Patents

Literature

281results about How to "Increase elastic strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

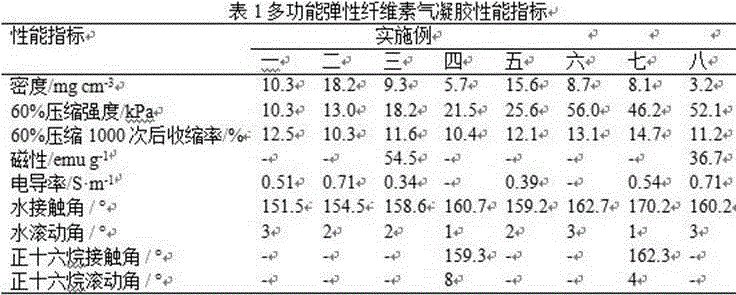

Preparation method of multifunctional cellulose elastic aerogel

The invention discloses a preparation method of a multifunctional cellulose elastic aerogel, belonging to the field of aerogel materials. The preparation method comprises the following steps: dispersing cellulose in water, carrying out pretreatment by adding sodium chlorite or / and in a solvothermal way, and cleaning with deionized water to obtain a purified cellulose dispersion solution; adding a modifier to perform chemical modification, thereby obtaining a modified cellulose suspension; dispersing the modified cellulose suspension in an organic solvent, forming, drying to form a modified cellulose gel, and finally, carrying out heat treatment on the modified cellulose gel to obtain the multifunctional cellulose elastic aerogel. The cellulose is subjected to pretreatment and chemical modification, thereby lowering the density of the aerogel, greatly enhancing the elasticity and mechanical strength of the aerogel, endowing the aerogel with excellent magnetism, electric conductivity, superhydrophobicity, superoleophobicity and many other functions, and widening the application range of the traditional cellulose aerogel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

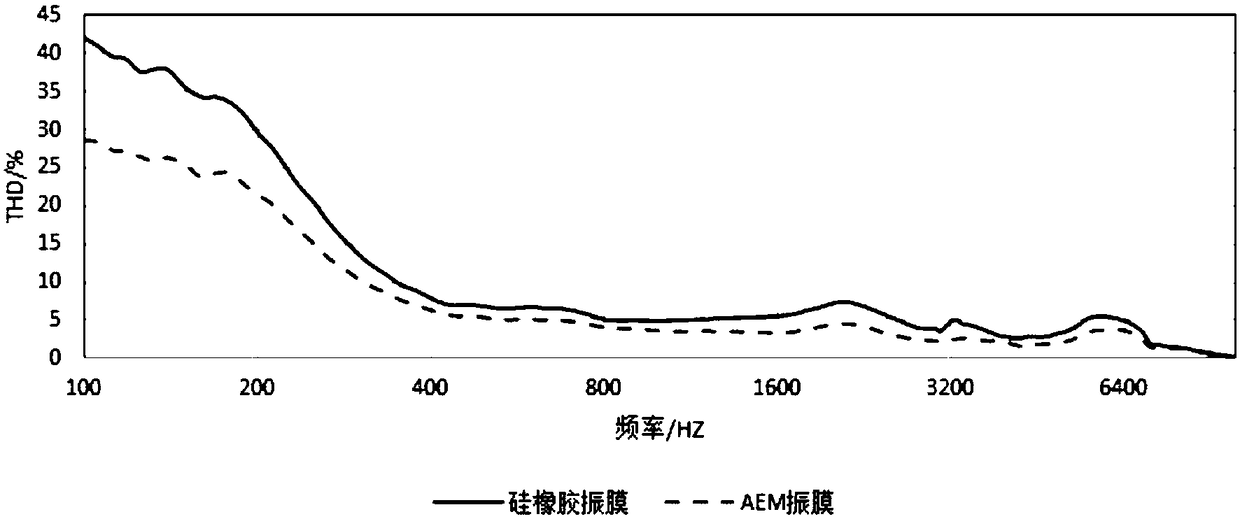

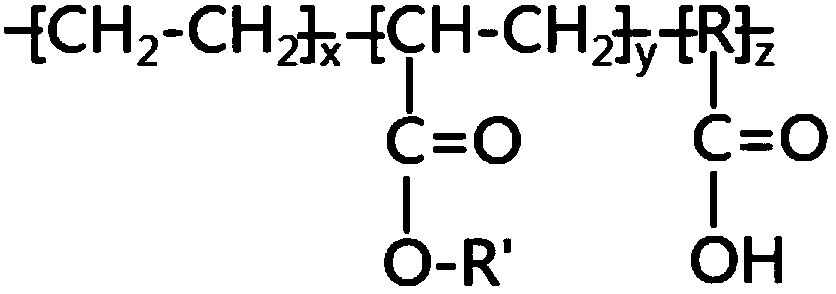

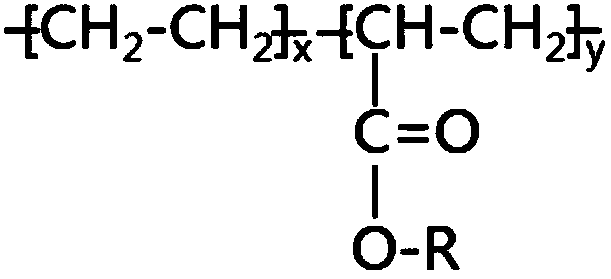

Diaphragm for sounding device, sounding device and assembling method thereof

PendingCN109218924AImprove loss factorReduced chemical structure symmetryDiaphragm extensionsPlane diaphragmsChemical structureCarboxylic acid

The invention discloses a diaphragm for a sounding device, a sounding device and an assembling method thereof. The diaphragm includes a diaphragm layer prepared by subjecting at least one of an ethylene-acrylate copolymer and an ethylene-acrylic ester-carboxylic acid copolymer to crosslinking reaction. The molecular structure of the diaphragm includes a vinyl-acrylic group. The group reduces the chemical structure symmetry of a material, reduces tacticity, and increase steric hindrance, so that the diaphragm has a high loss factor and the sounding device has a good damping effect.

Owner:GOERTEK INC

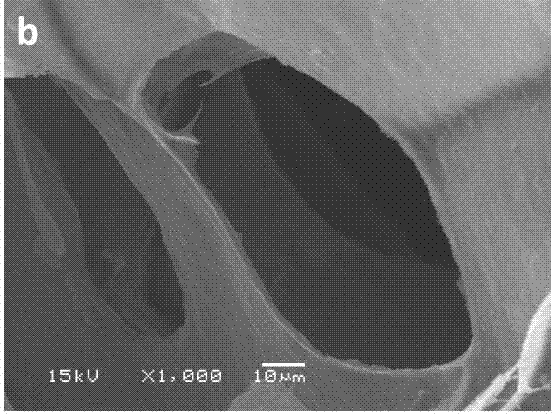

Polyolefine multiple micoporous film and preparing process thereof

InactiveCN1504498AChange stretching speedChange and optimize stretching speedPorosityPolymer science

The invention discloses a polyolefine microporous membrane and method for preparation, wherein the polyolefine microporous membrane is a microporous film with micropore diameter 20-500nm, overall porosity 30%-60%, and film thickness 0.5-25mum. The process for preparing the polyolefine microporous membrane according to the invention comprises the steps of, (1) polyolefine film preparation, (2) film annealing, (3) single time stretching for pore-forming, (4) film shaping. The present invention realizes films with thinness and high tensile strength.

Owner:李春香 +1

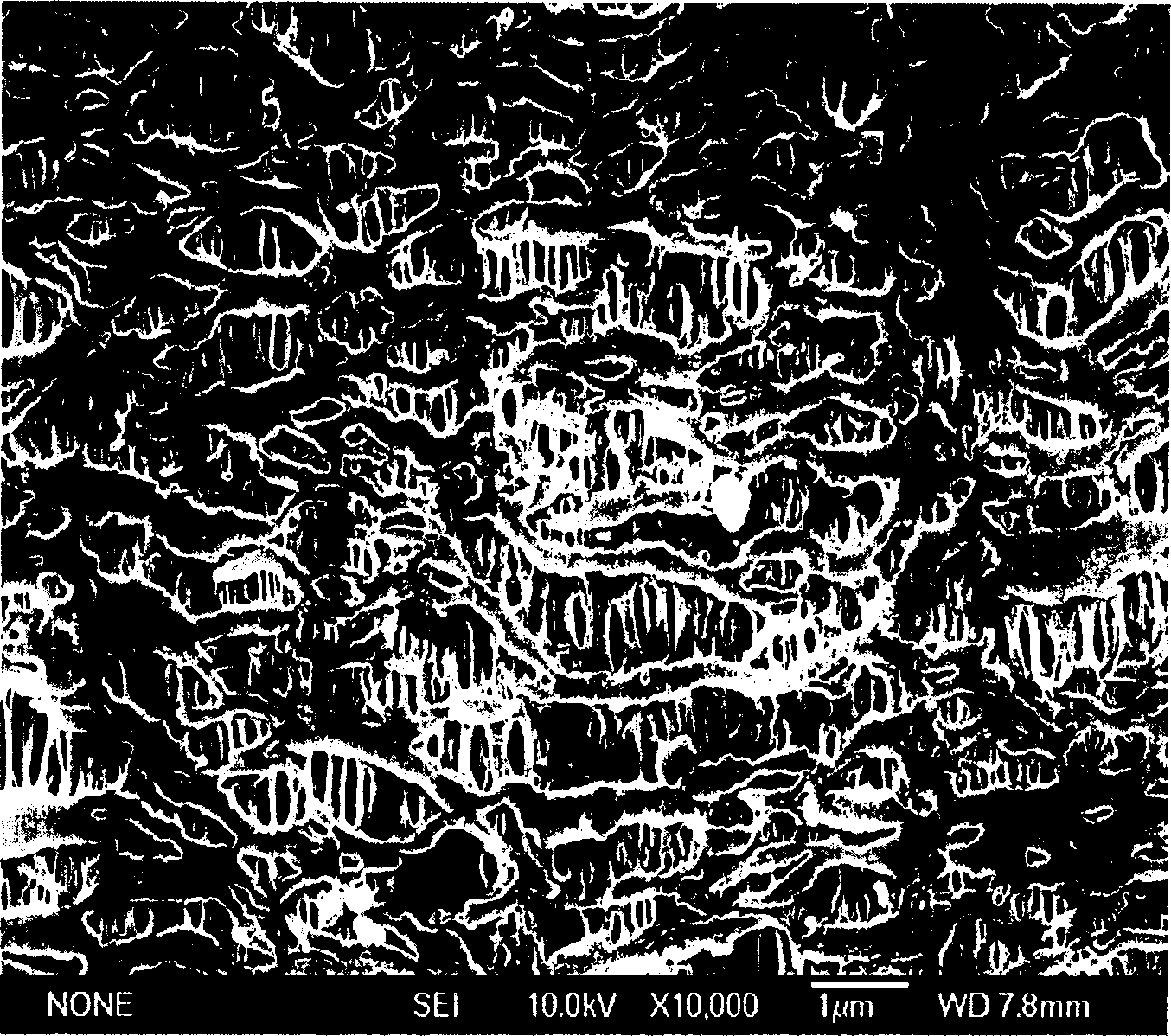

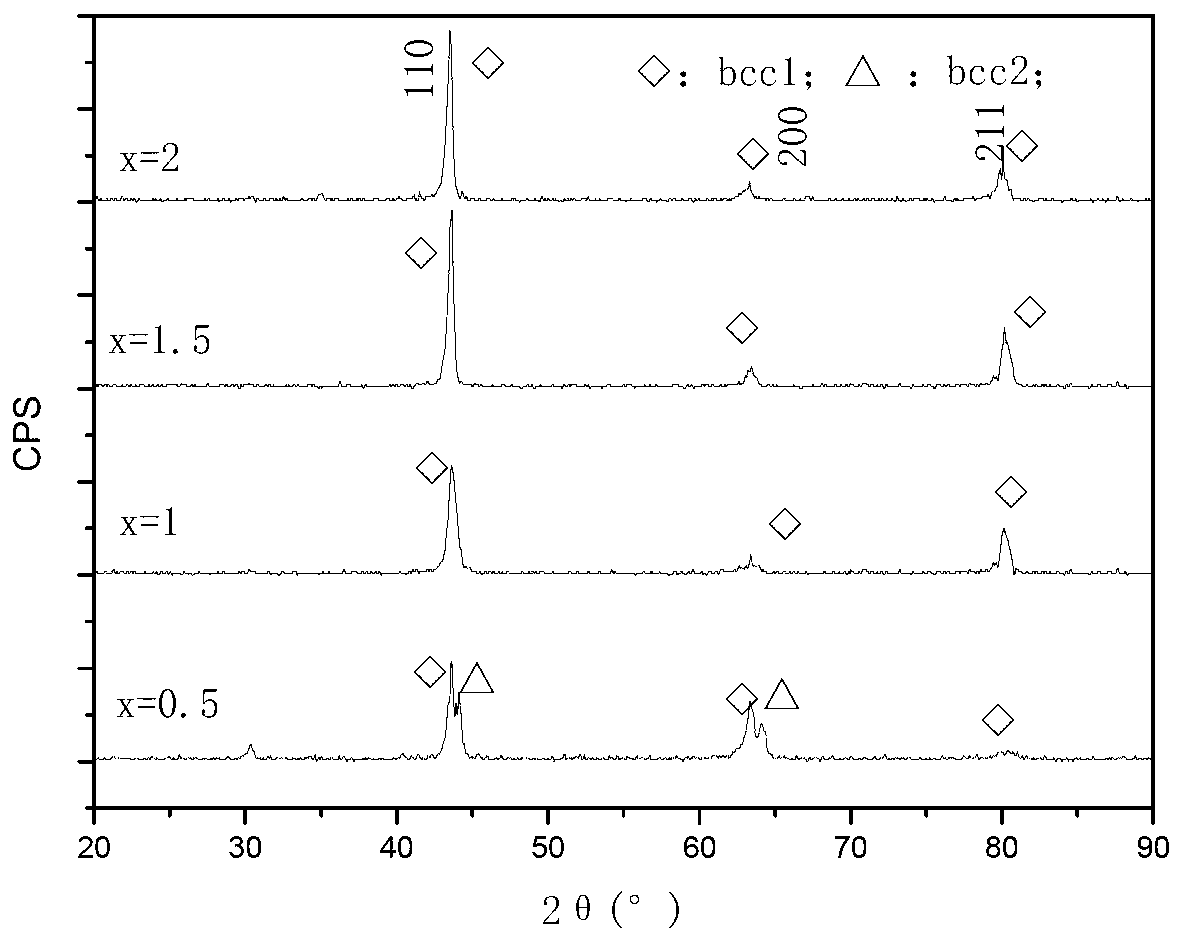

AlFeCoNiCrTiVx high-entropy alloy material and preparation method thereof

The invention relates to an AlFeCoNiCrTiVx high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlFeCoNiCrTiVx, wherein the value range of x is 0.5-2. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the high-entropy alloy material has very good strength, tenacity, elasticity, high-temperature performance and electrochemical performance.

