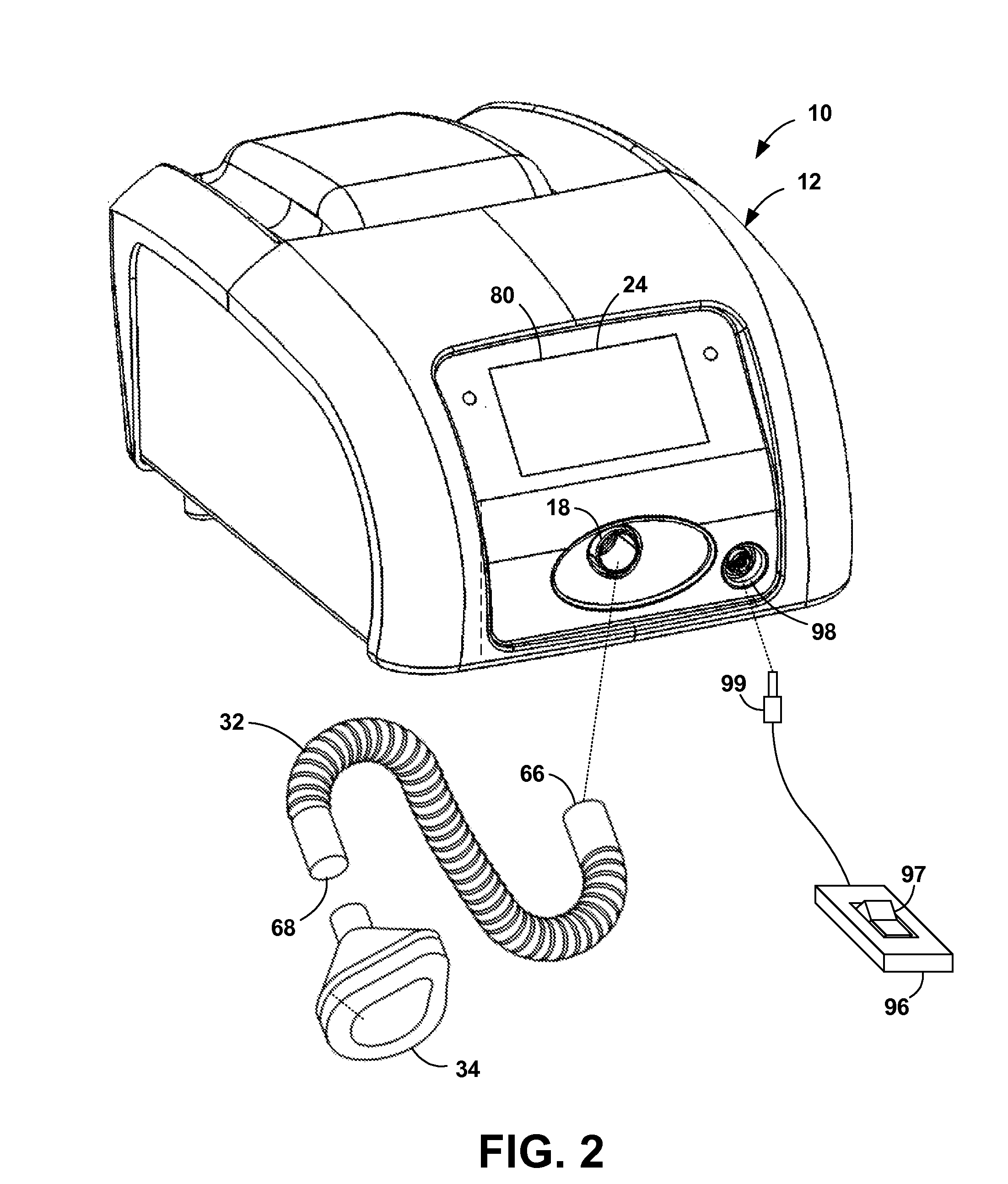

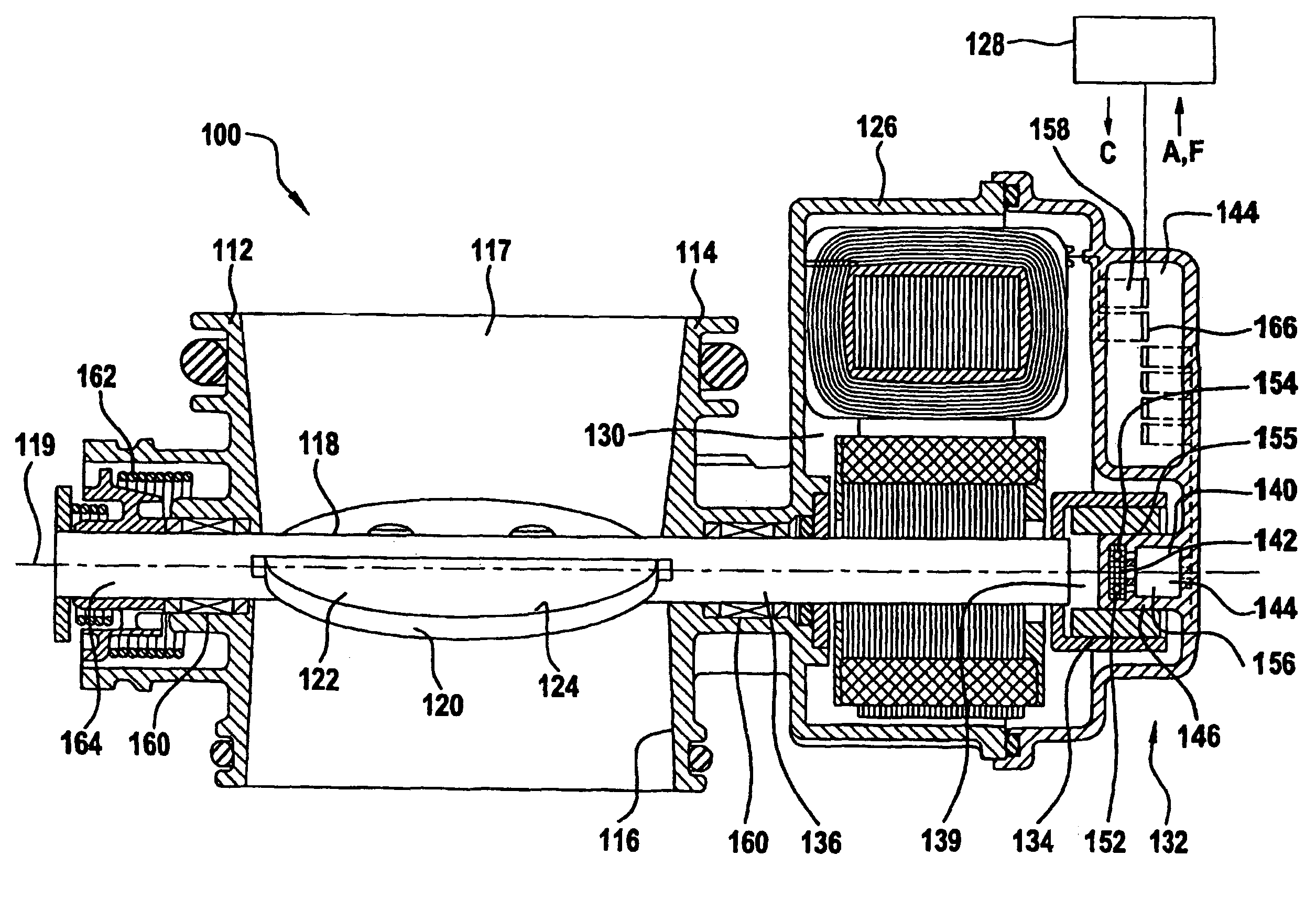

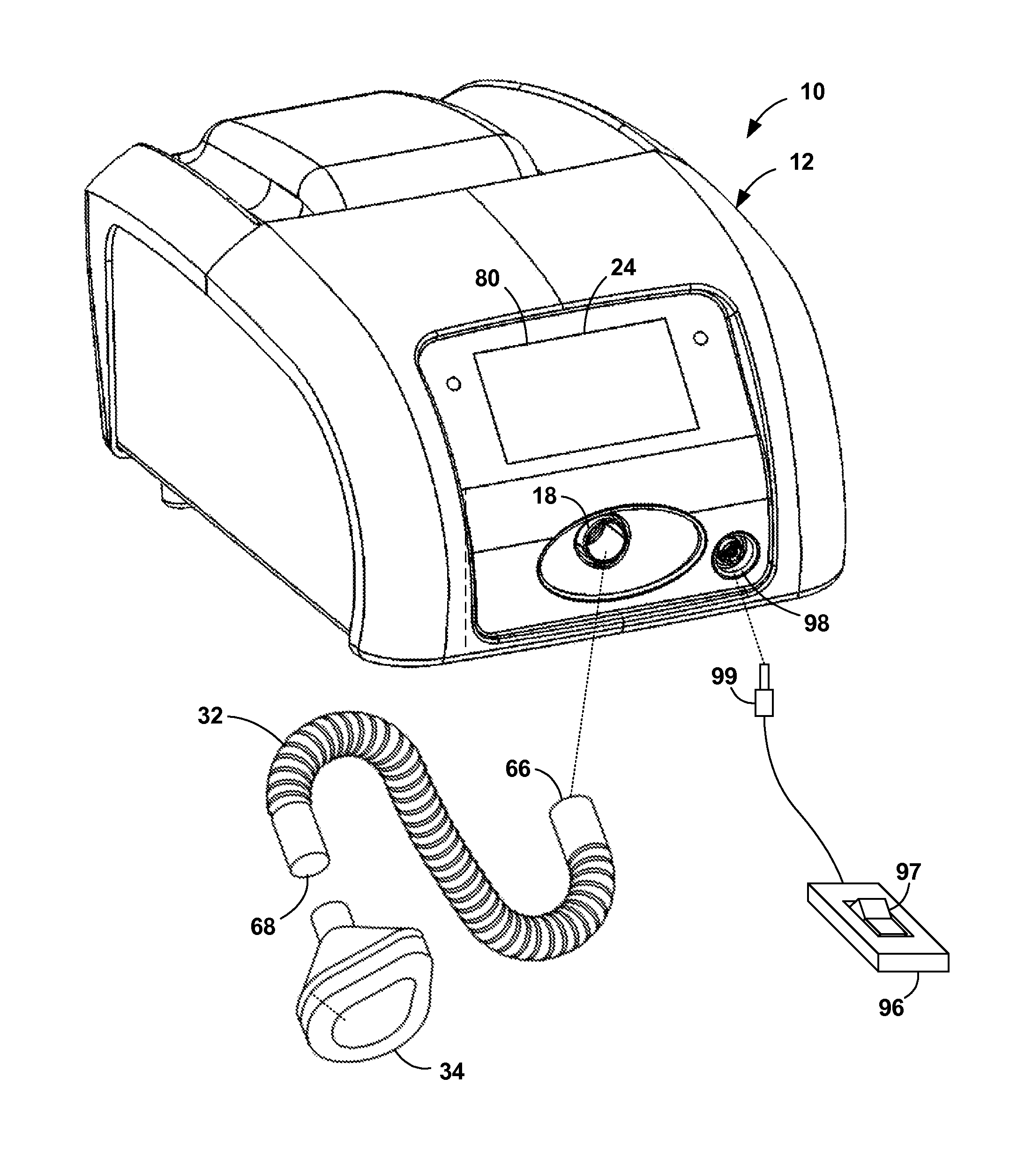

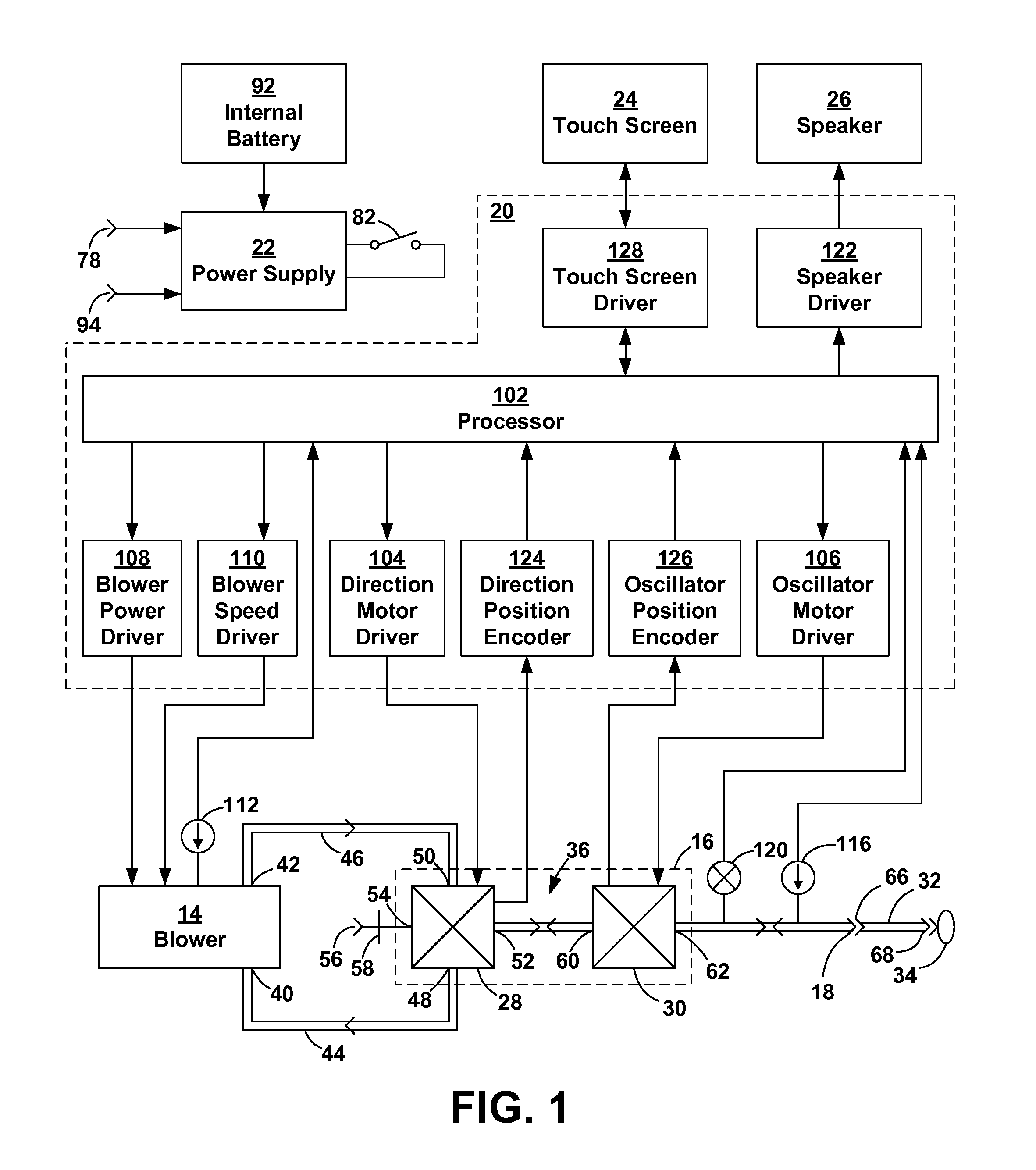

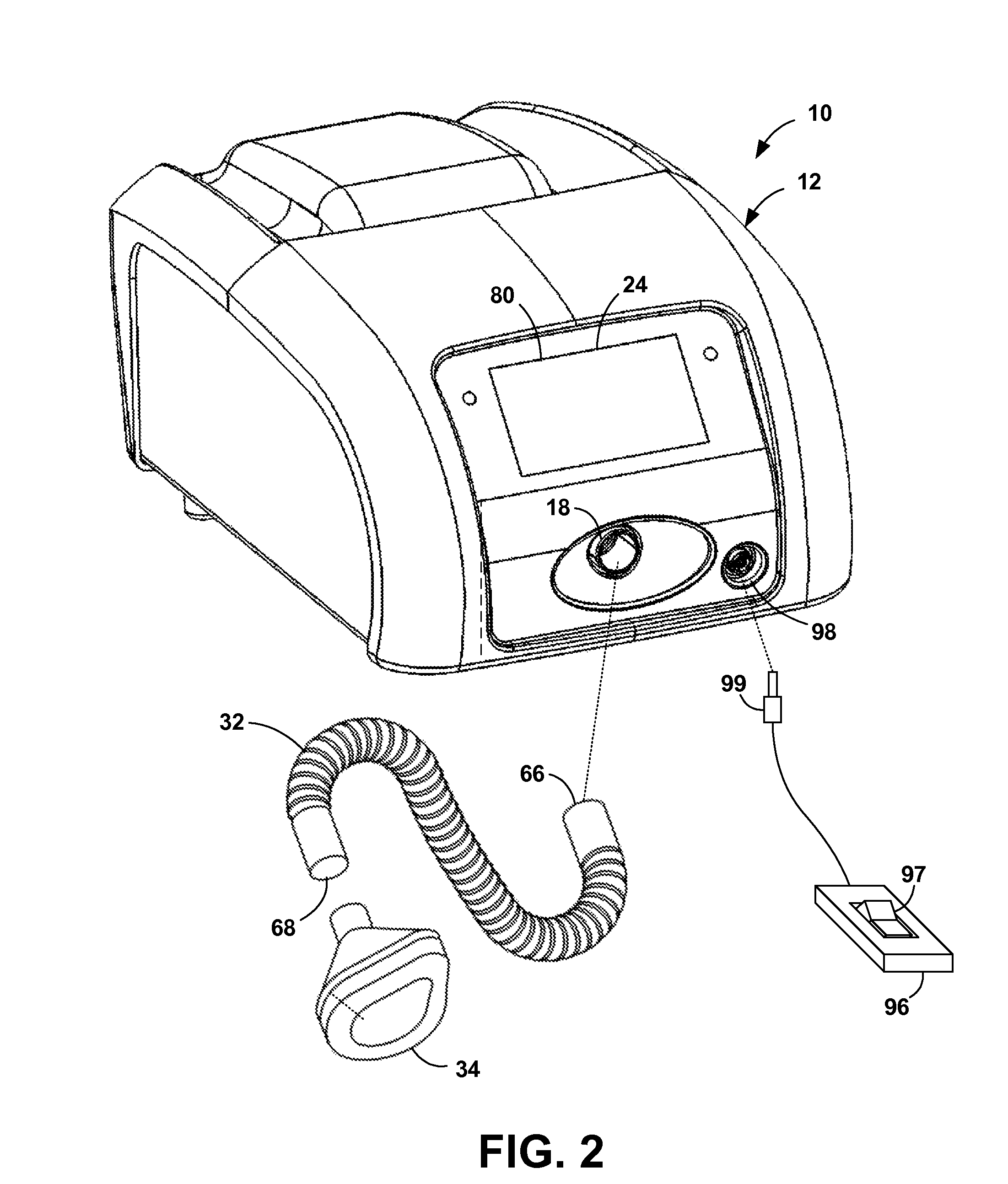

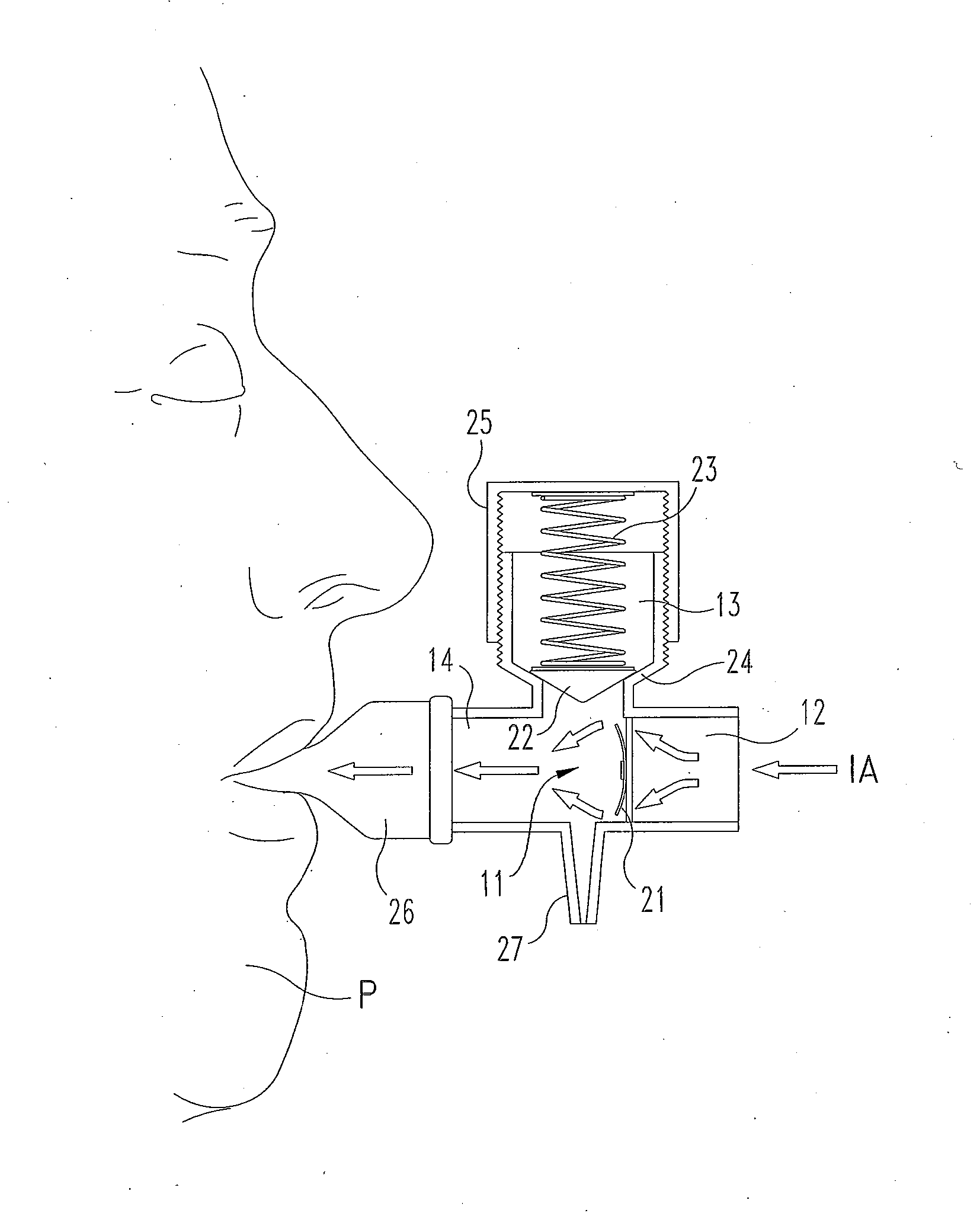

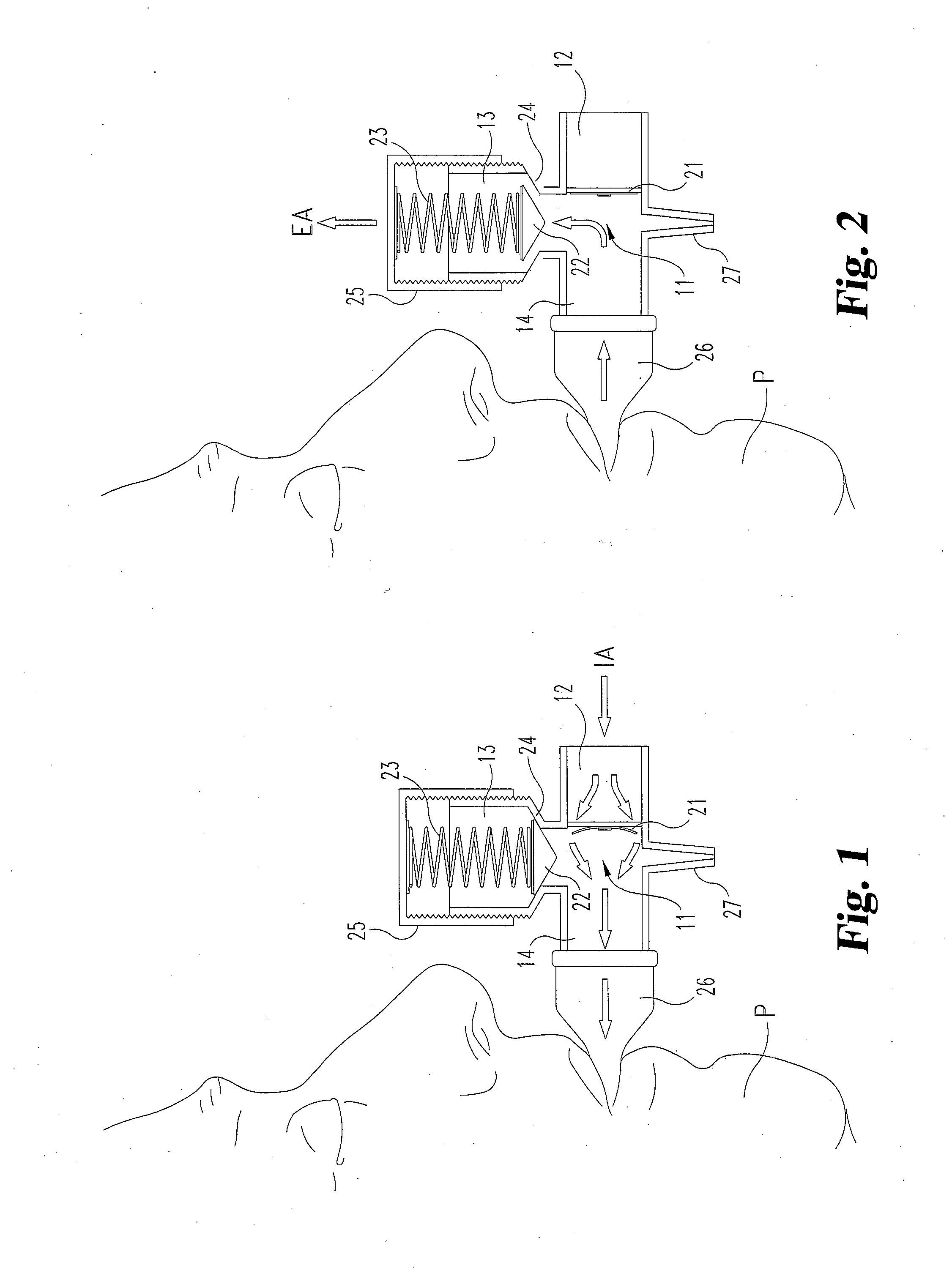

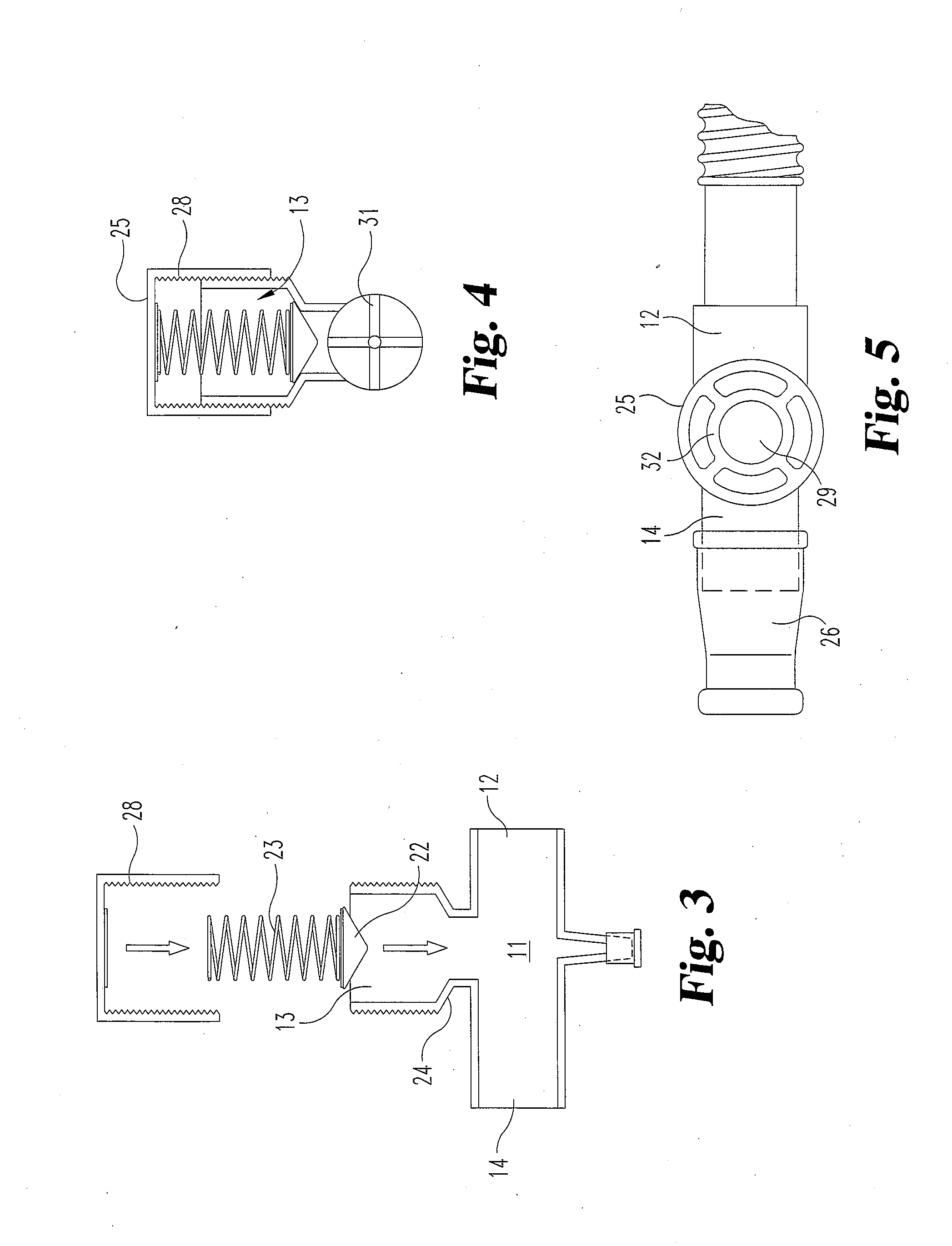

Mechanical Insufflation/Exsufflation Airway Clearance Apparatus

ActiveUS20120285460A1Maximize airflowOperating means/releasing devices for valvesBreathing filtersPositive pressureEngineering

An MIE apparatus has a blower, a direction valve, an oscillator, and a mask hose connector. The blower is connected to the direction valve, which is connected to the oscillator, which is connected to the hose connector. During insufflation, a direction valve connects exhaust of a blower to an oscillator, causing positive pressure at the hose connector. During exsufflation, the direction valve connects the blower intake to the oscillator, causing negative pressure at the hose connector. The oscillator is a butterfly valve with a 360° rotating disc. During insufflation, the disc is fixed to steadily modulate the airflow. During exsufflation, the oscillator is inactive or in flutter mode. When inactive, the disc is fixed to allow maximum air flow. In flutter mode, the disc continuously rotates so that the air flow rapidly alternates between maximum and minimum.

Owner:HILL ROM SERVICES

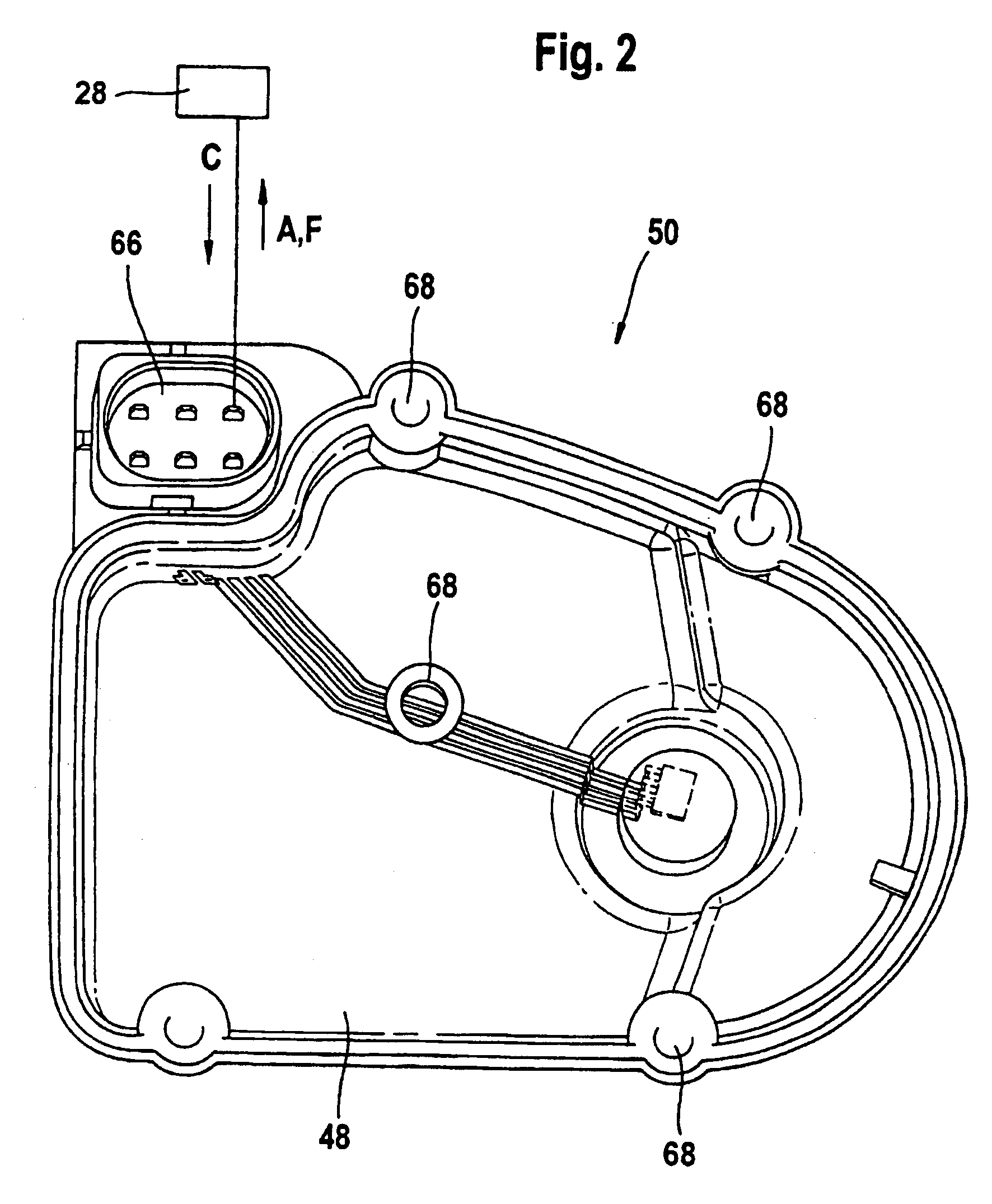

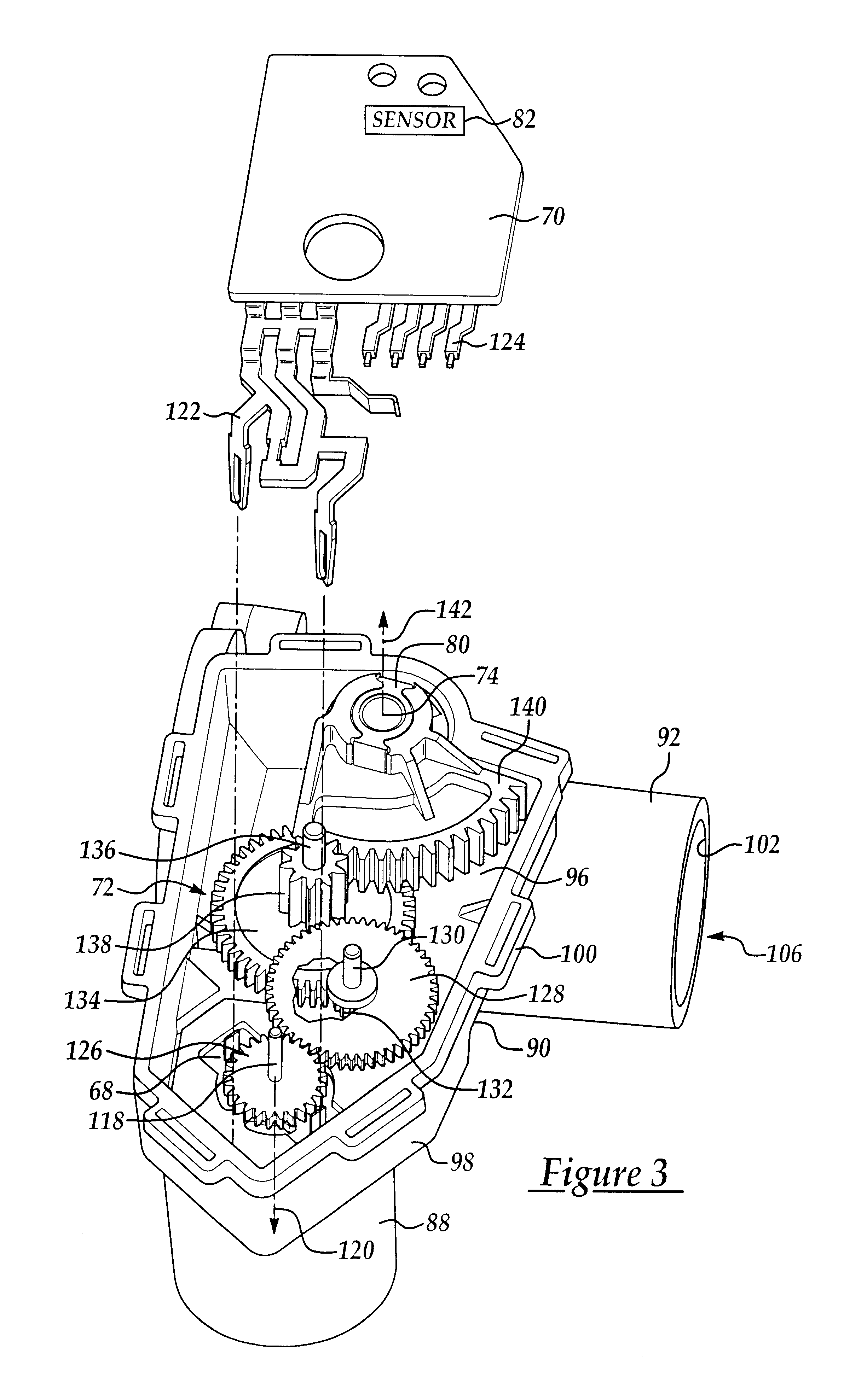

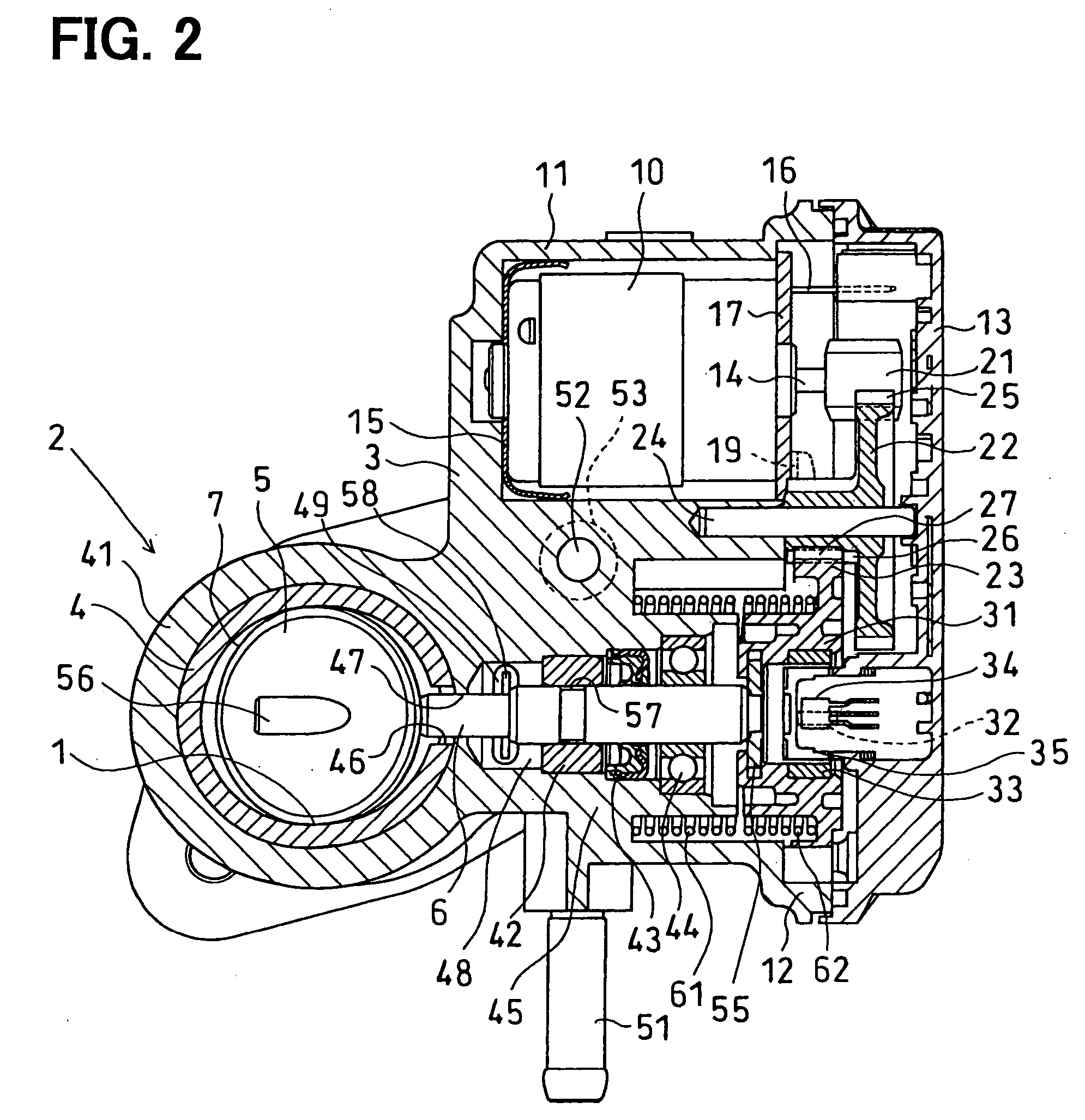

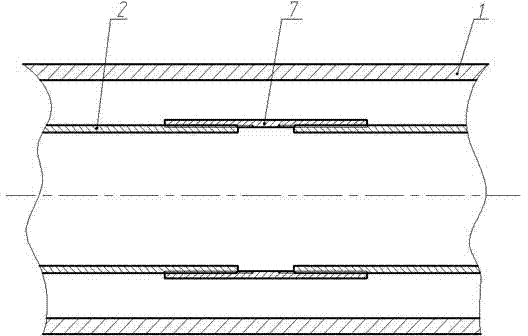

Method for the contactless detection of the position of a butterfly valve shaft of a butterfly valve connecting piece and butterfly valve connecting piece

InactiveUS7036791B2Accurate detectionHigh precisionOperating means/releasing devices for valvesUsing electrical meansControl signalButterfly valve

