Patents

Literature

45results about How to "Improve powder feeding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

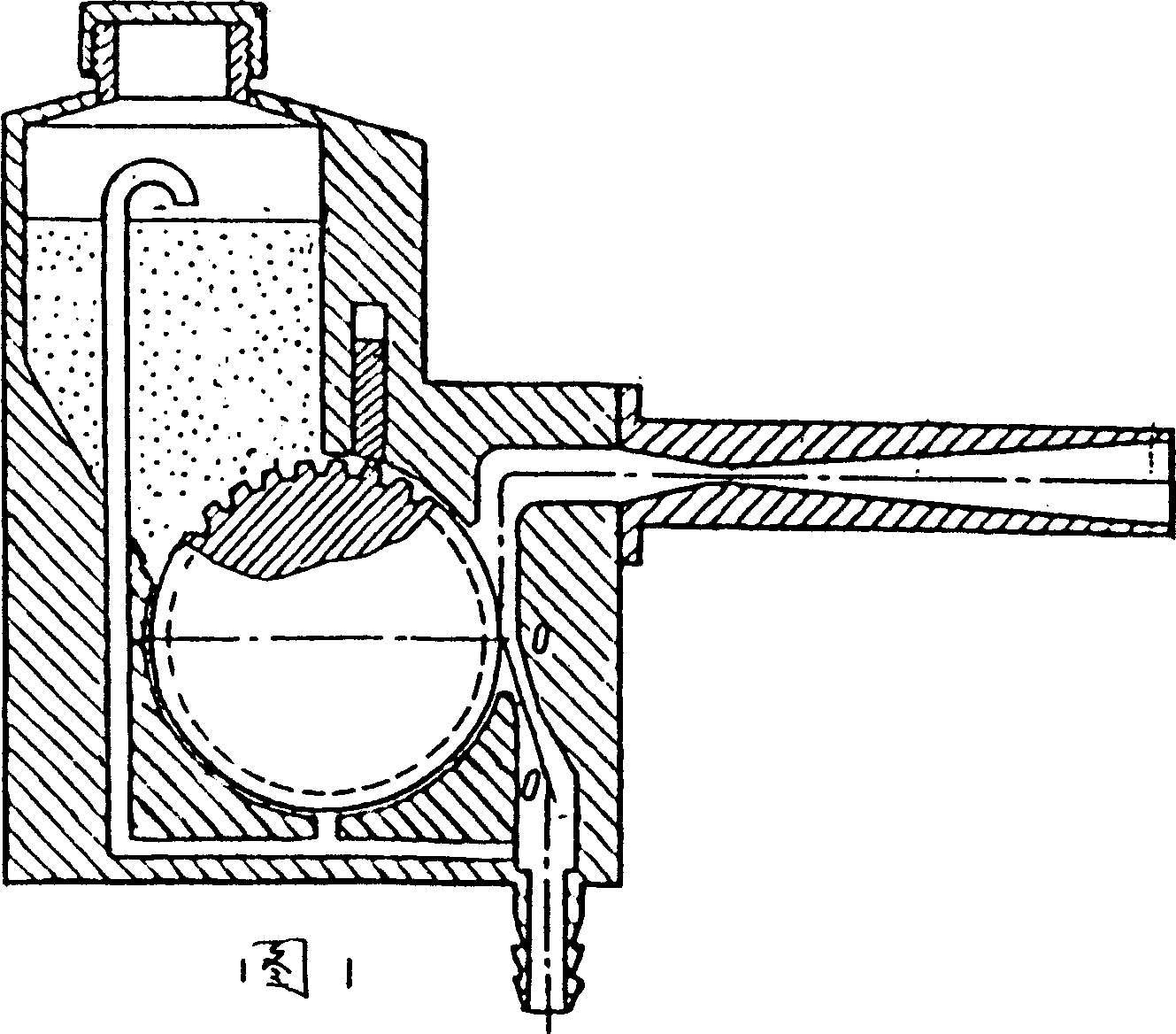

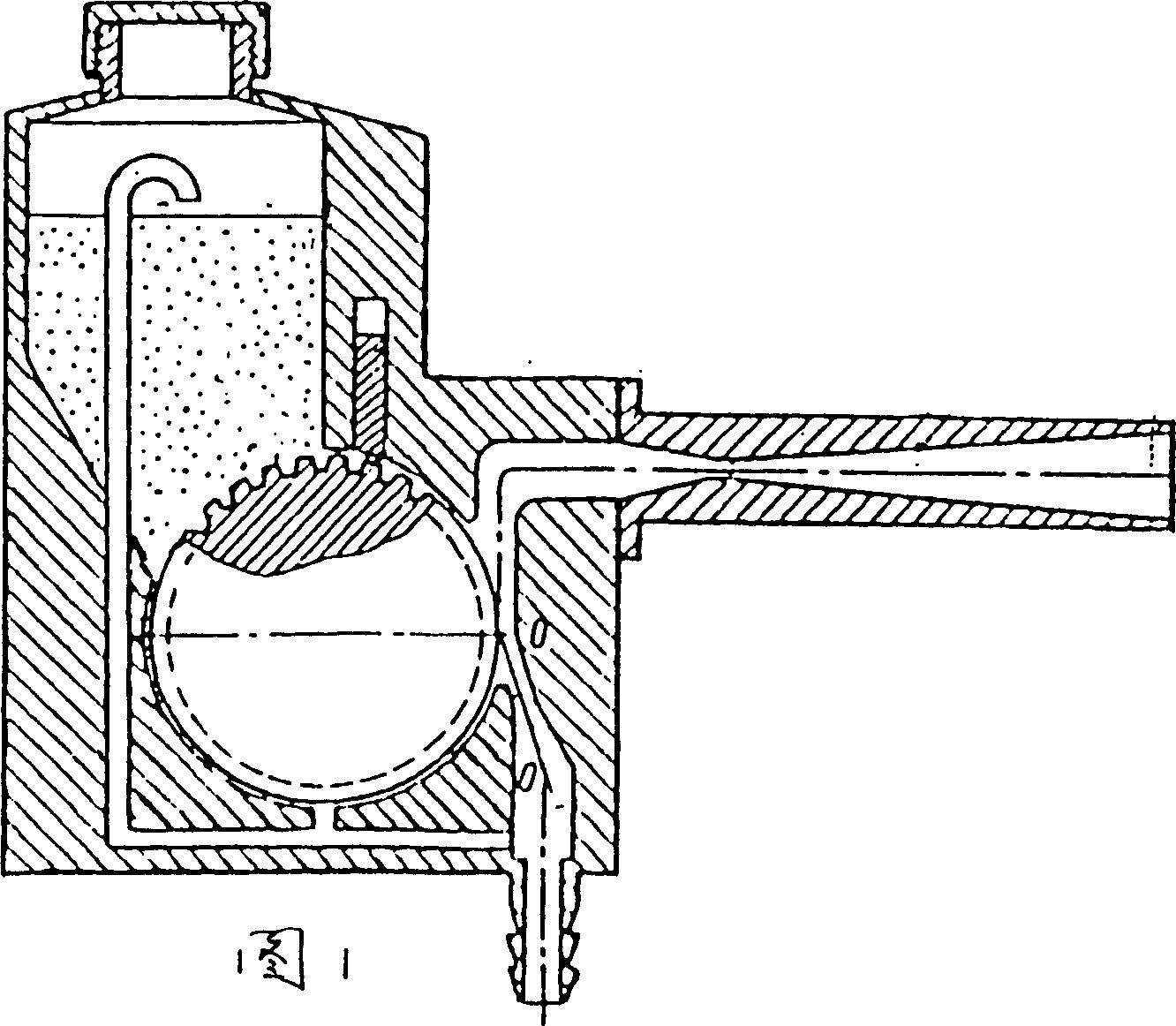

Cold air driven spray painter

InactiveCN1403210AImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

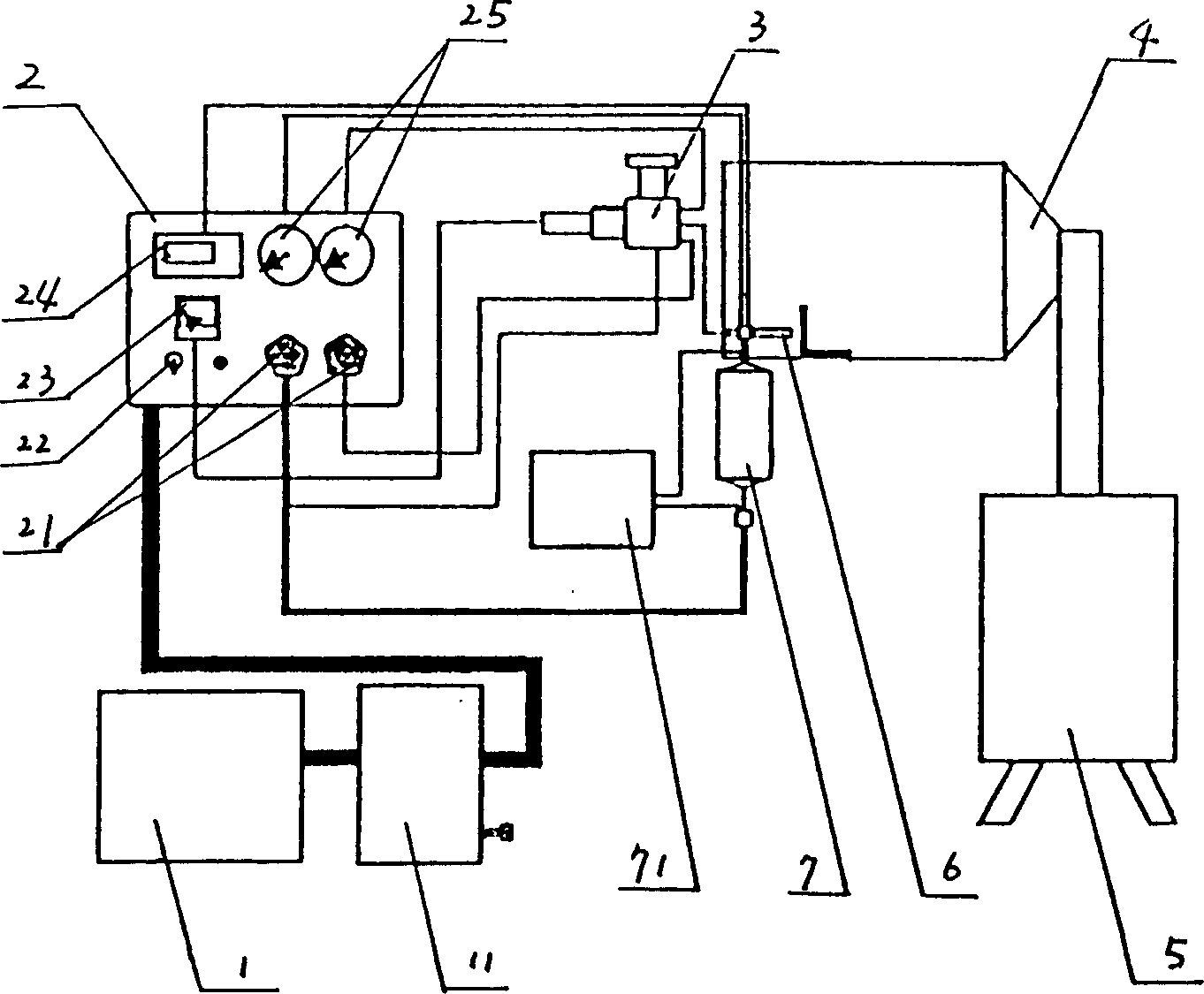

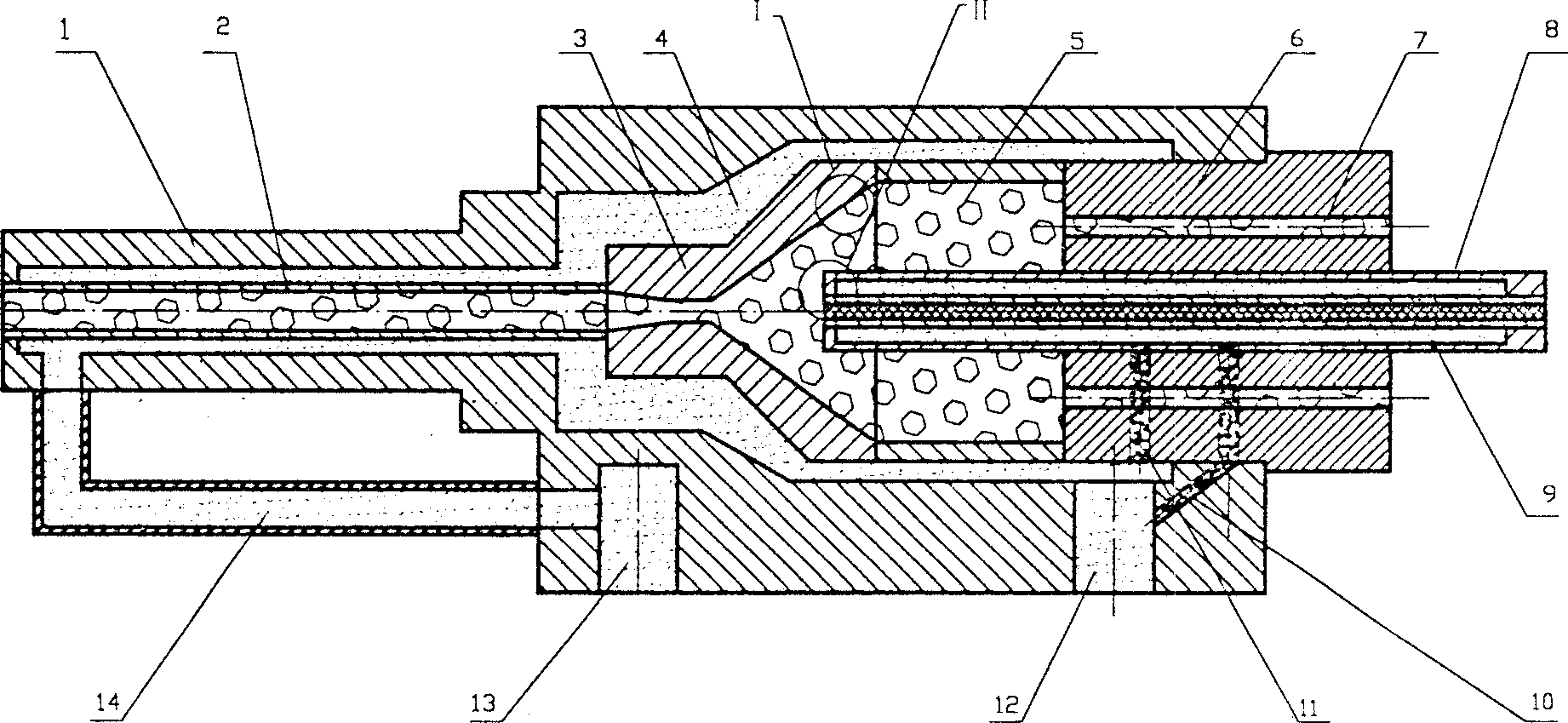

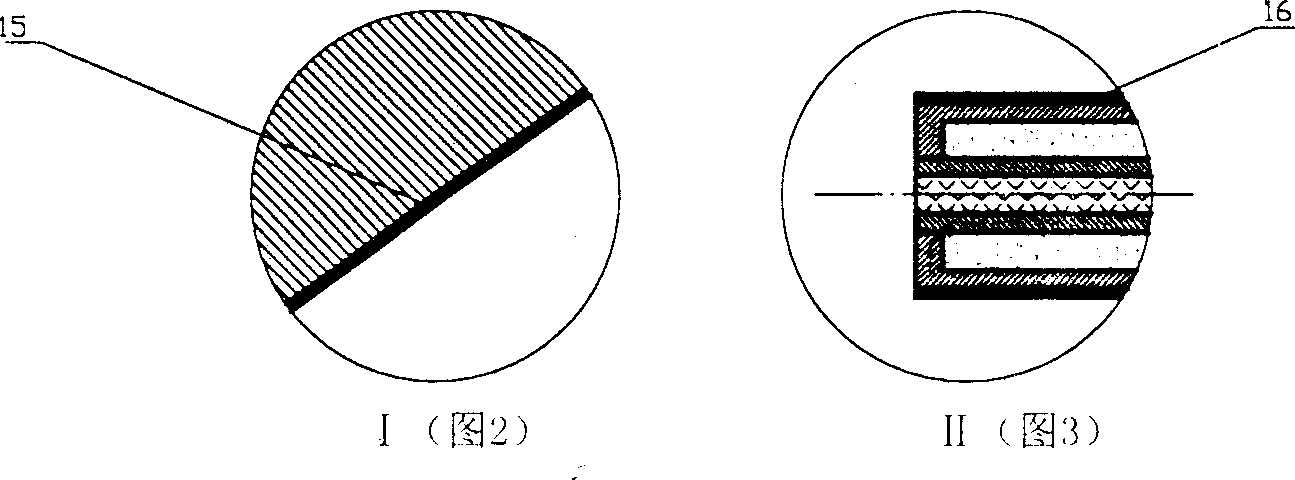

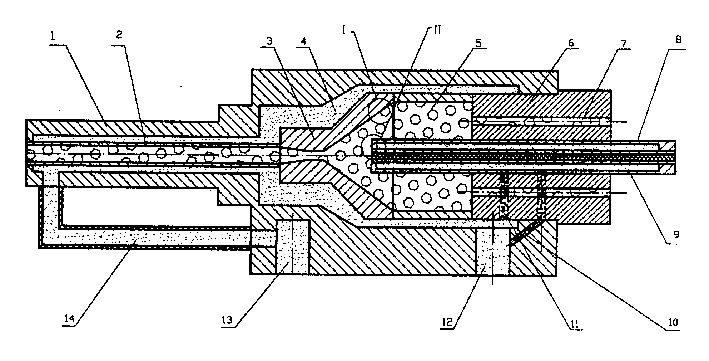

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cold air driven spray painter

InactiveCN1161188CImprove powder feeding methodImprove powder feeding efficiencyLiquid surface applicatorsMolten spray coatingCold airUltrasonic nozzle

The spray painter consists of ultrasonic nozzle, heater, powder feeder and other parts. The ultrasonic nozzle is mounted in the inlet of the spraying chamber, and the controller connected to the air compressor with air tank is connected via a powder feeding switch and pressure regulating switch to the heater and the powder feeder. The heater has one end connected to the ultrasonic nozzle. There is one powder recovering unit in the outlet of the spraying chamber. The ultrasonic nozzle is connected with the powder feeder and consists of three parts of contracting section, throat and expanding section. The present invention has high powder feeding efficiency, long service life and no oxidation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

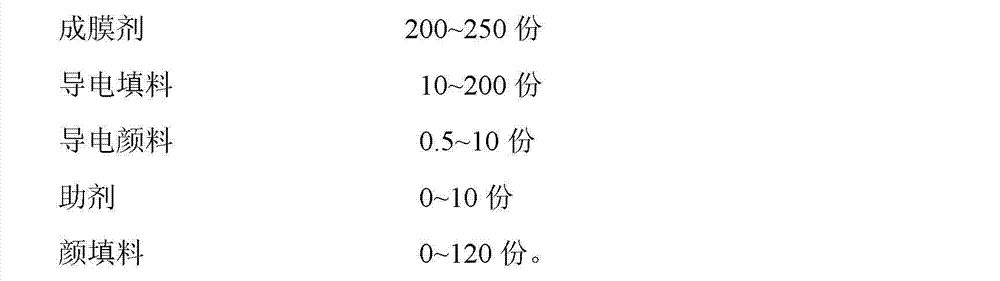

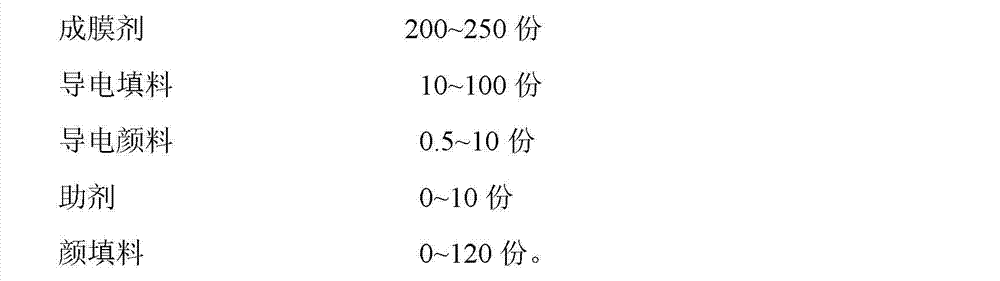

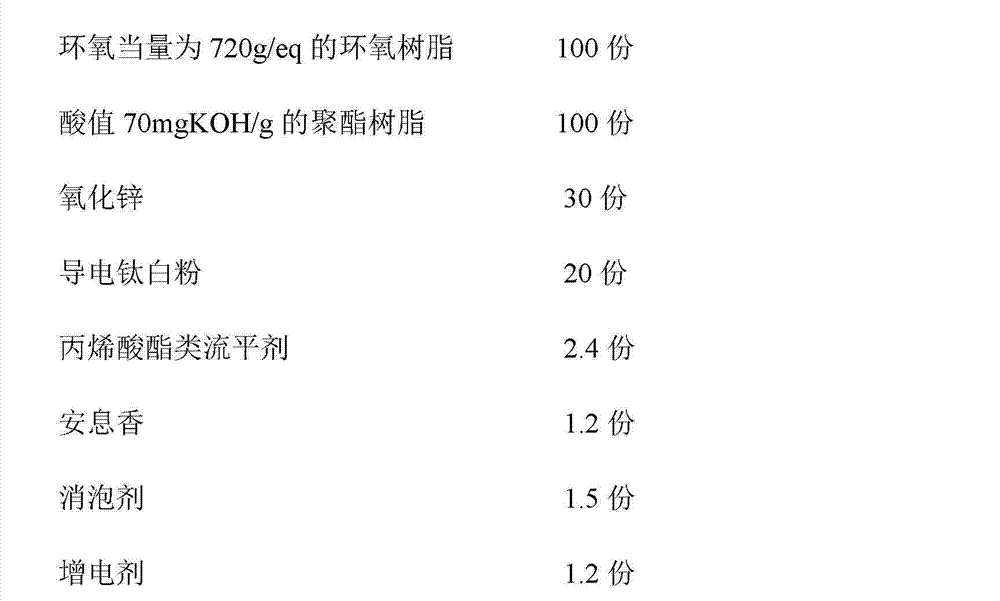

Low-temperature curing powder coating for coating medium-density fiber board and preparation method for coating

InactiveCN102898923AImprove electrical conductivityImprove powder feeding efficiencyPowdery paintsEpoxy resin coatingsMedium density fiberboardFiber

The invention discloses a low-temperature curing powder coating for coating a medium-density fiber board. The coating comprises 200 to 400 parts of conventional medium-density fiber board powder coating, 10 to 200 parts of conductive filler, and conductive pigment. The invention also discloses a preparation method for the powder coating. The powder coating for electrostatic coating can effectively overcome the defect that the conventional medium-density fiber board powder coating for electrostatic coating of the medium-density fiber board is difficult to coat.

Owner:CHINA NAT ELECTRIC APP RES INST +1

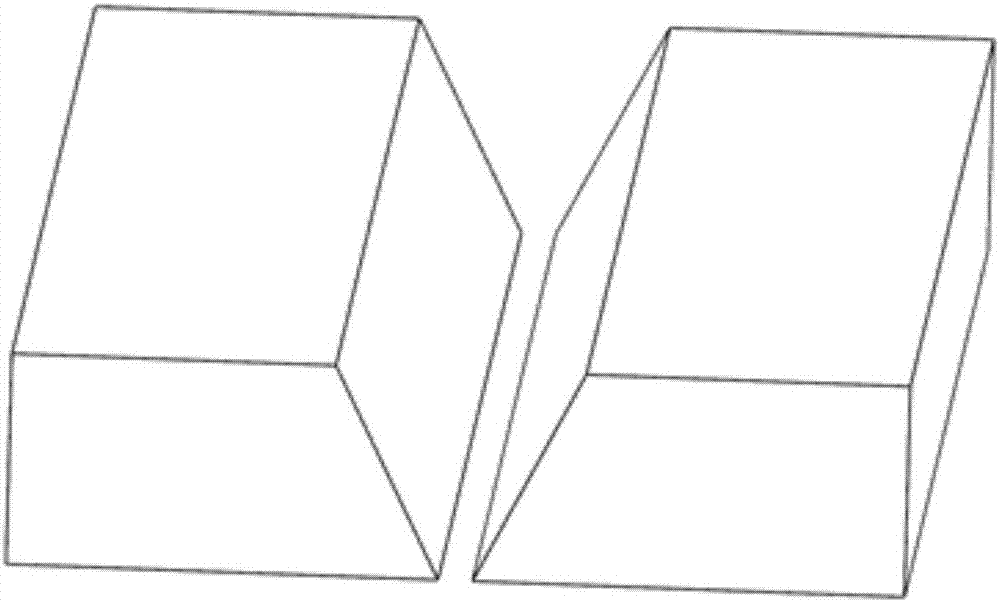

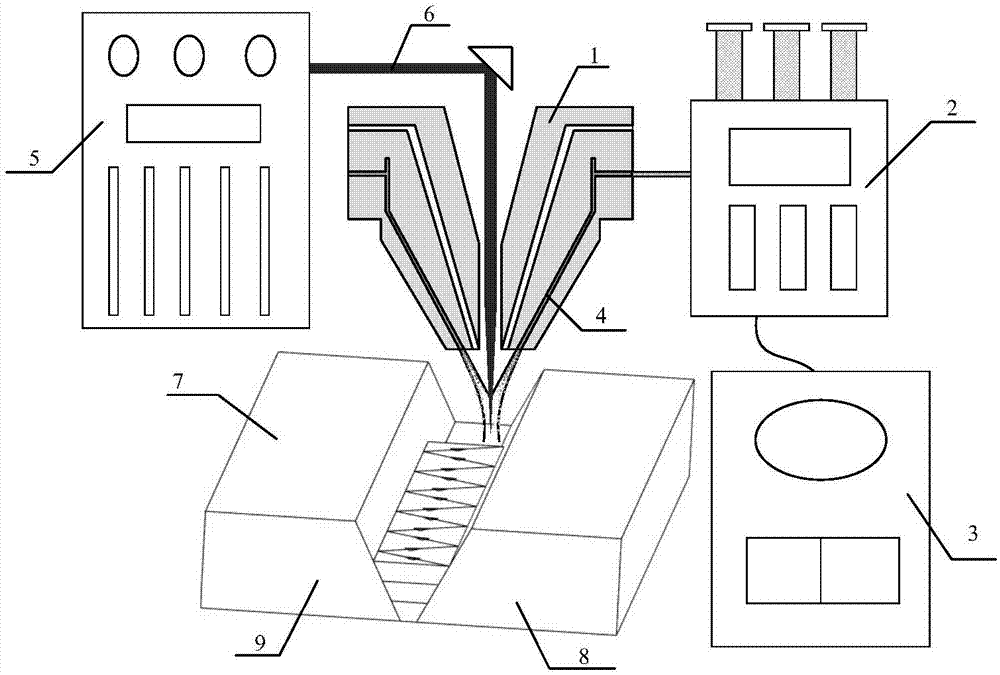

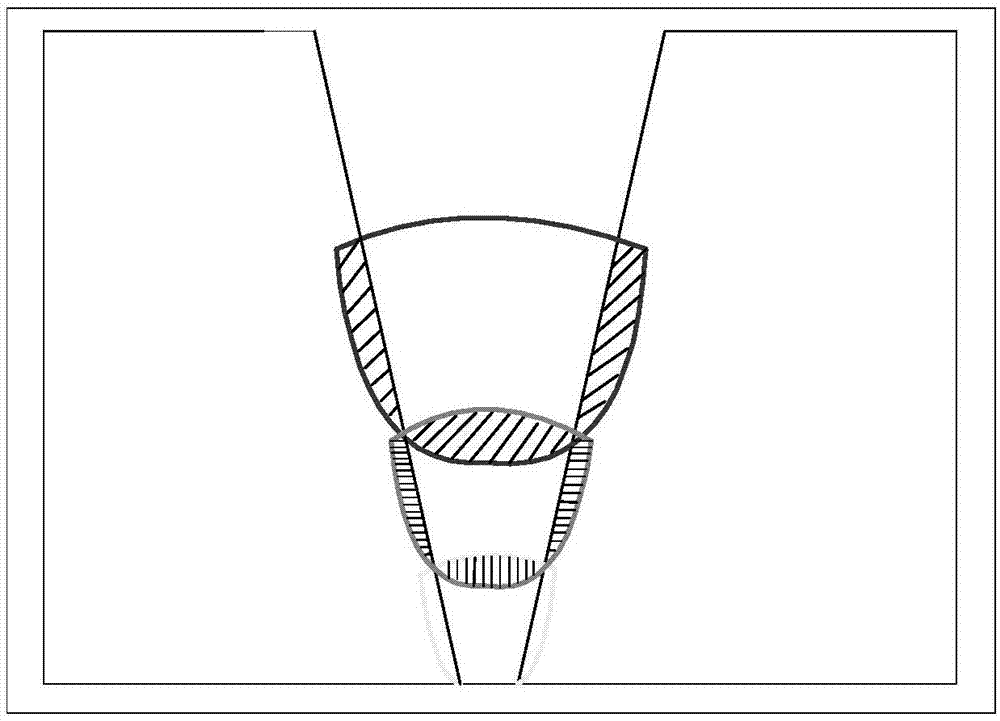

Additive welding method for large-thickness frame metal parts

InactiveCN107876985ASolving Welding DifficultiesSolve unfusedWorkpiece edge portionsLaser beam welding apparatusNumerical controlCoupling

The invention discloses an additive welding method for large-thickness frame metal parts, which comprises the following steps: (1) groove shape design and welding preparation: preparing a single-facegroove which is a U-shaped groove or a V-shaped groove, sanding the to-be-welded part with the groove, cleaning the part with acetone to remove surface impurities, taking out and blow-drying the to-be-welded part, and clamping the to-be-welded part by a reversible deformation method, wherein the welding flux is alloy powder by ball milling, and the particle diameter is 100 to 150 microns; (2) laser additive welding experiment: a powder head and a powder supply box are connected in a selected welding device, the powder supply device is connected with a numerical control machine tool on a welding machine tool, according to a preset track, the powder head supplies the alloy powder which is in a coaxial coupling relationship with the laser light output by a laser, the fused surface of the to-be-welded part and the alloy powder form a large multi-layered fused area, and the weld pool Is cooled and solidified to form a stack layer, and the connection between two to-be-welded parts is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

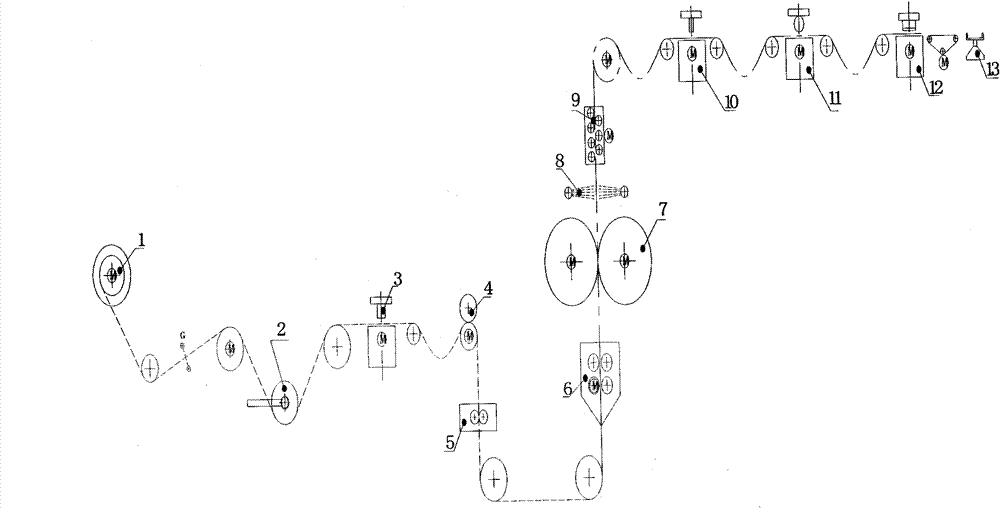

Axial sending-off powder type flame gun in supersonic speed using liquid fuel as energy sources

InactiveCN1519057AImprove powder feeding efficiencyIncrease flow rateLiquid surface applicatorsLiquid spraying apparatusCombustion chamberEngineering

An axially feeding powder type supersonic flame spraying gun using liquid fuel as energy source is composed of a casing and the serially connected gum tube, convergent divergent nozzle, combustion chamber and tail unit. A main water cooling channel is formed between said casing and the serially connected units. In said tail unit, their is a water cooled powder feeding tube surrounded by 2-12 liquid fuel spraying tubes. Its advantages are high flowing speed of powder, fully smelting of powder, and high quality of coated layer.