Owner:梧州漓佳铜棒有限公司

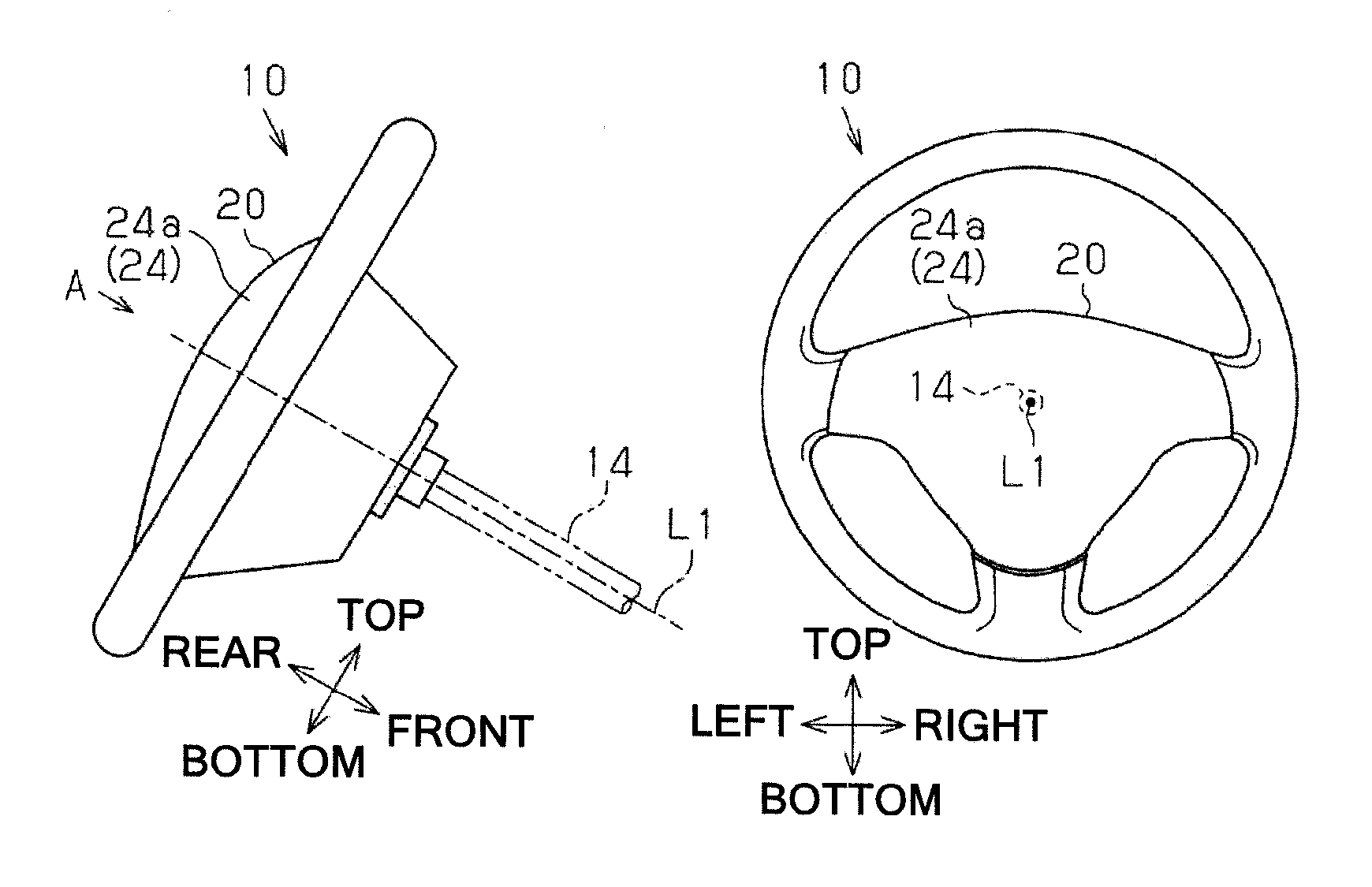

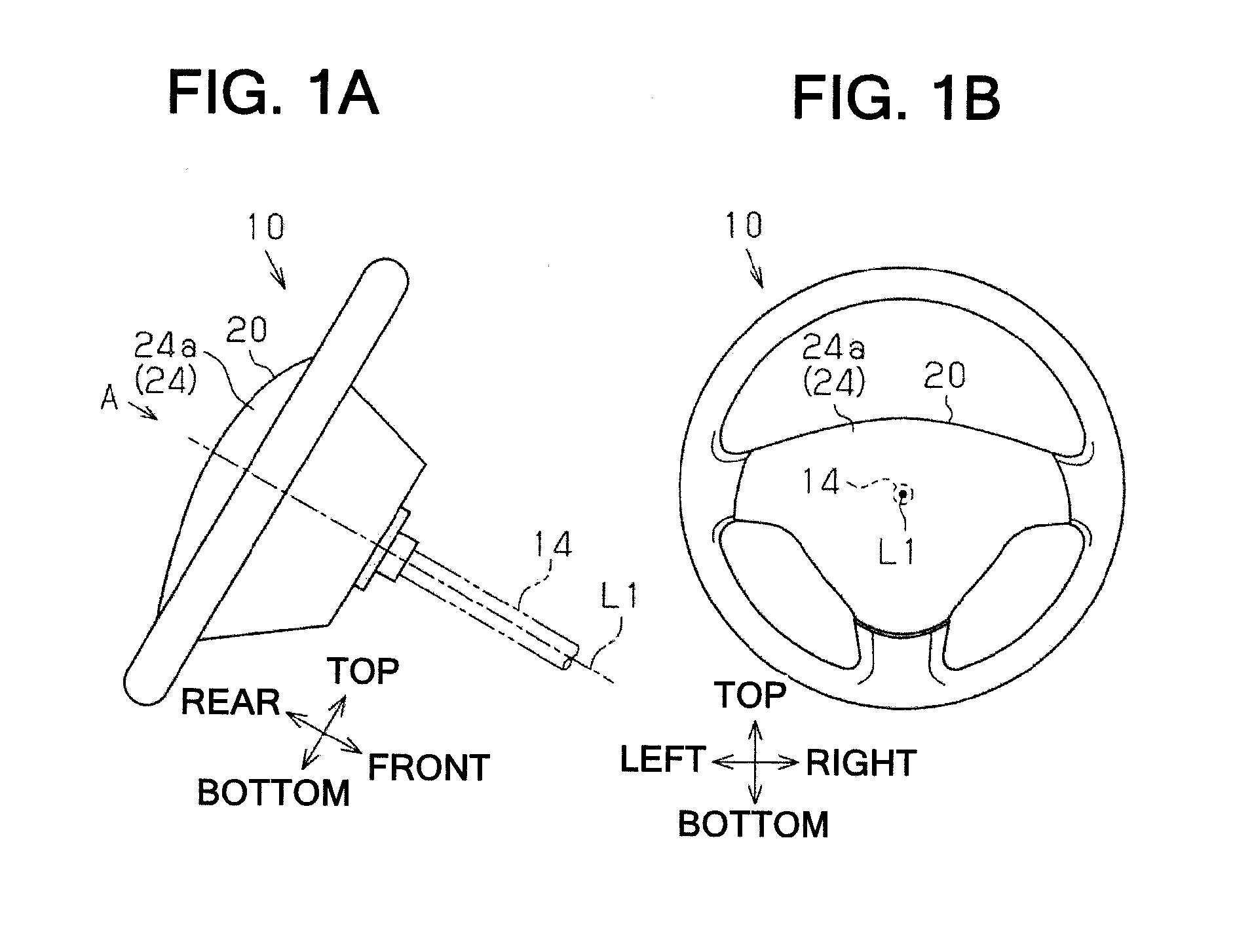

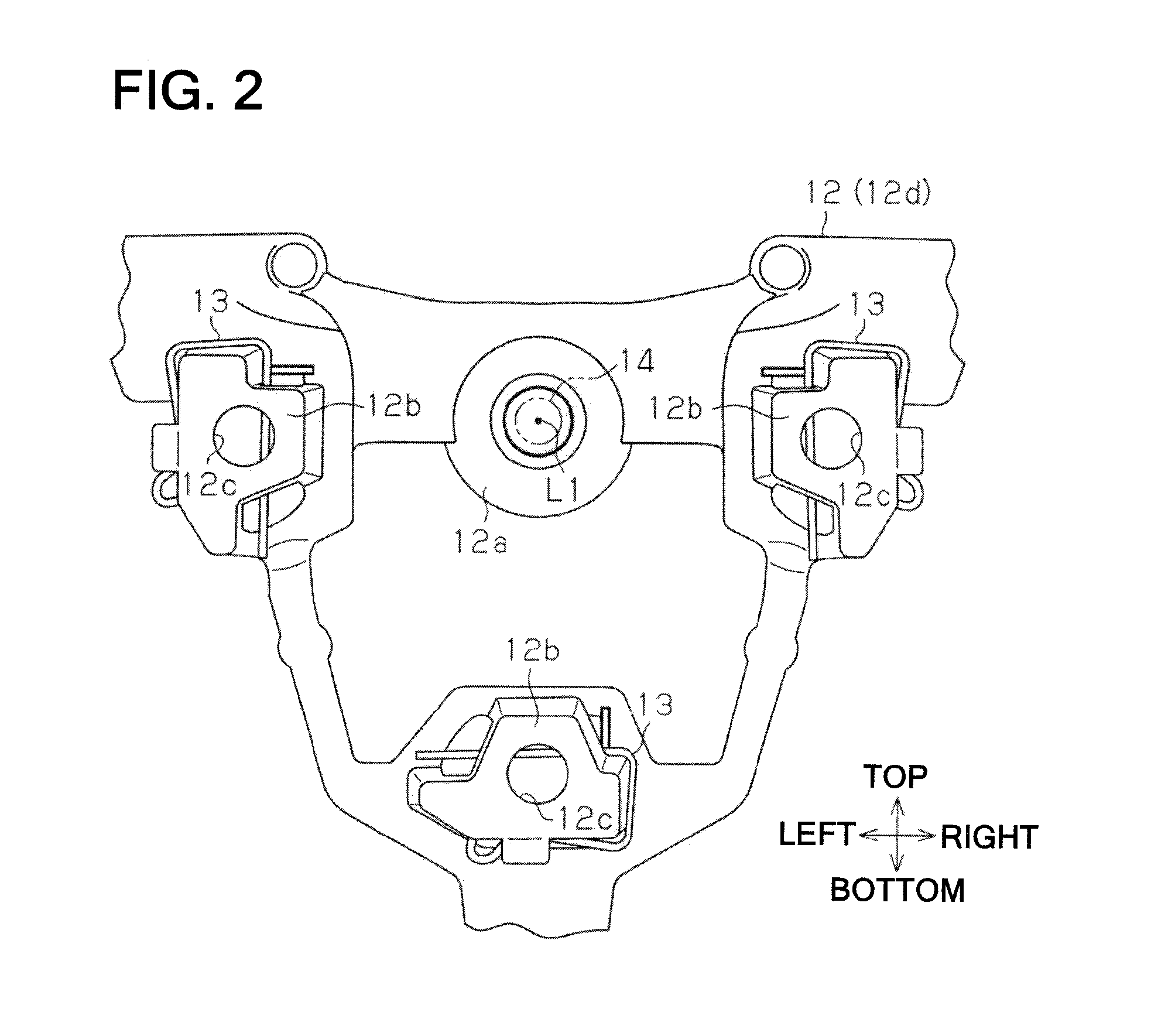

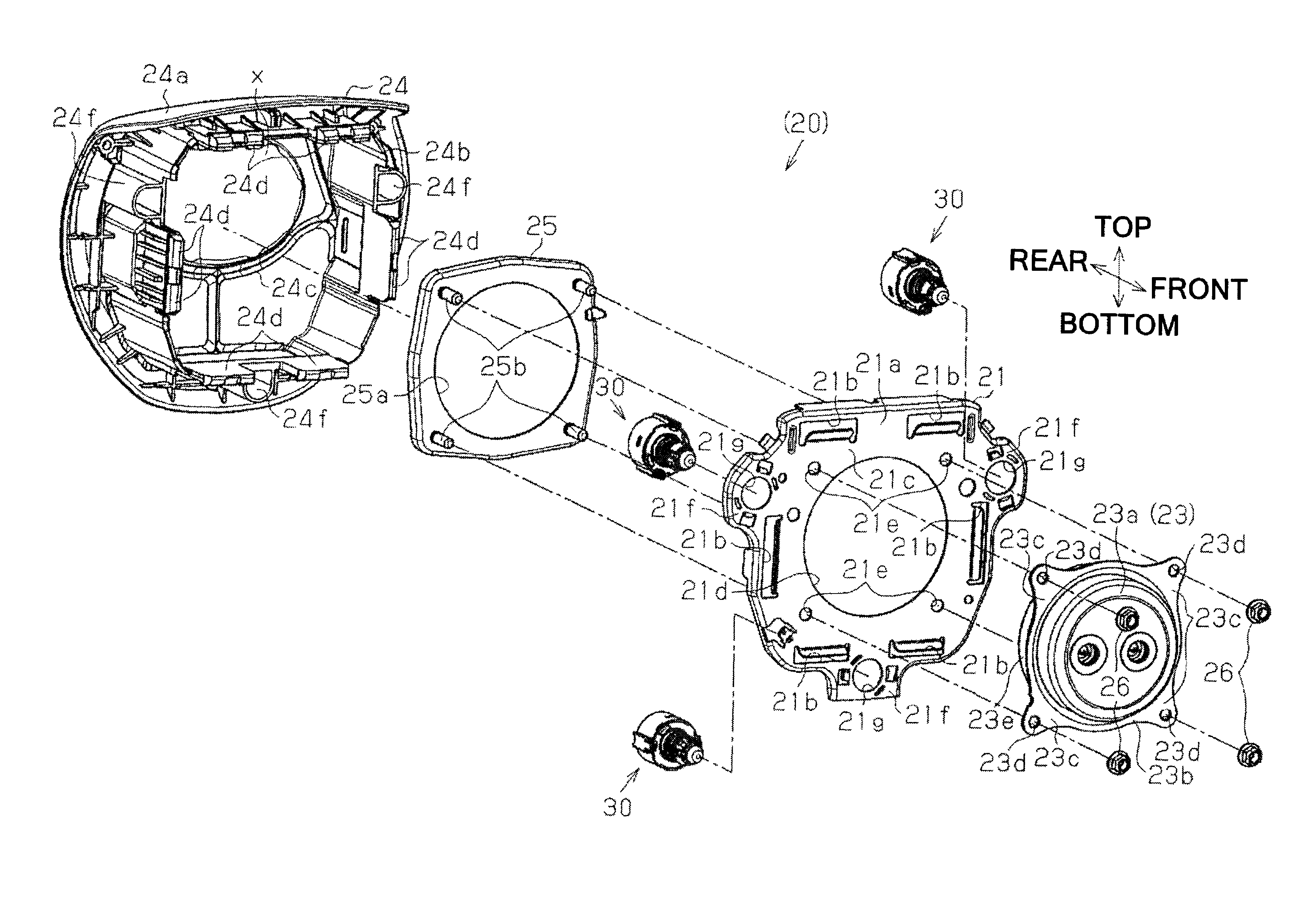

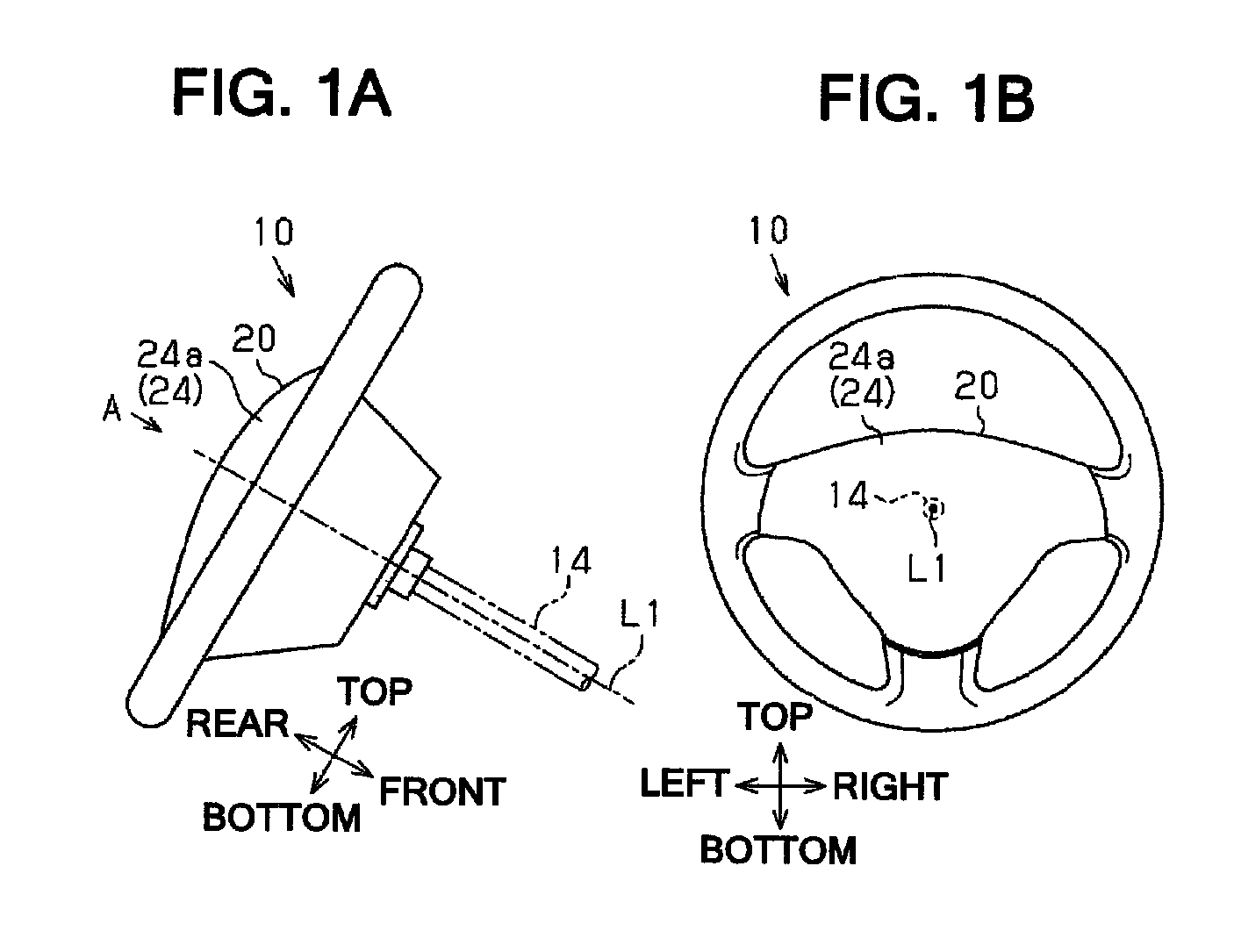

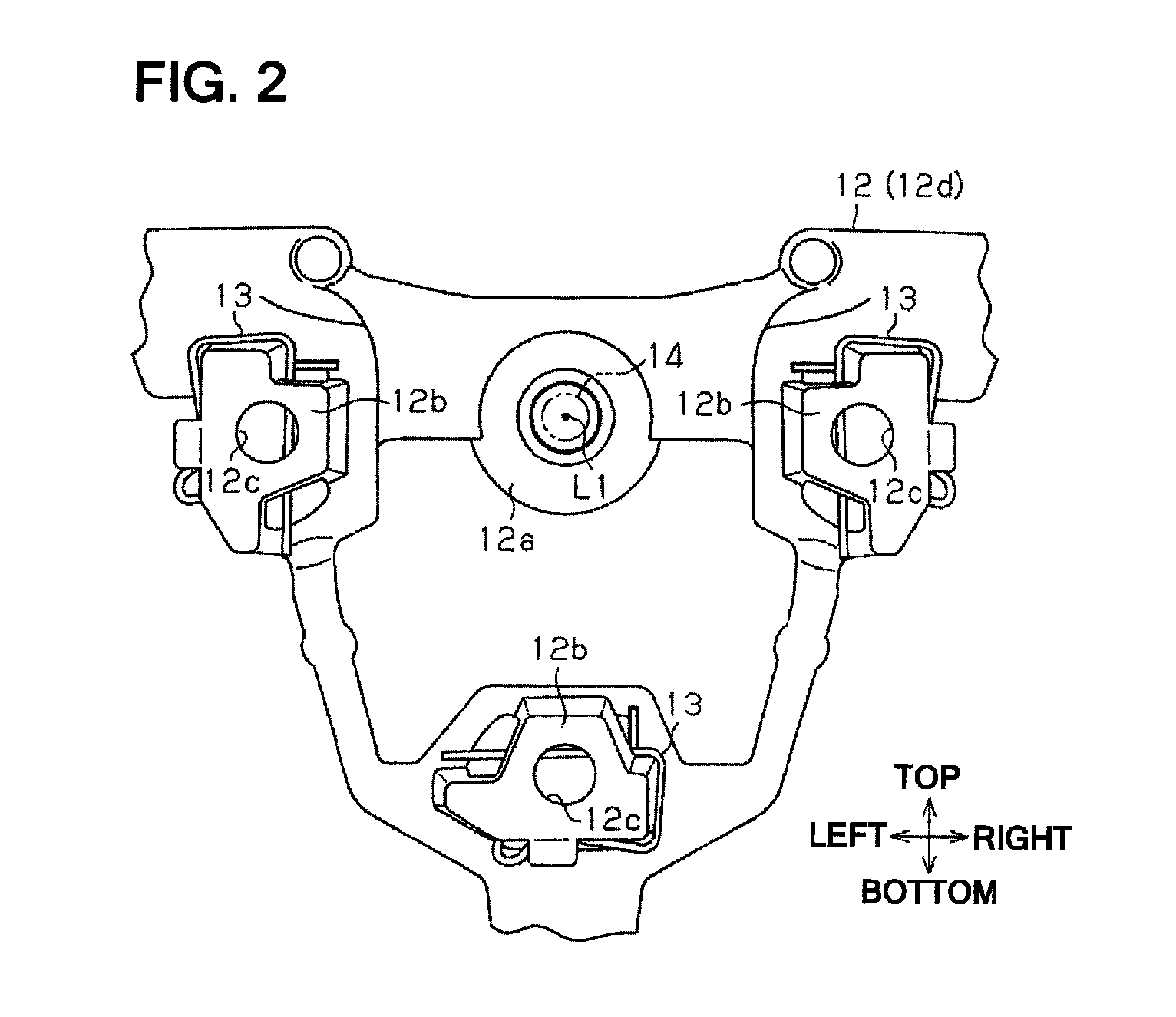

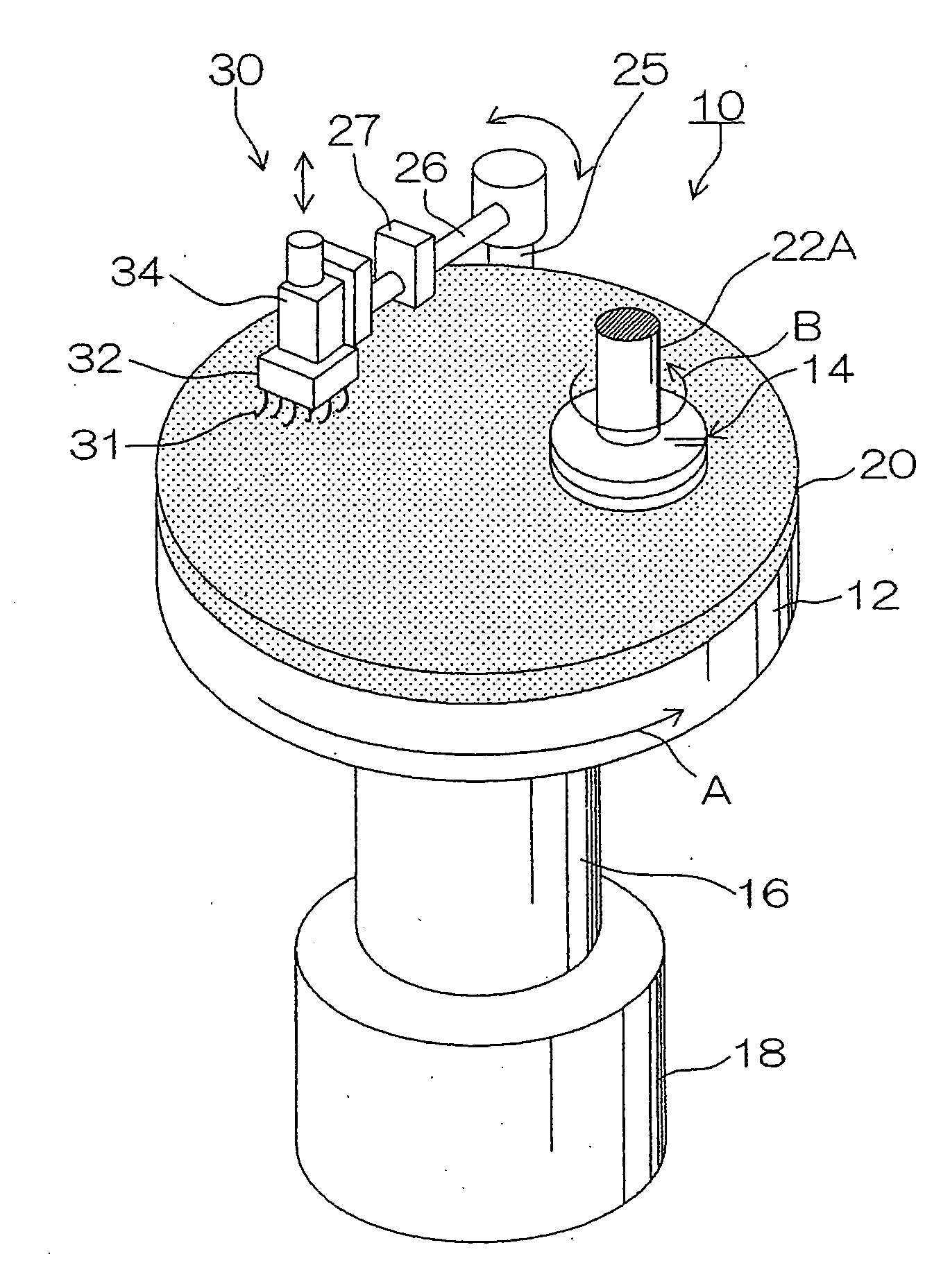

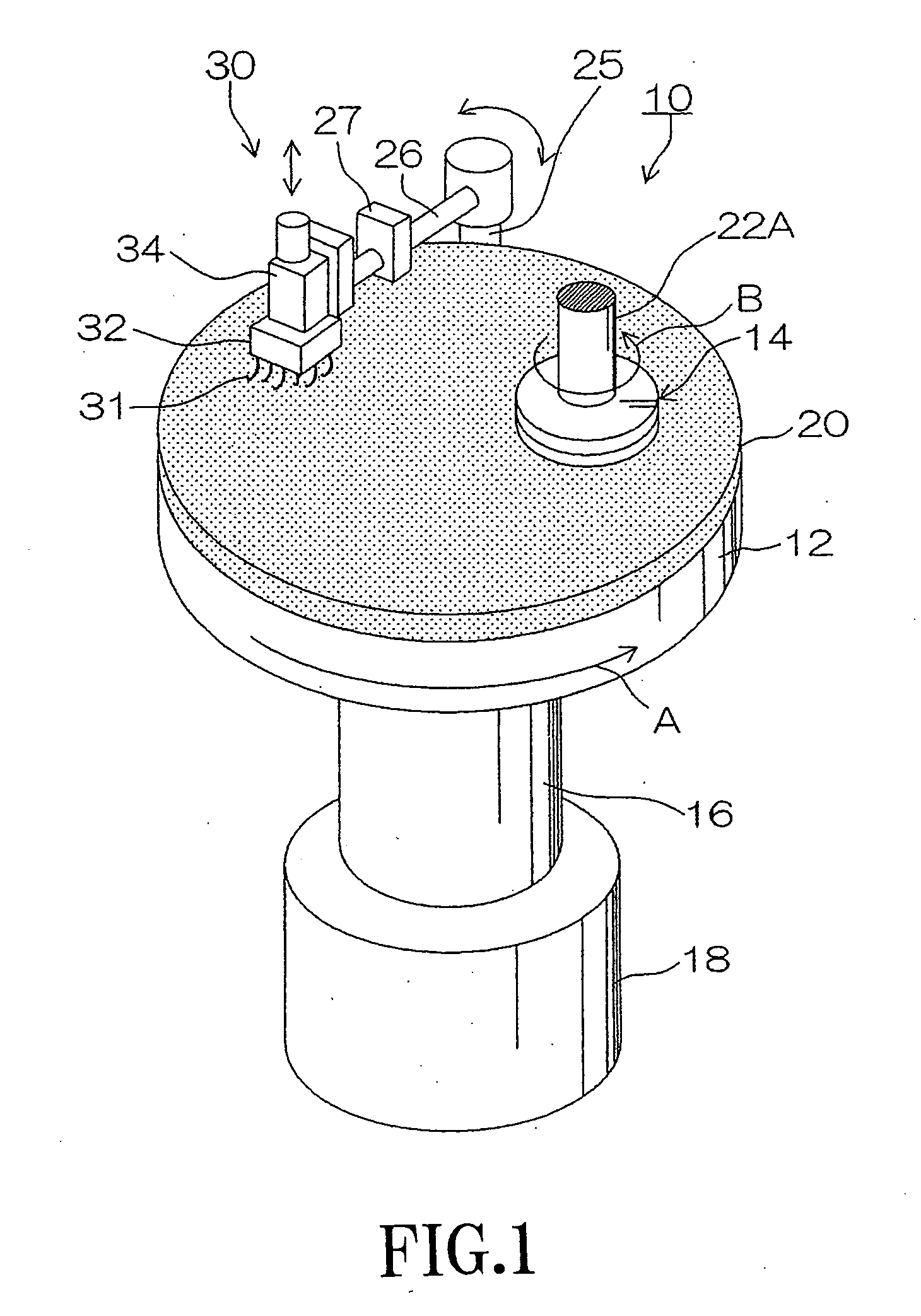

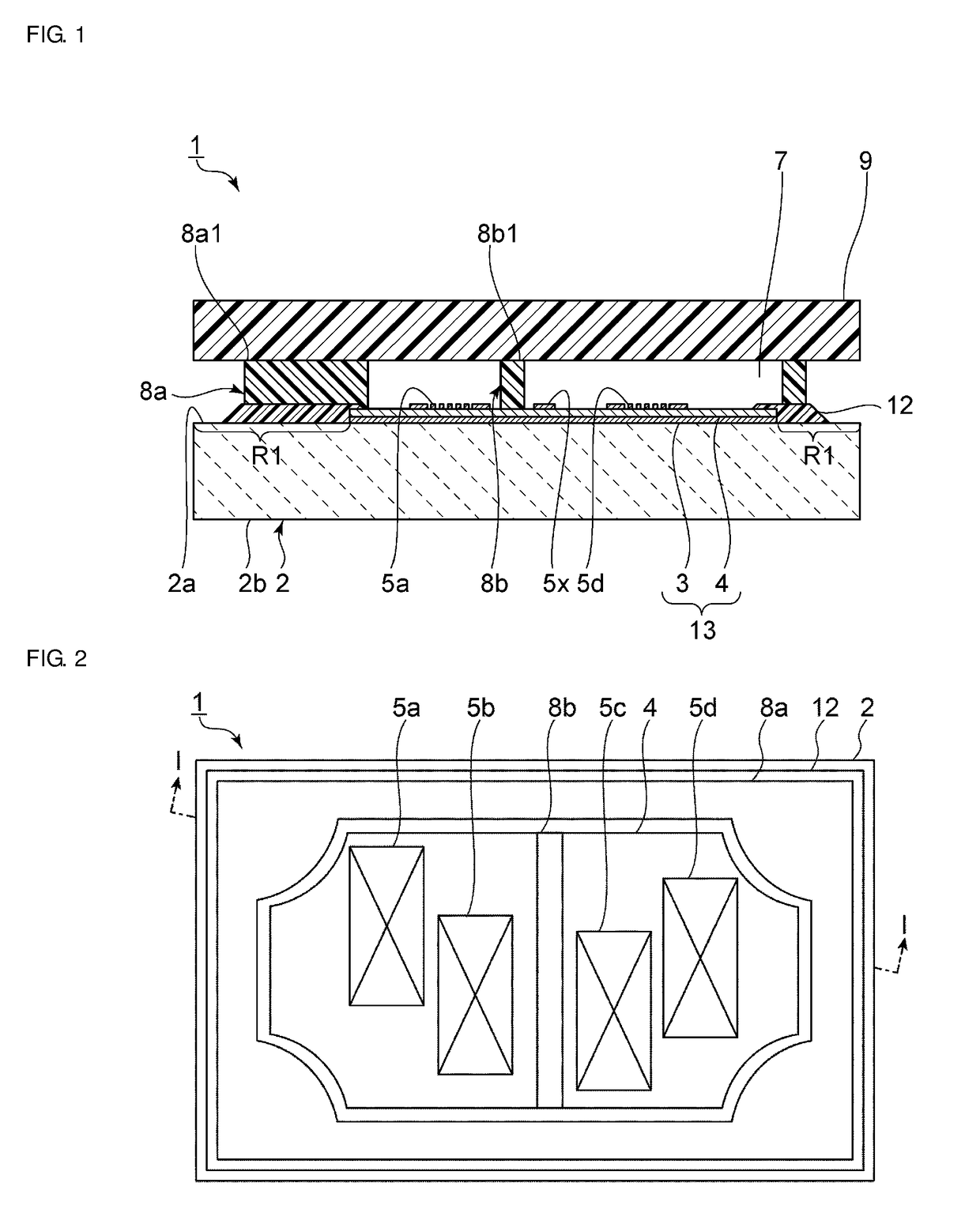

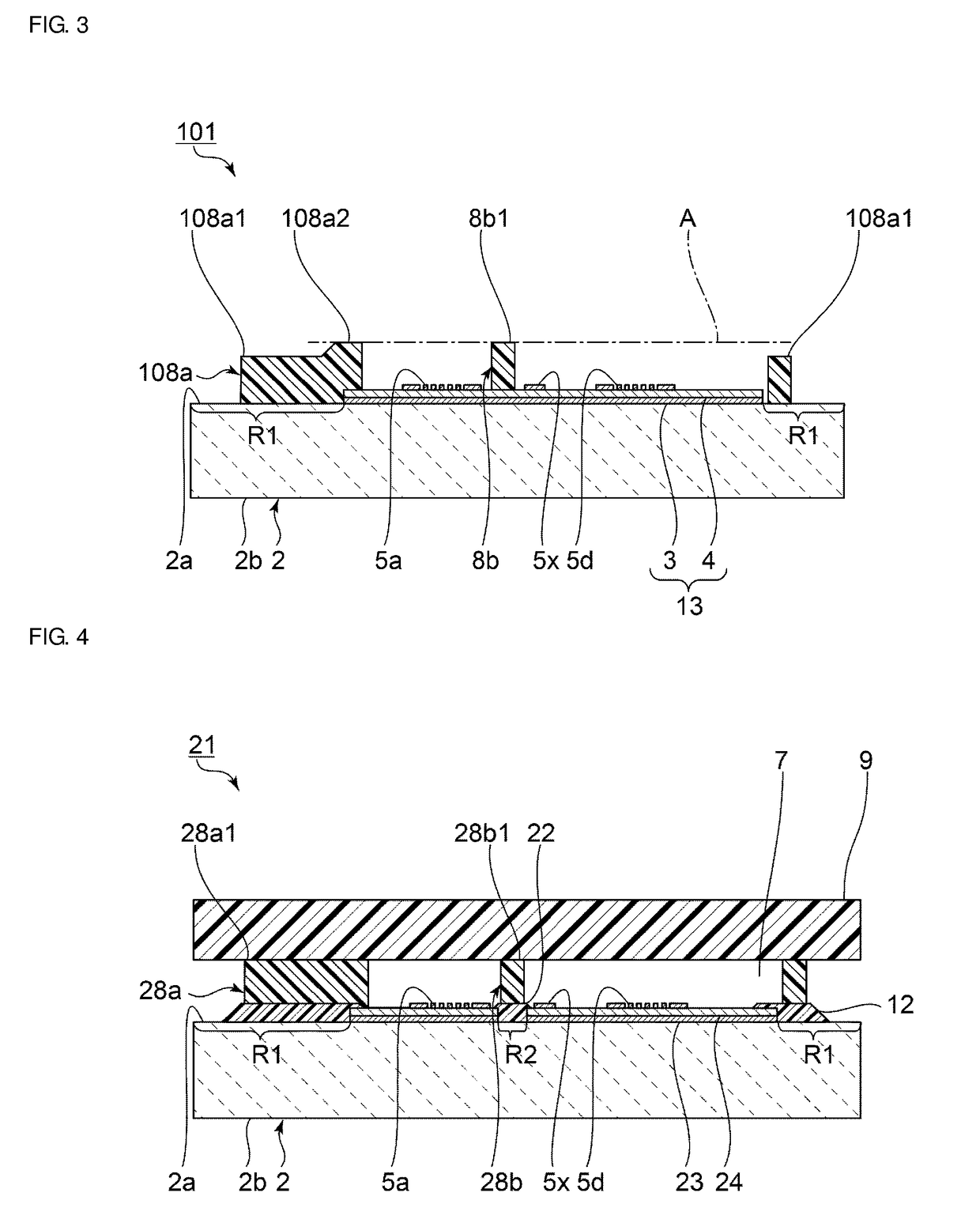

Vibration control structure for steering wheel

ActiveUS20140131982A1Increase elastic strengthImprove installation strengthPedestrian/occupant safety arrangementVibration controlSteering wheel

A vibration control structure includes a fixed member, an airbag device that is provided at a front portion thereof with a bag holder having a mounting hole and is disposed at a rear side of the fixed member, a horn switch mechanism that includes a support member supported by the fixed member in a state where the horn switch mechanism is inserted through the mounting hole and a slider disposed between the support member and the mounting hole so as to be slidable in the front-rear direction, and an annular elastic member that is disposed on the rear side of the bag holder while being mounted to the outside of the slider. The airbag device serves as a damper mass of a dynamic damper and the elastic member serves as a spring of the damper mass.

Owner:TOYODA GOSEI CO LTD

Vibration control structure for steering wheel

ActiveUS8794662B2Increase elastic strengthImprove installation strengthPedestrian/occupant safety arrangementVibration controlSteering wheel

