Patents

Literature

5312results about "Shaping press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

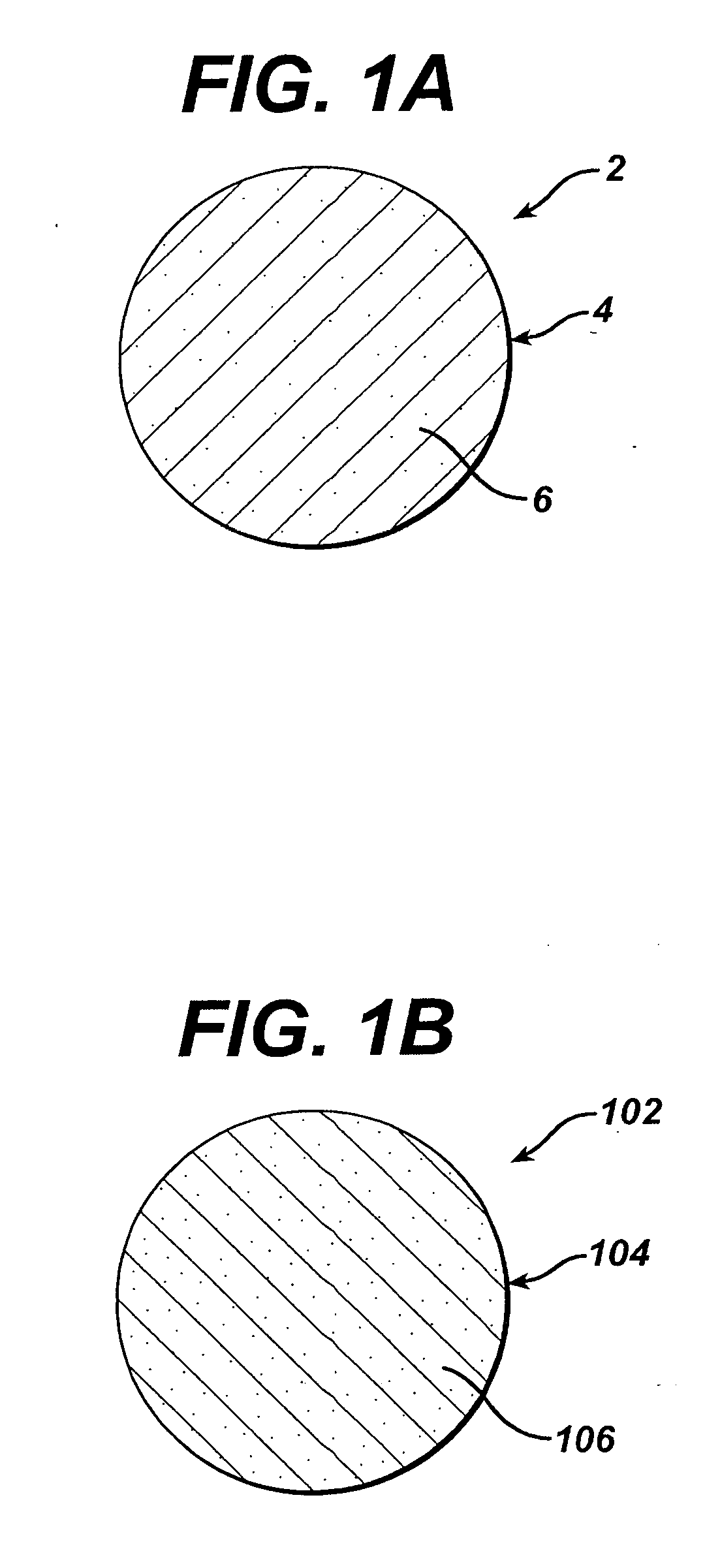

Process for large-scale ammonothermal manufacturing of gallium nitride boules

ActiveUS20100031875A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessEngineering

A method for large-scale manufacturing of gallium nitride boules. Large-area single crystal seed plates are suspended in a rack, placed in a large diameter autoclave or internally-heated high pressure apparatus along with ammonia and a mineralizer, and grown ammonothermally. The seed orientation and mounting geometry are chosen to provide efficient utilization of the seed plates and of the volume inside the autoclave or high pressure apparatus. The method is scalable up to very large volumes and is cost effective.

