Patents

Literature

13002results about "Plastic/resin/waxes insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

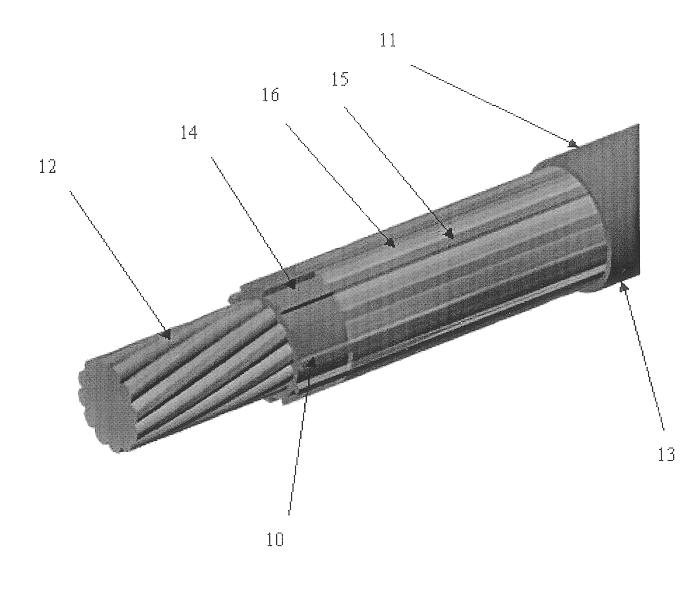

Surface modified overhead conductor

ActiveUS20140041925A1Lower operating temperatureMaintaining distance between parallel conductorsPlastic/resin/waxes insulatorsPolymer chemistryElectrical conductor

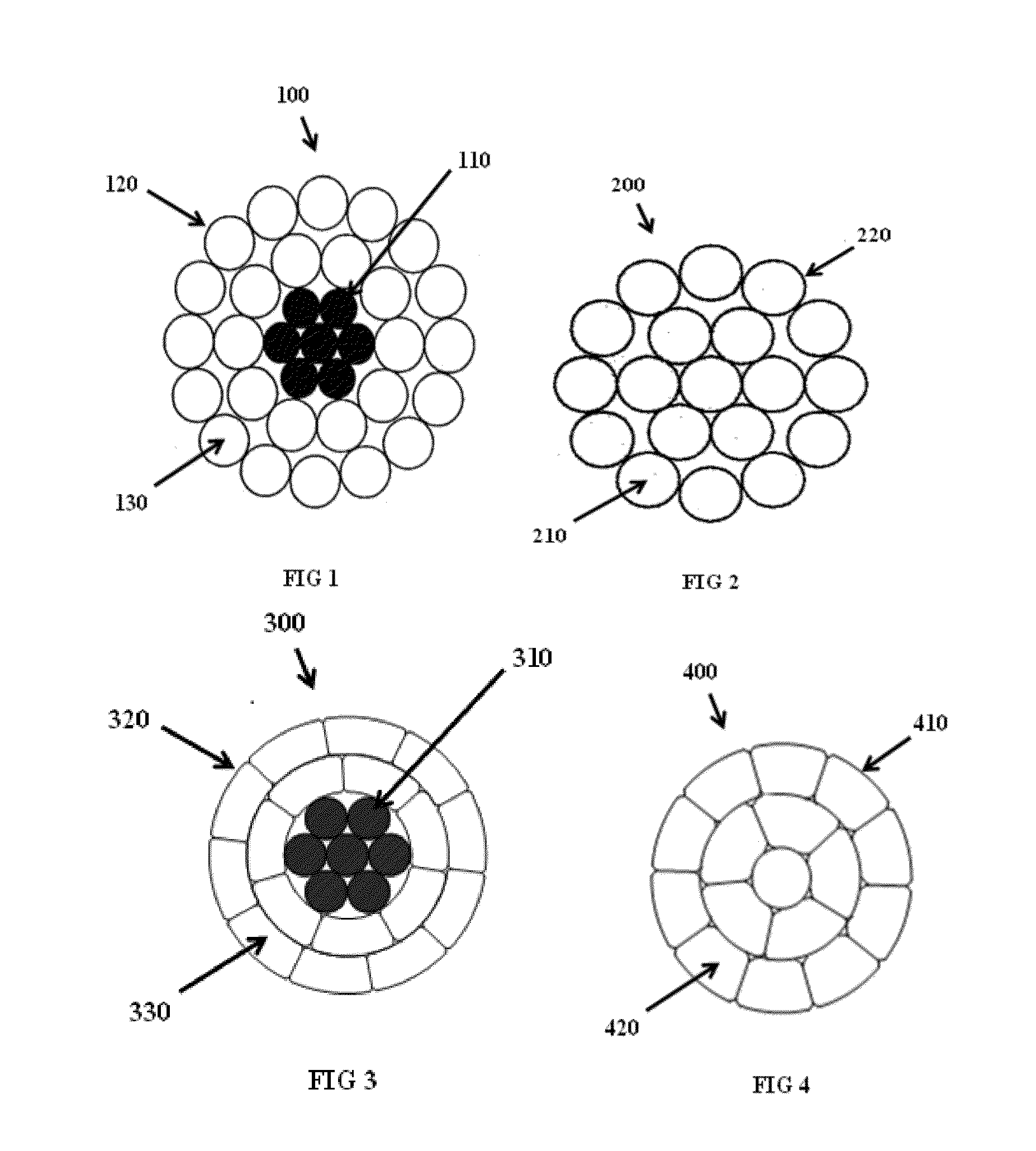

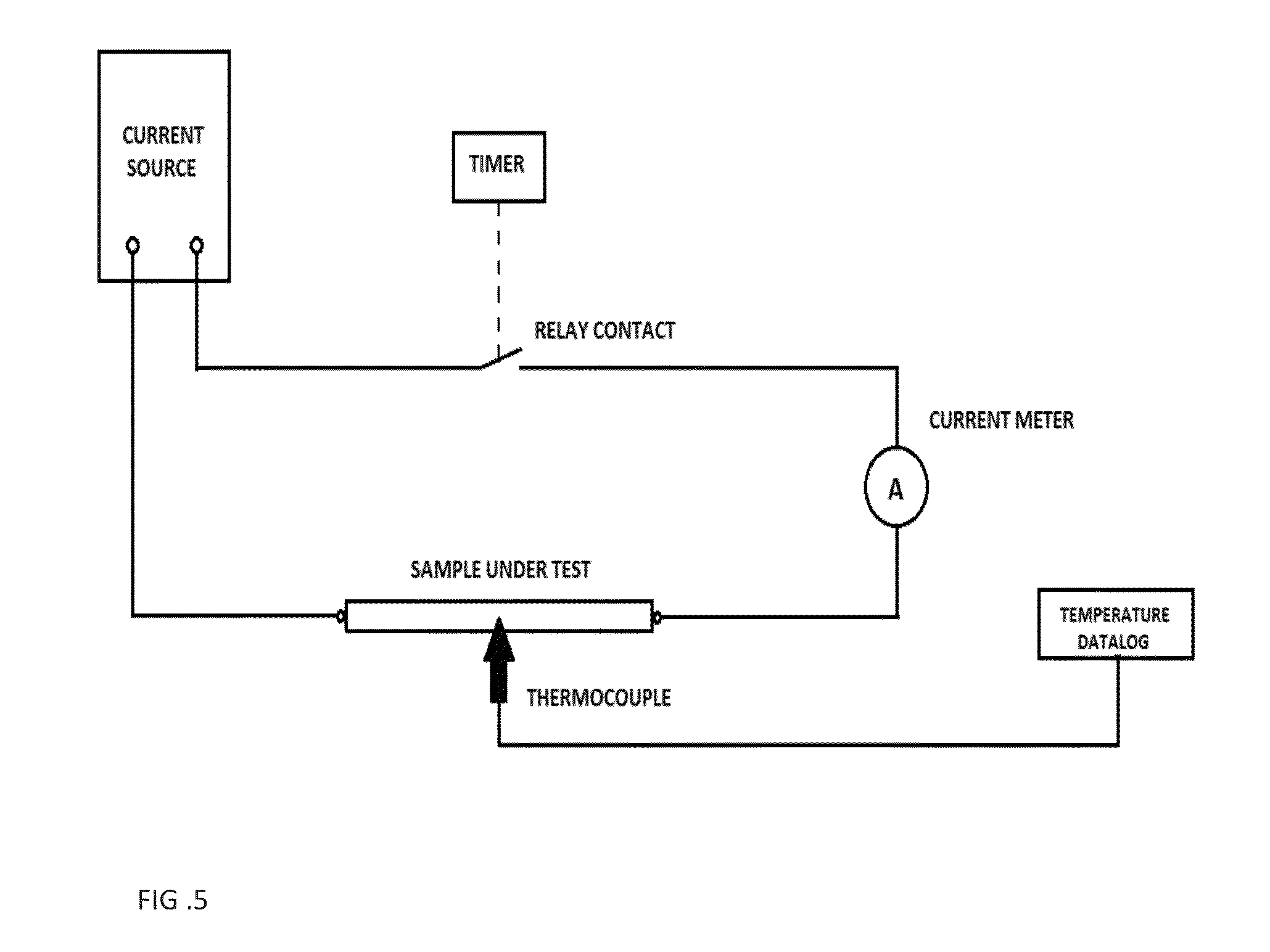

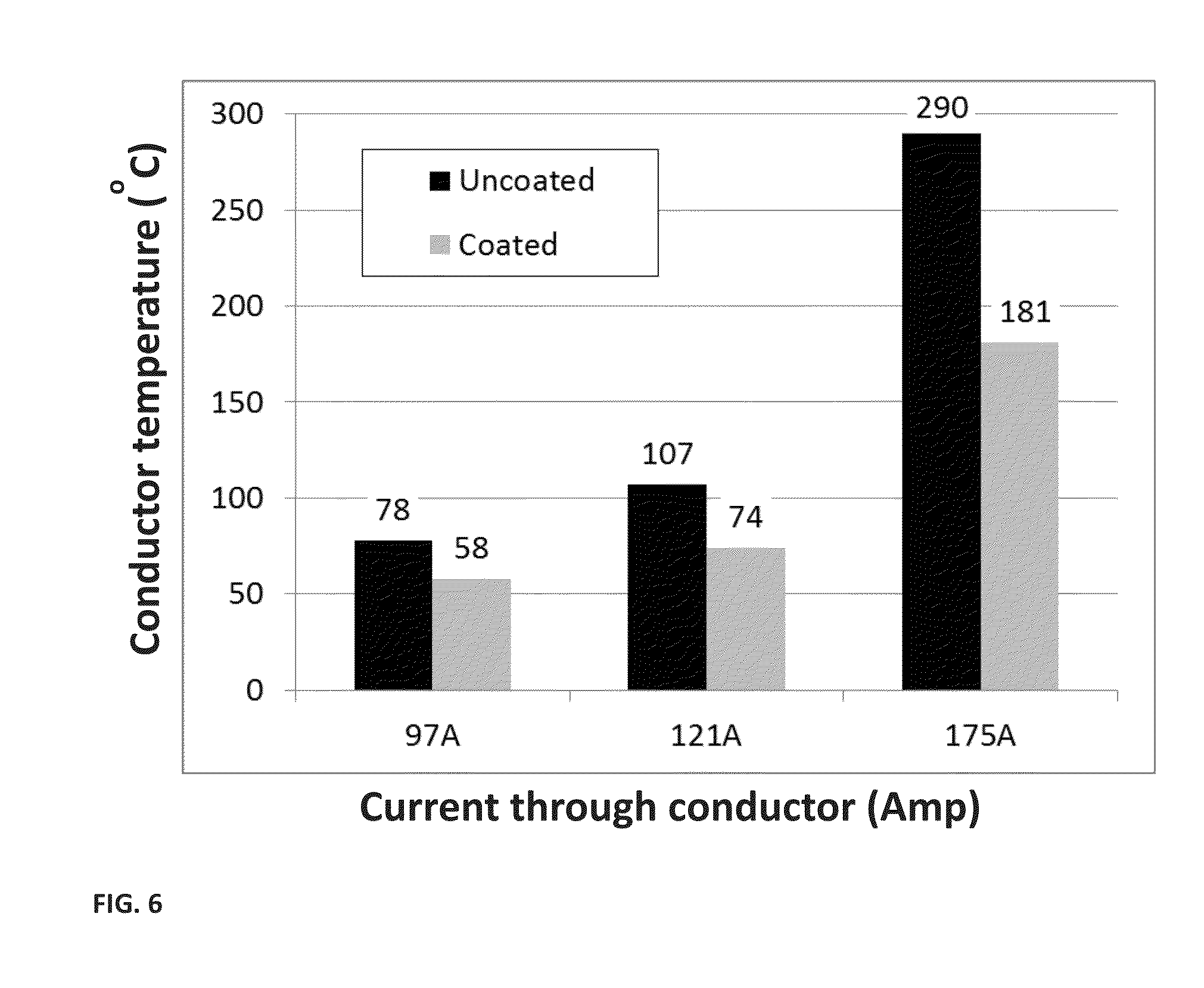

The present invention relates to a surface modified overhead conductor with a coating that allows the conductor to operate at lower temperatures. The coating is an inorganic, non-white coating having durable heat and wet aging characteristics. The coating preferably contains a heat radiating agent with desirable properties, and an appropriate binder / suspension agent. In a preferred embodiment, the coating has L* value of less than 80, a heat emissivity of greater than or equal to 0.5, and / or a solar absorptivity coefficient of greater than 0.3.

Owner:GENERAL CABLE TECH CORP

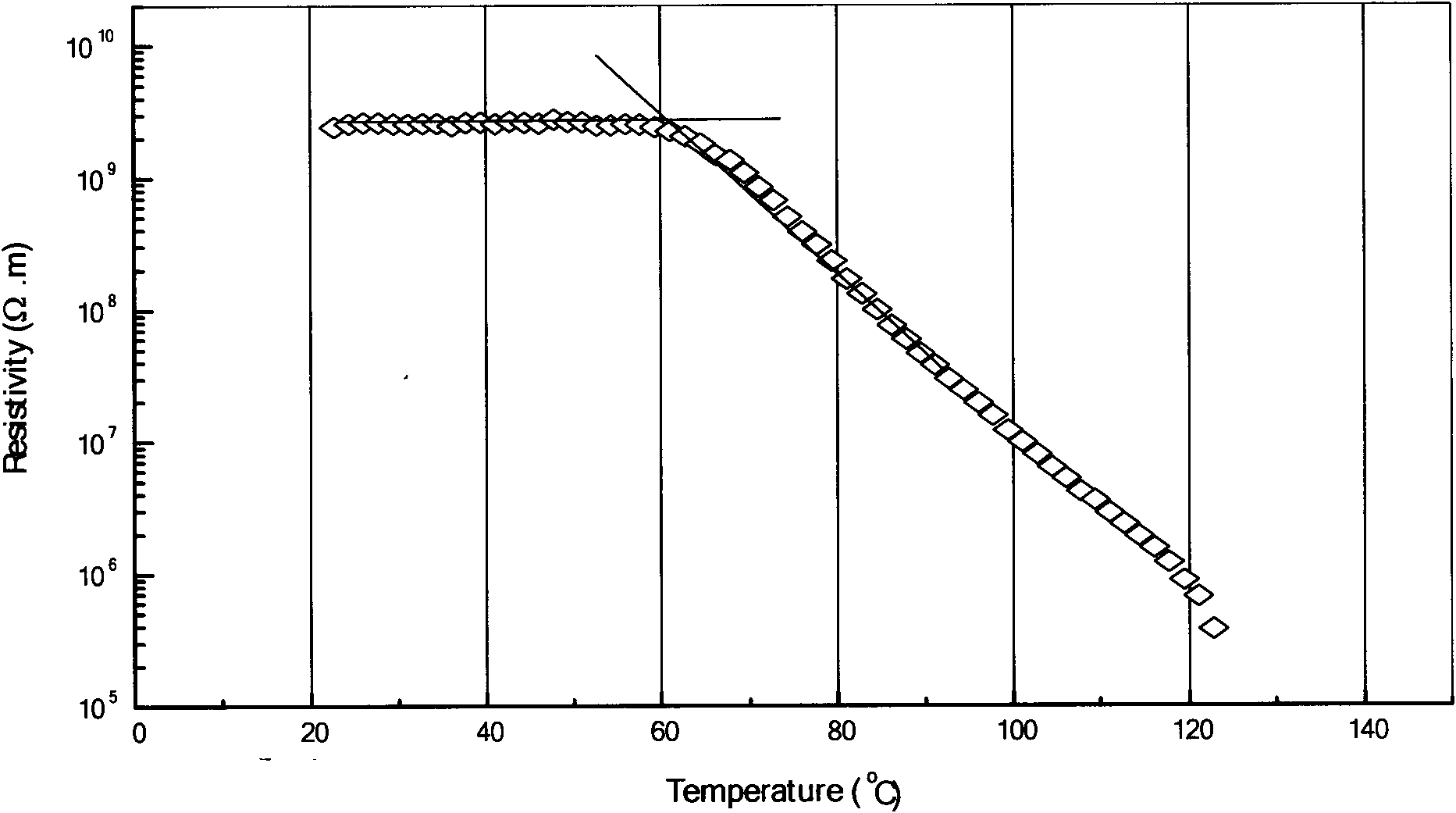

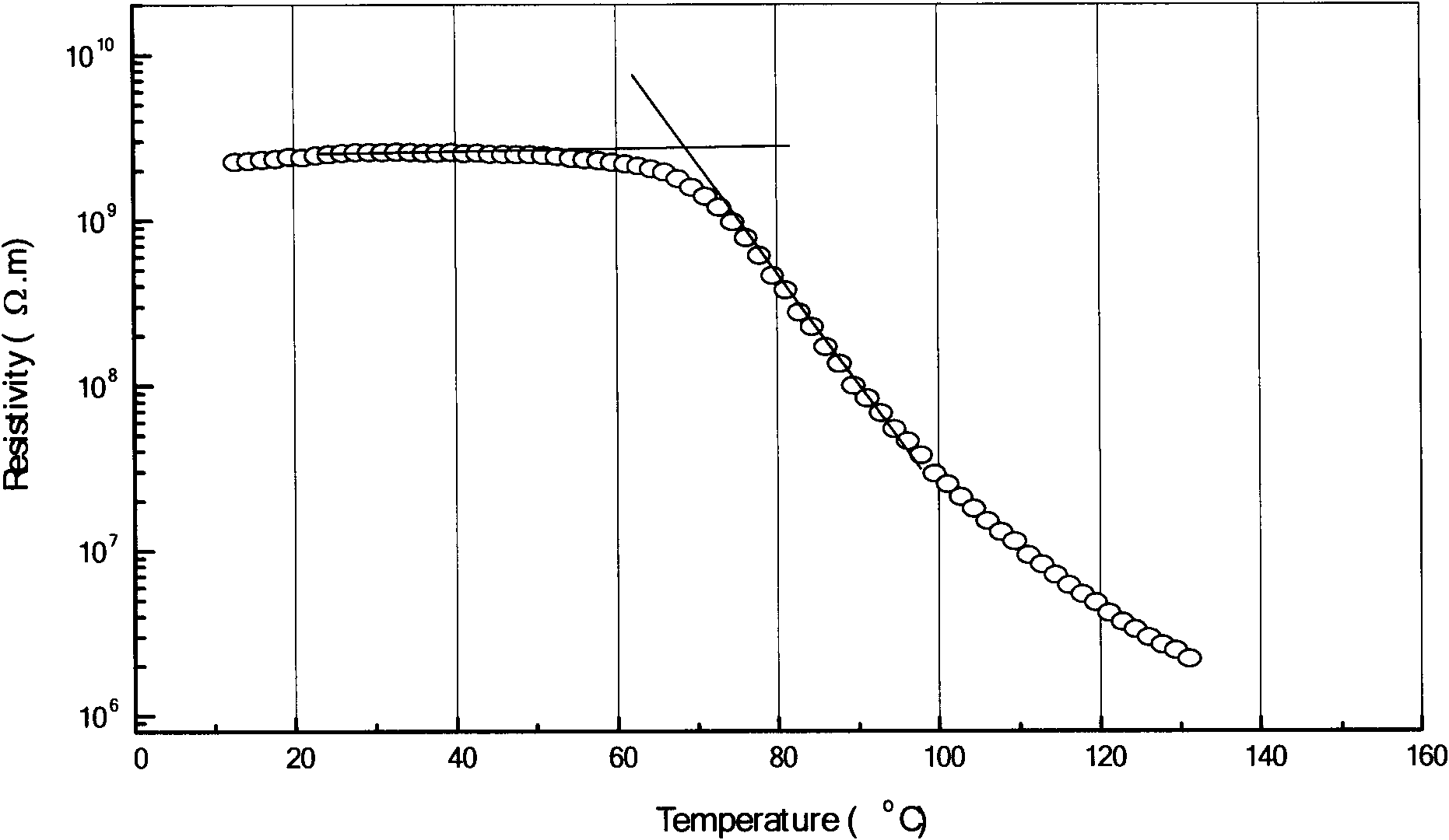

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

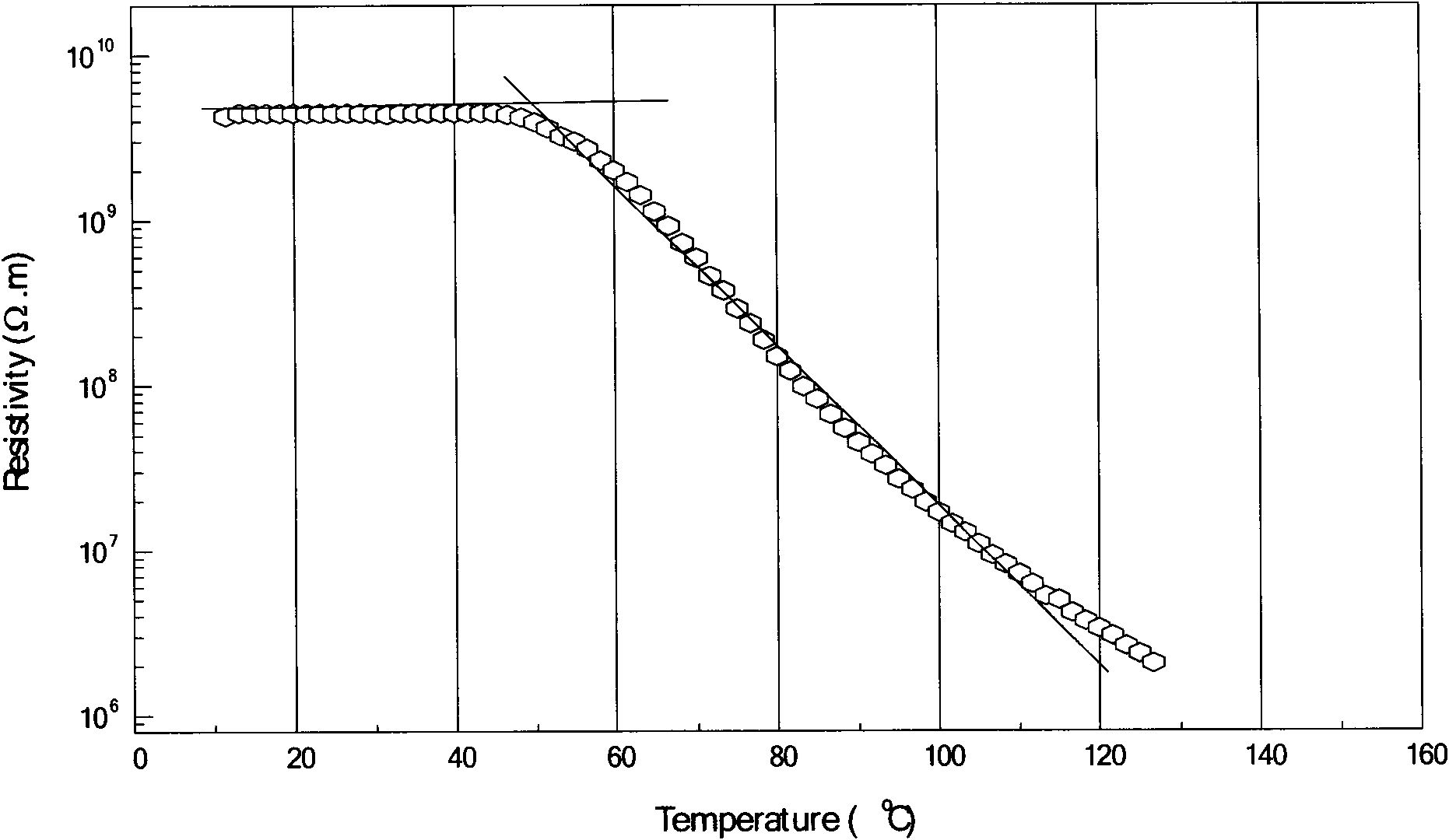

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

Electrically optimized hybird "last mile" telecommunications cable system

InactiveUS6091025AEqual performanceEquivalent signal performanceCoaxial cables/analogue cablesQuad constructionsElectrical conductorTelecommunications cable

A cable system is provided which can accomodate electrical and optical cabling. The conductors of the system employ a layer which is impedance-matched to space, decreasing their cross-section to electromagnetic interference. The conductors of the system also employ a layer which symmetrizes electromagnetic interference signals, reducing the effect of interference and crosstalk on the signals carried by the conductors. The system also includes a node interface device for connection to a global electrical and fiber network. The node interface device connects to a user interface device through the cable.

