Patents

Literature

2093 results about "Metal impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High purity nanotube fabrics and films

InactiveUS20050058797A1High standard of non-toxicity and purityMaterial nanotechnologyLayered productsLiquid mediumMetal impurities

Owner:ZEON CORP

Spin-coatable liquid for formation of high purity nanotube films

ActiveUS20050058590A1Lower Level RequirementsPigmenting treatmentMaterial nanotechnologyLiquid mediumSpins

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid for formation of a nanotube film includes a liquid medium containing a controlled concentration of purified nanotubes, wherein the controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity, and wherein the spin-coatable liquid comprises less than 1×1018 atoms / cm3 of metal impurities. The spin-coatable liquid is substantially free of particle impurities having a diameter of greater than about 500 nm.

Owner:ZEON CORP

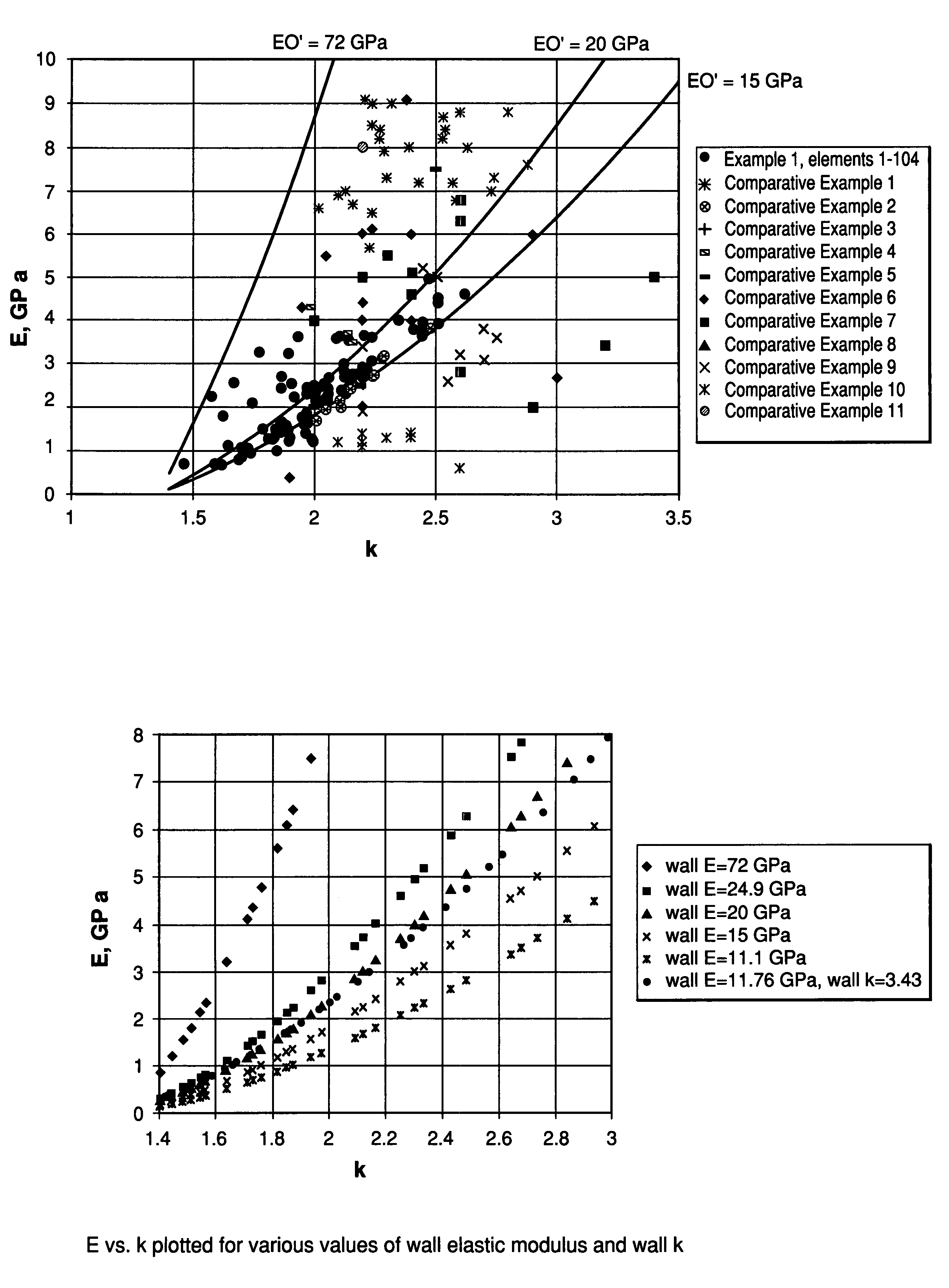

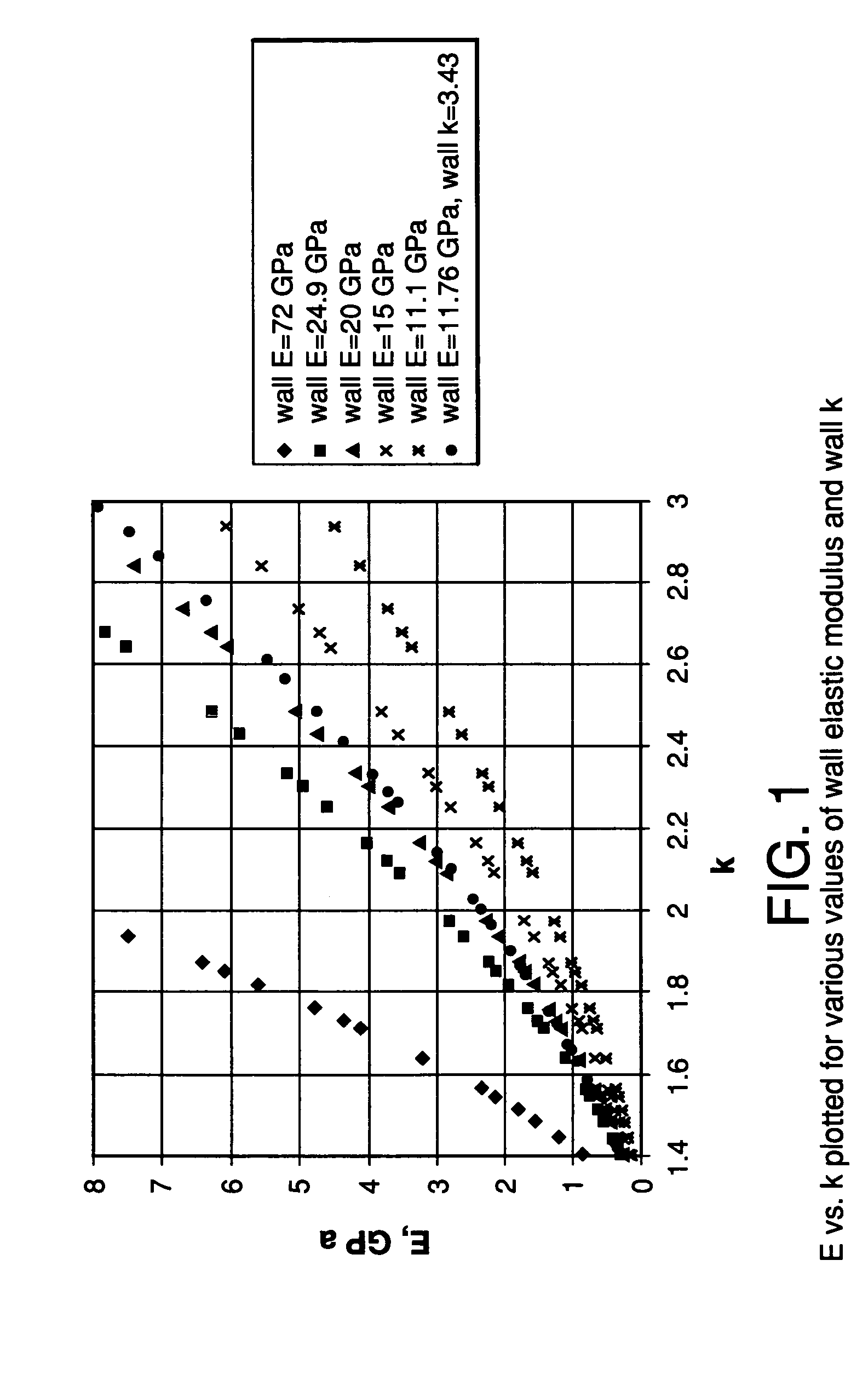

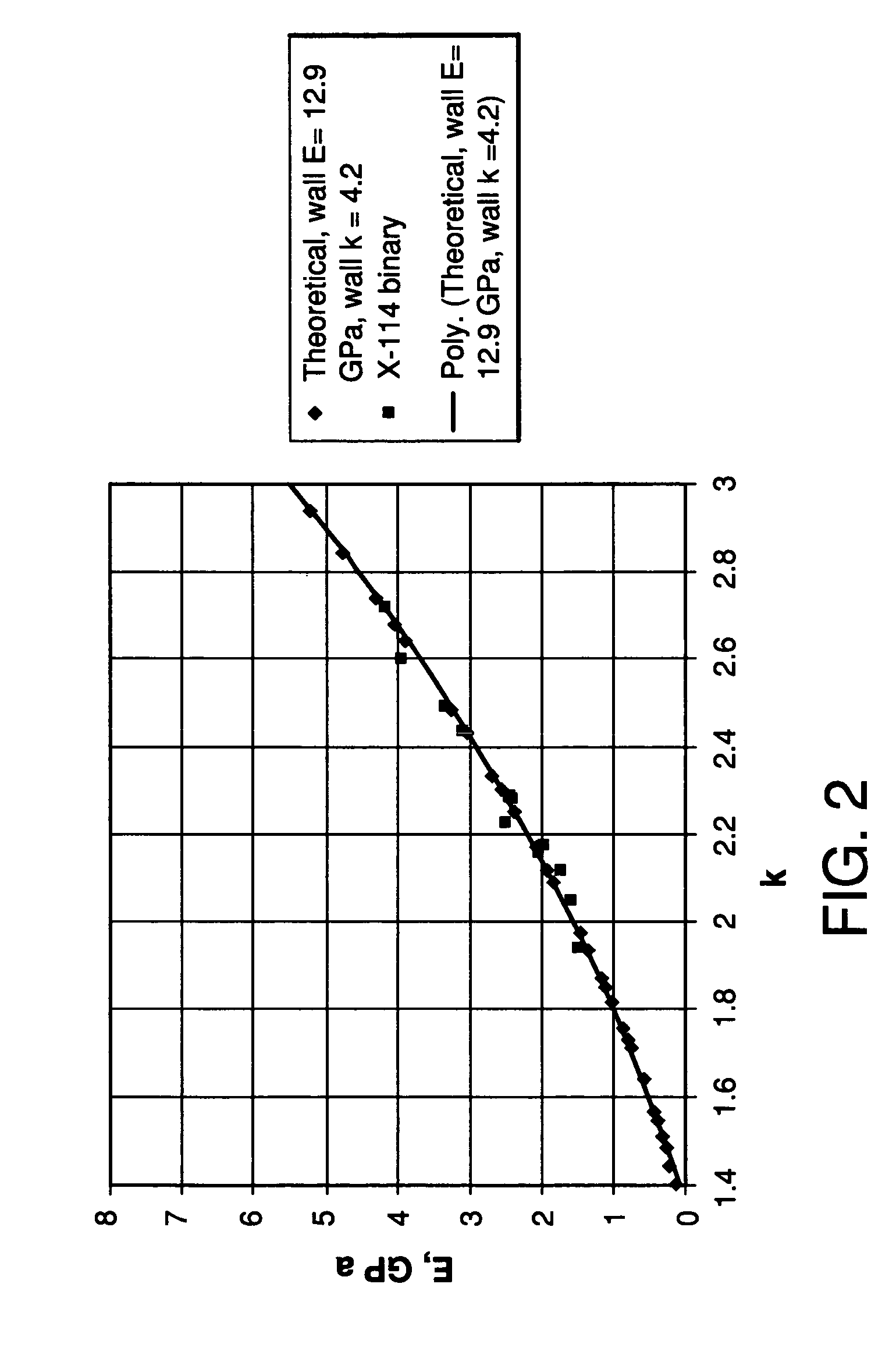

Low dielectric materials and methods for making same

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. These materials are characterized as having a dielectric constant (κ) a dielectric constant of about 3.7 or less; a normalized wall elastic modulus (E0′), derived in part from the dielectric constant of the material, of about 15 GPa or greater; and a metal impurity level of about 500 ppm or less. Low dielectric materials are also disclosed having a dielectric constant of less than about 1.95 and a normalized wall elastic modulus (E0′), derived in part from the dielectric constant of the material, of greater than about 26 GPa.

