Patents

Literature

388results about How to "Reduce cooling load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

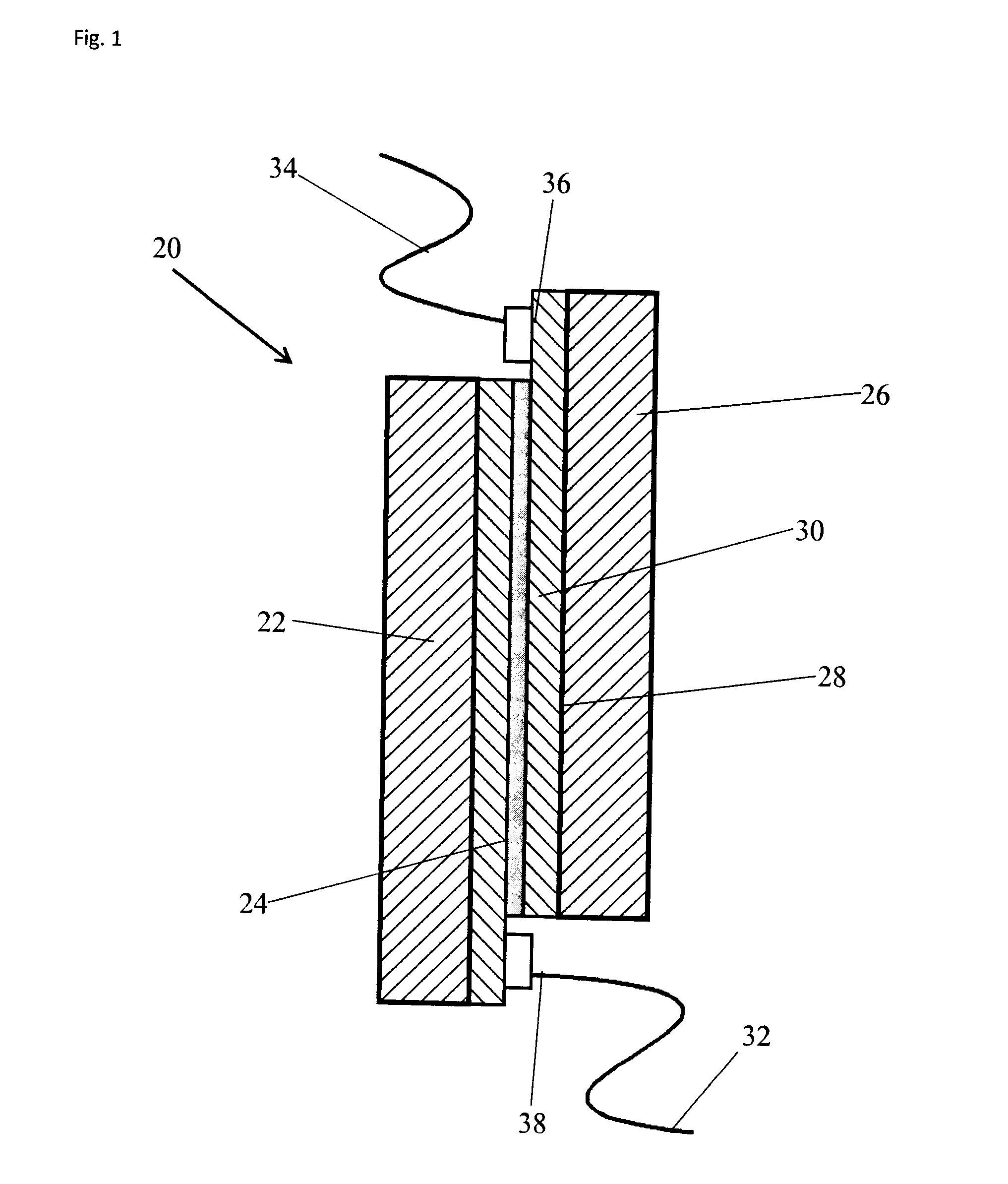

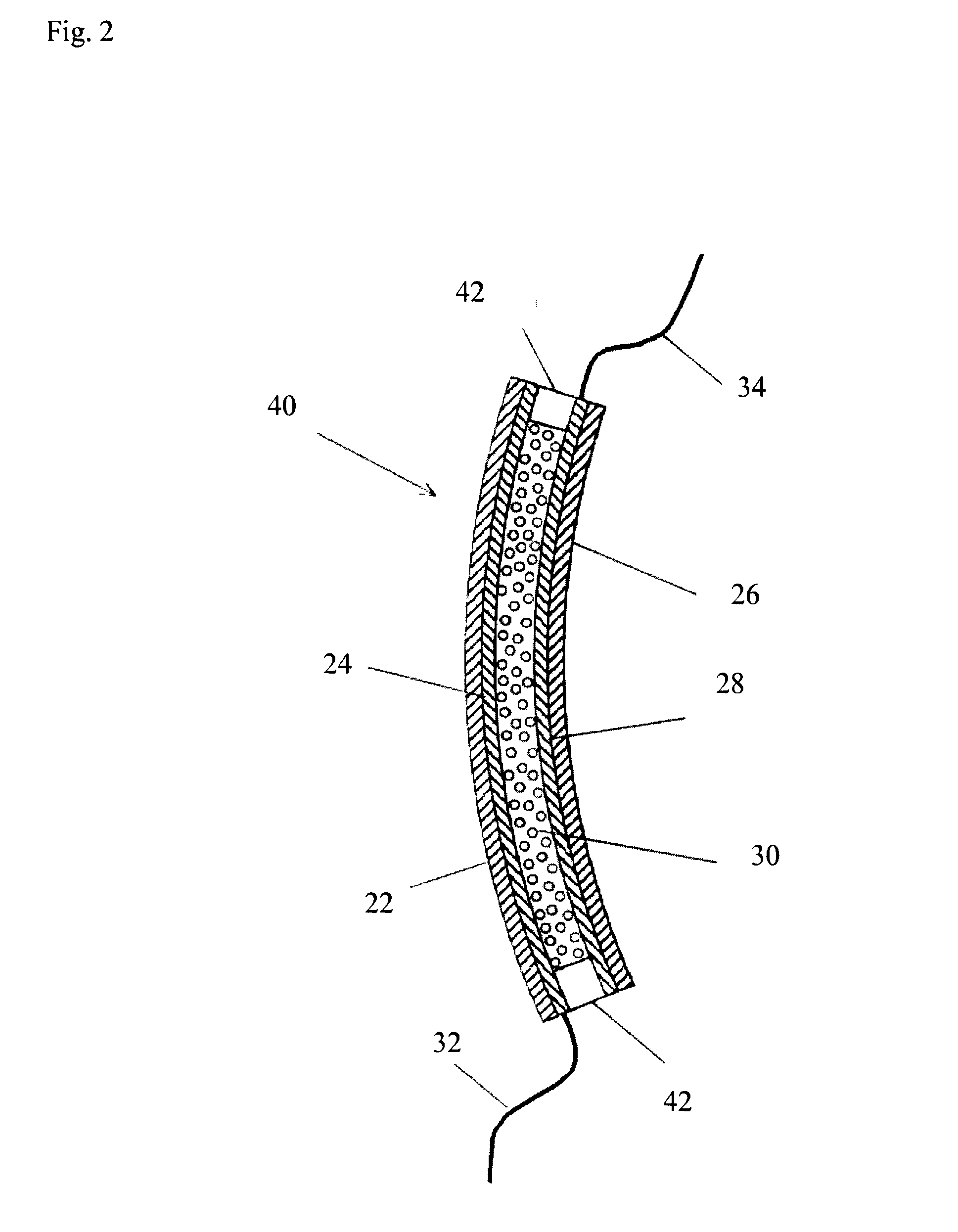

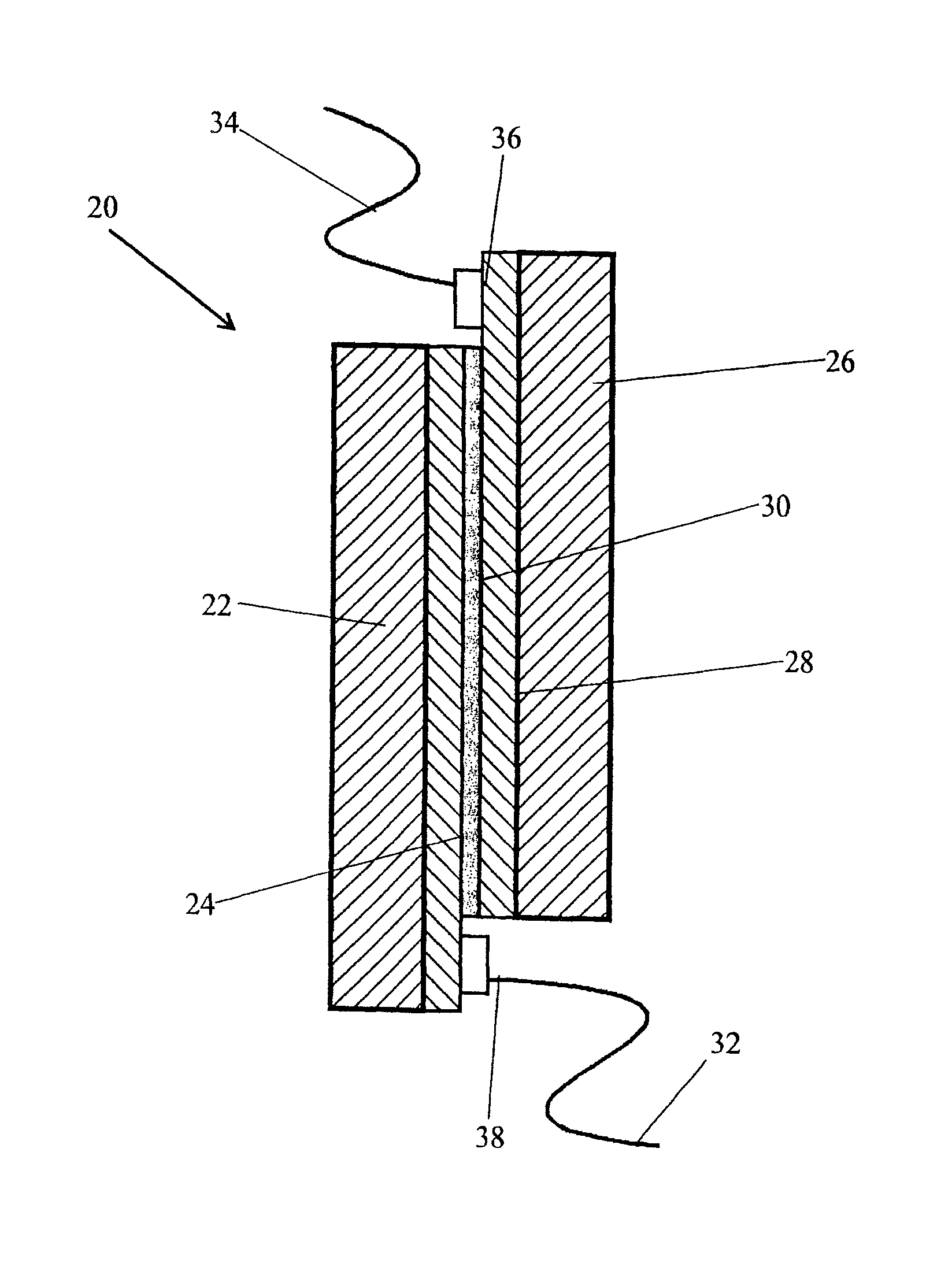

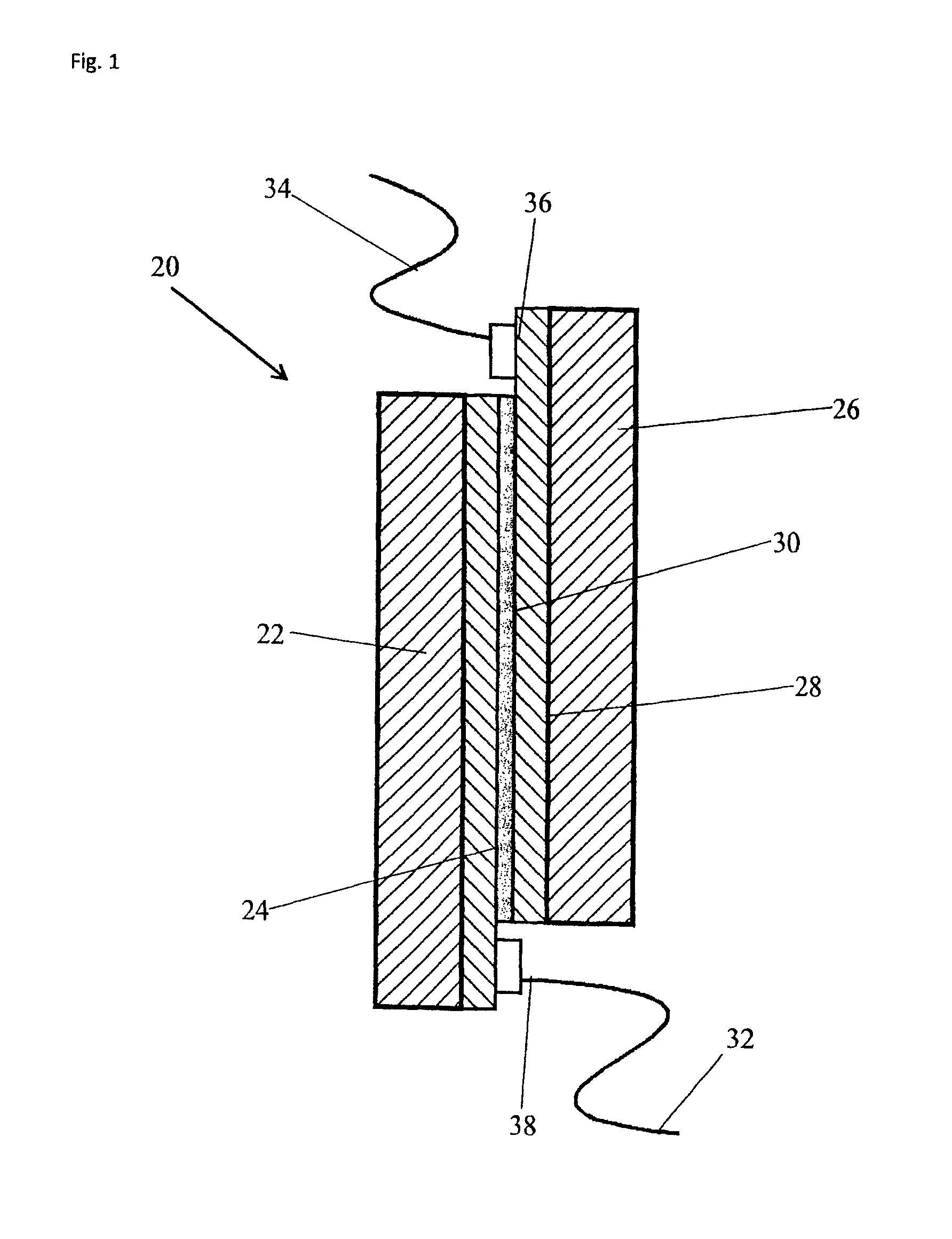

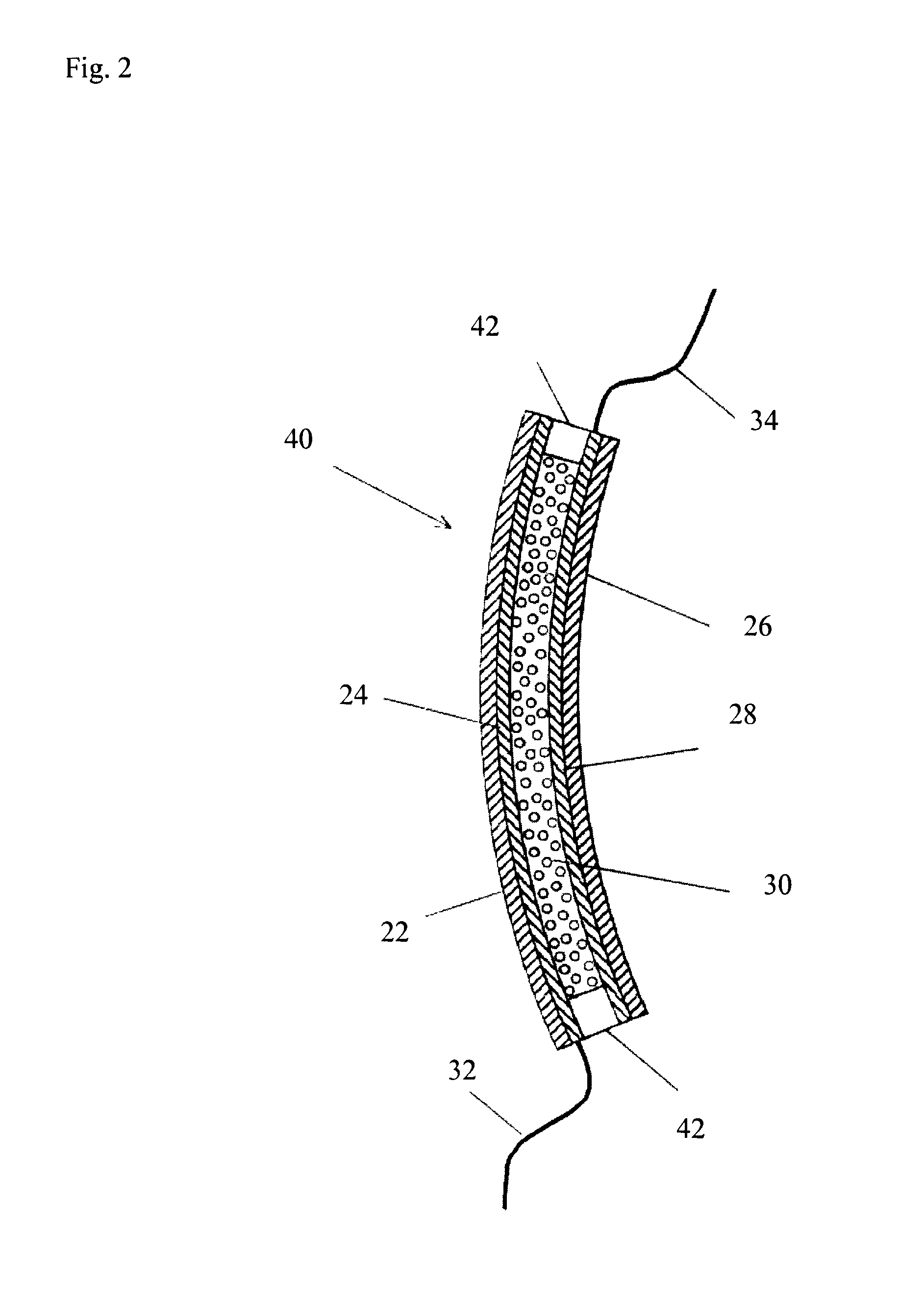

Variable transmittance optical devices

ActiveUS20130278989A1Reduce solar heat gainReduce cooling loadAntiglare equipmentStatic indicating devicesThermal energyElectricity

A self-powered variable transmittance optical device, such as a smart window or other device, and associated method are provided. The device comprises one or more transparent substrates, with a switching material disposed thereon or therebetween. The switching material may be a hybrid photochromic / electrochromic material capable of transitioning from a first transmittance state to a second transmittance state with application of electricity, and from second state to first state due to another stimulus, such as UV radiation. Electrodes are coupled to the switching material for applying electricity. An electrical system provides for controllable application of the electricity, and may store energy. Energy is provided by an energy-harvesting power source such as a solar cell or other photovoltaic source, or array thereof, or another device for harvesting vibrational or thermal energy. Energy harvesting, energy storage capacity and / or switching material may be configured to provide at least a predetermined level of device operability.

Owner:SOLUTIA CANADA INC

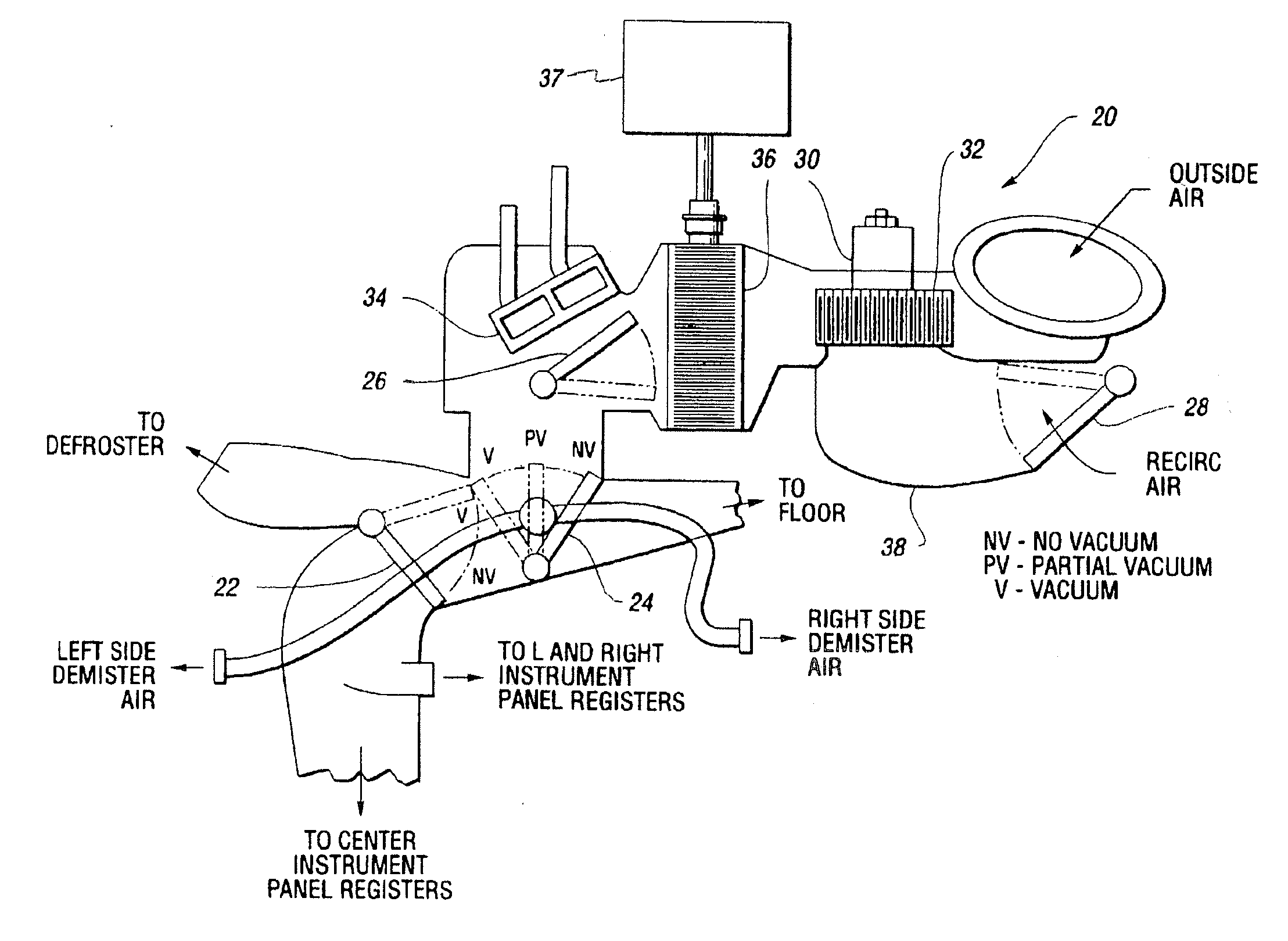

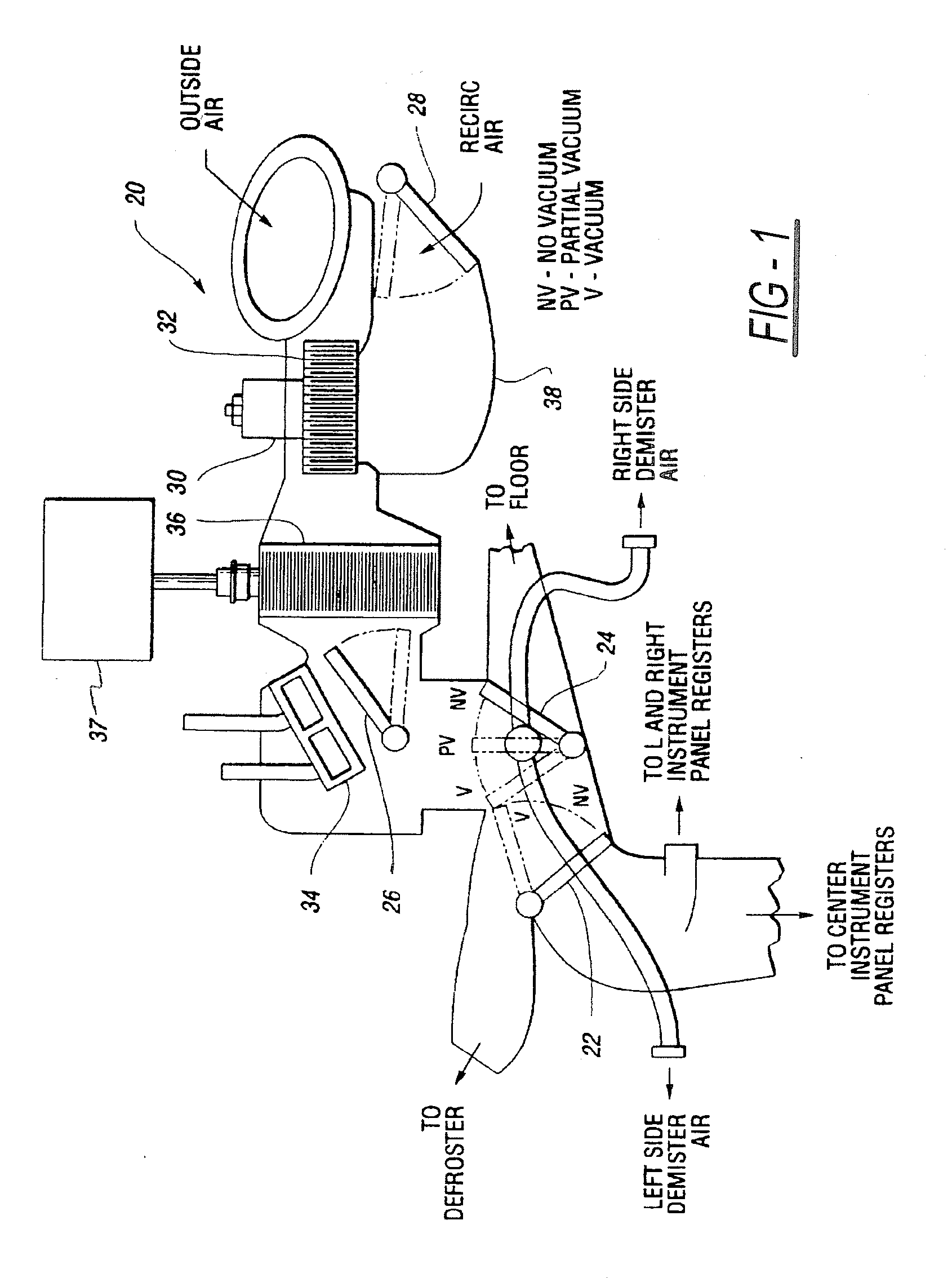

Partial air inlet control strategy for air conditioning system

ActiveUS20120009859A1Improve noiseIncrease vibrationAir-treating devicesRailway heating/coolingCombustionFresh air

A system and method of selecting air intake between 100% fresh air mode and 100% recirculated air mode for optimum heating / cooling performance, fuel economy and / or high voltage (HV) battery power consumption is disclosed. The system and method includes a partial recirculation control strategy in which the air inlet door is moved progressively to any position by taking into account cooling / heating loads and cabin fogging probability. As cooling / heating loads increase the air inlet door moves toward 100% recirculation mode. As fogging probability increases the air inlet door moves toward 100% fresh air mode. By selectively choosing a position between 100% recirculation and 100% fresh air, fuel economy and / or HV battery power consumption is optimized without compromising passenger comfort or causing fogging on interior glass surfaces. In cooling applications the compressor load is minimized and air conditioning performance is improved due to the reduced evaporator cooling load. The direct result of this improvement is increased fuel economy in the case of the internal combustion vehicle, reduced engine on time in the case of the hybrid electric vehicle (due to reduced HV battery power consumption), and reduced HV battery power consumption in the case of the hybrid electric vehicle (HEV) and the electric vehicle (EV). In heating applications, as the heating load is reduced the fuel economy of the internal combustion (IC) engine will be improved, the engine on time is reduced in the case of the HEV, and HV battery power consumption is reduced in the case of the EV.

Owner:FORD GLOBAL TECH LLC

Variable transmittance optical devices

ActiveUS9176357B2Reduce solar heat gainReduce cooling loadAntiglare equipmentStatic indicating devicesThermal energyElectricity

A self-powered variable transmittance optical device, such as a smart window or other device, and associated method are provided. The device comprises one or more transparent substrates, with a switching material disposed thereon or therebetween. The switching material may be a hybrid photochromic / electrochromic material capable of transitioning from a first transmittance state to a second transmittance state with application of electricity, and from second state to first state due to another stimulus, such as UV radiation. Electrodes are coupled to the switching material for applying electricity. An electrical system provides for controllable application of the electricity, and may store energy. Energy is provided by an energy-harvesting power source such as a solar cell or other photovoltaic source, or array thereof, or another device for harvesting vibrational or thermal energy. Energy harvesting, energy storage capacity and / or switching material may be configured to provide at least a predetermined level of device operability.

Owner:SOLUTIA CANADA INC

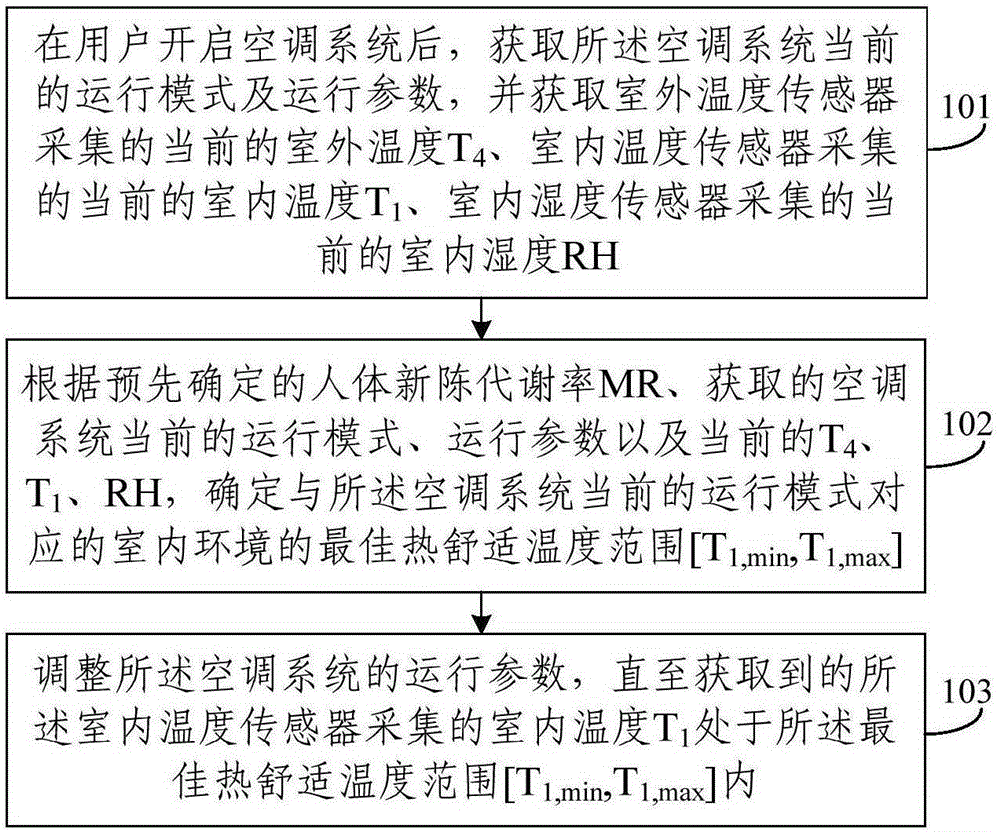

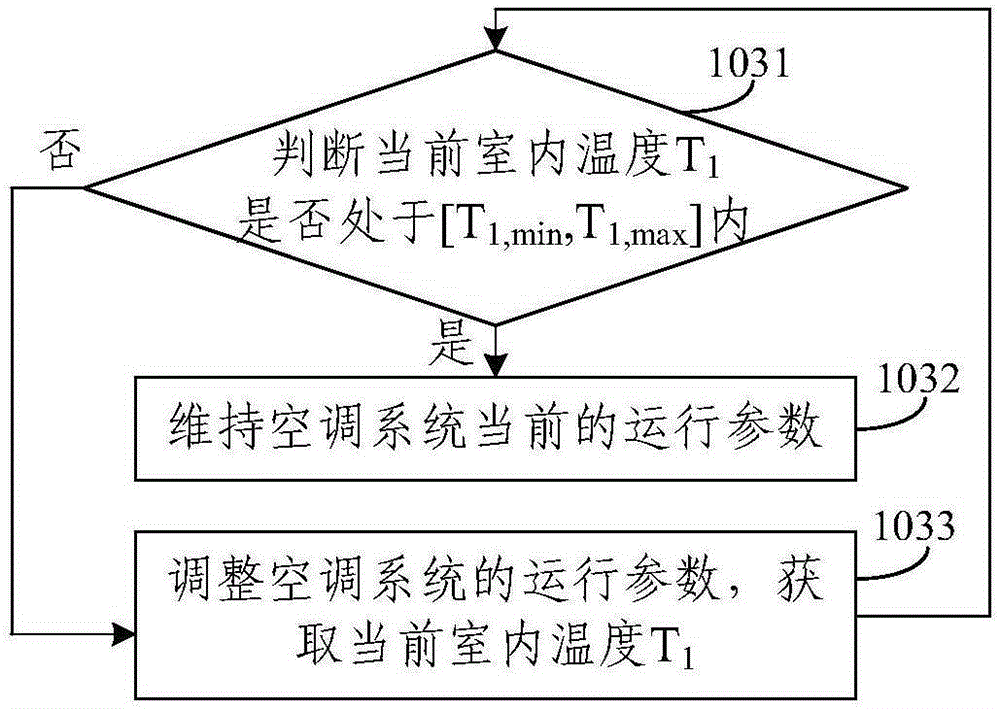

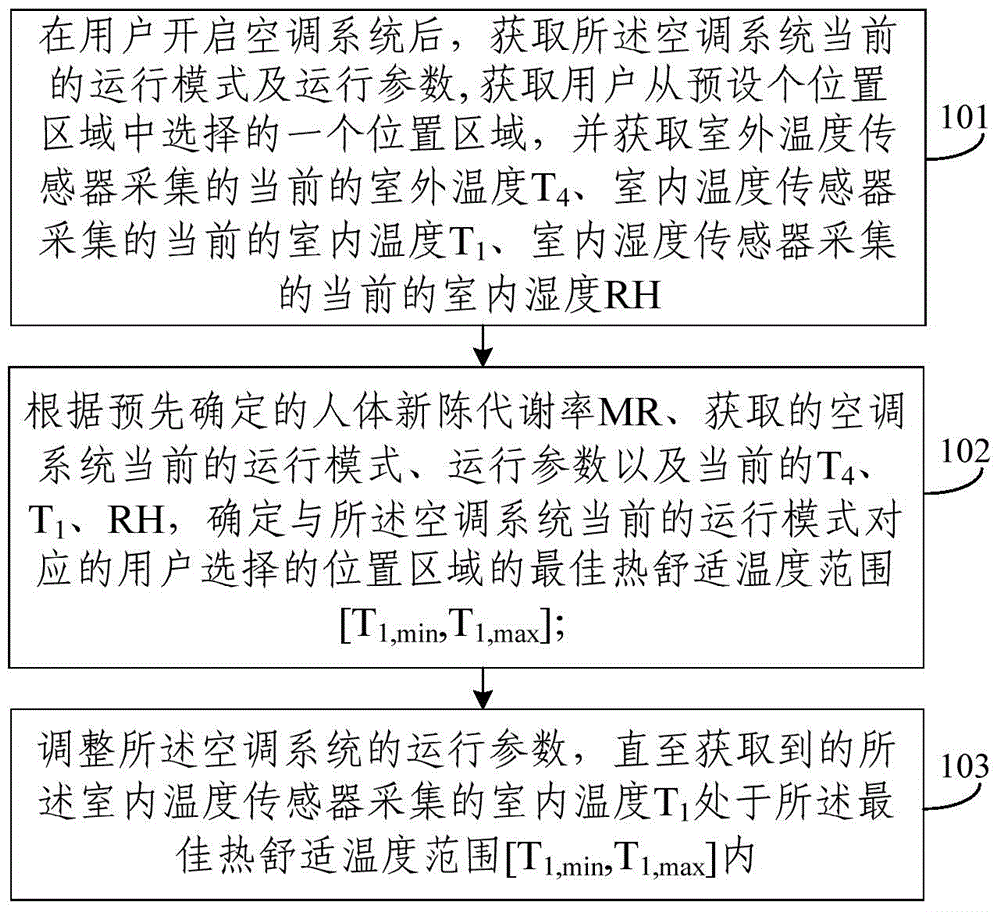

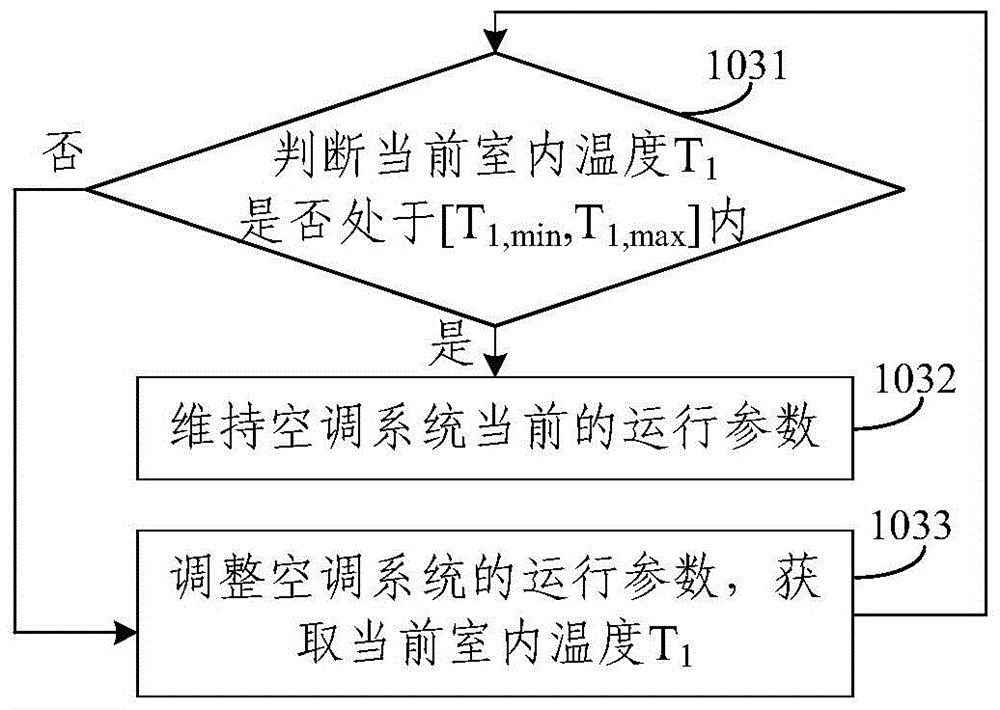

Comfort control method, controller and air-conditioning system

ActiveCN105222271AOptimal thermal comfortImprove comfort qualitySpace heating and ventilation safety systemsLighting and heating apparatusOutdoor temperatureEngineering

