Patents

Literature

85results about How to "Improve layer performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

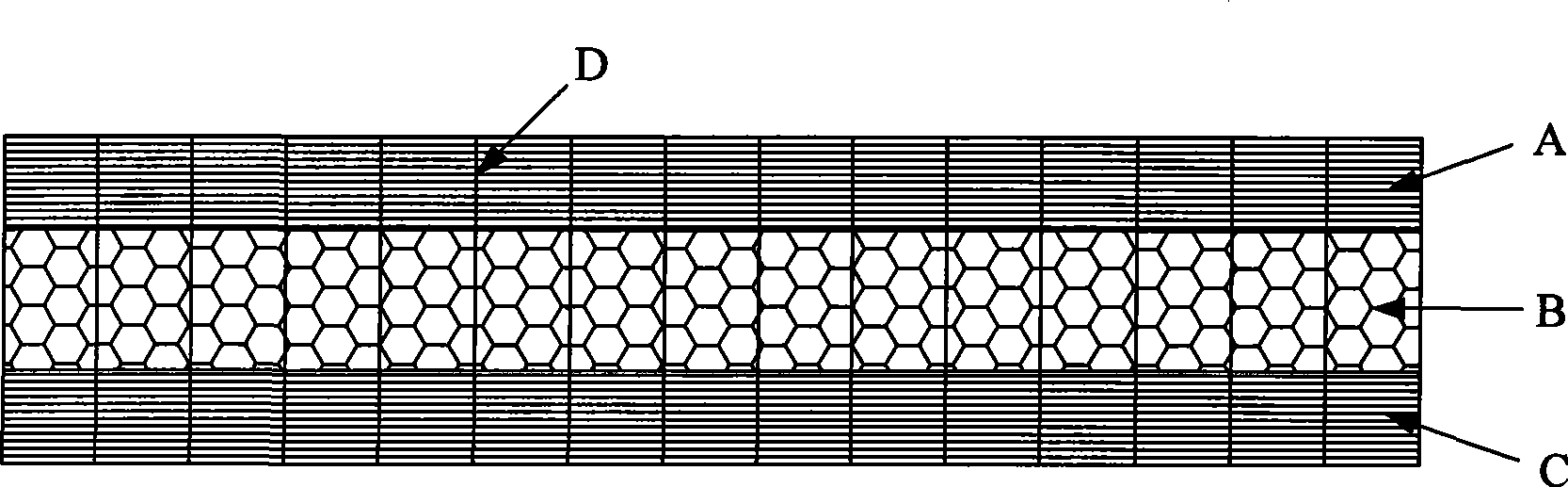

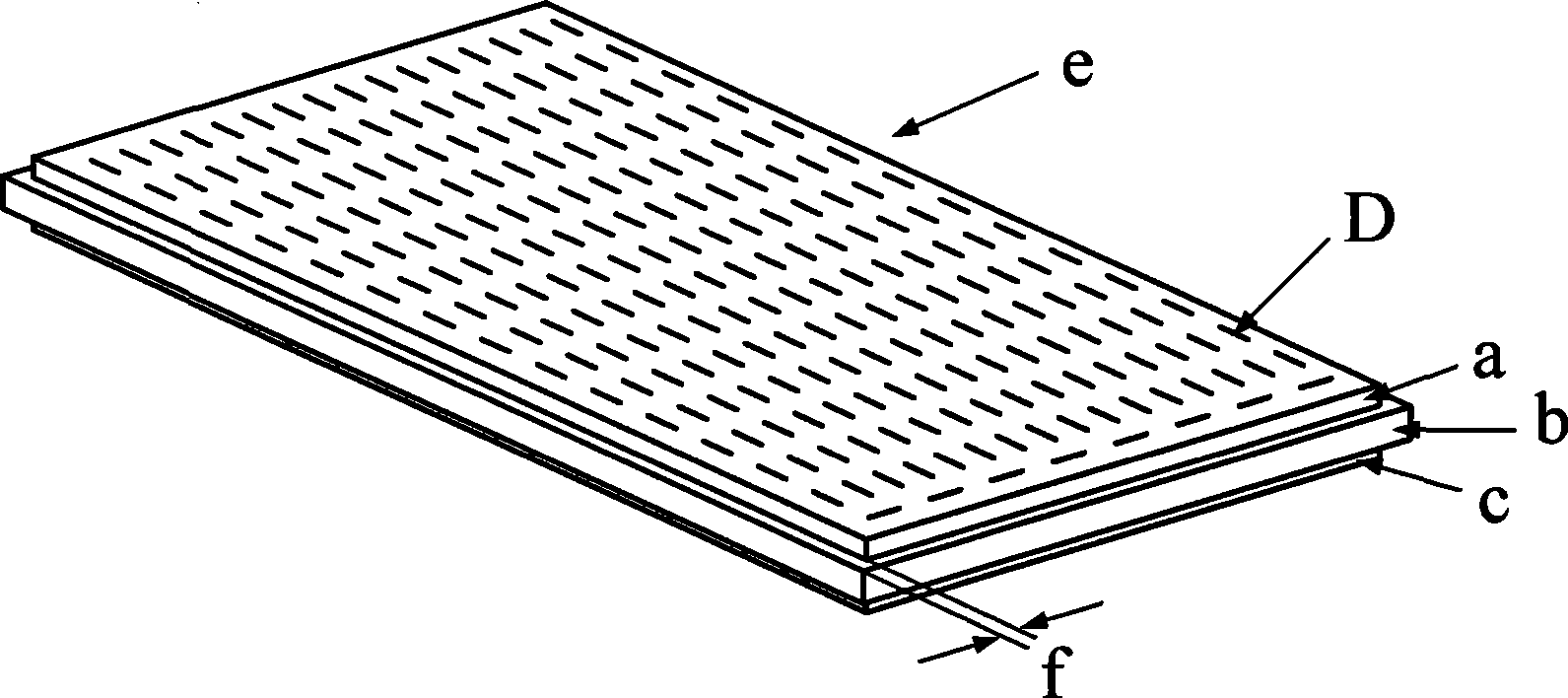

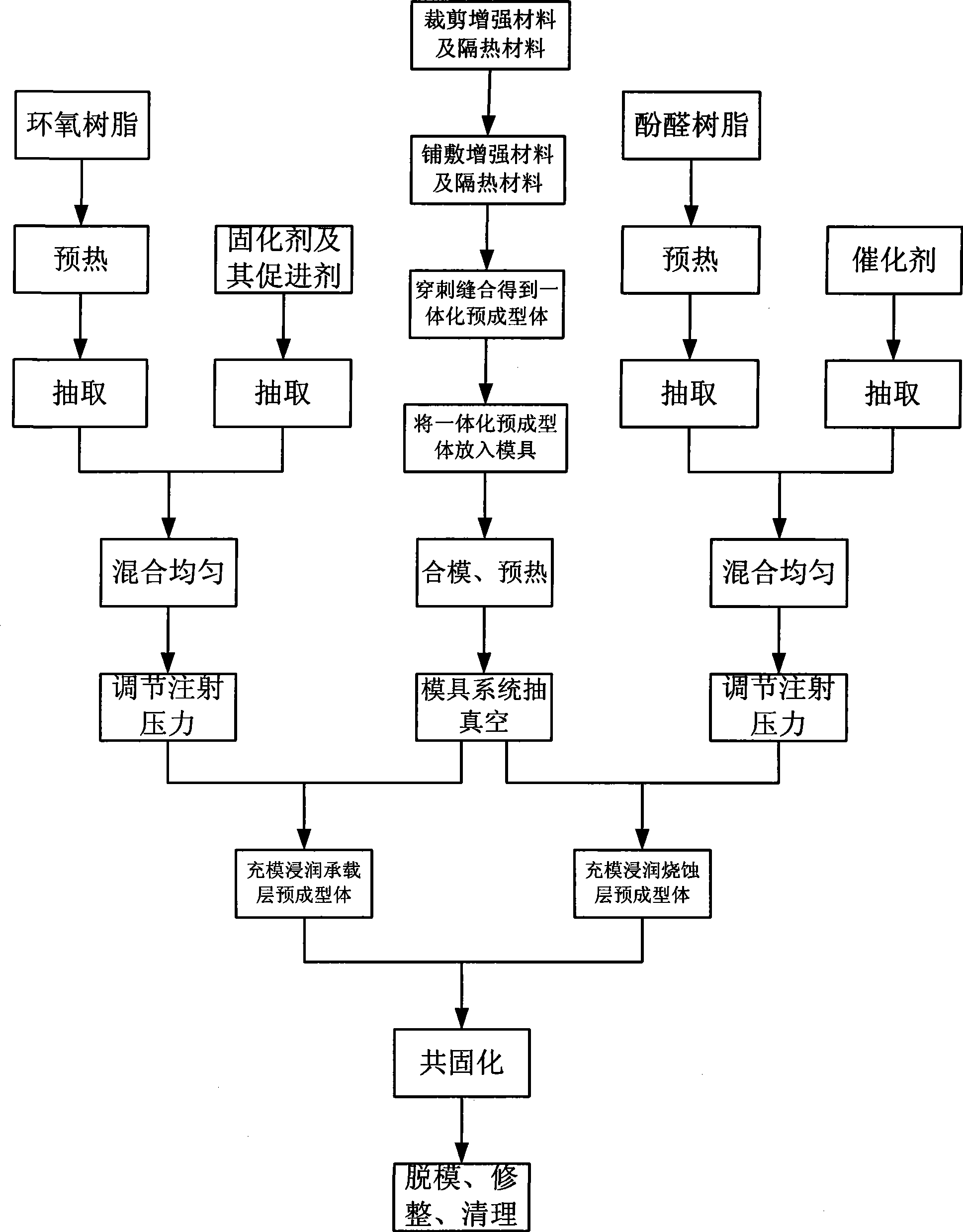

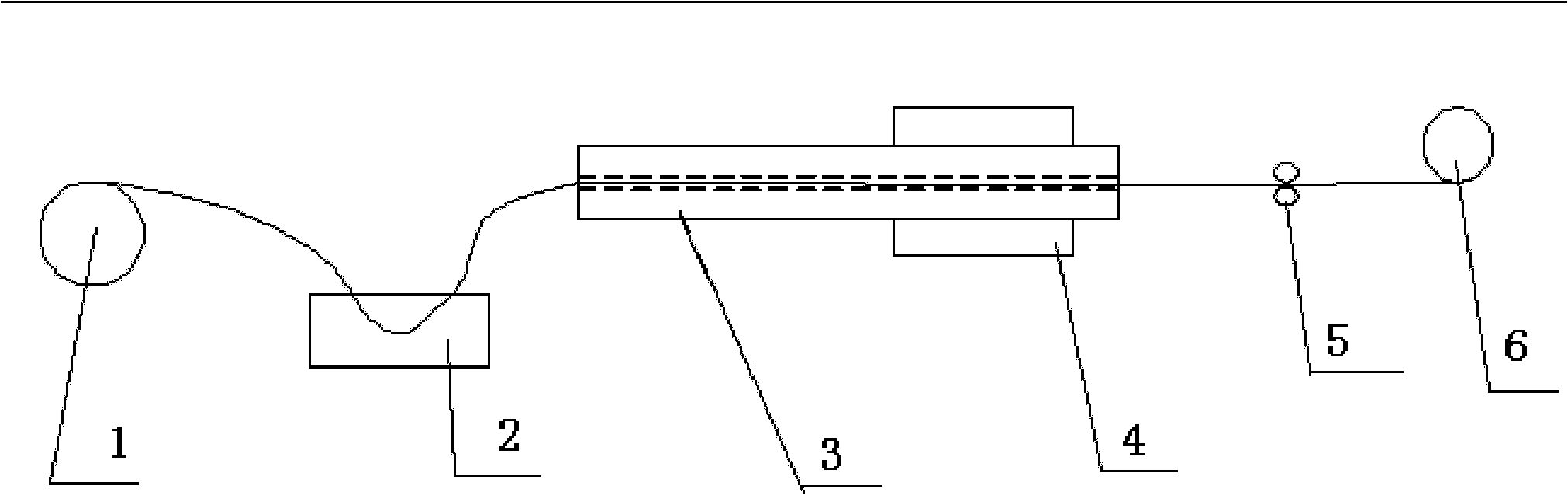

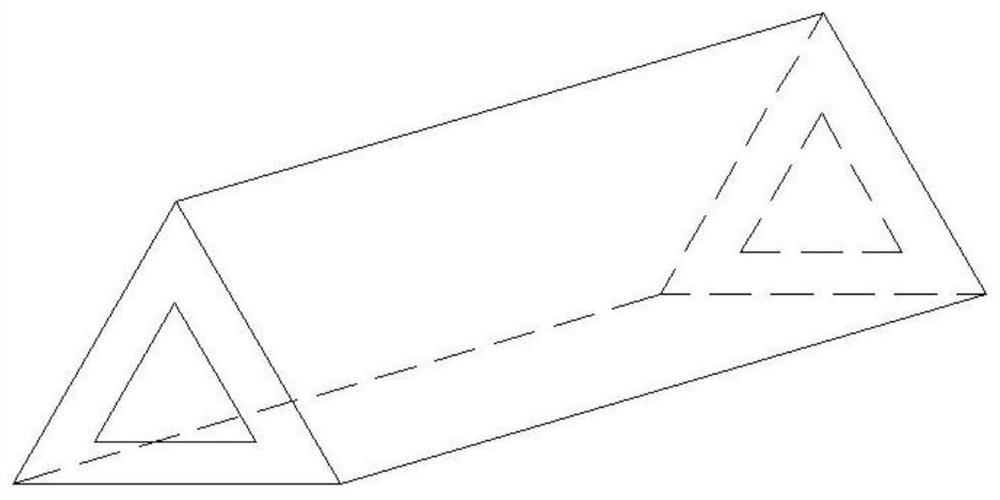

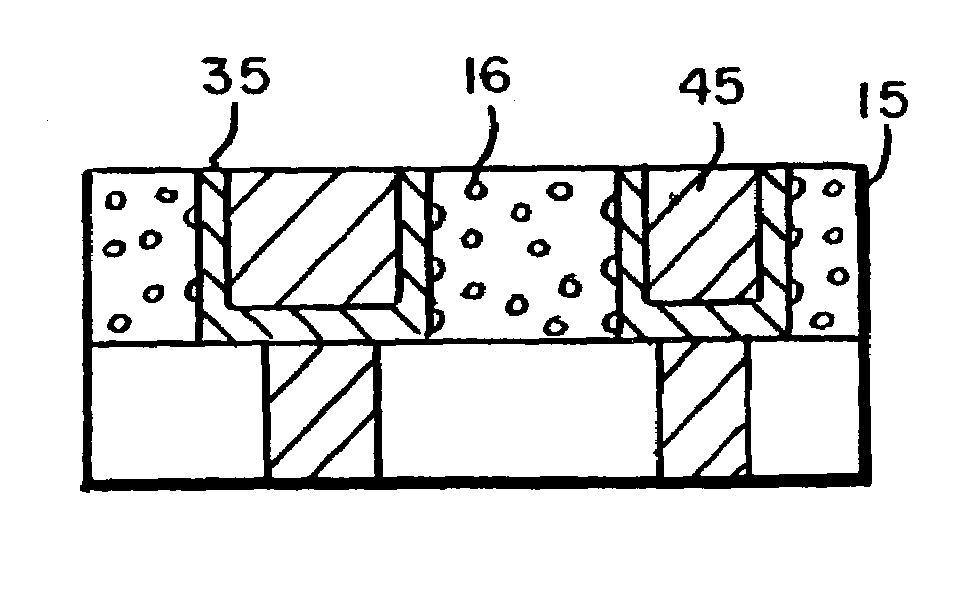

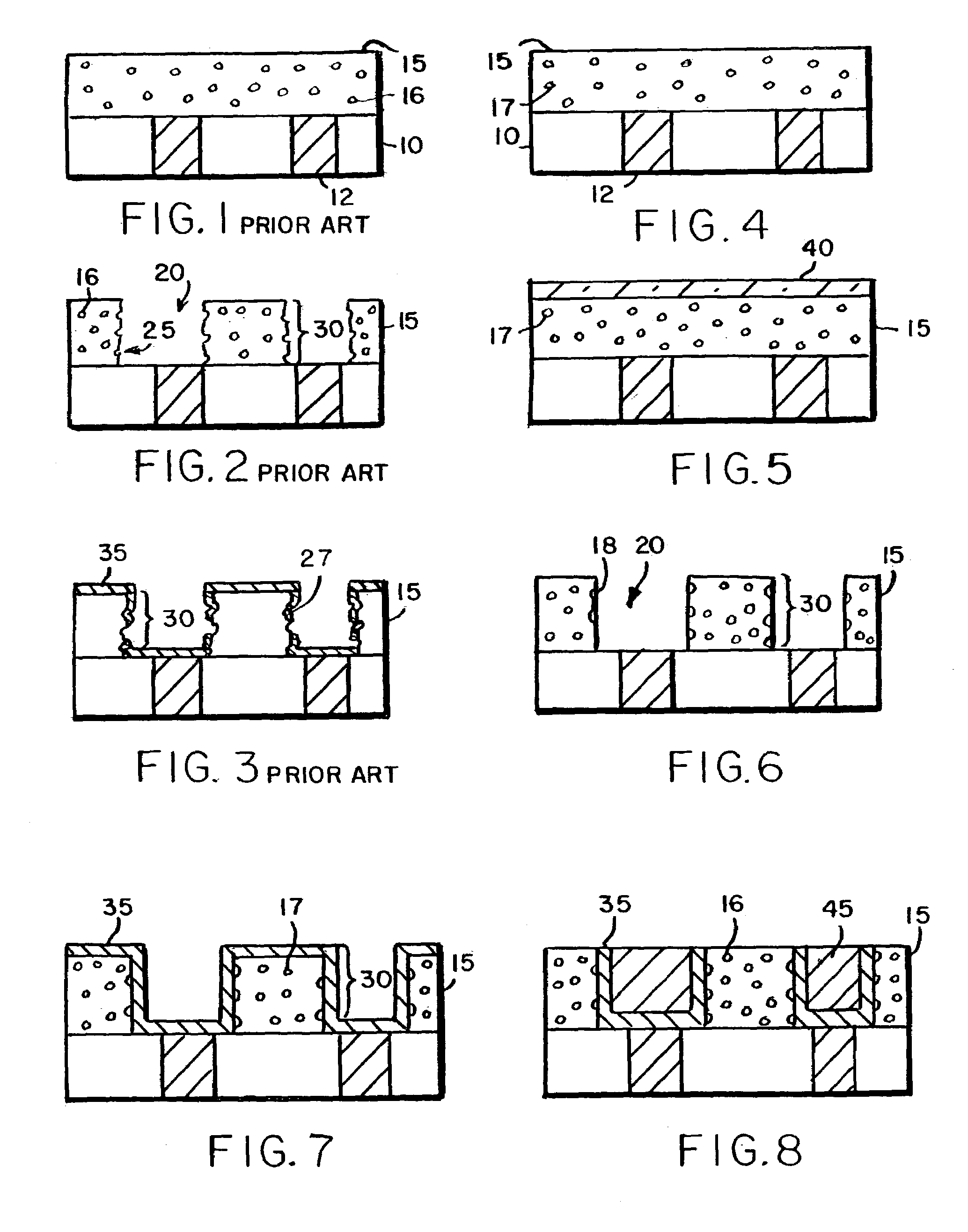

Bearing/insulating/ablating all-in-one sandwich structure composite material and preparation method thereof

InactiveCN101417516AImprove layer performanceIncreased interlaminar shear strengthLayered productsEpoxyInsulation layer

A composite material of sandwich structure integrating loading, heat insulation and ablation and the manufacturing method are characterized in that an integrated pre-forming body is acquired by puncture and suture of the reinforcing material of a bearing layer, the reinforcing material of an ablating cover, and a heating insulation layer positioned between the two layers; an epoxy resin system and a phenolic resin system are injected simultaneously into a vacuum-pumped mould, in which the integrated forming body is pre-placed, by two sets of RTM injection systems respectively, then, the reinforcing materials of the bearing layer and the ablating layer are soaked by epoxy resin and phenolic resin respectively; and the composite material of sandwich structure integrating loading, heat insulation and ablation can be obtained by solidified molding after mould filling. The invention has the advantages that the composite material of sandwich structure integrating loading, heat insulation and ablation is put forward and can be integrally formed by one-time operation, the function of the interlayer between every layer of the composite material is enhanced greatly, the integrality is good; the stratifying and peeling of the composite can be reduced effectively, and the products have good designable property and can be widely applied to the structural parts of aerospace which need heating insulation and thermal protection.

