Patents

Literature

1371 results about "Surface heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vapor deposition of tungsten nitride

ActiveUS20060125099A1Uniform thicknessImprove efficiencyMirrorsSemiconductor/solid-state device detailsElectrical conductorGas phase

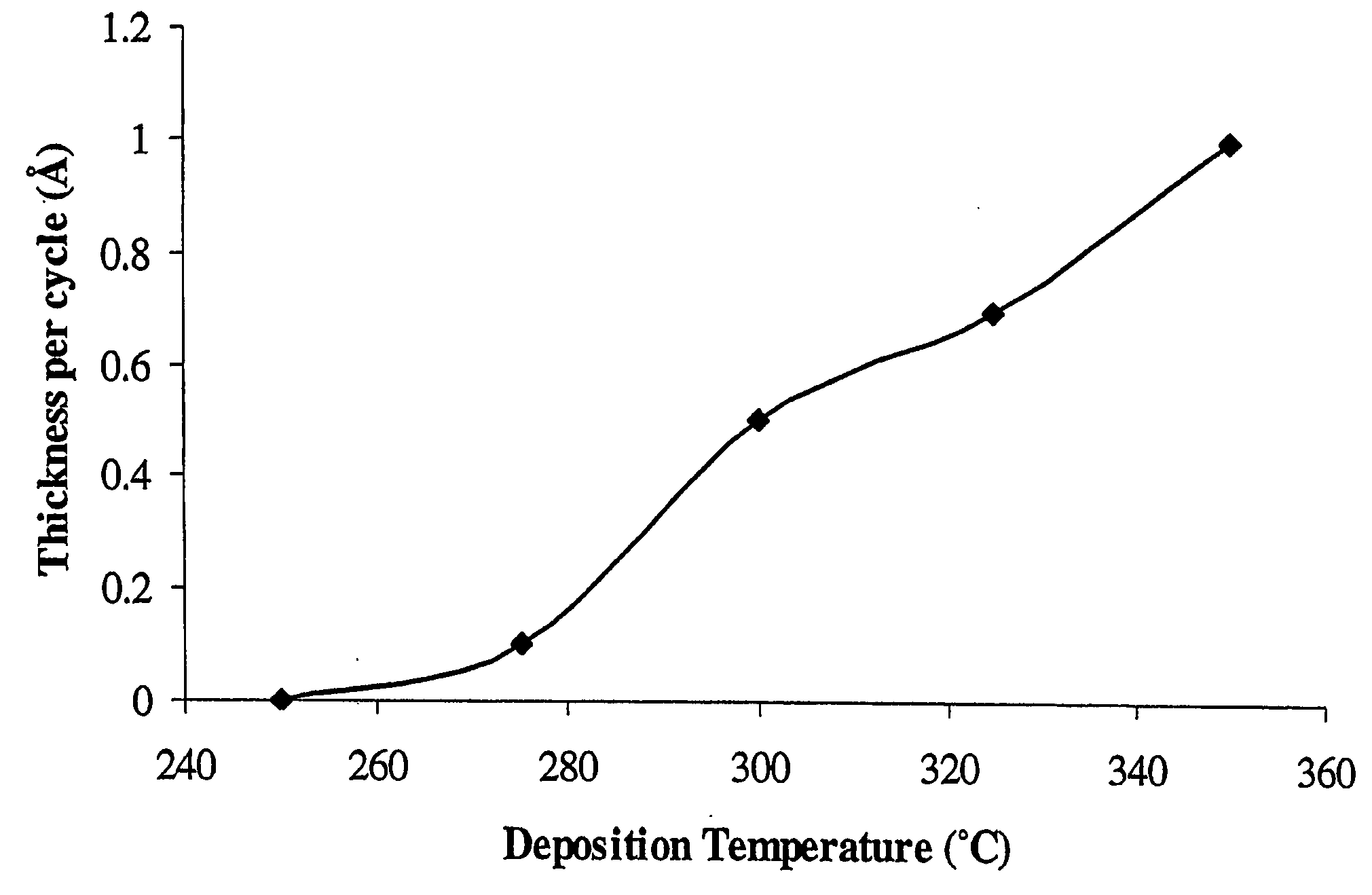

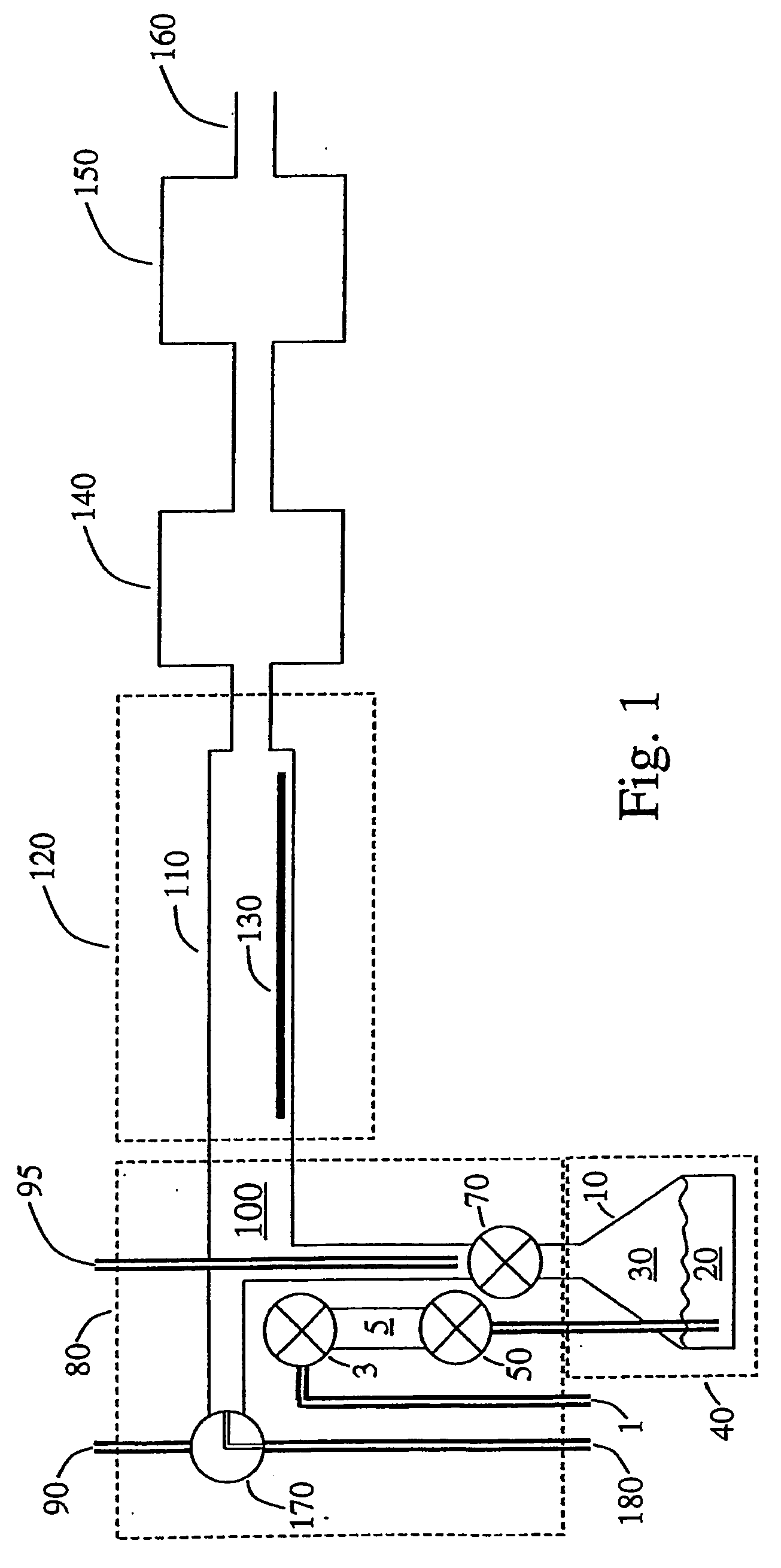

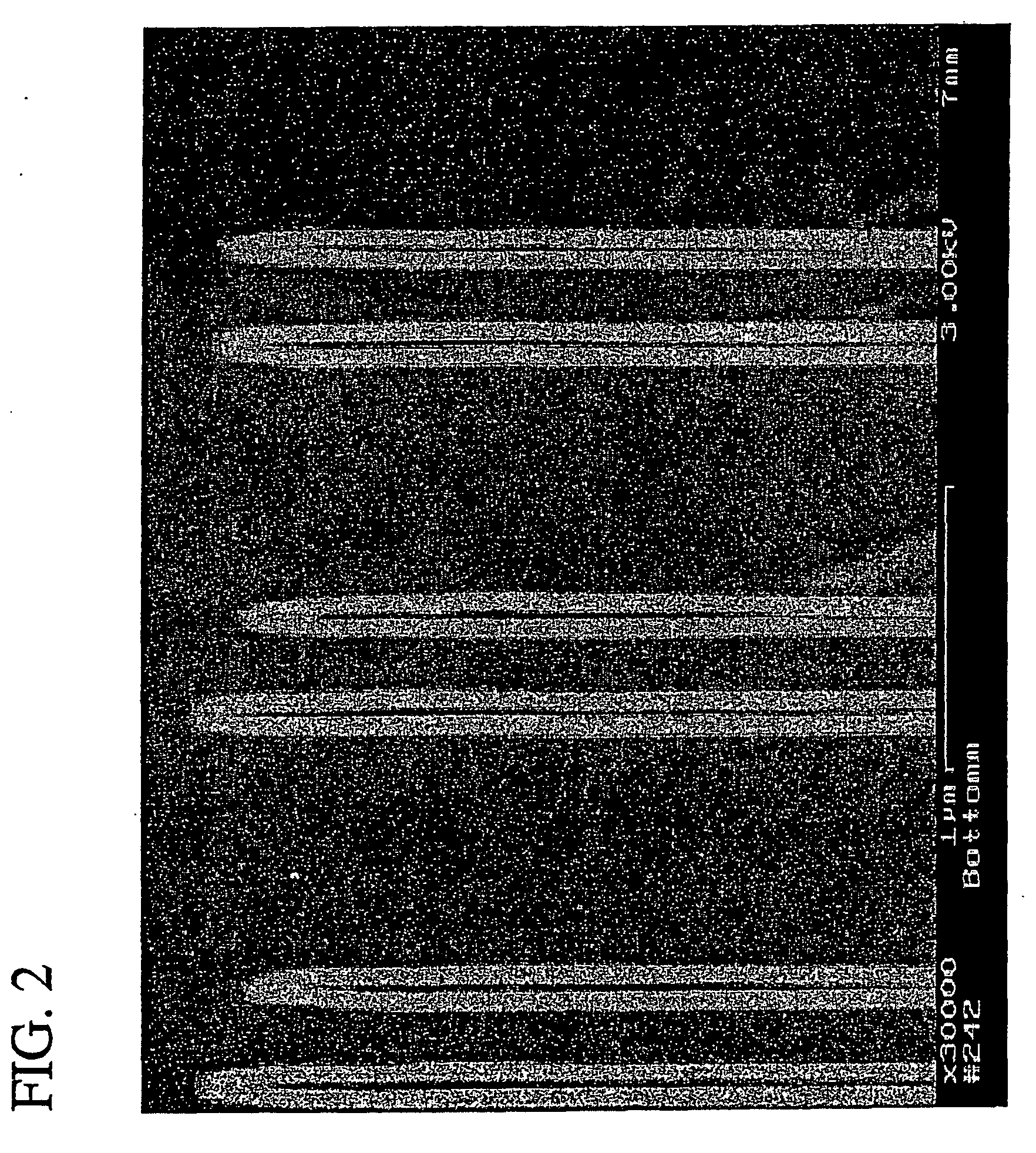

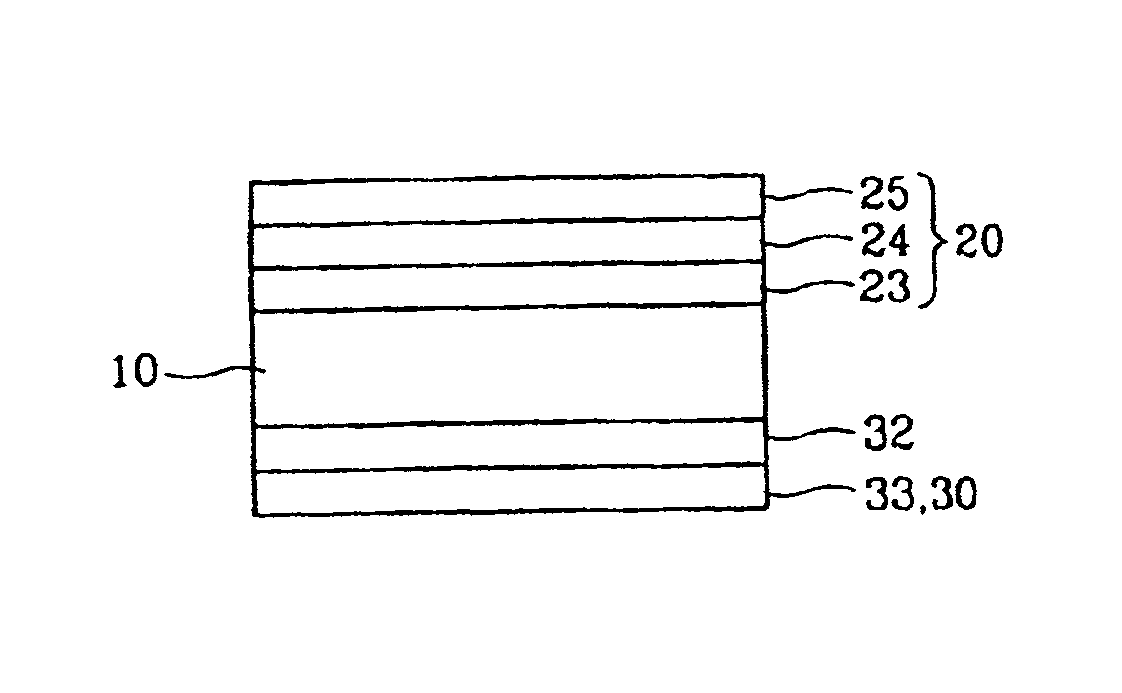

Tungsten nitride films were deposited on heated substrates by the reaction of vapors of tungsten bis(alkylimide)bis(dialkylamide) and a Lewis base or a hydrogen plasma. For example, vapors of tungsten bis(tert-butylimide)bis(dimethylamide) and ammonia gas supplied in alternate doses to surfaces heated to 300° C. produced coatings of tungsten nitride having very uniform thickness and excellent step coverage in holes with aspect ratios up to at least 40:1. The films are metallic and good electrical conductors. Suitable applications in microelectronics include barriers to the diffusion of copper and electrodes for capacitors. Similar processes deposit molybdenum nitride, which is suitable for layers alternating with silicon in X-ray mirrors.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

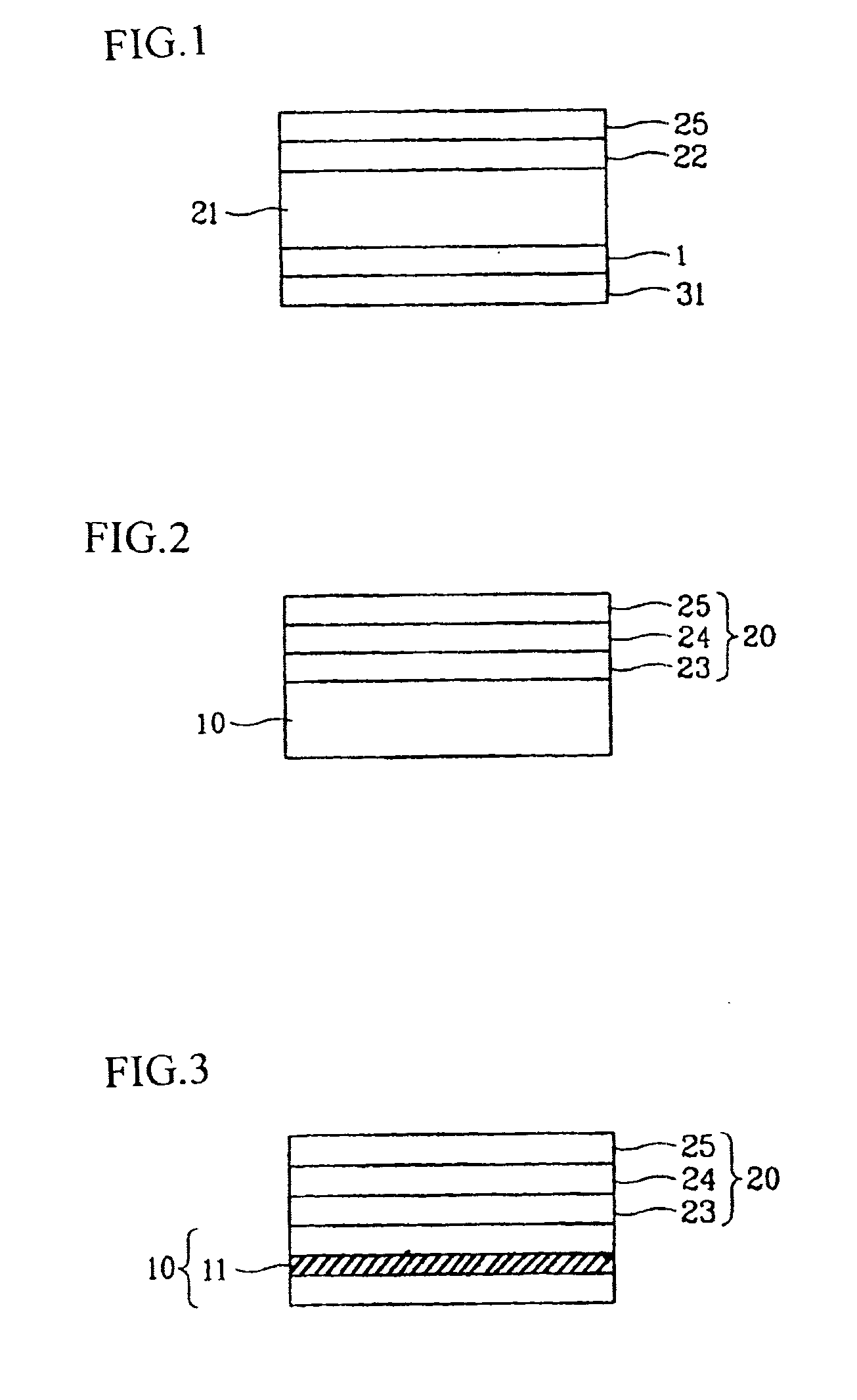

Decorative floor covering comprising polyethylene terephthalate film layer in surface layer and manufacturing method of the same

InactiveUS6933043B1Superior surface printing sharpness and realismEasy to installSynthetic resin layered productsPaper/cardboard layered productsSurface layerPolyethylene terephthalate

The present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein the surface layer comprises a polyethylene terephthalate film layer, and a method for preparing the same. Furthermore, the present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein a light weight back layer is further comprised under the substrate layer, and a method for preparing the same. A decorative floor covering of the present invention is a decorative floor covering which has superior surface heat resistance, printing sharpness and realism, and it can be installed conveniently since not only can non-foamed polyvinyl chloride resin be used as a substrate layer, but also the weight of a floor covering is light when a light weight back layer is comprised under the substrate layer.

Owner:LG CHEM LTD

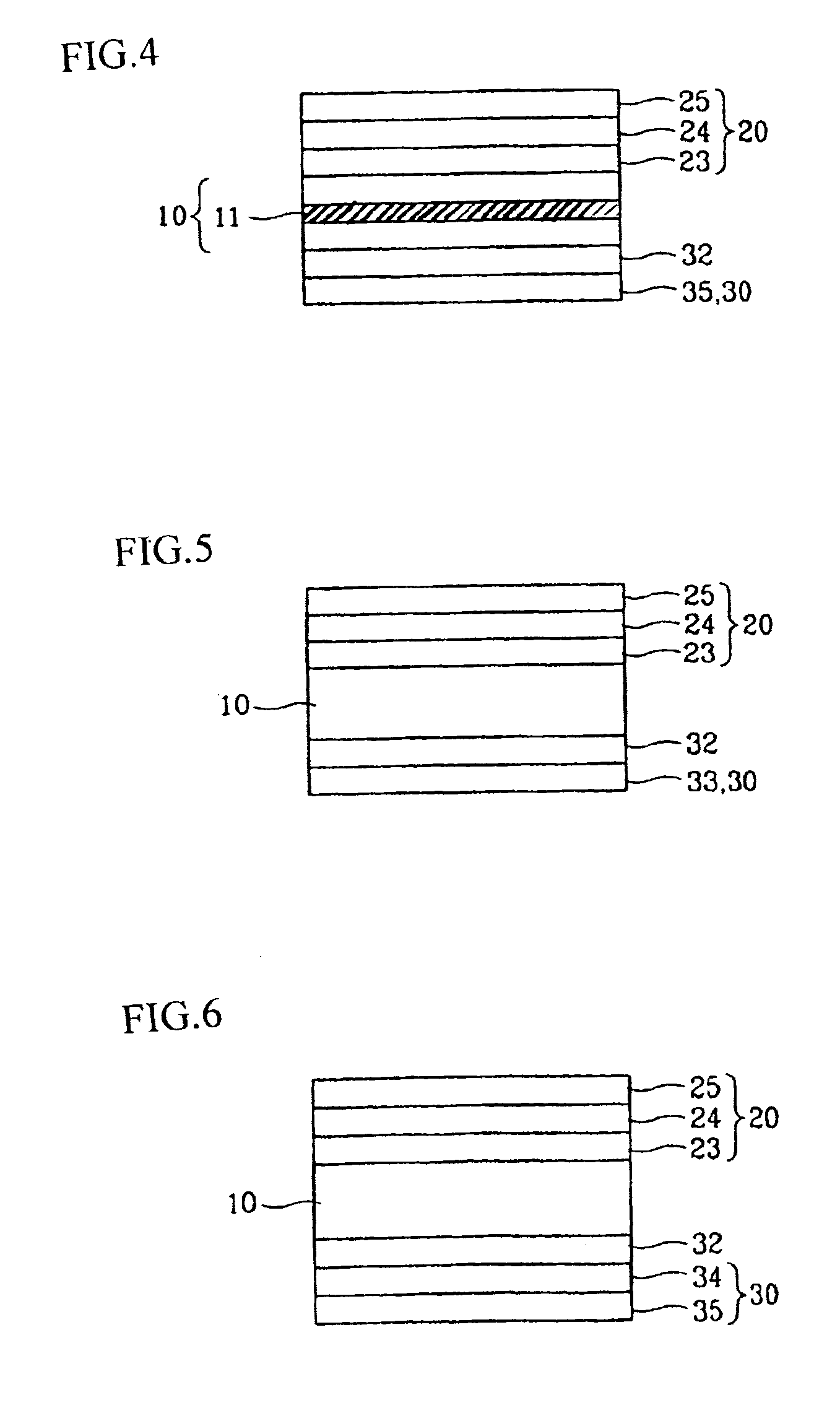

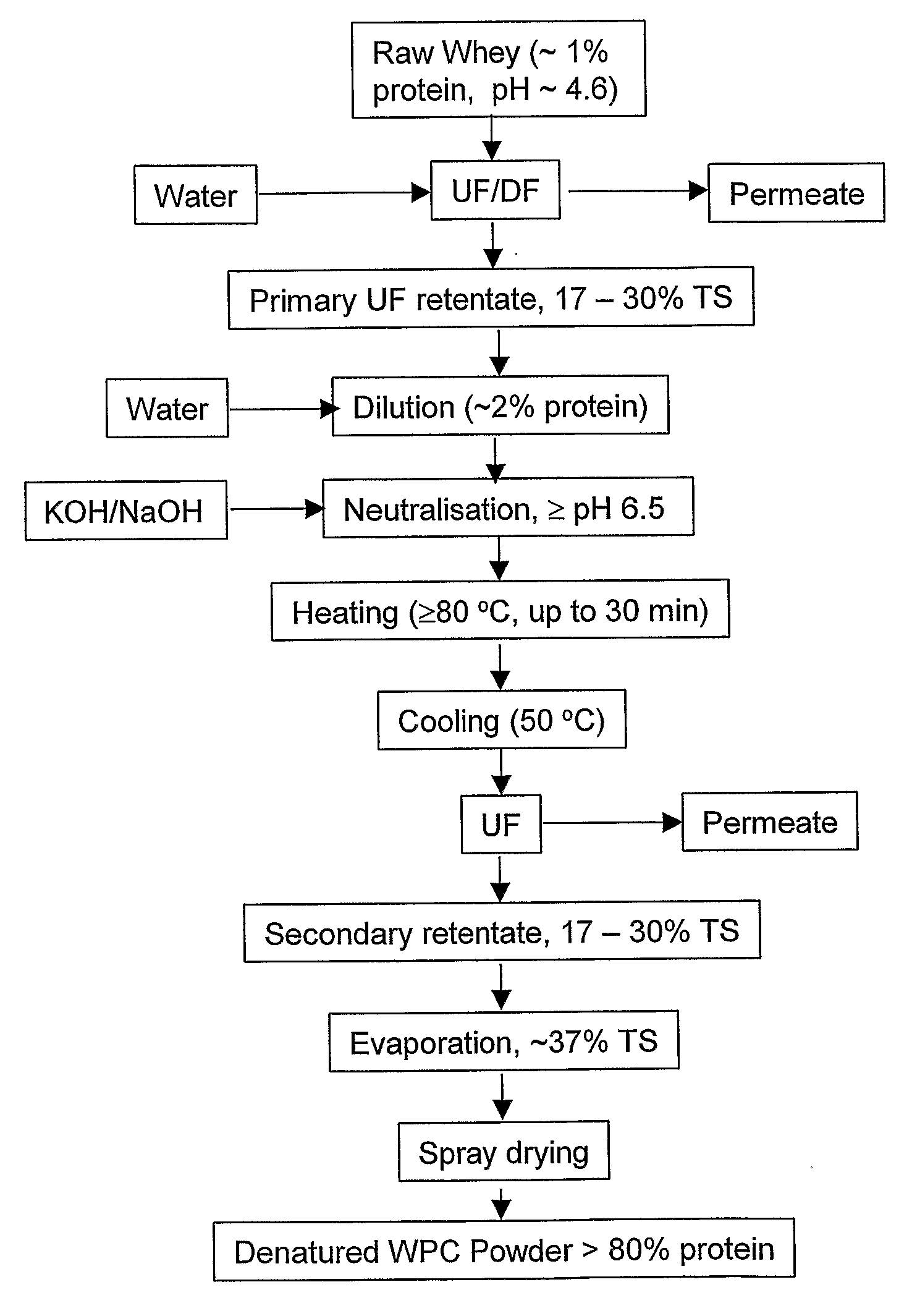

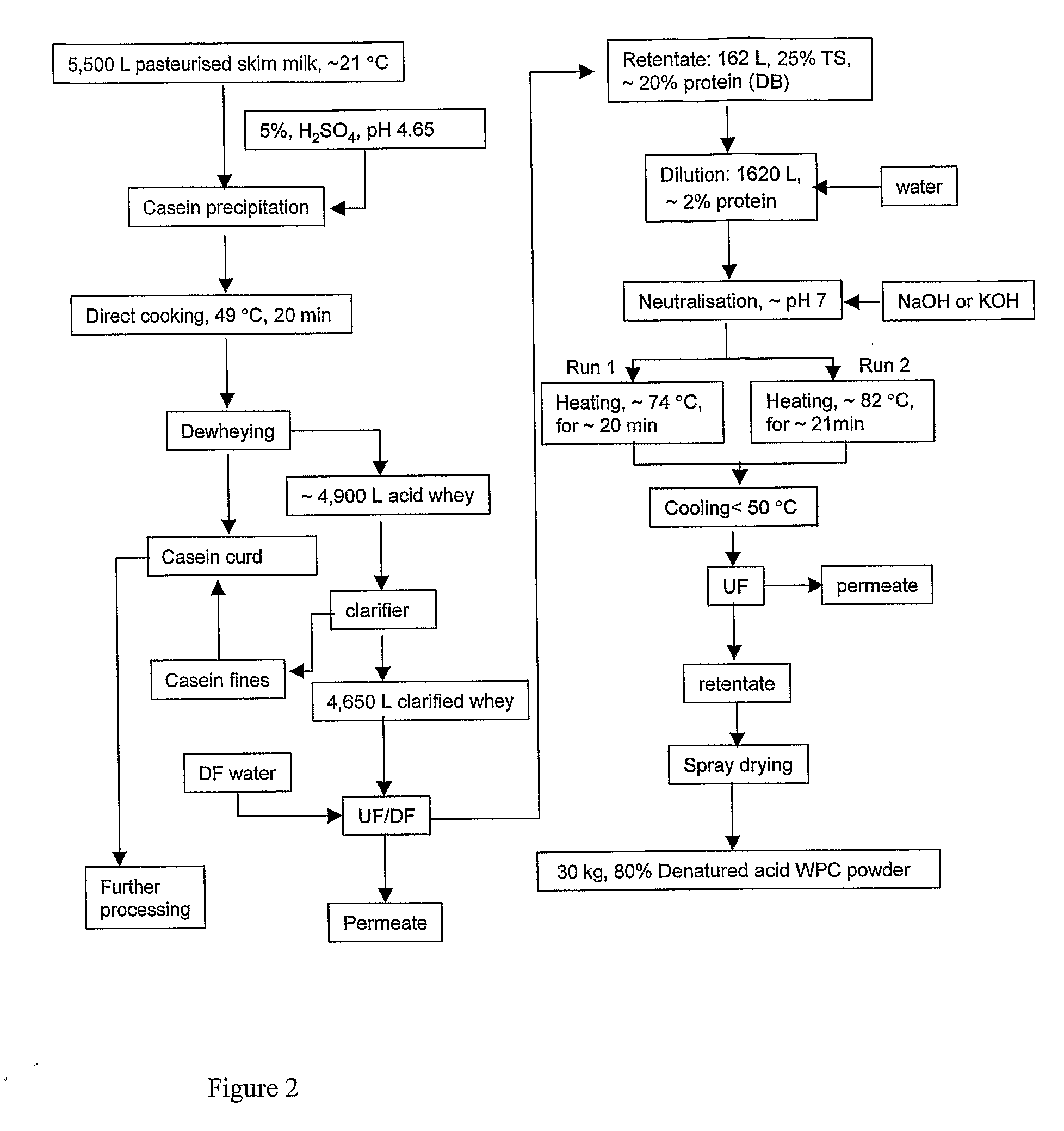

Whey Product and Process

InactiveUS20080305235A1High viscosityHigh in proteinMilk preparationFood ingredient as viscosity modification agentWhey proteinSurface heat

The invention provides a process for preparing a dried modified whey protein concentrate. A whey protein solution is used having less than 5% total solids and a combined calcium and magnesium concentration of less than 70 mmol / kg on a dry basis and a pH of 6.0-7.5. It is heated to greater than 70° C. for up to 60 minutes to denature the whey protein. The solution is then cooled to 40° C.-60° C.; and subsequently spray dried. Alternatively a higher initial concentration of total solids may be used in an embodiment where the heating is carried out on a scraped surface heat exchanger.

