Patents

Literature

73495results about How to "Firmly connected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

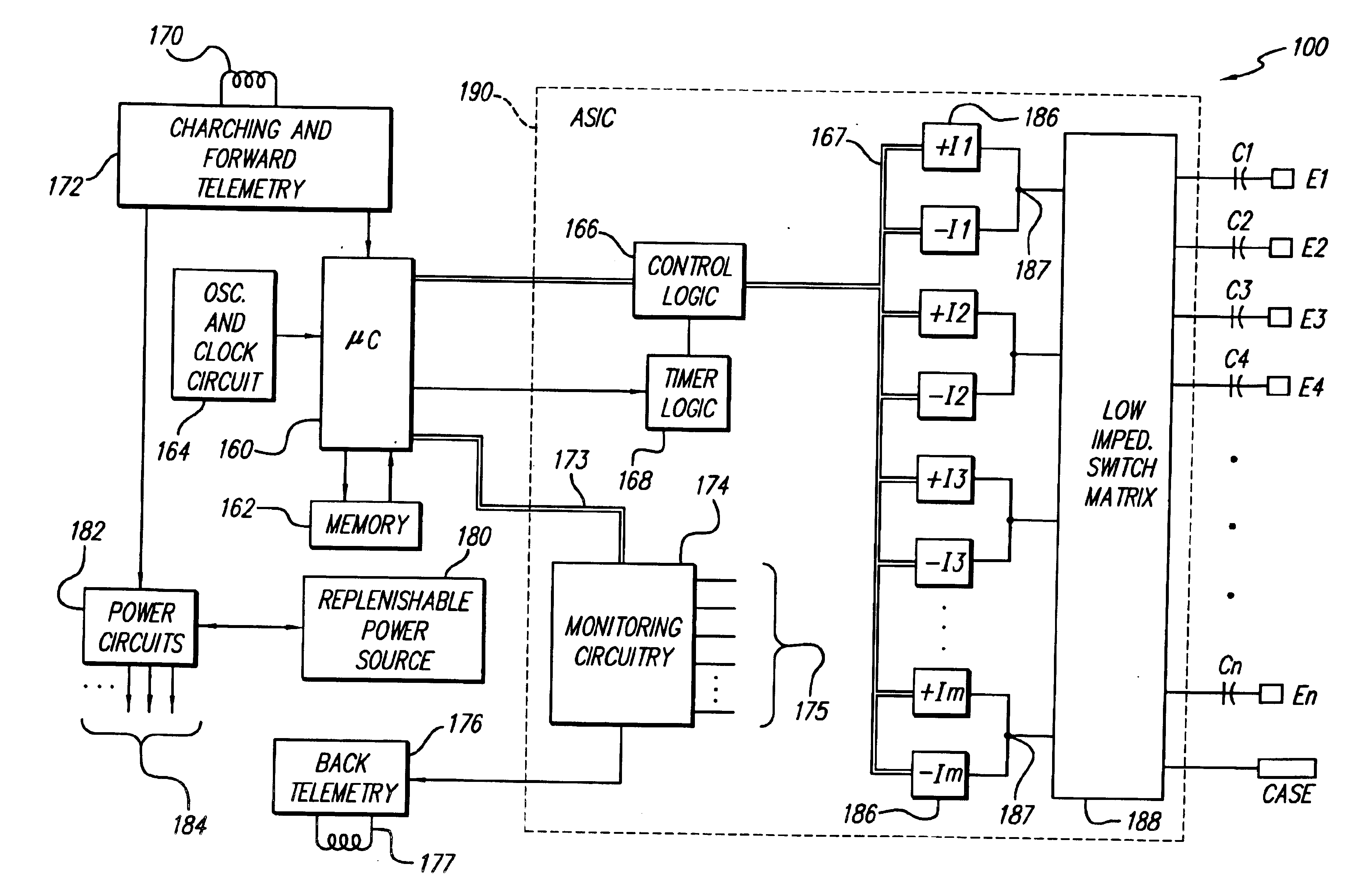

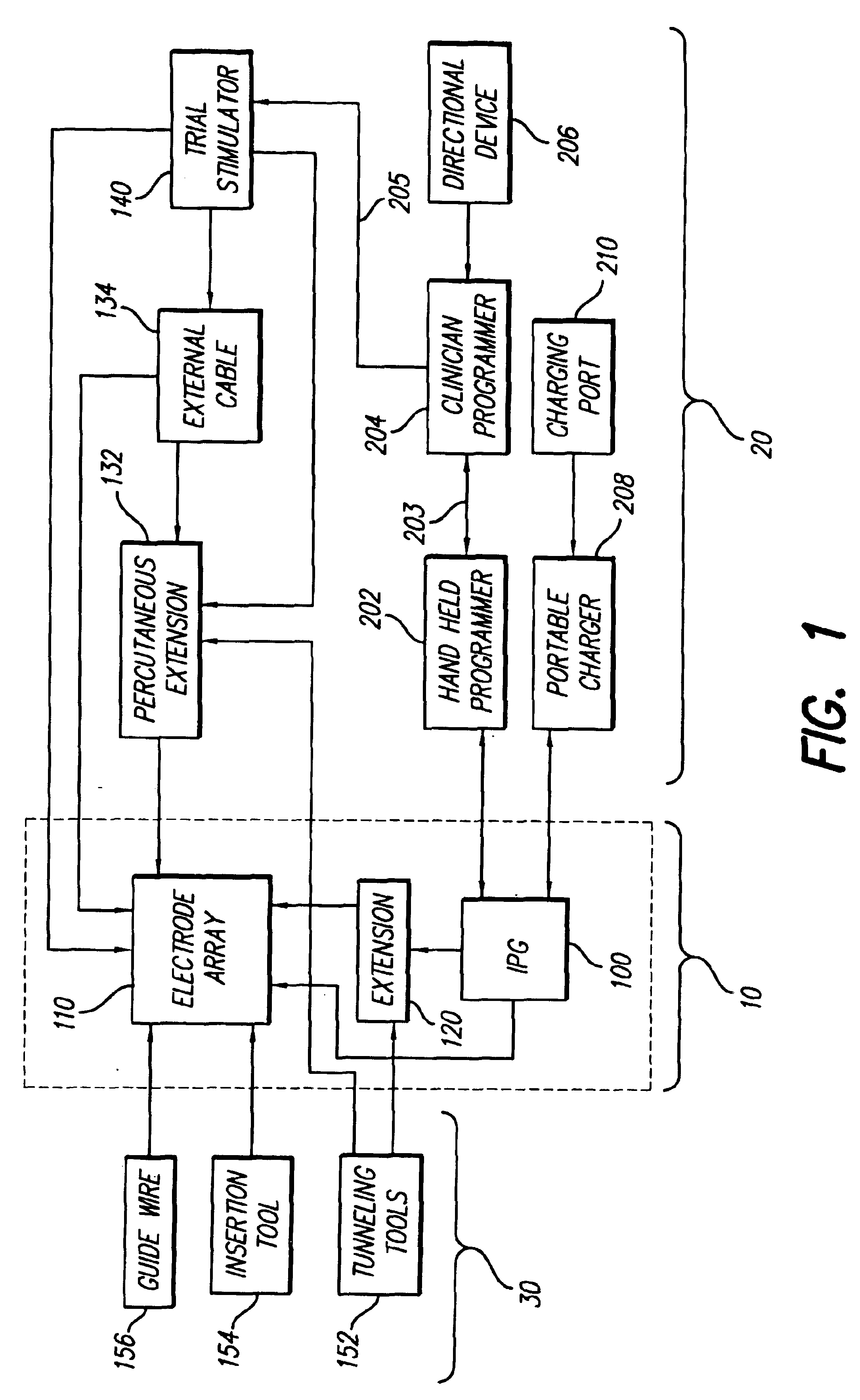

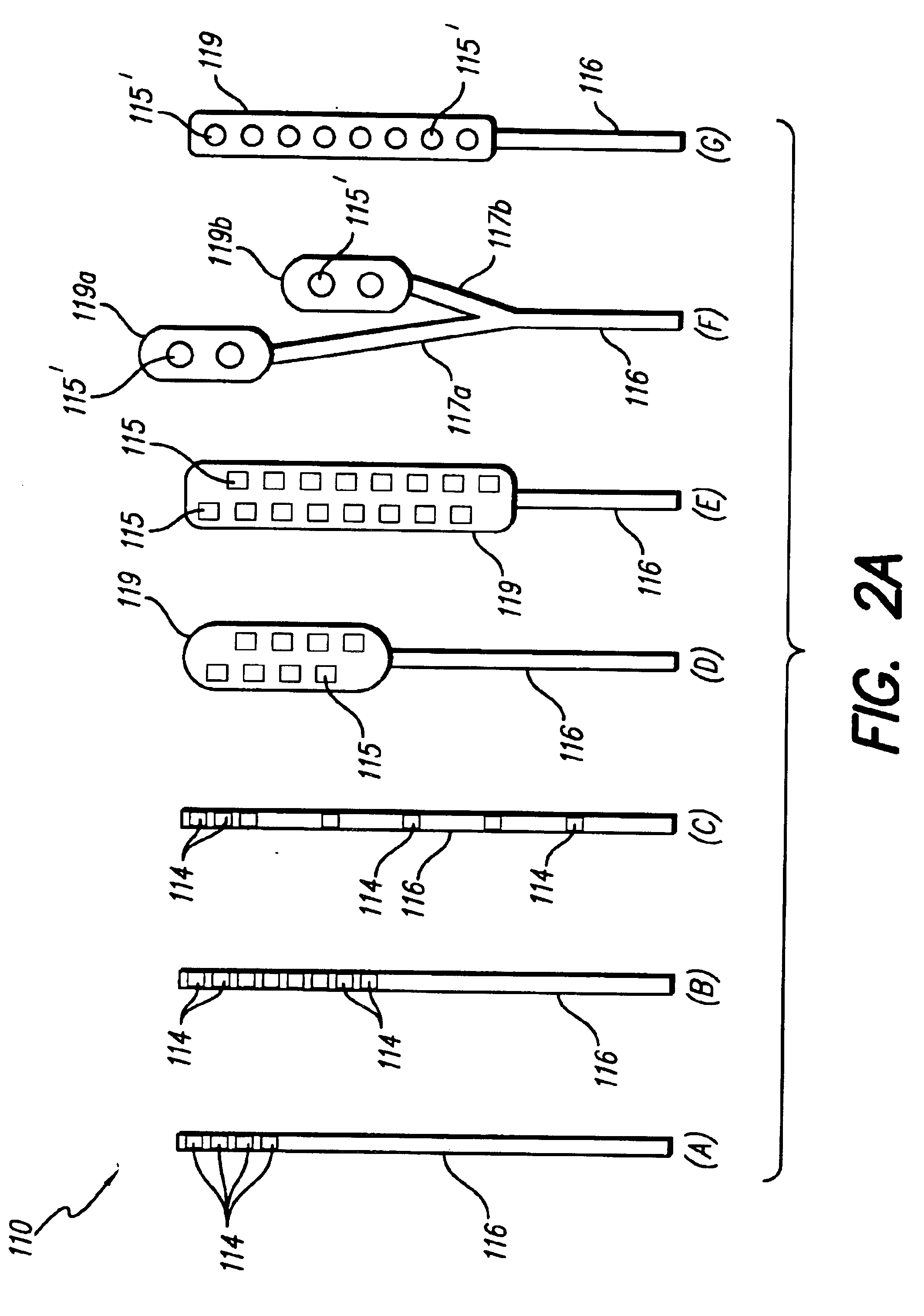

Rechargeable spinal cord stimulator system

InactiveUS6895280B2Provide comfortAvoid displacementSpinal electrodesCircuit arrangements on support structuresReal-time clockElectrical battery

A spinal cord stimulation (SCS) system includes multiple electrodes, multiple, independently programmable, stimulation channels within an implantable pulse generator (IPG) which channels can provide concurrent, but unique stimulation fields, permitting virtual electrodes to be realized. The SCS system includes a replenishable power source (e.g., rechargeable battery), that may be recharged using transcutaneous power transmissions between antenna coil pairs. An external charger unit, having its own rechargeable battery can be used to charge the IPG replenishable power source. A real-time clock can provide an auto-run schedule for daily stimulation. An included bi-directional telemetry link in the system informs the patient or clinician the status of the system, including the state of charge of the IPG battery. Other processing circuitry in the IPG allows electrode impedance measurements to be made. Further circuitry in the external battery charger can provide alignment detection for the coil pairs.

Owner:BOSTON SCI NEUROMODULATION CORP

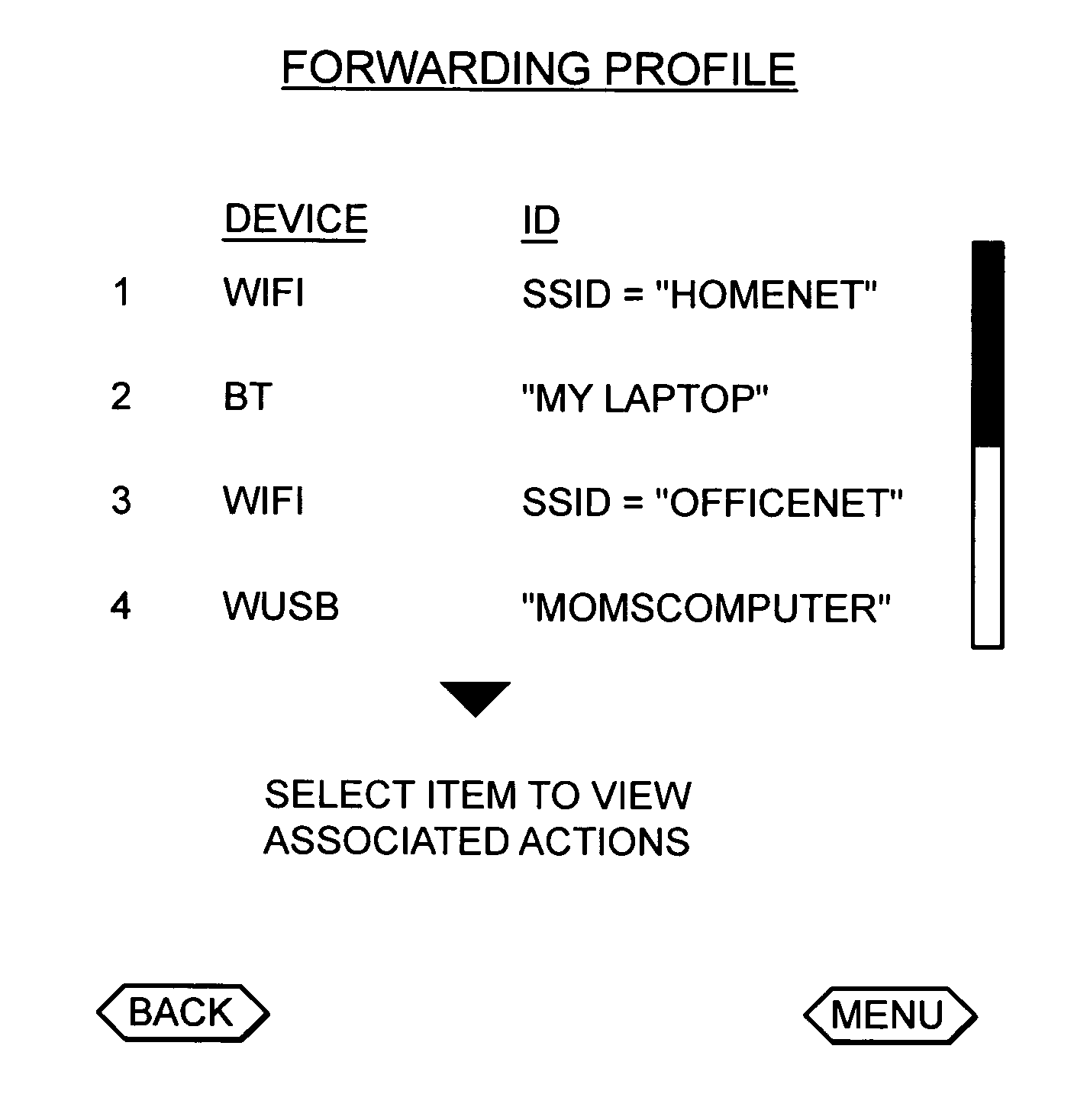

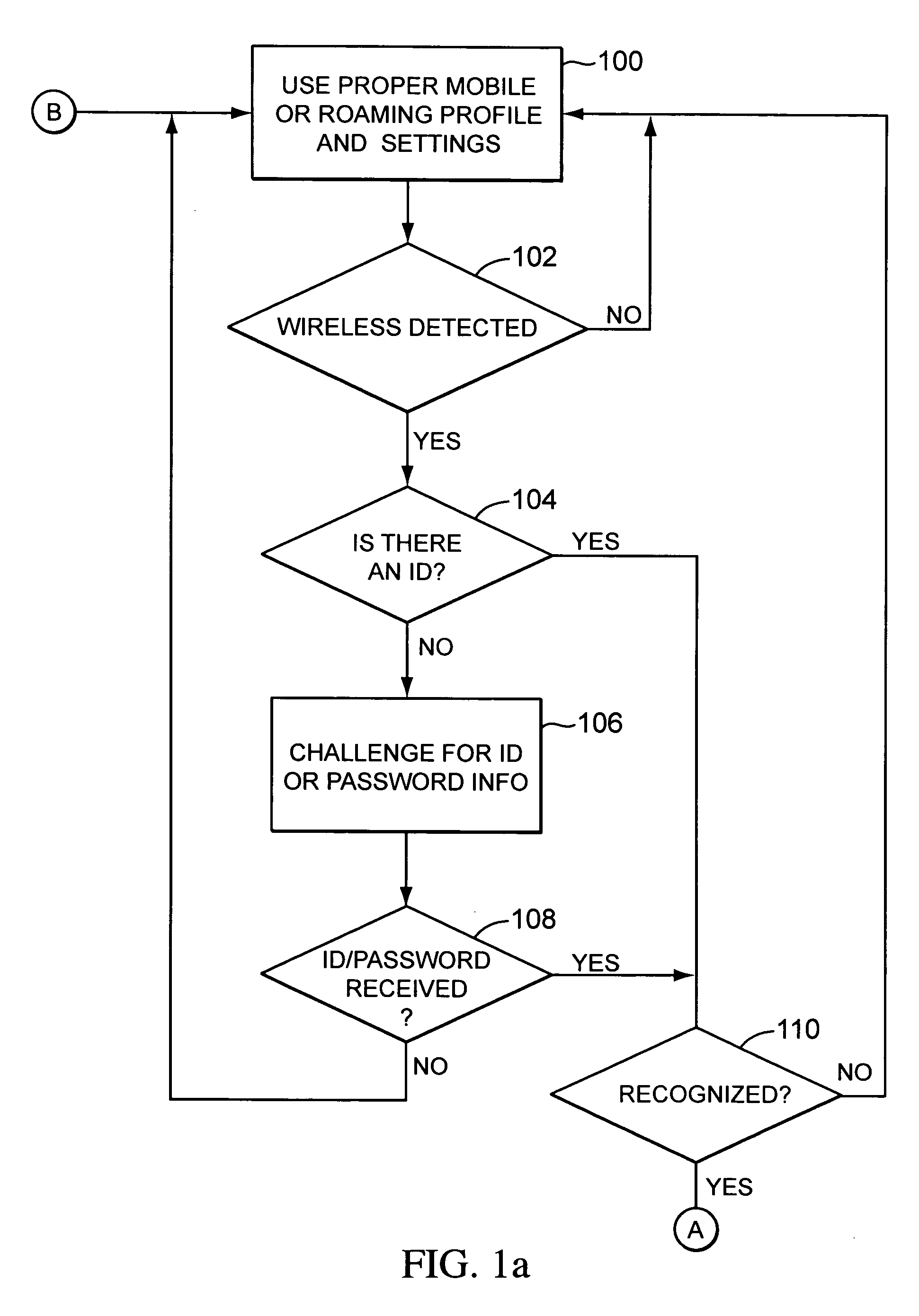

Realtime, location-based cell phone enhancements, uses, and applications

ActiveUS20070032225A1Use minimizedMaximizing its battery powerMechanical apparatusLighting and heating apparatusMethod selectionComputer science

Enhancements of and to cell phone operations are based in whole or in part on determining the location of the cell phone. Systems and methods select and determine locations or areas of importance or relevance, and based on that information and other programmed factors affect or alter the operations of the cell phone. While the systems and methods are illustrated by use of cell phone embodiments and applications, they are equally applicable to virtually any portable or mobile communication device, including for example, wireless laptop computers and PDAs.

Owner:RESIGHT LLC

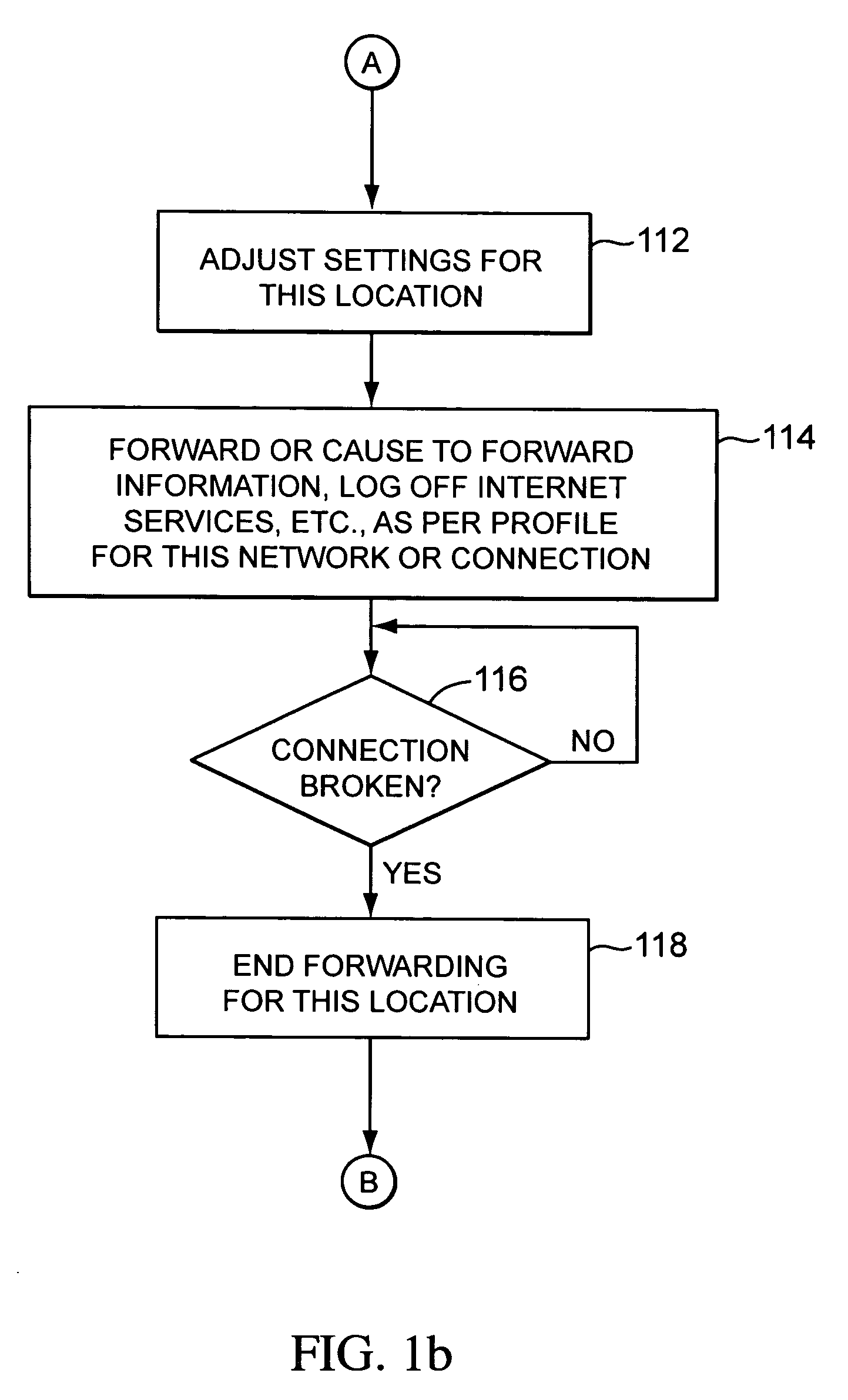

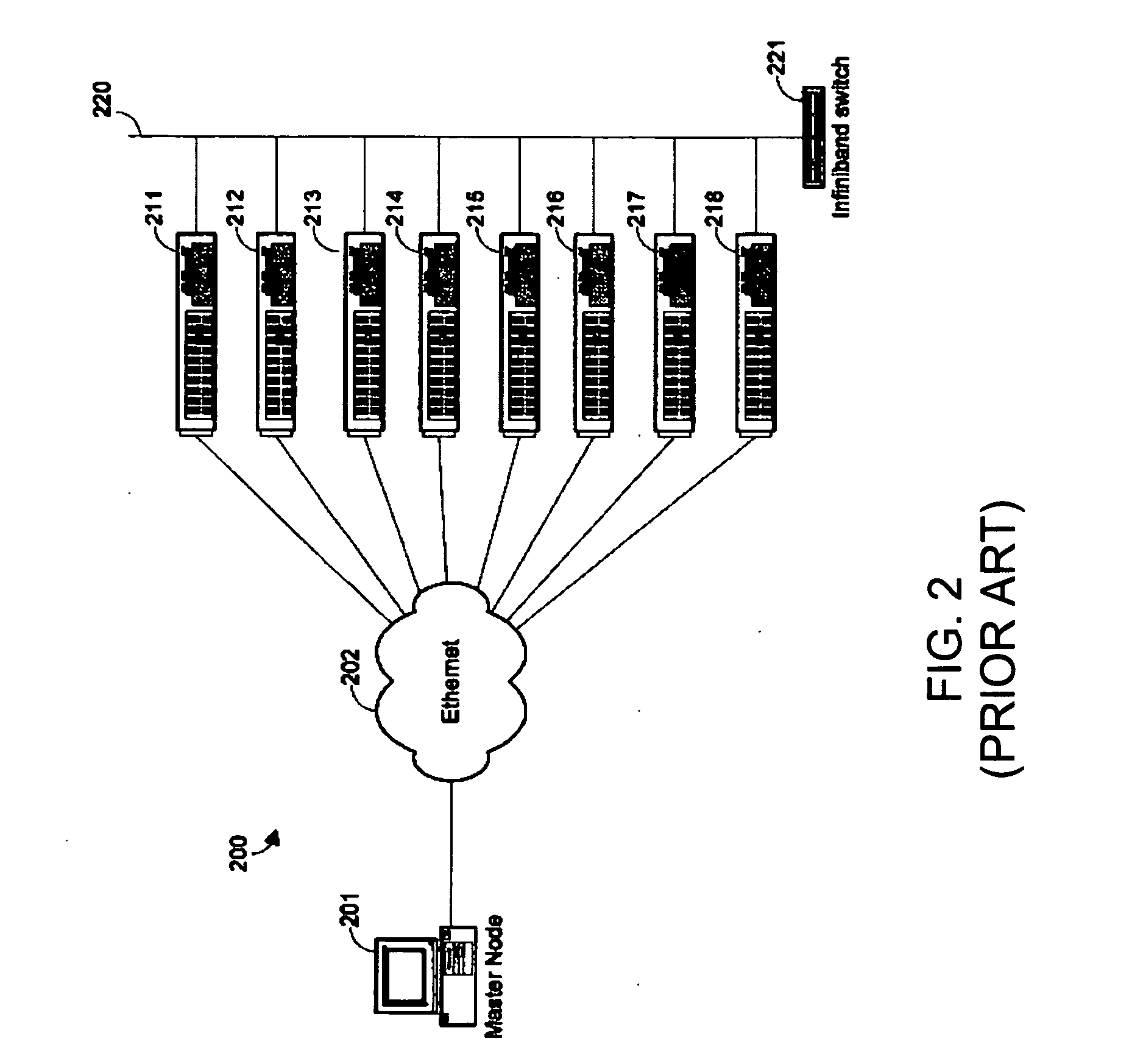

Apparatus, method and system for rapid delivery of distributed applications

ActiveUS20070078988A1Virtualized networkFirmly connectedEnergy efficient ICTMultiple digital computer combinationsVirtualizationVirtual device

An apparatus, method and system are disclosed for visually constructing and rapidly delivering distributed applications. The system includes a virtual appliance apparatus and a composite appliance apparatus, as well as a system for virtualizing hardware resources and for provisioning, executing and scaling distributed applications.