A vibration control structure includes a fixed member, an airbag device that is provided at a front portion thereof with a bag holder having a mounting hole and is disposed at a rear side of the fixed member, a horn switch mechanism that includes a support member supported by the fixed member in a state where the horn switch mechanism is inserted through the mounting hole and a slider disposed between the support member and the mounting hole so as to be slidable in the front-rear direction, and an annular elastic member that is disposed on the rear side of the bag holder while being mounted to the outside of the slider. The airbag device serves as a damper mass of a dynamic damper and the elastic member serves as a spring of the damper mass.

Owner:TOYODA GOSEI CO LTD

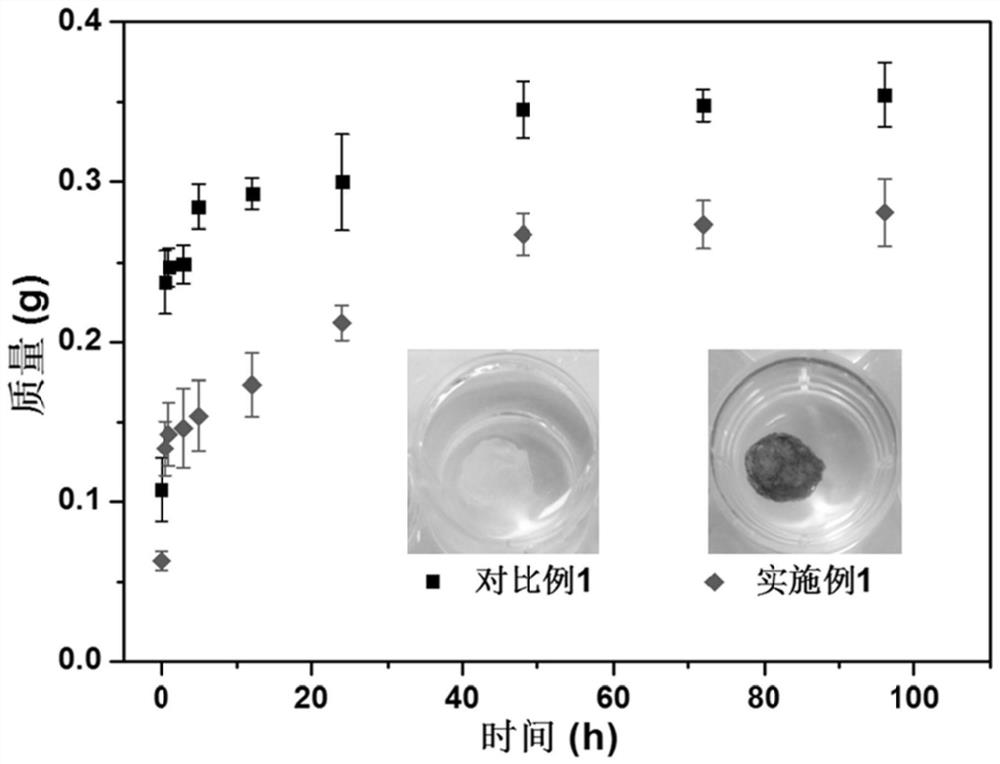

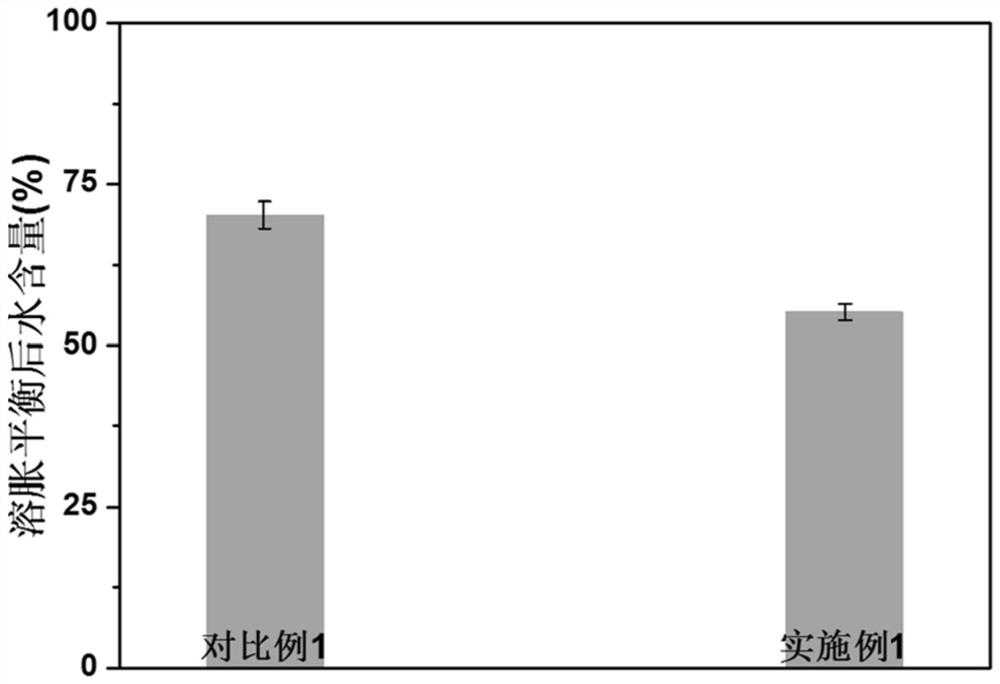

Oil-water separation type sodium alginate/graphene oxide composite aerogel and preparation method thereof

InactiveCN106853296AEasy to separateImprove separation efficiencyAerogel preparationLiquid separationOxide compositeGraphite oxide

The invention relates to an oil-water separation type sodium alginate / graphene oxide composite aerogel and a preparation method thereof. The preparation method of the oil-water separation type sodium alginate / graphene oxide composite aerogel comprises the following steps: preparing a sodium alginate / graphene oxide mixed solution, preparing an uncrosslinked sodium alginate / graphene oxide composite aerogel, and preparing the oil-water separation type sodium alginate / graphene oxide composite aerogel. The oil-water separation type sodium alginate / graphene oxide composite aerogel has a highly porous structure, a complete three-dimensional network and a high separation efficiency, has a separation rate of above 99.9%, has high salt resistance, is suitable for being used in high-salinity sea environments, and also has the advantages of good elasticity, high mechanical strength, oil pollution resistance, realization of almost no reduction of the separation efficiency after reuse 40 times or more, and good reuse ability.