Owner:KHAMSIN TECH LLC

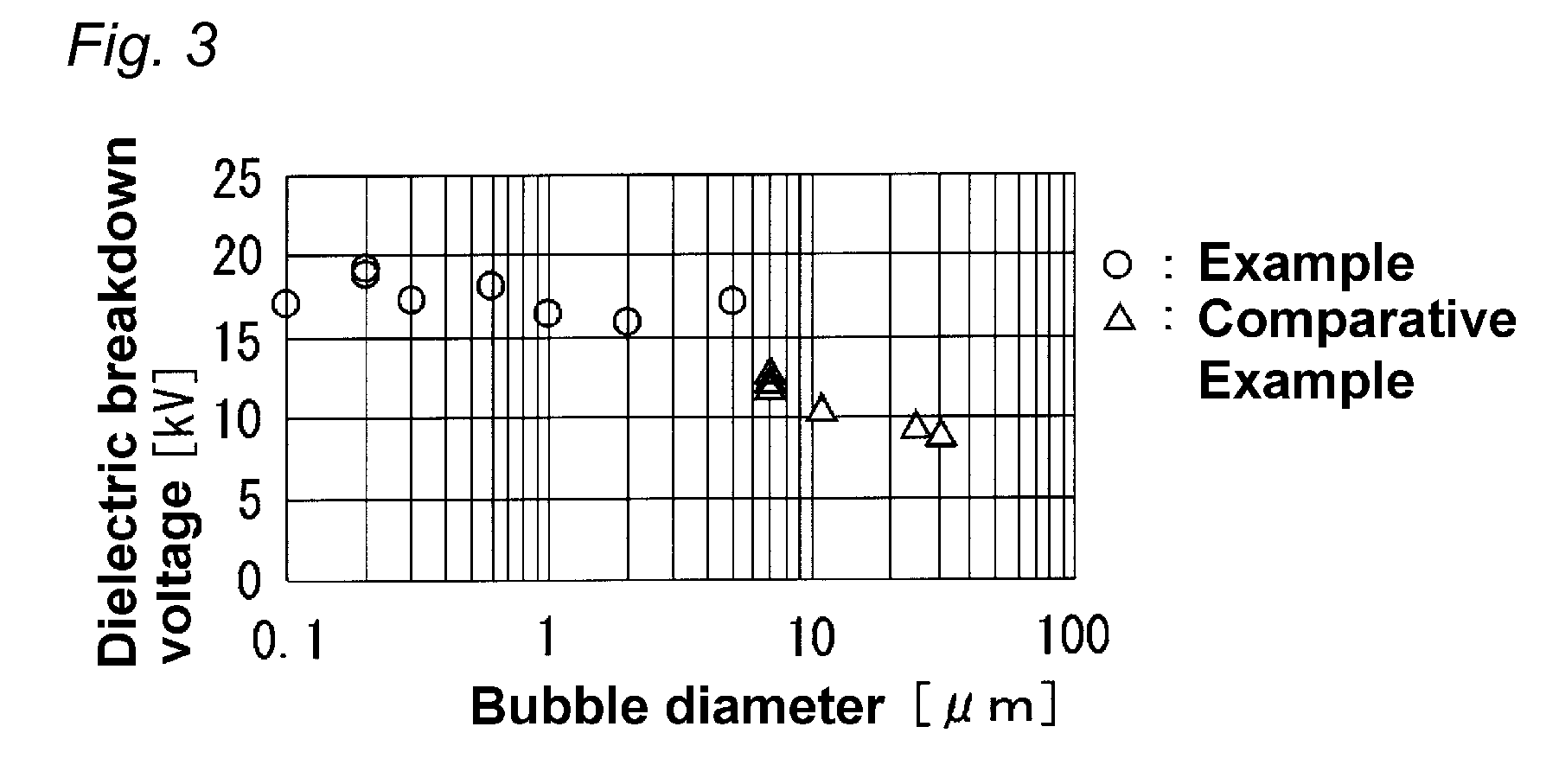

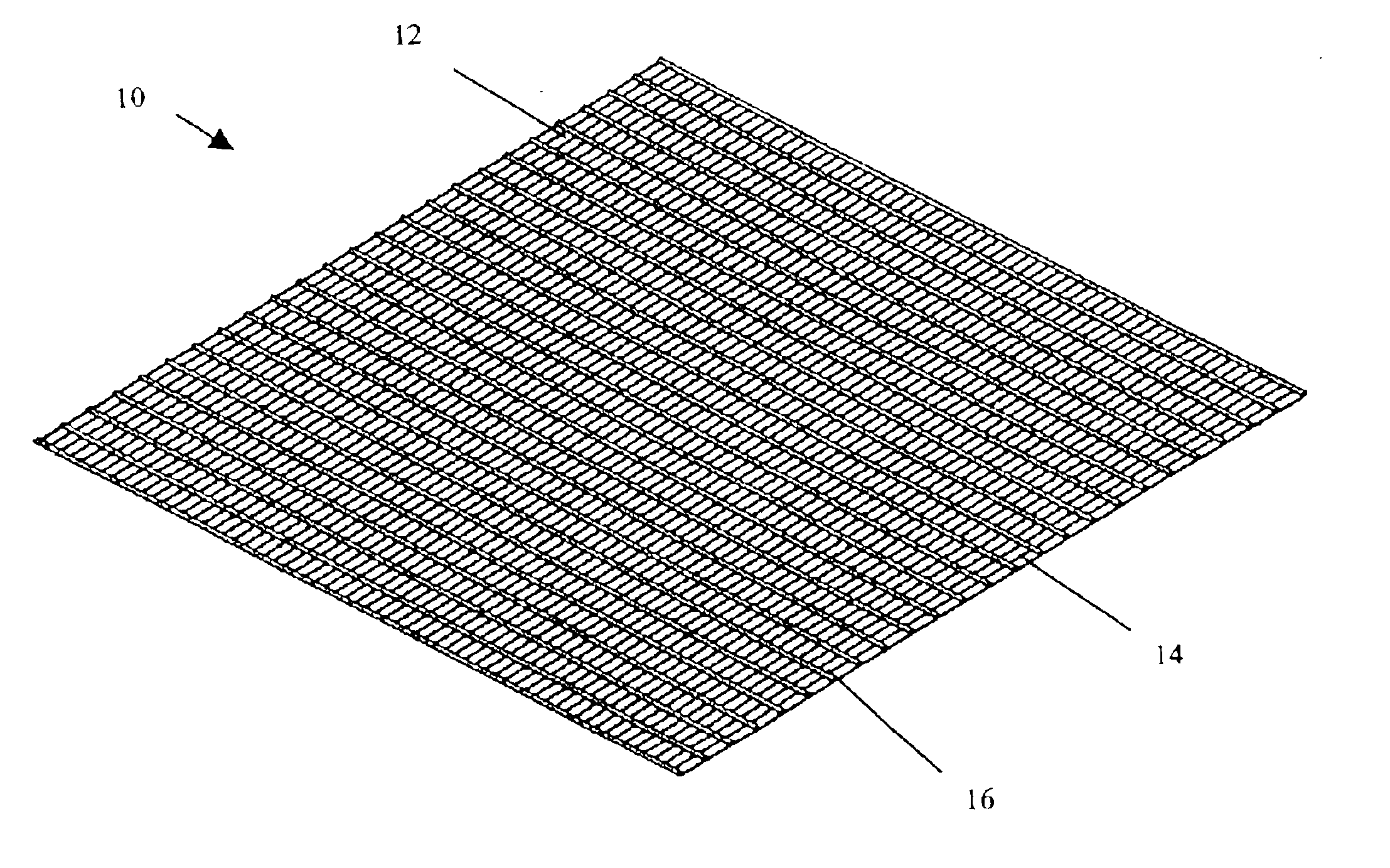

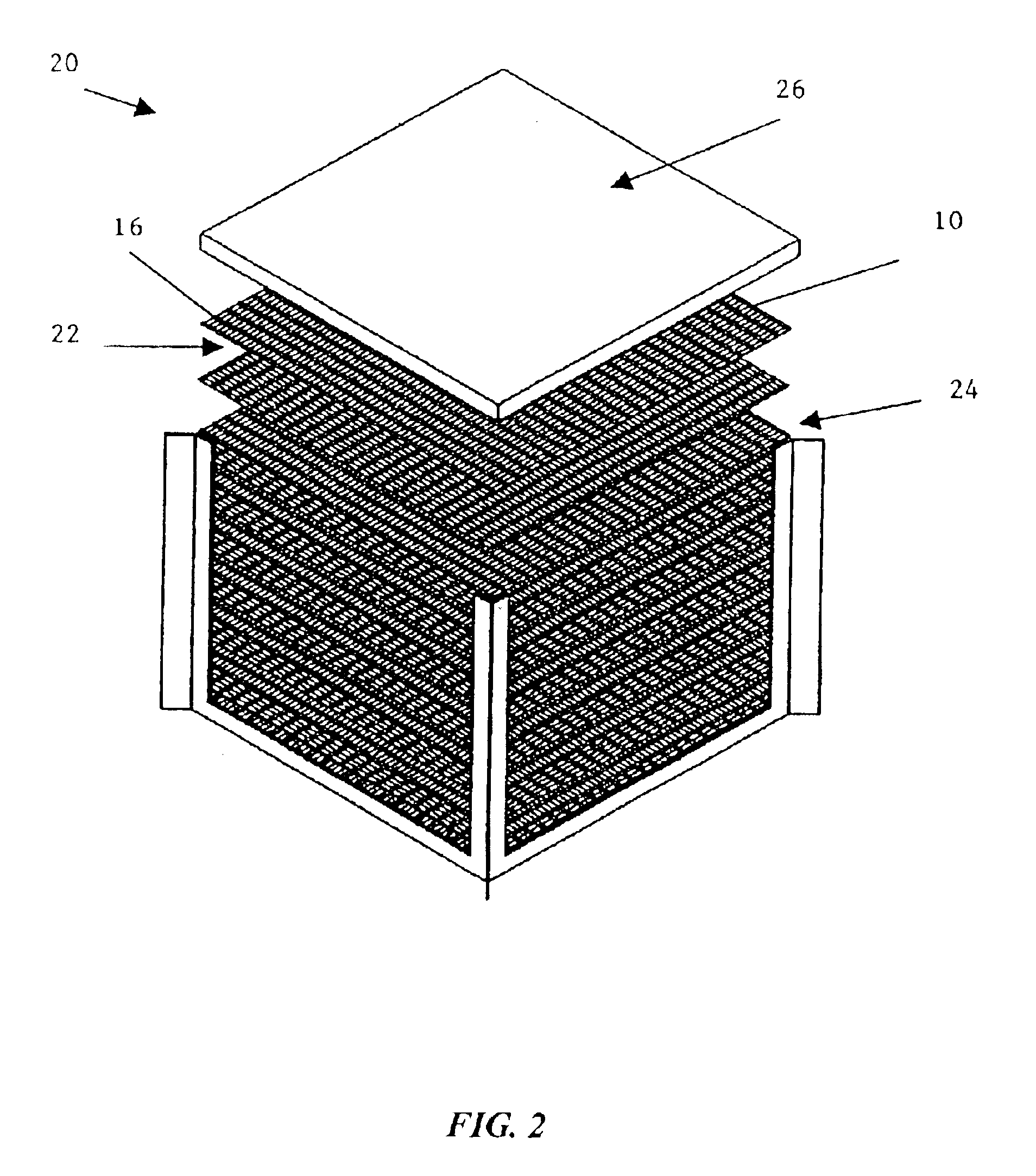

Foamed electrical wire and a method of producing the same

ActiveUS9142334B2Increase resistanceGood partitionPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorGlass transition

A foamed electrical wire, containing: a conductor; and a foamed insulating layer; in which the foamed insulating layer comprises a thermoplastic resin that is a crystalline thermoplastic resin having a melting point of 150° C. or more or a non-crystalline thermoplastic resin having a glass transition temperature of 150° C. or more, and the average bubble diameter of the foamed insulating layer is 5 μm or less.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

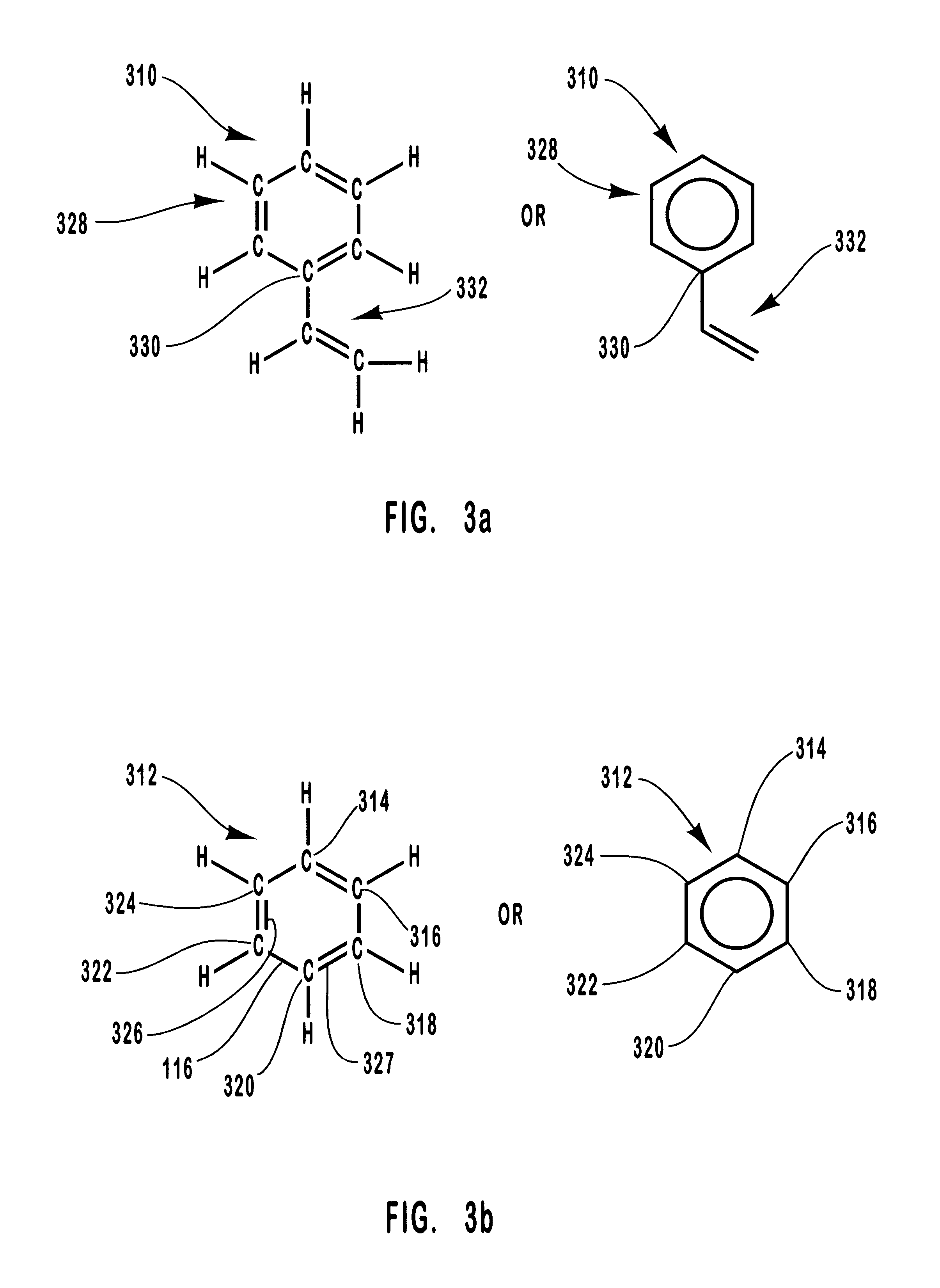

Crosslinked polymer electrolyte membranes for heat and moisture exchange devices

InactiveUS6841601B2Improve permeabilityLow costSpace heating and ventilationIndirect heat exchangersEnergy recoveryMoisture

A unitary humidity exchange cell (HUX) is dislosed that includes at least one composite membrane, disposed between at least one first chamber for flow of the first fluid therethrough and at least one second chamber for flow of the second fluid therethrough. The composite membrane include an at least partially sulfonated humidity-conducting polymer comprising residues derived from at least one arylvinyl monomer; and a reinforcing substrate bonded thereto. The product finds utility in a variety of physical and chemical processes and products whereby moisture or other highly polar liquid or gas transfer, exchange removal or delivery is important. A notable application is the Membrane Energy Recovery Ventilator (MERV) in which both heat, ions and moisture is transferred between two air streams, one intake and one exhaust, from an air-conditioned building.