Owner:FONTERRA COOP GRP LTD

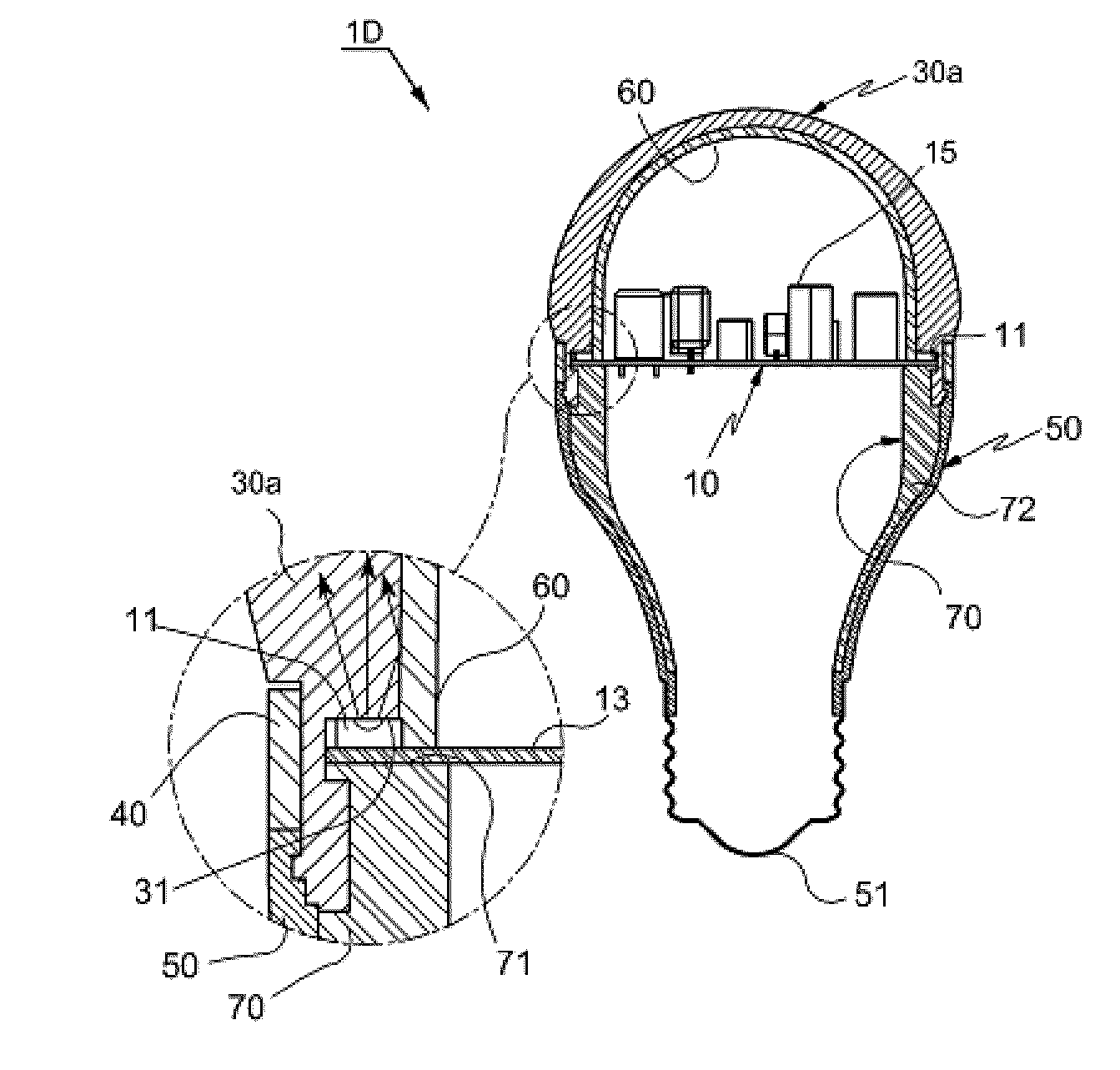

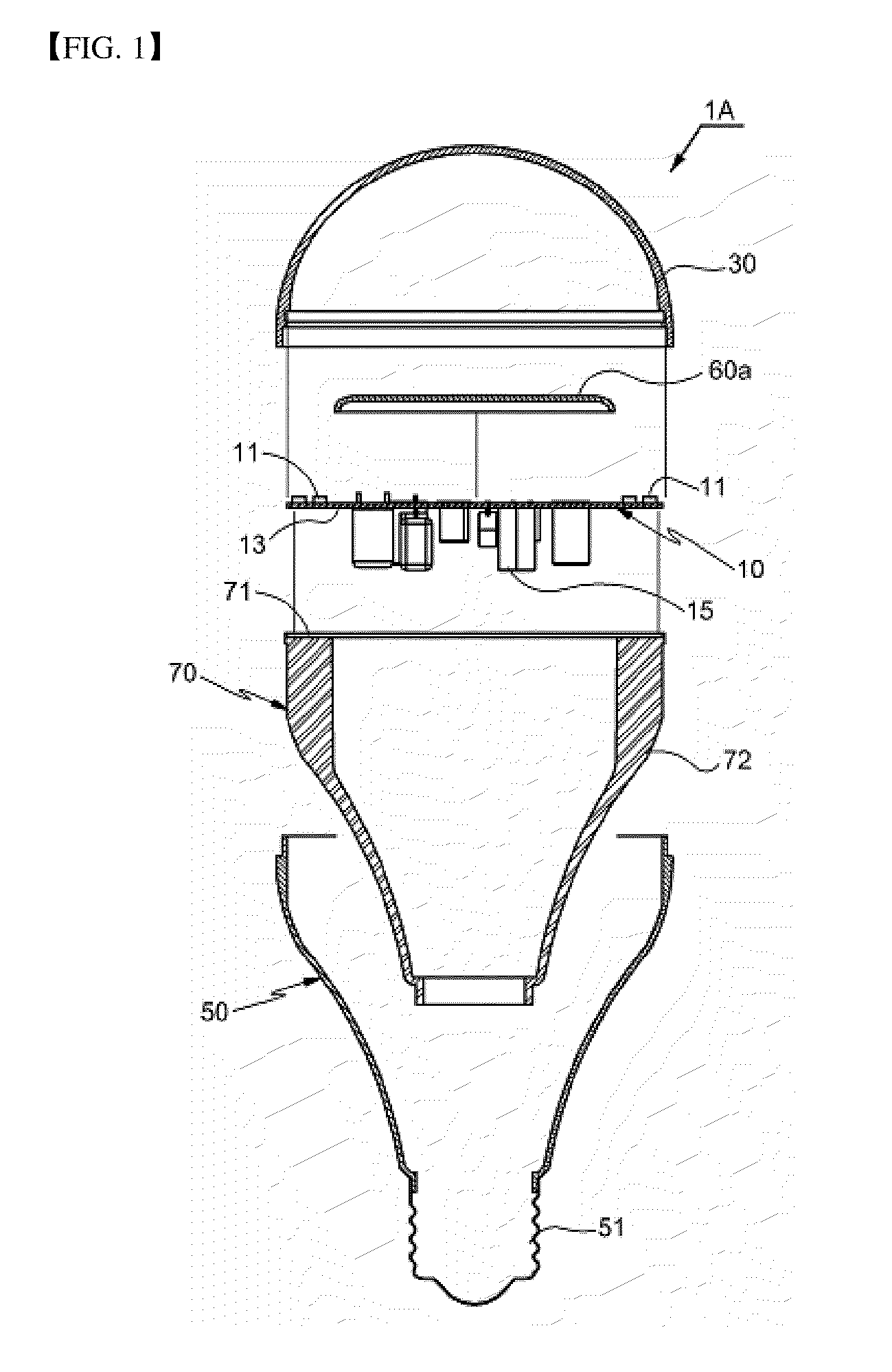

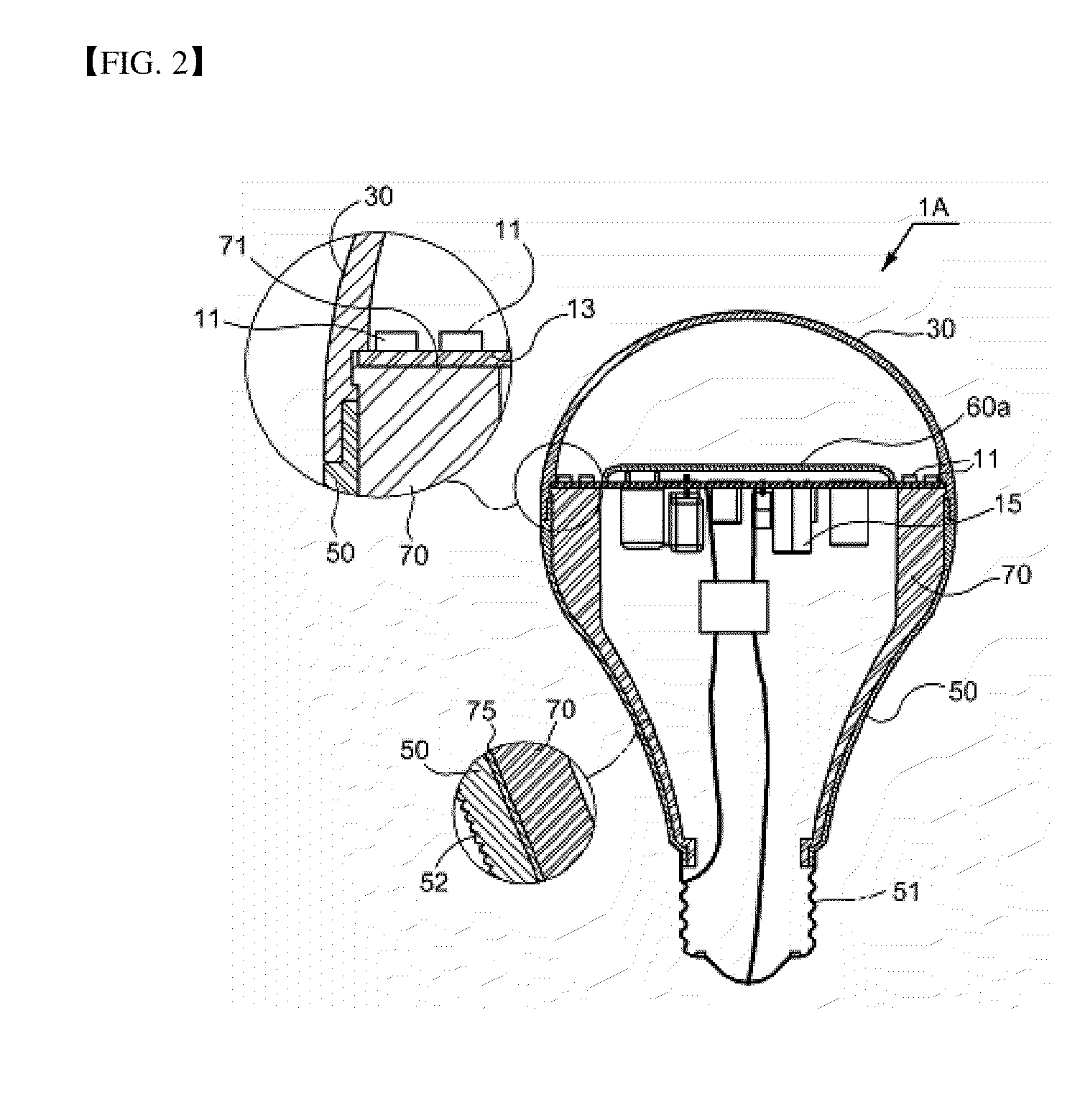

LED lamp

InactiveUS20110101861A1Increase emission rateConstant gainPoint-like light sourceElongate light sourcesEngineeringPolycarbonate

The present invention relates to an LED lamp in which, because the lamp has therein a heat dissipation transfer member and the power source base thereof is made of materials including polycarbonate, etc. with a high emission rate of radiation so as to enhance its surface heat dissipation constant, the power source base has sufficient heat dissipation performance and, thus, a separate insulation circuit is not necessary, thereby improving reliability and productivity of the lamp as well as reducing the cost of manufacturing.To this end, the present invention provides an LED lamp comprising one or more LEDs mounted on a PCB, a floodlight cover that transmits light from the LEDs, and a power source base coupled to the floodlight cover and having a terminal at one end thereof, wherein the power source base is made of an insulation material; and the LED lamp also comprises a heat dissipation transfer member that has a heat sink in contact with the PCB on which the LEDs are mounted, and is formed and installed so as to overlap with and be in tight contact with the inner face of either the power source base or the floodlight cover or both.

Owner:YOO YOUNG HO +1

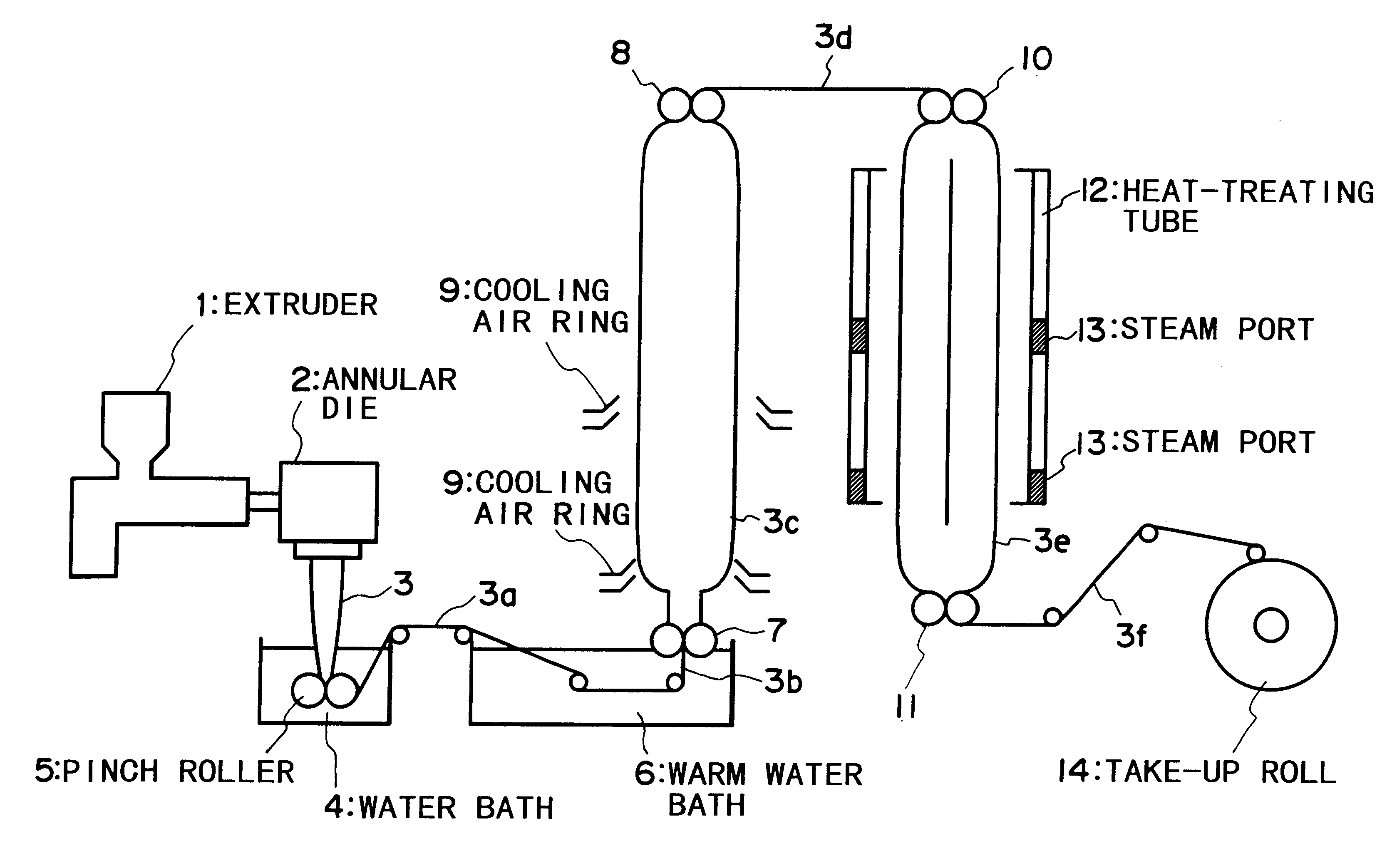

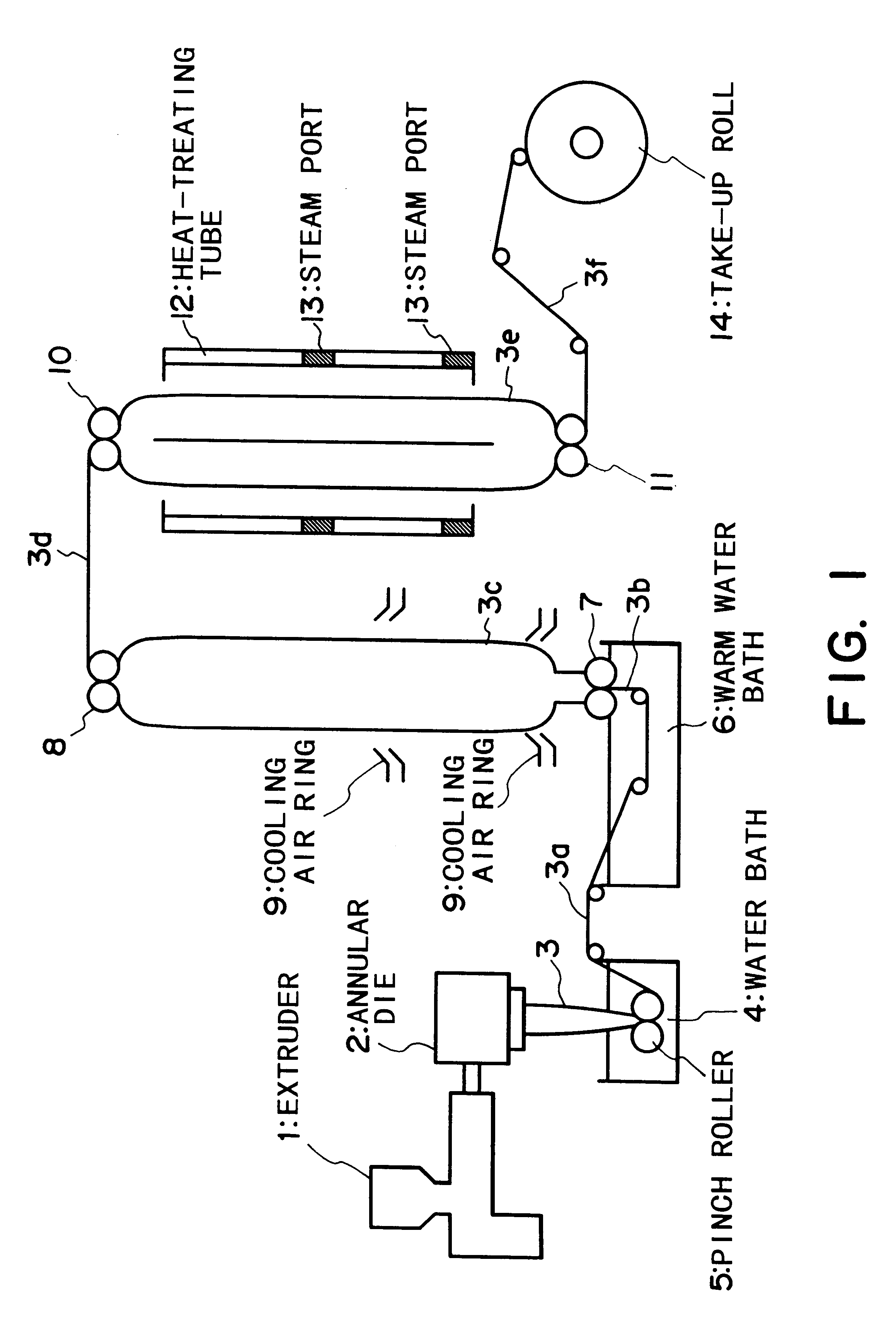

Heat-shrinkable multilayer film

A polyester-surfaced heat-shrinkable multilayer film exhibiting good printability and adaptability to various automatic packaging processes is provided, including an outer surface layer (a) comprising a polyester resin, an intermediate layer (b) comprising a polyamide resin and an inner surface layer (c) comprising a sealable resin. The film exhibits a heat-shrinkable stress at 50° C. of at most 3 MPa both in longitudinal direction and in transverse direction, and a hot water shrinkability at 90° C. of at least 20%.

Owner:KUREHA KAGAKU KOGYO KK

Vapor deposition of metal oxides, silicates and phosphates, and silicon dioxide

InactiveUS6969539B2Good step coverageNarrow structureOxygen/ozone/oxide/hydroxideAluminium silicatesAlkylphosphatePhosphate

Metal silicates or phosphates are deposited on a heated substrate by the reaction of vapors of alkoxysilanols or alkylphosphates along with reactive metal amides, alkyls or alkoxides. For example, vapors of tris-(ter-butoxy)silanol react with vapors of tetrakis(ethylmethylamido)hafnium to deposit hafnium silicate on surfaces heated to 300° C. The product film has a very uniform stoichiometry throughout the reactor. Similarly, vapors of diisopropylphosphate react with vapors of lithium bis(ethyldimethylsilyl)amide to deposit lithium phosphate films on substrates heated to 250° C. supplying the vapors in alternating pulse produces these same compositions with a very uniform distribution of thickness and excellent step coverage.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

