Patents

Literature

33results about How to "Good rubber elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Block copolymer

InactiveUS20050085592A1Excellent in thermal decomposition resistanceImprove the heating effectThin material handlingPolymer scienceMeth-

The present invention relates to a block copolymer (A) including a (meth)acrylic polymer block (a) and an acrylic polymer block (b). The (meth)acrylic polymer block (a) is preferably copolymerized with a monomer having a functional group having high cohesive force, such as a carboxyl group, so that the 5%-weight-loss temperature is 300° C. or more or the tensile strength is 3 MPa or more, and the hardness measured by a type A durometer according to JIS K6253 is 50 or less, and a compression set measured after 22 hours at 70° C. is 45% or less. The block copolymer (A) exhibits excellent thermal decomposition resistance and low compression set at high temperatures. The block copolymer (A) can be used as a soft material for automobile, and has low hardness, high adhesion, high oil resistance, high weather resistance, high heat resistance, high recycling property, high tensile properties, and high wax remover resistance.

Owner:KANEKA CORP

Curable resin composition

InactiveUS20060074199A1High elongationGood rubber elasticityPhotomechanical apparatusEpoxidised polymerised polyene adhesivesAdhesiveIsoprene

A curable resin composition includes (A) a cationically polymerizable-compound, (B) a cationic photopolymerization initiator, and (C) an epoxidized polyisoprene containing an epoxy group at 0.15 to 2.5 meq / g in the molecule and having a number-average molecular weight of 15000 to 200000. The curable resin composition shows excellent elongation properties and high break elongation even in a cured state and can give a cured product having superior compatibility, transparency, flexibility and waterproofness. Accordingly, the composition is suitable for use as adhesives, coating agents, encapsulating materials, inks, sealing materials and the like.

Owner:KURARAY CO LTD

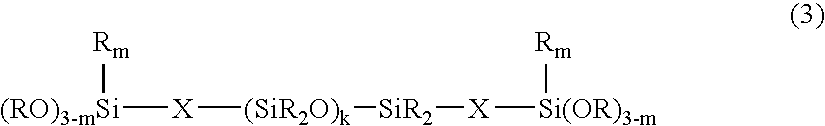

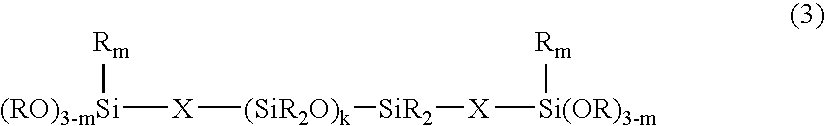

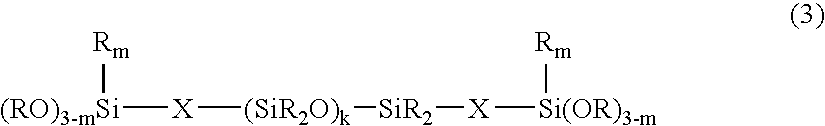

Room temperature-curable organopolysiloxane compositions

InactiveUS20070088123A1High bonding strengthGood rubber elasticitySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceRubber elasticity

A RTV organopolysiloxane composition comprising (A) an organopolysiloxane containing at least two Si—OH or organoxy radicals and having a viscosity of at least 500 mPa-s at 25° C., (B) an organosilane containing at least two organoxy radicals, (C) an organotin catalyst, and (D) an Si—OH radical-containing organopolysiloxane having a viscosity of up to 300 mPa-s at 25° C. It has shelf stability and discoloration resistance in the uncured state and exhibits rubber elasticity and adhesion in the cured state.

Owner:SHIN ETSU CHEM IND CO LTD

Thermoplastic Elastomer Composition

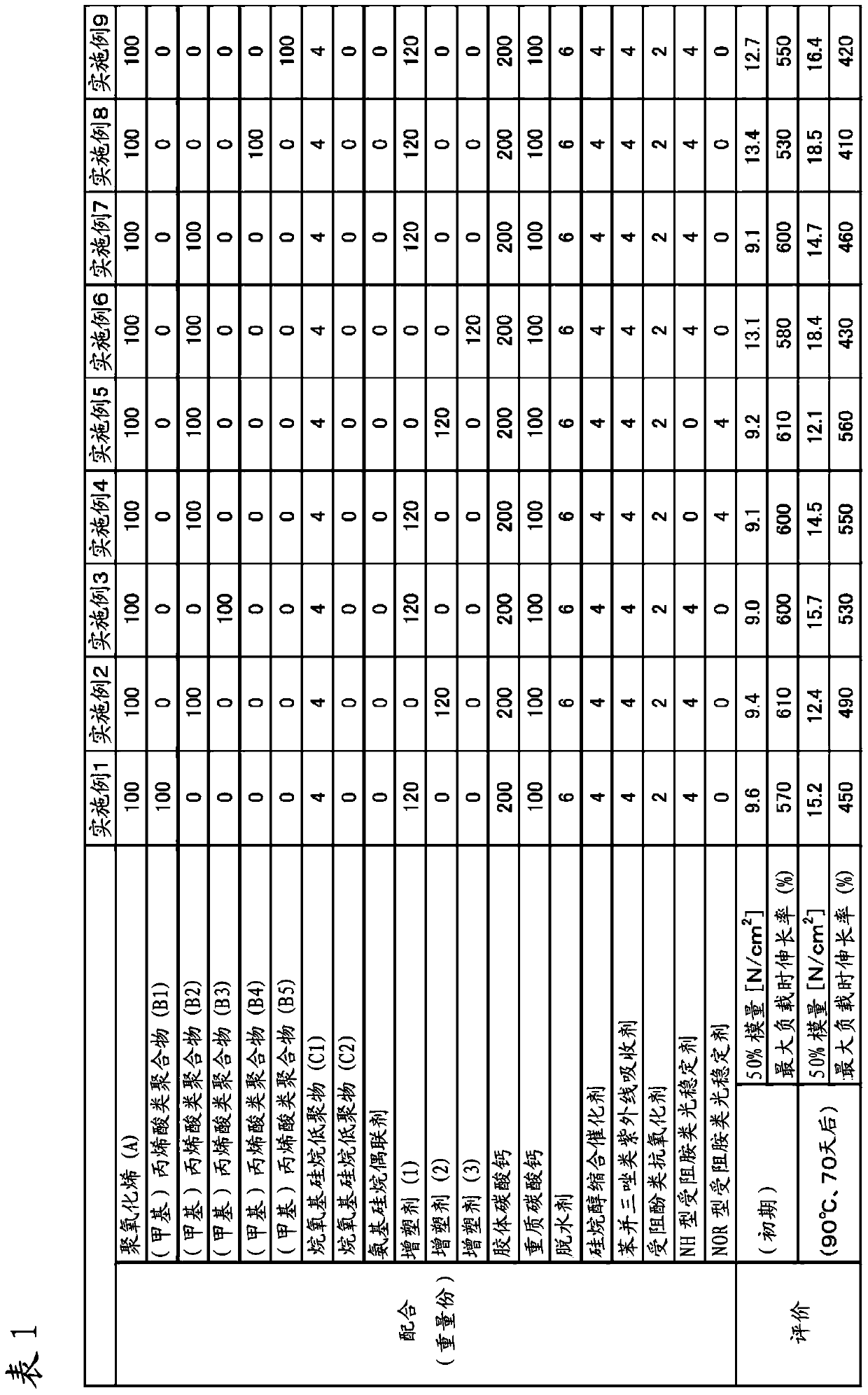

InactiveUS20080227905A1Improve balanceGood rubber elasticityFilm/foil adhesivesElastomerPolymer science

The object of the present invention is to provide a thermoplastic elastomer composition having a good balance between the hardness and the mechanical strength, exhibiting superior rubber elasticity, high-temperature creep characteristics and formability in a wide range of temperature, and having oil resistance and heat resistance. The thermoplastic elastomer composition comprises (A) (meth)acrylic block copolymer; (B) a compound containing at least two amino groups in its molecule; and (C) a thermoplastic resin. The (meth)acrylic block copolymer (A) comprises (A1) a (meth)acrylic copolymer block and (A2) an acrylic copolymer block. A1 least one of the polymer blocks has at least one acid anhydride group. The (meth)acrylic block copolymer (A) and the compound (B) are dynamically vulcanized in the thermoplastic resin (C).

Owner:KANEKA CORP

Thermoplastic elastomer composition, formed article and sealing material having low hardness

InactiveUS20070173591A1Excellent rubber elasticity and mechanical strengthLow hardnessOrganic dyesSolventCompression set

A thermoplastic elastomer composition comprising the following components [A], [B], [C], and [D]: [A] 5 to 60 mass % of an ethylene-α-olefin-based copolymer having a limiting viscosity of 3.5 dl / g or more measured in a decalin solvent at 135° C., [B] 1 to 20 mass % of a polyolefin-based resin, and [C] 30 to 94 mass % of a mineral oil-based softening agent, provided that the total of the components [A], [B], and [C] is 100 mass %, and for 100 parts by mass of the components [A], [B], and [C], [D] 0.1 to 50 parts by mass of a hydrogenated diene-based polymer, at least [A] the ethylene-α-olefin-based copolymer and [B] the polyolefin-based resin being dynamically treated with heat in the presence of a cross-linking agent, or the above thermoplastic elastomer composition wherein [A] is replaced with an oil-extended rubber comprising [A1] 20 to 80 mass % of an ethylene-α-olefin-based copolymer having a limiting viscosity of 3.5 dl / g or more measured in a decalin solvent at 135° C. and [C1] 20 to 80 mass % of a mineral oil-based softening agent, provided that the total of [A1] and [C1] is 100 mass %. This thermoplastic elastomer composition excels in molding processability, has low hardness, is free from bleed-out of a mineral oil-based softening agent, has high flexibility and superior rubber elasticity (rebound resilience and compression set), and excels in recycling efficiency.

Owner:JSR CORPORATIOON

Thermoplastic elastomer composition

A thermoplastic elastomer composition that exhibits excellent rubber elasticity, etc. is obtained by dynamically heating a polymer composition in the presence of the crosslinking agent, the polymer composition including an α-olefin thermoplastic resin (A), and an oil-extended ethylene copolymer (B) that includes an ethylene copolymer that satisfies given conditions, and 50 to 150 parts by mass of a first mineral oil-based softener based on 100 parts by mass of the ethylene copolymer, the content of the oil-extended ethylene copolymer (B) being 30 mass % or more based on the total amount (=100 mass %) of the polymer component including the α-olefin thermoplastic resin (A) and the oil-extended ethylene copolymer (B).