Owner:FUJIAN AGRI & FORESTRY UNIV

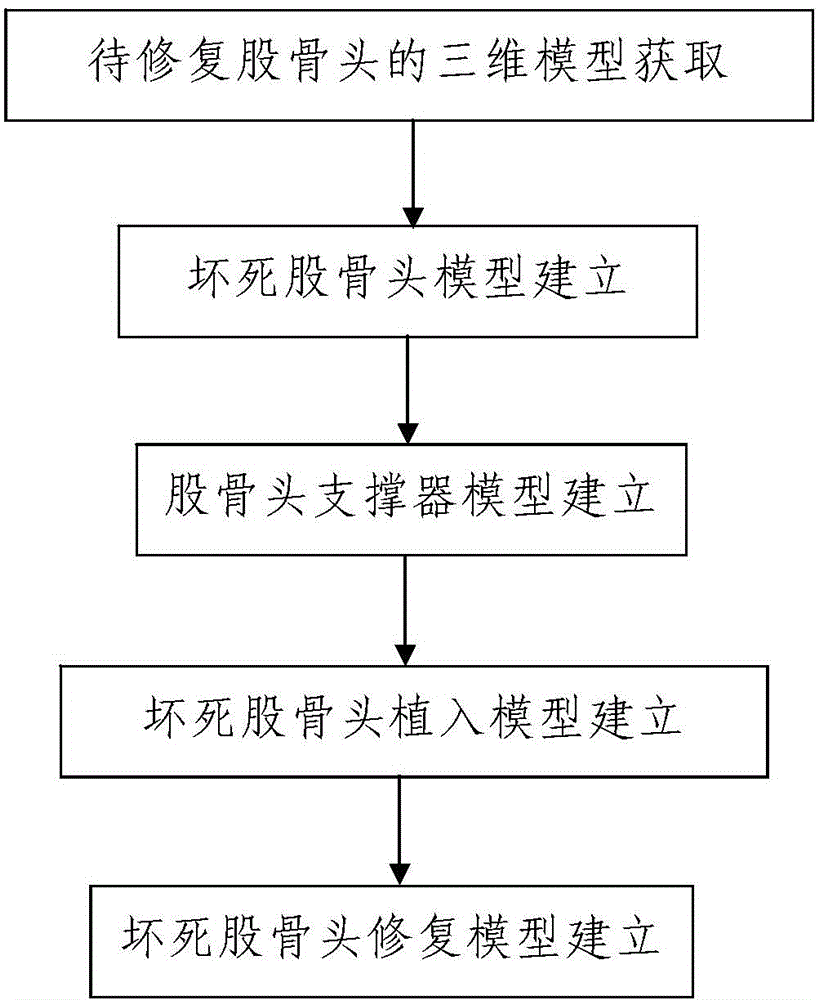

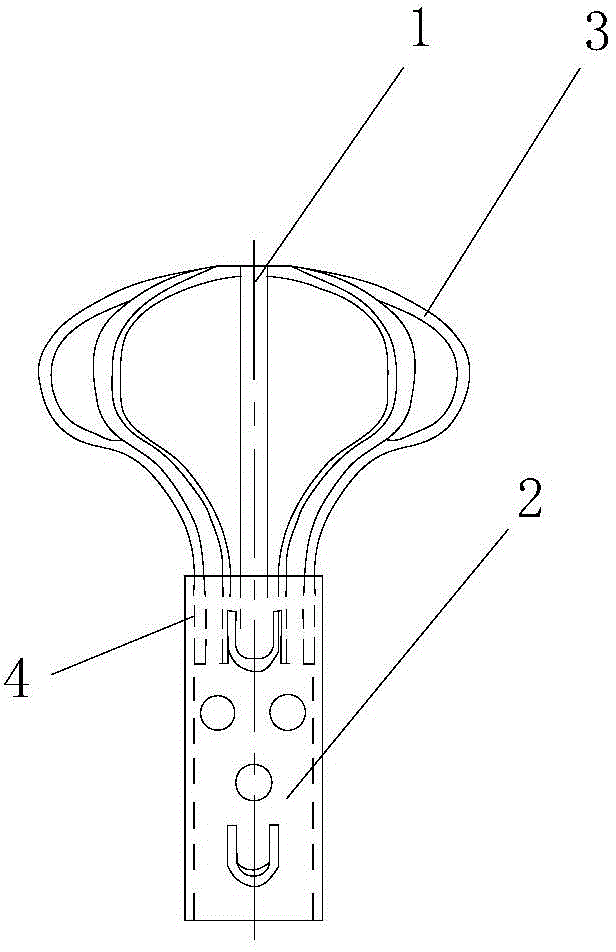

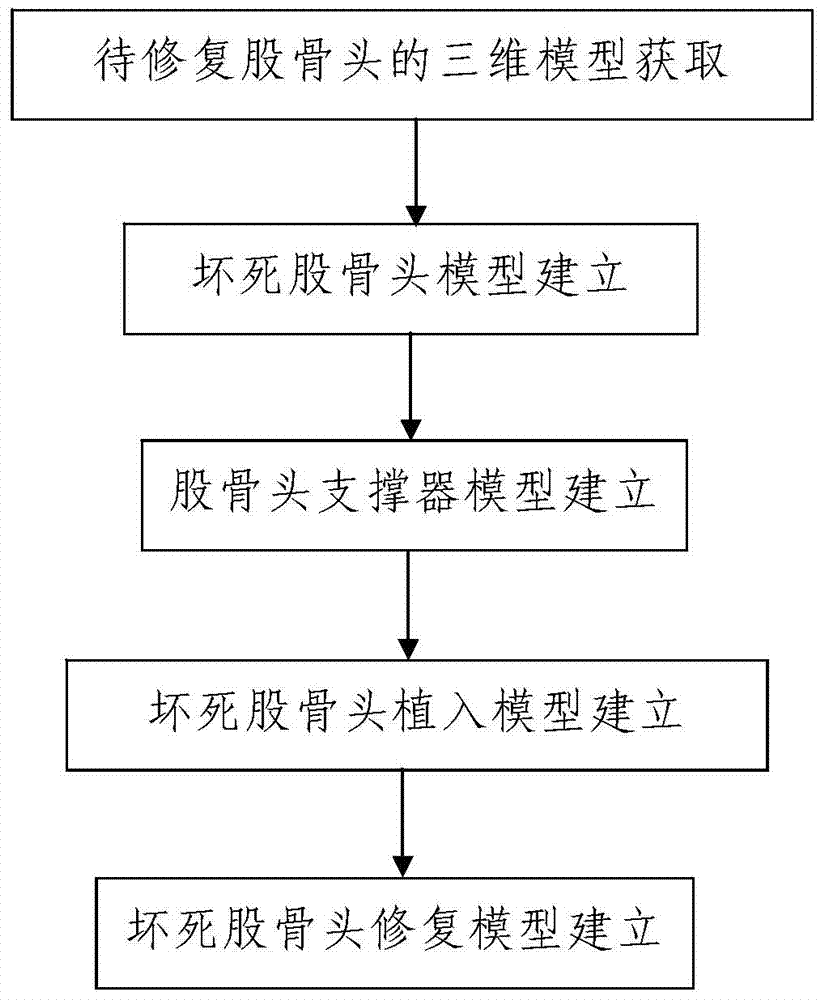

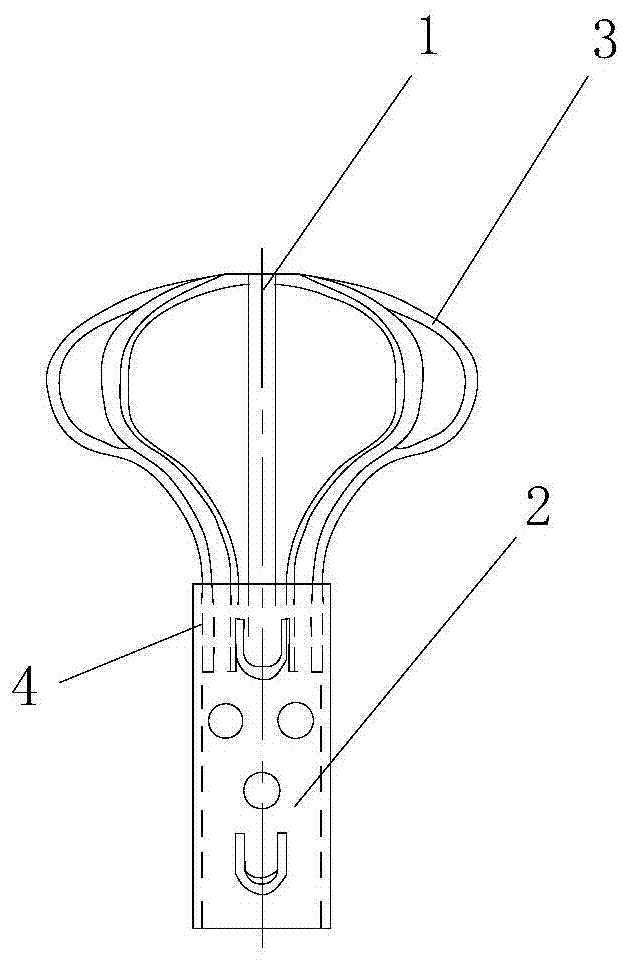

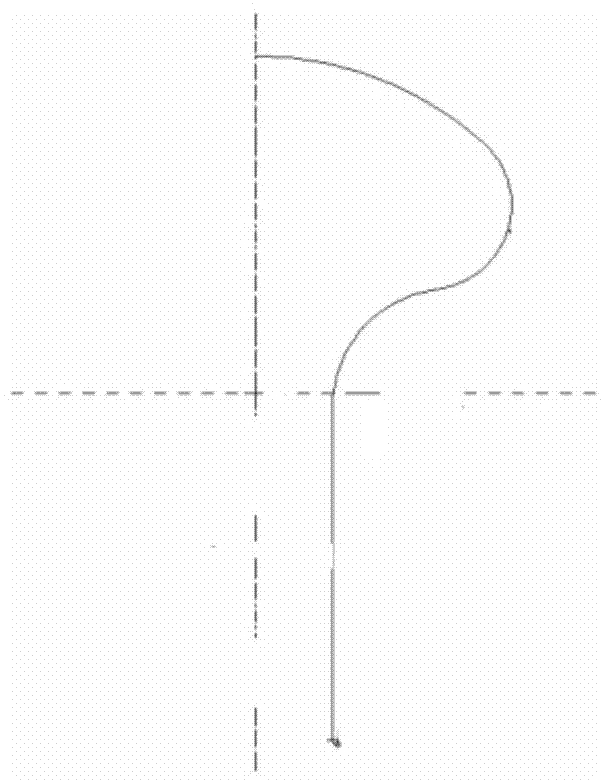

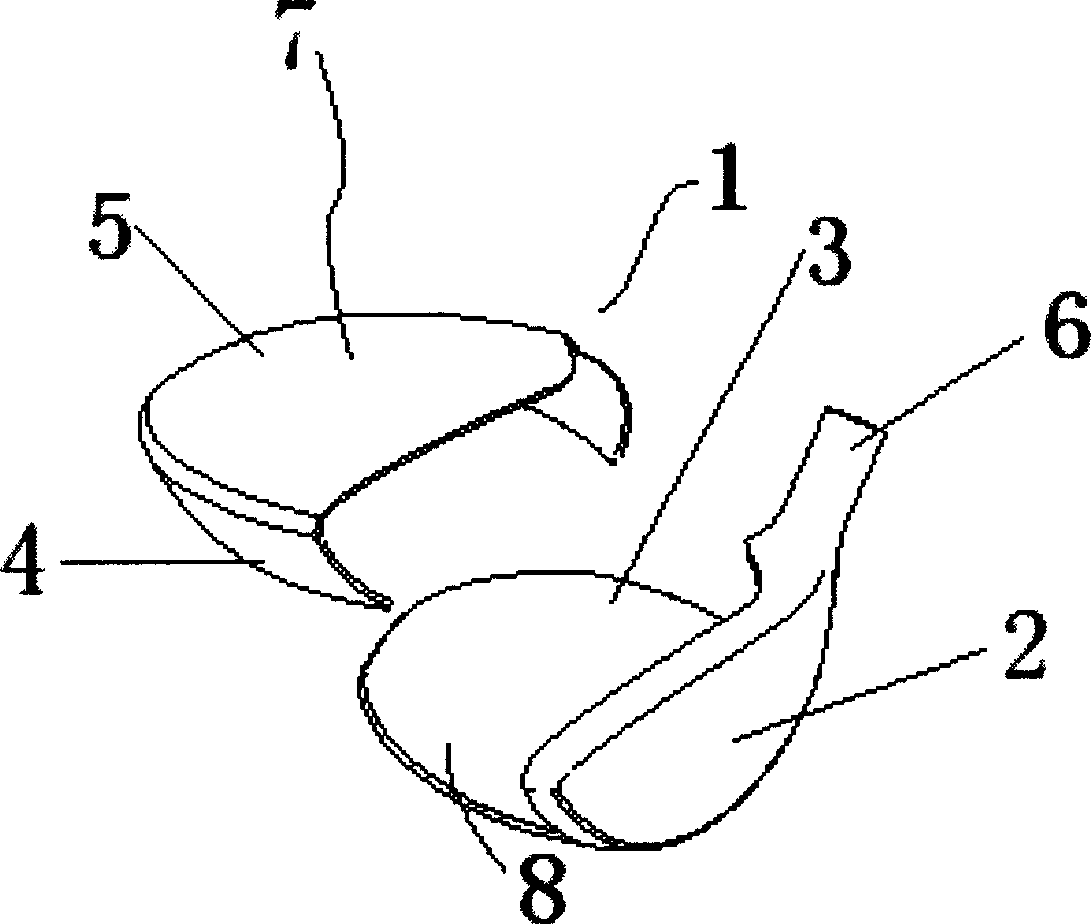

Modeling method of necrosis caput femoris restoring model based on umbrella-shaped caput femoris supporter

InactiveCN104462636AThe method steps are simpleReasonable designSpecial data processing applications3D modellingThighModel method

The invention discloses a modeling method of a necrosis caput femoris restoring model based on an umbrella-shaped caput femoris supporter. The modeling method comprises the steps that firstly, a three-dimensional model of a to-be-restored caput femoris is obtained, wherein the NURBS curved surface model of the to-be-restored caput femoris is obtained, the to-be-restored caput femoris is a caput femoris which exists in the thigh tissue necrosis area and is pre-restored by the caput femoris supporter, and the caput femoris supporter is composed of an umbrella-shaped supporter body and a supporting sleeve; secondly, the necrosis area needing to be separated is determined according to the shape of the umbrella-shaped supporter body, and a necrosis caput femoris model is established; thirdly, a caput femoris supporter model is established; fourthly, a necrosis caput femoris implantation model is established, wherein the necrosis caput femoris implantation model with an implantation channel and a three-dimensional model of an implanted bone are established; fifthly, the necrosis caput femoris restoring model is established. The modeling method is simple in step, reasonable in design, convenient to achieve and good in using effect, the restoring model of the caput femoris supporter implanted into the necrosis caput femoris can be easily, conveniently and quickly established, and the quality of the established restoring model is high.

Owner:XIAN UNIV OF SCI & TECH

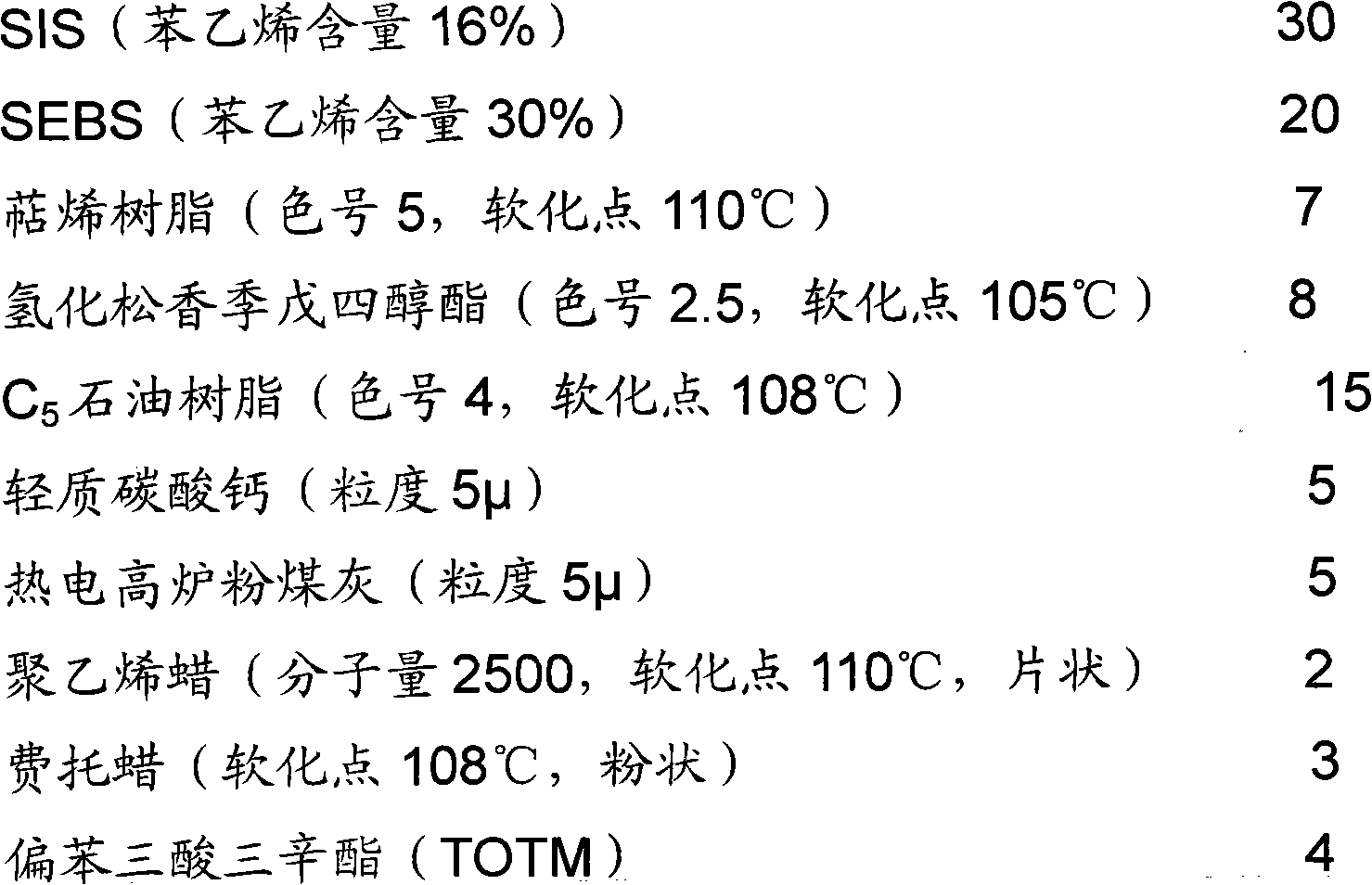

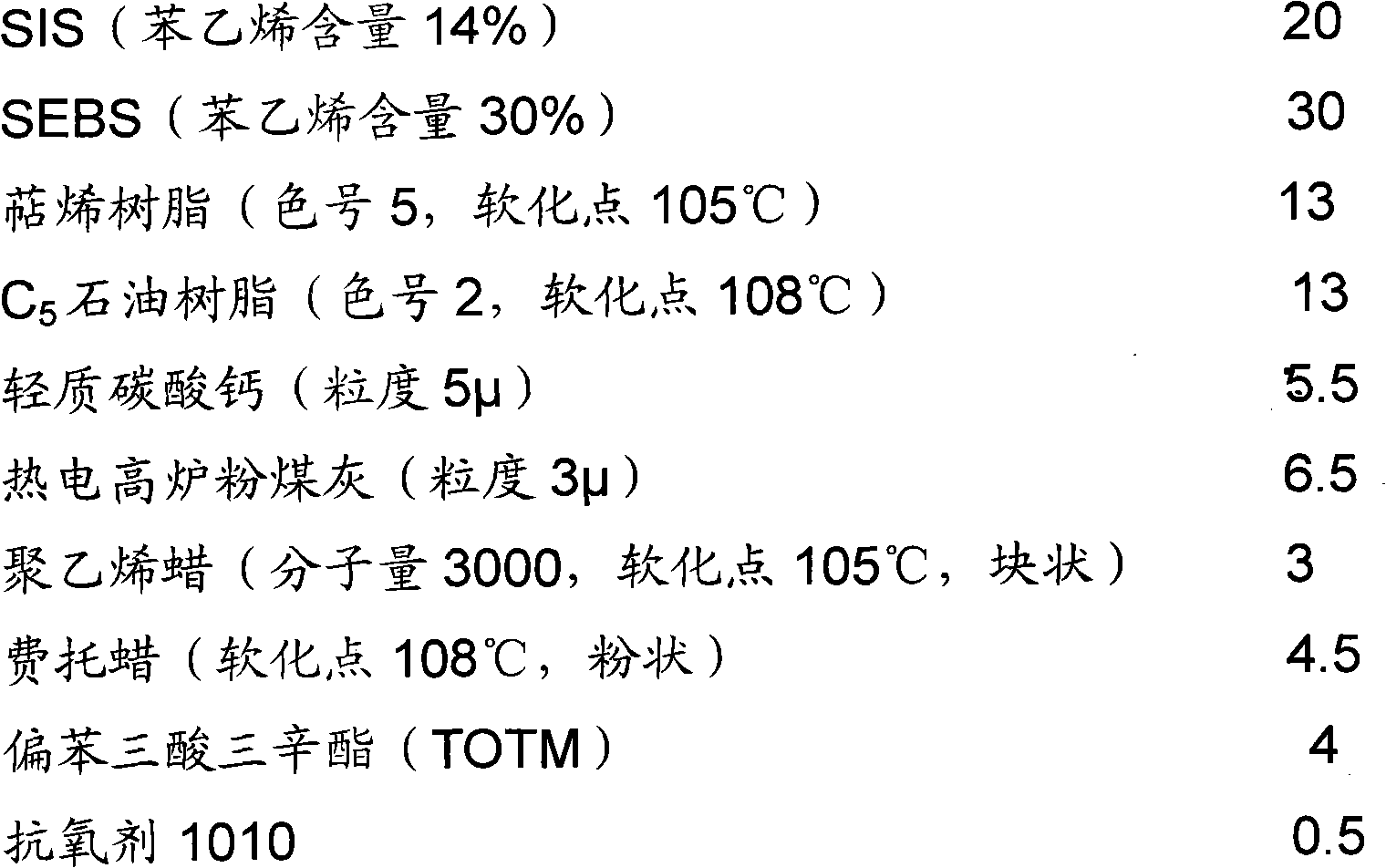

Automobile hot-melt lamp adhesive

An automatic hot-melt lamp adhesive for plastic, metal and glass automobile lamps comprises the following components in percent by mass: 20-30% of styrene-isopentadiene-styrene block copolymer with styrene content of 14-16%, 2030% of styrene-ethylene-butene-styrene block copolymer with styrene content of 30-33%, 25-35% of tackifying resin, 5-10% of light calcium carbonate, 5-10% of thermoelectric blast furnace fly ash, 3-8% of process additive, 2-5% of plasticizer and 0.5-1% of antioxidant. The materials sequentially added into a horizontal kneading machine according to a proportion for heating and kneading, injected in a square mould for molding and encapsulated by using release paper after cooled to demould. The automatic hot-melt lam lamp adhesive has the advantages of high bonding strength, good vibration resistance, low cost and environmental protection, and the like.