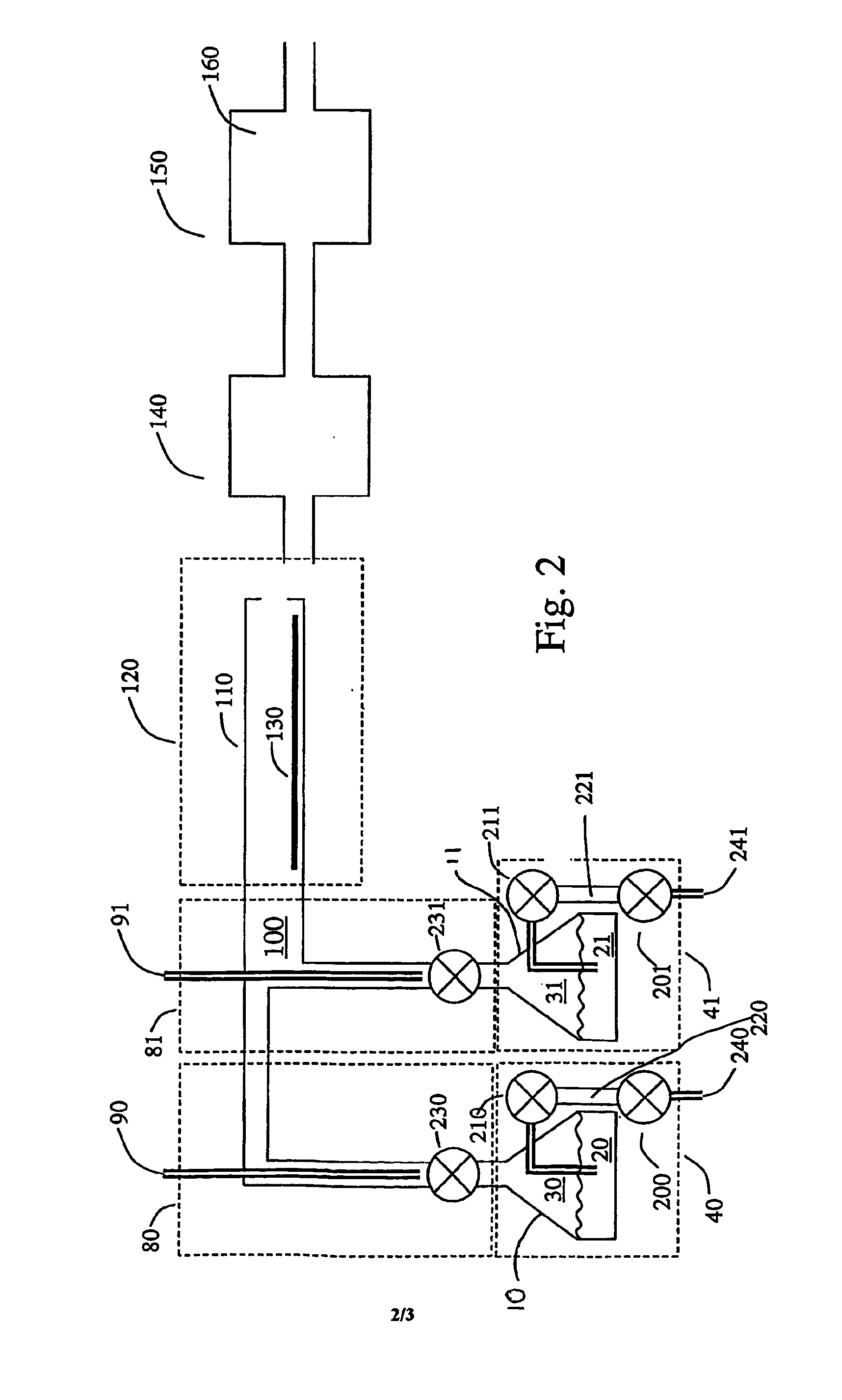

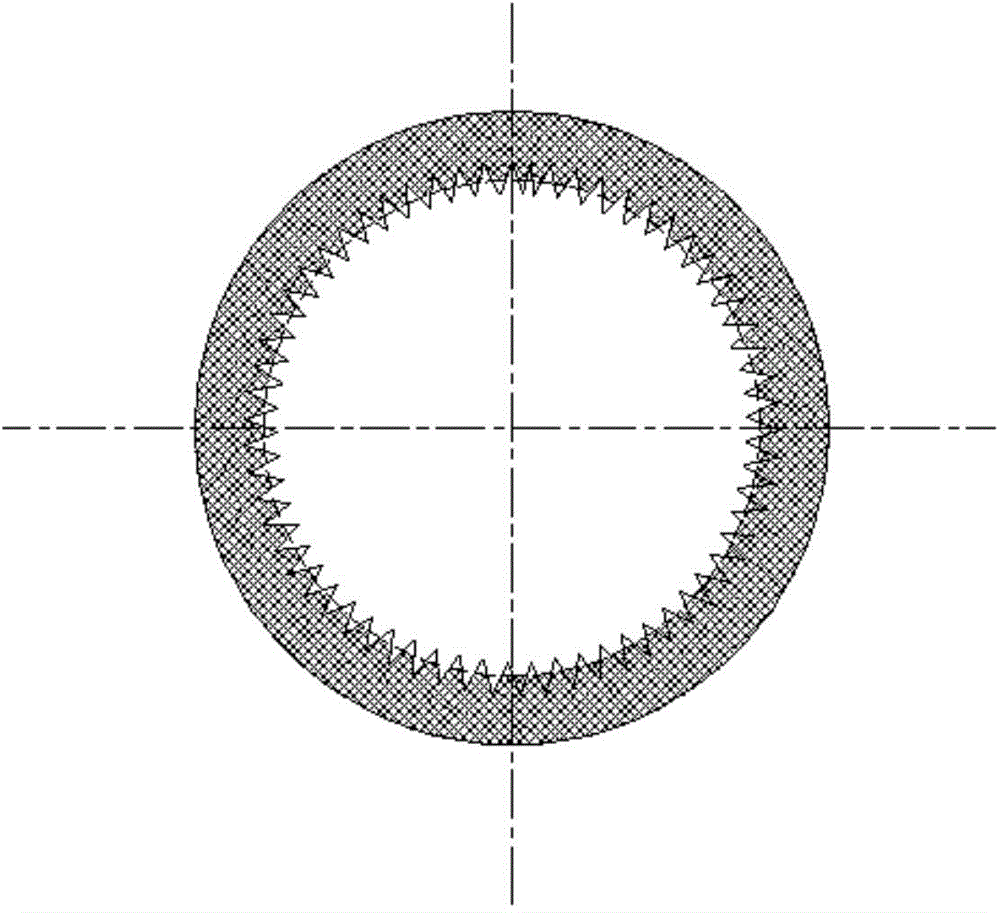

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

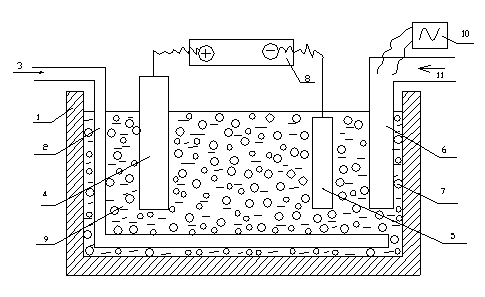

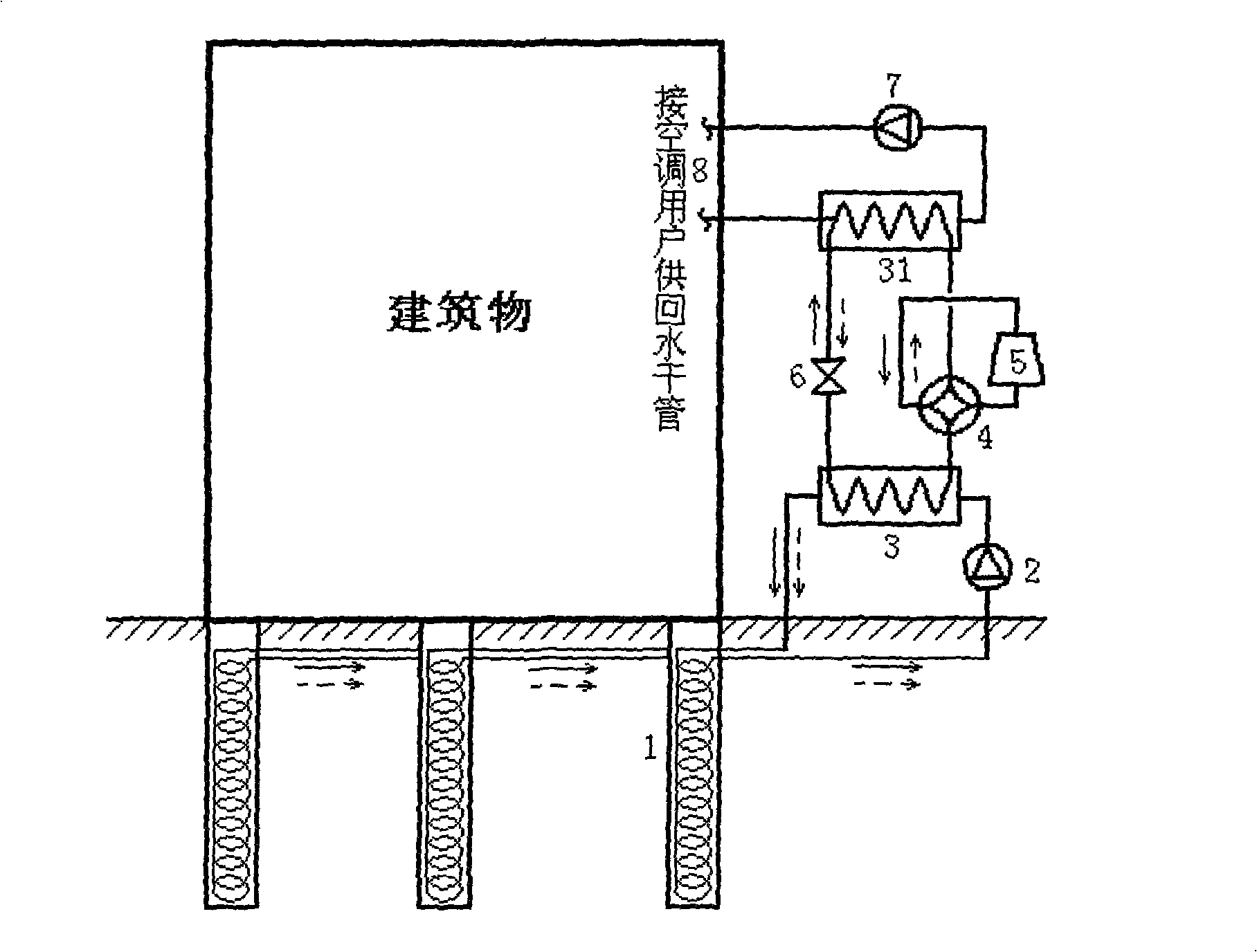

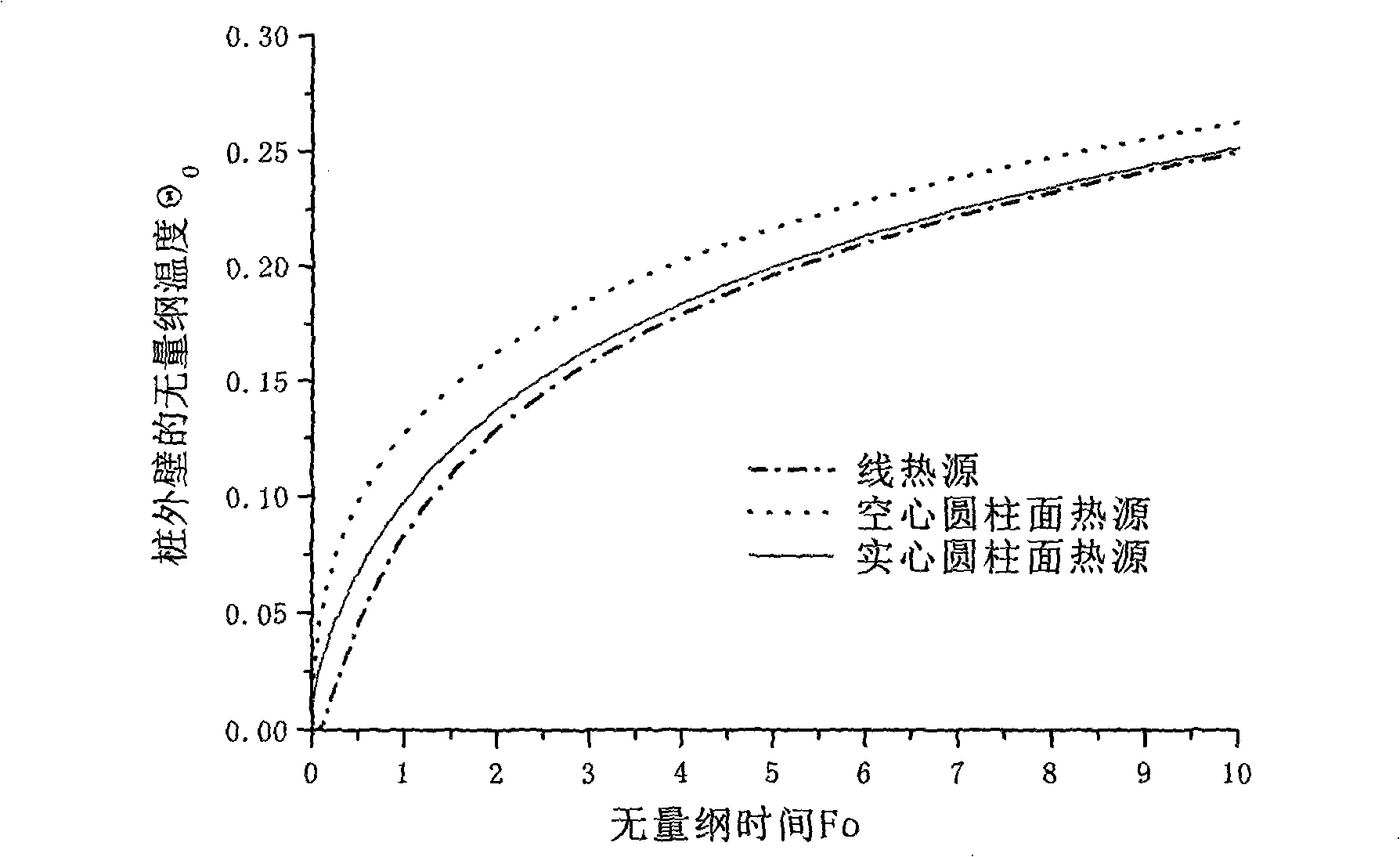

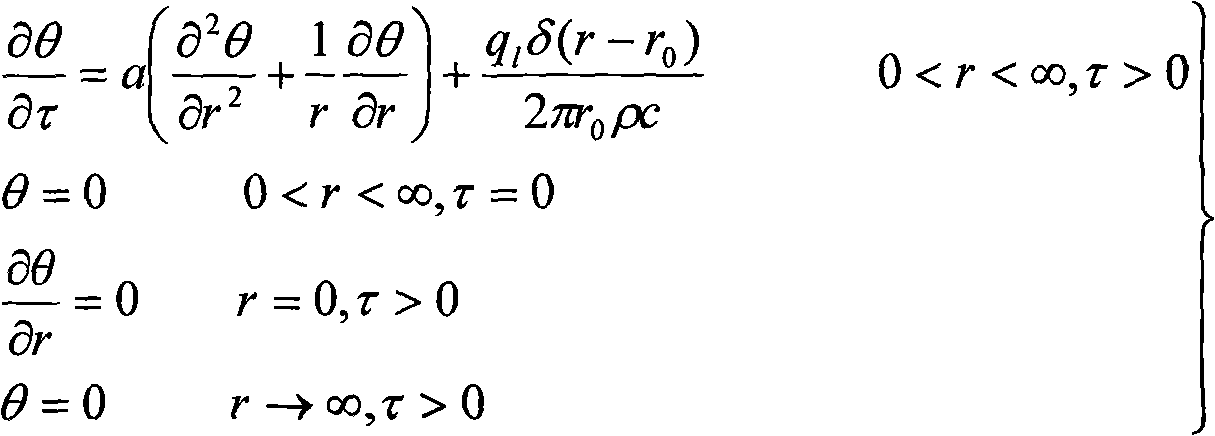

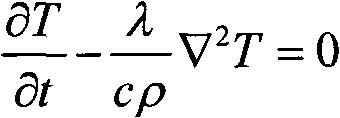

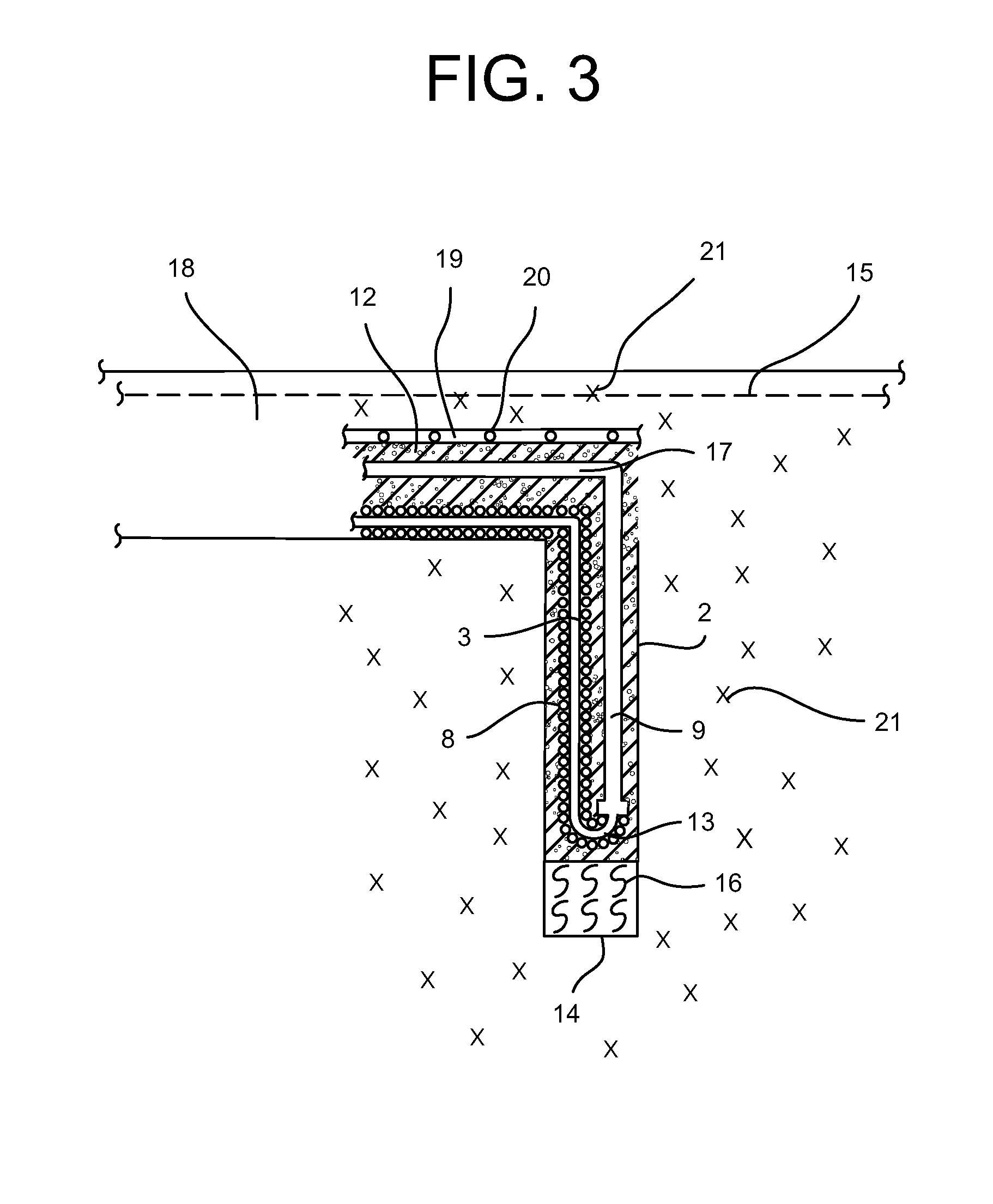

Pile imbedded helix tube type ground source heat pump system and heat transferring model of terrestrial heat exchanger thereof

ActiveCN101408359ASmall footprintReduce initial investmentHeat pumpsOther heat production devicesHeat transmissionEnd system

The invention discloses a pile-embedding spiral pipe typed ground source heat pump system and a heat transmission model of a geothermal heat exchanger thereof. A solid cylindrical surface heat source model is put forward for the first time and two analytic solution expressions of the heat transmission model is worked out by the Green function method. The system can sufficiently utilizes the underground area of a building, saves a great amount of expenses for boring and pipe embedding, reduces the initial investment of the ground source heat pump system, improves the construction efficiency and has convenient and quick construction. Furthermore, the heat transmission model of the pile-embedding spiral pipe geothermal heat exchanger can quantitatively analyze the effects of all parameters of the pile-embedding spiral pipe geothermal heat exchanger on the heat transmission capability and provides a basis for the engineering design. The structure of the pile-embedding spiral pipe typed ground source heat pump system comprises the geothermal heat exchanger which is connected with an air conditioning heat pump system by pipelines; the air conditioning heat pump system is connected with a conveying and end system in the building; the geothermal heat exchangers have the quantity of more than one; and each geothermal heat exchanger forms the pile-embedding spiral pipe-typed geothermal heat exchanger by building pile foundations and spiral pipes which are embedded in the pipe foundations.