Owner:ENEOS MATERIALS CORP

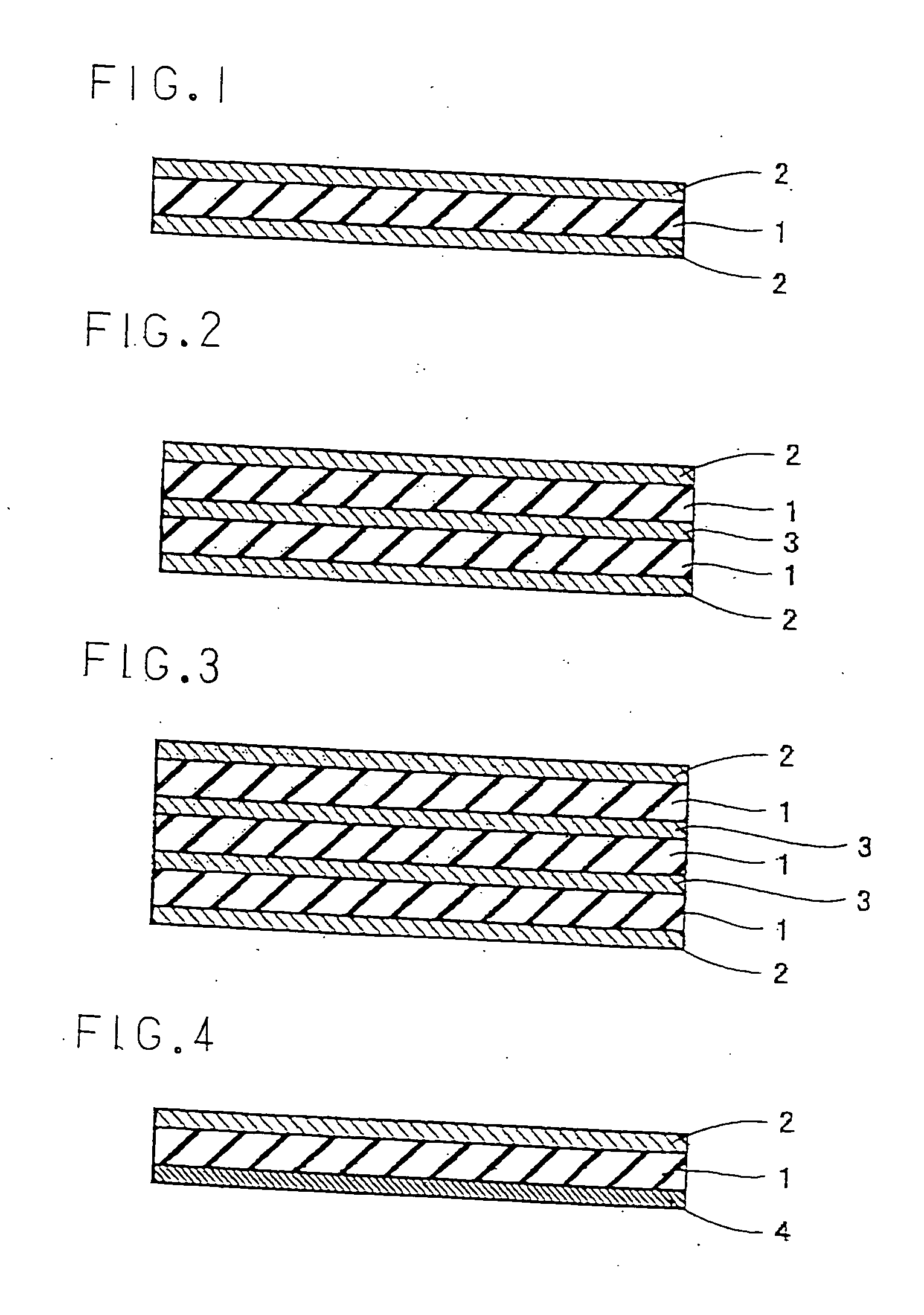

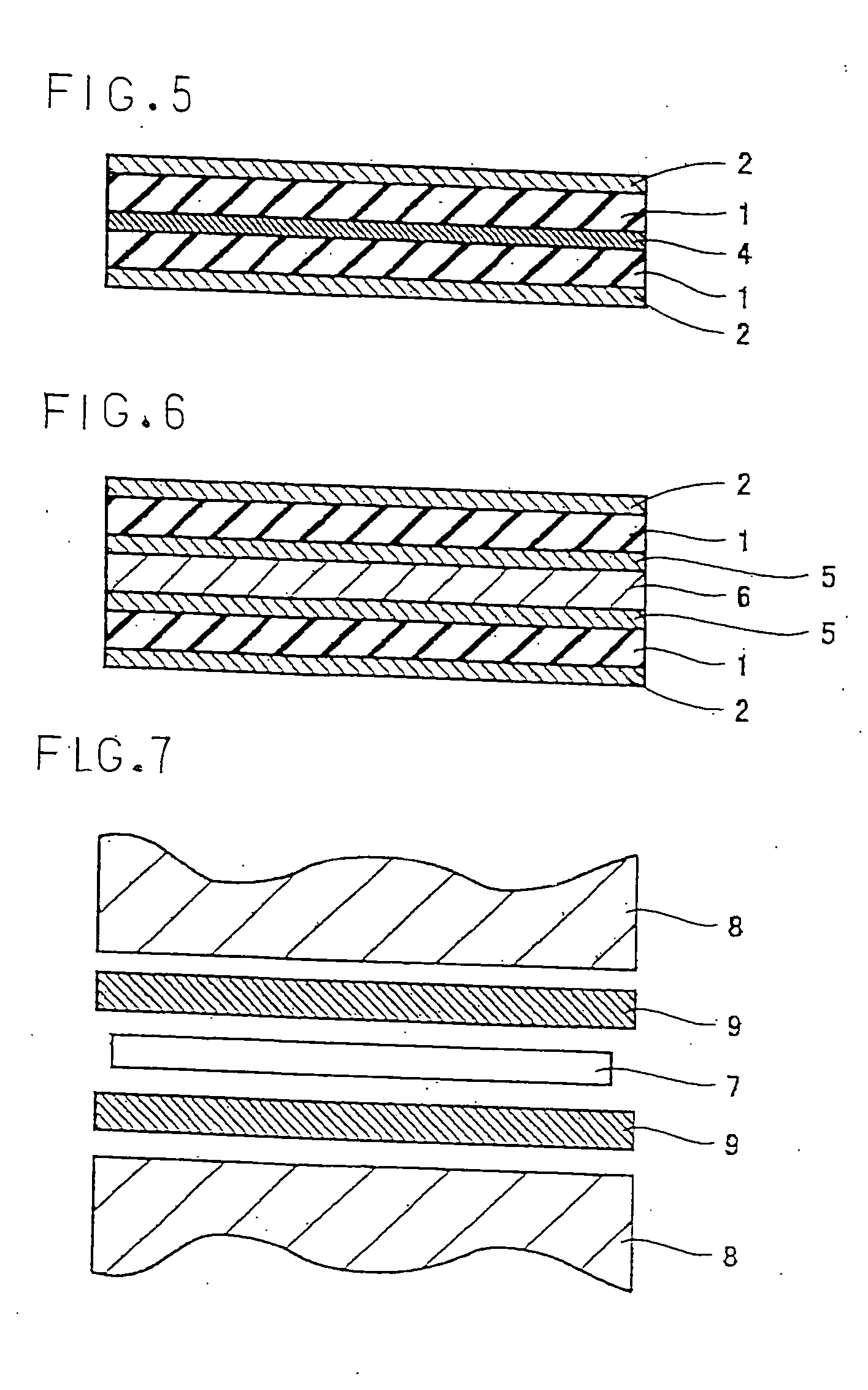

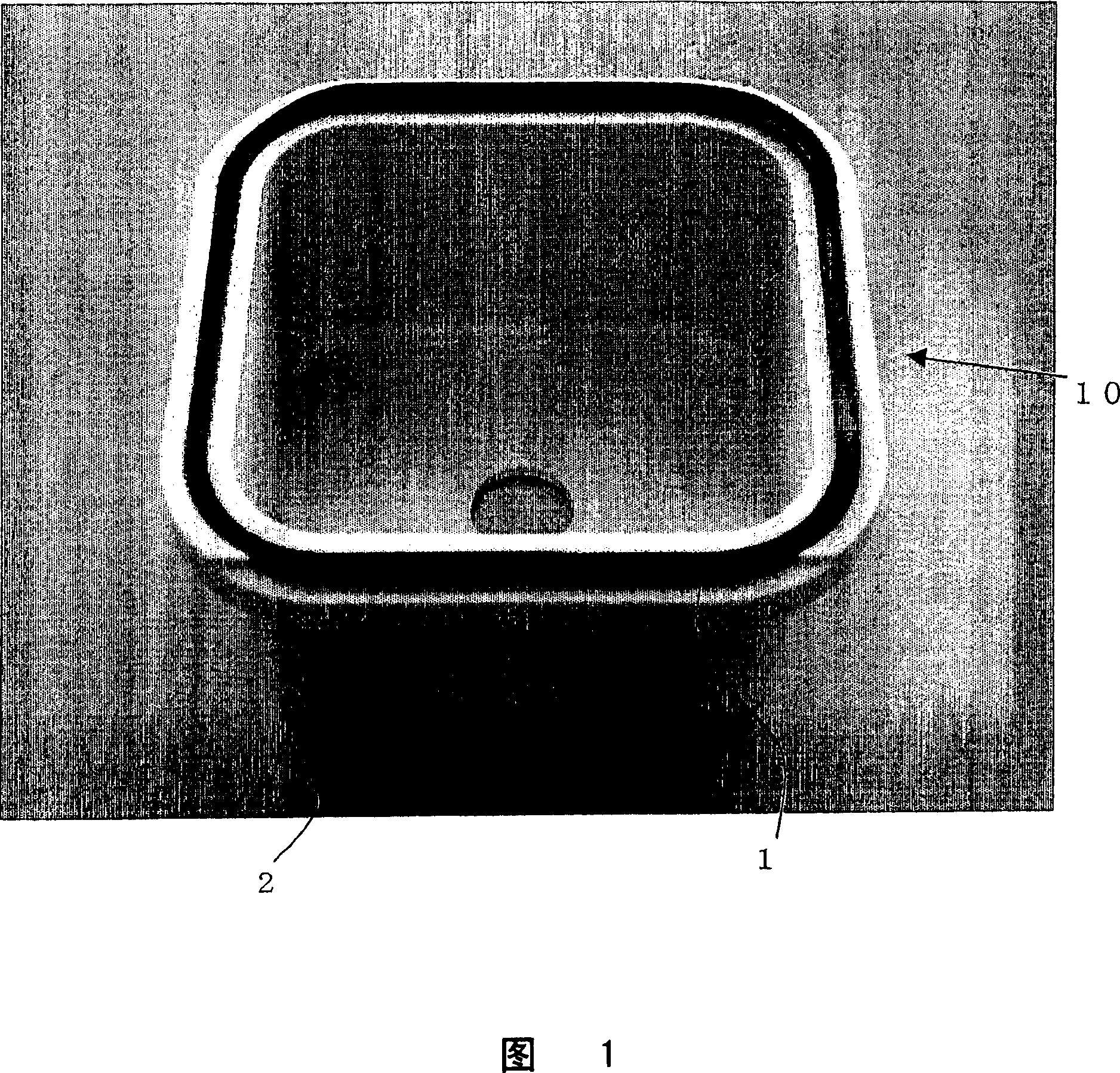

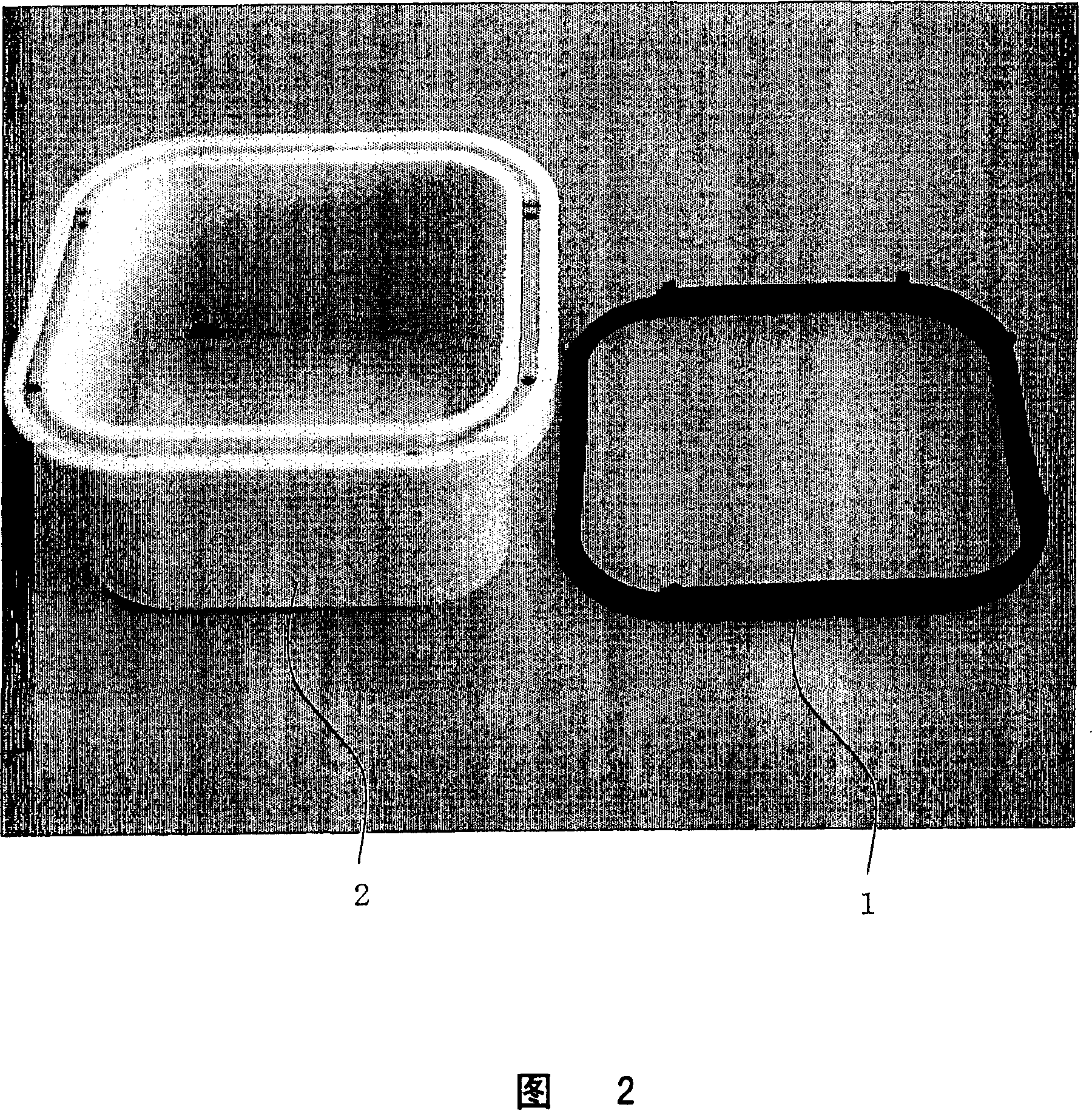

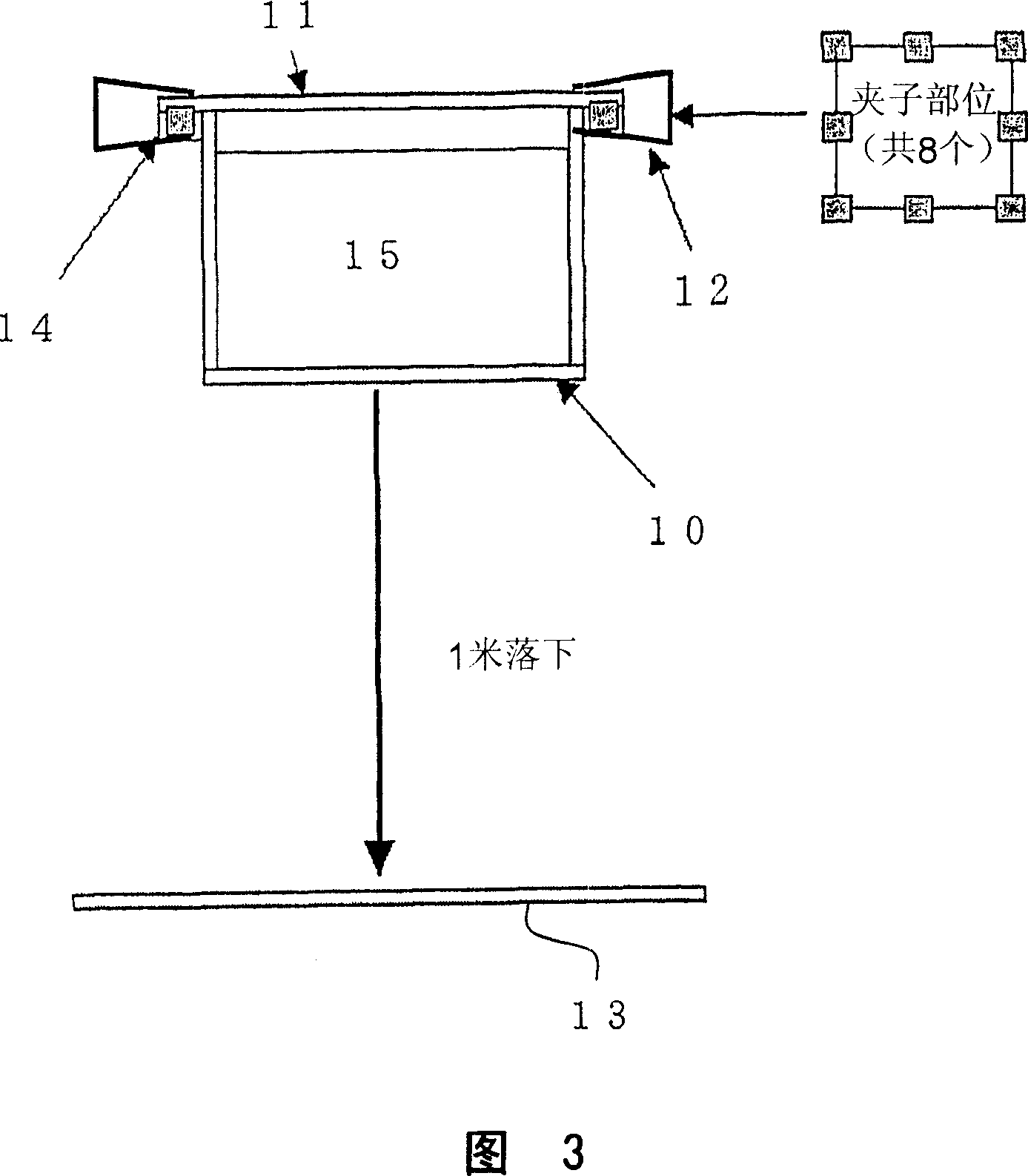

Cushioning material for hot pressing and process for producing the same

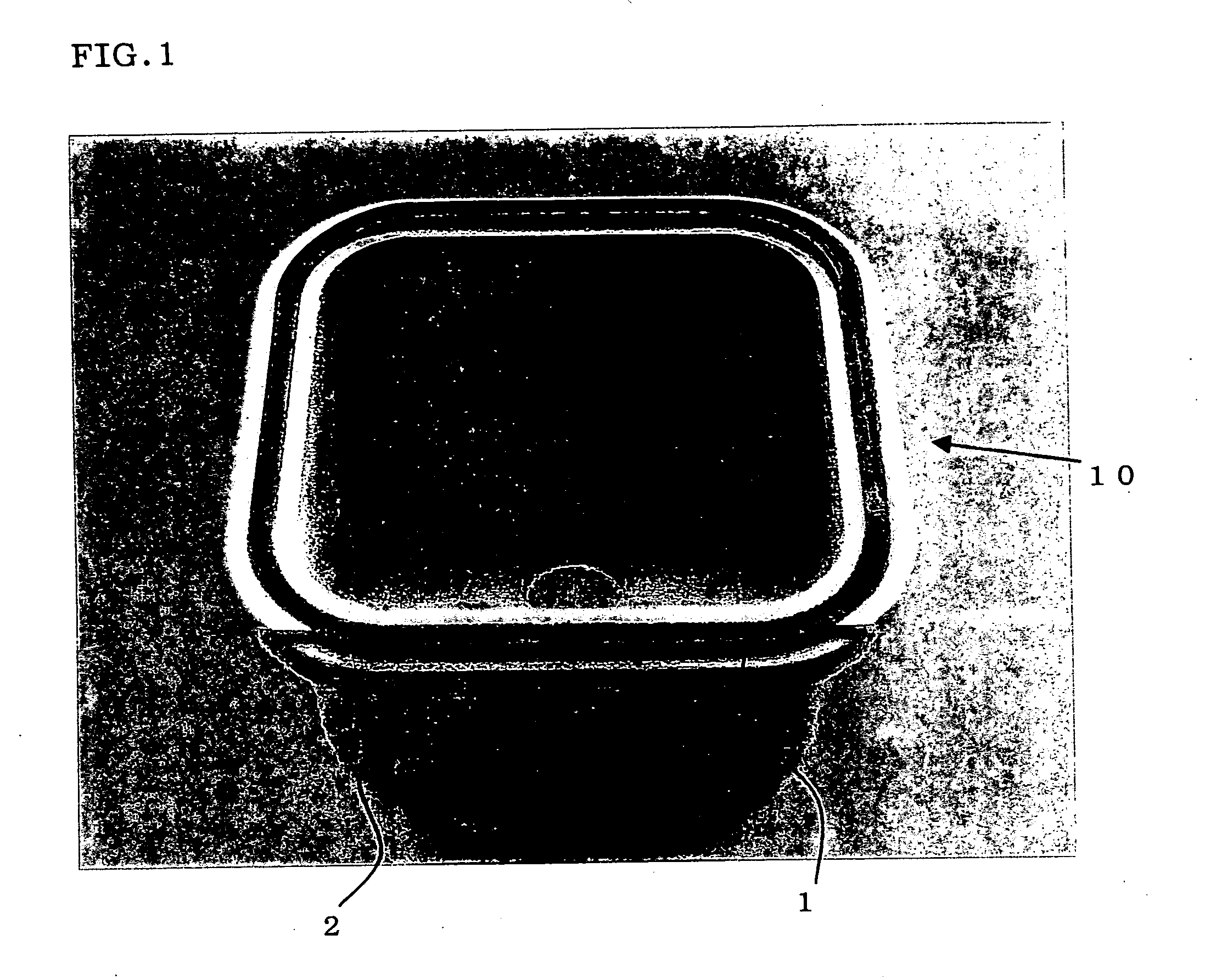

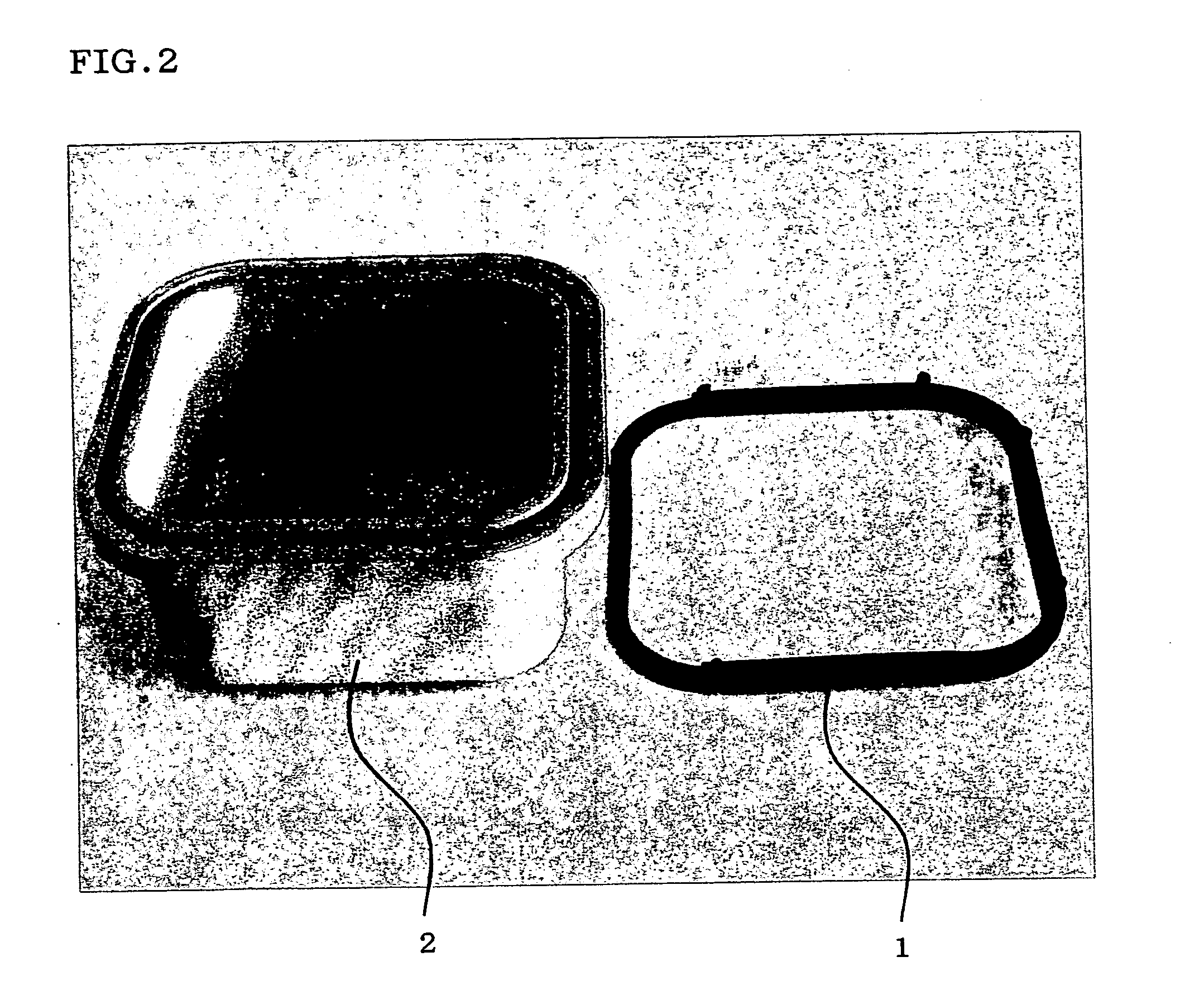

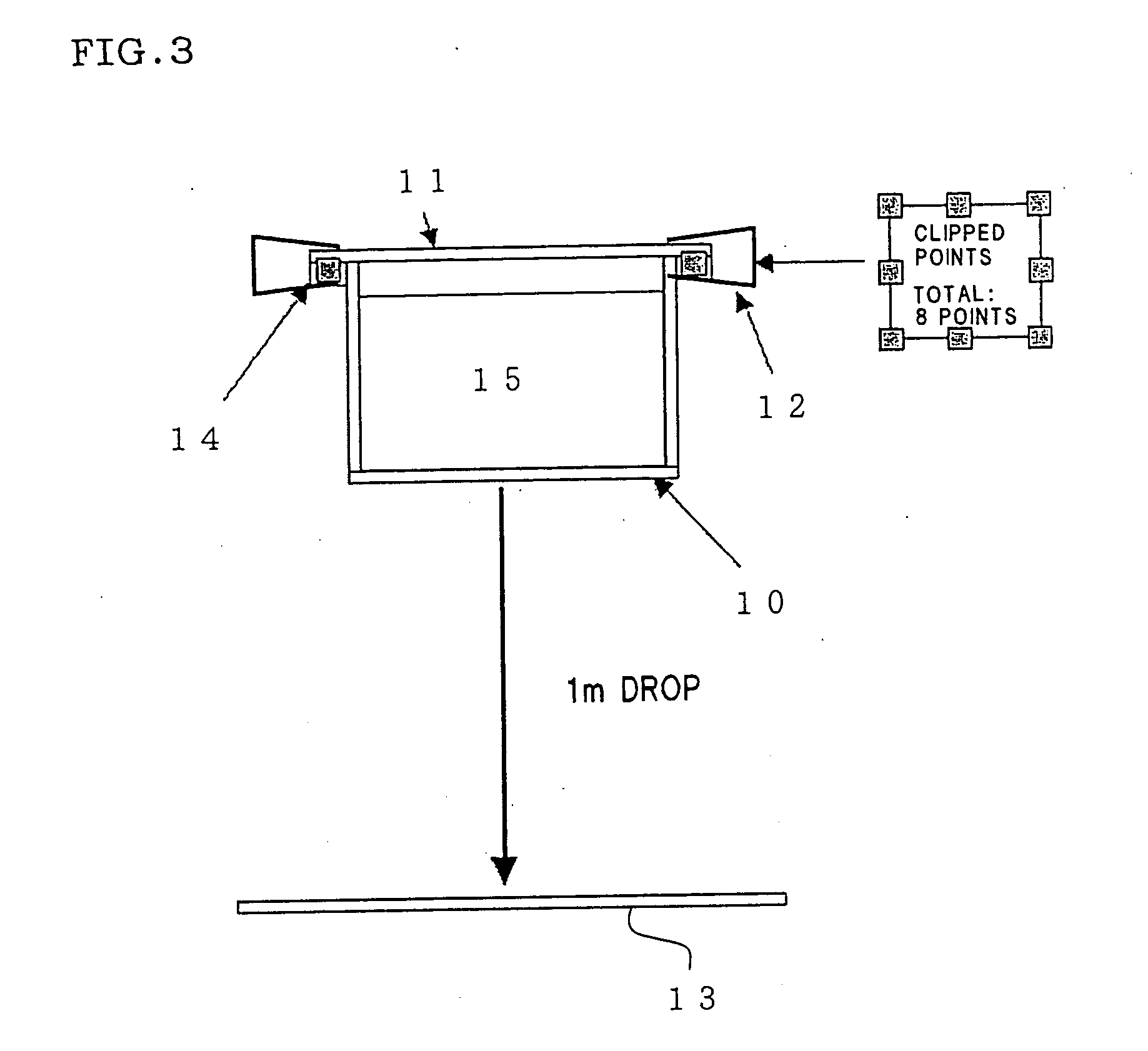

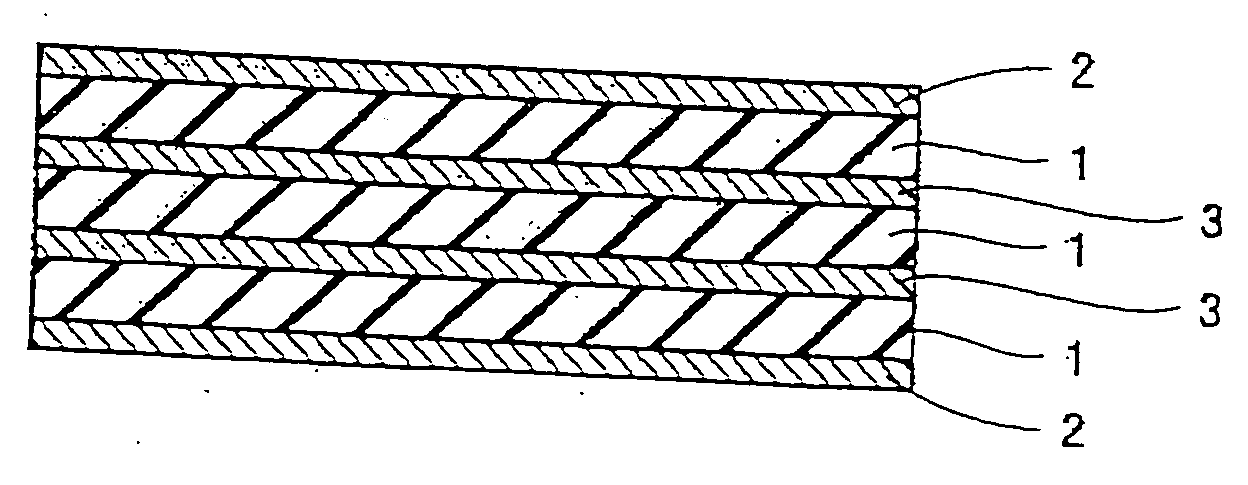

InactiveUS20050001351A1Good release effectAnxiety is also removedRecord carriersConfectionerySurface layerPolymer science

