Continuous fiber reinforced thermal protection material and preparation method thereof

A heat protection material and continuous fiber technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the separation of heat protection and heat insulation functions, low heat protection efficiency, large redundant mass, etc. problems, to achieve excellent heat insulation performance and ablation resistance, which is conducive to precise attitude control and low volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

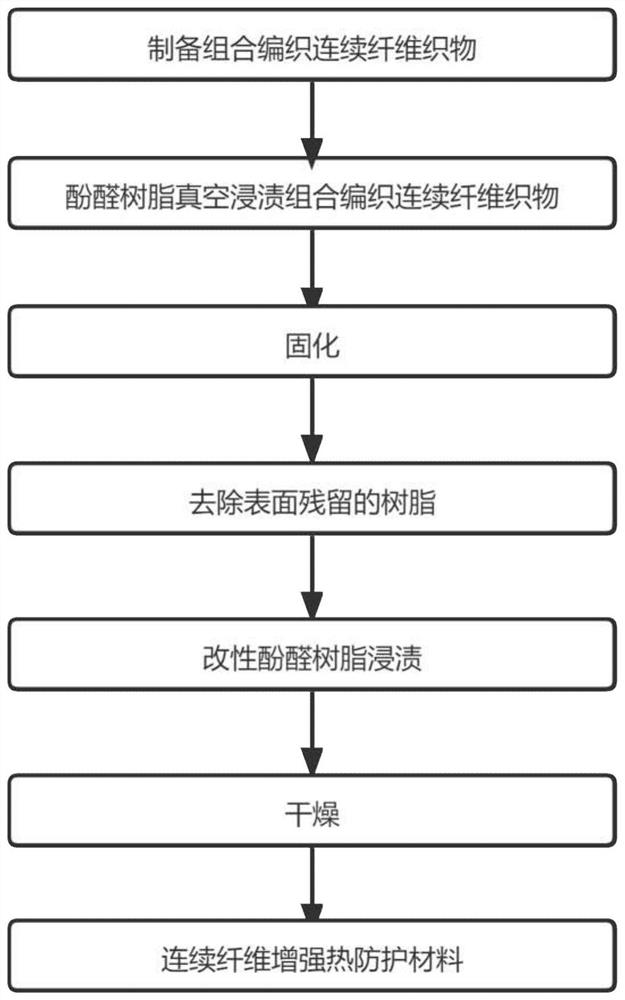

[0059] The preparation process of the continuous fiber reinforced thermal protection material in this embodiment is shown in figure 1 , including the following steps:

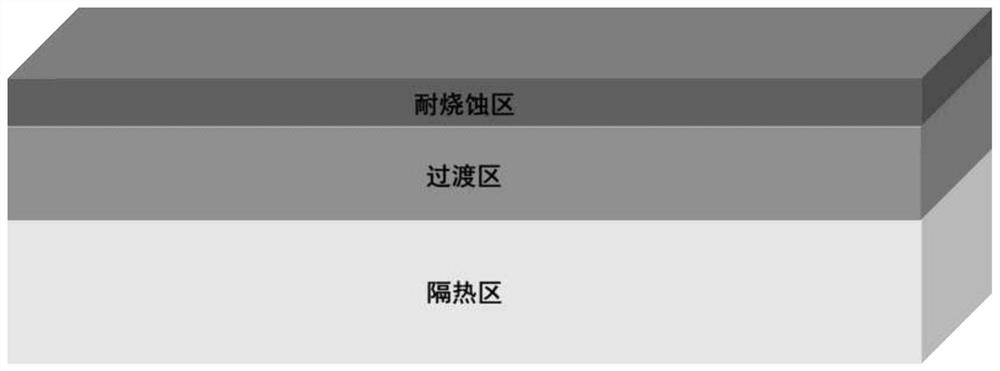

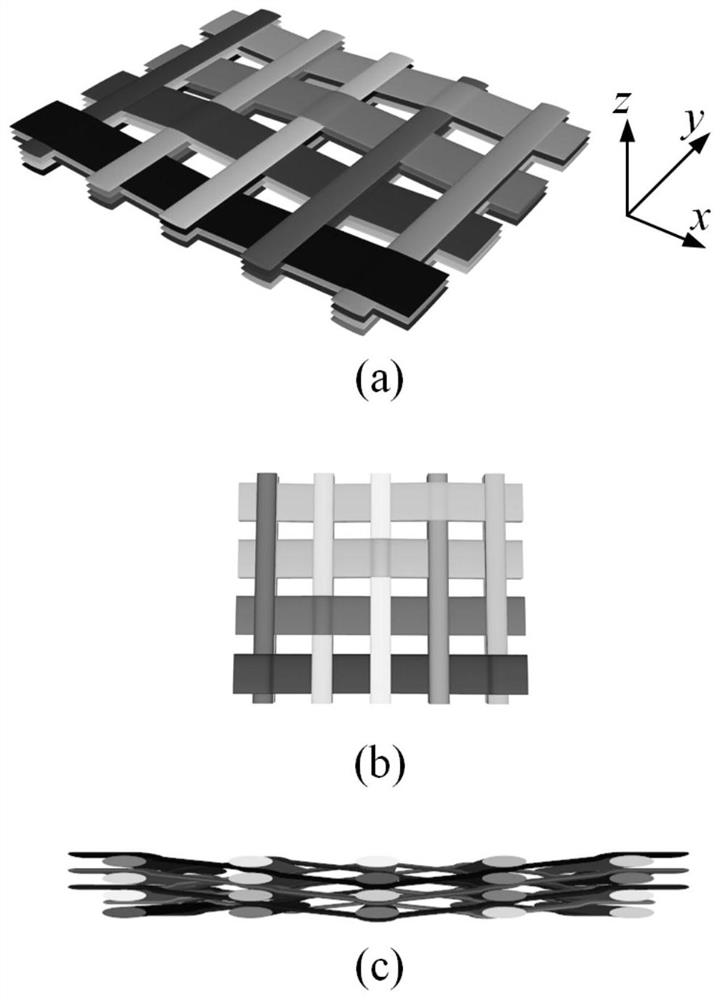

[0060] 1. Weave continuous carbon fiber through orthogonal three-way weaving as a continuous fiber fabric in the ablation-resistant zone, with a thickness of 6mm. The partial weaving structure is shown in Figure 5 As shown; then the continuous carbon fiber is woven through the 2.5D shallow cross-bending layer angle interlocking weaving method as a continuous fiber fabric in the transition zone, with a thickness of 8mm, and its local weaving structure diagram is as follows Figure 4 As shown; then use continuous carbon fiber to weave the continuous fiber fabric as the heat insulation area through the 2.5D shallow cross-direction layer angle interlocking weaving method, the thickness is 26mm, and its partial weaving structure diagram is as follows image 3 Shown; continuous fiber fabric in ablation-resistant zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com