Owner:山东中瑞新能源科技有限公司

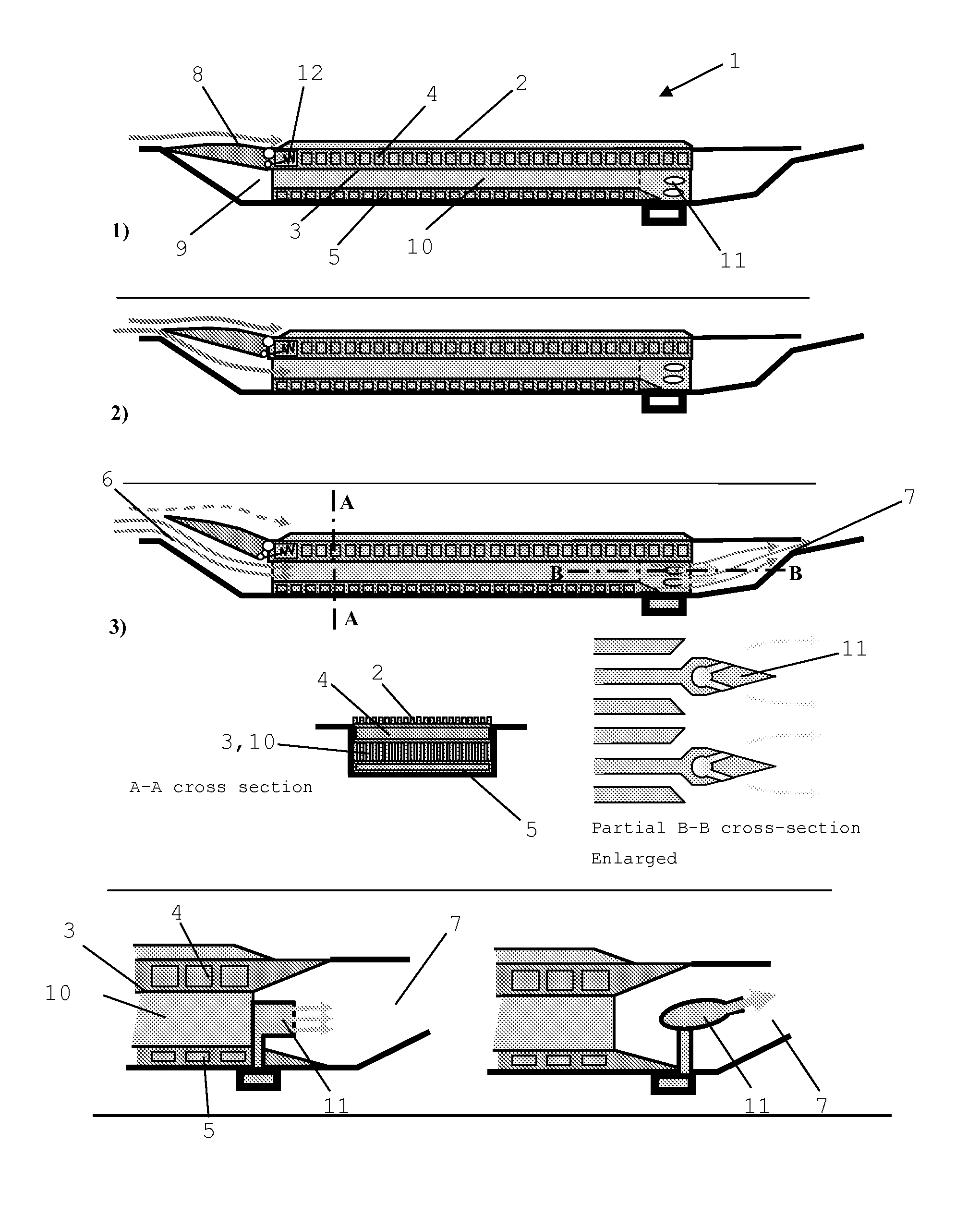

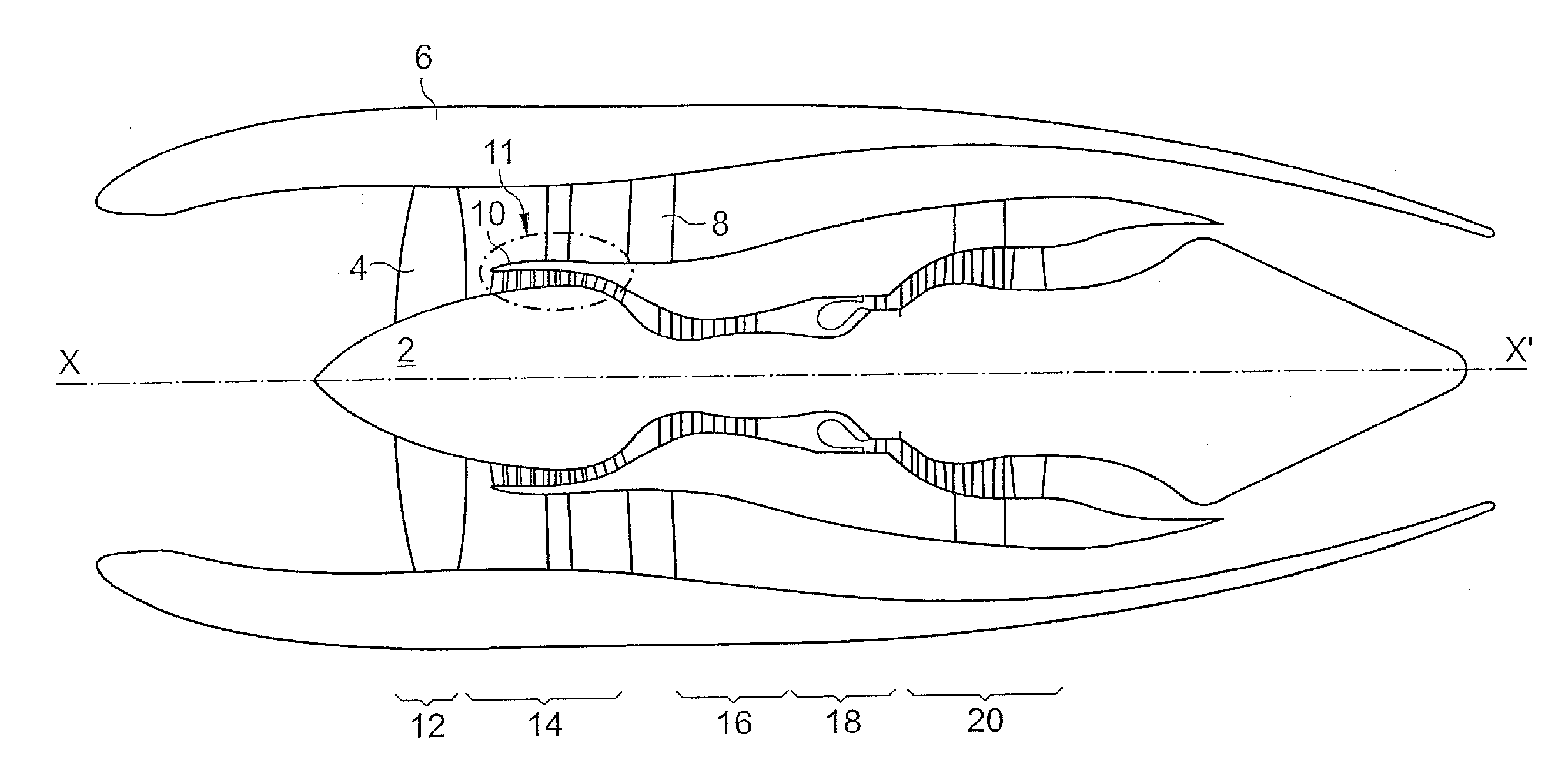

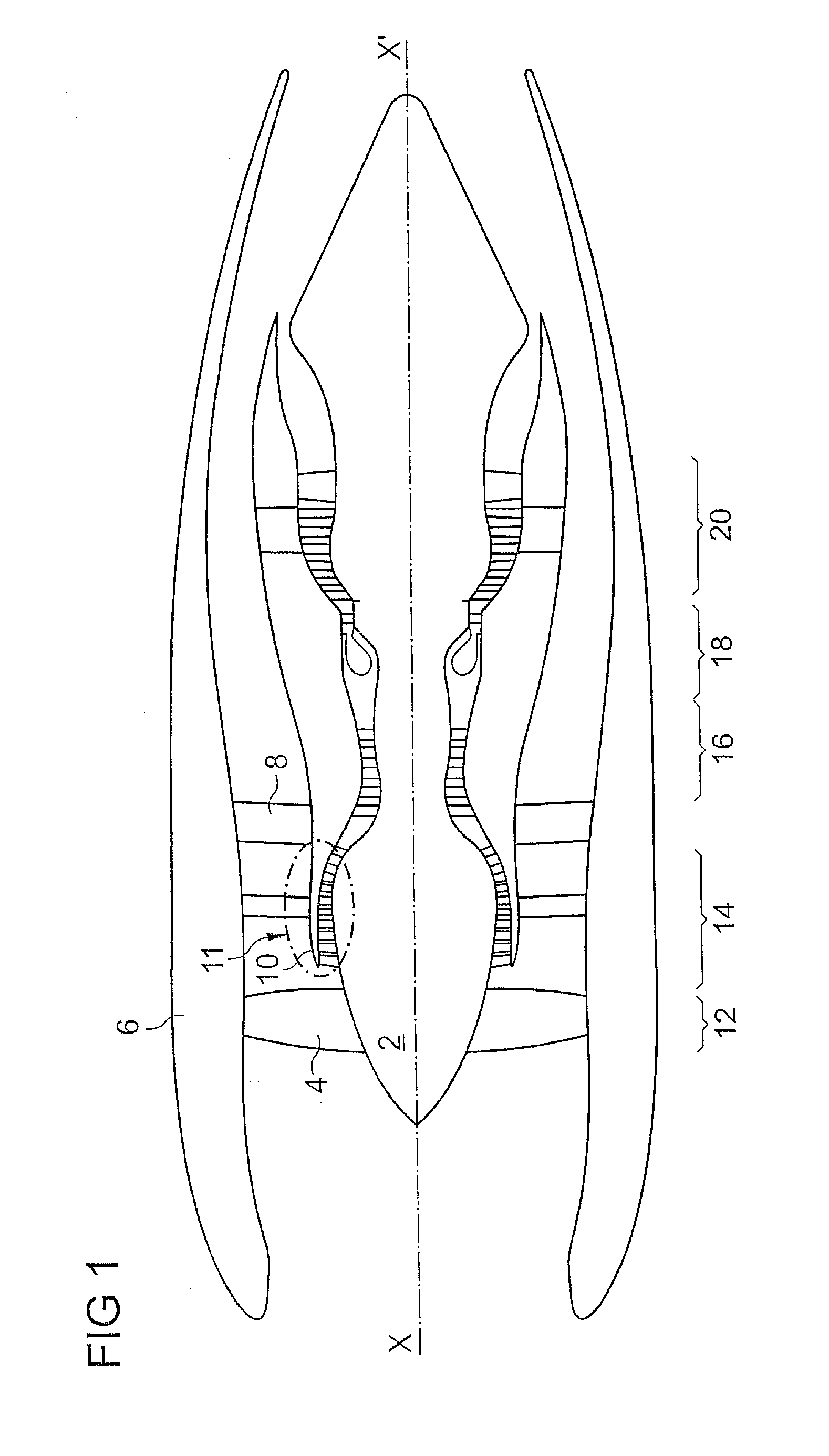

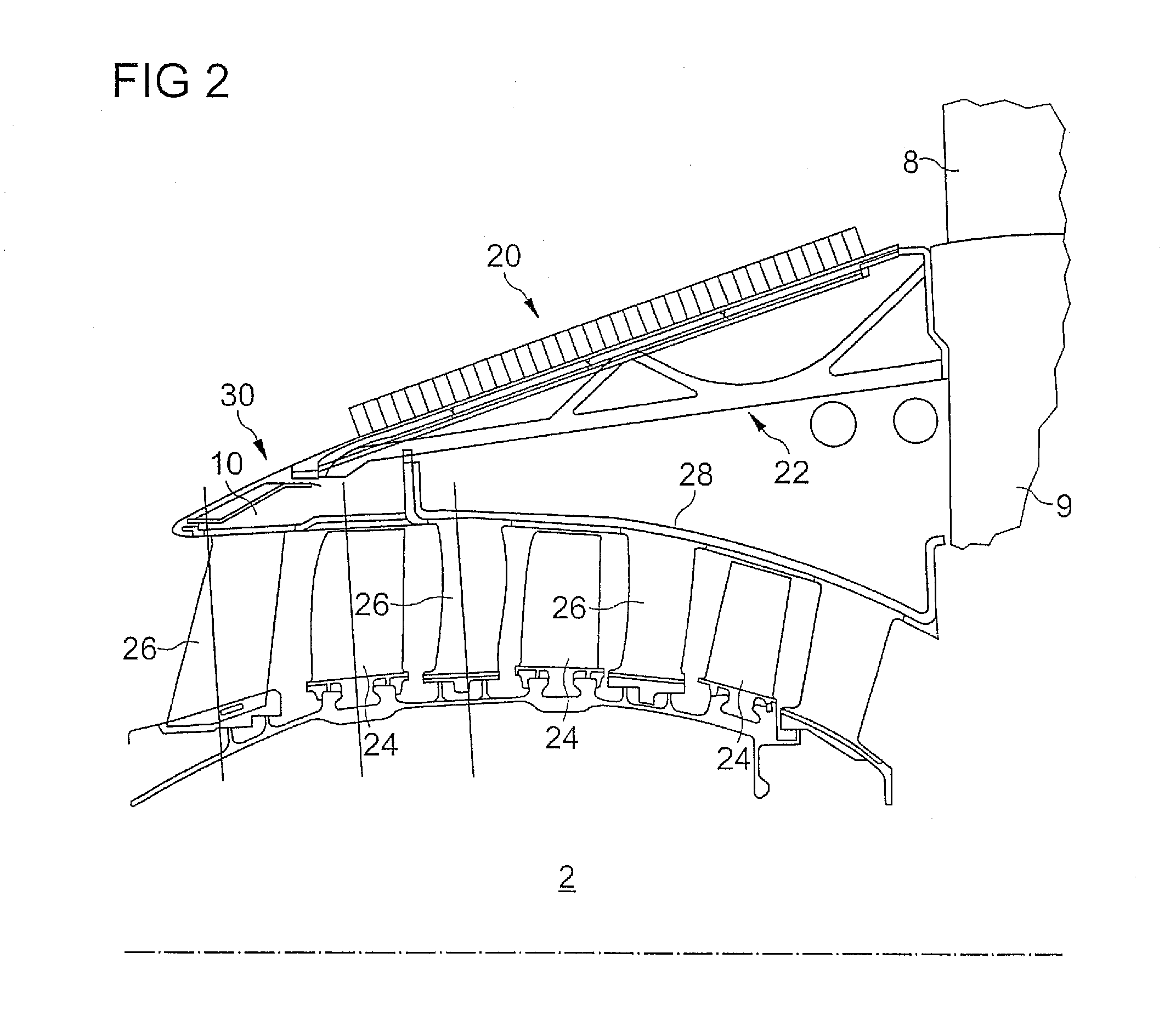

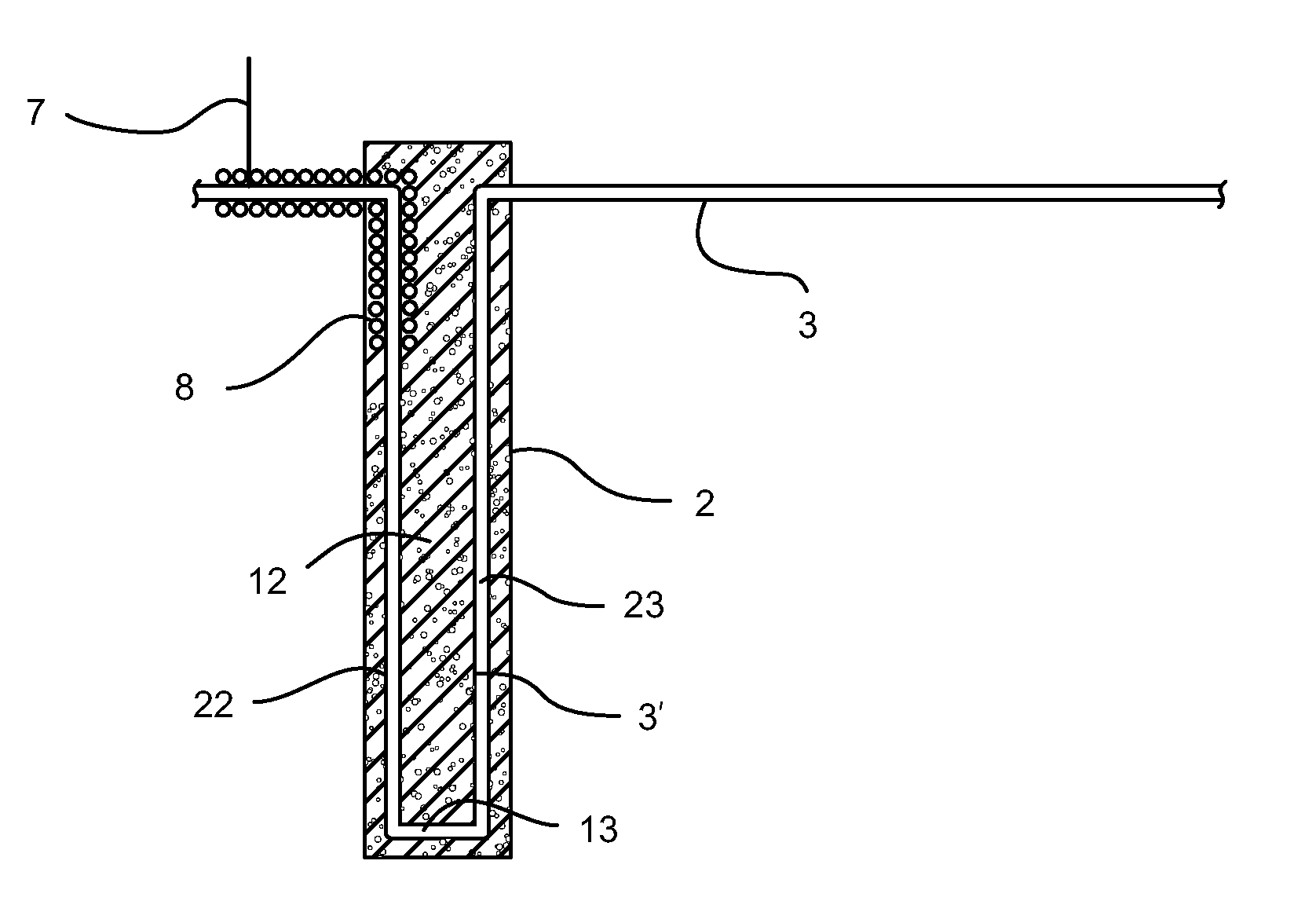

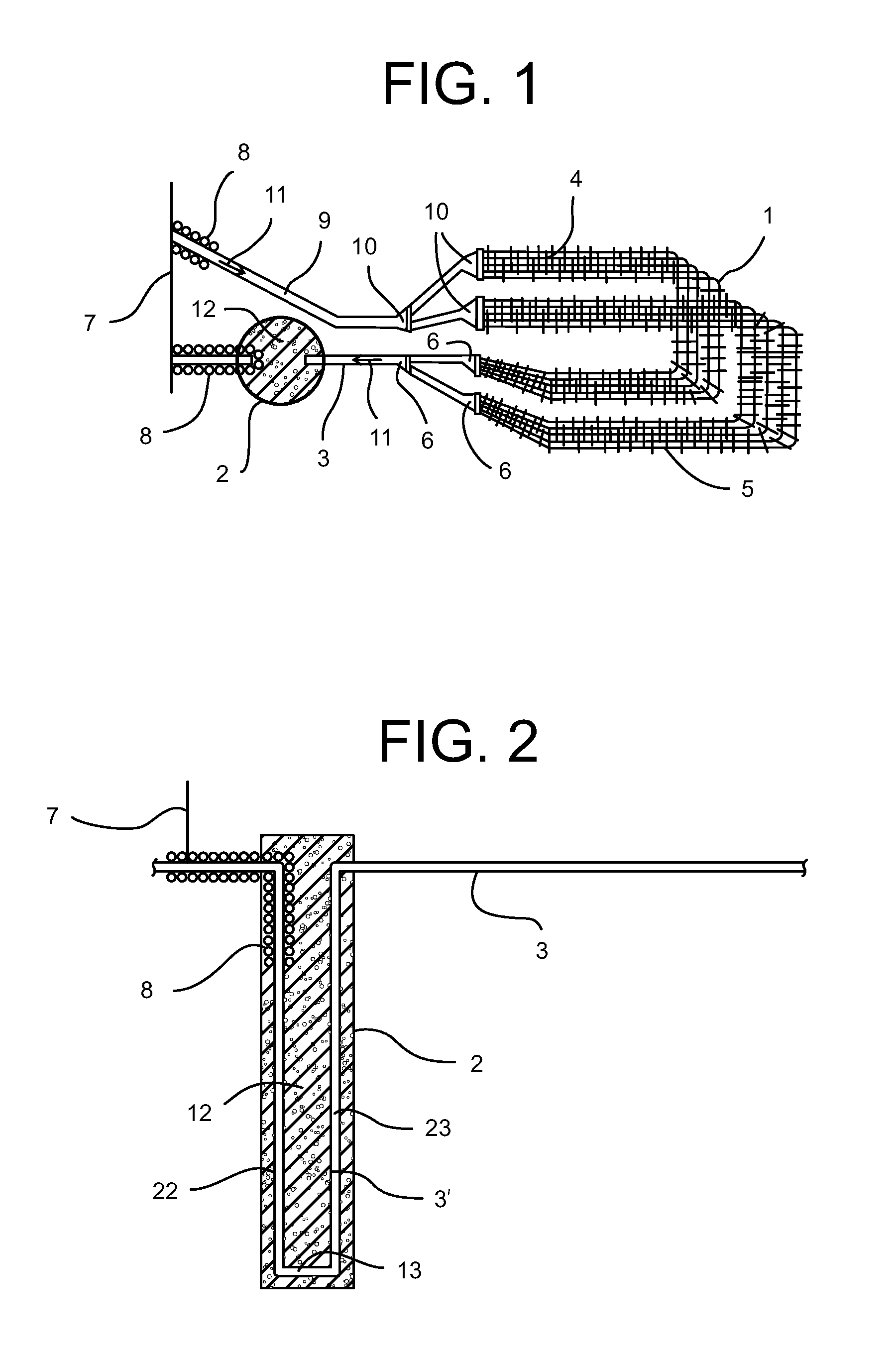

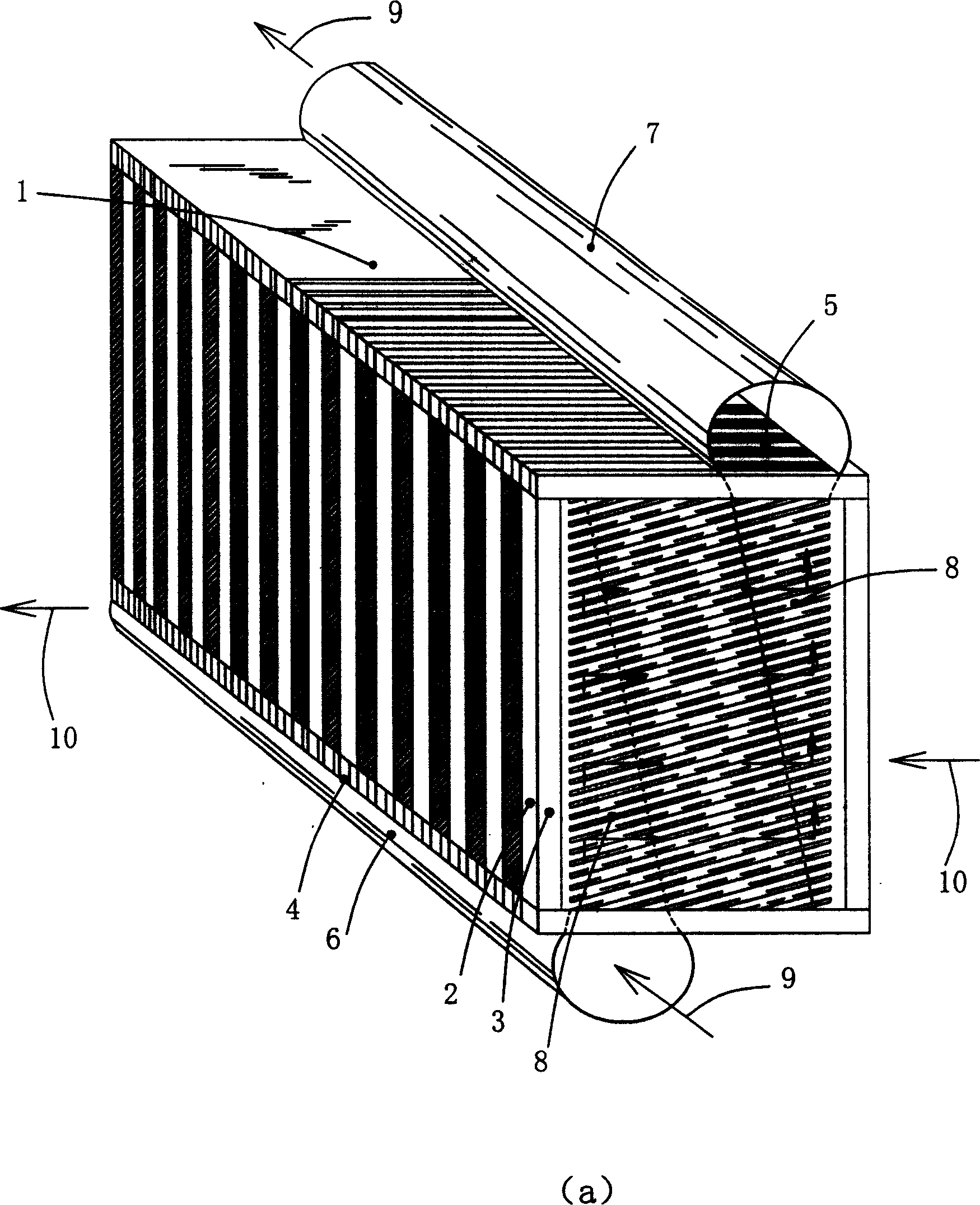

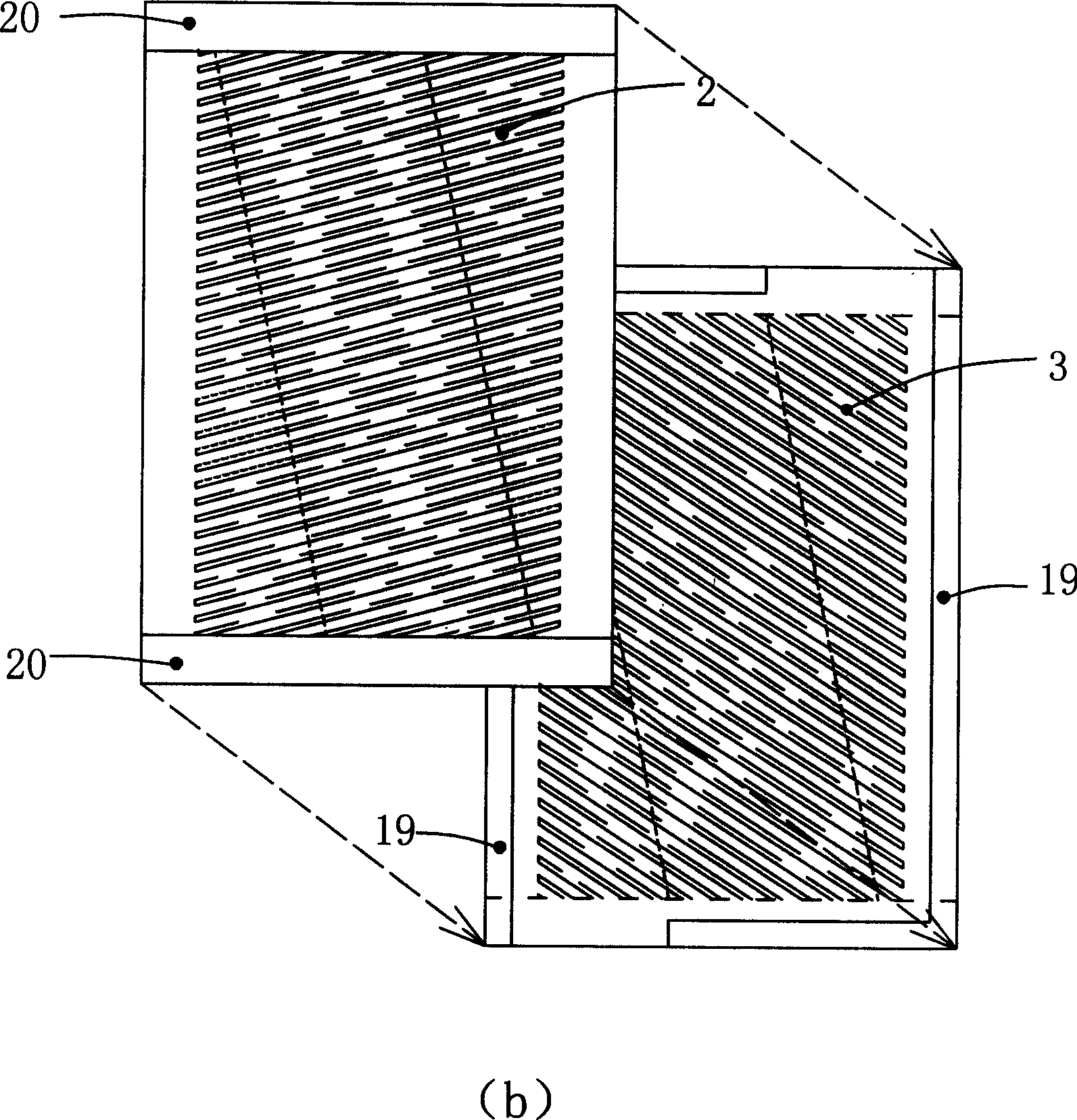

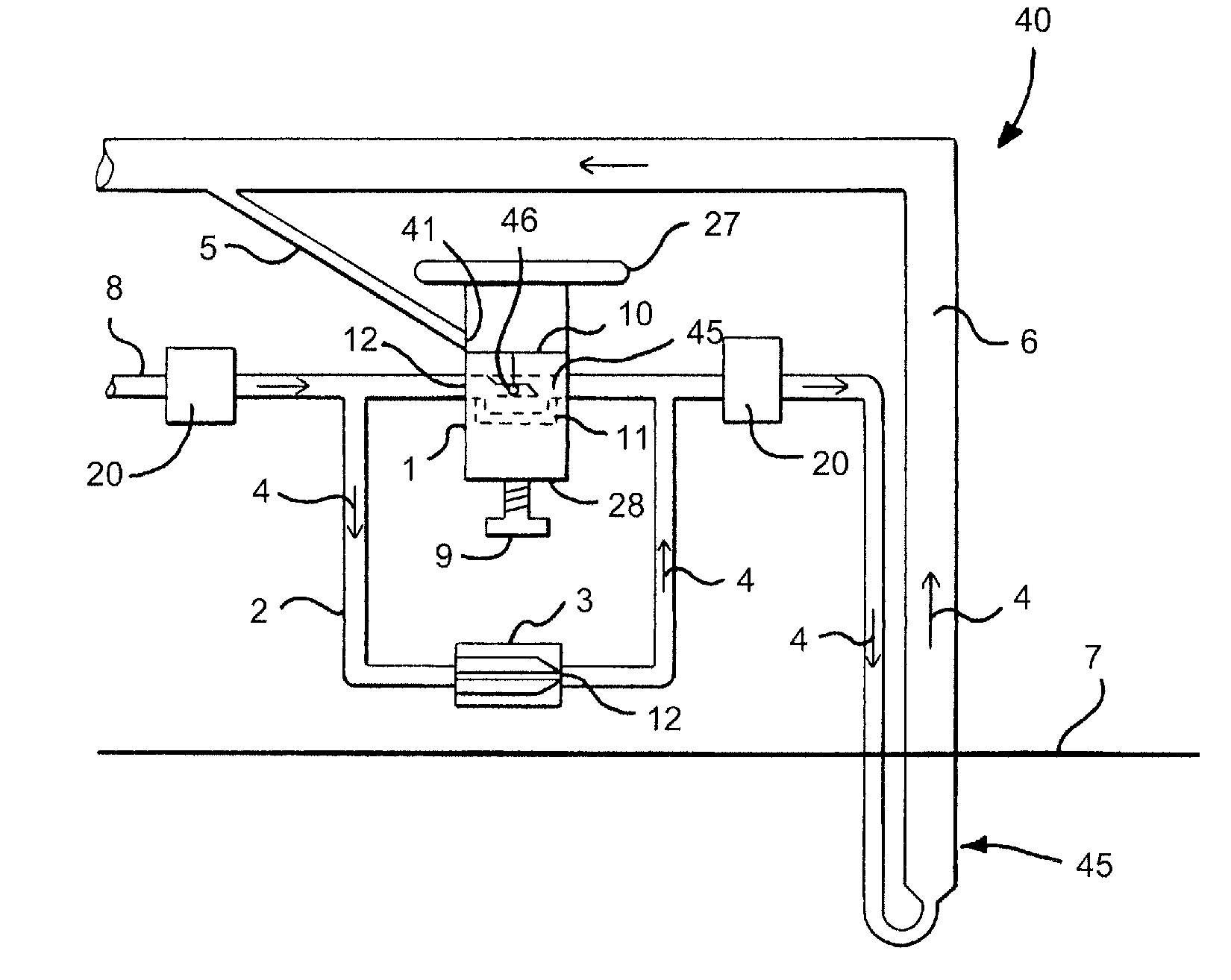

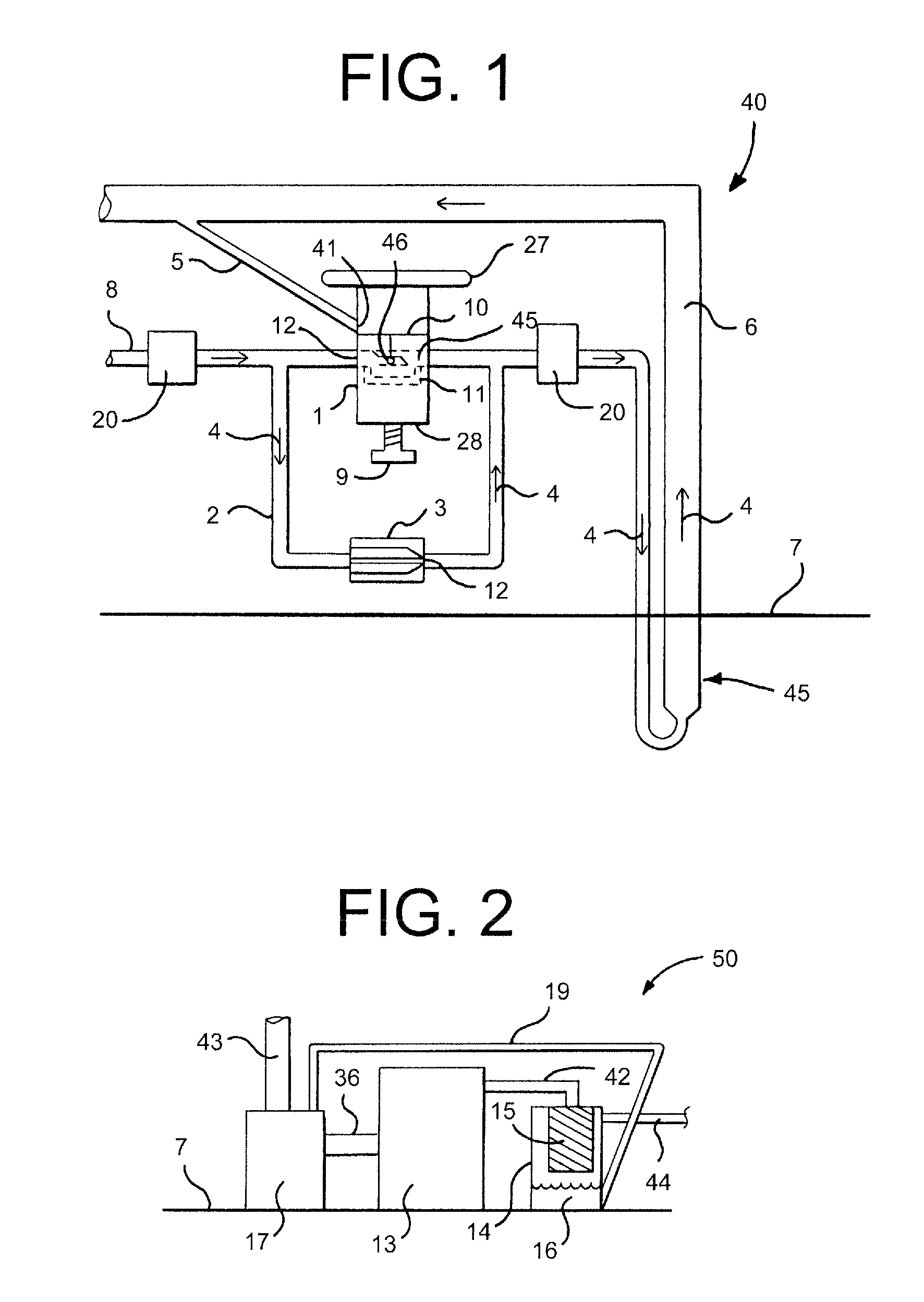

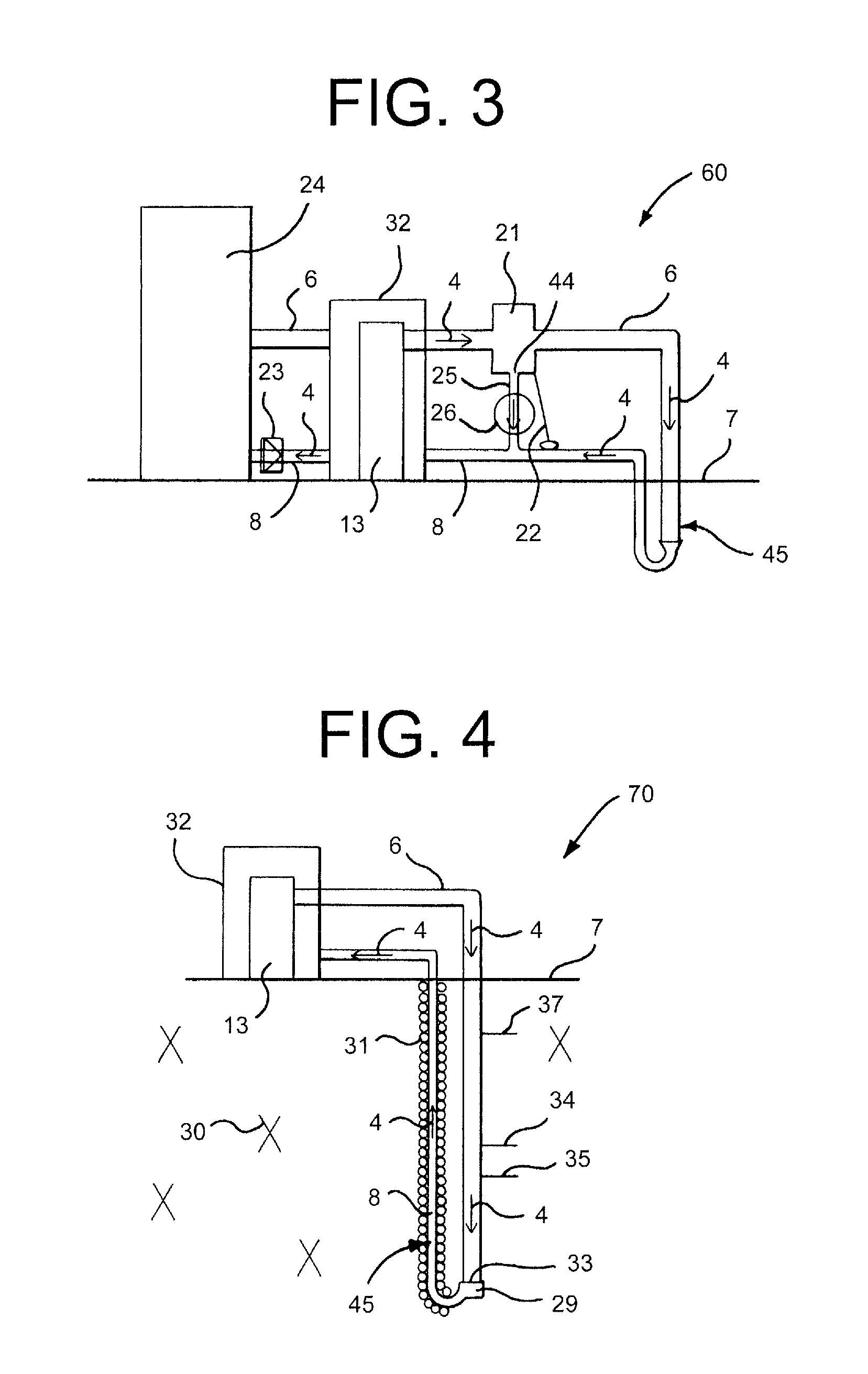

Integration of a surface heat-exchanger with regulated air flow in an airplane engine

The present invention relates to a surface air-cooled oil cooler (1) in an airplane engine comprising at least one first oil circuit (4) and at least a first (2) and a second (3) exchange surface positioned on either side of the first oil circuit (4) and each able to be swept by an air flow, said second exchange surface (3) being positioned in the cavity (9) provided with an air inlet (6) and an air outlet (7), said inlet (6) and / or said outlet (7) comprising covering means (8) that allow to regulate the air supply on the second exchange surface (3).