Owner:SLT TECH

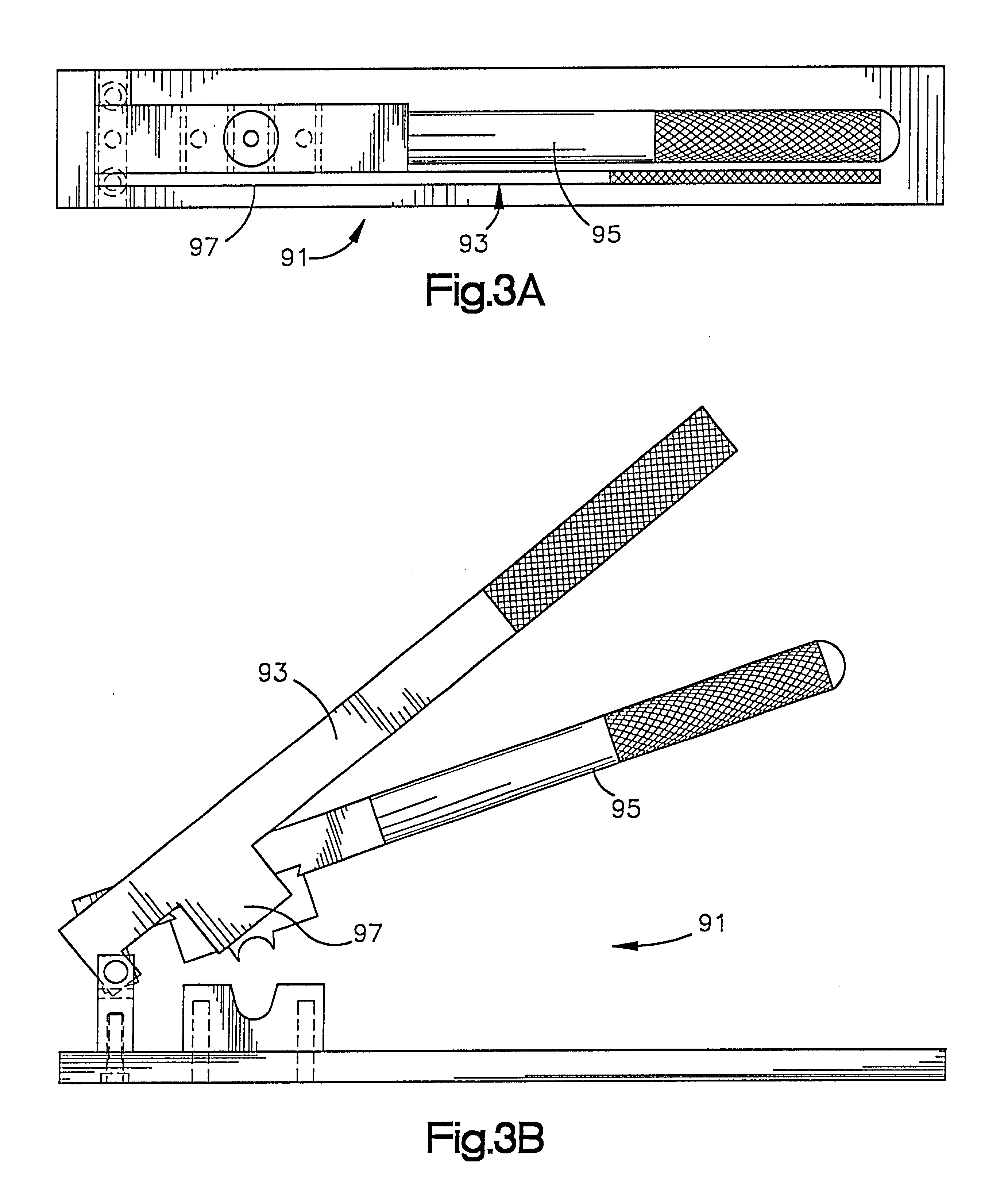

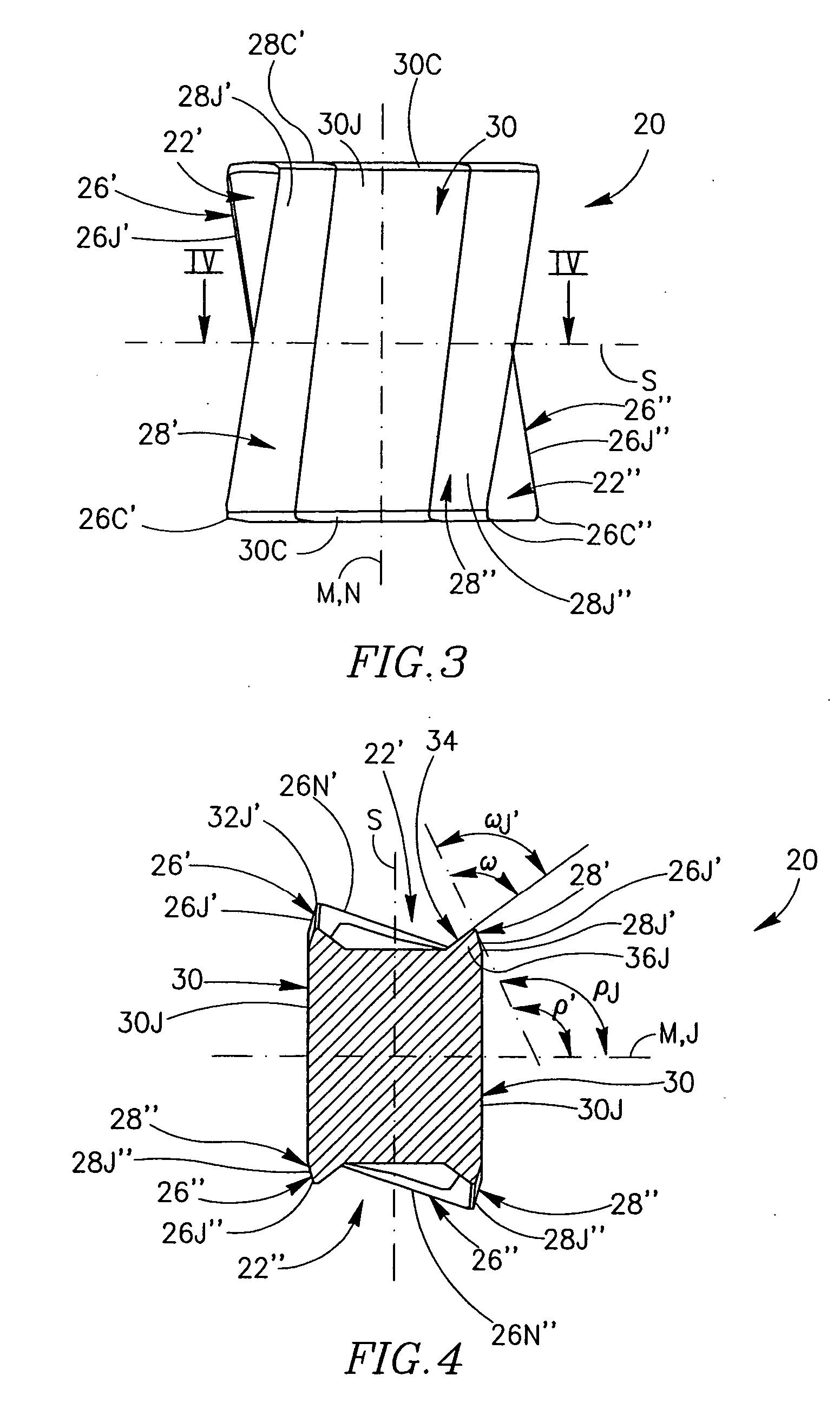

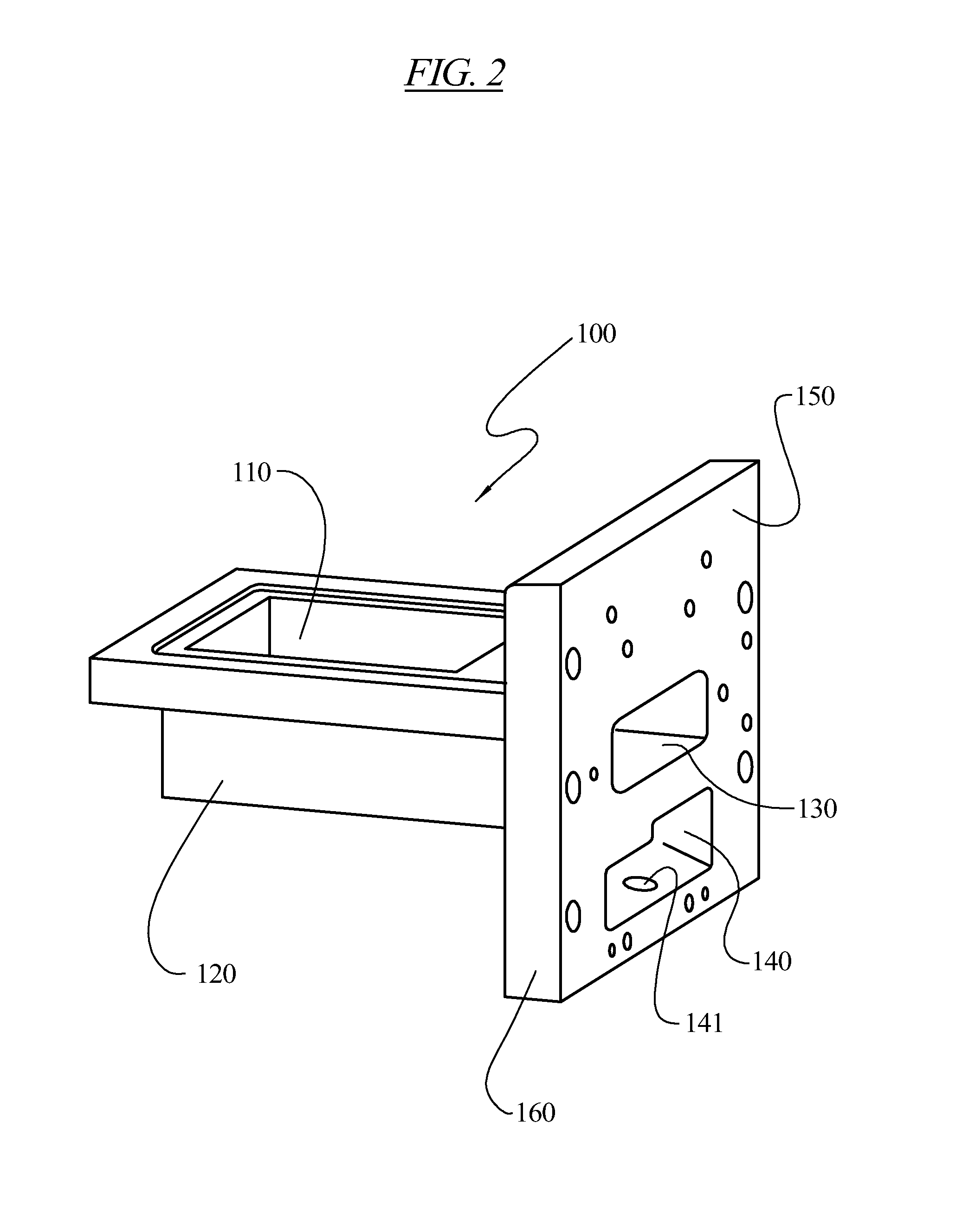

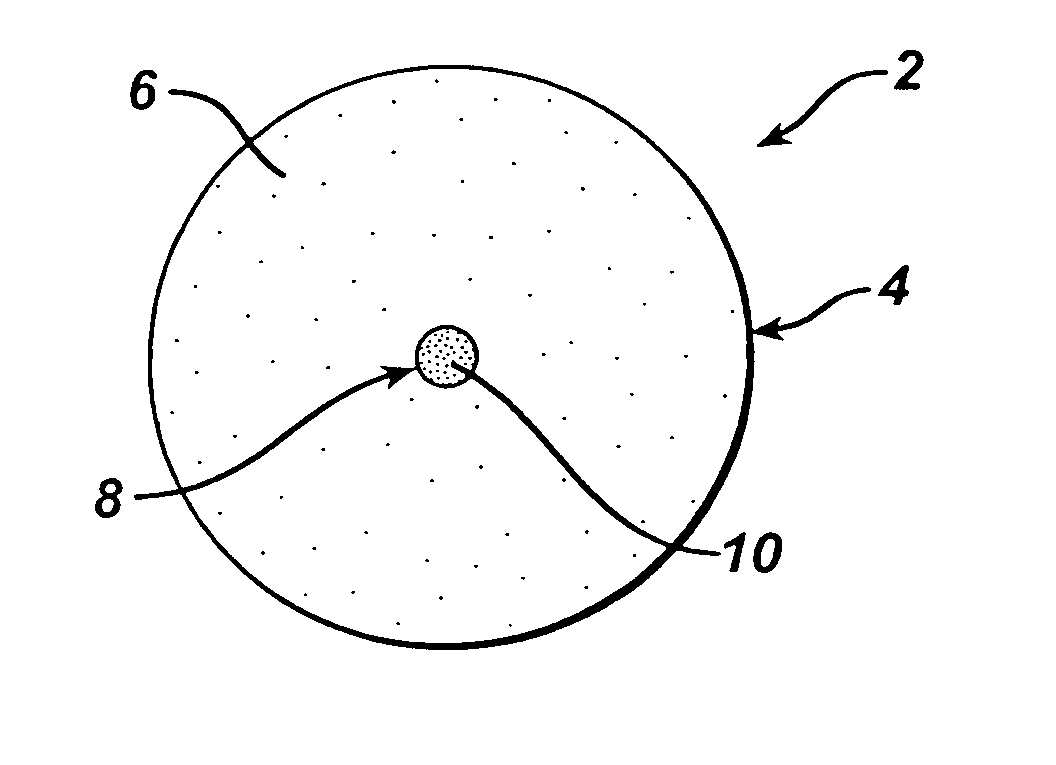

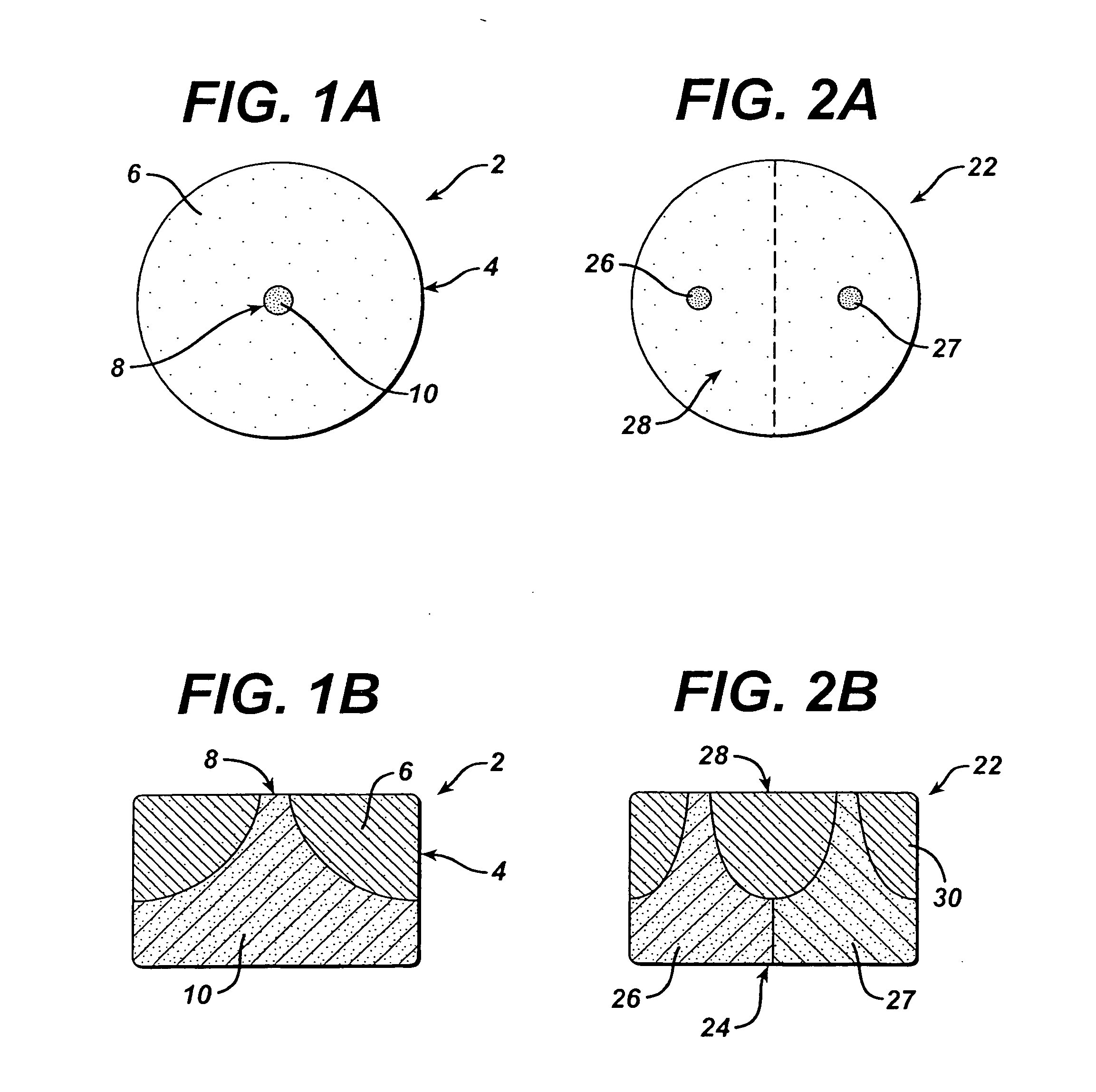

Tissue press and system

InactiveUS6132472AReduce retentionReduce capacitySuture equipmentsInternal osteosythesisTissue GraftEngineering

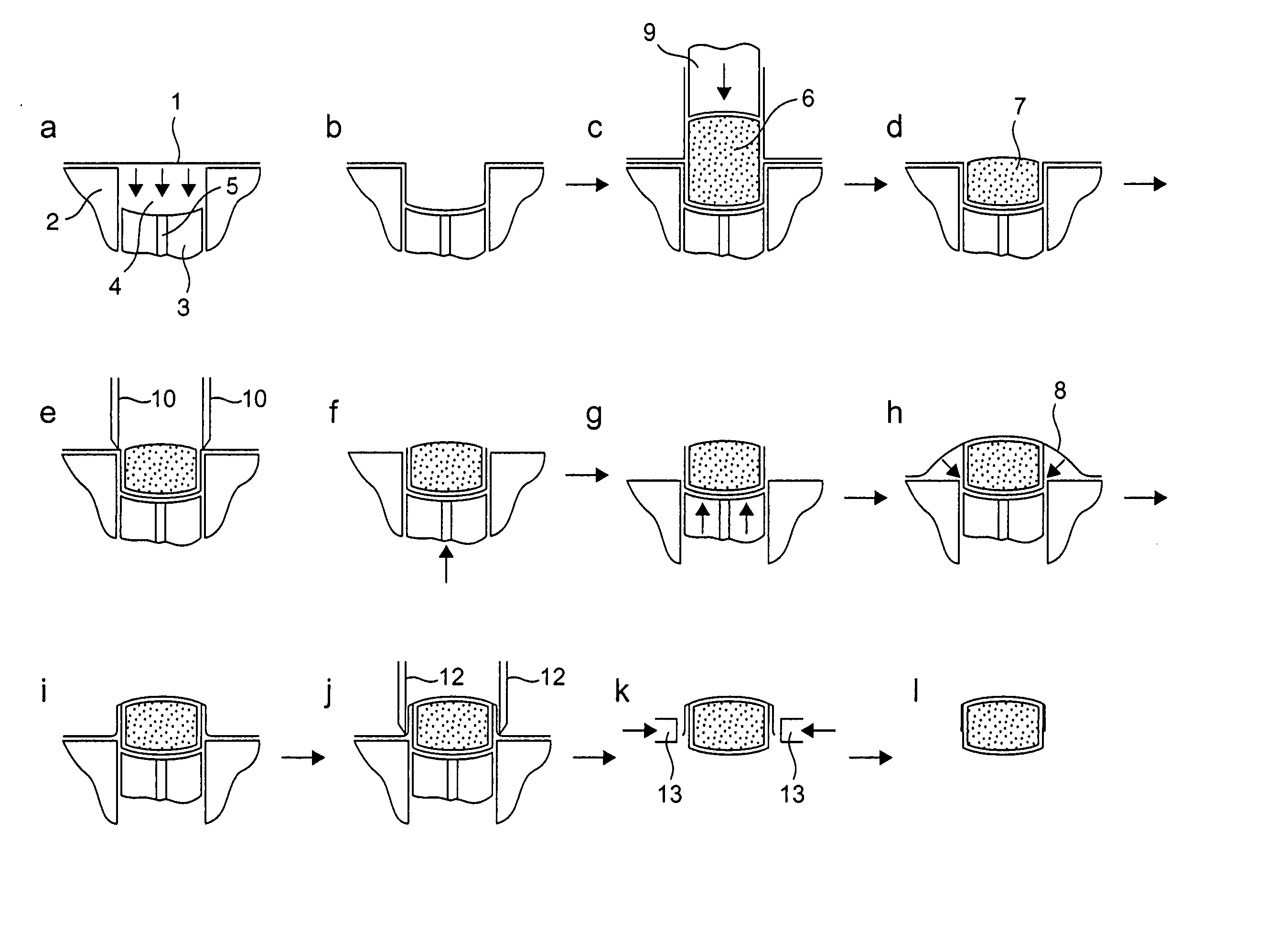

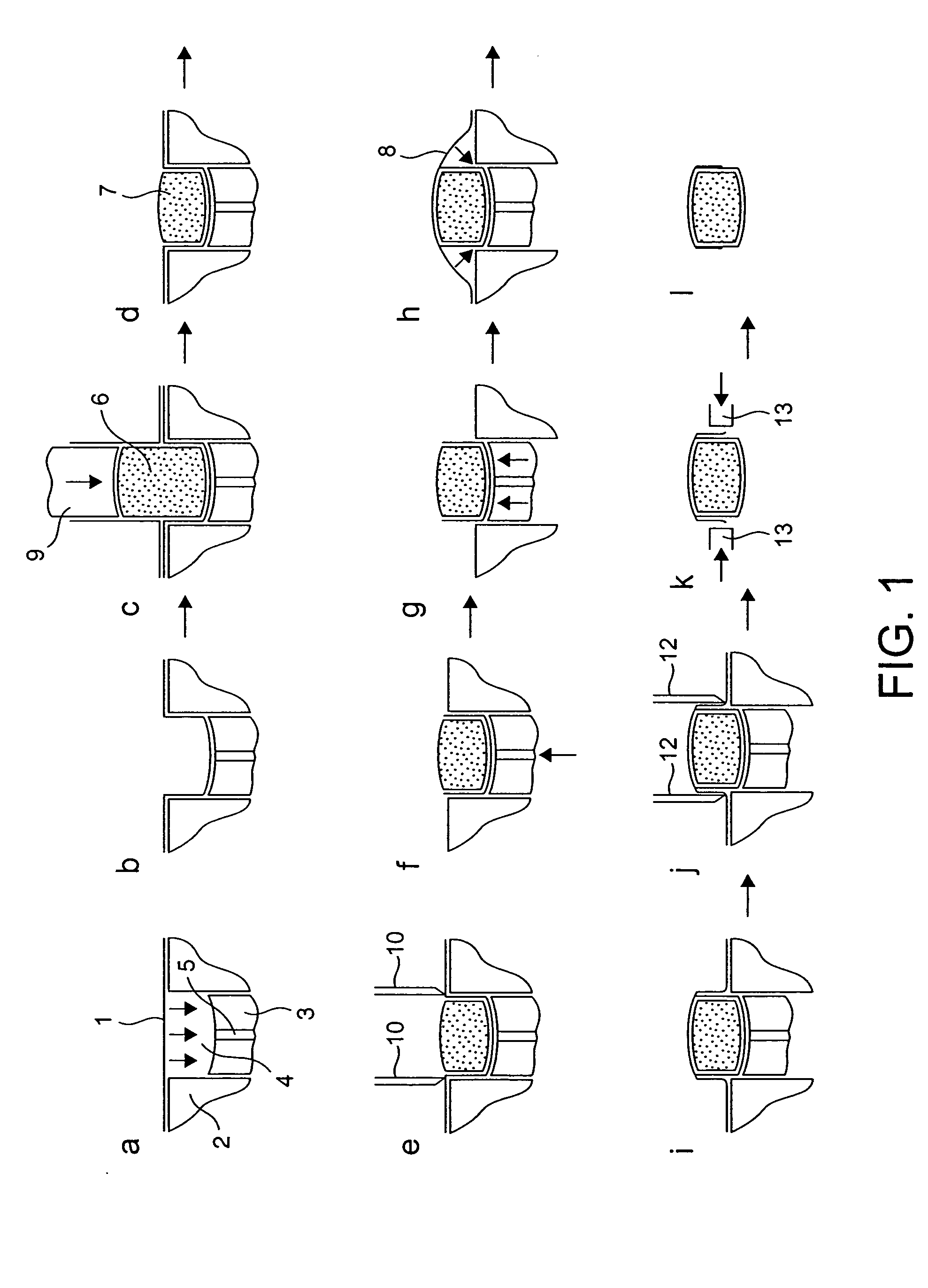

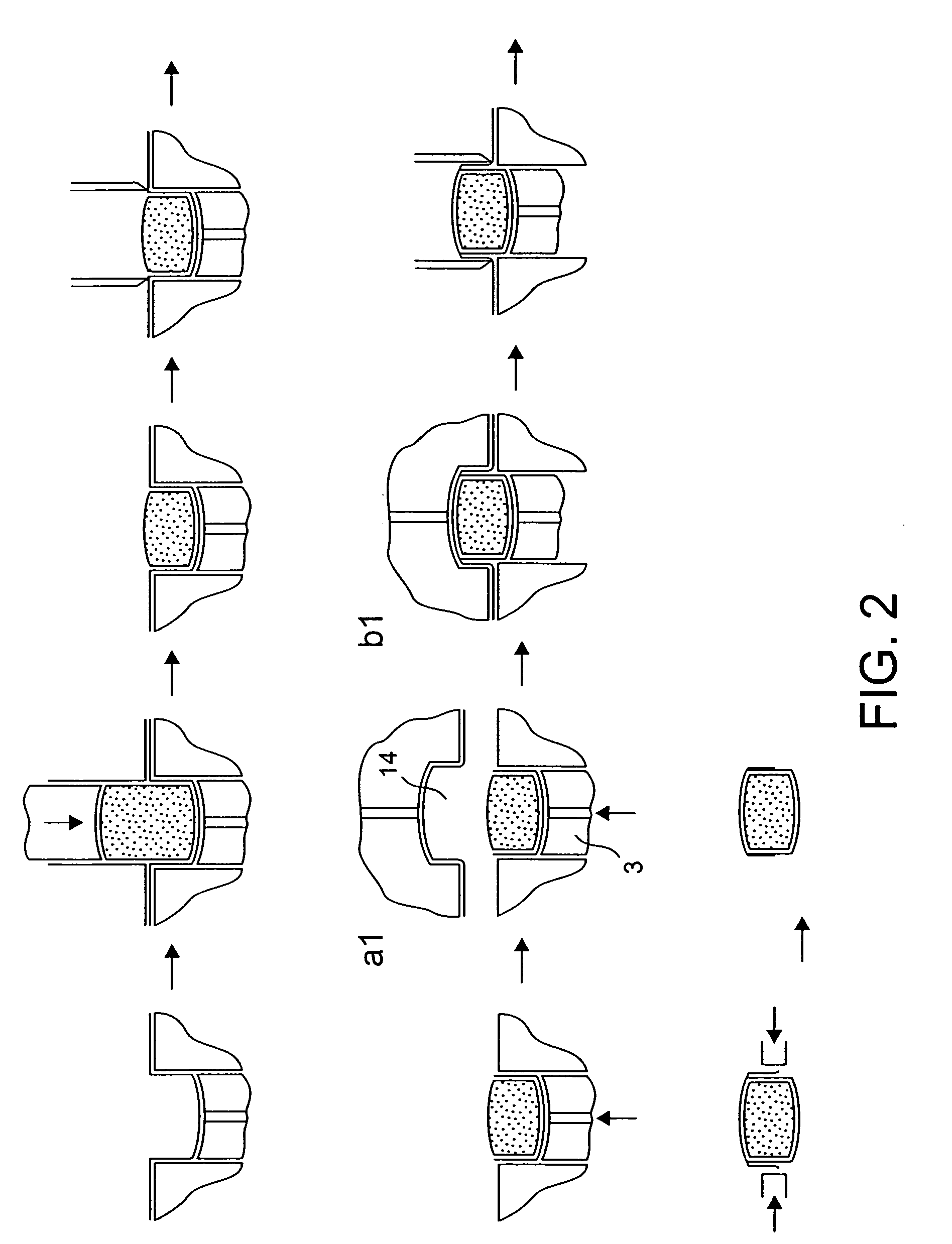

A tissue press and method for shaping or compressing a piece of tissue comprises first and second members movable relative to each other. A first forming element of a predetermined shape is selectively engageable on the first member. A second forming element of predetermined shape is selectively engageable on the second member. The first and second forming elements are positionable on opposite sides of the piece of tissue. The first and second members are relatively movable between a first spaced apart condition and a second condition in which the piece of tissue is held between the first and second forming elements. Means are preferably provided for monitoring and controlling the amount of pressure applied to the piece of tissue, in order to maintain the tissue in a viable living condition. Means may also be provided for draining off fluid from compressed tissue, so that the tissue can be implanted in a compressed state and imbibe fluid from the host site. A retainer, which may be expandable, can be used to maintain the tissue graft in a compressed condition.

