Patents

Literature

5544 results about "Pumping vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

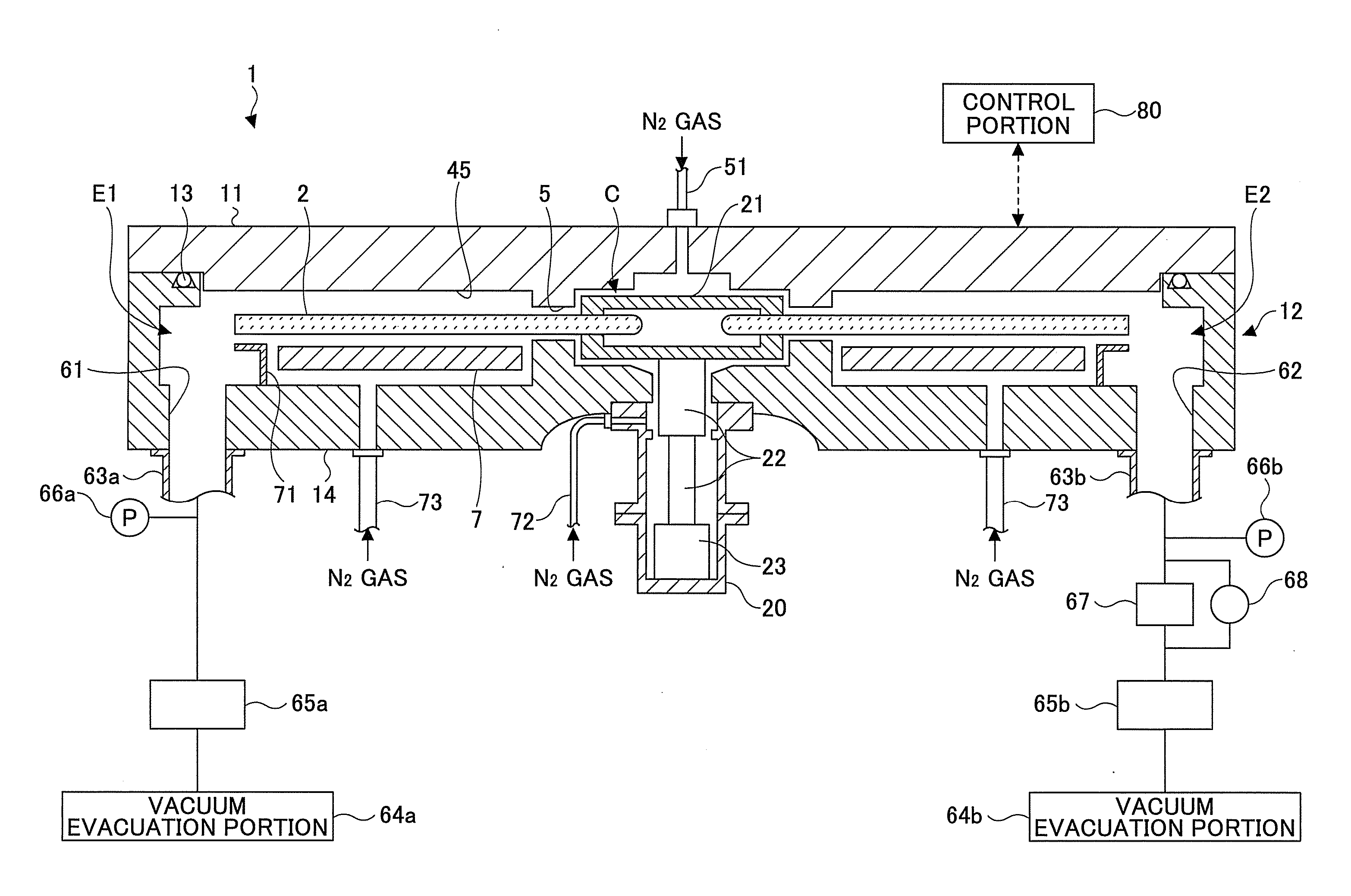

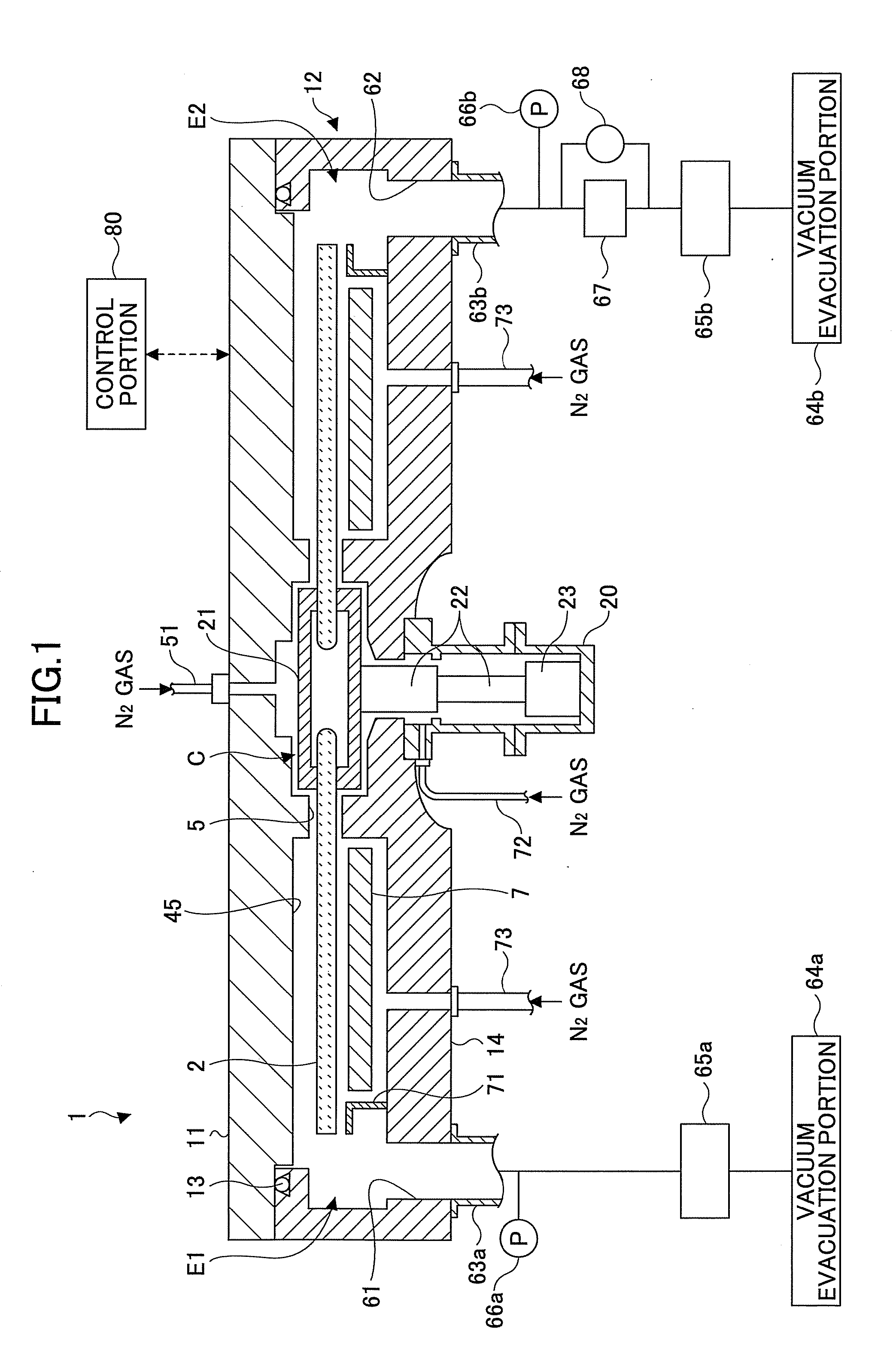

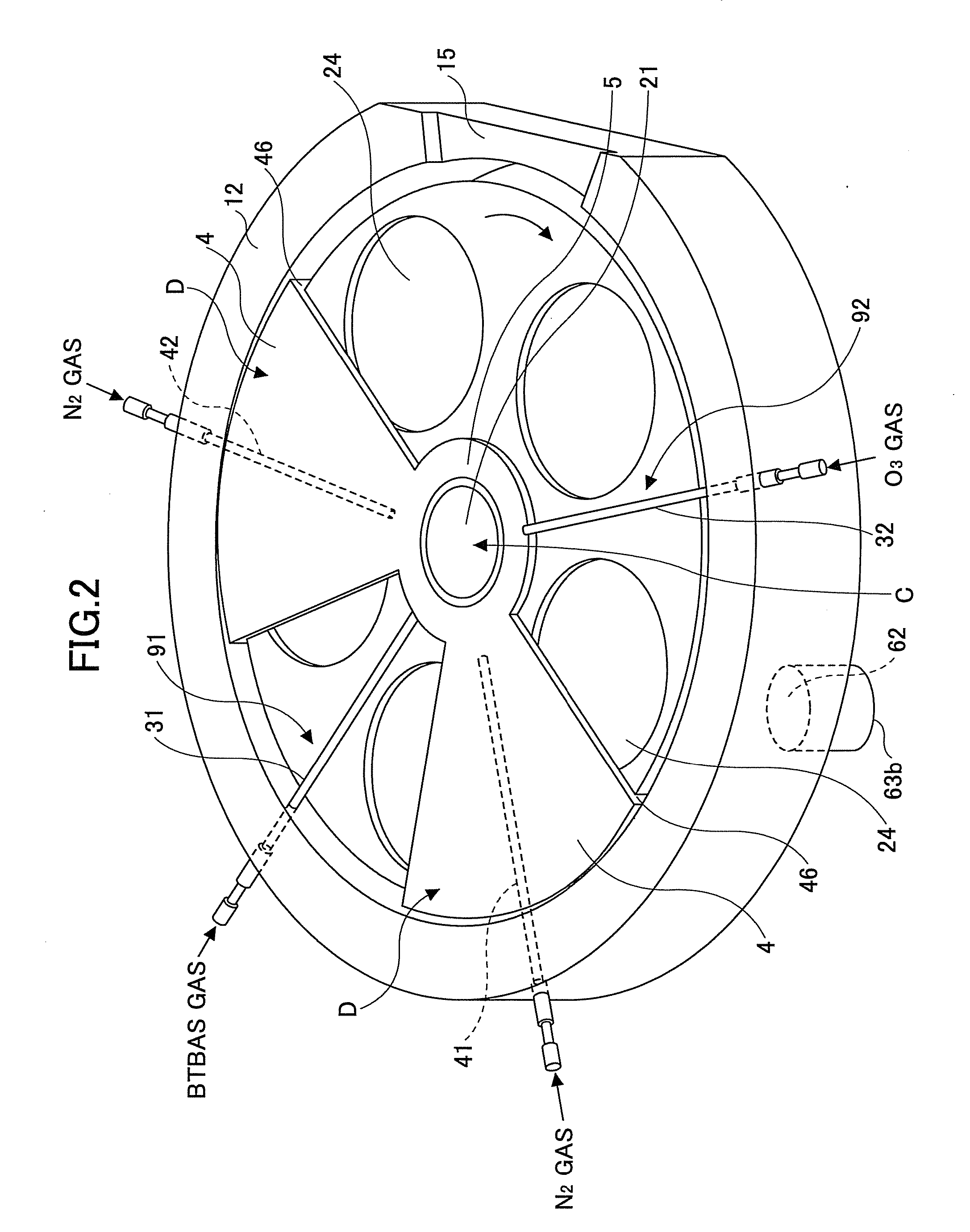

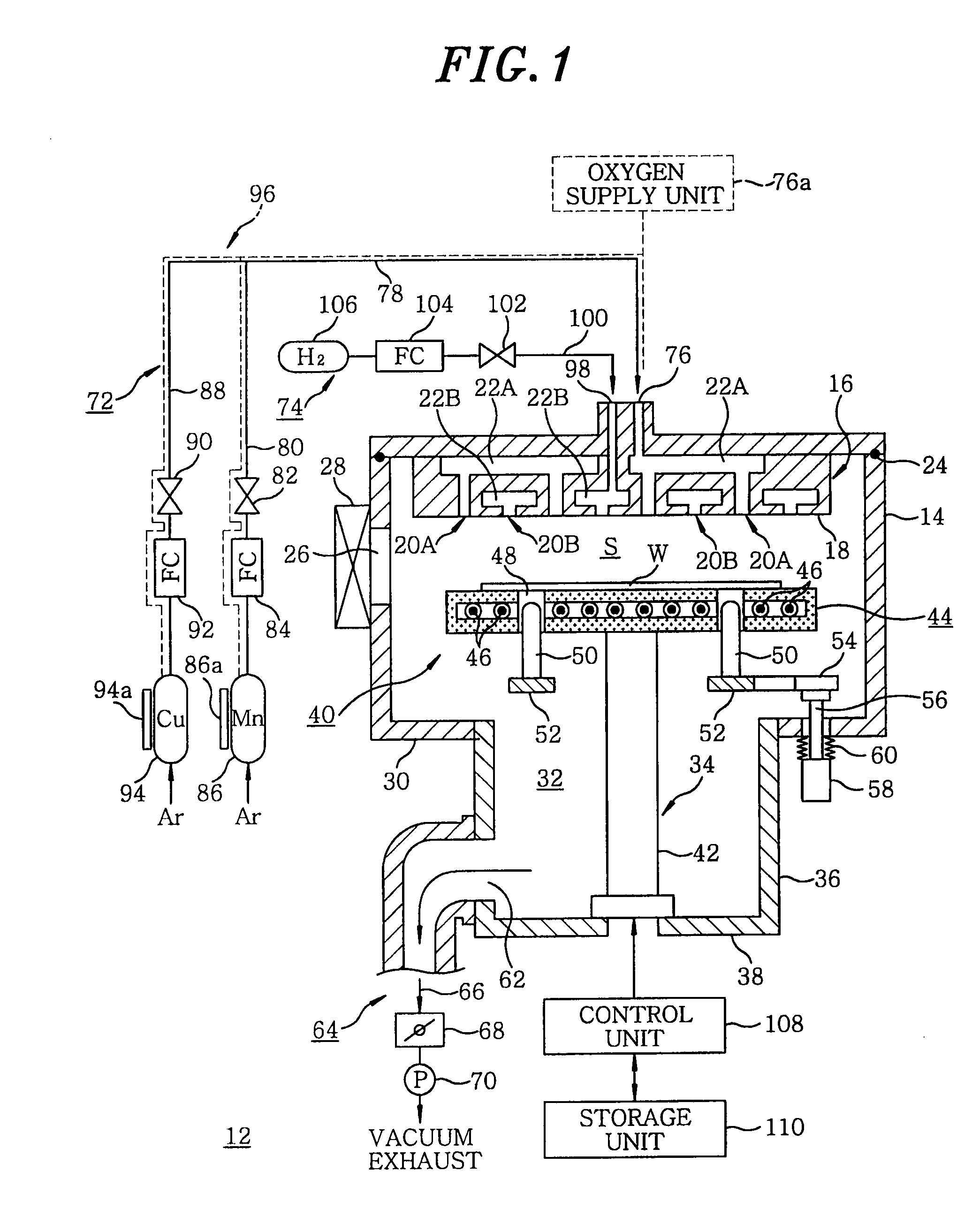

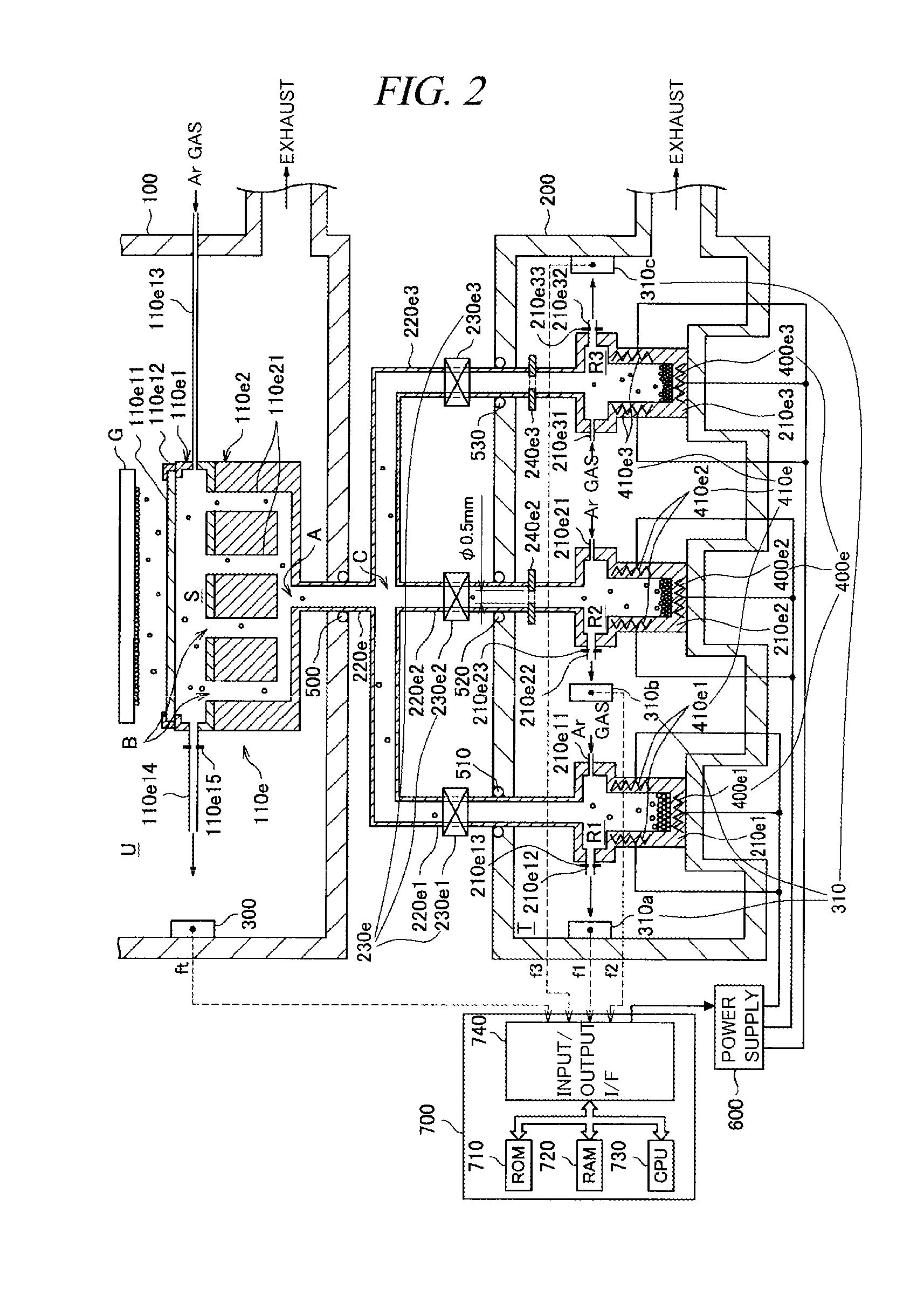

Substrate process apparatus, substrate process method, and computer readable storage medium

ActiveUS20110100489A1Servomotor componentsSemiconductor/solid-state device manufacturingDifferential pressureEngineering

A vacuum chamber is evacuated through a first evacuation passage provided with a first valve and a second evacuation passage provided with a second valve. An opening degree of the first valve is adjusted so that a pressure in the vacuum chamber becomes substantially equal to a process pressure P; an opening degree of a butterfly valve further provided in the second evacuation passage is adjusted to substantially equal to a set value determined by a table in order to set flow rates of gases to be evacuated through the first evacuation passage and the second evacuation passage to be substantially equal to corresponding set values determined by the recipe; and an opening degree of the second valve is adjusted so that a measurement value of a differential pressure gauge further provided in the second evacuation passage becomes substantially equal to a differential pressure written in the table.

