Patents

Literature

20549results about How to "Simple manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

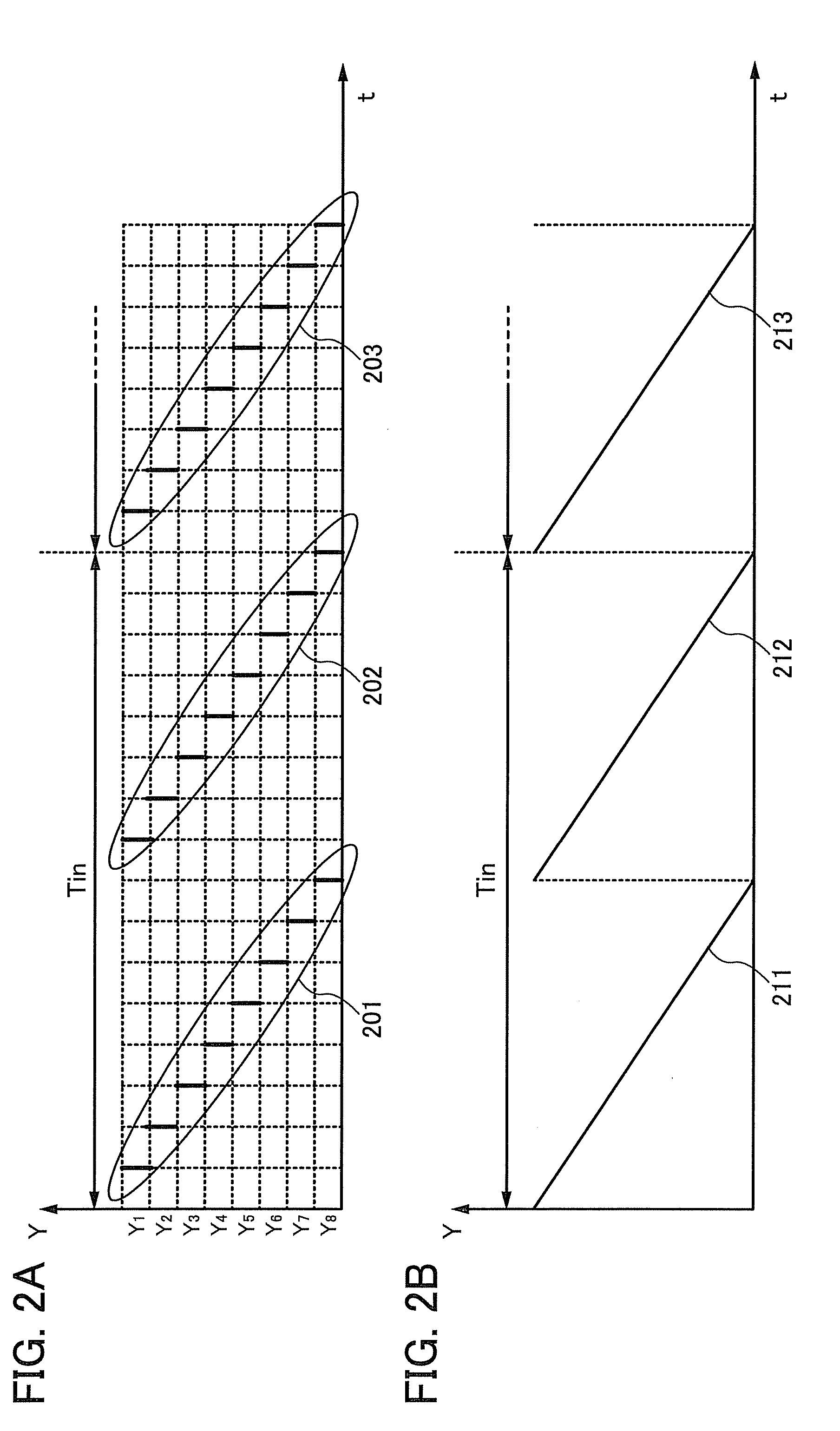

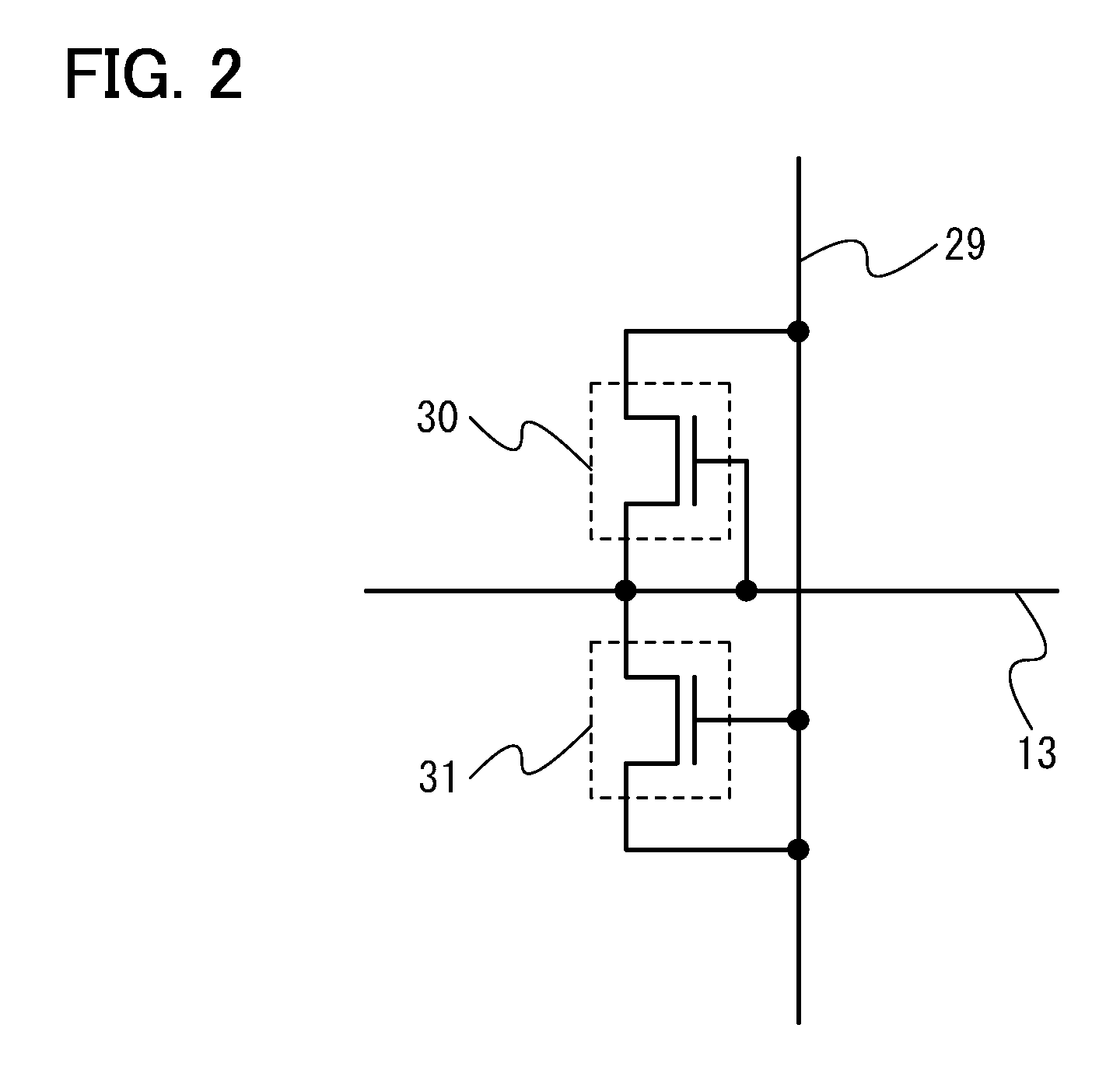

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060170111A1Stable formationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialShortest distance

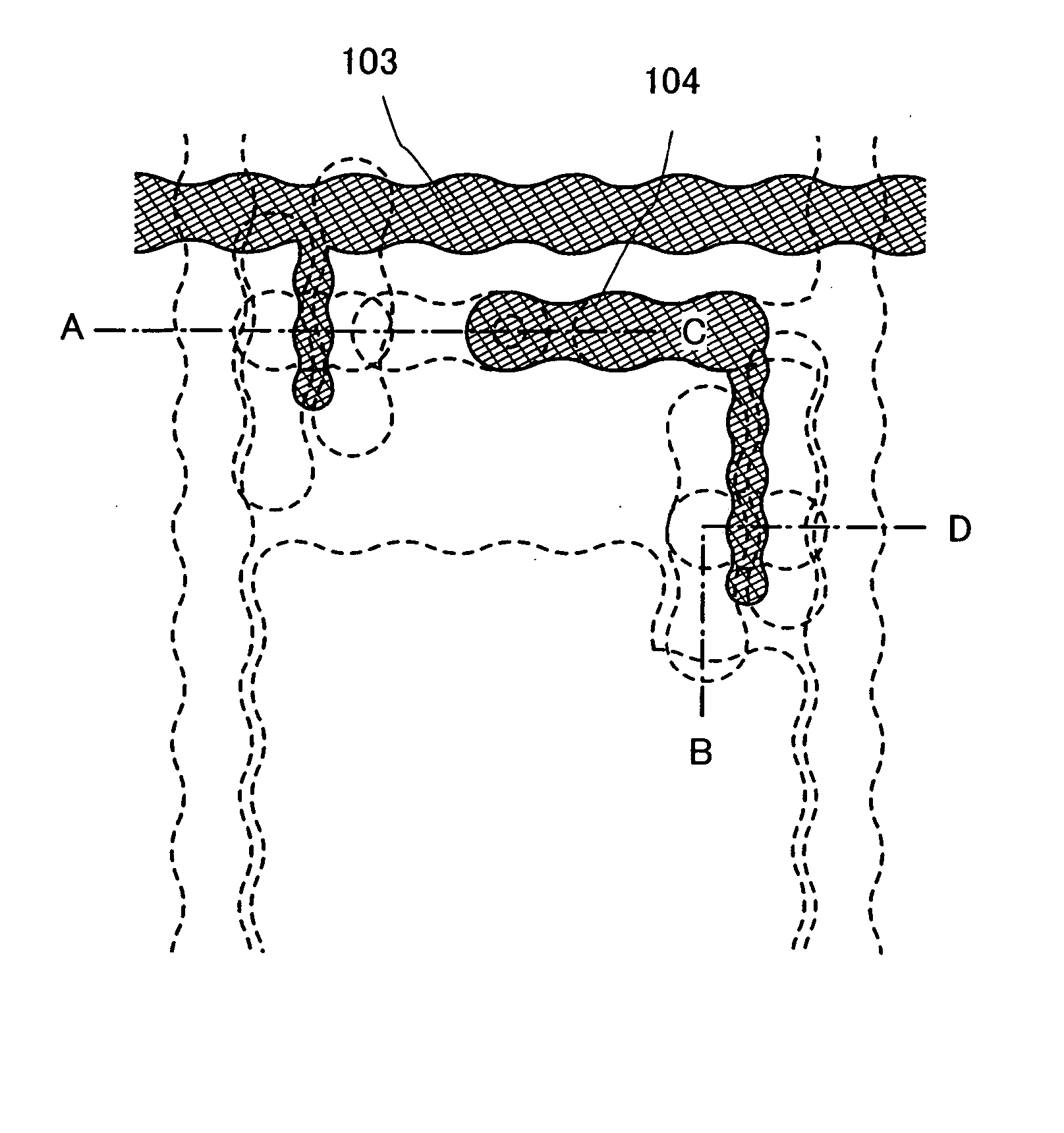

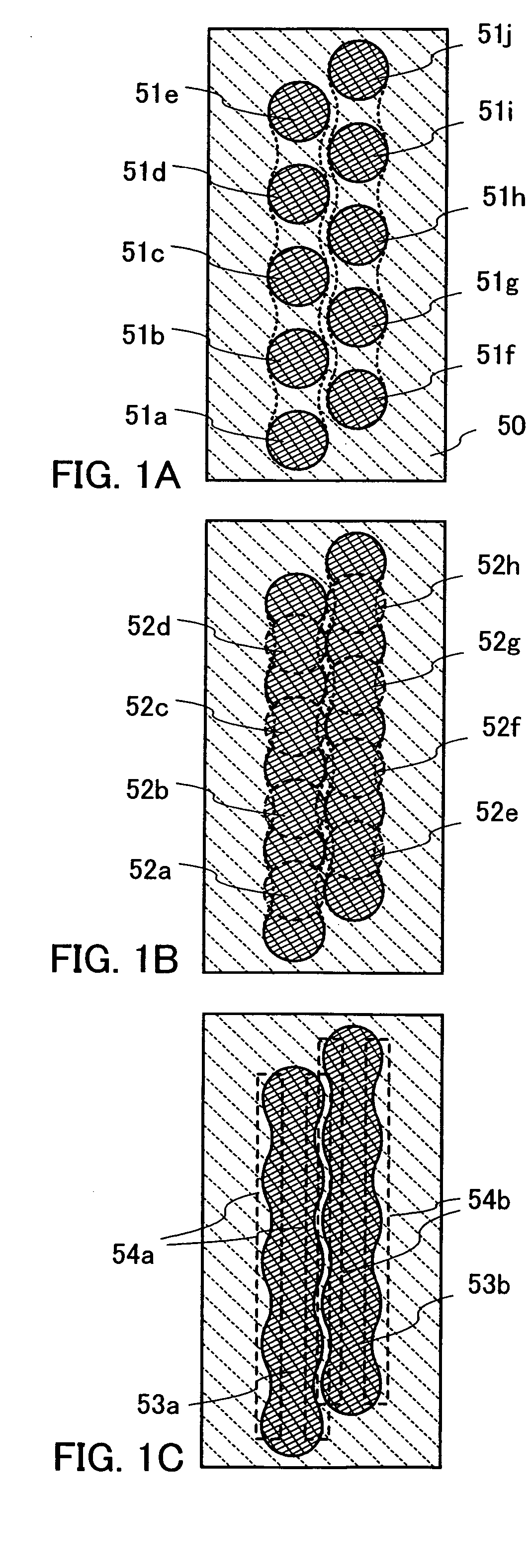

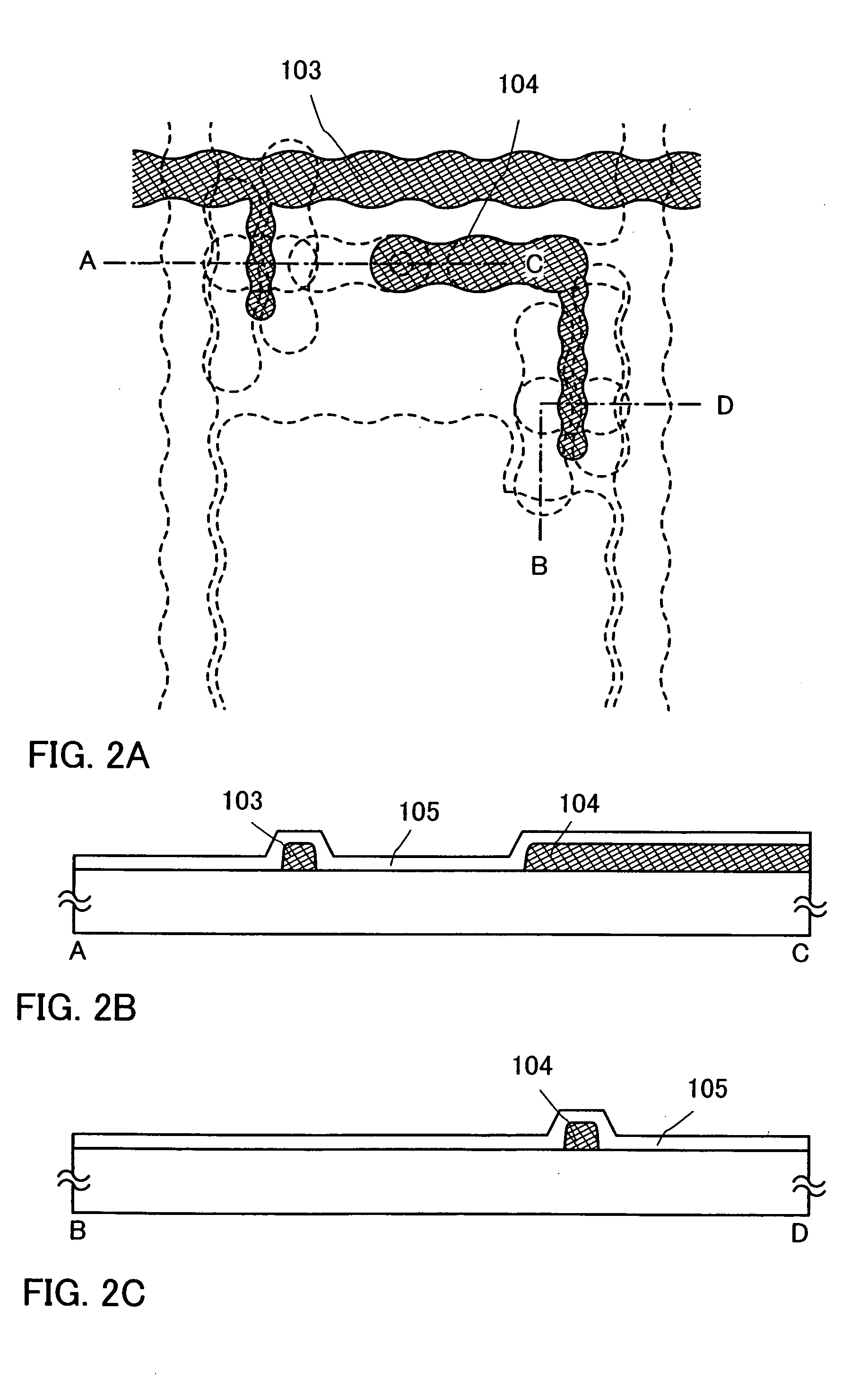

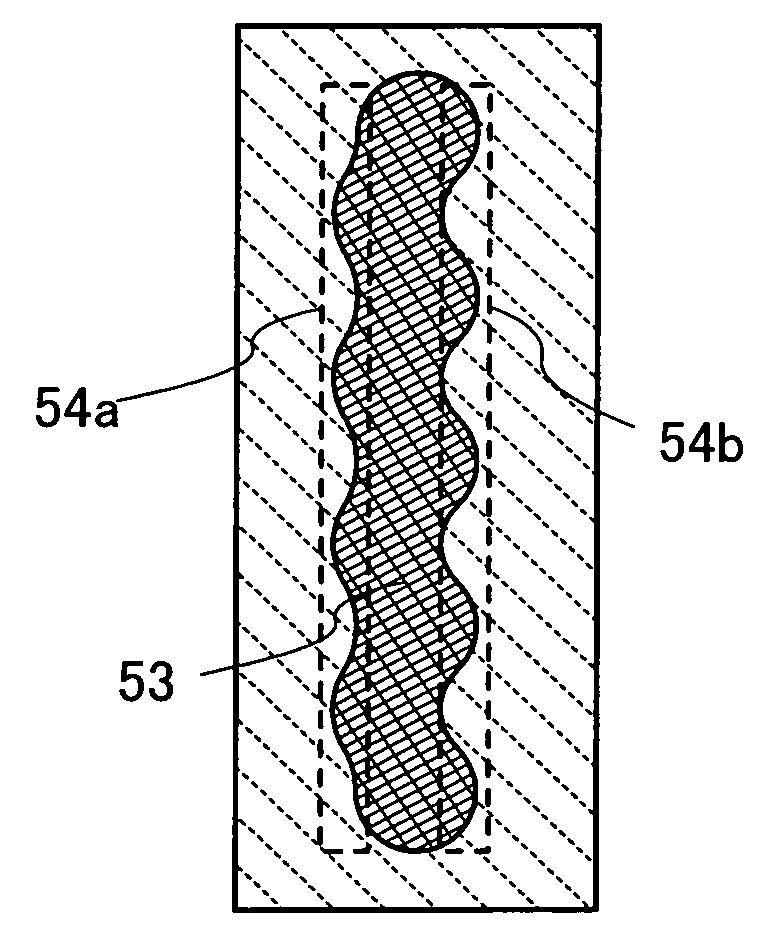

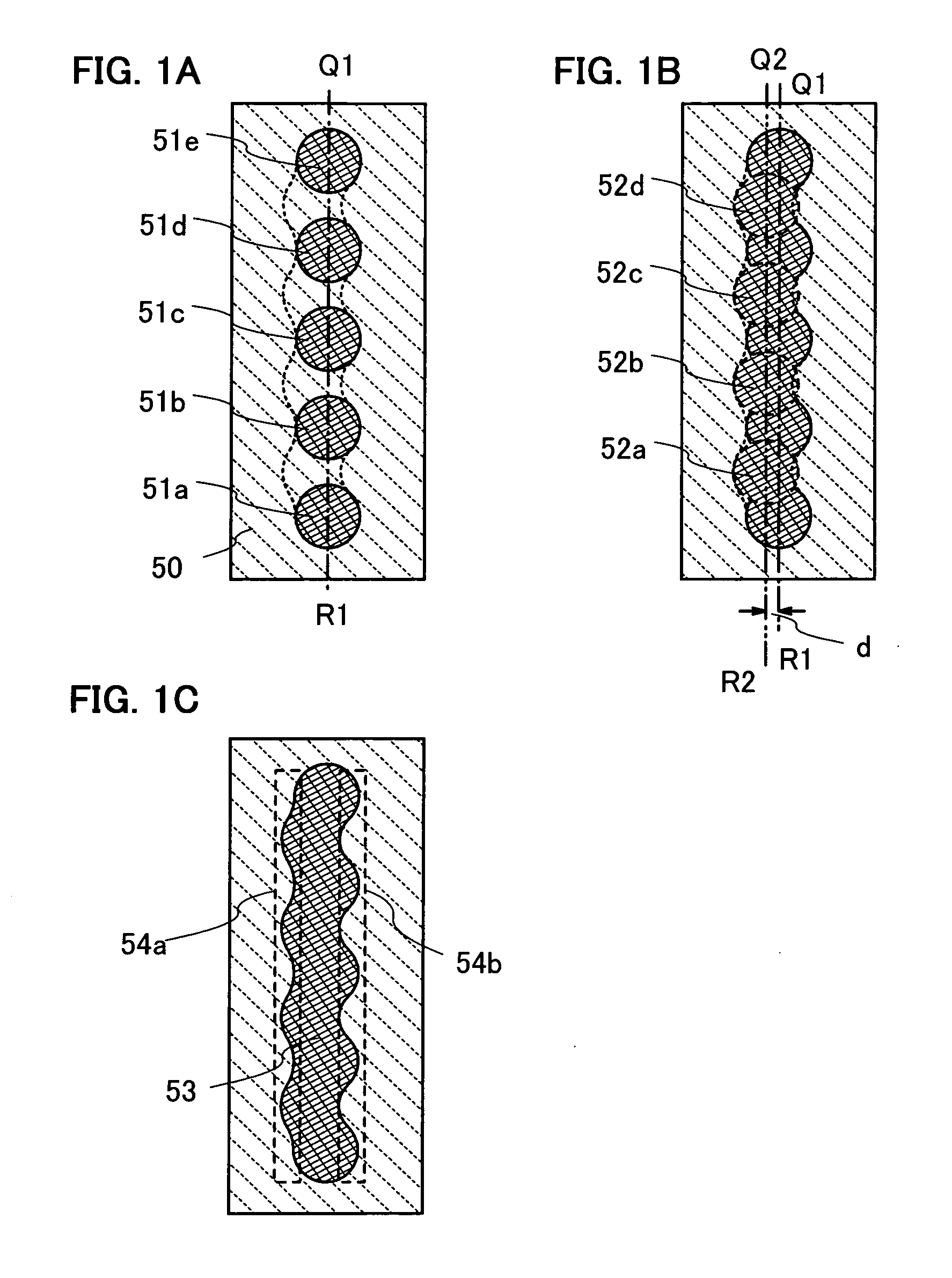

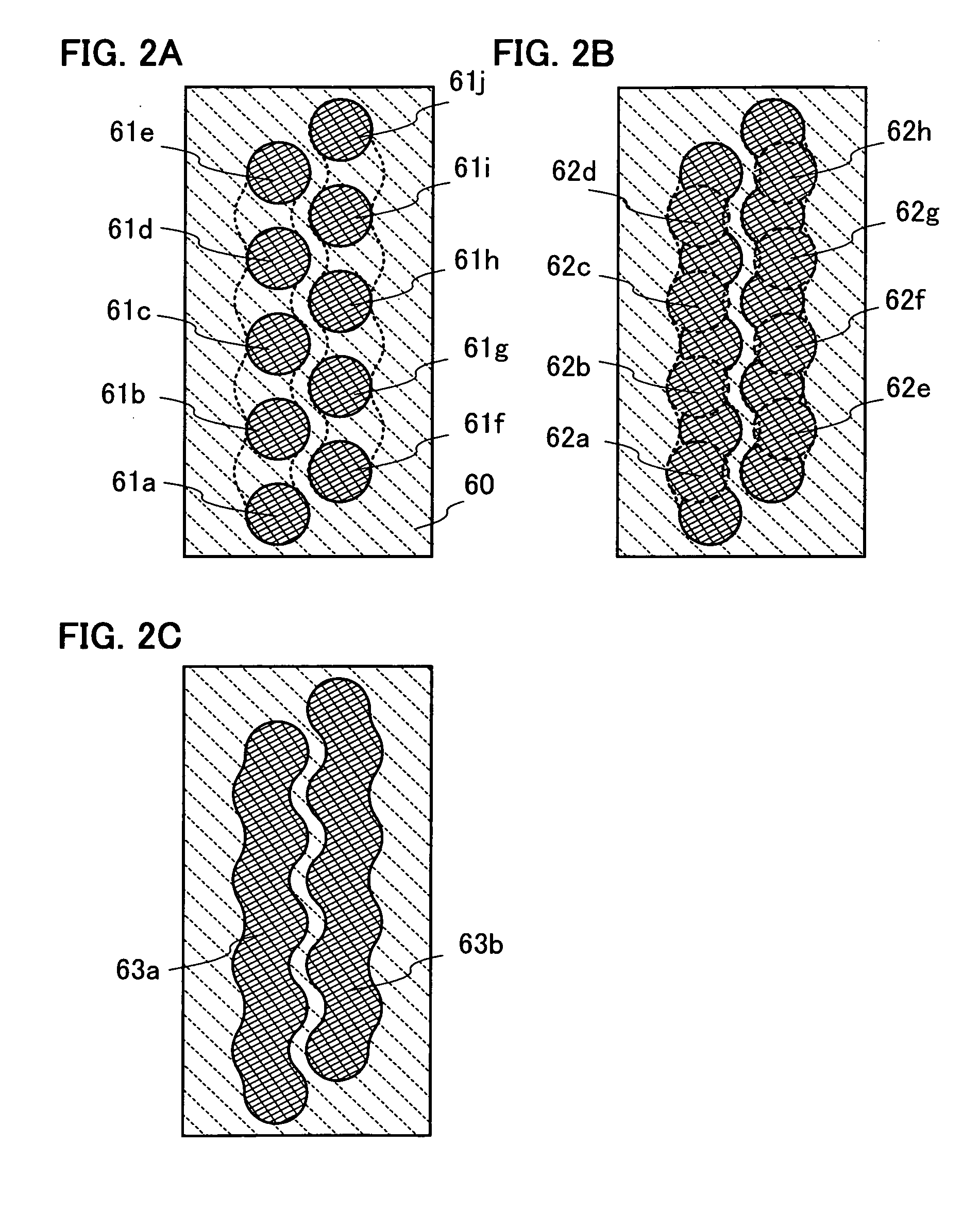

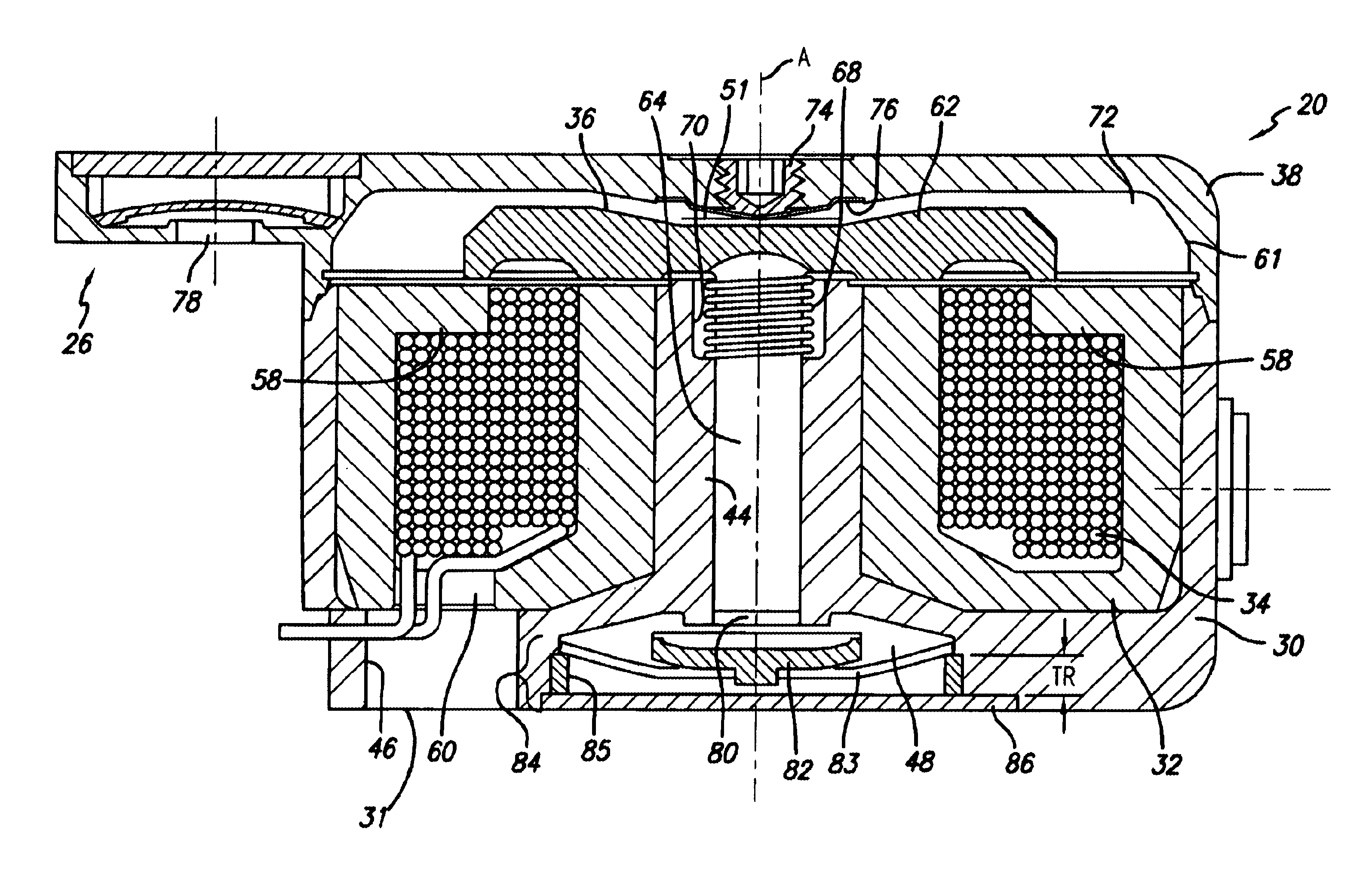

Conductive layers having knots are adjacently formed with uniform distance therebetween. Droplets of the conductive layers are discharged to stagger centers of the droplets in a length direction of wirings so that the centers of the discharged droplets are not on the same line in a line width direction between the adjacent conductive layers. Since the centers of the droplets are staggered, parts of the conductive layers each having a widest line width (the widest width of knot) are not connected to each other, and the conductive layers can be formed adjacently with a shorter distance therebetween.

Owner:SEMICON ENERGY LAB CO LTD

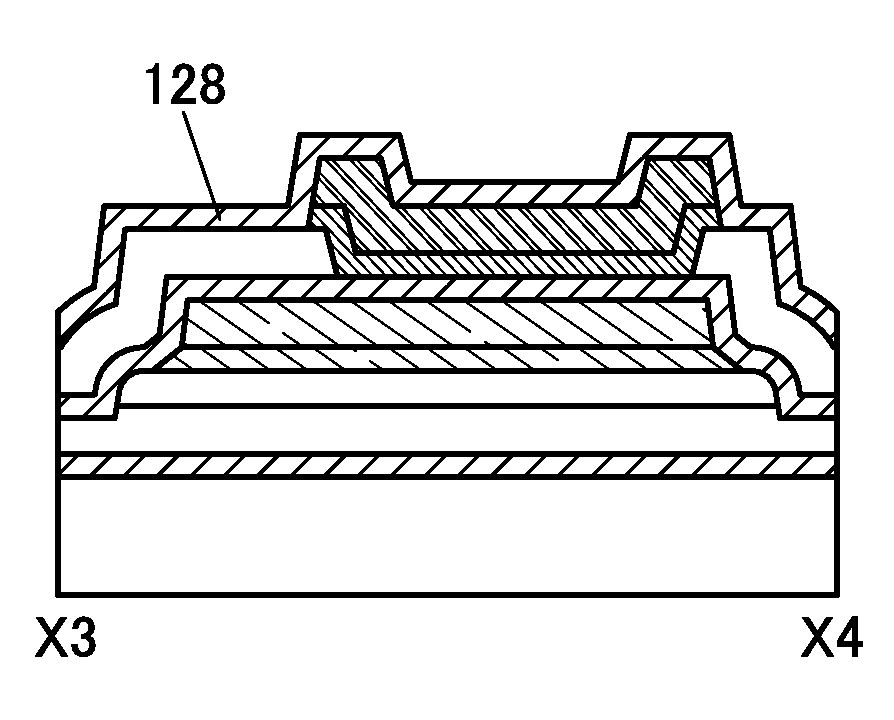

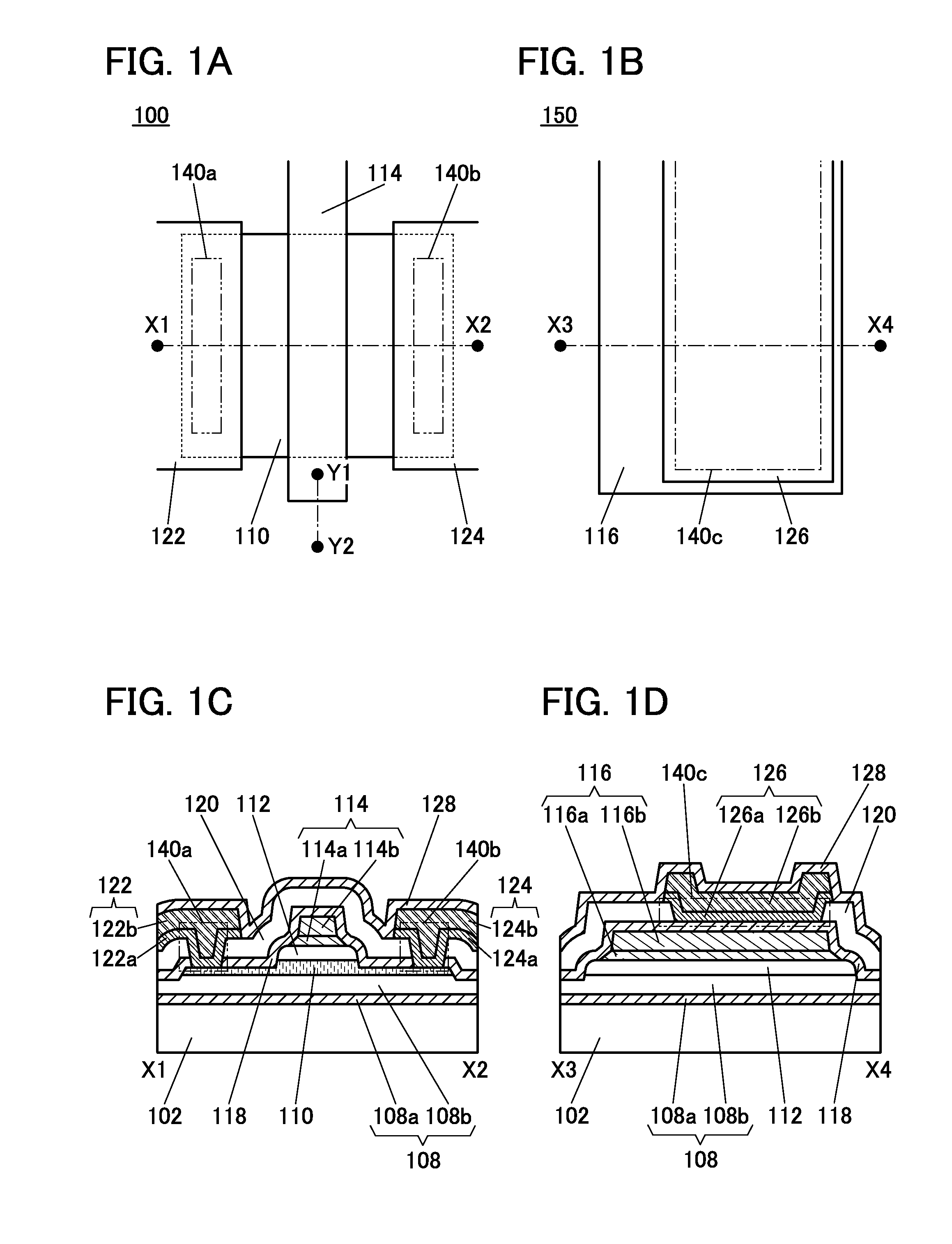

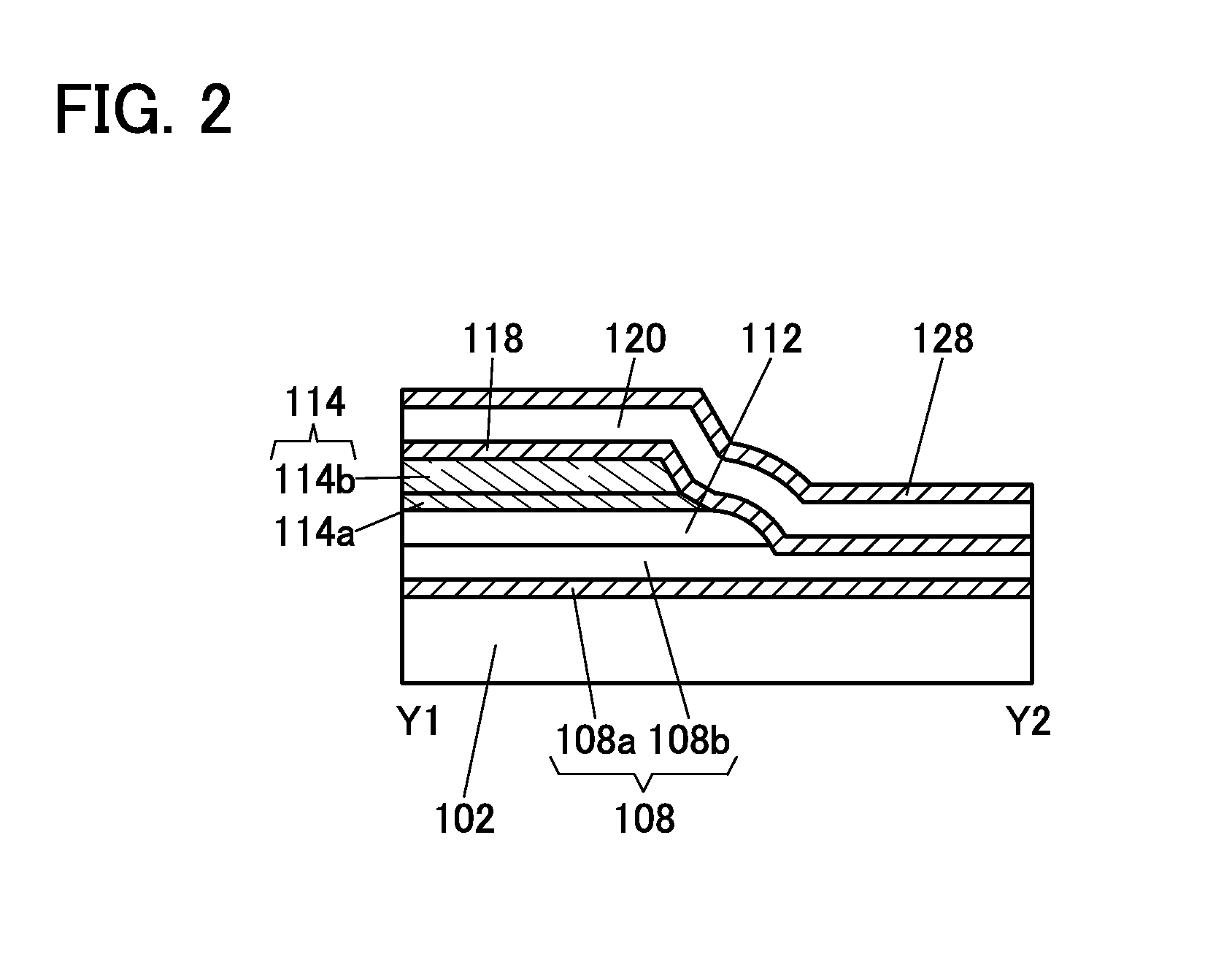

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060169973A1Stable formationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

