Bulkhead forming material for plasma display device

A technology of plasma and barrier ribs, which is applied in the field of barrier rib forming materials for plasma display panels. It can solve the problems of limitation and difficulty in making light-transmitting barrier ribs, and achieve the effect of ensuring shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

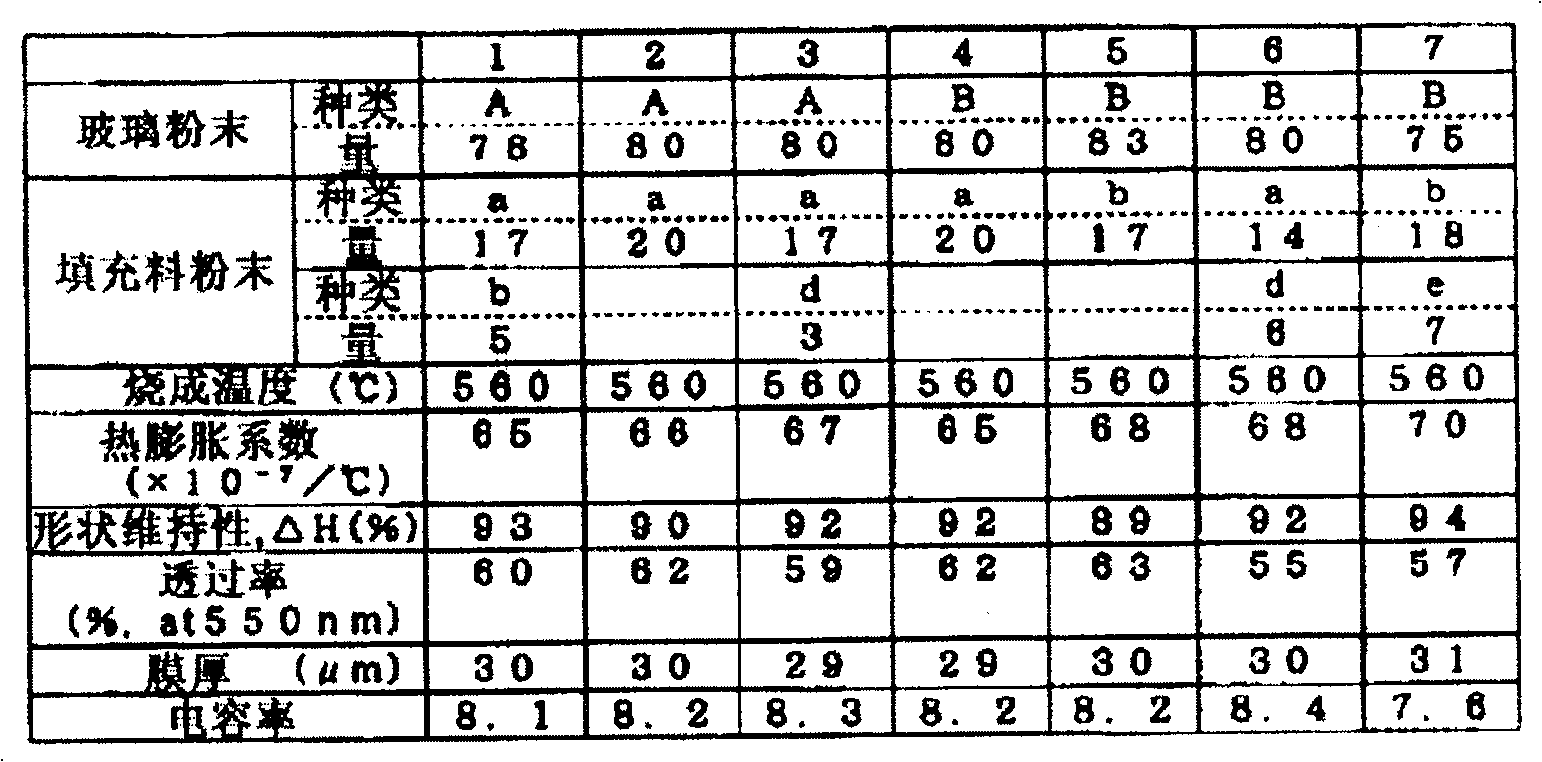

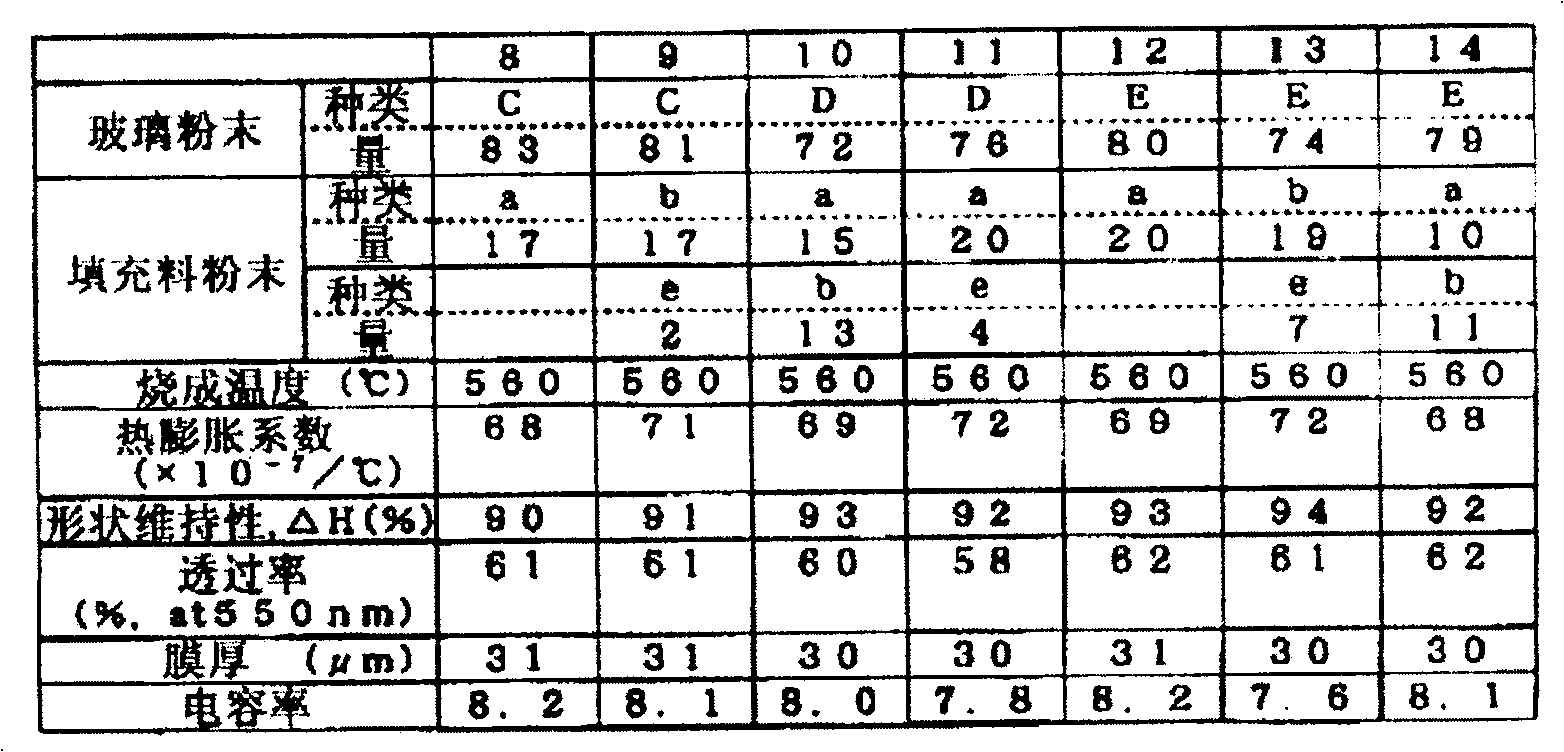

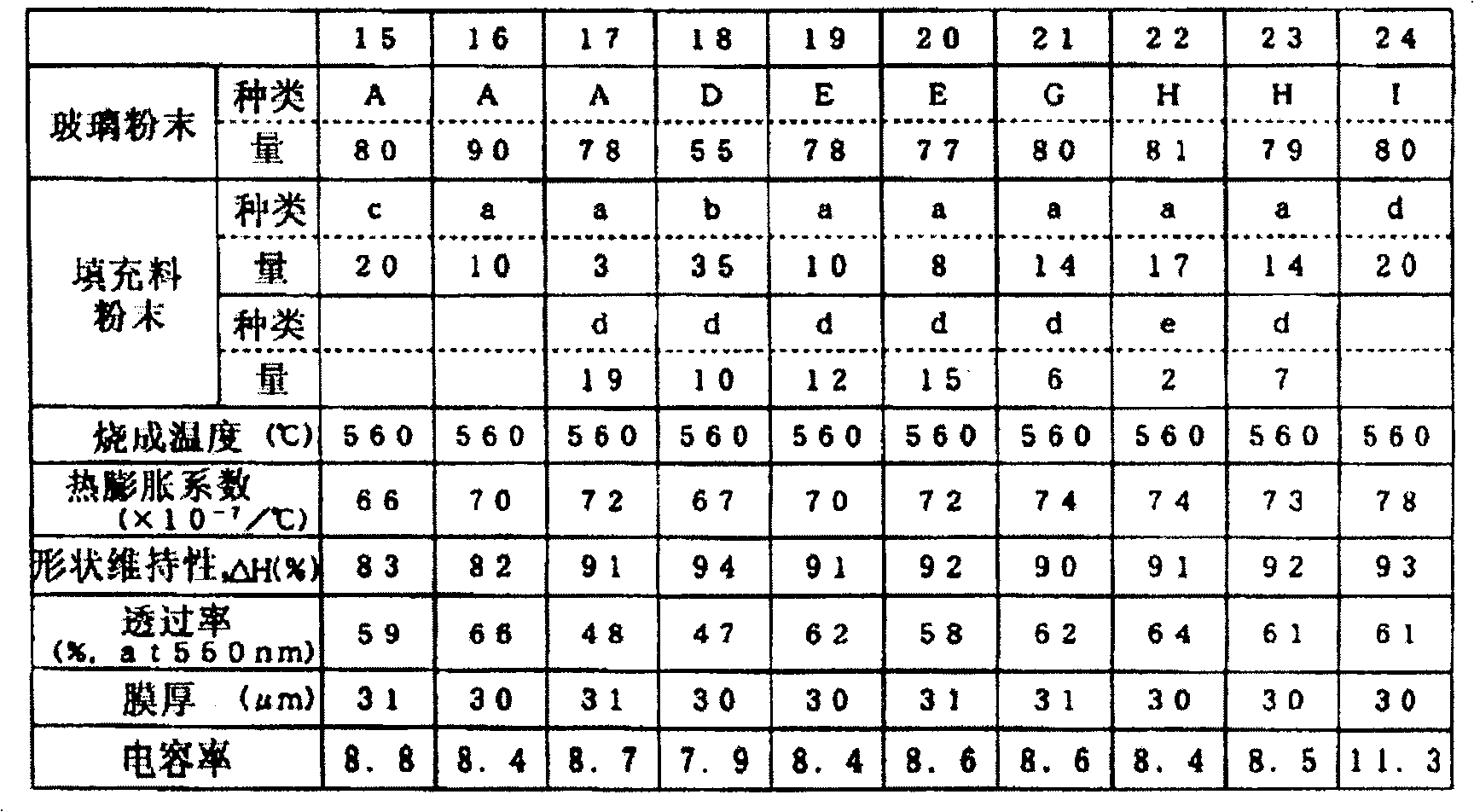

Examples

Embodiment Construction

[0017] According to investigations by the inventors of the present invention, when mullite powder is used instead of alumina powder, even when ZnO-B with a small BaO content is used, 2 o 3 In the case of glass powder, translucent partition walls can also be formed. Therefore, it is speculated that this is because this ZnO-B 2 o 3 The glass of the glass tends to have a refractive index closer to that of mullite than that of alumina.

[0018] Hereinafter, the partition wall forming material of the present invention will be described in detail.

[0019] The partition wall forming material for a plasma display panel of the present invention includes ZnO-B 2 o 3 It is glass powder and filler powder. The ratio of the two is ZnO-B 2 o 3 60-90% by mass of glass powder, 10-40% by mass of filler powder, preferably ZnO-B 2 o 3 60-85 mass % of glass powder, 15-40 mass % of filler powder, more preferably ZnO-B 2 o 3 The glass powder is 63-84% by mass, and the filler powder is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com