The invention relates to a method for the contactless detection of the position of a butterfly-valve shaft of a butterfly valve connecting piece, the butterfly-valve shaft being driven by an electric actuator and having a magnet at one end, which is aligned in a contactless manner with a sensor that is located on a cover. An aim of the invention is to reliably guarantee the detection of the position of the butterfly-valve shaft, even over particularly long periods of time using a contactless position detection device. To achieve this, the sensor has a first and a second magnetoresistive sensor element, an approximately sinusoidal signal being generated in the first sensor element and an approximately cosinusodial signal being generated in the second sensor element by means of the magnet, during the rotation of the butterfly-valve shaft. According to the method, an approximately arc tangential signal is generated in the butterfly-valve connecting signal. The control signal is fed to the actuator that is located in the butterfly-valve connecting piece, to adjust the position of the butterfly-valve shaft.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Mechanical insufflation/exsufflation airway clearance apparatus

ActiveUS8539952B2Operating means/releasing devices for valvesBreathing filtersPositive pressureEngineering

An MIE apparatus has a blower, a direction valve, an oscillator, and a mask hose connector. The blower is connected to the direction valve, which is connected to the oscillator, which is connected to the hose connector. During insufflation, a direction valve connects exhaust of a blower to an oscillator, causing positive pressure at the hose connector. During exsufflation, the direction valve connects the blower intake to the oscillator, causing negative pressure at the hose connector. The oscillator is a butterfly valve with a 360° rotating disc. During insufflation, the disc is fixed to steadily modulate the airflow. During exsufflation, the oscillator is inactive or in flutter mode. When inactive, the disc is fixed to allow maximum air flow. In flutter mode, the disc continuously rotates so that the air flow rapidly alternates between maximum and minimum.