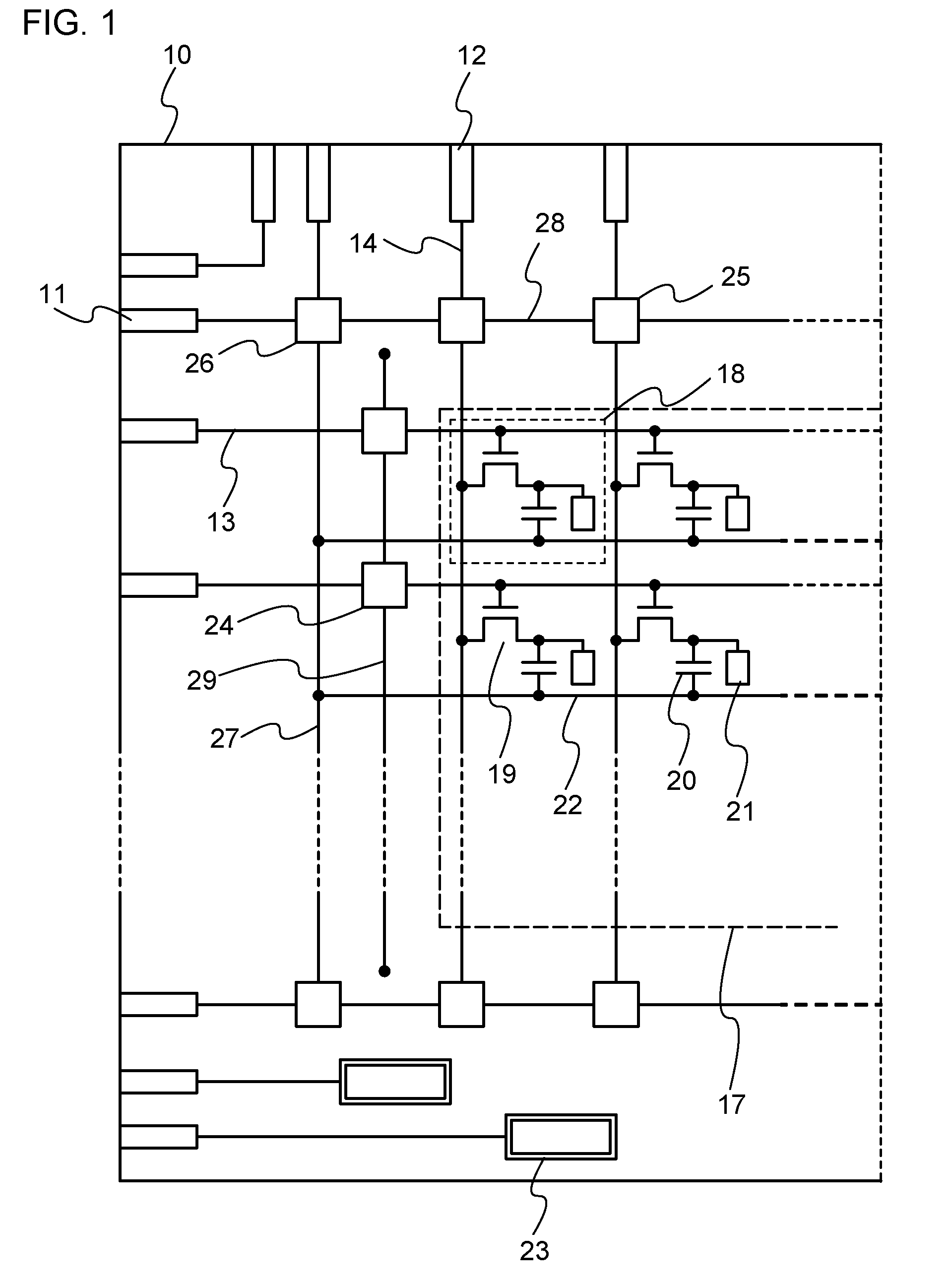

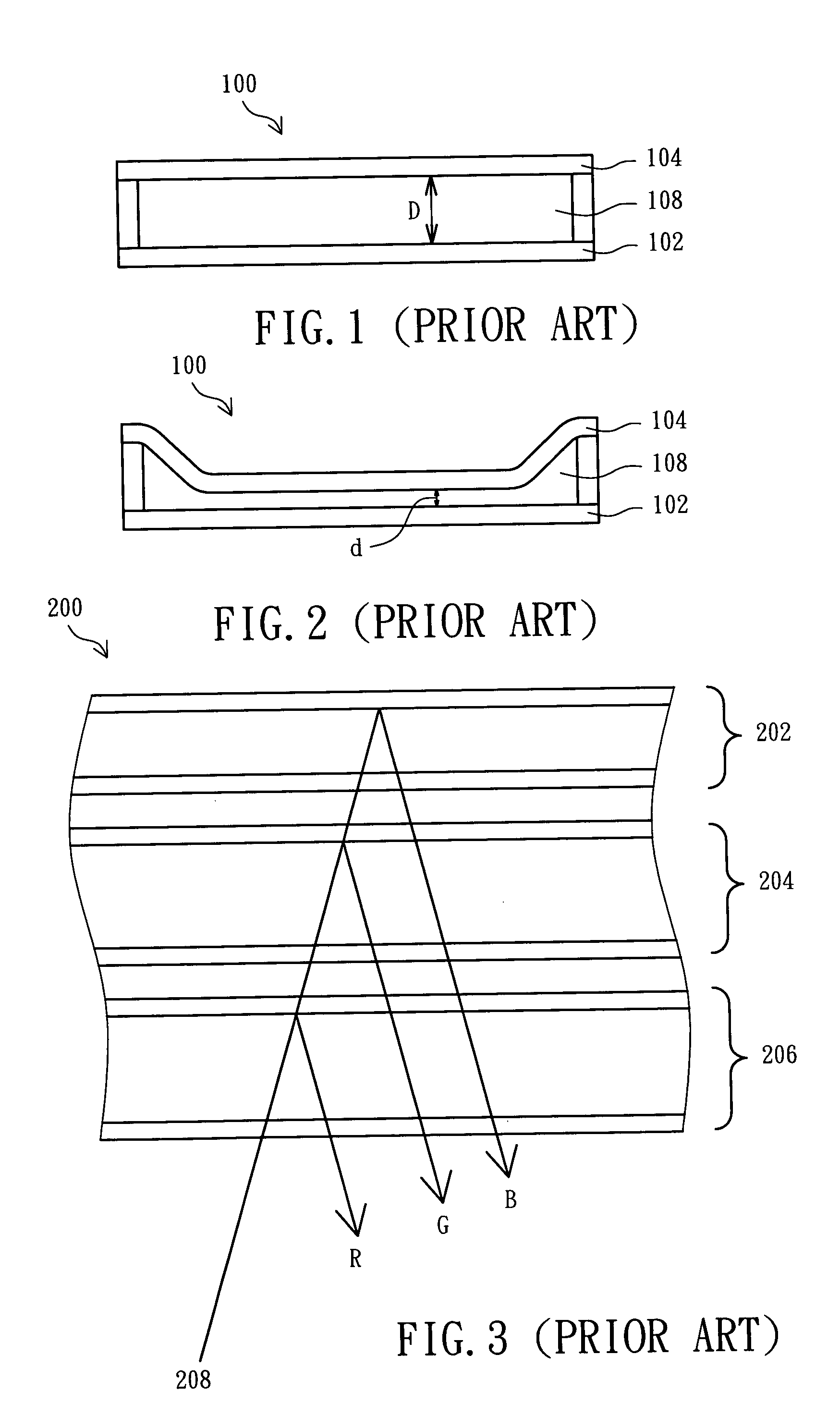

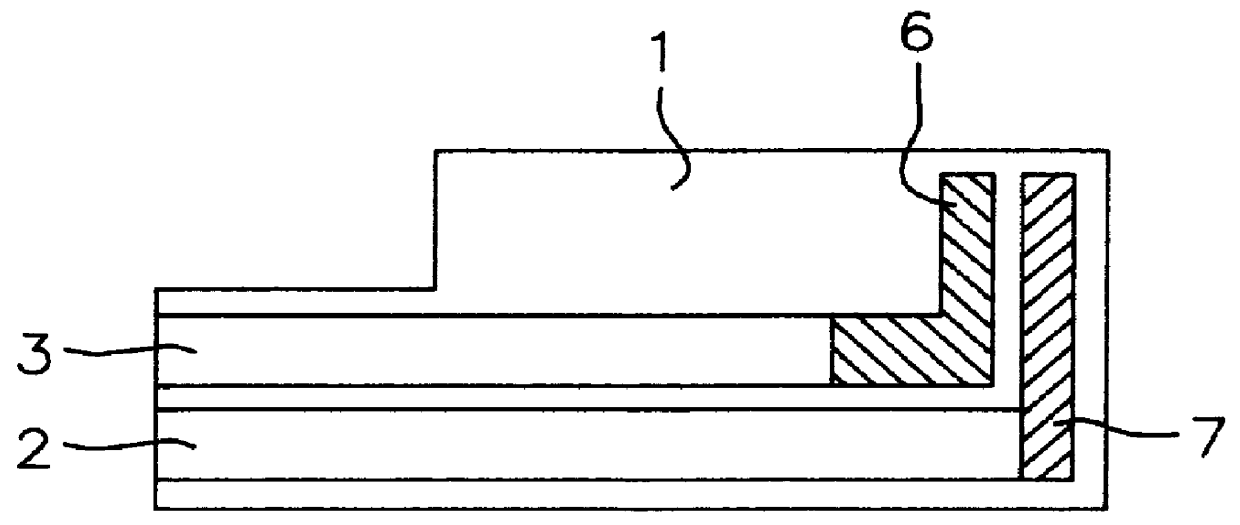

Enzyme electrode structure

InactiveUS6071391AEasy to manufactureEasy to measureImmobilised enzymesBioreactor/fermenter combinationsEnzyme electrodeWorking electrode

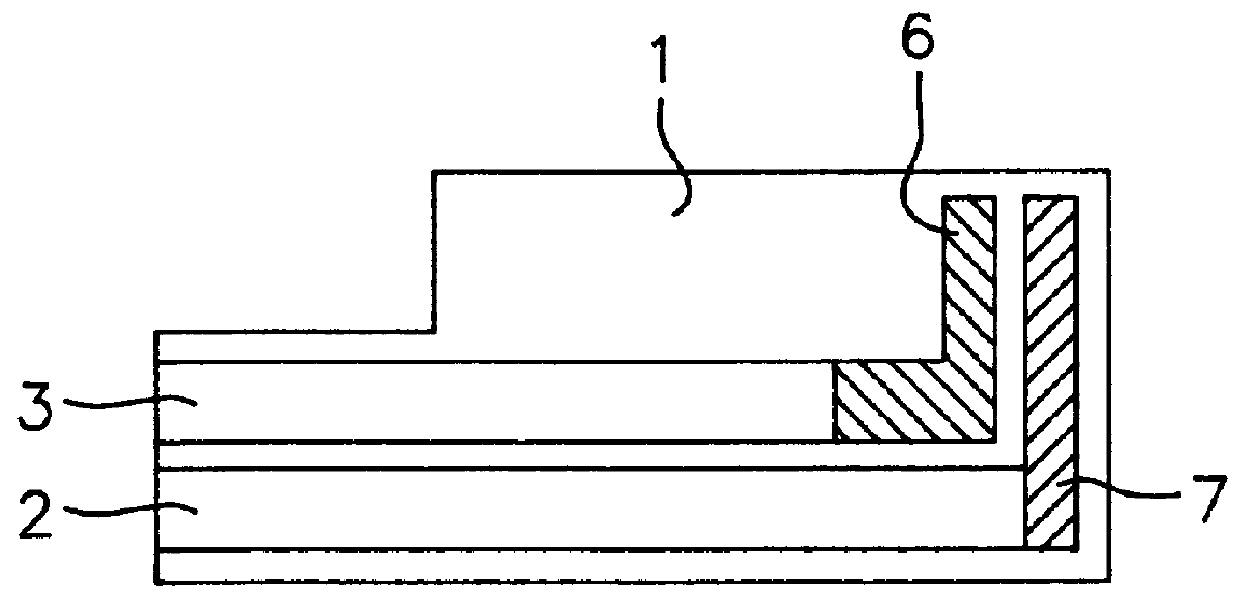

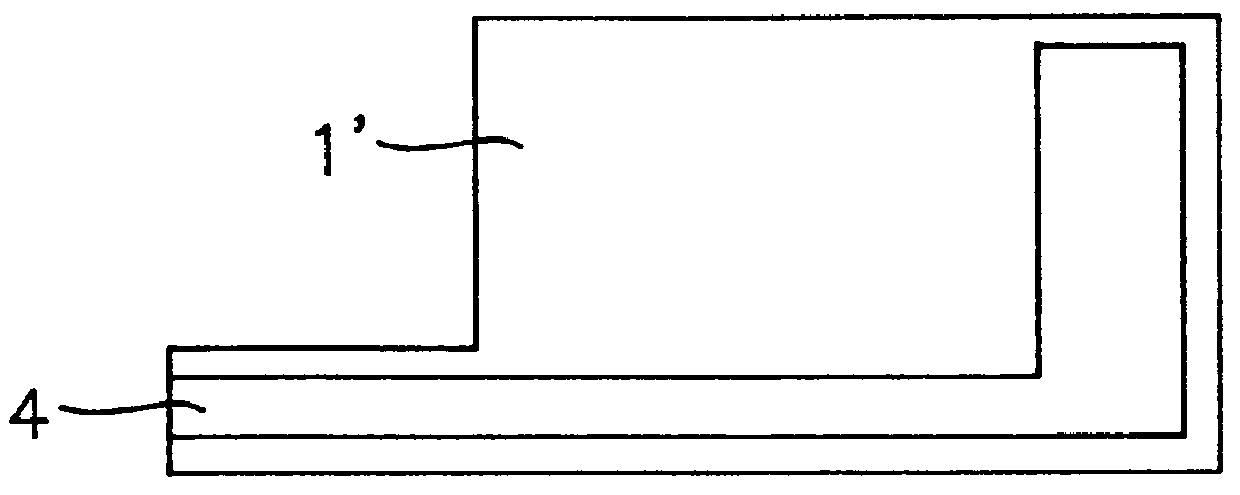

A biosensor comprises a space part for sucking and housing a sample formed of two upper and lower plates, the two plates being stuck together by an adhesive layer, the space part for sucking and housing the sample being constituted so as to be partially opened in the peripheral part and partially closed by the adhesive layer, and has a working electrode having at least glucose oxidase immobilized thereon and a counter electrode on the same plane of the plate.