Owner:TANGREDI PATRICIA

Foamed elastomers for wafer probing applications and interposer connectors

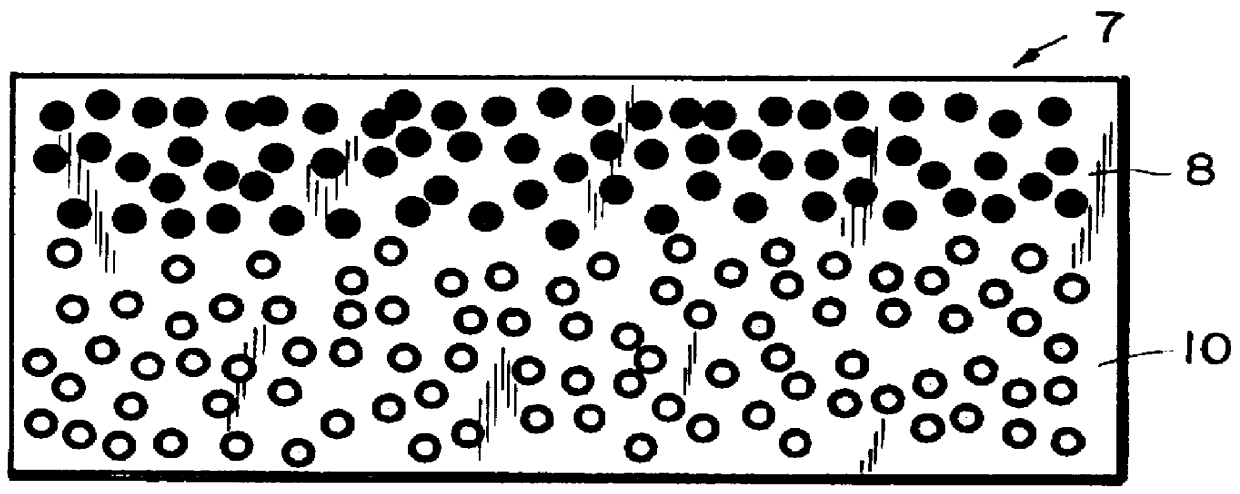

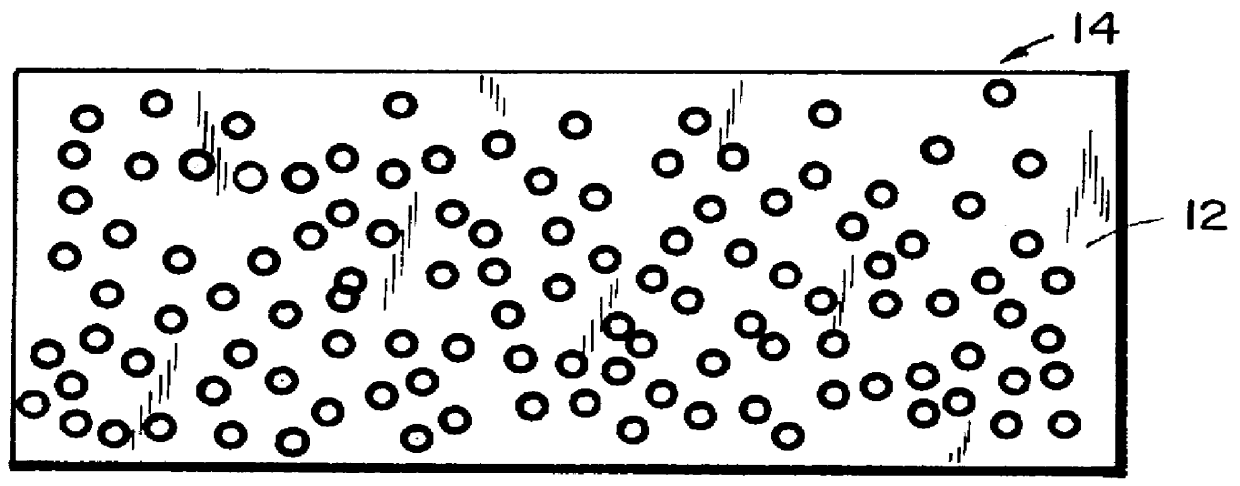

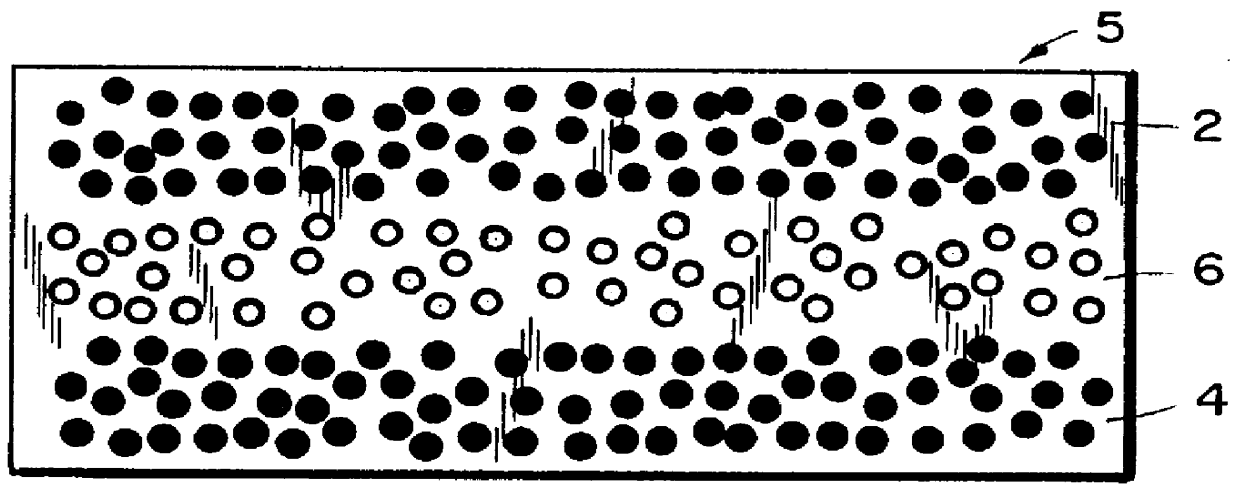

InactiveUS6054651AEasy to optimizeSimple structurePlastic/resin/waxes insulatorsInsulated cablesElastomerEngineering

The present invention is directed to a new foamed elastomer composition including elastomer, hollow fillers, and reinforced fillers for supporting the conducting wires in the test probes for wafer level testing and burn in and interposer connector applications. The thermally stable elastomer resin is mixed with hollow fillers and reinforced fillers before filling into the probe or connector mold with an array of elongated conducting wires, then is crosslinked by a crosslinking agent and a catalyst. The use of compressible hollow fillers to foam the elastomer has been successful to enhance the compliance and resilience, and to reduce the thermal expansion, density, and dielectric constant of the elastomer.

Owner:GLOBALFOUNDRIES INC

Thermally conductive thermoplastic resin compositions

InactiveUS20050176835A1Plastic/resin/waxes insulatorsSemiconductor/solid-state device detailsLiquid crystallinePolymer chemistry

Thermally conductive thermoplastic polymer resin compositions comprising thermoplastic polymer, calcium fluoride, and, optionally, one or more of fibrous filler, liquid crystalline polymer, and polymeric toughening agent. The compositions are particularly useful for molded or extruded parts.

Owner:EI DU PONT DE NEMOURS & CO

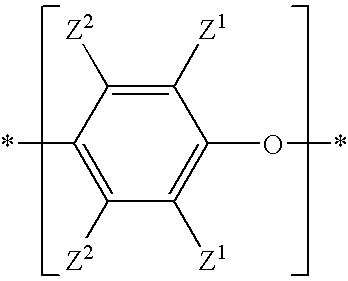

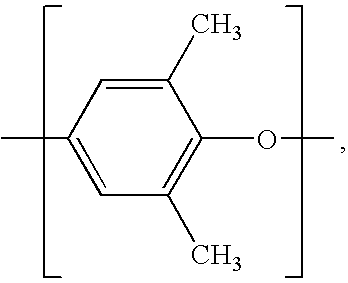

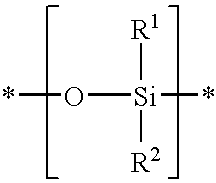

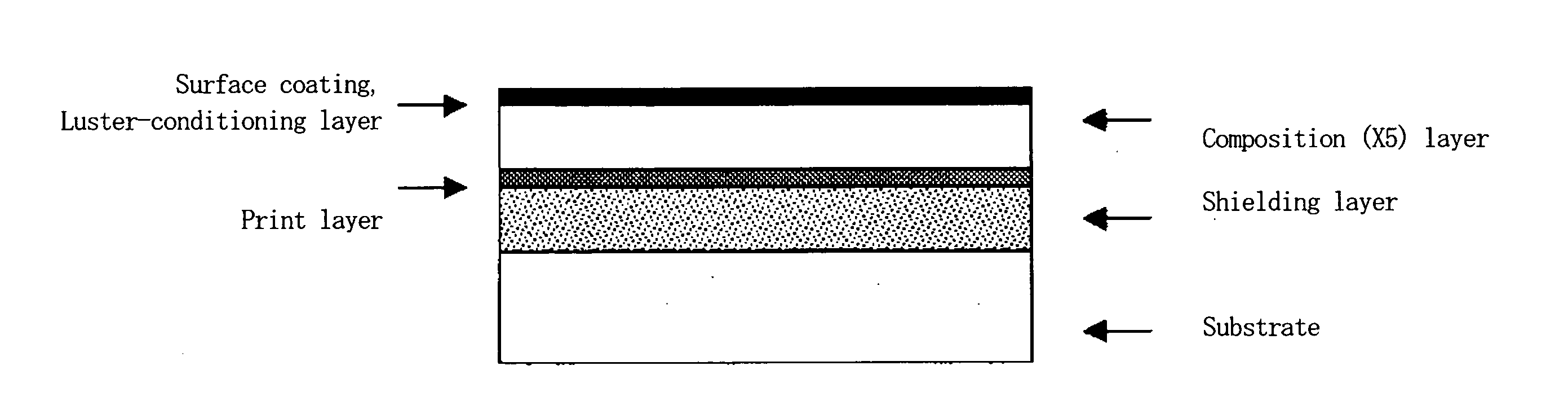

Poly(arylene ether) composition and extruded articles derived therefrom

A poly(arylene ether) composition includes a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, a flame retardant, and a poly(arylene ether)-polysiloxane block copolymer reaction product that itself includes a poly(arylene ether)-polysiloxane block copolymer. The composition is useful for forming extruded articles, including insulation for wire and cable. The poly(arylene ether)-polysiloxane block copolymer contributes improved flame retardancy and, in many cases, improved physical properties to the composition.

Owner:SHPP GLOBAL TECH BV

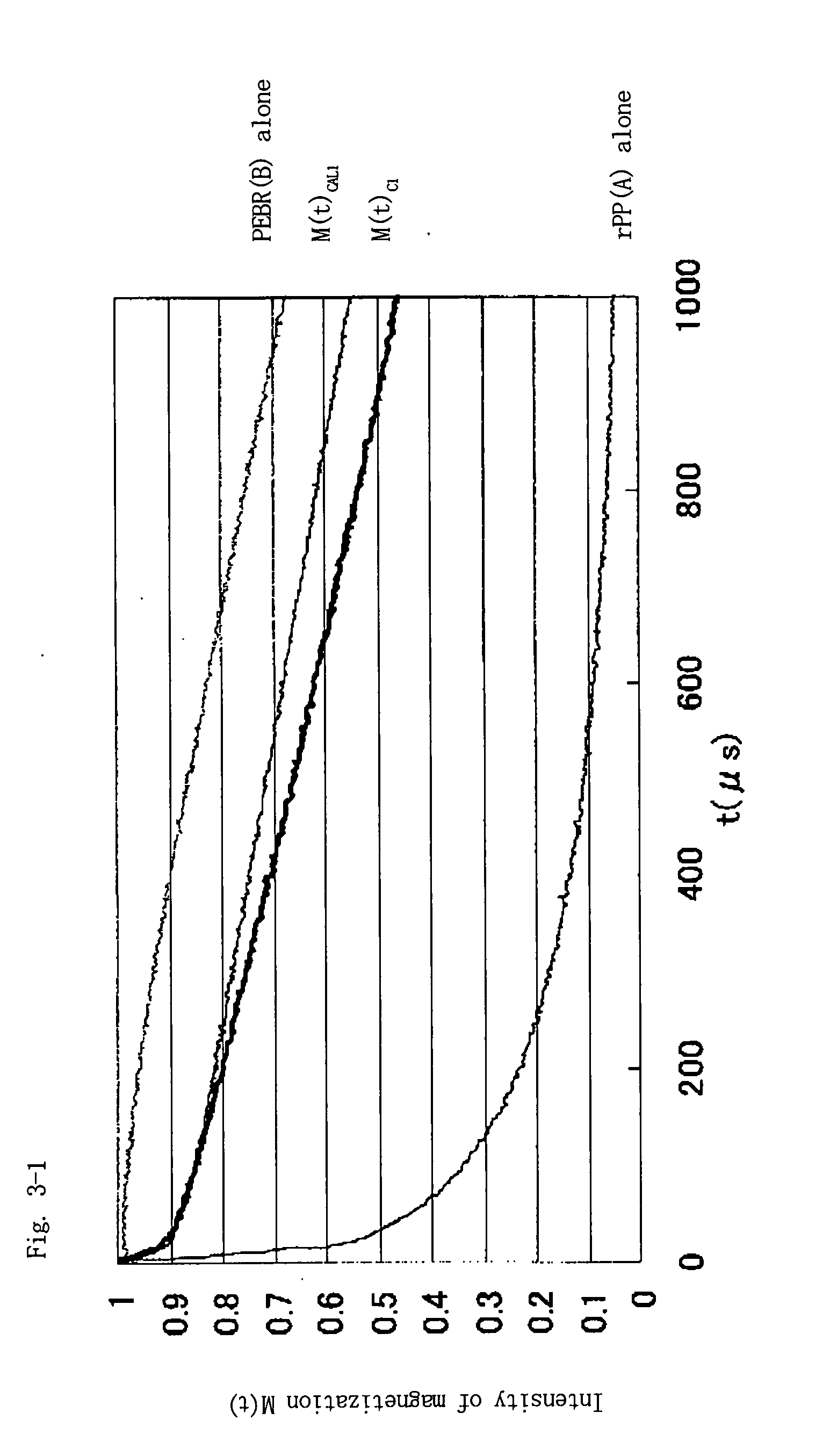

Propylene resin composition and use thereof

ActiveUS20070251572A1Improve mechanical propertiesGood rubber elasticitySolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (Xi) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below: 1 to 90 wt % of an isotactic polypropylene (A1); 9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol% of propylene-derived structural units, 10 to 25 molt of ethylene-derived structural units, and optionally, 0 to 30 mol% of C4-C20 α-olefin-derived structural units (a1); 1 to 80 wt % of a styrene-based elastomer (C1); and 0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

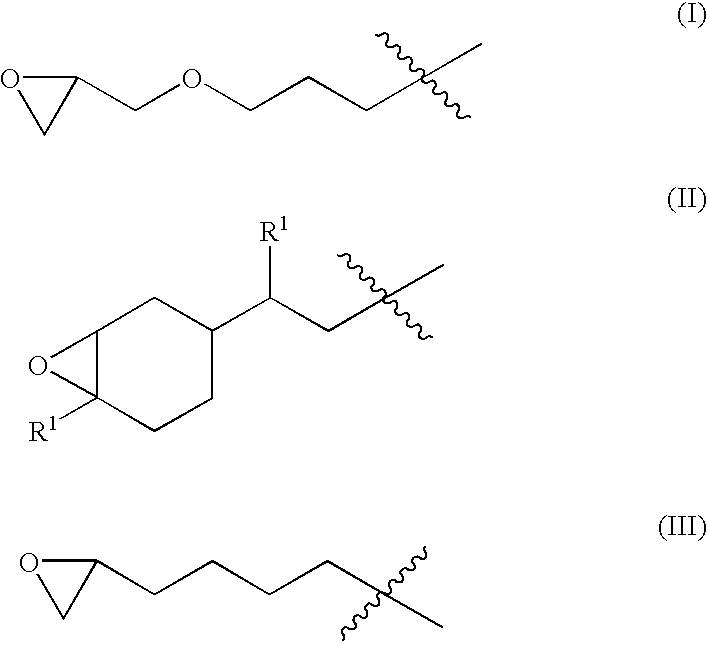

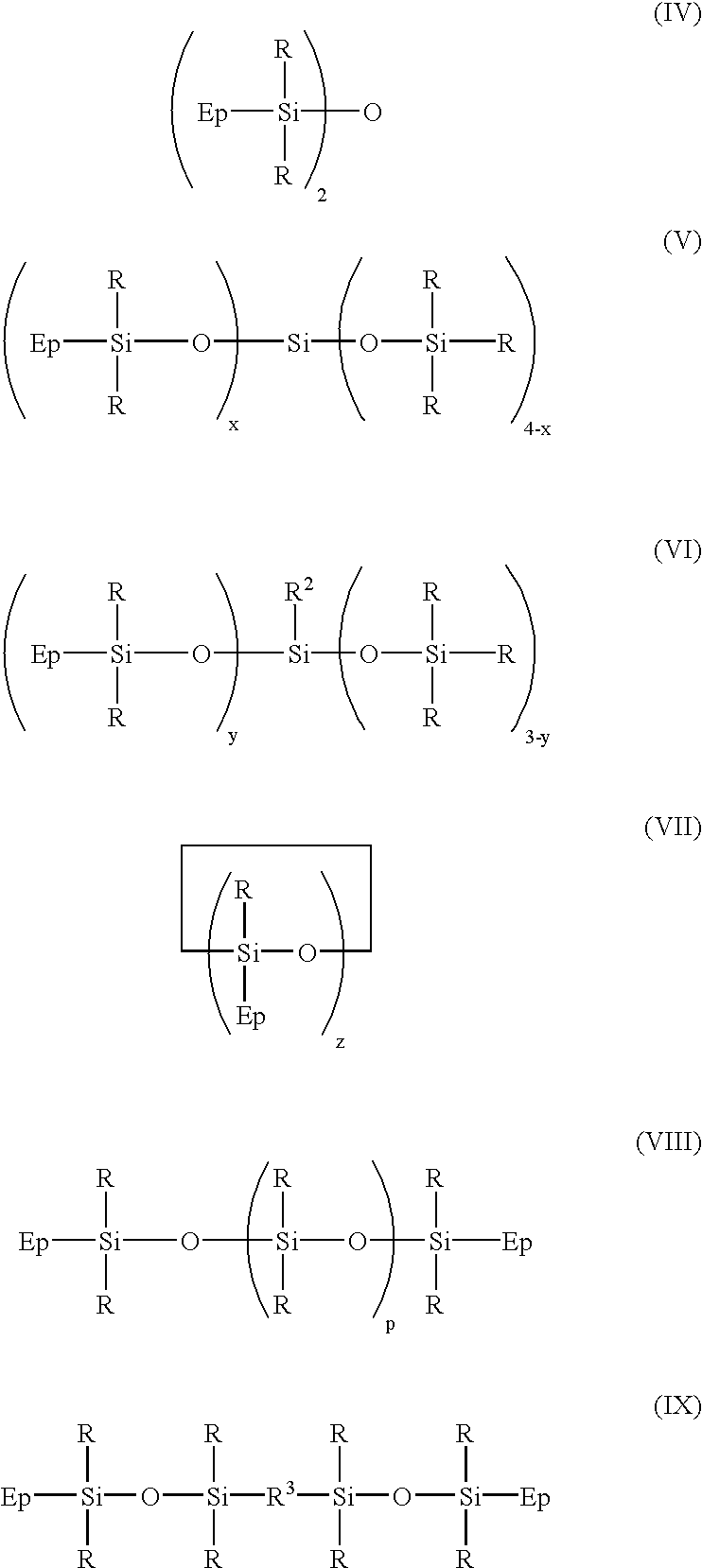

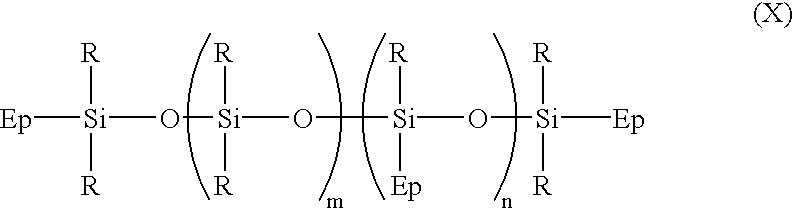

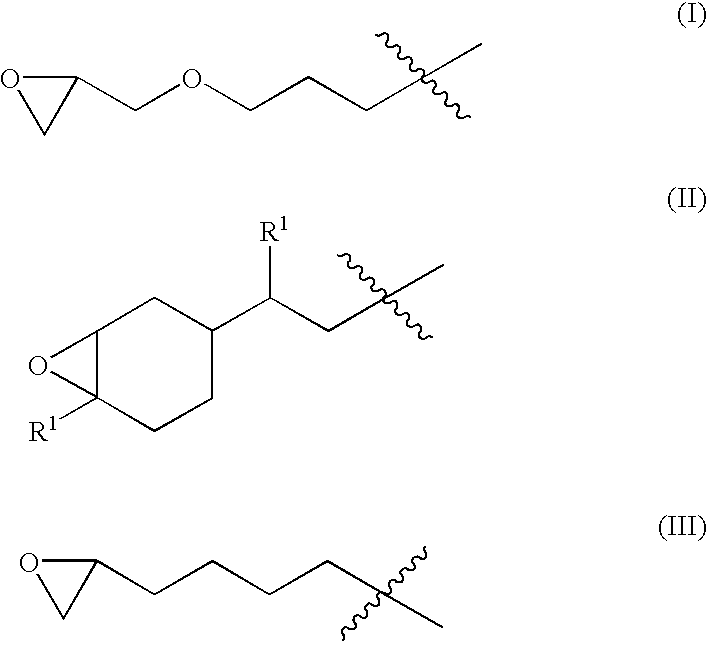

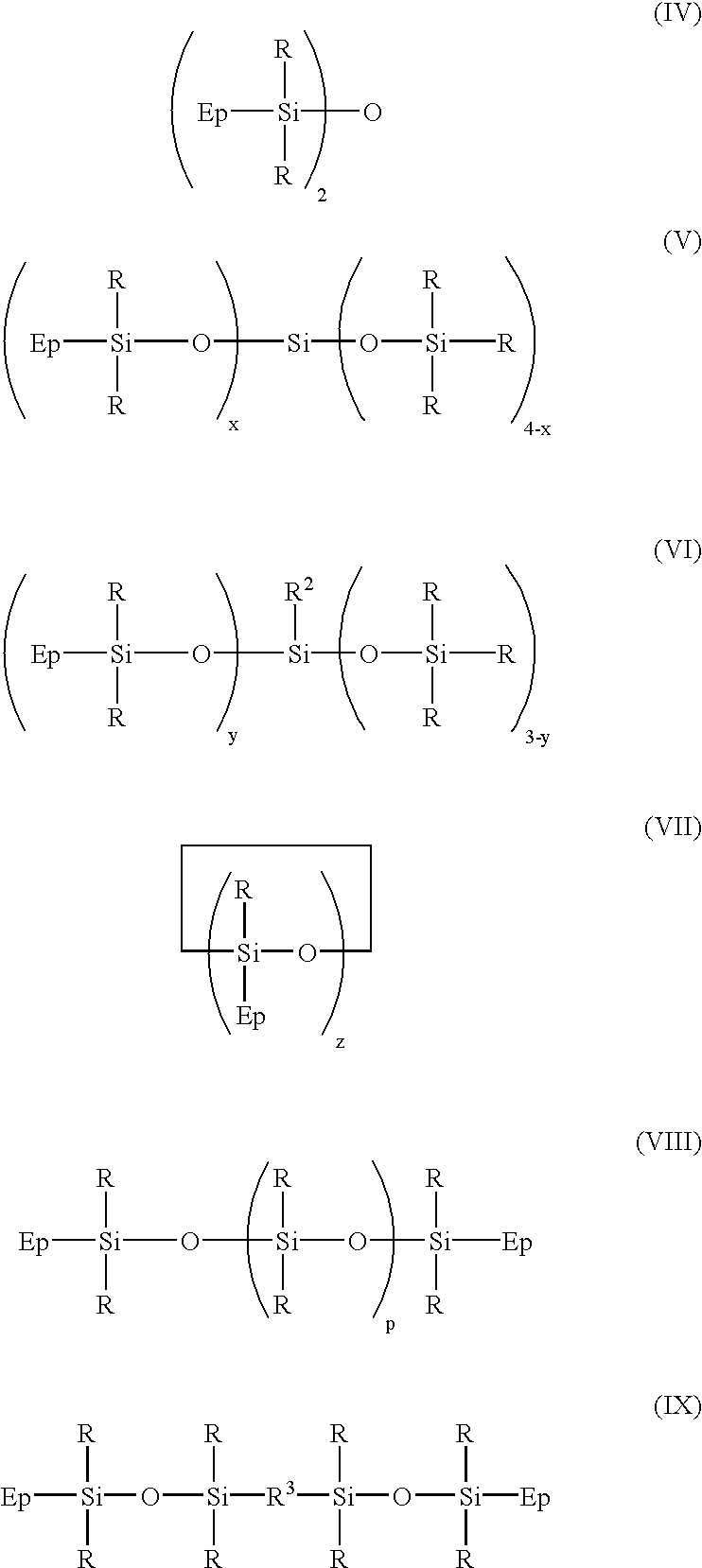

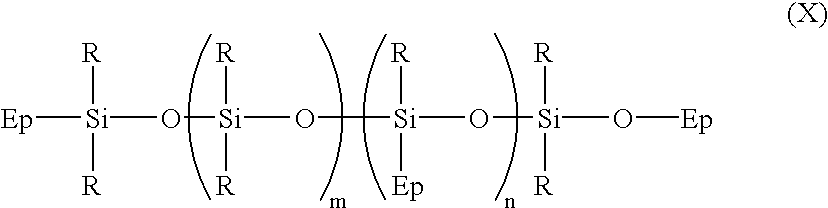

Composition comprising silicone epoxy resin, hydroxyl compound, anhydride and curing catalyst

