Patents

Literature

260results about How to "Component stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

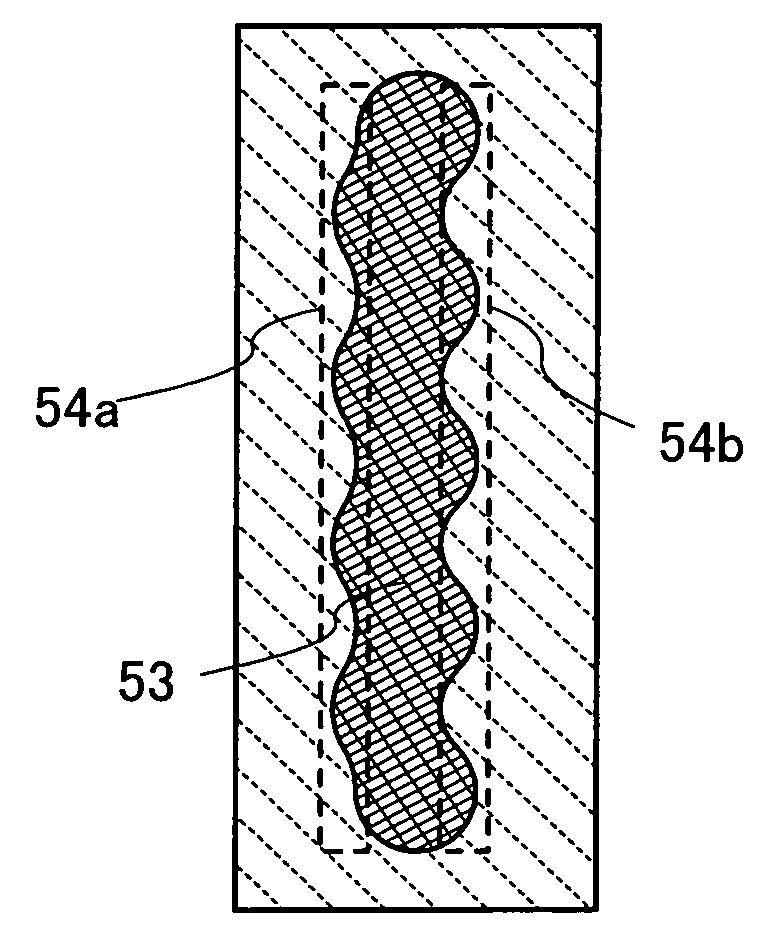

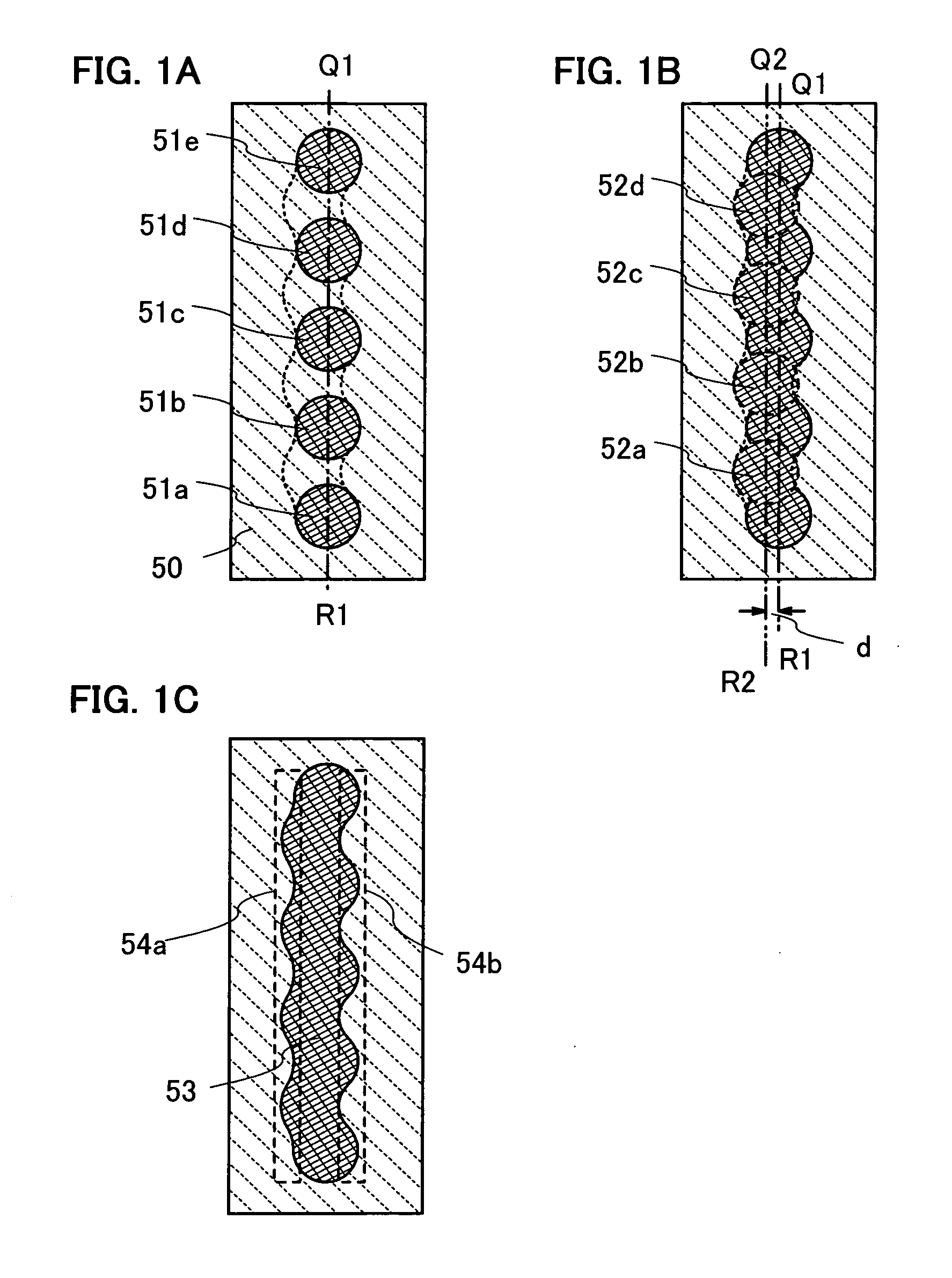

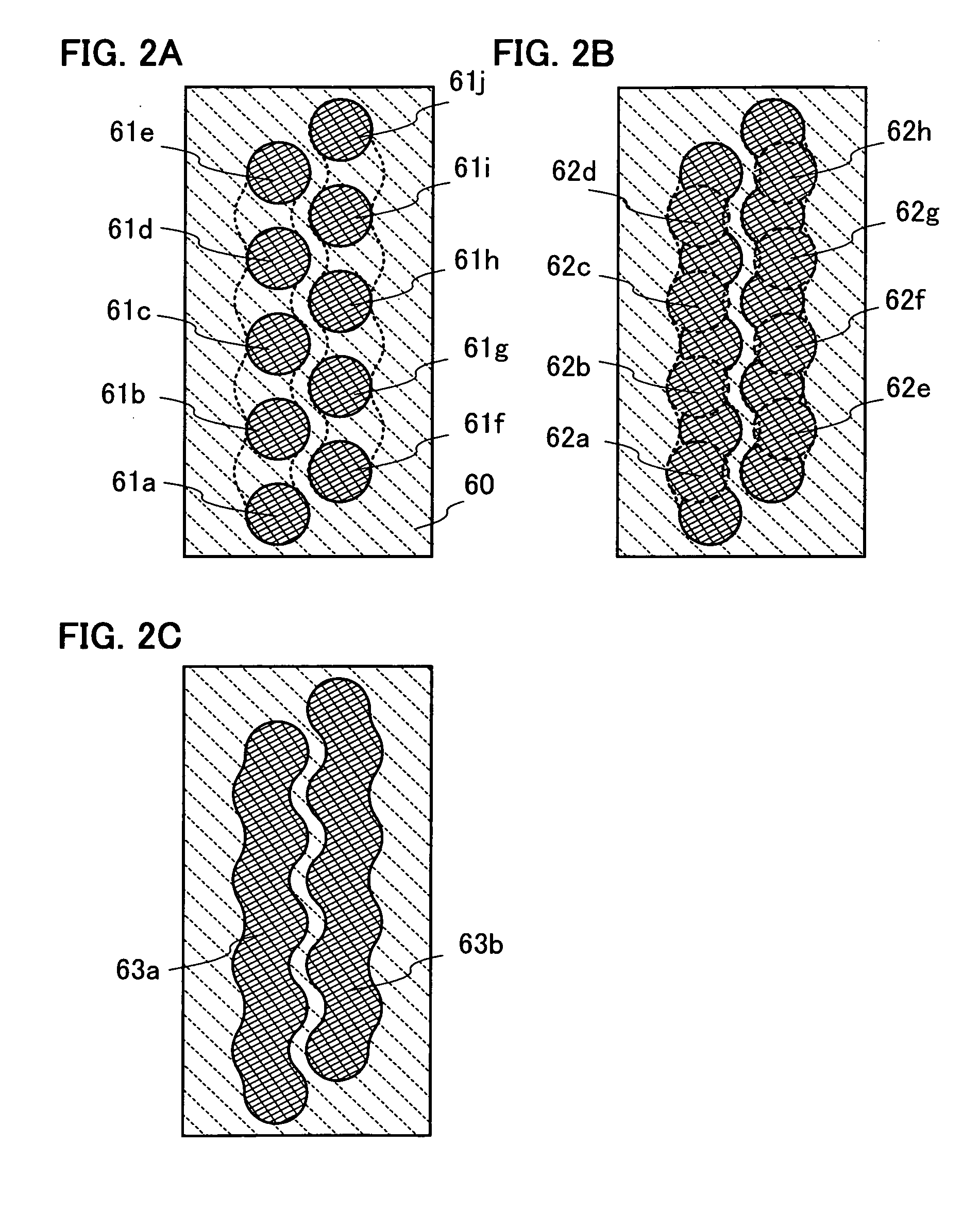

Semiconductor device, electronic device, and method of manufacturing semiconductor device

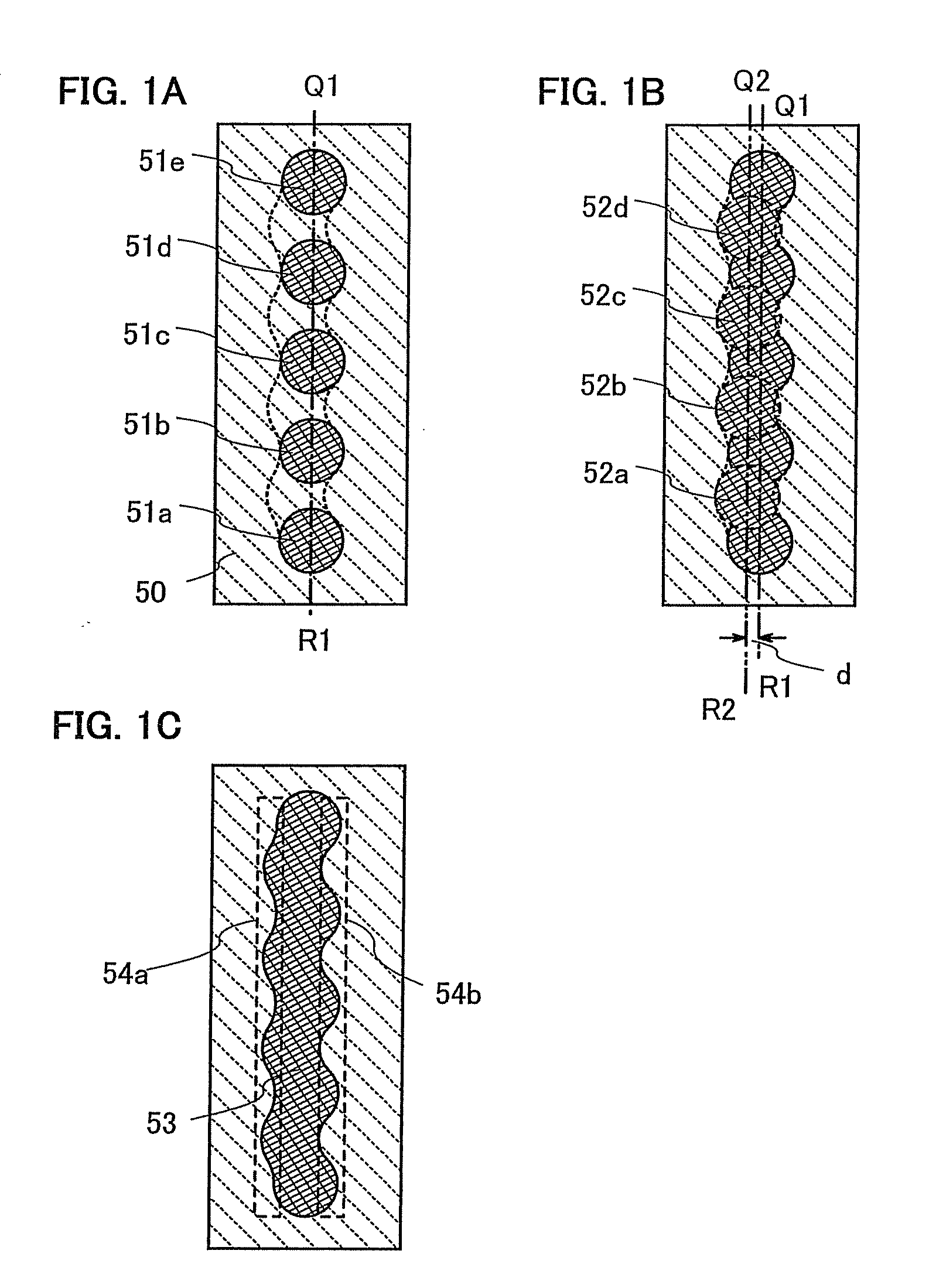

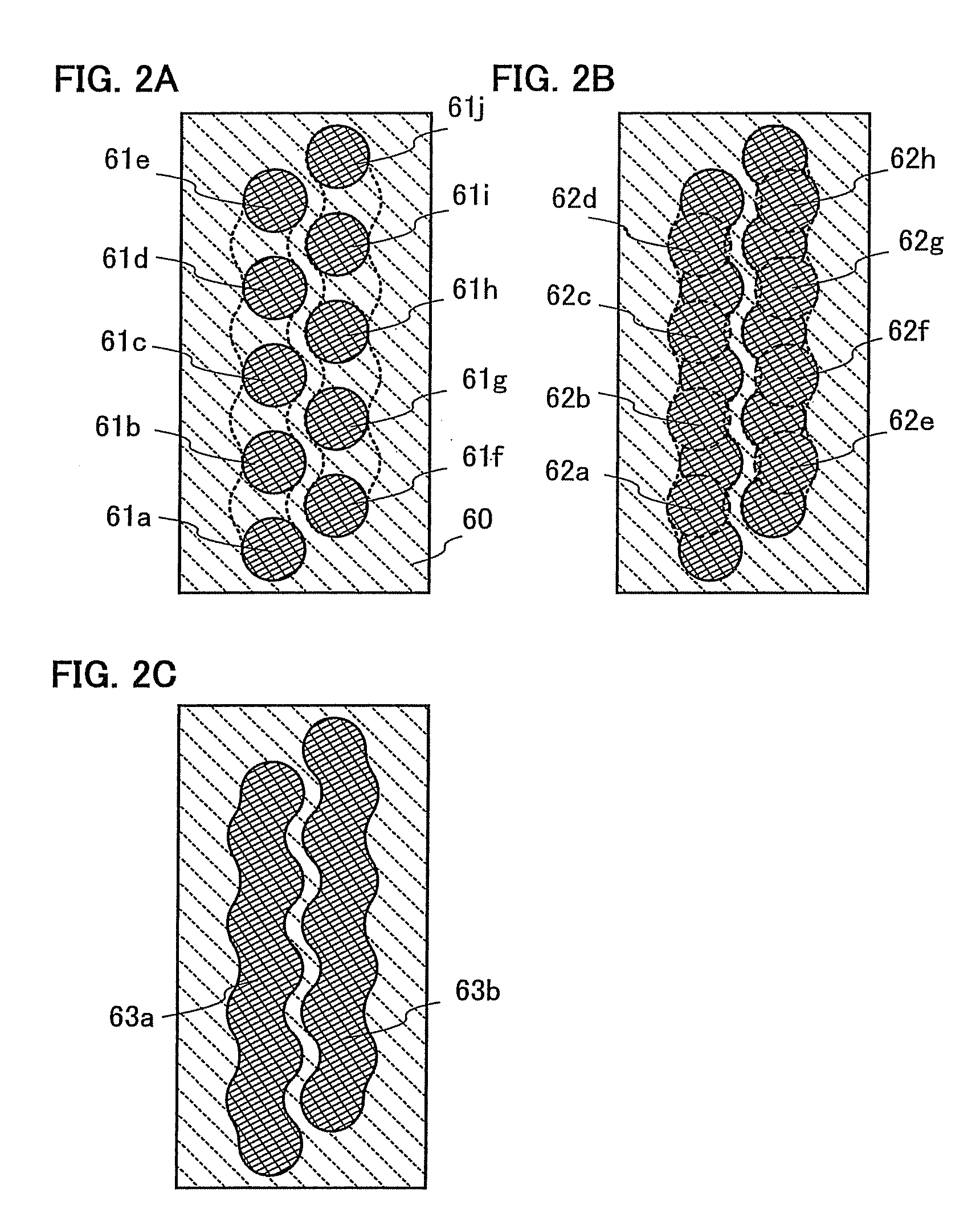

InactiveUS20060169973A1Stable formationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

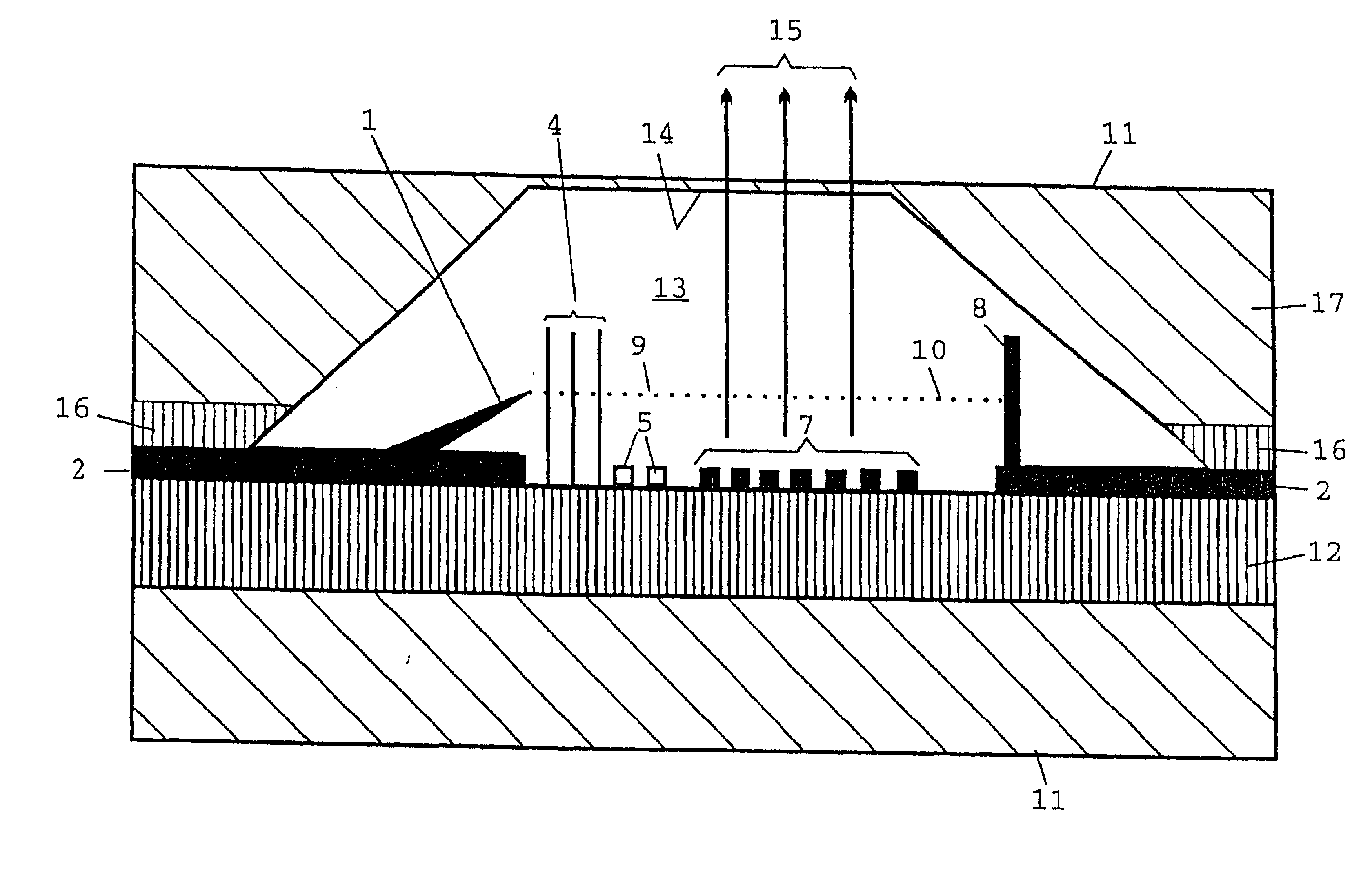

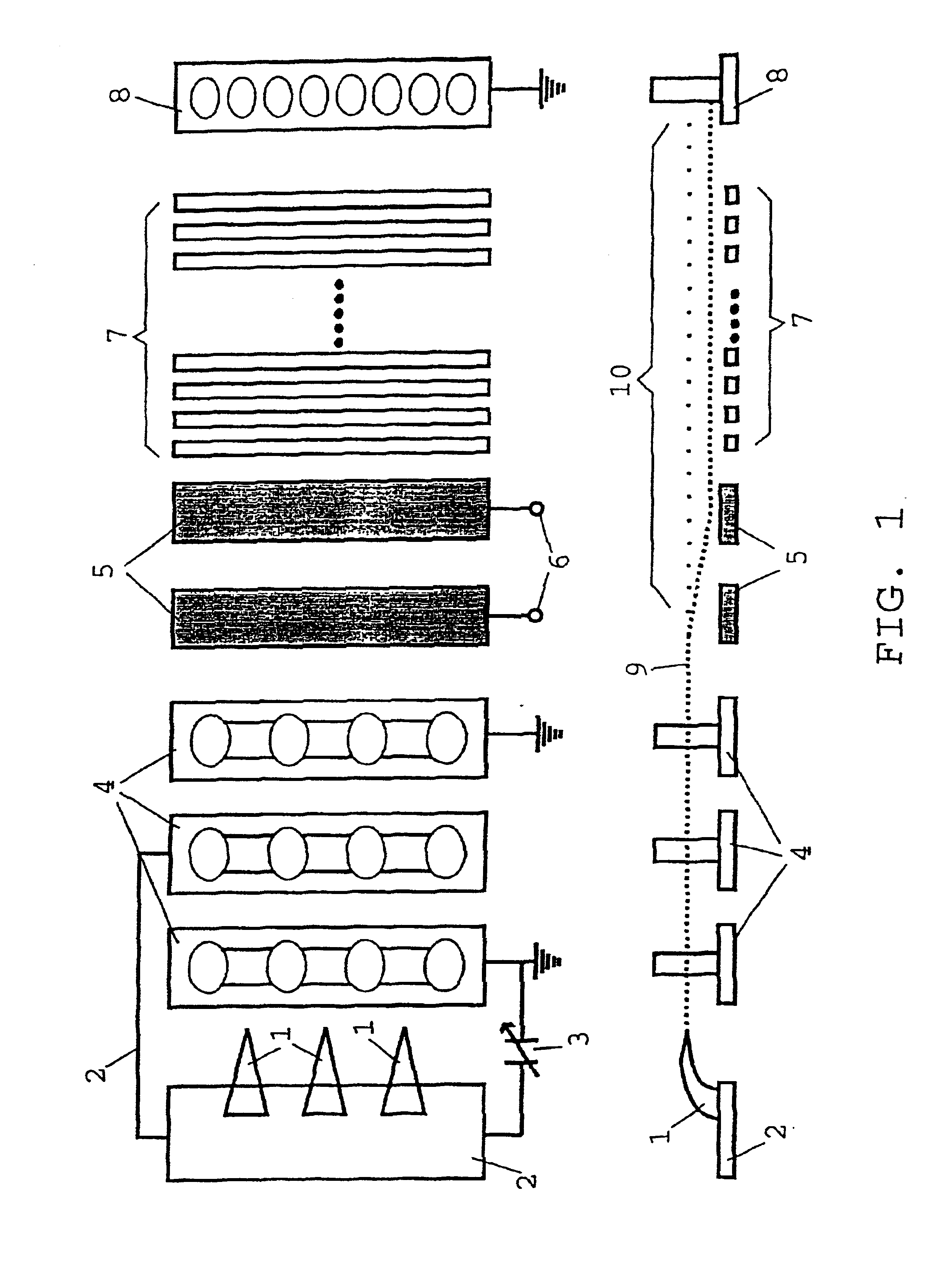

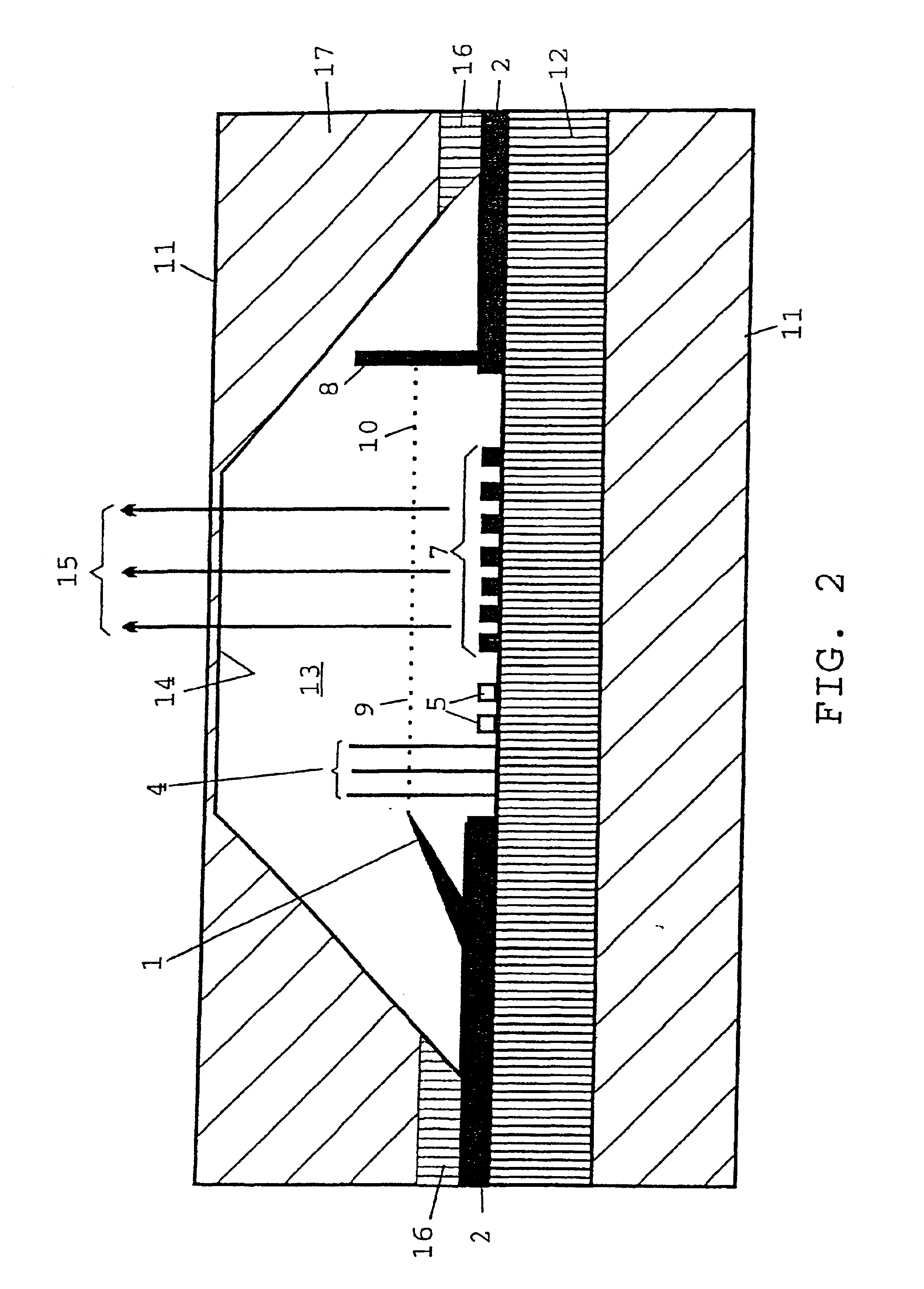

Miniaturized terahertz radiation source

InactiveUS6909104B1High spatial resolutionHighly coherentLaser using scattering effectsExcitation process/apparatusPhysicsElectrostatic lens

A miniaturized terahertz radiation source based on the Smith-Purcell effect is provided, in which, from a focused electron source, a high-energy bundle of electrons is transmitted at a defined distance over a reflection diffraction grating composed of transversely disposed grating rods, so that, in response to oscillating image charges, electromagnetic waves of one wavelength are emitted, the wavelength being adjustable as a function of the periodicity of the lines and of the electron velocity. The elements of the radiation source, such as field emitter (1), electrostatic lens (4), beam deflector (5), grating (7) of metal, and a second anode (8), are integrated on a semiconductor chip using additive nanolithographic methods. The field electron source is constructed to project, as a wire, out of the surface, using additive nanolithography, and is made of readily conductive material having stabilizing series resistance. The wire is constructed, using computer-controlled deposition lithography, in a straight or curved, free-standing design. In its surface area, the base material bears a conductor structure for the electrical terminals and connections (2), including controllable voltage sources (3) for supplying the field emitter tips (1), lens (4), and control electrodes (5, 8). The terahertz radiation source is designed to be a powerful component that is available in modular form and is usable in any spatial situation.