Owner:BONUTTI 2003 TRUST A THE +1

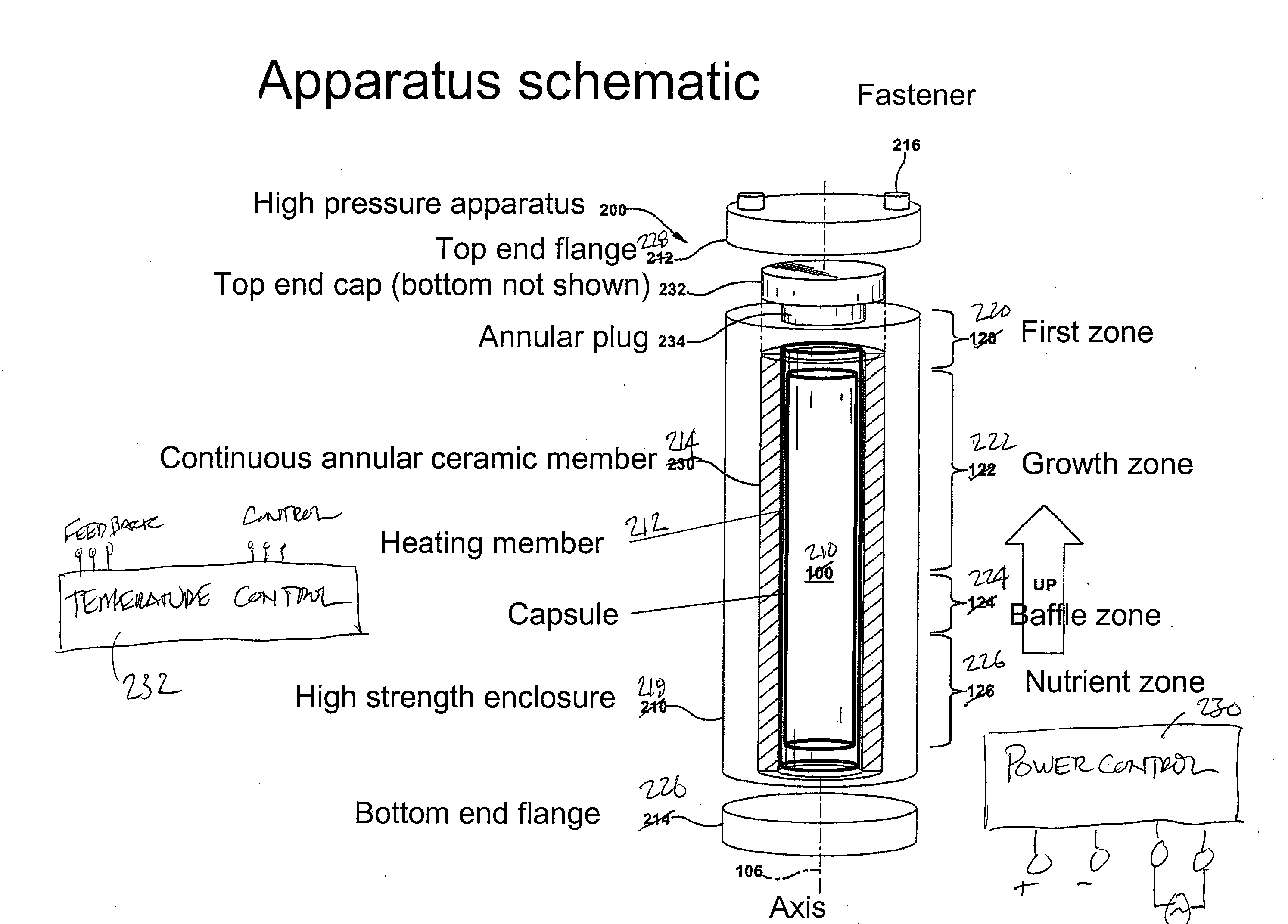

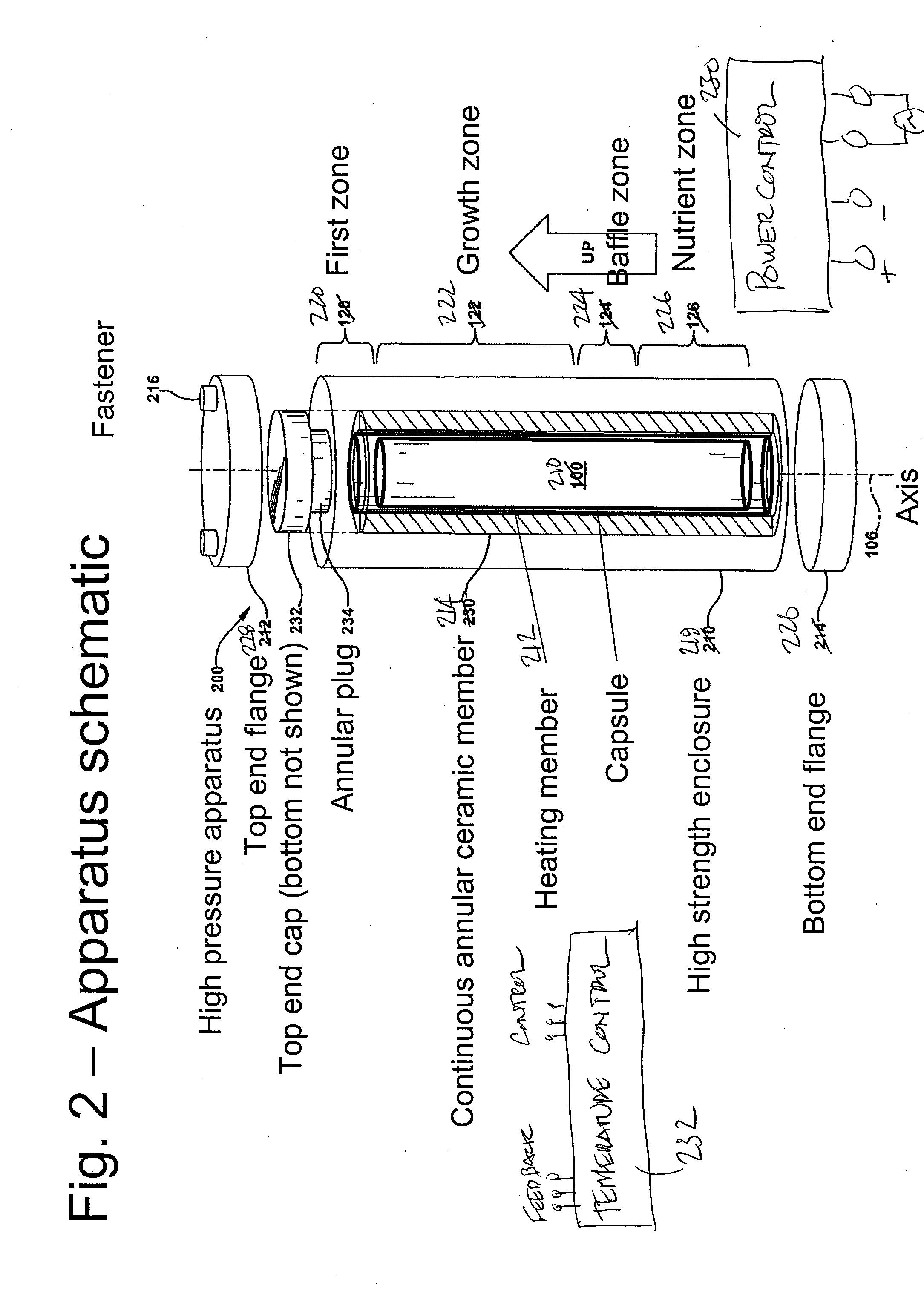

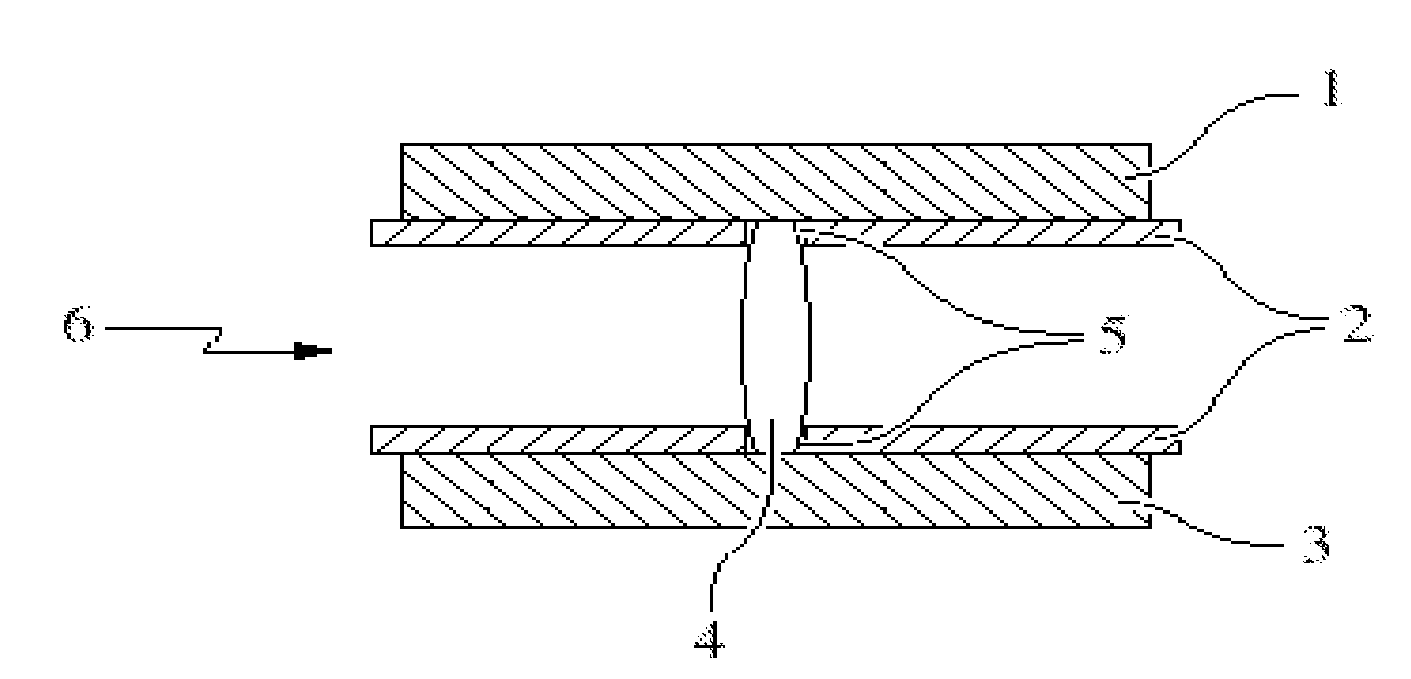

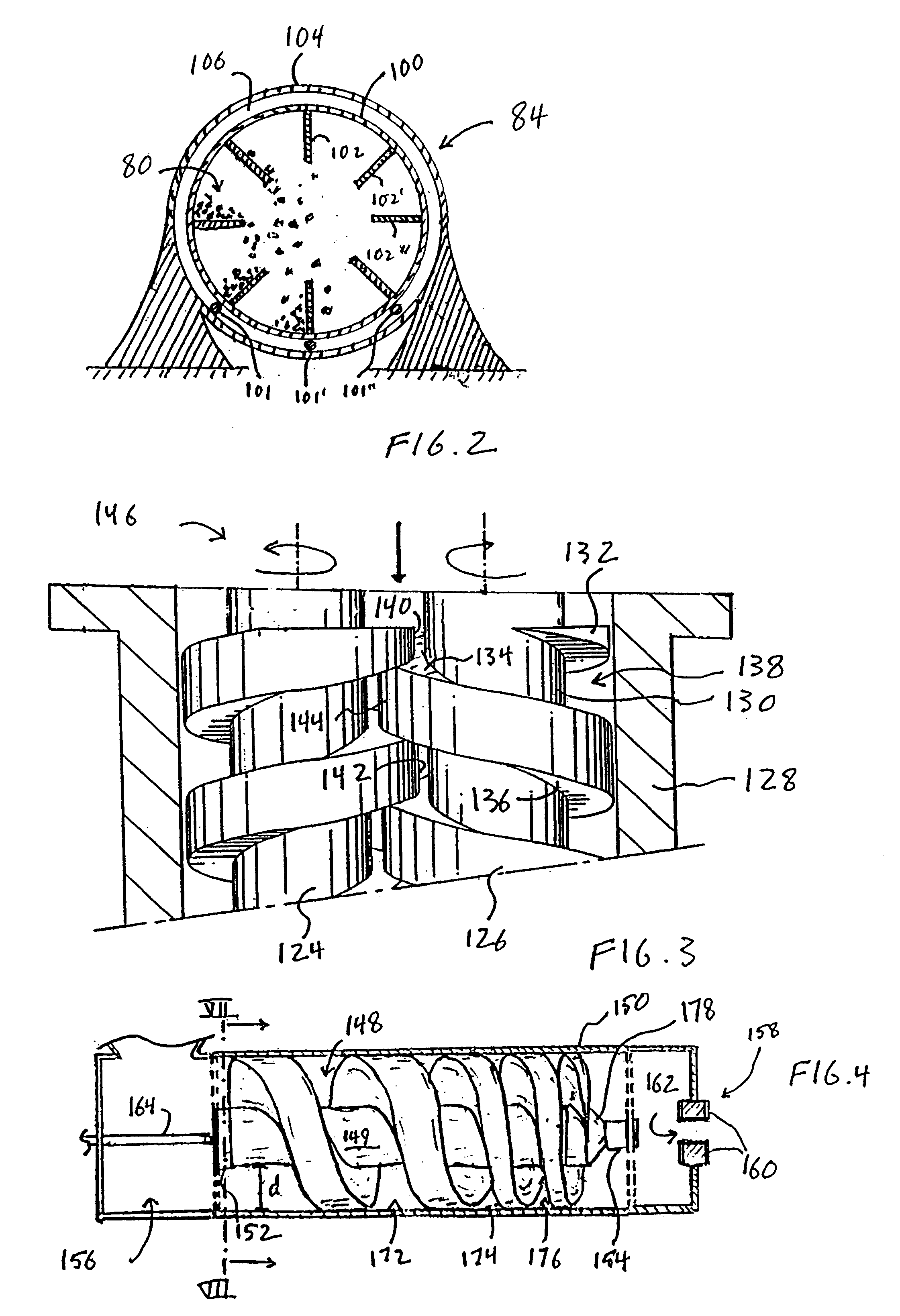

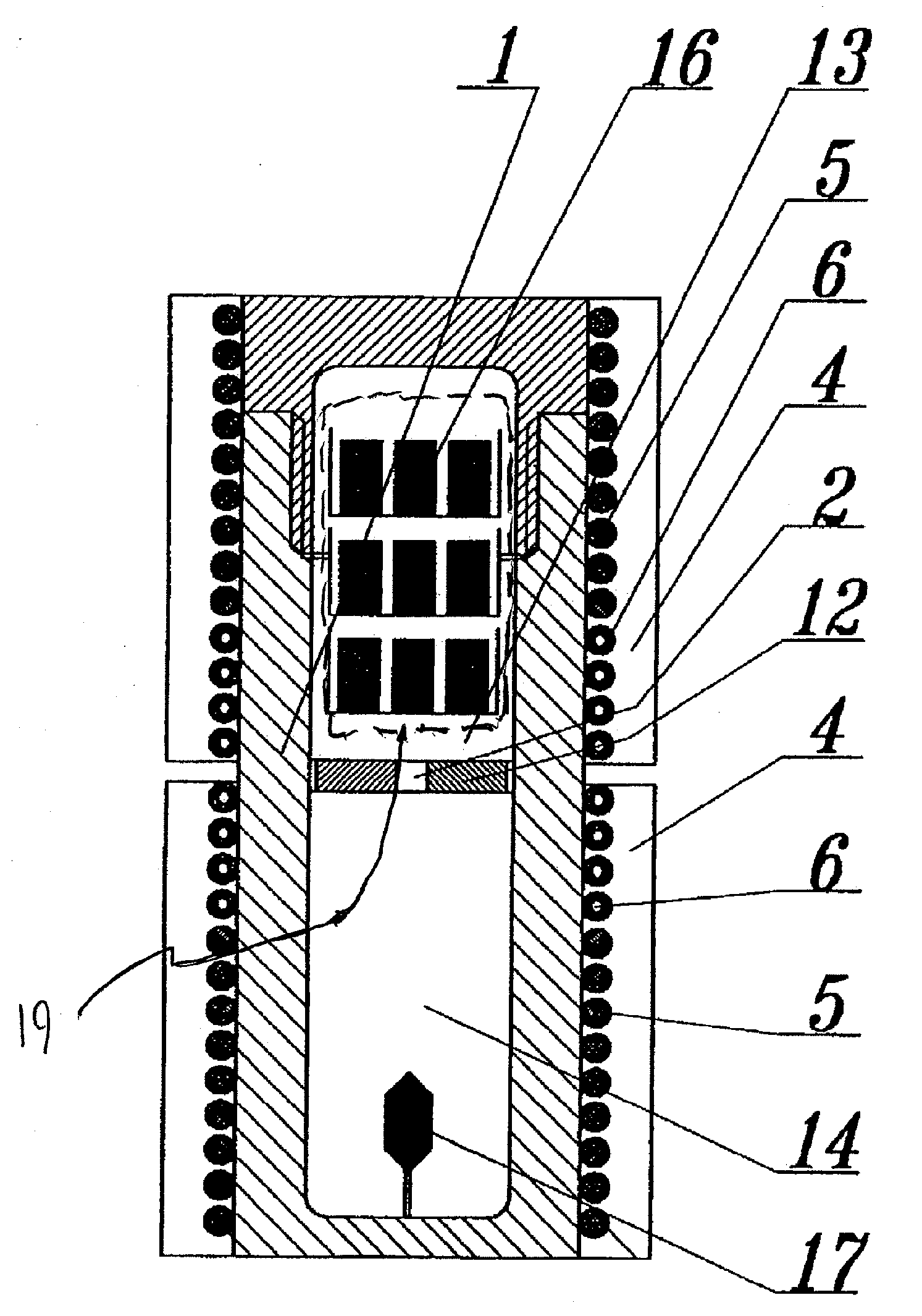

