Patents

Literature

96 results about "Ultrasonic nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic nozzles are a type of spray nozzle that uses high frequency vibration produced by piezoelectric transducers acting upon the nozzle tip that will create capillary waves in a liquid film. Once the amplitude of the capillary waves reaches a critical height (due to the power level supplied by the generator), they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization.

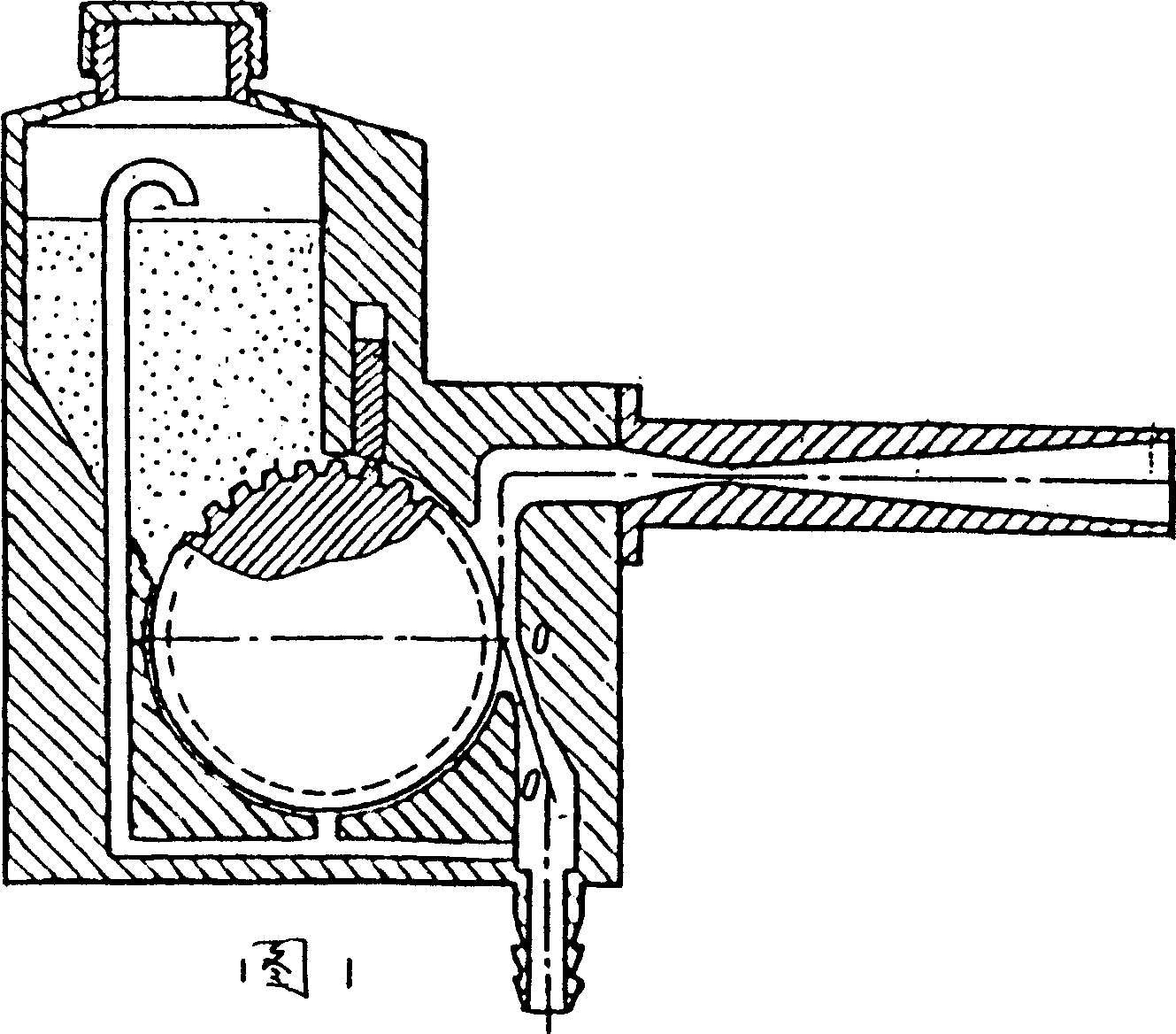

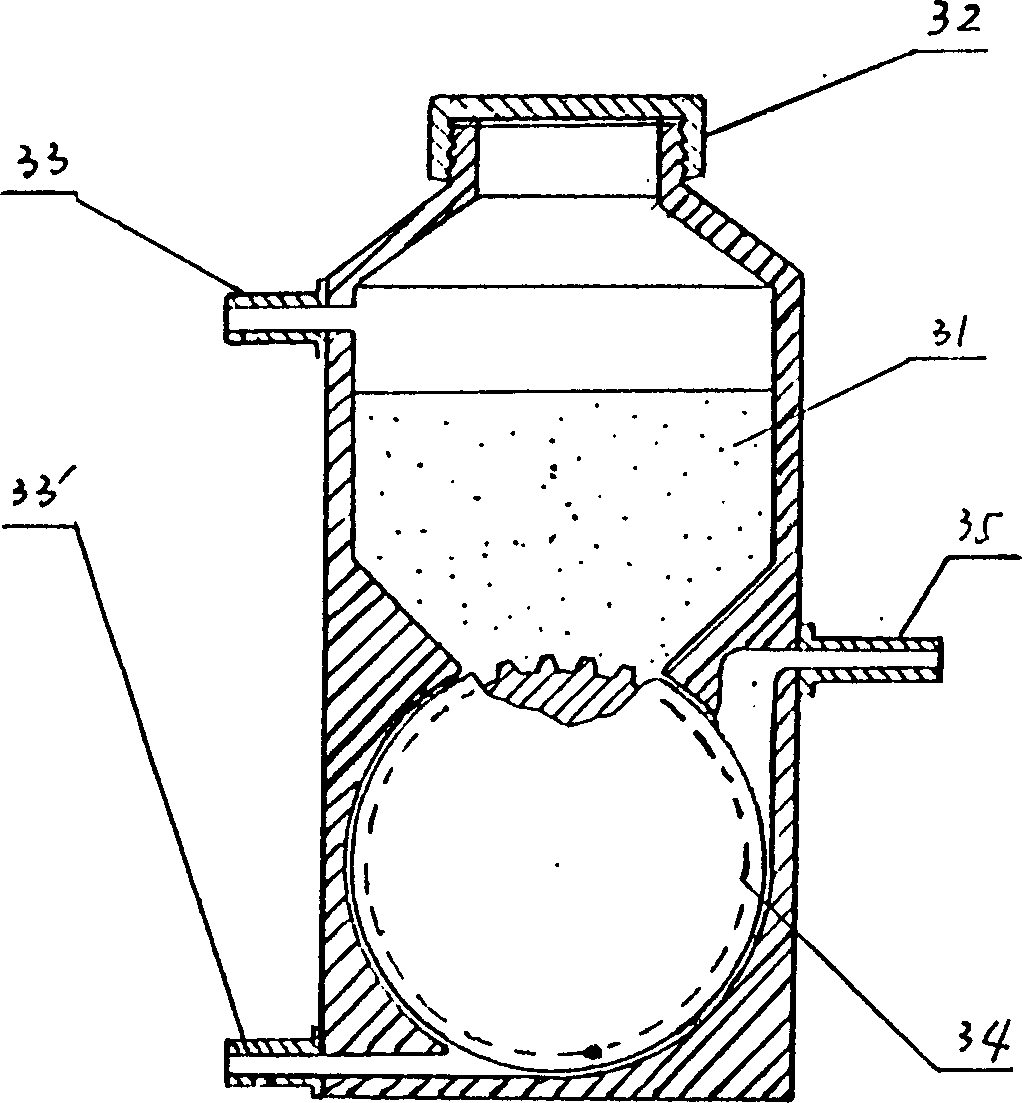

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

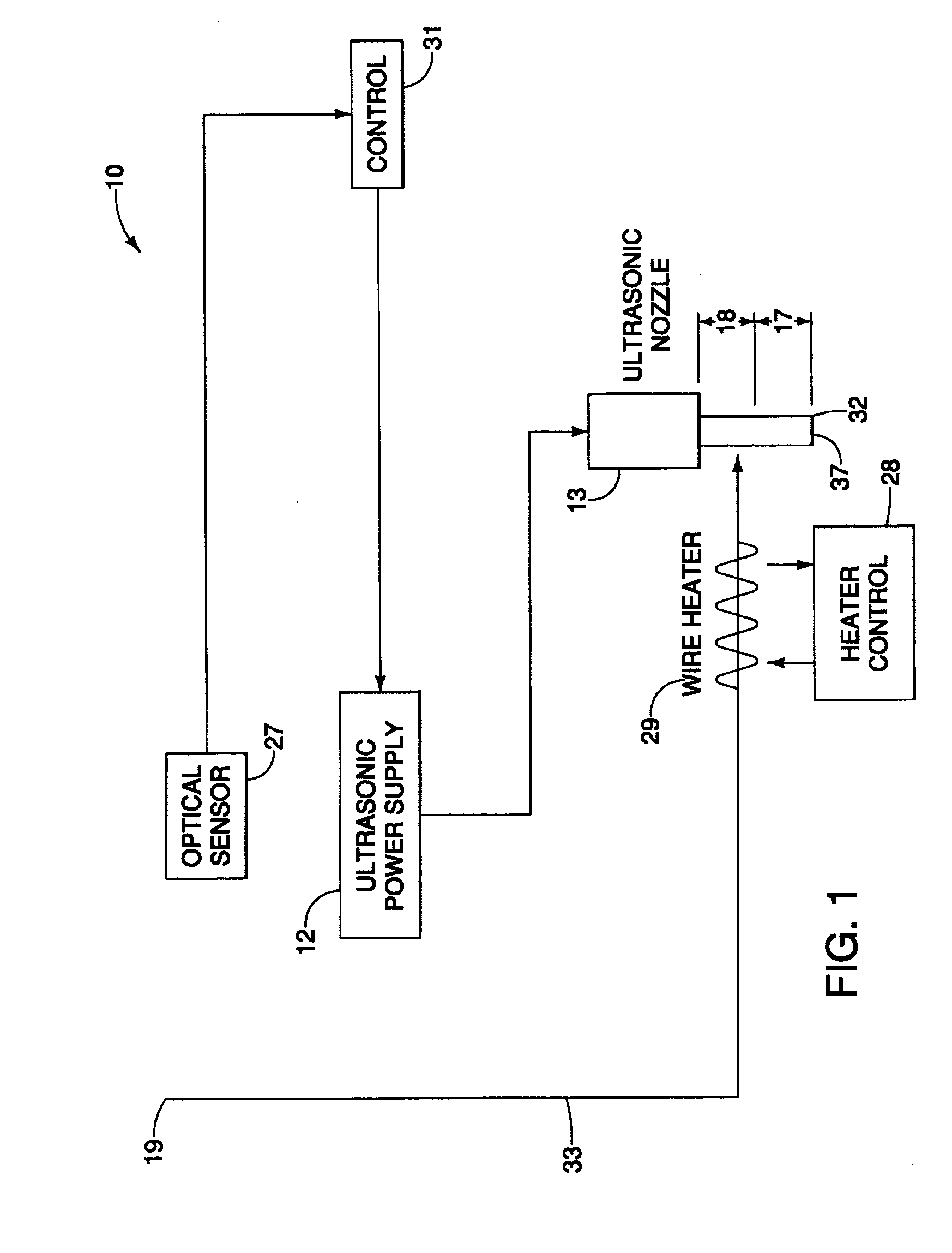

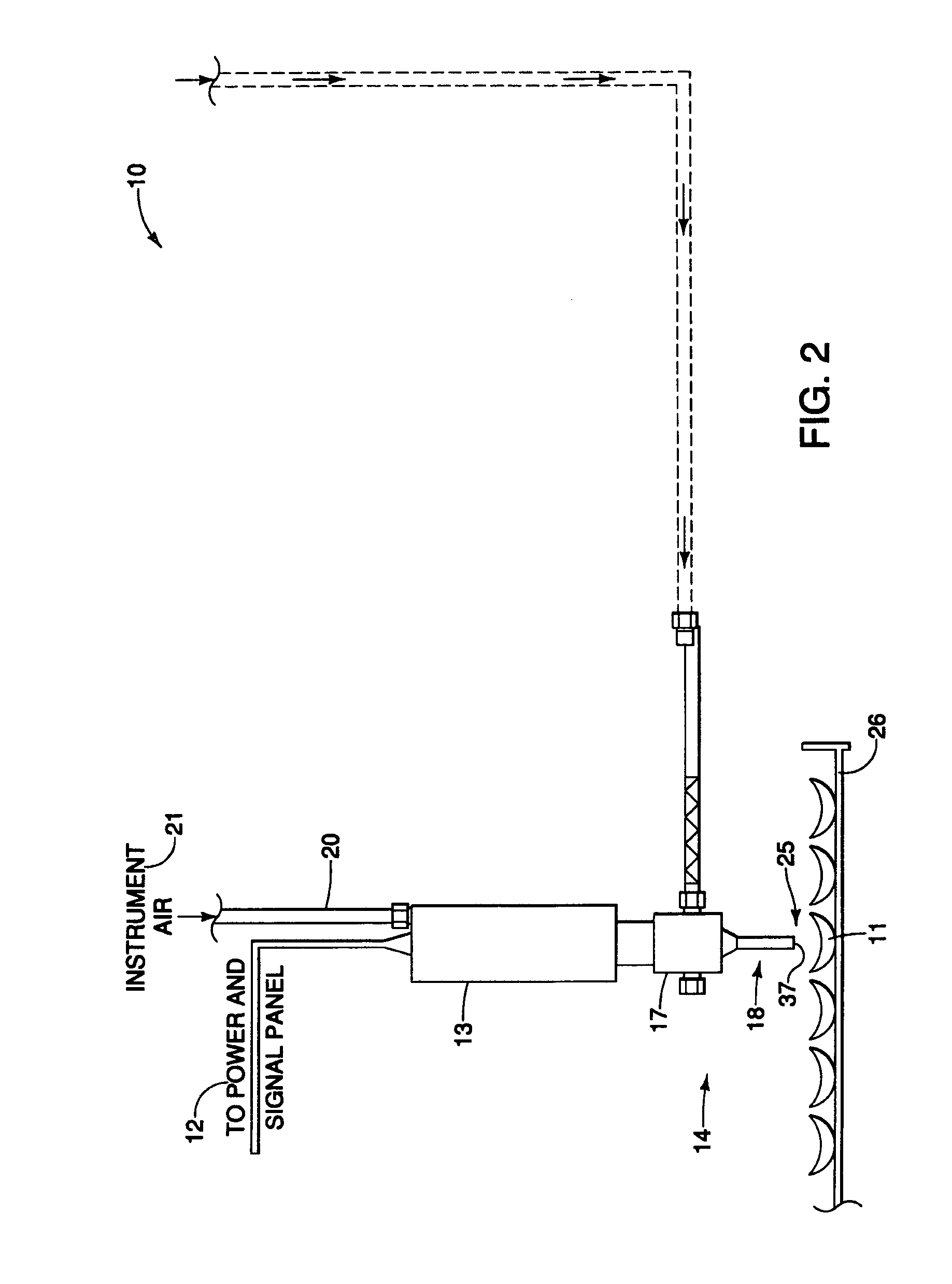

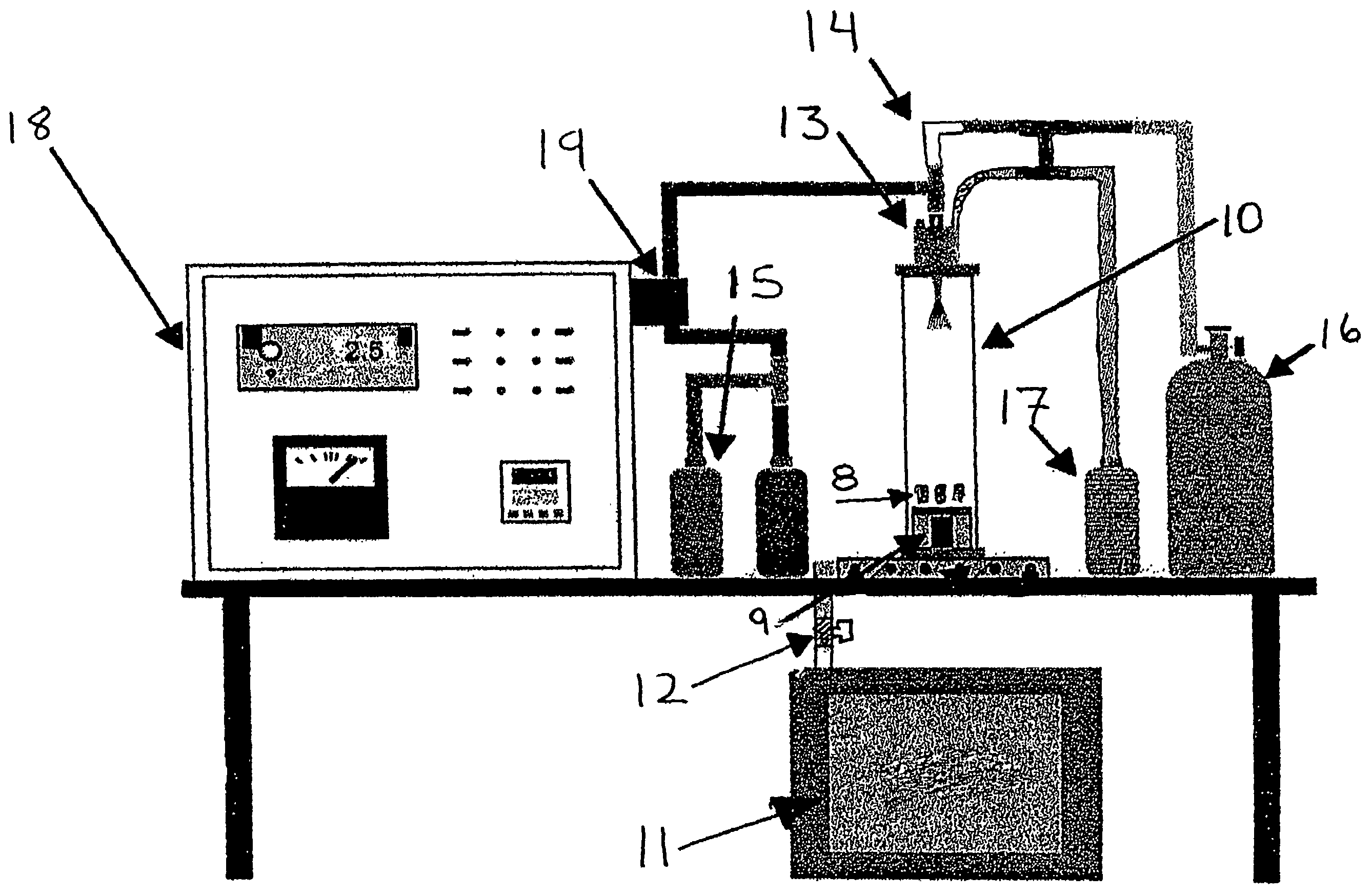

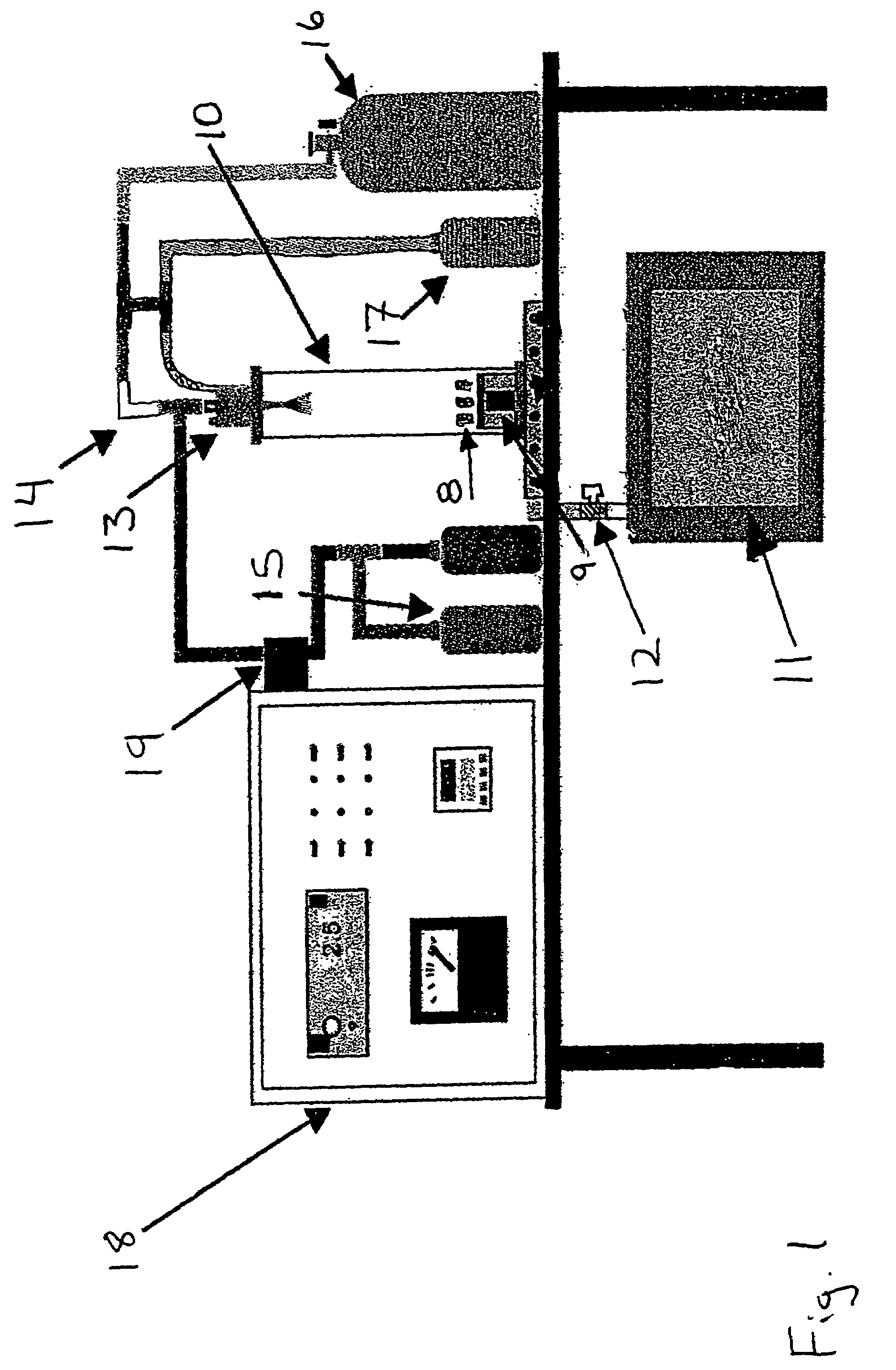

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

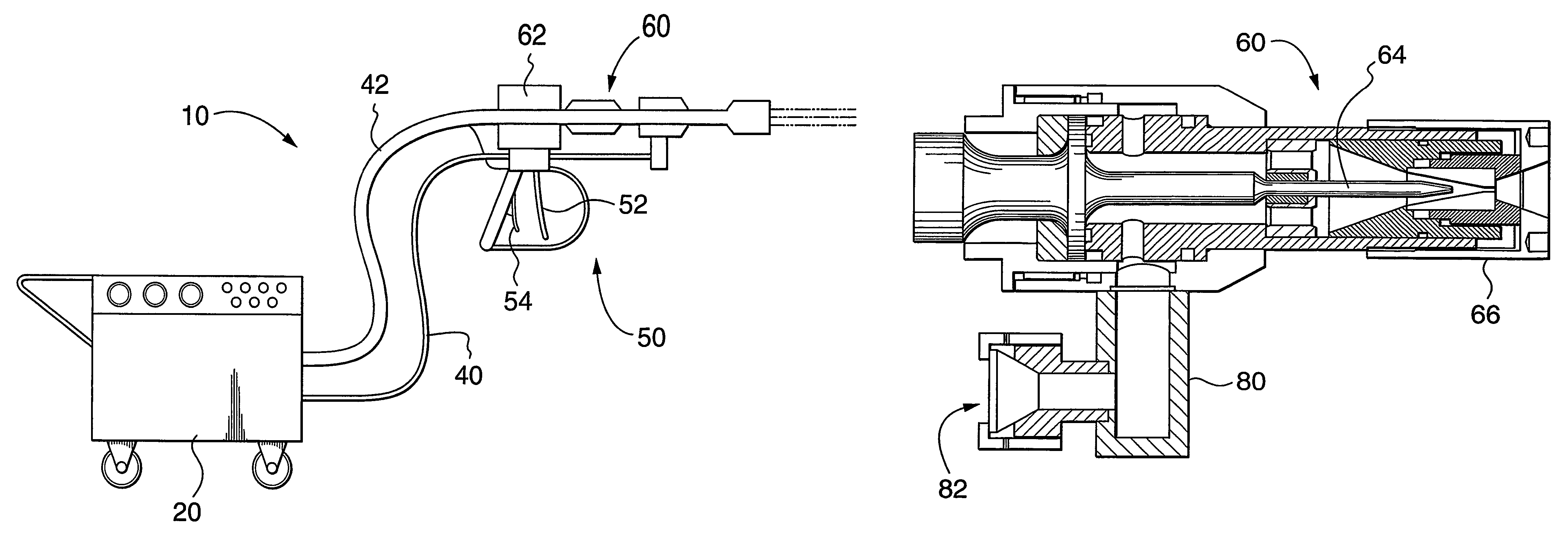

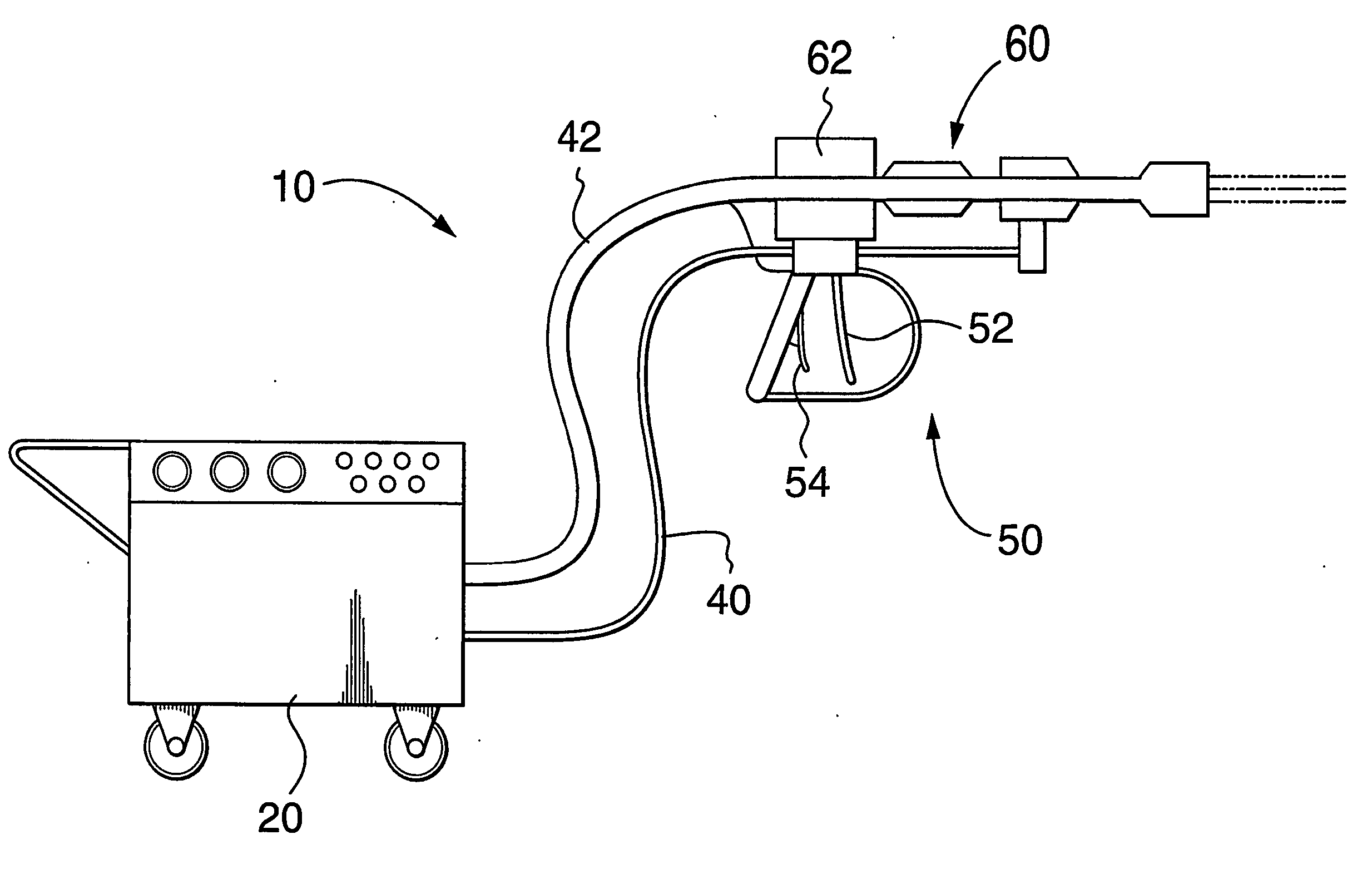

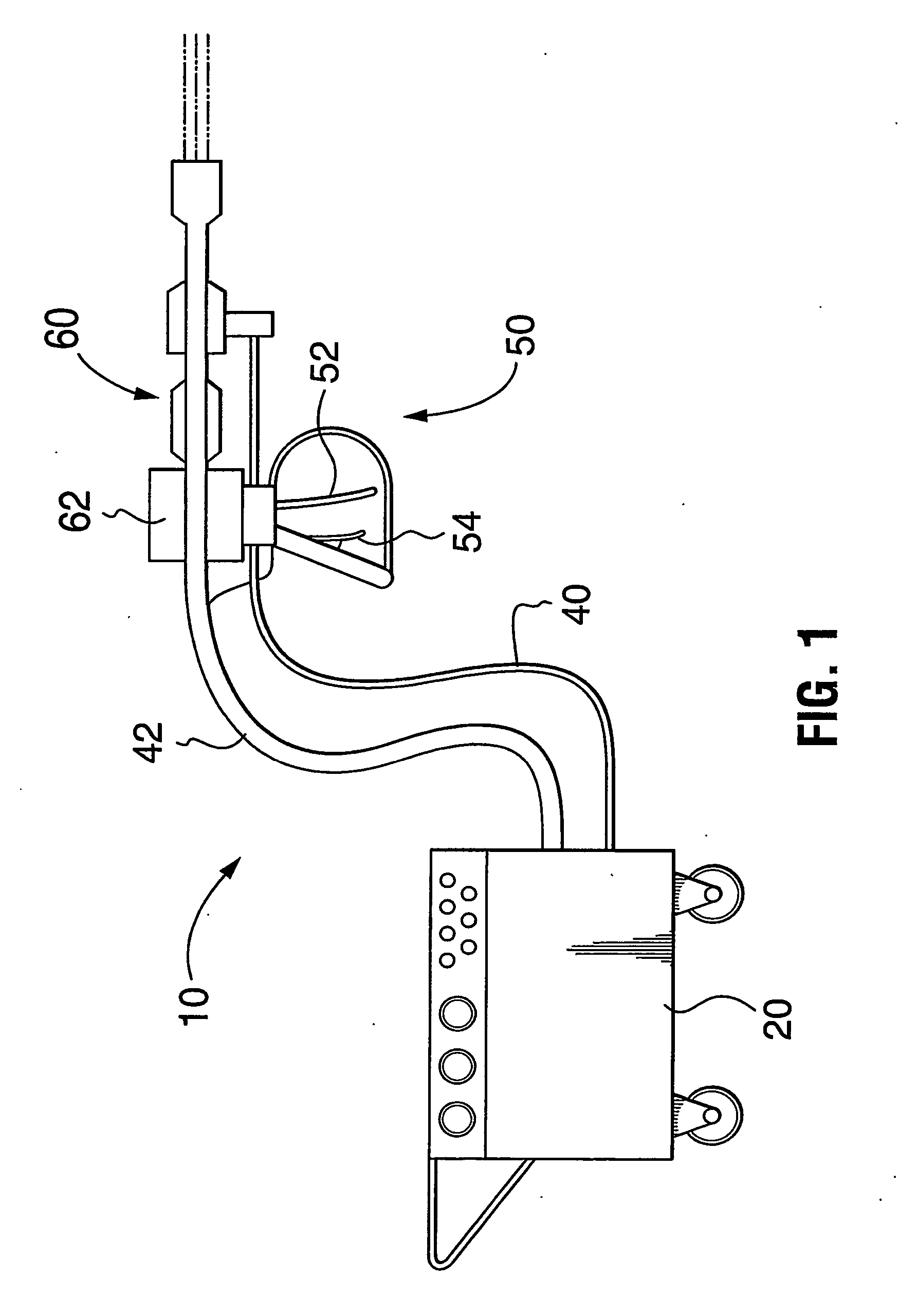

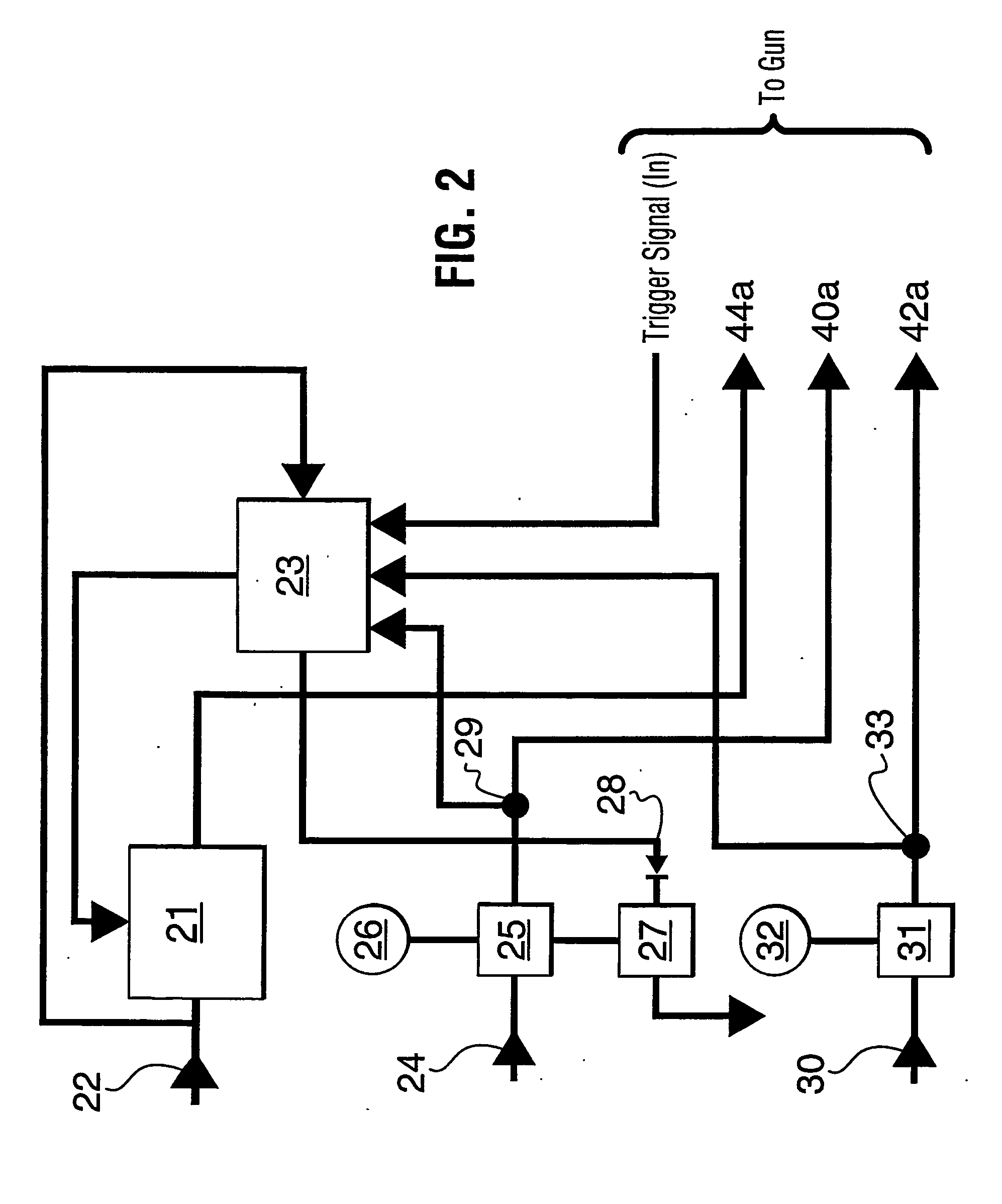

Ultrasonic waterjet apparatus

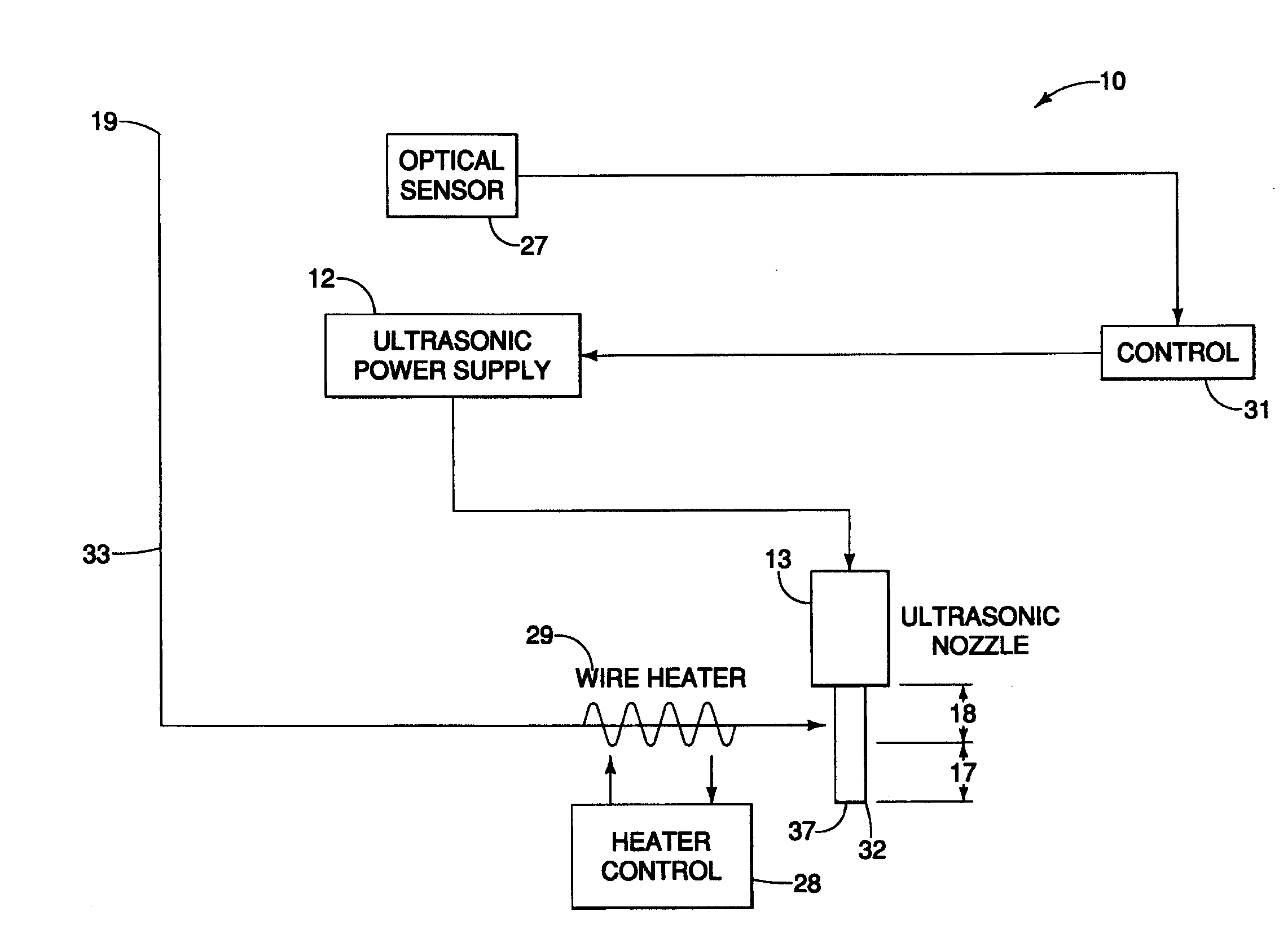

ActiveUS7594614B2Reduce cleaningReduce pressureLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesSonic nozzleUltrasonic nozzle