Owner:SYMYX SOLUTIONS +1

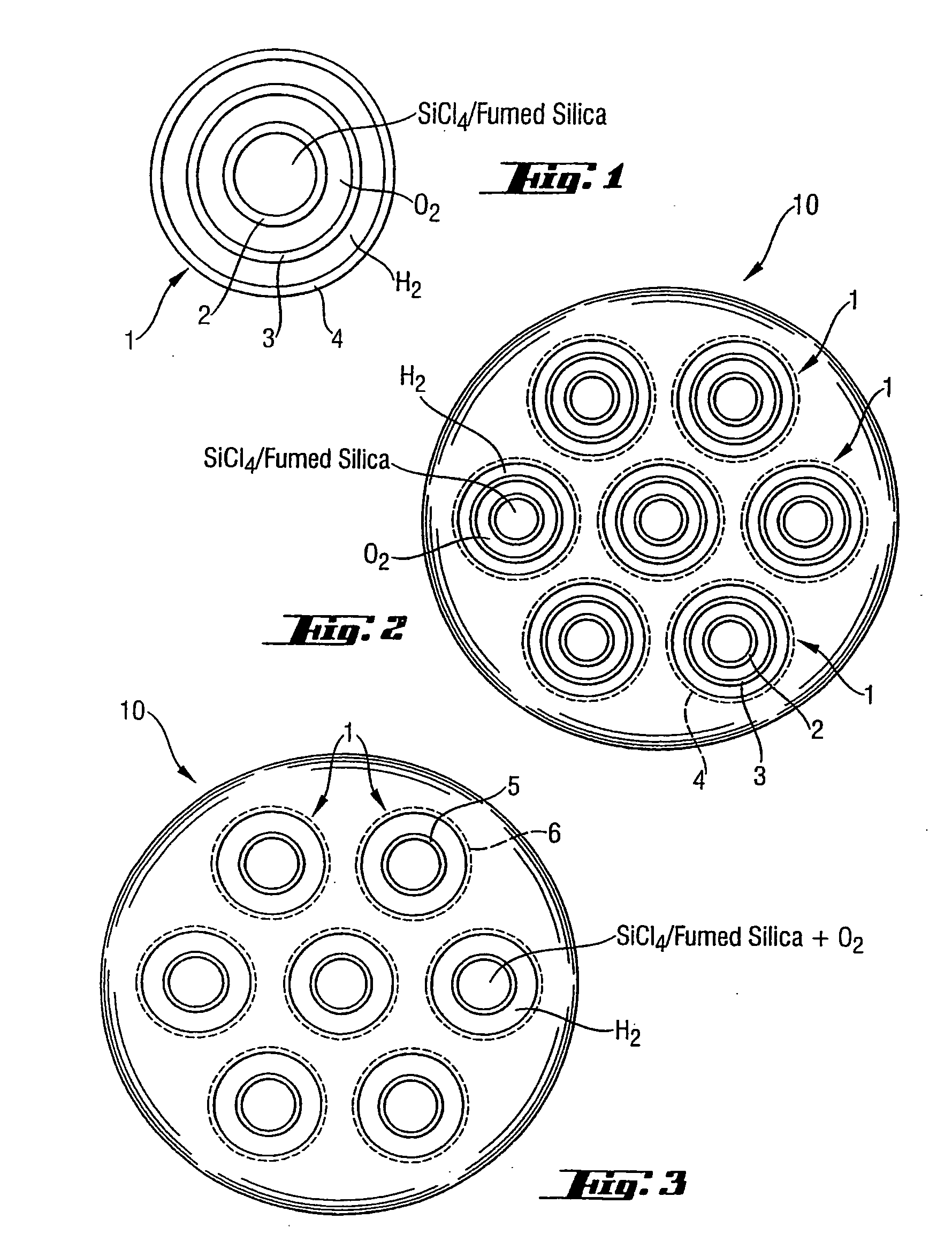

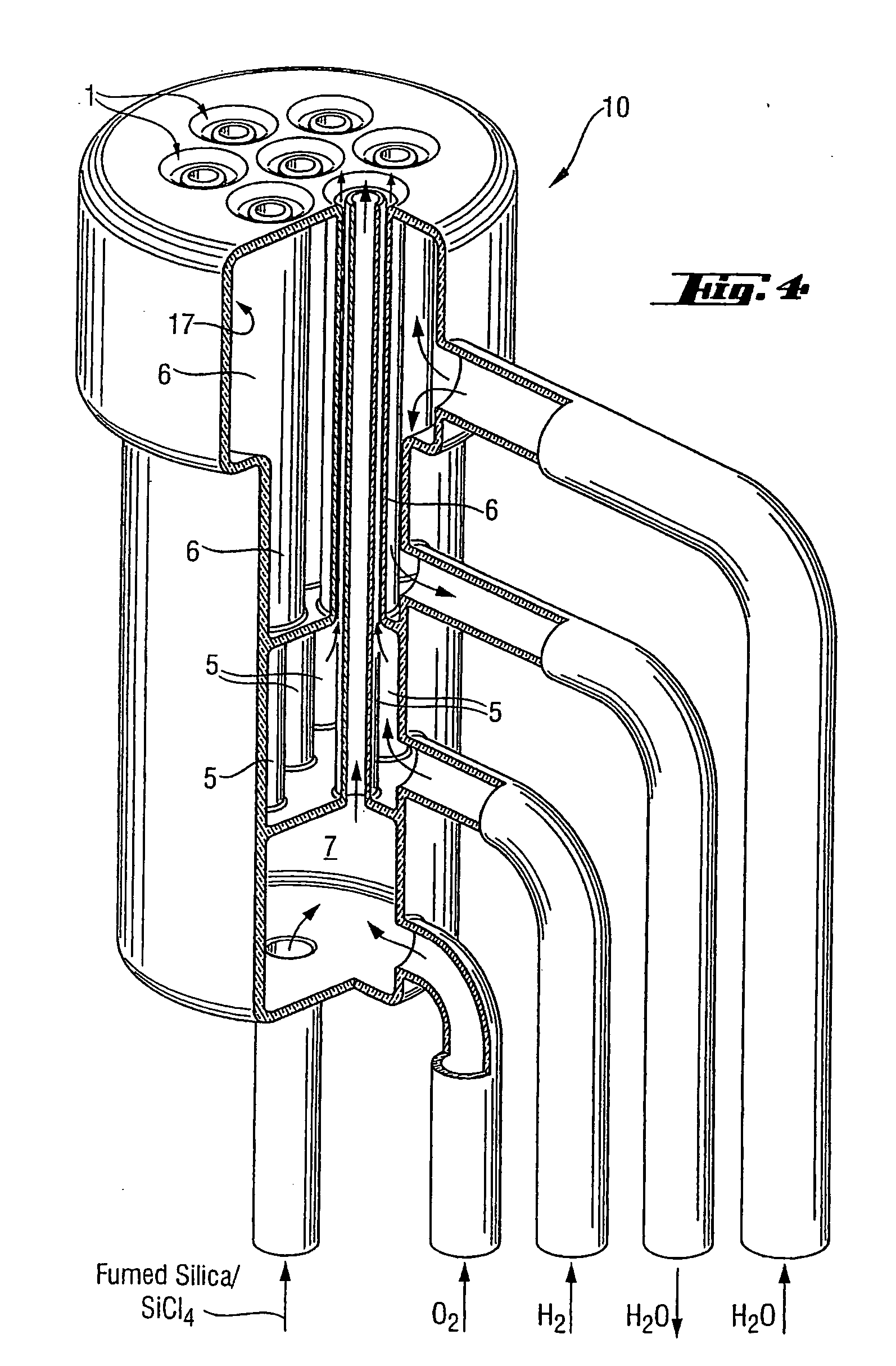

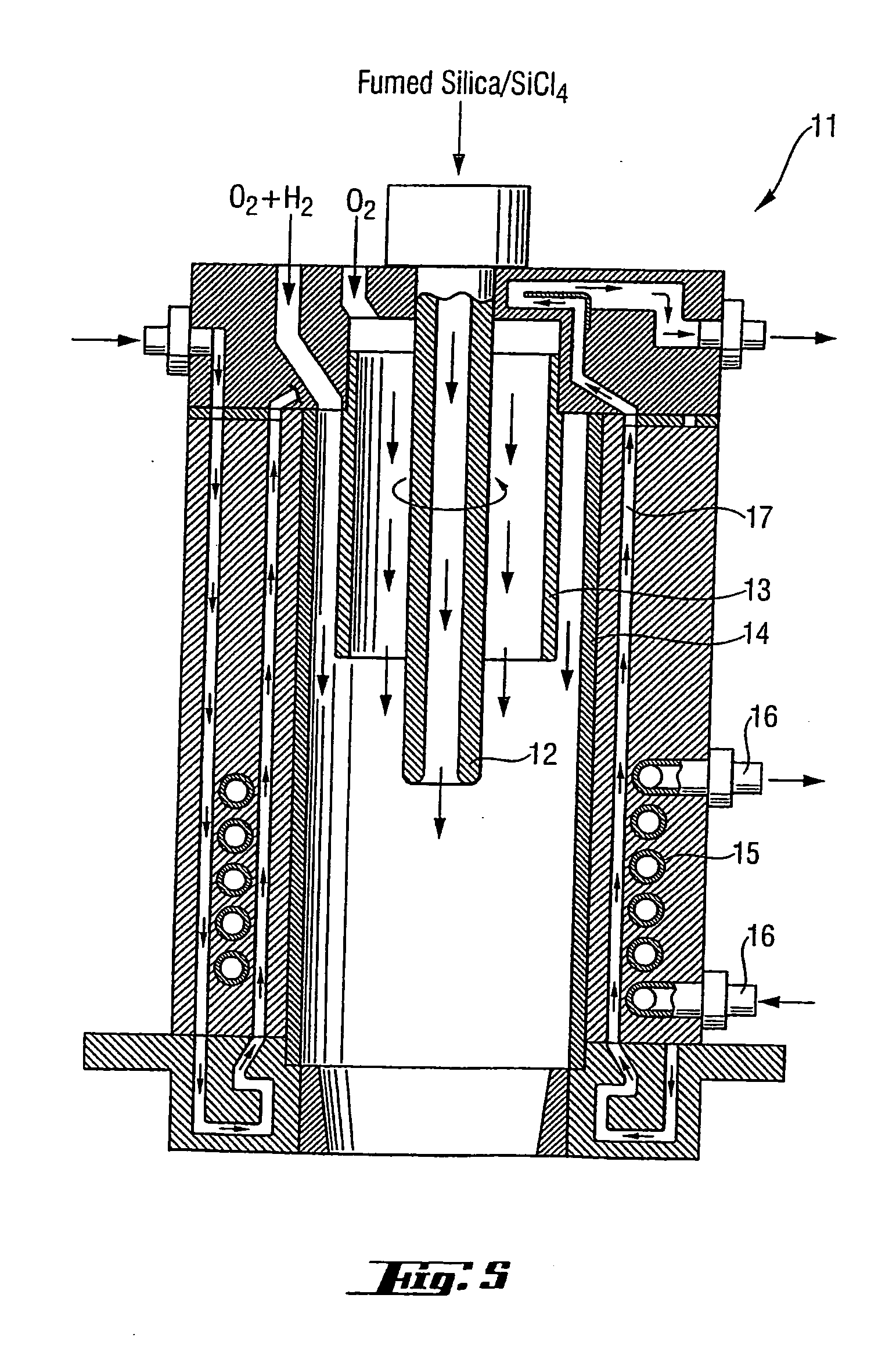

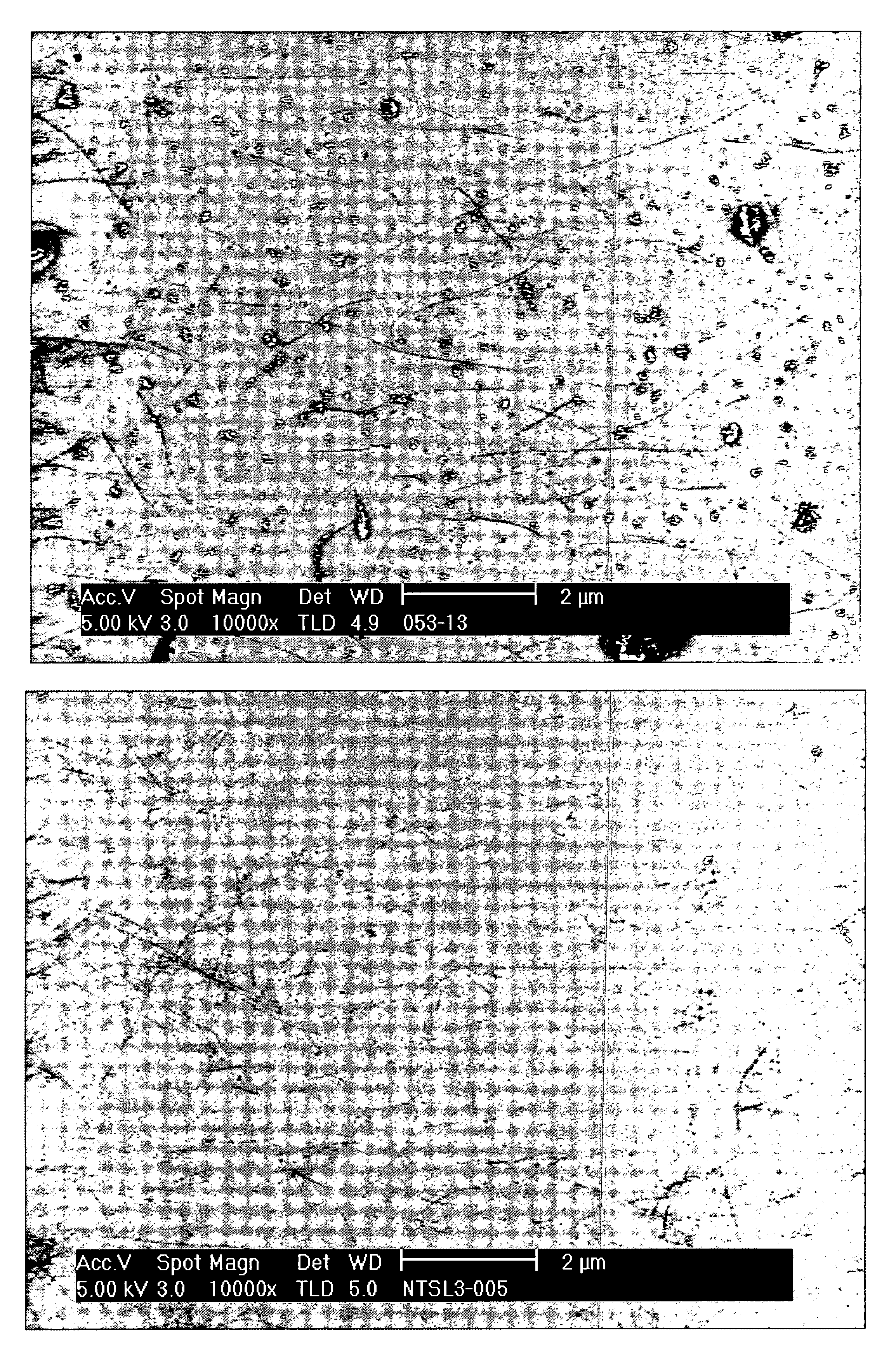

High-purity silica powder, and process and apparatus for producing it

Use of a flame hydrolysis apparatus for preparing fumed silica particles or a plasma torch apparatus for sintering fumed silica particles to fused silica particles is capable of producing highly pure silica with non-silicon metal impurities less than 500 pb, when at least an inner nozzle is constructed of a silicon-containing material having a low level of non-silicon metal impurities. Preferably, all surfaces in the respective apparatus which contact silica are of similar construction. The silica contains a low level of impurities as produced, without requiring further purification.

Owner:WACKER CHEM GMBH

Spin-coatable liquid for formation of high purity nanotube films

ActiveUS7375369B2Lower Level RequirementsPigmenting treatmentMaterial nanotechnologyLiquid mediumMetal impurities

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid for formation of a nanotube film includes a liquid medium containing a controlled concentration of purified nanotubes, wherein the controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity, and wherein the spin-coatable liquid includes less than 1×1018 atoms / cm3 of metal impurities. The spin-coatable liquid is substantially free of particle impurities having a diameter of greater than about 500 nm.

Owner:ZEON CORP

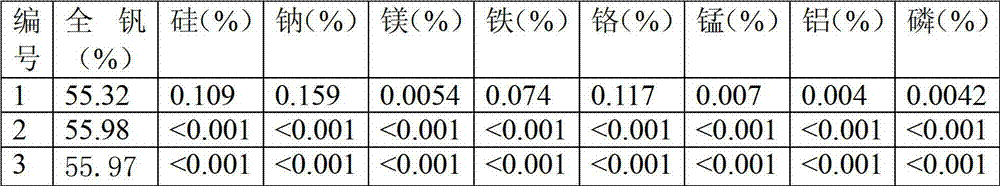

Preparation method of high-purity vanadium pentoxide

InactiveCN102923775AEfficient removalReduce pollutionVanadium oxidesMetal impuritiesAmmonium metavanadate

The invention discloses a preparation method of high-purity vanadium pentoxide. The preparation method comprises the following steps of: returning and dissolving coarse vanadium in aqueous alkali, and filtering the solution to remove metal impurities, which are subjected to precipitation reaction with the aqueous alkali, in the coarse vanadium, thus obtaining a primary returned solution; slowly pouring the primary returned solution into a sulfuric acid solution, adjusting the pH value of the solution to be 1.0-2.0 to obtain a liquid-solid mixture, and performing solid-liquid separation on the liquid-solid mixture; filtering and washing precipitates obtained from the solid-liquid separation of the mixture, and returning and dissolving the mixture into the aqueous alkali, thus obtaining a secondary returned solution; adding ammonium sulfate into the secondary returned solution for precipitating vanadium, and filtering the solution to obtain ammonium metavanadate; and processing the ammonium metavanadate to obtain the high-purity vanadium pentoxide. The preparation method adopting multiple stages of returned dissolving can be used for effectively removing the metal canon impurities of the vanadium pentoxide, and further obtaining the high-purity vanadium pentoxide with the metal canon impurity contents of less than 0.001% and the vanadium pentoxide content of 99.99%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Polycrystalline silicon and method for production thereof

Polycrystalline silicon of the invention contains: (a) polycrystalline silicon fragments, wherein at least 90% of the fragments have a size from 10 to 40 mm, (b) <15 ppmw of silicon dust particles having particle sizes <400 μm; (c) <14 ppmw of silicon dust particles having particle sizes <50 μm; (d) <10 ppmw of silicon dust particles having particle sizes <10 μm; (e) <3 ppmw of silicon dust particles having particle sizes <1 μm; and (f) surface metal impurities in an amount ≦0.1 ppbw and ≧100 ppbw. A polycrystalline silicon production method of the invention includes fracturing polycrystalline silicon deposited on thin rods in a Siemens reactor into fragments; classifying the fragments by size; and treating the fragments with compressed air or dry ice to remove silicon dust from the fragments without wet chemical cleaning.

Owner:WACKER CHEM GMBH

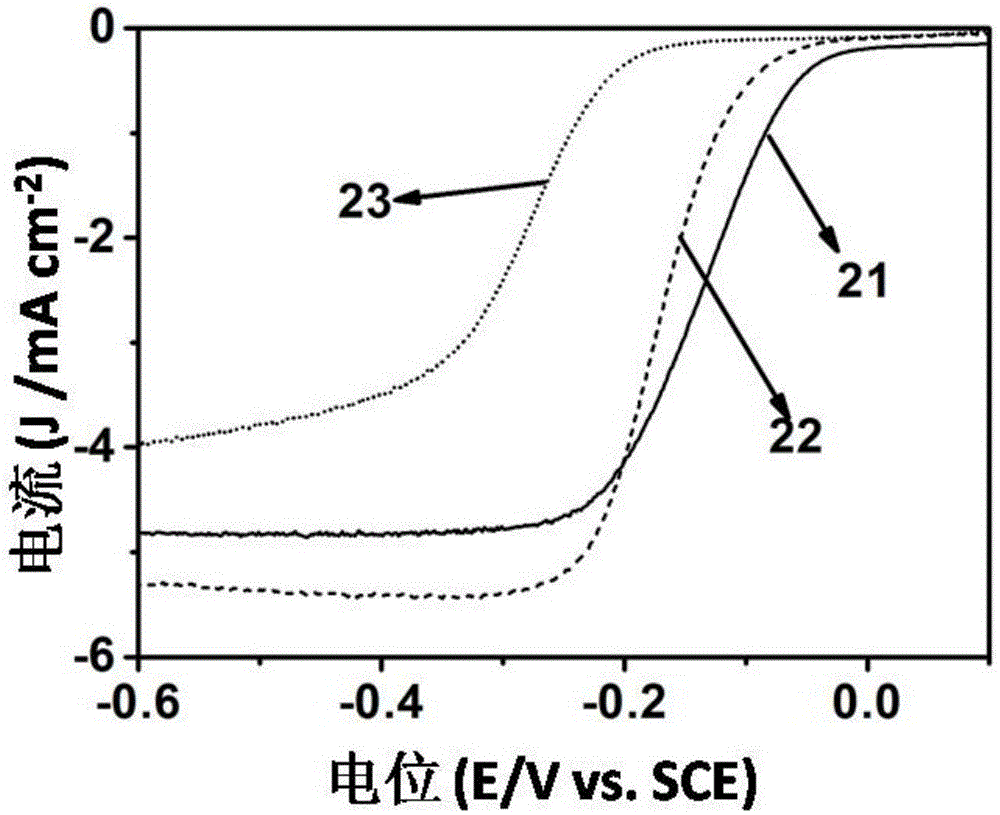

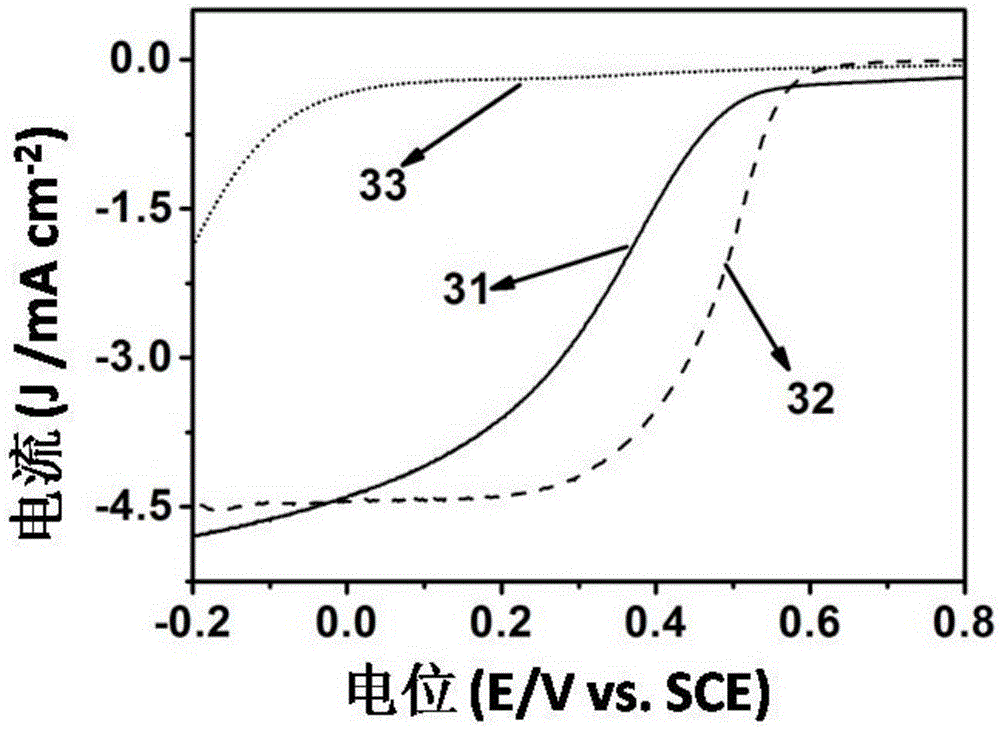

Catalyst with dispersed single platinum atoms and preparation method of catalyst

The invention relates to a catalyst with dispersed single platinum atoms and a preparation method of the catalyst, and aims at solving the technical problems that a precious metal oxygen reduction catalyst is high in preparation cost and low in utilization rate of platinum in the prior art. The catalyst with dispersed single platinum atoms is prepared by stirring, refluxing, evaporating, drying and grinding a carbon support, a nonmetal heteroatom reagent and a platinum compound as raw materials, and carrying out high-temperature treatment and interaction in a sliding rail furnace. A test result shows that the platinum element in the catalyst exists in a form of single atoms platinum; the catalytic activity is high; in acid and alkaline systems, the initial oxygen reduction potential and the half-wave potential are equivalent to those of a commercial carbon-supported platinum catalyst with the platinum content of 20%; other metal impurities are not introduced in the preparation process; and the stability is relatively good. The preparation method of the catalyst provided by the invention is relatively low in cost, simple and feasible. The catalyst is suitable for preparation of a fuel cell; the utilization rate of the platinum is greatly improved; the cost of the catalyst is reduced; and the commercialization process of the fuel cell can be promoted.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

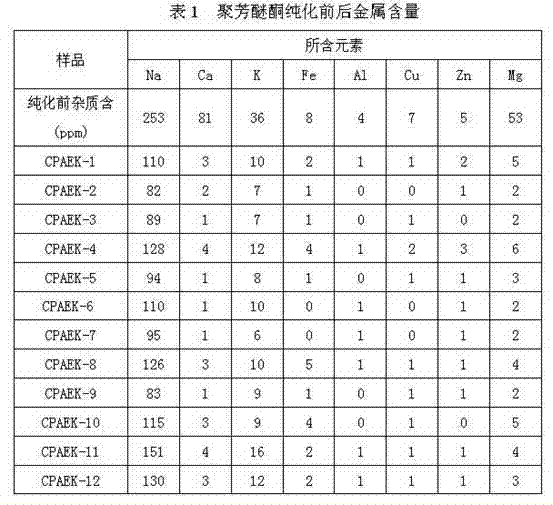

Method for reducing metal impurities in poly(aryl ether ketone) polymer

The invention belongs to the technical field of polymer material, and relates to a method, used in a production process, for reducing metal impurities in poly(aryl ether ketone). The method comprises the following steps: 1) purification: fully mixing poly(aryl ether ketone) with hydroxy ethidene diphosphonic acid aqueous solution with mass concentration of 0.1-2% at 40-100 DEG C for 0.5-3 h, wherein time for mixing and stirring is preferably 1-2 h, and filtering; 2) washing: washing the purified poly(aryl ether ketone) with distilled water, until conductivity of the aqueous solution is below 20 muS / cm; and 3) drying: drying the washed poly(aryl ether ketone) at 120-140 DEG C for 4-6 h to obtain poly(aryl ether ketone) with metal impurities removed. The method can not only reduce content of the metal impurities in the poly(aryl ether ketone) and improve product quality; besides the used reagents have excellent chemical stability, small dosage, and no self toxicity or pollution, can be treated with biochemical degradation in a later period of production, and will not harm the environment.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

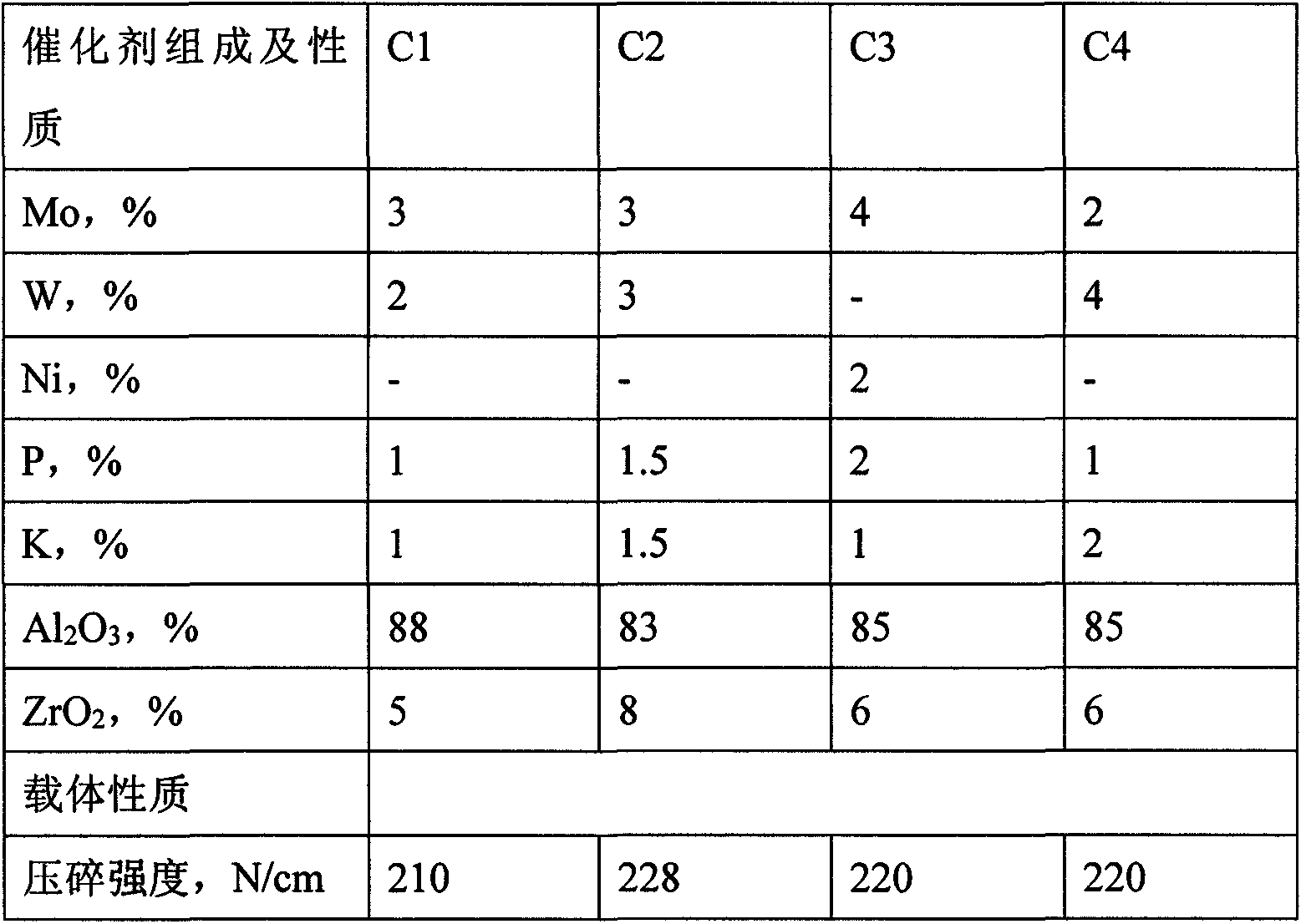

Protective agent of coal tar hydrogenation catalyst and preparation method of protective agent

ActiveCN103706408ASmall pressure dropHigh activityCatalyst protectionHydrocarbon oil crackingPotassiumMetal impurities