In order to prevent any surface swelling, resulting from bleeding of a low molecular weight compounding agent contained in rubber, a cushioning pad for hot pressing has a rubber sheet 1, and a surface layer material 2 made of a porous heat-resistant resin film laminated on at least one face of rubber sheet 1. The porous film has an average pore diameter of 10 μm or less and the porous film has gas permeability of 0.1 cm3 / cm2·sec or more.

Owner:YAMAUCHI CORP

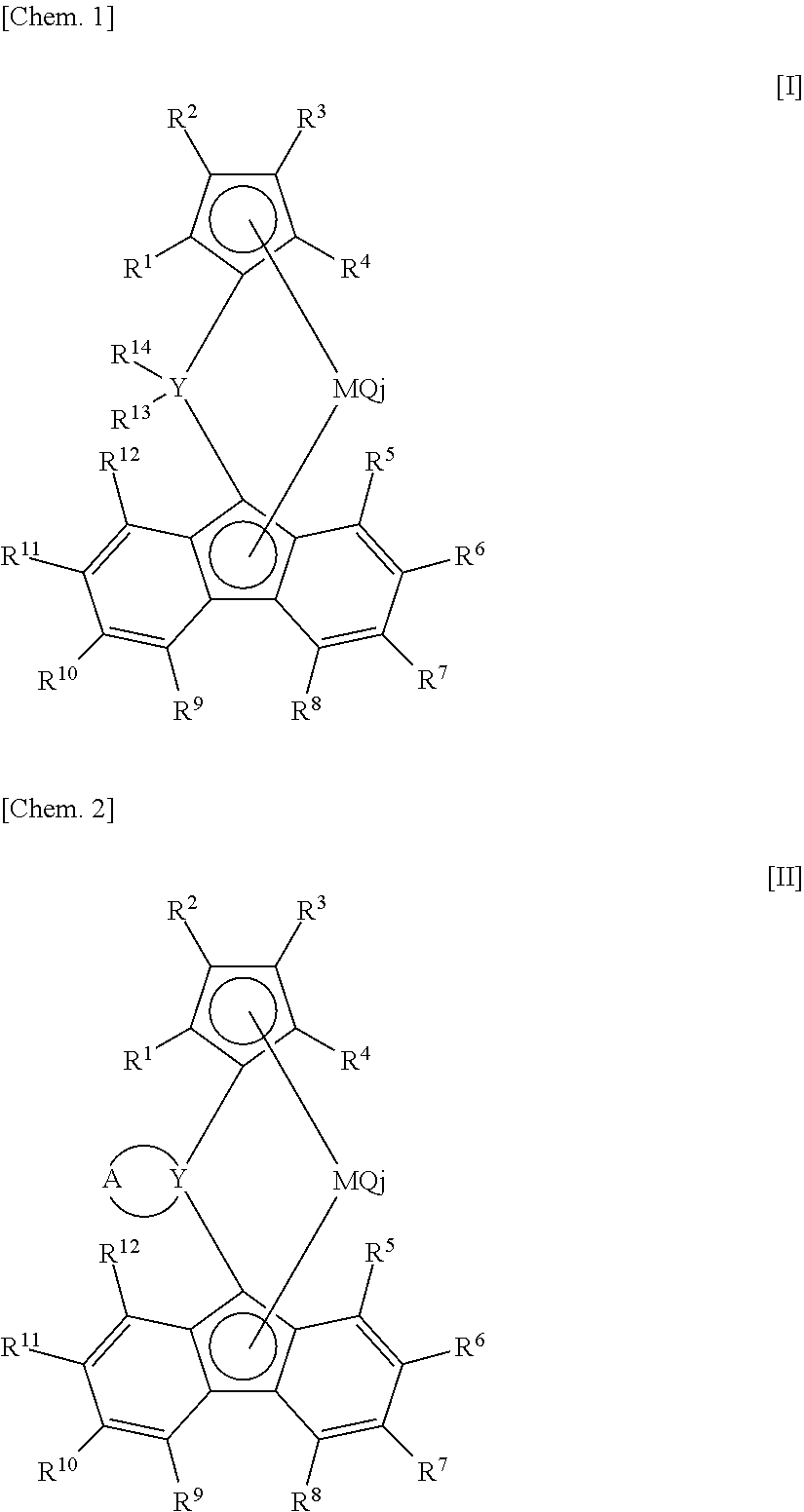

Block copolymer

InactiveUS20050272865A1Excellent in thermal decomposition resistanceGood rubber elasticityThin material handlingPolymer scienceMeth-