Owner:TOKYO ELECTRON LTD

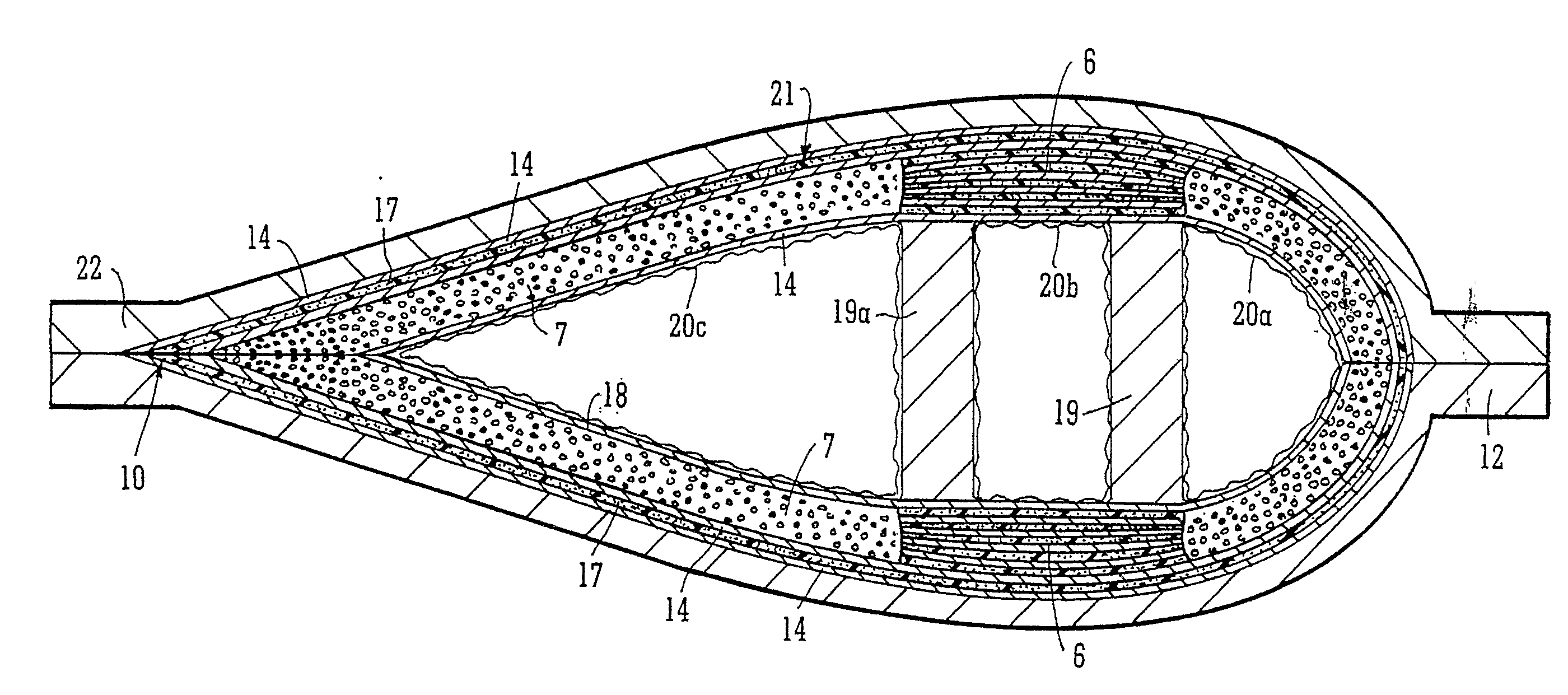

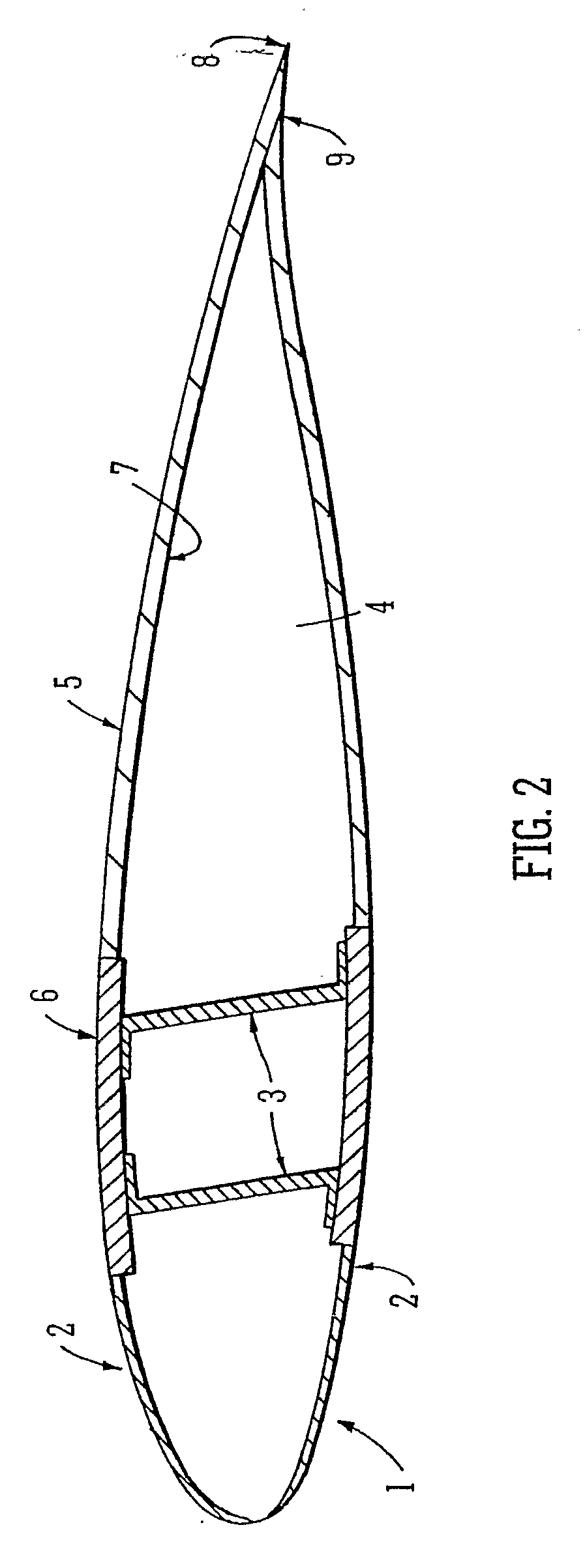

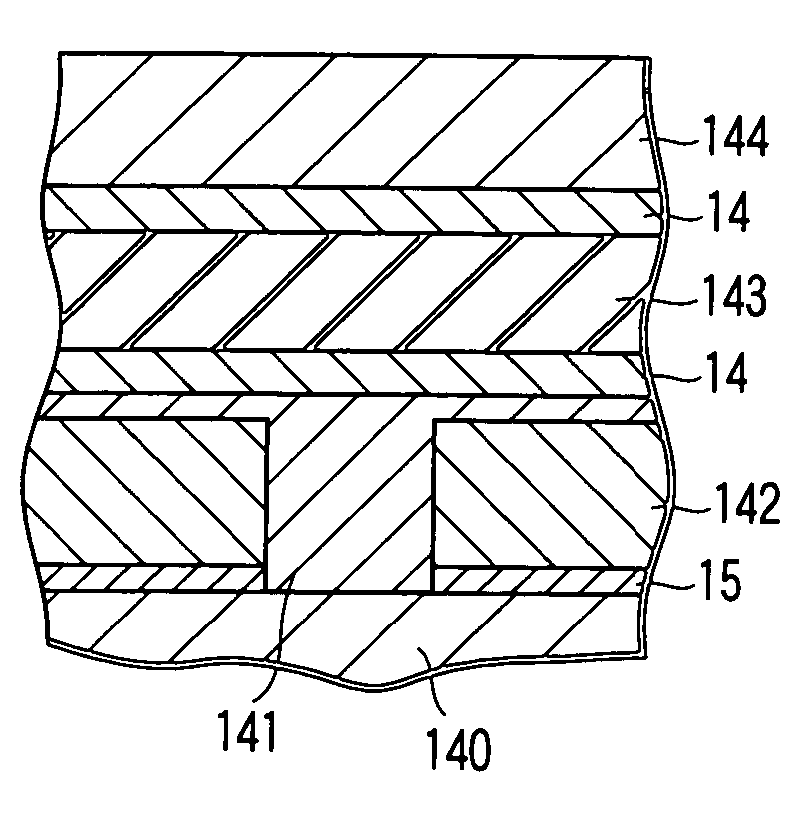

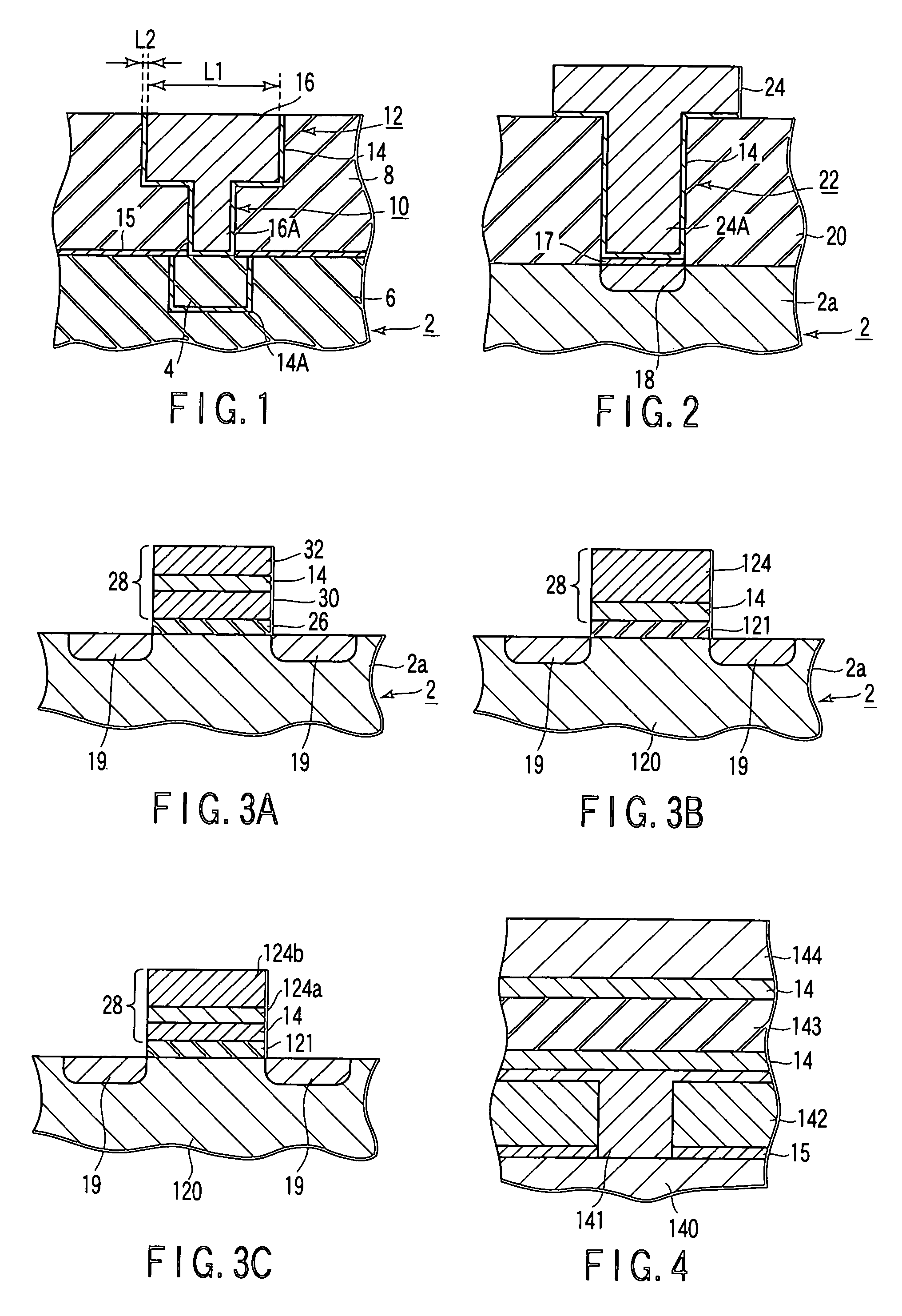

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

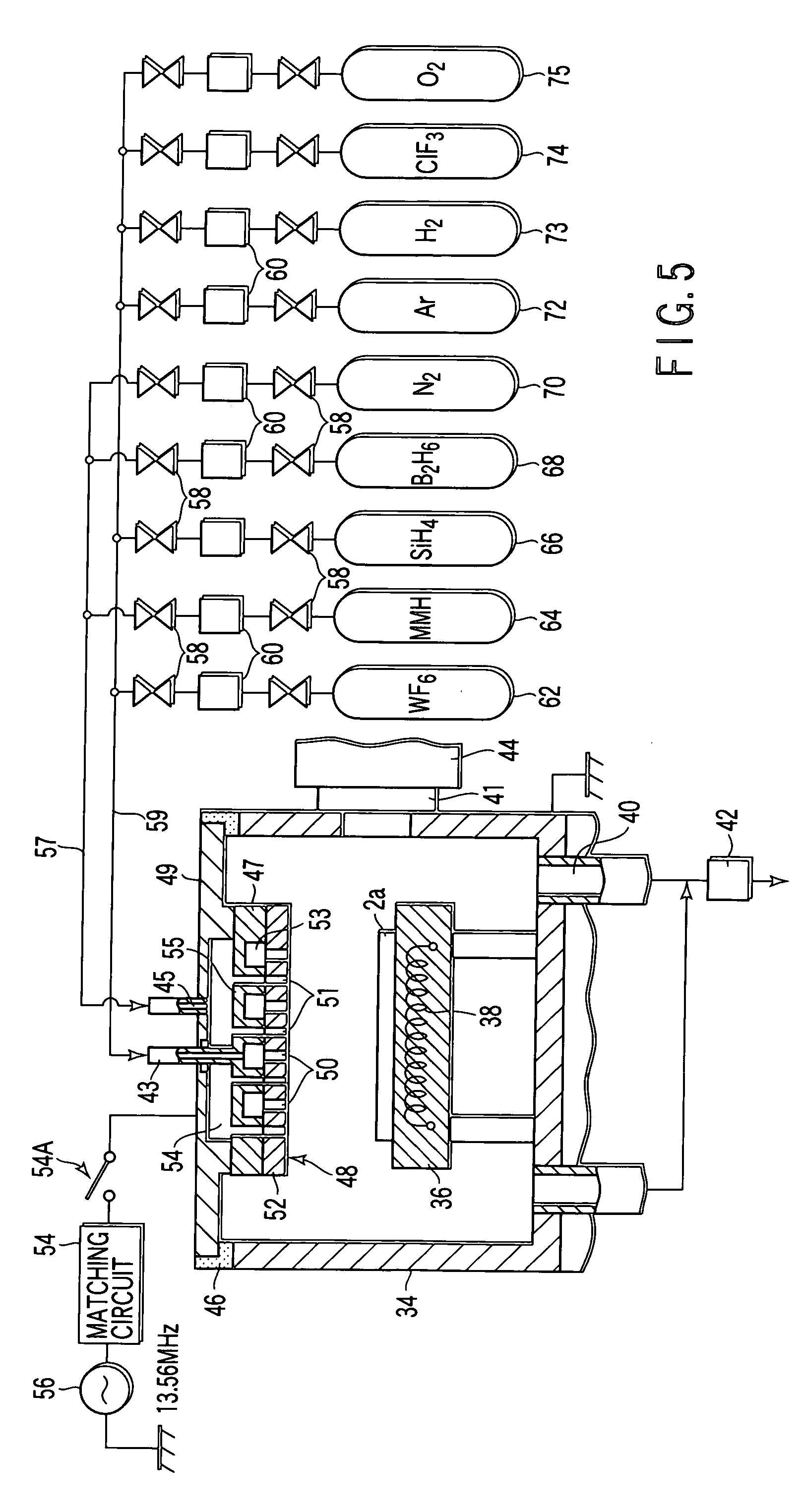

Method of forming a metal film for electrode

InactiveUS20050191803A1Semiconductor/solid-state device detailsSolid-state devicesGroup elementProcess engineering

A method of forming a refractory metal film doped with III or V group elements. The first process gas is supplied from a first gas source through a first gas introducing member to and through a gas supply mechanism toward a substrate within a processing vessel. The second process gas is supplied from a second gas source through a second gas introducing member to and through the gas supply mechanism toward the substrate within the processing vessel. The processing vessel is purged by evacuating the processing vessel by an evacuating mechanism, while supplying the inert gas from a third source through a third gas introducing member to and through the gas supply mechanism into the processing vessel. The supplying the first process gas and the supplying the second process gas are repeated with the supplying the purging gas being carried out between supplying the first and second gases performed so that residual gas present in the processing vessel after performing the supplying of the first and second process gases is reduced to a level of 1 to 30% based on the entire capacity of the processing vessel.

Owner:TOKYO ELECTRON LTD

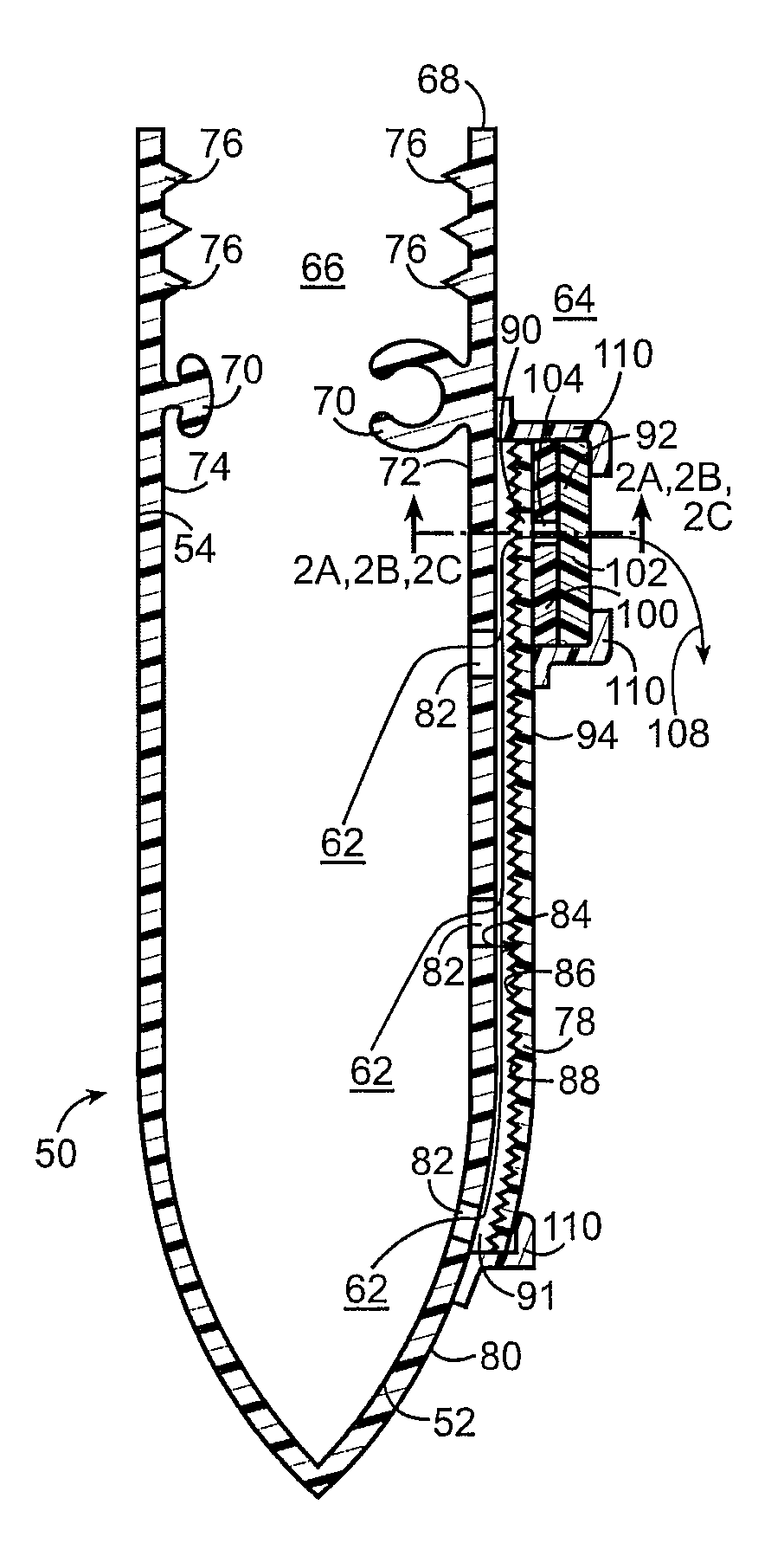

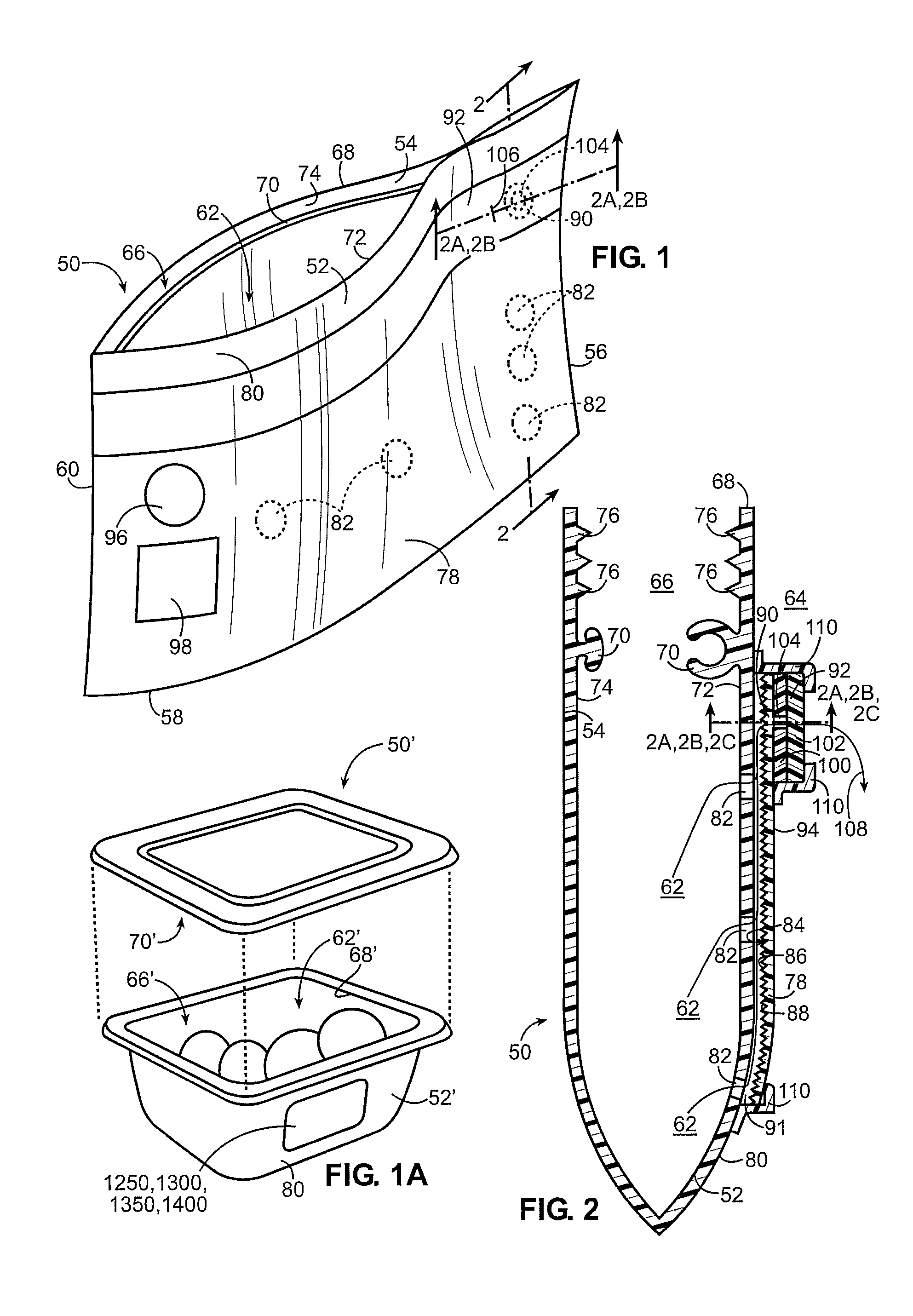

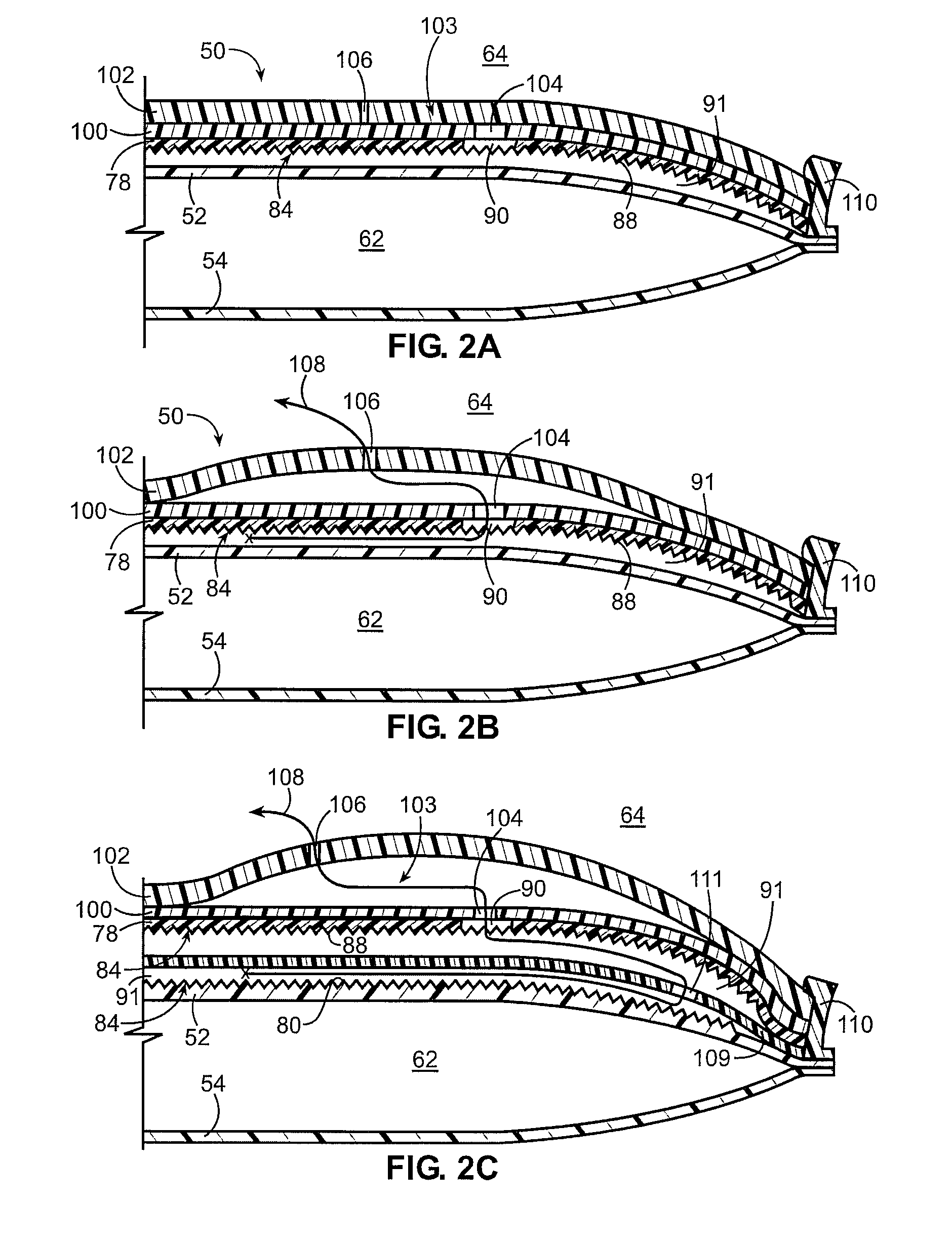

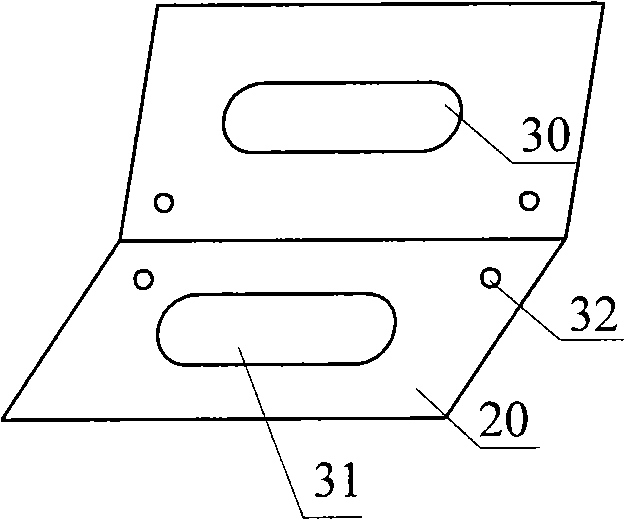

Evacuable container and evacuation strip therefor

An evacuable container includes a first side wall having an interior surface and an exterior surface. The first side wall includes an aperture between the interior surface and the exterior surface. A second side wall has an interior surface and an exterior surface. The second side wall is connected to the first sidewall such that the interior surfaces of the first and second side walls form an interior of the container. A sheet has a first surface and a second surface. The first surface faces the exterior surface of the first side wall. The sheet is sealingly attached to the exterior surface of the first side wall so as to form a flow chamber between the first side wall and the sheet. The sheet includes (i) a plurality of flow channels disposed on the first surface, and (ii) an aperture between the first surface and the second surface. A check valve is disposed in fluid communication with the aperture in the sheet. An evacuation path can be formed from the interior of the container to an exterior of the container through the aperture in the first side wall, the flow chamber, the aperture in the sheet, and the check valve.