The invention discloses a comfort control method, a controller and an air-conditioning system. The comfort control method comprises the steps that after the air-conditioning system is started by a user, the current operating mode and operating parameters of the air-conditioning system are obtained, and the current outdoor temperature T4 acquired by an outdoor temperature sensor, the current indoor temperature T1 acquired by an indoor temperature sensor and the current indoor humidity RH acquired by an indoor humidity sensor are obtained; the optimum heat comfort temperature of range [T1, min,T1, max], corresponding to the current operating mode of the air-conditioning system, of the indoor environment is determined according to the human body metabolism rate MR determined in advance, the obtained current operating mode and operating parameters of the air-conditioning system, the current T4, the current T1 and the current RH; and the operating parameters of the air-conditioning system are adjusted till the obtained indoor temperature T1 acquired by the indoor temperature sensor is within the optimum heat comfort temperature range [T1, min,T1, max]. According to the comfort control method, the controller and the air-conditioning system, indoor users can be in the optimum heat comfort state by controlling indoor environment parameters.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

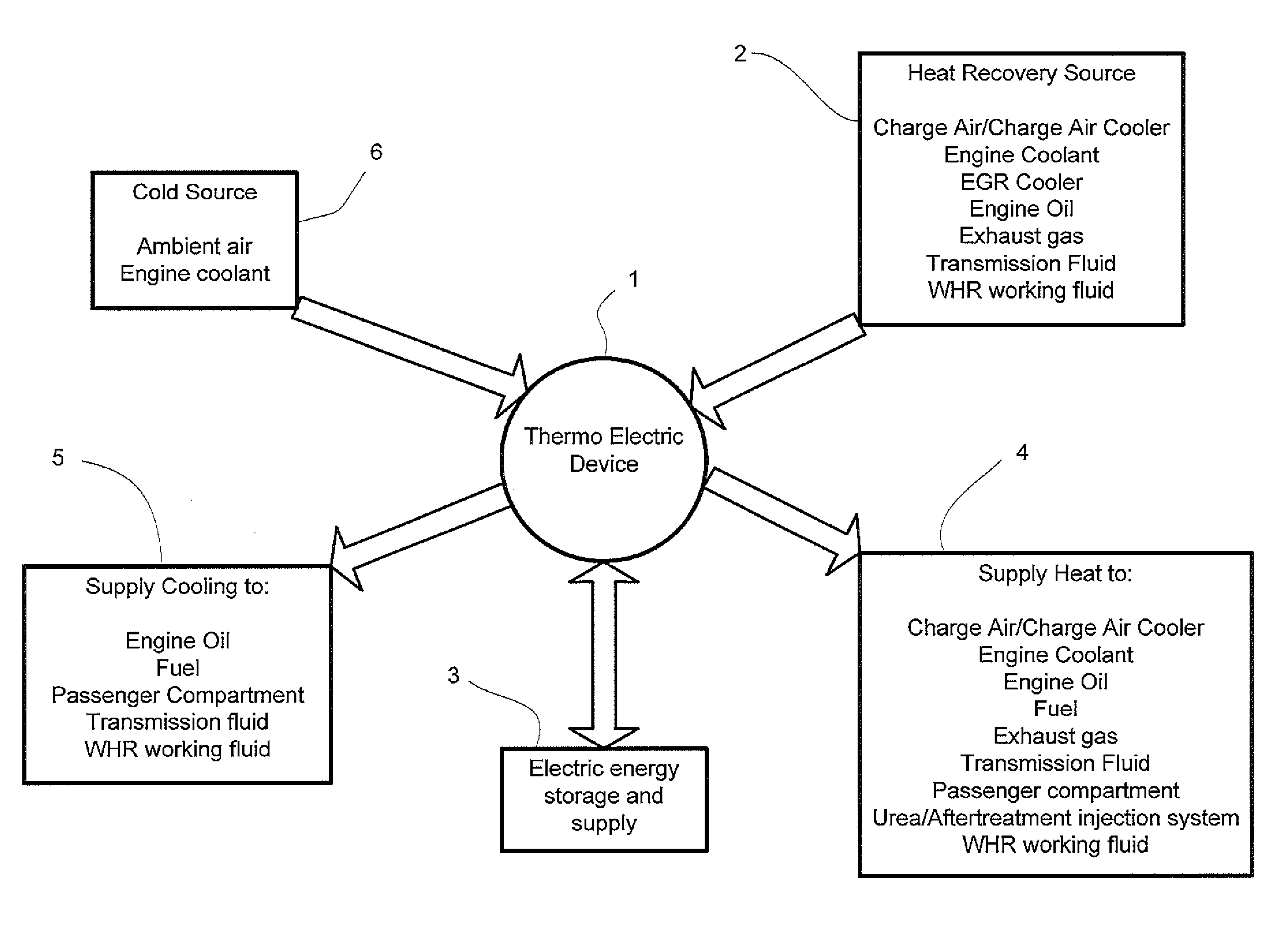

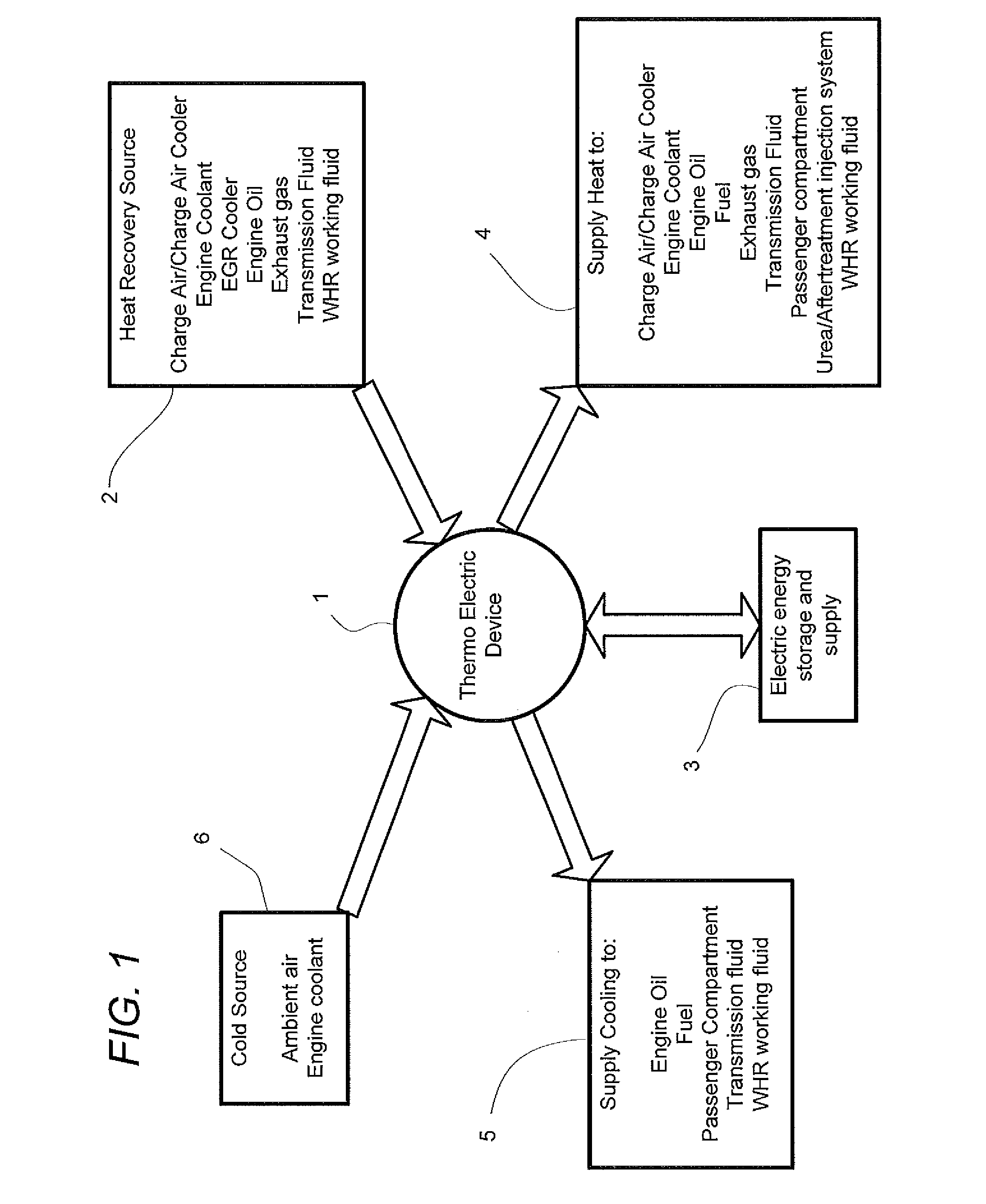

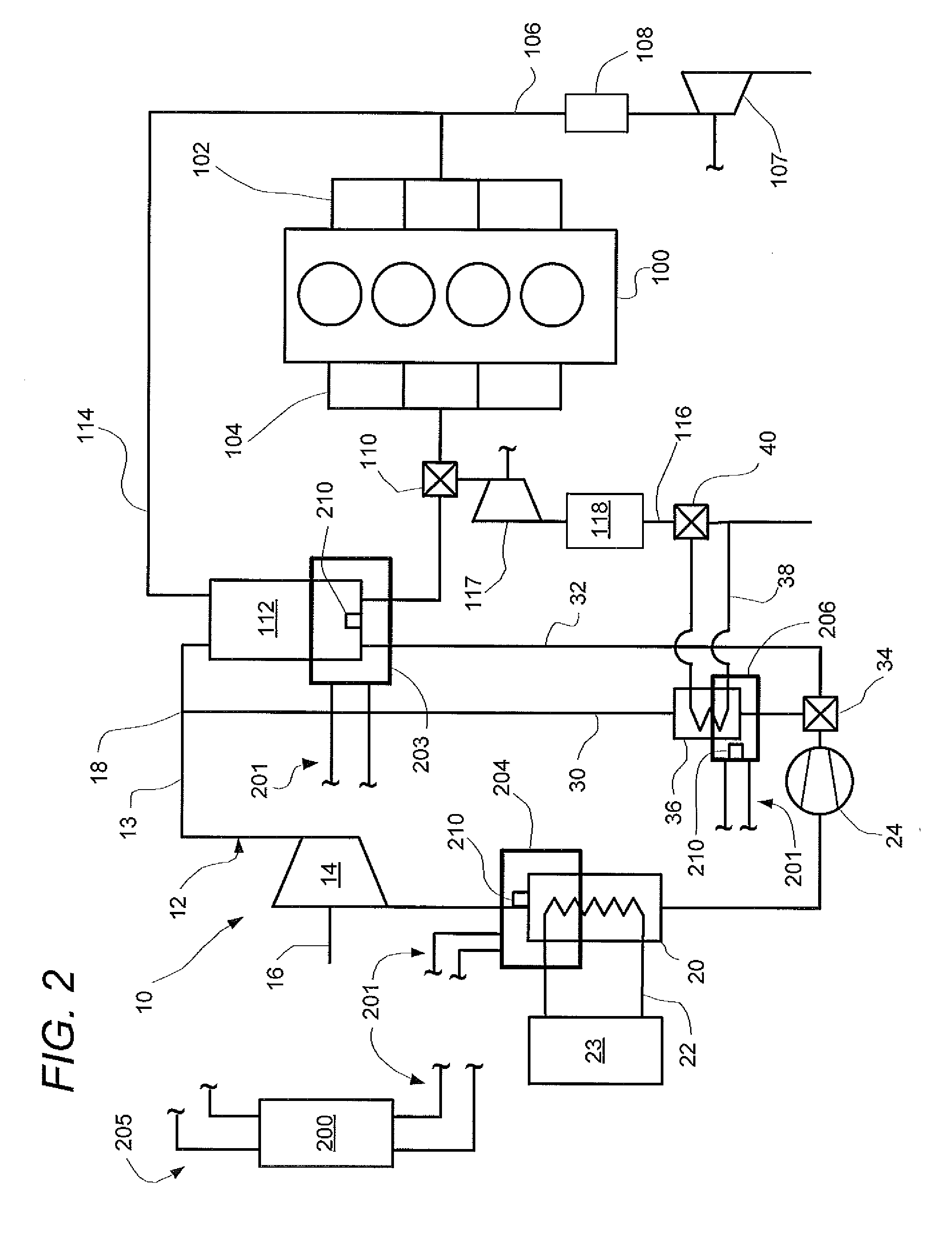

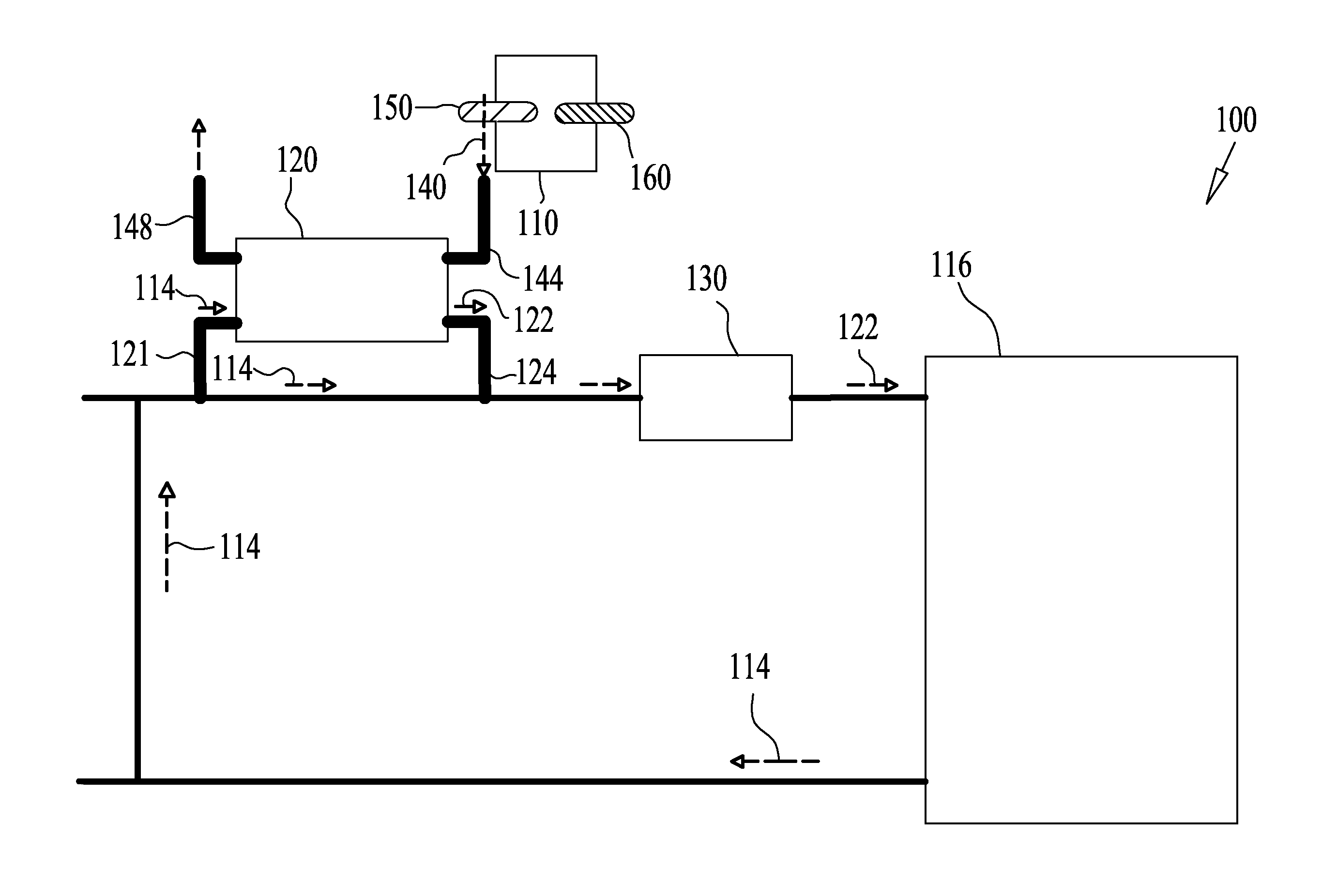

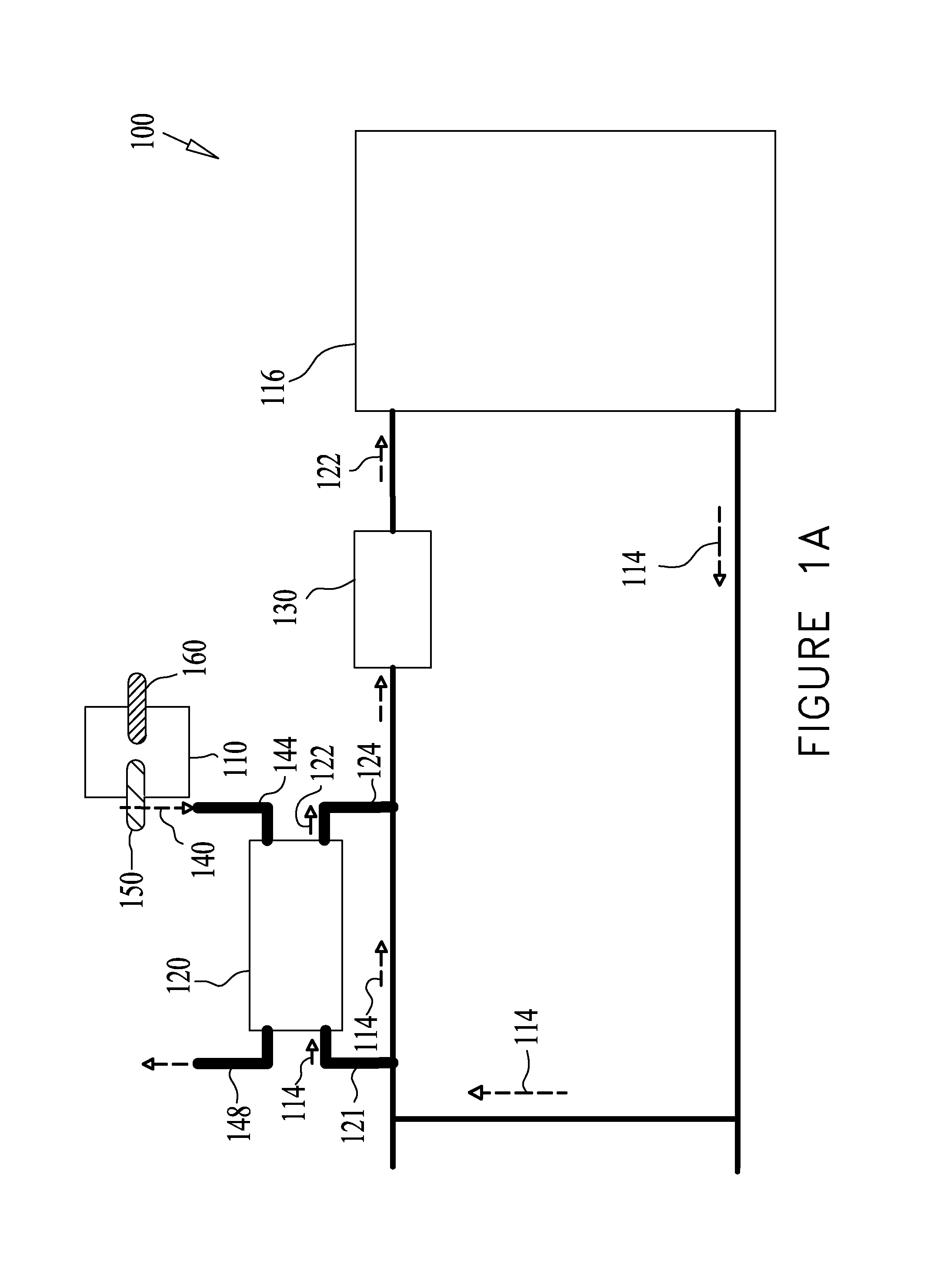

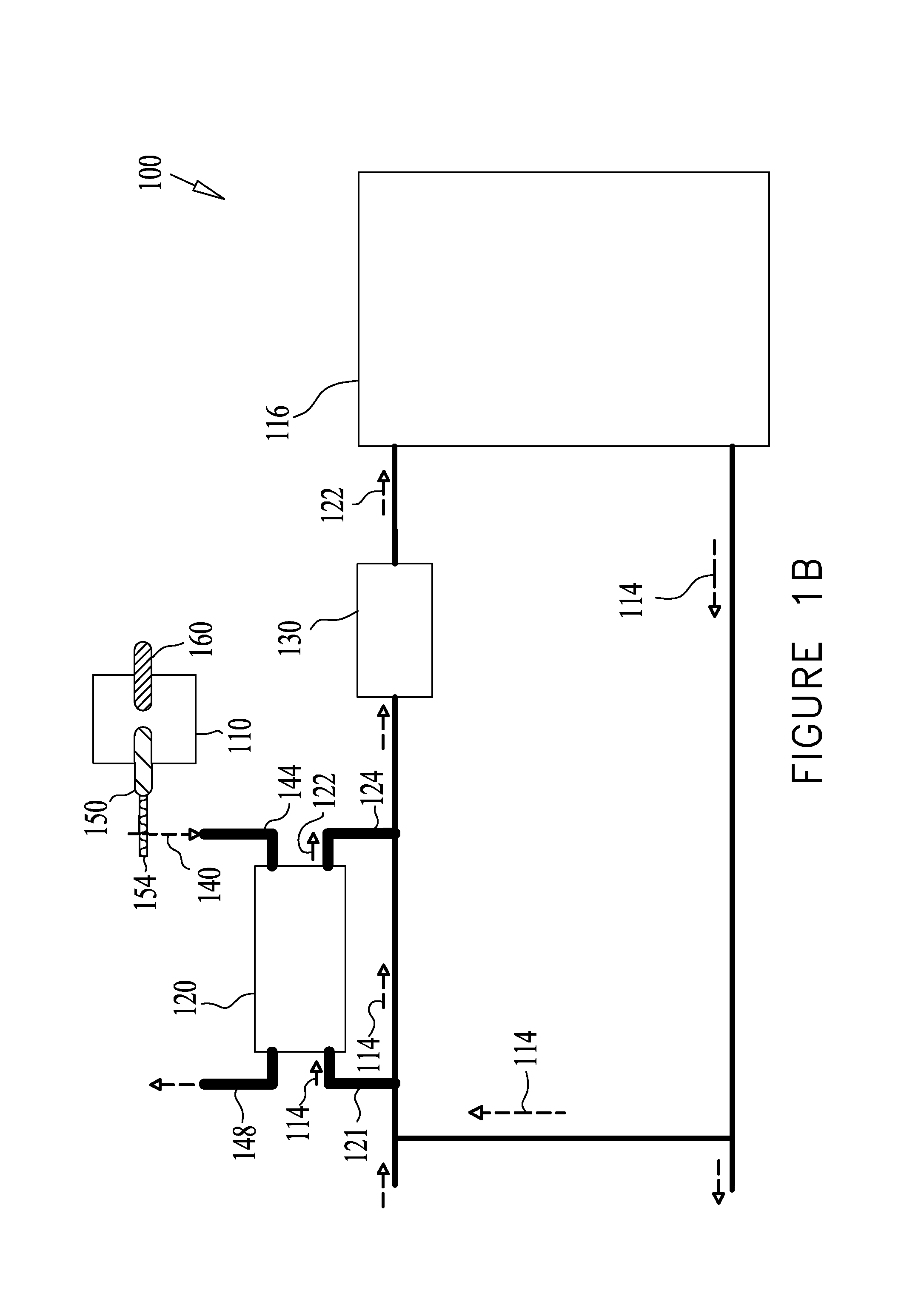

Thermoelectric recovery and peltier heating of engine fluids

InactiveUS20130219872A1Shorten the timeFacilitates heat recoveryElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

A waste heat recovery apparatus and process for use with an internal combustion engine includes a thermo electric apparatus that connects to components of the internal combustion engine to transfer heat between components, generate electric energy from heat extracted from components needing cooling, and convert electric energy to heat energy to transfer to components needing heating.

Owner:MACK TRUCKS

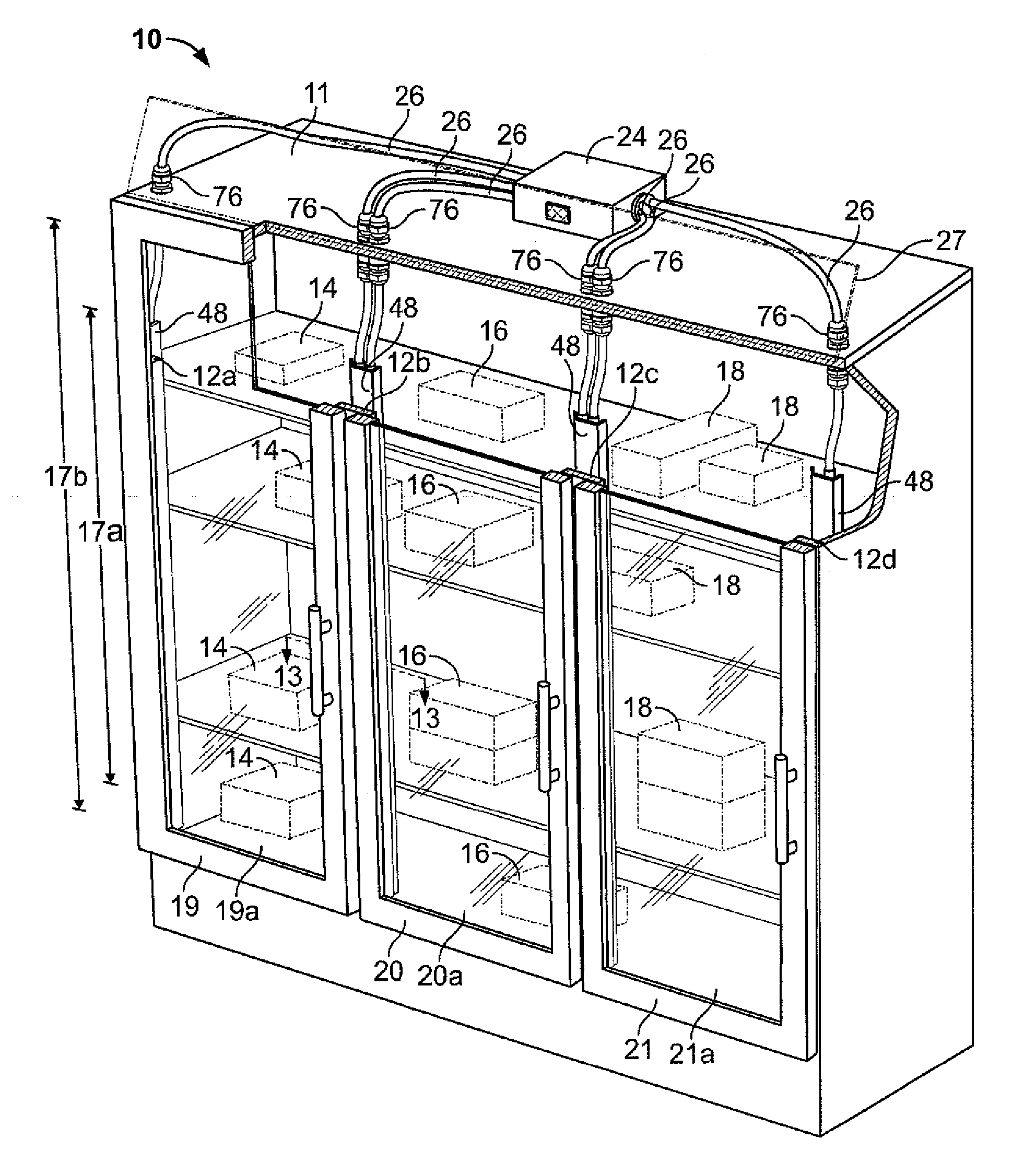

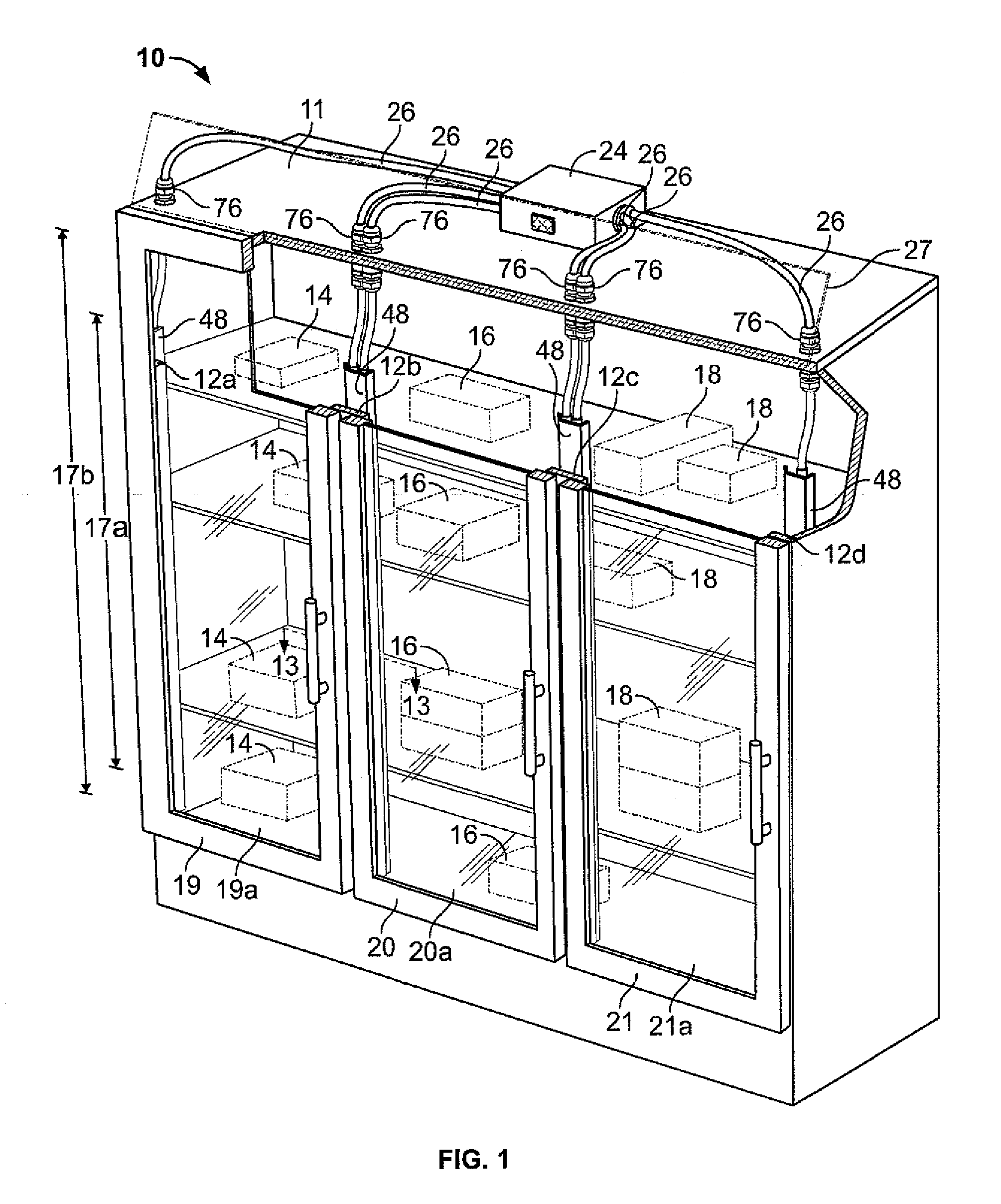

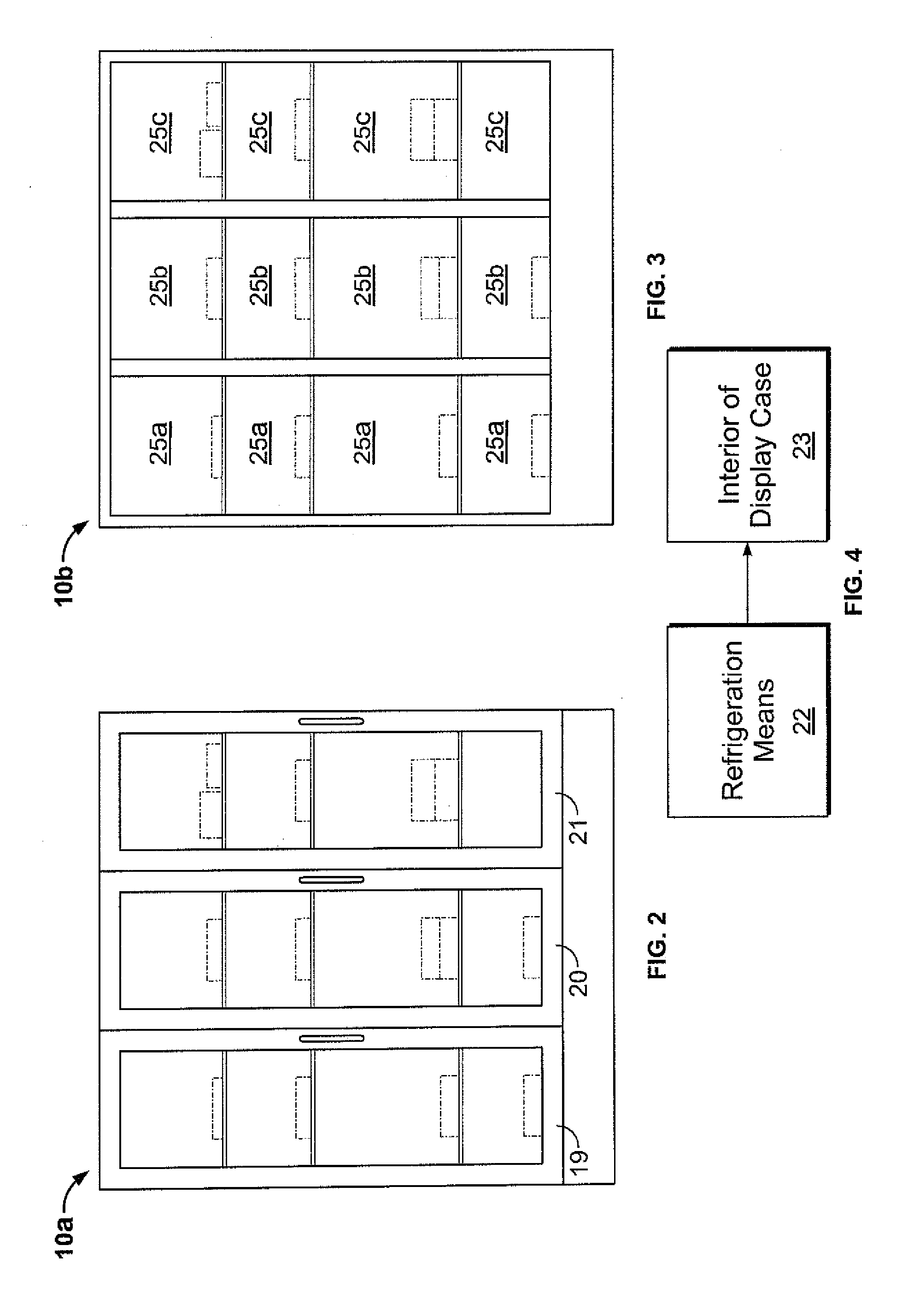

Lighted Refrigerated Display Case with Remote Light Source

ActiveUS20070247831A1Reduce cooling loadReducing cooling attendant costMechanical apparatusFurnace componentsFiberLight delivery

Lighted refrigerated display case with remote light source comprises a closed container with an interior of the container refrigerated to a temperature below 7 C. The container is thermally insulated from ambient, having internal and external walls. A solid fiber optic luminaire is at least partially mounted within the container, having an elongated side-light emitting portion for emitting light from the side of the luminaire onto contents in an interior of the display case. The side-light emitting portion comprises an extractor of light arranged to preferentially extract light from the luminaire and direct the light in at least one radial direction along the length of the side-light emitting portion to at least one target area of said contents along a longitudinal axis of the side-light emitting portion. A light-delivery system provides light to the fiber optic luminaire, having a light source mounted remotely from the interior of the container.