Owner:王泰兴

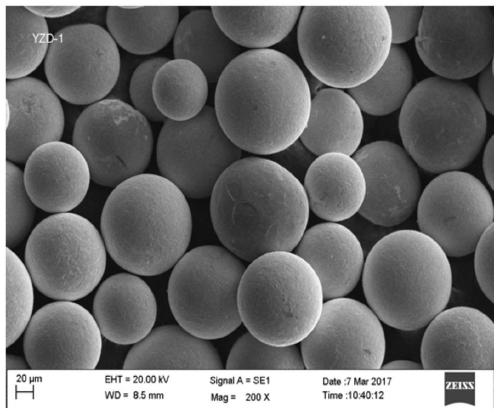

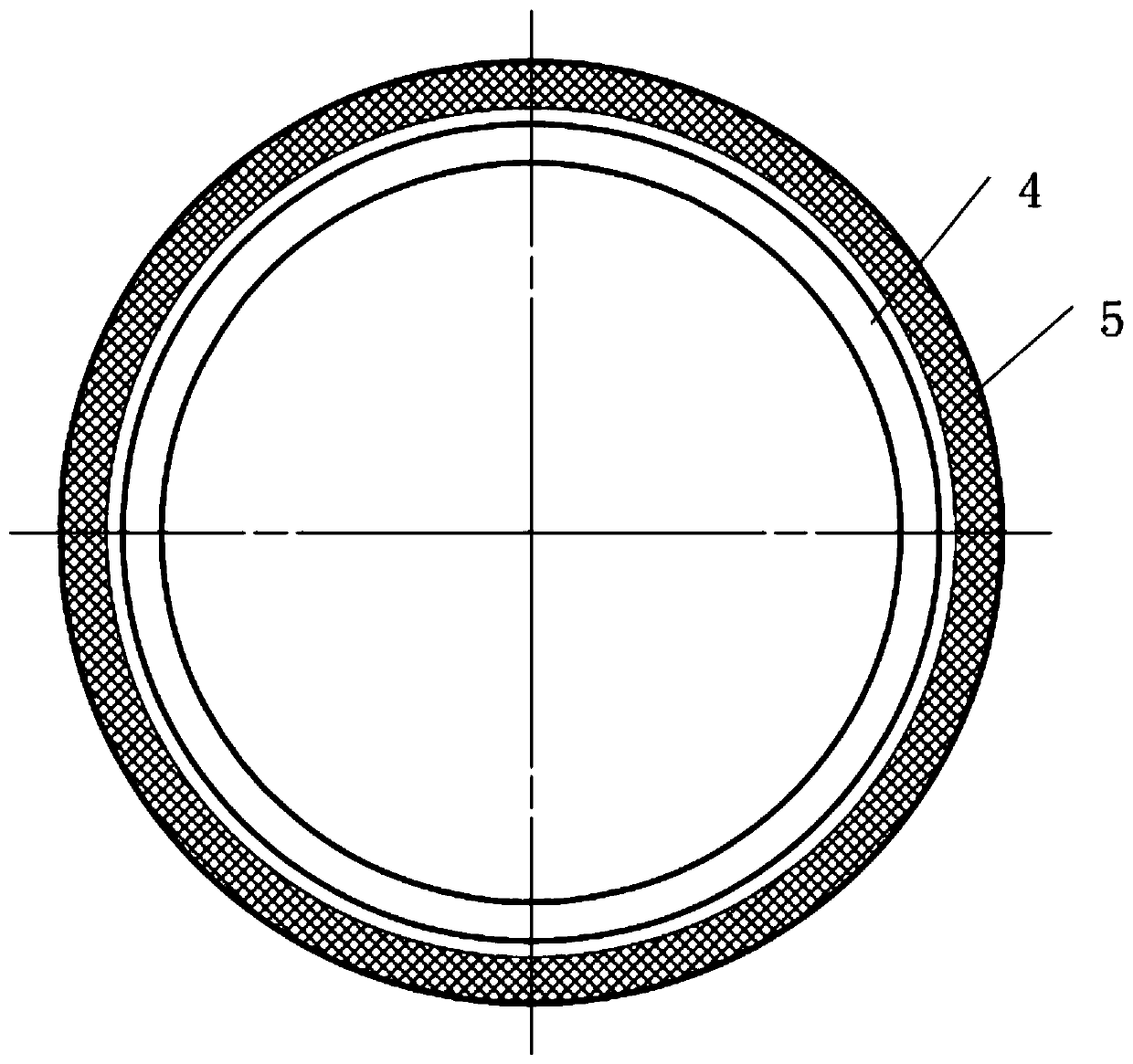

Wear-resistant alloy material and plasma surfacing welding process of shield tunneling machine wear-resistant cutter ring

InactiveCN110421242AImprove wear resistanceExtended service lifePlasma welding apparatusAlloyShield tunneling

The invention belongs to the technical field of shield cutters, and particularly relates to a wear-resistant alloy material and a plasma surfacing welding process of a shield tunneling machine wear-resistant cutter ring. The problems of poor wear resistance, low production efficiency and poor quality stability of a shield tunneling machine cutter ring in the prior art are solved. According to thetechnical scheme, the wear-resistant alloy material comprises NiCrBSi alloy and spherical cast tungsten carbide, wherein the mass percentage of the NiCrBSi alloy is 35%-45%, the mass percentage of thespherical cast tungsten carbide is 55%-65%, the plasma surfacing welding process comprises a. cleaning treatment, b. preheating treatment, c. adjusting of surfacing welding process parameters of a welding machine, d. positioning of a welding gun, e. surfacing starting, and f. heat preservation and cooling. The wear resistance of the shield tunneling machine cutter ring is improved, the service life of the cutter ring is prolonged, the consumption of the cutter ring and the workload of equipment maintenance are reduced, and the unit excavation cost is reduced. The material is suitable for manufacturing the shield tunneling machine wear-resistant cutter ring.

Owner:中德云岭(成都)科技有限公司

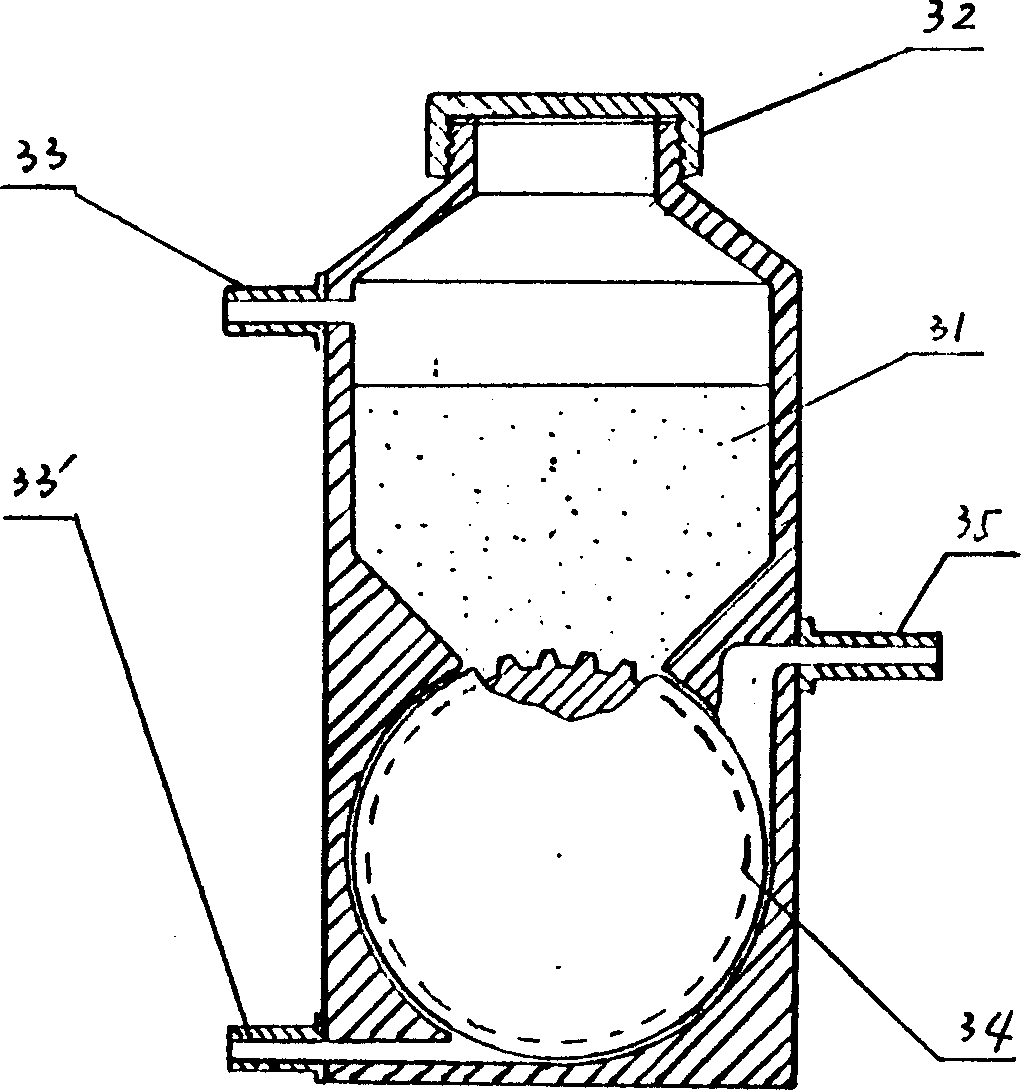

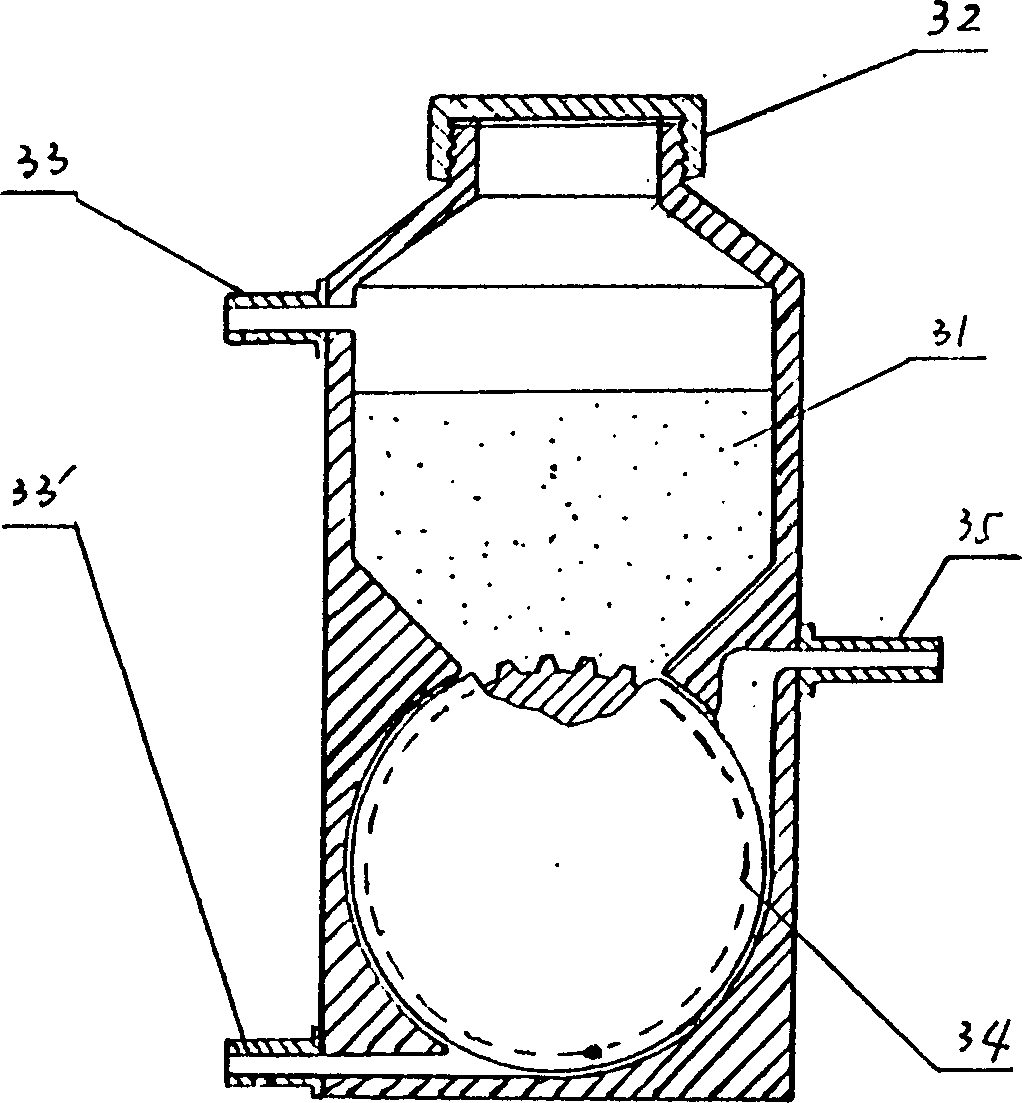

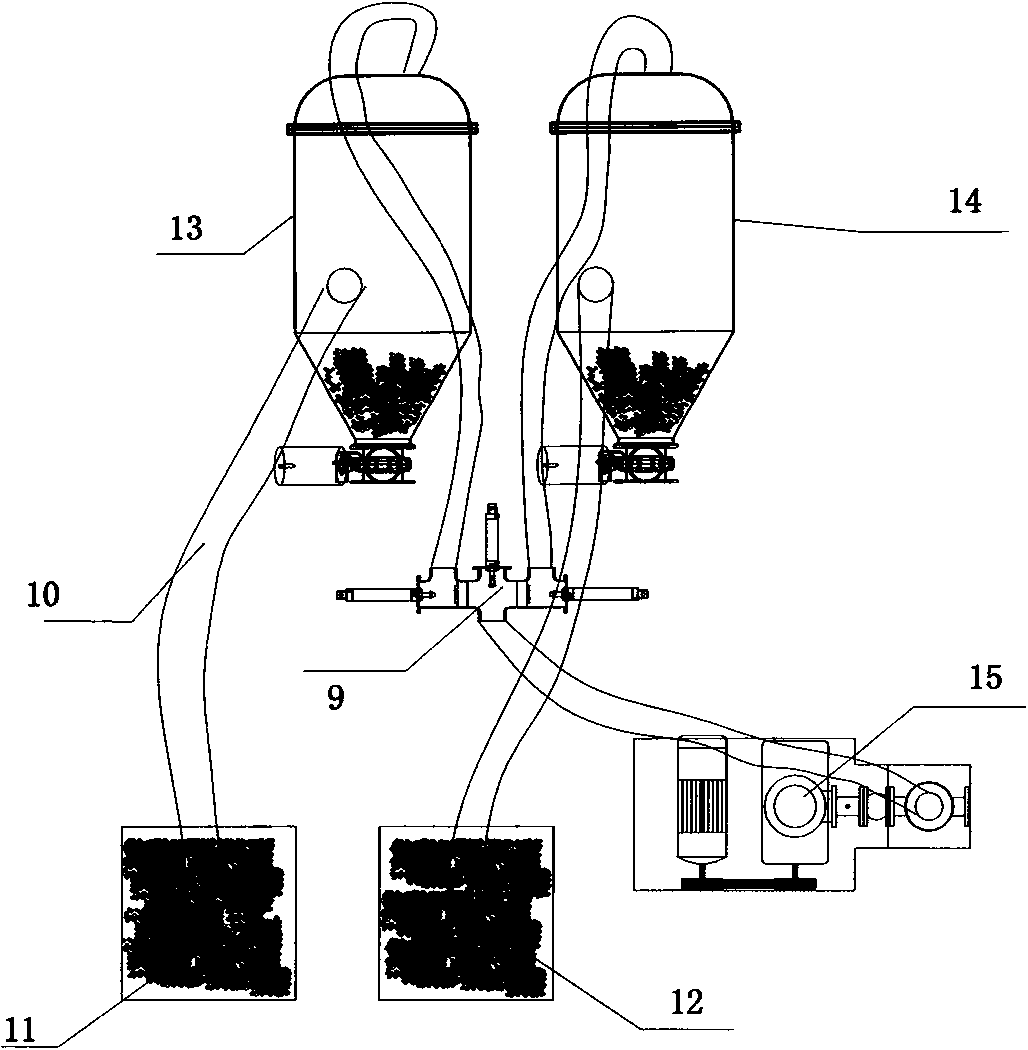

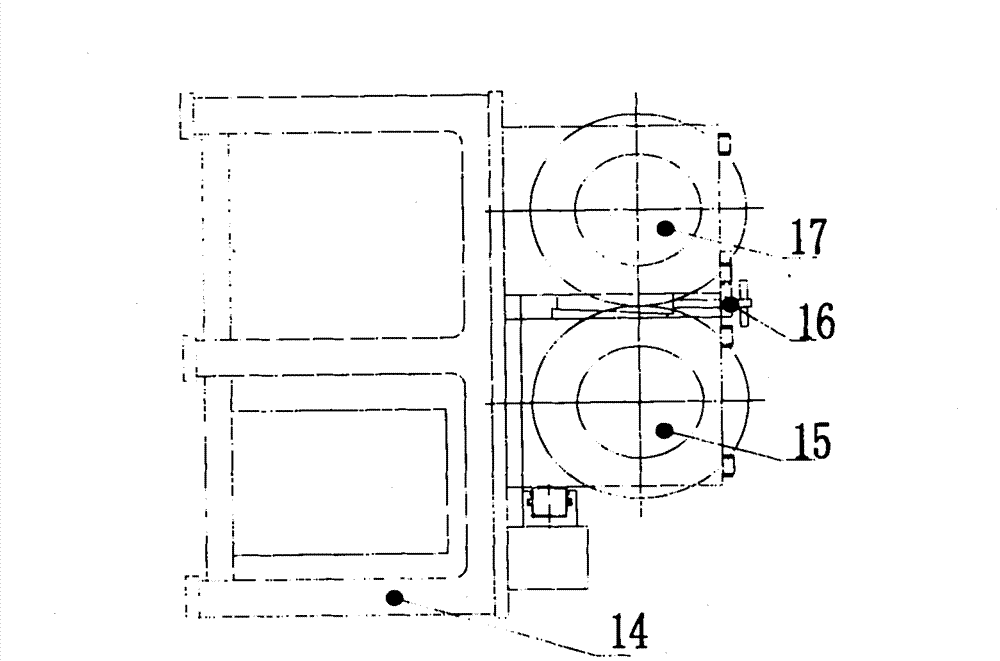

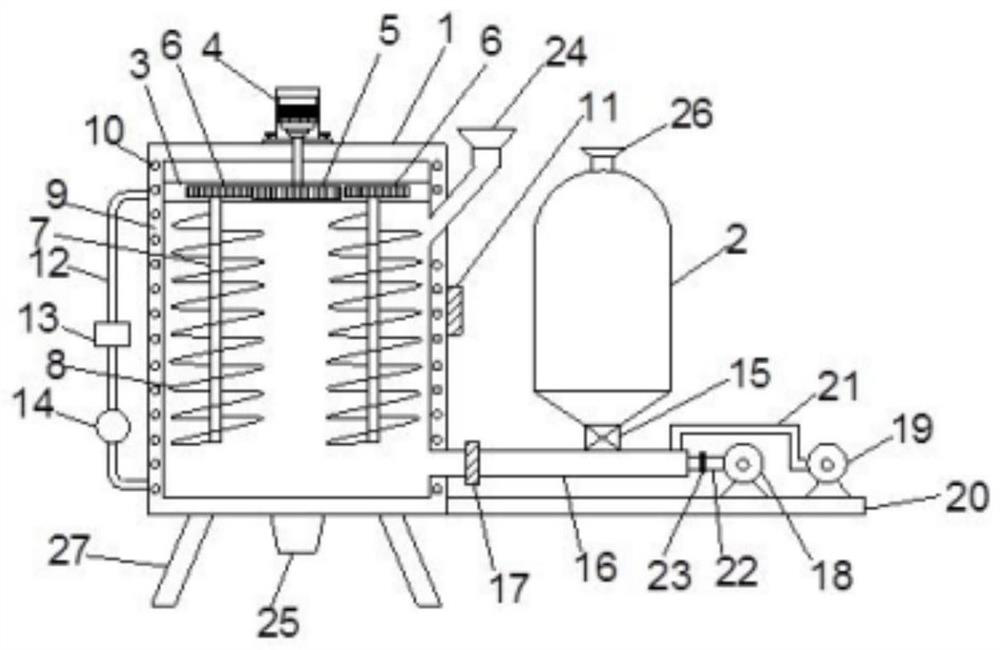

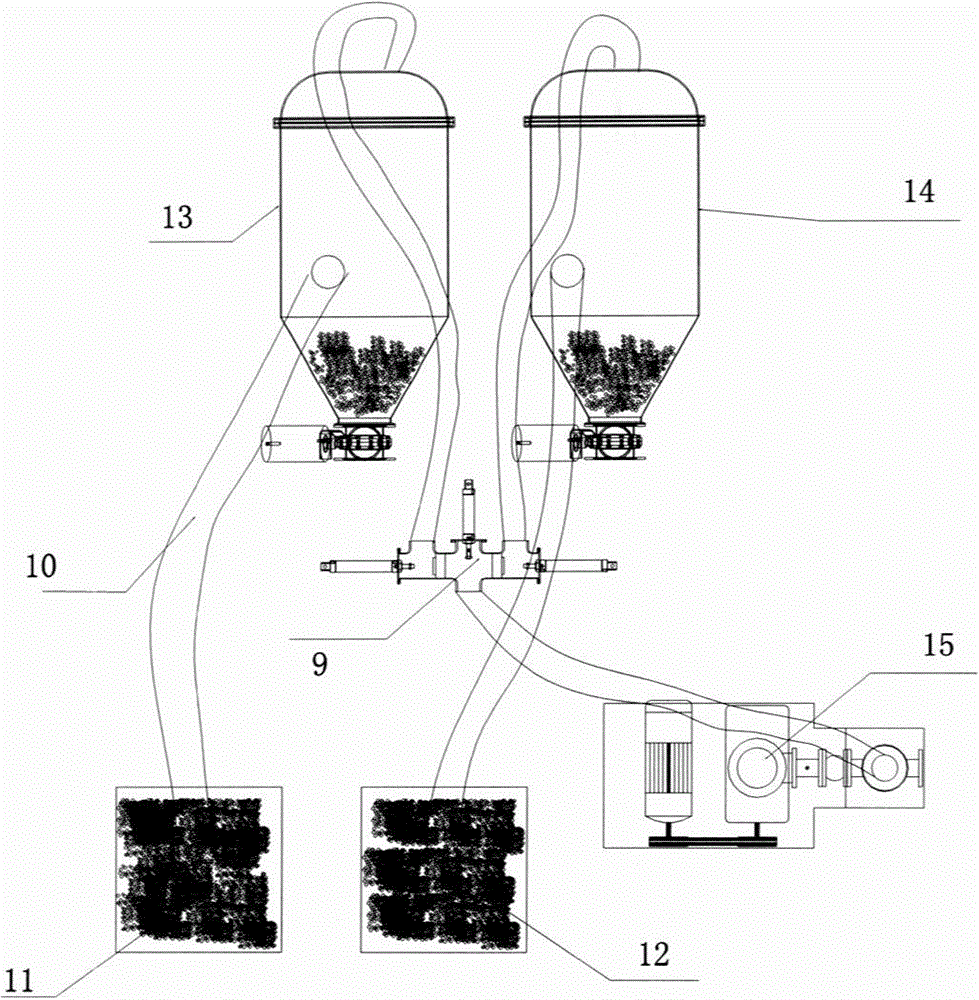

Uninterrupted twin-bucket vacuum powder supply system and using method thereof

InactiveCN103359489AImprove powder feeding efficiencyBulk conveyorsLoading/unloadingMetallurgyWaiting time

The invention discloses an uninterrupted twin-bucket vacuum powder supply system which is characterized by comprising a first powder bin, a second powder bin, a first powder container, a second powder container, a four-way vacuum valve and a vacuumizing fan, wherein the first powder bin is connected with the first powder container by a hose; the second powder bin is connected with the second powder container by a hose; the four-way vacuum valve comprises two air inlets and an air outlet; the two air inlets are connected with the first powder container and the second powder container by hoses respectively; and the air outlet is connected with the vacuumizing fan by a hose. According to the uninterrupted twin-bucket vacuum powder supply system and a using method thereof, vacuum powder pumping can be conducted on the two powder containers uninterruptedly and alternately, so that the vacuumizing fan is in a working state all the time, no waiting time exists, and the powder supply efficiency is improved greatly.