Owner:HILL ROM SERVICES

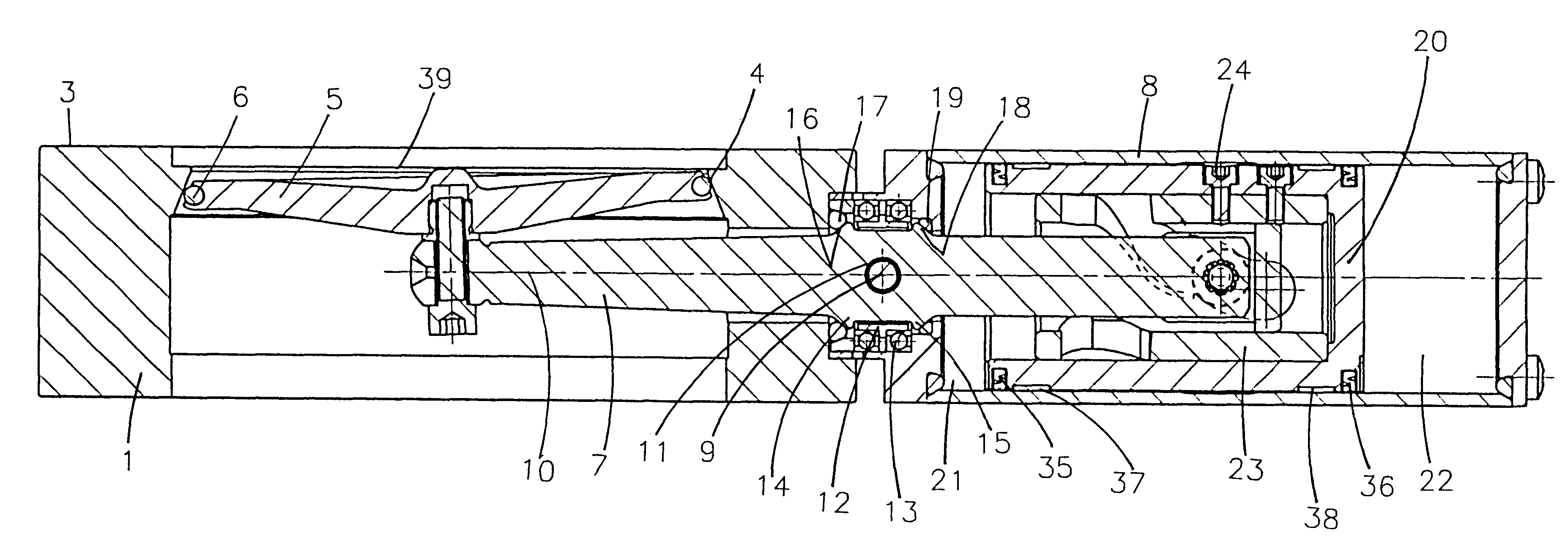

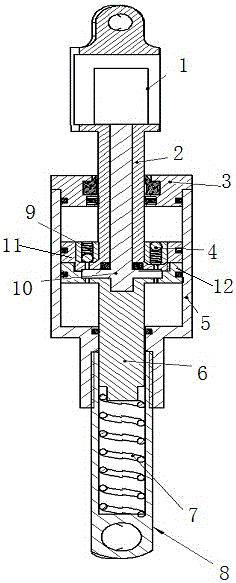

Electric control hydraulic damping cylinder structure for intelligent knee joint

ActiveCN105769395ARealize two-way independent controlDamping adjustment continuousProsthesisKnee JointElectric control

The invention relates to an electric control hydraulic damping cylinder structure for an intelligent knee joint. The electric control hydraulic damping cylinder structure is characterized in that an upper piston is provided with a hollow piston rod and an upper piston block, the upper piston block is positioned at the lower end of the hollow piston rod, two hydraulic oil channels of upper and lower chambers are arranged on the upper piston block, and check valves with opposite flow shutting directions are respectively arranged in the two hydraulic oil channels of the upper and lower chambers; a lower piston is provided with a lower piston rod and a lower piston block, the lower piston block is positioned at the upper end of the lower piston rod, two fan-shaped holes which are used as hydraulic oil channels of upper and lower chambers are formed in the lower piston block, the upper piston block and the lower piston block are connected with each other in a cylinder block, and a butterfly valve plate is arranged between the upper piston block and the lower piston block, is connected with a stepper motor by a valve element stem in the hollow piston rod and can rotate under the control of the stepper motor, so that the flow passage areas of the hydraulic oil channels of the upper and lower chambers in the lower piston block can be changed, and the flow rates of the upper and lower chambers of a hydraulic cylinder can be changed. The electric control hydraulic damping cylinder structure has the advantage that bending and stretching damping of the prosthetic knee joint can be bidirectionally independently controlled by the single motor.

Owner:上海理工资产经营有限公司

Micro volume actuator for an air turbine starter

InactiveUS6694746B2Operating means/releasing devices for valvesEngine manufactureButterfly valveActuator

An air turbine starter system and air turbine starter valve that has a microvolume actuator to prevent the connected butterfly valve from opening too quickly. Air turbine starter valves can in some circumstances freeze shut, but may be opened by normal actuator operation. Such operation may open the valve too quickly due to stored potential energy. A sharp pressure transient may be inflicted upon the connected air turbine starter which can cause damage. The microvolume actuator air turbine starter system set forth herein allows generation of sufficient force to break ice and move the valve while minimizing stored potential energy that could open the valve too quickly.

Owner:HONEYWELL INT INC

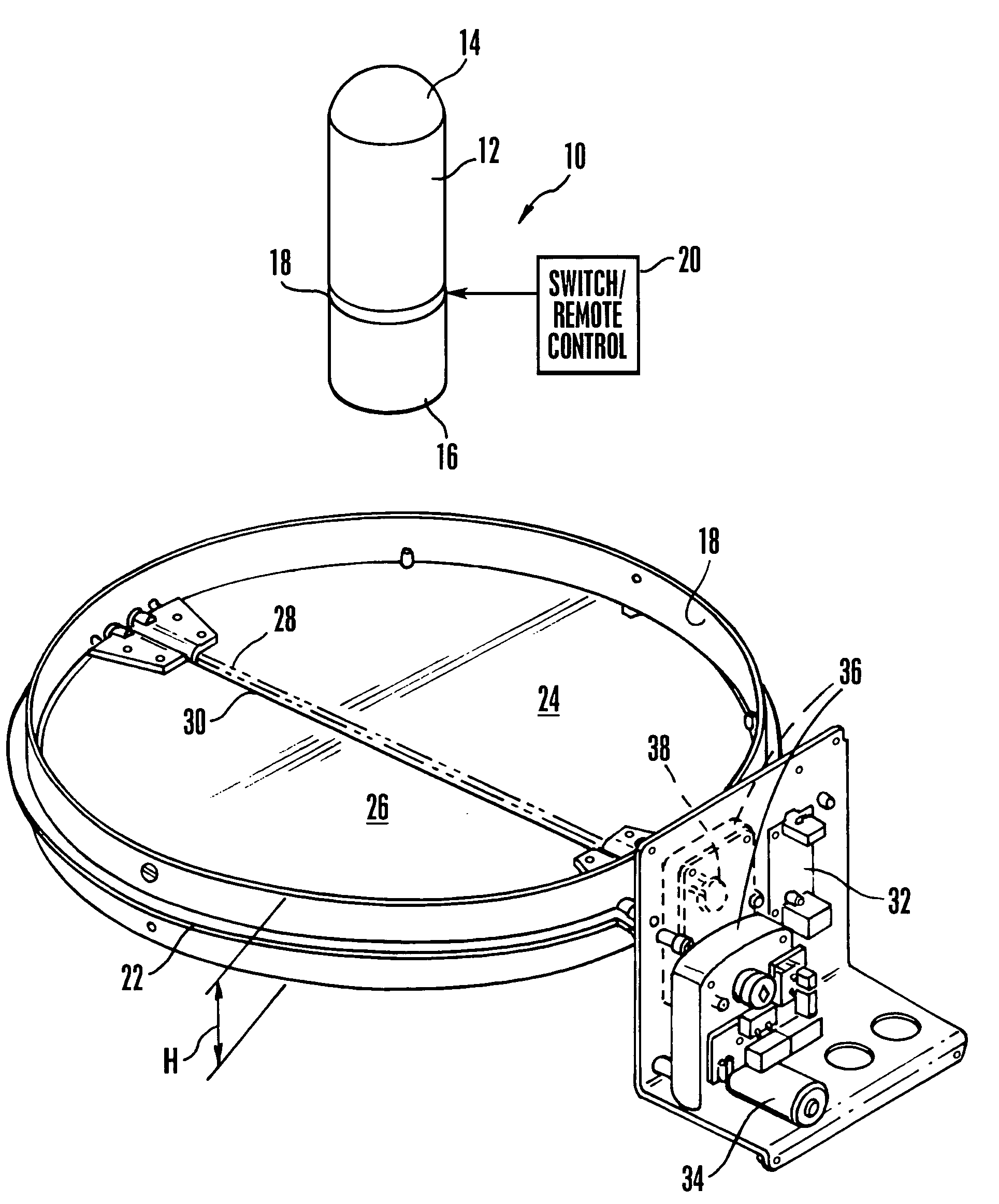

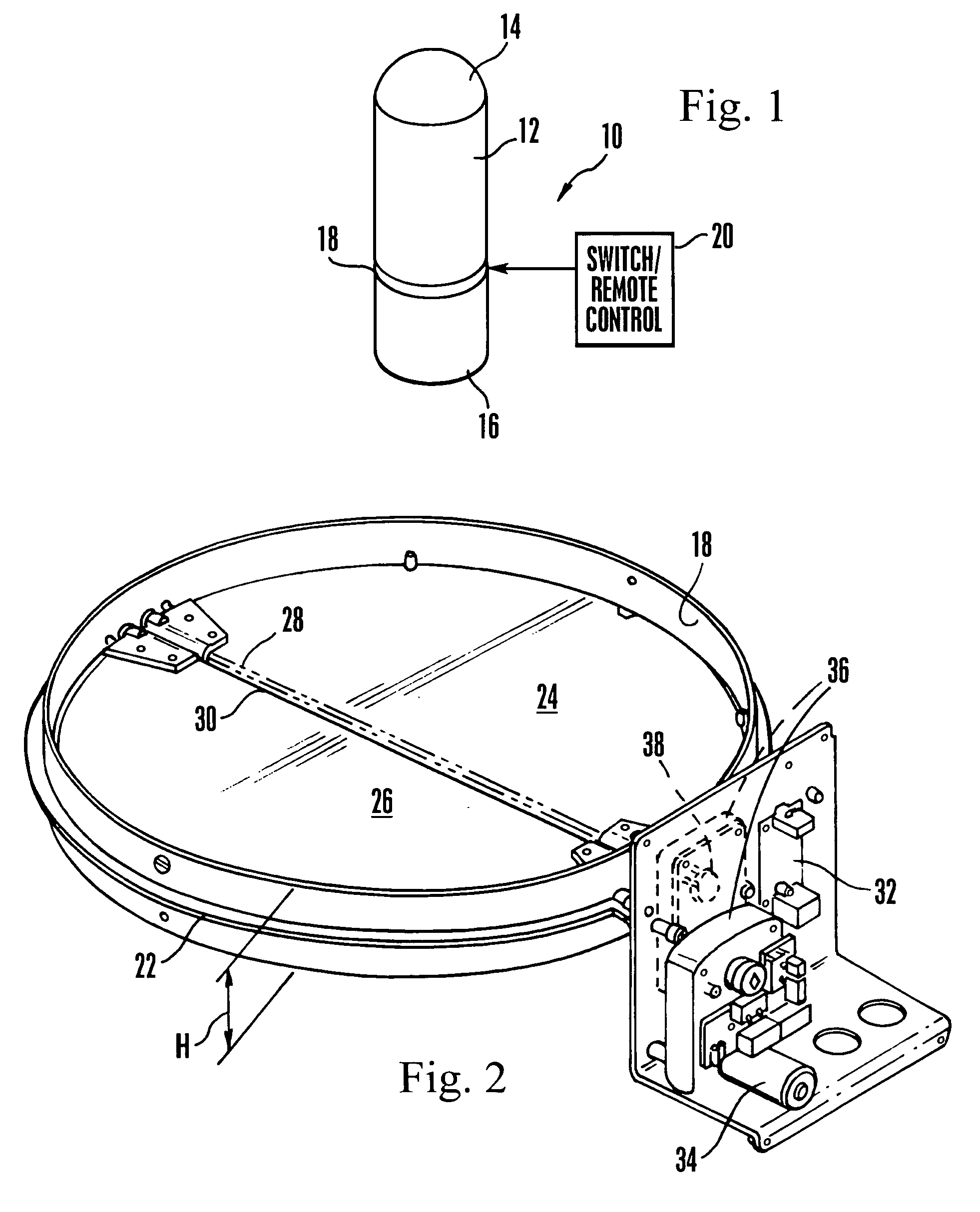

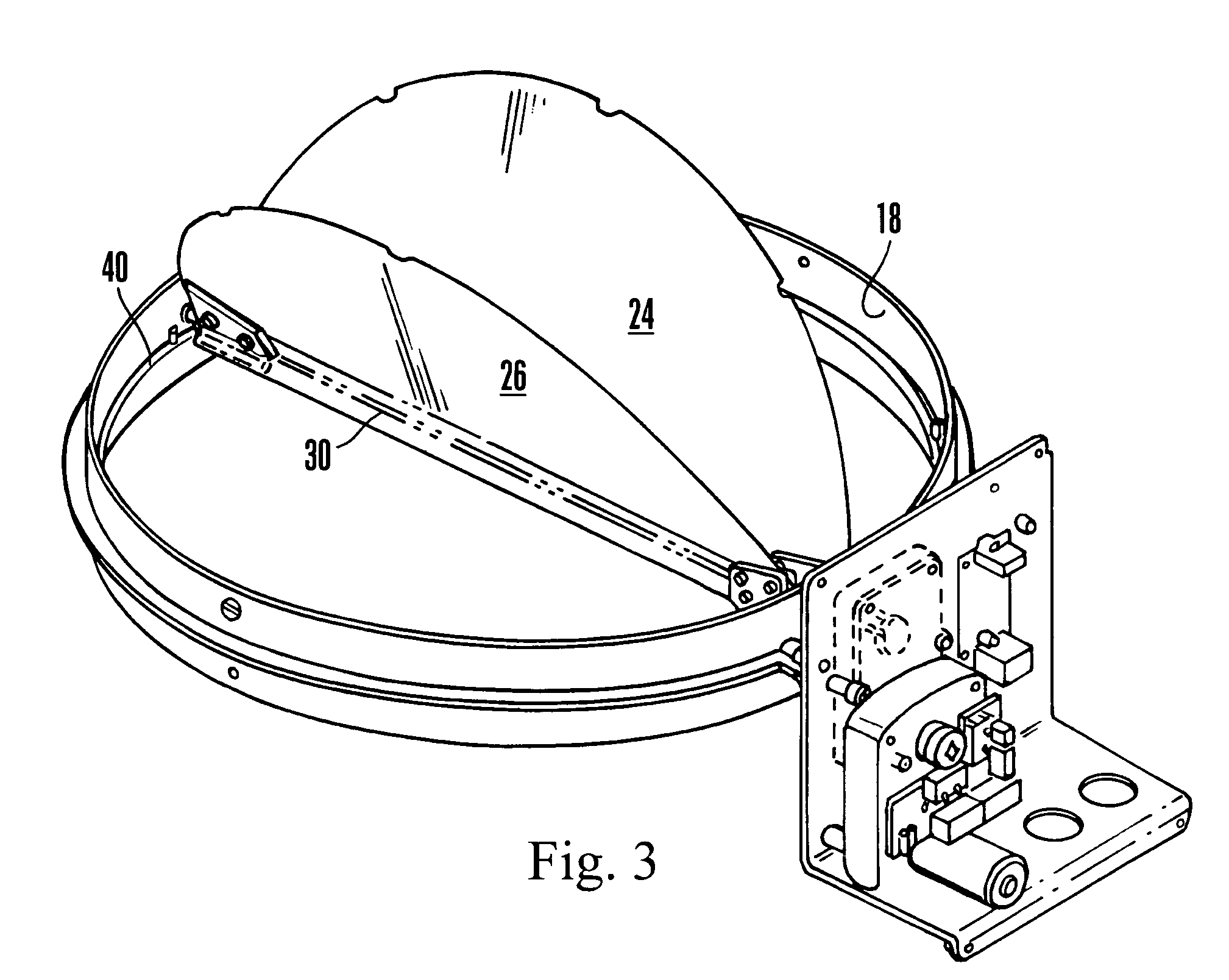

Butterfly valve for skylight

A valve for selectively blocking the light passageway of a skylight includes a cylindrical shroud and first and second semicircular butterfly valve elements that pivot on respective axles within the shroud to selectively block the skylight. The axles can ride on a common motor-driven cam between a horizontal orientation to block the skylight and a vertical orientation to allow light to pass. The motor can be powered by a universal power supply that can operate at anywhere from below 100 volts to above 270 volts.

Owner:SOLATUBE INT INC

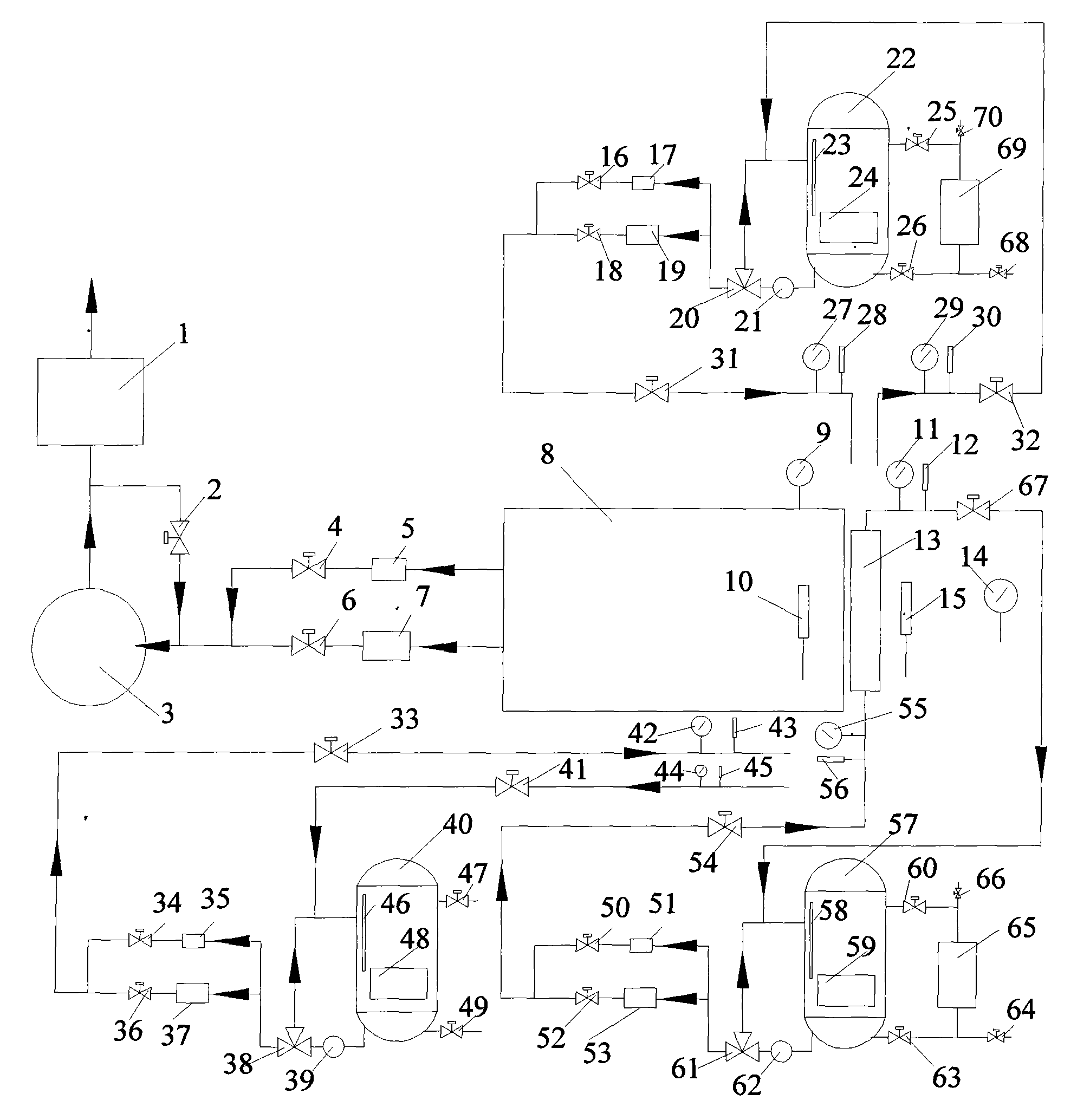

System for testing heat-transfer performance of gas-water-oil heat interchanger

InactiveCN101587027AEasy to operateReduce the human factorMaterial thermal conductivityStructural/machines measurementExpansion tankPilot system

The invention relates to a system for testing heat-transfer performance of a gas-water-oil heat interchanger, and is composed of a steady air system, a cold water system, a hot water system and a oil system. The steady air system: a voltage-stabilizing case output end is connected with inlets between the first steady air flow gauge and the first steady air pneumatic butterfly valve or the second flow gauge and the second steady air pneumatic butterfly valve and high-pressure centrifugal fan, wherein, steady air bypass electric control valve is connected between the inlet and the outlet of the high-pressure centrifugal fan; the hot water system: an expansion water tank, an electric heater water tank and an outlet are connected to the water pump, and water enters into the heat interchanger to be measured through the bypass of the electric three-way valve, the water flow gauge and the electromagnetic valve, thereby forming a closed loop system; the cold water system: compared with the hot water system, the system does not have an expansion water tank; the oil loop system is a open and close type circulating system: the outlets of the expansion fuel tank and the fuel-tank are connected to the oil pump, oil enters into the heat interchanger to be measured through the bypass of the electric three-way valve, the oil flow gauge and the electromagnetic valve, thereby forming a closed circulation for testing the heat exchange performance of the oil-water, oil-gas heat interchanger.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