Owner:SC JOHNSON & SON INC

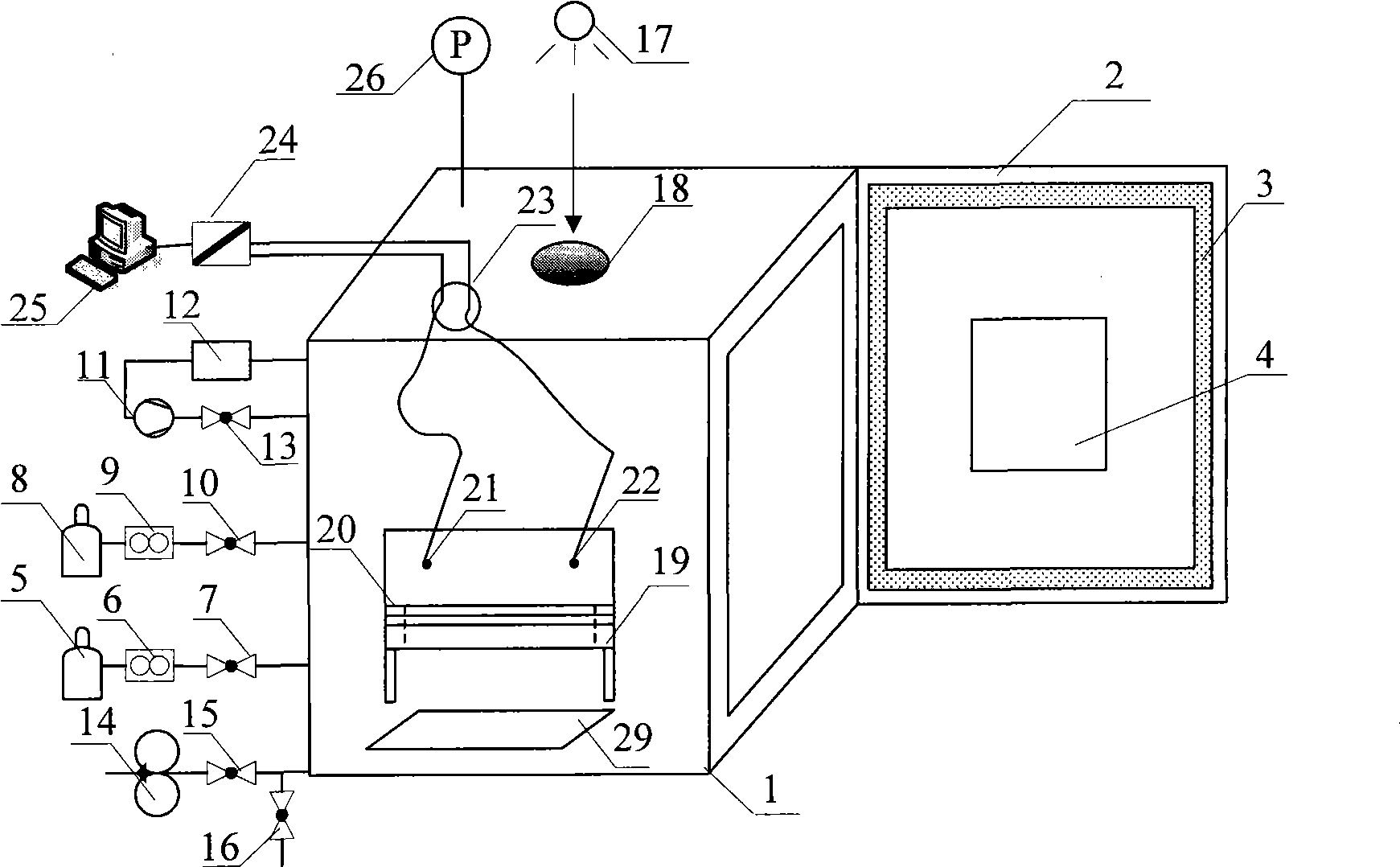

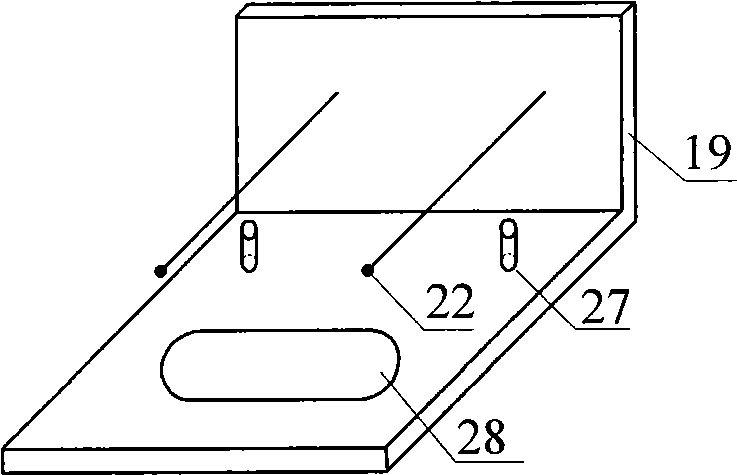

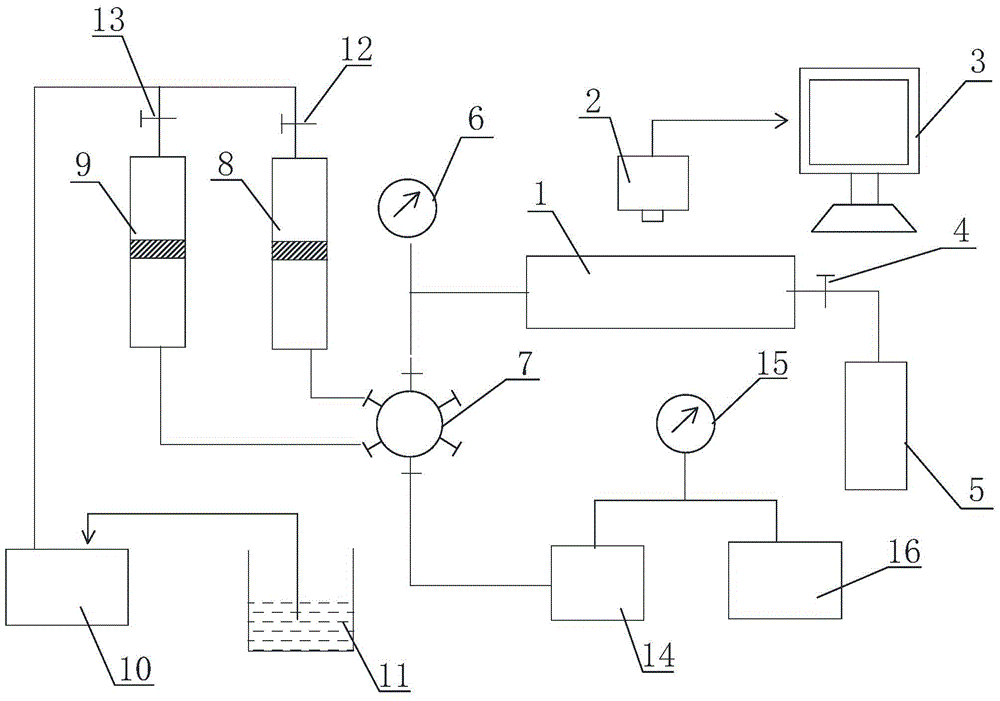

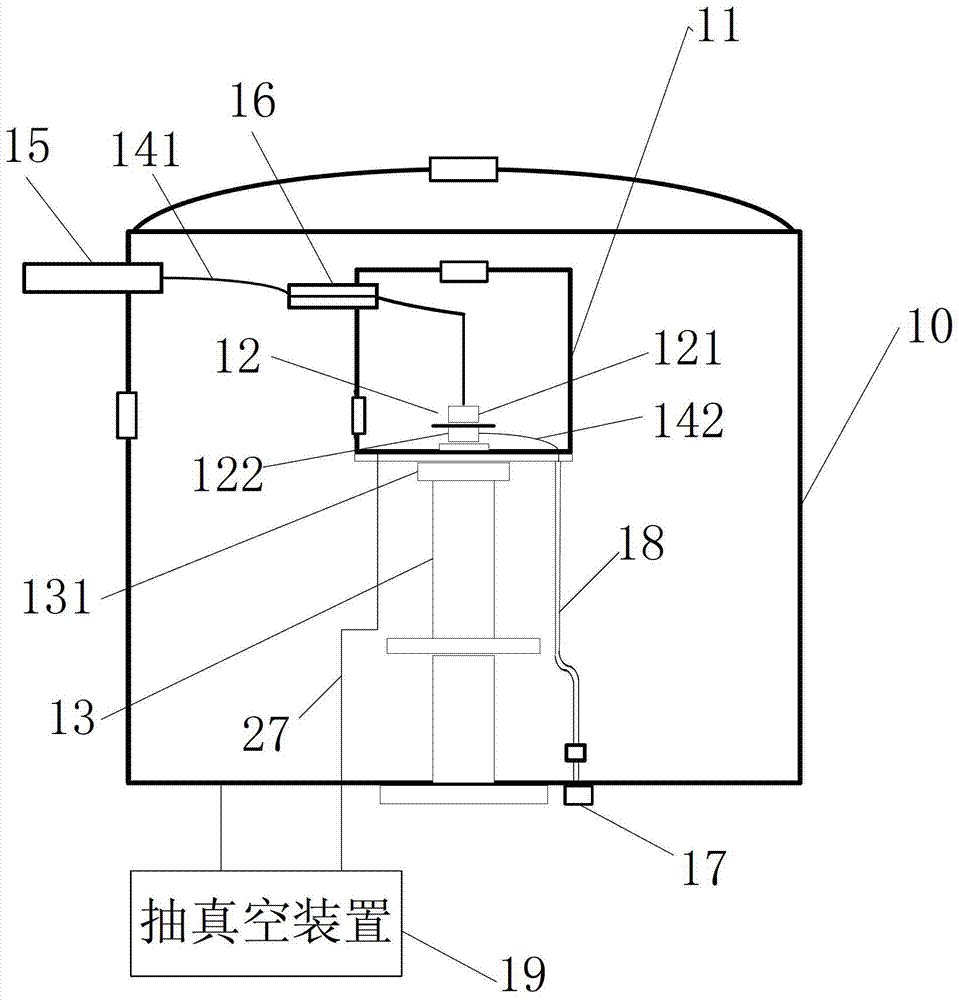

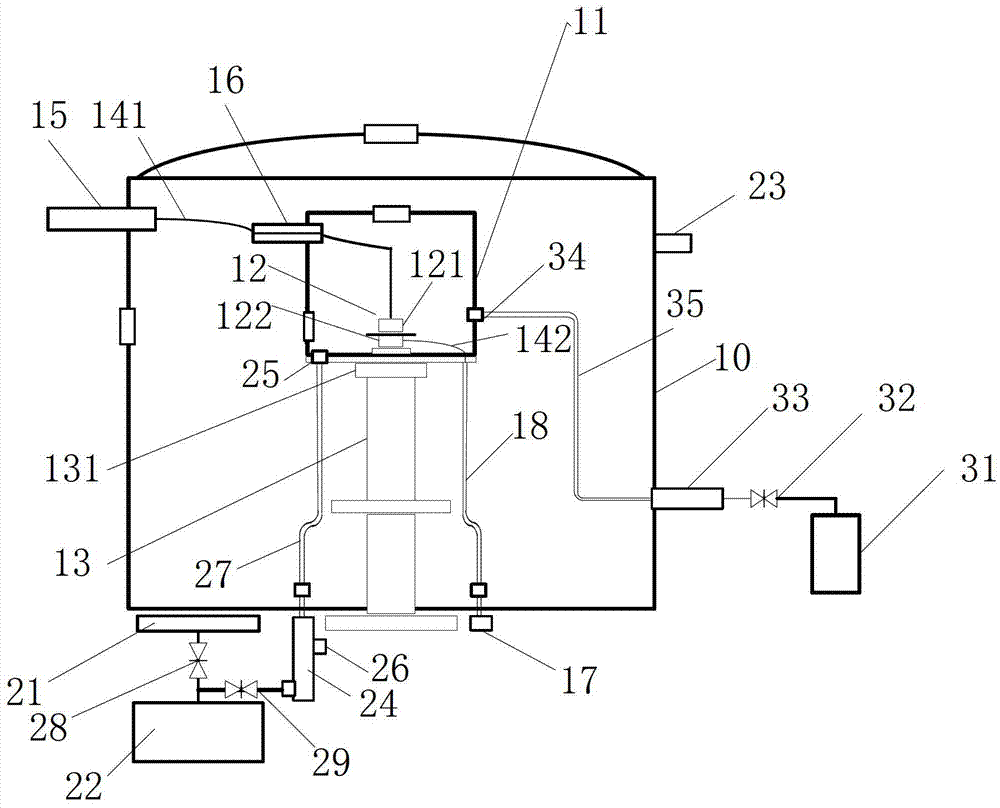

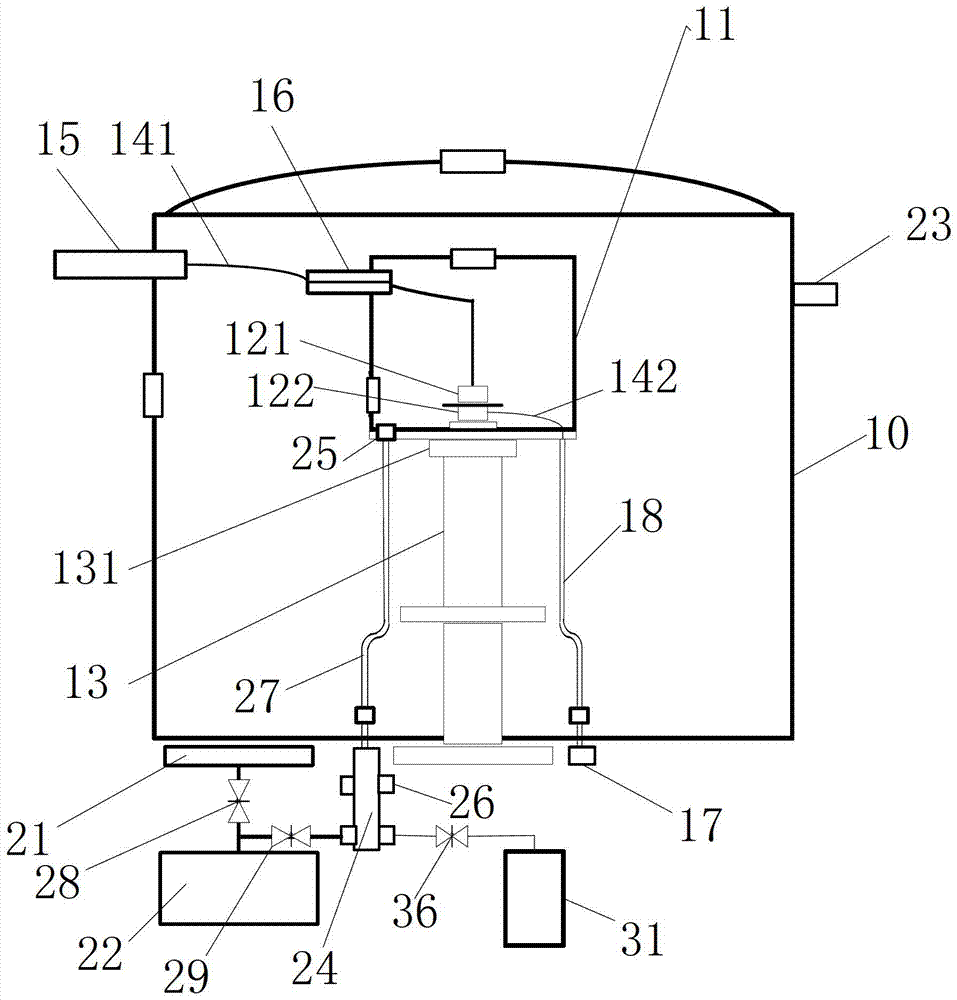

Device and method for gas bearing shale-seepage-temperature coupling and displacement experiment

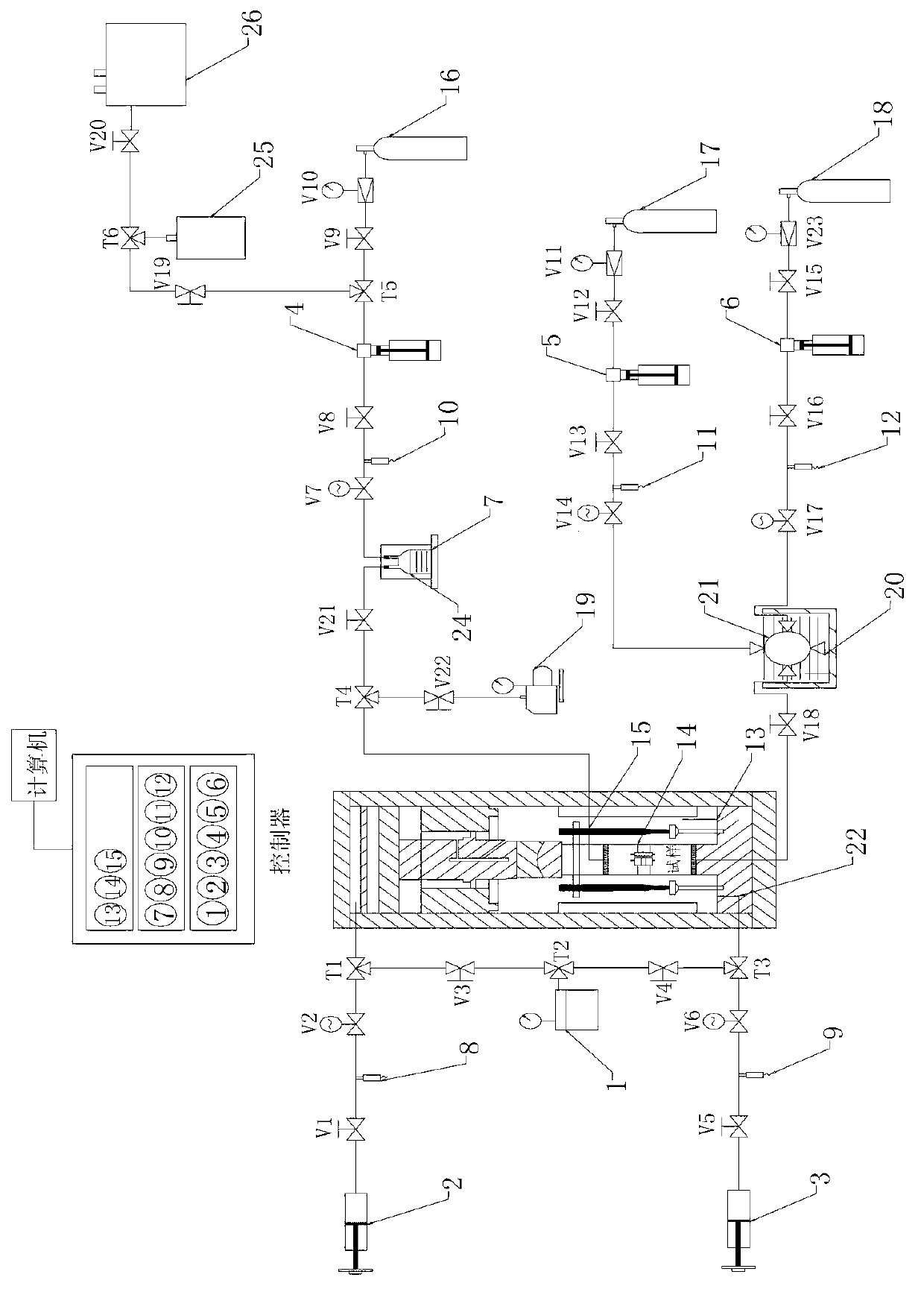

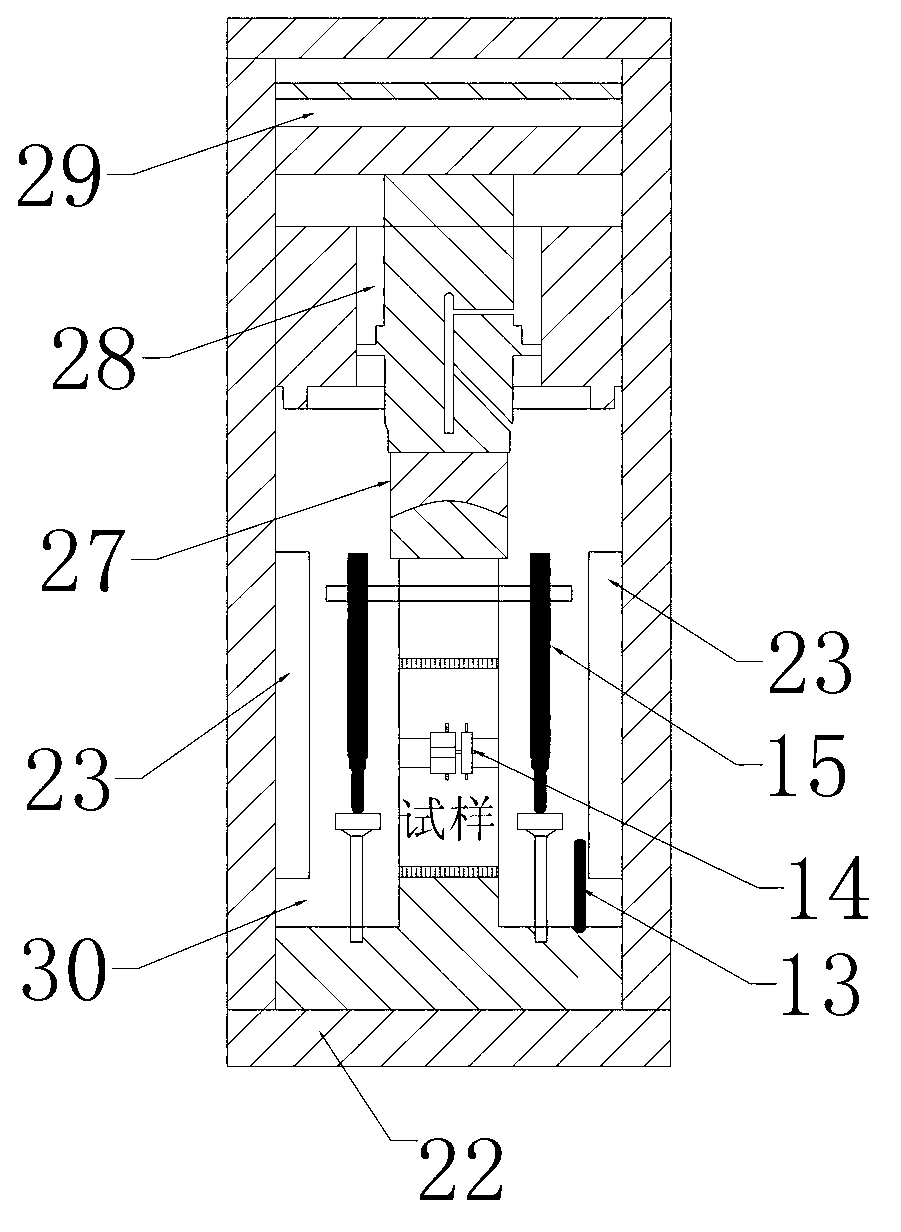

ActiveCN103278428AEnables permeability determinationImprove stabilitySurface/boundary effectMaterial strength using tensile/compressive forcesRock engineeringAxial pressure

The invention belongs to the field of rock engineering, and in particular relates to a device and a method for a gas bearing shale-seepage-temperature coupling and displacement experiment. The experimental device comprises a triaxial pressure cavity, an axial pressure loading system, a confining pressure loading system, an upstream gas pressure loading system, an upstream liquid pressure loading system, a downstream gas pressure loading and collecting system, a downstream liquid collecting system, a multi-component mixed gas collecting system, a vacuumizing device, a heating system and a data collection control system. The experimental method comprises the following steps of: fixing a test piece; applying confining pressure; applying axial pressure; heating; vacuumizing; applying upstream liquid pressure (or pre-saturated methane); applying upstream gas pressure (or applying upstream gas pressure); injecting multi-phase mixed fluid (or applying another upstream liquid pressure); performing pre-adsorptive saturation by the test piece (injecting multi-component constant-proportion mixed gas); and collecting. The experimental device can be used for applying triaxial stress to the test piece according to the actual stress condition, and remolding a stress environment according to the fact.

Owner:NORTHEASTERN UNIV

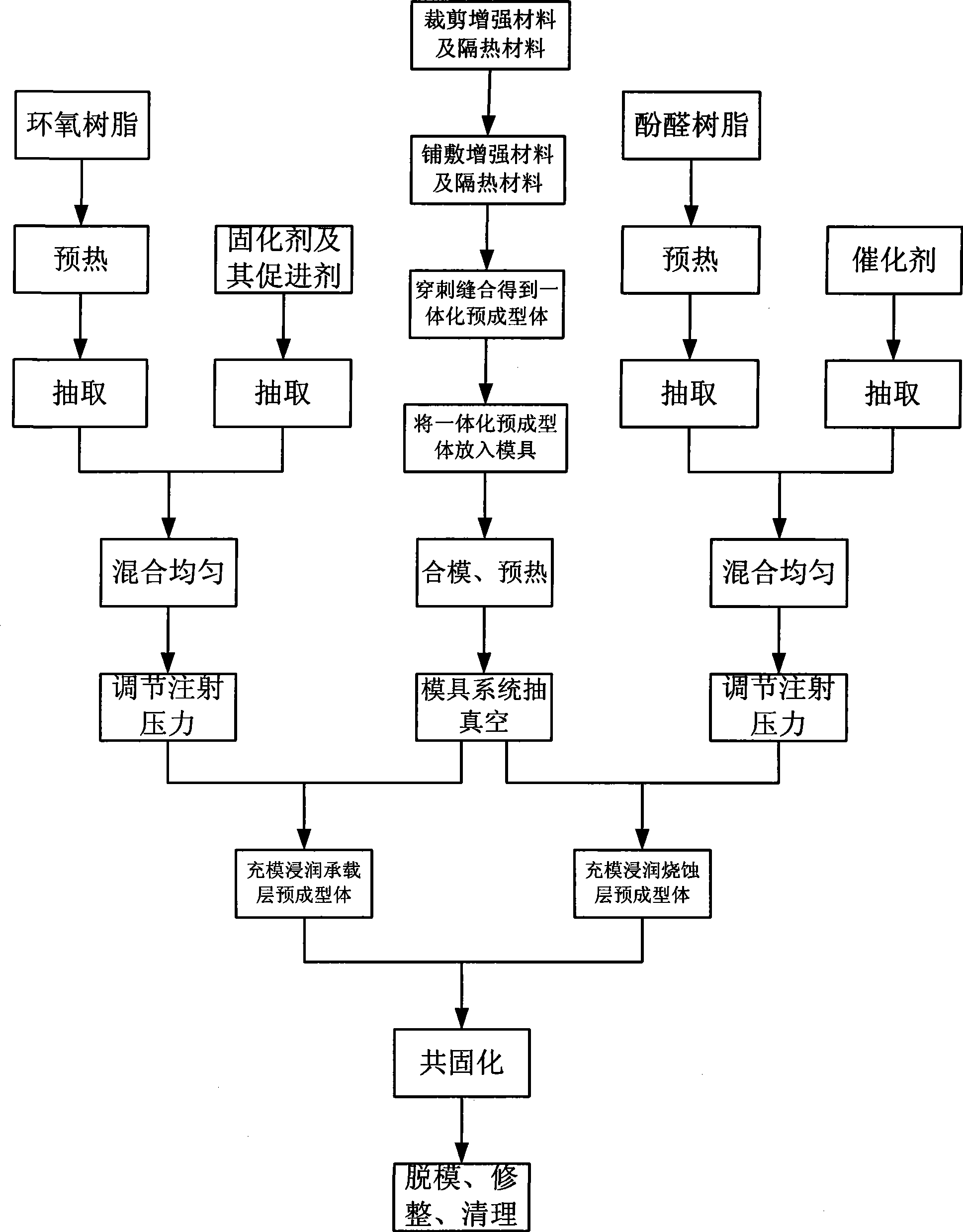

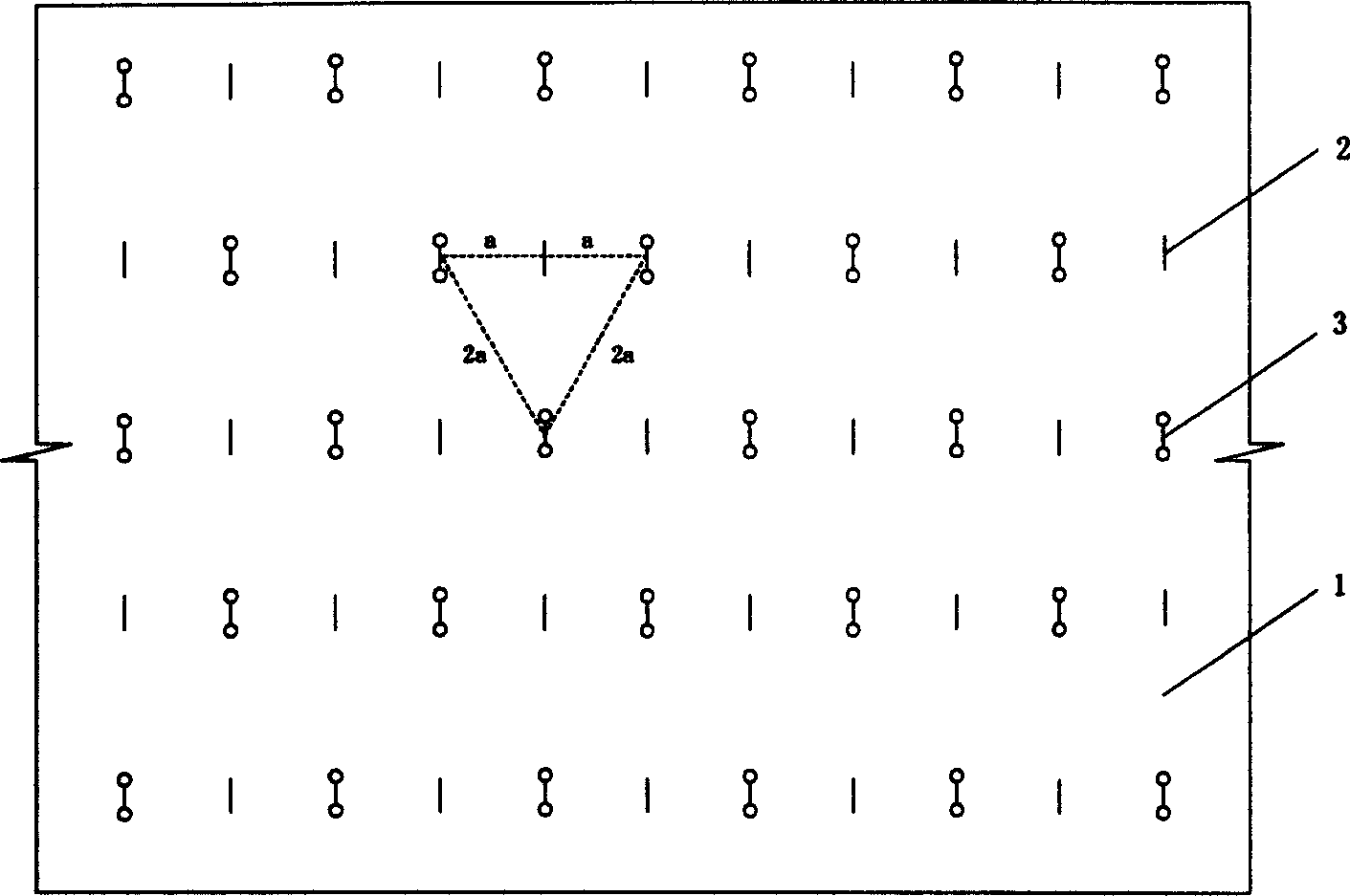

Bearing/insulating/ablating all-in-one sandwich structure composite material and preparation method thereof

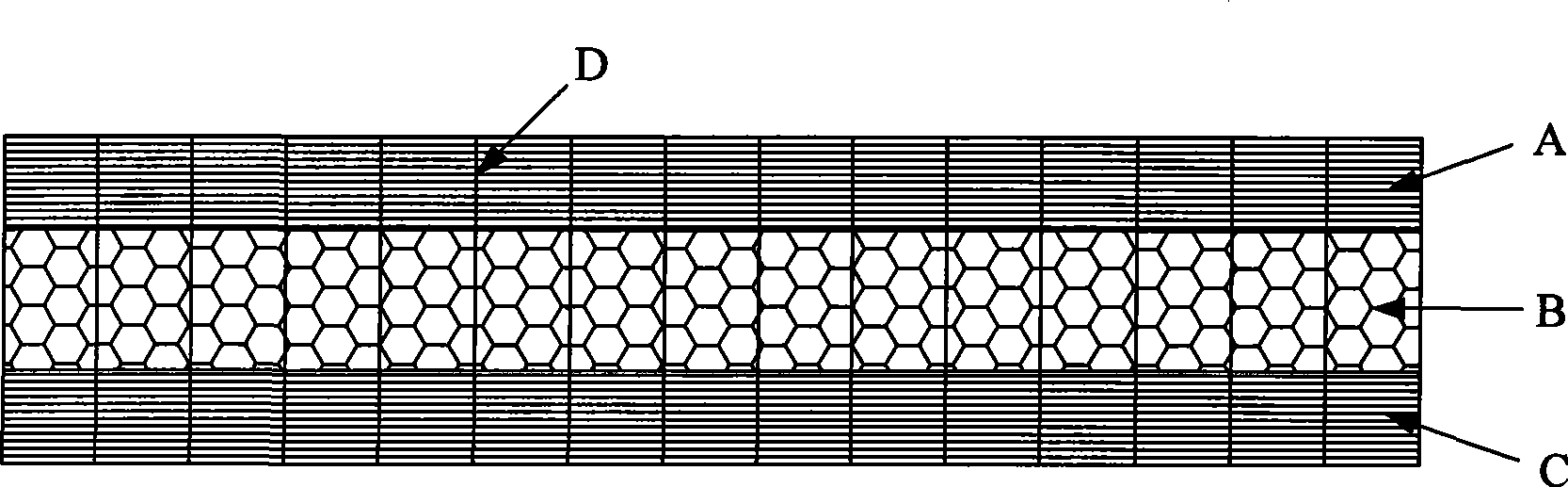

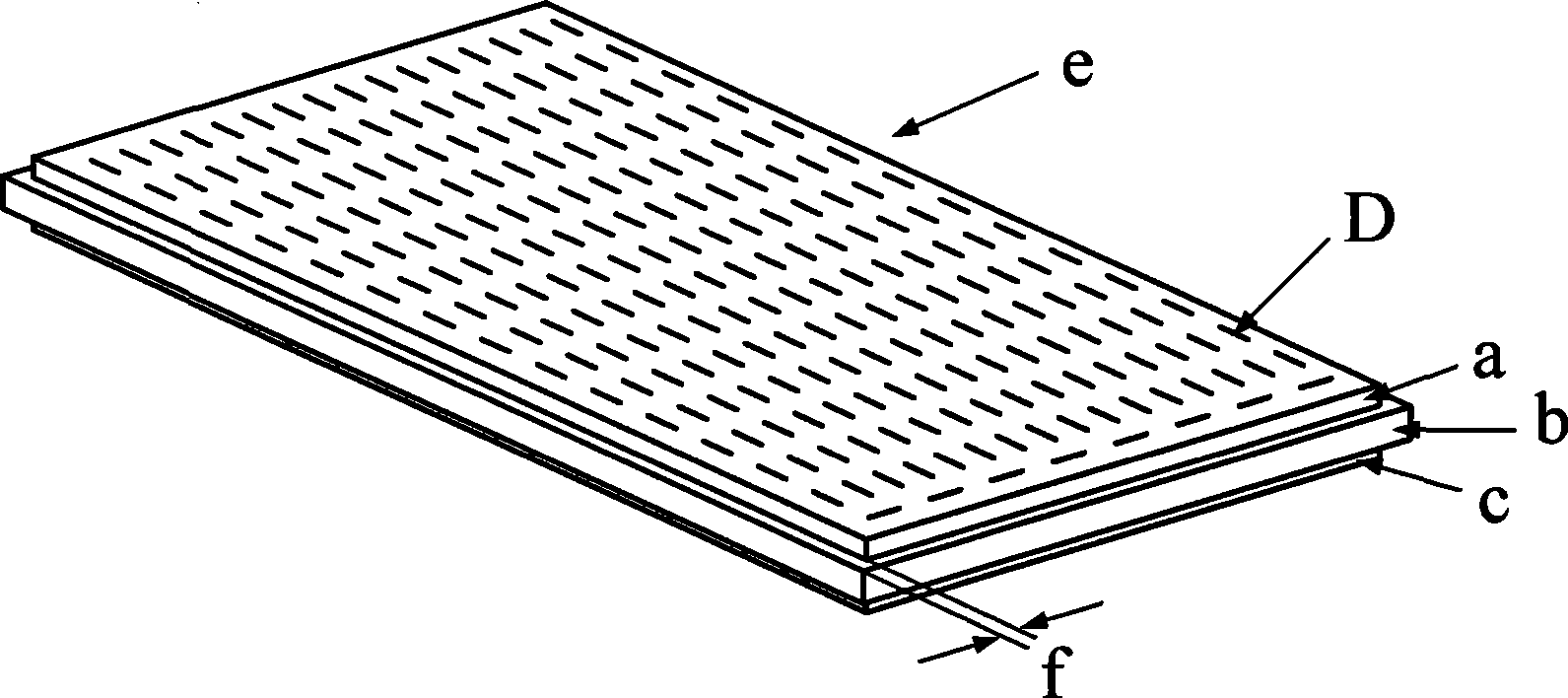

InactiveCN101417516AImprove layer performanceIncreased interlaminar shear strengthLayered productsEpoxyInsulation layer

A composite material of sandwich structure integrating loading, heat insulation and ablation and the manufacturing method are characterized in that an integrated pre-forming body is acquired by puncture and suture of the reinforcing material of a bearing layer, the reinforcing material of an ablating cover, and a heating insulation layer positioned between the two layers; an epoxy resin system and a phenolic resin system are injected simultaneously into a vacuum-pumped mould, in which the integrated forming body is pre-placed, by two sets of RTM injection systems respectively, then, the reinforcing materials of the bearing layer and the ablating layer are soaked by epoxy resin and phenolic resin respectively; and the composite material of sandwich structure integrating loading, heat insulation and ablation can be obtained by solidified molding after mould filling. The invention has the advantages that the composite material of sandwich structure integrating loading, heat insulation and ablation is put forward and can be integrally formed by one-time operation, the function of the interlayer between every layer of the composite material is enhanced greatly, the integrality is good; the stratifying and peeling of the composite can be reduced effectively, and the products have good designable property and can be widely applied to the structural parts of aerospace which need heating insulation and thermal protection.