Owner:NAWOTEC

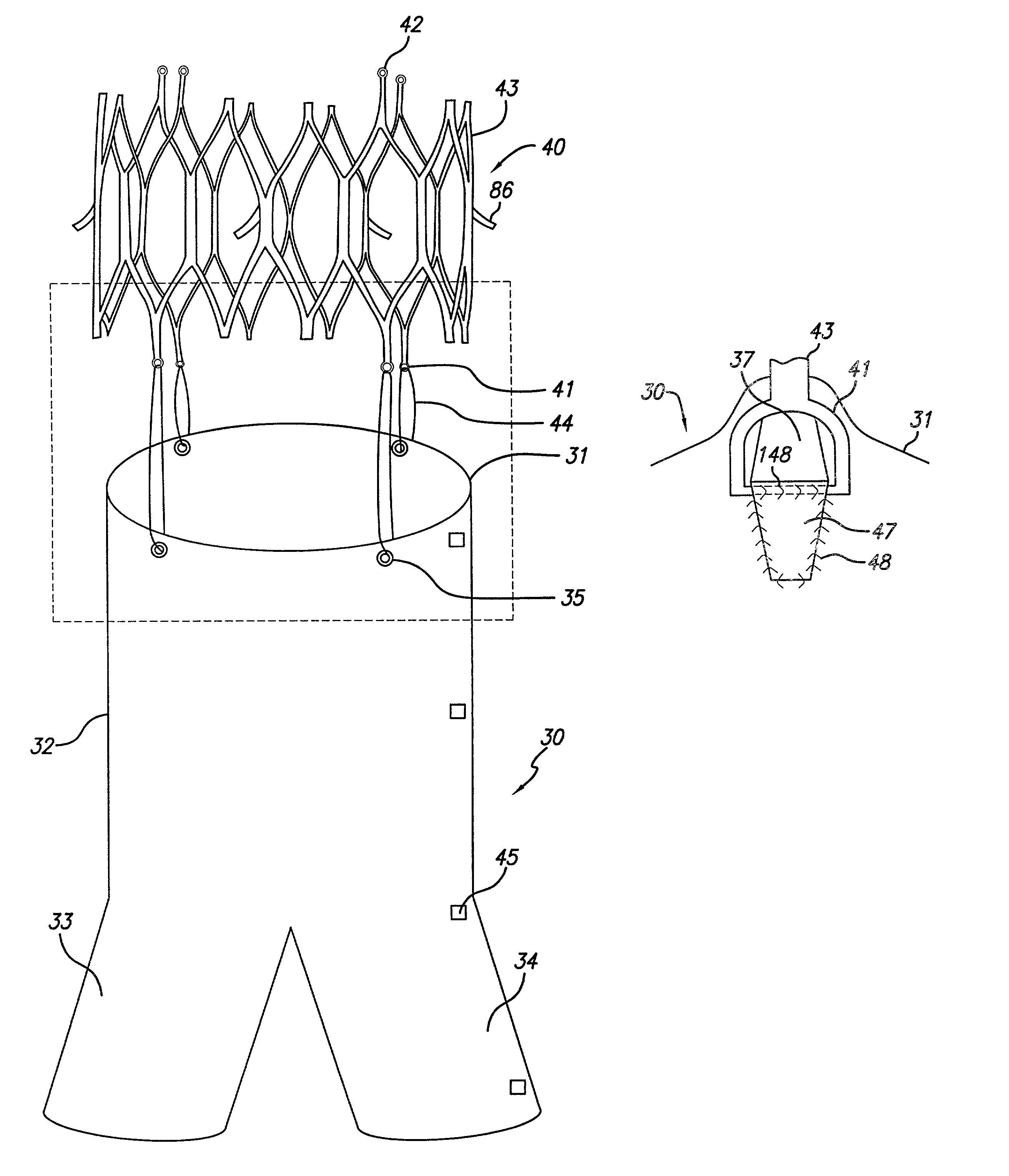

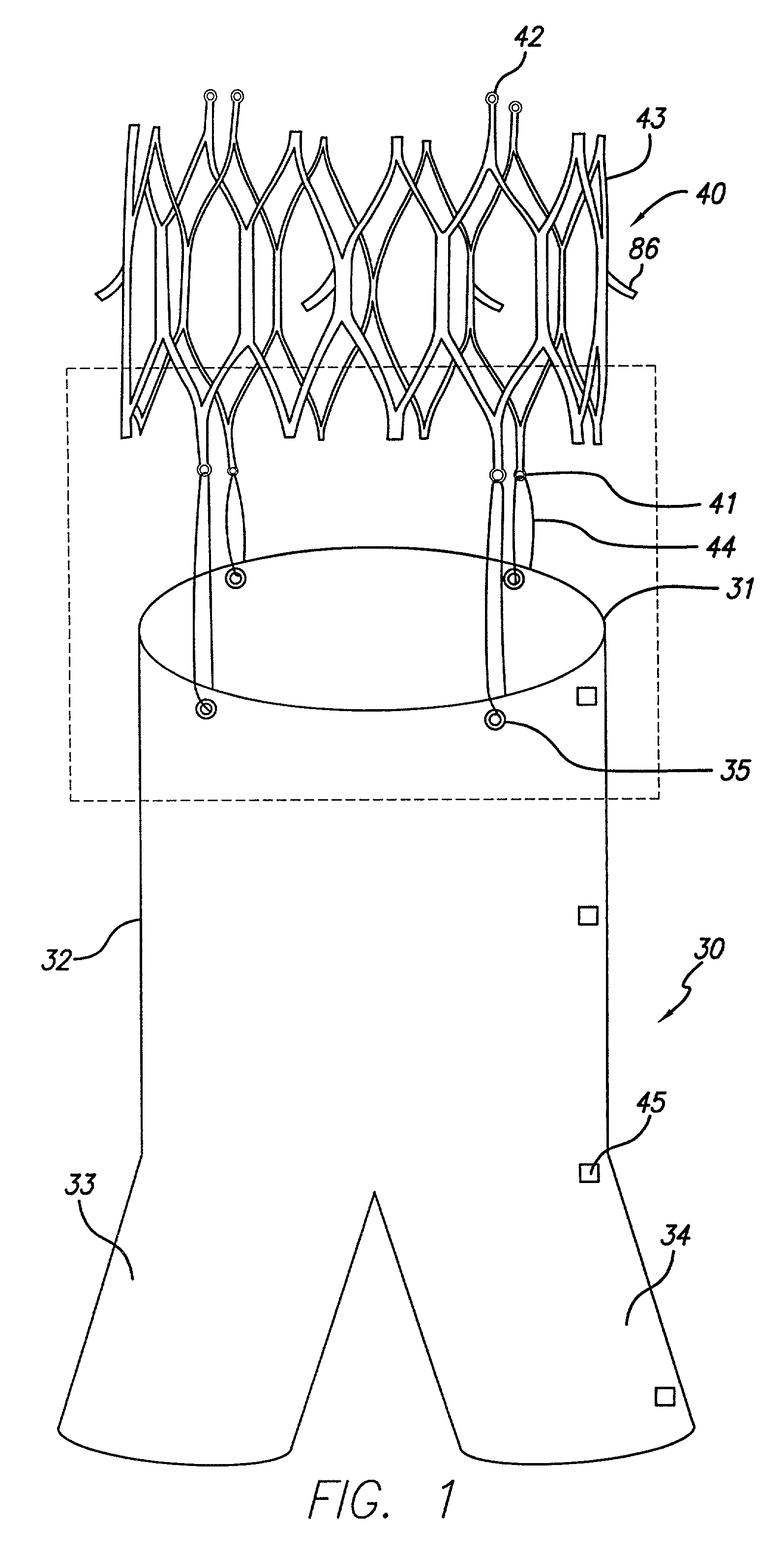

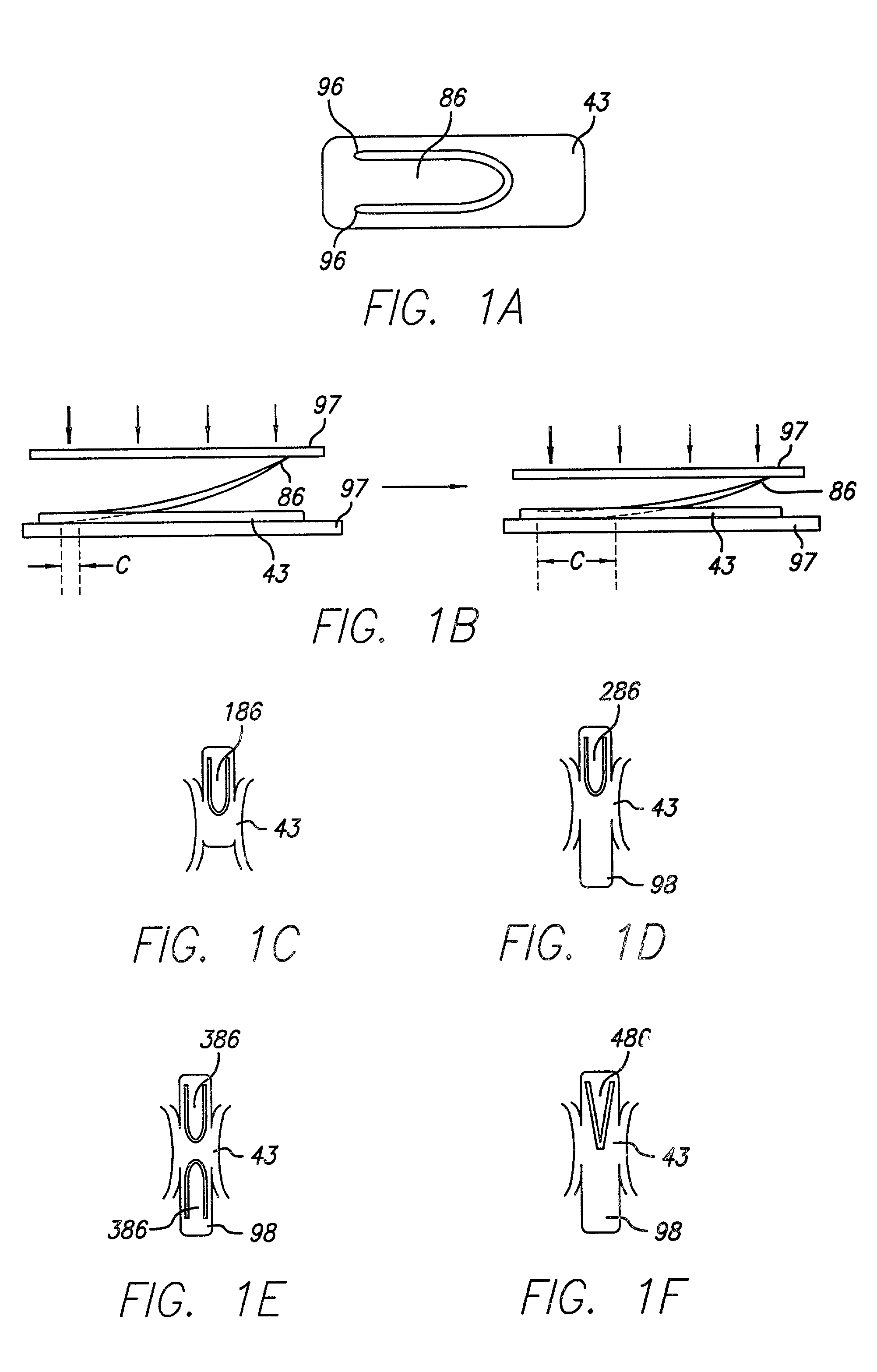

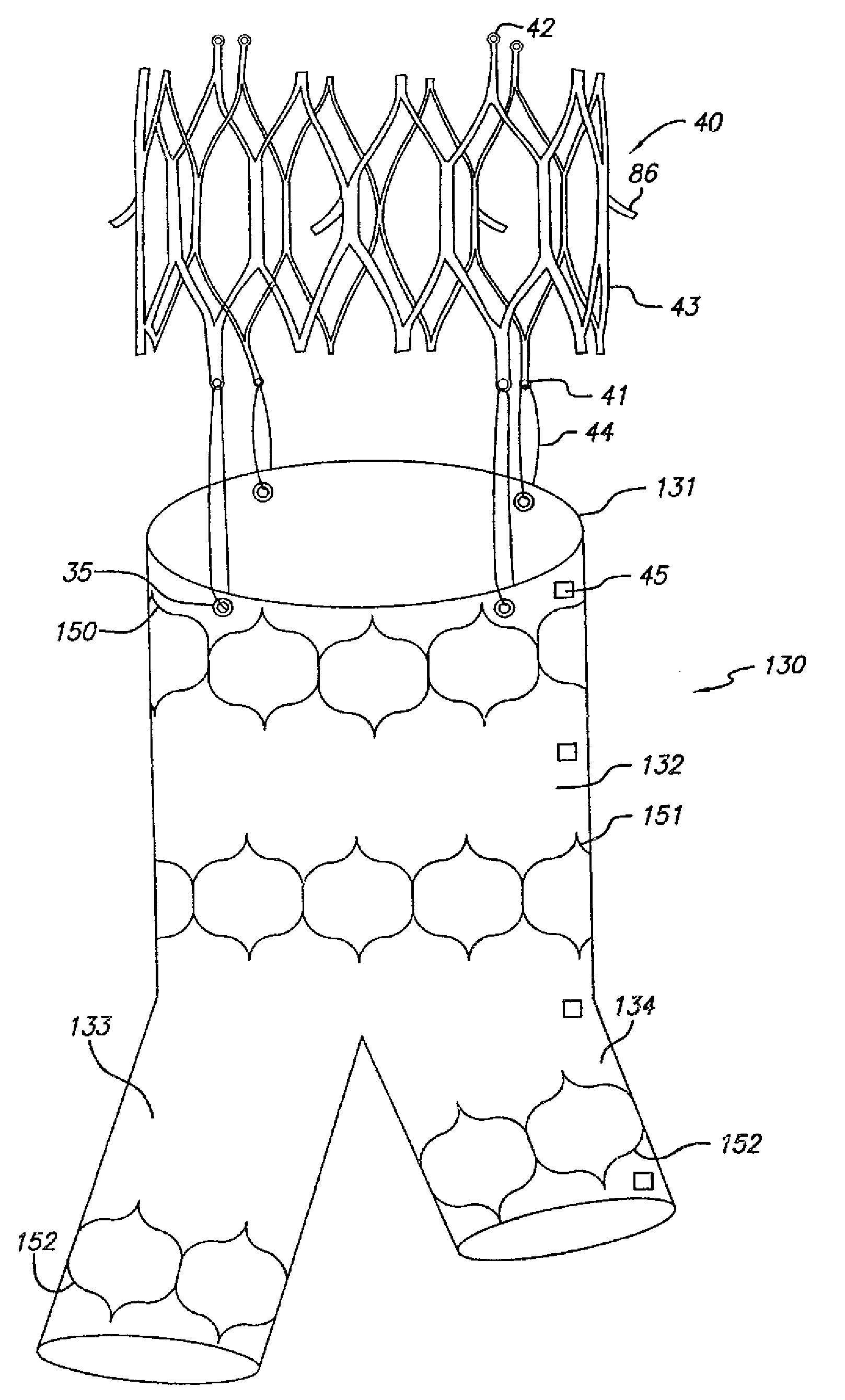

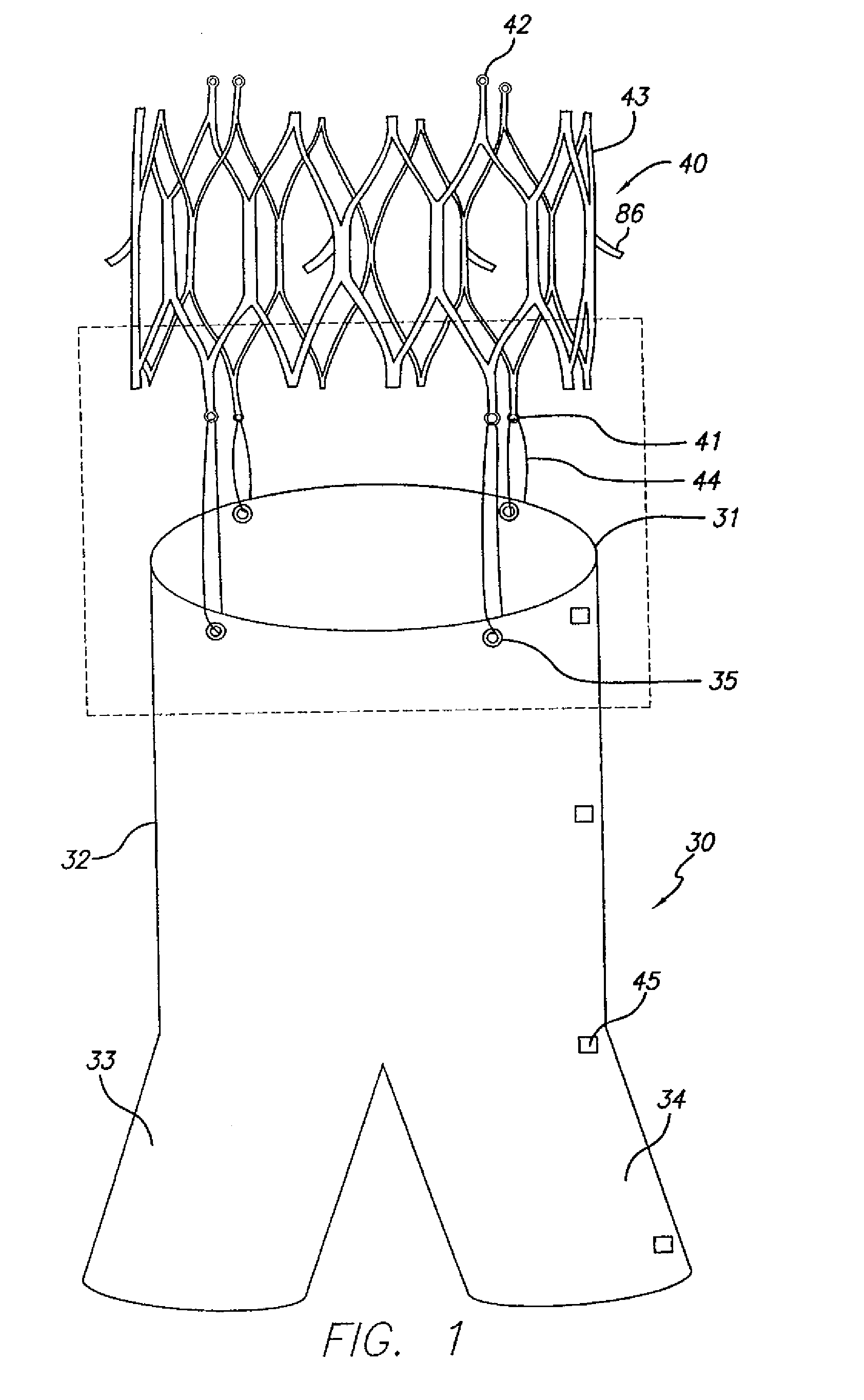

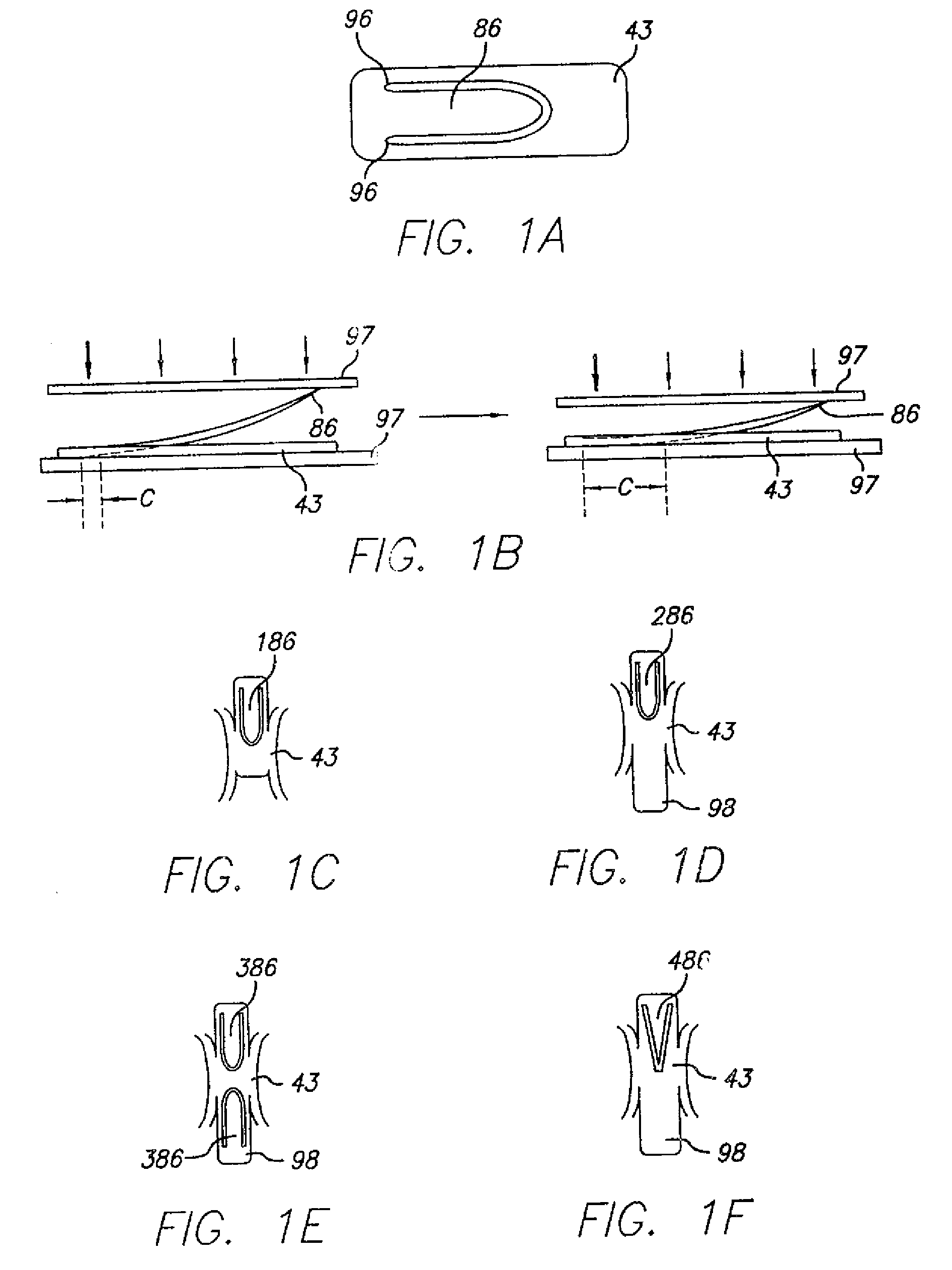

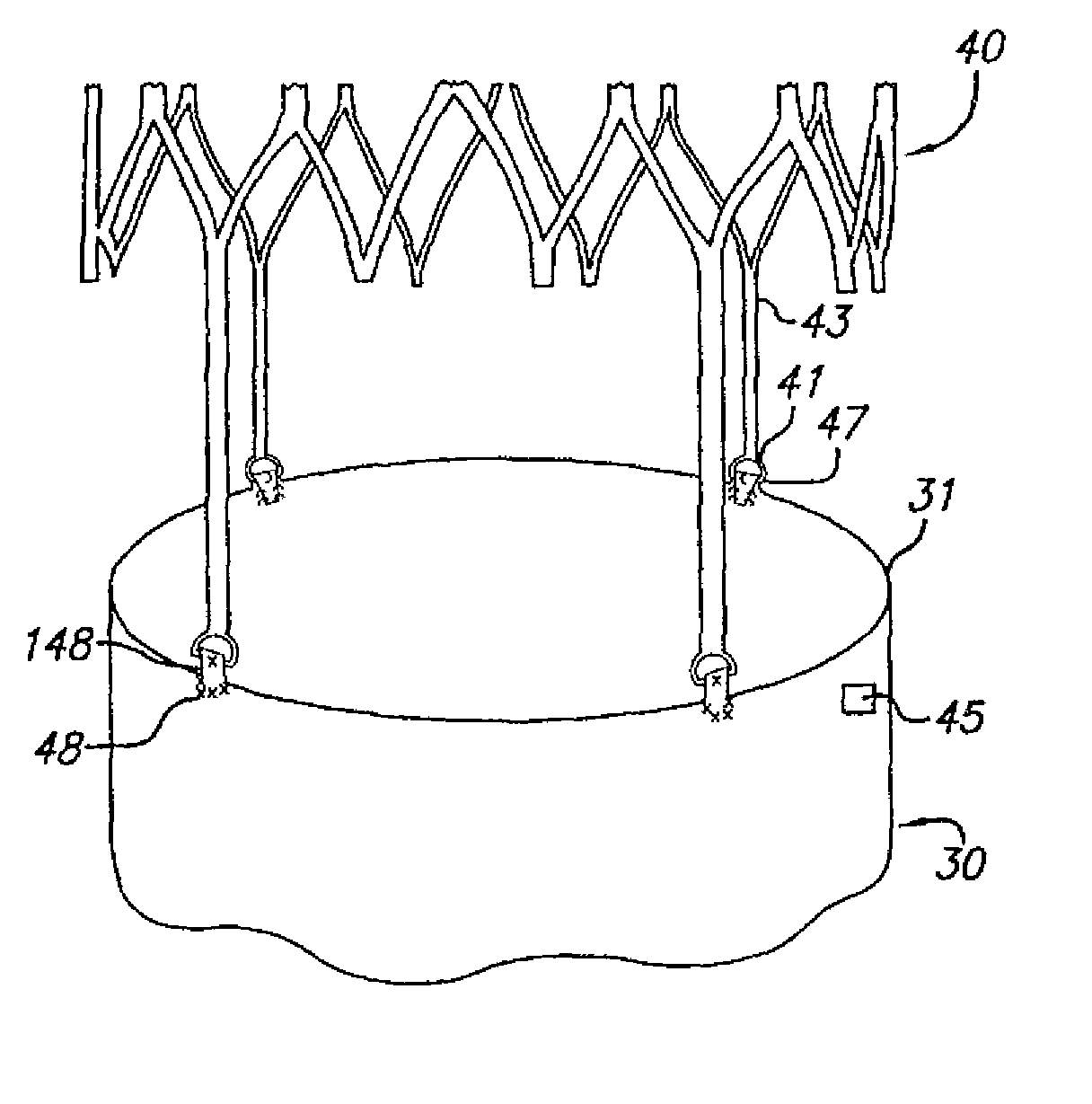

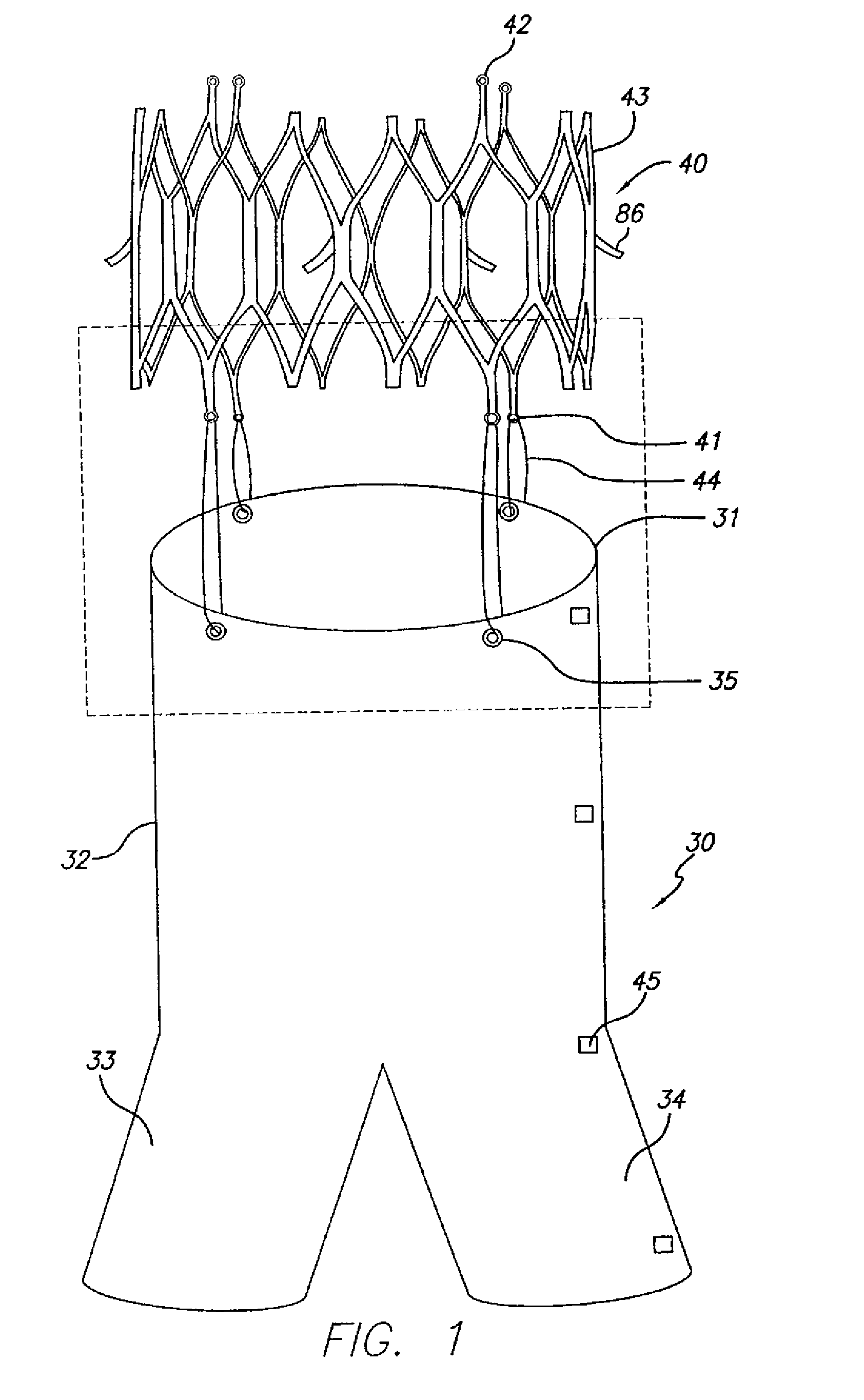

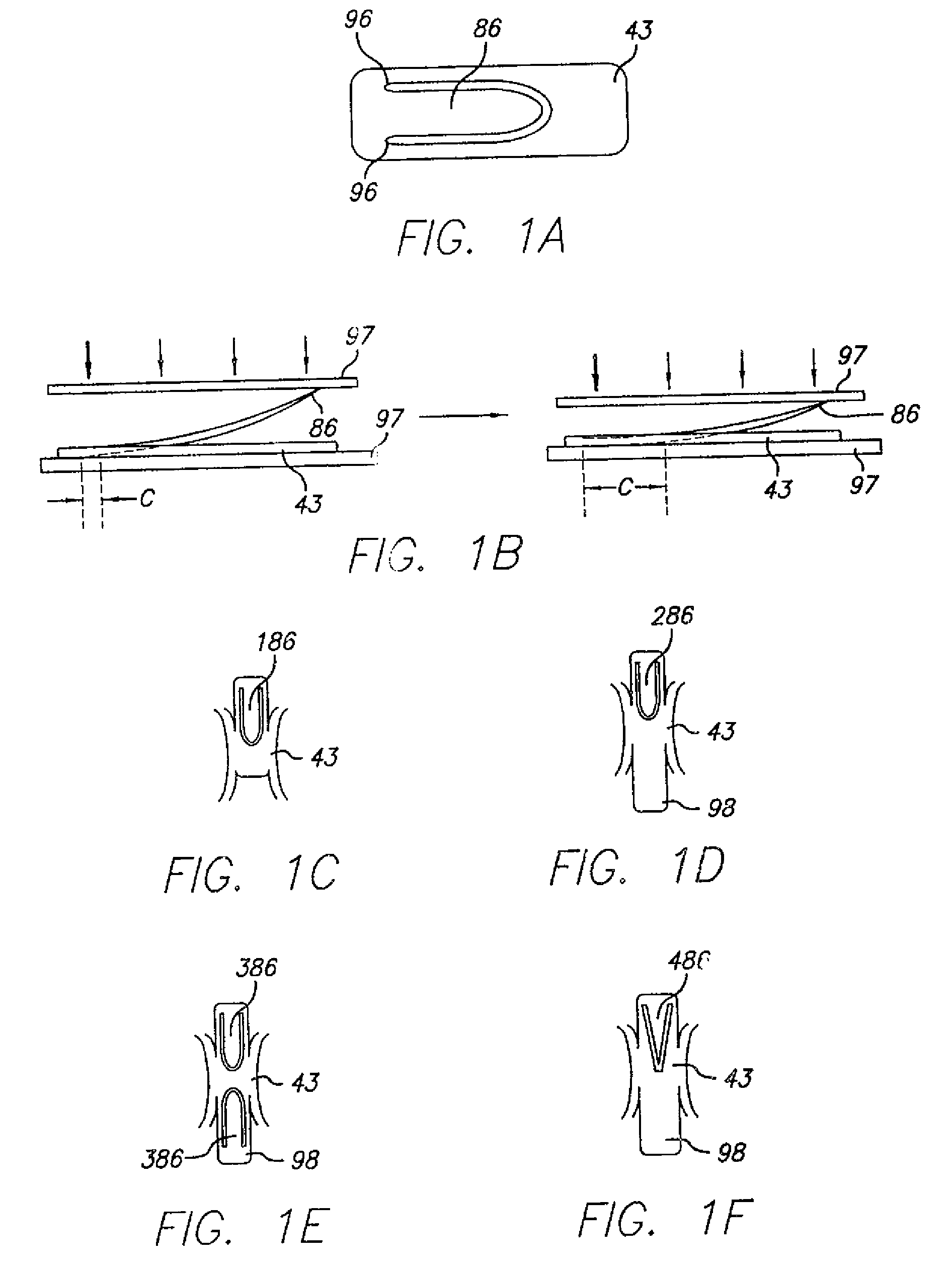

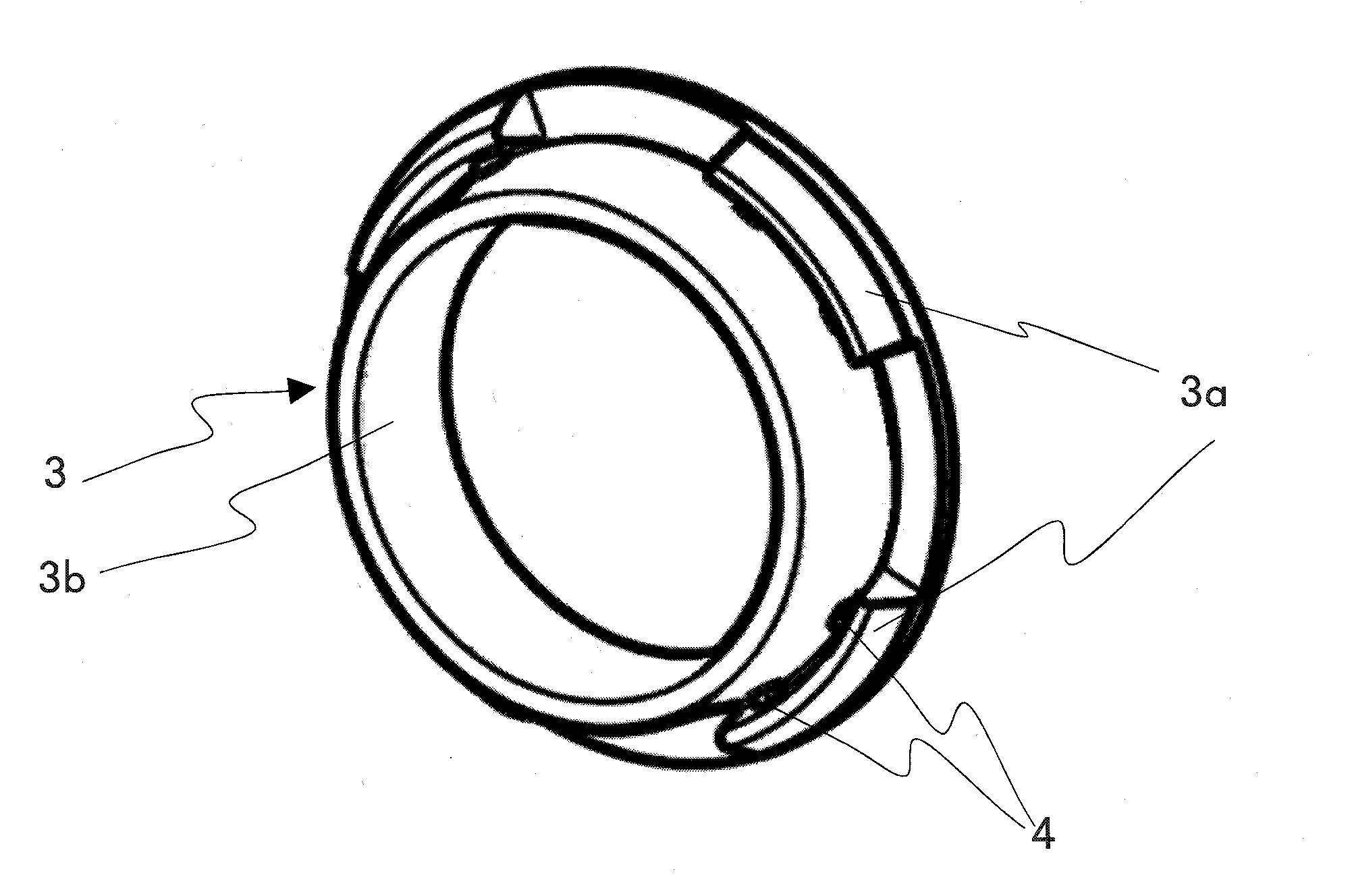

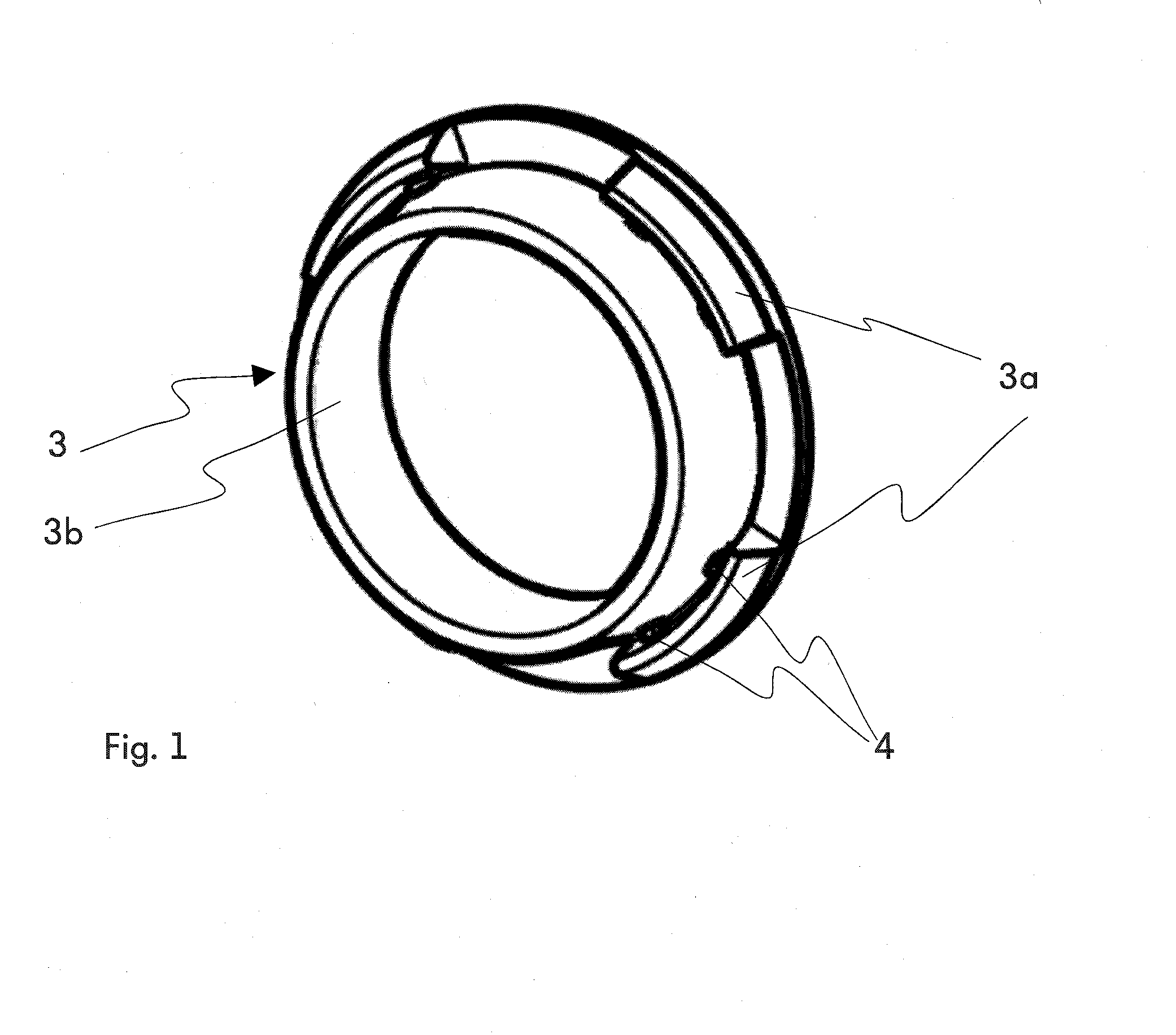

Endovascular graft device and methods for attaching components thereof

InactiveUS7708771B2Facilitate accurate catheterizationEasy to deployStentsBlood vesselsBlood vesselBiomedical engineering

Owner:LIFEPORT SCI

Endovascular graft device and methods for attaching components thereof

InactiveUS20100161028A1Facilitate accurate catheterization and deploymentReduce the possibilityStentsBlood vesselsBiomedical engineeringBlood vessel

Owner:LIFEPORT SCI

Stability of progestogen formulations

InactiveUS20060257472A1Extended shelf lifeImprove stabilityOrganic active ingredientsBiocideCellulosePhysiology

In a preparation for hormone replacement therapy having a low content of progestogen, the stability of the progestogen component can be enhanced by using a cellulosic binder, for example hydroxypropylcellulose, in stead of a non-cellulosic binder.

Owner:NOVO NORDISK AS

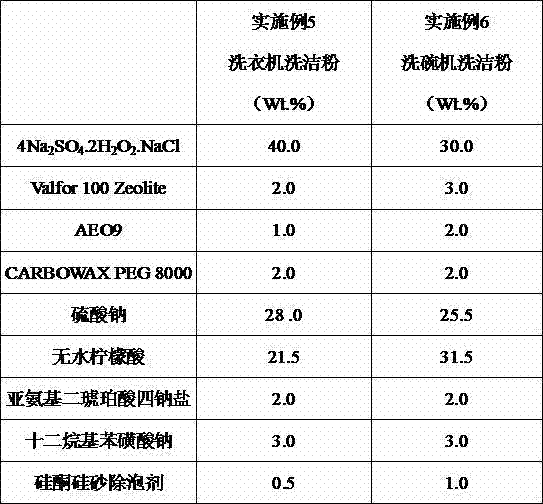

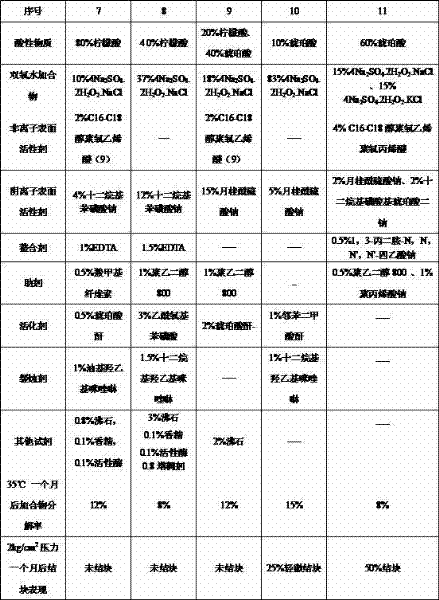

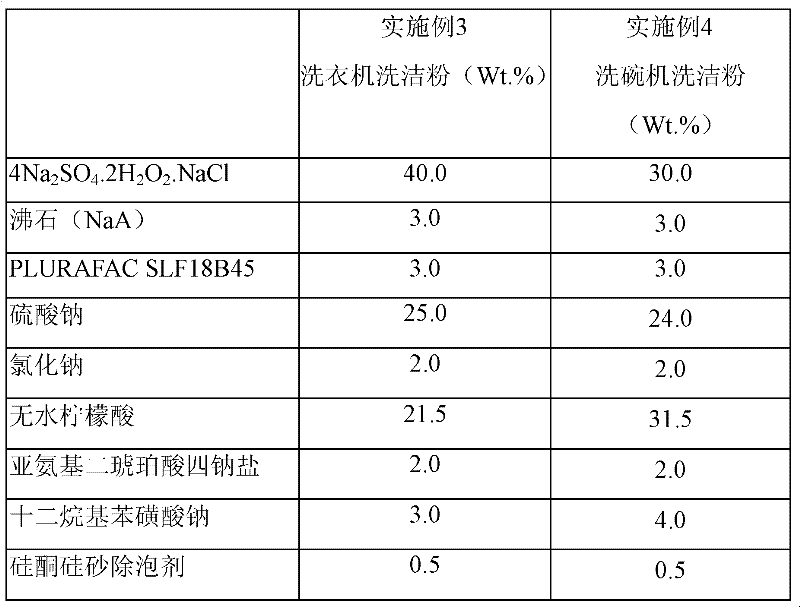

Acidic cleaning composition

InactiveCN102559399ALong term storageImproved bleaching and disinfection functionNon-ionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsLaundry washing machineActive agent