Owner:ENERGY FOCUS INC +1

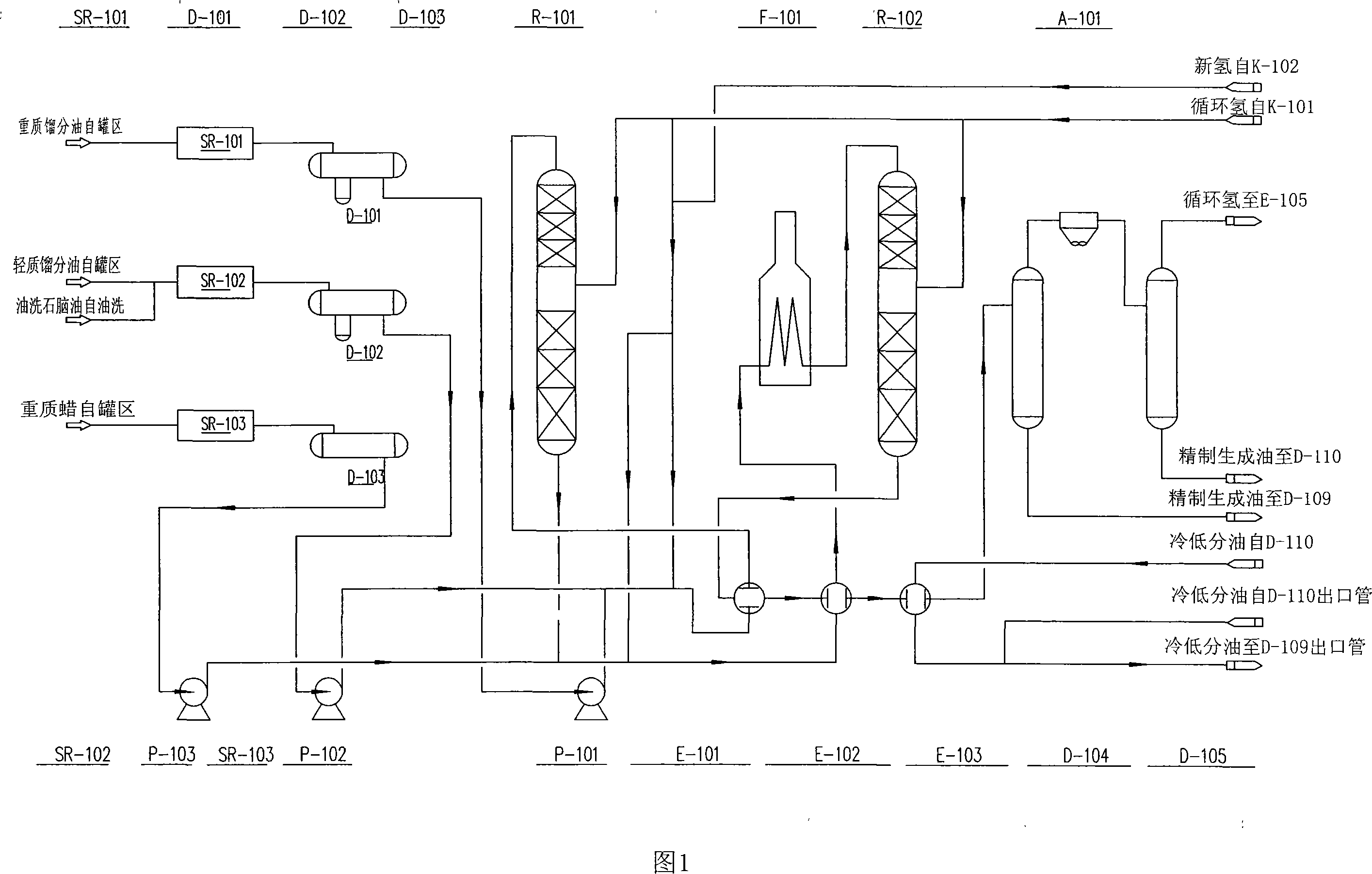

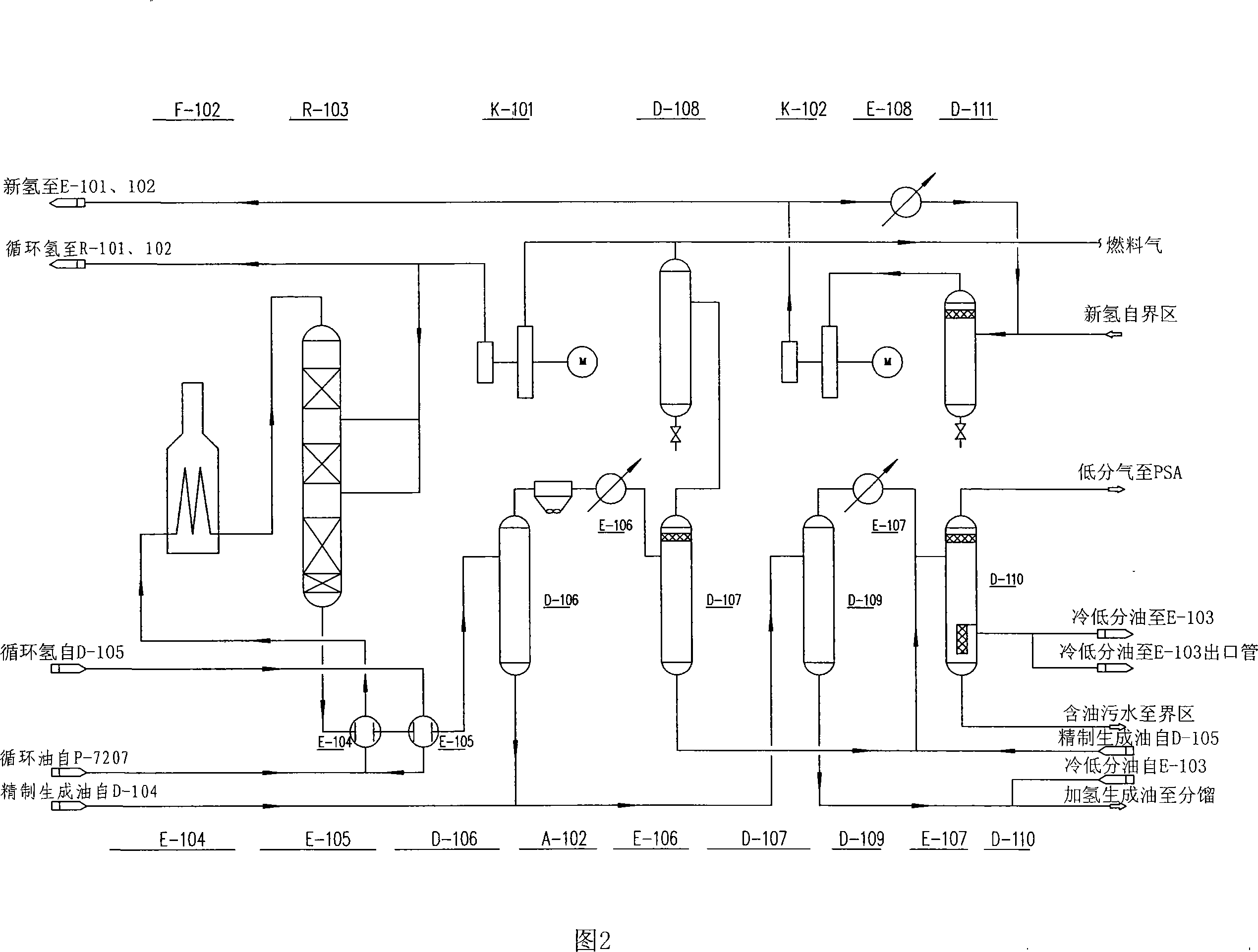

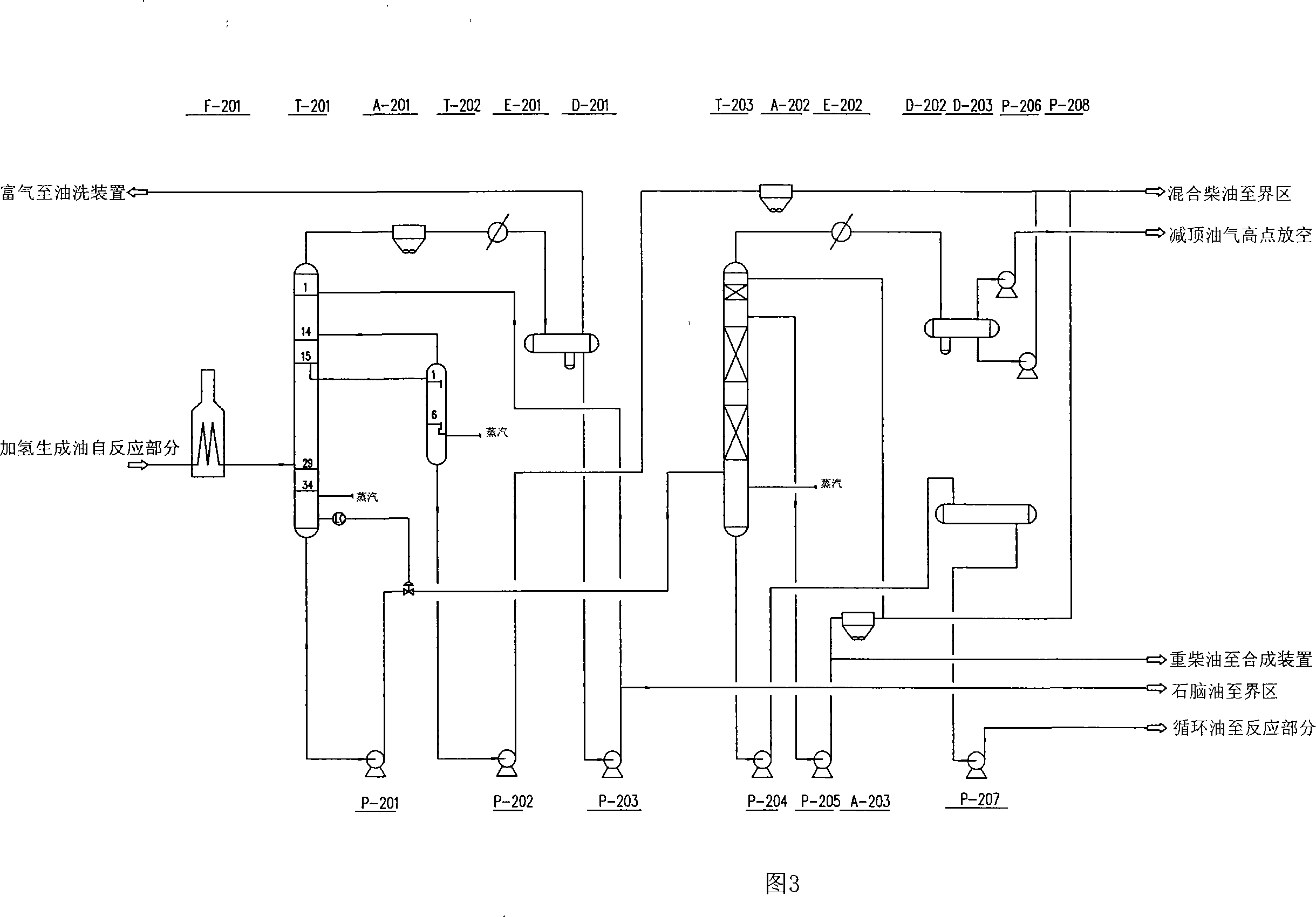

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

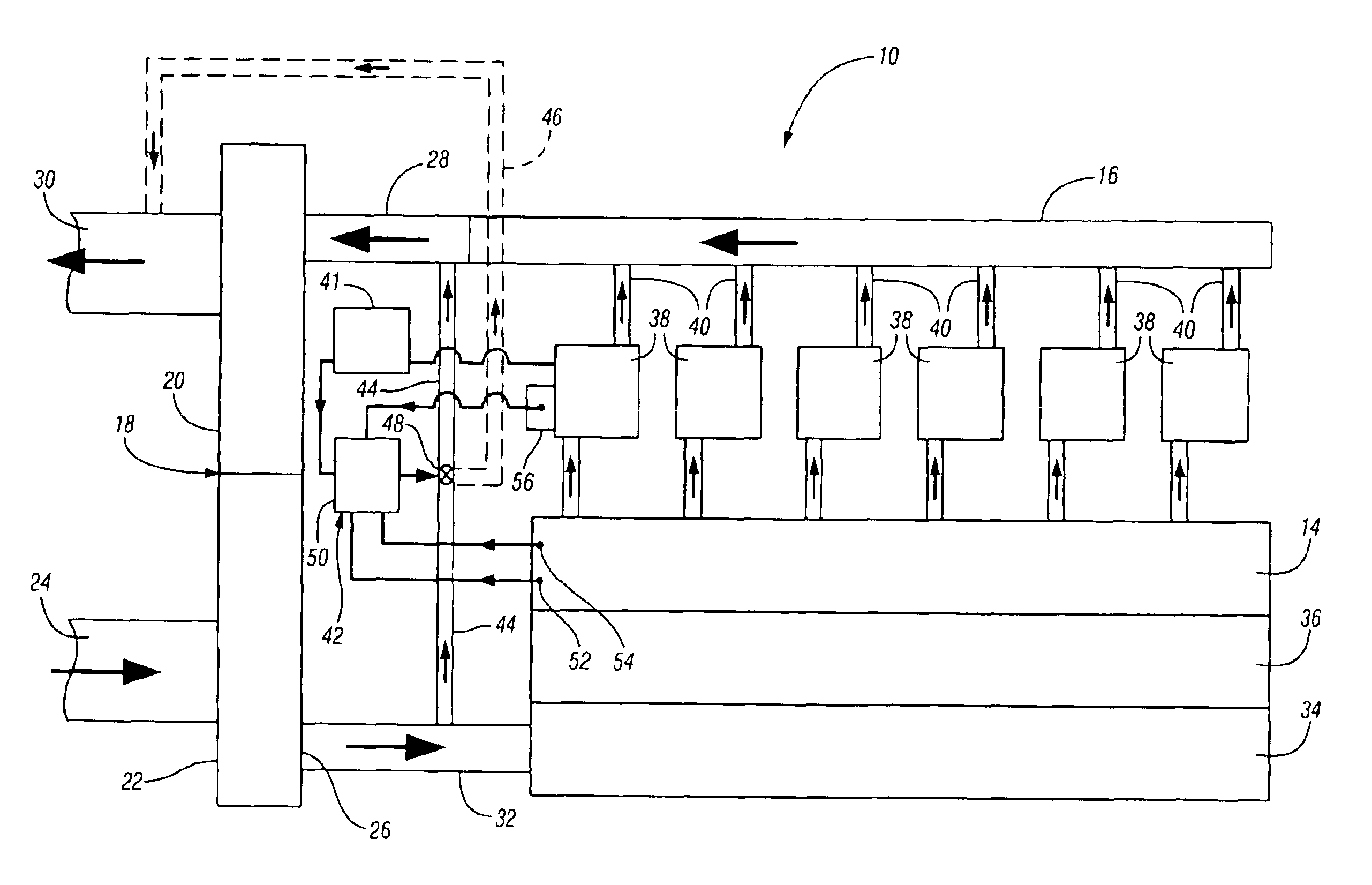

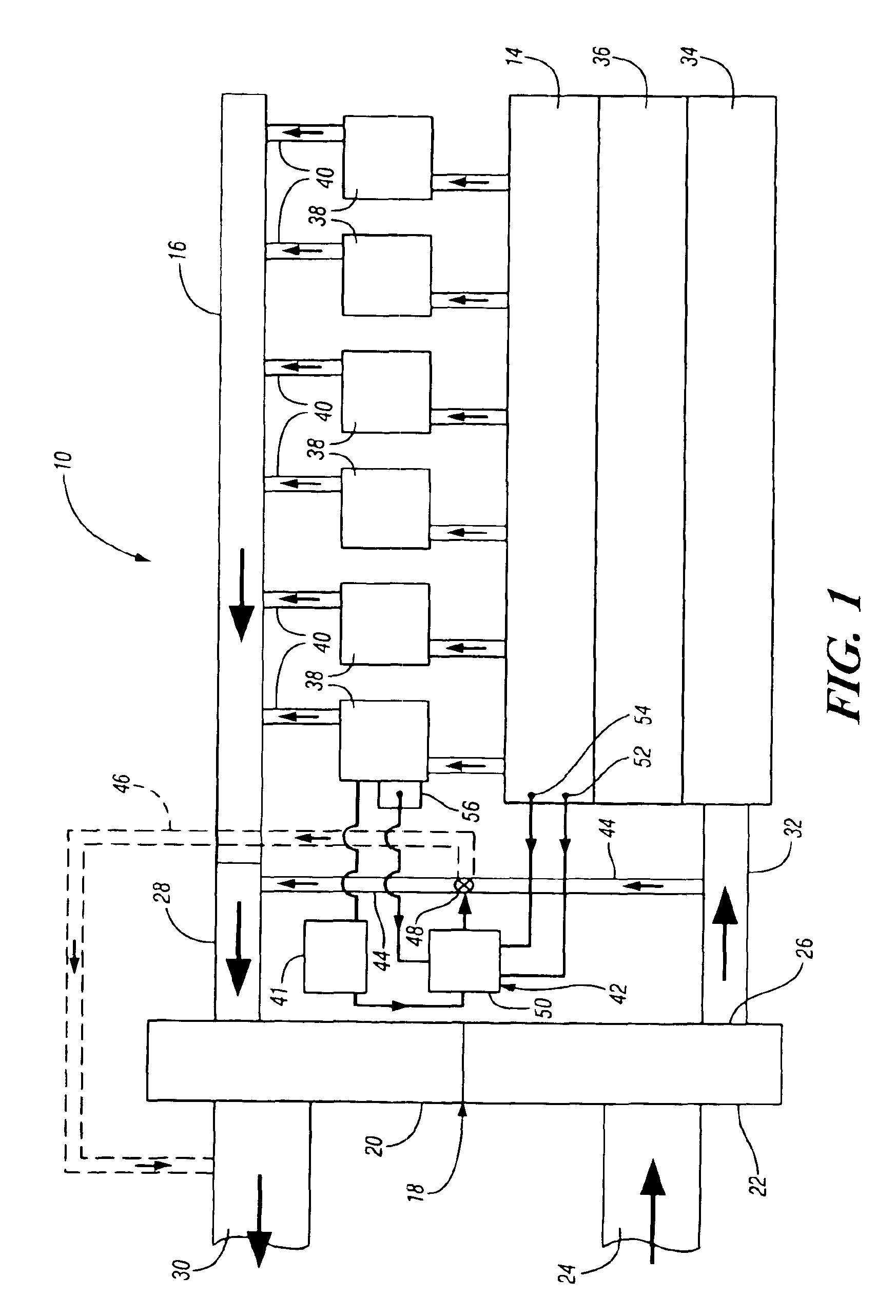

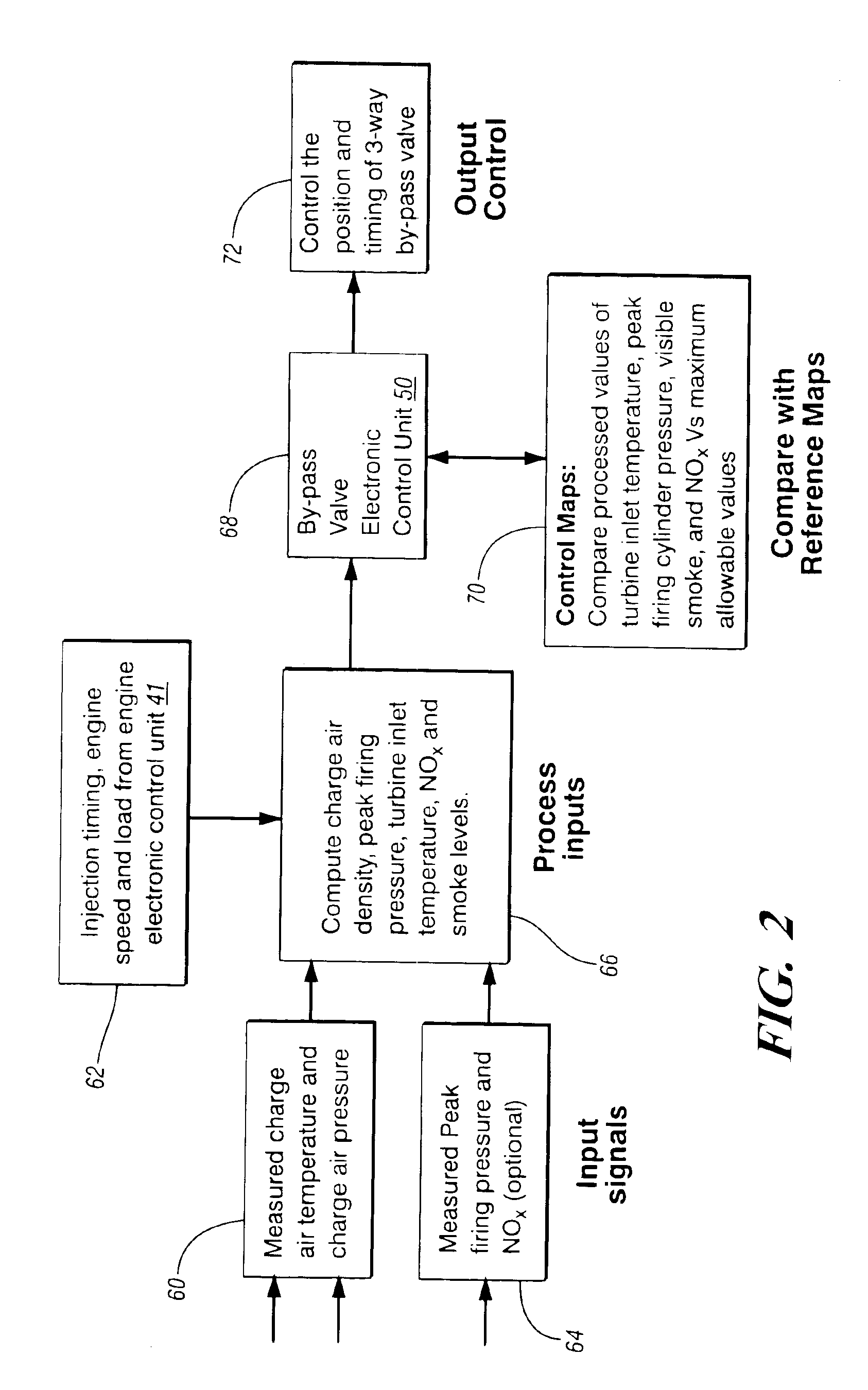

Method for engine condition control with turbocompressor controllable bypass

InactiveUS6912852B2Fast dynamic responseHigh pressureInternal combustion piston enginesEngine controllersTurbochargerExhaust fumes

A system for a turbocharged internal combustion engine includes an engine having a charge inlet connected to the compressor outlet and an exhaust outlet connected to the turbine inlet for driving the turbocharger with hot exhaust gas and supplying compressed air to the engine for combustion. A bypass duct connects the compressor outlet to the turbine inlet for diverting a portion of the compressed air around the engine to the turbine inlet or exhaust. A control device selectively controls the diversion of air. An operating method for the system involves controlling peak cylinder firing pressure and / or maximum turbine inlet temperature, optionally with exhaust NOx and smoke in order to limit these variables to acceptable limits with a minimum of operational limitations.

Owner:ELECTRO-MOTIVE DIESEL

Systems And Methods For Regenerating Adsorbents For Indoor Air Scrubbing

ActiveUS20140020559A1Minimize consumptionReduce energy costsNitrous oxide captureGas treatmentSorbentIndoor air

Some embodiments of the disclosure correspond to, for example, a system for scrubbing a mixture of gases and / or contaminants from indoor air from an enclosed space to remove at least one gas and / or contaminant from the mixture of gases and / or contaminants. The system may include one or more adsorbent materials configured to be cycled between adsorption and regeneration of at least one of gas and / or contaminant from the mixture of gases and / or contaminants via a temperature swing adsorption cycle (for example), regeneration means configured to regenerate one or more adsorbent materials. The regeneration means may be configured at a regeneration temperature to regenerate the one or more adsorbent materials.

Owner:ENVERID SYST

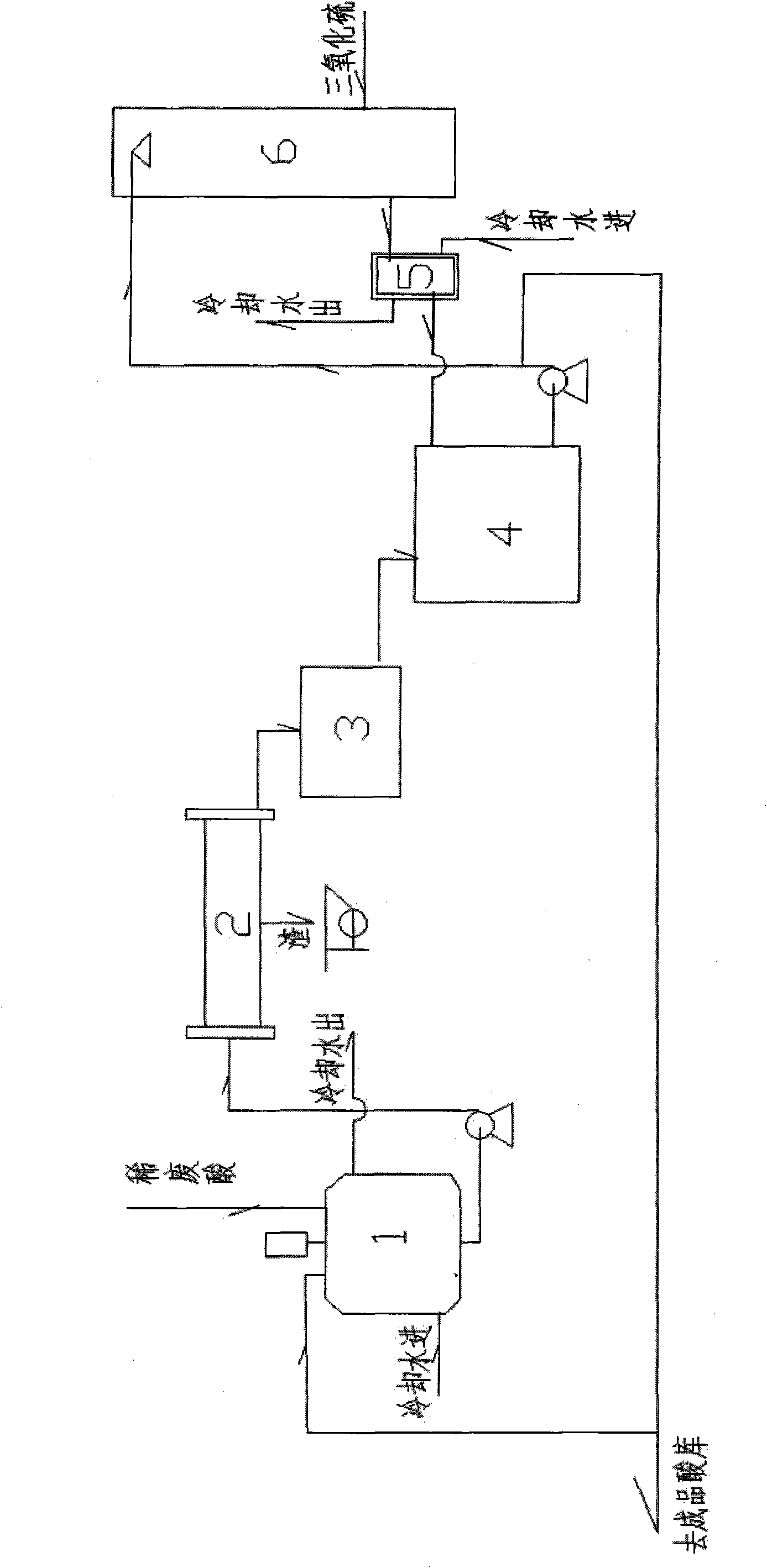

Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

ActiveCN101538021ASolving production challenges of reuseIncrease productionSulfur-trioxide/sulfuric-acidSulfurSulfate

The recycling of diluted waste acid produced in the production process of sulfate process titanium dioxide is a bottleneck limiting the development of the sulfate process titanium dioxide. In addition, manufacturers of sulfate process titanium dioxide usually have sulfate acid production devices due to the need of a large amount sulfate acid. The invention relates to a method and a device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production. The method comprises the following steps: firstly, performing the pre-concentration of the diluted sulfate acid; secondly, removing most impurities carried by the diluted sulfate acid through settlement; and finally, using the sulfate acid subjected to pre-concentration and impurity removal to replace make up water of a sulfate production system, adding the sulfate acid into a sulfate circulating tank of a sulfate acid absorption tower to produce concentrated sulfate acid after sulfate acid absorption tower absorbs sulfur trioxides, and thus recycling the diluted sulfate acid. The method has the advantages of making a plurality of achievements at one time, namely changing pre-concentrated diluted sulfate acid into concentrated sulfate acid without extra energy consumption and equipment addition while reducing the cooling load of sulfate acid flowing out from the tower at the same time.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