Owner:ABBOTT DIABETES CARE INC

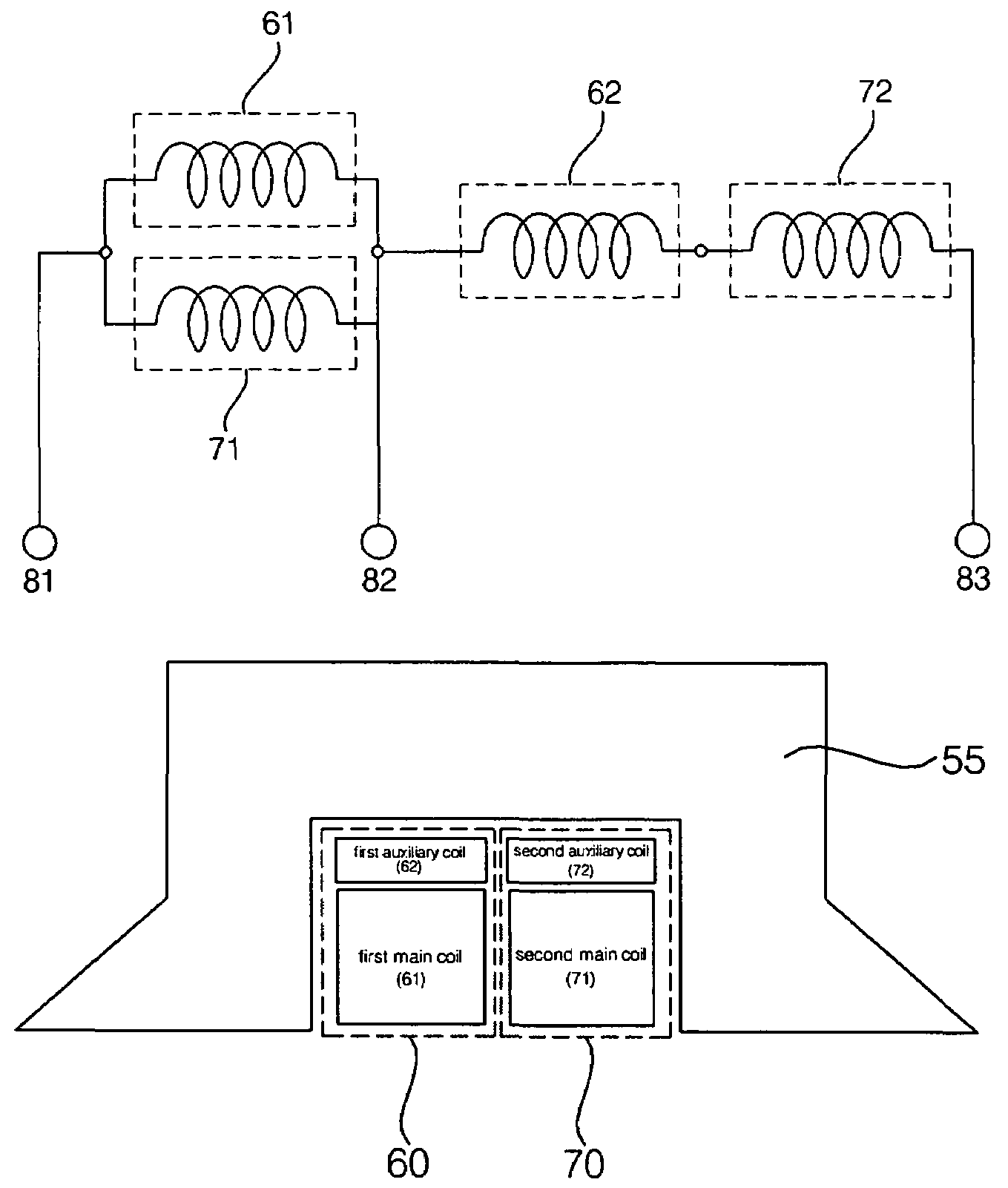

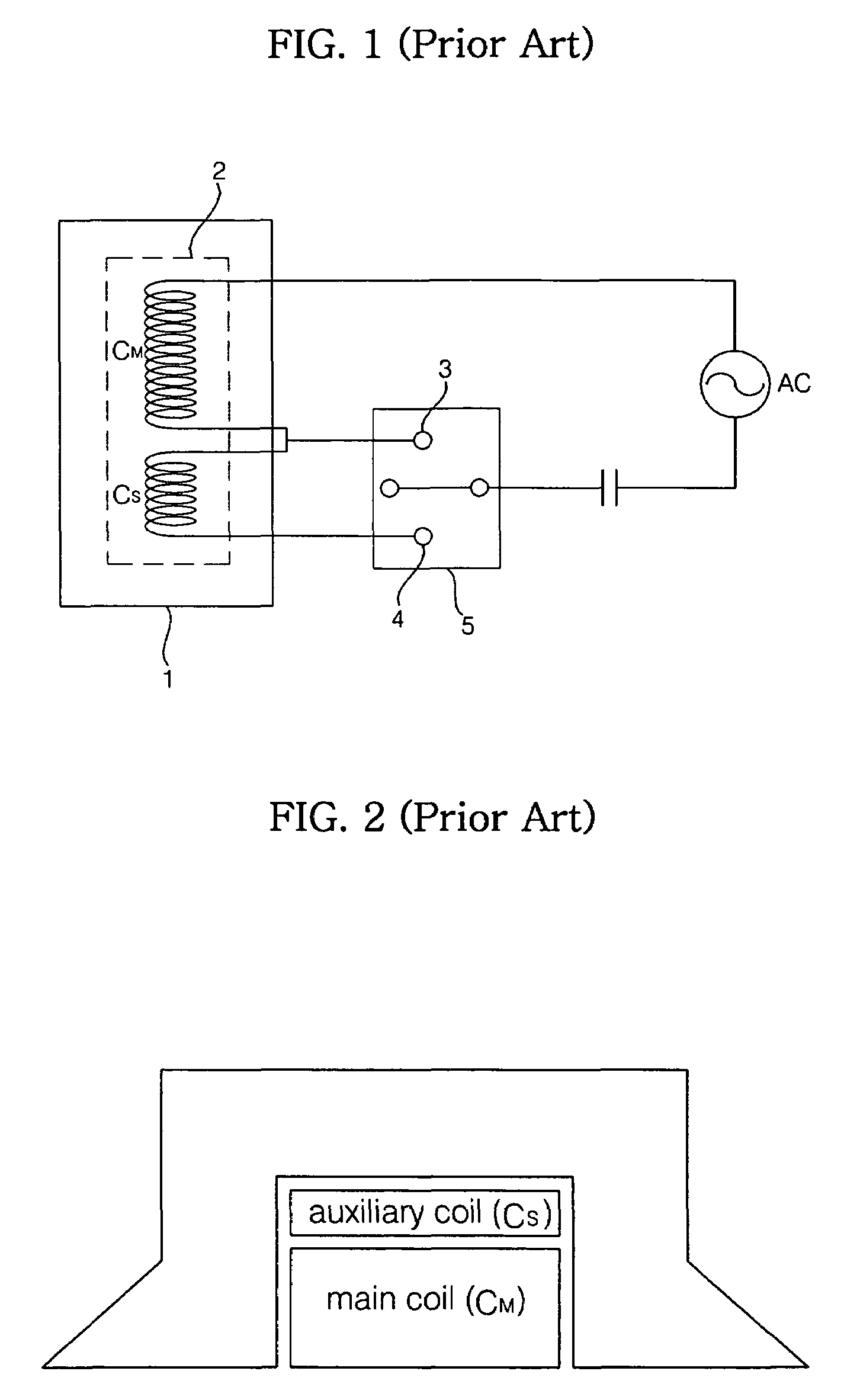

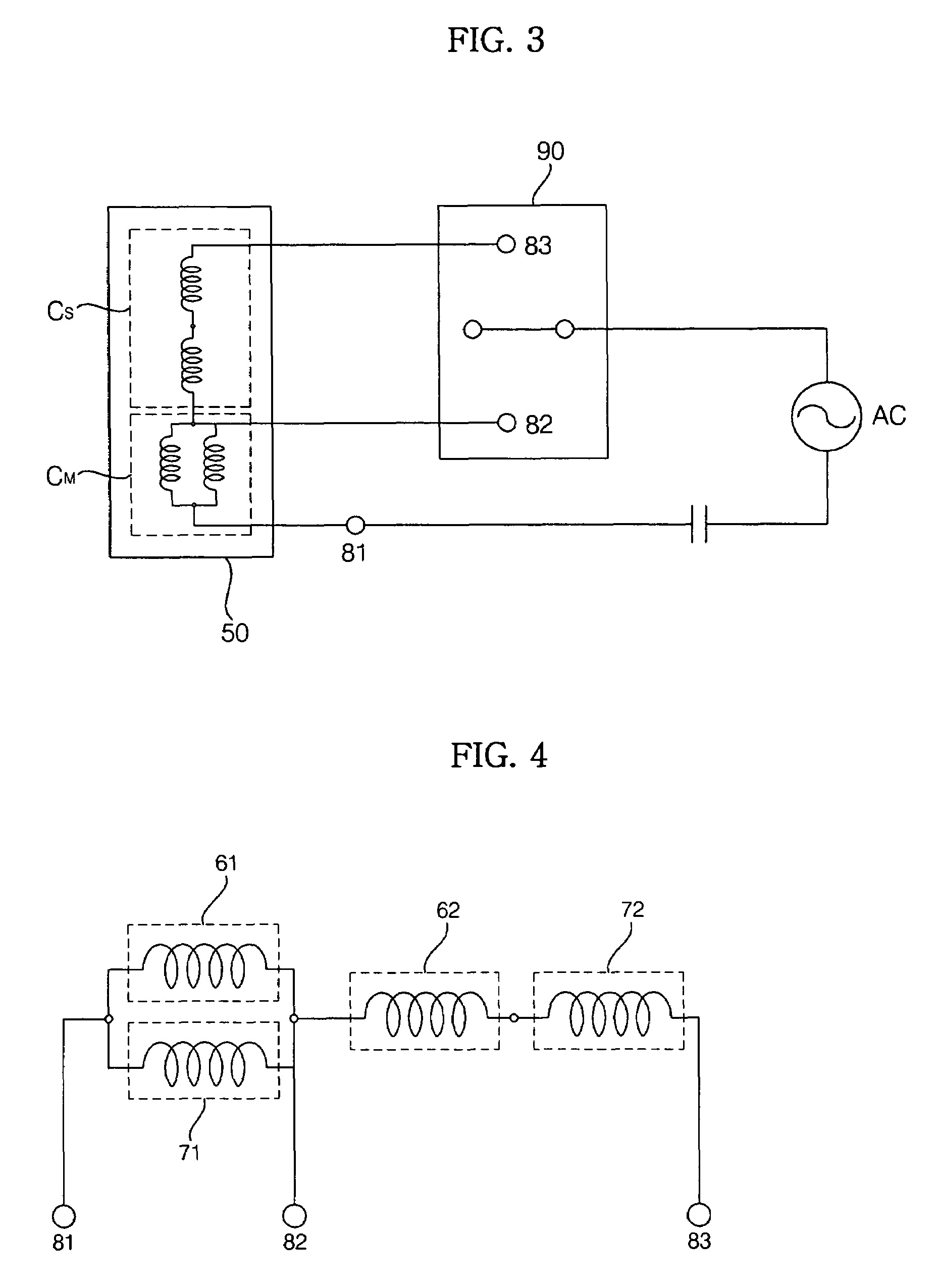

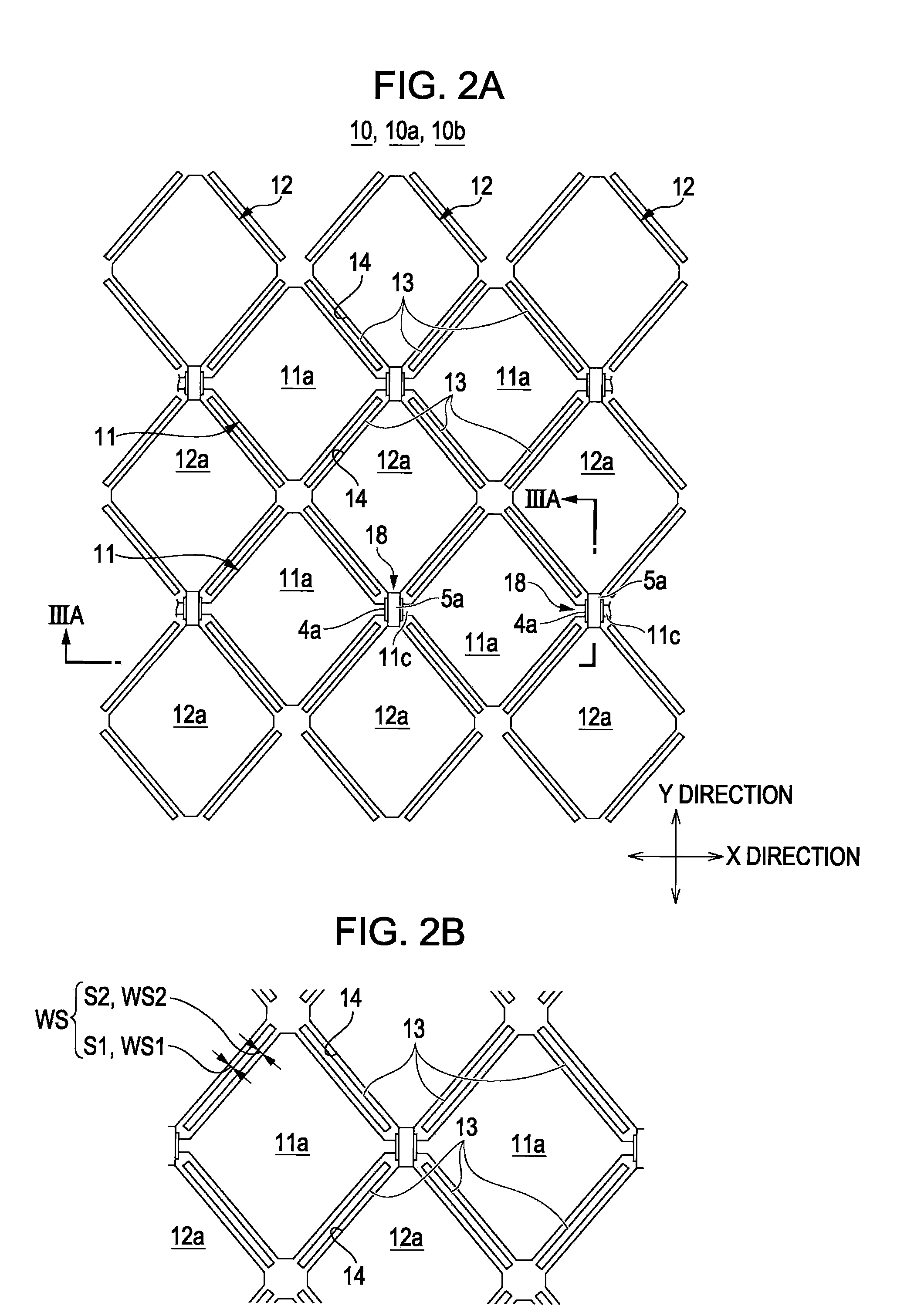

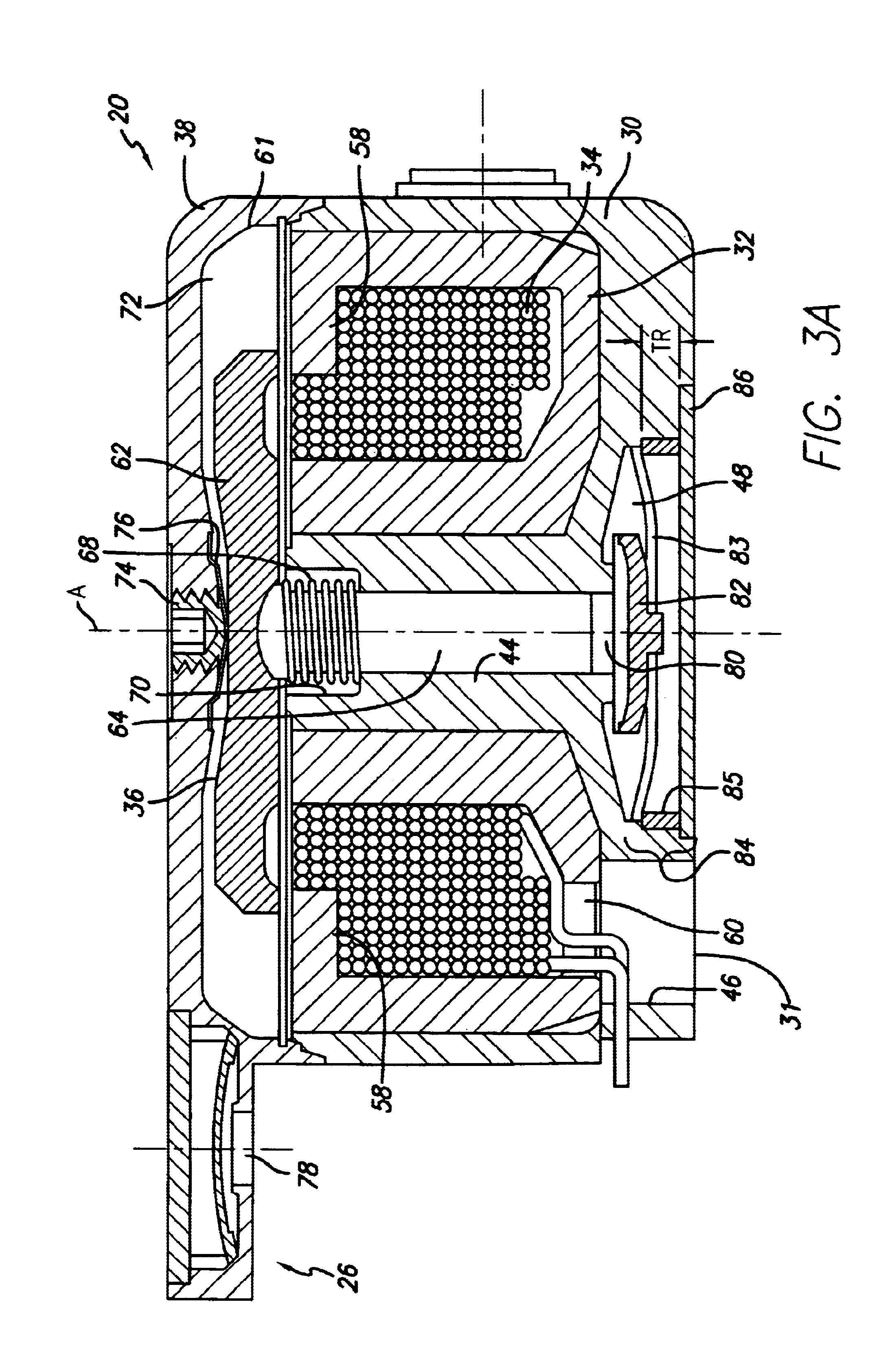

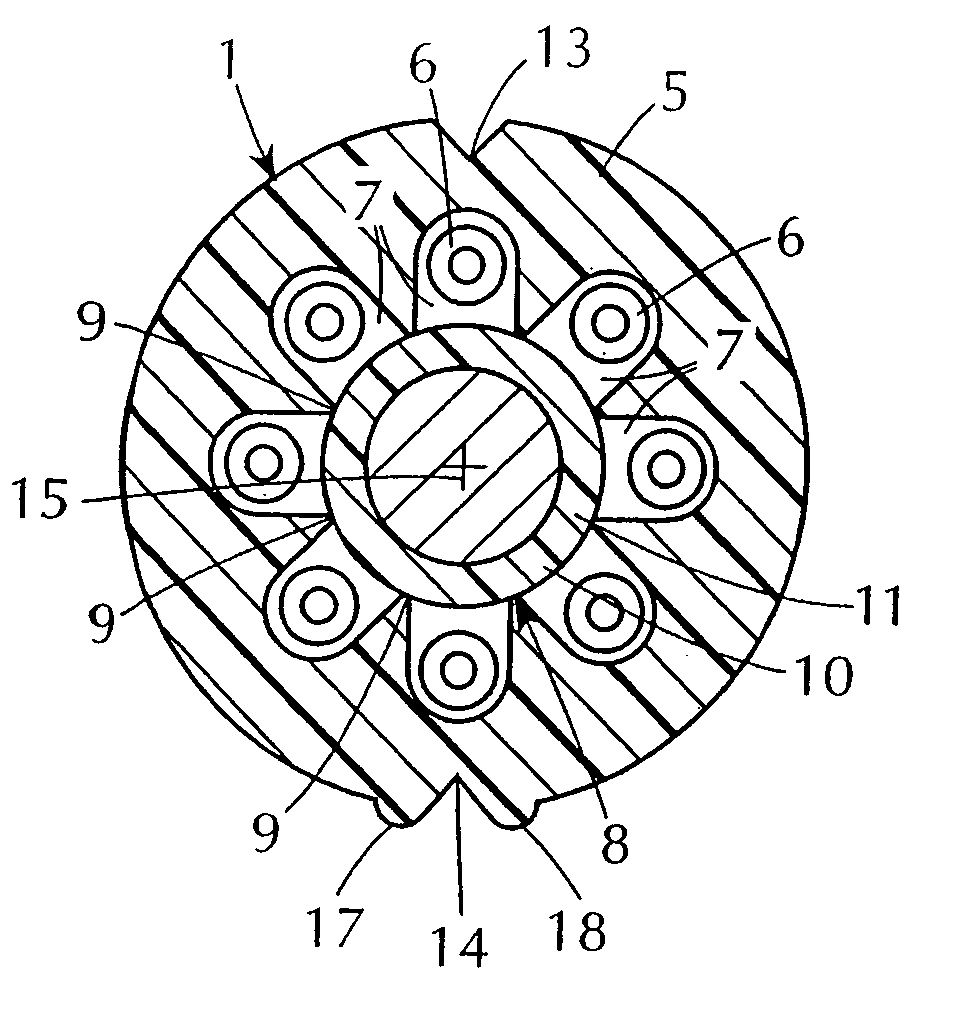

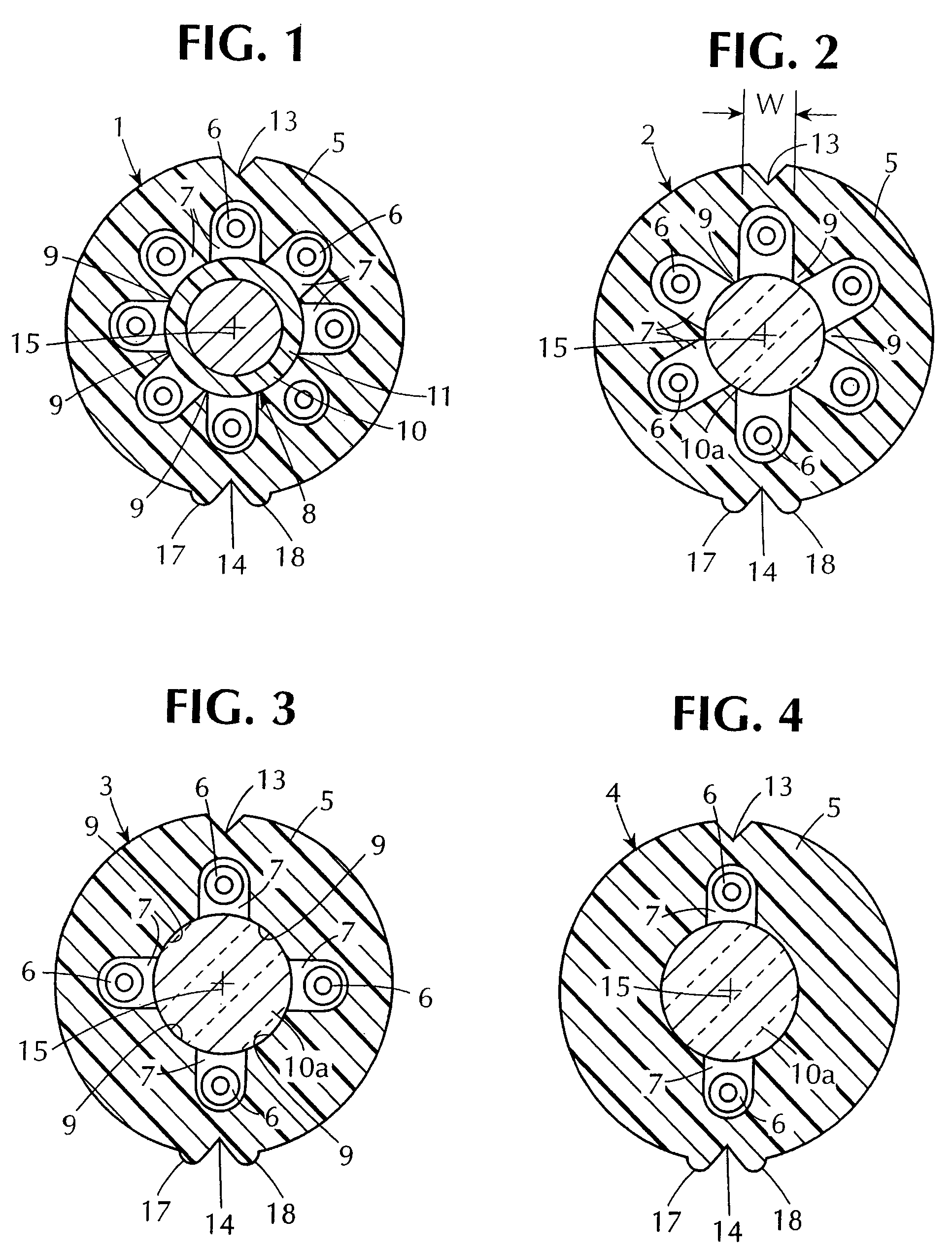

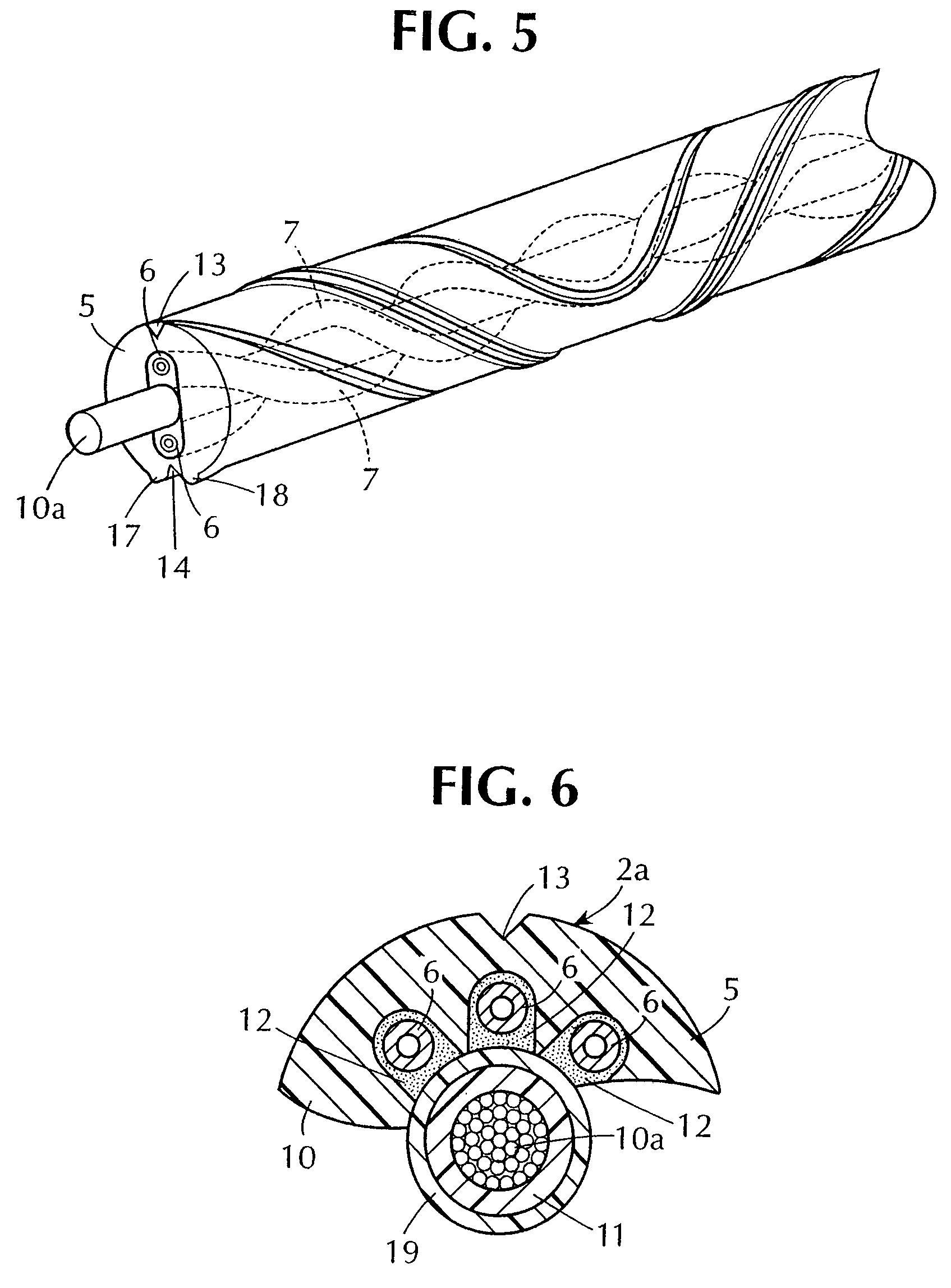

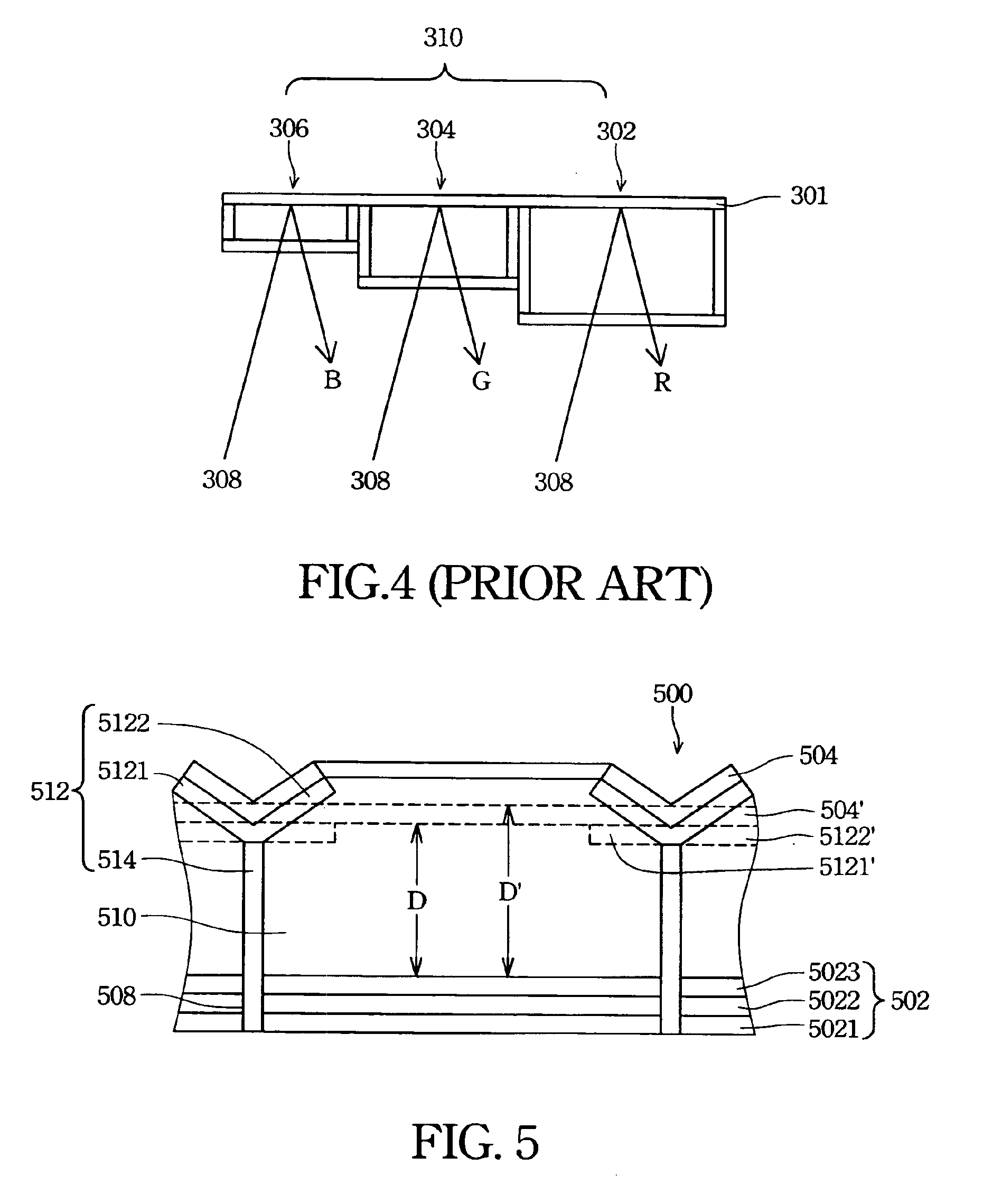

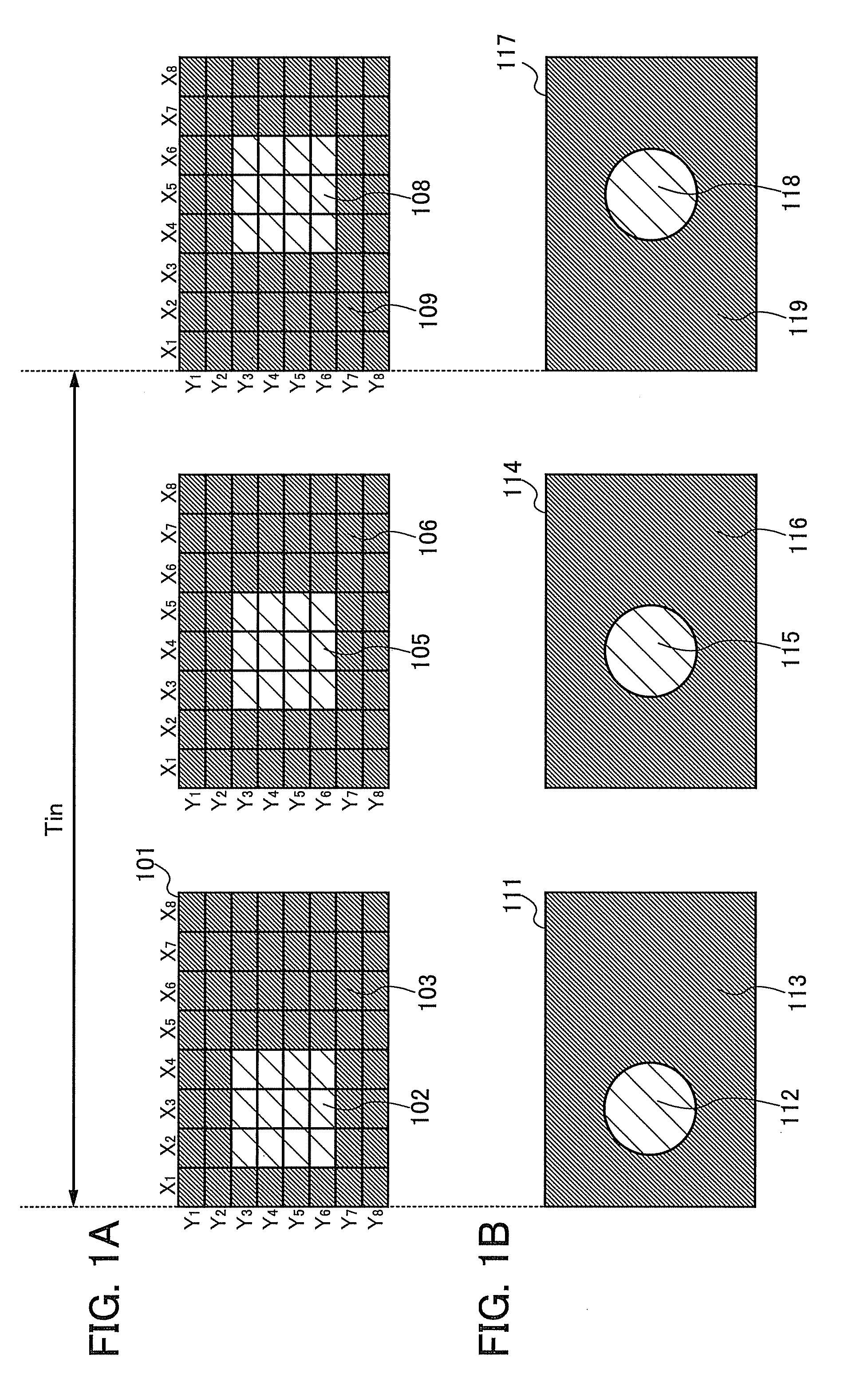

Linear motor and linear compressor using the same

ActiveUS7489055B2Improve efficiencySmall sizeAC motor controlDC motor speed/torque controlBobbinElectrical conductor

Disclosed herein is a linear motor in which a plurality of coil groups are connected in series or in parallel and driving power is applied to part or all of the coil groups according to load applied to the linear motor, thereby achieving improved motor efficiency with a reduced motor size. The linear motor includes a bobbin, the plurality of coil groups wound on the bobbin, the plurality of coil groups being connected in series or in parallel to allow the driving power to be applied to part or all of the coil groups, and a magnet adapted to be linearly reciprocated by a magnetic field produced by the coil groups depending on load current flowing through the coil groups. As a result of connecting the plurality of coil groups, which are formed of a plurality of coil conductors, in series or in parallel, the capacity of the coil groups is variable depending on the load of the motor, resulting in improved motor efficiency. Also, using the coil conductors having a small cross sectional area enables reduction in the size of the motor.

Owner:LG ELECTRONICS INC

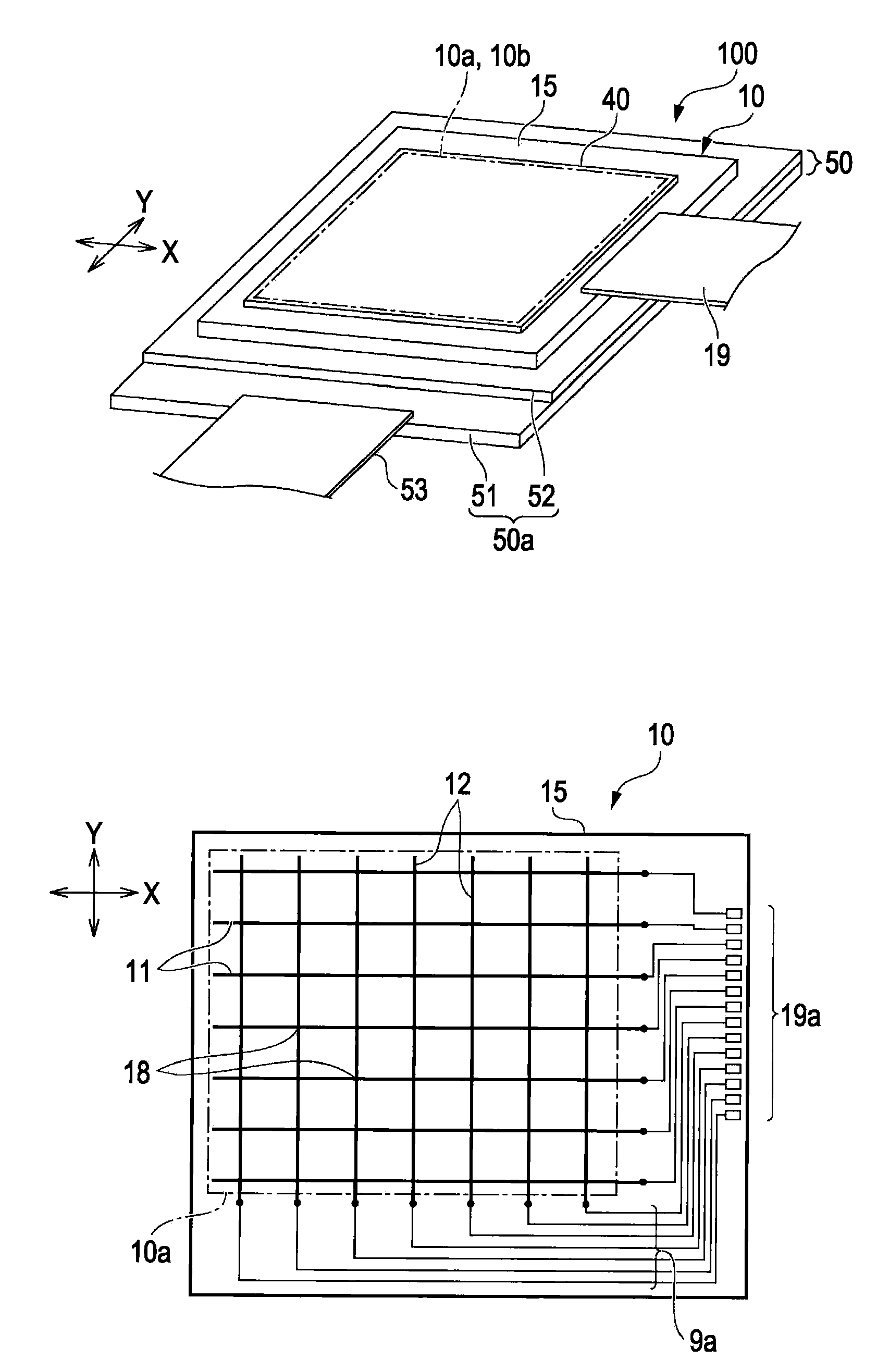

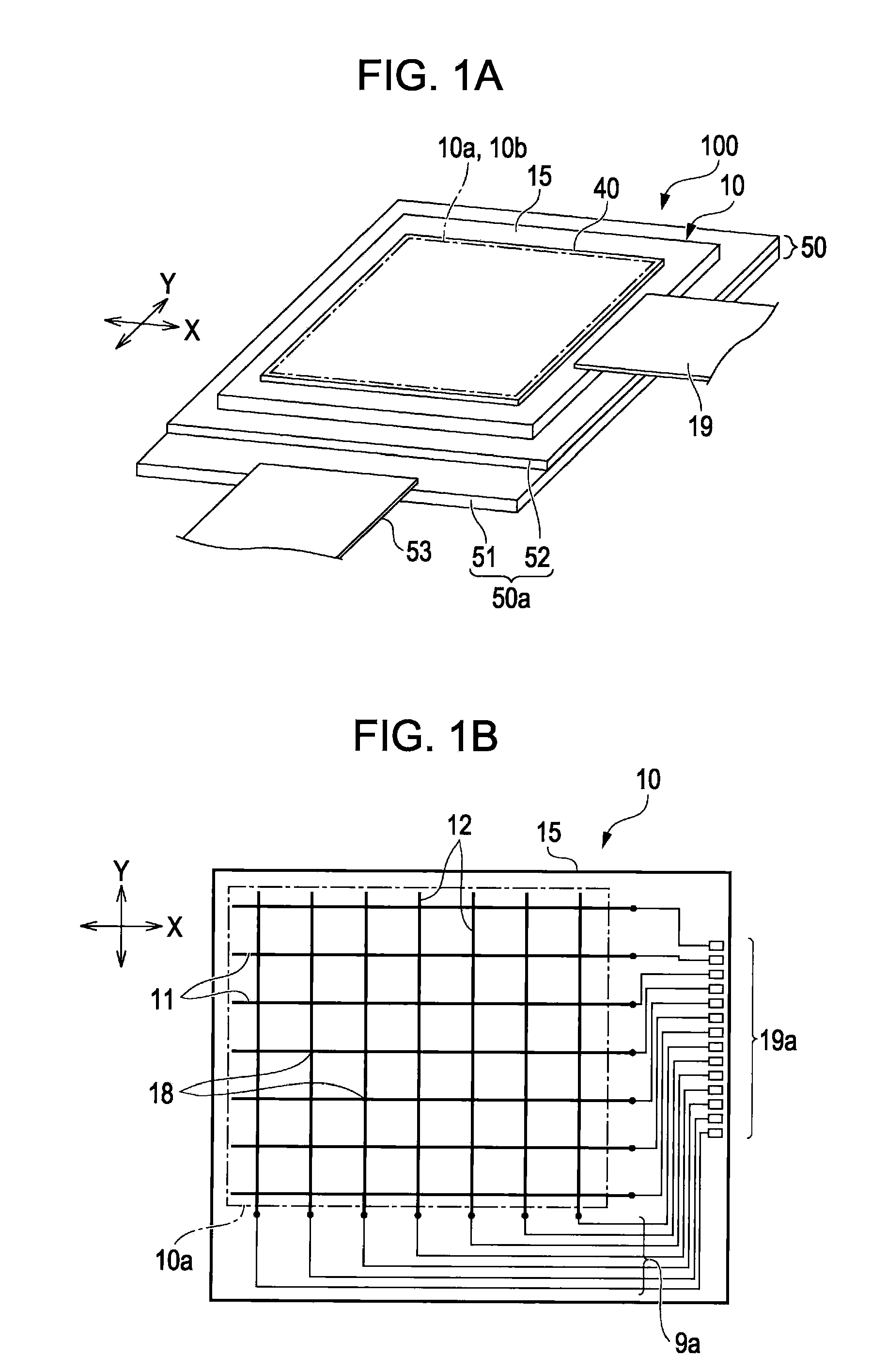

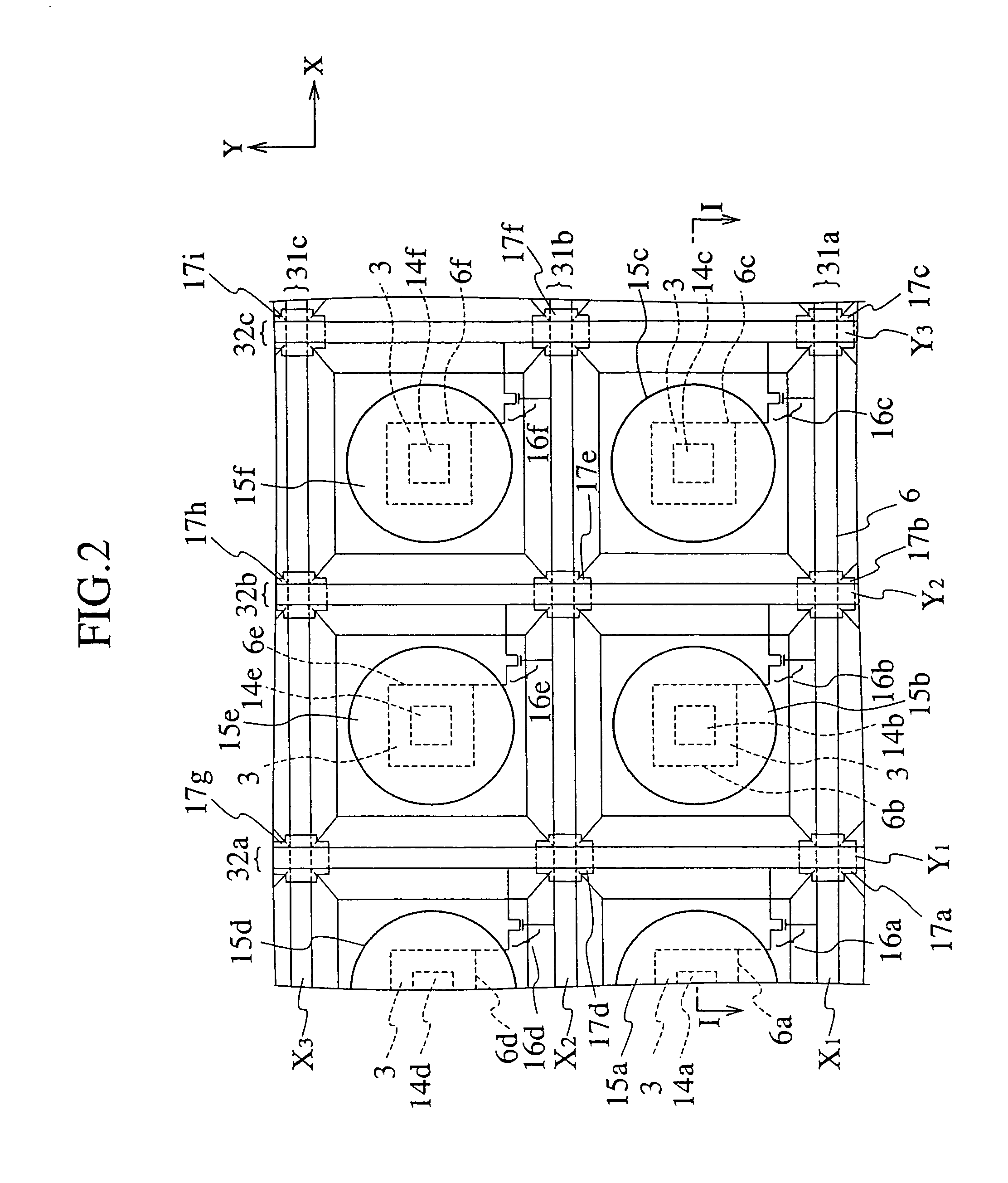

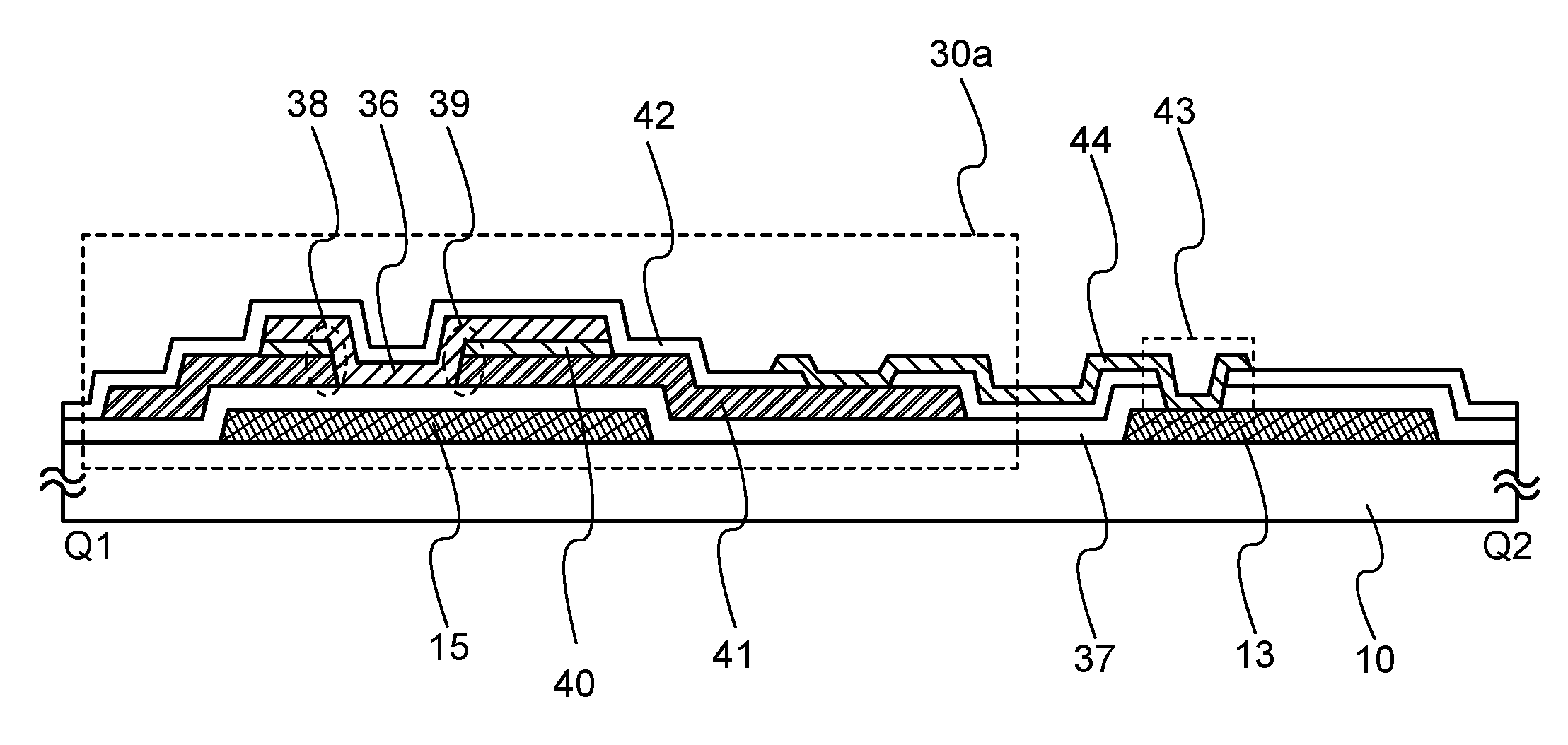

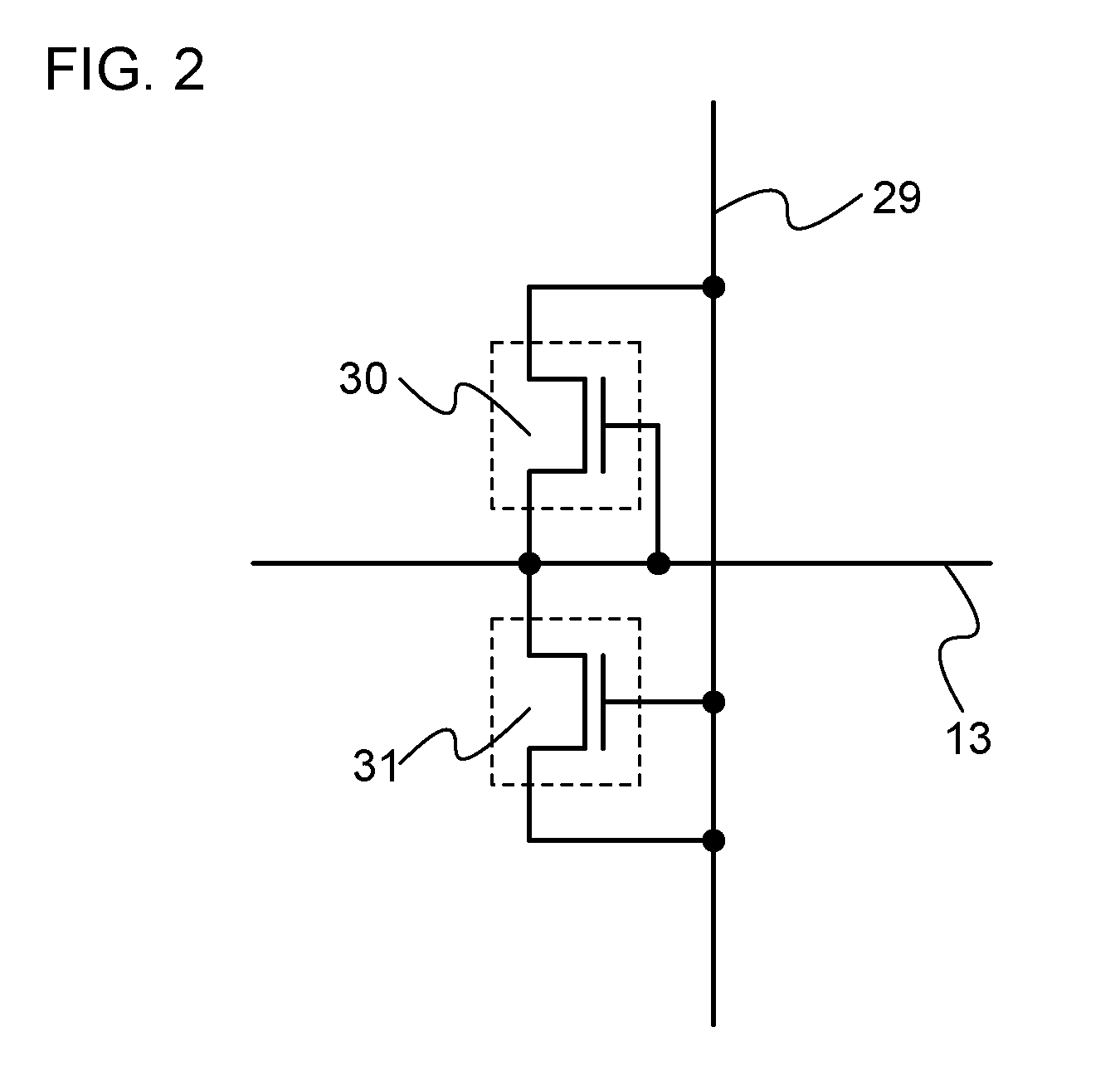

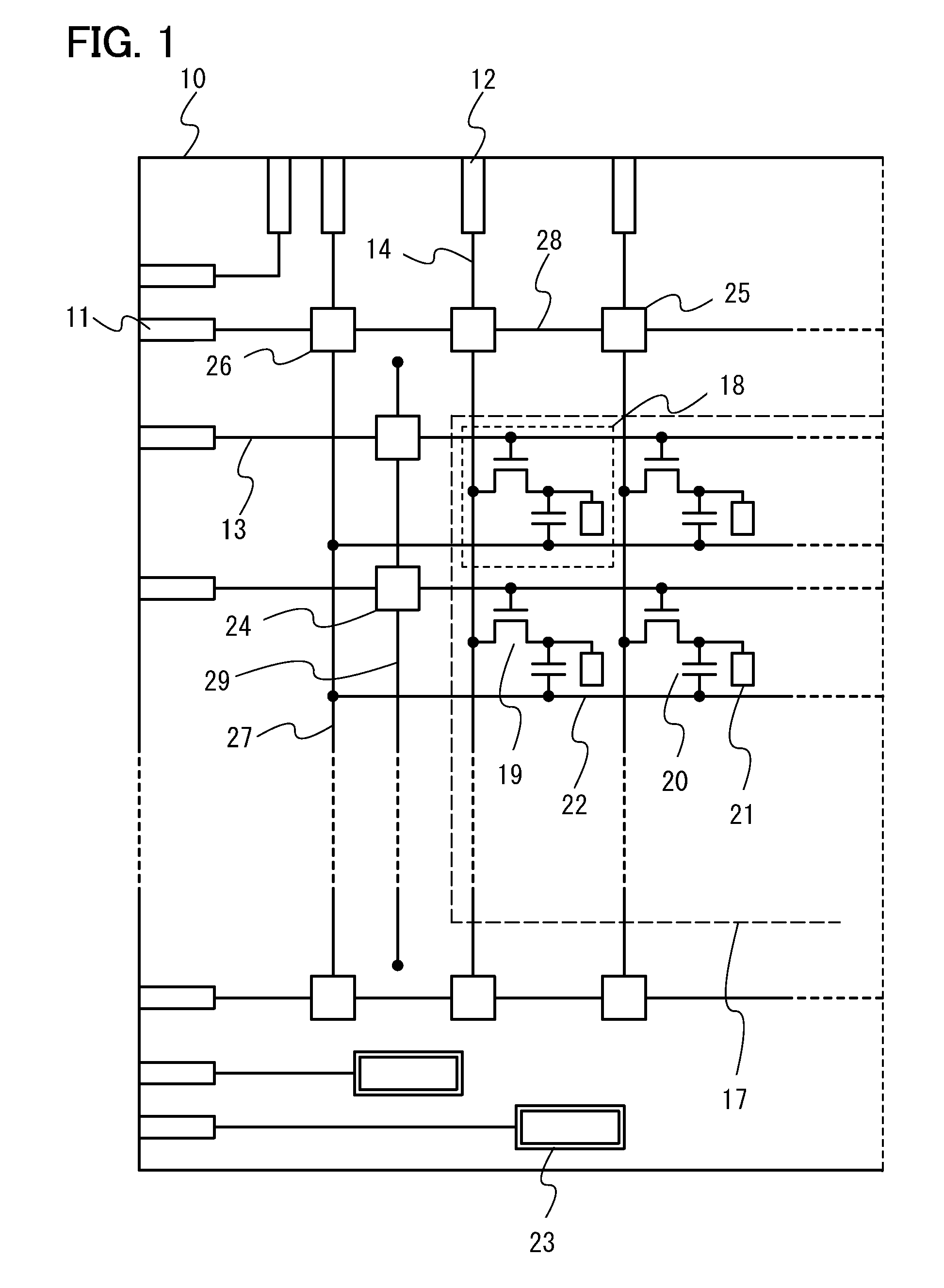

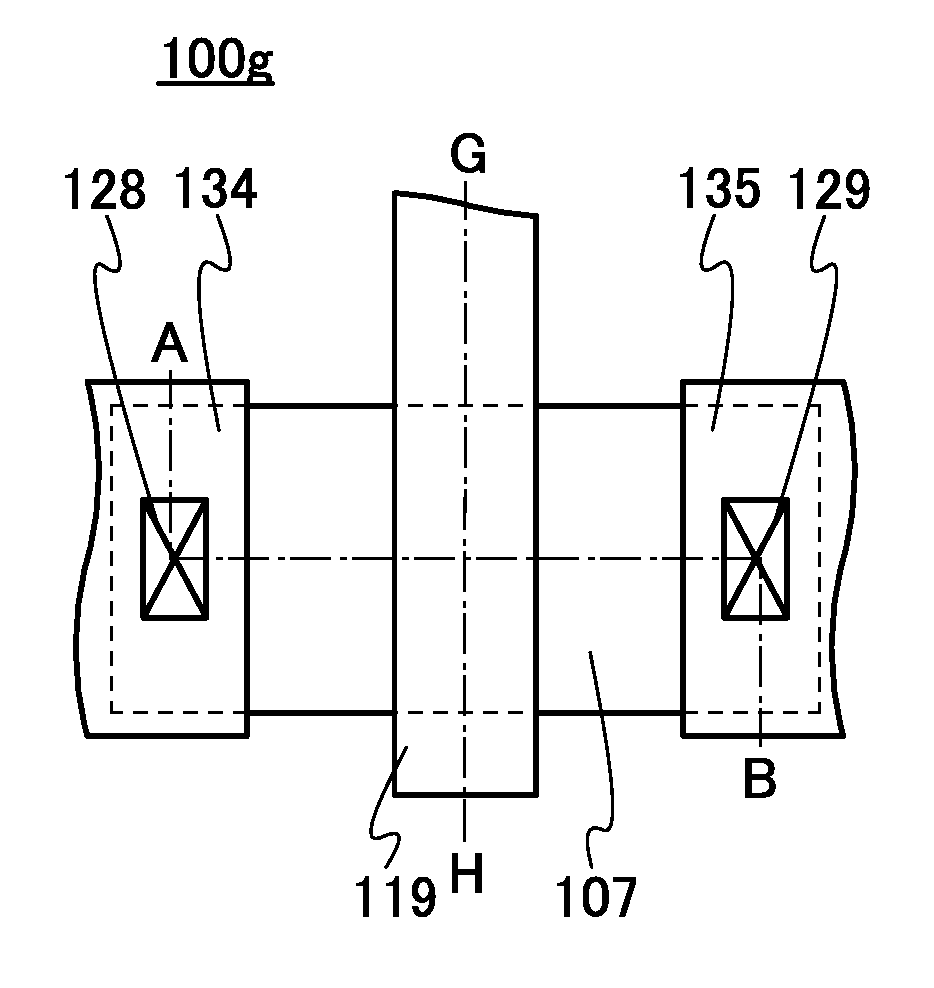

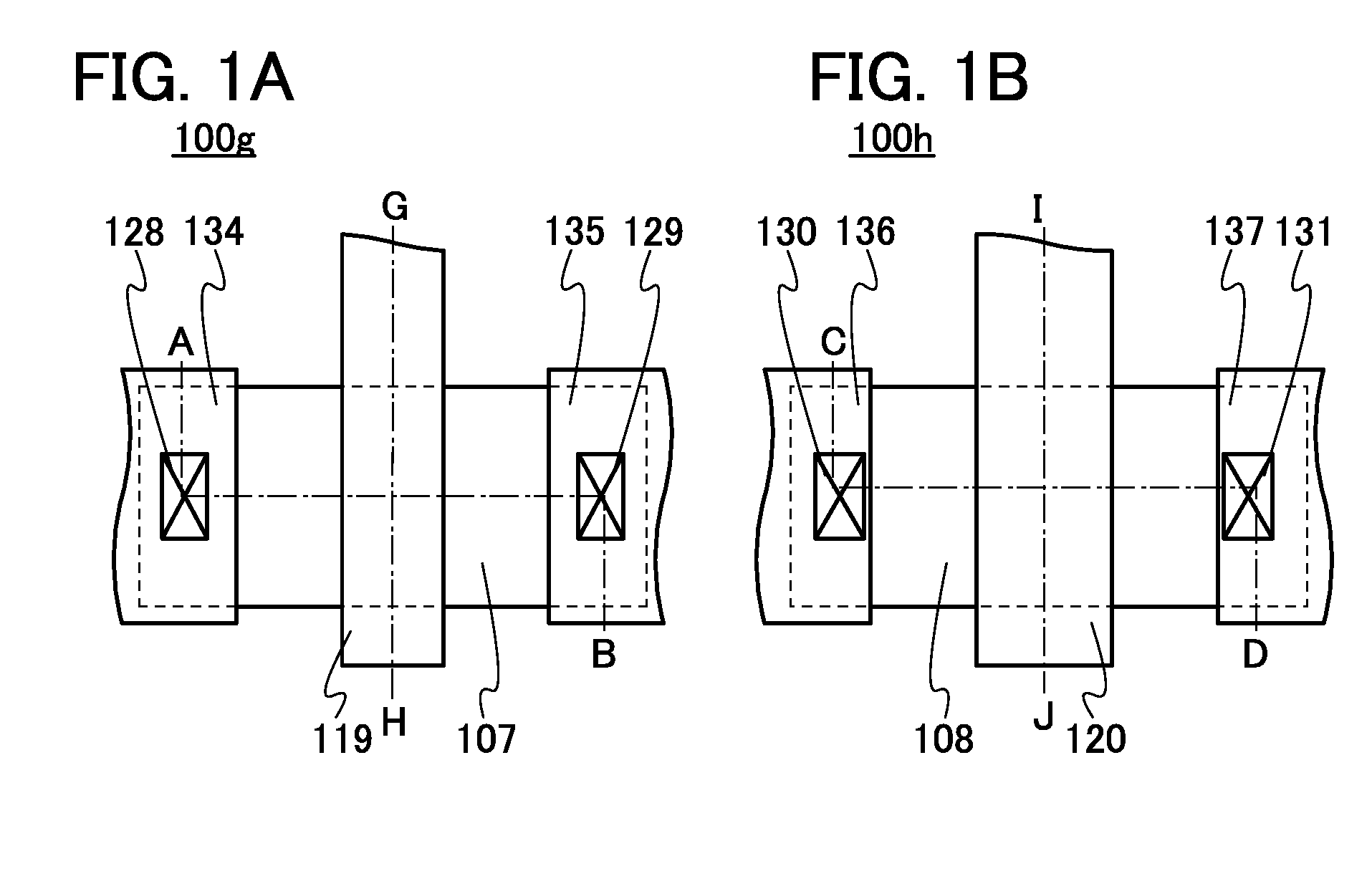

Capacitance type input device and display device with input function

ActiveUS20090315854A1Simple configurationResistance of light lightInput/output processes for data processingCapacitanceDisplay device

Provided is a capacitance type input device, in which a plurality of first light transmission electrodes extending in a first direction and a plurality of second light transmission electrodes extending in a second direction crossing the first direction are formed in an input region of a light transmission substrate, wherein, when the light transmission substrate is viewed from the top, dummy patterns formed of the same light transmission conductive film as the first light transmission electrodes and the second light transmission electrodes are formed in regions sandwiched between the first light transmission electrodes and the second light transmission electrodes.