The invention discloses an acidic cleaning composition. The acidic cleaning composition is characterized in that the composition comprises the following components by weight percent: 10-90% of hydrogen peroxide adduct which is stable under the acidic condition, 10-90% of acidic material, 0-50% of anionic surfactant, 0-20% of nonionic surfactant, 0-10% of chelating reagent, 0-90% of additive, 0-40% of activator, 0-10% of corrosion inhibitor and 0-15% of other reagents. The acidic cleaning composition disclosed by the invention has multiple functions of bleaching, descaling, disinfecting, removing the biofilm and the like; and the composition is mainly used as the surface cleaning agent, and can be dispersed in water to wash the inside of the washing machine and the inside of the dish-washing machine or used to clean and disinfect the common hard surface, etc.

Owner:ZHANGJIAGANG RENDER CHEM

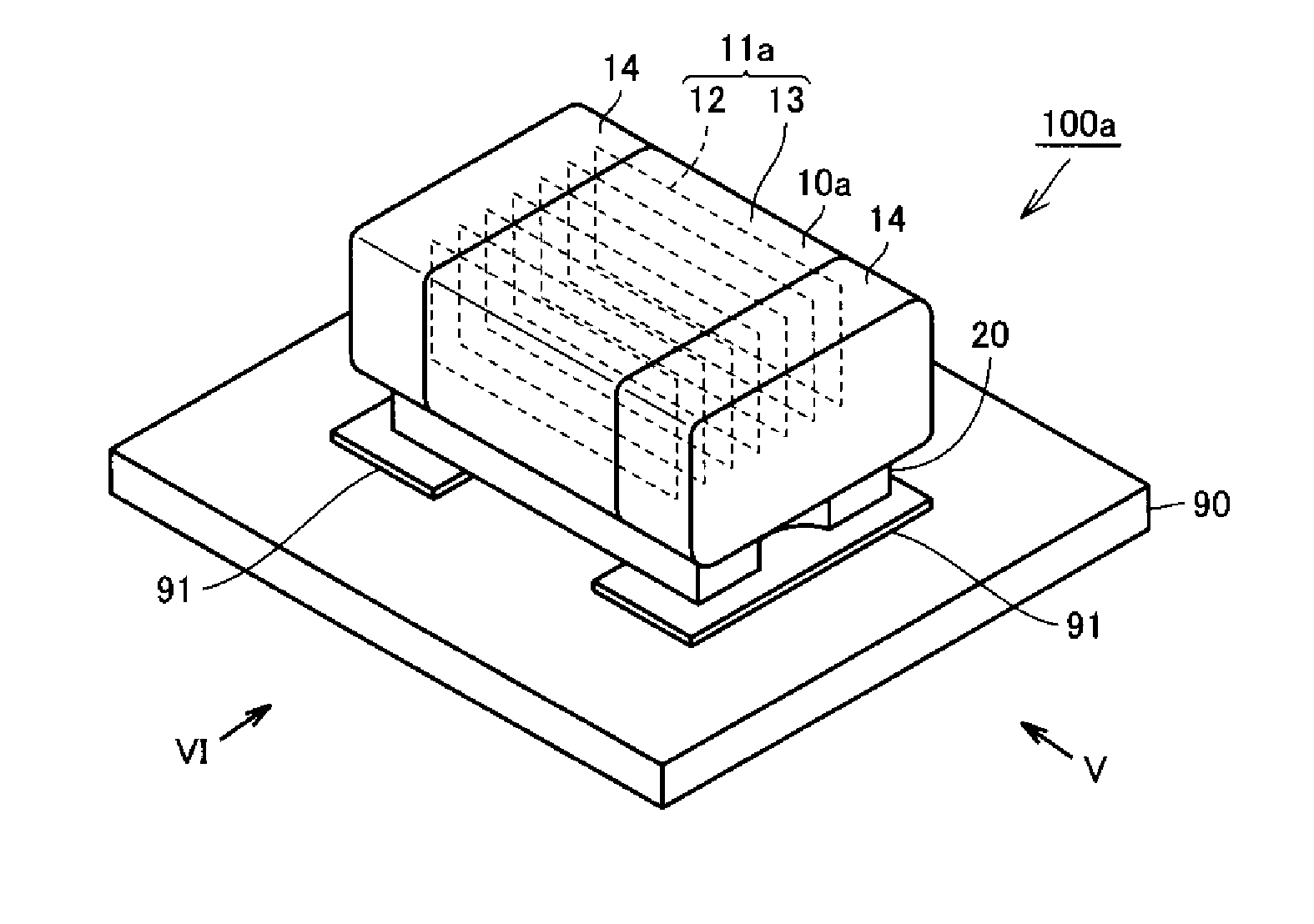

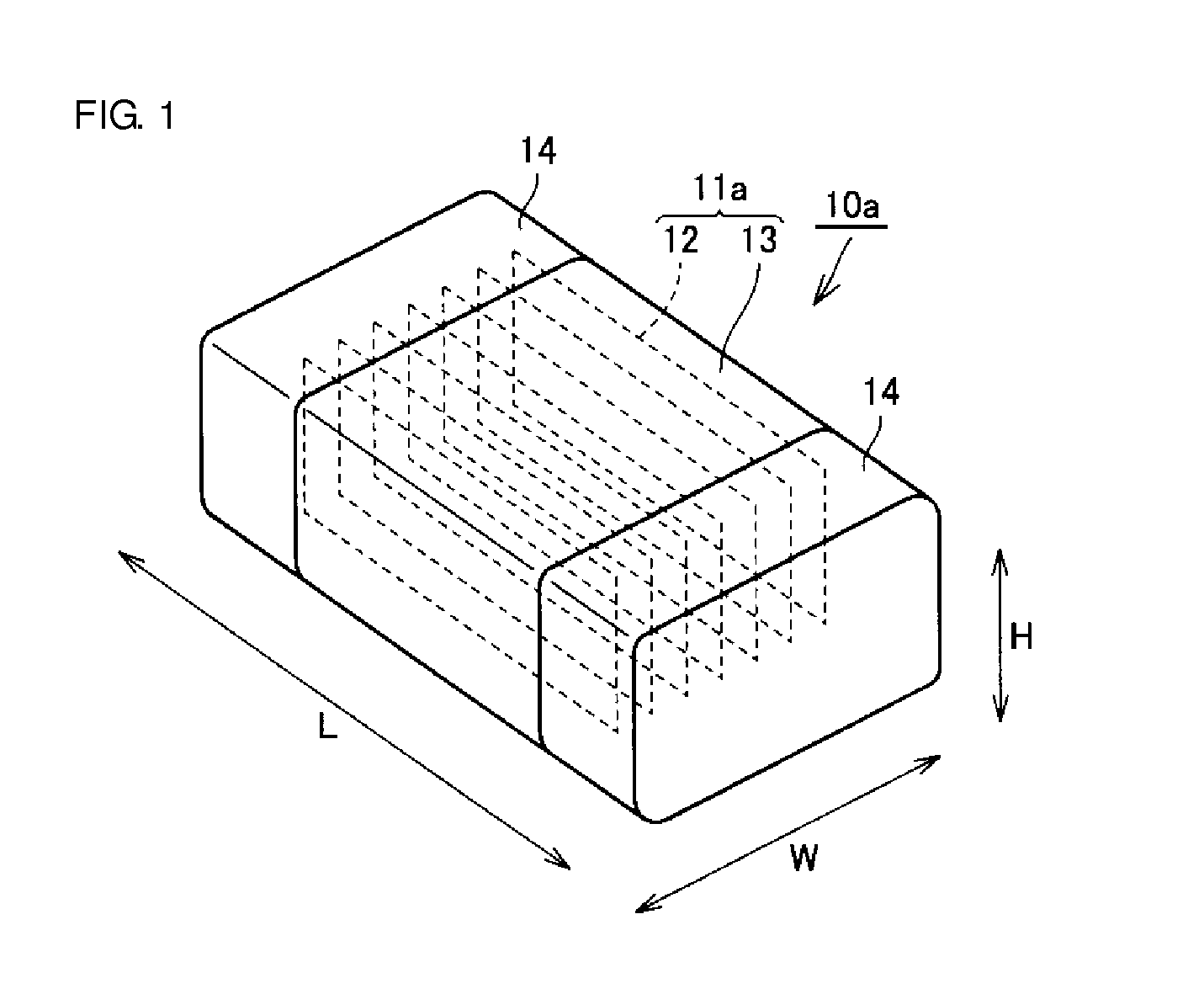

Electronic component

ActiveUS20150270068A1OccurrenceAvoid glitchesResistor terminals/electrodesFixed capacitor dielectricEngineeringElectronic component

An electronic component includes an electronic element including external electrodes on a surface and a substrate terminal on which the electronic element is mounted. The substrate terminal includes a first main surface, a second main surface opposite the first main surface, and a peripheral surface joining the first main surface and the second main surface. The substrate terminal includes mounting electrodes provided on the second main surface and electrically connected to the external electrodes of the electronic element, and connection electrodes provided on the first main surface and electrically connected to lands of a circuit substrate. A maximum width of the connection electrodes is greater than a maximum width of the mounting electrodes.