Owner:KANEKA CORP

Propylene resin composition and use thereof

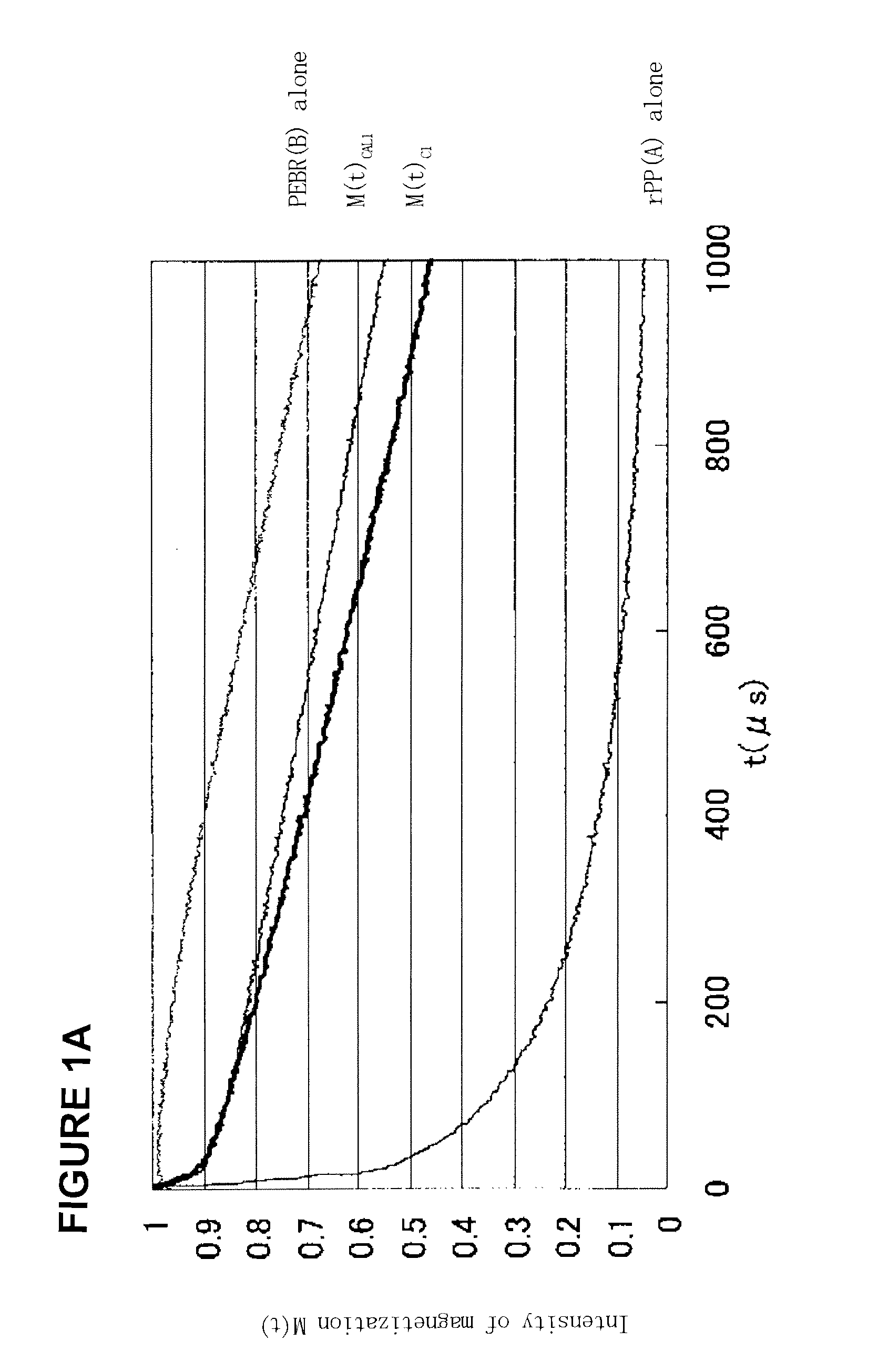

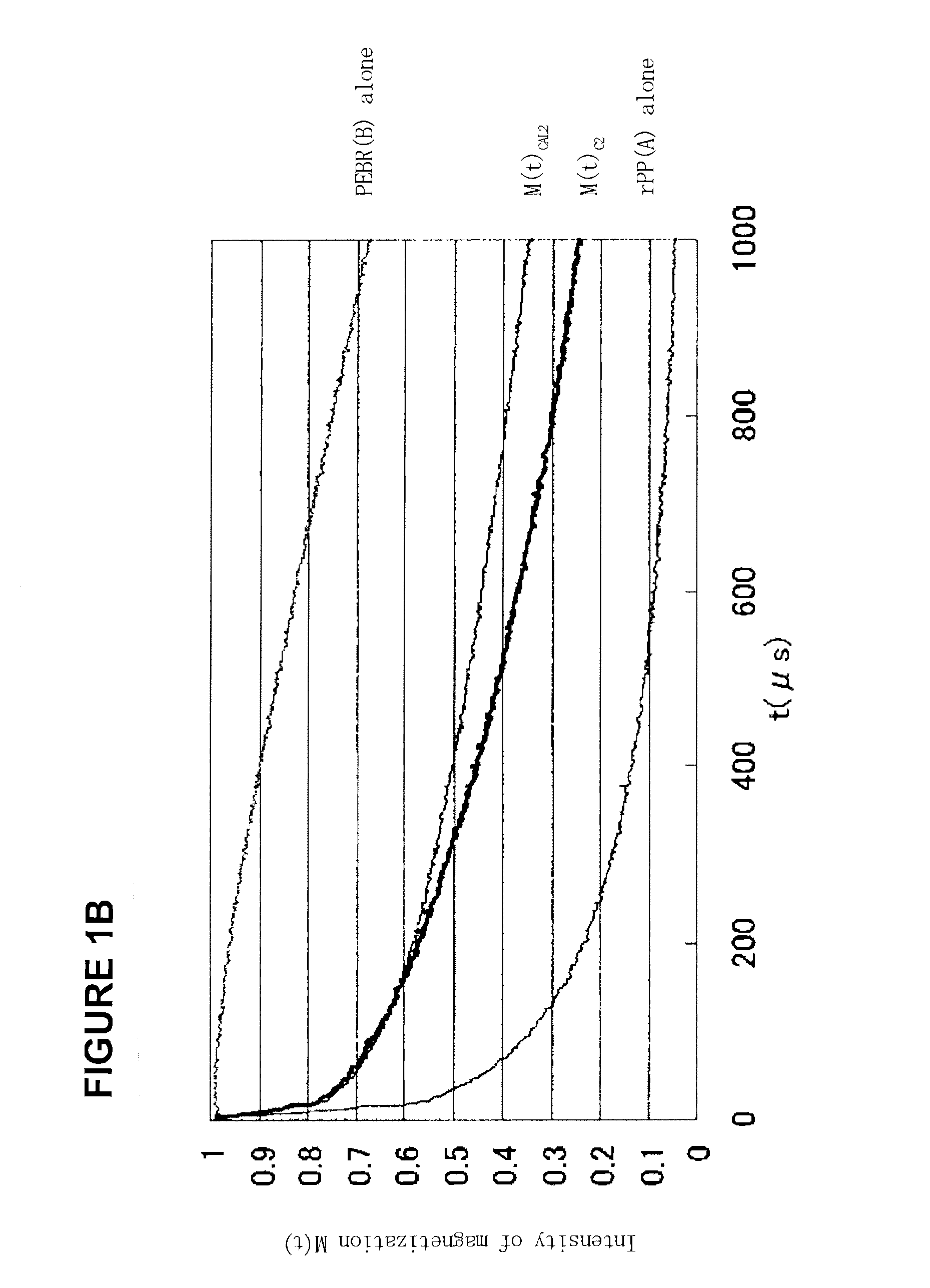

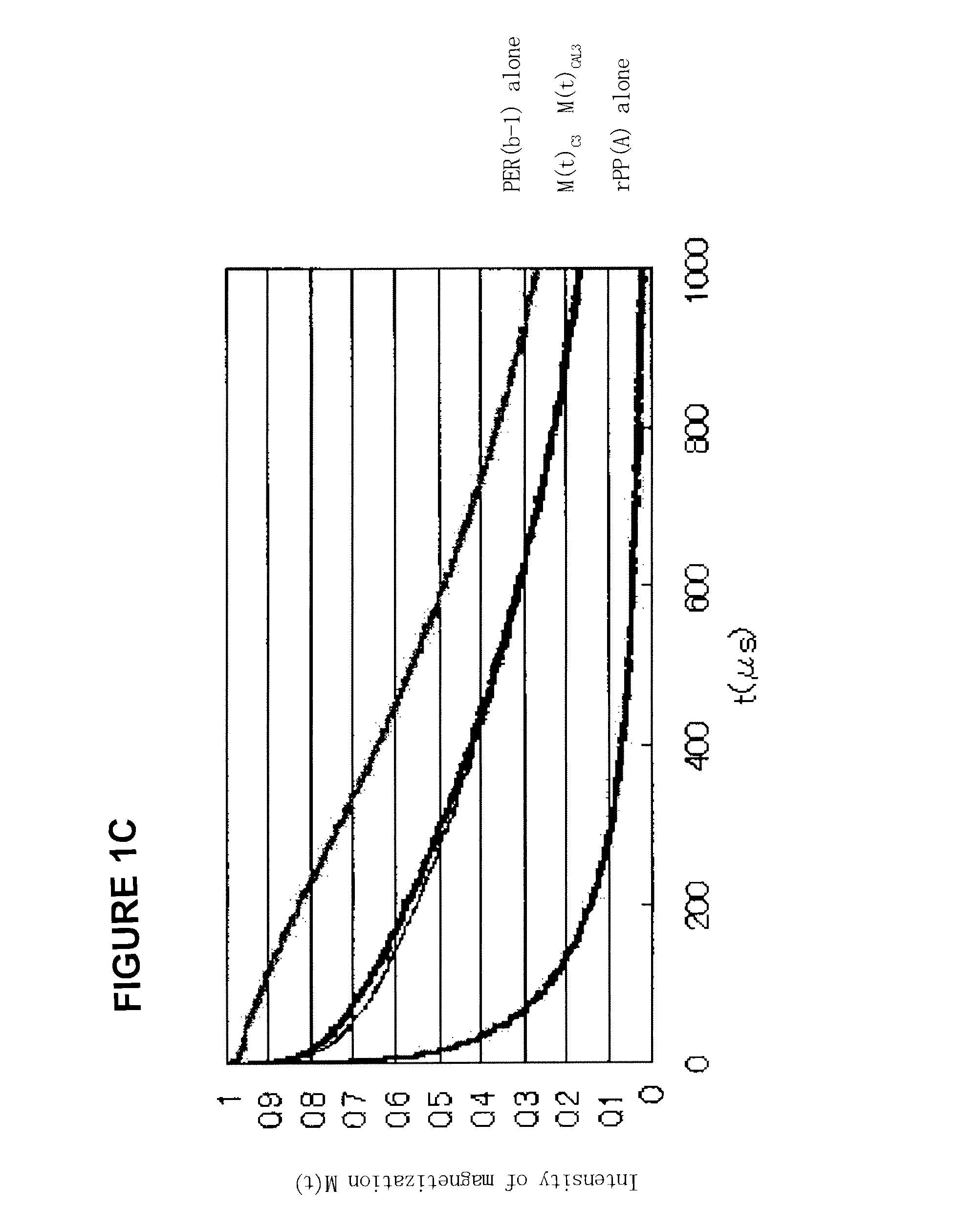

ActiveUS8338697B2Increase elasticityMaintain good propertiesSolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (X1) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below:1 to 90 wt % of an isotactic polypropylene (A1);9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol % of propylene-derived structural units, 10 to 25 mol % of ethylene-derived structural units, and optionally, 0 to 30 mol % of C4-C20 α-olefin-derived structural units (a1);1 to 80 wt % of a styrene-based elastomer (C1); and0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

Process for production of thermoplatic elastomer composition

InactiveUS7169849B2Good flexibilityGood rubber elasticityFilm/foil adhesivesElastomerPolymer science

A process for production of a thermoplastic elastomer composition by melt-kneading a mixture in one step to thereby conduct dynamic crosslinking, wherein the mixture comprises a hydrogenated block copolymer (a1) which is prepared by hydrogenating a block copolymer comprising a vinyl aromatic polymer block (A1) and a conjugated diene polymer block (B1) and has number-average molecular weight of 200000 or above and, if necessary, a non-hydrogenated block copolymer (a2) comprising a vinyl aromatic polymer block (A2) and a conjugated diene polymer block (B2), and contains a non-aromatic rubber softening agent (b), a peroxide-crosslinkable olefin resin (c) having a density of 0.94 g / cm3 or above, a peroxide-decomposable olefin resin (d), an organic peroxide (e), and a crosslinking aid (f), the amount of (b) being 50 to 250 parts by mass per 100 parts by mass of the sum of (a1) +(a2), the amount of (c) being 2.5 to 50 parts by mass per 100 parts by mass of (a); and the amount of (d) being 0.5 to 10 times that of (c) by mass.

Owner:KURARAY CO LTD

Ethylene copolymer, composition including the copolymer, and shaped article and film or sheet formed from the ethylene copolymer or the composition

ActiveUS20140296423A1Excellent mechanical propertiesExcellent formabilityInksProduction rateRubber elasticity

Objects of the invention are to obtain ethylene copolymers which have excellent rubber elasticity even without being crosslinked and maintain sufficient shaping processability even when filled with significantly large amounts of additives, and to provide methods for producing with good productivity films or sheets having flexibility and high stretchability. The invention is directed to an ethylene copolymer (X) including structural units derived from a component [A], a component [B] and a component [C] which are ethylene [A], an α-olefin of 3 to 20 carbon atoms [B] and a polyene and / or a cyclic olefin [C]. In the ethylene copolymer, (1) the content of structural units derived from the ethylene [A] is in the range of 50 to 90 mol % in 100 mol % of all the structural units in the copolymer (X); (2) the content of structural units derived from at least one polyene and / or the cyclic olefin [C] is in the range of 1.0 to 5.0 mol % in 100 mol % of all the structural units in the copolymer (X); and (3) the intrinsic viscosity [η] of the ethylene copolymer (X) as measured at 135° C. in a decalin solution is in the range of 7.8 to 13.0 dl / g. The invention also concerns with a composition including the ethylene copolymer (X), and uses.

Owner:MITSUI CHEM INC

Block copolymer

InactiveUS7407694B2Excellent in thermal decomposition resistanceGood rubber elasticityClosuresClosure using stoppersPolymer scienceMeth-

The present invention relates to a block copolymer (A) including a (meth)acrylic polymer block (a) and an acrylic polymer block (b). The (meth)acrylic polymer block (a) is preferably copolymerized with a monomer having a functional group having high cohesive force, such as a carboxyl group, so that the 5%-weight-loss temperature is 300° C. or more or the tensile strength is 3 MPa or more, and the hardness measured by a type A durometer according to JIS K6253 is 50 or less, and a compression set measured after 22 hours at 70° C. is 45% or less. The block copolymer (A) exhibits excellent thermal decomposition resistance and low compression set at high temperatures. The block copolymer (A) can be used as a soft material for automobile, and has low hardness, high adhesion, high oil resistance, high weather resistance, high heat resistance, high recycling property, high tensile properties, and high wax remover resistance.

Owner:KANEKA CORP

Mud-resistant cable sheath rubber material and preparation method thereof

InactiveCN105254995AImprove crack resistanceFlame retardantRubber insulatorsInsulated cablesRubber materialCrack resistance

The invention relates to the technical field of novel materials, in particular to a mud-resistant cable sheath rubber material. The mud-resistant cable sheath rubber material is prepared from, by weight, 100 parts of levapren rubber, 2.5-6.5 parts of vulcanizing agents, 0.5-1.5 parts of accelerant, 90-145 parts of fire retardant, 1.0-2.0 parts of release agents, 1.0-2.0 parts of stearic acid, 0.5-1.0 part of anti-aging agents, 1.5-2.0 parts of coupling agents, 1.5-13.5 parts of plasticizer and 5.0-10.0 parts of reinforcing filler. The prepared mud-resistant cable sheath rubber material has excellent rubber elasticity and good crack resistance and is applicable to drilling platforms.

Owner:CHANGZHOU MARINE CABLE

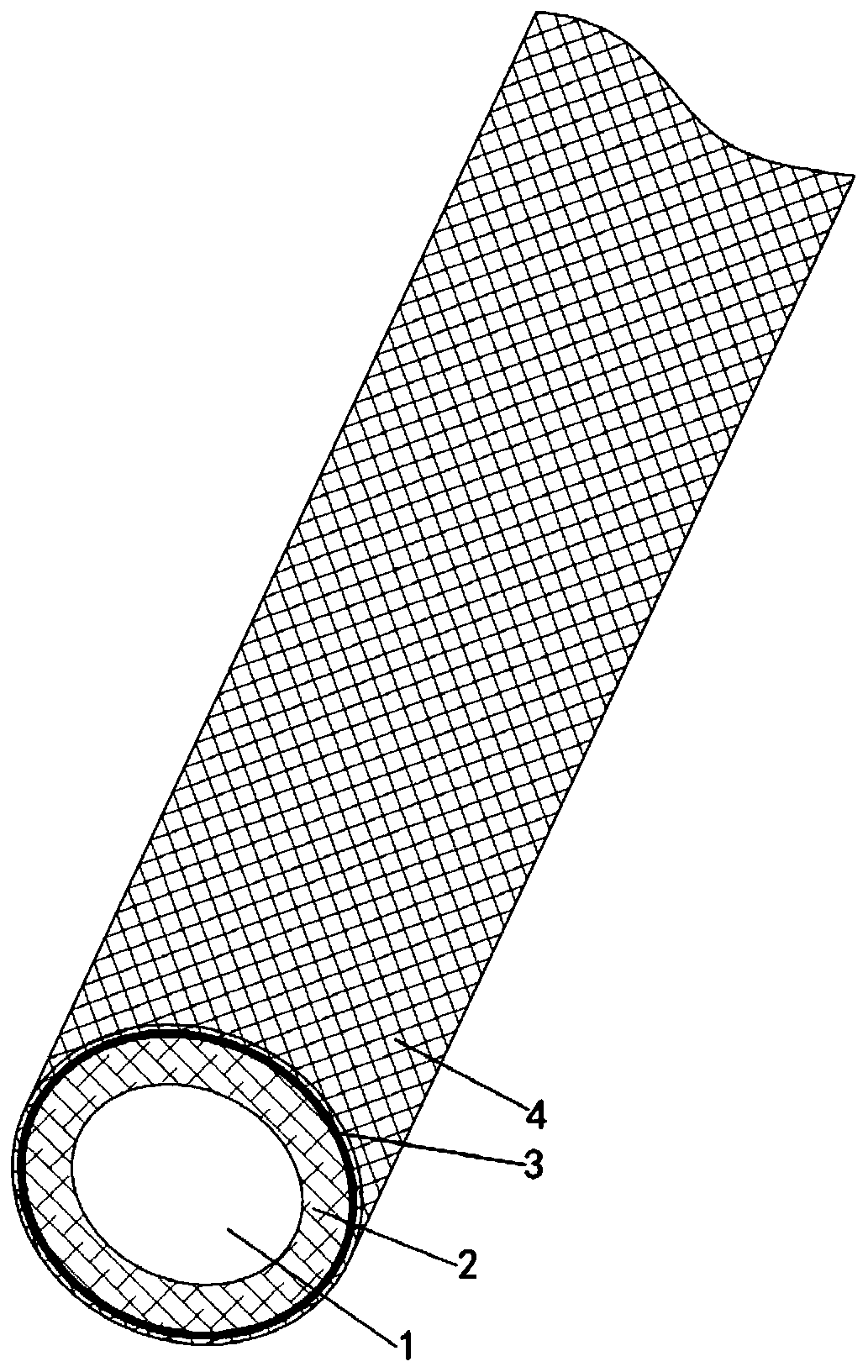

Metal weaving type conductive silica gel sleeve and preparation method thereof

InactiveCN109874287ALower volume resistivityReduce surface resistanceMagnetic/electric field screeningAdhesivesRubber elasticityElectromagnetic shielding

The invention discloses a metal weaving type conductive silica gel sleeve and a preparation method thereof. The conductive silica gel sleeve comprises a core, a binding layer and an electromagnetic shielding layer which are sequentially arranged from inside to outside, the core is a pipe formed by extruding high-elasticity silicone rubber by an extrusion machine, the binding layer is a high-strength organic silicon binding layer coated on a surface of the core, the thickness of the binding layer is 0.05-0.1 millimeter, and the electromagnetic shielding layer is a metal weaving layer combined onto the surface of the core by the binding layer. By the metal weaving layer on the surface, the volume resistivity of the conductive silica gel sleeve is small, and the surface resistance is lower tobe 10 milliohms; with the core formed by extruding the high-elasticity silicone rubber, the conductive silica gel sleeve has very good rubber elasticity, and the permanent deformation rate after compression is lower to be 5%; and by combining the core and the metal weaving, the weight of the conductive silica gel sleeve is reduced by 20% compared with the same-volume metal shielding pipe.