InactiveUS6632892B2High refractive indexImprove matchPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsEpoxyRefractive index

Epoxy resin compositions are disclosed which comprise (A) at least one silicone epoxy resin, (B) at least one hydroxyl-containing compound, (C) at least one anhydride curing agent, (D) at least one ancillary curing catalyst, and optionally at least one of thermal stabilizers, UV stabilizers, cure modifiers, coupling agents, or refractive index modifiers. Also disclosed are packaged solid state devices comprising a package, a chip (<HIL><PDAT>4< / BOLD><PDAT>), and an encapsulant (<HIL><PDAT>11< / BOLD><PDAT>) comprising an epoxy resin composition of the invention. A method of encapsulating a solid state device is also provided.< / PTEXT>

Owner:GENERAL ELECTRIC CO

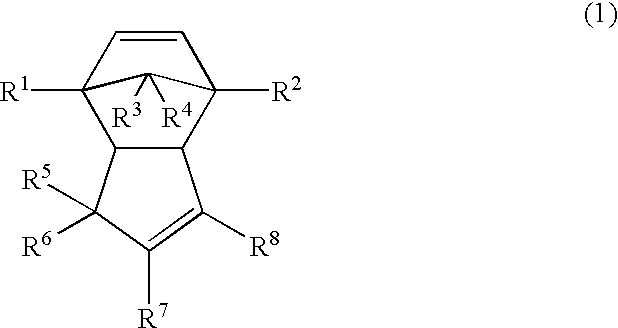

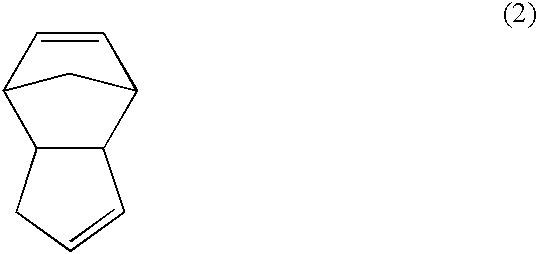

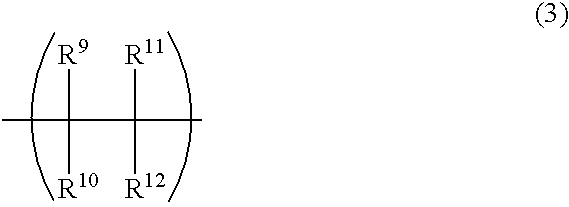

Thermoplastic dicyclopentadiene-base open-ring polymers, hydrogenated derivatives thereof, and processes for the preparation of both

InactiveUS6511756B1Improve efficiencyGood moldabilityPlastic/resin/waxes insulatorsSynthetic resin layered productsThermoplasticDouble bond

A thermoplastic dicyclopentadiene ring-opening polymer obtained by ring-opening polymerization of a monomer component containing a dicyclopentadiene monomer, characterized in that polycyclic rings which are repeating units of the polymer are bonded in cis-position relative to the carbon-carbon double bond of the main chain of the polymer in 50 mol % or more of the repeating units based on the total repeating units and the content of a low-molecular weight component of 2,000 or less in molecular weight is 10% by weight or less based on the total polymer components, and a hydrogenation product obtained by hydrogenating the carbon-carbon unsaturated bond of the thermoplastic dicyclopentadiene ring-opening polymer.

Owner:ZEON CORP

Elastomeric podalic pads

InactiveUS6187837B1Readily conformsSoft and deformableCosmetic preparationsImpression capsCushioningMicrosphere

Podalic foot pads of various shapes and configurations which utilize a padding material that is primarily an A-B-A triblock copolymer and a plasticizer. A-B diblock copolymers may be compounded into the padding material. An anti-bleed agent is preferably employed. The plasticizer may be a resin, mineral oil or otherwise. A detackifier may be employed such as grape seed oil or another slip agent. Antioxidants, pigments and micropsheres may be added to the material. The material has good cushioning properties.