Owner:TECHSPACE AERO

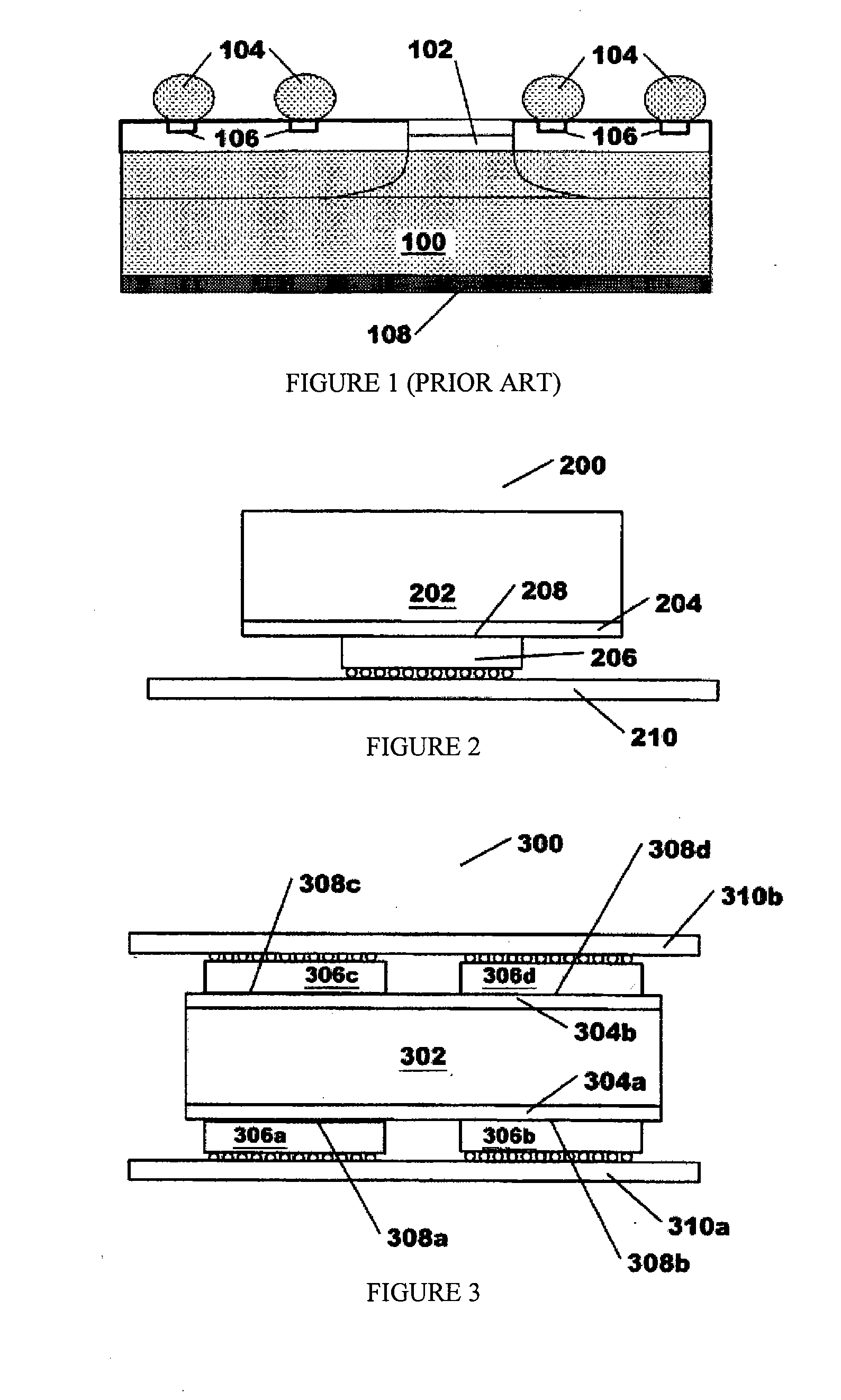

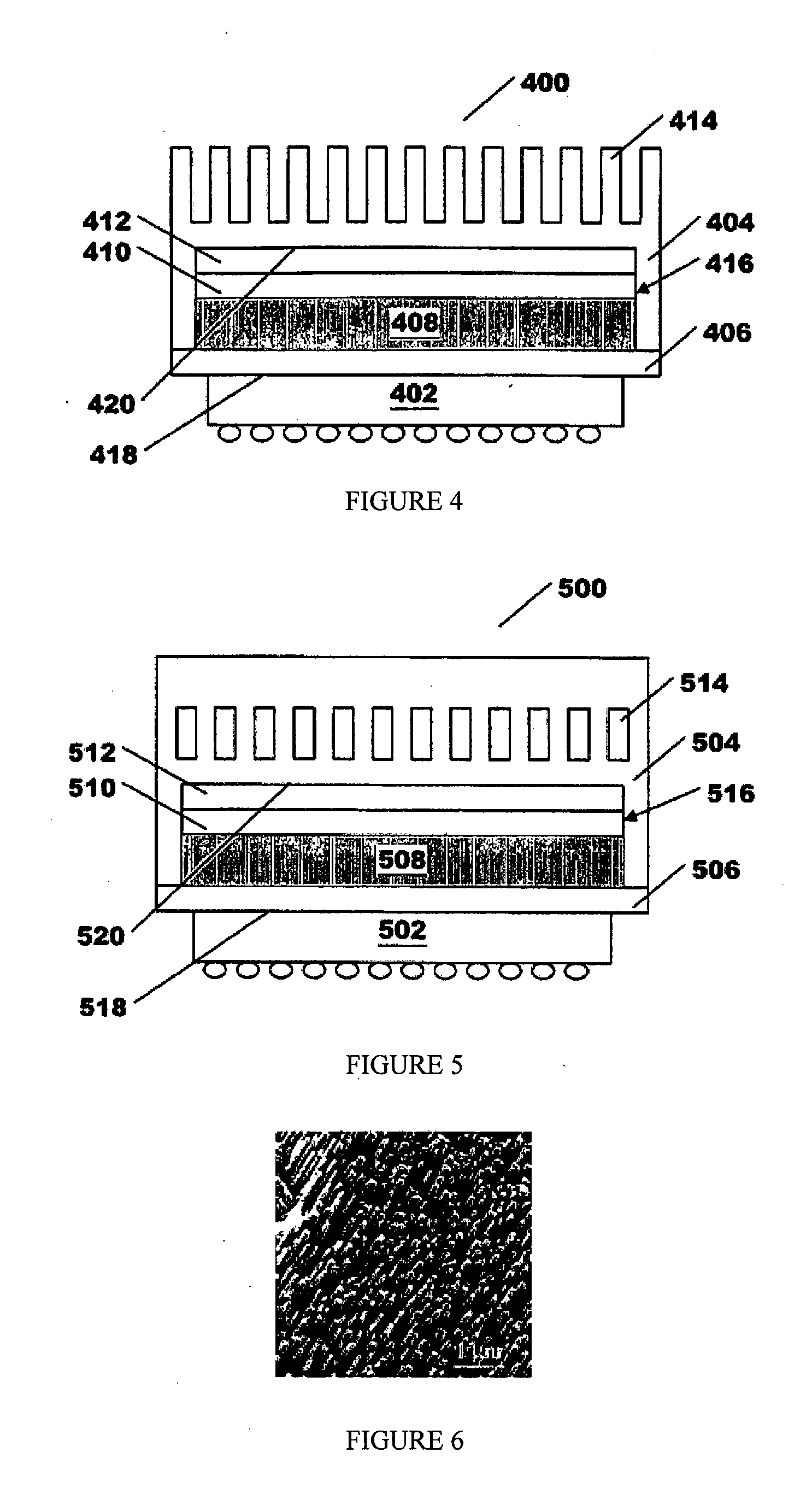

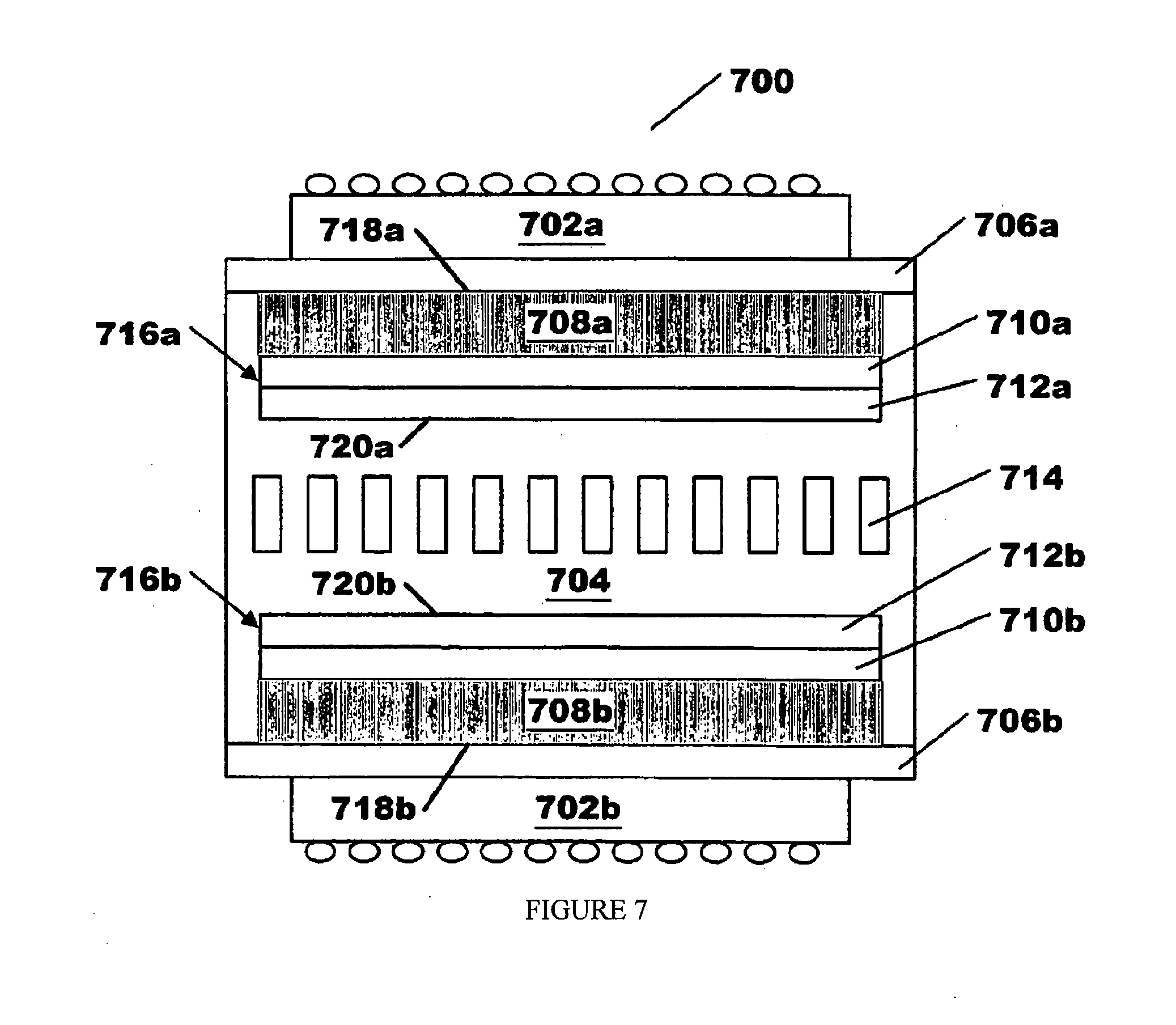

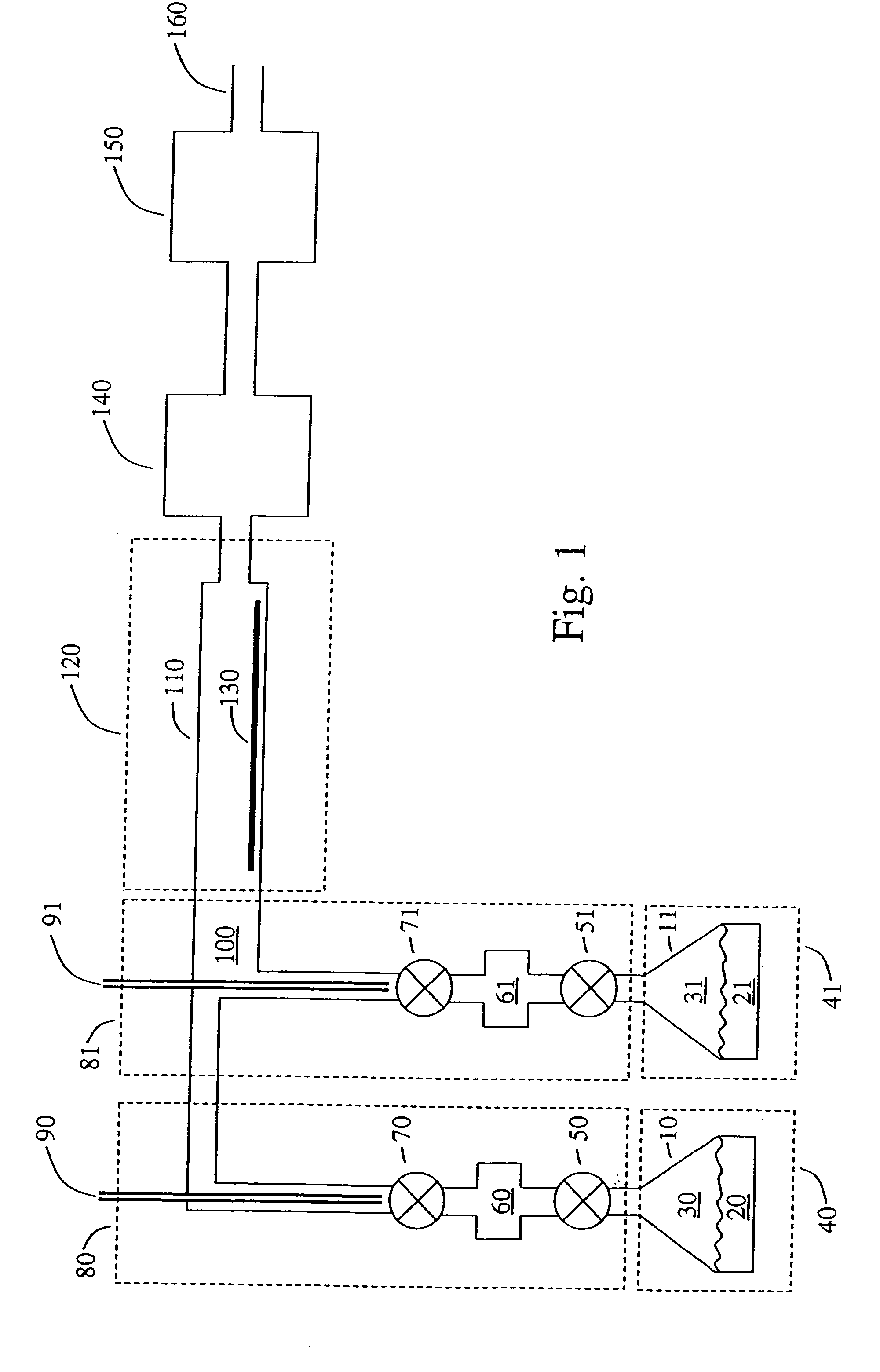

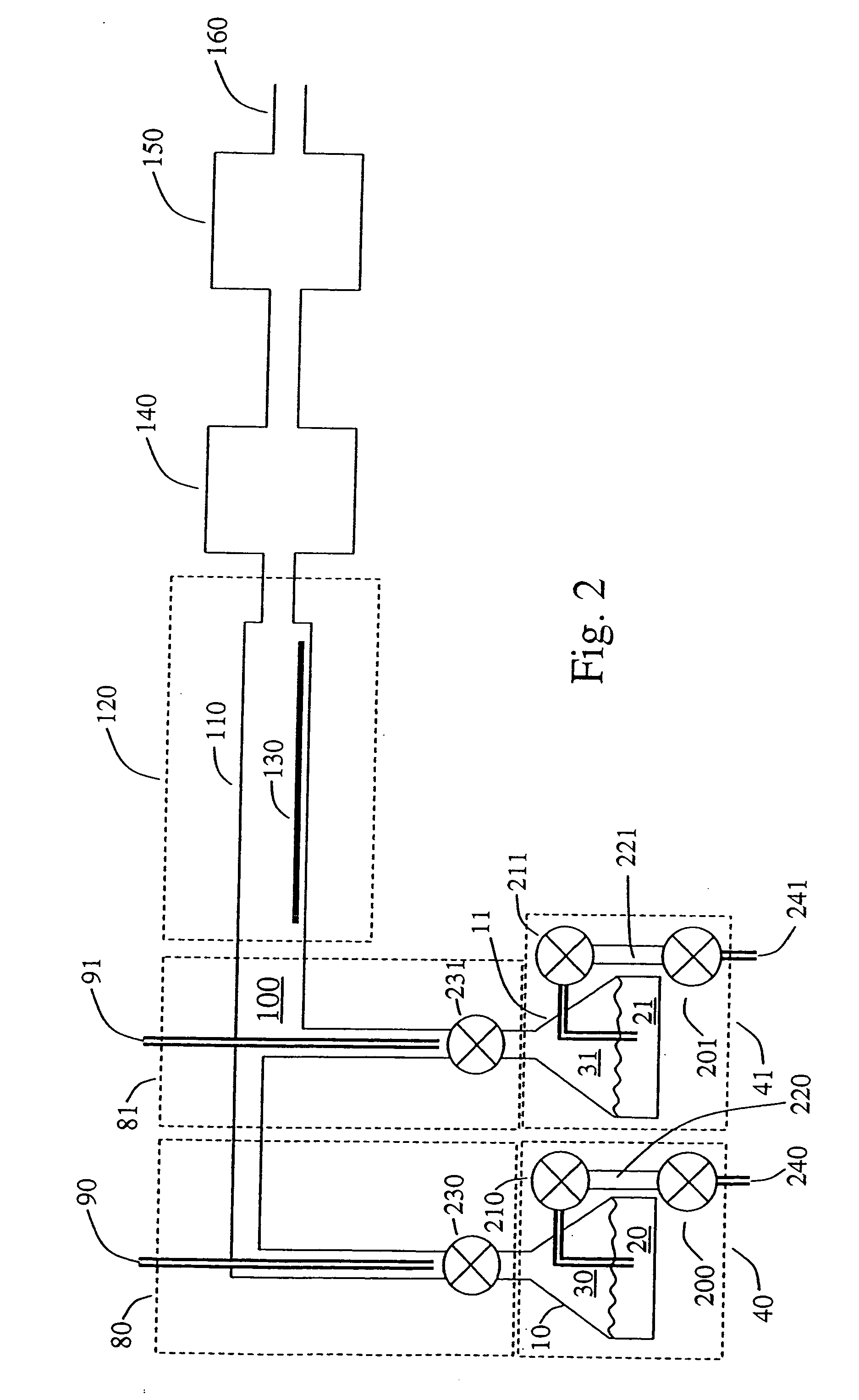

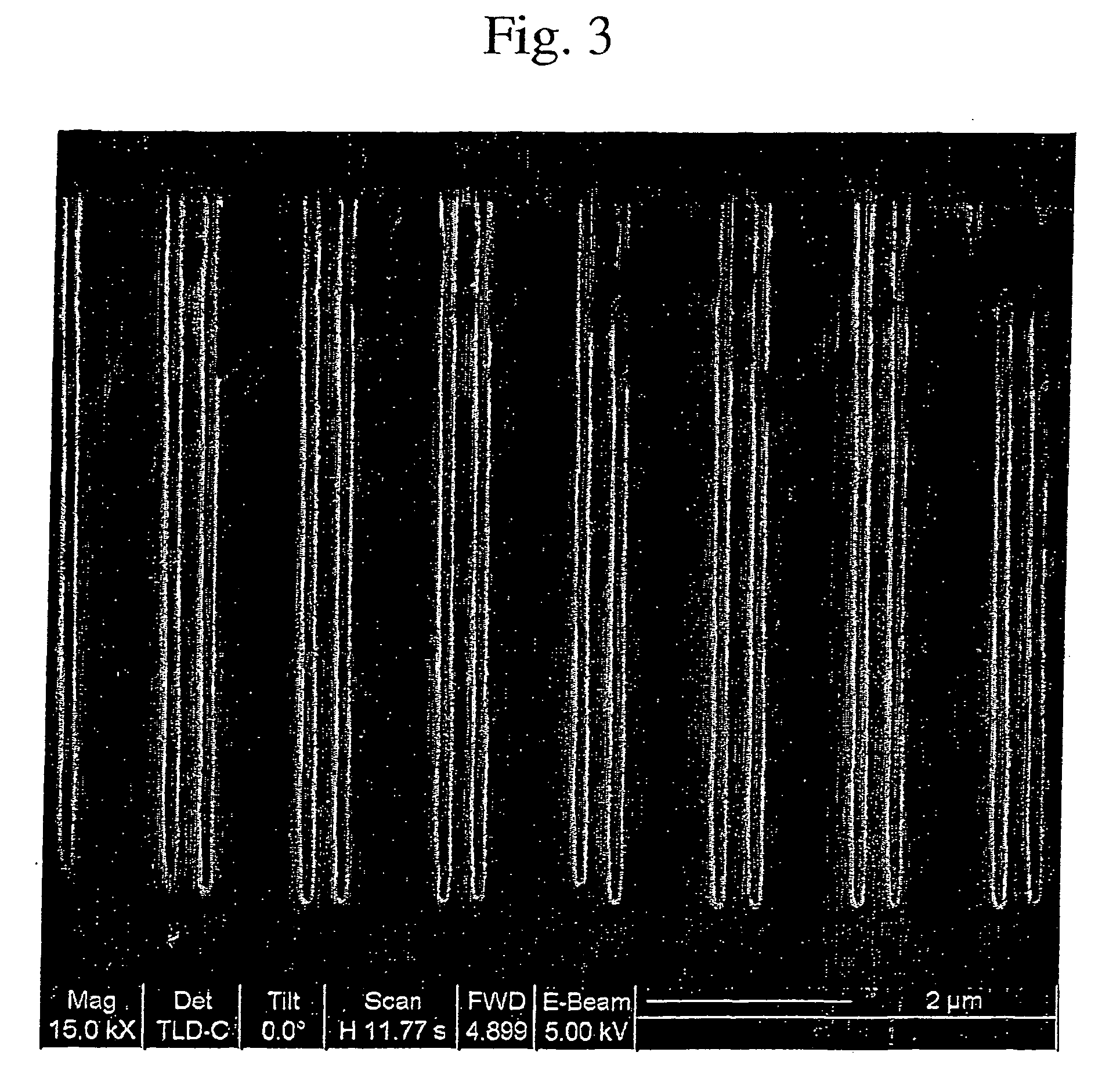

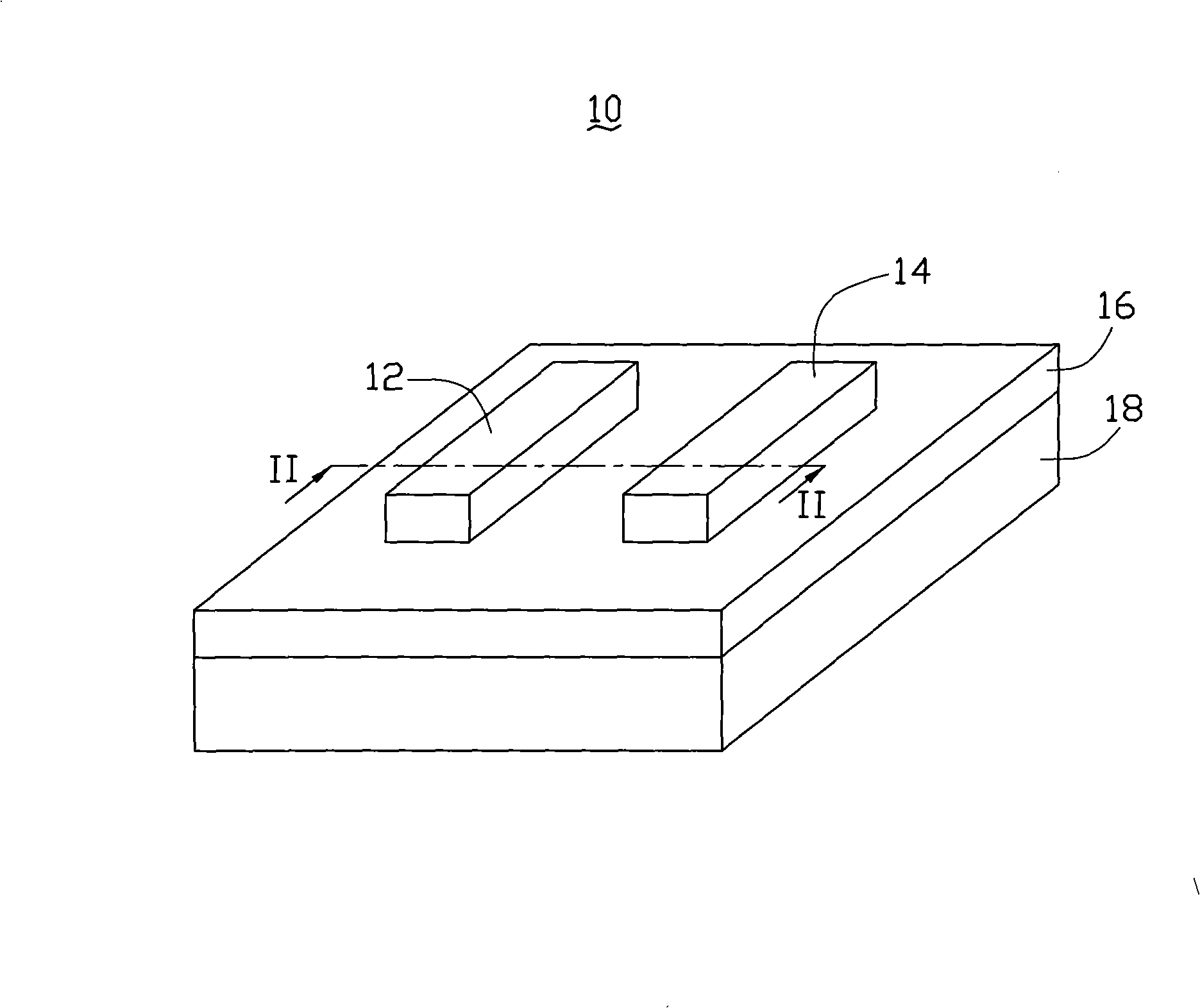

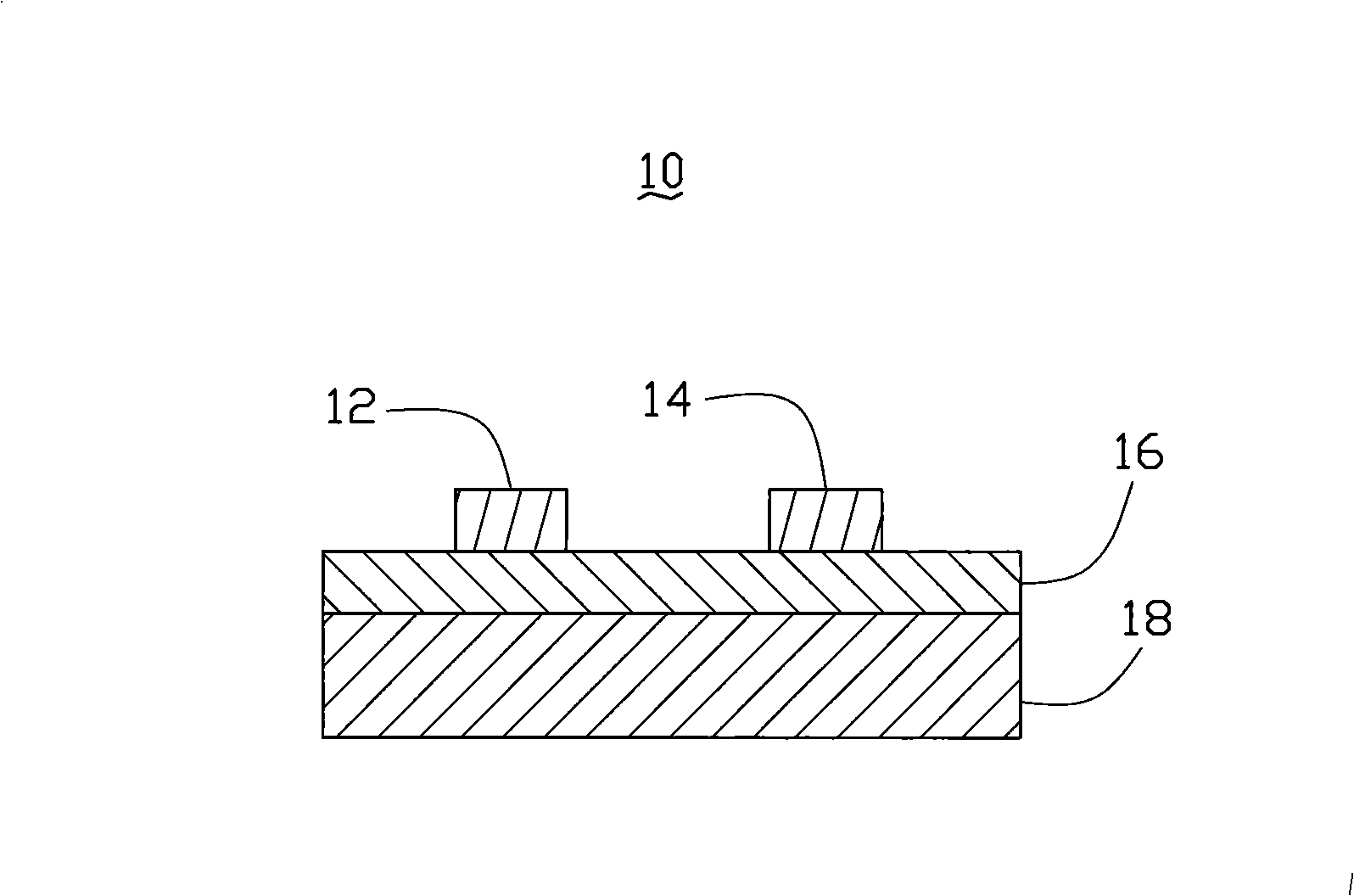

Integrated Circuit Micro-Cooler Having Tubes of a CNT Array in Essentially the Same Height over a Surface

InactiveUS20070126116A1Semiconductor/solid-state device detailsNanoinformaticsNanowire arrayNanometre

Heat sink structures employing carbon nanotube or nanowire arrays to reduce the thermal interface resistance between an integrated circuit chip and the heat sink, where the nanotubes are cut to essentially the same length over the surface of the structure, are disclosed. Carbon nanotube arrays are combined with a thermally conductive metal filler disposed between the nanotubes. This structure produces a thermal interface having high axial and lateral thermal conductivities.

Owner:NANOCONDUCTION

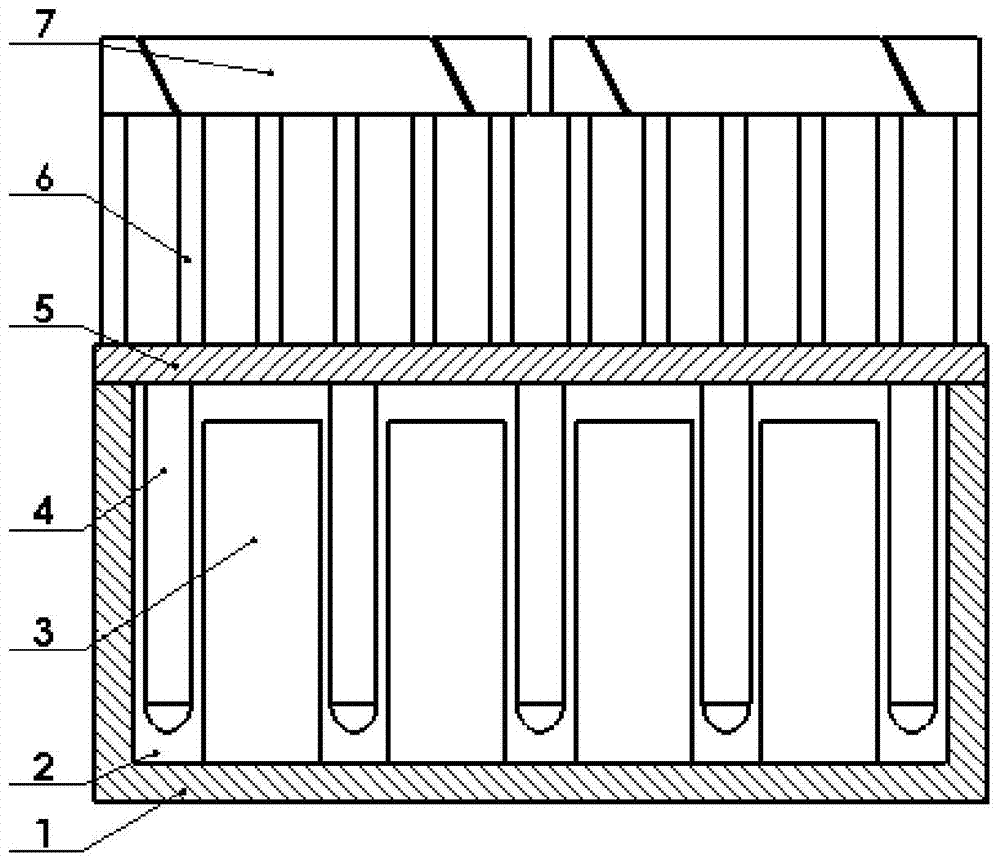

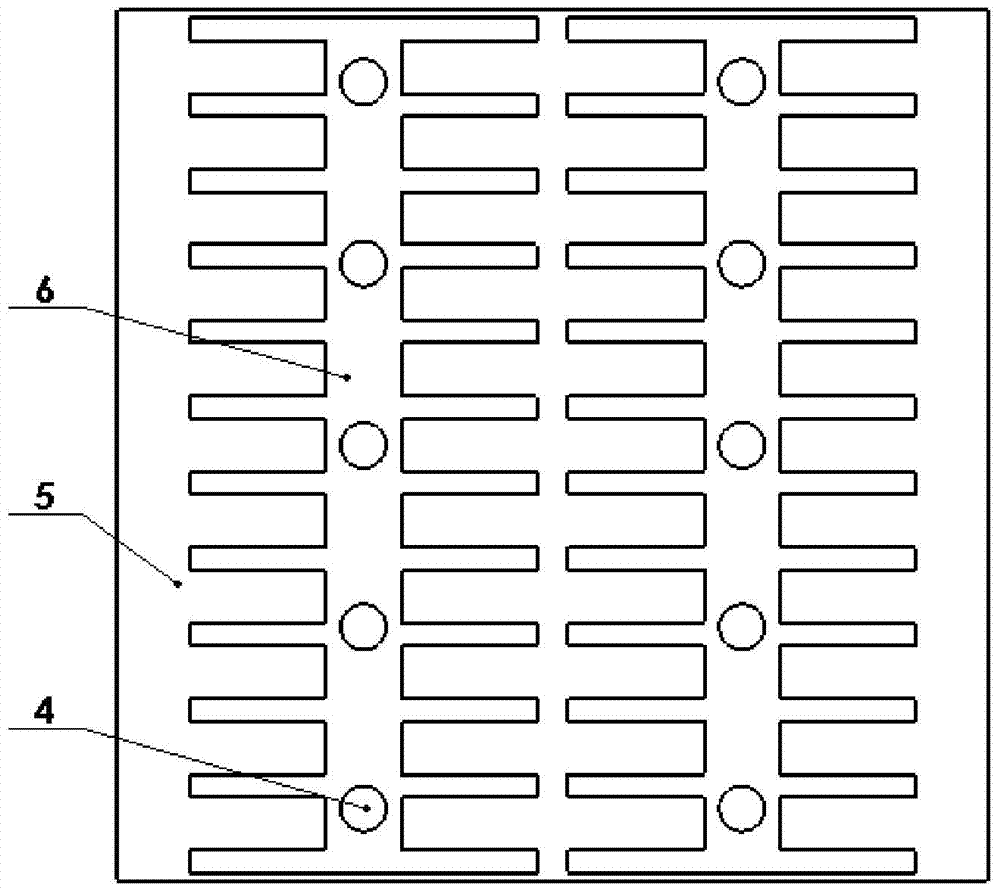

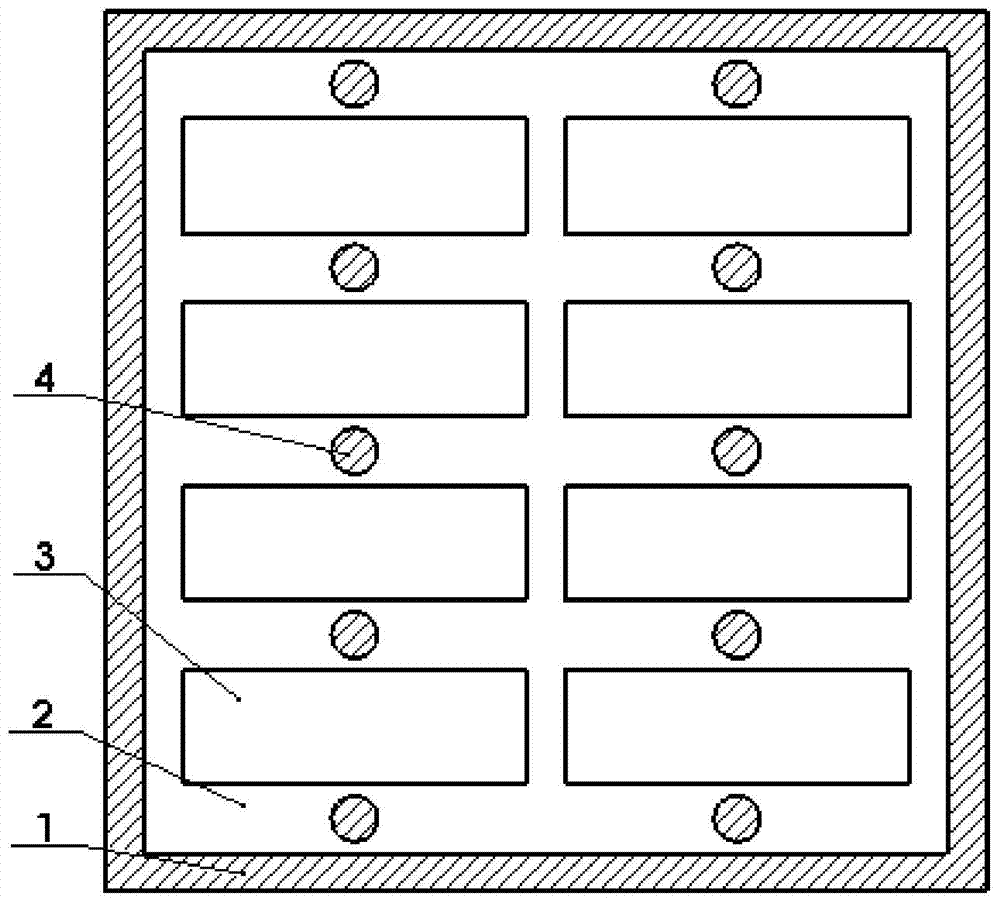

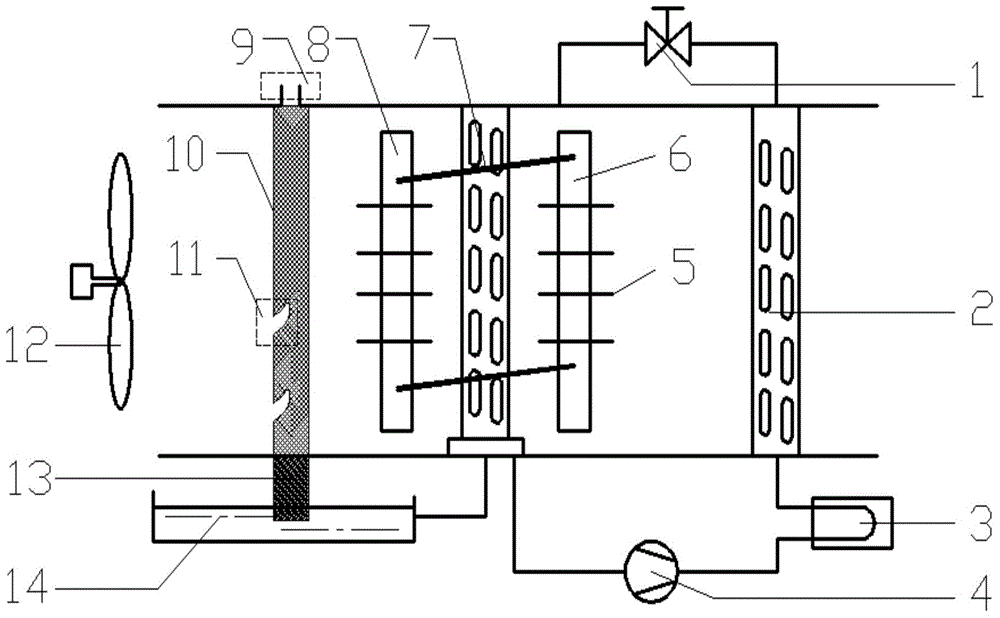

Combined heat dissipation device of power battery pack

InactiveCN103682517ADownsizing and shrinkingEasy to integrateSecondary cellsPower batteryEngineering

The invention discloses a combined heat dissipation device of a power battery pack. The combined heat dissipation device comprises a box body, a cover plate, battery cells, phase change material layers, porous surface heat pipes, radiating fins and fans, wherein the battery pack comprising the plurality of battery cells is arranged in the box body; a gap is formed between every two adjacent battery cells and filled with the phase change material layer; the porous surface heat pipes are embedded into the phase change material layers and filled with liquid cooling working mediums; the radiating fins are mounted on the cover plate; the porous surface heat pipes are connected with the radiating fins; the cover plate is in seal fit with the box body; the fans are mounted at the top ends of the radiating fins. Heat generated by the battery pack is stored through the phase change material layers, and the heat in the phase change material layers is transferred to the radiating fins through the porous surface heat pipes and finally guided to an external environment; the number of started fans is decided according to the heat generated by the battery pack to forcedly dissipate the heat so as to keep the original temperature of a battery, prevent the temperature of the battery from being increased due to the rapidly increased heat generated by the battery pack, improve the safety of the battery and prolong the service life of the battery.