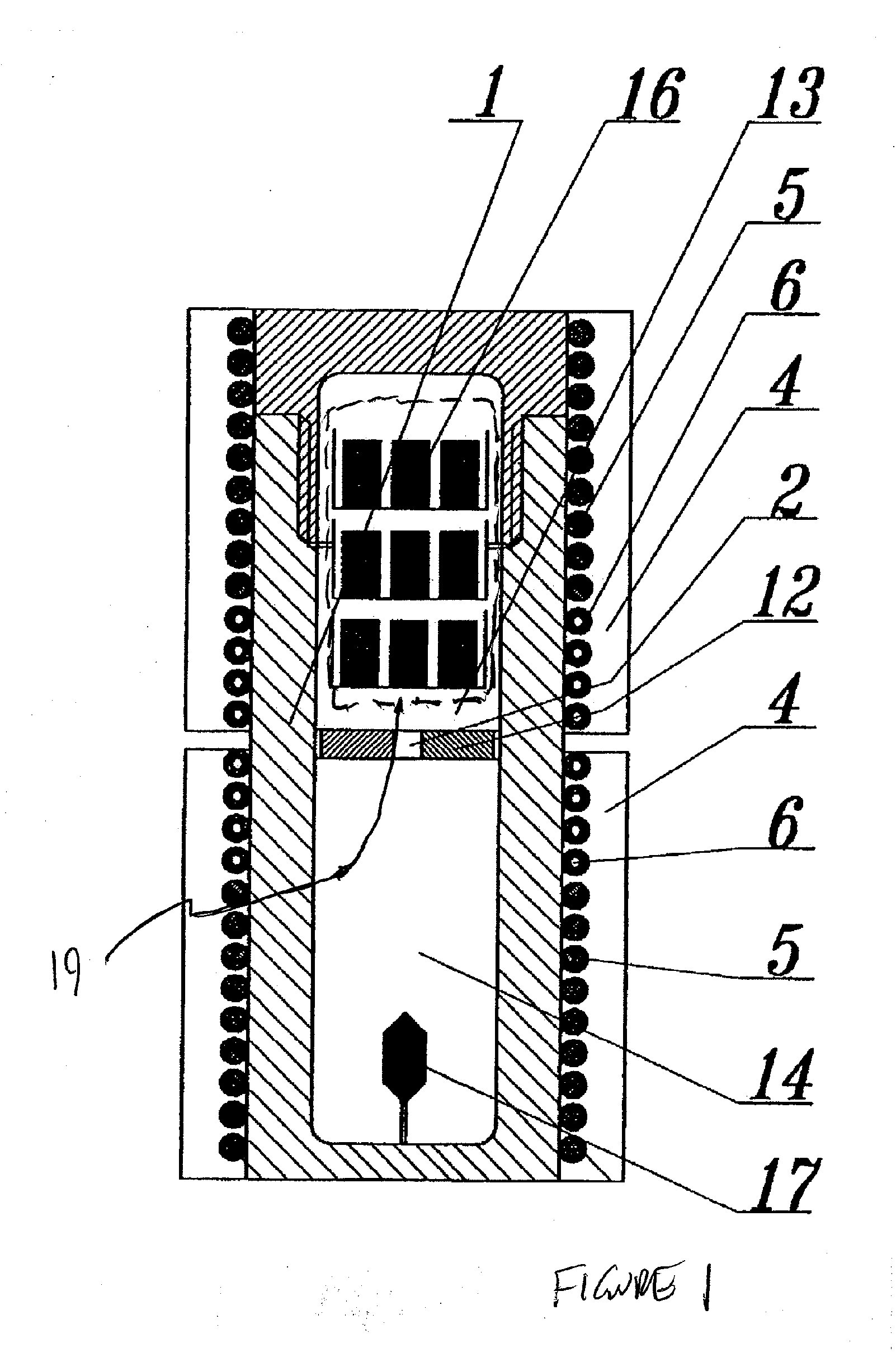

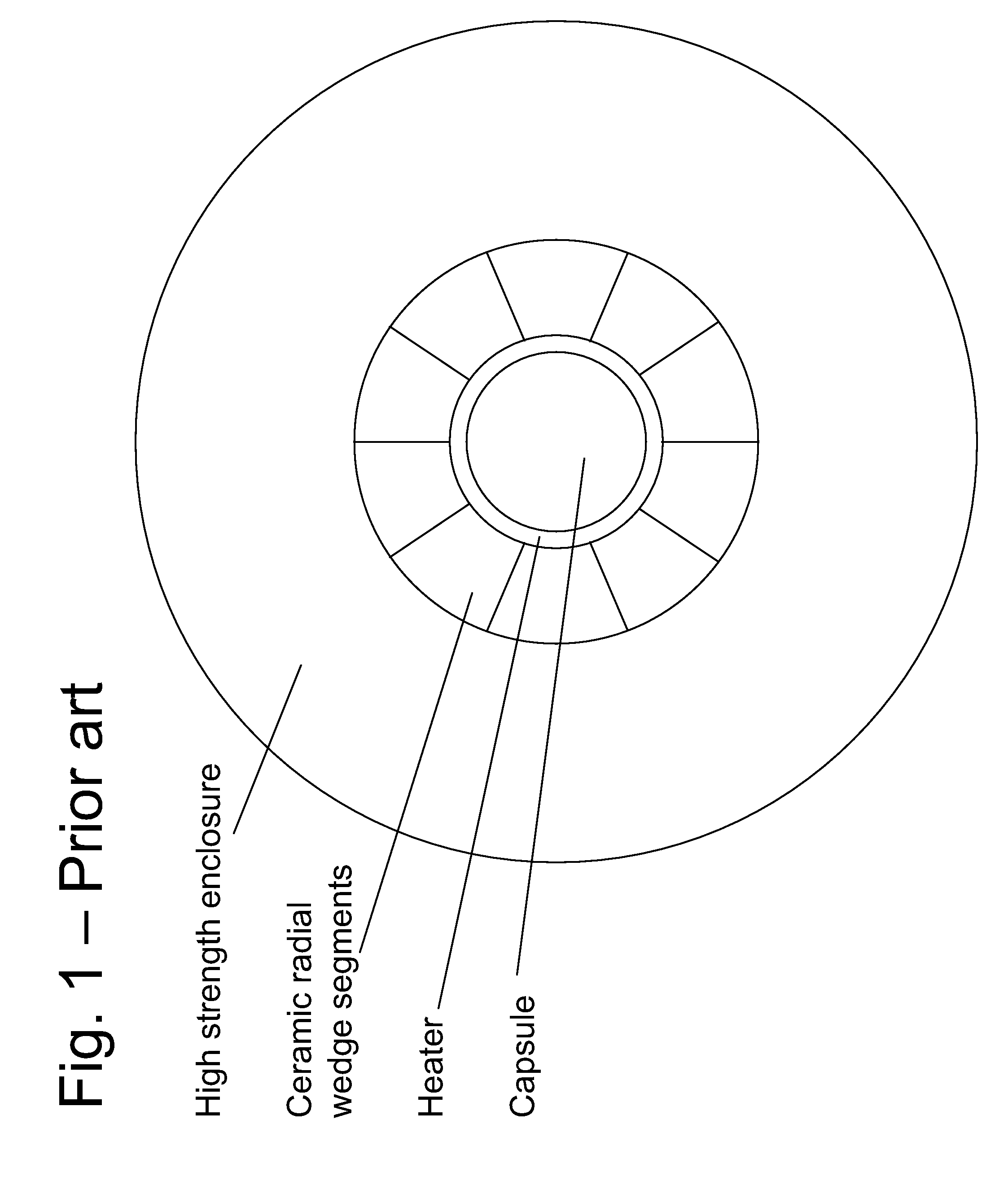

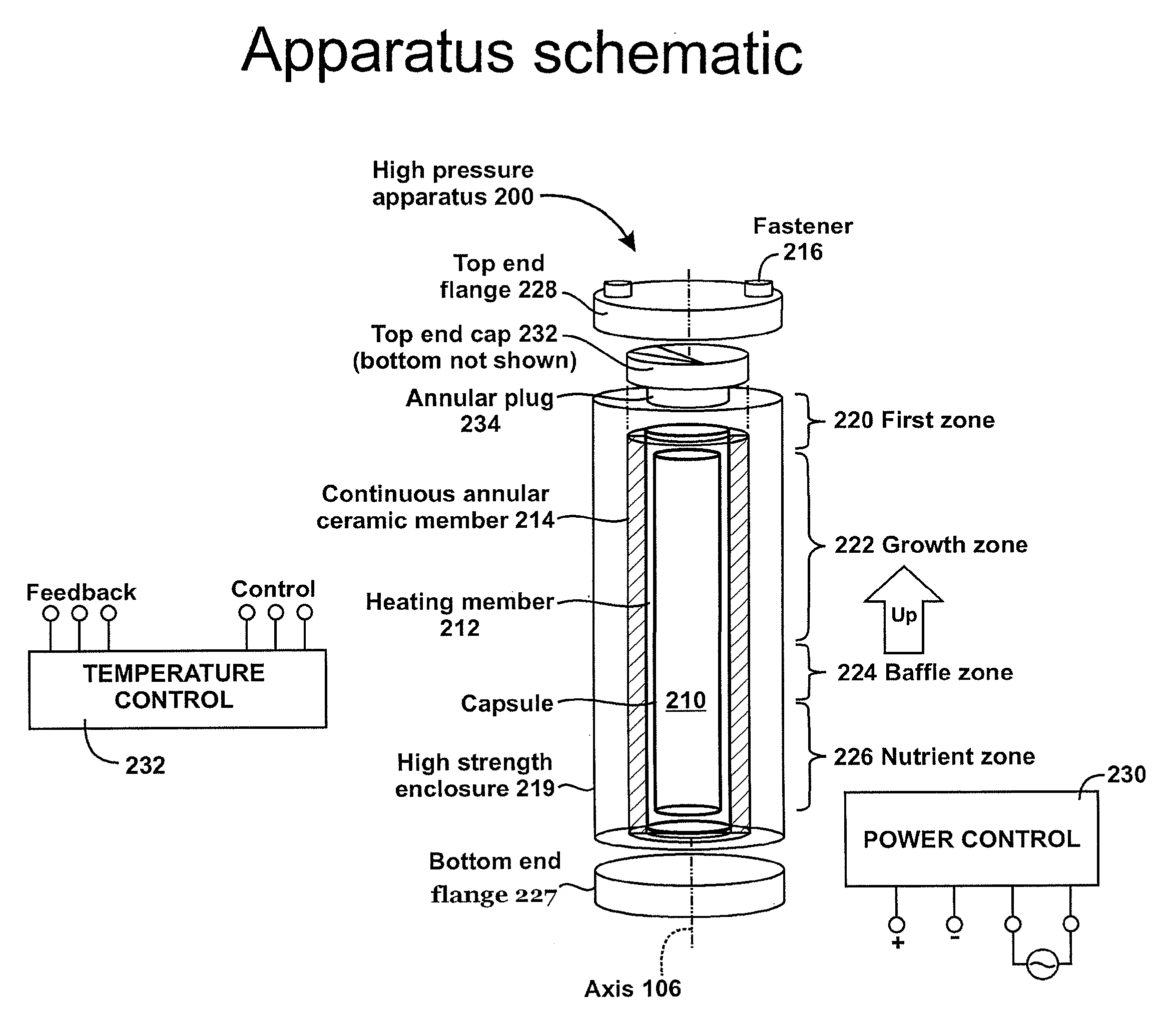

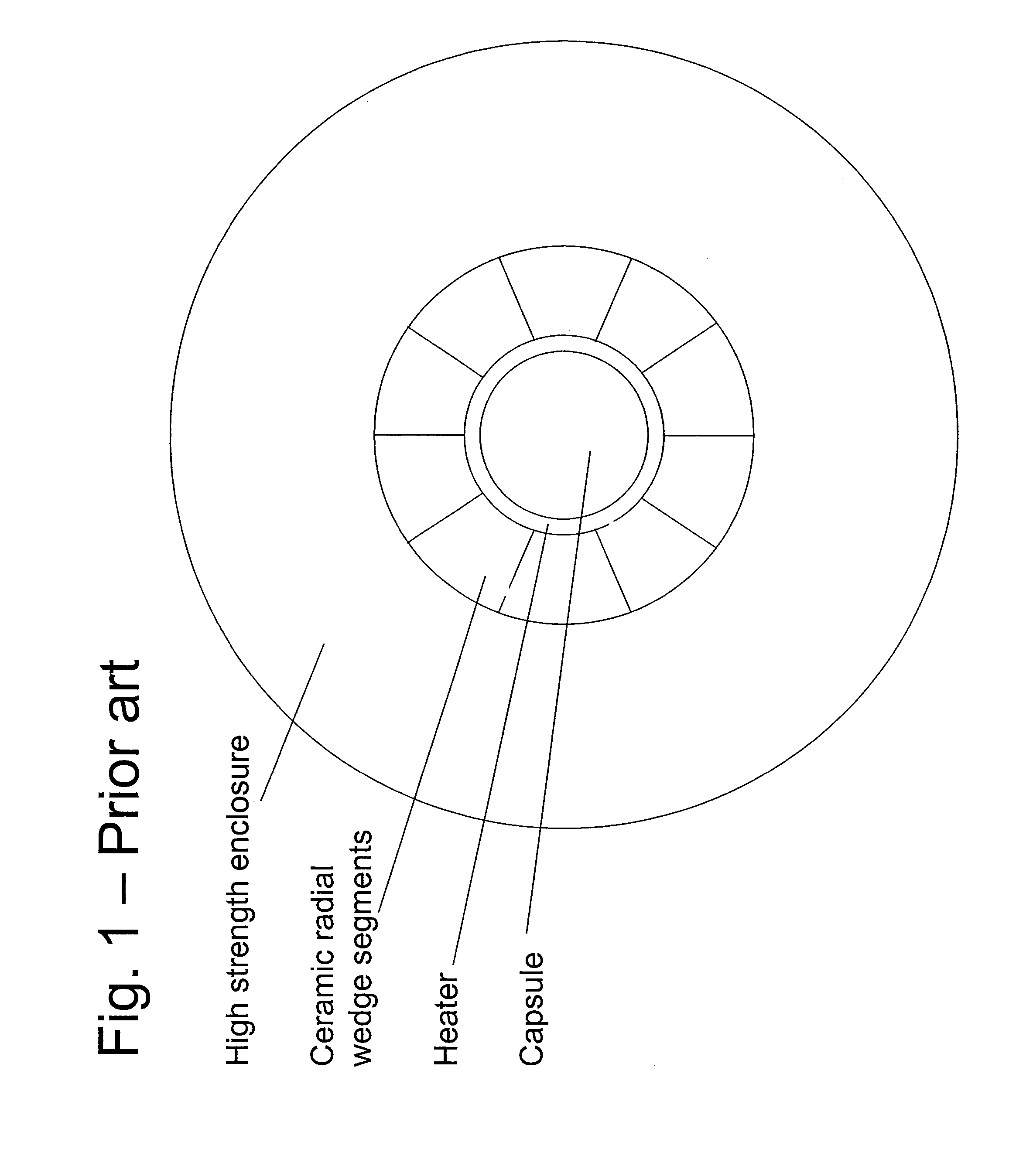

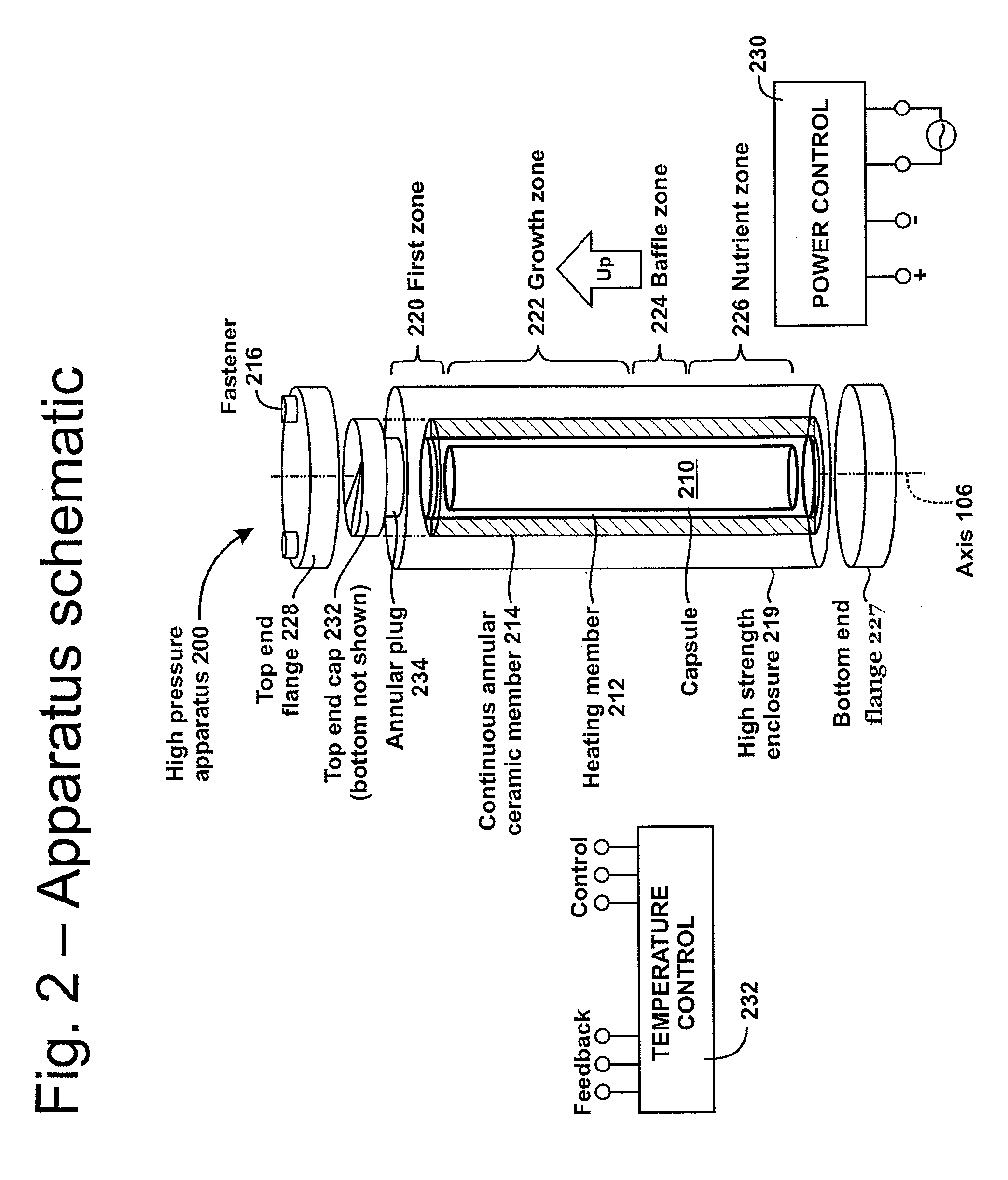

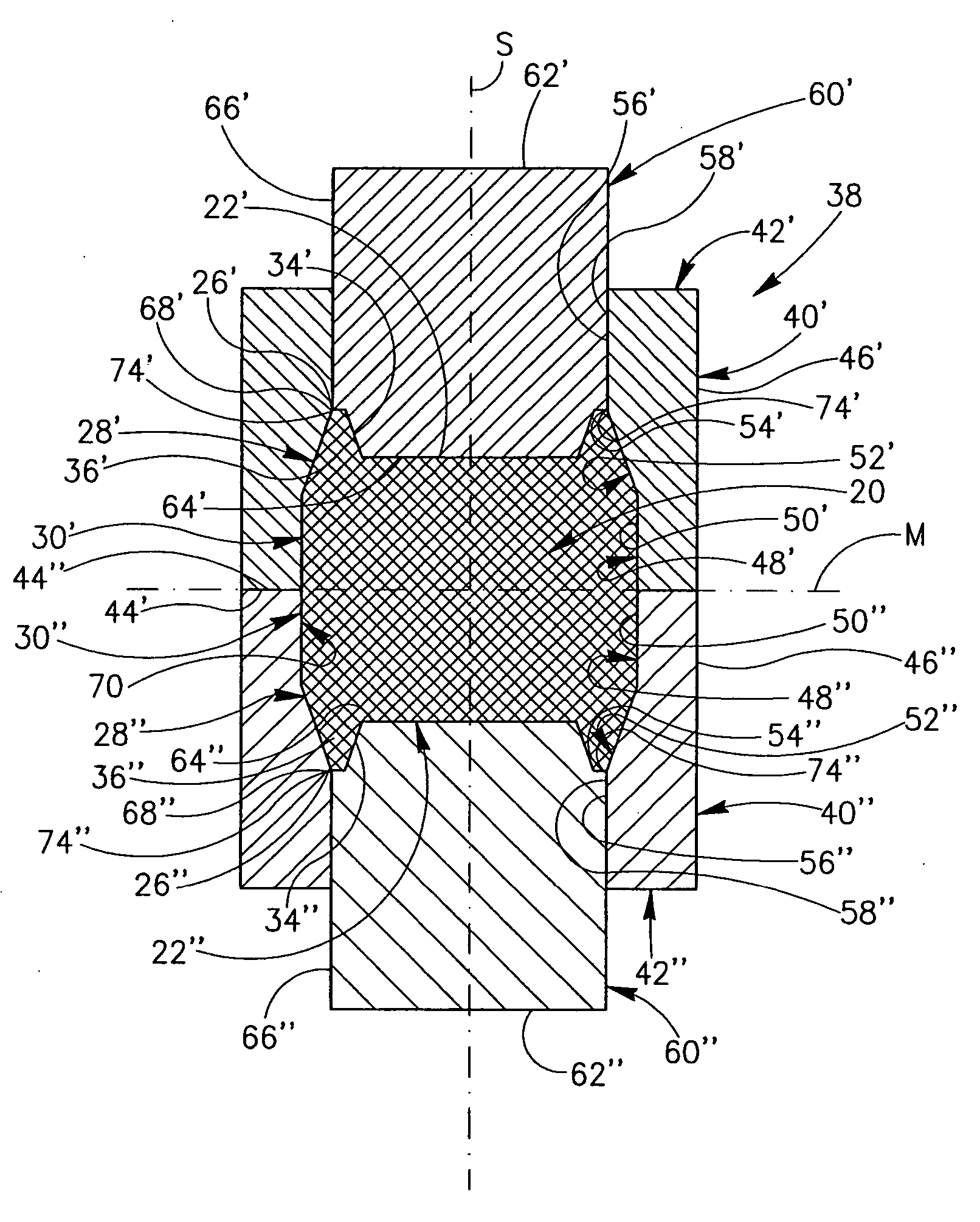

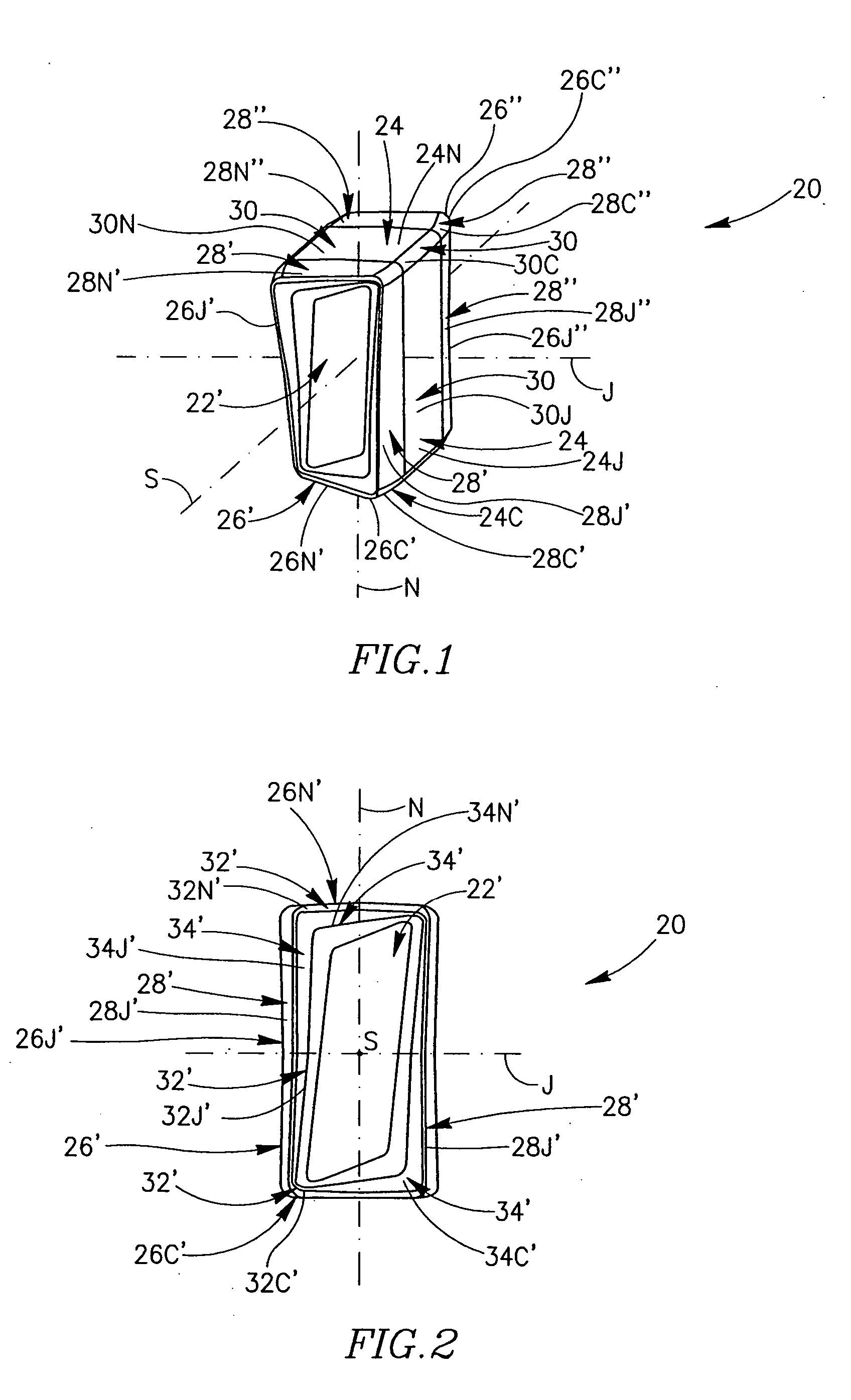