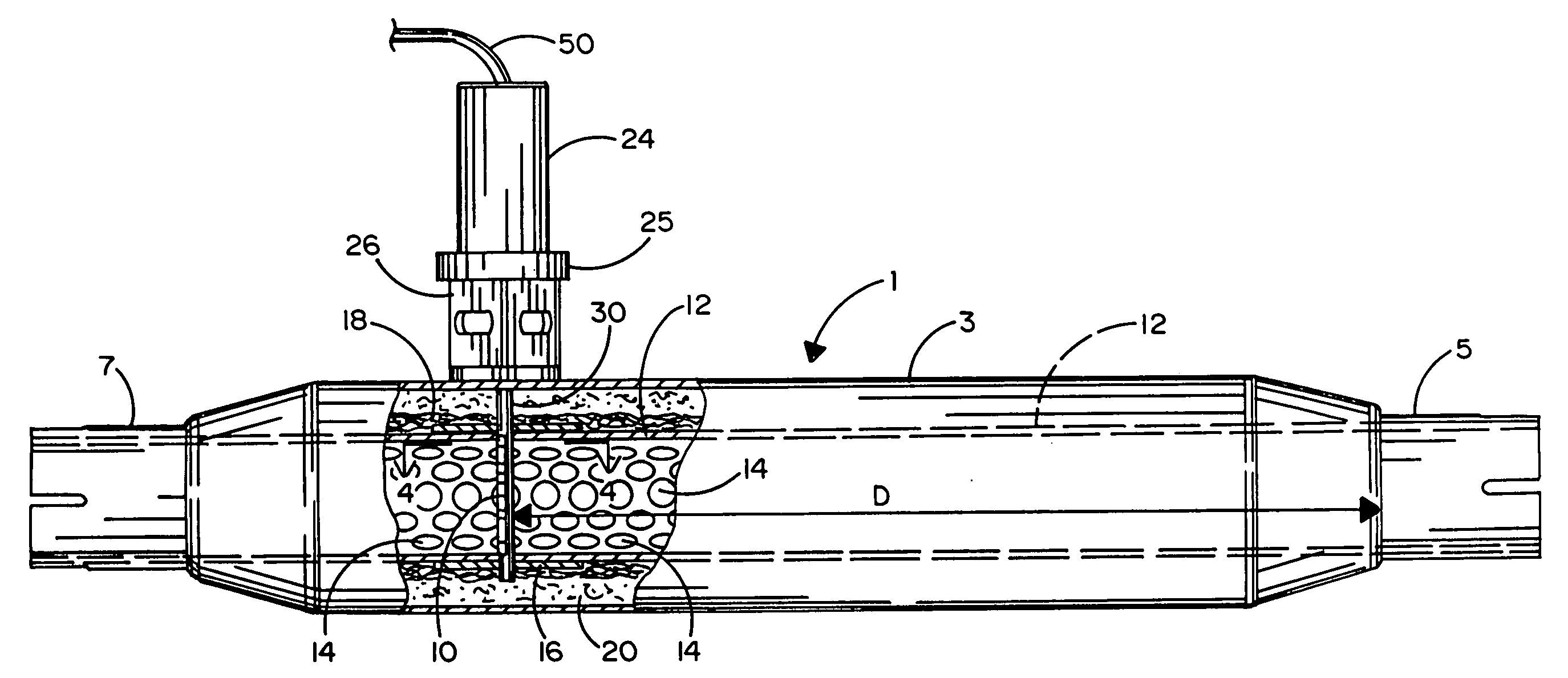

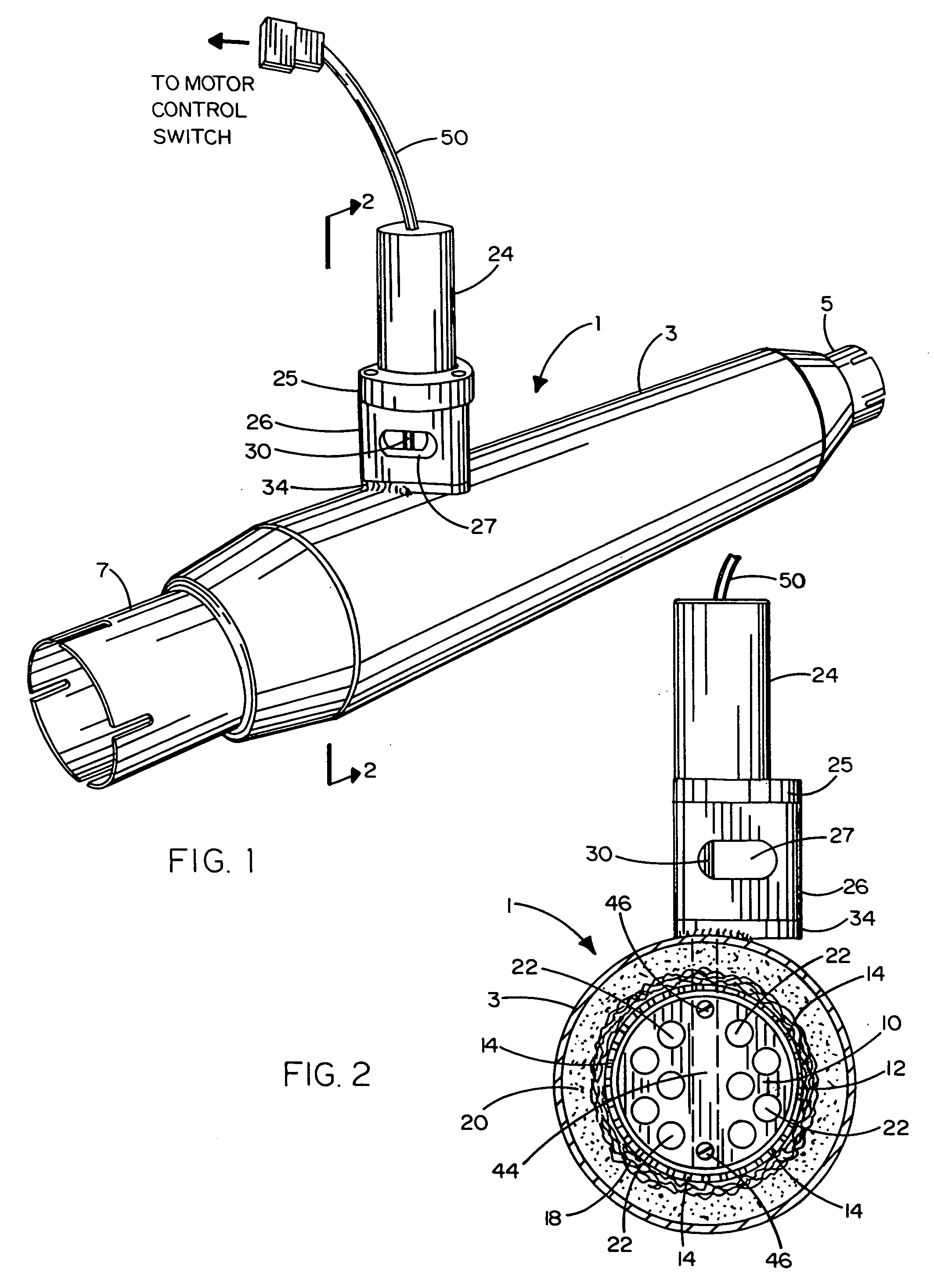

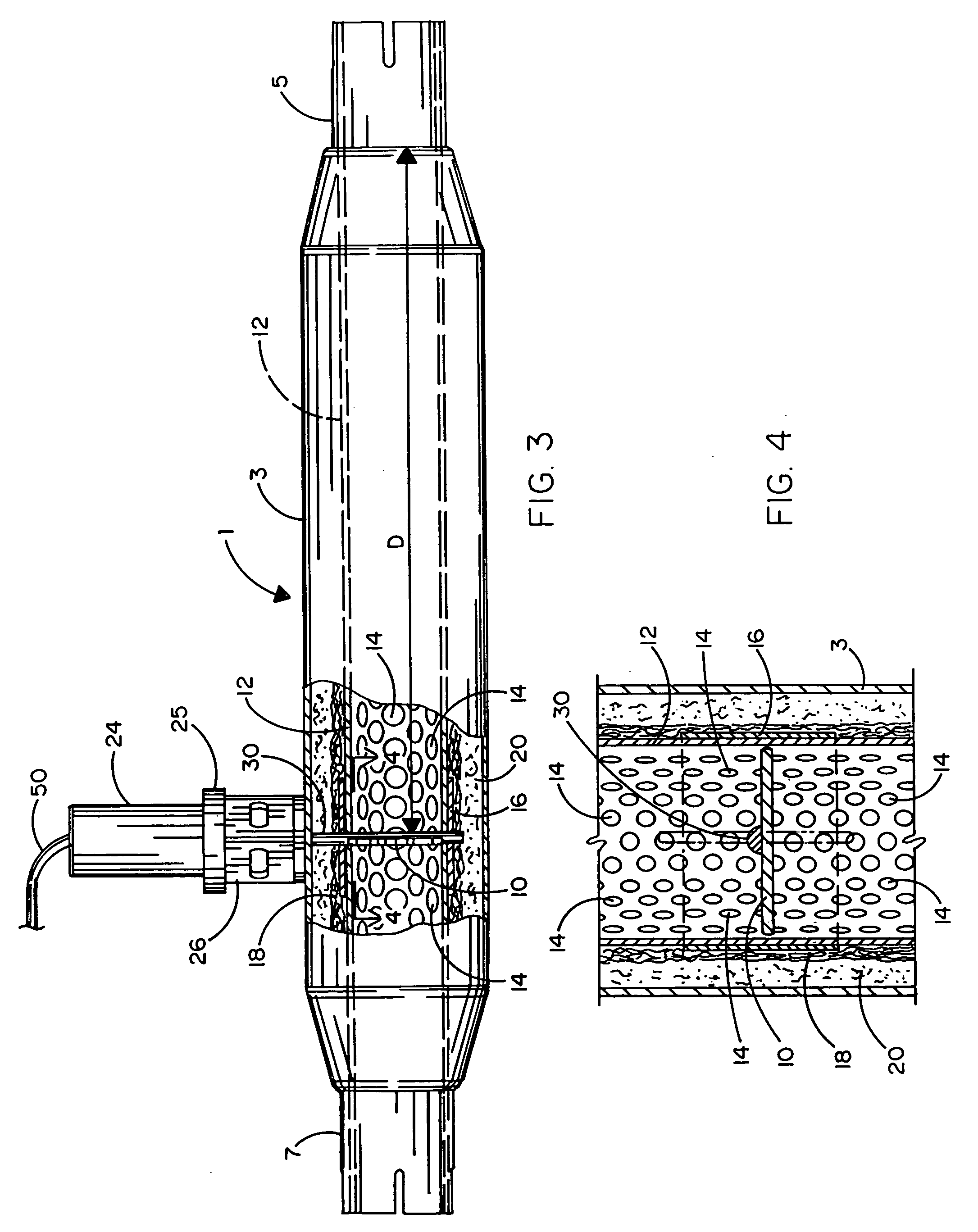

Muffler having adjustable butterfly valve for improved sound attenuation and engine performance

InactiveUS20080023264A1Minimize sound levelImprove fuel economySilencing apparatusEqualizing valvesUltrasound attenuationMobile vehicle

A muffler to be coupled to the engine of a motor vehicle (e.g., a car, truck, motor cycle, boat, and the like) so that exhaust gases emitted by the engine can be exhausted to the atmosphere. The muffler includes an outer cylindrical body and an inner cylindrical liner having a plurality of apertures formed therethrough. Sound absorbing packing material is located in an annular space between the outer body and the inner liner. An adjustable butterfly valve is located within the inner liner and rotatable between open and closed positions to control the gas flow through the liner, the sound generated by the muffler as a result thereof, and the performance of the engine to which the muffler is coupled. The rotation of the butterfly valve is controlled by an external DC motor or a continuous cable. The shaft of the motor or the cable is connected through the outer body and inner liner of the muffler to the butterfly valve. By closing a manually accessible motor control switch electrically connected to the motor or by pulling on the cable, the operator of the motor vehicle has the ability to control the rotation of the butterfly valve connected to the motor shaft or the cable while the vehicle is in motion.