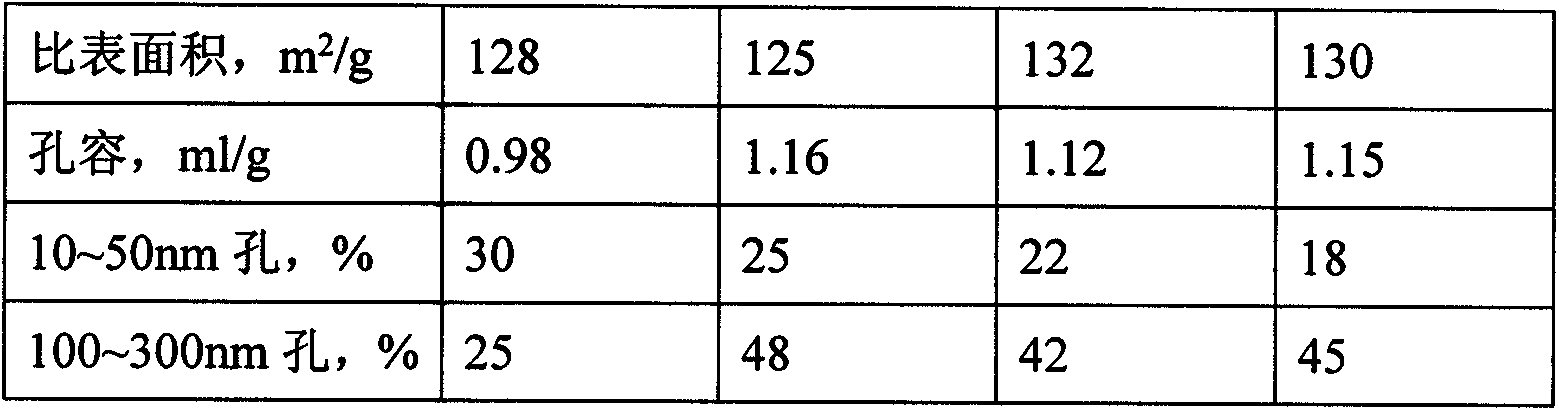

The invention discloses a protective agent of a coal tar hydrogenation catalyst and a preparation method of the protective agent. The protective agent is composed of three parts, namely carriers, active components and assistants, wherein the carriers include aluminium oxide and zirconium oxide in common; the active components include oxides of molybdenum, nickel or tungsten in common and account for 1-10% of total mass of the catalyst; the assistants include potassium and phosphorus in common, and account for 0.5-6% of total mass of the catalyst, and the balance is the carriers. The preparation method comprises preparation of the carrier and preparation of the protective agent. The protective agent has the advantages that the carrier comprises fine holes and thick holes, of which the apertures are relatively concentrated, wherein the thick holes are beneficial to containing metal impurities and carbon residue; a pressure drop of a catalyst bed is reduced, the hydrogenation catalyst is protected, removal of metal impurities such as vanadium is facilitated by the thin holes, the demetallization activity of the protective agent is properly improved, and different pore volumes and hole distribution of carriers can be prepared by adjusting the ratio of two pore forming materials. In addition, the preparation method of the protective agent is simple in technology, and convenient and stable to fabricate.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

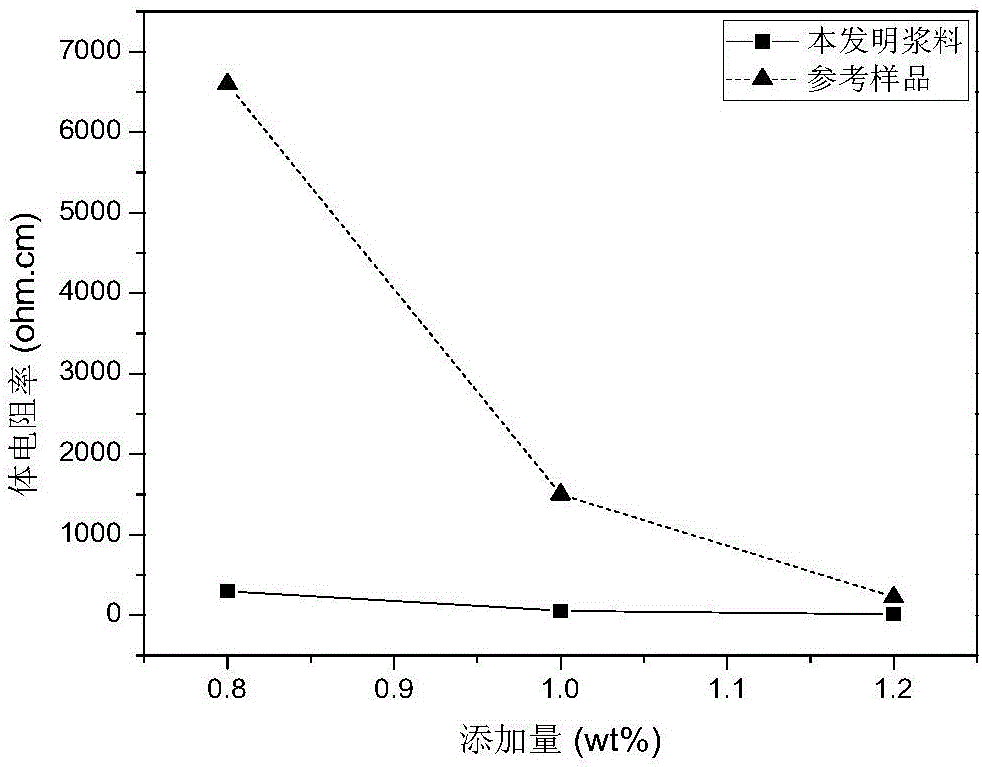

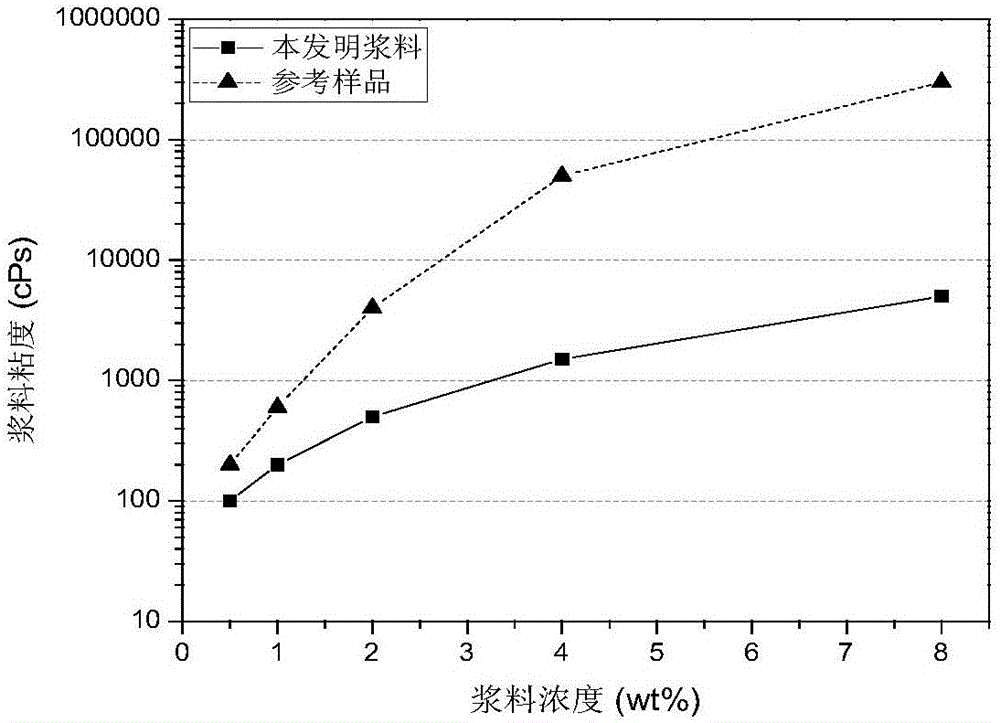

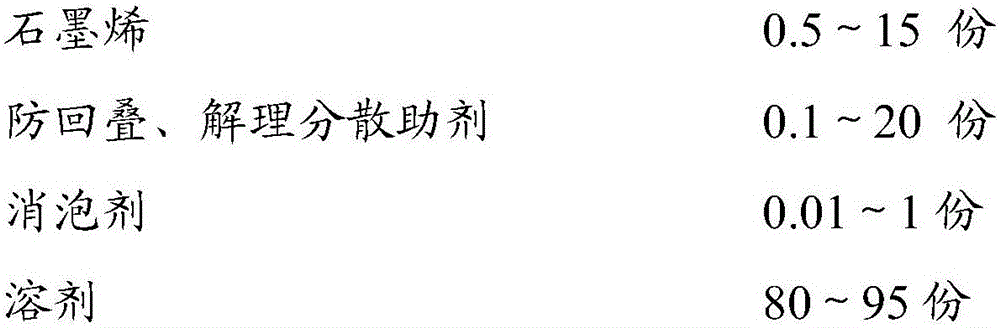

High-concentration and high-purity graphene slurry and preparation method and application thereof

InactiveCN105895870AAchieve high concentration cleavageLow viscosityCell electrodesSecondary cellsHigh concentrationPhysical chemistry

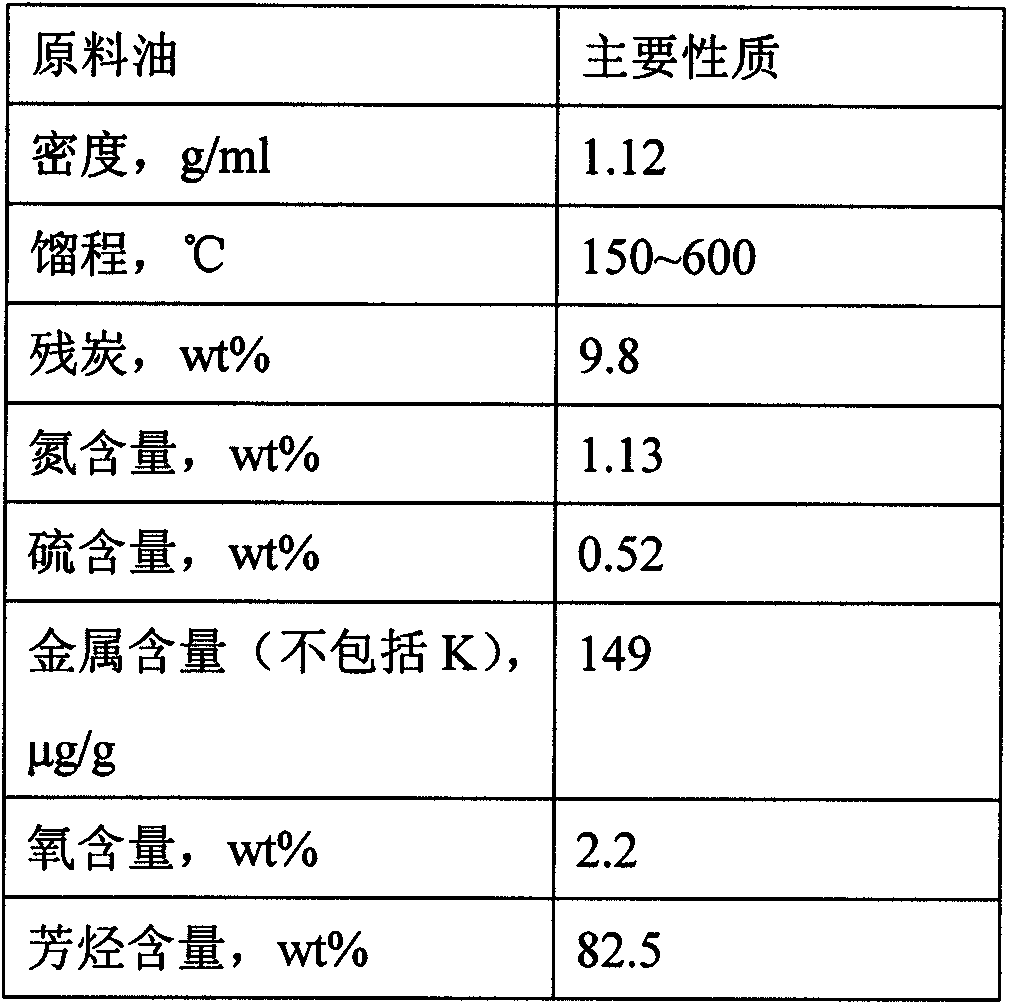

The invention belongs to the technical field of new materials, and particularly relates to high-concentration and high-purity highly pre-dispersed graphene slurry and a preparation method and an application of thereof. The graphene slurry is prepared from the following raw materials in parts by weight: 0.5-15 parts of graphene, 0.1-20 parts of an anti-fold cleavage dispersing agent, 0.01-1 part of a defoamer and 80-95 parts of a solvent; the graphene slurry is prepared through high-energy cleavage and dispersion; the viscosity of the prepared graphene slurry is smaller than 10,000cPs; and the metal impurity content in the slurry is smaller than 100ppm. High-concentration cleavage and folding prevention can be achieved; and the graphene slurry has the properties of extremely high purity and low viscosity, is very easy to be dispersed for the second time, and is suitable for an automatic feeding system.

Owner:SUPERCDONGGUAN TECH

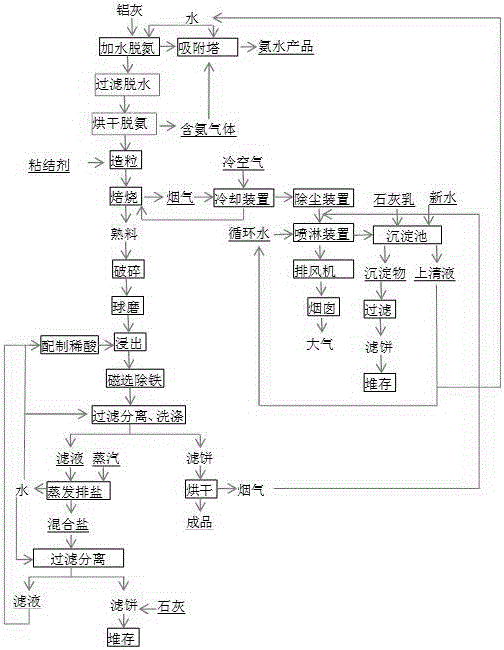

Resourceful treatment method for aluminum ash

ActiveCN106694514AIncrease profitImprove protectionSolid waste disposalTransportation and packagingMetallic aluminumResource utilization

The invention provides a resourceful treatment method for aluminum ash. Firstly, denitrification treatment, defluorination treatment and arsenic removal treatment are conducted so that nitrogen in the aluminum ash can be separated out in the form of ammonia gas to be recycled, harmful substances such as fluorine and arsenic are volatilized out, roasting is conducted, and aluminum ash clinker is obtained; and then metal impurity removing treatment is conducted, the roasted aluminum ash clinker is broken and finely ground and then is leached through diluted acid, metal impurities such as K2O, Na2O, CaO and MgO in the aluminum ash clinker are dissolved out, iron is removed through magnetic separation, and after pressure filtration separation, a finished aluminum oxide product is obtained through drying. According to the resourceful treatment method for the aluminum ash, aluminum oxide, metallic aluminum and the like in the aluminum ash can be recycled, byproducts such as ammonia water and iron are obtained, waste is turned into wealth, the social resource utilization rate is increased, meanwhile, components of fluorine and arsenic in the aluminum ash are removed, innocent treatment is done, and environment protection is facilitated.

Owner:三门峡华森新型材料有限公司 +1

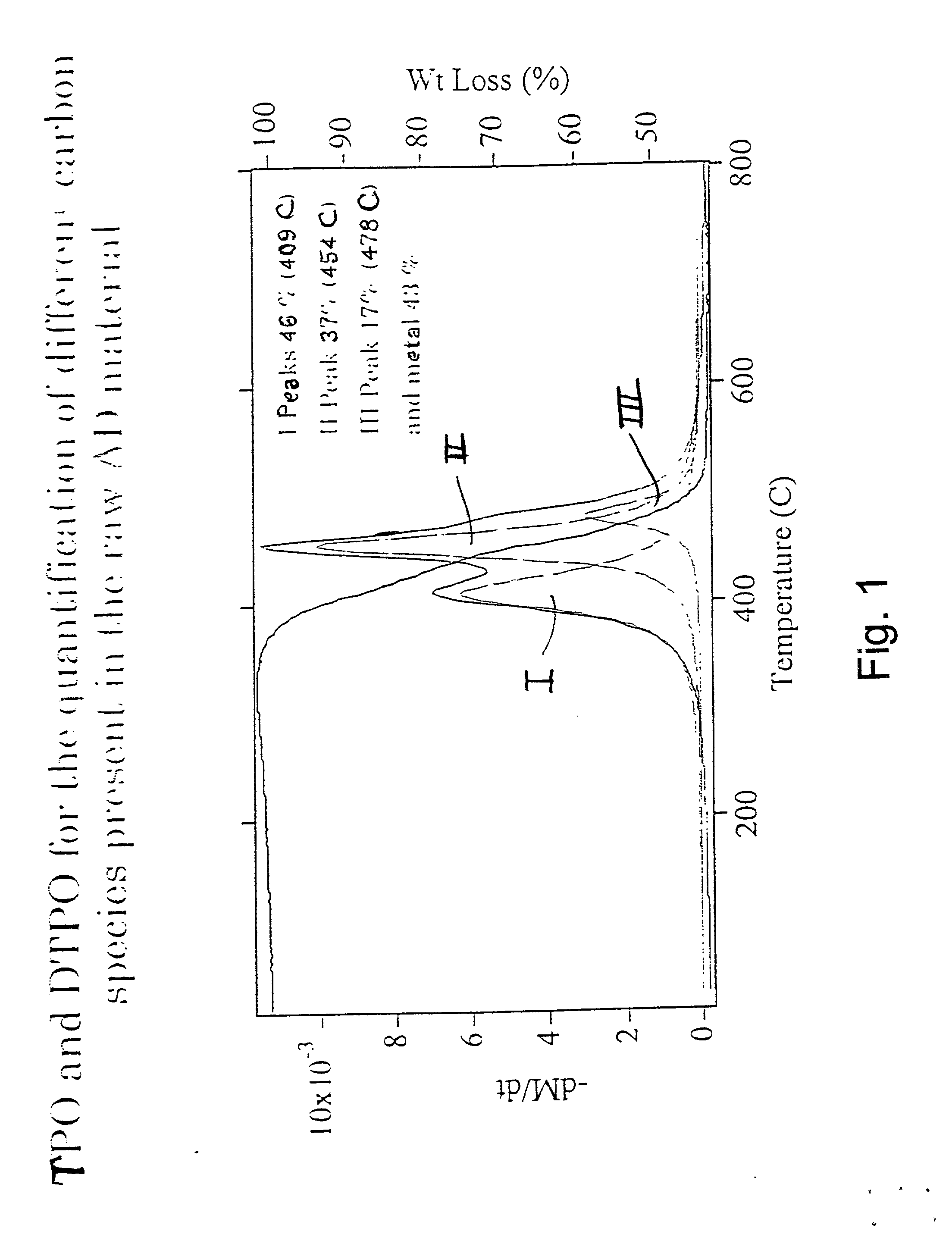

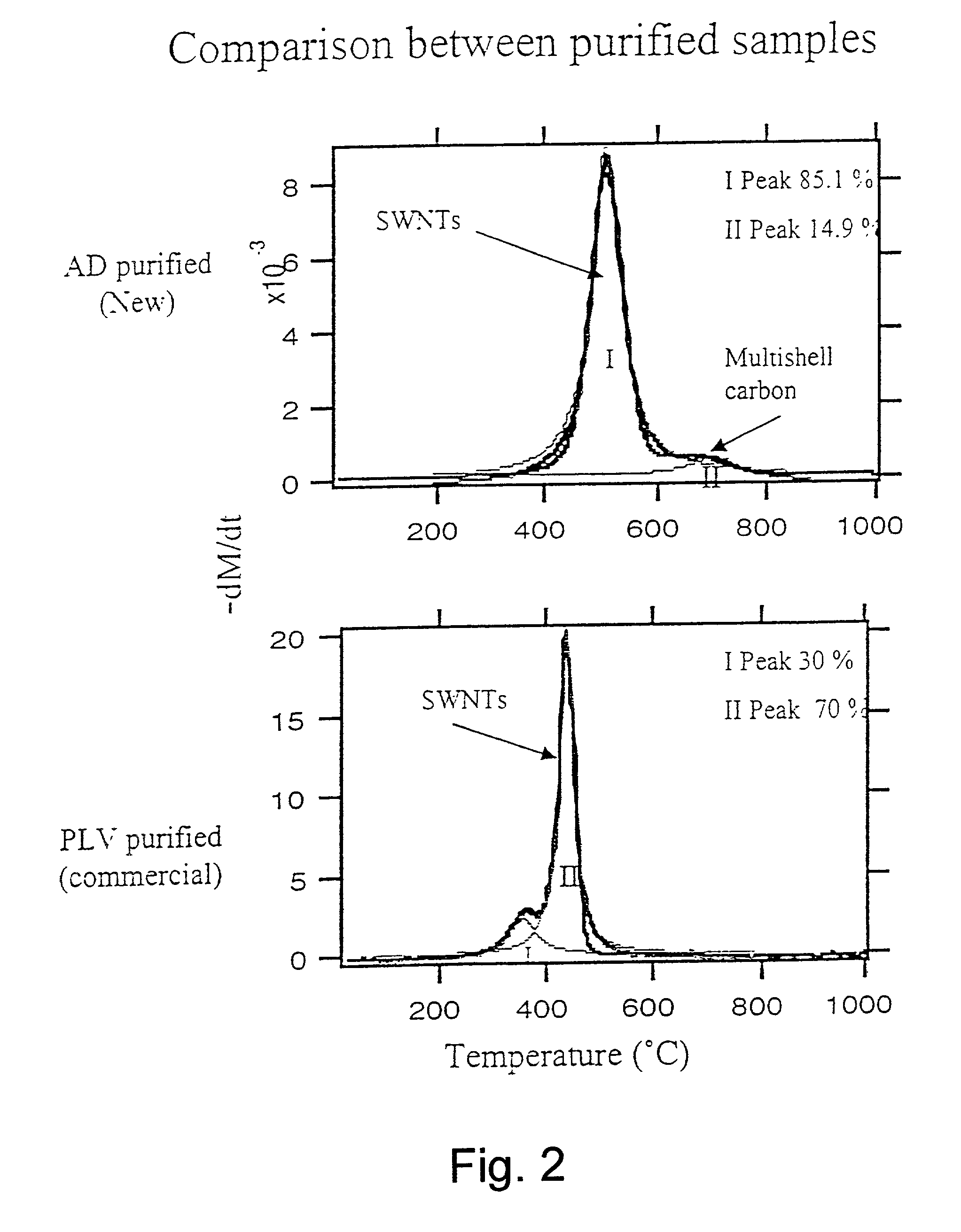

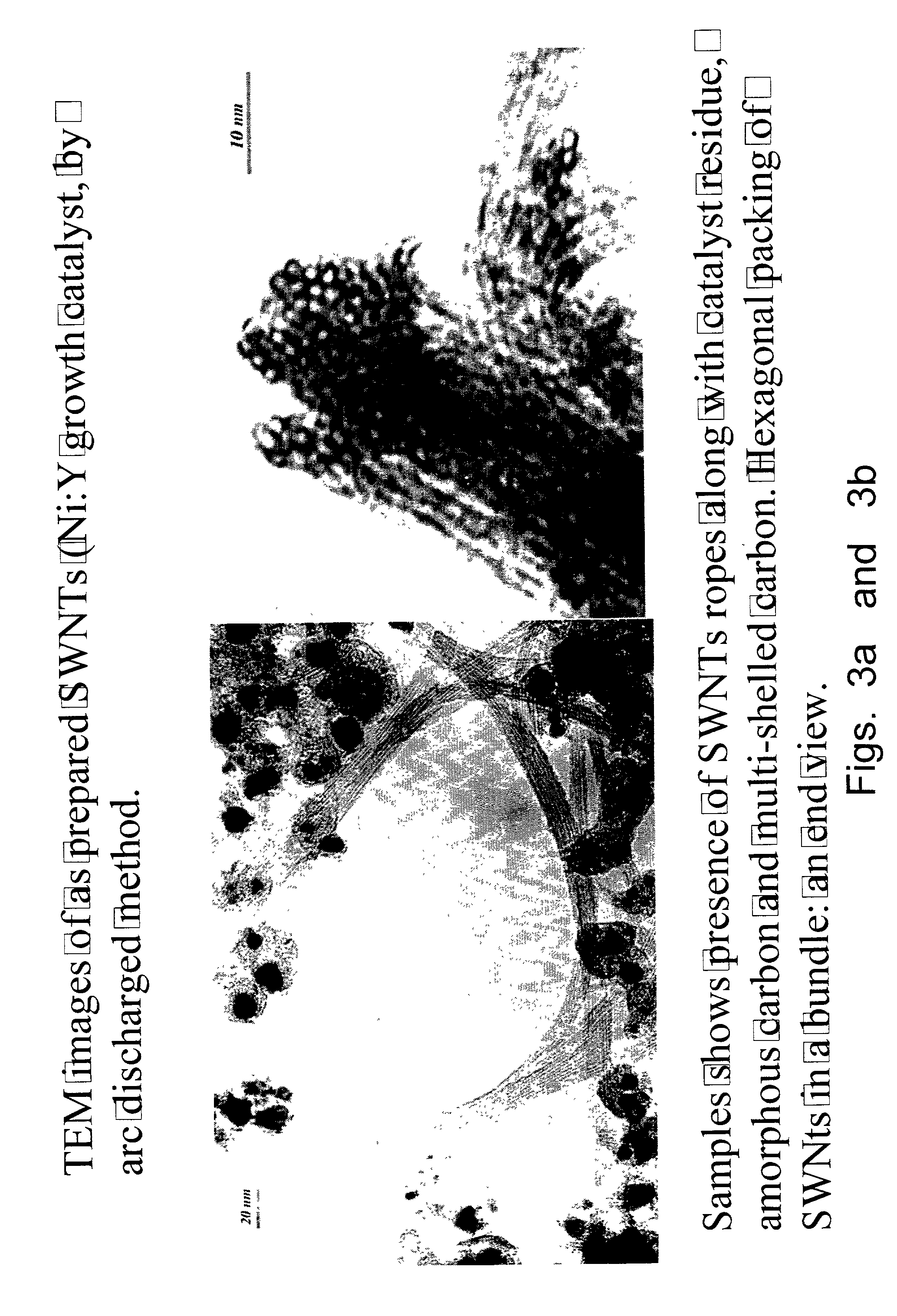

Purification of carbon filaments and their use in storing hydrogen

InactiveUS20030031620A1High yieldReduce the amount requiredMaterial nanotechnologyReversible hydrogen uptakeMetal impuritiesPhysical chemistry