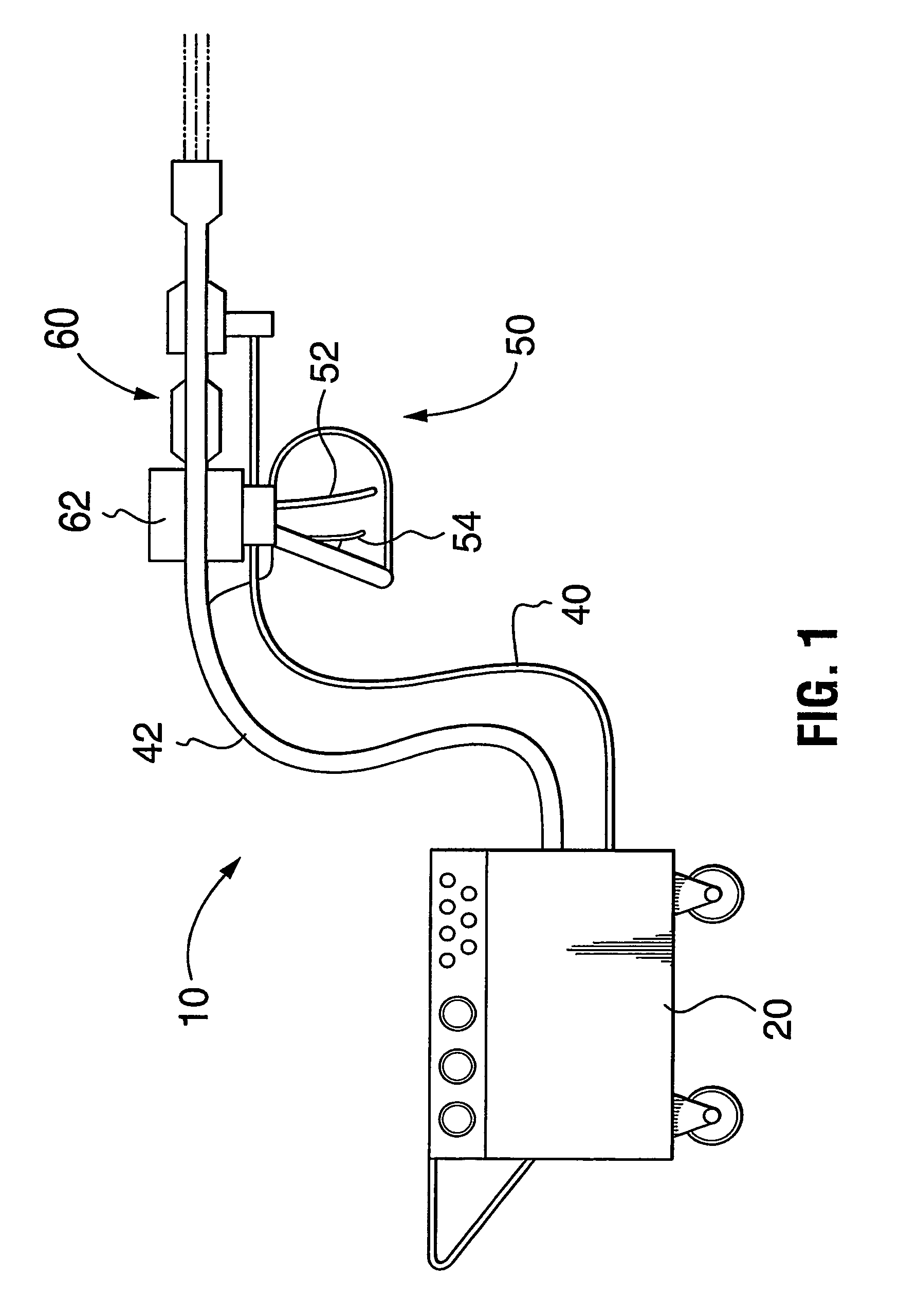

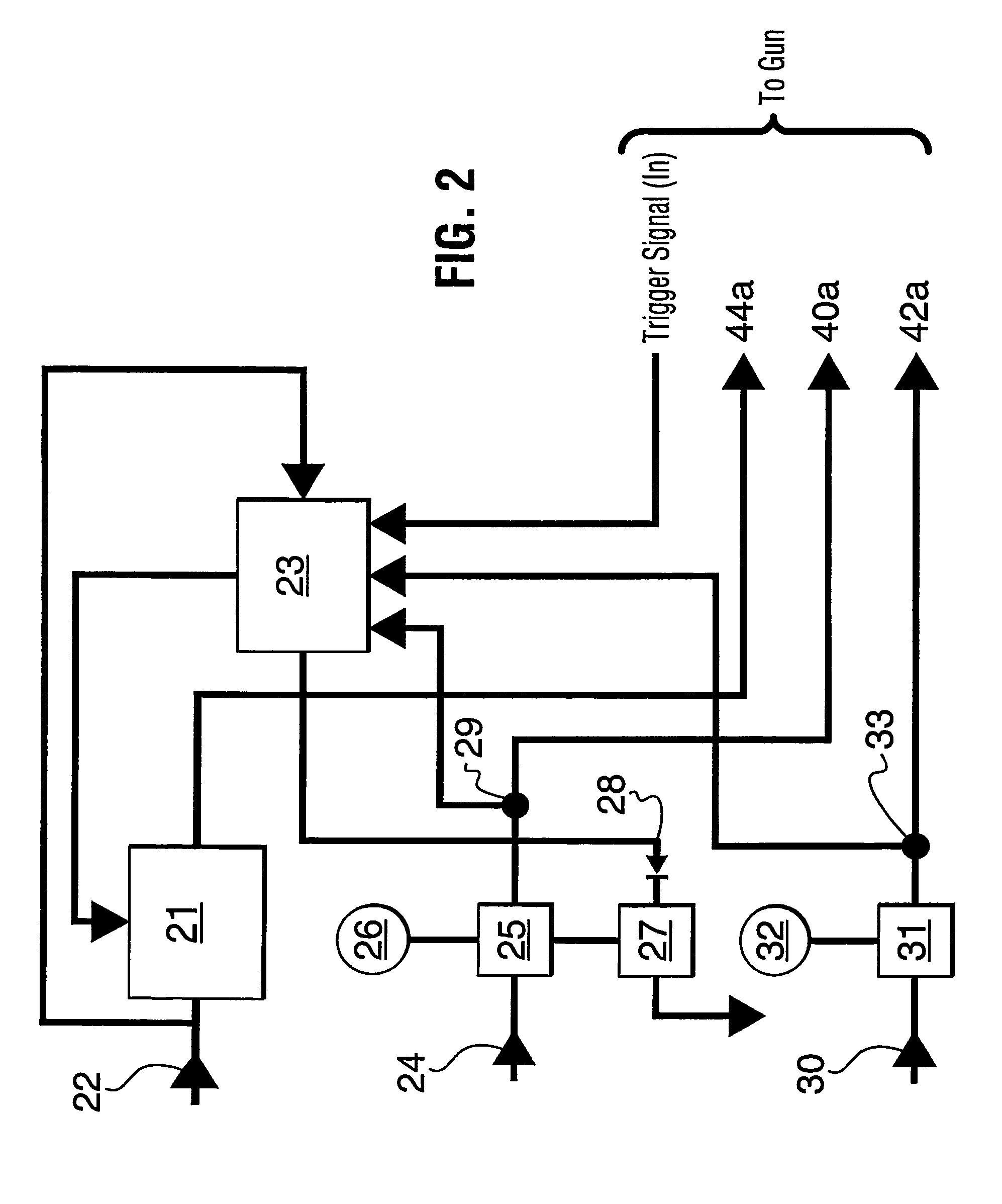

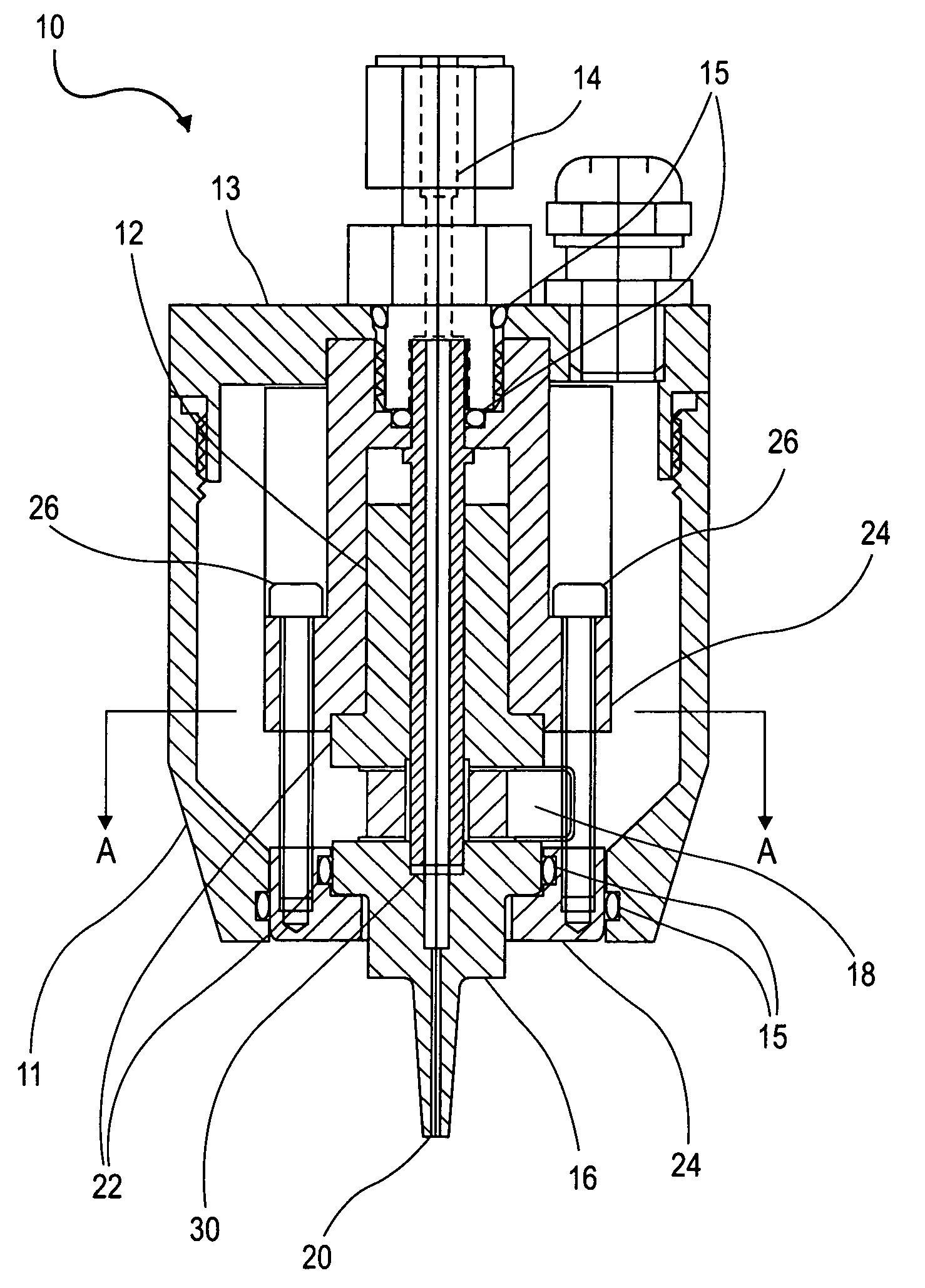

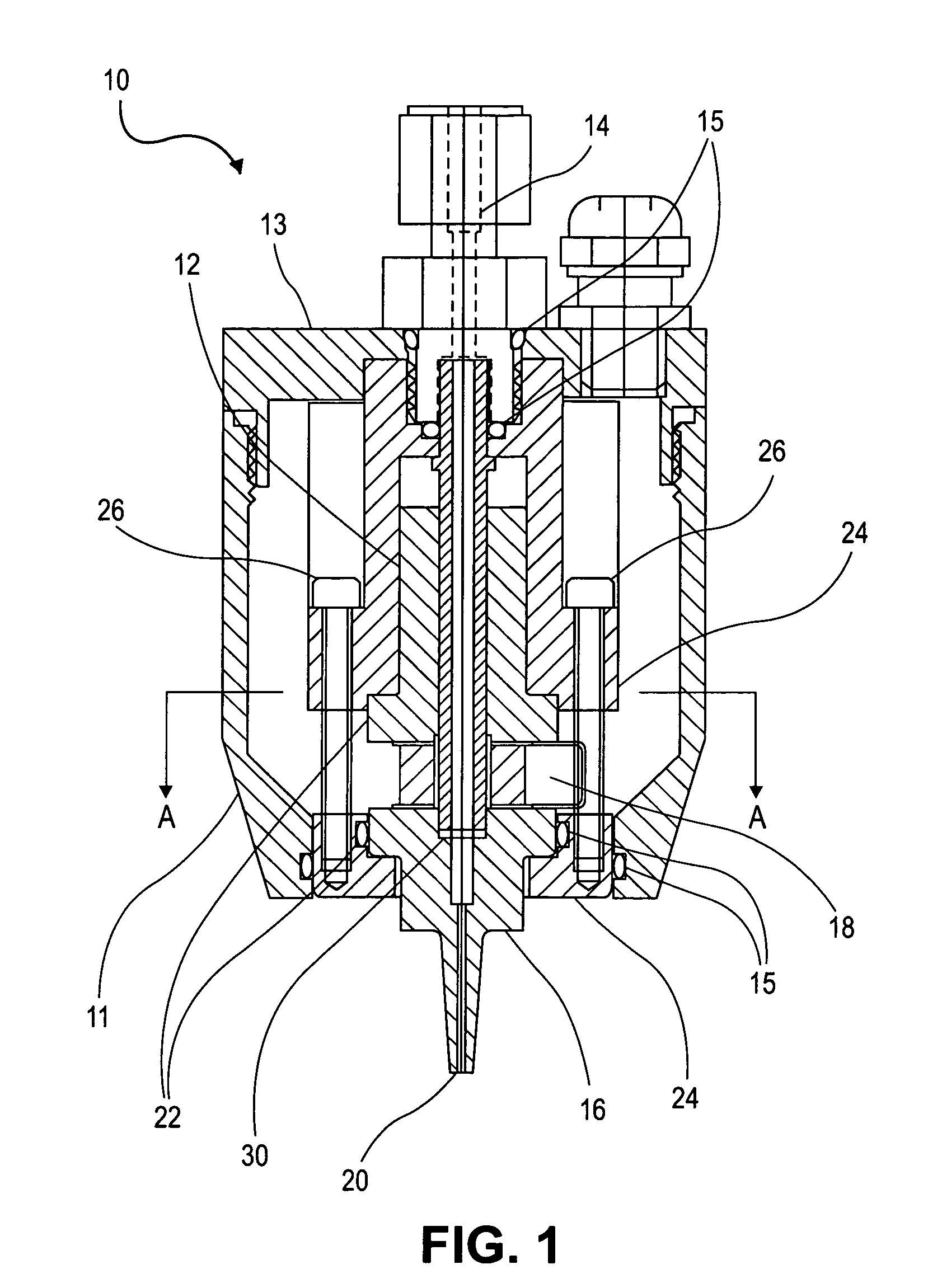

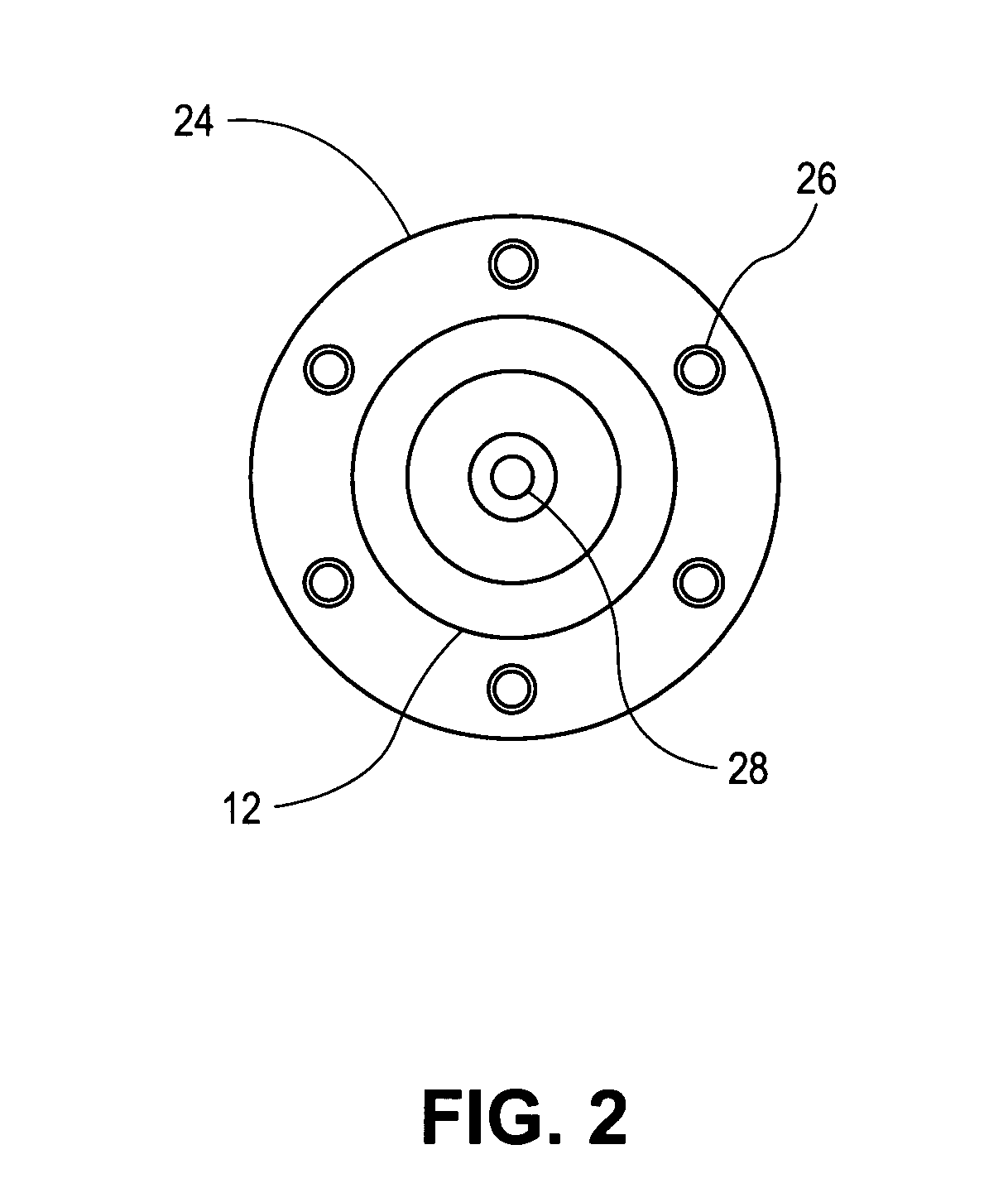

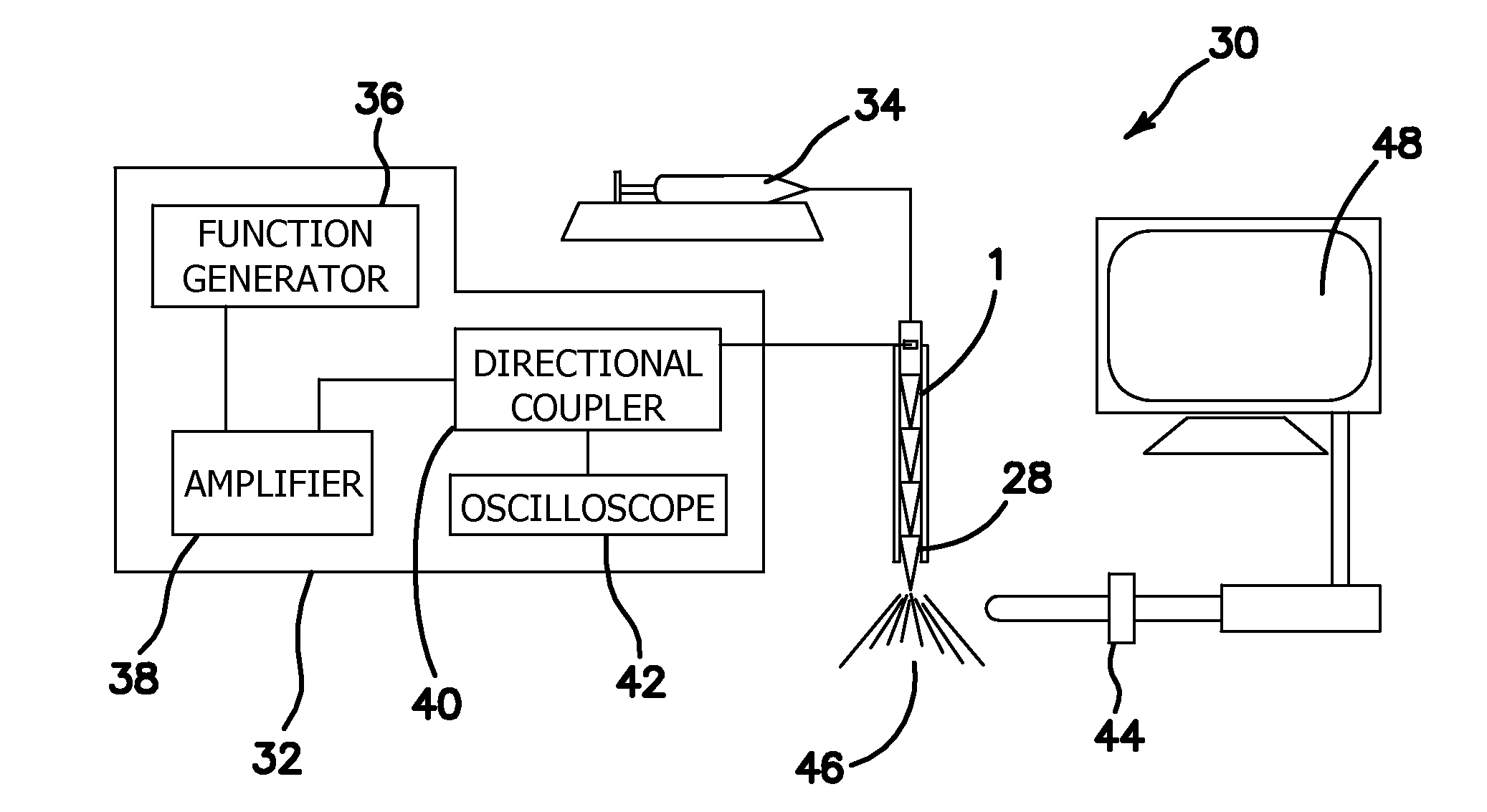

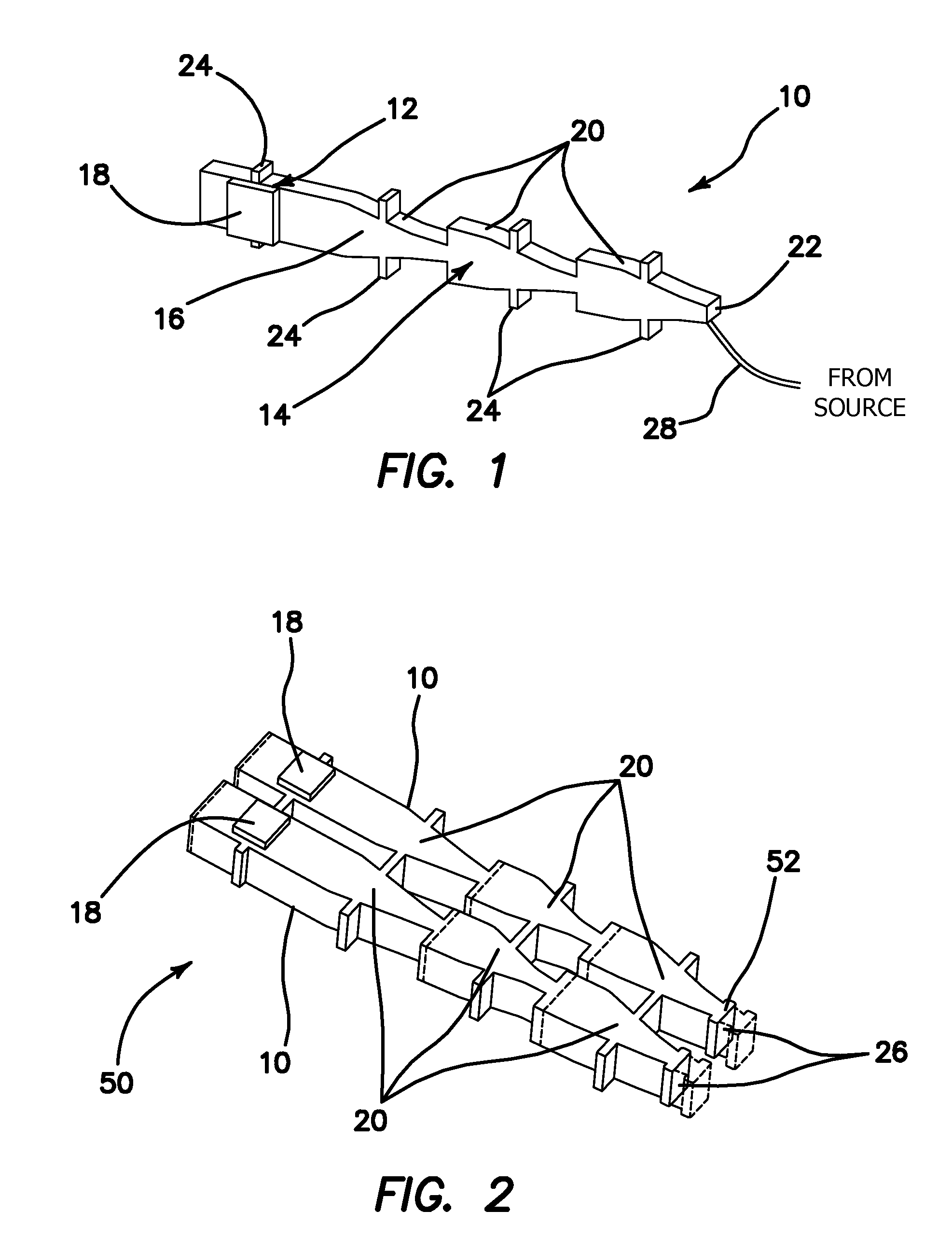

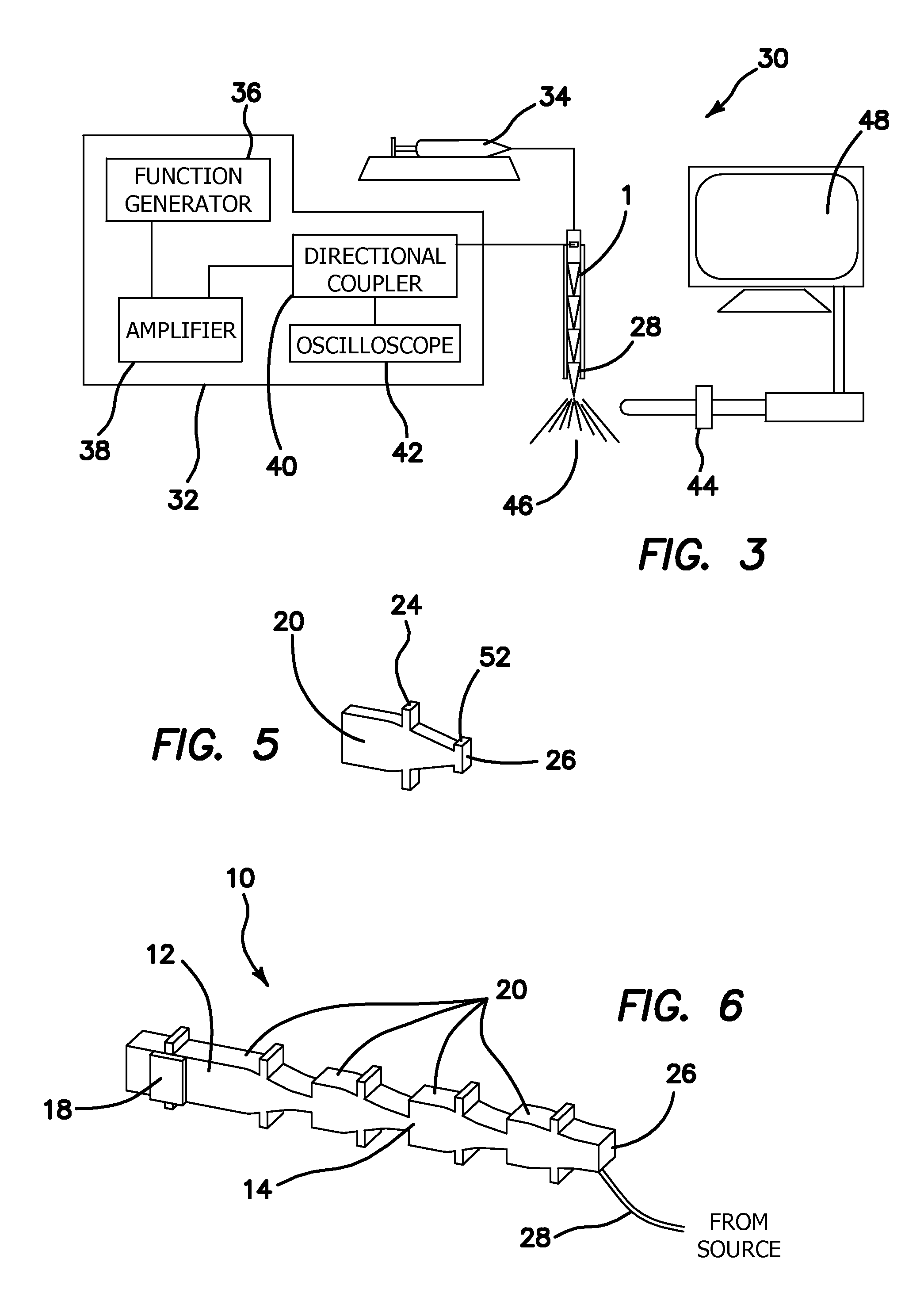

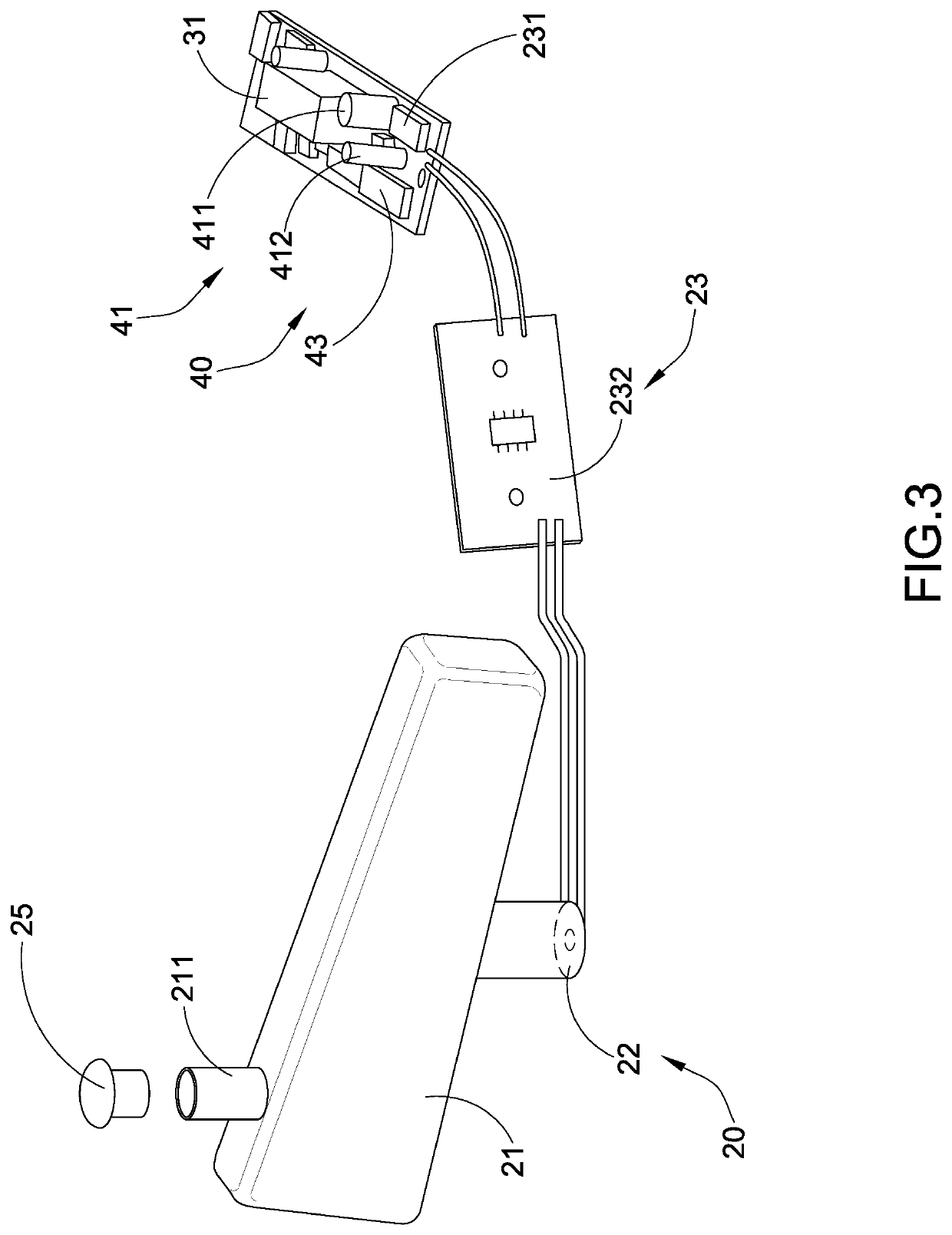

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect. A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

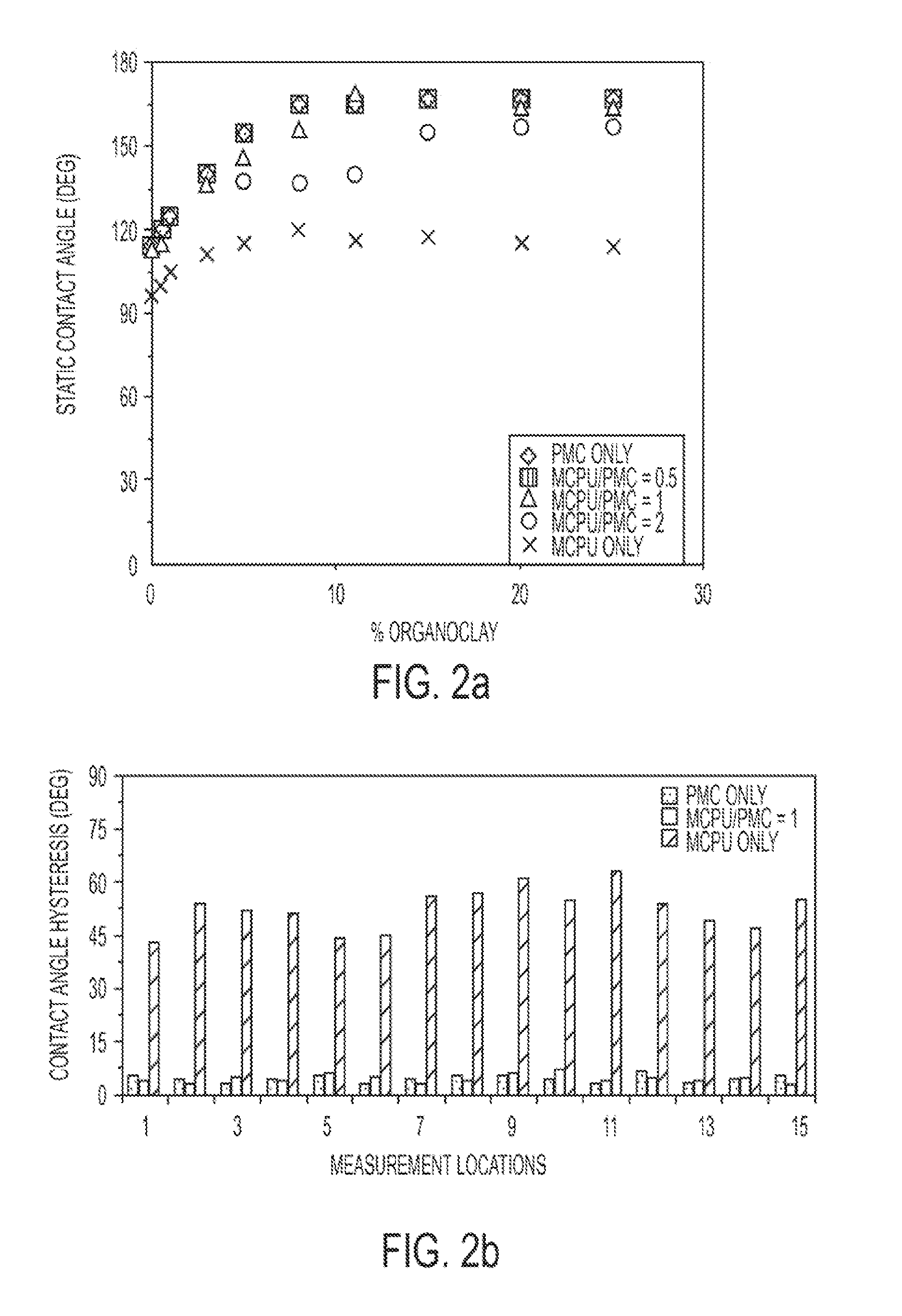

Superhydrophobic nanocomposite coatings

InactiveUS20140113144A1Fouling preventionSynthetic resin layered productsOrganic solventUltrasonic nozzle

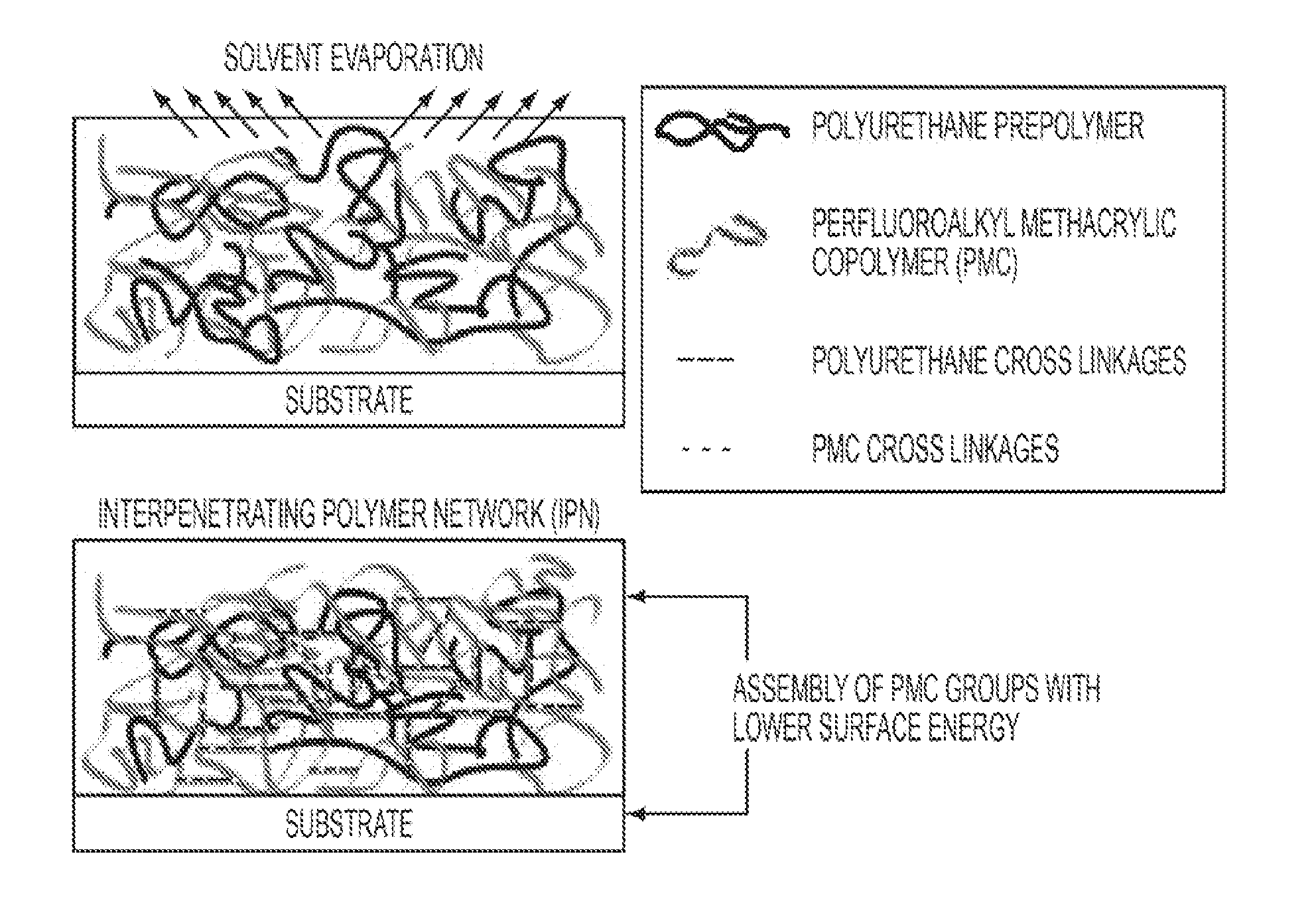

The invention relates to a superhydrophobic coating composition containing a polyurethane; a fluoropolymer; a nanofiller; and an organic solvent. The polyurethane to fluoropolymer are present in a weight ratio from about 1:2 to about 15:1. Coated substrate having at least a portion of one surface coated with a hydrophobic coating using the superhydrophobic coating composition are disclosed as are methods for forming a superhydrophobic coating on a substrate. The invention also relates to a method of forming a superhydrophobic coating on a surface of a substrate by spray casting a superhydrophobic coating composition onto a surface of a substrate to form a coating using an ultrasonic nozzle or at an air pressure of about 20 to about 60 psi and from a height of about 3 to about 12 inches above the surface to form a coating, and curing the coating.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Ultrasonic waterjet apparatus

ActiveUS20070063066A1Higher effective impact pressureReduce cleaningLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic nozzleHand held

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

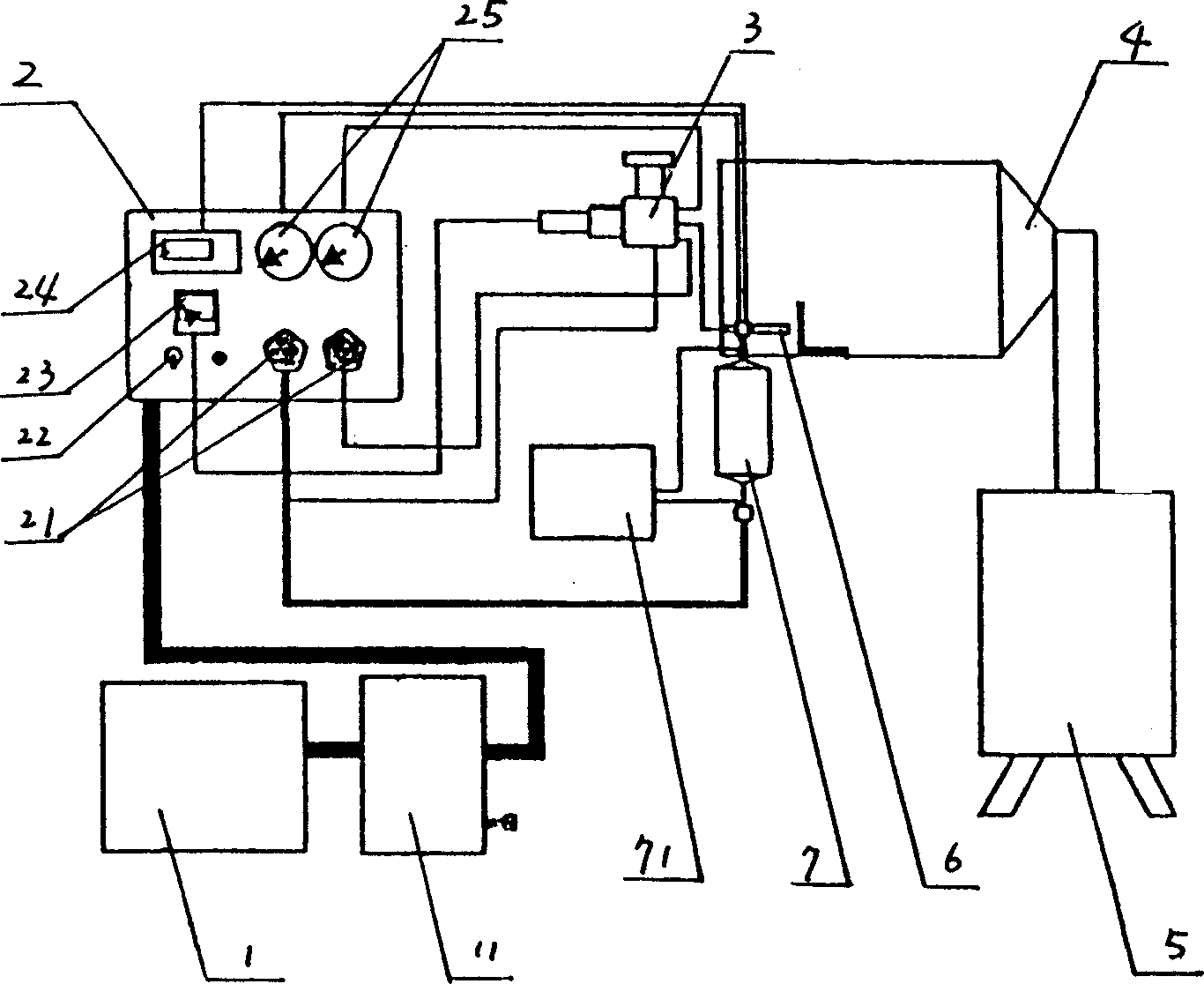

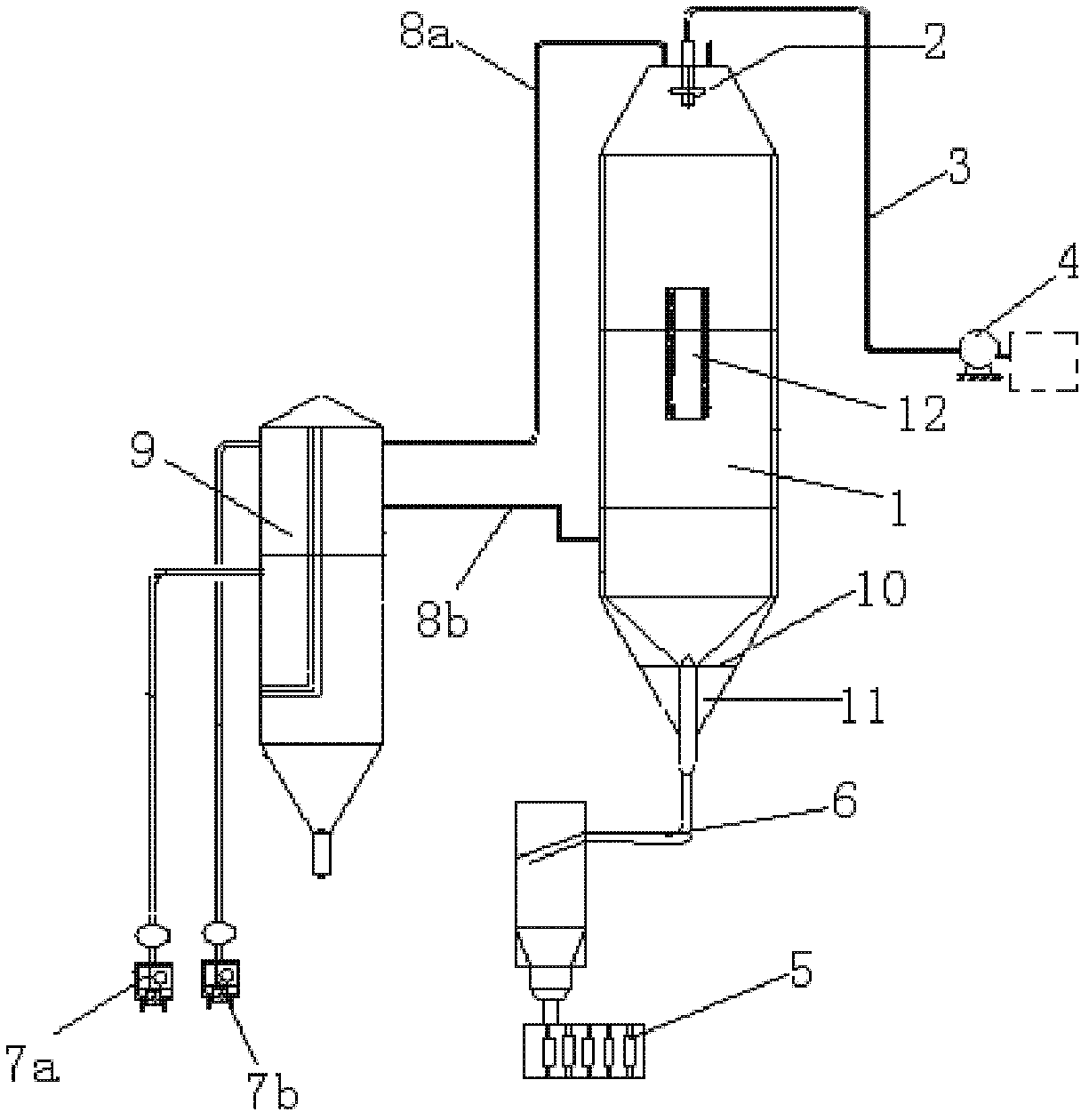

Indoor air PM2.5 (fine particulate matter) control system and control method thereof

InactiveCN103727608AReduce concentrationMeet the needs of lifeSpace heating and ventilation safety systemsLighting and heating apparatusCycloneControl system