Owner:SUZHOU JIAHONG MACHINERY

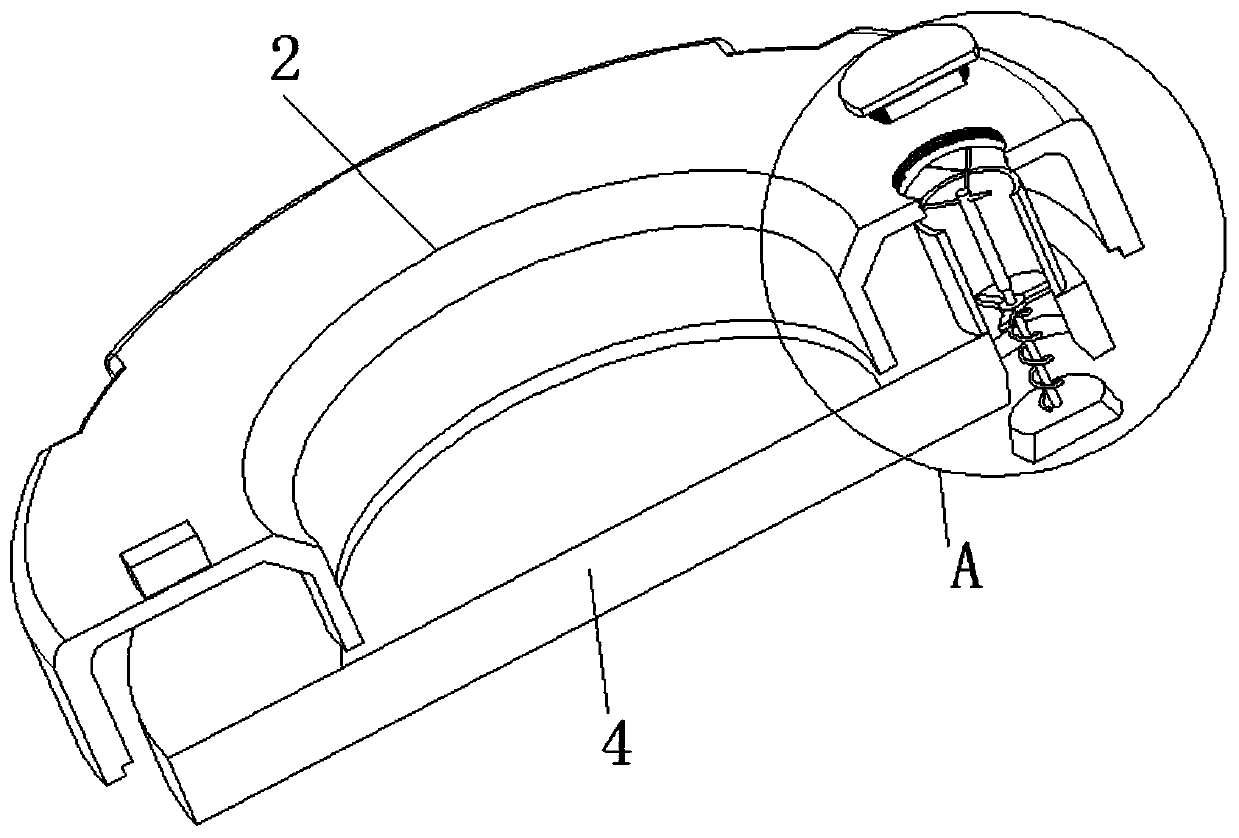

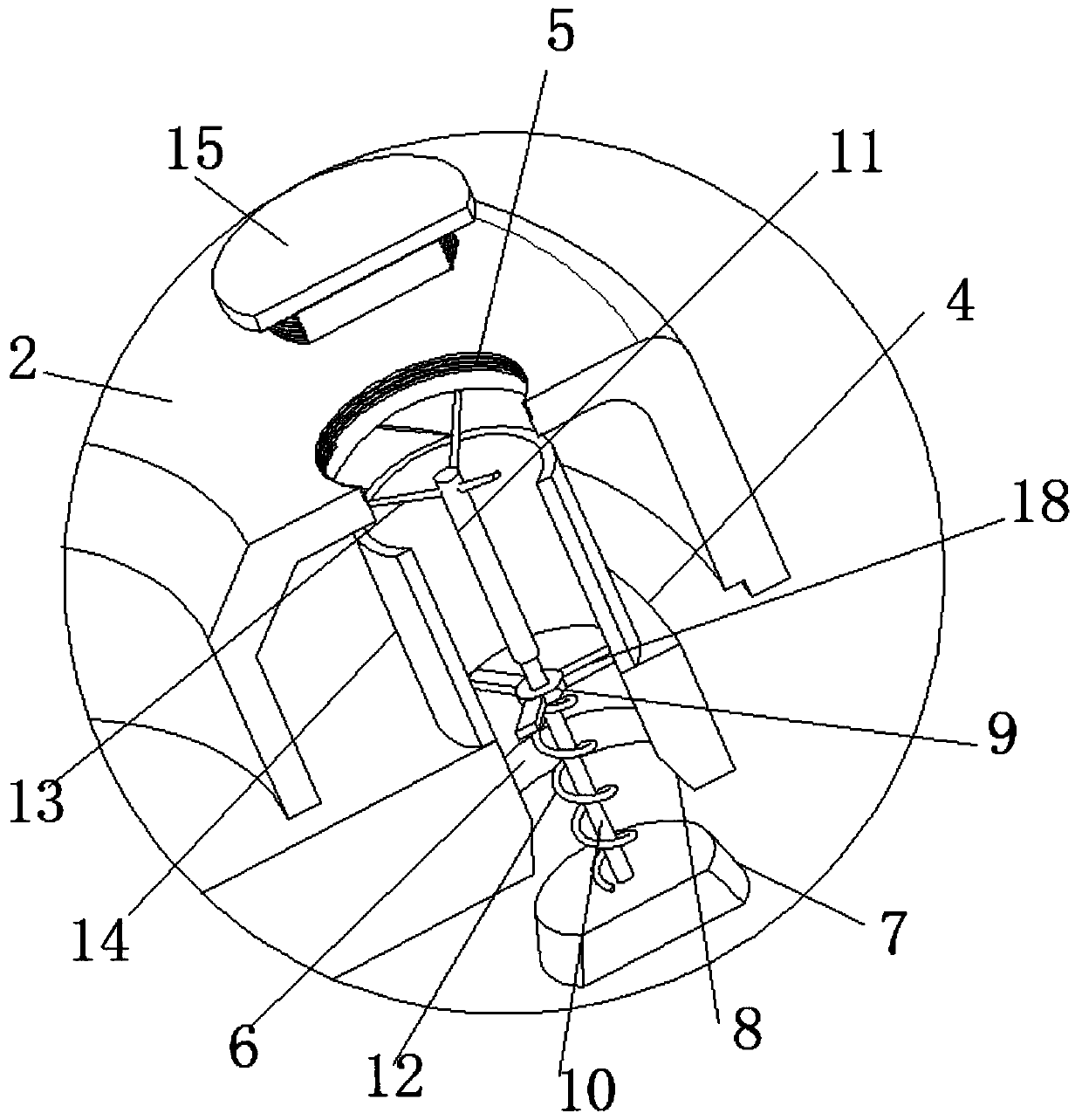

Toner supply supplementing container

PendingCN106873330AReduce and avoid agglutinationPrevent accumulation and cloggingElectrographic process apparatusMechanical engineeringComposite material

The invention discloses a toner supply supplementing container, which comprises a powder container, an auxiliary powder feeding frame, a stirring blade and a container cover, wherein the stirring blade is arranged in the auxiliary powder feeding frame which is clamped on the inner side of a container opening of the powder container, the outer side of the container opening of the powder container is covered and connected with the container cover through a buckle structure, a sponge sealing ring is arranged between a powder outlet cover and a powder outlet, the powder outlet is formed in the container cover, the powder outlet cover is arranged at the powder outlet, and powder outlet sponge is arranged between the powder outlet cover and the powder outlet. By all-point full contact and stirring of the stirring blade and the periphery, powder at the powder outlet part can be enabled to be fully transmitted for supply without any dead angle, and the inner wall is simultaneously cleaned, so that long-term accumulation and adhesion is prevented, and the flowability can also be improved. In addition, the powder discharge rate and the utilization rate are increased.