Owner:NAT UNIV OF DEFENSE TECH

Method for manufacturing carbon fiber reinforced resin matrix composite structure

The invention relates to a method for manufacturing a carbon fiber reinforced resin matrix composite structure, which comprises the following steps: (1) utilizing a pulling and extruding forming technique to prepare a micro-diameter carbon fiber rod with the diameter of 0.3mm-0.5mm; (2) using a numerical control embedded machine to implant the carbon fiber into a foam carrier according to a designed direction and distribution density; (3) guiding the micro-diameter carbon fiber rod from the foam carrier into a resin base composite material pre-soaking material blank by using an ultrasonic auxiliary implanting device, wherein the volume ratio of carbon fiber rod to resin base composite material is 0.44%-3.14%; and (4) after removing foams, co-curing the micro-diameter carbon fiber rod with a prepreg piece, so as to acquire a multi-directional enhanced resin base composite material co-curing component. By using the method, all sub-layers of the composite material having the layered structure are fixedly combined along the direction vertical to a paving layer. Compared with the composite material having no multi-directional enhanced layered structure, the interlayer fracture toughness of the multi-directional enhanced composite material having the layered structure is obviously increased, thereby improving the interlayer property.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

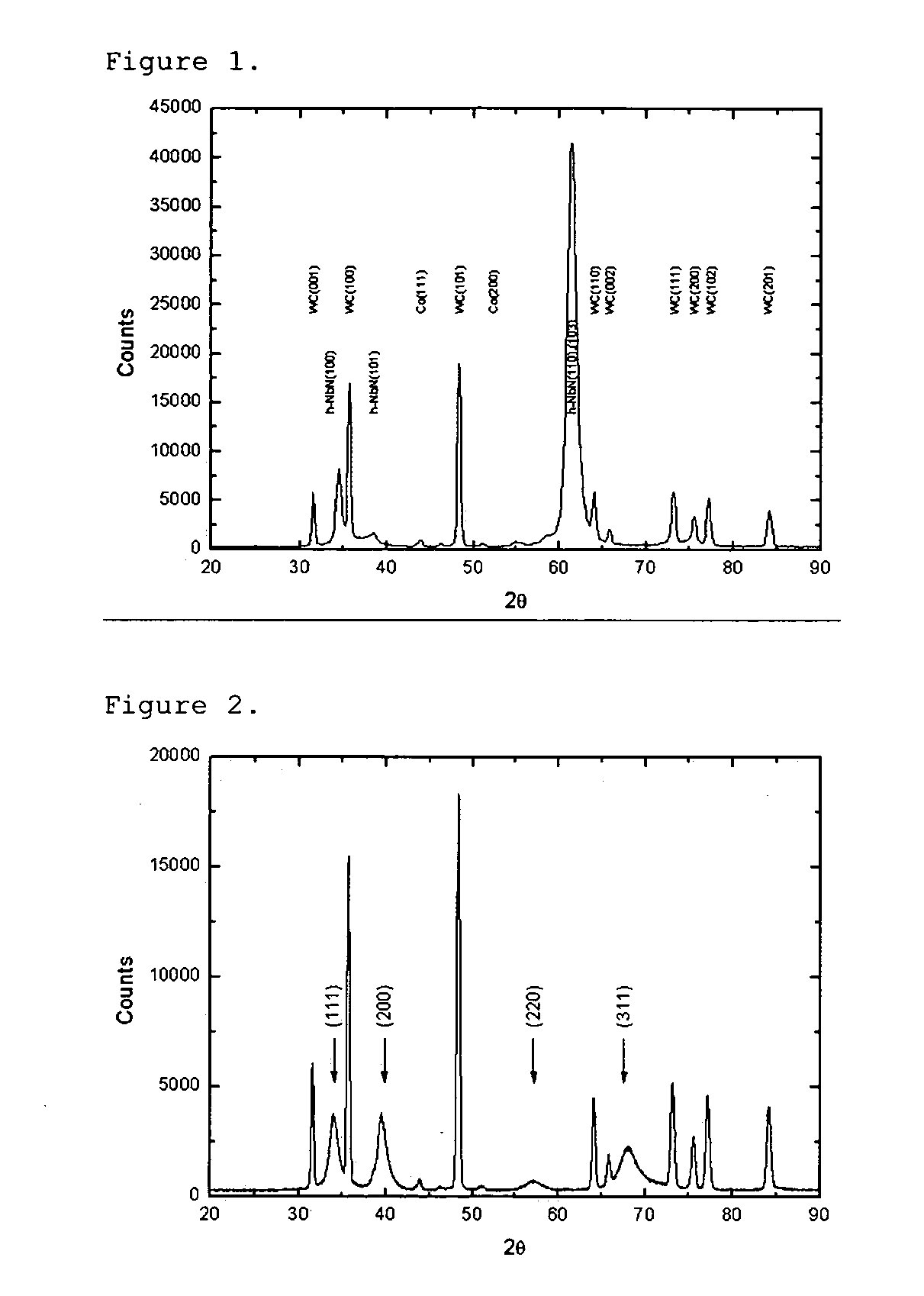

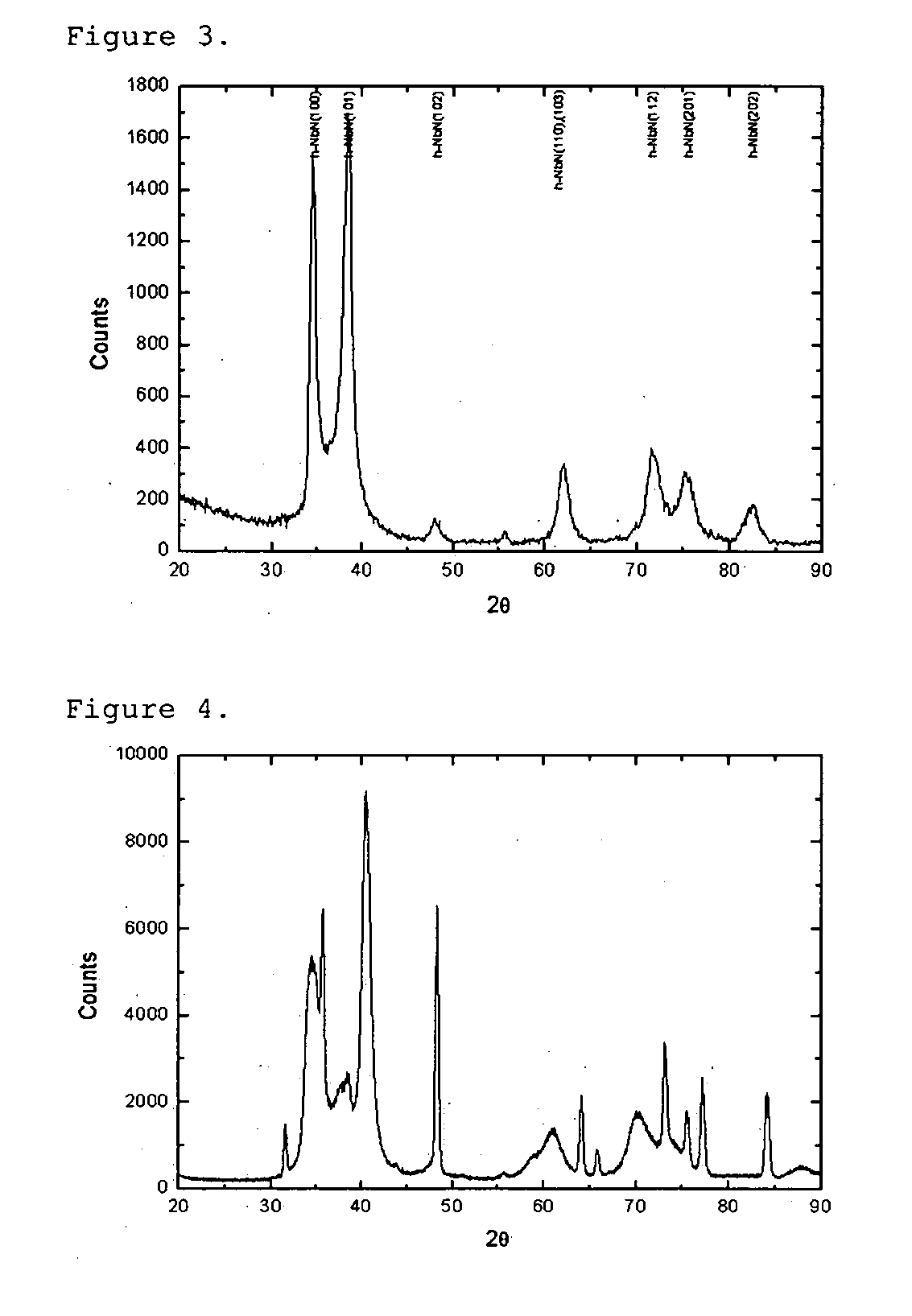

Thin wear resistent coating

InactiveUS20070178330A1Improve performanceImprove layer performancePigmenting treatmentOther chemical processesMilling cutterEnd mill

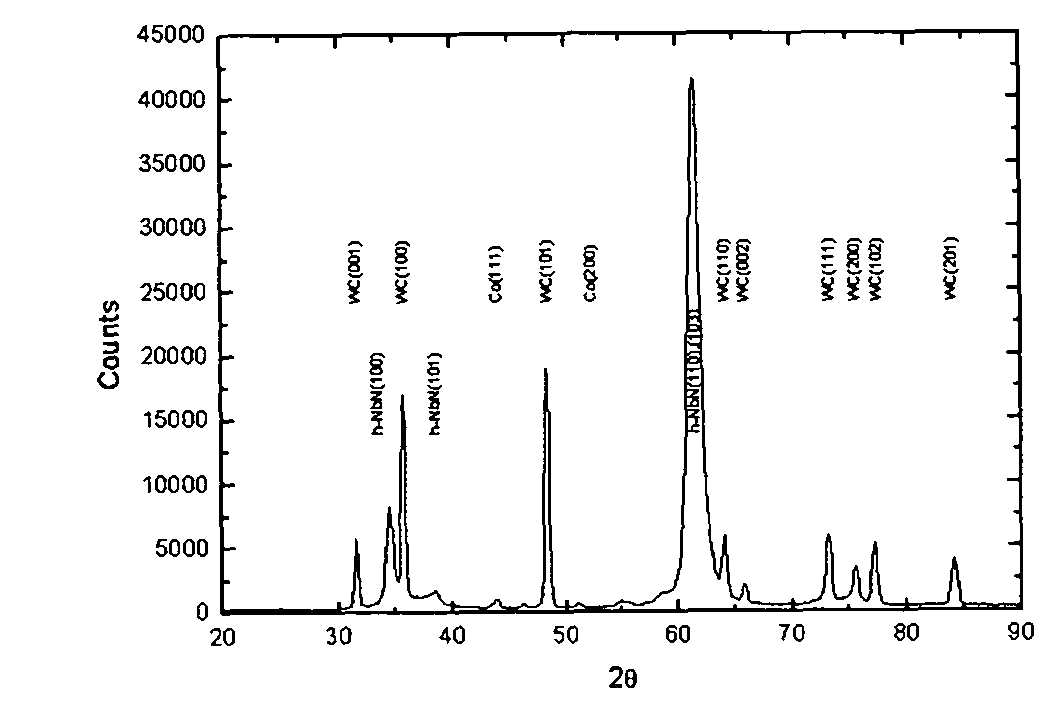

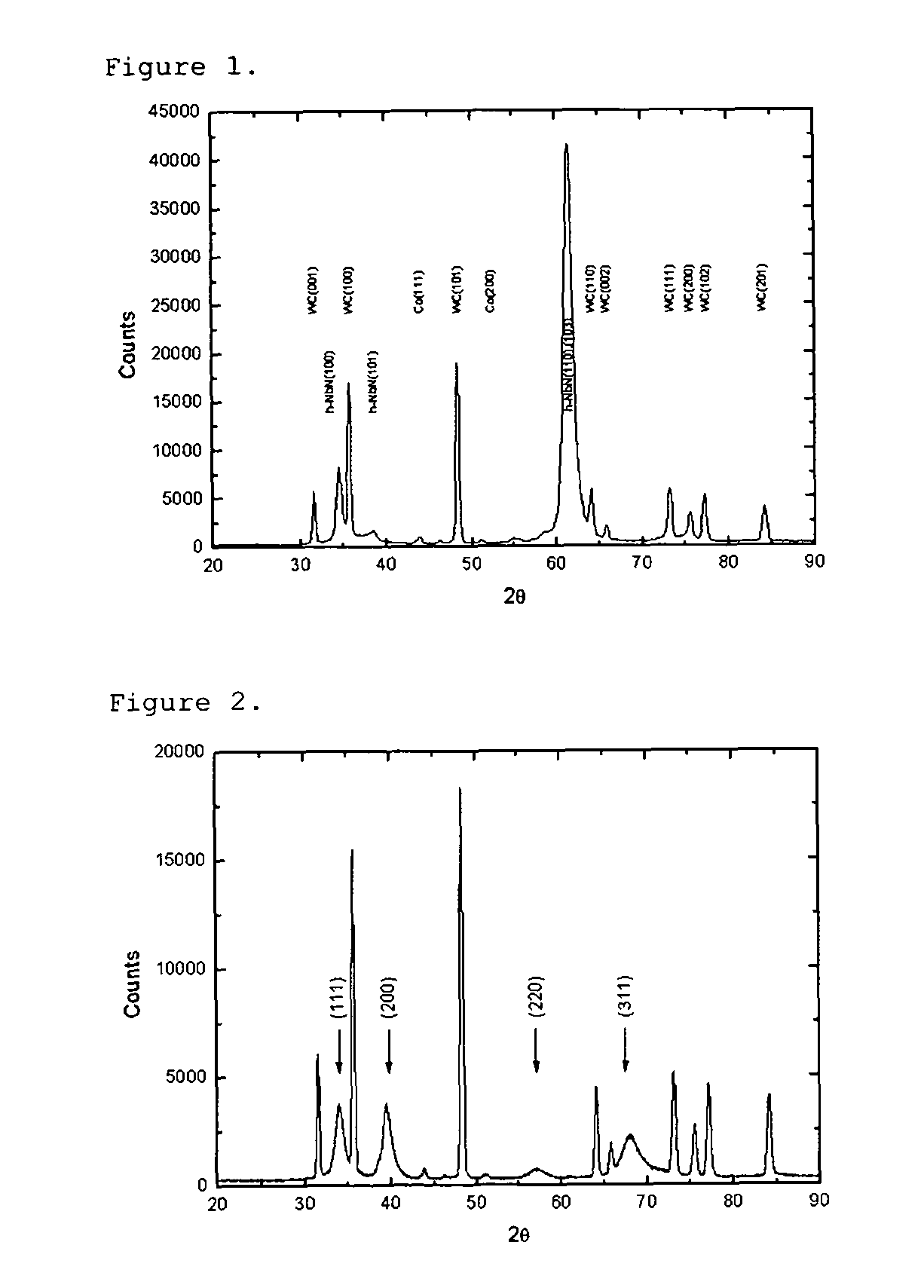

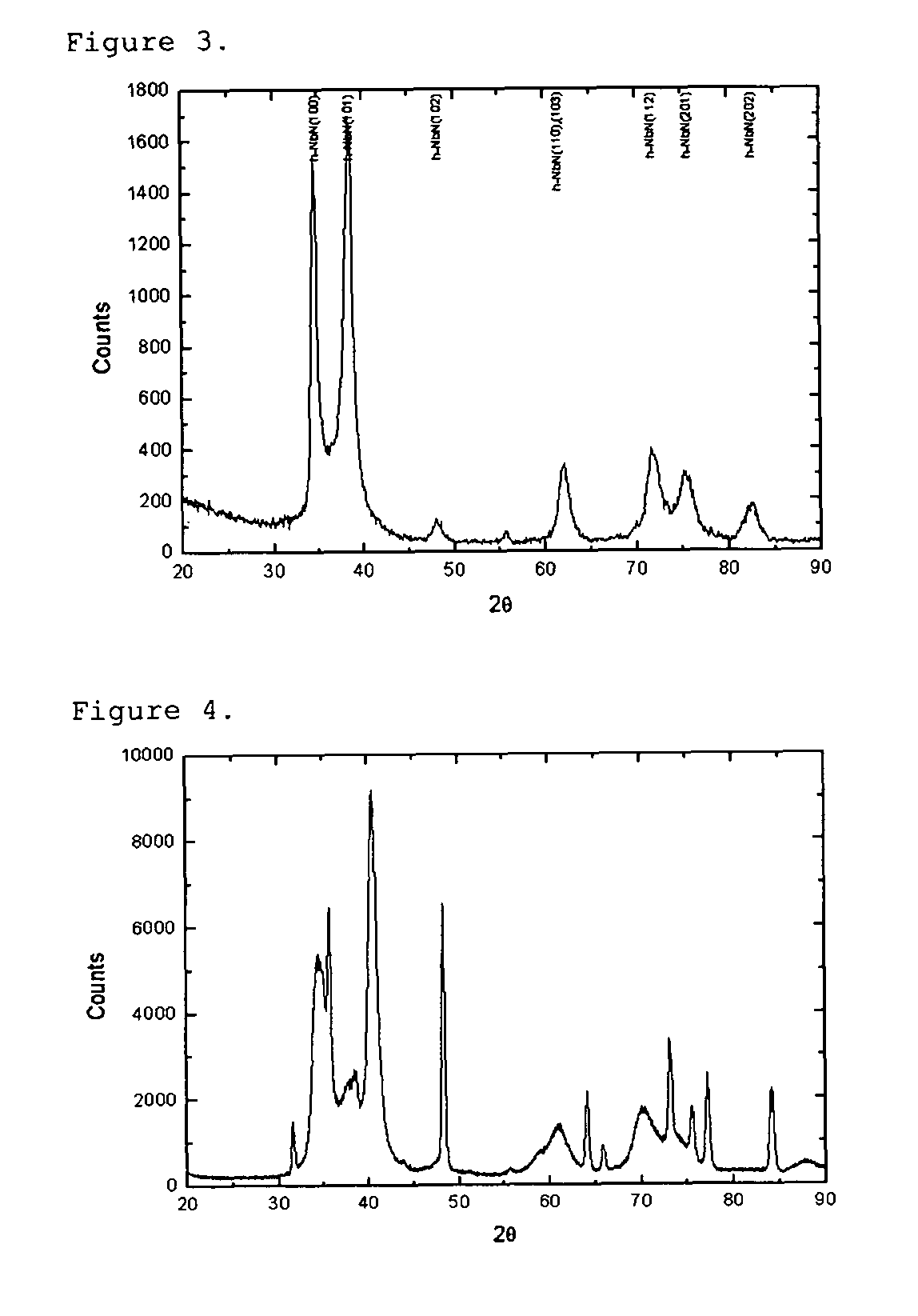

The present invention relates to a cutting tool insert, solid end mill, or drill, comprising a substrate and a coating. The coating is composed of one or more layers of refractory compounds of which at least one layer comprises a h-Me1Me2X phase, where Me1 is one or several of the elements V, Cr, Nb, and Ta and Me2 is one or several of the elements Ti, Zr, Hf, Al, and Si and X is one or several of the elements N, C, O or B. The ratio R=(at-% X) / (at-% Me1+at-% Me2) of the h-MelMe2X phase is between 0.5 and 1.0, preferably between 0.8 and 1.0 and X contains less than 30 at-% of O+B. This invention is particularly useful in metal cutting applications where the chip thickness is small and the work material is hard e.g. copy milling using solid end mills, insert milling cutters or drilling of hardened steels.

Owner:SECO TOOLS AB

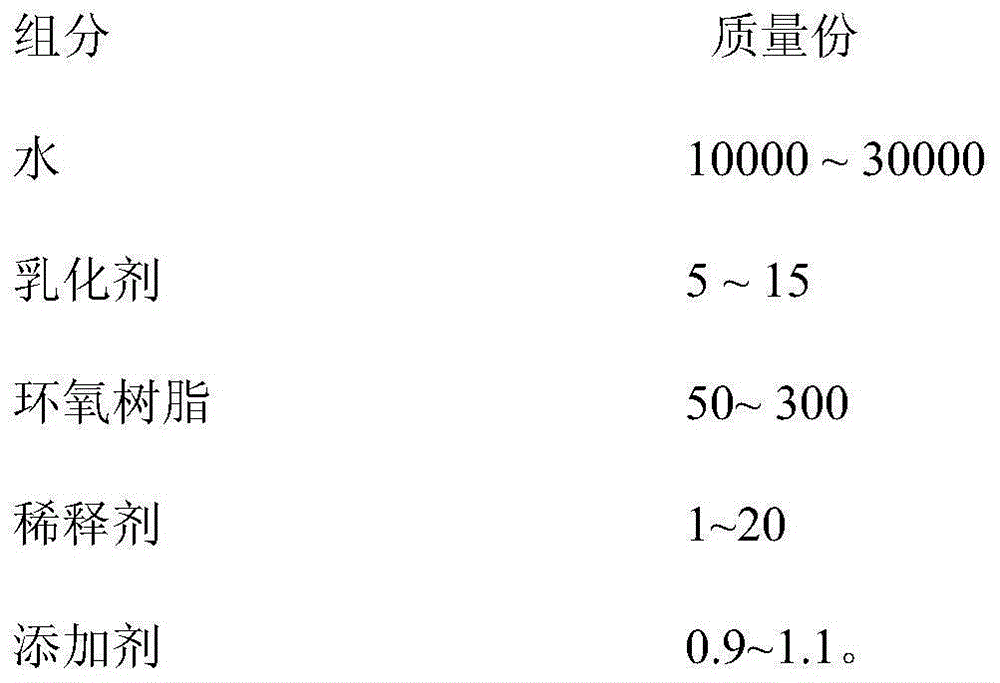

Carbon fiber sizing agent and preparation method thereof

The invention provides a carbon fiber sizing agent and a preparation method thereof. The sizing agent is prepared from the following raw materials in parts by mass: 10,000 to 30,000 parts of water, 5 to 15 parts of an emulsifier, 50 to 300 parts of epoxy resin, 1 to 20 parts of a diluent, 0.9 to 1.1 parts of an additive. According to the invention, organic-inorganic oligomeric silsesquioxane nanoparticles are added to the carbon fiber sizing agent, so that the nanometer effect enables the composite material prepared by the sized carbon fibers to be better in heat resistance, toughness and interfacial properties.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

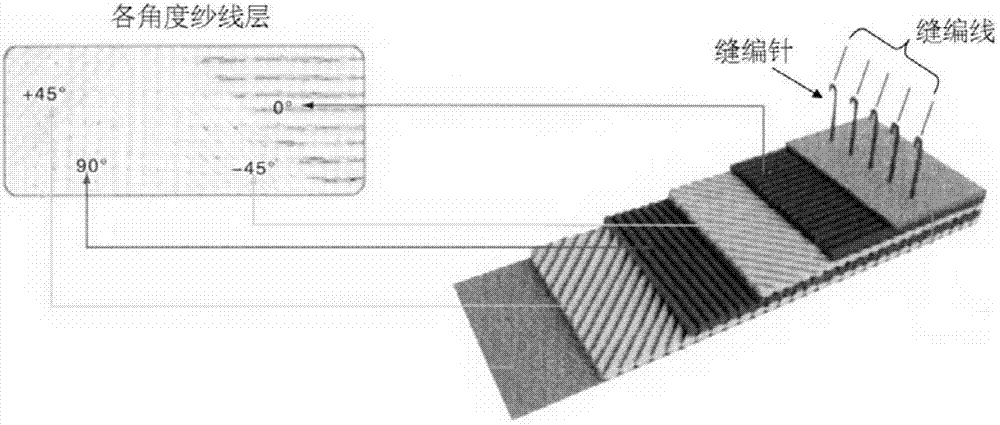

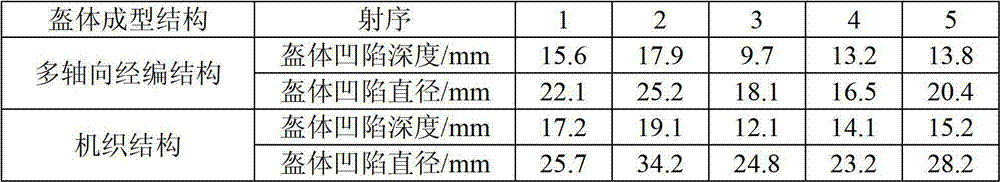

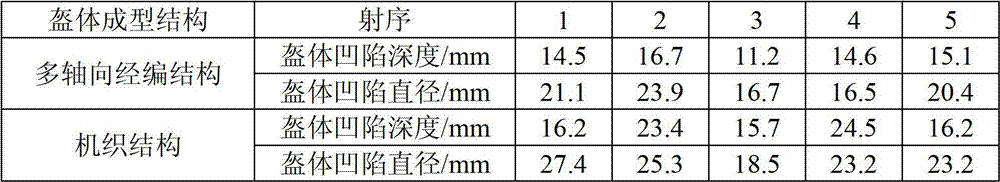

Bulletproof helmet body and preparation method thereof

ActiveCN102806716AReduce manufacturing costImprove impact resistanceLayered productsWarp knittingImpact resistanceBraid

The invention discloses a bulletproof helmet body and a preparation method thereof. The preparation method for the bulletproof helmet comprises the following steps of: after yarns are weaved into lamella-shaped warp knitted fabric, the obtained lamella-shaped warp knitted fabric and release paper covered with a glue film are subjected to hot pressing to obtain cutting characterized in that the glue film is coated between layers; and the obtained cut lamella-shaped warp knitted fabric coated with the glue film is arranged in a helmet-shaped mould to be subjected to mould pressing to obtain the bulletproof helmet body. According to the novel bulletproof helmet body, because the advanced multi-axial warp knitted technology and the advanced shuffling technology are adopted on the structural design of the helmet body material, the bulletproof helmet body disclosed by the invention has a better impact resistance if being compared with the helmet body with the same material. The bulletproof helmet body has the characteristics of light weight, high strength, good impact resistance, low cost and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