The invention provides an indoor air PM2.5 (fine particulate matter) control system and a control method thereof, relates to the technical field of air-conditioners, and solves the technical problem of reducing the concentration of indoor air fine particulate matters. The system comprises a control terminal, an air purifying box, at least one monitoring gateway and a plurality of dust sensors. Each dust sensor is connected to the control terminal through each monitoring gateway. The air purifying box is mounted at the fresh air inlet of a central air-conditioner, a cyclone and a water jetting rack are arranged in the air purifying box, and a water tank is mounted on the air purifying box. The water jetting rack is located between the air outlet end of the cyclone and the air outlet of the air purifying box, and a plurality of ultrasonic nozzles are fixed on the water jetting rack. The outlet of the water tank is connected to water inlets of the ultrasonic nozzles through a pressure pump. The control terminal is provided with a water jetting signal output end connected to the control end of the pressure pump. The system and the method have the advantages that the concentration of the indoor air fine particulate matters can be lowered.

Owner:SHANGHAI JIANKUN INFORMATION TECH

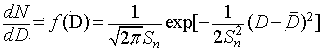

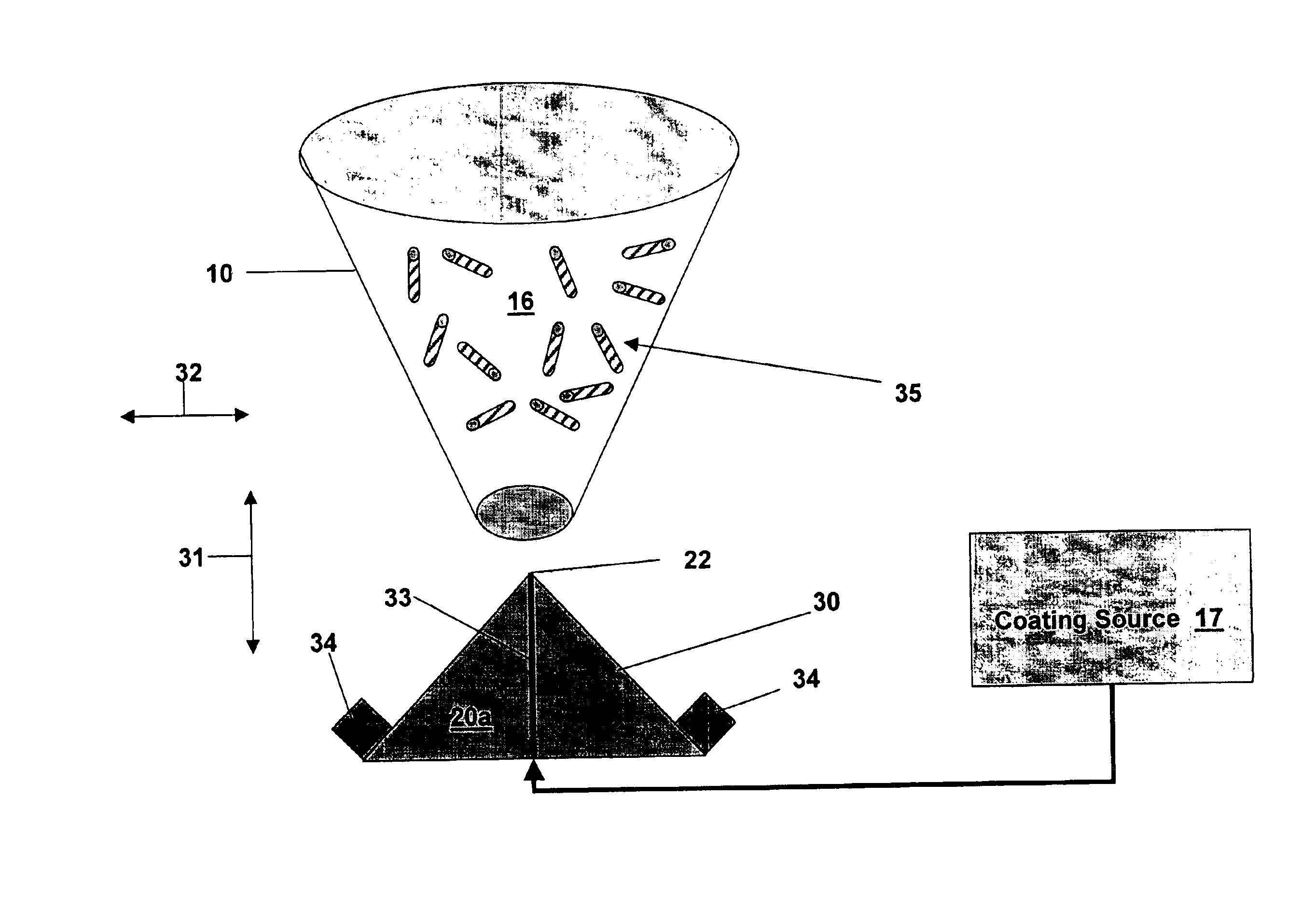

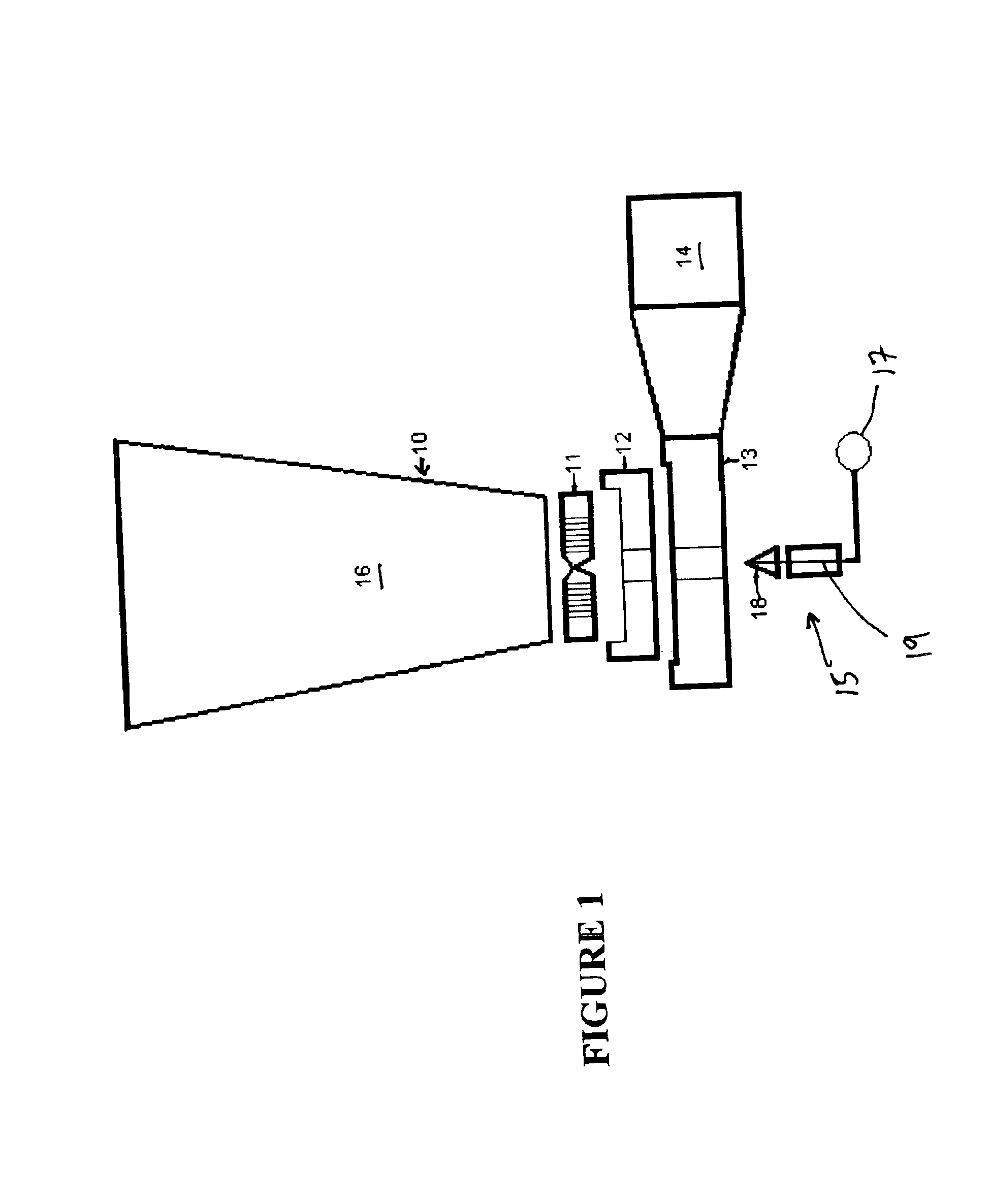

Method for using an ultrasonic nozzle to coat a medical appliance

A method for coating a medical appliance includes suspending the medical appliance with a fluidizing gas flow and directing a coating onto an ultrasonic nozzle. The ultrasonic nozzle is directed towards the medical appliance. The method also includes vibrating the ultrasonic nozzle at a rate sufficient to atomize the coating. A device for coating a medical appliance includes a fluidizing gas source adapted to suspend the medical appliance in a suspension area and an ultrasonic nozzle directed at the suspension area and adapted to vibrate. The device also includes a coating source adapted to direct coating onto the ultrasonic nozzle. A medical appliance is provided which has a coating applied by the method.