Carbon structures, e.g. carbon nano-fibers, suitable for absorbing hydrogen at low pressures and low temperatures are produced by a selective oxidation and / or acid reflux process. The process includes heating an impure mixture containing a crystalline form of carbon in the presence of an oxidizing gas at a temperature and time sufficient to selectively oxidize and remove a substantial amount of any amorphous carbon impurities from the mixture. Metal containing impurities can be removed from the mixture by exposing the desired carbon and accompanying impurities to an acid to produce a carbon fiber that is substantially free of both non-fiber carbon impurities and metal impurities. Another aspect of the present invention includes purified carbon structures that can store hydrogen at low pressures and temperatures.

Owner:PENN STATE RES FOUND

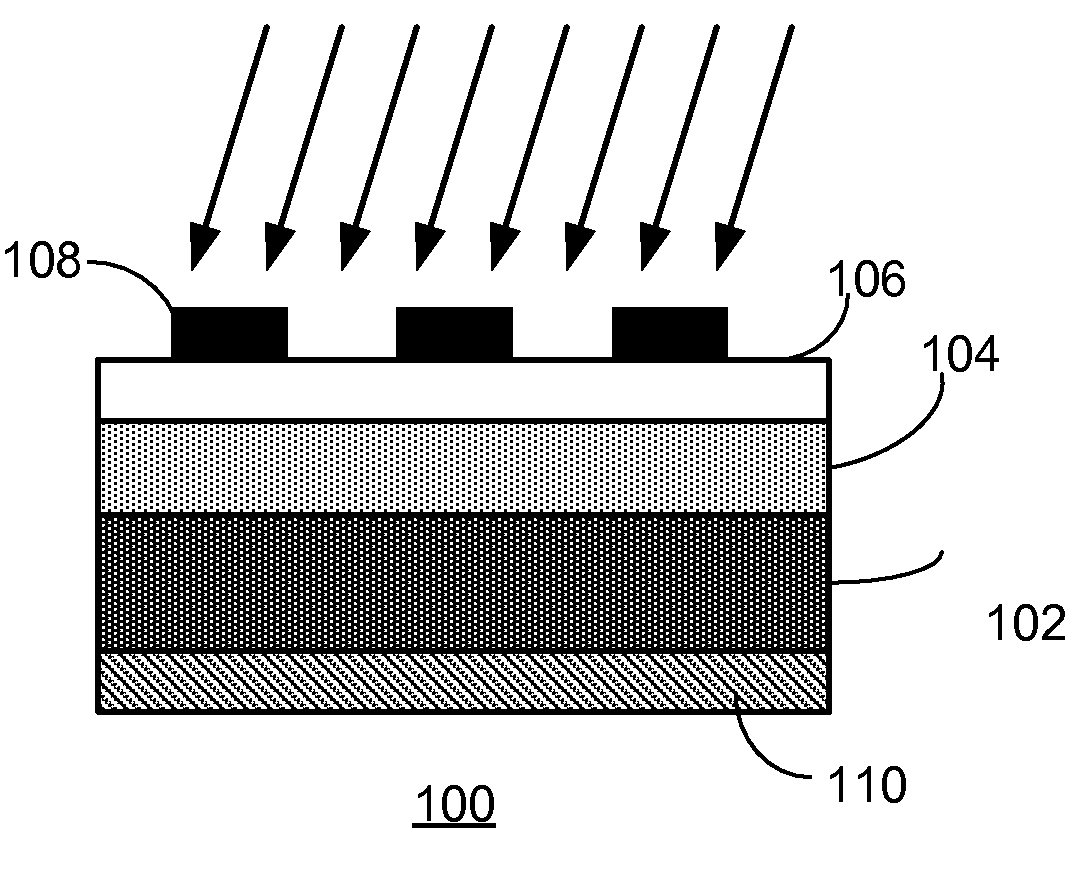

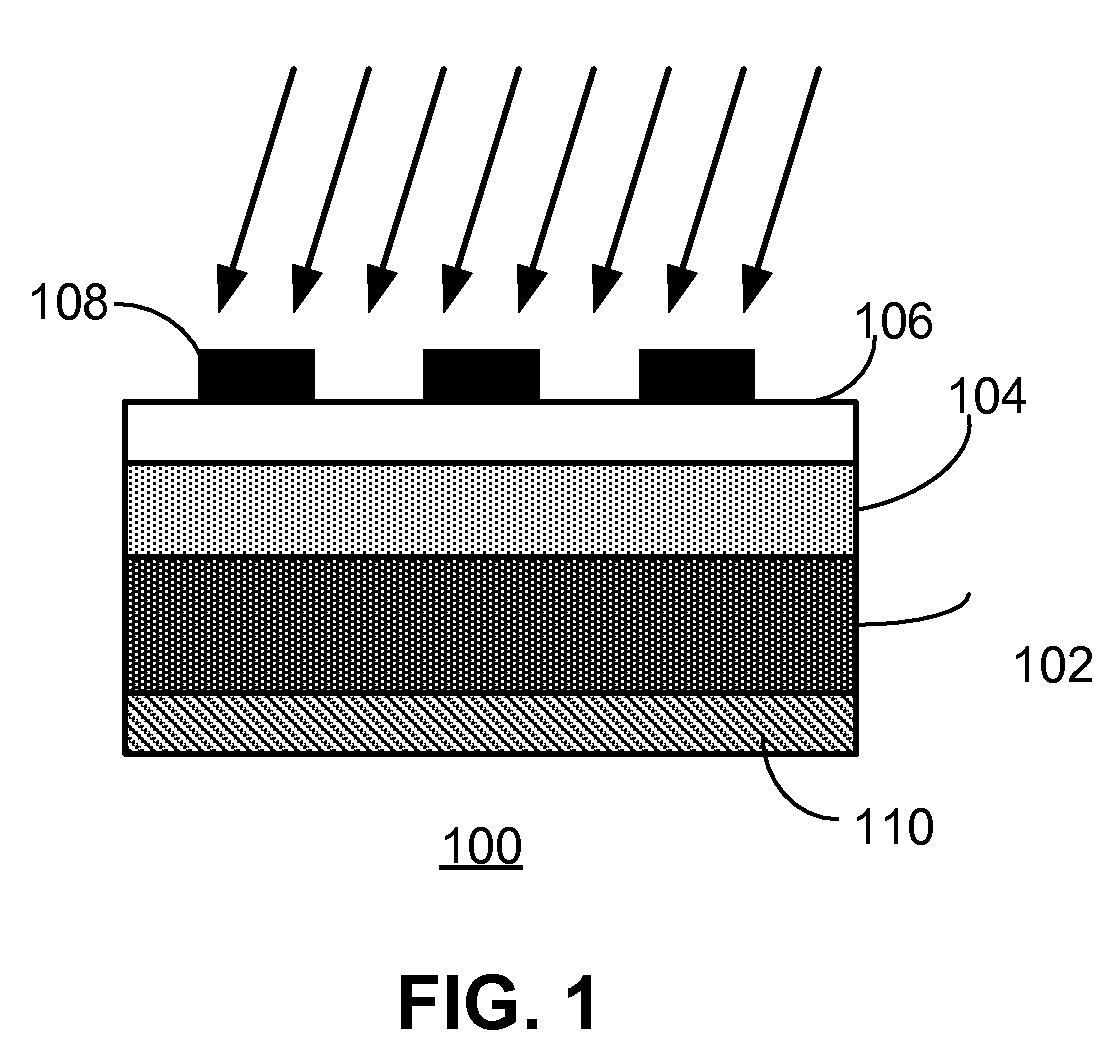

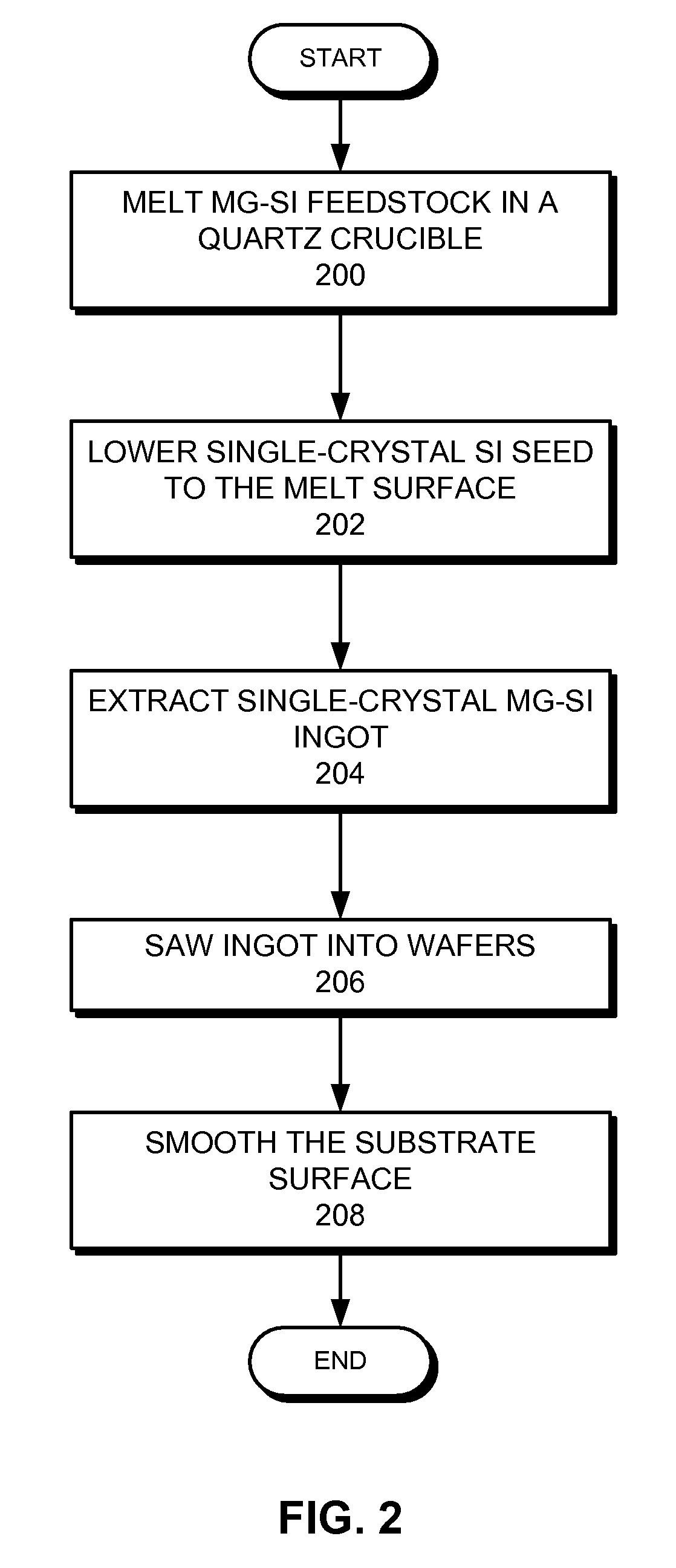

Solar cells fabricated by using CVD epitaxial si films on metallurgical-grade si wafers

One embodiment of the present invention provides a method for fabricating a solar cell. The method includes: melting a metallurgical-grade (MG) Si feedstock, lowering a single-crystalline Si seed to touch the surface of the molten MG-Si, slowly pulling out a single-crystal Si ingot of the molten MG-Si, processing the Si ingot into single crystal Si wafers to form MG-Si substrates for subsequent epitaxial growth, leaching out residual metal impurities in the MG-Si substrate, epitaxially growing a layer of single-crystal Si thin film doped with boron on the MG-Si substrate, doping phosphor to the single-crystal Si thin film to form an emitter layer, depositing an anti-reflection layer on top of the single-crystal Si thin film, and forming the front and the back electrical contacts.

Owner:TESLA INC

Detergent composition

InactiveUS20030158059A1Slightly corrodedEasy to cleanNon-ionic surface-active compoundsDetergent mixture composition preparationMetal impuritiesSemiconductor

To provide a detergent composition which has little corrosion to a wiring material and is excellent in cleaning ability of a semiconductor substrate or semiconductor device on which the fine particles and the metal impurities are deposited. A detergent composition comprising a reducing agent, wherein the detergent composition has an oxidation-reduction potential at 25° C. of +0.2 V or less, and a pH at 25° C. of from 3 to 12; and a cleaning process of a semiconductor substrate or a semiconductor device using the detergent composition.

Owner:KAO CORP

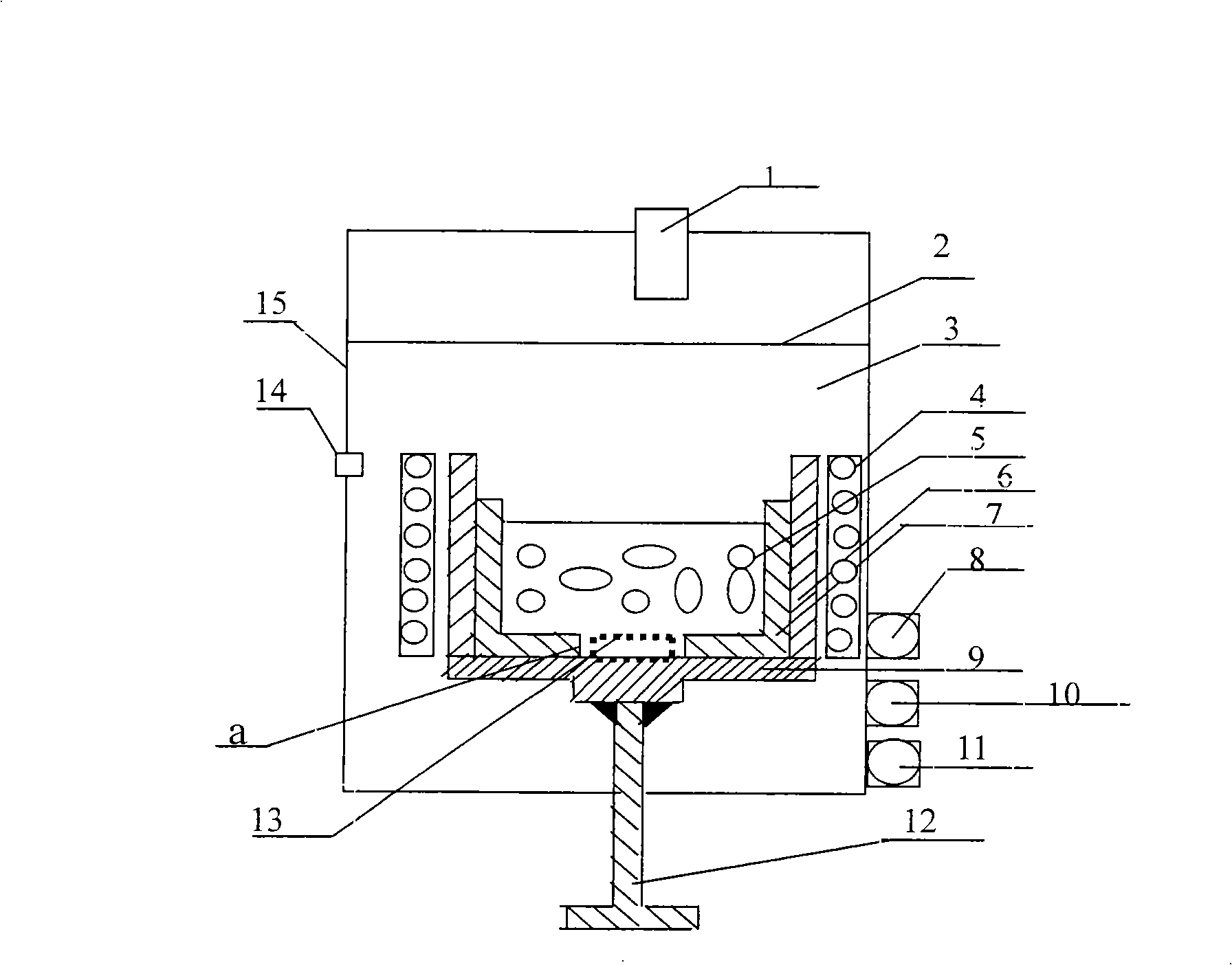

Process and device for removing phosphorus and metal impurities in polycrystalline silicon

InactiveCN101289188AHigh purityImprove efficiencyChemical industrySilicon compoundsMetal impuritiesLow vacuum

The invention relates to a method and a device for removing impurity phosphorus and metal impurities in polycrystalline silicon, which pertains to the technical field of purifying the polycrystalline silicon by a physical metallurgy technology, particularly relates to the method for removing the impurity phosphorus and the metal impurities in the polycrystalline silicon by an electron-beam fusion technology. Cooperative ways of electron-beam fusion and induction heating are used for completing the fusion and solidification process of the polycrystalline silicon. Silicon powder with high purity is used for spreading in a hollow-out space at a water cooled copper base which is filled with quartz crucibles; polycrystalline silicon material is put into the quartz crucibles and the cover of a vacuum device is closed; in the process of vacuumization, a mechanical pump and a lodz pump are firstly used for vacuumizing a vacuum room to low vacuum and then a diffusion pump is used for vacuumizing to high vacuum; the device used is provided with a vacuum device cover and a vacuum drum which are formed into the outer shell of the device; the inner cavity of the vacuum drum is the vacuum room, in which a fusion system is arranged. The method and the device of the invention effectively improve the purity of the polycrystalline silicon, which have the advantages of high efficiency, simple device and saving energy.