Owner:PACINI LARRY W +1

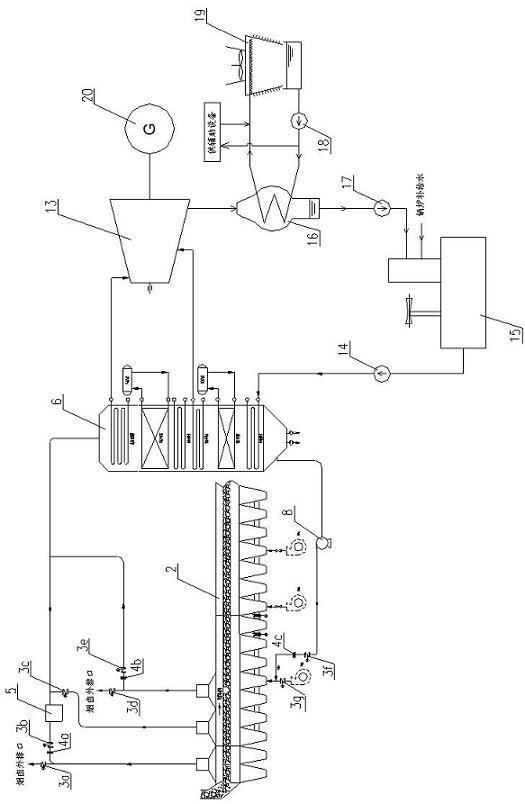

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

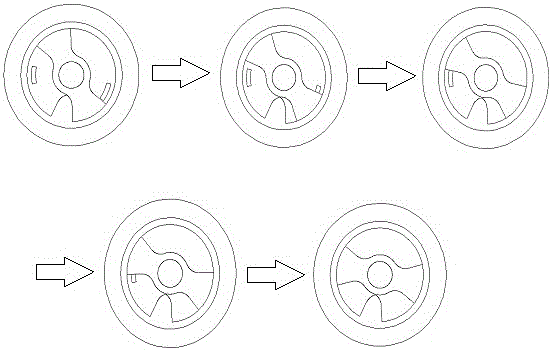

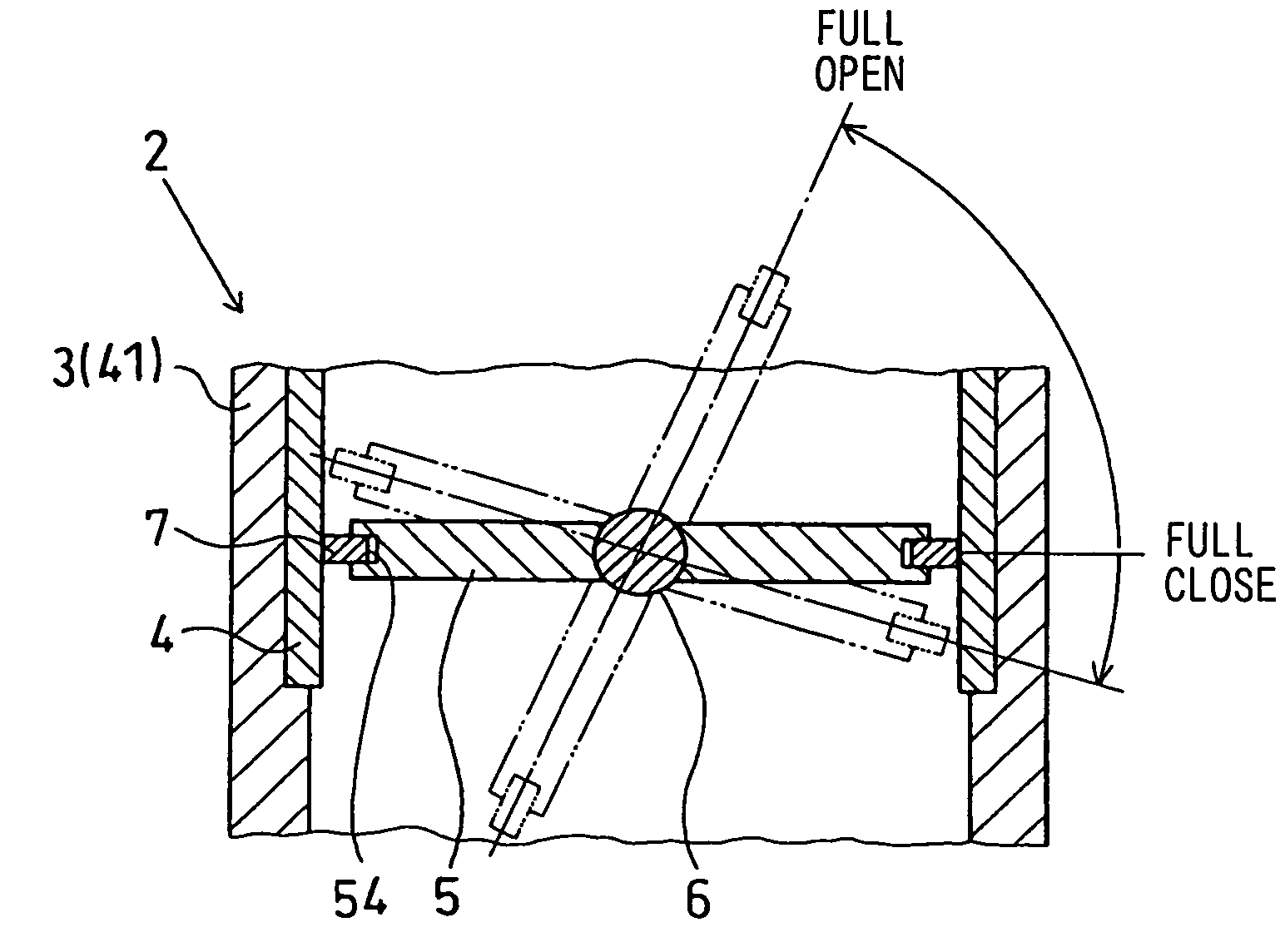

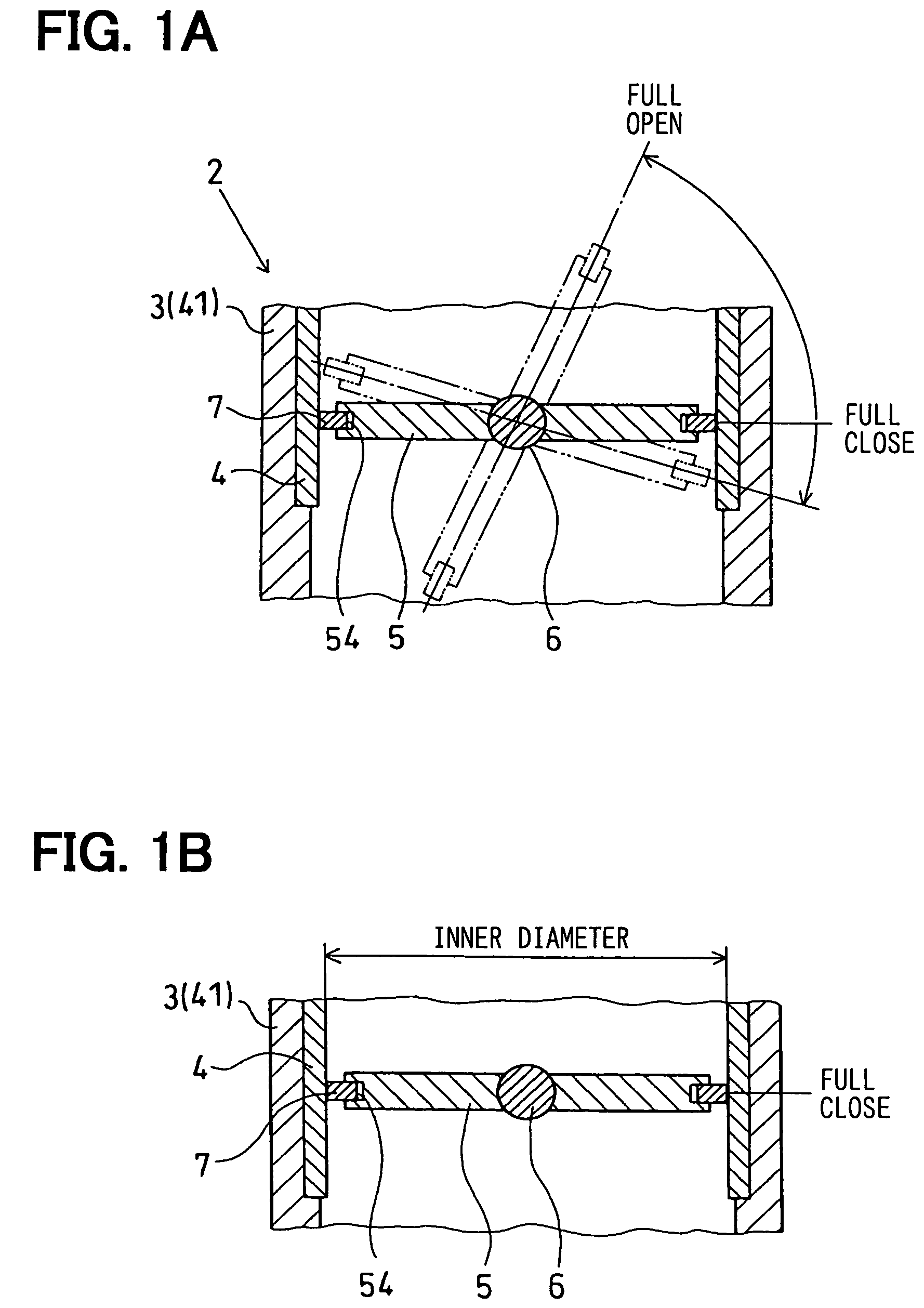

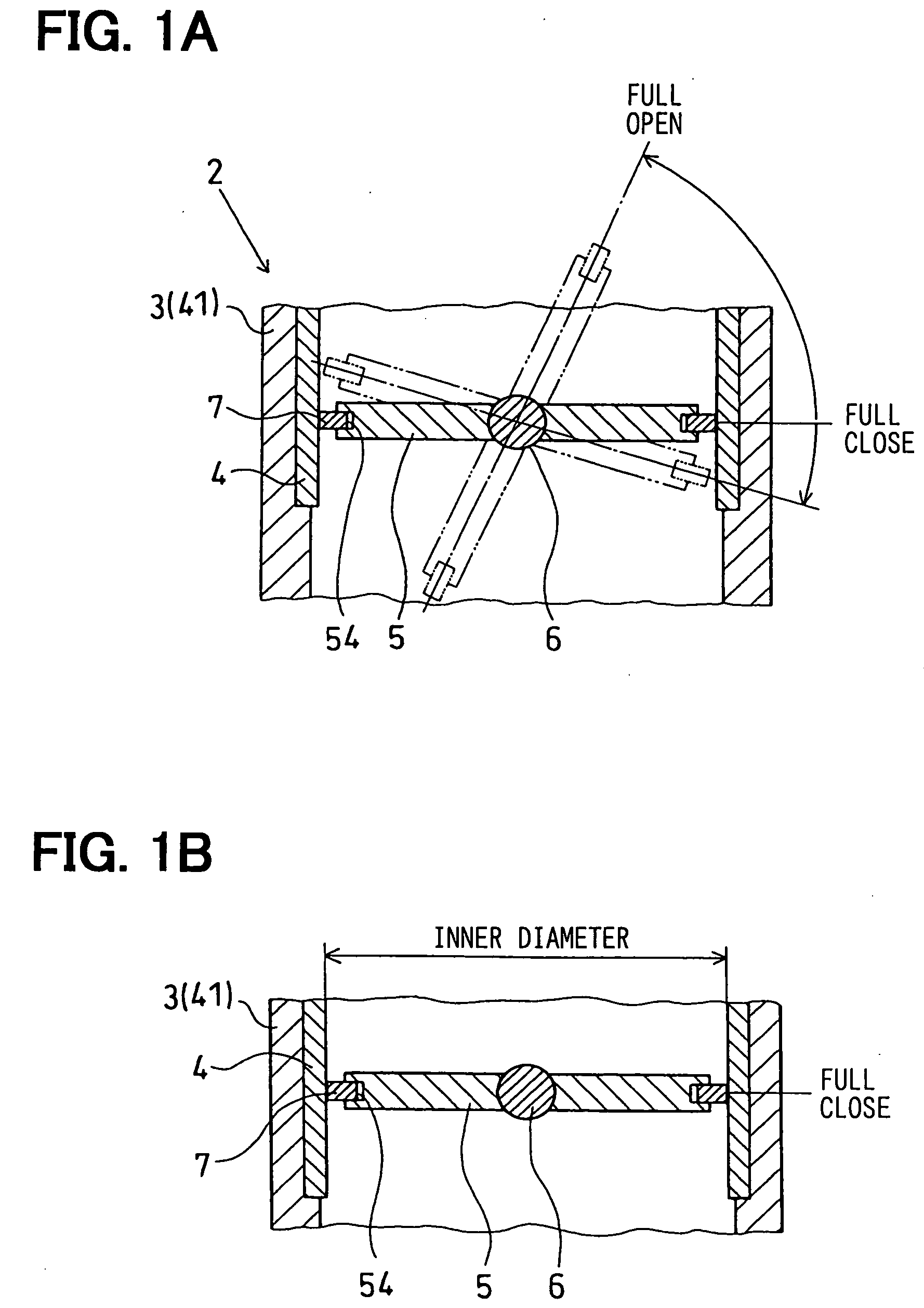

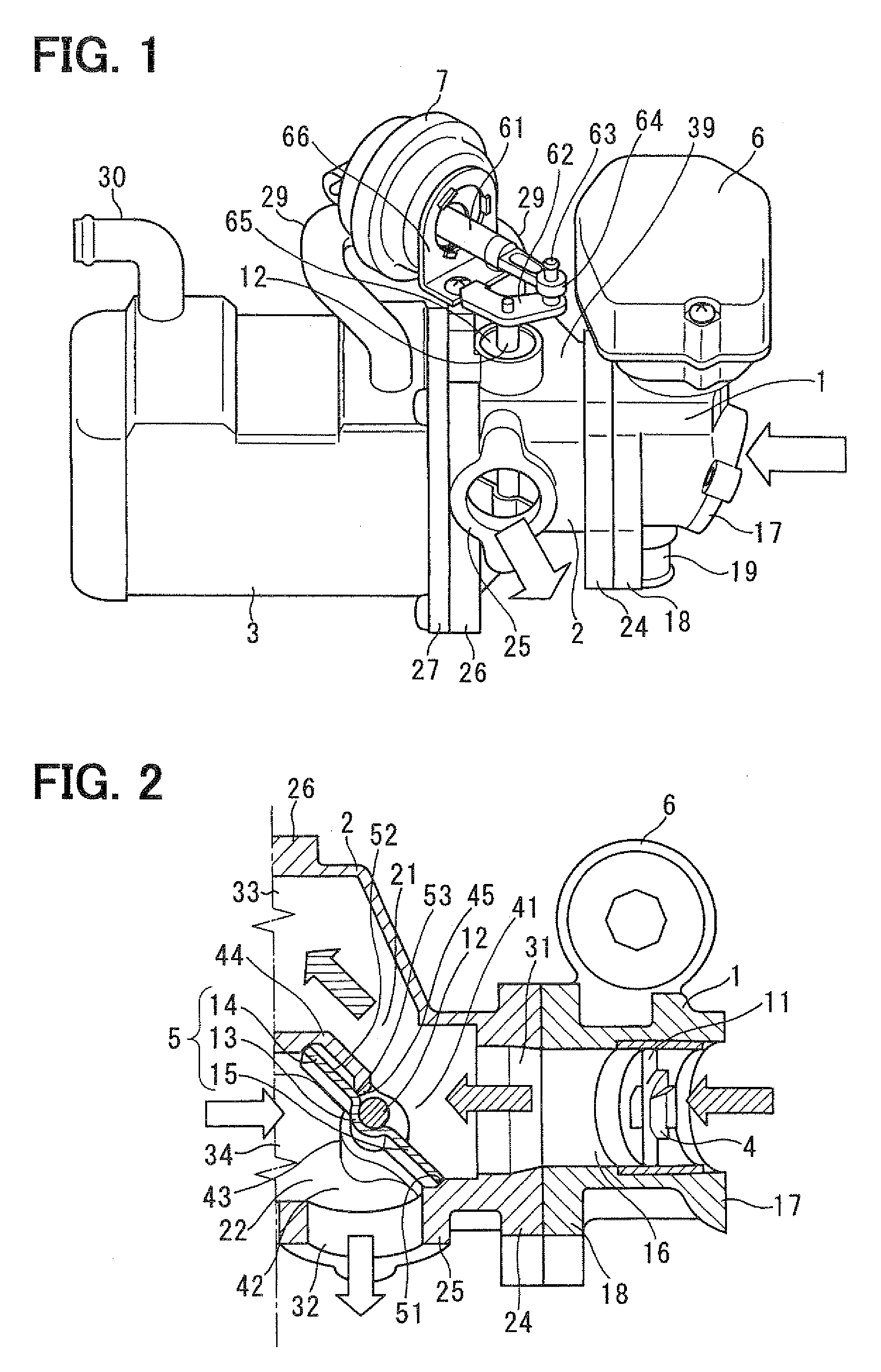

Emission gas recycling equipment having butterfly valve

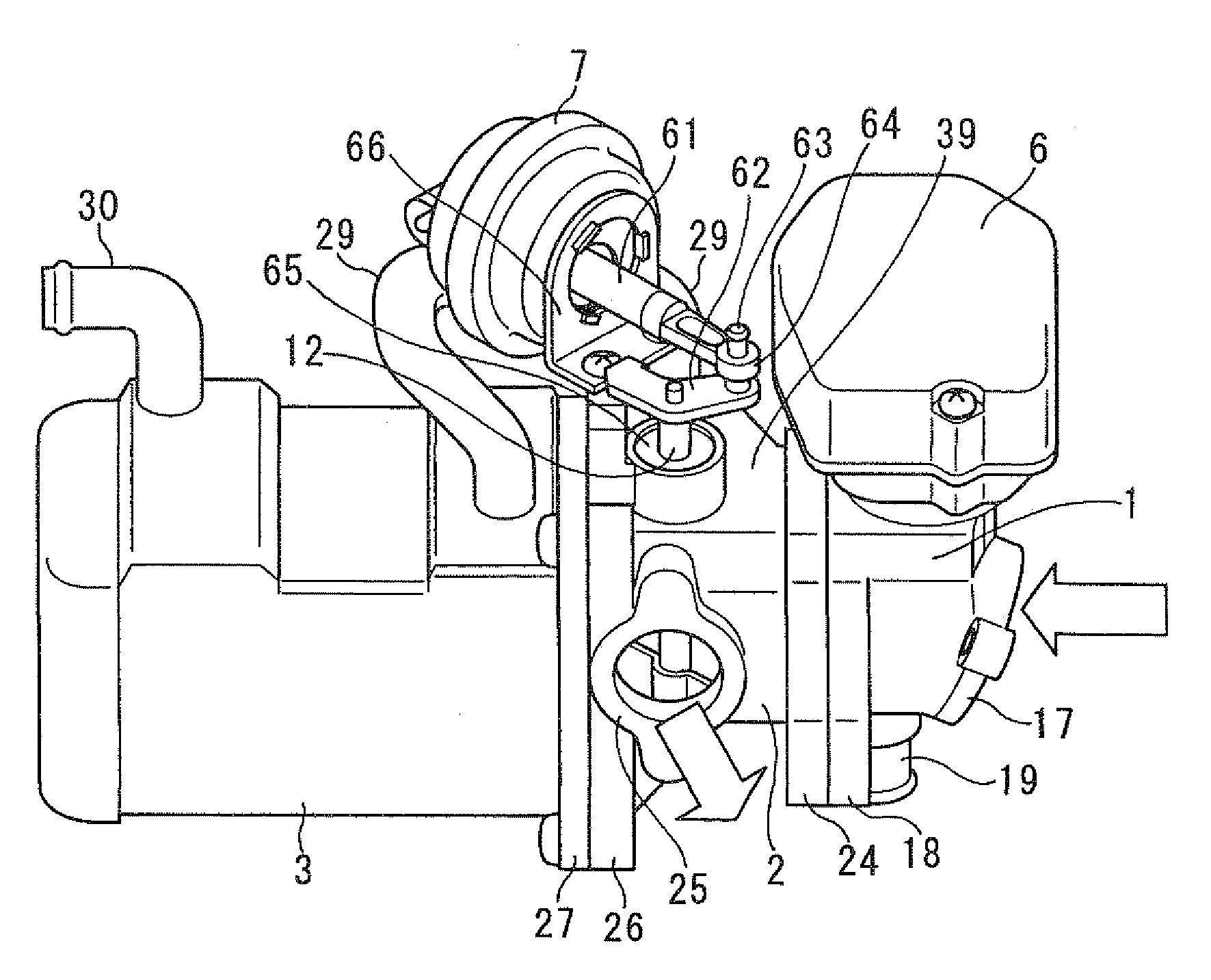

ActiveUS7168682B2Avoid expansionGuaranteed uptimeOperating means/releasing devices for valvesDrill bitsEngineeringProduct gas

Emission gas recycling equipment includes a passage for recycling a part of an emission gas and a control valve for controlling an amount of the part of the emission gas. The control valve includes: a housing having a pipe portion; a butterfly valve accommodated in the pipe portion rotatable in a first direction and a second direction; a seal ring for sealing a clearance; and valve open / close operation means for stopping the butterfly valve at the valve full close position after the valve open / close operation means operates the butterfly valve to open and to close equal to or more than one cycle across the valve full close position at the time when the engine stops or after the engine stops.

Owner:DENSO CORP

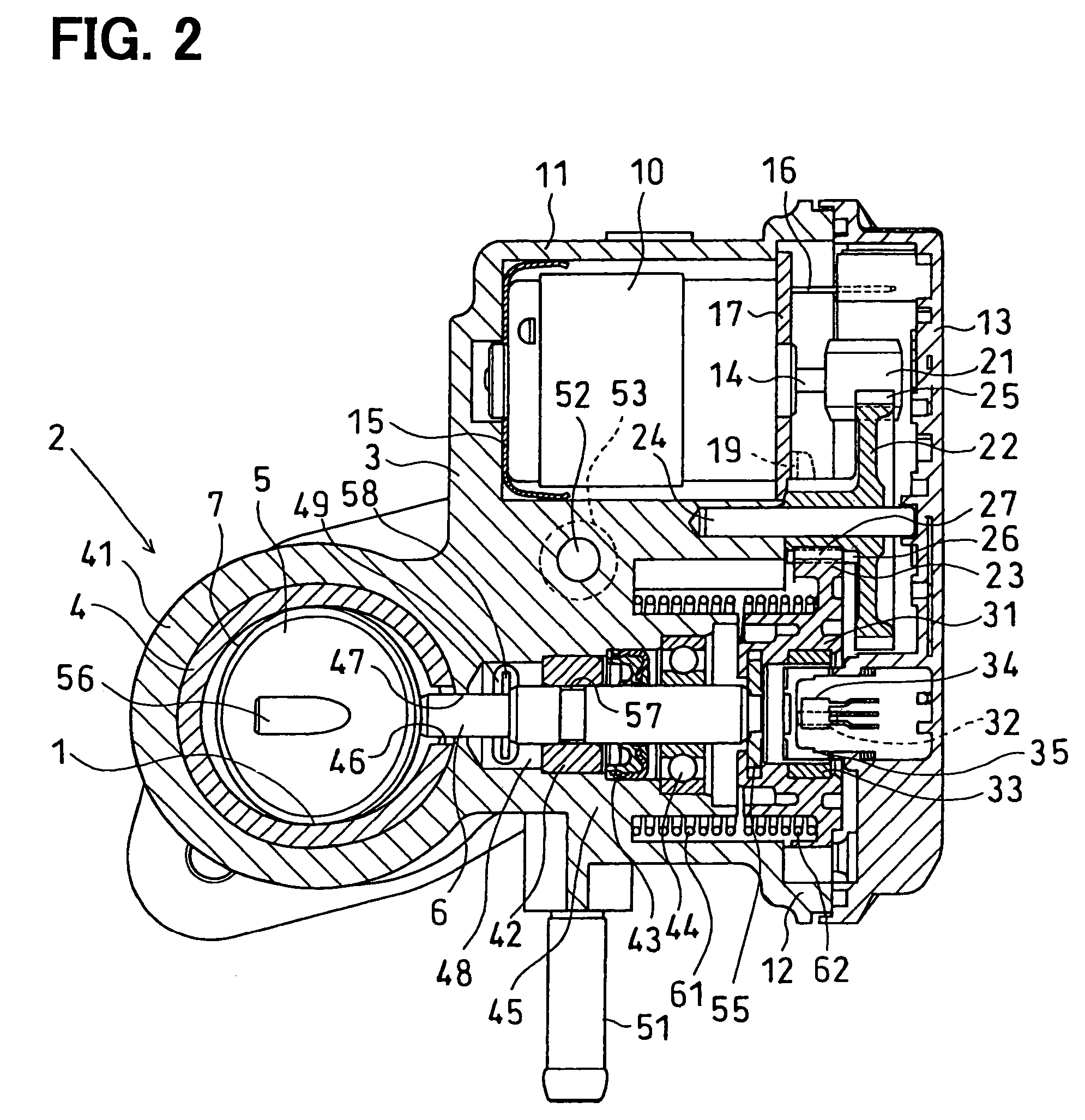

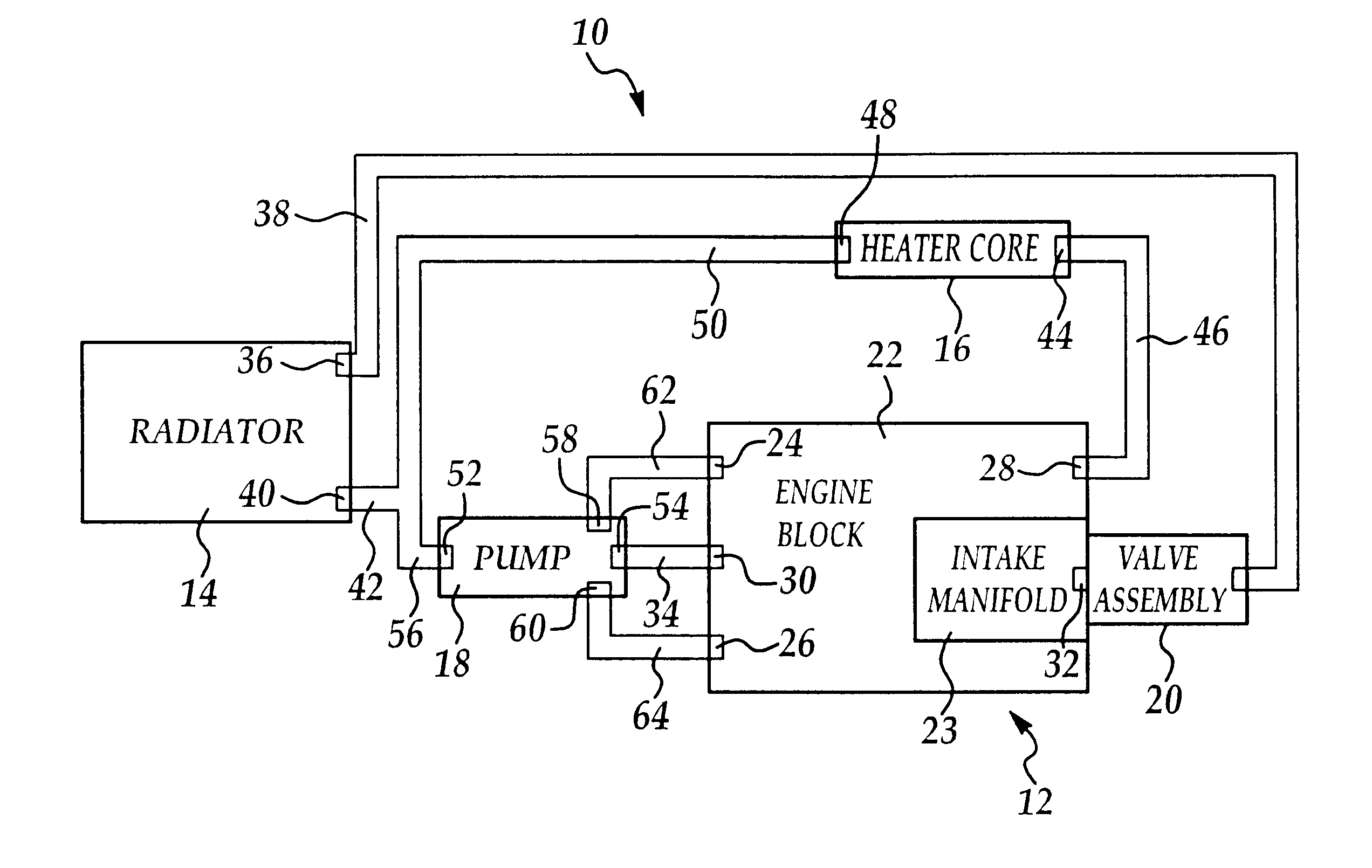

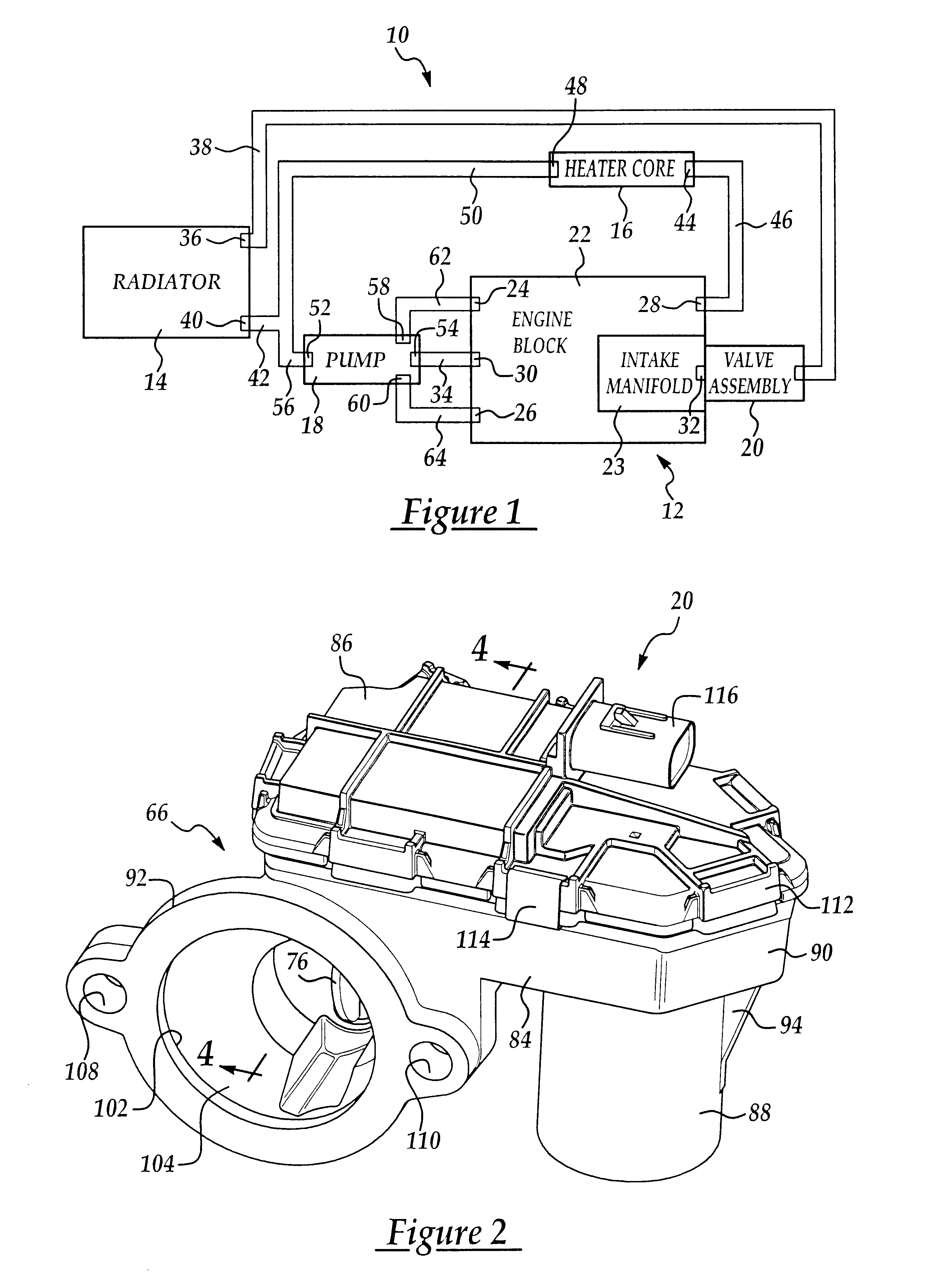

Valve assembly for controlling coolant flow exiting an engine

InactiveUS6659050B1Less effectEasy to packOperating means/releasing devices for valvesCoolant flow controlCoolant flowActuator

A valve assembly for controlling the amount of coolant exiting an engine is provided. The valve assembly includes a valve housing that is mounted to the engine and defines a passage that is in fluid communication with a coolant outlet in the engine. A motor in the valve housing drives a valve shaft that extends into the passage and on which a butterfly valve plate is mounted. The physical geometry of the inventive assembly is not significantly effected by changes in coolant temperature or coolant contamination and the integrates the valve member and actuator in a single assembly to improve packaging and material use and eliminates potential coolant leak points.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Emission gas recycling equipment having butterfly valve

ActiveUS20050183705A1Direction be limitedAvoid expansionDrill bitsOperating means/releasing devices for valvesButterfly valveControl valves

Emission gas recycling equipment includes a passage for recycling a part of an emission gas and a control valve for controlling an amount of the part of the emission gas. The control valve includes: a housing having a pipe portion; a butterfly valve accommodated in the pipe portion rotatable in a first direction and a second direction; a seal ring for sealing a clearance; and valve open / close operation means for stopping the butterfly valve at the valve full close position after the valve open / close operation means operates the butterfly valve to open and to close equal to or more than one cycle across the valve full close position at the time when the engine stops or after the engine stops.