Owner:NAT UNIV OF DEFENSE TECH

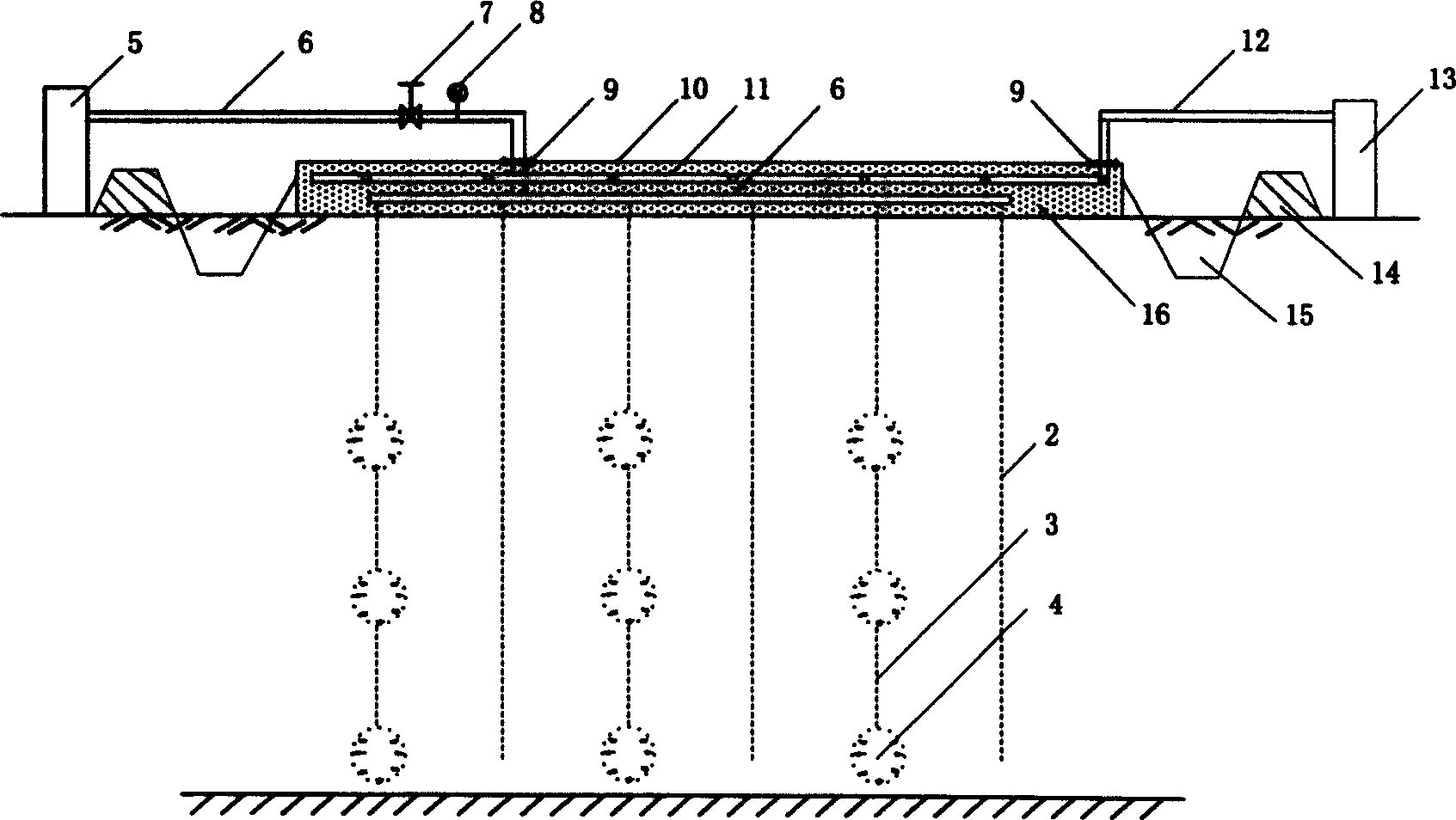

Operation method for consolidating soft soil foundation by pneumatic flerry vacuum preloading method

The invention relates to an air pressure splitting off vacuum pre-pressing method to reinforce soft soil that is a method to process groundsill. The process is that: cleaning the field, laying plastic draining board, setting high pressure gas transferring system, setting the vacuum system, inflicting high pressure gas, pumping to vacuum, and repeating to inflict high pressure and pumping according to the demand.

Owner:SOUTHEAST UNIV

Method for smelting nickel-based high temperature alloy in vacuum induction furnace

The invention relates to a method for smelting a nickel-based high temperature alloy in a vacuum induction furnace. The method sequentially comprises the following steps of: I, putting alloy raw materials into the furnace in a ratio; II, closing a furnace cover, vacuumizing, and performing power transmission to melt furnace burden; III, melting at the speed of less than or equal to 1 / 2 maximum furnace capacity / hour; IV, after the furnace burden is completely melted, starting performing bottom argon blowing, and refining for 20 to 25 minutes; V, stopping argon blowing, adding Al and Ti, and alloying; VI, after Al and Ti are completely melted, performing bottom argon blowing, and refining; VII, after refining is finished, closing a vacuum pump, and filling argon into the furnace and an ingot mold; VIII, alloying at the finishing point, namely adding B, Zr and a rare earth element, and adding a Ni-Mg alloy; and IX, performing electrified tapping after 3 to 4 minutes, and casting into an alloy ingot. By the method for smelting the nickel-based high temperature alloy in the vacuum induction furnace, refining time is 35 to 40 minutes, and the nickel-based high temperature alloy with very low carbon content can be obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Low pressure dryer

InactiveUS6154980ADrying solid materials with heatDrying solid materials without heatPiston cylinderMechanical engineering

A low pressure dryer for granular or powdery material includes a plurality of hoppers rotatable about a common vertical axis serially among material filling and heating, vacuum drying and material discharge positions; pneumatic piston-cylinder means for rotating the hoppers about said axis among said filling and heating, vacuum drying and discharge positions; means for heating contents of a hopper at said filling and heating positions; means for sealing a hopper at said vacuum and drying positions; means for drawing vacuum within a hopper at said vacuum drying position and means for selectably permitting downward flow of dried granular or powdery material out of a hopper at said discharge position where said hoppers move collectively and unitarily one with another.

Owner:MAGUIRE STEPHEN B

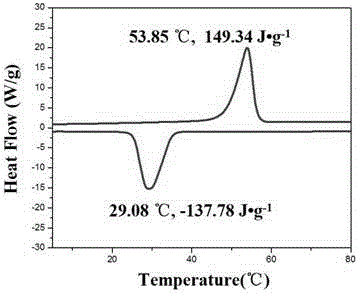

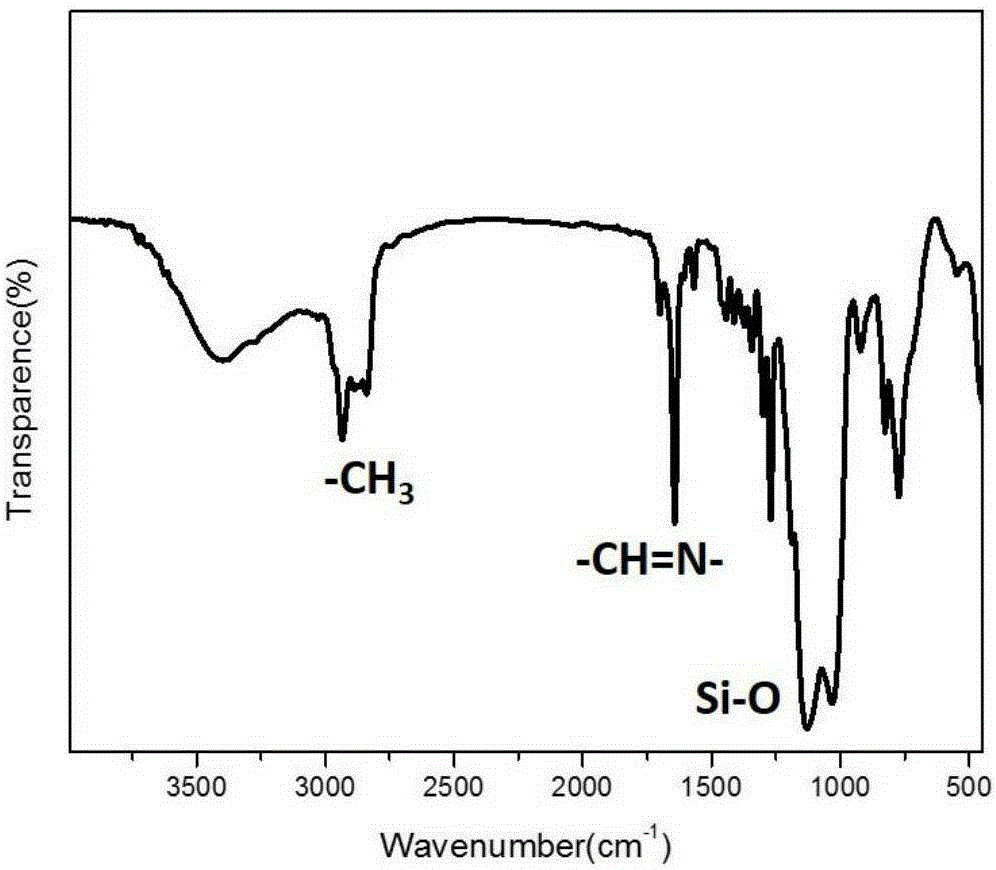

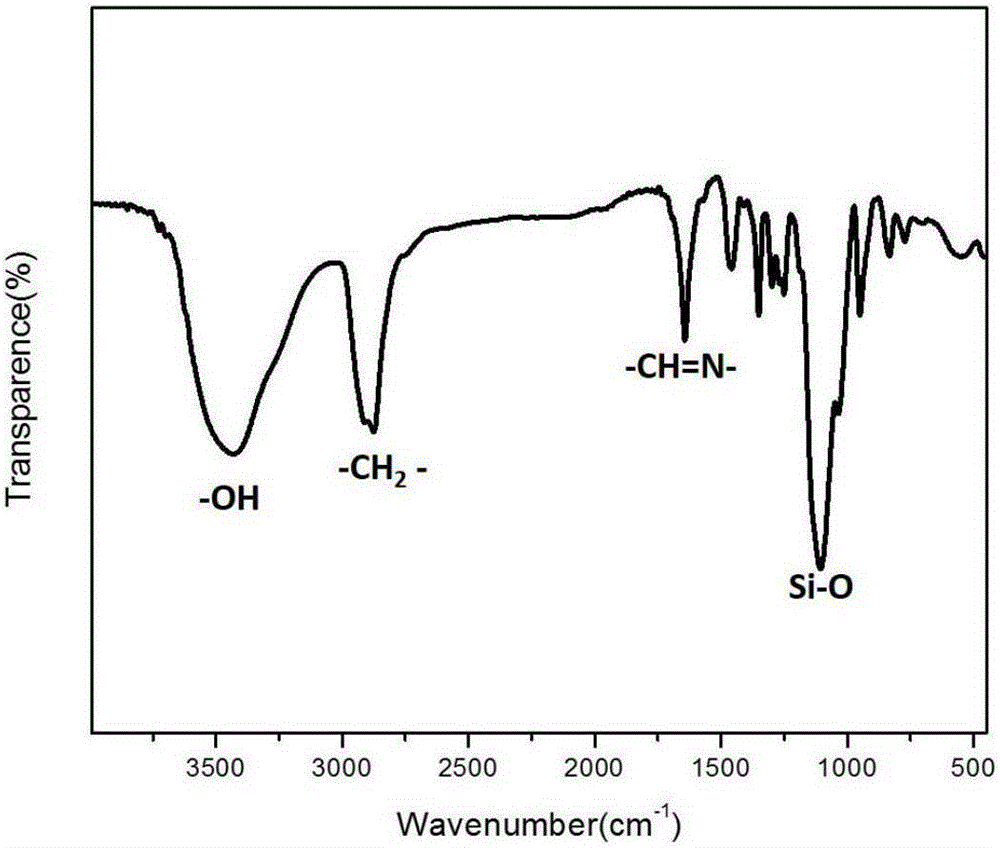

Preparation method of modified aerosil-based composite phase-change material

The invention discloses a preparation method of a modified aerosil-based composite phase-change material. The preparation method includes the steps that a modified aerosil carrier material is prepared first, prepared modified aerosil is placed into a prepared phase-change material solution after being subjected to vacuum drying, a phase-change core material is adsorbed based on the large specific area and the nanopore structure of the modified aerosil carrier material, and after drying, the modified aerosil-based composite phase-change material with a shaping effect is obtained. The preparation method has the advantages that the novel modified aerosil-based composite phase-change material is developed; the prepared modified aerosil-based composite phase-change material can effectively prevent leakage, corrosion and other problems, the loading capacity of the porous phase-change material can be improved, and the service life of the porous phase-change can be prolonged; the method just needs mild reaction conditions and is simple in process, short in period and suitable for industrial production.

Owner:南京逸柔蒂雯新材料科技有限公司

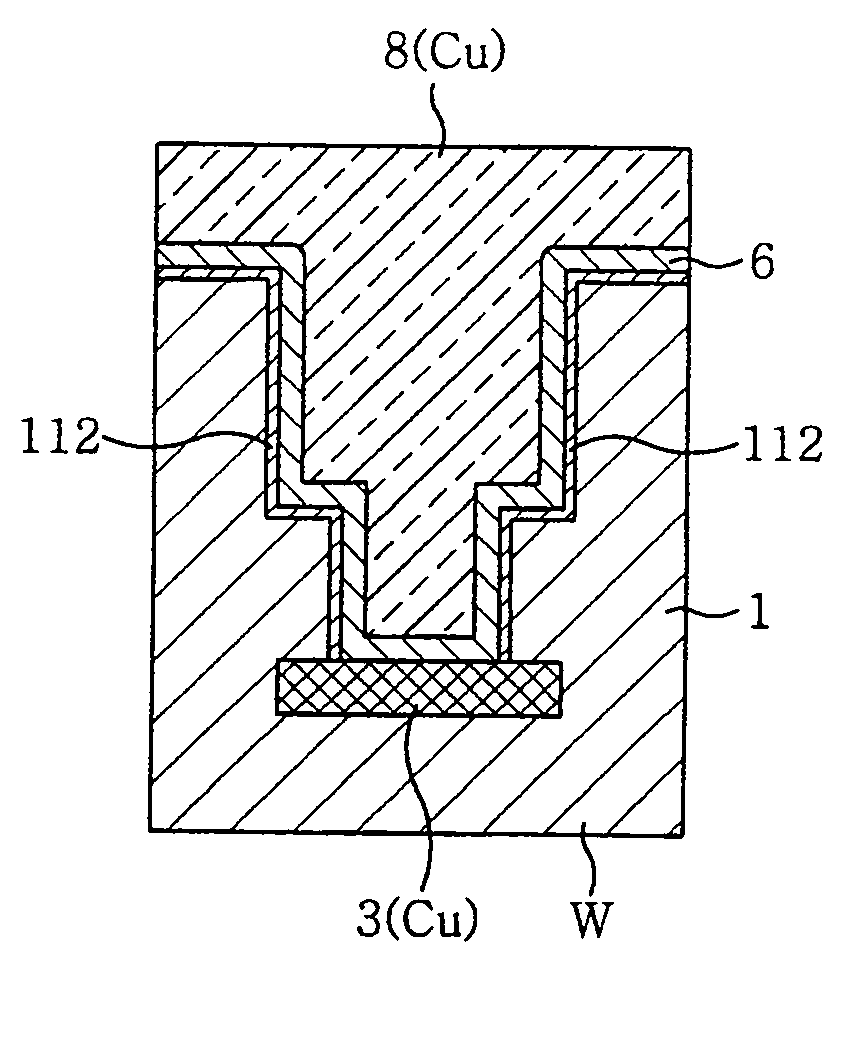

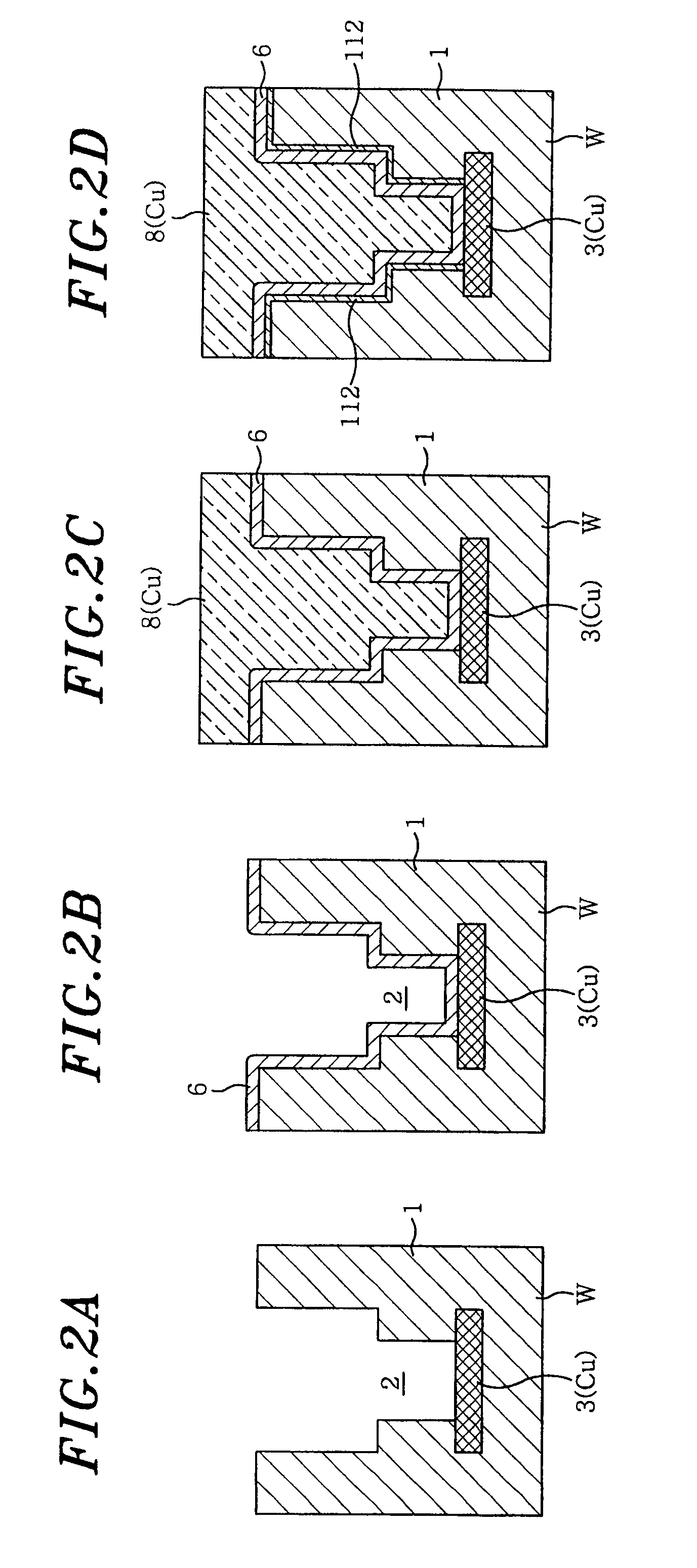

Film forming apparatus, film forming method, computer program and storage medium

InactiveUS20100233876A1Good effectHigh step coverageSemiconductor/solid-state device detailsSolid-state devicesProduct gasEngineering

In a film forming method, a substrate is first loaded into a vacuum-evacuable processing chamber. At least a transition metal-containing source gas and a reduction gas are supplied into the processing chamber, and the substrate is heated. Then, a thin film is formed in a recess in the surface of the substrate by heat treatment. Accordingly, the surface recess of the substrate can be filled with a copper film.

Owner:TOKYO ELECTRON LTD +1

Composite sanitary napkins with heating element and method for preparing and packing thereof

ActiveCN101273938ARelieve dysmenorrheaImprove antibacterial effectAbsorbent padsBaby linensActivated carbonMelt blowing

The invention relates to a heater composite sanitary napkin and a preparation and packaging method thereof. The heater composite sanitary napkin is composed of a conventional sanitary napkin and a heater combined layer, the heater combined layer is composed of upper and lower surface layers of air-permeable layers with the same structures and materials and a middle heating substance sheet layer, the middle sheet of the air-permeable layers is melt blowing nonwoven fabric, the upper and lower layers are nonwoven fabric which is made by the composite technology; and the heating substance sheet layer is formed by mixing and pressing metal signal substance, sodium chloride and activated carbon according to the proportion. The heating sheet layer is firstly arranged in the heater combined layer which is provided with seven layers and is formed between the two pre-made air-permeable layers by hot rolling and then is fixed between an absorption layer and a mesh surface layer of the sanitary napkin by binding or hot rolling, the vacuum pumping is carried out or protective gas is introduced, the exterior thereof is packaged by an oxygen isolating thin film, and the formed package body can be stored for a long time. The reaction is activated by tearing the thin film. The product has the effects of waterproof, anti-leakage, convenient and long-term stable heating, warming uterus and reducing dysmenorrheal. The preparation method is simple and the packaging effect is good.

Owner:DONGHUA UNIV +1

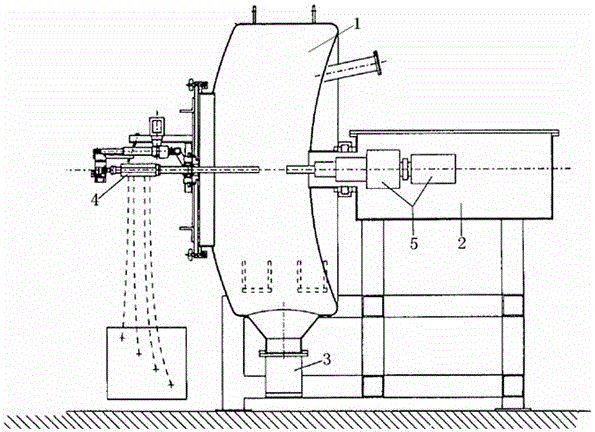

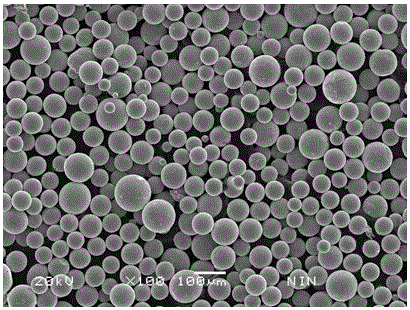

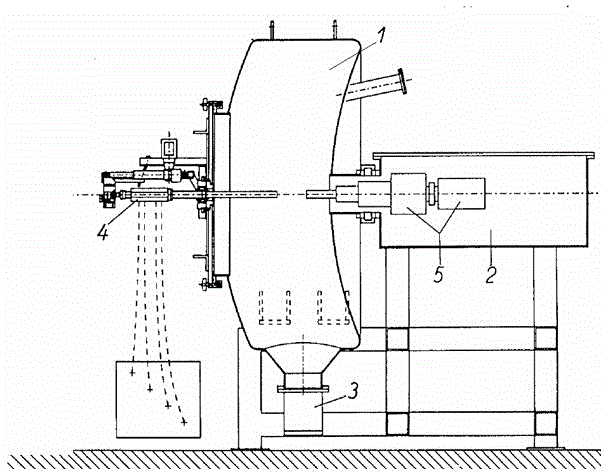

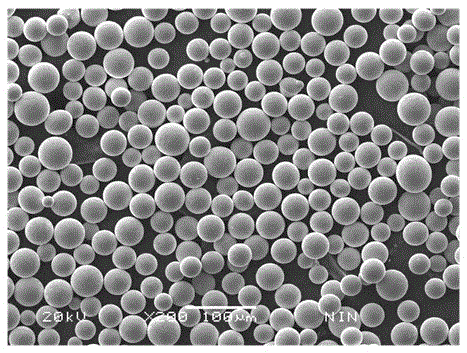

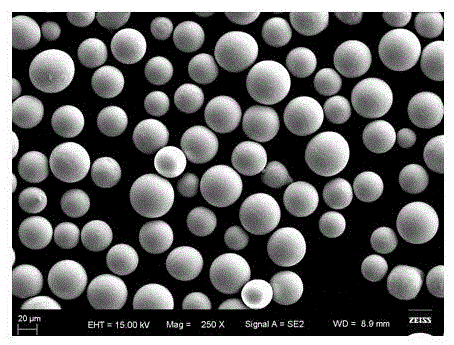

Method for preparing Inconel 625 alloy spherical powder

InactiveCN105689730AFast pure meltingReduce the introductionTransportation and packagingMetal-working apparatusPlasma torchPressure range

A method for preparing Inconel 625 alloy spherical powder comprises following steps: according to the AMS 5666G standard, two-time vacuum smelting of alloy ingredient compositions and a master ingot is carried out; through forging and mechanical machining, the master ingot is made into an alloy electrode bar; atomizing equipment is subject to pre-vacuum-pumping treatment, mixed inert shielding gas is led into the atomizing equipment, and the pressure ranges from 0.1*105 Pa to 3*105 Pa; the electrode bar is fed into an atomizing chamber through a feeding system, a plasma torch is used for heating the end face of the electrode bar, metal liquid drops are prepared through the centrifugal effect of a rotating electrode, and the metal liquid drops are instantly solidified into the spherical metal powder; and a powder collecting device containing an electrostatic separation component carries out inclusion removing treatment and pure powder collection on the metal spherical powder. The method has the beneficial effects of being high in production efficiency, high in batch stability, high in fine powder yield and the like and can easily prepare the Inconel 625 alloy spherical powder with the high purification, the good sphericility degree and the high liquidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Combustible burning rate test device in plateau artificial oxygen-enriched environment

InactiveCN101509908AStable and reliable test performanceChemical analysis using combustionMaterial heat developmentCombustion chamberGas composition

The invention provides a testing device for the combustion rate of combustibles in a plateau artificial oxygen-enriched environment, belonging to a field of fire safety. The testing device consists of the following seven parts: a combustion chamber, a positioning mechanism, an air distribution system, an airflow-circulation and concentration-monitoring system, a vacuum-pumping system, an ignition system and a data acquisition system. A sample is arranged on a sample support by a sample clamper, and then vacuum-pumping is carried out to a sealed chamber by the vacuum-pumping system; each single high-purity gases are mixed in the sealed chamber after passing through a mass flowmeter and a flow regulating valve; the total pressure of the gases is displayed by a high-precision vacuum manometer; when the requirements of the total pressure of the gases and gas compositions are met, a micro-air pump is started to mix the airflow in the sealed chamber; a laser light source is started to ignite the sample after the concentration of the gas compositions is steady; the sample combustion flame passes through two thermocouples sequentially; temperature change curves of the thermocouples are obtained by A / D conversion and the data acquisition system; and the time between two maximum temperature points of the curves corresponding to the two thermocouples is taken as the combustion time of the sample between the thermocouples with fixed distance, thus obtaining the combustion rate of the sample under the total pressure of the gases and the concentration of the gas compositions. The testing device has stable and reliable testing performance, and is simple and convenient.

Owner:UNIV OF SCI & TECH BEIJING

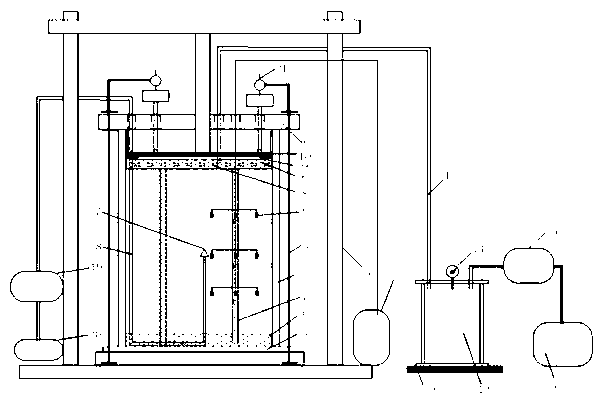

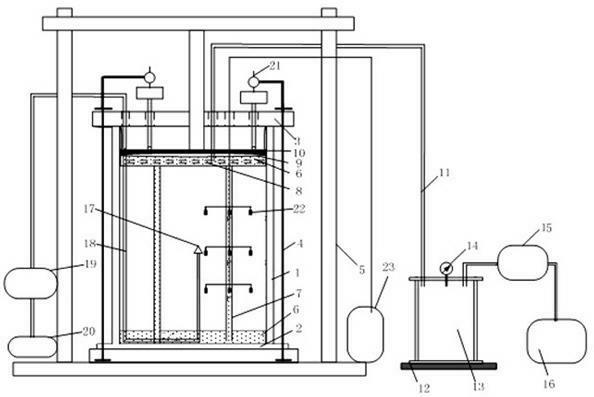

Indoor model testing device and testing method employing air-pressure splitting vacuum preloading method

ActiveCN102707034AEasy constructionLow costEarth material testingSoil preservationPore water pressureData acquisition

The invention discloses an indoor model testing device employing an air-pressure splitting vacuum preloading method. The indoor model testing device comprises a model groove, a pile-loading system, a vacuum loading system, an air-pressure splitting system and a measuring system, wherein the model groove comprises a plastic cylinder, a plastic cylinder base, a plastic cylinder top cover and reinforcing steel bars; the pile-loading system is a lever type loading device; the vacuum loading system comprises a drainage system, a sealing system and a vacuum-pumping system; the air-pressure splitting system comprises an air nozzle, an air conveying pipe, a pressure flow speed controller and an air compressor; and the measuring system comprises a displacement sensor, a pore water pressure meter and a data acquirer. The invention also discloses an application method of the indoor model testing device employing the air-pressure splitting vacuum preloading method. The indoor model testing device is reasonable and simple in structure and convenient to operate and can be used for performing model test of reinforcing soft soil by using the air-pressure splitting vacuum preloading method.

Owner:SOUTHEAST UNIV

An EB cold hearth smelting method of TC4 titanium alloy ingots

The invention relates to an EB cold hearth smelting method of TC4 titanium alloy ingots. The method adopts an electron beam cold hearth smelting furnace and can produce TC4 titanium alloy ingots of big size: 1050mm*210mm*8000mm. The method uses sponge titanium, titanium scrap, pure aluminum and intermediate alloy of aluminum and vanadium with different proportions as raw materials. When the electron beam cold hearth smelting furnace is used for smelting TC4, first, raw materials are put in a feeder, secondly, each part of the furnace is separately sealed and vacuum pumping is performed, etc. The method has the advantages of enhancing the efficiency of smelting titanium alloy and the quality of ingots, remarkably shortening the production time, improving the smelting quality, reducing energy consumption, and being capable of producing more than 10000kg of titanium alloy ingots at a time.