Owner:QINGDAO NEW ENERGY SOLUTIONS

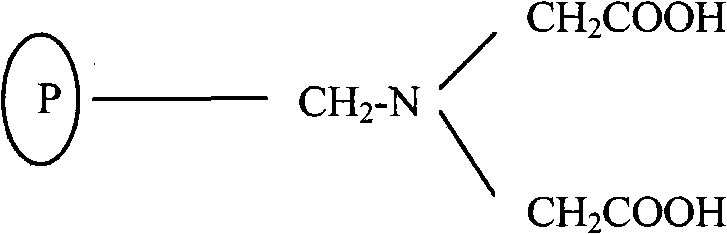

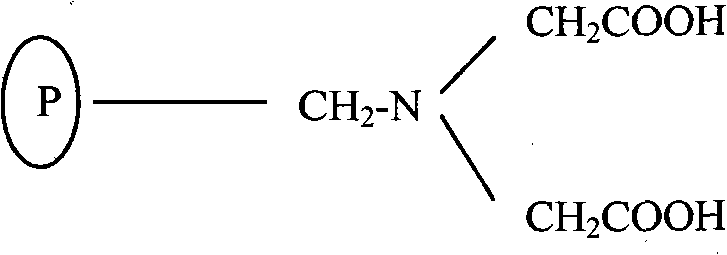

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

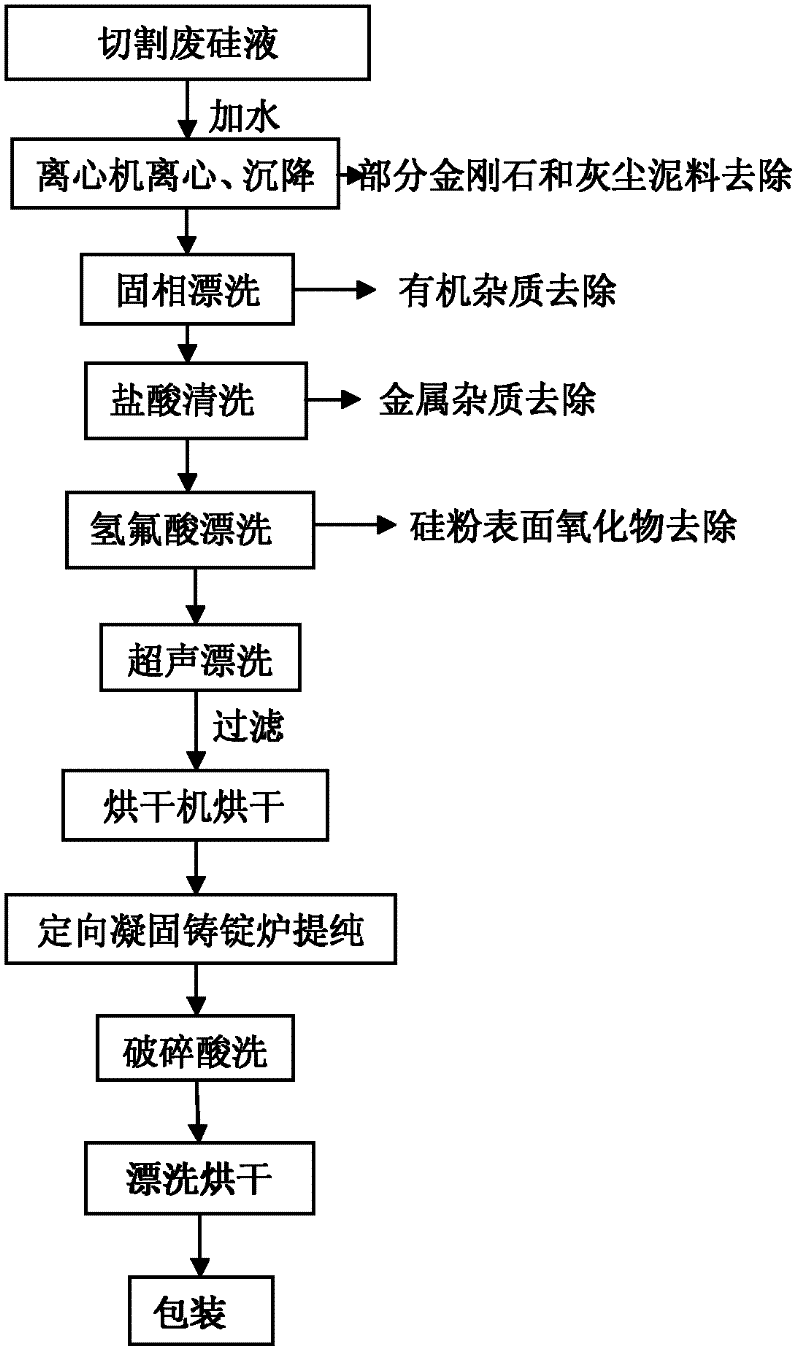

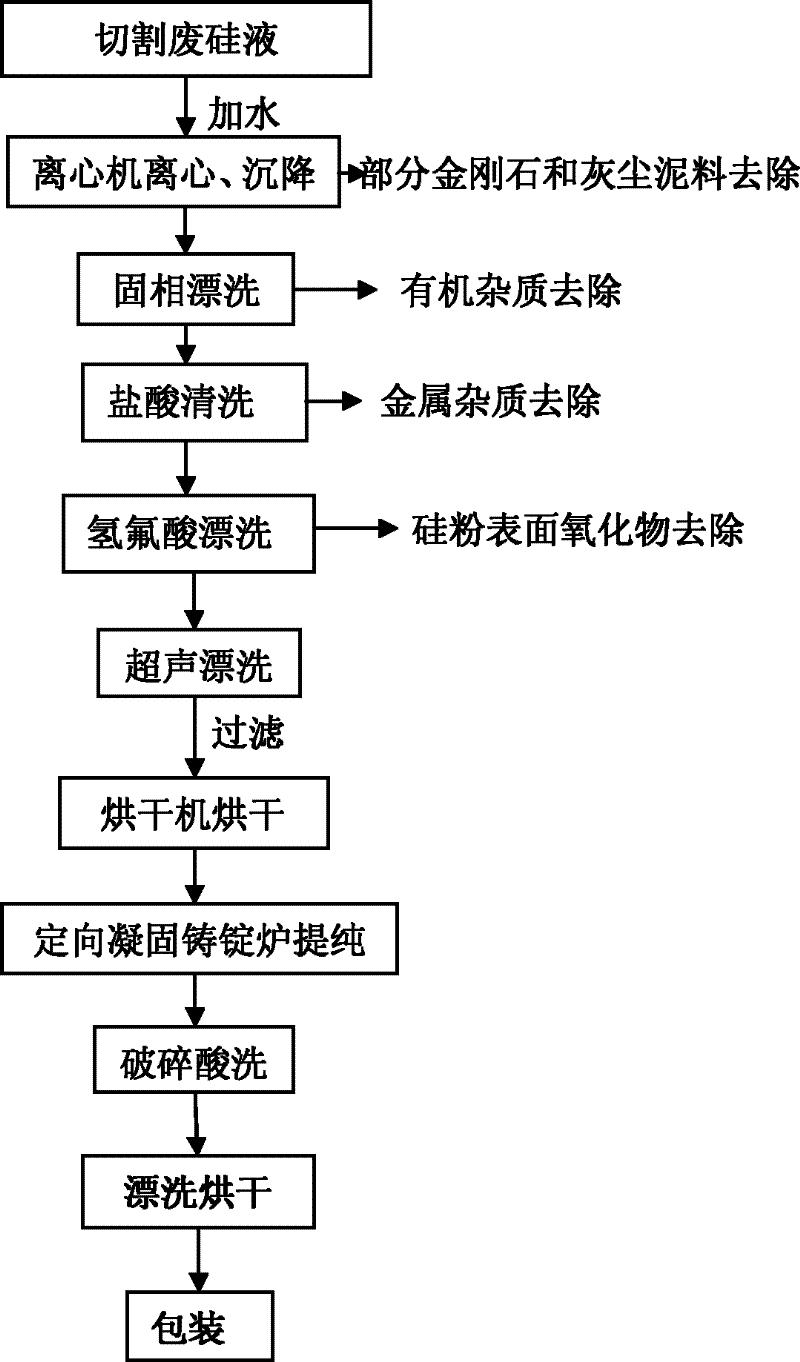

Method for recovering silicon material from waste materials in cutting crystalline silicon by diamond wire

The invention discloses a method for recovering silicon material from waste materials in cutting crystalline silicon by a diamond wire. The method is characterized by comprising the following steps of: feeding the collected waste materials to a centrifugal machine to centrifuge and settle, thus obtaining silicon material sediment; carrying out solid-phase rinsing on the silicon material sediment to remove organic matter type impurities and part of diamond powder from residual liquid in solid, thus obtaining silicon powder with certain purity; pickling the solid-phase silicon powder with hydrochloric acid to remove metal impurities; after rinsing the silicon powder subjected to hydrochloric acid pickling with pure water, rinsing the silicon powder with hydrofluoric acid to remove oxide from the surface of the silicon powder; carrying out ultrasonic rinsing and drying on the silicon material rinsed with hydrofluoric acid; carrying out directional solidification, ingot casting and purification on the dried silicon material, thus obtaining a solar grade silicon material; and at last, carrying out packaging after smashing, pickling, rinsing and drying the silicon material. The method is simple and convenient, the equipment cost is low, the operation is easy to control, the treatment recovery rate is high and the overall recovery rate can achieve over 99.99%.

Owner:ZHENJIANG HUANTAI SILICON TECH

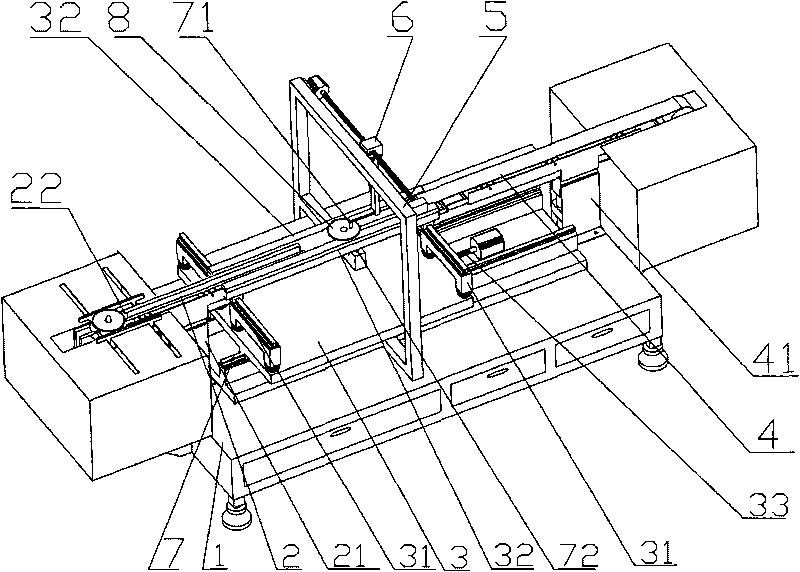

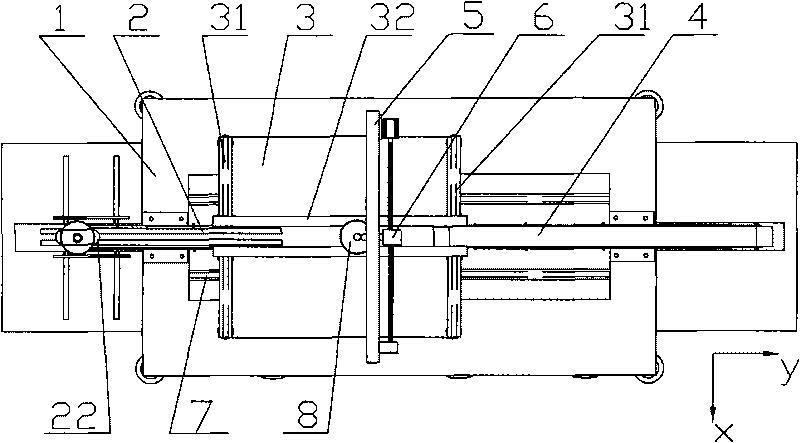

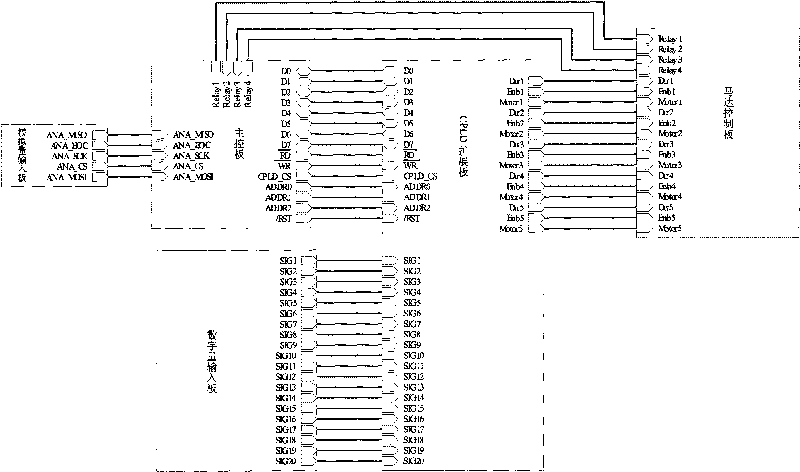

Automatic test device of flatness and thickness of metal sheet

InactiveCN101726243AGuaranteed correctnessRealize coordinated and continuous operationElectric/magnetic roughness/irregularity measurementsElectrical/magnetic thickness measurementsTest efficiencyAutomatic test equipment

The invention relates to an automatic test device of the flatness and thickness of a metal sheet, which comprises a machine frame, a feeding mechanism, a test platform and a discharging mechanism. The machine frame and the test platform are connected through a Y-directional track. The test platform comprises a test frame, guide rails, a test cross beam, a cantilever fixing frame, a cantilever, an upper test probe, a lower test probe, a Y-directional ball screw mechanism and a measuring circuit. The automatic test device has the following beneficial effects that: the test is accurate; the test efficiency and the test precision are improved because the probes always cover the effective test range of a saw blade; mechanical and electrical integration technology is fully used, the structure is simple, the operation and maintenance are convenient, and the application in the field of the test of the flatness and thickness of other metals can be realized with a little improvement, and the promotion and use are easy; and an eddy induction principle is used to realize the test of the flatness and the thickness of the metal sheet, the interference of water and other non-metal impurities on the saw blade is eliminated effectively, precise positioning of the saw blade is not required in test, the price is low, and the operation is simple.

Owner:WUHAN TEXTILE UNIV

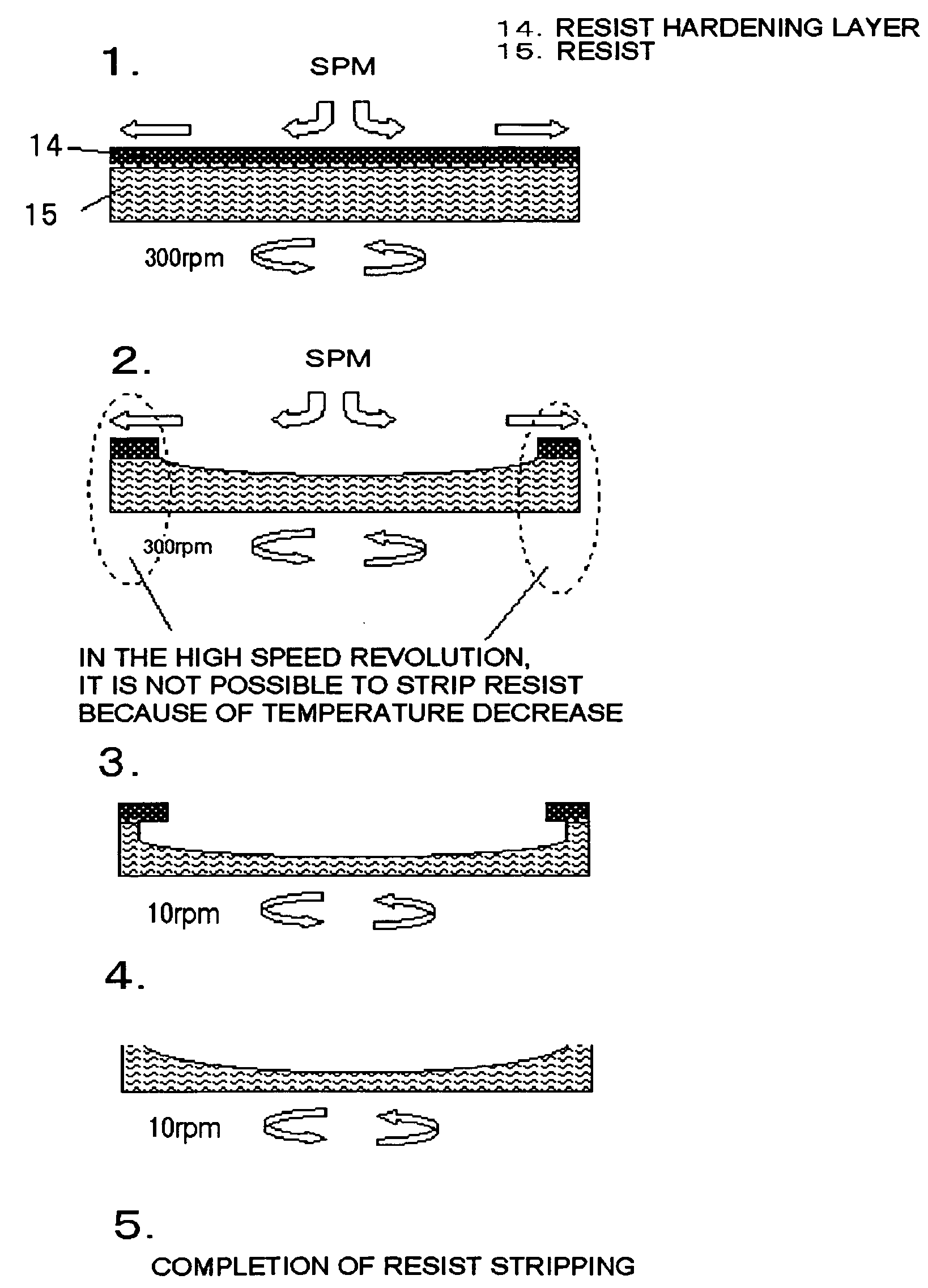

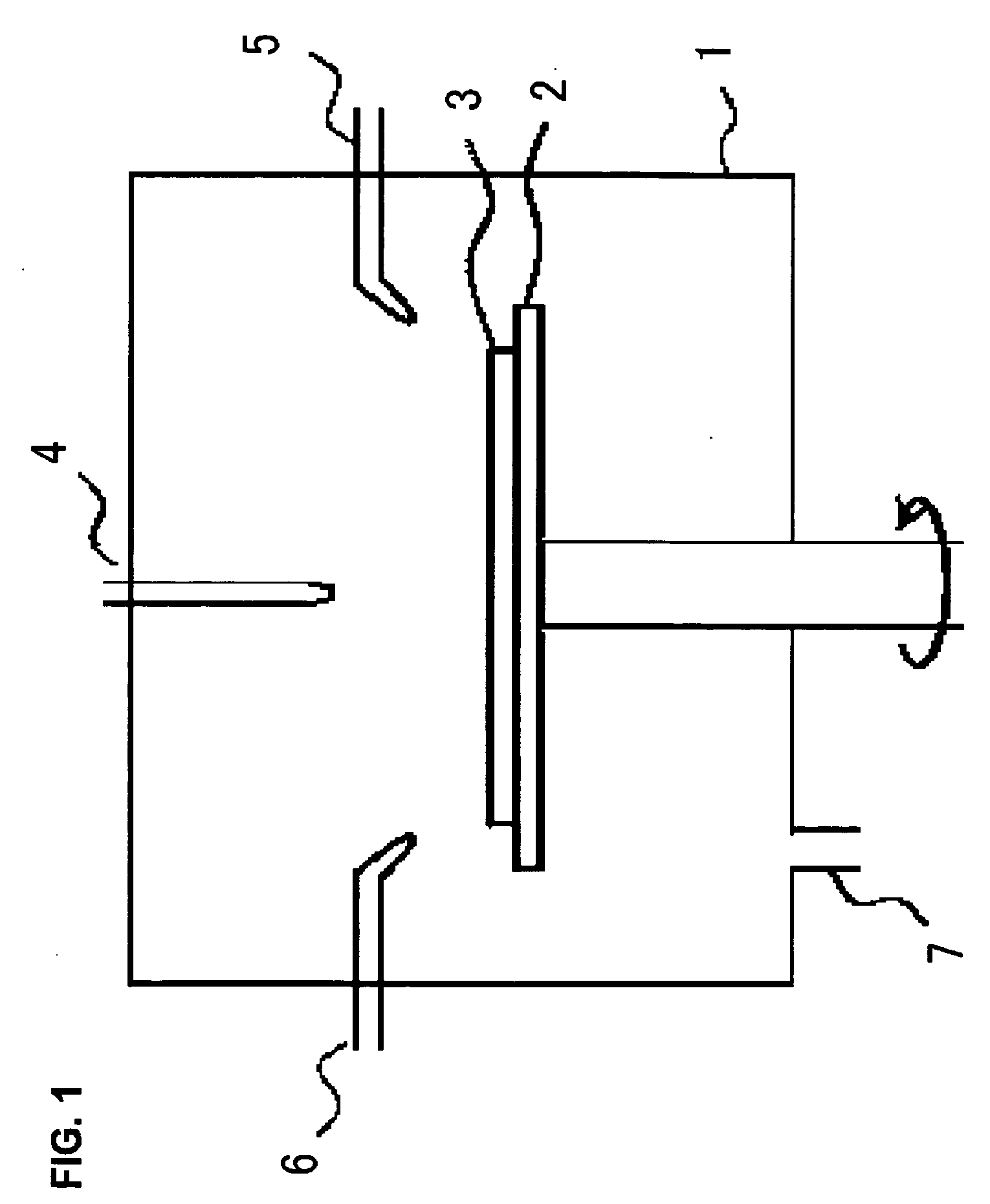

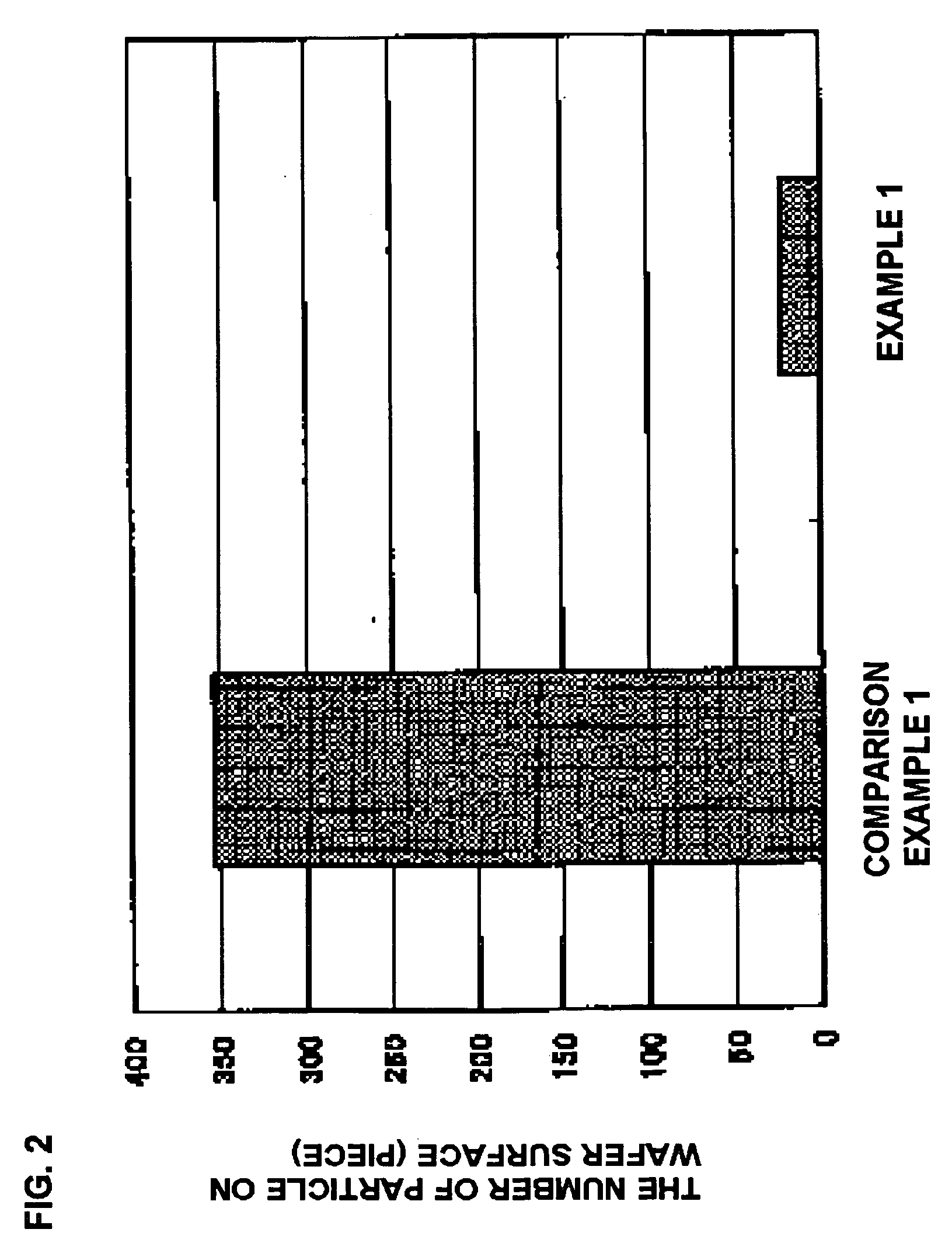

Method for manufacturing a semiconductor device and a cleaning device for stripping resist

InactiveUS20050158671A1Superior in element characteristicHigh yieldSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusLithography processMetal impurities

A method for manufacturing a semiconductor device and a cleaning device for stripping resist provide semiconductor device with superior element characteristic in a sufficient yield, in such away that, after dry etching of the lithography process, wet cleaning removes resists, and particles or metal impurities are made to sufficiently remove without damaging fine pattern. The method for manufacturing the semiconductor device comprises: forming a resist pattern on a film provided for the semiconductor substrate, forming a fine pattern of conductive film while performing dry etching using the resist pattern as a mask, stripping the resist pattern by single-wafer system treatment upon supplying resist stripping liquid to fine pattern forming surface of the semiconductor substrate, and carrying out rinse treatment of the semiconductor substrate.