Owner:JAPAN DISPLAY WEST

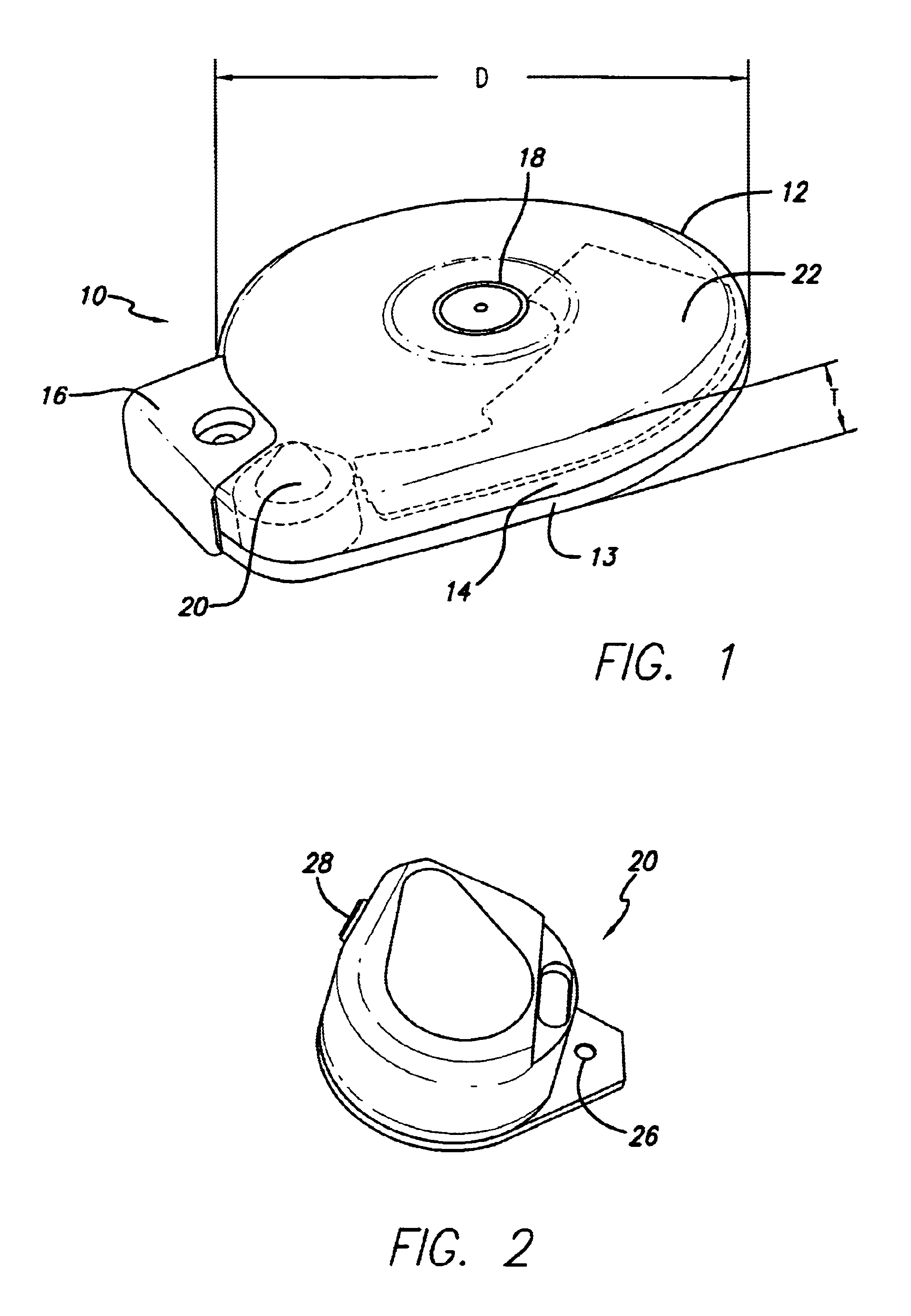

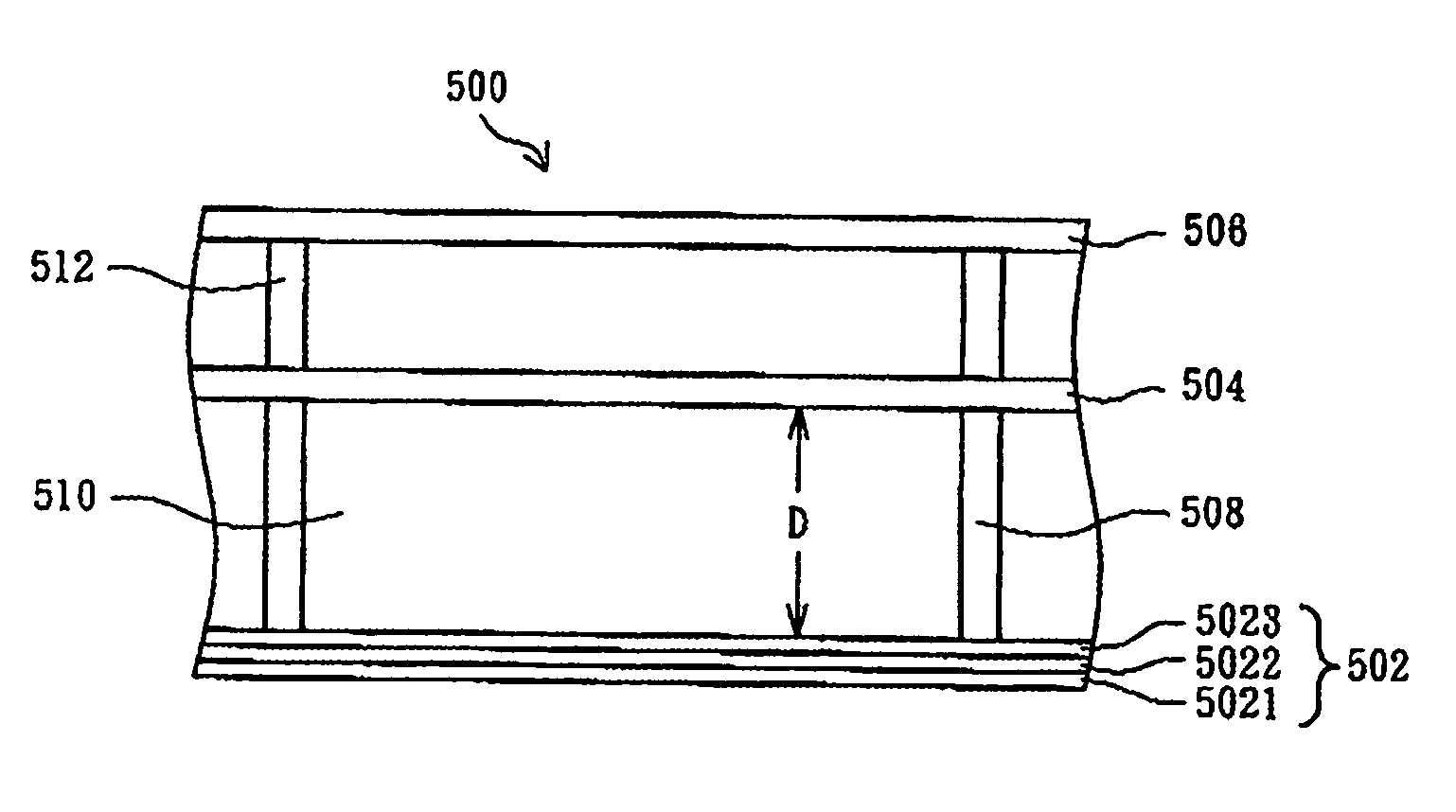

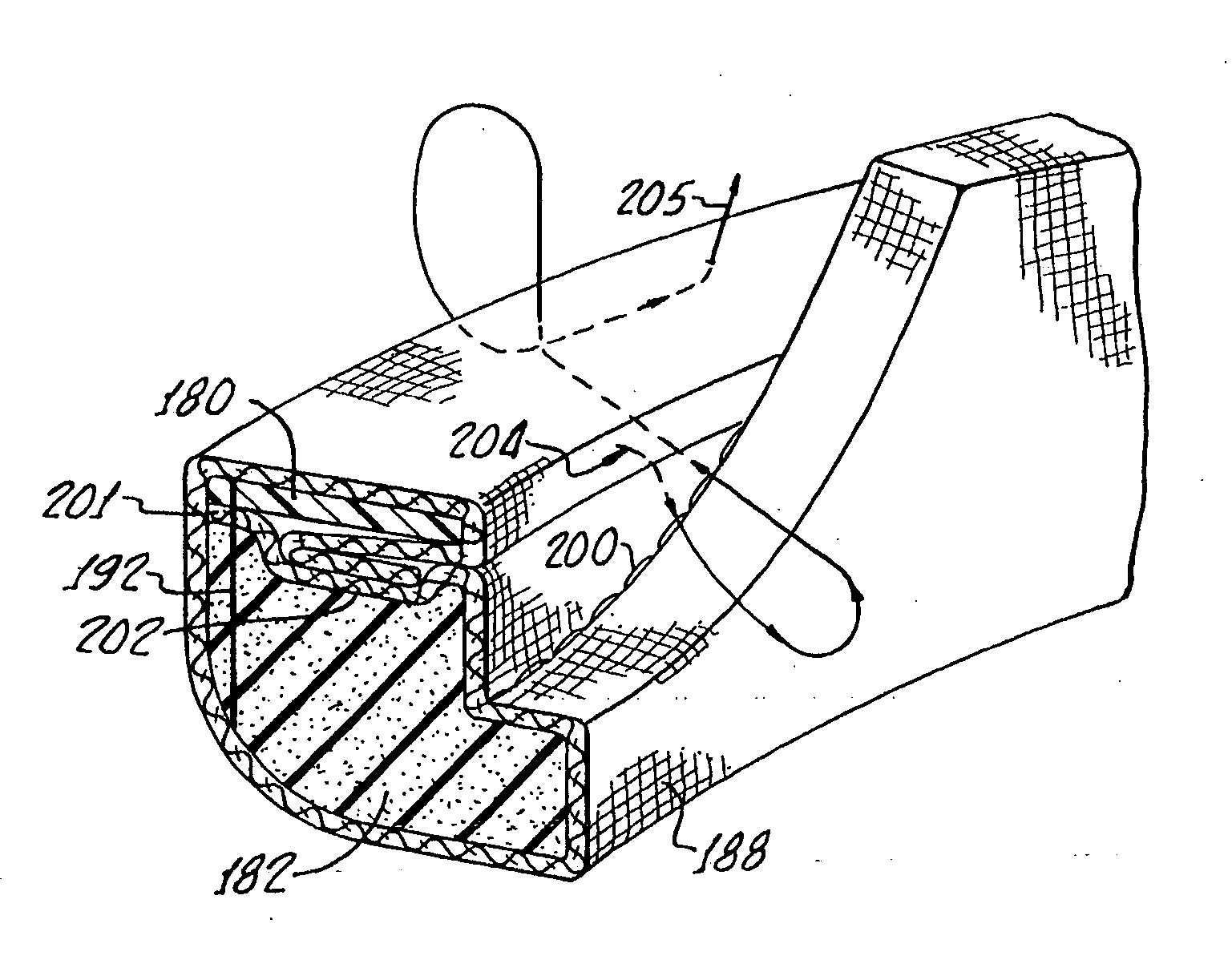

Infusion device and driving mechanism and process for same with actuator for multiple infusion uses

InactiveUS6932584B2Small thickness dimensionMinimize traumaIntravenous devicesPiston pumpsEngineeringActuator

Owner:MEDTRONIC MIMIMED INC

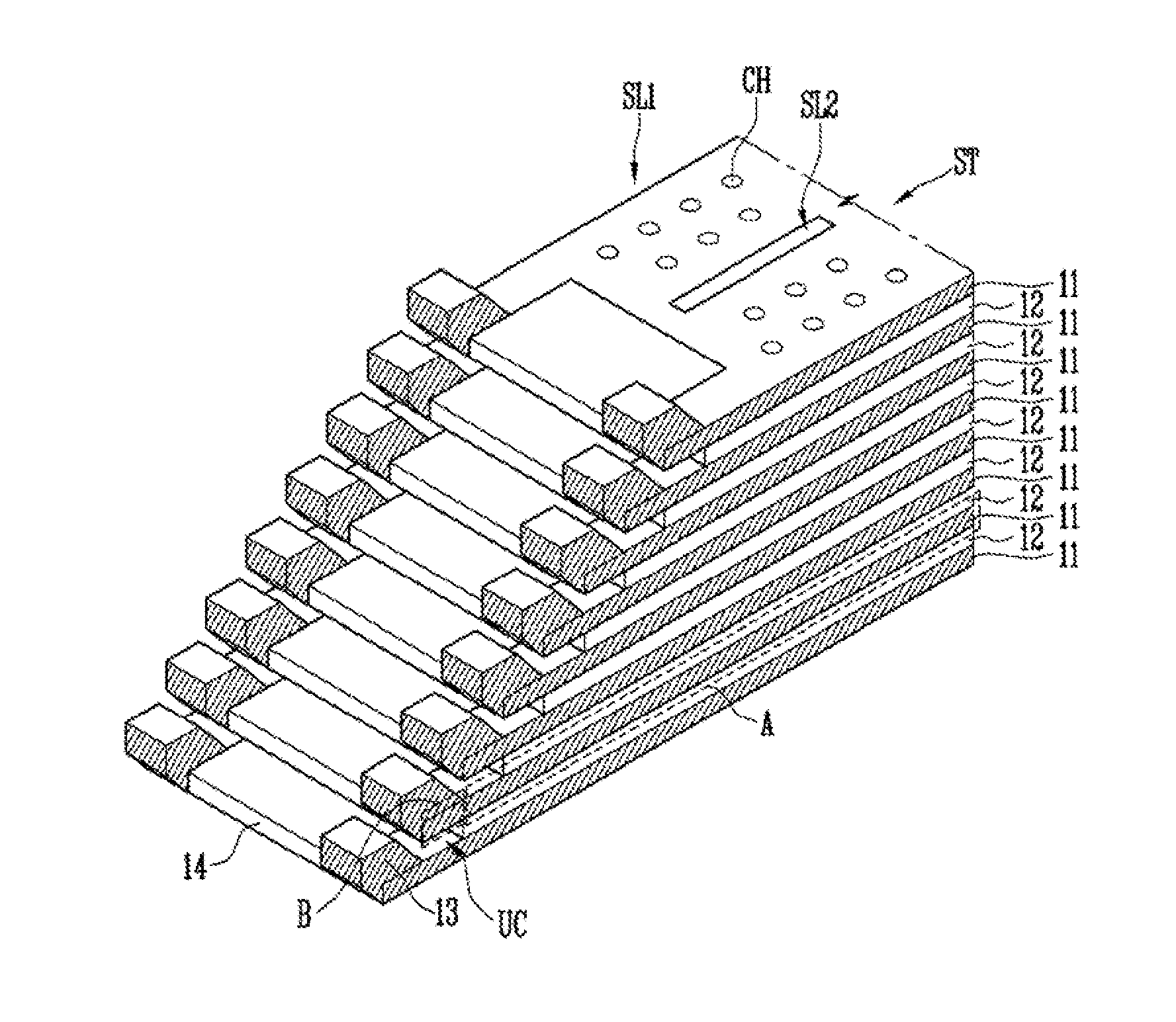

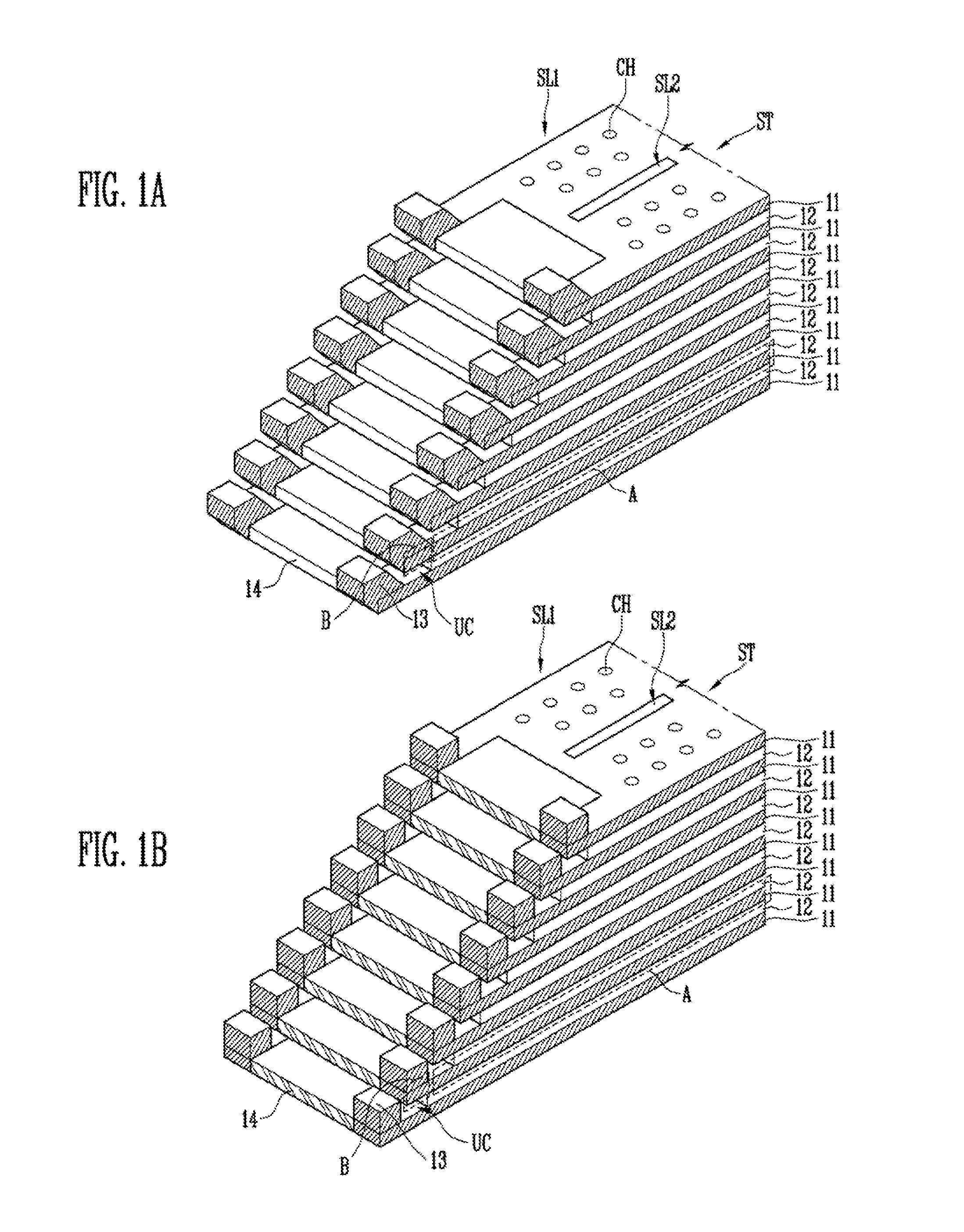

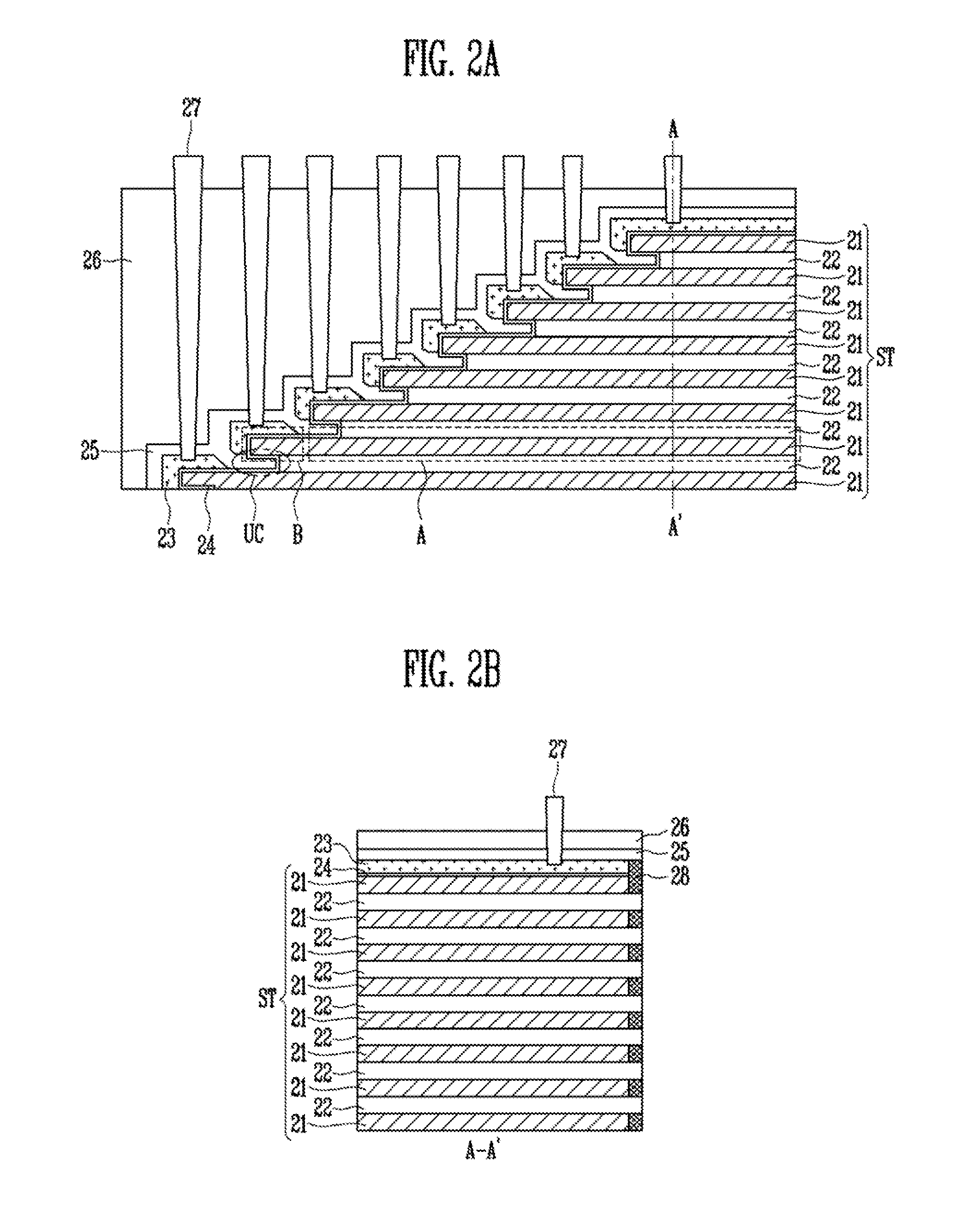

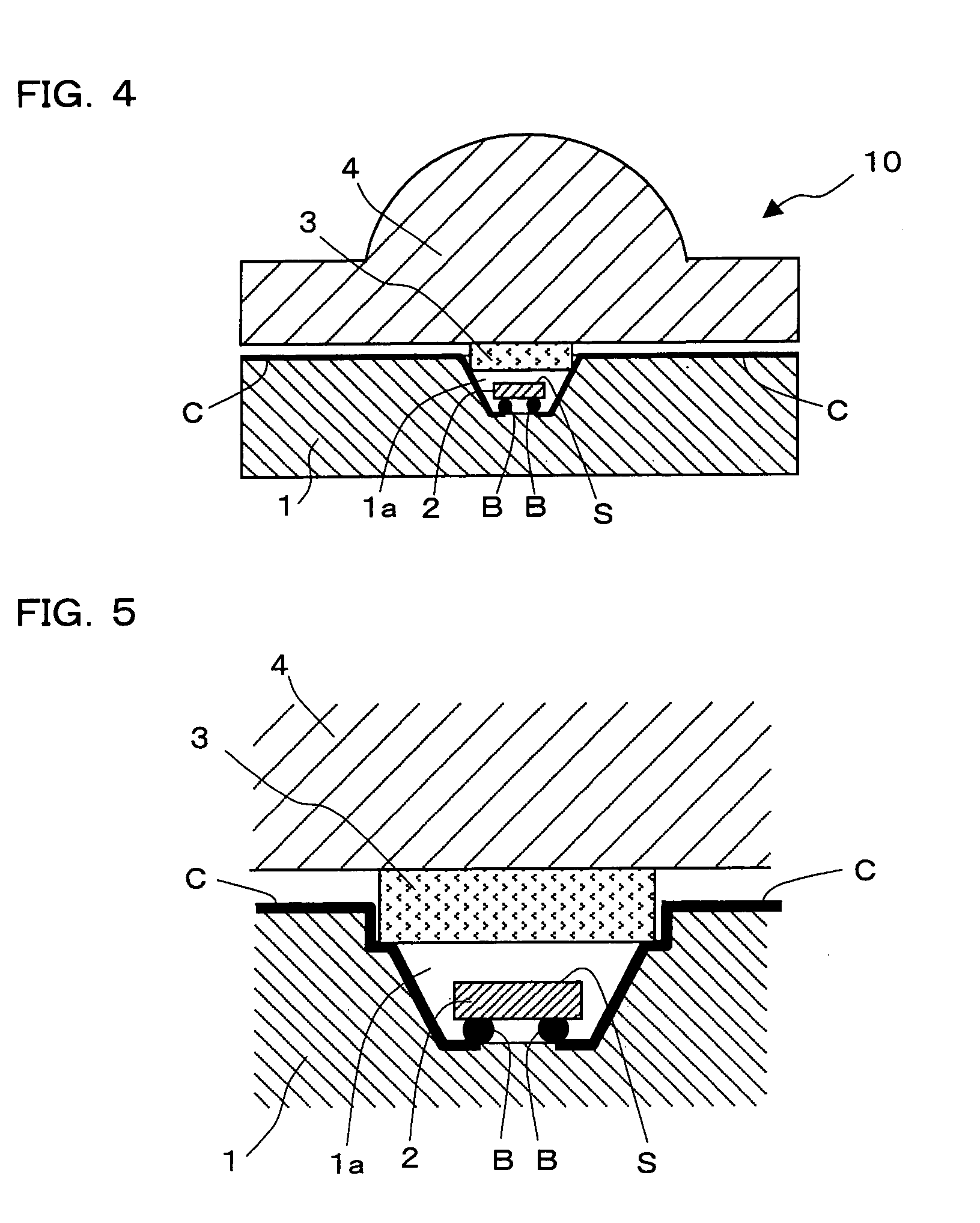

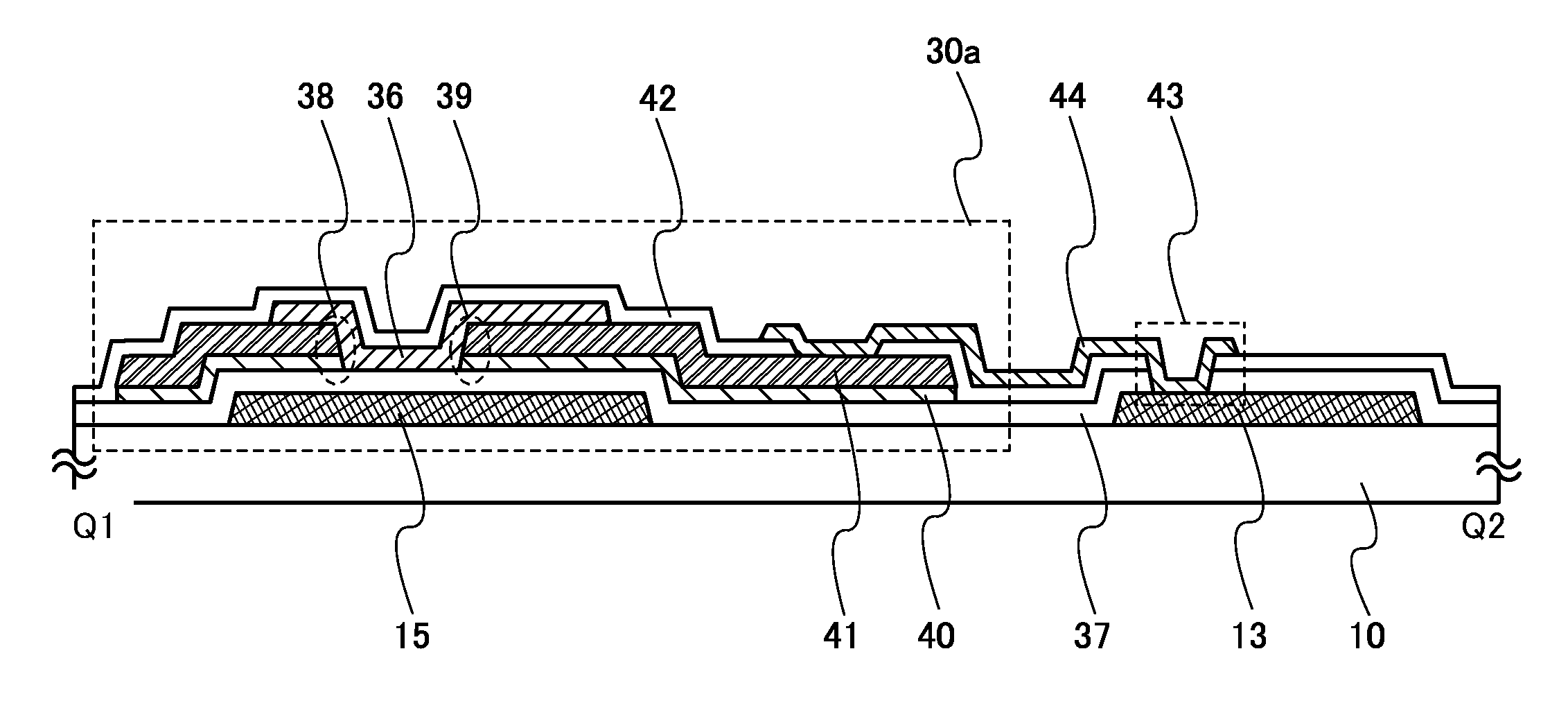

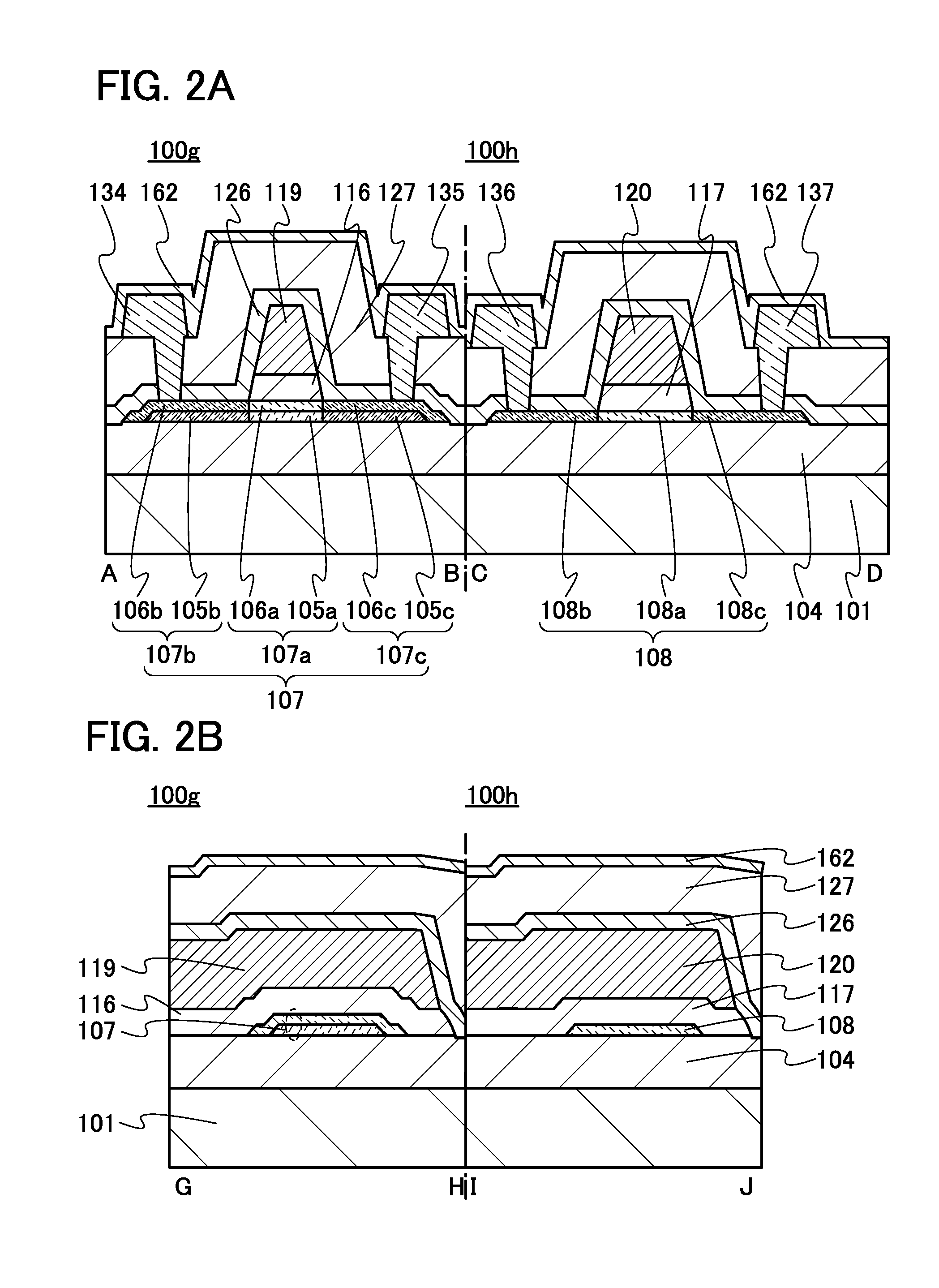

Semiconductor device and method of manufacturing the same

ActiveUS20150179564A1Simple manufacturing processStable structureSemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor

A semiconductor device includes a stacked structure having first conductive layers stacked stepwise and first insulating layers interposed between the first conductive layers, wherein undercuts are formed under the first conductive layers and each of the first conductive layers includes a first region covered by the first conductive layer and a second region extending from the first region, contact pads coupled to the second regions of the respective first conductive layers, and a liner layer formed on the contact pads and filling the undercuts.

Owner:SK HYNIX INC

Optical fiber cable with fiber receiving jacket ducts

InactiveUS7123801B2Manually readily rupturedImprove protectionFibre mechanical structuresFiberPull force