Owner:ZHUHAI CHINAMATE TECH

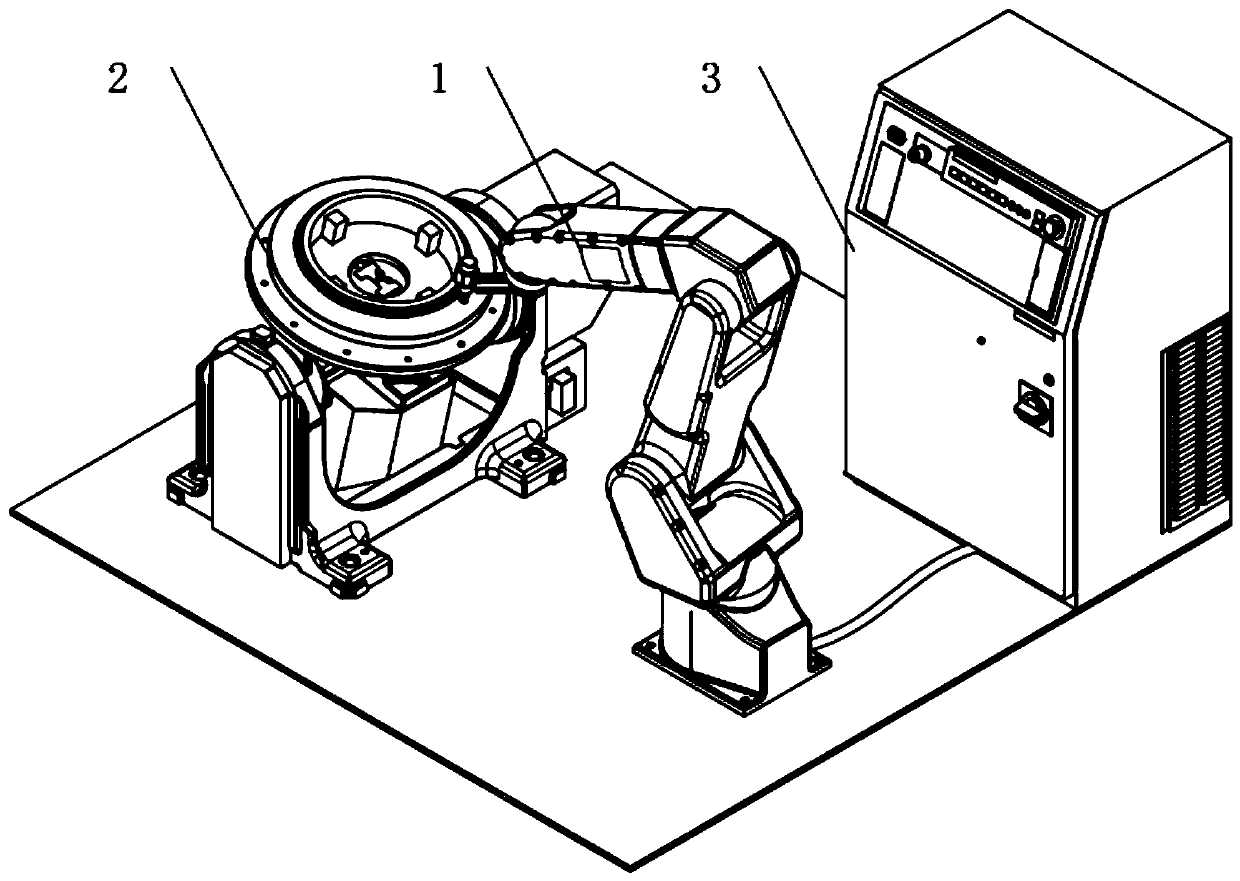

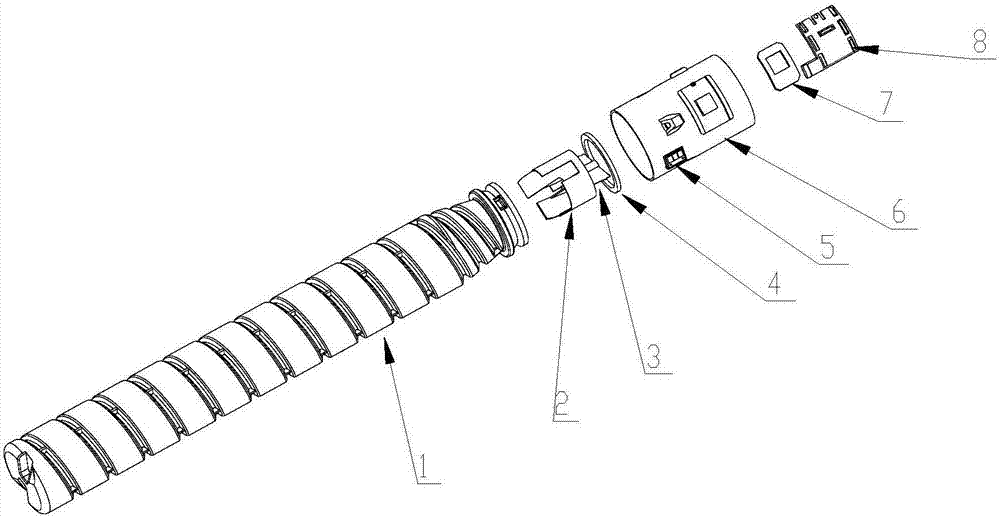

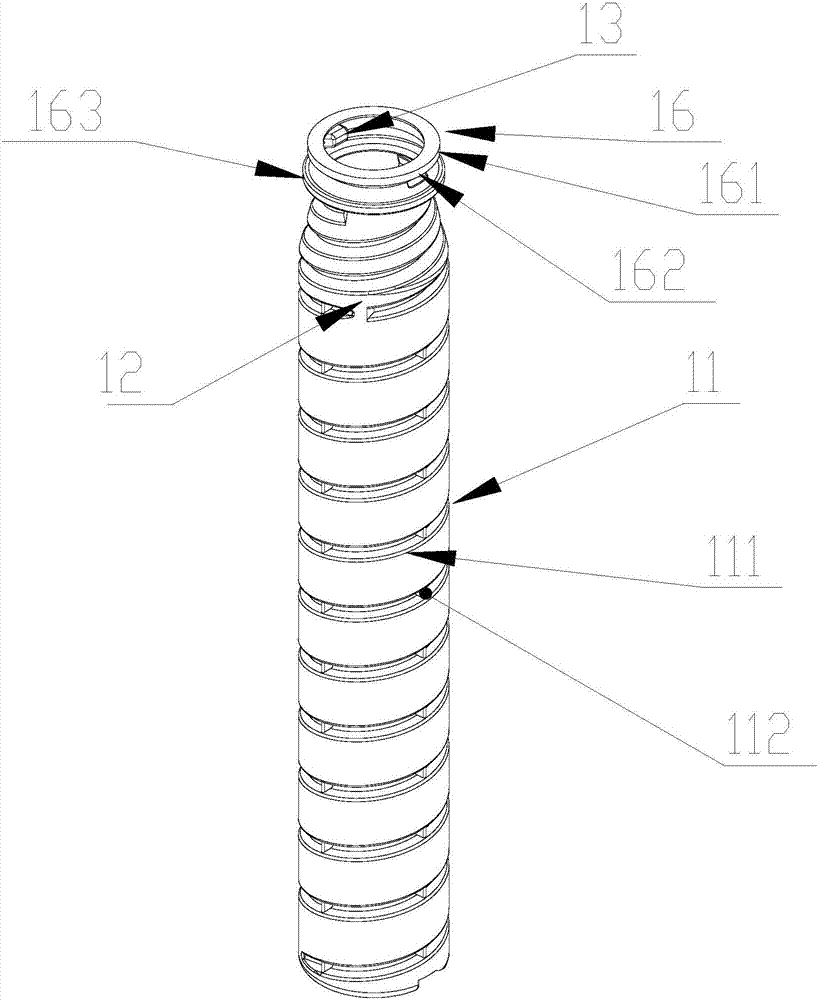

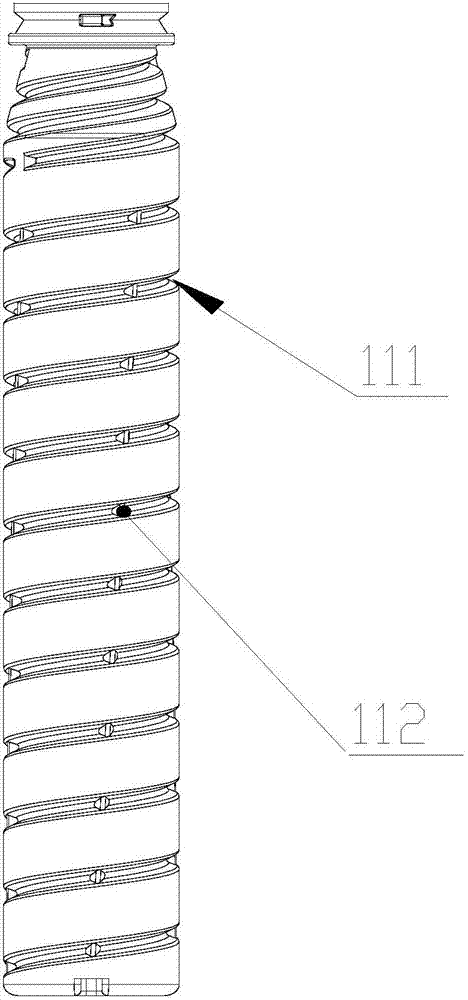

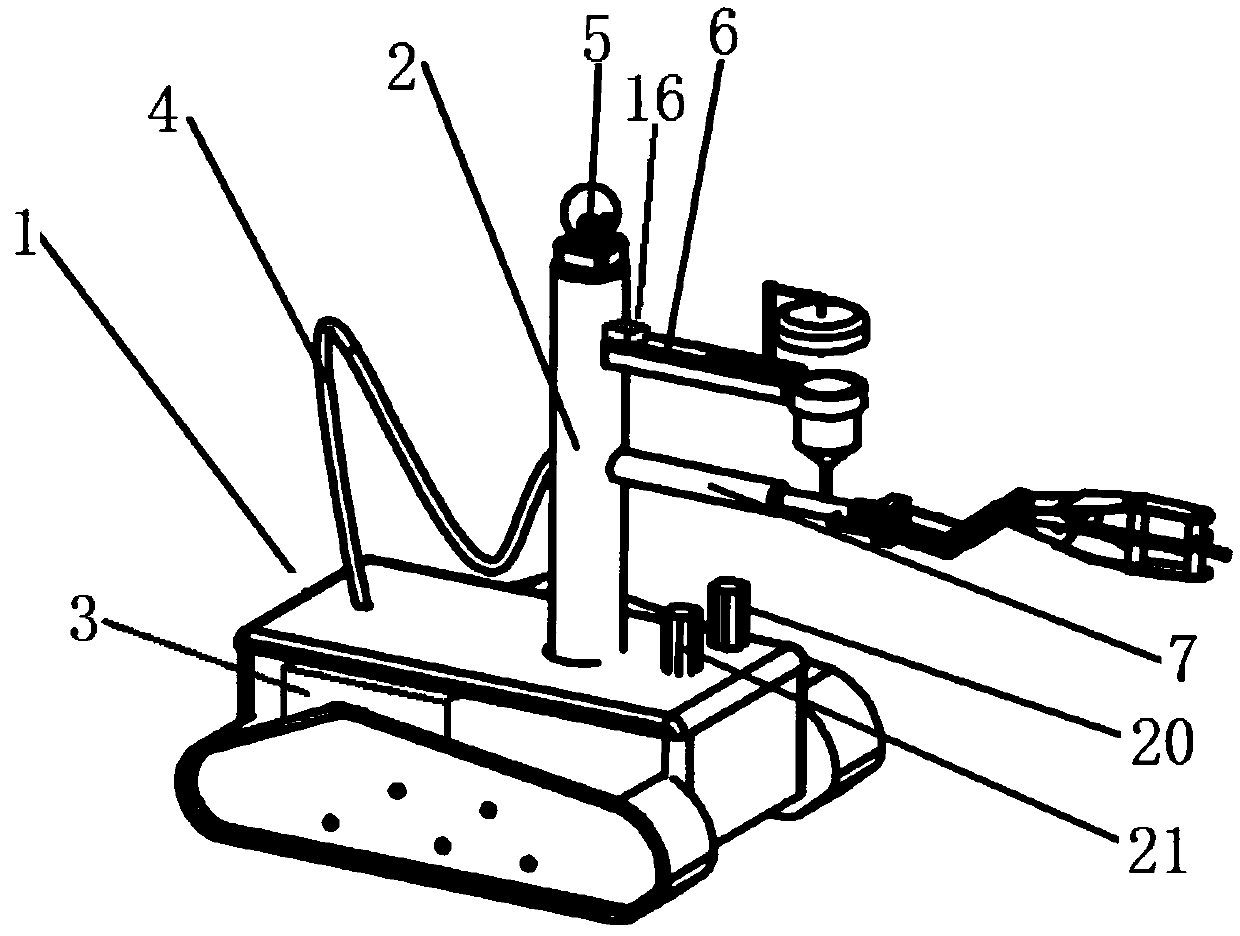

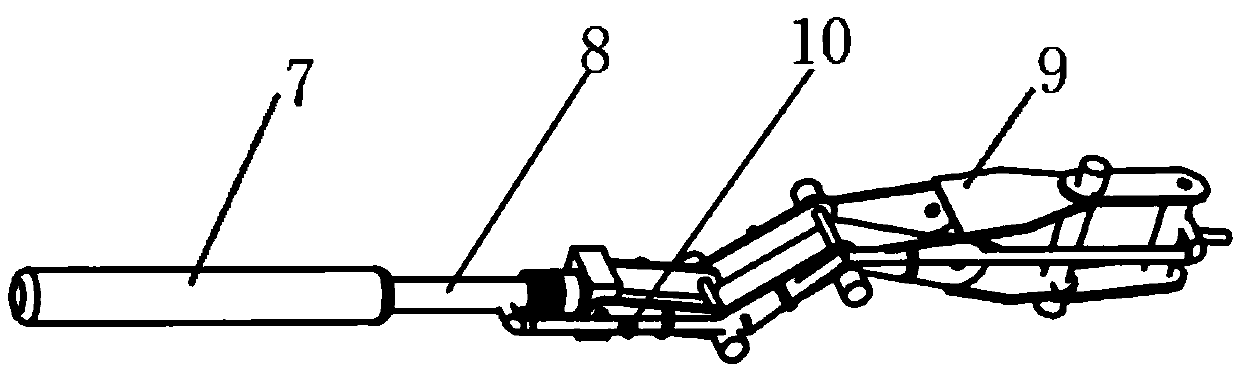

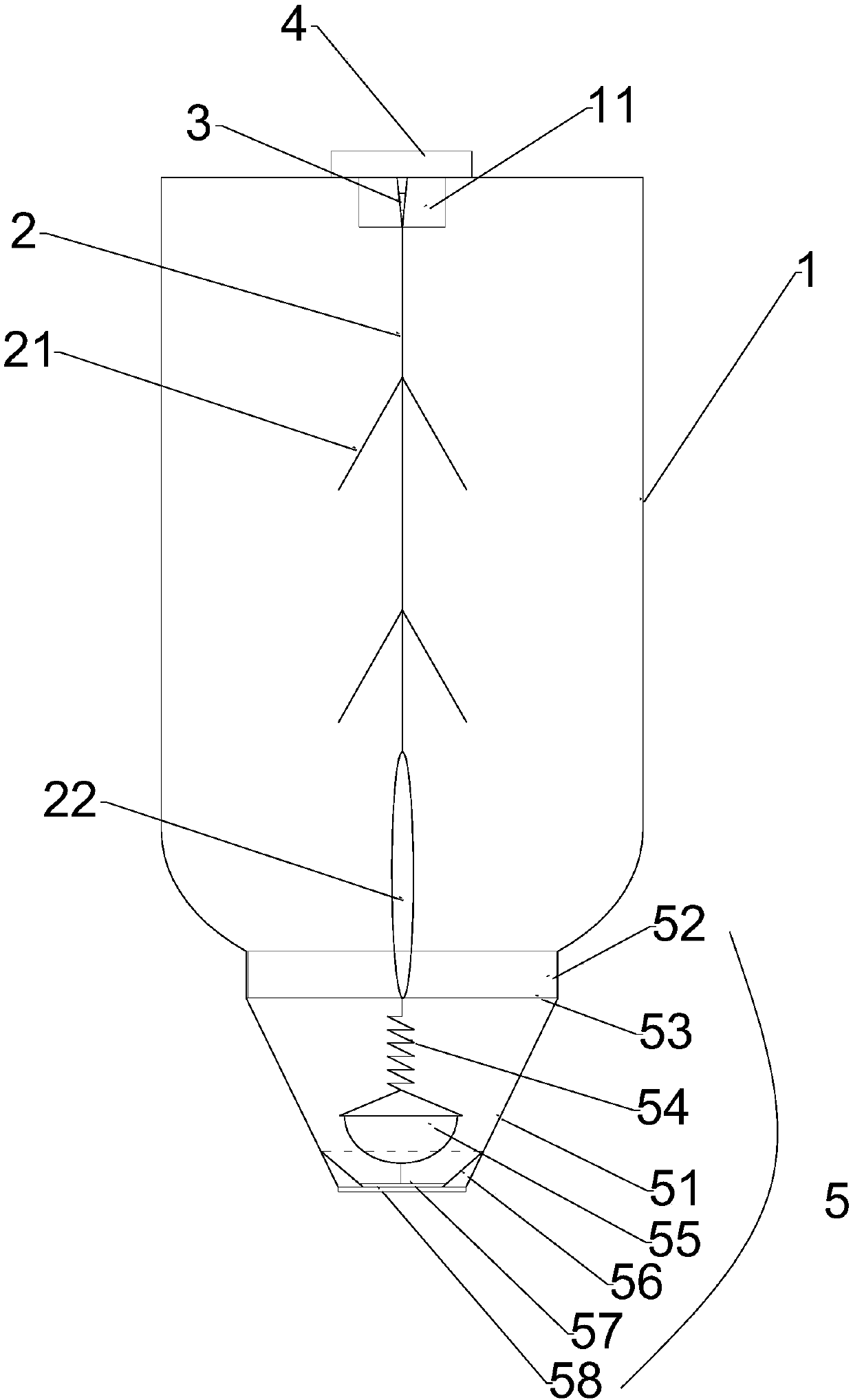

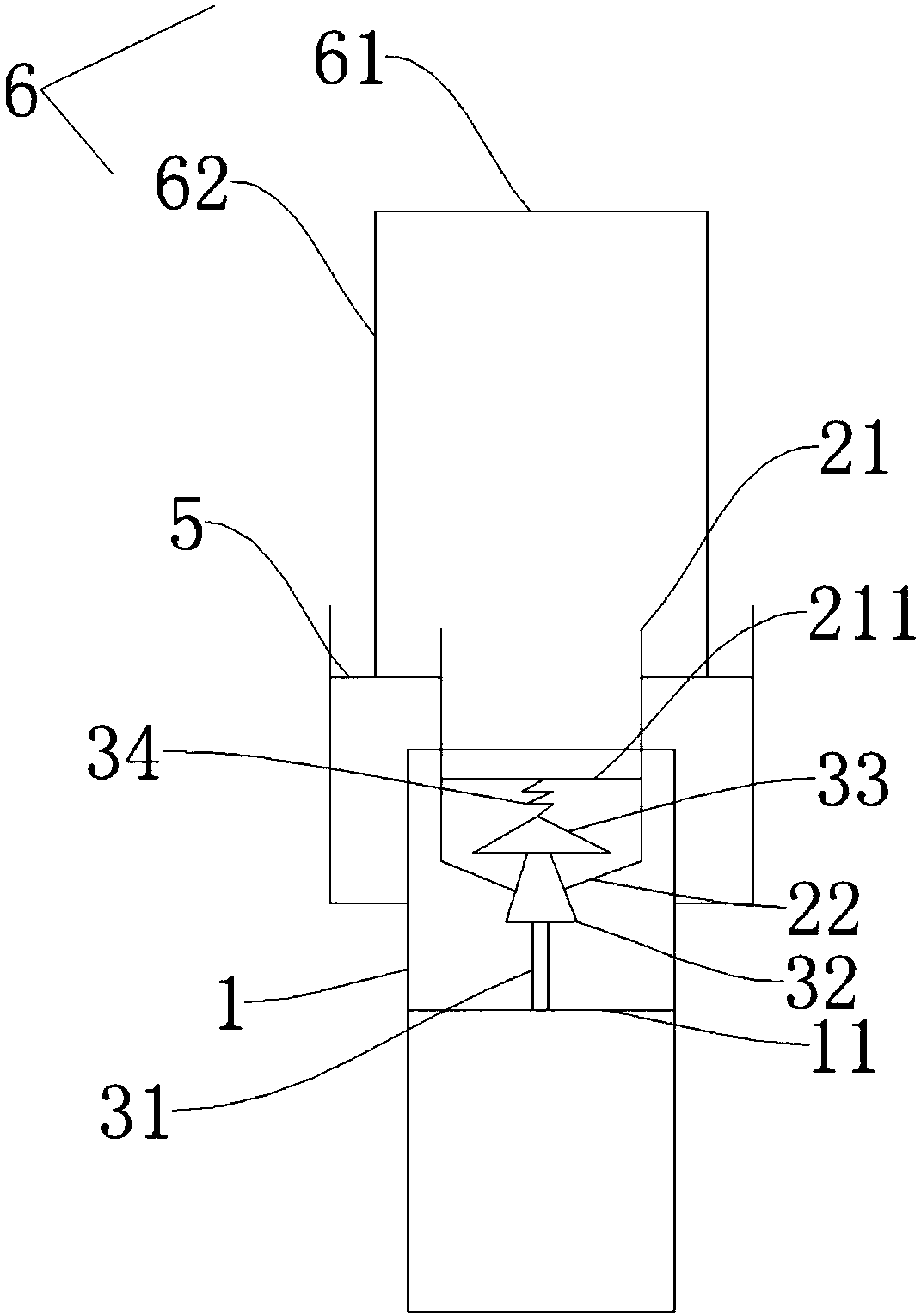

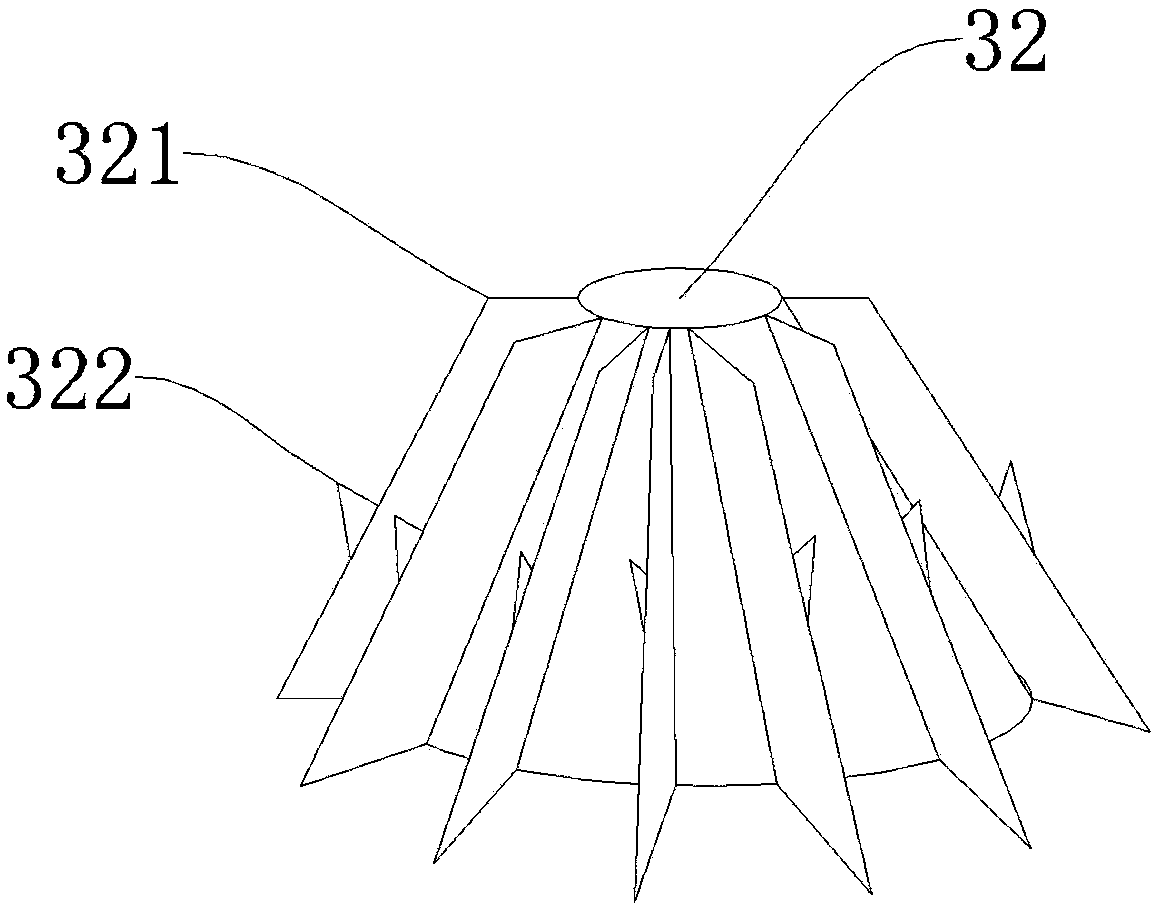

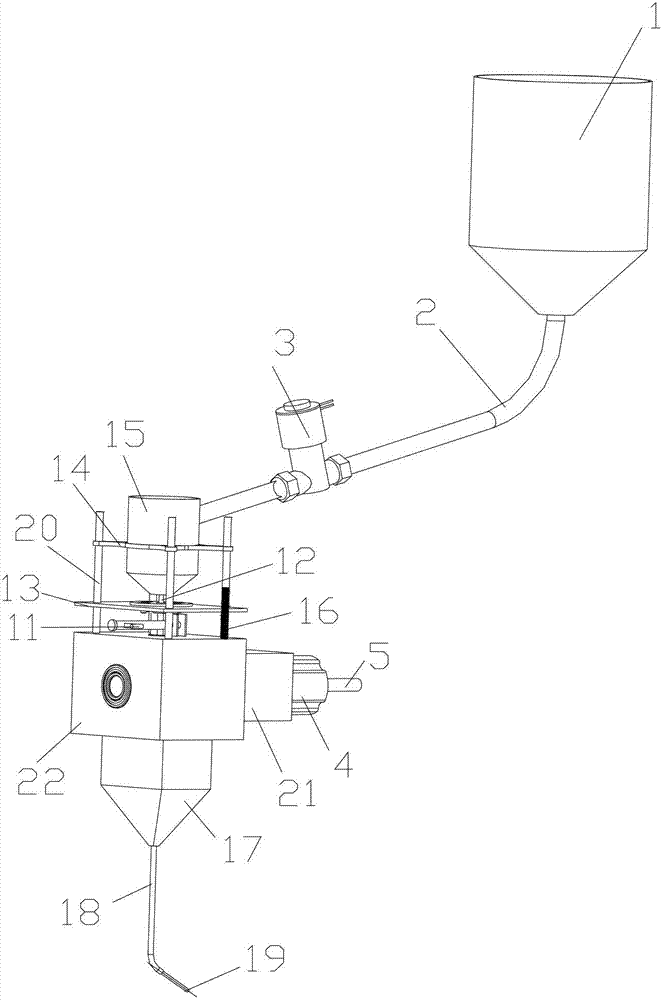

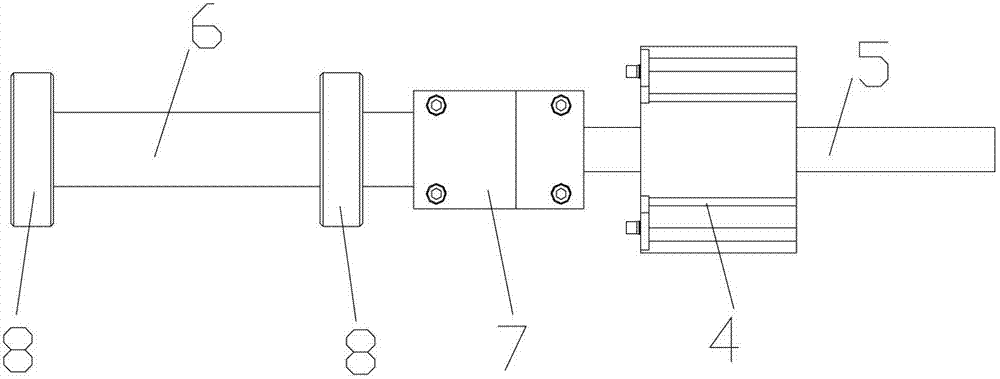

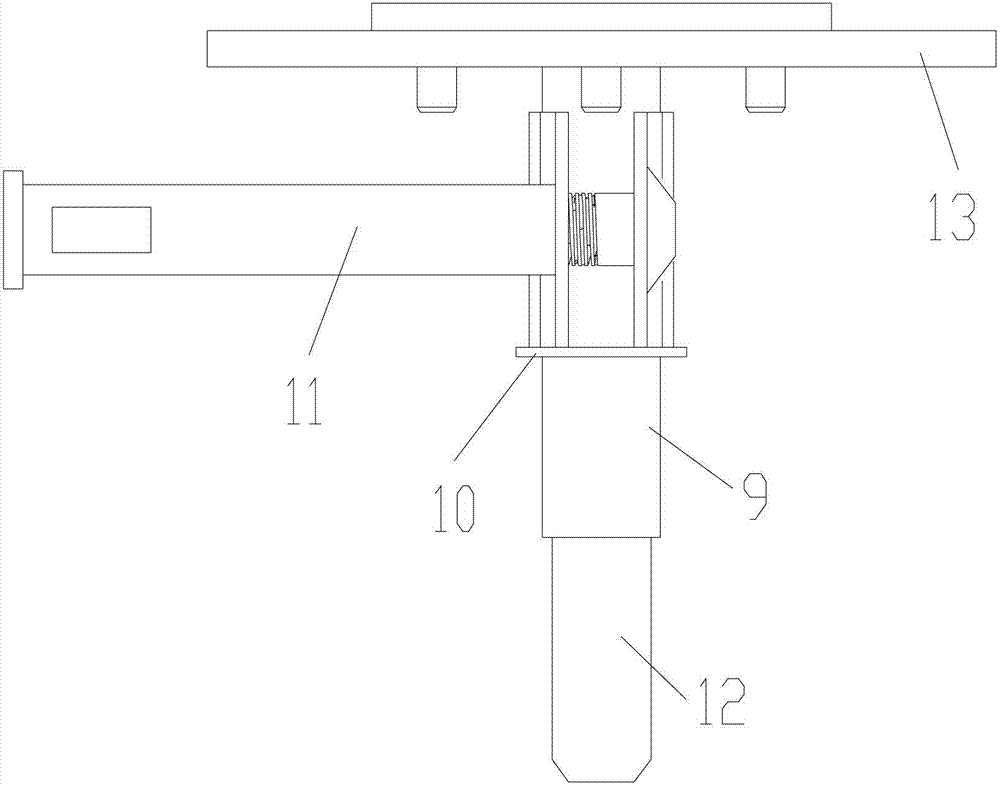

Single-gun pollination robot

ActiveCN109618912AImprove spraying efficiencyRealize powder spraying operationAgriculturePlant genotype modificationPollinationEngineering

The invention relates to a single-gun pollination robot. Images obtained by a pan-tilt type image capture device (5) are adopted as the basis, a control module is used for performing advancing controlon a driving device carrier (1), the position of a plant to be sprayed is determined through the obtained images, the direction of the end of a powder spraying hose (10) to the plant to be sprayed isobtained through a mechanical arm (9), due to a designed air pump (3), on the basis of the powder supply motion of a powder supply device, the powder spraying operation of the plant to be sprayed isachieved, and the plant spraying efficiency is effectively improved.

Owner:GANSU AGRI UNIV

Method for preparing positive plate of nickel hydrogen battery

ActiveCN101867045BImprove consistencyImprove performanceAlkaline accumulator electrodesBiochemical engineeringKey factors

The invention relates to a method for full-automatically preparing a positive plate of a nickel hydrogen battery, which comprises the processes of automatically discharging, automatically feeding and welding a nickel plate, prepressing, gluing, feeding powder, rolling, detecting thickness, softening, automatically welding a nickel wire, automatically rubberizing, automatically splitting, and automatically weighing. The whole process of manufacturing and processing the positive plate is full-automatic, so that the consistency of the positive plate, which is a key factor influencing the consistency of the battery, can be improved; and the method has the advantages of shortening the manufacturing time, saving labor cost, reducing the influence of personal factors, contributing to tracing theproblems of products, along with wide industrial application prospect.

Owner:先进储能材料国家工程研究中心有限责任公司

Button cell automatic pressing device

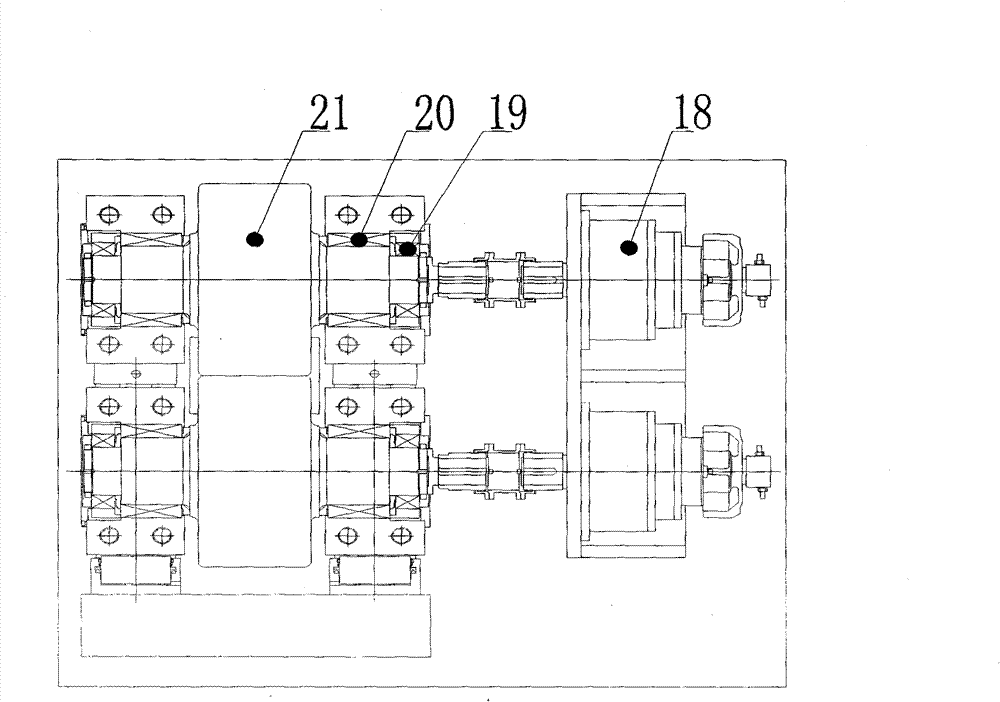

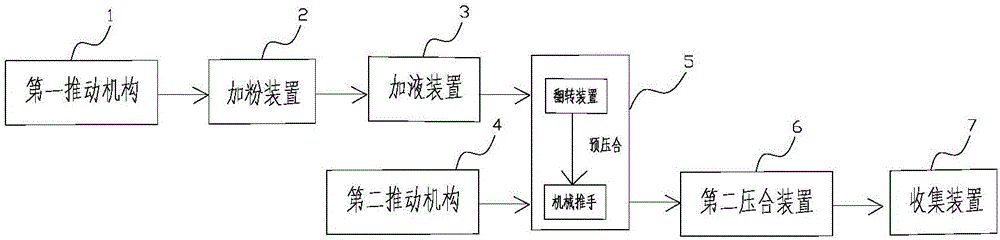

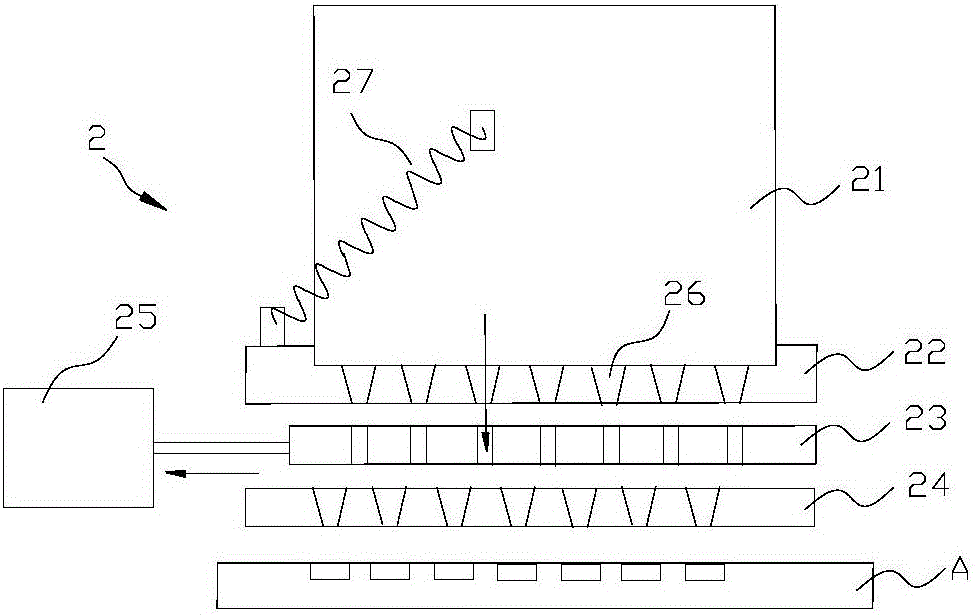

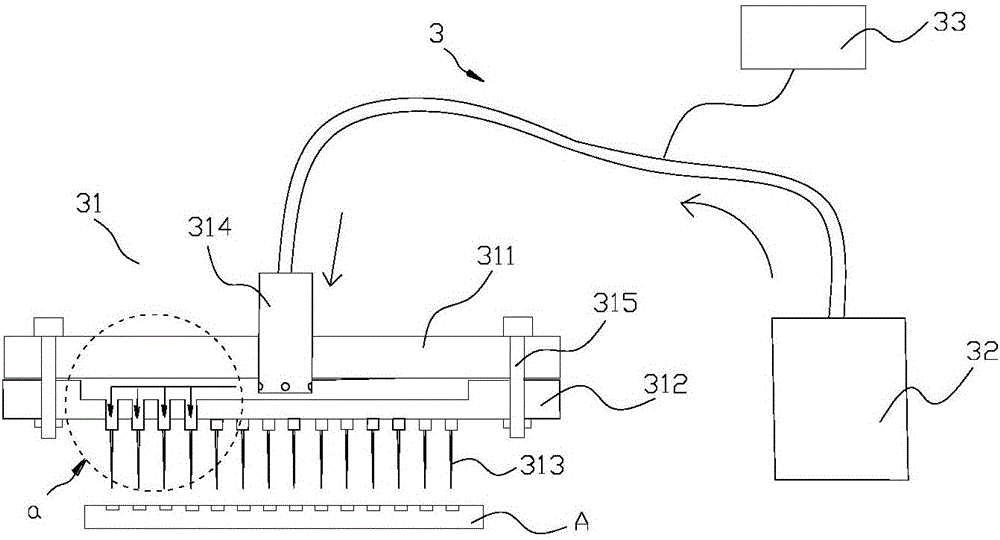

ActiveCN106025305AReduce labor costsImprove powder feeding efficiencyPrimary cell manufactureAssembling battery machinesButton batteryEngineering

The invention discloses a button cell automatic pressing device, which comprises a first pushing mechanism, a powder adding device, an electrolyte adding device, a second pushing device, a first pressing device and a second pressing device, wherein the first pushing mechanism is used for pushing a bottom cover material plate; the powder adding device is used for adding battery powder onto a bottom cover arranged on the bottom cover material plate; the electrolyte adding device is used for adding electrolyte into the bottom cover; the second pushing mechanism is used for pushing a face cover material plate; the first pressing device is used for pre-pressing the bottom cover and a face cover; the second pressing device is used for tightly pressing a pre-pressing button cell; the powder adding device, the electrolyte adding device and the first pressing device are sequentially arranged in the conveying direction of the first pushing mechanism; the second pressing device is arranged in the conveying direction of the second pushing mechanism. Through the arrangement of the fully automatic powder adding device, the electrolyte adding device, the first pressing device and the second pressing device, the automatic powder addition, electrolyte addition and pressing are realized; the work efficiency is improved; the labor cost is reduced.

Owner:佛山市南海区琪德新能源科技有限公司

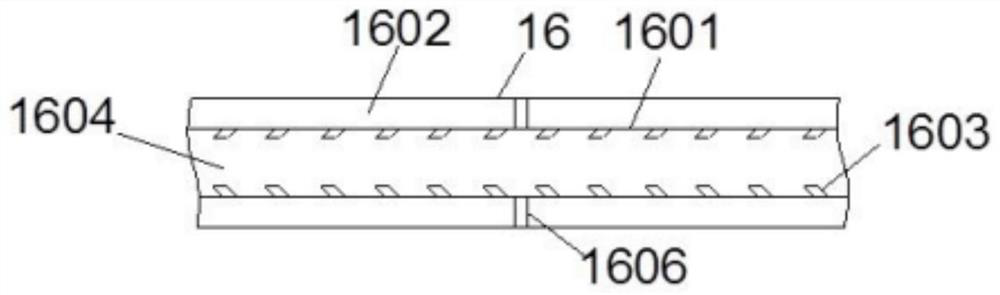

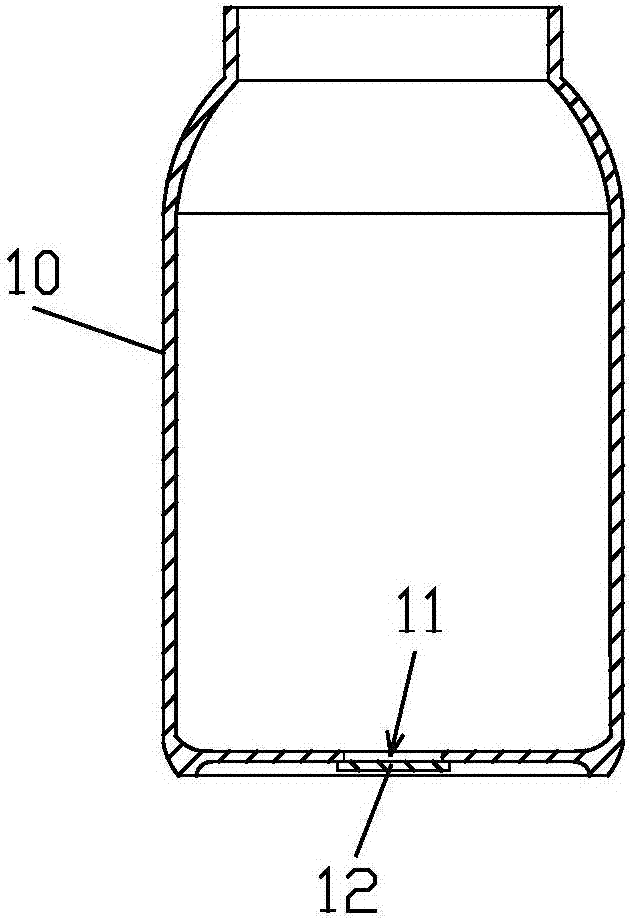

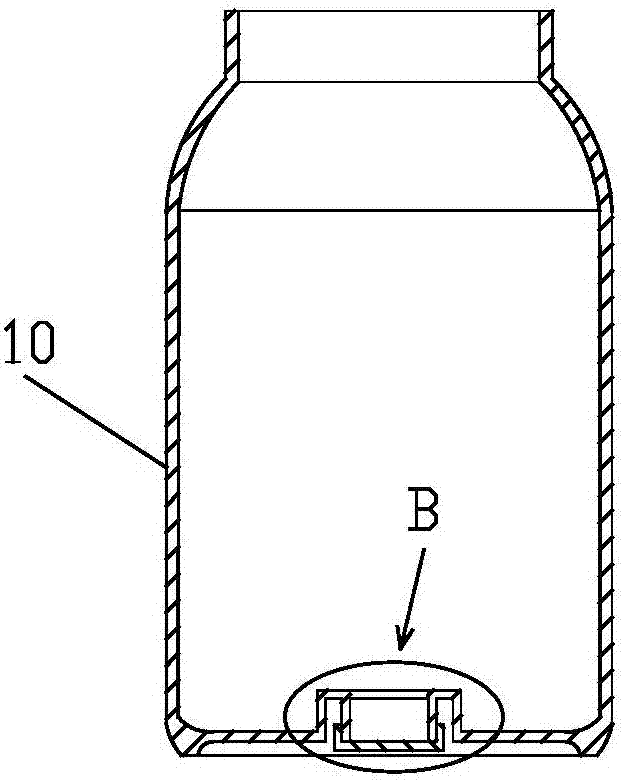

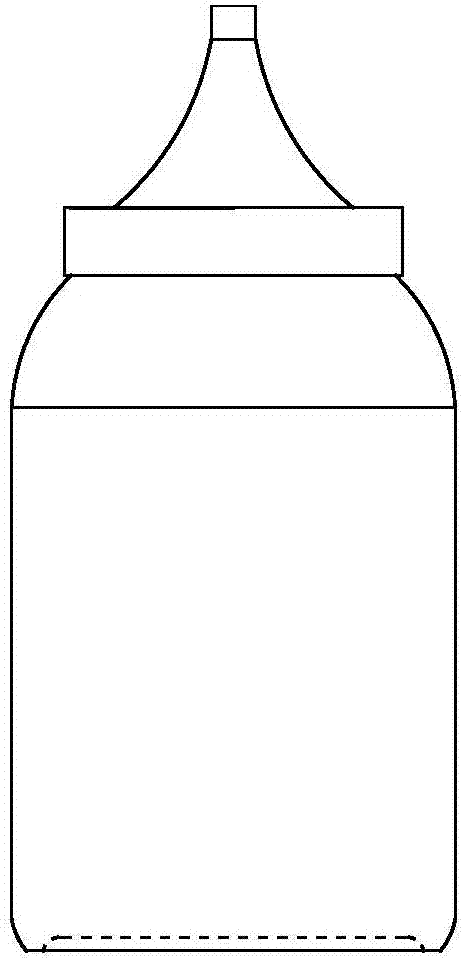

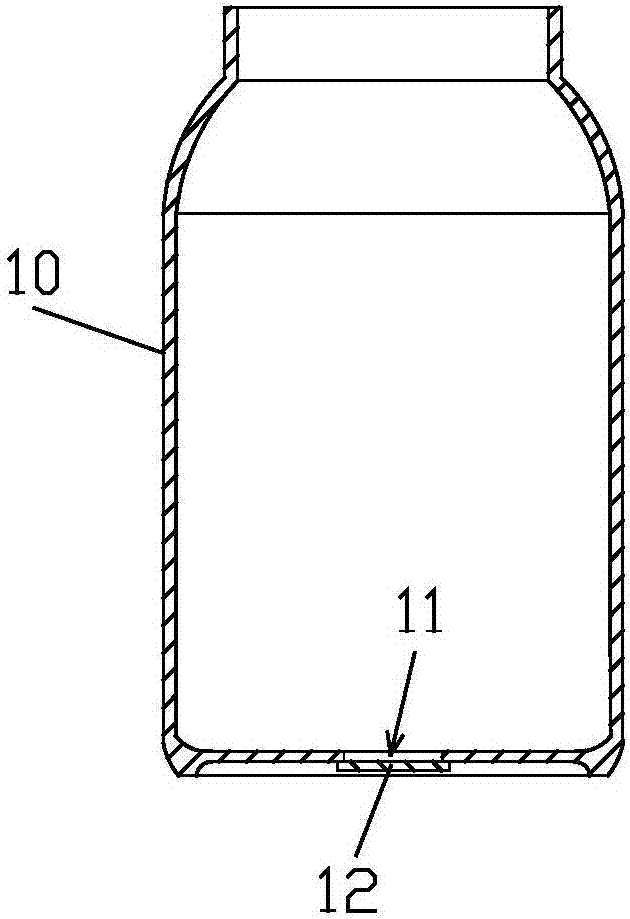

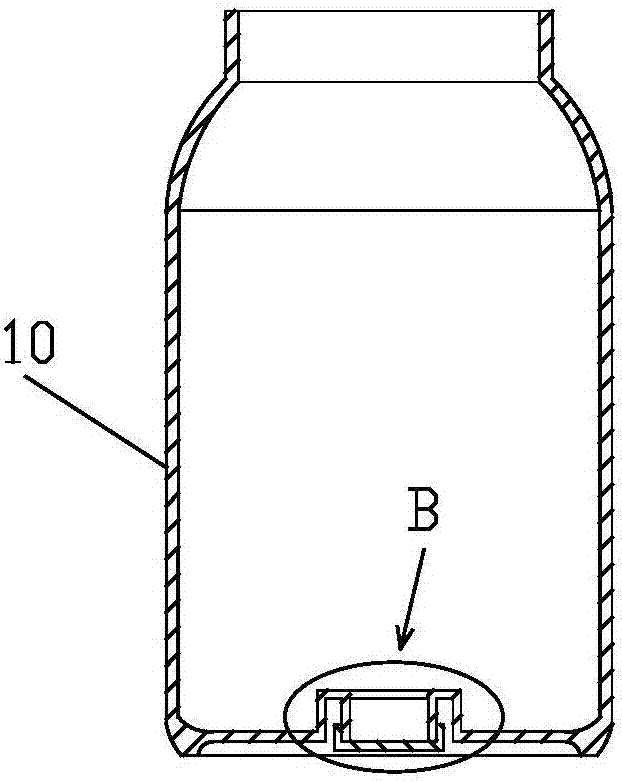

Toner feeding barrel with toner feeding holes and toner feeding box

InactiveCN110347026AImprove powder feeding efficiencyFirmly connectedElectrographic process apparatusPistonEngineering

The invention discloses a toner feeding barrel with toner feeding holes and a toner feeding box and belongs to the field of printer toner feeding boxes. The toner feeding barrel with the toner feedingholes comprises a toner barrel. The toner feeding barrel further comprises an upper cover, a piston, a first toner feeding hole, a second toner feeding hole, a conical sealing plug, and a conical opening; the upper cover is connected with the upper end of the toner barrel; the piston is slidingly connected into the toner barrel in a sealed manner; the first toner feeding hole is formed in the upper cover; the second toner feeding hole is formed in the piston and is corresponding to the first toner feeding hole; the conical sealing plug is arranged at the lower end of the second toner feeding hole; and the conical opening is formed in the lower end of the second toner feeding hole and is corresponding to the conical sealing plug. According to the toner feeding barrel with the toner feeding holes of the invention adopted, the conduction of the toner barrel can be realized through the first toner feeding hole and the second toner feeding hole, so that toner feeding can be carried out;after the toner feeding is completed, resetting can be performed; the conical sealing plug can be tightly attached onto the conical opening under the action of a tension spring so as to plug the conical opening; and toner feeding can be carried out without disassembling the upper cover required, and therefore, toner feeding efficiency is high.