Owner:中国航天科技集团公司第四研究院第四十二所

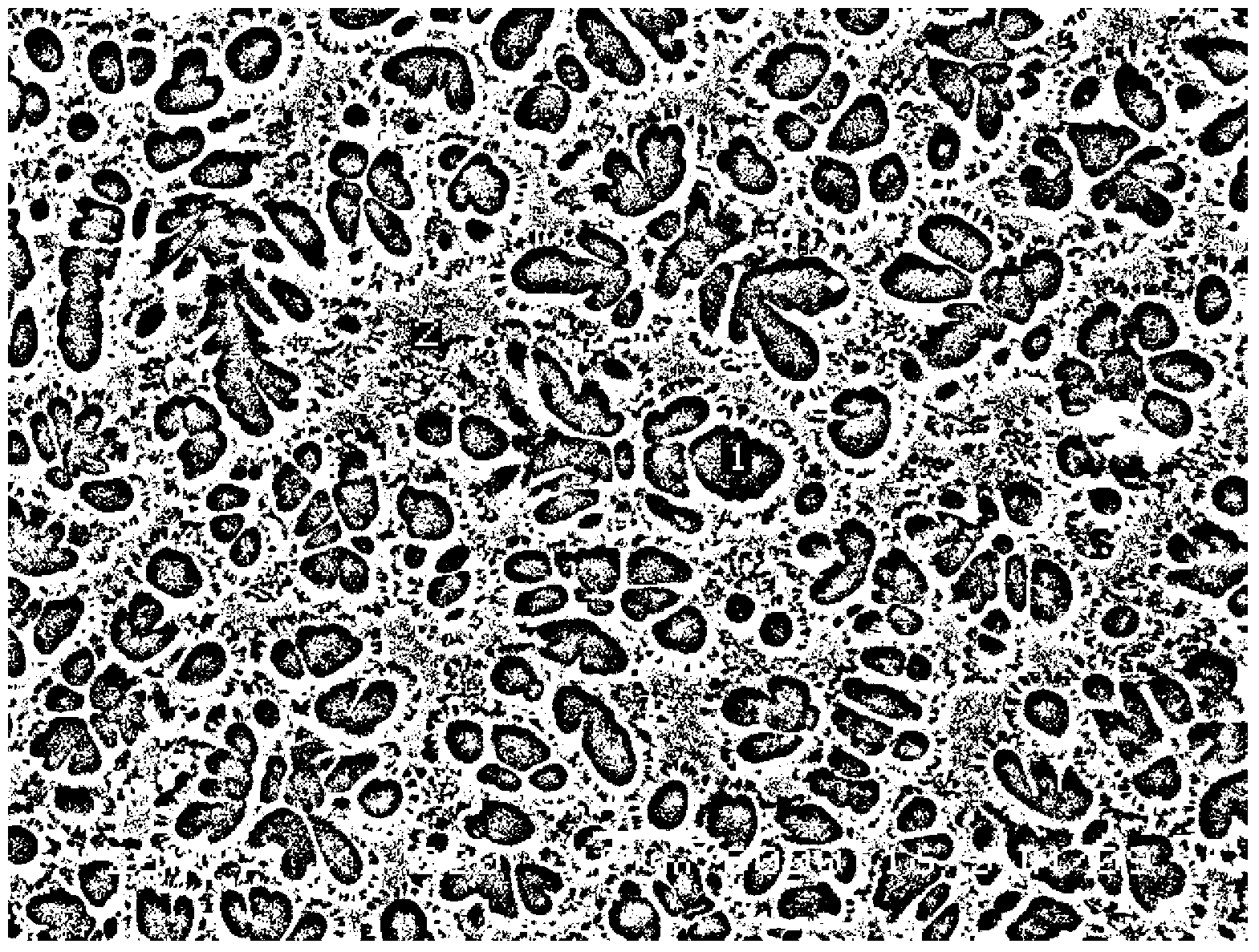

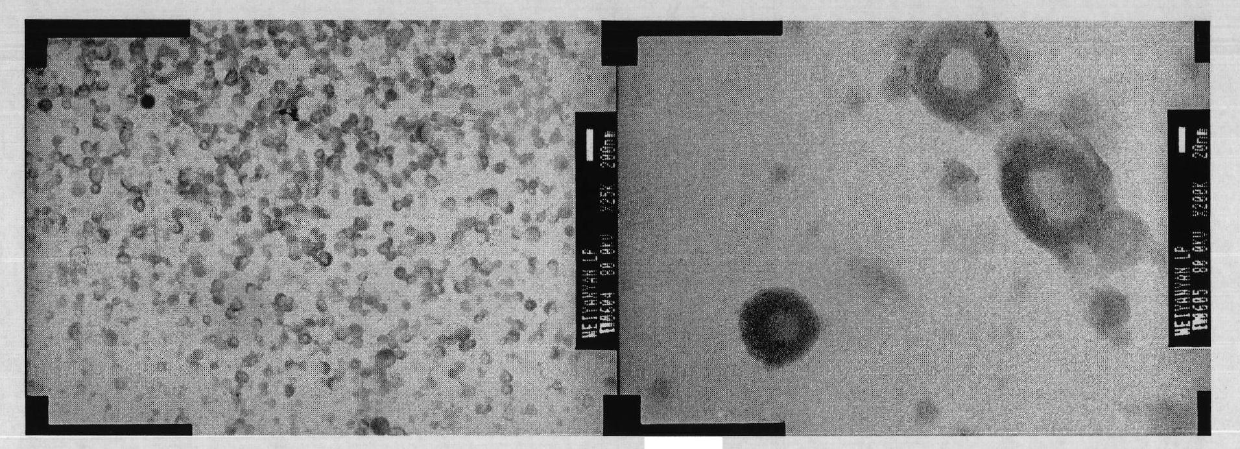

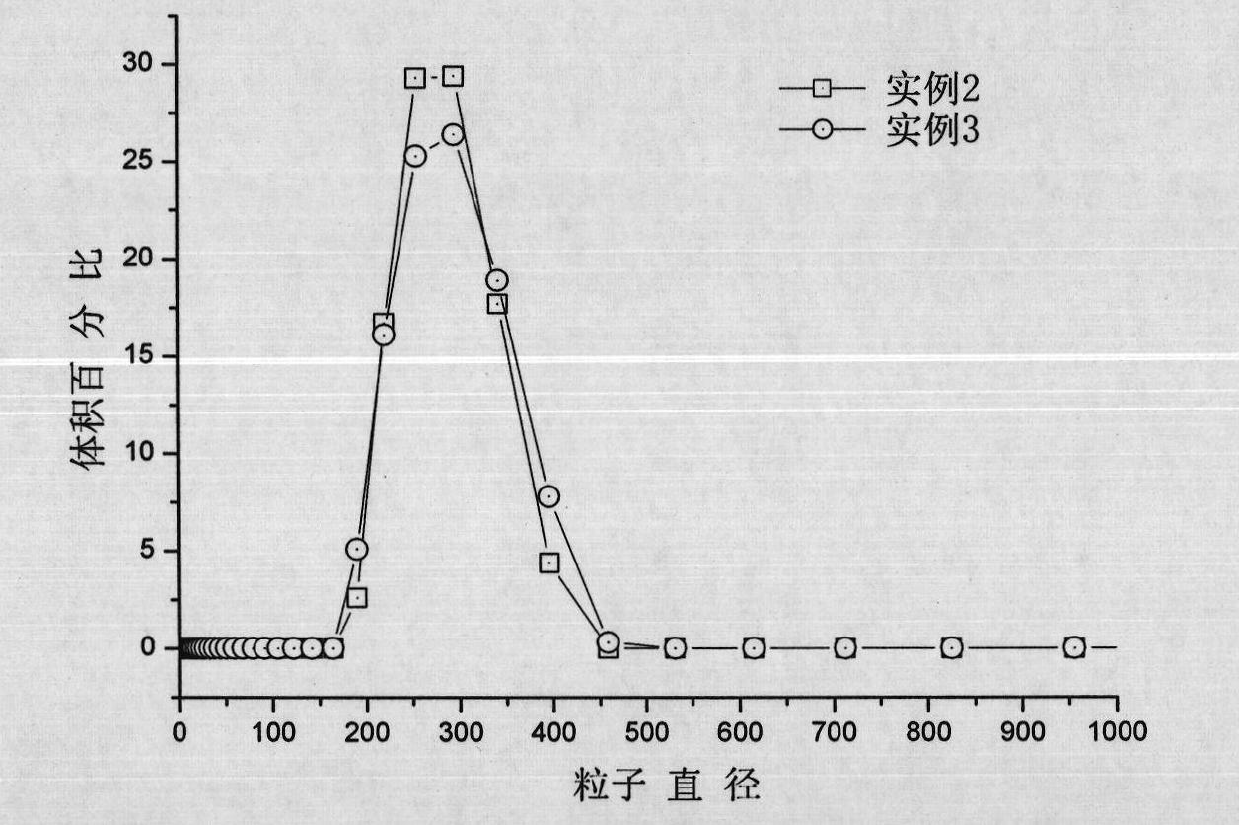

Preparation method of polyurethane (PU) nano-encapsulated phase-change material (NEPCM)

InactiveCN102198386AEliminate the effects ofSimple ingredientsMicroballoon preparationMicrocapsule preparationBody ThermoregulationPolymer chemistry

The invention relates to a method for preparing nano-encapsulated phase-change material (NEPCM) by taking amphiphilic polyurethane (PU) or a composite amphiphilic PU material as a capsule wall without adding an emulsifier. The method comprises the following steps: dispersing PCM and a small quantity of vinyl monomers by utilizing the amphiphilic PU; and then chemically cross-linking the PU capsule wall through emulsion polymerization initiated by free radicals to finally obtain the NEPCM. By utilizing the novel method for preparing the NEPCM provided by the invention, the obtained nano-capsules have good dispersion stability and good re-dispersibility and average particle size of 50nm-800nm, wherein a core material accounts for 1%-80% of the weight of one capsule. In addition, the NEPCM can be used in latent functionally thermal fluid in the form of suspension, and can be compounded with other materials in the form of powder so as to achieve a thermoregulation function.

Owner:QINGDAO UNIV OF SCI & TECH

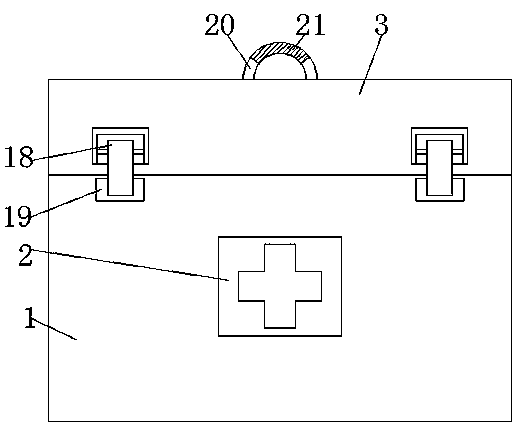

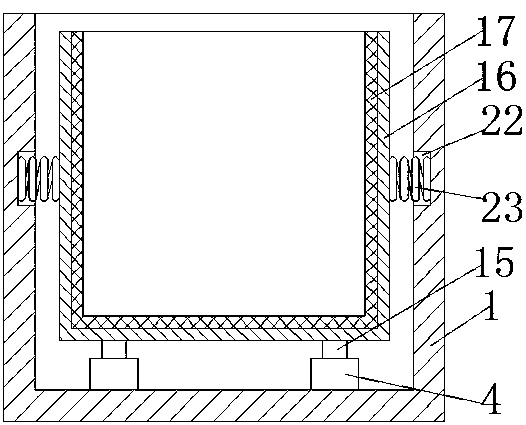

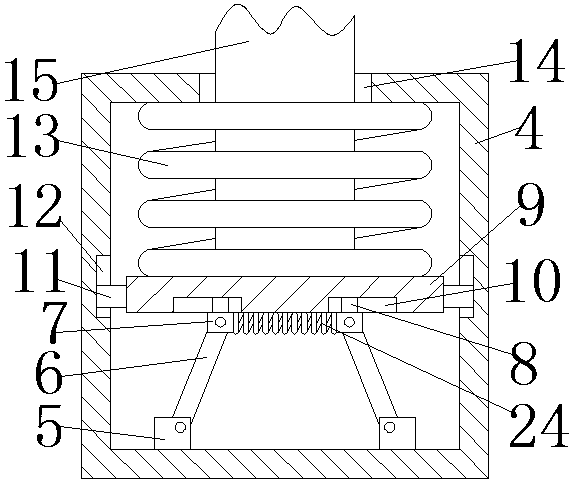

Medical instrument storage device

InactiveCN107582173ASolve the problem of not having shock absorption functionAvoid collision damageSurgical furnitureFirst-aid kitsDamping functionEngineering

The invention discloses a medical instrument storage device which comprises a box, wherein a medical identifier is fixedly connected with the front side of the box; a box cover is moveably connected with the top of the rear side of the box through a hinge; first fixing blocks are fixedly connected with the two sides of the bottom of the inner wall of the box; second fixing blocks are fixedly connected with the two sides at the bottom of the inner chambers of the first fixing blocks; first moveable rods are moveably connected with the tops of the second fixing blocks. According to the invention, the first fixing blocks, second fixing blocks, first moveable rods, third fixing blocks, moveable plates, tension springs, second moveable rods and a cushion are used together for solving the problem that the present medical instrument storage device has no damping function. The medical instrument storage device has the advantage of damping function, is capable of preventing the medical instruments in the box from being collided and damaged, is capable of effectively protecting the medical instruments, is capable of accelerating the rescuing for the wounded personnel and saving the life of the wounded personnel and is worthy of popularization and application.

Owner:徐浩

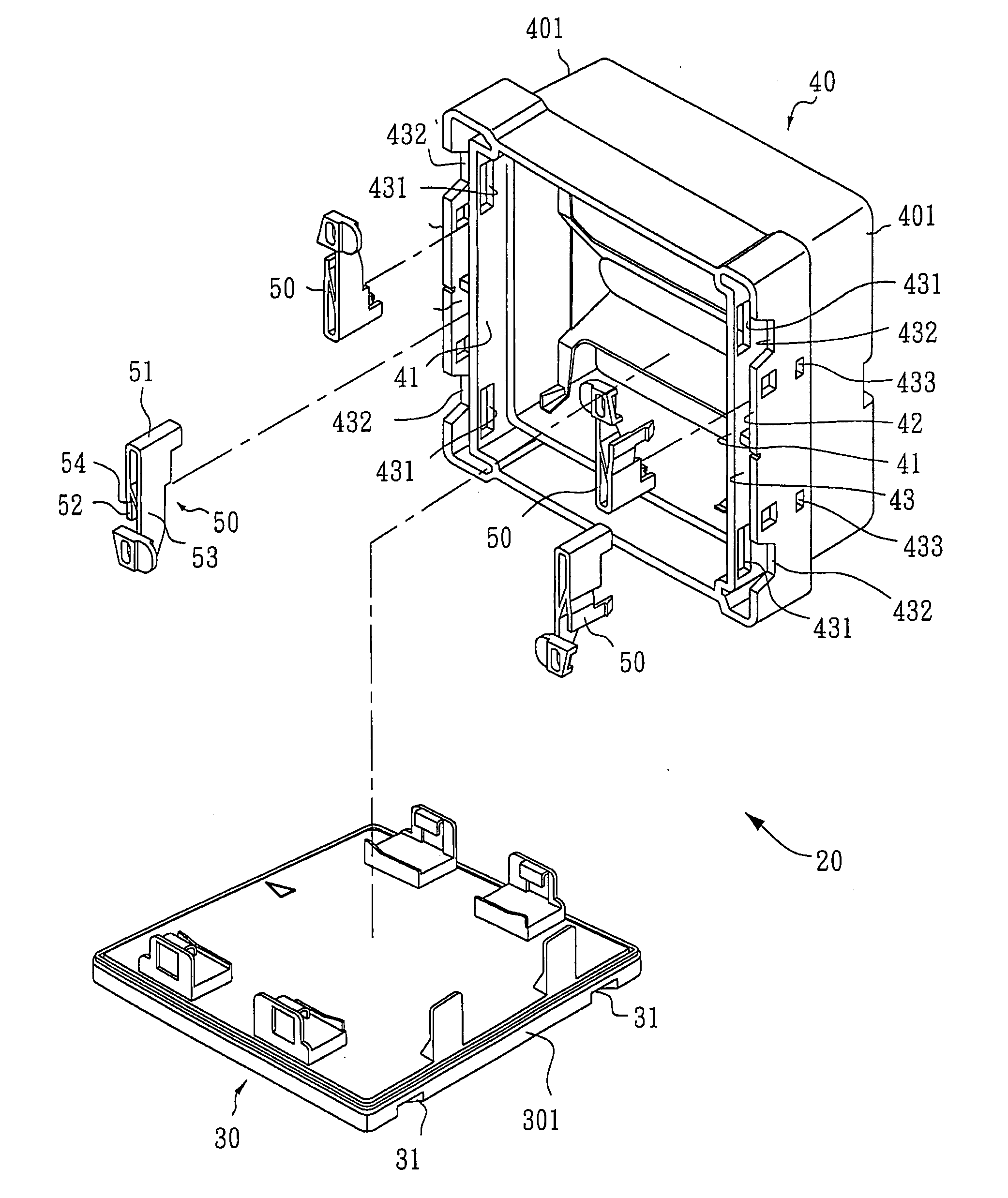

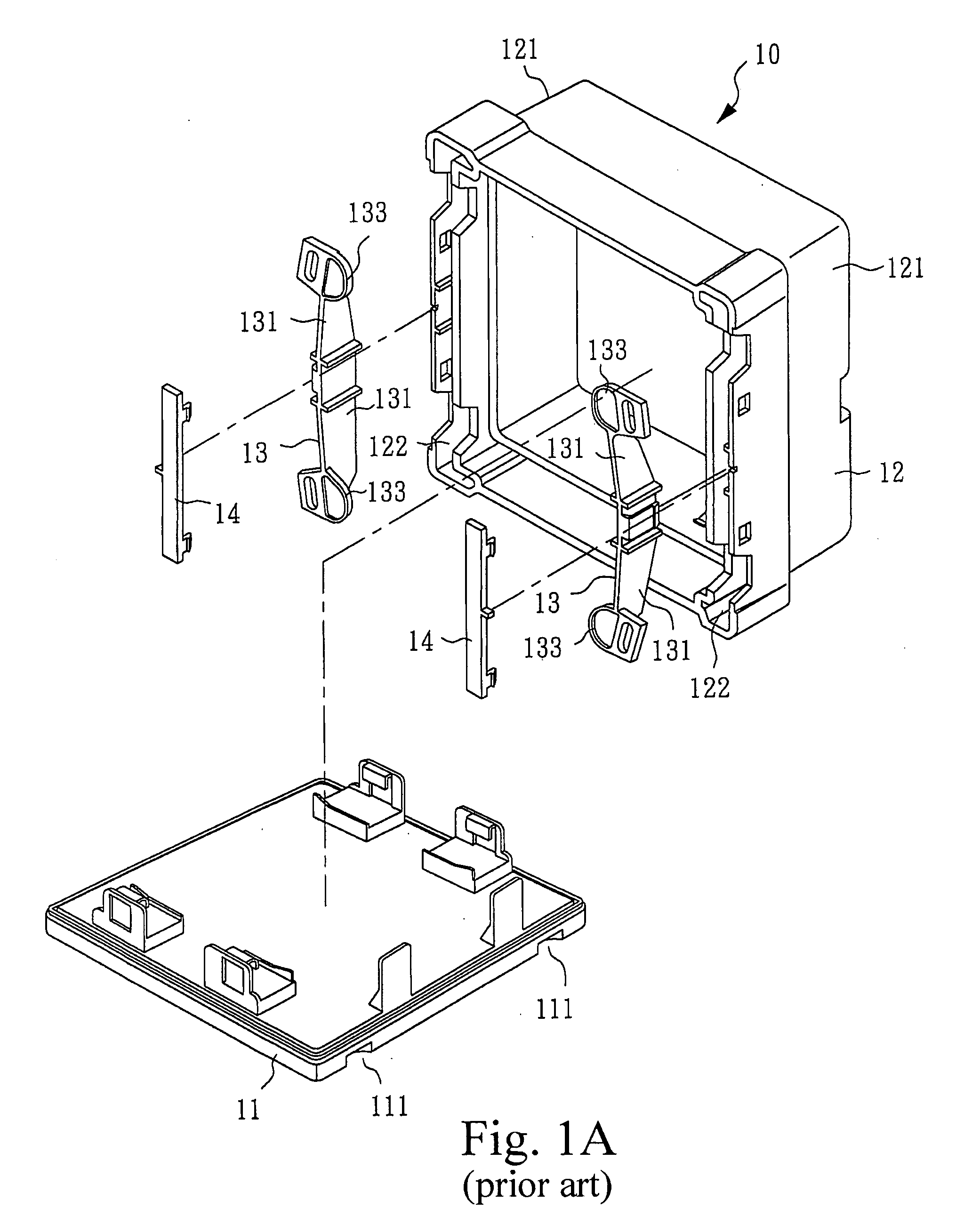

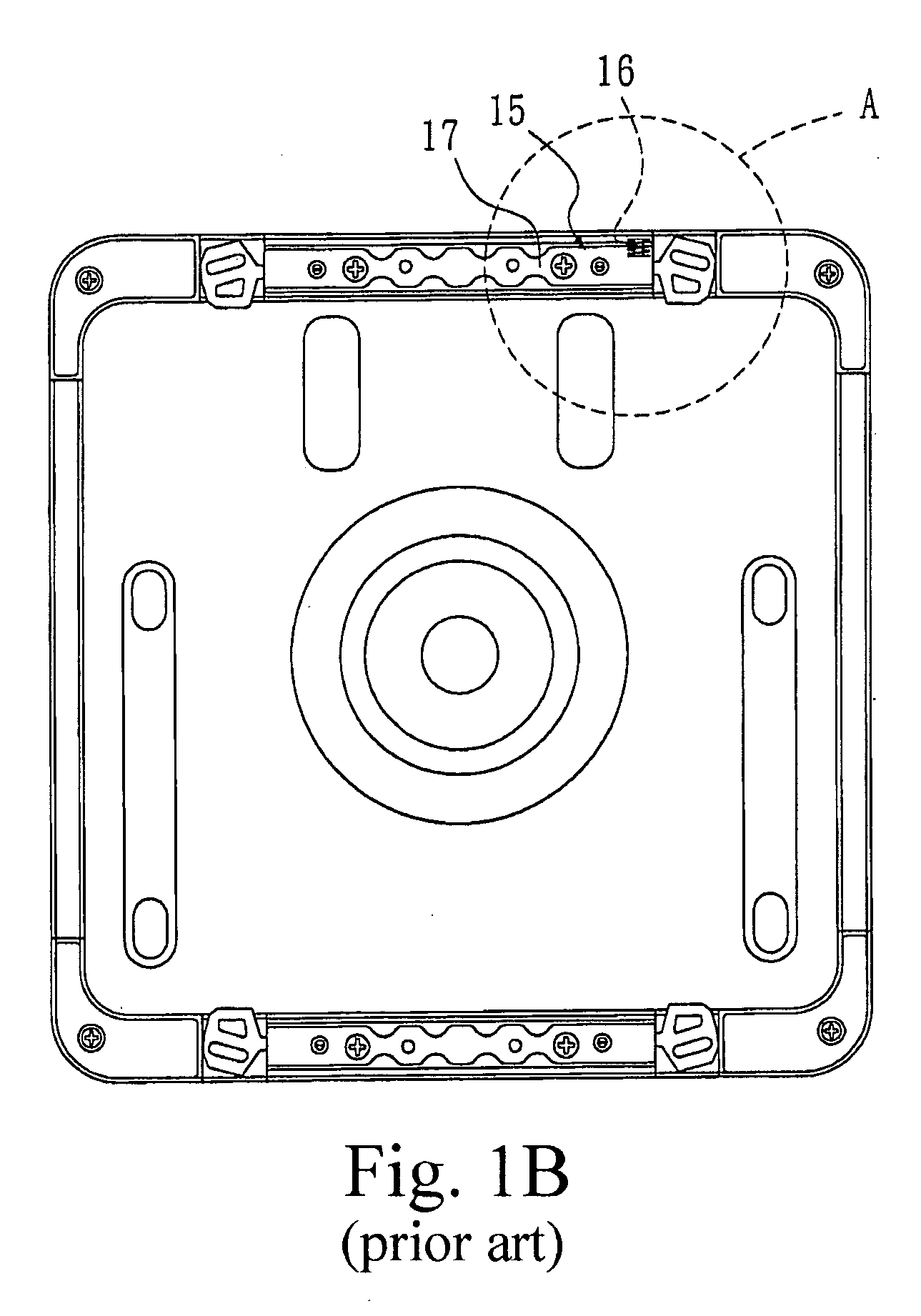

Fastening structure of clean container

A fastening structure of a clean container is combined on a cover of the clean container with a dismountable fastener member, such that the cover is closed or opened on a base of the clean container. The fastener member includes a body, a positioning portion, and an elastic fastening arm, that are one-piece formed. The positioning portion extends from one side of the body to form a flat spring. A flange is formed on the flat spring to fasten the fastener member on the cover. The elastic fastening arm has an elastic arm, and a lateral flange is formed on one end of the elastic arm, and extends into the base to be buckled. The fastener member further includes an elastic auxiliary arm formed between the elastic arm and the body, so as to increase an elastic strength of the elastic fastening arm.

