Patents

Literature

1226results about How to "Volatile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for glycolide

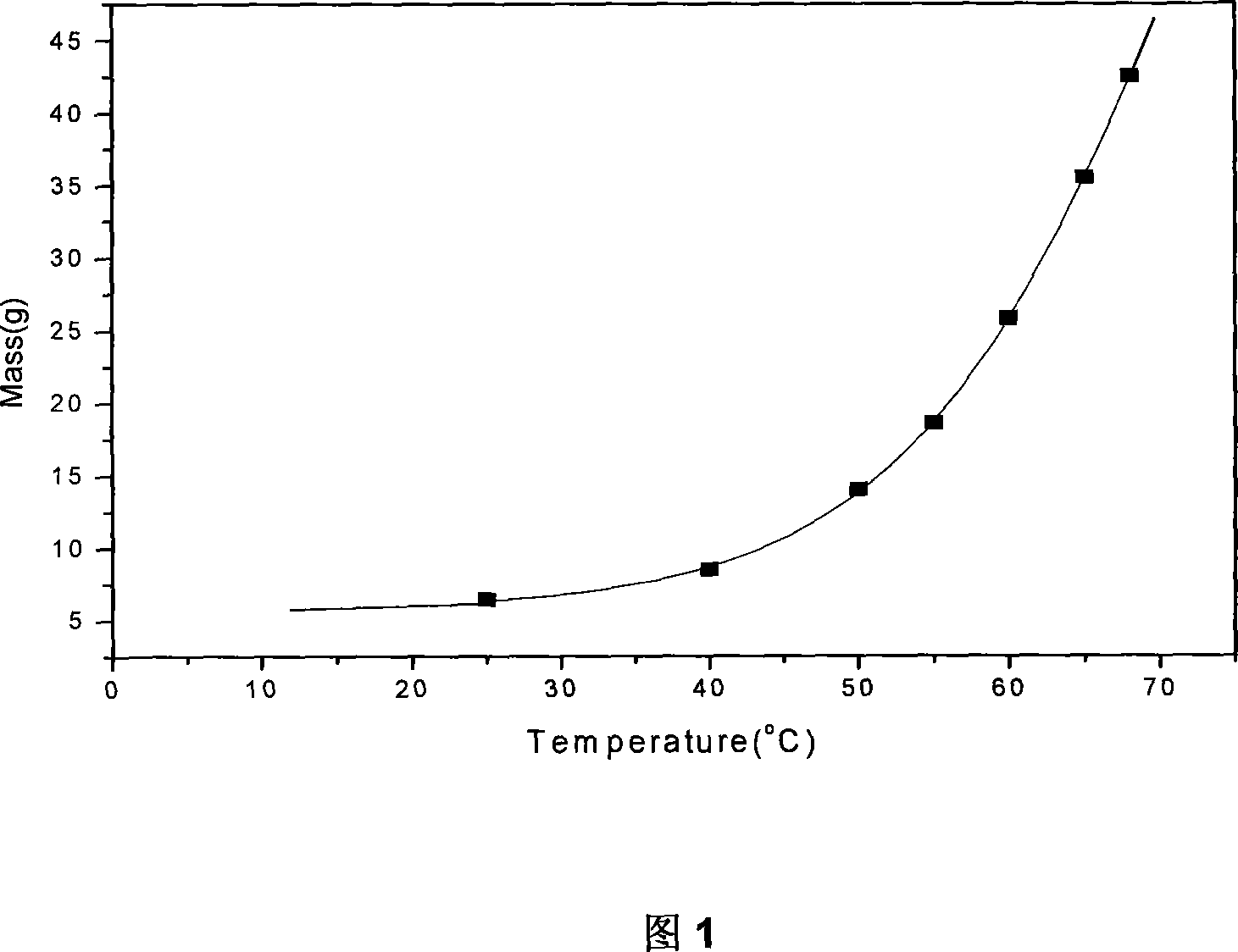

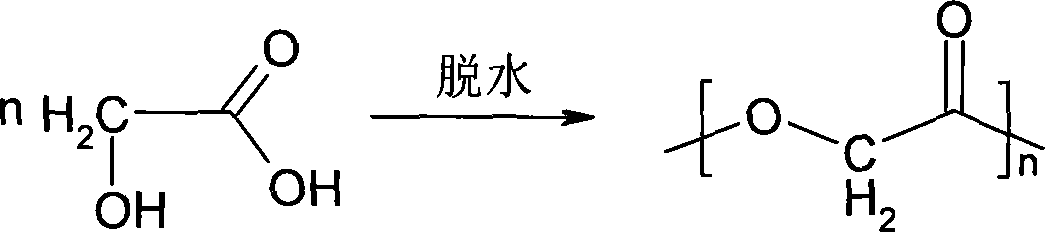

The present invention belongs to the technology field for preparing cyclocompound, specific as preparation method of glycolide. The method synthesizes high purity and high productivity glycolide crystal with high-purity glycolic acid crystal as raw material through a series of steps including dewatering polycondensation, melting polycondensation, depolymerization reaction and recrystallization purifying etc. The present invention prepares glycolide through depolymerizing polyglycolic acid oligomer which is prepared by polycondensating glycolic acid in presence of coexistent two catalysts, and purify primary product of glycolide through controlling recrystallization of glycolide by dropping low boiling point solvent at appropriate temperature.The method guarantee the high conversion rate of polyglycolic acid oligomer in depolymerization procedure and stability of crystal formation of glycolide in procedure of recrystallization, and can increase productivity of glycolide.

Owner:FUDAN UNIV

Preparation method and application of electrospinning nanofiber

PendingCN108866820AWith slow release functionPromote growthCosmetic preparationsCigar manufactureFiberFluorescence

The invention relates to a preparation method and application of electrospinning nanofiber. The preparation method is as follows: synthetic and / or natural polymer materials are dissolved in a volatilesolvent under normal temperature and normal pressure, functional substances are added, and nanofibers are obtained by electrospinning; the functional substances comprise, but are not limited to an odor substance, an organic fluorescent compound, a pigment, a temperature sensitive luminescent and color changing material, a cell growth factor, a hemostatic substance, one or a plurality of nutrientsincluding hyaluronic acid, collagen, and the like which promote skin growth. The nanofiber made by electrospinning has the special effects of sterilization, aromatic odor, fluorescent luminescence, multiple colors, temperature sensitive luminescence and color-changing, promoting wound healing, promoting inhibition and interfering with body function, maintaining skin cell vitality and the like. The method can be used in air purification, automotive air purification, fresh air systems, medical, beauty care, and other nanofiber products.

Owner:SHENZHEN RUXIANGJU TECHCAL DEV LTD

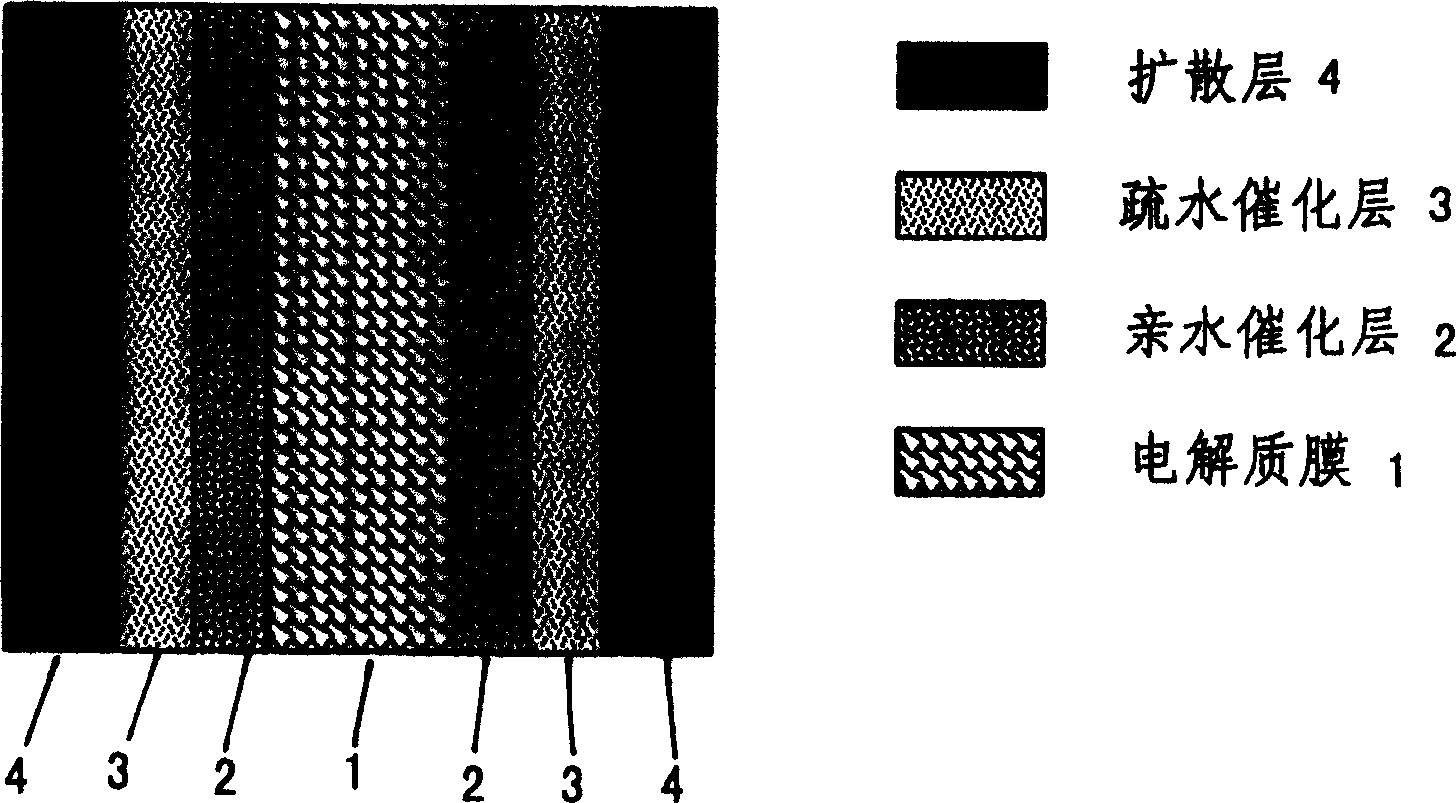

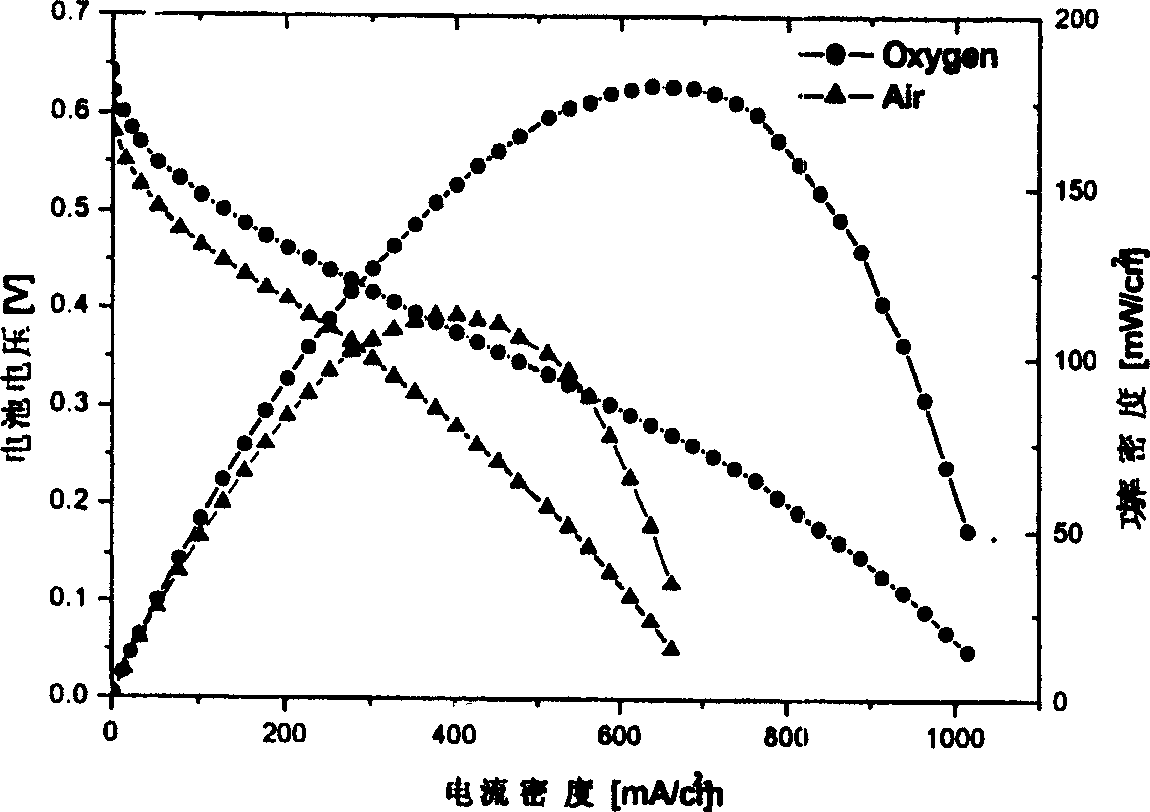

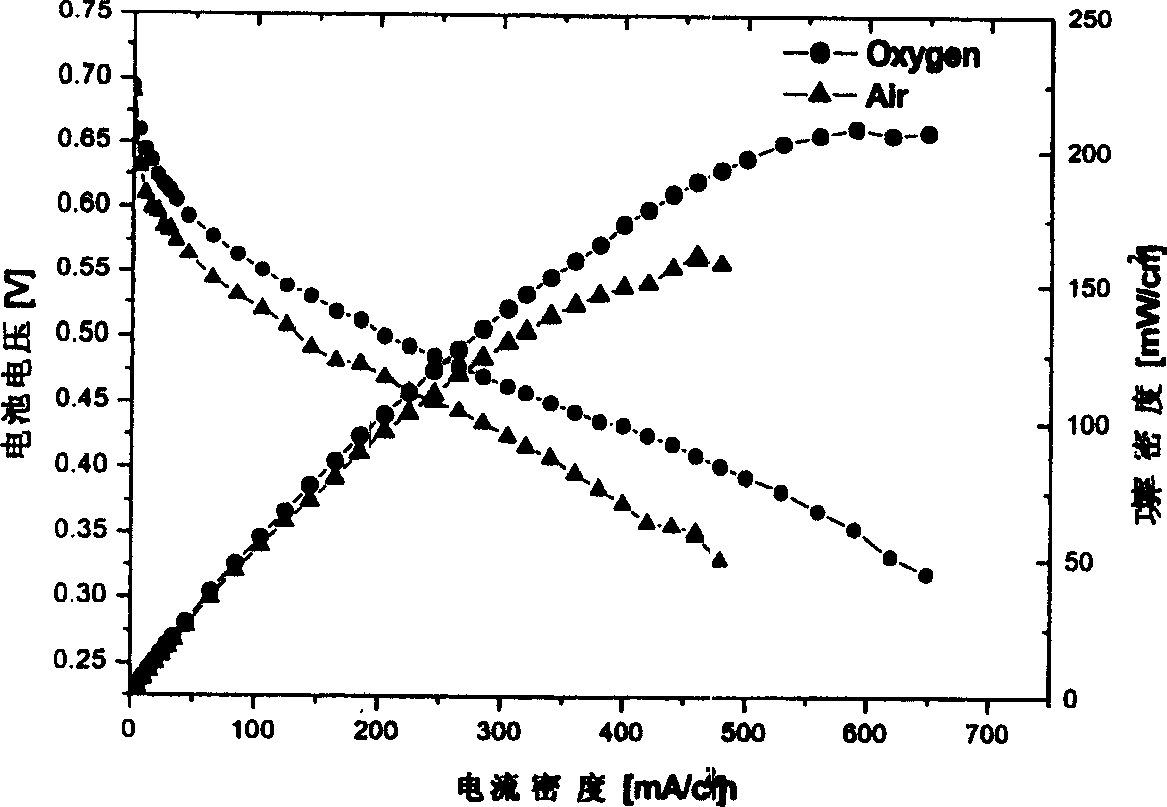

Membrane electrode structure for proton exchange membrane fuel cell and its preparing method

In structure of electrode, catalysis layer is in structure of multiple layers. The said catalysis layer composed of composite two layers including hydrophilic catalysis layer and hydrophobic catalysis layer covering on surface of membrane. Catalysis layer composed of composite two layers is fabricated through steps: catalyst and Nation are dispersed on membrane directly or dispersed on membrane through transferring press of polytetrafluoroethylene (PTFE) film indirectly. Advantages are: in favor of discharging CO2 from anode and O2 from cathode, reducing loss caused by polarization of mass transfer, increasing ultimate current density so as to raise performance of electrode and use ratio of catalyst prepared from noble metal.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

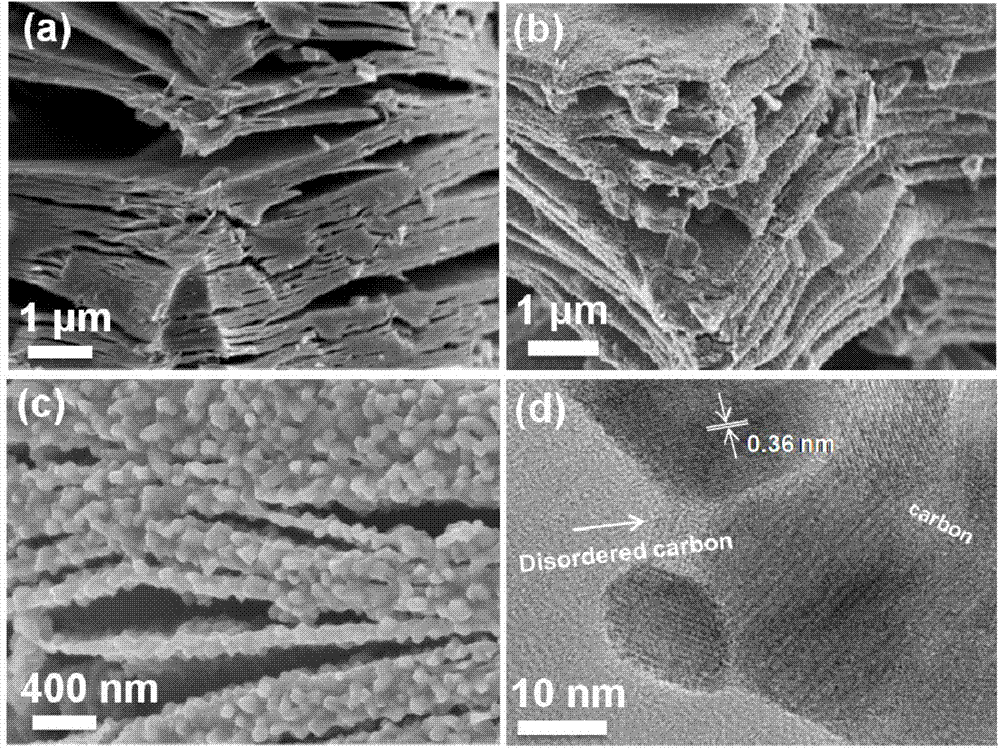

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

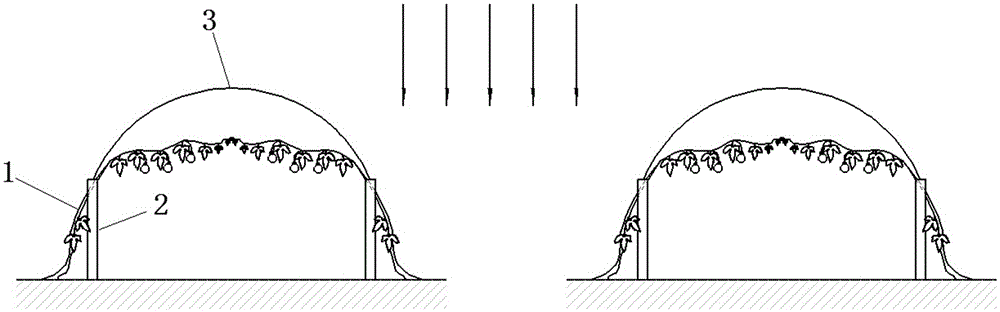

Method for planting organic passion fruit trees

ActiveCN105145253AHigh in sugarIncrease productionExcrement fertilisersBioloigcal waste fertilisersFruit juicePassion fruit

The invention discloses a method for planting organic passion fruit trees. The method includes the steps of variety selection, site selection, soil preparation, soil pH adjustment, establishment of a passion fruit tree foundation, field planting, reshaping and pruning, field management, blossoming, fruit yielding and the like. According to the method, organic fertilizer and a low-toxicity prevention method are adopted in fertilization and pest control, so that the pulp of produced passion fruits is full of yellow fruit juice, the content of sugar is high, the color is bright, the yield reaches up to 2 tons per mu each year, pollution is avoided, and five seasons of fruits can be harvested each year. The successful planting of the organic passion fruit trees provides a theoretical and practical basis for creating incomes of local farmers. According to the method, a leeward apricus flat ground is selected, and the place where a good source of water is obtained, the soil layer is thick, fertility of the soil is above the average and transportation is convenient is used as a planting foundation, so that it is guaranteed that the passion fruit trees can grow in a good environment, the roots of nursery-grown plants are planted in furrows and exposed to the sun, hence, the roots can better absorb sunshine, and fertilization and weeding are further facilitated.