Owner:BOSTON SCI SCIMED INC

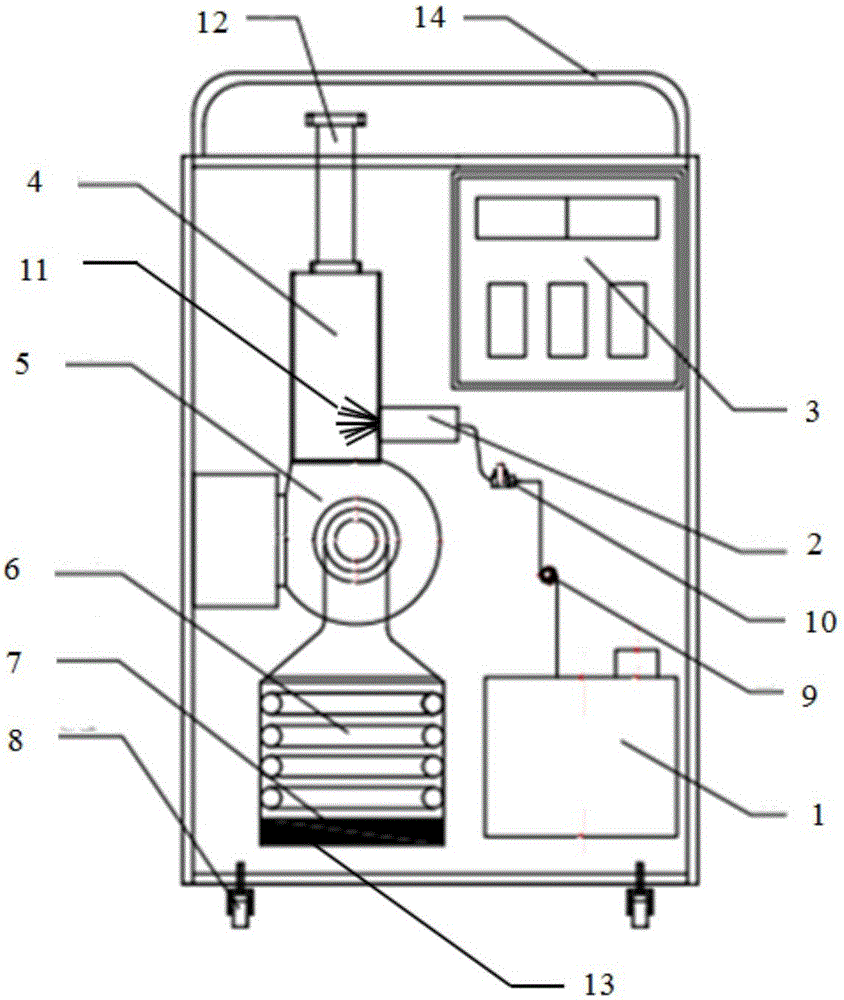

Hydrogen peroxide sterilization device and method

InactiveCN104984378AReduce the temperatureSuitable for sterilizationGaseous substancesChemicalsUltrasonic nozzleAir blower

A hydrogen peroxide sterilization device comprises a hydrogen peroxide liquid storage barrel, an ultrasonic atomizer, an electrical control unit, a vaporizing chamber, a metering pump, an solenoid-controlled valve, an air blower, a heater, a filter device, an air inlet and a steam outlet pipe; the ultrasonic atomizer is further provided with an ultrasonic nozzle provided with an air flue to evenly diffuse atomized hydrogen peroxide microdroplets in the vaporizing chamber, the vaporization efficiency is improved, the atomized hydrogen peroxide microdirplets can be vaporized rapidly at a lower temperature, and the energy is saved. Indoor air serves as carrier gas, outside air is not introduced, and secondary pollution is avoided. Hydrogen peroxide big droplets which are not vaporized in the vaporizing chamber can drop back on the heater under the action of gravity to be vaporized again. By controlling various related parameters, a dew point temperature of output vaporized hydrogen peroxide is made to be lower than the indoor temperature all the time, a steady flow is guaranteed for the vaporized hydrogen peroxide, and the water mist condensation phenomenon which occurs in the transport process are avoided.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV

Production process of feeding lactobacillus microcapsule and microcapsule, application and premix thereof

ActiveCN103156063AImprove protectionHigh bacterial survival rateFeeding-stuffAnimal feeding stuffFreeze-dryingUltrasonic nozzle

The present invention relates to the technical field of lactobacillus coating, specifically relates to a production process of feeding lactobacillus microcapsules and microcapsules, application and a premix thereof. Trehalose and lactose which can rapidly form vitrification protection state at a low temperature are used, sodium glutamate, manganese sulfate, glycerin, and polyvinyl pyrrolidone are used as main components for a wall material, special ultrasonic wave spray drying equipment is used, an ultrasonic spray nozzle is used for atomization, vacuum and a protective gas such as nitrogen are used for drying at room temperature, thus the effects of low temperature of low temperature freeze-drying and high temperature of high temperature spray drying on lactobacillus activity are prevented, and survival rate of the bacteria can reach more than 90%. The process of the invention achieves that lactobacillus is dried at room temperature, the preparation process is easy to control, the obtained product has a long storage period, and the storage time of the product can be significantly extended.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

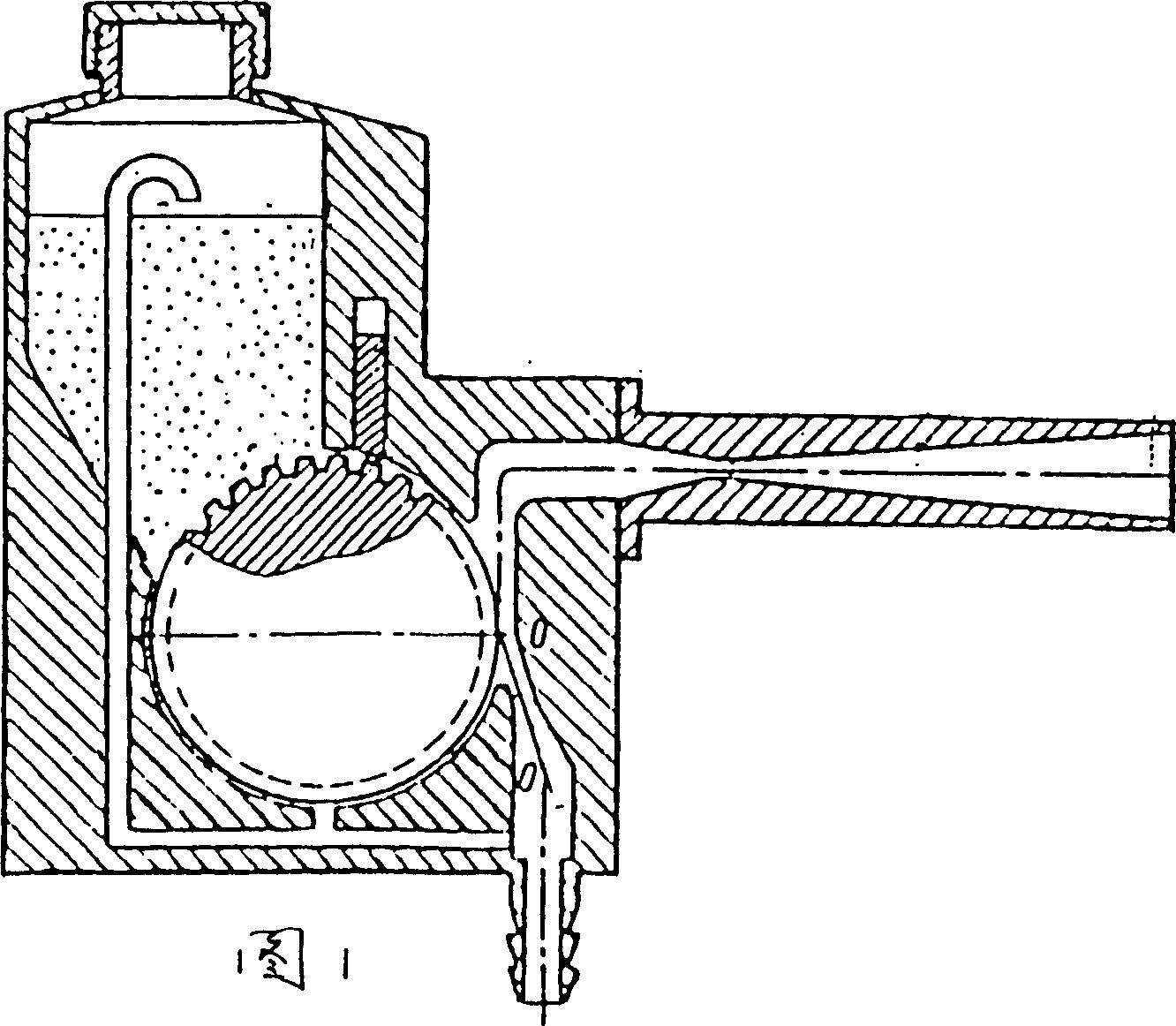

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ultrasonic nozzle

An ultrasonic nozzle for applying a coating to an exterior surface of a substrate. The ultrasonic nozzle has an ultrasonic nozzle having an amplitude. The amplitude is greater than 120 microns.

Owner:KELLOGG NORTH AMERICA

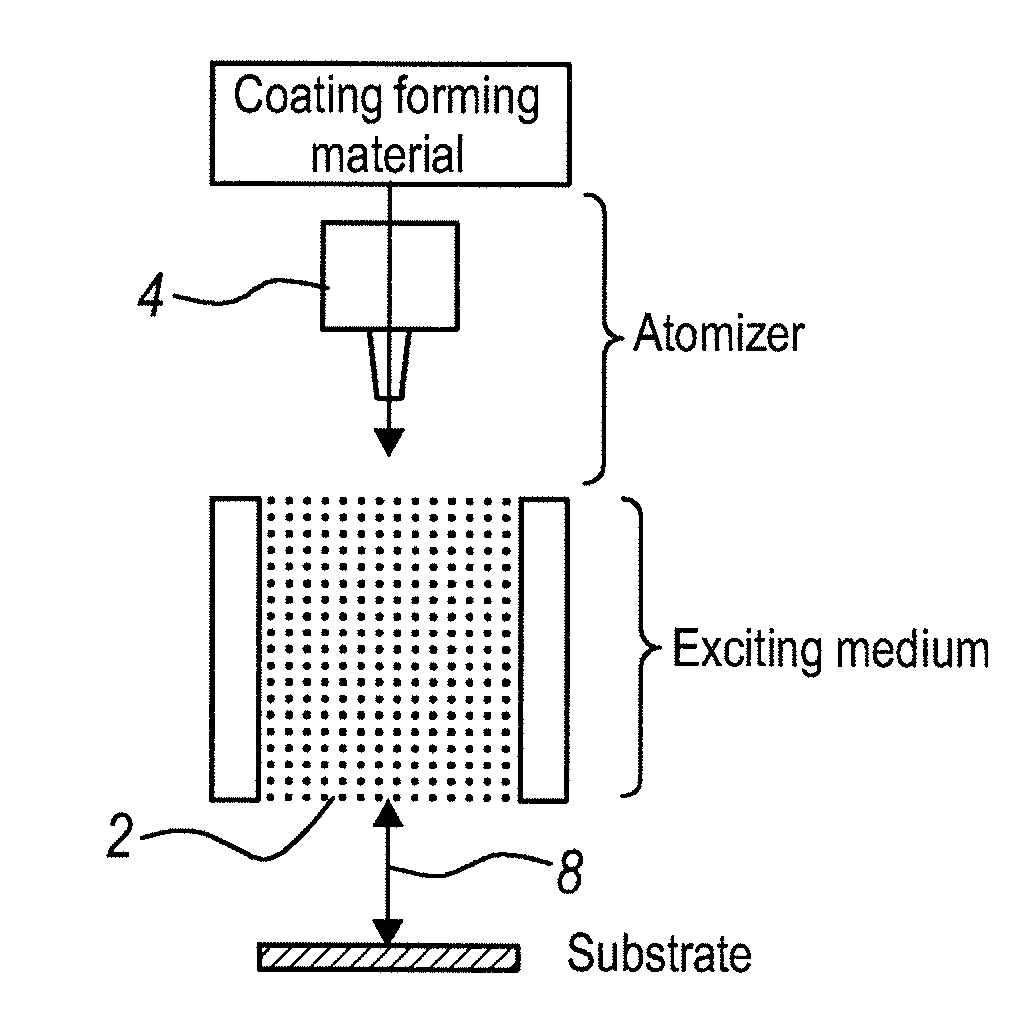

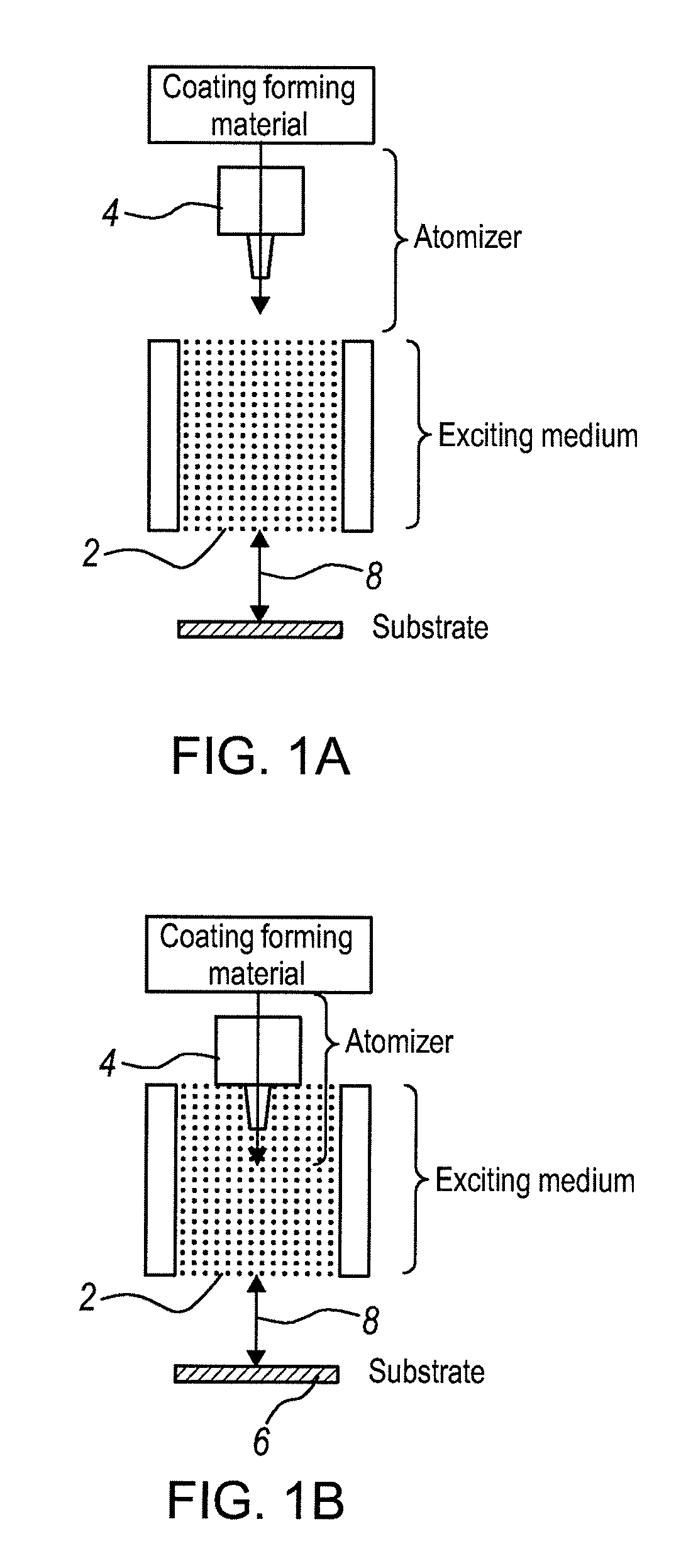

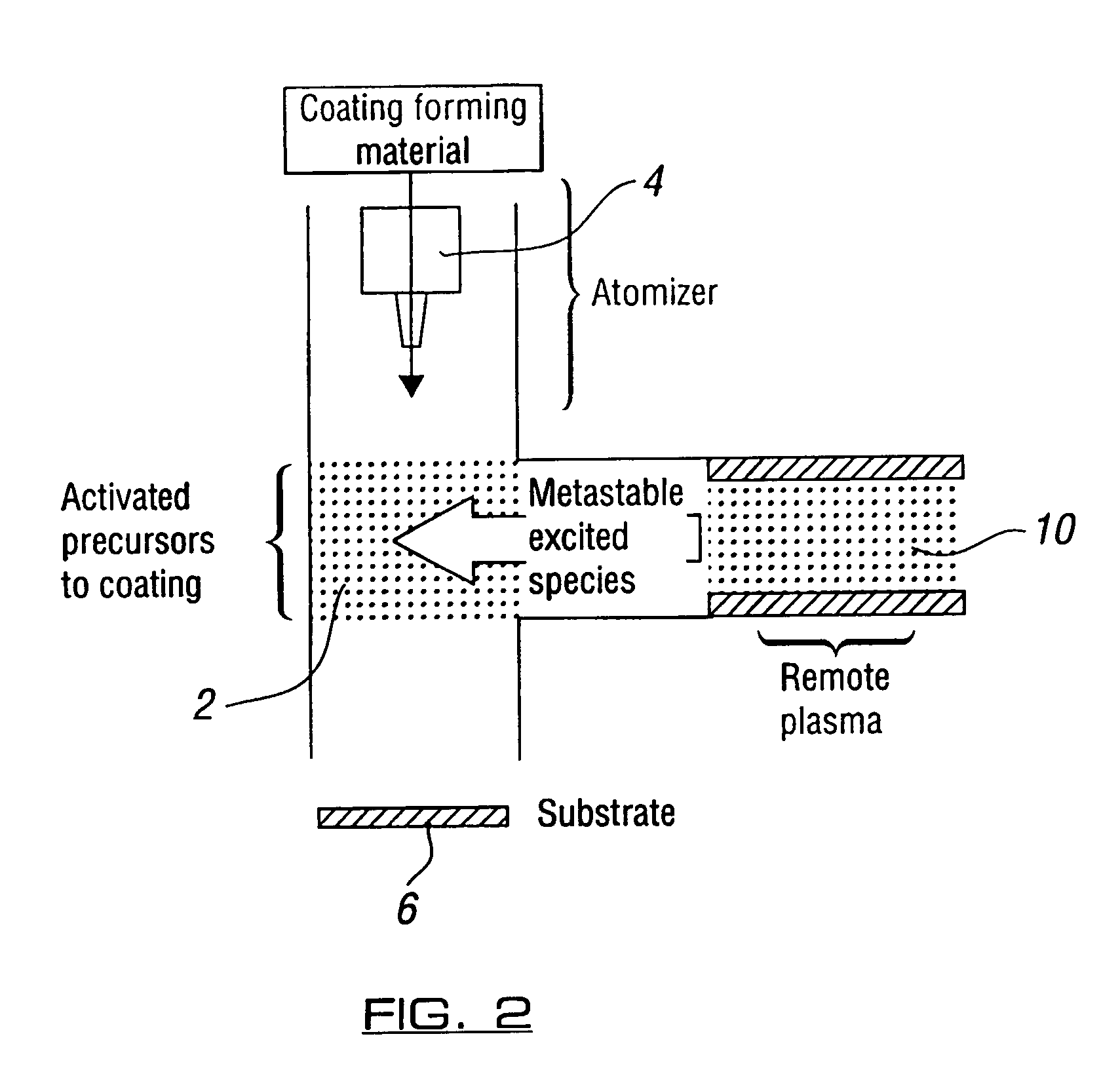

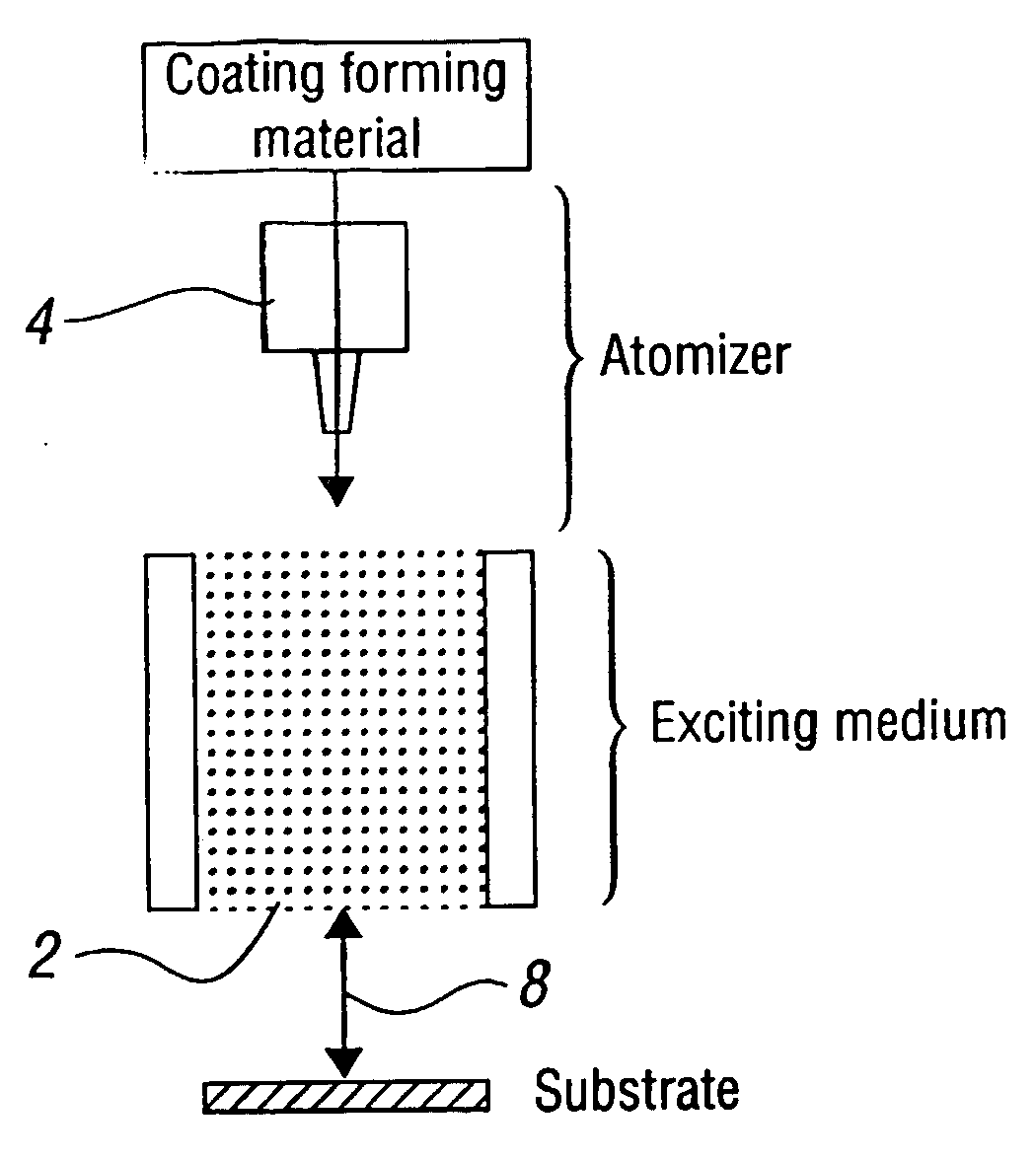

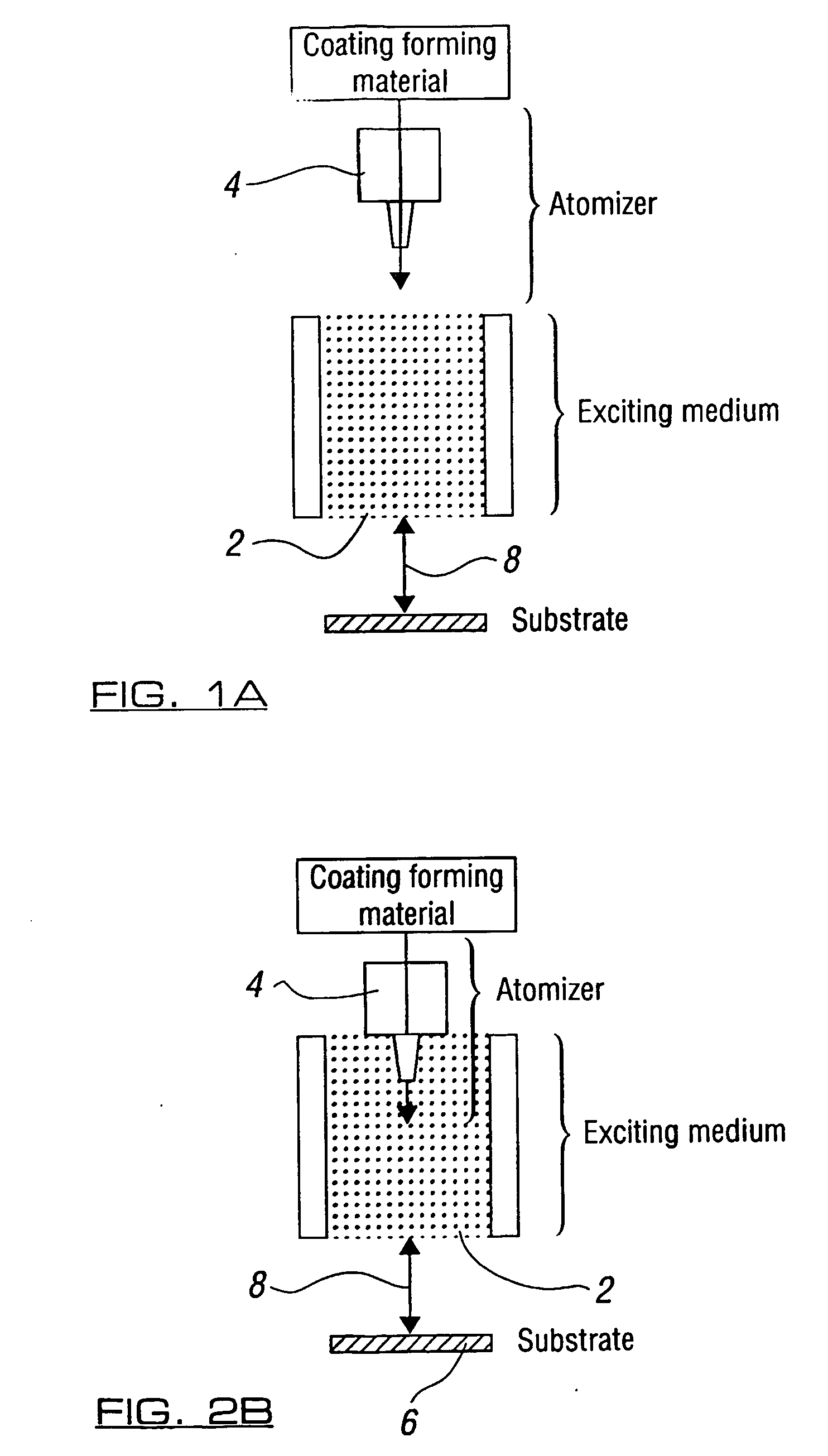

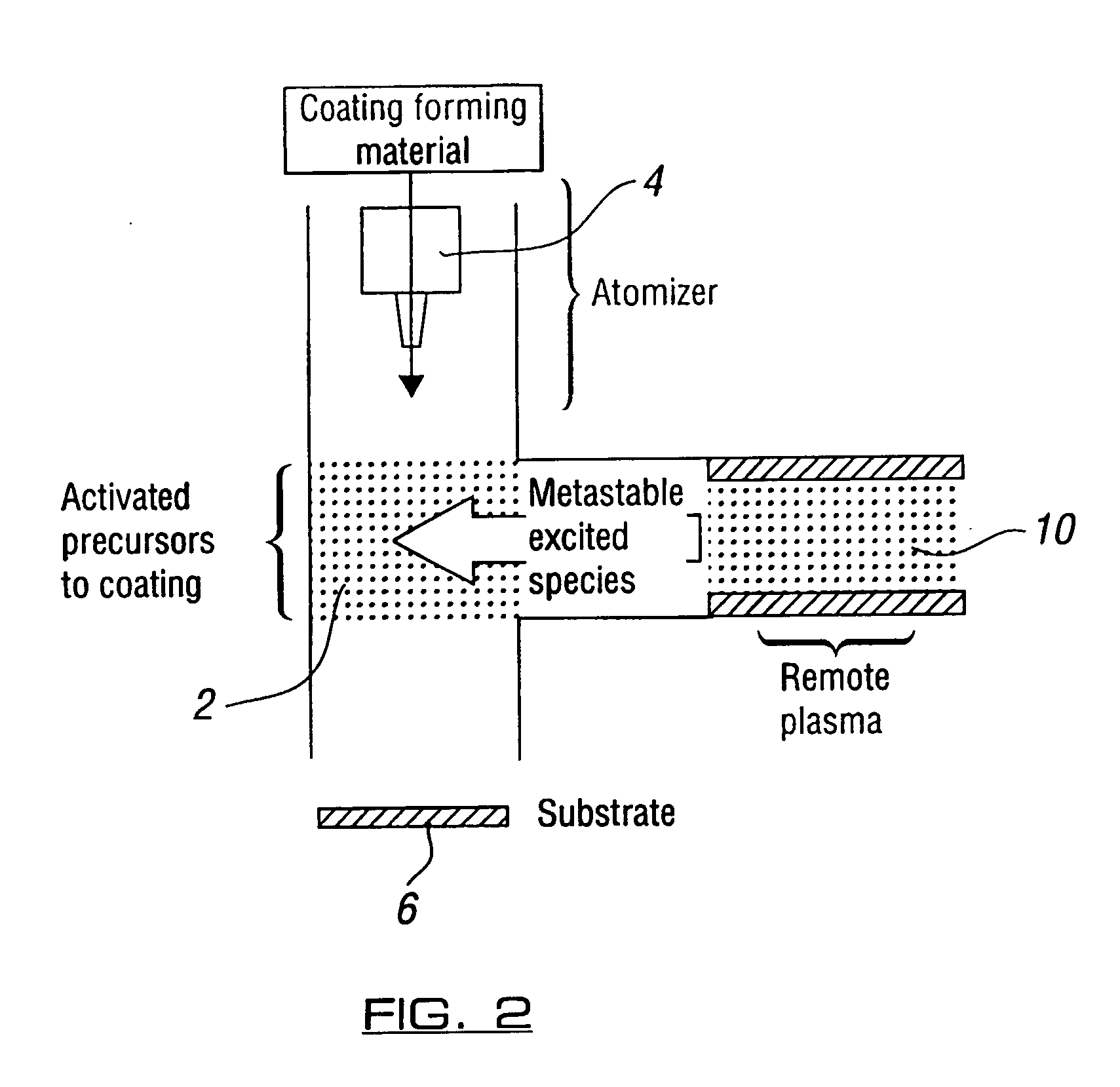

Atomisation of a precursor into an excitation medium for coating a remote substrate

InactiveUS7968154B2Avoid damageImprove hydrophobicLiquid surface applicatorsChemical vapor deposition coatingNebulizerUltrasonic nozzle

The invention relates to a method and apparatus for applying and forming a coating on a substrate surface by the application of at least one atomized coating forming material onto the substrate to form the coating. The atomized coating forming material, upon leaving a suitable atomizer which can be an ultrasonic nozzle or nebulizer for example, passes through an exciting medium and, upon leaving the exciting medium, passes to the substrate. The substrate is positioned remotely from the exciting medium.

Owner:SURFACE INNOVATIONS LTD

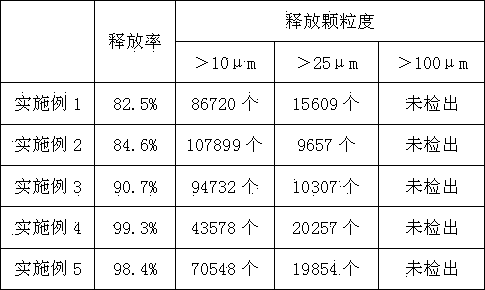

Method for preparing balloon dilatation catheter medicinal coating for treatment

The invention relates to a method for preparing a balloon dilatation catheter medicinal coating for treatment. The method comprises the following steps: adding a diluted solvent into a glass bottle filled with a medicine for treating vascular endothelial re-proliferation, oscillating to completely dissolve the medicine to prepare a medicine solution; mixing the medicine solution and an interference solvent which is incompatible with the medicine, and feeding into a dual-channel ultrasonic nozzle to coat a balloon dilatation catheter; drying, sterilizing and packaging the coated balloon dilatation catheter. According to the method, the medicine solution is mixed with another incompatible interference solvent before ultrasonic coating, so that the shape of the medicine in the solution is changed, and the mixture is fed into the ultrasonic nozzle to perform ultrasonic coating to achieve the aims of controlling the coating granularity, increasing the coating binding force and controlling the releasing rate of the medicine. The medicine coating formed by the method has the characteristics of uniformity, strong binding force with balloon, controllable crystal granularity, durable drug effect and the like.