Owner:YUNNAN TITANIUM IND

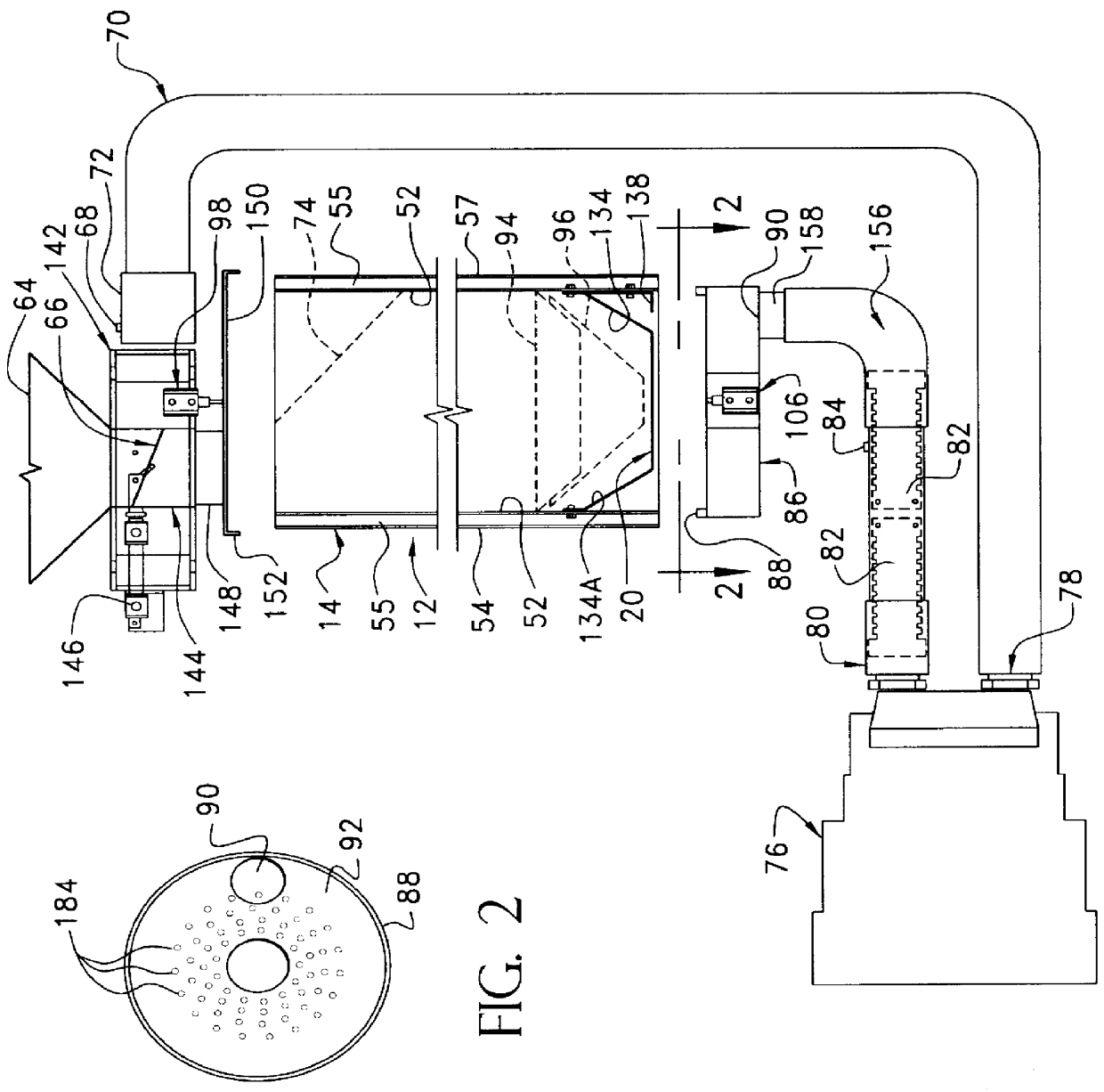

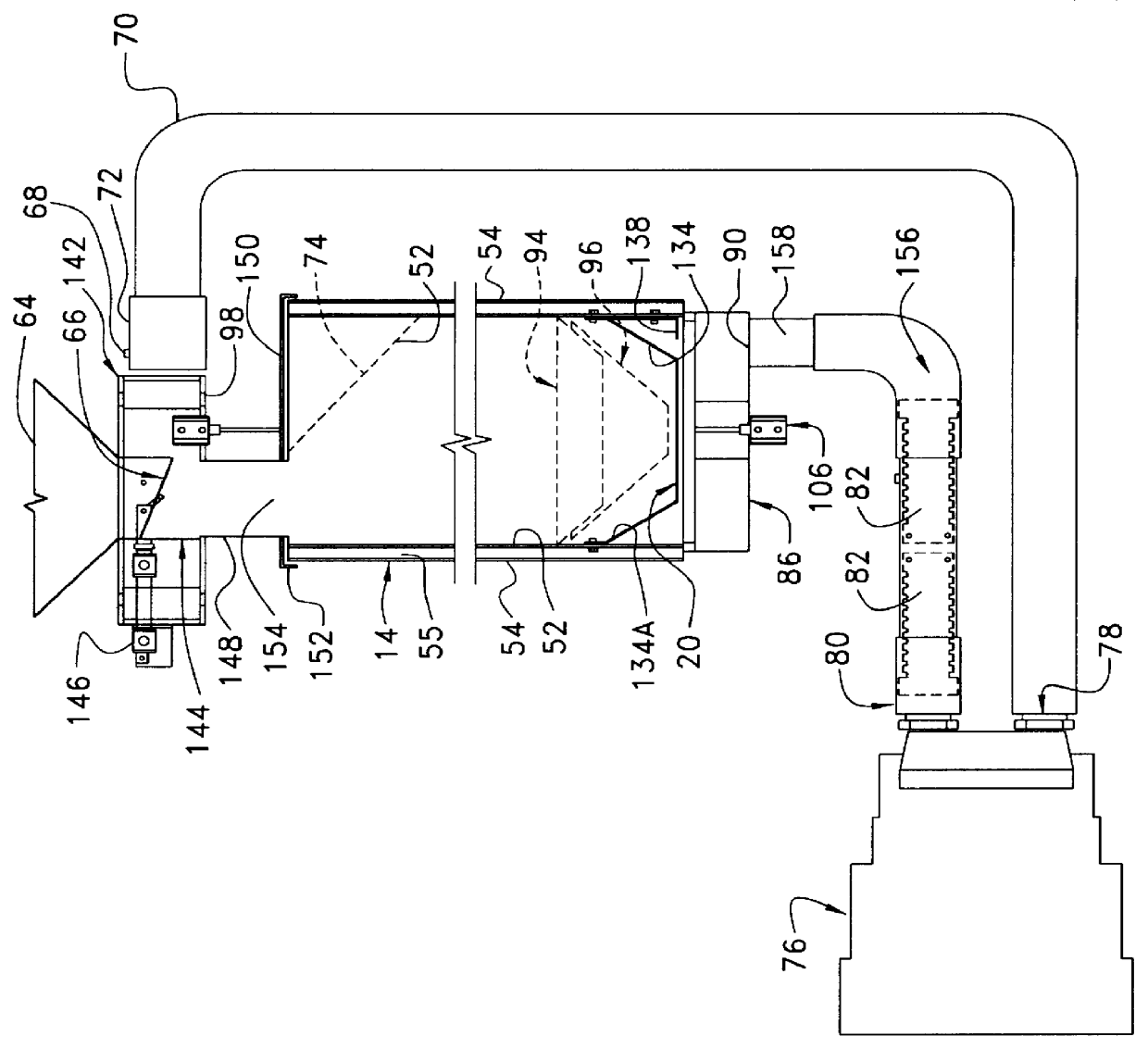

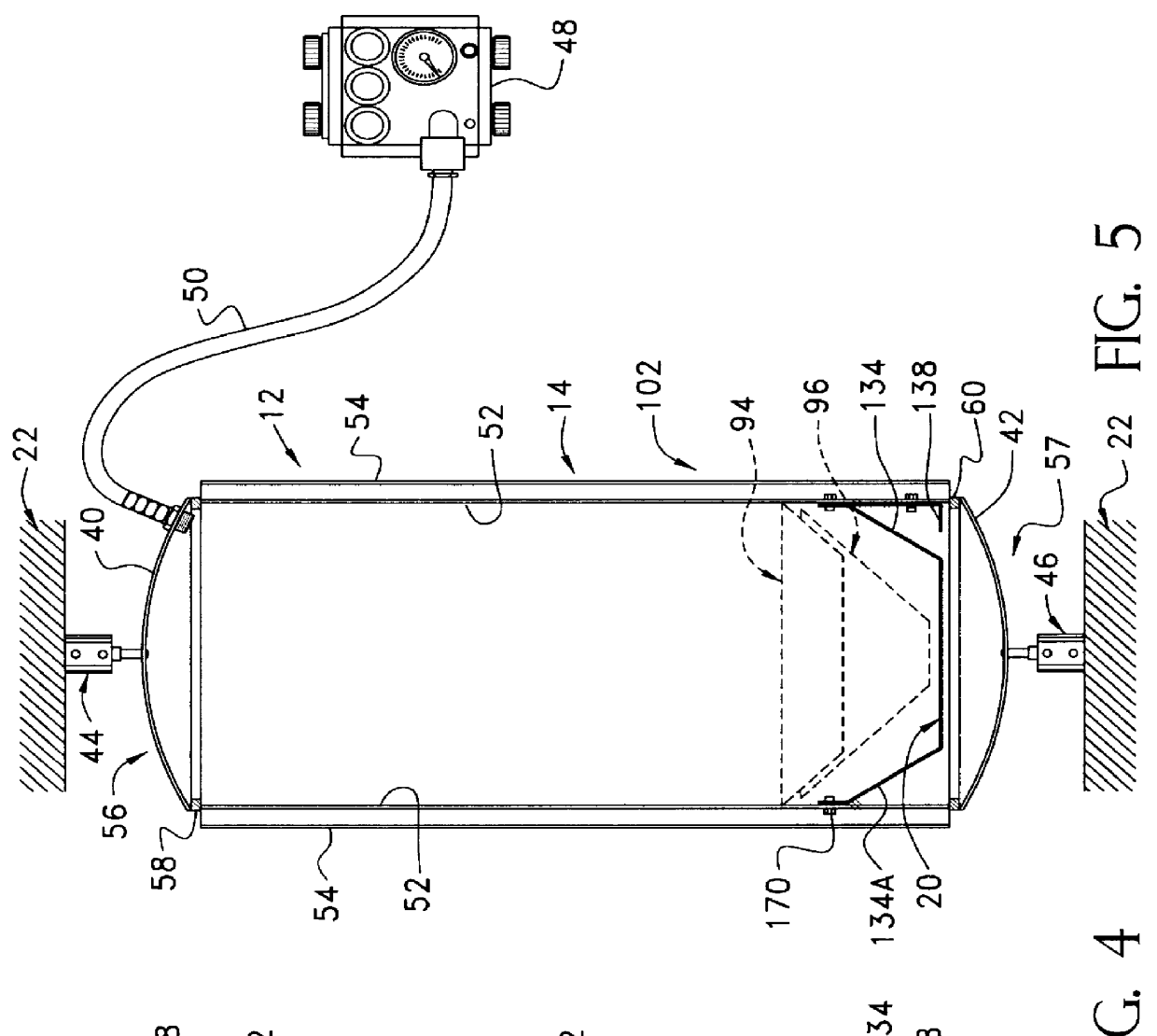

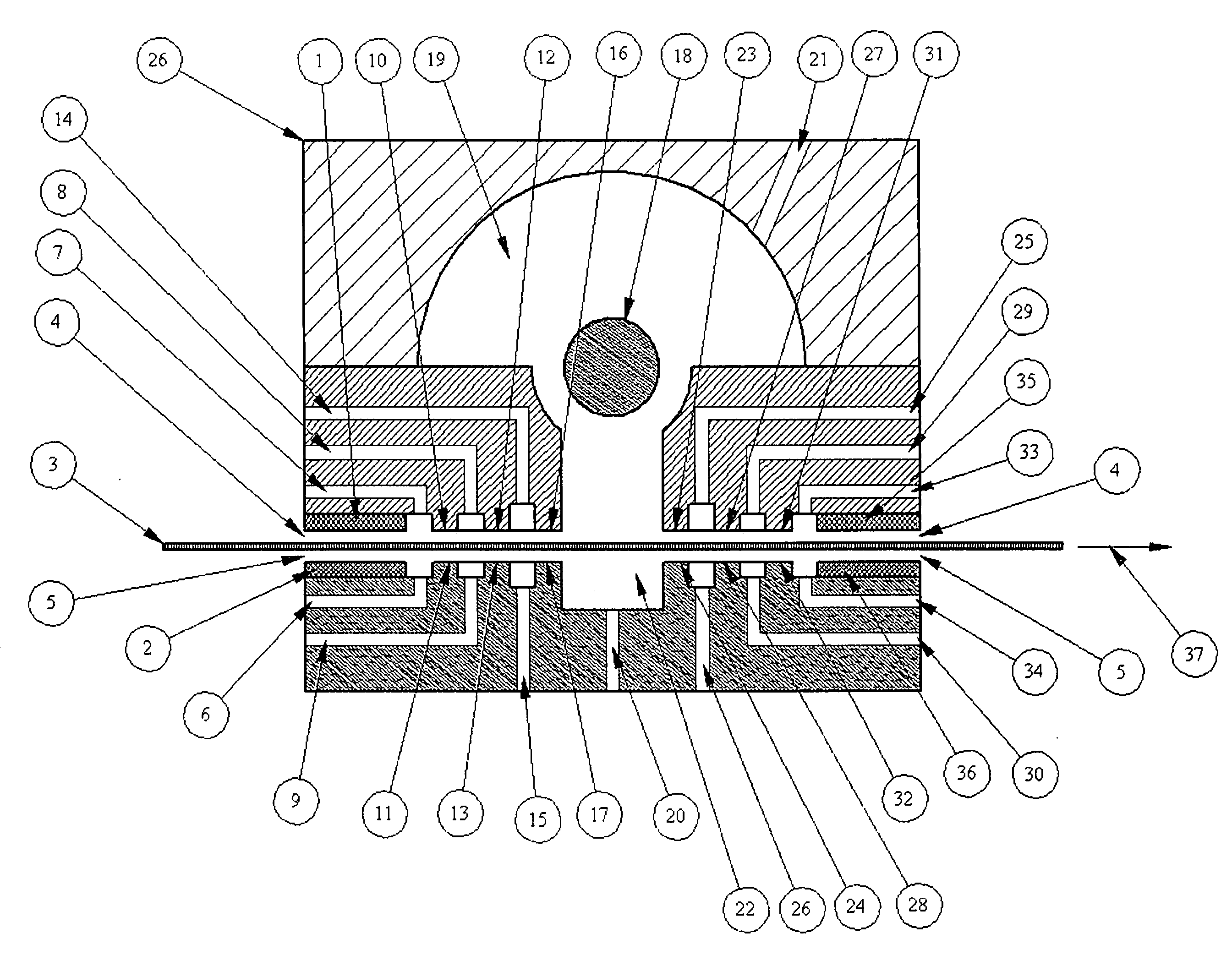

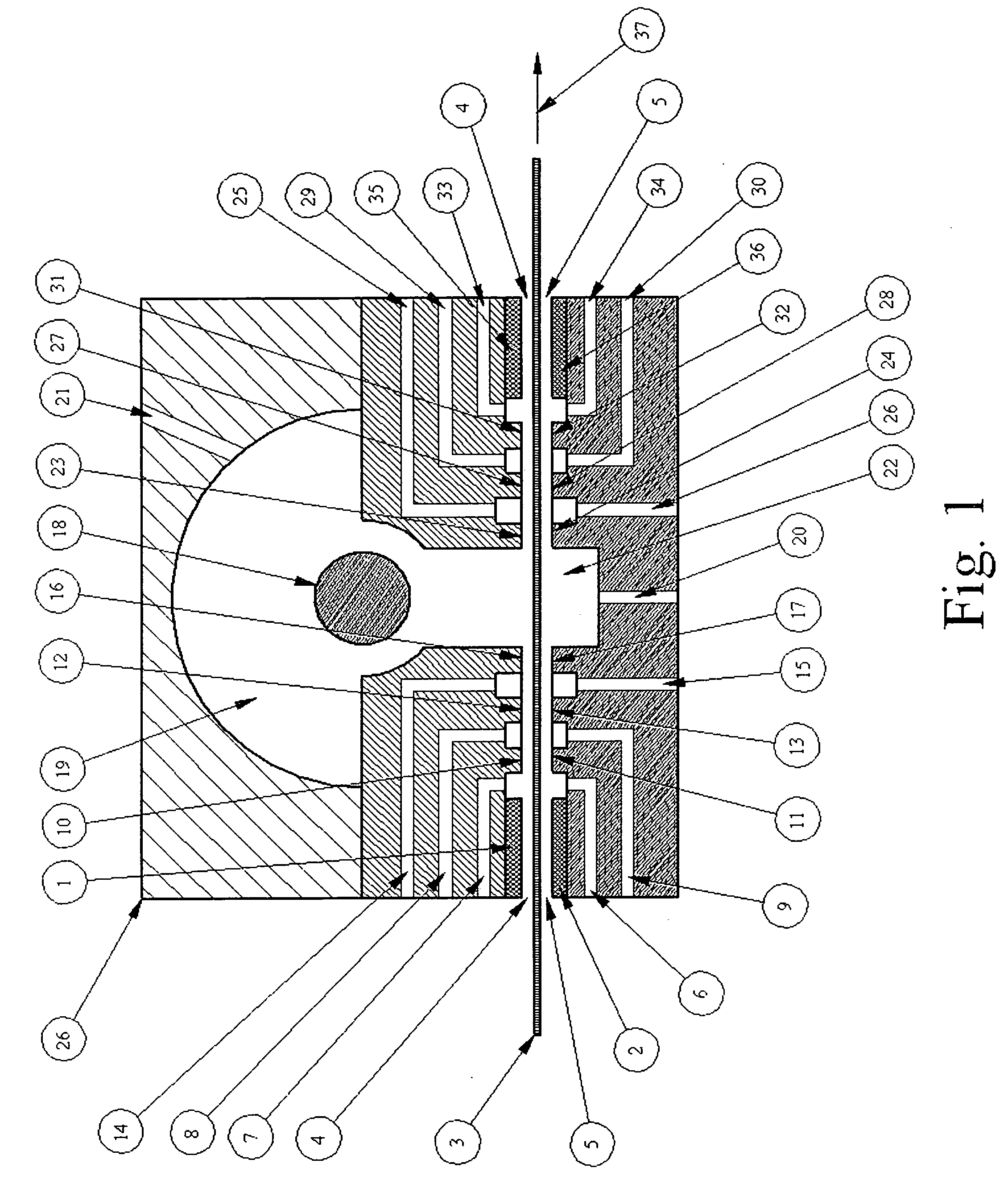

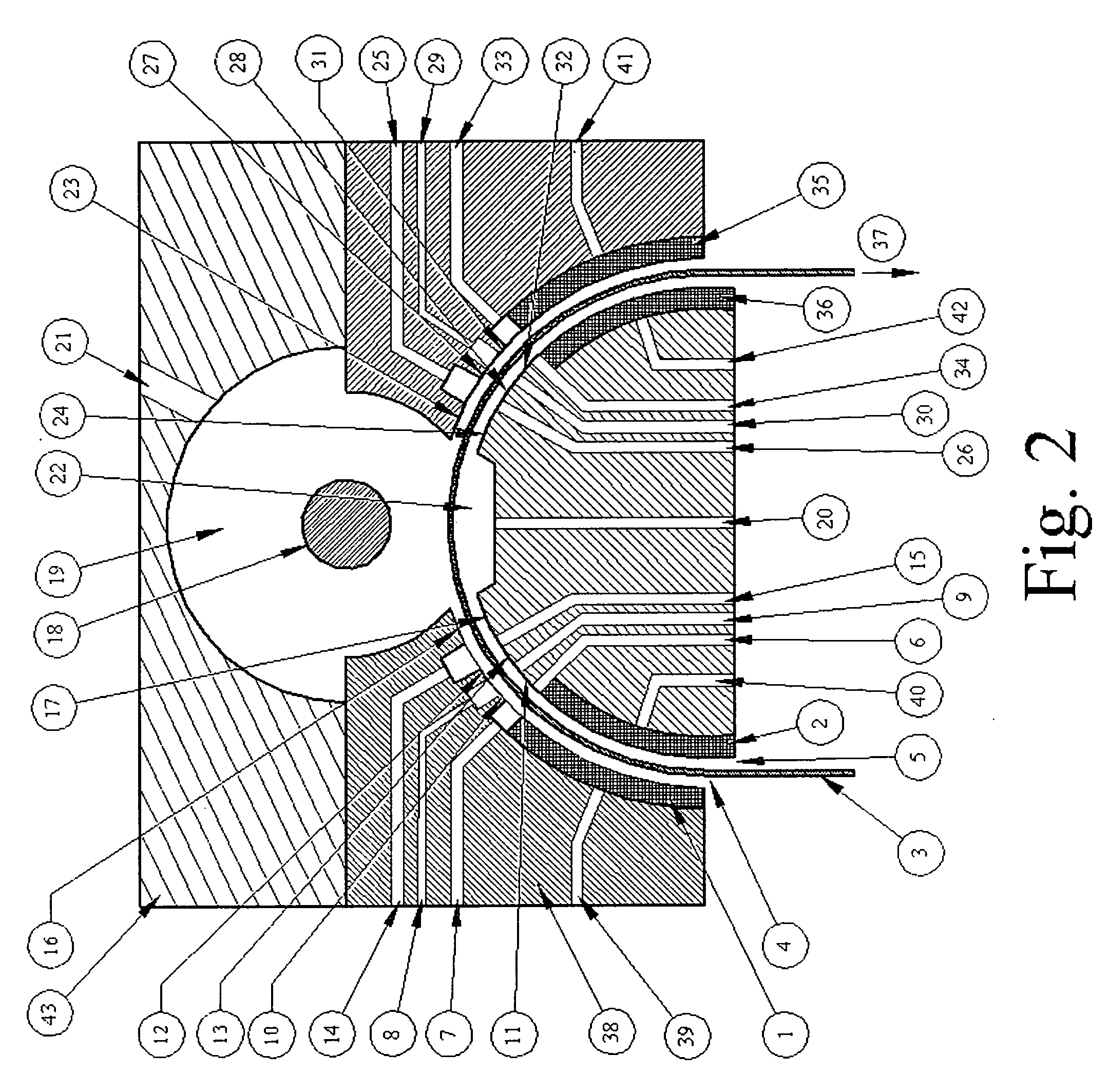

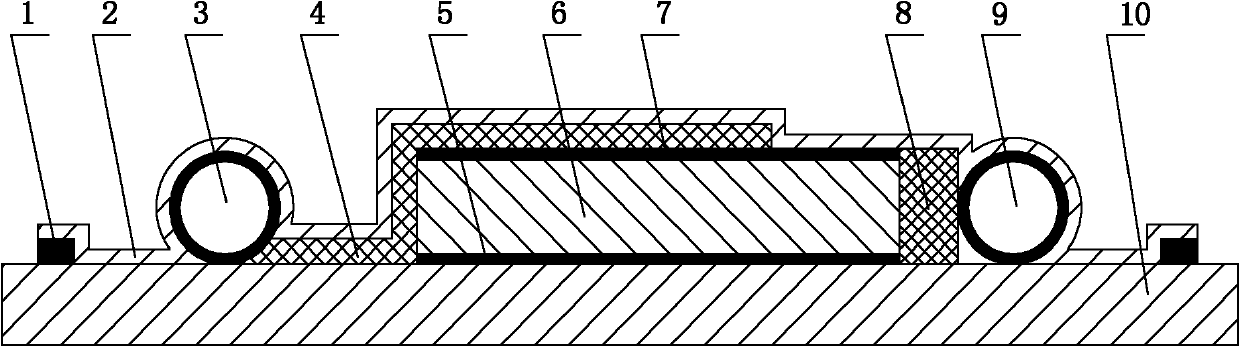

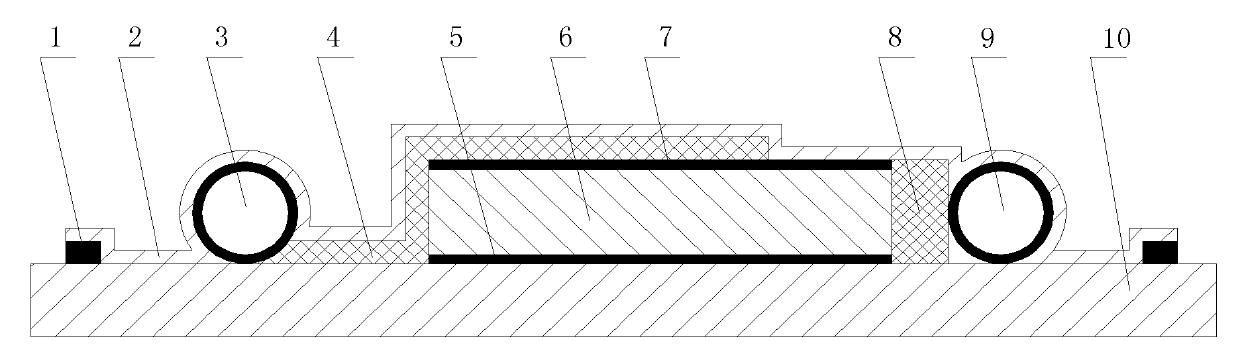

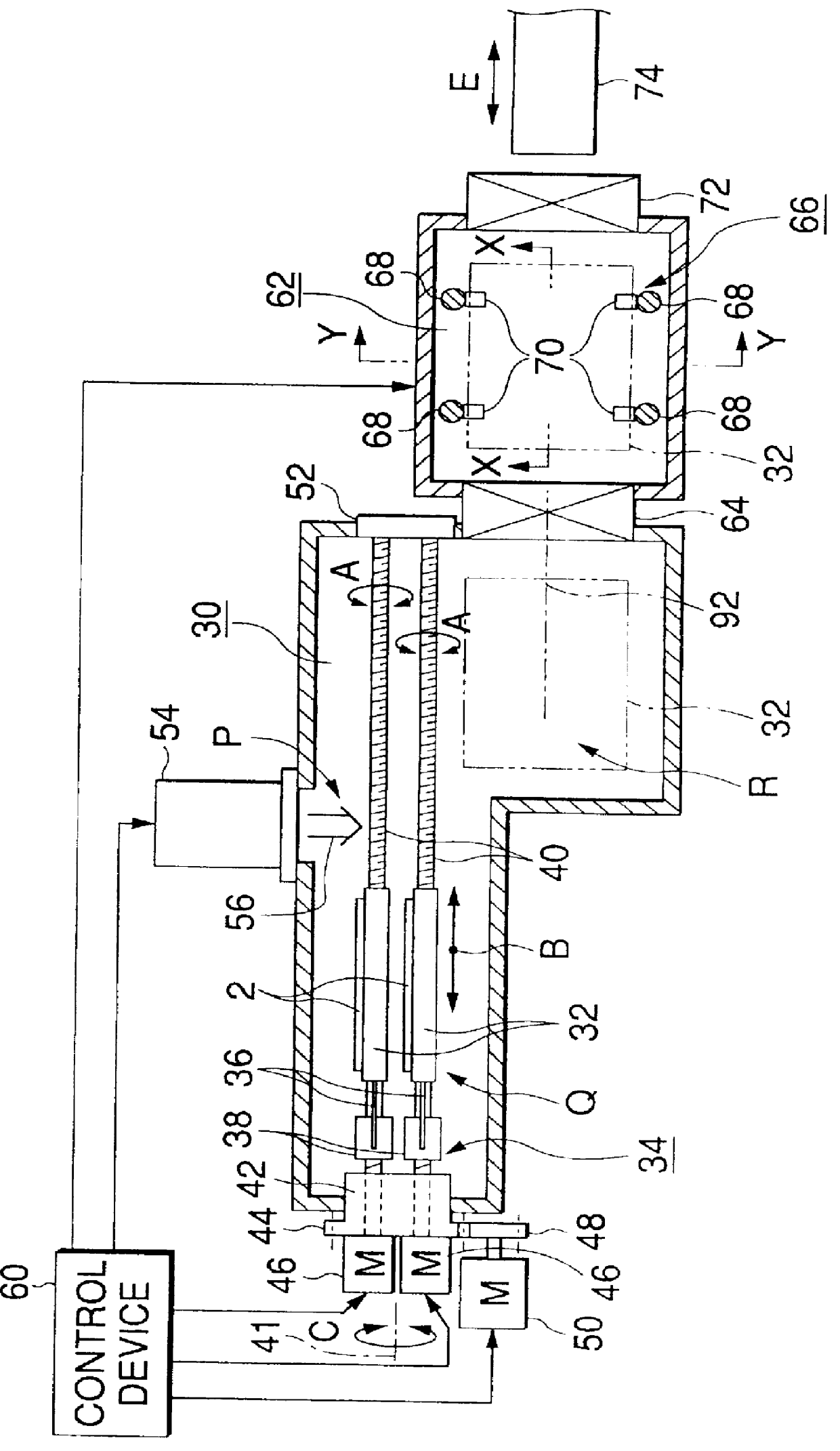

Method and a device for depositing a film of material or otherwise processing or inspecting, a substrate as it passes through a vacuum environment guided by a plurality of opposing and balanced air bearing lands and sealed by differentially pumped groves and sealing lands in a non-contact manner