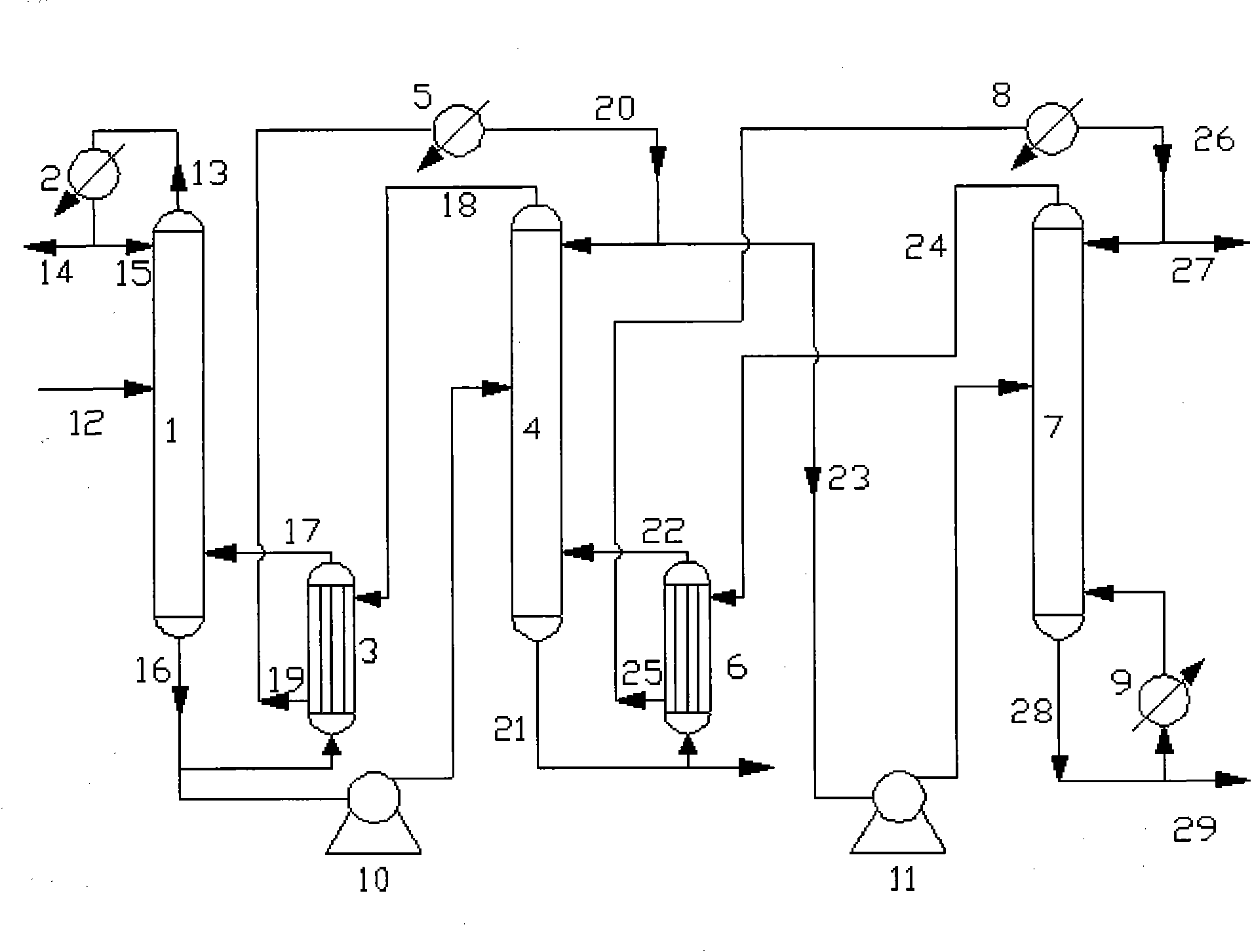

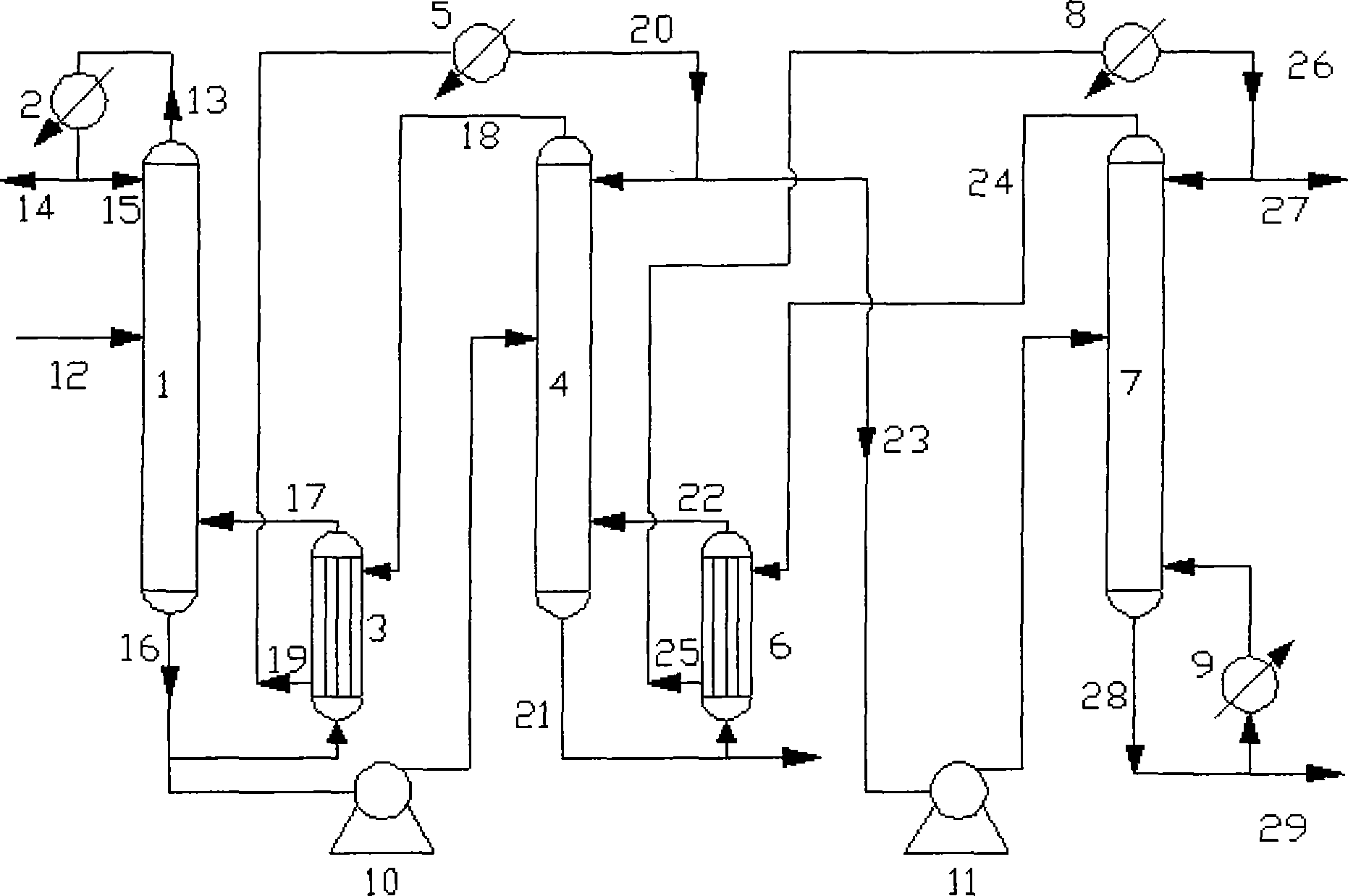

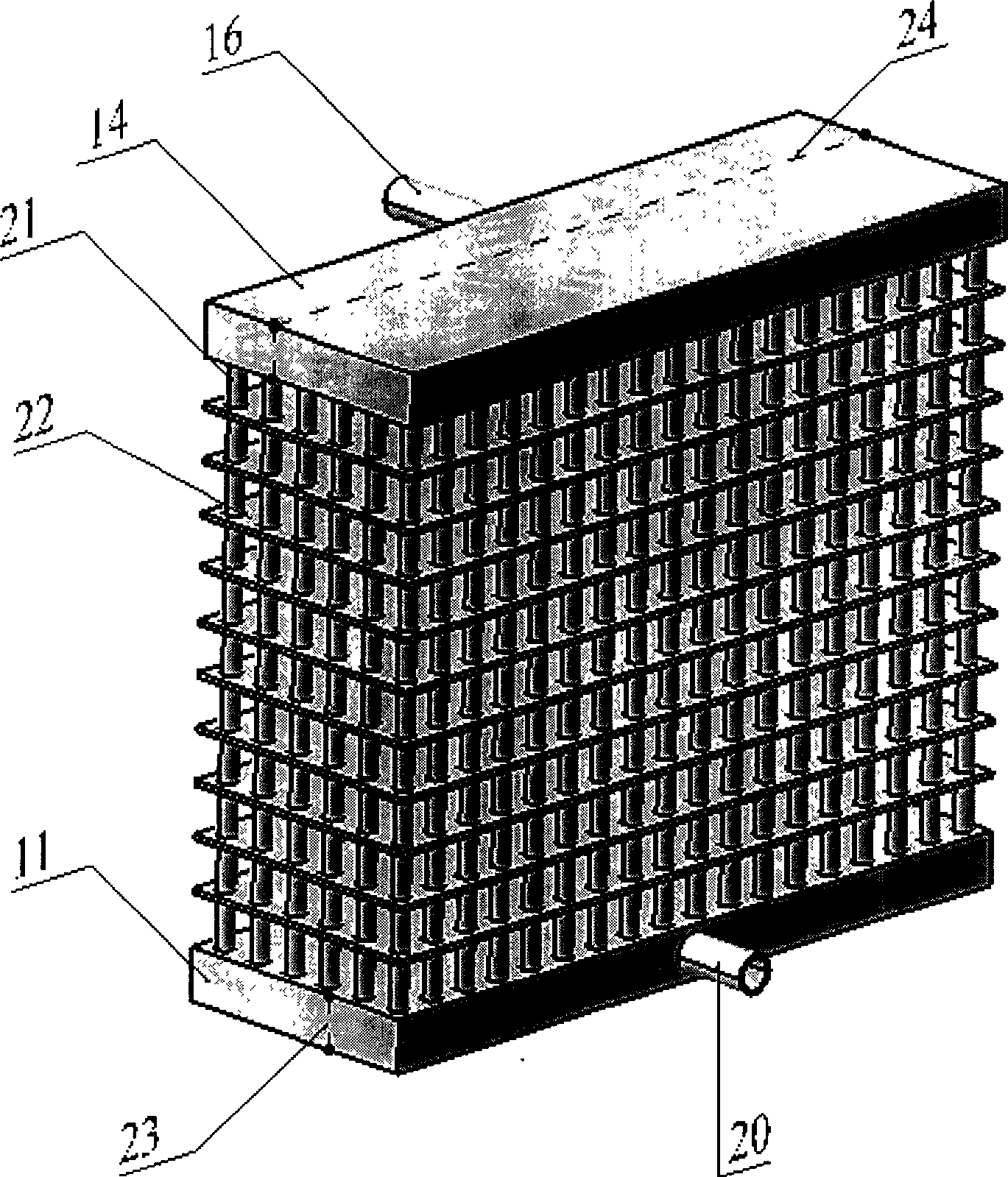

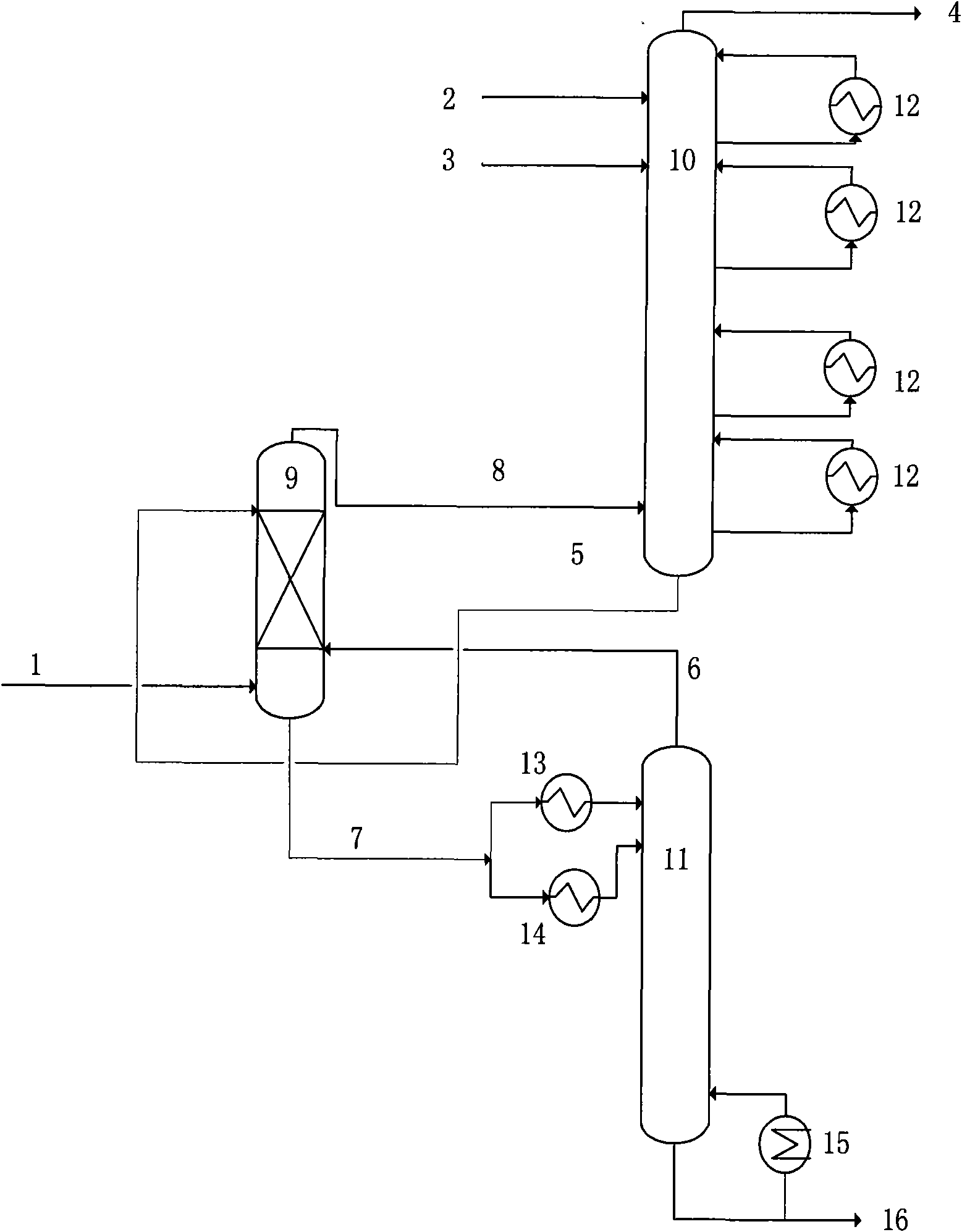

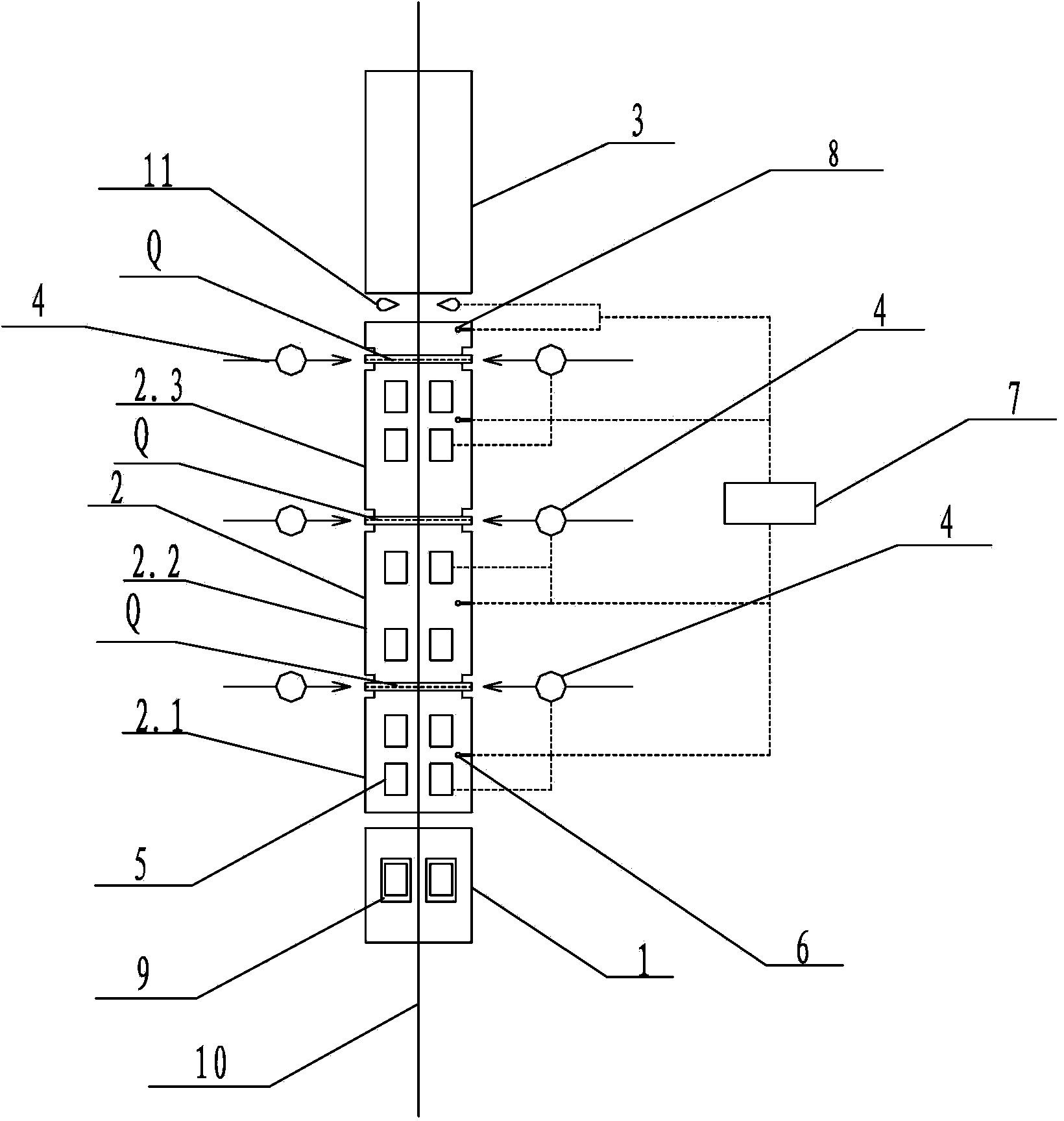

Trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and operating method

ActiveCN101786630ASave heating and energy saving lossReduce cooling loadChemical industryHalogenated silanesDifferential pressureProcess engineering

The invention relates to a trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and an operating method. The trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system comprises a primary tower, a secondary tower and a tertiary tower; the three towers are connected in series from low pressure to highpressure or from high pressure to low pressure, and a condensation re-boiler is arranged between the primary tower and the secondary tower and between the secondary tower and the tertiary tower respectively; and the three towers can be used for light removal, heavy removal and light removal in turn, and also can be used for combining light removal, heavy removal and light removal. According to the characteristics of approach full tower composition and approach temperature in the process of rectifying the trichlorosilane, the invention provides a trichlorosilane differential pressure coupling rectifying process which is expected to greatly reduce the production cost and energy consumption and theoretically rectify and save energy by nearly 70 percent. The technology remarkably improves themarket competitiveness of polycrystal silicon materials and promotes the development of a photovoltaic and information material industry chain.

Owner:TIANJIN UNIV

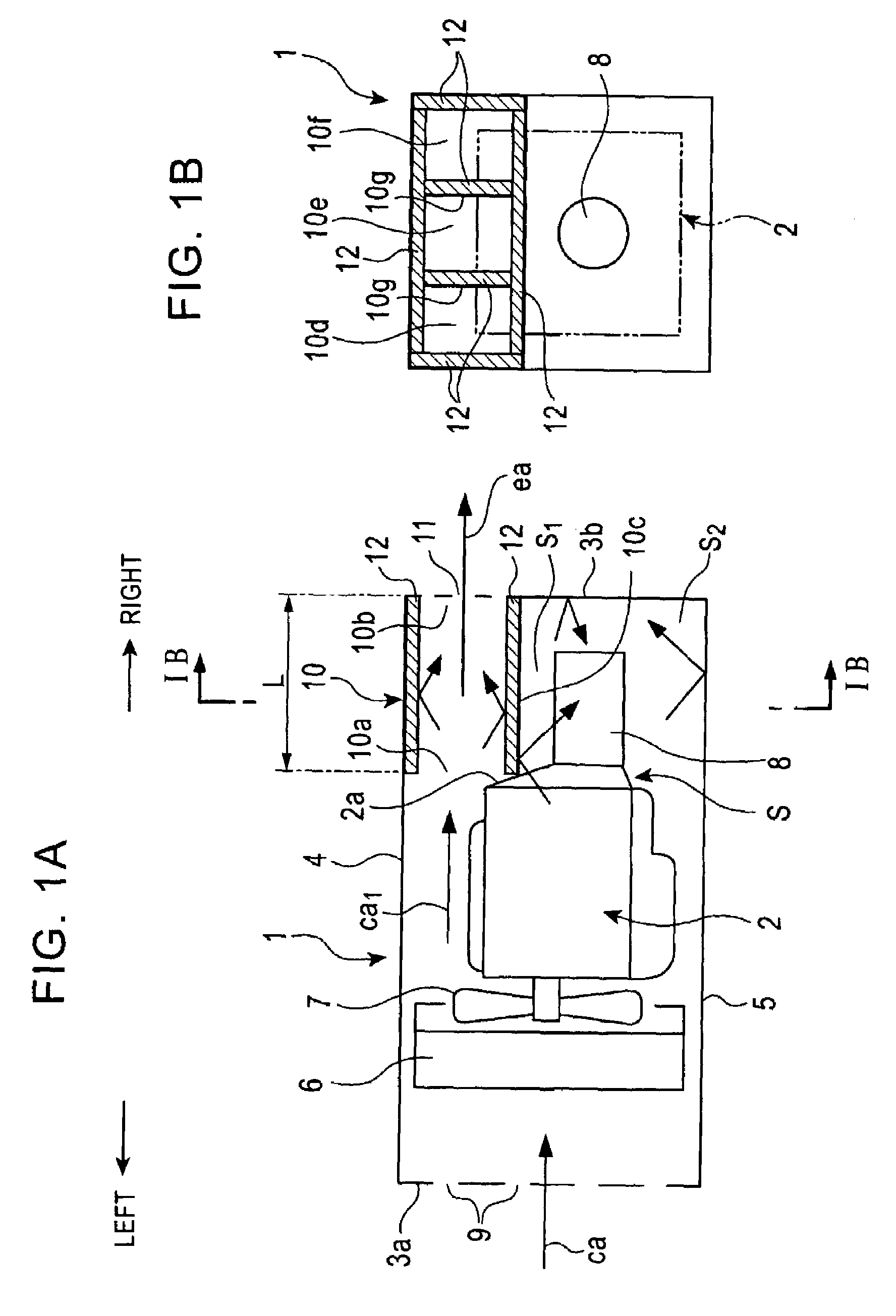

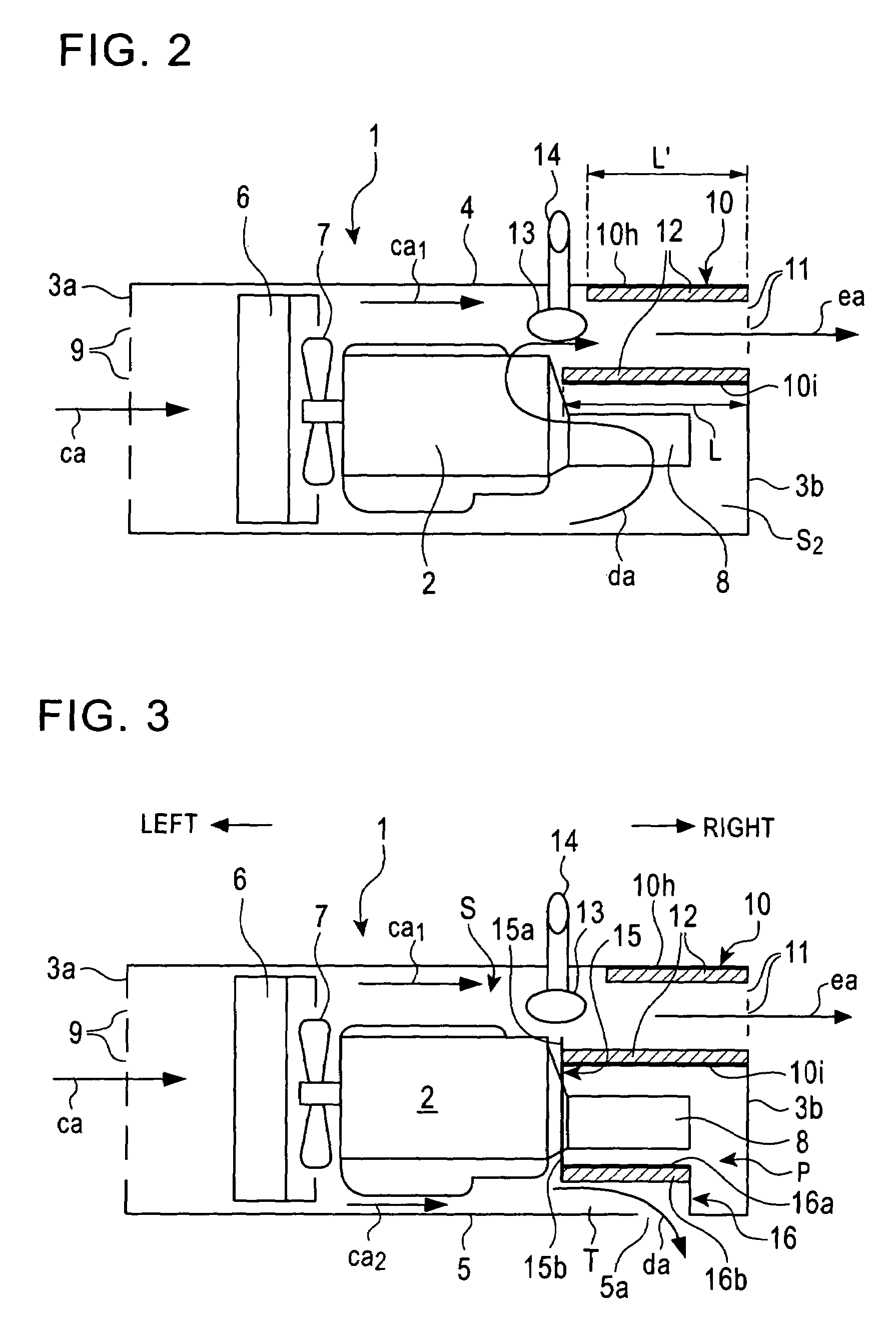

Construction machine

ActiveUS7131422B2Reduce cooling loadSuppress noiseNon-fuel substance addition to fuelSoil-shifting machines/dredgersBuilding constructionAerospace engineering

A construction machine includes an engine guard, an engine, a cooling fan, and a device for being cooled by the cooling fan, and an exhaust duct. The engine guard accommodates the engine and has intake and exhaust openings. The intake opening and the exhaust opening are disposed in different side covers. The side covers correspond to the left and right side walls of the engine guard. The engine, the cooling fan, and the device are accommodated in the engine guard. The exhaust duct is disposed above and behind the engine, parallel with the flow of a fan air which has been used for cooling the engine, and substantially horizontally. The exhaust duct has an exit connected to the exhaust opening. The fan air introduced from the intake opening flows substantially linearly along the cooling fan, the engine, and the exhaust duct and is discharged from the exhaust opening.

Owner:KOBELCO CONSTR MASCH CO LTD

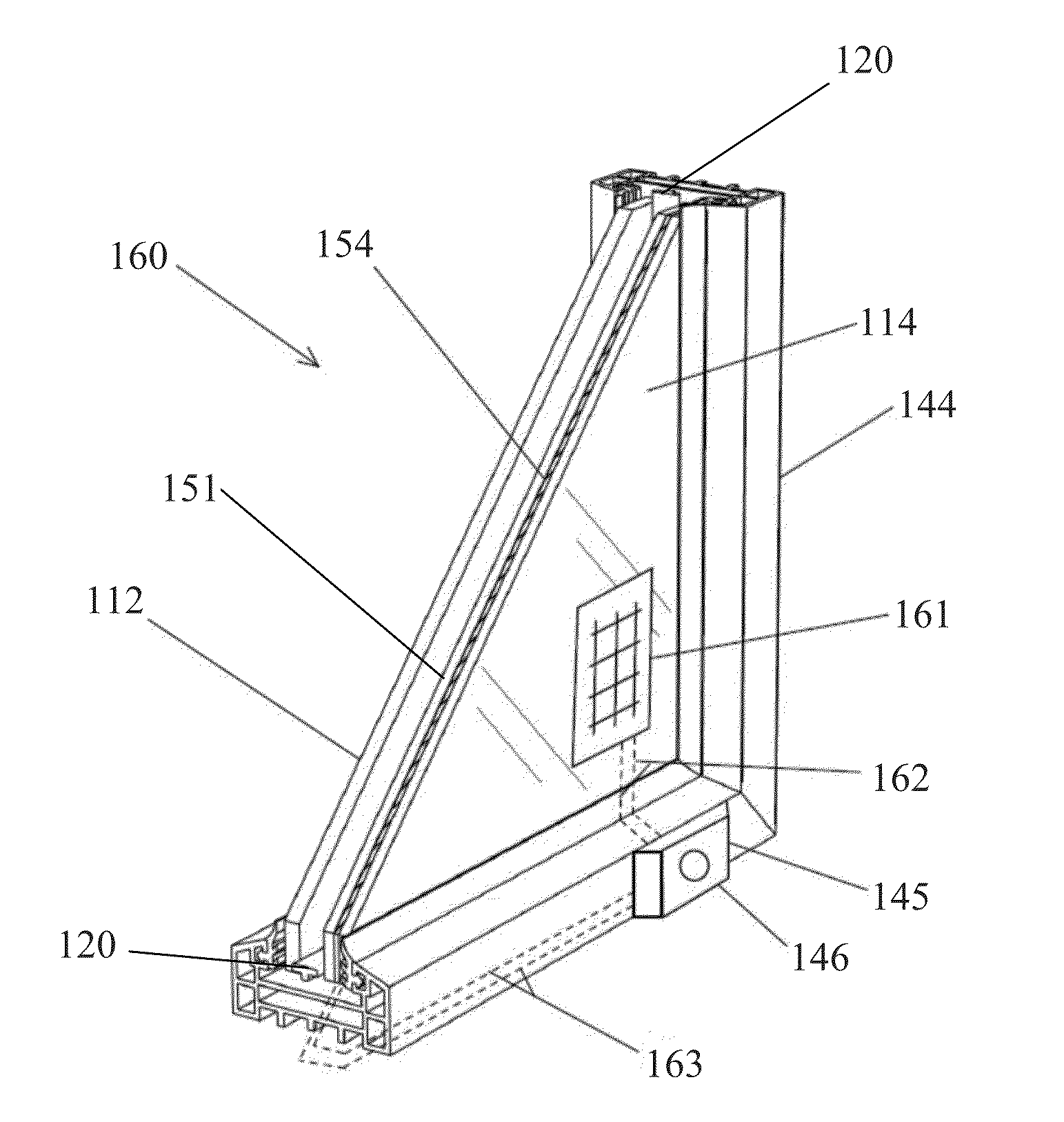

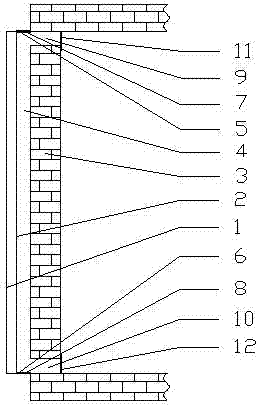

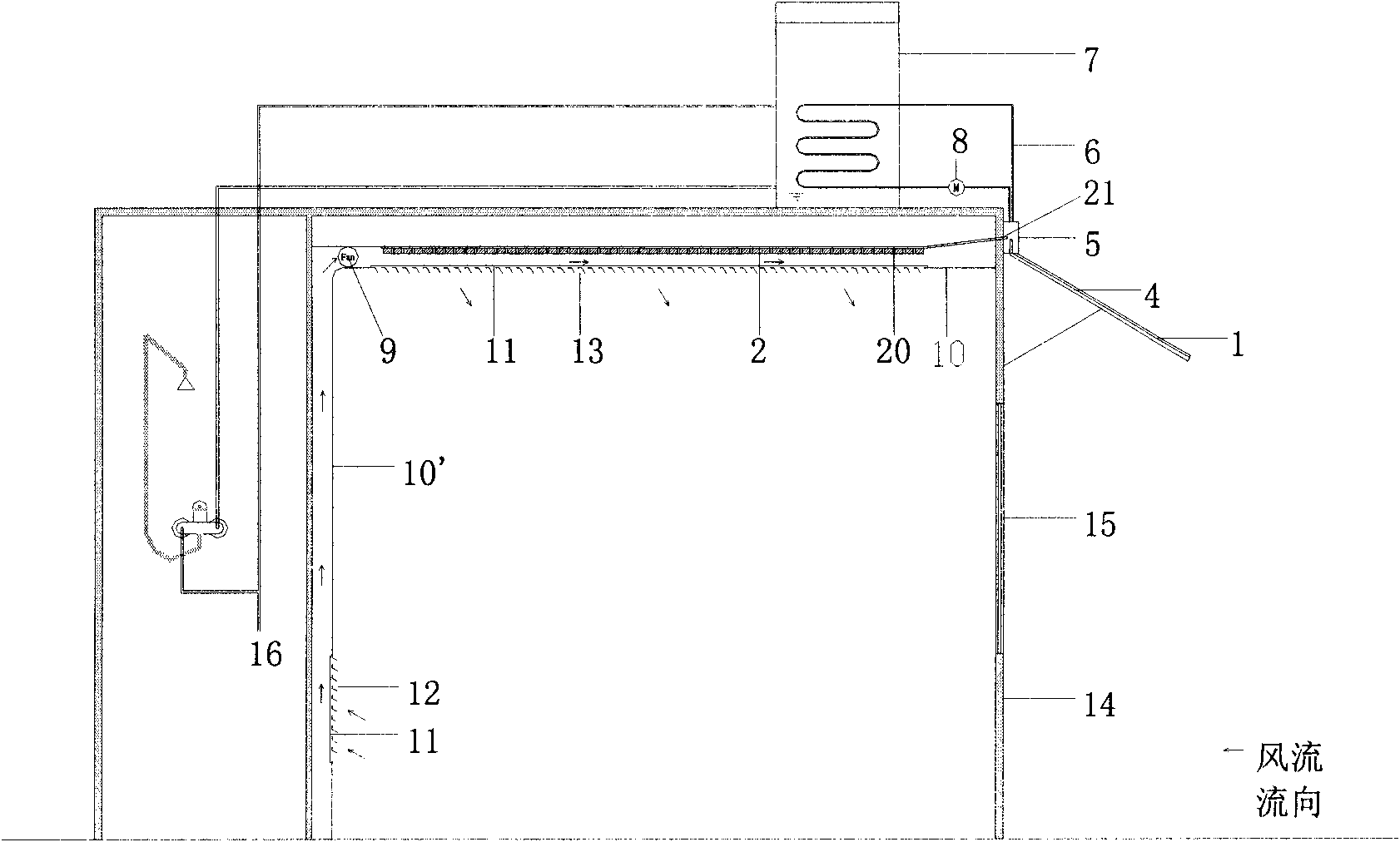

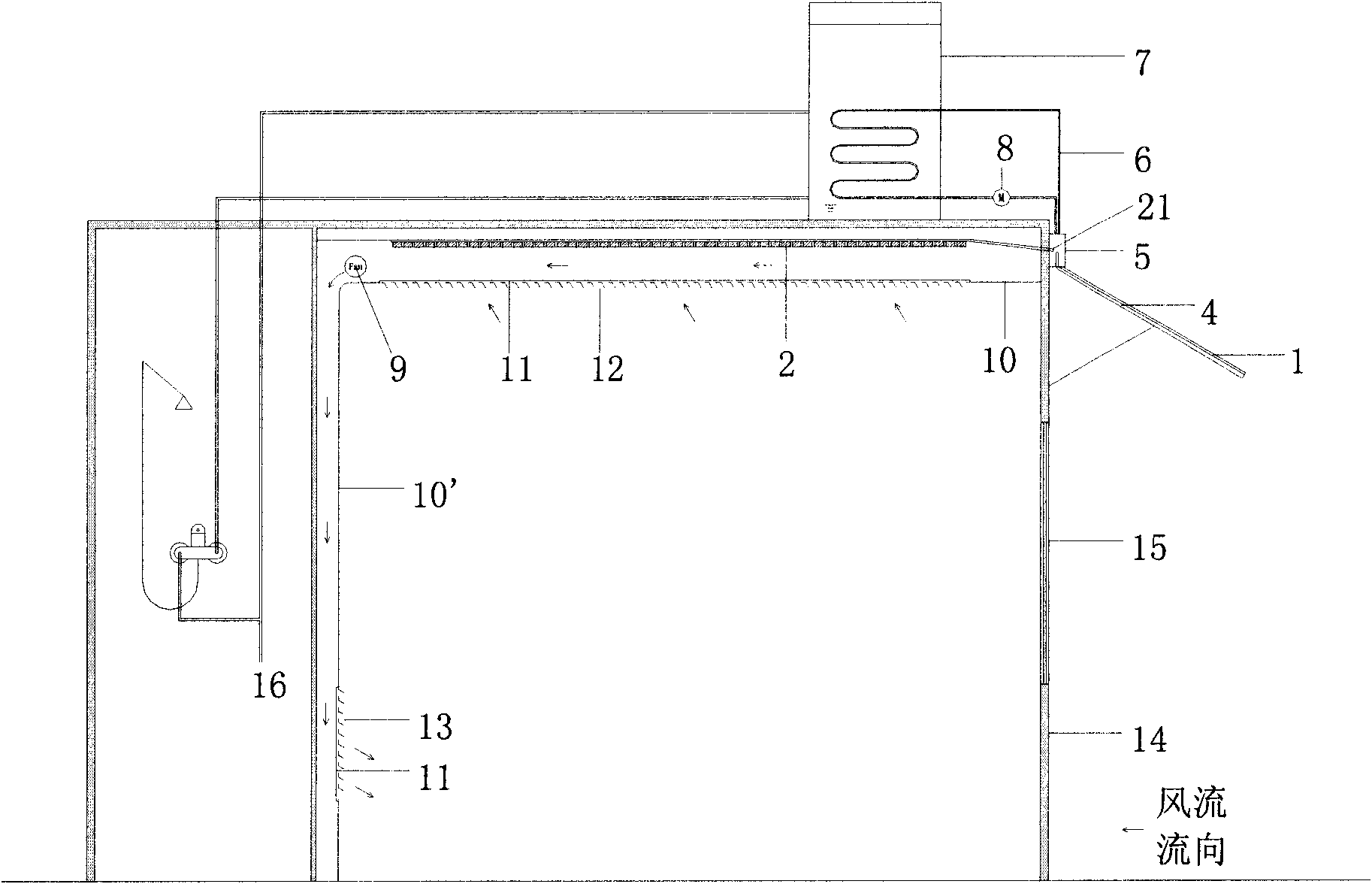

Trombe wall with comprehensive application of solar heat collection and radiation refrigeration

ActiveCN103790244AReduce heat loadSolve the shortcoming of single function only for heatingSolar heating energyWallsFull waveEngineering

The invention relates to a Trombe wall with the comprehensive application of solar heat collection and radiation refrigeration. The Trombe wall comprises a transparent cover plate, a heat collection and storage wall, an air flow channel, upper ventilation openings, lower ventilation openings and baffles. The transparent cover plate is made of full-wave band high transmittance material. A venetian blind is arranged on the inner side face of the transparent cover plate, one side faces of slats of the venetian blind are coated with selective absorbing coatings, and absorptivity of the coatings ranges from 90% to 95% within the solar radiation wave band ranging from 0.2 micrometer to 3 micrometers. The other side faces of the slats of the venetian blind are selective radiation surfaces, emissivity of the selective radiation surfaces ranges from 80% to 90% within the atmospheric window wave band ranging from 8 micrometers to 13 micrometers, and emissivity of the selective radiation surfaces ranges from 60% to 90% within other wave bands. The Trombe wall can heat a room in the daytime and preserve heat of the room at night in winter, and can reduce heat loads of the room in the daytime and refrigerate the room at night in summer, and therefore the problem that a traditional Trombe wall can only heat the room and is single in function is solved; the defect that the appearance of the traditional Trombe wall is not attractive enough is overcome due to the utilization of the venetian blind attractive in appearance.