Owner:IND TECH RES INST

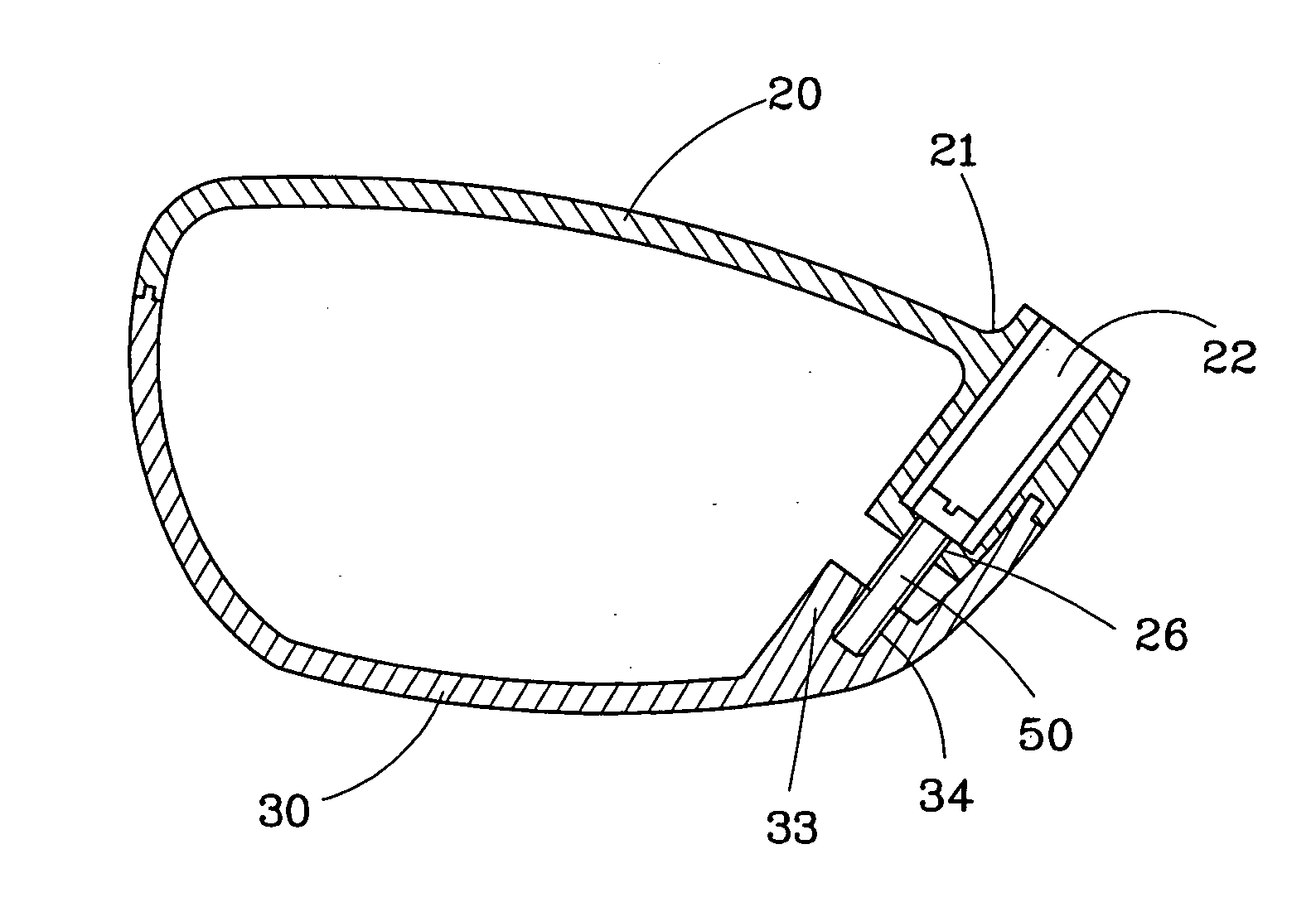

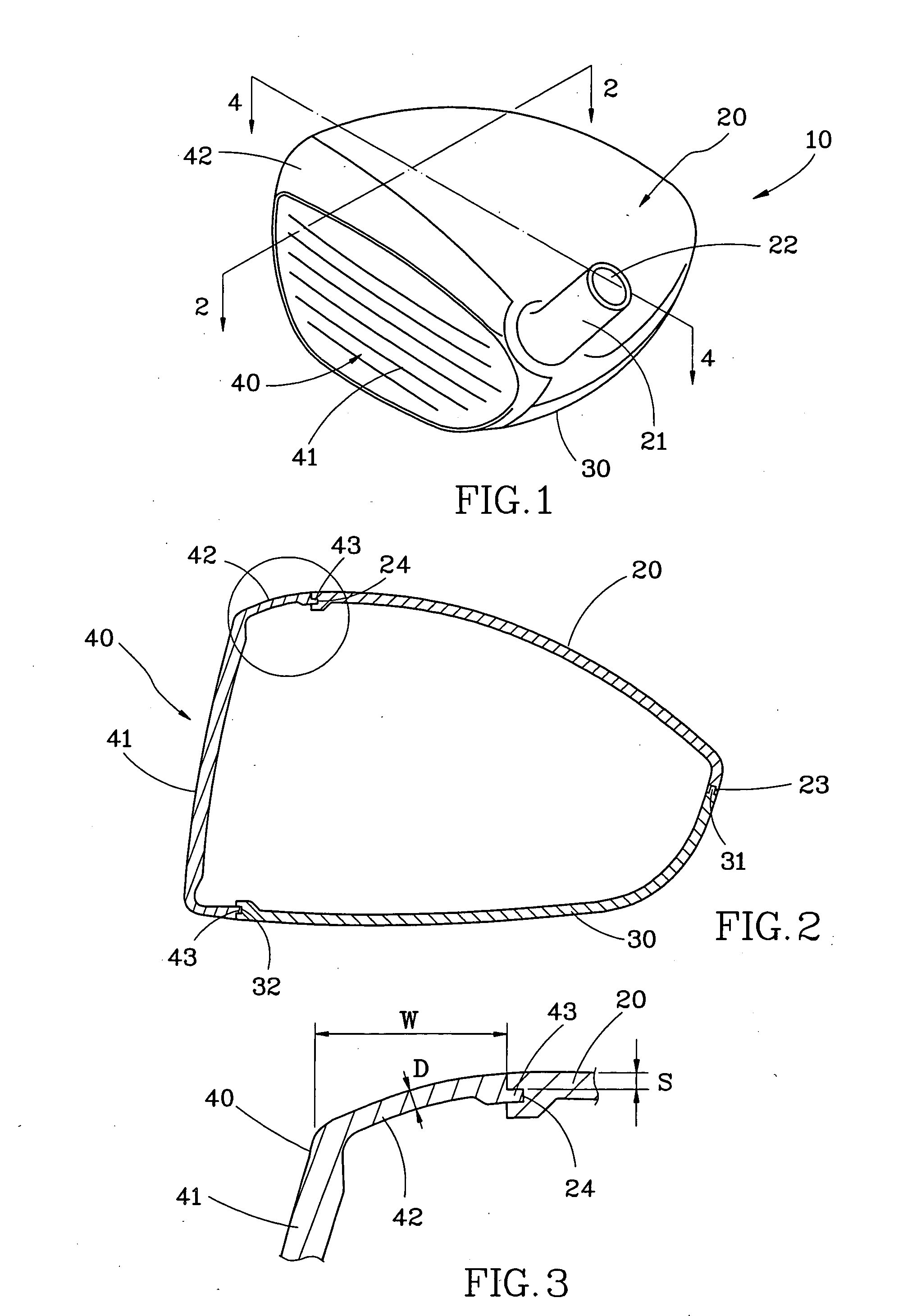

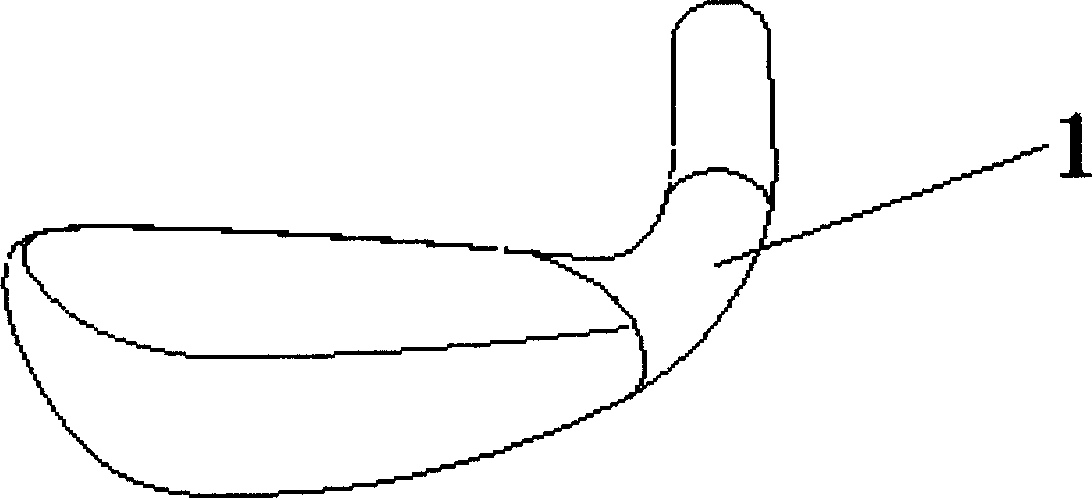

Golf head

InactiveUS20080102976A1Simple structureImprove bending elasticityBall sportsGolf clubsEngineeringGolf Ball

A golf head of present invention comprising: A top part makes from light materials with the specific gravity is under 3. The top part provides a neck portion with an axis hole therein for a golf club to plug in. A bottom part mounts under the top part and makes from metals with the specific gravity is over 4. A face part with cup shape has a face and the edge of the face extrudes backward to from a plate potion, the face part mounts in front of the bottom part and the top part and makes from elastic metals like titanium alloy, stainless steel or maraging steel.

Owner:CHEN ARCHER C C

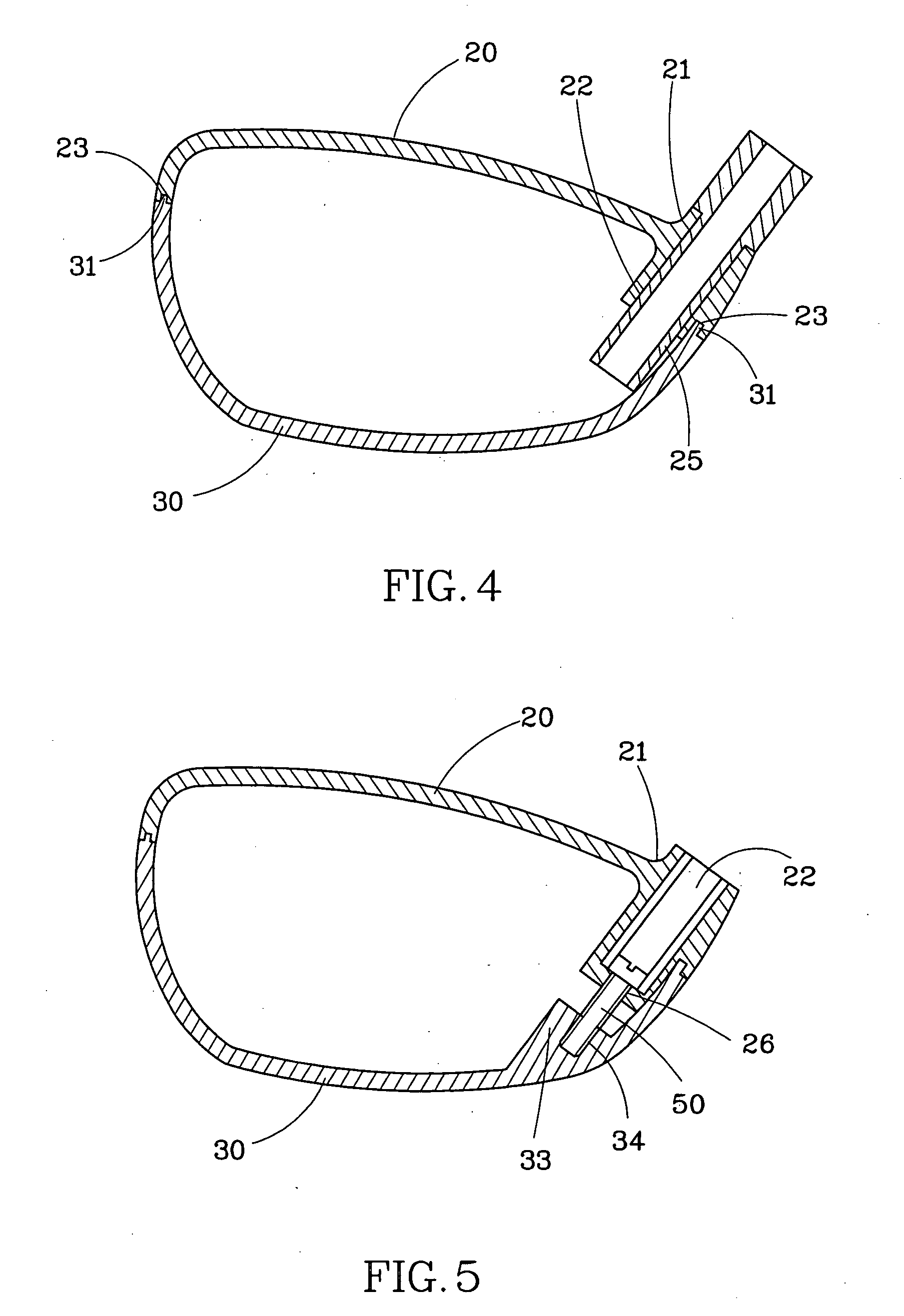

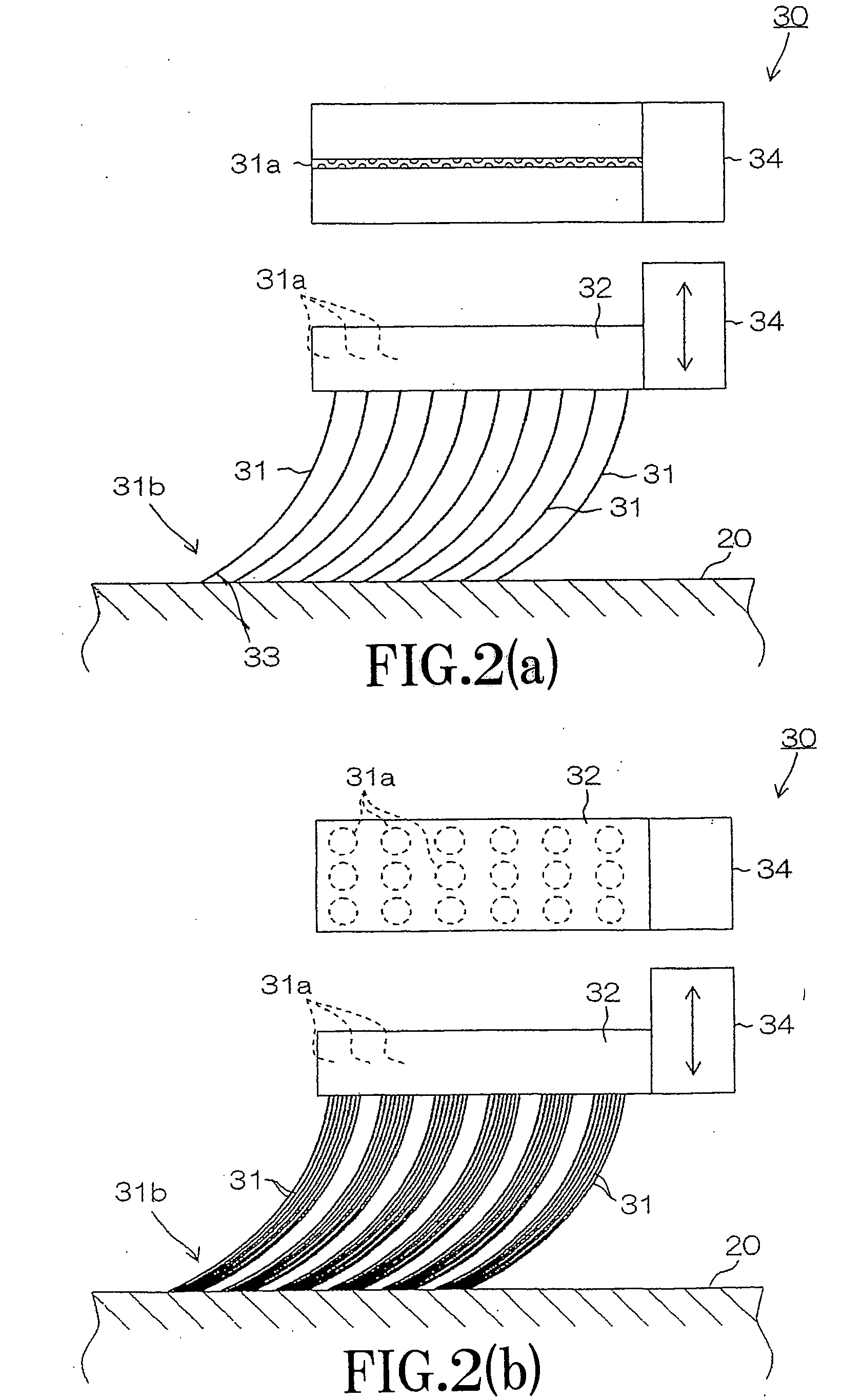

Pad dresser, polishing device, and pad dressing method

InactiveUS20090221216A1Reduce stiffnessIncrease elastic strengthEdge grinding machinesGrinding drivesEngineeringBiomedical engineering

Elastic member bundled by pencil band is mounted to the lower edge of support part. Elastic member is composed with tungsten wires which are 25 mm in the length and 0.15 mm in diameter bundled with every 30 wires in one bundle. The tip part of each element wire of elastic member contacts polishing pad with the tip end cut round and performs dressing of polishing pad. The wire size of the tip part of each element wire of elastic member is made to be fine and the cutting width on polishing pad is made to be narrow, and at the same time, the rigidity of elastic member is made to be enhanced by bundling each element wire of elastic member with pencil band, and a large pressure is made to be pressed to the fine tip part of each element wire. Therefore, the tip part of elastic member can give an effective incision depth to polishing pad.

Owner:TOKYO SEIMITSU

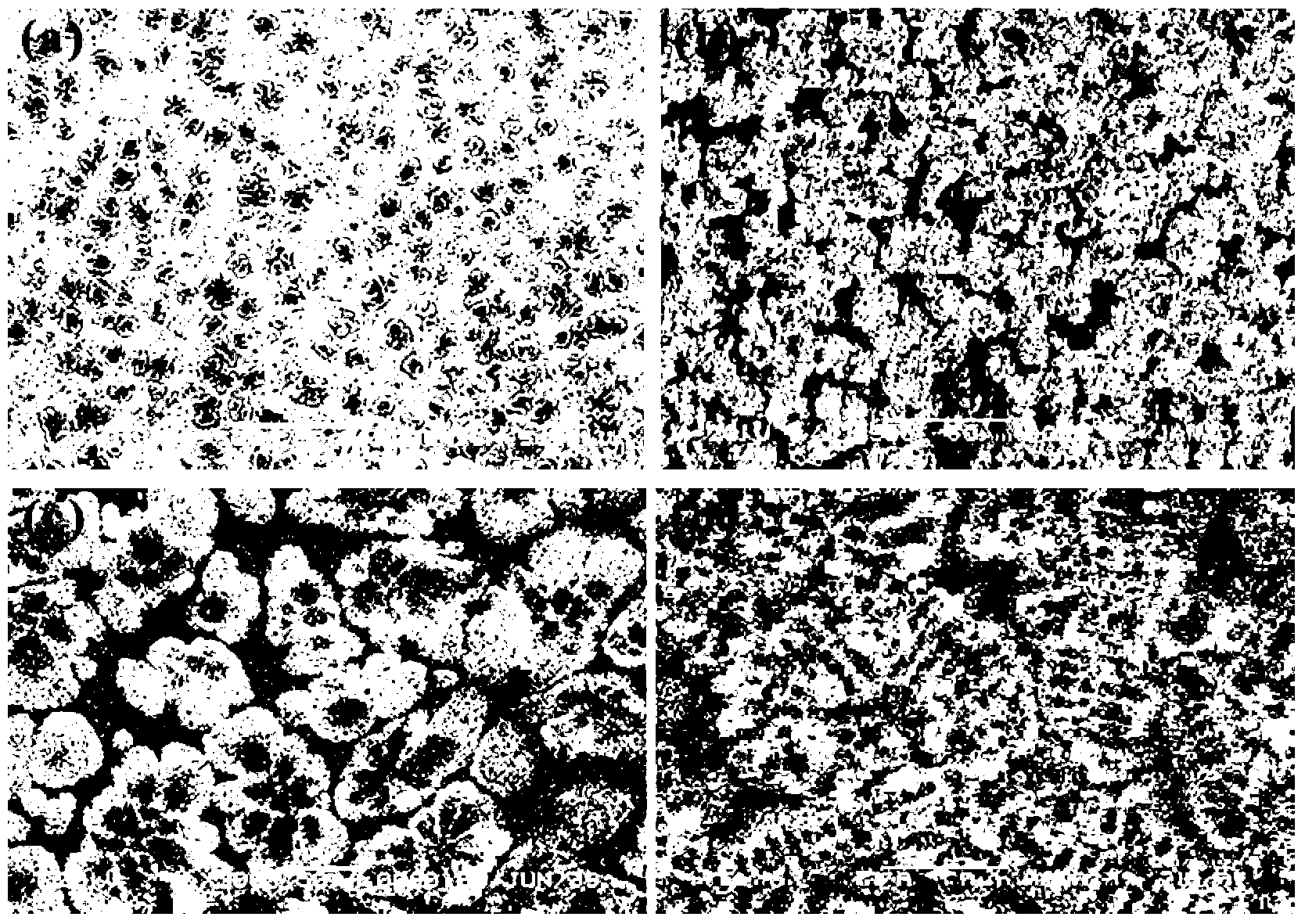

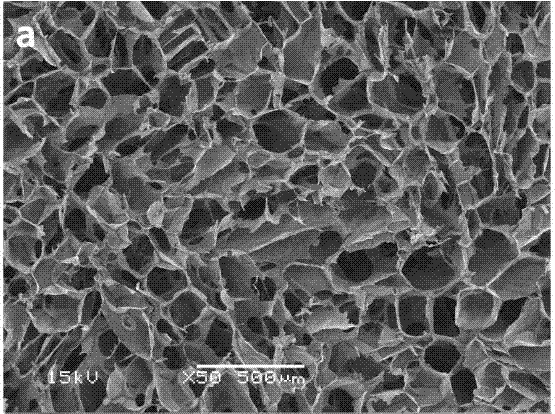

Coated magnetic alloy material and method for the manufacture thereof

InactiveCN102246248AExcellent mechanical propertiesImprove application feasibilityInorganic material magnetismLiquid/solution decomposition chemical coatingCrystal structureMaterial physics