Owner:CA TECH INC

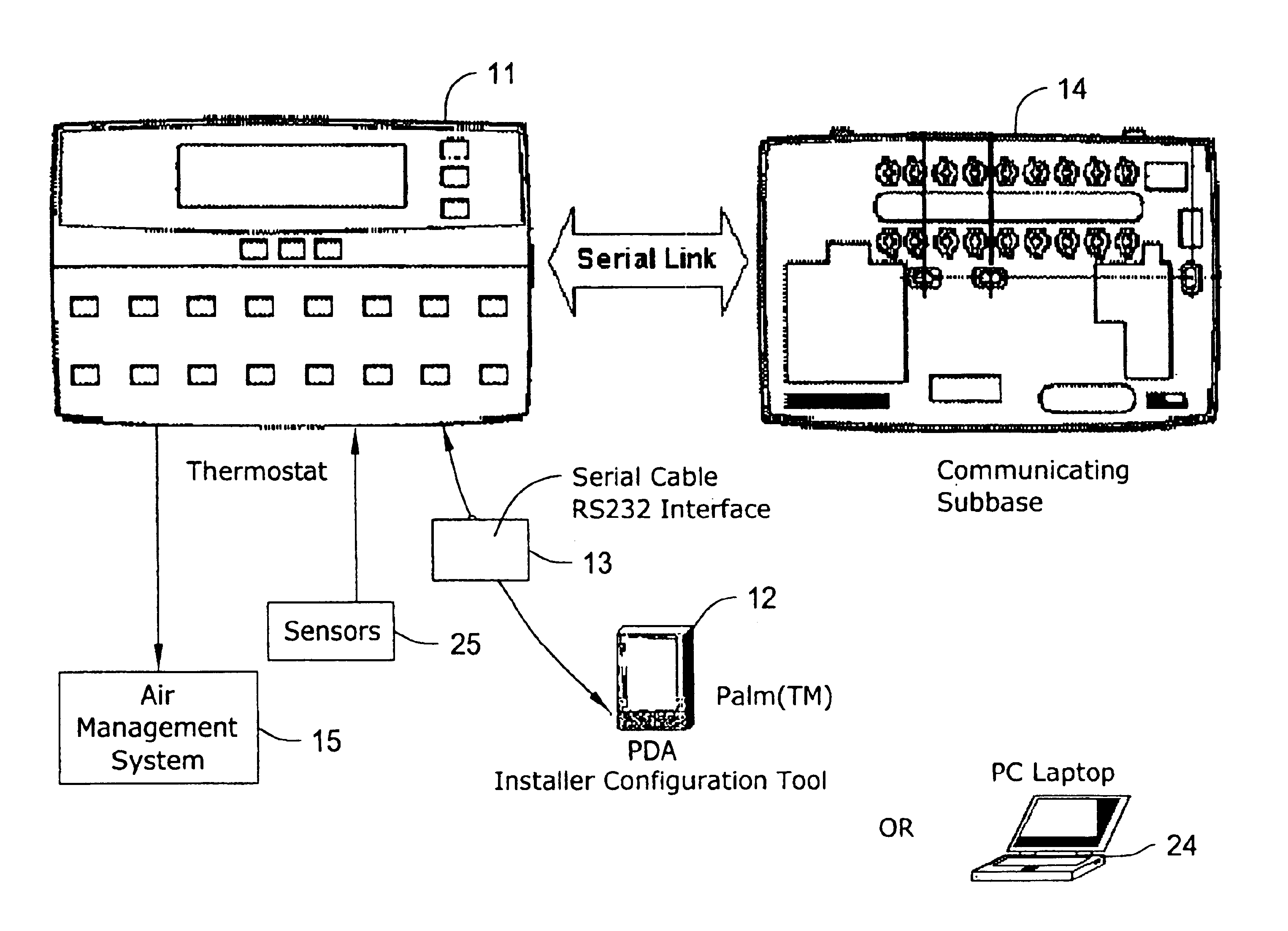

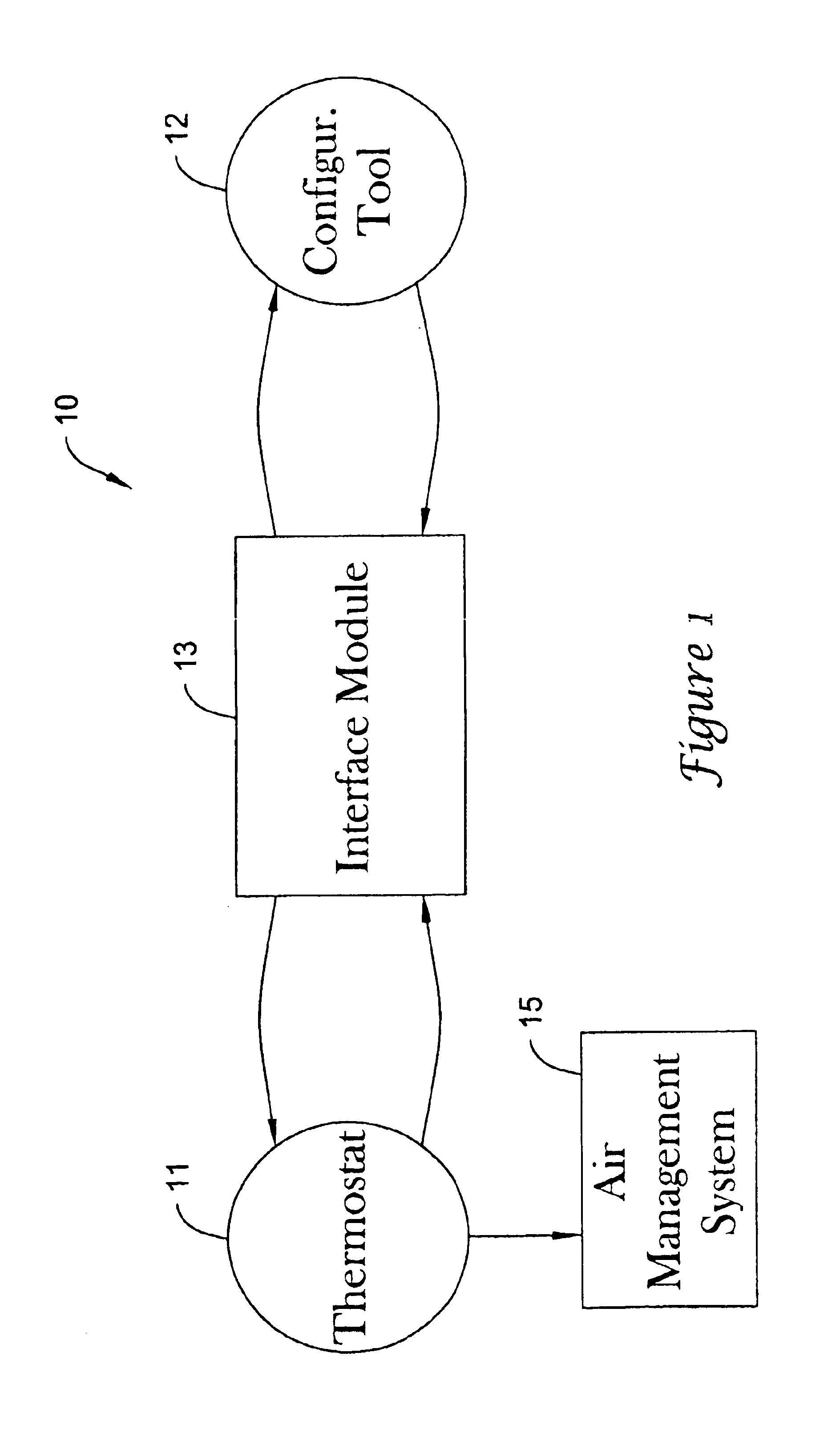

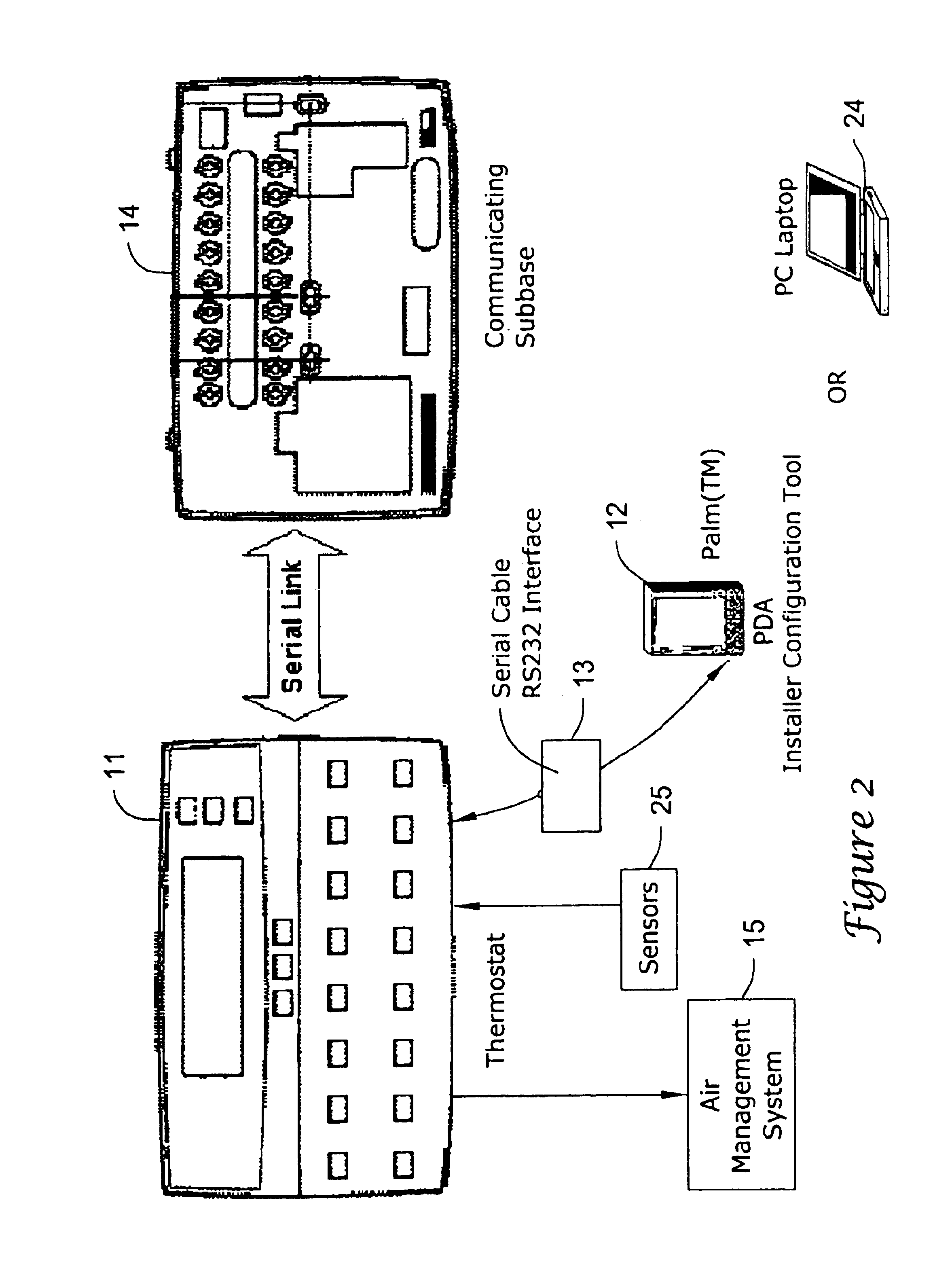

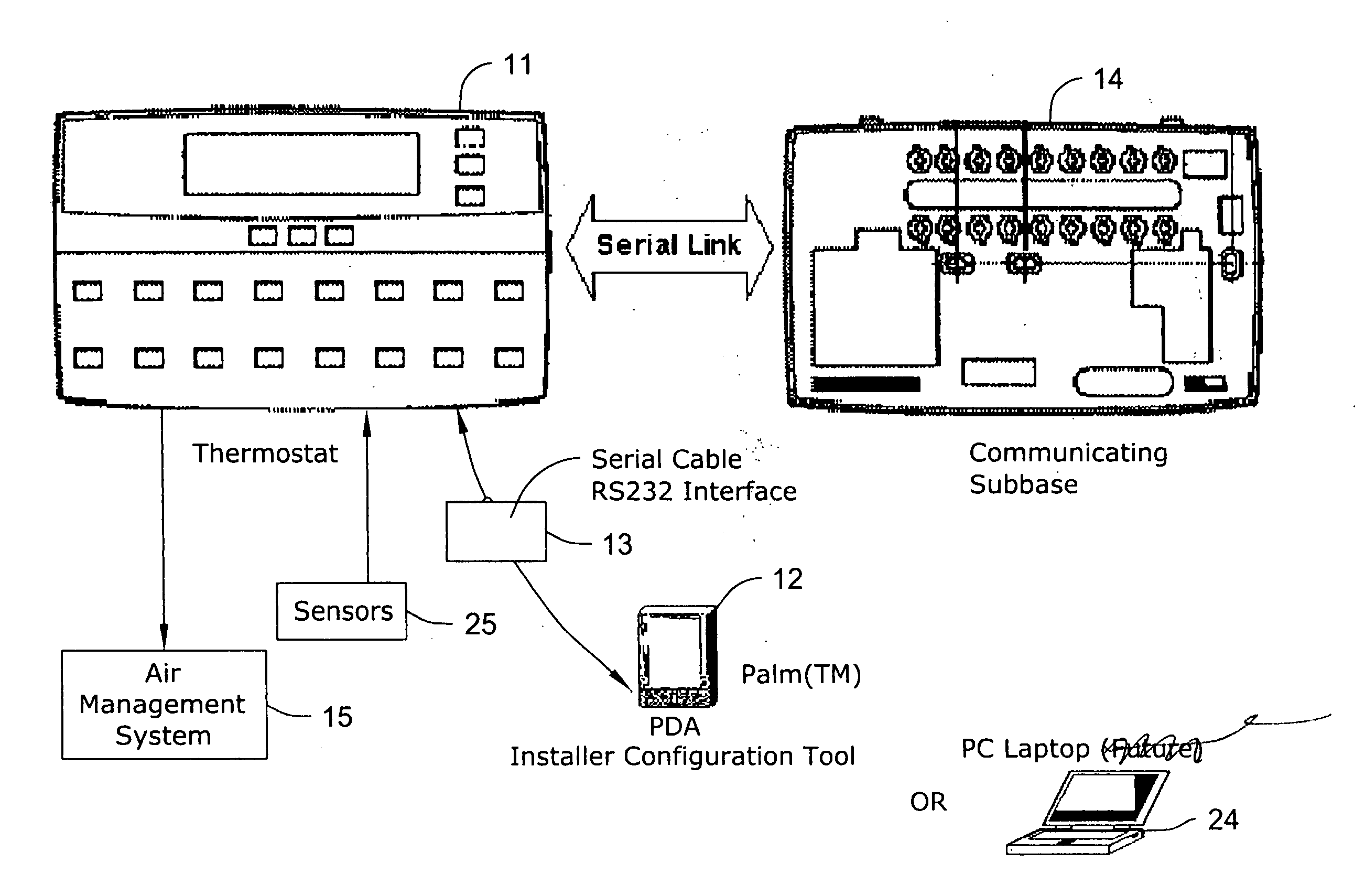

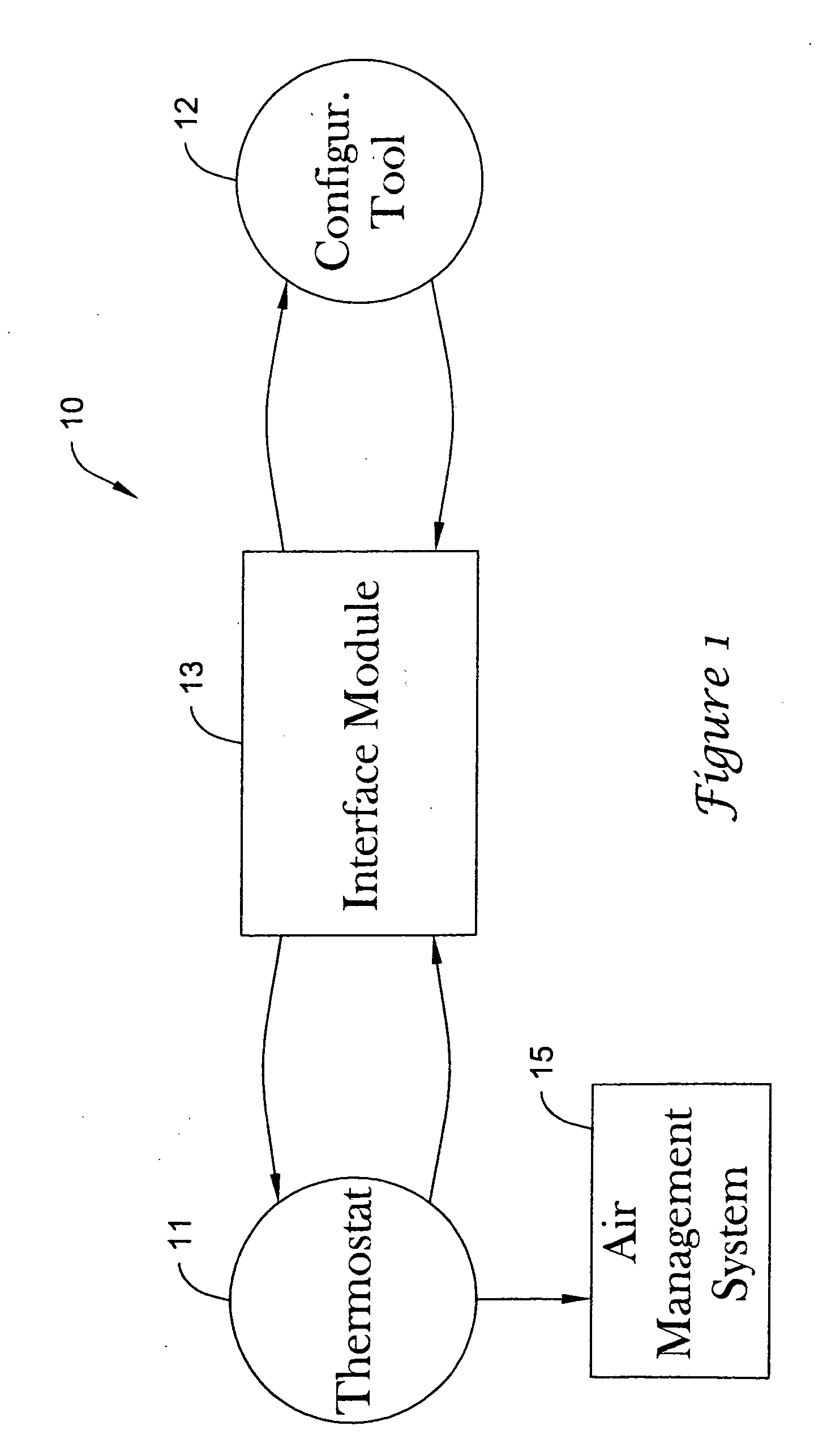

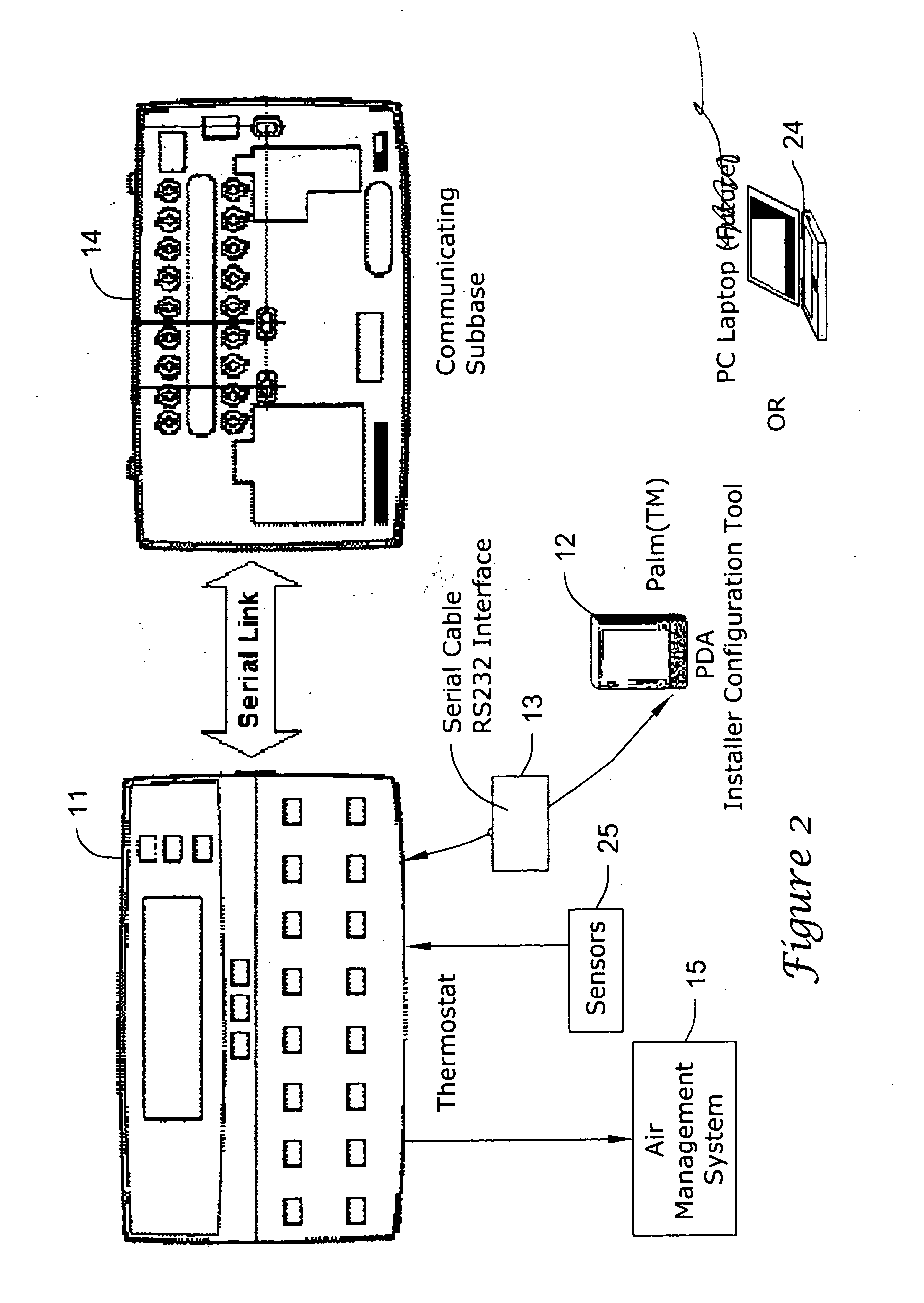

PDA diagnosis of thermostats

InactiveUS6851621B1Less expertiseActivity can be delayedMechanical apparatusStatic/dynamic balance measurementThermostatSet point

A system PDA-based on line diagnostics for automatically discovering a thermostat configuration, turning off normal controller delays, temporary overriding sensor inputs and set points, and verifying proper output action including the monitoring the discharge air temperature for the resulting temperature behavior based on the equipment stages activated. The diagnosis may include the testing of sensors, set points, the fan, cooling equipment, heating equipment and the wiring connecting the controls with the fan, and the cooling and heating equipment. Problems discovered may be reported, automatically recorded and the original operating parameters may be restored.

Owner:HONEYWELL INT INC

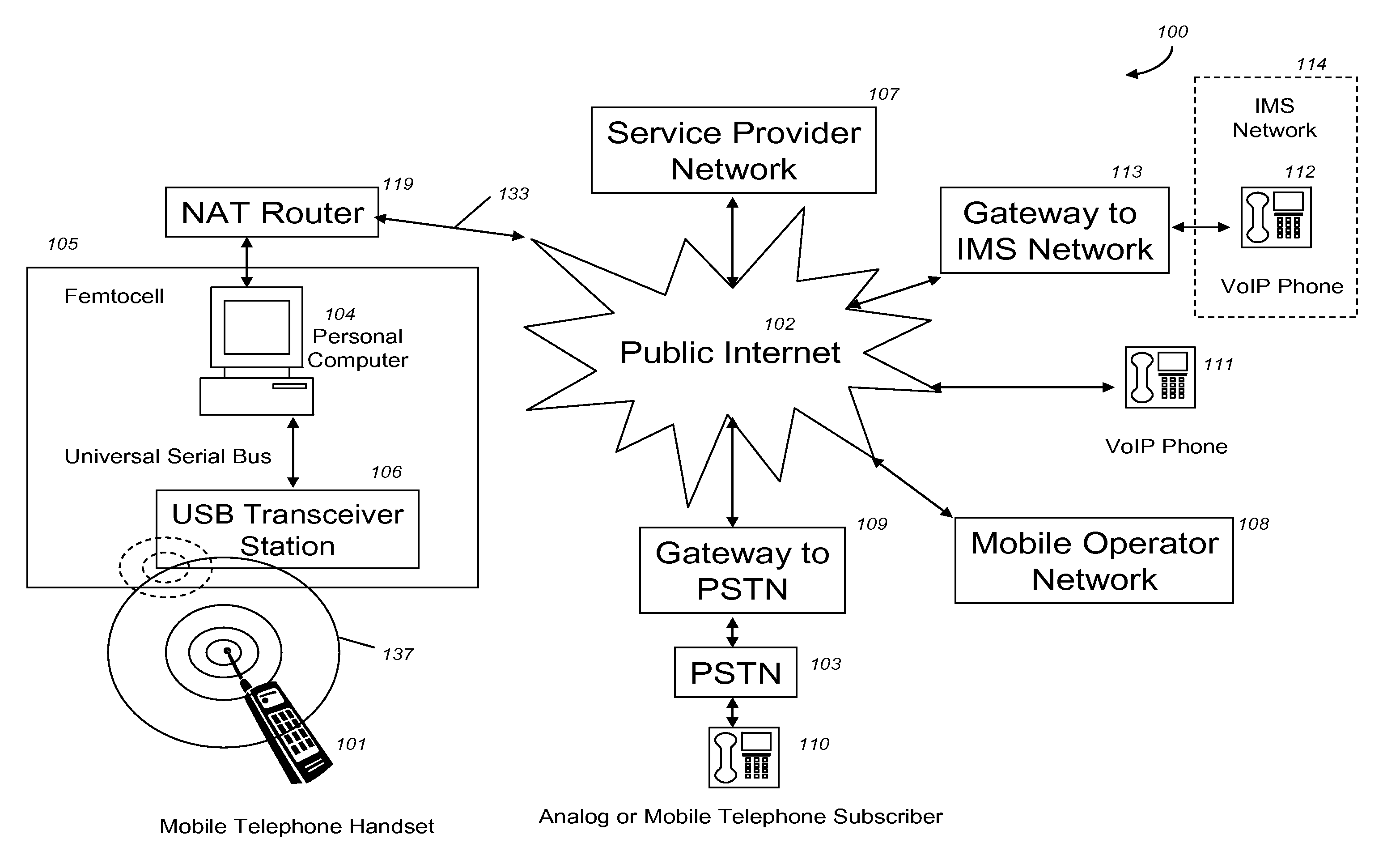

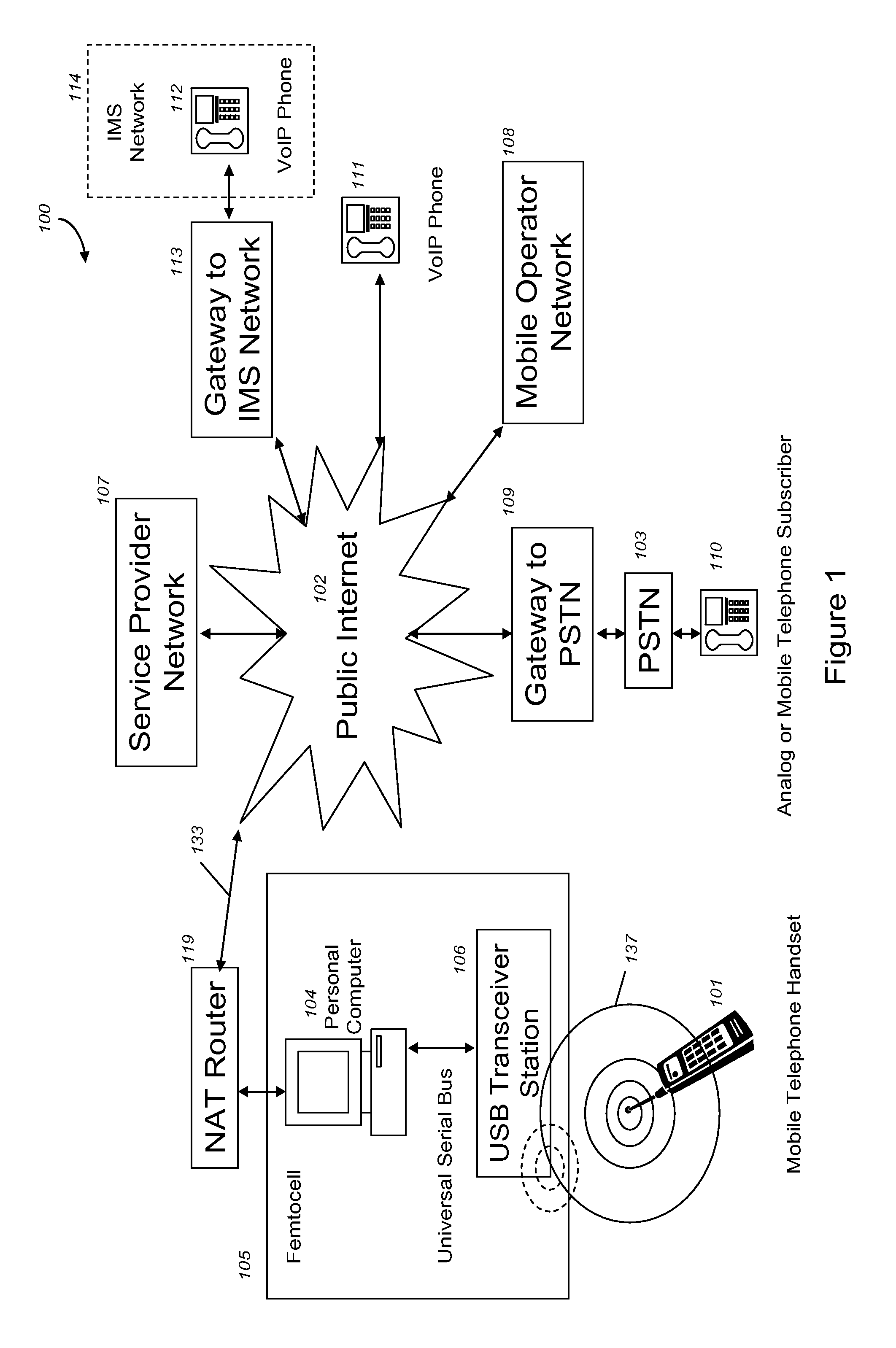

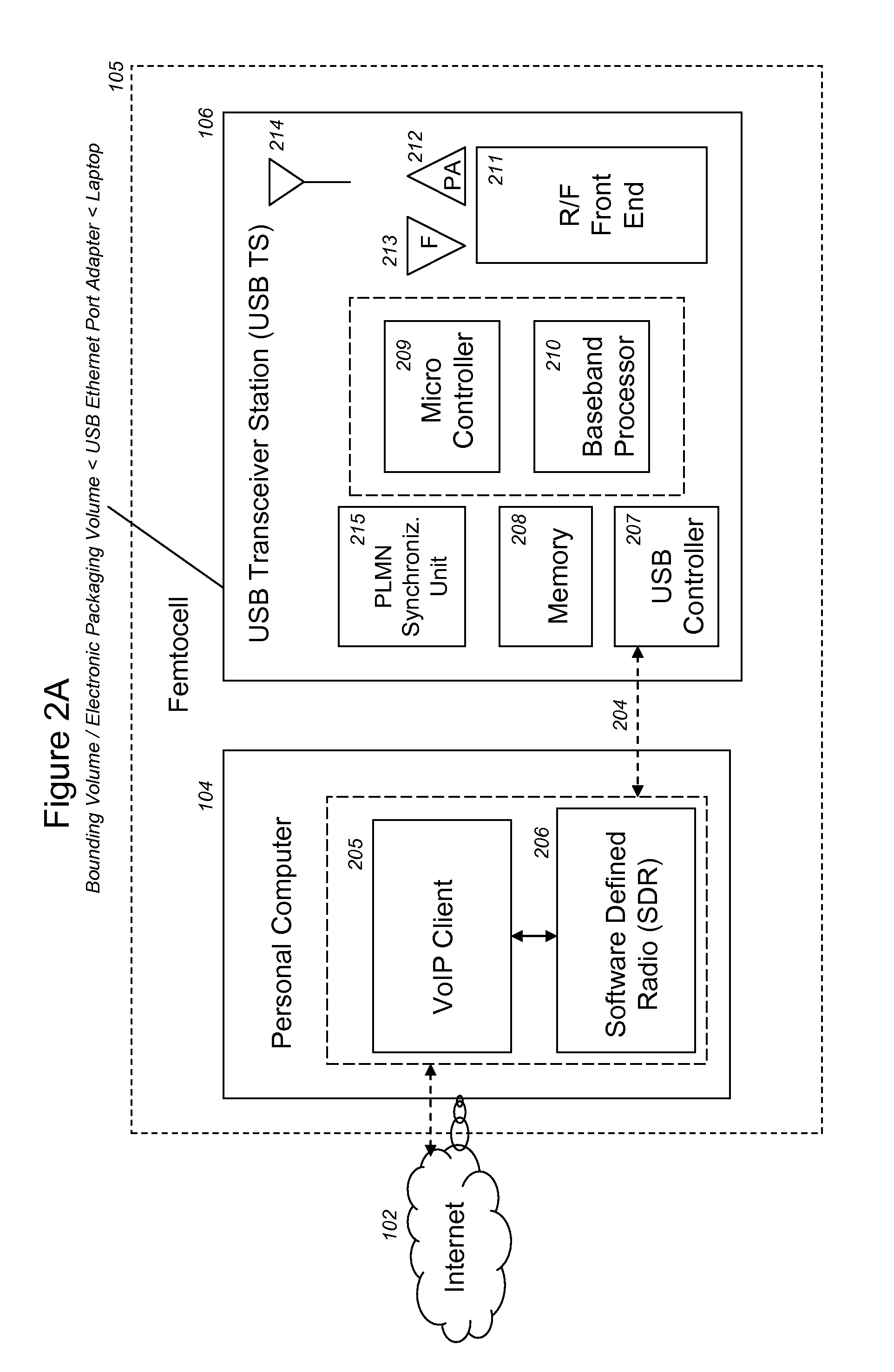

VoIP Enabled Femtocell with a USB Transceiver Station

InactiveUS20080244148A1High quality audioLow costNetwork topologiesSubstation equipmentMicrocontrollerRF front end

Telephone calls between a mobile station (MS) and the mobile network or PSTN are routed through the Internet via VoIP using a femtocell, as opposed to the traditional macrocellular network. The femtocell can comprise a USB Transceiver Station that is connected to a personal computer through a universal serial bus port, which provides both power and a multi-megabit per second connection between the personal computer and the USB transceiver station. The USB transceiver station can comprise a microcontroller to manage signaling between the RF front end / baseband processor and the personal computer, as well as a precise timing mechanism to assist the synchronization of femtocell timing with the surrounding macrocellular network, if it is present. The USB transceiver station can have a compact form factor that that facilitates a high degree of portability by the subscriber, such as being readily attachable to their keychain.

Owner:SMALL CELL INNOVATIONS

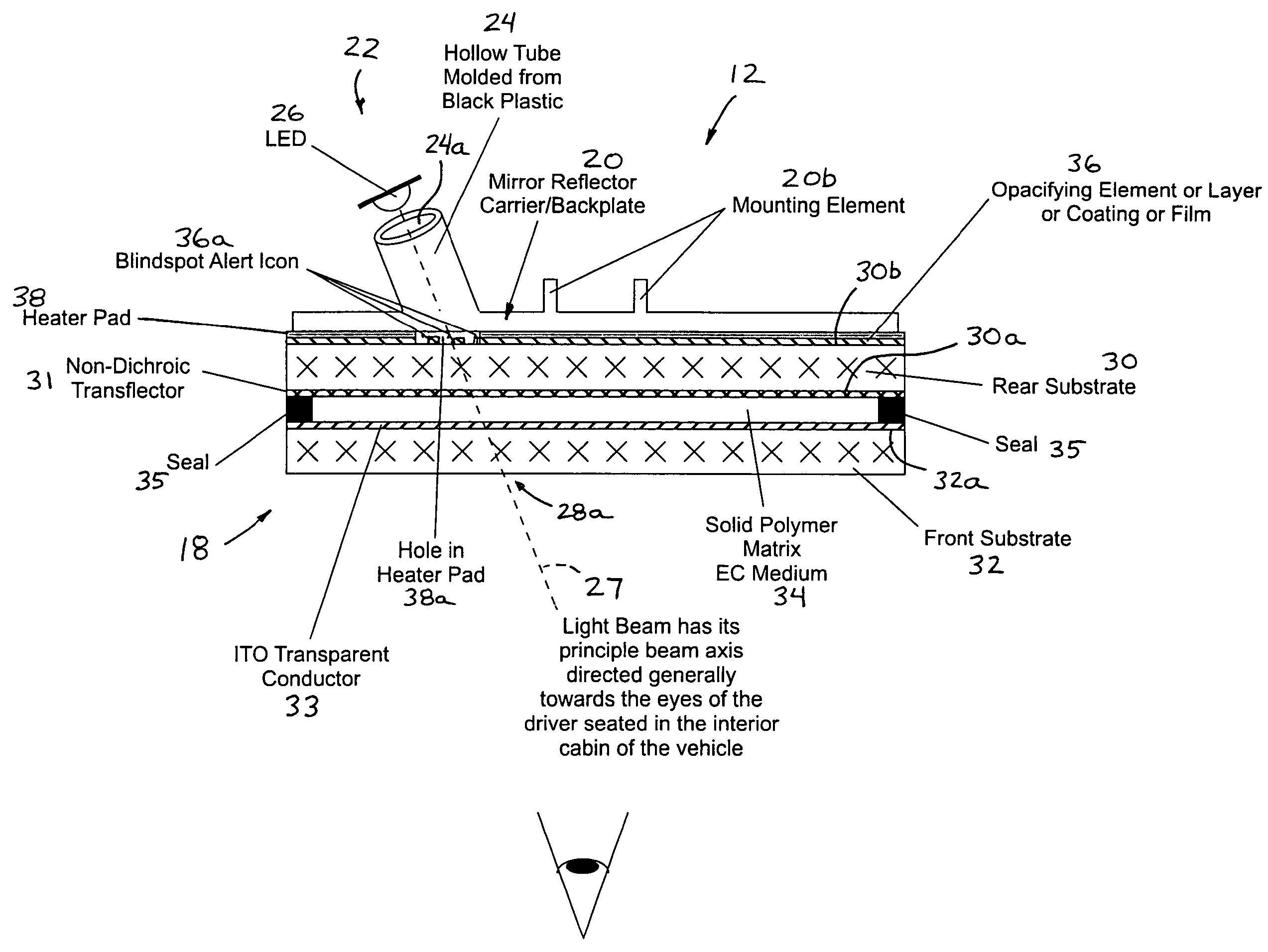

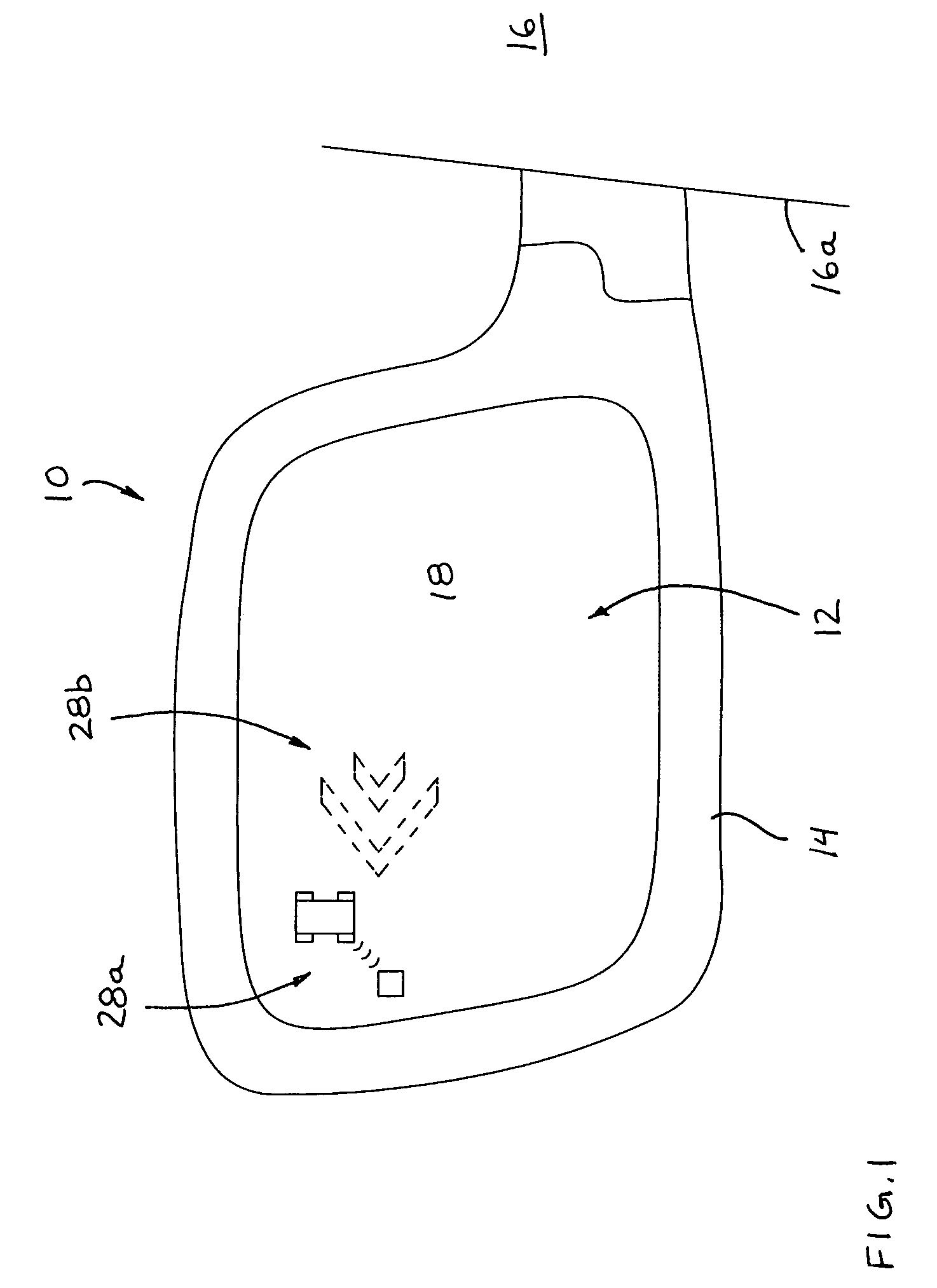

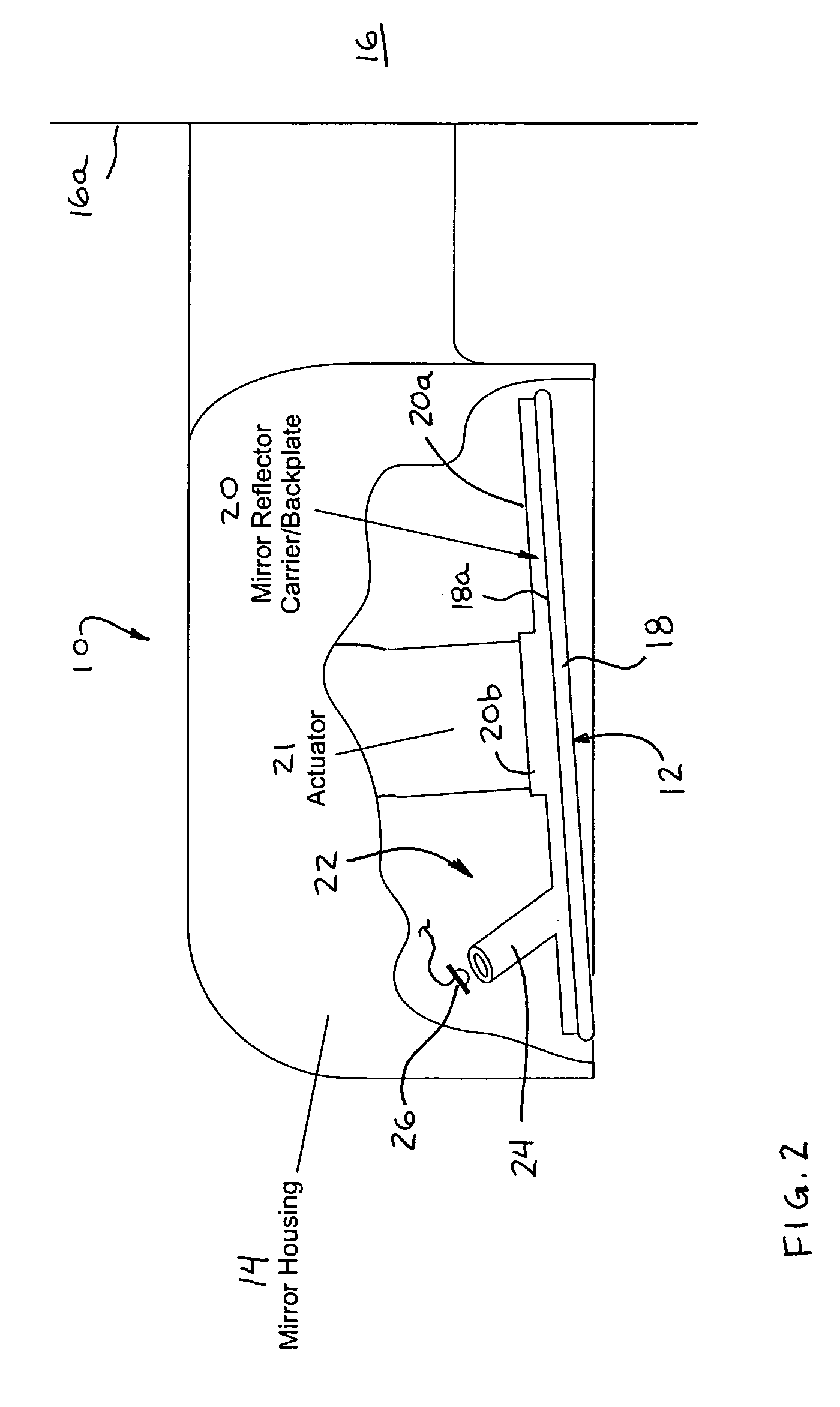

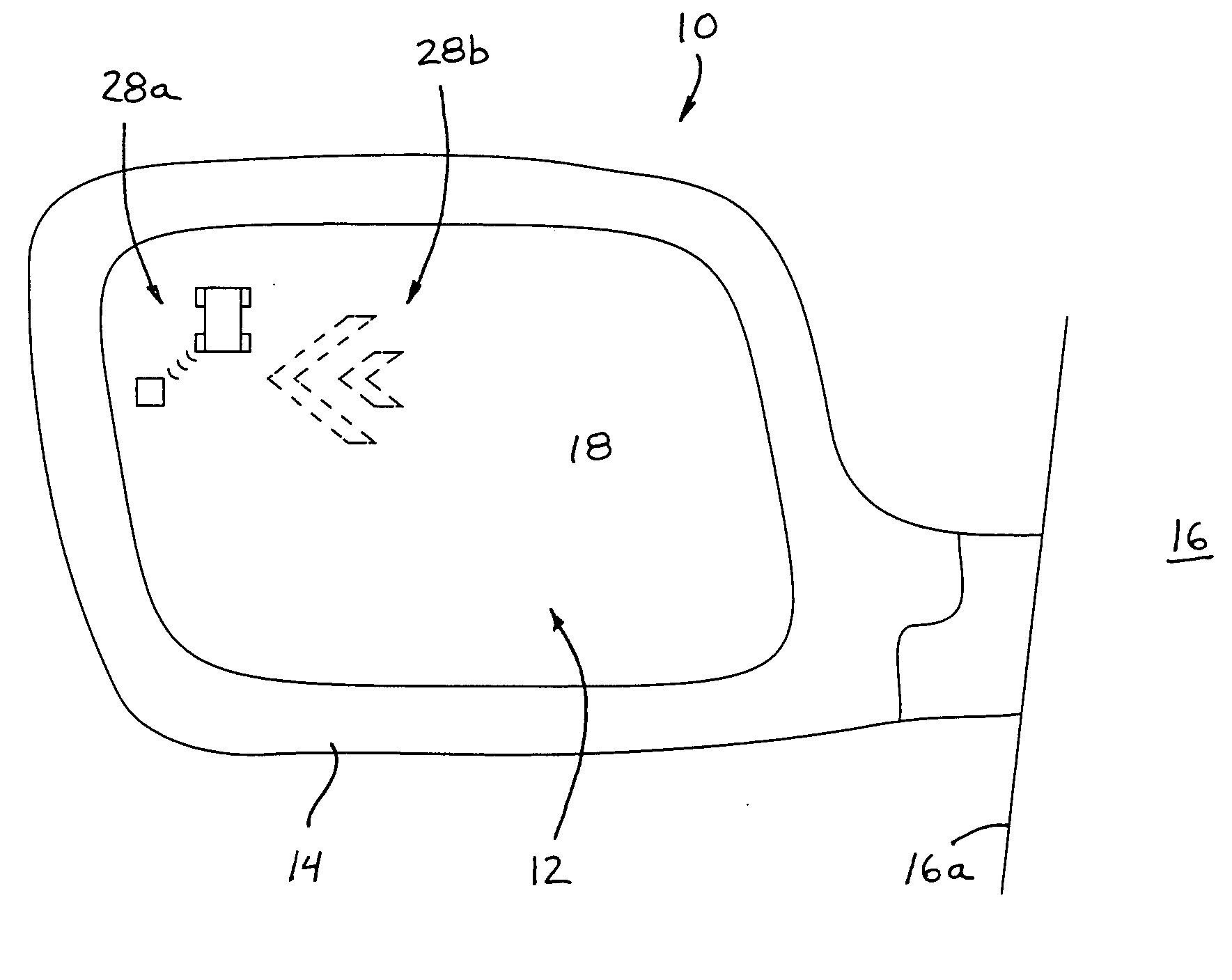

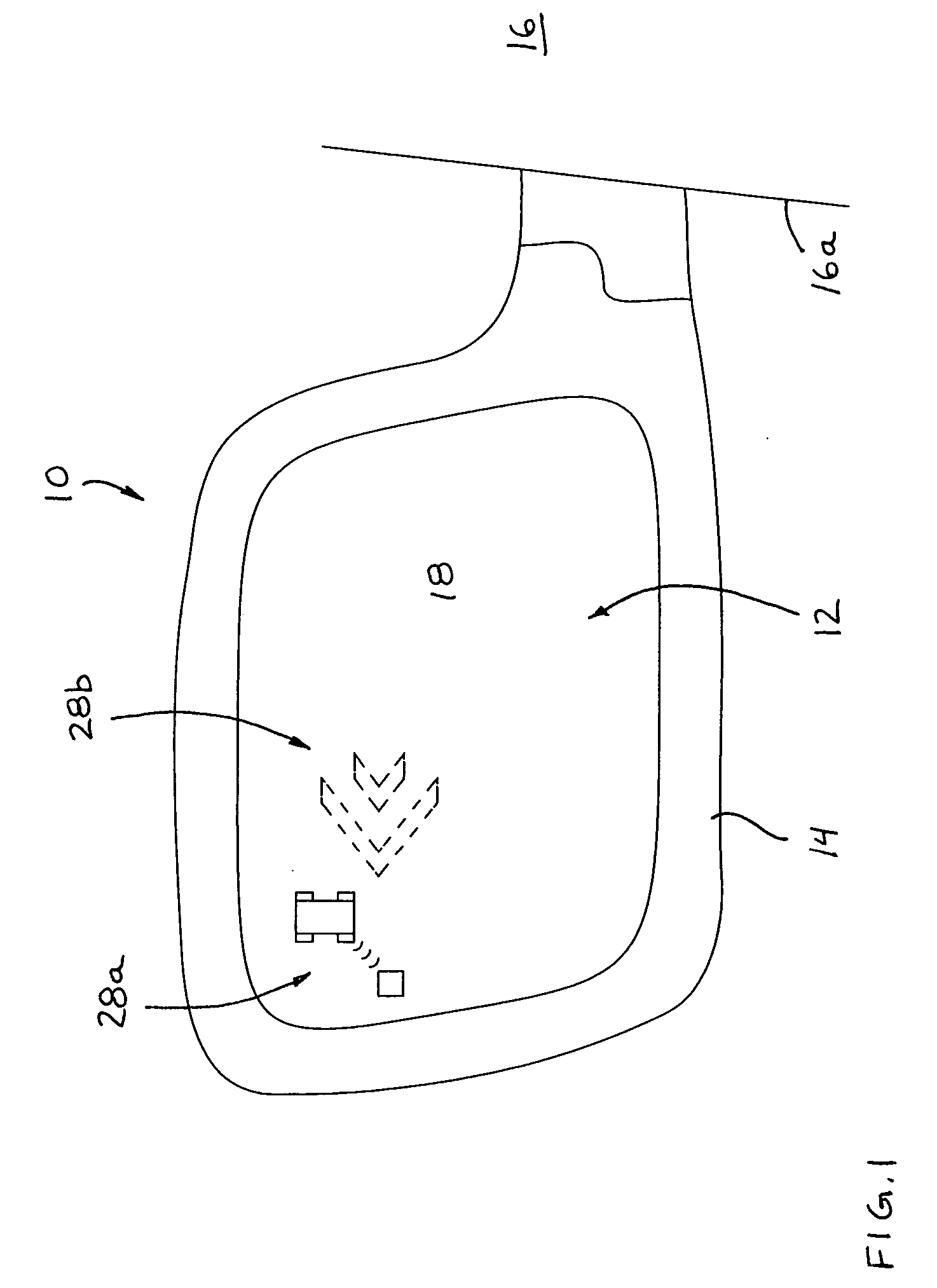

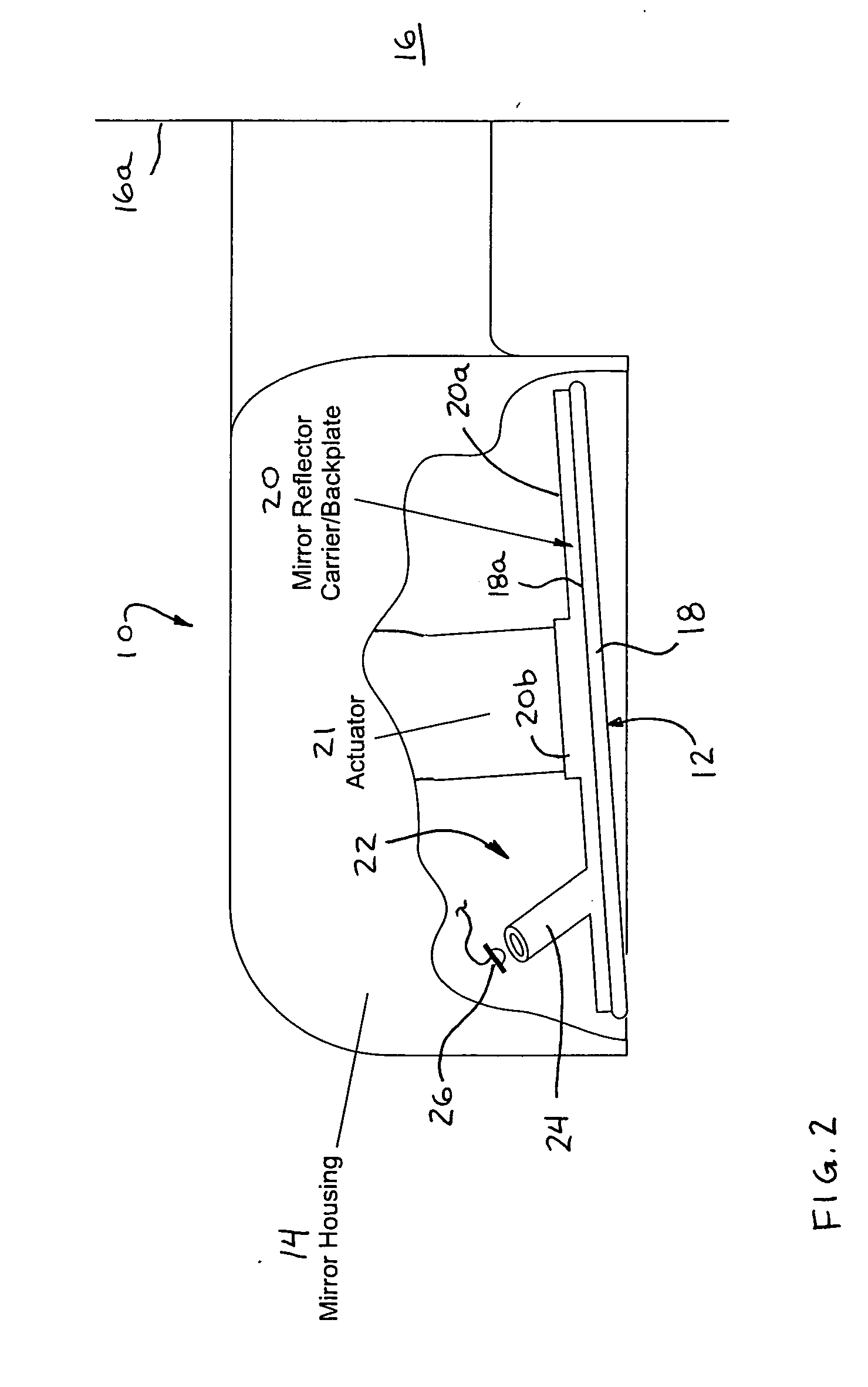

Display device for exterior rearview mirror

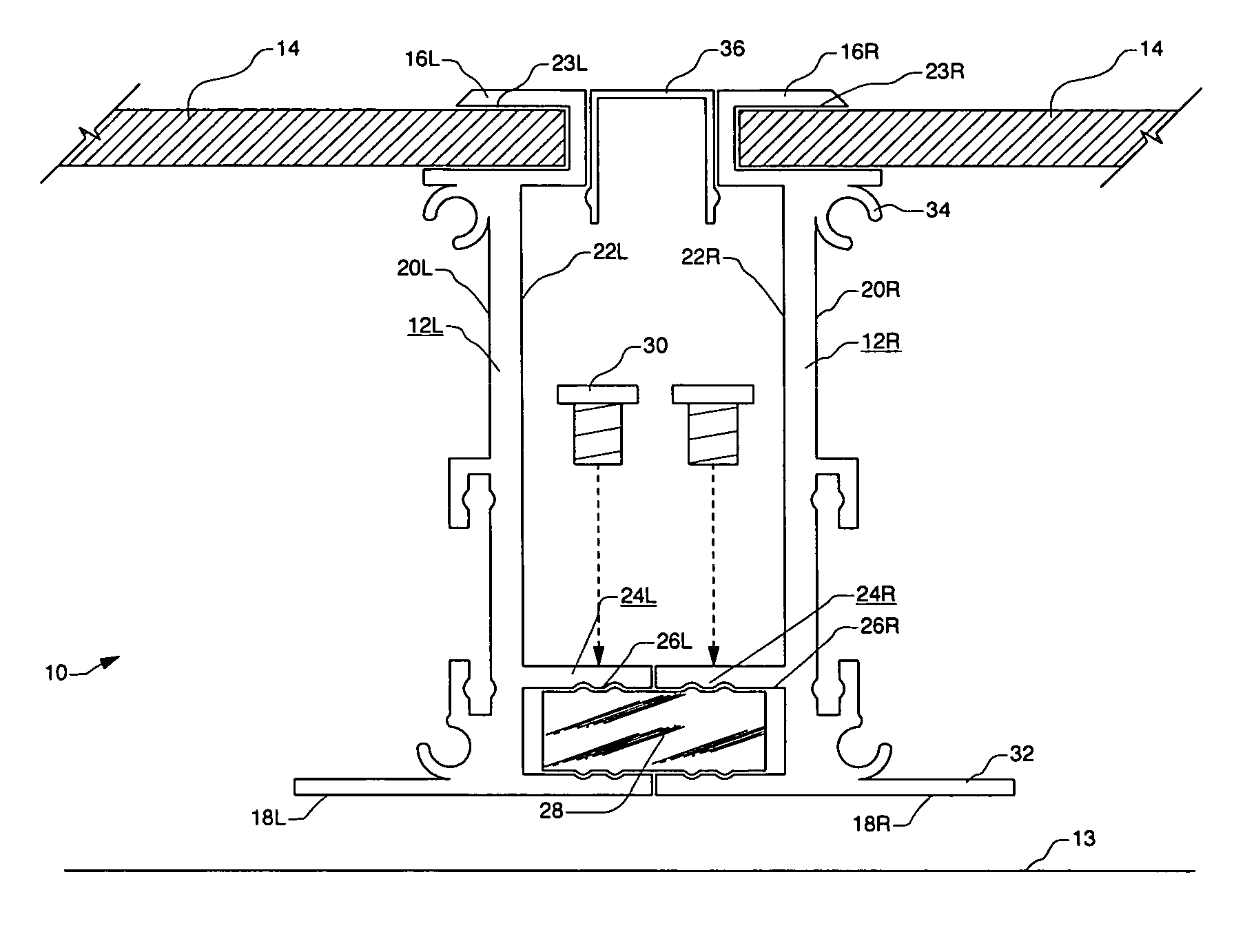

InactiveUS7581859B2Good adhesionEasy to assembleOptical signallingOptical viewingDisplay deviceOptoelectronics

An exterior mirror sub-assembly includes a reflective element, a back plate, and a display element having a light source that is activatable to emit light. The display element attaches to a display receiving portion of the back plate and the light source is activatable to emit light through the display receiving portion. The display receiving portion may be configured to orient the display element at a predetermined angle so that light exiting the display element when the light source is activated may be directed (a) generally away from the vehicle when the mirror assembly is mounted to the vehicle so as to be principally viewed by drivers of other vehicles or (b) generally toward the driver of the vehicle when the mirror assembly is mounted to the vehicle so as to be principally viewed by the driver of the host vehicle.