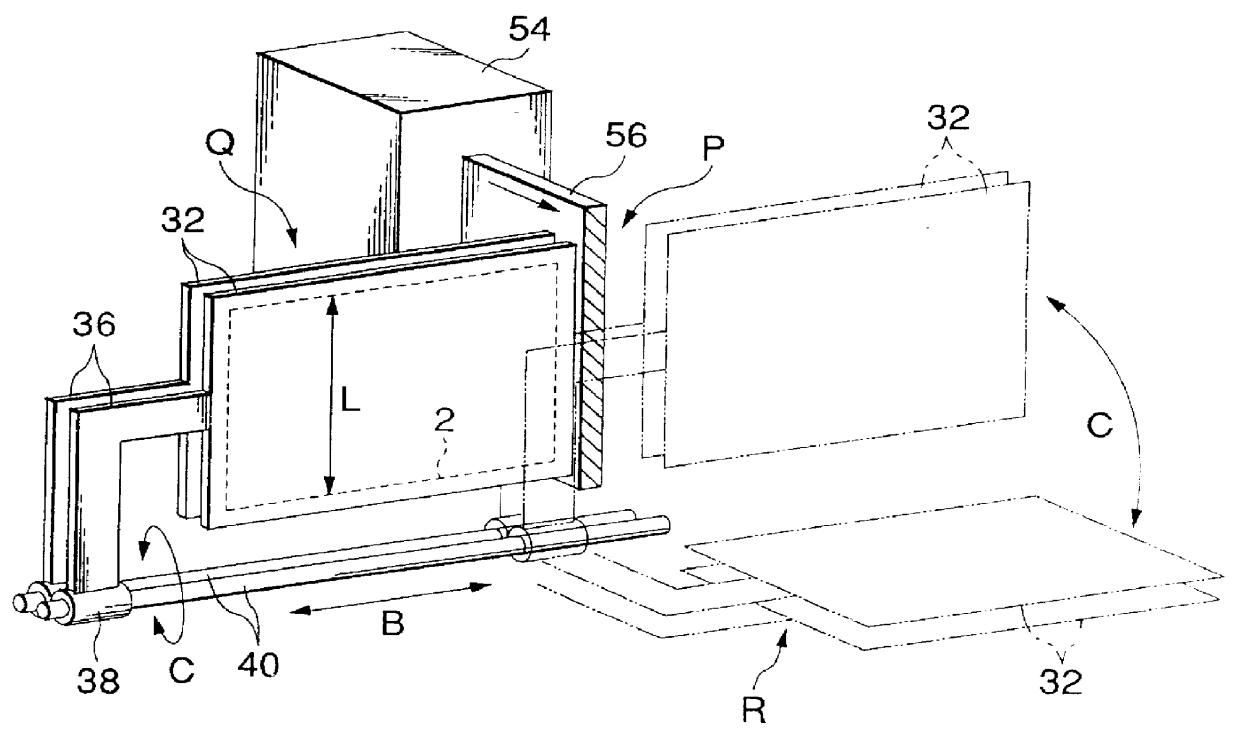

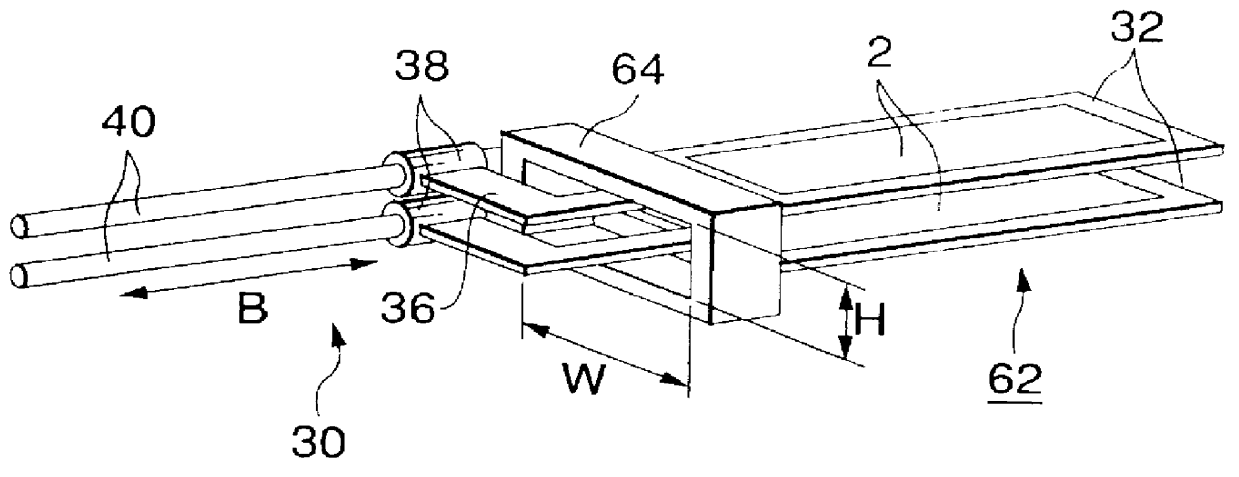

ActiveUS20070031600A1Quantity minimizationIncrease the areaLiquid surface applicatorsVacuum evaporation coatingAir bearingPorous medium

A method and apparatus for coating and baking and deposition of surfaces on glass substrate or flexible substrate, such as films and thin glass sheets or other similar work pieces as it transitions thru and between small gaps of aero-static or hydro-static porous media bearings and differentially pumped vacuum grooves, in a non-contact manner, in order to process within a vacuum environment. The process is also intended to incorporate simultaneous and immediately sequential ordering of various processes.

Owner:NEW WAY MACHINE COMPONENTS

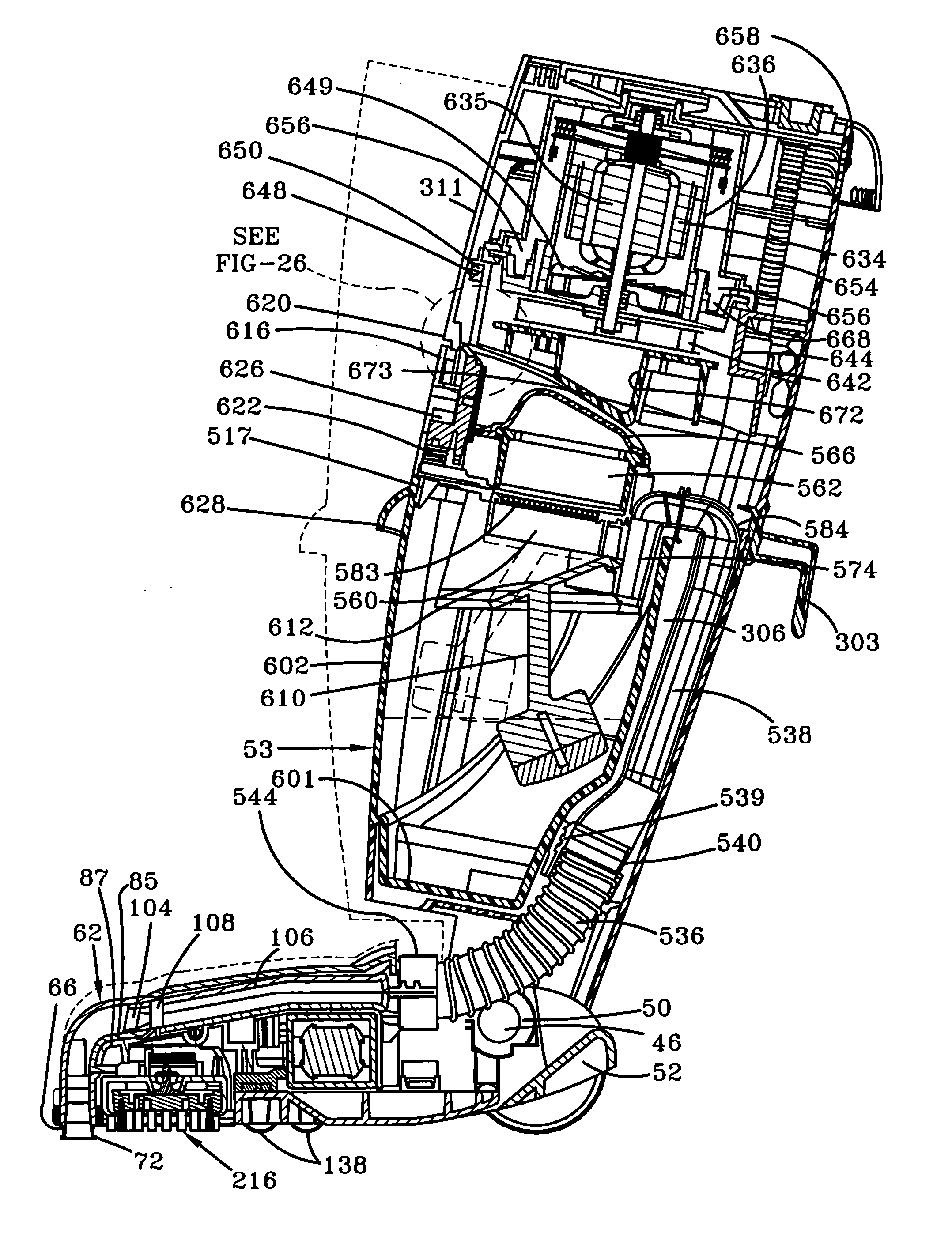

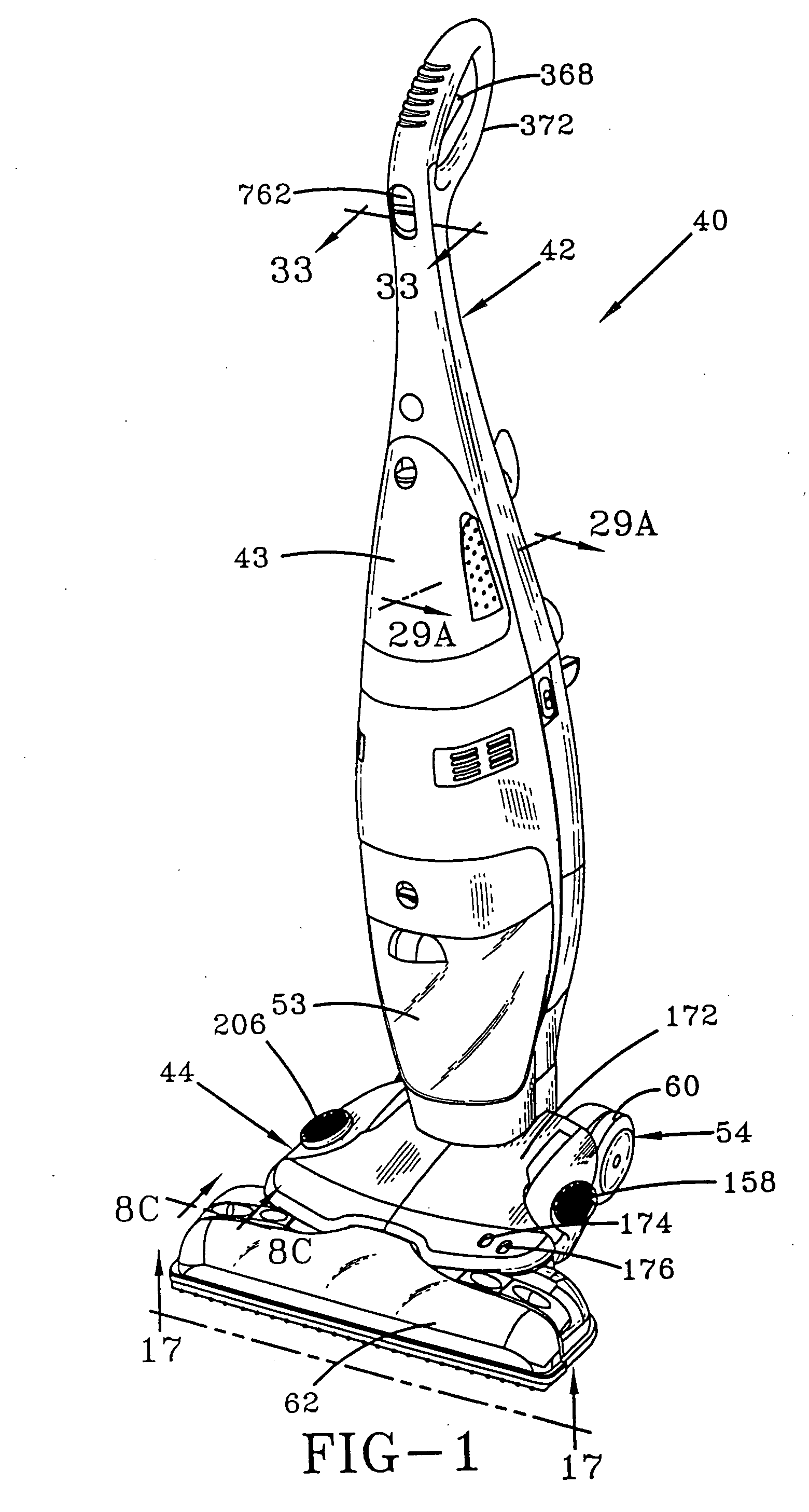

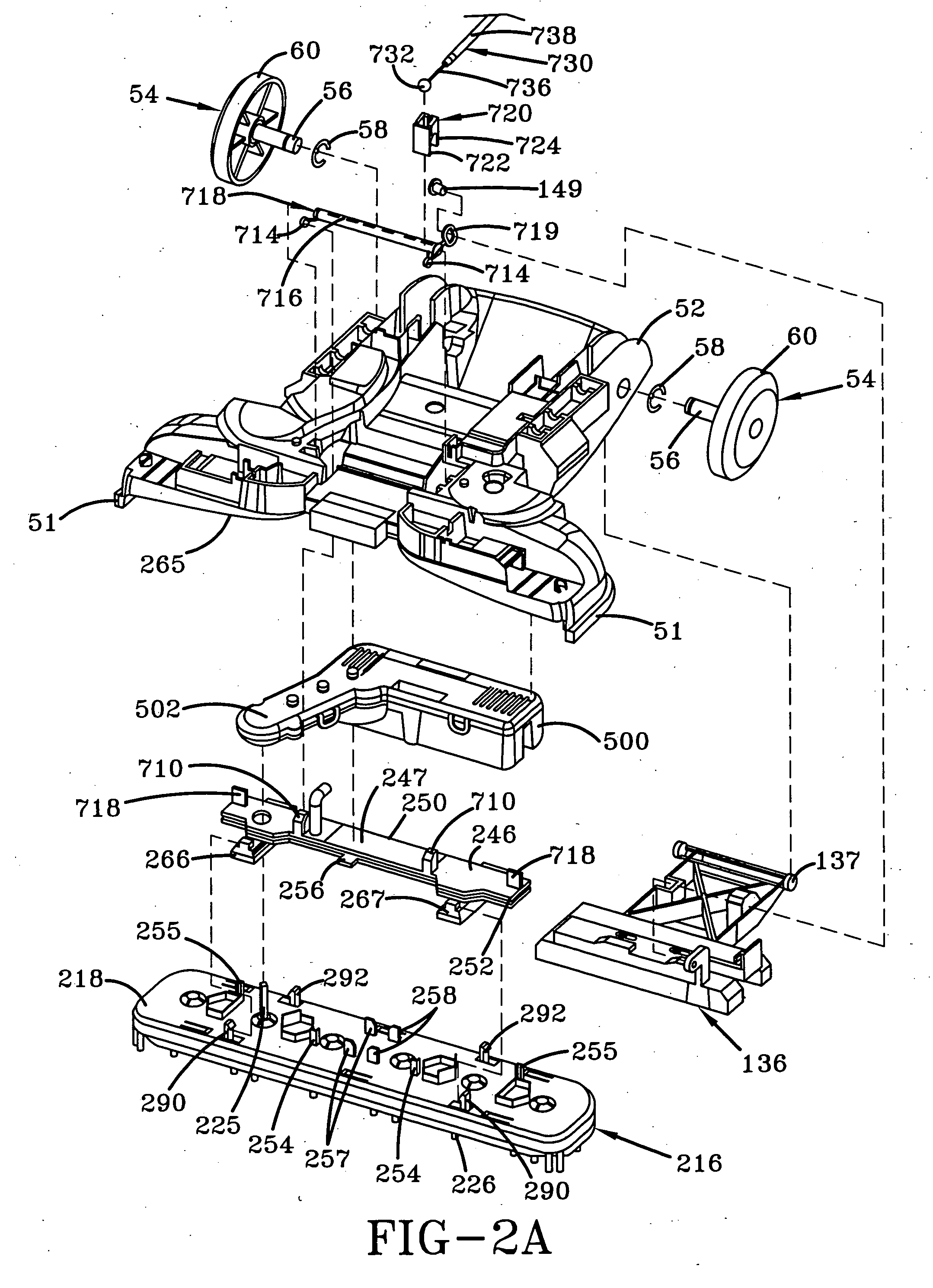

Wet/dry floor cleaning unit and method of cleanig

A floor cleaning device comprises a base portion for movement along a surface and a handle portion pivotally connected to the base. The base portion further includes a suction nozzle and a brush assembly for agitating the surface, wherein the brush assembly and the nozzle assembly are in a first position raised off of the surface for vacuuming the surface, and the nozzle assembly is lowered to a second position contacting the surface for collecting and picking up liquid and dirt from the surface. A method of cleaning a surface by first dry vacuuming the surface using a cleaning unit in which the nozzle assembly is raised to pick up particles and then wet vacuuming the floor with the nozzle assembly lowered to collect and pick up dirt from the floor mixed with cleaning solution distributed on the floor.

Owner:MORGAN JEFFERY A +9

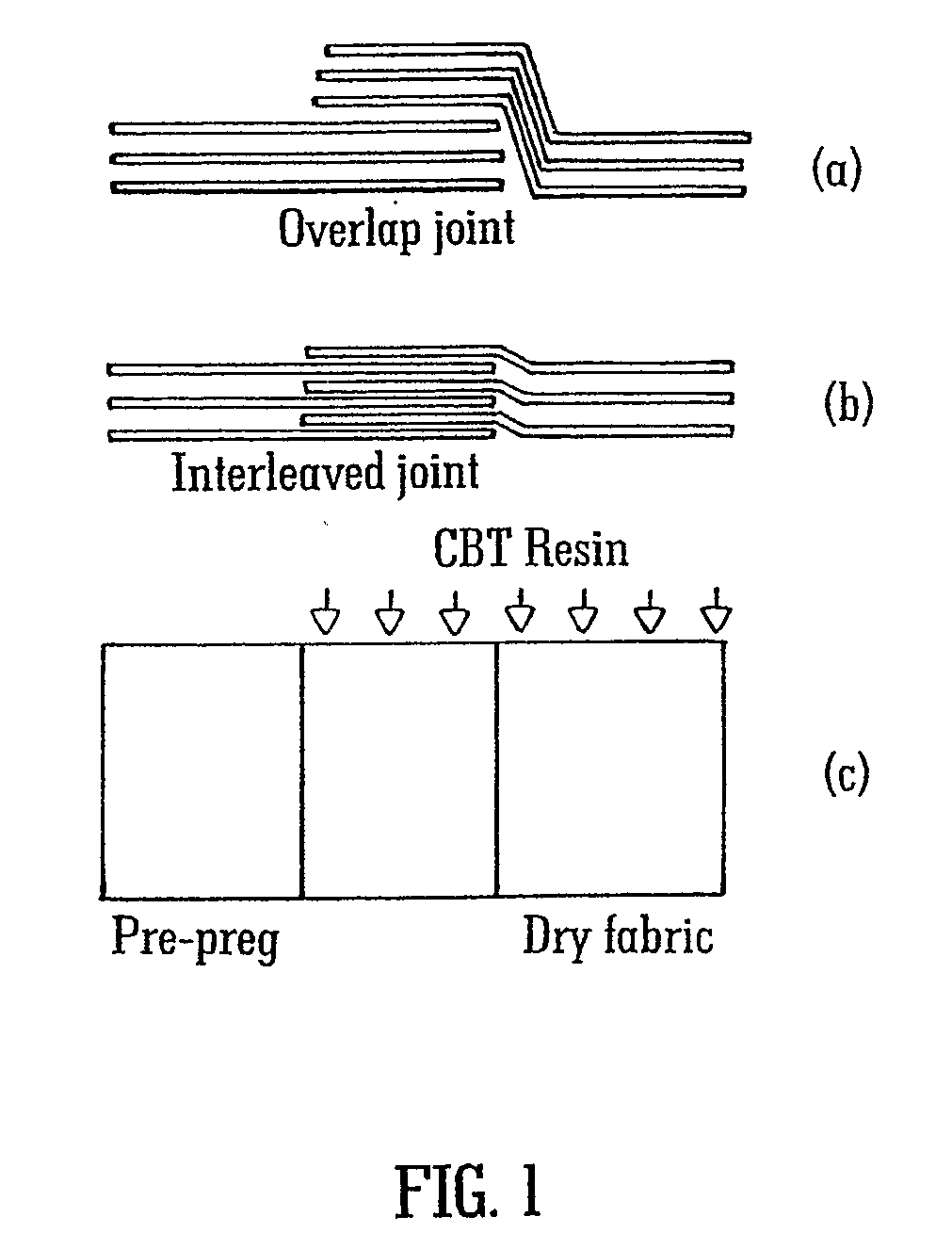

Forming process of fiber reinforced thermoplastic composite material

The invention discloses a low-cost high-efficiency forming process of a fiber reinforced thermoplastic composite material, comprising the following steps of: arranging a workpiece to be formed, which is prepared by laying fiber reinforced materials, in a closed space containing a mold template; laying demolding cloth and a diversion grid in sequence on the workpiece; laying or coating a demolding material under the workpiece; arranging an impregnating pipe on one side of the width direction of the workpiece; arranging a vacuum pipeline on the other side along the length direction of the workpiece and parallel to the side surface; arranging a breathable material between the vacuum pipeline and the workpiece; then pumping vacuum in the closed space through the vacuum pipeline, simultaneously raising the temperature of the mold template to the impregnating temperature of 50-250 DEG C; and finally filling molten thermoplastic resin or the precursor of the thermoplastic resin of which the temperature is 50-250 DEG C and the viscosity is 0.15-1.0Pa.s into the workpiece from the impregnating pipe, and then insulating for polymerization or reducing the temperature for cooling and forming. The forming process needs not to prepare a pre-impregnated belt in advance and has low cost and high efficiency, and the workpiece can be formed easily and has superior toughness and damage tolerance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

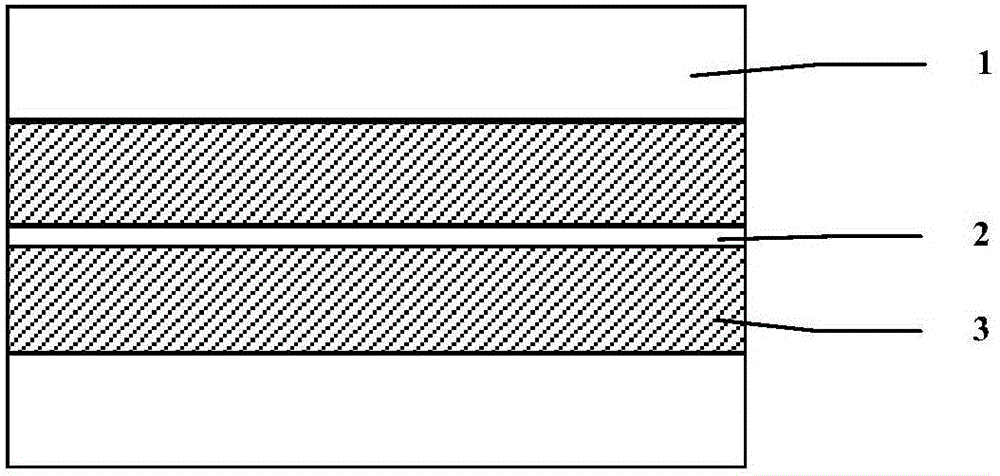

Carbon steel and duplex stainless steel composite steel plate and production method thereof

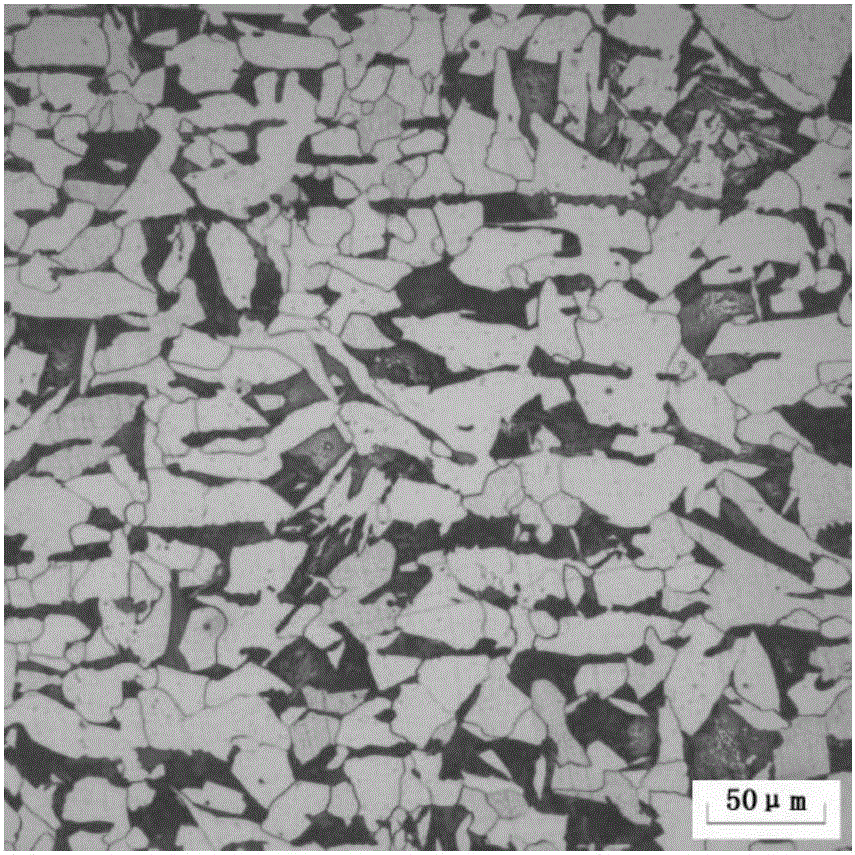

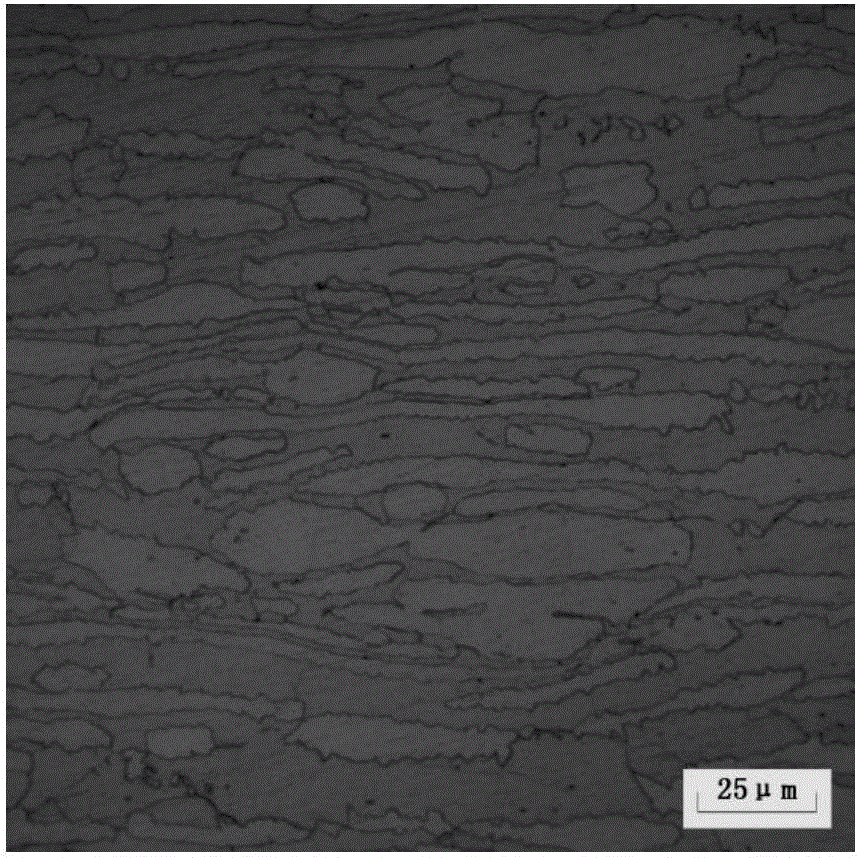

InactiveCN105772507AComposite goodStrong resistance to intergranular corrosionTemperature control deviceMetal rolling arrangementsWater coolingComposite plate

The invention discloses a carbon steel and duplex stainless steel composite steel plate and a production method of the steel plate, and belongs to the technical field of production of metal composite plates. The steel plate is completed through a steel billet assembly, heating, direct rolling, air cooling or water cooling and tempering process route. Symmetric composite assembly is adopted, the upper layer and the lower layer are Q245R carbon steel, S32205 duplex stainless steel is arranged on the two layers of the middle, scaling powder is not added into the position between the carbon steel and duplex stainless steel, a separant is added to the position between the duplex stainless steel, four-side welding and side sealing are carried out on a steel billet, and vacuumizing treatment is carried out. The carbon steel and duplex stainless steel composite steel plate has the beneficial effects of being good in composite effect and having the higher mechanical property and intergranular corrosion resistance.