Owner:ZHEJIANG BELONGS TO A MEDICAL INSTR

Process for coating three-dimensional substrates with thin organic films and products

InactiveUS7241478B2Controlled morphologyPretreated surfacesAntithrombogenic treatmentOrganic filmUltrasonic nozzle

The present invention relates to an apparatus and process for producing a thin organic film on a substrate using an ultrasonic nozzle to produce a cloud of micro-droplets in a vacuum chamber. The micro-droplets move turbulently within the vacuum chamber, isotropically impacting and adhering to the surface of the substrate. The resulting product has a smooth, continuous, conformal, and uniform organic thin film, when the critical process parameters of micro-droplet size, shot size, vacuum chamber pressure, and timing are well-controlled, and defects such as “orange peel” effect and webbing are avoided. The apparatus includes an improved ultrasonic nozzle assembly that comprises vacuum sealing and a separate, independent passageway for introducing a directed purging gas.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC +1

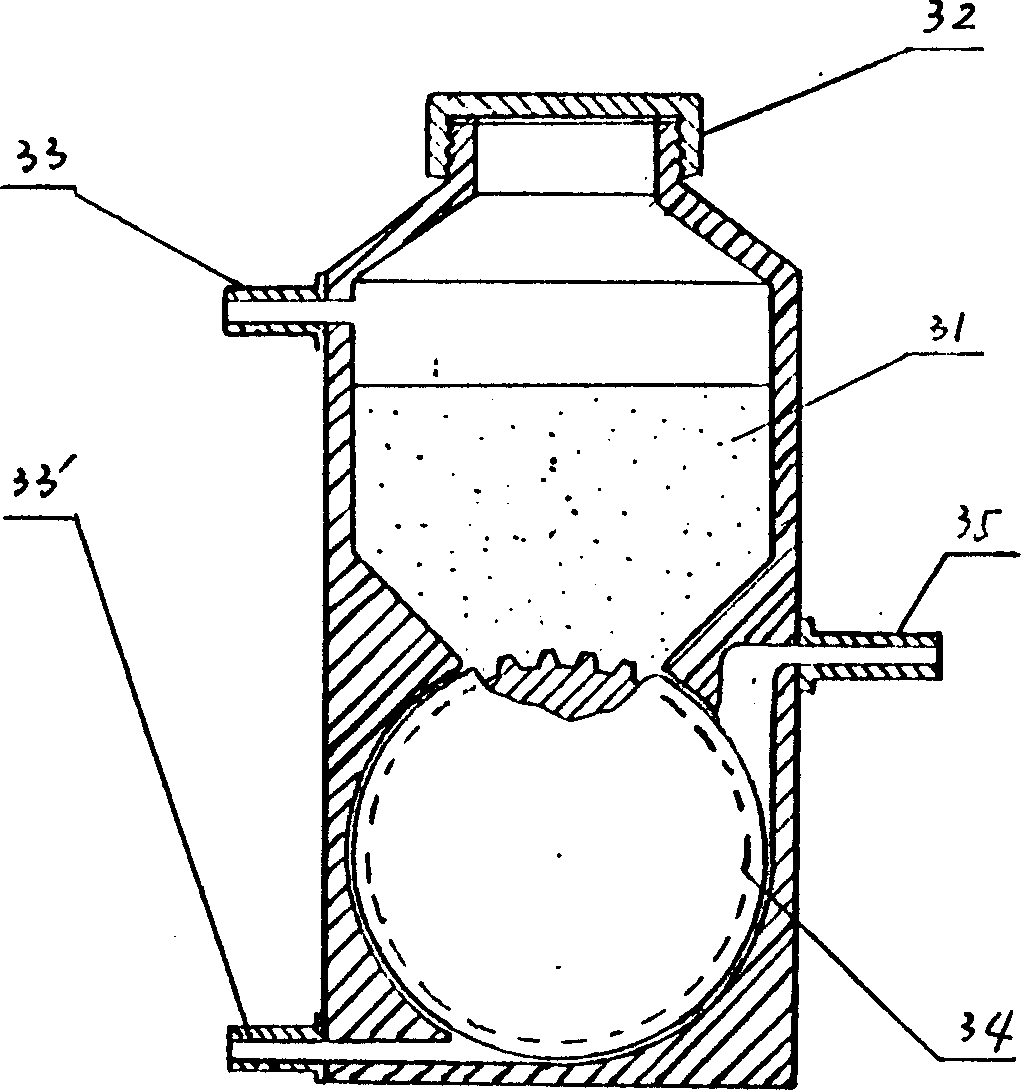

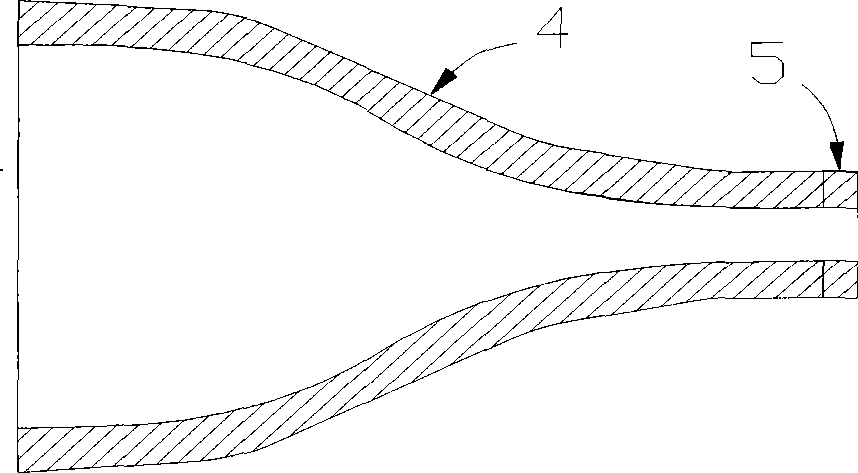

Supersonic nozzle of supersonic speed rotational flow natural gas separator

InactiveCN101387469AAchieve expansion and coolingAchieve separationSolidificationLiquefactionCycloneUltrasonic nozzle

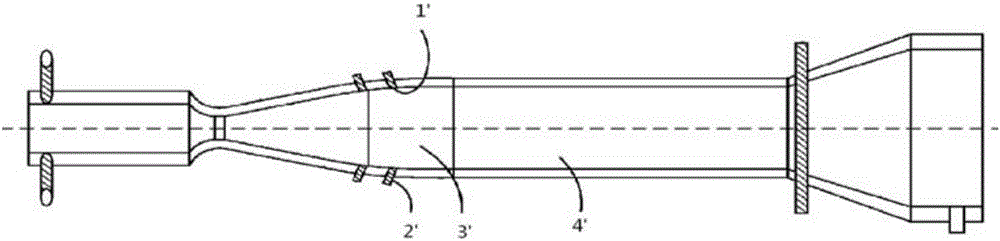

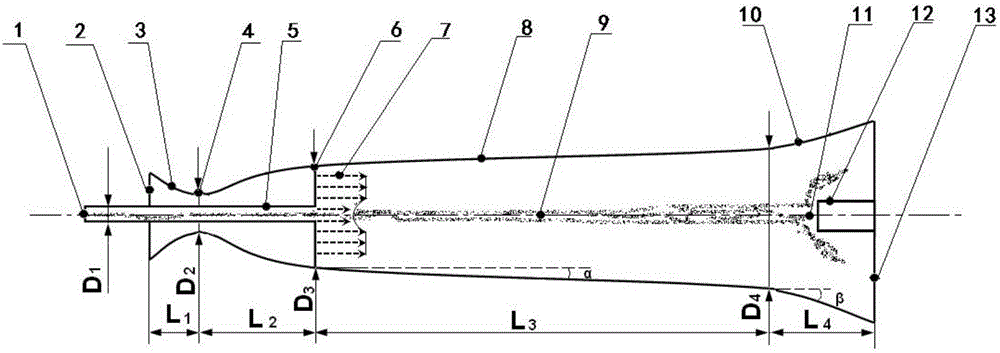

The invention provides a supersonic jet tube used for a supersonic cyclone natural gas separator, which is a key part of the separator, and consists of a contraction tube section, an extension tube section and a rectifying tube section. A moulding surface curve of the contraction tube section is higher-order polynomial, and natural gas airflow is expanded and accelerated in the section to achieve sonic velocity so as to form a straight sonic flow. The moulding surface curve of the extension tube section consists of a plurality of sections of curve, and the sections are smoothly connected to reduce disturbance to the airflow. The moulding surface curve of the supersonic jet tube at inlet and outlet changes flatly, has small curvature change, and has weak influence on the flowing of fluid upstream and downstream without obvious inlet and outlet effect. The extension tube has smooth inlet transition with small disturbance to the fluid. The extension tube section has flat change of moulding surface curve, small airflow expansion rate and good flow speed evenness, thereby helping droplet condensation nucleus grow larger grain diameter for separating. The supersonic jet tube not only evenly accelerates the airflow, improves evenness and stability of flow field, and reduces turbulivity, so that outlet airflow has better airflow quality, and can form droplets with larger grain diameter to improve the separation efficiency of the supersonic cyclone natural gas separator.

Owner:曹学文

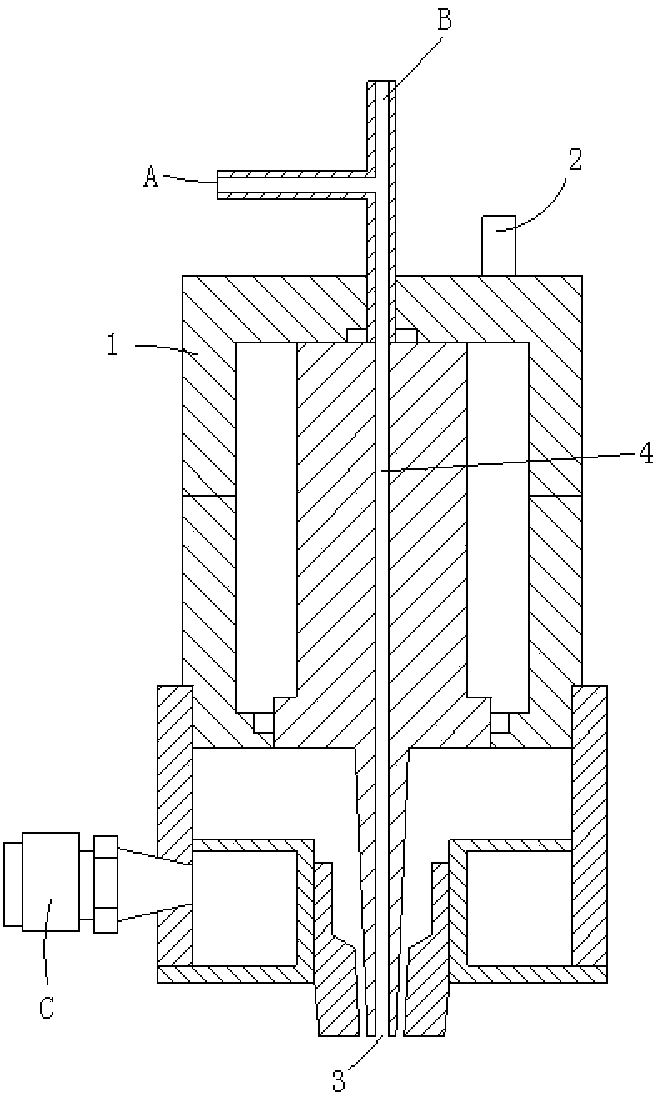

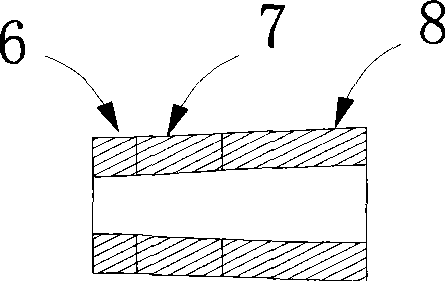

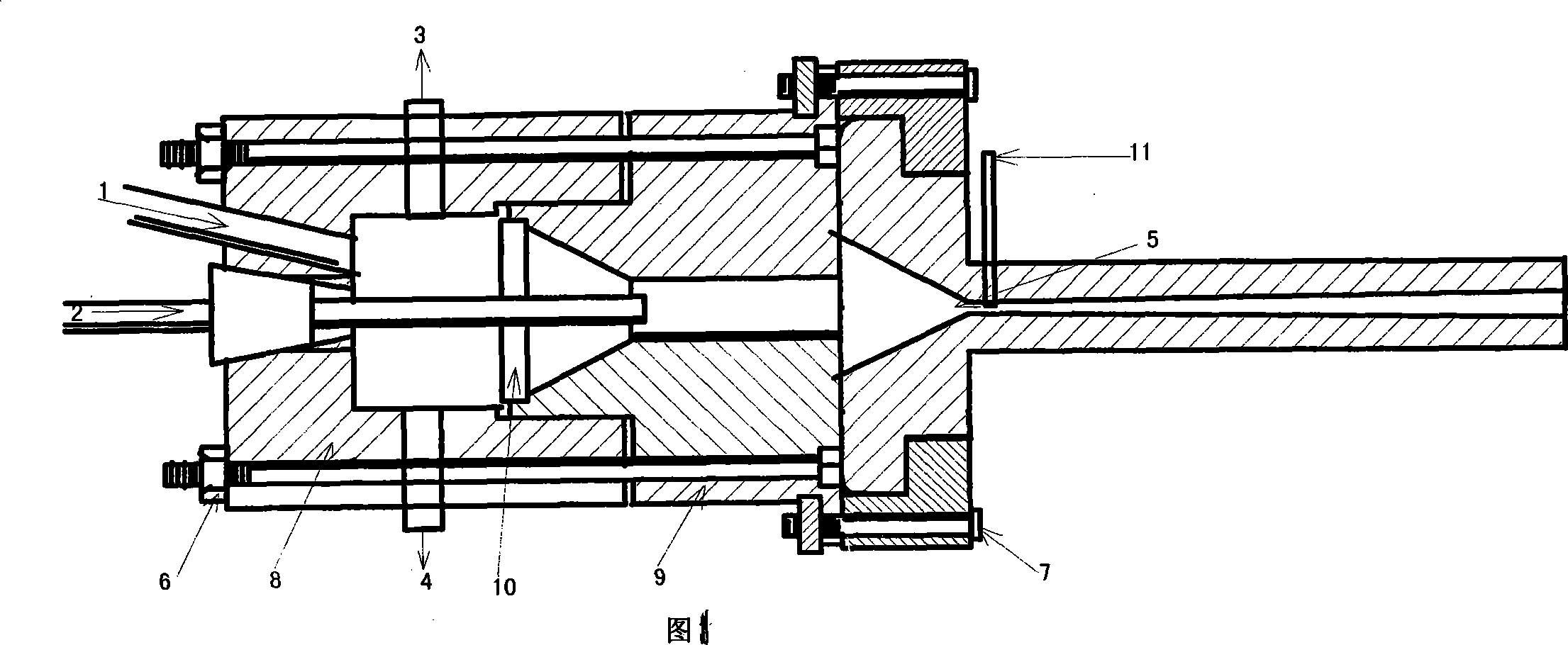

De-Laval-Type nozzle for cold spraying

InactiveCN101116849AReduce speed dropSpray nozzlesLiquid spraying apparatusThermal sprayingUltrasonic nozzle

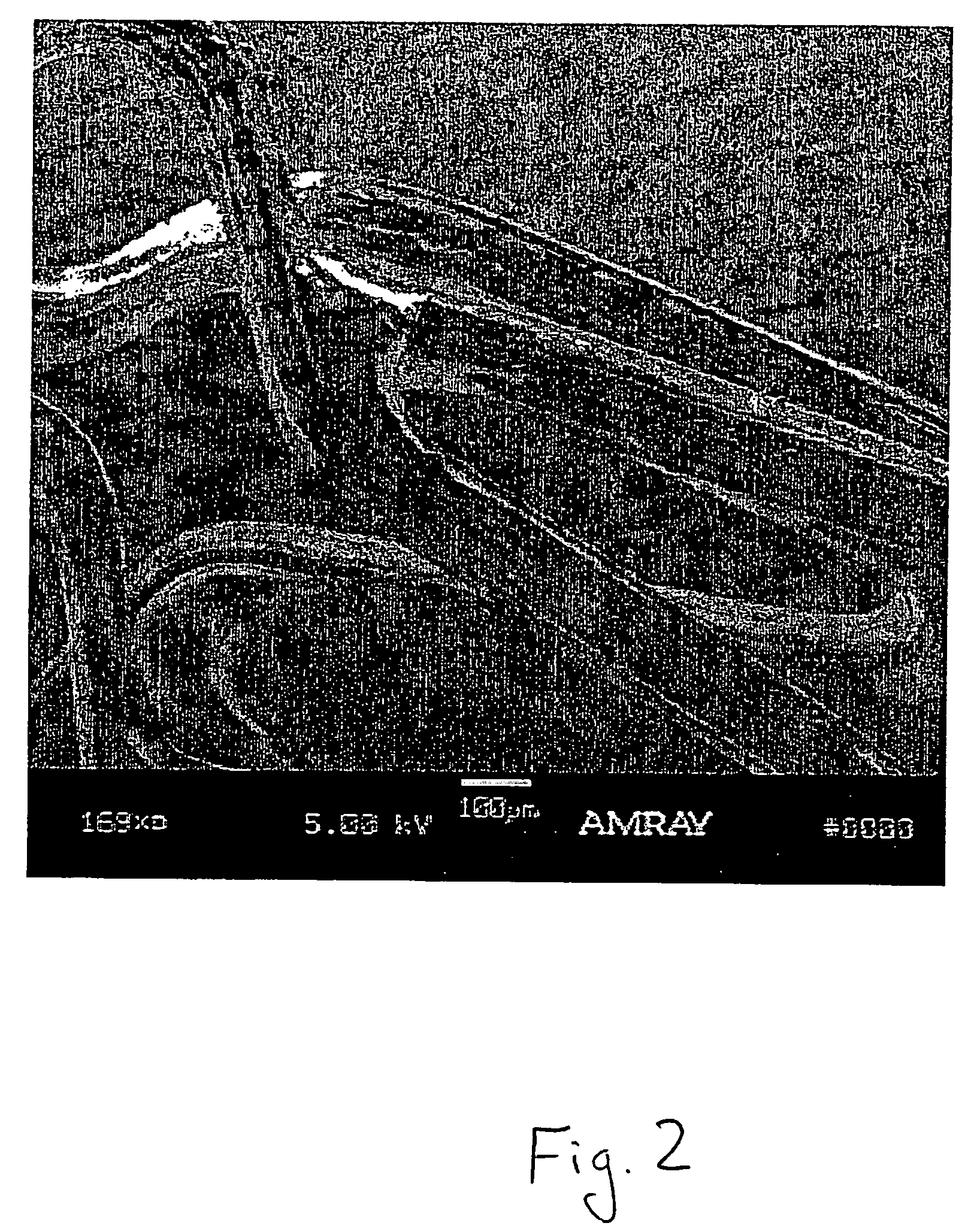

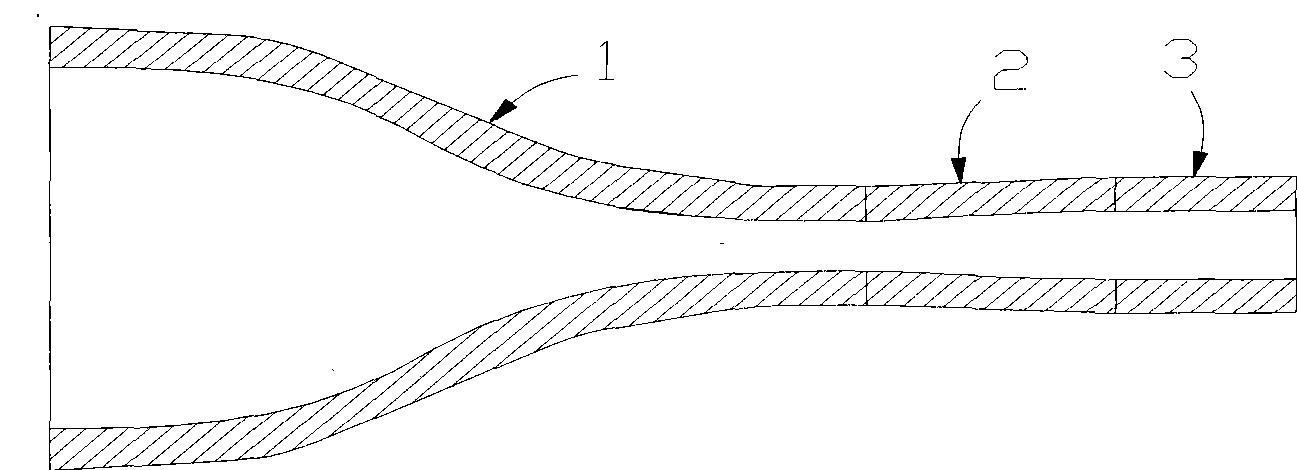

The present invention belongs to the thermal spraying field of the surface treatment engineering, which relates to a laval nozzle of rapid prototyping supersonic converging-diverging tube structure for cold spraying the titanium and aluminum metal coating. The major structure comprises an inlet of the main gas path, a main power feeding gas path, an assistant power feeding gas path, an interface of pressure probe, an interface of temperature probe, an ultrasonic nozzle, a fixing bolt, a gas chamber, an air locker structure, and a gasket. The laval nozzle is characterized in that the air chamber and the split air chamber structure are fixedly connected by the fixing bolt and formed a whole structure of axial symmetry, and the center of the back end of the main body of the nozzle is provided with the main power feeding gas path; the up side of the main power feeding gas path is provided with the angle-inserting inlet of the main gas path, and the up and down sides of the main air chamber of the main body of the nozzle are provided with the interface of the pressure probe and the interface of the temperature probe separately; the inlet of the main gas path and the main power feeding gas path are converged at the inside of the nozzle body and communicated with the ultrasonic nozzle separately, and the nozzle of the ultrasonic nozzle is provided with the assistant power feeding gas path; the present invention reduces the speed of the particles along the interface direction, and spraying can be realized by a common typical nozzle.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

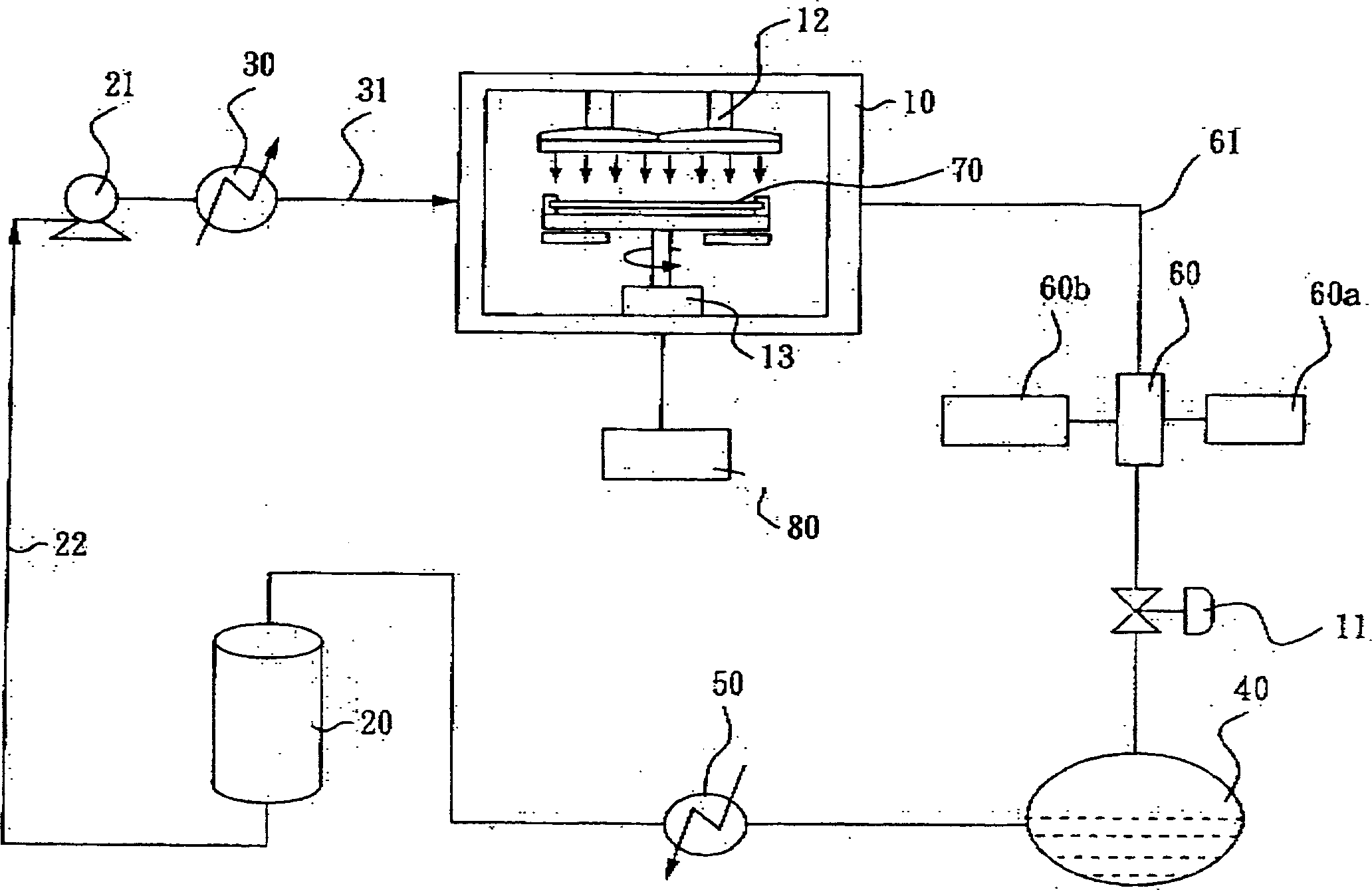

Basal plate cleaning system and method

InactiveCN1799710AReduce surface tensionLow viscosityCleaning using liquidsTemperature controlUltrasonic nozzle

The invention relates to a base plate cleaning system, comprising: a sealed cleaning chamber; a cleaning solution supply device; a carbon dioxide liquid storage device; a pressure controller; a temperature controller; and a online detector. Wherein, said cleaning solution supply device is connected to the carbon dioxide liquid storage device via a connection pipe; the carbon dioxide liquid storage device is connected to the pressure controller via a connection pipe; the pressure controller is connected to the temperature controller via a connection pipe which is connected to the sealed cleaning chamber via a through pipe to feed the above-critical carbon dioxide mixture into sealed cleaning chamber and utilize the ultrasonic nozzles in dual number to spray the mixture on the basic plate; and said online detector is connected to the sealed cleaning chamber via a sampling pipe.

