Membrane electrode structure for proton exchange membrane fuel cell and its preparing method

A proton exchange membrane and electrode structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as unfavorable anode discharge, cathode diffusion and water discharge, and achieve improved electrode performance and precious metal catalyst utilization. , the effect of reducing the loss of mass transfer polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

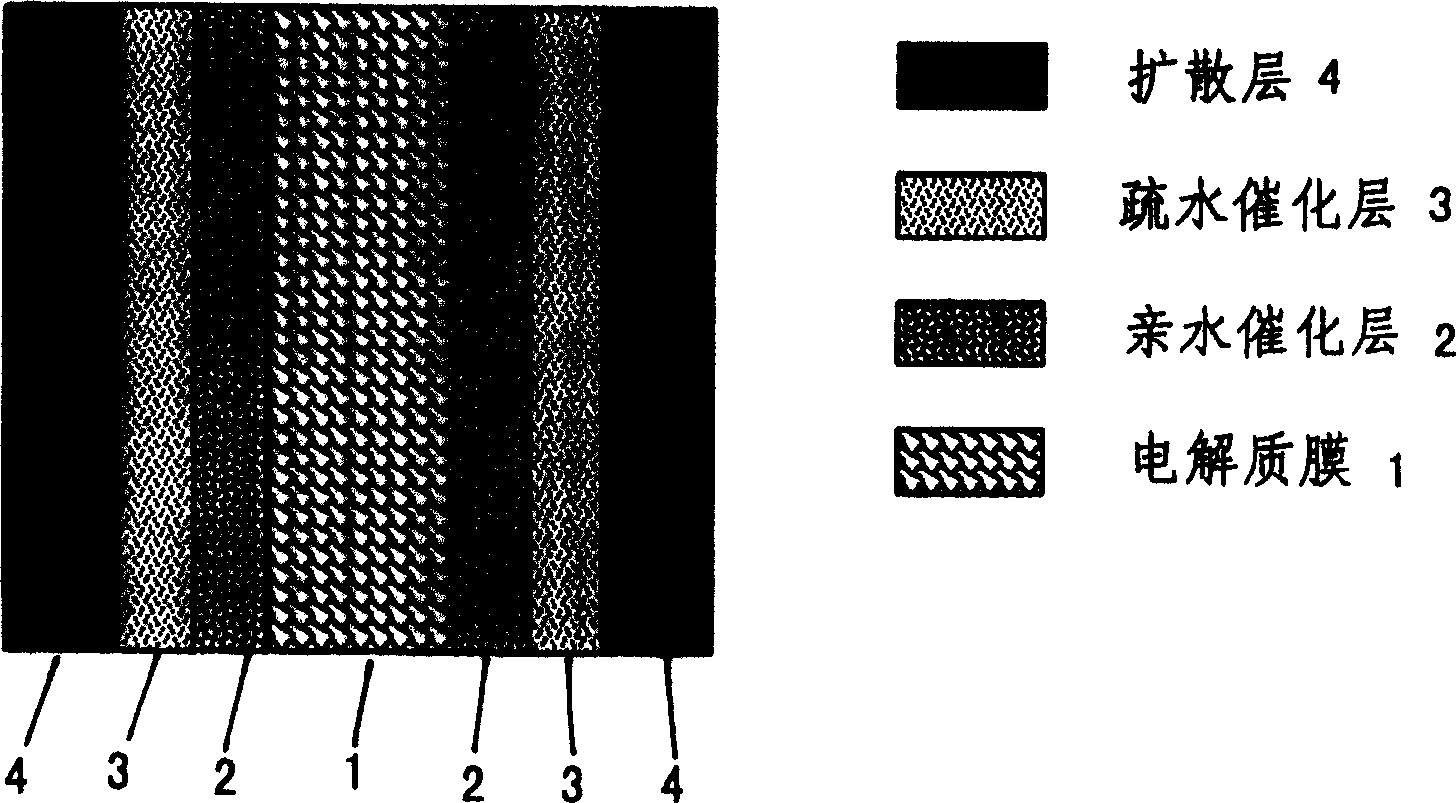

[0049] The preparation method of the membrane electrode that is used for proton exchange membrane fuel cell of the present invention comprises the following steps:

[0050] The first step, catalyst slurry preparation: weigh a certain amount of catalyst and Nafion solution, then add a certain amount of mixed solvent of alcohols and water, and mix well. The alcohol solvents include C1-C5 monohydric alcohols such as ethanol and isopropanol, and C2-C5 polyhydric alcohols such as ethylene glycol and glycerin. The mass ratio relationship between alcohol and water in the mixed solvent is water:alcohol=1:1-10.