Owner:SOUTH CHINA UNIV OF TECH

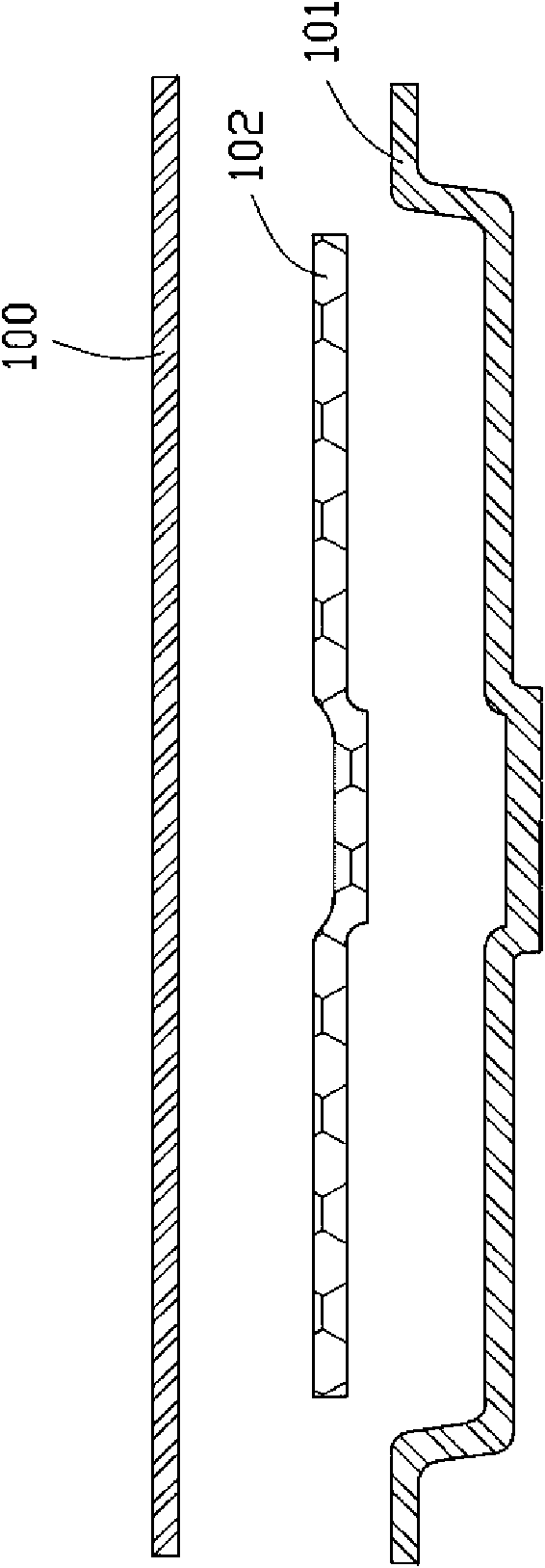

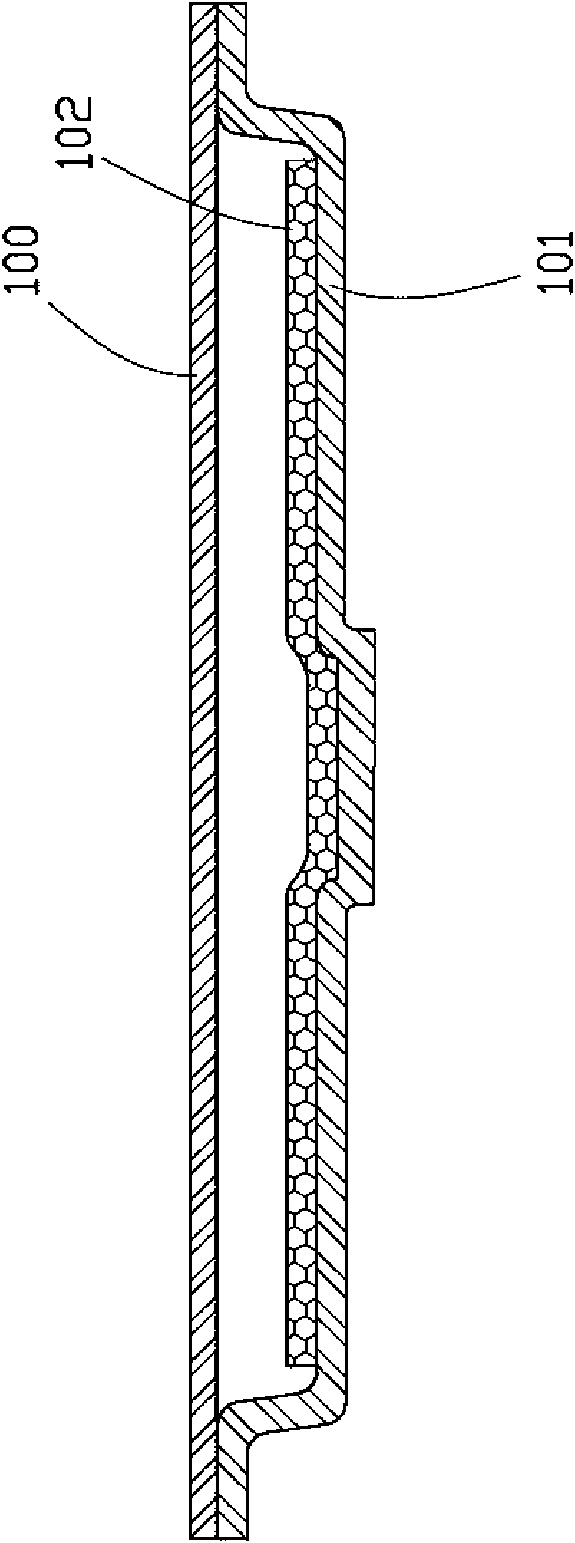

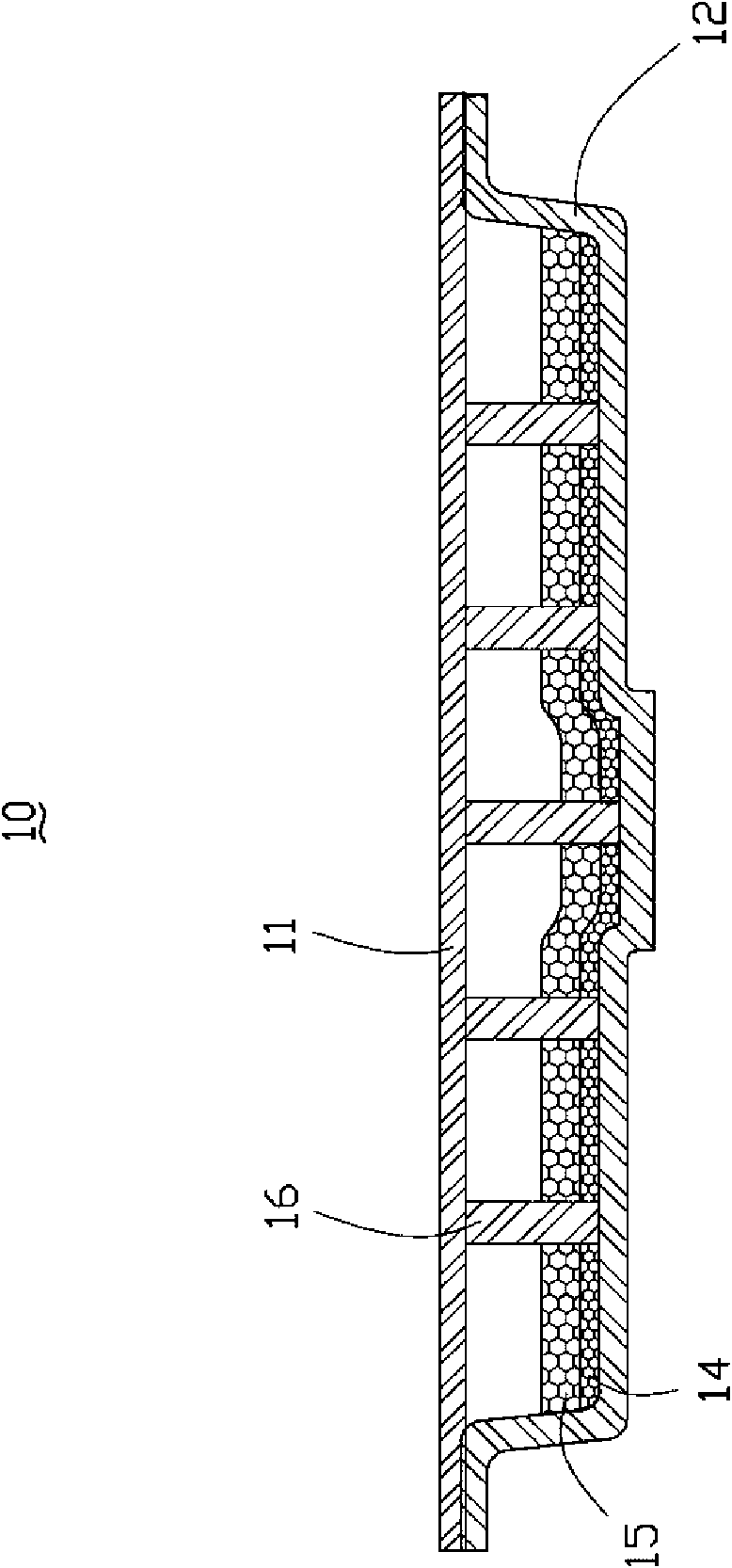

Method for manufacturing flat-plate heat tube

InactiveCN101639331AAppropriate intensityAppearance and shapeIndirect heat exchangersVacuum pumpingWorking fluid

The invention relates to a method for manufacturing a flat-plate heat tube. The method comprises the following steps: (1) providing an upper cover plate and a lower cover plate; (2) providing a plurality of first metal powders, and after being sintered, the first metal powders form a plurality of supporting columns; (3) arranging one end of each of the supporting columns on the upper surface of the lower cover plate, and correspondingly, the height of each supporting column is equivalent to the distance between the corresponding positions of the upper cover plate and the lower cover plate; (4)providing a plurality of second and third metal powders, filling the bottom of the lower cover plate with the metal powders, arranging the metal powders in the way of surrounding the supporting columns, and sintering the lower cover plate at a high temperature so as to enable the second metal powders to form a first capillary structure attached to the upper surface of the lower cover plate and toenable the third metal powders to form a second capillary structure attached to the upper surface of the first capillary structure; (5) welding the supporting columns and the lower cover plate on thelower surface of the upper cover plate so as to form a rough blank; and(6) processing the rough blank by vacuum-pumping, working fluid injection, degasification, sealing and surface heat treatment, thereby obtaining the final product of the flat-plate heat tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

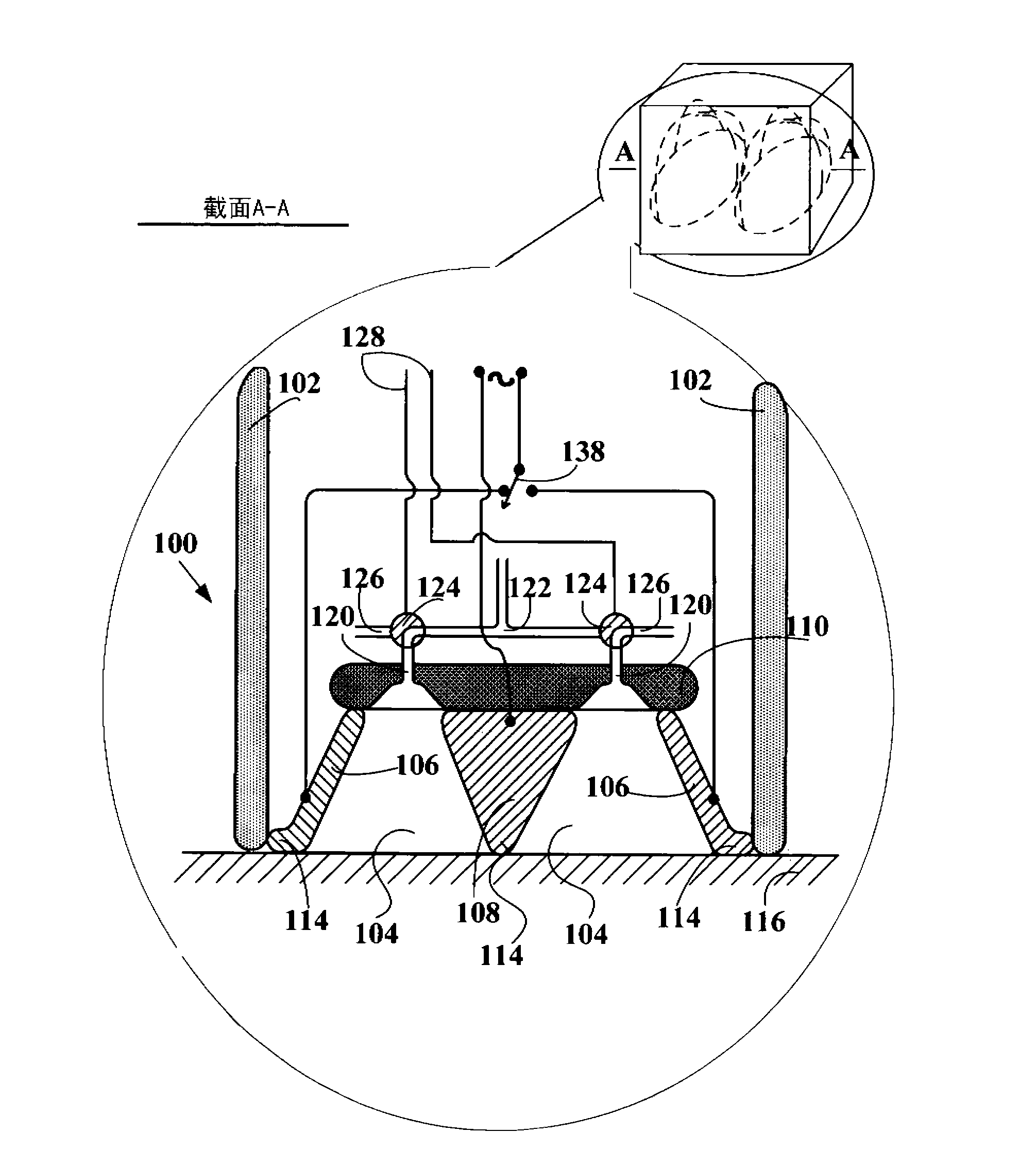

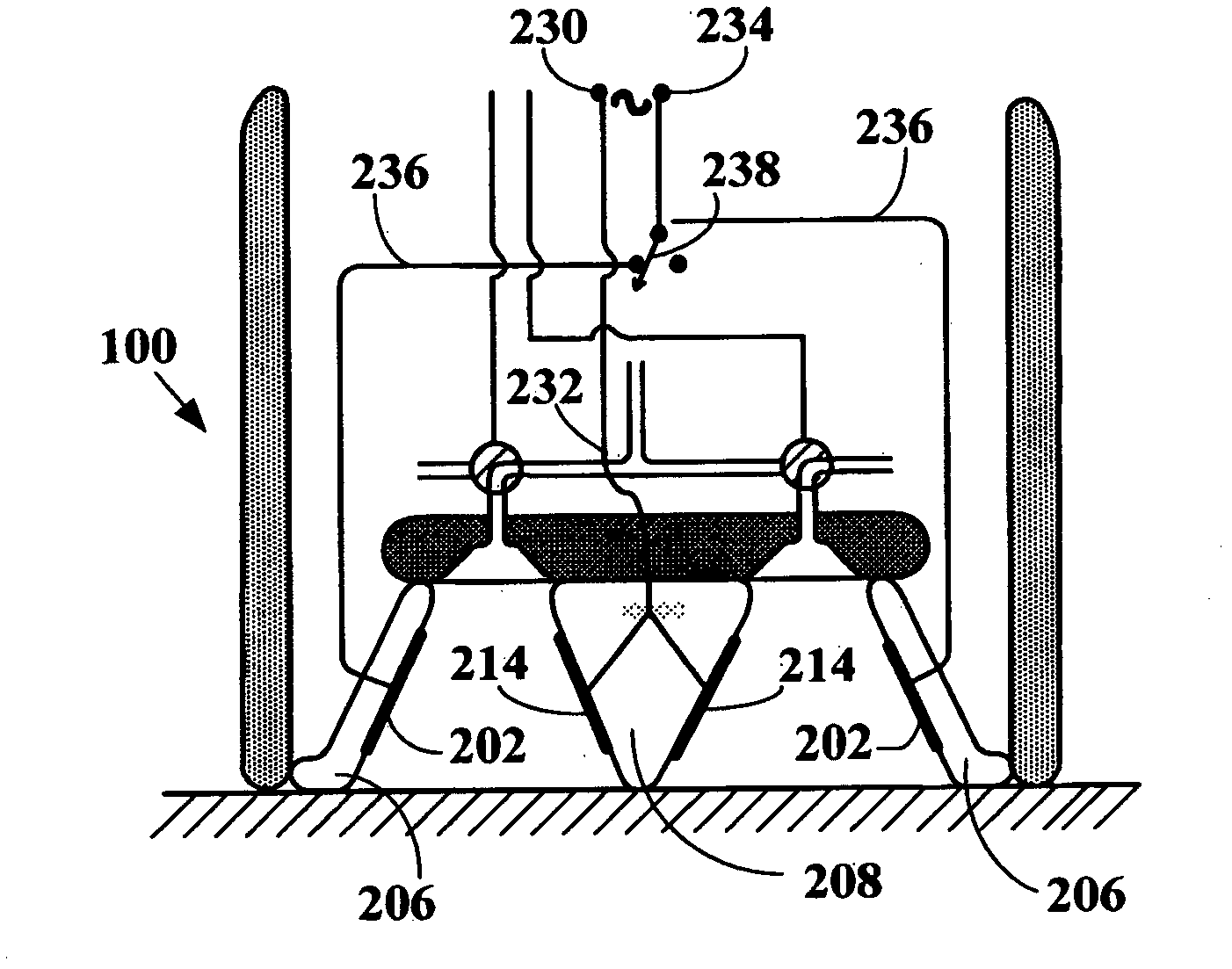

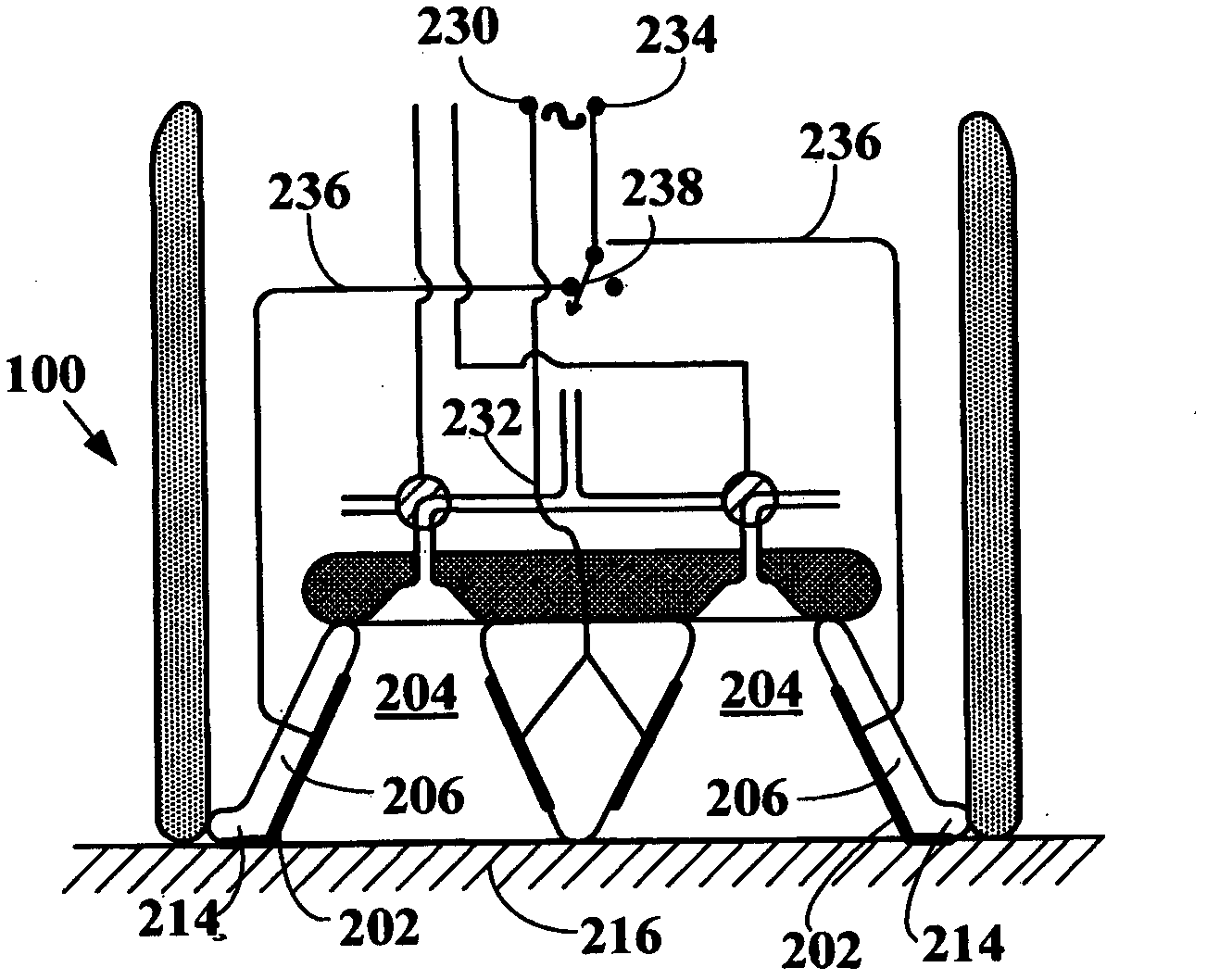

Method and apparatus for non- invasive aesthetic treatment of skin and sub-dermis.

An apparatus for massaging of skin and sub-dermis and treating the massaged skin by heat. The apparatus includes housing with two adjacent vacuum chambers sharing a common wall between them and an energy delivery surface. A source of negative pressure communicates with the vacuum chambers and alternates the negative pressure between the chambers to effect back and forth massaging movement of skin tissue in parallel to the surface of the skin. The energy delivery surface heats the skin in the chambers.

Owner:SYNERON MEDICAL LTD

Method for manufacturing bevel gear of axle gear box for diesel locomotives

The invention discloses a method for manufacturing a bevel gear of an axle gear box for diesel locomotives, which comprises the steps of blank forging, blank heat-treatment, gear-blank processing, gear-shape processing, gear-end processing, gear-surface heat-treatment, precise reference modification and gear-shape finish-machining, wherein the step of blank heat-treatment comprises the sub-steps of normalizing and thermal refining; the step of gear-blank processing comprises the sub-steps of rough turning and finish turning; the step of gear-shape processing comprises the sub-steps of gear milling, gear hobbing or gear shaping; the step of gear-surface heat-treatment comprises the sub-steps of nitriding, surface quenching and tempering; the step of precise reference modification comprises the sub-steps of end face modification and centre hole modification; and the step of gear-shape finish-machining comprises the sub-steps of gear grinding and polishing. By using the method disclosed by the invention, the production efficiency of the bevel gear can be improved, and the consumption amount and production cost of raw materials can be reduced; and meanwhile, the method is simple in process, and the manufactured bevel gear is long in service life.

Owner:常州市万航工矿设备有限公司

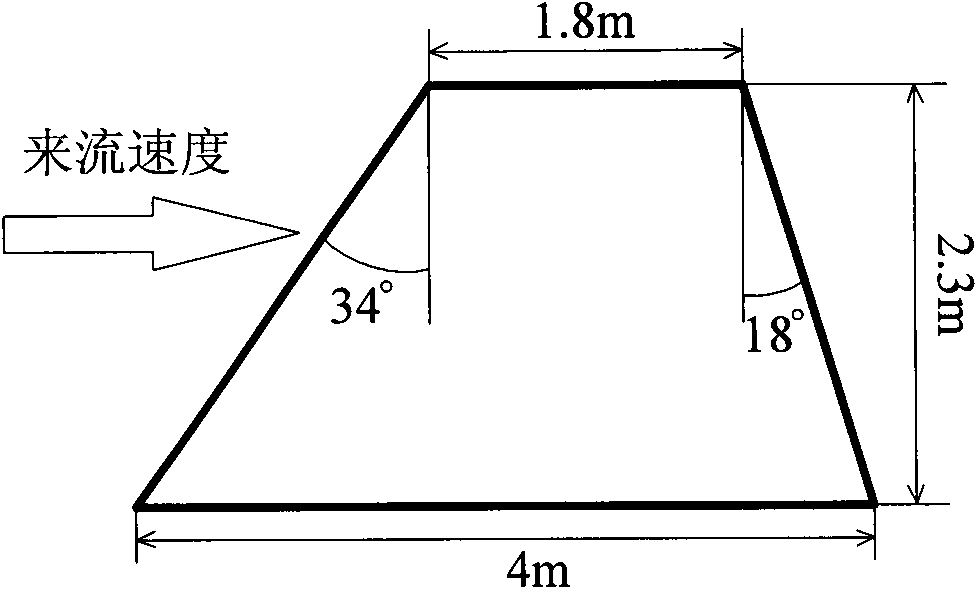

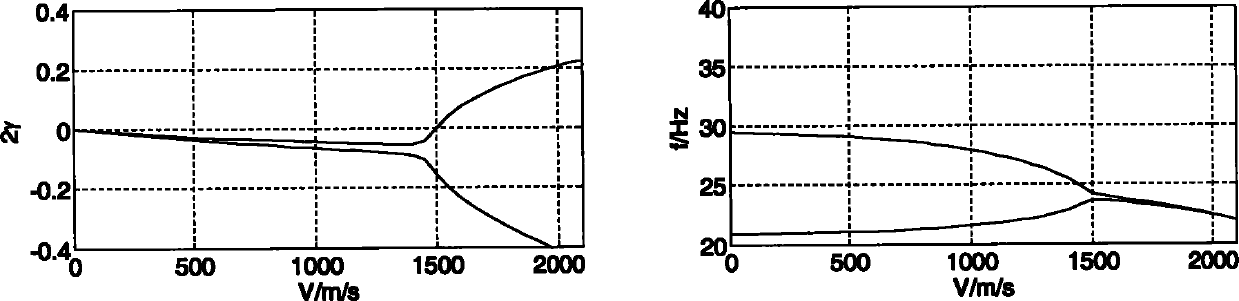

High-speed aircraft lifting surface aerodynamic heating structure multidisciplinary optimization design platform

InactiveCN101916314AImprove efficiencySimple planSpecial data processing applicationsEngineeringModelling analysis

The invention relates to a high-speed aircraft lifting surface aerodynamic heating structure multidisciplinary optimization design platform belonging to the technical field of modern high-speed aircraft designs. In the invention, by aiming at the demands of lifting surface heat vibration analysis in an aerodynamic heating environment when a high-speed aircraft lifting surface is designed and considering the positive correlation among aerodynamic heating structures, an aerodynamic heating structure integrated analysis method including aerodynamic heating calculation, transient heat conduction analysis, structural heat model analysis and non-constant aerodynamic force and heat vibration analysis is researched, and the aerodynamic heating structure multidisciplinary optimization design taking the most dangerous heat vibration speed as the constraint and taking the lifting surface structural quality as a target function is researched to achieve the goal of the optimization design on the high-speed aircraft lifting surface. The invention breaks through the problem that the multidisciplinary design optimization is carried out without combining with the influence of three aspects of aerodynamic heating on the structure in the traditional high-speed aircraft design, provides a set of high-speed aircraft lifting surface aerodynamic heating structure optimization design methods and waysand has the advantages of simple scheme and high efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

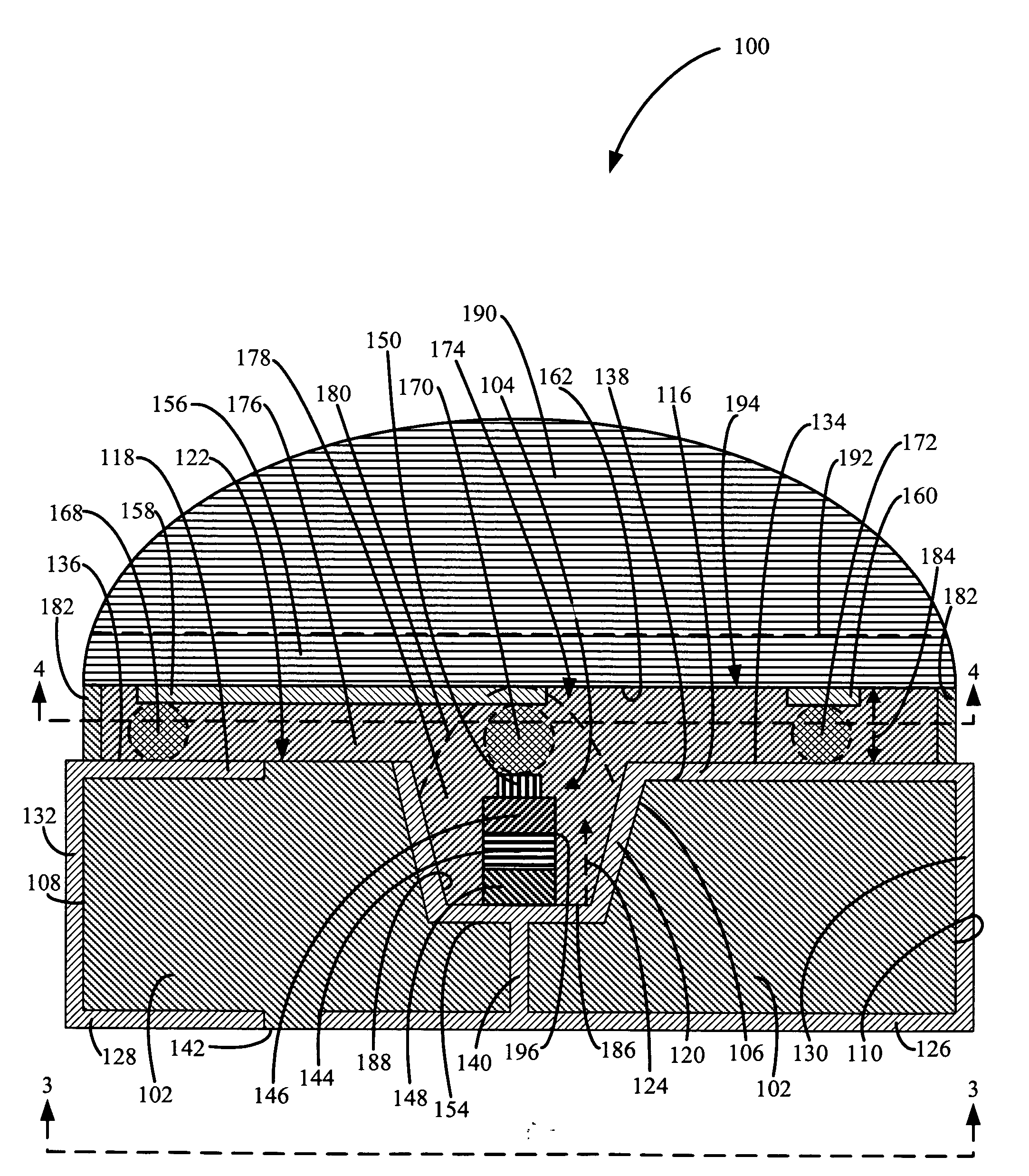

LED device having a top surface heat dissipator

An LED Device Having a Top Surface Heat Dissipator is provided. The LED Device Having a Top Surface Heat Dissipator includes a substrate body, and a light emitting diode over the substrate body. The LED Device Having a Top Surface Heat Dissipator also has an electrically and thermally conductive heat dissipator over the substrate body. A method of dissipating heat from an LED device is also provided.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

