Oil-water separation type sodium alginate/graphene oxide composite aerogel and preparation method thereof

A graphene composite, sodium alginate technology, applied in aerogel preparation, separation methods, chemical instruments and methods, etc., can solve problems such as complex actual operation, achieve simple preparation process, expand the scope of application, unique anti-oil pollution effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

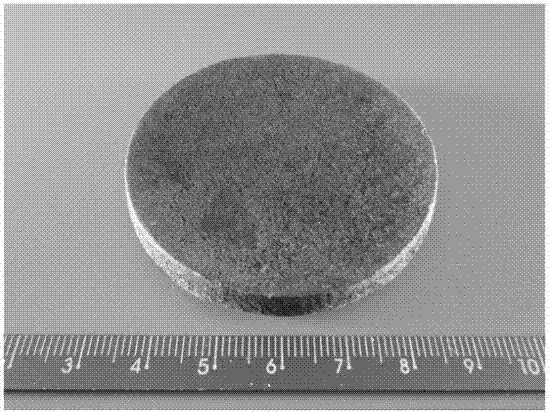

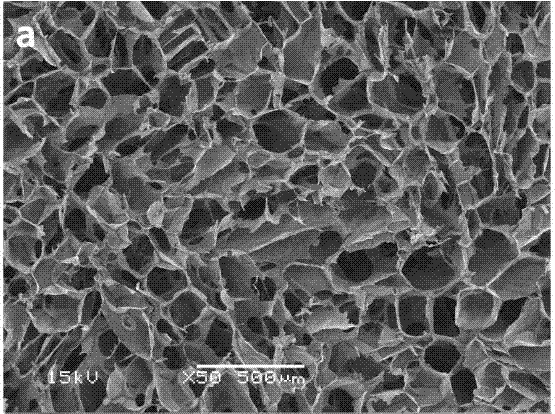

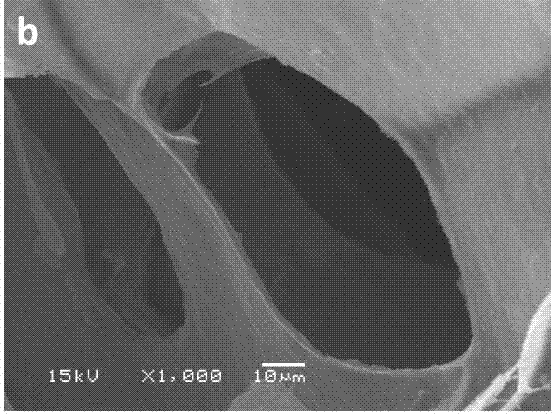

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of preparation method of oil-water separation type sodium alginate / graphene oxide composite airgel comprises the following steps:

[0045] (1) Preparation of sodium alginate / graphene oxide mixture:

[0046] A. Preparation of sodium alginate solution: Dissolve sodium alginate in deionized water, stir magnetically at 1000 rpm for 1 hour, then gradually reduce the stirring speed to 500 rpm until it becomes a transparent solution, and prepare a sodium alginate solution with a concentration of 2wt%. ;

[0047] B, sonication concentration is 1wt% graphene oxide suspension 15min, then, add in the sodium alginate solution of step A, make graphene oxide and sodium alginate mass ratio be 1:10, 1500rpm magnetic stirring 2h, obtain Uniform sodium alginate / graphene oxide dispersion;

[0048] (2) Preparation of uncrosslinked sodium alginate / graphene oxide composite airgel:

[0049] Put the vessel containing the sodium alginate / graphene oxide dispersion obtaine...

Embodiment 2

[0067] Embodiment 2, a kind of preparation method of oil-water separation type sodium alginate / graphene oxide composite airgel, comprises the following steps:

[0068] (1) Preparation of sodium alginate / graphene oxide mixture:

[0069] A. Preparation of sodium alginate solution: Dissolve sodium alginate in deionized water, stir magnetically at 1200 rpm for 1 hour, then gradually reduce the stirring speed to 500 rpm until it becomes a transparent solution, and prepare a sodium alginate solution with a concentration of 4wt%.

[0070] B, ultrasonic treatment concentration is the graphene oxide suspension of 0.5wt% 15min, then, add in the sodium alginate solution of step A, make graphene oxide and sodium alginate mass ratio be 0.5:10, 2000rpm magnetic stirring 2h, Obtain sodium alginate / graphene oxide dispersion liquid;

[0071] (2) Preparation of uncrosslinked sodium alginate / graphene oxide composite airgel:

[0072] Put the vessel containing the sodium alginate / graphene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com