Owner:UNIV OF SCI & TECH OF CHINA

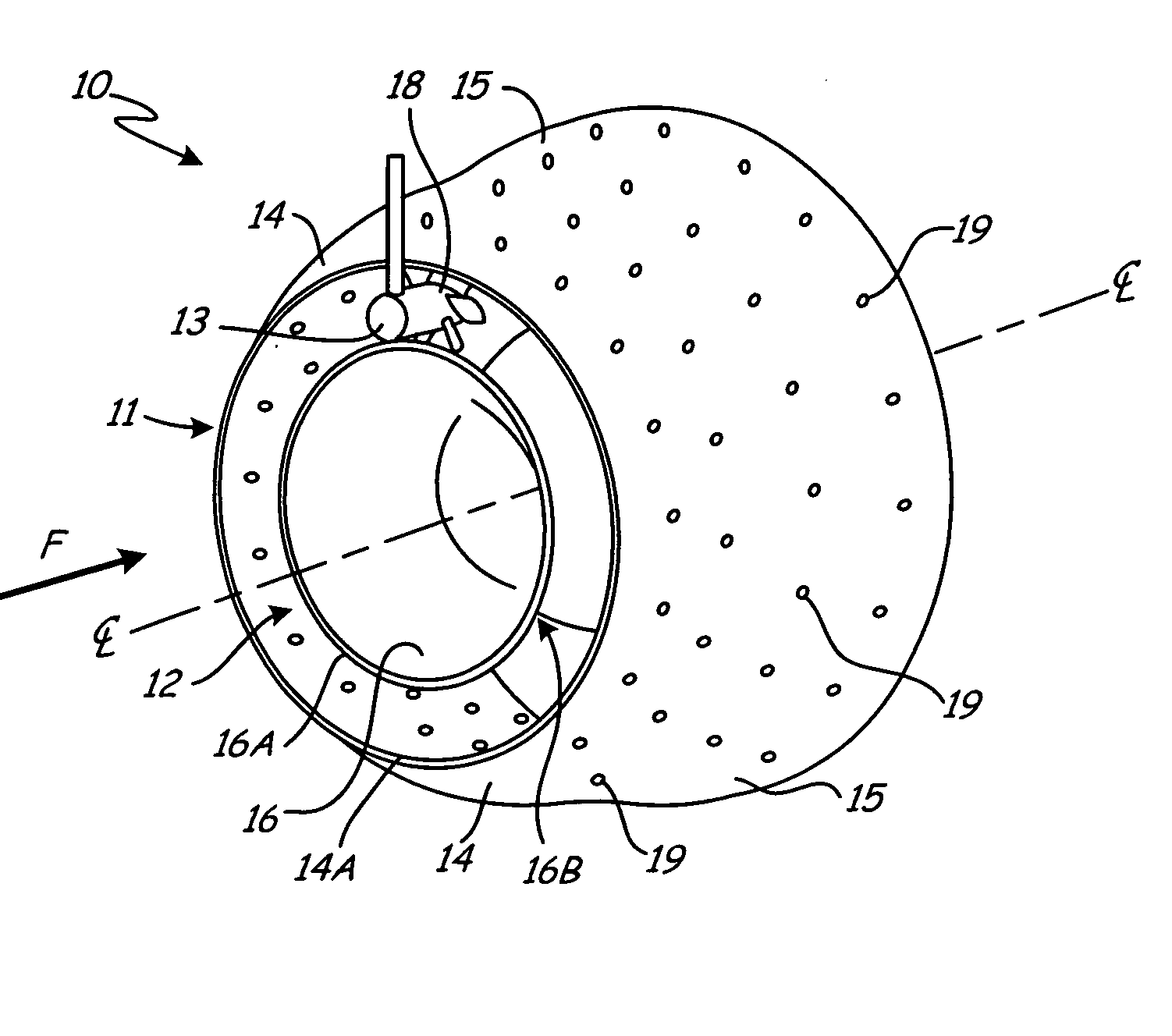

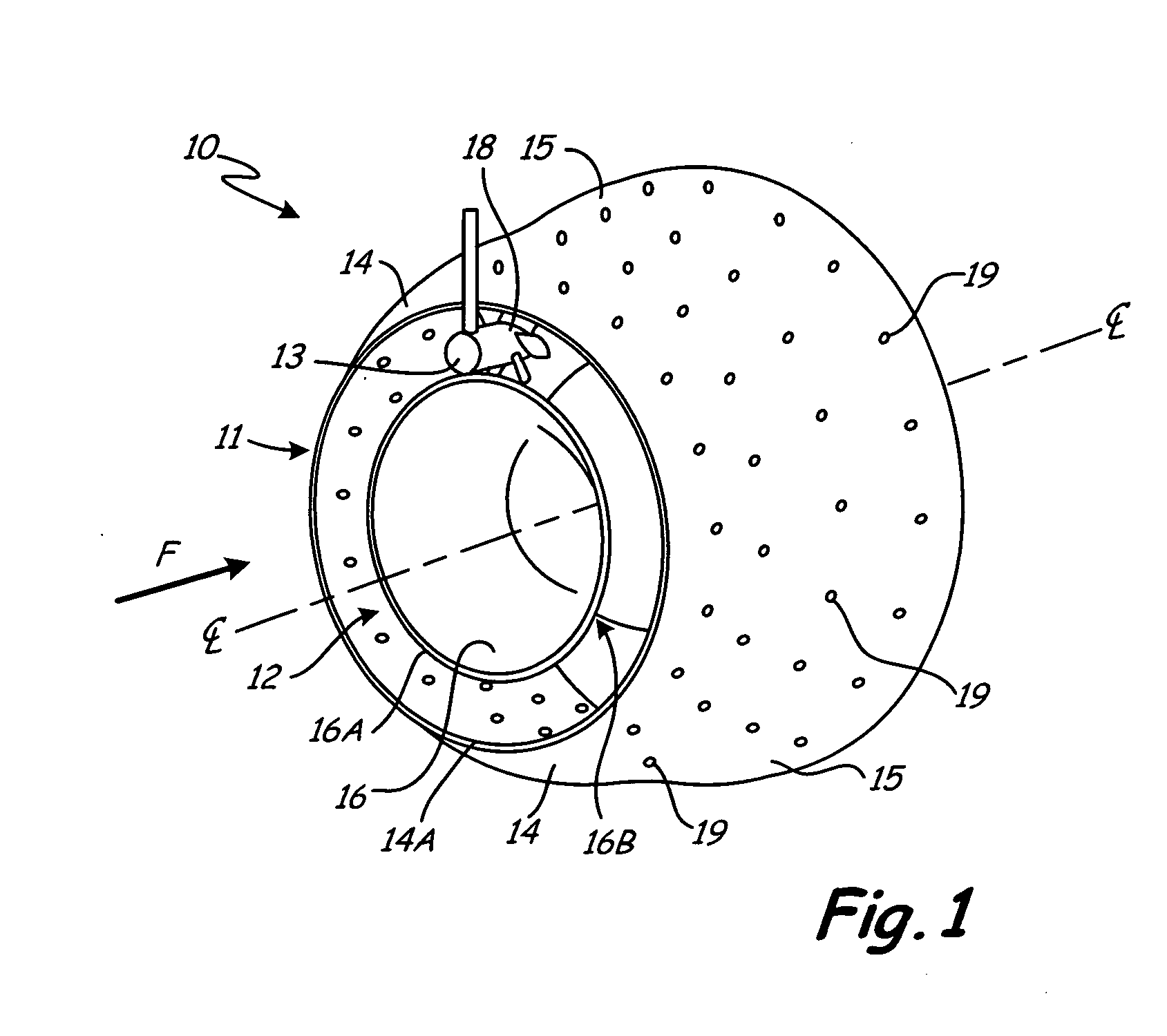

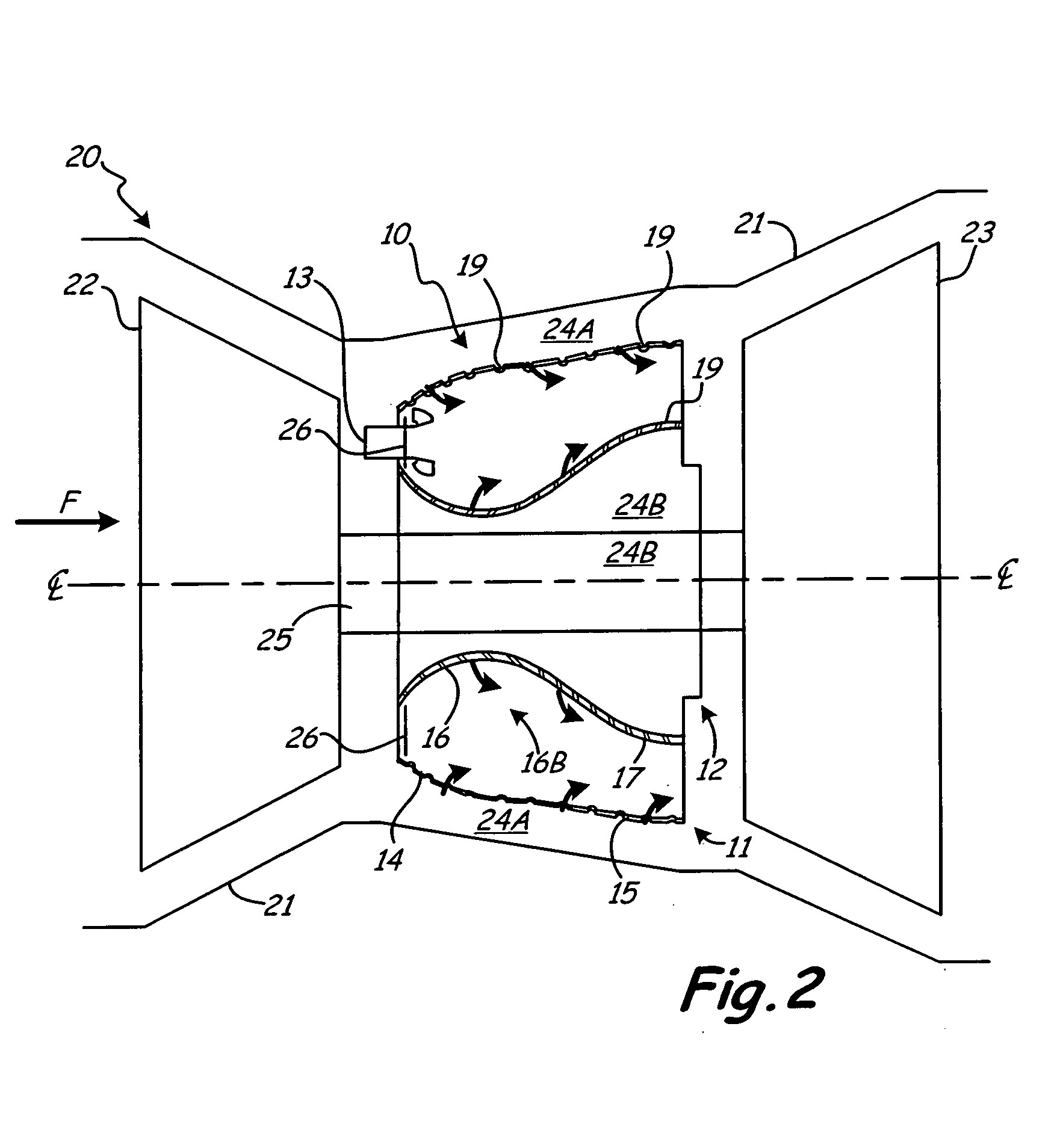

Scalable pyrospin combustor

InactiveUS20090199563A1Promote film coolingReduce cooling loadContinuous combustion chamberTurbine/propulsion fuel flow conduitsEngineeringEffusion

An axial-flow pyrospin combustor comprises inner and outer combustor liners and a plurality of pyrospin effusion holes. The inner liner is coaxially mounted inside the outer liner, about a central combustor axis. The pyrospin effusion holes are formed in at least one of the outer combustor liner and the inner combustor liner. Each of the pyrospin effusion holes has a down angle and a back angle, which control a global swirl flow about the central axis, and promote film cooling without detachment.

Owner:HAMILTON SUNDSTRAND CORP

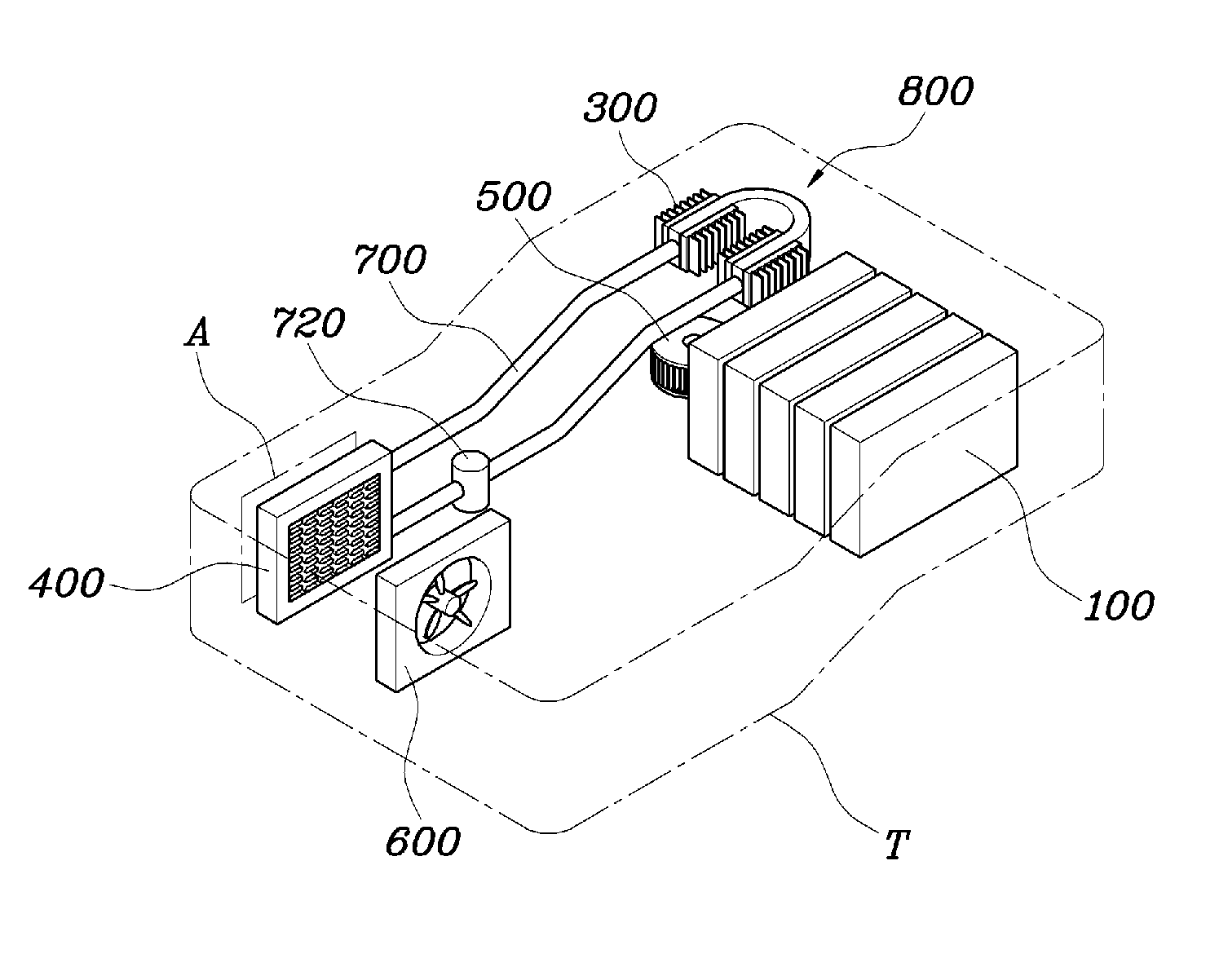

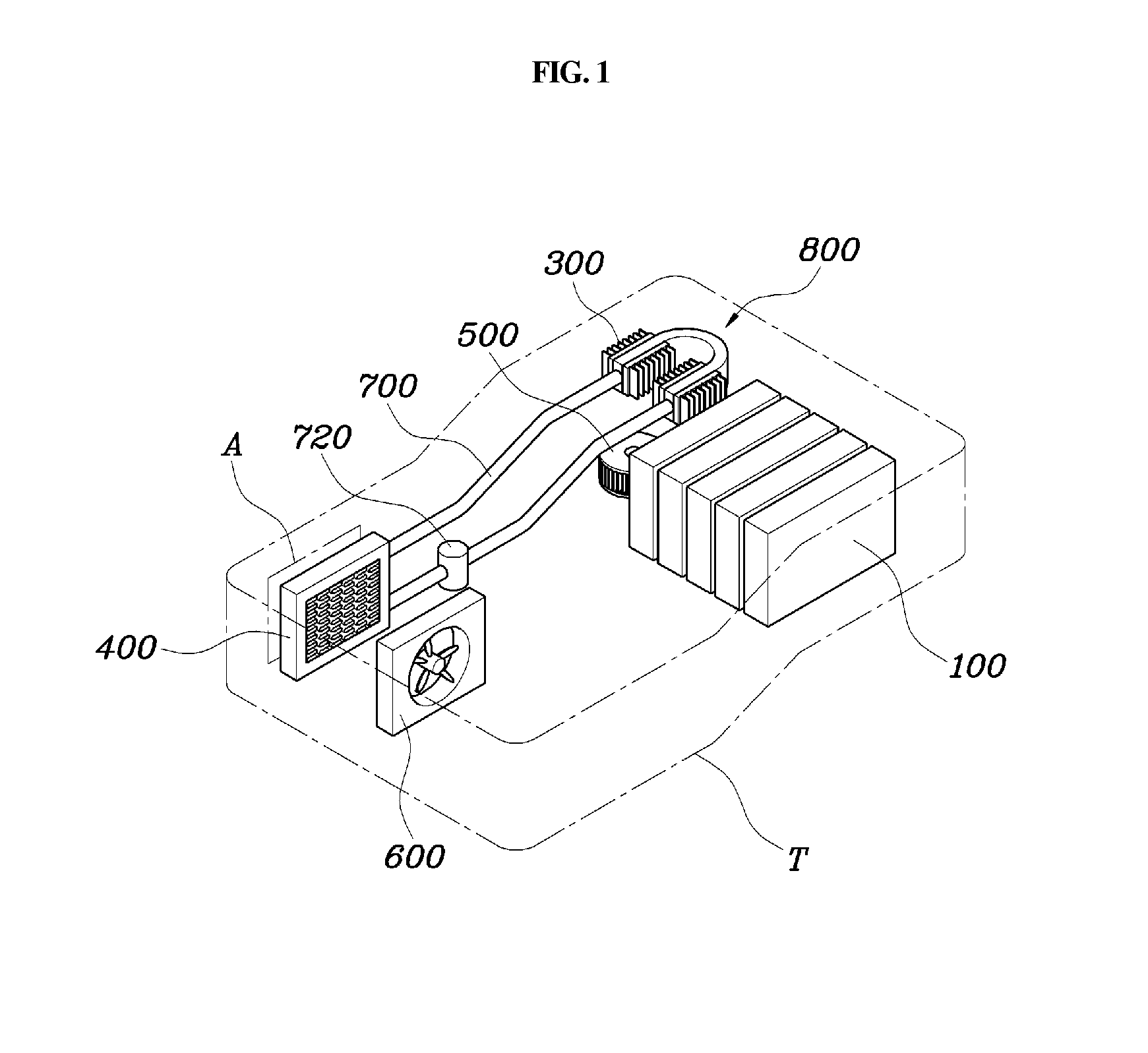

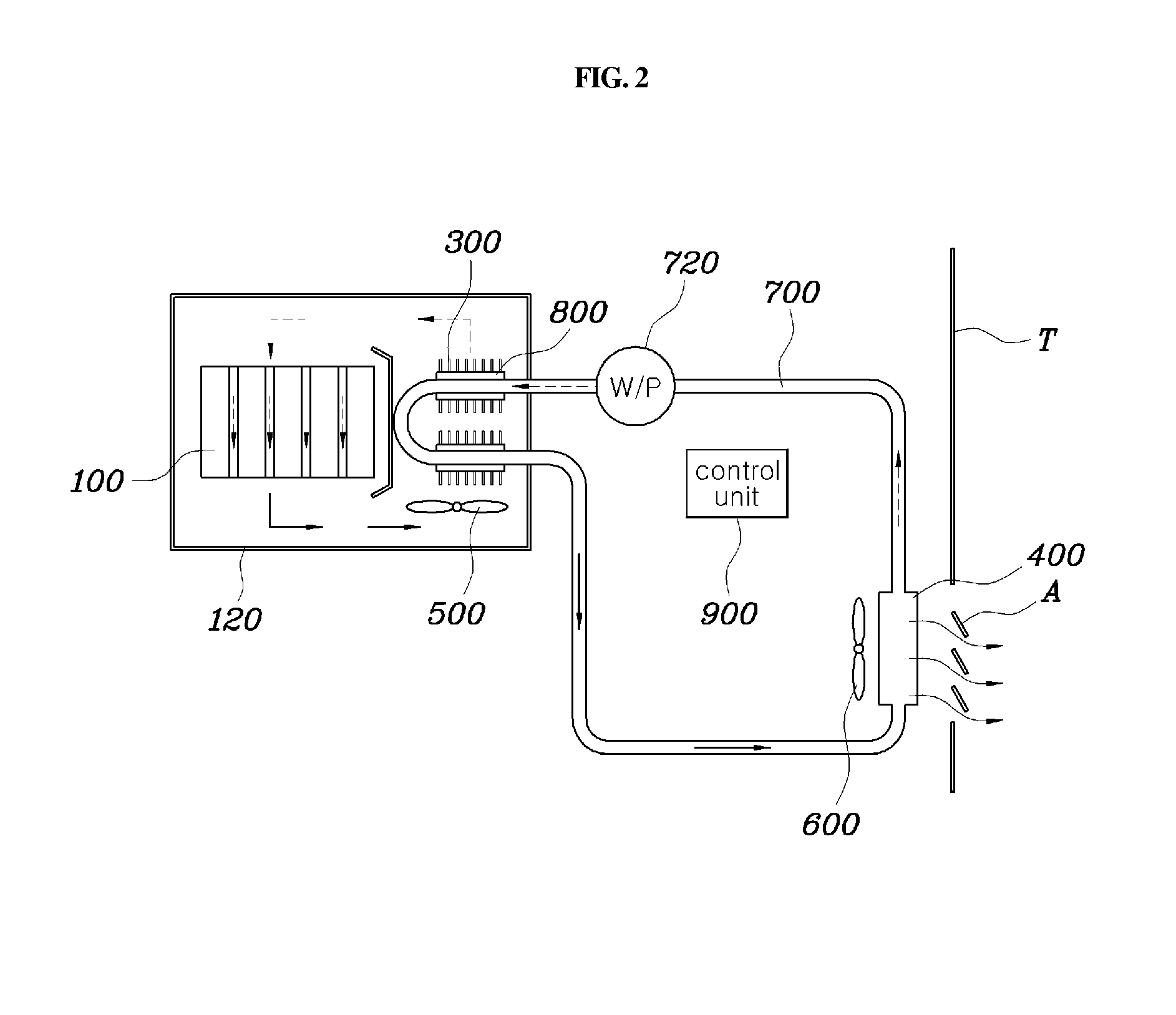

Air conditioning system and method for high-voltage battery of vehicle

InactiveUS20150101355A1Much is dissipated as heatEfficient executionAir-treating devicesCell temperature controlHigh voltage batteryEngineering

Air conditioning system and method for a high-voltage battery of a vehicle are provided. The system includes a first heat exchanger that is disposed within a battery housing and a first blower that supplies air to the first heat exchanger. A peltier element is combined with the first heat exchanger and a first surface of the peltier element comes into contact with the first heat exchanger. A second heat exchanger is disposed in an air extraction unit of a trunk room and a second blower supplies air to the second heat exchanger, to discharge air inside the trunk room to an exterior after performing heat exchange. A cooling line operates as a coolant circulating line, and a first end of the cooling line comes into contact with a second surface of the peltier element and a second end performs heat exchange between the second end and the second heat exchanger.

Owner:HYUNDAI MOTOR CO LTD

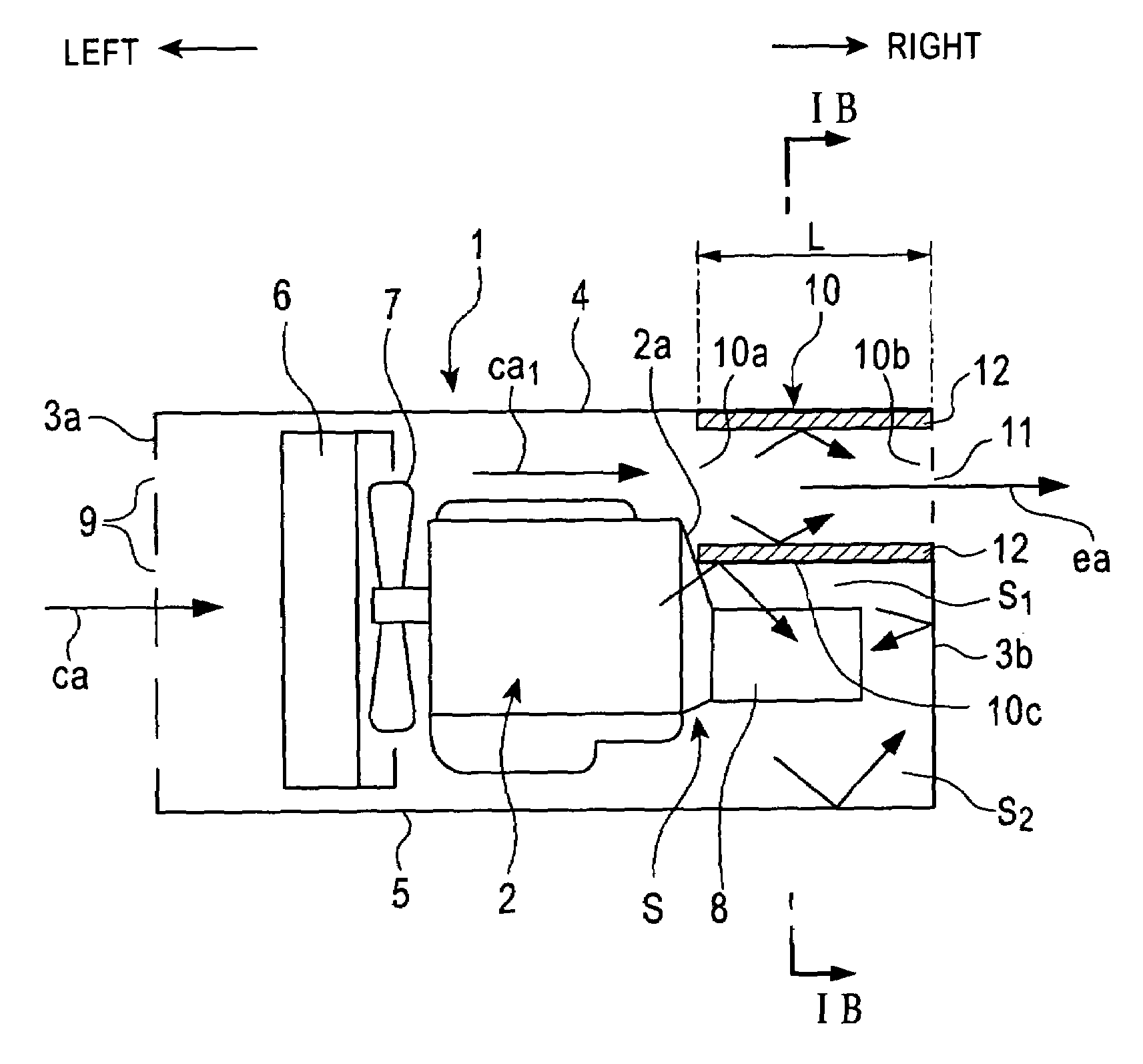

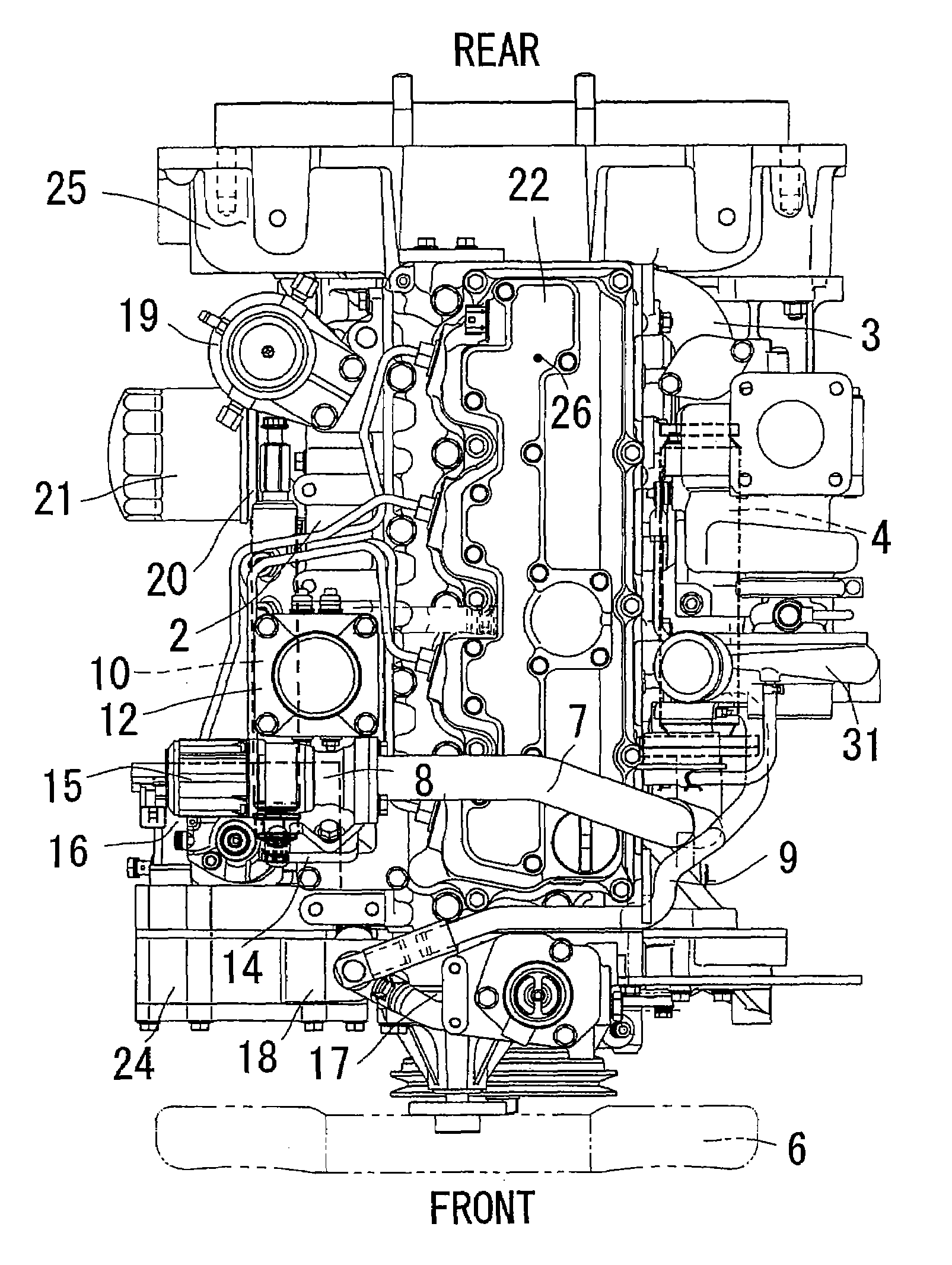

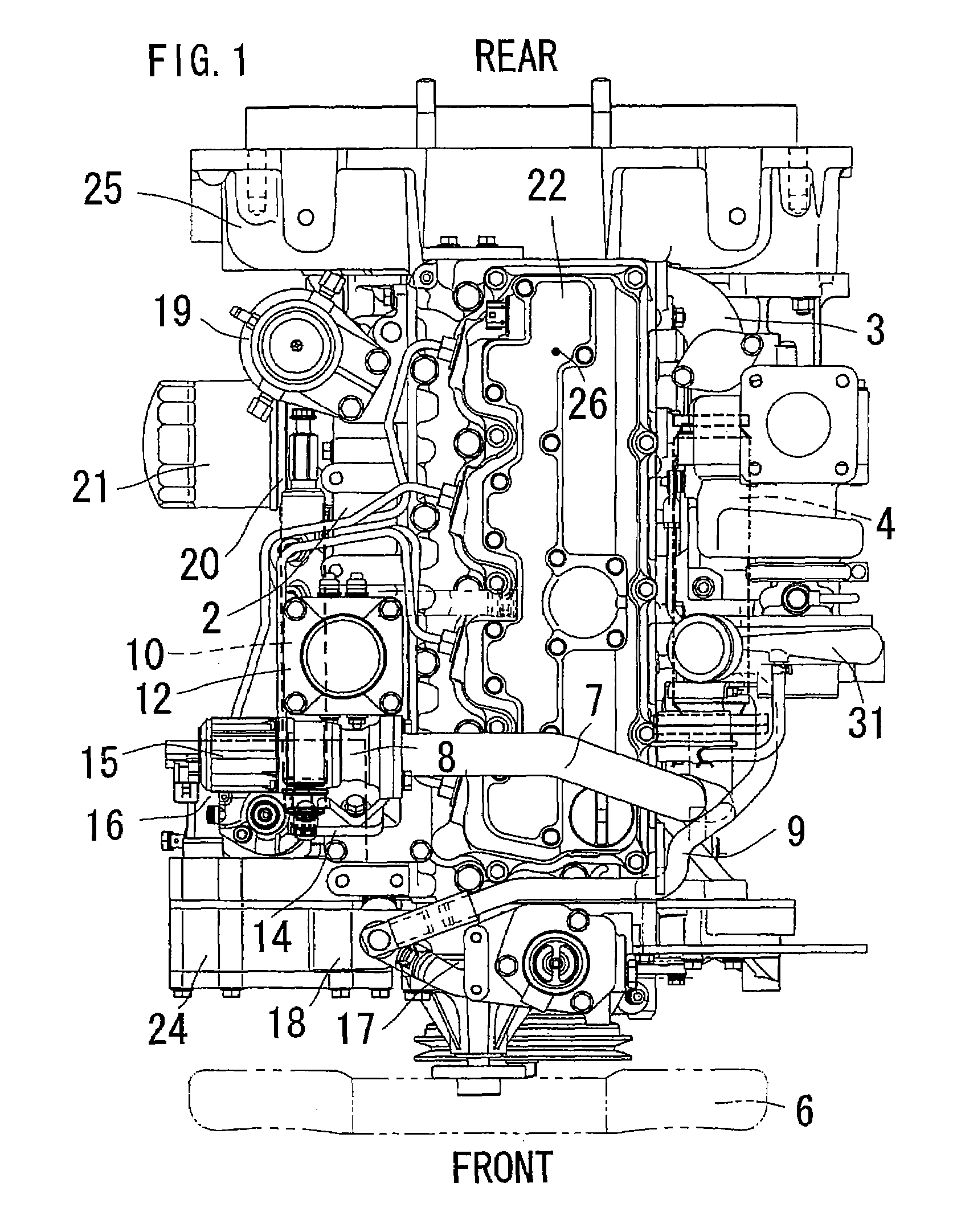

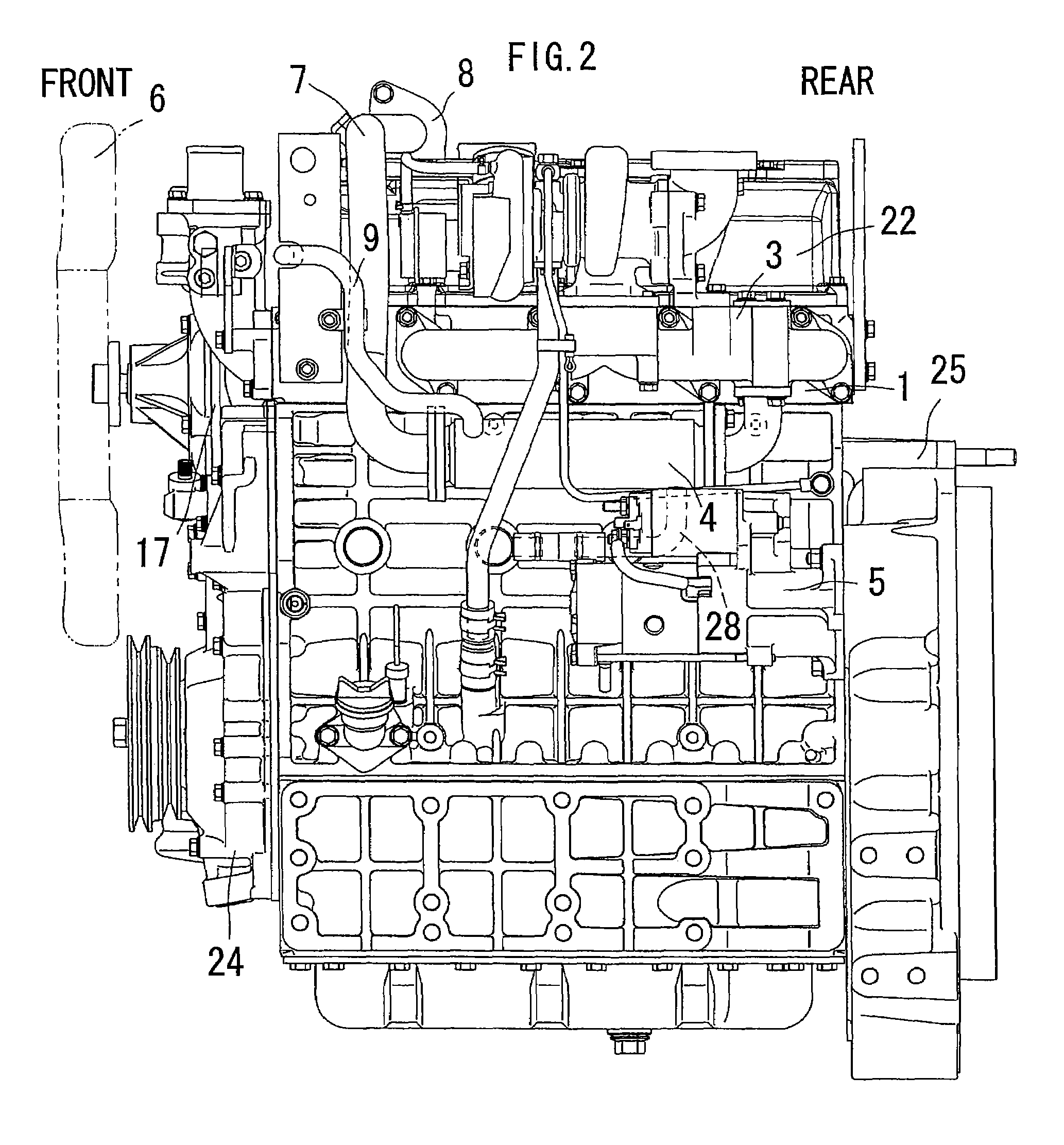

Multi-cylinder engine

ActiveUS7328691B2Reduce cooling loadInternal combustion piston enginesNon-fuel substance addition to fuelCylinder headEngineering

A multi-cylinder engine wherein a direction in which a crank shaft spans is a front and rear direction and a widthwise direction of a cylinder head (1) perpendicular to the front and rear direction is a lateral direction, the multi-cylinder engine comprising the cylinder head (1) which has one lateral side to which an intake-air distributing passage wall (2) is attached and has the other lateral side to which an exhaust-gas converging passage wall (3) is attached, an EGR cooler being interposed between an exhaust-gas converging passage and an intake-air distributing passage. In this multi-cylinder engine, the EGR cooler (4) spans in the front and rear direction laterally of a cylinder block (5) and the exhaust-gas converging passage wall (3) is positioned just above the EGR cooler (4). Preferably, an EGR gas lead-out pipe 7 conducted out of the EGR cooler (4) is arranged rearwards of an engine cooling fan (6) so that the engine cooling air produced by the engine cooling fan (6) might blow against the EGR gas lead-out pipe (7).