Owner:MAGNA MIRRORS OF AMERICA INC

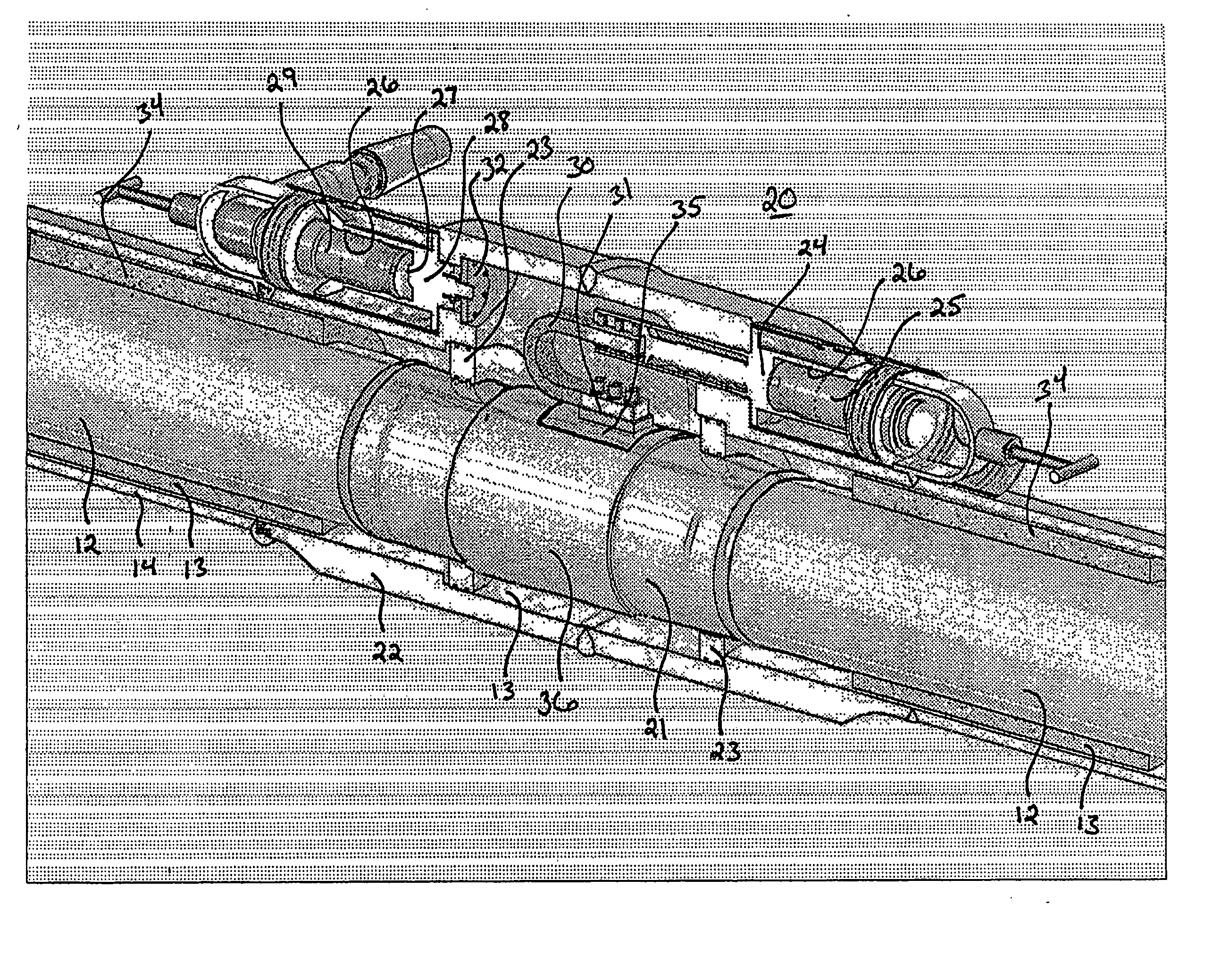

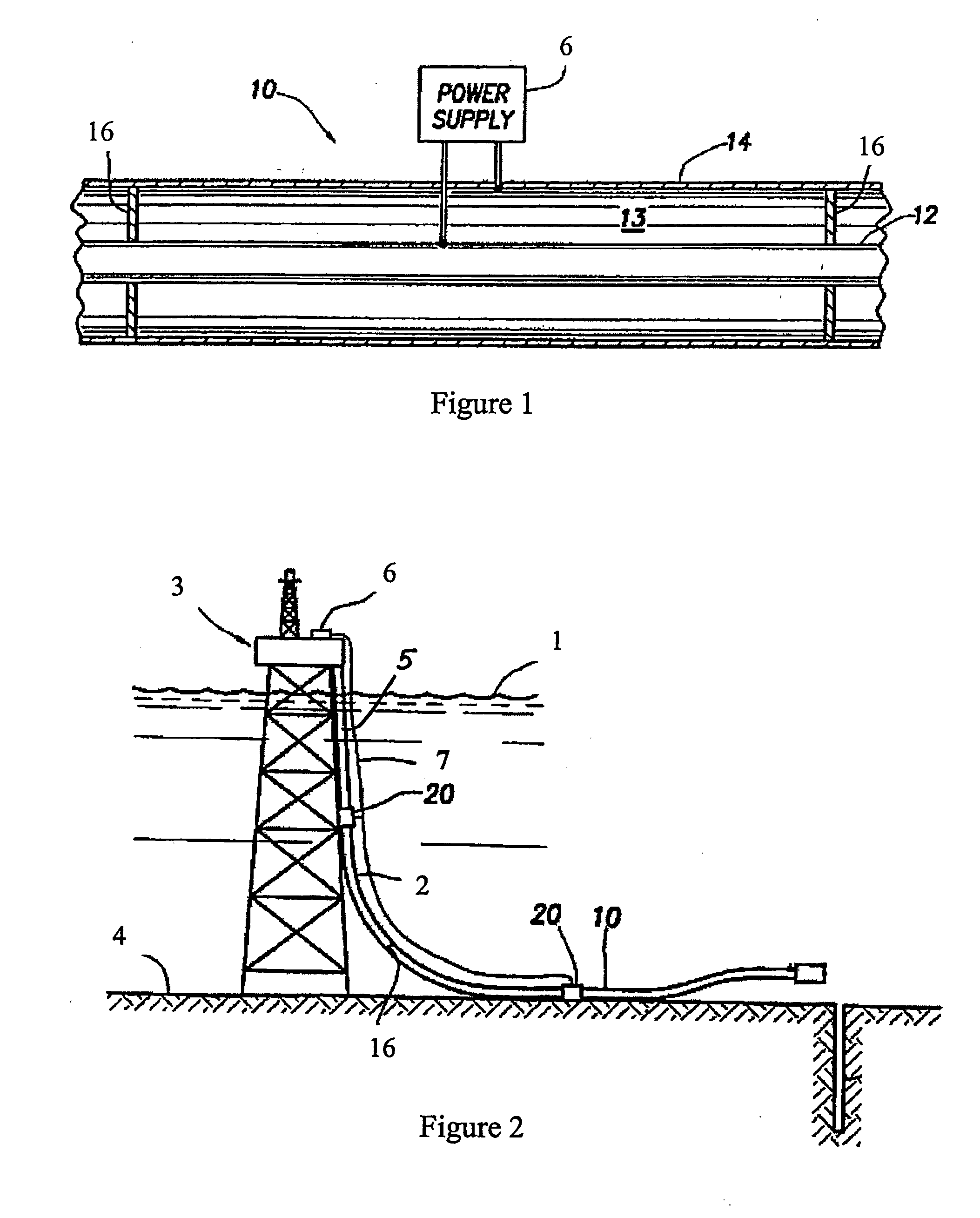

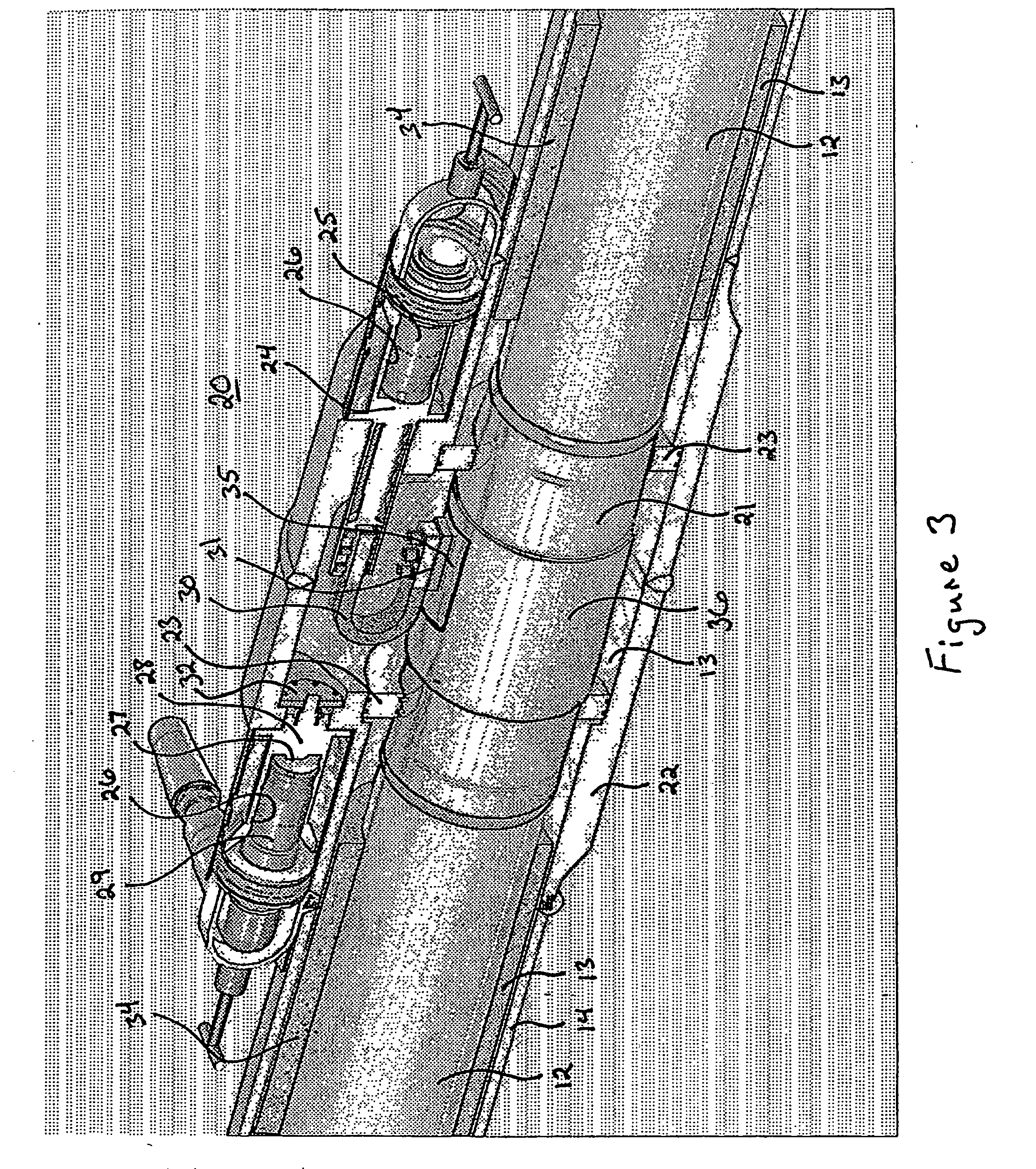

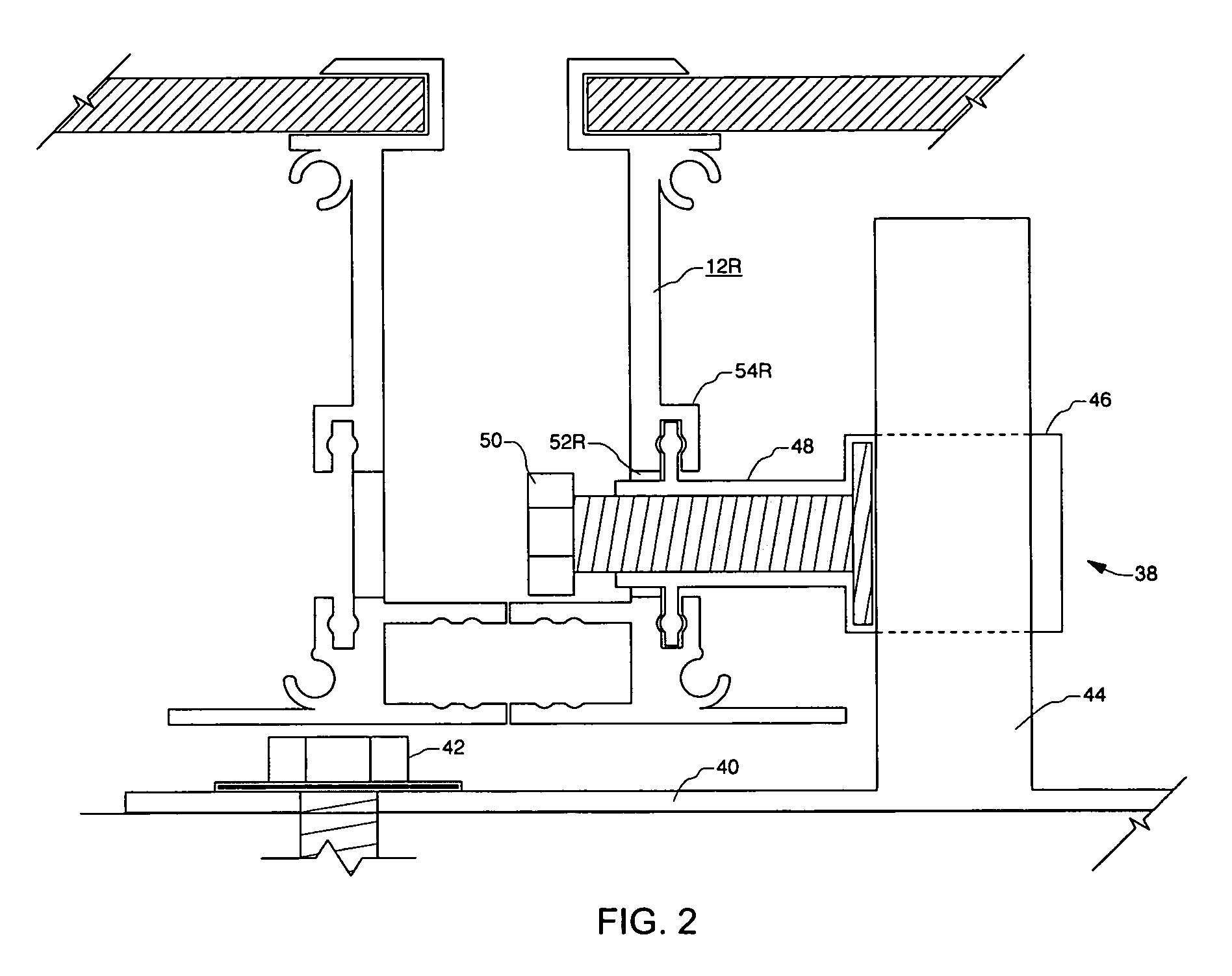

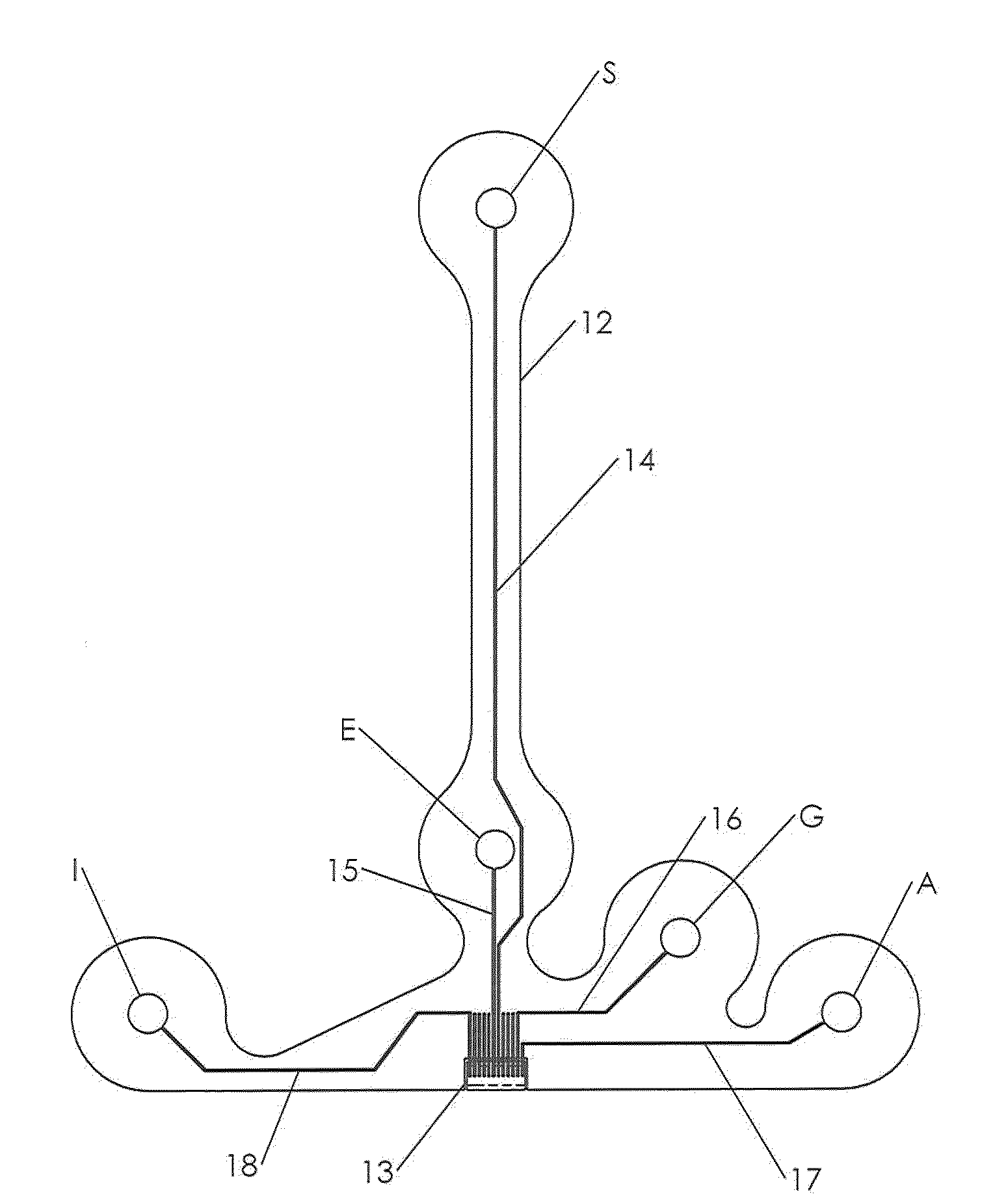

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS20050054228A1Increase axial loadAvoid local accumulationPipe heating/coolingPipe-jointsElectricityElectrical conductor

For heating a pipe-in-pipe pipeline with power provided through an electric cable, mid-line connector is provided including: a connector housing joinable to the outer pipe of the pipeline; a blank pipe positioned within the connector housing and joinable to the inner pipe of the pipeline; at least one pocket mounted in the connector housing, wherein the cable is mateable with the at least one pocket; a blank pipe conductor electrically coupled between the at least one pocket and the blank pipe; and an outer pipe conductor electrically coupled between the at least one pocket and the outer pipe.

Owner:SHELL OIL CO

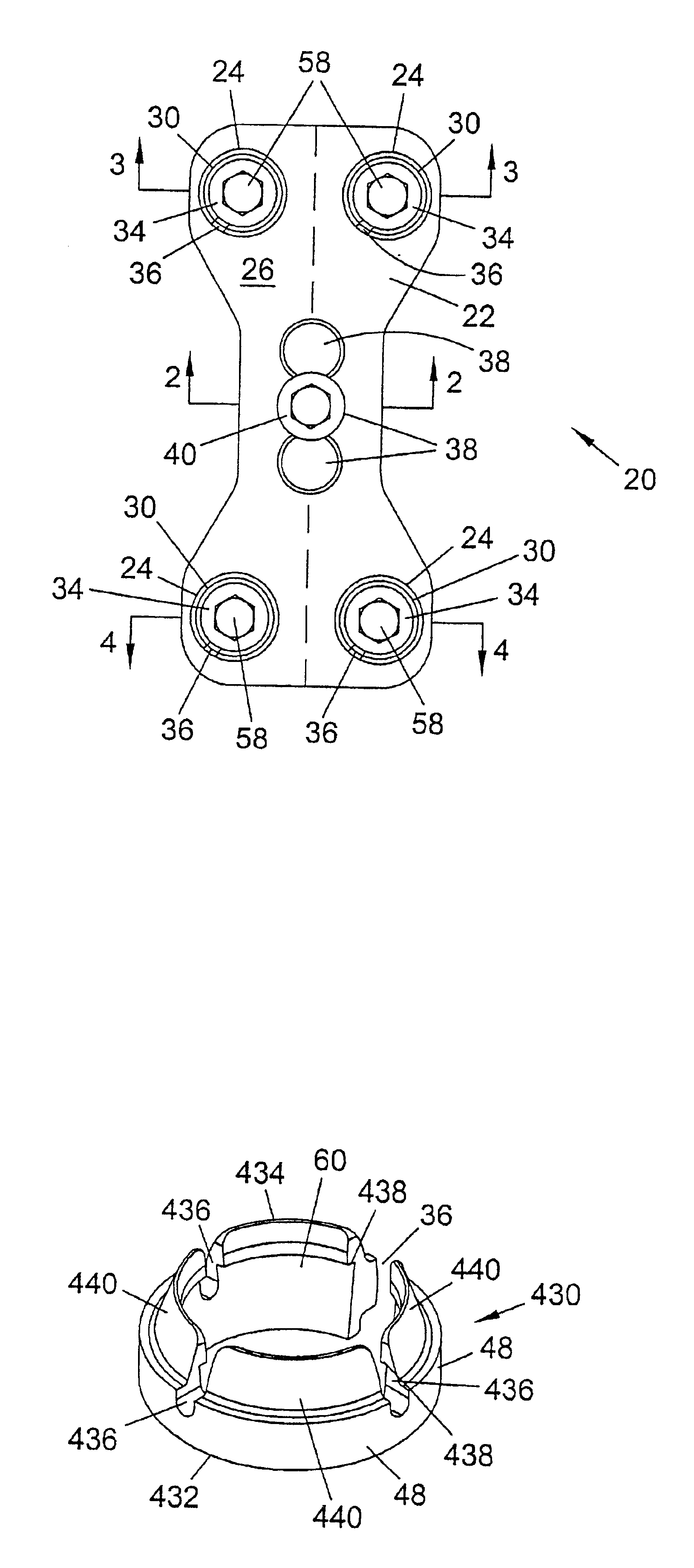

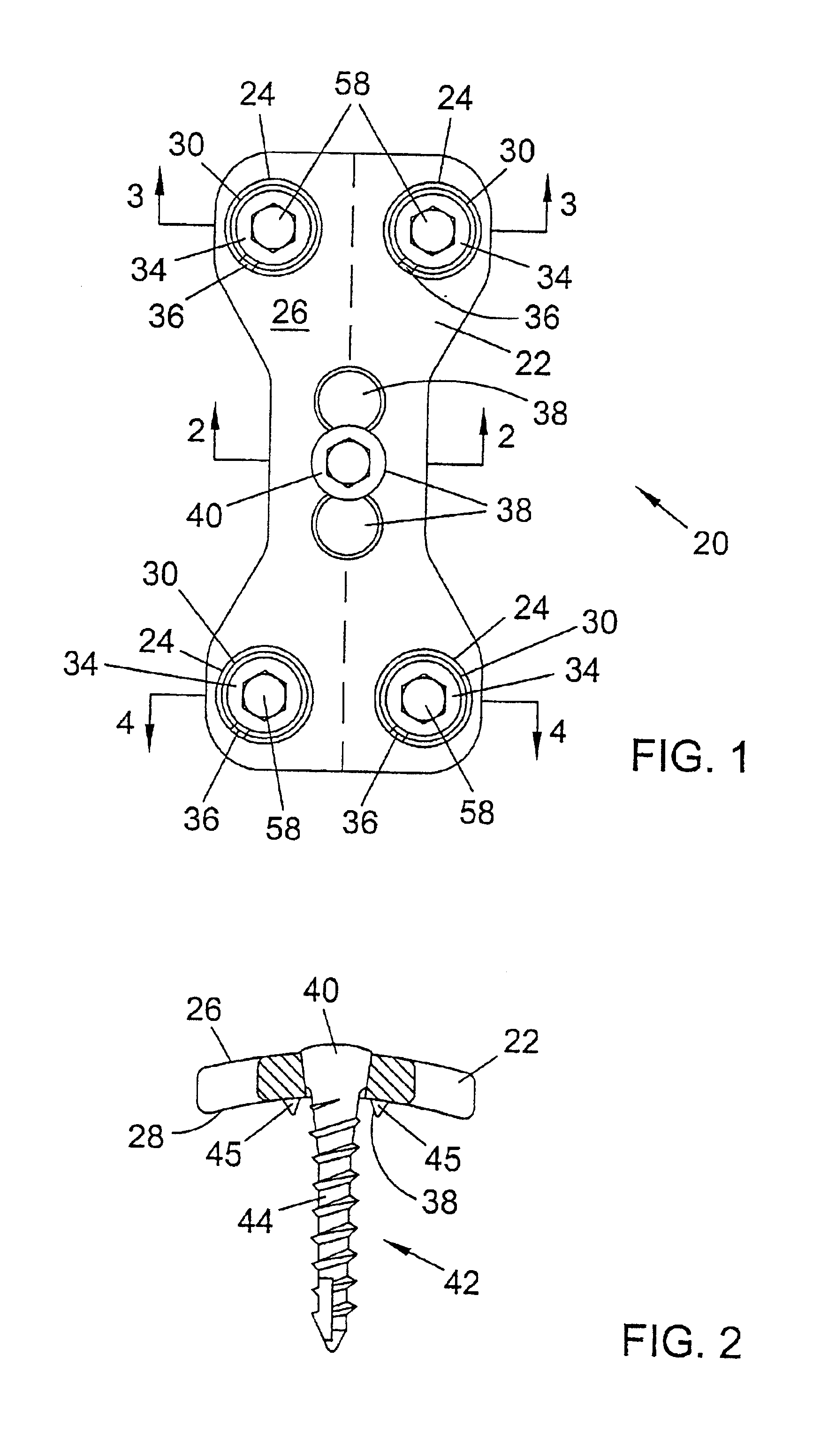

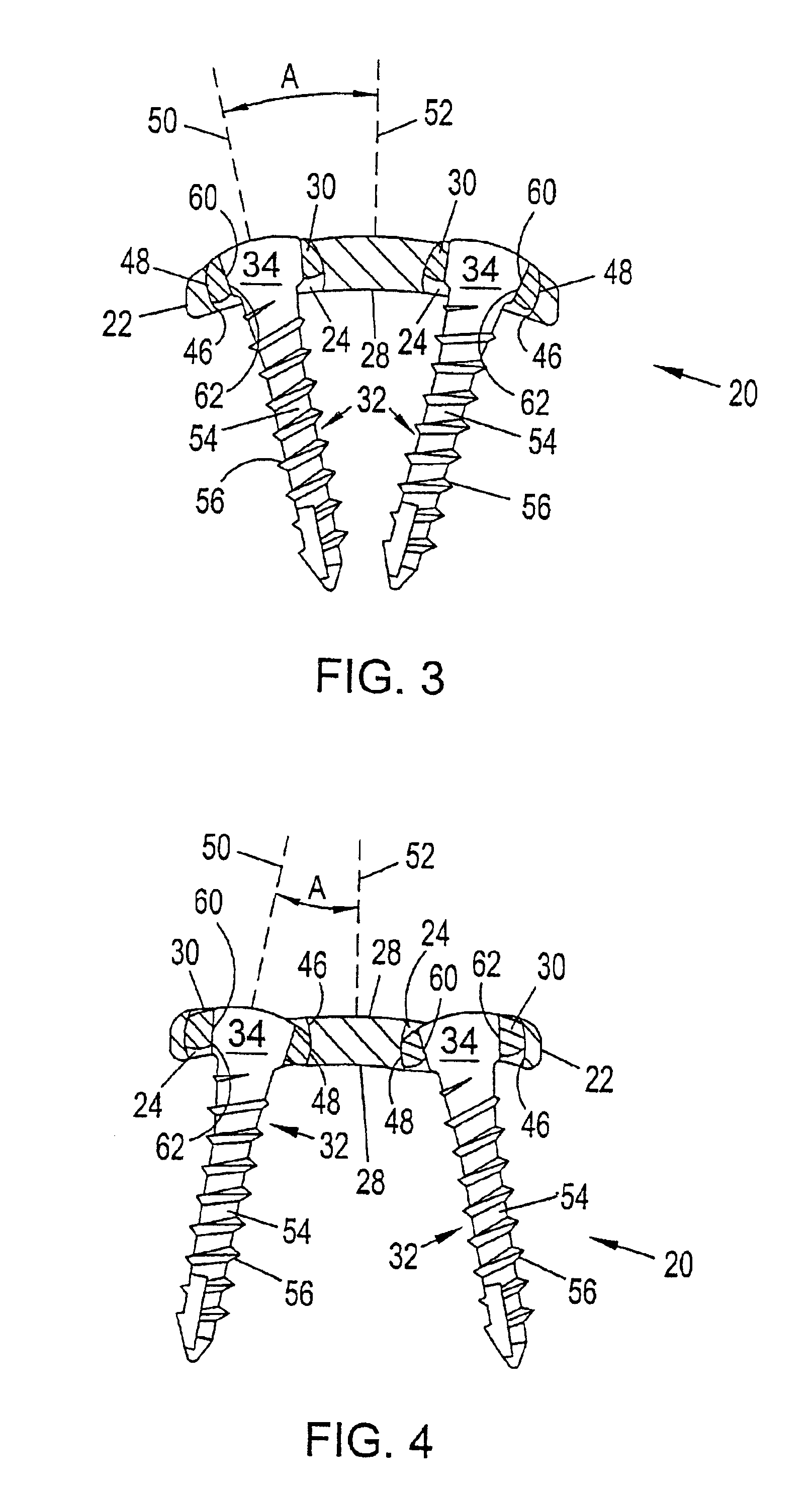

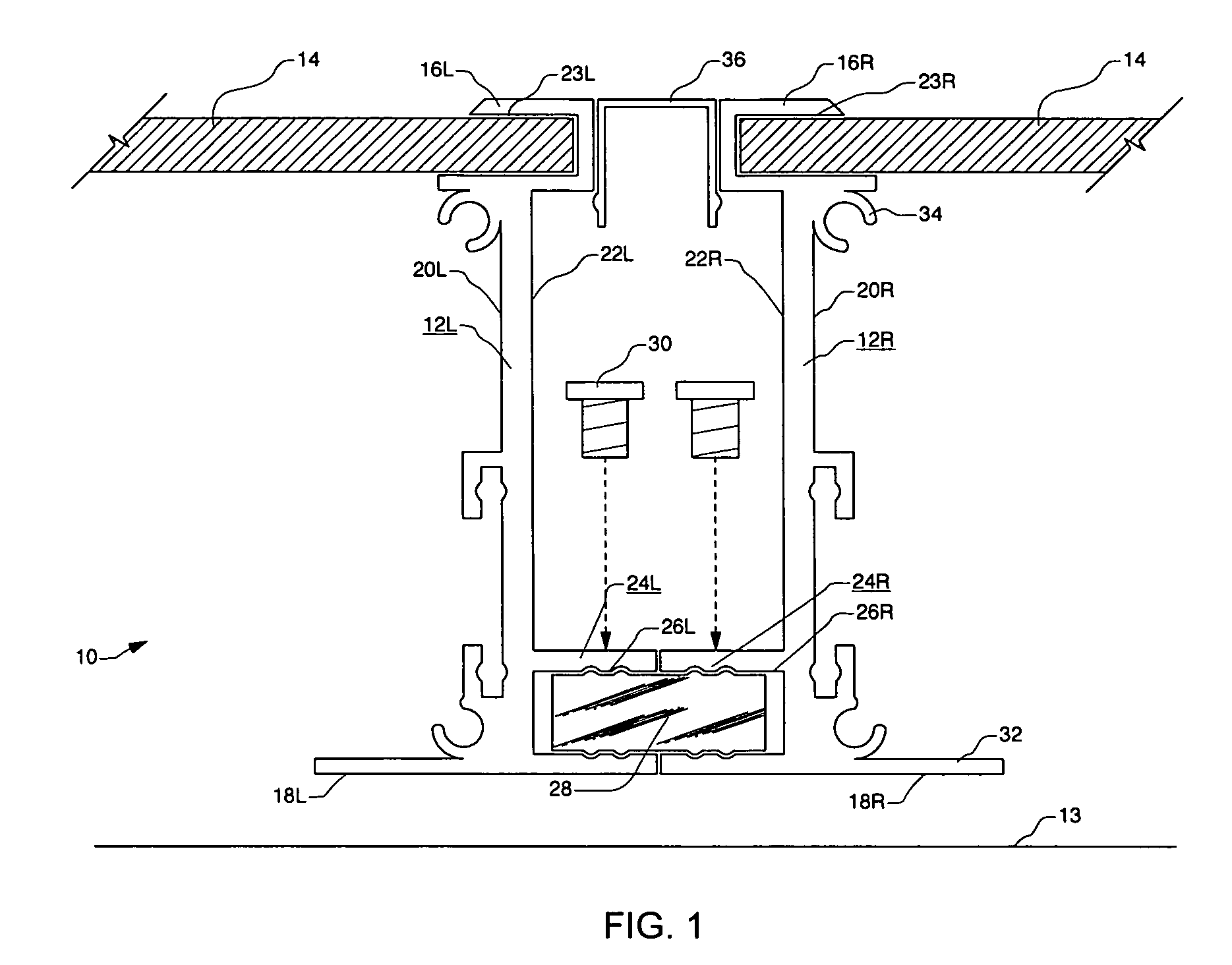

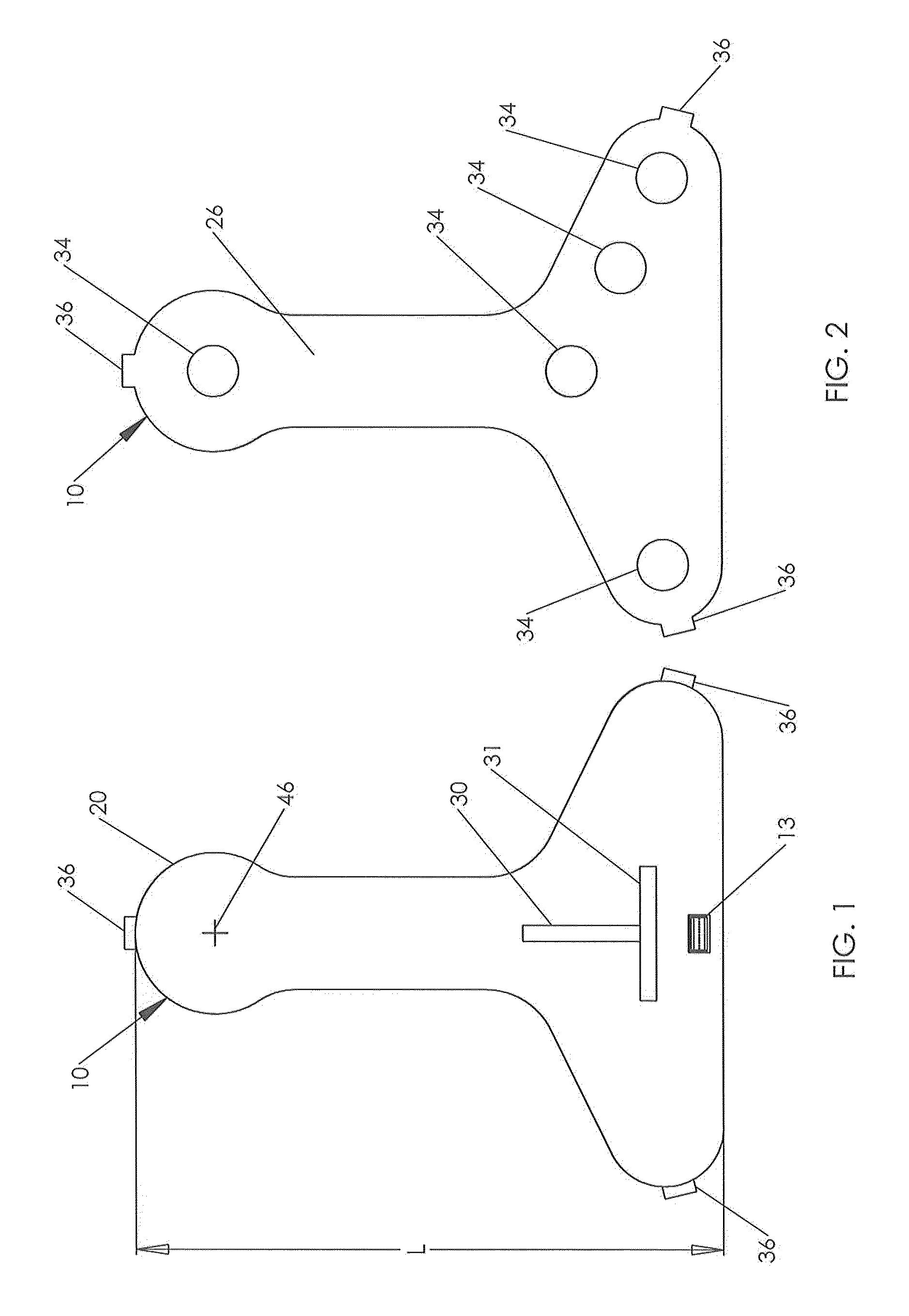

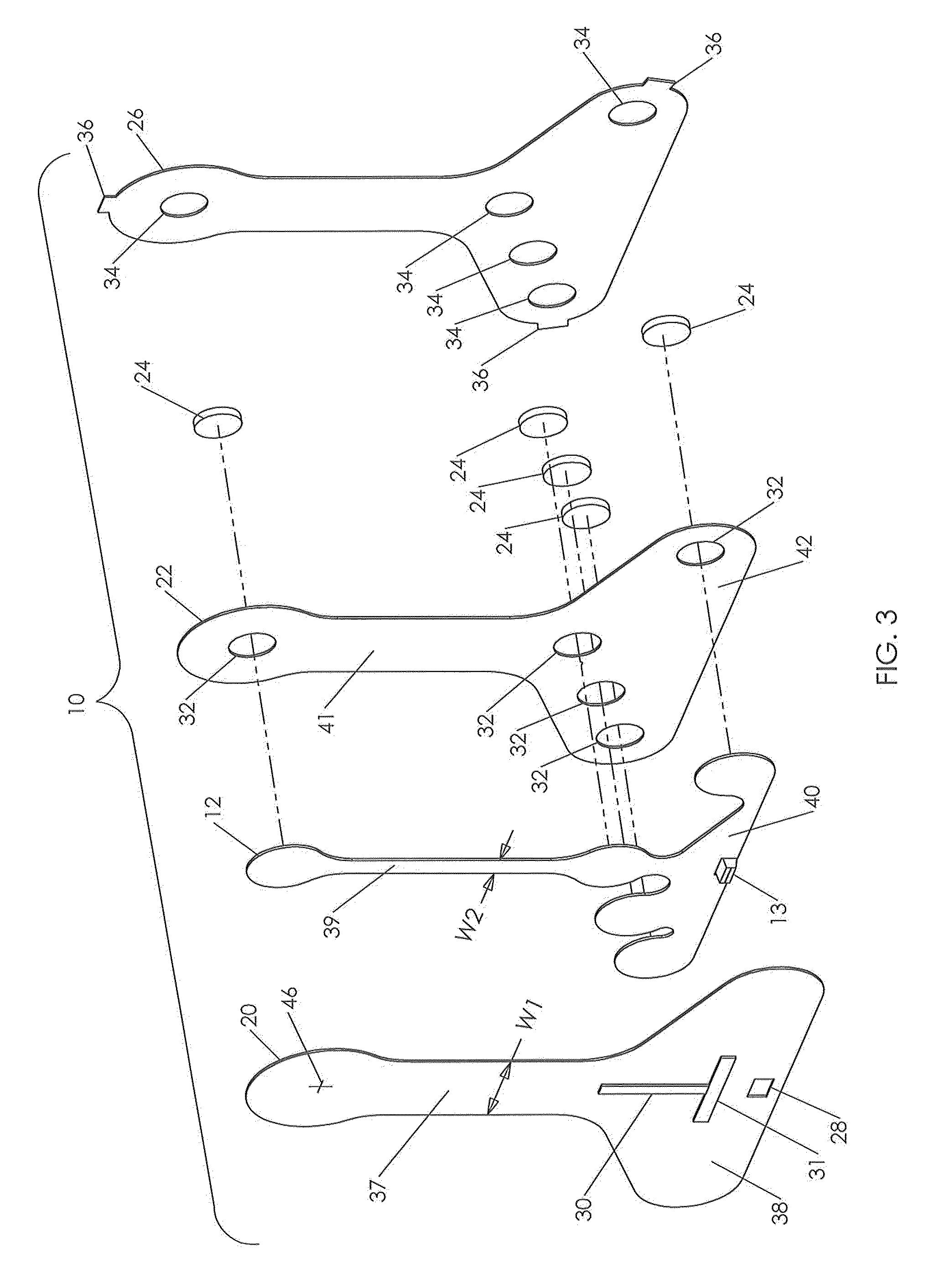

System and method for stabilizing the human spine with a bone plate

InactiveUS6964664B2Reduce risk of backoutFirmly connectedInternal osteosythesisFastenersEngineeringCoupling system

A spinal plate system and method for fixation of the human spine is provided. In an embodiment, the spinal fixation system includes a plate, a coupling member, a locking system for substantially locking the coupling member in a desired position, and an anchoring system to secure the coupling member in the locking system. The plate may have a hole that allows the coupling member to couple the plate with a bone. At least a portion of the coupling member may swivel in the hole so that a bottom end of the member may extend at a plurality of angles substantially oblique to the plate. The locking system may lock the coupling member in desired positions relative to the plate. The anchoring system may secure the coupling member in the locking system to inhibit the coupling system from detaching from the locking system when stressed. An assembly tool may be used to engage and disengage the anchoring system during the installation or removal of the spinal fixation system.