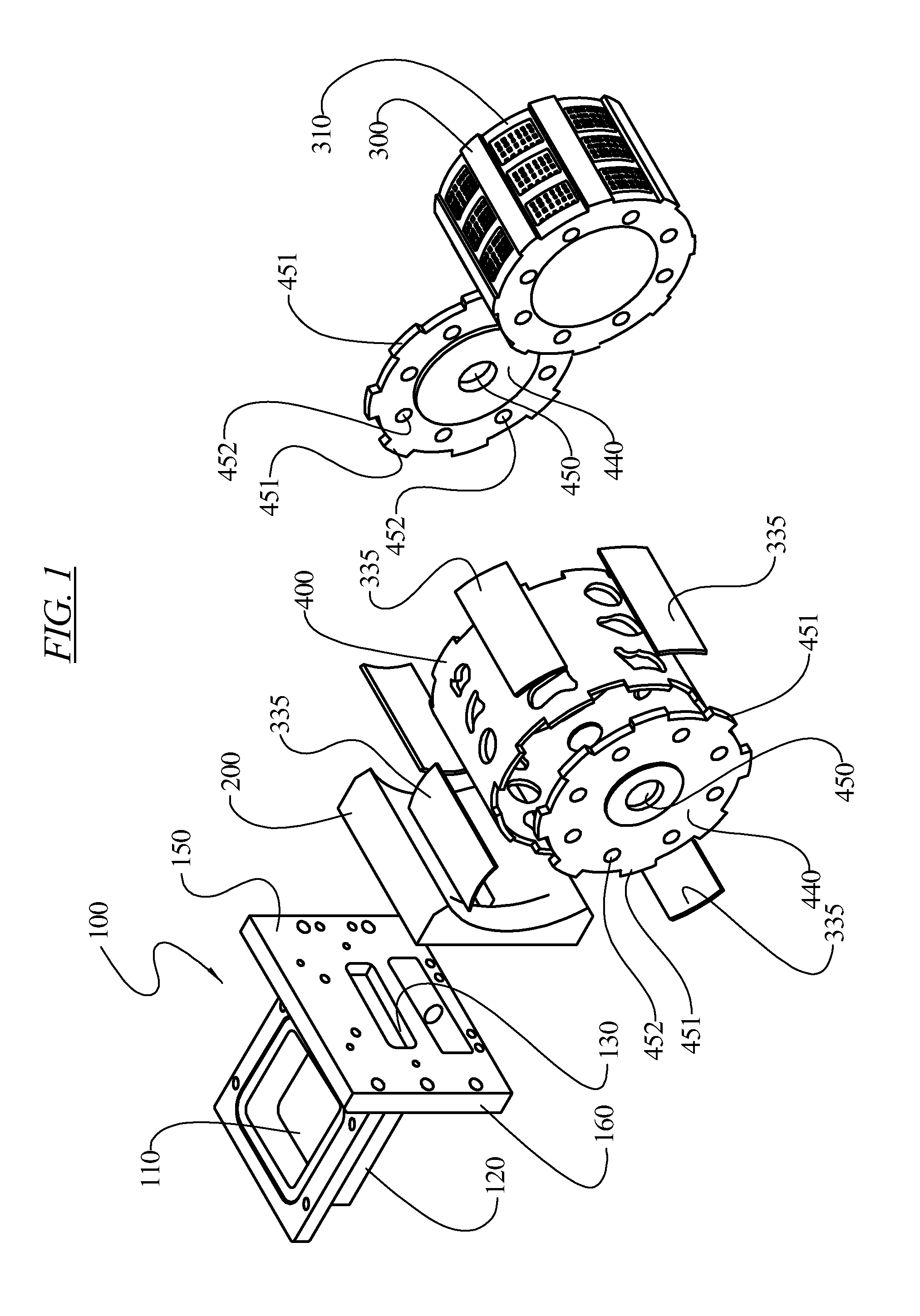

High pressure apparatus and method for nitride crystal growth

ActiveUS20090301387A1Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. IN a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