Owner:MURATA MFG CO LTD

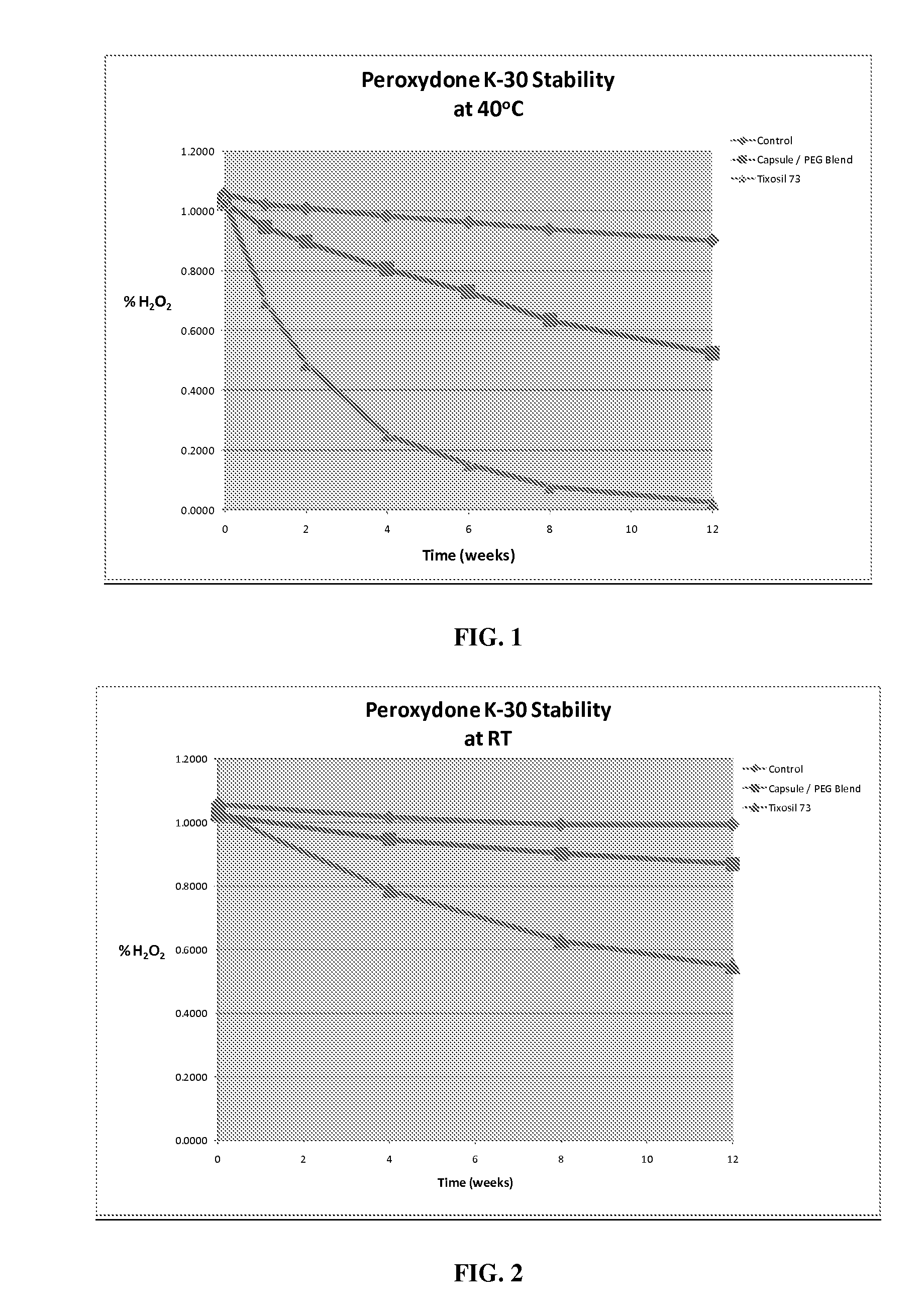

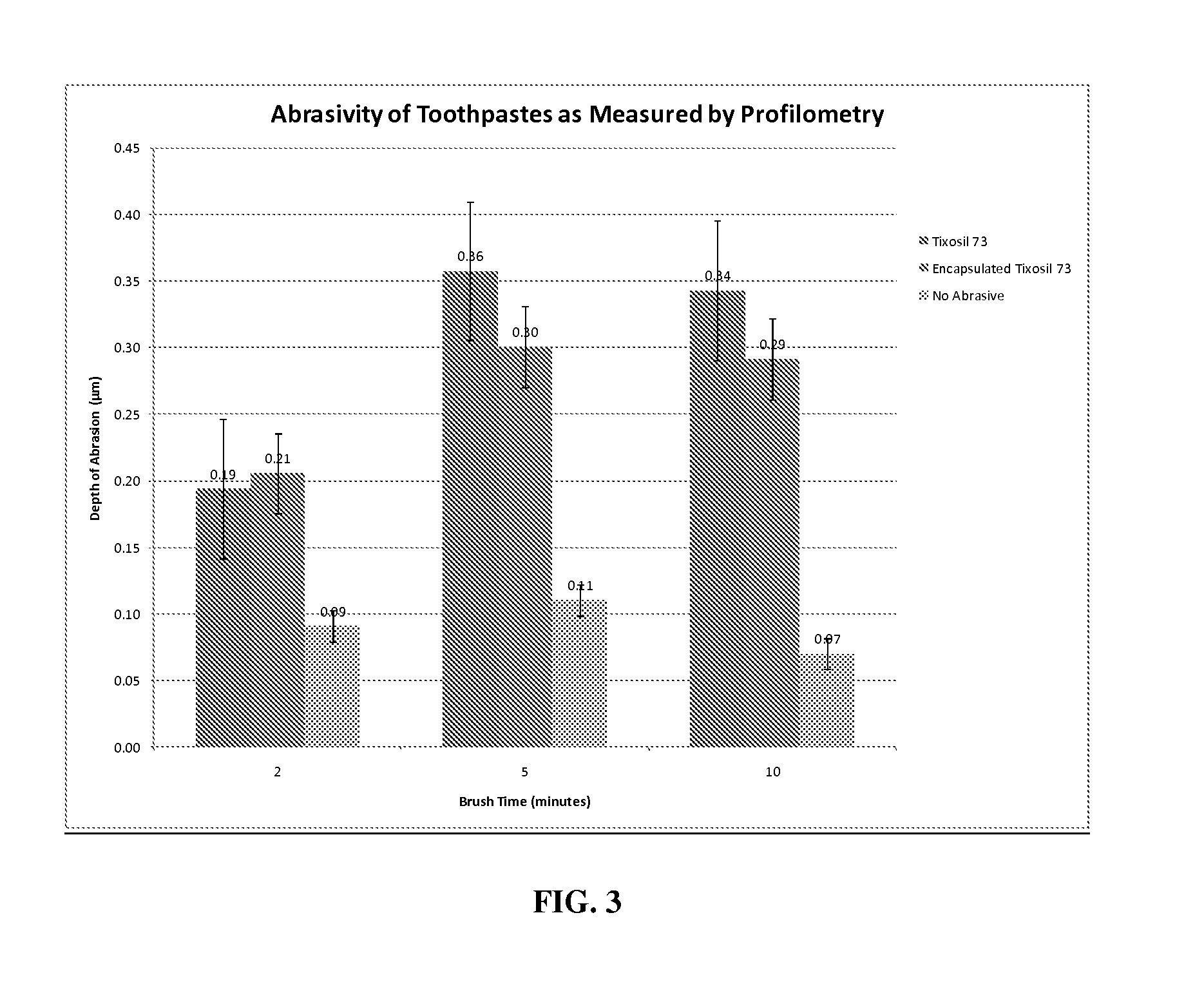

Peroxide-stabilized abrasive tooth whitening compositions, process for preparing and method of use

InactiveUS20120301522A1Maintain good propertiesComponent stabilityCosmetic preparationsToilet preparationsWater basedTooth whitening

Disclosed herein is a water-based, peroxide-stabilized, abrasive tooth whitening composition comprising: (i) a peroxide-polymer complex comprising (a) a peroxide component or a peroxide generating component; and (b) a vinyl lactam based polymer; (ii) coated abrasive particles; and one or more orally acceptable carriers. This application also provides methods for whitening the tooth surfaces by contacting with the compositions. Additionally disclosed is a process for preparing the compositions.

Owner:ISP INVESTMENTS INC

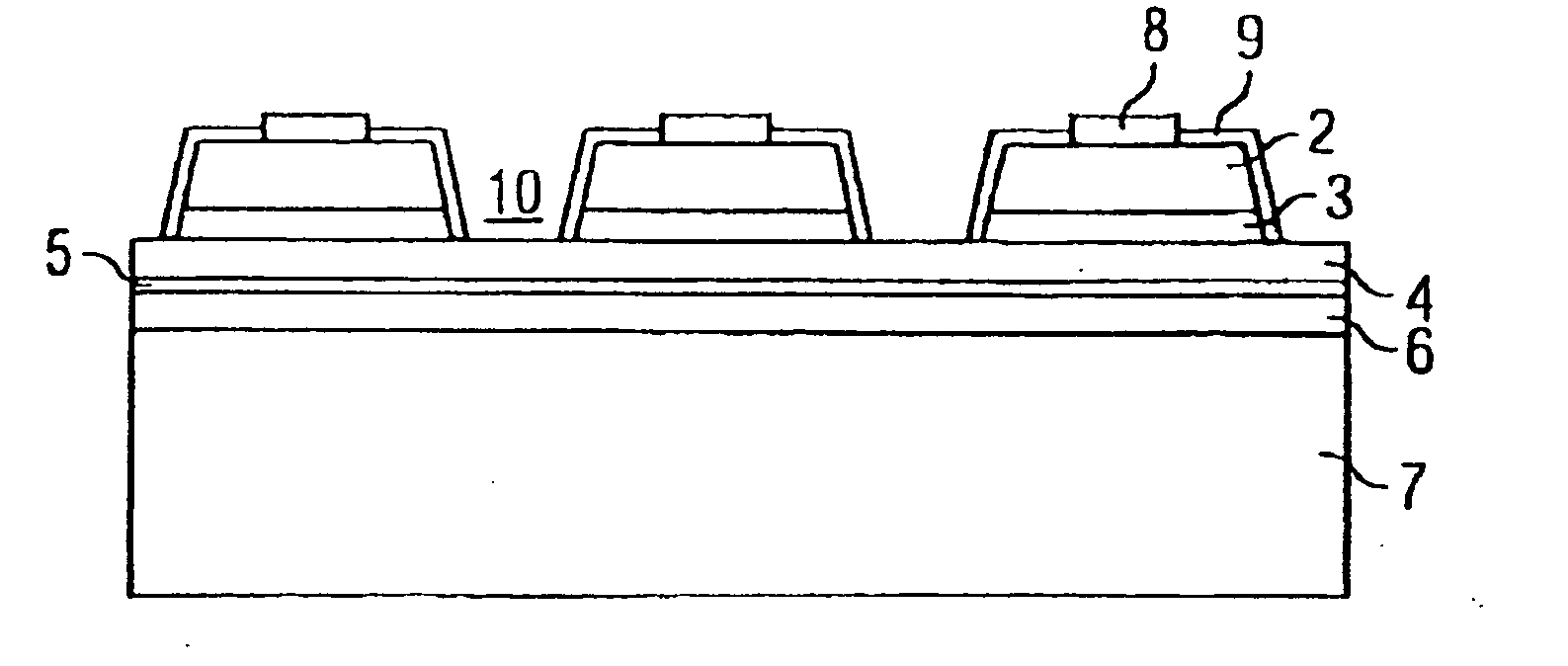

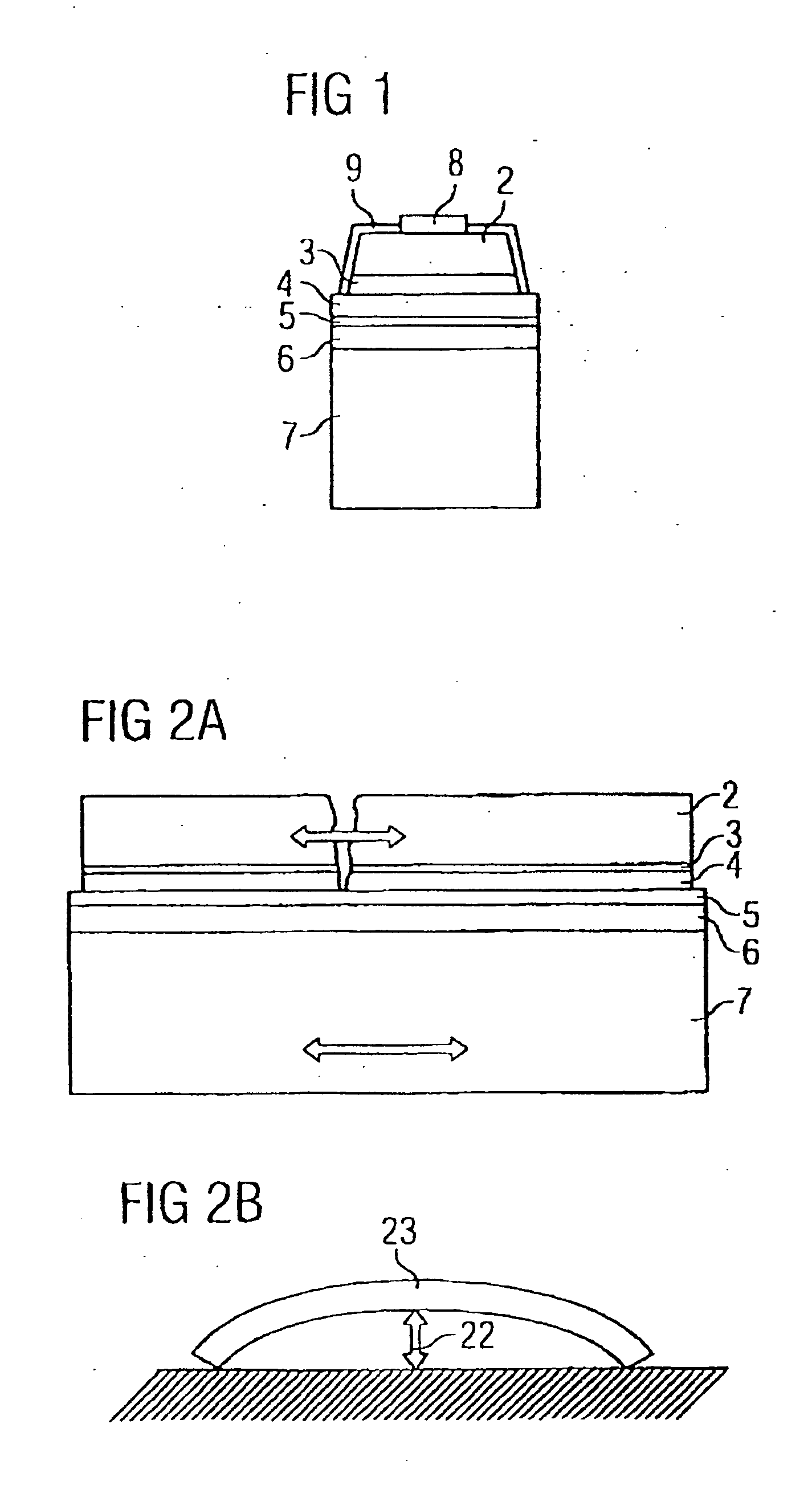

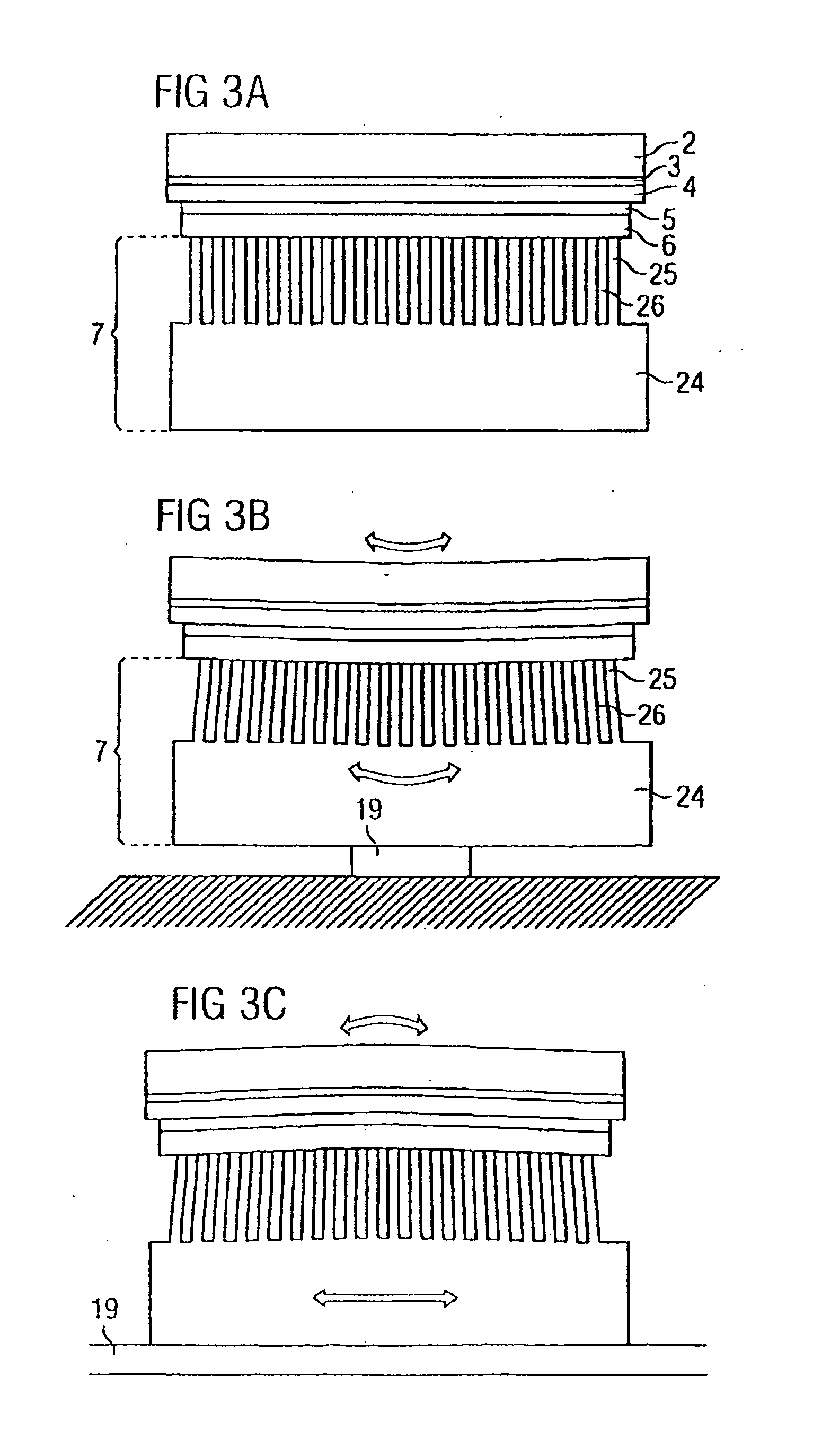

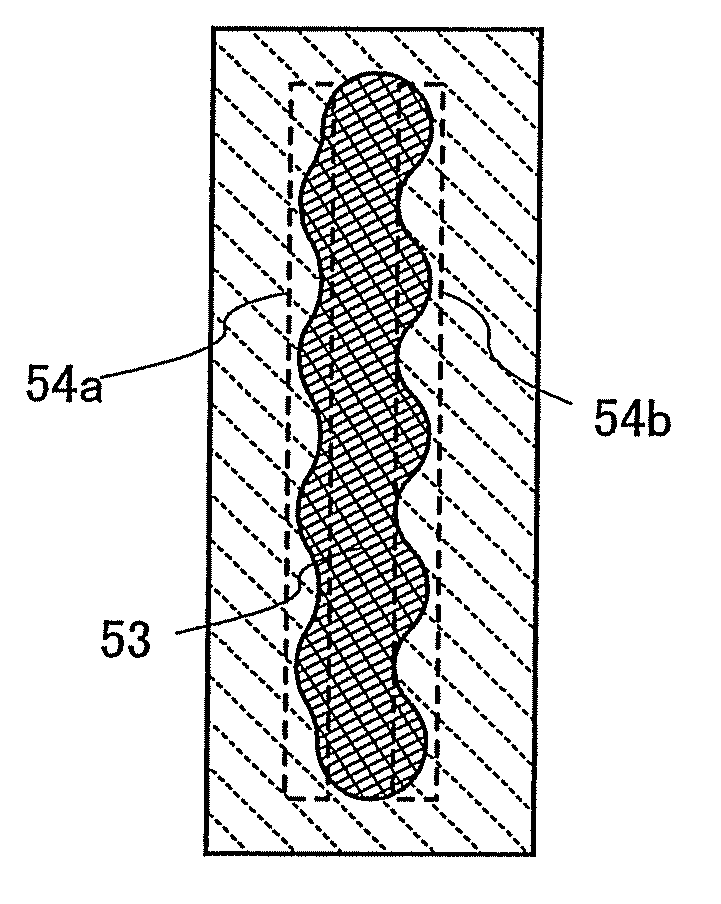

Semiconductor component

InactiveUS20070181891A1Reduce thermal stressFast preparationSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact position

A semiconductor component having a light-emitting semiconductor layer or a light-emitting semiconductor element, two contact locations and a vertically or horizontally patterned carrier substrate, and a method for producing a semiconductor component are disclosed for the purpose of reducing or compensating for the thermal stresses in the component. The thermal stresses arise as a result of temperature changes during processing and during operation and on account of the different expansion coefficients of the semiconductor and carrier substrate. The carrier substrate is patterned in such a way that the thermal stresses are reduced or compensated for sufficiently to ensure that the component does not fail.