Owner:NEC ELECTRONICS CORP

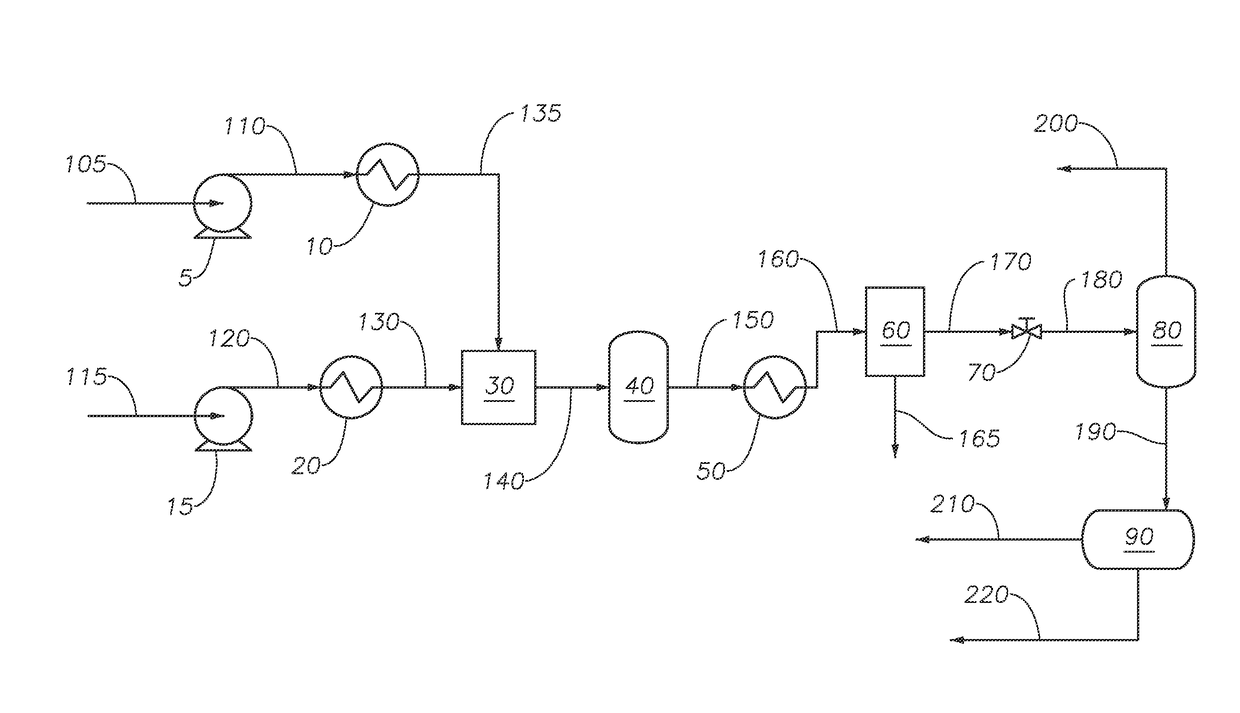

Method to remove metals from petroleum

ActiveUS20170107433A1Low sulfurThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productGas phase

A method to remove a metals impurity from a petroleum feedstock for use in a power generating process is provided. The method comprising the steps of mixing a heated feedstock with a heated water stream in a mixing device to produce a mixed stream; introducing the mixed stream to a supercritical water reactor in the absence of externally provided hydrogen and externally provided oxidizing agent to produce a reactor effluent comprising a refined petroleum portion; cooling the reactor effluent to produce a cooled stream; feeding the cooled stream to a rejecter configured to separate a sludge fraction to produce a de-sludged stream; reducing the pressure of the de-sludged stream to produce a depressurized product; separating the depressurized product to produce a gas phase product and a liquid product; separating the liquid product to produce a petroleum product, having a reduced asphaltene content, reduced concentration of metals impurity, and reduced sulfur.

Owner:SAUDI ARABIAN OIL CO

Method for regenerating inactivated hydrotreating catalyst

ActiveCN102451774ARestore pore structureCatalytic performance recoveryCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsMetallic NickelMetal impurities

The invention discloses a method for regenerating an inactivated hydrotreating catalyst. The method comprises the following steps: carrying out oil removal pretreatment on the inactivated hydrotreating catalyst, removing depositional metal impurities in the inactivated catalyst, carrying out carbon burning treatment on the inactivated catalyst; wherein a method for removing the depositional metalimpurities in the inactivated catalyst comprises the following steps: dipping the inactivated catalyst by an alkaline solution, filtering and pickling. The method of the invention is capable of removing the metal impurities like depositional nickel, vanadium and iron in the inactivated hydrotreating catalyst, and recovering a pore structure and catalysis performance of the catalyst, the method for regenerating the inactivated hydrotreating catalyst has the advantages of small investment, less pollution, simple process and easy industrialization.