Owner:广西优果百香农业发展有限公司

Method for preparing grapheme transparent conducting films by electrophoretic deposition

InactiveCN102877109ALow impurity contentGood electrical conductivity and light transmissionElectrophoretic coatingsThin membraneChemistry

The invention relates to a preparation method of grapheme transparent conducting films, comprising the following steps: taking natural graphite powder as raw materials; ultrasonically stripping in 0.5-1.0% by volume of AMP, 0.4% by volume of water and DMF solution to prepare high-concentration grapheme dispersion liquid; taking the prepared grapheme dispersion liquid as electrolyte; preparing grapheme conducting films by electrophoretic deposition, transferring the grapheme conducting films onto a glass substrate; controlling the electrophoretic deposition voltage and the electrophoretic deposition time to prepare the grapheme conducting films with different thicknesses and improving light transmission and conductivity of the grapheme conducting films through the heat treatment and acid processing technology. The grapheme transparent conducting films prepared by the method has flat surface and less defect; the prepared grapheme transparent conducting films has the light transmittance of 82.1% and the film resistance of 1.0 microhm / sq. Compared with the other preparation method, the method has the advantages of simple operation, easy control and lower coat and is suitable for large-scale preparation.

Owner:SICHUAN UNIV

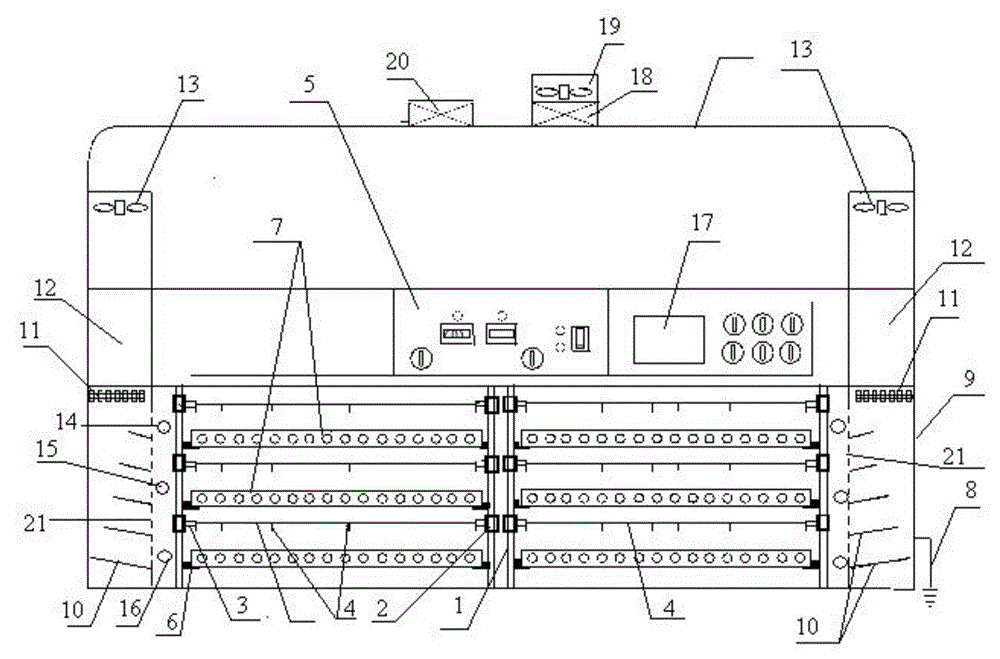

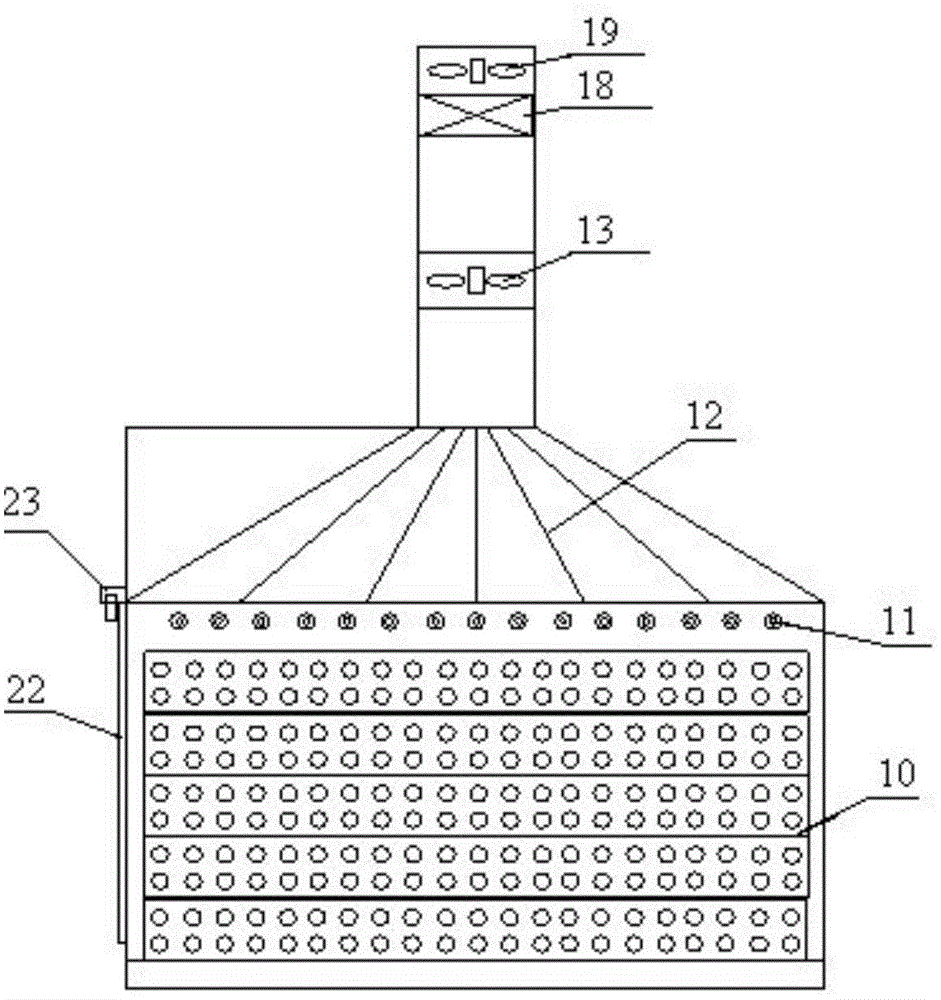

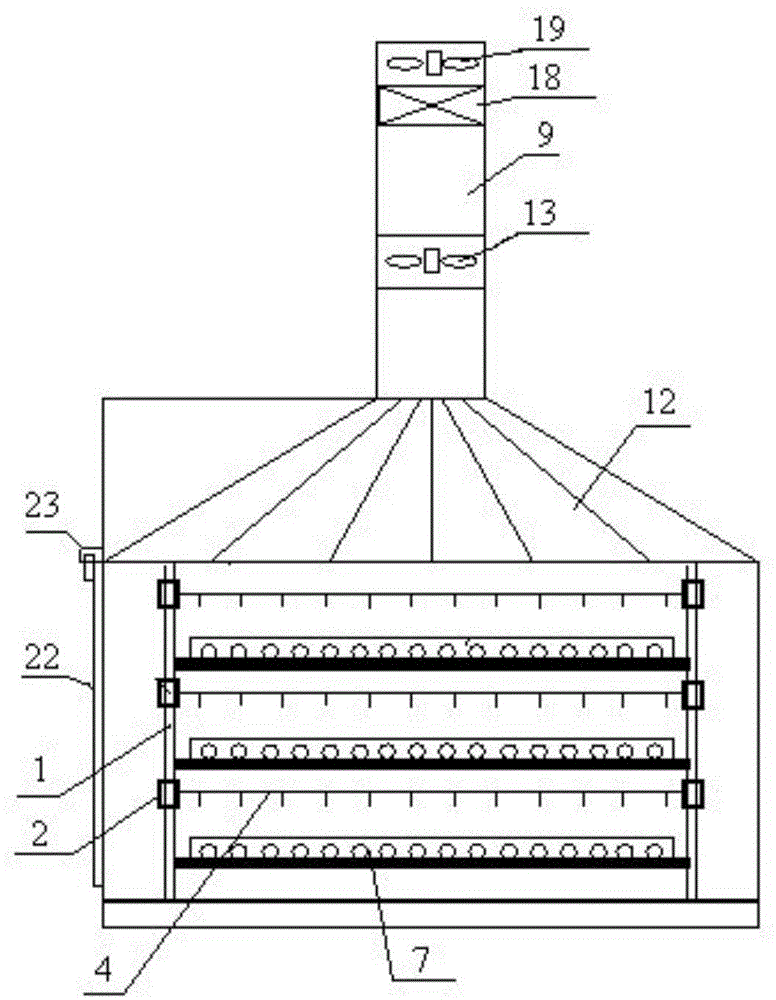

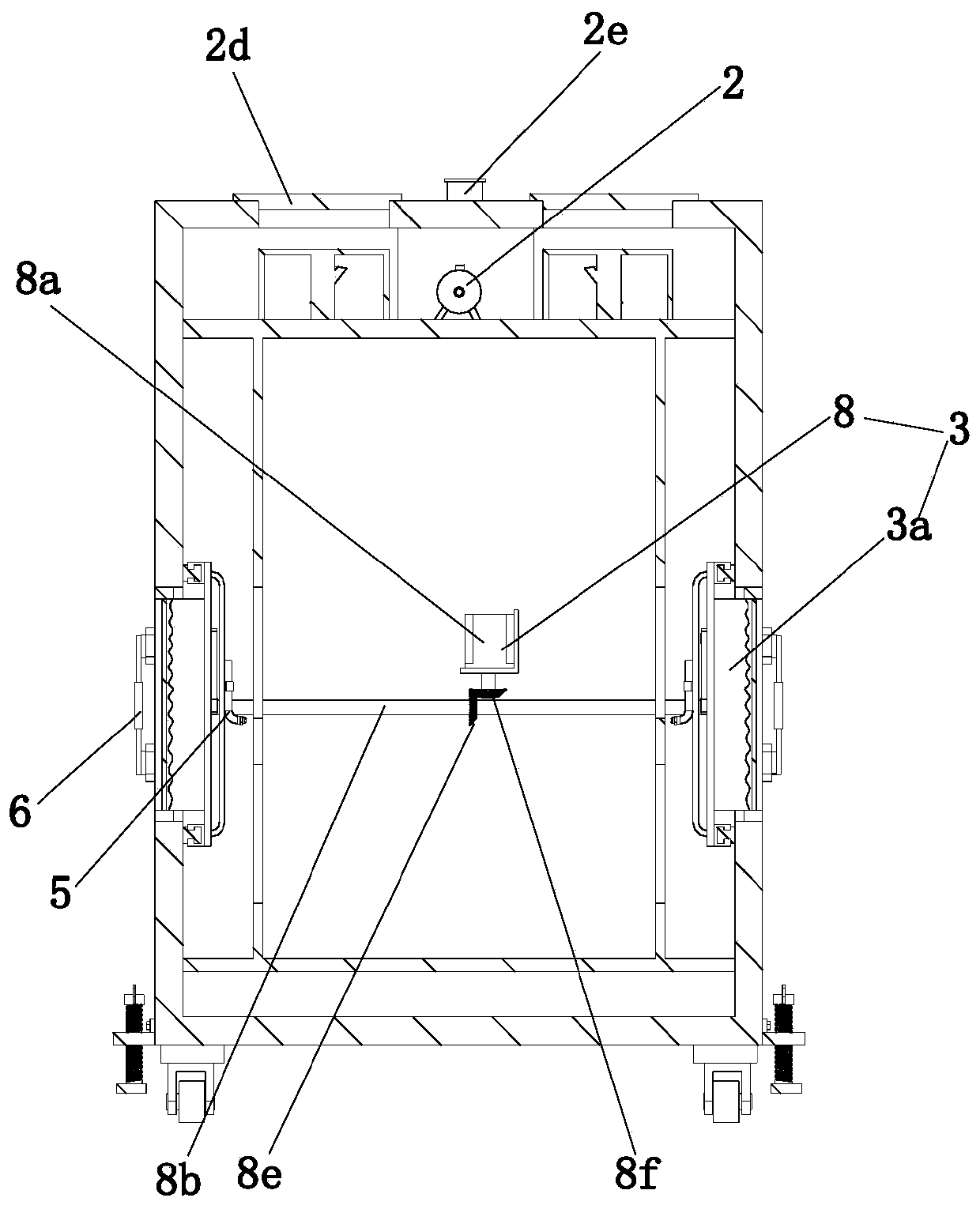

High-voltage electric field and hot air combined drying device

ActiveCN103983091AImprove retentionGood appearanceDrying gas arrangementsDrying chambers/containersThermal instabilityOperability

The invention discloses a high-voltage electric field and hot air combined drying device. The high-voltage electric field and hot air combined drying device comprises a box body, a high-voltage electric field drying system, a hot air circulation drying system and a monitoring control system, wherein the high-voltage electric field drying system, the hot air circulation drying system and the monitoring control system are arranged on the box body. According to the high-voltage electric field and hot air combined drying device provided by the invention, the structural design is reasonable, the operability is strong, and the use is convenient; compared with traditional hot air drying, the drying efficiency is high, the drying temperature is low, the drying time can be shortened by 50% than the drying time of drying by pure hot air under the same temperature, the drying energy consumption can be reduced by 51.9%, the high-voltage electric field and hot air combined drying device is particularly suitable for drying materials containing thermal-instability active components, for example, drying the materials of traditional Chinese medicine, medicinal slices, drug, agricultural products, food, biological products and the like, the appearance quality after the drying is good, the reservation degree of the active components is high, and the application range is very wide.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

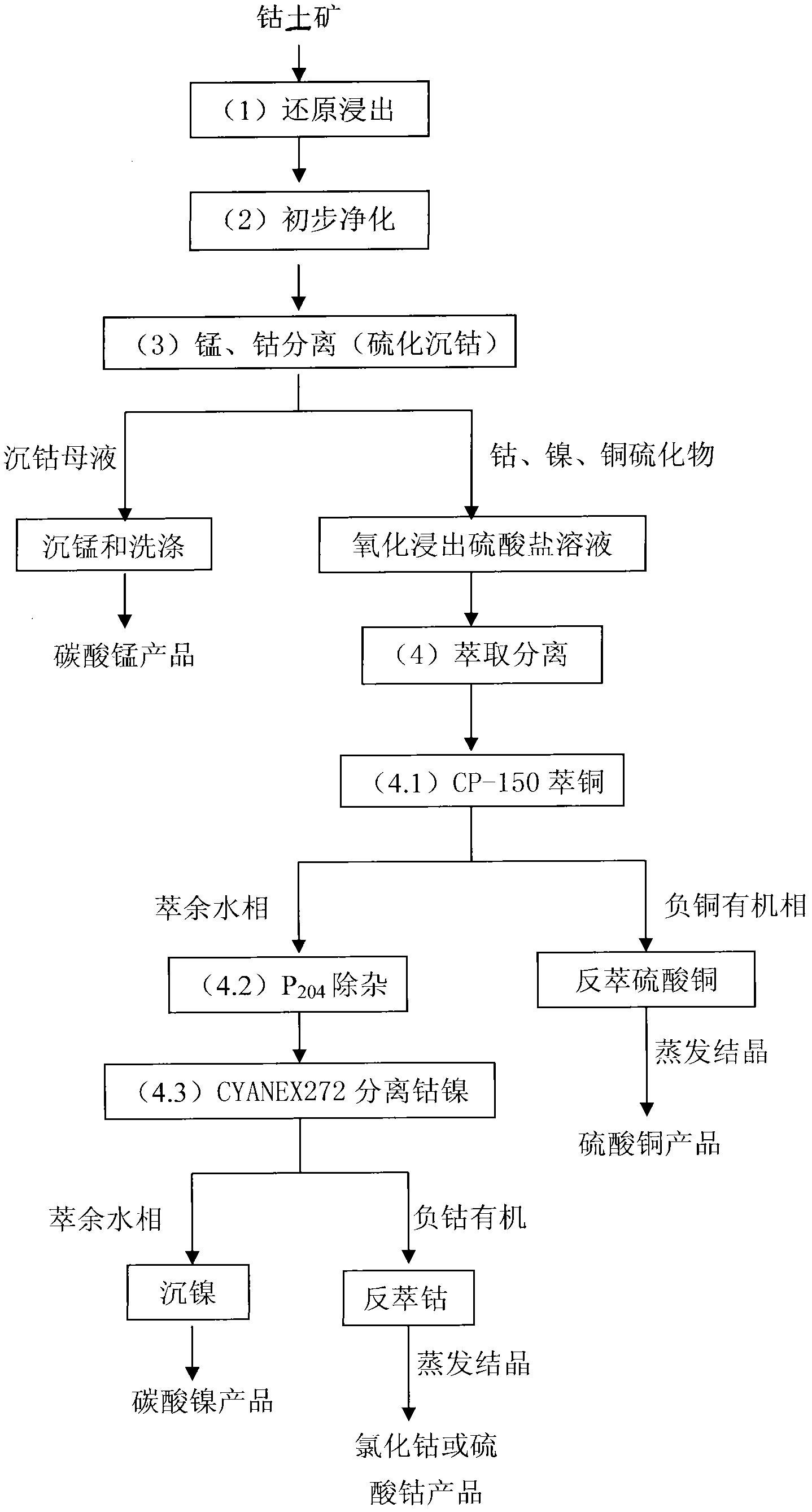

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

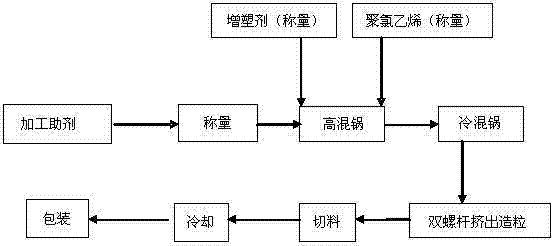

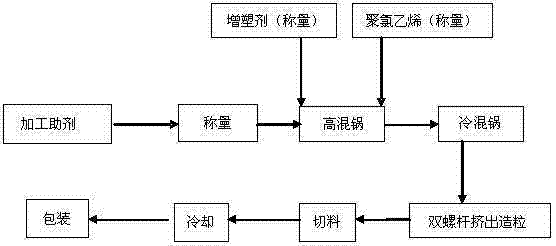

Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN102653618AImprove performanceHeat resistantPlastic/resin/waxes insulatorsAntioxidantDioctyl terephthalate