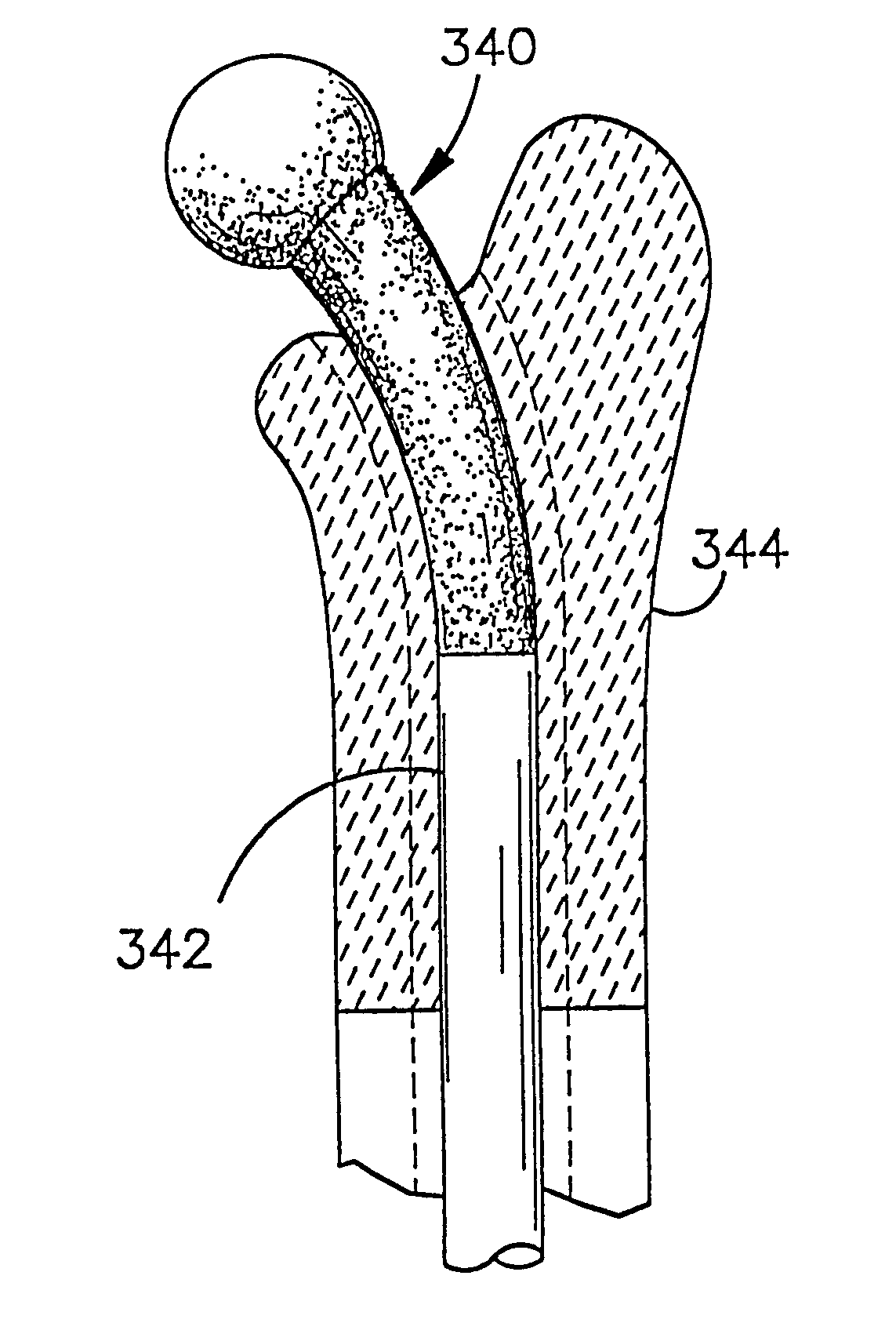

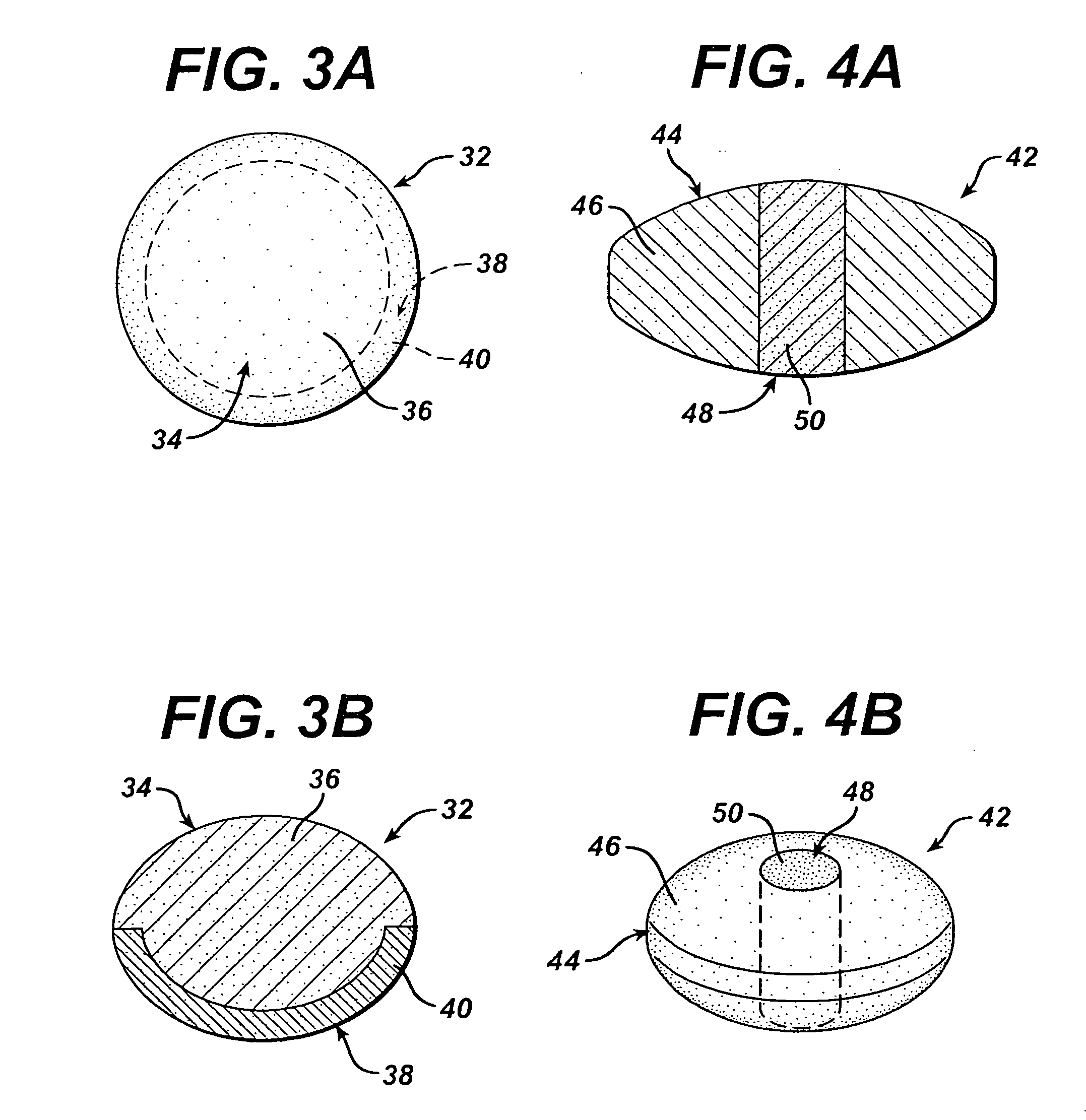

Expandable hip implant

InactiveUS6361565B1Reduce retentionReduce capacitySuture equipmentsInternal osteosythesisProsthesisBody fluid

An implant is formed of an expandable material. An opening is formed in a bone in a patient's body. At least a portion of the implant is positioned in the opening in the bone in the patient's body. The implant is retained against movement relative to the bone in the patient's body by absorbing body fluid with the implant and expanding the implant while the implant is disposed in the opening in the bone in the patient's body. The implant may be a hip replacement member.