Owner:PRYSMIAN COMM CABLES & SYST USA LLC

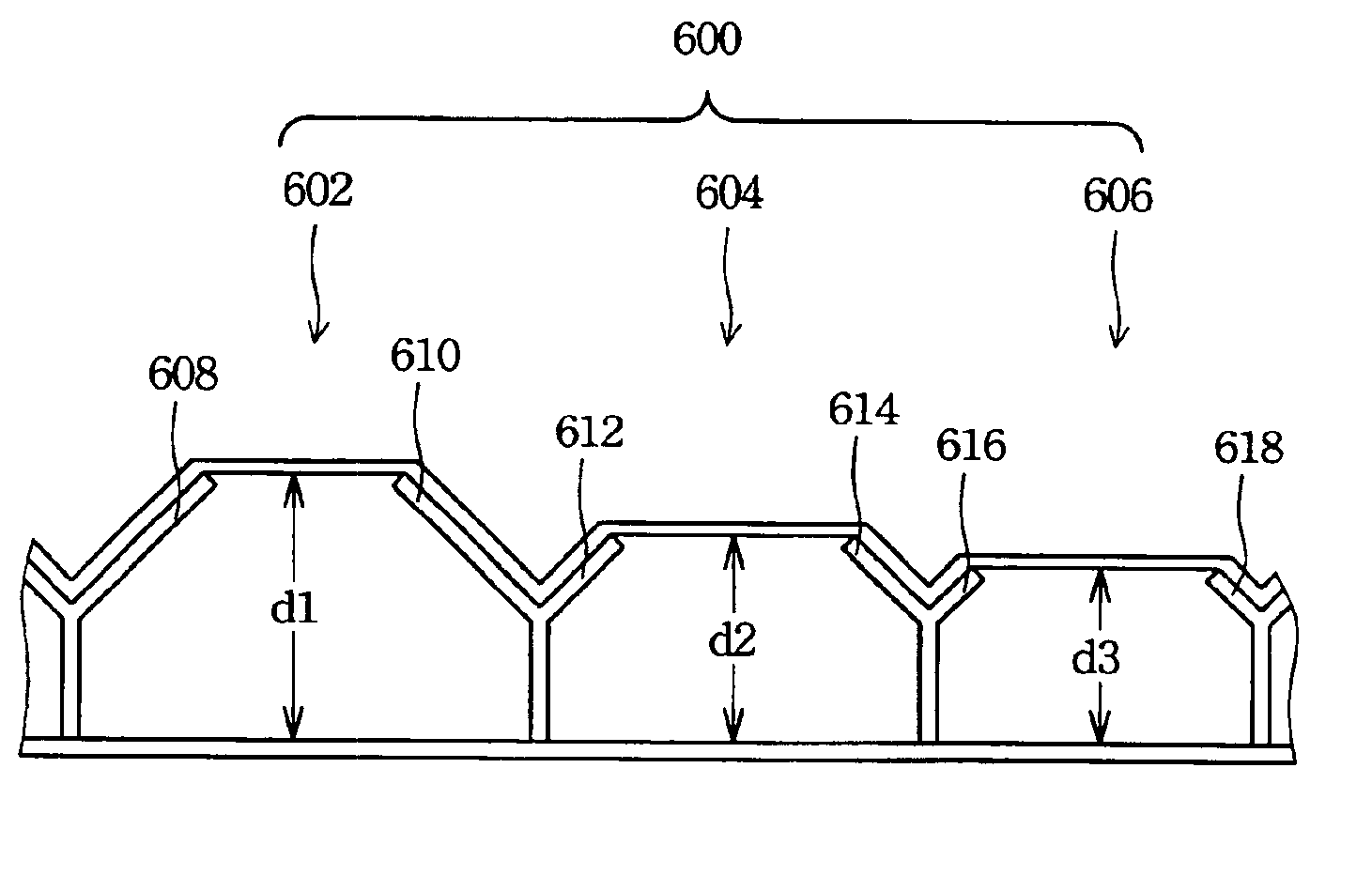

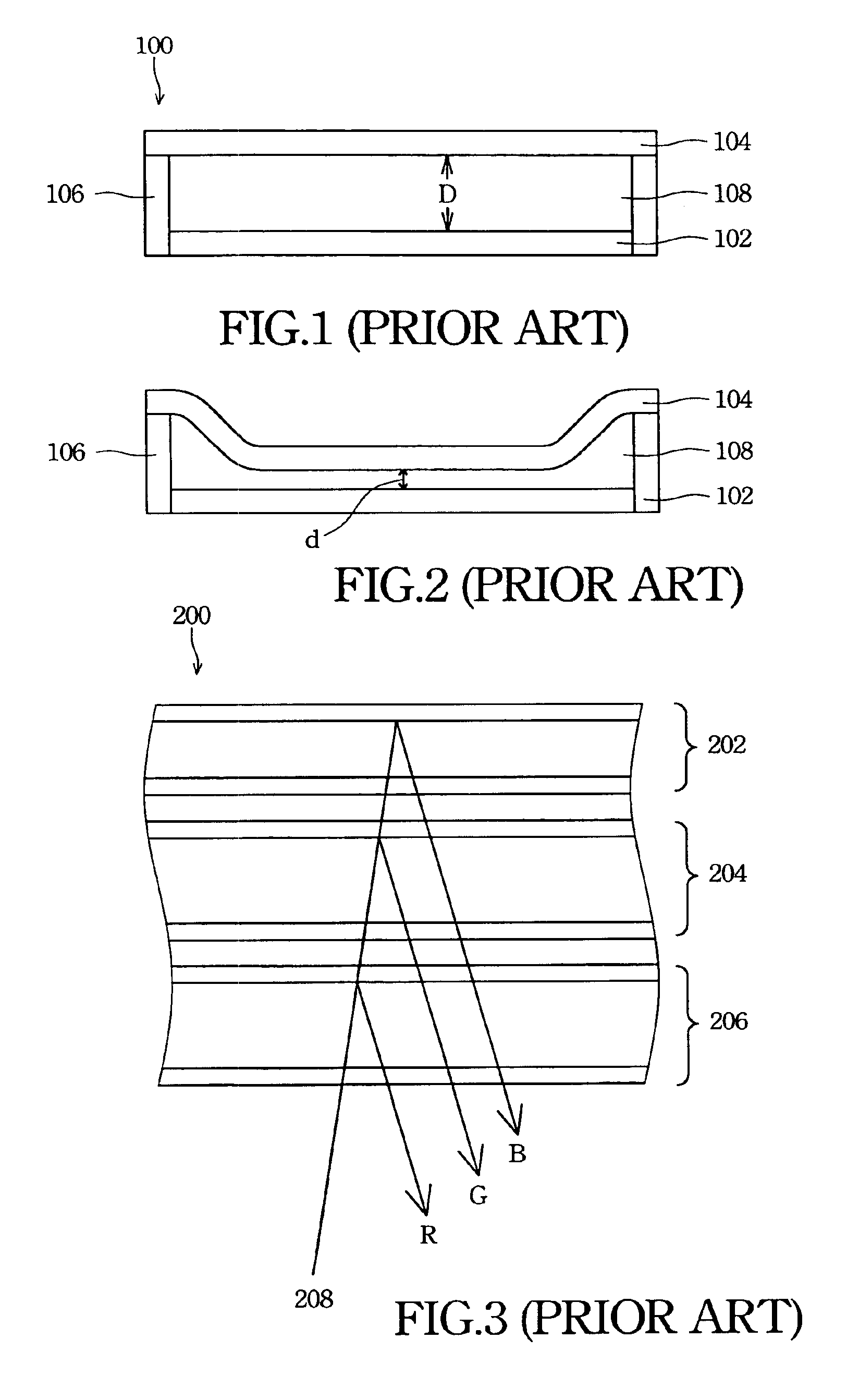

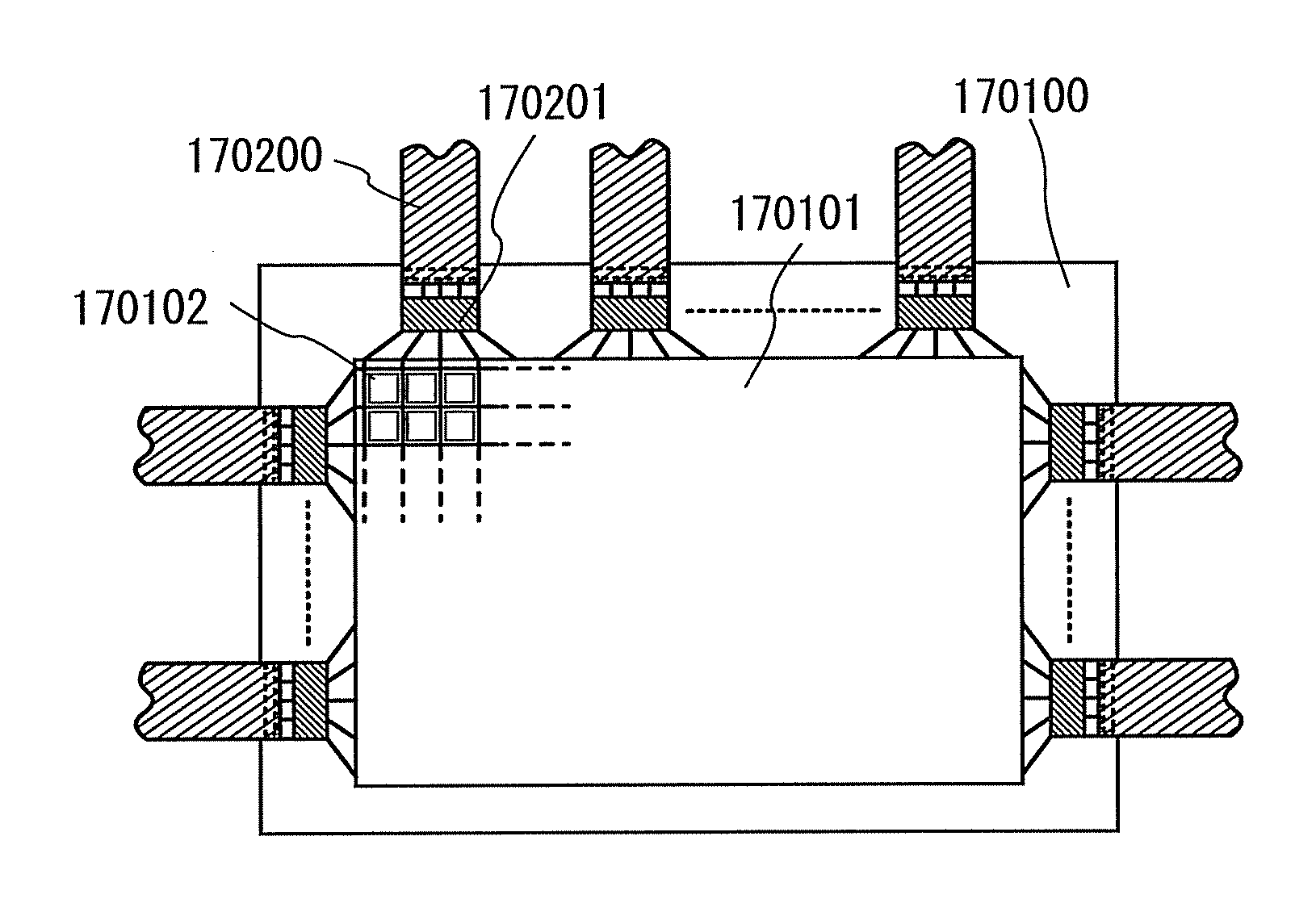

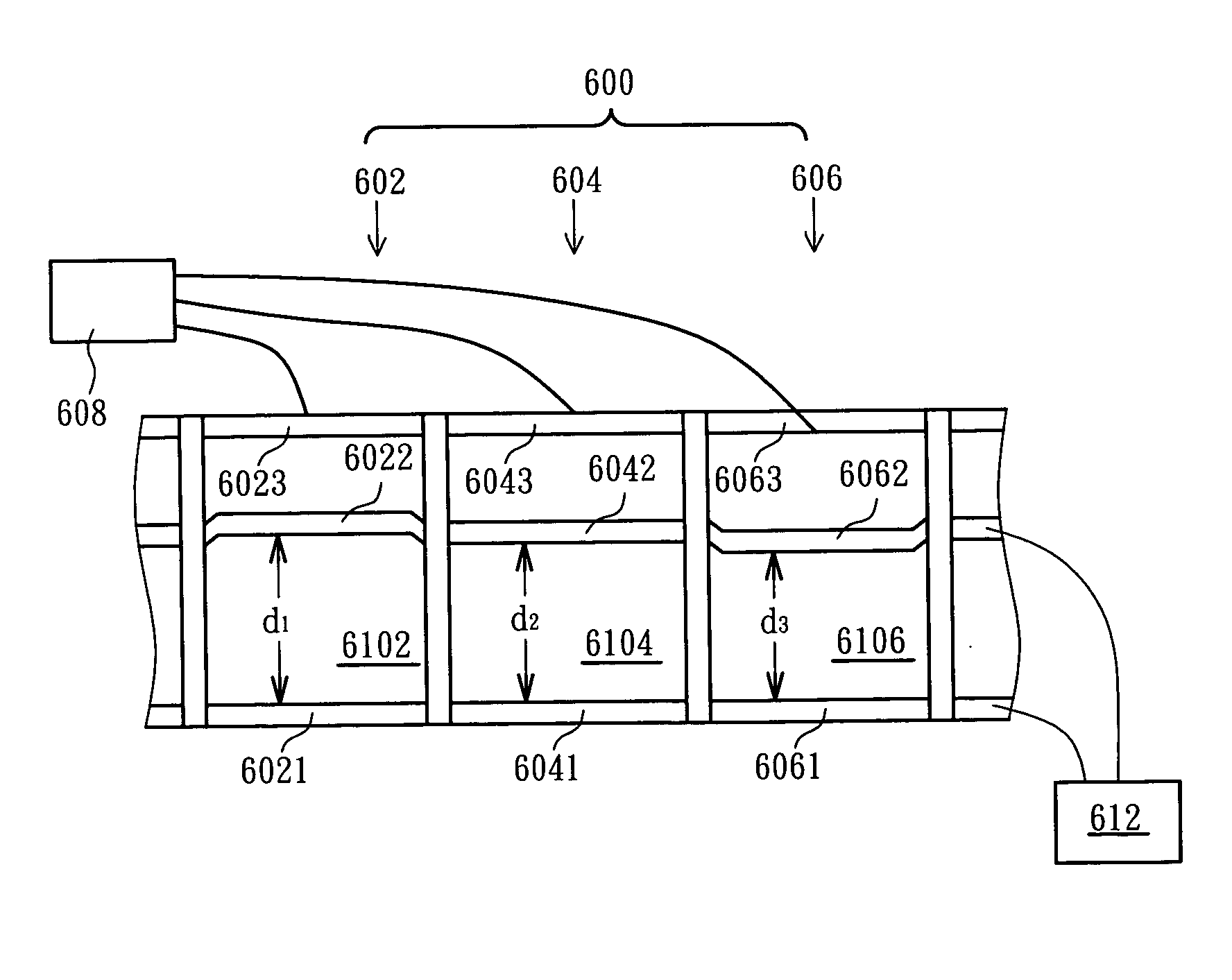

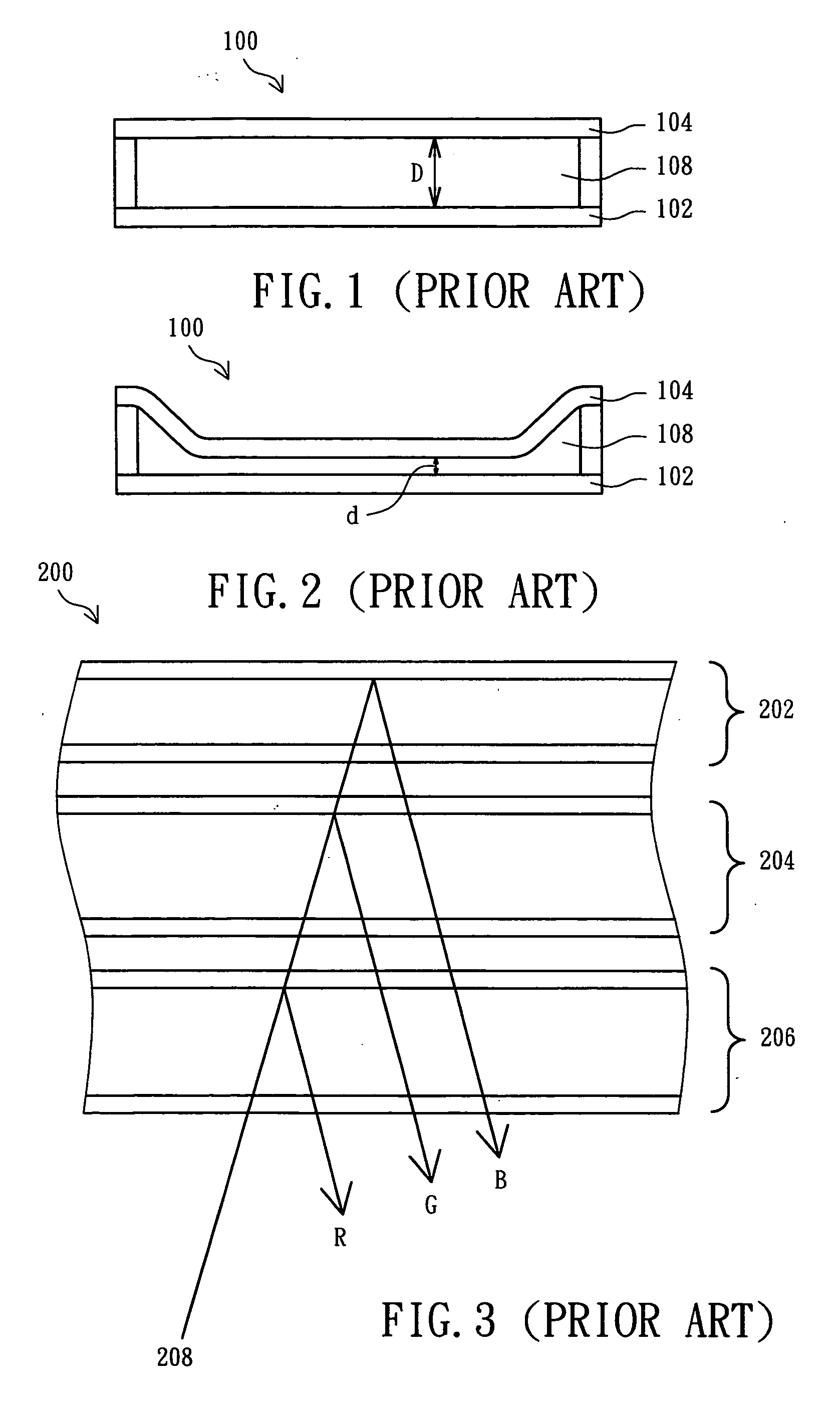

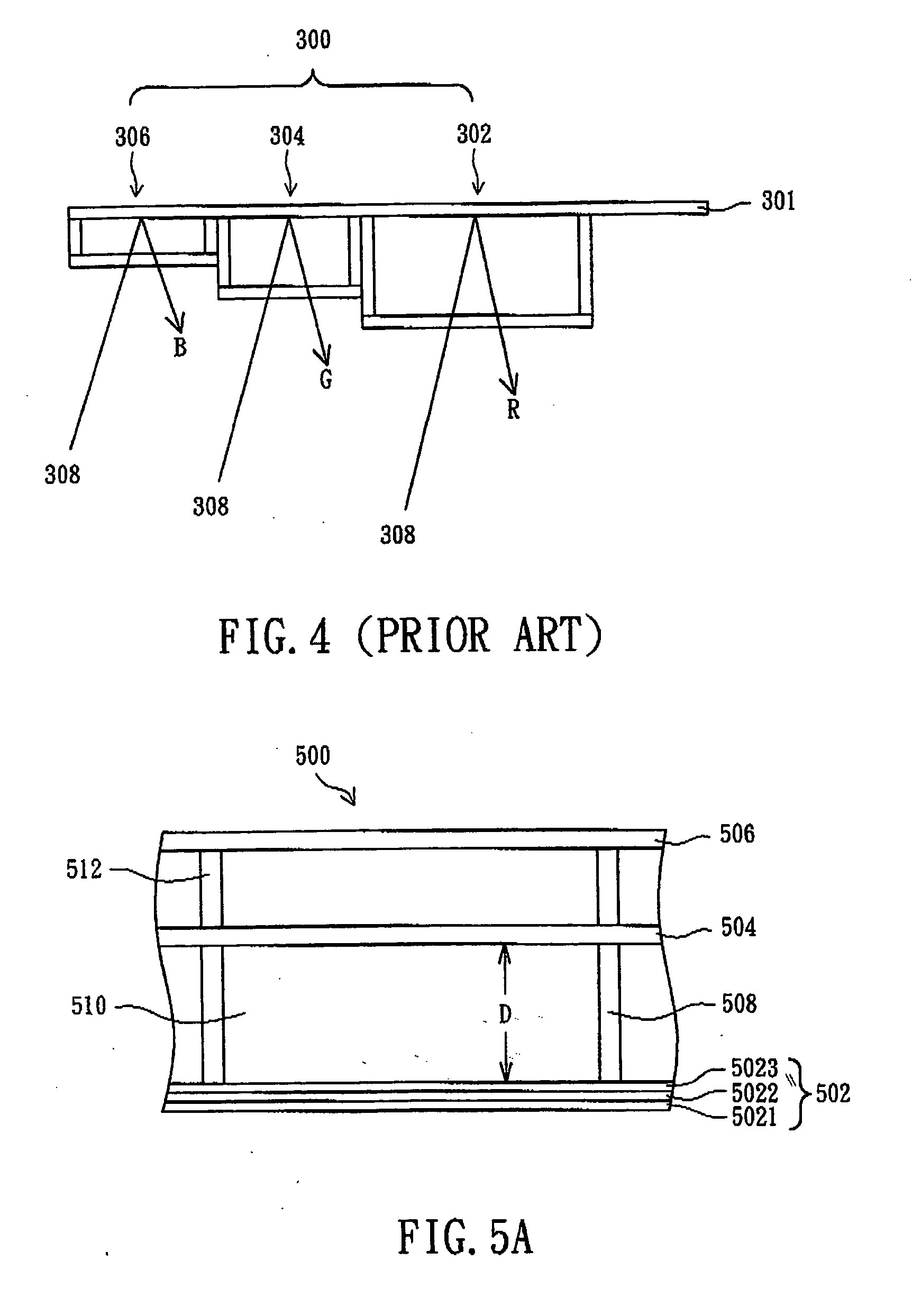

Structure of an optical interference display cell

A structure of an interference display cell is provided. The cell comprises a first plate and a second plate, wherein a support is located between the first plate and the second plate. The second plate is a deformable and reflective plate. An incident light from one side of the first plate is modulated and only specific frequency light reflects by the second plate. The frequency of the reflected light is related to the distance between the first plate and the second plate. The support has at least one arm. The arm's stress makes the arm hiking upward or downward. The distance between the first plate and the second plate is also changed. Therefore, the frequency of the reflected light is altered.

Owner:SNAPTRACK

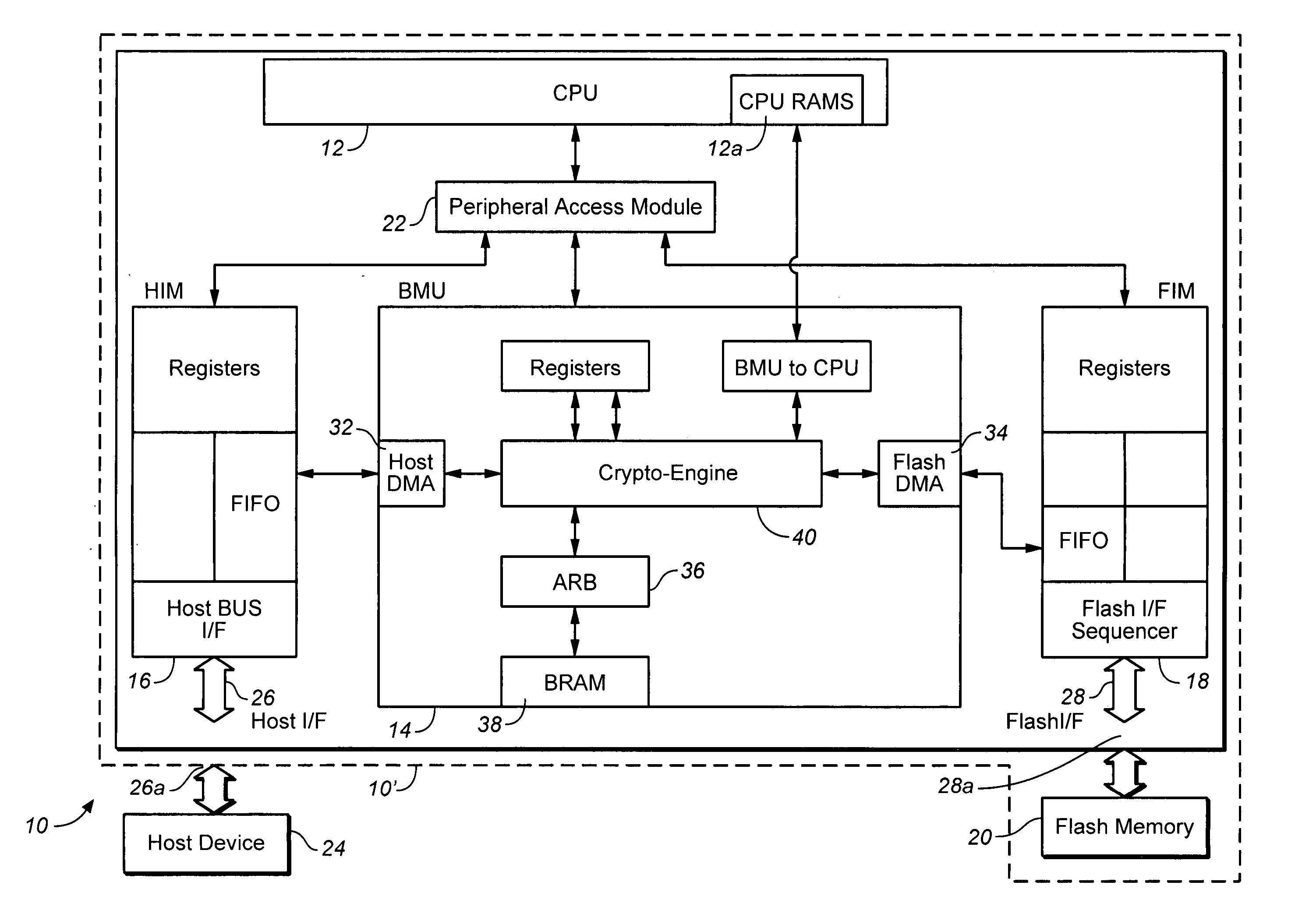

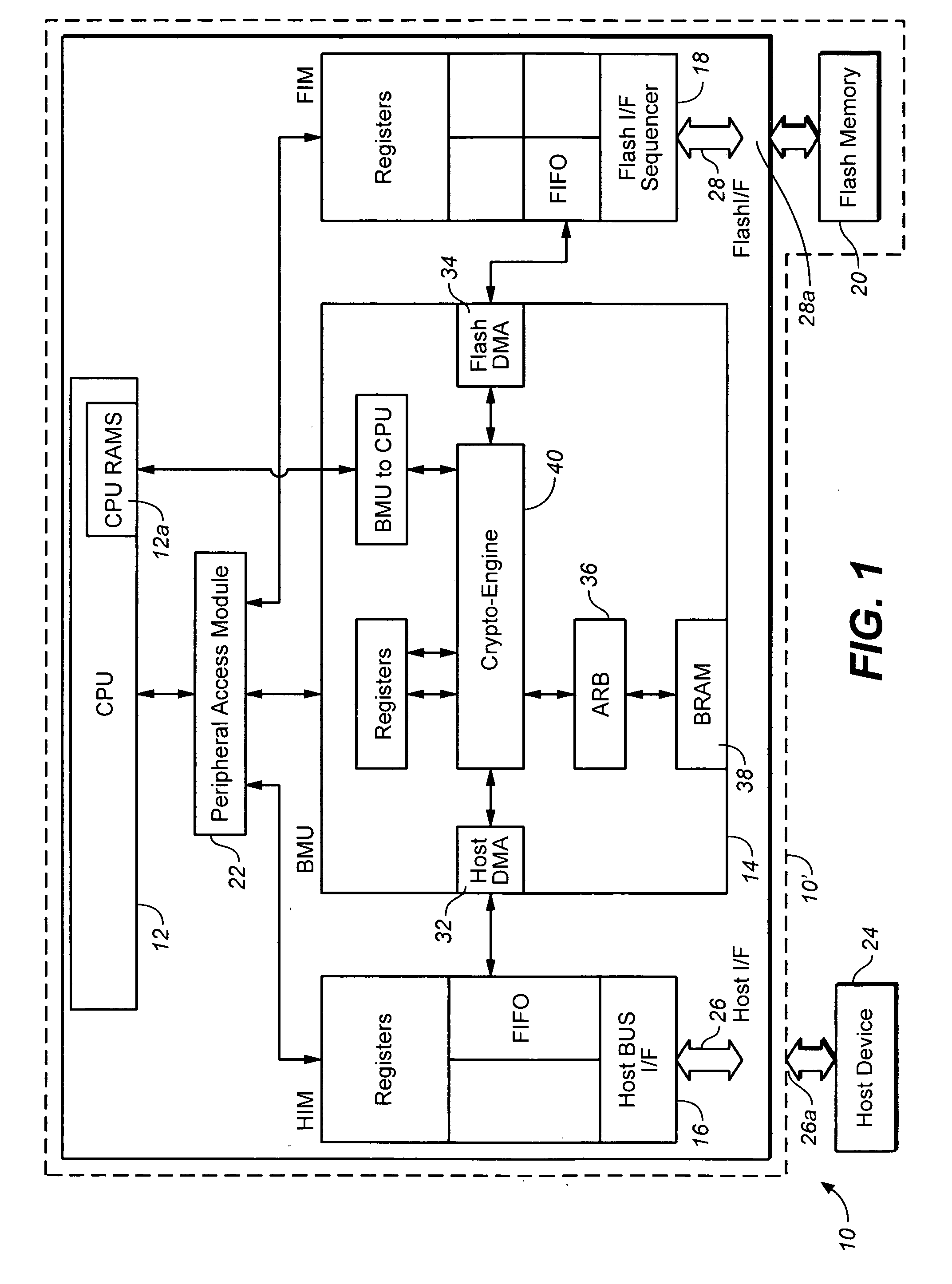

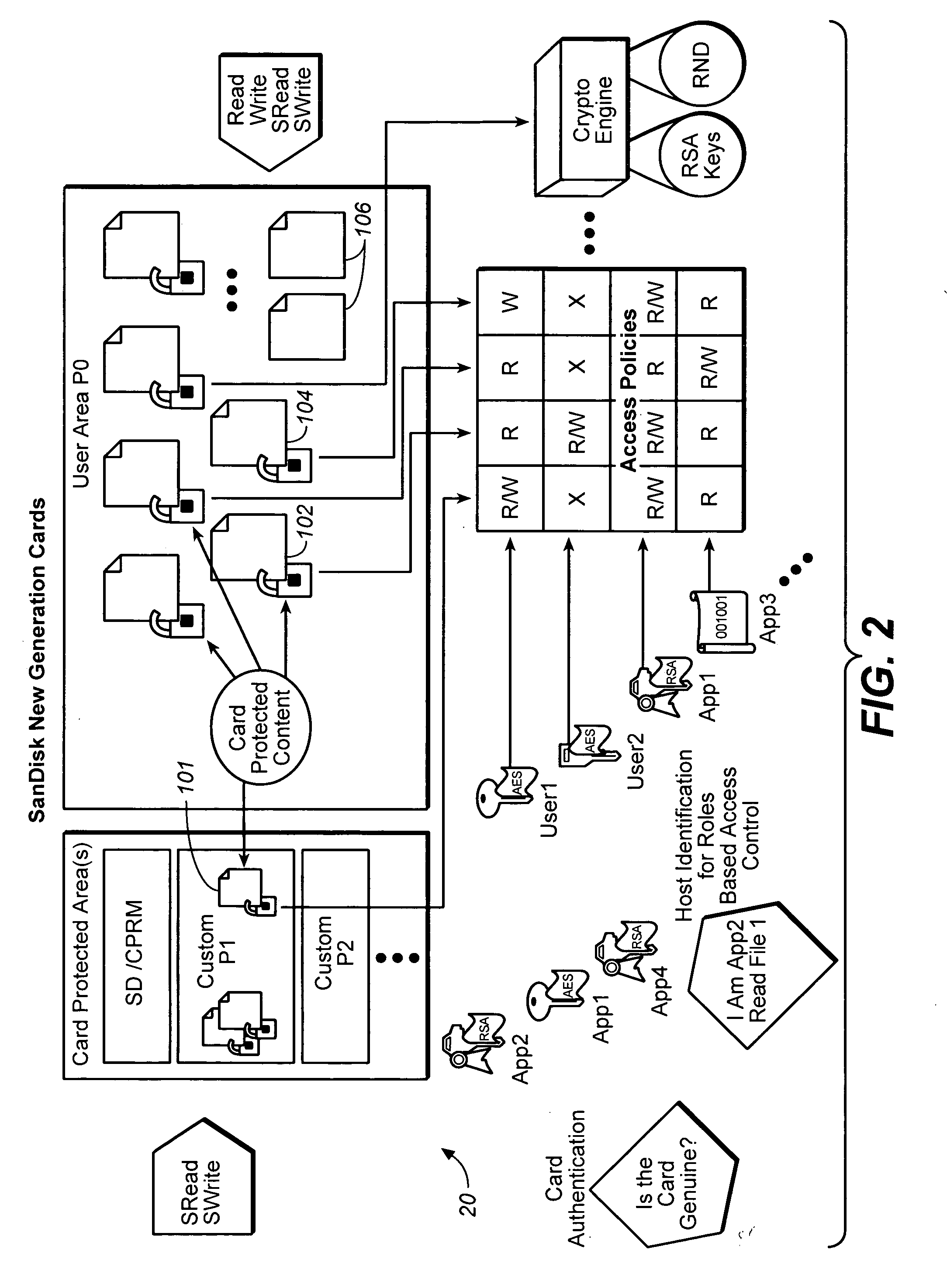

Method for secure storage and delivery of media content

InactiveUS20070043667A1Easy accessSimple manufacturing processRecord information storageInternal/peripheral component protectionContent distributionService provision

The memory device contains control structures that allow media content to be stored securely and distributed in a manner envisioned by the content owner, or service providers involved in the distribution. A wide variety of different avenues become available for distributing media content using such memory devices, such as where the devices contain one or more of the following: abridged preview media content, encrypted unabridged media content, prepaid content, rights and / or rules governing access to such content. The memory device has a type of control structures that enable a service provider (who can also be the content owner) to create a secure environment for media content distribution where end users and terminals register with the service provider, and gain access to the content in a manner controlled by the service provider. The various components to be loaded (e.g. abridged preview media content, encrypted unabridged media content, prepaid content, rights and / or rules governing access to such content) may be generated and loaded in a secure and efficient manner.

Owner:SANDISK TECH LLC

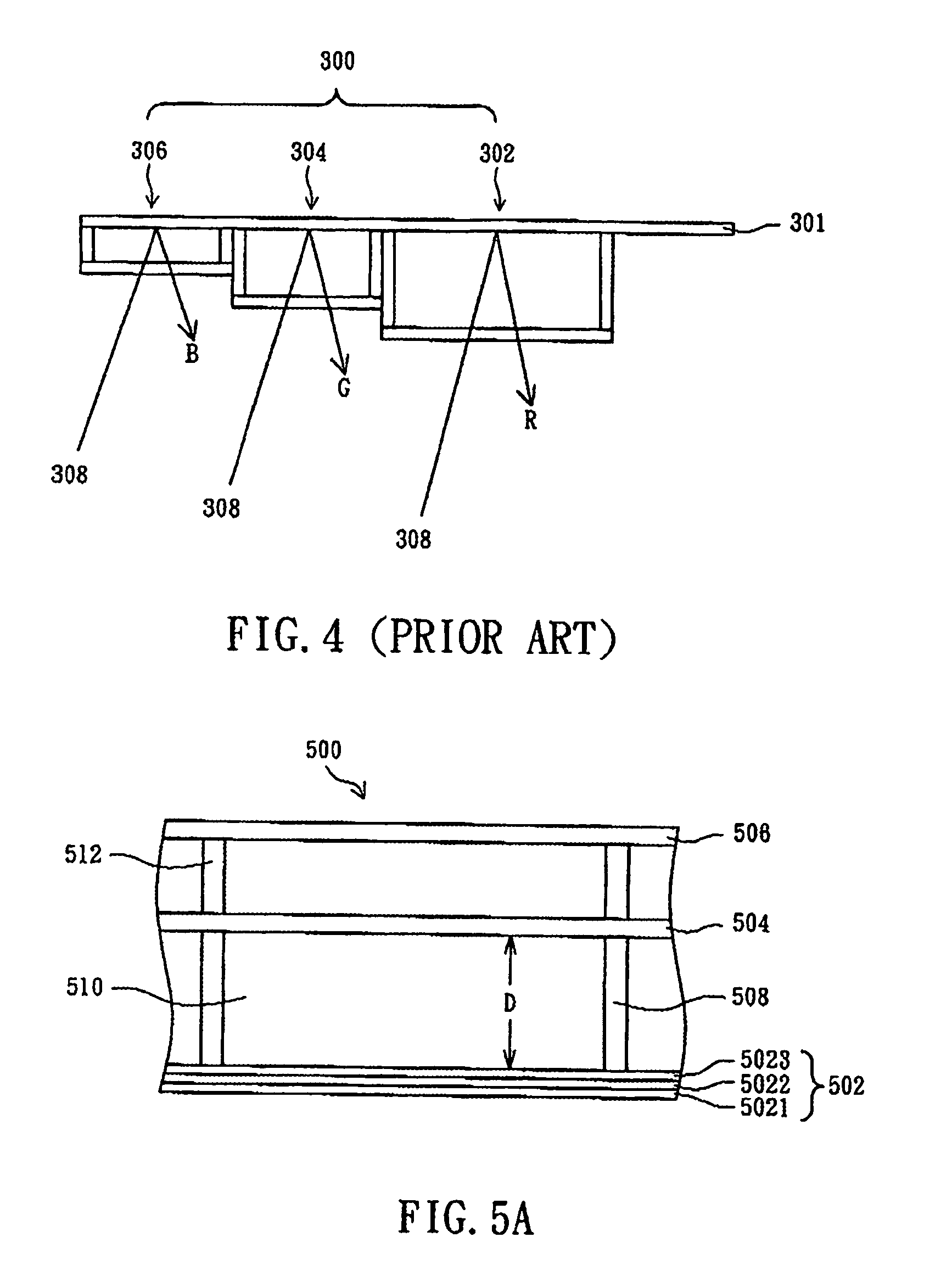

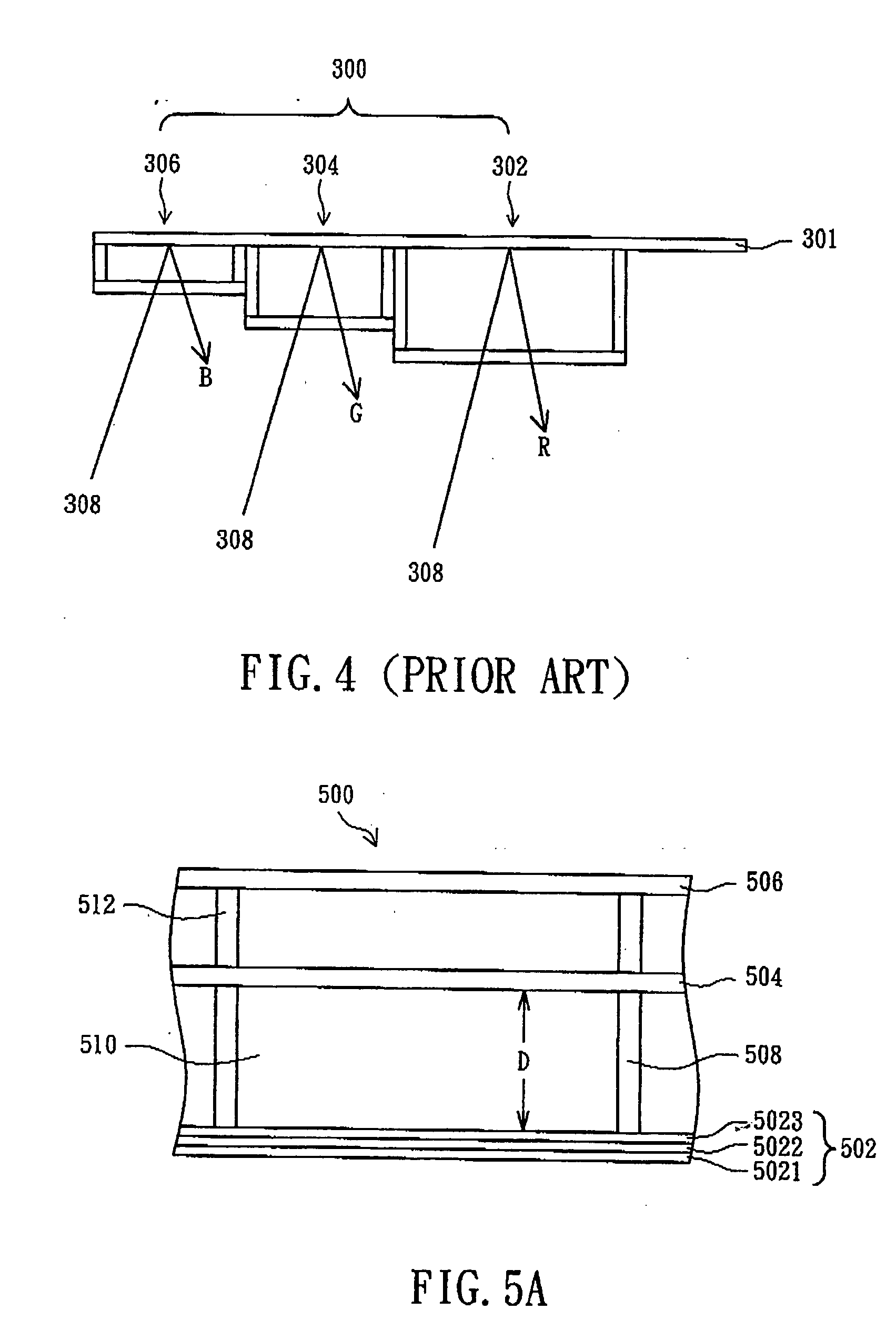

Color changeable pixel

InactiveUS6982820B2Increase brightnessHigh resolutionNon-linear opticsOptical elementsOptoelectronicsVoltage

Owner:SNAPTRACK

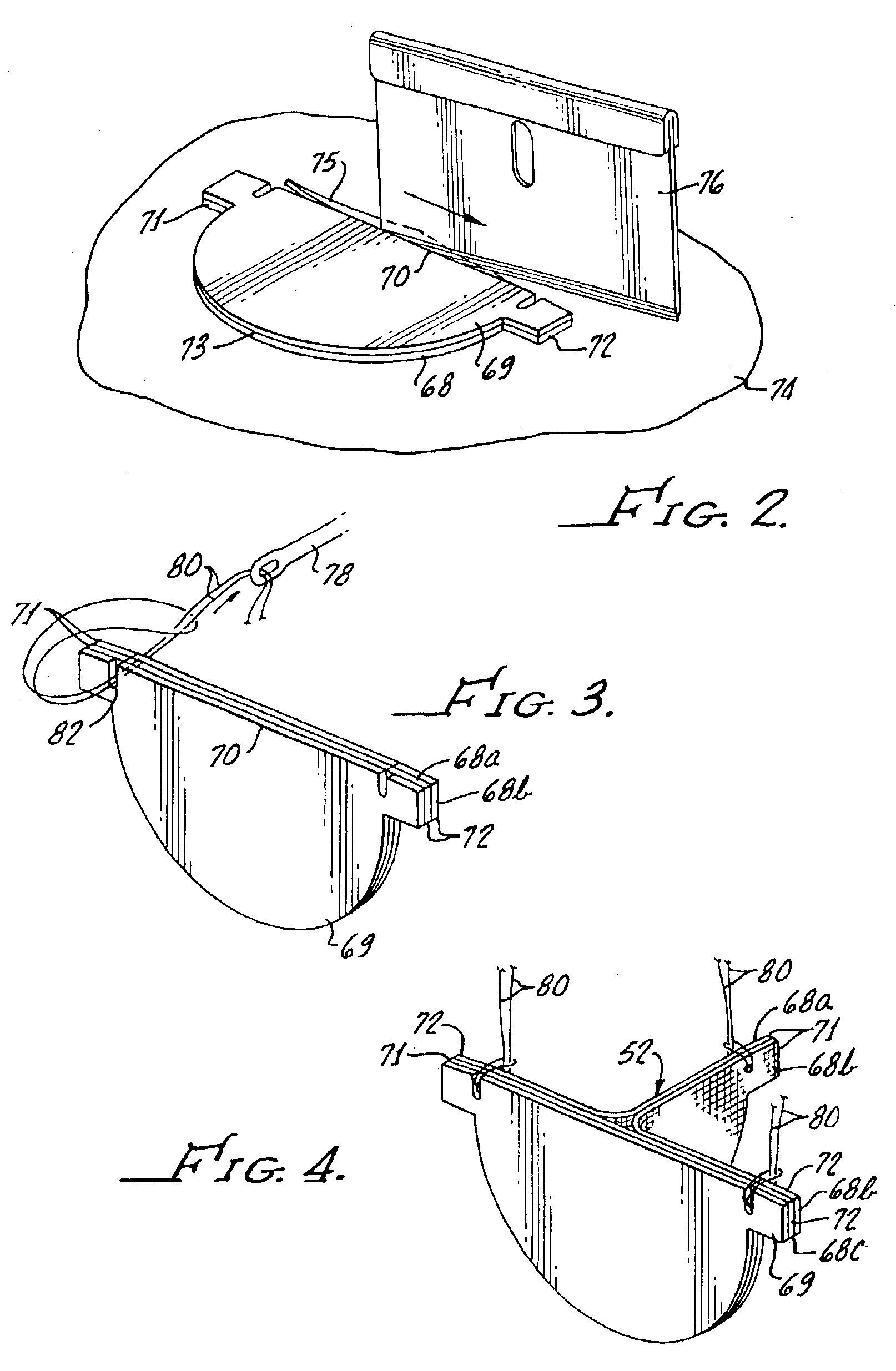

Liquid Crystal Display Device and Driving Method Thereof

ActiveUS20080284719A1Increase contrastImprove image qualityStatic indicating devicesSolid-state devicesLiquid-crystal displayDisplay device

In a display device including a backlight and a display panel, the area of the backlight is divided into a plurality of unit regions; the display panel includes pixels which are larger in number than the unit regions; a frame rate of image data input to the device is converted to perform display while part of the unit regions in which black is displayed is in a non-light emission state; and the driving frequency of the backlight is converted in accordance with the display.