The invention refers to the area of materials science and material physics and relates to a coated magnetic alloy material that can be used, for example, as a magnetic cooling material for cooling purposes. The object of the present invention is to provide a coated magnetic alloy material that exhibits improved mechanical and / or chemical properties. The object is accomplished by a magnetic alloy material having an Na Zn13-type crystalline structure and having a composition according to the formula Ra Fe100-a-x-y-z Tx My Lz, the surface of said alloy material being coated with a material comprising at least one element from the group of Al, Si, C, Sn, Ti, V, Cd, Cr, Mn, W, Co, Ni, Cu, Zn, Pd, Ag, Pt, Au or combinations thereof. The object is further achieved by a method in which the magnetic alloy material is coated by way of fluid phase processes.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

Weight-reducing jelly and preparation method thereof

The invention relates to a weight-reducing jelly which mainly comprises Jew's-ear, a sweetening agent without heat value, a gelling agent, an emulsifying agent and water. The preparation method of theweight-reducing jelly comprises the steps of preparing Jew's-ear slurry, preparing a jelly colloid and preparing the weight-reducing jelly. In the invention, the Jew's-ear has the functions of lowering blood sugar and blood fat, resisting cancers and beautifying the face, has brown color, soft handfeel, delicious taste and abundant nutrition and can be used in meat or vegetable dish; an auxiliaryagent is rivier giantarum micropowder with the functions of reducing the weight, cleaning the stomach, conditioning the bowel, expelling toxin and relaxing bowels; and aspartame can not cause the raising of the blood sugar and is suitable for a diabetic to use, and the added modified starch can obviously enhance the elasticity and the gel strength of the jelly. The jelly is a health-care food with the functions of lowering the blood sugar and the blood fat, reducing the weight, resisting the cancers, beautifying the face and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

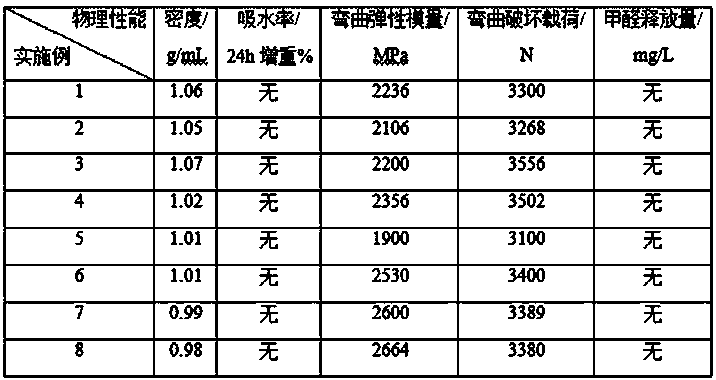

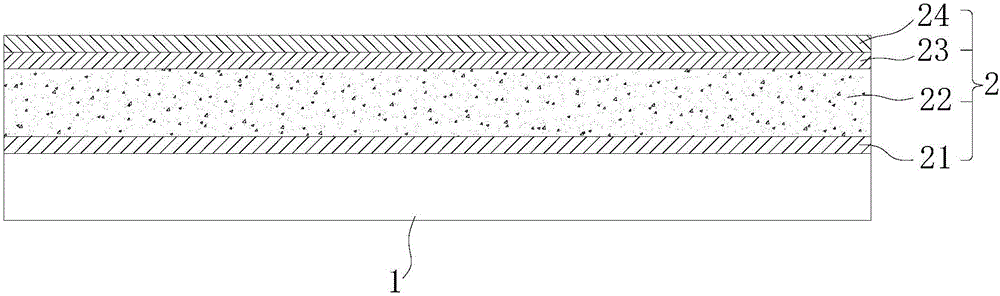

Microlite PVC foam floor

The invention relates to a microlite PVC (Poly Vinyl Chloride) foam floor and belongs to the technical field of chemical building materials. The microlite PVC foam floor is prepared from the following raw materials in parts by weight: 100-150 parts of PVC, 200-300 parts of microlite powder, 0.5-0.7 part of stabilizer, 0.6-1.0 part of foaming agent, 0.2-0.3 part of plasticizer, 0.5-0.7 part of lubricant and 0.5-0.7 part of flame retardant. The microlite PVC foam floor is extrusion-molded by using a plastic extruding machine; the obtained microlite PVC foam floor is low in density, wear-resistant, impact-resistant, high in elastic strength, natural in texture, and beautiful and elegant; the microlite PVC foam floor is also environment-friendly, non-toxic, tasteless and formaldehyde-free; the microlite PVC foam floor is further waterproof, damp-proof, skid-proof, wear-resistant, corrosion-resistant, fire-resistant, and recyclable.

Owner:HENAN LEISEN IND

Modeling method of necrotic femoral head repair model based on umbrella-shaped femoral head support

InactiveCN104462636BThe method steps are simpleReasonable designSpecial data processing applications3D modellingThighModel method

The invention discloses a modeling method of a necrotic femoral head repair model based on an umbrella-shaped femoral head supporter. The bone is the femoral head that has femoral tissue necrosis area and is pre-repaired with the femoral head supporter; Necrotic femoral head model; 3. Establishment of femoral head support model; 4. Establishment of necrotic femoral head implant model: establishment of necrotic femoral head implant model with implant channel and 3D model of implanted bone; 5. Necrotic femoral head repair Model building. The method of the invention has simple steps, reasonable design, convenient implementation and good use effect, and can easily and rapidly establish a repair model for implanting a femoral head supporter into a necrotic femoral head, and the established repair model is of high quality.

Owner:XIAN UNIV OF SCI & TECH

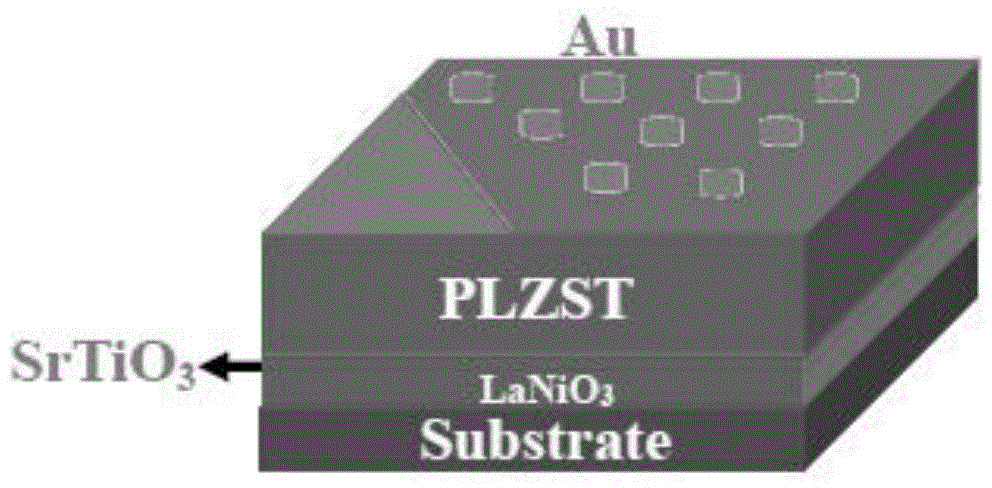

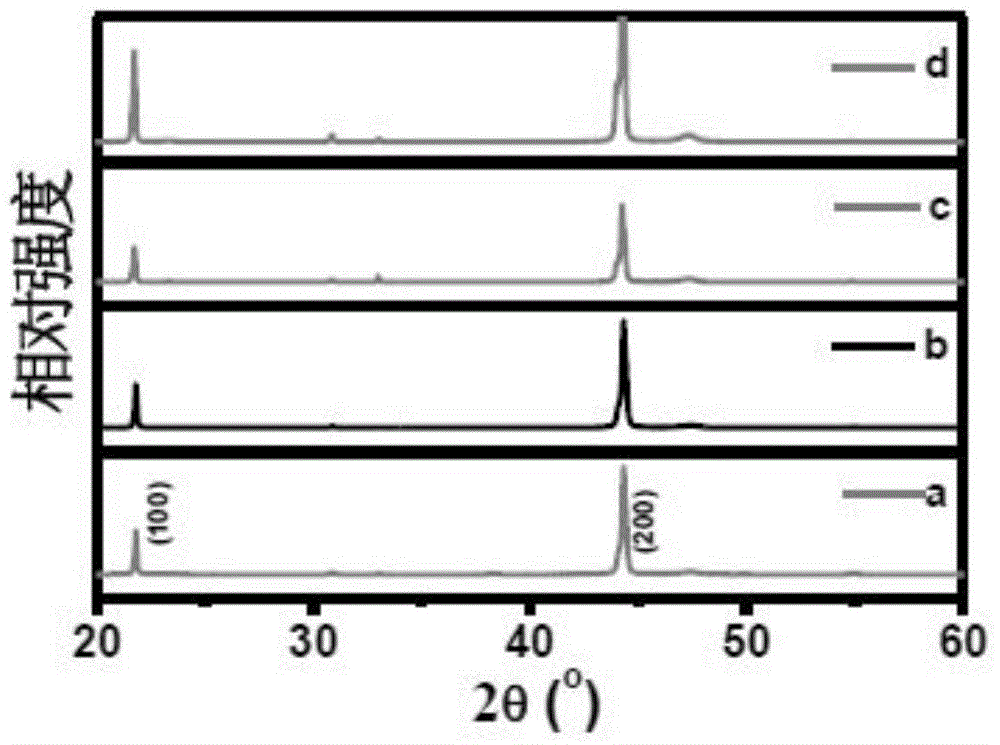

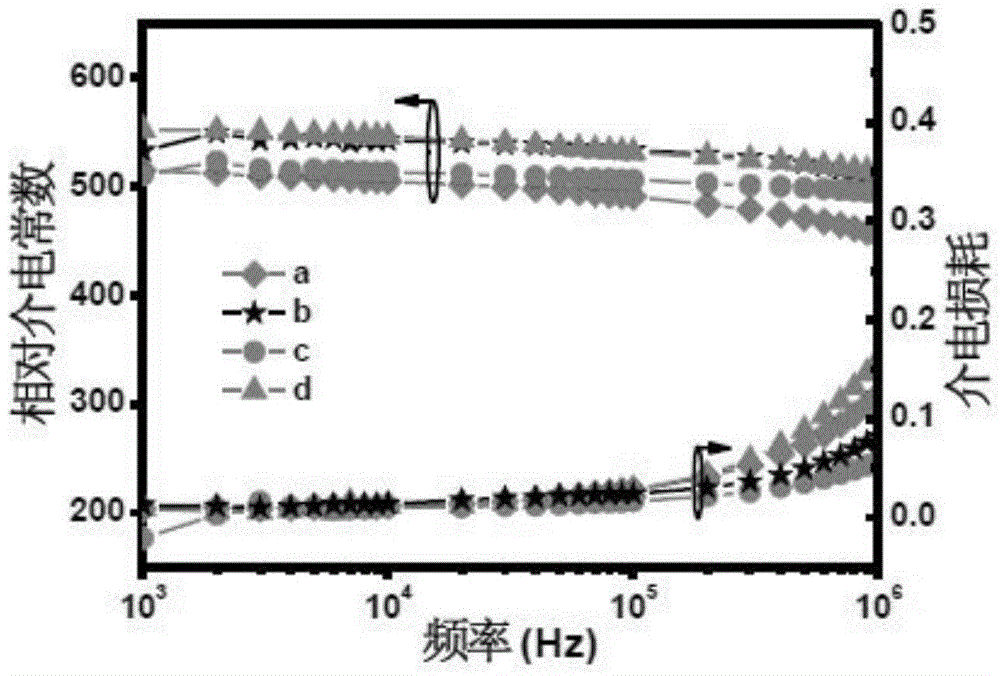

Electrocaloric effect refrigeration composite thick film material

ActiveCN104538539AHigh dielectric constantSolve the real problemThermoelectric device manufacture/treatmentThermoelectric device junction materialsRefrigerationFilm material

The invention relates to an electrocaloric effect refrigeration composite thick film material. The composite thick film material comprises a SrTiO3 buffer layer and a (Pb1-3z / 2Laz)(Zr1-x-ySnxTiy)O3 anti-ferroelectric thick film layer, wherein 0<=x<=0.45, 0<=y<=0.10, 0<=z<=0.06, and the SrTiO3 buffer layer is located between a substrate and the (Pb1-3z / 2Laz)(Zr1-x-ySnxTiy)O3 anti-ferroelectric thick film layer. The composite thick film material has a high dielectric constant and high refrigeration efficiency and energy conversion efficiency and is suitable for development of micro-refrigerators with high refrigeration efficiency and energy conversion efficiency.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for producing golf club head and golf club head structure

The process of producing golf club head includes the following steps: 1. making the lower metal member of integrated driving plane and club bottom; 2. prefabricating one die-casting die for integrated club side and cover; 3. fixing the lower metal member inside the die-casting die; 4. pouring metal liquid for die casting; and 5. de-molding to obtain the golf club head. Thus made golf club head is one hollow structure including one lower metal member and one upper metal member combined through die casting.

Owner:梁龙成

Flame-retardant ageing-resistant sealing ring rubber material

The invention discloses a flame-retardant ageing-resistant sealing ring rubber material which comprises the following raw materials in parts by weight: 80-100 parts of natural rubber, 20-40 parts of butadiene styrene rubber, 10-30 parts of ethylene propylene diene monomer, 10-30 parts of a phosphate modified polyurethane elastomer, 2-4 parts of dicumyl peroxide, 0.5-1 part of sulfur, 1-3 parts of an accelerant DM, 2-4 parts of an accelerant TAIC, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 6-10 parts of carbon black N660, 5-10 parts of titanium dioxide, 2-5 parts of quartz powder, 10-18 parts of calcite in powder, 6-15 parts of opal powder, 1-4 parts of a silane coupling agent, 2-8 parts of zinc borate, 1-4 parts of melamine, 1-2 parts of an anti-aging agent 4010NA, 2-4 parts of an anti-aging agent MB and 1-3 parts of an anti-aging agent AW. The rubber material disclosed by the invention has good flame-retardant property, ageing resistance and excellent weather resistance.

Owner:天长市康宁甘油科技有限公司

MXene material reinforced conductive hydrogel

PendingCN111748107AIncrease elastic strengthImprove conductivityElectrically conductivePolymer chemistry

The invention discloses MXene material reinforced conductive hydrogel. The MXene material reinforced conductive hydrogel is formed by hydrogen bond crosslinking of an MXene material, hydroxyl-containing hydrogel and metal cations. The preparation method of the MXene material reinforced conductive hydrogel comprises the following steps: (1) carrying out cross-linking on hydroxyl-containing hydrogeland an MXene material solution to obtain MXene cross-linked hydrogel; and 2) soaking the MXene cross-linked hydrogel in a solution containing metal cations for cross-linking to obtain the MXene material reinforced conductive hydrogel. The elastic strength of the MXene material reinforced conductive hydrogel is remarkably improved, the conductivity is remarkably enhanced, the comprehensive performance is remarkably improved, and the application prospect is wide.

Owner:GUANGDONG PROV MEDICAL INSTR INST

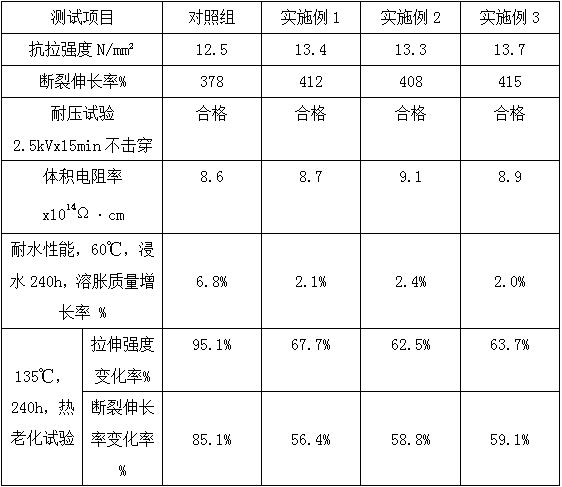

Pressure-proof water-proof anti-corrosion cable material for ocean device

InactiveCN108690272AImprove water resistanceNo swellingPlastic/resin/waxes insulatorsAntimony trioxideElectric power

The invention relates to the technical field of power cables and in particular to a pressure-proof water-proof anti-corrosion cable material for an ocean device. The cable material is prepared from the following components: ethylene-propylene-diene monomer, reinforced glue, calcined ceramic powder, hydrophobic modified filler, dioctyl phthalate, polyamide-modified alkyd resin, zinc oxide, a lubricant, a cross-linking agent, an anti-aging agent, a silane coupling agent and a composite flame retardant, wherein the reinforced glue is a rubber material prepared by compounding nitrile rubber and chloroprene rubber with multiple resins and modifiers, the lubricant is stearic acid, magnesium stearate or zinc stearate, and the composite flame retardant is a mixture of antimonous oxide, aluminum hydroxide and decabrominated diphenylethane, wherein a mass ratio of the three in the mixture is 3:5:1. The cable material has excellent weather resistance and good protective property, and especially has good pressure resistance, water resistance and corrosion resistance.

Owner:HEFEI PULFI WIRE TECH CO LTD

Elastic high-strength antistatic shoe sole material and preparation method thereof

The invention discloses an elastic high-strength antistatic shoe sole material, which comprises the following raw materials in parts by weight: 6-10 parts of organotin stabilizer, 7-9 parts of anti-slip agent, 2-4 parts of conductive filler, and 25-35 parts of hydroxylated polypropylene 50-60 parts of elastic filler, 4-8 parts of calcium carbonate, 5-7 parts of binder, 10-18 parts of reinforced inorganic fiber, 1-2 parts of antistatic agent, 3-5 parts of coupling agent, processing aid Dose 10-12 parts. The sole material of the present invention has good elasticity and mechanical strength, good anti-slip effect, excellent antistatic performance, excellent heat resistance, weather resistance and impact resistance; meanwhile, the raw material components of the present invention are safe and reliable, and have no pollution to the environment, and the raw material It is easy to obtain, low in cost, simple in process, low-carbon, environmentally friendly and pollution-free, and has high practical value and good application prospect.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