Owner:BONUTTI 2003 TRUST A THE +1

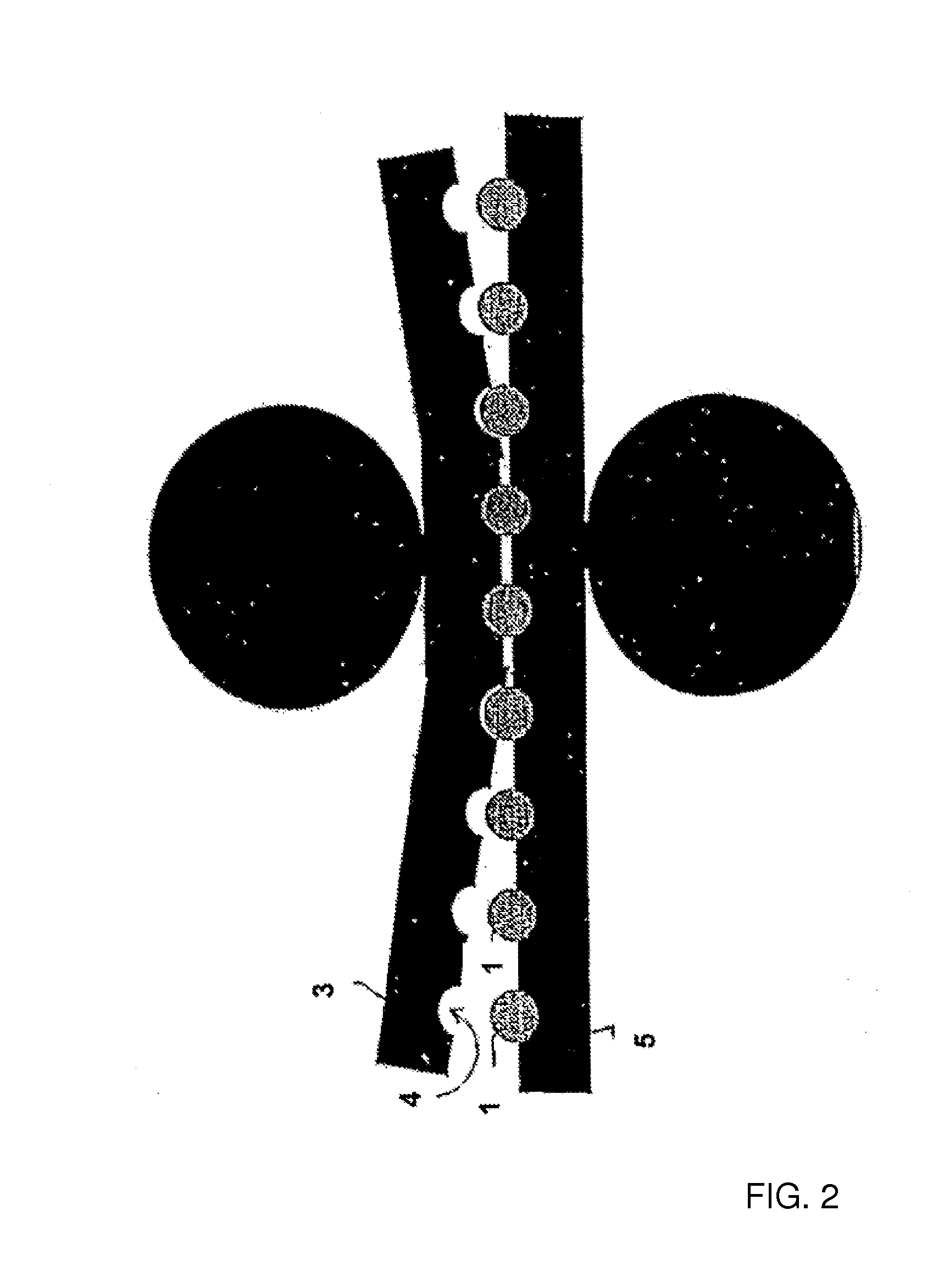

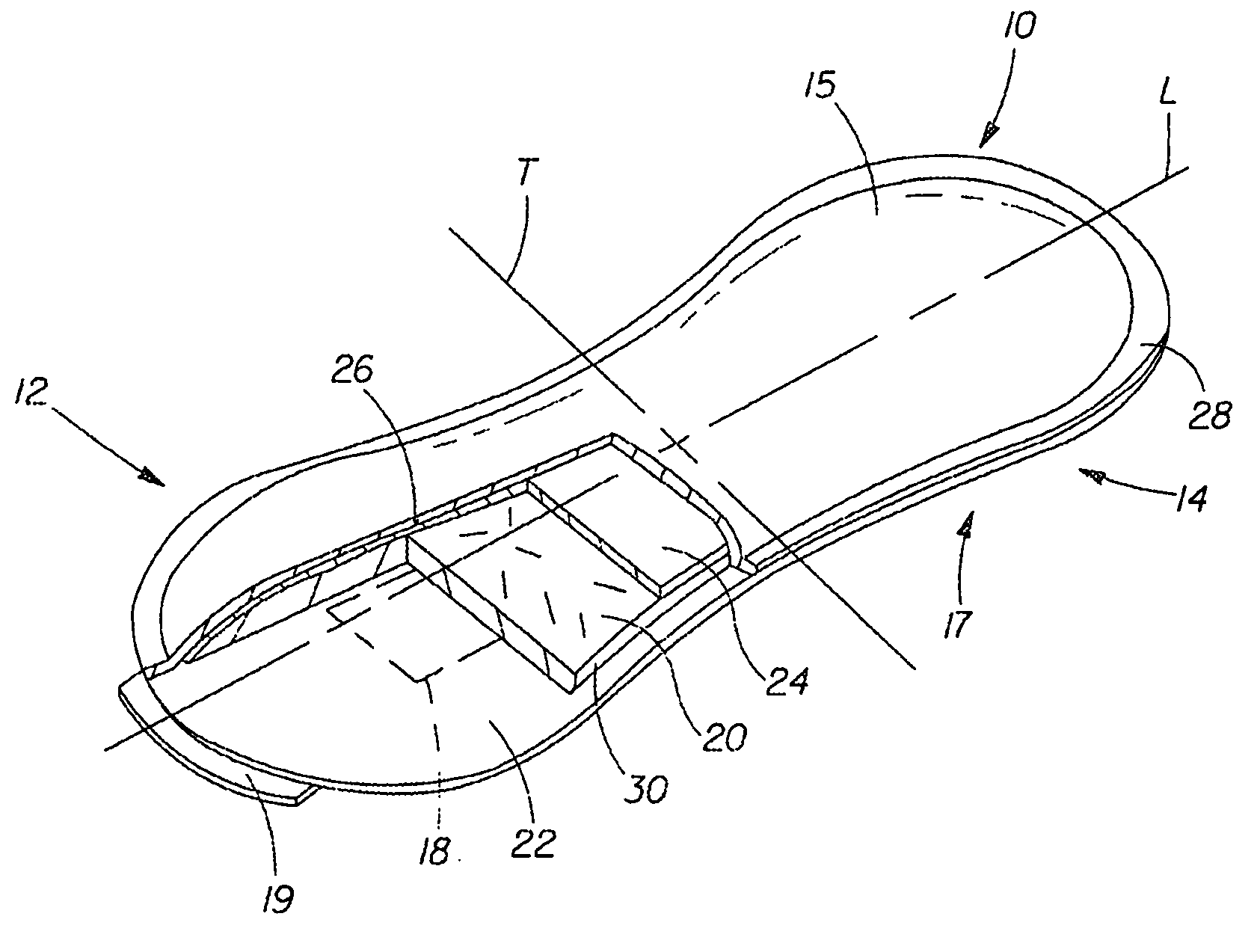

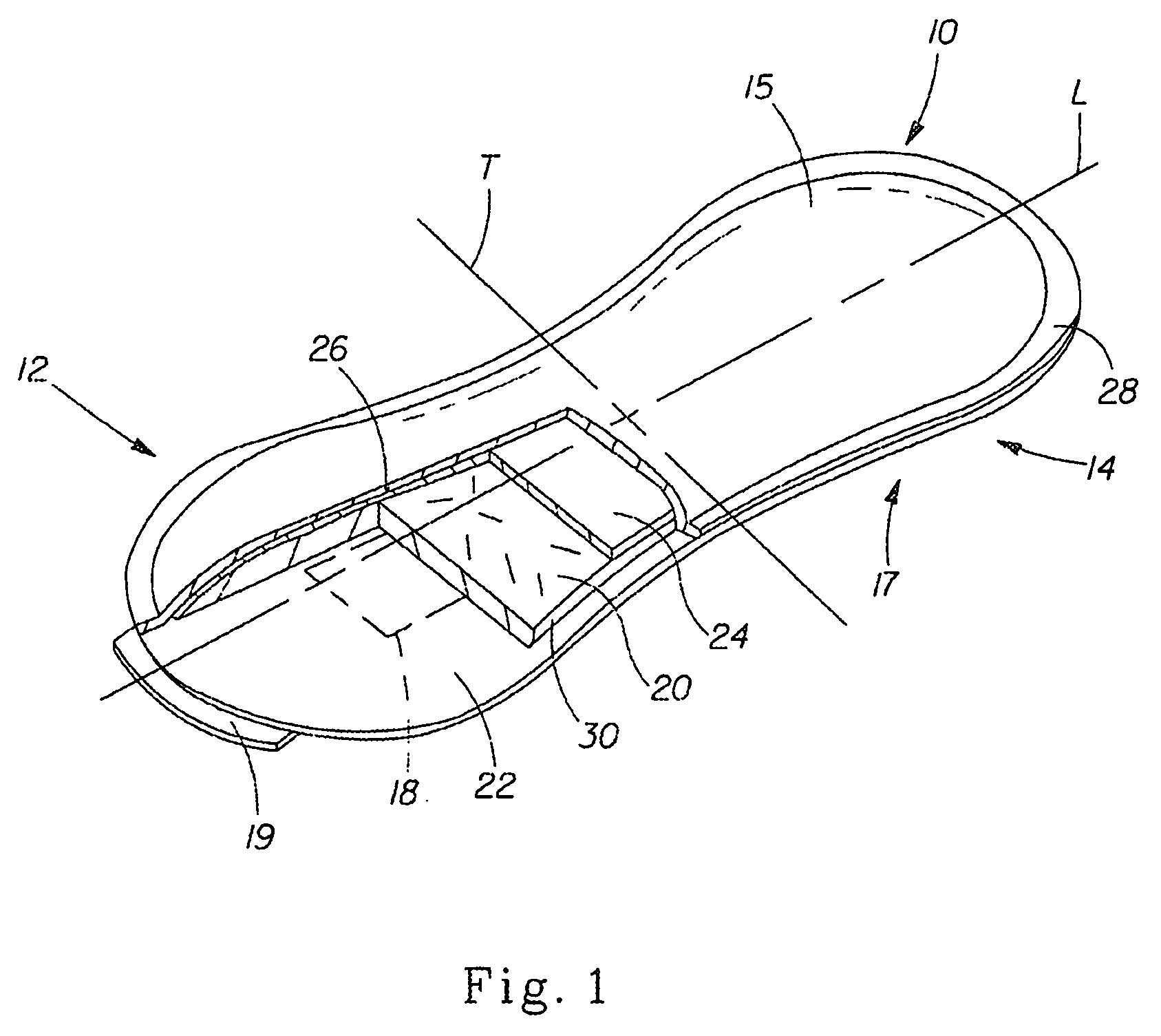

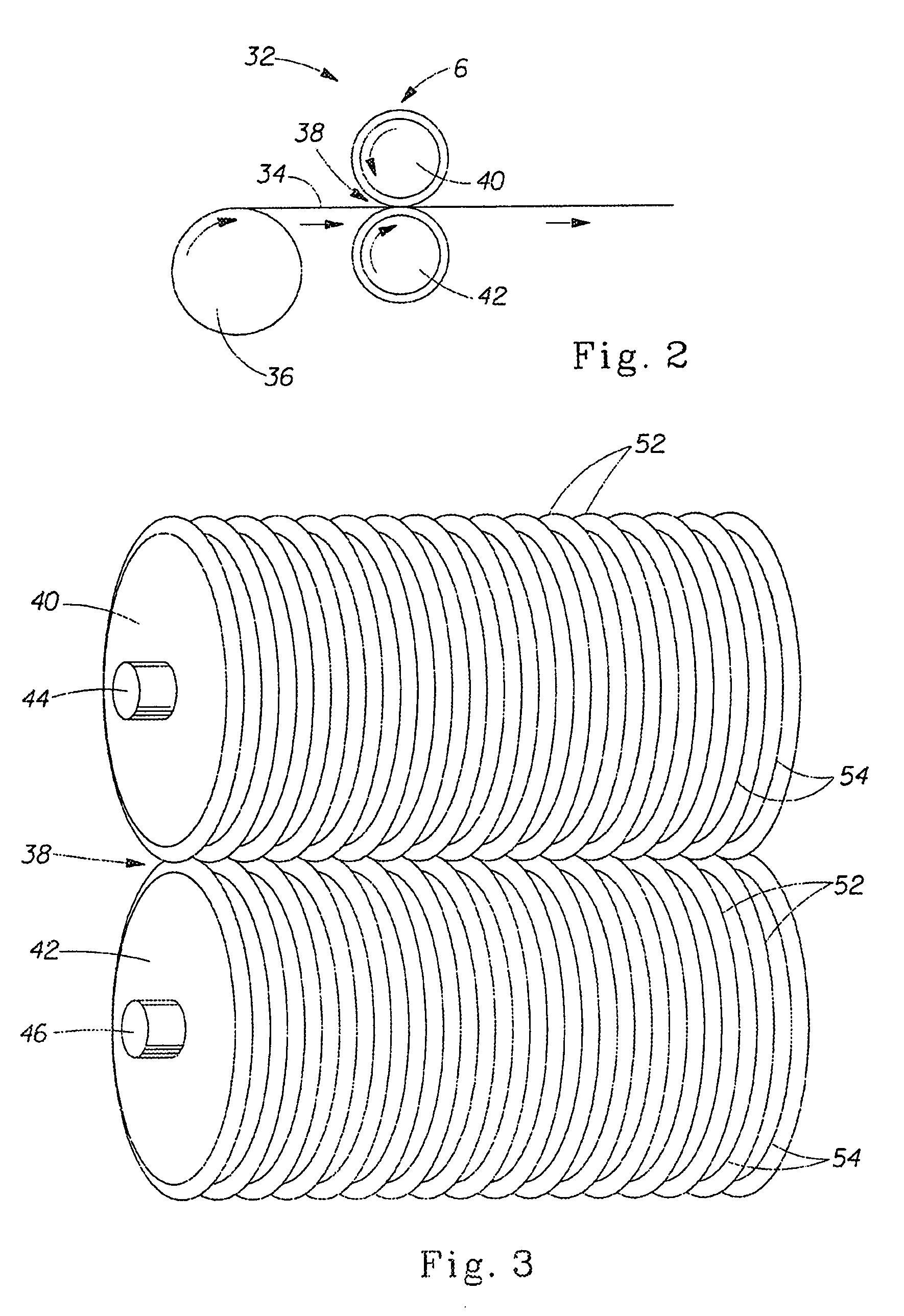

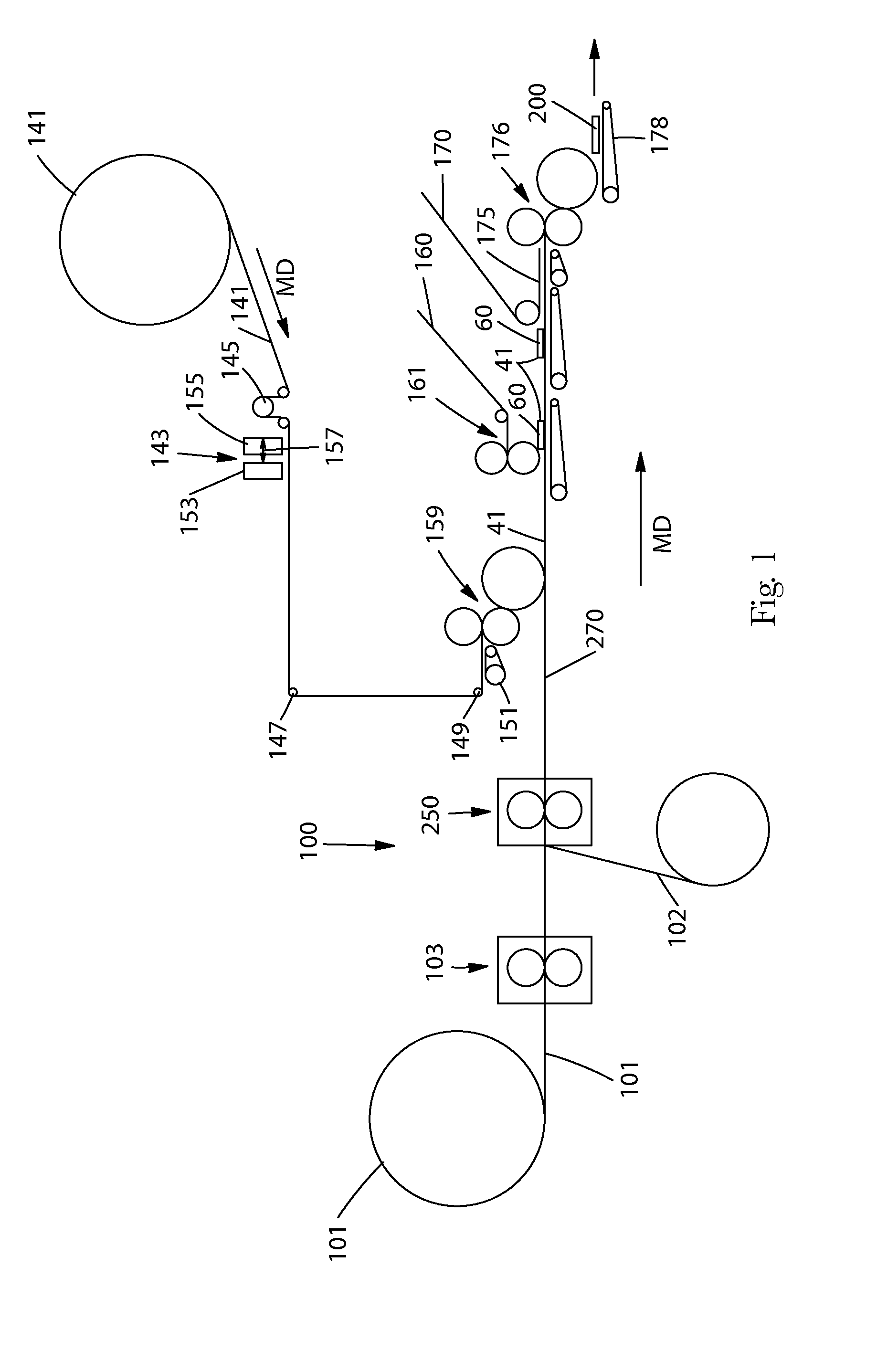

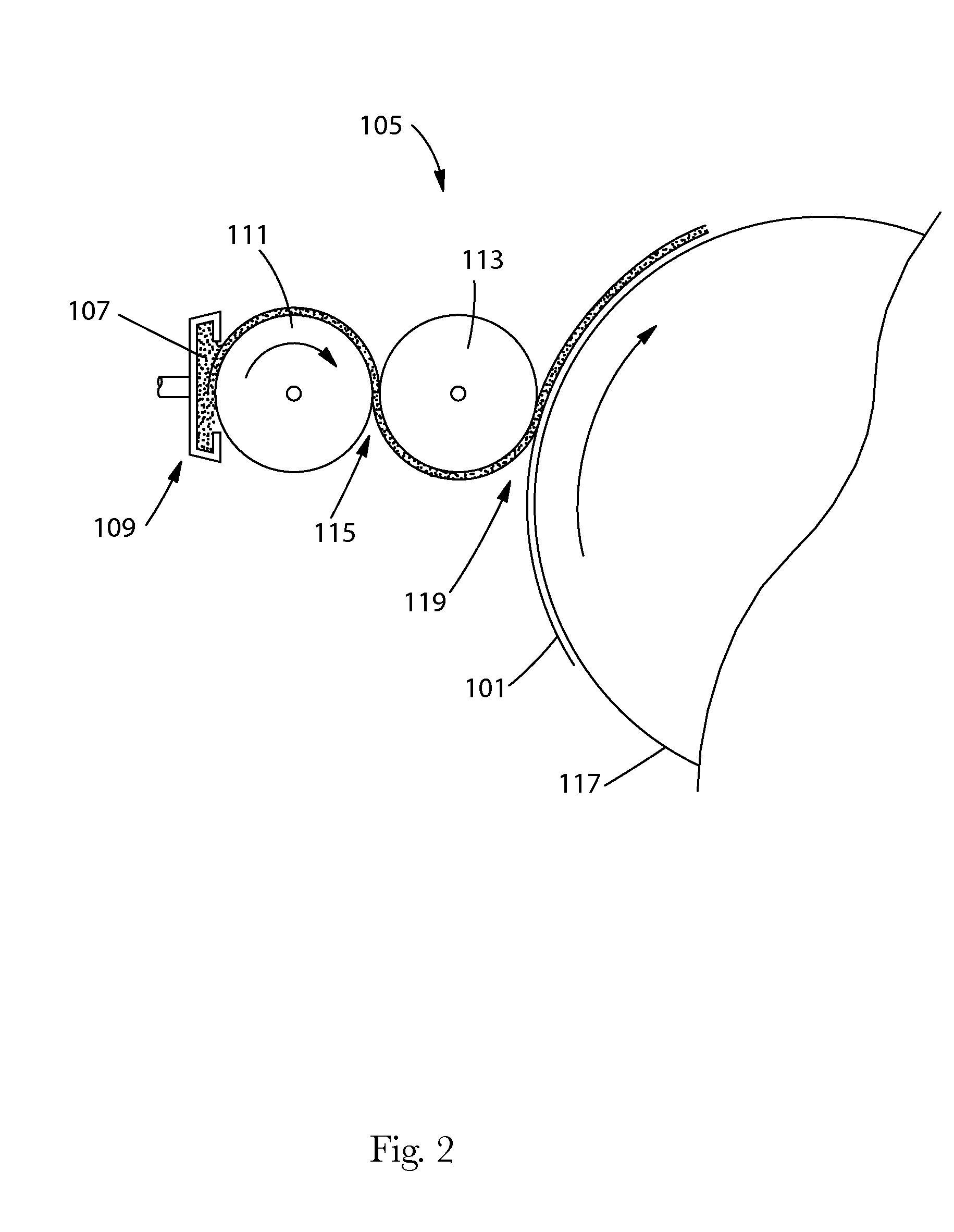

Absorbent core for disposable absorbent article

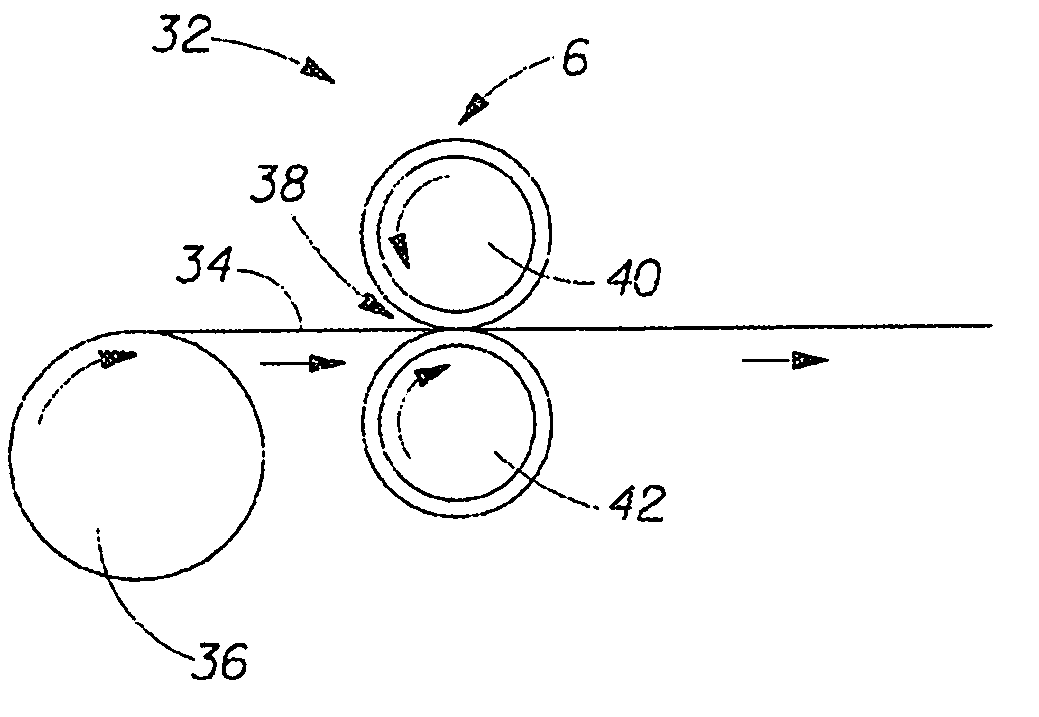

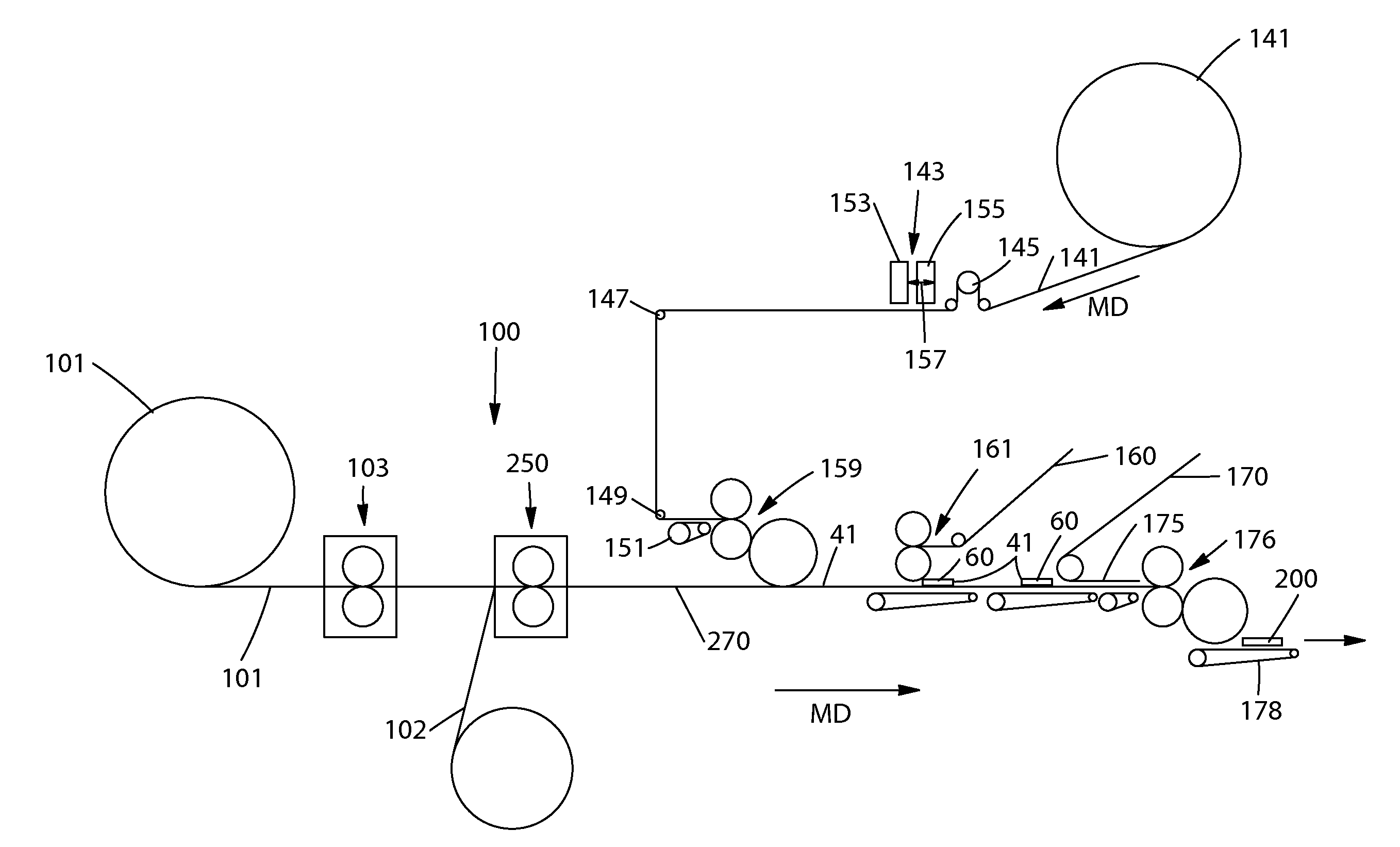

InactiveUS7935207B2Mechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

A method of making an absorbent core for use in an absorbent article. The method comprising the steps of:a. providing a first absorbent fibrous web material;b. providing a second absorbent fibrous web material;c. providing a pair of rolls forming a nip through which the first and second absorbent fibrous web materials can be processed, the pair of rolls being selected from the processes consisting of, ring rolling, SELF, micro-SELF, and rotary knife aperturing;d. deforming portions of the first absorbent fibrous web material by processing through the pair of rolls;e. deforming portions of the second absorbent fibrous web material by processing through the pair of rolls; andf. combining the first and second absorbent fibrous web materials to form the absorbent core.