Owner:SEMICON ENERGY LAB CO LTD

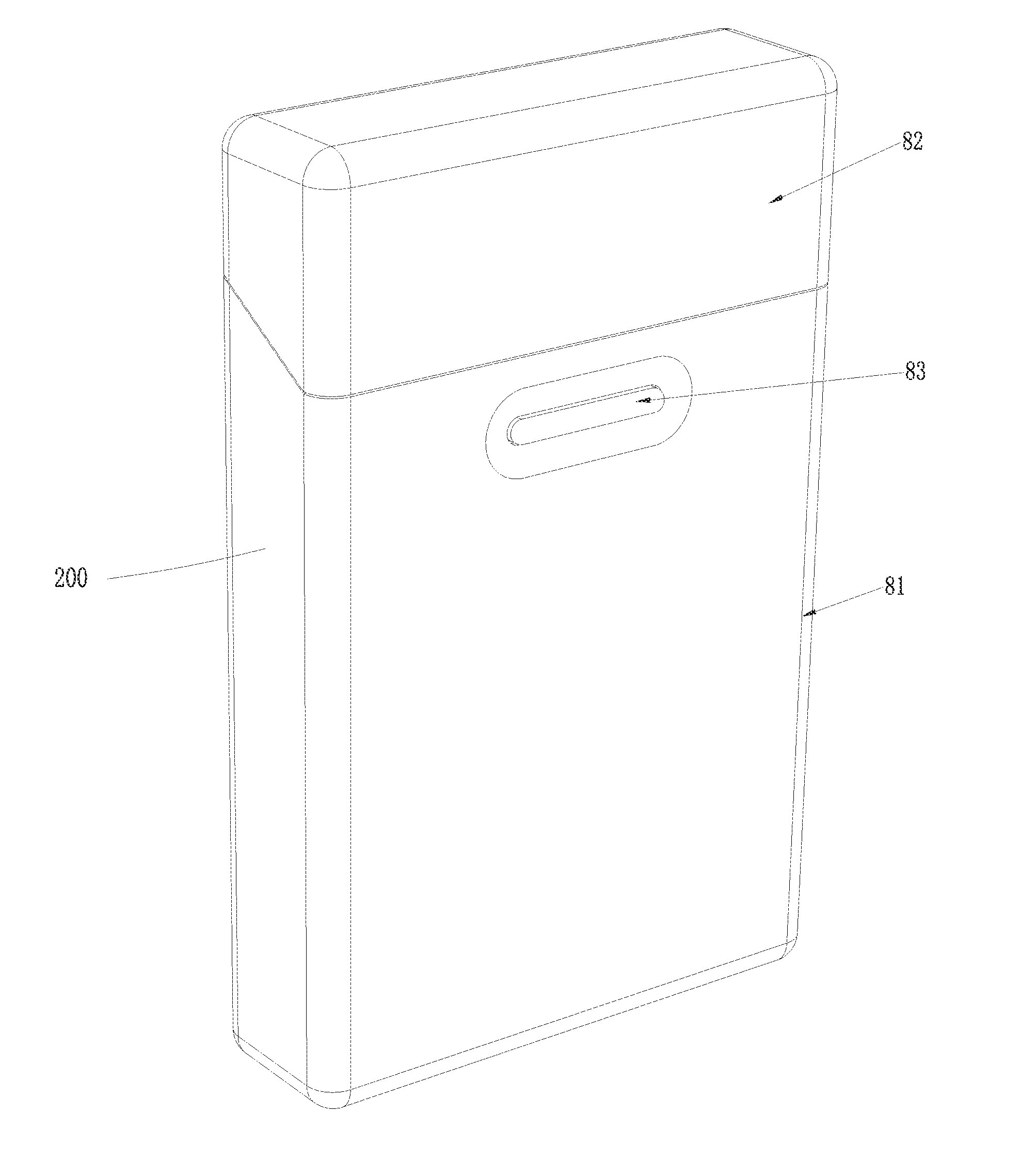

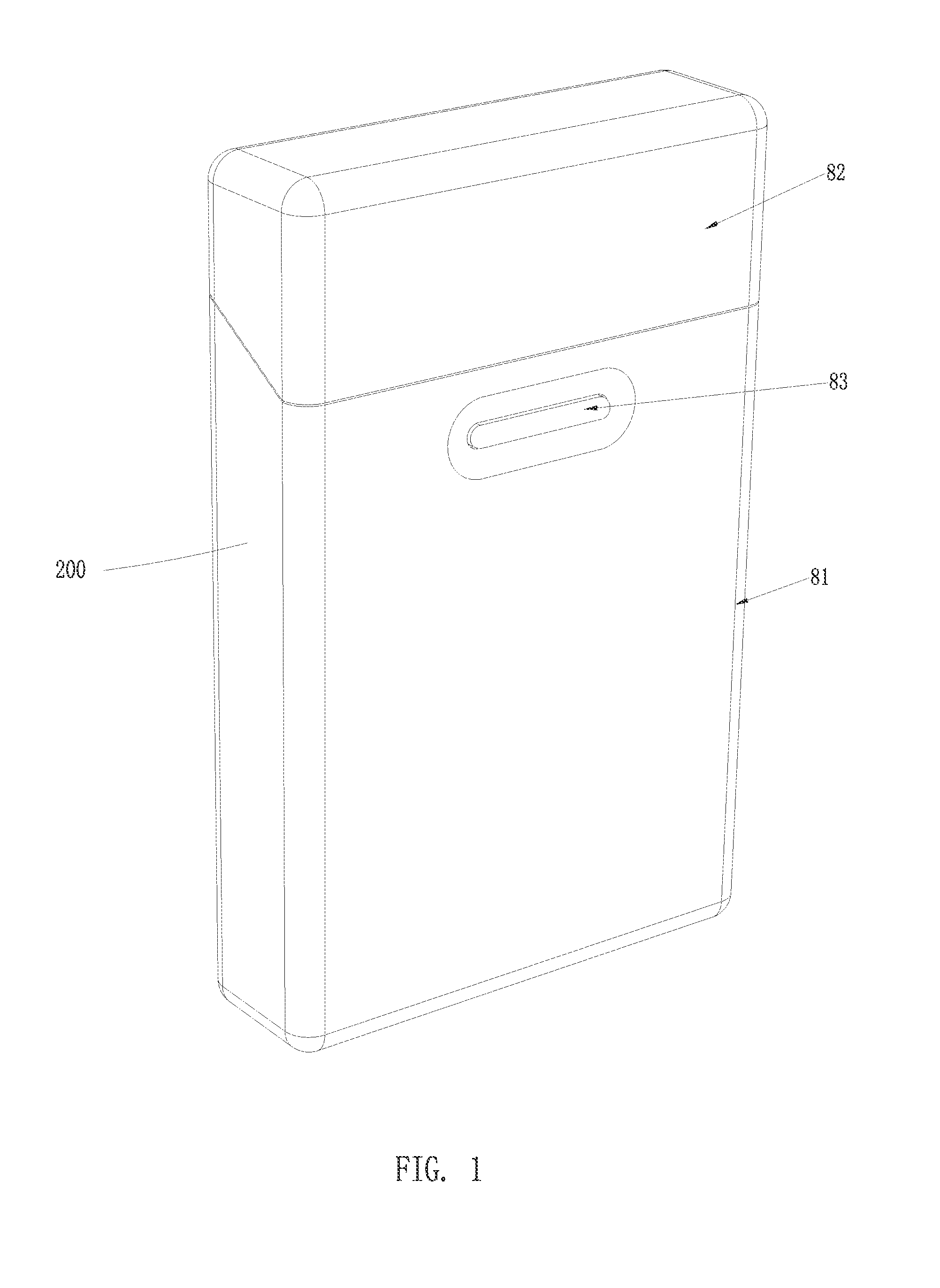

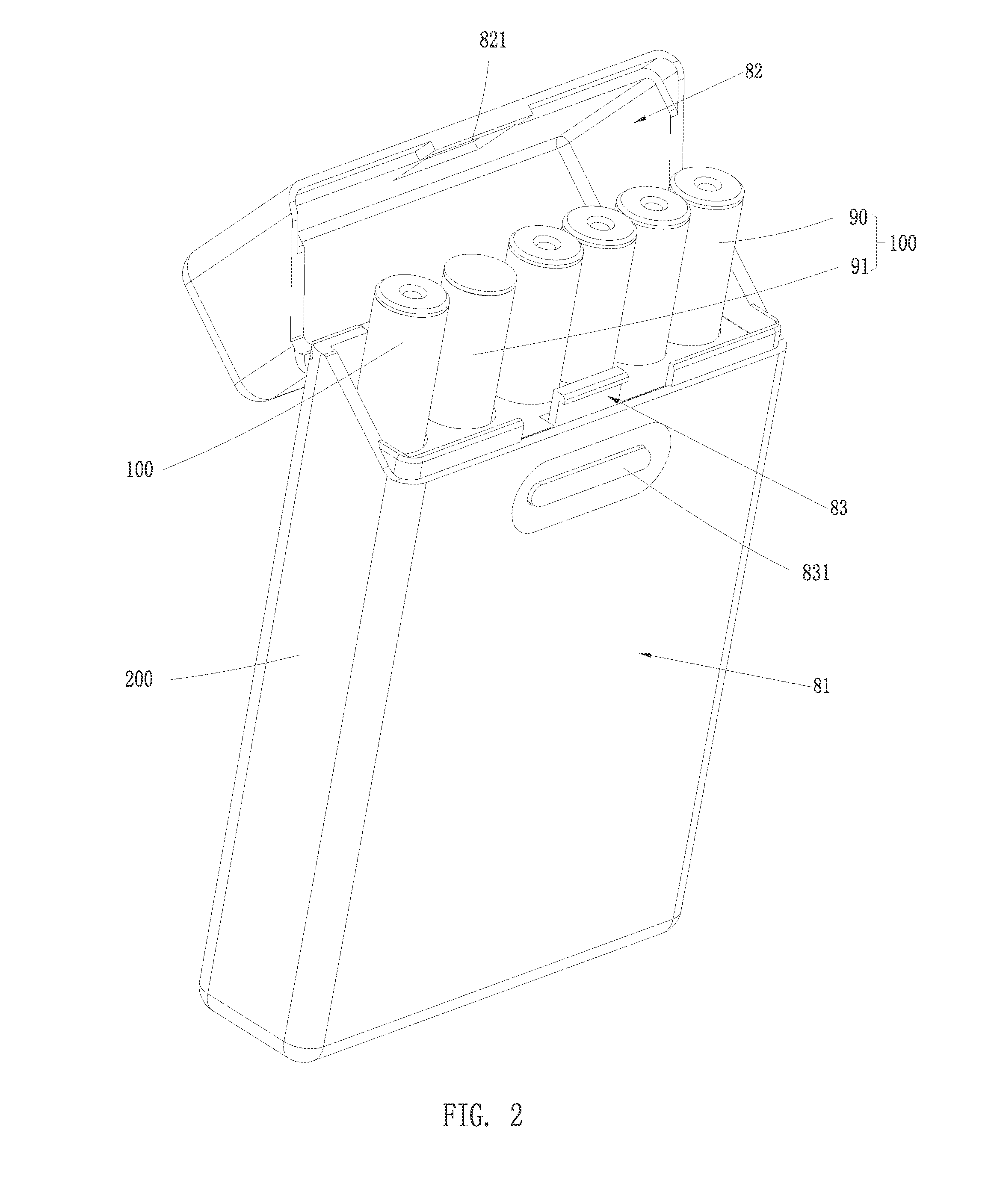

Electronic Cigarette Case

InactiveUS20130342157A1Ensure electrical connection reliabilitySimple manufacturing processBatteries circuit arrangementsTobacco pipesElement spaceElectricity

The present invention relates to an electronic cigarette case, includes a case body, a charging device disposed in the case body for charging electronic cigarettes. The charging device includes a charging base, a rechargeable battery, and a control circuit board integrated with a circuit processing unit. The charging base has an electrode support where first and second electrode elements, and a trigger element spaced apart from the second electrode element are all disposed on the electrode support. The second electrode element is flexibly deformable when one of the electronic cigarettes is inserted into the case body to create a charging circuit. The circuit processing unit automatically controls the rechargeable battery for charging the electronic cigarette being inserted until it is full of power, whereby the electronic cigarette case is readily to be assembled and to sue, and has a reliable electrical connection with an outer power source.

Owner:HUIZHOU KIMREE TECH

Electron device using oxide semiconductor and method of manufacturing the same

InactiveUS20080291350A1Process stabilityLow costSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorElectron

In an electron device in which plural thin film transistors each having at least a source electrode, a drain electrode, a semiconductor region including a channel, a gate insulation film and a gate electrode are provided on a substrate, a device separation region provided between the plural thin film transistors and the semiconductor region are constituted by a same metal oxide layer, and resistance of the semiconductor region is formed to be lower than resistance of the device separation region.

Owner:CANON KK

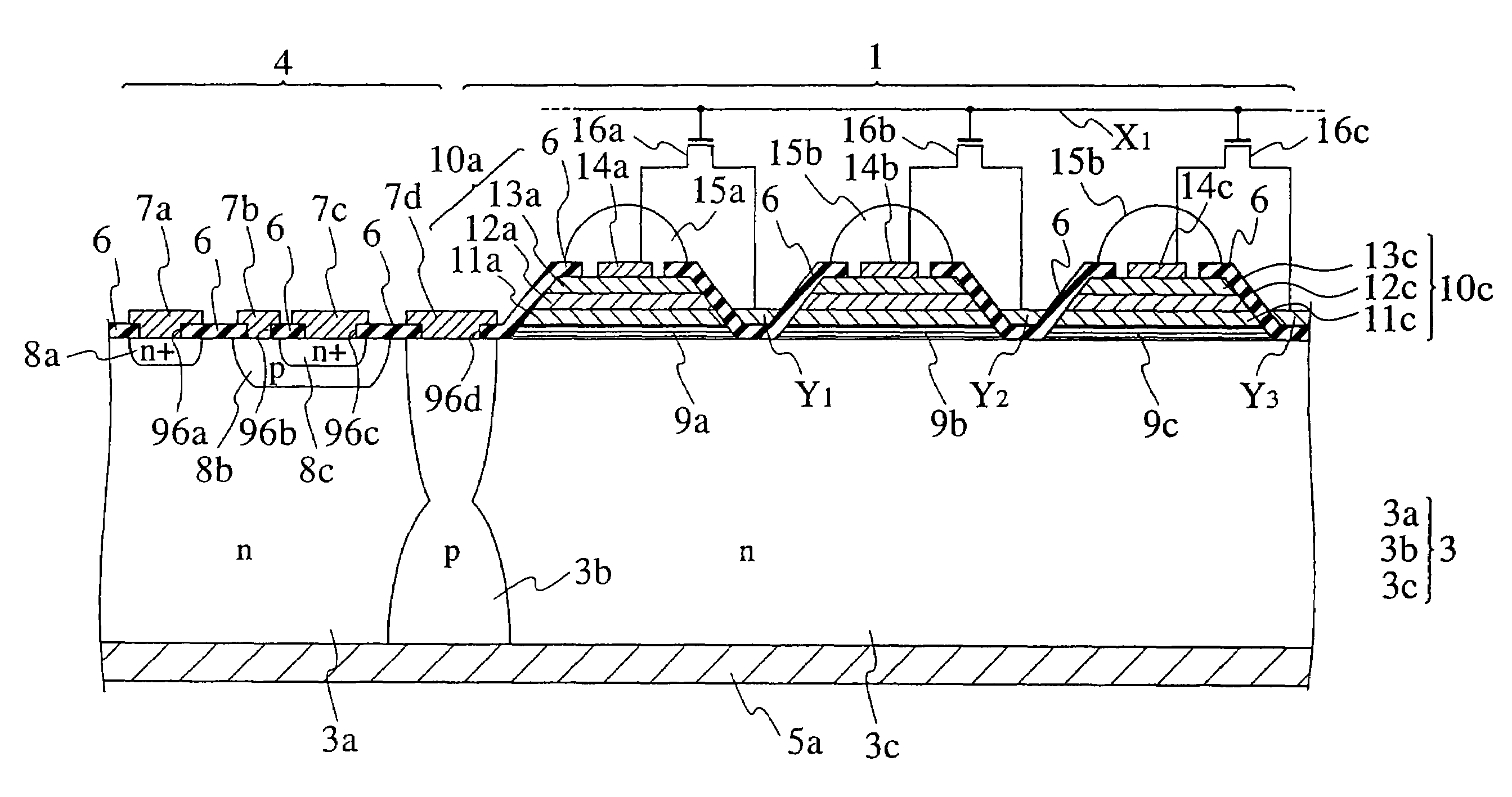

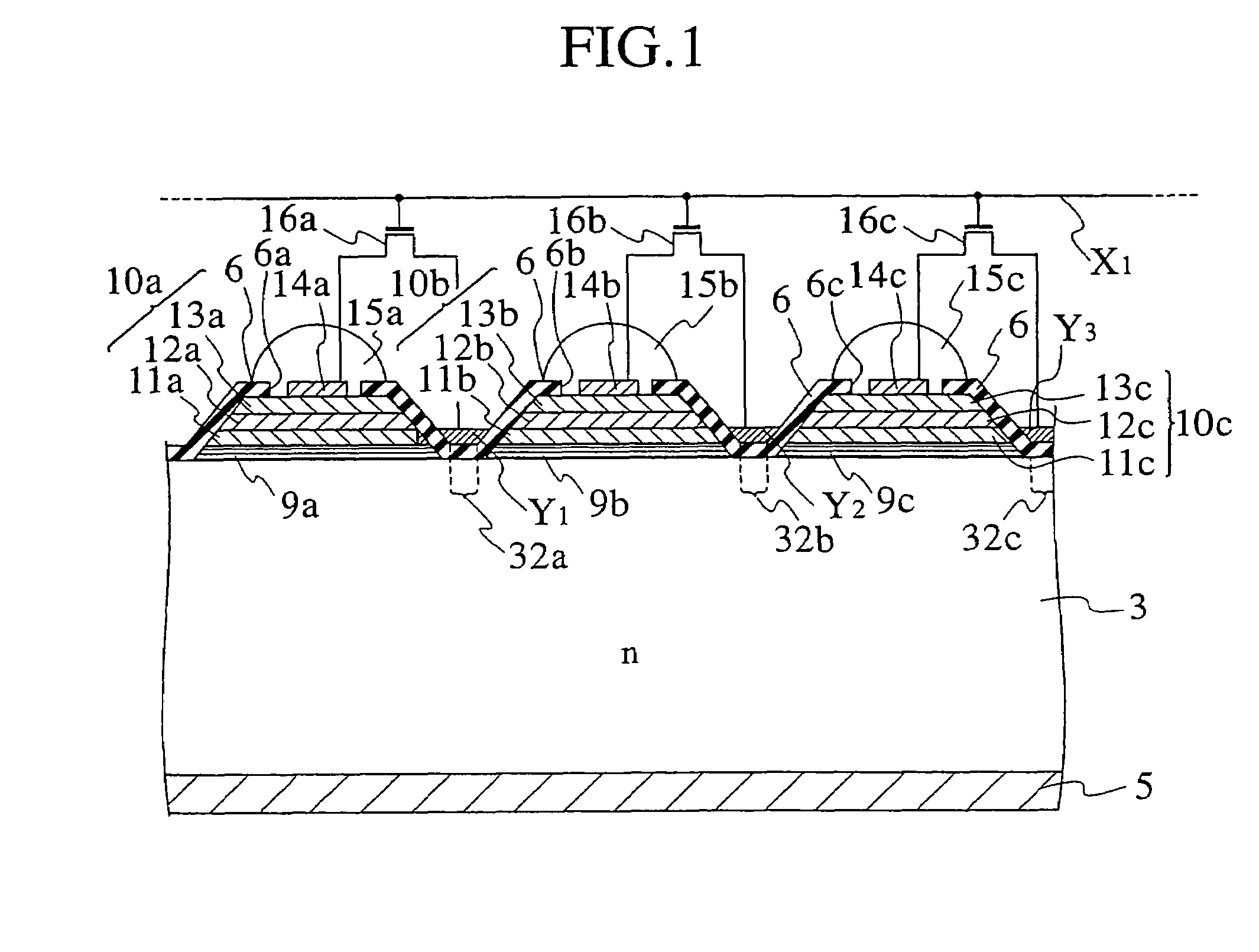

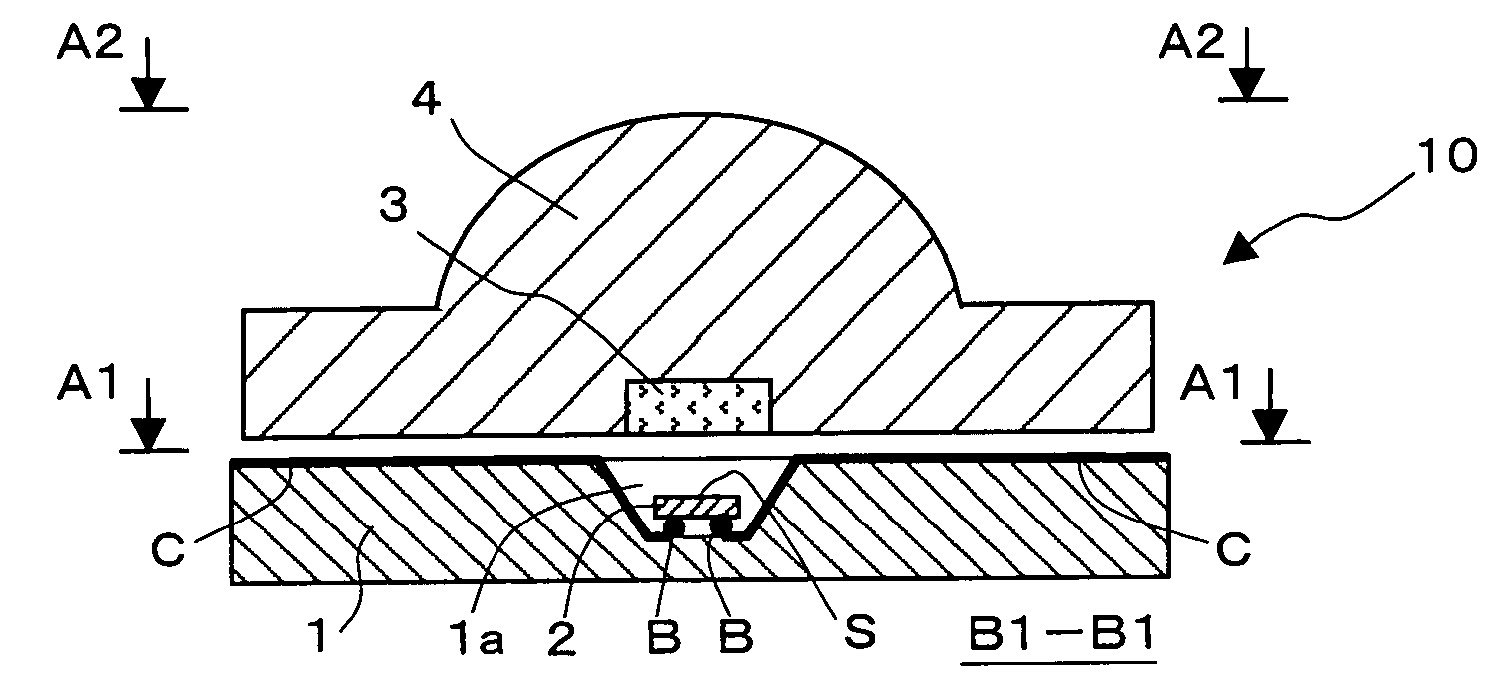

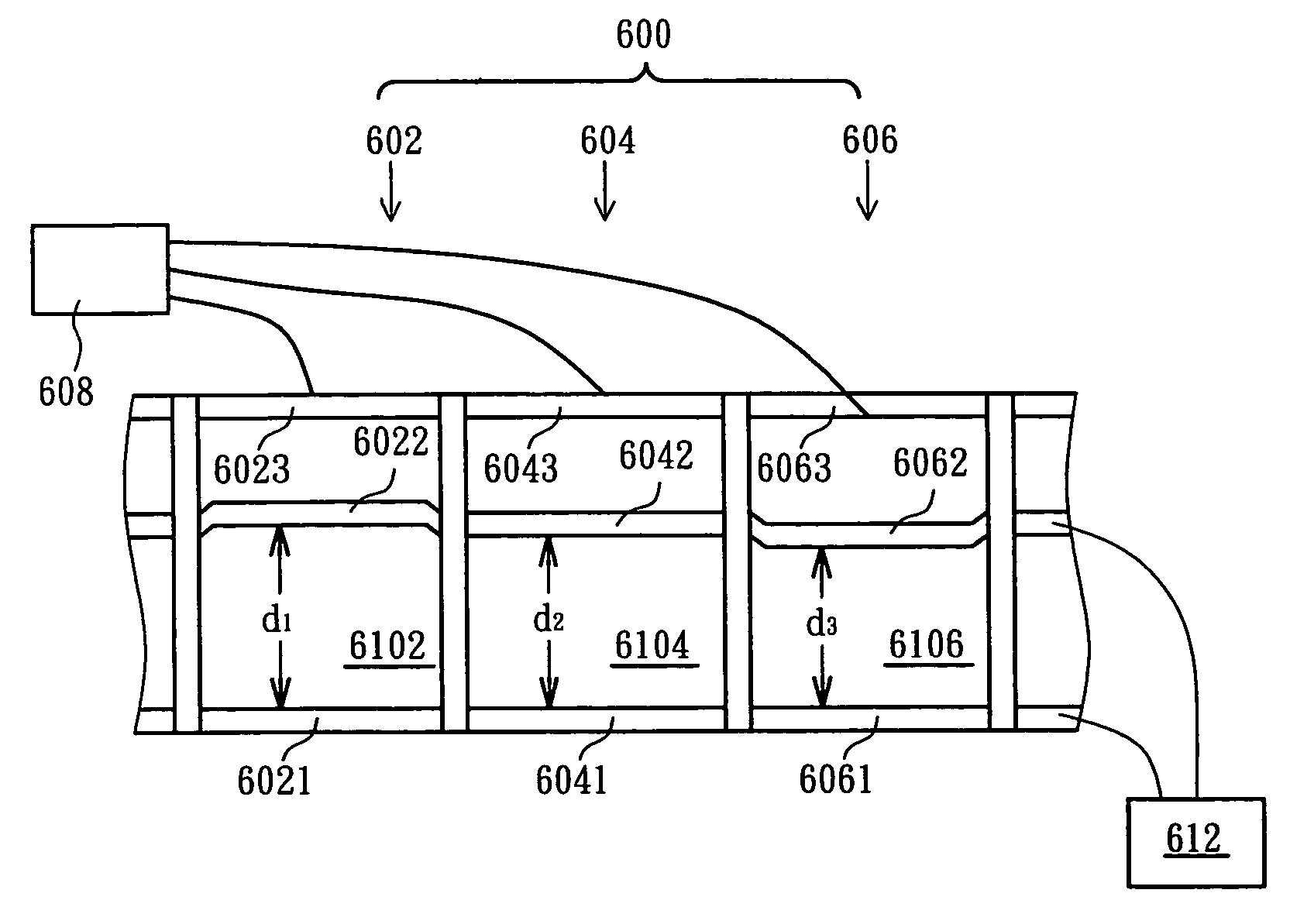

Semiconductor light-emitting device using phosphors for performing wavelength conversion

ActiveUS7323723B2Small lossImprove display speedDischarge tube luminescnet screensLamp detailsSemiconductor materialsPhosphor

A semiconductor light-emitting device includes substrate (3), a plurality of light-emitting-element-layers (10a, 10b, 10c, . . . ) of semiconductor material formed on the substrate (3) so as to be isolated from each other and having a wider band gap than the substrate (3), and phosphors (15a, 15b, 15c, . . . ) converting wavelengths of light from the light-emitting-element-layers (10a, 10b, 10c, . . . ) into other wavelengths.

Owner:SANKEN ELECTRIC CO LTD

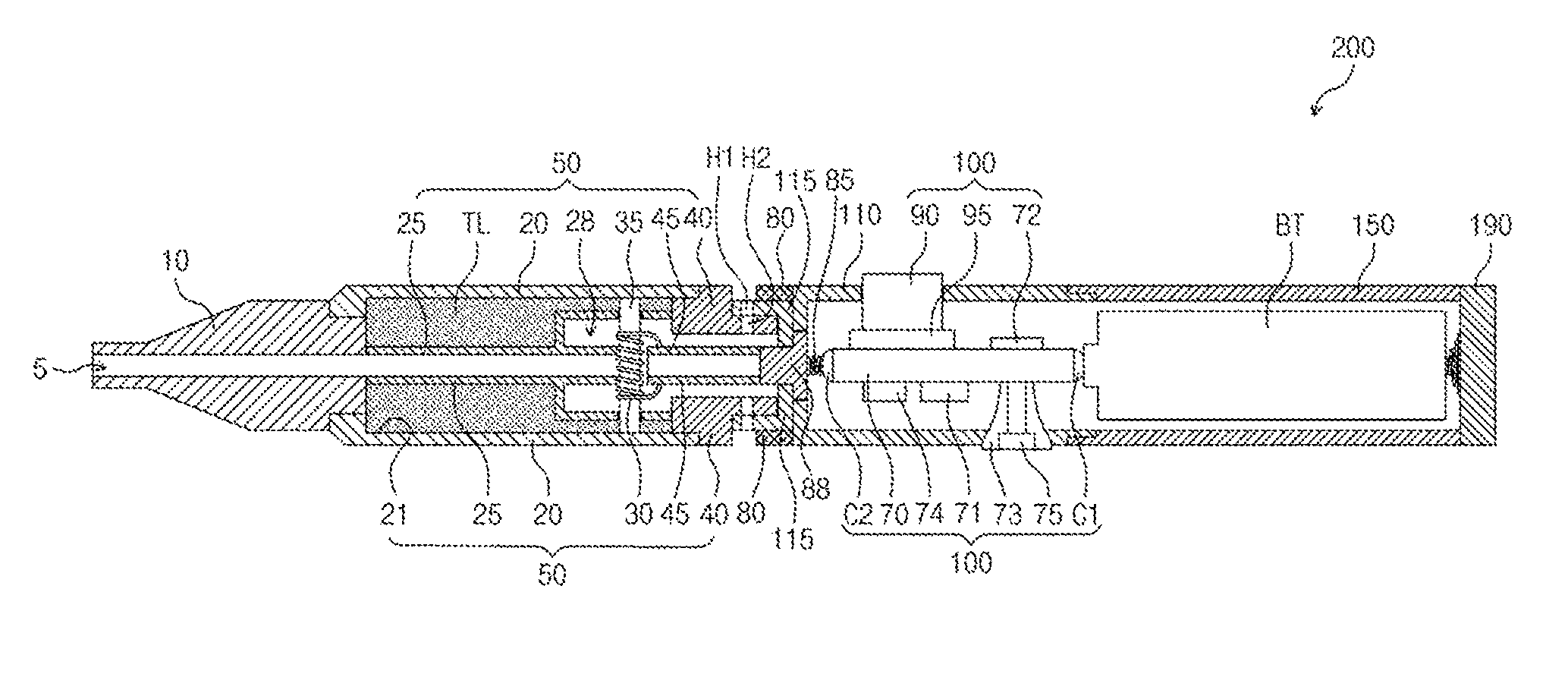

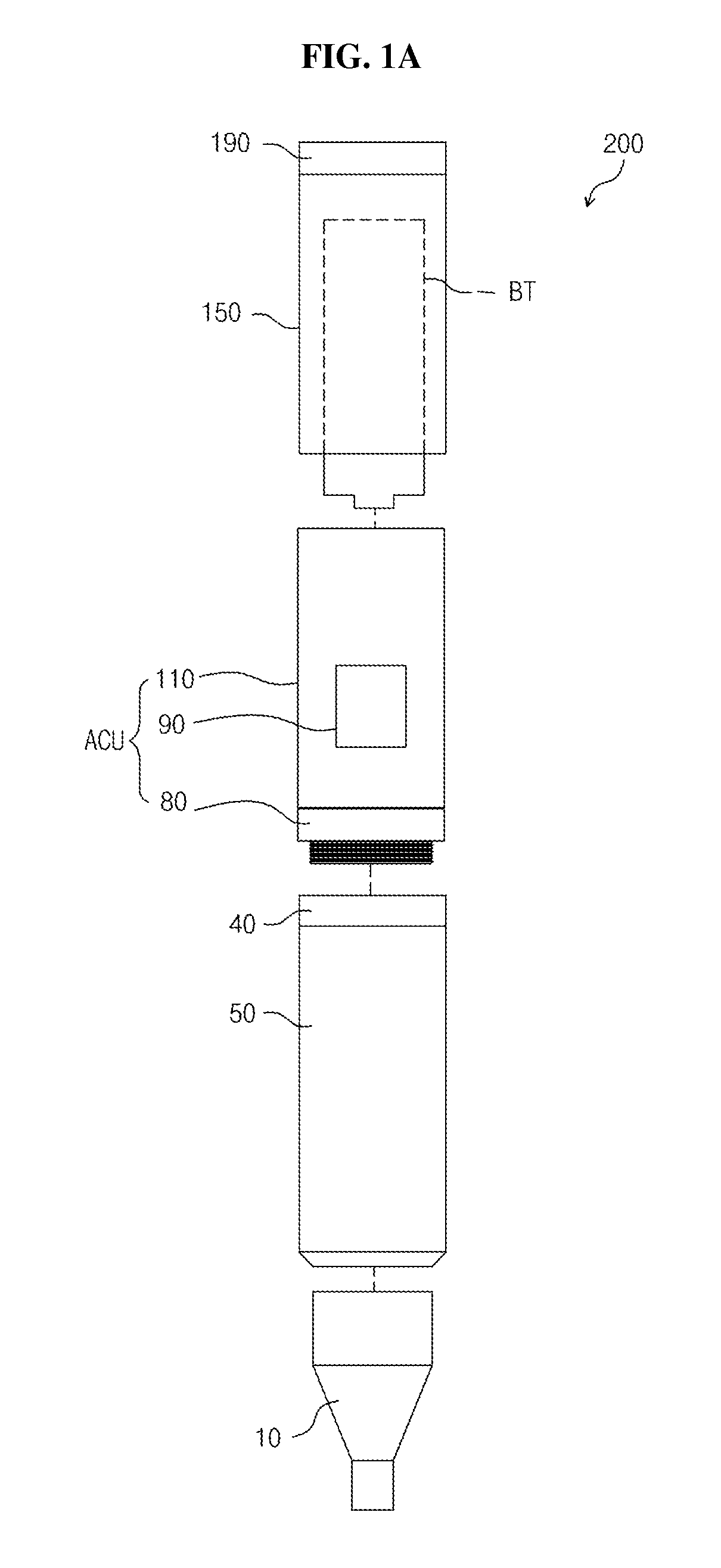

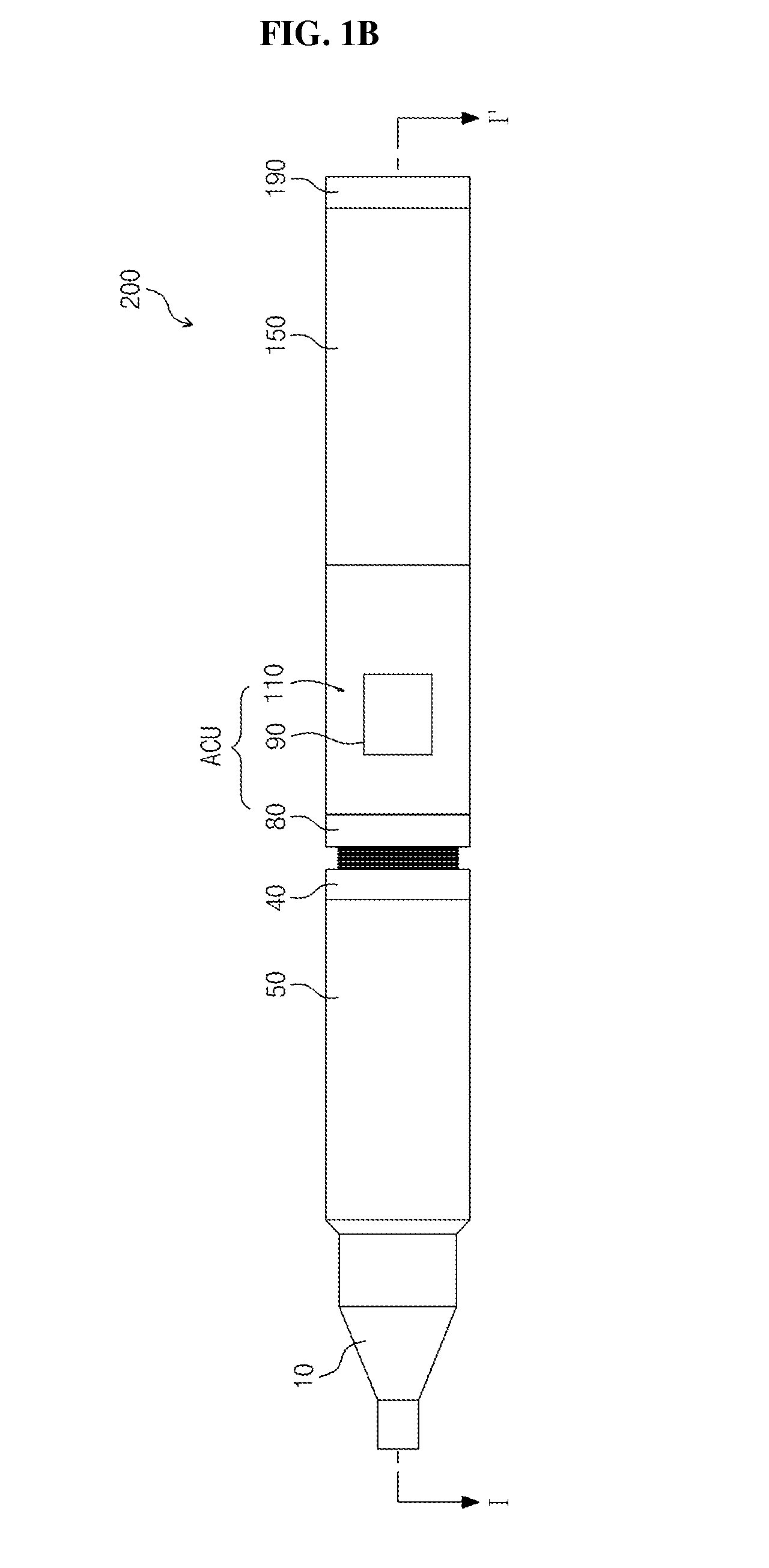

Atomization control unit and a portable atomizing apparatus having the same

InactiveUS20140334804A1Constant power supplyReduce smokeSteam generation heating methodsMedical devicesElectricitySource material

A portable atomizing apparatus according to the present invention includes a battery case, an atomizing device, a body case, a control unit, and a suction adjustment. The battery case receives a battery, and the atomizing device includes a heating member electrically connected to the battery for generating heat to atomize a source material. The body case is connected between the battery case and the atomizing device. Besides, the control unit is mounted inside the body case, electrically connected to the battery and to the heating member, so that the control unit receives an electrical power from the battery to control the output signal delivered to the heating member. Also, the suction adjustment opens or closes an air inlet of the atomizing apparatus so as to adjust the amount of air entering the atomizing apparatus.