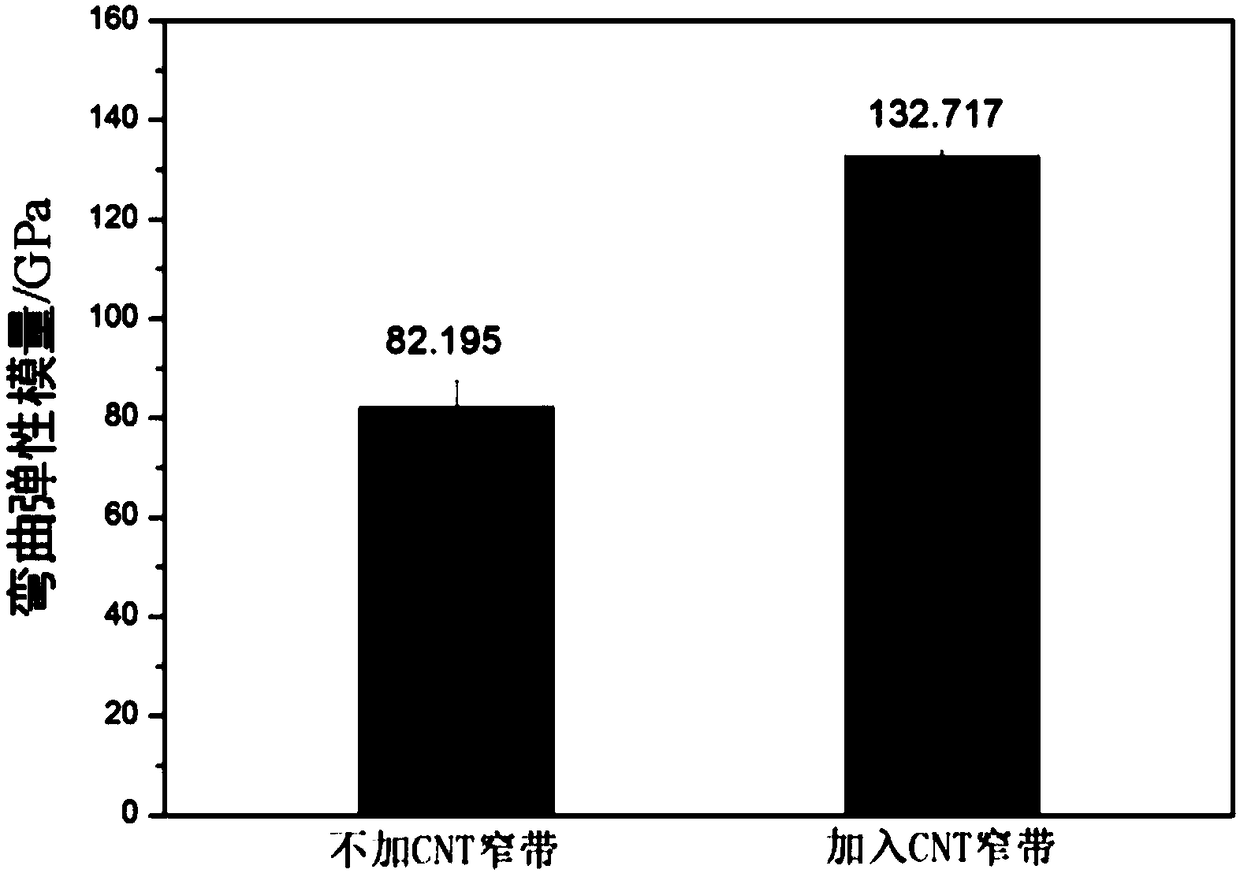

Interlayer toughened composite material and preparation method and application thereof

The invention discloses an interlayer toughened composite material and a preparation method and an application thereof. The preparation method comprises the following steps that a reinforcing body isprovided, the reinforcing body comprises a plurality of first fiber aggregates which are stacked in the thickness direction of the reinforcing body, wherein the first fiber aggregates comprise a plurality of first fibers which are arranged in a specified direction in an orientation manner; at least one braided body is woven with the plurality of first fiber aggregates in the thickness direction ofthe reinforcing body to form the braided structure, wherein each braided body continuously penetrates between every two adjacent first fibers in two or more first fiber aggregates; the weaving structure is soaked in a fluid containing a curable resin material, then curing treatment is carried out, and the interlayer toughened composite material is formed. According to the composite material and the method and the application, the nano-carbon material strips and the like are adopted as the weaving body to weave the reinforcing body in the thickness direction, gaps are avoided between the reinforcing bodies due to the fact that the strips are added, so that a large stress concentration point does not exist in the composite material, and the interlayer toughening performance of the compositematerial is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

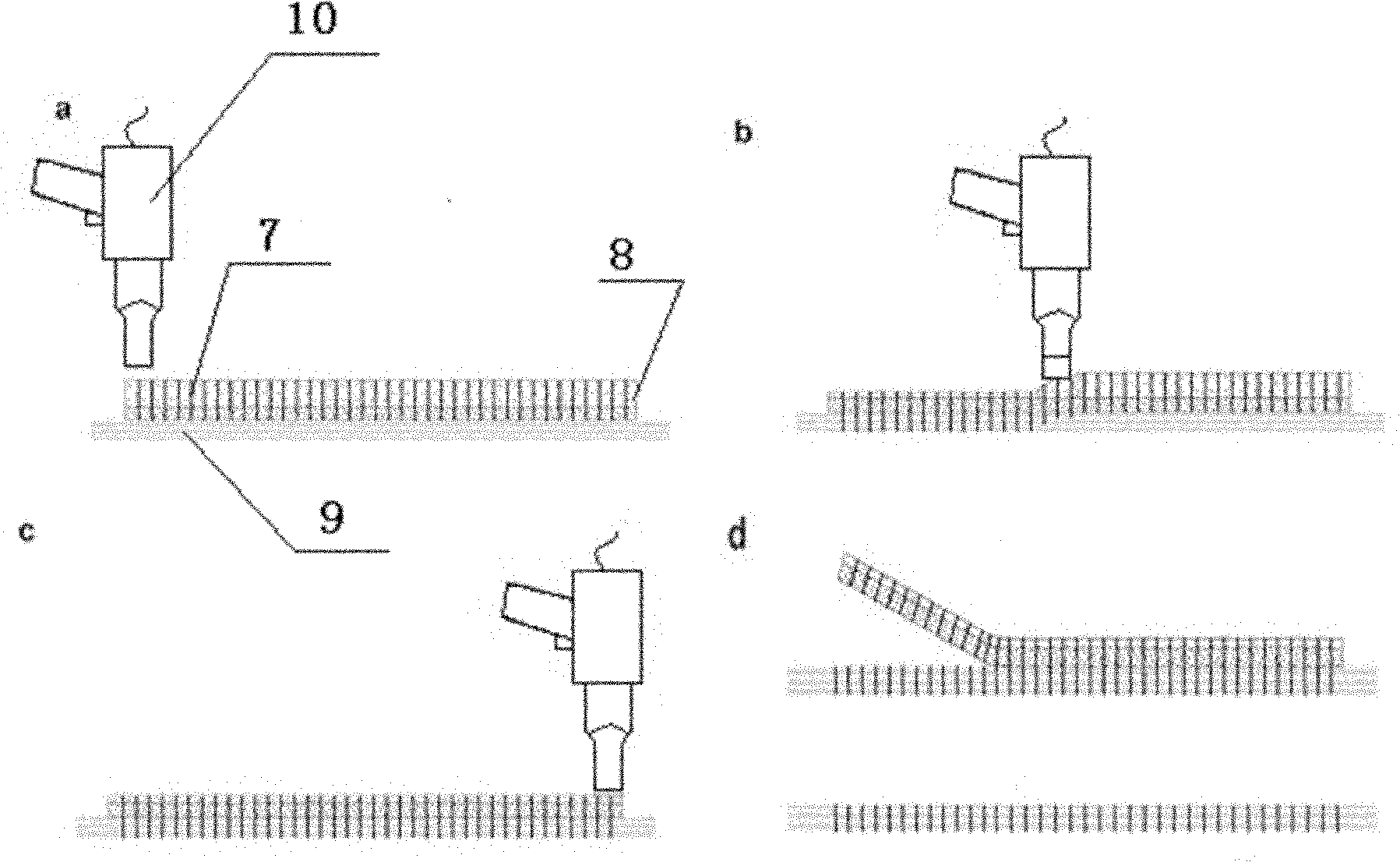

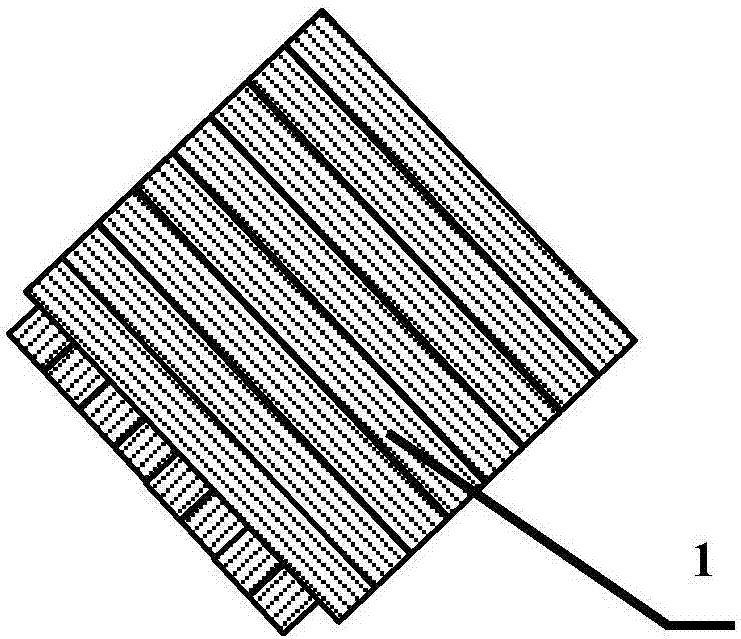

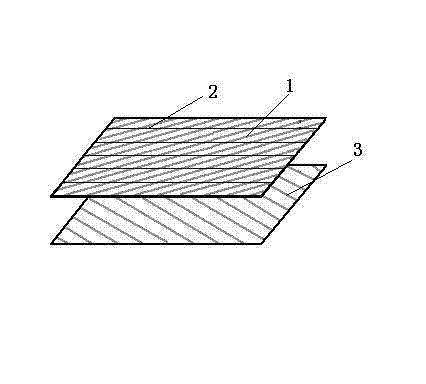

Manufacturing method of vehicle components, as well as vehicle components and vehicle

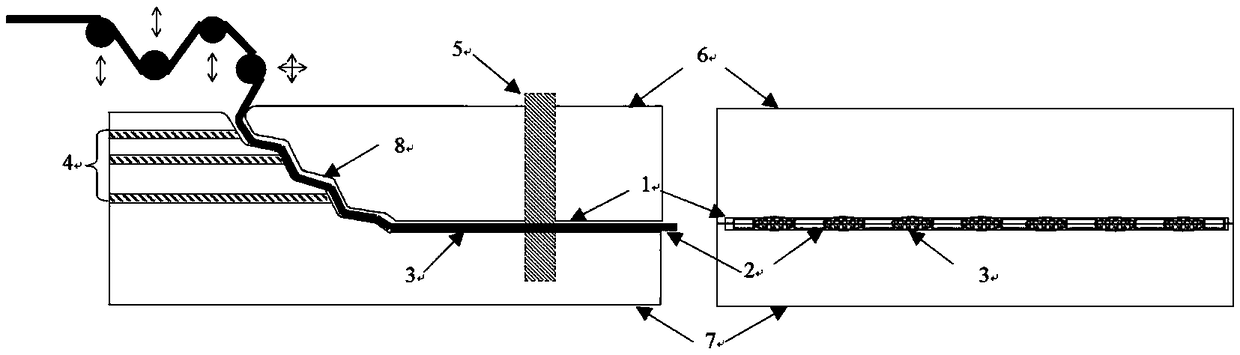

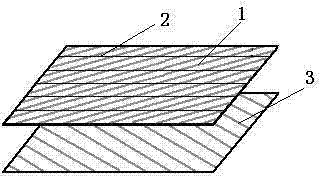

ActiveCN107053703AGood molding effectImprove layer performanceDomestic articlesFiberMarine engineering

The invention relates to manufacturing method of vehicle components, as well as vehicle components and a vehicle. The method comprises the following steps of: a, layering continuous-filament woven fabric to obtain a layering structure (1); b, laying a resin film (2) at the bottom of the layering structure (1), and then performing pre-cutting to obtain a fibrous preform (3); and c, placing the fibrous preform (3) in an injection mold with an injection molding space (8), after mold clamping, injecting an injection molding material (6) containing discontinuous fibers and thermoplastic resin into the injection mold, so that the injection molding space (8) is full of the injection molding material (6) through injection molding and the fibrous preform (3) is infiltrated with the injection molding material (6), and performing pressure maintaining and forming so as to obtain the vehicle components (7). The method belongs to revolutionary innovation of a conventional low-pressure injection molding process. The manufactured components can meet the requirements of mechanical properties and formability at the same time. The problems of difficult forming by the conventional laminating process and low mechanical performance of the conventional injection molding process are solved.

Owner:BEIJING AUTOMOTIVE IND CORP +1

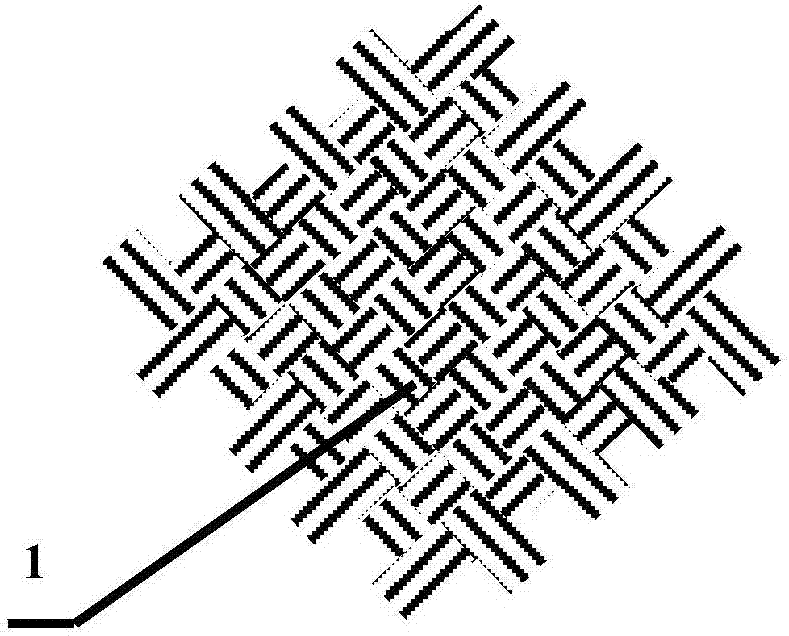

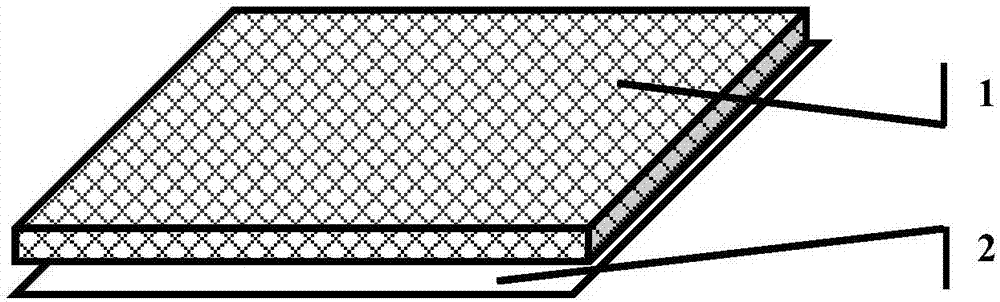

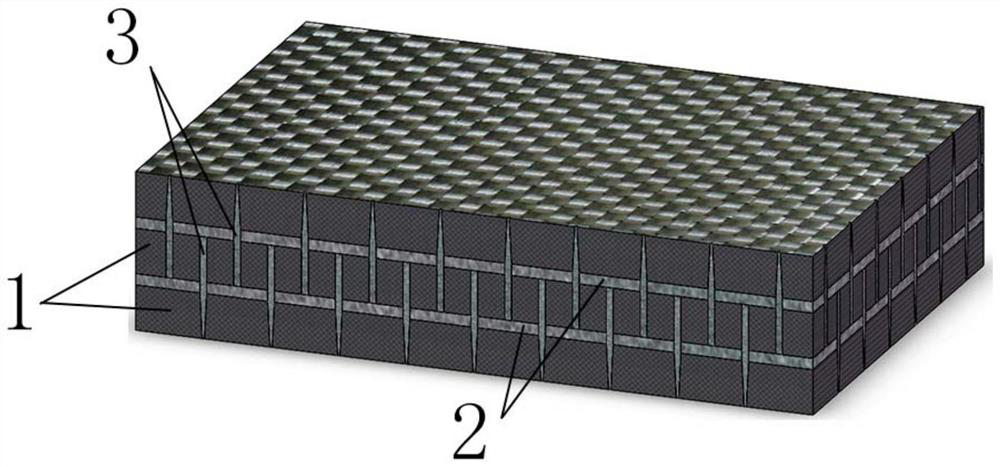

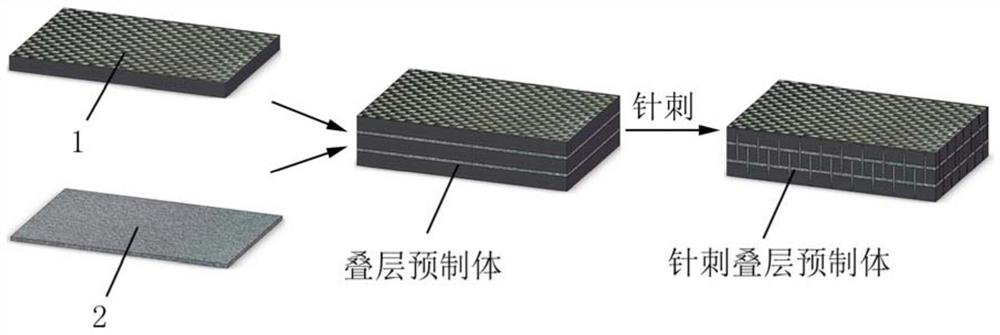

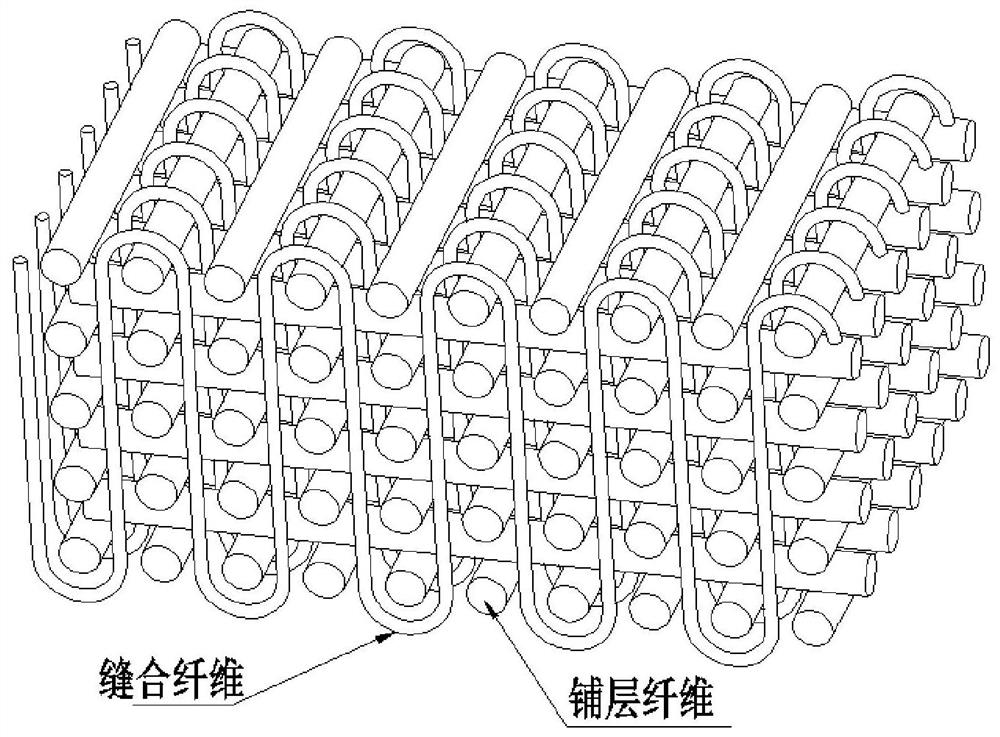

Three-dimensional fabric laminated needled composite material and preparation method thereof

InactiveCN111746061AImprove layer performanceIncrease productivityLamination ancillary operationsSynthetic resin layered productsFiberNeedle penetration

The invention discloses a three-dimensional fabric laminated needled composite material and a preparation method thereof. The three-dimensional fabric laminated needled composite material is formed bycompounding a three-dimensional fabric laminated needled prefabricated body and a base material, wherein the three-dimensional fabric laminated needled prefabricated body is a three-dimensional structure material obtained by paving staple fiber felt between three-dimensional fabric layers and then utilizing a needling process. According to the composite material obtained by laminating and needling according to a specific process, the interlayer performance of the composite material is improved, the number of layers laid in the production process is reduced, the production efficiency is improved, the production period is shortened, the production cost is reduced, and the composite material is suitable for large-scale production and application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

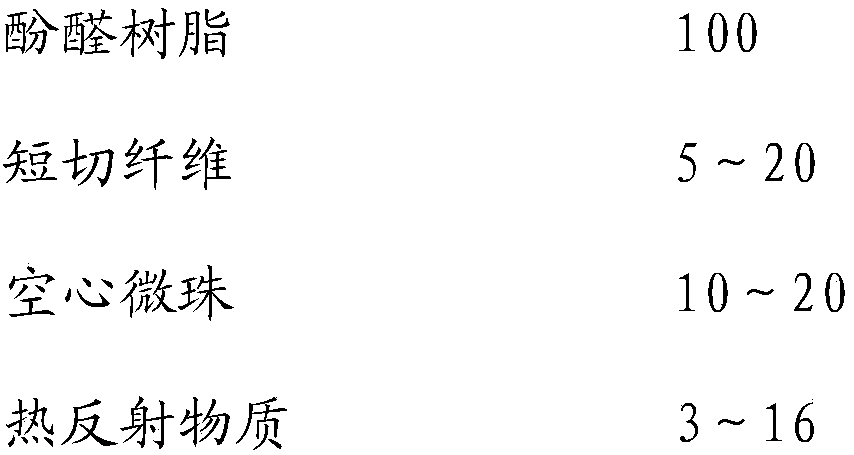

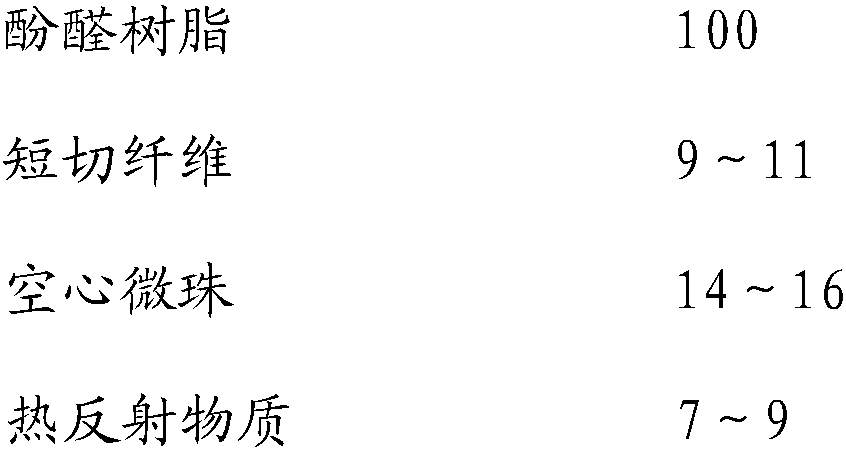

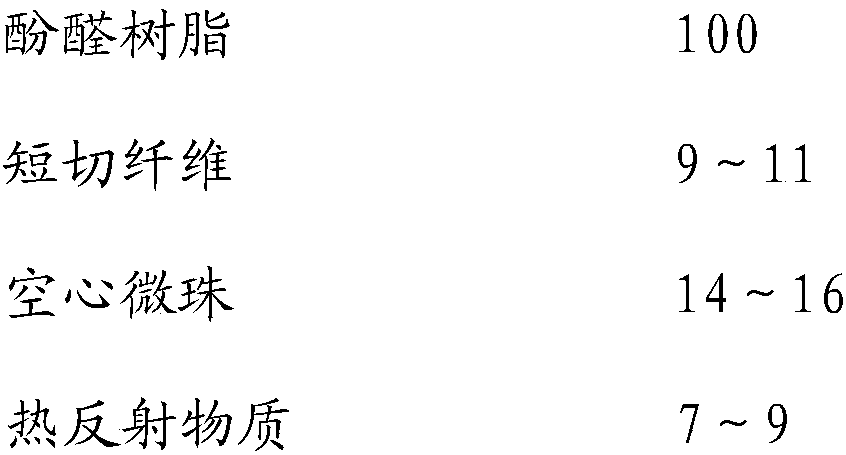

Modified phenolic resin, composite material, and preparation methods of modified phenolic resin and composite material