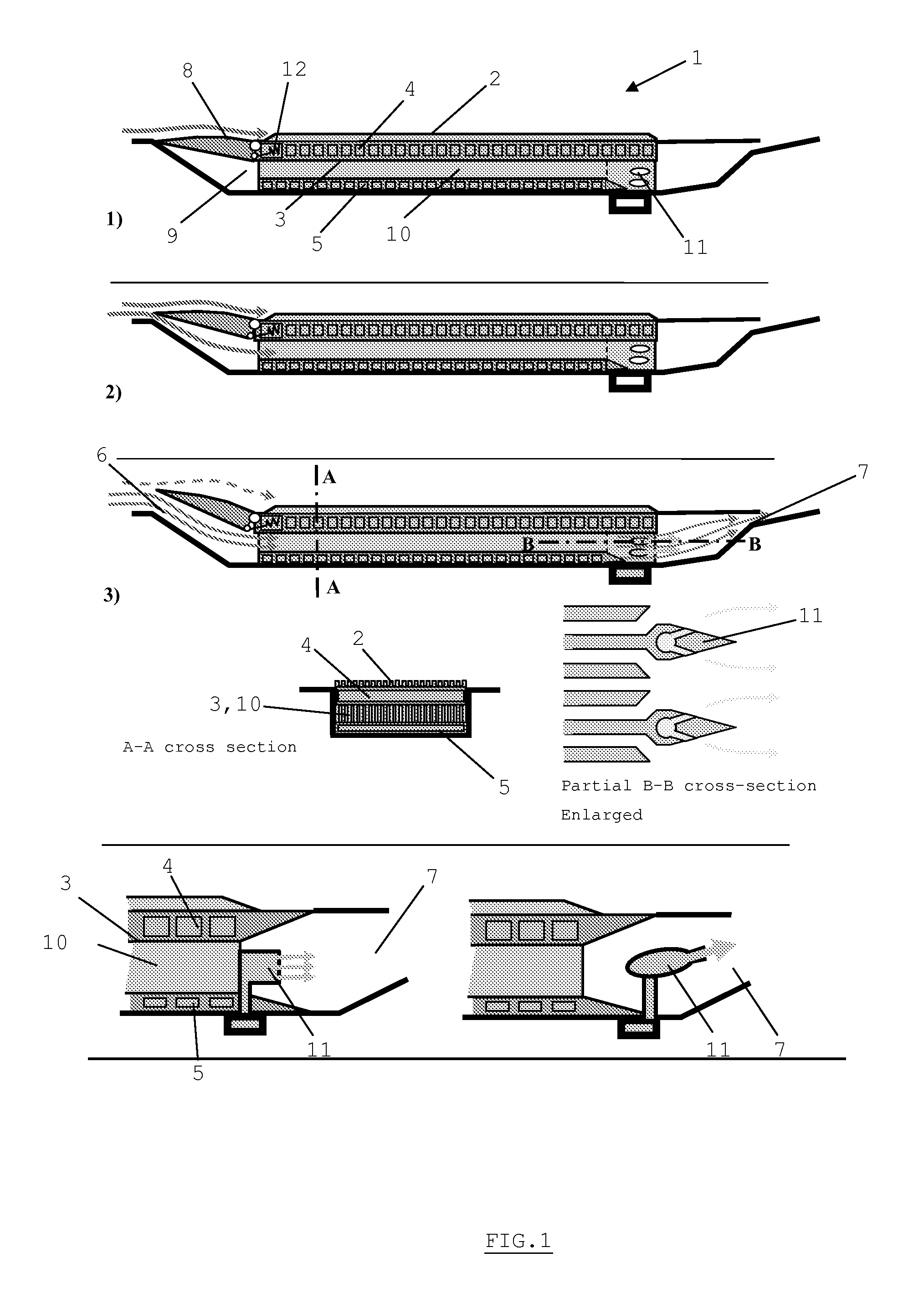

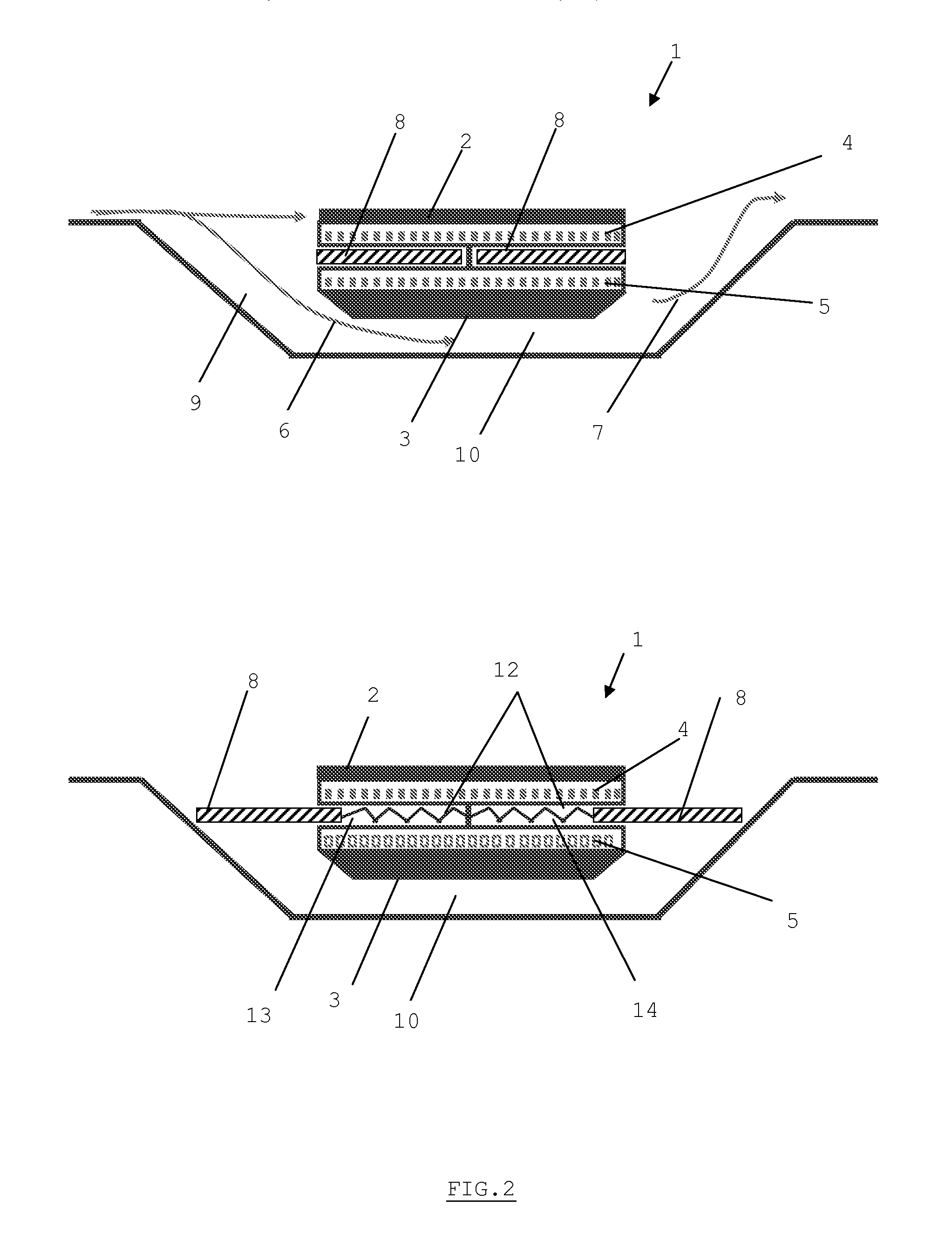

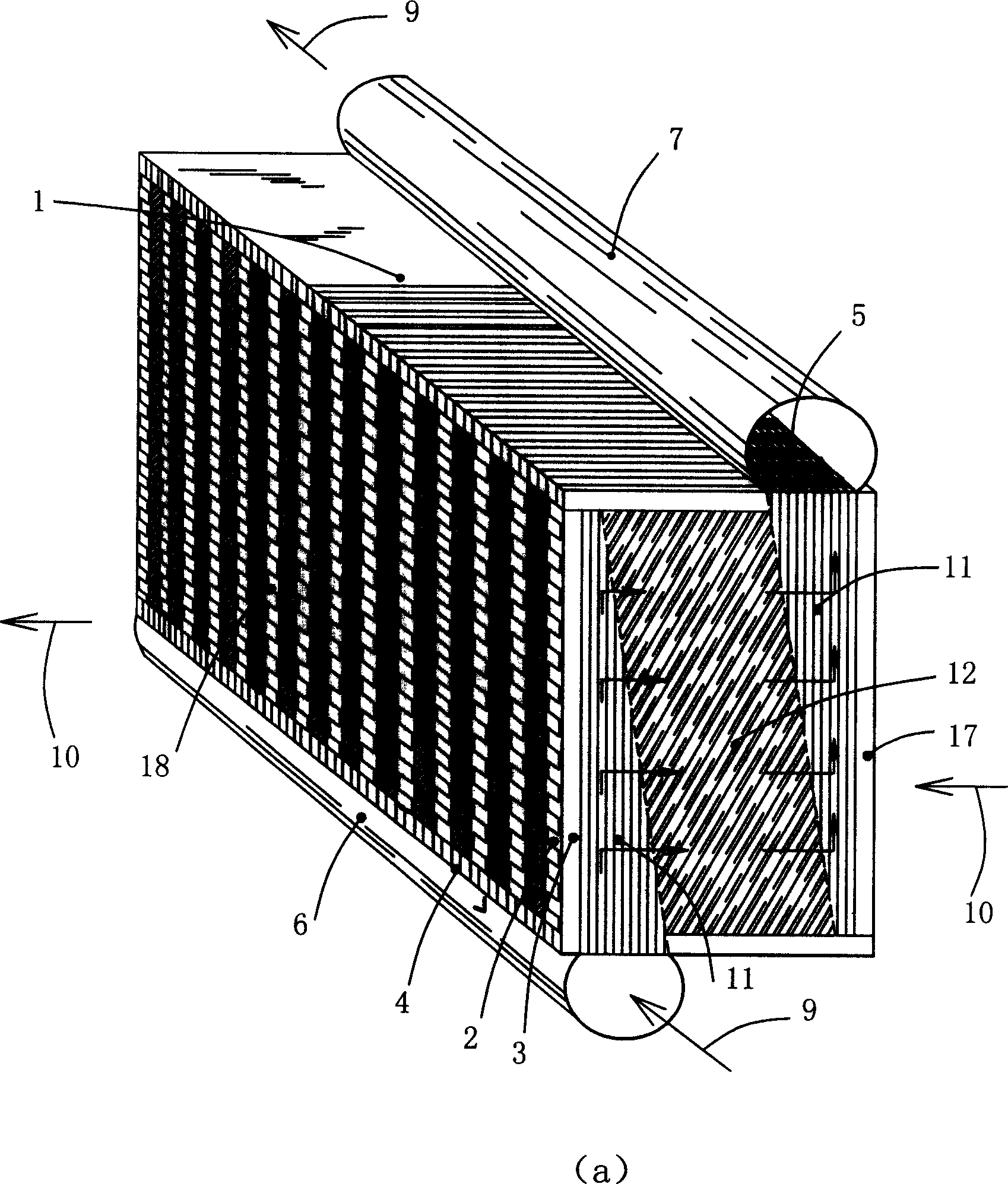

Integration of a Surface Heat Exchanger to the Wall of an Aerodynamic Flowpath by a Structure of Reinforcement Rods

Setting in place of one or several coolers in the wall of a secondary flow of a bypass turbomachine. The wall extends from an intermediate casing toward a leading edge of a separator nose between a primary flow and the secondary flow. The wall includes a series of support arms attached to an intermediate casing, distributed over the perimeter of the wall and directed upstream. A series of surface air-oil heat exchangers forming wall segments are arranged end-to-end on the support arms, so as to form an annular wall. A shroud having a leading edge is arranged and fixed in the area of the upstream edges of the heat exchangers, so as to complete the wall. The support arms include hydraulic connectors connected to one another on each arm, adapted to cooperate with corresponding connectors in the area of the heat exchangers and in the area of the intermediate casing.

Owner:TECHSPACE AERO

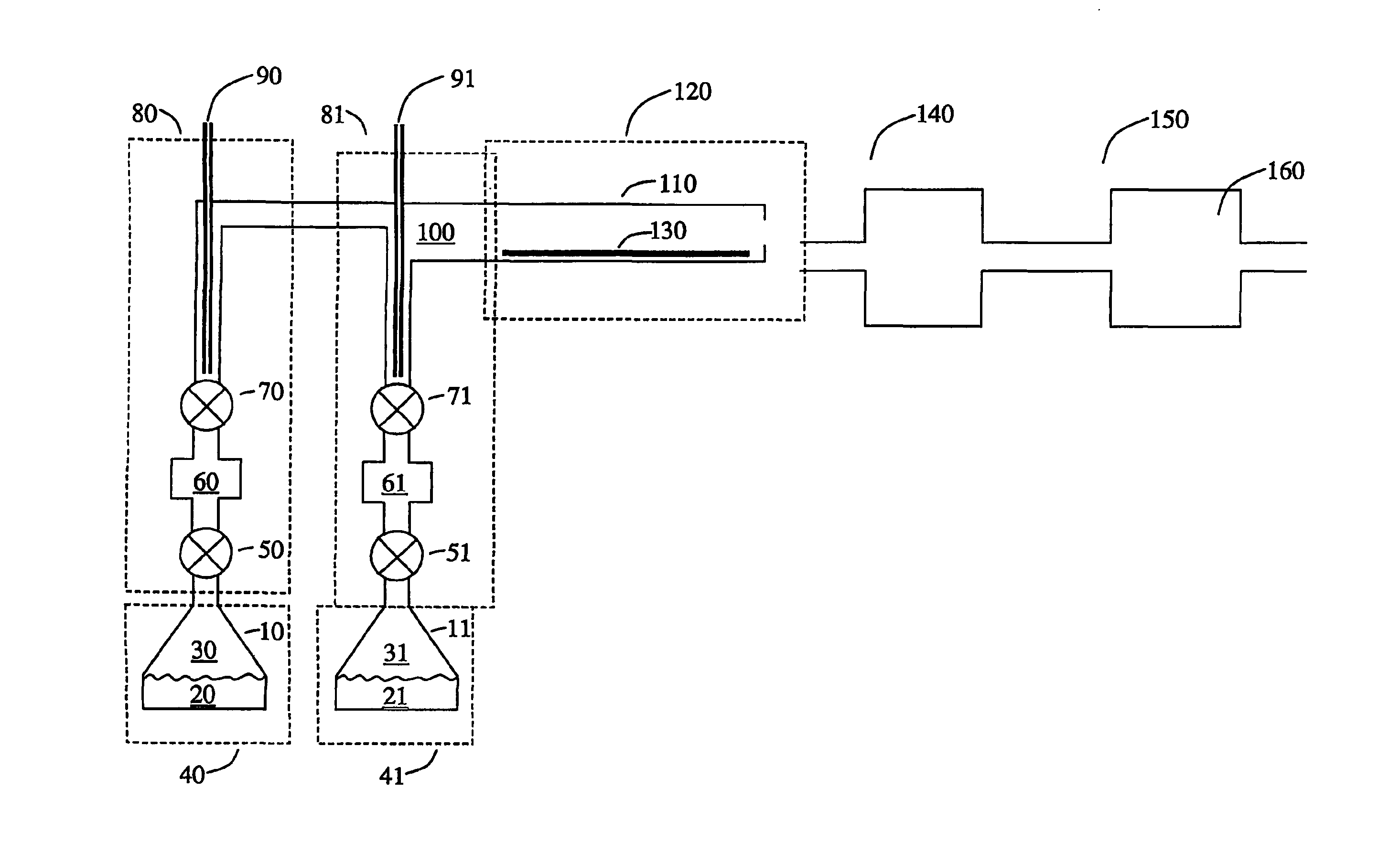

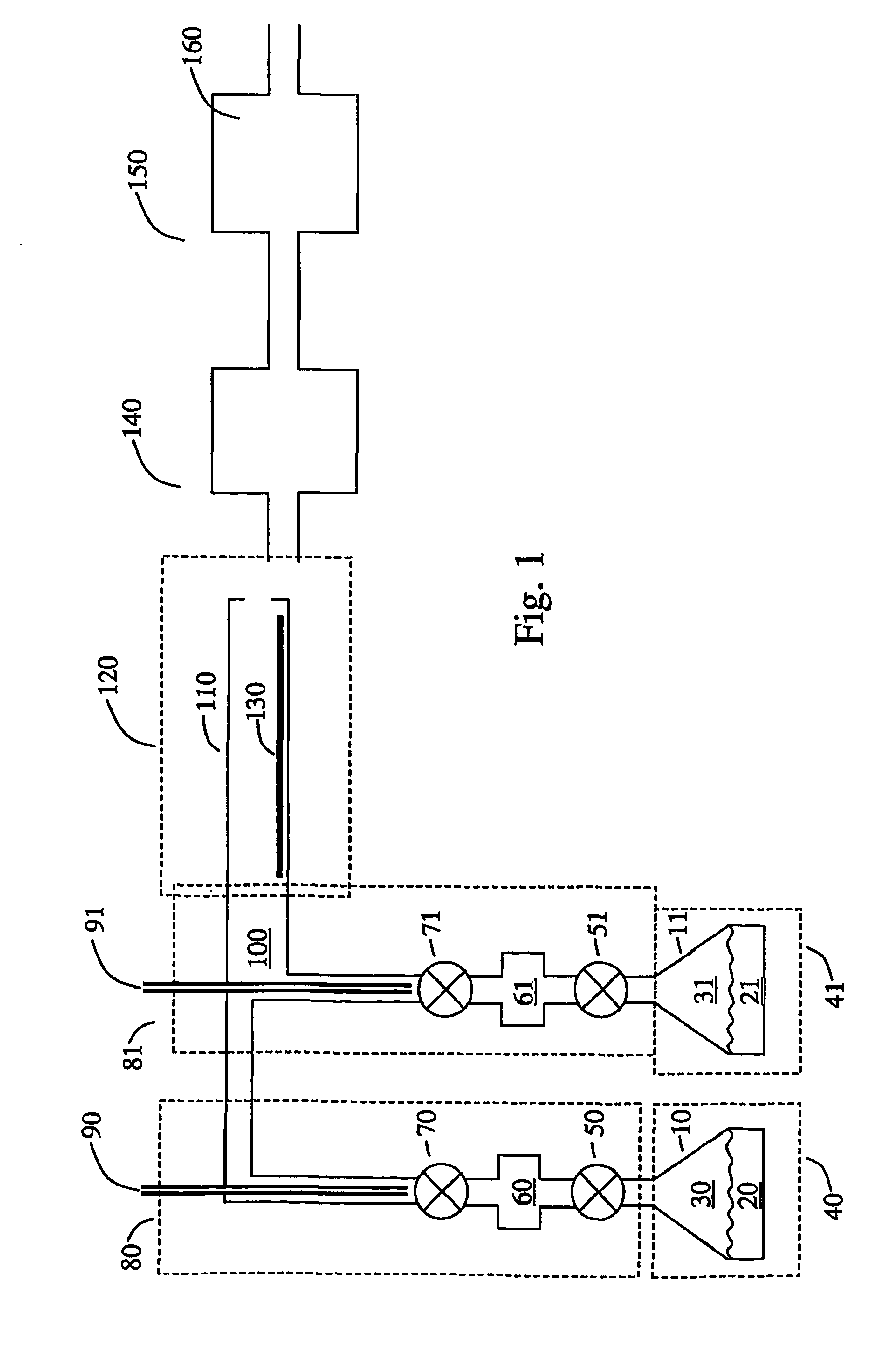

Meat Like Pet Food Chunks

ActiveUS20150320085A1Protein composition from eggsAnimal feeding stuffBiotechnologyAdditive ingredient

The present invention relates in general to the field of pet food. In particular the present invention relates to a meat like chunk that can be incorporated into a complete pet food. One embodiment of the present invention is a method of using multiple scraped surface heat exchangers and a steam tunnel to produce a meat like chunk. Another embodiment is a composition of meat ingredients, dried egg product, egg whites, and pea protein that results in a meat like chunk having an improved appearance that closely resembles that of actual pieces of meat.

Owner:USPET NUTRITION

Vapor deposition of metal oxides, silicates and phosphates, and silicon dioxide

InactiveUS20050277780A1Good step coverageOxygen/ozone/oxide/hydroxideAluminium silicatesAlkylphosphateGas phase

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

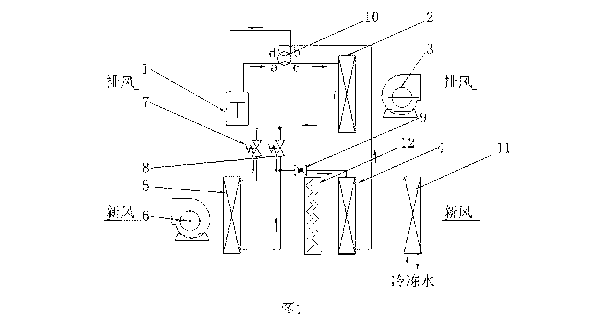

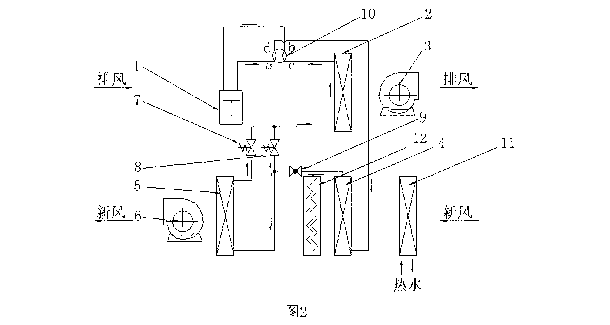

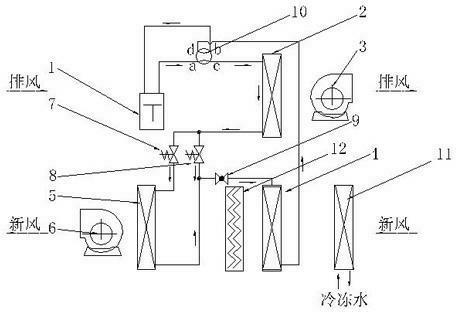

Double-cold-source heat pump total heat recovery humidity regulating and temperature controlling fresh air unit and control method thereof

InactiveCN102705920AReduce processing energy consumptionImprove qualityEnergy recovery in ventilation and heatingHeat recovery systemsTemperature controlFresh air

The invention discloses a double-cold-source heat pump total heat recovery humidity regulating and temperature controlling fresh air unit and a control method thereof, and belongs to the fields of energy utilization technology and air conditioning. The fresh air unit comprises an air exhaust part, a fresh air treatment part, a surface heat exchanger and a heat pump system, wherein the heat pump system comprises a compressor, a condenser, a condensation heat recoverer, an evaporator and a throttling component. The fresh air unit utilizes indoor low-temperature and low-humidity exhausted air to exhaust condensation heat of a refrigeration system in summer, and utilizes indoor high-temperature and high-humidity exhausted air to exhaust evaporation cold energy of the refrigeration system in winter. The surface heat exchanger aims at performing pre-cooling and pre-dehumidification to high-temperature and high-humidity fresh air through chilled water dew point temperature. The heat pump system provides required cold energy and heat as well as the lower dew point temperature that the chilled water is unaccessible to for the fresh air treatment part.

Owner:吕智 +1

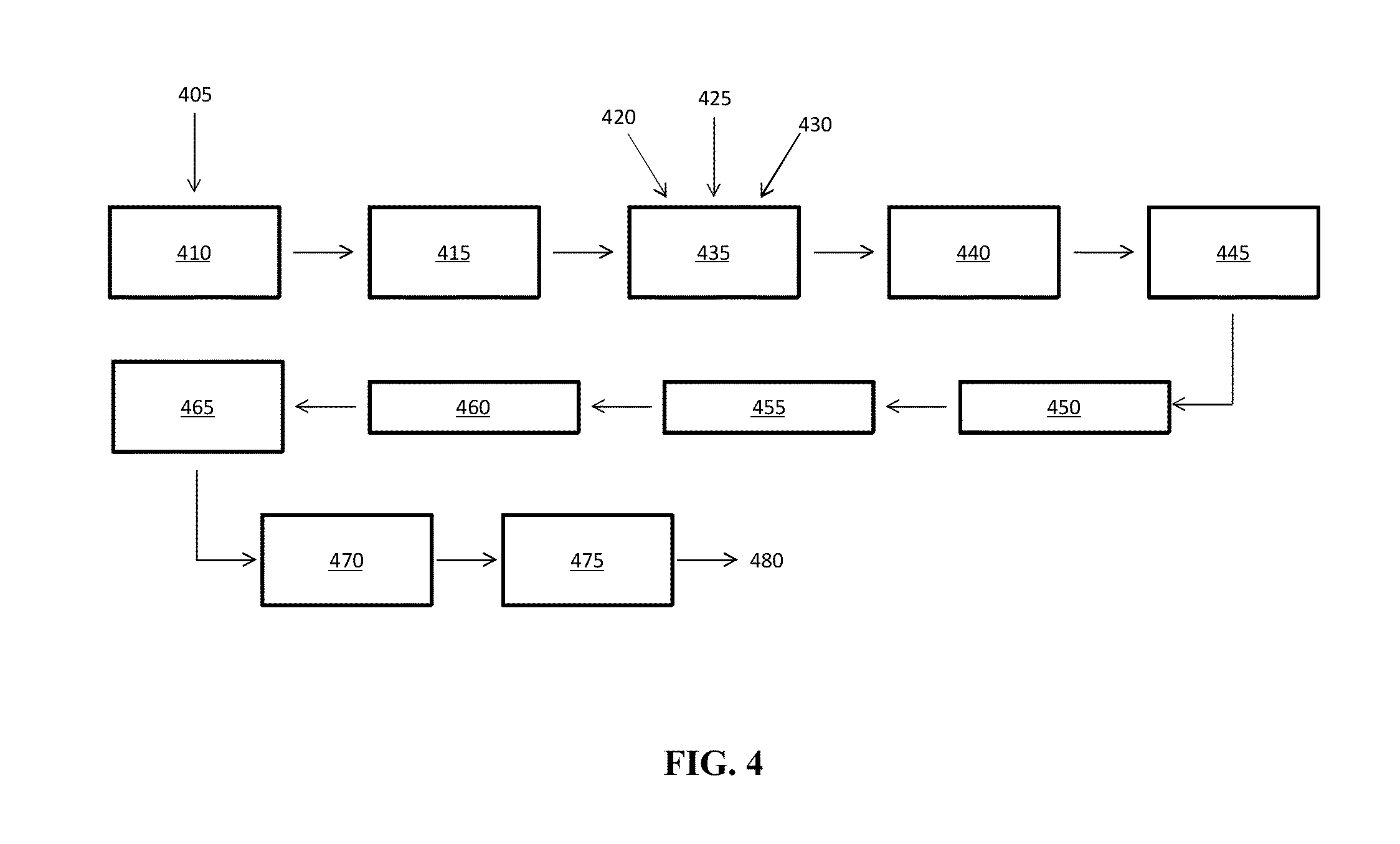

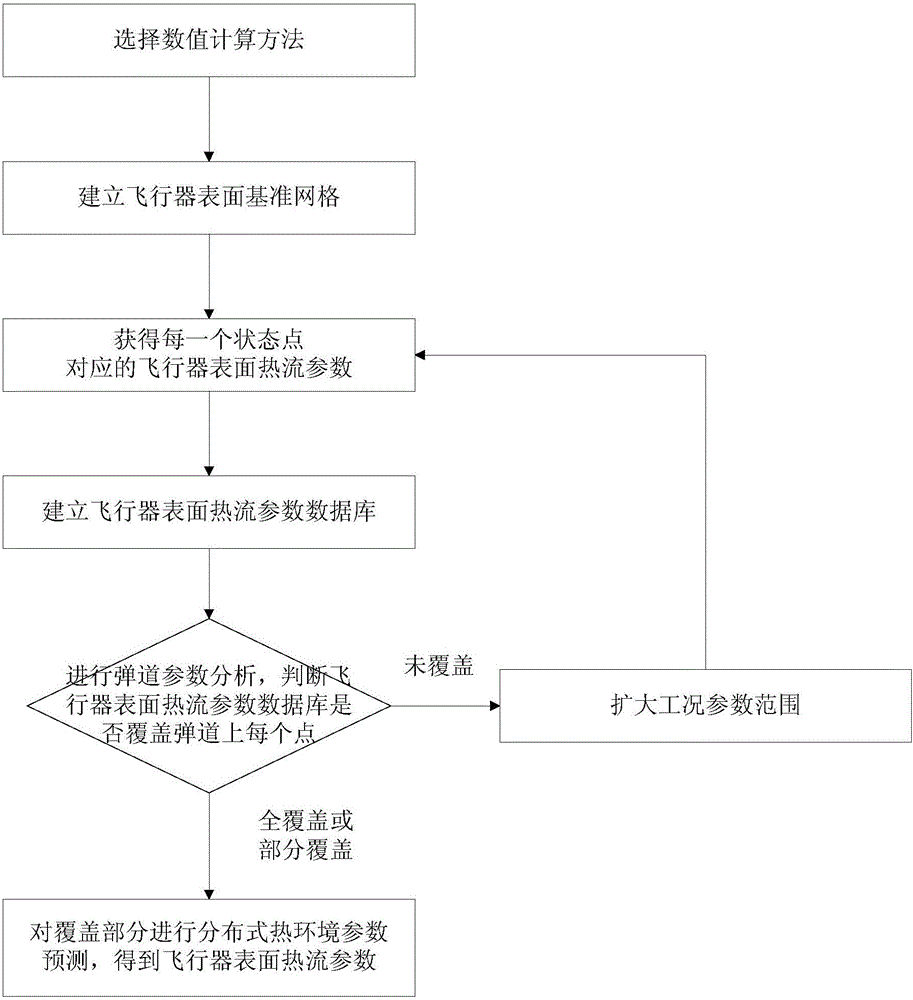

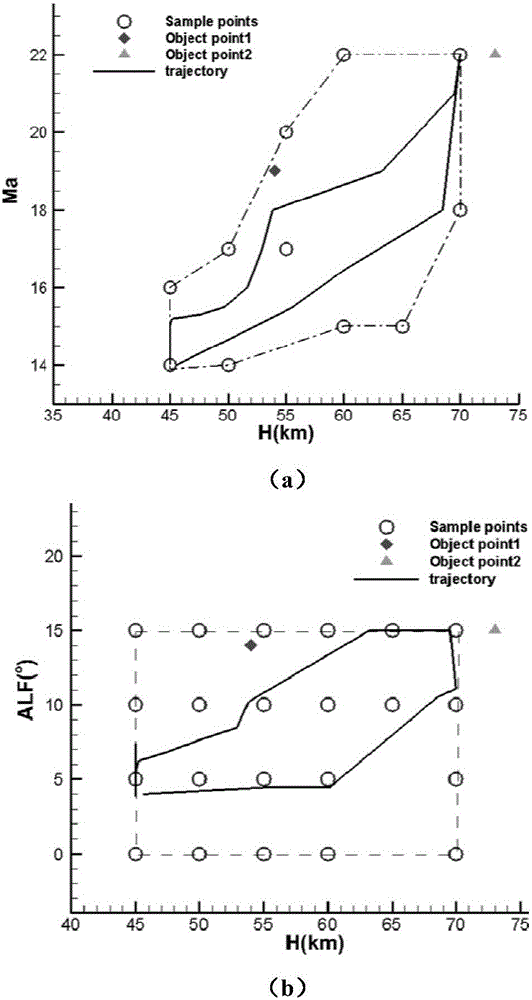

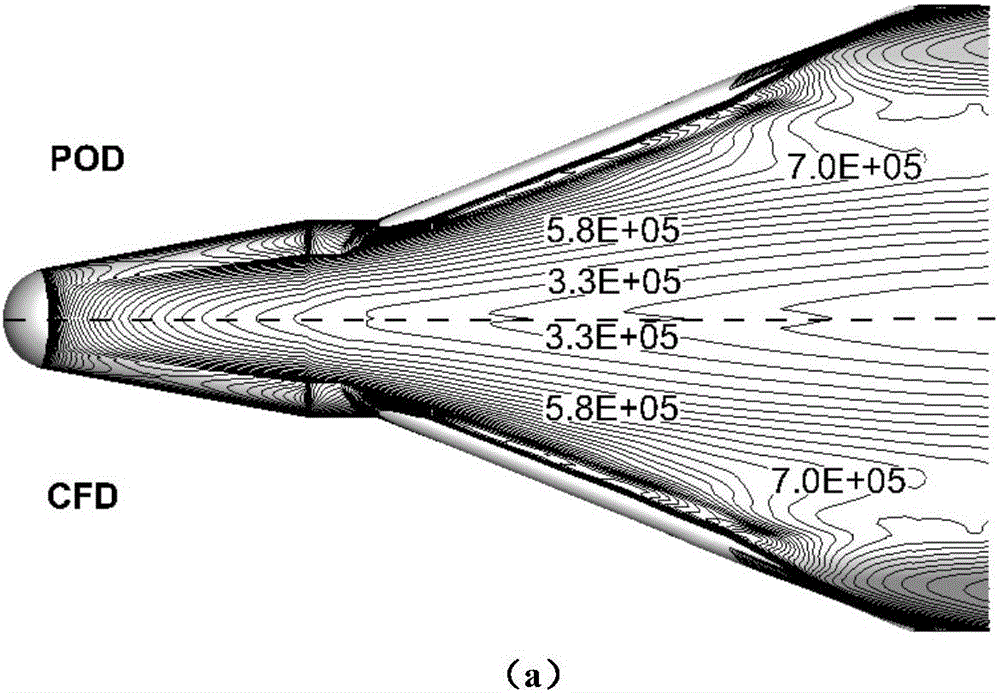

Database based complex-contour aircraft distributed heat environment parameter prediction method

ActiveCN106202804AAccurate predictionImprove design accuracyGeometric CADSustainable transportationEnvironmental designOrthogonal basis

The invention discloses a database based complex-contour aircraft distributed heat environment parameter prediction method and belongs to the field of aircraft heat environment design. The method comprises the steps that an aircraft surface heat flow database is established, order reducing processing is conducted on the database by utilizing a POD method to obtain orthogonal basis vectors of the database, and aircraft surface heat environment parameters can be predicted along a ballistic trajectory by combining with a corresponding basic coefficient interpolation method. The method can really reflect the space distribution characteristics and interference characteristics of the aerodynamic heat environment for all points on the surface of a complex-contour aircraft. Value result comparison shows that the method can remarkably improve the computational efficiency, and prediction precision is not lost. A surface distributed heat flow is provided for calculation of a heat proof temperature field through the points along the ballistic trajectory, more exquisite temperature distribution can be obtained, and accordingly the design level of a whole heat preventing and insulation system is improved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