Owner:DONGGUAN NYSTEIN ELECTRONICS MATERIALS CO LTD

Curable composition, and joint structure produced using same

ActiveCN105121544AGood adhesionGood rubber elasticityOther chemical processesBuilding constructionsOligomerSilylene

A curable composition according to the present invention is characterized by comprising (A) a polyalkylene oxide having a hydrolysable silyl group, (B) an acrylic polymer having a hydrolysable silyl group and (C) an alkoxysilane oligomer which is a hydrolytic condensation product of an alkylalkoxysilane with an aminoalkoxysilane and has a nitrogen atom content of 1 wt% or more.

Owner:SEKISUI FULLER

Thermoplastic resin composition

InactiveUS20110319548A1Increase flexibilityGood rubber elasticityFilm/foil adhesivesPolyolefinThermoplastic elastomer

The invention provides a thermoplastic elastomer composition that has an excellent balance between flexibility and heat resistance (creep resistance), shows little tackiness (stickiness) and is not deteriorated in design properties even when exposed to a high temperature.A thermoplastic elastomer composition (X) includes a propylene copolymer (A) satisfying all the requirements (A1) to (A3) described below, a crystalline polyolefin polymer (B) which is optional, and a styrene block copolymer (C). (A1) The Shore A hardness is in the range of 50 to 90. (A2) The copolymer gives a melting peak Tm in the range of 30 to 95° C., and the endothermic enthalpy ΔH corresponding to the melting peak is in the range of 1.0 to 20 J / g. (A3) The molecular weight distribution Mw / Mn is in the range of 1.2 to 3.0.

Owner:MITSUI CHEM INC

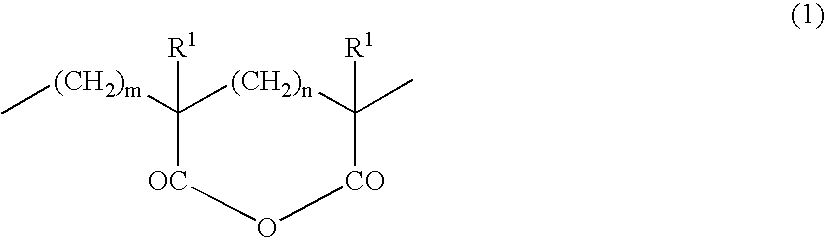

Curable composition

ActiveUS20060194923A1Good rubber elasticityHigh elongationPhotomechanical apparatusMethacrylateMeth-

A curable composition includes (A) a (meth)acrylate, (B) a radical polymerization initiator, (C) an epoxidized polyisoprene containing an epoxy group at 0.15 to 2.5 meq / g in the molecule and having a number-average molecular weight of 15000 to 200000, and (D) a curing accelerator. The curable composition shows high elongation and excellent rubber elasticity even in a cured state and has superior compatibility, transparency, waterproofness and flexibility, so that cracks and separation of cured products are reduced. Accordingly, the composition is suitable for use as adhesives, coating agents, encapsulating materials, inks, sealing materials and the like.

Owner:KURARAY CO LTD

Thermoplastic elastomer composition, formed article and sealing material having low hardness

A first thermoplastic elastomer composition which comprises 100 parts by mass of the sum of 5 to 60 mass % of [A] an ethylene.alpha-olefin based copolymer having a limiting viscosity of 3.5 dl / g or more as measured in a decalin solvent at 135 DEG C, 1 to 20 mass % of [B] a polyolefin based resin and 30 to 94 mass % of [C] a mineral oil based softening agent (provided that the sum of [A], [B] and [C] is 100 mass %), and 0.1 to 50 parts by mass of a hydrogenated diene based polymer, wherein at least the above [A] an ethylene.alpha-olefin based copolymer and [B] a polyolefin based resin have been subjected to a dynamic heat treatment in the presence of a cross-linking agent; or a second thermoplastic elastomer composition obtained by substituting [A] component of the first thermoplastic elastomer composition with an oil-extended rubber consisting of 20 to 80 mass % of [A1] an ethylene.alpha-olefin based copolymer having a limiting viscosity of 3.5 dl / g or more as measured in a decalin solvent at 135 DEG C and 20 to 80 mass % of [C1] a mineral oil based softening agent (provided that the sum of [A1] and [C1] is 100 mass %). The above thermoplastic elastomer composition is excellent in processability, has a low hardness, is free from the bleeding of a softening agent such as a mineral oil, has softness, is excellent in rubbery elastic properties (rebound, compression set) and further can be recycled.

Owner:JSR CORPORATIOON

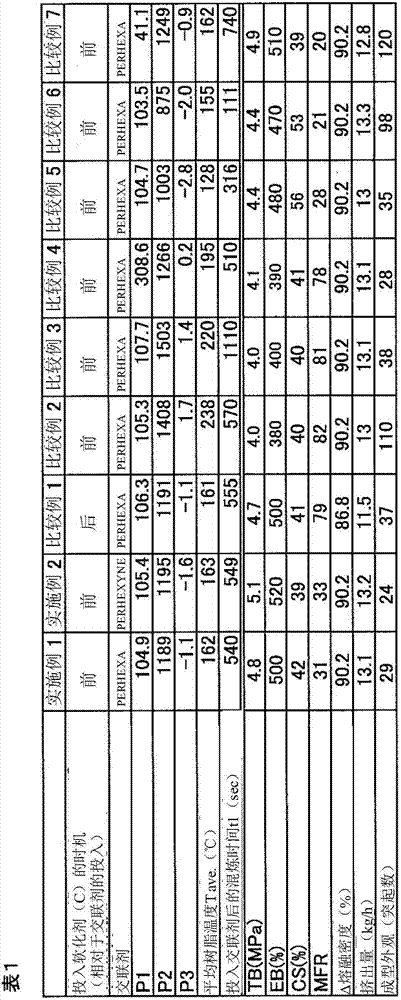

Thermoplastic elastomer composition and method for producing same

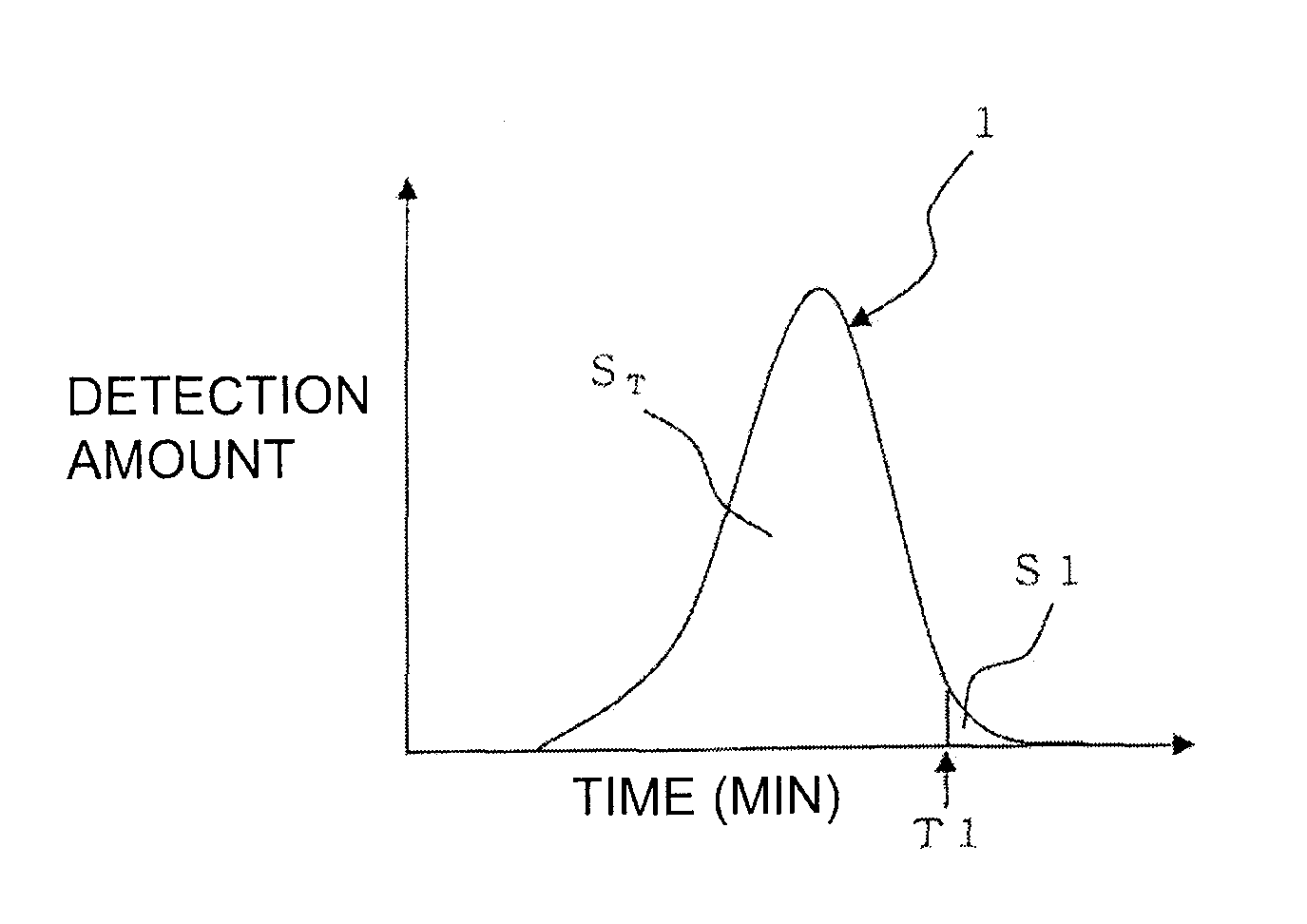

ActiveCN107250246AEfficient preparationImprove mechanical propertiesChemical/physical/physico-chemical stationary reactorsPolyolefinRetention time

The present invention is a thermoplastic elastomer composition which is obtained by dynamically crosslinking an ethylene / Alpha-olefin / non-conjugated polyene copolymer (A), a polyolefin resin (B), 1-200 parts by mass of a softening agent (C) per 100 parts by mass of the total of the copolymer (A) and the resin (B), and a crosslinking agent (D) with use of a batch mixer under conditions satisfying the following conditions (1)-(4). (1) 50 <=P1 <=300 (In this connection, P1 is defined by formula (i). P1 = Gamma ave. * Log(t1) (i) (In formula (i), t1 represents the retention time (sec) after the introduction of the crosslinking agent (D), and Gamma ave. represents the average rate (sec-1) of the shear rates Gamma at t1.)) (2) 900 <=P2 <=1450 (In this connection, P2 is defined by formula (ii). P2 = (Tave. + 273) * Log(t1) (ii) (In formula (ii), Tave. represents the average resin temperature (DEG C) after the introduction of the crosslinking agent (D), and t1 represents the retention time (sec) after the introduction of the crosslinking agent (D).)) (3) -2.5 <=P3 <=1.5 (In this connection, P3 is defined by formula (iii). P3 = Log(t1 / t2) (iii) (In formula (iii), t1 represents the retention time (sec) after the introduction of the crosslinking agent (D), and t2 represents the time (sec) necessary for the residual amount of the crosslinking agent (D) to be 1 ppm or less of the introduced amount thereof at the average resin temperature Tave. after the introduction of the crosslinking agent (D).)) (4) The crosslinking agent (D) is introduced into a batch mixer after the introduction of the ethylene / Alpha-olefin / non-conjugated polyene copolymer (A), the polyolefin resin (B) and the softening agent (C). A thermoplastic elastomer composition according to the present invention is able to produce a molded body that has excellent appearance and excellent mechanical properties such as rubber elasticity, while being capable of increasing the melt density and the extrusion amount, thereby improving the productivity.

Owner:MITSUI CHEM INC

Thermoplastic elastomer composition

Owner:ENEOS MATERIALS CORP

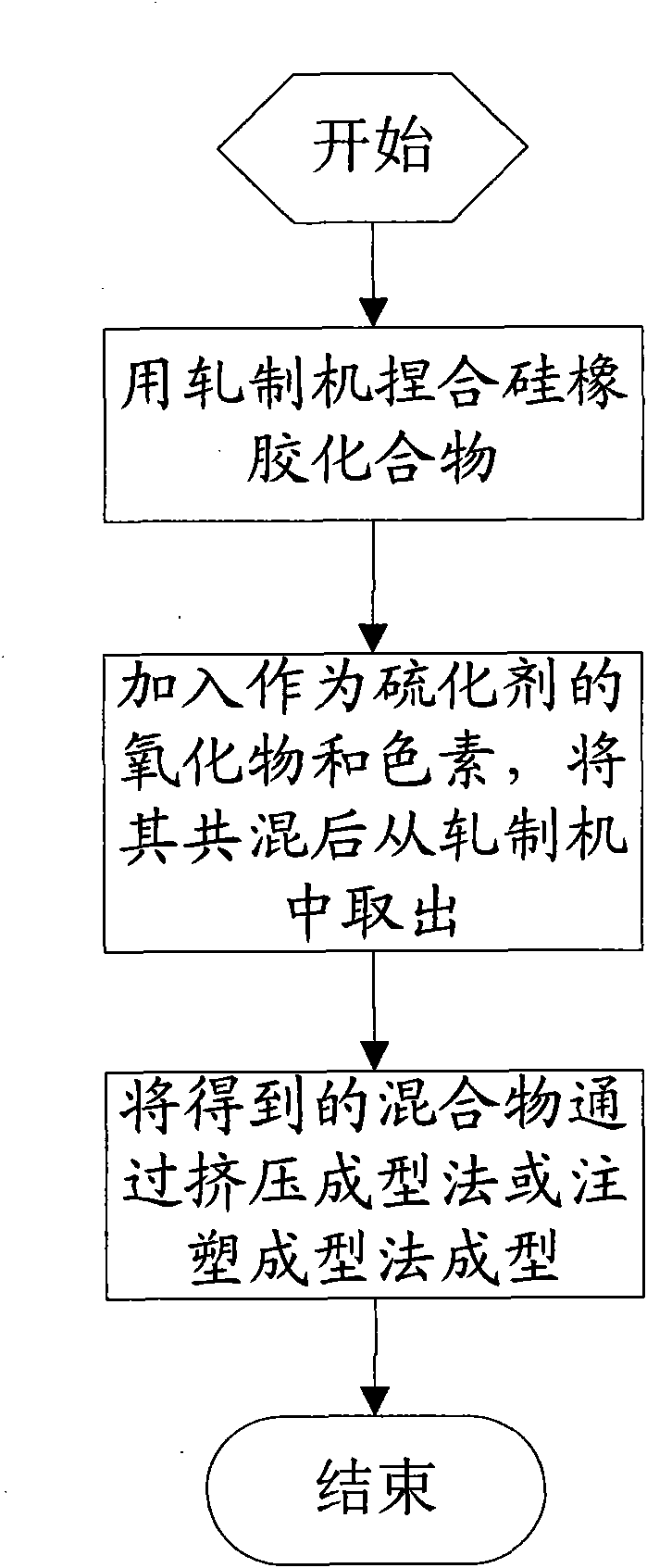

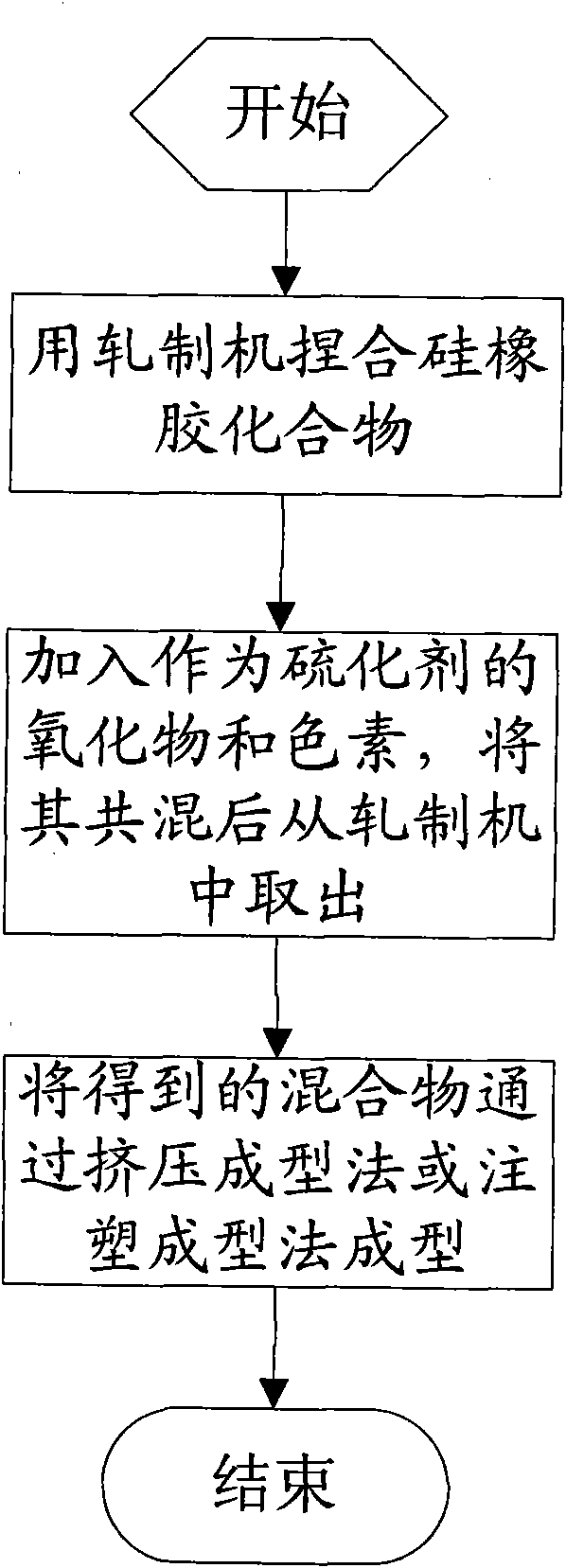

Method for manufacturing oven food mould

InactiveCN101953387AIncreased durabilityGood release effectBaking-tinsHeat resistanceInjection moulding

The invention discloses a method for manufacturing an oven food mould, which comprises the following steps of: a, kneading silicon rubber compound by using a roll mill; b, adding oxides and pigments serving as vulcanizing agents, blending, and taking the obtained product out of the roll mill; c, molding the obtained mixture by an extrusion molding method or an injection molding method. The oven food mould manufactured by the method is mainly used for baking cakes. The mould has the advantages of excellent durability and heat resistance and good demoulding property, and oil or grease or a layer of release paper does not need to be brushed or laid on the inner surface of the mould; in addition, bread raw materials containing lot of sugar and eggs can be easily broken away from the mould after baking.