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material and a preparation method thereof. The environment-friendly cold-resistant polyvinyl chloride cable material is prepared from the following raw materials in percentage by mass: 40-60% of polyvinyl chloride, 5-25% of dioctyl terephthalate, 5-25% of dioctyl adipate, 1-10% of chlorinated polyethylene, 5-25% of light activated calcium carbonate, 1-3% of lubricant, 2-8% of Ca-Zn composite stabilizer, 0.1-1% of antioxidant and 0.1-4% of pigment. The environment-friendly cold-resistant polyvinyl chloride cable material is mainly compounded from dioctyl terephthalate and dioctyl adipate. The cable material can be normally used in a low-temperature environment of -40 to -65 DEG C, has favorable shock resistance under low-temperature conditions, does not contain ortho-benzoic ether compounds, and is environment-friendly, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly and has poor shock resistance under low-temperature conditions.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD +1

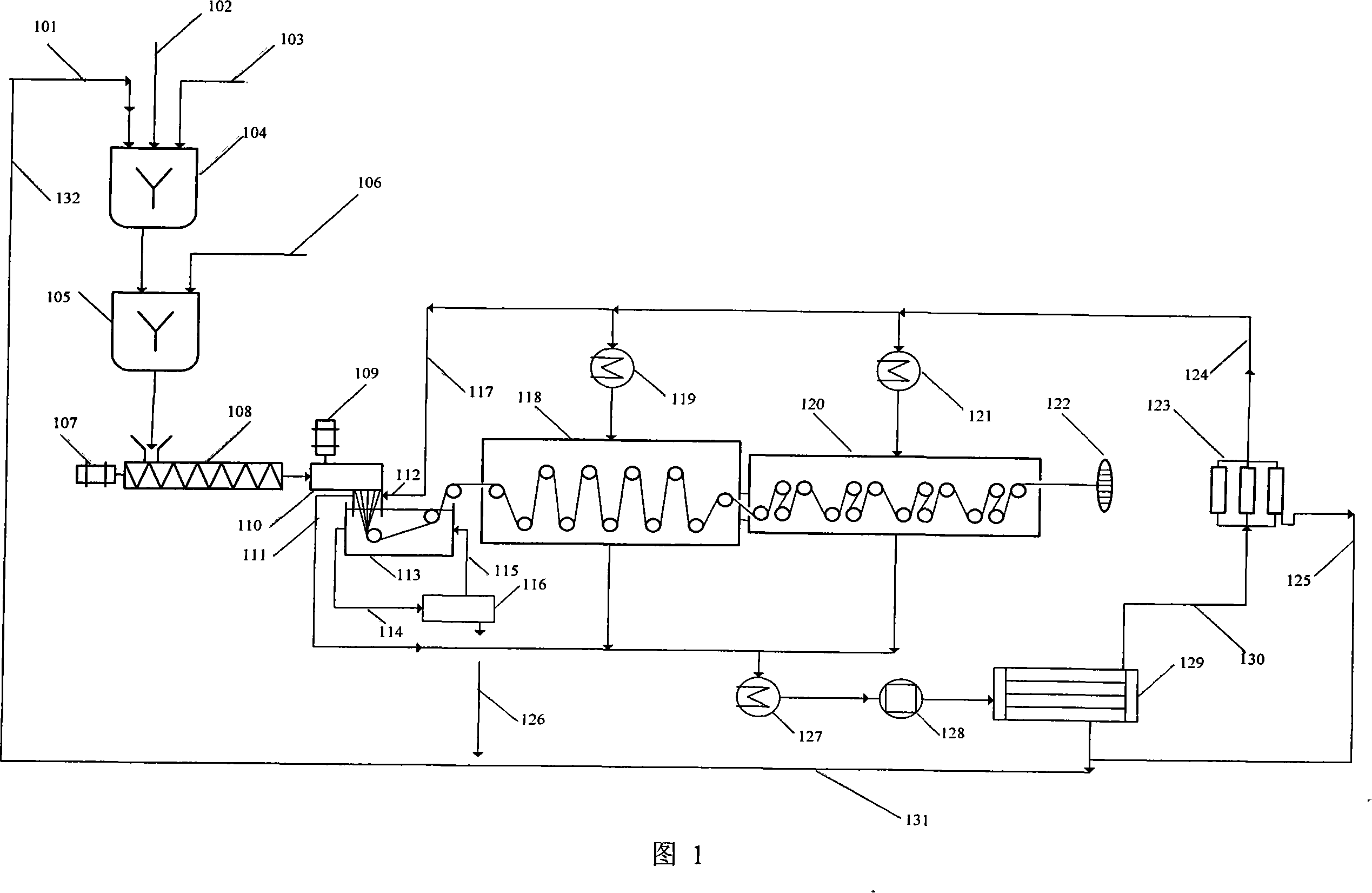

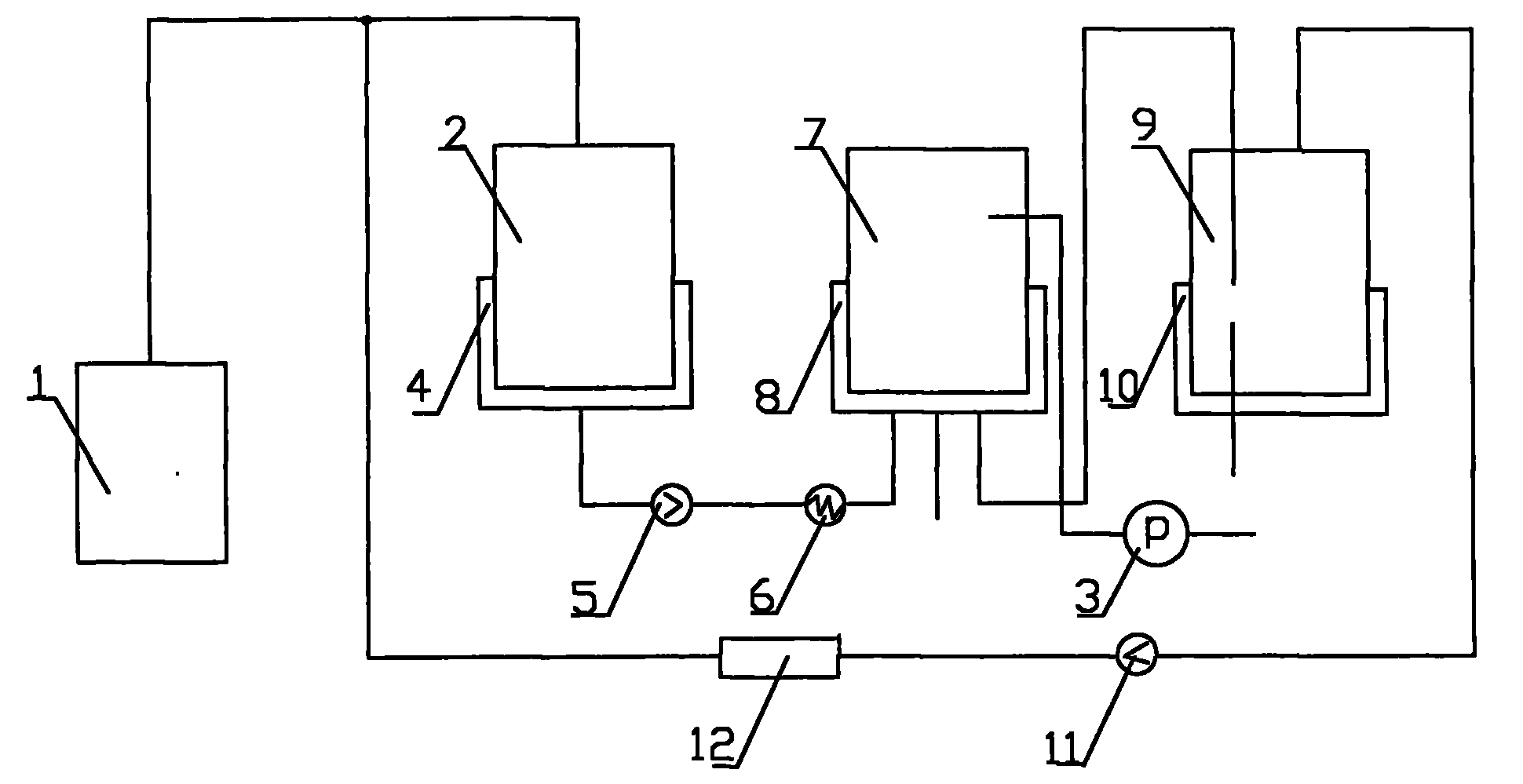

Method and device for extracting peony seed oil from peony seeds

InactiveCN101812370ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionEcologyWater content

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting peony seed oil from peony seeds. The method for extracting peony seed oil from peony seeds is characterized by comprising the following steps of: (1) firstly, drying the peony seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed peony seeds into an extracting kettle, pumping the vacuum to the pressure below 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the peony seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-50 DEG C, and the extraction time is 30-45 min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50 DEG C; (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final peony seed oil.

Owner:甘肃省轻工研究院有限责任公司

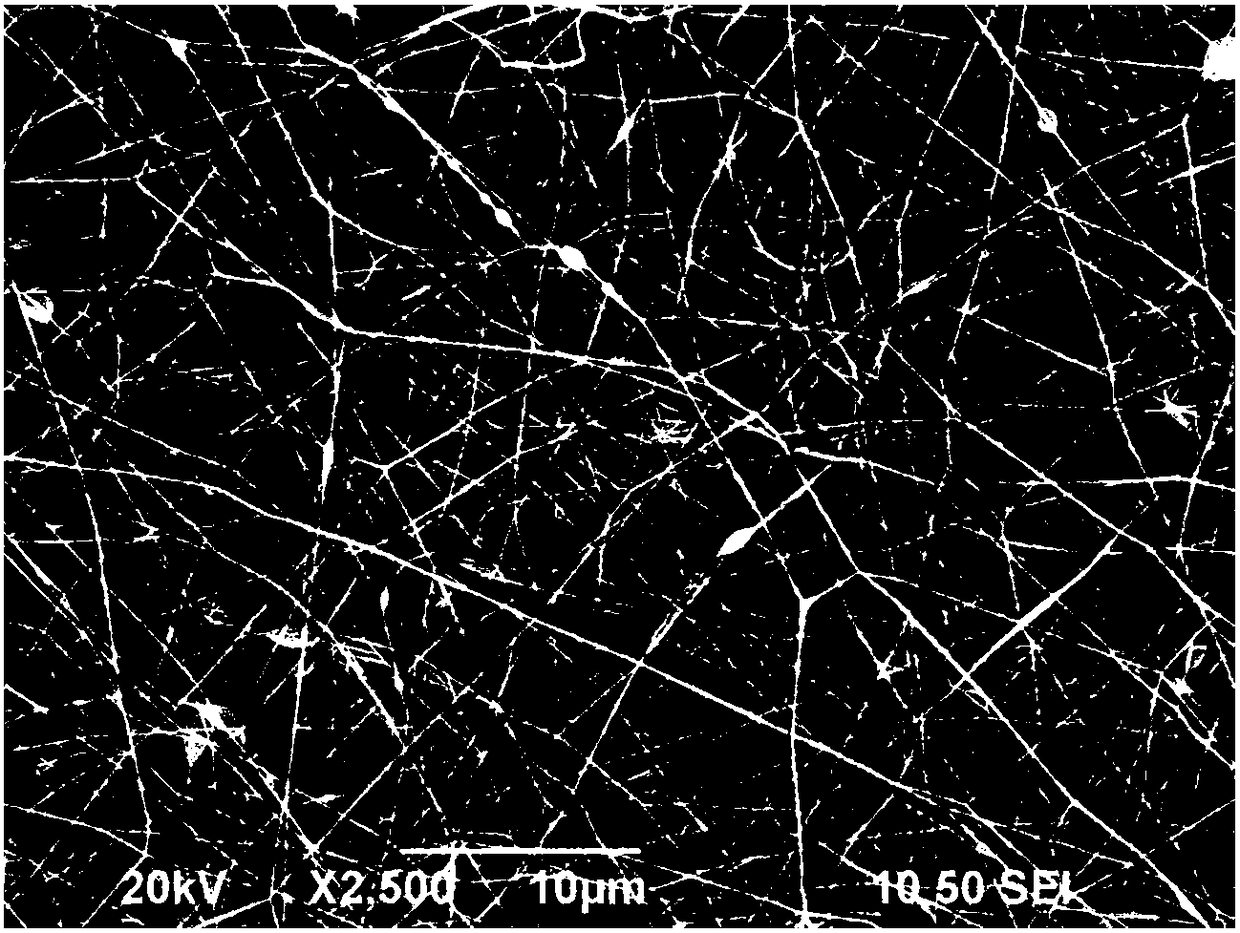

Dry-method spinning technique for preparing super high molecular weight polyethylene fibre

InactiveCN101148783AVolatileReduce manufacturing costFilament forming substance formingArtificial filament physical treatmentSolventCarbon dioxide

The present invention is dry spinning process for preparing ultrahigh molecular weight polyethylene fiber, and belongs to the field of polymer material preparing technology. The process includes: dissolving ultrahigh molecular weight polyethylene powder and assistant in xylene solvent; filtering and debubbling the solution, extruding in a screw extruder, spraying through a metering pump, spinning manifold and spinneret and solidifying to form, hot air drying to eliminate xylene from fiber, hot drafting and final winding the product. The present invention includes also condensing and adsorbing to separate xylene from N2 or CO2, reusing the separated xylene and reusing the separated N2 or CO2.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV

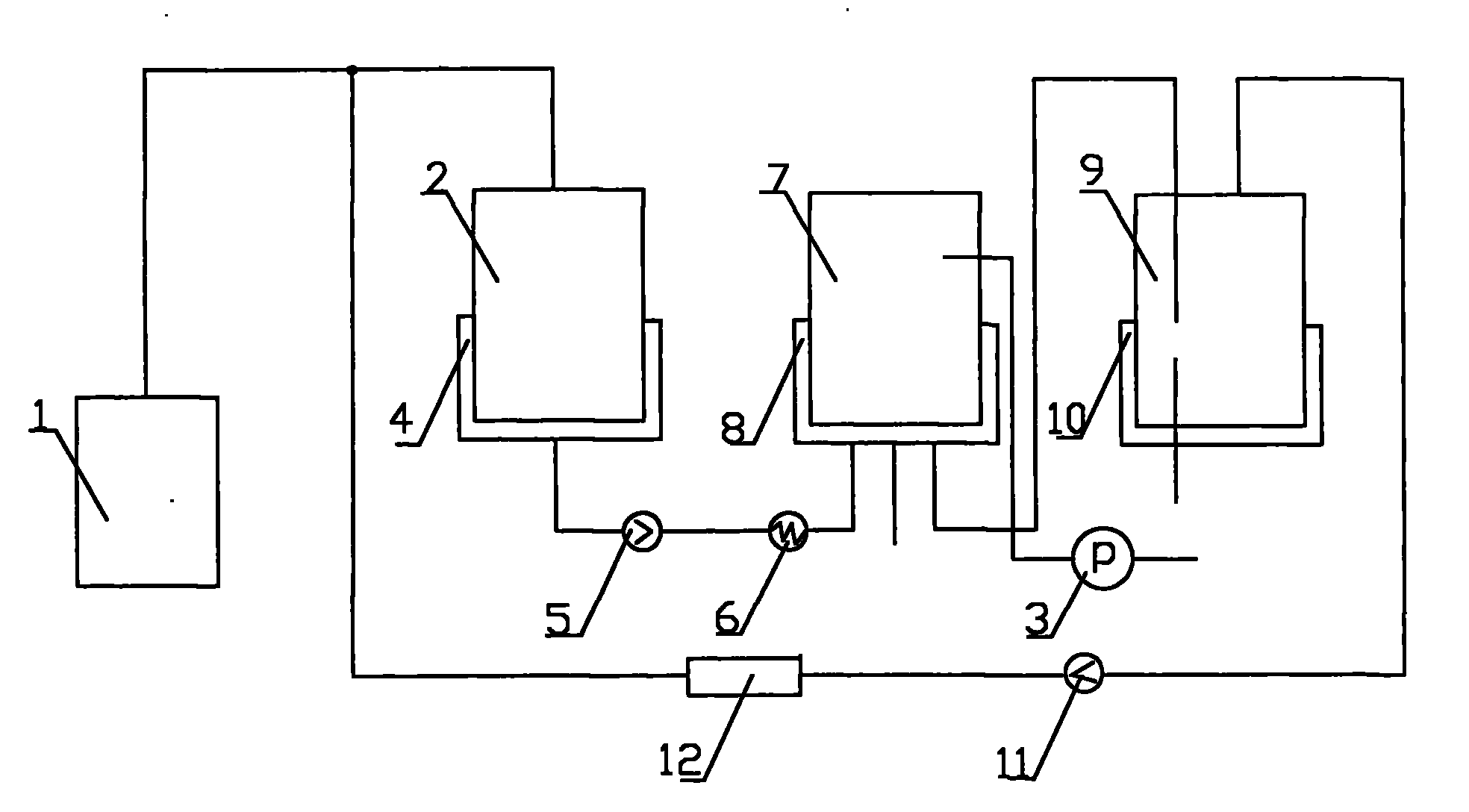

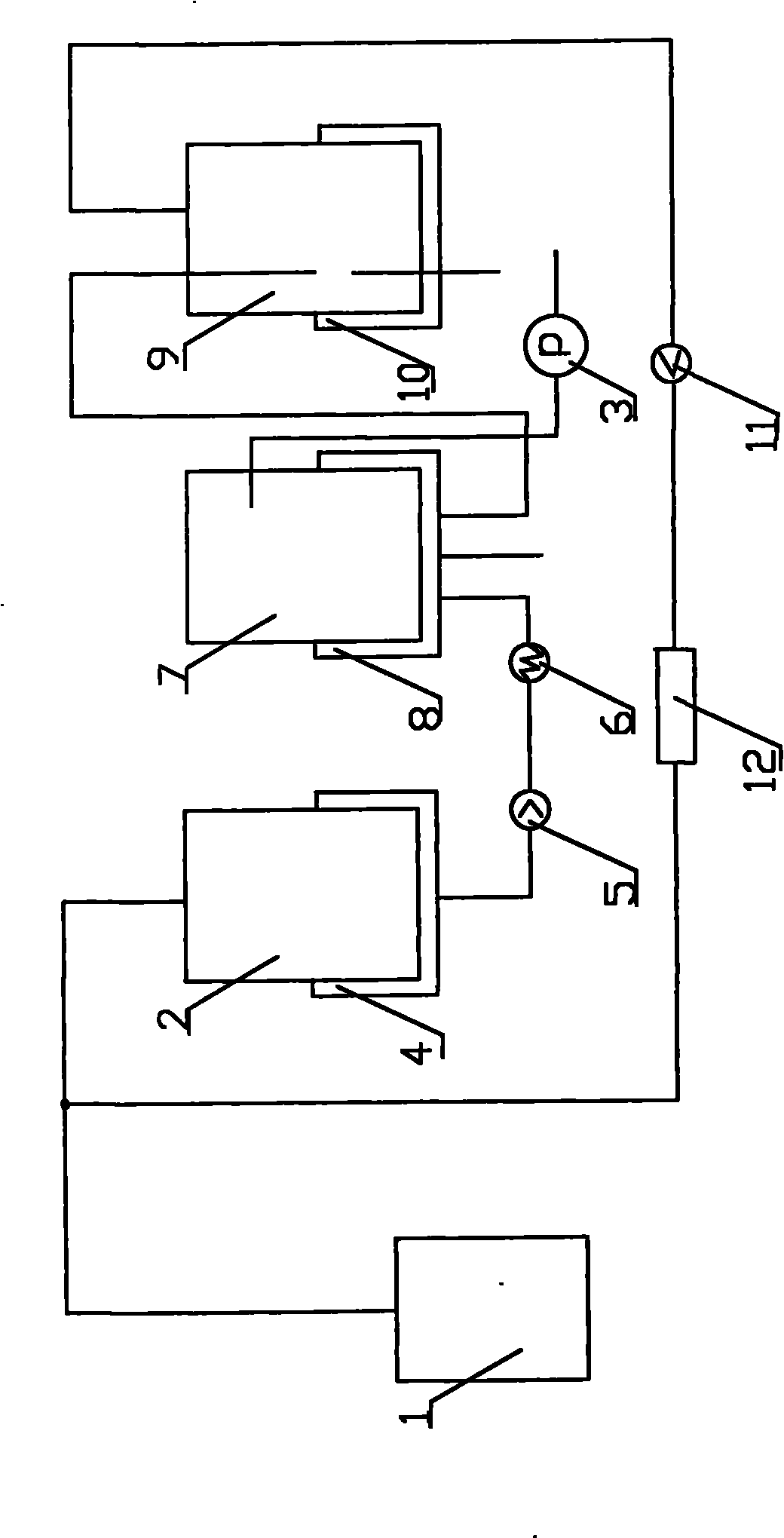

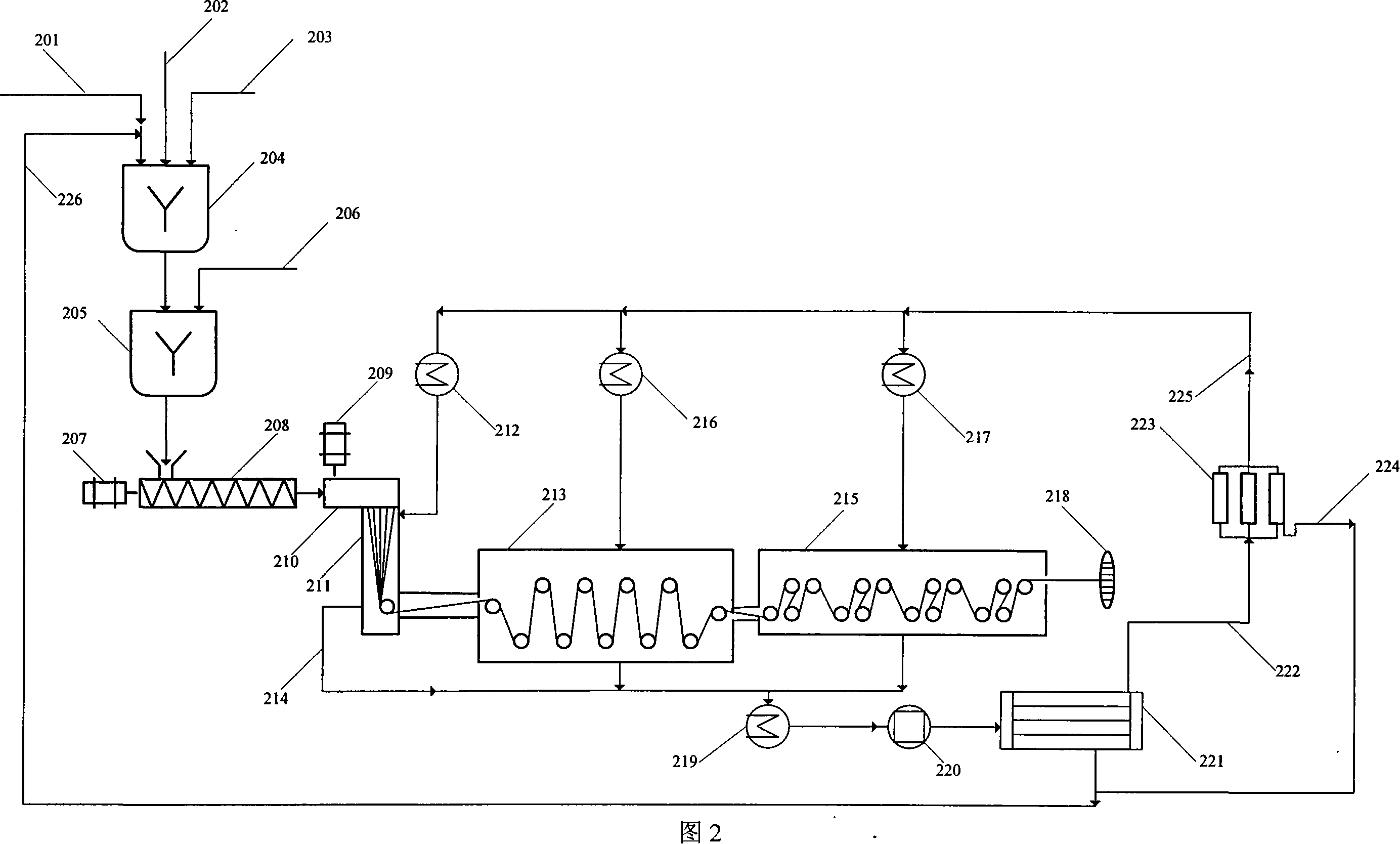

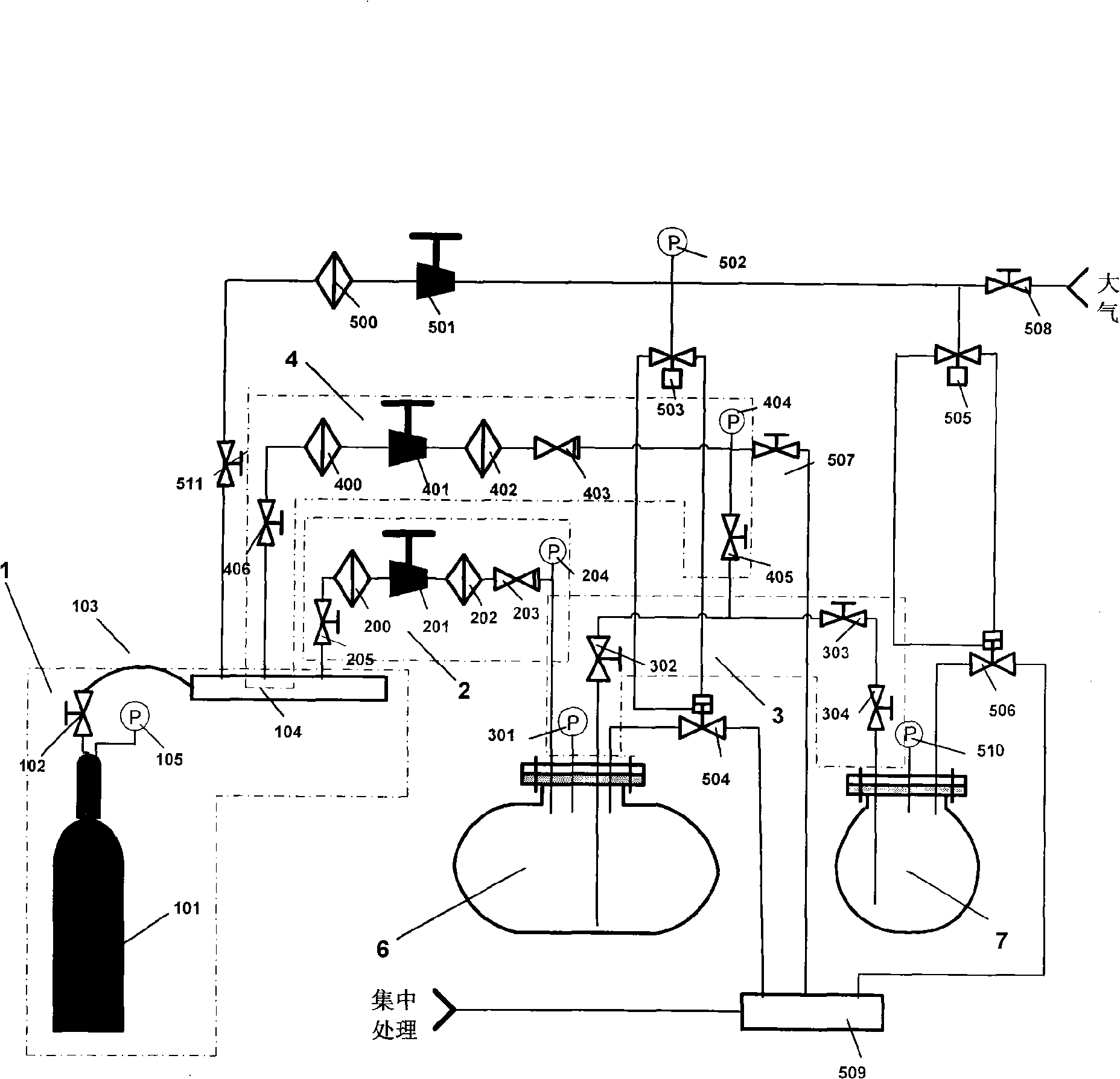

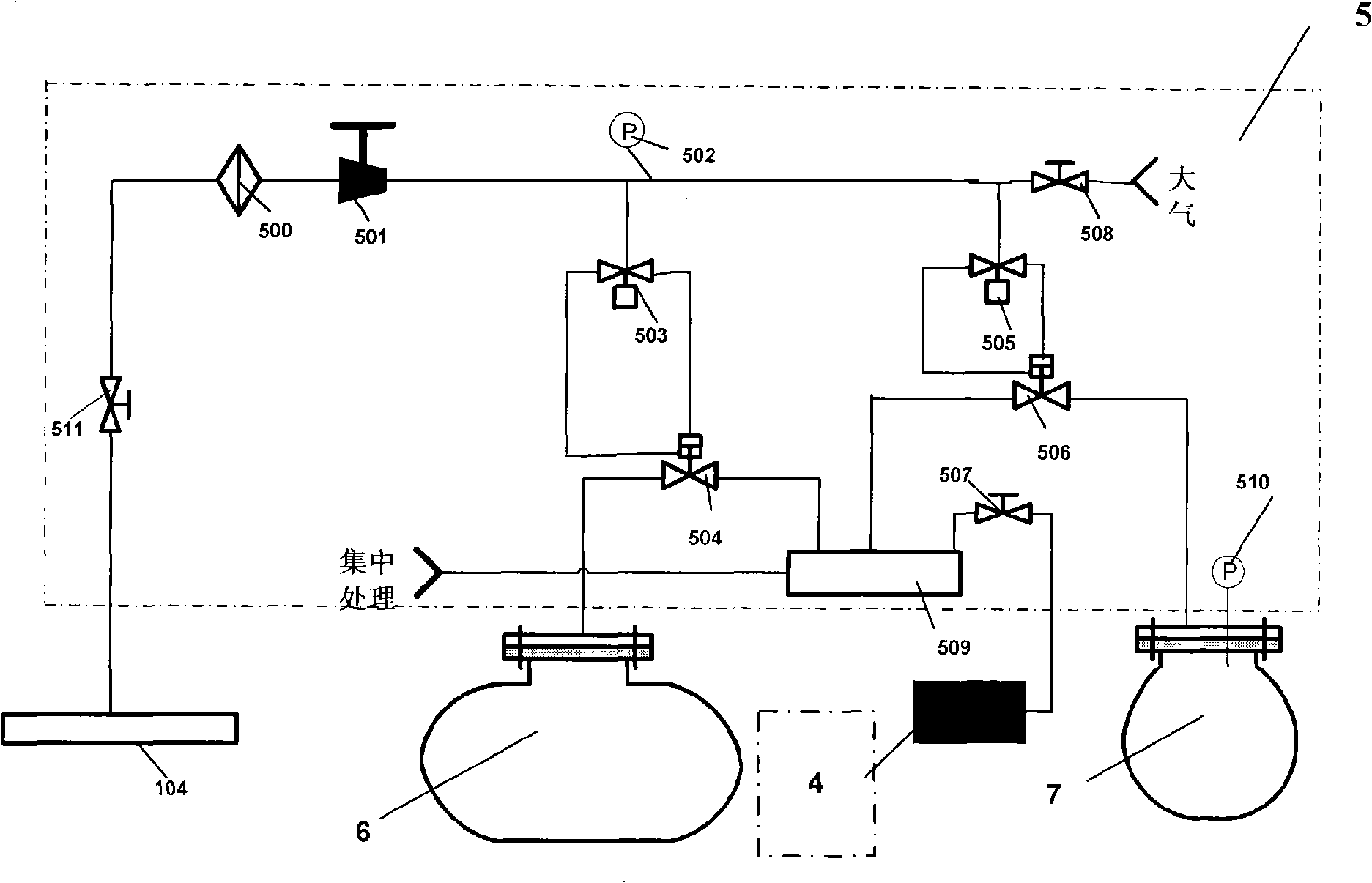

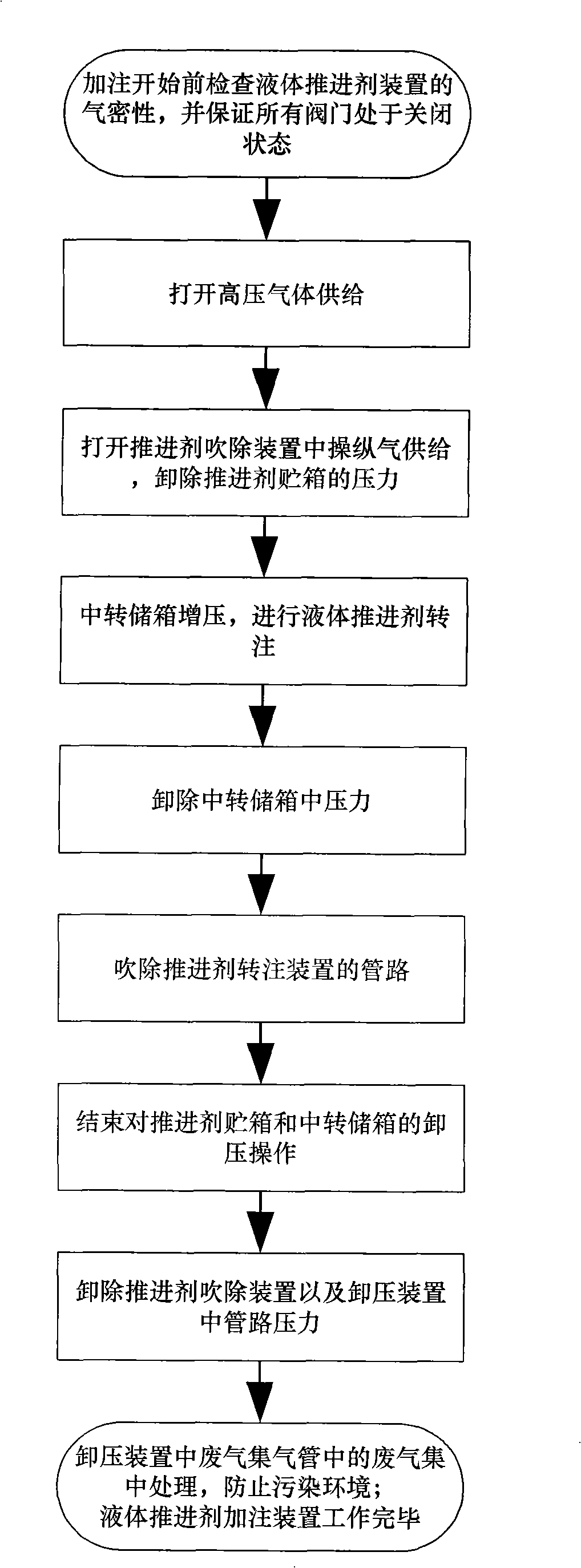

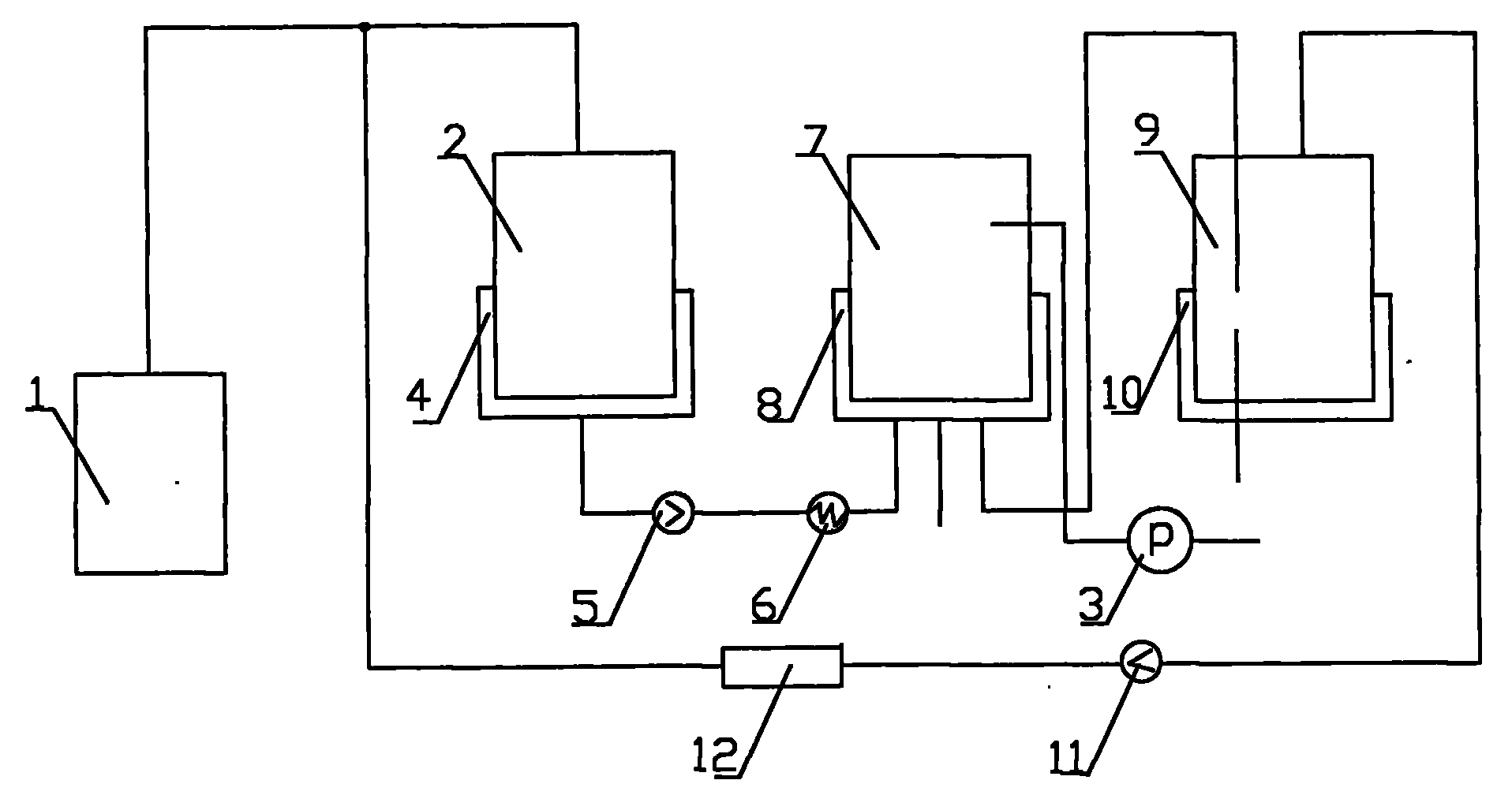

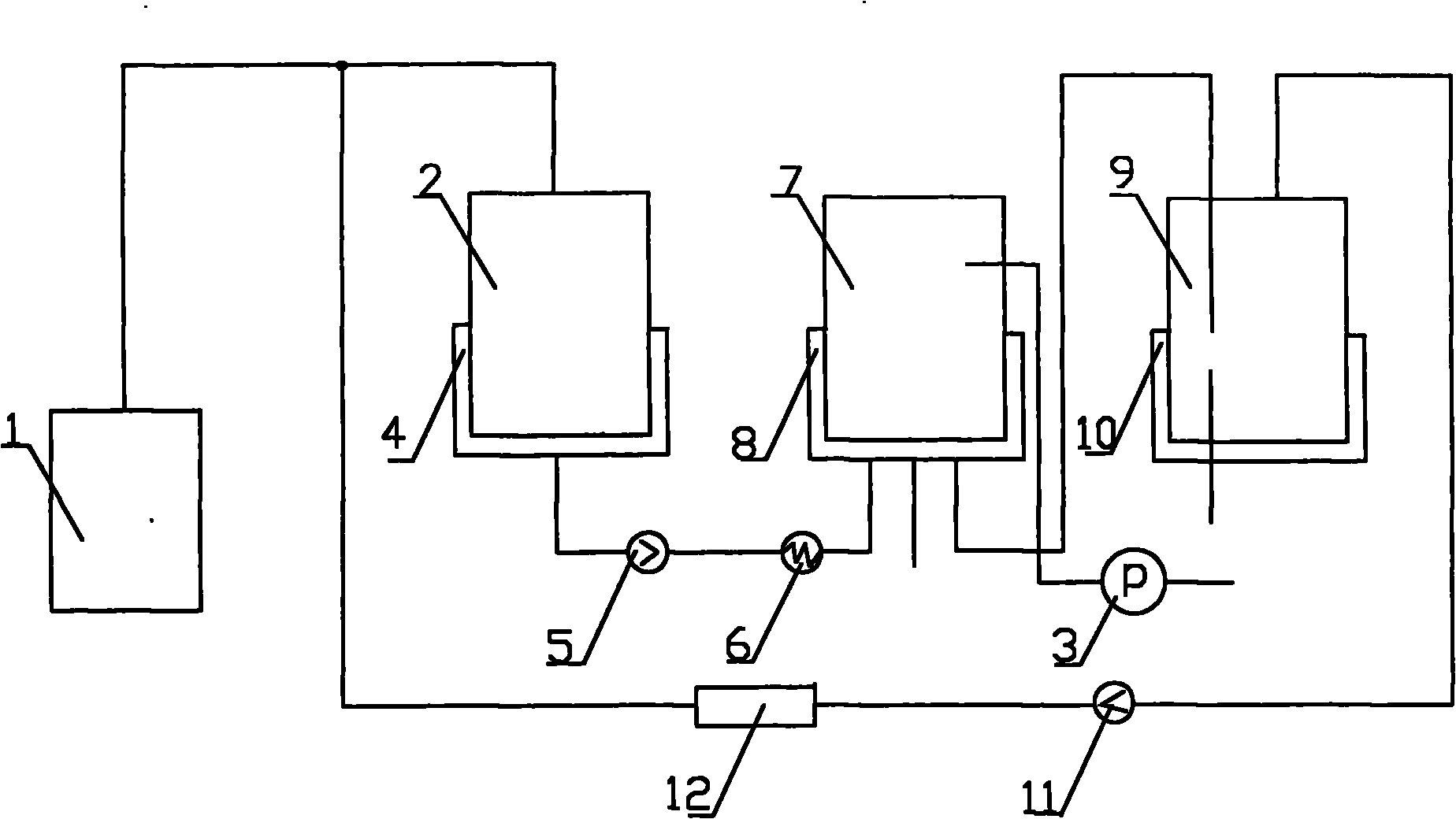

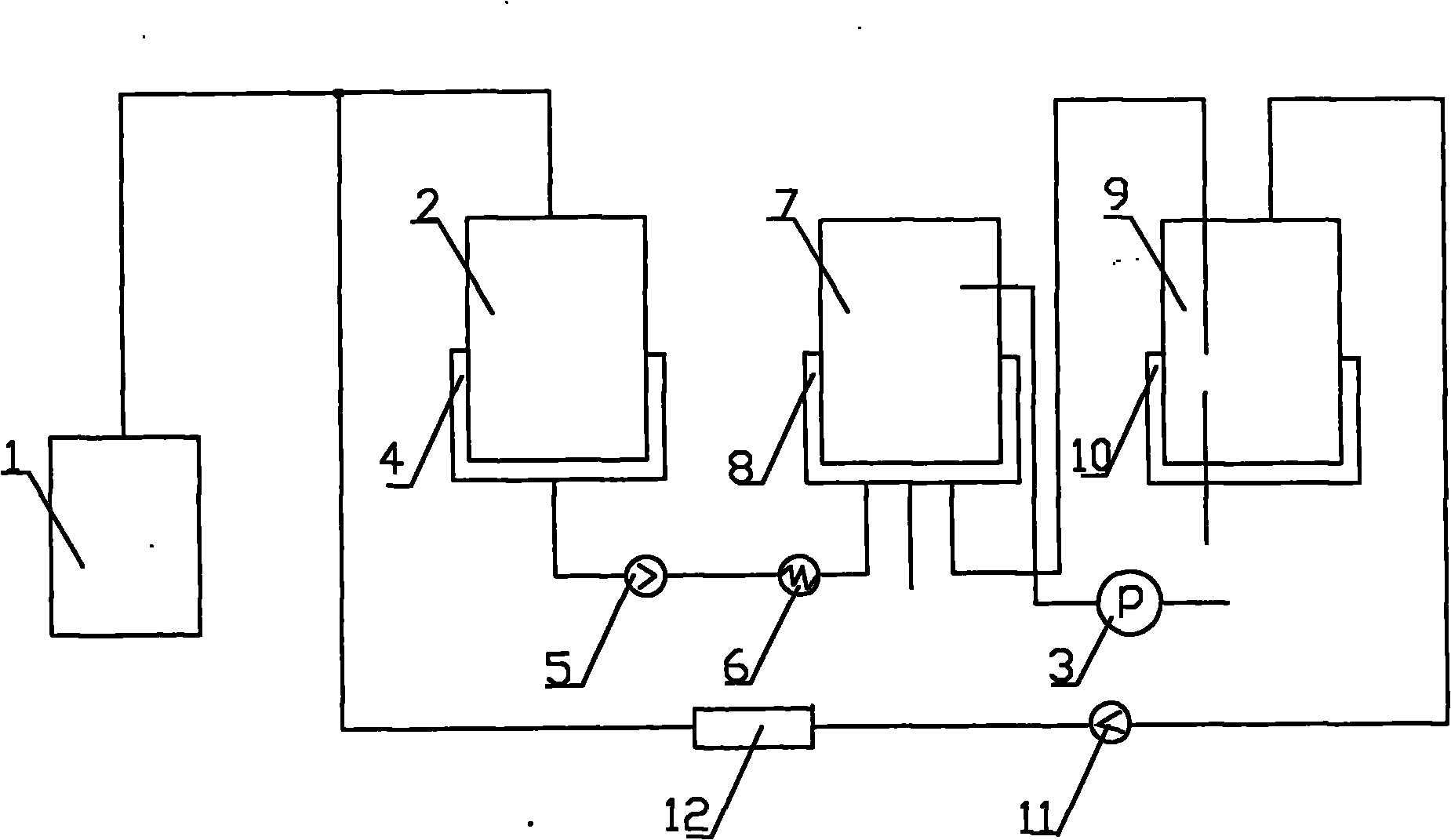

Filling device of liquid propellant and method thereof

The invention provides a filling device of a liquid propellant and a method thereof. The filling device of the liquid propellant comprises a high-pressure air source device, a pressurizing device of a transit storage tank, a propellant transfer filling device, a propellant blow-off device, a pressure relief device, the transit storage tank and a propellant storage tank. The device adopts a pressure difference method to carry out filling of the liquid propellant. The pressurization of the transit storage tank and blow-off of the propellant use high-purity nitrogen; the pressure relief device guarantees the pressure difference of the transit storage tank and the propellant storage tank so as to guarantee the normal proceed of the filling process; and the pressure relief device can relief the pressure of the pipeline so as to guarantee the test safety. The filling device of the liquid propellant and the method thereof also can be used for other occasions of liquid transferring.

Owner:BEIHANG UNIV

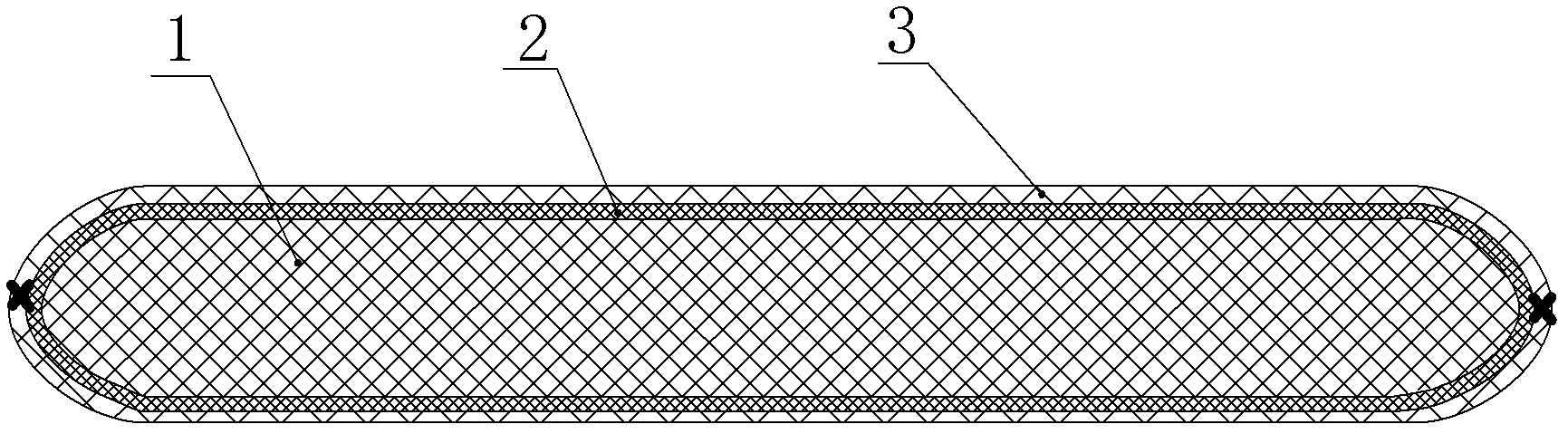

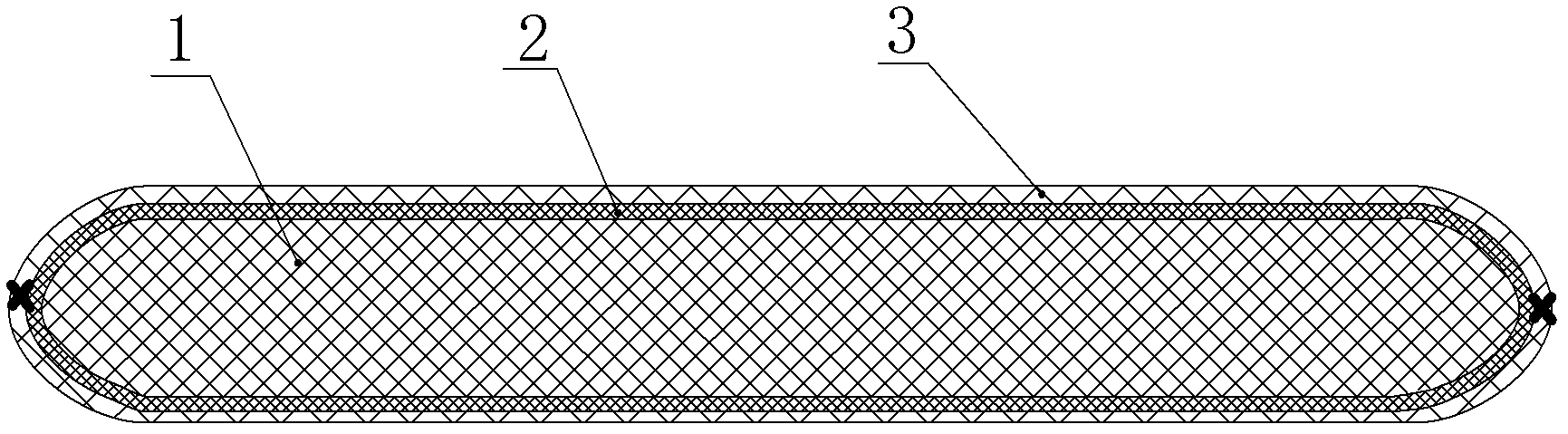

Cotton padding and preparation method thereof

The invention relates to a cotton padding, which comprises a cotton padding core, gauze screens and non-woven fabrics. Both upper surface and lower surface of the cotton padding core are provided with a layer of gauze screen and a layer of non-woven fabric in turn; the peripheries of the non-woven fabrics arranged on the upper surface and the lower surface are integrally quilted along the peripheral boundaries of the cotton padding core; the cotton padding core consists of the following components: cotton, hollow fibers, low-melting-point fibers and natural bamboo fibers; and the hollow fibers are at least one of far infrared hollow polyester short