The invention provides modified phenolic resin, a composite material, and preparation methods of the modified phenolic resin and the composite material. The modified phenolic resin comprises phenolicresin, chopped fibers, hollow microbeads and heat reflecting materials, and the hollow microbeads include hollow phenolic microbeads and hollow ceramic microbeads. The modified phenolic resin has theadvantages of non-ablative surface radiation and low thermal conduction, and ablative cracking heat desorption and mass ejection due to the special formula design; through blending of the hollow ceramic microbeads and inorganic masterbatches, the thermal insulation of the modified phenolic resin is enhanced, and the radiation resistance of the surfaces of ablative materials is improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

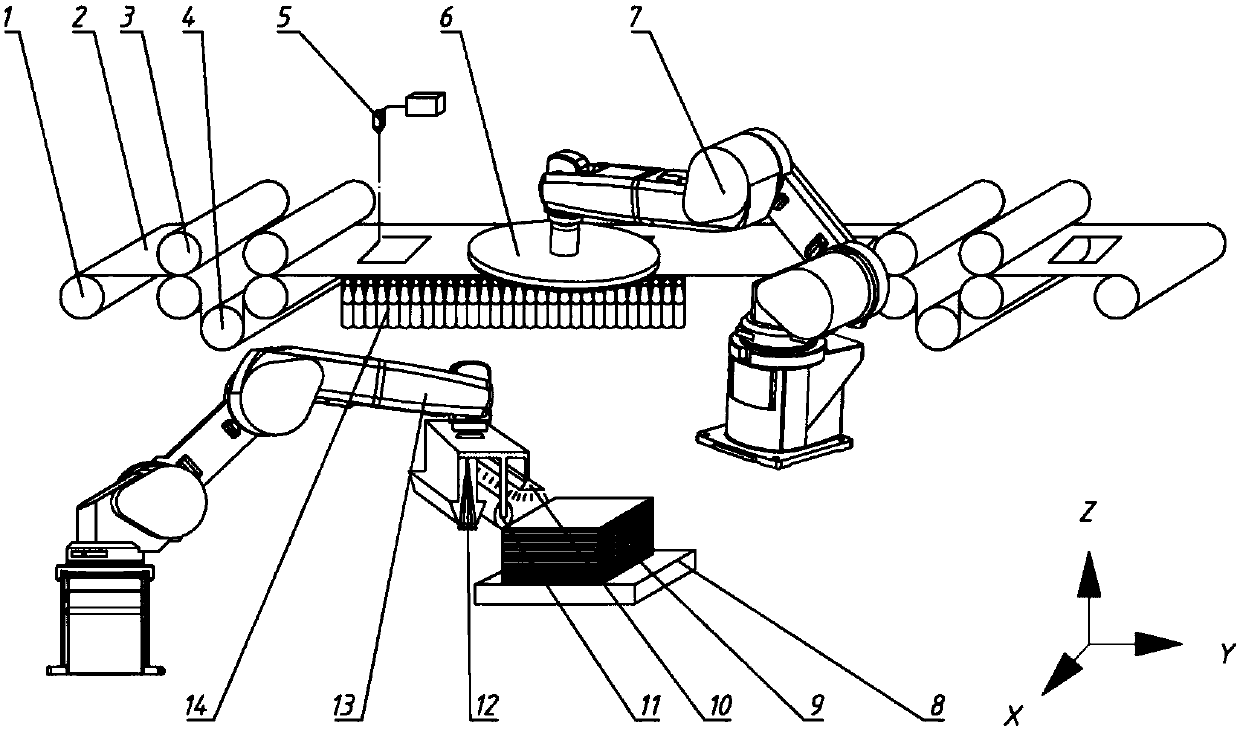

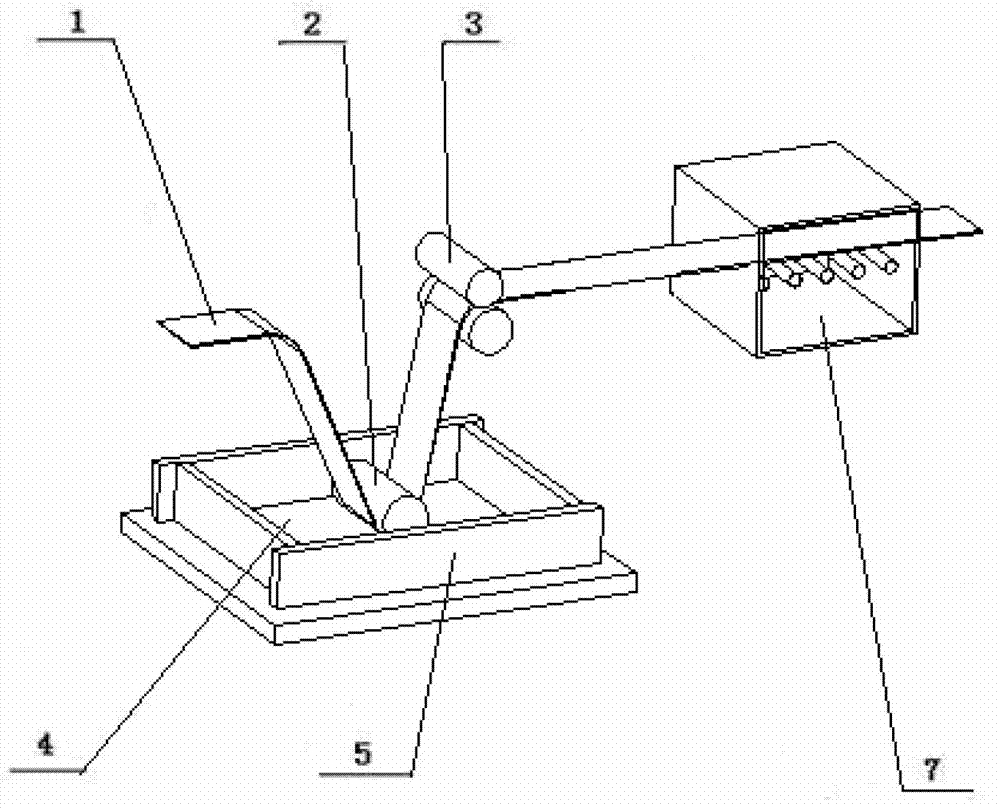

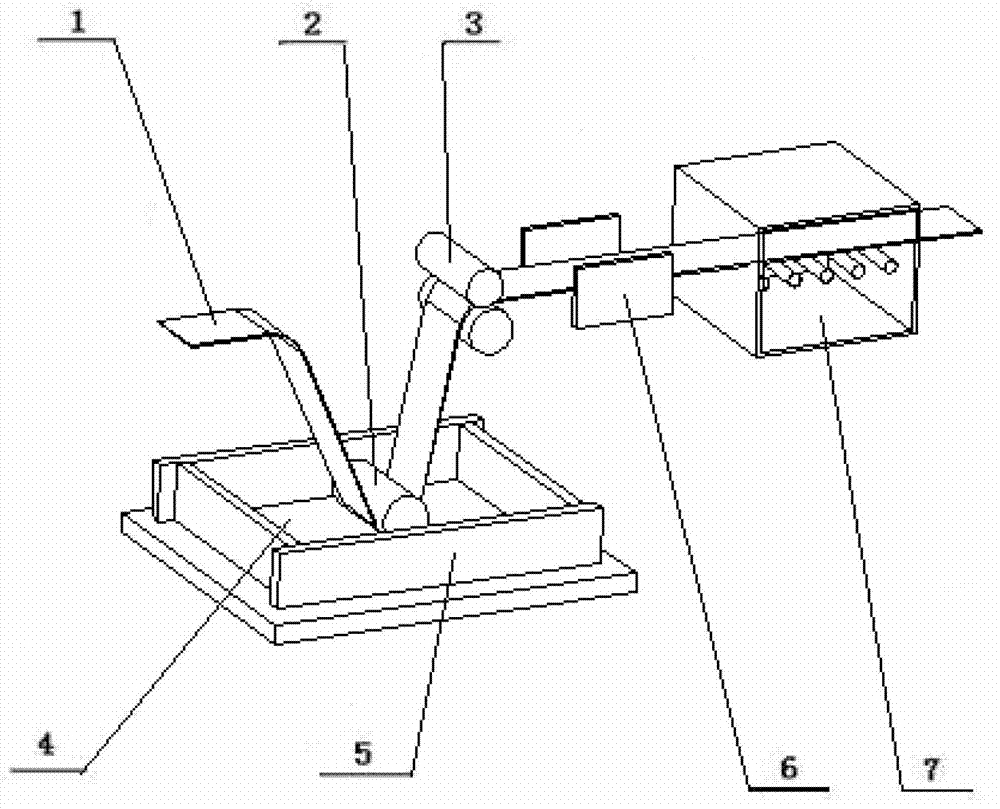

Electron beam curing LOM forming method and device of thermosetting resin matrix composites

ActiveCN107914392AImprove insulation performanceGood adhesionAdditive manufacturing apparatus3D object support structuresLaser transmitterFiber bundle

The invention relates to an electron beam curing LOM forming method and device of thermosetting resin matrix composites. A composite prepreg tape coil is arranged on a coil release roller, and conveyed to a multipoint support plate through a conveyor device; a composite prepreg tape is cut by a laser emitter; the composites properly cut are transferred to a semi-finished part through a first manipulator, heated by an infrared heat lamp, hot-pressed by a press roller, and finally cured by low energy electron beam irradiation through a low energy electron beam emitter, so that the molding of a layer is finished; and the above steps are repeated till the molding of the required parts is finished. The electron beam cured thermosetting resin matrix adopted by the device is resistant to corrosion and high temperature, excellent in insulation and adhesive properties, and high in strength, and the LOM technology is high in forming speed, free of warping, and small in deformation with no need of support. According the method provided by the invention, the forming size is unlimited, and the selection of fiber bundle materials is wide; and the thermosetting resin matrix is excellent in performance, and the fiber directions can be arranged according to the design requirements.

Owner:XI AN JIAOTONG UNIV

Preparation method for poly-p-phenylene benzobisoxazole fiber reinforced resin matrix composite material

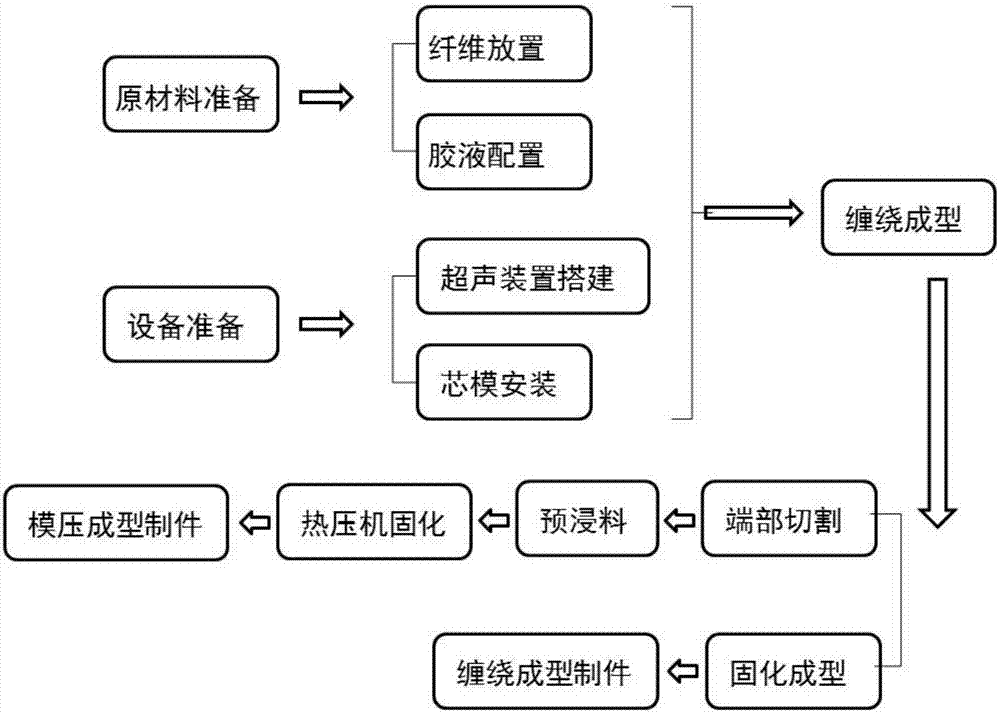

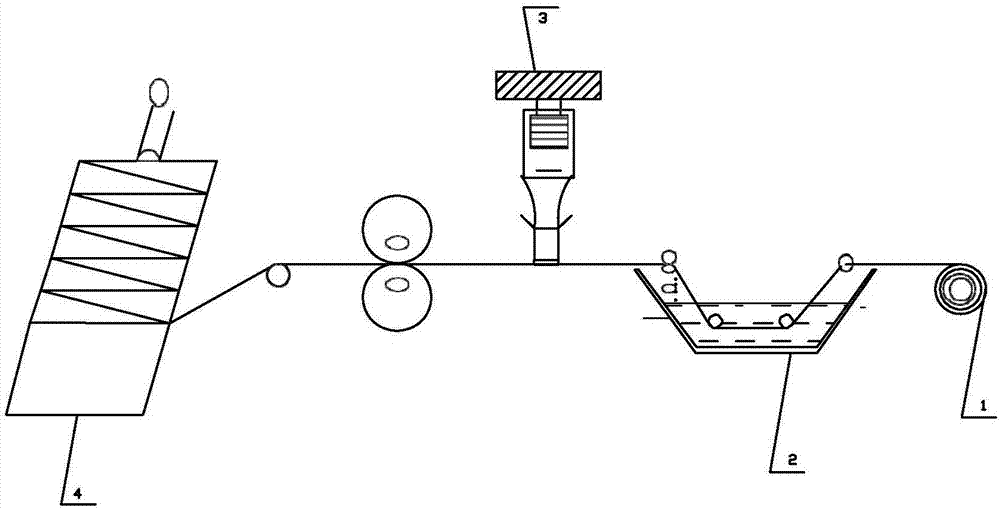

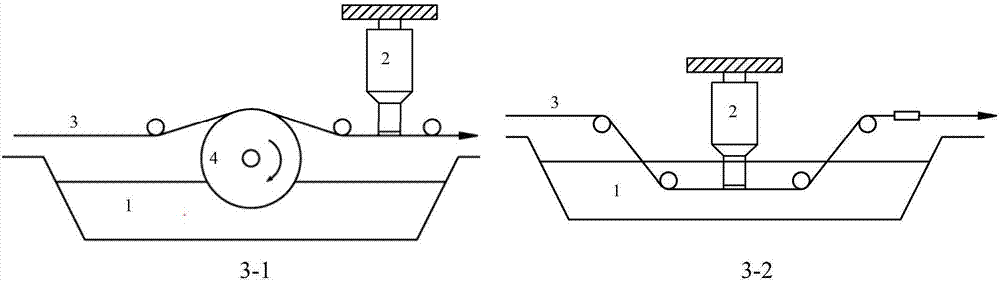

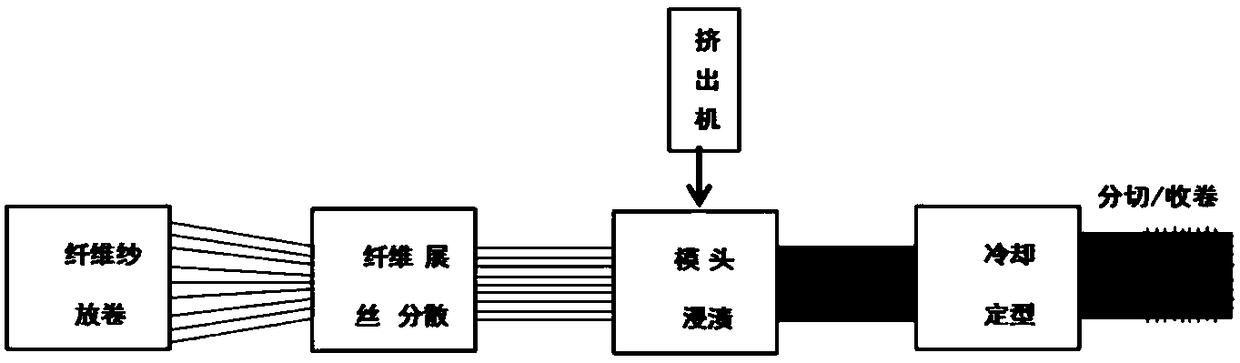

The invention discloses a preparation method for a poly-p-phenylene benzobisoxazole (PBO for short) fiber reinforced resin matrix composite material. According to the method, the PBO fiber reinforced resin matrix composite material is prepared by adopting a wet-process winding forming technology, and an online ultrasonic treatment device is introduced in the preparation process; the device is simple to install, easy to disassemble, convenient to operate, capable of performing production continuously and high in production efficiency; and the parameters and the installation position of the online ultrasonic treatment device can be adjusted, and therefore the improvement of the fiber infiltration quality of resin can be realized. The method can be used for preparing wet-process winding formed composite products, such as pressure vessels and pipelines and can also be used for preparing prepregs serving as intermediate materials of hot-press formed composite products. Compared with a composite material prepared by a traditional method, the PBO fiber composite material prepared by the method has the advantages that the defects are few, the interface bonding performance is high, and particularly the interlaminar shear strength can be obviously improved, and therefore the problem that the interlaminar performance of the PBO fiber reinforced composite material layer is poor can be solved, and the use performance and application benefits of the PBO fiber reinforced composite material can be effectively improved.

Owner:BEIHANG UNIV

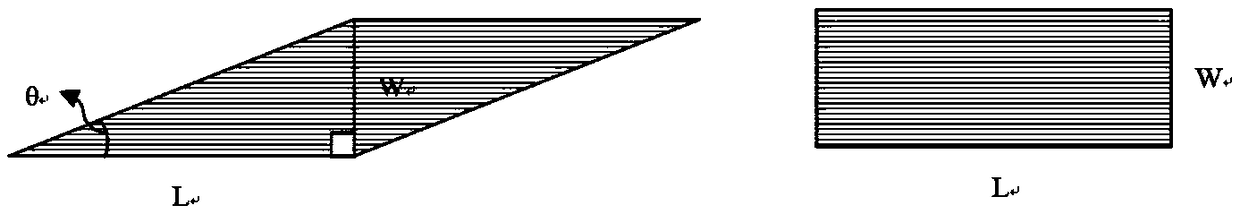

Discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and preparation method thereof

The invention provides a discontinuous long fiber reinforced thermoplastic composite material mold pressing precast body and a preparation method thereof. The mold pressing precast body comprises slices formed by slitting / cutting of continuous fiber reinforced thermoplastic composite material preimpregnated sheets / preimpregnated yarns, wherein the length L range of the slices is 5-200 mm, the width W range of the slices is 2-30 mm, and the weight percentage content of fibers in the slices is 20-90 wt%; and high-strength isotropous complicated parts with high size stability can be prepared through secondary mold pressing of the precast body, so that the defects of easy warpup, fiber length loss, weaker part performances, anisotropic mechanical performances of continuous fiber reinforced composite materials and difficult machining of different-thickness complicated parts after mold pressing injection molding of short-fiber and long-fiber particles are made up.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

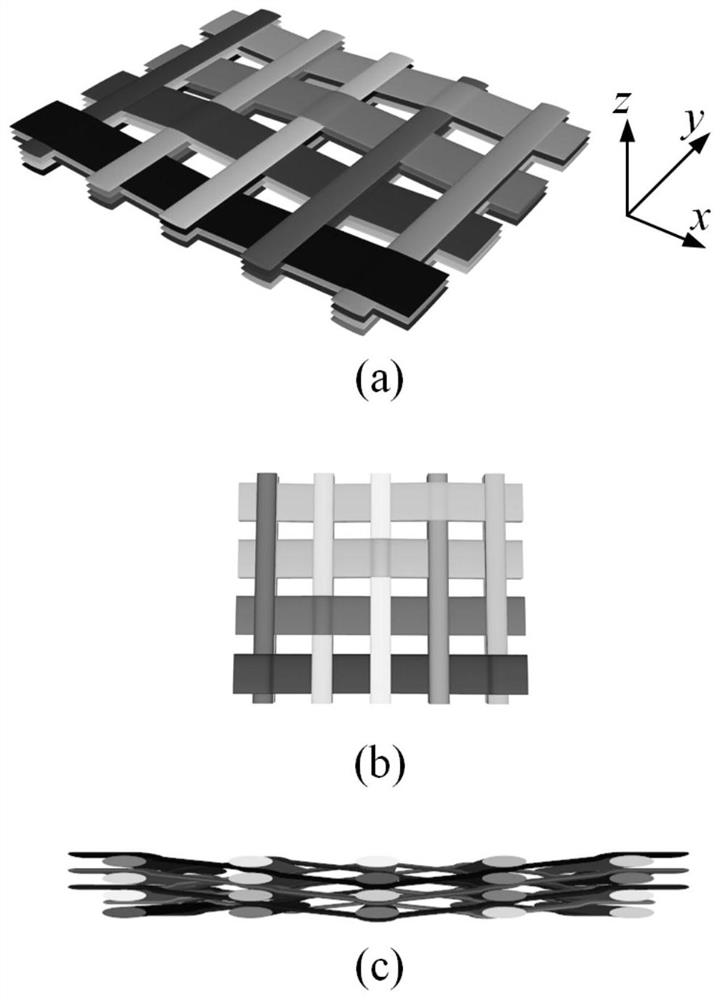

Composite shock-resisting structure and forming method thereof

ActiveCN106956472AExcellent impact damage resistanceMaximize mechanical propertiesLamination ancillary operationsLaminationFiberDamage tolerance

The invention relates to a composite shock-resisting structure and a forming method thereof, which aims at solving the problem of low-cost manufacturing of an annular shock-resisting structure, and belongs to the technical field of manufacturing of structural composite materials. The composite shock-resisting structure disclosed by the invention has an overlapped layer; the overlapped layer is of a gridding interweaved structure which is formed by interweaving and superposing adjacent laying pre-soaking tapes and a 2-dimensional laminating structure of a traditional composite laminating plate is changed into a 2.5-dimensional laminating structure, so that the interlayer performance and impact damage tolerance of the shock-resisting structure are increased by 15% or above and the shock resistance is better; annular layers of the composite shock-resisting structure have excellent fiber continuity and straightening property and the mechanical property of the composite material can be brought into play to the greatest extent; the overlapped layer tightly loops between the two annular layers, so that the damage tolerance and interlayer property of the overlapped layer can be further promoted; thus, the composite shock-resisting structure provided by the invention has the advantage of excellent shock and damage resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