Owner:SHOUGANG CORPORATION

Cathodic vacuum arc source film depositing device and method for depositing film

ActiveCN101792895AIncrease deposition rateCompact structureVacuum evaporation coatingSputtering coatingEngineeringLarge particle

The invention discloses a cathodic vacuum arc source film depositing device which comprises a magnetic filtering part capable of transferring plasma at high speed and effectively filtering macro-large particles, wherein the magnetic filtering part comprises a tube body and a magnetic field generator which is arranged at the external periphery of the tube body; the tube body comprises an inlet end surface of the tube body and an outlet end surface of the tube body, at least one bent tube is arranged between the inlet end surface of the tube body and the outlet end surface of the tube body, and an included angle between the axial lines of the tube body at two sides of the bent tube is 135 degrees; and the introducing amount of inert gases in the device is 10-50sccm, and the vacuum degree is 1.0*10-5 to 5.0*10-5Torr after the device is vacuumized. Compared with the prior art, the cathodic vacuum arc source film depositing device of the invention can realize the purposes of effectively filtering macro-large particles and simultaneously transferring plasma at high speed, thereby improving the quality and the deposition rate of the film. The method of the invention can be used for depositing the film at high speed, the deposited film has compact structure, smooth surface and large uniform region area, and the method can be used for depositing high-performance ta-C films.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Evaporating apparatus, apparatus for controlling evaporating apparatus, method for controlling evaporating apparatus and method for using evaporating apparatus

InactiveUS20100092665A1Improve exhaust efficiencyImprove efficiencyLiquid surface applicatorsElectroluminescent light sourcesAtmospheric airVacuum level

An evaporating apparatus includes a first processing chamber and a second processing chamber, and a blowing device accommodated in the first processing chamber and a vapor deposition source accommodated in the second processing chamber are connected with each other via a connection pipe. An exhaust mechanism for evacuating the inside of the first processing chamber to a preset vacuum level is connected with the first processing chamber. Organic molecules vaporized from the vapor deposition source are blown out from the blowing device via the connection pipe and is adhered on a substrate, whereby a thin film is formed on the substrate. By installing the first processing chamber and the second processing chamber separately, the first processing chamber is not opened to the atmosphere when a film forming material is replenished, so that exhaust efficiency can be improved.

Owner:TOKYO ELECTRON LTD

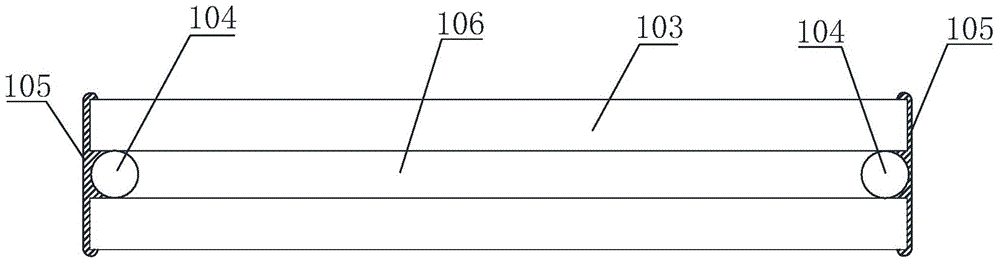

Visualization experiment device and method for profile control performance evaluation of weak gel of fractured reservoir

InactiveCN104314514ASimple structureReasonable designConstructionsSealing/packingWater transportEngineering

The invention discloses a visualization experiment device and method for profile control performance evaluation of weak gel of a fractured reservoir. The experiment device comprises a visualization crack module, a water transport intermediate container, a gel transport intermediate container, a displacement pump, a liquid container connected with a liquid inlet of the displacement pump, a measuring cylinder connected with a liquid outlet of the crack module and a vacuum pump for vacuumizing the crack model. The experiment method comprises the following steps: 1, carrying out a dynamic displacement experiment on weak gel in a crack; 2, replacing crack models with different crack widths, and carrying out injection performance and plugging performance evaluation experiments on the weak gel in a plurality of cracks under the conditions of different weak gel viscosities and injection speeds; 3, carrying out data processing. The visualization experiment and device are reasonable in design, favorable in visuality and good in simulation effect, provides convenience for observing the displacement and plugging processes of the weak gel and can be used for testing and recording the injection performance, the plugging performance and the plugging state of the weak gel in the cracks under the conditions of different weak gel properties and different crack widths.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

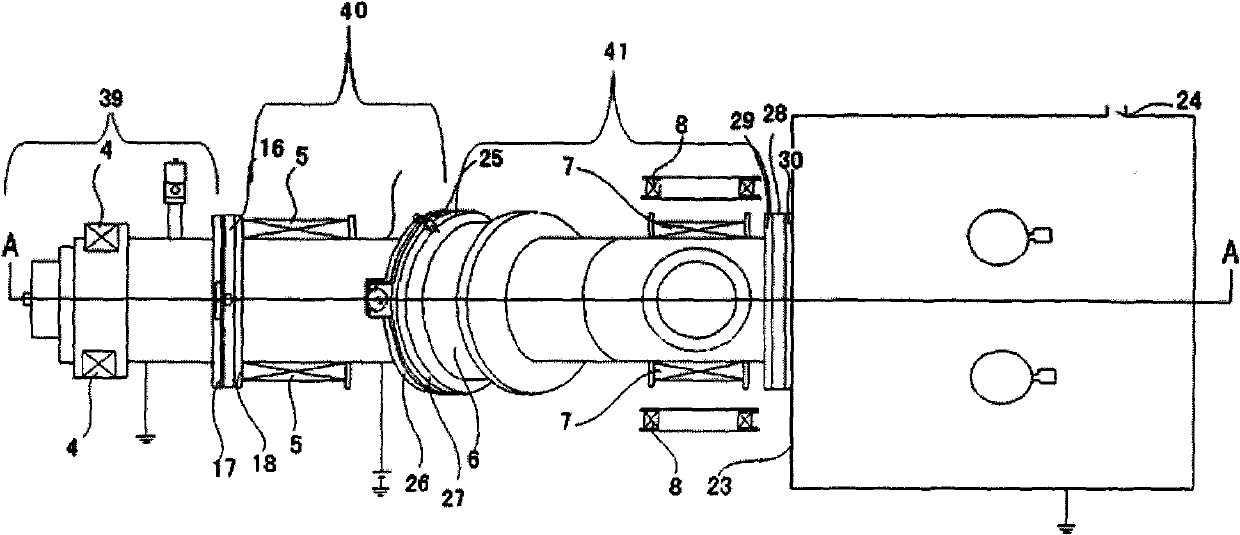

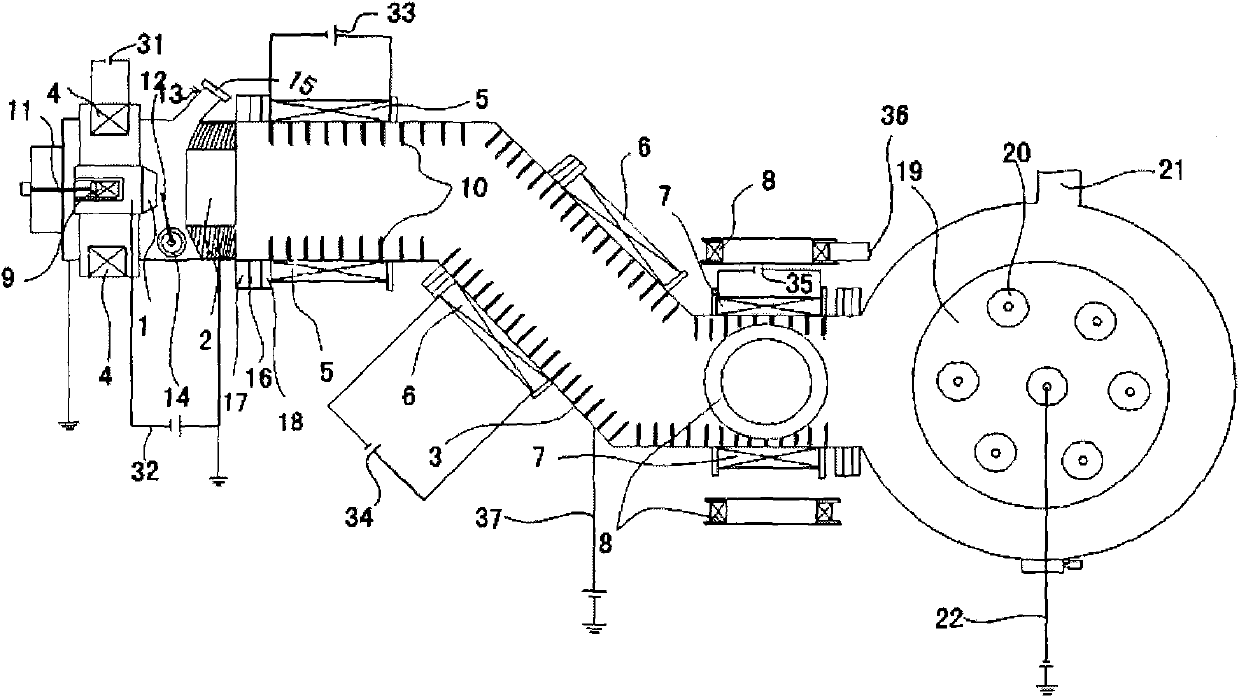

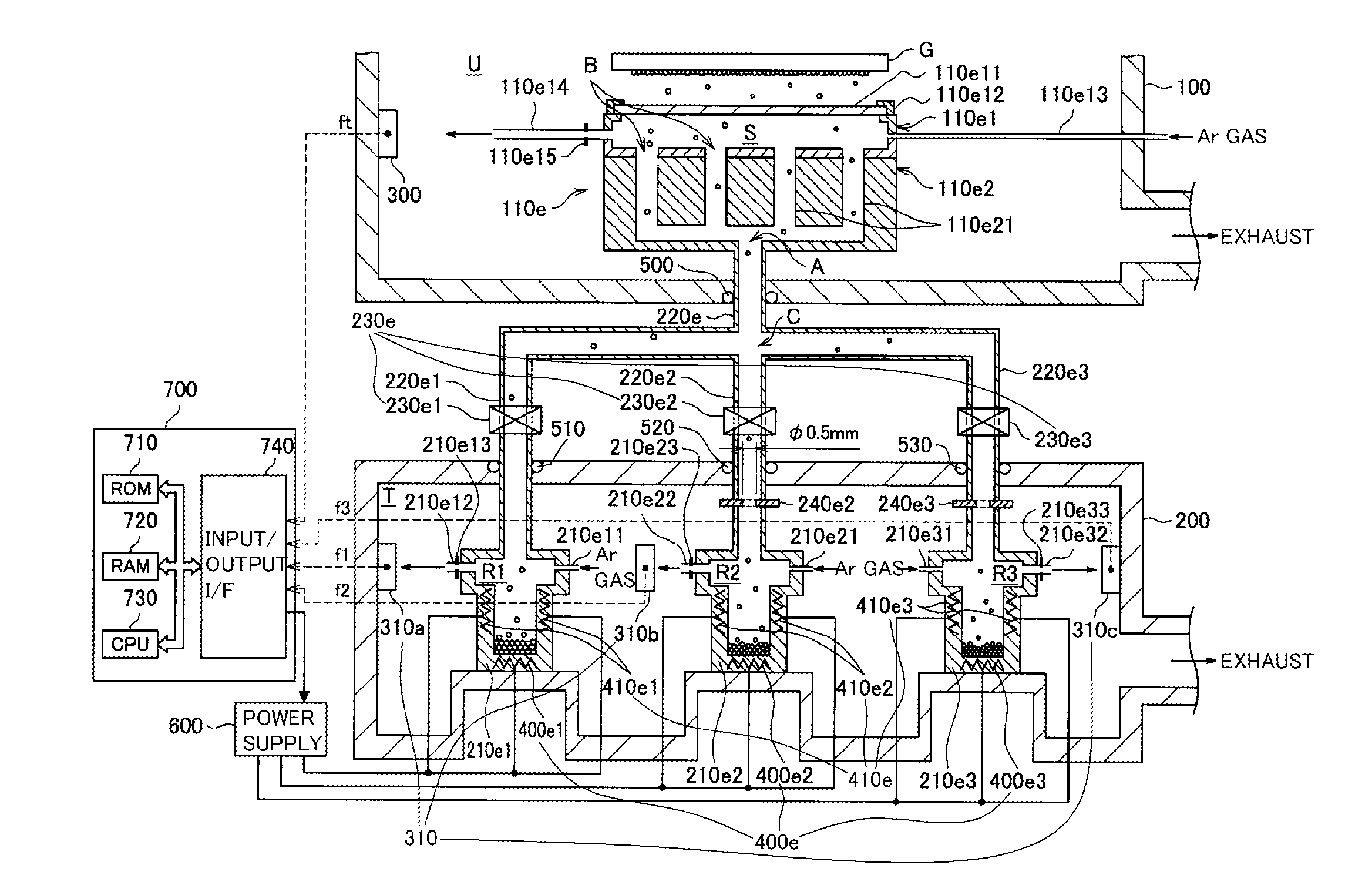

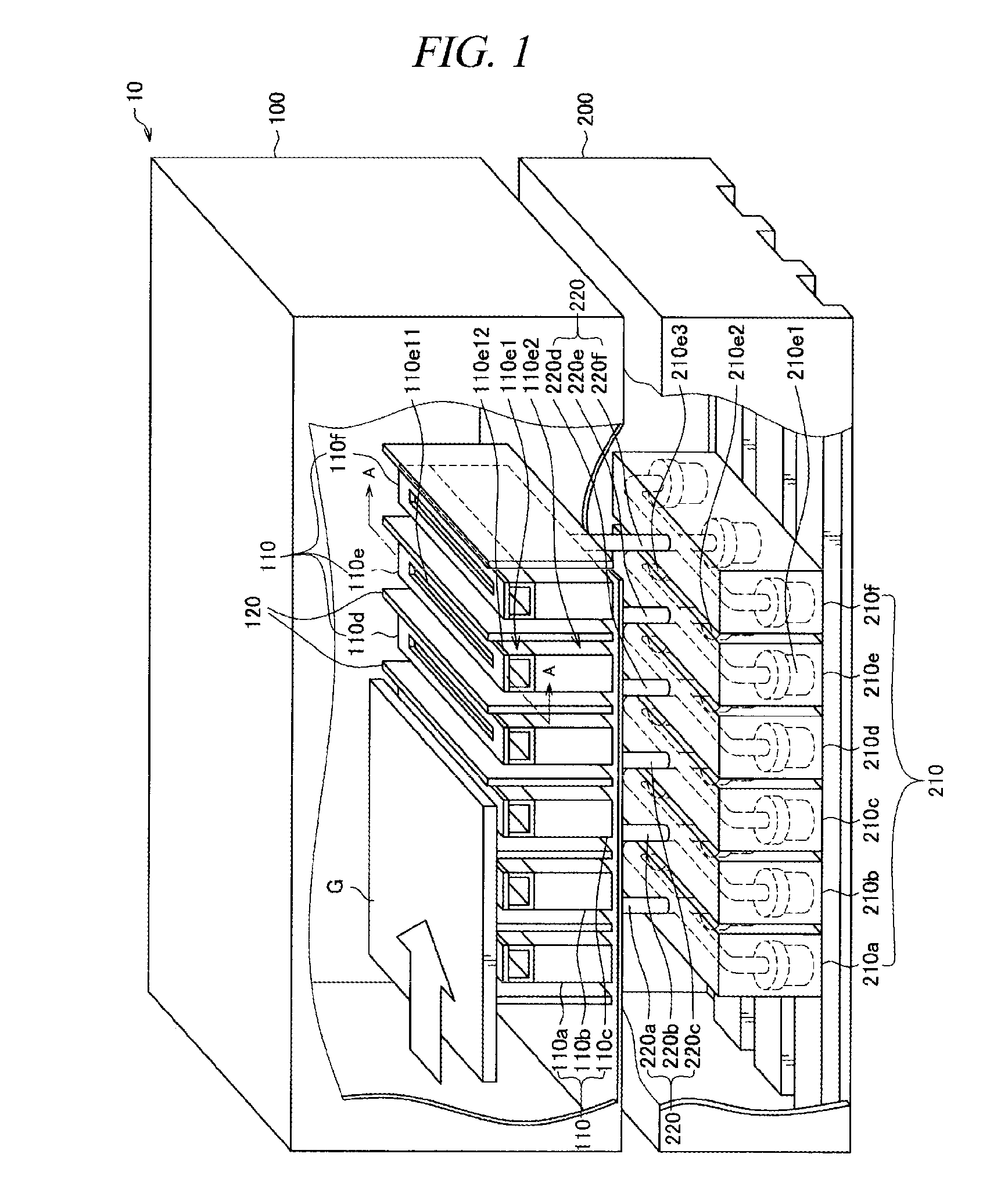

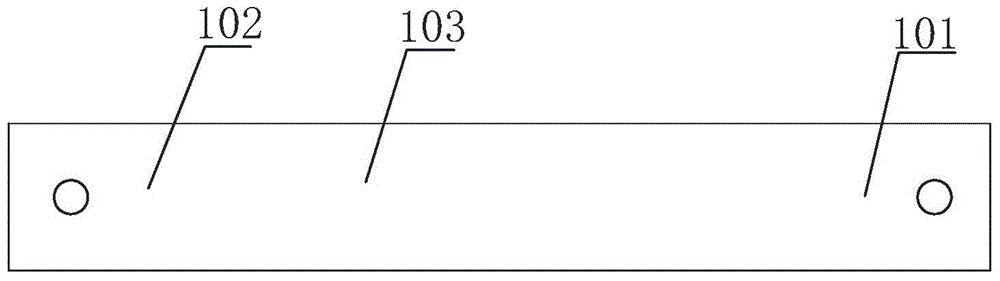

Apparatus and method for processing substrate

A substrate processing apparatus includes a processing chamber and a vacuum spare chamber adjacent thereto through a vacuum valve. The processing chamber houses two holders for holding substrates on their surfaces on the same side. The processing chamber is provided with an ion source for irradiating the substrate on each holder having reached a processing position P with an ion beam so that it is subjected to ion implantation. The processing chamber is internally provided with a holder moving mechanism for performing the operation of moving the two holders in parallel independently from each other so that they traverse the processing position P, and moving the two holders in parallel simultaneously between the insides of the processing chamber and vacuum spare chamber through the vacuum valve. The vacuum spare chamber is internally provided with a substrate replacing mechanism for replacing processed substrates and non-processed substrates with each other collectively for the two holders in cooperation with the holder moving mechanism.

Owner:NISSIN ELECTRIC CO LTD

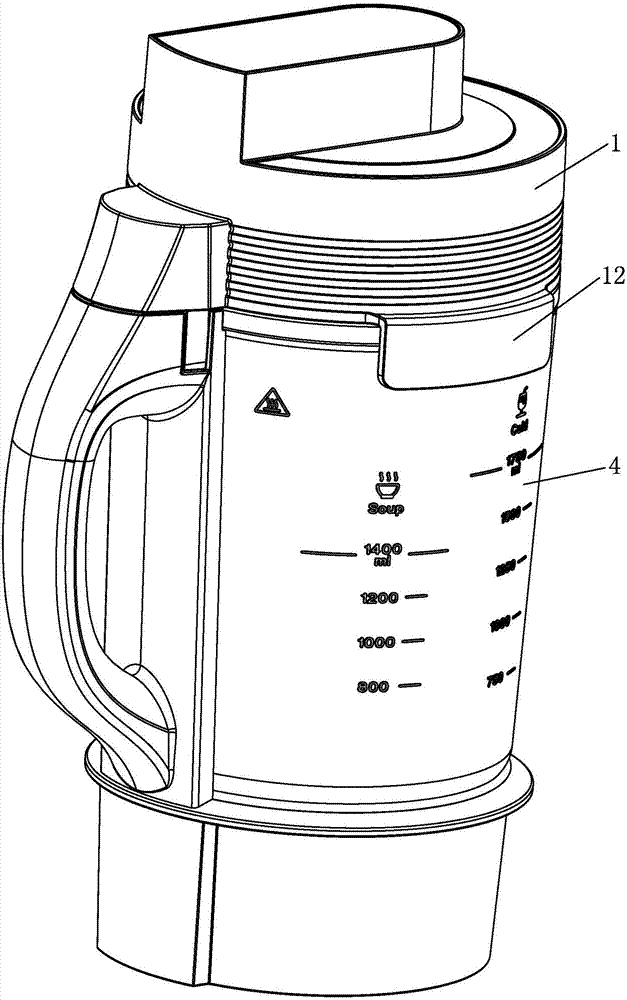

Vacuum high speed blender

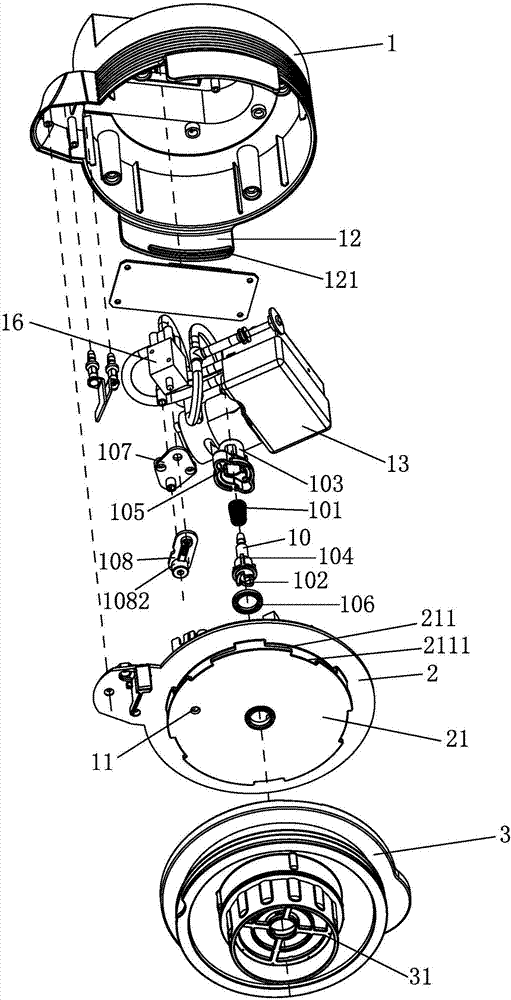

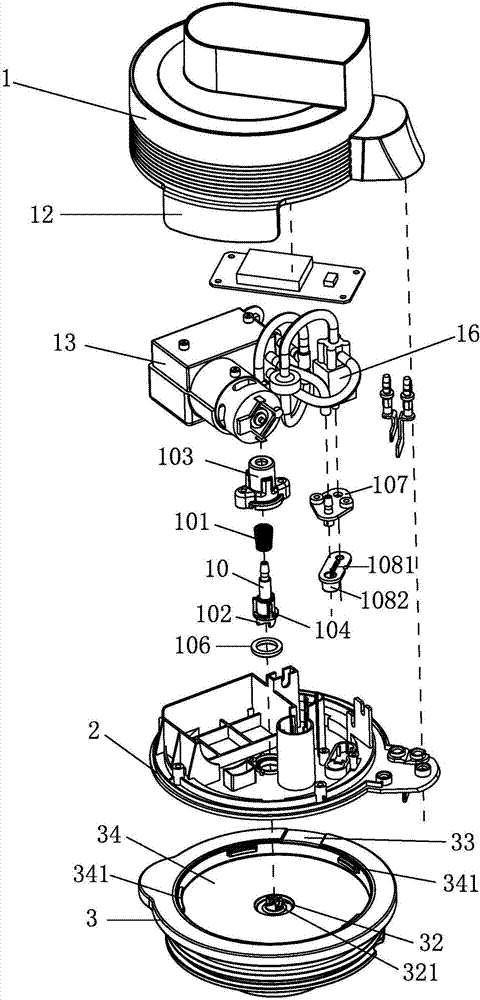

ActiveCN106974565AReduced sealing costsExtended service lifePlastic recyclingKitchen equipmentAir pumpPumping vacuum

The invention relates to a vacuum high speed blender which comprises a main cover composed of a cup cover and a bottom cover. The main cover is provided with an exhaust suction nozzle and an exhaust hole. The vacuum high speed blender further comprises an auxiliary cover, a vacuum nozzle is arranged on the auxiliary cover, and the bottom cover and the auxiliary cover are detachably assembled through a positive and negative turn-lock clasp; the exhaust suction nozzle is arranged on the bottom cover through an elastic device in a vertically stretchable and movable mode, an upper coupling portion is arranged on the exhaust suction nozzle, and a lower coupling portion is arranged on the vacuum nozzle; an air cavity is formed between the auxiliary cover and the bottom cover, the exhaust suction nozzle, the exhaust hole and the vacuum nozzle stretch into the air cavity, and the auxiliary cover or the bottom cover is provided with a ventilation groove communicating the air cavity with the external world. When the vacuum high speed blender is in use, no food residue is splashed to the main cover, only the auxiliary cover needs to be disassembled and washed, the main cover does not need to be flushed, and the service life of the air pump is prolonged. The main cover and the auxiliary cover are detachably assembled through the positive and negative turn-lock clasp, and in the assembling and disassembling process, coupling and separation of the exhaust suction nozzle and the vacuum nozzle are achieved. During vacuumizing of the cup body, the ventilation groove achieves the exhaust function, and the air leakage function is achieved during air return of the cup body.