fibers, antibacterial polyester hollow fibers, bamboo carbon hollow polyester fibers, three-dimensional crimped hollow fibers and seven-hole polyester fibers. A preparation method comprises the following steps of: mixing, opening, combing, processing by using a random roller, paving, compacting, processing at a constant temperature, shaping, laying a net, rubbing, and reshaping. The components are reasonably proportioned, the processing technology is simple, and the prepared cotton padding has the characteristics of no caking, bacteria resistance and inhibition, health care, moisture absorption and air permeability, and is soft and fluffy and suitable for industrial production.

Owner:HUNAN PROVINCE CHANGSHA CITY AIWANTING HOME TEXTILES

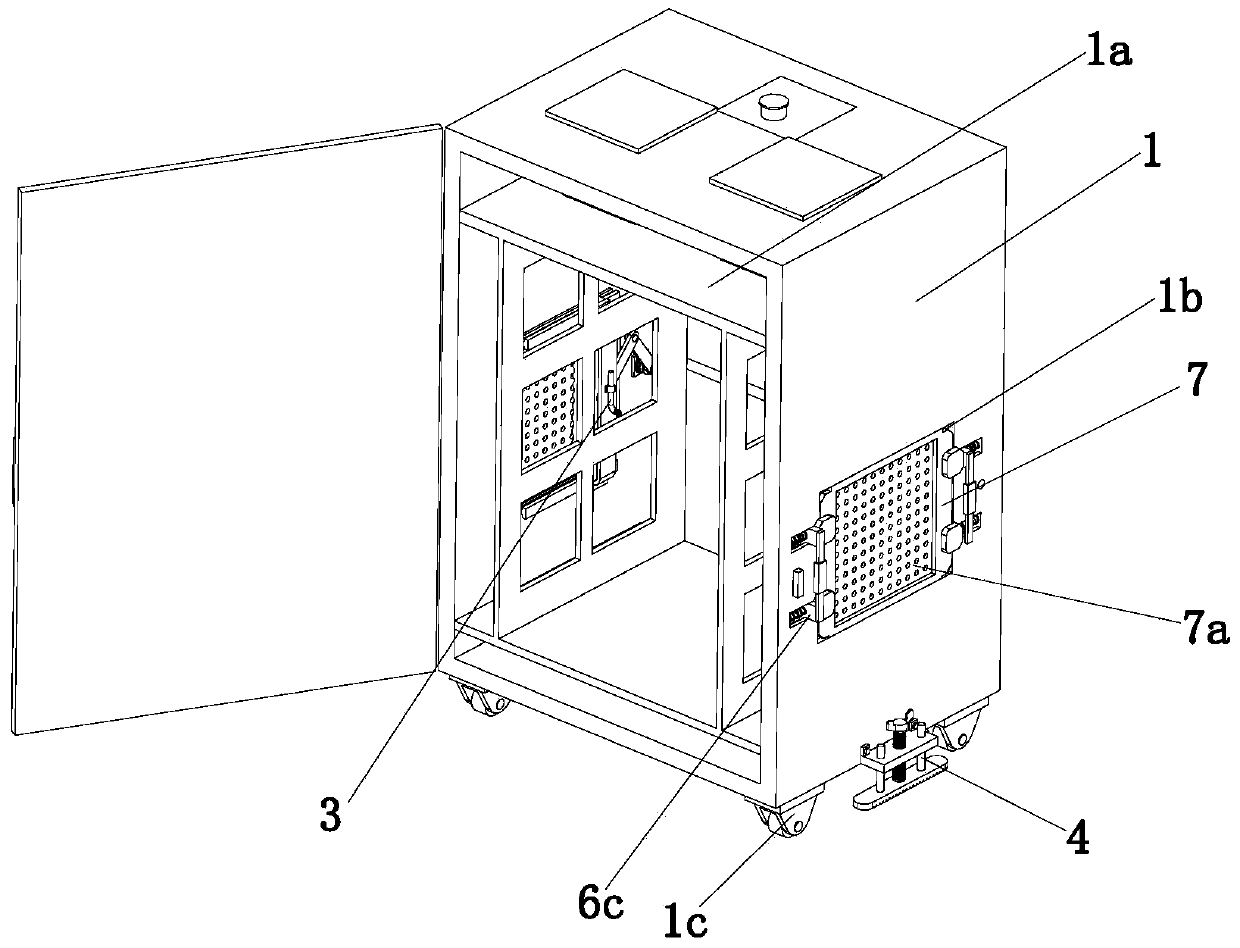

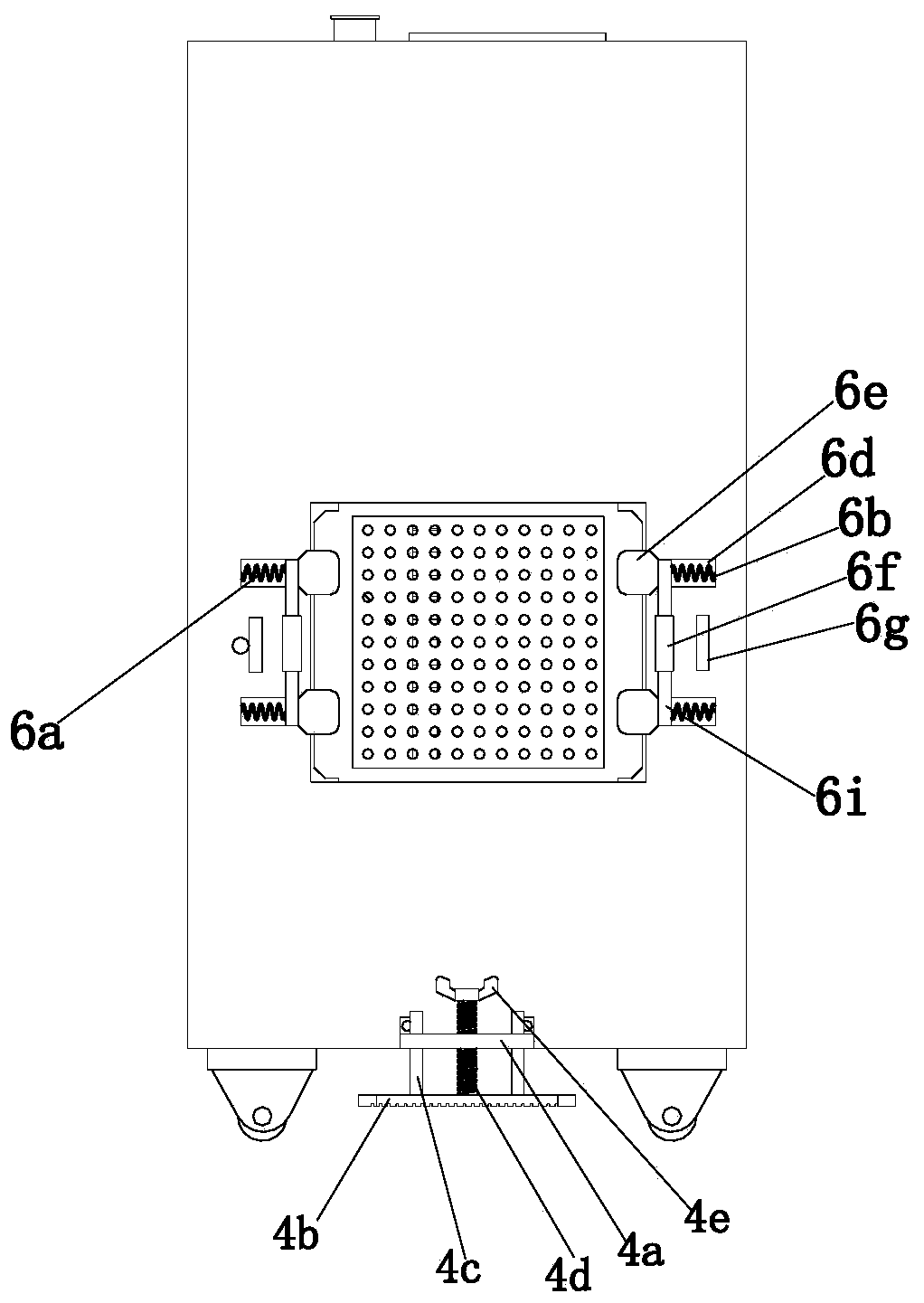

Dustproof and cooling type power equipment distribution cabinet

ActiveCN110445024AReduce laborQuick installationDispersed particle filtrationTransportation and packagingPower equipmentEngineering

The invention discloses a dustproof and cooling type power equipment distribution cabinet, and belongs to the technical field of electric cabinets. The cabinet comprises a cabinet body and a mountingrack; the cabinet body is internally provided with a quick cooling mechanism and a dust removal mechanism; the two sides of the cabinet body are provided with ventilation grooves; the bottom of the cabinet body is provided with four self-locking universal wheels distributed in a matrix manner; the two sides of the cabinet body are provided with stabilization assemblies; the dust removal mechanismcomprises a driving assembly and two dust removal assemblies symmetrically arranged on the two sides of the mounting rack; each dust removal assembly comprises a dust removal component, a quick mounting component and a mounting frame; and a dust screen is arranged in each mounting frame. Dust on the dust screens can be automatically cleaned through the dust removal mechanism; workers do not need to manually clean the dust; and the dust screens can be quickly mounted or dismounted through the quick mounting components, so that convenience is brought to replacement and maintenance of the dust screens by the workers.