Owner:OSRAM OLED

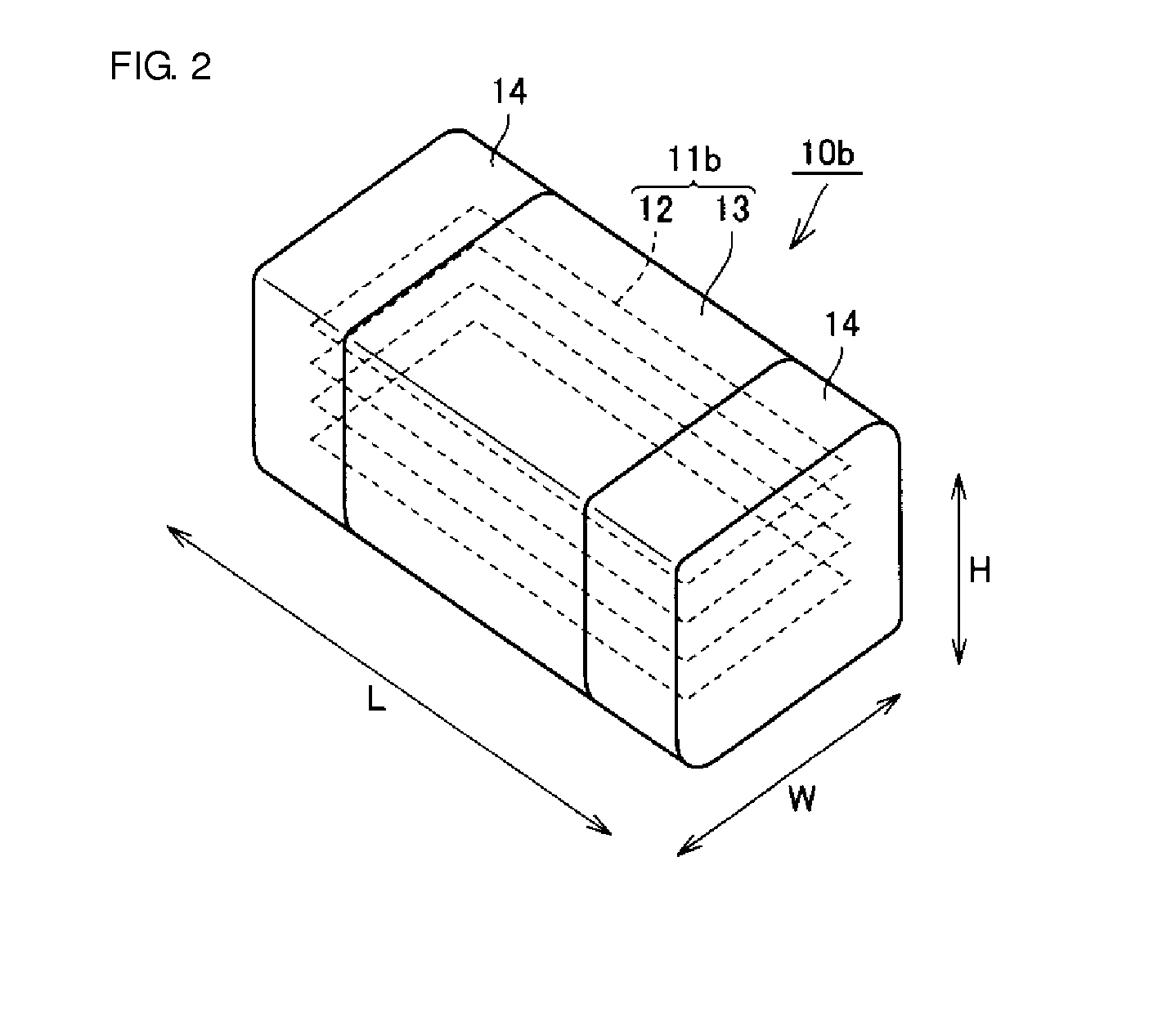

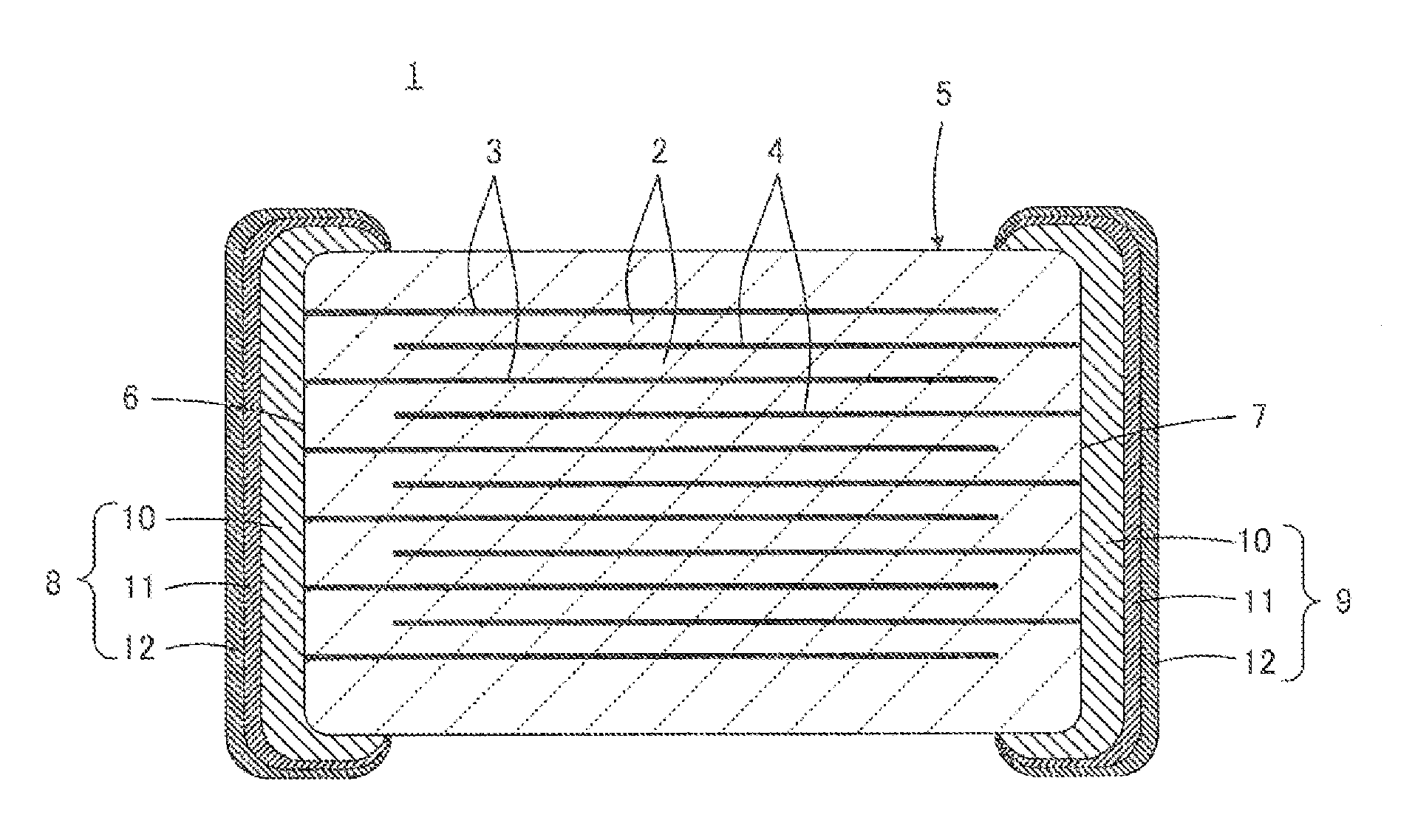

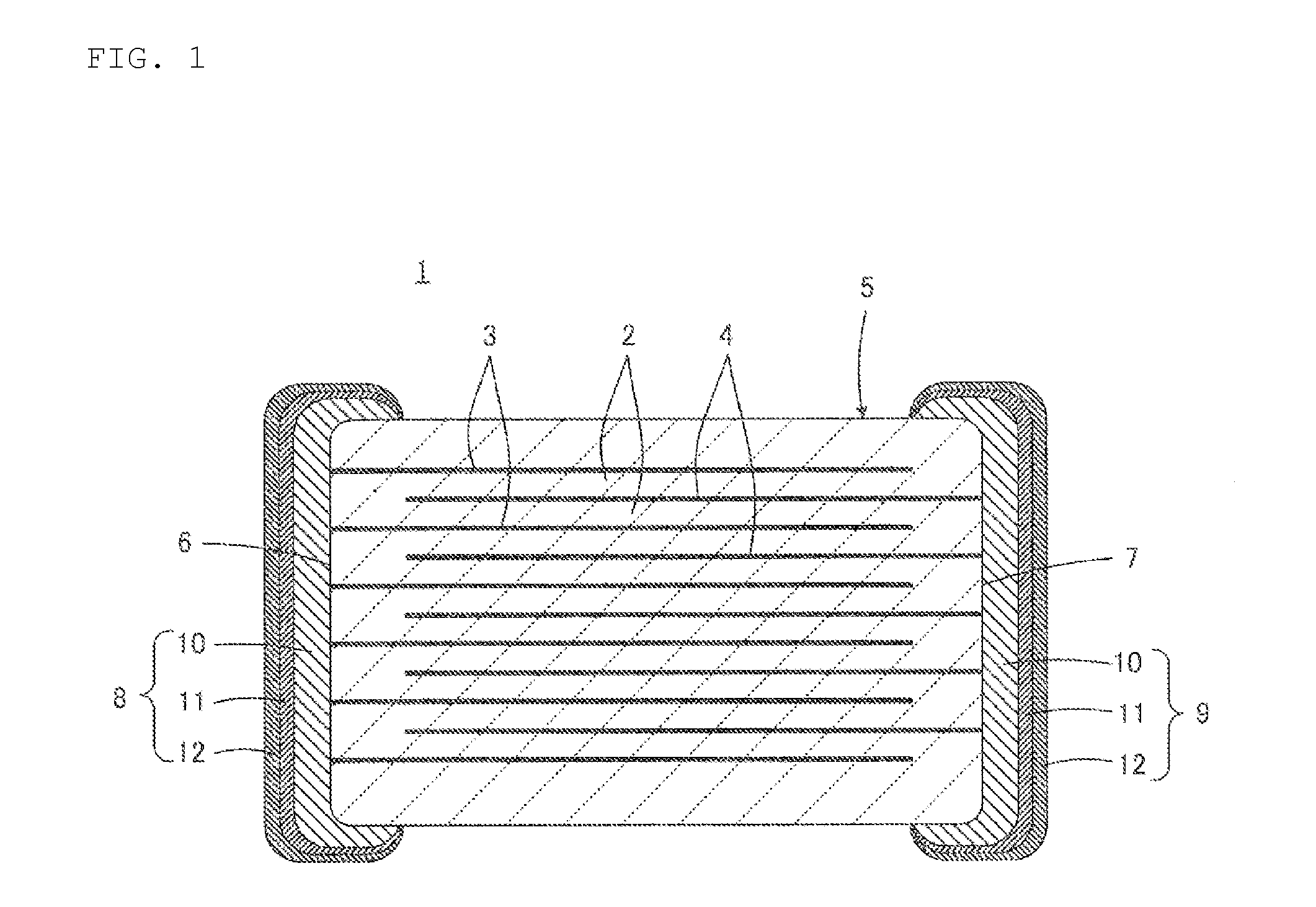

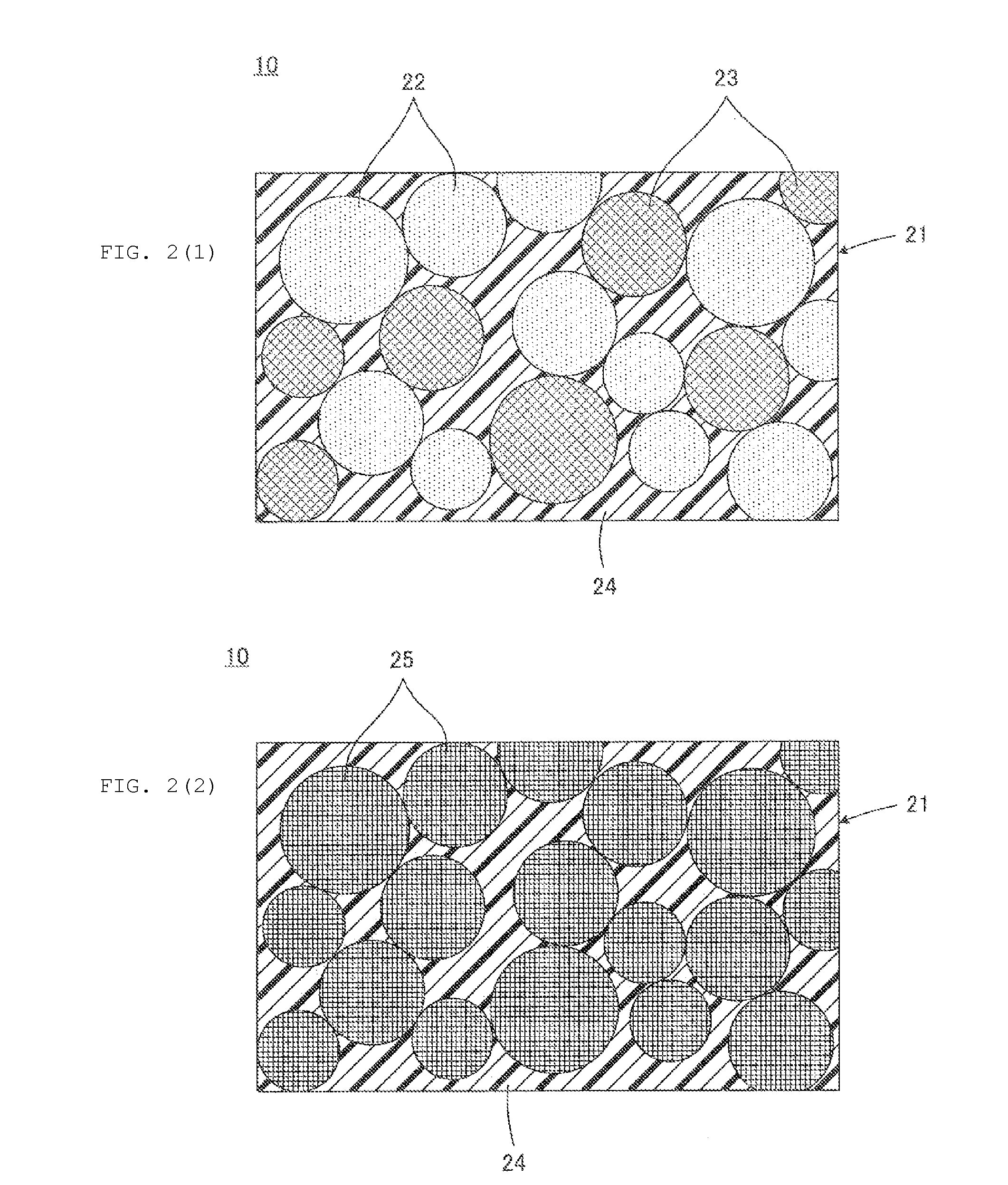

Laminated ceramic electronic component

ActiveUS20150279566A1Satisfactory bondabilityEnsure electrical stabilityFixed capacitor electrodesFixed capacitor dielectricElectrical connectionElectrode Contact

A laminated ceramic electronic component that includes a laminated body formed by laminating a ceramic layer and an internal electrode, and forming an external electrode on an outer surface of the laminated body so as to be electrically connected to the internal electrode. The external electrode includes a conducting layer that is in contact with the internal electrode, and the internal electrode contains Ni. The conducting layer contains metal particles containing a Cu3Sn alloy, and a thermosetting resin. The internal electrode and the conducting layer are bonded to each other with a CuSnNi alloy phase interposed therebetween.

Owner:MURATA MFG CO LTD

Endovascular graft device and methods for attaching components thereof

InactiveUS8172892B2Facilitate accurate catheterization and deploymentReduce the possibilityStentsBlood vesselsBiomedical engineeringBlood vessel

Owner:LIFEPORT SCI

Li-ion secondary battery formation method

ActiveCN101212067AAvoid delaminationIncrease capacityFinal product manufactureSecondary cells charging/dischargingLithiumEngineering

The invention relates to a formation method of lithium iron secondary battery. The method comprises the processes: the battery is charged under the formation temperature of the lithium iron secondary battery; the charge process comprises the processes: the continuous current of a first current is used for charging to the first voltage; the continuous voltage of the first voltage is used for charging to the cutoff current; the continuous current of a second current is used for charging to the second voltage. The second voltage is higher than the first voltage and the second current is higher than the first current. As the battery is carried out the formation using the formation method of the invention, the battery has a good comprehensive electrical-chemical performance such as a higher capacity, high-temperature circulation performance and a discharge performance for big current.

Owner:SHANGHAI BYD

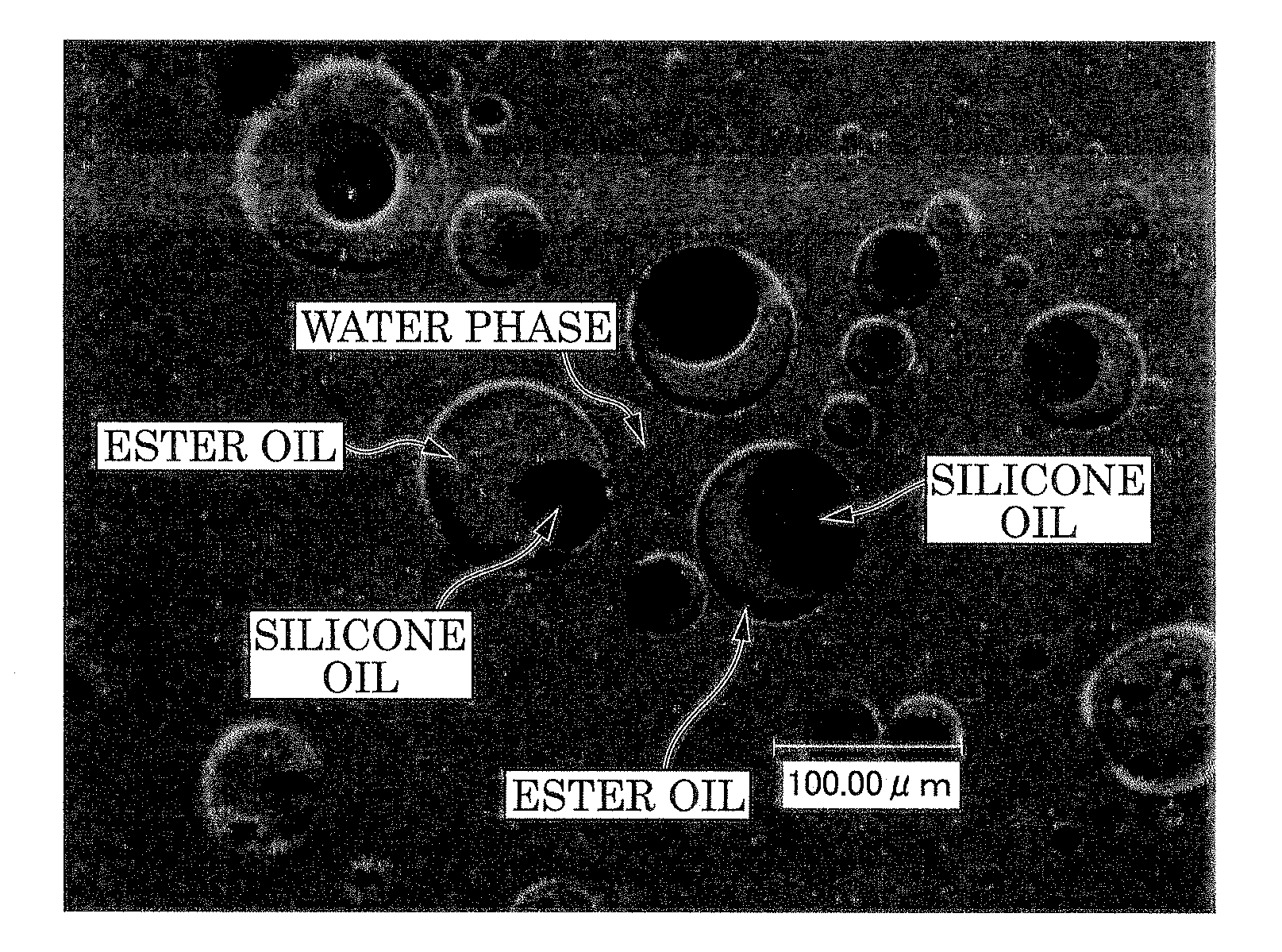

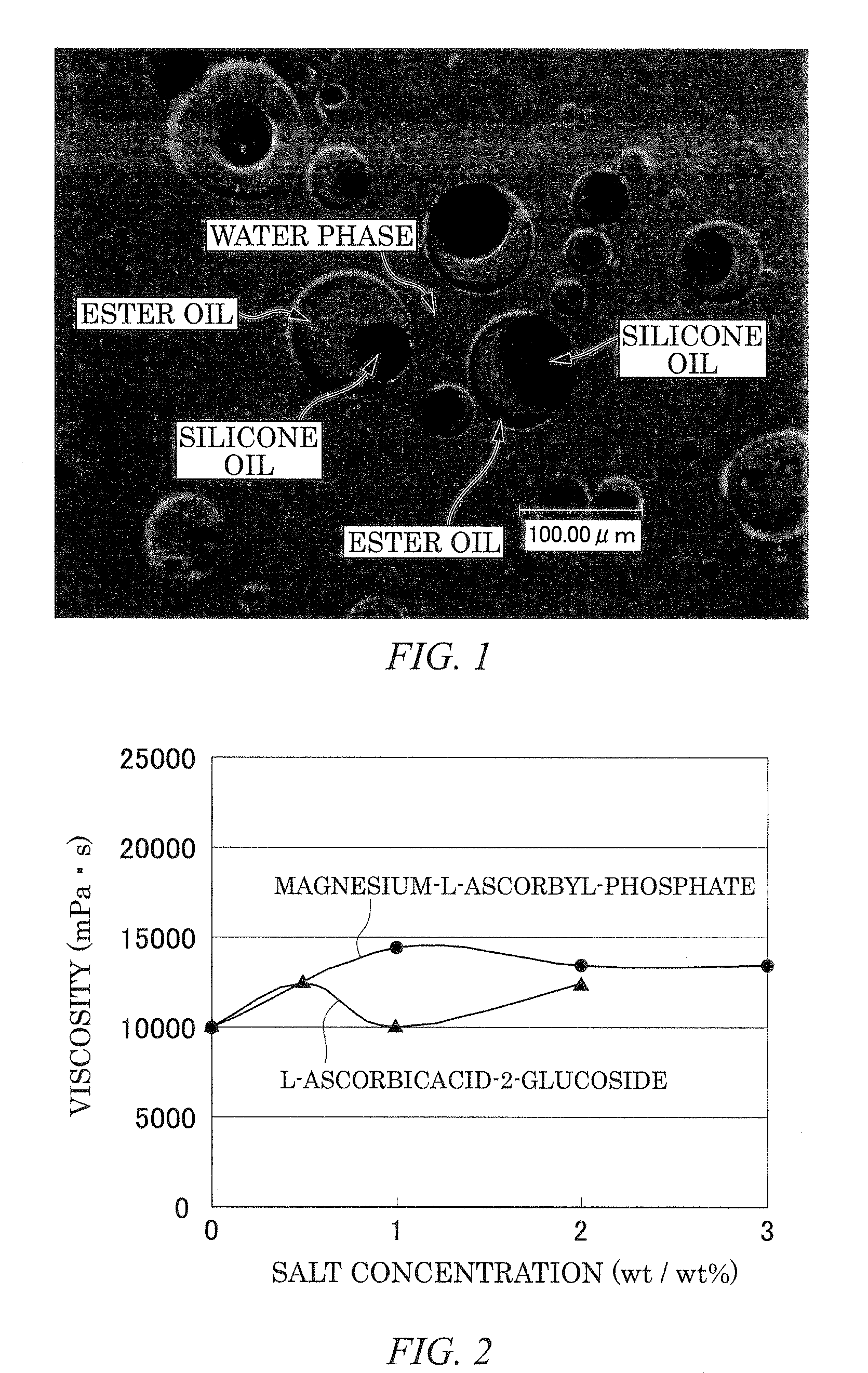

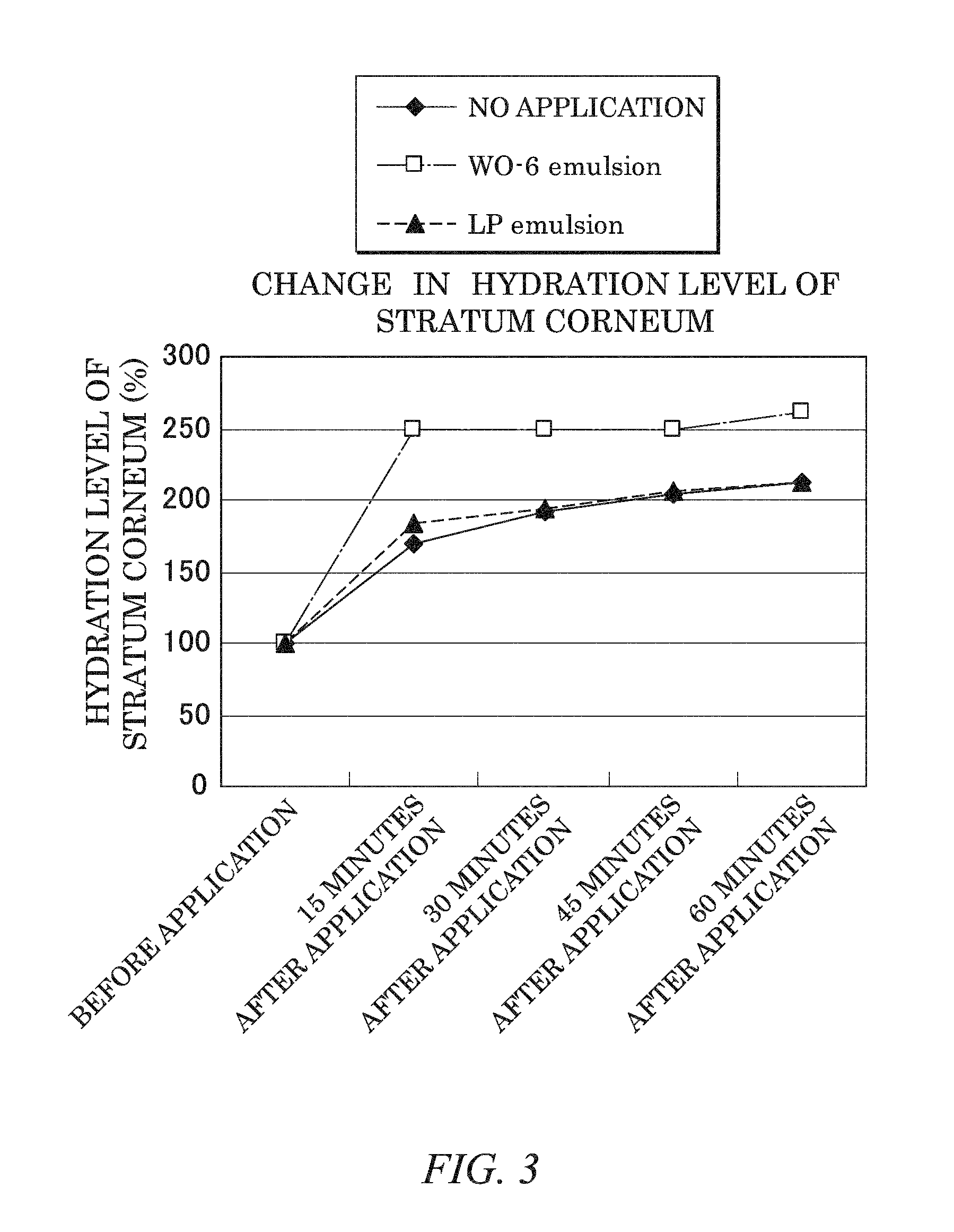

Composition for external use on skin, cosmetic, and cleaning agent

ActiveUS20130029932A1Spread skinNot impart feelingBiocideCosmetic preparationsWater soluble polymersMoisturizer

A composition for external use on skin that can be spread evenly on the skin, does not produce a liquid residue as a result of temperature change, and can suppress a feeling of sliminess of xanthan gum is provided. There are provided a composition for external use on skin containing 0.1% by mass to 10% by mass of a component (A) (a water-soluble polymer obtained by mixing agar with xanthan gum) and 30% by mass or more of a component (D) (water); the composition for external use on skin containing 0.5% by mass to 40% by mass of a divalent polyol as a component (B); the composition for external use on skin according to any one of the above compositions, which contains moisturizers as a component (C); and the composition for external use on skin according to any one of the above compositions, which contains oil as a component (E).