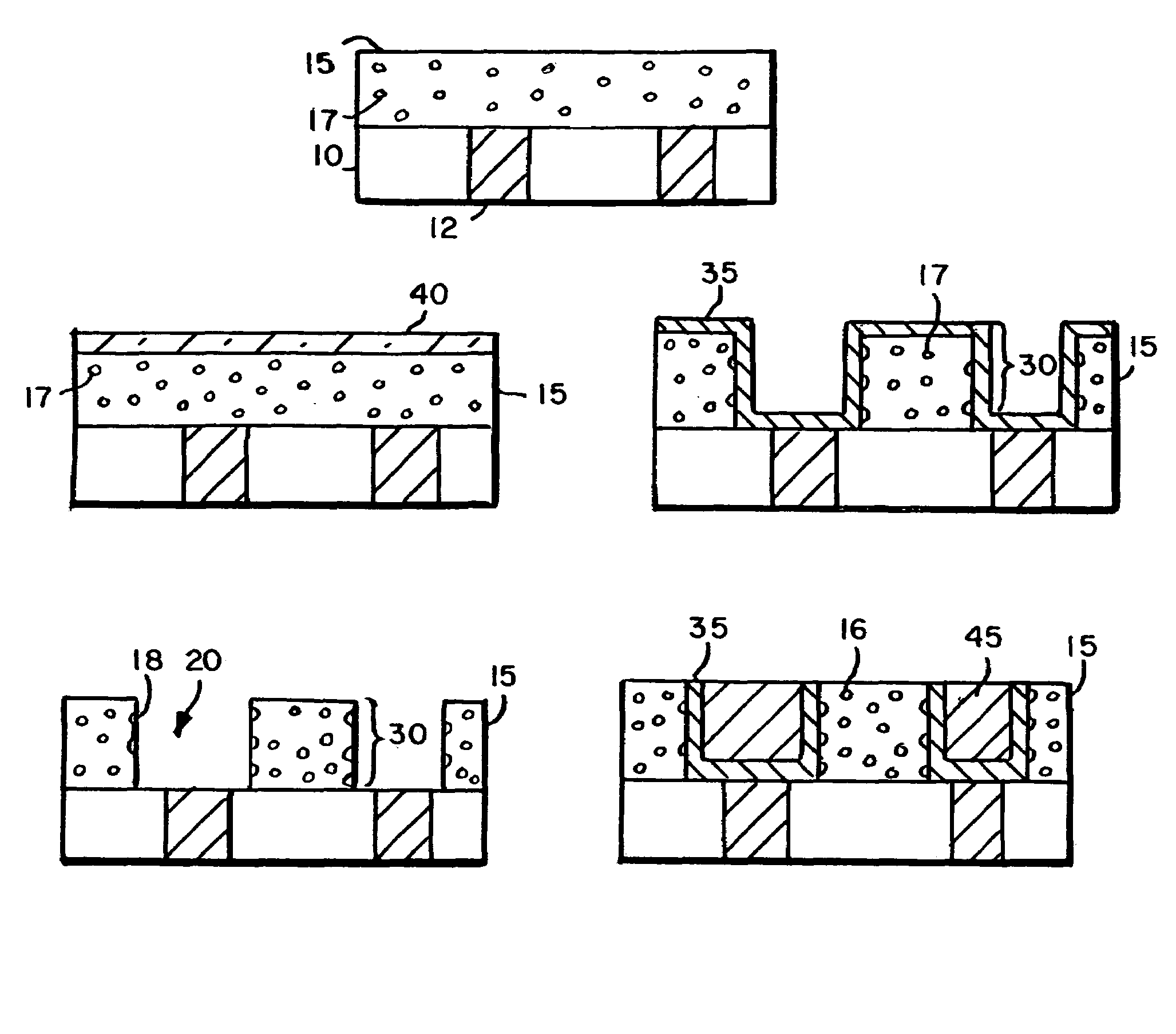

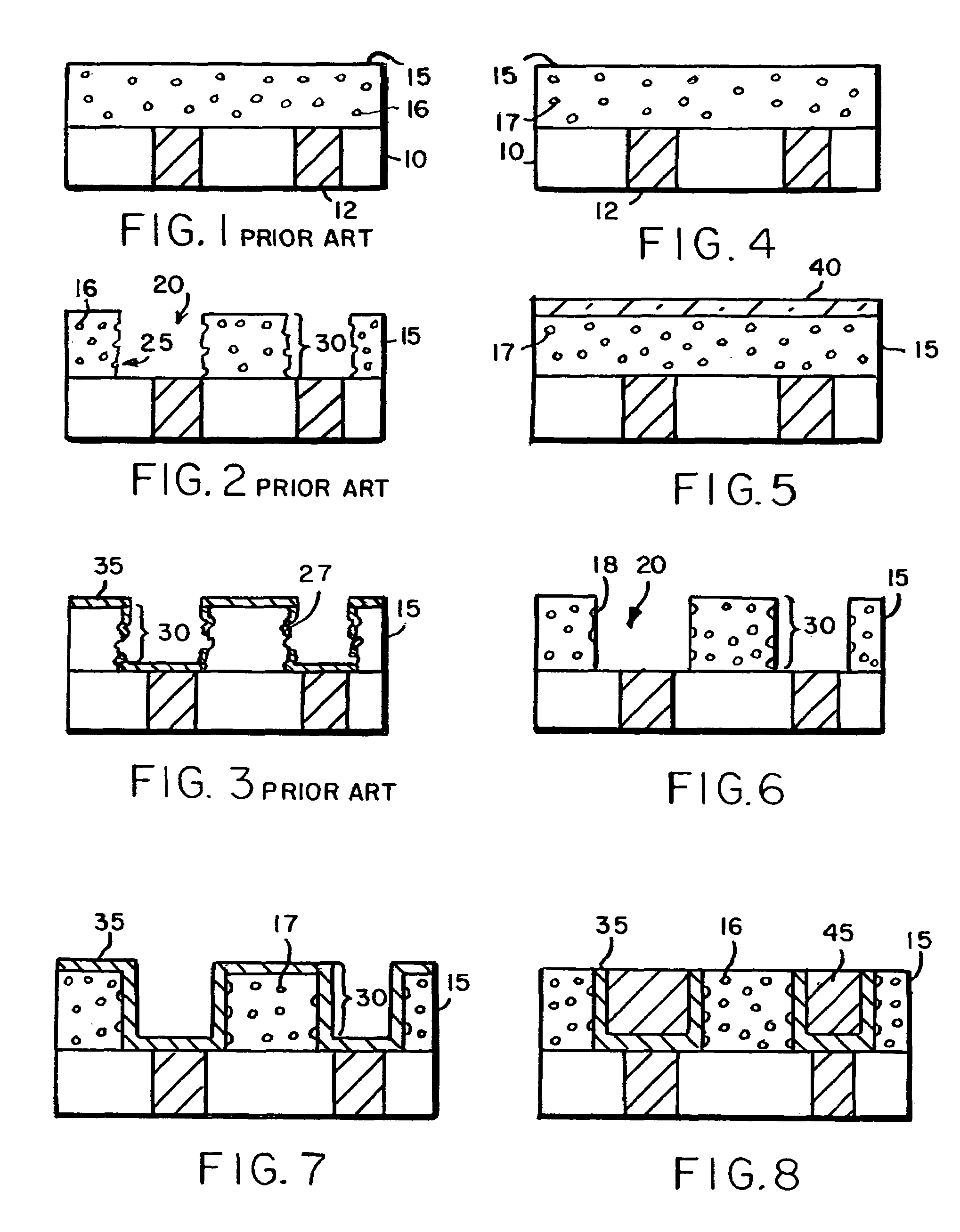

Electronic device manufacture

InactiveUS7294453B2Improve layer performanceLine edge or aperture sidewall roughness is reduced or eliminatedPorous dielectricsHigh frequency circuit adaptationsElectronMaterials science

Disclosed are methods of manufacturing electronic devices, particularly integrated circuits. Such methods include the use of low dielectric constant material prepared by using a removable porogen material.

Owner:SHIPLEY CO LLC

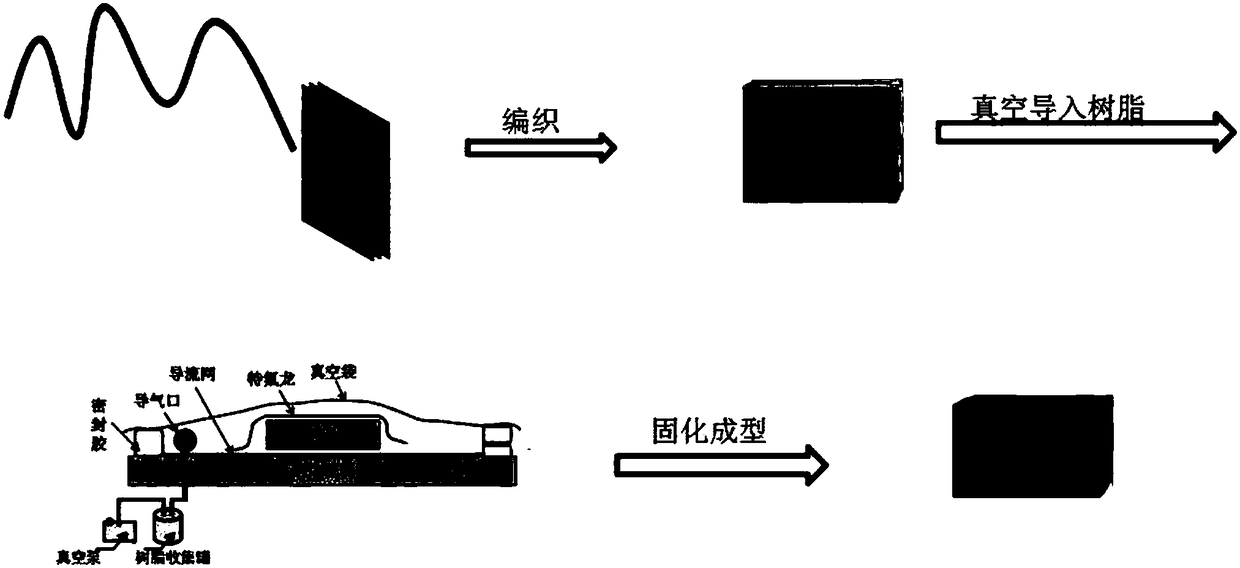

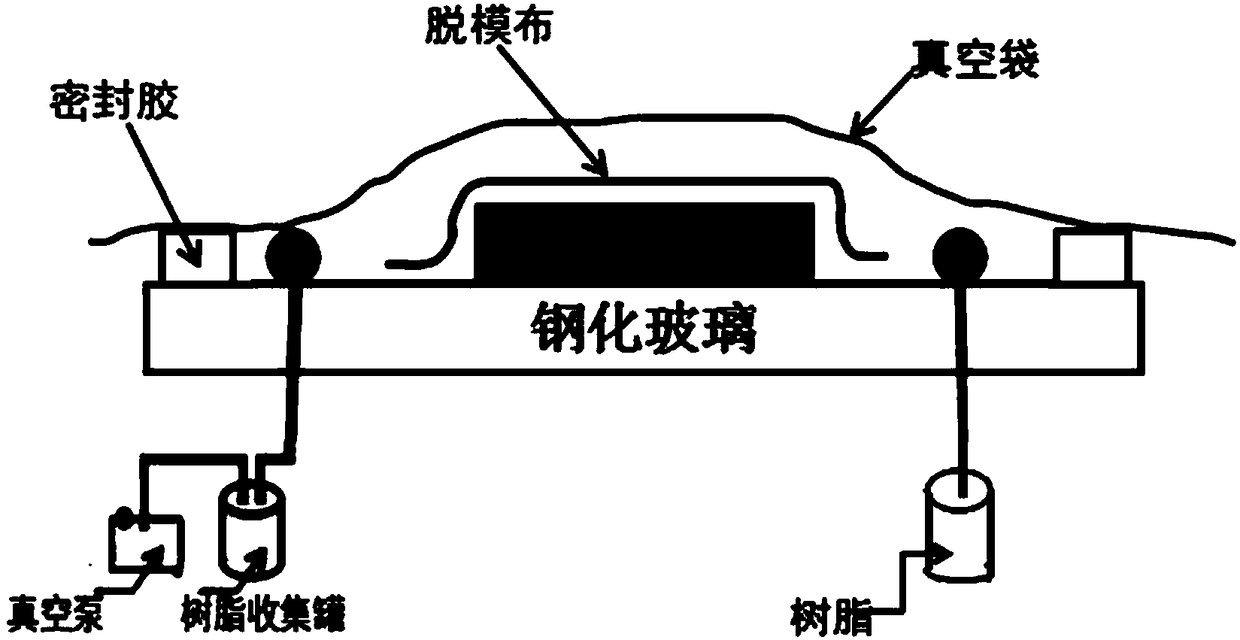

Molding method of unidirectional reinforced composite material with carbon nanotubes perpendicular to fiber direction

InactiveCN103286962AEasy to operateEasy to controlElectric fieldMechanical properties of carbon nanotubes

The invention belongs to the technical field of materials, relates to the technical field of fiber reinforced composite materials, and particularly relates to a molding method of a unidirectional reinforced composite material with carbon nanotubes perpendicular to a fiber direction. The molding method comprises the working procedures of glue solution preparation, nanotube orientation, glue dipping, winding and molding. The orderly arrangement of the carbon nanotubes (CNTs) in a glue solution is realized by applying a direct-current electric field to the CNTs dispersed in resin, and a direct-current electric field is applied again between an extrusion roller and a drying chamber to perform secondary orientation on the CNTs dipped on the surface of fiber bundles, so that the orientation degree of the CNTs in the composite material is high, and the interlayer mechanical properties and the electrical conductivity are substantially improved. The molding method of the unidirectional reinforced composite material with the carbon nanotubes perpendicular to the fiber direction provided by the invention is easy to operate and control, low in requirements on equipment transformation, less in investment, quick in effect, widely applicable to winding systems with a semi-dry process, and especially applicable to the molding of unidirectional prepregs and composite materials thereof.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

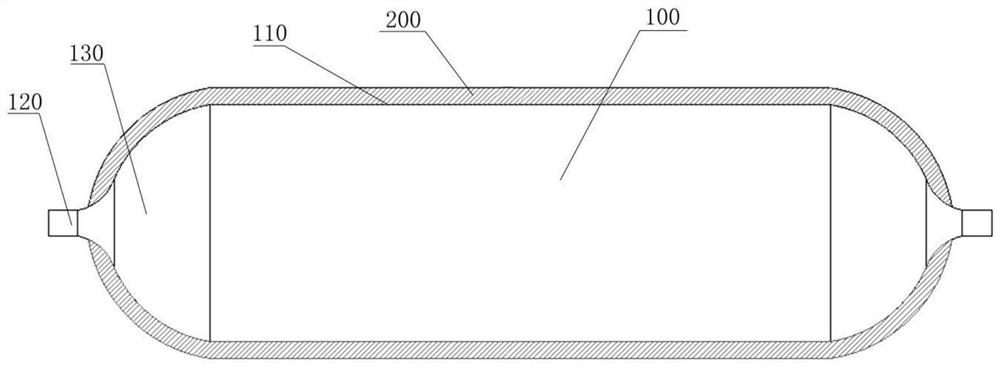

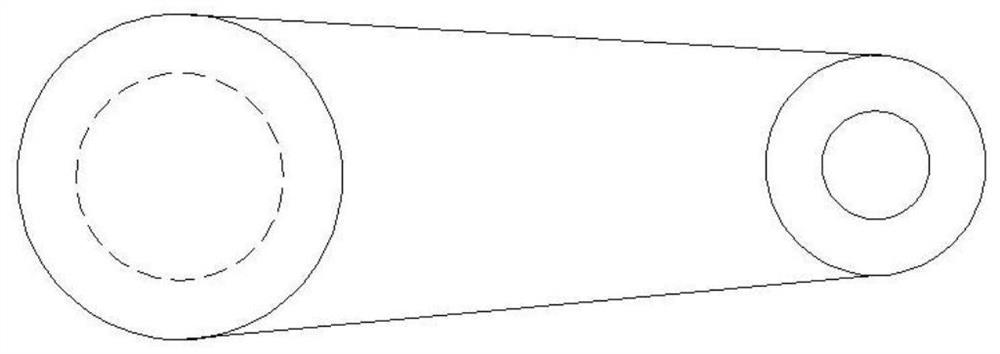

Fiber composite material high-pressure hydrogen storage cylinder and preparation method thereof

The invention provides a fiber composite material high-pressure hydrogen storage cylinder and a preparation method thereof. The preparation method comprises the steps that S100, a cylinder inner container is provided, and the cylinder inner container comprises an inner container body and a cylinder opening; S200, fiber yarns are adopted to conduct two-dimensional multi-spindle weaving on the outer surface of the cylinder inner container, so that a composite material weaving layer comprising multiple layers of fiber two-dimensional fabric is formed, the weaving angle of the fiber two-dimensional fabric at the position of the inner container body is 56-67 degrees, and the weaving angle of the fiber two-dimensional fabric at the position of the cylinder opening is 15-55 degrees; S300, in the composite material weaving layer, a sewing thread in the axis direction of the cylinder is additionally arranged between every 3-5 layers of adjacent fiber two-dimensional fabric for fixing, and a woven preformed body is obtained; and S400, resin is adopted to cure the woven preformed body through a vacuum bag vacuum resin infusion method, and the fiber composite material high-pressure hydrogen storage cylinder with the fiber composite material layer is obtained. The fiber composite material high-pressure hydrogen storage cylinder is light in weight, high in strength, resistant to fatigue, large in structural rigidity and good in high and low temperature impact resistance stability.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

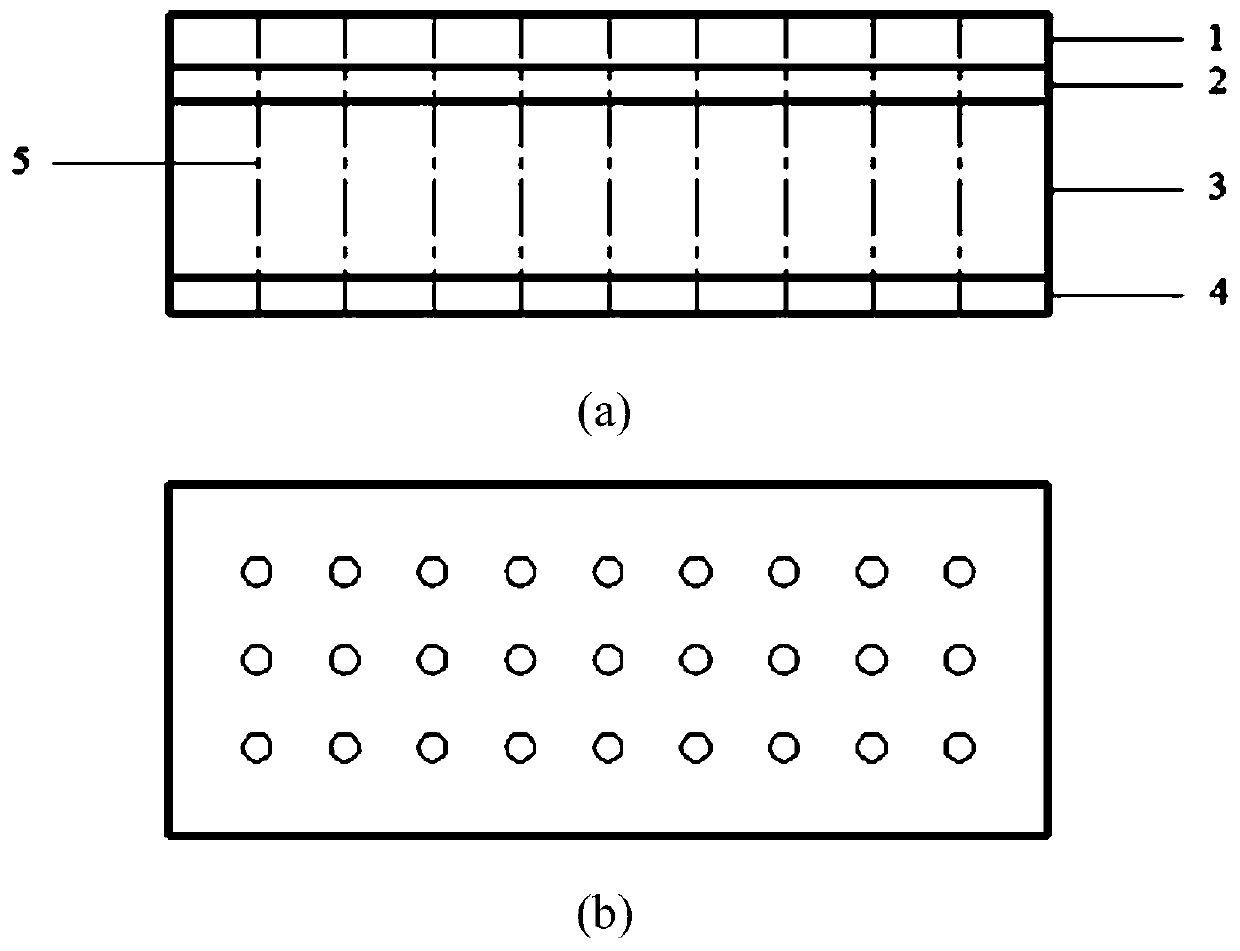

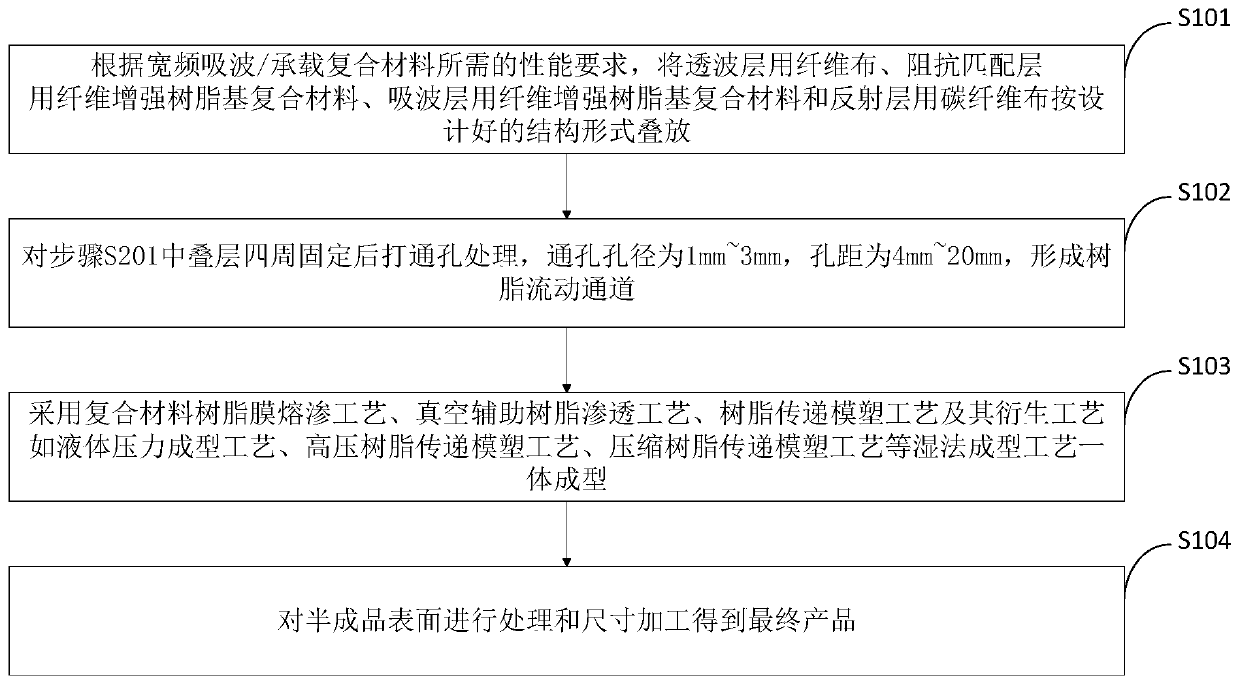

Resin column reinforced broadband wave-absorbing/bearing composite material and preparation method thereof