Owner:中山市索虹电器实业有限公司

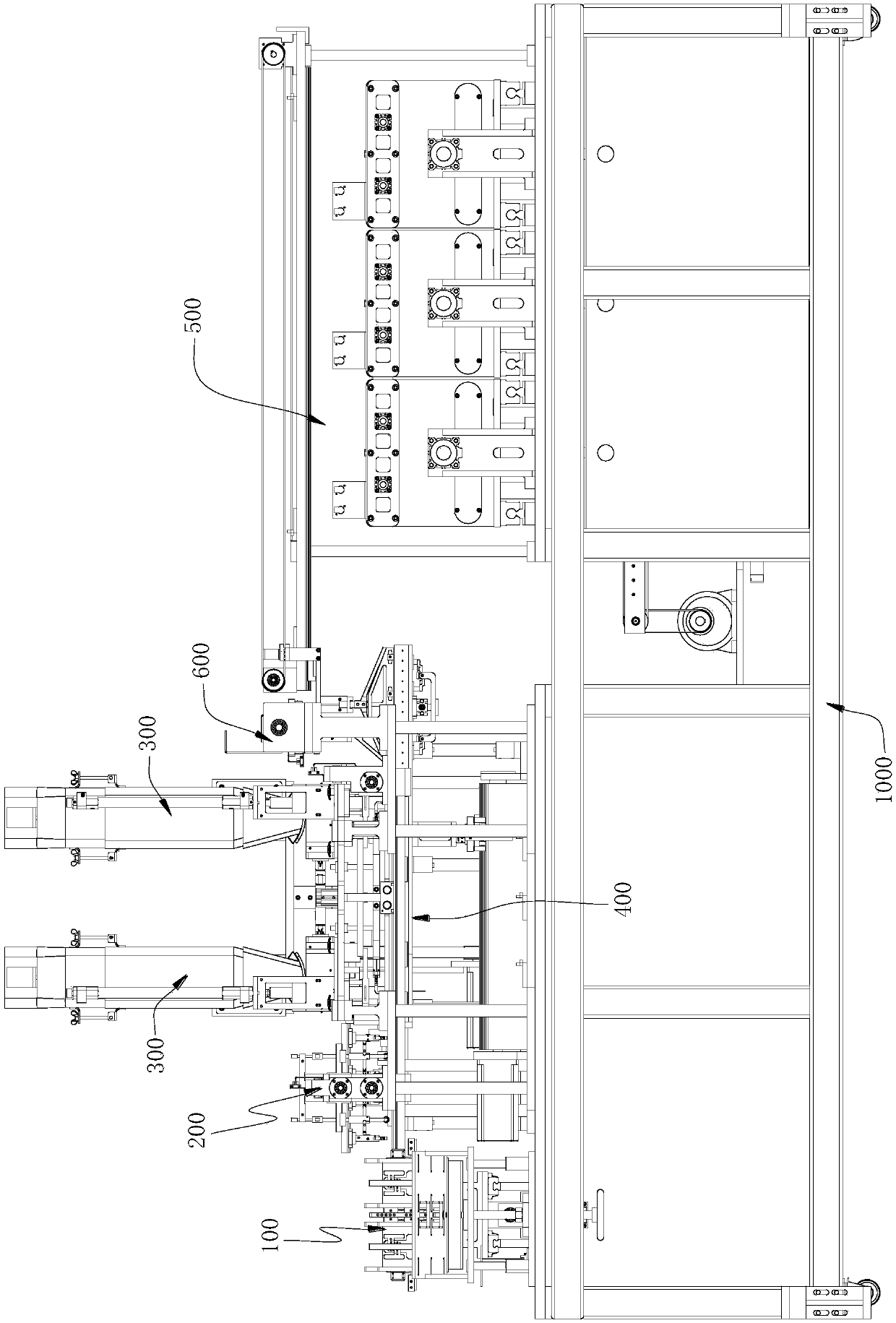

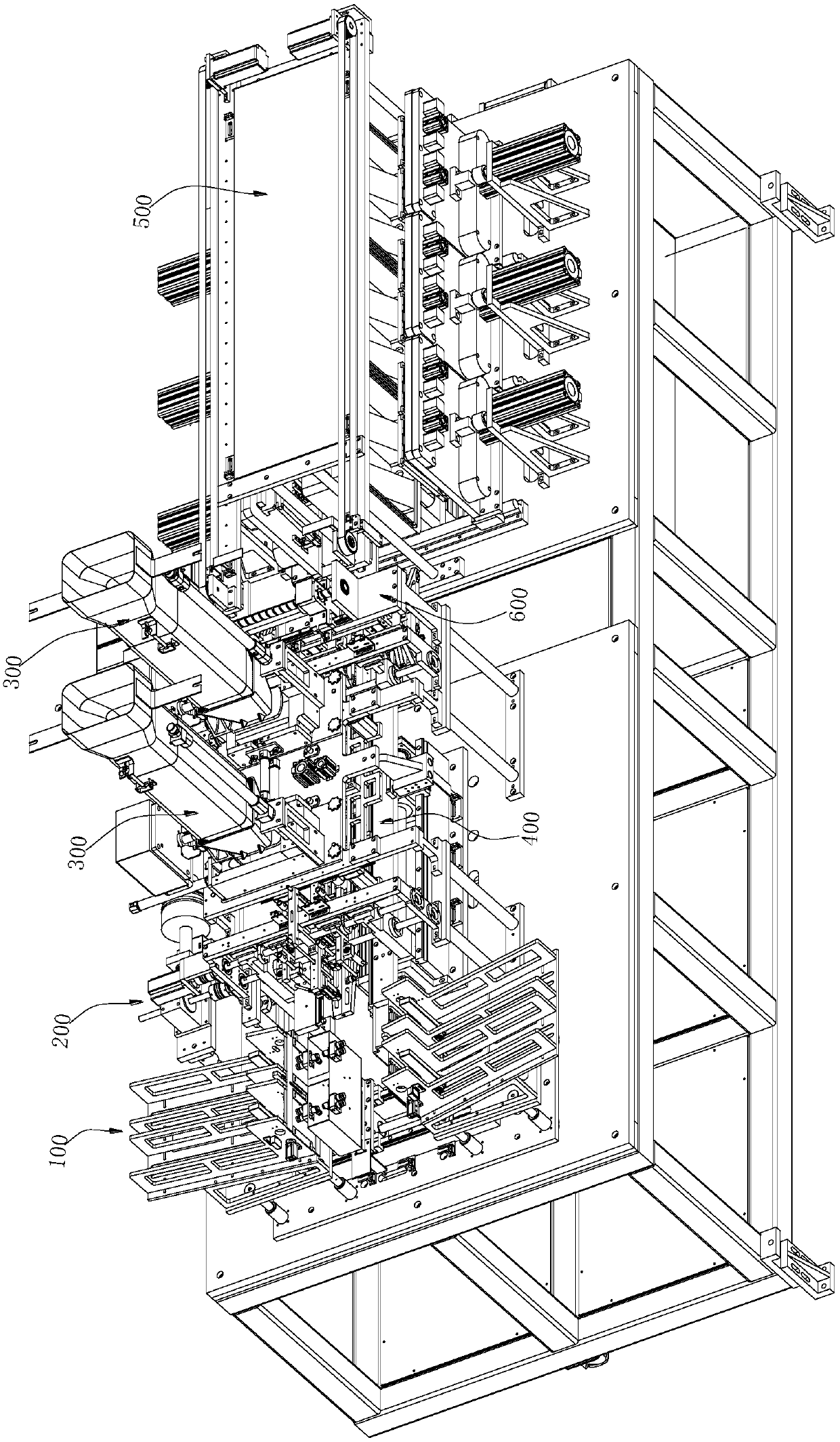

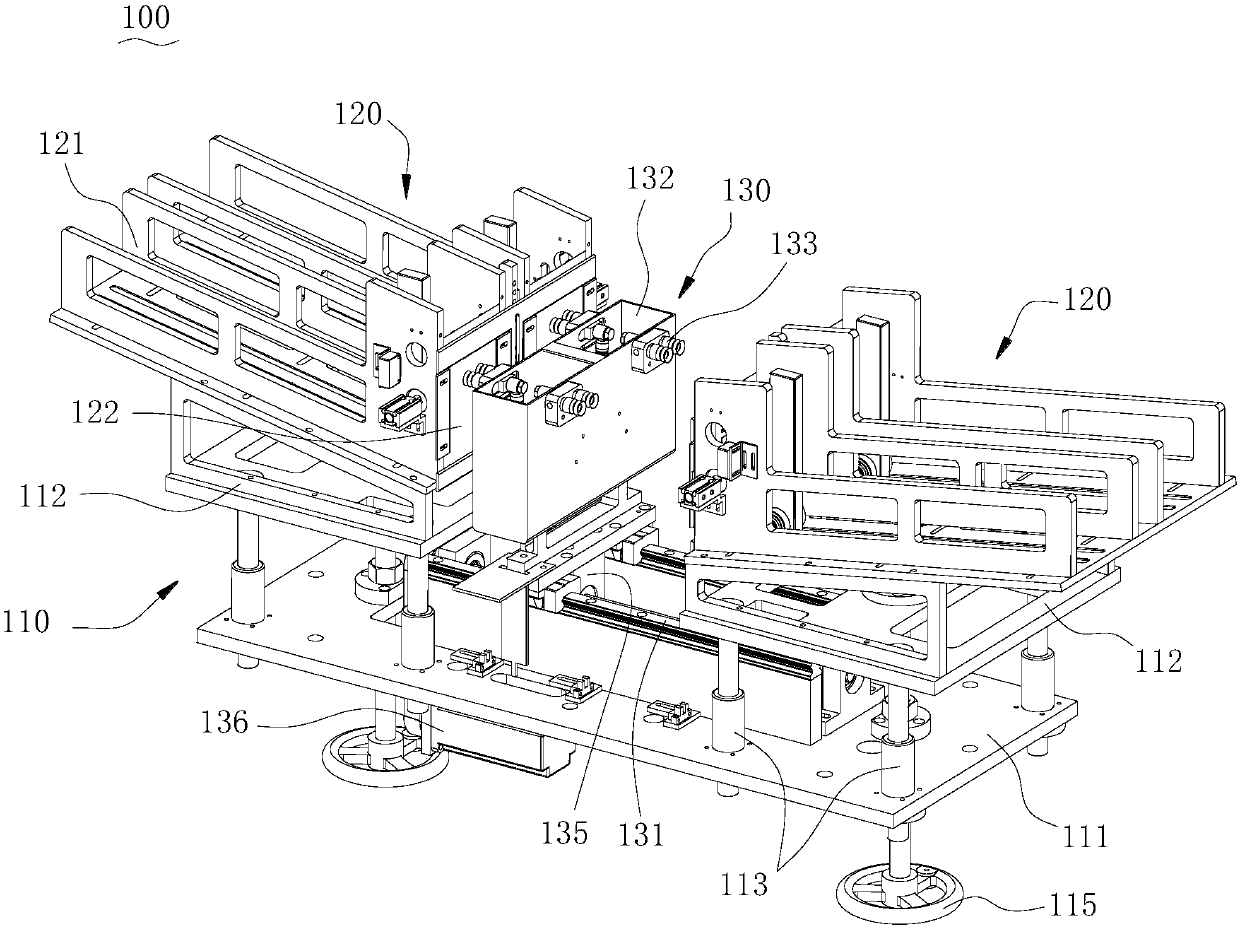

Full-automatic packaging machine

PendingCN107826323ACompact structureGuaranteed uptimePackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingEngineering

The invention discloses a full-automatic packaging machine. The full-automatic packaging machine comprises a rack, a packaging bag supply device, a bag opening device, a filling and discharging device, a grabbing and conveying device and a vacuum pumping and sealing device. The packaging bag supply device, the bag opening device, the filling and discharging device and the vacuum pumping and sealing device are transversely arranged on the rack in sequence. The packaging bag supply device comprises packaging bag supply racks and a bag sucking mechanism used for sucking packaging bags from the packaging bag supply rack. The grabbing and conveying device is arranged on the lower portions of the bag opening device and the filling and discharging device in sequence in a penetrating mode and usedfor clamping and conveying the packaging bags sucked by the bag sucking mechanism to the bag opening mechanism to open the bags, keeping the opened packaging bags in an opened state and clamping andconveying the packaging bags into the filling and discharging device for filling. By means of the structure design, the full-automatic packaging machine is simple and compact in structure, stable in operation and capable of effectively preventing equipment failure caused by food materials spilt out of the bags, and the packaging efficiency is greatly improved.

Owner:广东邦天智能制造有限公司

Method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder

The invention provides a method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder. The preparation method comprises the following steps: preparing materials of alloy components according to ASTM F1295 standards and carrying out two times of vacuum melting on a mother alloy ingot; preparing the mother alloy ingot into an alloy electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing mixed inert protective gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The method provided by the invention has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the Ti-6Al-7Nb medical titanium alloy spherical powder with high sphericity degree, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

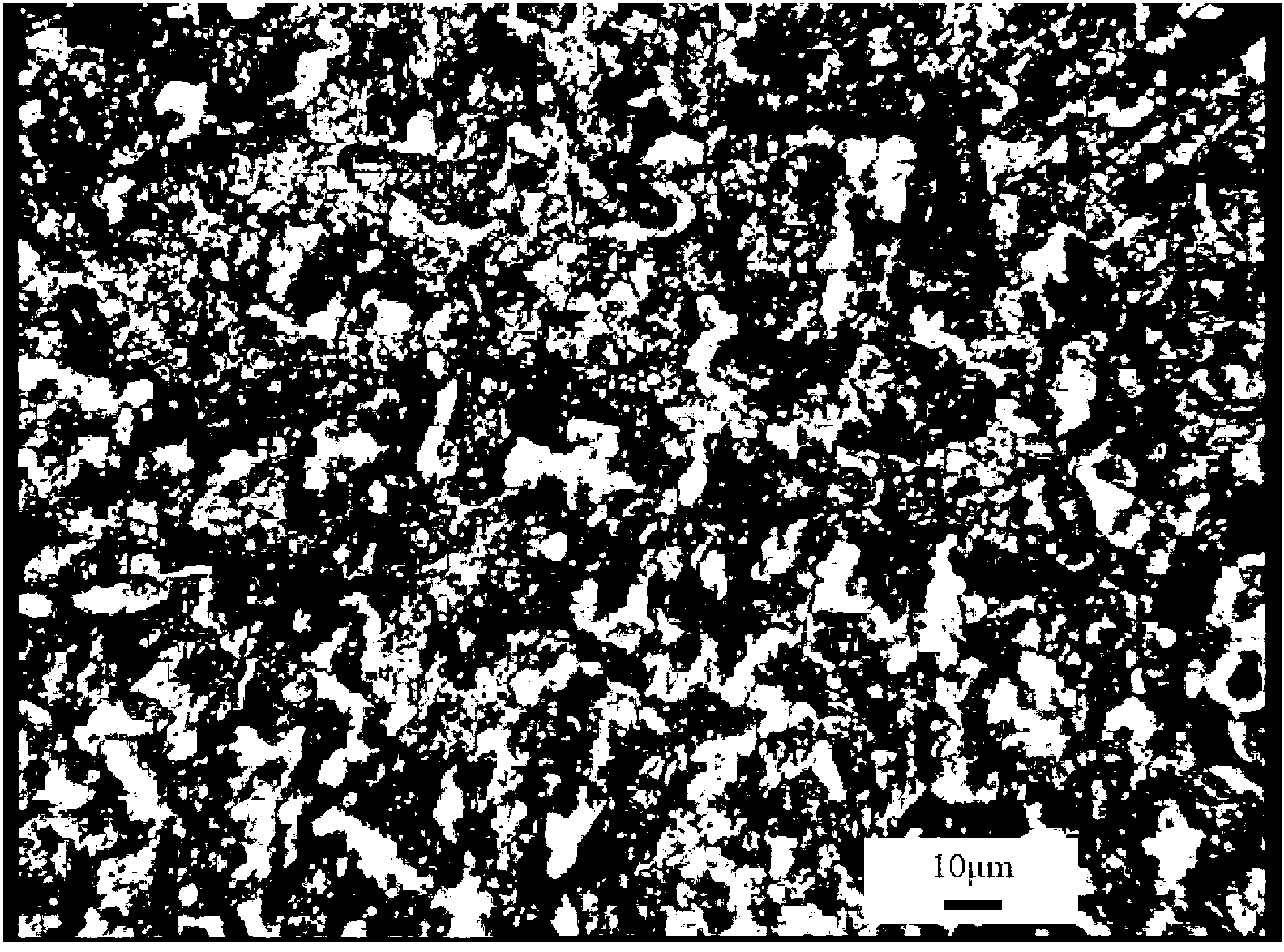

Production method of chromium-aluminium alloy target material

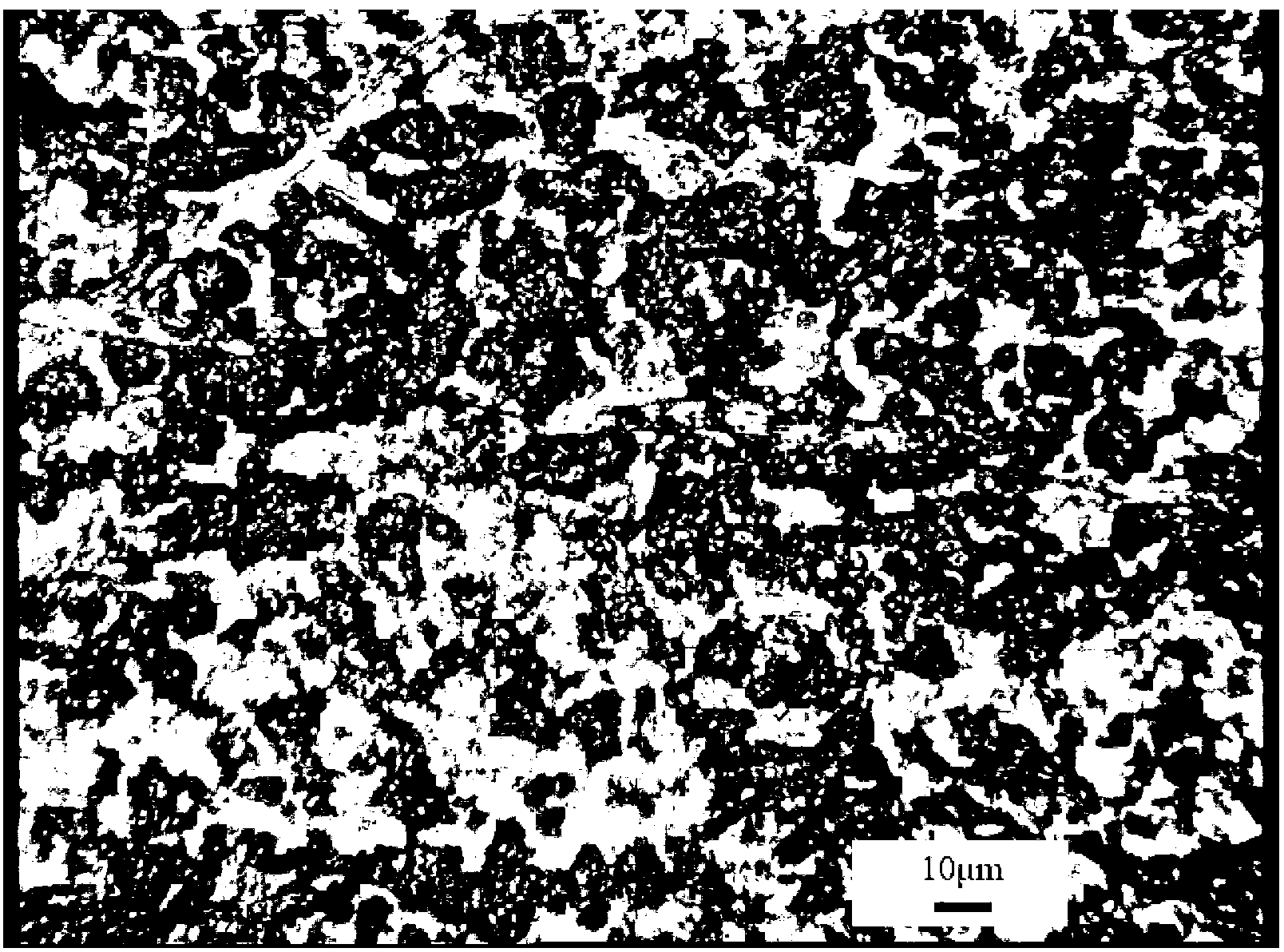

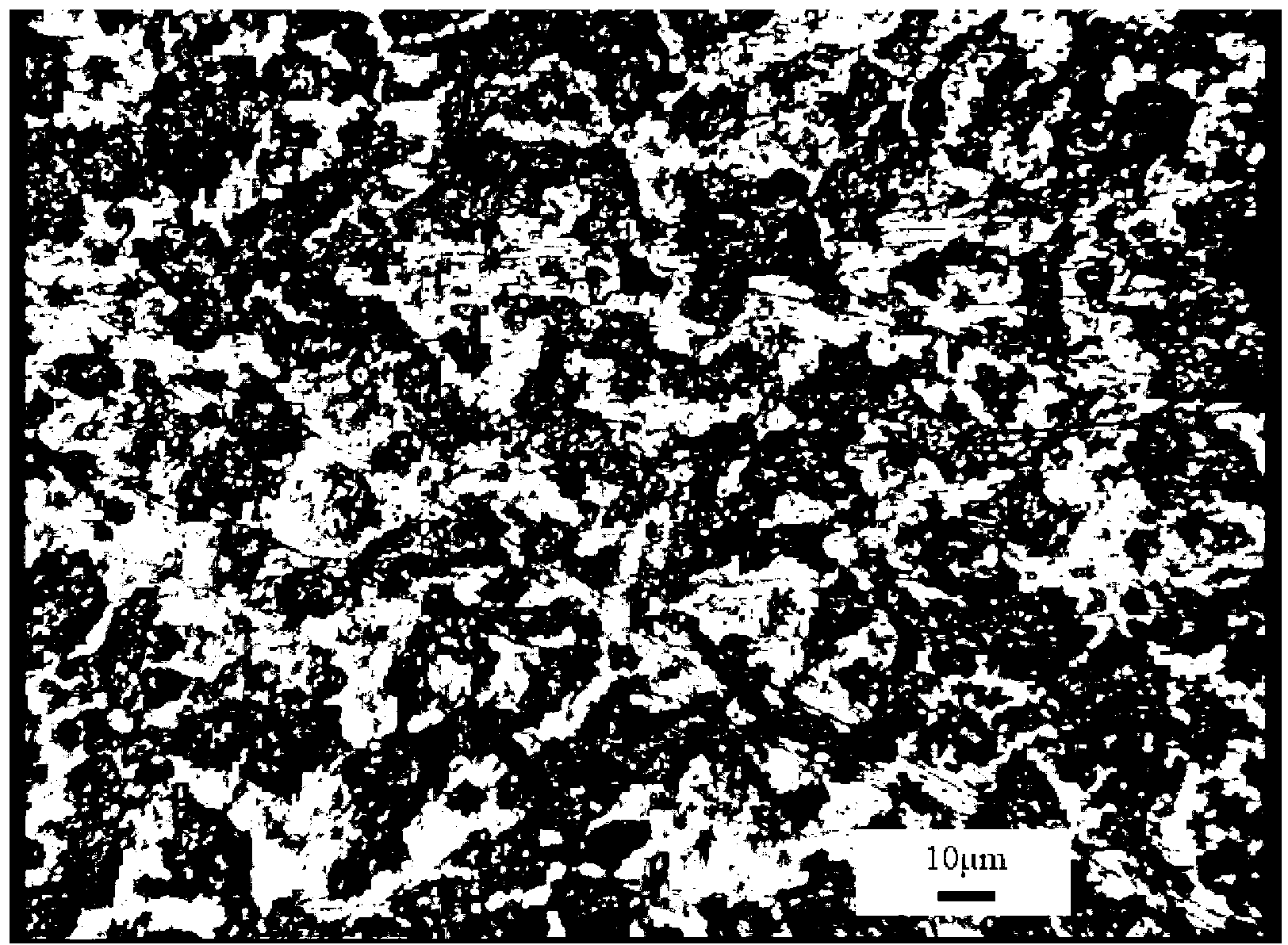

ActiveCN103182507AHigh densityUniform grain size distributionVacuum evaporation coatingSputtering coatingAl powderHigh density

The invention relates to a production method of a chromium-aluminum alloy target material, which includes the following steps: (1) placing chromium powder and aluminum powder into a V-shaped mixer for mixing; (2) placing the powder into a cold isostatic pressing sheath, vacuumizing, sealing, suppressing for 10 to 20 minutes, then placing in a vacuum self-propagating high-temperature synthetic furnace, and performing self-propagating reaction to acquire foamed chromium-aluminium alloy; (3) smashing the chromium-aluminium alloy into alloy powder with size of -200 mesh, placing the alloy powder in the cold isostatic pressing sheath for suppressing, so as to obtain a chromium-aluminium alloy blank; (4) placing the alloy blank in a steel sheath for vacuum degassing, then, performing hot isostatic pressing sintering treatment to obtain a chromium-aluminium alloy ingot; and (5) machining the chromium-aluminium alloy ingot to obtain a finished chromium-aluminium alloy target material. According to the invention, after the two raw materials are fully mixed and before the hot isostatic pressing sintering treatment is carried out, the alloying treatment in the step (2) is particularly adopted, so the prepared chromium-aluminum alloy target material has high density, uniform crystallite size distribution and excellent vacuum coating property.

Owner:北京九州新科科技有限公司

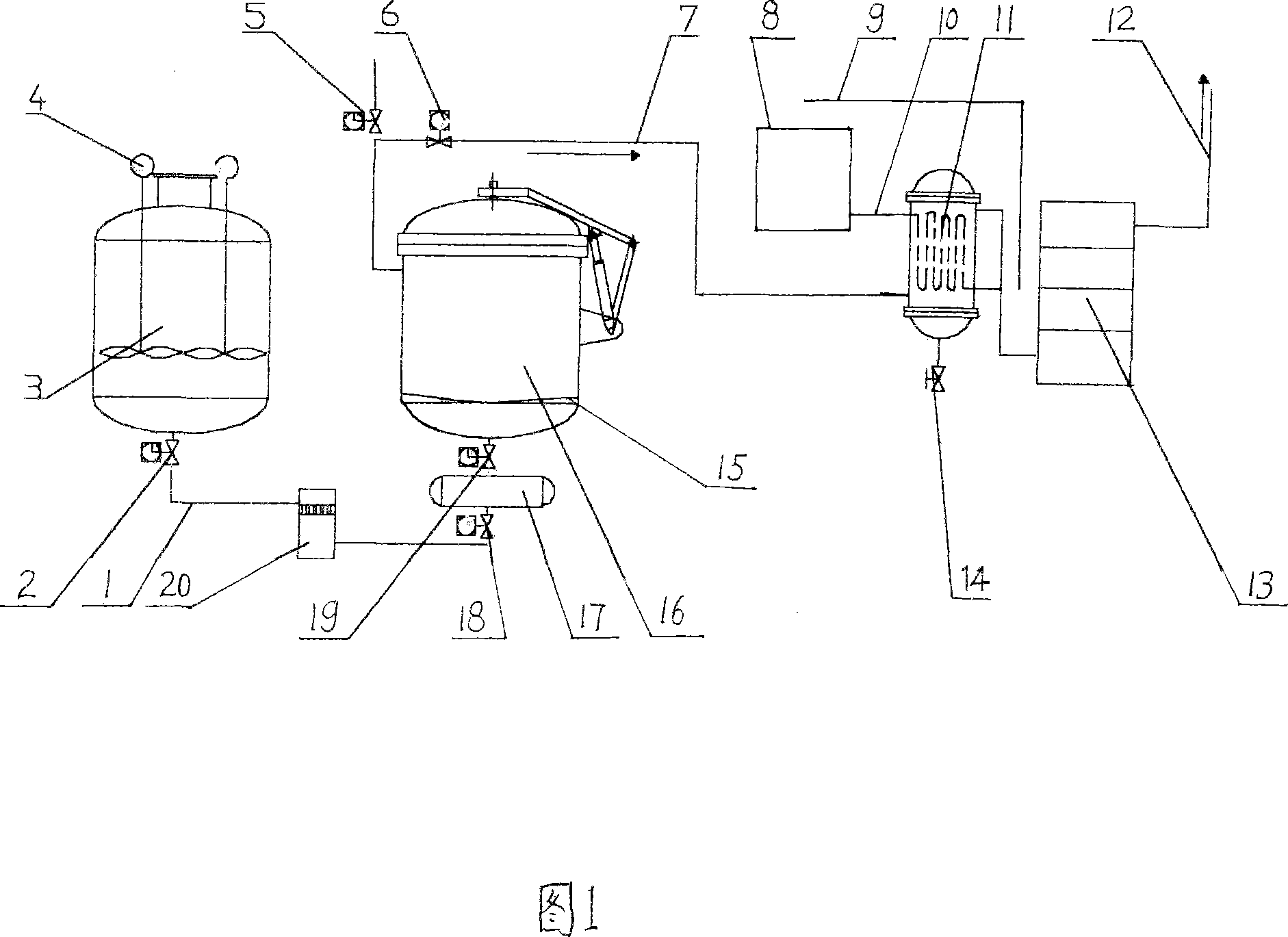

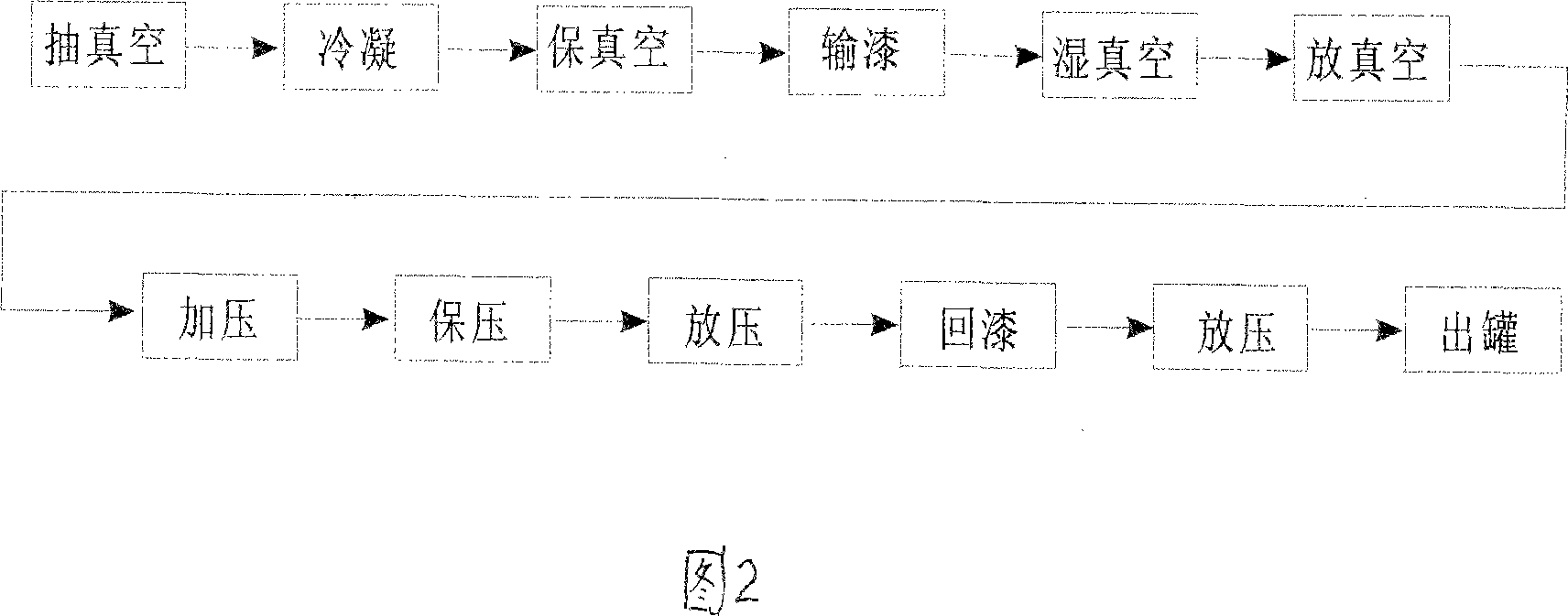

Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

InactiveCN101064456ASave raw materialsSmall dielectric lossLiquid surface applicatorsManufacturing dynamo-electric machinesSolventVacuum pressure

The invention relates to explosion-proof vacuum pressure impregnated insulation device and its process which is used in high-tension motor winding loop impregnated insulation paint, it characterized in that: condensator connected with refrigerator is set on the vacuum tube between the impregnating vessel and vacuum set, and collecting vessel is set on bottom of the impregnating vessel, one end of the collecting vessel is connected with the impregnating vessel, the another end is connected with the paint pipelines of storing vessel via transferring valve and returning valve. Using the device and the process, the remained insulation paint and dissolvent in the impregnating vessel can be solved, when the vacuum set vacuumizes the impregnating vessel, the explosive fuel phenylethene deflocculating agent can not be sucked to the vacuum set to gel and jam, it possesses practical effects of explosion-proof, safe reliability, saving raw material.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Superconductivity insulation material electrical characteristic test device

ActiveCN102928718APlay the role of isolating heat radiationReduce the temperatureTesting dielectric strengthSuperconducting CoilsRefrigerated temperature

The invention provides a superconductivity insulation material electrical characteristic test device which comprises a first casing, a second casing, a refrigerator, a test cable and a vacuumizing device. The first casing is provided with a first inner cavity, the second casing is made of heat conduction materials and arranged in the first inner cavity, the second casing is provided with a second inner cavity, a test electrode is positioned in the second inner cavity, a first cooling head of the refrigerator is fixedly connected with the second casing, the first end of the test cable is connected with the test electrode, the second end of the test cable is used for being connected with test equipment outside the first casing, the vacuumizing device is respectively connected with the first casing and the second casing and used for vacuumizing the first inner cavity and the second inner cavity, and the second casing is connected with the vacuumizing device through a first air pipe arranged in the first inner cavity. The technical scheme of the superconductivity insulation material electrical characteristic test device is that a test environment meeting work condition requirements of an international thermonuclear experimental reactor (ITER) device can be simulated in the second inner cavity to provide test methods for researching insulation material electrical characteristics when a superconducting magnet runs stably.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com