Owner:THE NISSHIN OILLIO GRP LTD

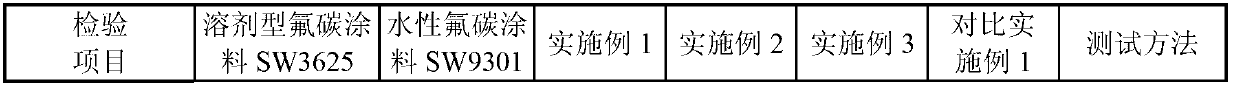

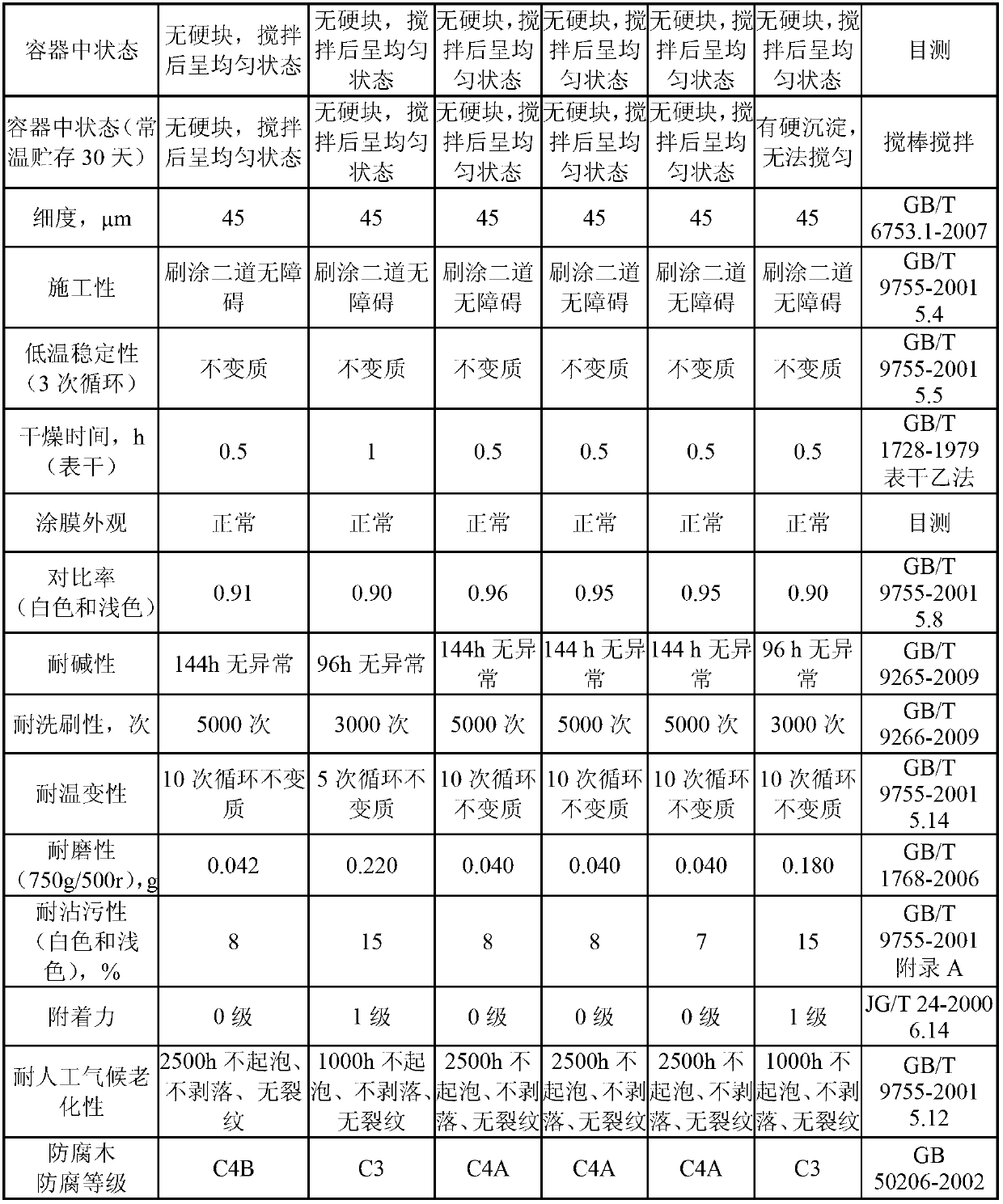

Waterborne fluorocarbon coating, and preparation method and application thereof

ActiveCN102898904AImprove wear resistanceGood alkali resistanceCoatingsMohs scale of mineral hardnessFoaming agent

The invention discloses a waterborne fluorocarbon coating, and a preparation method and application thereof. A formula for raw materials of the waterborne fluorocarbon coating comprises 13.0 to 48.0% of a waterborne fluorocarbon emulsion, 1.0 to 3.0% of hydroxyethyl cellulose, 10.5 to 18.8% of an inorganic pigment, 18.2 to 32.2% of a filling material, 5.0 to 7.0 % of wear-resistant powder, 0.6 to 2.3% of a wetting dispersant, 0.5 to 1.0% of a multifunctional auxiliary agent, 0.1 to 0.5% of a de-foaming agent, 0.4 to 4.0% of a bactericide, 0.1 to 3.2% of a thickening agent, 0.6 to 3.0% of a film forming auxiliary agent, 1.0 to 4.2% of an anti-freezing agent and 14.0 to 20.0% of water, wherein the pH value of the waterborne fluorocarbon coating is 8.0 to 9.5, and the Moh's hardness of the wear-resistant powder is more than 9.0. The waterborne fluorocarbon coating has no toxicity, no pollution and both functions of decoration and protection; a paint film formed by the coating has good wear resistance and weatherability and can improve anti-corrosive performance and wear resistance of a regenerated woodwork.

Owner:上海三银涂料科技股份有限公司

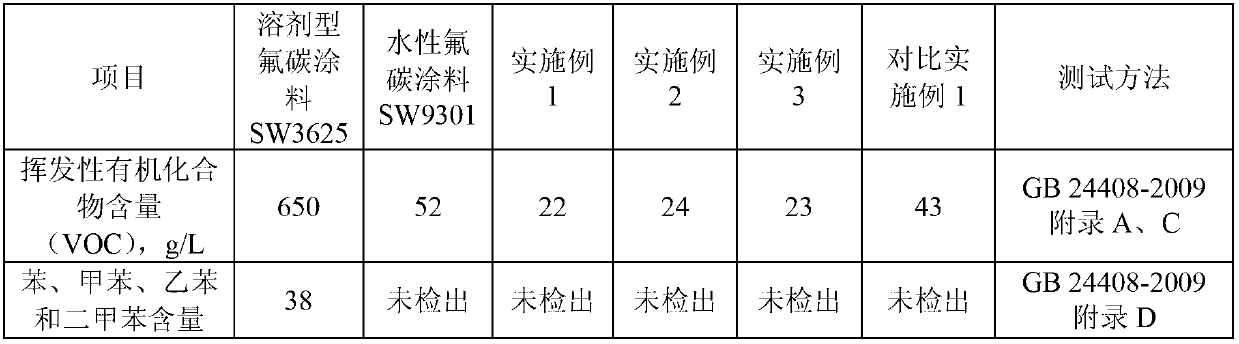

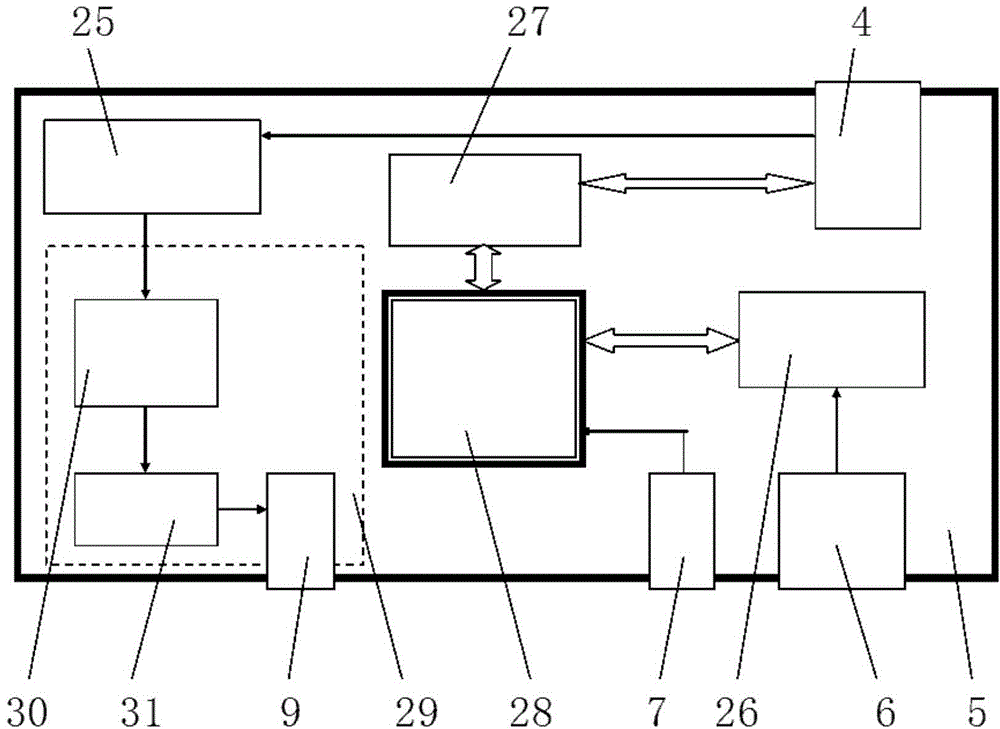

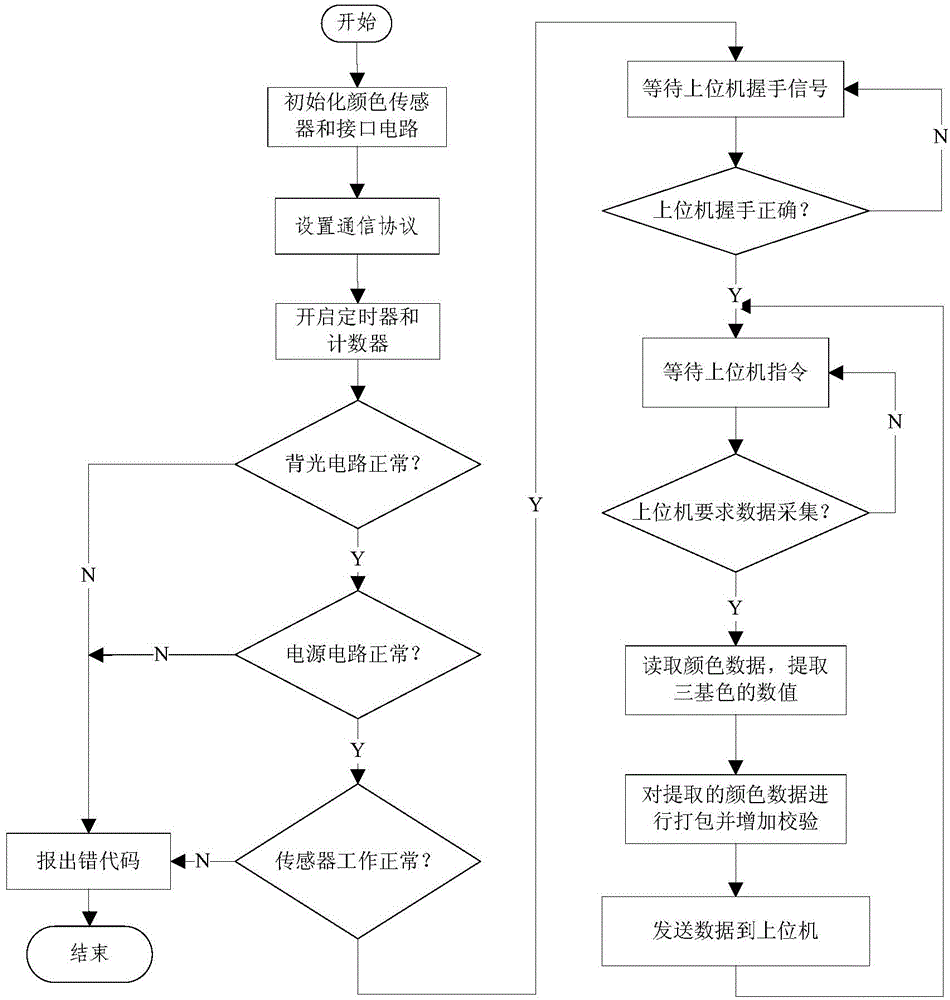

Quantitative analysis method of solution chromogenic reaction and detector thereof

ActiveCN104655572AThe result is accurateReduce accidental errorMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsData acquisitionHue

The invention relates to a quantitative analysis method of solution chromogenic reaction and a detector thereof. According to the invention, by utilizing the photopermeability characteristics of a solution generated by reaction between chromogenic substances and a chromogenic agent, and utilizing a calculation module designed according to color space concept, the three primary colors including red, green and blue which are shown by transmission light are converted into measurement points shown by performance numbers including lightness, green-red and blue-yellow, the hue and target color difference of the solution are calculated, a standard curve of hue, target color difference and concentration of chromogenic substances is fitted by a polynomial expression, and the concentration of a practical sample is calculated by an interpolation method. According to the principle, the designed detector consists of an upper computer and a lower computer which are connected by a communication data line (16), and comprises a lower computer circuit (5), a sample cell (2), an LED light source (14), an upper computer circuit (18), a color collecting system, a data acquisition and processing system, an operation system and working procedures. The detector is simple in structure, is convenient and rapid to operate, is accurate in result, and can be widely applied to the quantitative detection of the solution chromogenic reaction.

Owner:上海绿帝环保科技有限公司

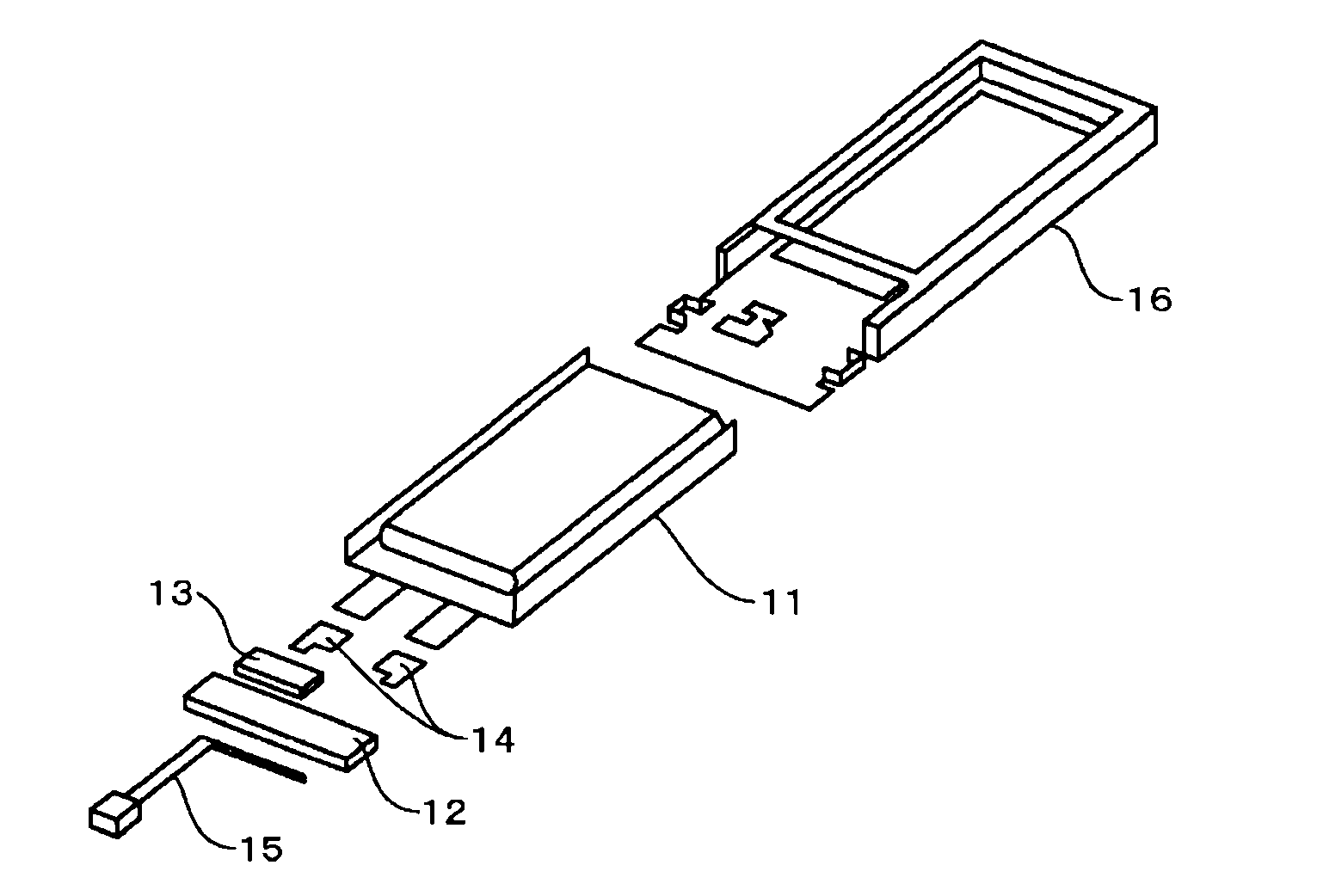

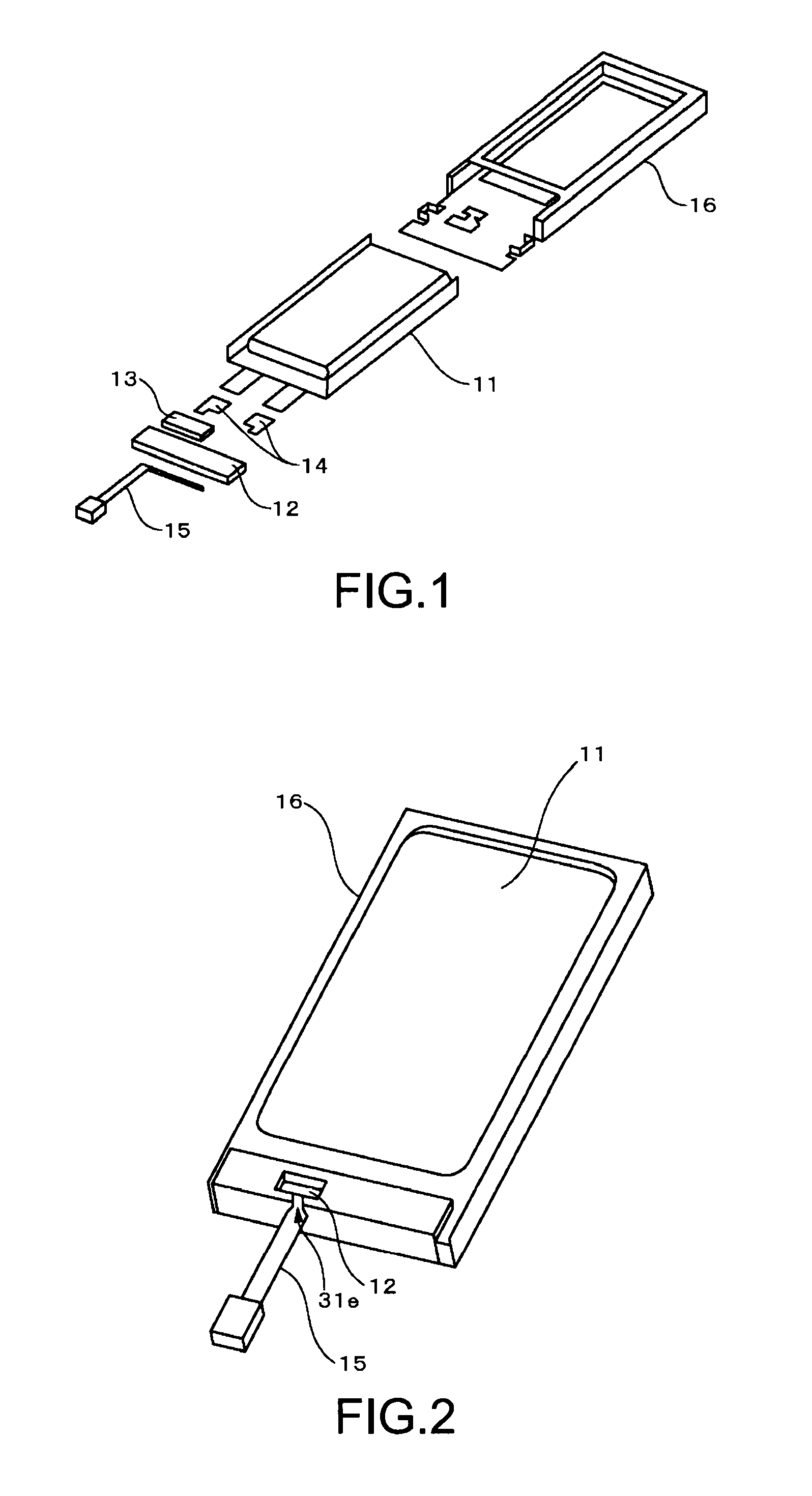

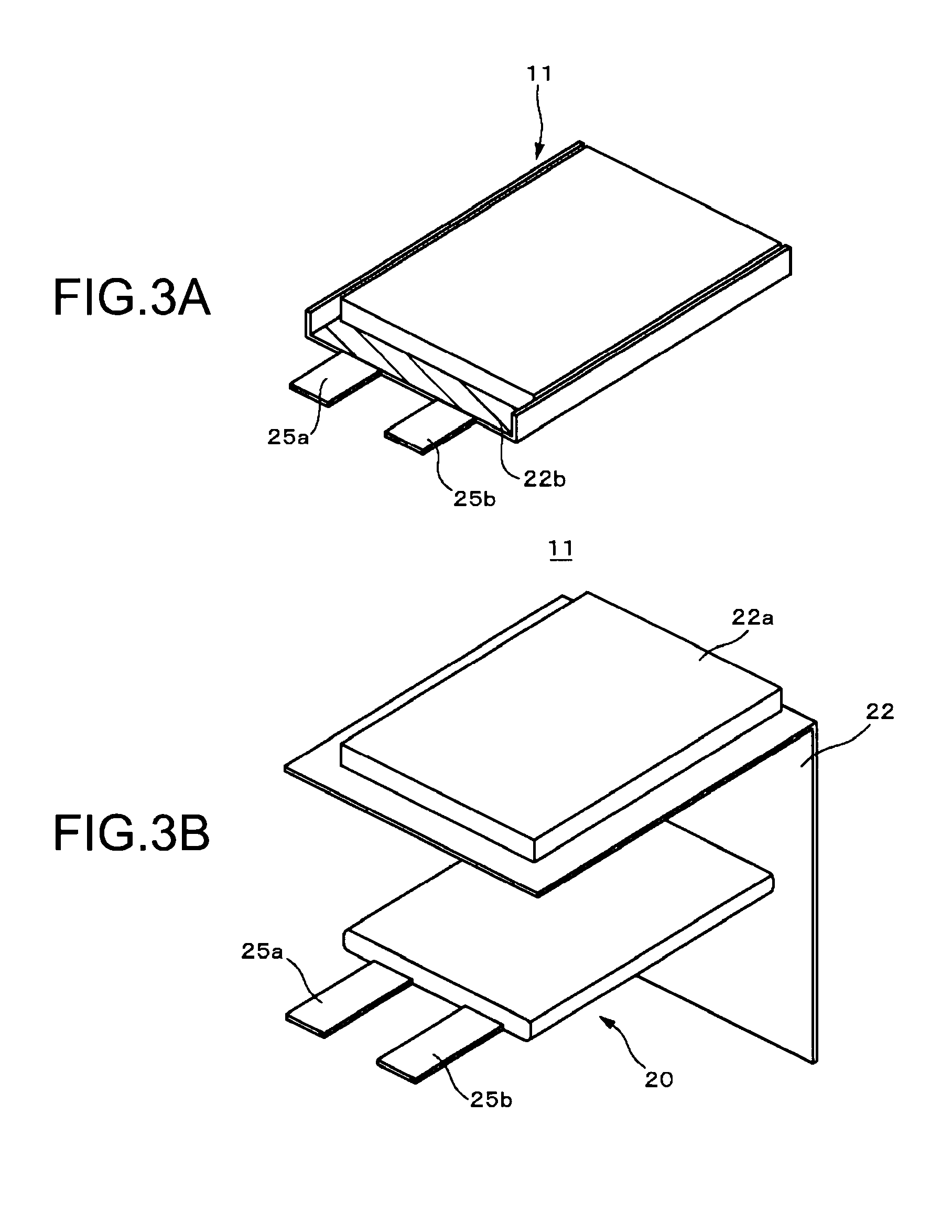

Battery pack

ActiveUS20100203374A1Reduce in quantityAvoid excessive changesCells structural combinationCell component detailsEngineeringBattery cell

A battery pack includes a battery cell, a circuit board, and a holder. The battery cell includes a battery device covered with a laminate film. The circuit board is connected to the battery cell. The holder includes a cell holder that covers the battery cell and a circuit board holder that covers the circuit board. In battery pack, the circuit board holder covering the circuit board is arranged in a space formed above a terrace portion of the battery cell covered with the cell holder.

Owner:MURATA MFG CO LTD

Hydrophobicizing additives

InactiveUS7956113B2Low protective colloid contentSlight propertyNon-fibrous pulp additionFibre treatmentMethacrylateMeth-

Hydrophobicizing additives are water-redispersible powders or aqueous dispersions containing:a) water-insoluble, film-forming base polymer(s) based on homopolymers or copolymers of one or more vinyl esters of optionally branched C1-15 alkylcarboxylic, (meth)acrylic esters of C1-15 alcohols, vinylaromatics, olefins, dienes and vinyl halides,b) one or more hydrophobic organosilicon compounds, fatty acids, or derivatives thereof, or hydrocarbon waxes, andc) one or more protective colloids,wherein the proportion of the component b) based on the total weight of the component a) is more than 30% by weight.