Owner:常德三欣电力电子科技有限公司

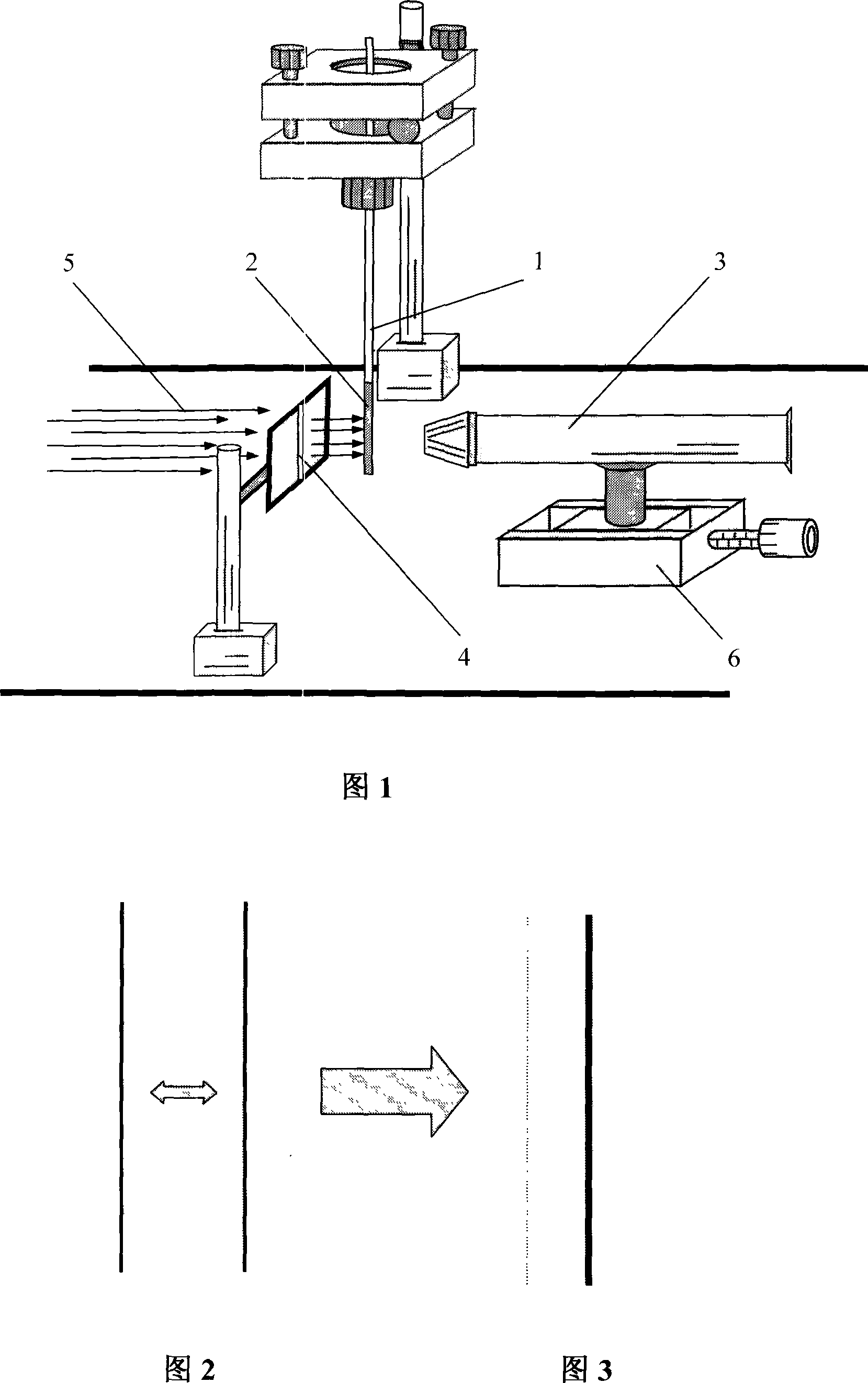

Method for accurate measuring trace quantity liquid refractivity

InactiveCN101082577AMeasuring instruments are simpleHigh measurement accuracyPhase-affecting property measurementsSpecial data processing applicationsChemical industryRefractive measurements

A method of precise measurement microscale refractive rate is the method of measurement the refractive of transparent and semi-transparent liquid or solid. The purpose of invention is measuring the refractive rate of transparent and semi-transparent liquid and solid medium. It accords the imaging principle of coaxial spherical optical system and measures the focal spot position of capillary with inhaling the measured liquid and gets the measured liquid's refractive rate by calculation. Select the properly capillary references according to the refractive measurement range of measured medium and then get the need of measurement precision. Example: measuring the multiple liquid medium with refractive n which is higher than 1.33 and lower than 1.48, and the standard deviation of measurement result is between 0.0002 and 0.001; the demand of sample is only 0.004ml. The sample is seal in the capillary and it is benefit to measure the microscale, toxic, irritating, effumable and inhaling liquid's refractive and also it can be used to measure the density of liquid. The invention's equipment is simple and measurement is convenience and reliable and it can be used in the research and producing department of chemical industry, medical, food, and fossil oil industry.

Owner:YUNNAN UNIV

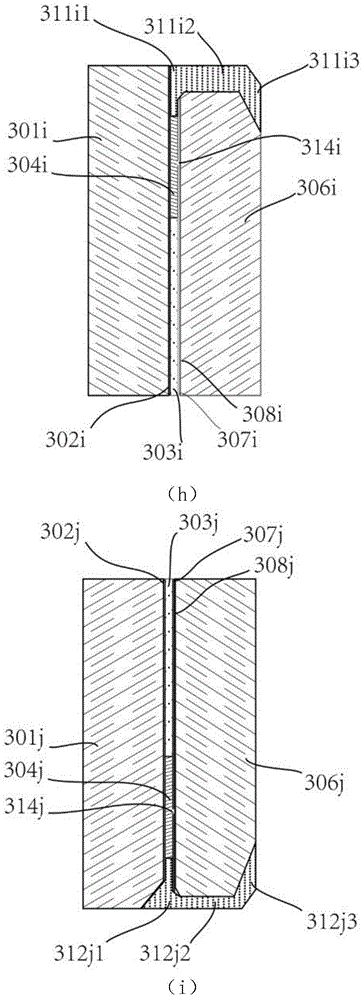

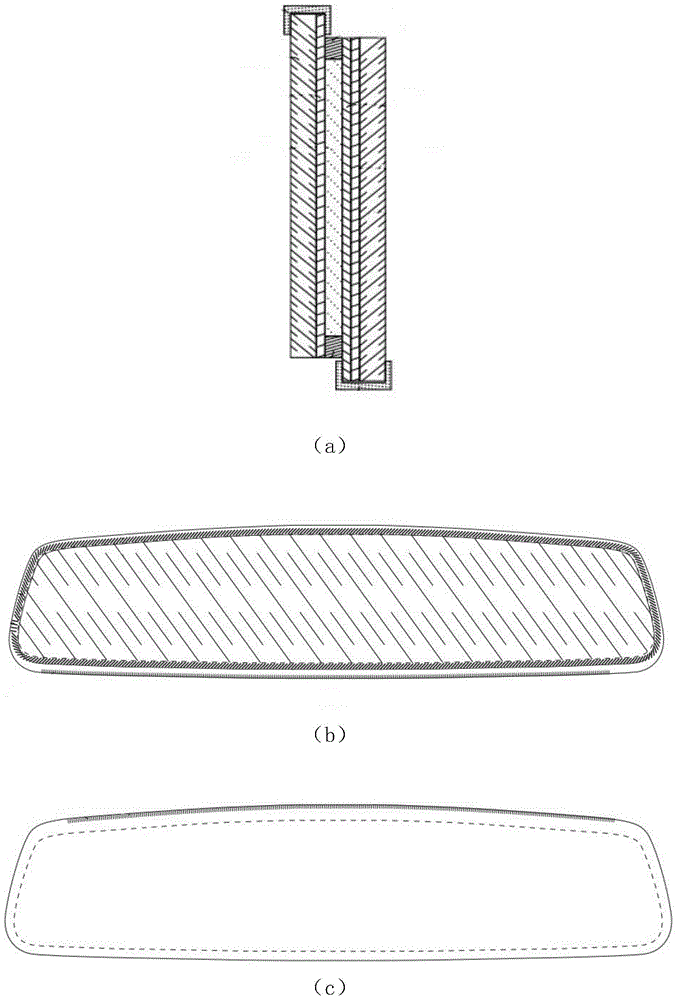

Manufacturing packaging method of electrochromic anti-dazzle device for vehicle

The invention relates to a packaging method of an electrochromic anti-dazzle device, and in particular relates to a packaging manufacturing method for edging and chamfering in a conduction region, where an electrode needs to be imported, of the conductive layer of the glass substrate of the electrochromic anti-dazzle device so as to increase the sectional area of a conductive silver adhesive; according to the requirements of reduce the package and the electrode leading-out region of the electrochromic anti-dazzle device and increasing the thermochromic device structure of a visible range, the packaging of the electrochromic anti-dazzle device is completed by use of the techniques of etching, vacuum electrochromic material pouring, sealant box hot pressing, silver adhesive pouring, heat treatment and the like. Compared with the traditional packaging of the electrochromic anti-dazzle device, the electrical conductivity of the silver adhesive after heat treatment is improved, the width of the conductive sealant is reduced and the production process and the equipment are simplified; the packaging method has obvious advantages; the height of the visual range of the electrochromic anti-dazzle device package is increased by 2-3mm.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

Economic anti-saltpetering inside and outside walls facing mortar

The invention provides an inside and outside walls facing mortar with little saltpetering phenomenon in use and less price; the facing mortar comprises the following components by weight percent: 30-40% of silicate cement, 15-25% of inert filler, 40-50% of sand, 1.0-2.0% of high active mineral filler and 3.0-5.0% of additives. The preparation method of the facing mortar of the invention adopts common silicate cement as cementitious material, and adds high active metakaolin with small particle size to react with excessful calcium hydroxide in the cement and obtain CSH gel so that the existing free Ca<2+> in the cement is greatly reduced, the compactibility of the facing mortar layer is increased and the external water is hard to enter; in addition, a defined amount of nanoscale water repellent agent is added in the mortar so that the channel of external water into the mortar is blocked, double barriers are formed between each other and the generation conditions of saltpetering can be well restrained. The facing mortar of the invention has reasonable formula, simple construction, and lower production cost which is greatly less than that of the existing anti-saltpetering mortar, thus being applicable to the inside and outside walls decoration of common houses or factories.

Owner:广东龙湖科技股份有限公司

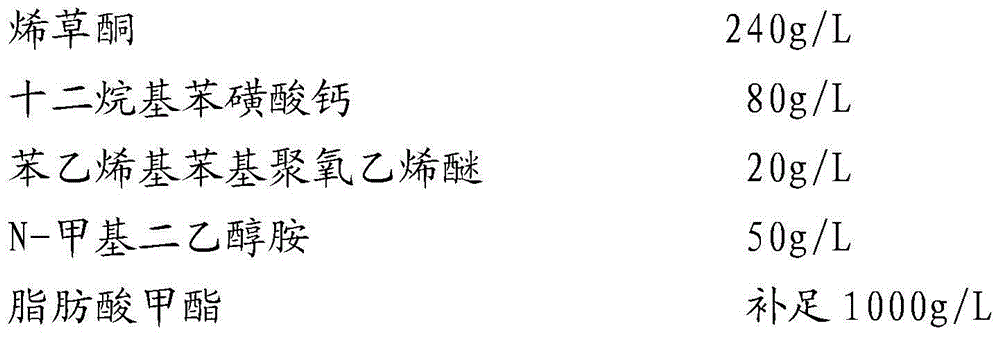

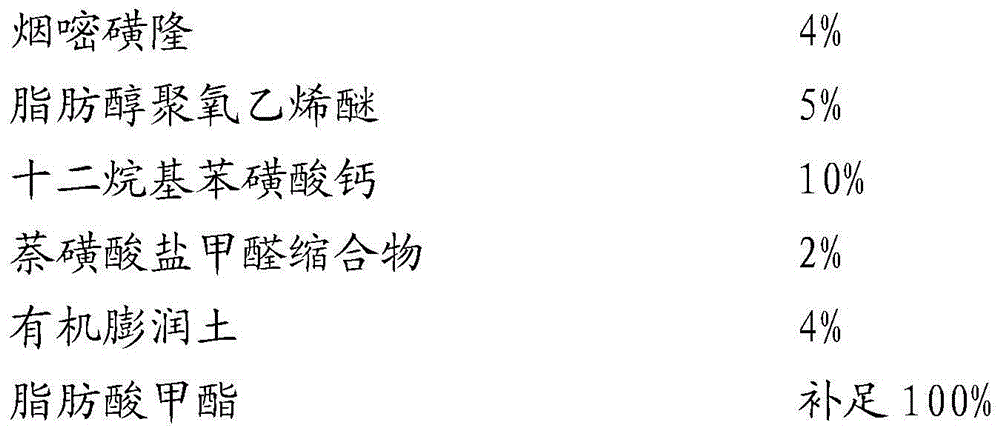

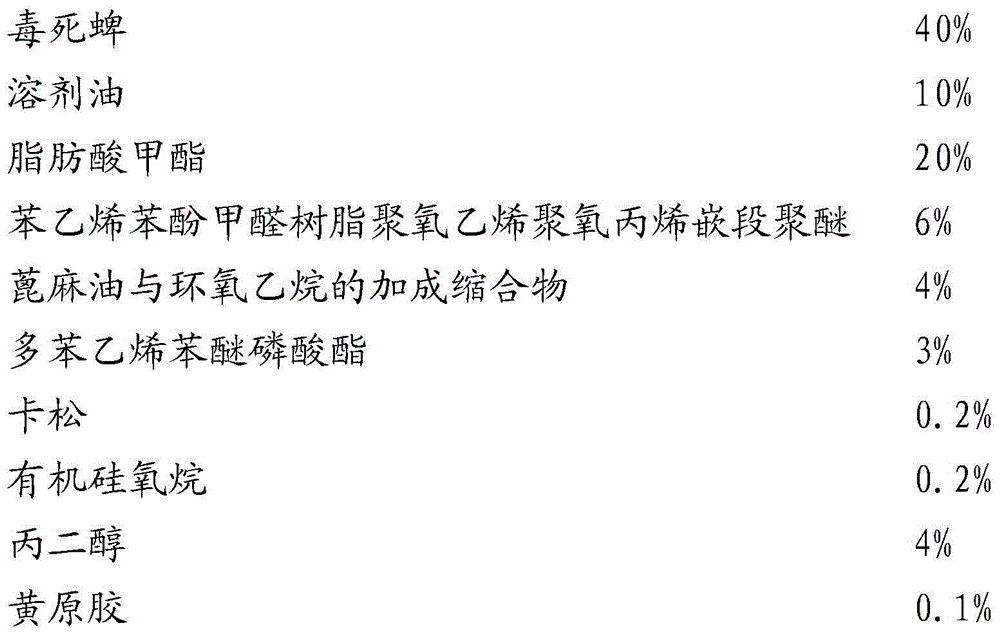

Development and application of fatty acid methyl ester serving as environment-friendly solvent in pesticide preparations

InactiveCN104823969AEasy to degradeSolve processing problemsBiocidePlant growth regulatorsChemical synthesisSolvent

The invention belongs to the technical field of farm chemicals and discloses development and application of fatty acid methyl ester serving as environment-friendly solvent in pesticide preparations. The fatty acid methyl is adopted for replacing high-toxicity solvents in massive use at present. The fatty acid methyl which serves as the environment-friendly solvent is directly added in production of the pesticide preparations and capable of dissolving and dispersing active ingredients of pesticides, and after the fatty acid methyl ester is combined with other additives, qualified pesticide preparation products can be made by stirring, mixing, shearing or grinding. The fatty acid methyl ester is applicable to all pesticide products such as mineral pesticides, biological pesticides, chemical synthetic pesticides and the like.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

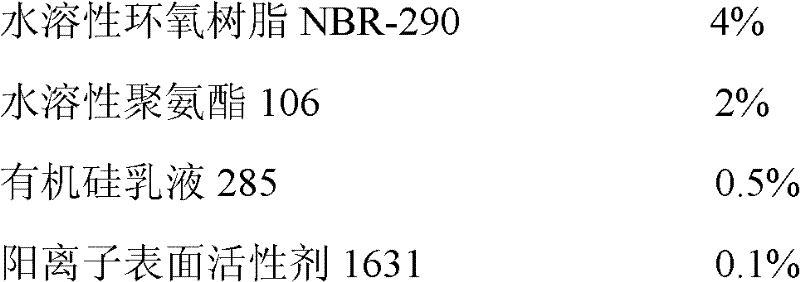

Pre-processing reinforced type impregnating agent for basalt fiber chopped spun yarn and preparation method of pre-processing reinforced type impregnating agent

The invention relates to a pre-processing reinforced type impregnating agent for a basalt fiber chopped spun yarn and a preparation method of the pre-processing reinforced type impregnating agent and belongs to the technical field of the impregnating agent. The pre-processing reinforced type impregnating agent comprises the following components by weight percent: 2-4% of water-soluble epoxy resins, 2-4% of water-soluble polyurethanes, 0.5-1% of organic silicon latexes, 0-0.1% of cation surface active agents, 0.5-1% of antistatic agents, 0.2-0.5% of organic silane coupling agents, 0.1-0.2% of pH adjusting agents and the balance water. The pre-processing reinforced type impregnating agent and the preparation method provided by the invention are simple in technology and are suitable for the production of the basalt fiber chopped spun yarn with a single fiber diameter of 3.5-7.5 microns. The basalt fiber chopped spun yarn produced by utilizing the pre-processing reinforced type impregnating agent is high in strength and excellent in flexibility; a produced high-temperature acupuncture filter felt is free from being subjected to heat treatment; silicon oil and tetrafluoro coatings can be directly coated; energy source is saved; environmental pollution is reduced; and the pre-processing reinforced type impregnating agent is excellently combined with an interface of a produced product substrate and is high in strength.

Owner:山东兴国大成特种纤维科技有限公司

Method and device for extracting prickly ash seed oil from prickly ash seeds

ActiveCN101812369ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionCrusherPlunger pump

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting prickly ash seed oil from prickly ash seeds. The method for extracting prickly ash seed oil from prickly ash seeds is characterized by comprising the following steps of: (1) firstly, drying the prickly ash seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed prickly ash seeds into an extracting kettle, pumping the vacuum to the pressure below 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the prickly ash seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-50 DEG C, and the extraction time is 30-45 min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50 DEG C; and (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final prickly ash seed oil.