[0051] The second step, preparation of multi-layer catalytic layer: (A) direct dispersion method: (1) use a spray gun, ultrasonic nozzle or other spraying equipment to uniformly (2) After the solvent has volatilized, continue to contain another low-loaded or high-loaded, non-loaded anode catalyst The slurry (ink) is evenly sprayed on the first anode catalyst layer to form tw...

Embodiment 1

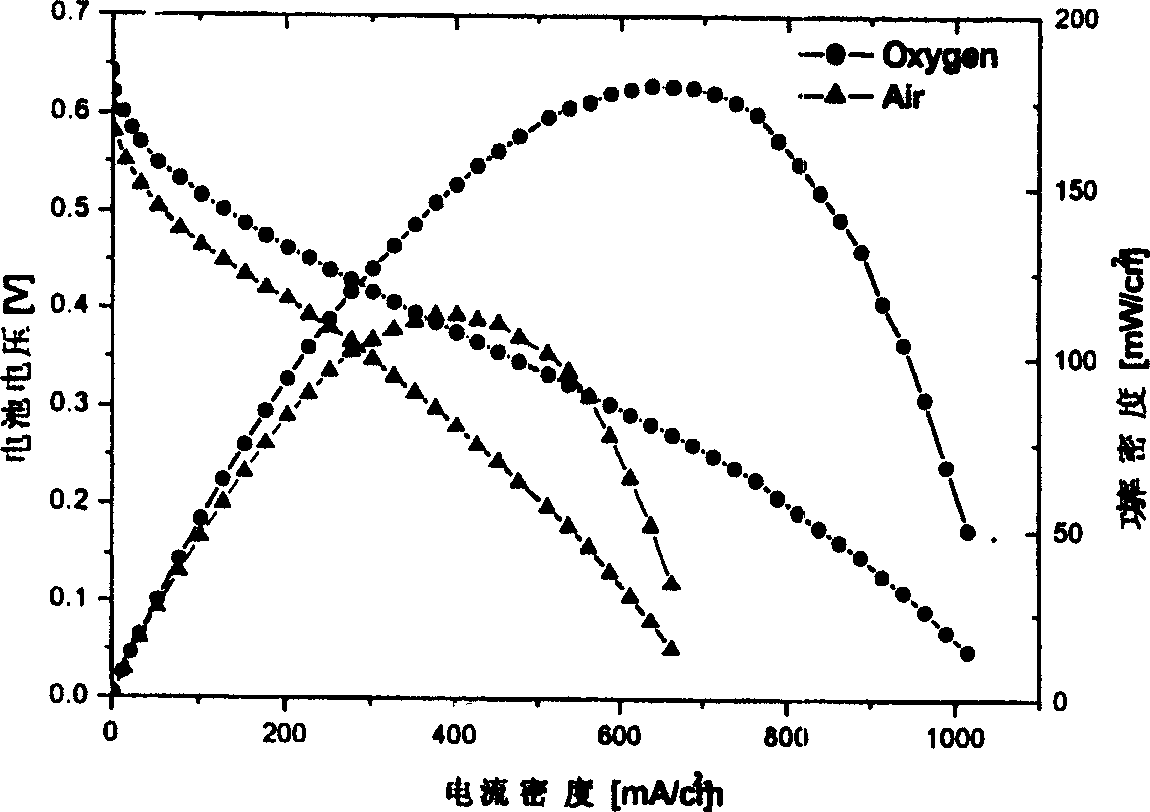

[0054] Operating conditions: battery temperature is 90°C; 1mol / L methanol aqueous solution is injected at 2ml / min; 0.2MPa oxygen or air, the flow rate is 4.3ml / s.

[0055] Accurately weigh 60mg 30wt.%Pt-15wt.%Ru / XC-72R Carbon (S BET =250m 2 / g) catalyzer, then add the mixed solvent of dehydrated alcohol and water (water: dehydrated alcohol=1: 10 volume ratio), mix homogeneously, then add 64mg 5%Nafion solution, continue to stir and mix homogeneously, obtain catalyst slurry, use The spray gun sprays this slurry evenly on the surface with a size of 8.6*8cm 2 On the polytetrafluoroethylene (PTFE) film, dry at room temperature, part of the catalyst slurry is lost during the spraying process, and the catalyst loading on the polytetrafluoroethylene (PTFE) film is 0.765mg / cm 2 , Nafion content is 5wt.%. Take by weighing 60mg 60wt.%Pt-30wt.%Ru black catalyst, catalyst slurry is evenly sprayed on the above-mentioned polytetrafluoroethylene (PTFE) that has been sprayed with 30wt.%Pt-...