Owner:WACKER CHEM GMBH

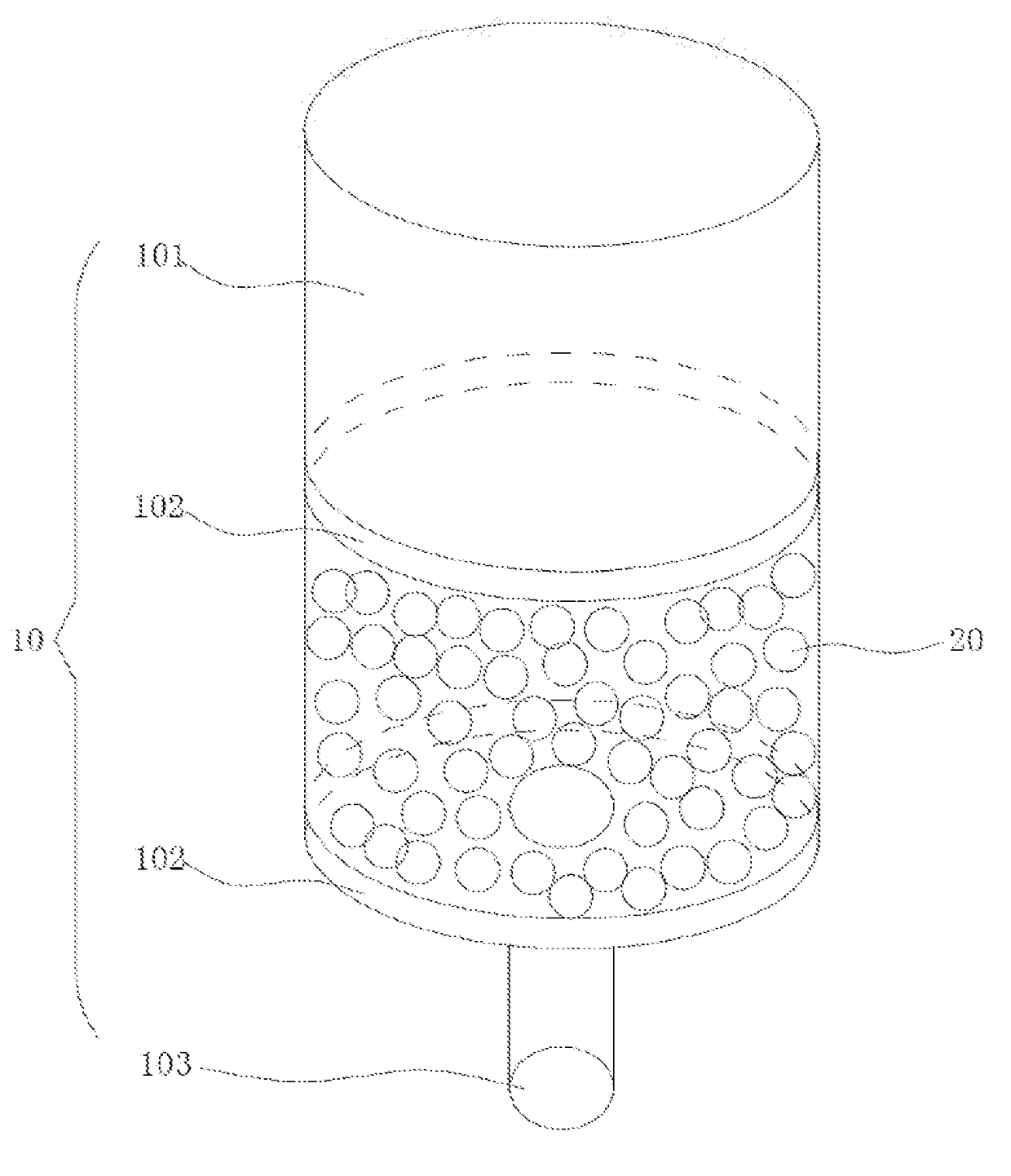

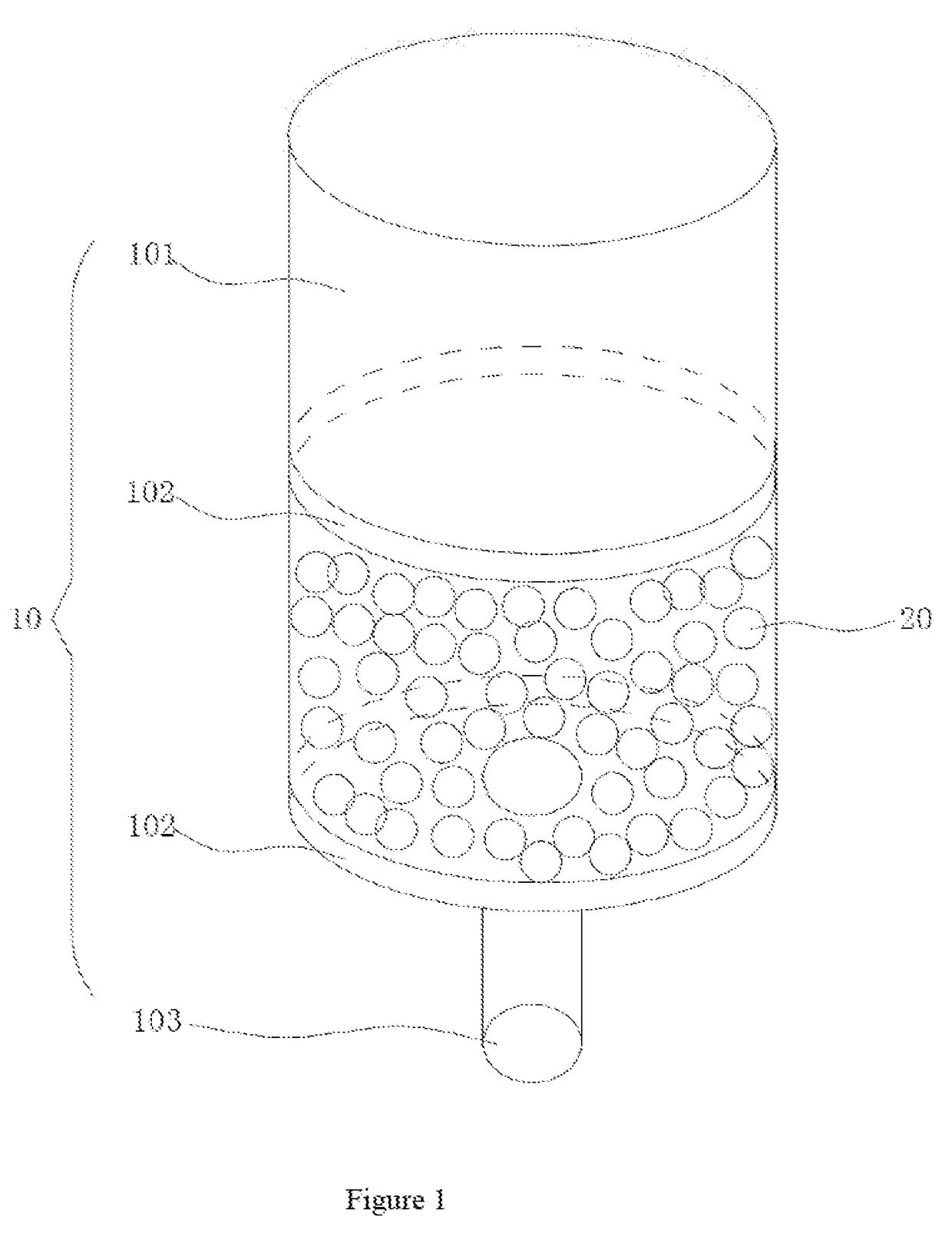

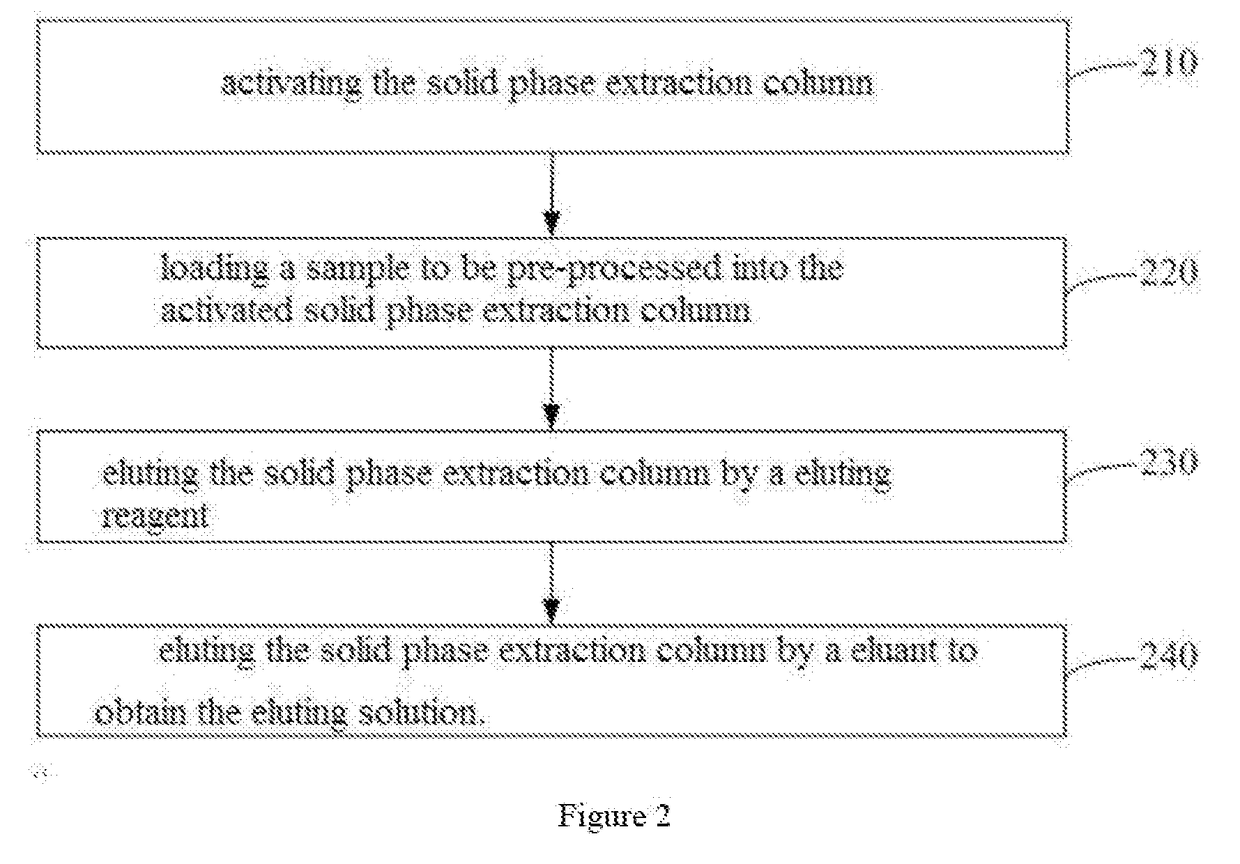

Solid phase extraction column, preparation method therefor, and pre-processing method of chemical sample based on solid phase extraction column

InactiveUS20170225149A1Different selectivityEasy to useSamplingCarbon compoundsPretreatment methodSolid phase extraction

A solid phase extraction column, preparation method therefor, and pre-processing method of chemical sample based on solid phase extraction column. The solid phase extraction column includes a separation column, and a solid phase extraction agent tilled within the separation column. The solid phase extraction agent is graphene or modified graphene. The solid phase extraction column is prepared by loading the solid phase extraction agent into the separation column, and vibrating to compact the solid phase extraction agent. The solid phase extraction column is used to pre-process a chemical sample to realize a highly effective separation effect. The problem of data distortion caused by being unable for a target component to be detected in a subsequent detection or being unable to detect a real value, is avoided.

Owner:SHENZHEN CANTONNET ENERGY SERVICES CO LTD

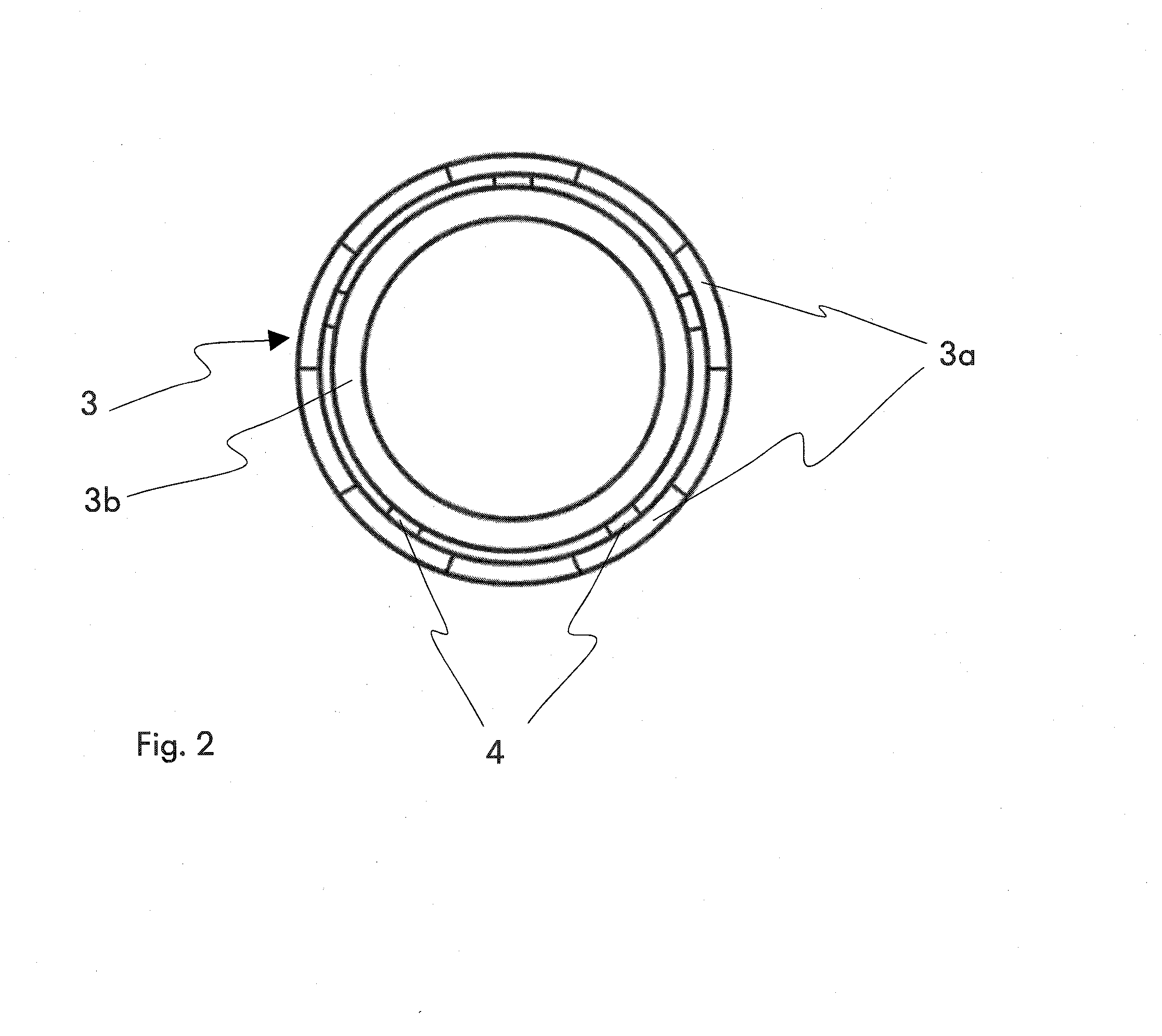

Arrangement on a component of a motor vehicle

ActiveUS20140347962A1Component stabilityMaterial consumptionSeismic signal receiversSound producing devicesEngineeringSelf positioning

An arrangement on a component of a motor vehicle, having a sensor with a substantially planar end surface, a sealing ring which encloses the sensor, and a carrier element for maintaining the spacing of the sensor in the axial direction relative to the component. The sensor extends with the sealing ring into a cut-out of the component. The sensor has a surrounding sealing ring, an additional ring element which lies further to the outside in a radial direction and has at least two cut-outs which are distributed over the circumference. The elastic ring element of the sealing ring or decoupling ring seals against water which enters from outside and for correct self-positioning in the cut-out of the component. The cut-outs according in the ring element, which lies on the outside, allow water which has entered to drain.

Owner:VOLKSWAGEN AG

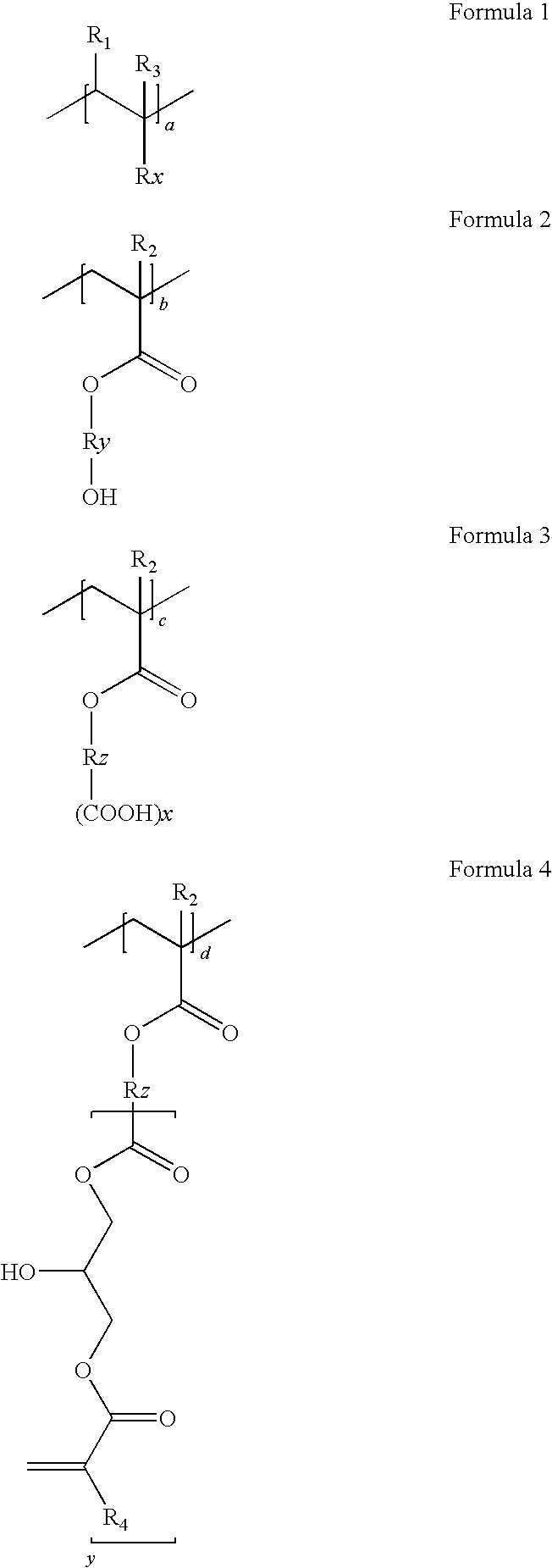

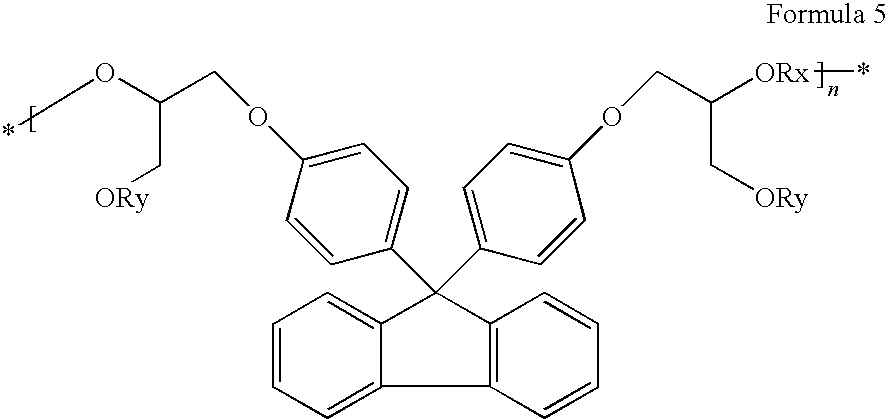

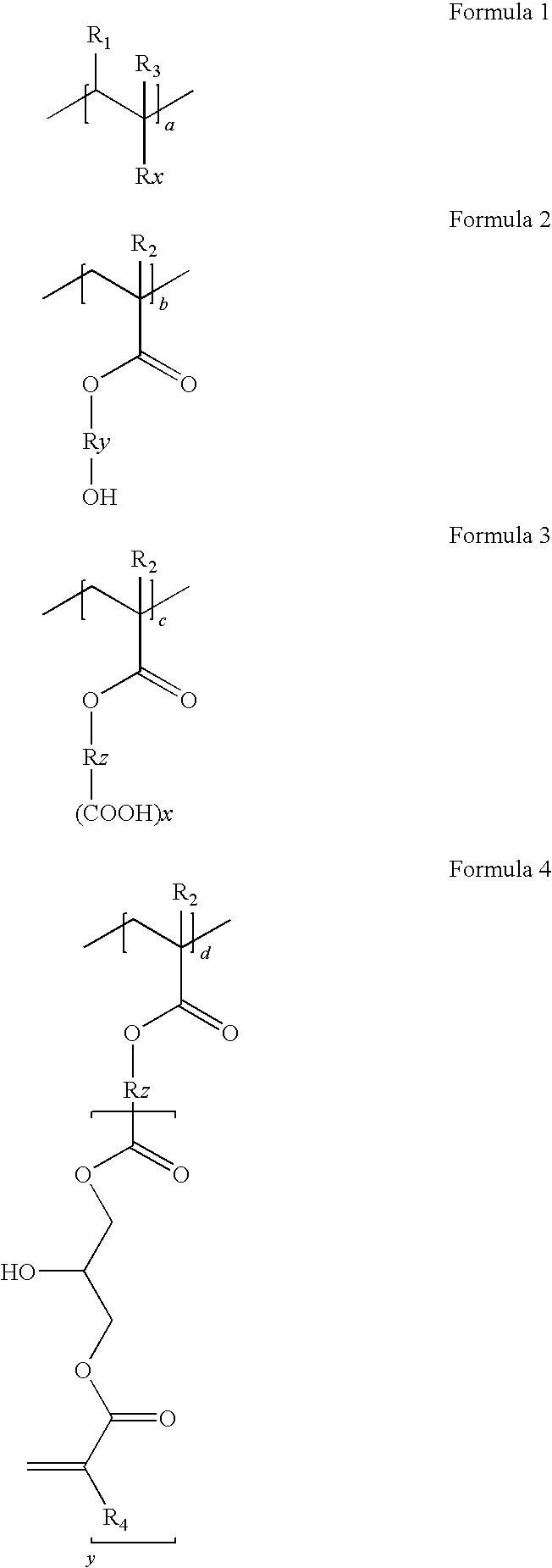

Colored dispersion, photoresist composition and black matrix

ActiveUS20100104981A1Improve adhesionWide process marginPhotosensitive materialsLayered productsDispersion stabilityResist

A colored dispersion according to the present invention comprises a resin including monomers of Formulas 1 to 4, as a binder resin.Accordingly, a photoresist composition for a black matrix of a high light shielding property, which has the dispersion stability of the colored dispersion according to the present invention, could be provided, and a black matrix of high sensibility having an uniform process characteristic while maintaining a high light-shielding property could be produced.

Owner:LG CHEM LTD

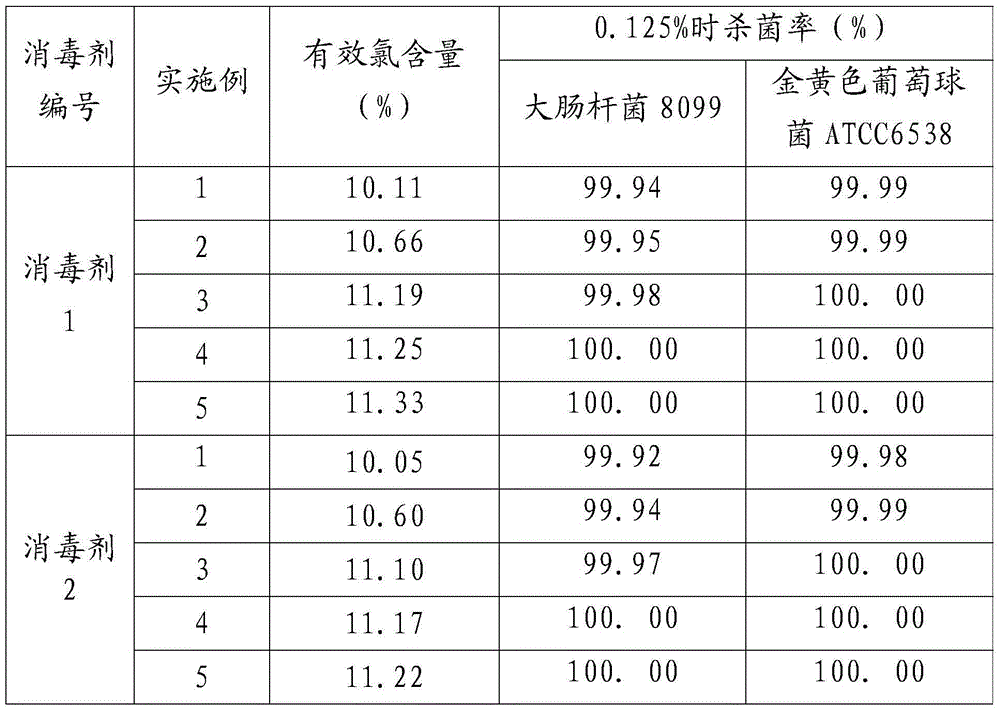

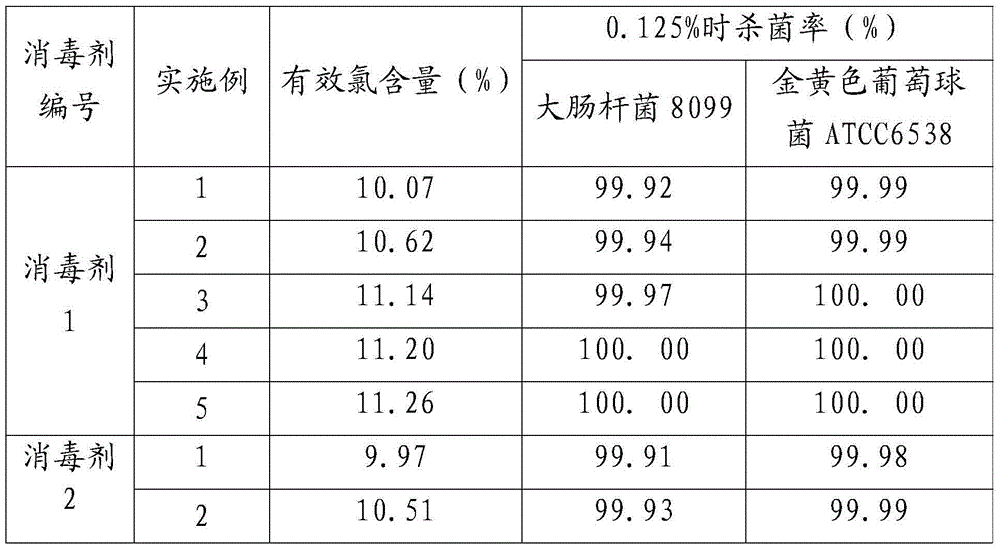

Compound potassium hydrogen persulfate powder sanitizer and preparation method thereof

ActiveCN105360162ANot easy to absorb moistureComponent stabilityBiocideDisinfectantsMoisture absorptionHydroxymethyl cellulose

The invention provides a compound potassium hydrogen persulfate powder sanitizer and a preparation method thereof. The sanitizer contains a sodium chloride wrapping substance. The sodium chloride wrapping substance is composed of a wrapped core material and a wrapping wall material, wherein the wrapping wall material is any one of high polymer slow release carriers including starch, methylcellulose, hydroxymethyl cellulose, Arabic gum and polyacrylic resin. Compared with an ordinary compound potassium hydrogen persulfate powder sanitizer with unwrapped sodium chloride, the compound potassium hydrogen persulfate powder sanitizer is not prone to moisture absorption, capable of preventing sodium chloride from making contact with an react with other components and high in stability.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

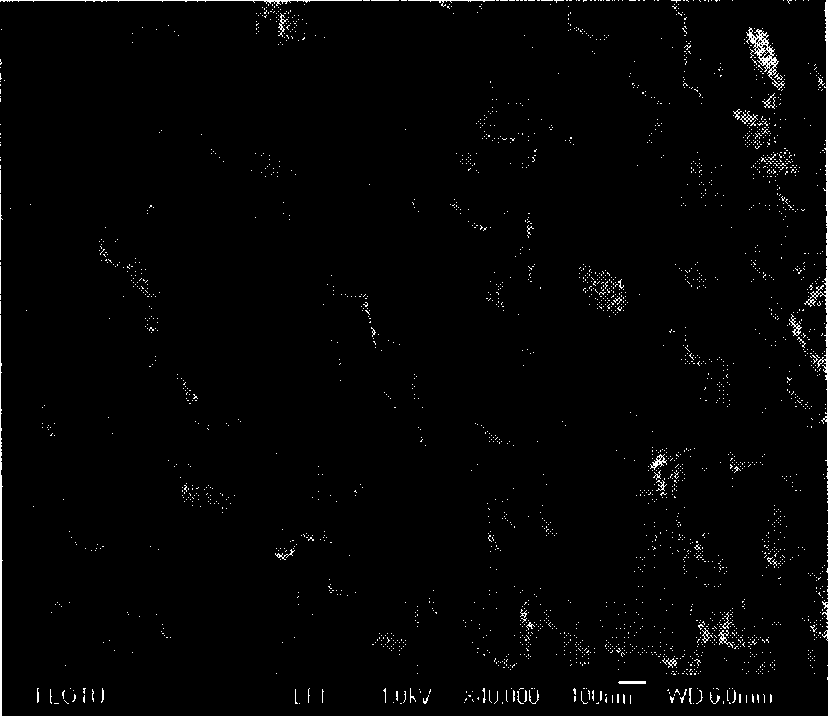

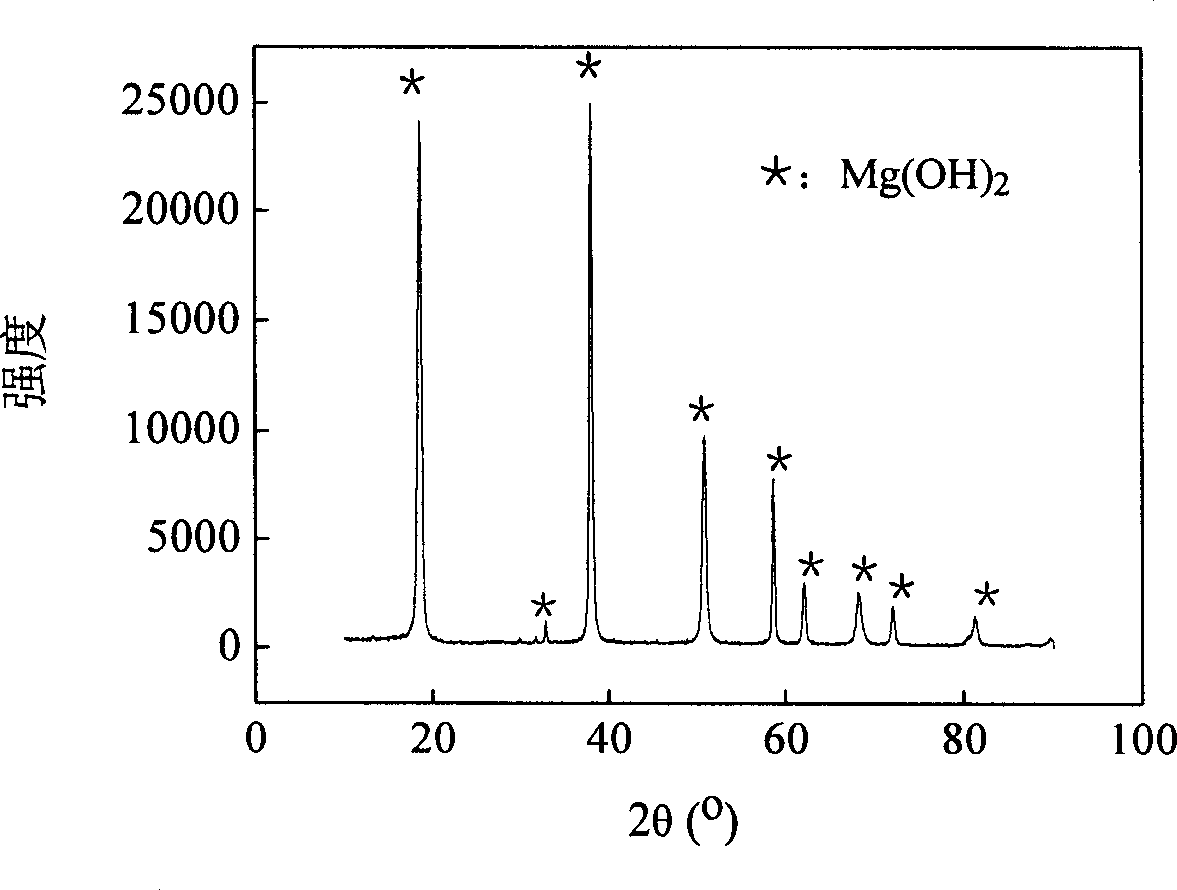

Water heat modification method for high dispersion magnesium hydroxide nanometer sheet

The invention discloses a substrate double-injection- hydrothermal modified method of high-dispersed magnesium hydroxide nanometer piece in the organic chemical technique domain, which is characterized by the following: adapting inorganic magnesium salt as raw material and inorganic alkaline as precipitant and inorganic chlorine salt as substrate solution; injecting the magnesium salt and inorganic chlorine salt solution at 10-80 deg.c; disposing the atmospheric product for 1-6 hours at 100-200 deg.c; improving the product structure through chlorine salt and hydrothermal environment to produce topographic regulation and good dispersion property magnesium hydroxide nanometer piece with 10-50nm even thickness, 30-300nm even diameter and 100 -600nm birdnesting particle size. The invention makes regular topographic, even grain size and good dispersing magnesium hydroxide nanometer piece, which is used in the plastic and rubber industry as high-property inorganic flame-proof brusque.