Owner:甘肃省轻工研究院有限责任公司

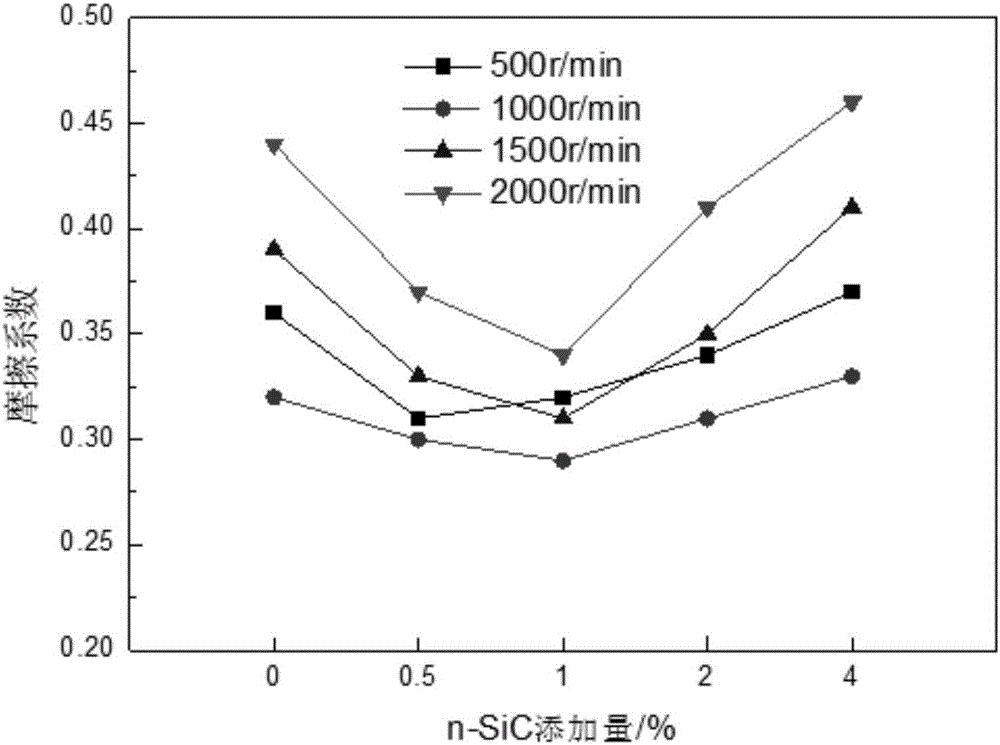

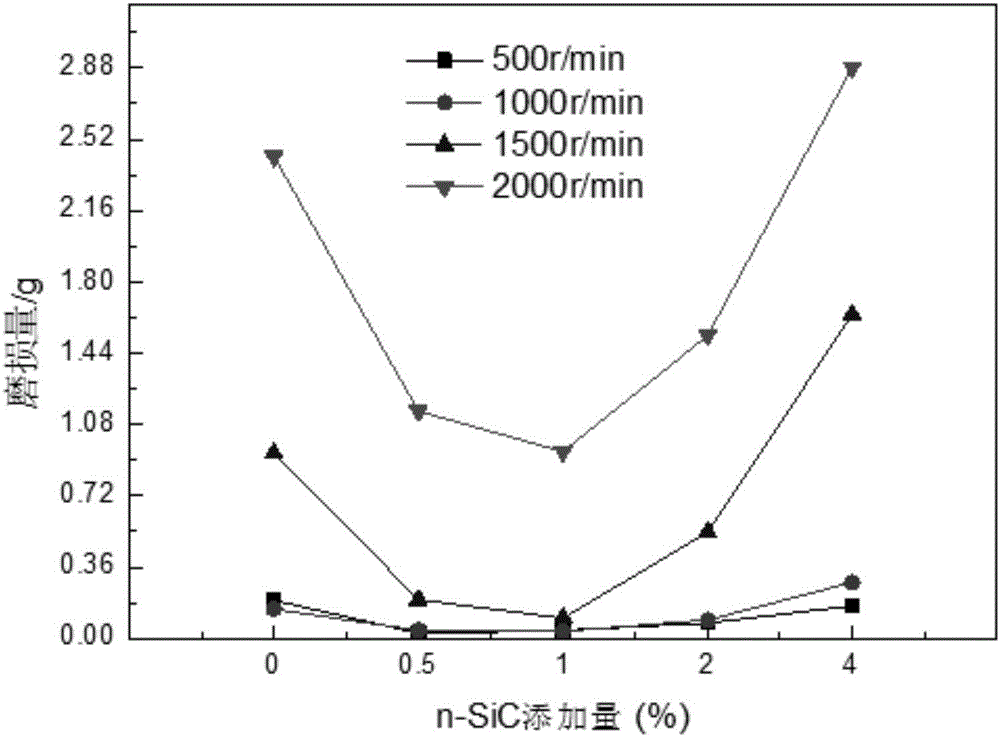

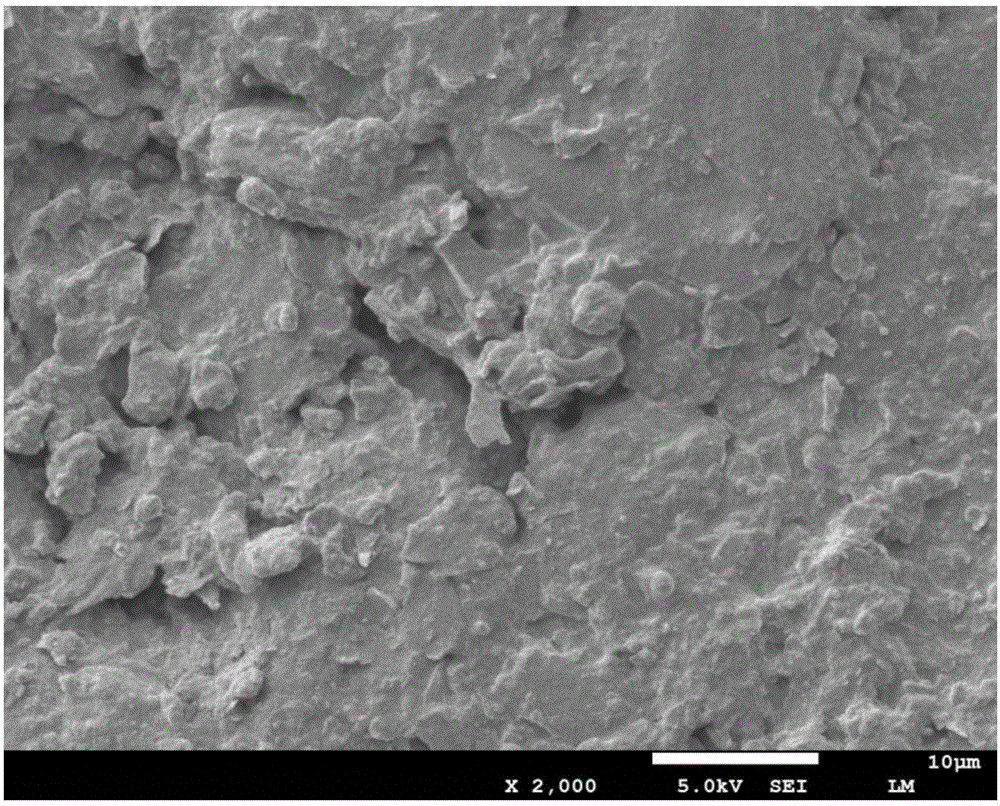

Copper-based powder metallurgy friction material and preparation method thereof

ActiveCN106702204AImprove thermal shock resistanceImprove high temperature friction performanceSlurrySilicon dioxide

The invention relates to a copper-based powder metallurgy friction material and a preparation method thereof, and relates to the technical field of materials. The copper-based powder metallurgy friction material is prepared by sintering raw materials, and comprises the following raw materials in percentage by mass: 6 to 8 percent of tin powder, 3 to 6 percent of iron powder, 4 to 7 percent of nickel powder, 4 to 7 percent of silicon dioxide, 5 to 6 percent of graphite powder, 0.5 to 4 percent of nano silicon carbide, and the balance of copper powder. The wear resistance of the copper-based powder metallurgy friction material is good. The preparation method comprises the following steps: mixing the nano silicon carbide and industrial ethyl alcohol; performing ultrasonic treatment to obtain first mixed slurry; adding the graphite powder, the tin powder, the iron powder, the nickel powder, the silicon carbide and the iron powder into the first mixed slurry; performing ultrasonic treatment and stirring; drying, and pressing the obtain mixed powder through cold pressing; sintering and moulding the obtained press blank; cooling. The strength and the wear resistance of the copper-based powder metallurgy friction material are effectively improved.

Owner:YANCHENG INST OF TECH

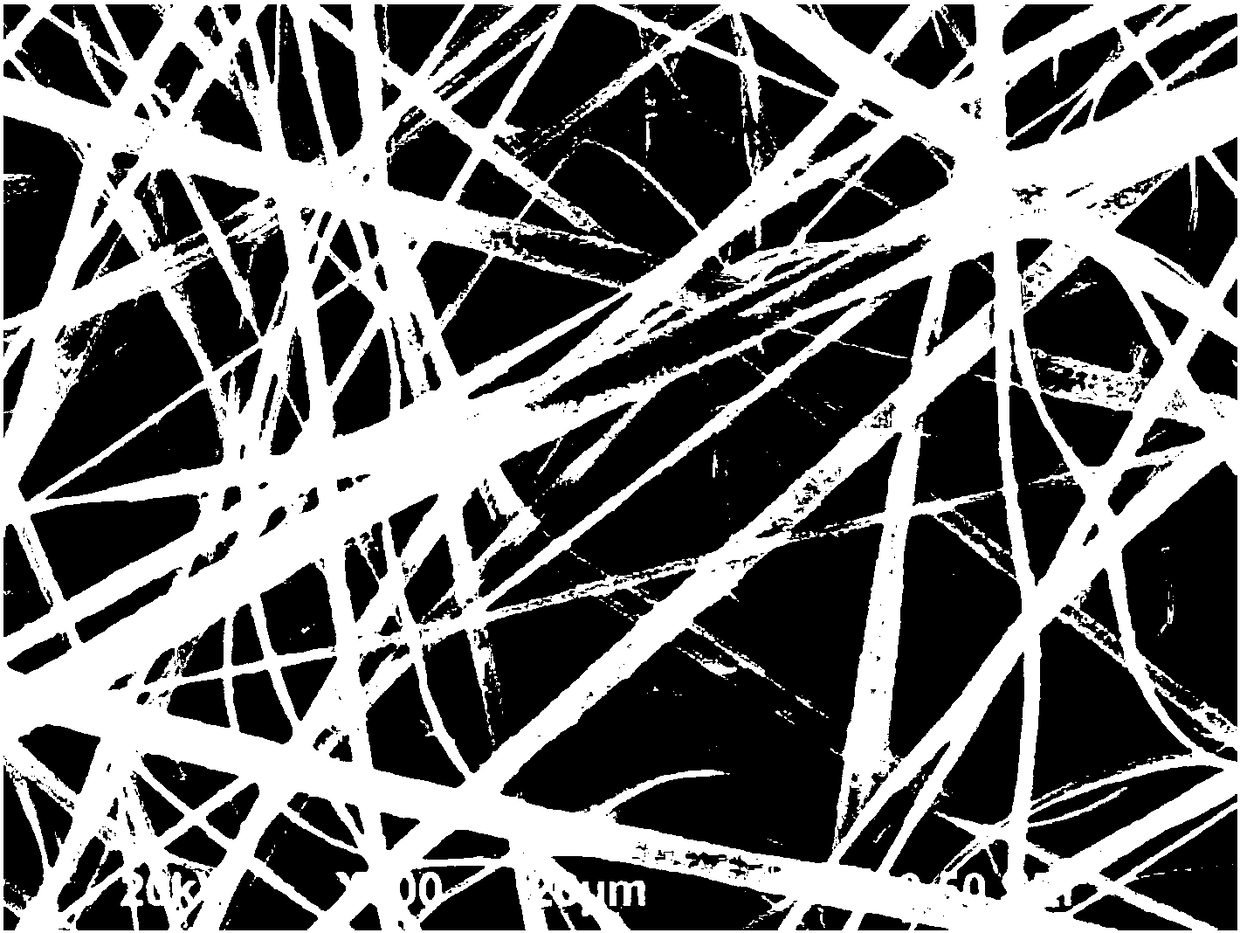

Manufacturing method for fibrous membrane for oil-water separation

ActiveCN104313796ANot easy to slipHigh breaking strengthElectro-spinningNon-woven fabricsFiberPorosity

The invention discloses a manufacturing method for a fibrous membrane of an extremely hydrophobic organic macromolecule chemical compound with an oil-water separation function in the technical field of fibrous membrane manufacturing. The manufacturing method comprises the following steps: synthetizing a copolymer with excellent electrostatic spinnability by regulating the compounding ratio of a monomer and controlling the condition of a suspension polymerization technology and by adjusting and controlling the compositions of a solution, processing parameters and the temperature and humidity conditions of environment, and spinning a copolymer solution into the fibrous membrane with the advantages of uniform and small bore diameters, high porosity, large flux and extremely hydrophobic and oleophylic properties by using an electrostatic spinning technique. The obtained fibrous membrane has the advantages that the specific surface area is large, the patterns are large, the stacking structure is proper, and the fibrous membrane is in a three-dimensional bore channel structure. Compared with an existing polymer-based oil-water separation member, the fibrous membrane has the advantages that the bore channel structure is more reasonable, the separation capacity is stronger, the separation efficiency is higher, the anti-pollution capacity is stronger, the membrane bores are not easy to block, the oil-water selectivity is stronger, the mechanical strength is higher, the flexibility and the temperature resistance are better, the preparation process is shorter, the consumed energy is little, the filtering rate is higher, and the cost is lower, so that the fibrous membrane can better satisfy the requirements of industrial practicality.

Owner:TIANJIN POLYTECHNIC UNIV

Zinc oxide-based nanoparticle ink and electroluminescent device

InactiveCN107099190AVolatileEvenly dispersedMaterial nanotechnologySolid-state devicesAlcoholNanoparticle

The invention provides zinc oxide-based nanoparticle ink. The zinc oxide-based nanoparticle ink comprises a solvent and zinc oxide-based nanoparticles uniformly dispersed in the solvent. The zinc oxide-based nanoparticle ink comprises, by mass, 0.01 to 20.00% of the zinc oxide-based nanoparticles and 80.00 to 99.99% of the solvent. The zinc oxide-based nanoparticle ink is characterized in that the solvent comprises at least one alcohol ether ester compound. The zinc oxide-based nanoparticle ink can solve the problem that the existing zinc oxide-based nanoparticle ink is not suitable for ink-jet printing and has poor film-forming quality. The invention provides an electroluminescent device. An electron transport layer of the device is prepared from the zinc oxide-based nanoparticle ink through ink-jet printing.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Method and device for extracting olive pomace oil from olive pomace

ActiveCN101805664ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionPomacePlunger pump

The invention relates to a method for extracting grease from oil seeds, in particular to a method for extracting and recycling olive pomace oil from olive pomace. The method is characterized by comprising the following steps of: (1) drying the olive pomace until the water content is less than 13%, and crushing to 40-80 meshes by a crusher; (2) putting the dried and crushed olive pomace into an extraction kettle, vacuumizing until the pressure is less than 1*10<4>pa, and discharging air in the extraction kettle; (3) injecting a tetrafluoroethane solution into the extraction kettle by a plunger pump until the level of the solution submerges raw materials of the olive pomace by using a sight glass for observation; (4) starting stirring and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature is 40-50 DEG C, and the extraction time is 45min; (5) decompressing, raising temperature, evaporating and separating in a separation kettle, wherein the extraction pressure is 0.1-0.5Mpa, and the temperature is 40-50 DEG C; and (6) after subcritical extraction, centrifuging to separate crude oil by a high-speed centrifuge, and filtering to obtain the final olive pomace oil.

Owner:LONGNAN XIANGYU OIL OLIVES DEV

Flame retardant adhesive without halogen in use for flexible printed circuit

ActiveCN1916101AExtended shelf lifeVolatileEster polymer adhesivesCircuit susbtrate materialsHalogenEmulsion

This invention discloses a method for preparing halogen-free and flame-retardant acrylate adhesive for flexible printing circuit board. The adhesive comprises: multiple acrylate monomers, allyl phosphate, crosslinking monomer, initiator, emulsifier, phosphorus-containing filler and inorganic filler. The method comprises: (1) adding multiple acrylate monomers, allyl phosphate, crosslinking monomer, initiator and emulsifier into a reactor; (2) adding deionized water, heaing and polymerizing under stirring to synthesize an emulsion; (3) adding the fillers into the emulsion to obtain the halogen-free and flame-retardant acrylate adhesive. The adhesive can be used for interlayer adhering of multi-layered flexible printing circuit board, and the obtained flexible printing circuit board has such adadvantages as good flame retardancy, high peel strength, good Sn weldability and good synthetic properties.

Owner:华烁电子材料(武汉)有限公司

Instant senecio cineraria tea cream and preparing process thereof

The invention discloses an instant senecio cineraria tea cream, which is prepared through the following processes of (1) crushing air-dried senecio cineraria; (2) adding the crushed senecio cineraria into water, wherein the mass ratio of feed liquid is 1: (8-12); and soaking and extracting for 1-3 times at the temperature of 35-50 DEG C; and (3) filtering soak extract obtained by the step (2), concentrating and vacuum drying the filter liquor, and crushing to obtain the instant senecio cineraria tea cream. According to the preparing process, the defect that natural components of the senecio cineraria are damaged and run off due to conventional boiling is overcome, and no additive is needed in the preparing process, so that the obtained instant senecio cineraria tea cream has milder and thicker taste, is safer to drink, is convenient to use and carry, and has the health-care efficacies of reducing blood press, lowering blood lipid, regulating blood sugar, suppressing tumor, defying age and the like.

Owner:唐军涛

Chinese herbal medicine preparation

ActiveCN104117083AHas a long-lasting sustained-release effectStable blood concentrationPillowsPowder deliveryMedicineCurative effect

The invention relates to a pharmaceutical composition which is stored in bedding articles and capable of enabling people to obtain curative effects of tranquilizing and allaying excitement. The Chinese herbal medicine preparation is powder or granule which is prepared by taking one or more of lavender, twinings, jasmine flower and liquorice as materials. According to the invention, a scientific process is adopted for preparing one or more of lavender powder, twinings powder, jasmine flower powder and liquorice powder into powder with a proper grain size or into a similar pharmaceutical granule. The substances with effects of tranquilizing and allaying excitement have effects of slowly releasing for a long time.

Owner:汪建

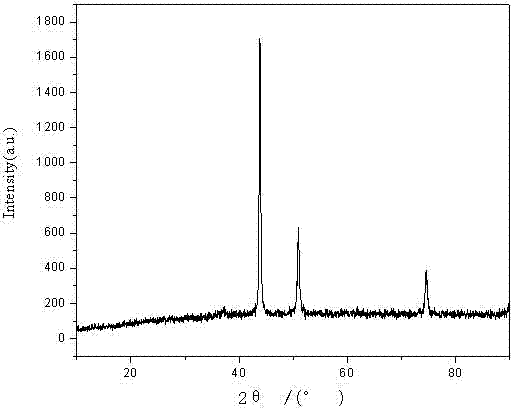

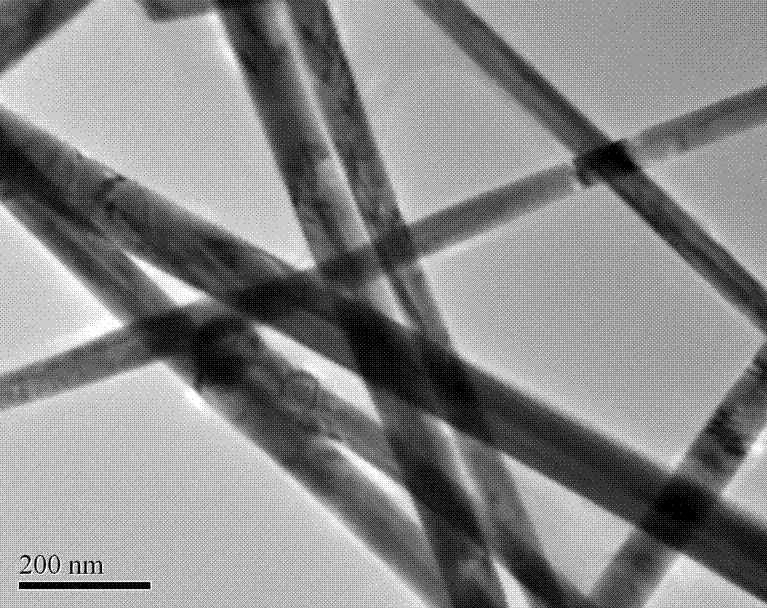

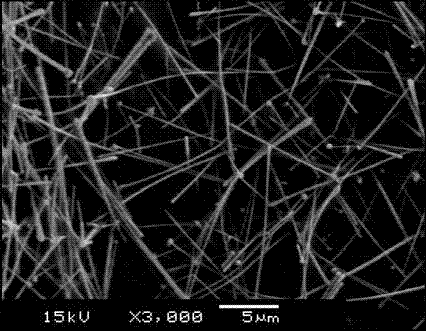

Preparation method for copper nanowire

ActiveCN103084581AEasy to removeVolatilePolycrystalline material growthFrom normal temperature solutionsHydroxylaminePotassium hydroxide

The invention belongs to the technical field of novel function nanometer material preparation, and discloses a preparation method for a copper nanowire. Reducing agent is added to copper source on the premise that morphology control agent and chemical potential control agent are exist in water solution, and the copper nanowire are obtained after separation and under the condition that reaction is carried out for at least one hour in temperature of 25 DEG C to 100 DEG C, wherein the copper source is one or combination of copper hydroxide and copper oxide, the morphology control agent is one kind or combination of more than two kinds of polyethylene polyamine, the chemical potential control agent is one or combination of sodium hydroxide and potassium hydroxide, and the reducing agent is one or combination of hydrazine hydrate and hydroxylamine. The preparation method for the copper nanowire has the advantages of being simple in technology and device, cheap and easy-getting in raw materials, low in cost, high in productivity, suitable for large-scale industrial production, and the like. Prepared copper nanometers are uniform in diameter, diameters and lengths of the copper nanometers can be controlled through changing concentration of the morphology control agent and concentration and reaction temperature of the copper resource.