Owner:CHINA PETROLEUM & CHEM CORP +1

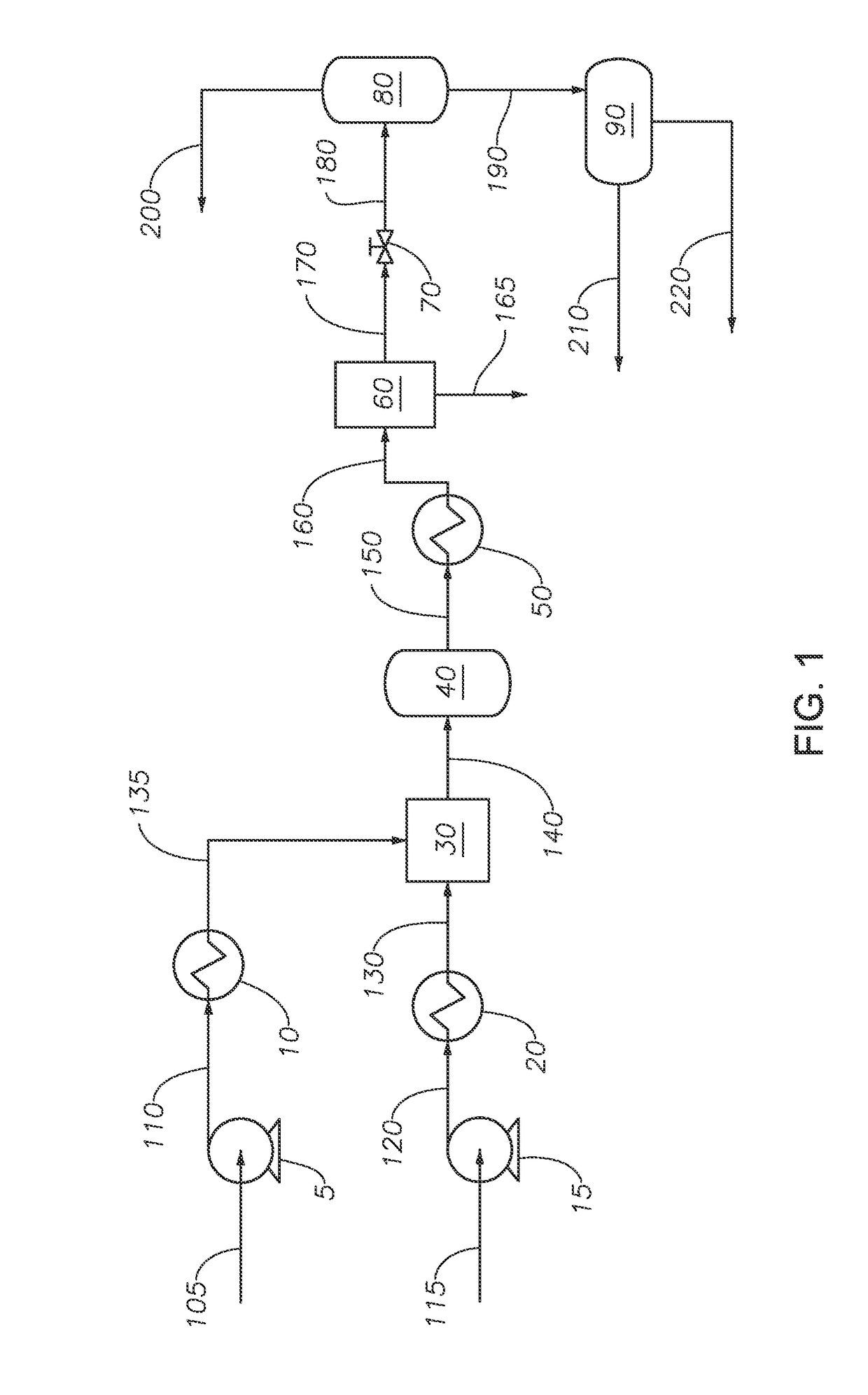

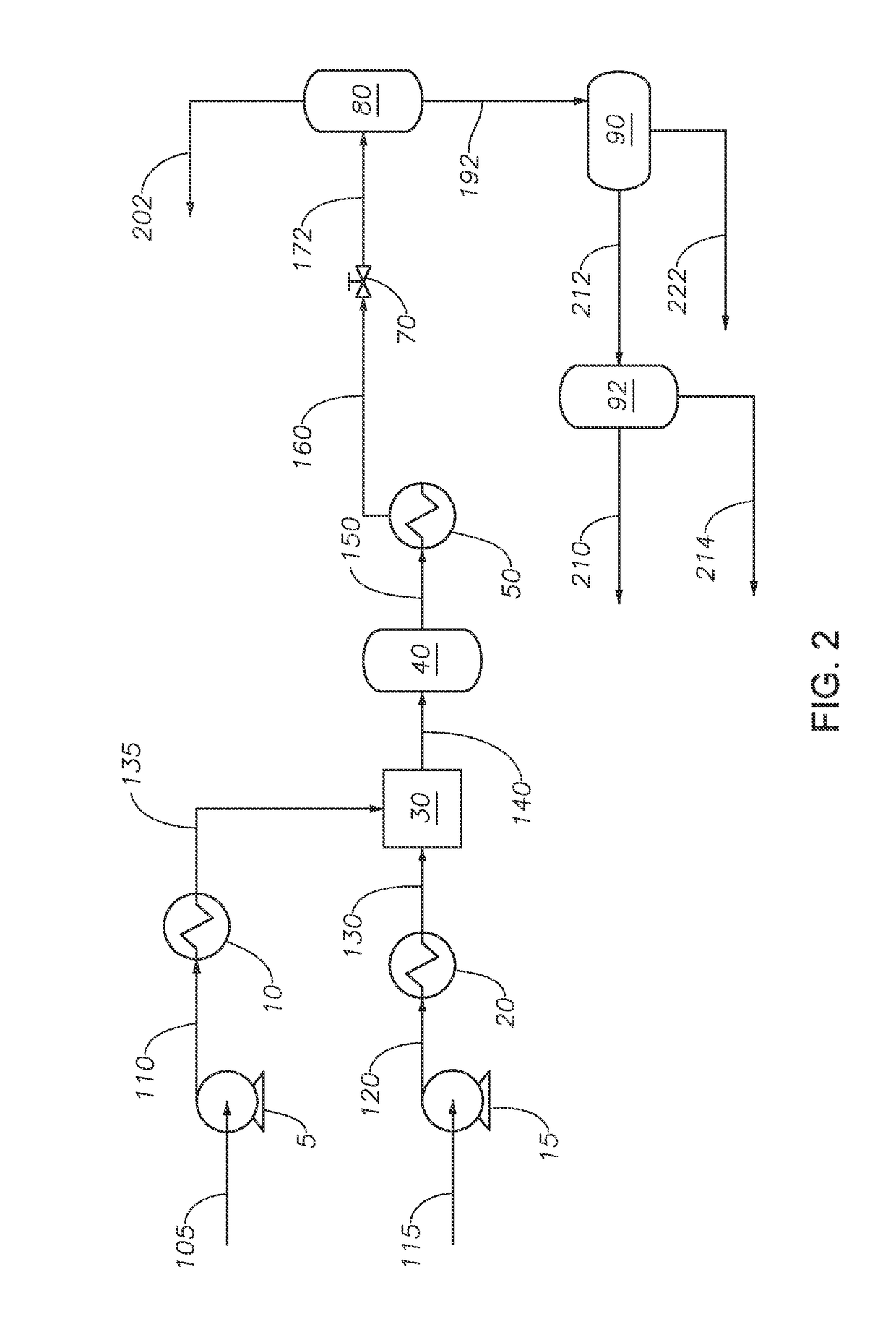

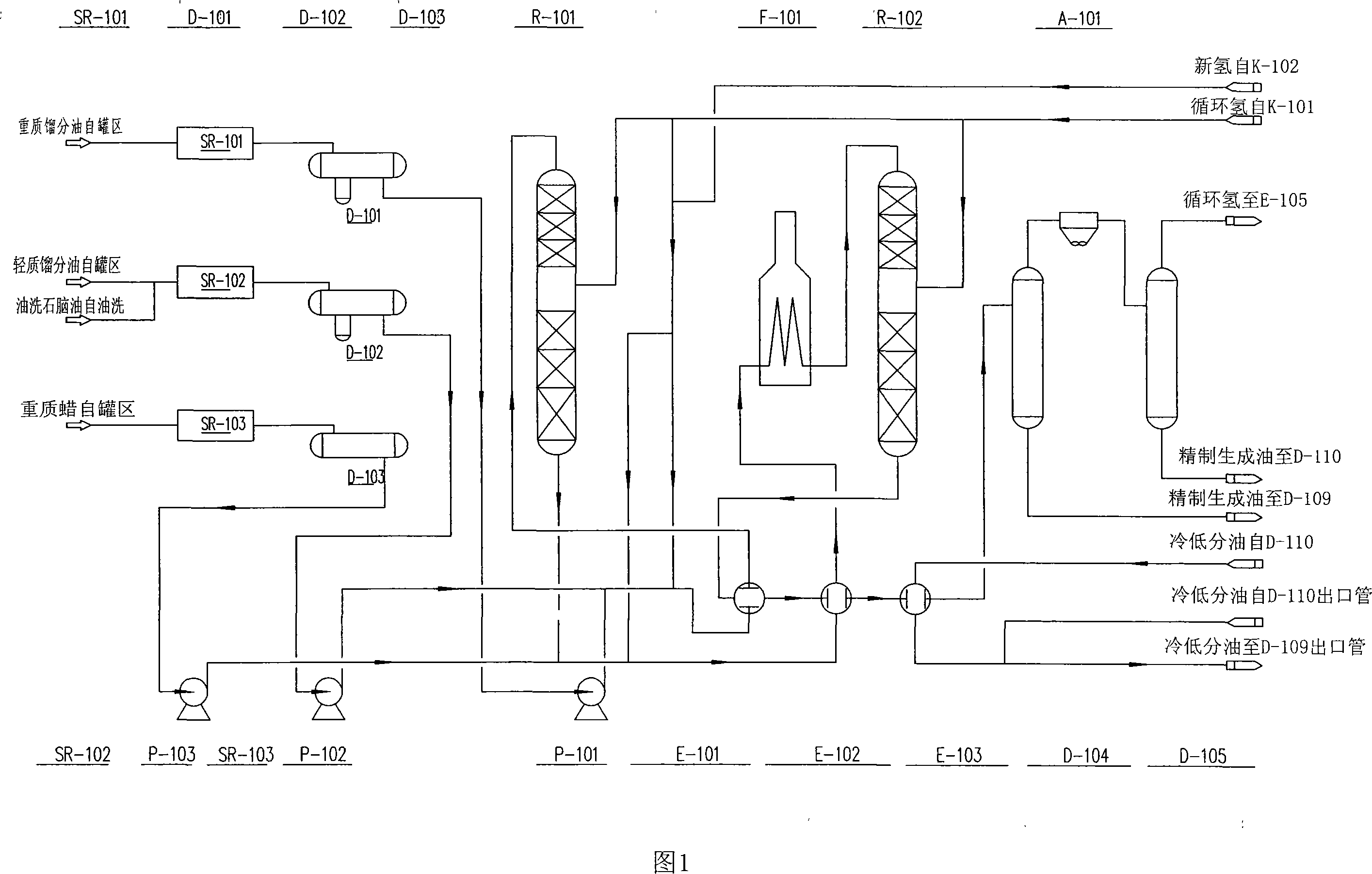

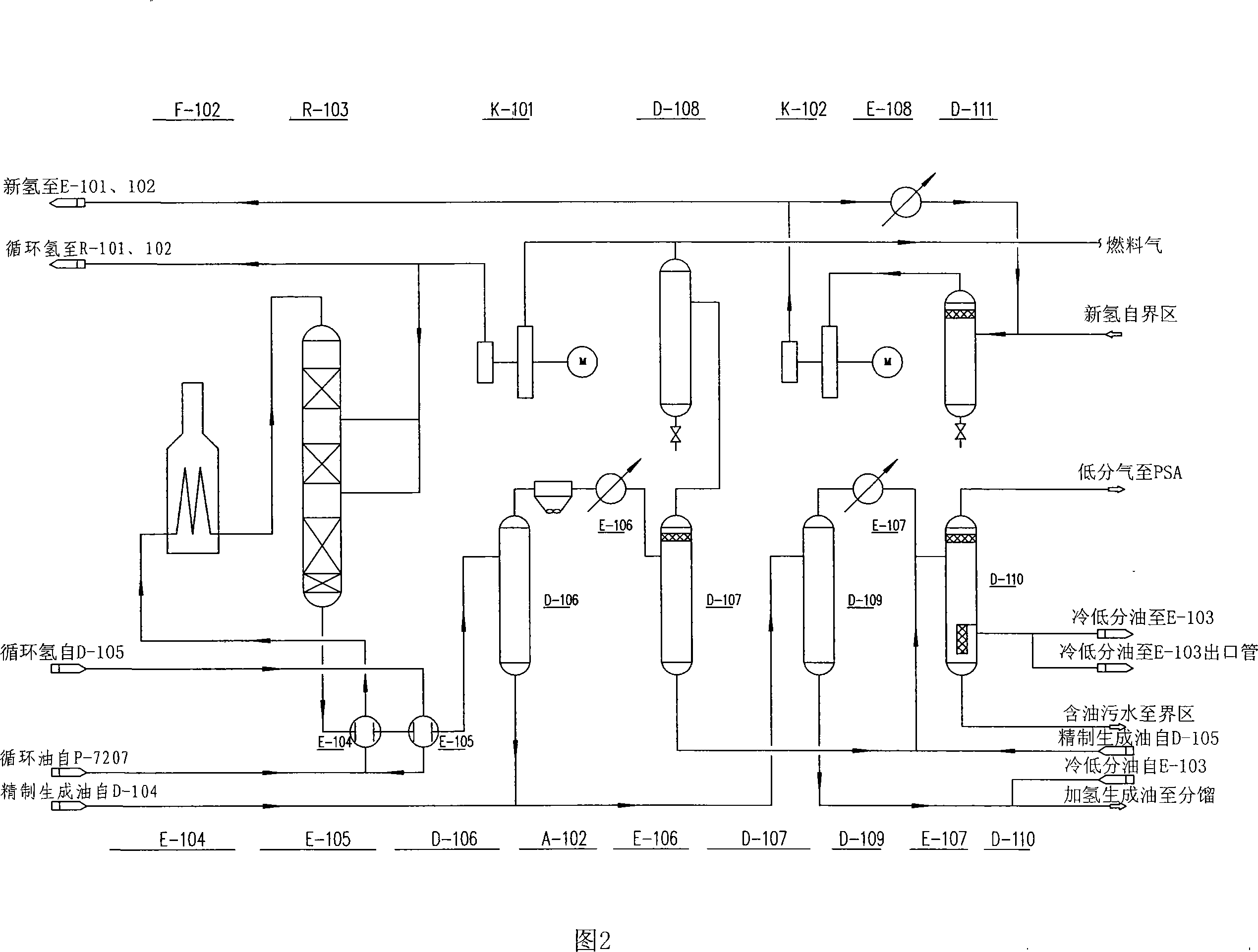

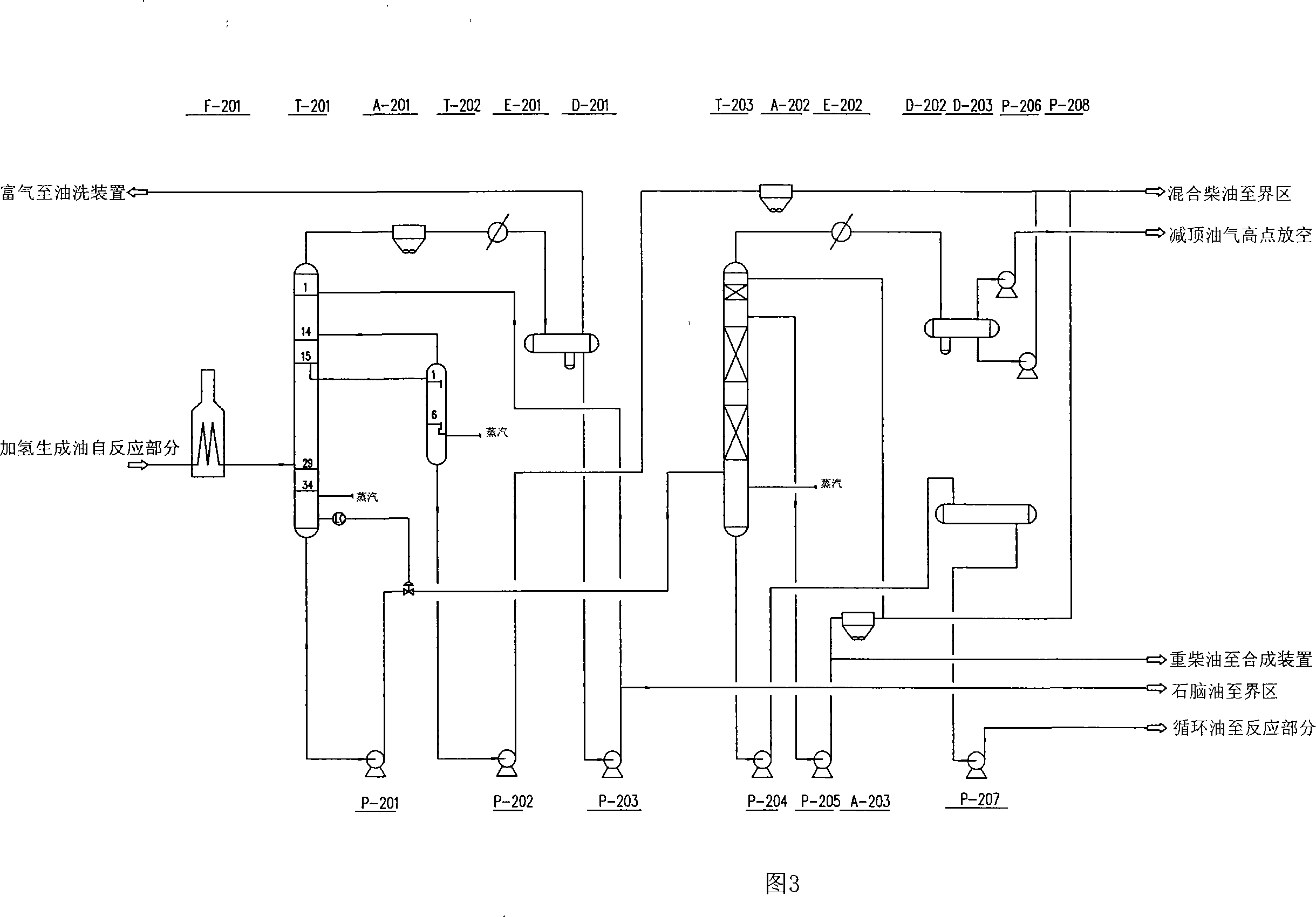

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

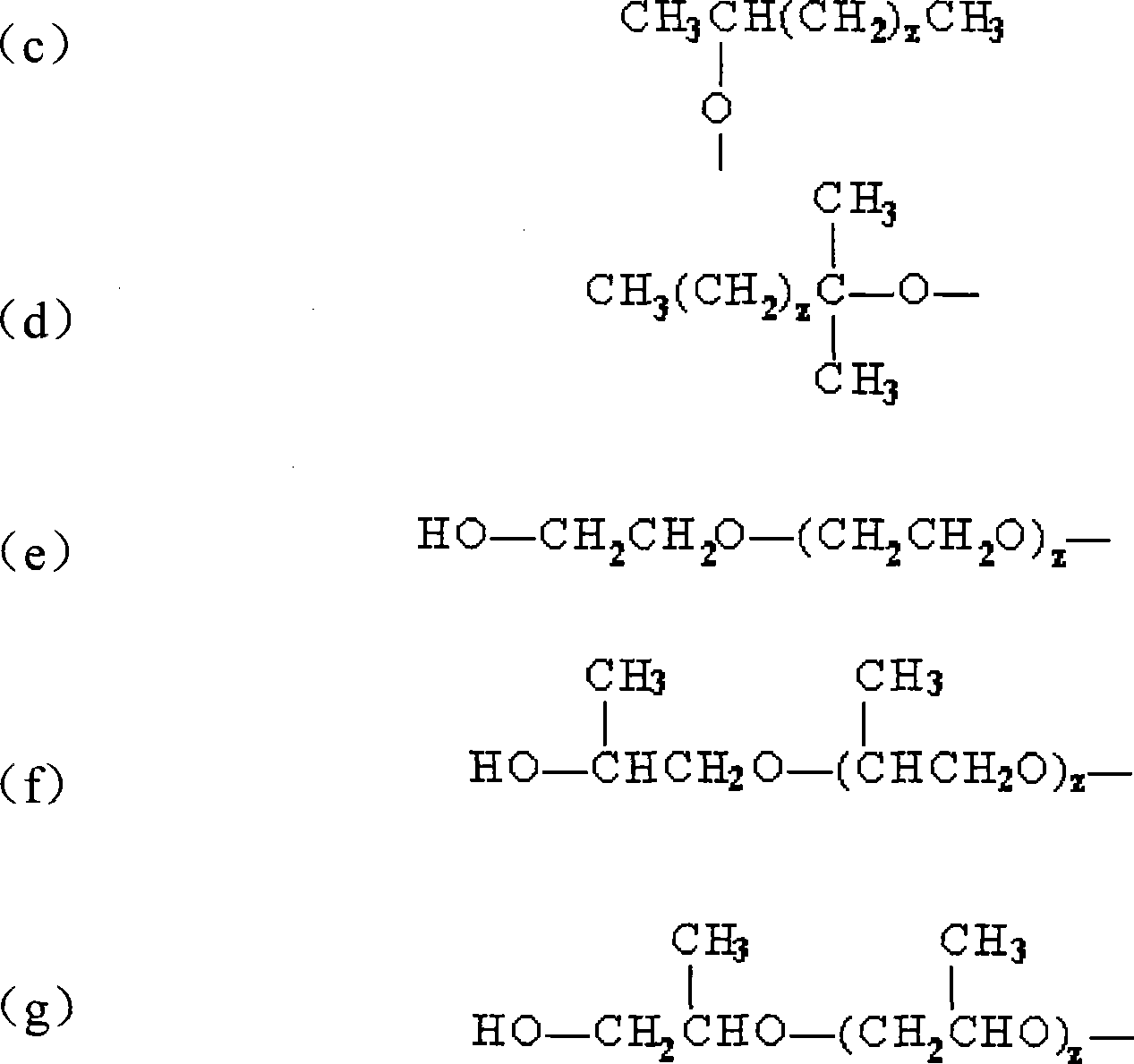

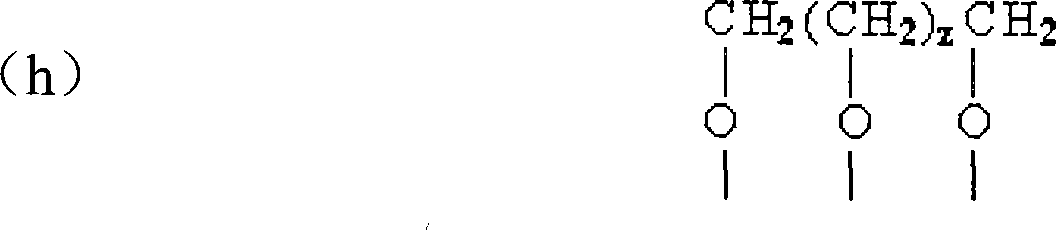

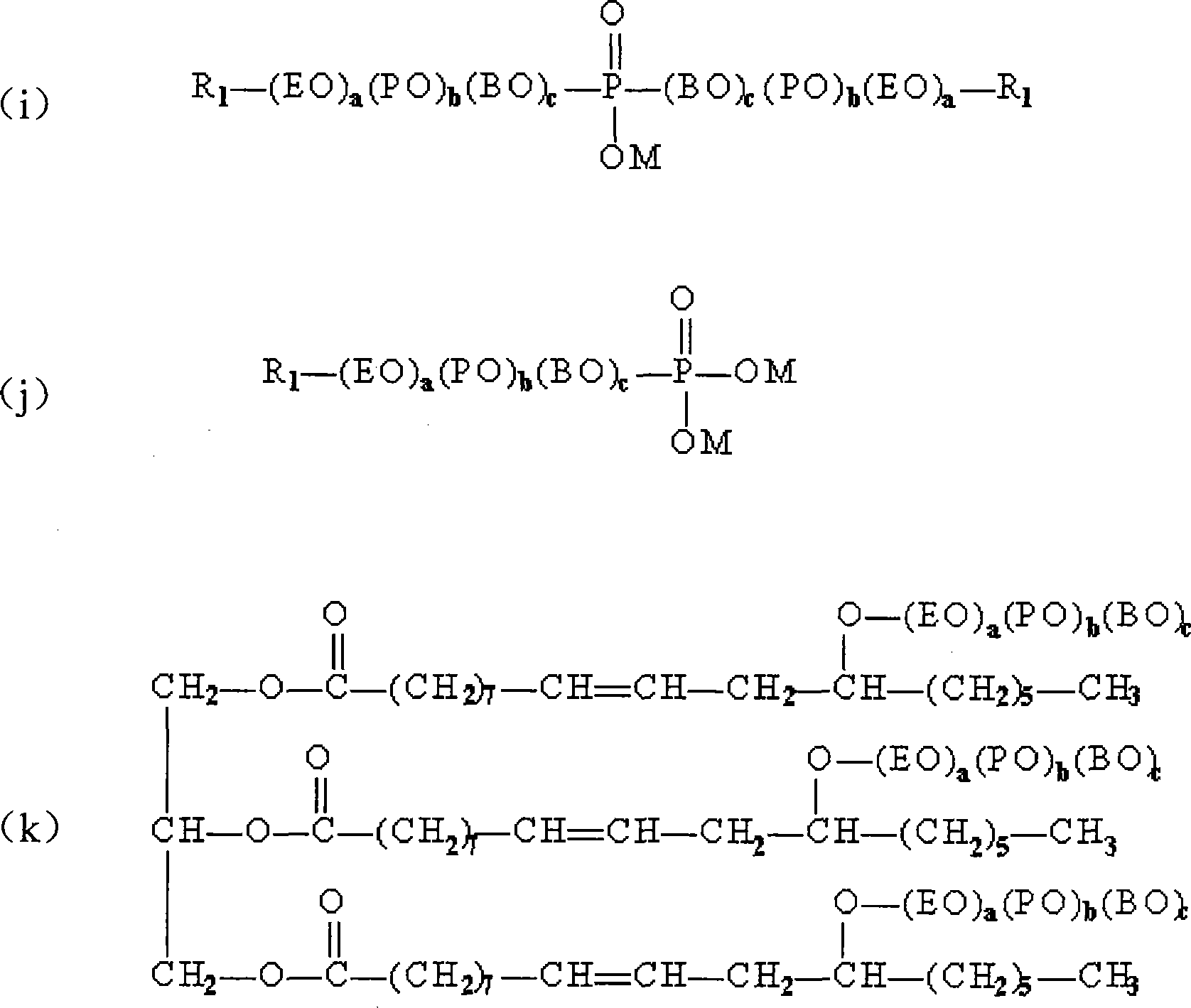

Cutting fluid for hard brittle material and uses thereof

ActiveCN101205498ANo pollution in the processFree from harmAdditivesBase-materialsMetal impuritiesWater soluble

The invention relates to a water-soluble cutting liquid used for processing hard brittle materials. The components of the invention by weight percentage are as follows: 70 to 100 percent of polyalkoxylated compound, 0 to 15 percent of extreme pressure resistant chelation anti-settling agent, 0 to 15 percent of dissolution promoter . The cutting liquid of the invention has the advantages of no pollution, low metal impurity content, high cutting sheet rate, and high finished product qualification rate and so on. The invention also relates to the application of the cutting liquid in the processing of monocrystalline silicon, polysilicon, germanium, gallium arsenide, quartz, Indium gallium nitride or precious stones.

Owner:LIAONING OXIRANCHEM INC +3

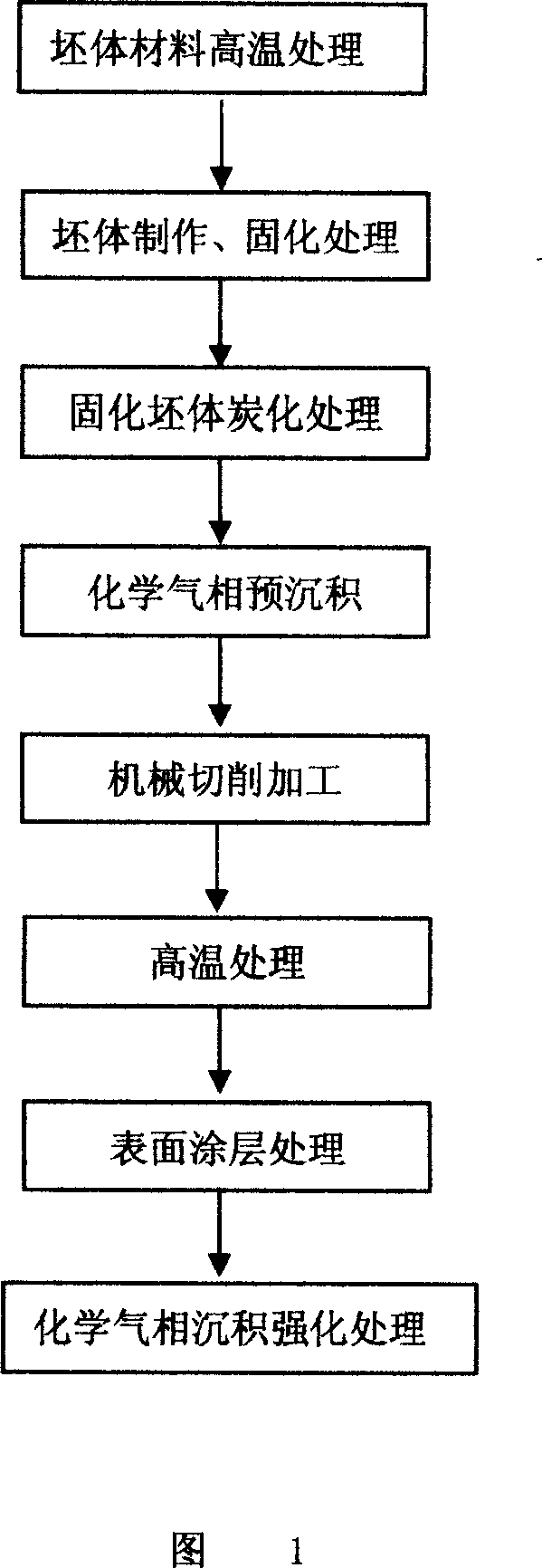

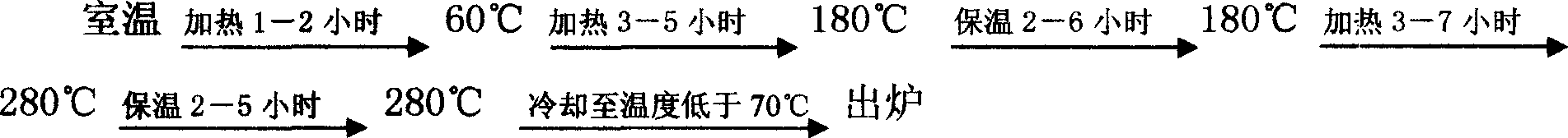

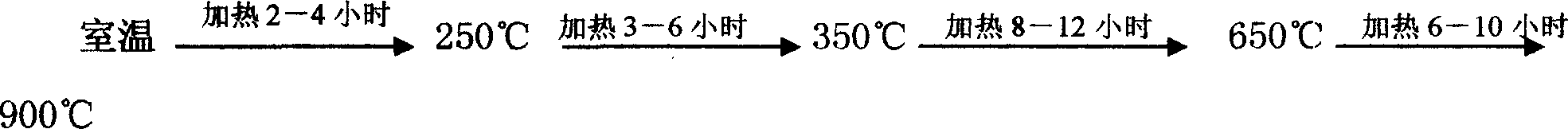

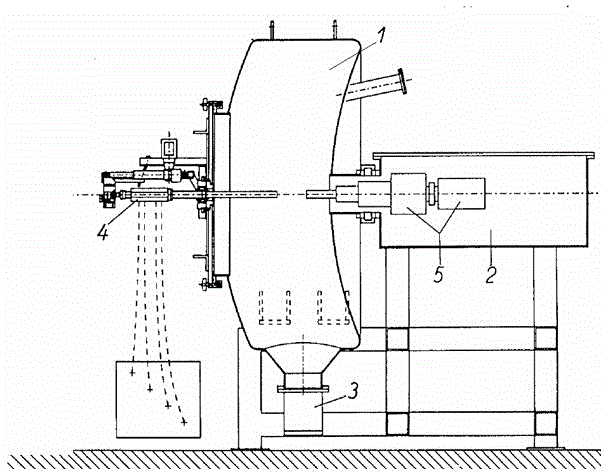

Production method of high purity cured charcoal felt silicon crystal growth oven

InactiveCN1994972AGuaranteed shape retentionMeet the use requirementsAfter-treatment apparatusBy pulling from meltGas phaseMetal impurities

The invention discloses a making method of high-purity solidified carbon cushion in the silicon crystal growing stove, which is characterized by the following: selecting flexible cushion with low metal impurity as blank material; disposing under high temperature to form graphite cushion; using graphite cushion as blank; solidifying the blank to shape with evenly permeable hardener; carbonizing the blank; proceeding chemical gas-phase deposition for blank; cutting part of element surface mechanically; disposing blank under high temperature; removing metal impurity and volatile substance; coating the working piece; strengthening the element surface; improving the corrosion resistant of blank surface.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder

The invention provides a method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder. The preparation method comprises the following steps: preparing materials of alloy components according to ASTM F1295 standards and carrying out two times of vacuum melting on a mother alloy ingot; preparing the mother alloy ingot into an alloy electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing mixed inert protective gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The method provided by the invention has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the Ti-6Al-7Nb medical titanium alloy spherical powder with high sphericity degree, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

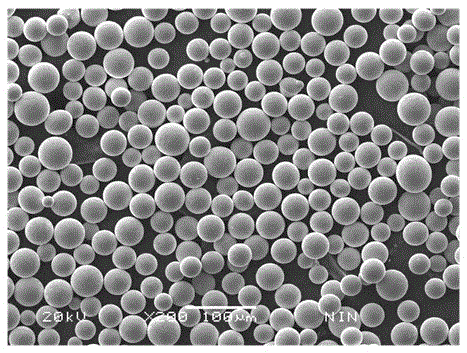

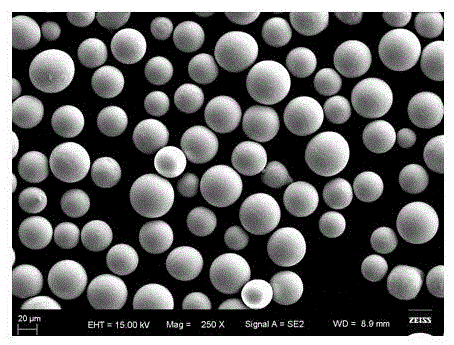

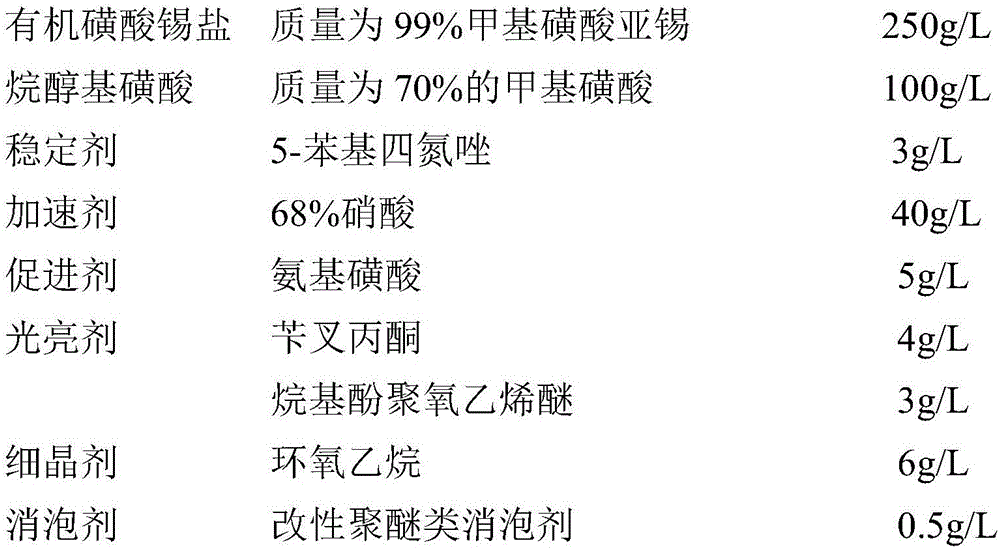

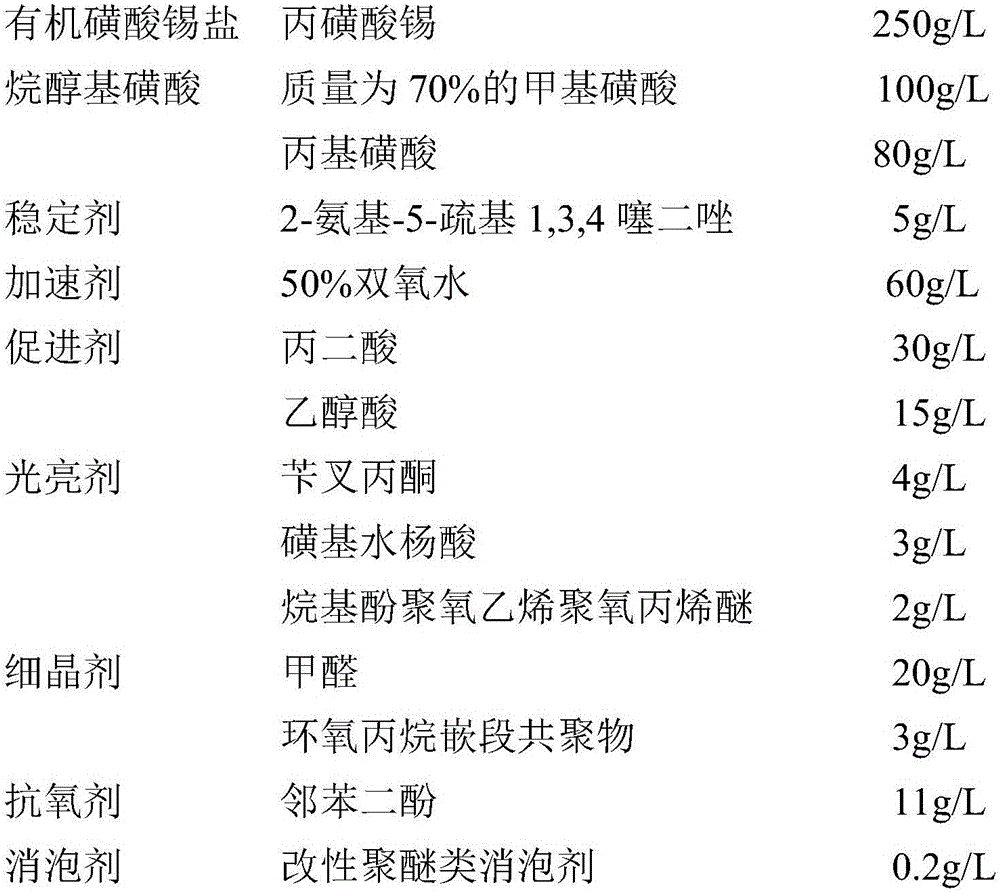

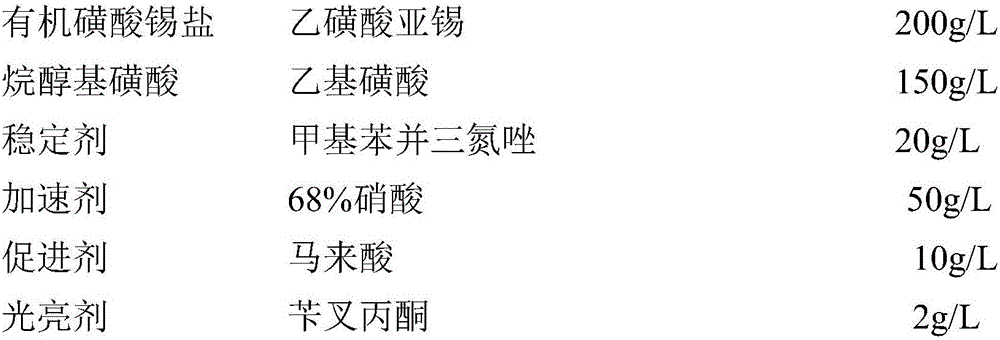

Tin stripping and tin plating liquid, preparing method of tin stripping and tin plating liquid and cyclic regeneration method for adopting tin stripping and tin plating liquid for recycling metal tin