Owner:佛山普瑞威尔科技有限公司

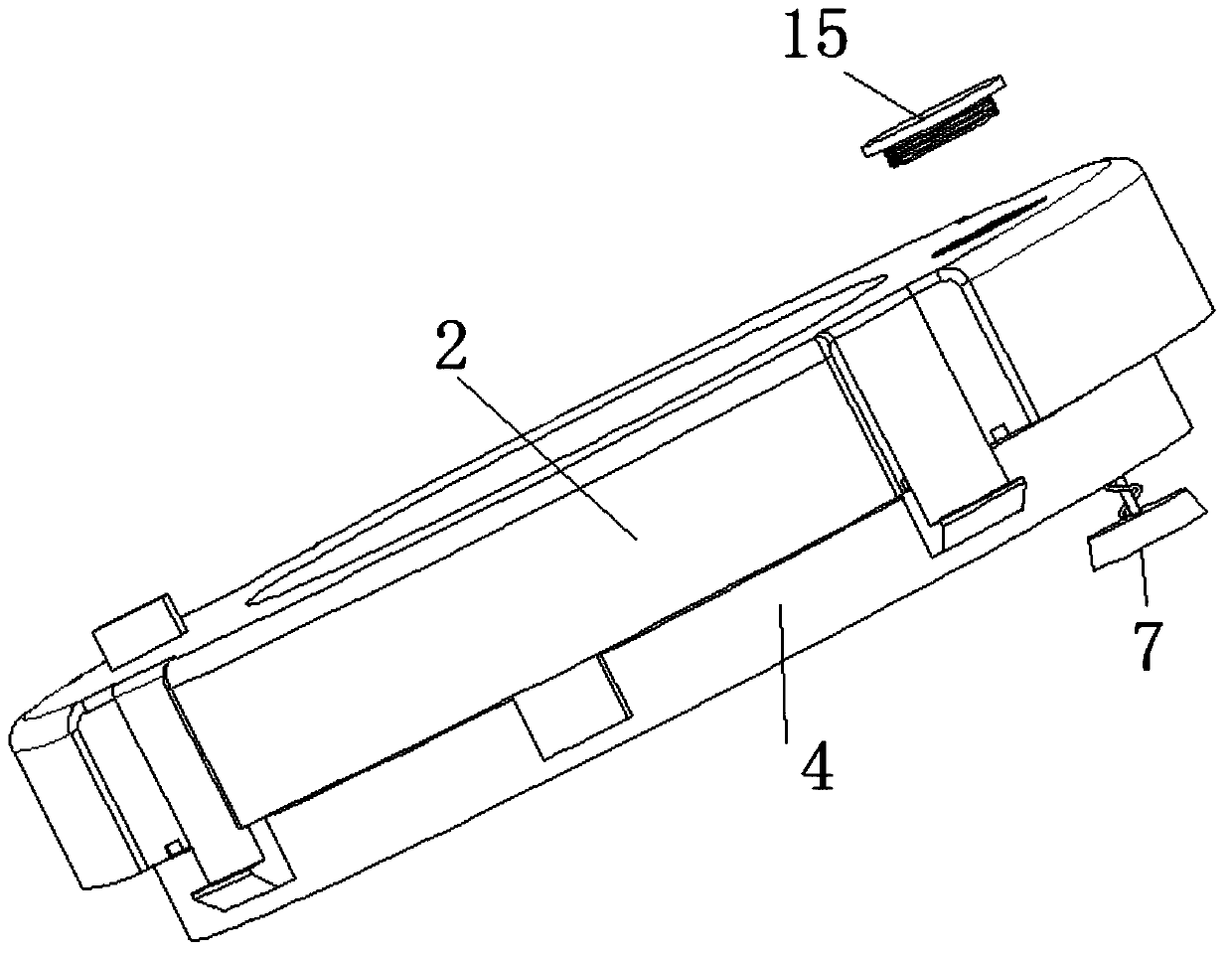

Easy-for-feeding-powder direct insertion type ink powder bottle for selenium drum

InactiveCN107643663AEasy to useSimple structureElectrographic process apparatusBottle neckEngineering

The invention discloses an easy-for-feeding-powder direct insertion type ink powder bottle for a selenium drum. The easy-for-feeding-powder direct insertion type ink powder bottle comprises a bottle body, an agitation strip and a powder feeder, wherein the center of the bottom of the bottle body is provided with a clamping groove; the center of the clamping groove is provided with a through hole;a first end of the agitation strip is inserted into the through hole to extend to a bottle neck; a second end of the agitation strip extends to the through hole in a bottle bottom to be connected witha telescopic strip; the other end of the telescopic strip is connected with a bottom cover; the bottom cover is connected with the clamping groove in a clamping manner; agitation thorns which are downwards inclined to be at included angles of 30 degrees are arranged between the first end and the second end; the powder feeder is detachably connected with a powder feeding passage of a powder storage bin of the selenium drum; a spring is arranged to be that an ejector pin at the lower part of a blockage structure is connected with a solid of a second supporting net in a butting manner to enablethe interior of a shell to be communicated with the powder feeding passage when a first cover body is not connected with a washer and the powder feeder is connected with the powder feeding passage, and when the first cover is not connected with the washer and the powder feeder is not connected with the powder feeding passage, a hemi-elliptical structure of the lower part of the blockage structureis connected with the washer in the butting manner to close a lower port of the shell. The ink powder bottle provided by the invention is high in powder feeding efficiency and is pollution-free in a powder feeding process.

Owner:北海市天硌打印耗材有限公司

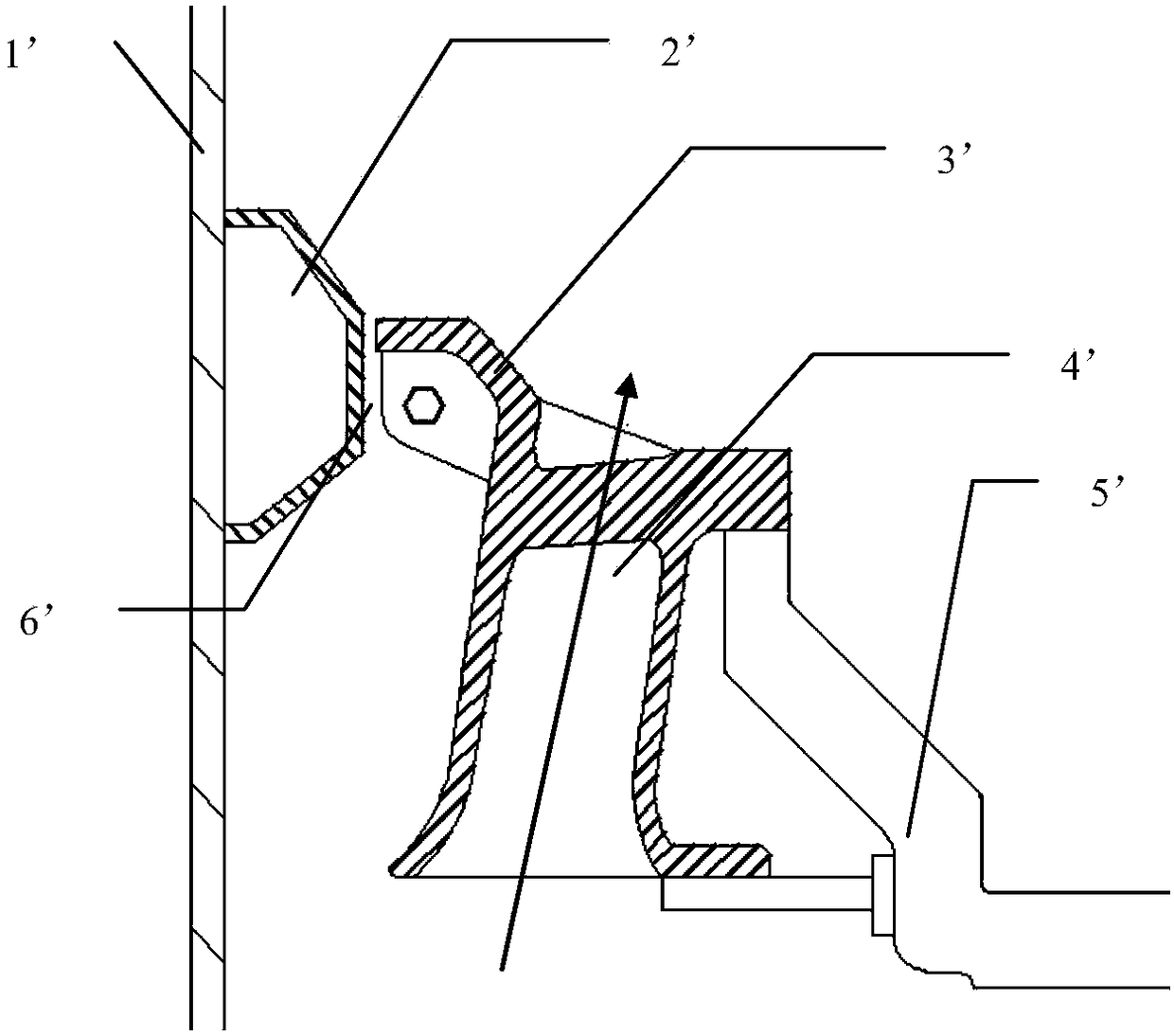

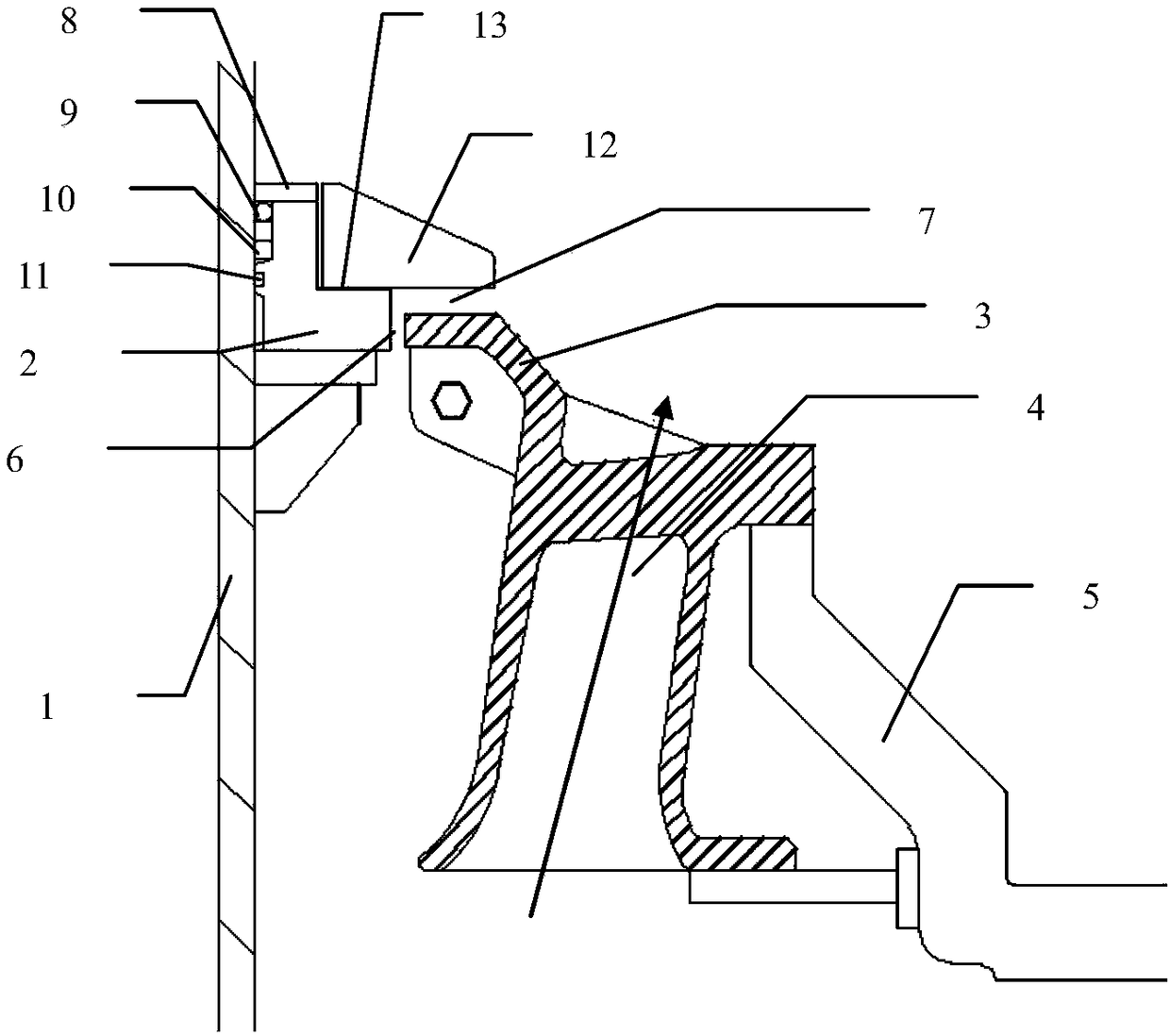

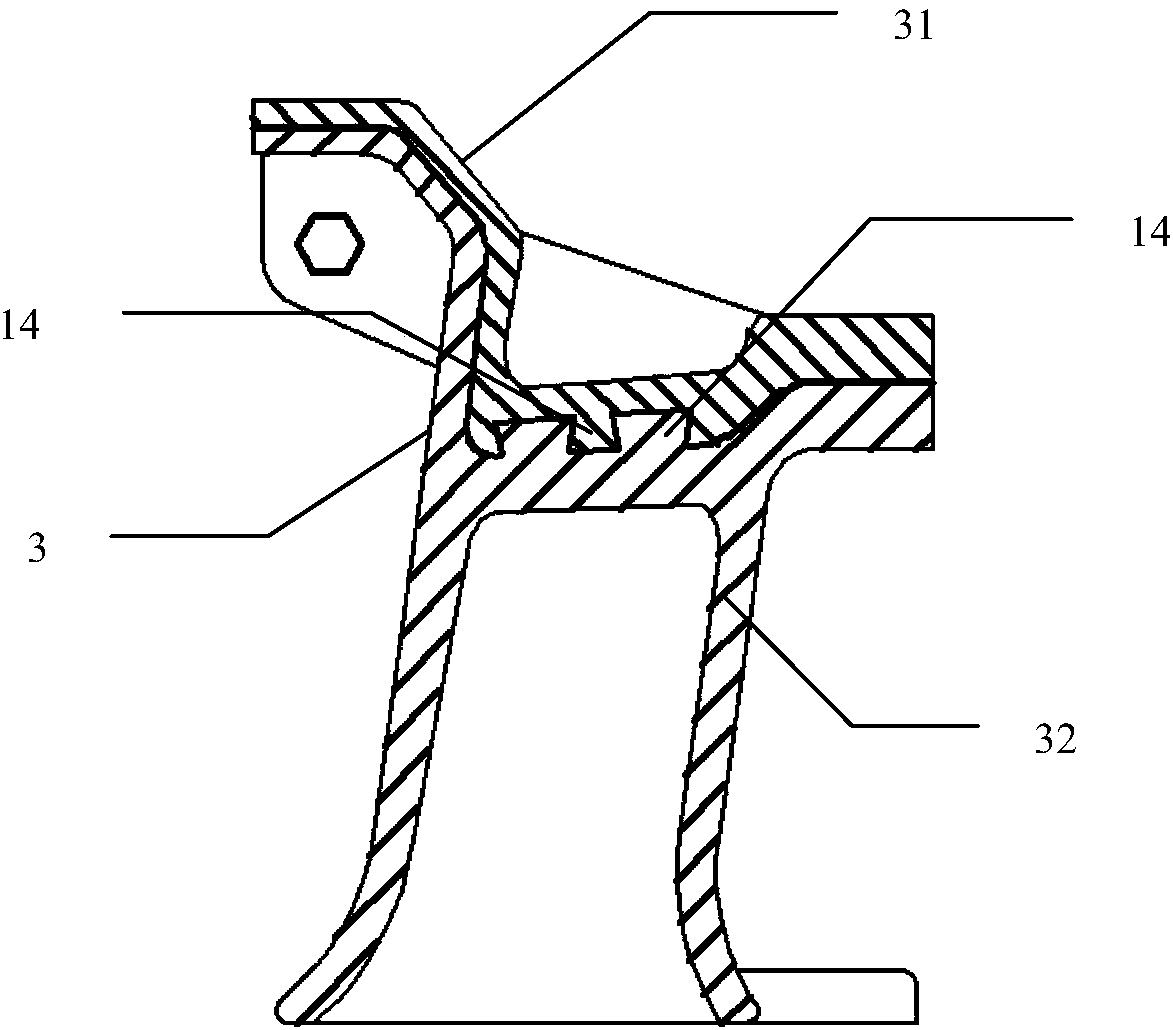

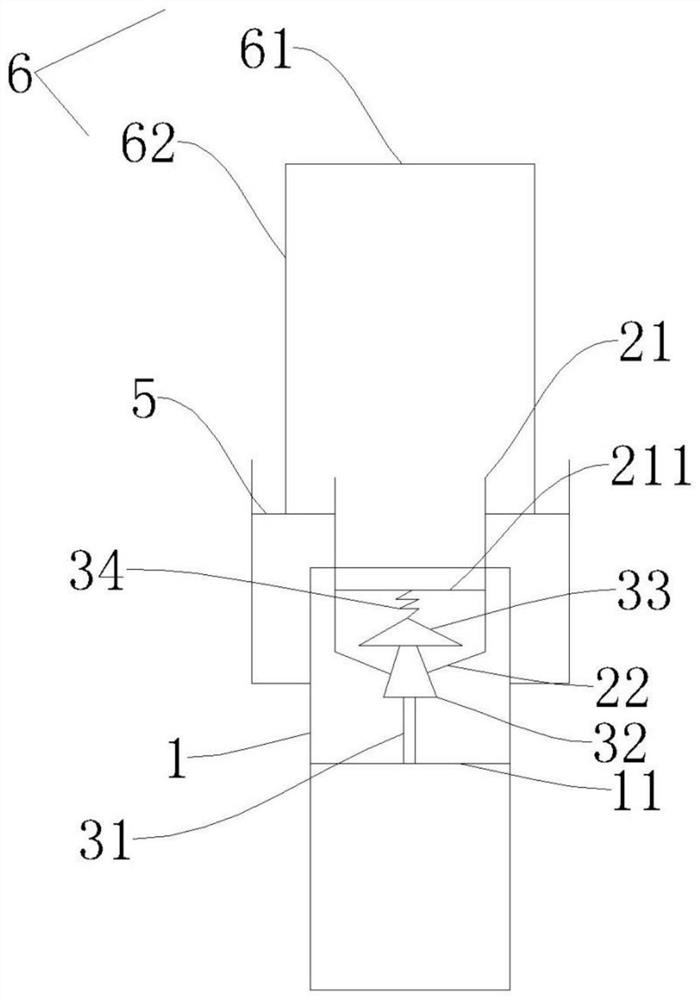

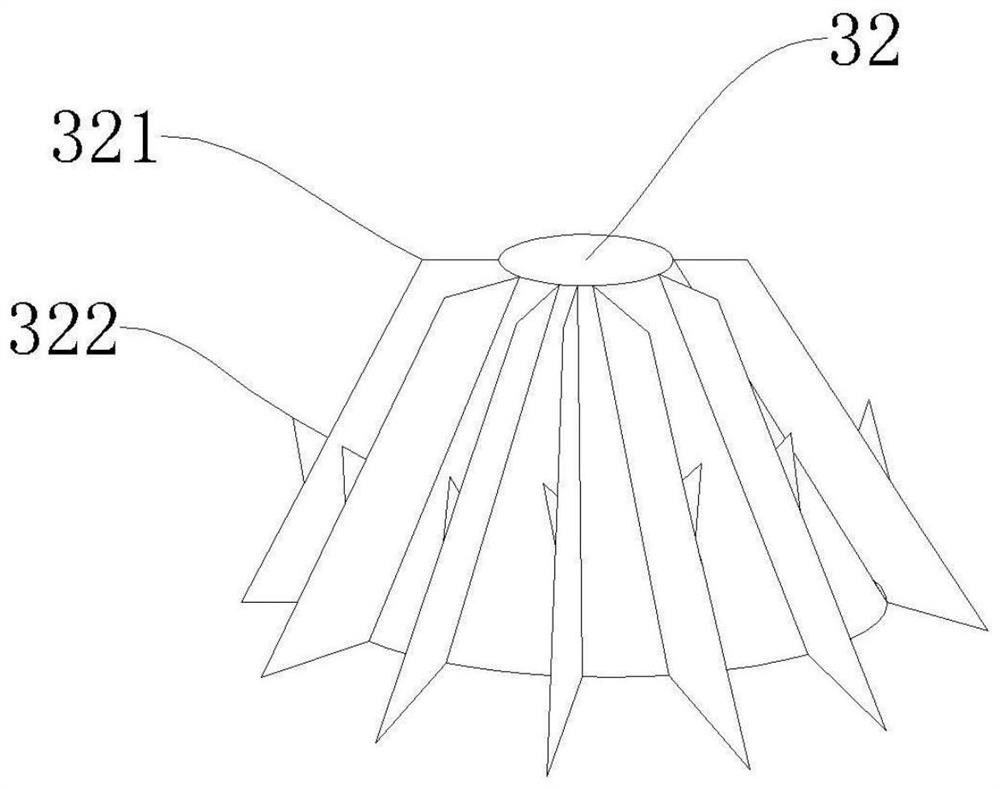

Rotary nozzle structure of medium-speed coal mill

ActiveCN108339655AGood wear resistance and impact resistanceGuaranteed tightnessGrain treatmentsElectricitySpray nozzle

The invention relates to a rotary nozzle structure of a medium-speed coal mill. According to the rotary nozzle structure, a stationary seal ring is arranged on a coal mill inner cylinder wall; a nozzle is arranged on a coal mill grinding disc; an air passage is formed in the nozzle; a sealing structure is arranged on the outer side of the upper part of the nozzle; a vertical gap and a horizontal gap are simultaneously formed between the sealing structure and the nozzle; a pressing plate, round steel, an asbestos packing and a stationary seal ring sealing tooth are sequentially arranged on theside of the stationary seal ring from top to bottom; the lower part of the asbestos packing presses the stationary seal ring sealing tooth; the lower plane of the pressing plate and the upper plane ofthe stationary seal ring are arranged in a matched mode so as to ensure sealing between the stationary seal ring and the coal mill inner cylinder wall; a baffle ring is arranged on the stationary seal ring; and a high-temperature asbestos gasket is arranged between the stationary seal ring and the baffle ring so as to ensure the sealing effect. The rotary nozzle structure has the advantages thatthe sealing effect of a gap between a rotating seal ring and the stationary seal ring can be improved, electricity consumption and air consumption for the coal mill can be reduced, the wear resistanceand the reliability of the nozzle of the coal mill can be simultaneously improved, and the service life of the nozzle can be remarkably prolonged.

Owner:北京蓝爱迪电力技术有限公司

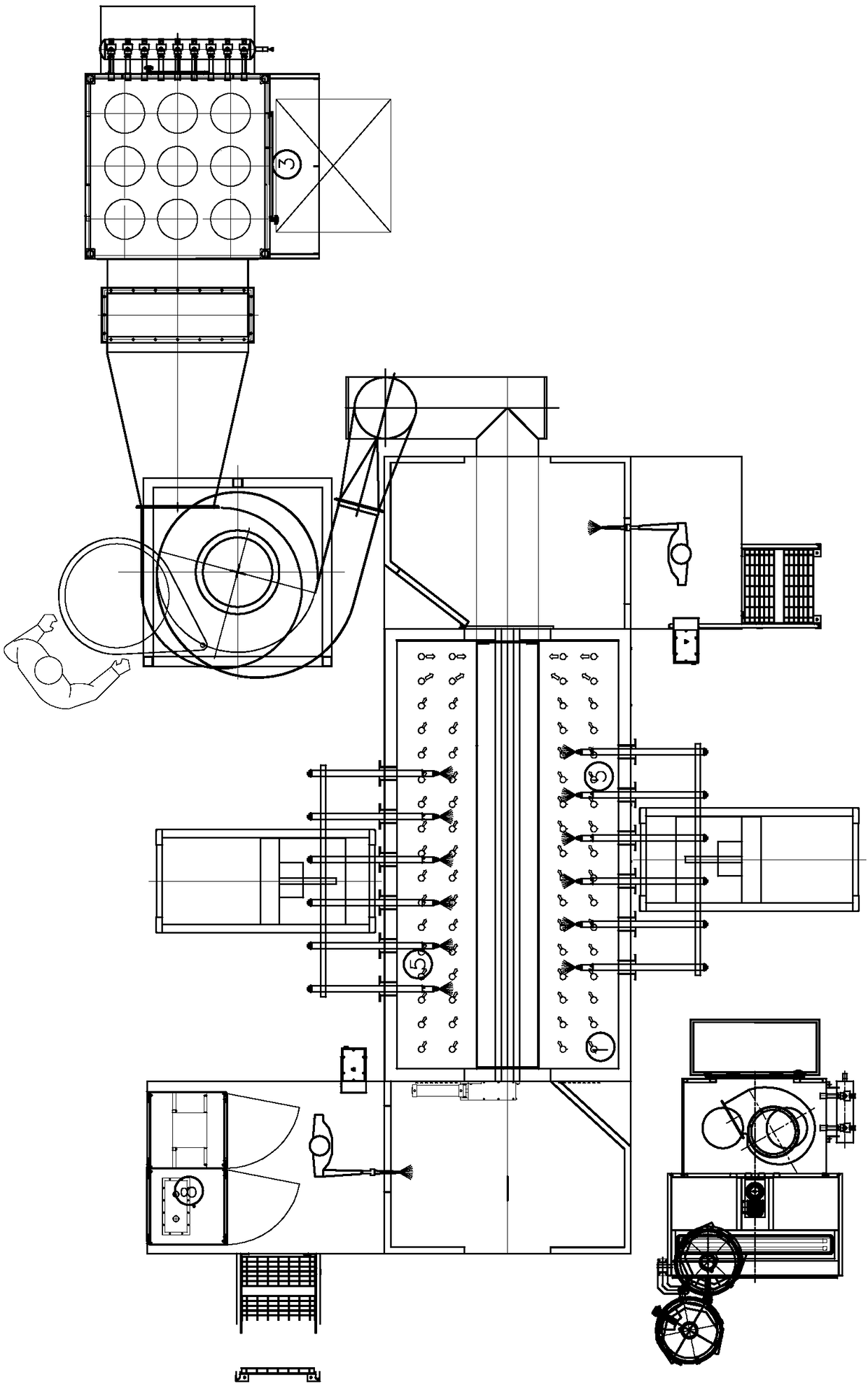

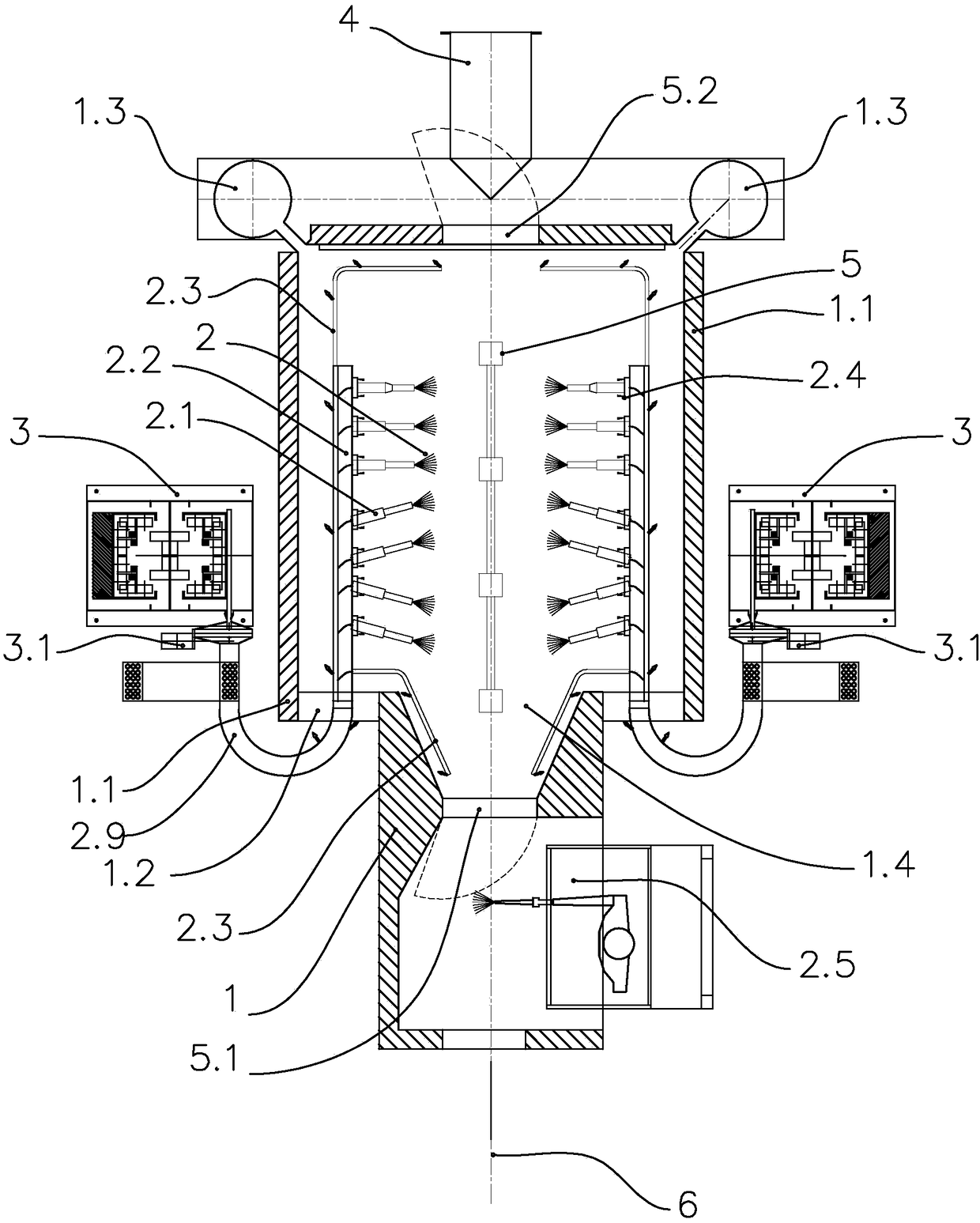

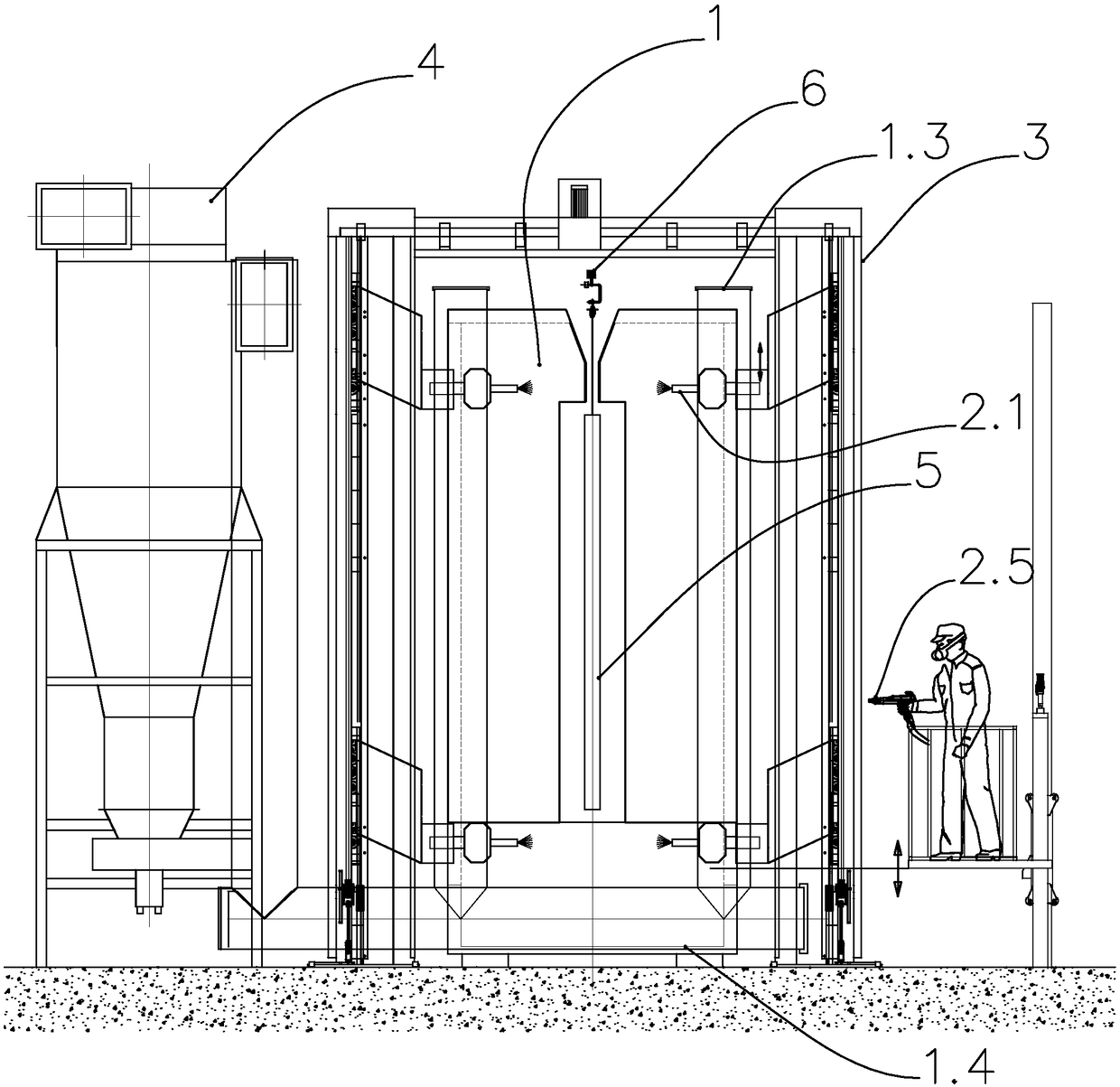

Powder spraying system convenient to clean

PendingCN108525909AImprove powder feeding efficiencyReduce leakageSpray boothsReciprocating motionEngineering

The invention discloses a powder spraying system convenient to clean. The powder spraying system convenient to clean comprises a spraying chamber body sued for enclosing a spraying region, an automatic spray gun system, an air extraction system and vertical reciprocating devices; each vertical reciprocating device comprises a spray gun beam arranged on the side surface in the spraying chamber bodyand a connection arm used for connecting the spray gun beam with each vertical reciprocating device; the automatic spray gun system comprises a plurality of automatic spray guns arranged on the spraygun beams respectively; and the spraying chamber body is provided with spray gun beam opening grooves through which the connection arms penetrate respectively. A powder leakage channel is arranged ateach spray gun beam opening groove only to reduce the powder leakage quantity, and the powder is difficultly blown out to an external space of a spraying room during cleaning, so that the color change cleaning efficiency is high, a color change cleaning work is rapid, the powdering efficiency of each automatic spray gun is more efficient, and each spray gun bean is selectively equipped with a cleaning device; and each vertical reciprocating device has a function of carrying the corresponding automatic spray gun to perform vertical reciprocating motion and a function of carrying each cleaningdevice in a spraying chamber at the same time, so that the color change cleaning time is further shortened, and the spraying efficiency is improved.