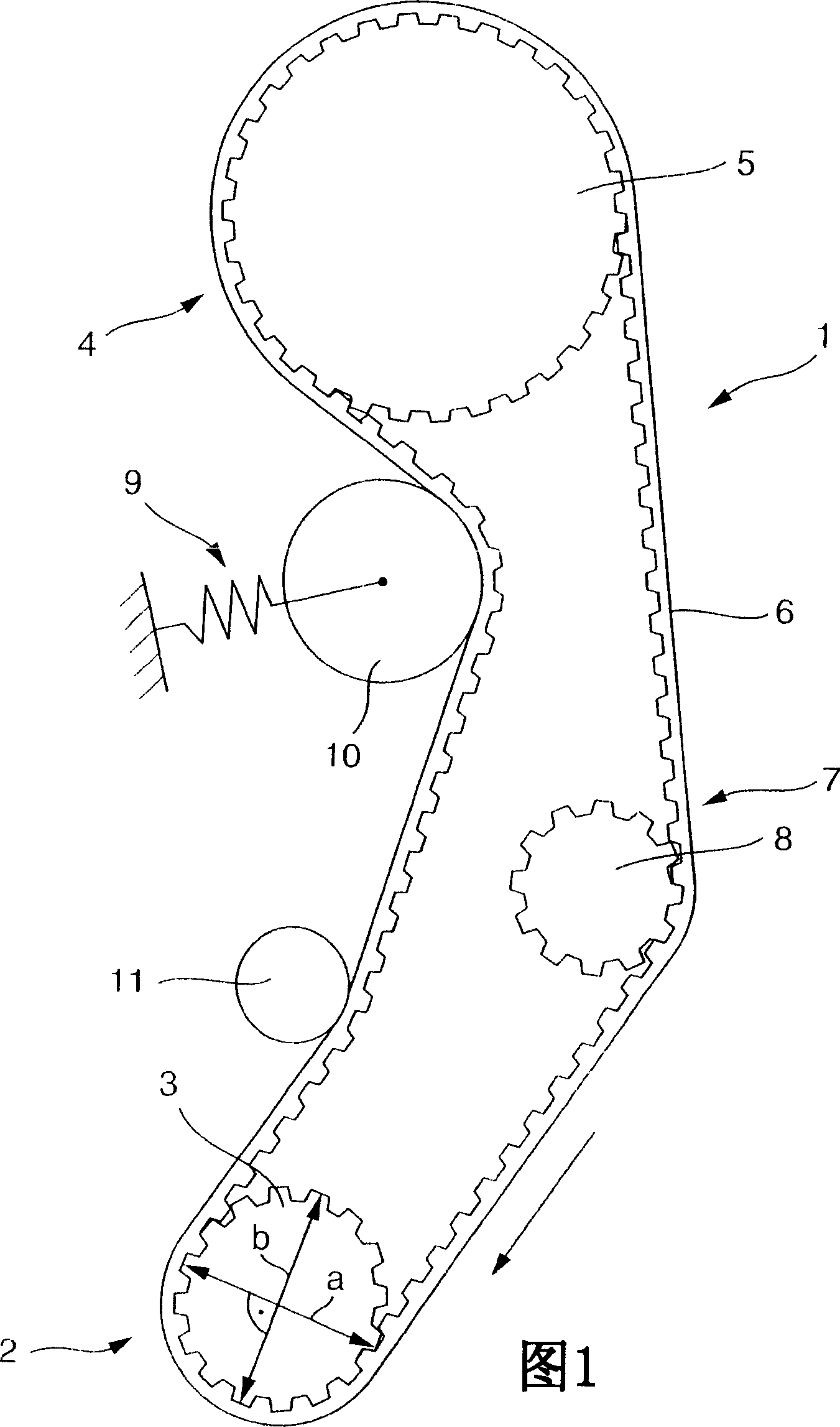

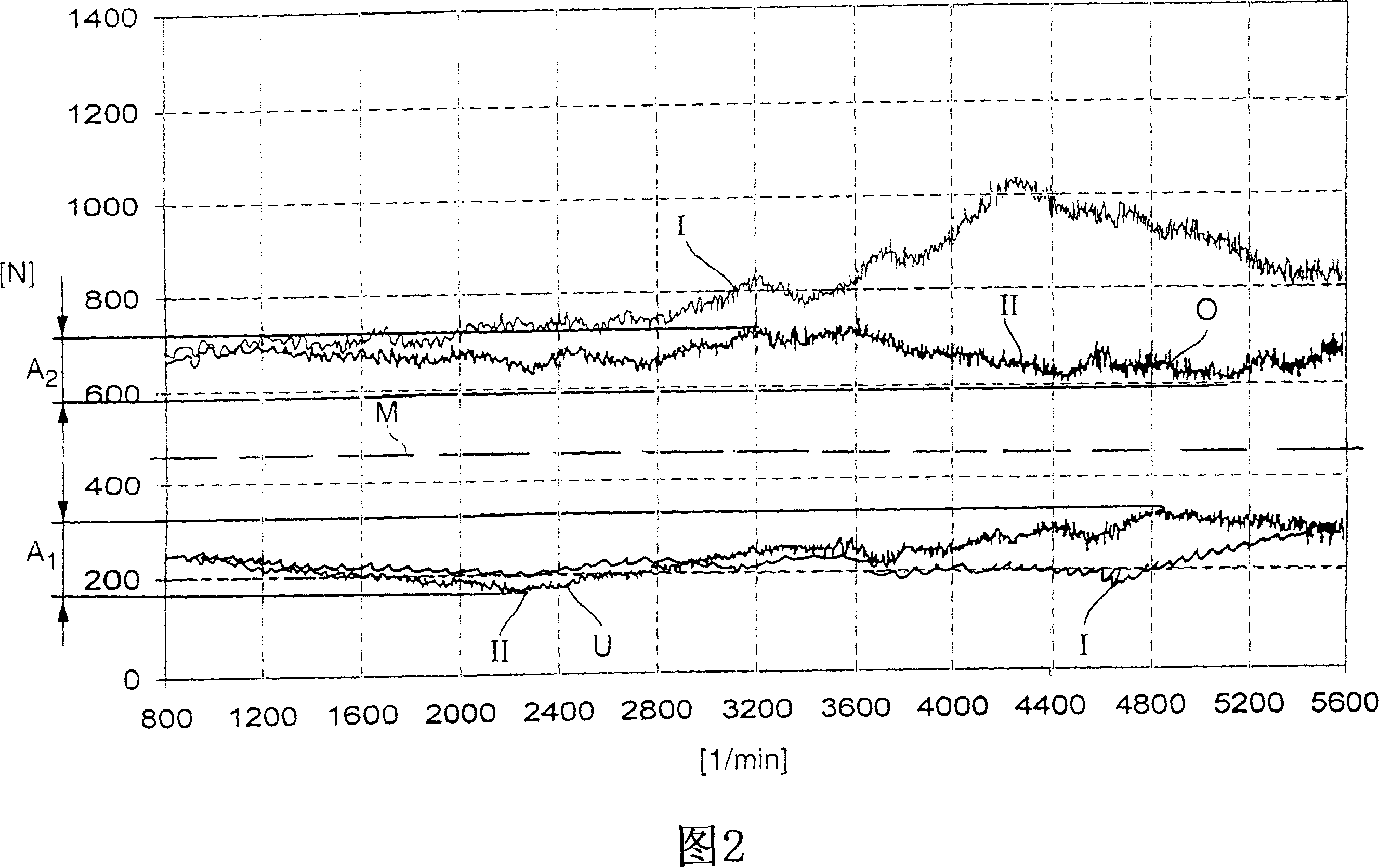

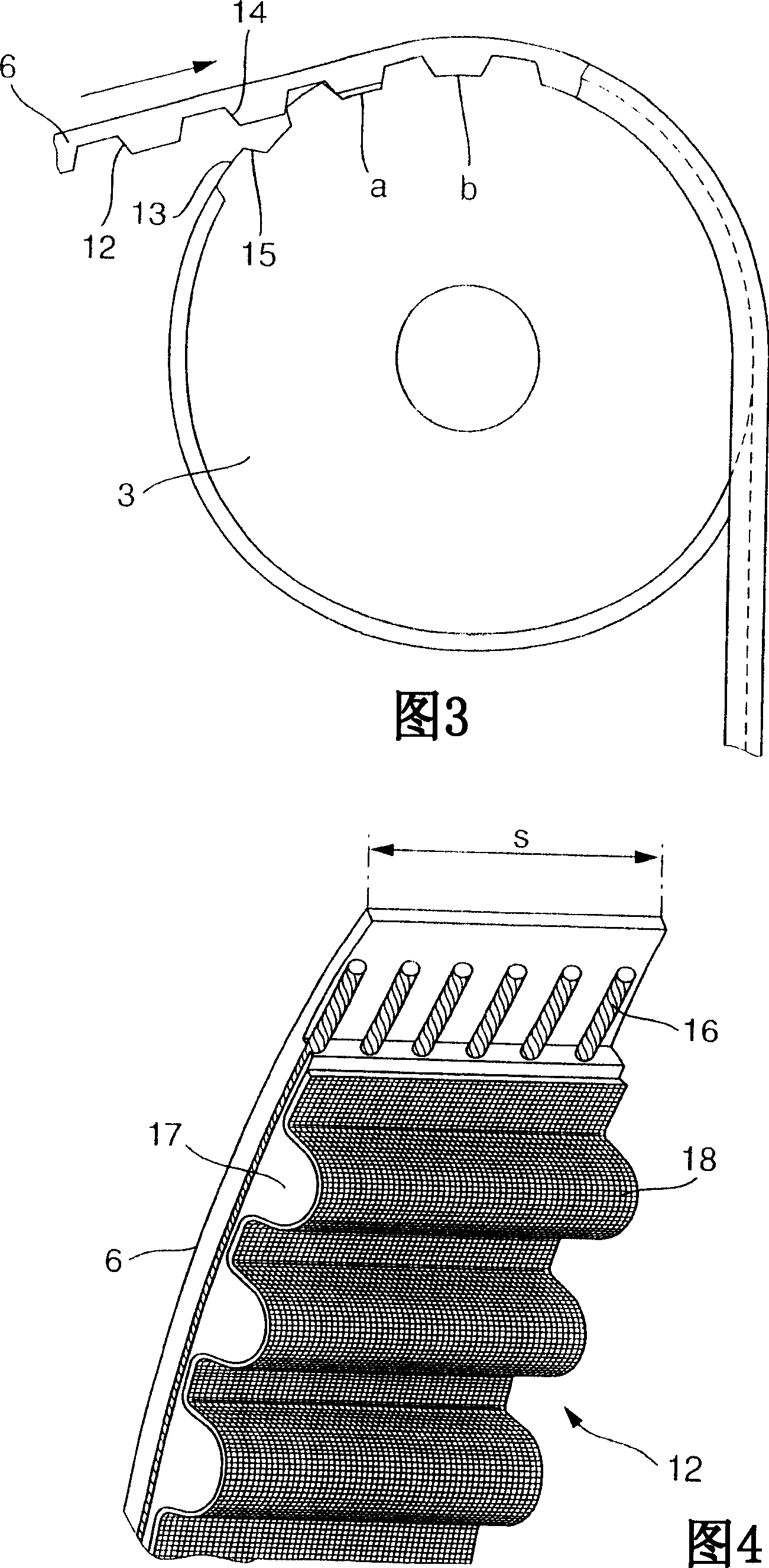

Cost-optimized traction mechanism

The present invention relates to a traction mechanism (1), comprising a driven member (2) and at least one driving member (4) which are connected via a traction device (6) designed as a toothed belt. To achieve a vibration-damped traction mechanism (1), the driven member (2) designed as a toothed belt pulley (3) has a nonround configuration.

Owner:SCHAEFFLER TECH AG & CO KG

Peelable and biodegradable polyurethane protective film, preparation method and application thereof

ActiveCN105907282AImprove mechanical propertiesIncrease elastic strengthAntifouling/underwater paintsPaints with biocidesPlasticizerThermoplastic polyurethane

The invention discloses a peelable and biodegradable polyurethane protective film, a preparation method and application thereof. The protective film comprises the following raw materials by weight: 40-70 parts of thermoplastic polyurethane, 10-30 parts of biodegradable polyester, 0.01-0.5 part of a corrosion inhibitor, 1-10 parts of filler and 5-30 parts of a plasticizer. The preparation method comprises: 1) selecting materials according to the composition and weight part of each component prescribed in the formula; 2) putting the raw materials into a banbury mixer, performing stirring at 140-180DEG C for 5-15min till uniform mixing melting; 3) carrying out extrusion granulation and cooling to obtain an anti-bump and anti-corrosion protective film particle semi-finished product, during use, heating the semi-finished product to 160DEG C to melt it into liquid, then spraying the liquid on a metal component surface, and conducting cooling so as to form a 3-5micrometer protective film. The peelable and biodegradable polyurethane protective film provided by the invention has a simple formula and no pollution, and is especially suitable for temporary protection of metal raw materials and semi-finished products. The peelable and biodegradable polyurethane protective film is convenient to make and use, has no residual protective film after peeling, and can be biodegradable after abandonment.

Owner:SHAANXI UNIV OF SCI & TECH

Silica gel skin of simulation robot and manufacturing technology thereof

InactiveCN109940805AIncrease elastic strengthHigh tensile strengthManipulatorManufacturing technologySilica gel

The invention relates to a silica gel skin of a simulation robot and a manufacturing technology of the silica gel skin of the simulation robot, and belongs to the technical field of robot manufacturing. In order to solve the problem that the skin of an existing simulation robot is low in flexibility and tensile property, the invention provides the manufacturing technology of the silica gel skin ofthe simulation robot. The manufacturing technology of the silica gel skin of the simulation robot comprises the following steps that an original clay sculpture male mold is manufactured; a gypsum female mold is duplicated; a putty male mold is duplicated; a glass reinforced plastic female mold and a lining are duplicated; and the silica gel skin is manufactured. According to the silica gel skin of the simulation robot and the manufacturing technology of the silica gel skin of the simulation robot, an elastic interlayer is added to the silica gel skin, and therefore the elasticity and the tensile strength of the silica gel skin are improved, the tensile strength of the silica gel skin is five times that of an ordinary silica gel skin, and the silica gel skin can be rapidly recovered afterthe silica gel skin is stretched; due to the addition of the elastic interlayer, the degree of the flexibility of the silica gel skin is also improved, the silica gel skin cannot be prone to being damaged, and the service life of the silica gel skin is prolonged. When the silica gel skin manufactured according to the manufacturing technology is applied to the technical field of simulation robot manufacturing, the simulation robot can have the high simulation performance in the static state and the dynamic state.

Owner:扬州哈工科创机器人研究院有限公司

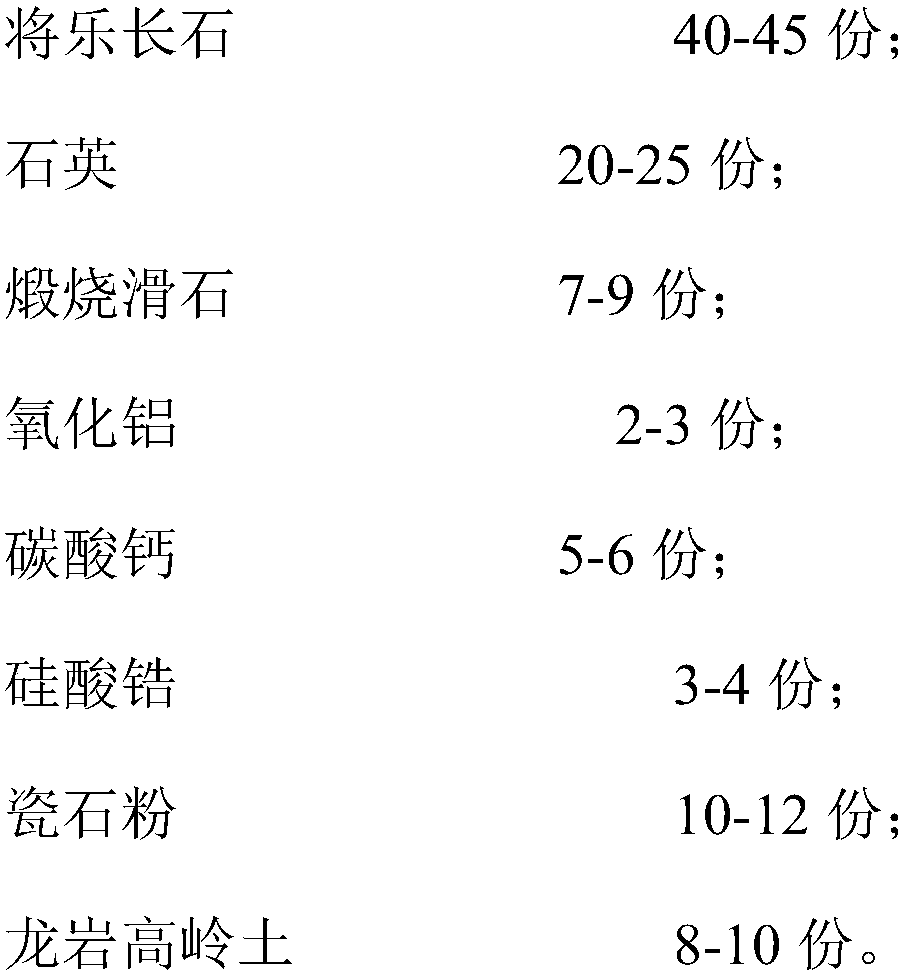

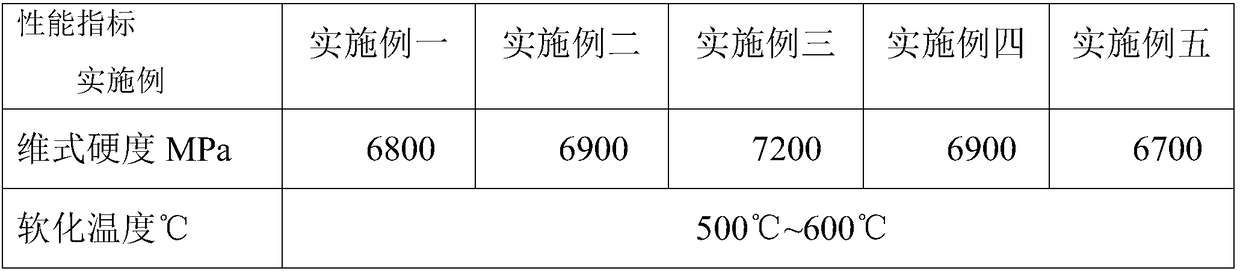

Glaze formula and preparation process thereof

The invention relates to a glaze formula and a preparation process thereof. According to the invention, feldspar, quartz, calcined talc, alumina, calcium carbonate, zirconium silicate, porcelain powder and kaolin of Longyan are ground and mixed, a glaze layer fired by the glaze formula has characteristics of bright glaze layer, uniform glaze thickness, wear resistance, and impact resistance, and can prevent the glaze from being damaged during the collision, and the firing qualification rate is more than 97%.

Owner:福州市陶瓷行业技术创新中心

Thick automobile inner chamber leather with pressure resistance and friction-resistant color fastness

InactiveCN106087458AReasonable structureGood high temperature resistanceTextiles and paperEmulsionHollow form

The invention discloses thick automobile inner chamber leather with pressure resistance and friction-resistant color fastness. The thick automobile inner chamber comprises a base cloth layer and a surface layer coating one surface of the base cloth layer, wherein the surface layer is a four-layer structure and comprises a water-base PU bottom layer, a water-base PU foamed layer, a water-base PU reinforcing layer and a water-base PU surface layer which are sequentially connected. According to the thick automobile inner chamber leather, the base cloth layer has the effects of resisting bacteria and ultraviolet light and retarding combustion; the surface layer is a four-layer structure and has strong leather sensation, and the four layers are made of a water-base polyurethane emulsion, so that the environmental protection property is good, the strength is high, and the water repellency and the gas permeability are strong; the PU foamed layer is of a hollow formed structure and is light, so that the automobile inner chamber leather is endowed with relatively rebound resilience and compression strength; nano-TiO2 powder, nano-ZnO powder and polyol fatty acid ester are further added into the water-base PU surface layer, so that the automobile inner chamber leather has relatively strong light aging resistance and static electricity resistance; by utilizing a Dow Corning DC-57 organosilicon polyether copolymer, the automobile inner chamber leather is smooth and wearable and has strong friction-resistant color fastness.

Owner:浙江嘉科新材料科技有限公司

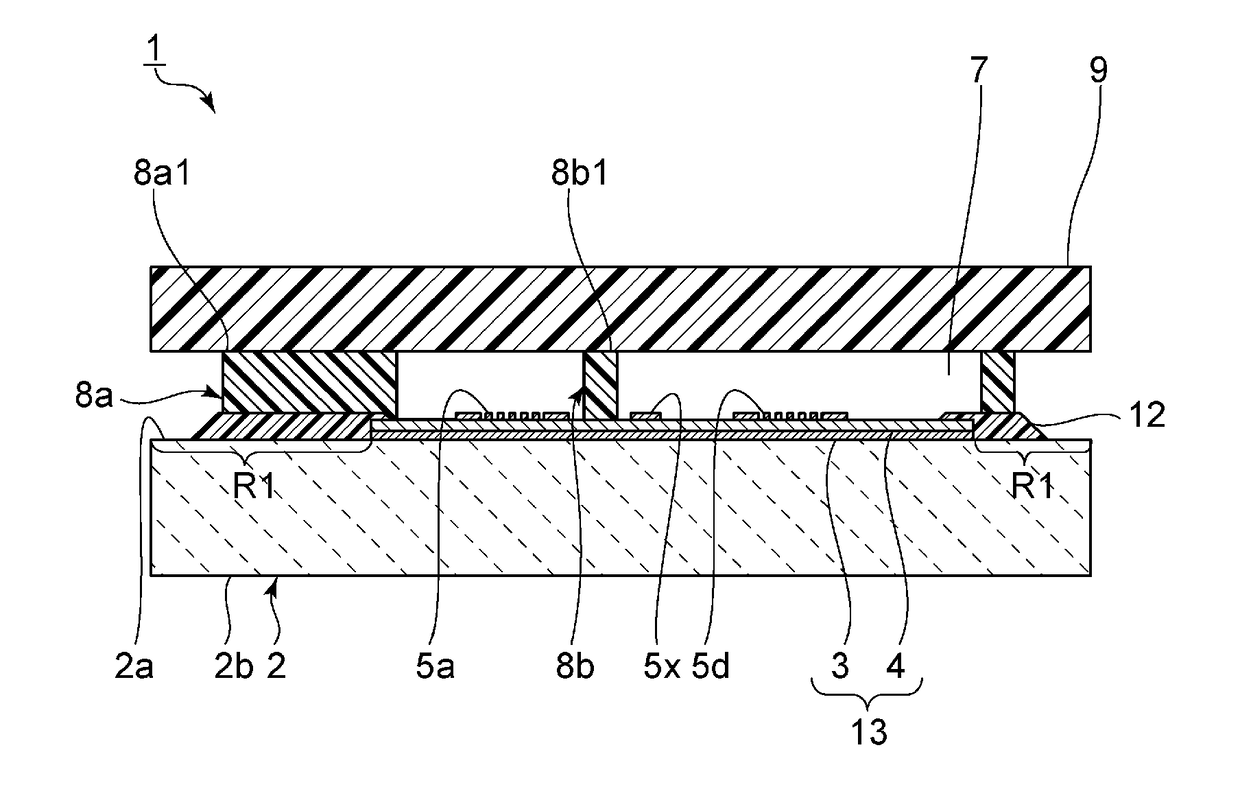

Elastic wave device

ActiveUS20180102757A1Improve productivityCracking and chipping of the piezoelectric thin film is reduced or preventedImpedence networksComputational physicsInterdigital transducer

An elastic wave device includes a multilayer film stacked on a support substrate. A first support layer surrounds a region including interdigital transducer electrodes. A second support layer is disposed in the region surrounded by the first support layer. A cover is fixed on the first support layer and the second support layer so as to close a cavity defined by the first support layer. The multilayer film is partially disposed on the support substrate, and an insulating layer is disposed in at least a portion of a region in which the multilayer film is not disposed. At least one of the first support layer and the second support layer is disposed on the insulating layer.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com