Owner:SUZHOU KABUL MOLD TECH

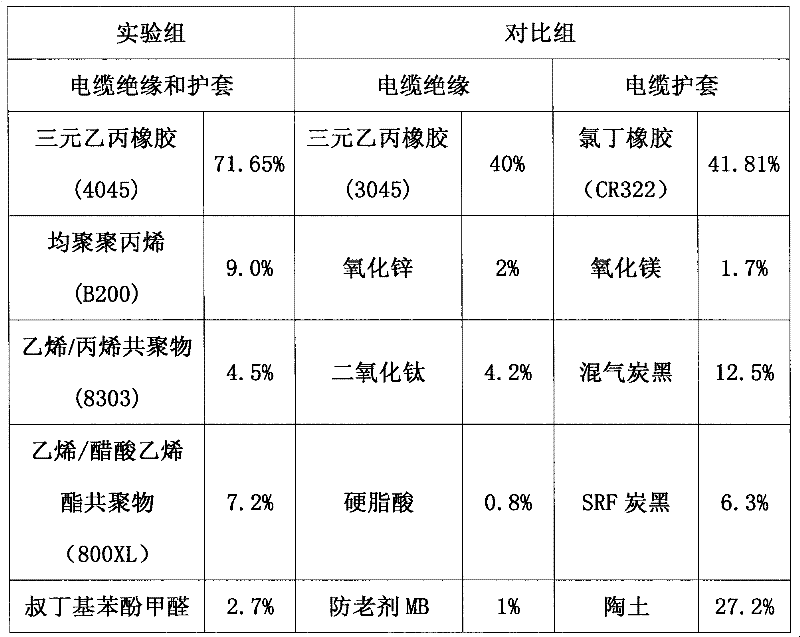

Application of thermoplastic elastomer on soft power cable for wind power generation

ActiveCN101792557BImprove insulation performanceHigh strengthRubber insulatorsPower cablesPolyolefinPower cable