Owner:ENBRIGHT

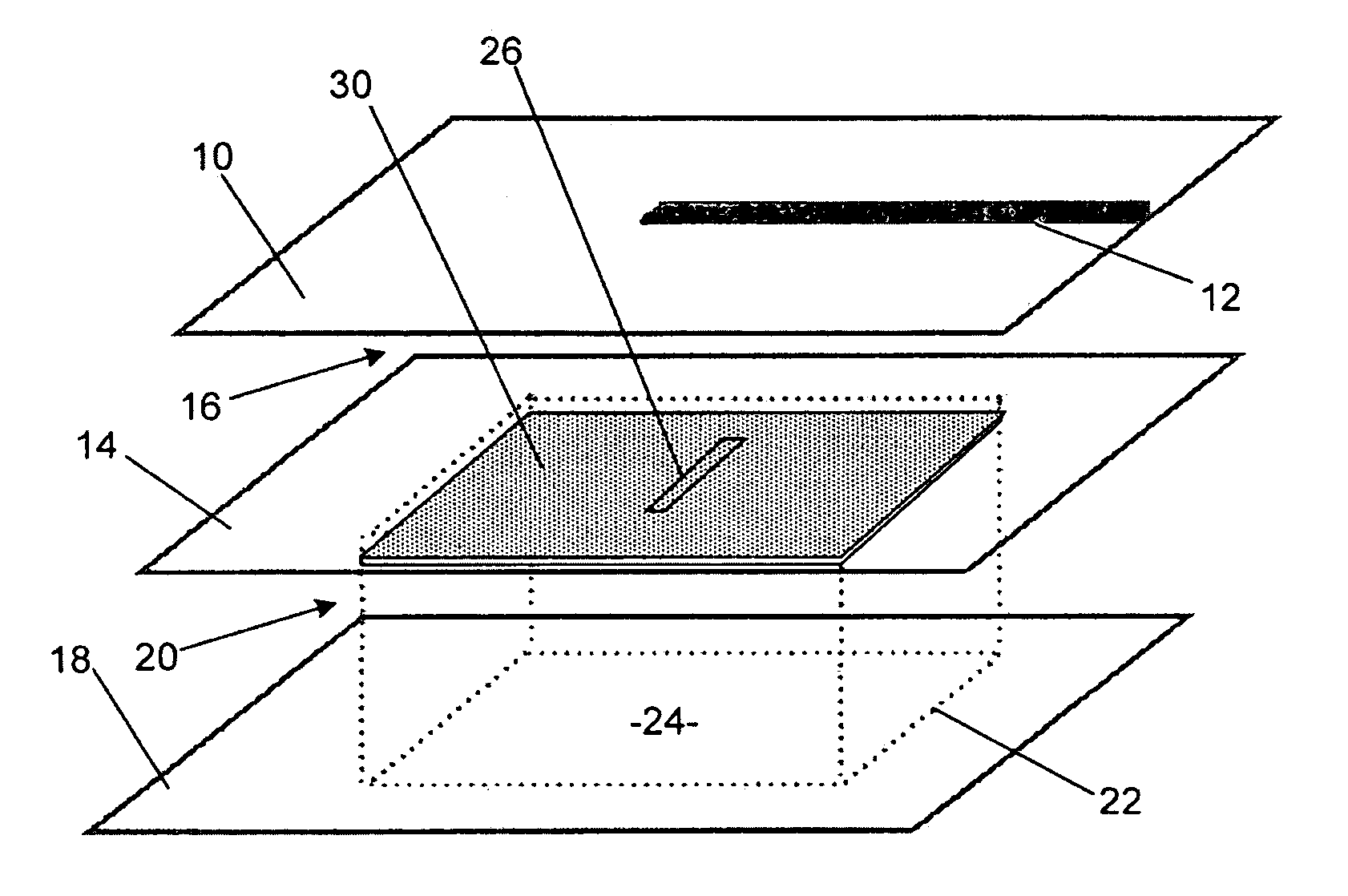

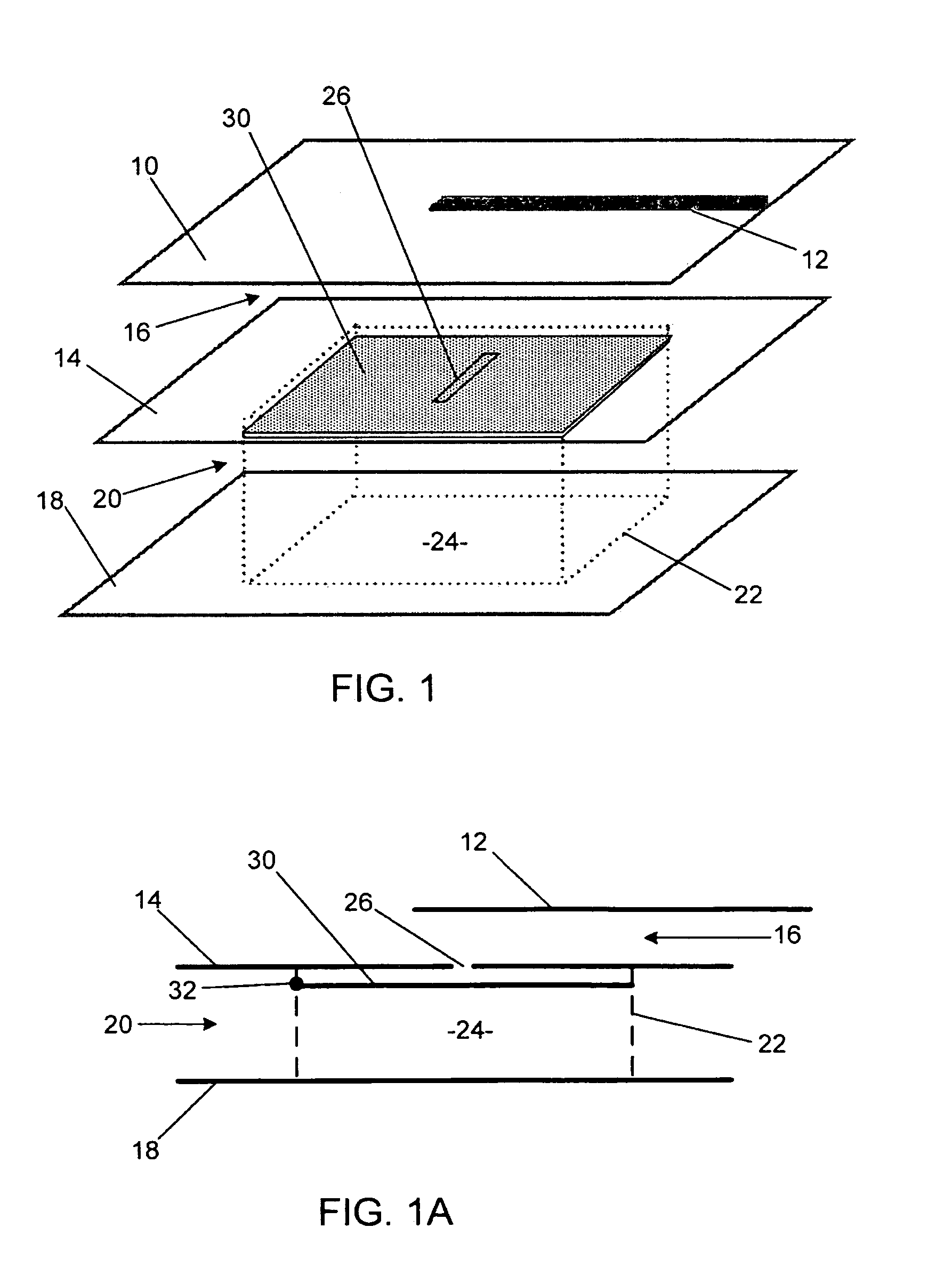

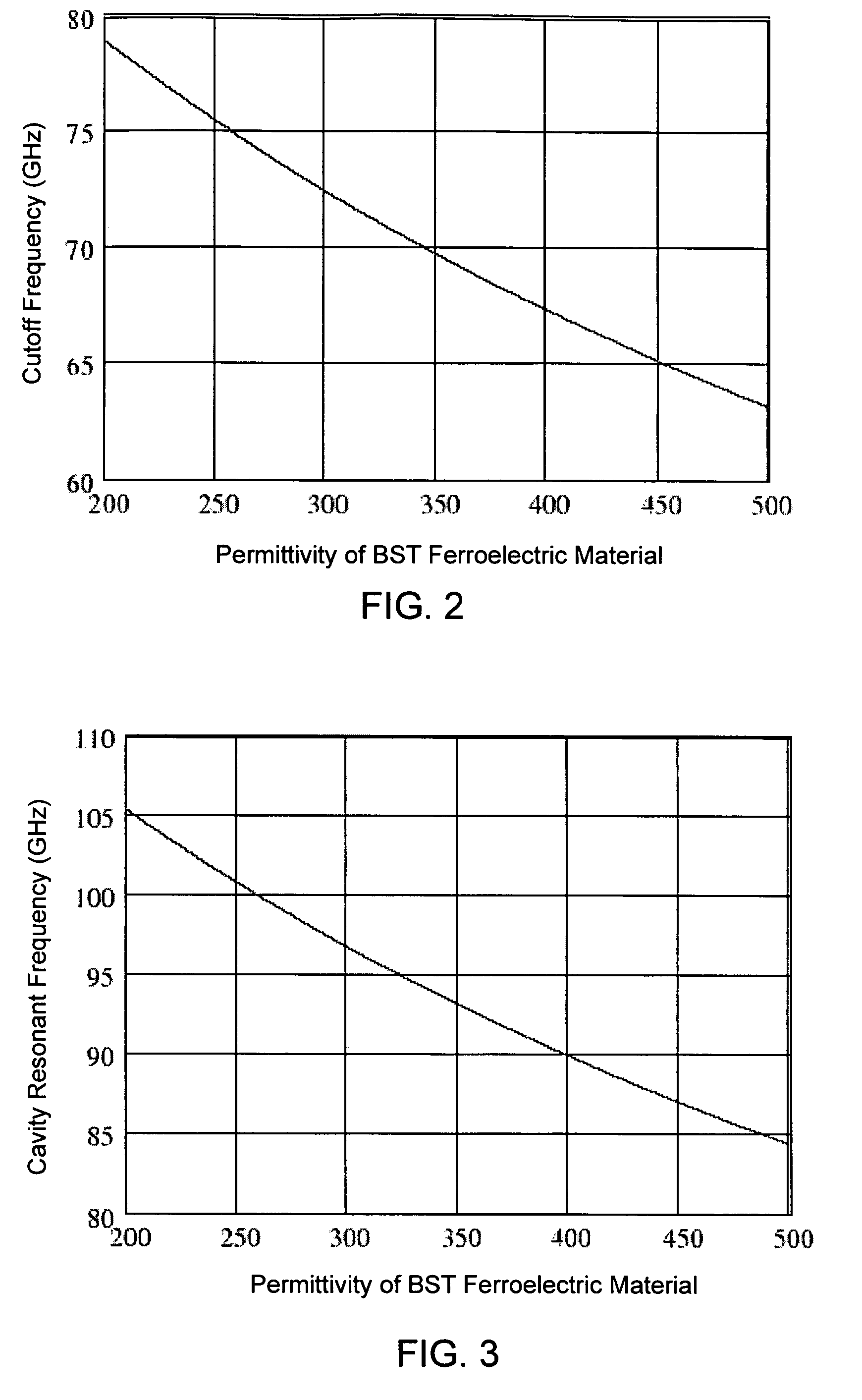

Monolithic microwave integrated circuit (MMIC) waveguide resonators having a tunable ferroelectric layer

ActiveUS7570137B2Improve scalabilityEasy to integrateResonatorsOscillations generatorsElectromagnetic couplingResonant cavity

A ferroelectric loaded waveguide resonator capable of operation at microwave, millimeter-wave and higher frequencies and suitable for integration into a three-dimensional monolithic microwave integrated circuit (3D MMIC) is disclosed. The resonator includes a resonator cavity, which, in one form of the invention, is formed by two parallel metal layers and a metallized wall structure extending between the metal layers. The cavity is filled with dielectric material and includes a layer of ferroelectric material, which is used to control the resonant frequency by varying a voltage bias applied to the ferroelectric layer. The cavity includes a slot in one of the metal layers and a coupling strip formed adjacent to the slot to provide electromagnetic coupling to other components, such as a voltage controlled oscillator (VCO). The invention can also be applied to other multi-metal semiconductor or wafer level packaging technologies.

Owner:NORTHROP GRUMMAN SYST CORP

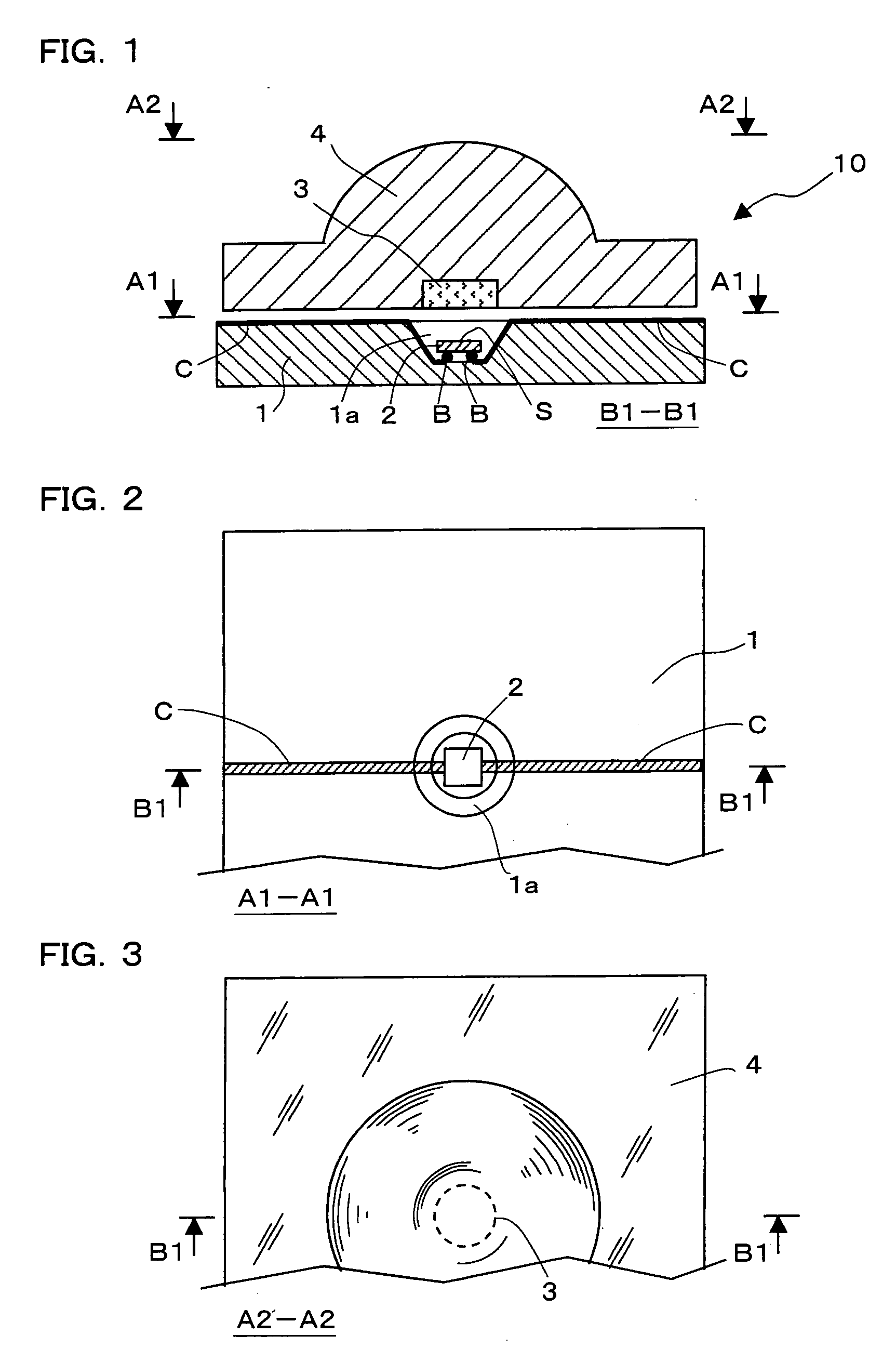

Light emitting device using led

InactiveUS20040190304A1Extended service lifeEffective coolingDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

A light-emitting device (10) using an LED is proposed. This light-emitting device (10) is provided with a packaging substrate (1), a light-emitting element (2) which is mounted on this packaging substrate (1) with its face down, a fluorescent member (3) that is arranged face to face with a light-extracting surface (S) of the light-emitting element (2) without contacting the light-emitting element (2) and an optical member (4) which receives light that has been emitted from the light-emitting element (2) and made incident thereon through the fluorescent member (3), and aligns the incident light toward the outside of the device. Light, emitted from the light-emitting element (2), is made incident on the fluorescent member (3) to excite the fluorescent material so that the fluorescent material re-emits light having a wavelength different from that of the incident light. Those light rays, emitted from the light-emitting element (2), which have not been absorbed by the fluorescent member (3) and have passed through the fluorescent member (3) and those light rays that have been emitted from the fluorescent material are made incident on the optical member (4) and are aligned. Because the fluorescent member (3) is not made in contact with the light-emitting element (2), it does not receive the heat from the light-emitting element (2) through heat conduction, and consequently becomes less susceptible to degradation due to heat. Moreover, with the face-down mounting structure, the fluorescent member (3) and the optical member (4) can be placed closer to the light-emitting element (2) as long as they dose not contact the light-emitting element (2). Consequently, the service life of the fluorescent material or the fluorescent-material-mixed resin that tends to deteriorate can be lengthened, lights can be extracted more efficiently, and light rays can be properly aligned in a predetermined direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

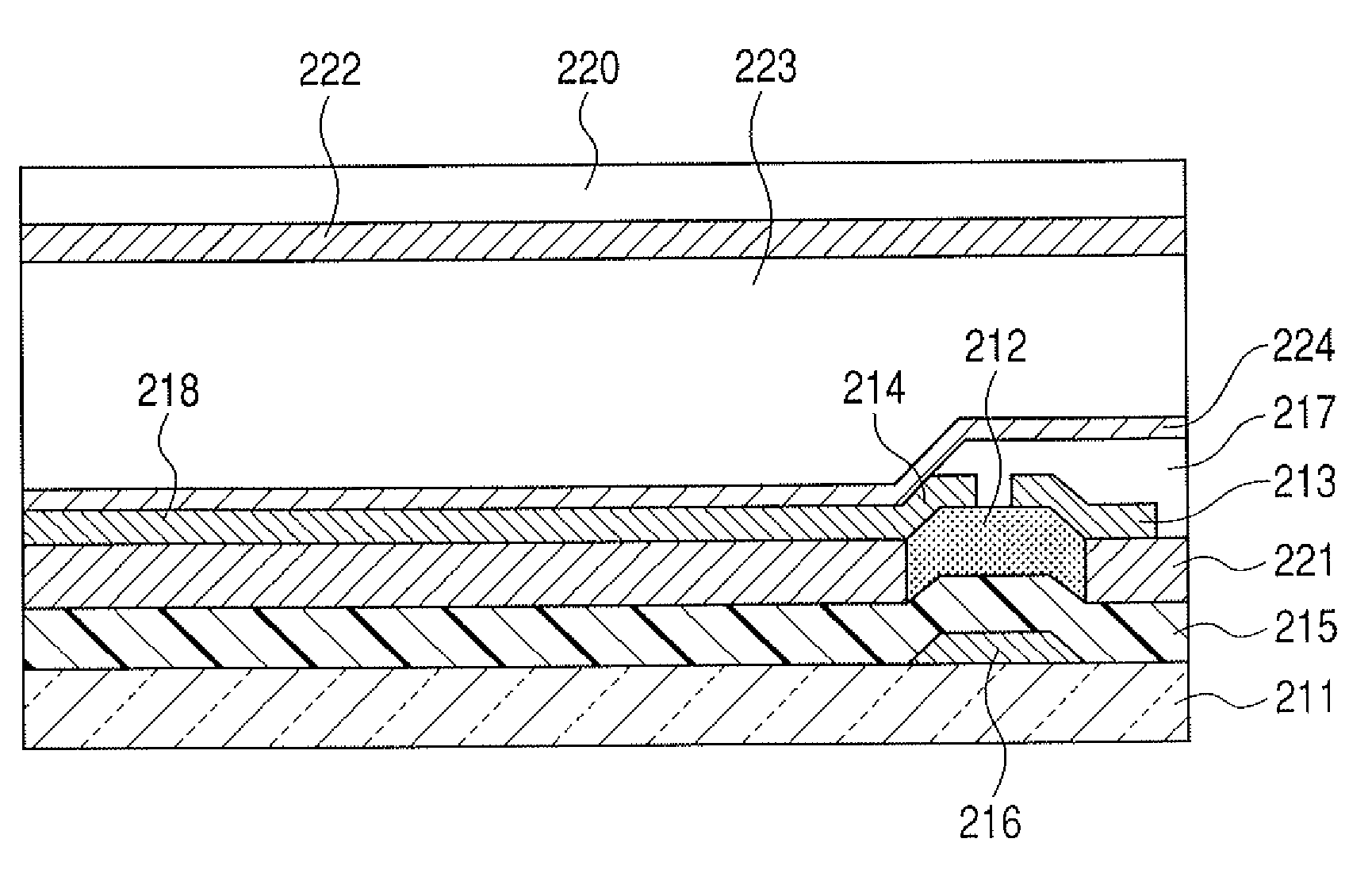

Display device

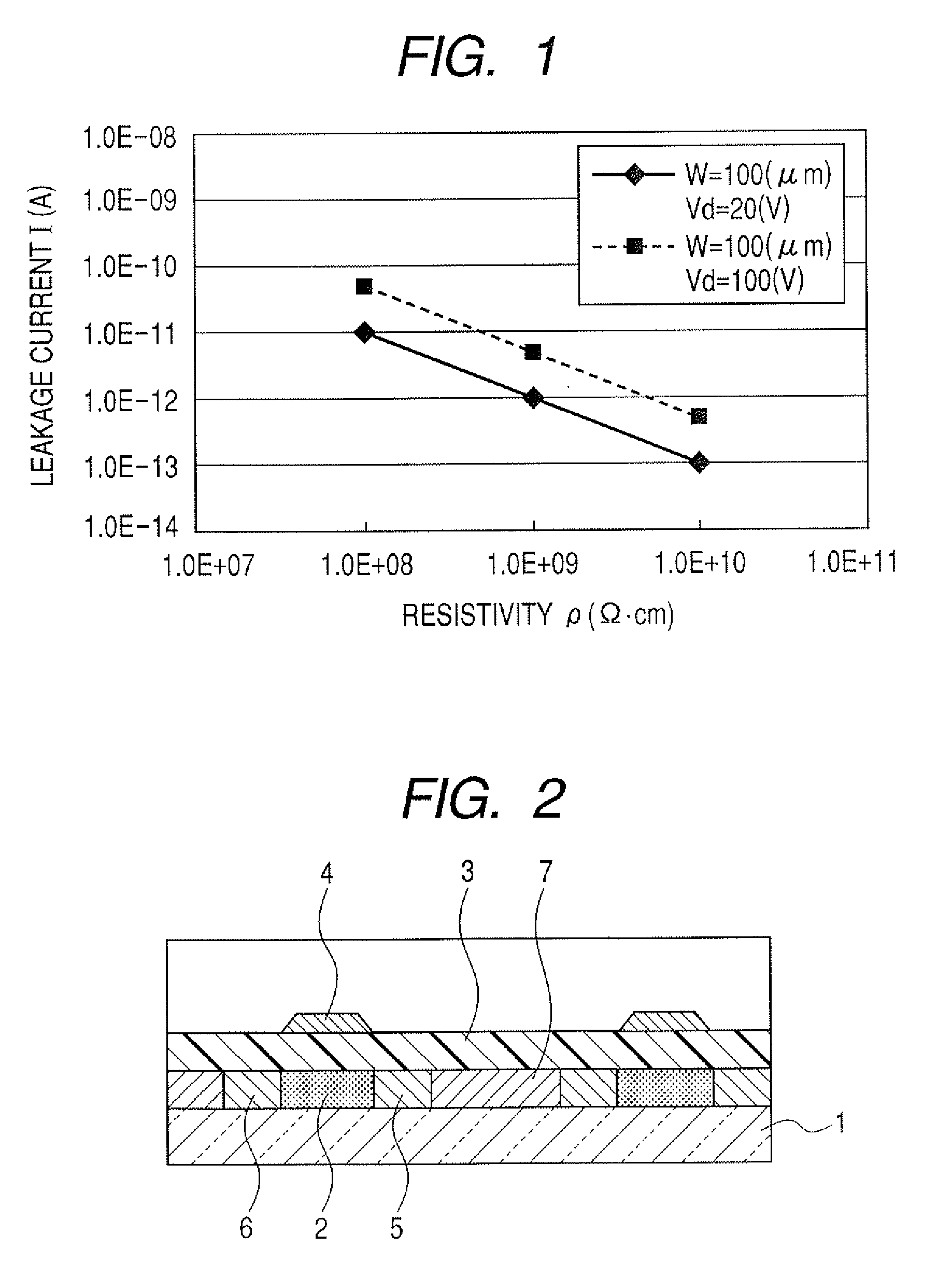

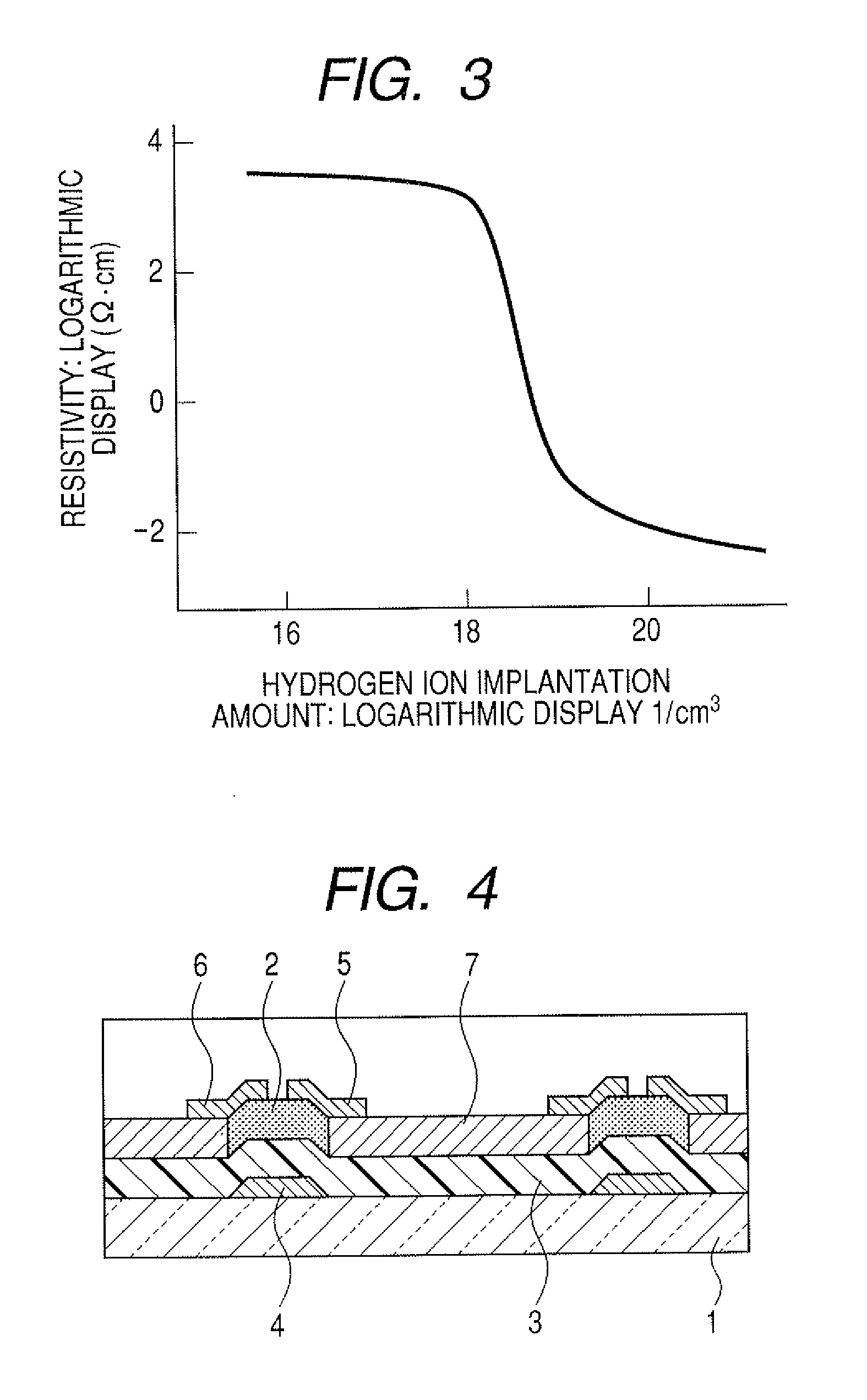

InactiveUS20100065840A1Improve conductivityGuaranteed uptimeTransistorSolid-state devicesJunction leakageLinear element

A protective circuit includes a non-linear element, which further includes a gate electrode, a gate insulating layer covering the gate electrode, a pair of first and second wiring layers whose end portions overlap with the gate electrode over the gate insulating layer and in which a conductive layer and a second oxide semiconductor layer are stacked, and a first oxide semiconductor layer which overlaps with at least the gate electrode and which is in contact with side face portions of the gate insulating layer and the conductive layer of the first wiring layer and the second wiring layer and a side face portion and a top face portion of the second oxide semiconductor layer. Over the gate insulating layer, oxide semiconductor layers with different properties are bonded to each other, whereby stable operation can be performed as compared with Schottky junction. Thus, the junction leakage can be decreased and the characteristics of the non-linear element can be improved.

Owner:SEMICON ENERGY LAB CO LTD

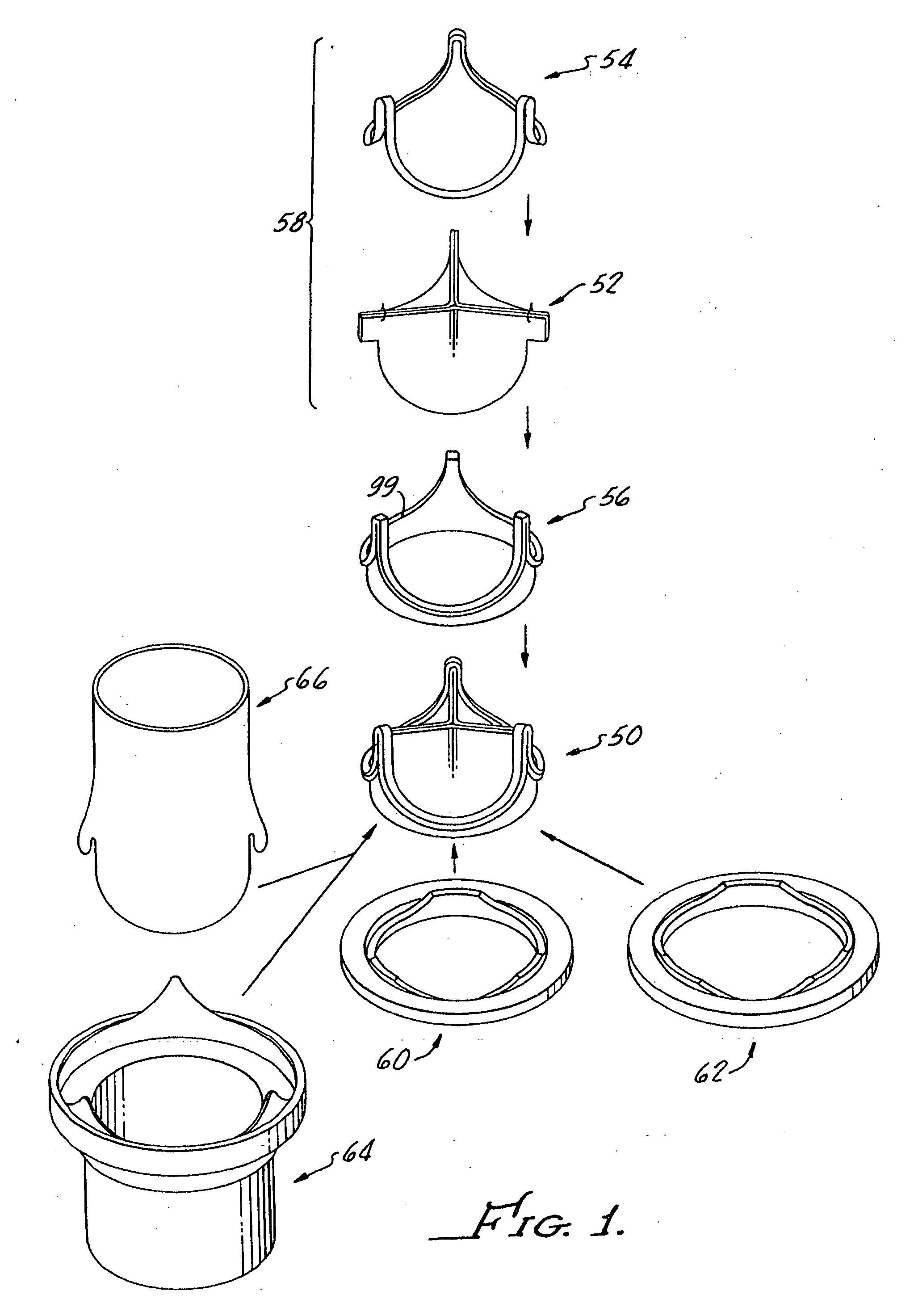

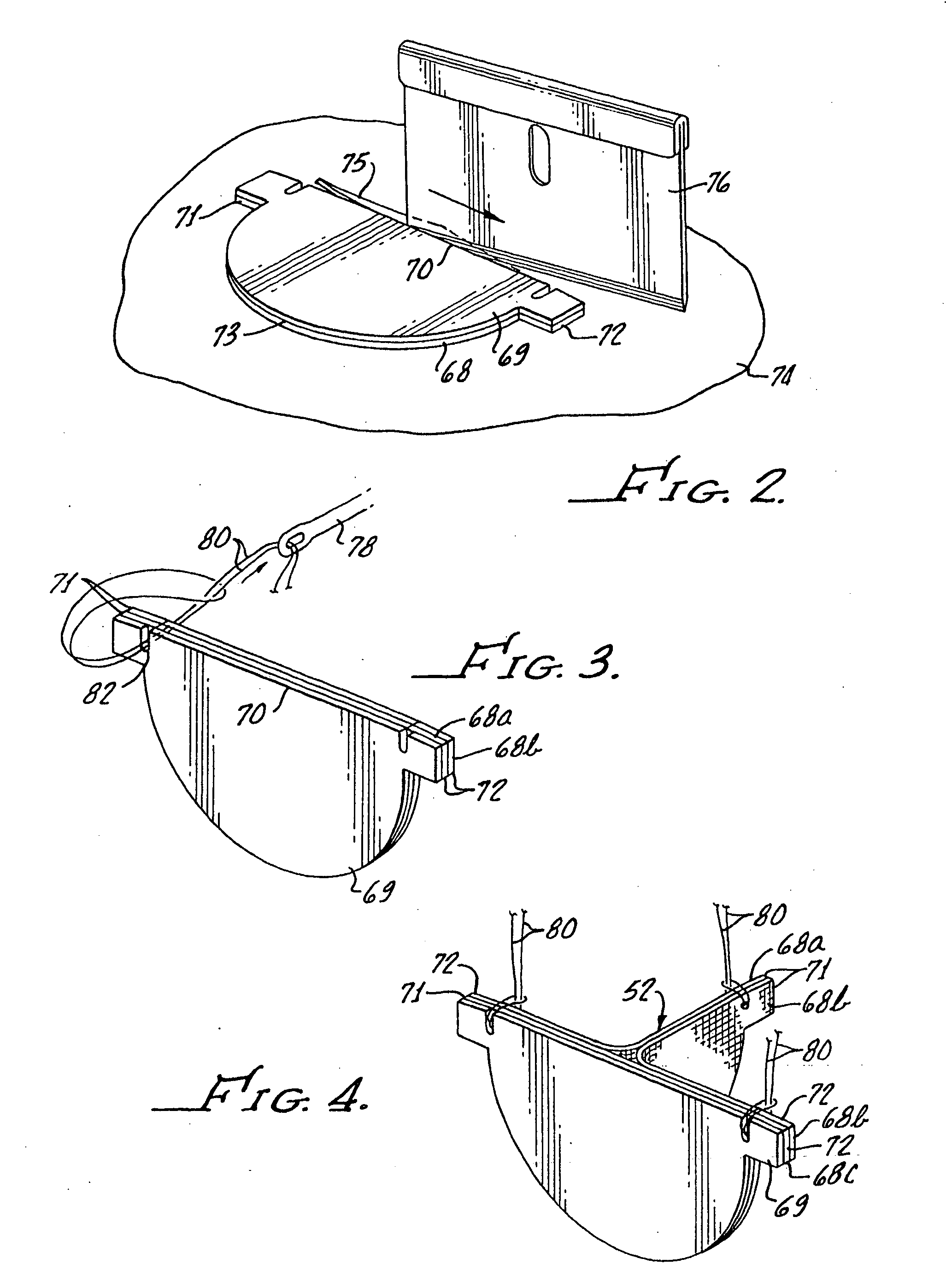

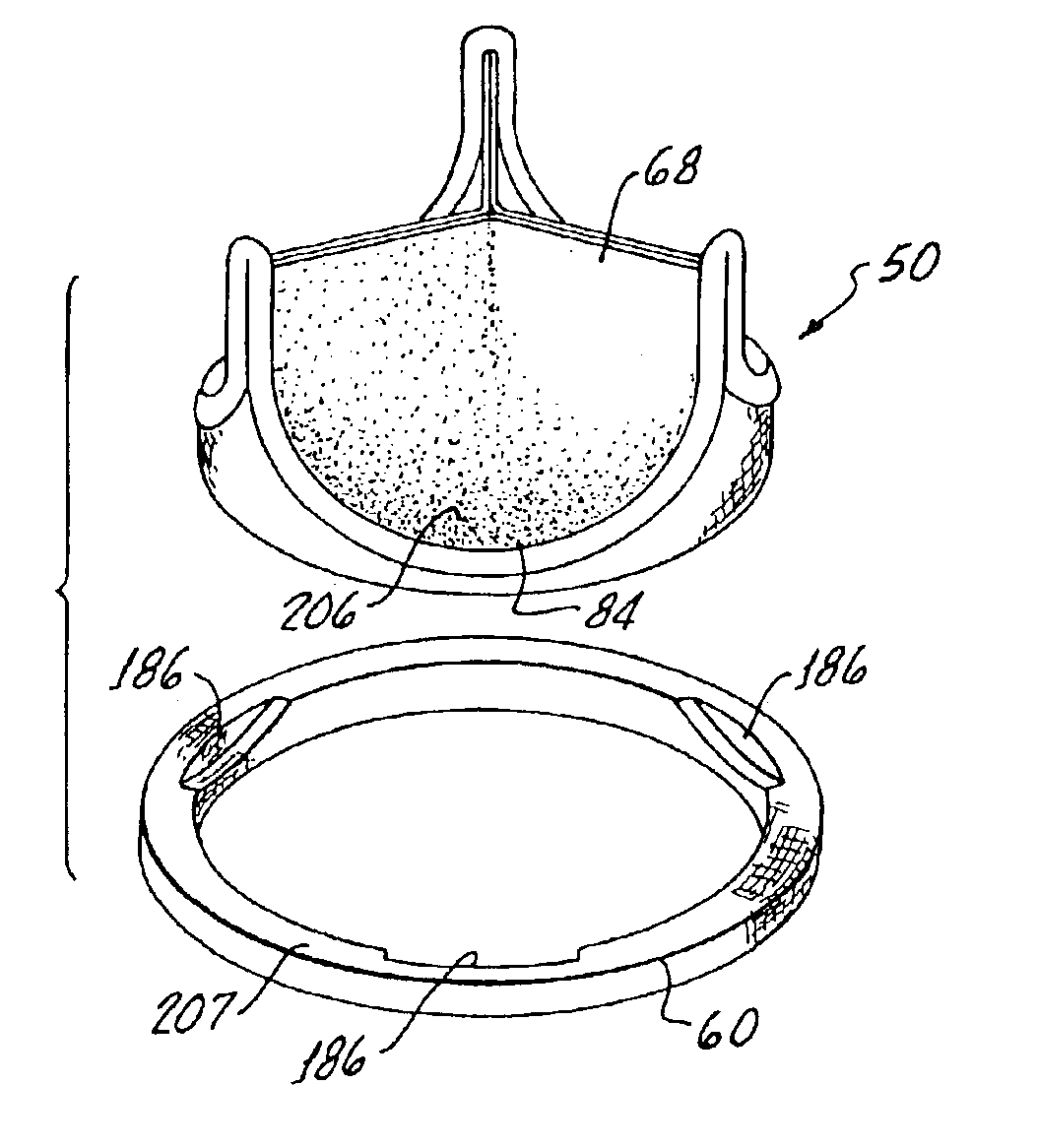

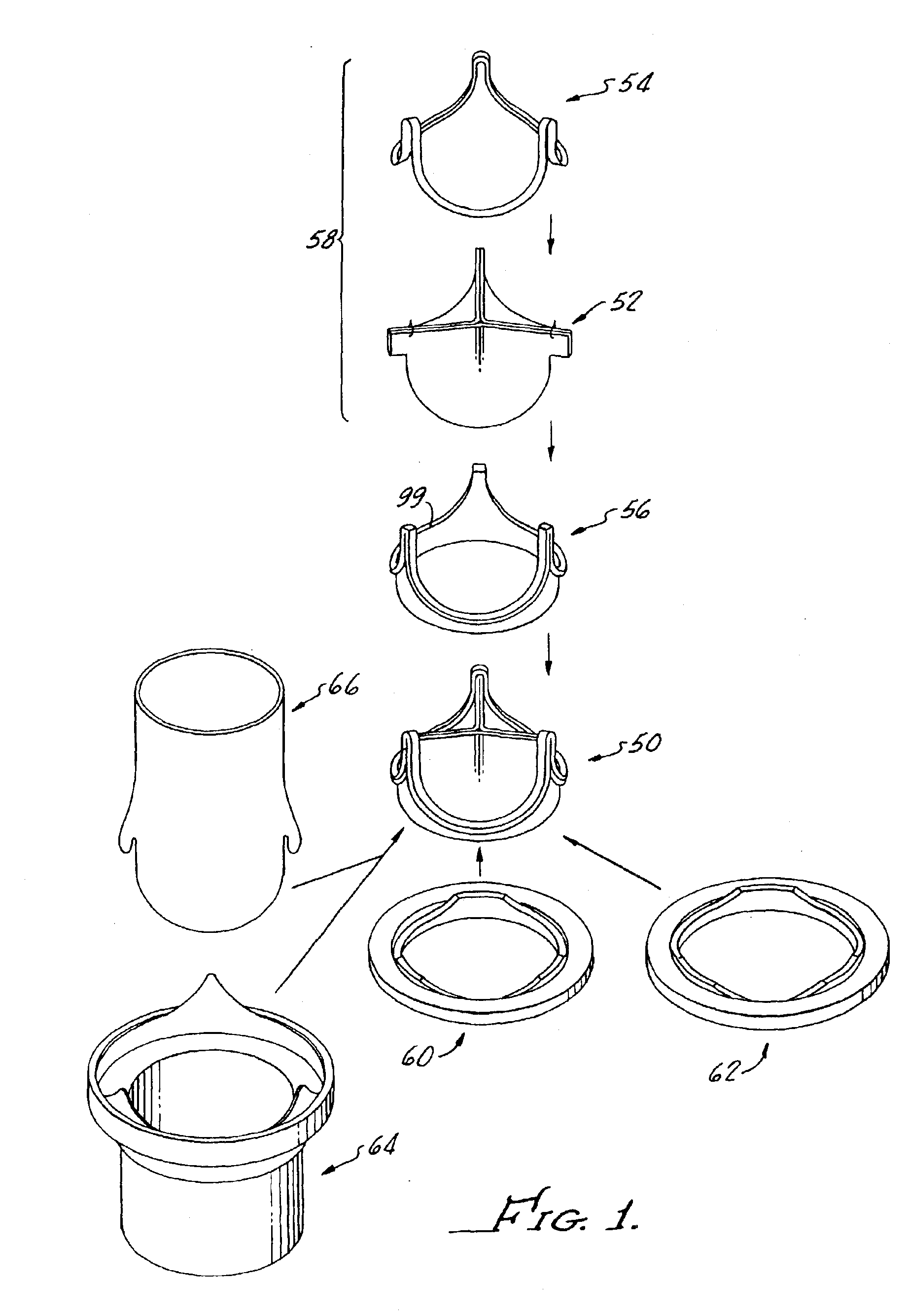

Contoured heart valve suture rings

InactiveUS20060009842A1Improving long-term functionalityReduce pointsHeart valvesInsertion stentCatheter