Owner:DENSO CORP

Airway pressure control devices with flutter valve

A positive pressure airway device for providing resistance in an air pathway for a patient exhaling. The device includes a central tube region, a inspiratory air passageway for passing air into the central tube region when a patient breathing through the device inhales, and an expiratory air passageway for passing air out of the central tube region when a patient breathing through the device exhales, A valve in the expiratory air passageway allows air to flow out only when a patient using the device exhales with an expiratory air pressure greater than a selected pressure. The valve includes a stopper and a stopper-biasing spring. The passageways and / or stopper and / or spring are adapted to provide unbalanced forces against the stopper, thus causing the stopper to flutter and providing an oscillating pressure drop as the patient exhales.

Owner:RUSHER MICHAELJ

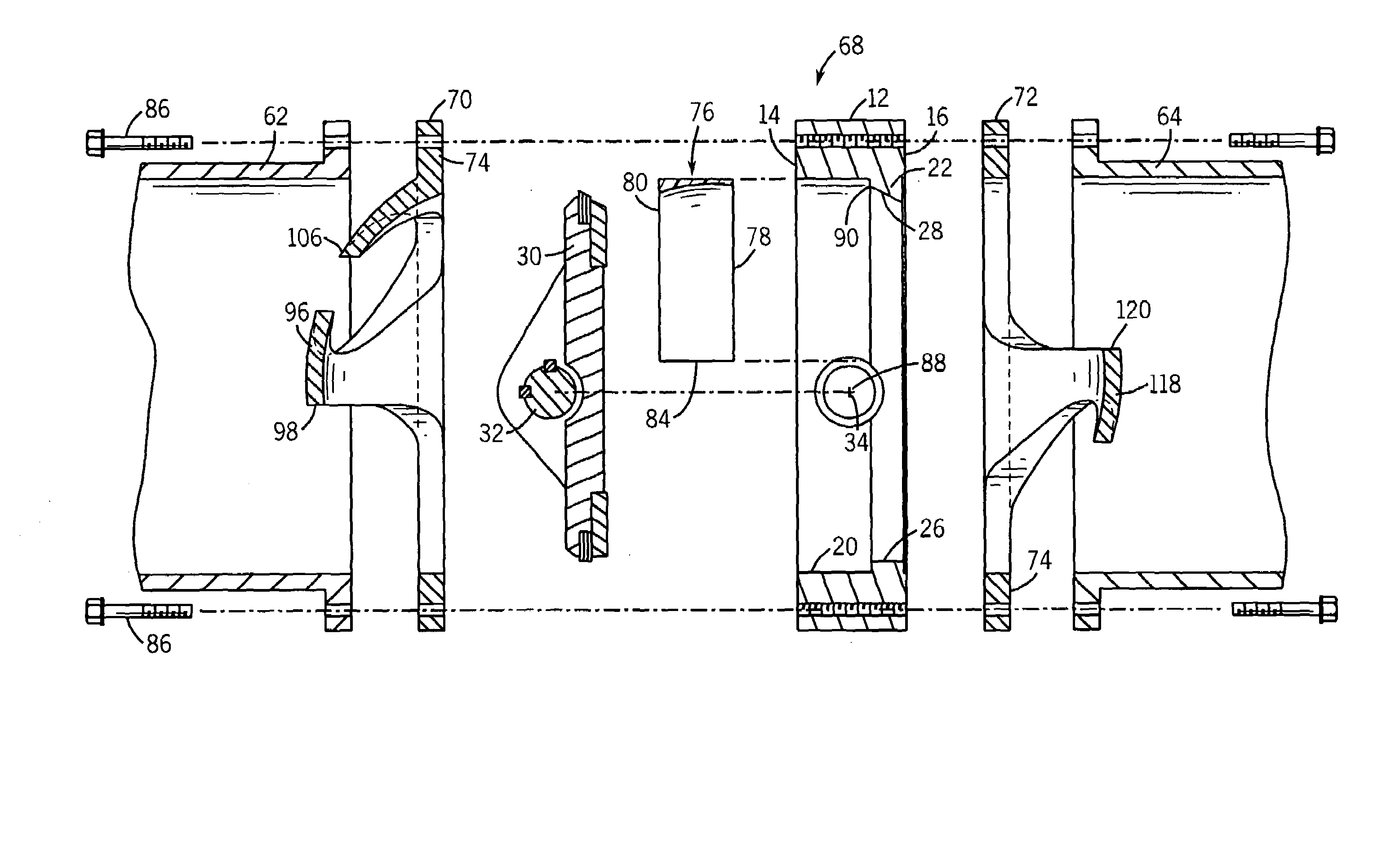

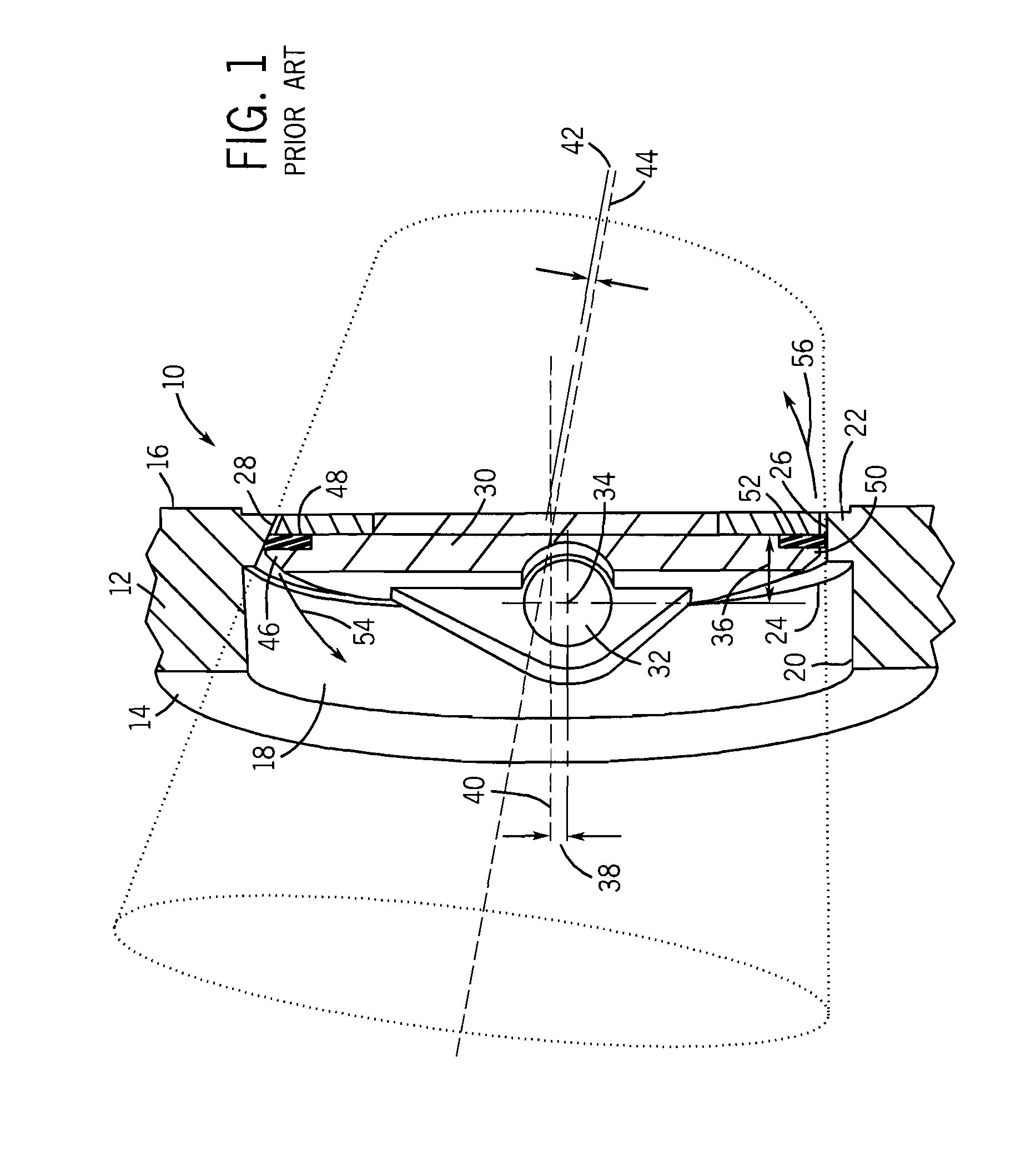

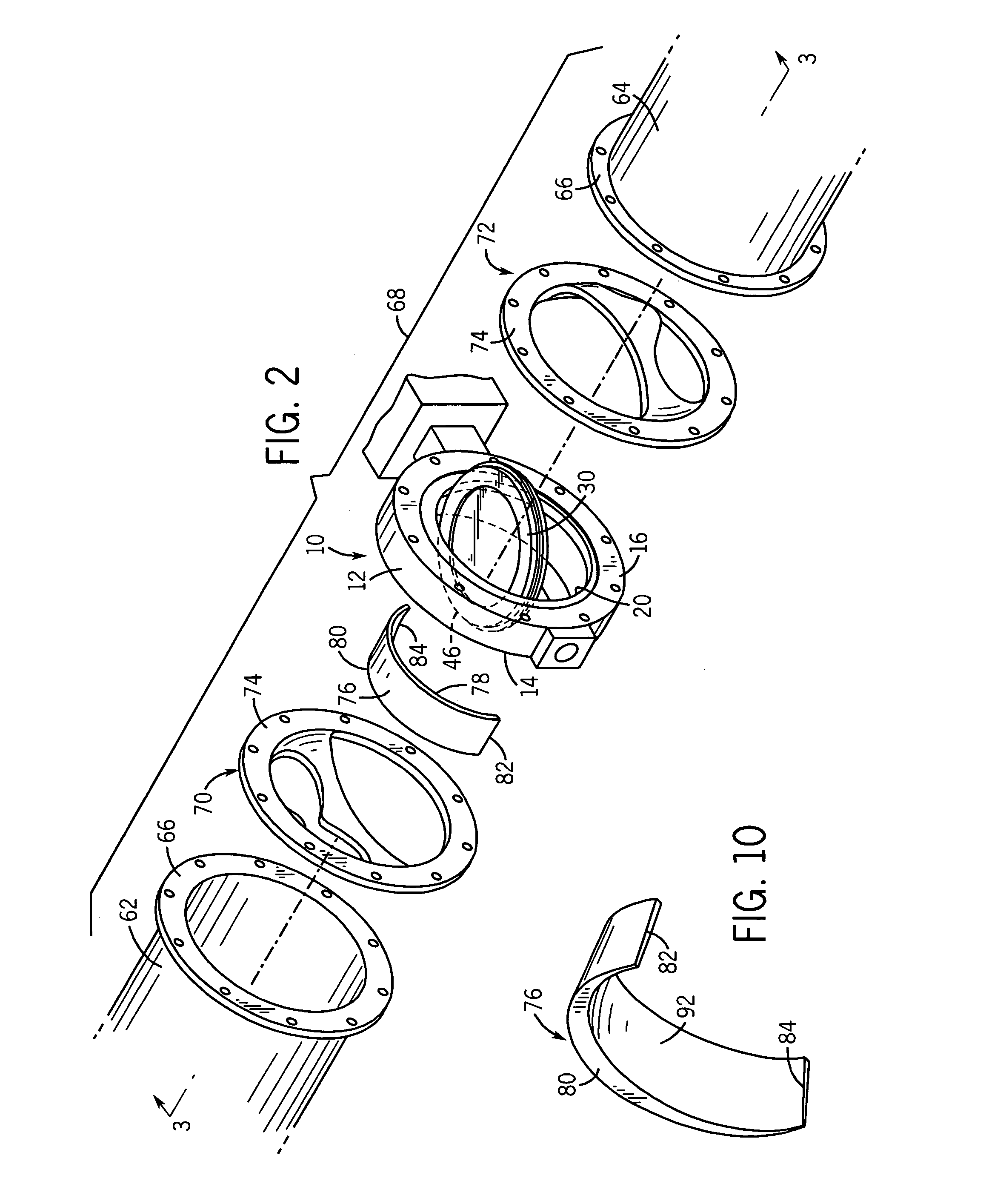

Butterfly valve assembly with improved flow characteristics

ActiveUS7264221B2Improve flow characteristicsImprove controllabilityValve members for absorbing fluid energyPipe elementsControl valvesButterfly valve

A control valve assembly that utilizes a butterfly valve having a valve body and a valve disc movable between a seated position and an open position. The control valve assembly includes a flow insert positioned along the interior of the valve body and generally aligned with a first outer sealing edge of the rotatable valve disc. The flow insert maintains close spacing to the first outer sealing edge of the valve disc as the valve disc initially moves away from the valve seat. The control valve assembly can also include a first, upstream butterfly cage and a second, downstream butterfly cage positioned on opposite sides of the valve body. The first and second butterfly cages aid in controlling the flow of fluid past the valve disc as the valve disc moves from its seated position to its open position.