Owner:PURPLE INNOVATION LLC

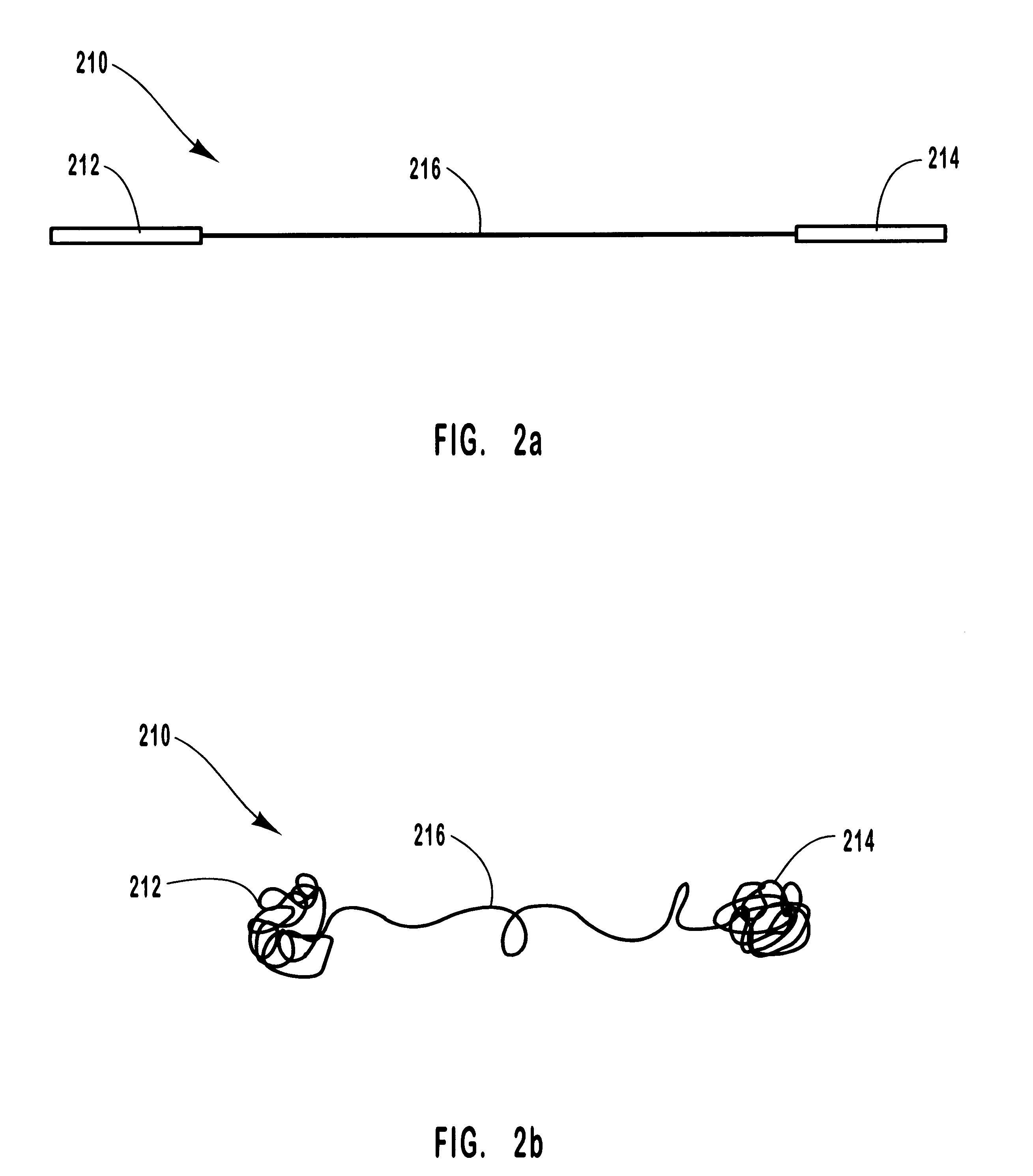

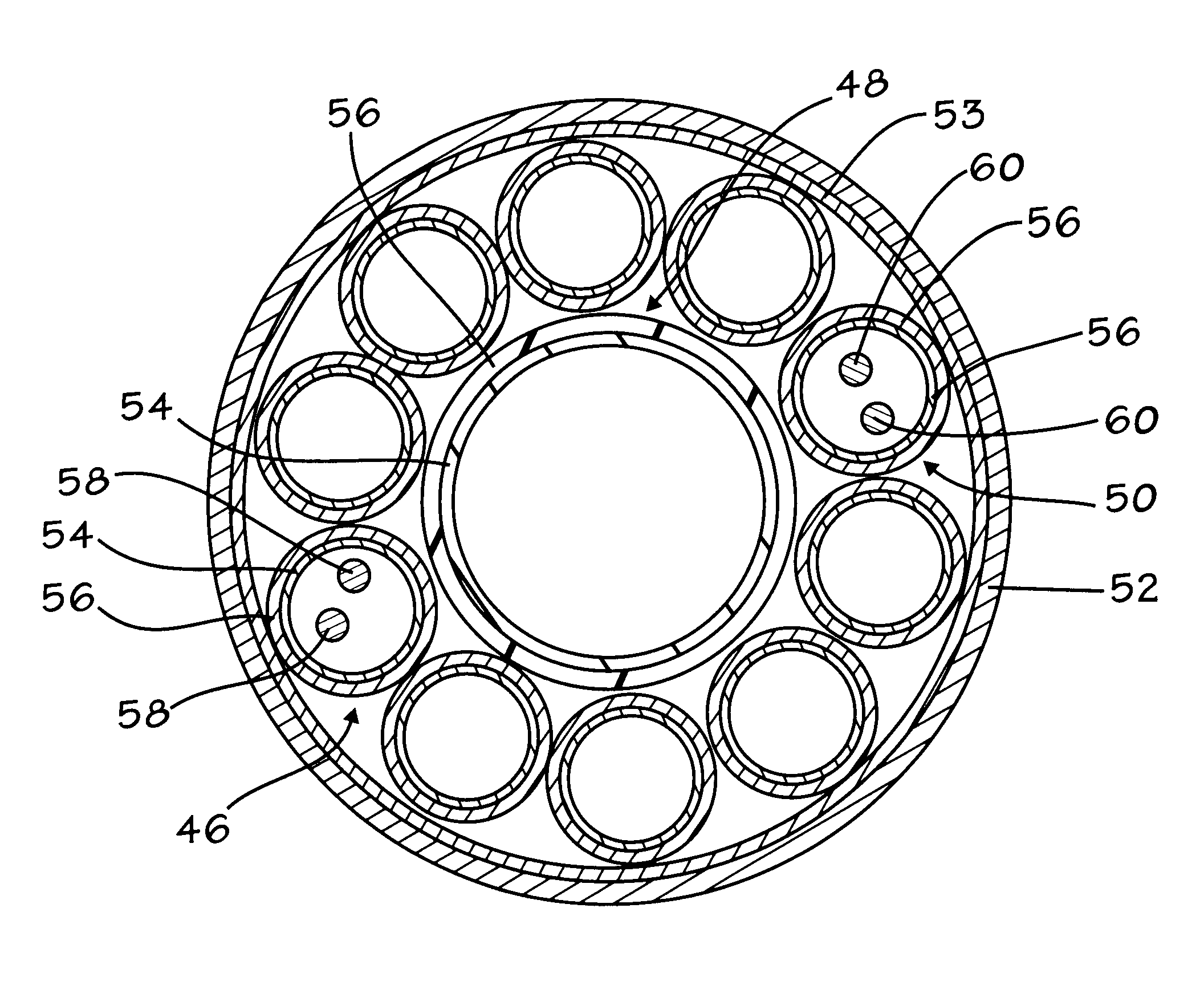

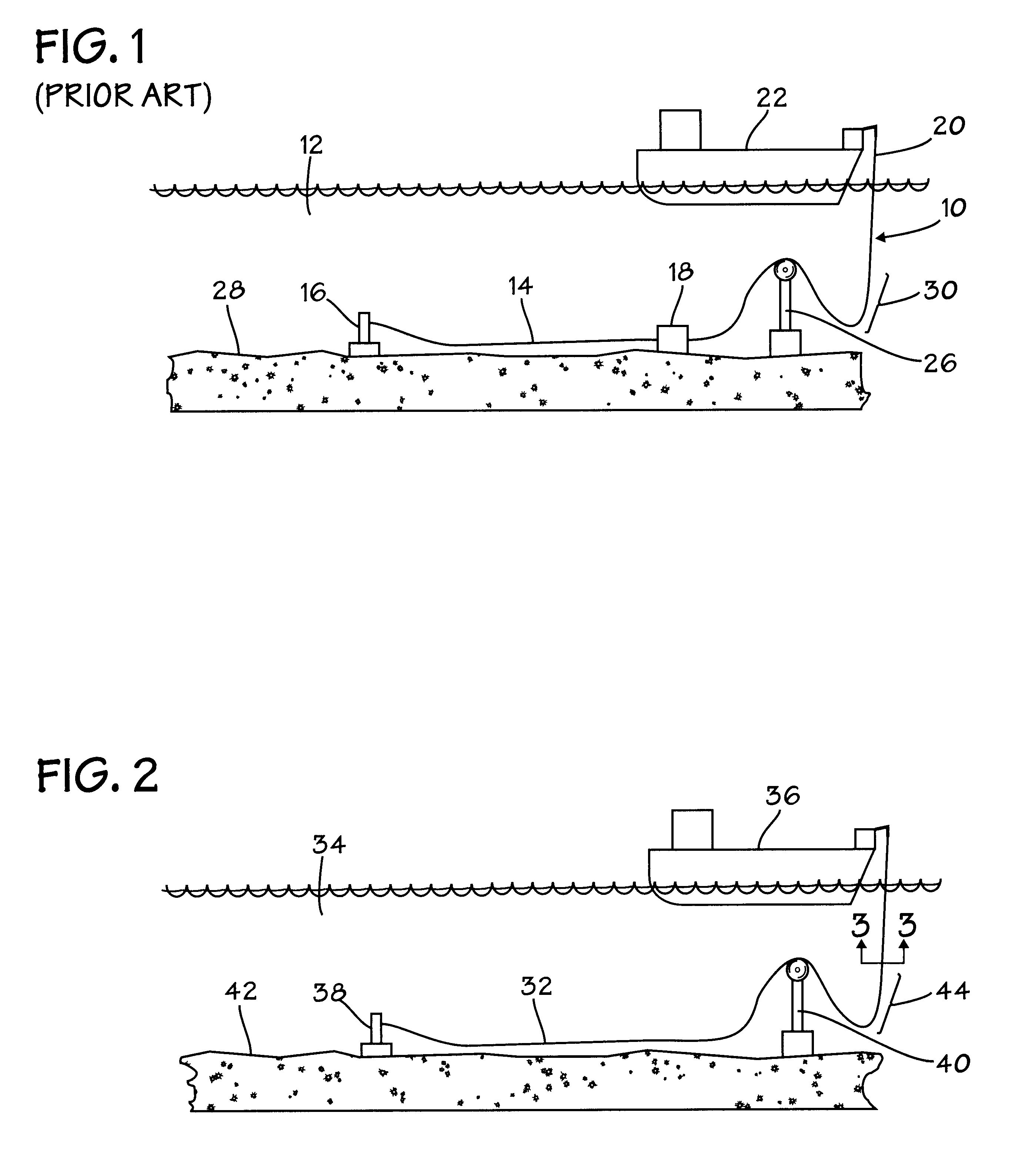

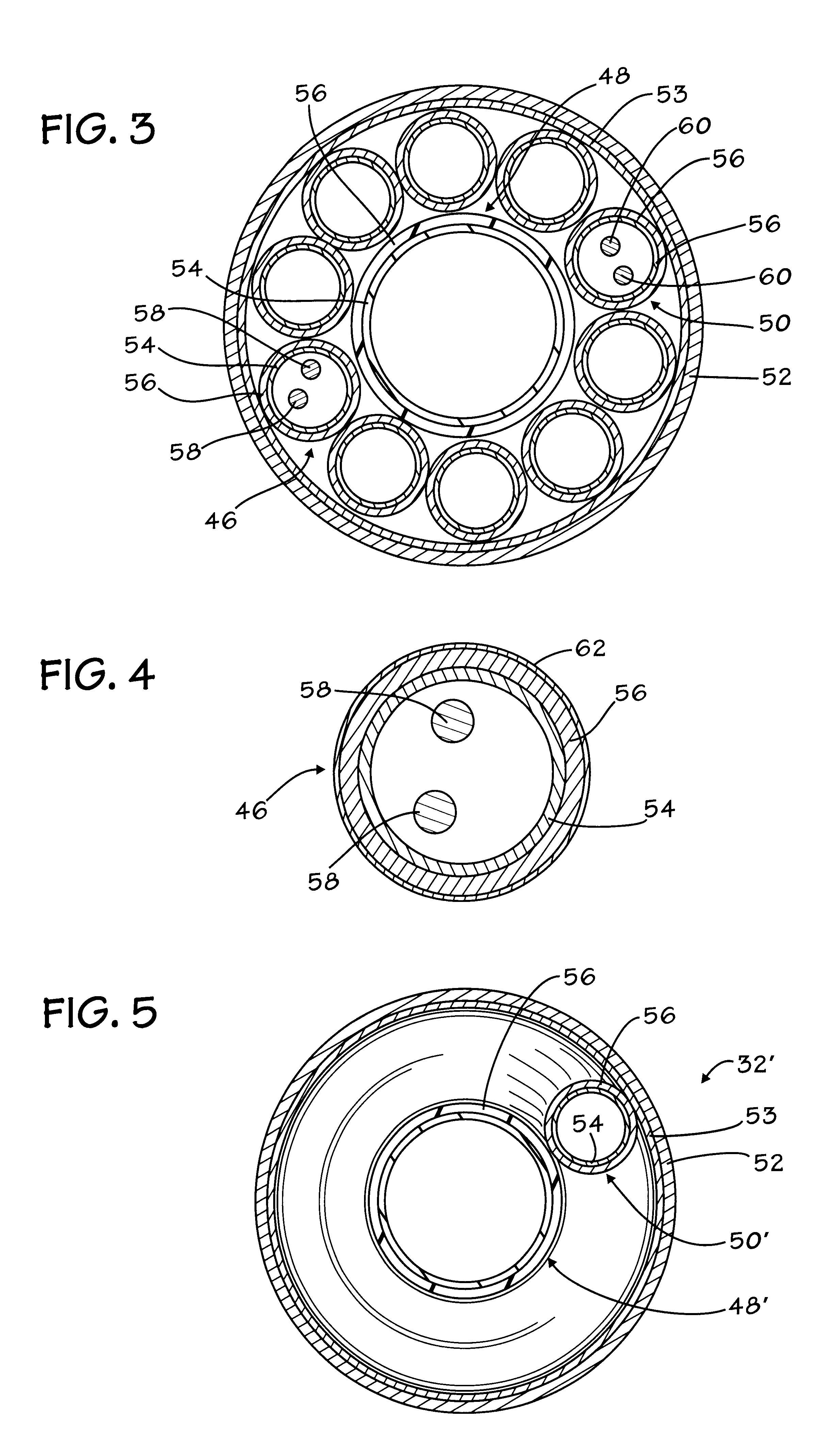

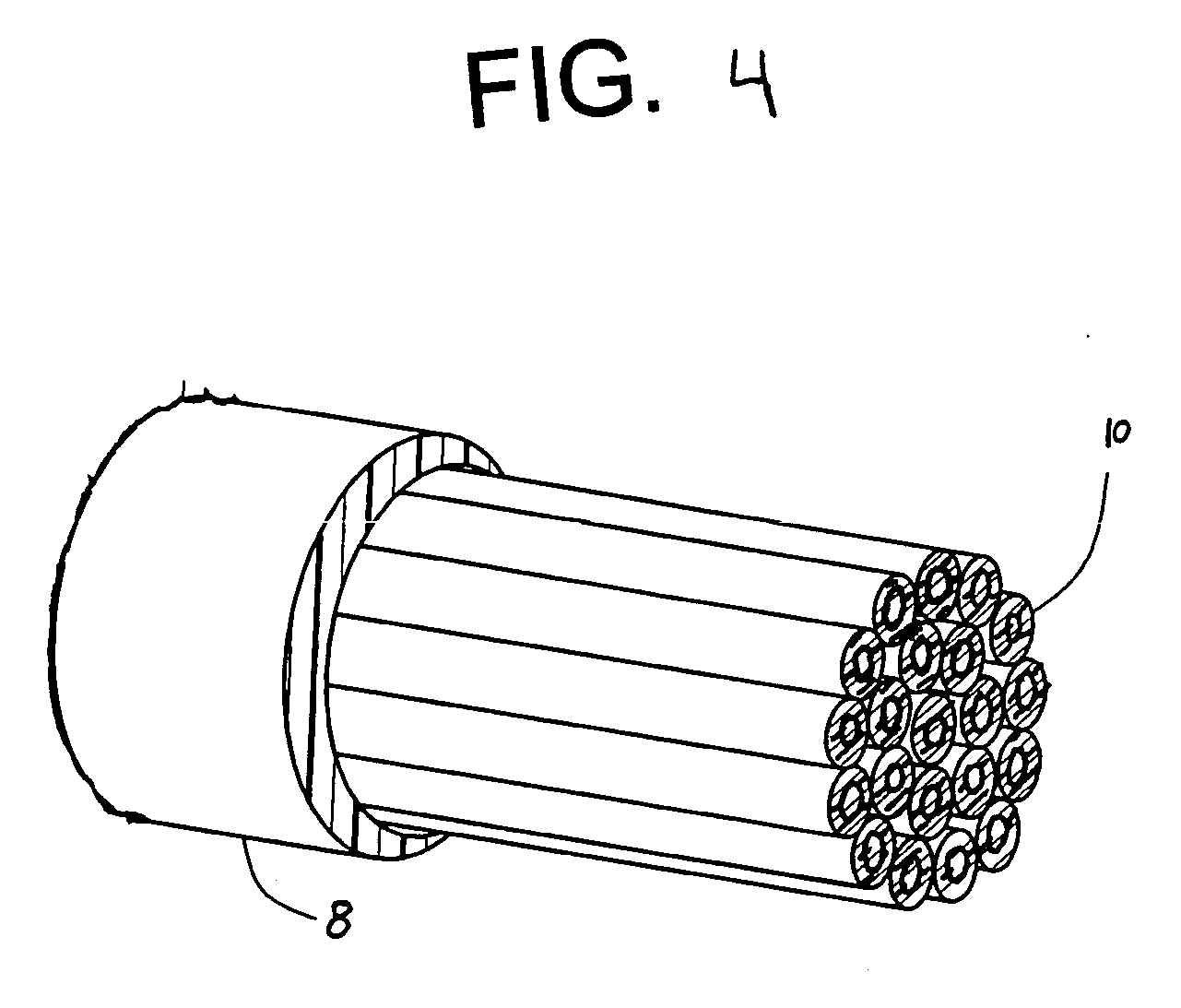

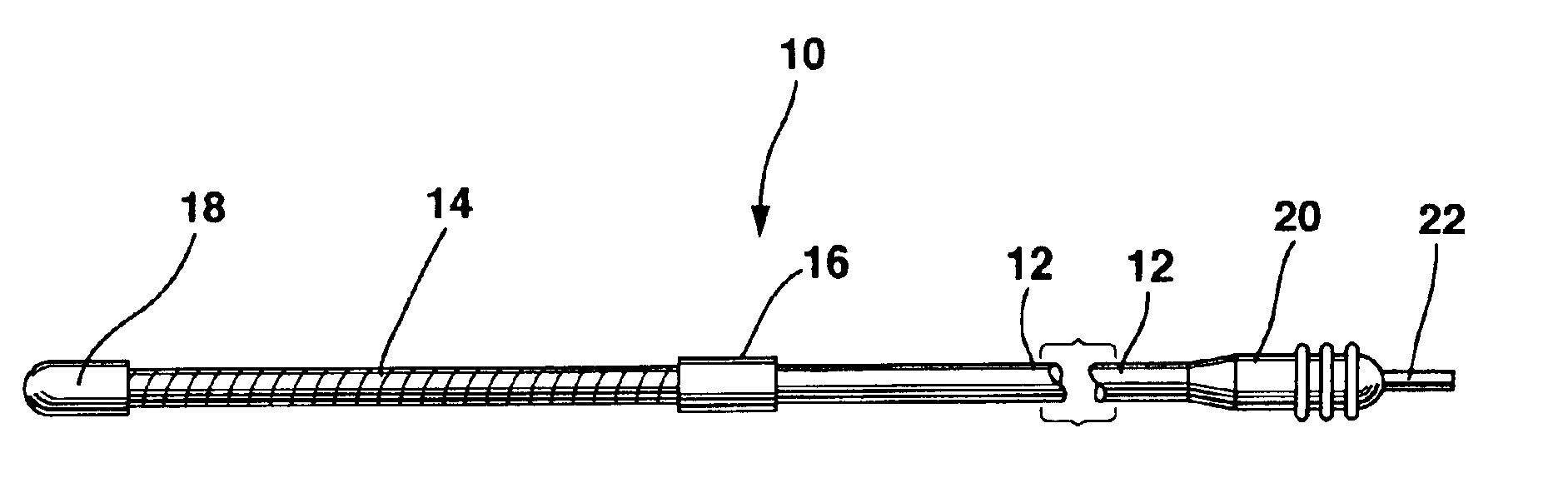

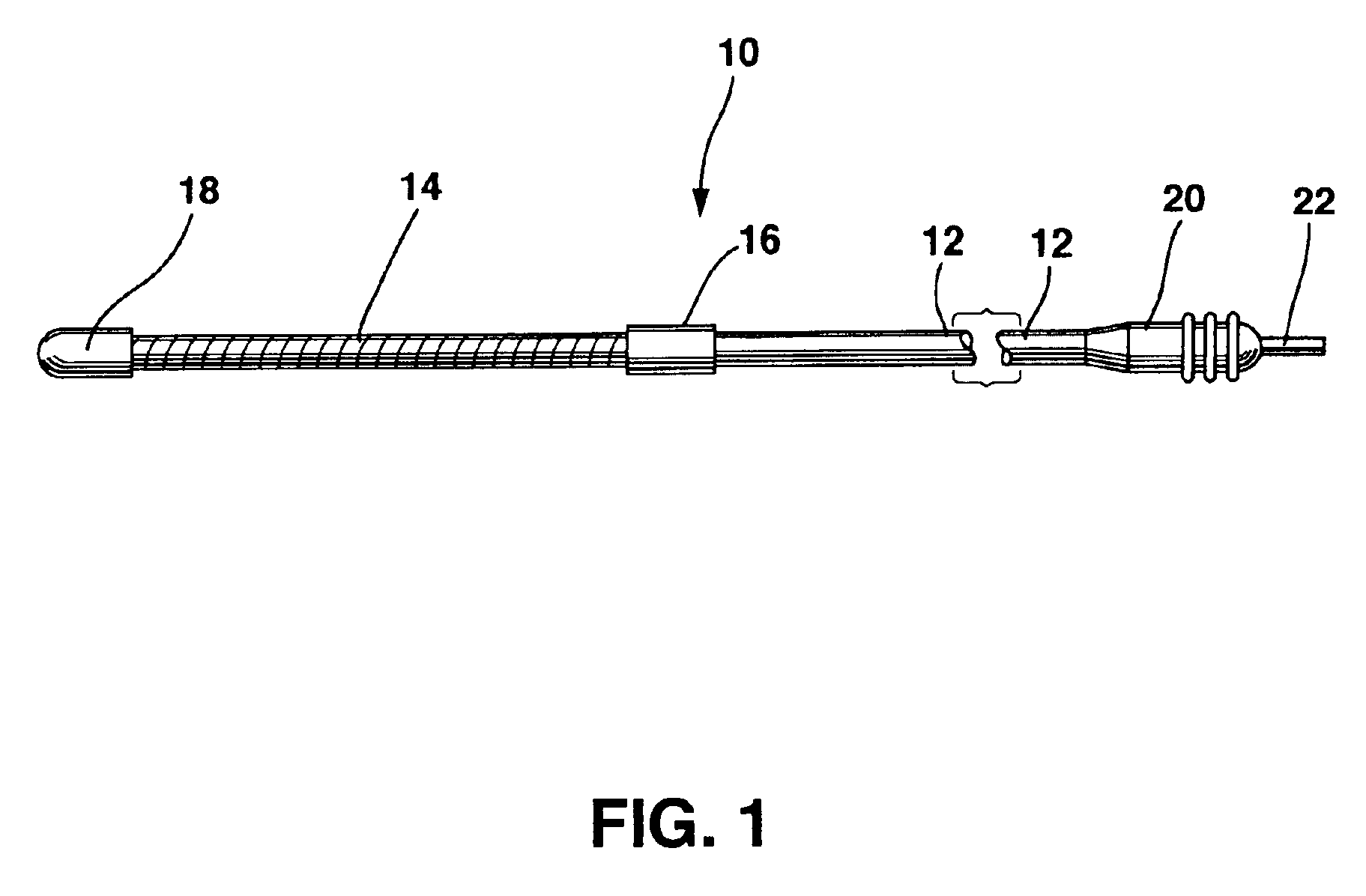

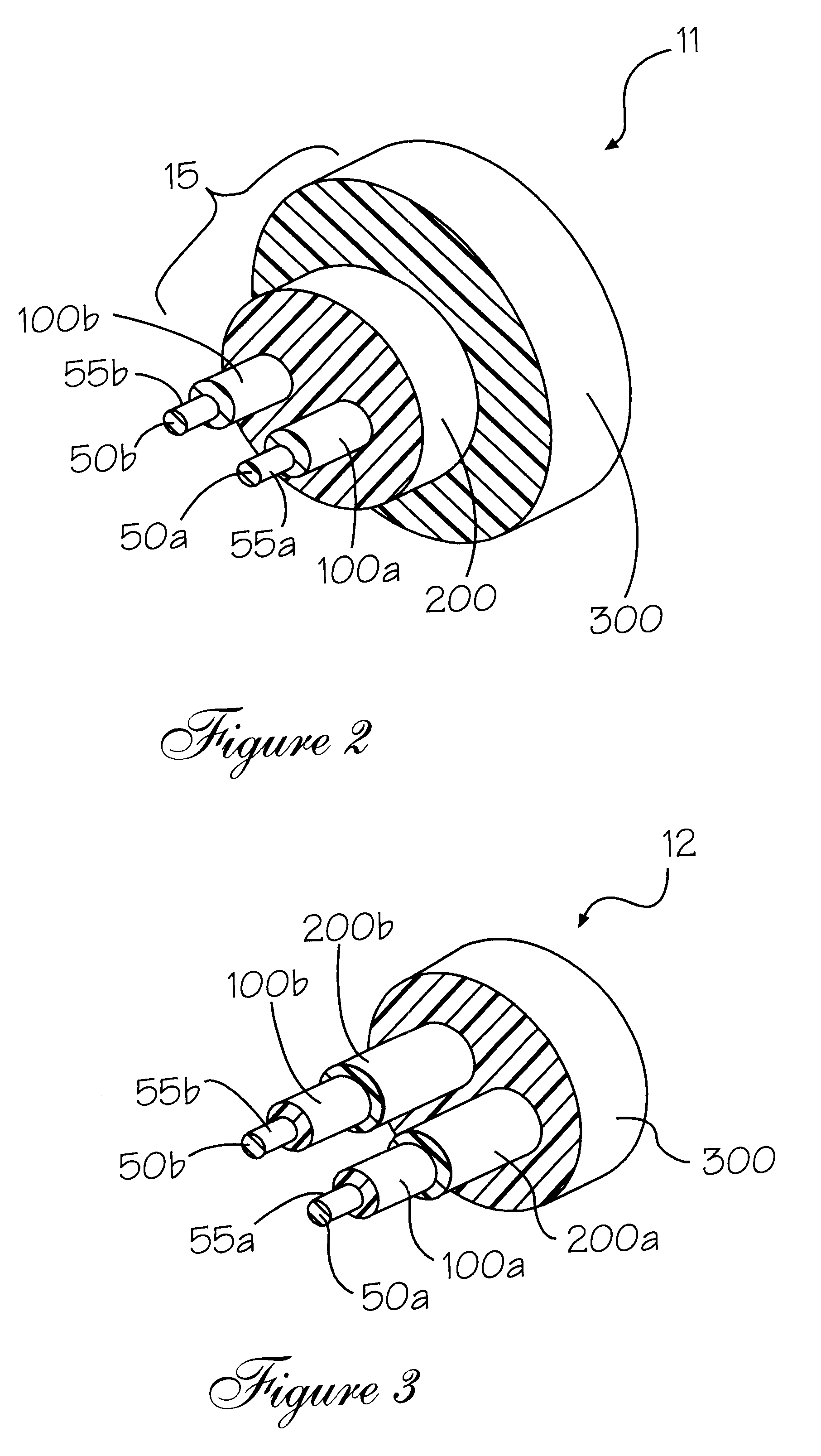

Marine umbilical

Various embodiments of an umbilical are provided. In one aspect, an umbilical is provided that includes a first tube, a second tube positioned in the first tube and a plurality of third tubes positioned in the first tube. Each of the plurality of third tubes has an inner polymer sleeve and an outer sleeve of carbon fibers in an epoxy matrix positioned around the polymer sleeve. The composite tubes yield a lighter umbilical that is easier to handle than a comparably sized conventional umbilical incorporating steel inner tubing and is more tolerant of dynamic bending and hydrostatic pressure loading.

Owner:MARINE INNOVATIONS

Heat conductive insulation material and preparation method thereof

InactiveCN101899209AExcellent formabilityImprove insulation performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsFiberMetallurgy

The invention discloses a heat conductive insulation material and a preparation method thereof. The heat conductive insulation material comprises the following components in percentage by weight: 15 to 50 percent of plastic substrate, 15 to 45 percent of heat conductive insulation filler A, 5 to 15 percent of heat conductive filler B, 10 to 30 percent of mineral fiber C, 0 to 2 percent of coupling agent and 0 to 2 percent of lubricant. The heat conductive insulation material has the advantages of perfect forming processing performance, high heat conductivity, higher uniformity and a small amount of gas content during processing; heat conductive fillers with different length-diameter ratios are combined, fillers with a large length-diameter ratio are arranged in melt flowing direction, and fillers with a small length-diameter ratio fill gaps left when the fillers with the large length-diameter ratio are arranged, so that the number of interfaces among filler components is greatly reduced, a conduction network is formed more easily, and heat conductivity is remarkably increased; moreover, the mineral fiber is added during the second machining process, so that the loss of material performance can be compensated due to the addition of high-powder fillers, and performance is better.