Owner:ZIMMER SPINE INC

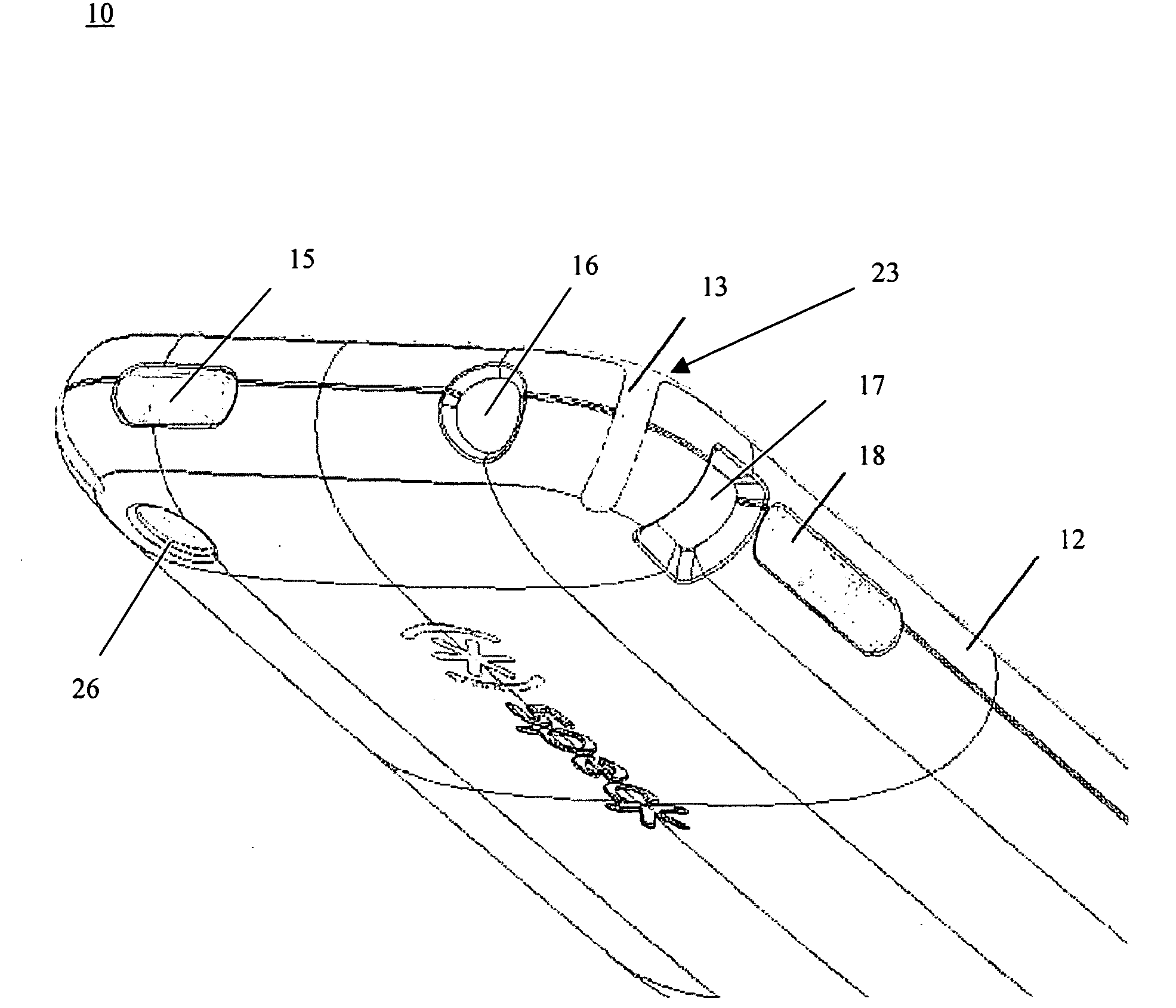

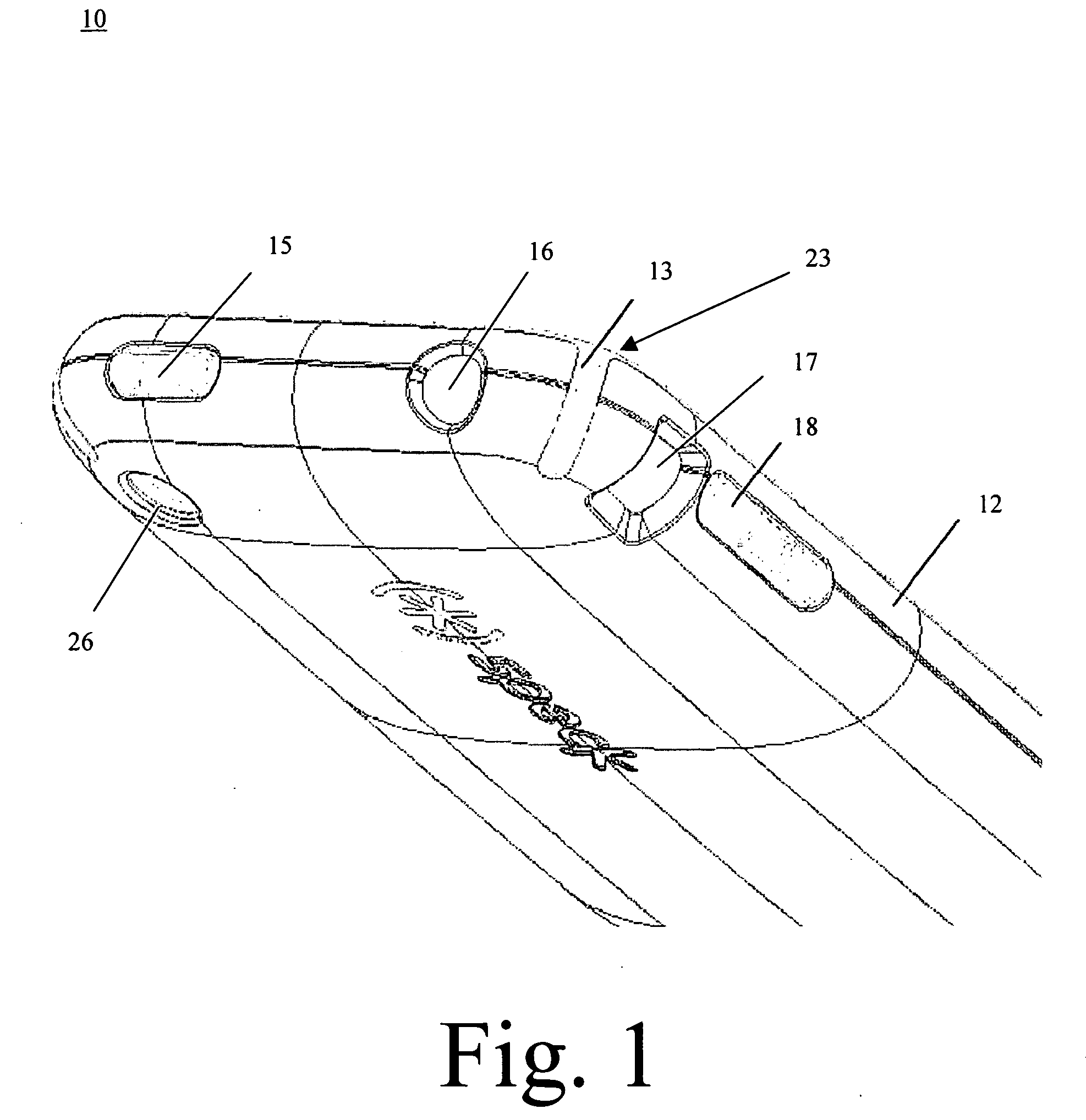

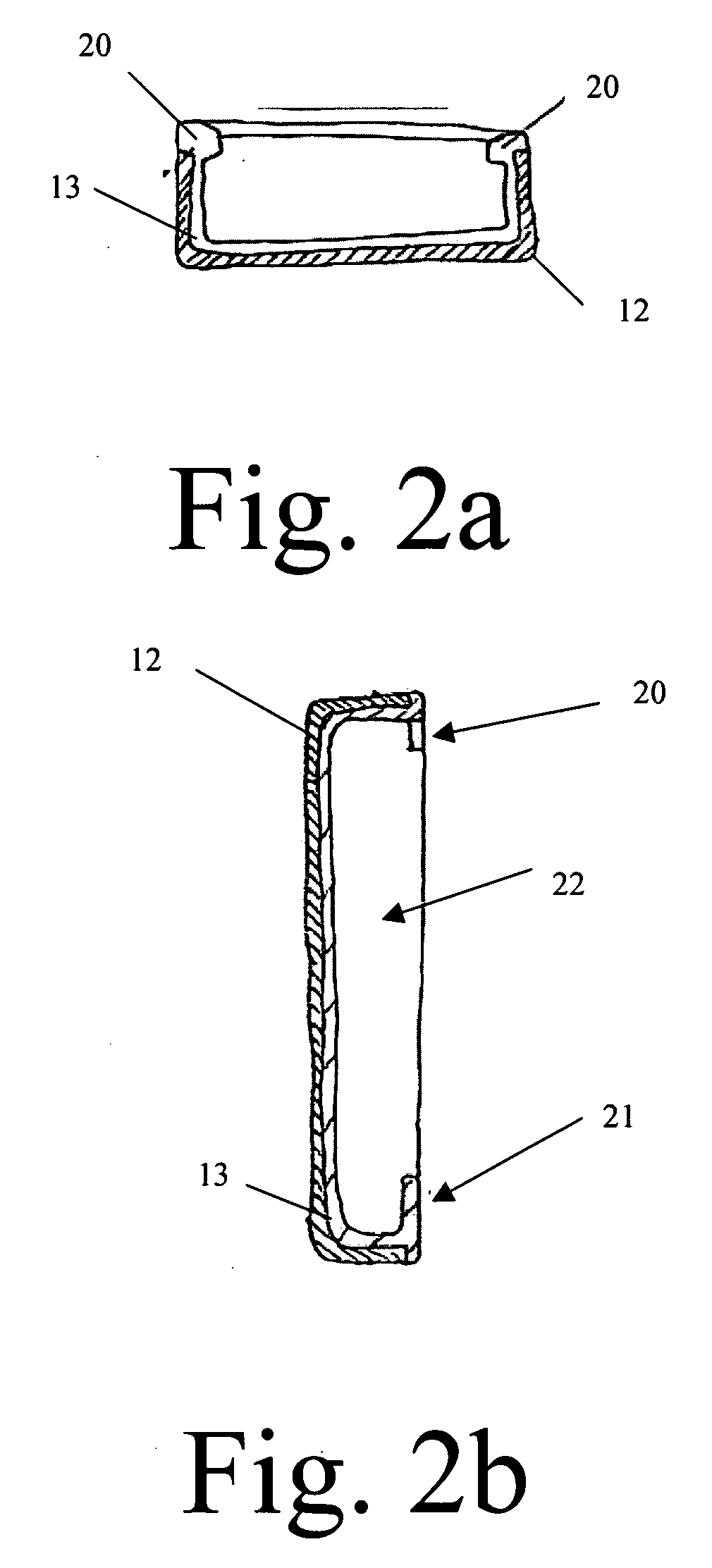

One Piece Co-formed Exterior Hard Shell Case with an Elastomeric Liner for Mobile Electronic Devices

ActiveUS20100203931A1Maximum protectionReduce coefficient of frictionTravelling carriersHoldersElastomerMechanical engineering

A one-piece co-formed exterior hard shell case with an elastomeric liner formed on the interior of the exterior hard shell for mobile electronic devices. This hard protective exterior shell allows the device maximum protection from impacts with sharp objects while the interior elastomeric portion that provides shock protection for the device from impacts. The exterior hard shell part is formed to fit the device closely with a small offset from the devices surface. The exterior hard shell raps around the edges of the device. To allow the shell to be able to be mounted on the device the corners of the hard shell are cut open. This allows each sidewall to flex away when a device is inserted and snap back once it is in place. The elastomeric material fills in the gaps created at the corners of the exterior hard shell to allow flex for mounting.

Owner:SPECULATIVE PROD DESIGN

Transfer of controller customizations

ActiveUS20050040250A1Minimizes of amountMinimize complexitySpace heating and ventilationTemperatue controlControl systemAir management

A device and method that may be used at nearly any place to set and adjust a control system such as a thermostat, controller or computer having numerous parameters and options that may be selected for desired operation of an air management system. One may remotely, via a personal digital assistant or computer, configure, commission, select, set or adjust the parameters and options of a control system. The configuration information may be shared with other personal digital assistants in a wireless or non-wireless manner. Further, enhanced diagnostics and repair may be achieved with the sending of configuration information from one PDA or computer to a PDA or computer at a diagnostic and repair facility. New modifications and calibration may be provided for the configuration. Such added information and configuring may be sent back to the originating PDA or computer for the providing to the controller or thermostat.

Owner:HONEYWELL INT INC

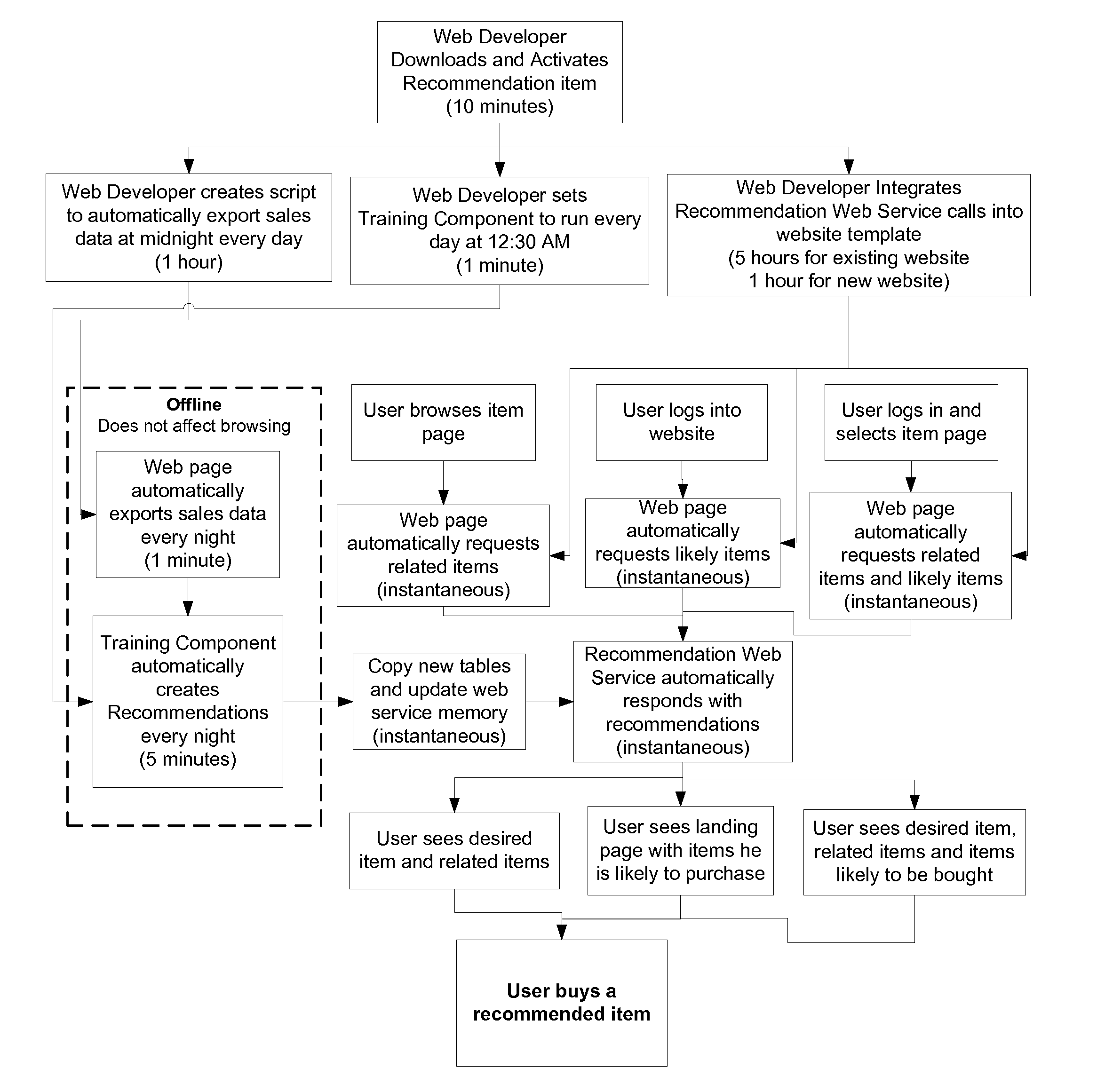

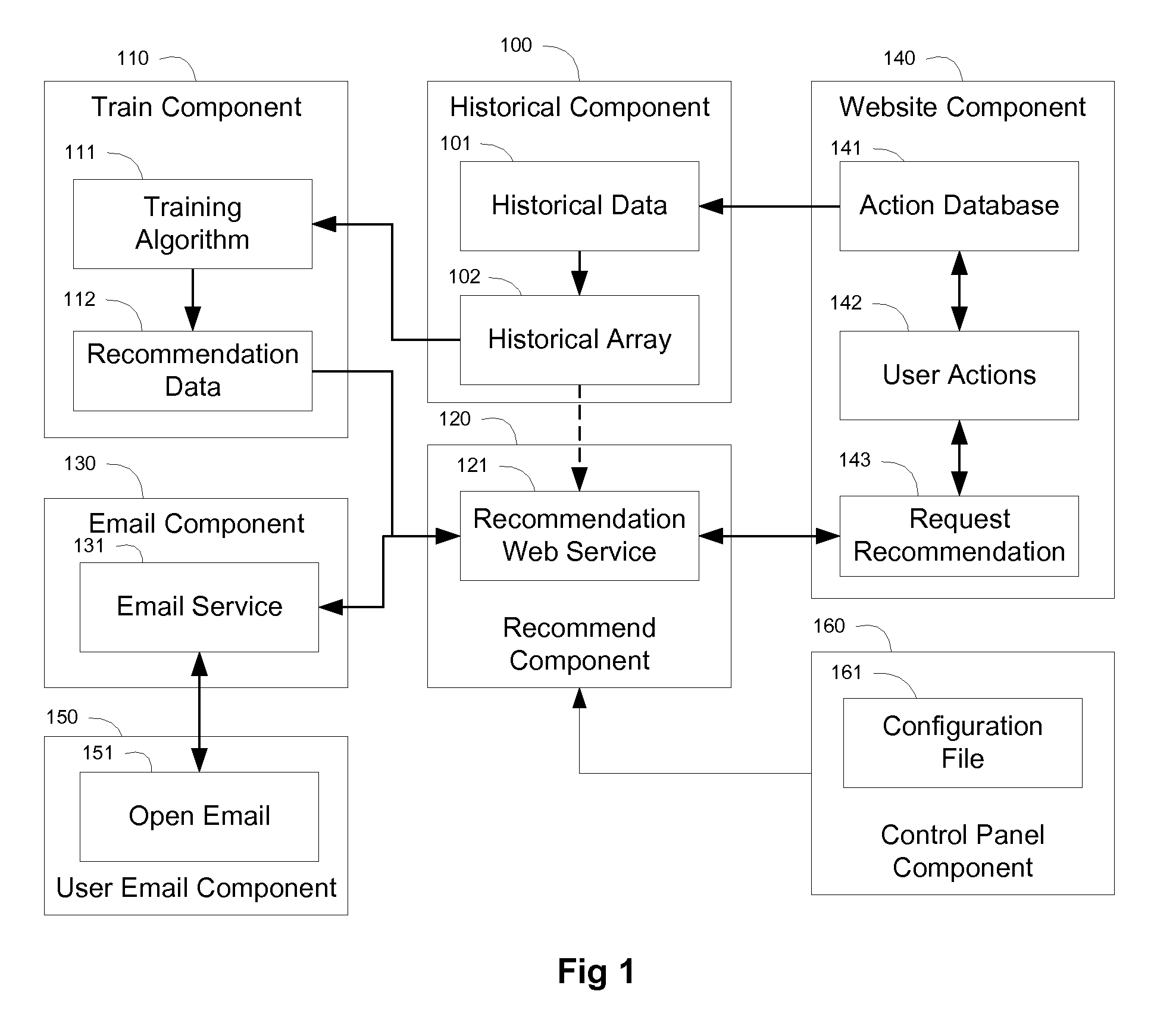

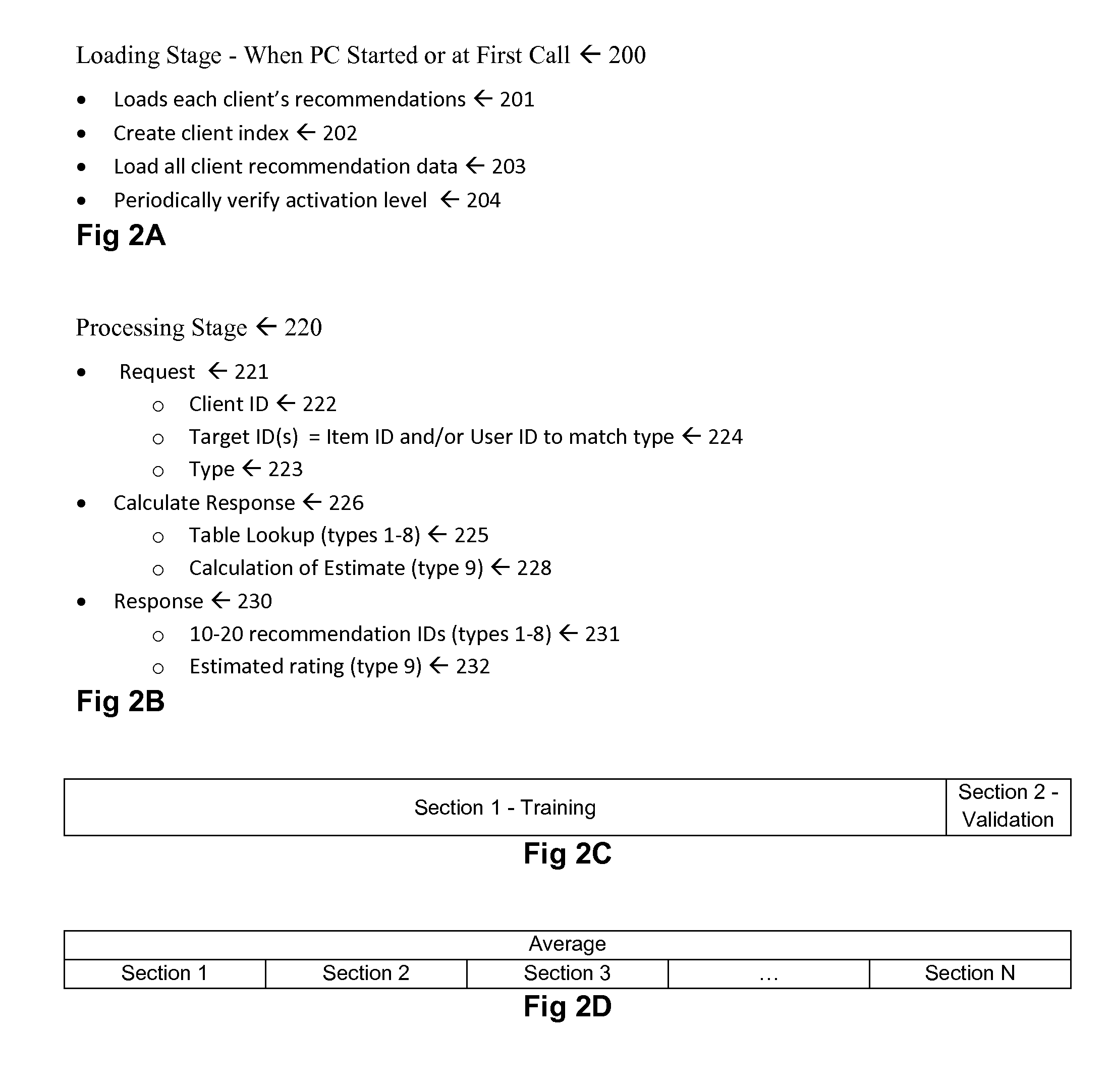

Recommendation Systems

InactiveUS20100268661A1Increase diversityFirmly connectedDigital data processing detailsSpecial data processing applicationsClient-sideOff the shelf

This invention deals with recommendation systems. The first embodiment is an off-the-shelf recommendation system is described, where it is easy to integrate with the website database and uses a web service for recommendations, as well as easy to integrate with email. The system receives client ID, item ID and user ID, and returns recommended item IDs. The recommendations include similar items, related items, related users, items likely to be acted upon by a given user (labeled likely items), and users likely to act upon an item (labeled likely users). The recommendations include categorical training, where recommended items are based upon similar categories, where the category types include as product type and brand. The recommendations include similar-to-related training, where similar items are used to find related items. These two intelligent methods work for items with no, few or numerous actions.

Owner:B7 INTERACTIVE LLC

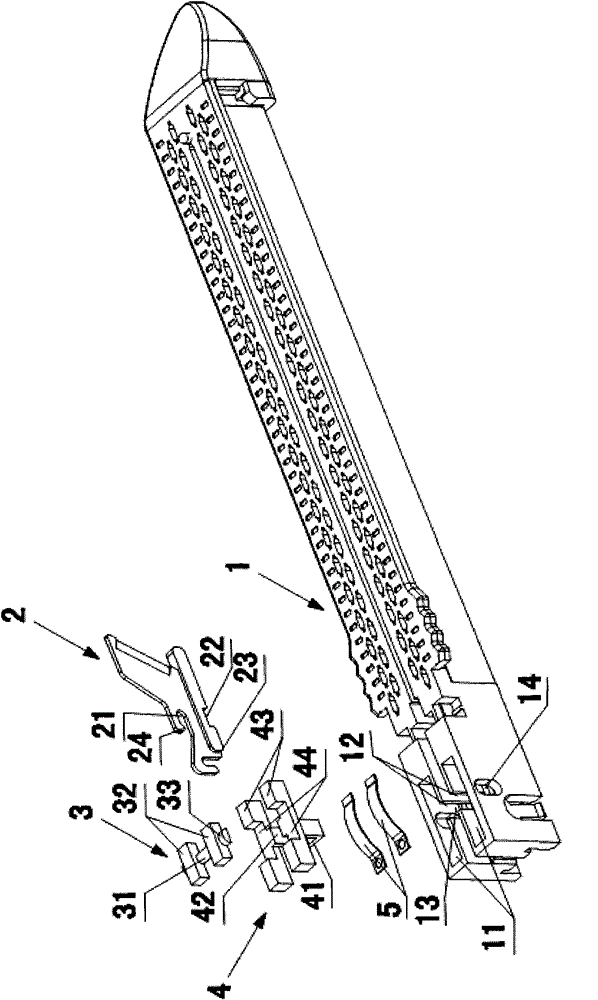

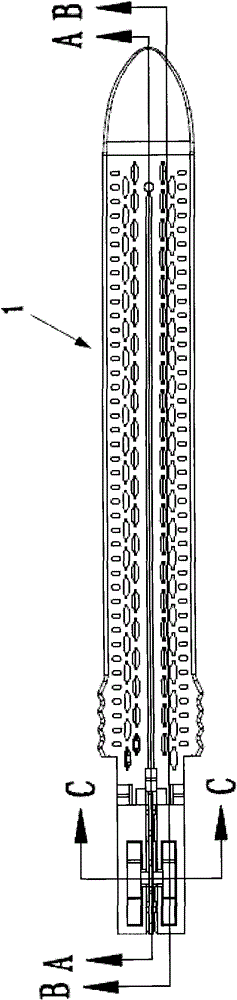

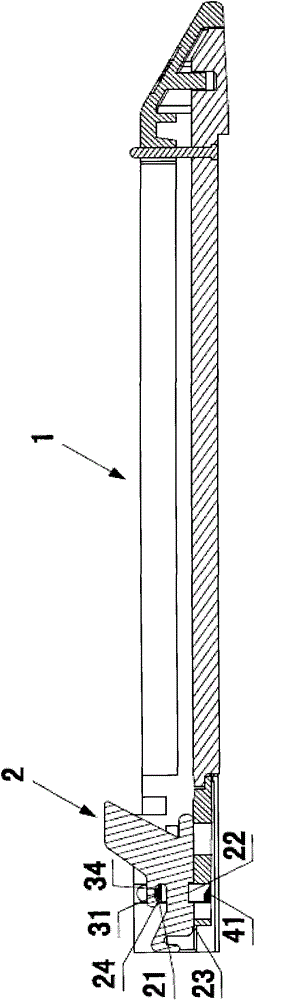

Linear cutting suturing device

The invention discloses a linear cutting suturing device, which comprises an upper tong clamp and a lower tong clamp, wherein the upper tong clamp and the lower tong clamp can realize the mutual closing or opening, the remote end of the lower tong clamp is provided with a nail cabin, a cutter feeding groove is arranged on the nail cabin in the axial direction, the lower tong clamp is in a U shape, a nail pushing rod and a cutter pushing rod are glidingly arranged inside the lower tong clamp, the remote end of the cutter pushing rod is provided with a cutter, the near end of the nail cabin is provided with a safety mechanism, the safety mechanism comprises a first press block, a triggering mechanism and at least one elastic element, the first press block is arranged in the nail cabin, the bottom end of the cutter is provided with a first notch, and the first notch can realize the longitudinal movement in the nail cabin under the effect of the elastic element and the triggering mechanism, so the first press block and the first notch can be selectively clamped and connected or separated. The linear cutting suturing device has the major beneficial effects that the structure is simple, the processing is convenient, safety and reliability are realized, and good popularization values are realized.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

LED light communication system

InactiveUS20080310850A1Easy to transportFirmly connectedPower distribution line transmissionElectric/electromagnetic visible signallingTransceiverPhotovoltaic detectors

An LED light and communication system includes at least one optical transceiver, the optical transceiver including a light support and a processor. The light support has a plurality of light emitting diodes and at least one photodetector attached thereto, the light emitting diodes receiving power from a power source. The processor is in communication with the light emitting diodes and the at least one photodetector, the processor capable of illuminating the light emitting diodes to simultaneously create at least one first light signal, and at least one second light signal, the first light signal being observable to the unaided eyes of an individual and the second light signal not being observable to the unaided eyes of the individual. The second light signal includes at least one data packet. The at least one data packet comprises global positioning system (GPS) location information.

Owner:FEDERAL LAW ENFORCEMENT DEV SERVICES

Method and apparatus for mounting photovoltaic modules

ActiveUS7592537B1Simple and cost-effectiveFirmly connectedPhotovoltaic supportsSolar heating energyElectrical and Electronics engineeringPhotovoltaics

An interlocking photovoltaic module mounting system that provides a one piece, integrated photovoltaic module frame portion that is directly mountable to a support structure and interlocks with separate adjoining photovoltaic module frame portions. The apparatus includes a frame member for enclosing the perimeter of a photovoltaic module, having an inside surface and outside surface, with the inside surface including a recess for capture of the panel. The frame member outside surface includes at least one interlocking means for affixation to the complementary outside surface of an adjacent frame-member. The frame member includes a height-adjustable foot portion for supporting the frame member on a roof, so that adjacent frame members may be interlocked to form an array, and the foot portion may be adjusted to level the formed array on the roof.

Owner:TESLA INC

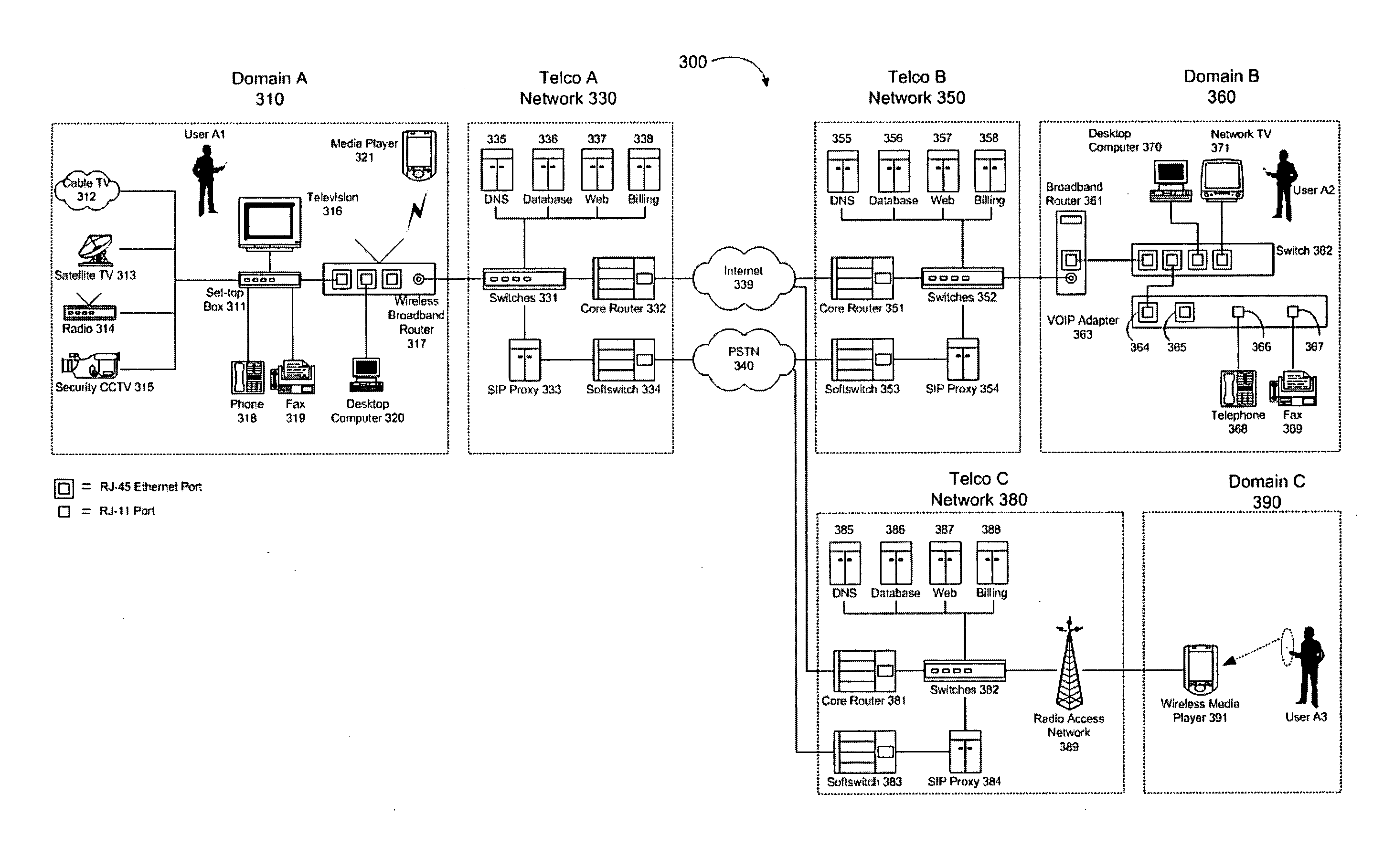

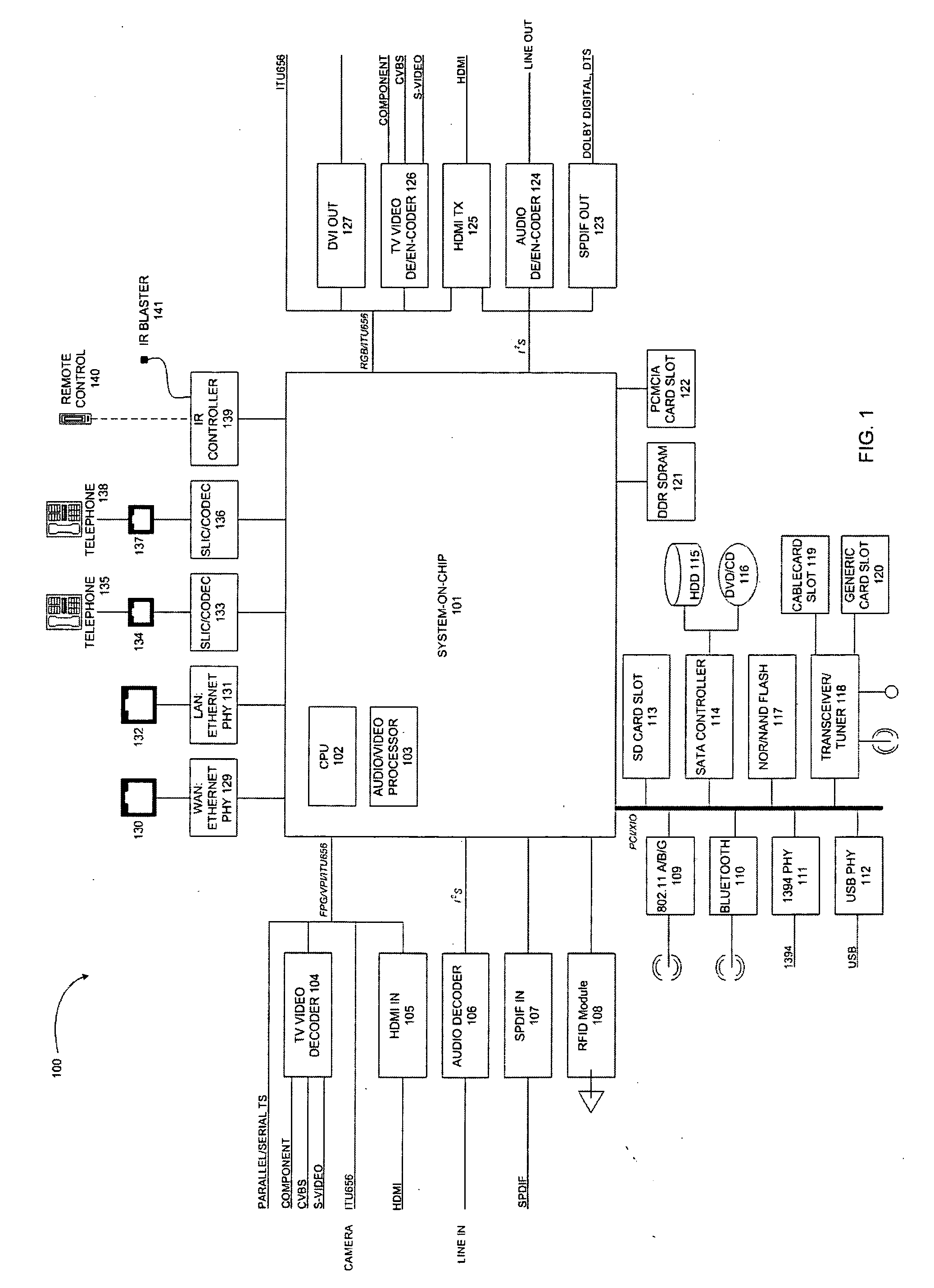

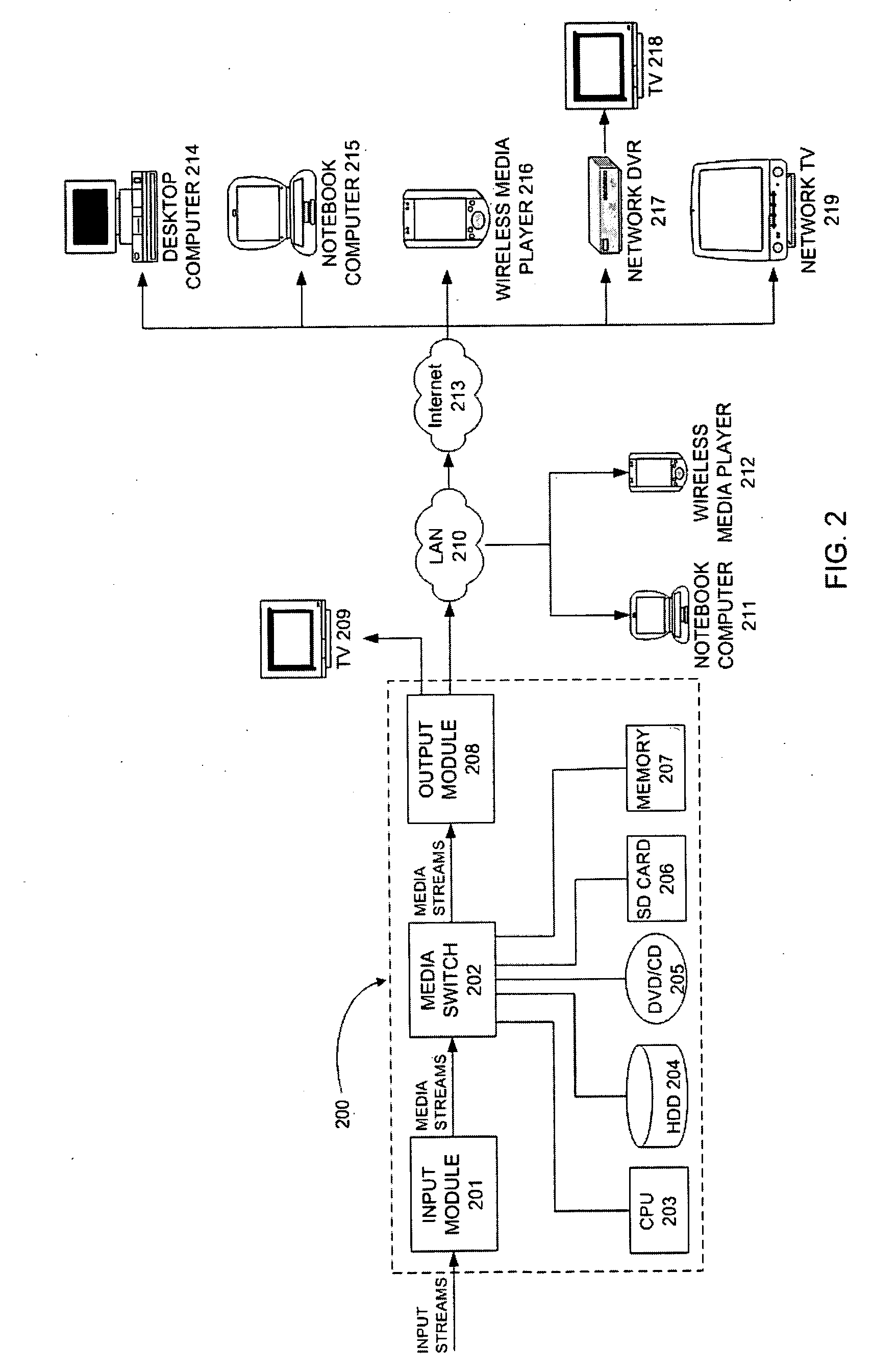

Method and system for accessing media content via the Internet

ActiveUS20070180485A1Rapidly initiate connectivityEasy to useTelevision system detailsAnalogue secracy/subscription systemsThe InternetDigital storage

A media storage and access system and methodology including a set-top box which receives and processes a plurality of signal sources and makes programming available locally through connected devices or via a data network such as a LAN, WAN, or the Internet. The system also integrates a multimedia storage system that allows programming content to be digitally stored. The system utilizes an integrated digital storage system and operating software to allow users to view a broadcast program (e.g., television, radio, etc.) with the option of instantly reviewing previous segments within the program. In addition, the system allows the user to store selected media programming while the user is simultaneously watching or reviewing another program. The system also allows stored media assets to be accessed locally via a media device connected to the unit or remotely via the Internet.