Owner:KUBOTA CORP

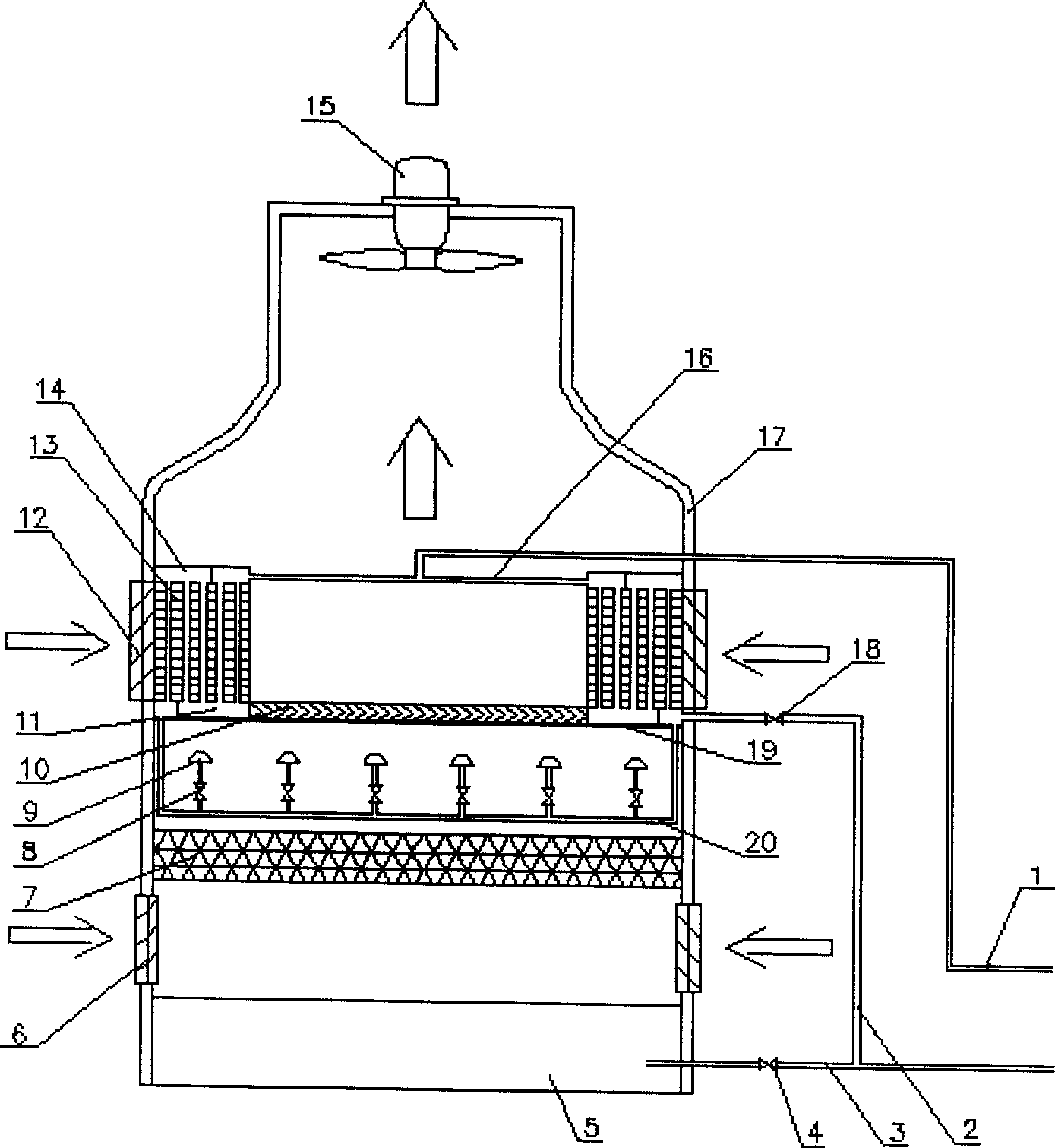

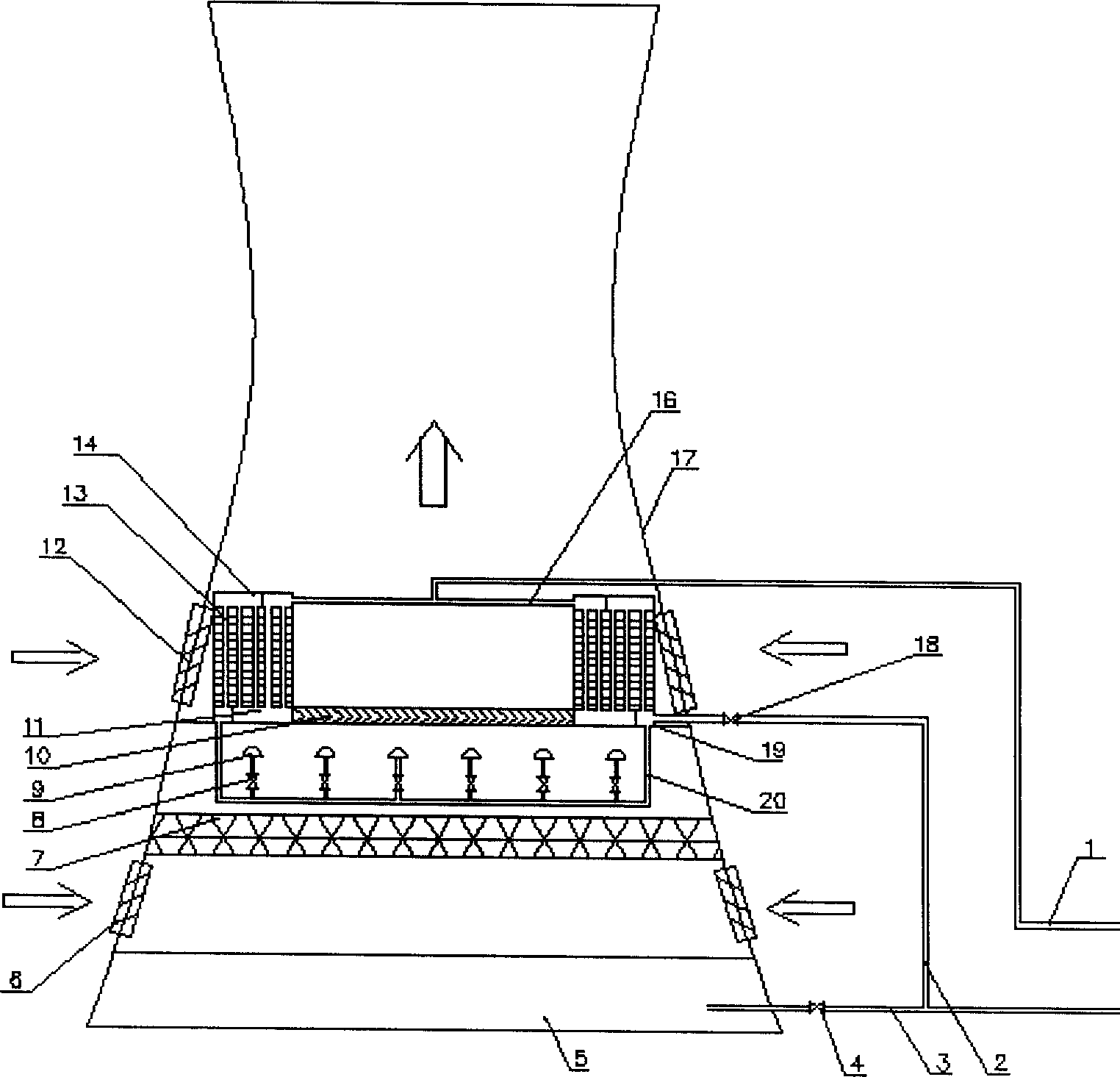

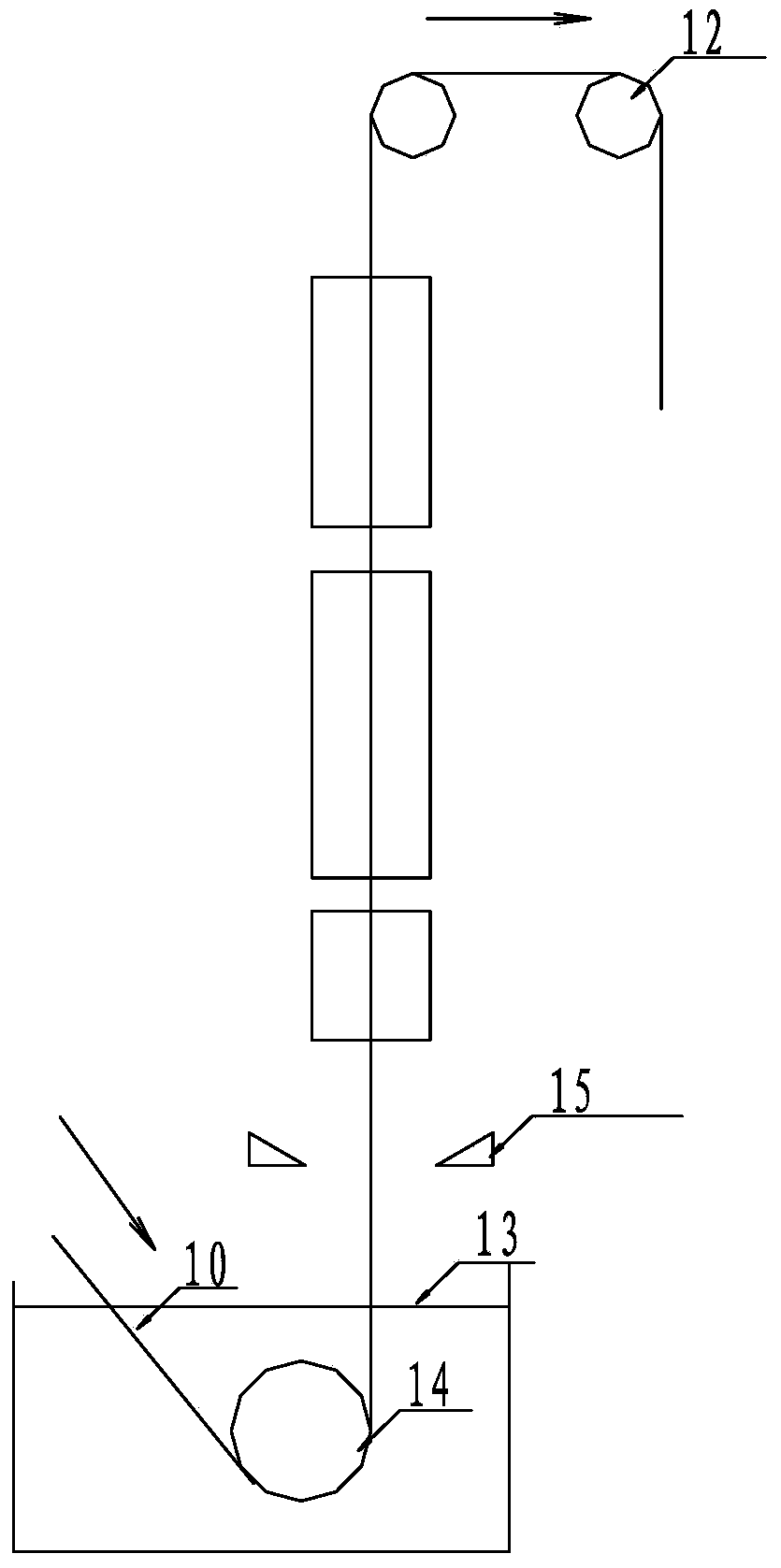

Environment-friendly water-saving cooling tower

The invention discloses an environment-friendly water-saving cooling tower, which is a cooler used in cycle water temperature decrease. Wherein, the side wall of tower is symmetry distributed with wind inlet shutters of air cooler; the inner side that near to the shutters is distributed with an air cooler; the water distributing tube at the inner side of air cooler is through to the water inlet tube of cycle water, while the water outlet tube of air cooler is through to the water distributor; the lower water tank of air cooler via the branch tube is through to the reflux tube of recycle water; the air cooler is above the water collector; the water distributor is between two air coolers. The invention uses air cooler to pre-cool the cycle water, to reduce the load of stuff section, the steam amount and the water consumption. And since the air is dry and heat via the air cooler, it can reduce the humidity of hot and humid air that exchanged heat with stuff layer, to reduce the fog at the tower.

Owner:TSINGHUA UNIV

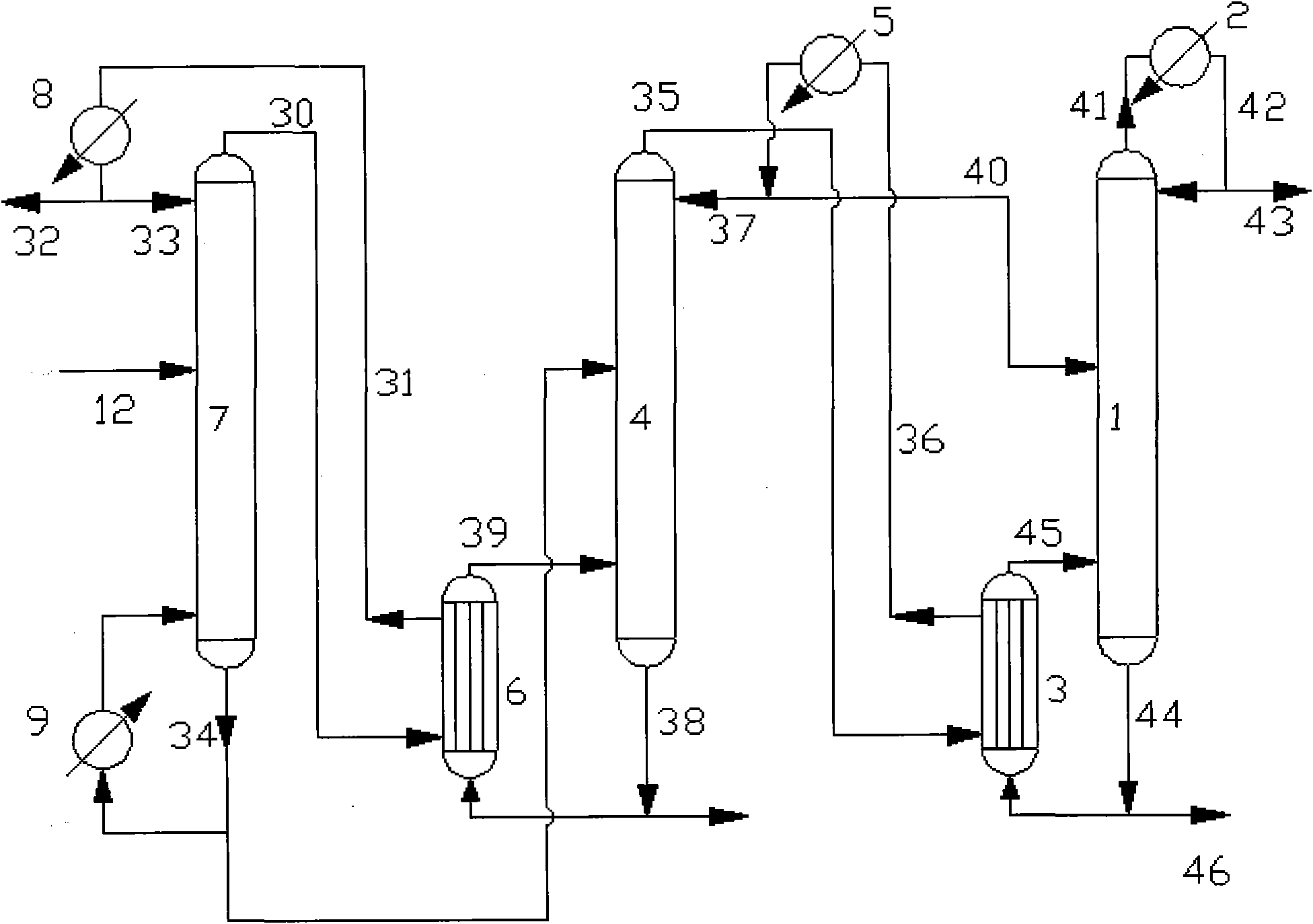

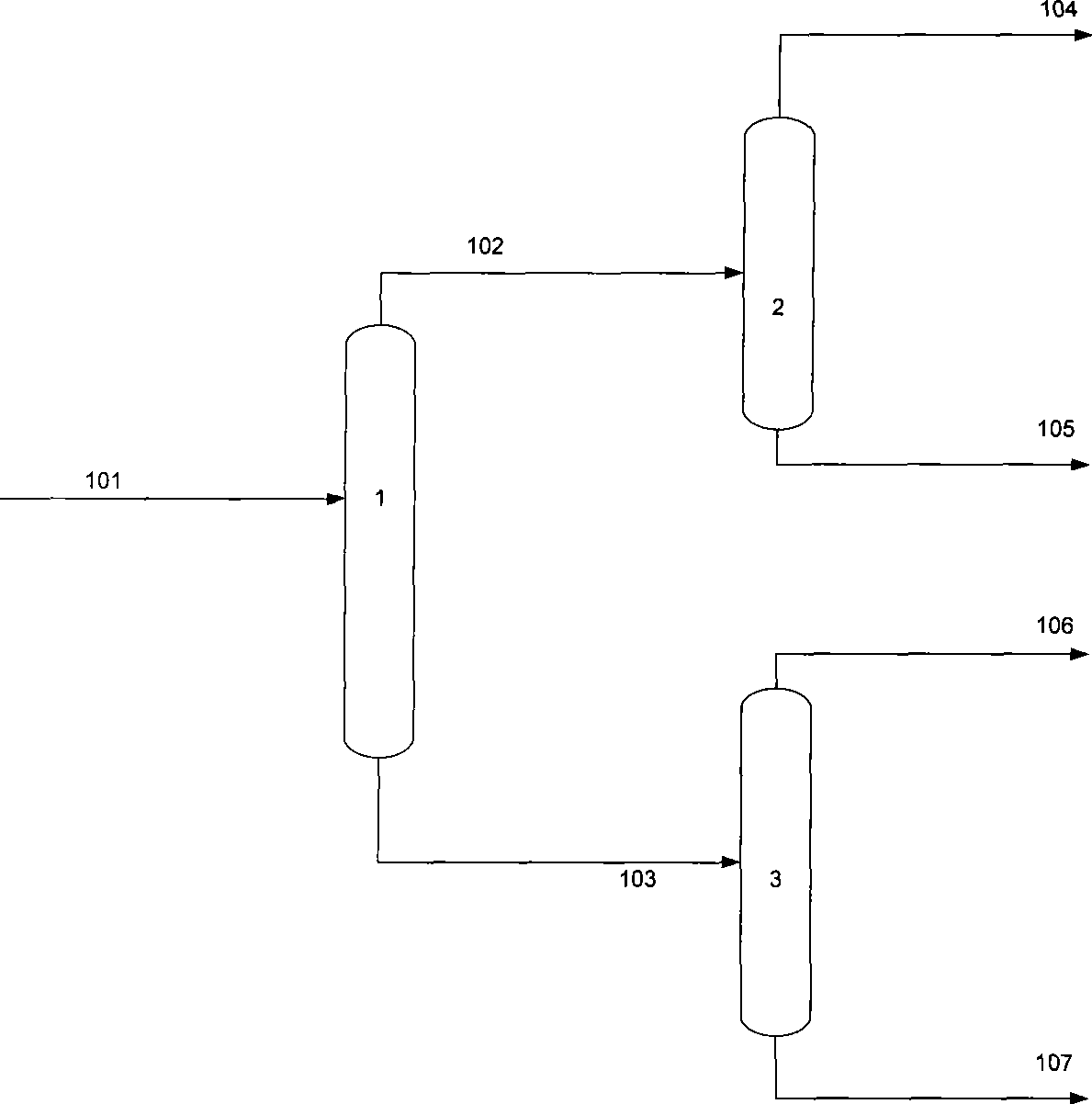

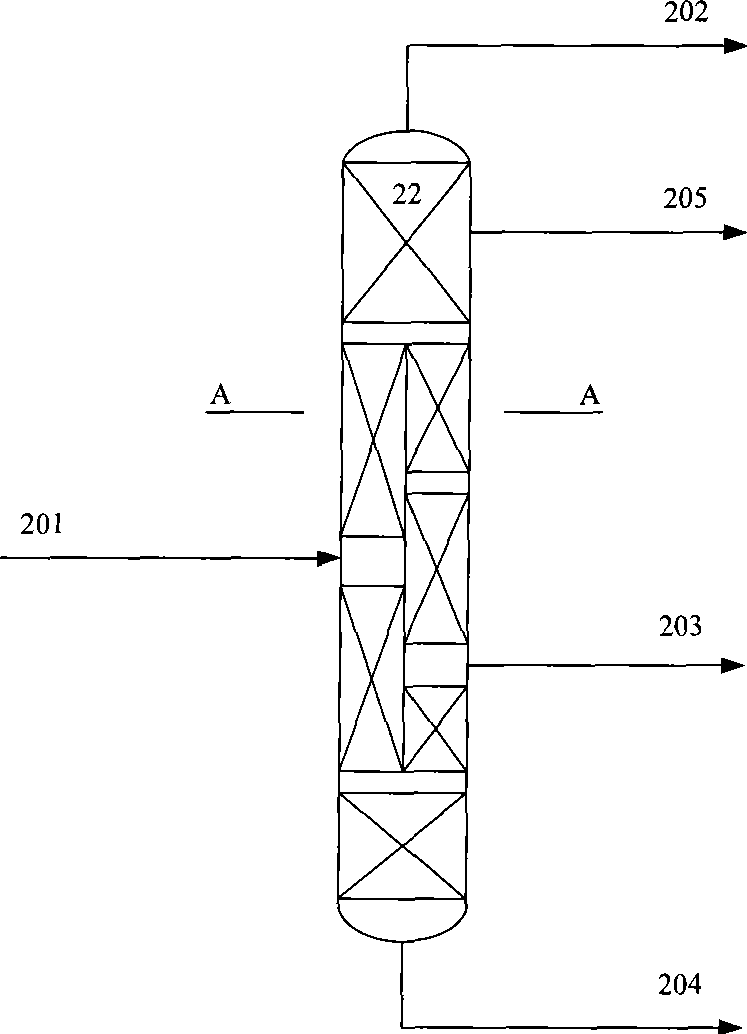

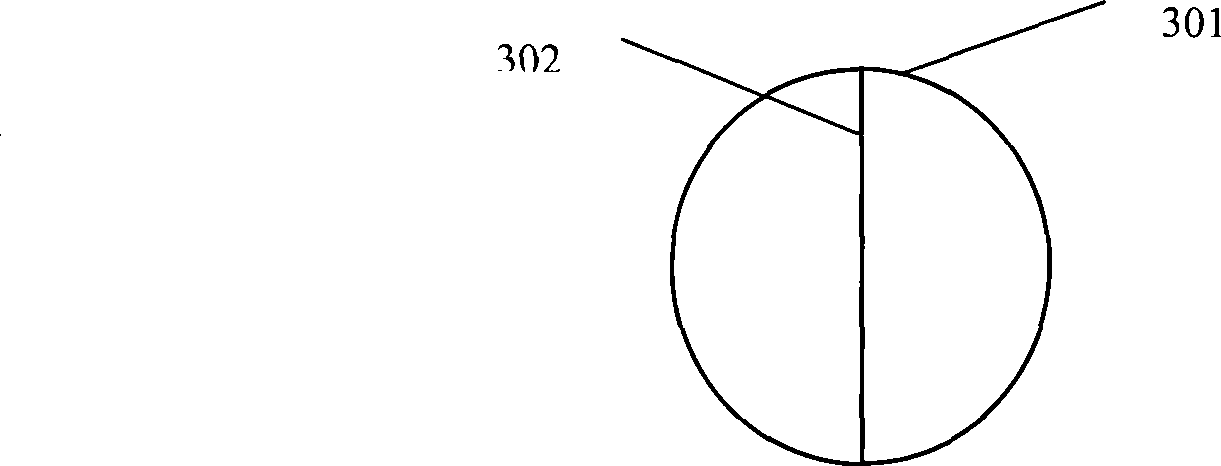

Bulkhead type rectification column for separating materials containing ethylbenzene and vinyl benzene

ActiveCN101429089AReduce lossesReduce cooling loadDistillation purification/separationFractional distillationHeating timeHigh energy

The invention relates to a bulkhead type rectifying tower used for separation material containing styrene and phenylethane , and mainly solves the technical problems of large number of styrene rectifying towers, large investment, high energy consumption, long heating time of the styrene and severe aggregation loss in the prior production process of the styrene. The bulkhead type rectifying tower well solves the technical problems through adopting the technical proposal that the bulkhead rectifying tower comprises a separation section under a bulkhead section, the bulkhead section and a separation section above the bulkhead section; a material inlet is positioned on one side of the bulkhead section; a material outlet for heavy compositions is arranged on the bottom of the separation section under the bulkhead section; the bulkhead section is provided with at least one outlet of product styrene; and the separation section above the bulkhead section is provided with at least one outlet of product phenylethane; the top of the separation section above the bulkhead section is also provided with an outlet for light compositions; the bulkhead section is provided with at least one clapboard to divide the bulkhead section into at least two zones along axial direction; and column plates or stuffing is arranged inside each zone. The bulkhead type rectifying tower solves the technical problems well and can be used in industrial production of producing the styrene by dehydrogenating the phenylethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