Owner:IND TECH RES INST

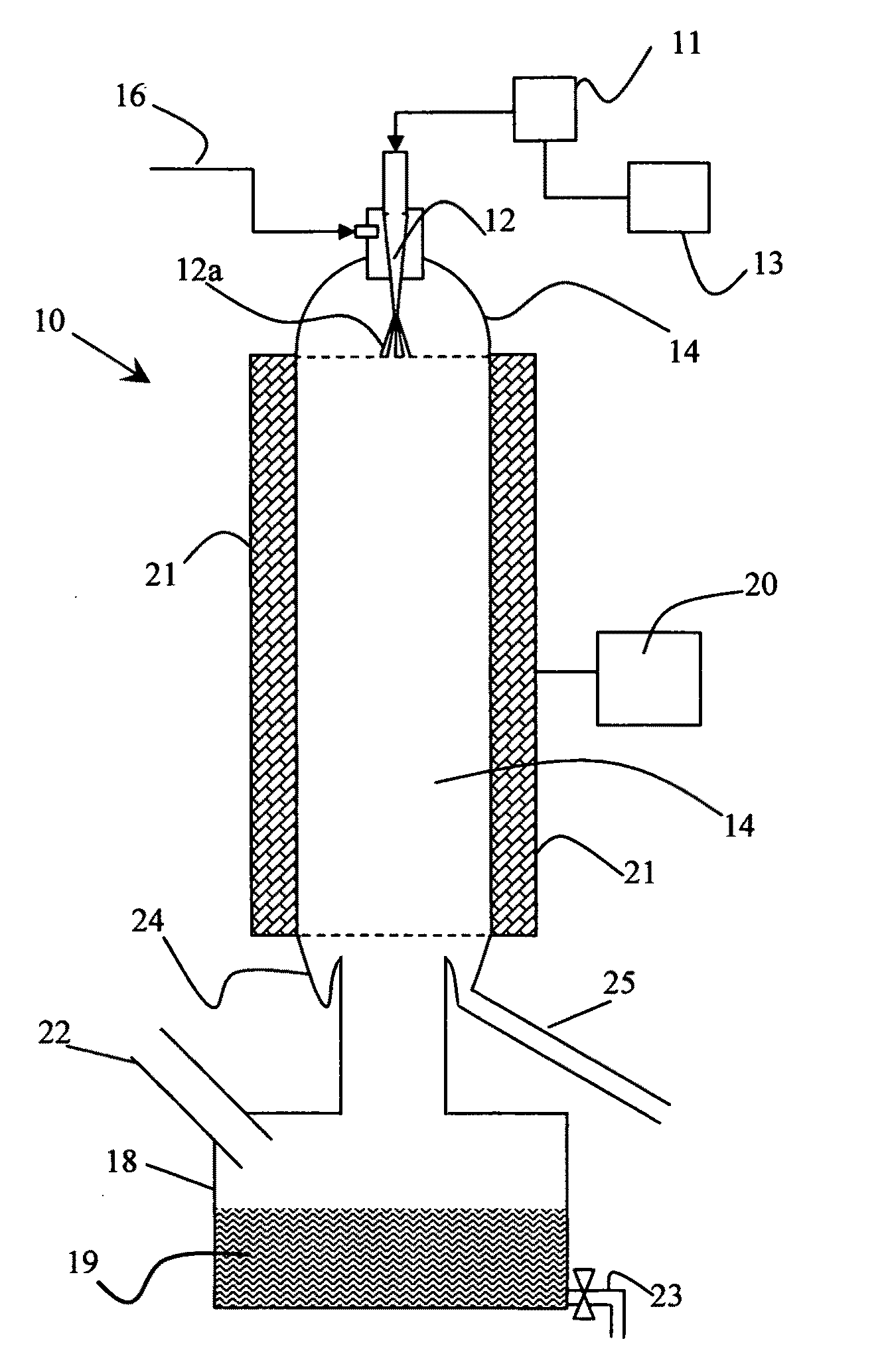

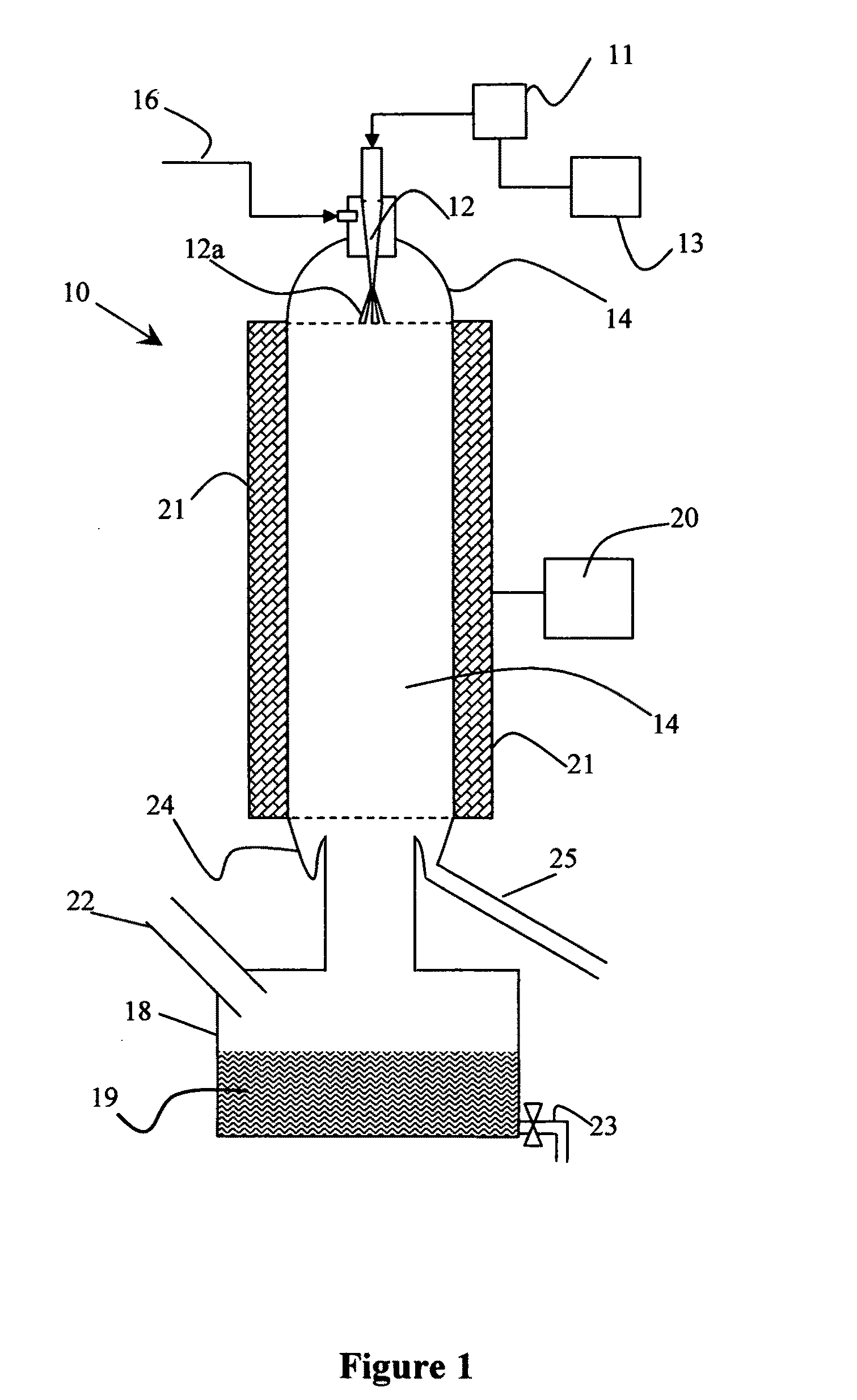

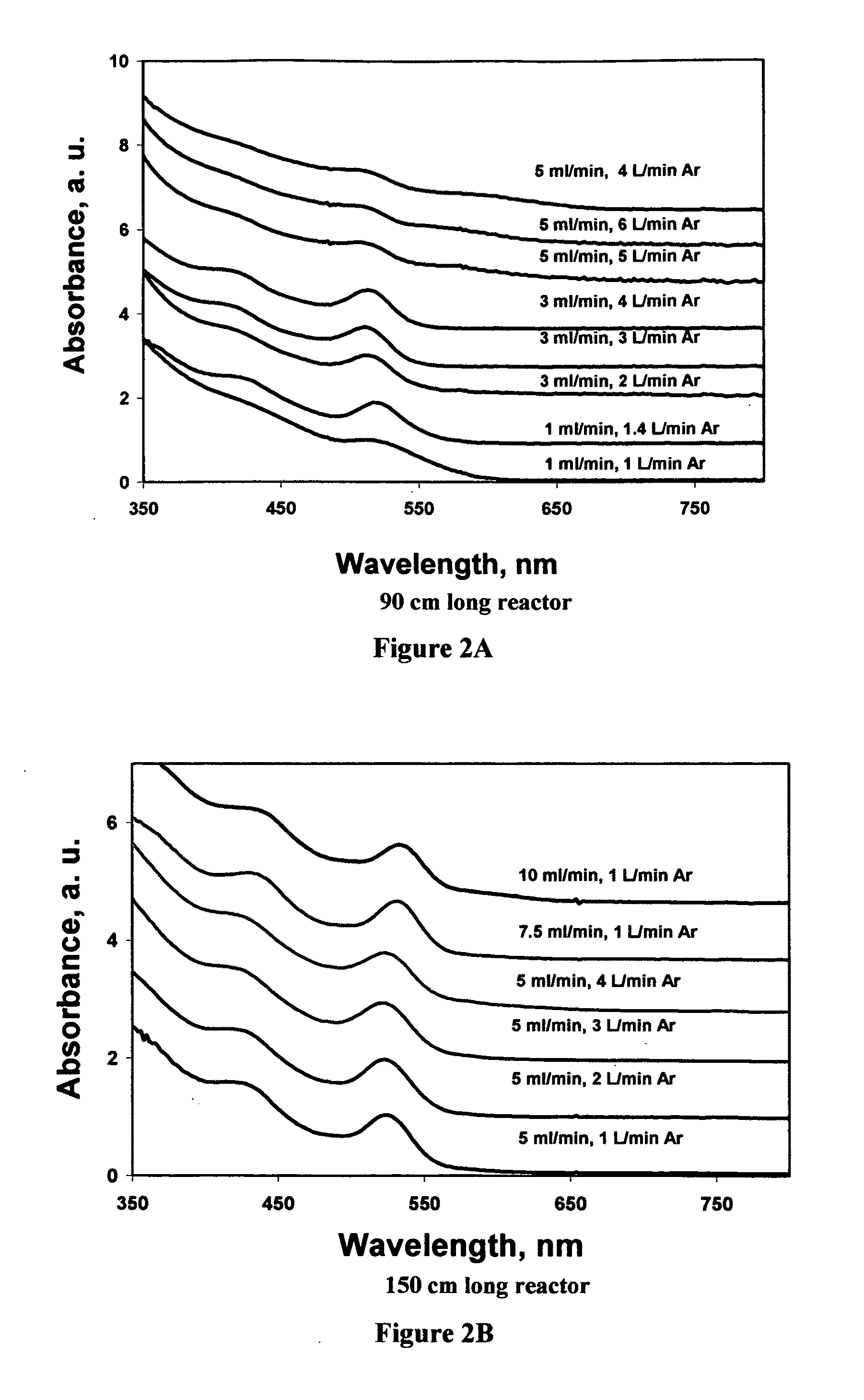

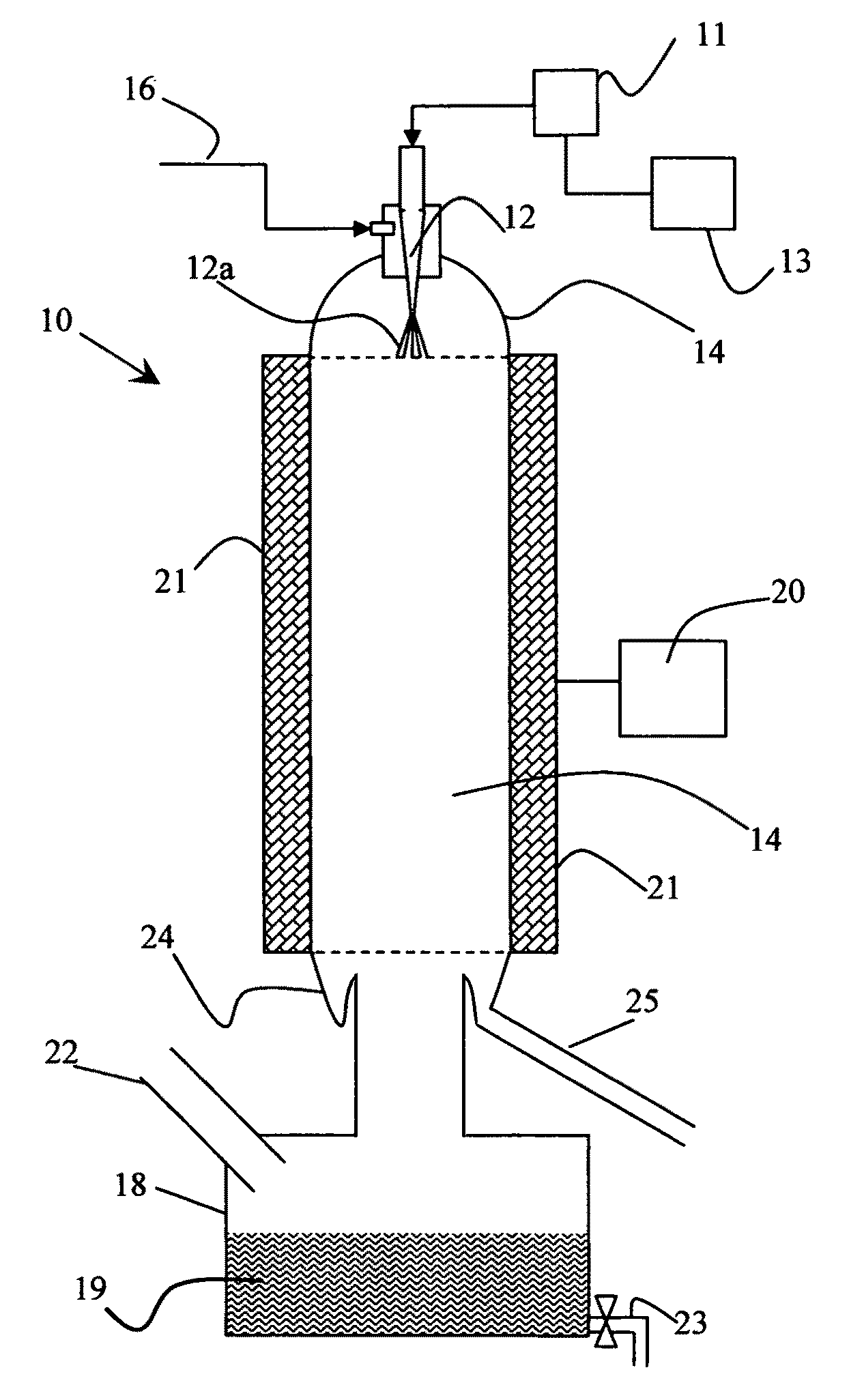

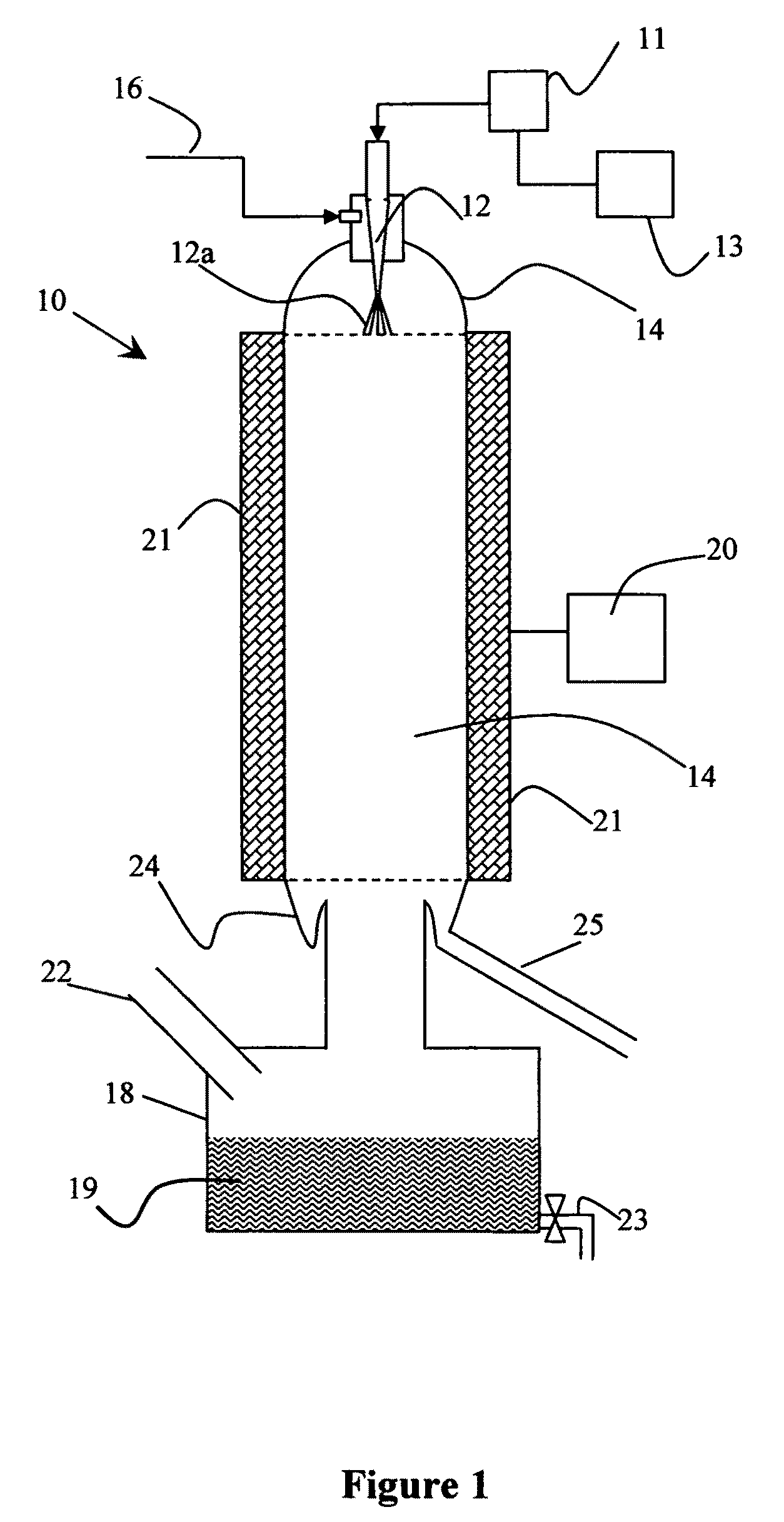

Controlled synthesis of nanoparticles using continuous liquid-flow aerosol method

InactiveUS20100028249A1Point becomes highEasy to depositFrom normal temperature solutionsSelenium/tellurium compundsUltrasonic nozzleBoiling point

A method and apparatus for producing surface stabilized nanometer-sized particles includes the steps of mixing reactants, a surface-stabilizing surfactant, and a high boiling point liquid to form a mixture, continuously passing the mixture through an ultrasonic spray nozzle to form a mist of droplets of the mixture, injecting the mist directly into a furnace to cause a reaction between species of the mixture, and collecting the nanometer-sized products. The ultrasonic nozzle is positioned directly at one end of the heating furnace, preferably the top end, for travel of the droplets through the furnace. The continuous liquid-flow process, along with certain operating parameters, eliminates the need for dilution of the high boiling point liquid with a low boiling point solvent as in the prior art, significantly increases the yield, improves the quality of the product, and makes the process scalable.

Owner:ORAMIC

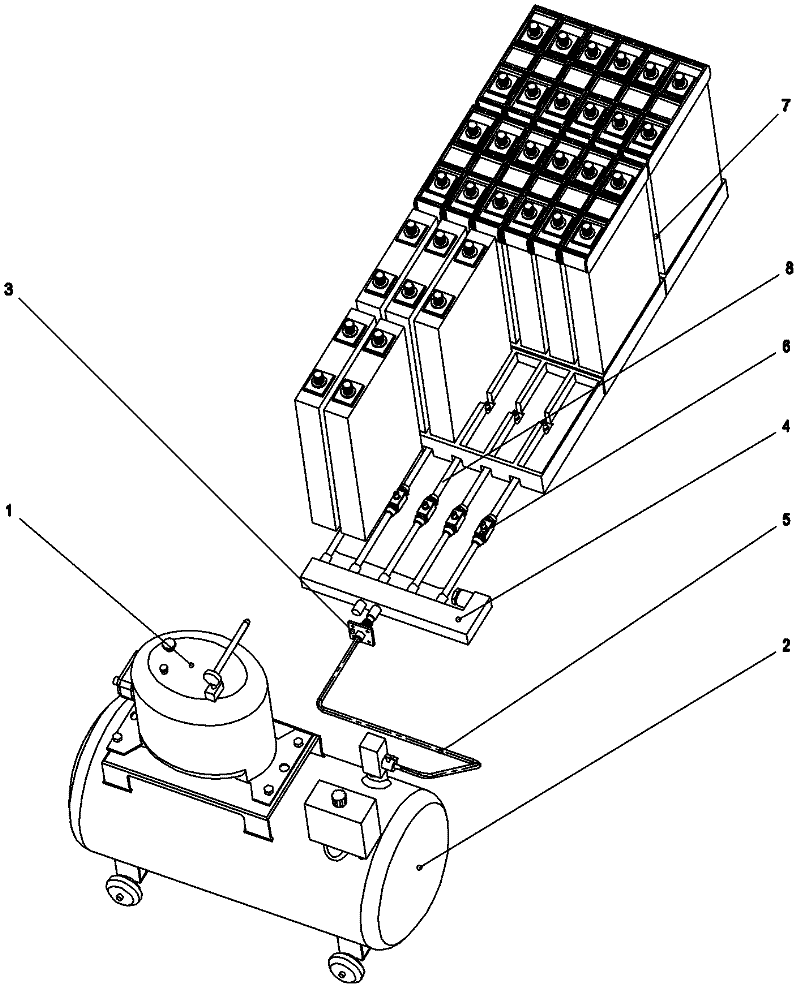

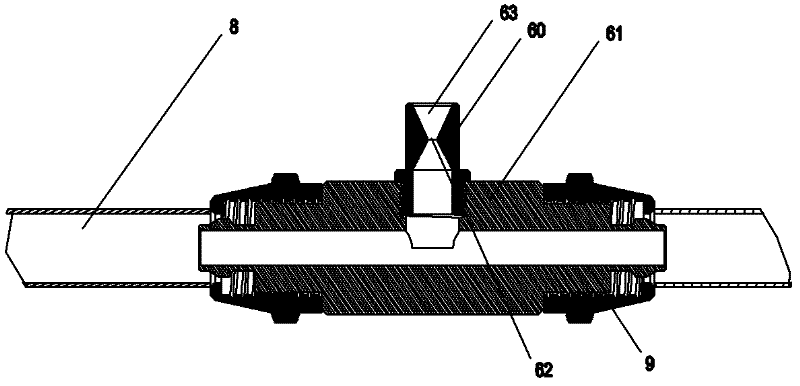

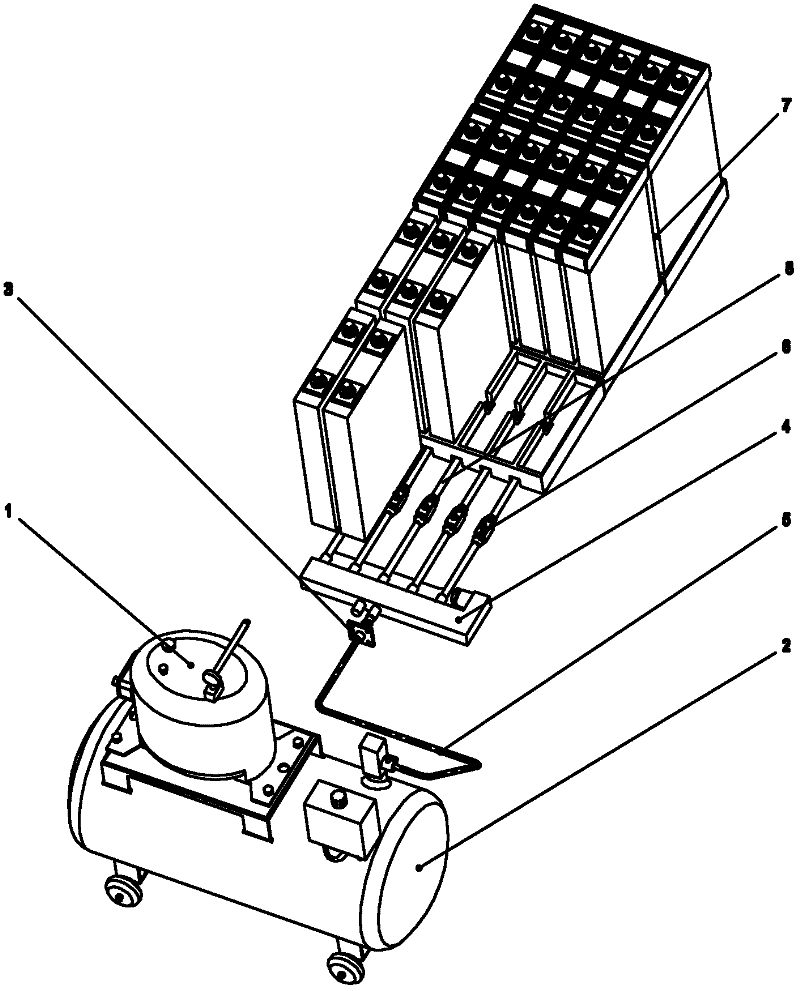

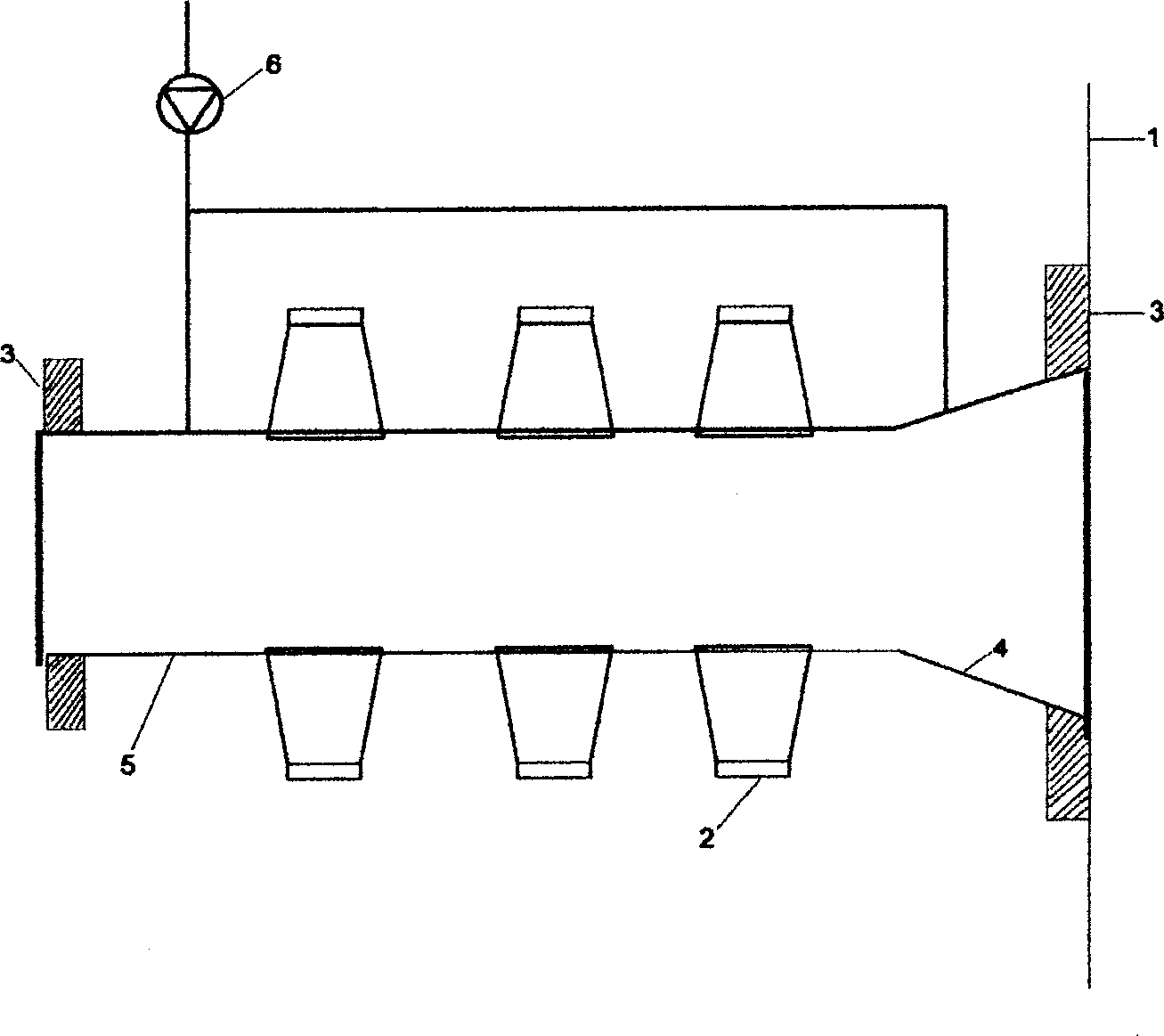

Forced air cooling system for large assembled lithium ion battery

ActiveCN102386460AInstantaneous pressure drop at ejectionReduce the temperatureSecondary cellsSolenoid valveUltrasonic nozzle

The invention provides a forced air cooling system for a large assembled lithium ion battery. The system is characterized in that: the system comprises a compressor, an air storage tank with a condenser, an air inlet interface, a solenoid valve, an air supply tube, ultrasonic nozzles, and an air outlet channel; the air storage tank is connected with the compressor, and compressed air which is compressed by the compressor enters the air storage tank and is cooled; the air storage tank is connected with one or more air supply tubes which are connected with the solenoid valve through the air inlet interface, the solenoid valve is connected with one or more branched air supply tubes which are respectively provided with one or more ultrasonic nozzles, and the one or more ultrasonic nozzles arearranged in a storage container of the assembled lithium ion battery. The system of the invention, which has the characteristics of simple structure, small occupation space, obvious cooling effect, light weight and the like and provides air cooling for assembled batteries of an automobile power battery pack module, an energy storage battery pack module and the like, has a very high practical value and a wide market prospect, and especially has a wide application space in fields of large capacity high voltage energy storage batteries and power batteries.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Turbine motor of a rotary atomizer

A turbine, e.g., with a blade arrangement, which receives an air flow in the radial direction and which is located on a carrier surface of the turbine wheel, is used as a drive motor for a rotary atomizer. The drive channel, which contains the turbine blades and which is limited by the carrier surface, is also closed on its other side by a cover element, which is attached to the turbine wheel and which rotates with the wheel for increasing efficiency. For an additional increase in efficiency, the inlet for the drive air of the turbine is configured as an ultrasonic nozzle with a cross section that expands continuously up to the opening.

Owner:DURR SYST INC

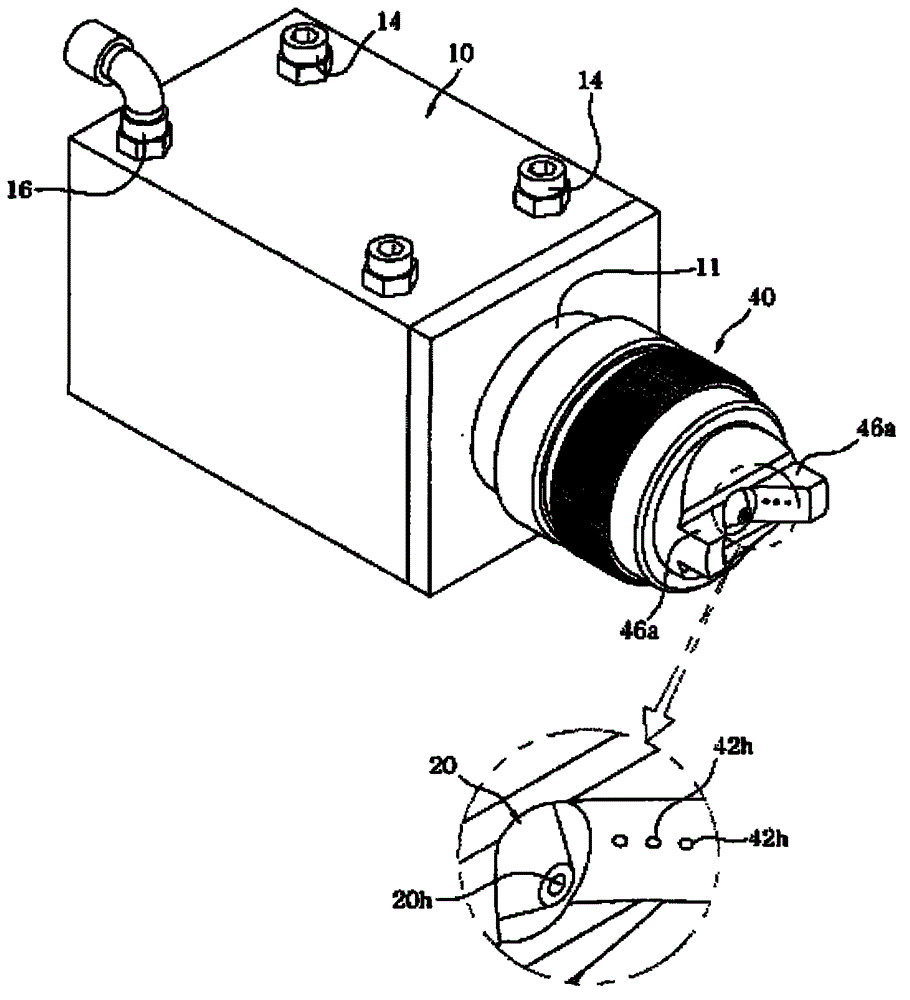

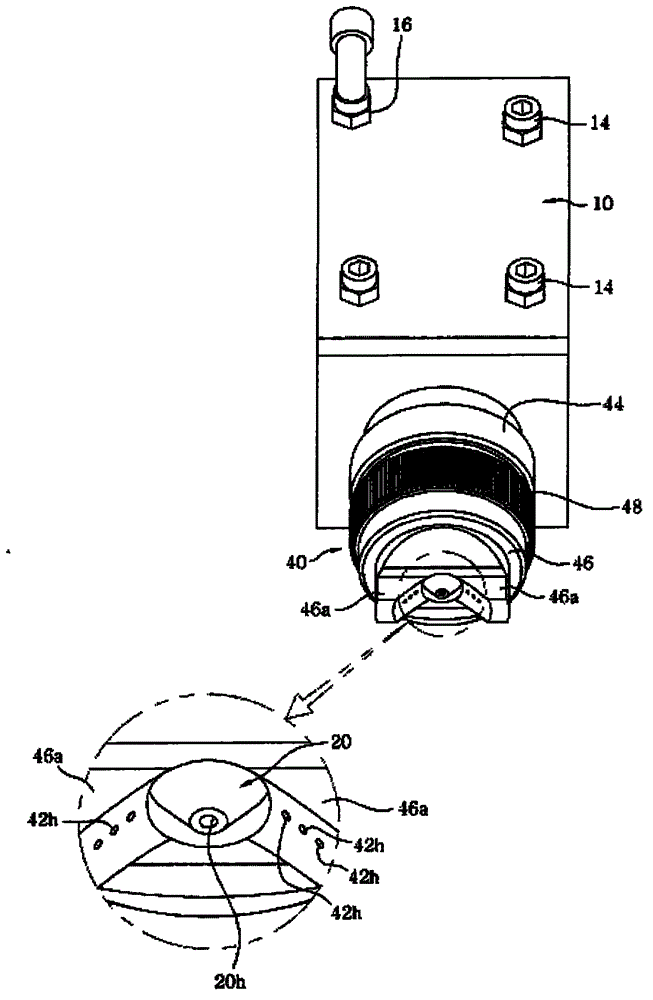

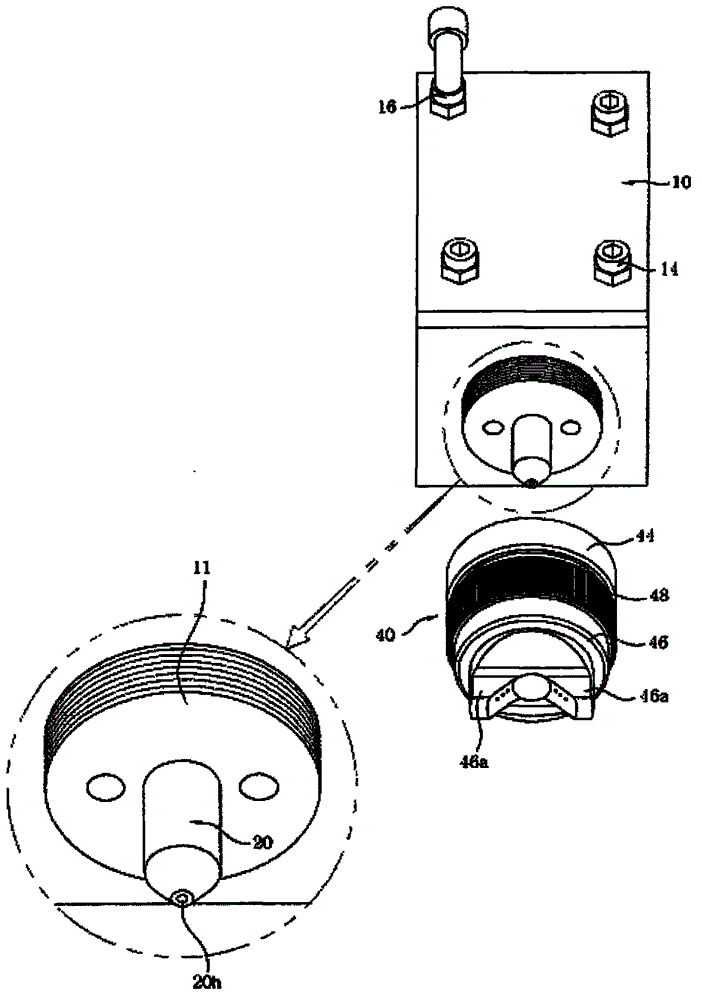

Ultrasonic spray nozzle integrated with spray width control device

InactiveCN104684655AImprove convenienceImprove efficiencyBurnersSpray nozzlesUltrasonic nozzleEngineering

The objective of the present invention is to provide an ultrasonic spray nozzle integrated with a spray width control device. According to the present invention, the ultrasonic spray nozzle integrated with a spray width control device is configured to include: a main container (10) in which a space portion is disposed; an upper supporter (20) coupled to the main container (10), wherein a flame outlet is disposed on the surface facing the lower side of the main container (10) and a roast plate support unit (22) is disposed at a location around the flame outlet; and a fuel container (30) in which a fuel charging unit is disposed and a section contact portion (34) is disposed in the peripheral portion of the fuel charging unit in such a manner as to be coupled to the main container (10), disposed at a position facing the flame outlet of the upper supporter (20), and in partial contact with the main container (10) via the section contact portion (34), wherein the other part is spaced apart from the main container (10).