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

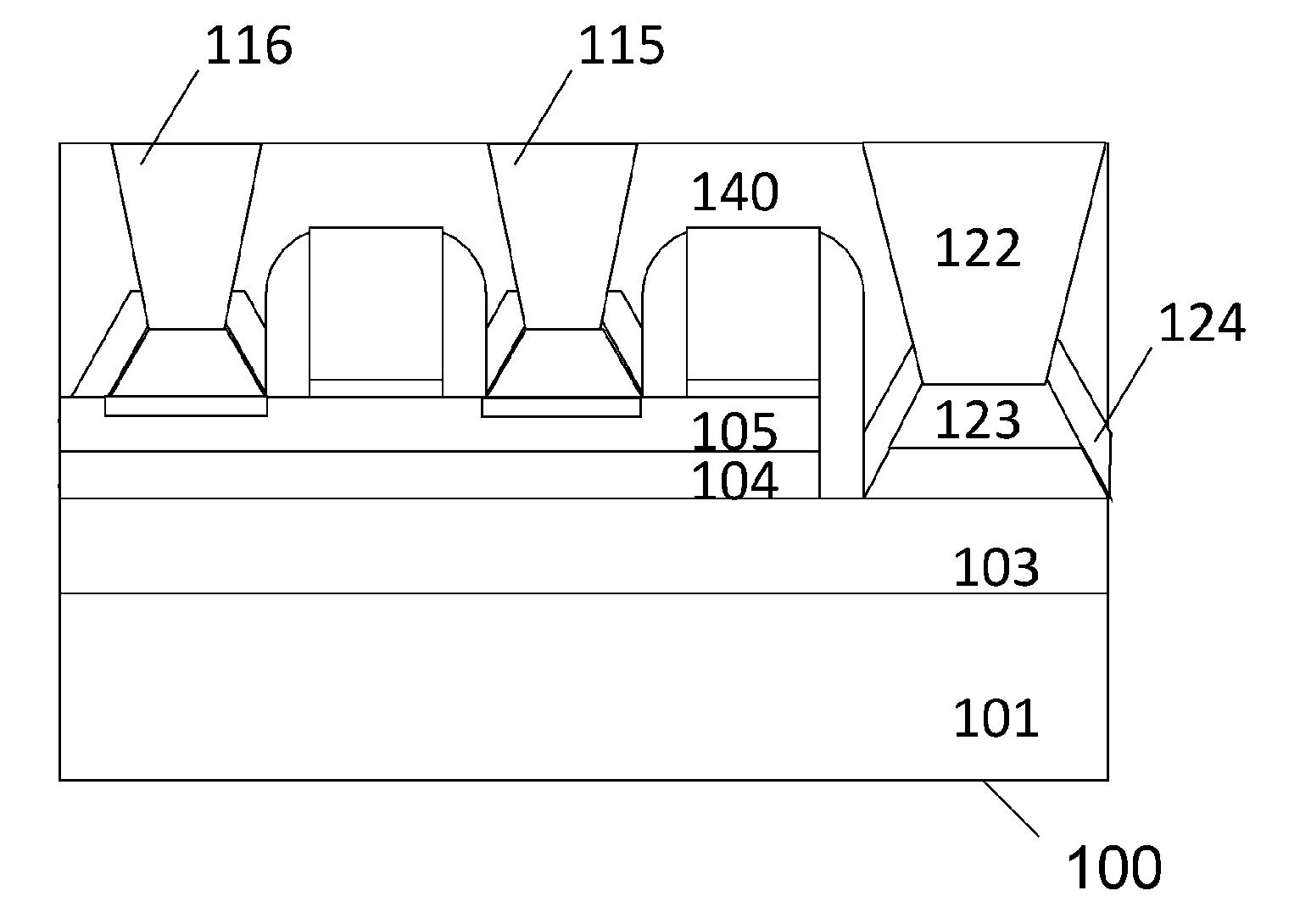

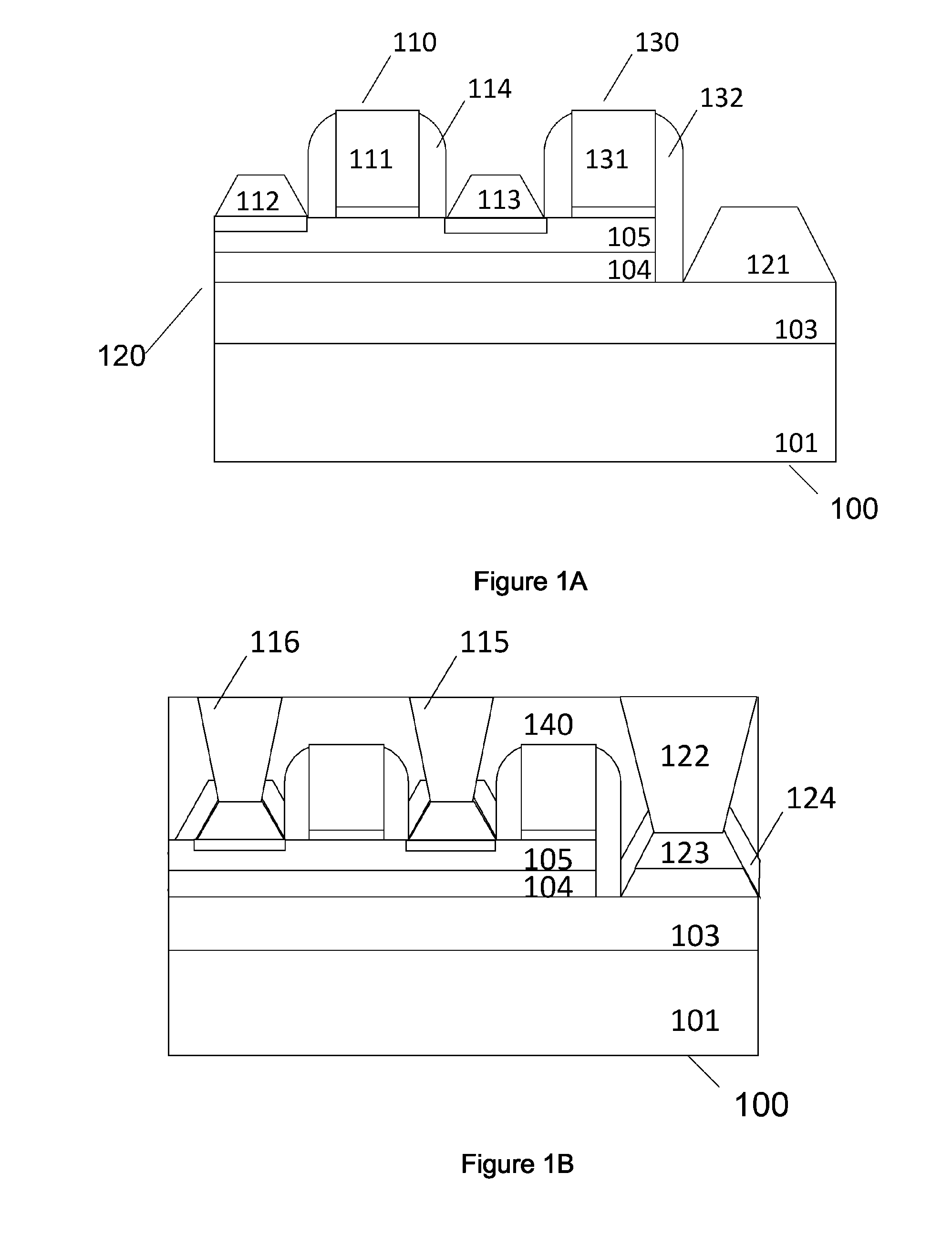

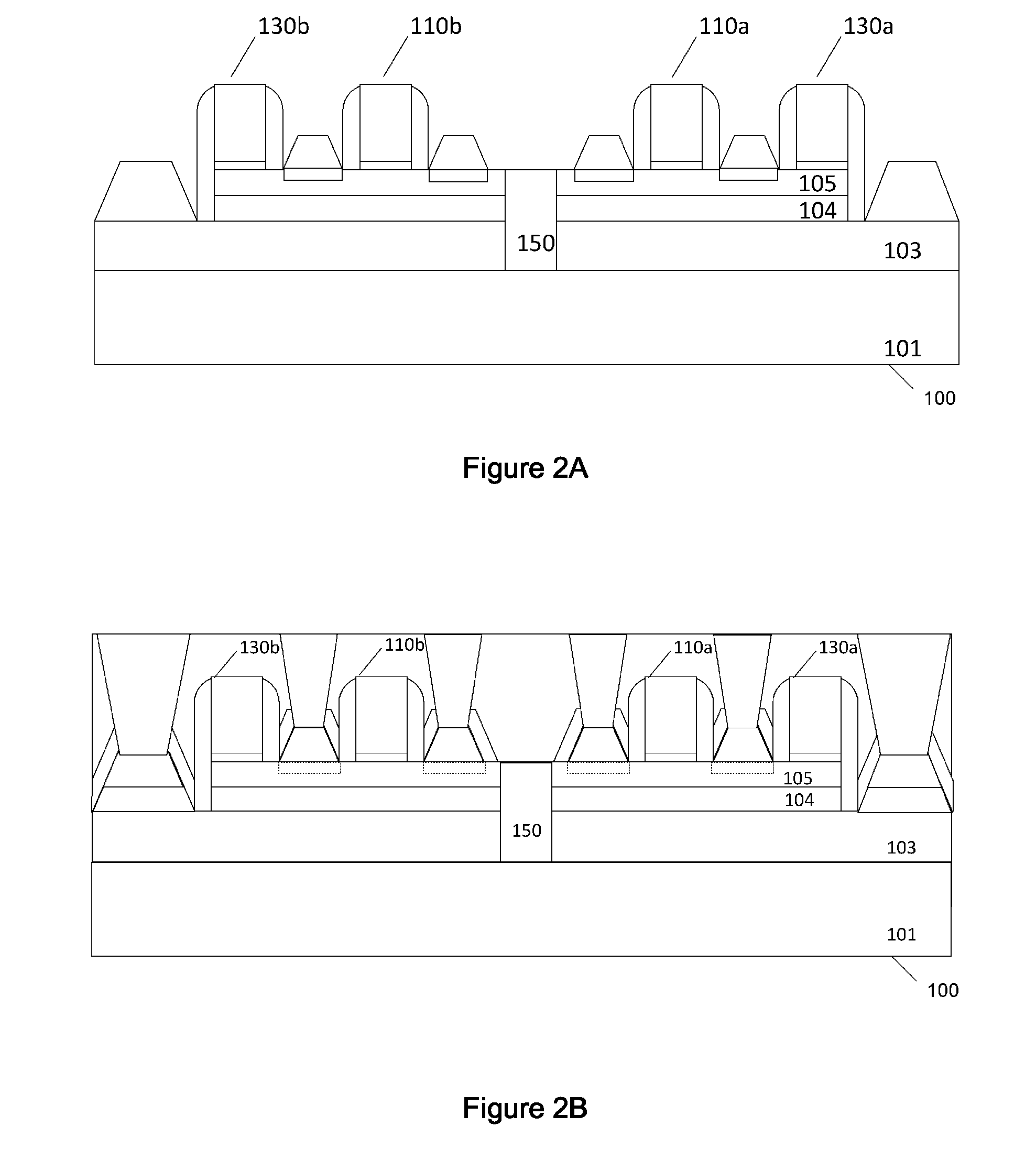

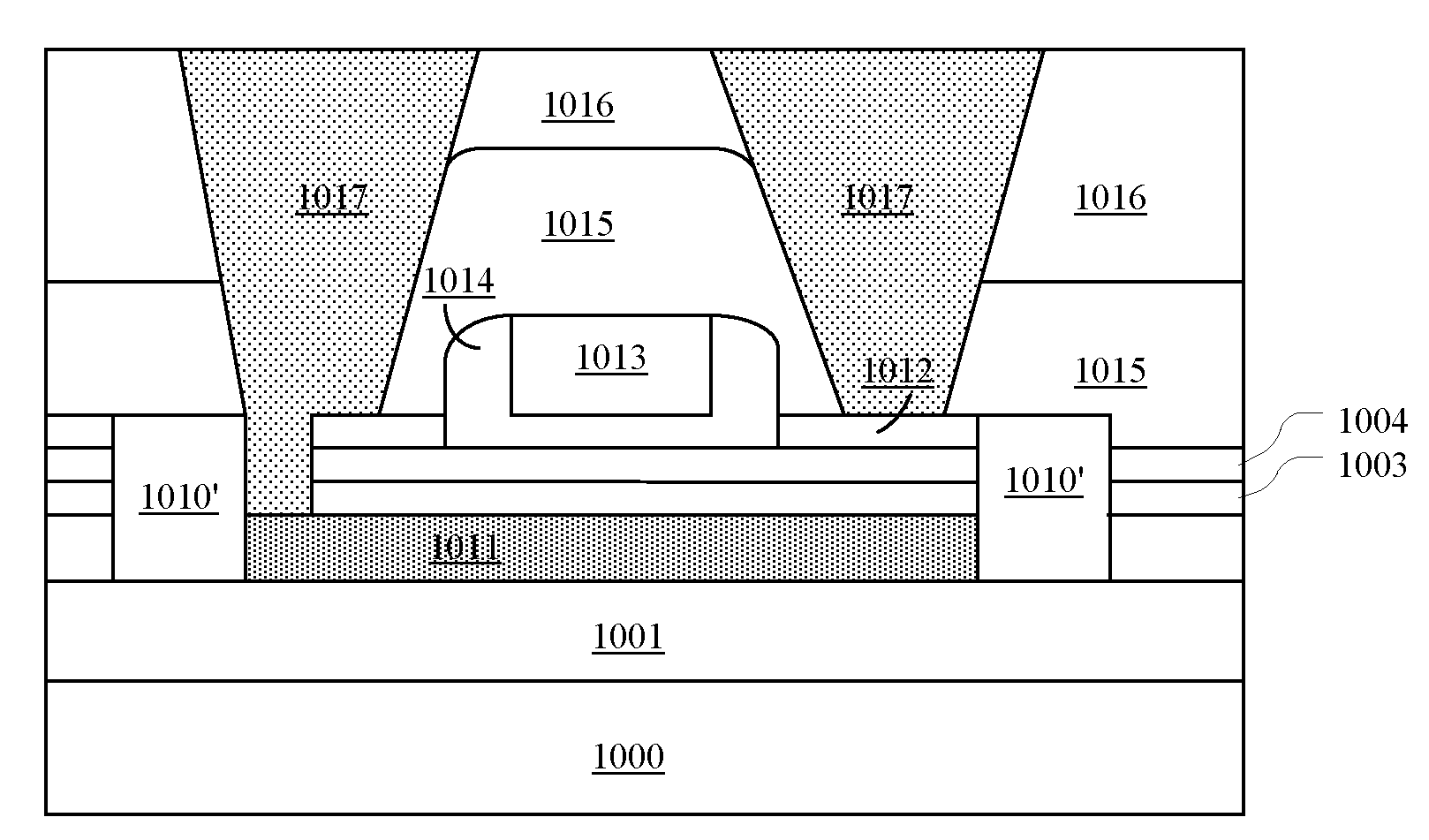

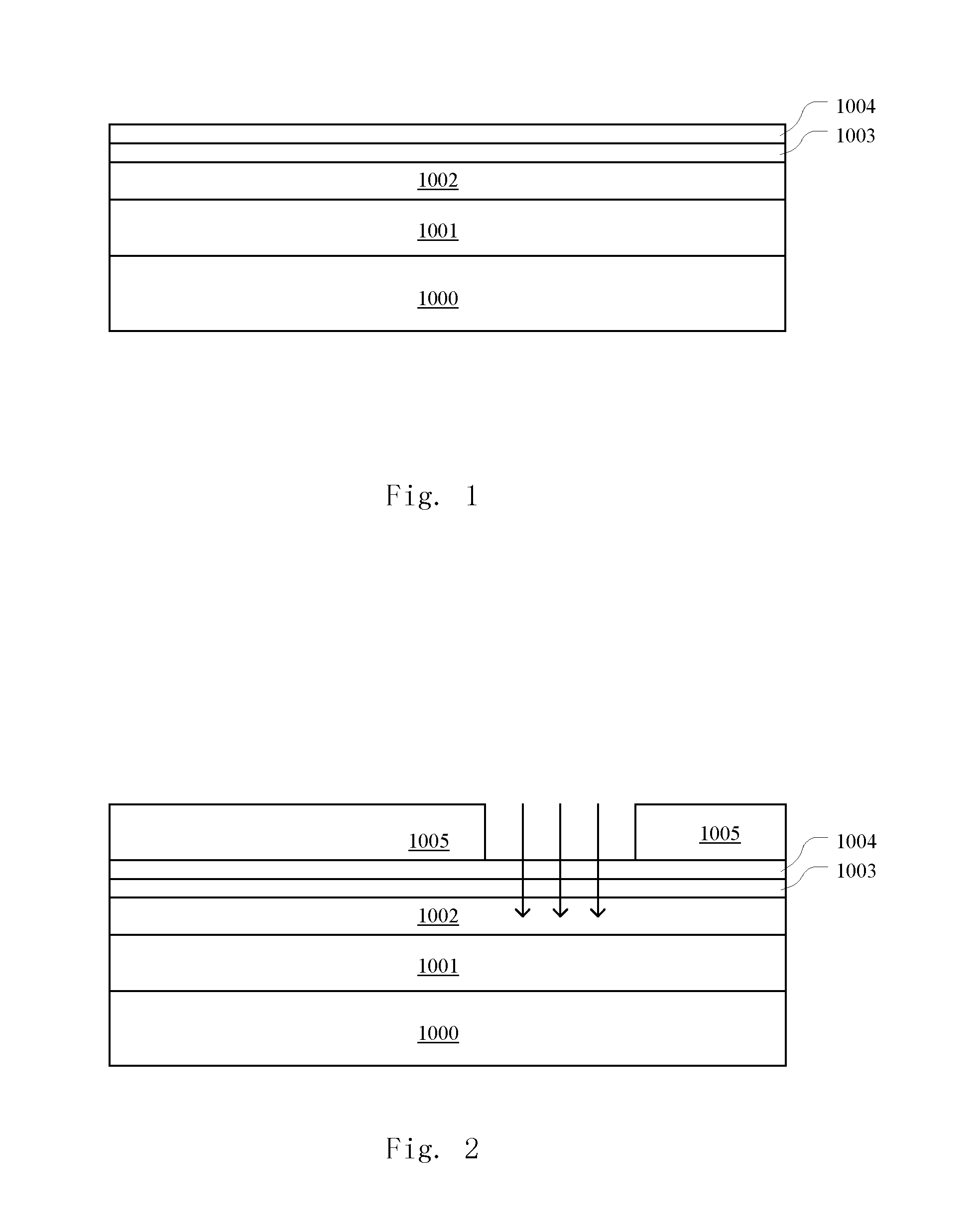

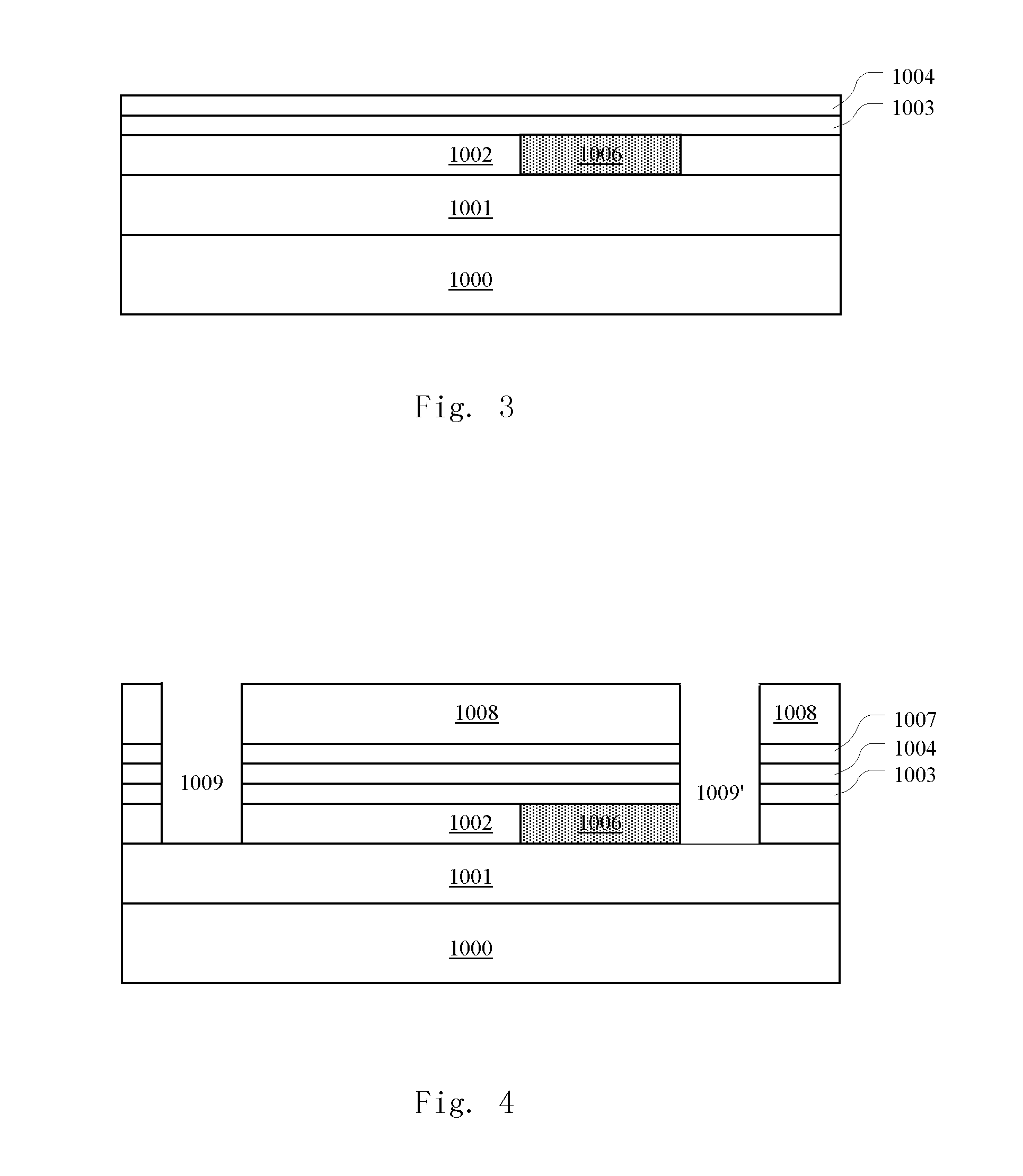

Transistor, Semiconductor Device Comprising the Transistor and Method for Manufacturing the Same

ActiveUS20120153393A1Simple manufacturing processReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

The invention relates to a transistor, a semiconductor device comprising the transistor and manufacturing methods for the transistor and the semiconductor device. The transistor according to the invention comprises: a substrate comprising at least a base layer, a first semiconductor layer, an insulating layer and a second semiconductor layer stacked sequentially; a gate stack formed on the second semiconductor layer; a source region and a drain region located on both sides of the gate stack respectively; a back gate comprising a back gate dielectric and a back gate electrode formed by the insulating layer and the first semiconductor layer, respectively; and a back gate contact formed on a portion of the back gate electrode. The back gate contact comprises an epitaxial part raised from the surface of the back gate electrode, and each of the source region and the drain region comprises an epitaxial part raised from the surface of the second semiconductor layer. As compared to a conventional transistor, the manufacturing process of the transistor of the invention is simplified and the cost of manufacture is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Heart valves and suture rings therefor

InactiveUS6945997B2Reduce stress pointImproving long-term functionalityHeart valvesInsertion stentTissues types

Improved, adaptable tissue-type heart valves and methods for their manufacture are disclosed wherein a dimensionally stable, pre-aligned tissue leaflet subassembly is formed and its peripheral edge clamped between and attached to an upper shaped wireform and a lower support stent. A variety of adaptable structural interfaces including suture rings, flanges, and conduits may be attached to the support stent with or without an outlet conduit disposed about the wireform to provide a tissue-type heart valve adaptable for use in either a natural heart or in mechanical pumping devices. The methods include forming individual leaflets with a template and using the template to attach the leaflets together to form a tissue leaflet subassembly. The template and leaflets include a straight edge terminating in oppositely directed tabs, and a curvilinear cusp edge extending opposite the straight edge. The template may include a guide slot in its straight edge and the assembly includes aligning two leaflet tabs with the template and passing sutures through the guide slot and through the leaflet tabs. The leaflet subassembly is mated to a wireform with the tabs extending through commissure posts of the wireform. A support stent having an upper surface matching the lower surface of the wireform sandwiches the edges of the leaflet subassembly therebetween. Separated tabs on the leaflet subassembly are passed through the wireform commissures and attached to adjacent stent commissures so as to induce clamping of the leaflet tabs between the stent commissures and wireform commissures upon a radially inward force being applied to the leaflets.

Owner:EDWARDS LIFESCIENCES CORP

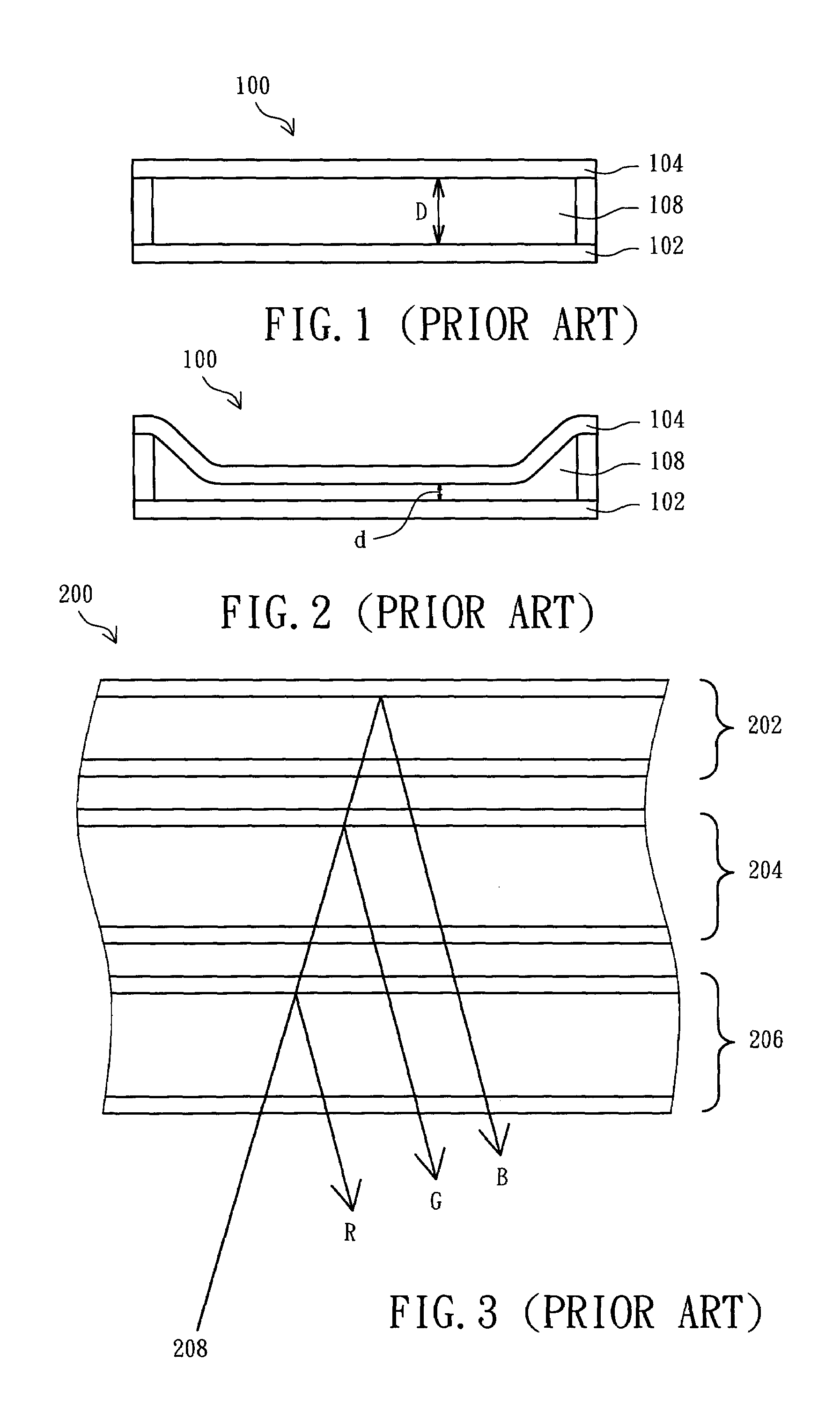

Color changeable pixel

InactiveUS20050068605A1Increase brightnessHigh resolutionNon-linear opticsOptical elementsOptoelectronicsVoltage

A color changeable pixel comprises a first plate, a second plate and a third plate. The three plates are settled in parallel. The second plate is a deformable and reflective plate. An incident light from one side of the first plate is modulated and only specific frequency light reflects by the second plate. The frequency of the reflected light is related to the distance between the first plate and the second plate. The second plate shifts by the voltage added on the third plate to change the distance between the first plate and the second plate. Therefore, the frequency of the reflected light is altered.

Owner:SNAPTRACK

Display device

ActiveUS20100065839A1Suitable structureAvoid defectsSolid-state devicesNon-linear opticsJunction leakageLinear element

A protective circuit includes a non-linear element, which includes a gate electrode, a gate insulating layer covering the gate electrode, a pair of first and second wiring layers whose end portions overlap with the gate electrode over the gate insulating layer and in which a second oxide semiconductor layer and a conductive layer are stacked, and a first oxide semiconductor layer which overlaps with at least the gate electrode and which is in contact with the gate insulating layer, side face portions and part of top face portions of the conductive layer and side face portions of the second oxide semiconductor layer in the first wiring layer and the second wiring layer. Over the gate insulating layer, oxide semiconductor layers with different properties are bonded to each other, whereby stable operation can be performed as compared with Schottky junction. Thus, the junction leakage can be decreased and the characteristics of the non-linear element can be improved.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor structure and method for manufacturing the same

ActiveUS20120104495A1Simple manufacturing processHighly integratedTransistorSolid-state devicesSemiconductor structureEngineering

The present application discloses a semiconductor structure and a method for manufacturing the same. The semiconductor structure according to the present invention adjusts a threshold voltage with a common contact, which has a portion outside the source or drain region extending to the back-gate region and provides an electrical contact of the source or drain region and the back-gate region, which leads to a simple manufacturing process, an increased integration level and a lowered manufacture cost. Moreover, the asymmetric design of the back-gate structure further increases the threshold voltage and improves the performance of the device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Color changeable pixel

InactiveUS20050068606A1Increase brightnessHigh resolutionNon-linear opticsReflectorsVoltageOptoelectronics

A color changeable pixel comprises a first plate, a second plate and a third plate. The three plates are settled in parallel. The second plate is a deformable and reflective plate. An incident light from one side of the first plate is modulated and only specific frequency light reflects by the second plate. The frequency of the reflected light is related to the distance between the first plate and the second plate. The second plate shifts by the voltage added on the third plate to change the distance between the first plate and the second plate. Therefore, the frequency of the reflected light is altered.

Owner:SNAPTRACK

Semiconductor device

ActiveUS20150228803A1Stable semiconductor characteristicSimple manufacturing processTransistorSolid-state devicesDriver circuitHydrogen

The semiconductor device includes a first transistor provided in a driver circuit portion and a second transistor provided in a pixel portion; the first transistor and the second transistor have different structures. In an oxide semiconductor film of each of the transistors, an impurity element is contained in regions which do not overlap with a gate electrode. The regions of the oxide semiconductor film which contain the impurity element function as low-resistance regions. Furthermore, the regions of the oxide semiconductor film which contain the impurity element are in contact with a film containing hydrogen. Furthermore, the first transistor provided in the driver circuit portion may include the oxide semiconductor film in which a first film and a second film are stacked, and the second transistor provided in the pixel portion may include the oxide semiconductor film which differs from the first film in the atomic ratio of metal elements.

Owner:SEMICON ENERGY LAB CO LTD

Enzyme electrode structure

InactiveUS6156173AEasy to manufactureEasy to measureImmobilised enzymesBioreactor/fermenter combinationsEnzyme electrodeWorking electrode

A biosensor comprises a space part for sucking and housing a sample formed of two upper and lower plates, the two plates being stuck together by an adhesive layer, the space part for sucking and housing the sample being constituted so as to be partially opened in the peripheral part and partially closed by the adhesive layer, and has a working electrode having at least glucose oxidase immobilized thereon and a counter electrode on the same plane of the plate.

Owner:ABBOTT DIABETES CARE INC

Semiconductor device, display device including the semiconductor device, display module including the display device, and electronic device including the semiconductor device, the display device, and the display module

ActiveUS20150221678A1Stable semiconductor characteristicSimple manufacturing processTransistorSolid-state devicesDisplay deviceCapacitor

To provide a semiconductor device including a planar transistor having an oxide semiconductor and a capacitor. In a semiconductor device, a transistor includes an oxide semiconductor film, a gate insulating film over the oxide semiconductor film, a gate electrode over the gate insulating film, a second insulating film over the gate electrode, a third insulating film over the second insulating film, and a source and a drain electrodes over the third insulating film; the source and the drain electrodes are electrically connected to the oxide semiconductor film; a capacitor includes a first and a second conductive films and the second insulating film; the first conductive film and the gate electrode are provided over the same surface; the second conductive film and the source and the drain electrodes are provided over the same surface; and the second insulating film is provided between the first and the second conductive films.

Owner:SEMICON ENERGY LAB CO LTD

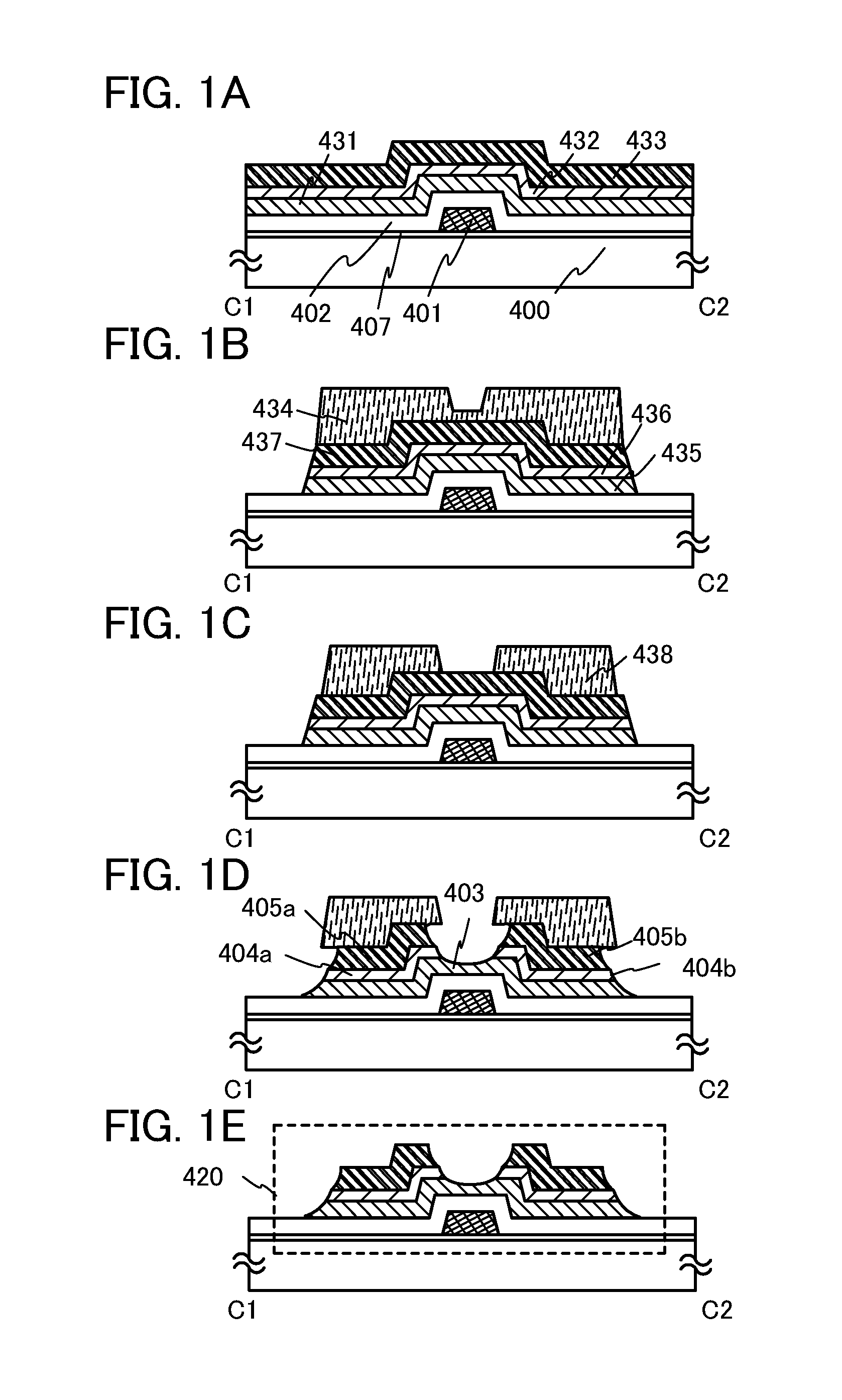

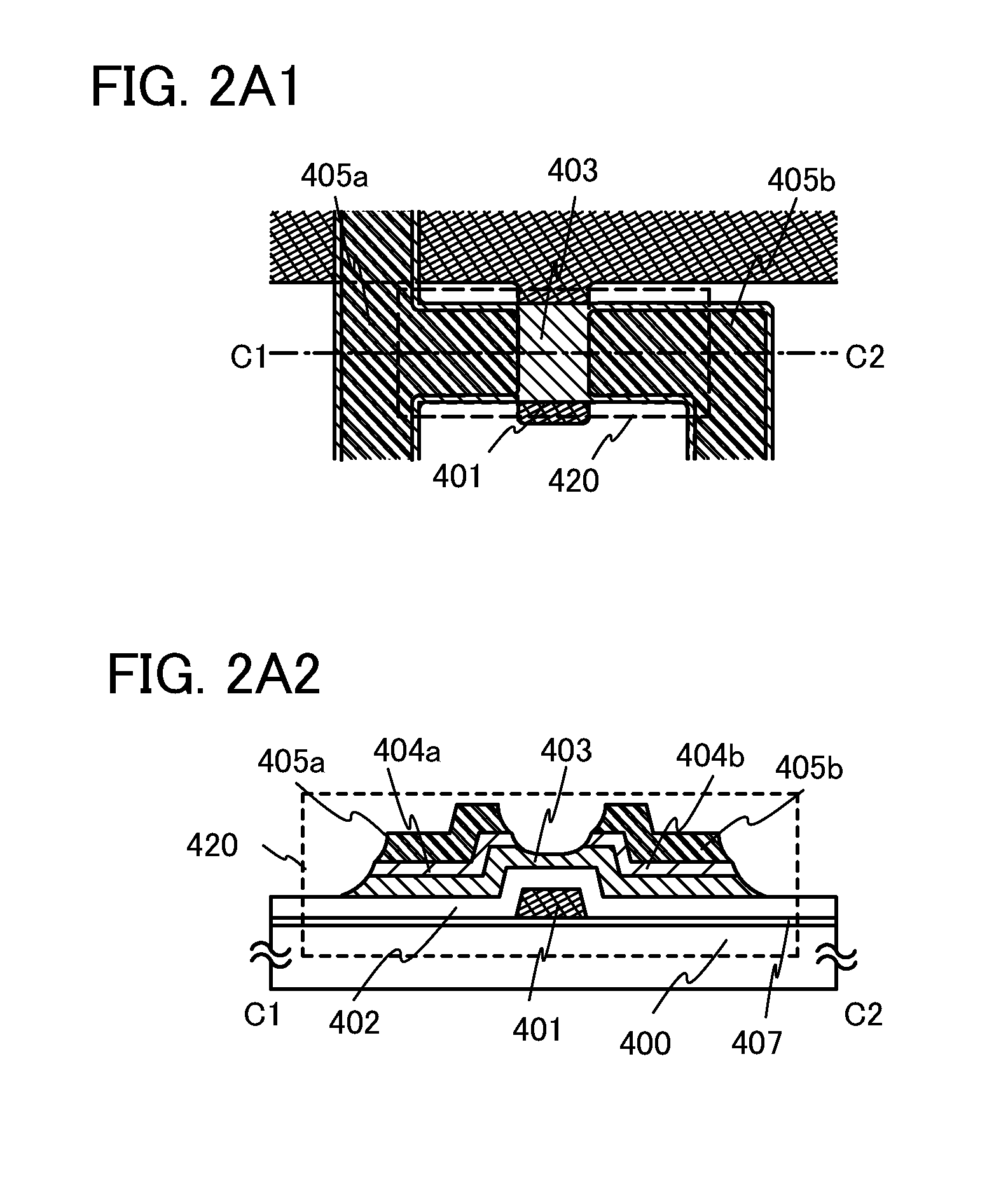

Method for manufacturing semiconductor device

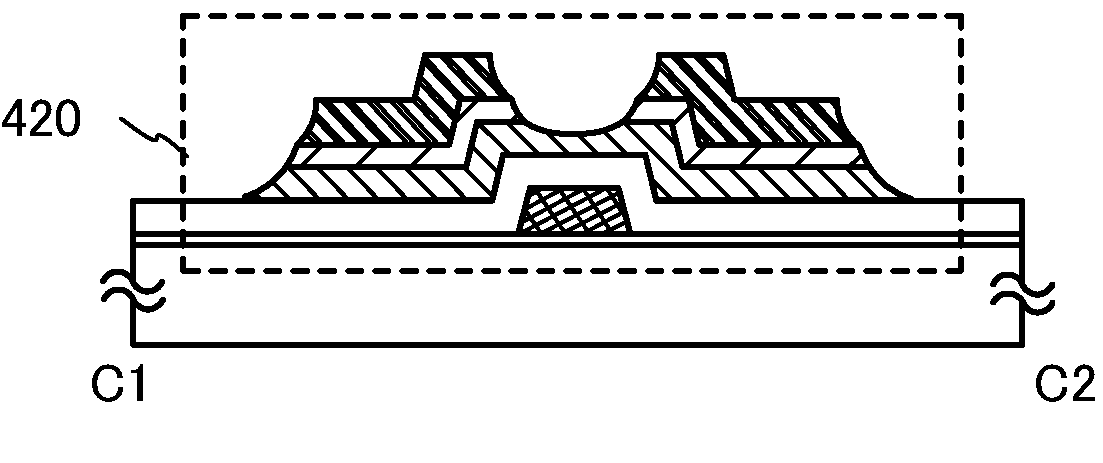

ActiveUS20100105163A1Reduce manufacturing costImprove productivityTransistorElectroluminescent light sourcesProduction rateLight exposure

An object is to manufacture a semiconductor device including an oxide semiconductor at low cost with high productivity in such a manner that a photolithography process is simplified by reducing the number of light-exposure masks. In a method for manufacturing a semiconductor device including a channel-etched inverted-staggered thin film transistor, an oxide semiconductor film and a conductive film are etched using a mask layer formed with the use of a multi-tone mask which is a light-exposure mask through which light is transmitted so as to have a plurality of intensities. In etching steps, a first etching step is performed by dry etching in which an etching gas is used, and a second etching step is performed by wet etching in which an etchant is used.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com