Owner:TSINGHUA UNIV

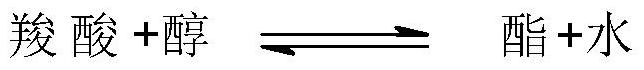

Iodine-containing disinfectant with stable component content and preparation method thereof

ActiveCN112704080AComponent stabilityStable disinfection and sterilization effectBiocideDisinfectantsPtru catalystAlcohol

The invention discloses an iodine-containing disinfectant with stable component content, which is characterized in that the iodine-containing disinfectant is prepared by reacting raw materials at 60-100 DEG C for 5-18 hours, raw materials for preparing the iodine-containing disinfectant comprise elemental iodine, iodide and any one of the following six components: (1) carboxylic acid and alcohol, (2) carboxylic acid, alcohol and water, (3) carboxylic acid, alcohol, carboxylic ester and water, (4) alcohol, carboxylic ester and water, (5) carboxylic acid, carboxylic ester and water, and (6) carboxylic ester and water, and the mass content of water in the iodine-containing disinfectant is not more than 30%. All the components of the iodine-containing disinfectant are balanced through a reversible esterification reaction under the condition that iodine is used as a catalyst. The iodine-containing disinfectant is stable in component stability, the contents of iodine, iodide and carboxylic acid of the iodine-containing disinfectant are kept stable after long-term storage (for at least two years), and the iodine-containing disinfectant has a stable disinfection and sterilization effect.

Owner:FOSHAN STANDARD BIO TECH

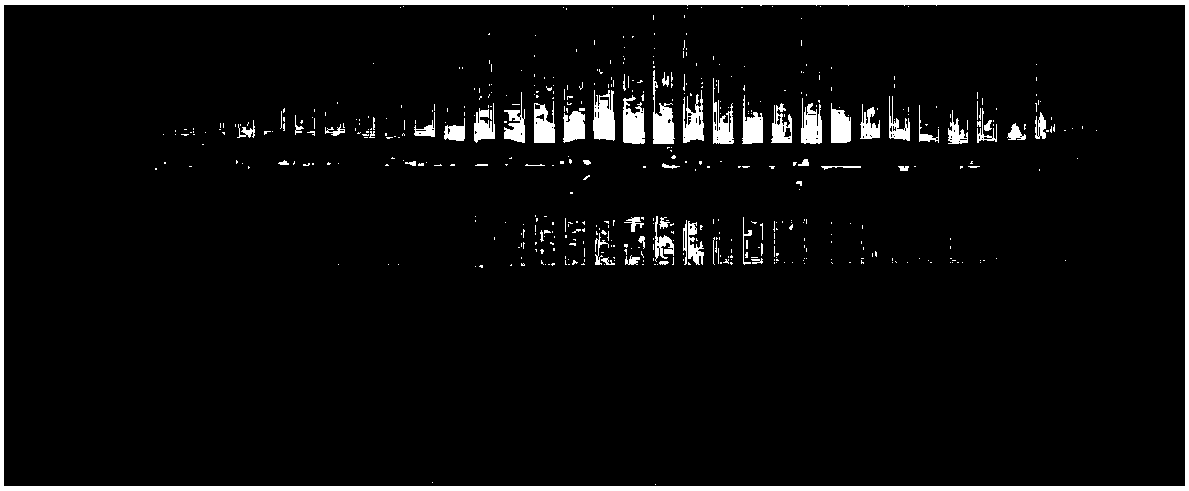

Intrinsic luminescent scintillation crystal magnesium tantalum oxide, and preparation method and use thereof

ActiveCN108221055AStable structureImprove flicker performancePolycrystalline material growthBy zone-melting liquidsHexagonal crystal systemScintillation crystals

The invention provides a scintillation crystal magnesium tantalum oxide. The chemical formula of the crystal is Mg4Ta2O9, the crystal belongs to a hexagonal crystal system and has an ilmenite structure, the scintillation light yield is 16000 photons / M eV, the decay time is 5 [mu]s, and the energy resolution is 6.2%. The invention also provides a use of the Mg4Ta2O9 as a scintillation crystal material, and a preparation method of the Mg4Ta2O9. The preparation method comprises the following steps: MgO and Ta2O5 which are used as initial powders are uniformly mixed according to a molar ratio of 4.04:1, and are processed to form a raw material rod, the raw material rod is pre-sintered to obtain a pure-phase, dense and uniform polycrystalline rod, and the colorless and transparent rod-shaped crystal having a size of phi 4 mm * L 62 mm grows by adopting an optical floating zone technology. The method has the advantages of stable melting zone, simplicity in operation, effectiveness in inhibition of the volatilization of MgO, and maintenance of uniform composition and stable crystal quality.

Owner:SHANGHAI INST OF TECH

Normal-temperature chromium-free passivation liquid for electroplated copper and passivation technology of normal-temperature chromium-free passivation liquid

InactiveCN105839093AImprove corrosion resistanceSimple componentsMetallic material coating processesChromium freeSodium molybdate

The invention provides normal-temperature chromium-free passivation liquid for electroplated copper. The normal-temperature chromium-free passivation liquid for electroplated copper is characterized by comprising benzotriazole (BTA), citric acid, hydrogen peroxide, phosphoric acid and a metal complexing agent, wherein the metal complexing agent is one or two selected from sodium molybdate, potassium fluotitanate, palladium chloride, cobalt nitrate and cerous nitrate. The invention further provides a production technology of performing passivation treatment on the surface of an electroplated copper substrate at normal temperature by using the environmentally friendly chromium-free passivation liquid. Based on an existing passivation production technology, the production technology is combined to the chromium-free passivation liquid provided by the invention to obtain a stable passivation system. A film formed on the surface of an electroplated copper workpiece treated by the passivation liquid is uniform and compact, and the anti-corrosion time is long.

Owner:山西腾源电力工程有限公司

Method for producing humic-acid coal balls

This invention relates to one kind of humic acid coal briquette the production method, after raw coal froth screening, smashing, is ready to be used; Joins the right amount clear water in the system fluid pot, pours into including the humic acid 45-55% lignite and the density is 96% fever alkali, passes over the steam to carry on the elevation of temperature, the vapor temperature for 100-105degree C, elevates temperature for 1-1.5 hours, the full agitation, causes the acid, the alkali to carry on and the response, forms the humic acid sodium solution; After will crush qualified the original dust coal after the leather belt input mixer, simultaneously even puts in the humic acid sodium solution the mixer and the original dust coal agitation is even, its area south of Yellow River dust coal and the humic acid sodium solution load ratio for 100:4, then the pile of bubbles 16-20 hours, causes the coal and the fluid infiltrates Run to adsorb fully; After piles the bubbles the Chalmette coal sends in the geosyncline, after the leather belt input powder lot machine, the elevator, the re-entry presses the ball machine, presses out fresh ball after class screen-out froth, by leather belt input helix, further after the froth lives the ball to distribute evenly in the coal spherical tank, carries on 15-18 hour elevation of temperature air seasoning to the wet bulb, after the coal briquette air seasoning, or gives the gas-producing fever after the coal briquette tank bottom department by the leather belt input coal briquette warehouse storage to use directly.

Owner:HENAN JUNHUA DEV

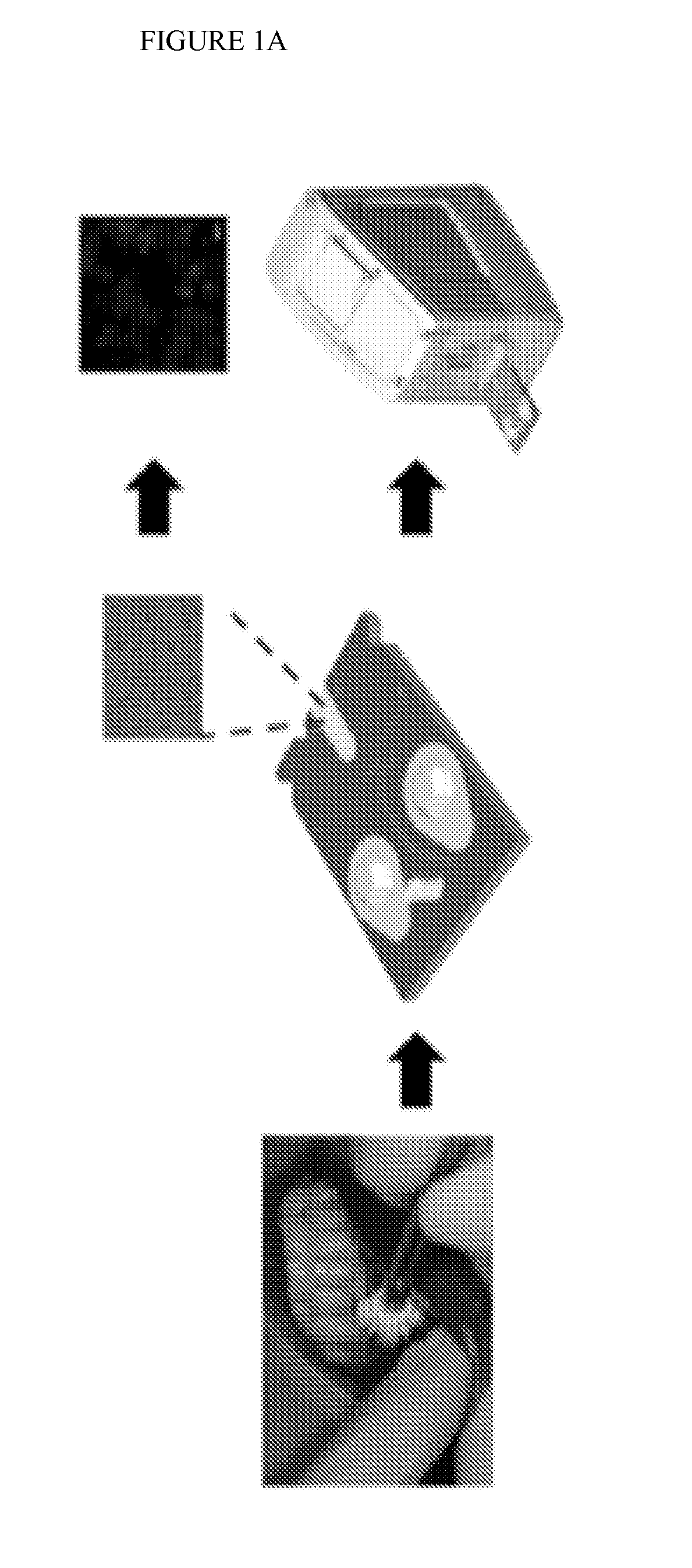

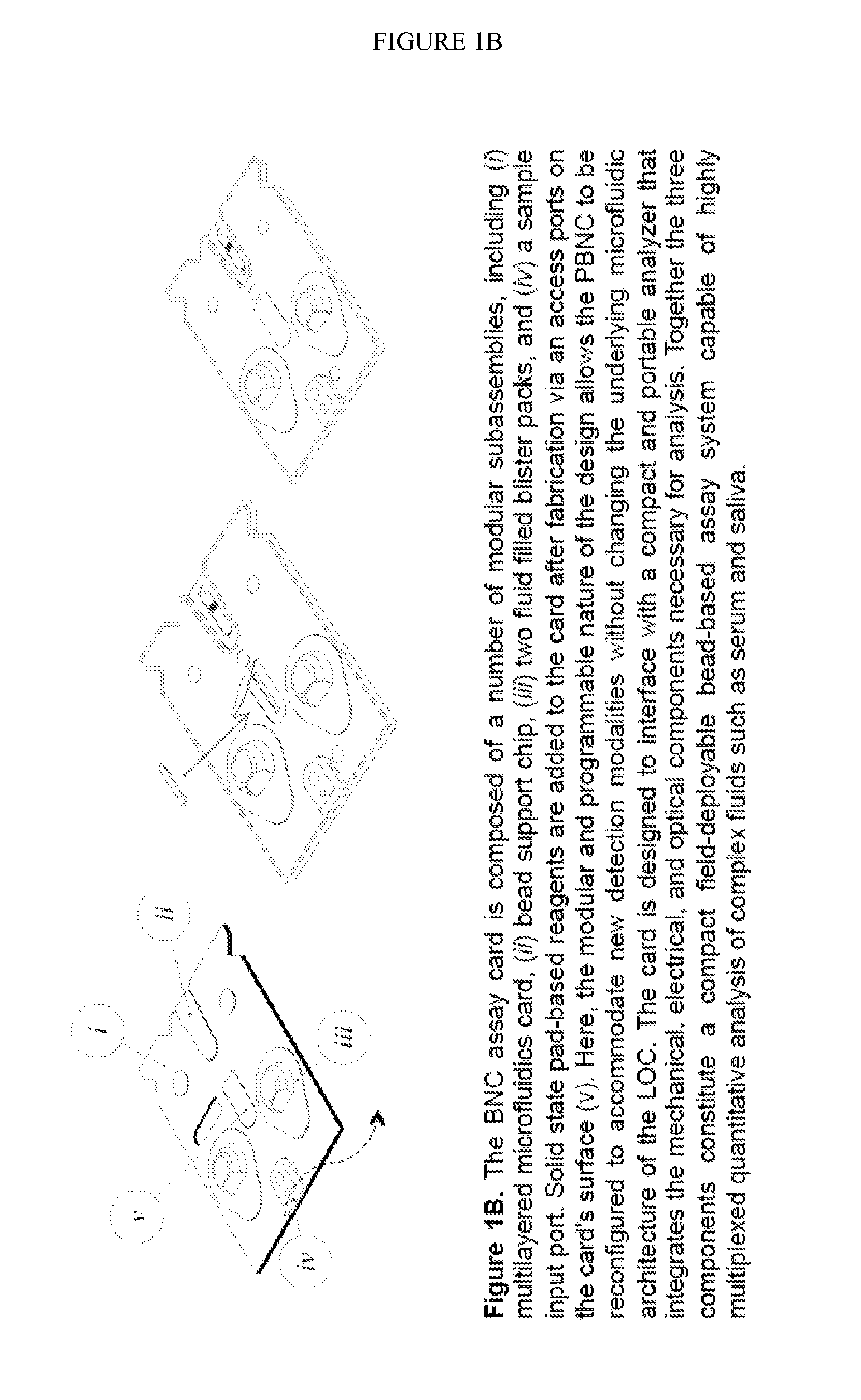

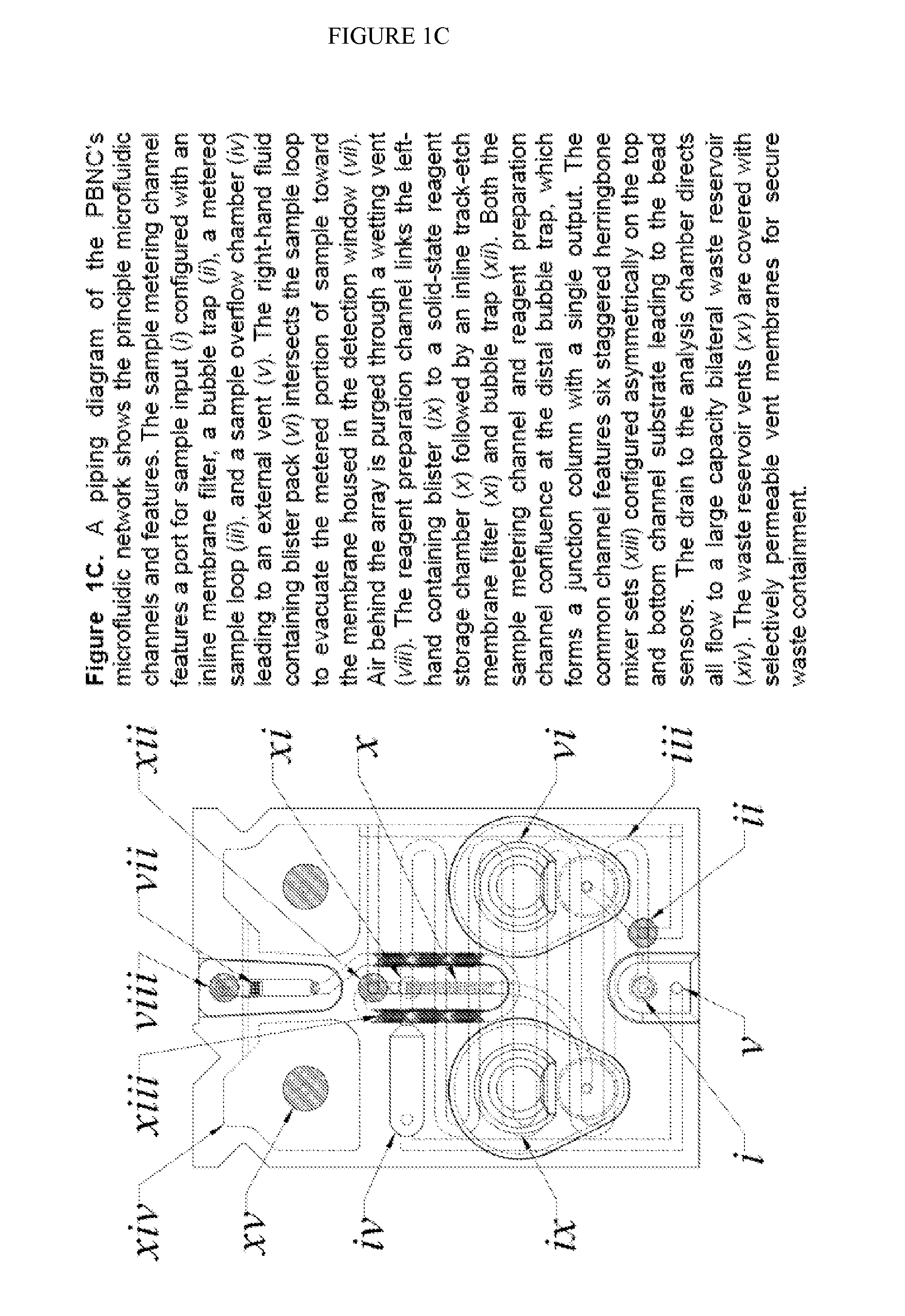

Oral cancer point of care diagnostics

ActiveUS20130295580A1Component stabilityImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsPatient riskPoint of care

A point of care diagnostic test, device and disposables for determining a patient risk for oral cancer in the same visit that a sample is collected.

Owner:RICE UNIV +2

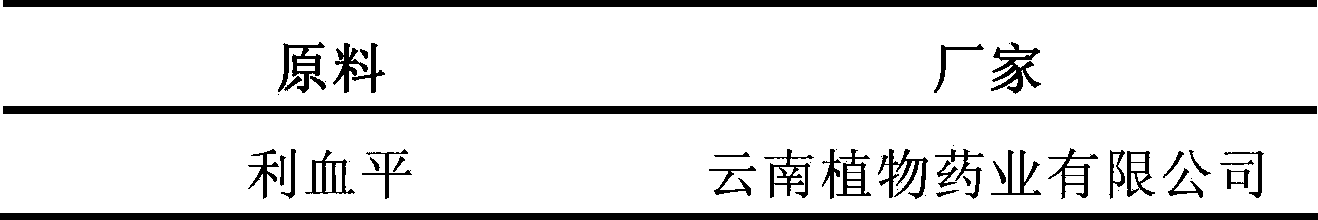

Pharmaceutical composition for treating hypertension and preparation method of pharmaceutical composition

ActiveCN103800367AComponent stabilityEasy to makePharmaceutical non-active ingredientsPill deliveryMedicinePotassium

A pharmaceutical composition for treating hypertension and a preparation method of the pharmaceutical composition are disclosed. The invention provides compound reserpine tablets, which comprise reserpine, hydrochlorothiazide, vitamin B6, vitamin B1, calcium pantothenate, magnesium trisilicate, potassium chloride, dihydralazine sulfate, promethazine hydrochloride and a pharmaceutically-acceptable carrier, wherein vitamin B1 is available in the form of coated granules.

Owner:SHANGHAI SINE PHARMA LAB

Semiconductor Device, Electronic Device, and Method of Manufacturing Semiconductor Device

ActiveUS20090224237A1High yieldLow costSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

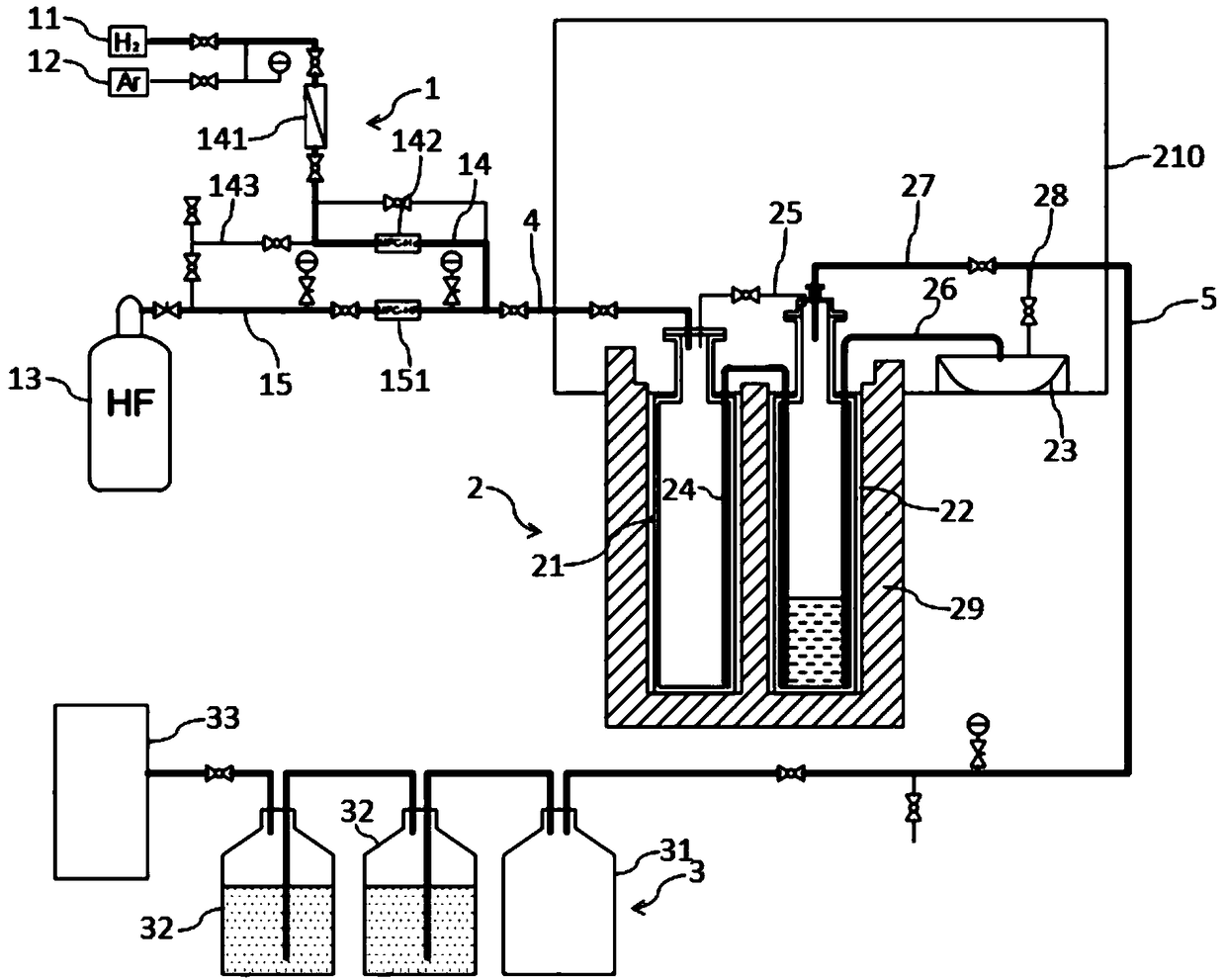

Preparation device and preparation method of fused salt reactor liquid fuel

ActiveCN109065196AComponent stabilityHigh purityNuclear energy generationReactors manufactureOxideInlet channel

The invention relates to a preparation device of a fused salt reactor liquid fuel. The preparation device of the fused salt reactor liquid fuel comprises an air circuit system, a fused salt preparation and purification system, and a tail gas absorption treatment system, wherein the air circuit system is used for controlling the flows of argon, hydrogen and hydrogen fluoride; the fused salt preparation and purification system is used for reducing oxide impurities in fused salt through the hydrogen, fluoridizing and deoxidizing the fused salt through hydrogen fluoride, and transferring liquid-state fused salt through the air pressure of the argon; the tail gas absorption treatment system is used for absorbing and retaining hydrogen fluoride tail gas and fused salt tail gas produced through the fused salt preparation and purification system; the air circuit system communicates with the fused salt preparation and purification system through an air inlet channel; the fused salt preparationand purification system communicates with the tail gas absorption treatment system. The invention also relates to a preparation method of the fused salt reactor liquid fuel. The preparation device andthe preparation method provided by the invention can be used for preparing fused salt reactor feeding base salt FLiBeZr and additive salt FLiU with stable Li, Be and Zr components, high purity and low impurity content.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com