Owner:TAESAN COATING ENG +1

Atomisation of a precursor into an excitation medium for coating a remote substrate

InactiveUS20060177598A1Remove and minimise any effectAvoid damagePretreated surfacesChemical vapor deposition coatingMetallurgyUltrasonic nozzle

The invention relates to a method and apparatus for applying and forming a coating on a substrate surface by the application of at least one atomized coating forming material onto the substrate to form the coating. The atomized coating forming material, upon leaving a suitable atomizer which can be an ultrasonic nozzle or nebulizer for example, passes through an exciting medium and, upon leaving the exciting medium, passes to the substrate. The substrate is positioned remotely from the exciting medium.

Owner:SURFACE INNOVATIONS LTD

Ultrasonic atomizing nozzle and method

An ultrasonic nozzle configured to form relatively small drops of liquid at relatively high rates. The nozzle includes two horns, at least one of which includes a ceramic material. The nozzle also includes one or more transducers that cause mechanical motion in at least one of the horns. In addition, a method of forming micrometer-scaled drops of liquid at relatively high rates is provided.

Owner:SONO TEK CORP

Supersonic nozzle

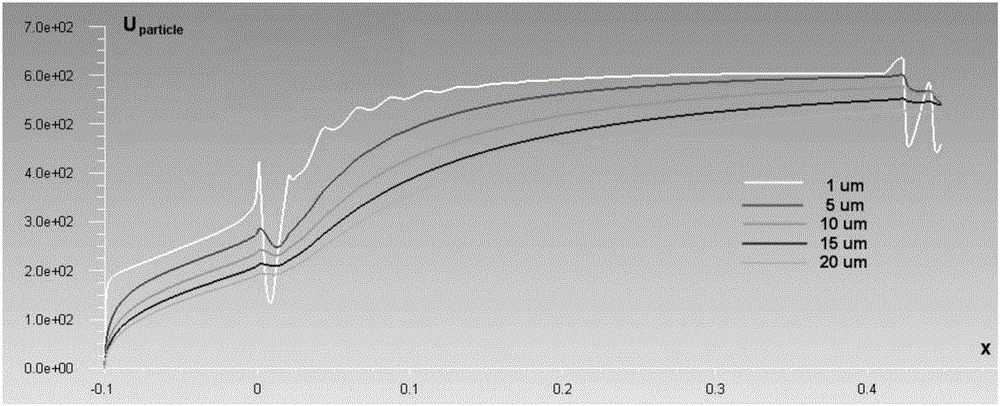

InactiveCN106693876AUniform flow fieldExact collisionChemical/physical/physico-chemical nozzle-type rreactorsSonic nozzleParticle dynamics

The invention relates to a supersonic nozzle which consists of a ring-shaped shrinking-expanding nozzle, an injected charging pipe, an accelerating pipe and a target head, wherein supersonic gas flow of the ring-shaped shrinking-expanding nozzle is used for injecting and accelerating low-speed gas flow of a central charging circular pipe to an supersonic state, so that material particles obtain enough dynamic energy along with the gas flow, and can be gathered at the gas flow center to crash the fixed target head at the downstream in a focused mode, and therefore, the problems such as difficult charging, low material particle dynamic energy and low collision reaction efficiency in high-speed gas flow solid-phase reaction are solved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Controlled synthesis of nanoparticles using continuous liquid-flow aerosol method

InactiveUS7811543B2Quality improvementGood reproducibilityFrom normal temperature solutionsSelenium/tellurium compundsNanoparticleUltrasonic nozzle

A method and apparatus for producing surface stabilized nanometer-sized particles includes the steps of mixing reactants, a surface-stabilizing surfactant, and a high boiling point liquid to form a mixture, continuously passing the mixture through an ultrasonic spray nozzle to form a mist of droplets of the mixture, injecting the mist directly into a furnace to cause a reaction between species of the mixture, and collecting the nanometer-sized products. The ultrasonic nozzle is positioned directly at one end of the heating furnace, preferably the top end, for travel of the droplets through the furnace. The continuous liquid-flow process, along with certain operating parameters, eliminates the need for dilution of the high boiling point liquid with a low boiling point solvent as in the prior art, significantly increases the yield, improves the quality of the product, and makes the process scalable.

Owner:ORAMIC

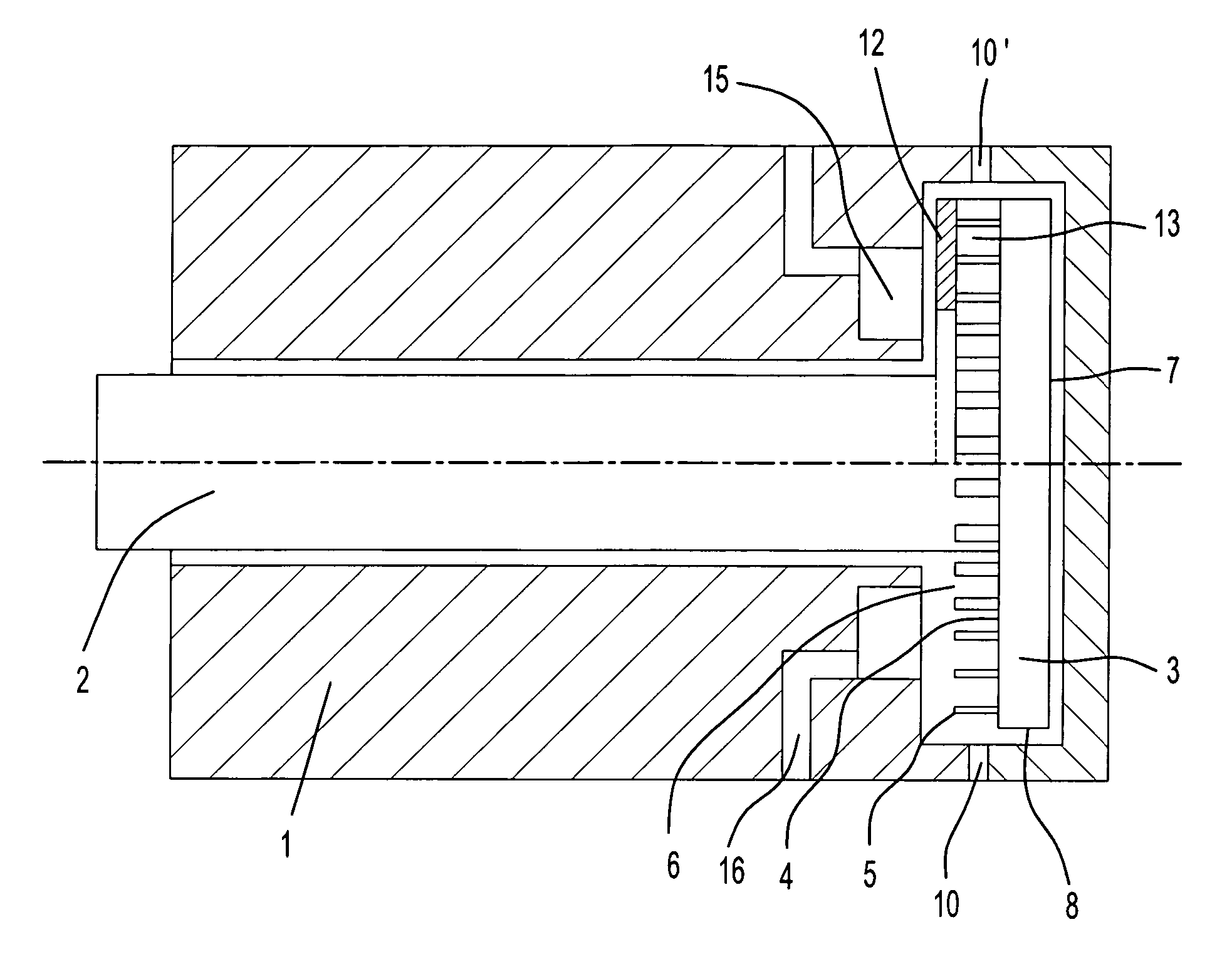

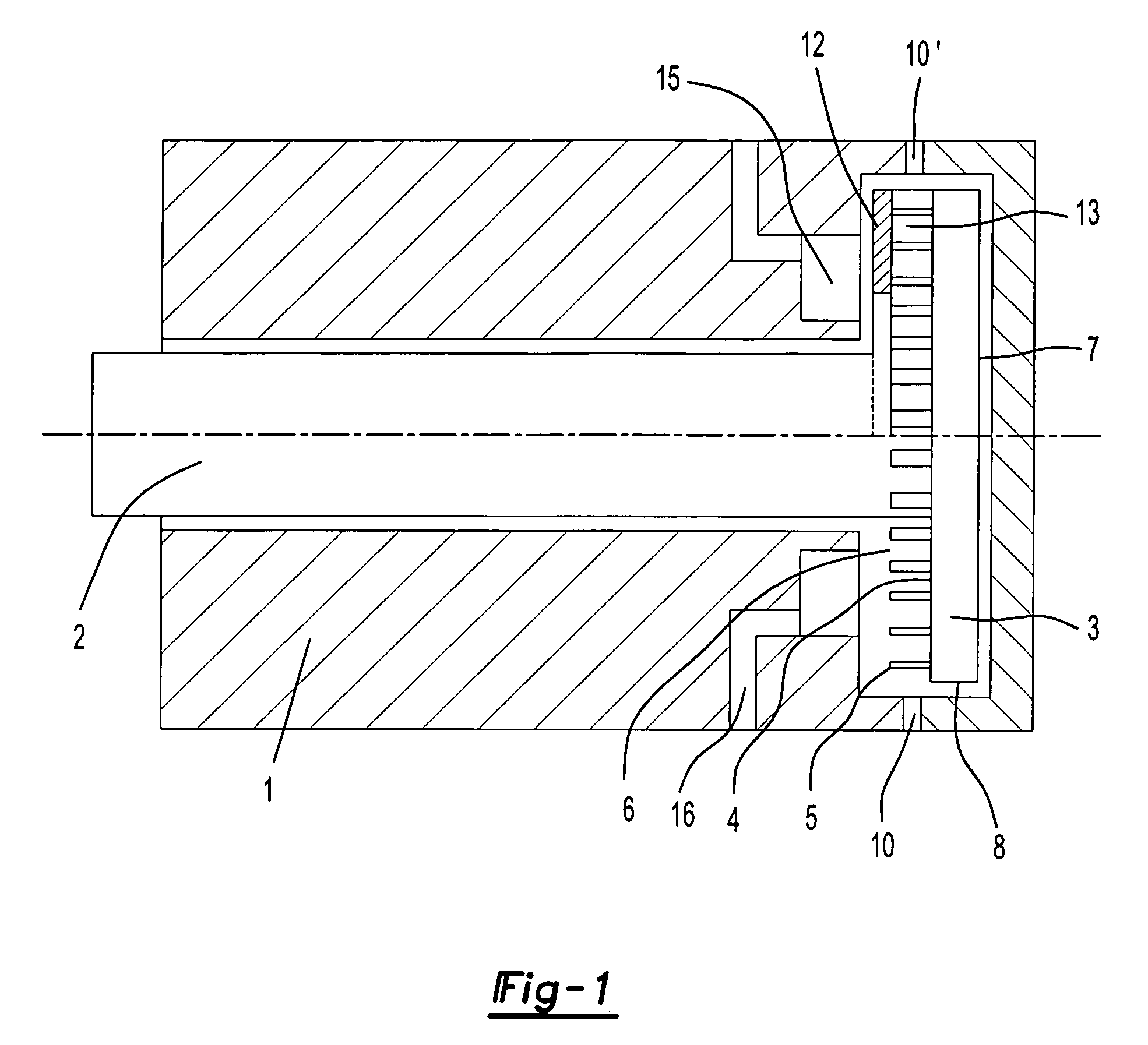

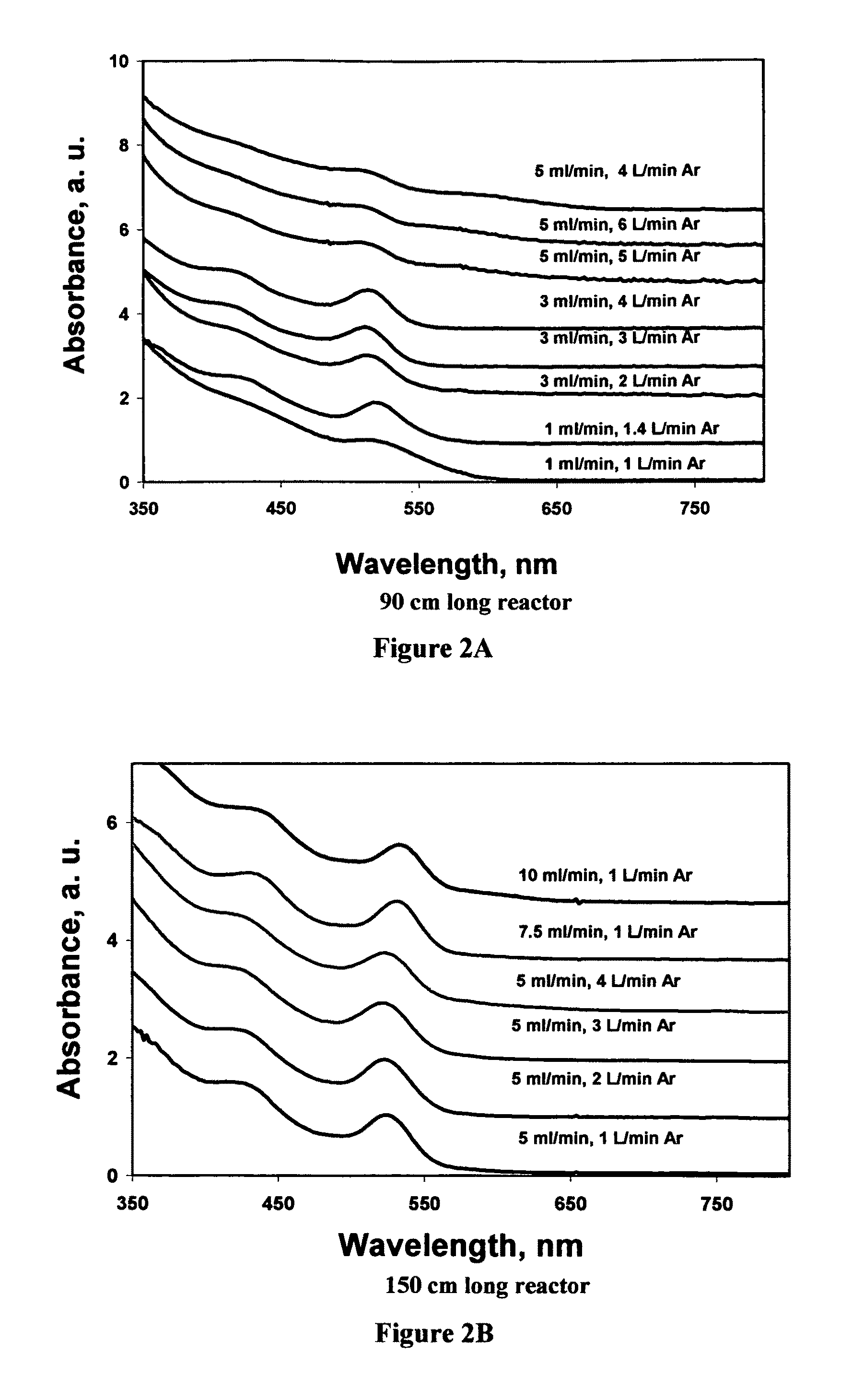

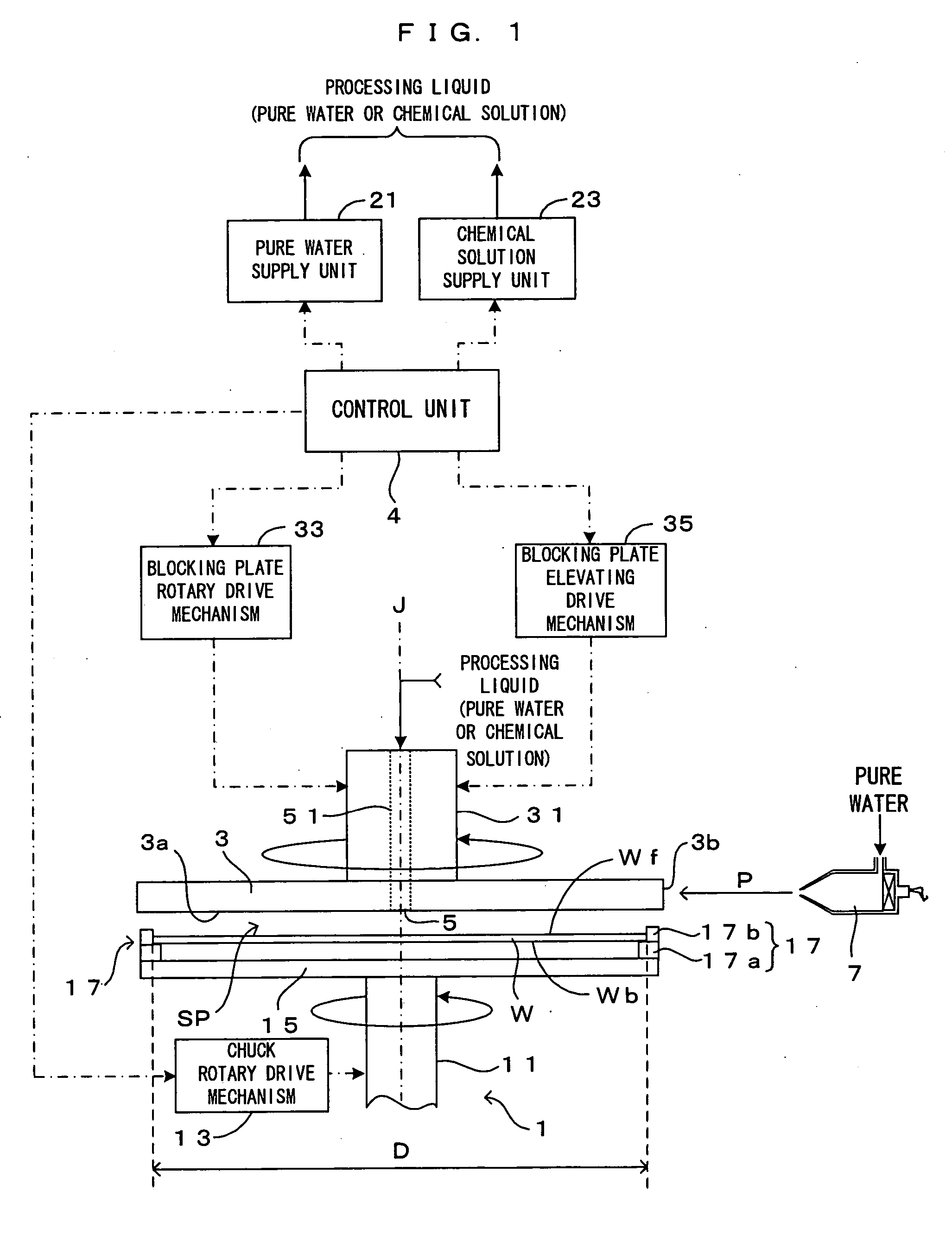

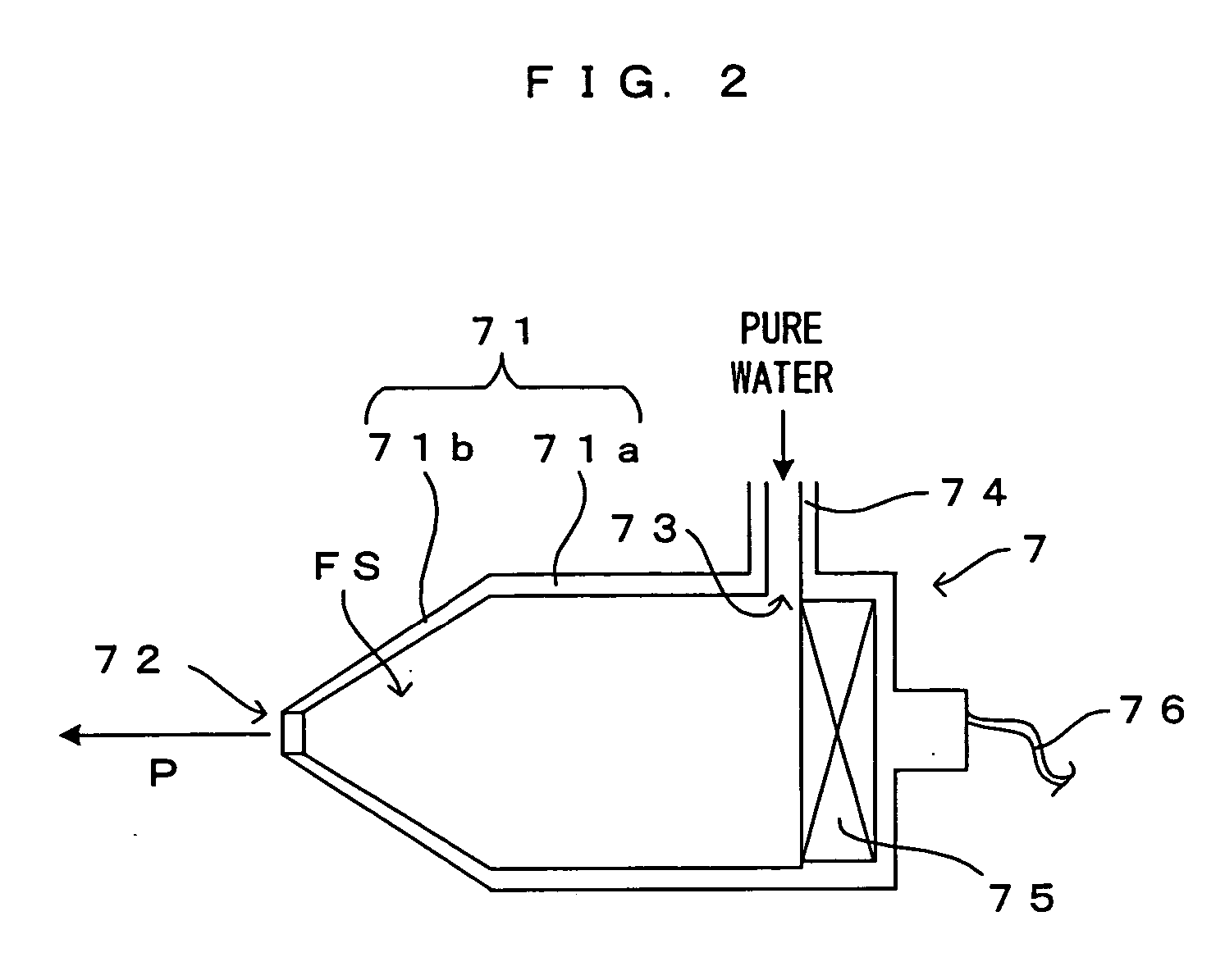

Apparatus and method for performing predetermined processing on substrate with ultrasonic waves

InactiveUS20060130872A1Damage suppressionUniform processingElectrostatic cleaningSemiconductor/solid-state device manufacturingUltrasonic nozzleEngineering

A blocking plate 3 is disposed opposing a substrate W which is held by plural chuck pins 17 and a processing liquid is supplied from a processing liquid nozzle 5 to a space SP between the front surface Wf of the substrate and an opposed surface 3a of the blocking plate 3, whereby the processing liquid attains the liquid-tight state. While the liquid-tight state with the processing liquid is maintained, the substrate W and the blocking plate 3 rotate. In this condition, a liquid (pure water) to which ultrasonic vibration has propagated is injected from an ultrasonic nozzle 7 approximately perpendicular to a side wall surface 3b of the blocking plate 3. While the ultrasonic vibration spreads inside the blocking plate 3 along the horizontal direction, some vibrational waves spread uniformly and widely from the opposed surface 3a to the processing liquid attaining the liquid-tight state and vibrate the processing liquid. This prevents concentration of the vibrational energy at the front surface Wf, which makes it possible to uniformly process the substrate W while suppressing damage to the substrate W.

Owner:DAINIPPON SCREEN MTG CO LTD

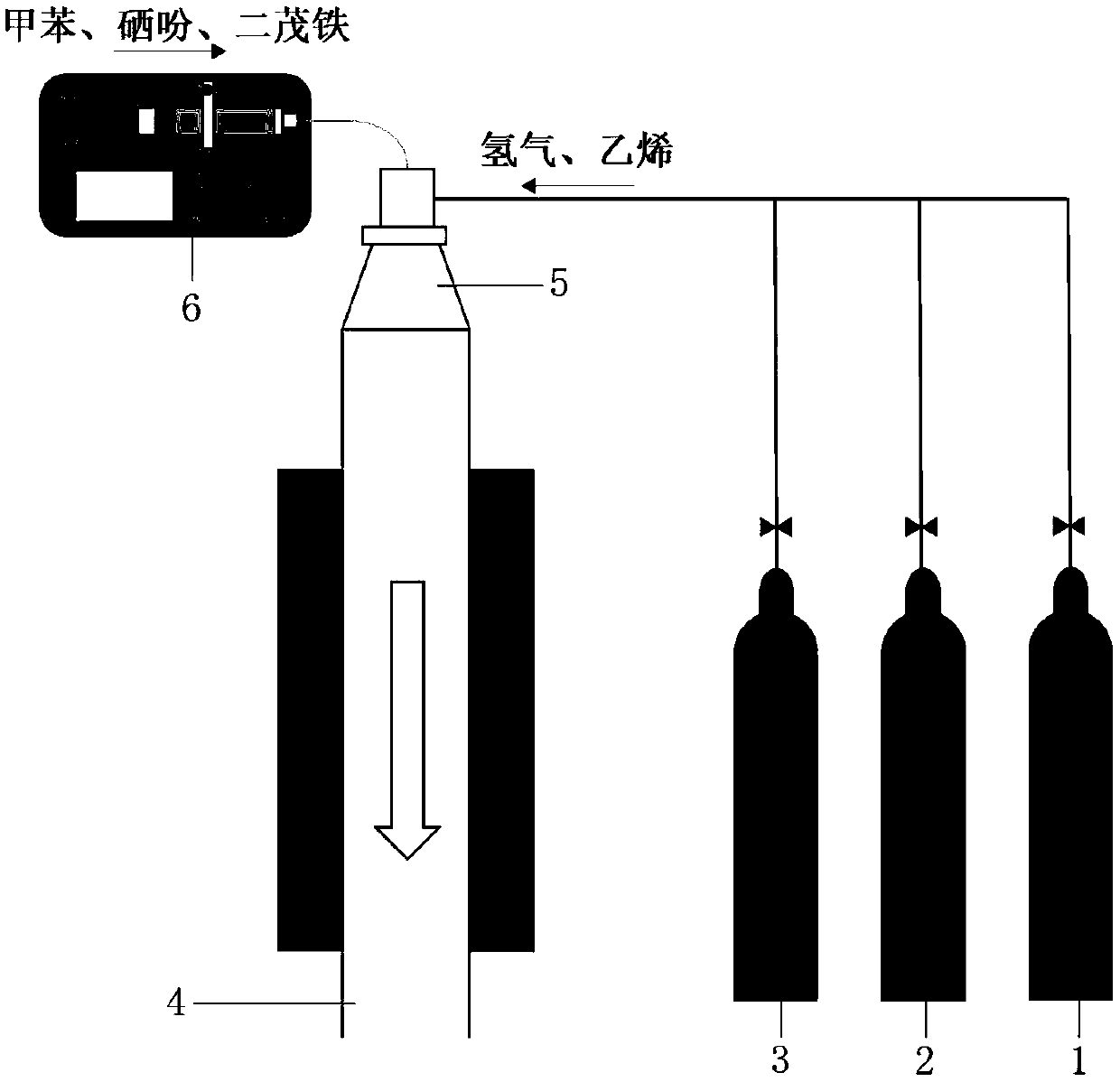

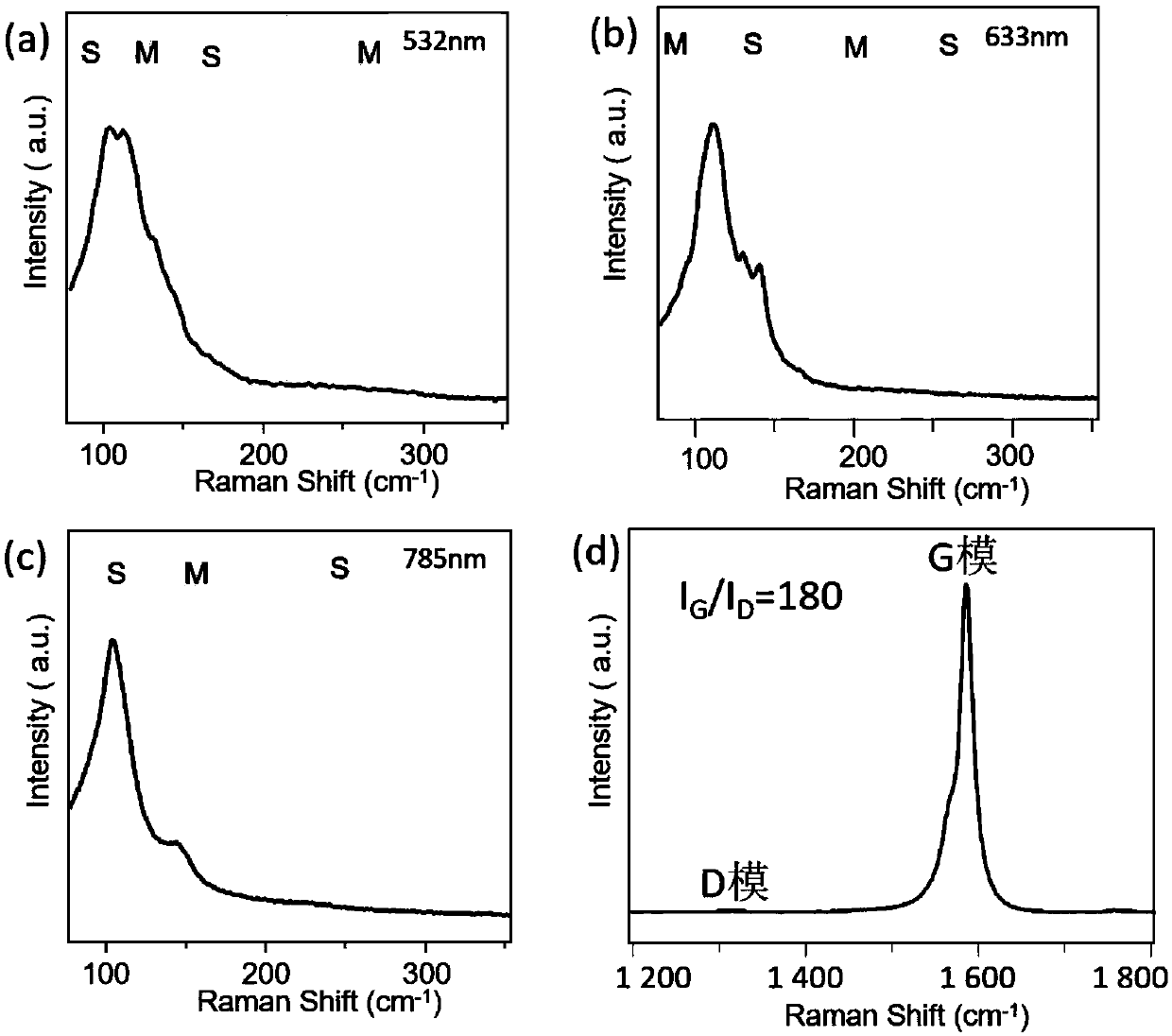

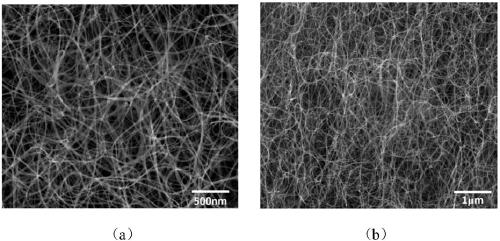

Controllable preparation method for single-walled carbon nanotube without sulfur impurities by growth promoter

ActiveCN109607513AEfficient growth processIncrease the scope of applicationCarbon nanotubesDecompositionUltrasonic nozzle

The invention relates to the field of controllable preparation of high-quality single-walled carbon nanotubes with low catalyst content and no sulfur impurities, in particular to a controllable preparation method for a single-walled carbon nanotube without sulfur impurities by a growth promoter. According to the method, selenophen is used as a precursor of the growth promoter, ferrocene is used asa catalyst precursor, and selenophen and ferrocene are dissolved in a toluene solvent; the formed solution is converted into aerosol by an ultrasonic nozzle, and then the aerosol is brought into a high-temperature zone by a carrier gas to catalyze ethylene decomposition and nucleation for growing a high-quality high-purity (IG / ID reaches 180 and the catalyst content is lower than 4.5 wt.%) single-walled carbon nanotube without sulfur impurities. The present invention uses selenium instead of sulfur as the growth promoter to achieve preparation of the high-quality single-walled carbon nanotubewith low catalyst residue and without sulfur impurities; and at the same time, hydrogen sulfide gas which is difficult to separate is avoided in tail gas of carbon nanotube growing, thus treatment and recycling of the tail gas are facilitated, and mass preparation of the high-quality single-walled carbon nanotube with a low catalyst content is achieved.