Owner:HENAN UNIVERSITY

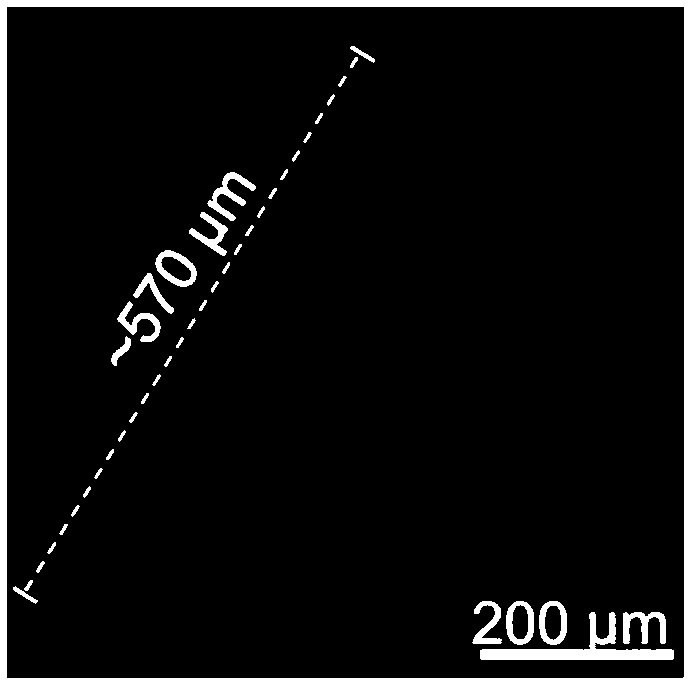

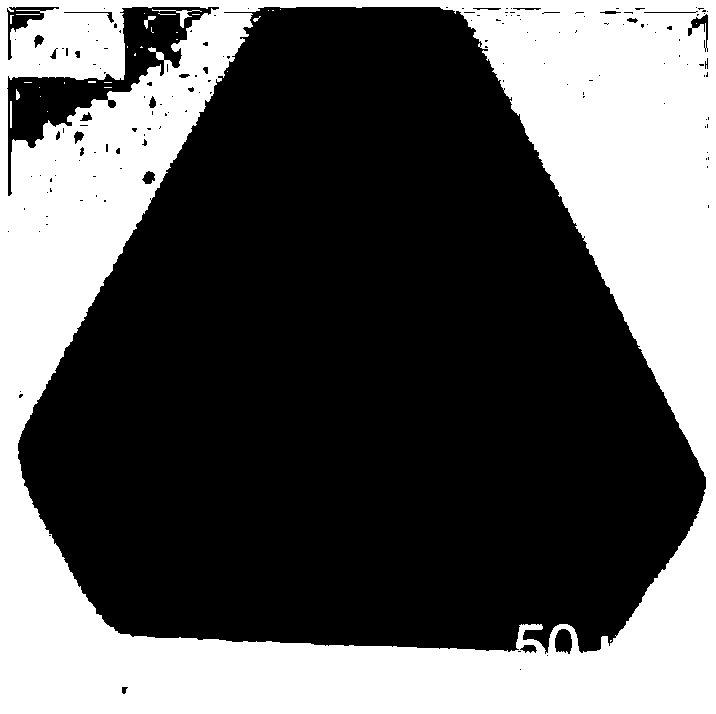

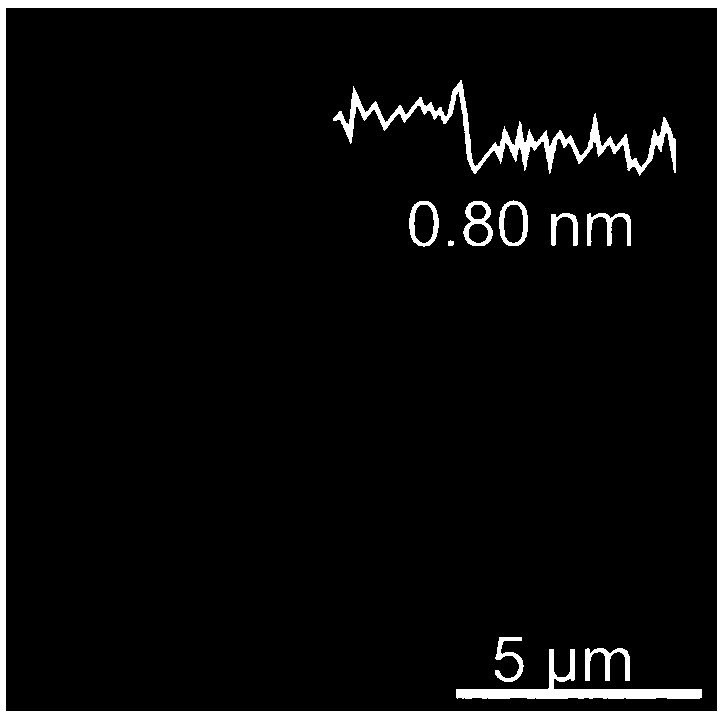

Disulfide single crystal and preparation method and application thereof

InactiveCN109183156ALarge domain sizeQuality improvementPolycrystalline material growthFrom chemically reactive gasesTube furnaceOxide

The invention relates to a disulfide single crystal and a preparation method and application thereof. The preparation method comprises: (1) placing a sulfur group elementary substance source and a transition metal oxide source doped with sodium chloride at positions in a tubular furnace with a heater at the middle, wherein the distances between the positions and a gas inlet of the tubular furnaceare respectively 25-35% and 45-55% the total length of the tubular furnace and placing a growth matrix above the transition metal oxide source, and (2) feeding protective gas into the tubular furnace,heating the tubular furnace to a chemical vapor deposition temperature and carrying out chemical vapor deposition. The preparation method can produce disulfide single crystals with high crystallization quality and an oversized domain size. The disulfide single crystal can be used for any one or at least two of nanodevices, optical devices and on-chip lasers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

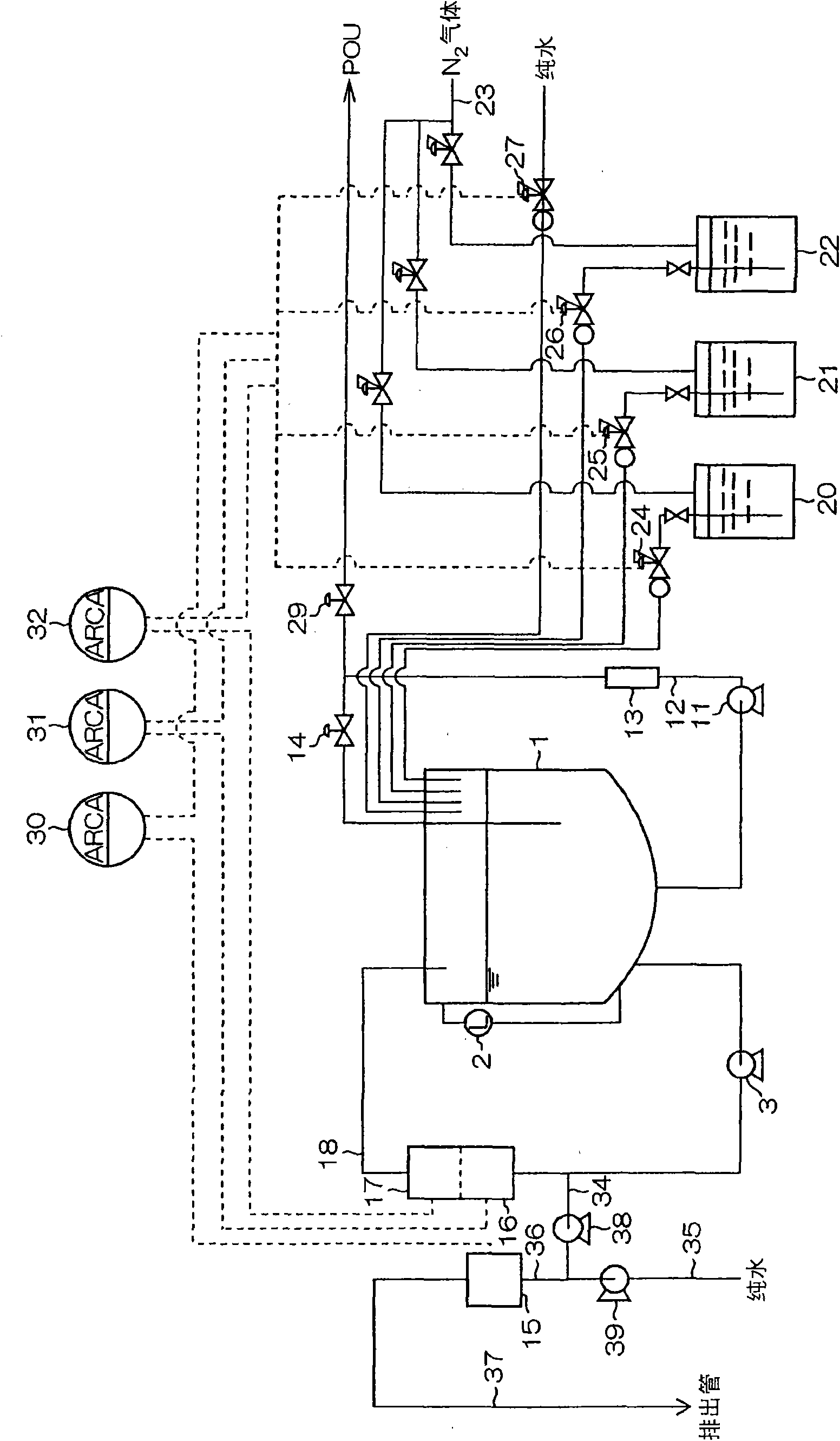

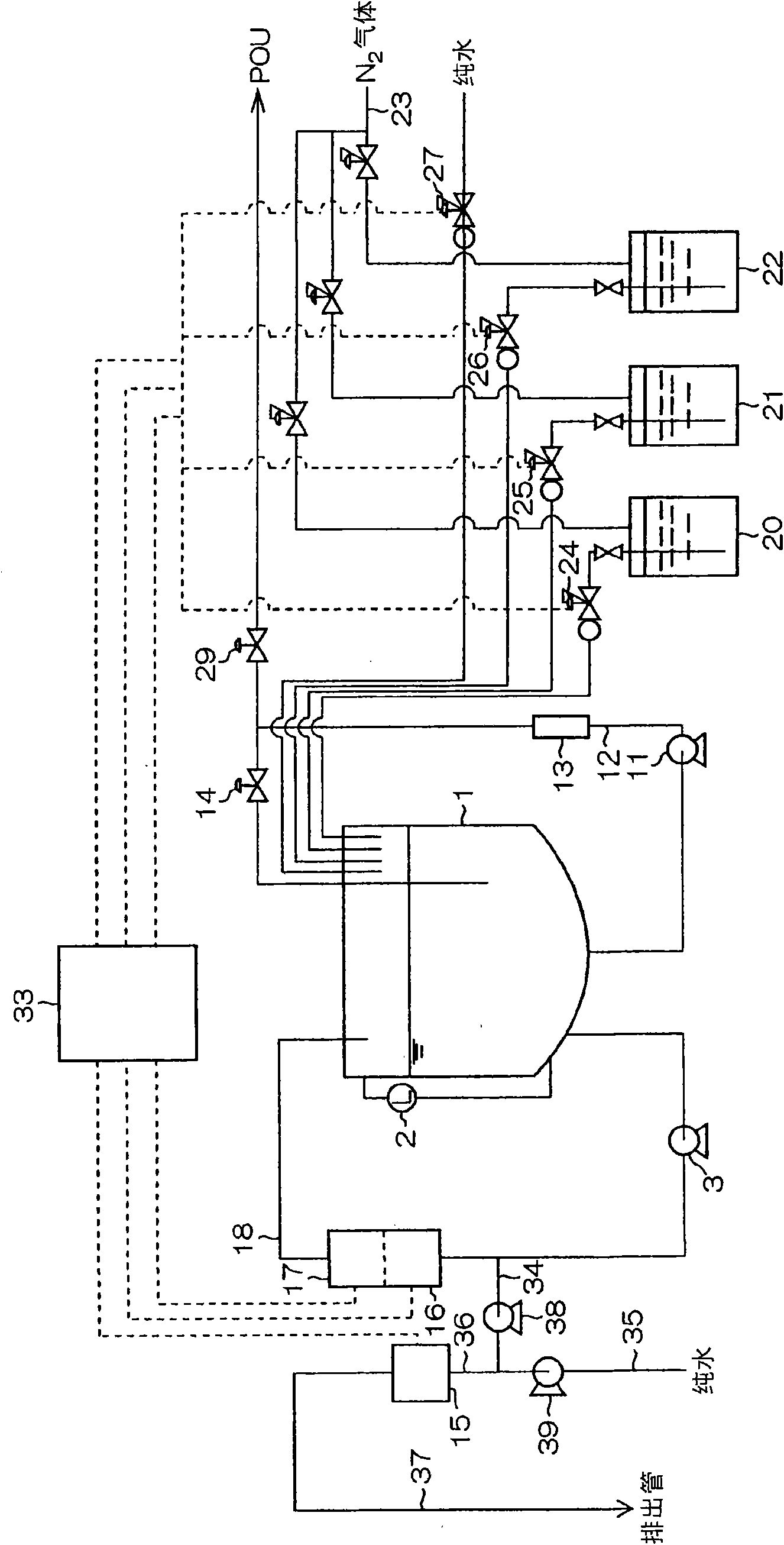

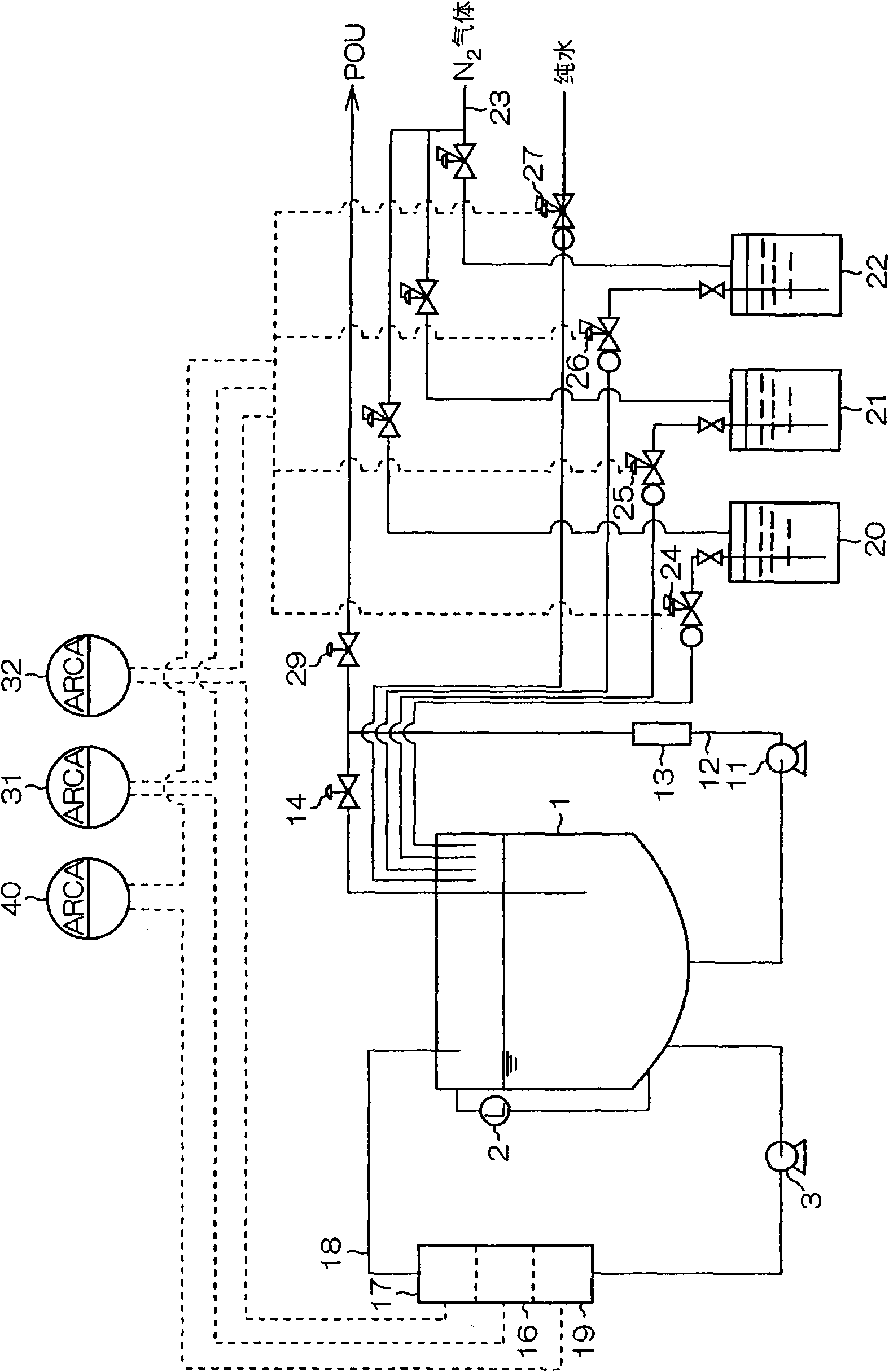

Device for blending etching solution and device for determinating concetration of etching solution

InactiveCN101567309AReal-time continuous determination of nitric acid concentrationGood and constant accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhosphoric acidDisplay device

The present invention provides a etching solution blending device which is used in a semiconductor manufacturing works or flat-panel display manufacturing works and is capable of constantly blending nitric acid concentration, moisture concentration, phosphoric acid concentration and acetic acid concentration of the etching solution. The device comprises: an electric conductivity meter for detecting the electric conductivity of the dilution formed by adding pure water into etching solution in a blending tank or an absorption spectrophotometer for detecting the nitric acid concentration of the etching solution, an absorption spectrophotometer for detecting the moisture concentration of the etching solution, an absorption spectrophotometer or a densitometer for detecting the phosphoric acid concentration of the nitric acid, a component concentration operation mechanism for operating the component concentration of the etching solution by multi-component operation method according to the electric conductivity value of the nitric acid concentration conductivity meter, the absorbency value of the moisture concentration absorption spectrophotometer, and the absorbency value of the phosphoric acid concentration absorption spectrophotometer or the density value of the densitometer, and a replenishing mechanism for replenishing at least one of acid original solution, mixed acid original solution and pure water into the blending tank.

Owner:HIRAMA LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com