Owner:YEARY & ASSOCS

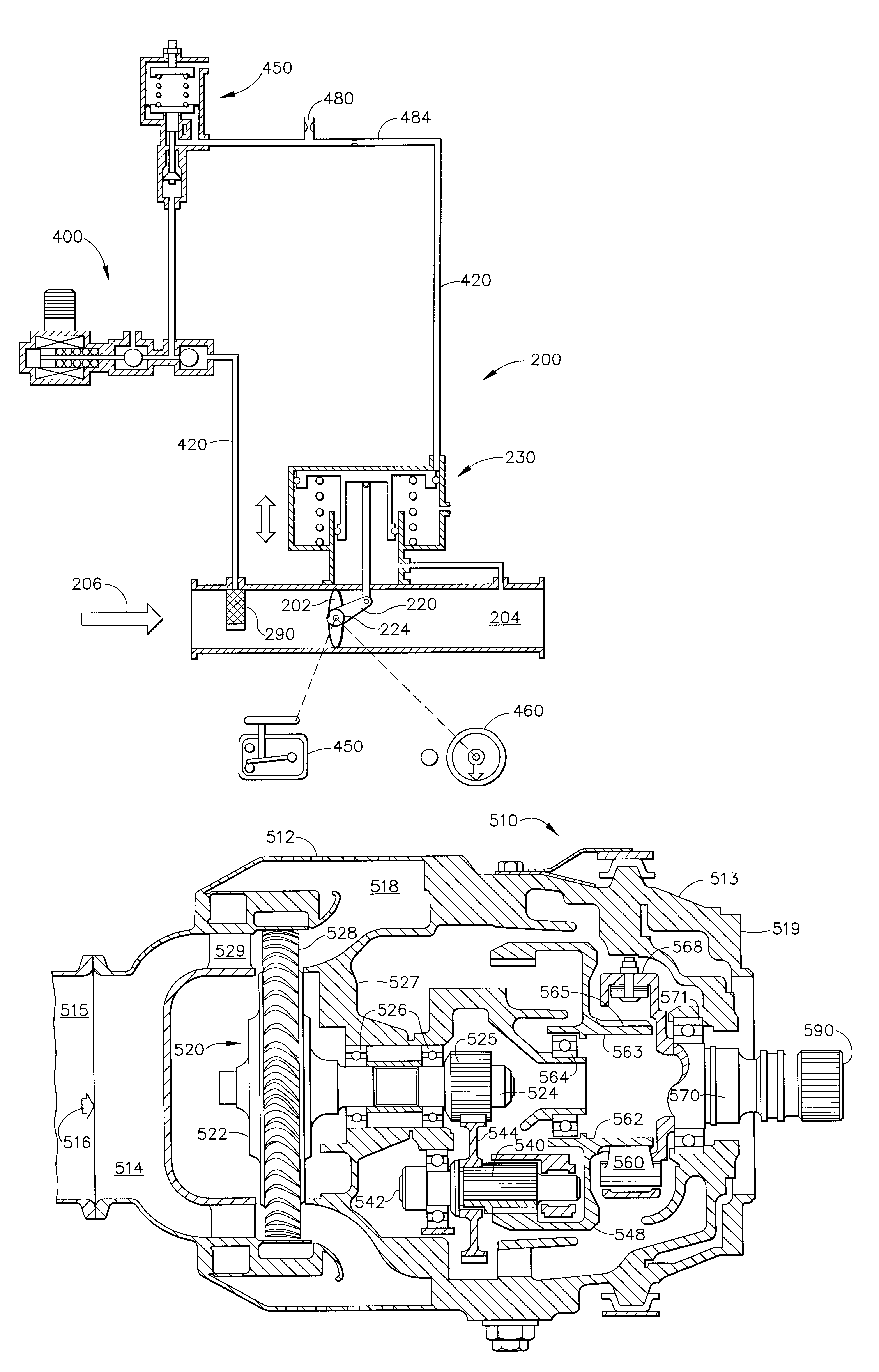

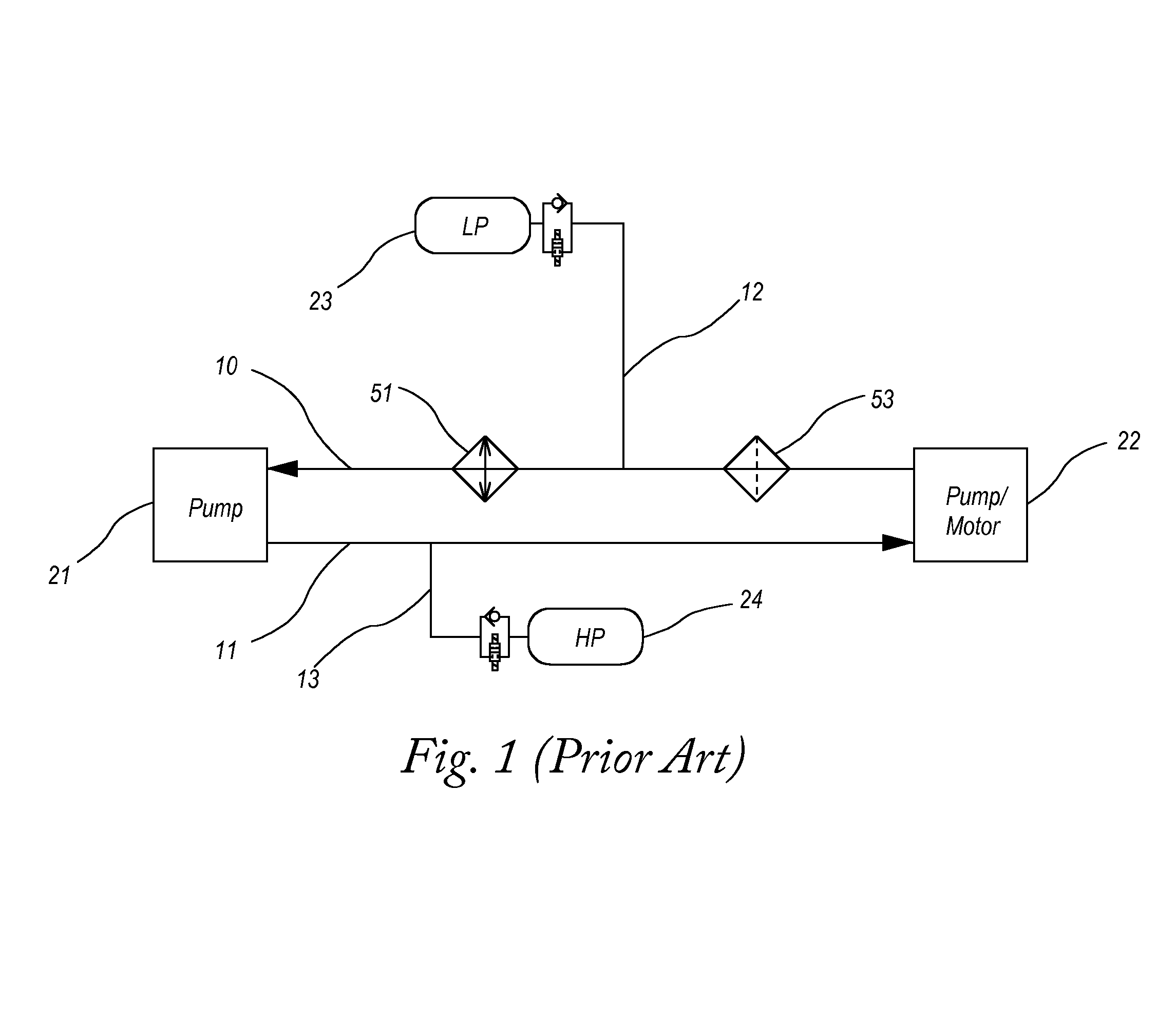

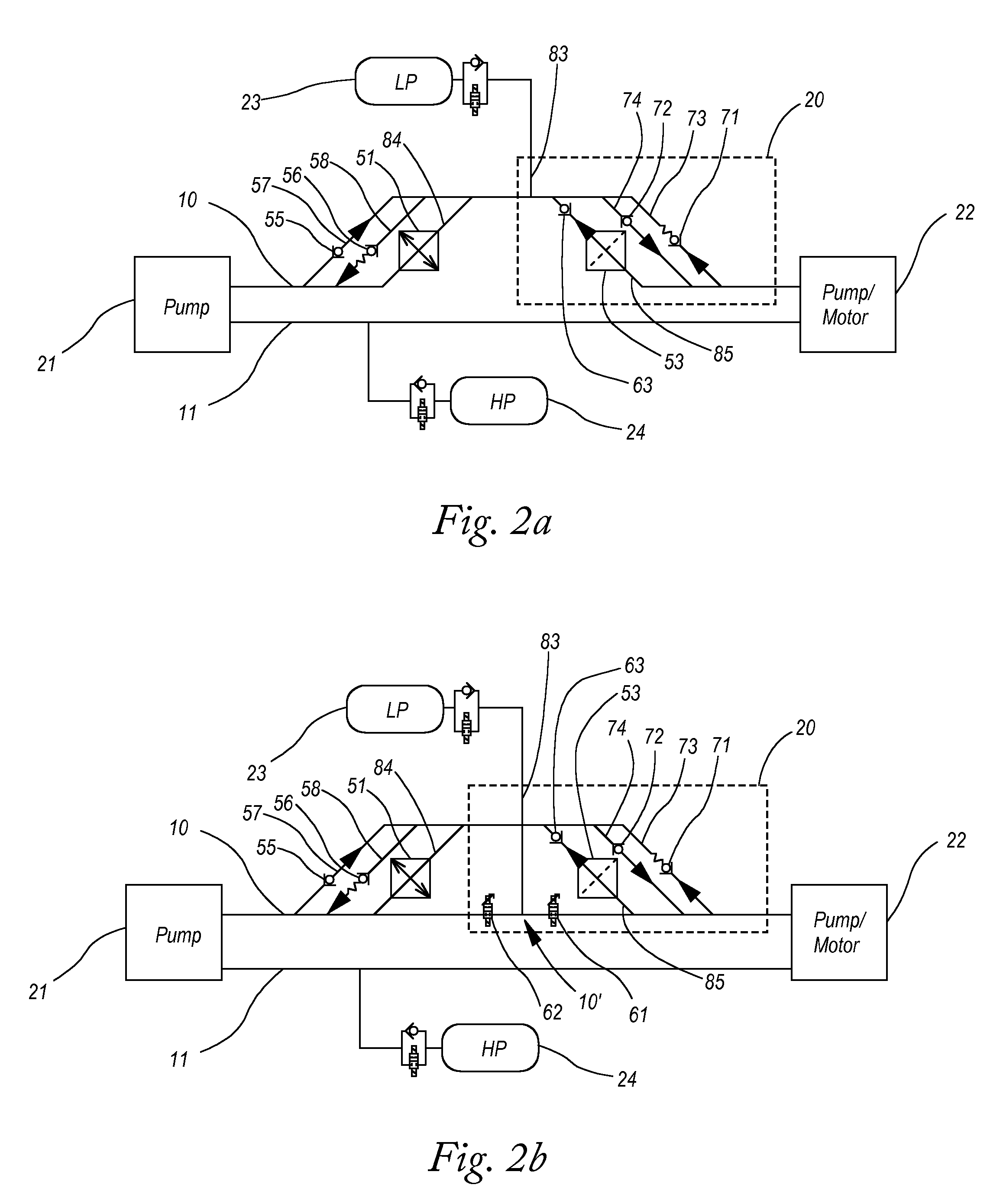

Hydraulic circuit and manifold with multifunction valve

InactiveUS8375982B2Minimize necessary numberEngine diaphragmsCheck valvesHydraulic circuitEngineering

A hydraulic manifold has features adapted to the needs of hybrid vehicle applications. In one embodiment, multifunction valves selectively regulate fluid flow among primary and auxiliary flow paths. A normally closed butterfly valve is biased by a relatively small secondary biasing force against rotation in first and second (opposite) directions, and by a relatively large principal biasing force against rotation in the first direction past a transitional angular position at which the principal biasing force takes effect. An actuator selectively controls the transitional angular position and the magnitude of the principal biasing force. In the first direction, flow must overcome only the secondary biasing force to pass the valve. In the second direction, any flow sufficient to overcome the secondary biasing force but not the principal biasing force will divide into a first flow passing the valve and a second flow induced to enter an auxiliary path upstream. Additional flow causing the principal biasing force to additionally be overcome will substantially pass the valve as part of the first flow. This and other embodiments provide a manifold that is controllable to allocate flow among primary and auxiliary paths while remaining responsive to sudden large changes in flow independently of immediate control response.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENVIRONMENTAL PROTECTION AGENCY EPA

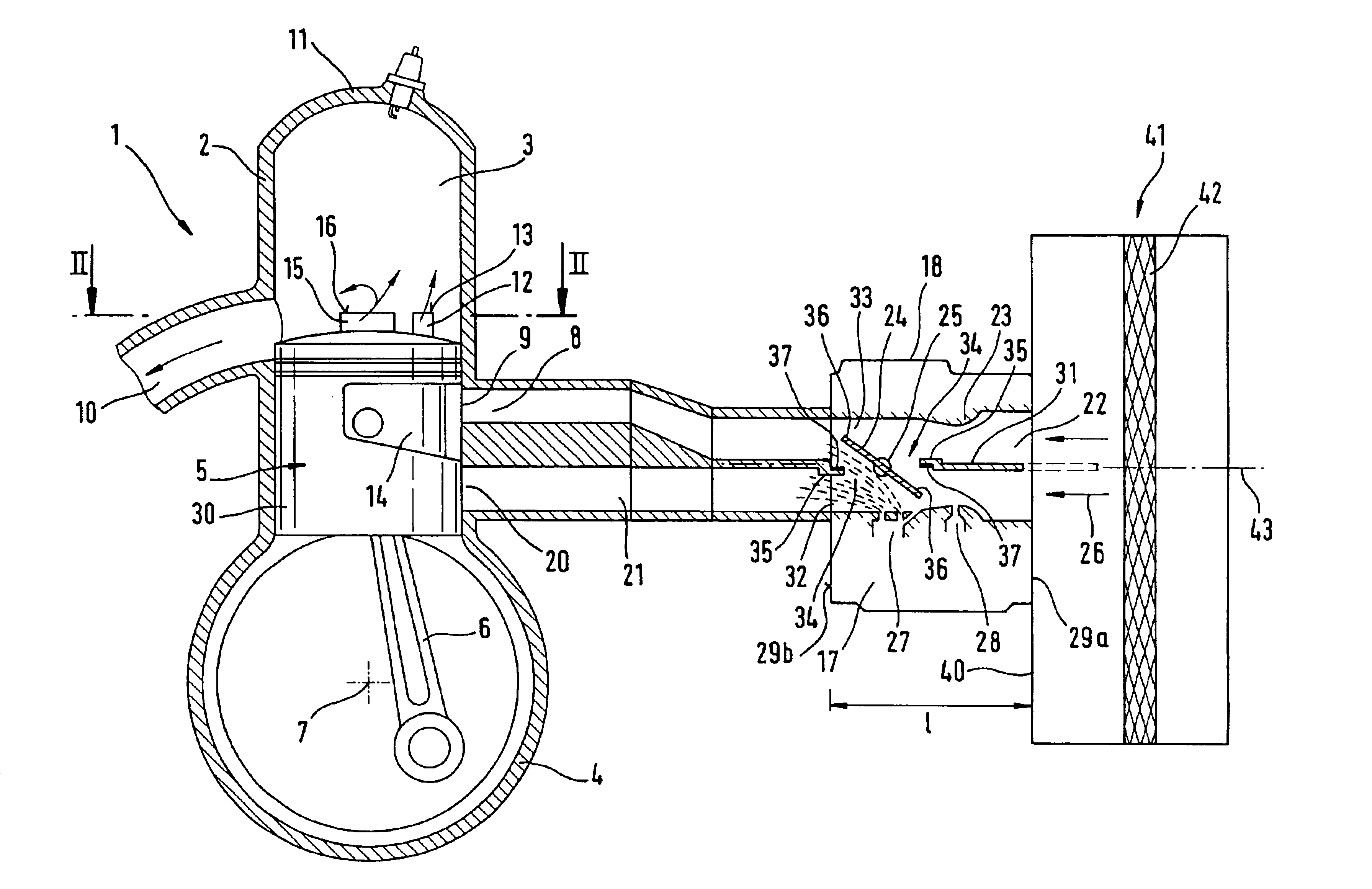

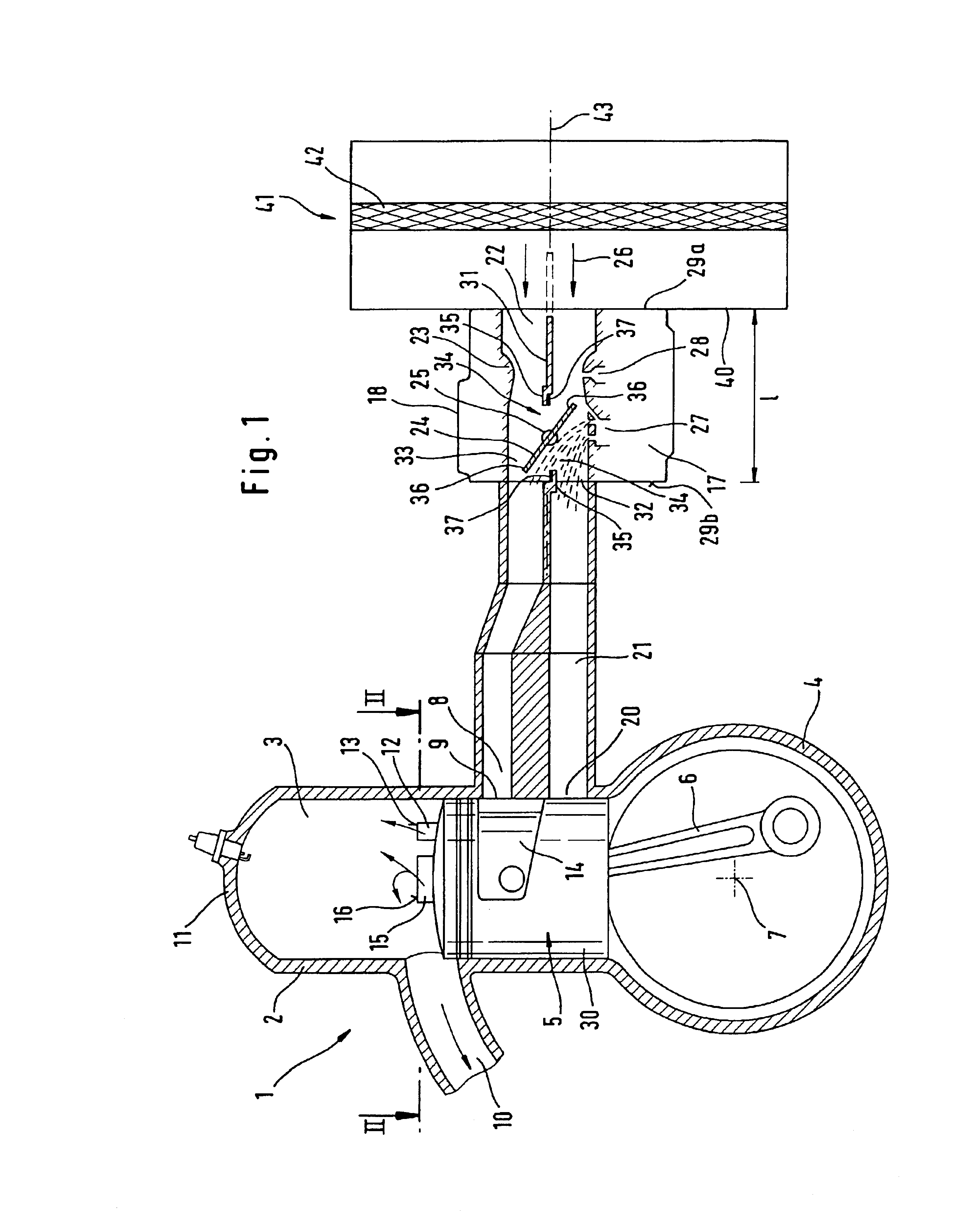

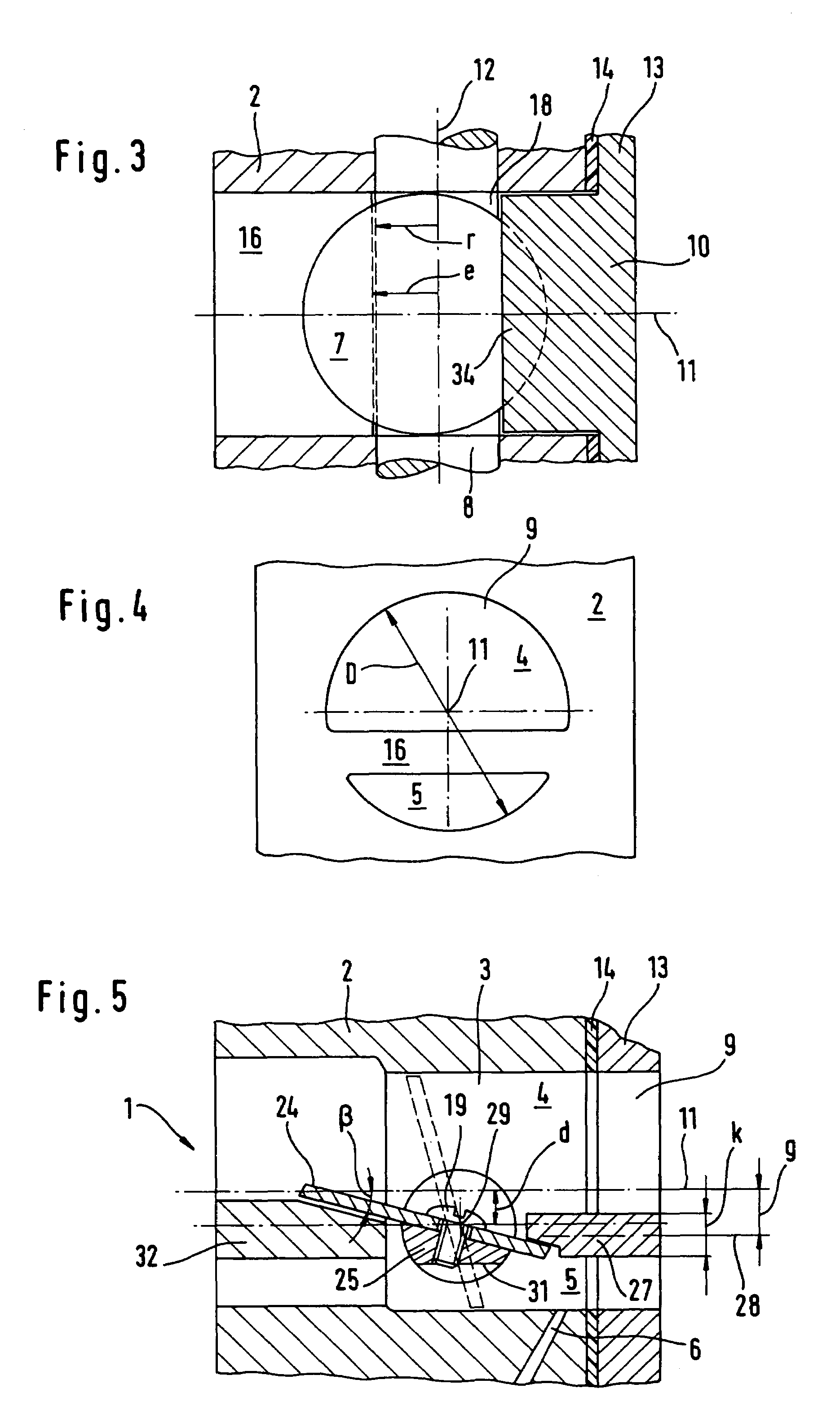

Two-cycle engine with forward scavenging air positioning and single-flow carburetor

InactiveUS6889637B2Avoid burnsGood effectMixing methodsCombustion-air/fuel-air treatmentCombustion chamberCarburetor

A two-cycle engine having forward scavenging is provided. Mixture drawn into the crankcase via a butterfly valve carburetor is conveyed into a combustion chamber via transfer channels in the cylinder. An air duct is connected via a controllable connection with a transfer channel to supply essentially fuel-free air thereto during a load state of the engine. To convey a fuel quantity adapted to drawn-in air during idling and partial load, yet during full throttle to achieve separated supply of air and mixture, a dividing wall extends in the direction of flow of air in the carburetor intake duct. In the pivot region of the butterfly valve, a connecting aperture in the dividing wall is closed in full throttle by a completely open butterfly valve. During idling and partial load the connecting aperture is open so that a uniform pressure can form in the intake duct in conformity with drawn-in air.

Owner:ANDREAS STIHL AG & CO KG

Intake device

ActiveUS7011298B2Improve sealingEasy to assembleLighting and heating apparatusUsing liquid separation agentEngineeringButterfly valve

An intake device having an intake channel that includes an intake channel section is provided. A butterfly valve is pivotably mounted in the intake channel section. A dividing wall is disposed downstream of the butterfly valve and divides the intake channel section into an air duct and a mixture duct. The air duct has a flow cross-section that is greater than the flow cross-section of the mixture duct. A fuel jet opens into the mixture duct.

Owner:ANDREAS STIHL AG & CO KG

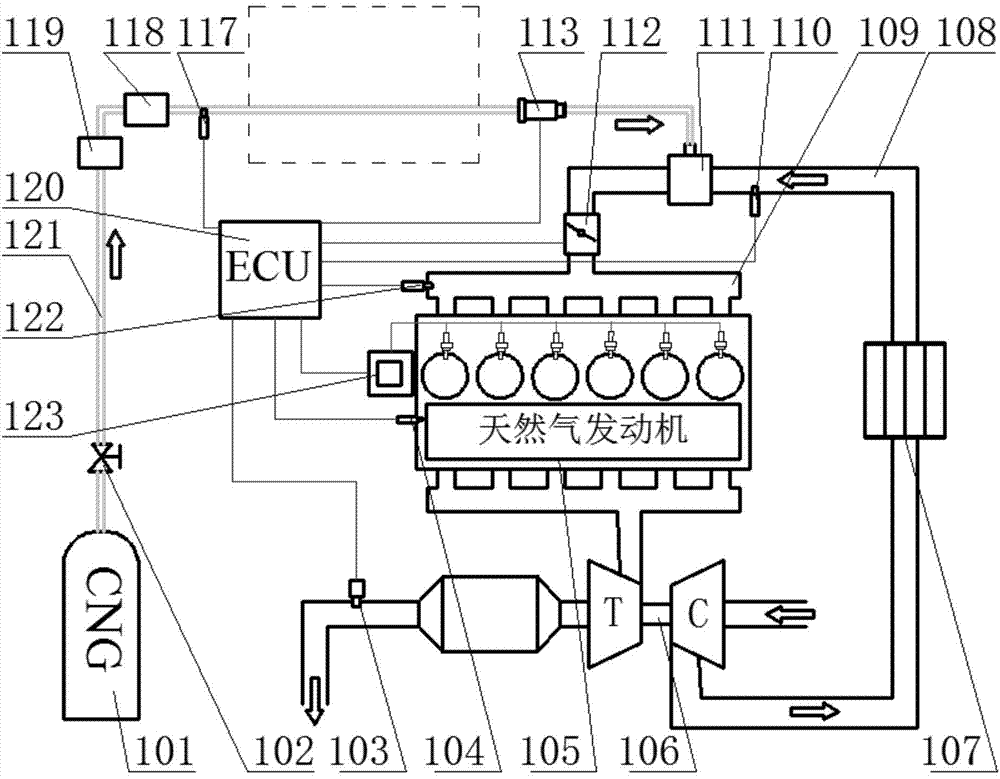

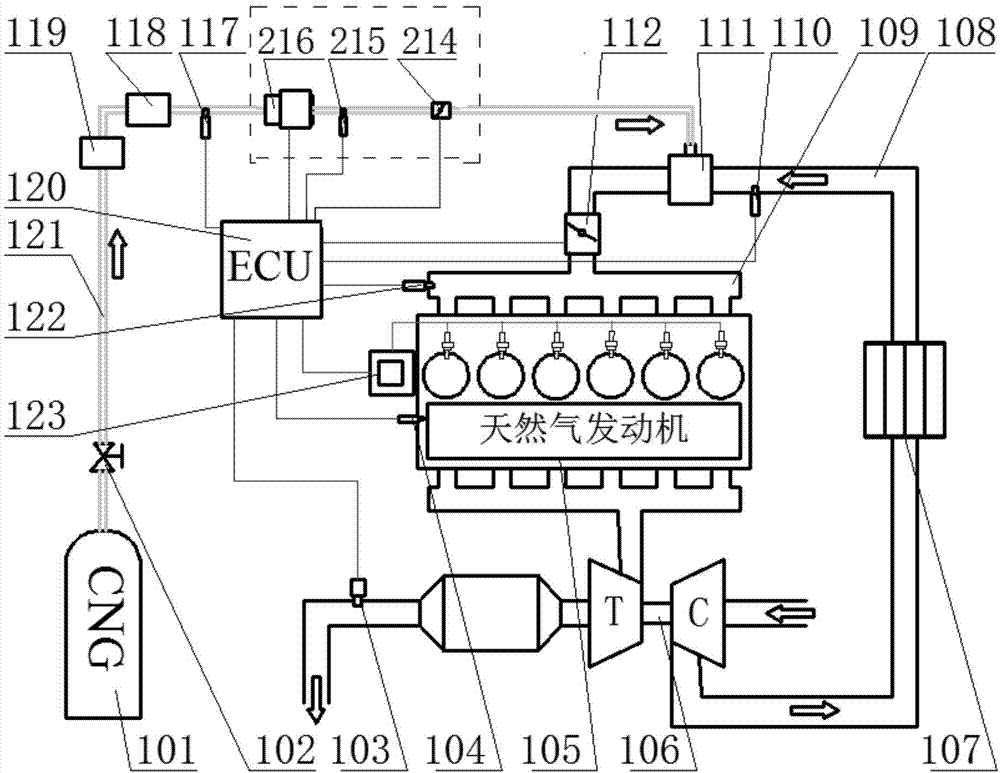

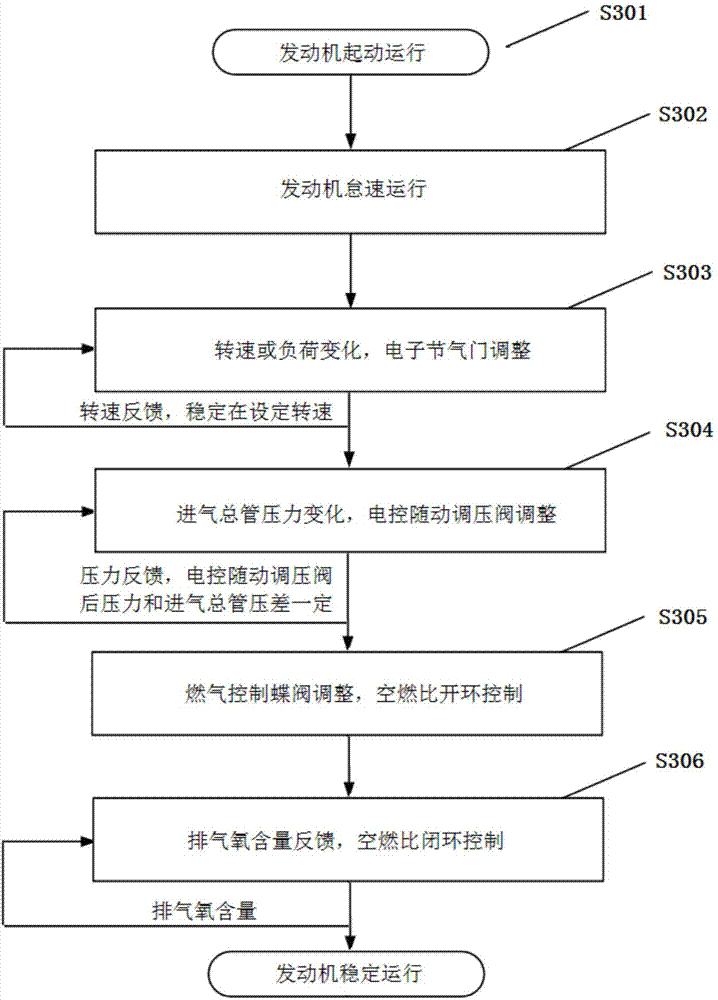

System and method for controlling air-fuel ratio of electronic control servo pressure regulating type natural gas engine