Owner:KINGFA SCI & TECH CO LTD +1

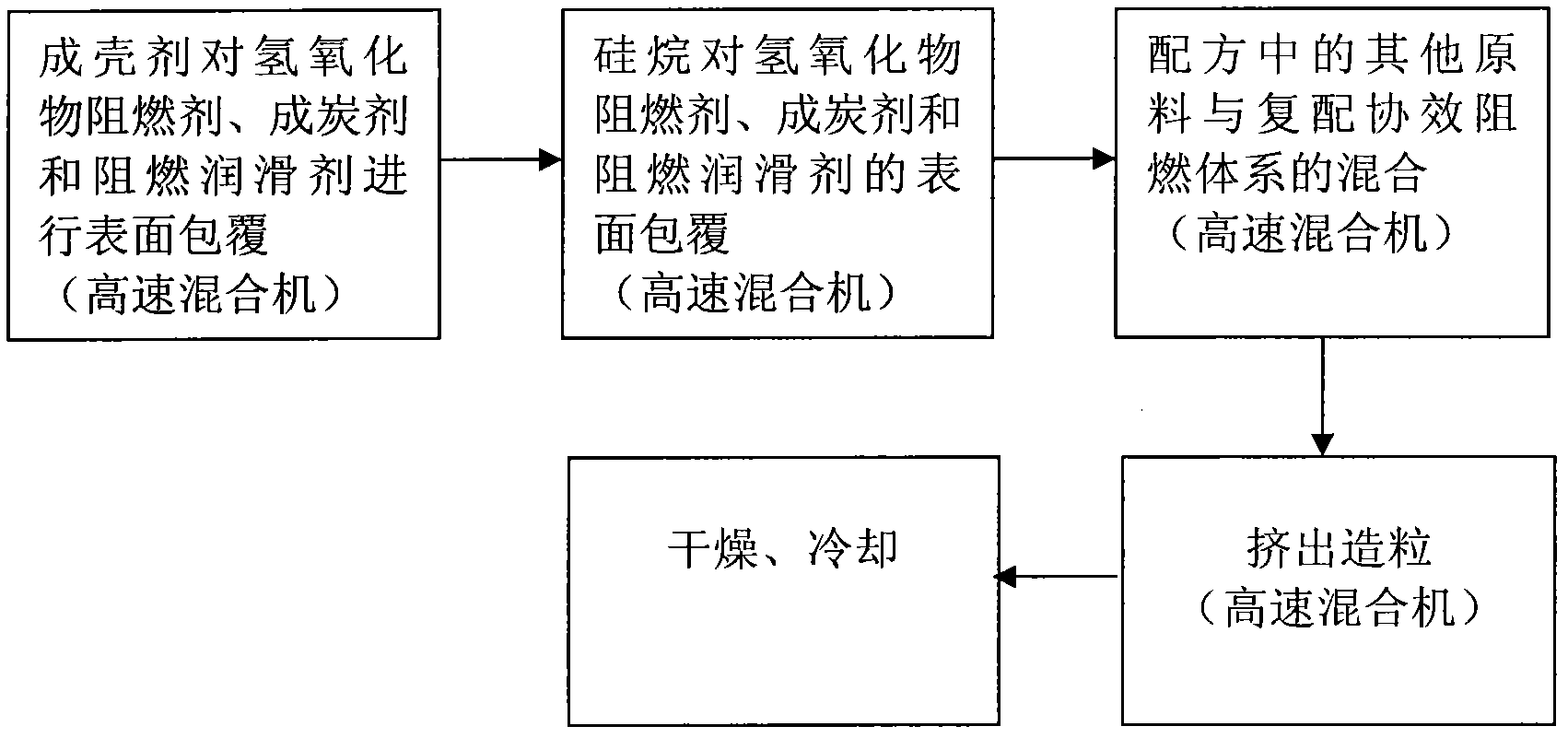

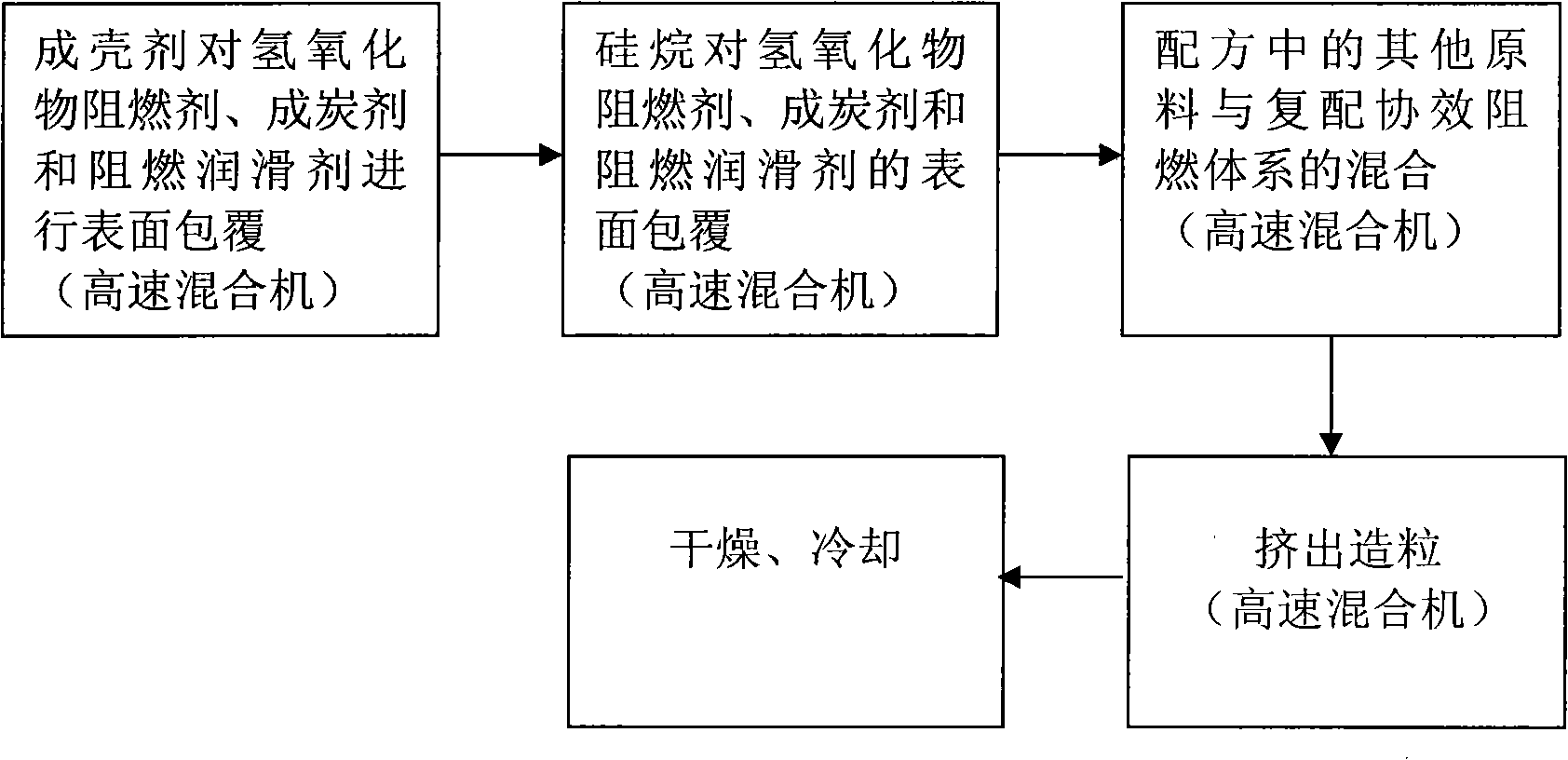

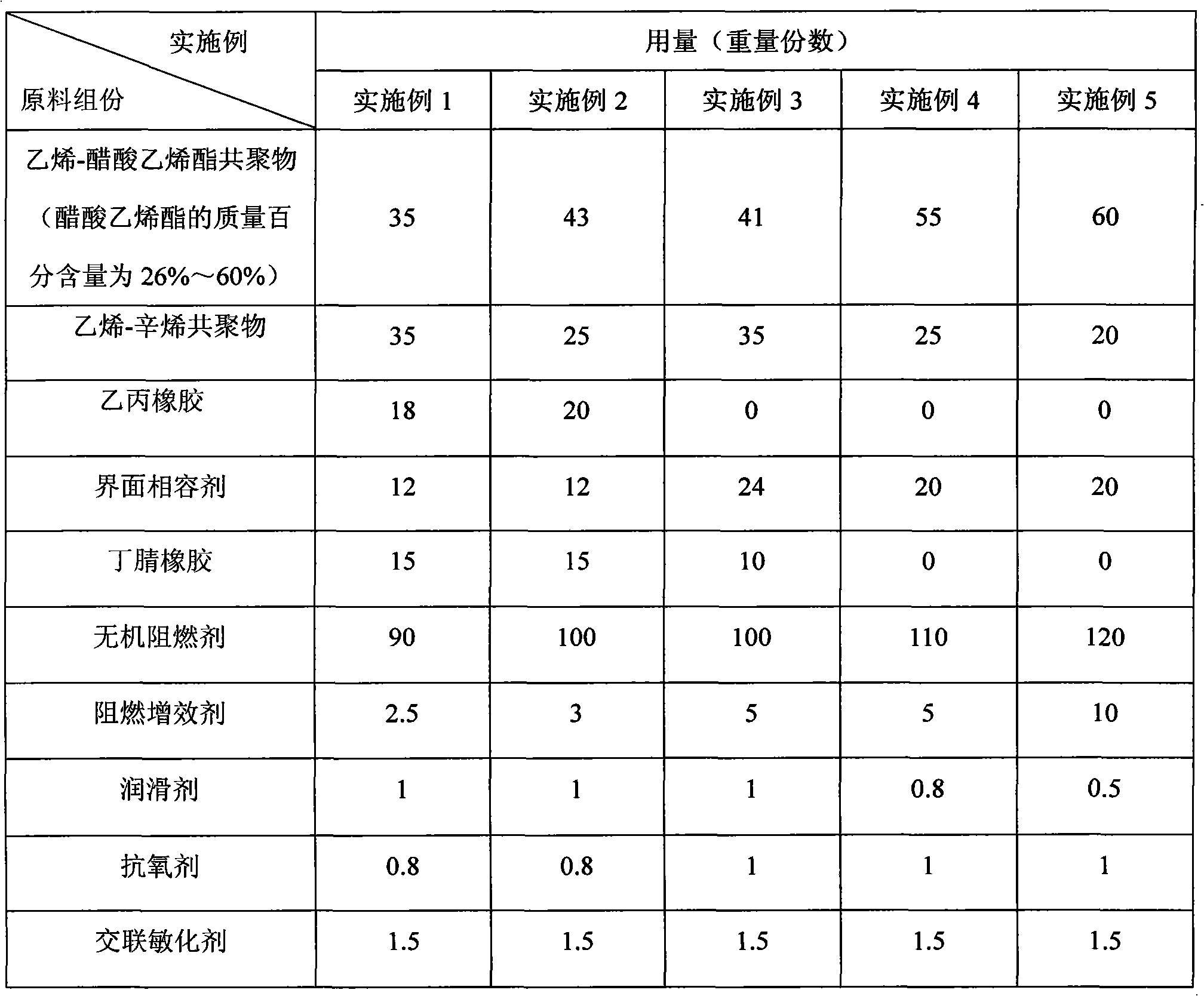

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

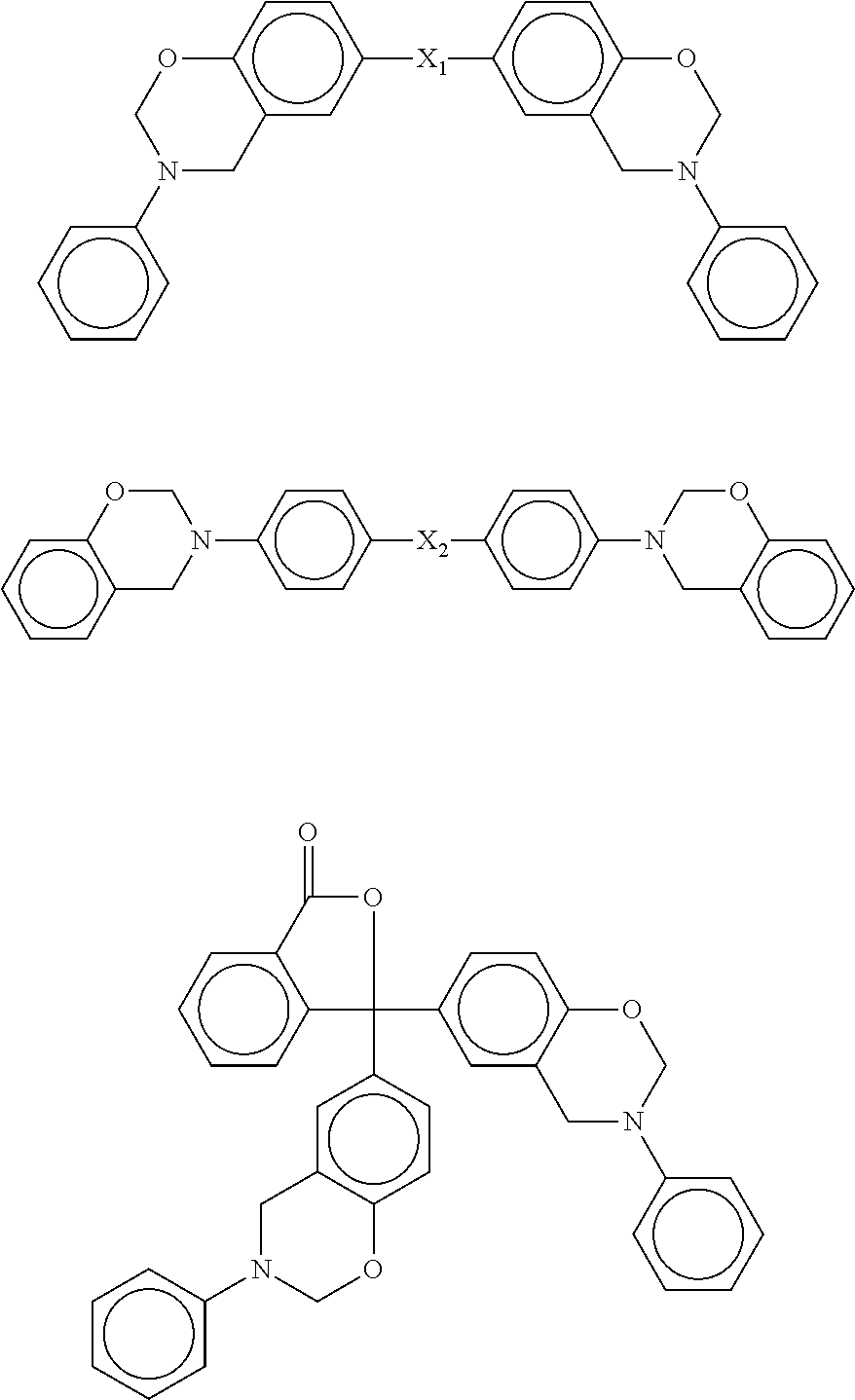

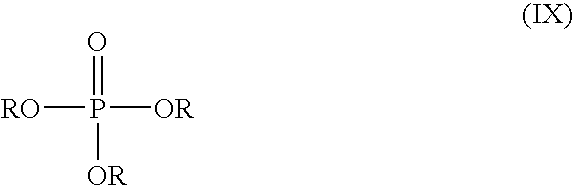

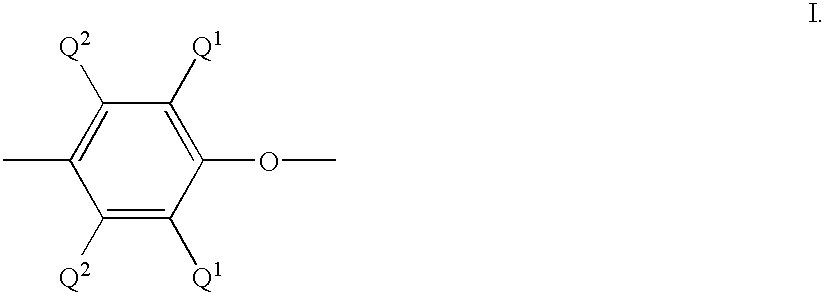

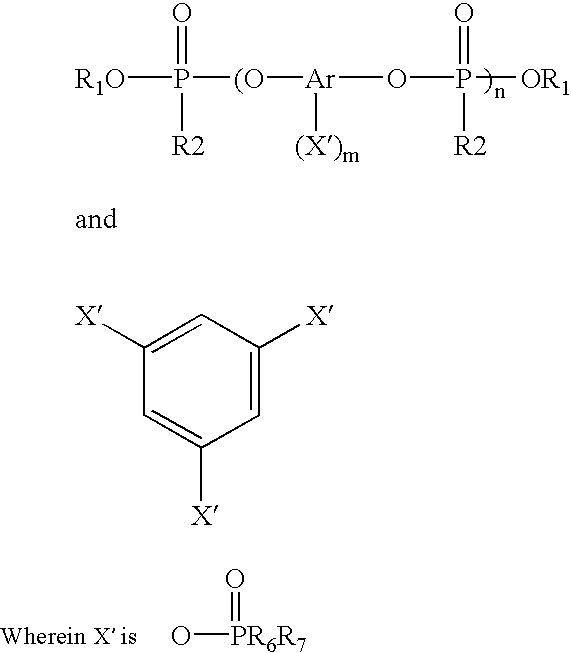

Halogen-free resin composition and its application for copper clad laminate and printed circuit board

ActiveUS20130161080A1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyLow dissipation

A halogen-free resin composition includes (A) 100 parts per hundred resin of epoxy resin; (B) 1 to 100 parts per hundred resin of benzoxazine resin; (C) 1 to 100 parts per hundred resin of styrene-maleic anhydride; (D) 0.5 to 30 parts per hundred resin of amine curing agent; and (E) 5 to 150 parts per hundred resin of halogen-free flame retardant. The composition obtains properties of low dielectric constant, low dissipation factor, high heat resistance and flame retardancy by specific composition and ratio. Thus, a prepreg or a resin film, which can be applied to a copper clad laminate and a printed circuit board, is formed.

Owner:ELITE MATERIAL

Flame retardant thermoplastic composition and articles comprising the same

A flame retardant thermoplastic composition comprises: a poly(arylene ether); an impact modifier; a polyolefin; a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide, and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate wherein the amount of phosphoric acid salt by weight is greater than or equal to the amount of organic phosphate by weight. The flame retardant composition is may be used in the production of electrical wires.