Embodiment 2

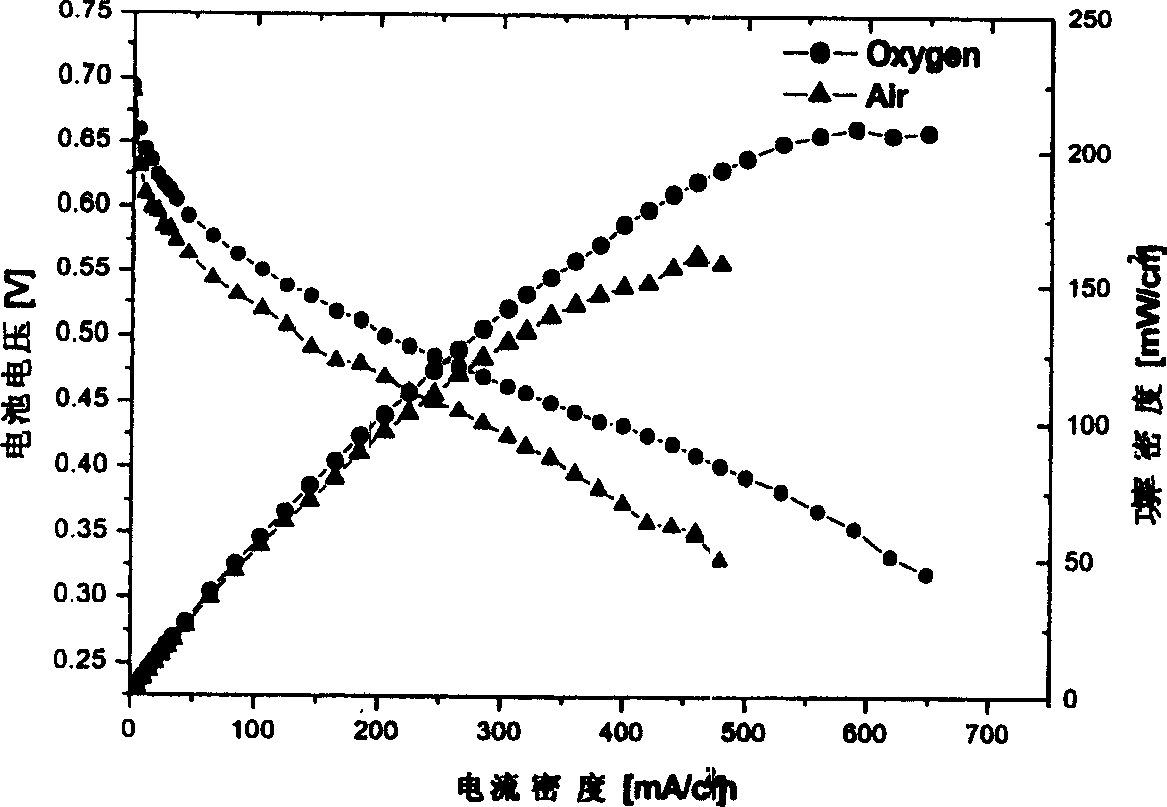

[0059] Operating condition is the same as embodiment 1.

[0060]Prepare the slurry according to the steps in Example 1, then spray the catalyst slurry on both sides of the Nafion membrane, and the electrode loadings are: anode; 0.877mg / cm 2 20wt.%Pt-10wt.%Ru / KetjenBlack carbon (S BET =1000m 2 / g), Nafion content 10wt.%, 0.976mg / cm 2 50wt.%Pt-25wt.%Ru / acetylene black carbon (S BET =50m 2 / g), Nafion content is 40wt.%; Negative electrode: 1.47mg / cm 2 40wt.% Pt-Fe / Ketjen Black carbon, Nafion content is 10wt.% 1.52mg / cm 2 80wt.% Pt / XC-72R carbon, Nafion content is 40wt.%. The performance of the membrane electrode (deleted) at 90°C is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com