Preparation device and preparation method of fused salt reactor liquid fuel

A technology for preparing a device and liquid fuel, applied in the nuclear fuel industry technology and chemical industry, can solve problems such as reports, and achieve the effects of satisfying oxygen tolerance, improving critical safety accidents, and improving oxygen tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

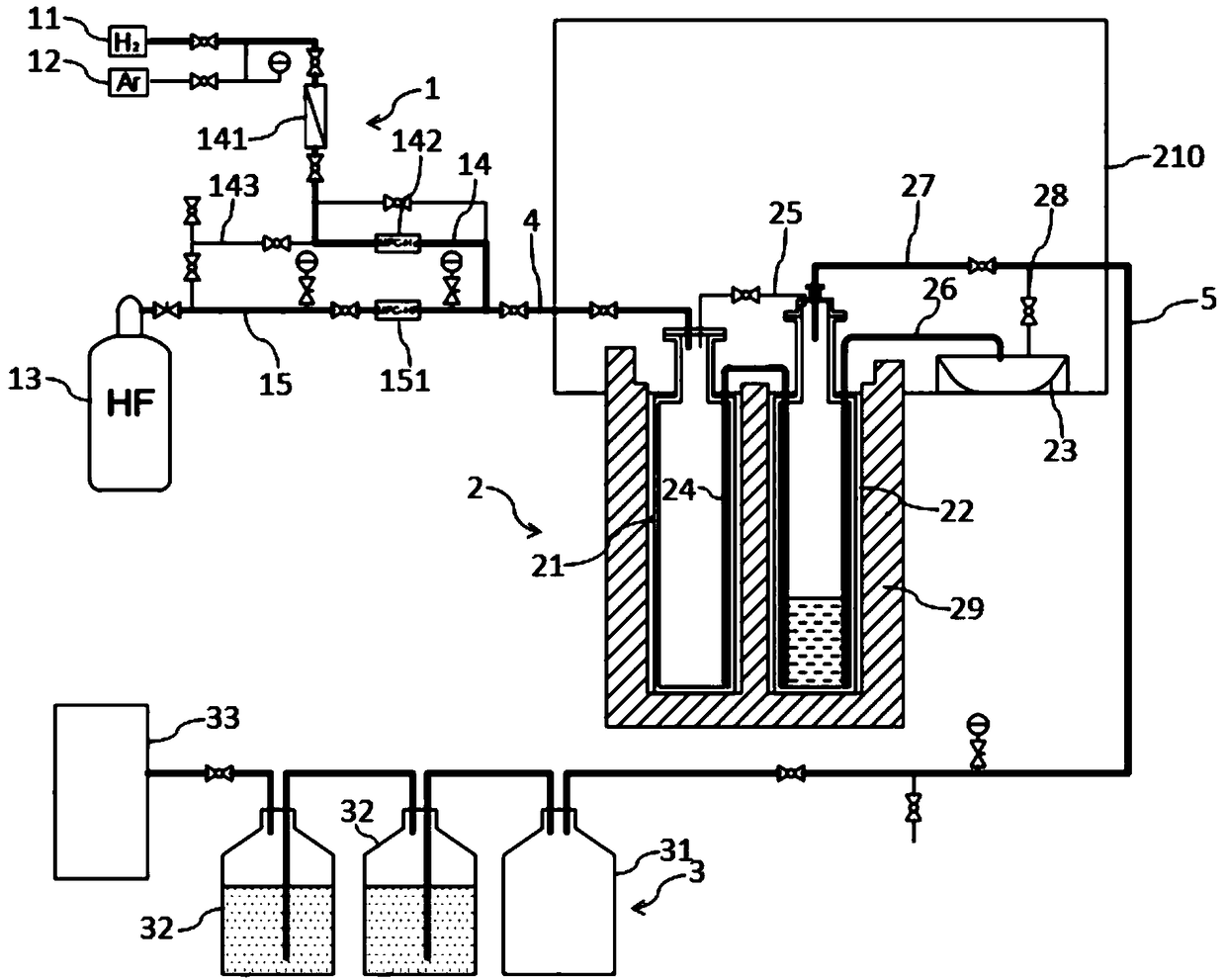

[0029] Such as figure 1 As shown, the preparation device for molten salt reactor liquid fuel according to a preferred embodiment of the present invention includes a gas circuit system 1, a molten salt preparation and purification system 2 and an exhaust gas absorption treatment system 3, wherein the gas circuit system 1 is suitable for argon, hydrogen The flow rate of the three gases and hydrogen fluoride is controlled, which communicates with the molten salt preparation and purification system 2 through the inlet passage 4; the molten salt preparation and purification system 2 transfers the liquid molten salt through the pressure of argon, and it communicates with the tail gas through the outlet passage 5 The absorption treatment system 3 is connected; the tail gas absorption treatment system 3 absorbs and retains hydrogen fluoride tail gas and beryllium-related uranium-related tail gas. The outlet passage 5 is provided with a heat tracing system to heat the gas in the outlet...

Embodiment 2

[0040] The preparation device of molten salt reactor liquid fuel is the same as that in Example 1.

[0041] The preparation method of the molten salt reactor liquid fuel firstly includes: powdery 860g lithium fluoride (LiF) and 716.55g beryllium fluoride (BeF 2 ) fully mixed in the glove box 210 and packed into the premelt tank 21; the Ar source 12 was opened to pass through the first gas pipeline 14, the air intake passage 4, the third gas pipeline 25, the fourth gas pipeline 27 and The air outlet channel 5 feeds into the premelting tank 21 with a flow rate of 150ml min -1 kg -1 The Ar of molten salt is purged; Turn on temperature regulating device 29 and premelt tank 21 and reaction tank 22 are all heated to 350 ℃ and carry out 12h insulation baking; Then by temperature regulating device 29, premelt tank 21 and reaction tank 22 are heated up to 600°C to make the LiF and BeF in the premelting tank 21 2 Complete melting to form molten salt; open the heating system of the fi...

Embodiment 3

[0046] The preparation device of molten salt reactor liquid fuel is the same as that in Example 1.

[0047] The preparation method of molten salt reactor liquid fuel firstly includes: 52.7g of powdered lithium fluoride (LiF) and 247.3g of uranium tetrafluoride (UF 4 ) fully mixed in the glove box 210 and packed into the premelt tank 21; the Ar source 12 was opened to pass through the first gas pipeline 14, the air intake passage 4, the third gas pipeline 25, the fourth gas pipeline 27 and The air outlet channel 5 feeds into the premelting tank 21 with a flow rate of 120ml min -1 kg -1 The Ar of molten salt is purged; Turn on temperature regulating device 29 and premelt tank 21 and reaction tank 22 are all heated to 350 ℃ and carry out 12h insulation baking; Then by temperature regulating device 29, premelt tank 21 and reaction tank 22 are heated up to 650°C to make the LiF and UF in the premelting tank 21 4 Complete melting to form molten salt; open the heating system of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com