Owner:SYNDEFENSE

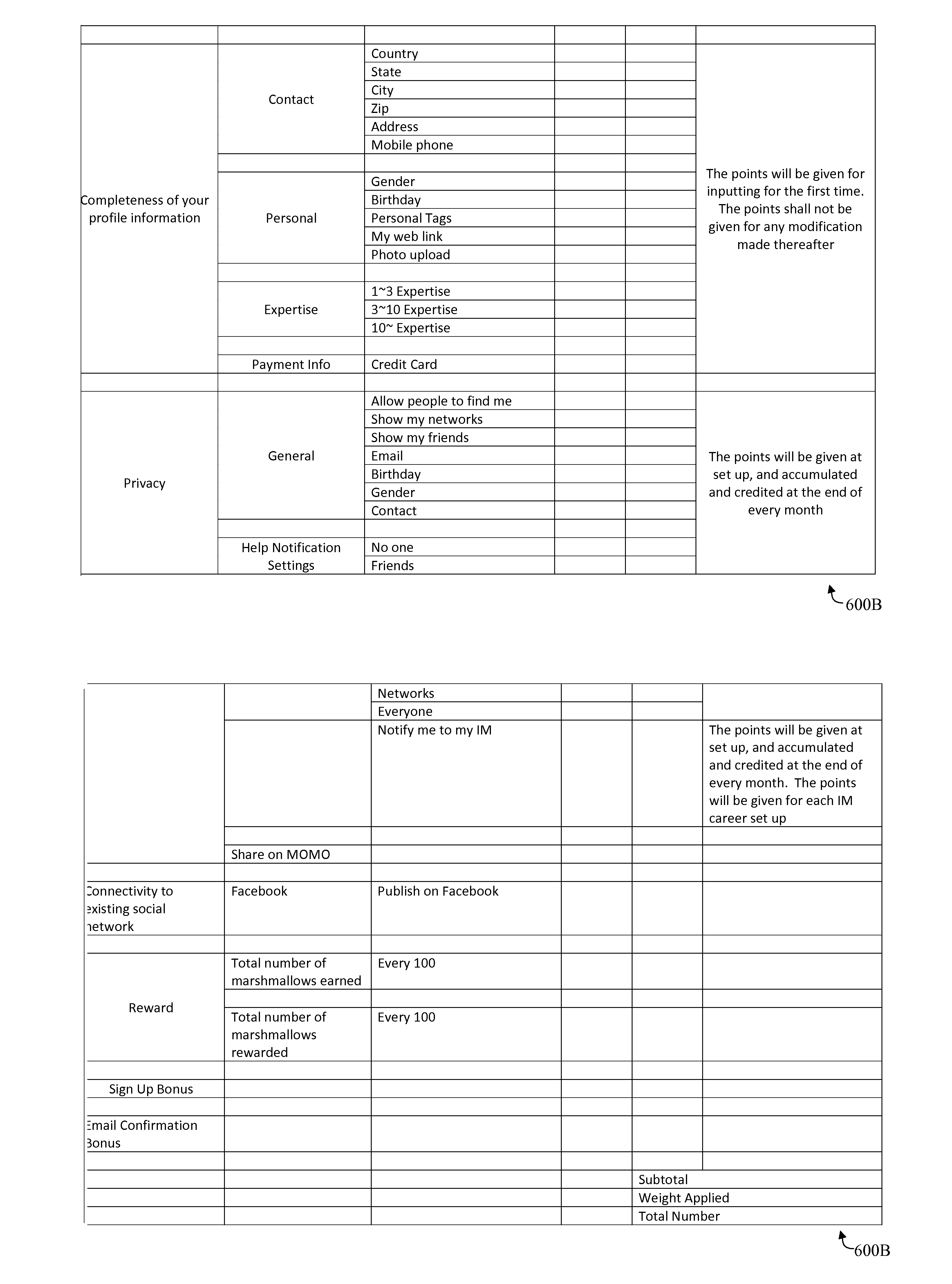

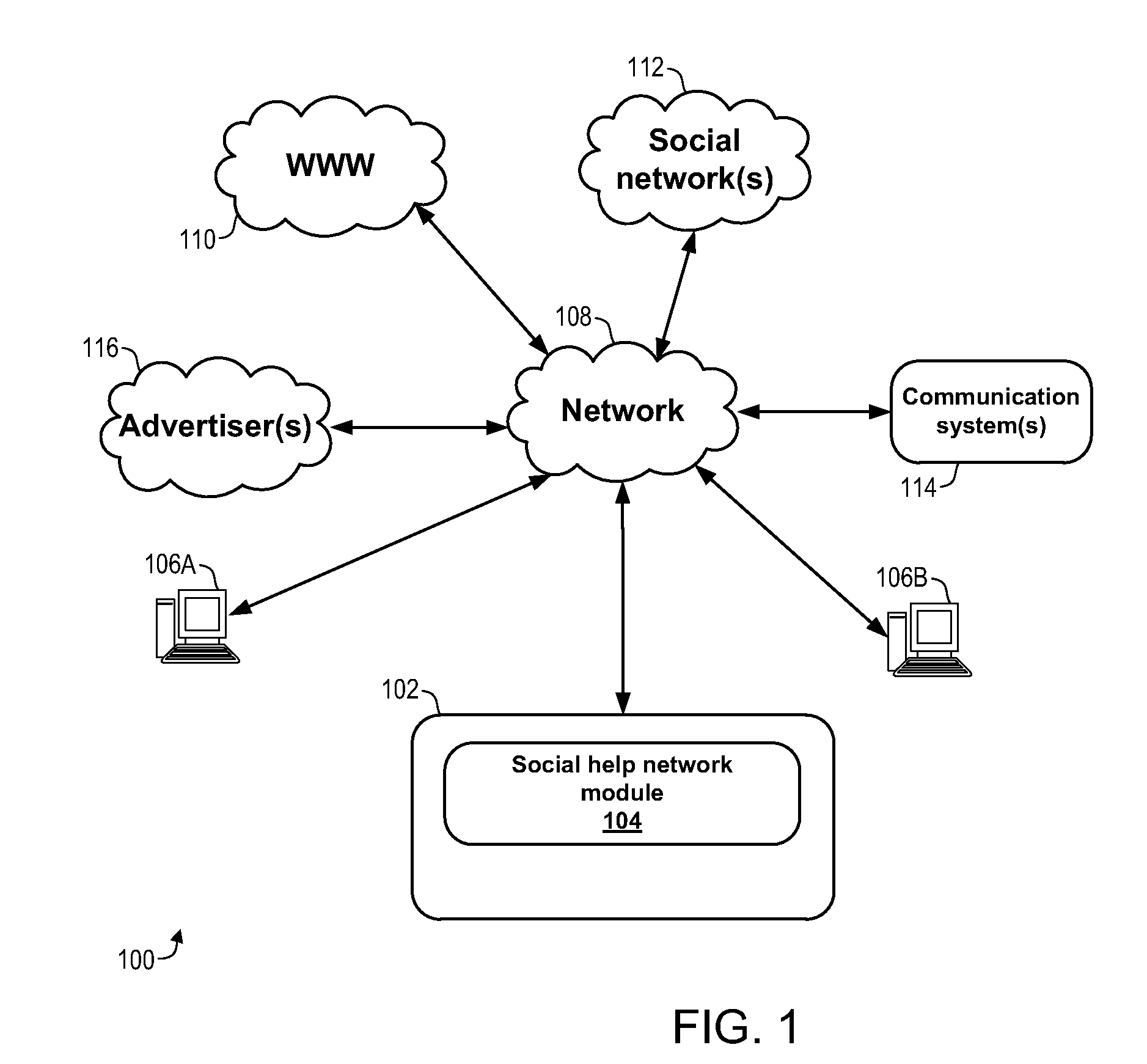

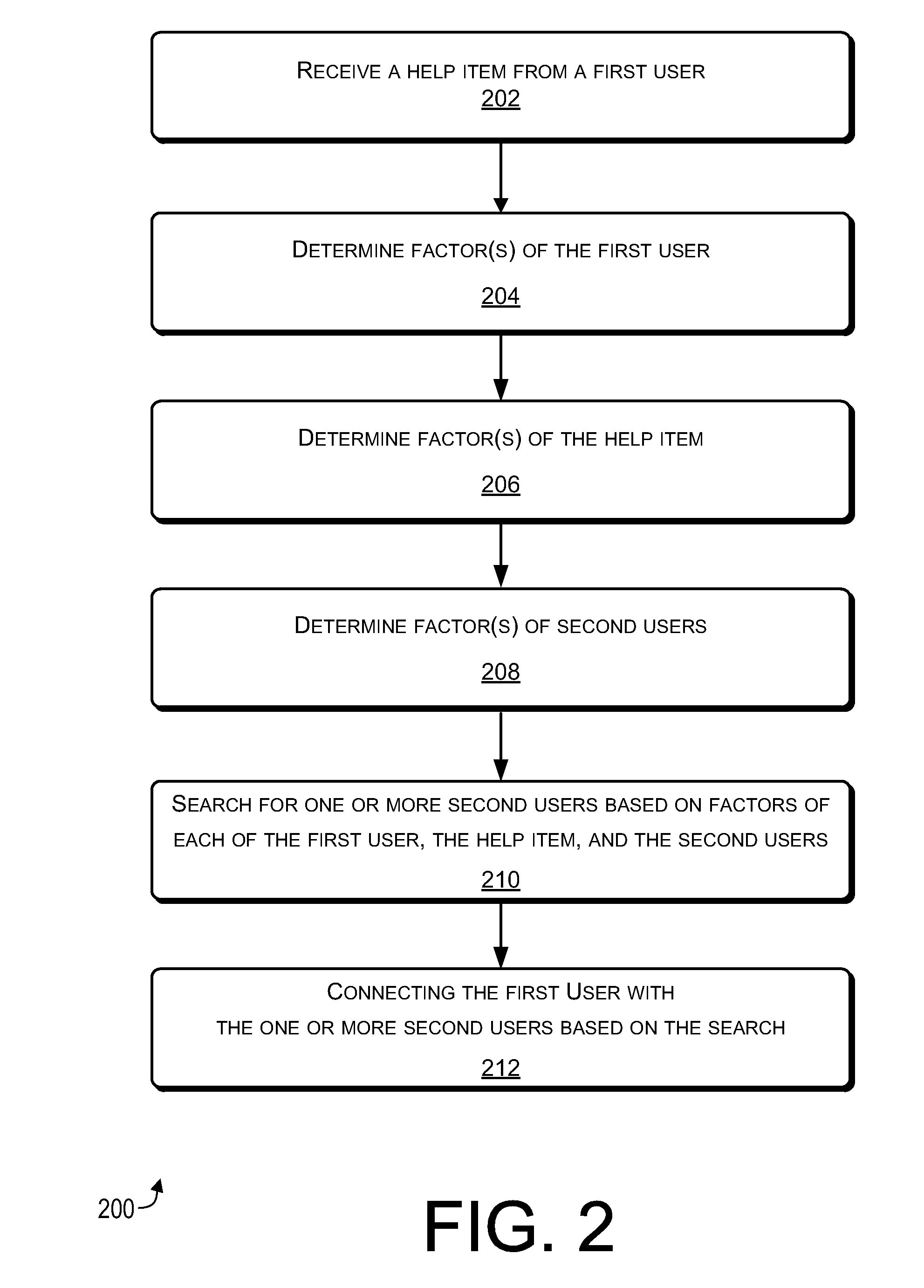

Social Help Network

InactiveUS20110238763A1Error minimizationFirmly connectedMultiple digital computer combinationsOffice automationGeographic siteGeolocation

A help item is received from a first user by using a social help network. The help item indicates a help service to be performed for the first user by a second user of the social help network, or by the first user for the second user. Factor(s) of the first user and other users of the social network are determined, such as a geographical location of each user. Factor(s) of the help item are determined, such as a geographical location where the help service is to be performed. Based on the factor(s) of each of the first user, the help item, and the other users, a search for potential second users is performed. Each potential second user can perform the help service for the first user, or each potential second user can have the help service performed by the first user.

Owner:MOMO NETWORKS

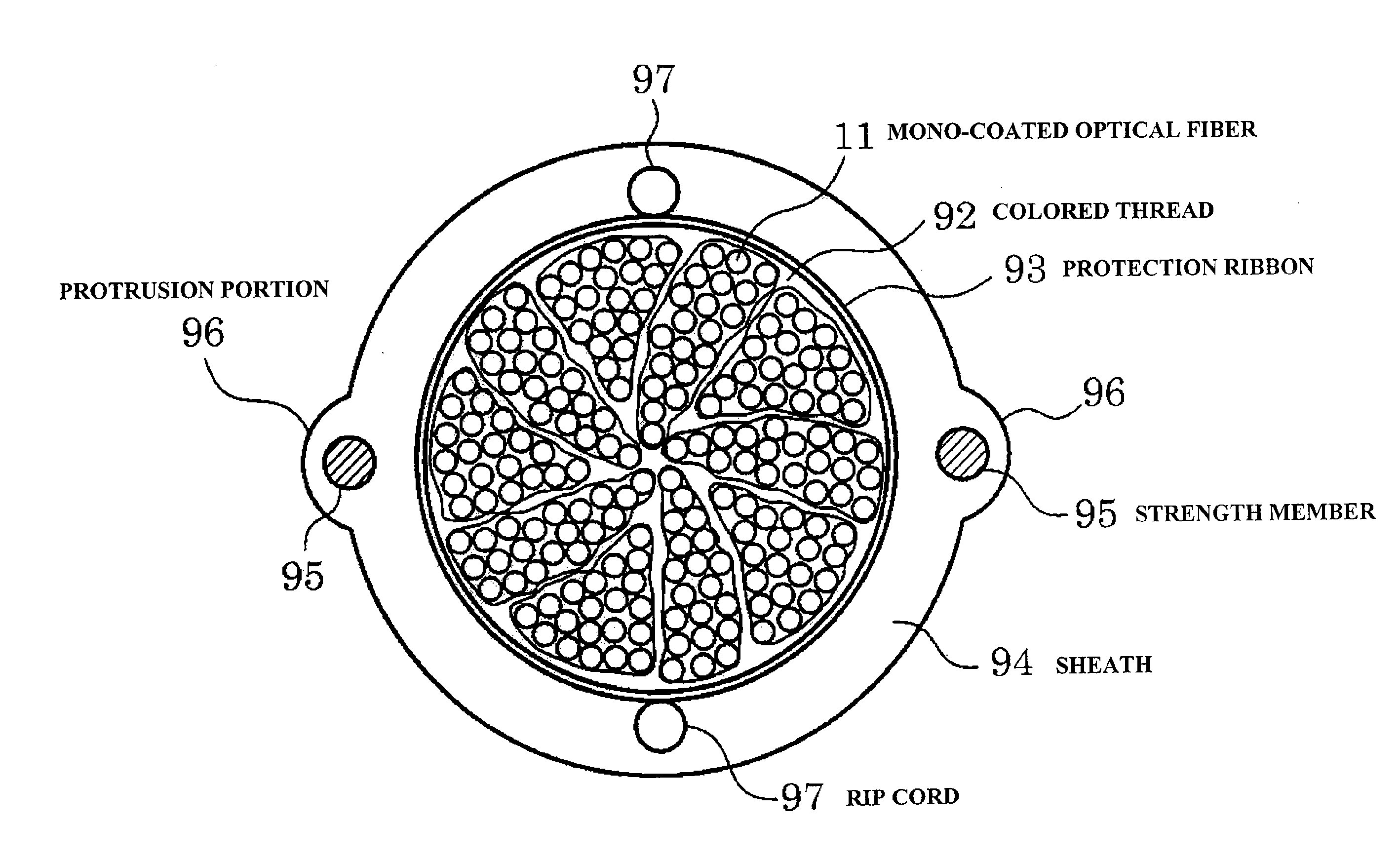

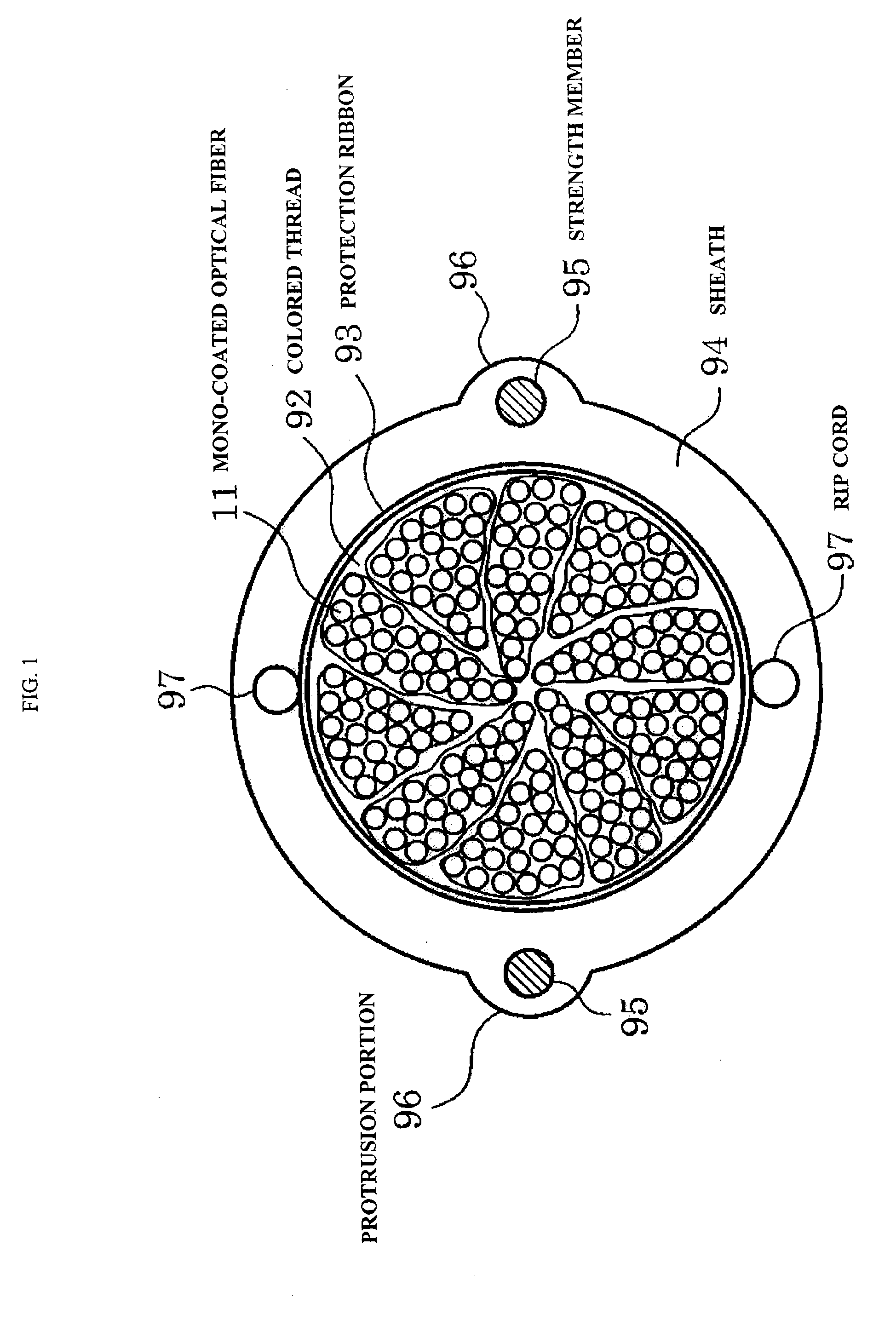

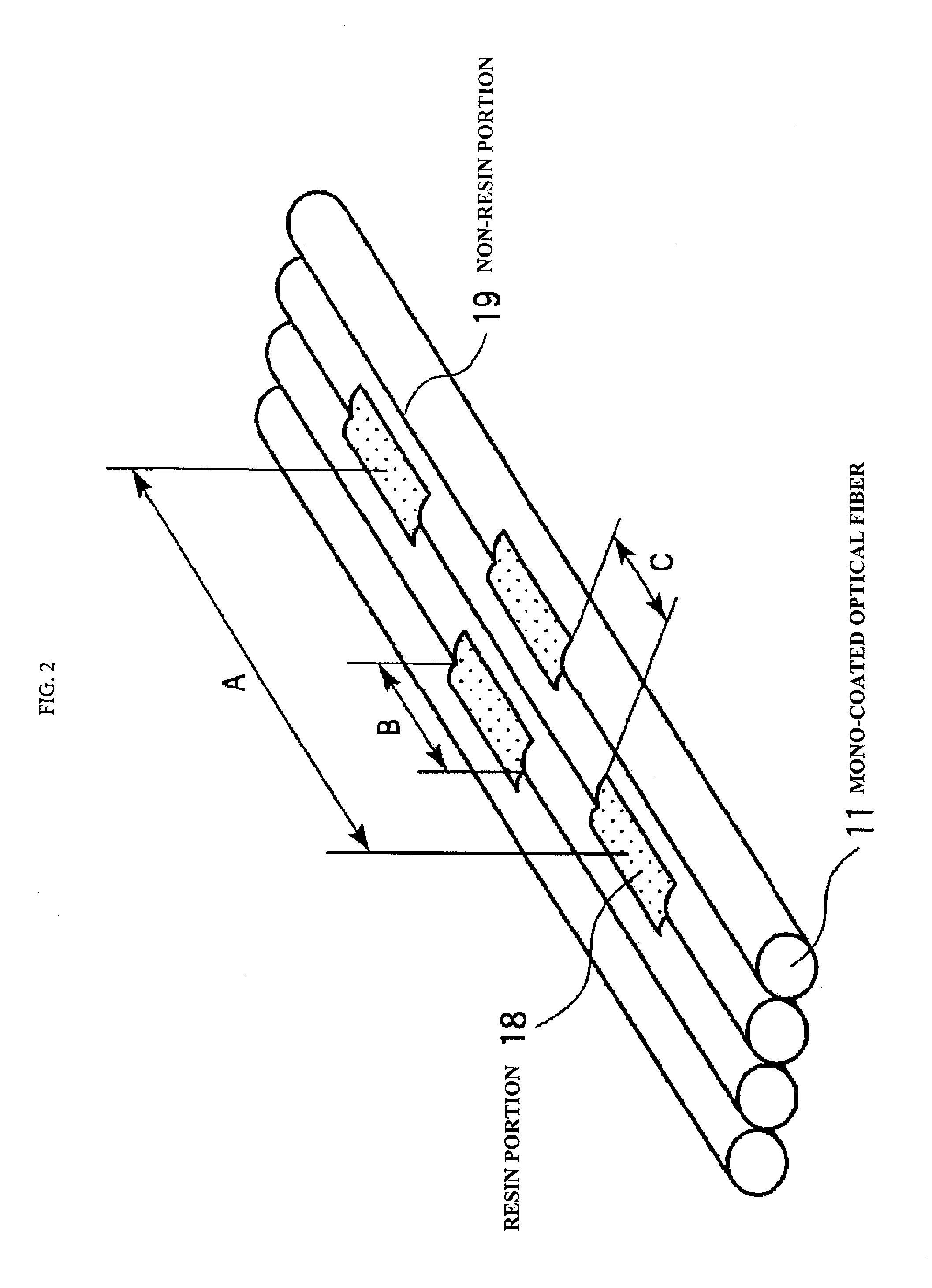

Optical fiber cable and optical fiber ribbon

ActiveUS8548294B2Stable optical loss characteristicReduce warpageFibre mechanical structuresEngineeringBend radius

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Display device for exterior rearview mirror

InactiveUS20070058257A1Good adhesionEasy to assembleMirrorsOptical signallingDriver/operatorDisplay device

An exterior mirror sub-assembly includes a reflective element, a back plate, and a display element having a light source that is activatable to emit light. The display element attaches to a display receiving portion of the back plate and the light source is activatable to emit light through the display receiving portion. The display receiving portion may be configured to orient the display element at a predetermined angle so that light exiting the display element when the light source is activated may be directed (a) generally away from the vehicle when the mirror assembly is mounted to the vehicle so as to be principally viewed by drivers of other vehicles or (b) generally toward the driver of the vehicle when the mirror assembly is mounted to the vehicle so as to be principally viewed by the driver of the host vehicle.

Owner:MAGNA MIRRORS OF AMERICA INC

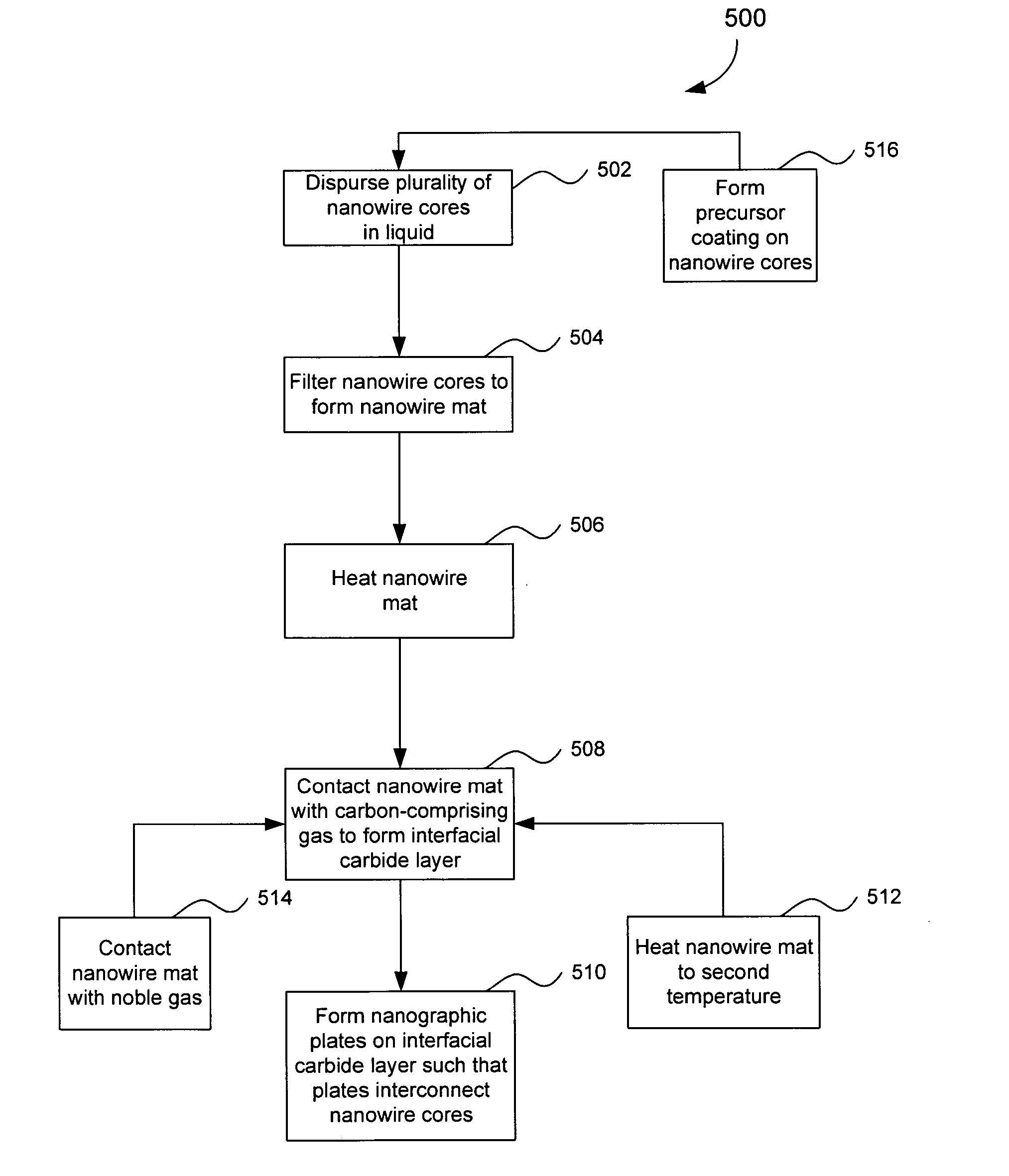

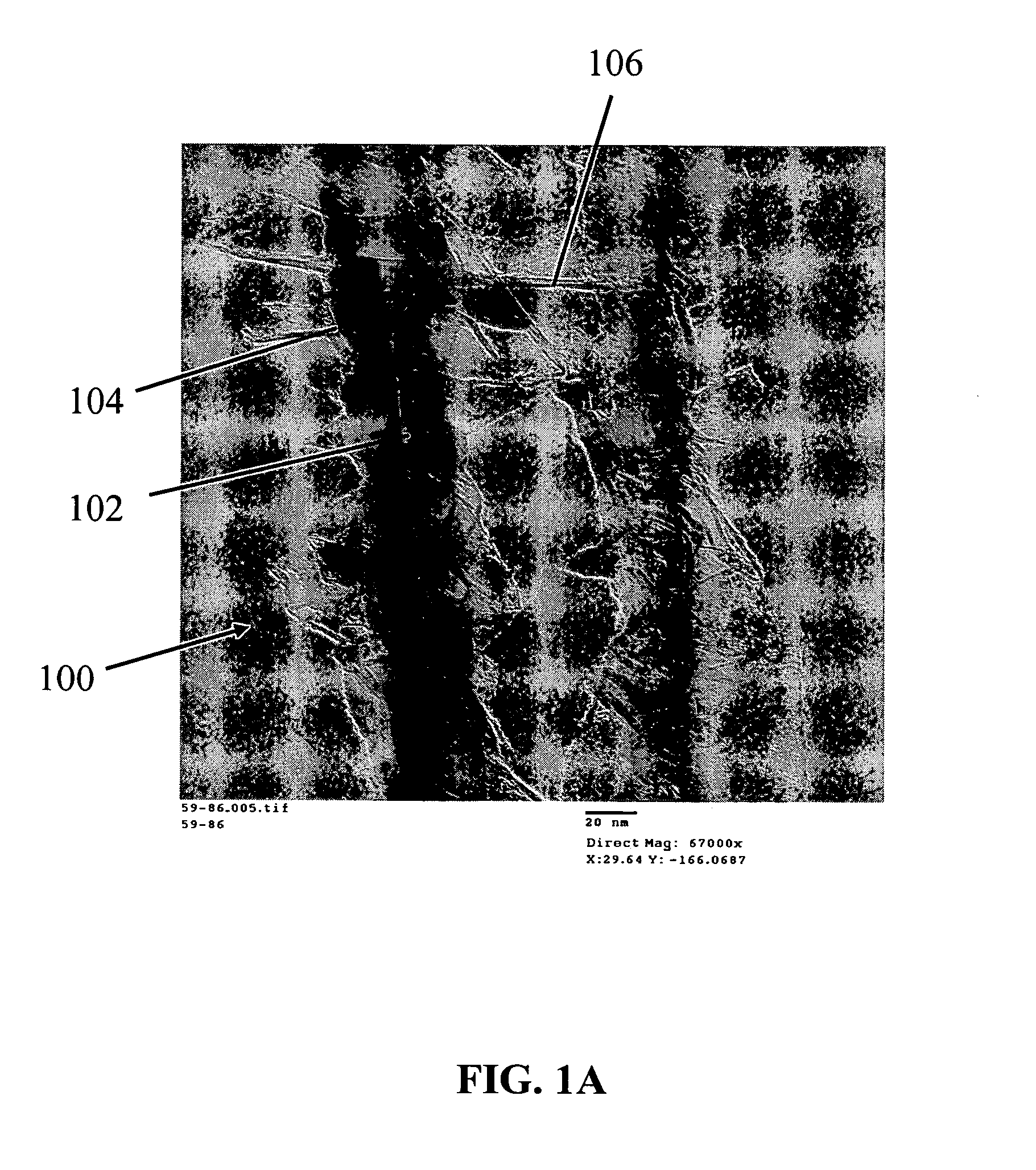

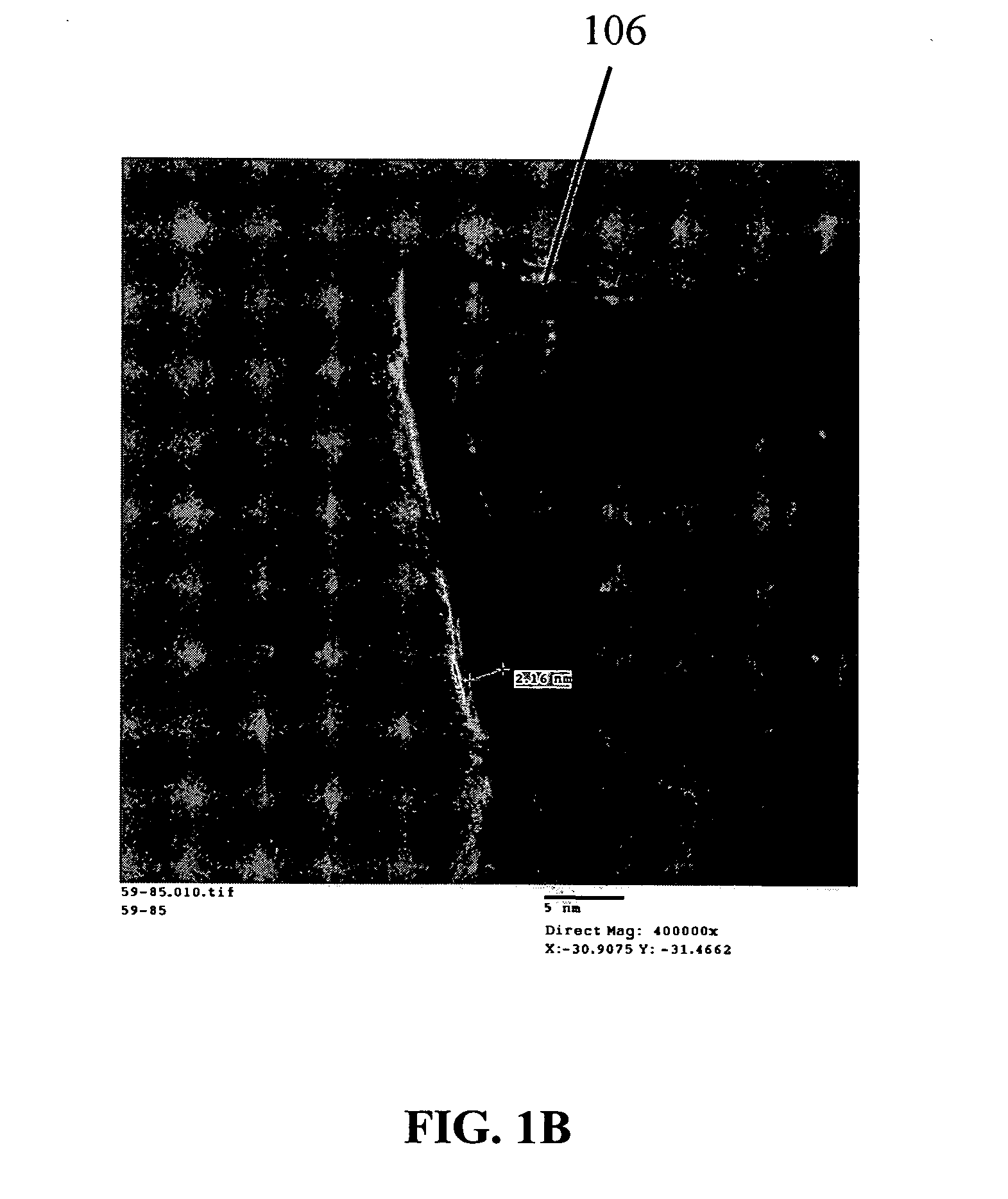

Nanowire structures comprising carbon

ActiveUS20070212538A1Low costImproved electrical connectivity and stabilityElectric discharge heatingFuel cells groupingNanometreMembrane configuration