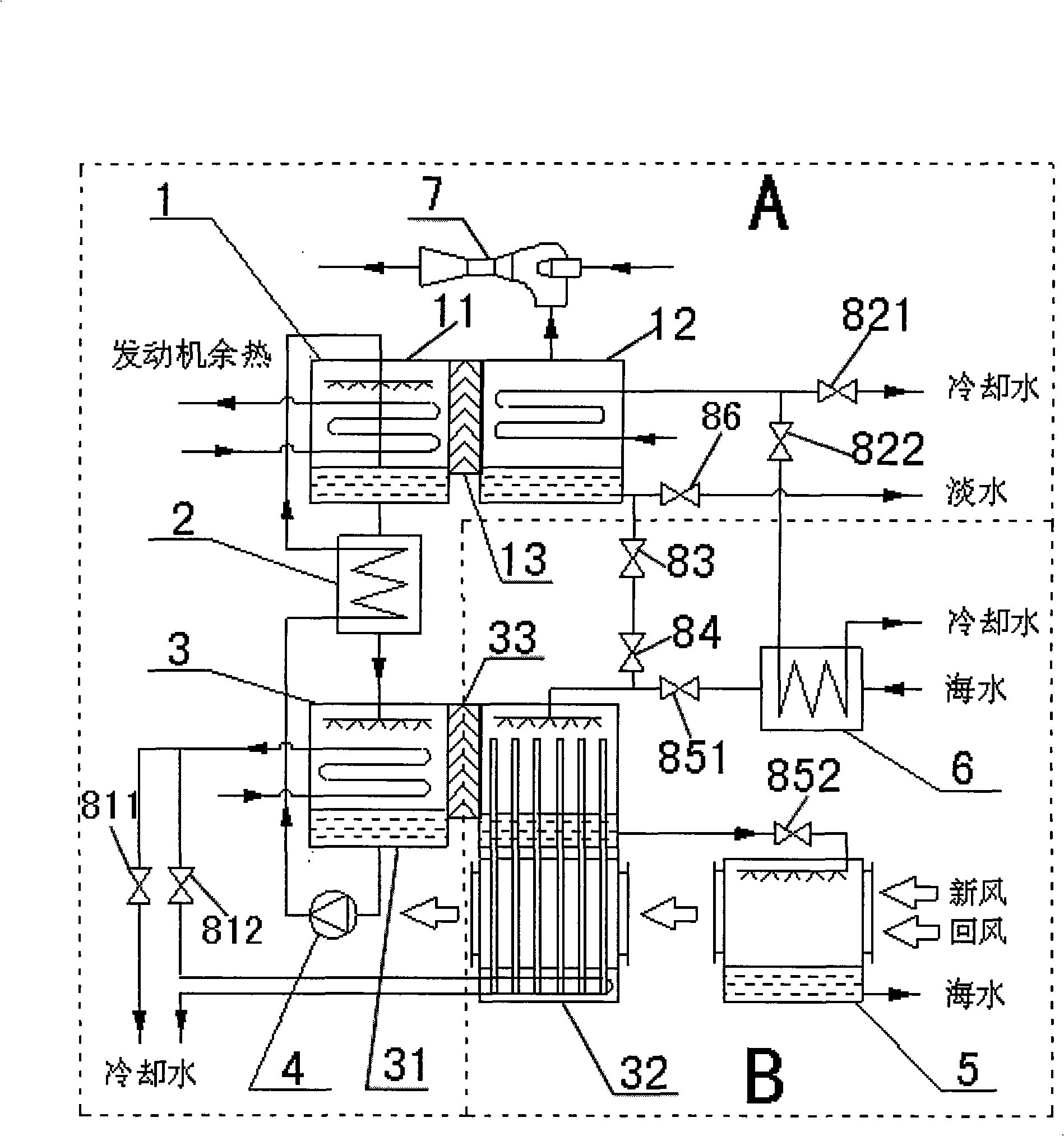

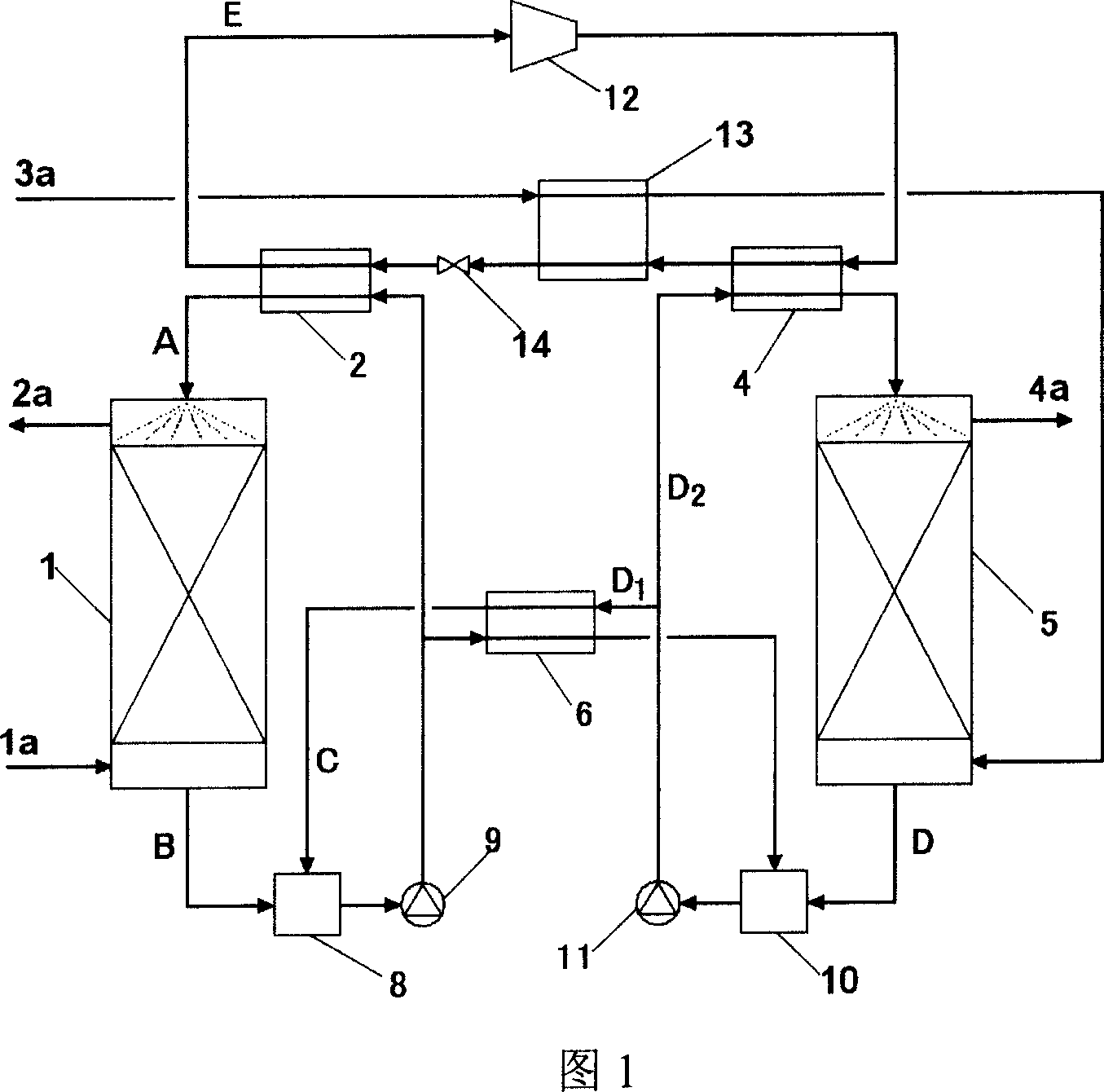

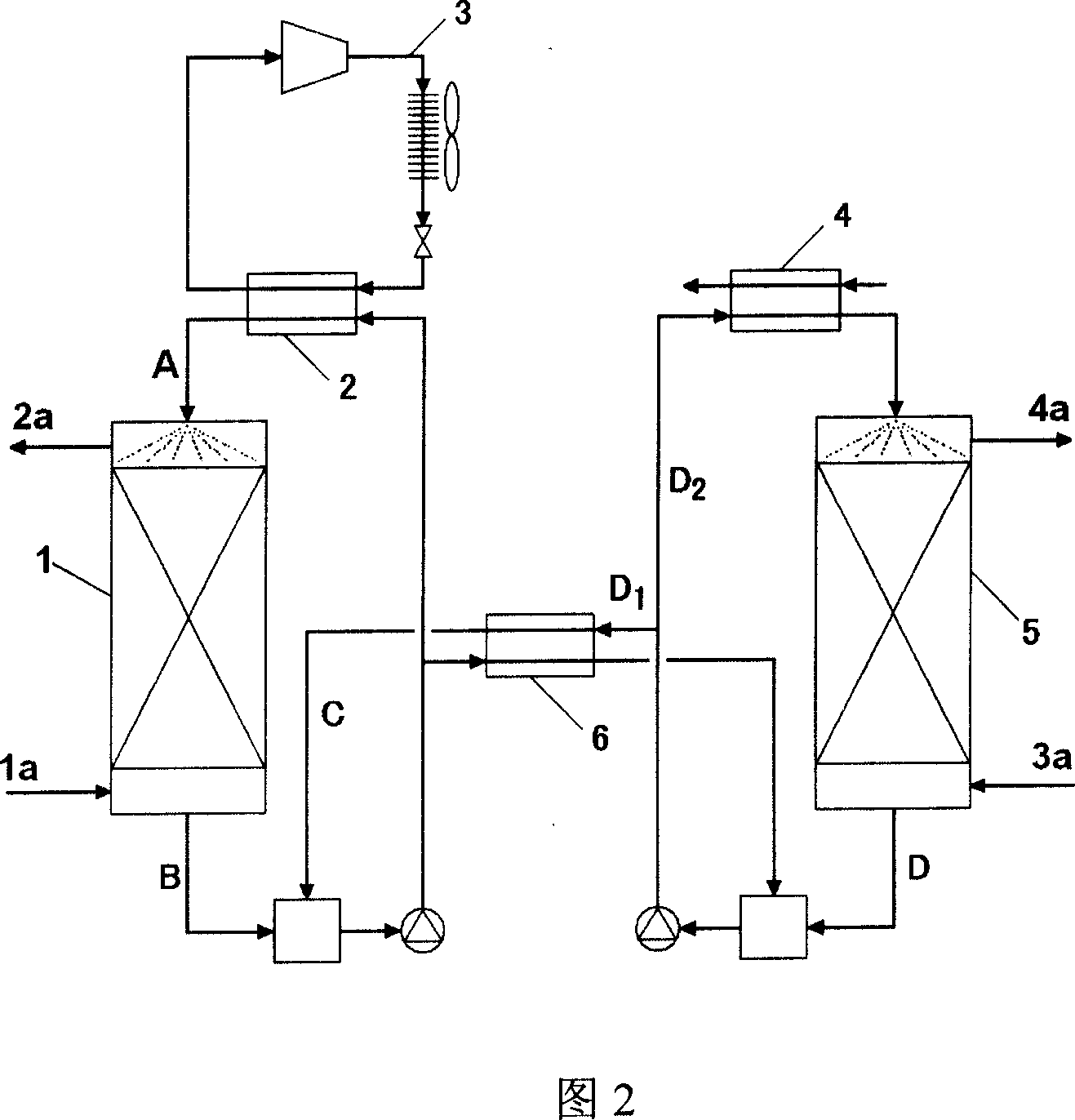

Air conditioner and sea water desalination combined operation system

InactiveCN101344298AImprove efficiencySimple pretreatment processGeneral water supply conservationSeawater treatmentLithium bromideSeawater

The invention relates to an air-conditioning and seawater desalination joint operation system which comprises a lithium bromide solution circulating water yielding system and a sea water evaporation and air processing system. The lithium bromide solution circulating water yielding system comprises: a generation condenser, a heat exchanger, an absorption evaporator, a circulating pump and a regulating valve group; wherein, the generation condenser comprises a generator and a condenser, and a water retaining device is connected between the generator and the condenser. The sea water evaporation and air processing system comprises: the absorption evaporator, a sea water spray chamber, a pre-heater, a regulating valve, a throttle valve and a valve group; wherein, the absorption evaporator comprises an absorber and an evaporator, and the water retaining device is connected between the absorber and the evaporator. The air-conditioning and seawater desalination joint operation system of the invention has the functions of air-conditioning and sea water desalination, simplifies the two separate separation systems of the prior air-conditioning system and the sea water desalination circulating system and effectively saves the energy.

Owner:SHANGHAI MARITIME UNIVERSITY

Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

PendingCN106348421AEasy to handleSave spaceSpecific water treatment objectivesWater contaminantsHigh concentrationEnergy consumption

The invention discloses a continuous wet oxidation process for degrading high concentration organic waste water, belonging to the field of water treatment. The continuous wet oxidation process for degrading high concentration organic waste water comprises the procedures: a waste water pressurizing procedure: pressurizing waste water to be treated; a waste water heat exchange procedure: carrying out direct and / or indirect heat exchange on the pressurized waste water and treated waste water so the temperature of the pressurized waste water rises; an oxidizer pressurizing procedure: pressurizing an oxidizer; a mixing procedure: thoroughly mixing the pressurized and heated waste water with the pressurized oxidizer; a reaction procedure: causing the mixed waste water and the oxidizer to generate oxidation reaction, obtaining the treated waste water and generating gas; and a separation procedure: continuously separating the treated waste water from gas. The continuous wet oxidation process for degrading high concentration organic waste water has the advantages of high efficiency, less energy consumption, stability of operation and the like.

Owner:羿太环保科技(上海)有限公司

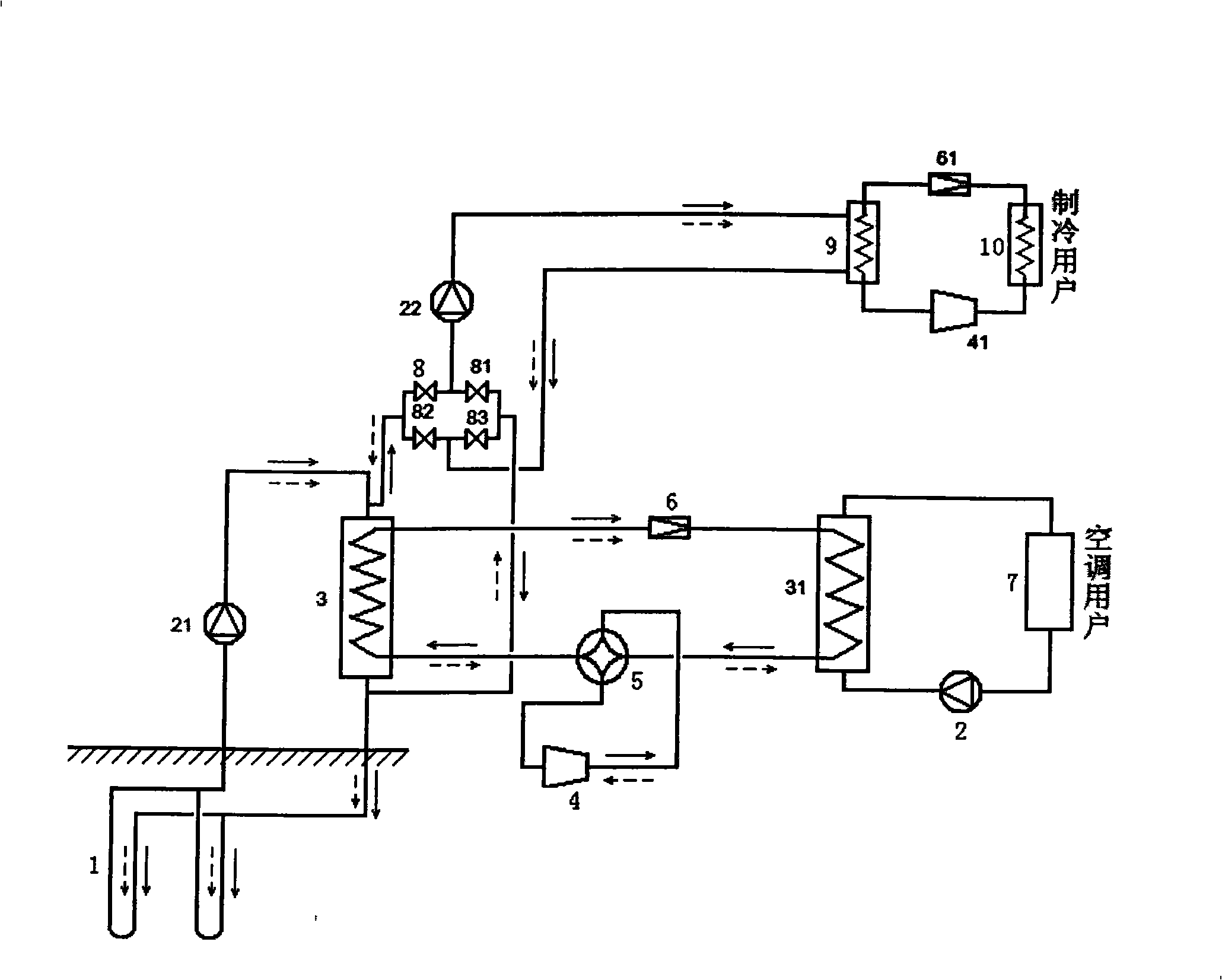

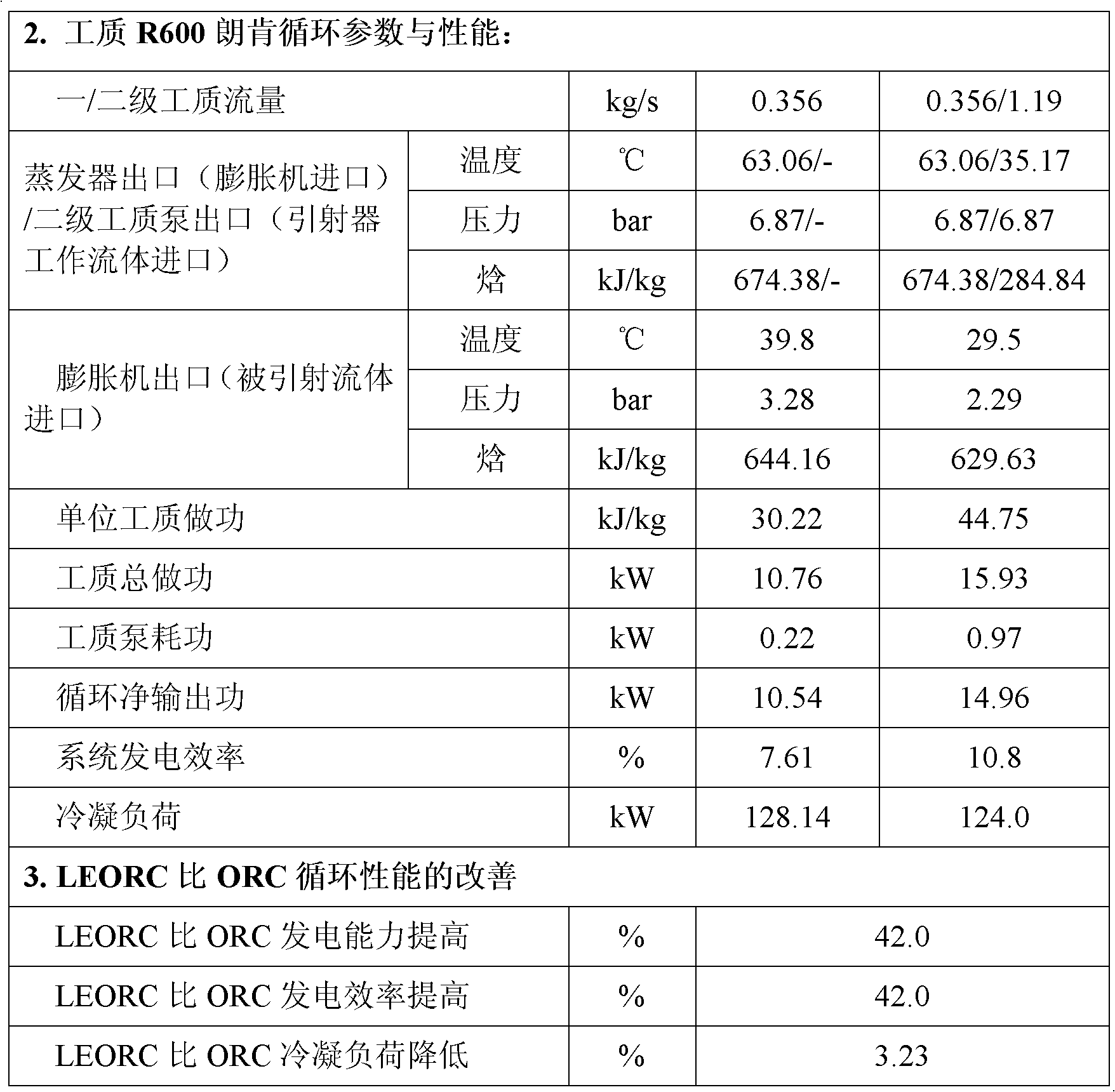

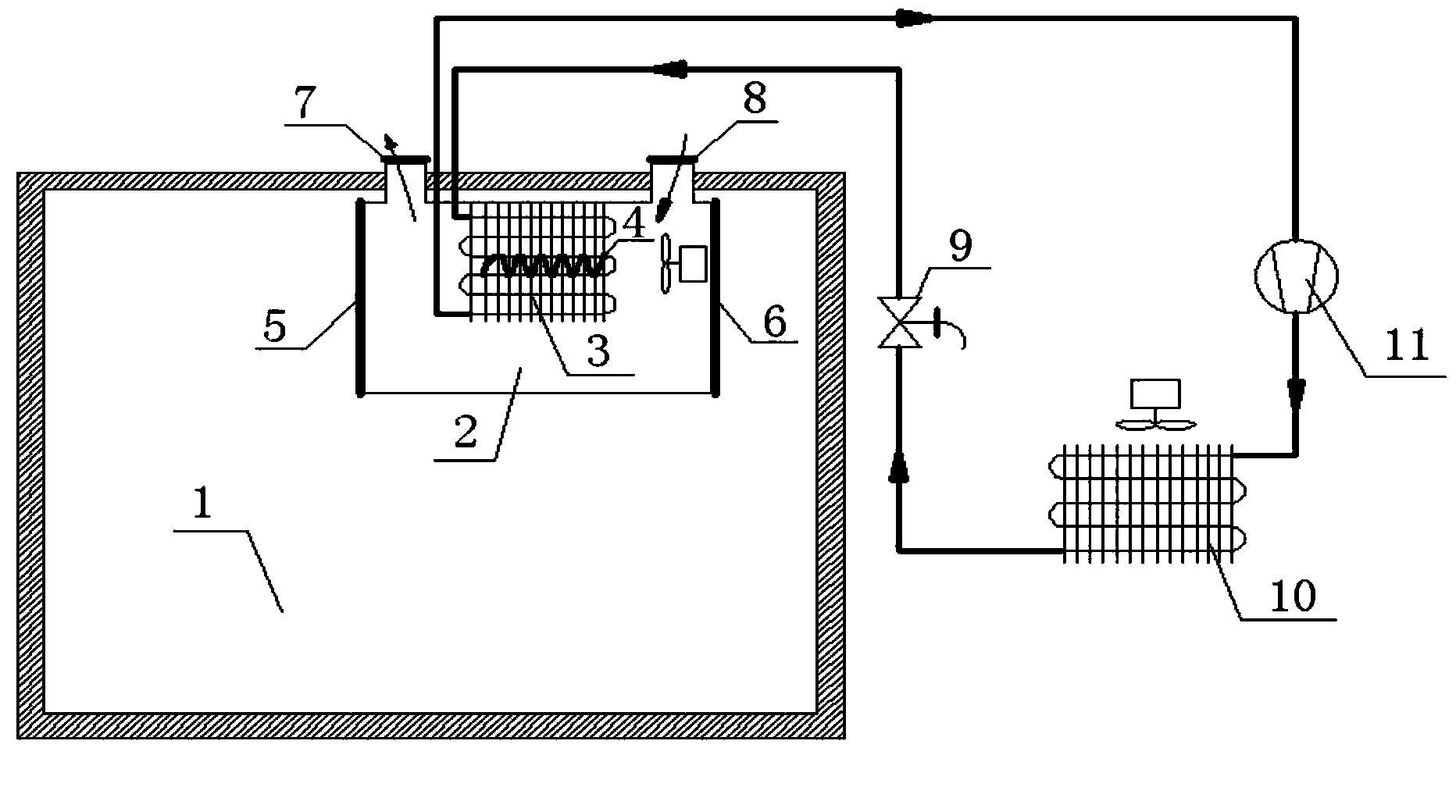

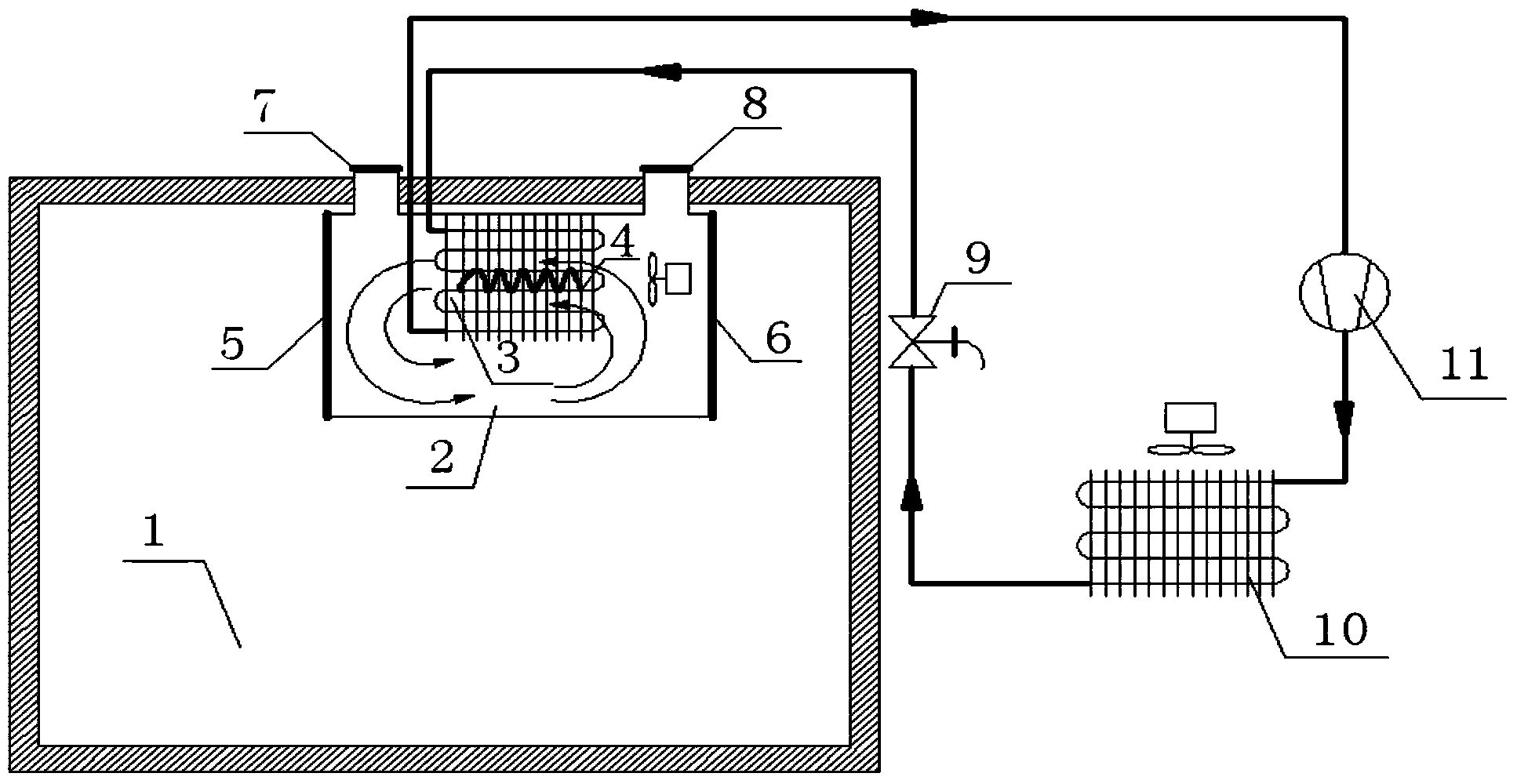

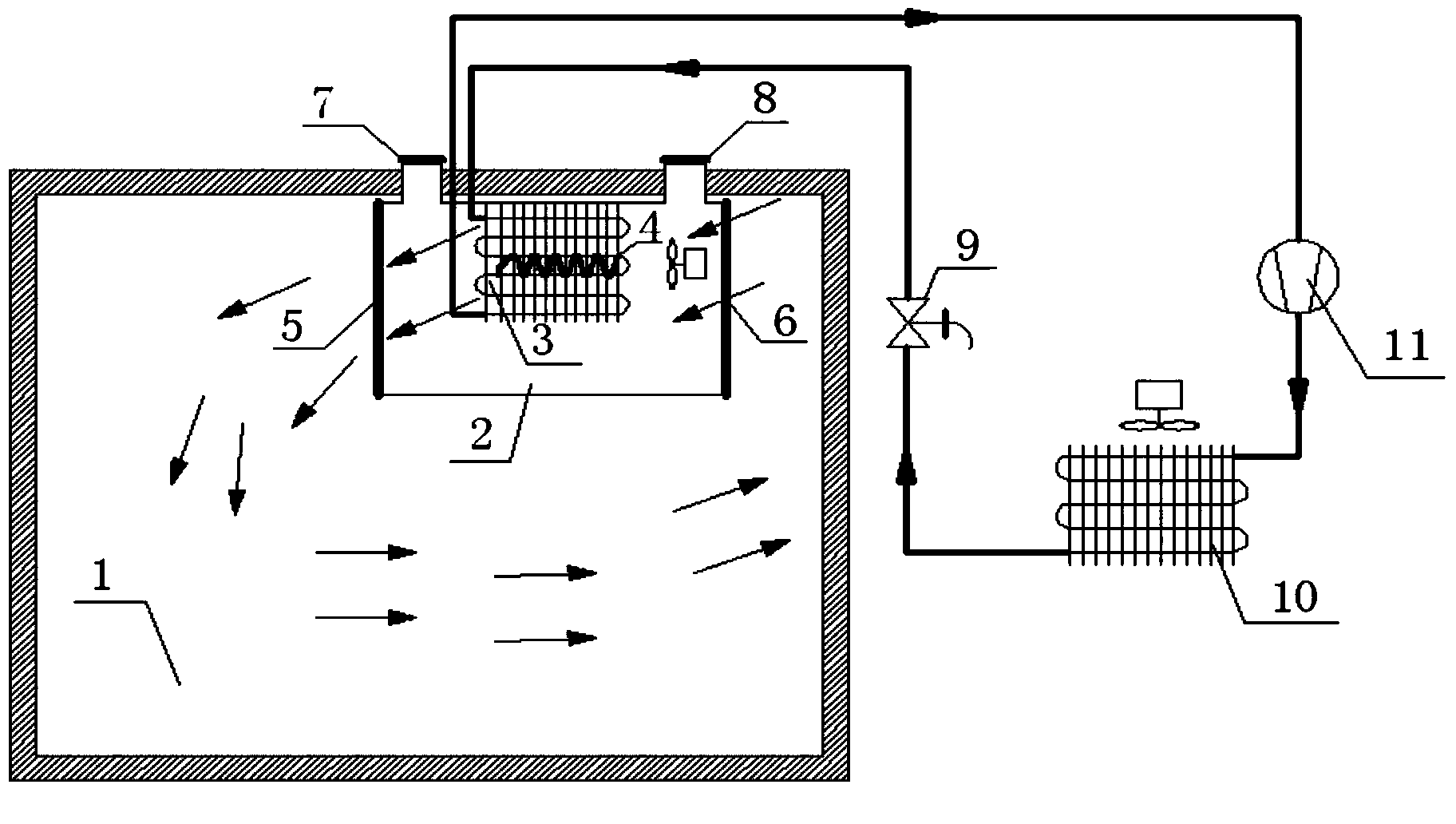

Geothermal heat pump air conditioning/refrigerating compound system

ActiveCN101270933AReduce cooling loadImprove efficiencyHeat pumpsCompression machines with reversible cycleHigh energyGeothermal heat pump

The invention discloses a ground source heat pump air conditioning / combined refrigeration system, which consists of five subsystems, including a buried pipe heat exchanger system, heat pump air conditioning system, air conditioning terminal system, a cooling system and a heat medium circulation system. The buried pipe heat exchanger system is the major cold / heat source of the ground source heat pump air conditioning; the cooling system adopts the mode of water cooling, the exhaust heat of the cooling system is used as an auxiliary heat source all the year round for the ground source heat pump air conditioning with high heat load, thus a peculiar ground source heat pump air conditioning / combined refrigeration system is achieved, thereby meeting the demands of air conditioning users and cooling system users all the year round and ensuring the performance of the system for long term operation. The buried pipe heat exchanger system is connected with the heat pump air conditioning system and the cooling system via the pipeline of the heat medium circulation system; the heat pump air conditioning system is connected with the air conditioning terminal system via the pipeline of the heat medium circulation system; and the control of cold / heat transfer is controlled through the adjustment of the heat medium circulation system. The invention has high energy-saving performance, the costs are low and the operation is reliable.