Owner:YU TUNG ZHONGSHAN ENG

Leak-proof device for powder addition of selenium drum

The invention discloses a leak-proof device for powder addition of a selenium drum. The selenium drum is provided with a powder storage bin, wherein a circle of clamping bulge is arranged on an innerwall of the powder storage bin in a surrounding manner; the leak-proof device is detachably propped against the top end of the clamping bulge and comprises a connection pipe, a first powder leaking pipe, a second powder leaking pipe, a blocking assembly and a bracket; a first support net is horizontally clamped into the connection pipe; a second support net is horizontally clamped into the first powder leaking pipe; the second powder leaking pipe communicates with the first powder leaking pipe; the blocking assembly comprises a support column, a limiting plug, a sealing plug and a first springwhich are fixedly connected in sequence from bottom to top; the bracket comprises a pair of L-shaped support rods, a pair of connecting rods and a positioning frame; an inner thread matched with an opening of a carbon powder bottle is arranged in the upper end of the first powder leaking pipe; and the positioning frame is pushed, the edge of the lower end of the second powder leaking pipe is propped against limiting lugs and carbon powder in the carbon powder bottle enters the powder storage bin. The leak-proof device is simple in structure, convenient to use, free of carbon powder leakage and high in powder adding efficiency, pollution-free powder addition is achieved and powder addition can be immediately stopped at any time.

Owner:北海市天硌打印耗材有限公司

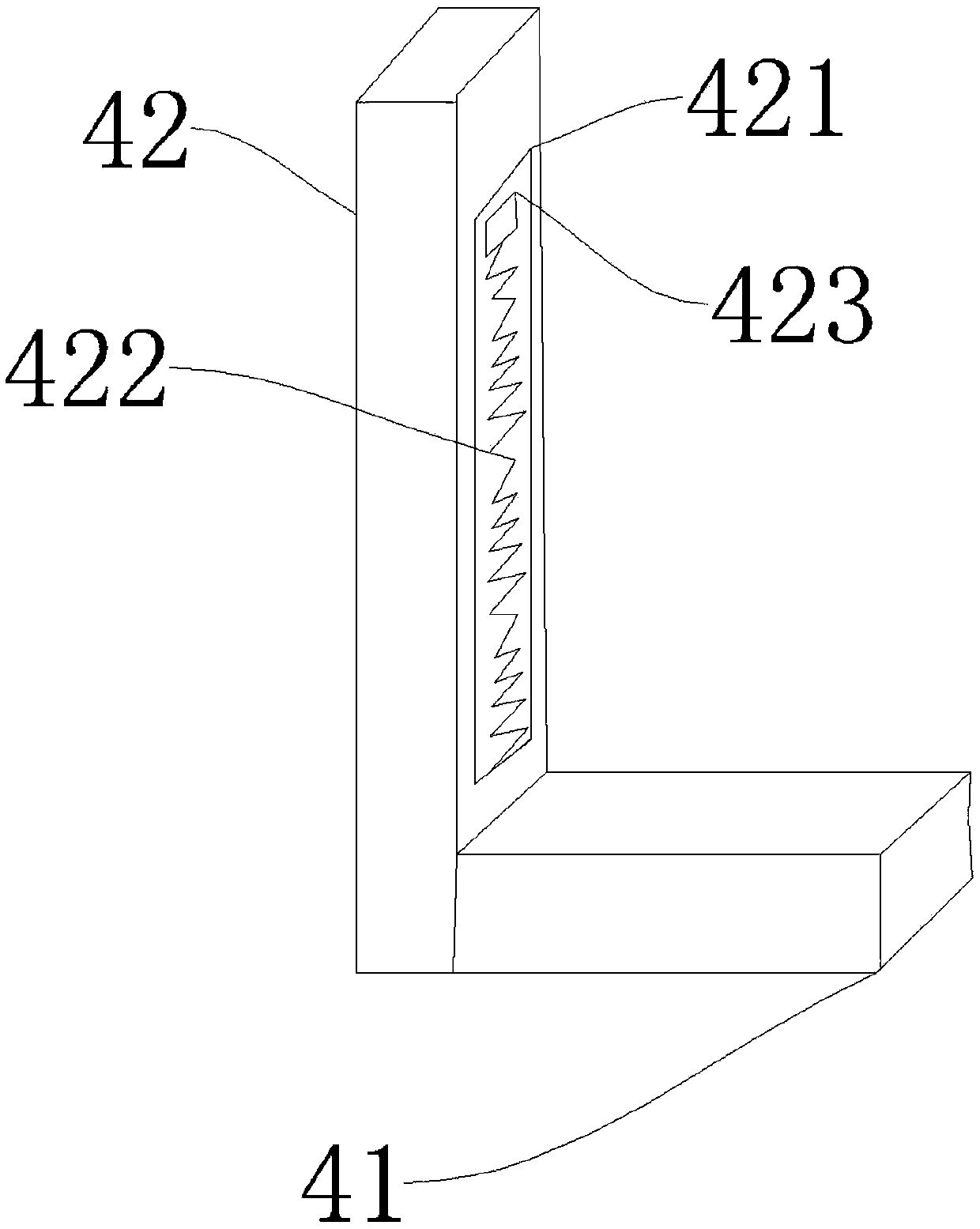

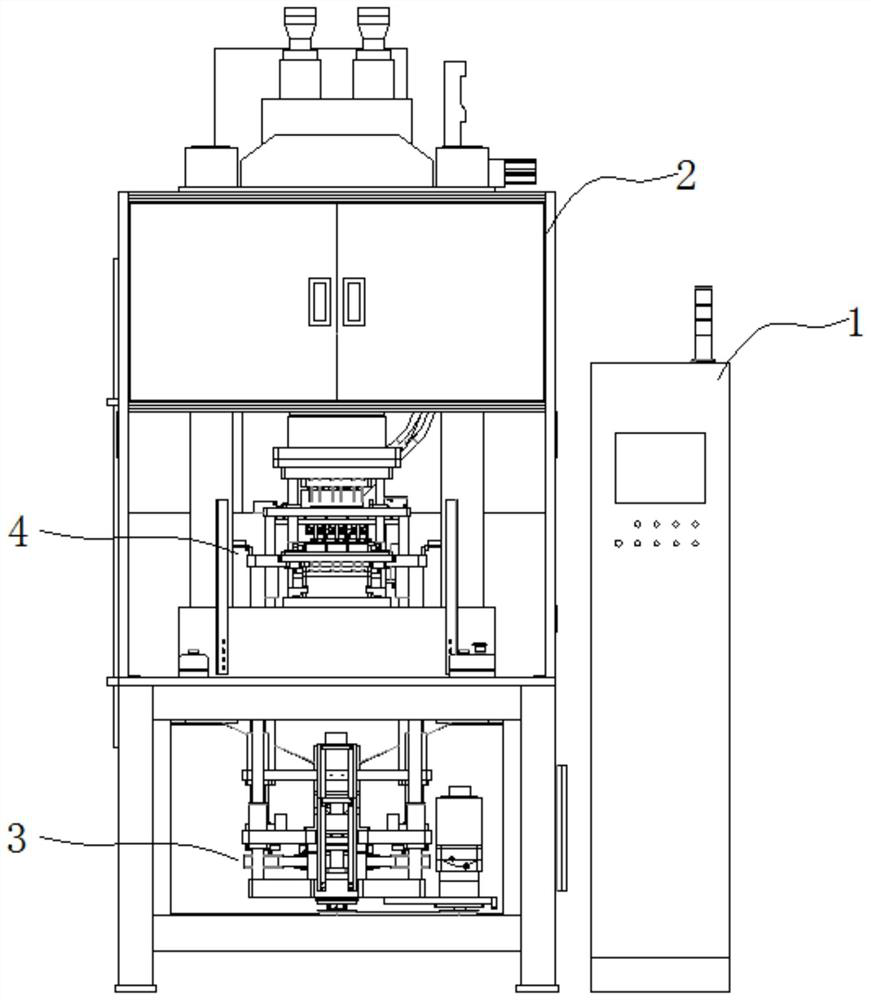

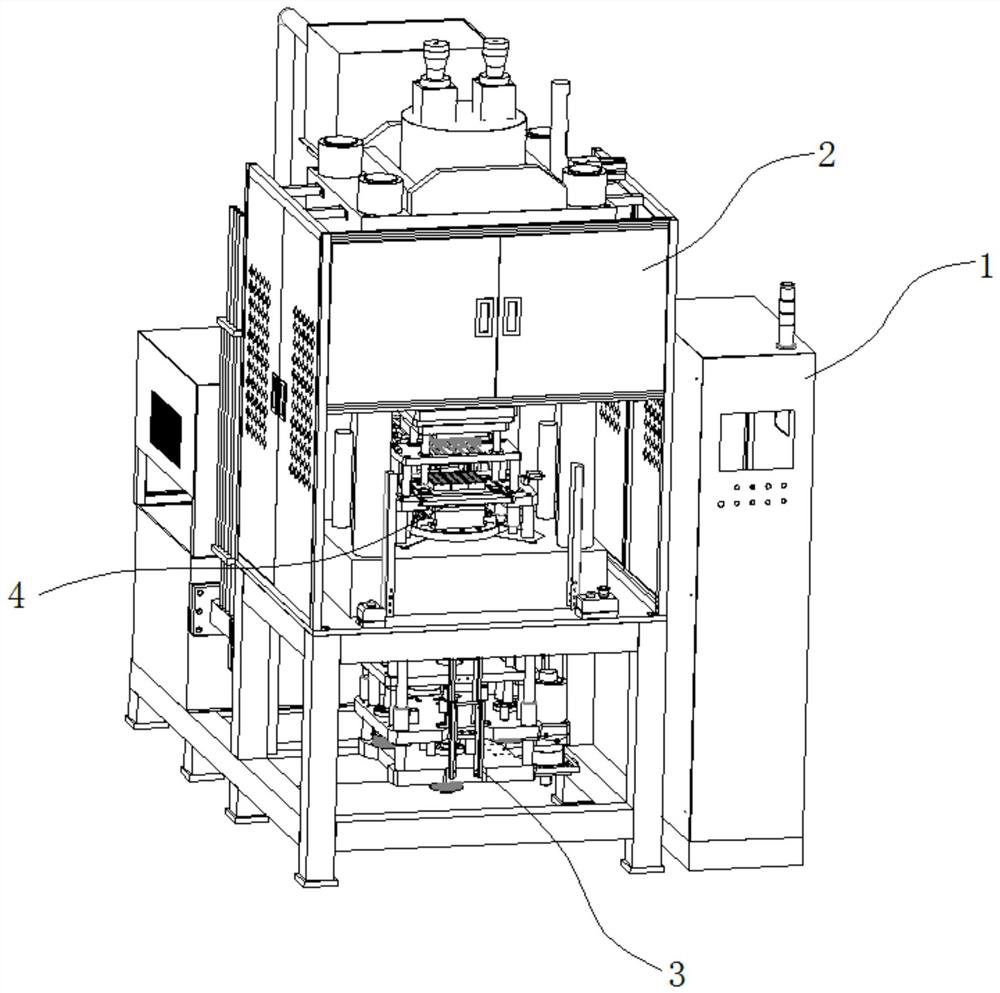

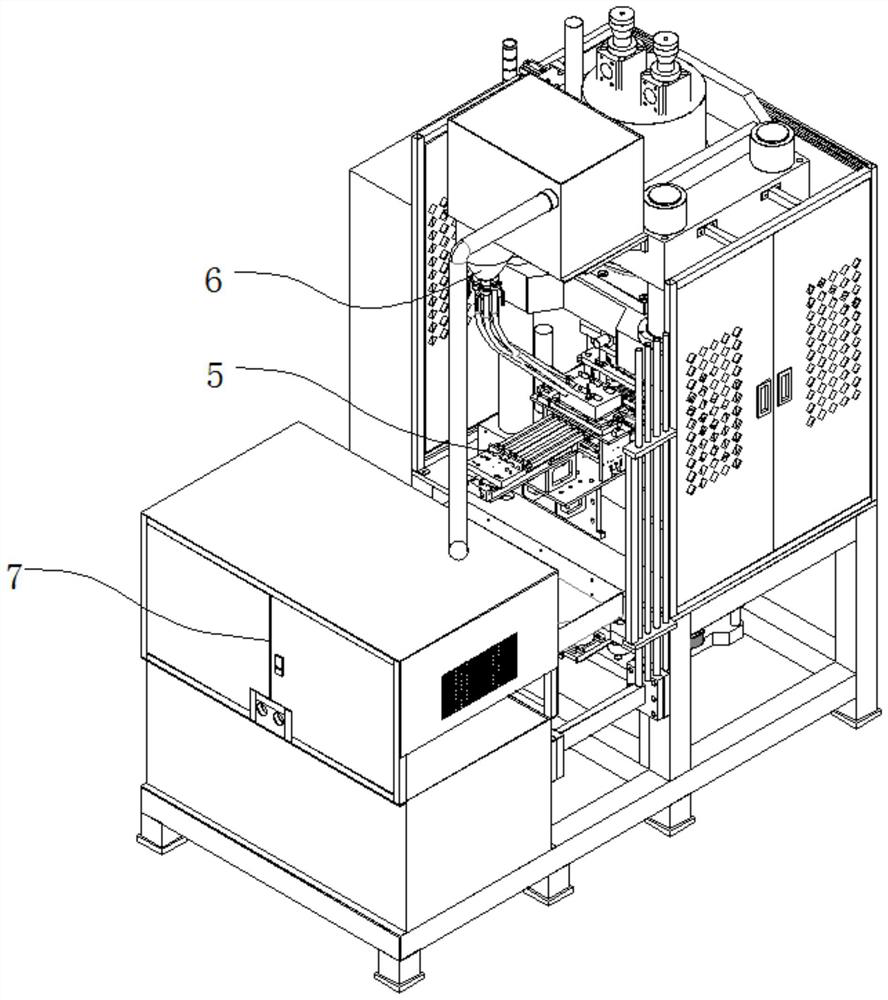

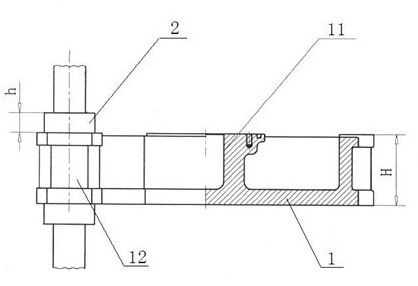

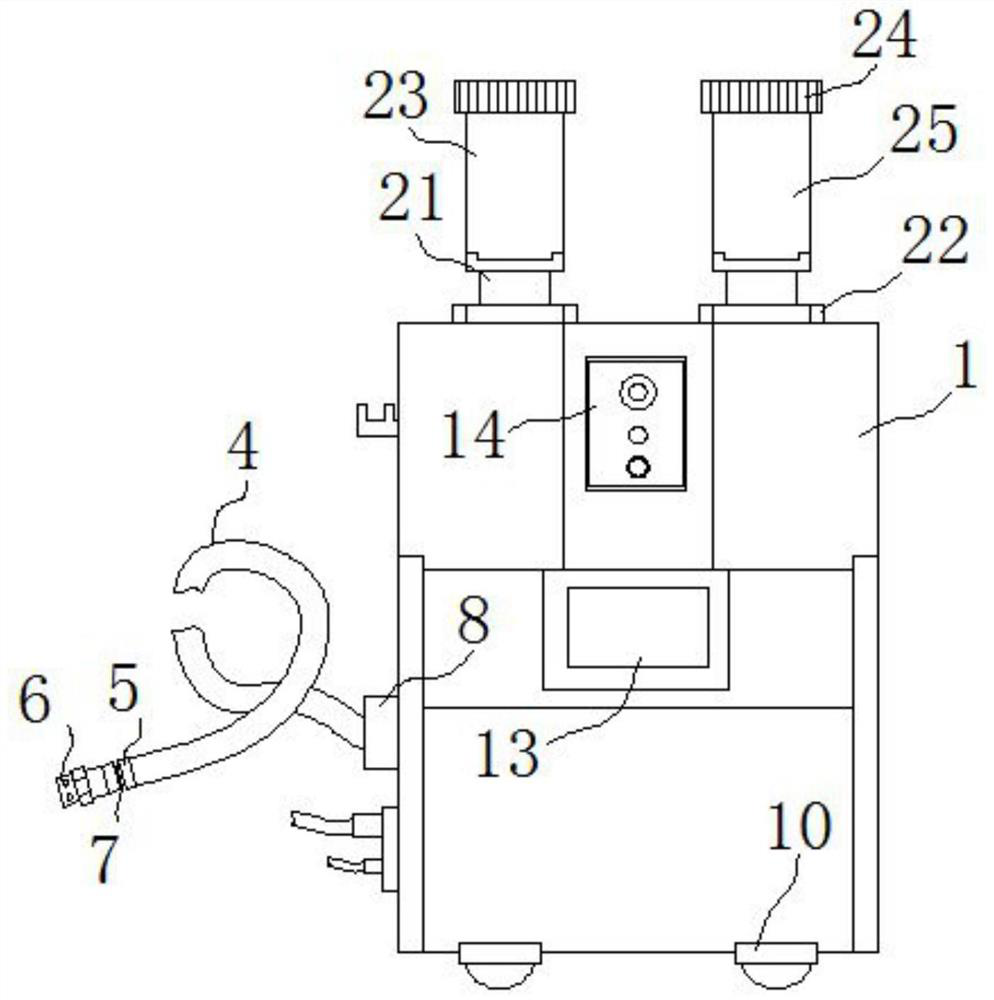

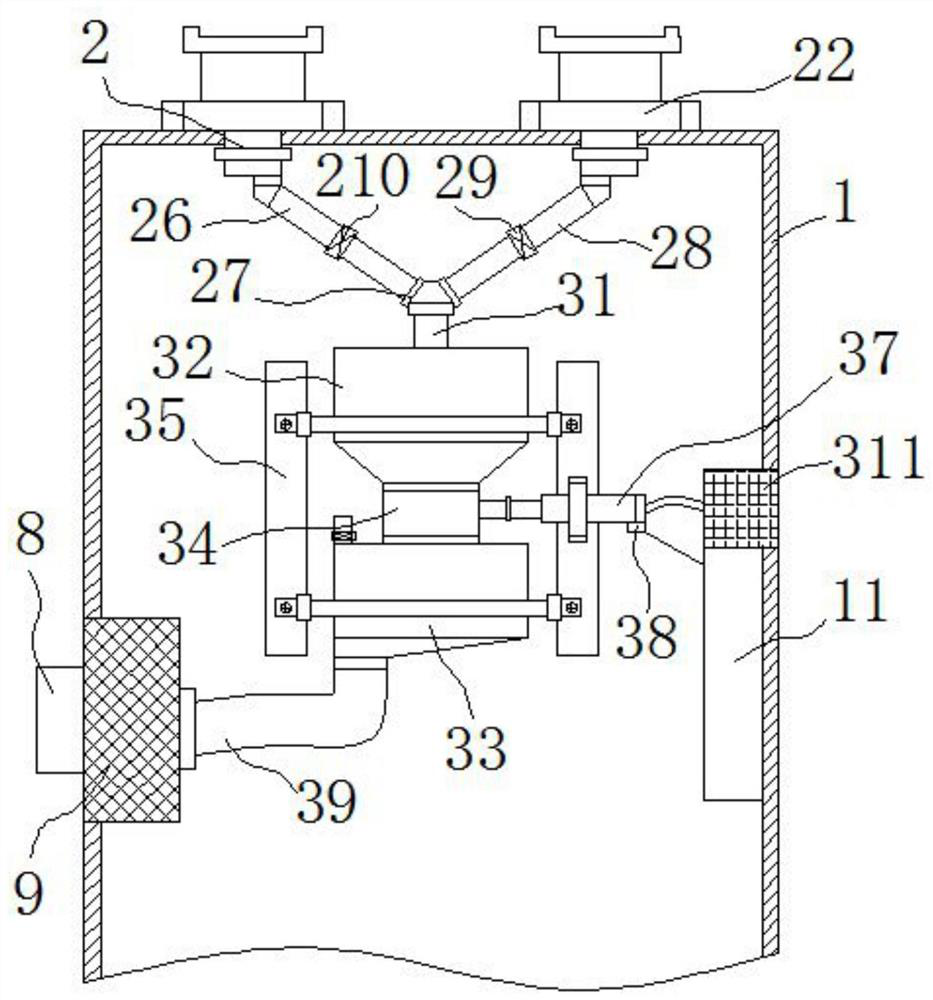

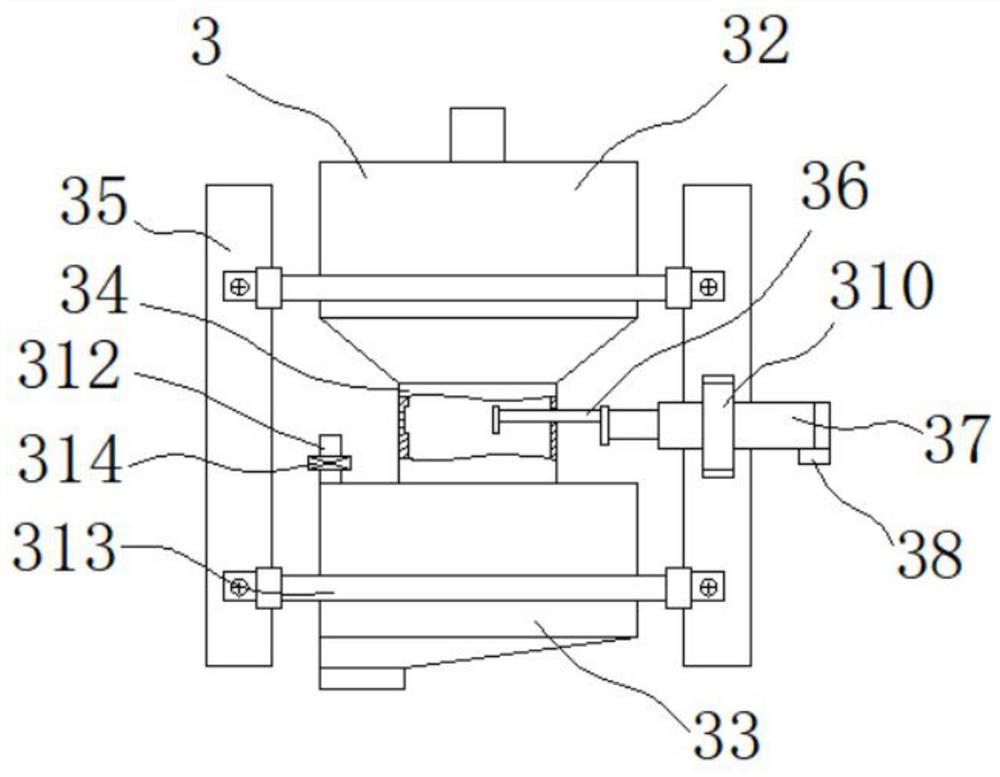

200T servo oil pressure integrated inductor powder forming machine

PendingCN113492551AGuaranteed pressing accuracyIncrease productivityInductances/transformers/magnets manufactureShaping pressInductorProcess engineering

The invention discloses a 200T servo oil pressure integrated inductor powder forming machine. The powder forming machine comprises an oil press, an electric appliance control box, a lower servo module, a forming die, a powder feeding module, a powder containing barrel and a servo pressurizing oil pump. wherein the oil press is located at the right side of the electric appliance control box; the electric appliance control box is located on the top of the forming die; the lower servo module is located at the bottom of the forming die; the powder containing barrel is located at the rear side of the electric appliance control box; the powder feeding module and the servo pressurizing oil pump are both located at the rear side of the forming die; the lower servo module comprises a middle die displacement lead screw fixing plate; and the right side of the middle die displacement lead screw fixing plate is fixedly connected with a middle die up-down movement servo motor fixing plate. The 200T servo oil pressure integrated inductor powder forming machine is suitable for pressing in a high-precision one-mold multi-cavity production mode; and the production efficiency is improved while the pressing precision is guaranteed, manpower can be saved by additionally arranging an automatic feeding and discharging machine in the later period, and unmanned production is achieved.