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

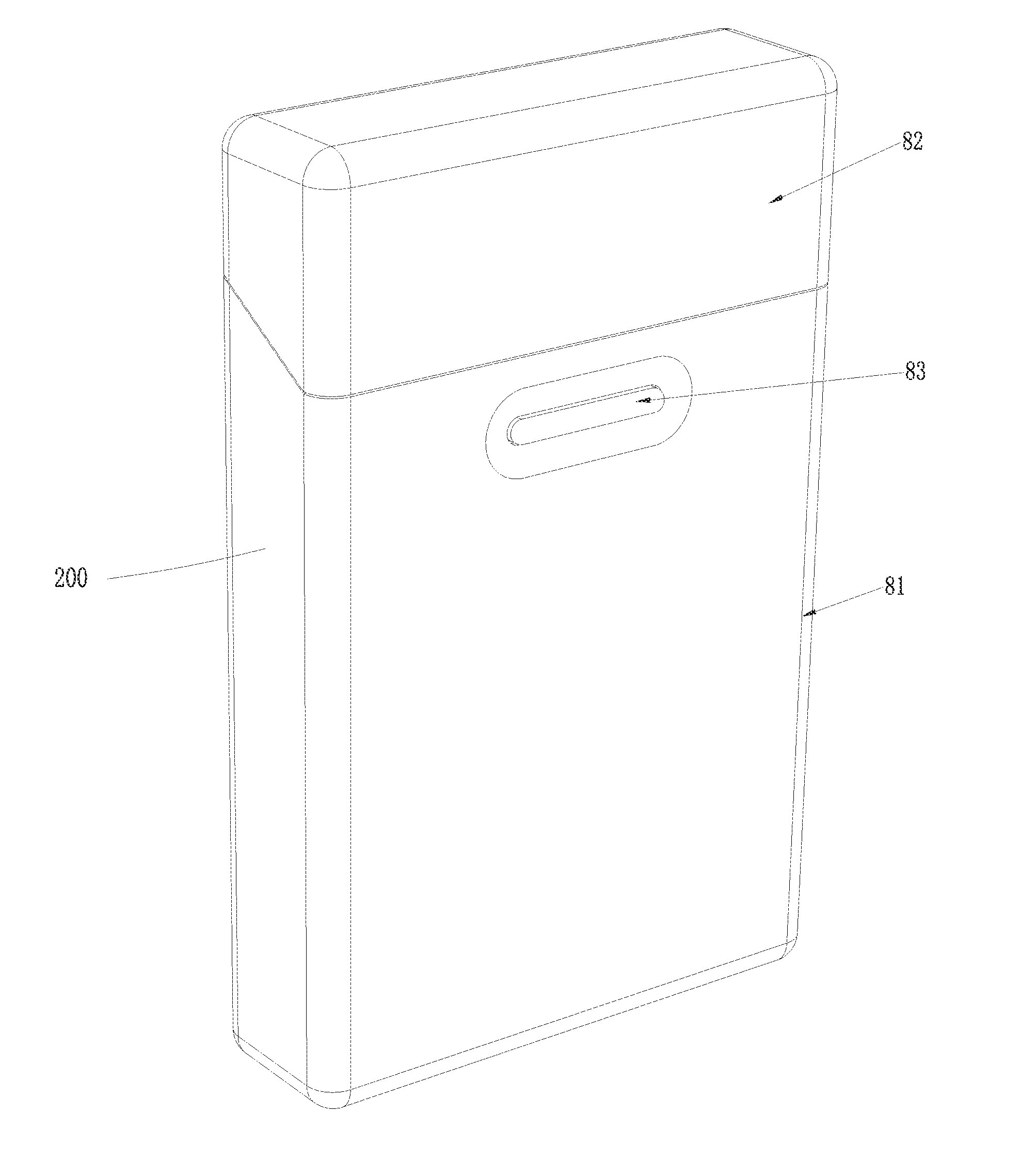

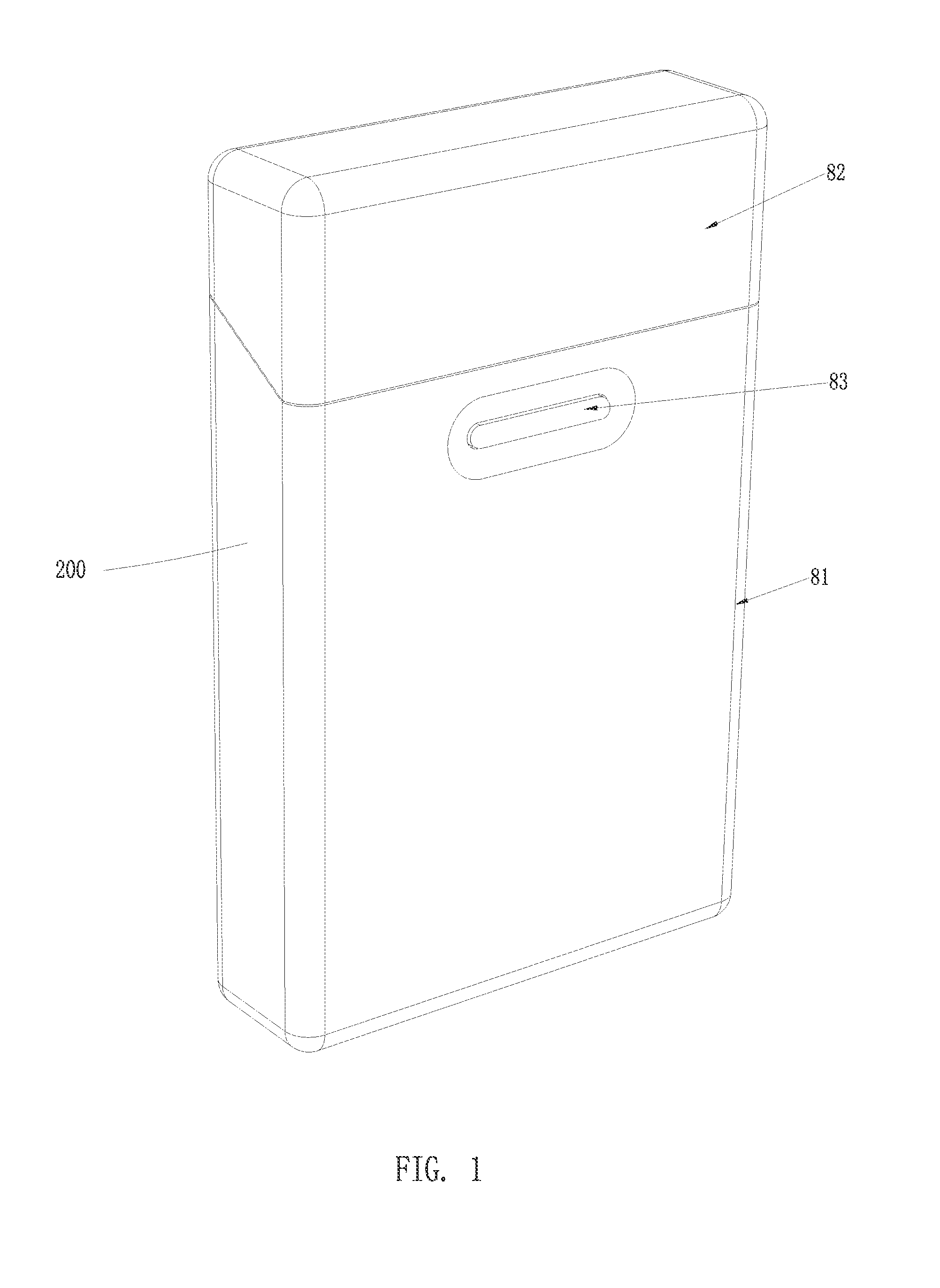

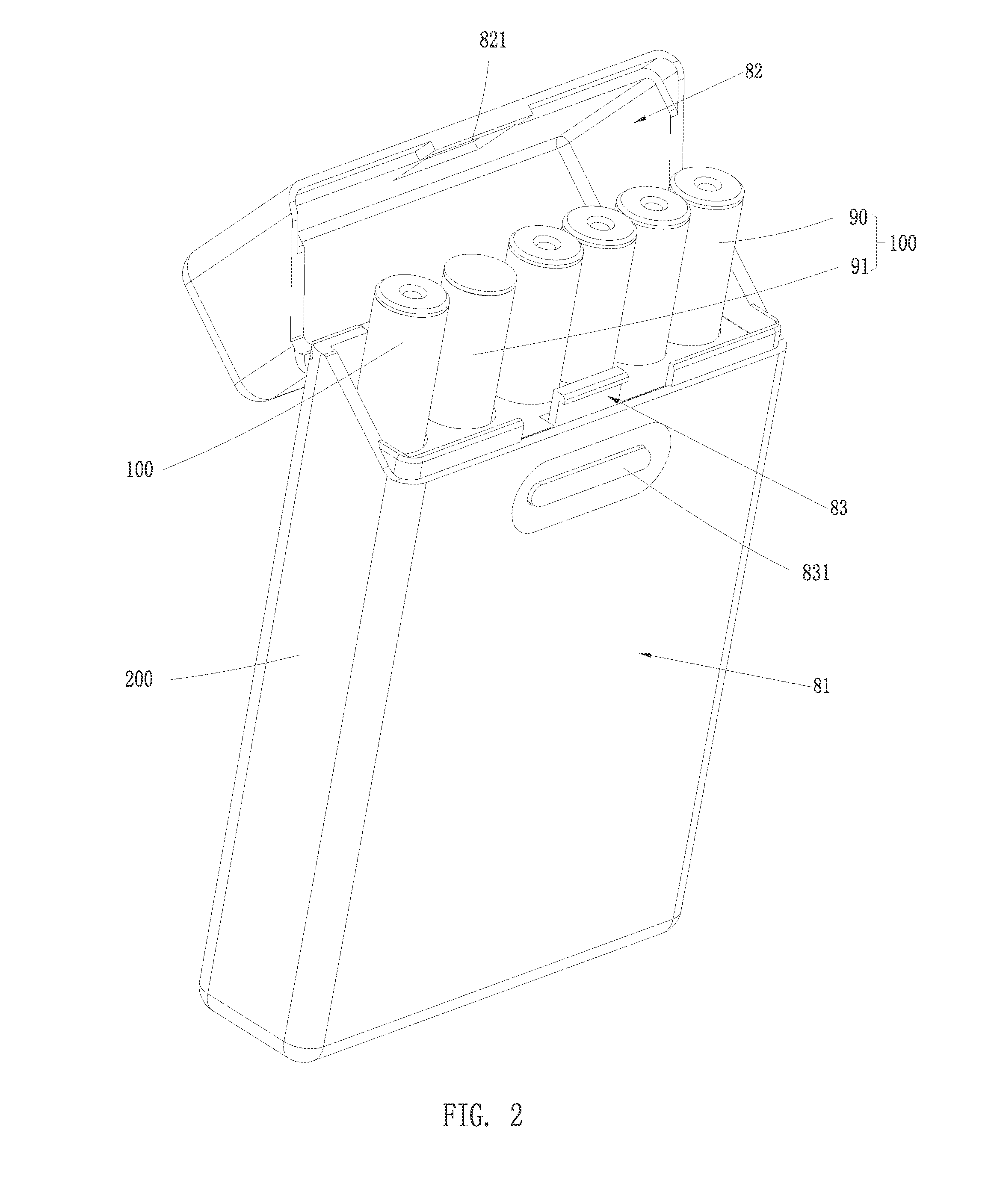

Electronic Cigarette Case

InactiveUS20130342157A1Ensure electrical connection reliabilitySimple manufacturing processBatteries circuit arrangementsTobacco pipesElement spaceElectricity

The present invention relates to an electronic cigarette case, includes a case body, a charging device disposed in the case body for charging electronic cigarettes. The charging device includes a charging base, a rechargeable battery, and a control circuit board integrated with a circuit processing unit. The charging base has an electrode support where first and second electrode elements, and a trigger element spaced apart from the second electrode element are all disposed on the electrode support. The second electrode element is flexibly deformable when one of the electronic cigarettes is inserted into the case body to create a charging circuit. The circuit processing unit automatically controls the rechargeable battery for charging the electronic cigarette being inserted until it is full of power, whereby the electronic cigarette case is readily to be assembled and to sue, and has a reliable electrical connection with an outer power source.

Owner:HUIZHOU KIMREE TECH

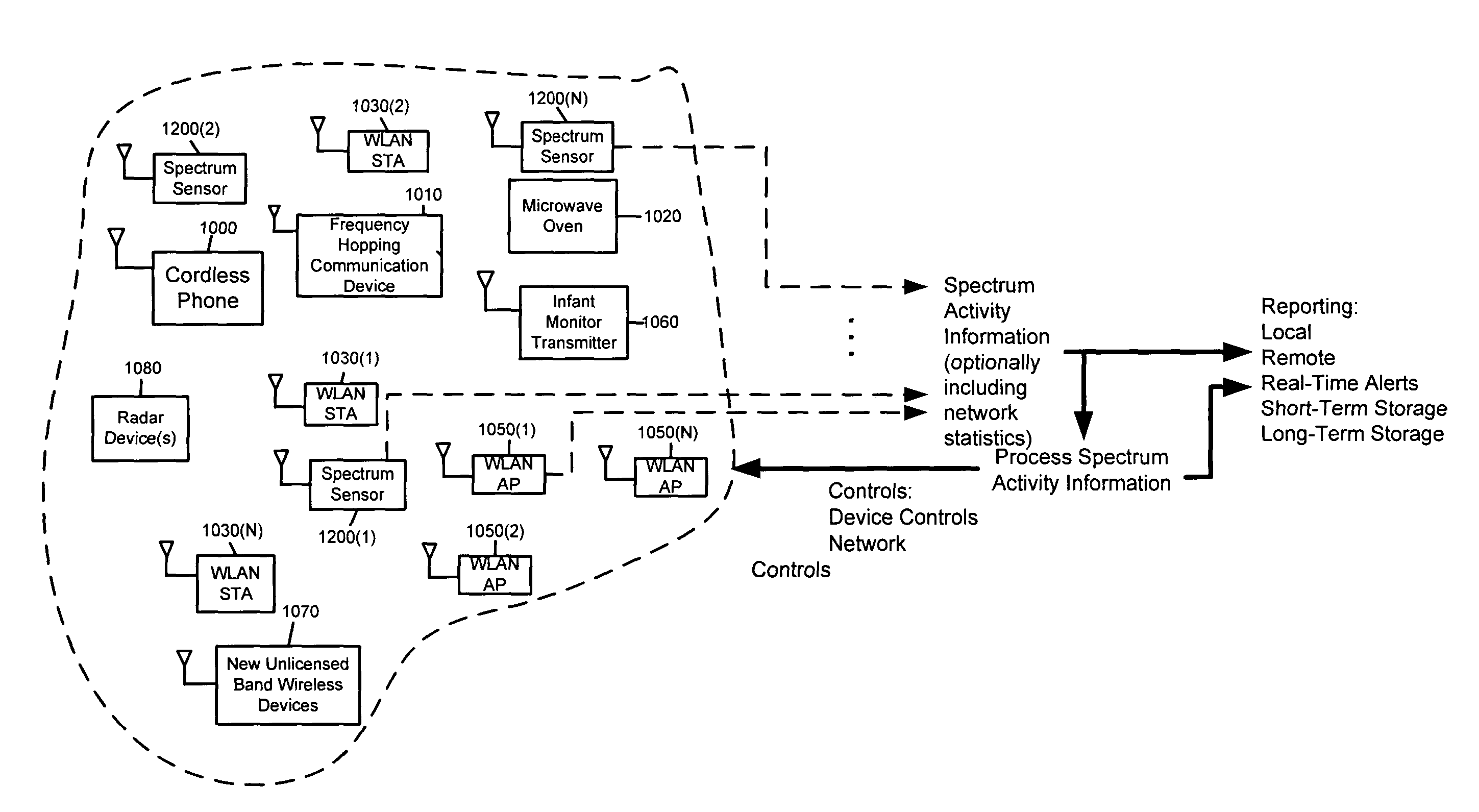

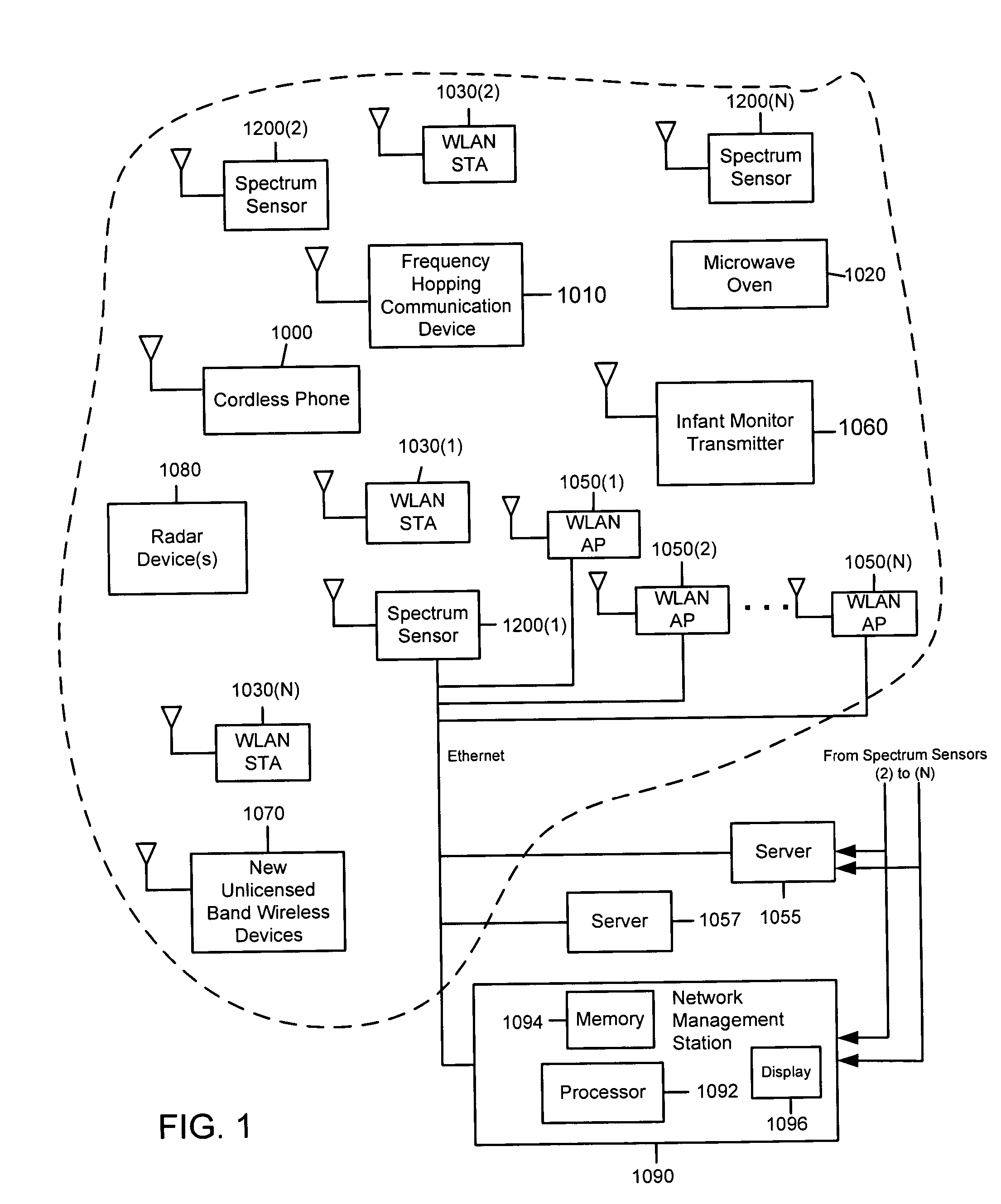

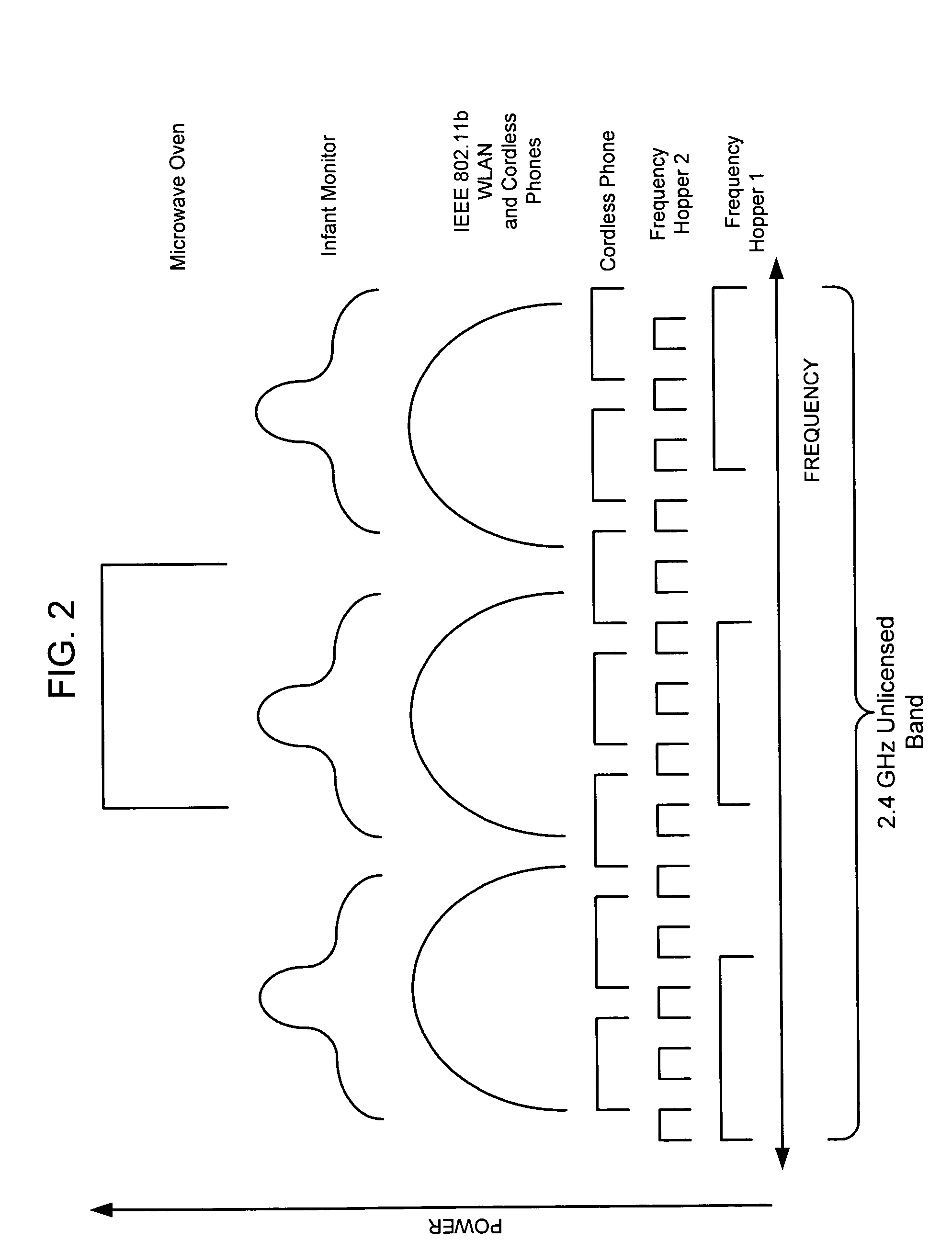

System and method for management of a shared frequency band using client-specific management techniques

ActiveUS7408907B2Increase capacityCell size be reduceError prevention/detection by using return channelNetwork traffic/resource managementClient-sideRadio frequency

Owner:CISCO TECH INC

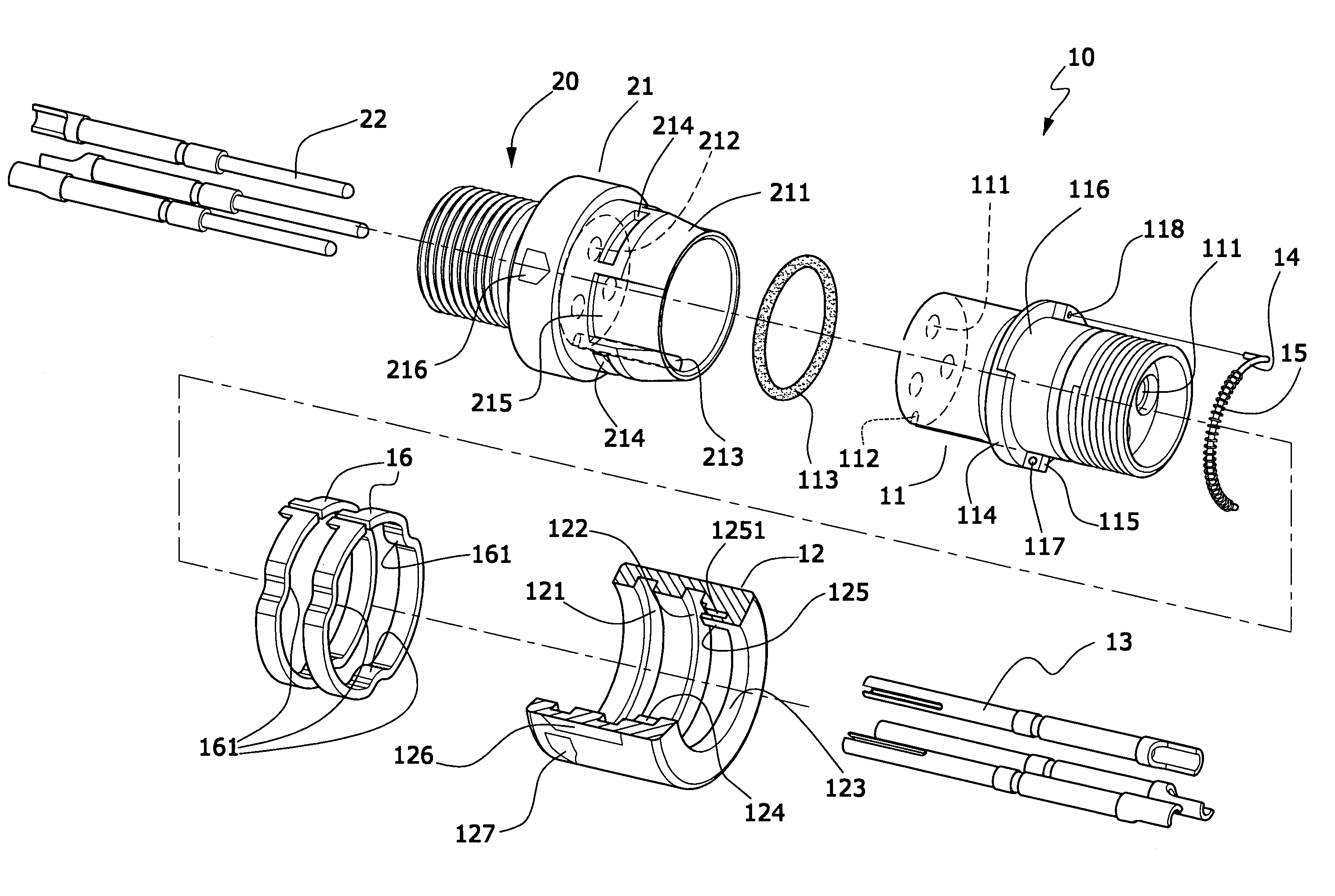

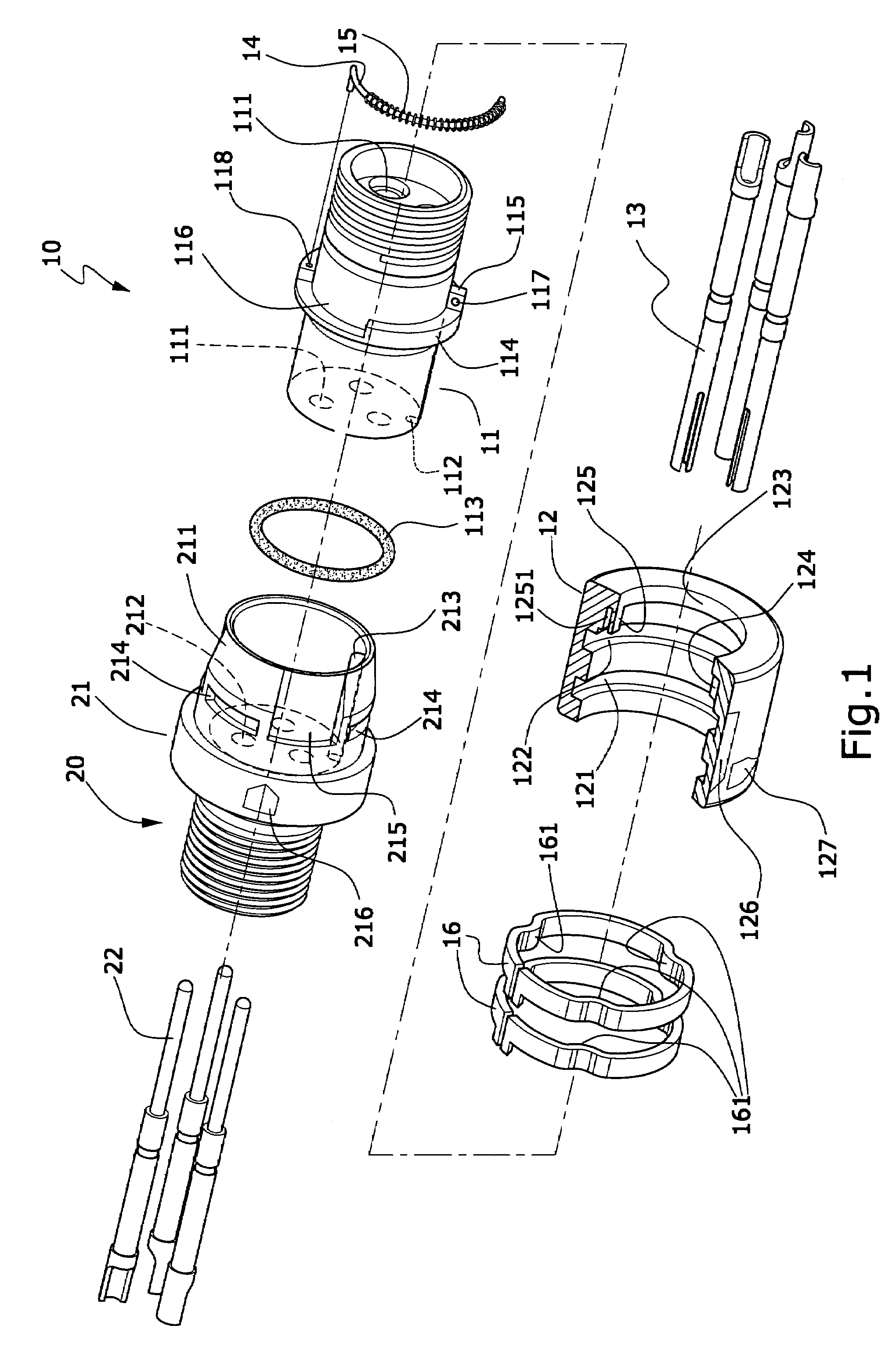

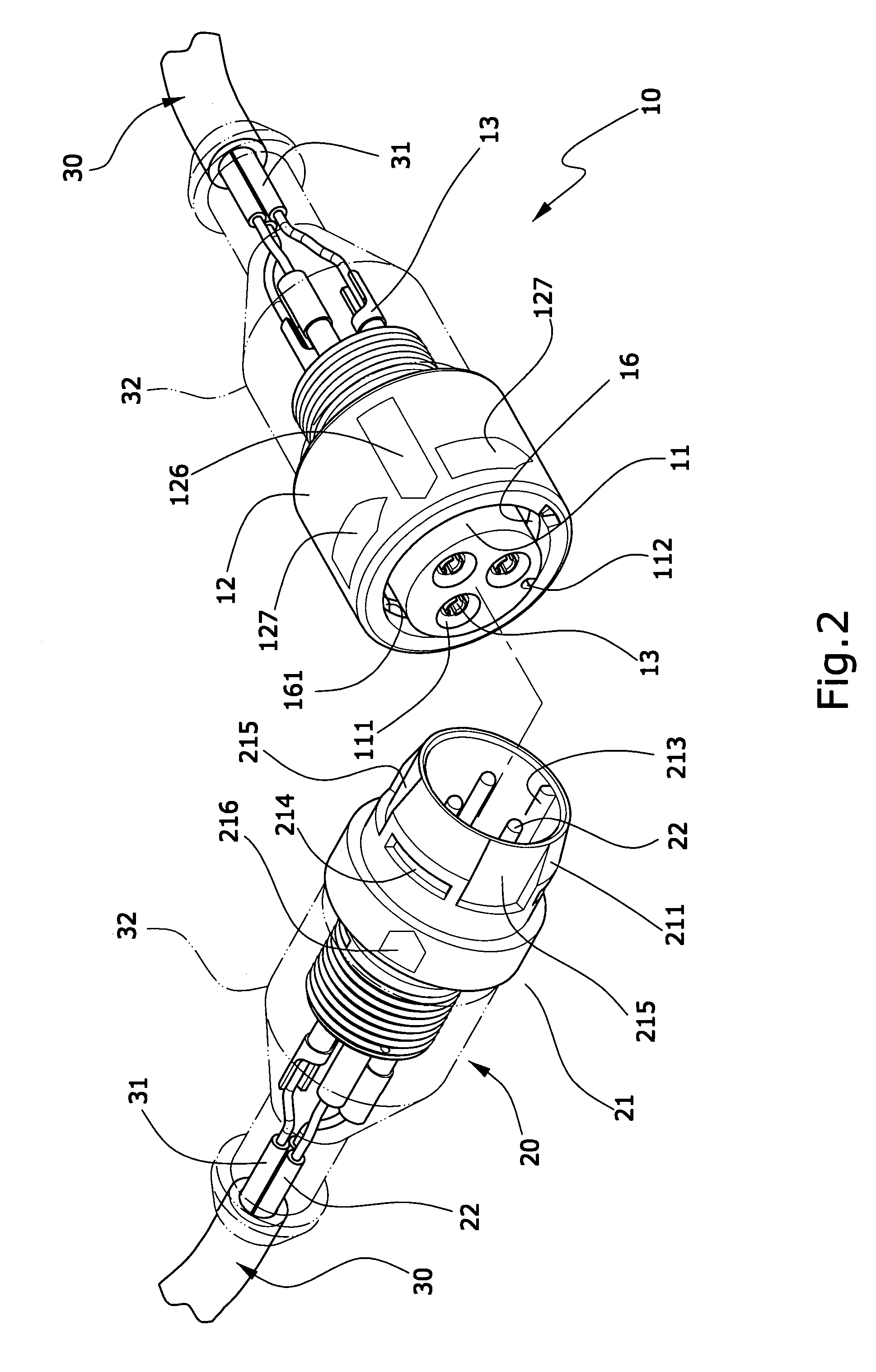

Fast coupling structure of waterproof cable connector

InactiveUS7422463B2Firmly connectedEasy to disassembleElectrically conductive connectionsSecuring/insulating coupling contact membersCouplingElectric power system

The invention relates to a fast coupling structure of waterproof cable connector, mainly comprising a male connecting joint and a female connecting joint, both are positioned on the cable end for connection of electric power source or signals on an electric apparatus; the invention enables both of the male and the female connecting joints to have the fast coupling function and the waterproof effects; therefore, a user is able to easily and quickly connect or disassemble the coupling structure.

Owner:KUO KO AN

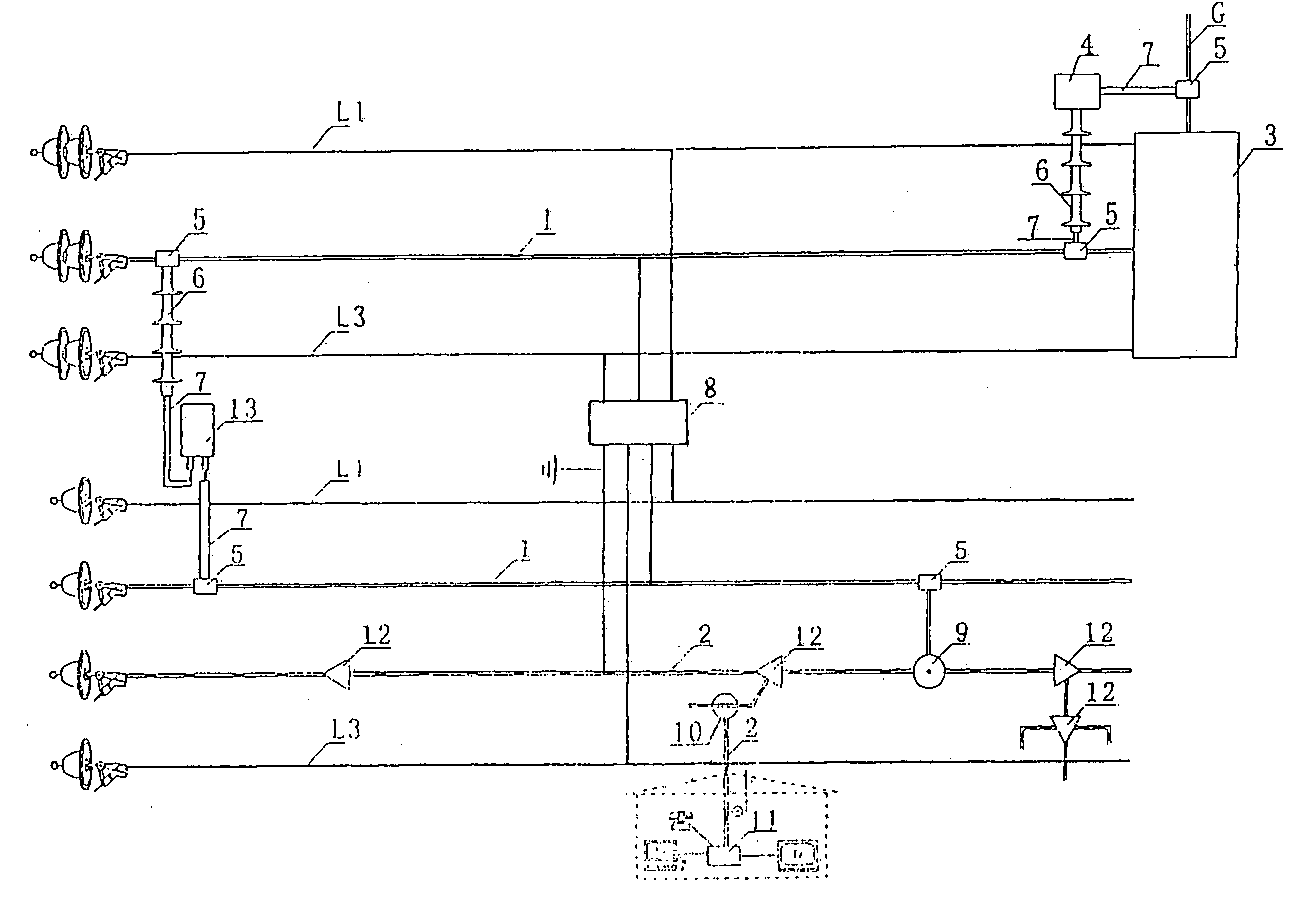

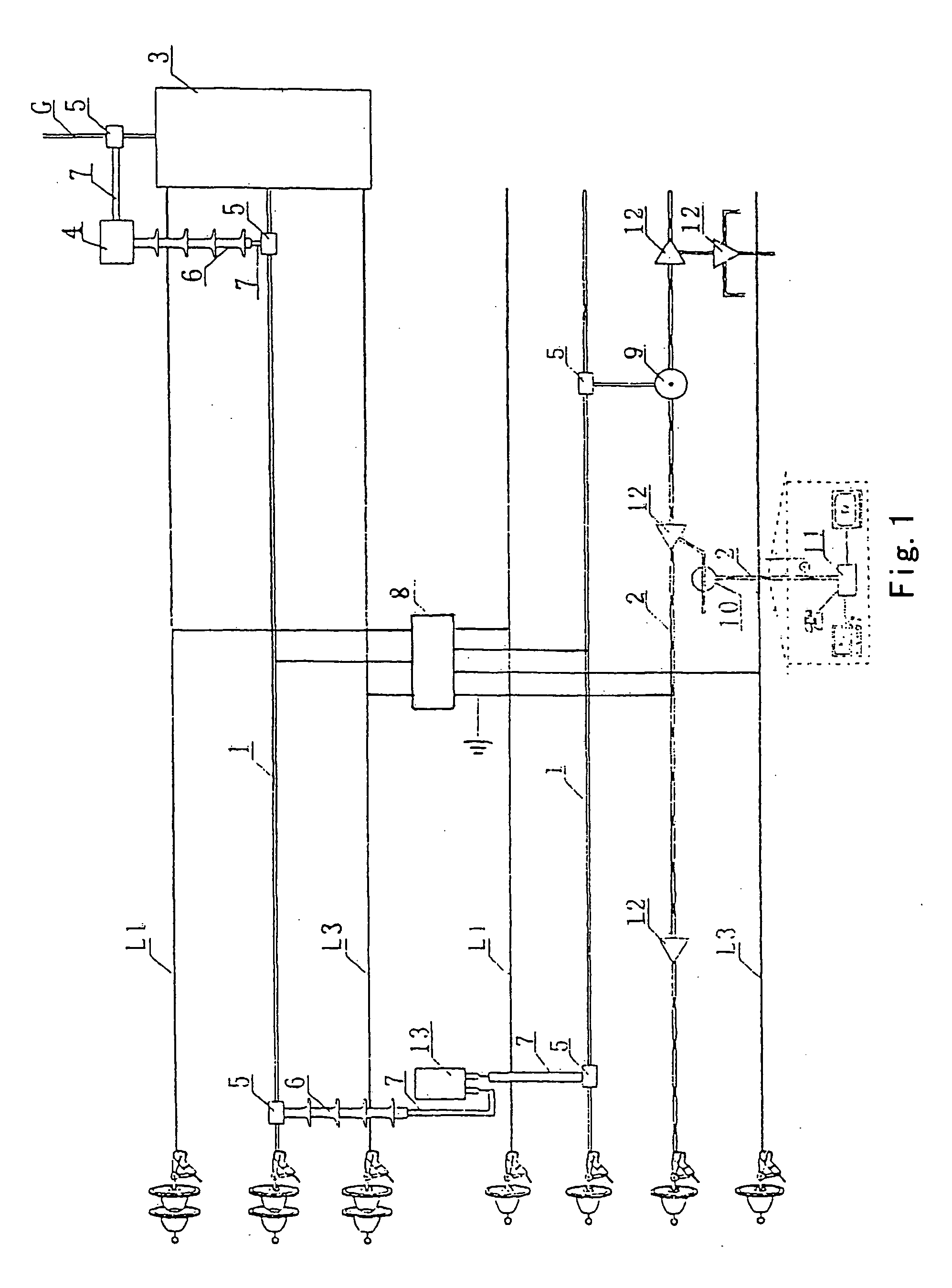

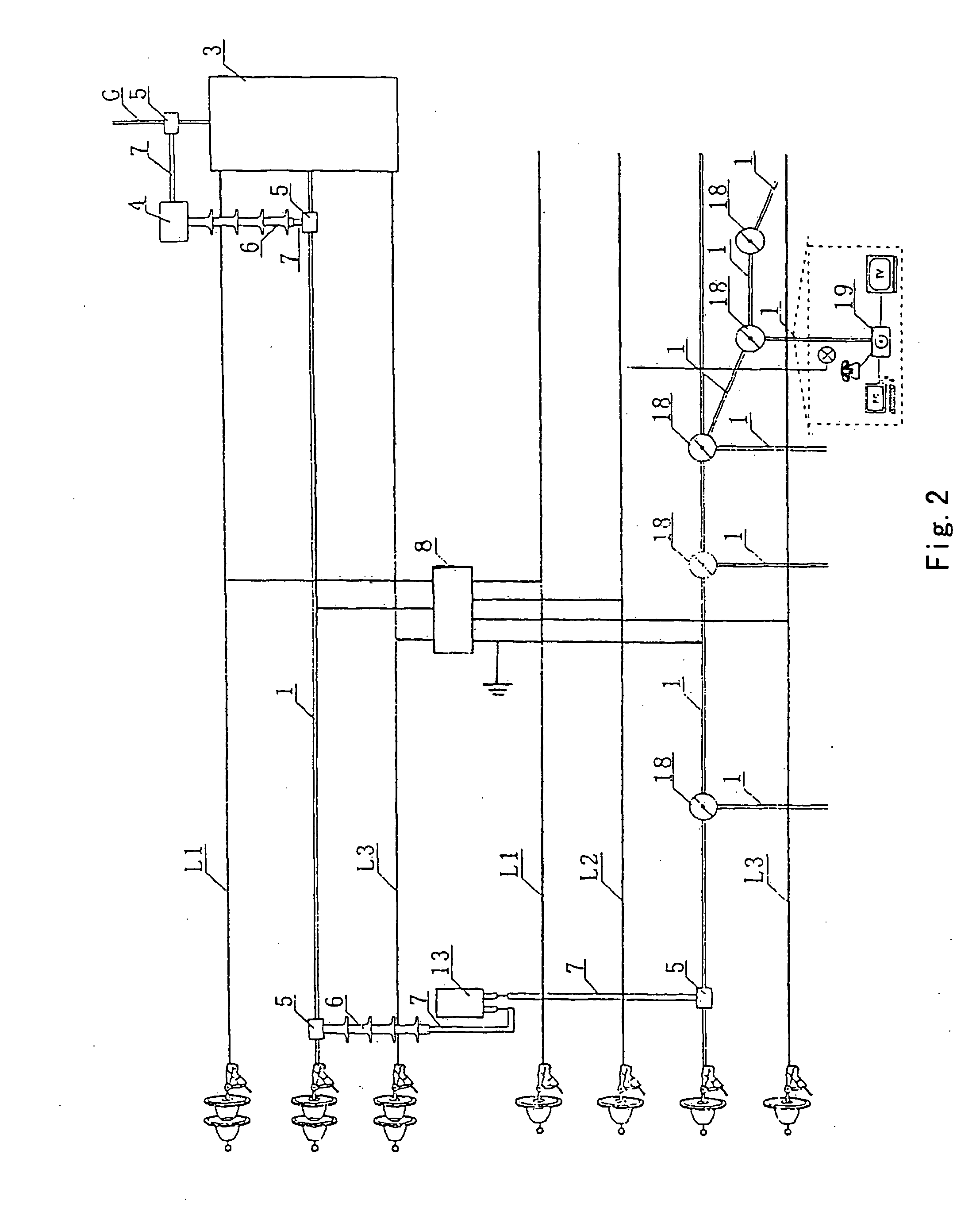

Broadband access transmission network integrating the functions of electric power network, telecommunication network, tv network and internet

InactiveUS20050030118A1Easy to implementConvenient maintain/administrationPulse modulation television signal transmissionOne-port networksElectric power transmissionModem device

A broadband access transmission network integrating the functions of electric power network, communication network, TV network and Internet relates to network transmission. It includes a broadband transmission network of 10 KV power distribution network and a broadband transmission network of low-voltage power distribution network. These two transmission networks are connected via distribution transformers and optical fiber connectors. The broadband transmission network of 10 KV power distribution network is composed of optical compound power lines, wires, transformer substations, machine rooms, taps, insulating jackets, insulating waterproofing outer jackets and optical fiber connectors. The broadband transmission network of low-voltage power distribution network is composed of optical compound power lines, coaxial cable compound power lines, taps, insulating jackets, optical access points, distributors, modems and two-way amplifiers. The invention can perform high-speed broadband communication and power transmission on the same compound wires. It utilizes the existing power network sufficiently and prevents the cost of rebuilding the communication network, cable TV network and Internet, and can simultaneously perform building, operating, maintaining and managing of these networks.