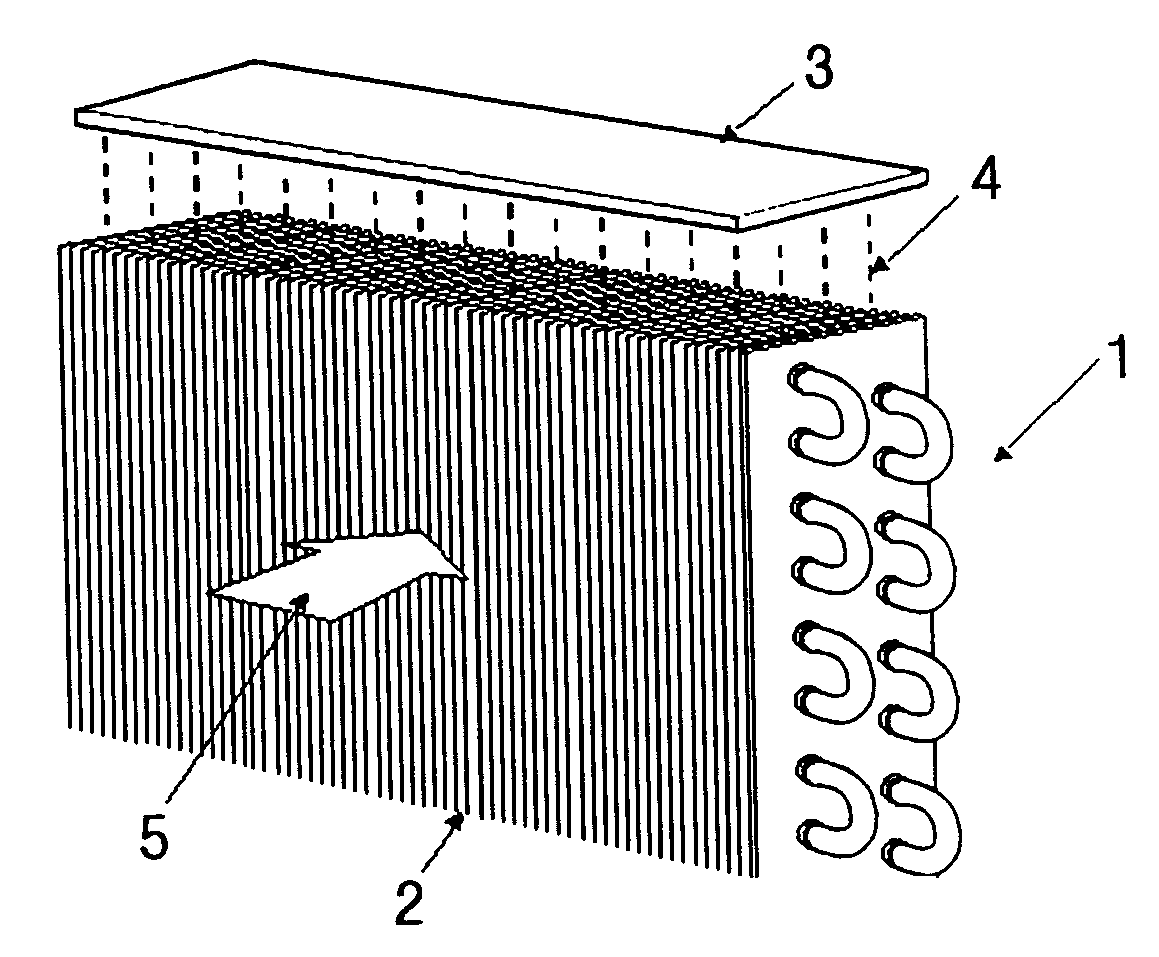

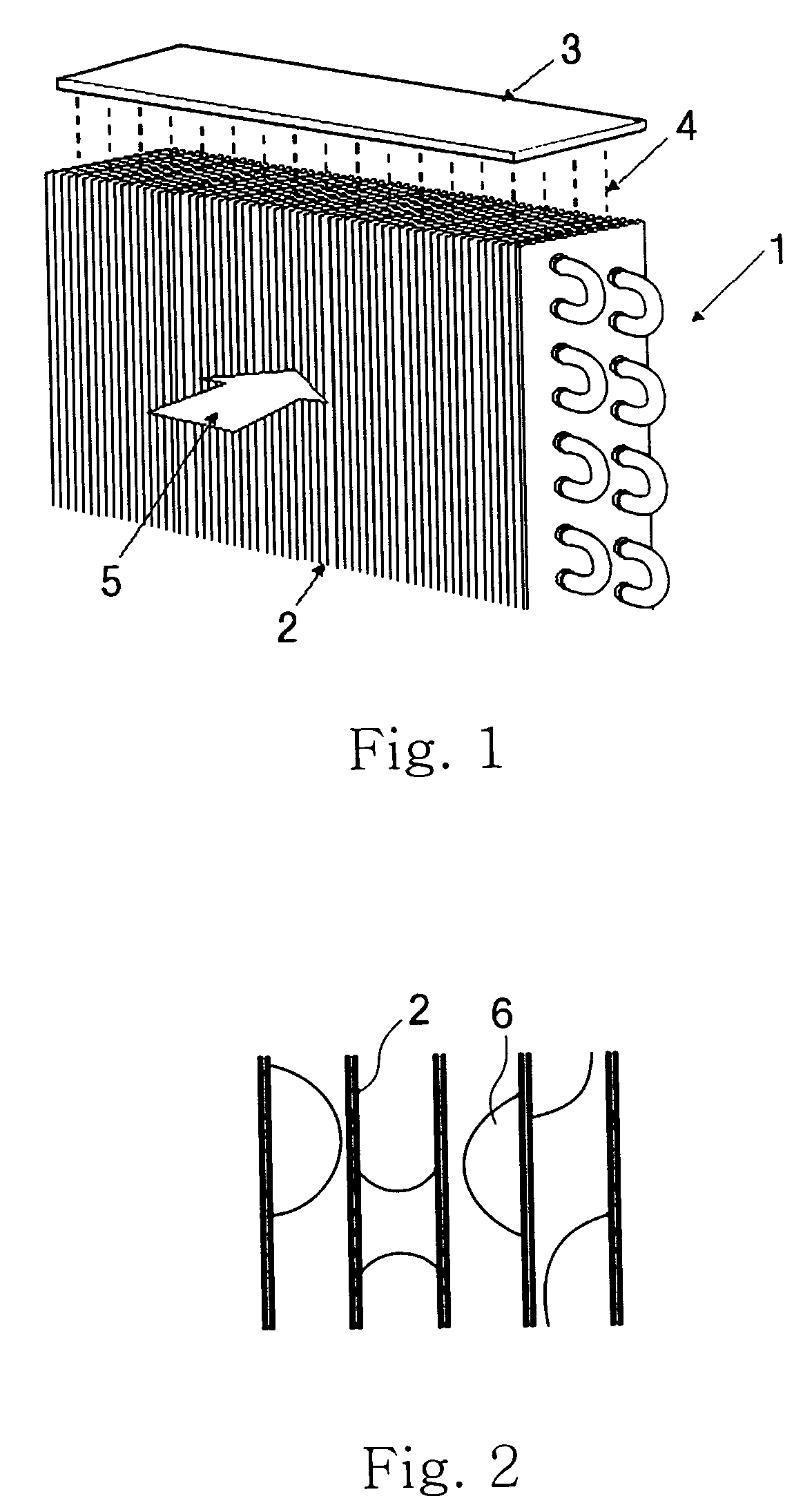

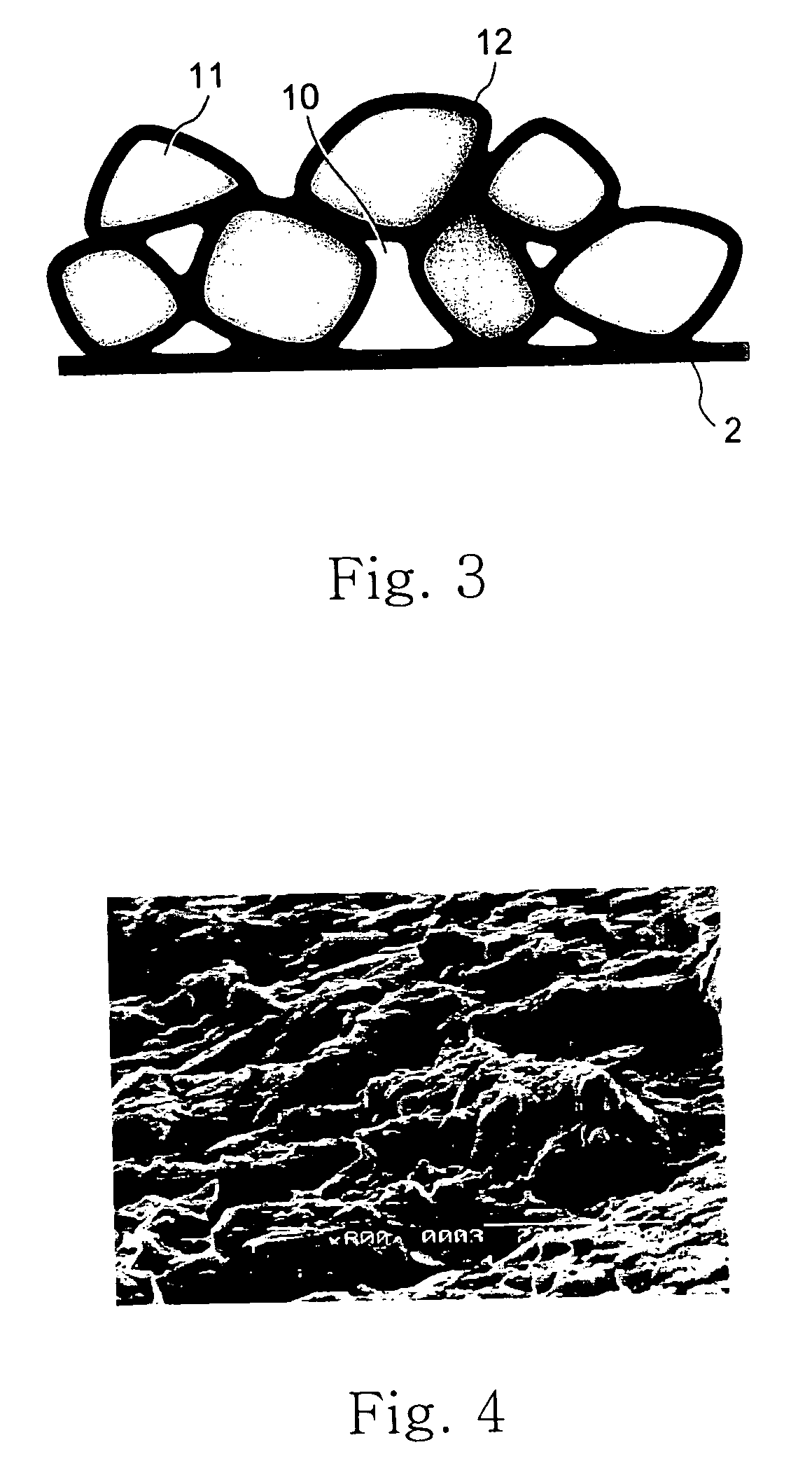

Surface treatment method for improving the surface wettability of wet surface heat exchangers

InactiveUS20040003619A1Improve surface wettabilityEasy to spreadMilk preservationCorrosion preventionHydrophilizationCoated surface

The present invention relates to the methods for hydrophilization, capable of greatly improving the surface wettability of wet surface heat exchangers by transforming the solid surface to an improved surface having hydrophilic porous structure. In order to form the hydrophilic porous structure on the surface, the present invention provides two methods. One method consists of the operations of making the coating composition by blending micro solid particles with the hydrophilic binders; spreading the coating composition onto the surface of a heat exchanger by means of spraying or dipping; and curing the coated surface of a heat exchanger. Another method to build the hydrophilic porous structure consists of the operation of roughening the surface of the heat exchanger by corroding the surface chemically or electrochemically, or by use of the physical process; and processing hydrophilization of the surface of said heat exchanger.

Owner:KOREA INST OF SCI & TECH

Polyester film capable of being subjected to heat seal directly and preparation method

ActiveCN102873954AReduce wasteLow costSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to a polyester film and a preparation method thereof and particularly discloses a polyester film capable of being subjected to heat seal direction and a preparation method. The polyester film comprises a layer A, a layer B and a layer C, wherein the layer B is a middle core layer and made of a PET (polyethylene terephthalate) ultra-glazed polyester slice, the layer A is a surface heat-seal layer and made of a copolymerized PETG (polyethylene terephthalate glycol) polyester slice, and the layer C is an anti-blocking layer and made of a PET anti-blocking agent master batch slice and a PET ultra-glazed polyester slice. The preparation method includes steps of preparing corresponding polyester slices, extruding and drawing via an extruder, forming with cooling, crystallizing, drawing to remove scrap edges, treating coronas, detecting the thickness and the like.

Owner:ZHEJIANG QIANGMENG IND

Salt bath nitrogenization heat treatment method for metal surface

InactiveCN101144148ASolve heat treatment problemsReduce distortionSolid state diffusion coatingPotassiumHeat treating

The present invention relates to a metal surface salt bath nitride nitriding heat treatment method which belongs to the metal part surface heat treatment technology field. The method is performed in the following technical process: first, loading and clamping: the metal part is hung and arranged in a charging basket; second, nitriding: the metal part hung and arranged in the charging basket is positioned in a nitriding furnace, heated and charged with nitriding salt for salt bath and nitriding, and heat is preserved for 30-80 minutes in the condition that the temperature is 540-570 DEG C; third, cleaning: the nitrided metal part is cleaned, and the water temperature is controlled at 60-80 DEG C; the nitriding salt in the nitriding working process comprises carbamide, potassium chloride or barium chloride, sodium carbonate, and K 2 S, etc., according to the weight percentage, the composition of each component is respectively: 30-40 percent of carbamide, 20-28 percent of potassium chloride or barium chloride, 38-44 percent of sodium carbonate, and 0.0001-0.1 percent of K 2 S, and the sum of the weight percentage of each component is 100 percent. The present invention has the advantages of smaller deformability, short time, high efficiency, and wide application range; and also can achieve the effect of reducing the cost obviously.

Owner:孙国飞

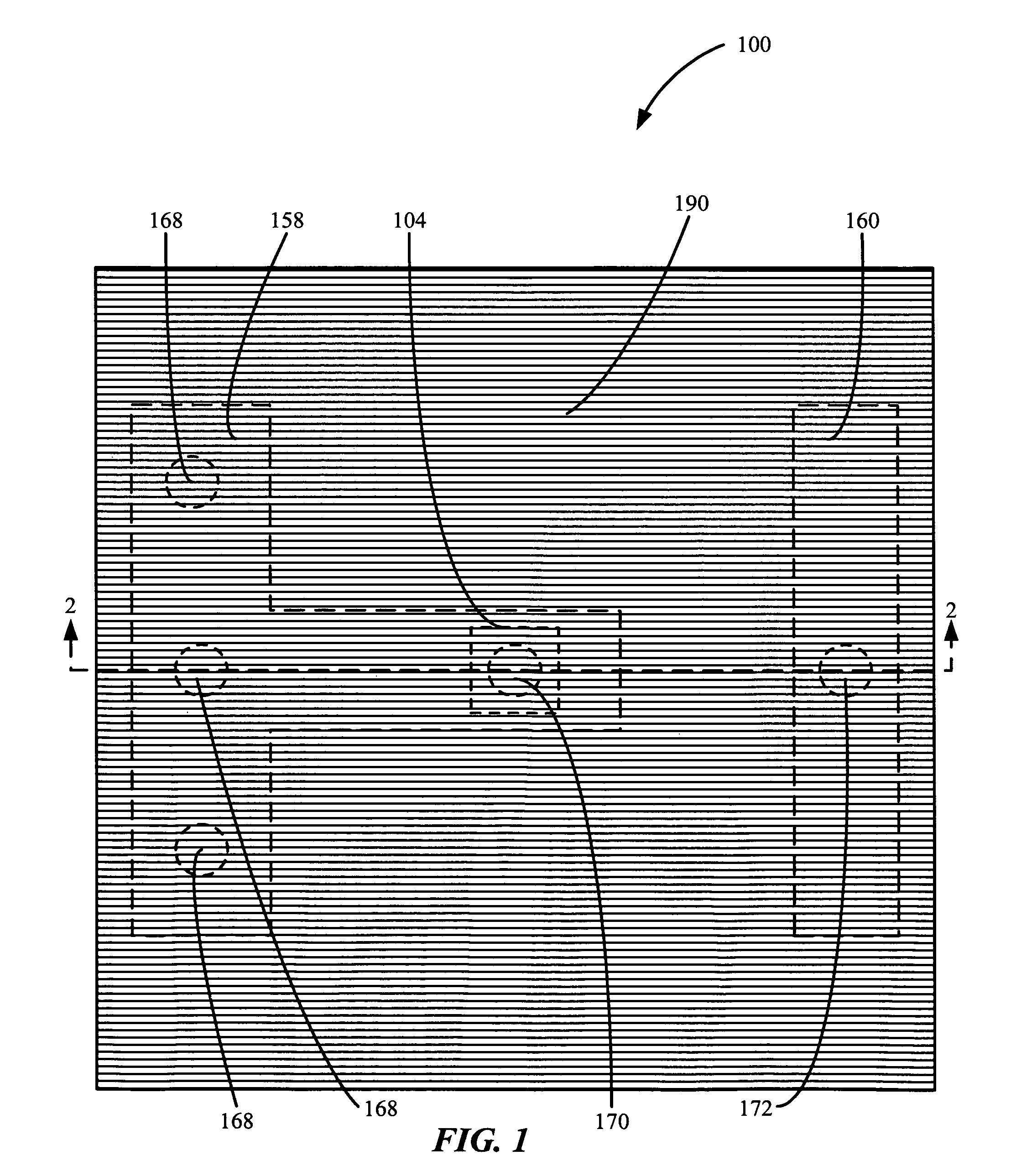

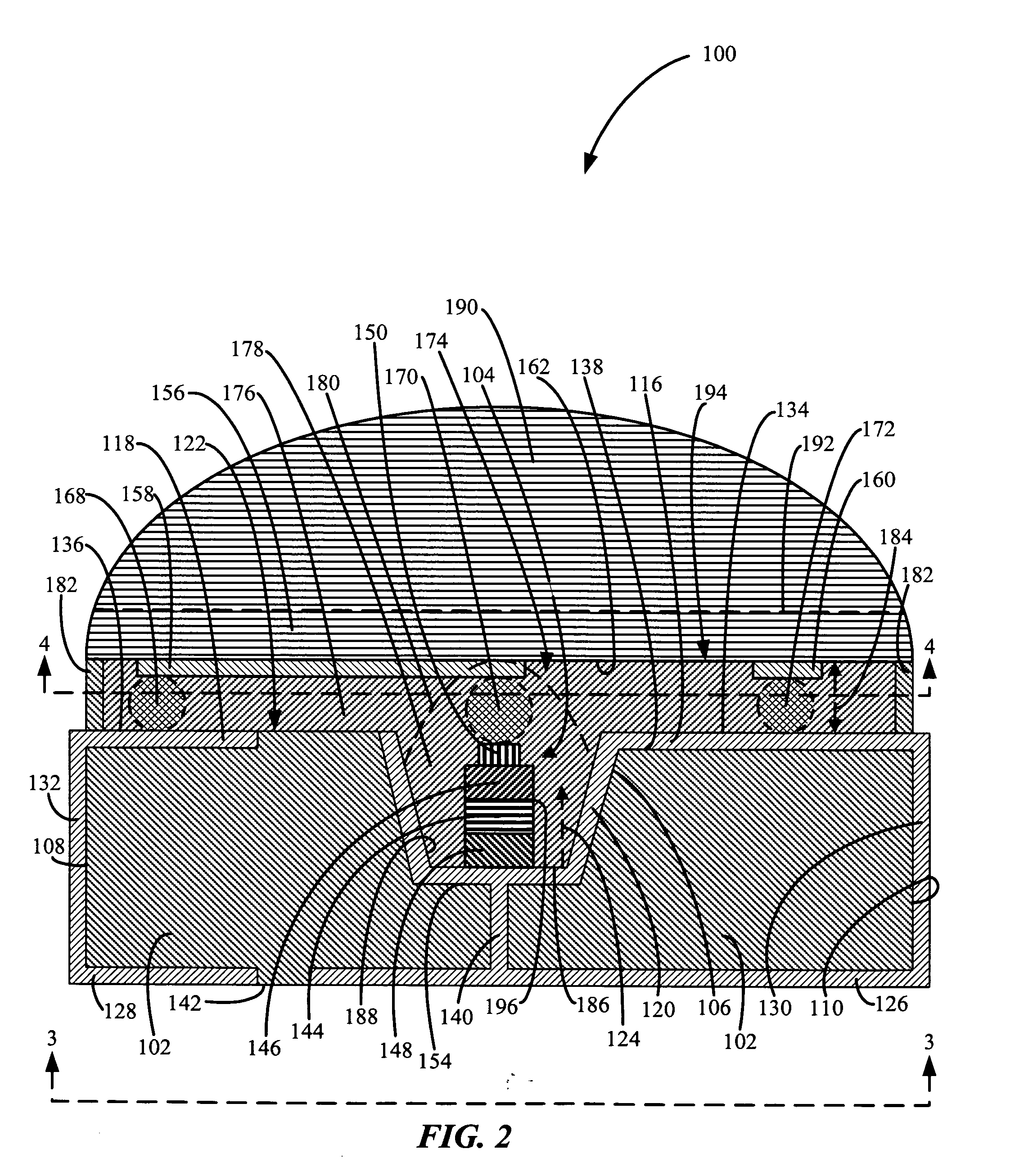

Direct exchange geothermal heating/cooling system sub-surface tubing installation with supplemental sub-surface tubing configuration

InactiveUS7856839B2InhibitionImprove thermal conductivityHeat pumpsDomestic cooling apparatusGeothermal heatingRefrigerant

A sub-surface tubing arrangement for use in a direct exchange (DX) geothermal heating / cooling system includes a primary sub-surface liquid refrigerant transport line, a primary sub-surface vapor refrigerant transport line, at least one sub-surface heat exchange refrigerant transport line functionally connecting the primary sub-surface liquid refrigerant transport line to the primary sub-surface vapor refrigerant transport line, and either vertical or horizontal supplemental sub-surface refrigerant line connected to one of the primary sub-surface liquid or vapor refrigerant transport lines.

Owner:EARTH TO AIR SYST

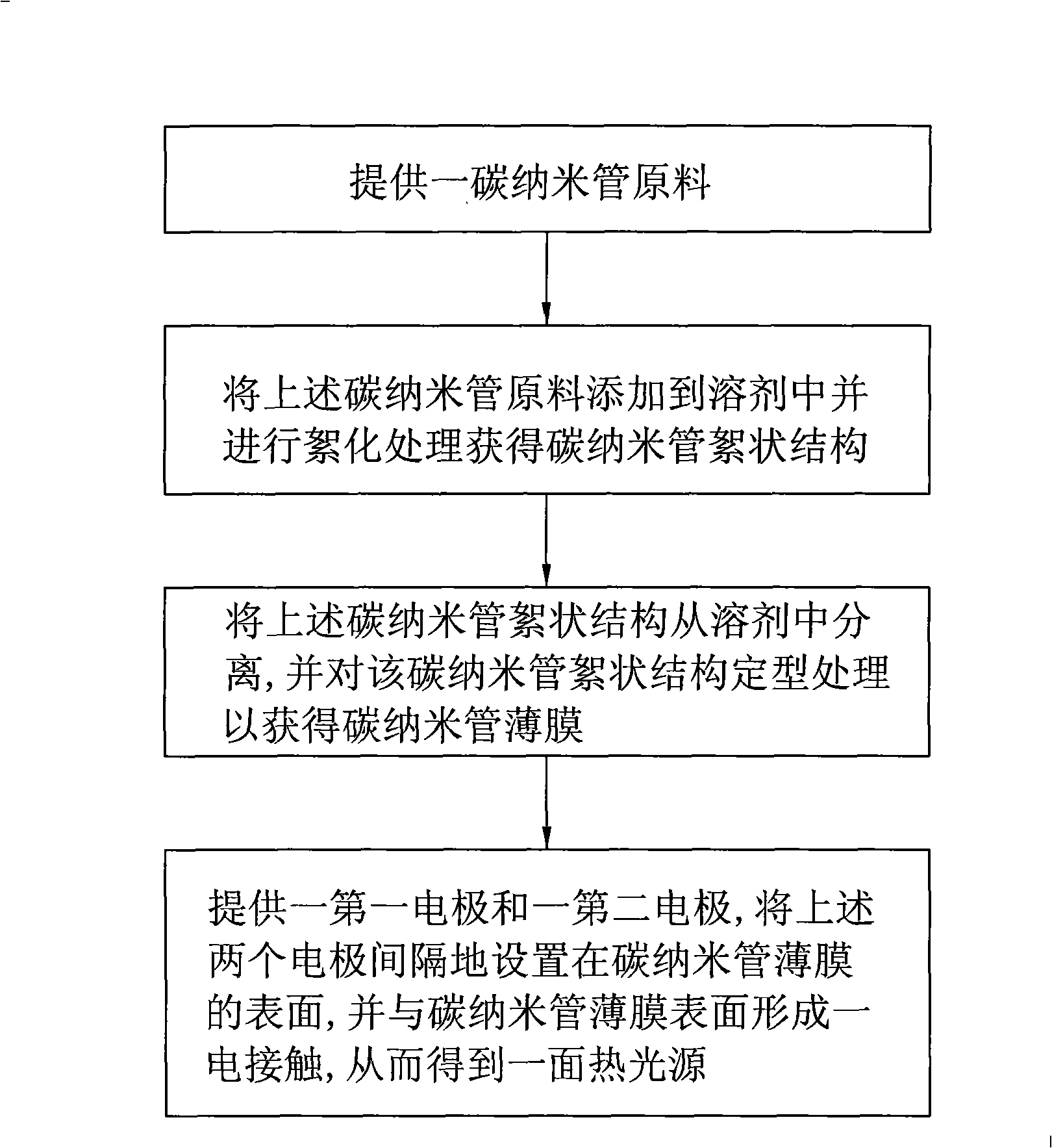

Surface heat light source, preparation method thereof and method for heating object using the same

ActiveCN101409961AImprove conductivityImprove thermal stabilityNanotechCathode ray tubes/electron beam tubesSolventNanotube

The invention relates to a surface heating light source, comprising a first electrode, a second electrode and a carbon nano-tube film; the first electrode and the second electrode are arranged on the carbon nano-tube film; the first electrode and the second electrode have a certain distance and electrically contact with the surface of the carbon nano-tube film; the carbon nano-tube film internally comprises carbon nano-tubes which enwind each other. The invention also relates to a preparation method used for preparing surface heating light source, comprising the steps as follows: carbon nano-tube raw material is provided; the carbon nano-tube raw material is added in solvent and carries out flocking disposal, thus gaining a carbon nano-tube floceulent structure; the carbon nano-tube floceuelent structure is separated from the solvent and shapes the carbon nano-tube floceulent structure so as to gain a carbon nano-tube film; the first electrode and the second electrode are provided; the first electrode and the second electrode are intermittently arranged on the surface of the carbon nano-tube film and form electric contact on the surface of the carbon nano-tube, thus gaining a surface heat light source. The invention also relates to a method used for heating the article by adopting the surface heat light source and comprises the steps as follows: an article to be heated is provided; the article is provided with a surface; the carbon nano-tube film in the surface heat light source is arranged closely to the surface of the article to be heated; voltage is applied to the electrodes in the surface heat light source so as to heat the article.

Owner:TSINGHUA UNIV +1

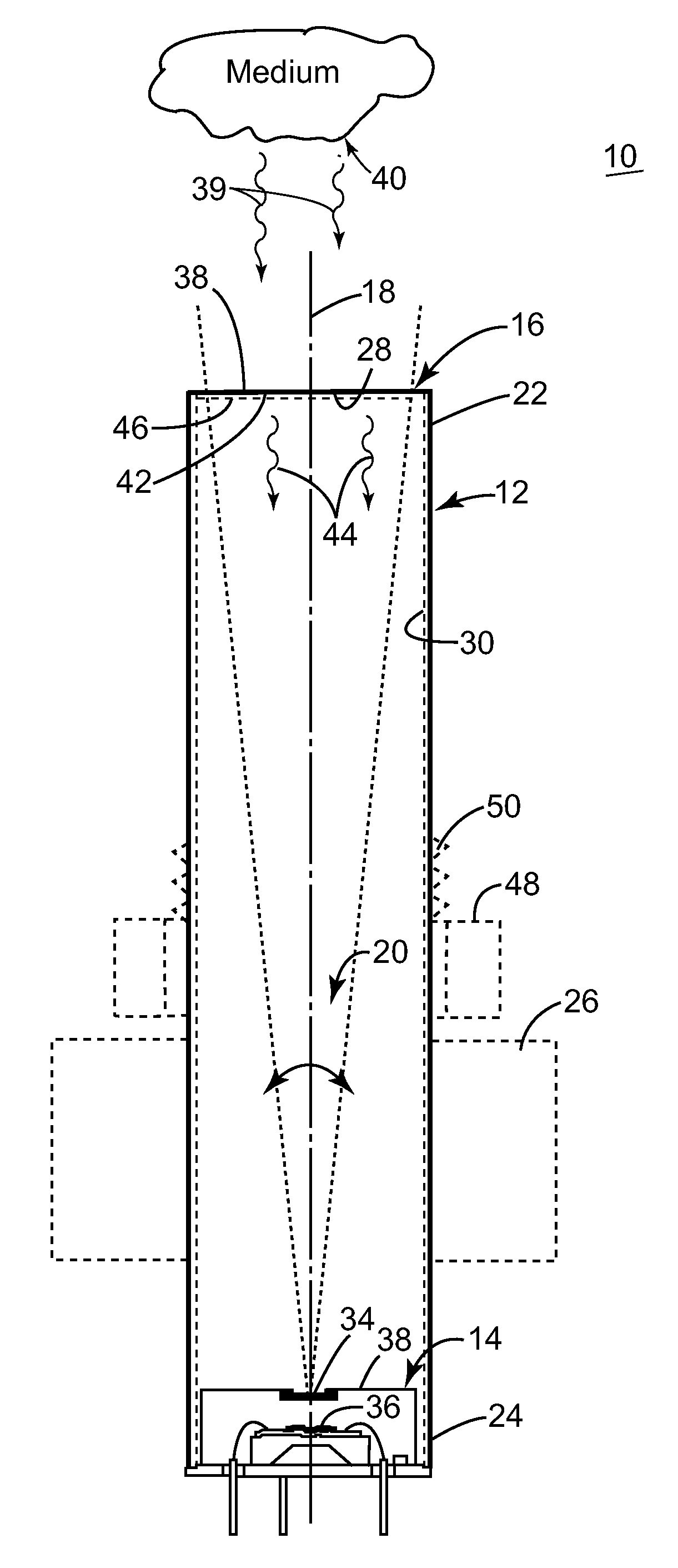

Infra-red temperature sensor

InactiveUS20090206264A1Fast response timeHarsh environmentRadiation pyrometryMaterial analysis by optical meansEngineeringField of view

An infra-red temperature sensor for sensing the temperature of a medium includes a housing; a thermal infra-red sensor element having a predetermined field of view and disposed in the housing; and a diaphragm closing the housing spaced along an axis from and in the field of view of the thermal sensor element for absorbing on its outer surface heat from the medium and emitting radiation from its inner surface to the thermal sensor element representative of the temperature of the medium.

Owner:GENERAL ELECTRIC CO

Two-stage precooling dehumidification device and method

InactiveCN103982958AReduce cooling loadIncrease the dehumidification capacity per unit input powerEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringWater cooling

The invention discloses a two-stage precooling dehumidification device and method, which break through a traditional dehumidification system form. The two-stage pre-cooling dehumidification device comprises an indirect evaporative circular tube surface heat exchanger, a heat pipe heat exchanger, a refrigeration dehumidification system and a condensed water collecting device, all of which sequentially form a primary fresh air precooling section, a secondary precooling section, a dehumidification section and a coolant recovery section. According to the two-stage precooling dehumidification device and method, cooling capacity of high-graded exhaust air and condensed water is sufficiently used for precooling fresh air, so that the cooling load of an evaporator of a dehumidification unit is reduced, and thus the unit input power can be less when the unit achieves the same dehumidification workload. Therefore, economic and better selection can be realized on accessory model selection of the unit.

Owner:NANJING NORMAL UNIVERSITY

Heat regenerator of original surface for gas turbine

InactiveCN1560437AExtended service lifeImprove heat transfer efficiencyTurbine/propulsion engine coolingGas turbine plantsInlet channelMicro gas turbine

The invention relates to a regenerator for a micro gas turbine, concretely is a original surface heat exchanger for increasing the heat efficiency of the gas turbine, it can increase the compactness and the service life of regenerator. The gas inlet and outlet channels are arranged on the right lower horn and the left upper horn, the high pressure air flows into the regenerator through the air inlet channel, flows out from the air outlet channel, the left and right frames of the heat exchanging board are welded and formed a air in / out aperture, the fuel gas can flow into the regenerator through the aperture, flows out form aperture on another side, the centre is heat exchanging corrugation plates, the flatten area at two sides of the plates is used to place flow guiding plate, the heat exchanging board has a side frame for welding and sealing. The flow speed at two sides has a little difference, the heat exchanging effect is the best, and it can upgrade the heat exchanging efficiency.

Owner:XI AN JIAOTONG UNIV

Advanced DX System Design Improvements

InactiveUS20090095442A1Reduced surface area requirementHigh work pressureMechanical apparatusHeat pumpsGeothermal heatingSystems design

A direct exchange geothermal heating / cooling system has a self-adjusting expansion valve and a bypass flow path to improve efficiency when the system operates in a heating mode. The expansion valve may operate based solely on pressure from the vapor refrigerant transport line. The system may alternatively include an accumulator, a compressor, and an oil separator, wherein an oil return line returns oil from the oil separator to the accumulator. Additionally, a direct exchange geothermal heating / cooling system may include a hot-gas bypass valve for diverting heated vapor refrigerant to the liquid refrigerant line. Finally, a direct exchange geothermal heating / cooling system having a sub-surface heat exchanger extending to a depth of at least 300 feet may use a refrigerant particularly suited for such an application.

Owner:EARTH TO AIR SYST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com