Owner:昆山欣建群精密工业有限公司

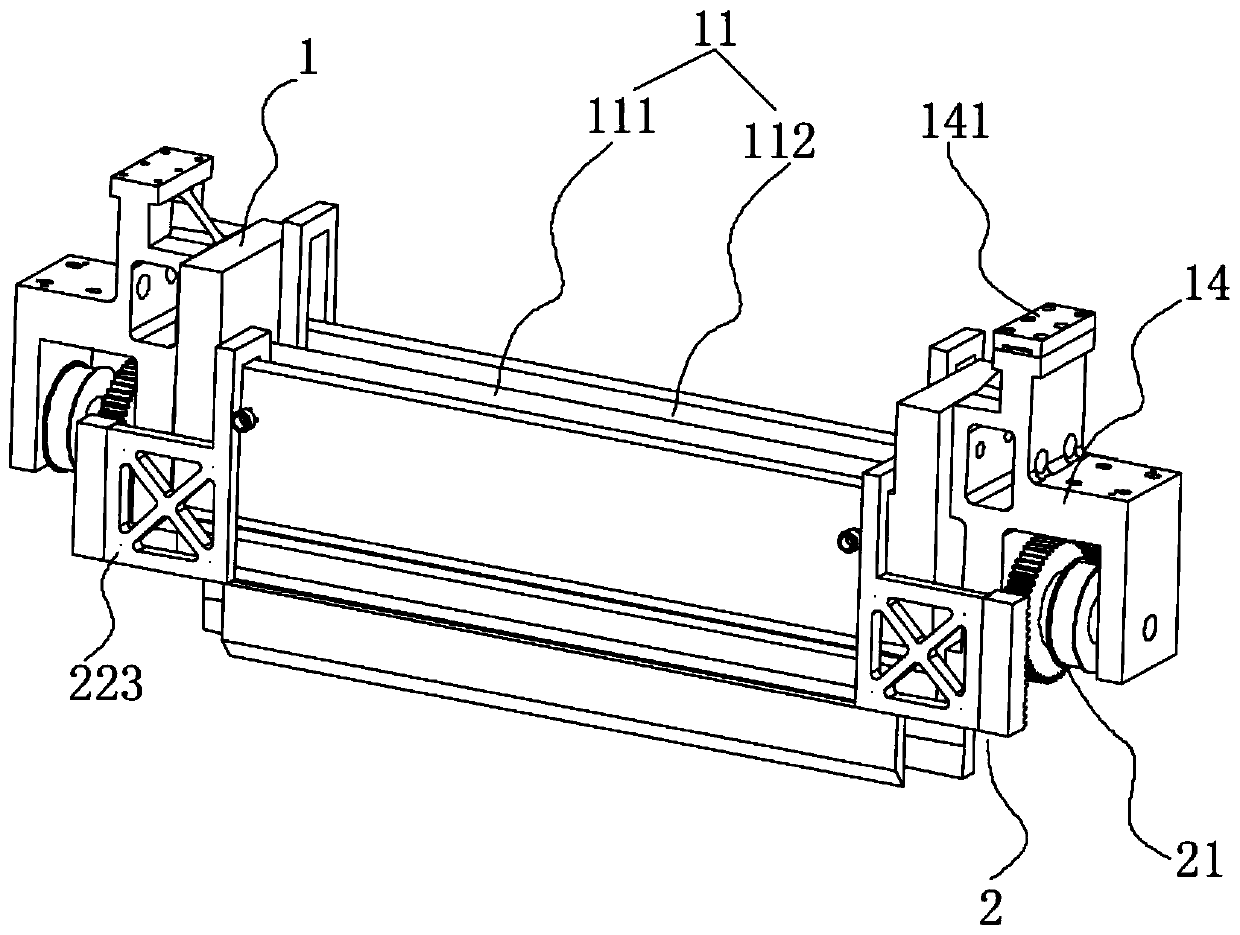

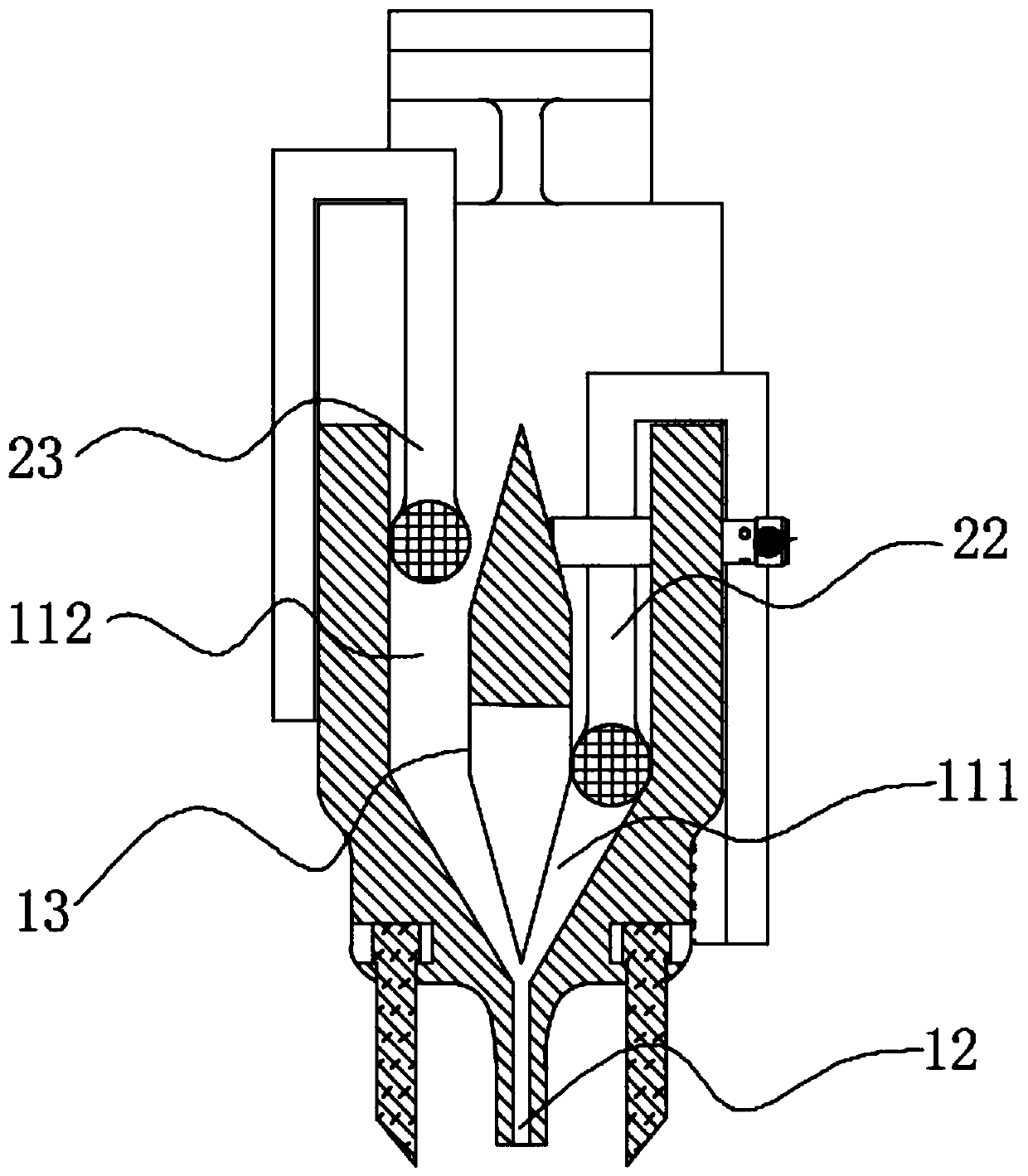

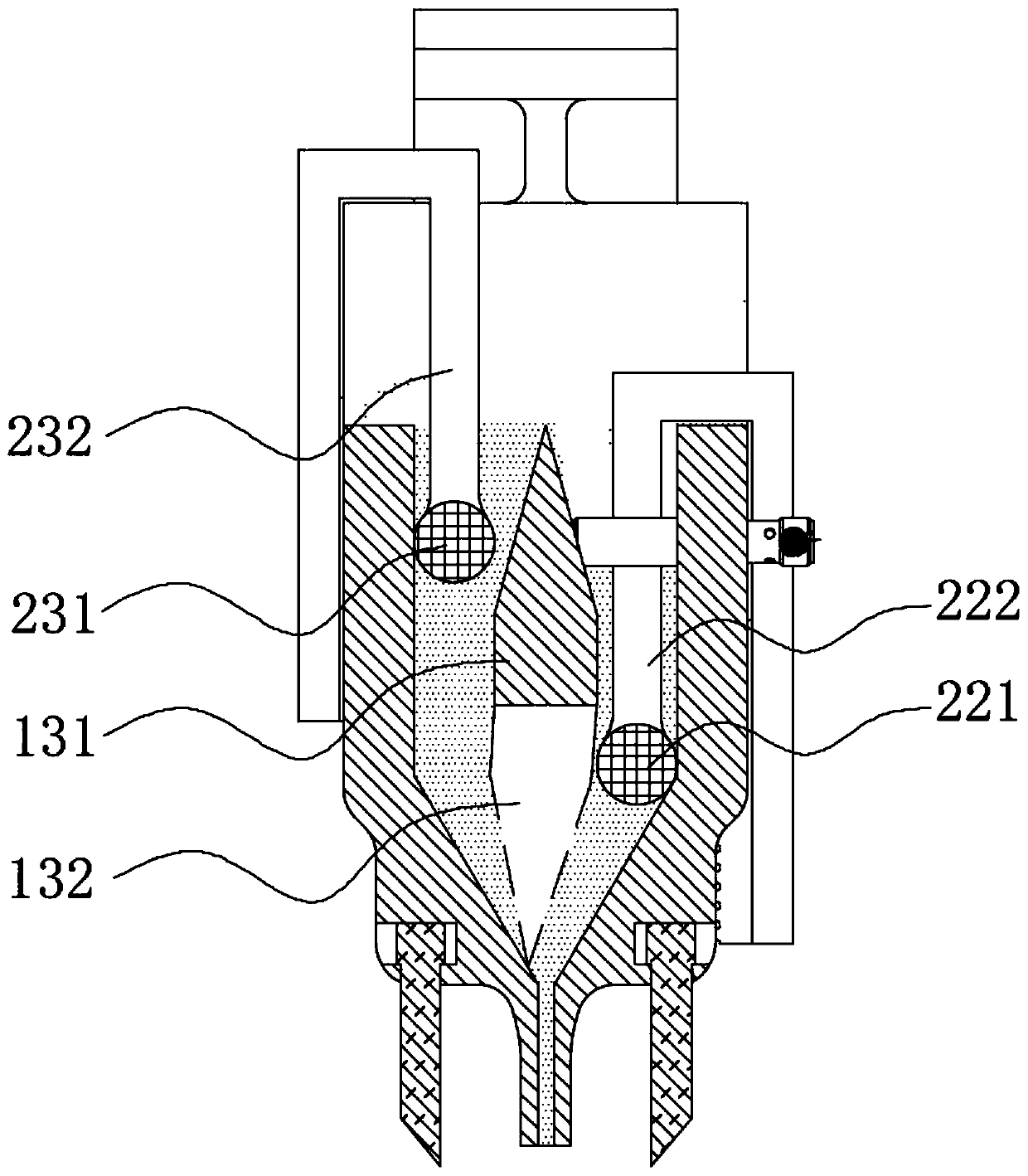

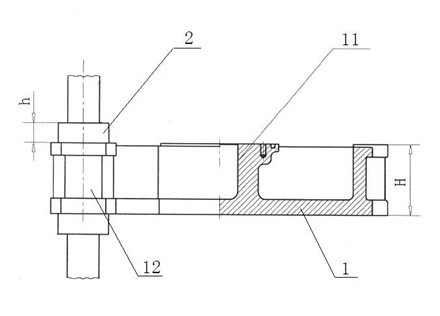

Powder paving device

ActiveCN111468717AUnlimited movement speedImprove powder feeding efficiencyAdditive manufacturing apparatusStructural engineeringMechanical engineering

The invention relates to a powder paving device. A powder paving box with a powder storage cavity and a powder pushing mechanism are included. The powder storage cavity is internally provided with a partition plate for dividing the powder storage cavity into a first powder storage groove and a second powder storage groove. The powder pushing mechanism comprises a power input mechanism, a first powder pushing piece and a second powder pushing piece. The first powder pushing piece and the second powder pushing piece are arranged in the first powder storage groove and the second powder storage groove, when the power input mechanism drives the first powder pushing piece to downwards move, the partition plate closes the second powder storage groove, and powder flows out of the first powder groove under thrust of the first powder pushing piece. When the power input mechanism drives the second powder pushing piece to downwards move, the partition plate closes the first powder storage groove,and powder flows out of the second powder groove under thrust of the second powder pushing piece. Powder flows out of a first powder outlet under the action of thrust of the first powder pushing pieceor the second powder pushing piece, and therefore the powder discharging efficiency can be improved, and the bridging phenomenon can be avoided as well.

Owner:HANS LASER TECH IND GRP CO LTD +1

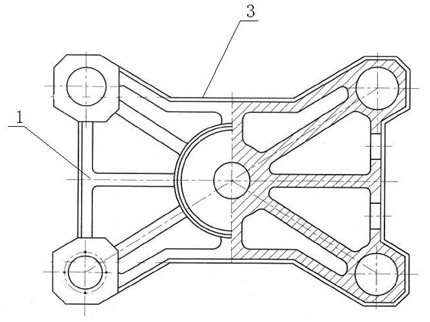

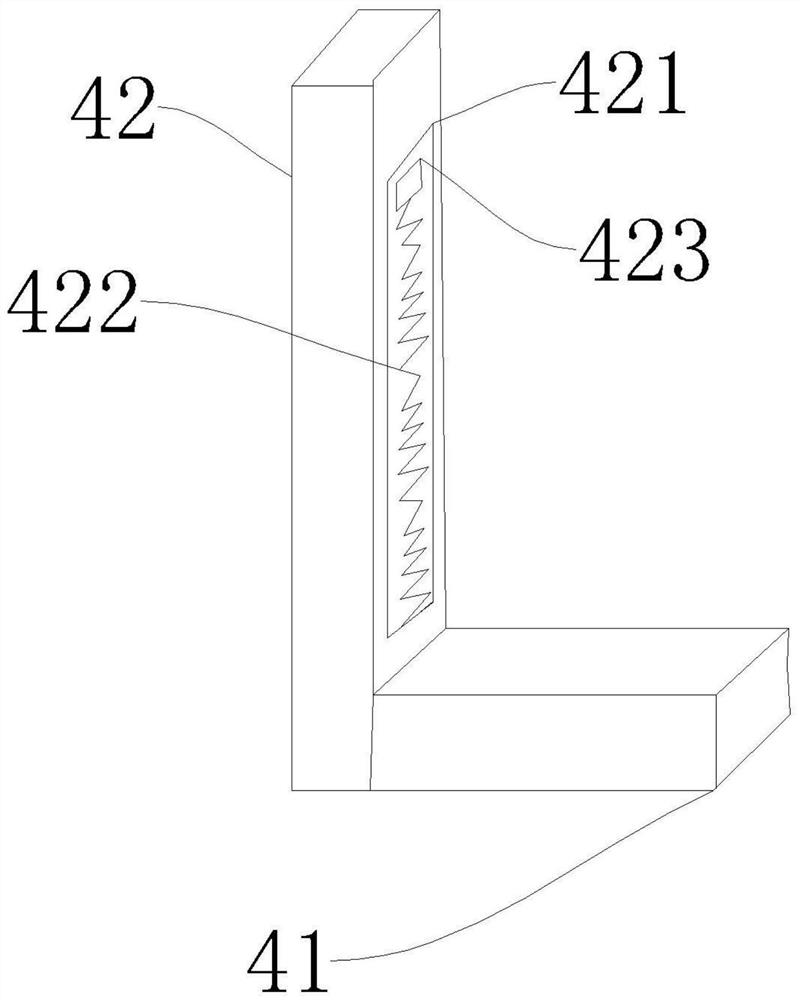

Slider structure for three-beam and four-post hydraulic press

The invention relates to a slider structure for a three-beam and four-post hydraulic press, which comprises a slider body. A main cylinder piston rod connecting seat is arranged at the center of the slider body, guide sleeve mounting seats are arranged at four corners of the slider body, guide sleeves are arranged in the guide sleeve mounting seats, upper flanges and lower flanges of the guide sleeves extend out of upper end faces and the lower end faces of the guide sleeve mounting seats respectively, and the extension direction of each flange is 1 / 4-1 / 3 of the thickness of each guide sleeve mounting seat. The thickness of the slider body is decreased while the length of the slider body is unchanged, so that manufacturing materials and costs are greatly saved. As an inward concave notch is arranged on a long side wall of the slider body, when the slider structure is applied to the three-beam and four-post dry powder forming hydraulic press, by the aid of the notch, a powder feeding mechanism can move forwards, the travel of a powder feeding cylinder can be shortened, powder adding efficiency is improved, front operation space is enlarged, assembly, disassembly, mould adjustment and manual takeout of products are facilitated, and safety is improved.

Owner:南通富仕液压机床有限公司

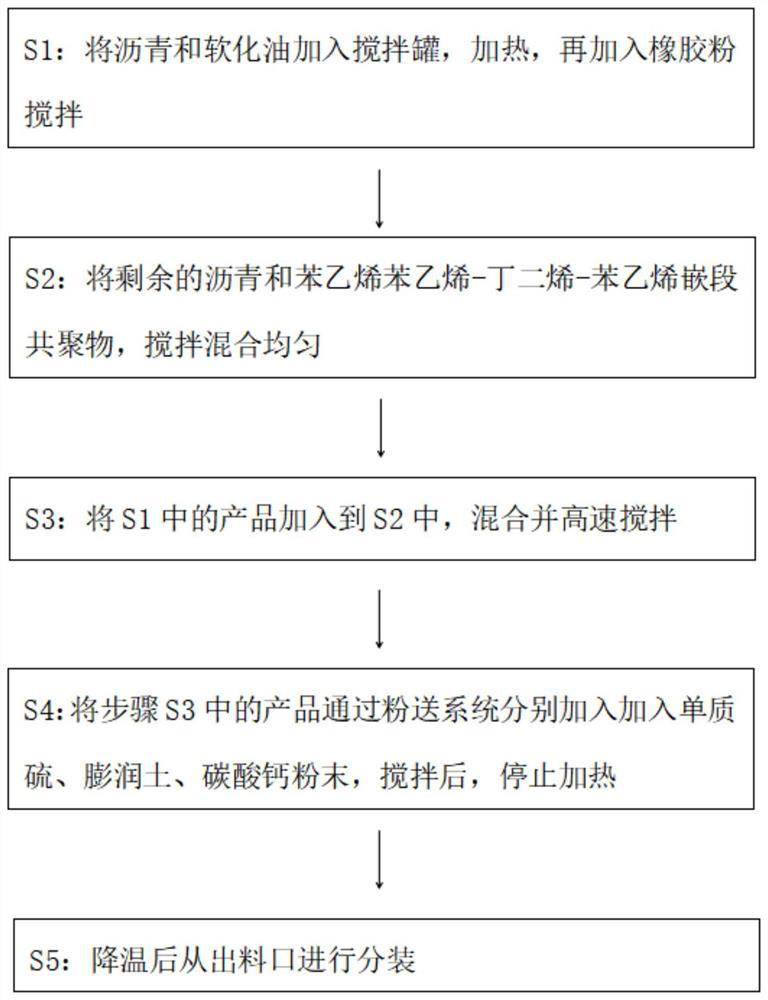

Preparation method of road sealant

InactiveCN111763495APrevent standingAvoid health effectsNon-macromolecular adhesive additivesTransportation and packagingButadiene DioxideCirculating pump

The invention discloses a preparation method of a road sealant, which comprises the following steps: S1, adding asphalt and softening oil into a stirring tank, heating, adding rubber powder, and stirring; S2, stirring and uniformly mixing the remaining asphalt and the styrene-butadiene-styrene block copolymer; S3, adding a product obtained in the step S1 into the step S2, mixing and stirring at ahigh speed; S4, respectively adding elemental sulfur, bentonite and calcium carbonate powder into a product obtained in the step S3 through a powder conveying system, stirring, stopping heating, starting a circulating pump and a condenser, and cooling through a condensation pipe; and S5, after cooling, carrying out sub-packaging from a discharge port. According to the preparation method of the road sealant, the rubber powder can be fully and completely fused with the asphalt, and the high temperature resistance of the rubber powder is fully exerted. After the process, the product is fine and smooth in colloid and free of any granular sensation, and the melting temperature during construction is lower than that of a product without a shearing process.

