Production method of high purity cured charcoal felt silicon crystal growth oven

A manufacturing method and technology of a growth furnace, which are applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as inability to clean up, inconvenient operation and use, and difficulty in crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

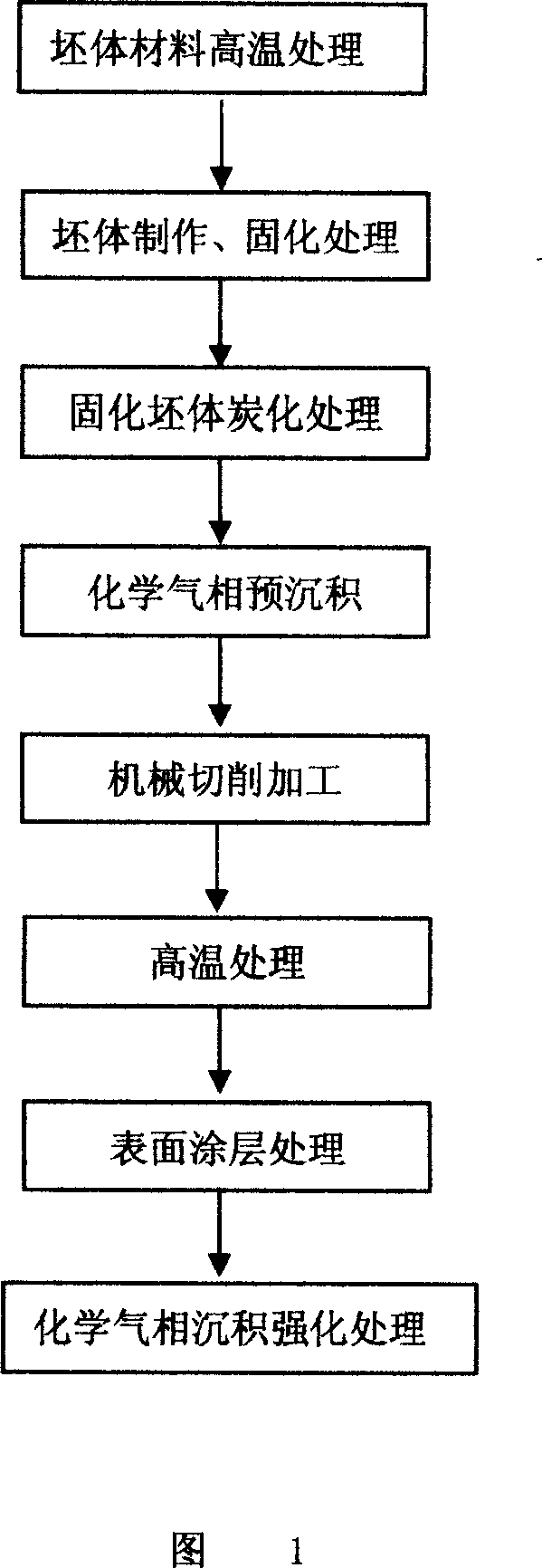

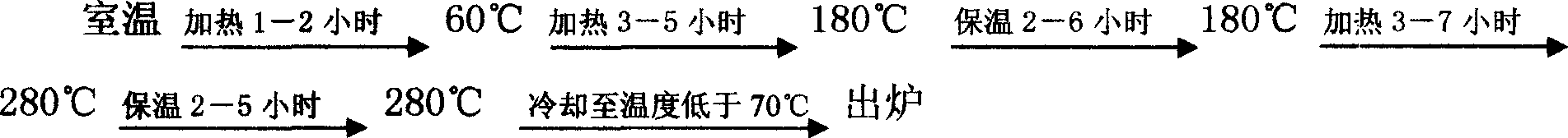

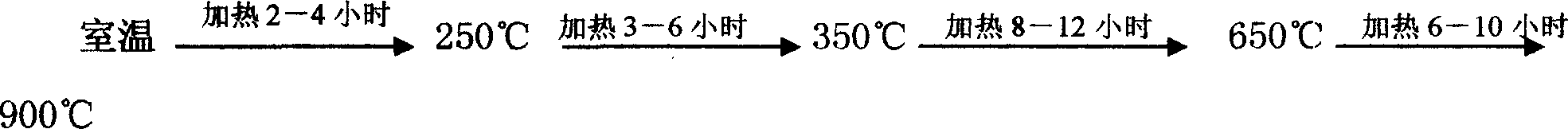

[0016] As shown in Figure 1, the process flow of the high-purity solidified carbon felt manufacturing method for silicon crystal growth furnaces is as follows: select soft graphite felt body with very low metal impurity content as the green body material, and pretreat the graphite felt body at high temperature; according to the user's requirements Drawings, design suitable tooling molds, use high-temperature heat-treated felt body to make green body, and infiltrate an appropriate amount of curing agent into the green body; according to a certain curing process, heat the preformed green body that has infiltrated an appropriate amount of curing agent, The felt body impregnated with curing agent is solidified and shaped; the cured green body is carbonized; the formed green body is put into a vacuum chemical vapor deposition furnace for chemical vapor deposition; some parts of the green body need to be machined to Ensure the shape and size of the parts; treat the blank at high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com