Owner:SHPP GLOBAL TECH BV

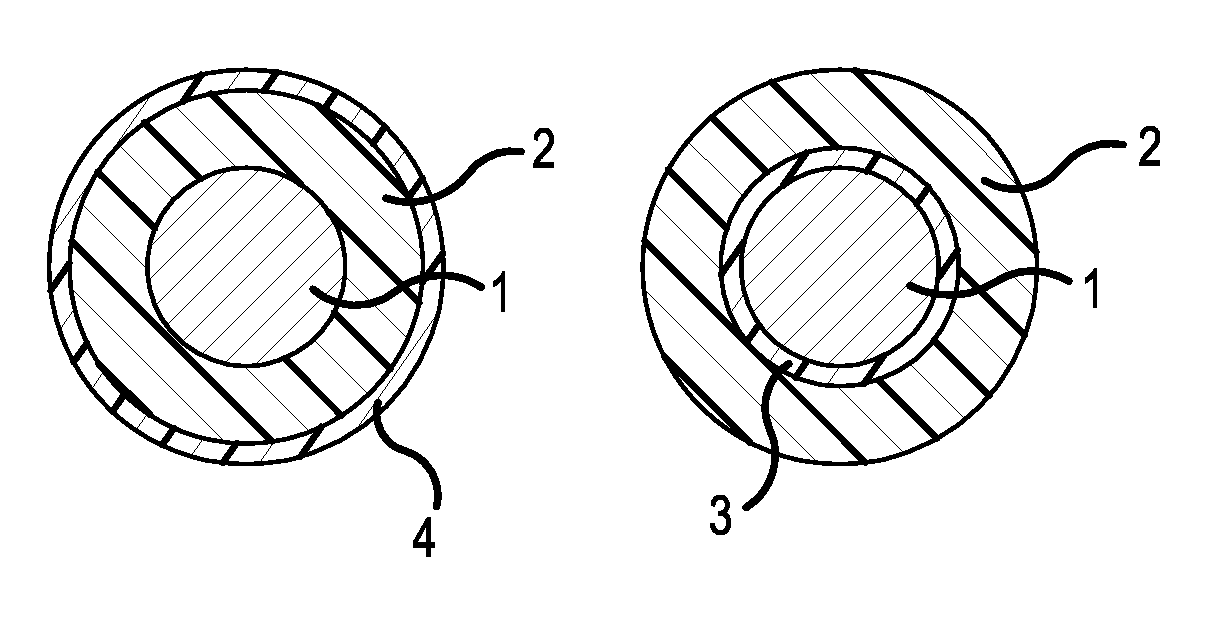

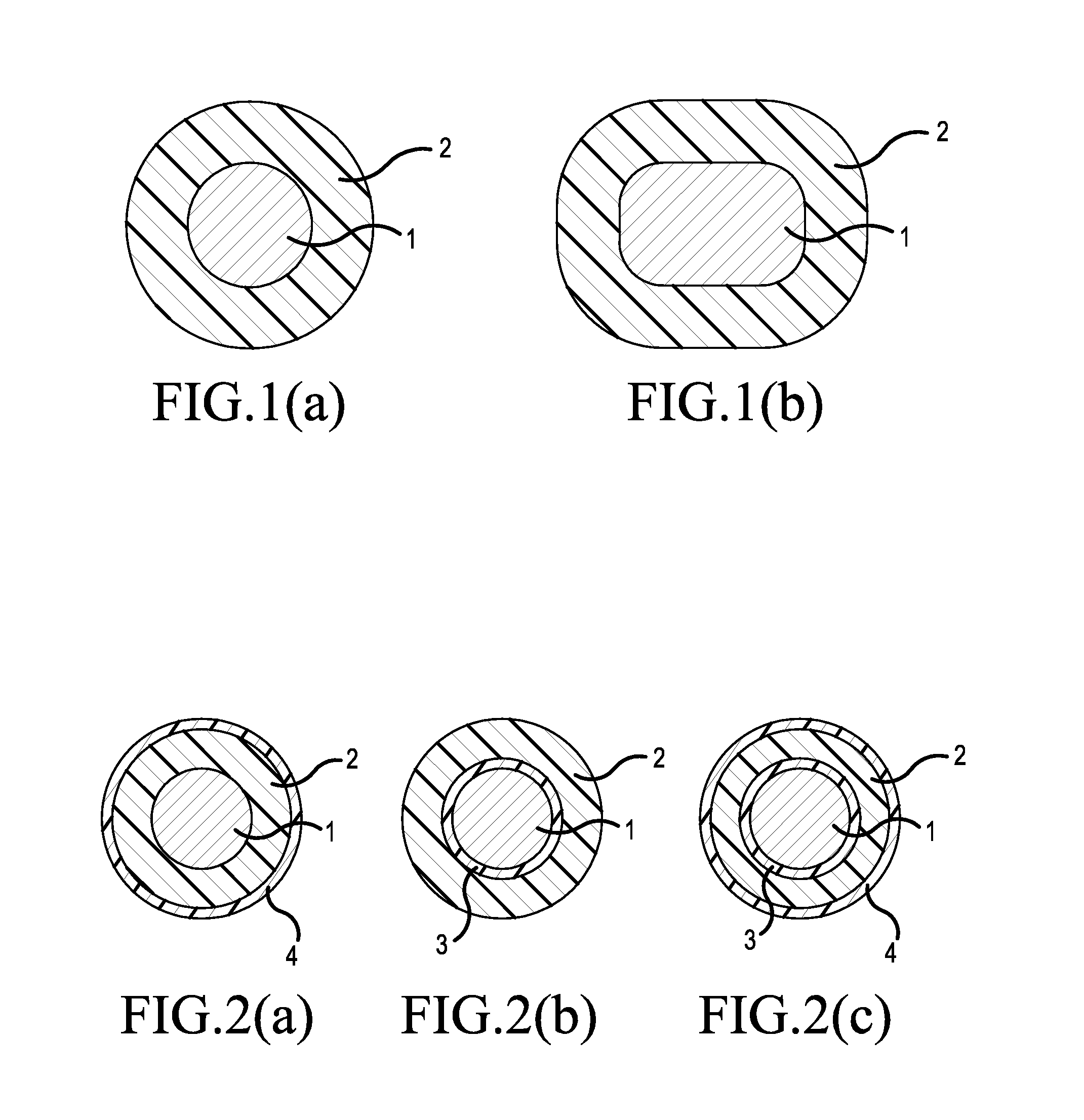

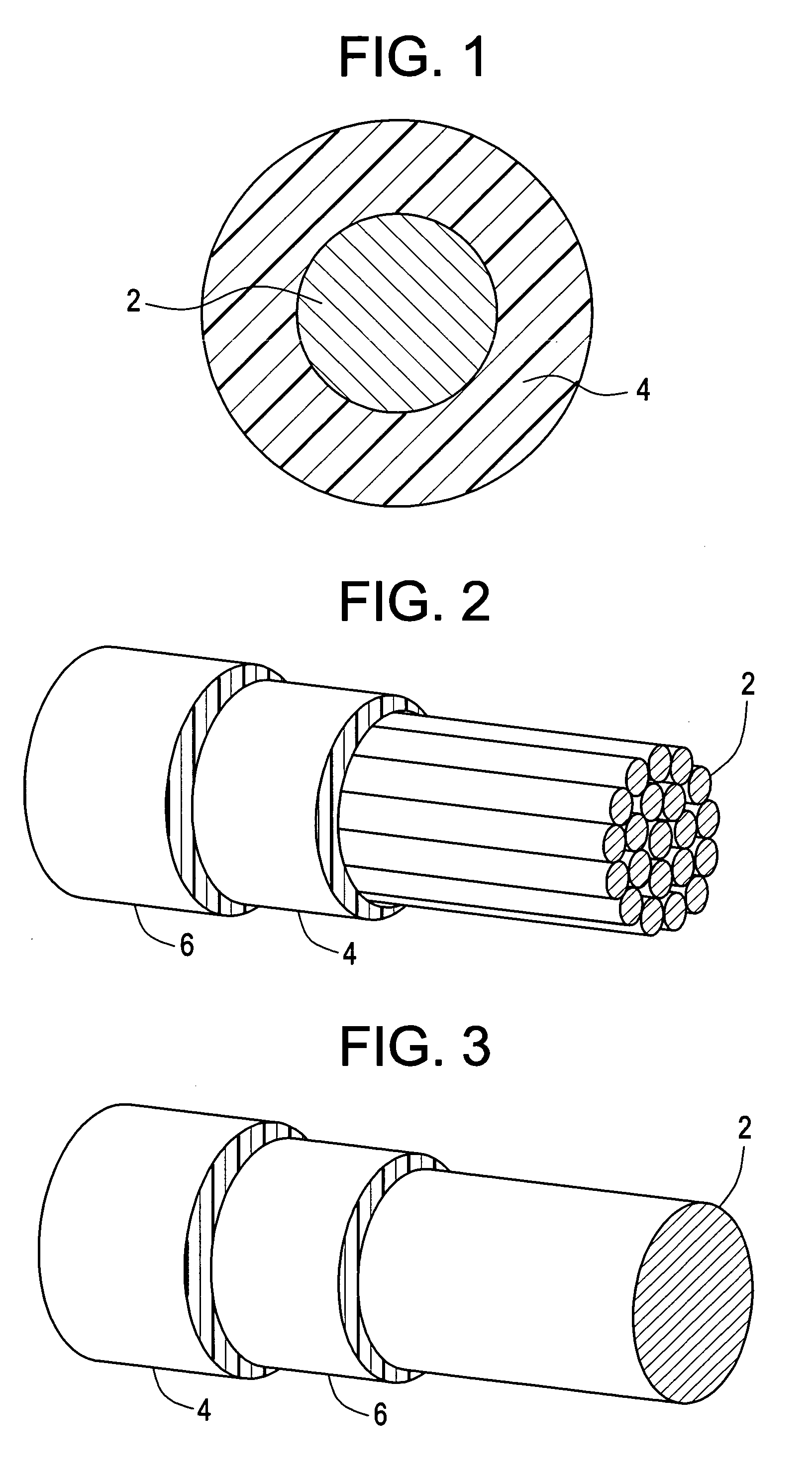

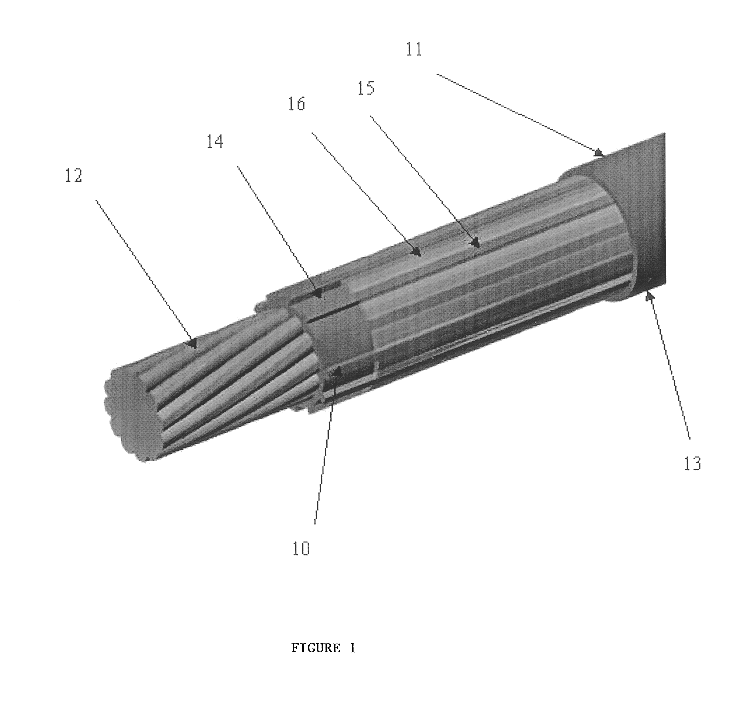

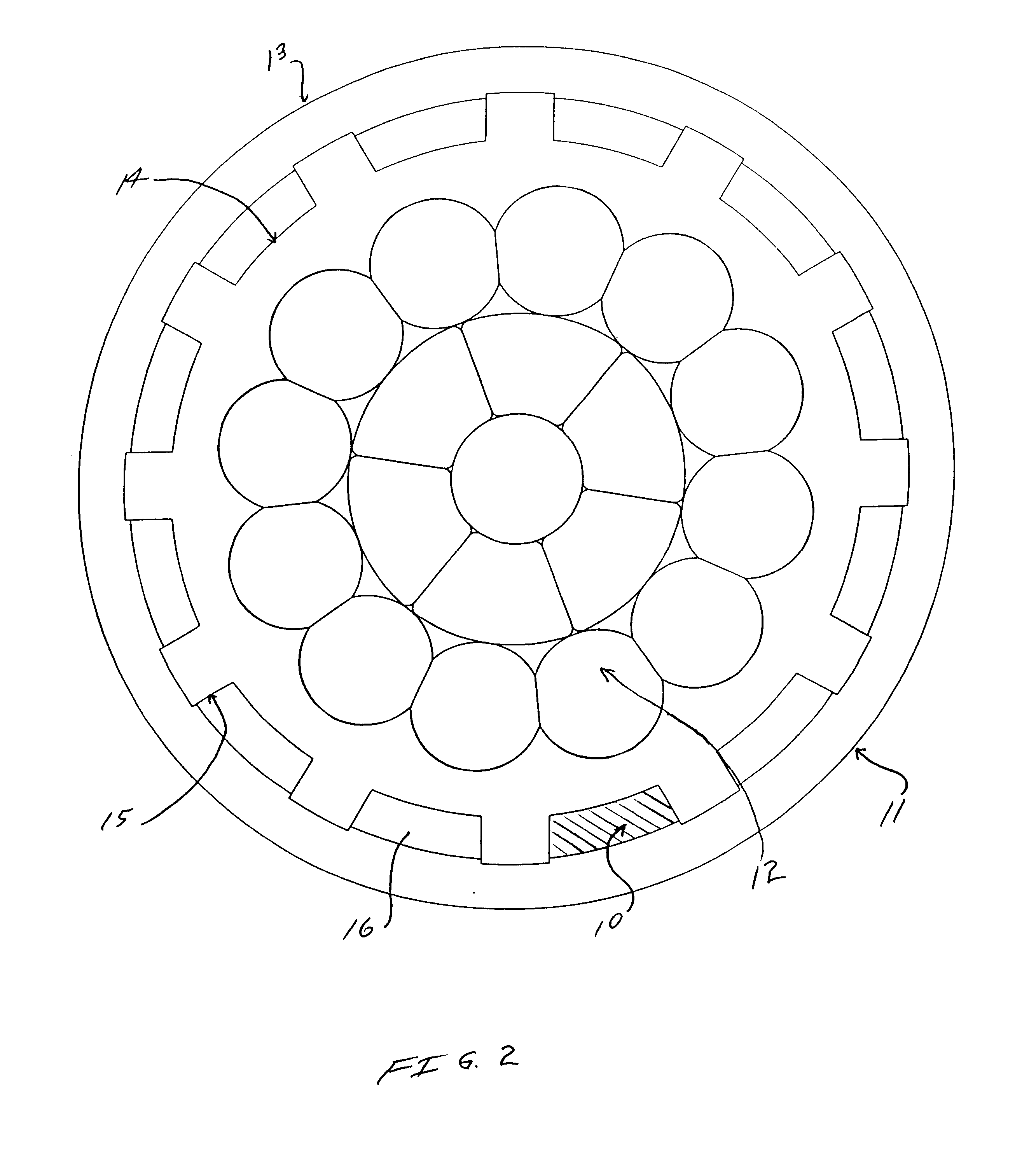

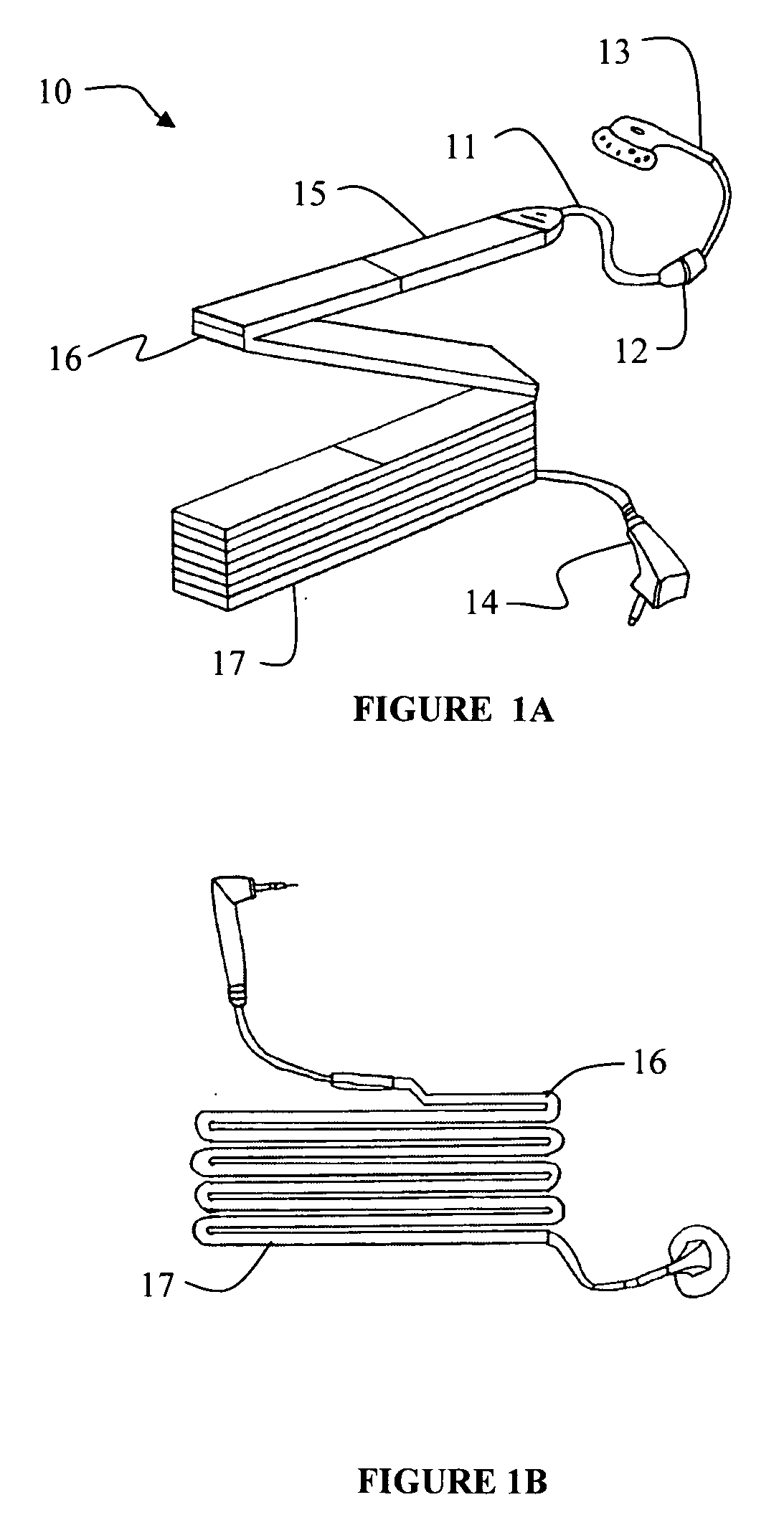

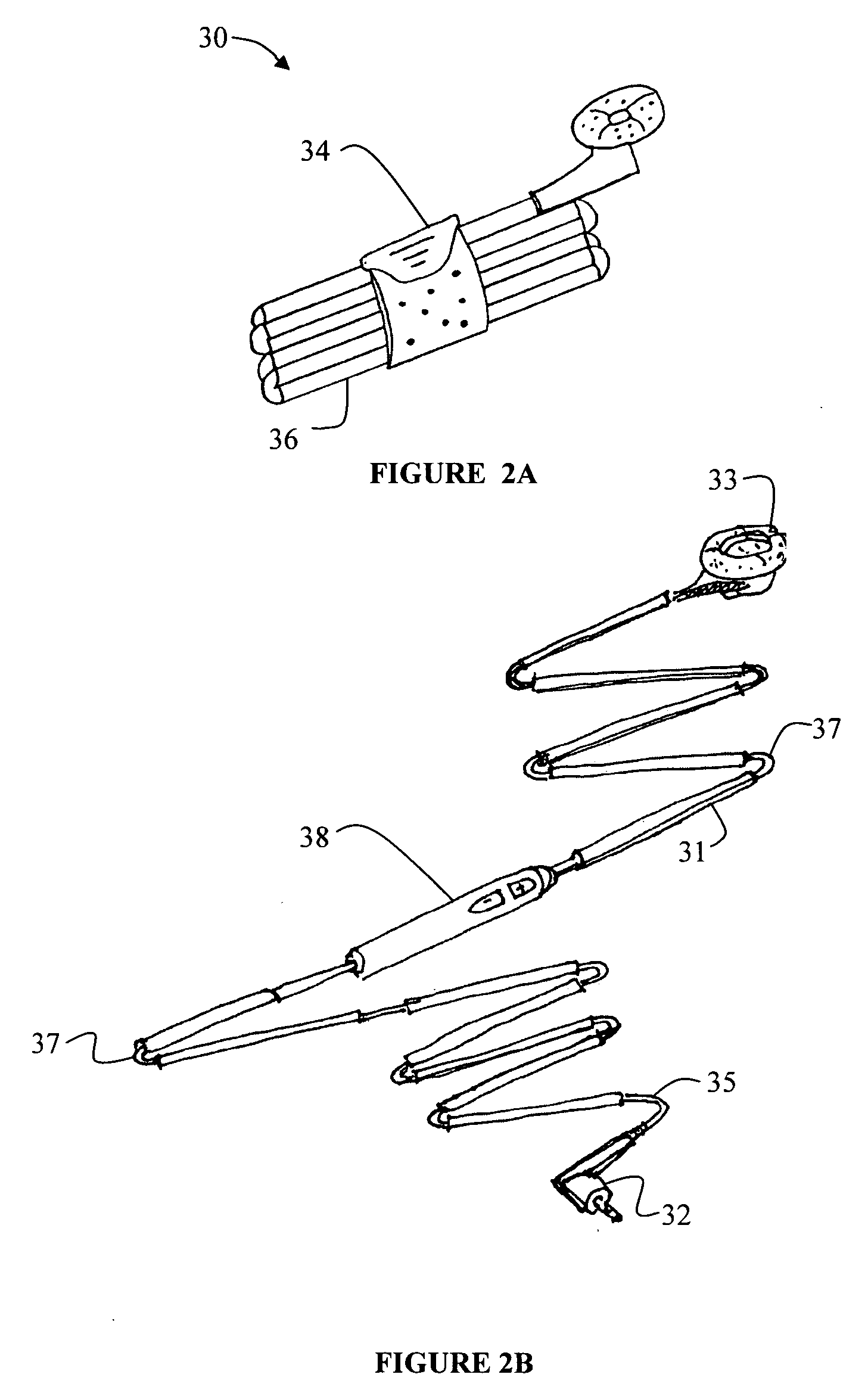

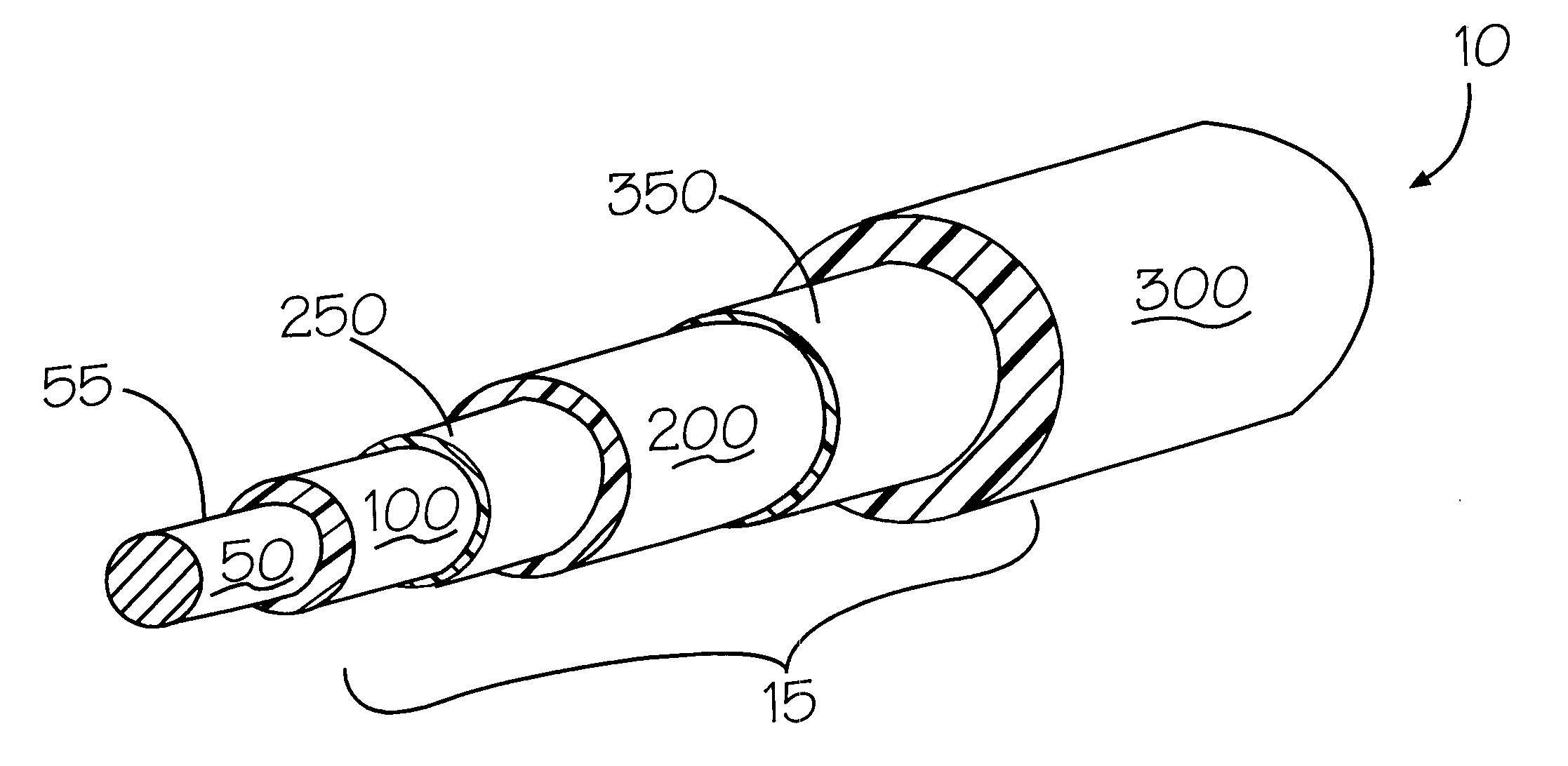

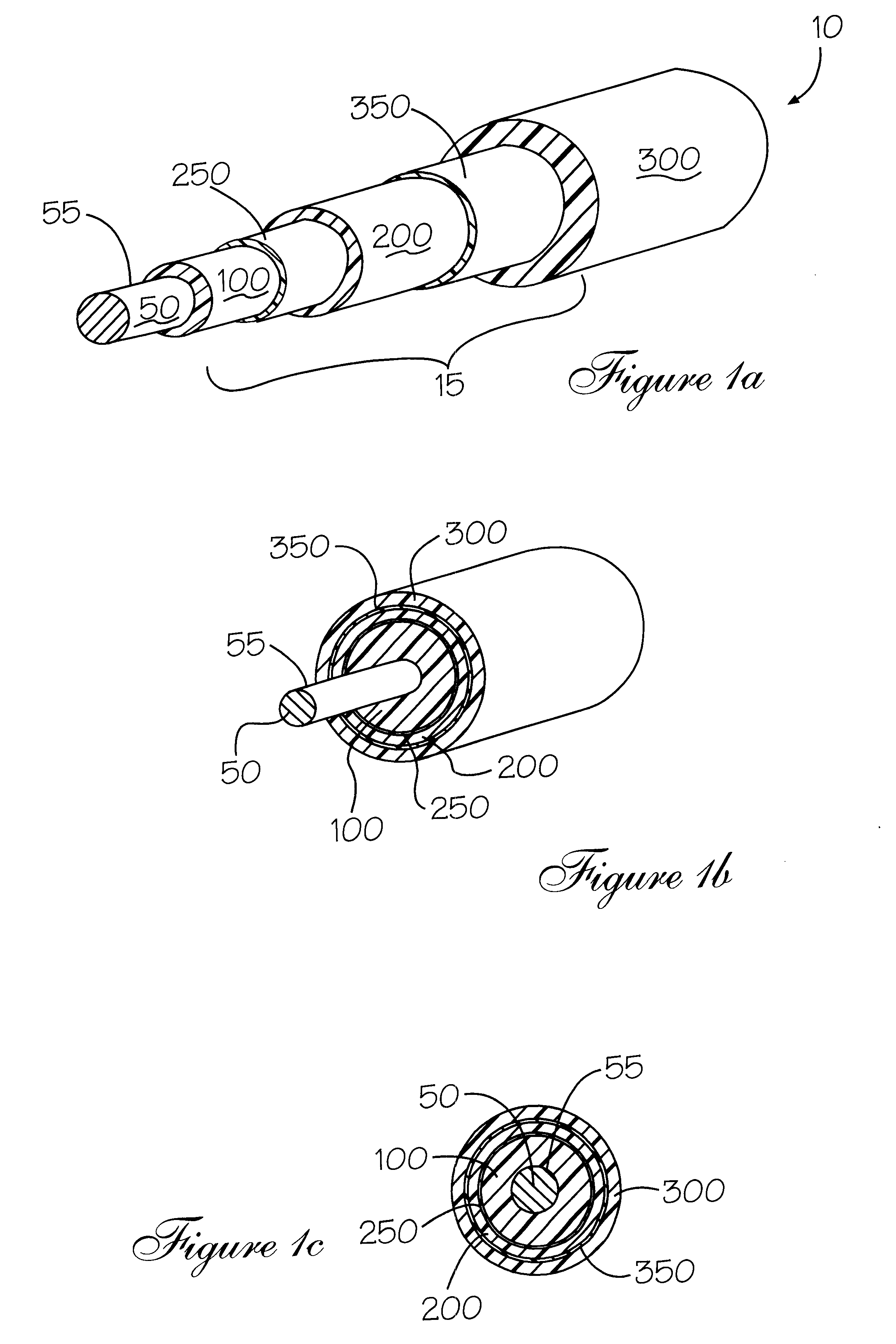

Self-sealing electrical cable having a finned inner layer

InactiveUS6573456B2Plastic/resin/waxes insulatorsClimate change adaptationElectrical conductorInsulation layer

An electrical cable and a method for manufacturing the electrical cable are provided in which a plurality of conductors have an inner protective layer extruded thereabout, a ribbed or finned surface exterior thereto which includes a plurality of longitudinally extending ribs or fins between which exist a plurality of channel regions, an outer insulation layer thereabout, and a material within the channel regions which provides self-sealing properties to the cable, all applied to the conductor as a combined multilayer, the inner layer and outer layer merging to form the fins therebetween.

Owner:SOUTHWIRE CO LLC

Polymeric materials with improved dielectric breakdown strength

InactiveUS6879861B2Plastic/resin/waxes insulatorsHeart defibrillatorsDielectric breakdown strengthUltimate tensile strength

A novel polymeric electrically insulating material that includes a linked voltage stabilizing agent. Also provided are methods of making the novel material and articles and devices that incorporate the novel material, particularly implantable medical devices.