InactiveCN110920158AStable electrical performanceImprove layer performanceLamination ancillary operationsSynthetic resin layered productsBroadbandMechanical properties of carbon nanotubes

The invention belongs to the technical field of wave-absorbing materials and discloses a resin column reinforced broadband wave-absorbing / bearing composite material and a preparation method thereof. The preparation method comprises the steps of sequentially stacking an impedance matching layer playing a role in impedance gradual change, a wave-absorbing layer containing an absorbent and a reflecting layer are on a lower portion of a wave-transmitting layer to form a laminated structure, and punching through holes in the formed laminated structure, enabling resin to flow into the through holesby adopting a wet forming process, and forming resin column structures penetrating through the whole laminated structure at the positions of the through holes. According to the invention, the throughholes are punched in advance in the thickness direction of a multi-layer structure prefabricated body, the process characteristics of wet molding of the composite material are used, the resin is poured into the through holes in the prefabricated body filling process to form Z-direction resin column structures, the effect of enhancing the interlayer performance is achieved, the forming process is simple, the mechanical property is excellent, the interlayer performance is greatly enhanced through the resin column structures formed at the through holes, and the defect that a current wave-absorbing composite material wave-absorbing layer is easily layered can be effectively overcome.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

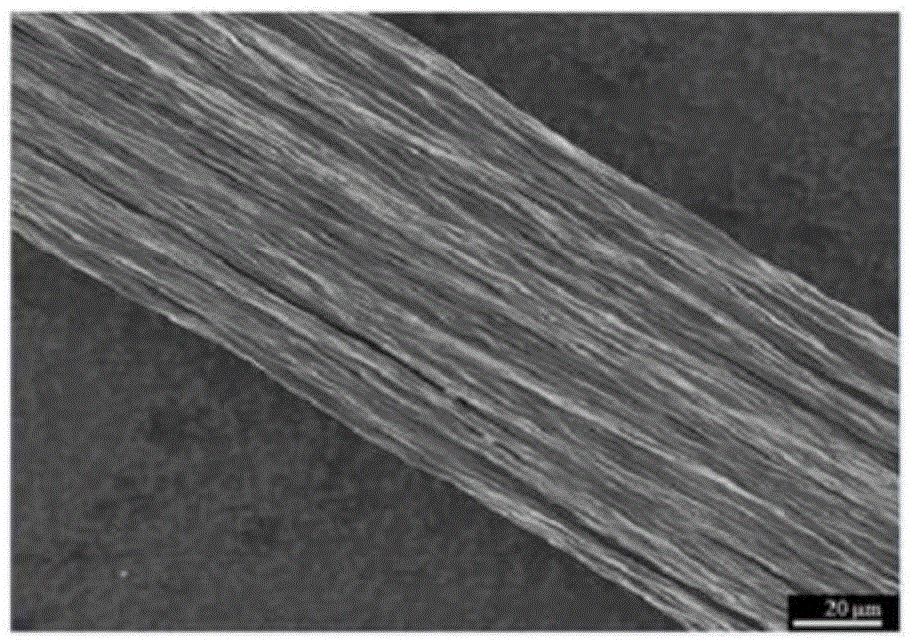

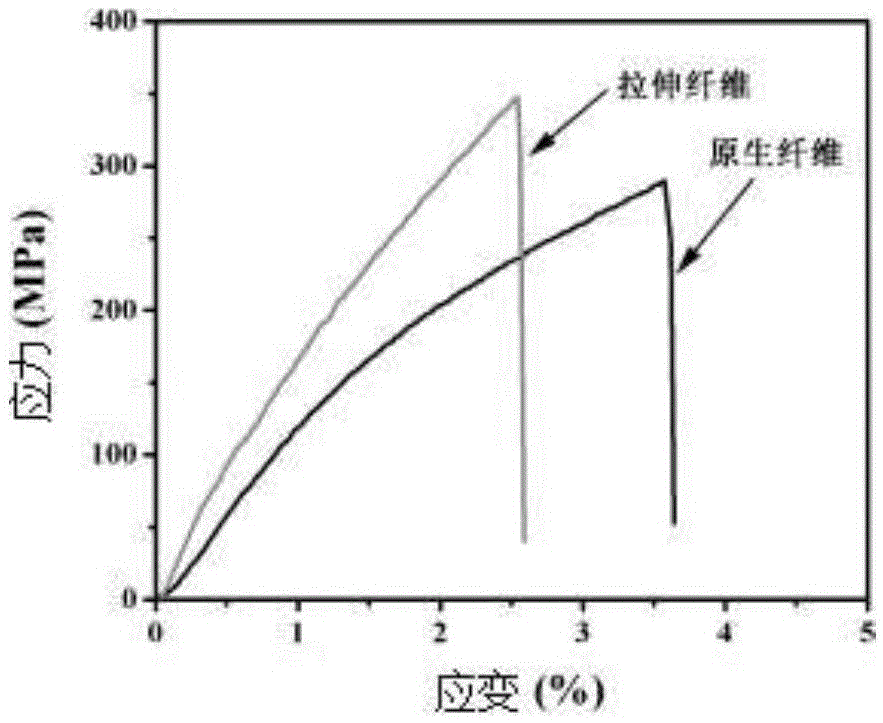

Preparing method for oriented graphene oxide fibers

InactiveCN105603580AImprove mechanical propertiesEffective stackingFibre chemical featuresWet spinning methodsFiberCvd graphene

The invention belongs to the technical field of preparation of graphene fiber materials and particularly relates to a preparing method for oriented graphene oxide fibers. The preparing method comprises the following steps that graphene oxide is prepared with lamellar graphene as a raw material, and a graphene oxide spinning solution is prepared; with a wet spinning method, the graphene oxide spinning solution flows into a solidifying solution, and primary graphene oxide fibers are prepared; at a certain temperature, the graphene oxide fibers are subjected to radial stretching and drying, and the oriented graphene oxide fibers are obtained. The preparing method is easy to implement and low in cost, the stretching rate of the fibers can be precisely controlled, and a good stretching effect can be achieved. The oriented graphene oxide fibers prepared through the method are significantly improved on the aspect of tensile strength compared with the primary graphene oxide fibers, a simple and effective method is provided for preparing high-performance fiber materials based on graphene, and the application of the graphene fibers in practical production and living can be promoted.

Owner:YANCHENG ZENGCAI SCI & TECH

Integral preparation method of ceramic-based composite lattice structure

ActiveCN110204319AImprove use reliabilityImprove interlayer strengthMould fastening meansBatch productionCeramic matrix composite

The invention provides an integral preparation method of a ceramic-based composite lattice structure. An integral forming mold for a composite lattice structure fiber preform is used to realize the simple preparation of the ceramic-based composite corrugated plate lattice structure, improve the interlayer performance and achieve a high profile dimension control precision, batch production and product net-forming. The prepared ceramic-based composite corrugated plate lattice structure has the advantages of good high temperature resistance, good oxidation resistance and good mechanical properties, can be reused, and is especially suitable for being applied to the high temperature (1000-1650 DEG C) oxidizing environment.

Owner:湖南远辉复合材料有限公司

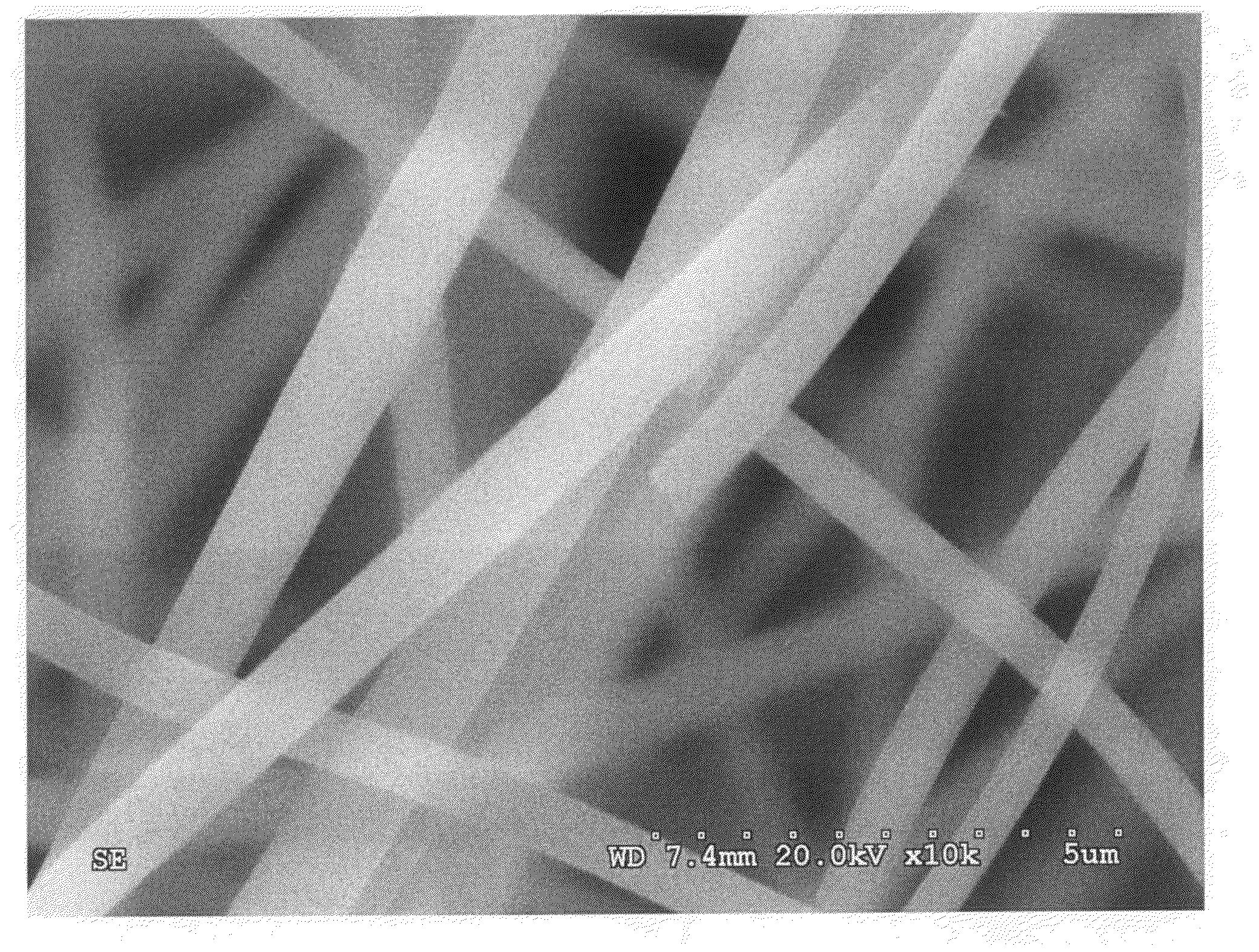

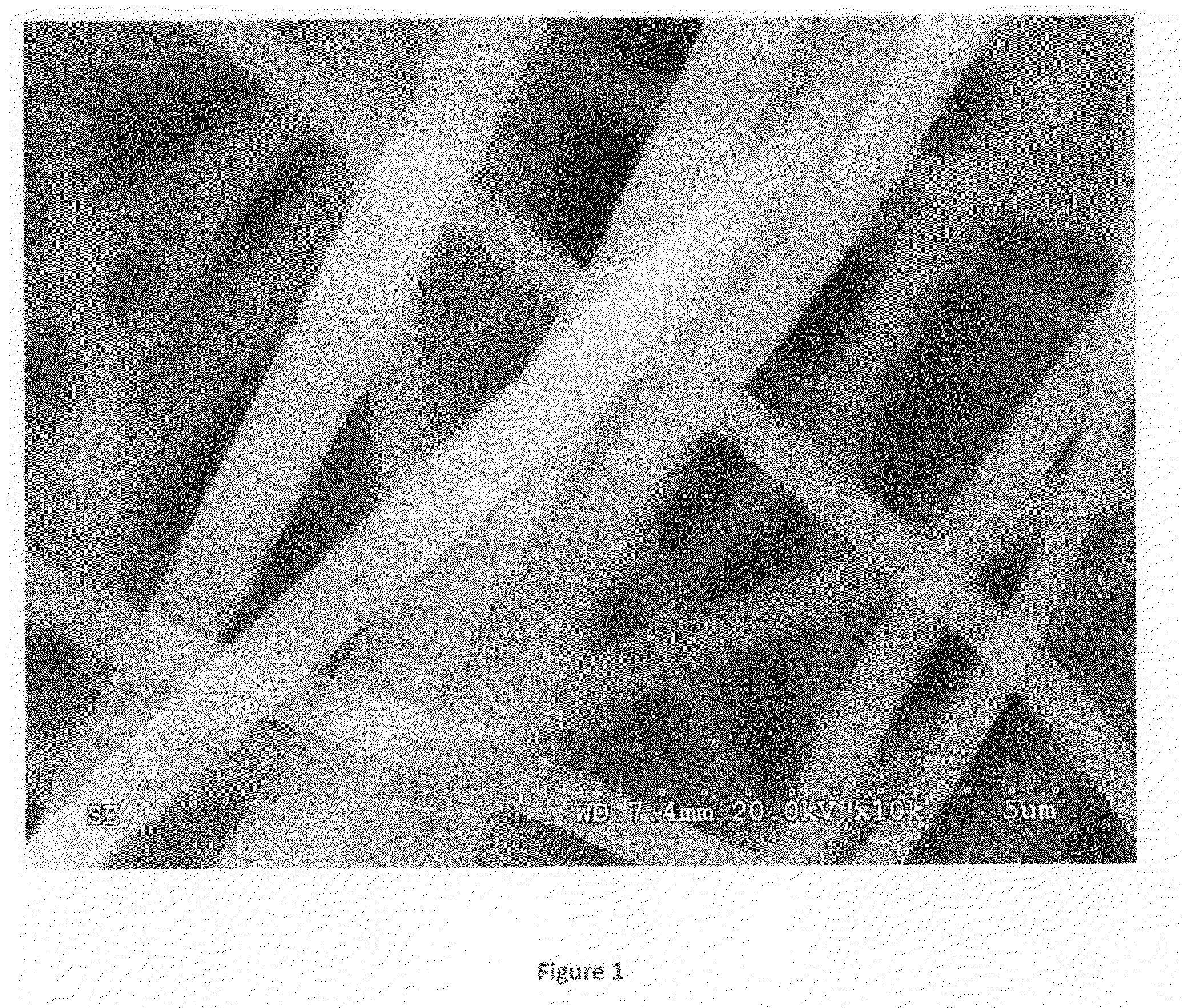

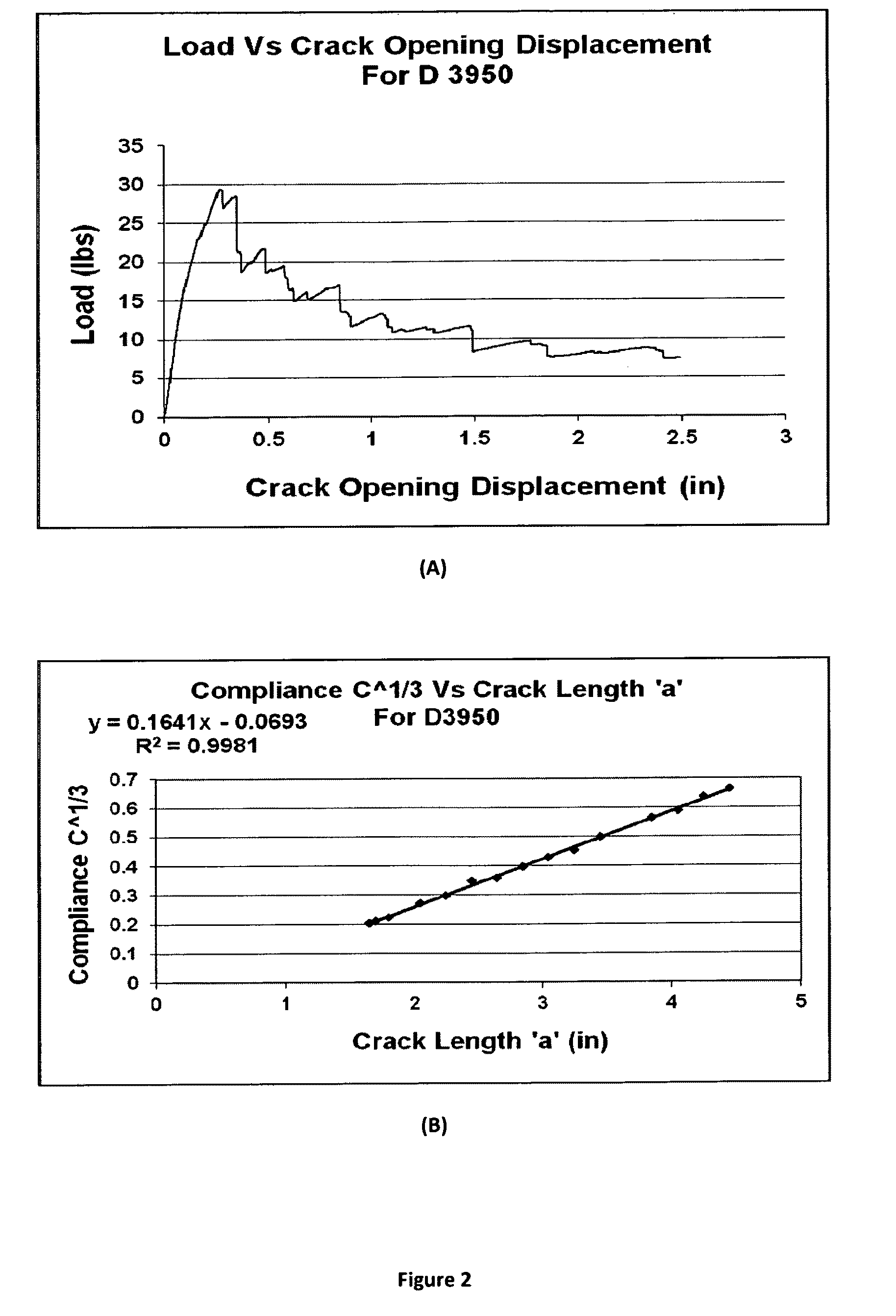

Electrospun NANO fabric for improving impact resistance and interlaminar strength

InactiveUS20110064949A1Improve layer performanceImprove propertiesElectric discharge heatingInorganic material artificial filamentsUltimate tensile strengthMaterials science

The present invention provides a process for forming a composite material having improved interlaminar properties.

Owner:NORTH CAROLINA AGRICULTURAL AND TECHNICAL STATE UNIVERSITY

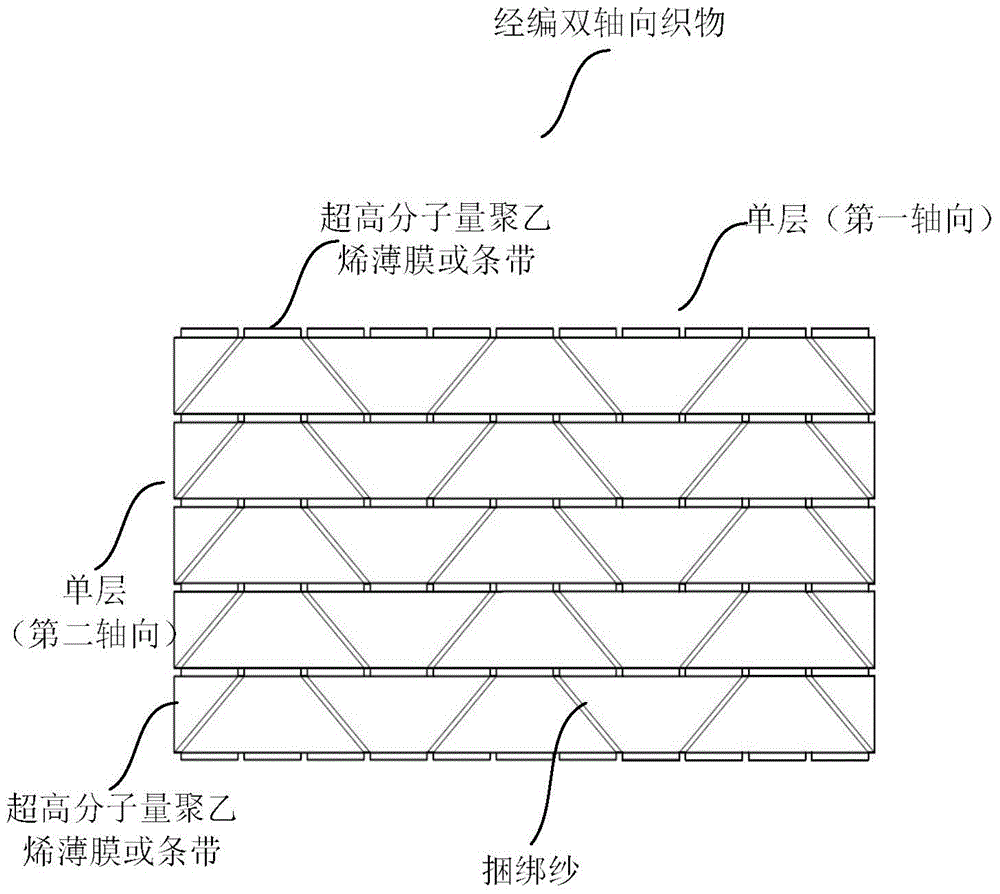

+/-45-degree angle biaxial carbon fiber warp-knitted cloth

InactiveCN102454034AIncrease frictionImprove layer performanceLayered productsWarp knittingFiberTear resistance

The invention relates to a + / -45-degree angle biaxial carbon fiber warp-knitted cloth and belongs to the field of carbon fiber composites. The cloth is characterized in that one layer of parallel straight carbon fiber yarns are uniformly arranged in the direction at an angle of +45 degrees; the other layer of parallel straight carbon fiber yarns are uniformly arranged in the direction at an angle of minus 45 degrees; the models of the carbon fiber yarns are 3-50K; the mass per unit area of each layer of the parallel straight and uniformly arranged carbon fiber yarns is not less than 75g / m<2> and not more than 400g / m<2>; the laying density of the warp knitting threads is five threads per inch; and the mass per unit area of the laid warp knitting threads is not less than 5g / m<2> and not more than 12g / m<2>. The cloth has the following beneficial effects: the excellent performances of each component of the carbon fibers can be fully utilized, so that the tensile strength, the shear performance and the tear resistance are improved; and due to yarn binding, the friction between the yarns is improved and the interlayer performance of the fabric is enhanced, thus expanding the application range of the carbon fibers.