Owner:沈阳军航电源科技有限公司

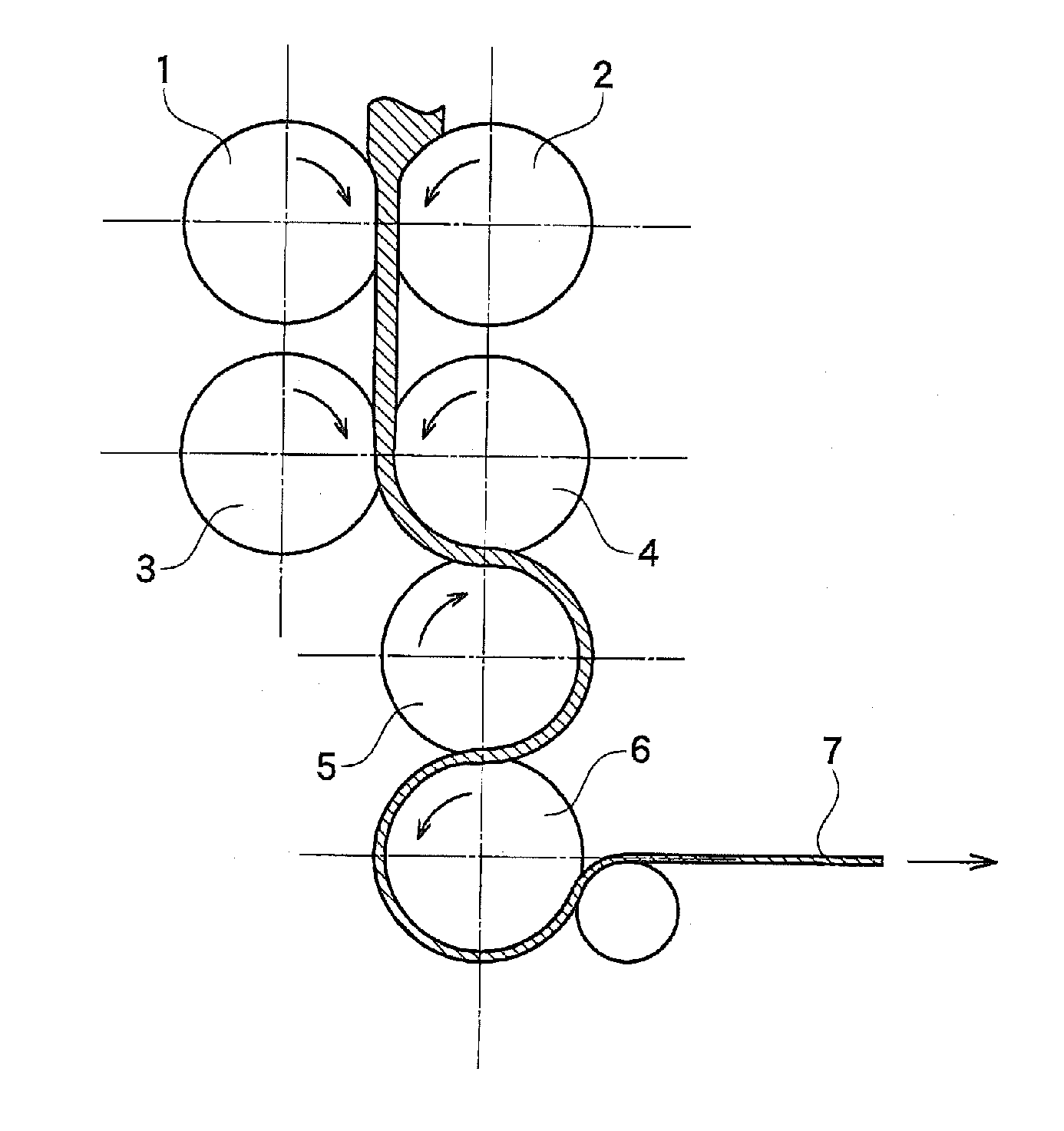

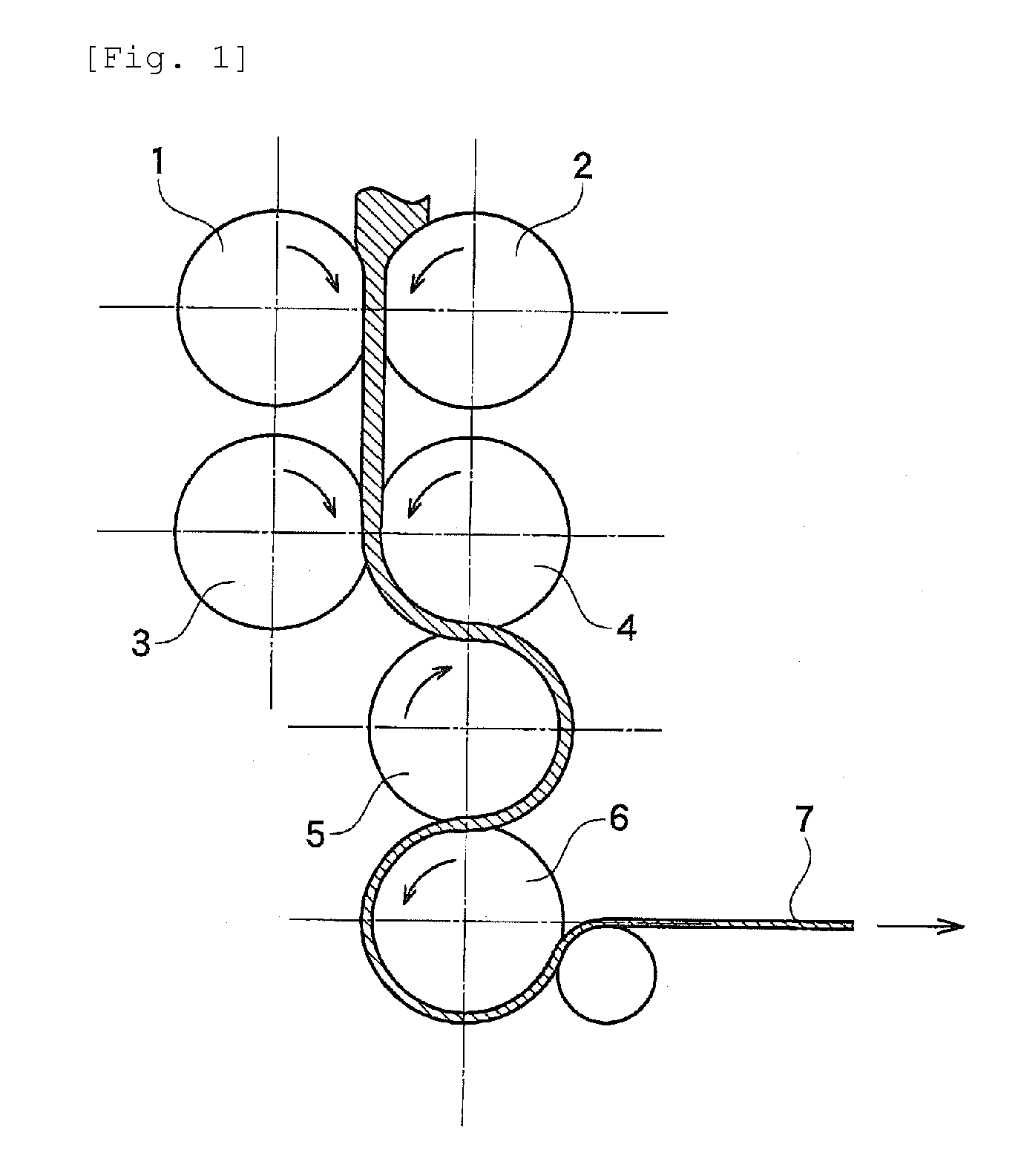

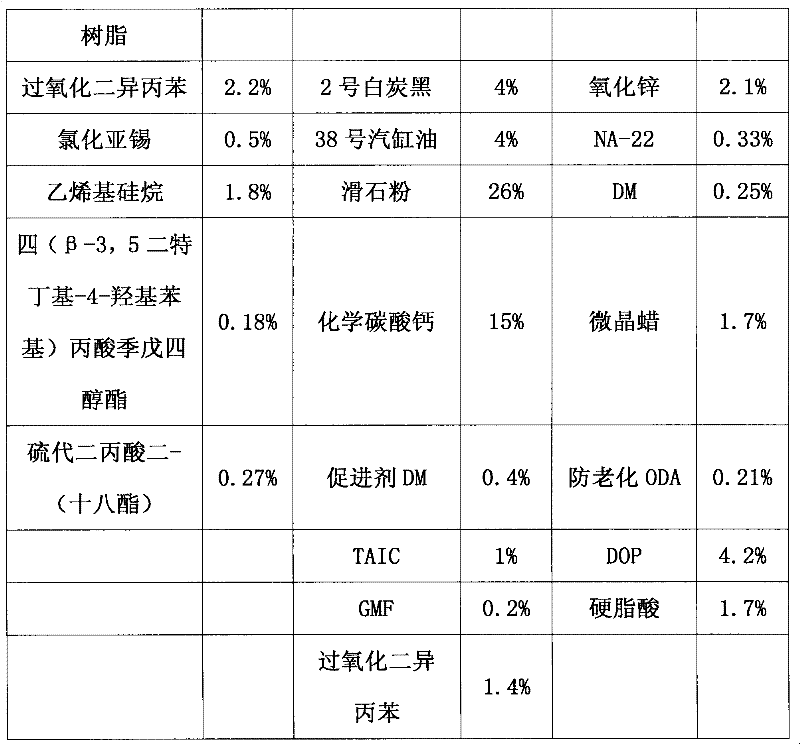

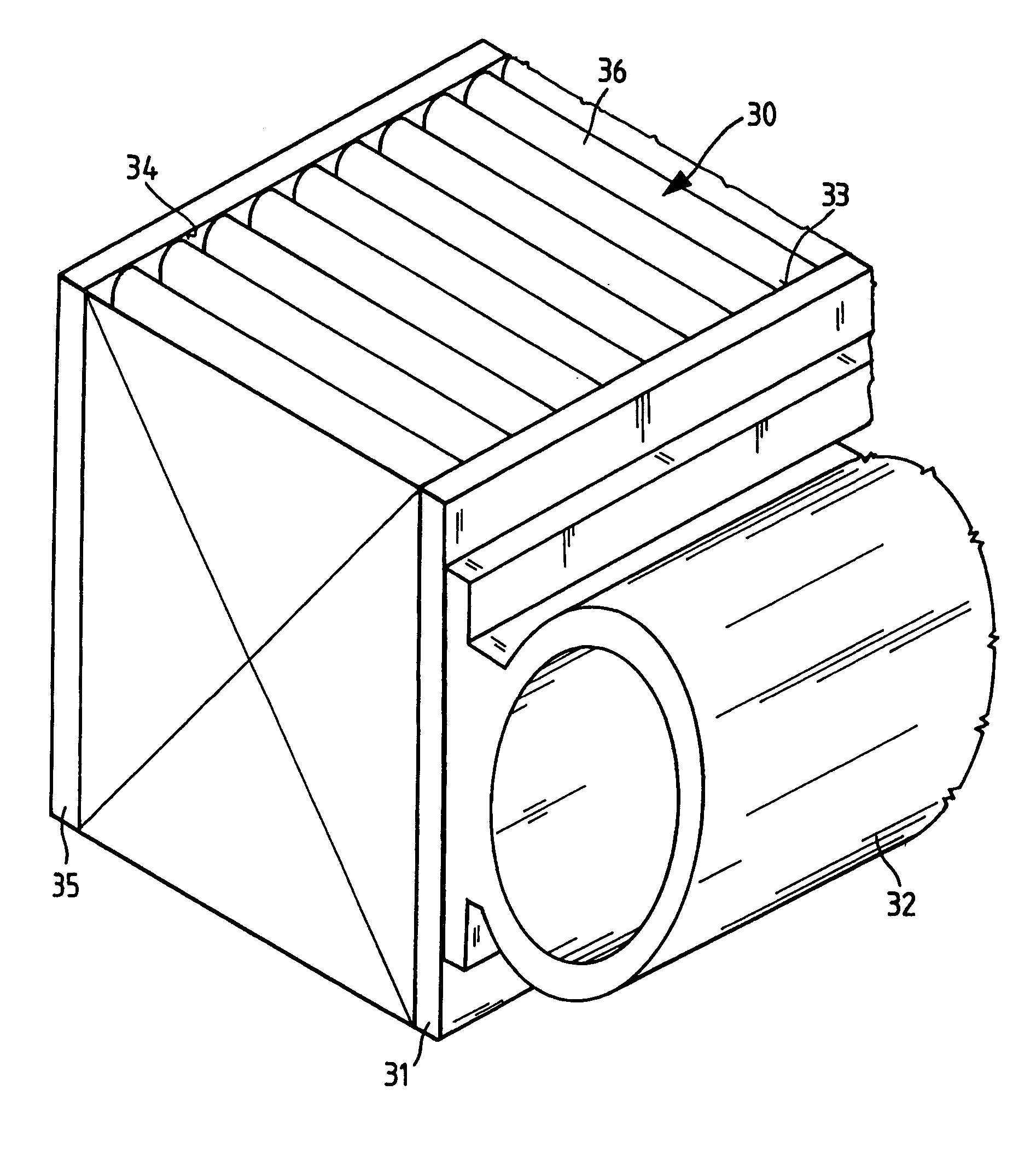

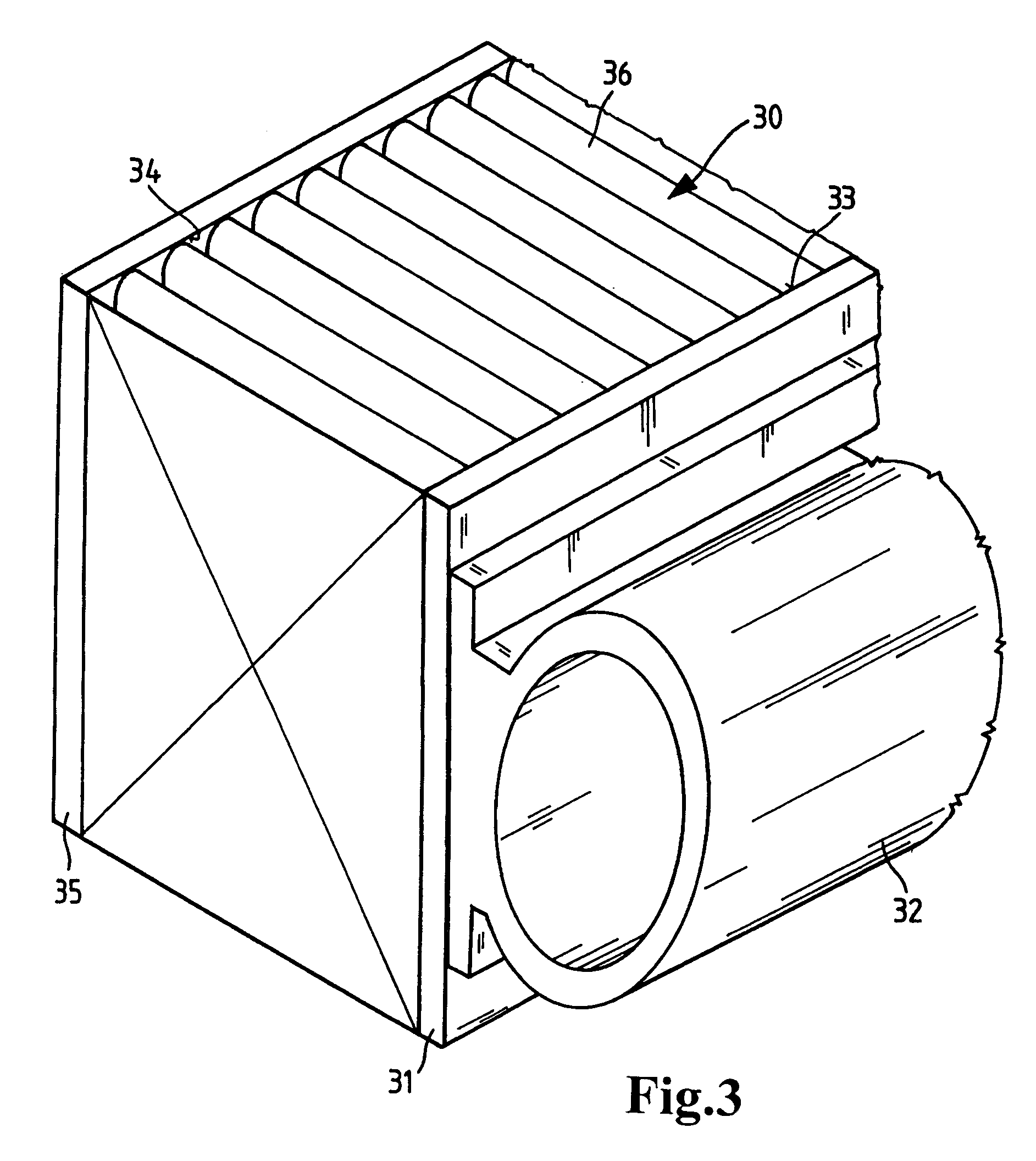

Extruded seal

ActiveUS7837755B2Increased cost-effectivenessGood rubber elasticityGas treatmentDispersed particle filtrationFiberFilter media

A filter element, including a filter medium, on which a seal is situated indirectly or directly, which is used for separating the filter intake side from the filter discharge side. The filter medium comprises a fibrous material. The seal is applied indirectly or directly to the filter medium in the extrusion method (FIG. 1).

Owner:MANN HUMMEL GMBH

Curable composition

InactiveUS8013075B2High elongationGood rubber elasticityPhotomechanical apparatusRubber elasticityAdhesive

A curable composition includes (A) a (meth)acrylate, (B) a radical polymerization initiator, (C) an epoxidized polyisoprene containing an epoxy group at 0.15 to 2.5 meq / g in the molecule and having a number-average molecular weight of 15000 to 200000, and (D) a curing accelerator. The curable composition shows high elongation and excellent rubber elasticity even in a cured state and has superior compatibility, transparency, waterproofness and flexibility, so that cracks and separation of cured products are reduced. Accordingly, the composition is suitable for use as adhesives, coating agents, encapsulating materials, inks, sealing materials and the like.

Owner:KURARAY CO LTD

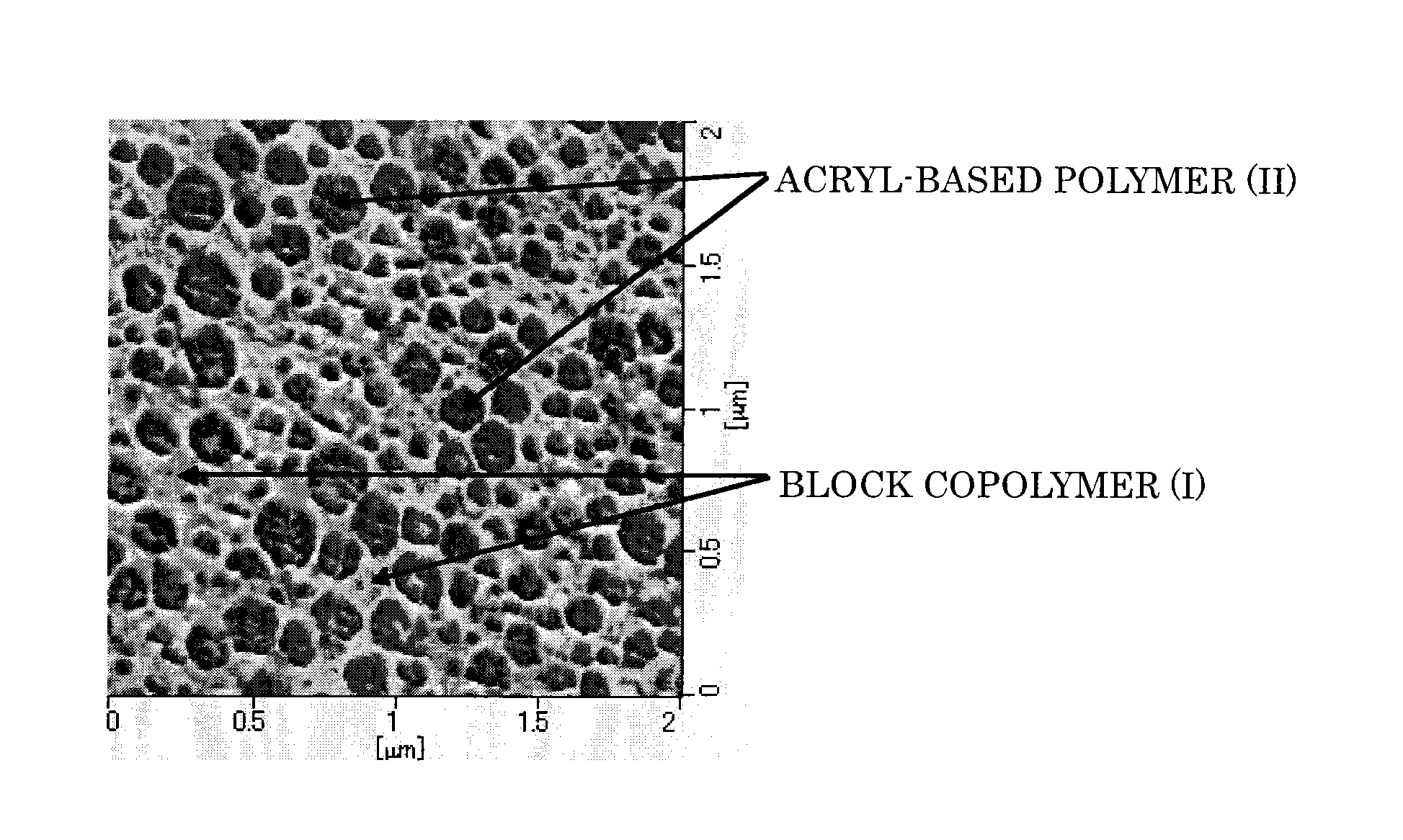

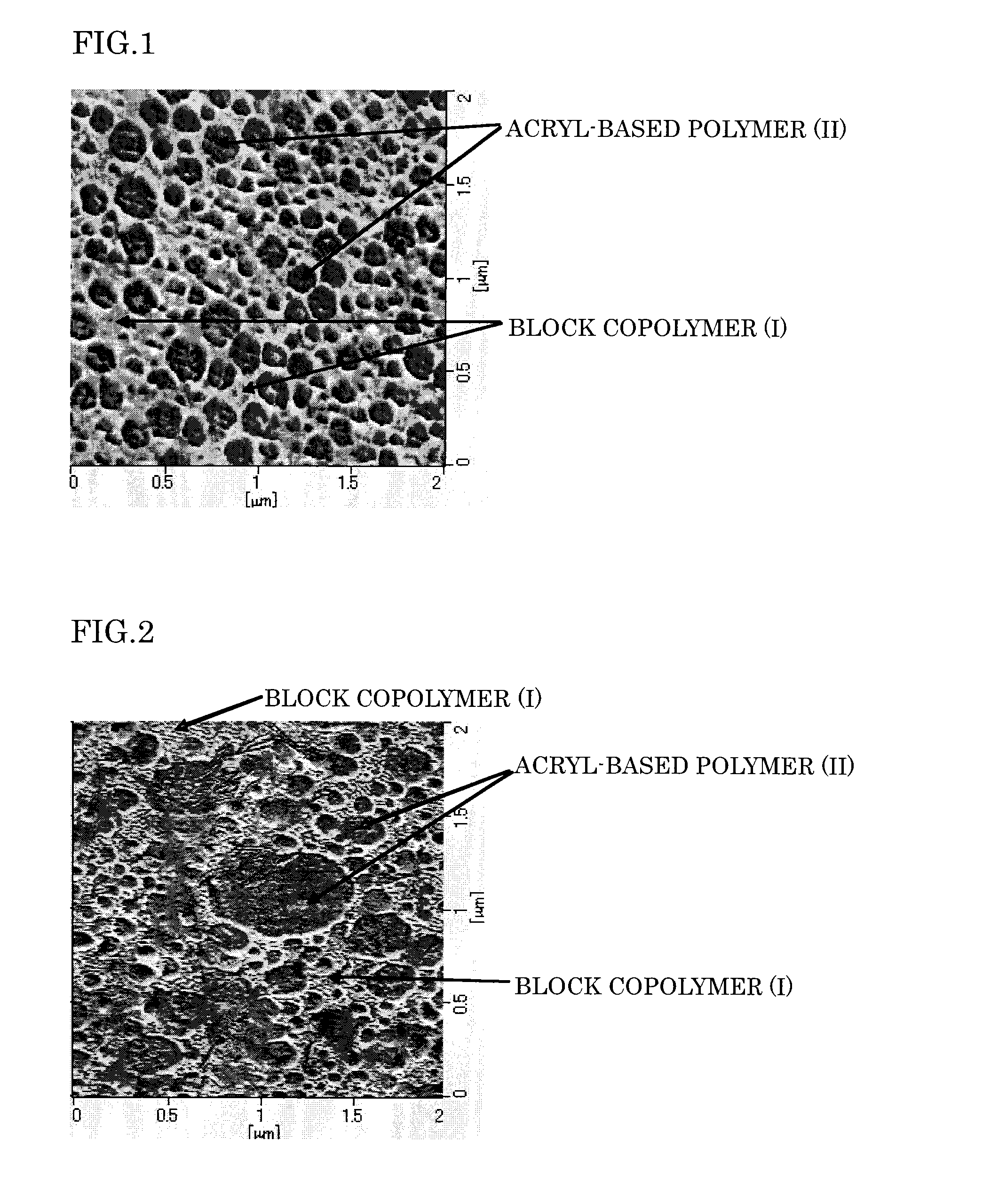

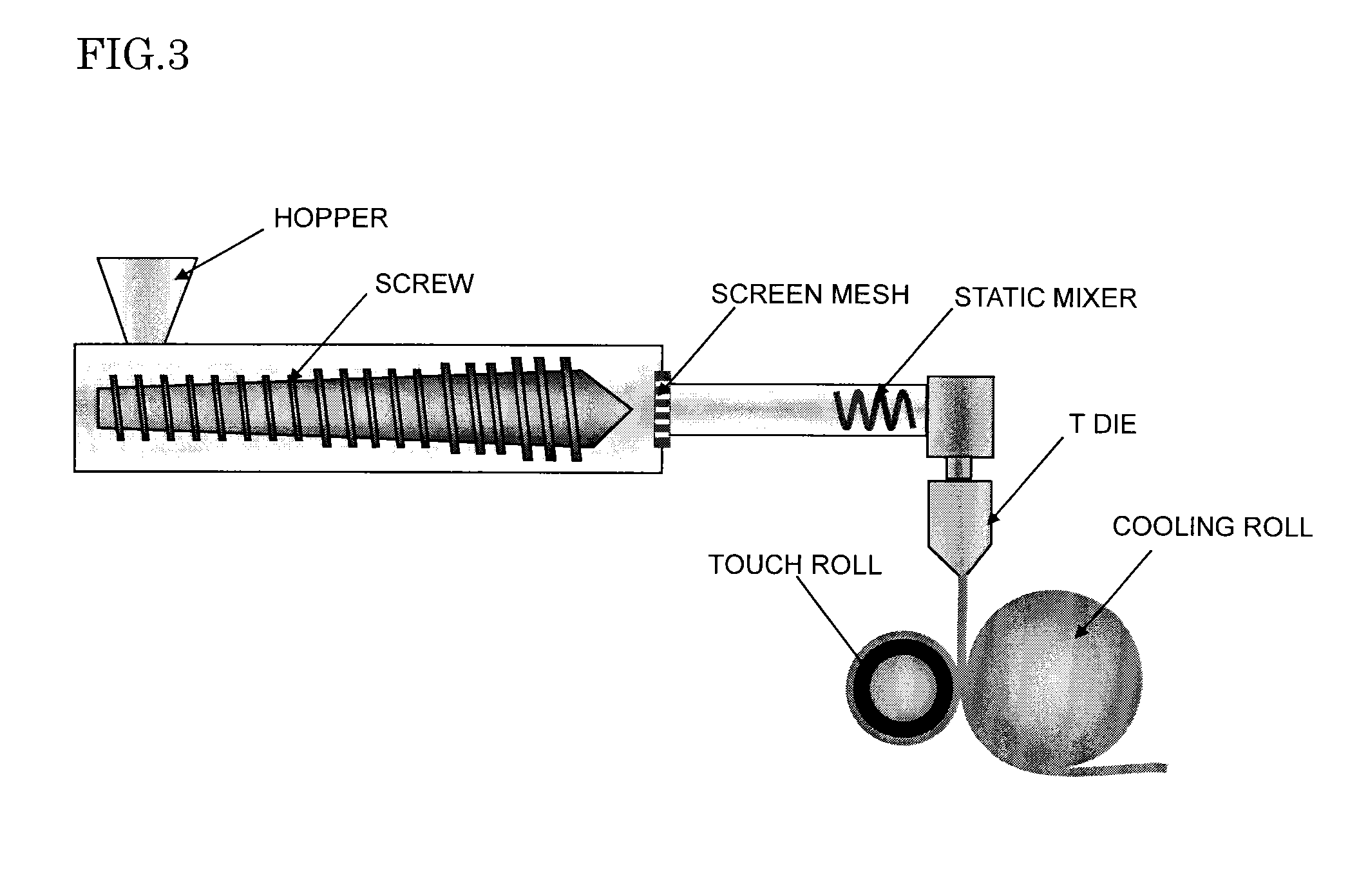

Thermoplastic polymer composition, sheet or film, and multi-layered film

ActiveUS20150368456A1High transparencyMaintaining resistance abrasionFilm/foil adhesivesSynthetic resin layered productsPolymer scienceMeth-

Provided are a thermoplastic polymer composition having good mold processability, flexibility, rubber elasticity, scratch resistance, abrasion resistance, transparency, ease of coating, and mechanical properties when formed into a sheet or film, a sheet or film produced using the thermoplastic polymer composition, and a multi-layered film. The thermoplastic polymer composition includes (I) a block copolymer having a number average molecular weight of 30,000 to 200,000, or a hydrogenated product thereof, which has a polymer block (A) mainly composed of α-methylstyrene units and a polymer block (B) mainly composed of conjugated diene compound units or isobutylene units, (II) an acryl-based polymer, and (III) a softening agent at a ratio satisfying the formulae (1) and (2) as described in claim 1, and has a sea-island structure in which the components (II) are dispersed in the form of particles in a continuous phase including the component (I), in which the average dispersed particle diameter of the dispersed particles of the components (II) is 200 nm or less, and 35% by mass or more of the dispersed particles have dispersed particle diameters of less than 60 nm.