Owner:SHANDONG FANGYA GSHP TECH

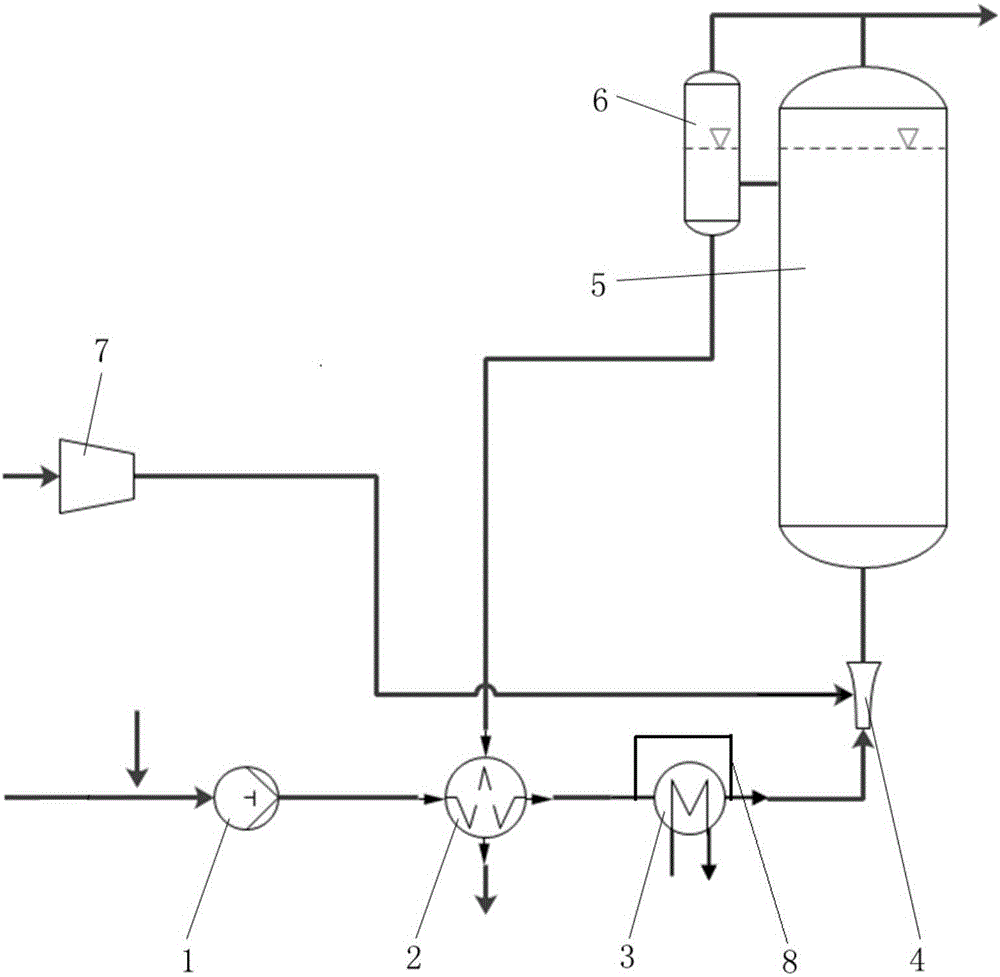

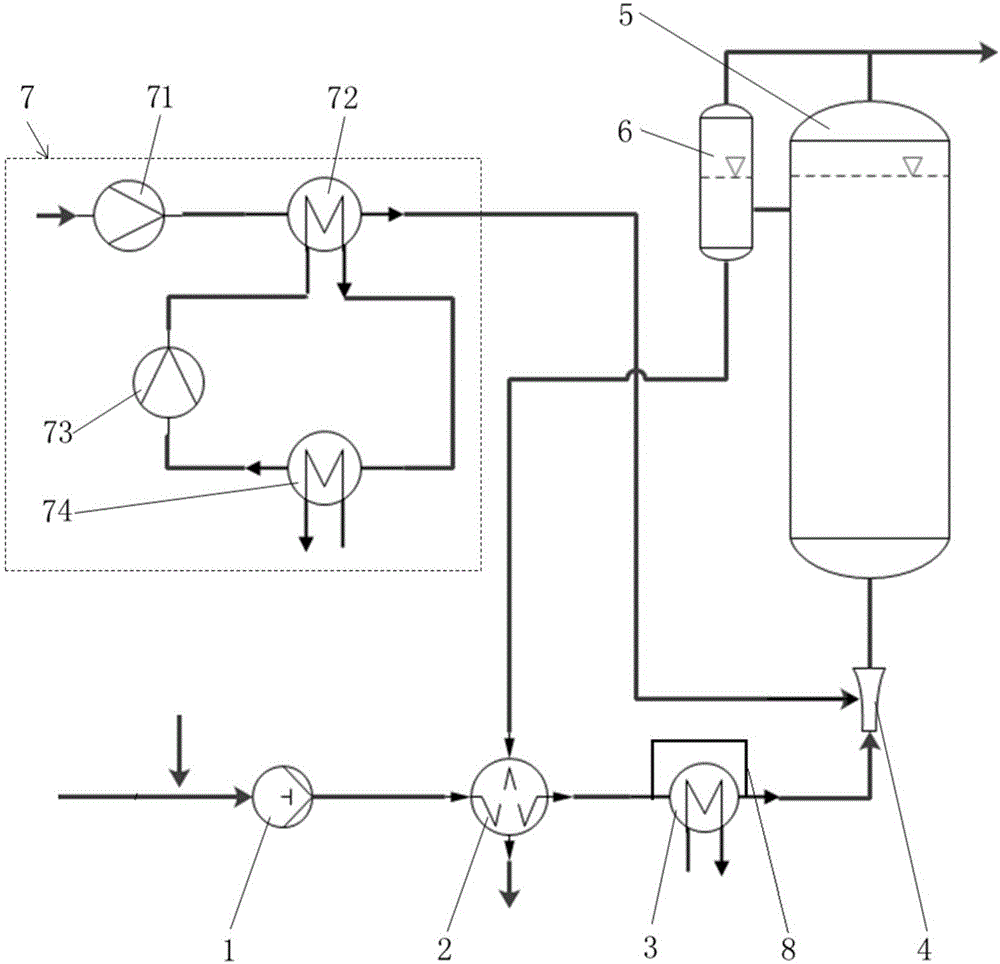

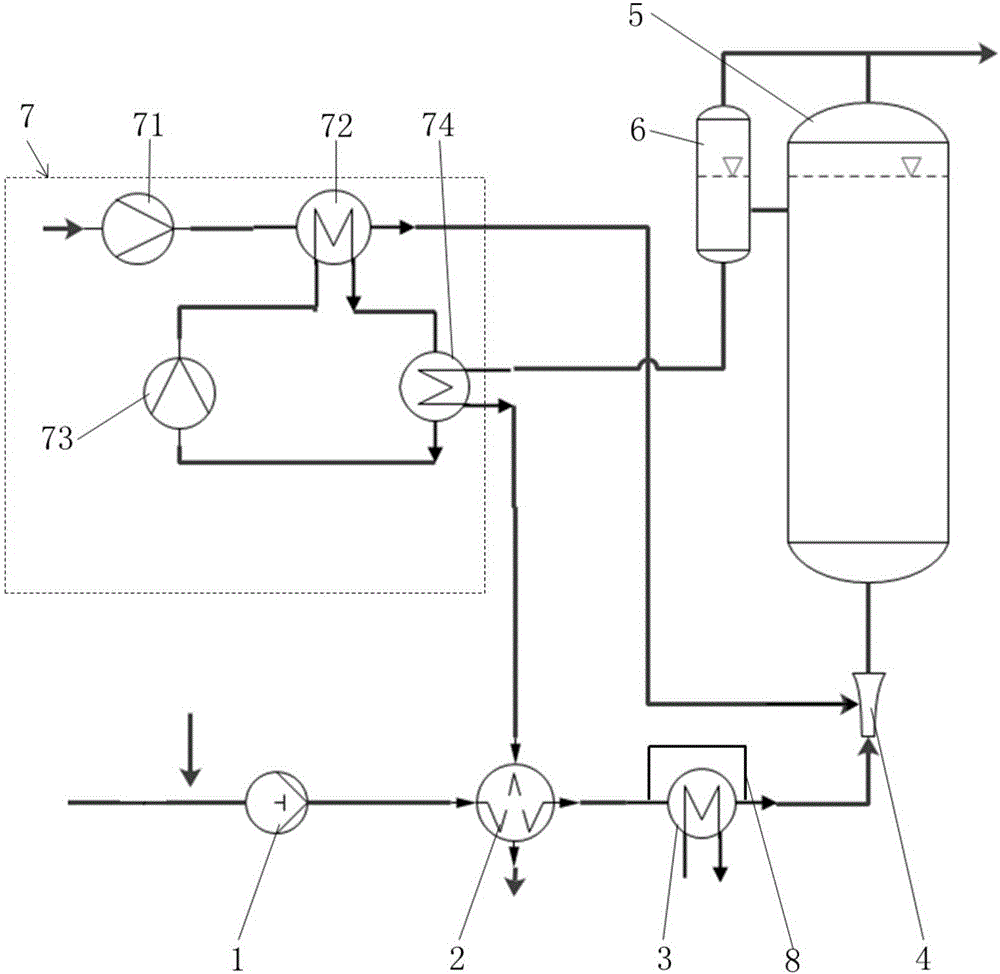

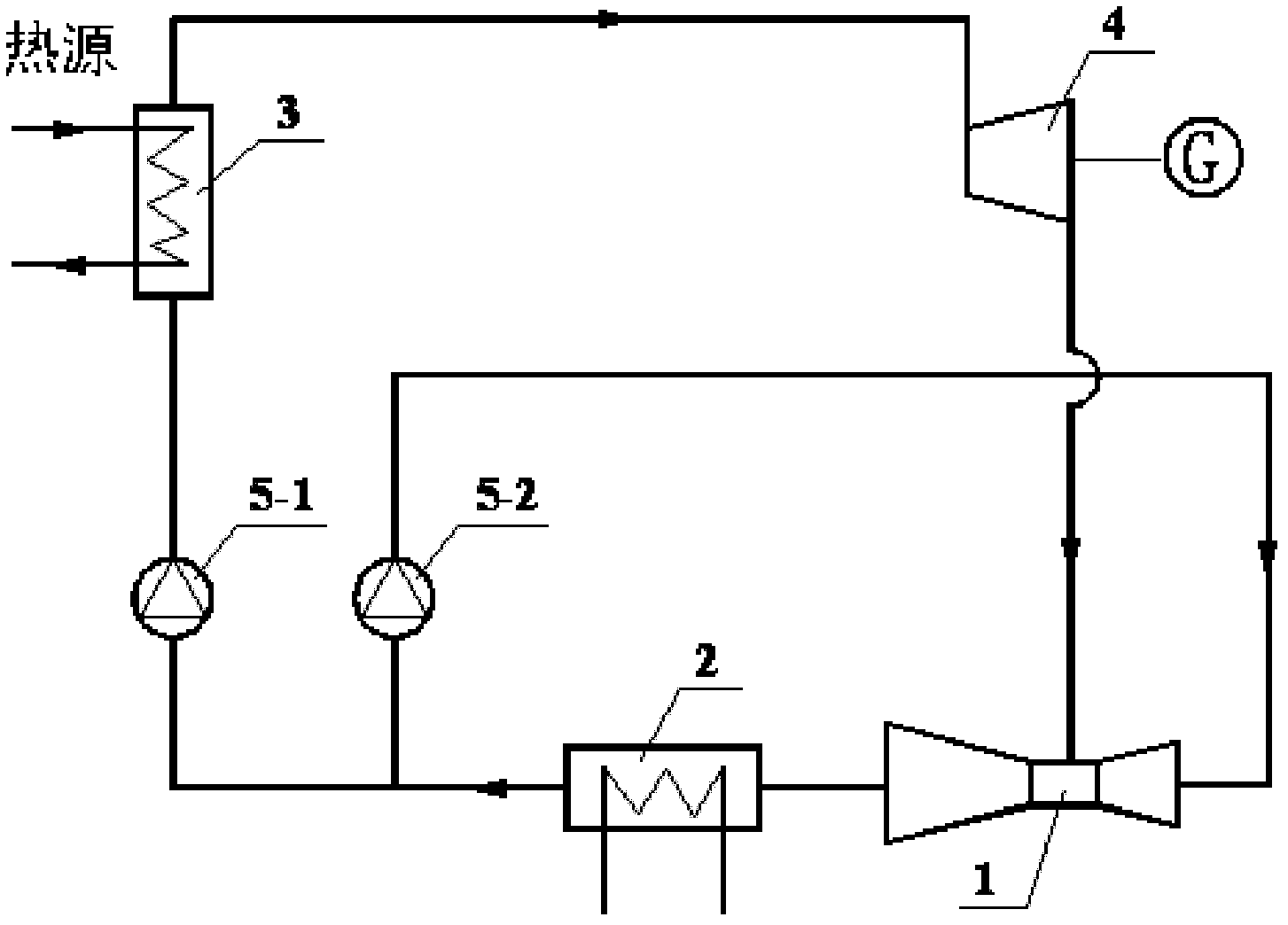

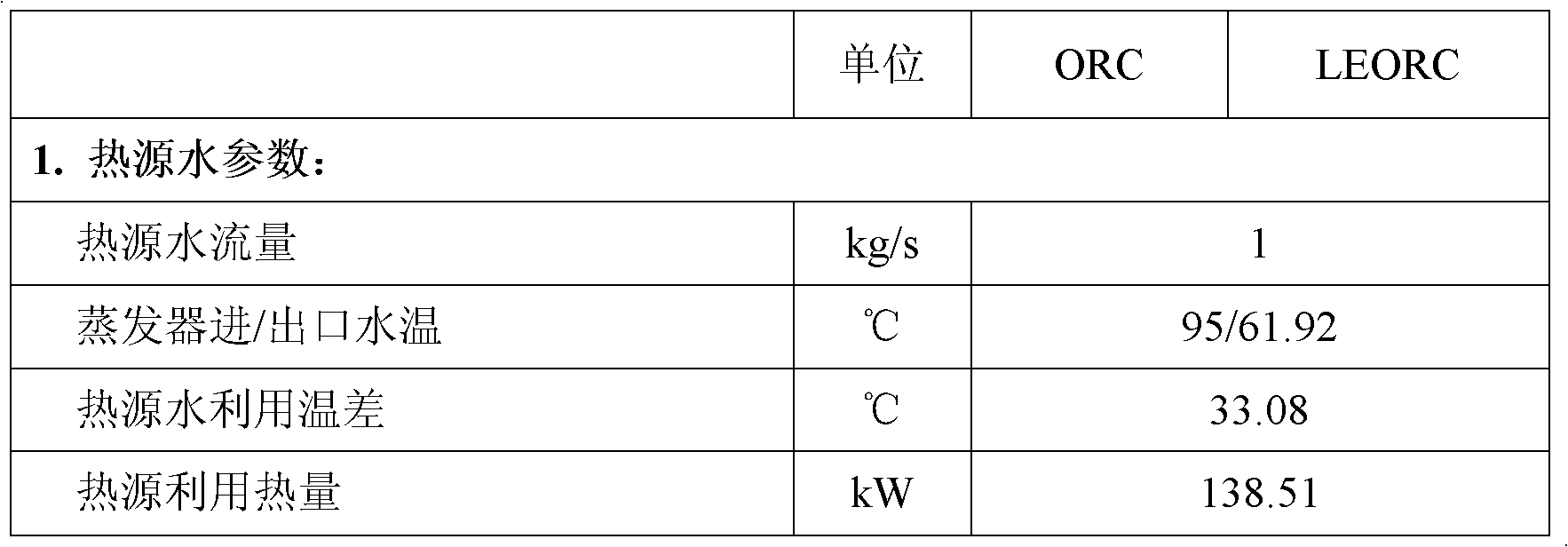

Organic Rankine cycle power generation system with liquid ejection device

InactiveCN102562179AReduce cooling loadLess investmentSteam engine plantsWorking fluidOrganic Rankine cycle

The invention discloses an organic Rankine cycle power generation system with a liquid ejection device. The organic Rankine's cycle power generation system is mainly characterized in that: a liquid ejector and a working medium pump are additionally arranged between an expander and a condenser in a Rankine cycle system; the working fluid inlet of the liquid ejector is connected with a secondary working medium pump; the inlet of a fluid ejected by the liquid ejector is connected with the outlet of the expander; the mixed fluid outlet of the liquid ejector is connected with the inlet on the working medium side of the condenser; the working medium side outlet is connected with the primary working medium pump and the secondary working medium pump respectively; and the primary working medium pump is connected in series with an evaporator, the expander, the inlet of fluid ejected by the liquid ejector and the condenser sequentially to form a closed loop. The exhausted gas of the expander is used as the ejected fluid, the back pressure of the expander can be reduced, the working pressure difference is increased, and the working capacity of the Rankine cycle system can be improved. Meanwhile, the non-steam liquid ejection is adopted, and heat input of the ejector is prevented, so that the output work of the Rankine cycle system is increased, and the thermal efficiency is obviously improved under the condition of inputting the same amount of heat.

Owner:TIANJIN UNIV

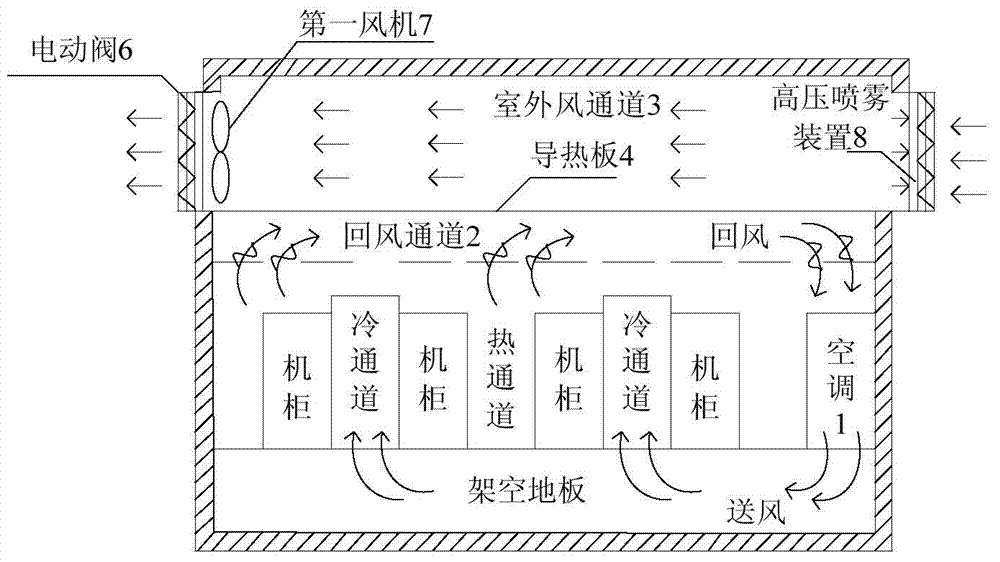

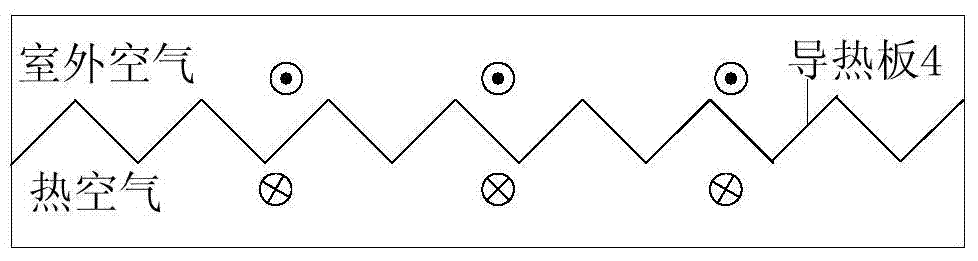

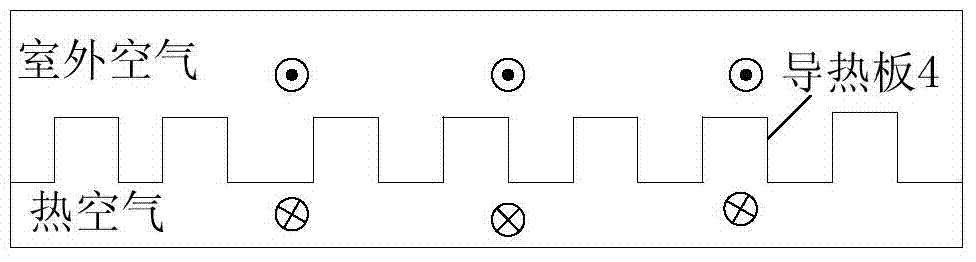

System for reducing machine room temperature

InactiveCN103615780AReduce the temperatureReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusRoom temperatureEngineering

The invention provides a system for reducing machine room temperature. The system comprises an air conditioner, a return air channel, an outdoor air channel, a heat transfer plate and a controller. The return air channel is used for enabling hot air in a machine room to flow back to the air conditioner. The outdoor air channel is used for enabling outdoor air to circulate in the outdoor air channel. The heat transfer plate is arranged between the return air channel and the outdoor air channel, and carries out heat exchange on the hot air in the return air channel and the outdoor air in the outdoor air channel. The controller is used for controlling the air conditioner to carry out refrigeration according to a preset condition. According to the system, the machine room temperature is reduced, the cooling load of the machine room is reduced, mechanical refrigeration operating time is shortened, the total energy consumption of a data center is reduced, and the energy saving effect is obvious.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

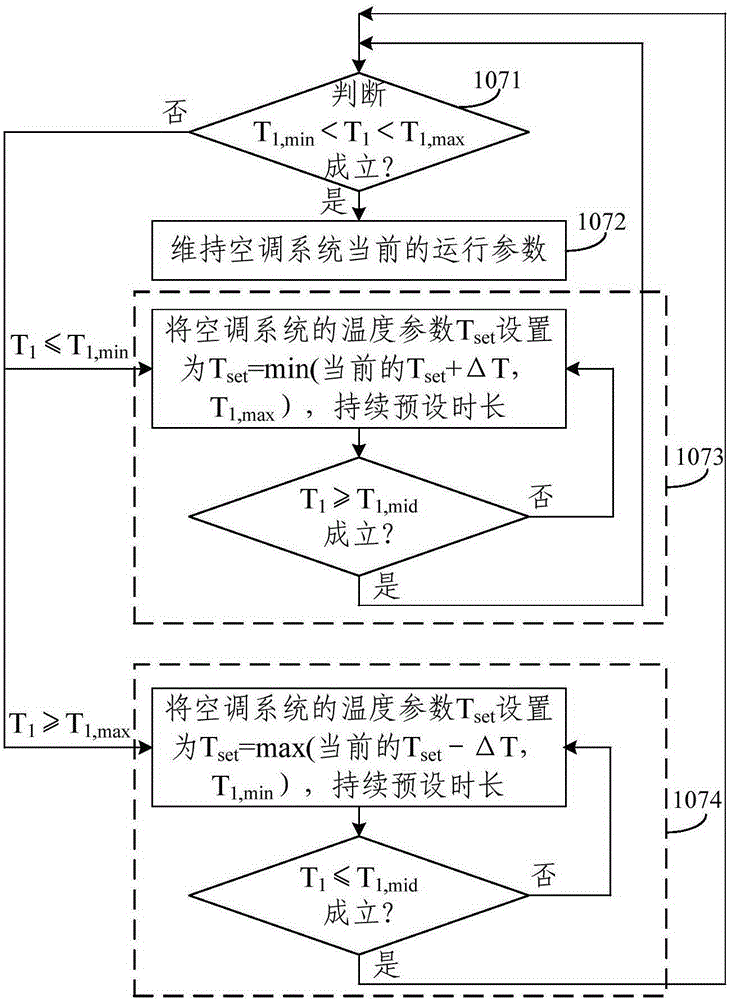

Comfort control method, controller and air-conditioning system

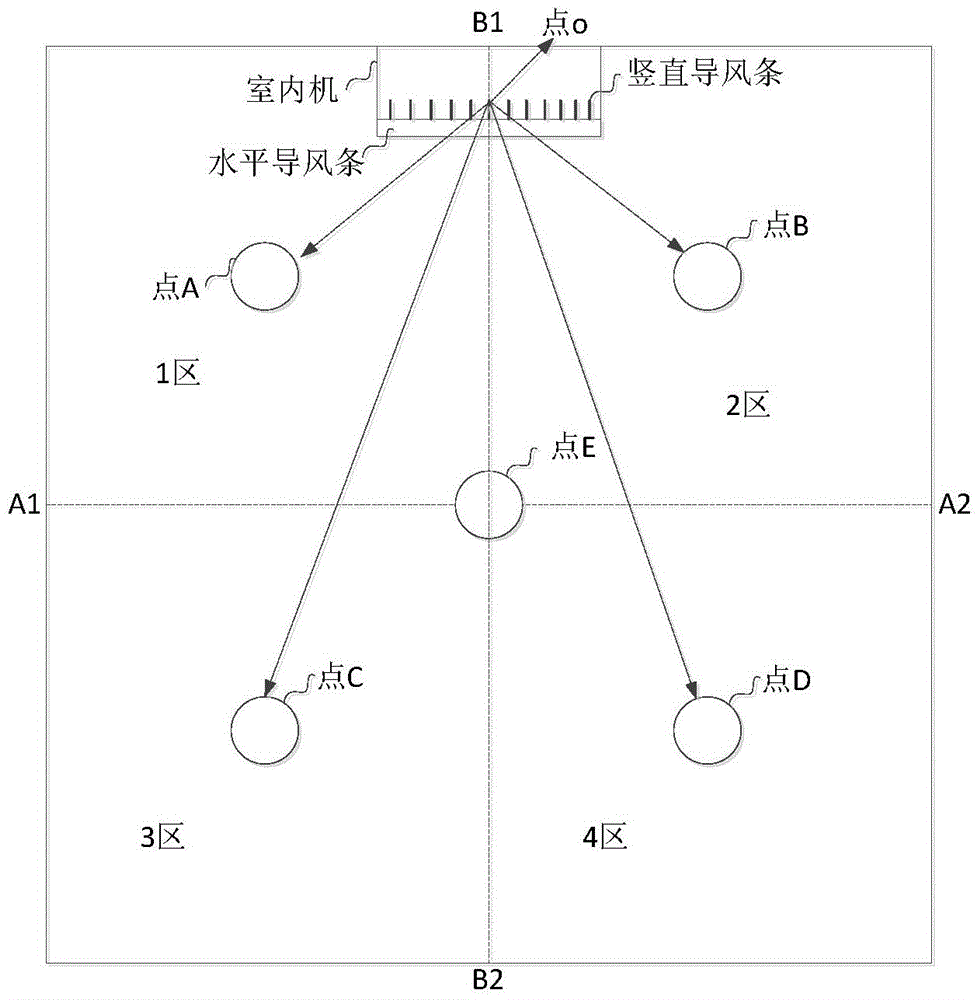

ActiveCN105222272AOptimal thermal comfortImprove comfort qualitySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringOutdoor temperature

The invention discloses a comfort control method, a controller and an air-conditioning system. The comfort control method comprises the steps that the current operating mode and operating parameters of the air-conditioning system are obtained, a position area selected by a user is obtained, and the current outdoor temperature T4, the current indoor temperature T1 and the current indoor humidity RH are obtained; the optimum heat comfort temperature range, corresponding to the current operating mode of the air-conditioning system, of the position area selected by the user is determined according to the human body metabolism rate, the current operating mode and the operating parameters of the air-conditioning system and the current T4, T1 and RH; and the operating parameters of the air-conditioning system are adjusted till the obtained T1 is within the optimum heat comfort temperature range. According to the comfort control method, the controller and the air-conditioning system, by zoning an indoor space, comfort control is conducted in the area where the user is located so that indoor users in different positions can be in the optimum heat comfort state, and the comfort quality is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

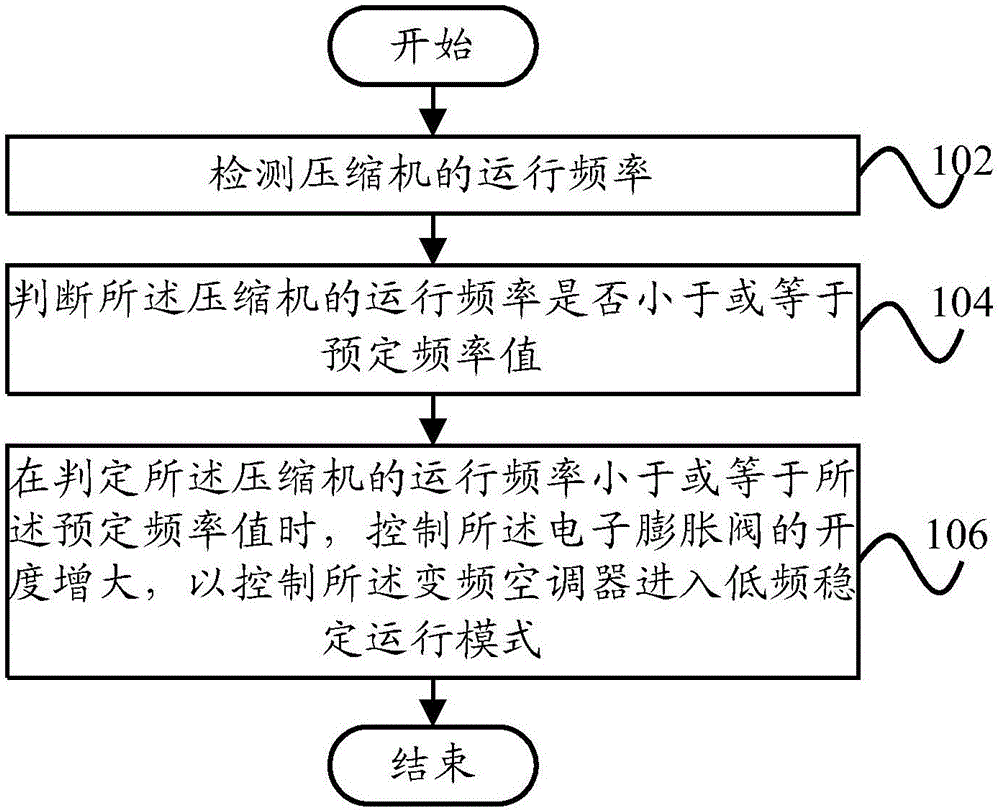

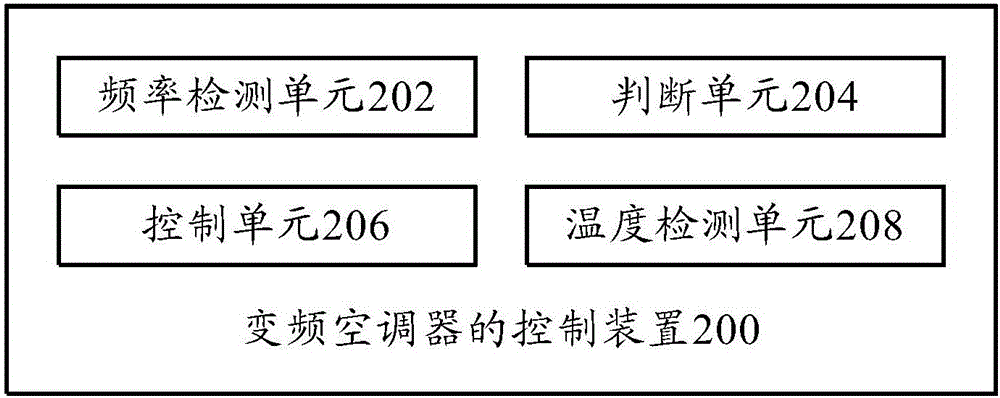

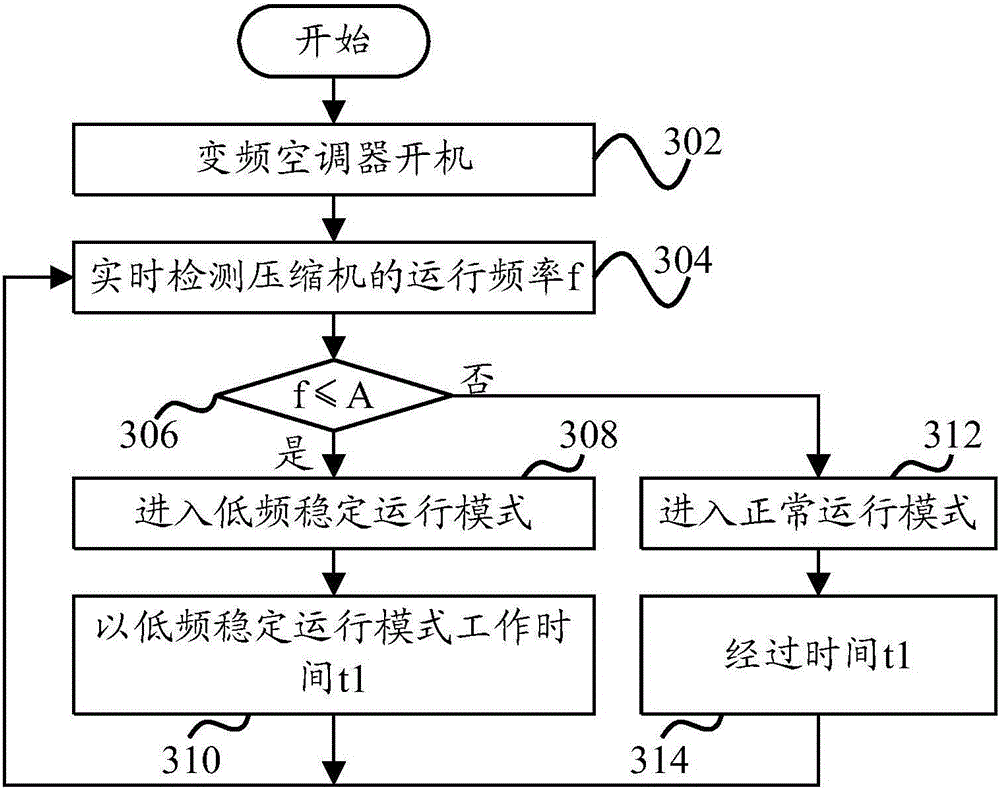

Controlling method and controlling device for variable-frequency air conditioner

ActiveCN105091251AControl openingImprove accuracyMechanical apparatusSpace heating and ventilation safety systemsCoolant flowOperation mode

The invention provides a controlling method and a controlling device for a variable-frequency air conditioner. The variable-frequency air conditioner comprises a compressor and an electronic expansion valve for adjusting the coolant flow. The controlling method for the variable-frequency air conditioner comprises the steps of detecting the operation frequency of the compressor; judging whether the operation frequency of the compressor is smaller than or equal to a preset frequency value; and controlling the openness of the electronic expansion valve to be increased when the operation frequency of the compressor is smaller than or equal to the preset frequency value to control the variable-frequency air conditioner to be in a low-frequency stable operation mode. By means of the technical scheme, the stability of the variable-frequency air conditioner in low-frequency operation is improved, zero fluctuation or smaller fluctuation of indoor temperature is guaranteed, and the user comfortableness is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

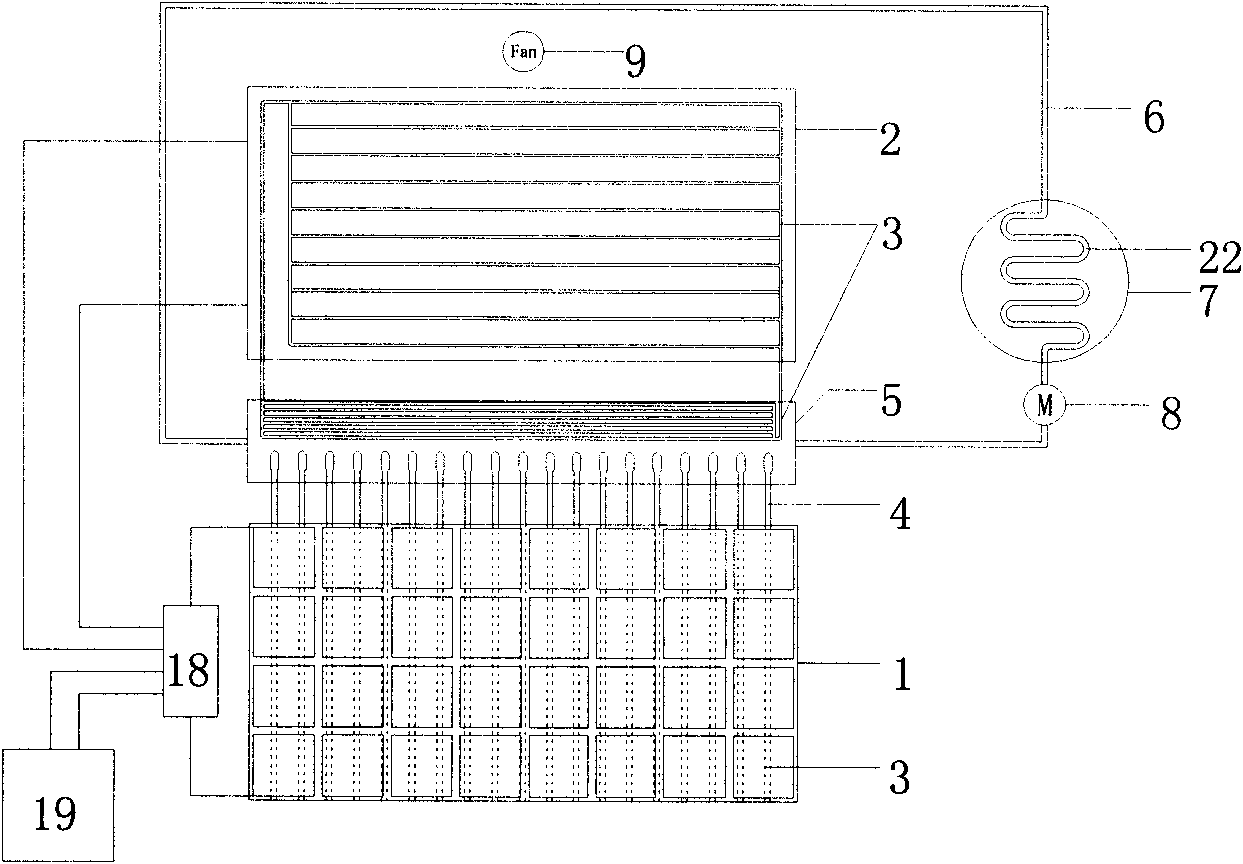

Composite solar photovoltaic hot-water cold supply and heating system for building

InactiveCN101806514ATake advantage ofVersatileSolar heating energySolar heat devicesEngineeringSolar power

The invention discloses a composite solar photovoltaic hot-water cold supply and heating system for a building, which mainly comprises a solar photovoltaic hot water sunshade plate, a semiconductor refrigerating assembly, a separate heat pipe with a short pipe bundle, an integral gravity heat pipe, a heat exchange header and the like. The system is characterized in that the solar photovoltaic hot water sunshade plate and the semiconductor refrigerating assembly form a loop to realize indoor refrigeration and heat supply in summer and in winter by using solar power generation respectively; and the separate heat pipe, the integral gravity heat pipe, the heat exchange header, a coil pipe, a water tank and the like form a hot water system to generate hot water when cooling and heating of the semiconductor refrigerating assembly are realized in summer and in winter respectively. The system solves the problem that heating and hot water generation cannot be realized at the same time in the combined application of the traditional solar photovoltaic power generation and semiconductor refrigerating assemblies; and the introduction of the separate heat pipe and the gravity heat pipe improves the refrigerating and heating efficiency and enlarges the application range.

Owner:UNIV OF SCI & TECH OF CHINA

Coking, absorbing and stabilizing energy-saving process

ActiveCN101602960ARelieve loadAvoid the "cold before heat" processGaseous mixture working upGas phaseDesorption

The invention discloses a coking, absorbing and stabilizing energy-saving process. The process comprises the following steps: (1) feeding compressed rich gas from refined and coked gasoline and diesel, desorbed gas taken out from the tower top of a desorption tower and rich absorption oil taken out from the tower bottom of an absorption tower to the bottom, middle part and top of a fluid contact heat exchange tower respectively to carry out contact and heat exchange; and (2) feeding the total gas phase at the tower top of the fluid contact tower directly used as a feeding material to the bottom of the absorption tower, simultaneously dividing the liquid phase at the tower bottom of the fluid contact heat exchange tower into two parts, cooling one part of the liquid phase to 40 DEG C through a condenser and feeding the cooled liquid phase as a cooling material to the top of the desorption tower, exchanging heat between the other part of the liquid phase and stabilized gasoline to between 70 and 80 DEG C through a heat exchanger and feeding the heat-exchanged liquid phase as a heating material to the middle upper part of the desorption tower. The process changes the prior direct mixing of the compressed rich gas, the rich absorption oil and the desorbed gas into heat exchange through the fluid contact tower, greatly reduces the cooling load, achieves the aim of saving energy, and has the advantages of reducing energy consumption, reducing desorption gas amount and relieving the load in the desorption tower.

Owner:苏州盛泽科技创业园发展有限公司

Device for assisting in defrosting through electric heating by utilizing air outside refrigerating chamber and operating method of device

ActiveCN103868309AReduce cooling loadOvercoming Secondary FrostingLighting and heating apparatusDefrostingElectric heatingElectricity

The invention discloses a device for assisting in defrosting through electric heating by utilizing air outside a refrigerating chamber and an operating method of the device. A heat insulating box is arranged at the upper part of a cold storage chamber, a first electric air valve is arranged at an inlet of the heat insulating box, a second electric air valve is arranged at an outlet of the heat insulating box, the top of the heat insulating box is provided with two air passages extending out of the cold storage chamber, a third electric air valve and a fourth electric air valve are arranged in the two air passages, an evaporator is arranged inside the heat insulating box, an electric heater is arranged in the evaporator, an air circulating air passage is formed between the bottom of the evaporator and a bottom plate of the heat insulating box, an inlet of the evaporator is connected with a throttling device, an outlet of the evaporator is connected with an air suction port of a compressor, an inlet of a condenser is connected with an exhaust port of the compressor, and an outlet of the condenser is connected with the throttling device. In the process of defrosting through electric heating, the air outside the refrigerating chamber and opening and closing of the electric air valves are utilized for assisting in defrosting through electric heating, so that the time of defrosting through electric heating is reduced, the operating energy consumption of the whole system is reduced, and relative stable temperature in the storage during defrosting is ensured.

Owner:TIANJIN UNIV

Air conditioning method combining solution absorbed moisture removing with compression refrigeration cycle

InactiveCN101033874AOvercoming the problem of frosting at dehumidification dew point below zeroOvercoming the Frosting ProblemLighting and heating apparatusAir conditioning systemsLiquid stateEngineering

The invention relates to an air condition method which compounds the desiccation by solution absorb and compressing refrigeration loop. The desiccation loop includes the desiccation loop part and the recovering loop part. The refrigerating evaporator of the compressing refrigeration loop provides the cold quantity needed by the absorbing cooler of the desiccation loop, at the same time, the liquid refrigerating medium of low temperature vapors after absorbing the solution thermal; the much higher temperature of the gas refrigerant is leaded into the condenser which provides the thermal for the heater of the recovering loop. Because the thermal of the absorber cool load is as the thermal load of the recover, the thermal load of the system recover can be decreased; even it can be saved completely. The evaporating temperature can be improved greatly and the energy cost can be lowered. So the cost can be decreased more.

Owner:BEIJING UNIV OF CHEM TECH

Segmented precise control type heat treatment process of hot-galvanized strip steels and alloying furnace thereof

ActiveCN104032250ASolve unevenSolve the problem prone to \"chimney effect\"Hot-dipping/immersion processesFurnace typesElectrical resistance and conductanceProgrammable logic controller

The invention discloses a segmented precise control type heat treatment process of hot-galvanized strip steels and an alloying furnace thereof. The process comprises the following steps: the heating, the heat insulation and the cooling are sequentially performed for strip steels output from a zinc pot; and finally, the alloying of the strip steels is realized; the key is to oppositely inject air on the two side surfaces of the strip steels, so that a plurality of high-temperature air screens perpendicular to the conveying direction of the strip steels are formed in a middle heat insulation section; and temperature signals in all partition areas of the high-temperature air screens are timely transmitted to a center control PLC (Programmable Logic Controller) processor, so that the center control PLC processor controls the ejection speed of the high-temperature air screens, the temperature of the air screens and the power of resistive heaters in each of the partition areas in real time so as to precisely control the heat insulation temperature in each of the partition areas. The alloying furnace comprises a bottom heating section, the middle heat insulation section and an upper cooling section, wherein sealing air knife generators are respectively arranged in outlets of three partition sections of the middle heat insulation section. The process and the alloying furnace can restrain the generation of the chimney effect, reduce the heat emission of the heat insulation section, and improve the heat treatment efficiency.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com