Owner:WEIHAI GUANGWEI COMPOSITES

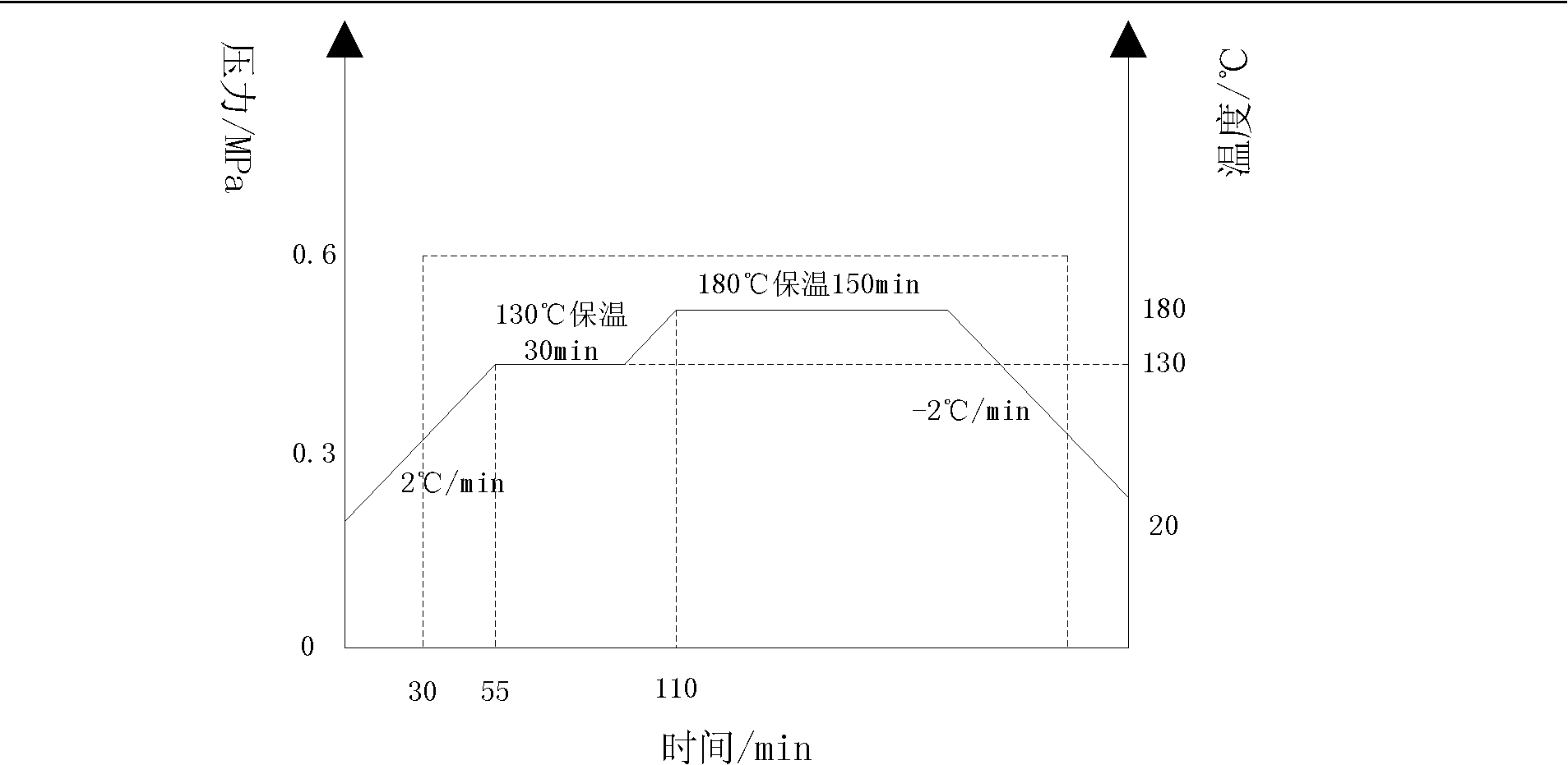

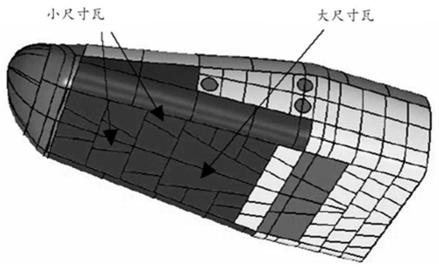

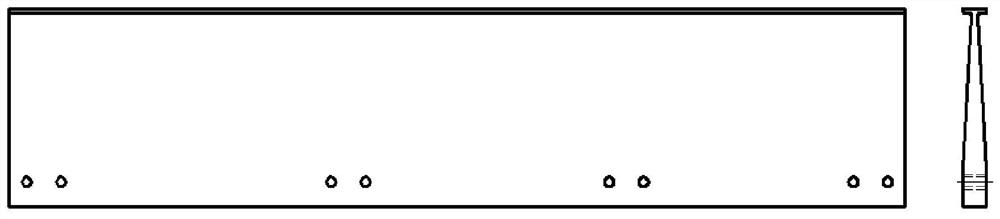

Edging slender composite material airfoil and forming method thereof

ActiveCN111746000AImprove layer performanceMake up for the shortcomings of weak interlayer performanceDomestic articlesCarbon fibersFibrous body

The invention provides an edging slender composite material airfoil and forming method thereof. The edging slender composite material airfoil is subjected to ladder-like symmetrical overlaying with asection center through a carbon fiber UD cloth, after overlaying, Z-direction seaming is executed for toughening, and an autoclave / VARTM combined technology of injecting resin into a prefabricated reinforcement and curing based on the autoclave is used to realize forming. According to the invention, for the edging slender composite material airfoil, integral overlaying integrated forming is used,seaming for toughening is executed in overlaying Z direction, forming is realized through the autoclave / VARTM technology, a defect of relatively weaker interlayer performance of a product prepared through the conventional overlaying technology is made remedied, interlayer performance is improved, relatively higher fiber volume content and product forming quality are kept, and comprehensive performance of the composite material airfoil is guaranteed.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

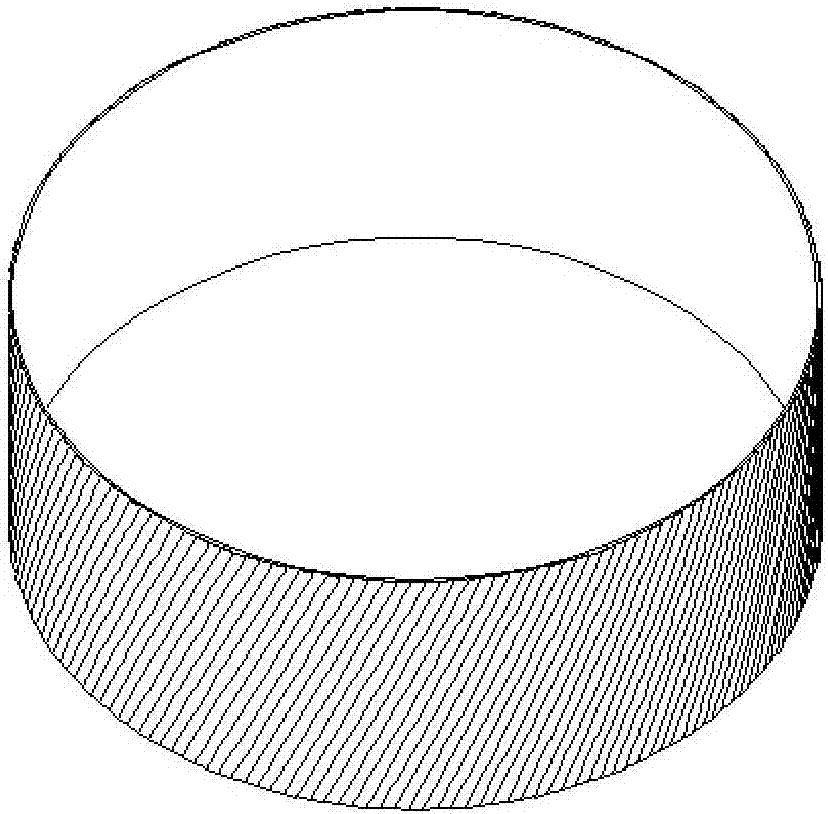

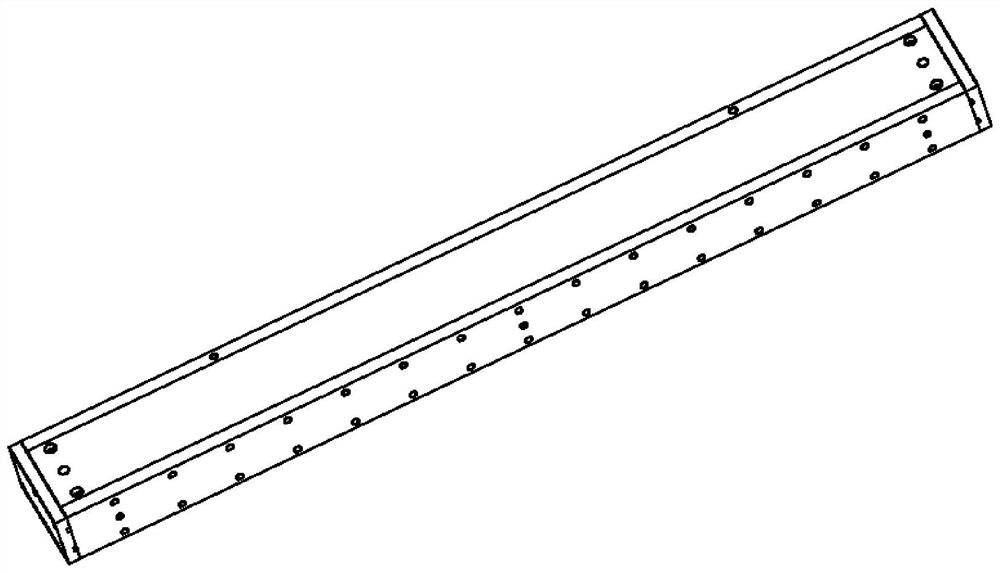

Tubular three-dimensional fabric and rapid forming preparation method thereof

The invention discloses a tubular three-dimensional fabric and a rapid forming preparation method thereof. The tubular three-dimensional fabric is composed of a multi-layer fabric and normal fibers, wherein the multi-layer fabric is formed by overlapping single-layer copied woven sleeves designed according to fabric performance requirements layer by layer; the single-layer copied woven sleeves can be woven and formed through one or more continuous weaving processes according to designed weaving parameters; and the normal fibers can be introduced through one or more processes of sewing, Z-Pin, needling and the like. The tubular three-dimensional fabric disclosed by the invention has the advantages of various weave structures, large fabric size control range, various section shapes, strong designability, strong universality, suitability for continuous weaving, excellent interlayer performance and the like, so that the fabric can meet the molding requirements of composite materials in application requirements of materials with complex shapes and complex stress loads; and the fabric can be widely applied to the fields of spaceflight, aviation, ships, automobiles, buildings and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

Electronic device manufacture

ActiveUS7163780B2Improve layer performanceLine edge or aperture sidewall roughness is reduced or eliminatedPorous dielectricsLayered productsElectronMaterials science

Disclosed are methods of manufacturing electronic devices, particularly integrated circuits. Such methods include the use of low dielectric constant material prepared by using a removable porogen material.

Owner:SHIPLEY CO LLC

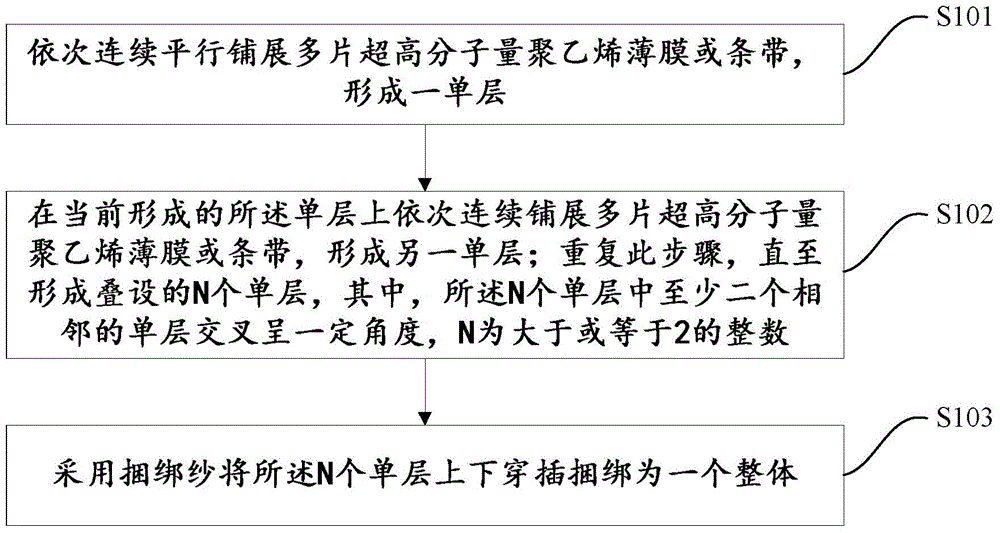

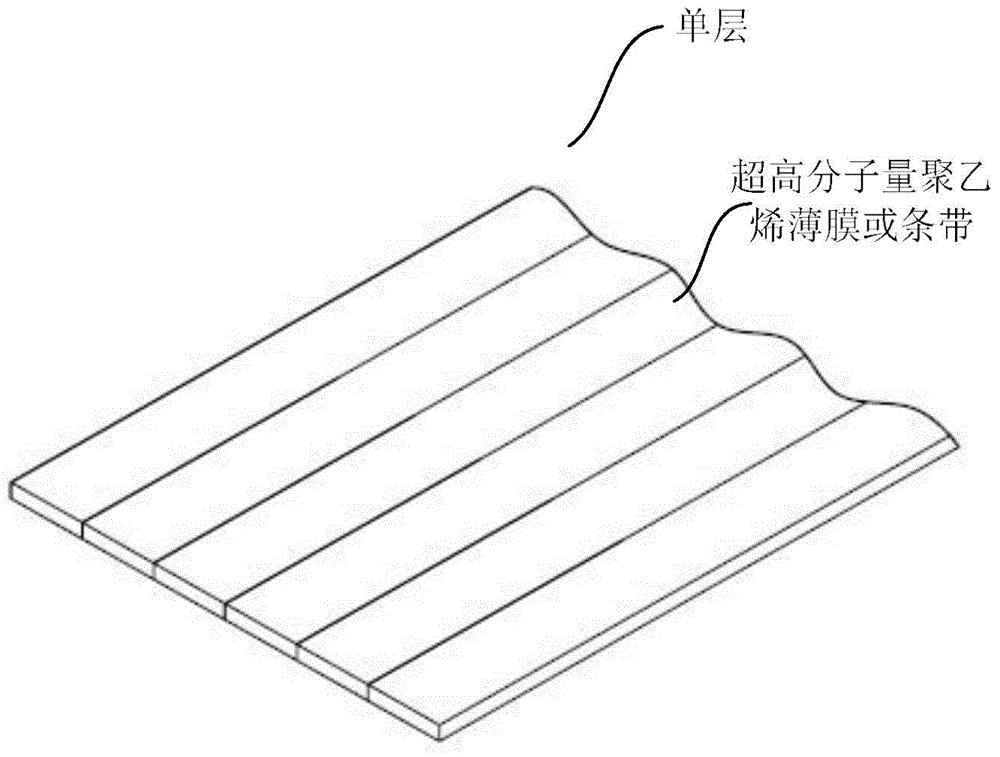

Fabric and manufacturing method thereof, and protection product

ActiveCN104964606AImprove layer performanceEasy to stretchSynthetic resin layered productsWarp knittingYarnEngineering

The invention discloses a fabric and a manufacturing method thereof, and a protection product. The manufacturing method for the fabric comprises: continuously parallelly spreading a plurality of ultra-high molecular weight polyethylene films or strips in sequence to form a single layer; continuously spreading a plurality of ultra-high molecular weight polyethylene films or strips in sequence on the formed single layer, to form another single layer; and repeating the step until N stacked single layers are formed, in the N single layers, at least two adjacent single layers intersecting and being in a certain angle, wherein the N is an integer larger than or equal to 2; and using binder yarns to pass through the upper parts and the lower parts of the N single layers to bind the N single layers to an integrated body. The fabric has good stretching, tensile, and shock resistance, and other properties. The protection product made based on the fabric has good bulletproof property.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

Three-dimensional preformed composite fiber and machining process thereof

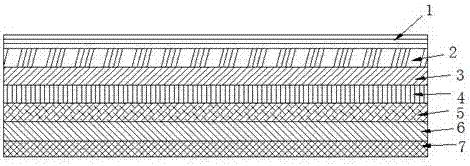

The invention discloses a three-dimensional preformed composite fiber and a machining process thereof, and relates to the technical field of textiles. The fiber comprises a 0-degree layer, a short cut yarn layer, a +45-degree layer, a 90-degree layer, a guide sandwich layer, a - 45-degree layer and a surface layer, wherein the 0-degree layer, the short cut yarn layer, the +45-degree layer, the 90-degree layer, the guide sandwich layer, the minus 45-degree layer and the surface layer are arranged from top to bottom in sequence. By adopting the fiber, the stability of a glass fiber / carbon fiber textile can be greatly improved, the tensile strength of the textile can be also improved, the textile is relatively high in bending strength, the product pass percent is greatly increased, and relatively good practicability is achieved.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Thin wear resistant coating

InactiveUS8507108B2Improve layer performancePigmenting treatmentOther chemical processesMilling cutterWear resistant

The present invention relates to a cutting tool insert, solid end mill, or drill, comprising a substrate and a coating. The coating is composed of one or more layers of refractory compounds of which at least one layer comprises a h-Me1Me2X phase, where Me1 is one or several of the elements V, Cr, Nb, and Ta and Me2 is one or several of the elements Ti, Zr, Hf, Al, and Si and X is one or several of the elements N, C, O or B. The ratio R=(at-% X) / (at-% Me1+at-% Me2) of the h-MelMe2X phase is between 0.5 and 1.0, preferably between 0.8 and 1.0 and X contains less than 30 at-% of O+B. This invention is particularly useful in metal cutting applications where the chip thickness is small and the work material is hard e.g. copy milling using solid end mills, insert milling cutters or drilling of hardened steels.

Owner:SECO TOOLS AB

Prepreg with electromagnetic shielding function and preparation method thereof

The invention belongs to the technical field of functional composite materials, and particularly relates to a prepreg with an electromagnetic shielding function and a preparation method thereof. The preparation method includes the specific steps that a resin matrix, a flexibilizer and nanofiller are mixed to be uniform, then the mixture is compounded with a fiber layer and an electromagnetic shielding layer through a hot melting method preimpregnation process, and the electromagnetic shielding prepreg is obtained. The prepreg has the characteristics of excellent manufacturability, stable electromagnetic shielding performance, high shielding effect and good mechanical properties. An electromagnetic shielding composite material product prepared from the prepreg has the characteristics of reliable shielding effect and no process influence, and can be used for preparing a composite material product with an electromagnetic shielding function.