Owner:唯碳纳米科技(沈阳)有限公司

Method or transporting a liquid for atomization and a method and devices for atomizing the same

ActiveUS8434473B2Reduced drive power requirementsLarge coefficientMovable spraying apparatusSpray nozzlesElectricityUltrasonic nozzle

Ultrasonic nozzle devices without a central channel but employing a design of cascaded multiple Fourier horns in resonance produce micrometer-sized monodisperse or narrowly-sized droplets with greatly reduced electrical drive power requirements. The liquid to be atomized is brought externally to or adjacent to the endface of the nozzle tip. The above liquid transport method is equally applicable to the ultrasonic nozzle-array devices that are comprised of a plurality of ultrasonic single-nozzle devices configured in parallel. The longitudinal length, transverse width, shape, and area of the nozzle endface of single-nozzle and nozzle-array devices may be tailored or designed (e.g. enlarged) to obtain optimum or large quantities of product droplets to achieve high throughput. By increasing the drive frequency to 8 MHz or higher, sub-micrometer-sized monodisperse or narrowly-sized droplets can be produced using the ultrasonic single-nozzle and nozzle-array devices or any solid endface.

Owner:TSAI CHEN S +1

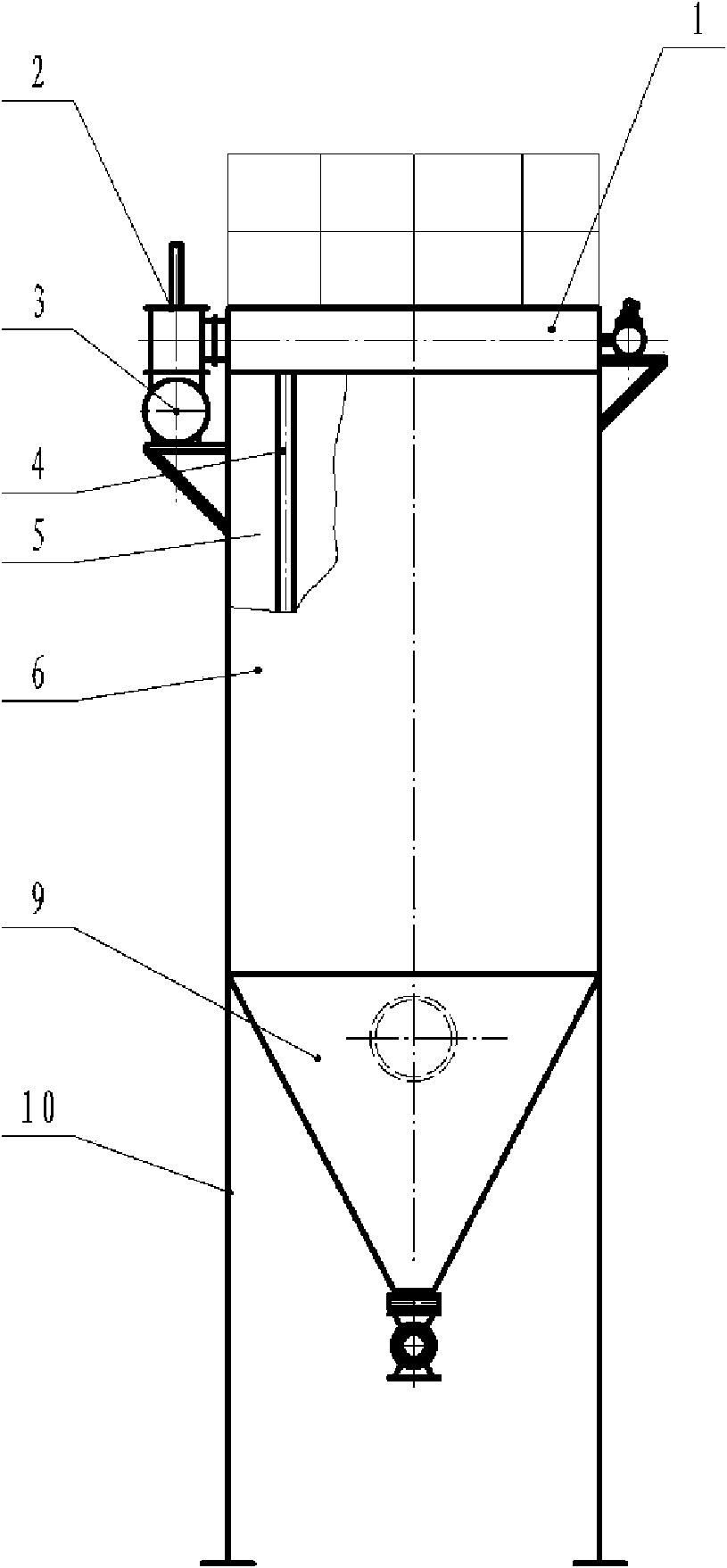

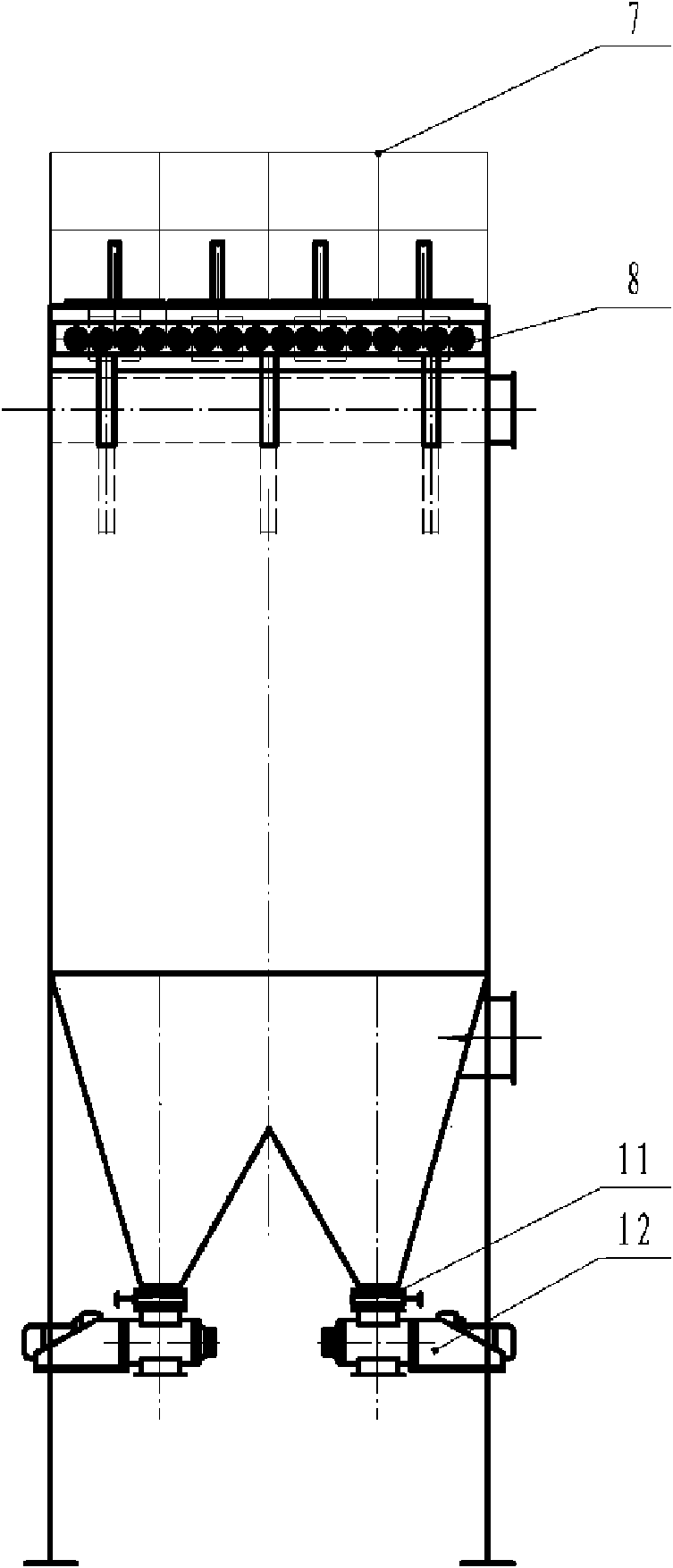

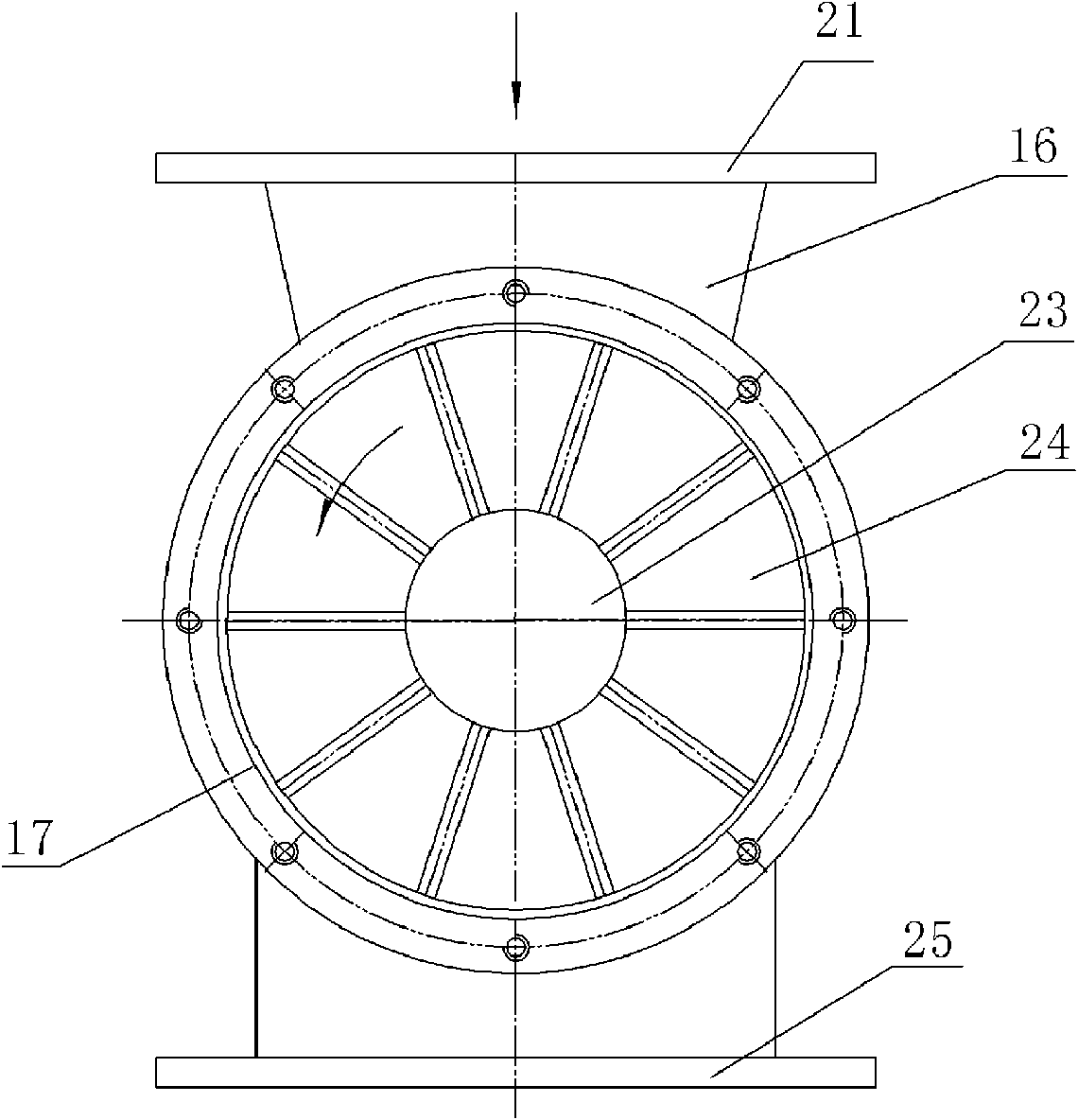

Pulse bag filter

InactiveCN101670214AReduce resistanceExtended service lifeDispersed particle filtrationUltrasonic nozzleBaghouse

The invention discloses a pulse bag filter, mainly solving the technical problems that the existing pulse bag filter has poor dust-removing effect and short service life and easily occur equipment accident when be used under high-temperature working condition and the like. The technical scheme thereof has the following key points: the pulse bag filter consists of a gas-purifying chamber (1), a filter bag (5), a filter bag skeleton (4), a filter bag (6), a blowing device (8), an ash hopper (9), a bracket (10), an inserting board valve (11) and a star-shaped rotating valve (12), wherein the dustremover is internally provided with a Venturi tube; a nozzle tube of the blowing device (8) is coupled with an ultrasonic nozzle in a movable coupling manner; the central line of the ultrasonic nozzle aligns to the central line of a bag hole; and a ladder-type Venturi tube is adopted. By adopting an ultrasonic draining nozzle, the ladder-type Venturi tube and the adjustable sealed rotating valve,the invention greatly improves ash-cleaning effect, prolongs the service life of the filter bags, expands the use range of the pulse bag filter, improves the use reliability, reduces use cost and canbe used under high-temperature working condition.

Owner:XIANGXIANG MACHINERY FACTORY

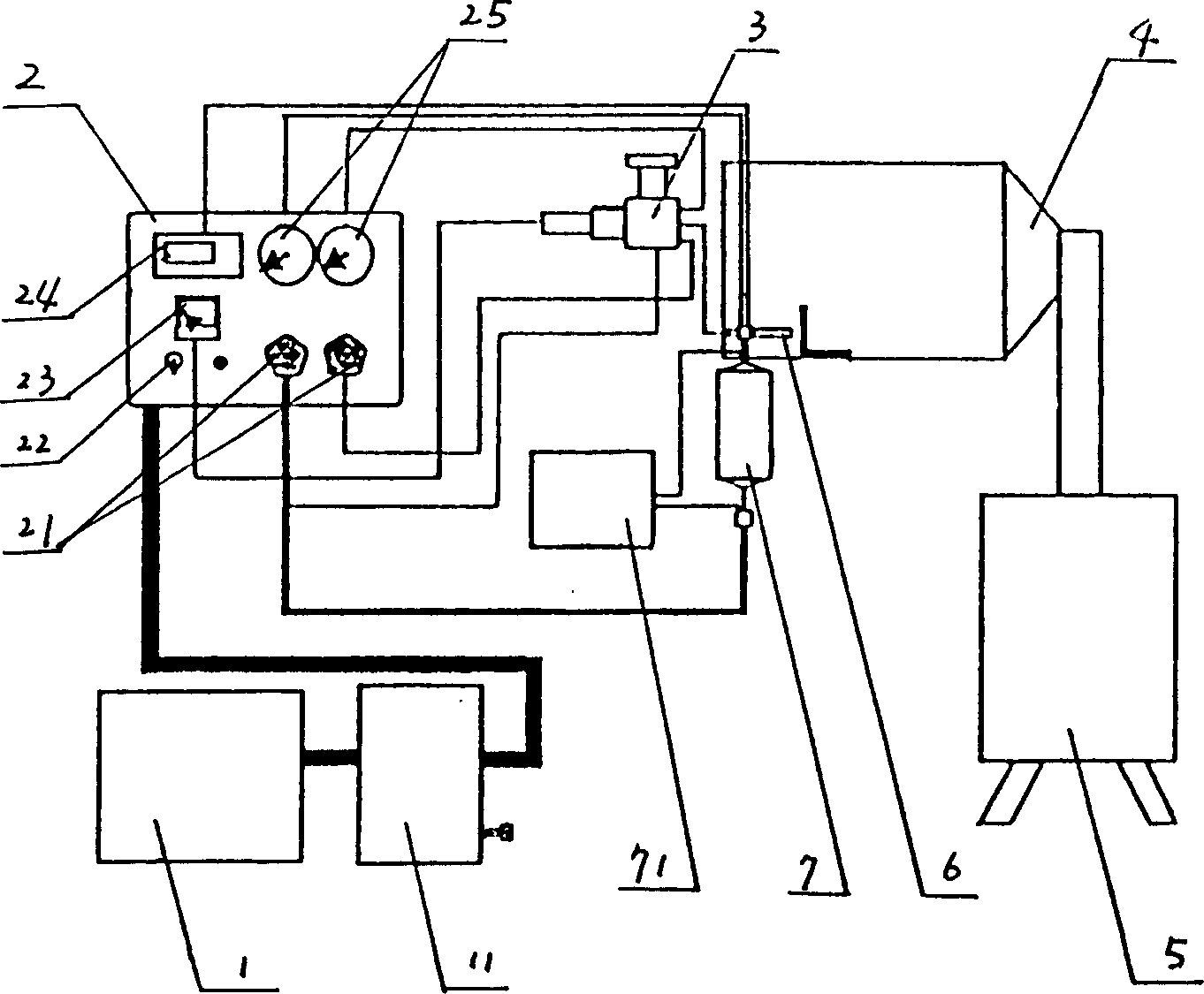

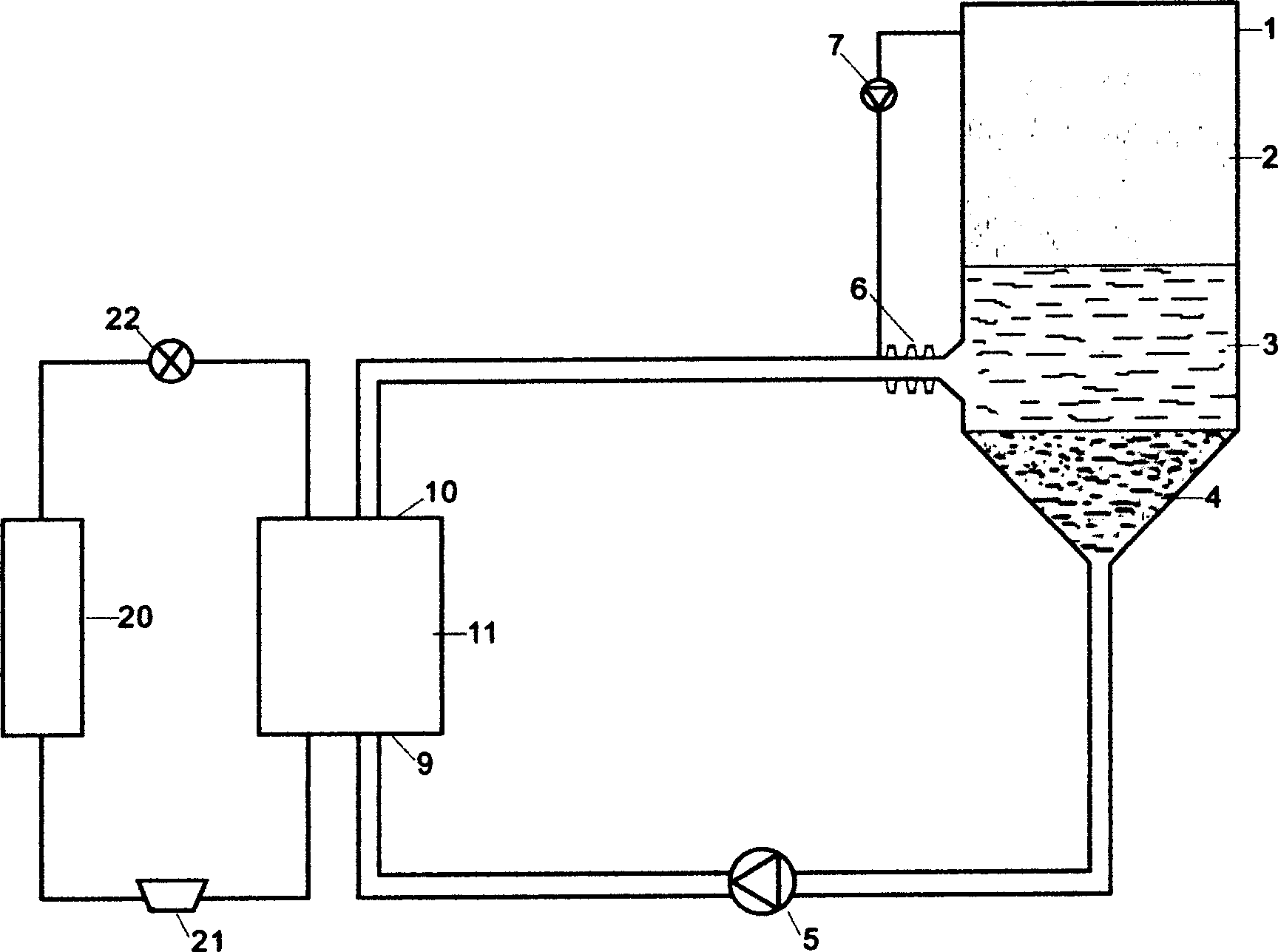

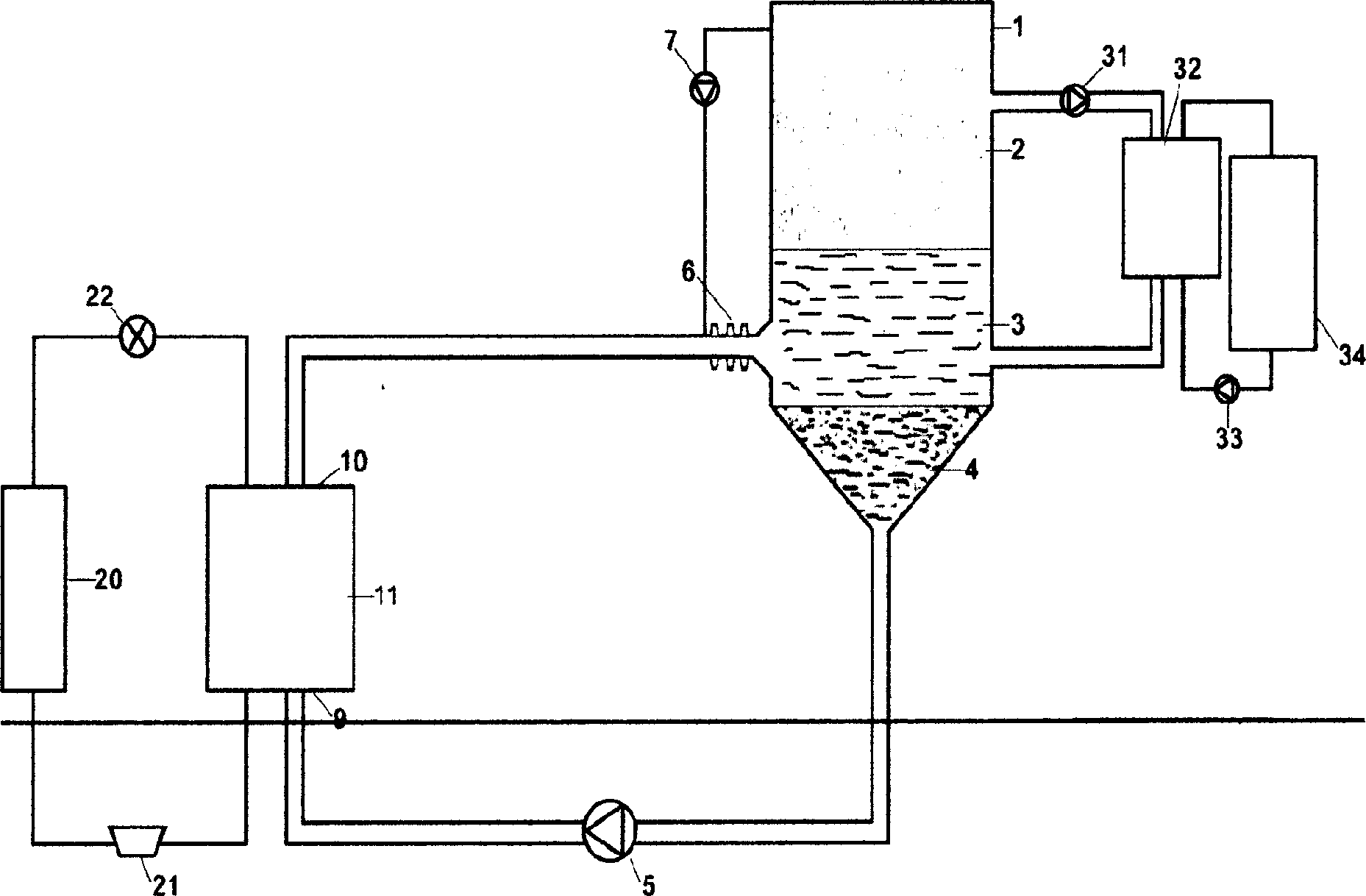

Dynamic ice cool storage method and apparatus thereof

InactiveCN1712829ASolve the blockageImprove cycle efficiencyLighting and heating apparatusAir conditioning systemsUltrasonic nozzleEngineering

A method for accumulating cold by dynamic ice includes such steps as loading the mixture of water and the cold medium in the form of liquid colloid deposited under water in a conic energy accumulator, pumping said cold medium from the bottom of said conic energy accumulator into heat exchanger, heat exchanging for cooling it to the temp lower than zero deg.C, holding it in the form of liquid as its setting point is lower than zero deg.C, spraying it into upper water layer in said accumulator by ultrasonic nozzle, and crystallizing the water to form floating ice crystals while depositing said cold medium. Its apparatus is also disclosed.

Owner:朱上翔 +1

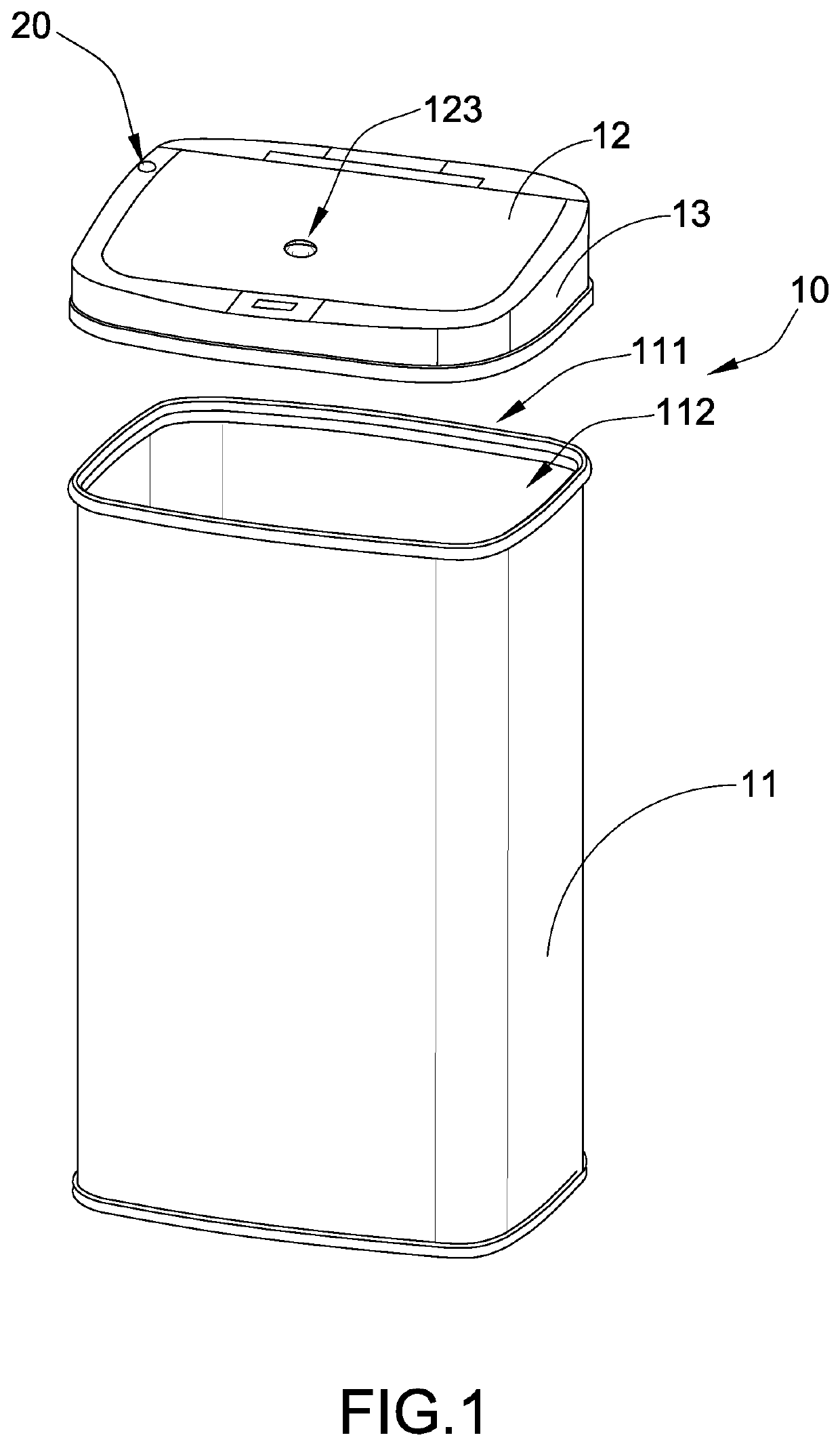

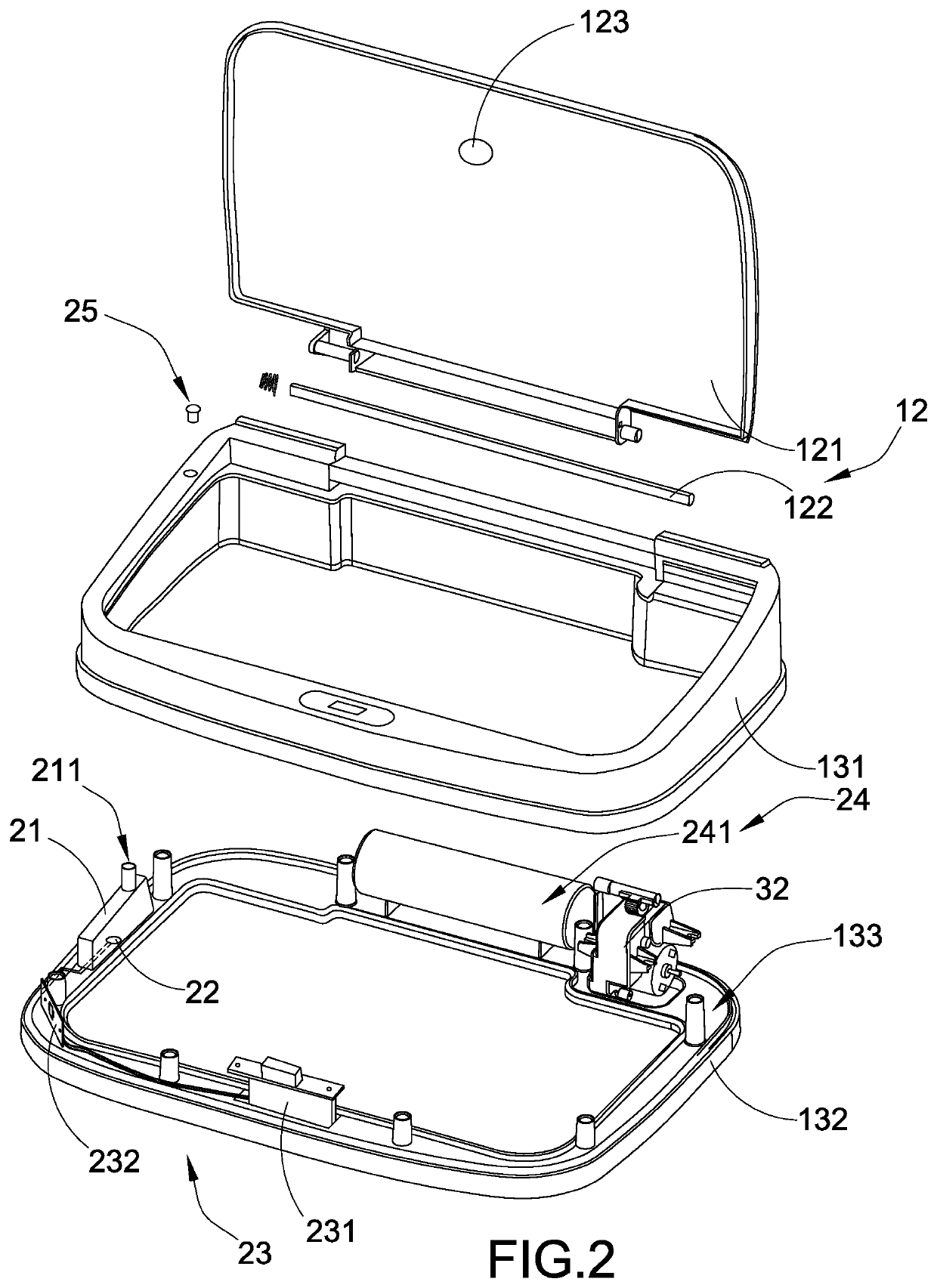

Trash Container

ActiveUS20200391939A1Eliminating waste odorEasy to operateLavatory sanitoryRefuse receptaclesUltrasonic nozzleMechanical engineering

A trash container includes a container unit and an ultrasonic deodorizing device. The container unit includes a container having a top opening and a container cavity, and a container cover being moved between an opened position and a closed position. The ultrasonic deodorizing device includes a deodorizing carrier supported above the top opening of the container body for containing deodorant in liquid form, an ultrasonic nozzle operatively coupled at the deodorizing carrier for downwardly injecting the deodorant in an atomization manner below the top opening of the container body, and a nozzle controller configured to control and activate the ultrasonic nozzle.

Owner:NINE STARS GRP U S A INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com