Owner:河南公路卫士交通科技有限公司

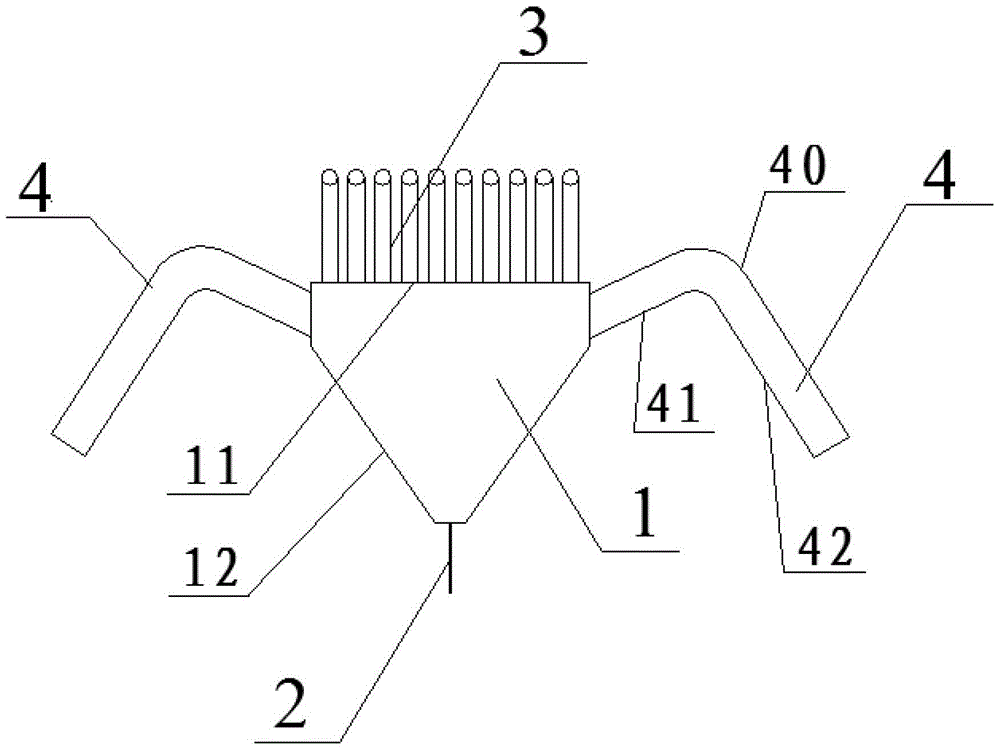

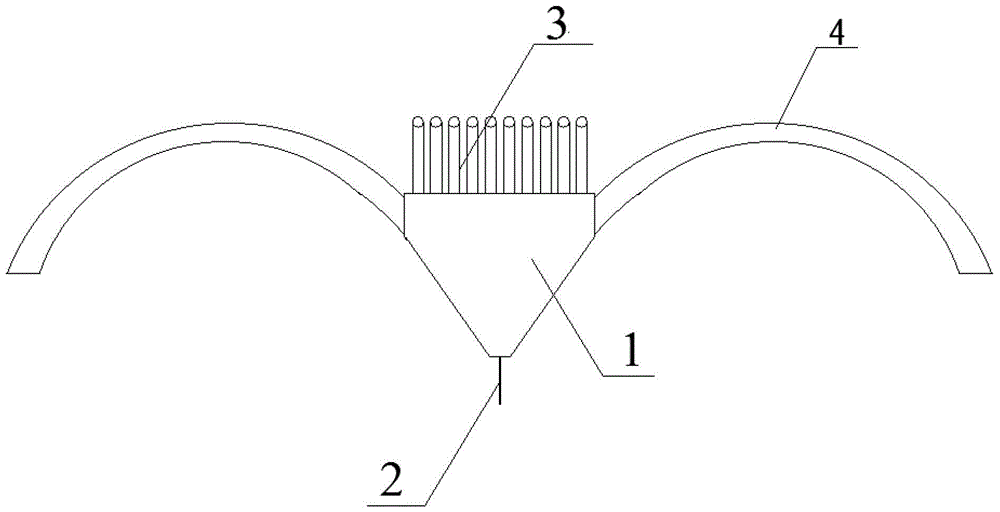

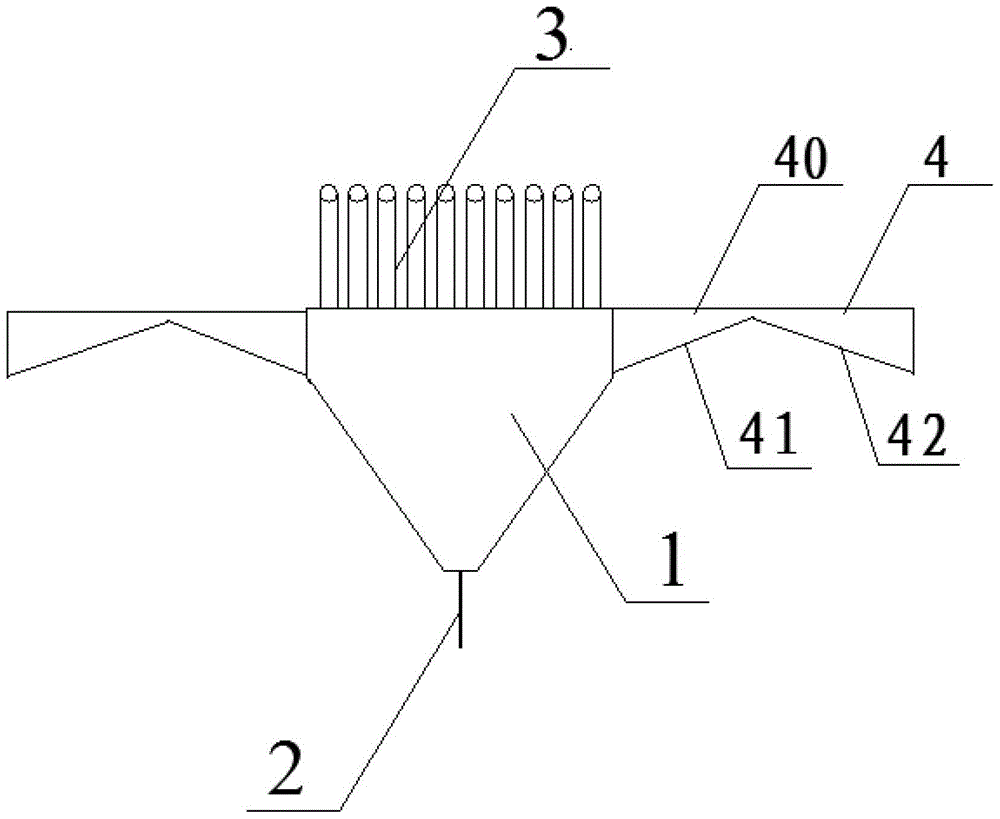

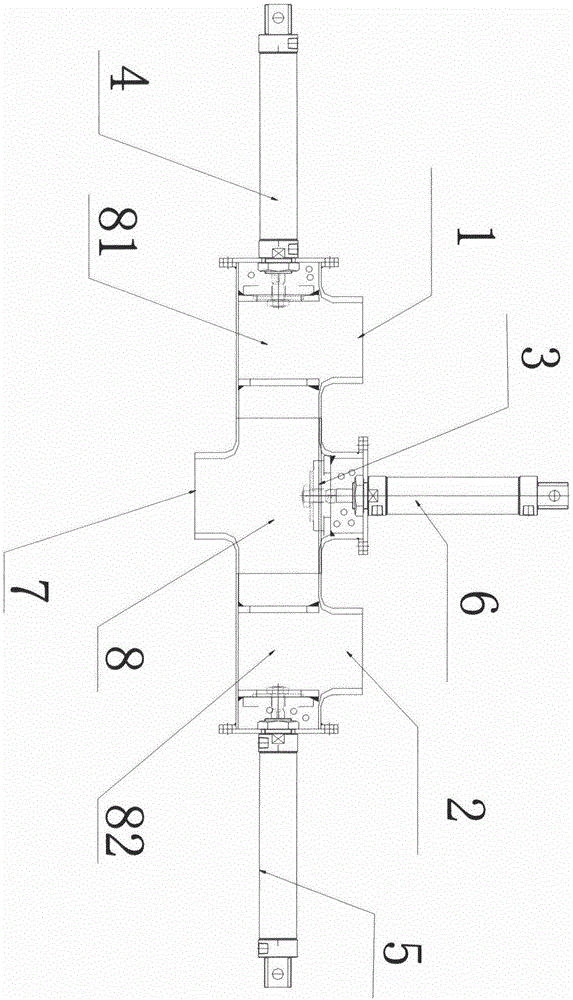

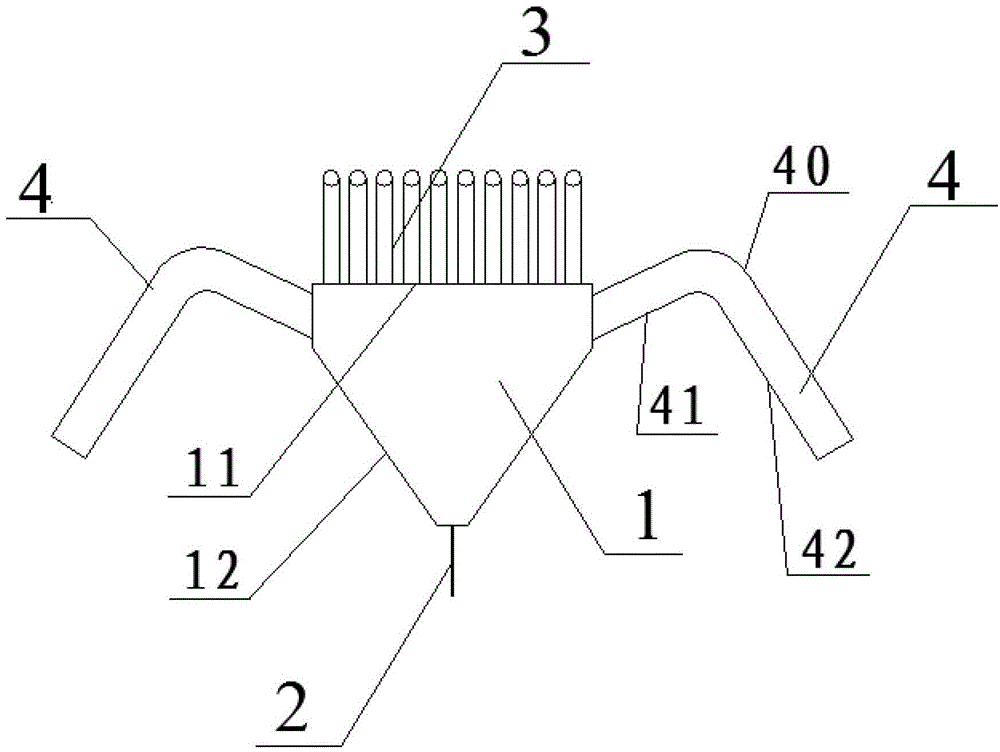

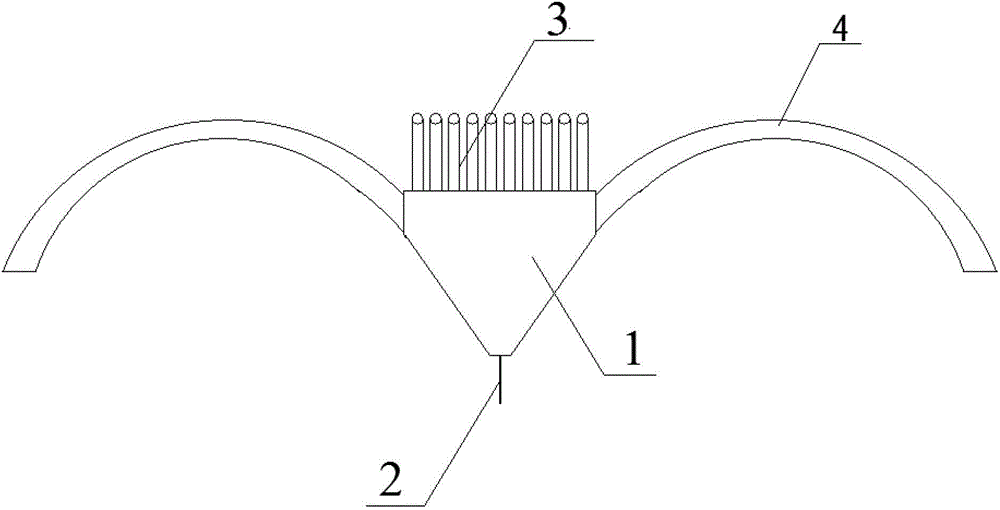

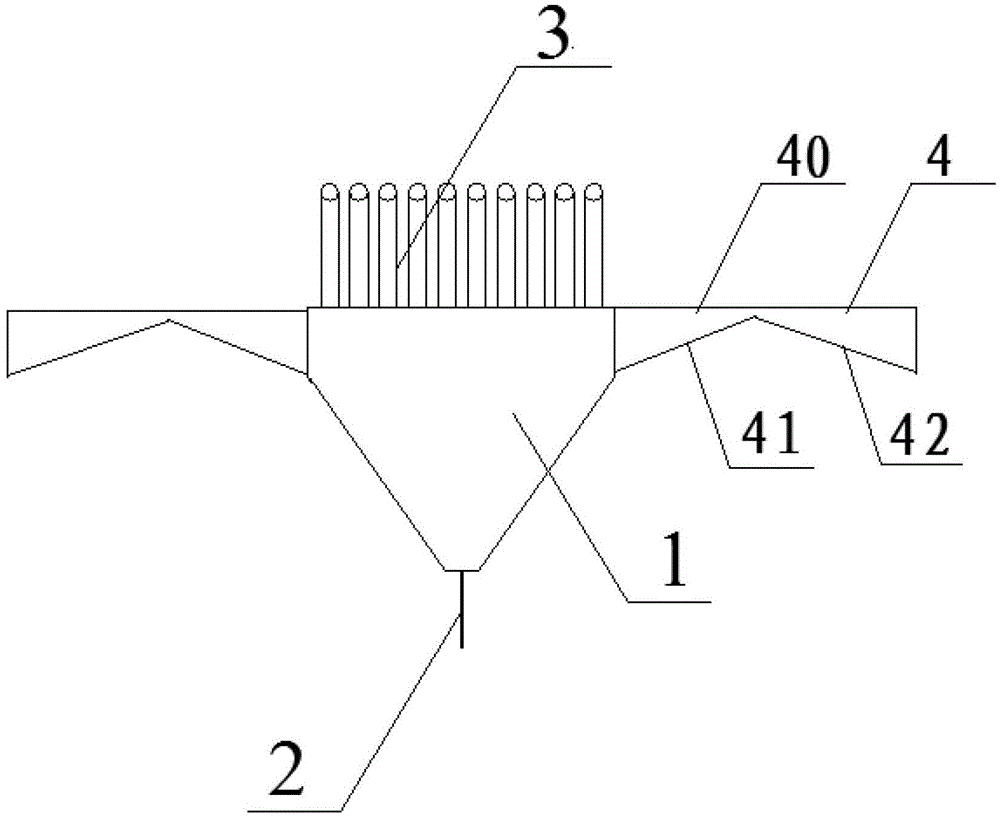

Exhaust gas powder feeding device and exhaust gas powder feeding system for coal-fired power plants

ActiveCN104421953BSolve technical problems that are easy to depositImprove securityLump/pulverulent fuel feeder/distributionEngineeringExhaust pipe

The invention discloses a tertiary-air powder feeding device and a tertiary-air feeding system applied to a coal-fired power plant, relates to the technical field of thermal power generation and solves the technical problem of the prior art that coal powder is prone to deposition during tertiary air powder feeding. The tertiary-air powder feeding device comprises an air box, a powder exhaust pipe, at least one powder feeding air duct and at least one tertiary air pipeline. The lower pipeline wall of each tertiary air pipeline comprises a first segment communicated with the air box and a second segment connected with the first segment. In a direction from the air box to an inlet of each tertiary air pipeline, the first segment gradually rises, and the second segment gradually descends. The tertiary-air powder feeding system comprises the tertiary-air powder feeding device provided in any technical schemes. In this way, coal powder deposition is avoided during the tertiary air powder feeding, and safety is improved during the tertiary air powder feeding.

Owner:YANTAI LONGYUAN POWER TECH

Double bucket uninterrupted vacuum powder supply system and its application method

InactiveCN103359489BImprove powder feeding efficiencyBulk conveyorsLoading/unloadingMetallurgyWork status

The invention discloses an uninterrupted twin-bucket vacuum powder supply system which is characterized by comprising a first powder bin, a second powder bin, a first powder container, a second powder container, a four-way vacuum valve and a vacuumizing fan, wherein the first powder bin is connected with the first powder container by a hose; the second powder bin is connected with the second powder container by a hose; the four-way vacuum valve comprises two air inlets and an air outlet; the two air inlets are connected with the first powder container and the second powder container by hoses respectively; and the air outlet is connected with the vacuumizing fan by a hose. According to the uninterrupted twin-bucket vacuum powder supply system and a using method thereof, vacuum powder pumping can be conducted on the two powder containers uninterruptedly and alternately, so that the vacuumizing fan is in a working state all the time, no waiting time exists, and the powder supply efficiency is improved greatly.

Owner:SUZHOU JIAHONG MACHINERY

Tertiary-air powder feeding device and tertiary-air powder feeding system applied to coal-fired power plant

ActiveCN104421953ASolve technical problems that are easy to depositImprove securityLump/pulverulent fuel feeder/distributionEngineeringExhaust pipe

The invention discloses a tertiary-air powder feeding device and a tertiary-air feeding system applied to a coal-fired power plant, relates to the technical field of thermal power generation and solves the technical problem of the prior art that coal powder is prone to deposition during tertiary air powder feeding. The tertiary-air powder feeding device comprises an air box, a powder exhaust pipe, at least one powder feeding air duct and at least one tertiary air pipeline. The lower pipeline wall of each tertiary air pipeline comprises a first segment communicated with the air box and a second segment connected with the first segment. In a direction from the air box to an inlet of each tertiary air pipeline, the first segment gradually rises, and the second segment gradually descends. The tertiary-air powder feeding system comprises the tertiary-air powder feeding device provided in any technical schemes. In this way, coal powder deposition is avoided during the tertiary air powder feeding, and safety is improved during the tertiary air powder feeding.

Owner:YANTAI LONGYUAN POWER TECH

Powder adding device used for printer powder adding

InactiveCN106997163ASolve easy blockageImprove powder feeding efficiencyElectrographic process apparatusIsoetes triquetraEngineering

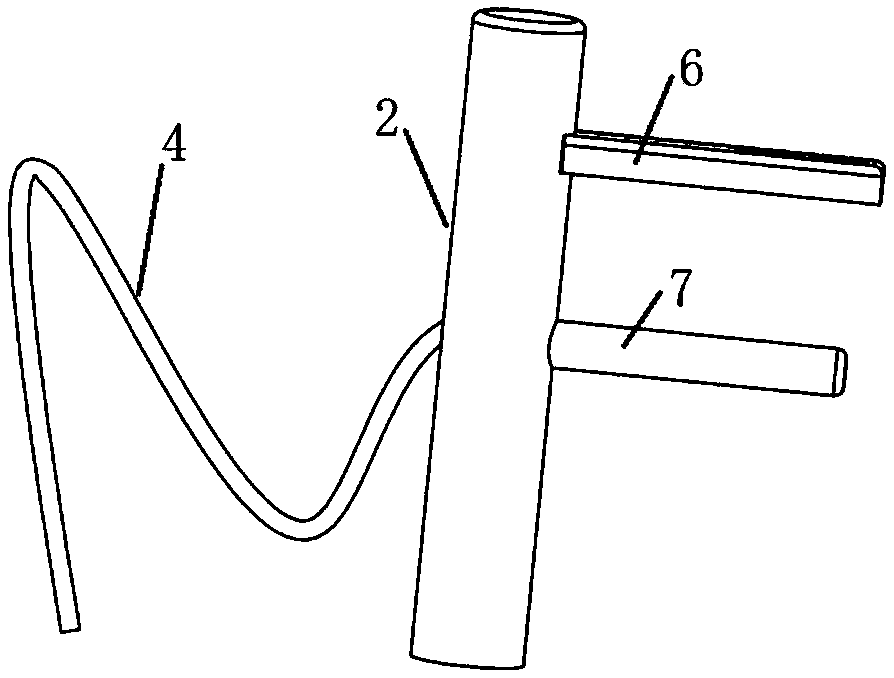

The invention relates to a powder adding device used for printer powder adding. The powder adding device comprises a working segment, a connecting segment and a holding segment, wherein the connecting segment is positioned between the working segment and the holding segment; the projection, on a plane A, of the working segment is a projection A, the plane A is a plane arranged vertical to a direction f, and the direction f is a height direction of the powder adding device; the projection, on the plane A, of the holding segment is a projection B; the shape of the projection A is the same as that of a diagram N1; the diagram N1 is obtained by deforming a diagram M1 through the following method: the diagram M1 is an equilateral triangle including a side a1, a side b1 and a side c1, the side c1 of the equilateral triangle is bent towards the interior of a triangle to form an arc-shaped arc edge c1', and the diagram obtained after circular bead processing is carried out at the joint of the side a1 and the side b1 is the diagram N1. Through the scheme, when the powder adding device is inserted into a novel toner bottle for adding toner into a toner cartridge, the problem of toner blockage can be effectively solved, and the problems of pollution and waste caused by the fact that outside leakage appears during toner adding are avoided.

Owner:安徽智汇和科技服务有限公司

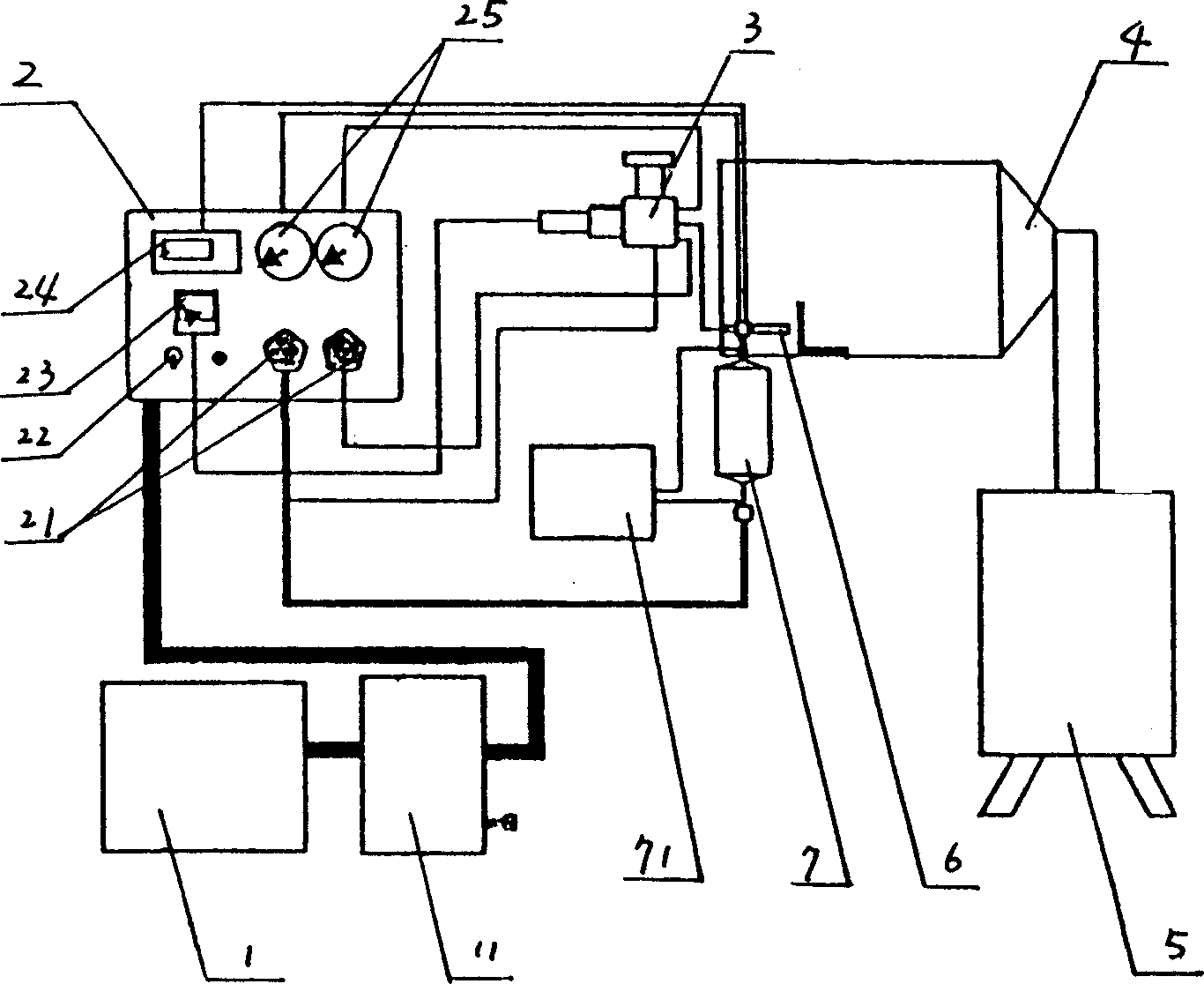

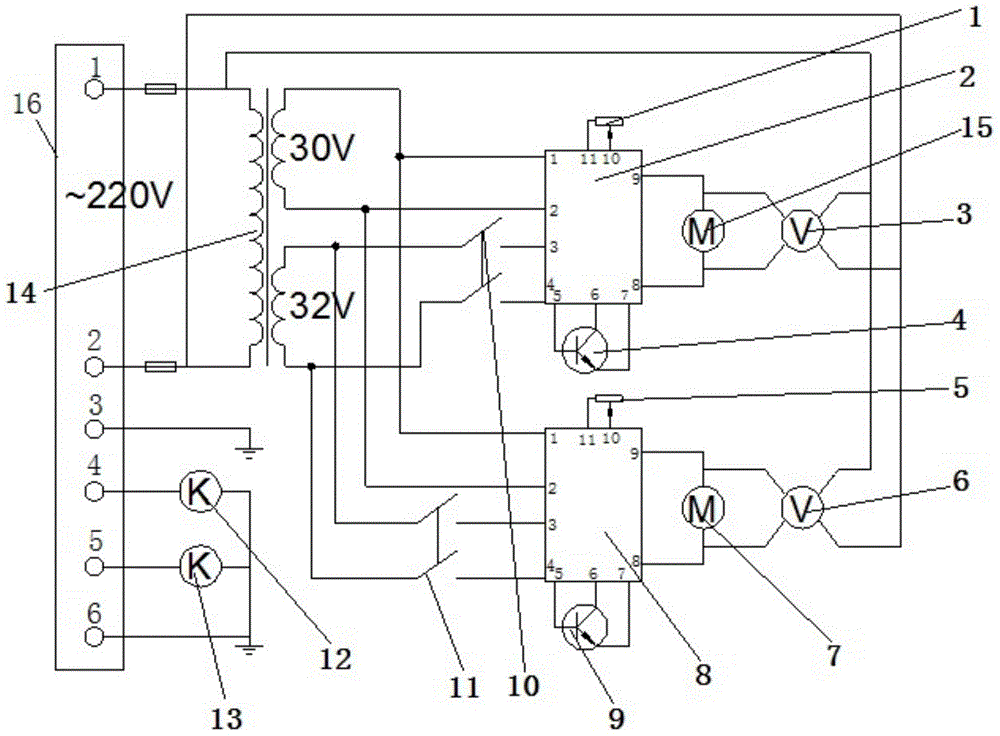

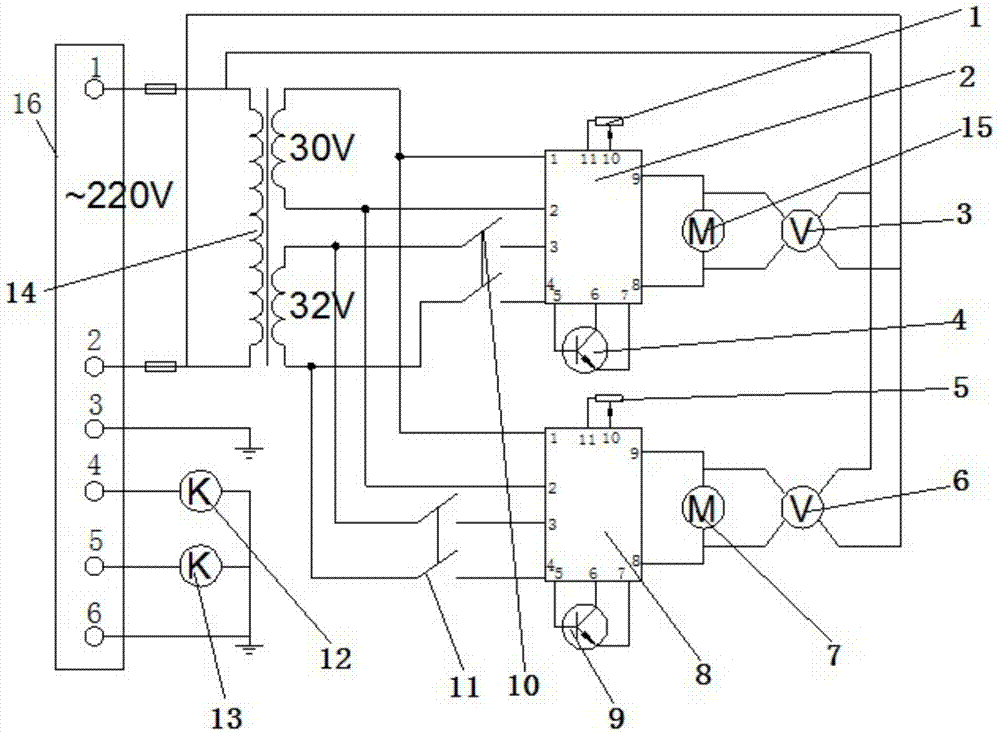

Control circuit of powder feeder for hypersonic flame spraying

ActiveCN104950787AImprove powder feeding efficiencyLow costProgramme control in sequence/logic controllersTransformerVoltmeter

The invention relates to a control circuit of powder feeder for hypersonic flame spraying, comprising a first potentiometer, a first speed control panel, a first voltmeter, a first power tube, a second potentiometer, a second voltmeter, a second motor, a second speed control panel, a second power tube, a first switch, a second switch, a first electromagnetic valve, a second electromagnetic valve, a transformer, a first motor and a power strip. The first motor and the second motor allows two feeding branches to be controlled; compared with the traditional single-channel feeding way, the feeding way using the two motors has the advantages that feeding efficiency is improved, the single device is used for two hypersonic flame spraying devices, the production cost is lowered, a replacement function is good, if one feeding branch has a control fault, the other feeding branch can be controlled instead, and smooth spraying is guaranteed.

Owner:WUHU DINGHENG MATERIAL TECH

Anti-leakage powder device for toner cartridge refilling

The invention discloses an anti-leakage powder device for adding powder to a toner cartridge. The toner cartridge has a powder storage bin, and a ring of locking protrusions is arranged on the inner wall of the toner storage bin. The anti-leakage powder device is detachably pressed against the top of the protrusion. Including: connecting pipe, the first supporting net is horizontally clamped inside; the first powder leaking tube, the second supporting net is horizontally clamped inside; the second powder leaking tube is connected with the first powder leaking tube; the plugging component , including a support column, a limit plug, a sealing plug, and a first spring fixed in sequence from bottom to top; a bracket, including a pair of L-shaped struts, a pair of connecting rods, and a positioning frame; wherein, the first powder leakage pipe The upper end is provided with an internal thread that matches the mouth of the toner bottle. When the positioning frame is pressed down, the lower end edge of the second powder leaking tube abuts against the limit tab, and the toner in the toner bottle enters the toner storage bin. The invention has simple structure and convenient use, realizes pollution-free powder feeding, can stop powder feeding immediately at any time, has no carbon powder leakage, and has high powder feeding efficiency.

Owner:北海市天硌打印耗材有限公司

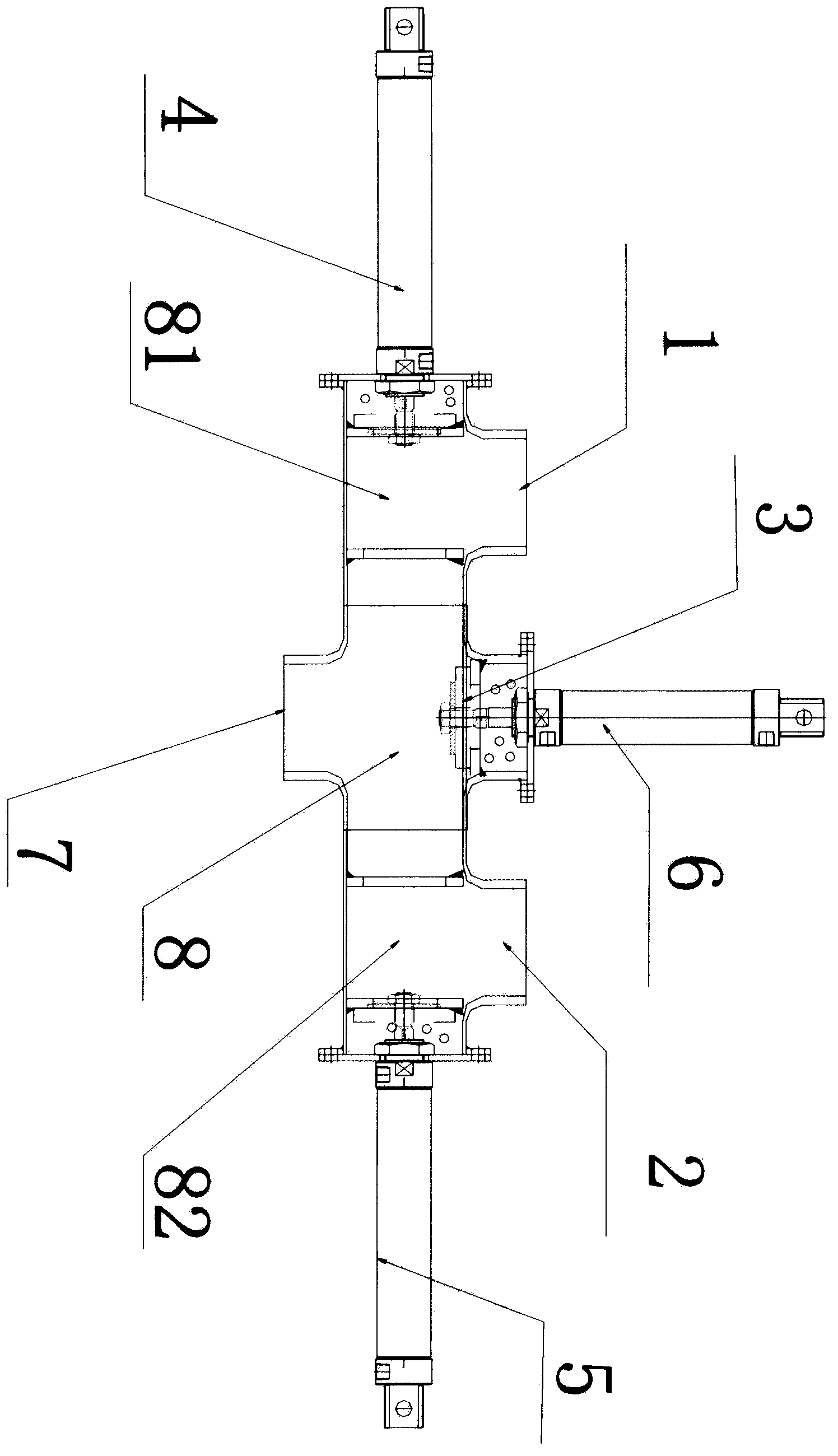

Synchronous powder feeding device for laser cladding machining

InactiveCN103014696BAvoid intermittent powder feedingIncrease the level of automationMetallic material coating processesSynchronous motorSolenoid valve

The invention provides a synchronous powder feeding device for laser cladding machining. The synchronous powder feeding device comprises a large-size powder storage chamber, a small-size powder storage chamber, a powder hopper, a motor and a shell; the large-size powder storage chamber and the small-size powder storage chamber are connected through a plastic hose I, and a solenoid valve is arranged between the large-size powder storage chamber and the small-size powder storage chamber; the upper end of a powder feeding shaft is communicated with the small-size powder storage chamber; the lower end of the powder feeding shaft is arranged above a rotating shaft, and an interval is reserved between the lower end of the powder feeding shaft and the rotating shaft; the powder feeding shaft can adjust a distance between the powder feeding shaft and the rotating shaft through an adjusting device; the rotating shaft is connected with an output shaft of the motor, and the rotating shaft is supported on the shell through a bearing; the upper end of the powder hopper is communicated with the shell; and the lower end of the powder hopper is connected with a nozzle through a plastic hose II. According to the synchronous powder feeding device provided by the invention, a powder falling amount can be adjusted by controlling a distance between the lower end of the powder feeding shaft and the rotating shaft. Particularly, when the powder feeding amount is large, a phenomenon of discontinuous powder feeding caused by limit on the distance between the lower end of the powder feeding shaft and the rotating shaft can be avoided. Furthermore, the time interval of two times of connection of the solenoid valve can be set, so that automatic feeding can be realized, and the production efficiency can be improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Powder addition tool of cartridge

InactiveCN107037706AImprove powder feeding efficiencySolve easy blockageElectrographic process apparatusPhysicsPollution

The invention relates to a powder addition tool of a cartridge. The powder addition tool comprises a working segment, a connection segment and a handheld segment, wherein the connection segment is arranged between the working segment and the handheld segment, the projection of the working segment on a plane A is projection A, the plane A is a plane perpendicular to a direction f, the direction f is a tool height direction, the projection of the handheld segment on the plane A is projection B, the projection A is a polygon, the projection B is arranged in an external circle of the projection A, each side surface of the working segment is arranged in a groove shape, and the groove length direction of the groove shape is consistent with the direction f. In the scheme, when the tool is inserted into a novel carbon powder bottle for adding carbon powder into the cartridge, the problem of carbon powder plug can be effectively solved, and the problem of pollution and waste caused by leakage during carbon powder addition is prevented.

Owner:安徽智汇和科技服务有限公司

A powder feeding device for laser cladding machine

ActiveCN110819987BRealize the powder feeding functionGood quantitative effectAdditive manufacturing apparatusMetallic material coating processesEngineeringExpansion joint

The invention discloses a powder feeding device for a laser cladding machine, which comprises a casing, a pollination mechanism and a quantitative mechanism, the side of the casing is fixedly connected with a hose seat, and a Pneumatic conveyor. In the present invention, the powder material to be used is stored through the first material storage tank and the second material storage tank. During the powder feeding process through the first powder feeding chamber and the second powder feeding chamber, the movable plate is driven by the pneumatic expansion joint to The powder in the connection chamber is quantified. When the second powder feeding chamber is filled, the powder in the second powder feeding chamber can be conveyed through the pneumatic feeder, and then the powder to be used is passed through the hose The powder feeding function is achieved by ejecting from the nozzle. This device can convey different powder materials separately and has a good quantitative effect and high powder feeding efficiency; the powder ejected through the nozzle covers the objects to be clad, which can be used with The printing cladding process is suitable, and the powder spraying effect is good.

Owner:芜湖舍达科技有限公司

A control circuit of a powder feeder for supersonic flame spraying

ActiveCN104950787BImprove powder feeding efficiencyLow costProgramme control in sequence/logic controllersTransformerElectric machine

The invention relates to a control circuit of powder feeder for hypersonic flame spraying, comprising a first potentiometer, a first speed control panel, a first voltmeter, a first power tube, a second potentiometer, a second voltmeter, a second motor, a second speed control panel, a second power tube, a first switch, a second switch, a first electromagnetic valve, a second electromagnetic valve, a transformer, a first motor and a power strip. The first motor and the second motor allows two feeding branches to be controlled; compared with the traditional single-channel feeding way, the feeding way using the two motors has the advantages that feeding efficiency is improved, the single device is used for two hypersonic flame spraying devices, the production cost is lowered, a replacement function is good, if one feeding branch has a control fault, the other feeding branch can be controlled instead, and smooth spraying is guaranteed.

Owner:WUHU DINGHENG MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com