Owner:WANG DEGING

Physiological data collection system

InactiveUS20110237924A1Cost-effectiveEasily attachableElectrotherapyElectrocardiographyCollections dataEngineering

A physiological data collection system facilitates acquiring, recording, transferring and analyzing physiological signals generated from the skin of a human subject that may be used in generating an electrocardiogram for a patient in a continuous manner over an extended period of time of twenty four to forty eight hours. The physiological data collection system is an assembly of a disposable physiological sensor device and a reusable data collection module. Collected physiological data may be transmitted for analysis via either a cable or a wireless communication system.

Owner:HALTHION MEDICAL TECH INC

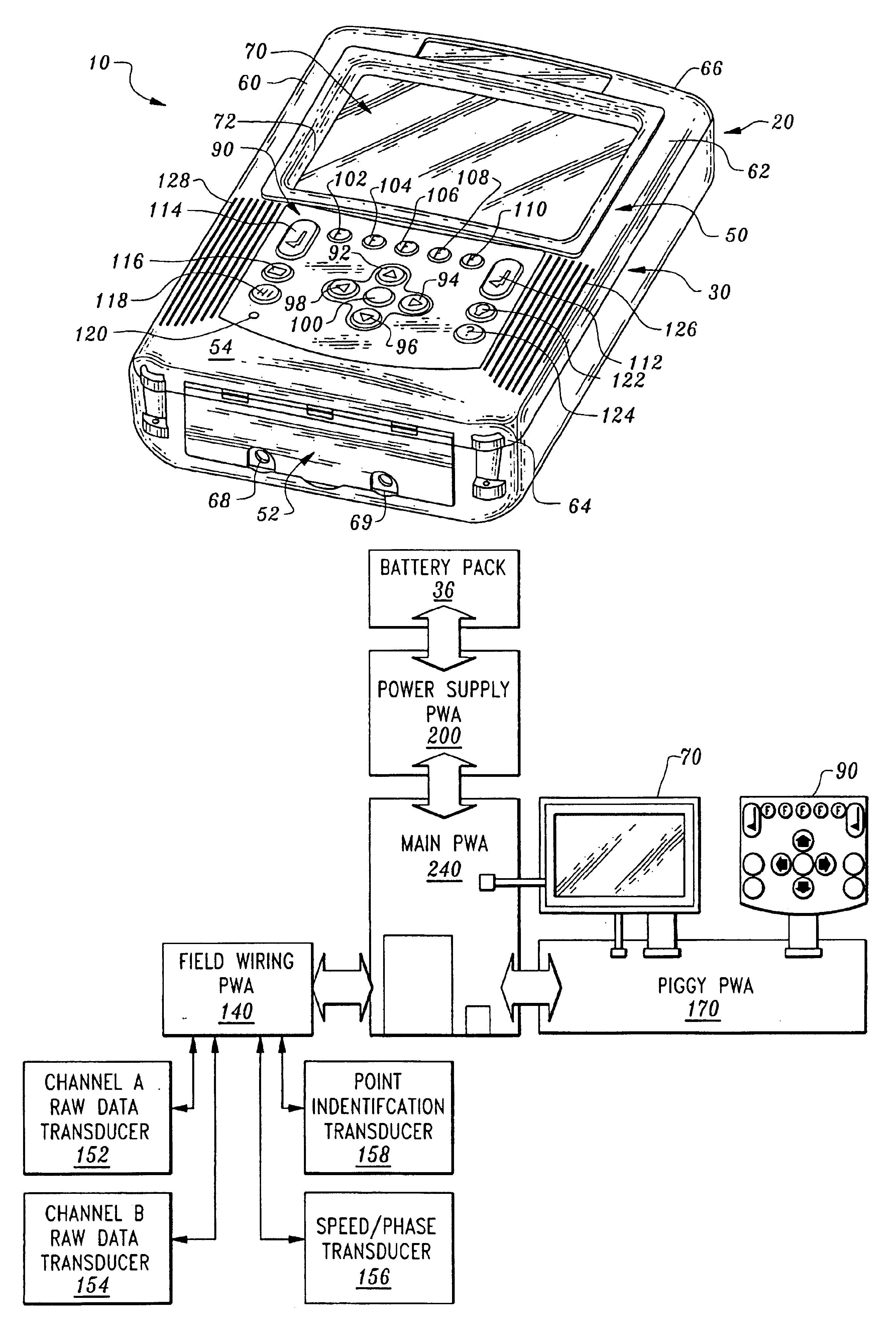

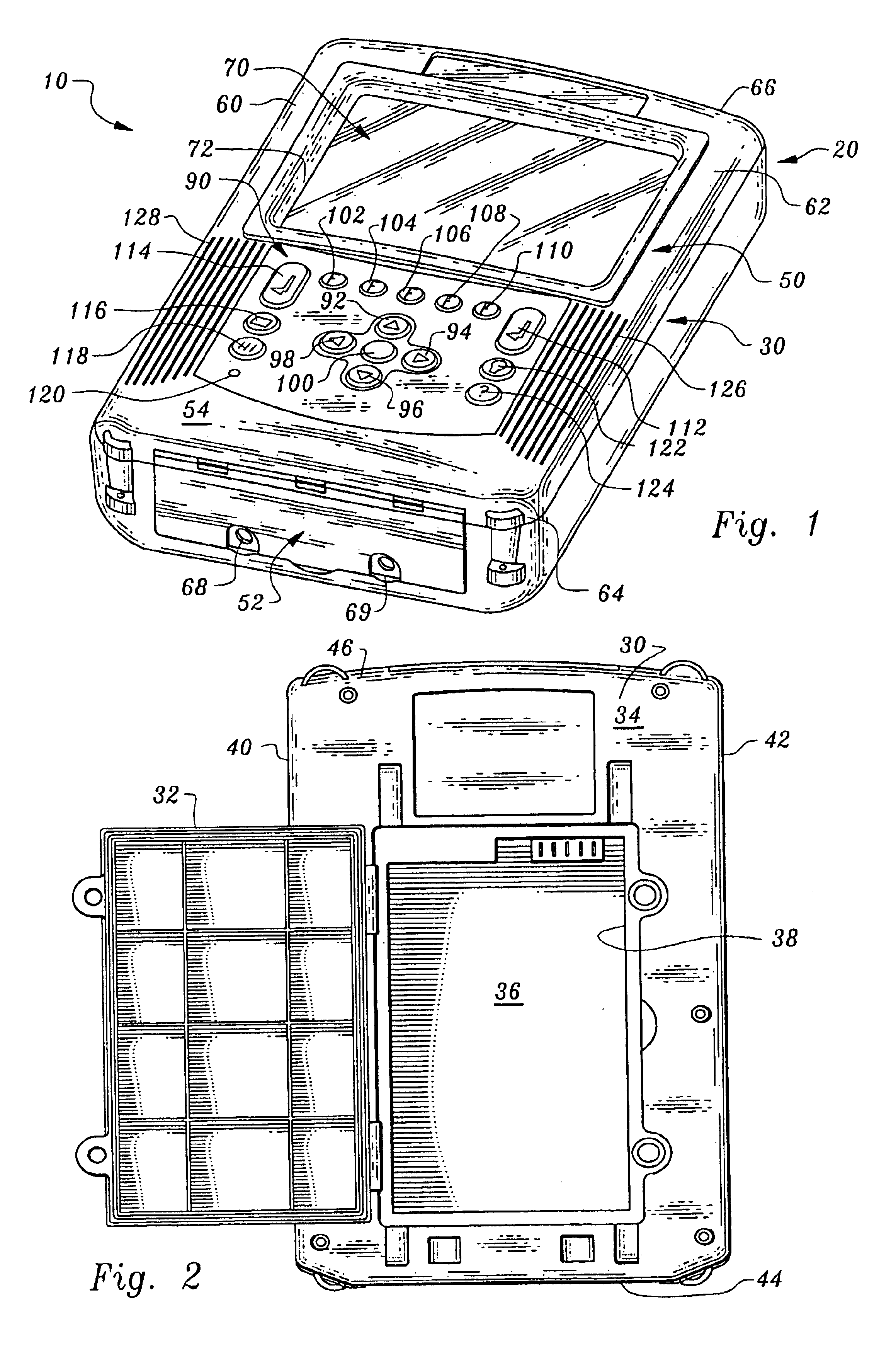

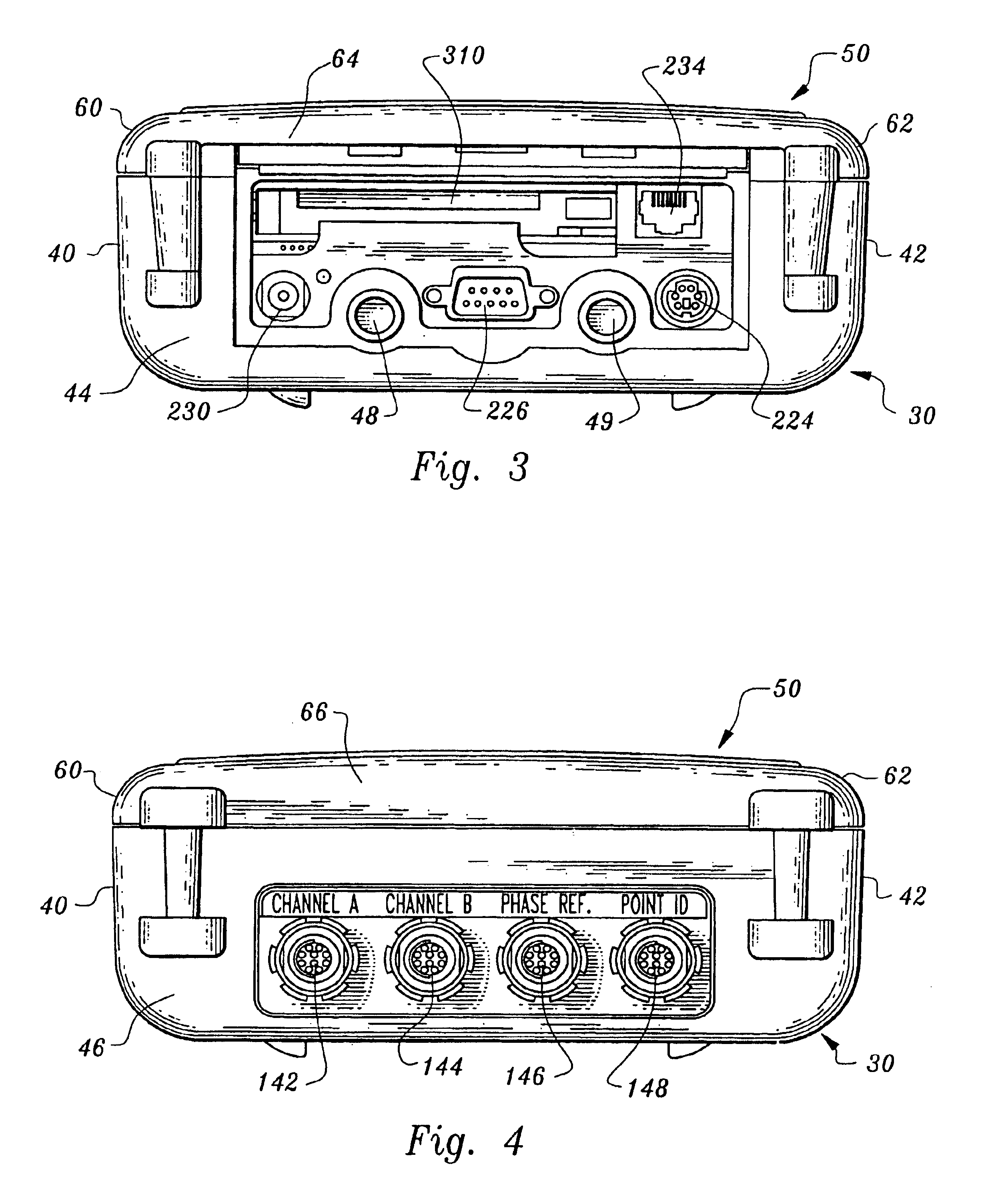

Portable data collector and analyzer: apparatus and method

InactiveUS6789030B1Efficient solutionIncreasing signal processing speedSpectral/fourier analysisNuclear monitoringFrequency spectrumTransducer

A portable data collector and analyzer apparatus and method provides predictive and preventative maintenance of a multiplicity of assets through the use of a unique architecture that allows a variety of different application programs to be downloaded to the apparatus for providing a single multi-purpose portable data collector and analyzer apparatus that can employ the variety of different application programs for configuring, inter alia, different measurements types, different transducers types and different signal processing types for collecting and analyzing sensed physical data from a variety of different assets found in industrial plants. A unique frequency shifting and decimation method is employed for spectrum calculation that, inter alia, retains DSP addressing efficiency and increases signal processing speed. Additionally, a unique synchronous sampling method is employed that generates synchronous sample waveforms from asynchronous sample waveforms. Furthermore, a unique clear touch screen overlying a quarter VGA display, an ergonomically designed keypad, and an intuitive user interface allow quick and easy setup and operation for in-field data acquisition, analysis and display.

Owner:BENTLY NEVADA INC

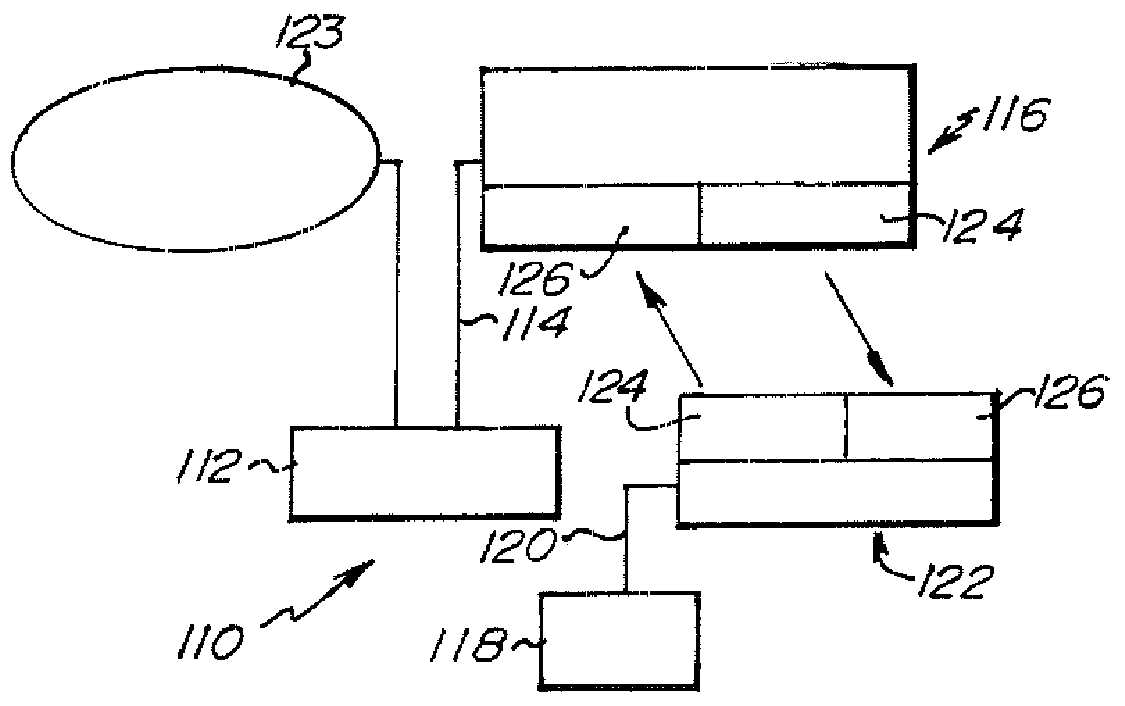

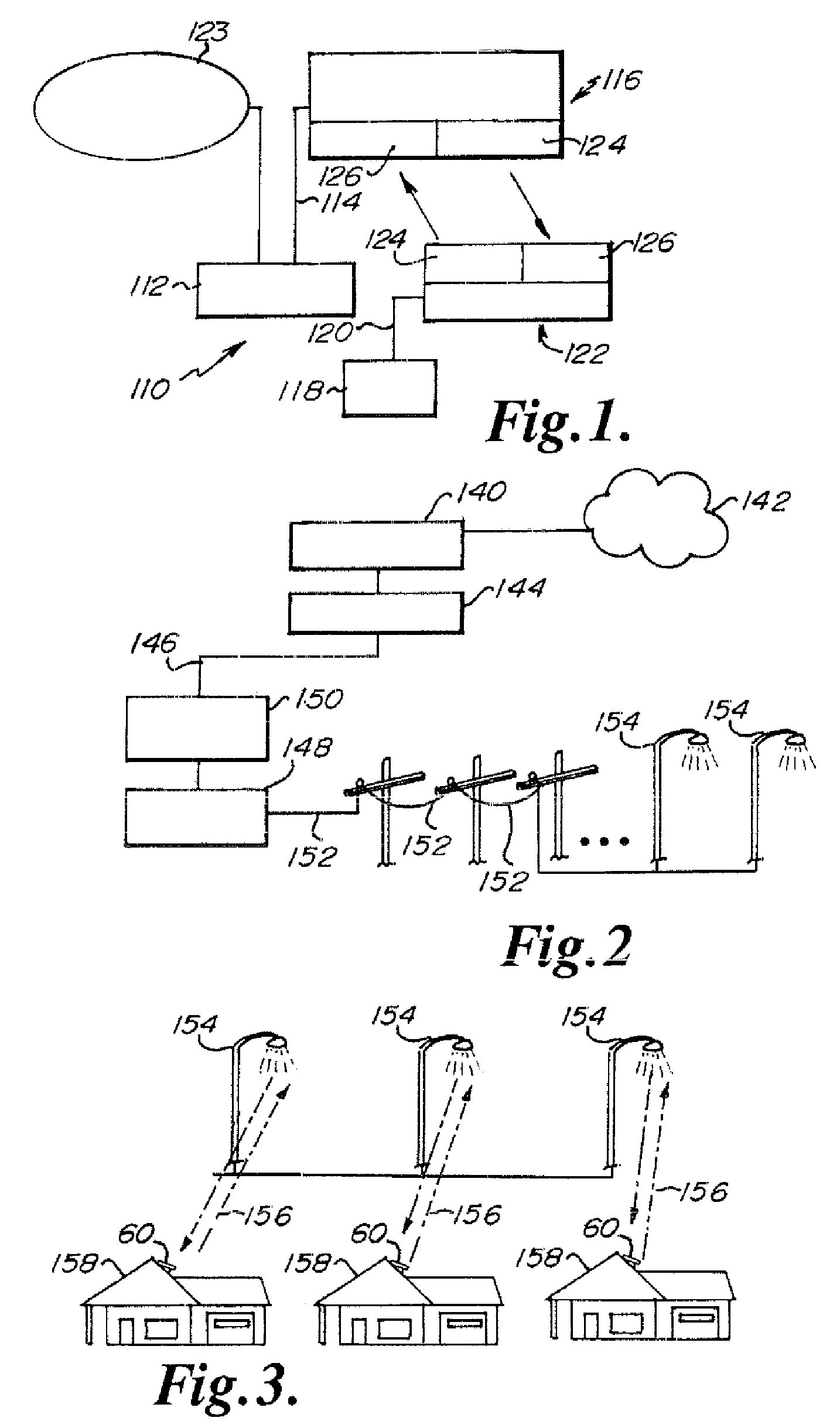

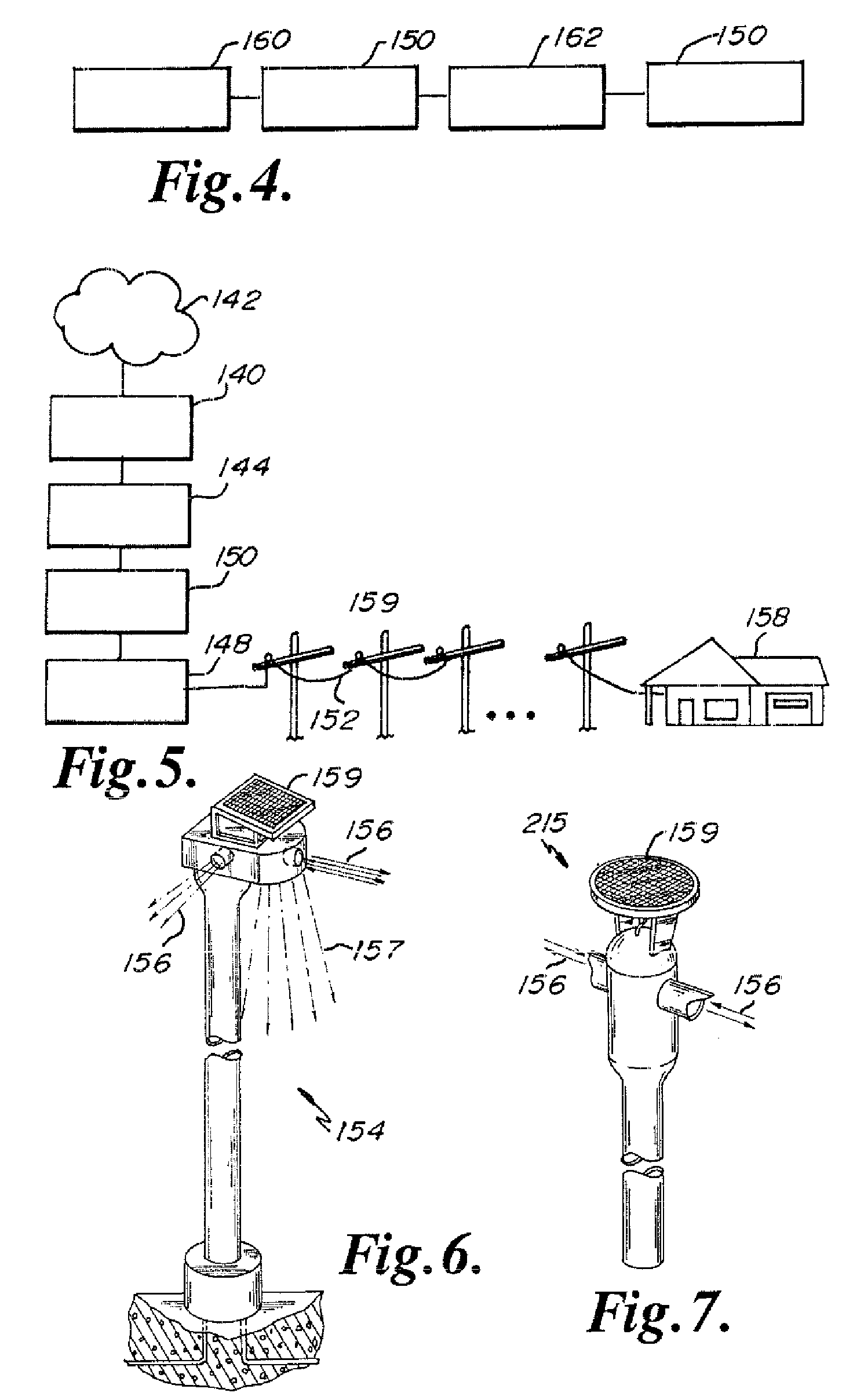

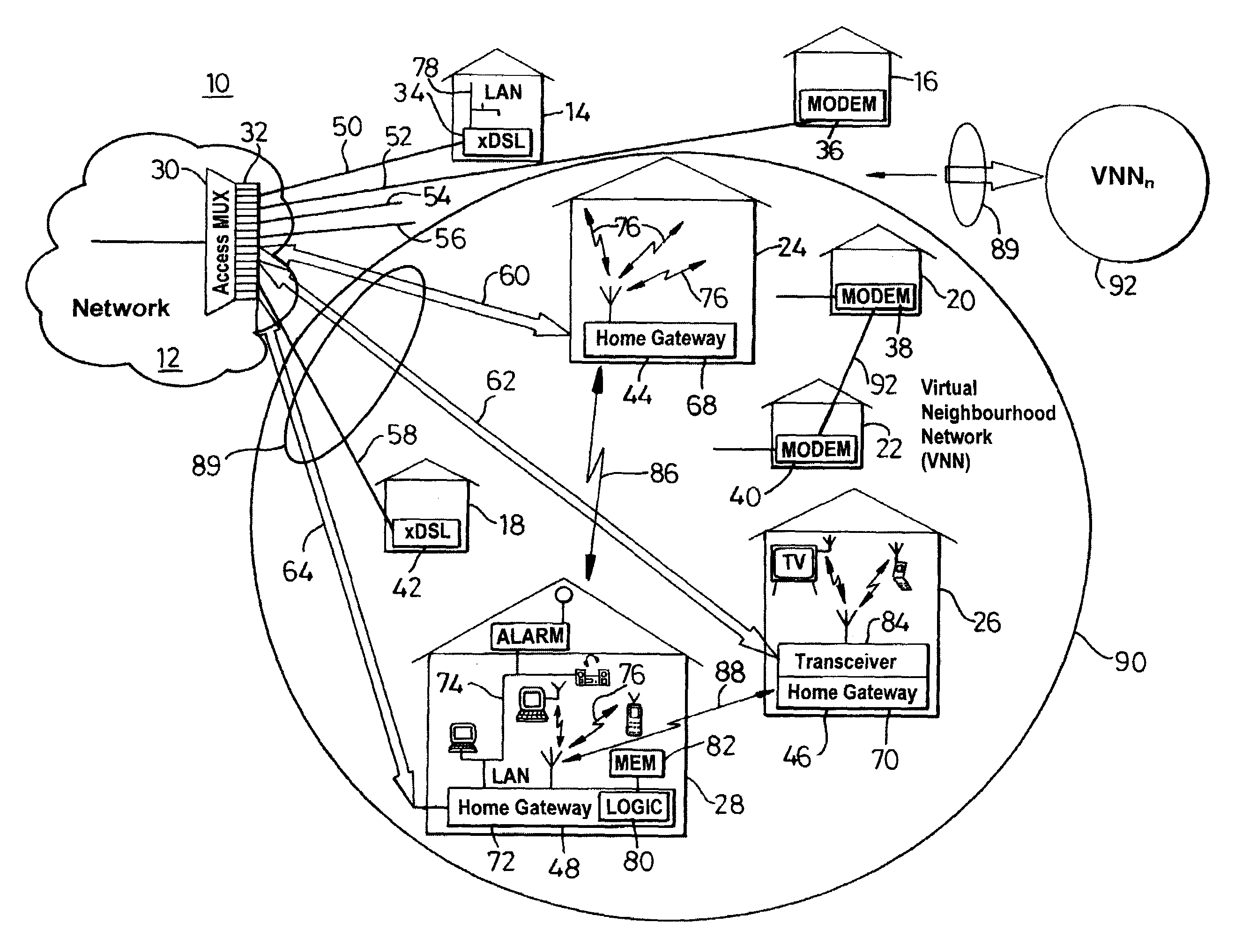

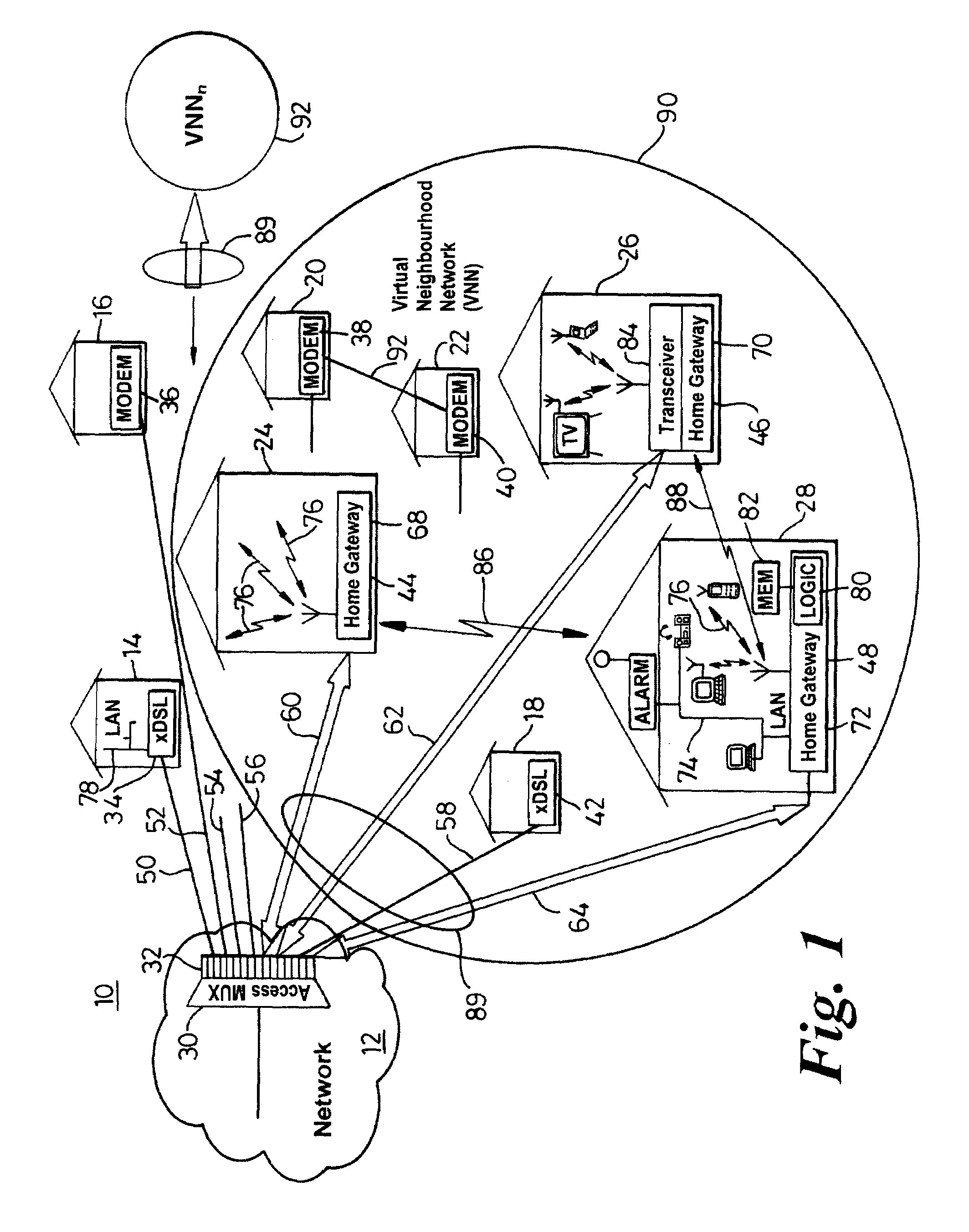

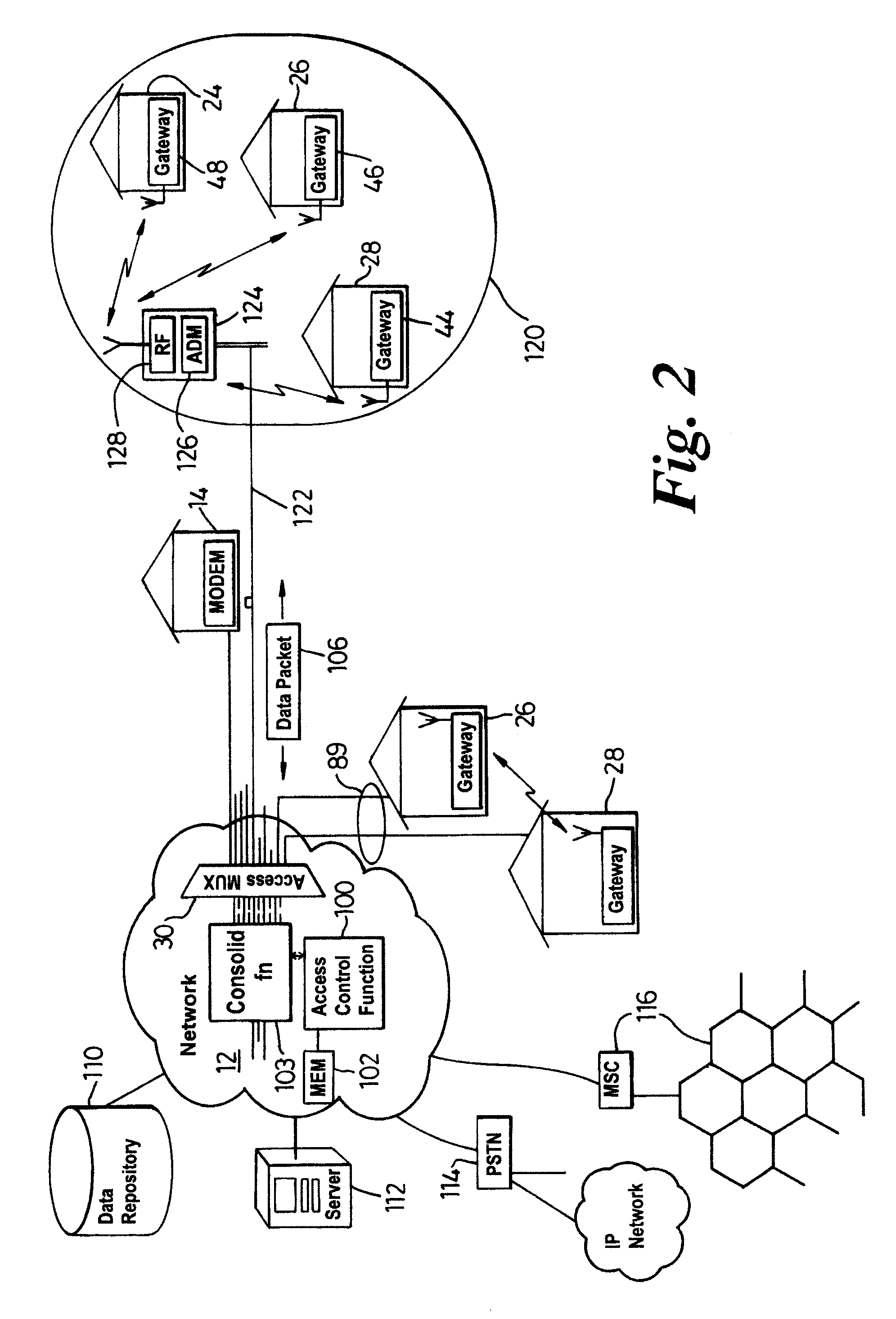

Communication system architecture and operating methodology providing a virtual neighborhood network

InactiveUS7142503B1Overcome bandwidth limitationIncreased peak bandwidth capacityError preventionFrequency-division multiplex detailsEnd-to-end encryptionTransceiver

A communication system (10) supports the provision of a plurality of dedicated communication resources (50–64), such as copper drops, RF links and optical fibers, to dedicated home-gateway devices (44–48) or distribution points (124). The communication resources (50–64) support broadband interconnection (104) between the dedicated home-gateway devices (44–48) or distribution points (124) and an access multiplexor (30) in a network (12). Each gateway device (44–48) or distribution point (124) generally includes a local RF transceiver (84) and associated control logic (80–82) that allows local communication (86) between gateway devices (44–48) and hence statistically multiplexed access (60–64, 89) to multiple communication resources, thereby providing increased bandwidth in uplink and / or downlink directions. With the control logic (80) operable to provide a routing and prioritisation / arbitration function, each gateway (44–48) is able to selectively engage use of supplemental, non-reserved communication resources usually associated with a dedicated ono-to-one connection between the access network (12) and at least one secondary gateway. Physical layer access to information routed via a secondary gateway within a virtual neighborhood network (90–92) comprising several gateways is restricted through an end-to-end encryption algorithm between an originating gateway and, at least, the access multilpexor (30).