Owner:MEDTRONIC INC

Flame retardant composition

Owner:NIPPON YUNIKAA

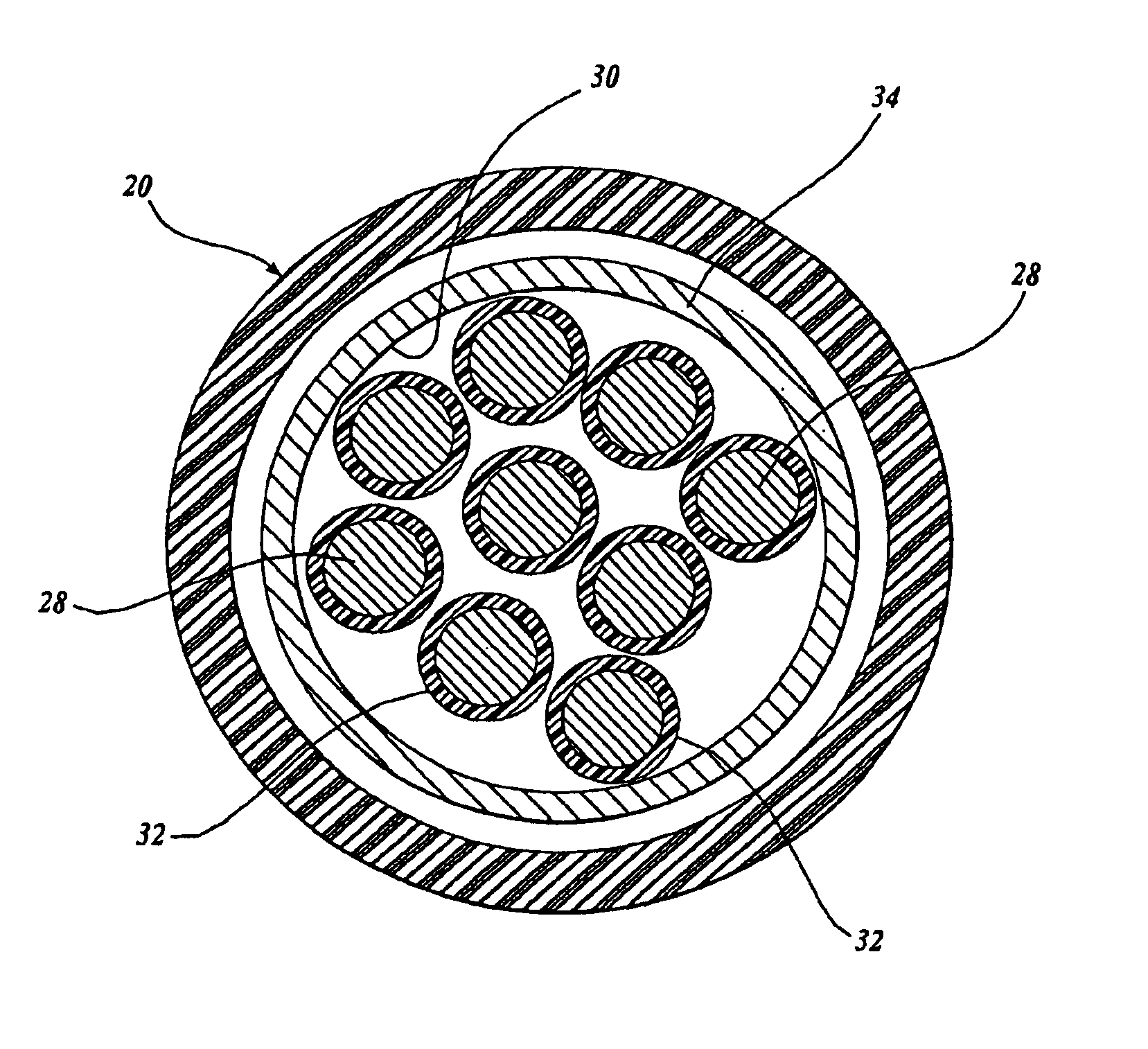

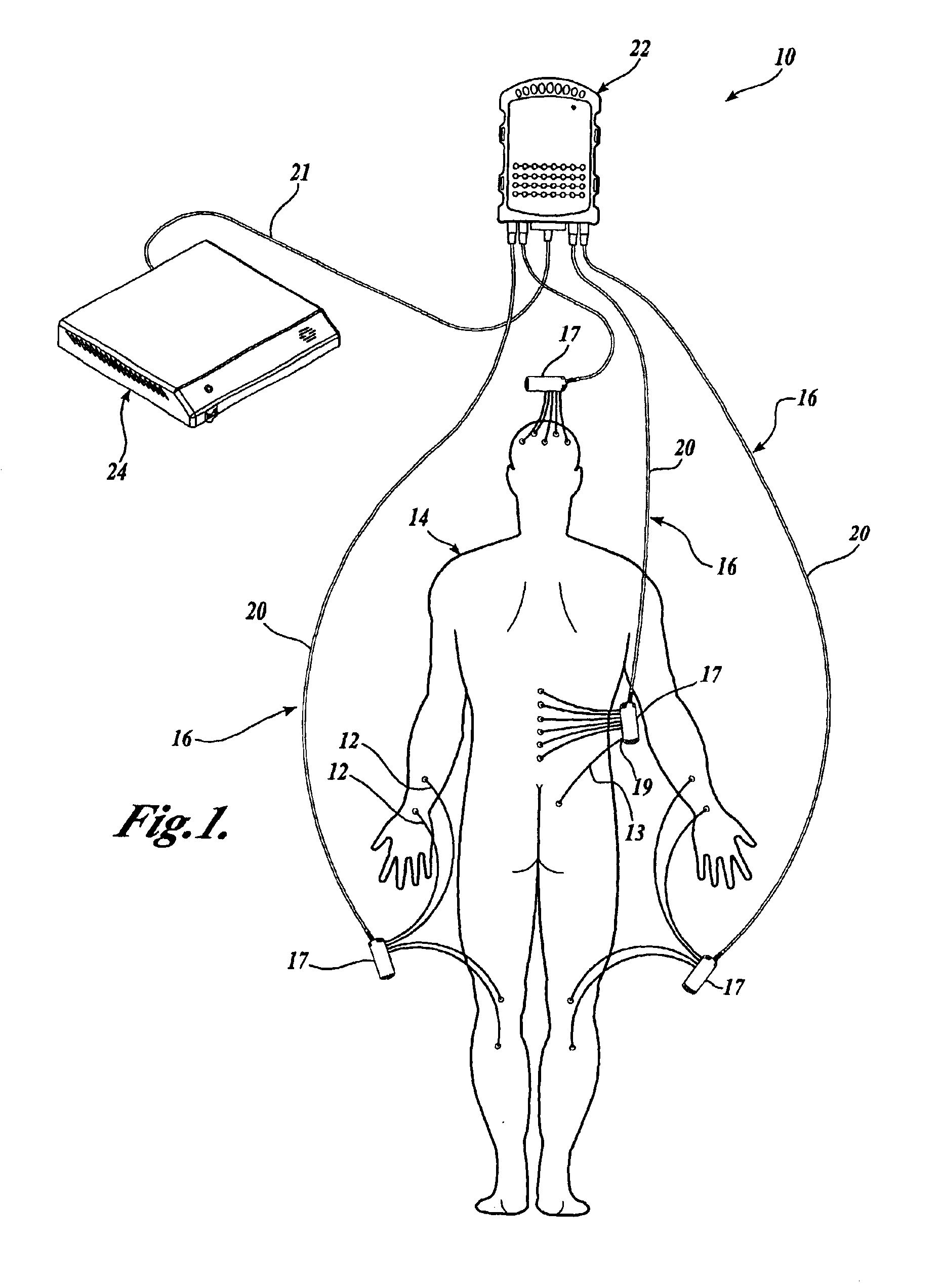

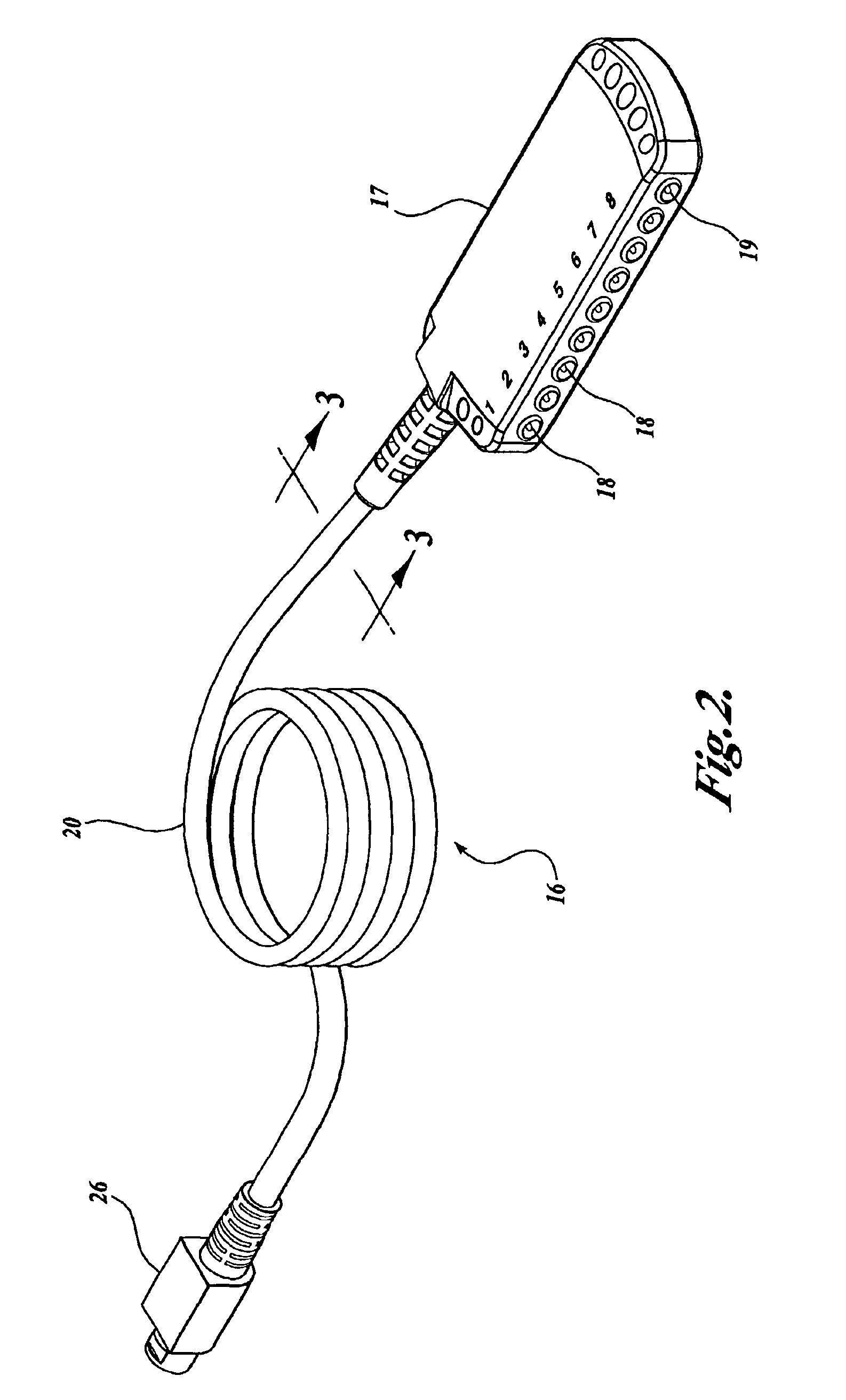

System and device for reducing signal interference in patient monitoring systems

InactiveUS6870109B1Reduce signal interferenceBioelectric signal measurementPlastic/resin/waxes insulatorsShielded cableMonitoring system

A system and device for mitigating interference in patient physiological monitoring is provided, particularly in surgical environments. One or more sets of electrodes are placed on a patient's body and connected to corresponding terminals of an input extender. The terminals of the input extender are connected to a set of signal wires encased by a ferrous shielded cable. The ferrous shielded cable connects to a signal processing unit, which includes a differential amplifier and an active drive topology to drive the shield with a common mode signal. The signal processing unit connects to physiological monitoring equipment.

Owner:CADWELL INDS

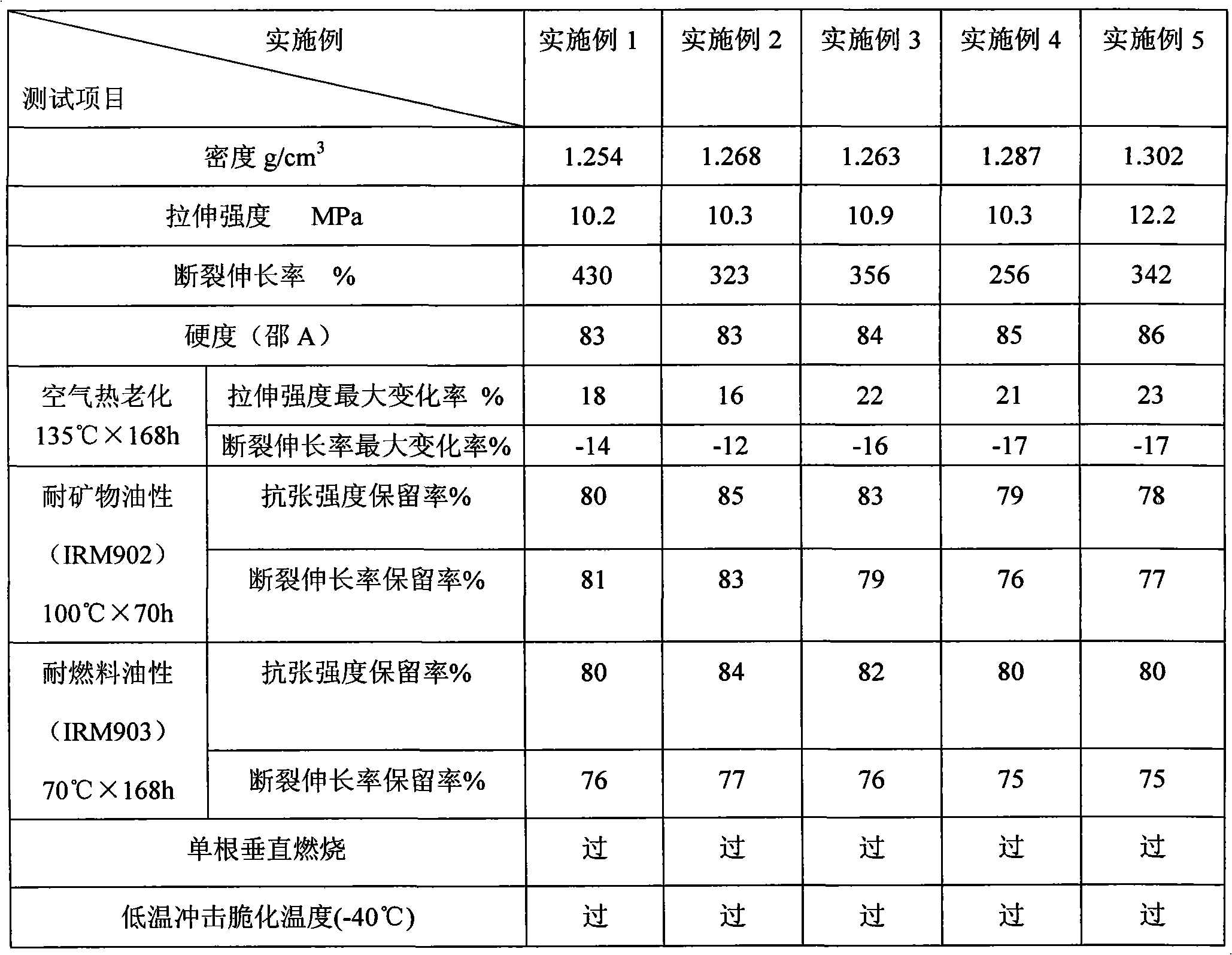

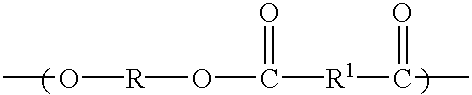

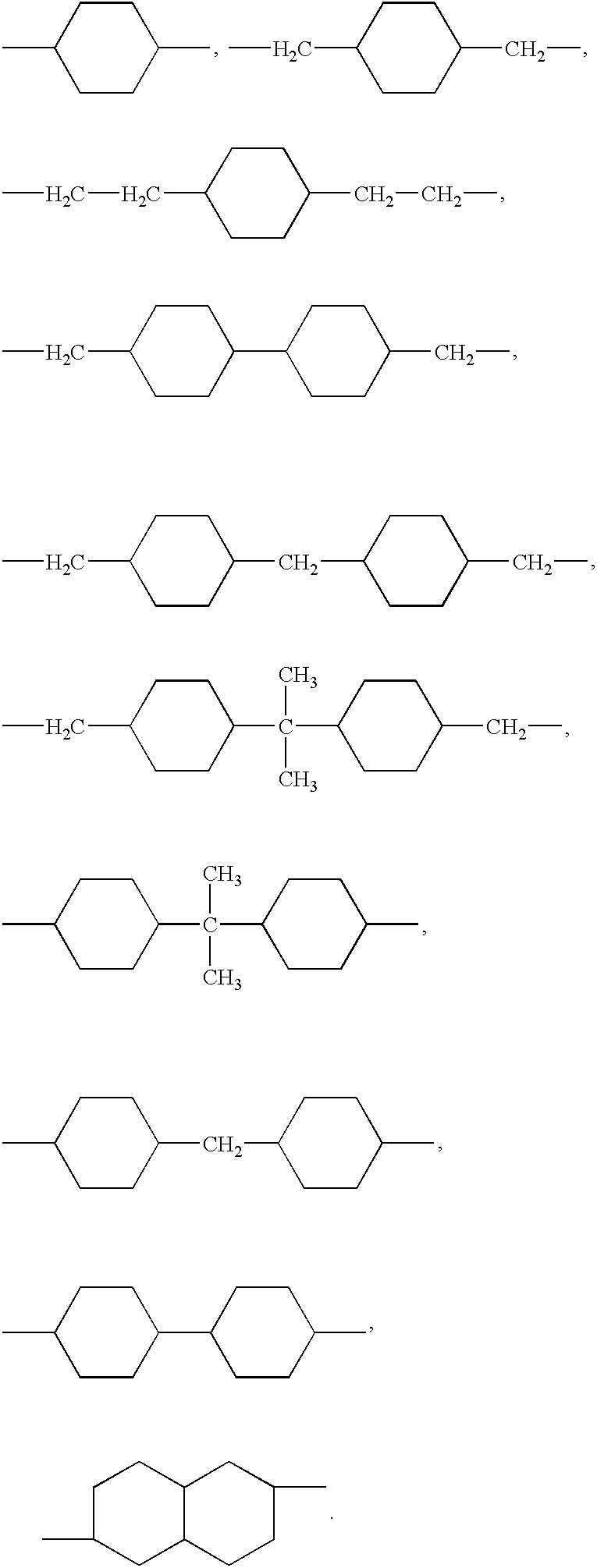

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

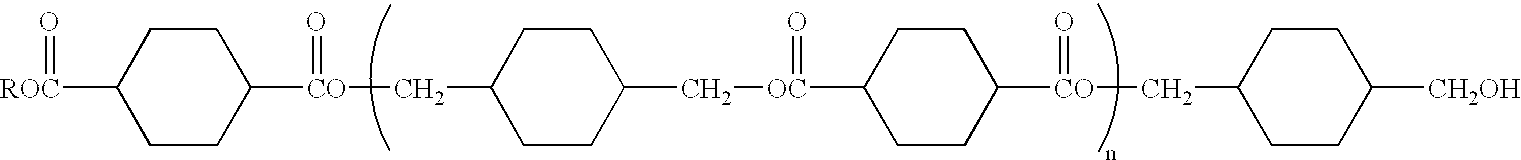

Flame retardant polycarbonate polyester composition

InactiveUS20020128357A1Improve performanceImprove impact performancePlastic/resin/waxes insulatorsDyeing processPass ratePolyester resin

A transparent / translucent flame redardant composition comprises a uniform blend of a miscible resin blend of a polycarbonate resin and a cycloaliphatic polyester resin wherein the composition has at least a 80% pass rate in 10 test specimen in the Norme Francaise NF-P-92-505 flammability test of L'Association Francaise de Normalisation using test specimens with weight between about 1.0 to about 6.0 kilograms per square meter.

Owner:GENERAL ELECTRIC CO

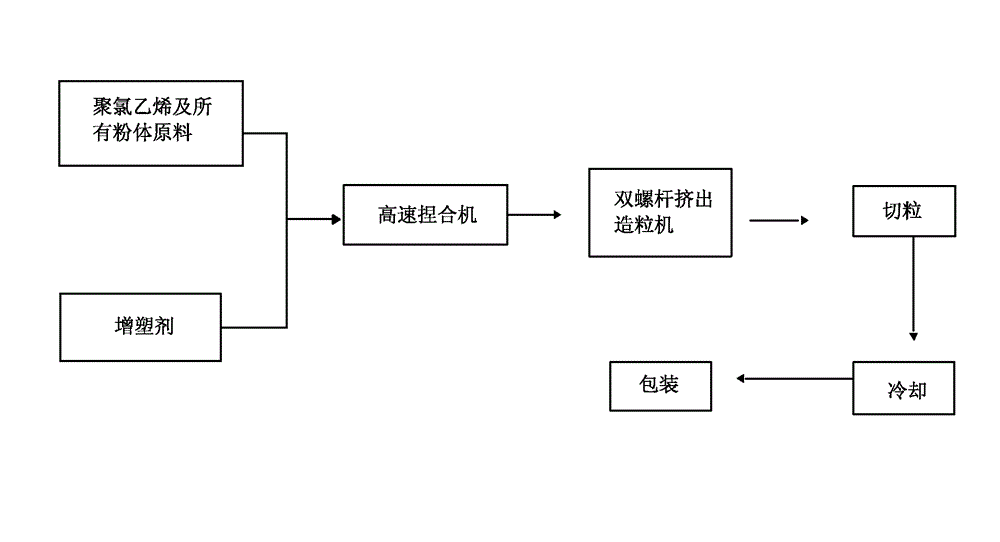

Wear-resisting flame-retardant polyvinyl chloride insulation and sheathing materials

ActiveCN102719040AImprove wear resistanceExcellent squeeze performancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention relates to insulation materials and sheathing materials, and in particular relates to a wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material. The wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40 to 60 parts of plasticizer, 6 to 30 parts of wearable modifying agent, 4 to 8 parts of stabilizing agent, 4 to 32 parts of fire retardant, 10 to 40 parts of filling agent, and 0.8 to 3 part(s) of lubricating agent. The insulating and sheathing material has good wear-resisting and flame-retardant properties, high squeezing performance, high rolling performance and high flexing performance, as well as high flexibility and processability.

Owner:SUZHOU SILVER AGE TECH CO LTD

Epoxy resin compositions, solid state devices encapsulated therewith and method

InactiveUS20030071366A1High refractive indexImprove matchPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsPolymer sciencePtru catalyst

Epoxy resin compositions are disclosed which comprise (A) at least one silicone epoxy resin, (B) at least one hydroxyl-containing compound, (C) at least one anhydride curing agent, (D) at least one ancillary curing catalyst, and optionally at least one of thermal stabilizers, UV stabilizers, cure modifiers, coupling agents, or refractive index modifiers. Also disclosed are packaged solid state devices comprising a package, a chip (4), and an encapsulant (11) comprising an epoxy resin composition of the invention. A method of encapsulating a solid state device is also provided.

Owner:GENERAL ELECTRIC CO

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

High flow polyphenylene ether formulations

A high flow polyphenylene ether resin composition with improved HDT values and flame retardance comprising a blend of at least two polyphenylene ether resins, a first resin having an intrinsic viscosity of at least 0.3 dl / g, and a second resin having an intrinsic viscosity of less than 0.25 dl / g and preferably having a particle size of at least about 100 mum. The composition preferably contains less than 30 wt % of the low viscosity polyphenylene ether based on the weight of the total composition. Fiber reinforced and flame retarded compositions also exhibit high HDT values.

Owner:SABIC INNOVATIVE PLASTICS IP BV

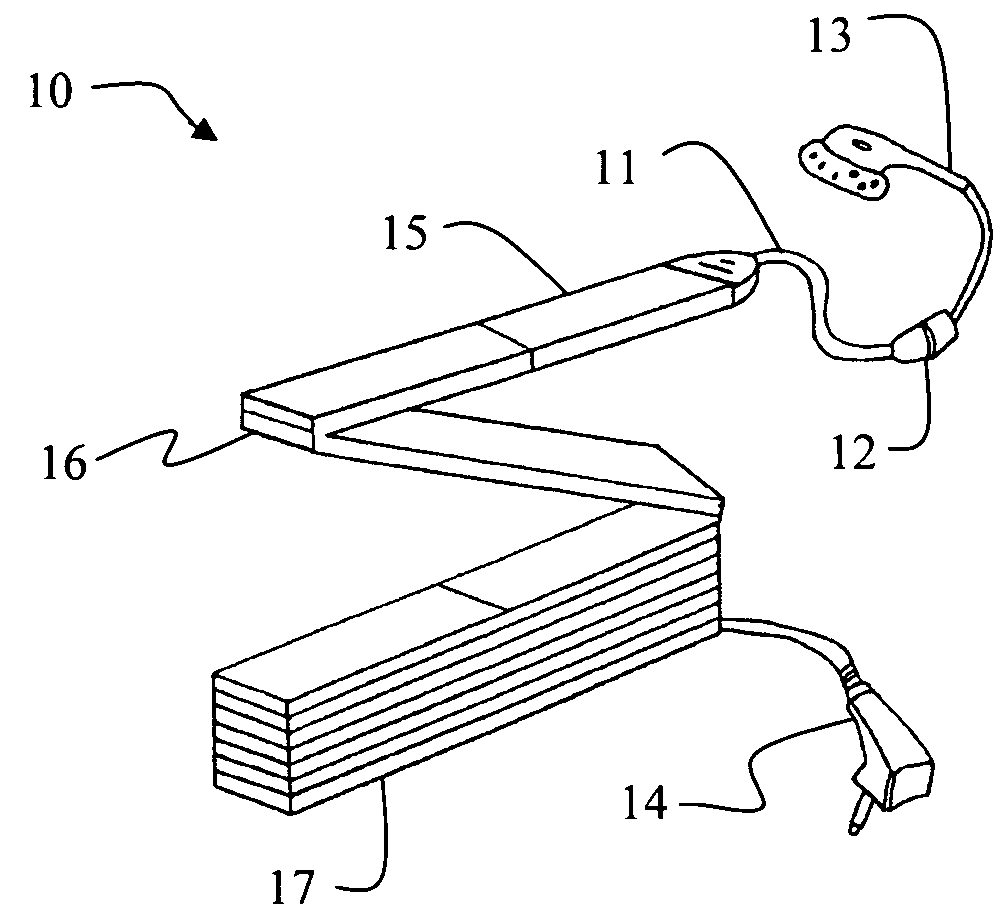

Folding cord with rigid sections and magnets

Owner:BEVIRT JOEBEN +1

Automotive-wire insulation

InactiveUS6359230B1Excellent physical toughnessResistant to oxidationPlastic/resin/waxes insulatorsInsulated cablesPolyesterInter layer

The invention pertains to multi-layer polymeric formulations for protecting or insulating metallic objects, and, more particularly, to an integrated, tri-layer, thin-wall insulation composite, for use in a high temperature, automotive-wire article. The tri-layer design comprises an inner layer of a fluoropolymer, polyether sulfone, polyether-ketone, polyetherimide, or thermoplastic polyester; a middle layer comprising a polyolefin; and an outer layer comprising a fluoropolymer. The inner and outer layers serve to protect the middle polyolefinic layer from degradation.

Owner:CHAMPLAIN CABLE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com