Owner:KURARAY CO LTD

Thermoplastic crosslinked rubber composition

InactiveUS7488776B2Superior in rubber elasticityImprove in printability and coating performanceDouble bondThermoplastic

A thermoplastic crosslinked rubber composition comprising (A) from 1 to 99 parts by weight of a hydrogenated rubber obtained by hydrogenating not less than 50% of total double bonds of at least one homopolymer rubber of a conjugated diene type monomer or a random copolymer rubber consisting of a conjugated diene type monomer unit and an aromatic vinyl monomer unit and (B) from 1 to 99 parts by weight of an olefinic thermoplastic resin, total amount of (A) and (B) being 100 parts by weight, said (A) being partially or completely crosslinked, wherein said (A) is crystalline rubber, having a crystallization temperature in a range of from −50 to 70° C. and a heat quantity of crystallization at peak in a range of from 3 to 100 J / g in differential scanning calorimetry (DSC method).

Owner:ASAHI KASEI KK

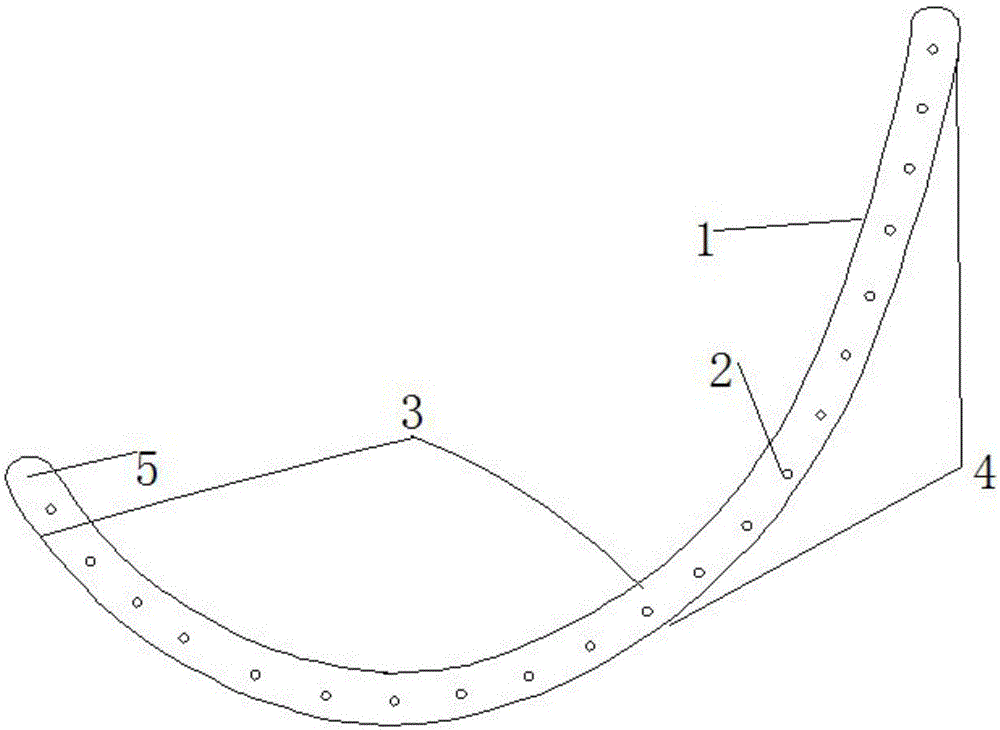

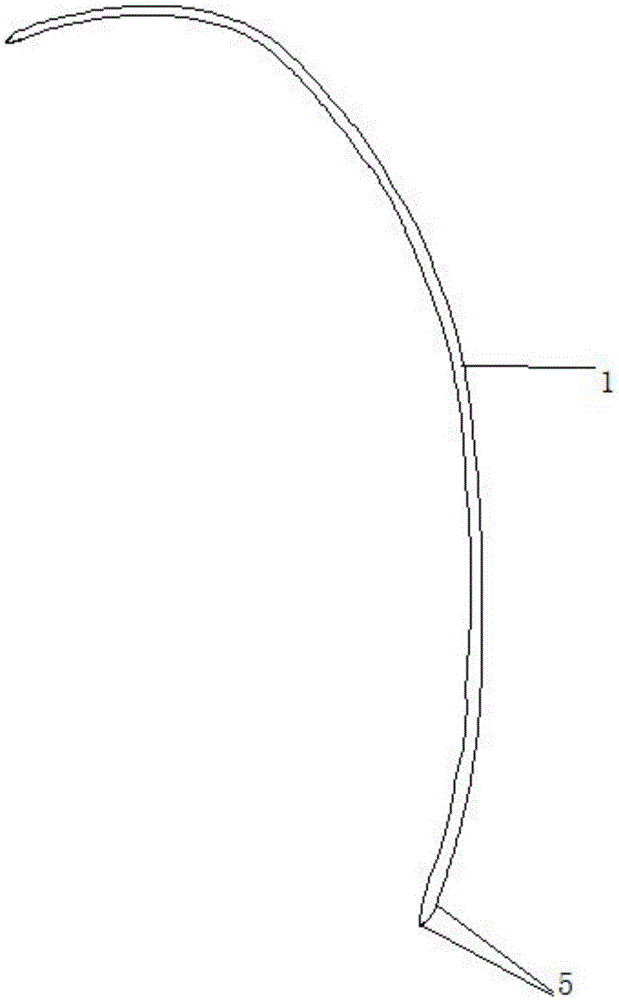

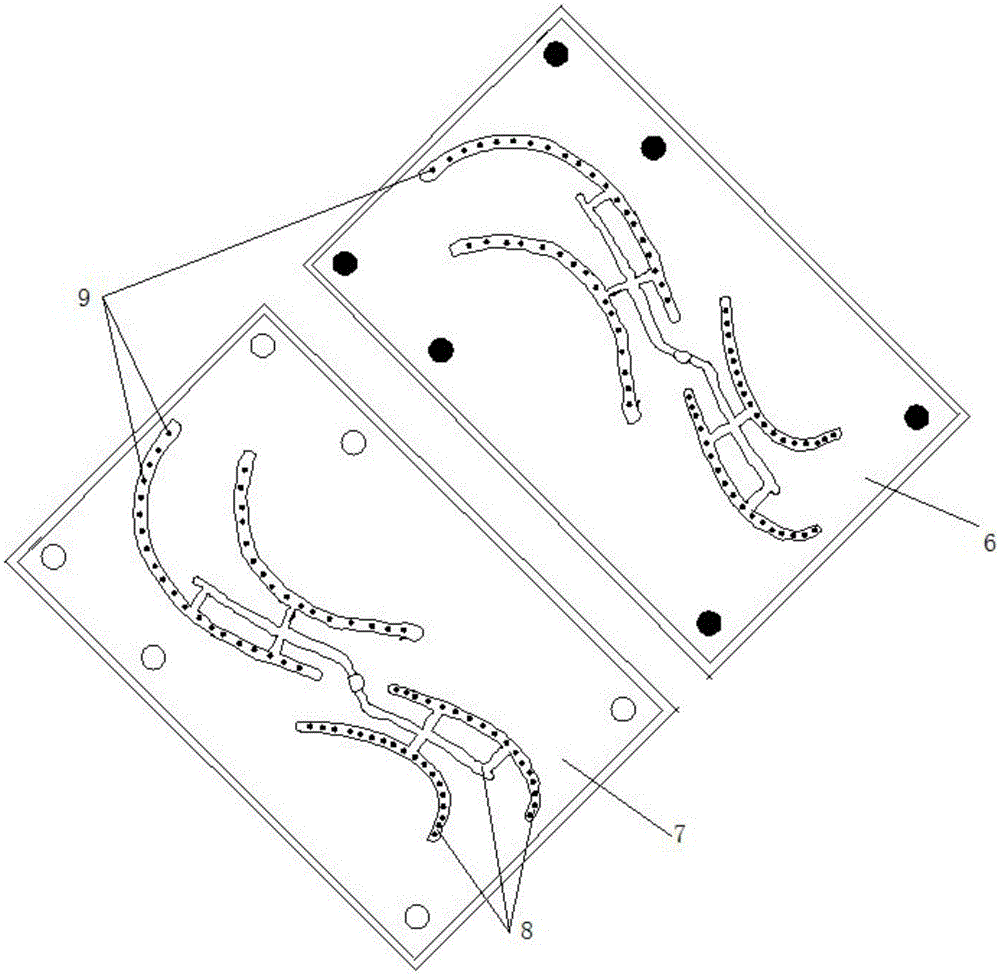

Improved bra underwires, processing method thereof and bra product provided with same

InactiveCN106307645AGood rubber elasticityImprove water resistanceBrassieresEconomic benefitsThermoplastic polyurethane

The invention relates to the technical field of underwear and in particular discloses a kind of improved bra underwires. The improved bra underwires are formed by injecting modified thermoplastic polyurethane elastomer into a mould and then carrying out integral moulding, and relatively dense grooves are accordingly formed in the front and back of the underwires from one end to the other end, so that an inner layer and an outer layer of a bra cup can be closely embedded into the grooves to be connected and fixed with the underwires after being sequentially subjected to glue spraying, cold laminating and mould pressing. The invention also discloses a processing method of the improved bra underwires and a bra product applying the underwires. The improved bra underwires disclosed by the invention is low in cost, a one-time moulding manufacturing process is adopted, environmental protection is realized, resource is greatly saved, and the grooves in the underwires are closely embedded with a bra body, so that the formed bra has good fixity and washing resistance, is difficult to deform, can replace expensive like products and has extremely high marketing value and good economic benefit.

Owner:何斌

Ionomer, method for producing same and molded article

Disclosed is an ionomer which is obtained by reacting metal compound particles having an average particle diameter of not more than 1 [mu]m and a polymer having a structural unit derived from an unsaturated dicarboxylic acid anhydride. Such an ionomer has flexibility and molding workability similar to those of conventional olefin thermoplastic elastomers, while exhibiting good mechanical characteristics, oil resistance and abrasion resistance. In addition, such an ionomer is particularly excellent in tensile break strength and scratch resistance. Also disclosed are a method for producing such an ionomer and an molded article made of such an ionomer.

Owner:JSR CORPORATIOON

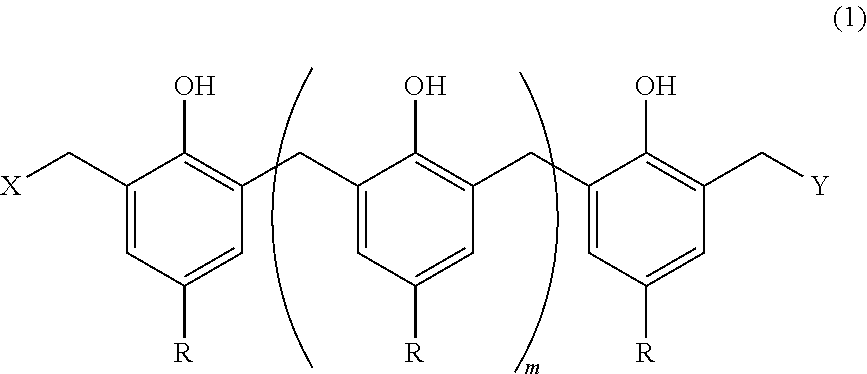

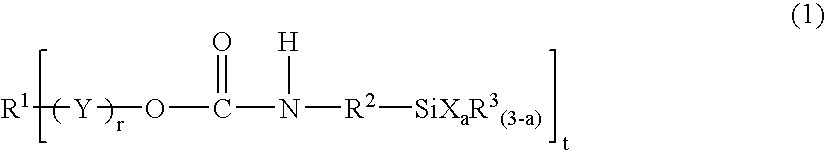

Silyl group-containing polymer and its production process

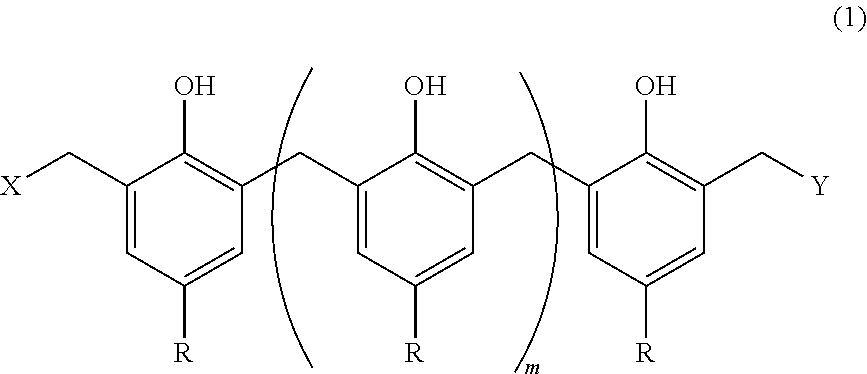

InactiveUS7534850B2Excellent in antifouling property and weather resistanceCured quickly and stronglySilicon organic compoundsEmulsion paintsPolymer scienceRubber elasticity

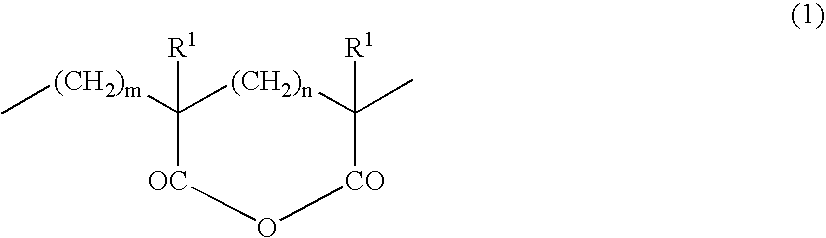

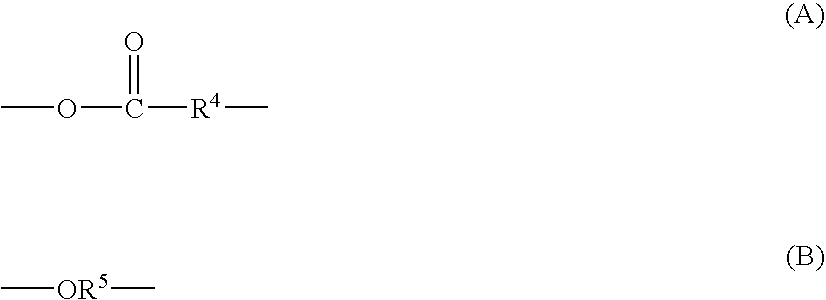

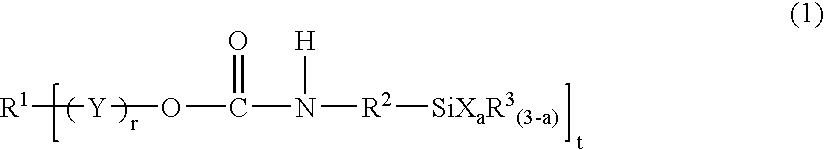

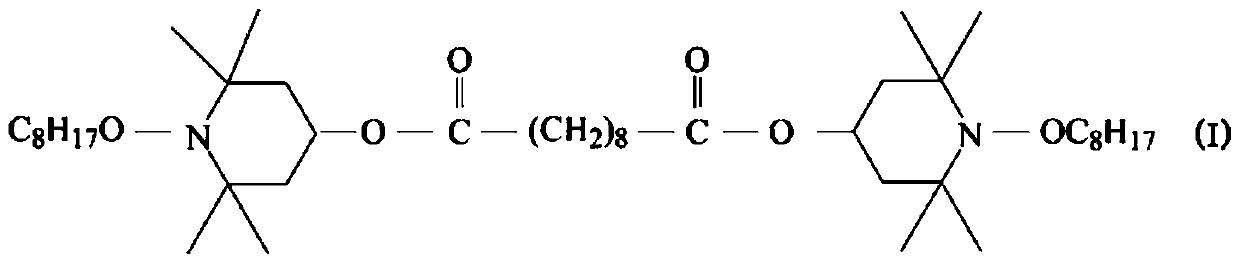

A silyl group-containing polymer which can be cured quickly and strongly, and from which a cured product excellent in antifouling properties and weather resistance while maintaining favorable rubber elasticity can be obtained, and having the following formula (1):wherein R1: a group having a hydroxyl group(s) removed from a monohydroxy or polyhydroxy compound having t hydroxyl group(s) in its molecule, R2: a bivalent organic group, R3: a C1-20 monovalent organic group which may have a substituent, X: a hydroxyl group or a hydrolysable group, Y: a bivalent group of the following formula (A) or (B), “a”: an integer of from 1 to 3, r: an integer of from 1 to 1,000, and t: an integer of from 1 to 8, provided that when the silyl group-containing polymer of formula (1) has a plurality of Y's in its molecule, the plurality of Y's may be the same or different, and when t is from 2 to 8, a plurality of monovalent groups bonded to R1 may be the same or different:in the formula (A), R4: a C2-8 alkylene group, and in the formula (B), R5: a C2-4 alkylene Group; and its production process.

Owner:ASAHI GLASS CO LTD

Curable composition and joint structure formed using the same

ActiveCN105121544BGood adhesionGood rubber elasticityOther chemical processesBuilding constructionsSilyleneOligomer

The present invention provides a curable composition comprising: a polyoxyalkylene (A) having a hydrolyzable silyl group, an acrylic polymer (B) having a hydrolyzable silyl group, and an alkoxysilane oligomer ( C), the alkoxysilane oligomer (C) is a hydrolysis condensate of an alkylalkoxysilane and an aminoalkoxysilane, and the nitrogen atom content is more than 1% by weight.

Owner:SEKISUI FULLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com