Owner:RPX CLEARINGHOUSE

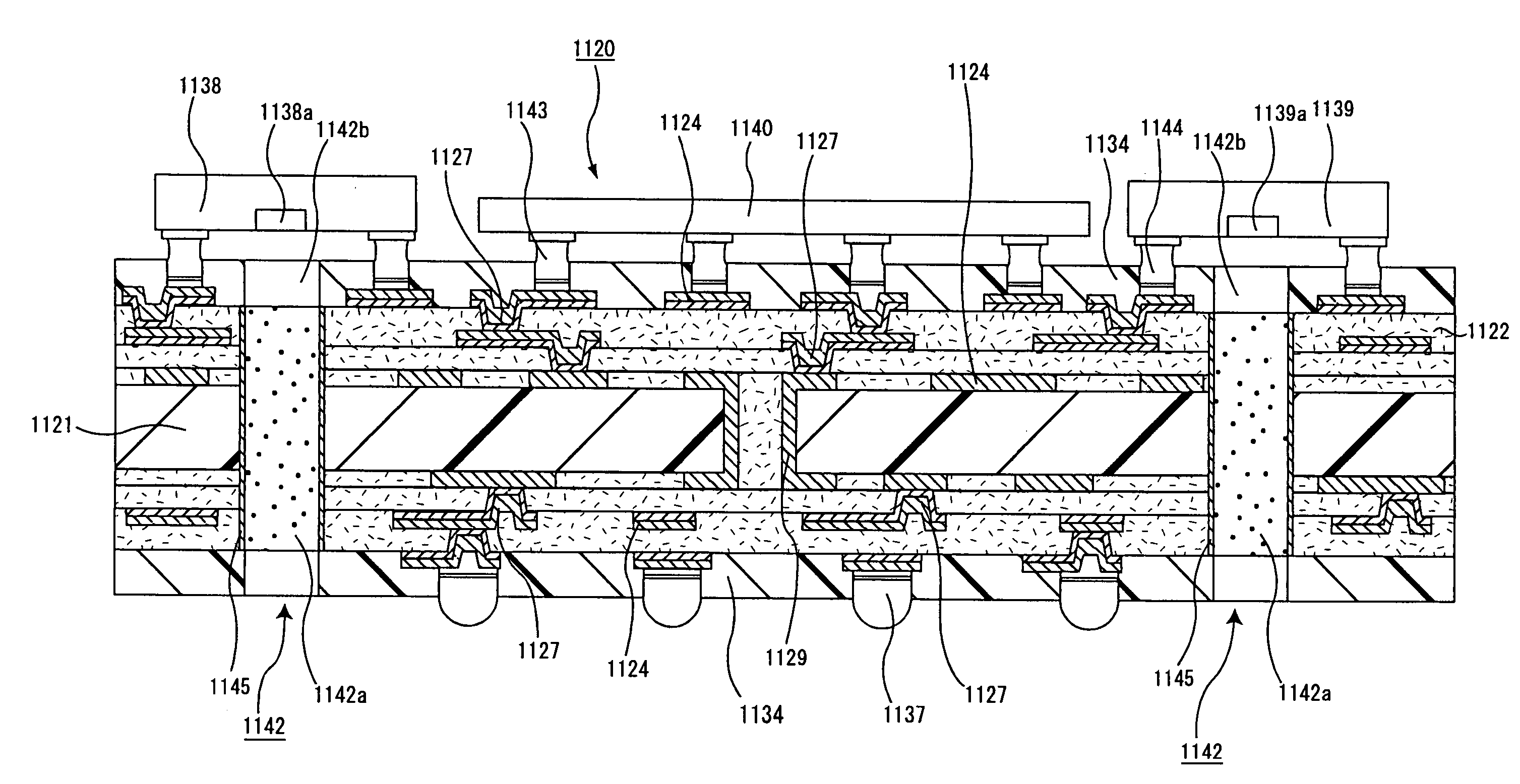

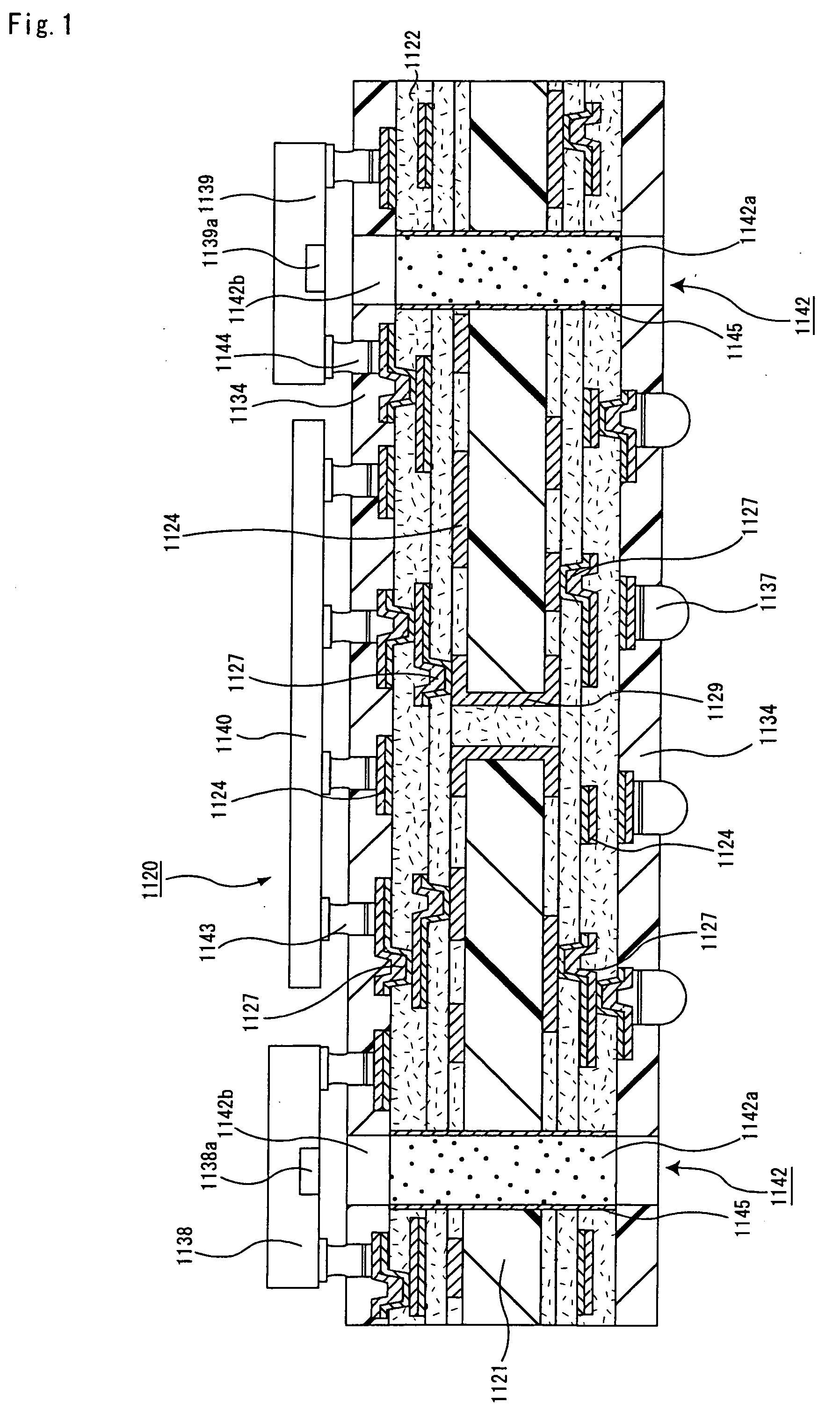

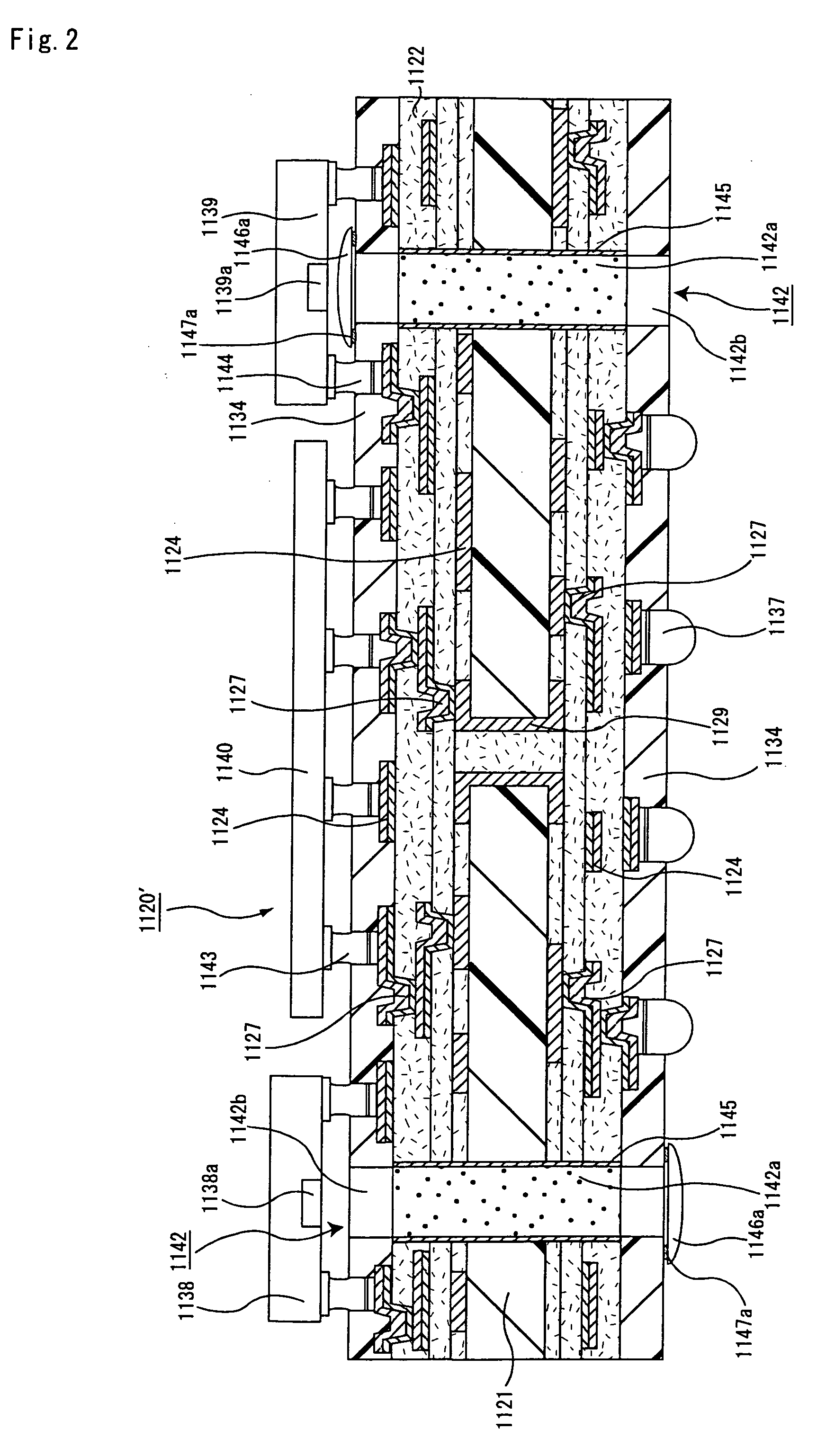

Ic chip mounting substrate, ic chip mounting substrate manufacturing method, optical communication device, and optical communication device manufacturing method

InactiveUS20060012967A1Improve connection reliabilitySmall sizeCircuit optical detailsSolid-state devicesResistElectrical conductor

An object of the present invention is to provide a substrate for mounting an IC chip which is a component for optical communication having an IC chip and an optical component integrally provided thereon, which can ensure a short distance between the IC chip and the optical component, which is excellent in electric signal transmission reliability and which can transmit optical signal through an optical path for transmitting optical signal. The substrate for mounting an IC chip of the present invention is a substrate for mounting an IC chip comprising: a substrate and, as serially built up on both faces thereof, a conductor circuit and an interlaminar insulating layer in an alternate fashion and in repetition; a solder resist layer formed as an outermost layer; and an optical element mounted thereto, wherein an optical path for transmitting optical signal, which penetrates the substrate for mounting an IC chip, is disposed.

Owner:IBIDEN CO LTD

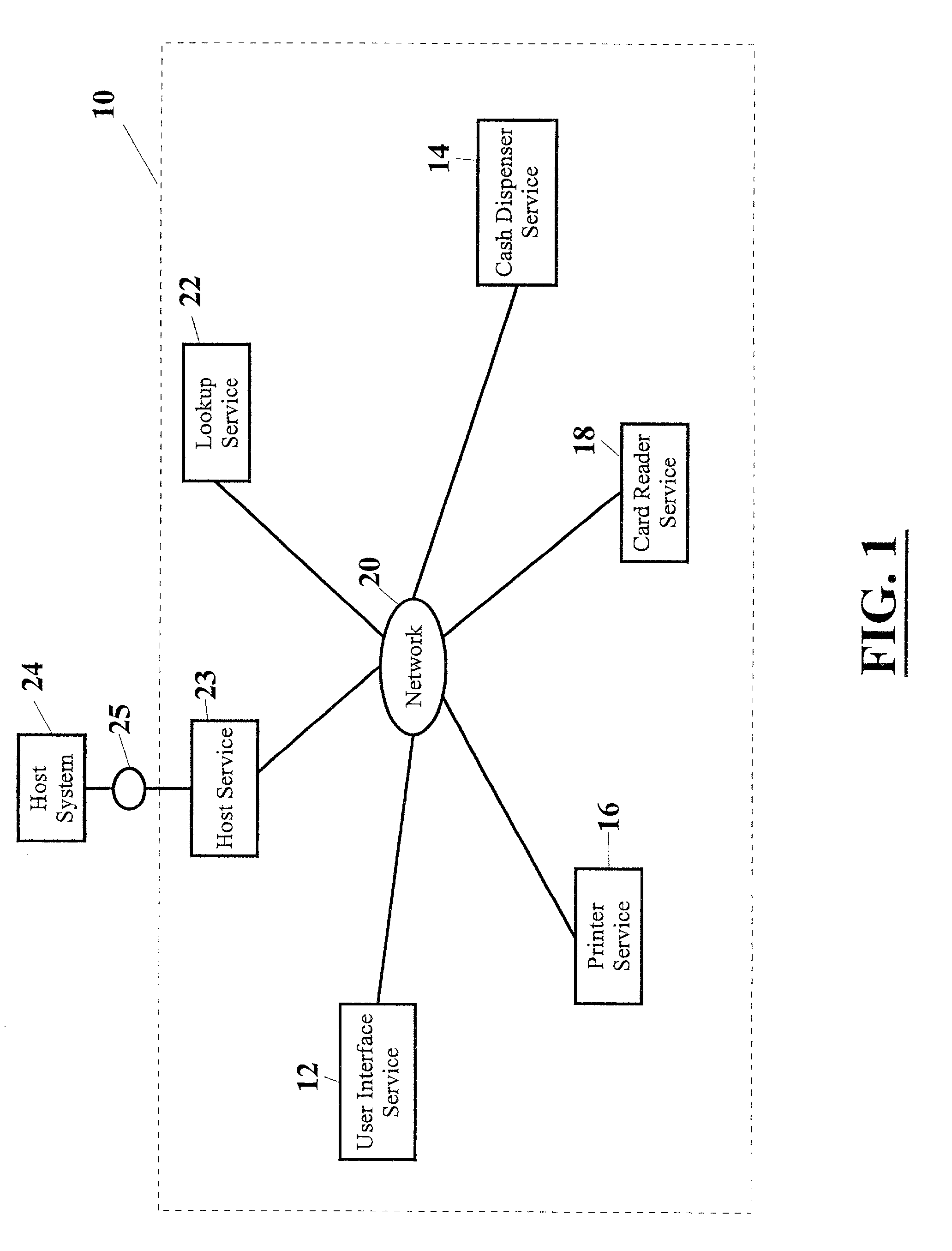

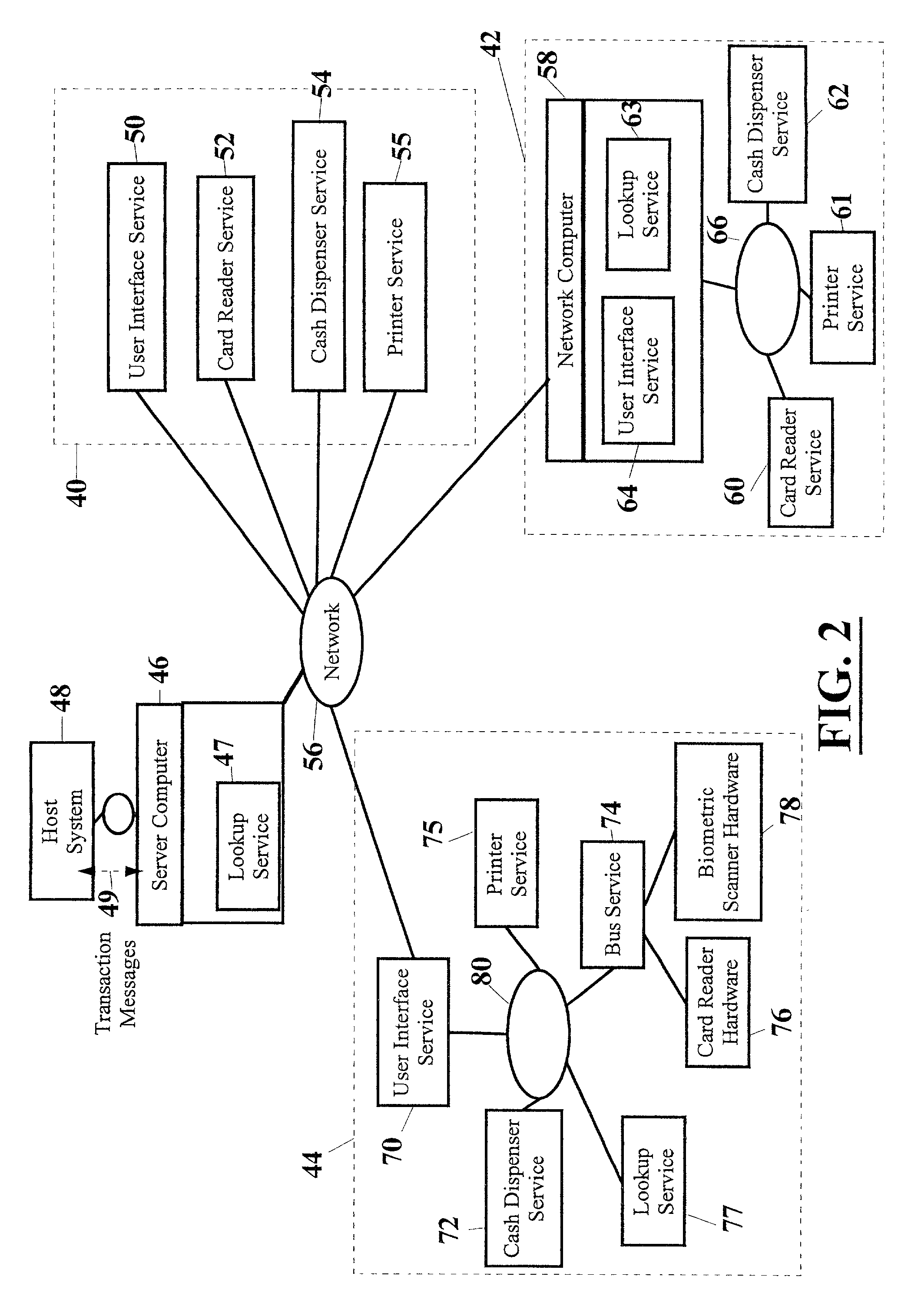

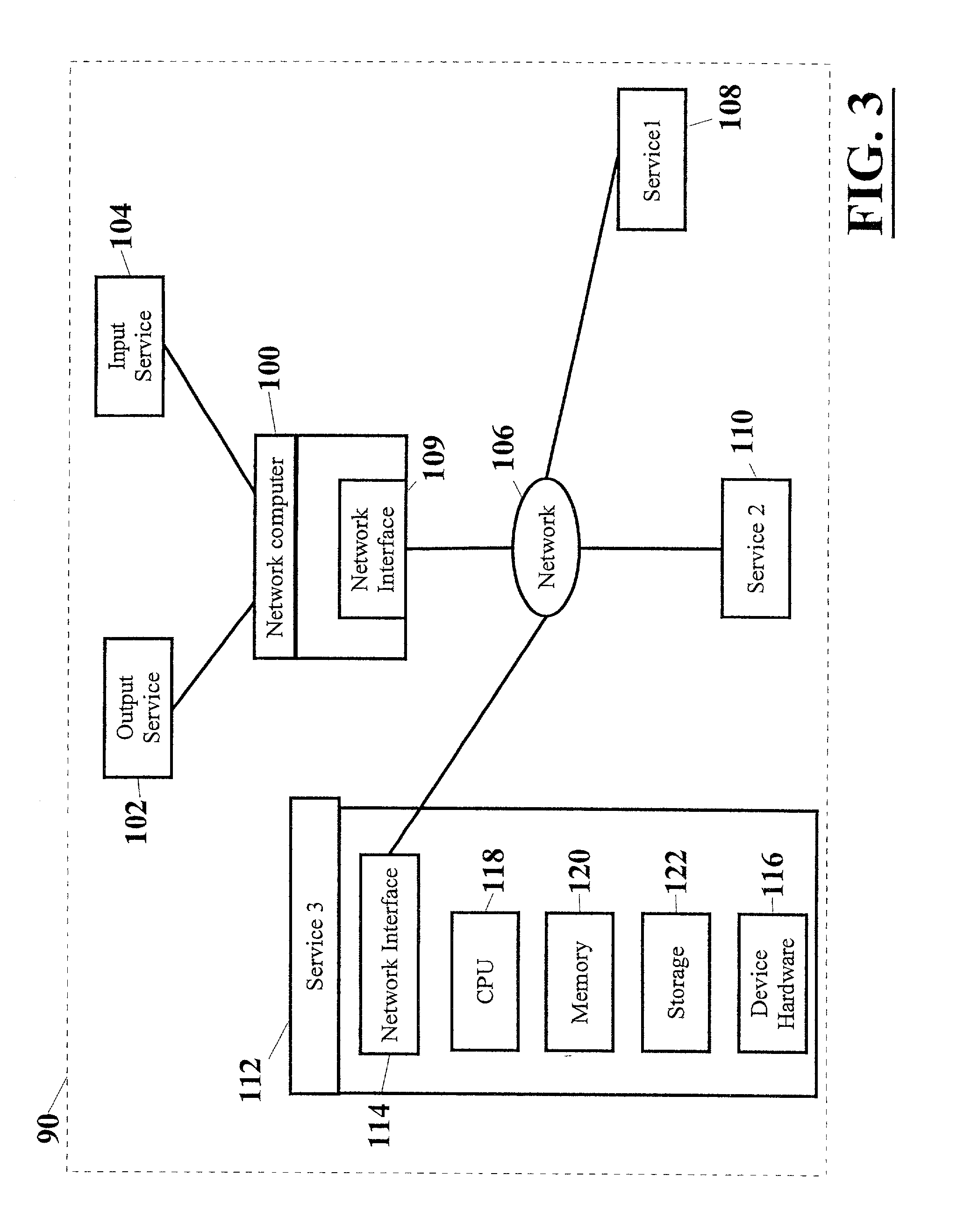

Automated transaction machine and method

InactiveUS20010014881A1Firmly connectedExtension of timeComplete banking machinesFinanceTransaction serviceCard reader

A system for connecting transaction services to an ATM (10, 500) that includes a network (20). A user interface service (12) and a lookup service (22) are in operative connection with the network. Transaction services such as a printer service (16), card reader service (18), and cash dispenser service (14) are also in operative connection with the network. These transaction services are operative to register with the lookup service and to upload a service proxy to the lookup service. The user interface service is operative to locate transaction services on the network by invoking a remote lookup method on the lookup service. The lookup service is operative to return service proxies that match the type of service that is required. The user interface service is further operative to invoke methods of the service proxies that remotely control the functionality of the transaction services on the network. The user interface service is further operative to register events with the service proxies for notification when certain events on the services occur.

Owner:DIEBOLD NIXDORF

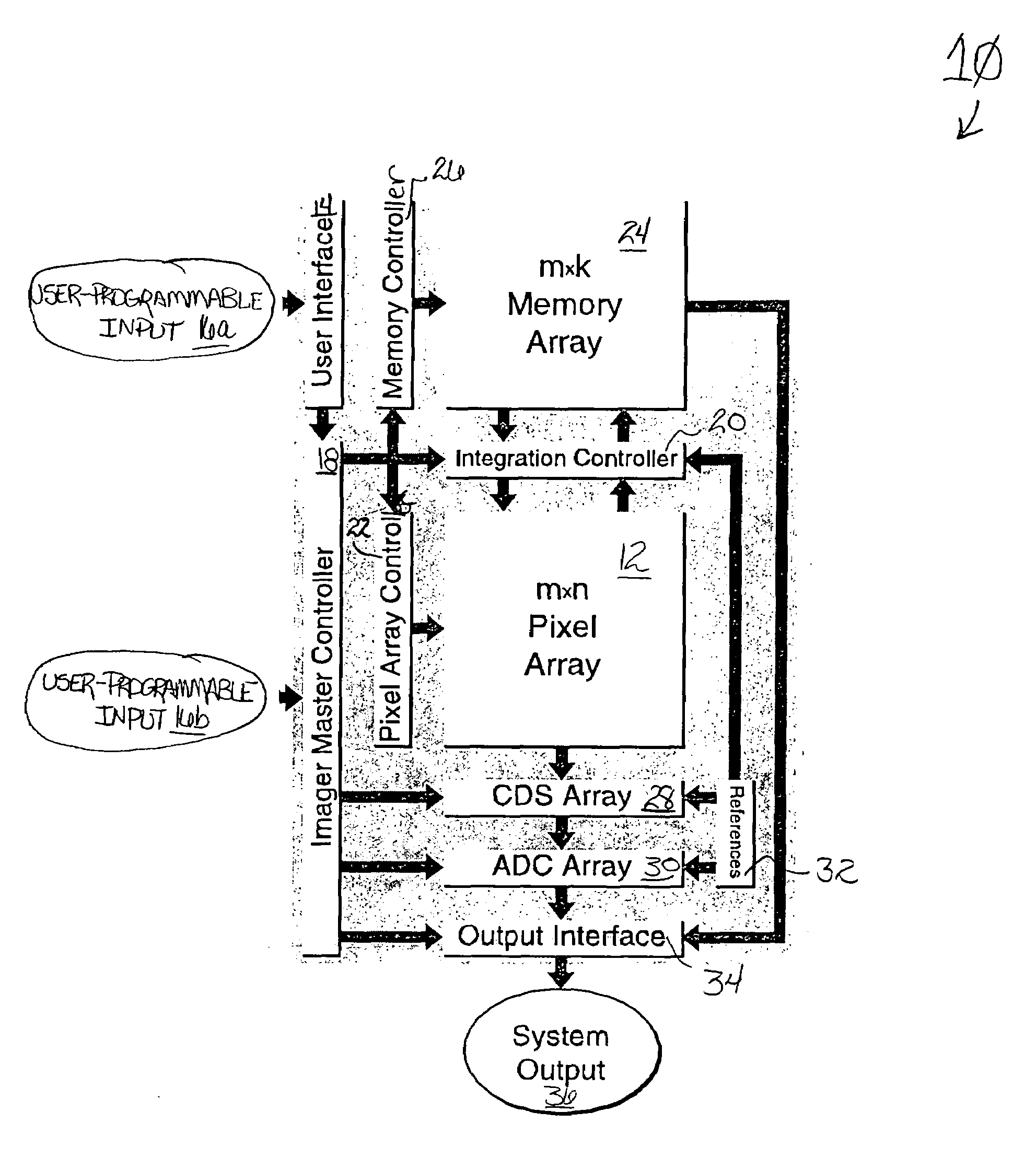

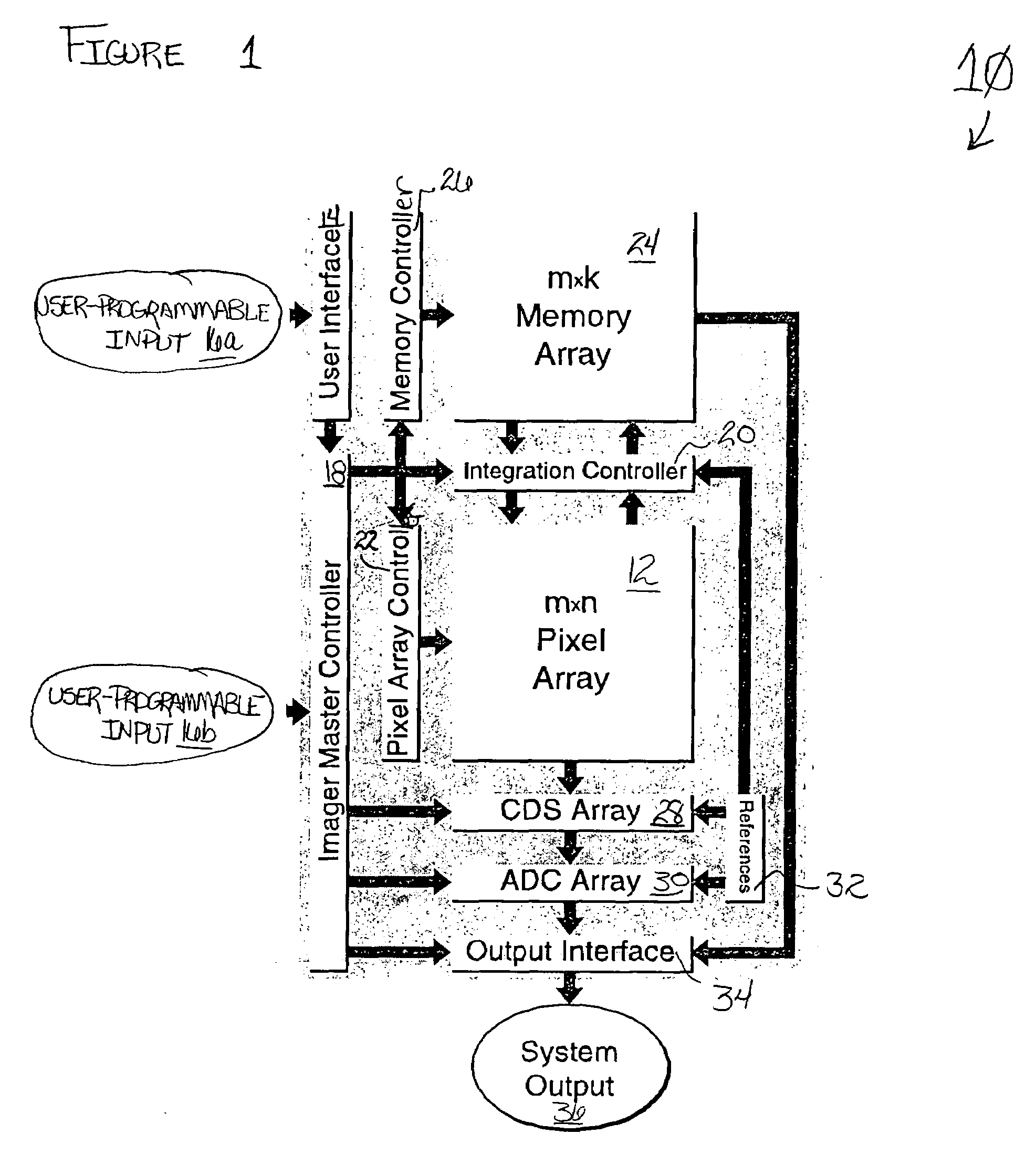

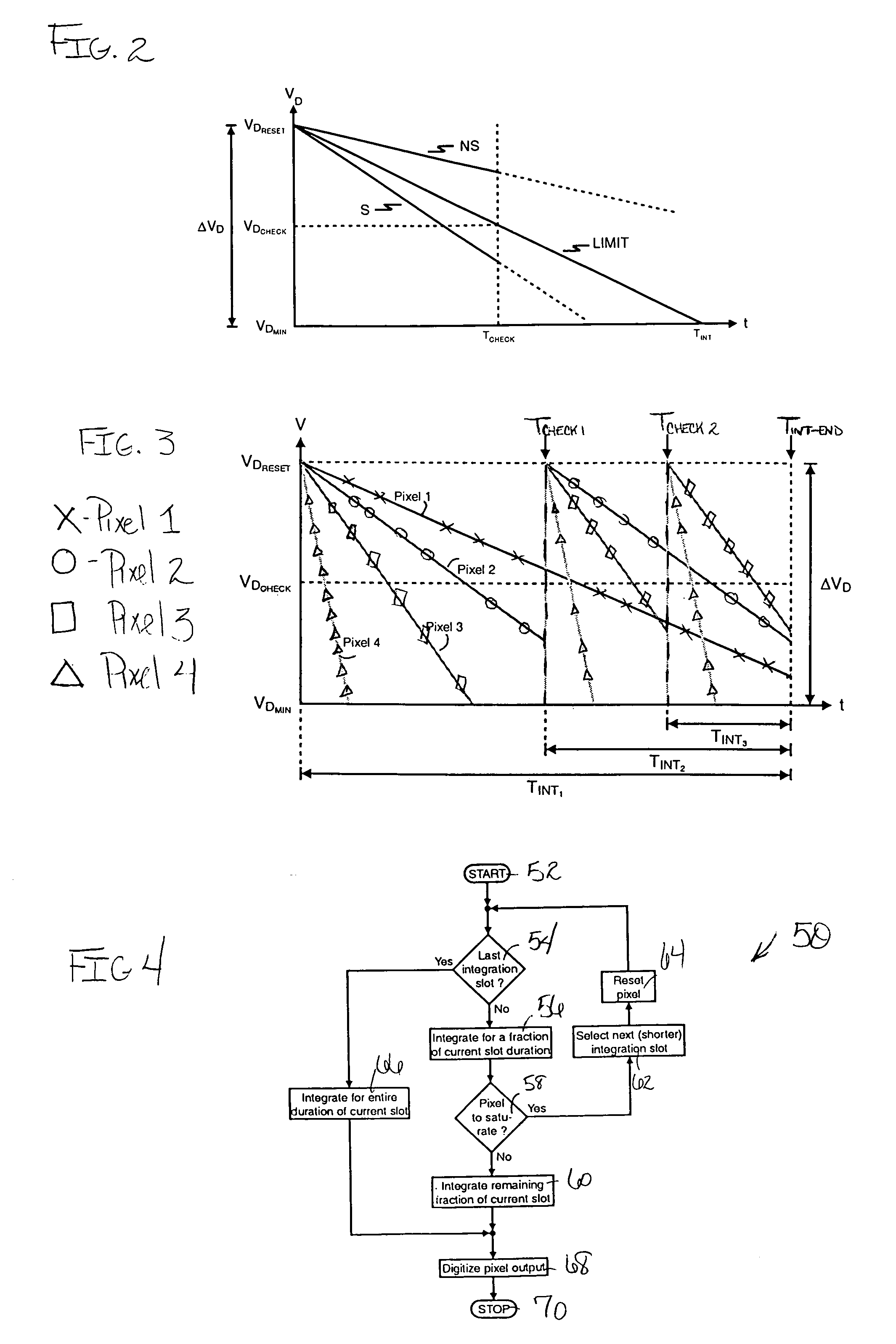

Single-chip imager system with programmable dynamic range

InactiveUS6977685B1Elegantly simple input/output connectionProduced cost-effectivelyTelevision system detailsTelevision system scanning detailsControl signalEngineering

The imager system of the invention, provided in a semiconductor substrate, includes a plurality of photosensitive, charge integrating pixels that are arranged in rows and columns of a pixel array for capturing illumination of a scene to be imaged. Each pixel includes a photogenerated charge accumulation region of the semiconductor substrate and a sense node at which an electrical signal, indicative of pixel charge accumulation, can be measured without discharging the accumulation region. Pixel access control circuitry is connected to pixel array rows and columns to deliver pixel access signals generated by the access control circuitry for independently accessing a selected pixel in the array. An input interface circuit is connected to accept a dynamic range specification input for the array pixels. Integration control circuitry is connected to access a selected pixel of the array to read the sense node electrical signal of the selected pixel, and configured to generate pixel-specific integration control signals delivered to the selected pixel, independent of other pixels, based on dynamic range specification input provided by the input interface circuit. An output interface circuit is connected to the pixel array to produce output image data based on sense node electrical signals from the pixel array.

Owner:MASSACHUSETTS INST OF TECH

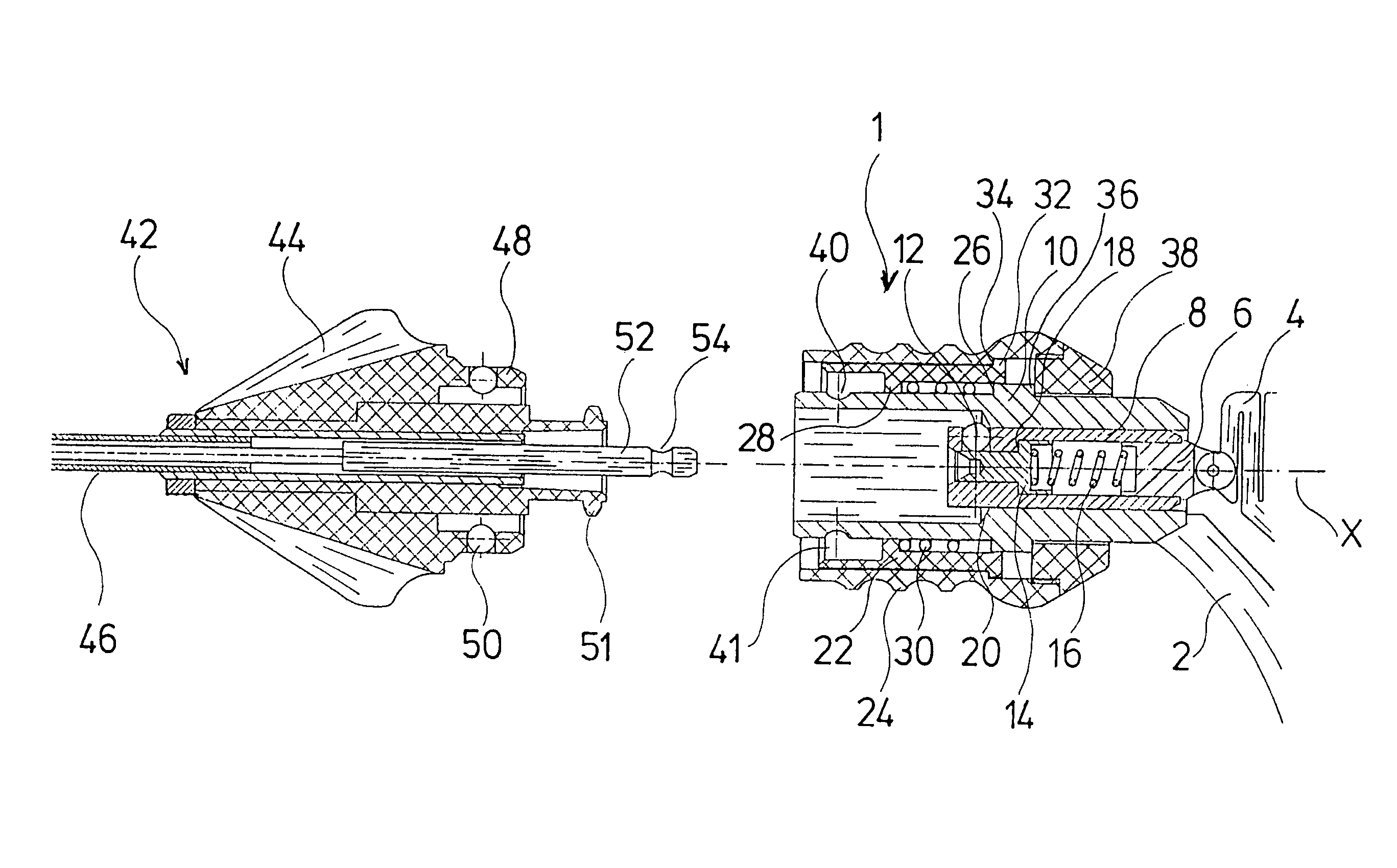

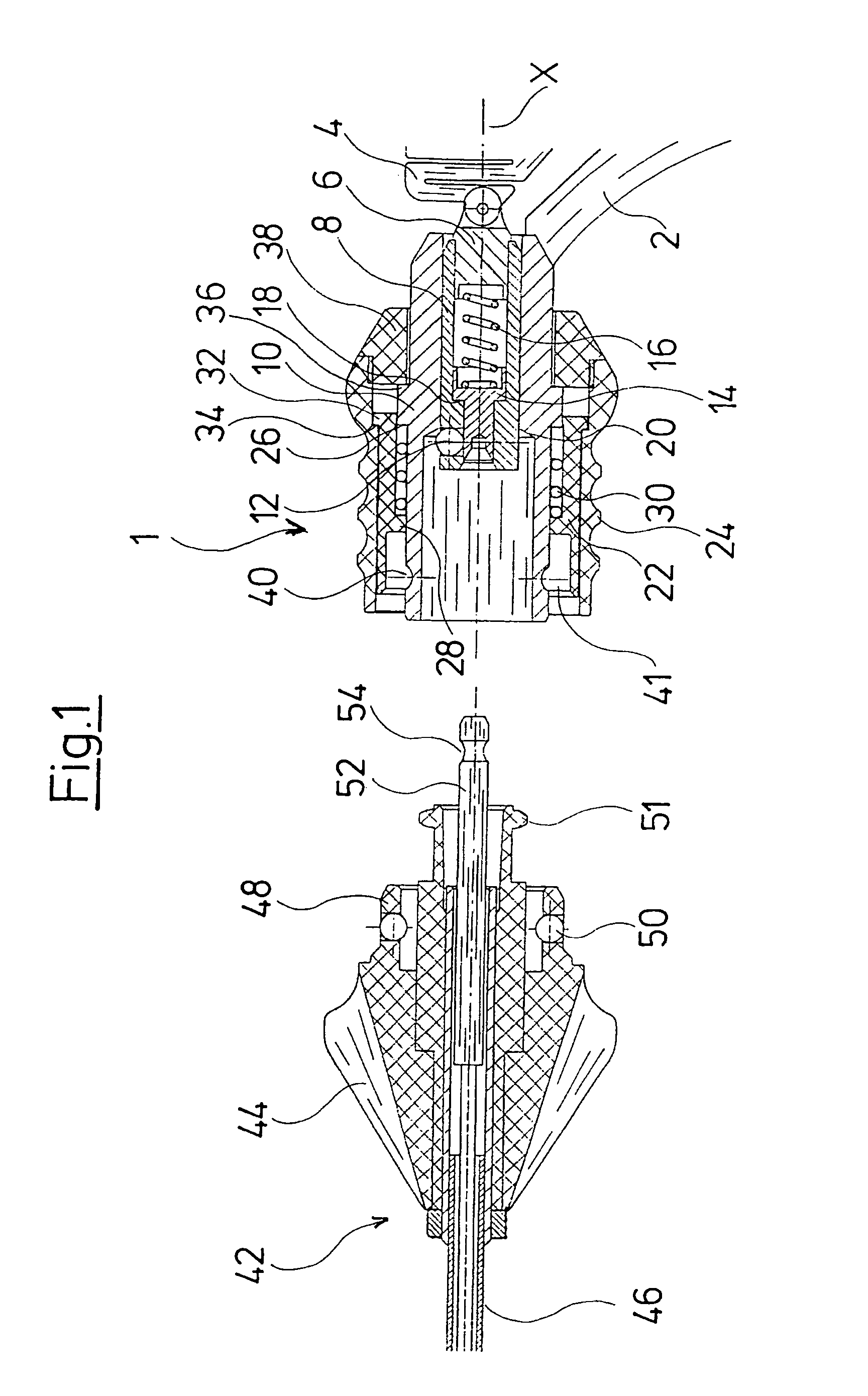

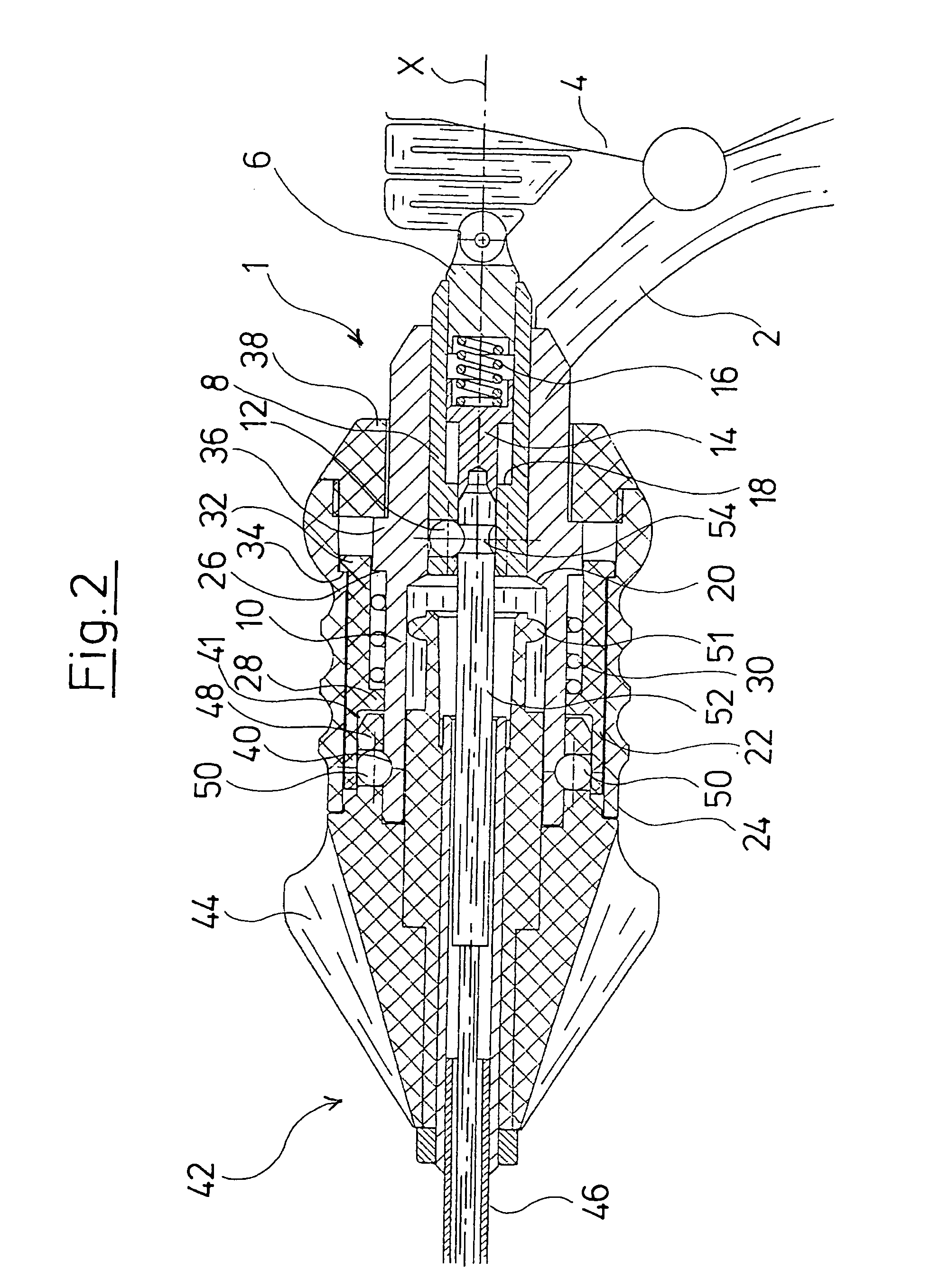

Medical instrument

ActiveUS8114118B2Firmly connectedEasy to identifySleeve/socket jointsFirst-aid kitsEngineeringMedical instruments

A medical instrument has an instrument insert and an instrument handle, which are detachably connected to one another. An actuation rod of the instrument insert is releasably connectable to a movable grip of the instrument handle via a locking connection. A blocking element is provided which blocks the movable grip when the actuation rod has been released.

Owner:RICHARD WOLF GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com