Owner:嘉兴得一复合材料科技有限公司

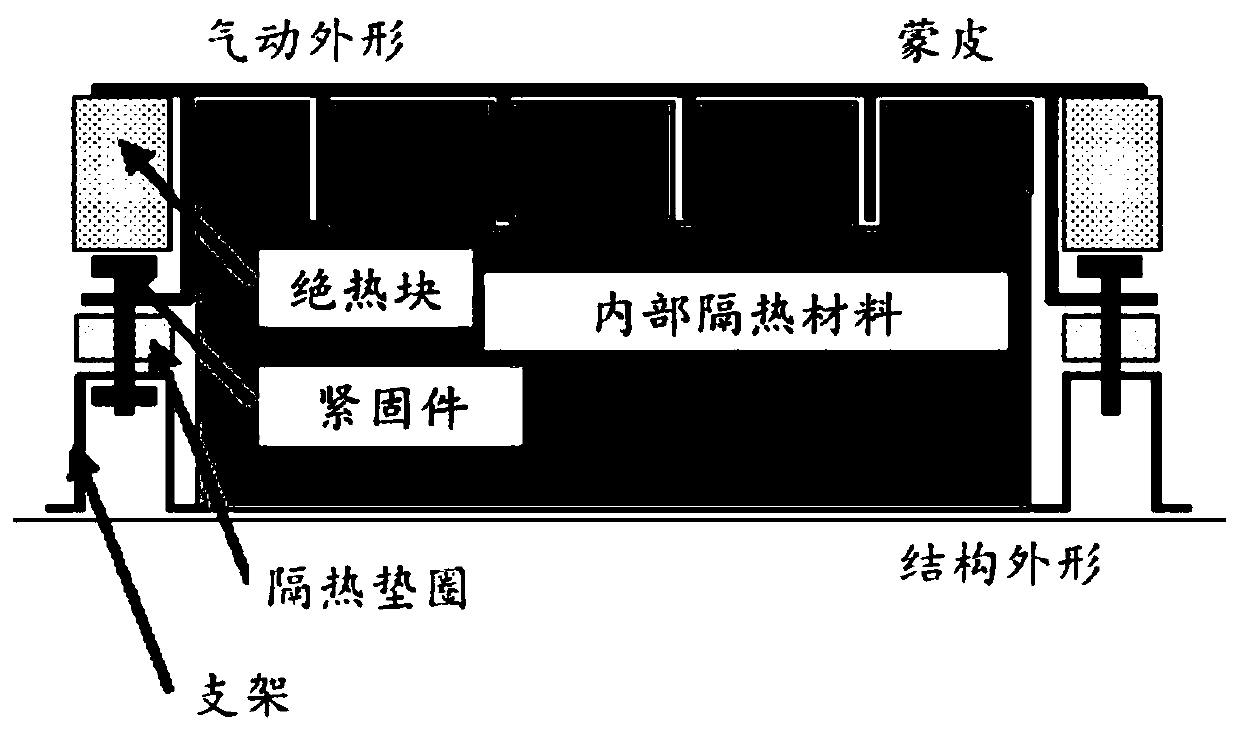

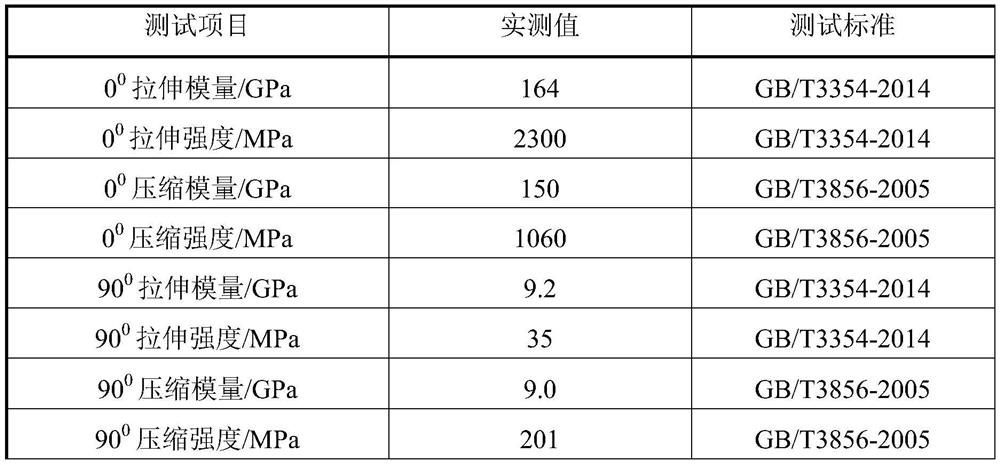

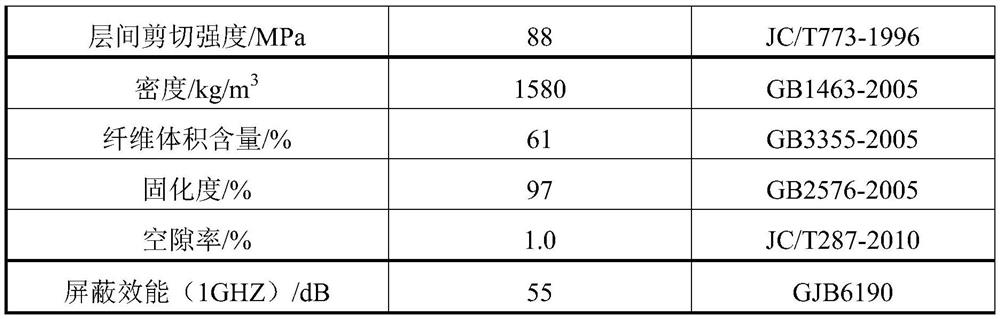

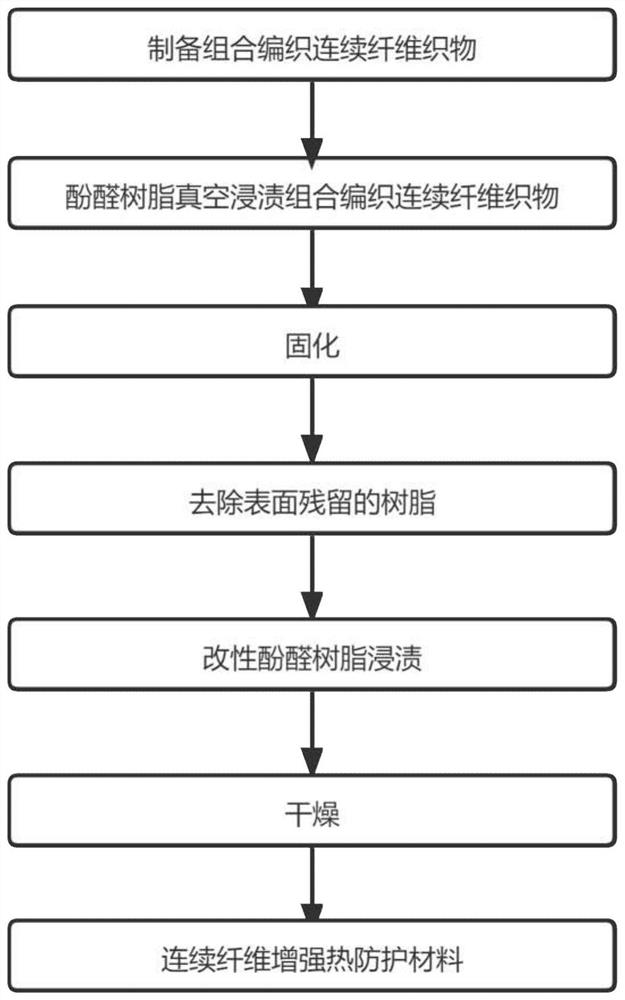

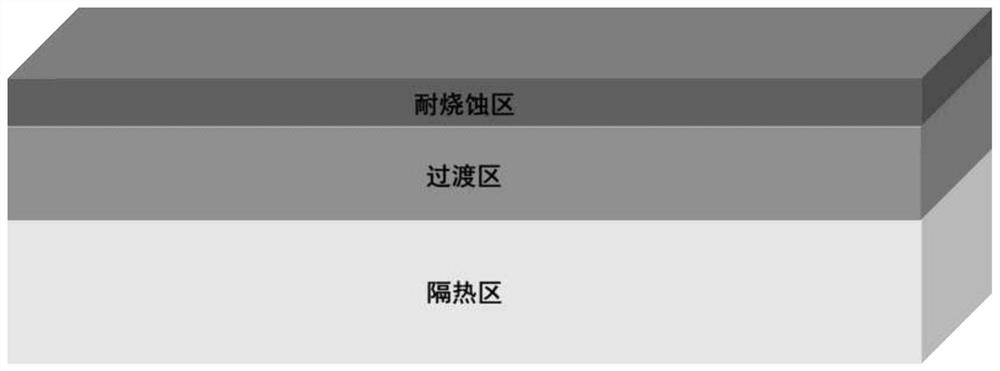

Continuous fiber reinforced thermal protection material and preparation method thereof

PendingCN113997652AImprove stabilityGood heat insulationSynthetic resin layered productsThermal insulationFlight vehicle

The invention discloses a continuous fiber reinforced thermal protection material and a preparation method thereof. The continuous fiber reinforced thermal protection material comprises an ablation-resistant area, a transition area and a thermal insulation area from surface to inside; the transition area and the thermal insulation area are formed by compounding and curing continuous fiber fabric and thermosetting resin; the ablation-resistant area is formed by compounding and curing a continuous fiber fabric and thermosetting resin and then impregnating with modified phenolic resin, the fiber volume fraction of the ablation-resistant area is greater than that of the transition area, and the fiber volume fraction of the transition area is greater than that of the thermal insulation area. The continuous fiber reinforced integrally-formed multifunctional thermal protection material provided by the invention has the excellent characteristics of light weight, surface ablation resistance, low internal heat conductivity coefficient, strong pyrolysis heat absorption, good surface heat protection effect and the like, and has a reusable application value in a thermal protection system of a hypersonic aircraft.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

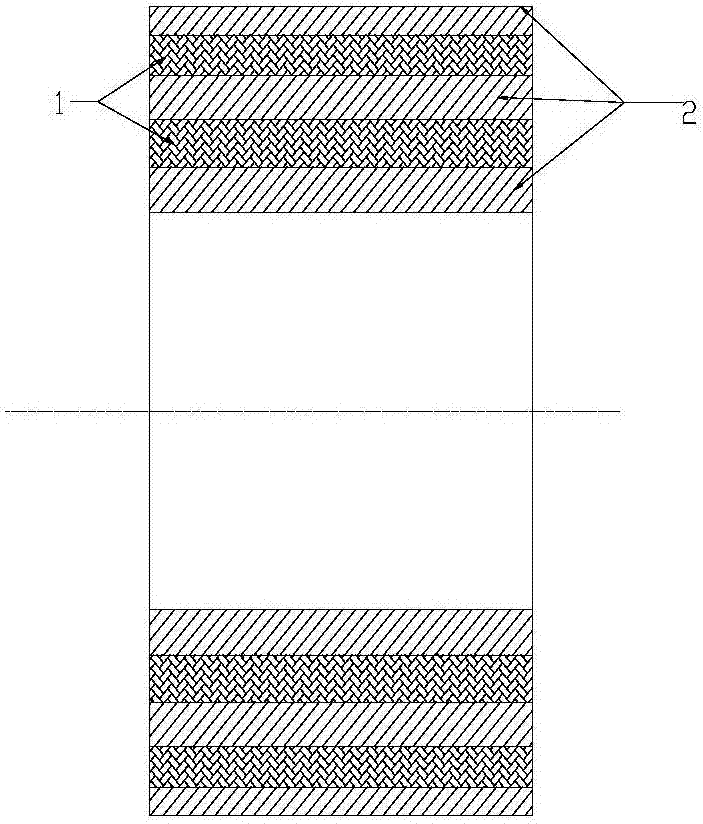

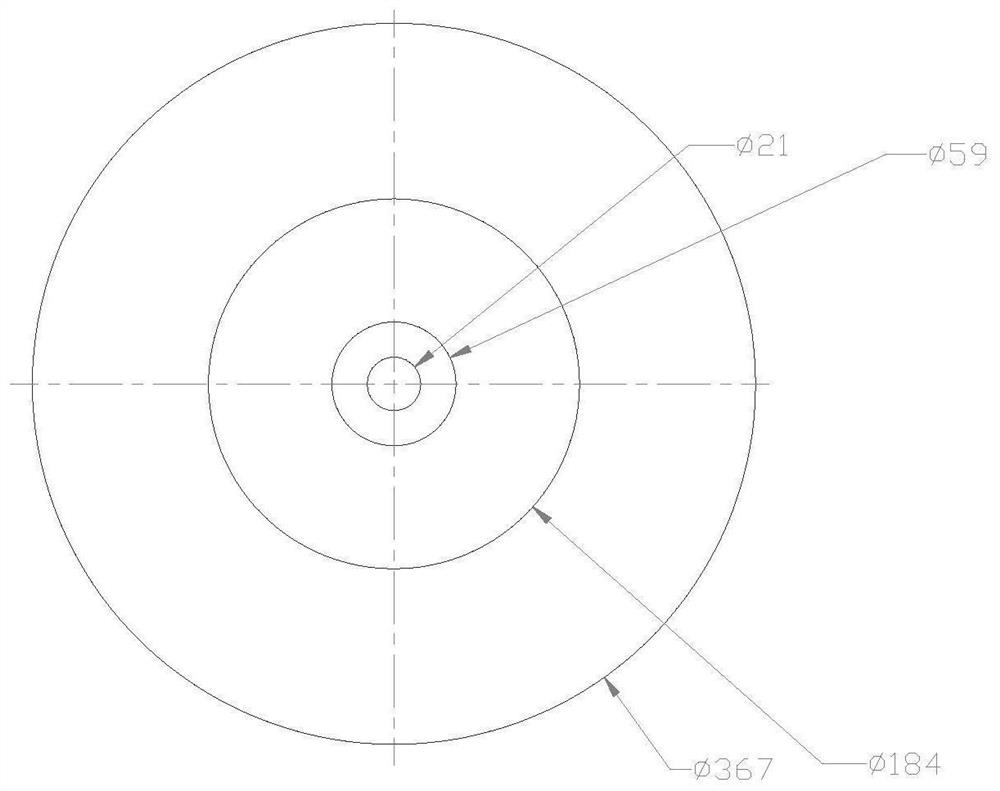

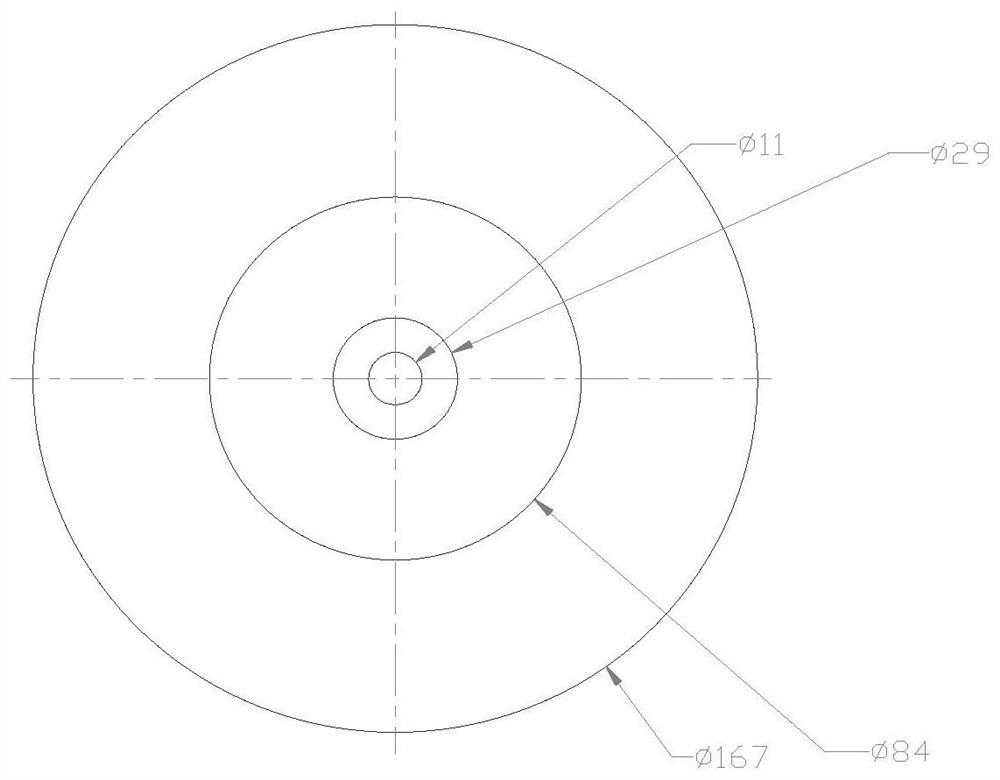

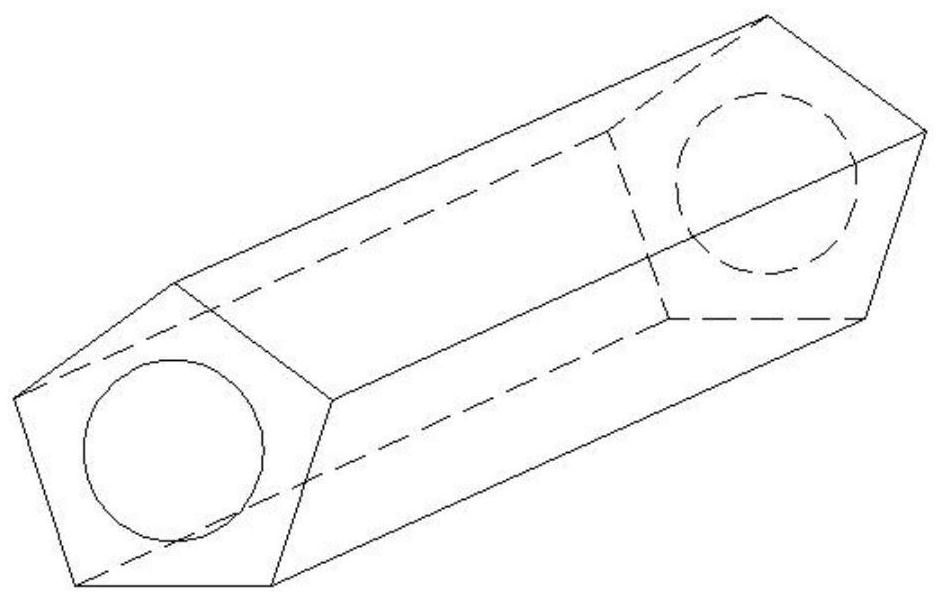

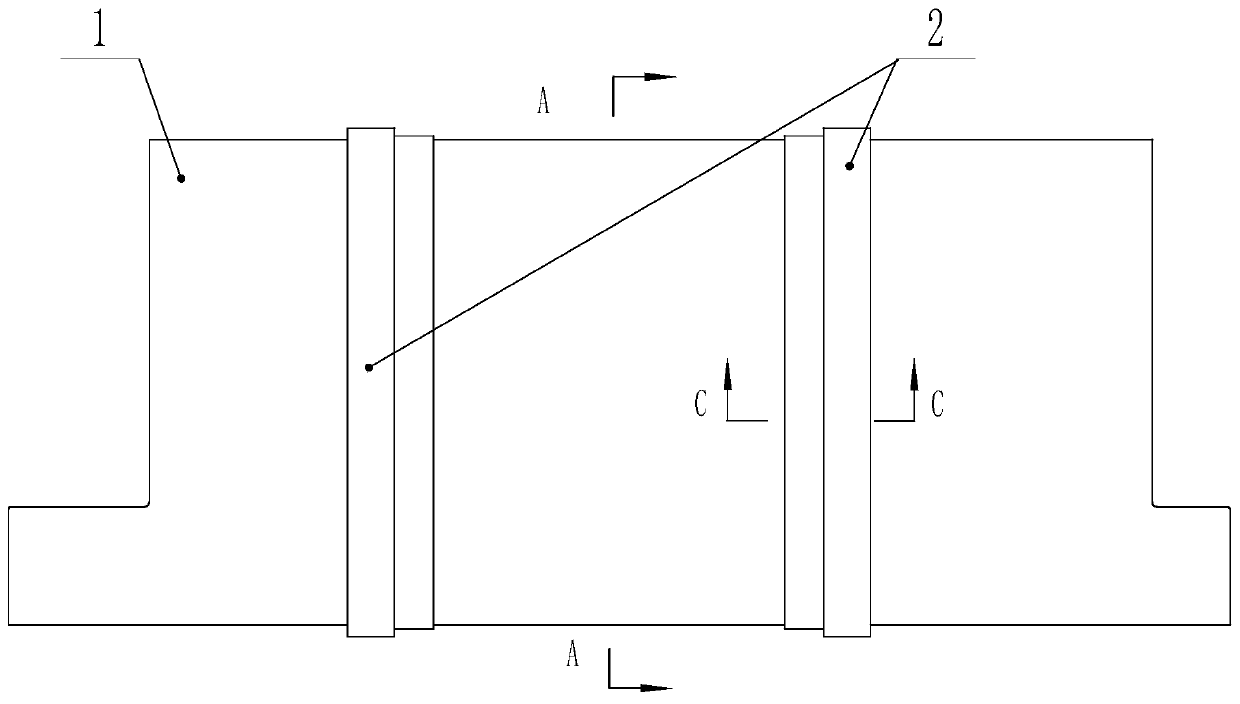

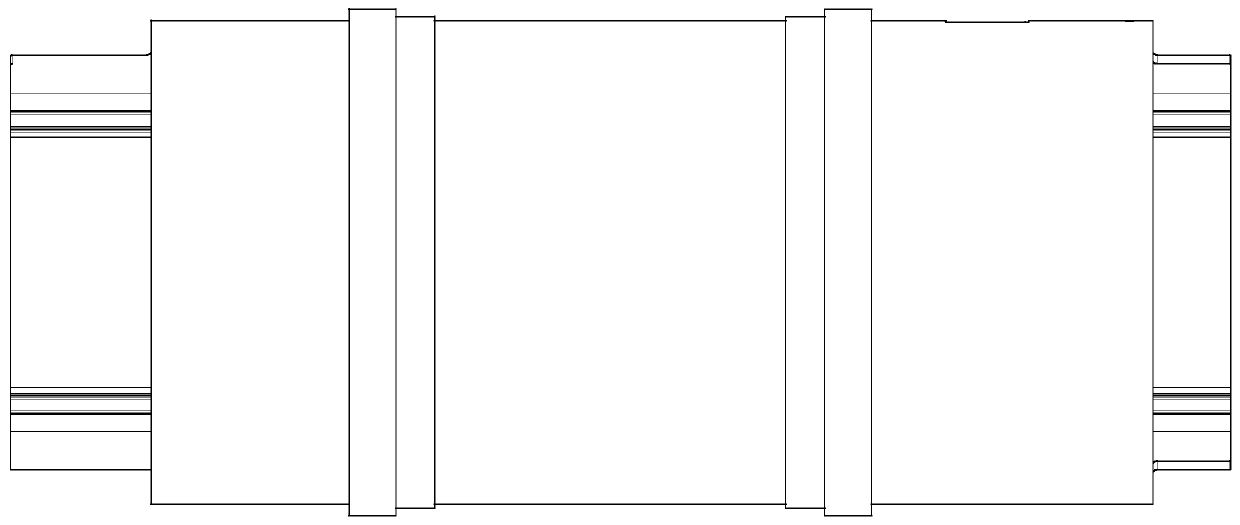

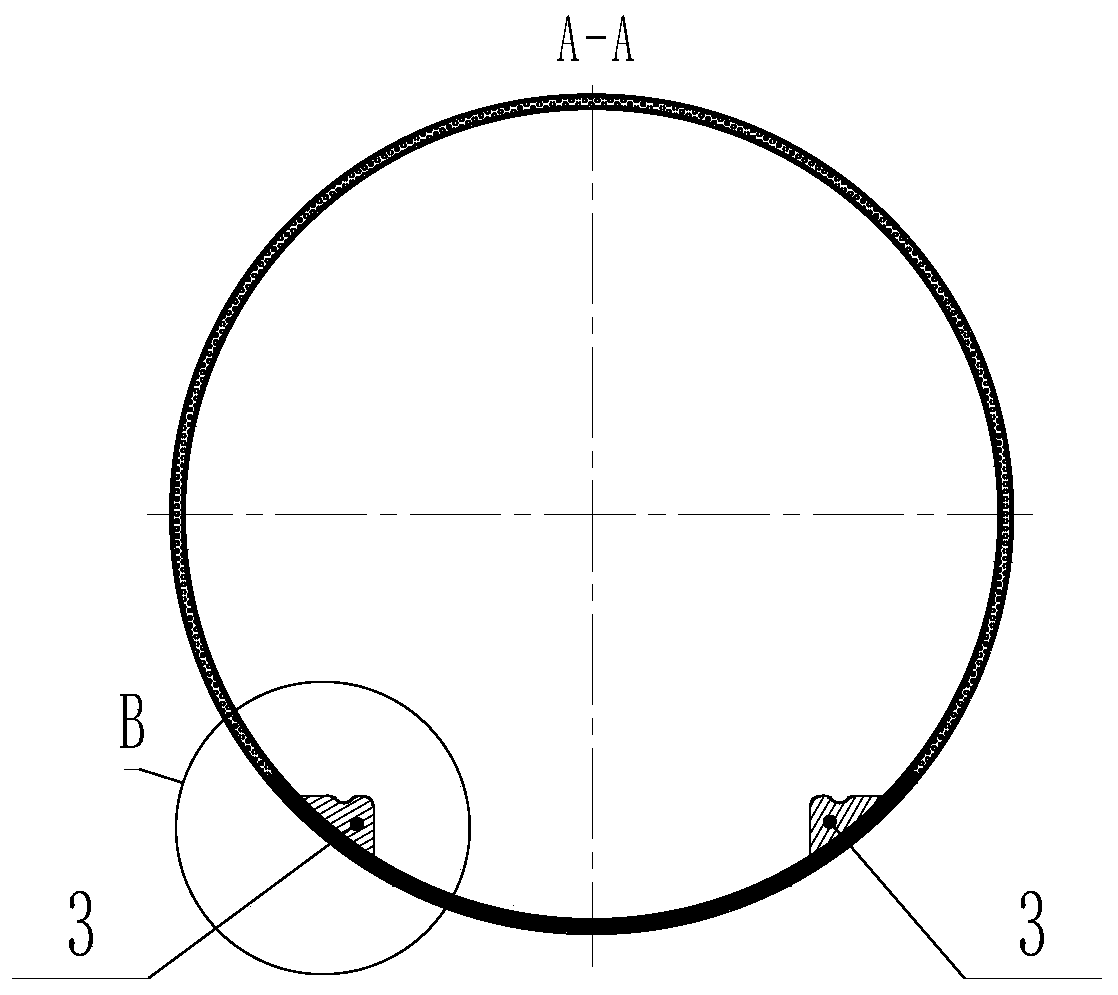

Preparation method for cylinder of nuclear magnetic resonance imager

InactiveCN110722864AEasy to operateSave spaceLamination ancillary operationsLaminationEpoxyCompression molding

The invention relates to a preparation method for a cylinder of a nuclear magnetic resonance imager. The structural component of the cylinder comprises a main body (1) serving as a shell, wherein themain body (1) is of a cylindrical structure; a reinforcing ring (2) is arranged on the outer circumference of the main body (1); and a guide rail (3) is arranged on the inner surface of the main body(1) and is used for placing a bed board for a patient to lie down. The cylinder is characterized in that the main body (1) is made of an aramid honeycomb sandwich structure; the lower area of the guide rail (3) is removed, and a solid prepreg layer (4) is adopted in the lower area; the reinforcing ring (2) is laid on the outer side of the main body (1) through unidirectional prepreg; the main body(1) and the reinforcing ring (2) are integrally formed in a co-curing mode; and the guide rail (3) is formed by compression molding of glass fiber prepreg and then bonding epoxy resin with the main body (1). The cylinder adopts the aramid honeycomb sandwich structure, and the solid prepreg layer is locally designed, so the effects of reducing the weight of the cylinder and improving the production efficiency and safety are achieved, and the cylinder has more excellent heat insulation and sound insulation properties.

Owner:AVIC COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com