ActiveCN104121115AEasy to controlElectrical controlInternal combustion piston enginesCompressed natural gasDifferential pressure

The invention discloses a system and method for controlling the air-fuel ratio of an electronic control servo pressure regulating type natural gas engine. The system comprises a fuel gas supply device, a compressed natural gas cylinder is connected with a natural gas pressure reduction and stabilization device through a natural gas pipeline, the natural gas pressure reduction and stabilization device is connected with an electronic control servo pressure regulating device through a natural gas filter, the electronic control servo pressure regulating device is connected with one end of a mixer through an air-fuel ratio control device, the other end of the mixer is sequentially connected with an electronic throttle valve, an intake manifold and the natural gas engine, the third end of the mixer is connected with an intercooler and a pressurizer through an air pipeline, and an electronic control system controls the opening degree of a fuel gas control butterfly valve. The flow of natural gas is controlled, the air-fuel ratio of air and the natural gas is precisely controlled, the electronic control system regulates the pressure of the natural gas by utilizing the electronic control servo pressure regulating device according to the pressure of the intake manifold of the natural gas engine, the pressure difference of the pressure in front of the fuel gas control butterfly valve and the pressure of the intake manifold is kept within the set range, and responsiveness and precision of control over the air-fuel ratio are improved.

Owner:SHANDONG UNIV

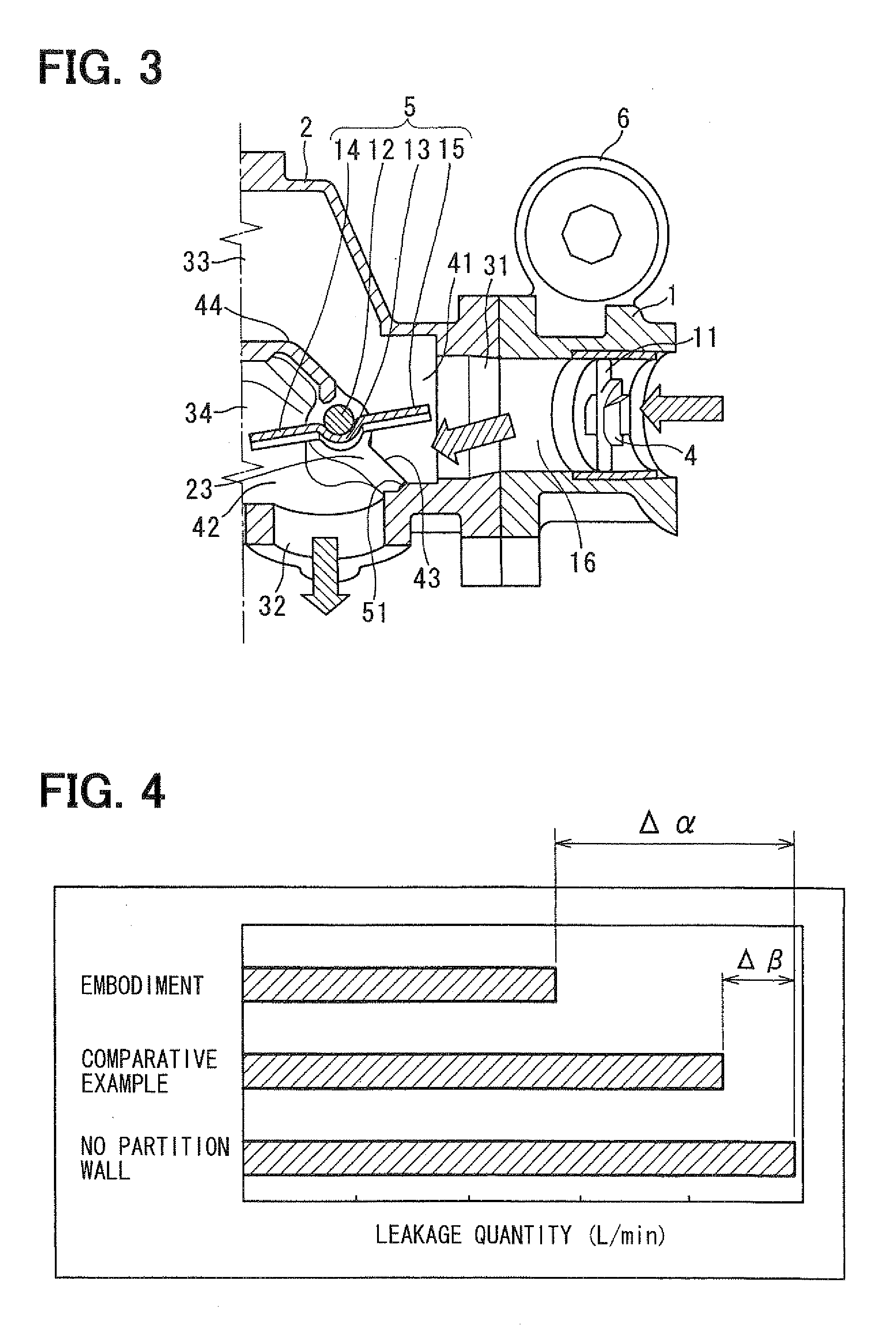

Exhaust gas switching valve

InactiveUS20090235654A1Lower performance requirementsDeterioration can be suppressedNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringButterfly valve

A partition wall partitioning a cooler inlet port and a cooler outlet port extends from a cooler connecting surface of a connecting portion to a vicinity of a shaft supporting a four-way butterfly valve. An EGR gas leakage around a first valve plate can be restricted. Thus, an increase in temperature of EGR gas flowing through an EGR gas outlet port can be restricted at a cooled mode. A deterioration of emission reducing performance can be avoided.

Owner:DENSO CORP

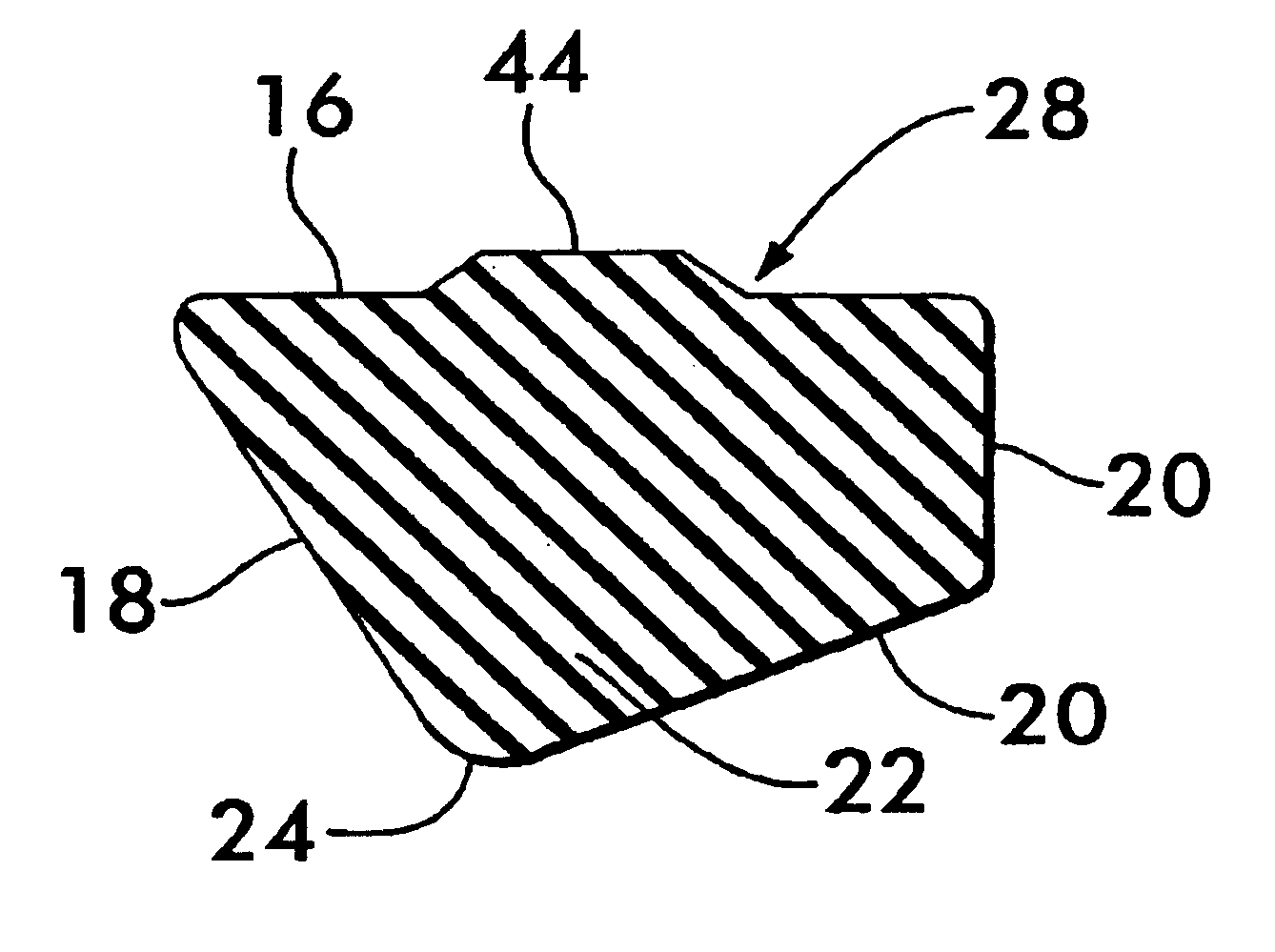

Valve seal with pressure relief channels and expansion voids

Owner:VICTAULIC

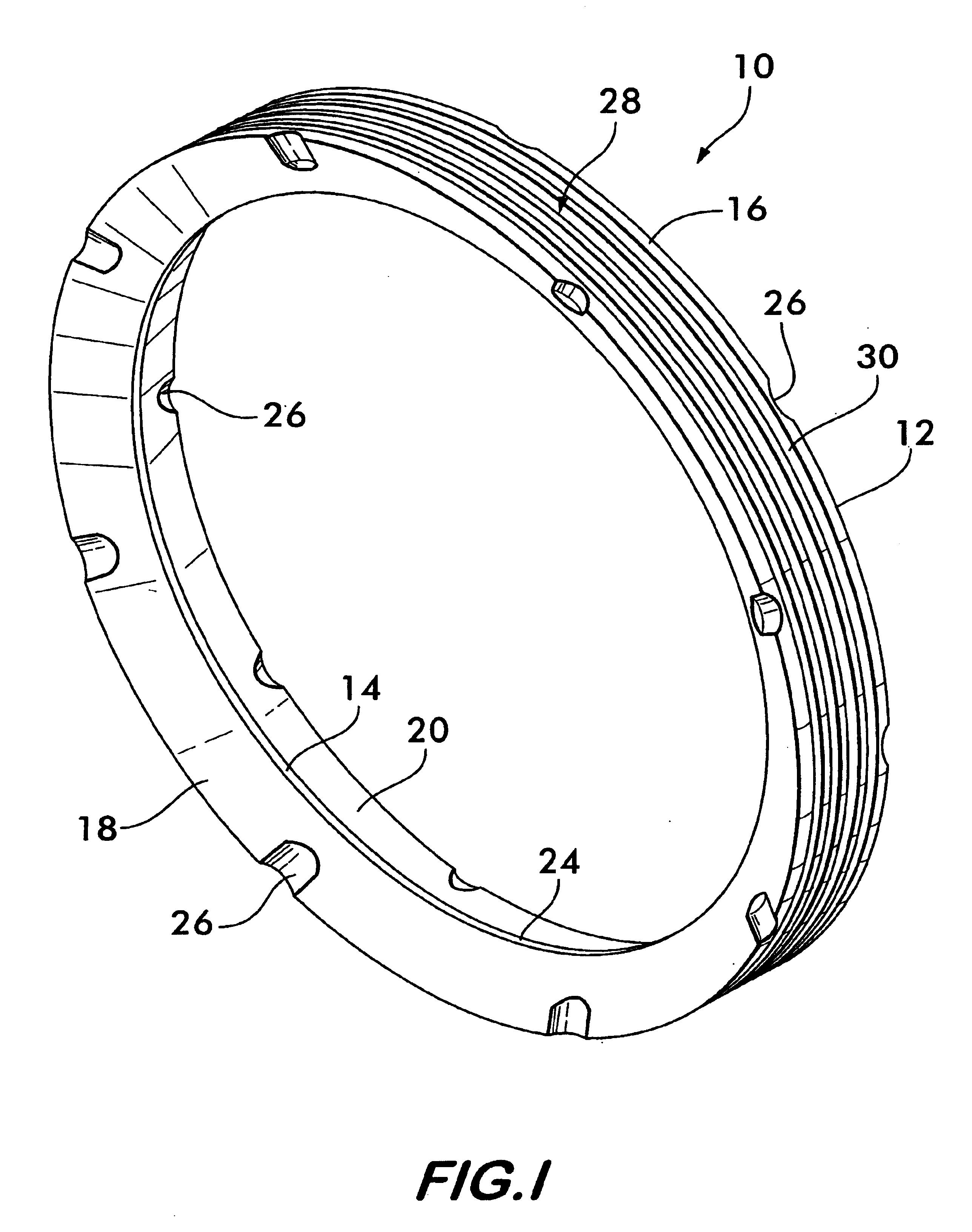

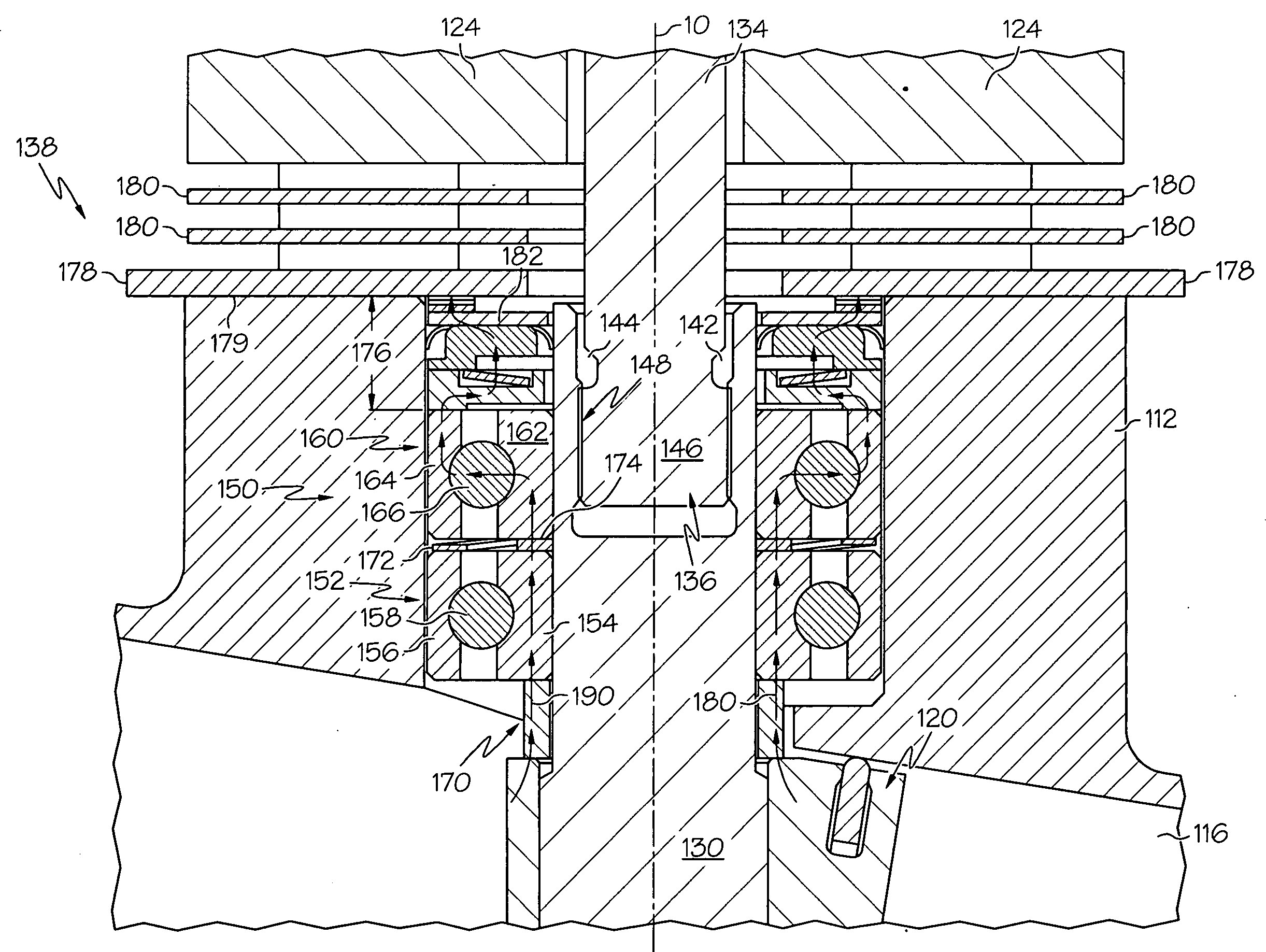

Butterfly valve assembly including a bearing assembly for serrated spline constraint

InactiveUS20100270489A1Minimize misalignmentMinimize couplingBearing assemblyAir-treatment apparatus arrangementsCouplingEngineering

Butterfly valves assemblies are provided that include a flowbody, a butterfly plate, an actuator and an upper chimney and a lower chimney disposed within the flowbody. The flowbody has an inner surface defining a channel. The butterfly plate is disposed in the channel, is rotationally mounted to the flowbody, and has an outer periphery. The actuator has an actuator output shaft that is coupled to the valve shaft via a serrated spline coupling. The upper chimney and the lower chimney are configured to include bearing assemblies that constrain radial loads and thrust loads exerted upon the valve shaft and minimize misalignment of the serrated spline coupling.

Owner:HONEYWELL INT INC

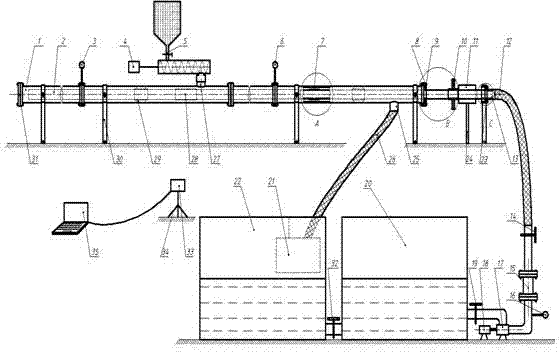

Horizontal well rock debris transportation simulation experiment set and experiment method

The invention relates to a horizontal well rock debris transportation simulation experiment set and experiment method which are used for simulating oil drilling and coal bed gas drilling. The horizontal well rock debris transportation simulation experiment set comprises a drill fluid system, a rock debris transportation system, a rock debris supply system, a power system, a data processing system and a rock debris recovering system. The drilling liquid system is composed of a liquid storage tank, a motor, a centrifugal pump, a flowmeter and a butterfly valve which are connected. The rock debris transportation system is composed of a converting connector, a glass tube, a PVC tube, a rock carrying tool, an eccentric triangular plate and the like. The rock debris supply system is composed of a spiral feeder and a rock debris filling device. The power system is composed of a speed regulating motor and a speed changing gear. The rock debris recovering system is composed of a recovering tube, a filter and a rock debris recovering pool. The horizontal well rock debris transportation simulation experiment set and the experiment method can be used for visually observing the transportation condition of horizontal well rock debris, and the influence of different discharge capacities, drill stem rotating speeds, the eccentricity between a drill stem and a borehole, rock debris amounts and rock debris grain sizes on a horizontal well rock debris transportation rule can be simulated. The horizontal well rock debris transportation simulation experiment set is simple and practical, and low in construction cost.

Owner:SOUTHWEST PETROLEUM UNIV

Fuel and air purge system for diaphragm carburetors

InactiveUS6374810B1Reducing gaseous phase presenceReduce presenceMachines/enginesLiquid fuel feedersHigh elevationSystems design

Owner:WALBRO ENGINE MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com