ActiveCN105734620AEasy to handleImprove antioxidant capacityPhotography auxillary processesProcess efficiency improvementOrganic sulfonic acidFoaming agent

The invention discloses tin stripping and tin plating liquid, a preparing method of the tin stripping and tin plating liquid and a method for adopting the tin stripping and tin plating liquid for recycling metal tin from tin-containing waste. The tin stripping and tin plating liquid includes various effective components such as organic sulfonic acid tin salt, alkanol group sulfoacid, a stabilizing agent, an accelerating agent, an accelerator, a brightening agent, a grain fining agent, antioxidant and a foaming agent, and all the components are in synergy. The defect of traditionally recycling tin from tin stripping waste liquid is overcome, interference of other metal impurities is avoided, and high-purity metal tin can be efficiently recycled from the waste liquid. In addition, the operation steps for adopting the tin stripping and tin plating liquid for recycling the metal tin from the tin-containing waste are simple and convenient and fast to implement, the high-quality metal tin can be recycled, furthermore, the tin stripping liquid can be regenerated at the same time to be repeatedly utilized, and the problems that traditional tin stripping waste liquid is large in amount, resources are wasted, and the environment is seriously polluted are solved.

Owner:SHENZHEN CYPRESS IND DEV CO LTD

Low-temperature phosphorus gettering diffusion process based on removal of metal impurities in polycrystalline silicon

InactiveCN102703987AGet rid ofImprove battery efficiencyFinal product manufactureDiffusion/dopingMetal impuritiesPolycrystalline silicon

The invention discloses a low-temperature phosphorus gettering diffusion process based on removal of metal impurities in polycrystalline silicon. The method mainly comprises the following steps of: (1) feeding into a boat; (2) stably heating; (3) performing first-step deposition; (4) performing second-step deposition; (5) propelling; (6) absorbing impurities; (7) propelling once again at a low temperature; and (8) cooling, annealing and discharging out of the boat. Through innovation of a polycrystalline silicon diffusion process in a solar industrial production process, the removal of metal ions in a type B polycrystalline silicon wafer with short minority carrier lifetime and improvement on the structure of a silicon wafer crystal are realized, the photoelectric conversion efficiency of a solar cell produced by using the type B wafer with short minority carrier lifetime is increased, the average value of the minority carrier lifetime of the type silicon wafer is not less than 12mus, and the efficiency of a battery produced by using the type silicon wafer is 0.2 percent higher than that of a battery produced by using a normal process.

Owner:TIANWEI NEW ENERGY HLDG +1

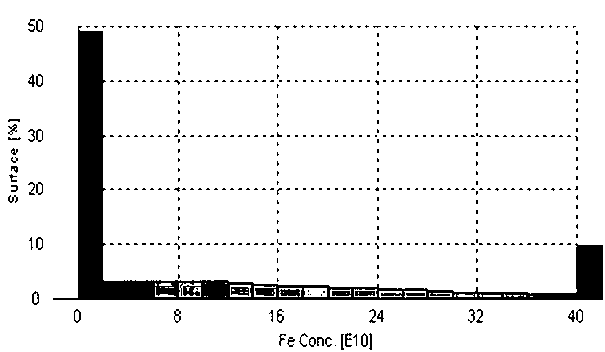

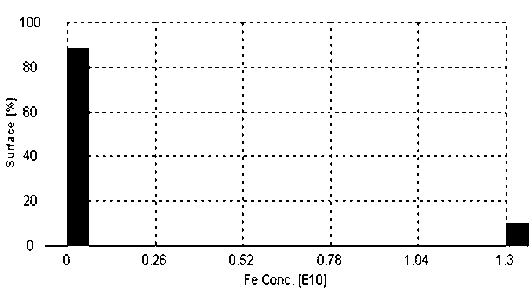

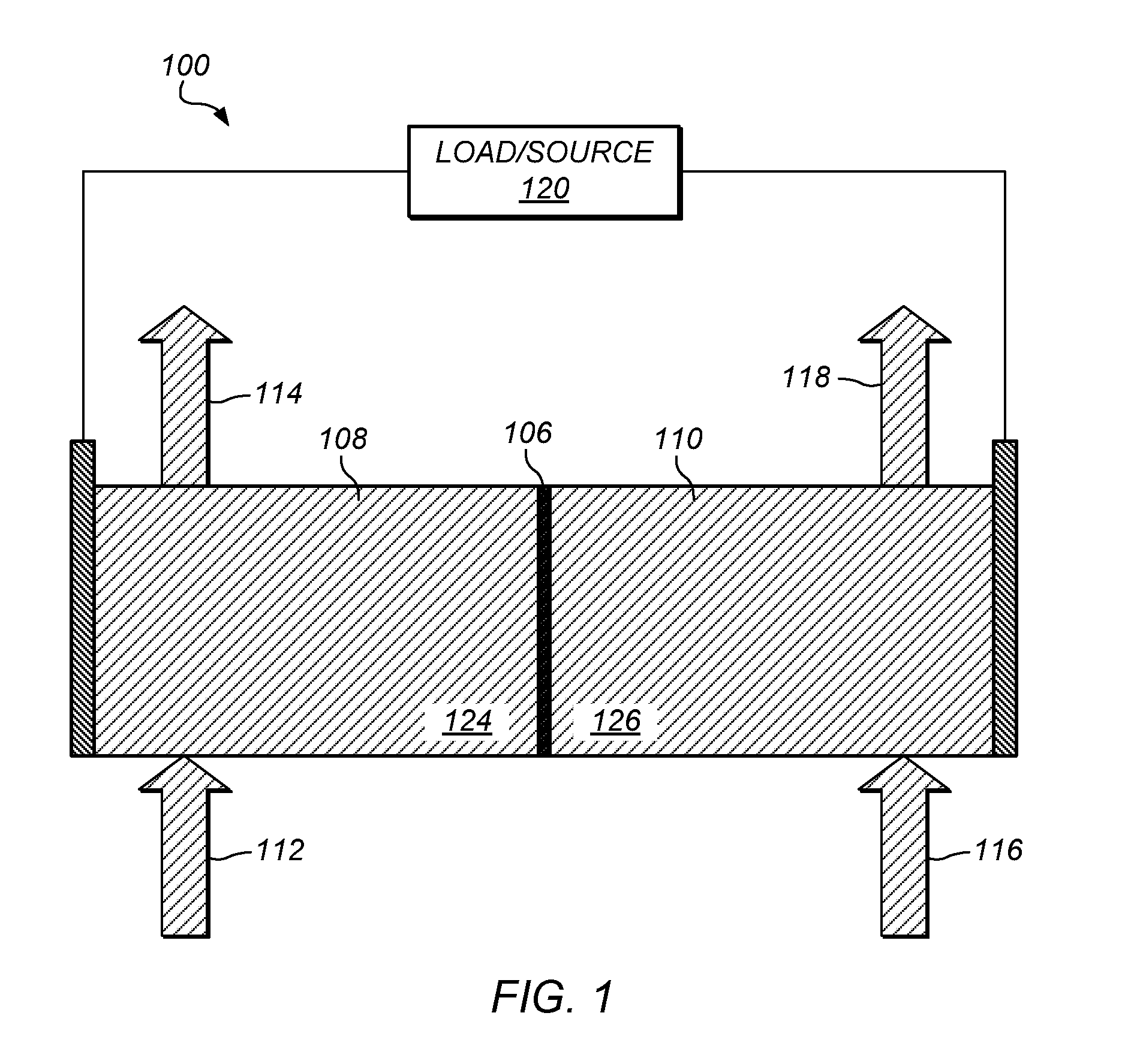

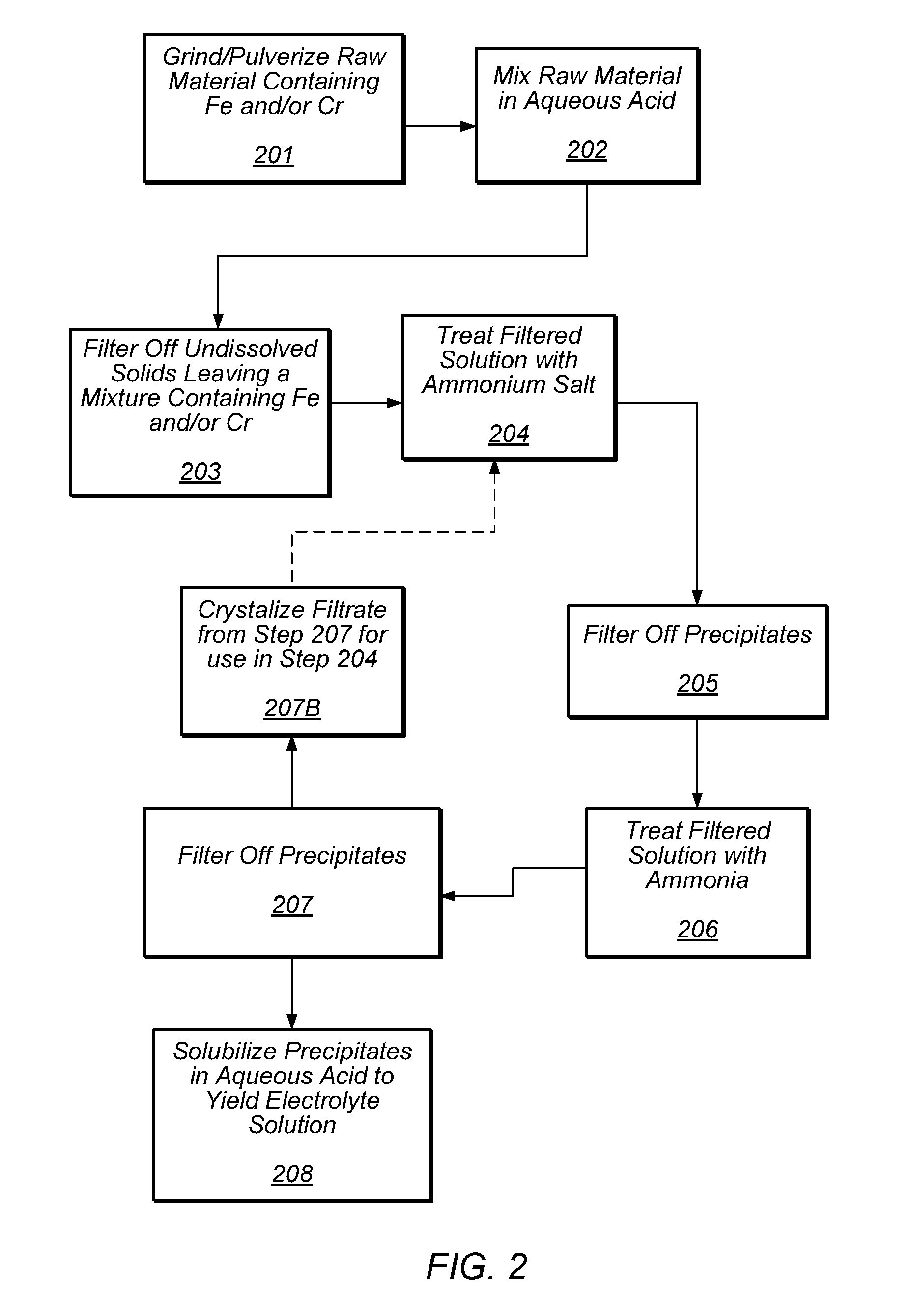

Preparation of flow cell battery electrolytes from raw materials

A method for preparing a redox flow battery electrolyte is provided. In some embodiments, the method includes the processing of raw materials that include sources of chromium ions and / or iron ions. The method further comprises the removal of impurities such as metal ions from those raw materials. In some embodiments, an ammonium salt may be used to remove metal impurities from an aqueous mixture of chromium ions and / or iron ions. Further provided is a redox flow battery comprising at least one electrolyte prepared from the above-identified methods.

Owner:IMERGY POWER SYST

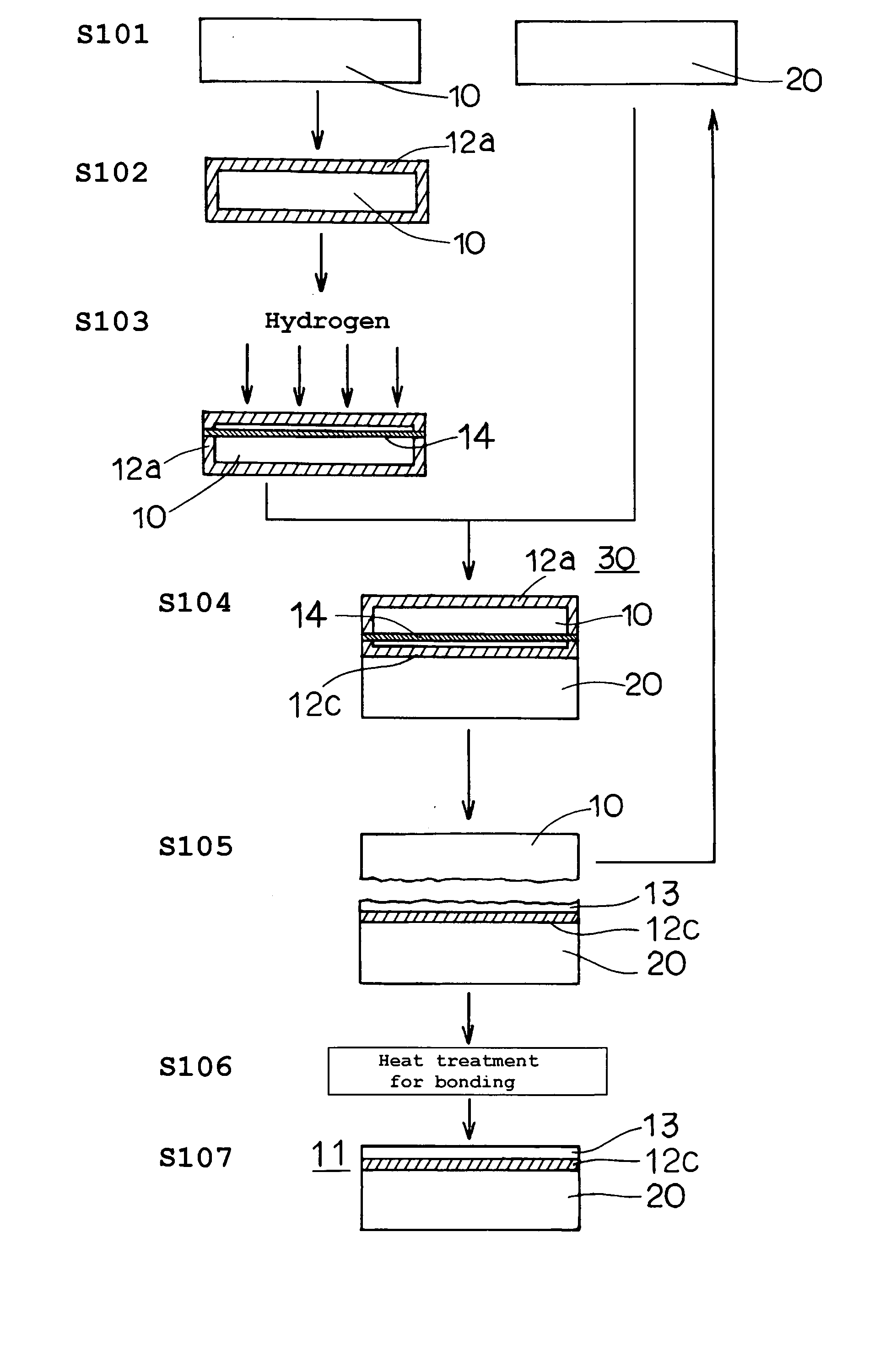

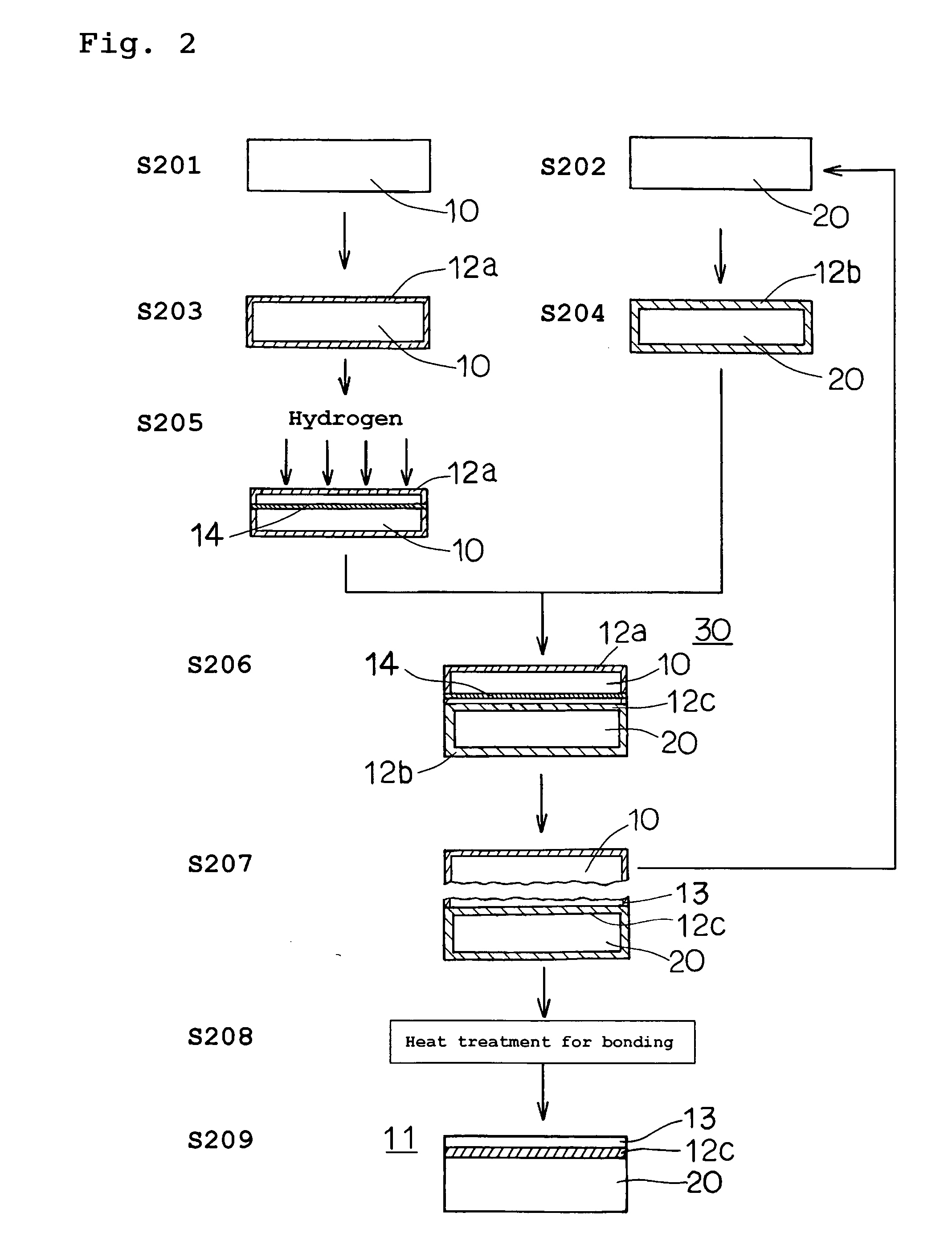

Soi wafer and its manufacturing method

InactiveUS20070032043A1Lower levels of contaminationLower Level RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingWaferingMetal impurities

Since a supporting wafer contains boron of 9×1018 atoms / cm3 or more, therefore a part of the metal impurities in an active layer wafer and the metal impurities in the wafer can be captured by the boron during the heat treatment for bonding. As a result, metal contamination in the active layer can be reduced. Moreover, the wafer strength is enhanced, thus preventing the wafer slipping. Since the wafer has no COP, micro voids are not detected in the LPD evaluation of the active layer, thereby improving the reliability of the evaluation. Such a bonded wafer can be manufactured at a low cast.

Owner:SUMCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com