Owner:PROCTER & GAMBLE CO

Process for the production of an abuse-proofed dosage form

InactiveUS20090005408A1Pulverisation of the dosage form is considerably more difficultComplicating or preventing the subsequent abuseBiocideNervous disorderBreaking strengthMedicine

The present invention relates to a process for the production of abuse-proofed, thermoformed dosage forms containing, apart from one or more active ingredients with potential for abuse and optionally physiologically acceptable auxiliary substances, at least one synthetic or natural polymer with a breaking strength of at least 500 N.

Owner:GRUNENTHAL GMBH

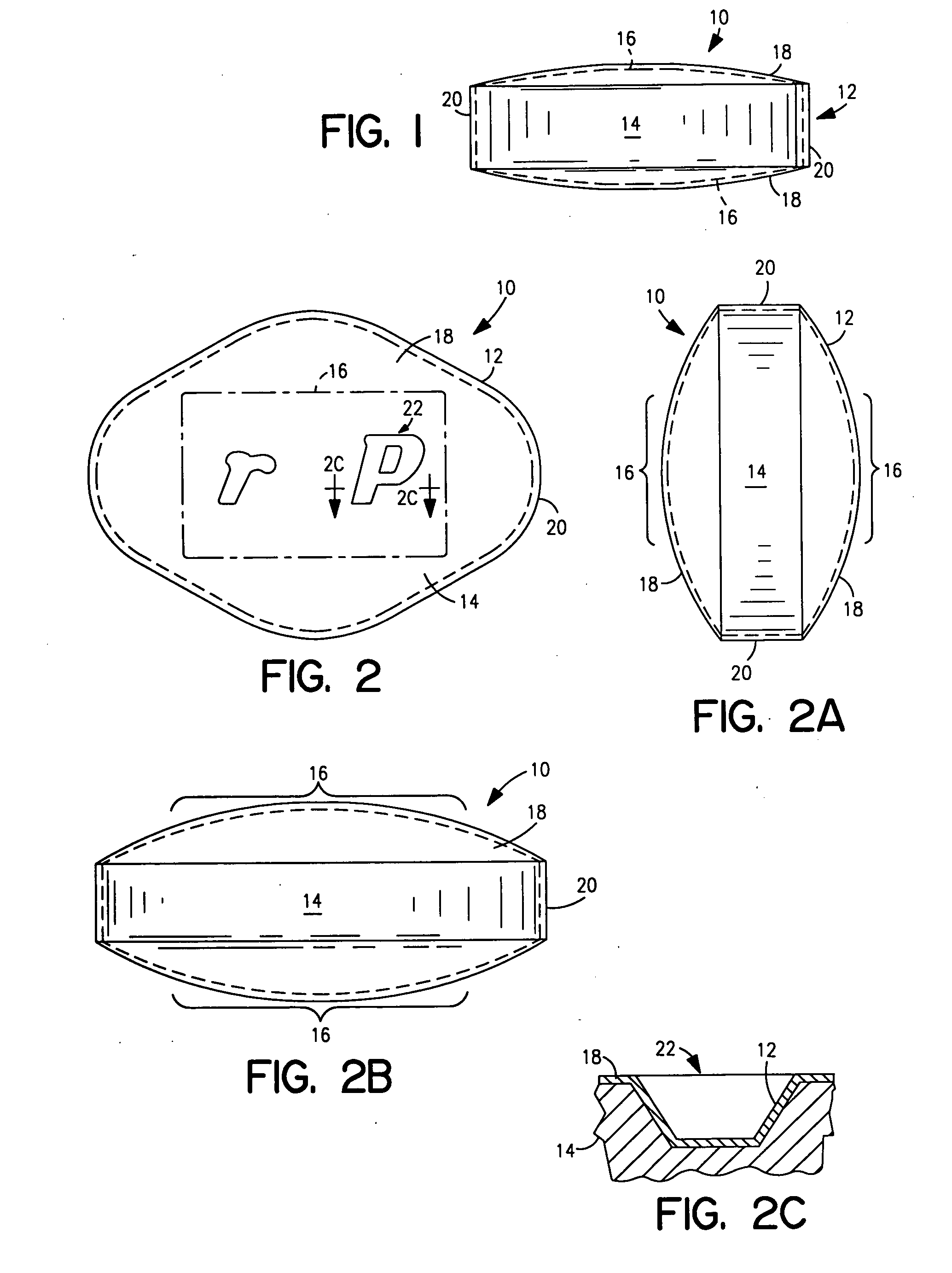

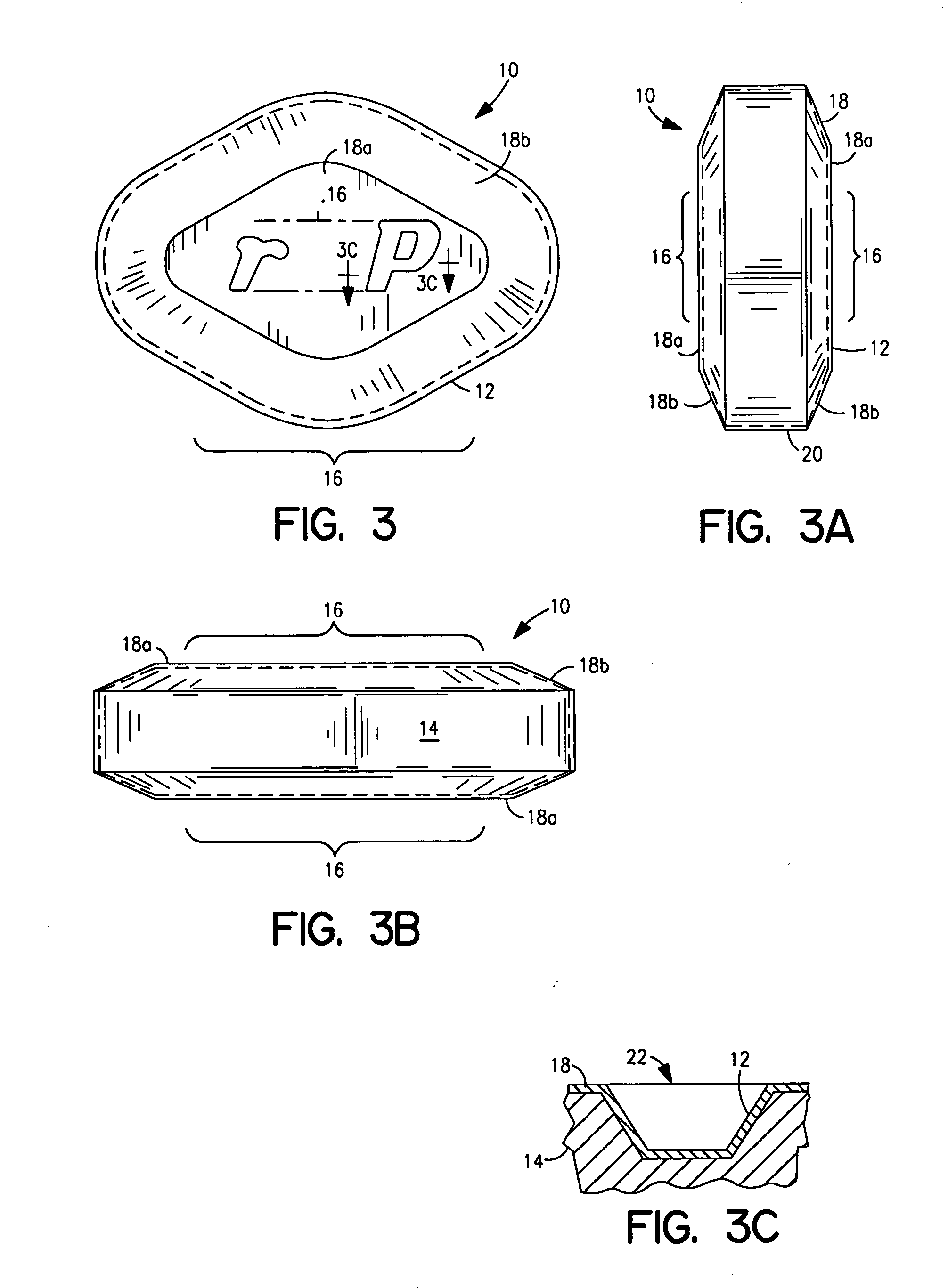

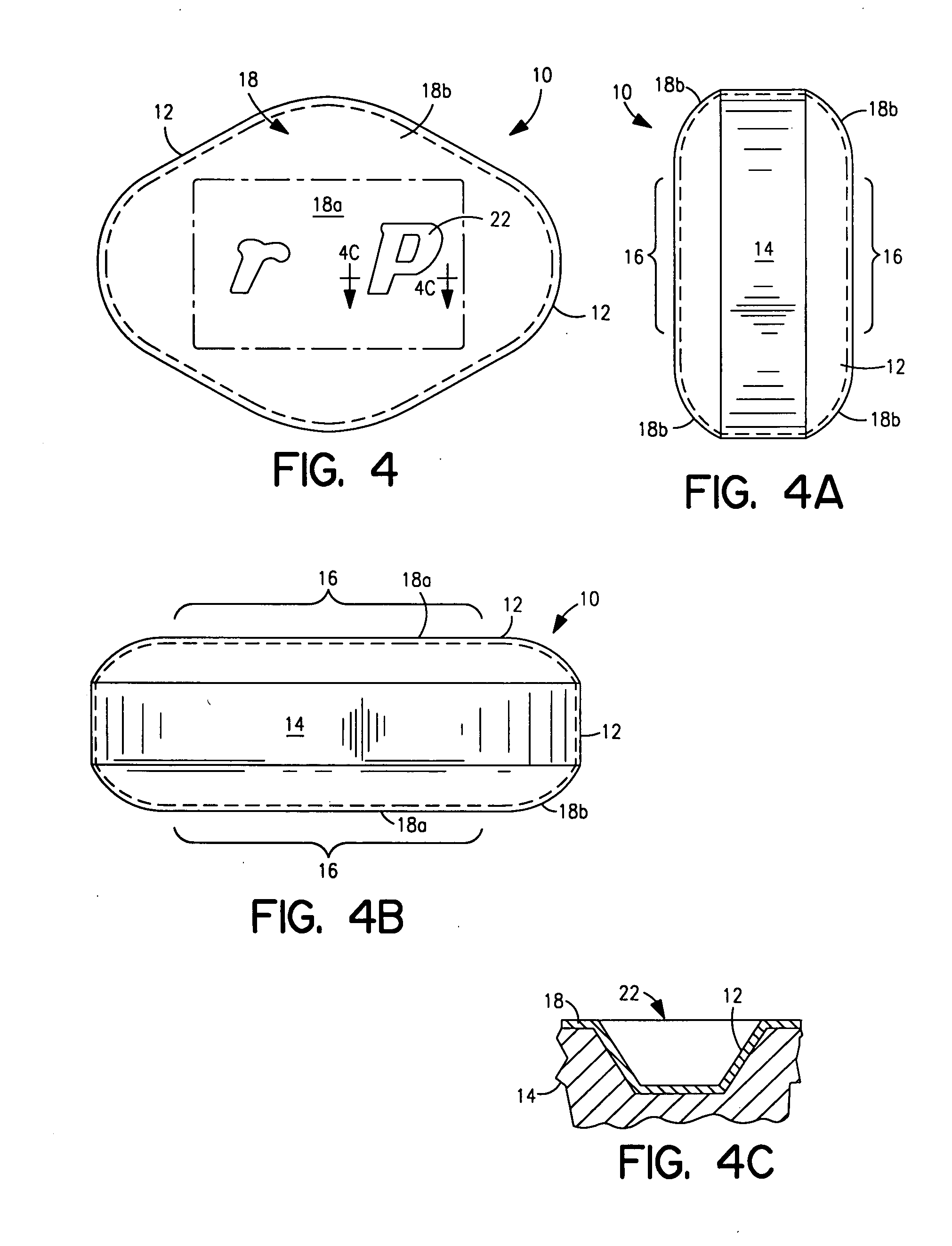

Edible holographic products, particularly pharmaceuticals and methods and apparatus for producing same

InactiveUS20060068006A1Preserve product integrityCheap productionPretreated surfacesDiffraction gratingsCoated tabletsPlasticizer

An edible product such as a unit dosage form of a pharmaceutically active substance includes a layer of a material that can receive and retain a high resolution microrelief that can convey information. The microrelief is themo-formable, preferably formed from an aqueous solution of HPMC and / or HPC plus a plasticizer and colorant. Other additives such as strengtheners, surfactants and adherents may be used depending on the application. The materials are selected and proportioned to control the fading or change in color of the visual image or effect produced by the relief to indicate exposure to an unacceptable degree of heat or humidity. The dosage form can be the relief-containing layer itself with the pharmaceutical carried therein. In a preferred form, the layer is an outer coating over a core containing the pharmaceutically active substance. Coated tablets are configured to resist twinning. To produce such dosage forms, the coated core is transported in unison with a flexible mold or transfer plate that can heat-replicate the microrelief on the outer layer of the dosage form, followed by a cooling and release of the transfer plate from the coating.

Owner:EDWARDS ANGELL PALMER & DODGE

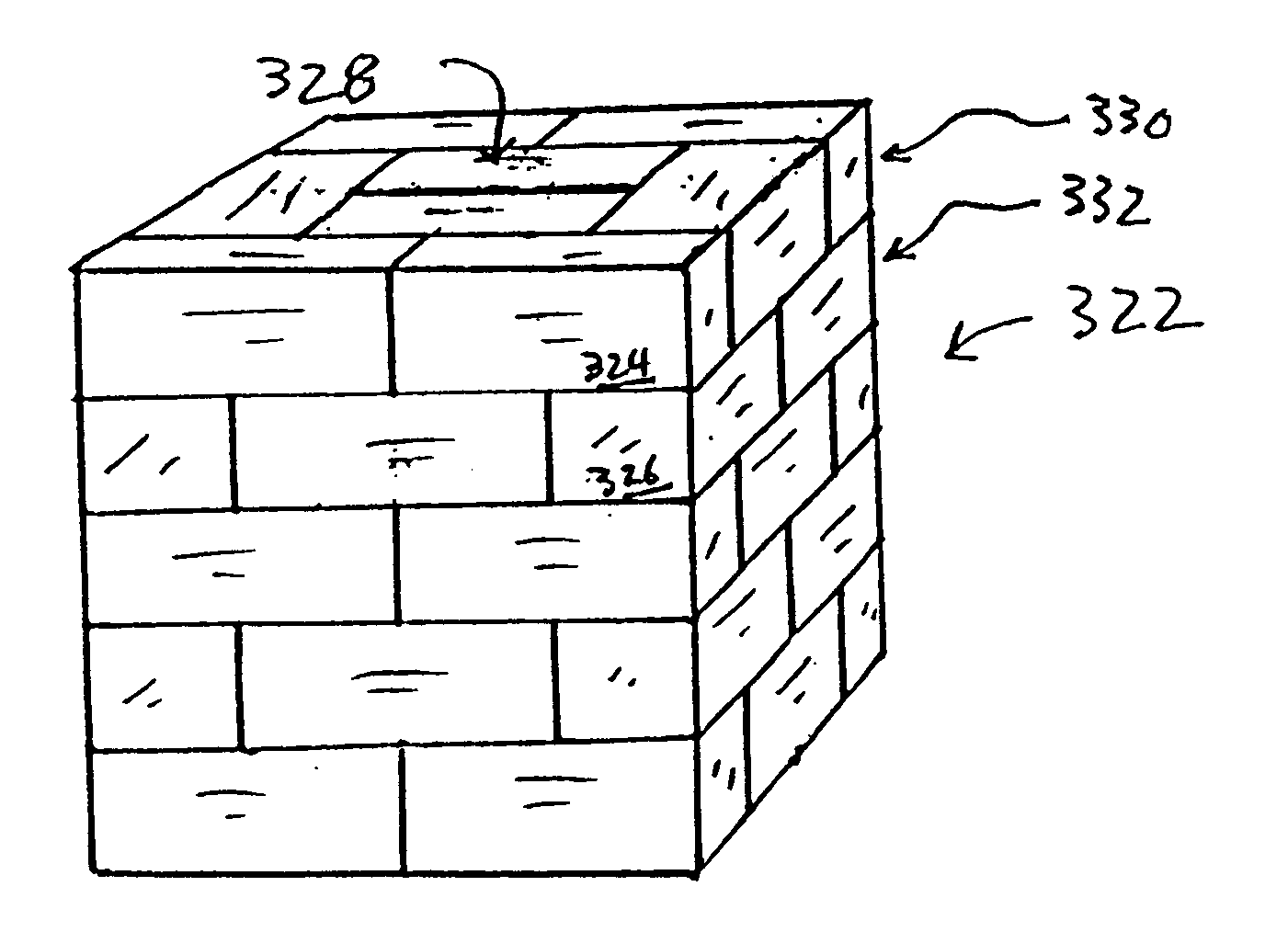

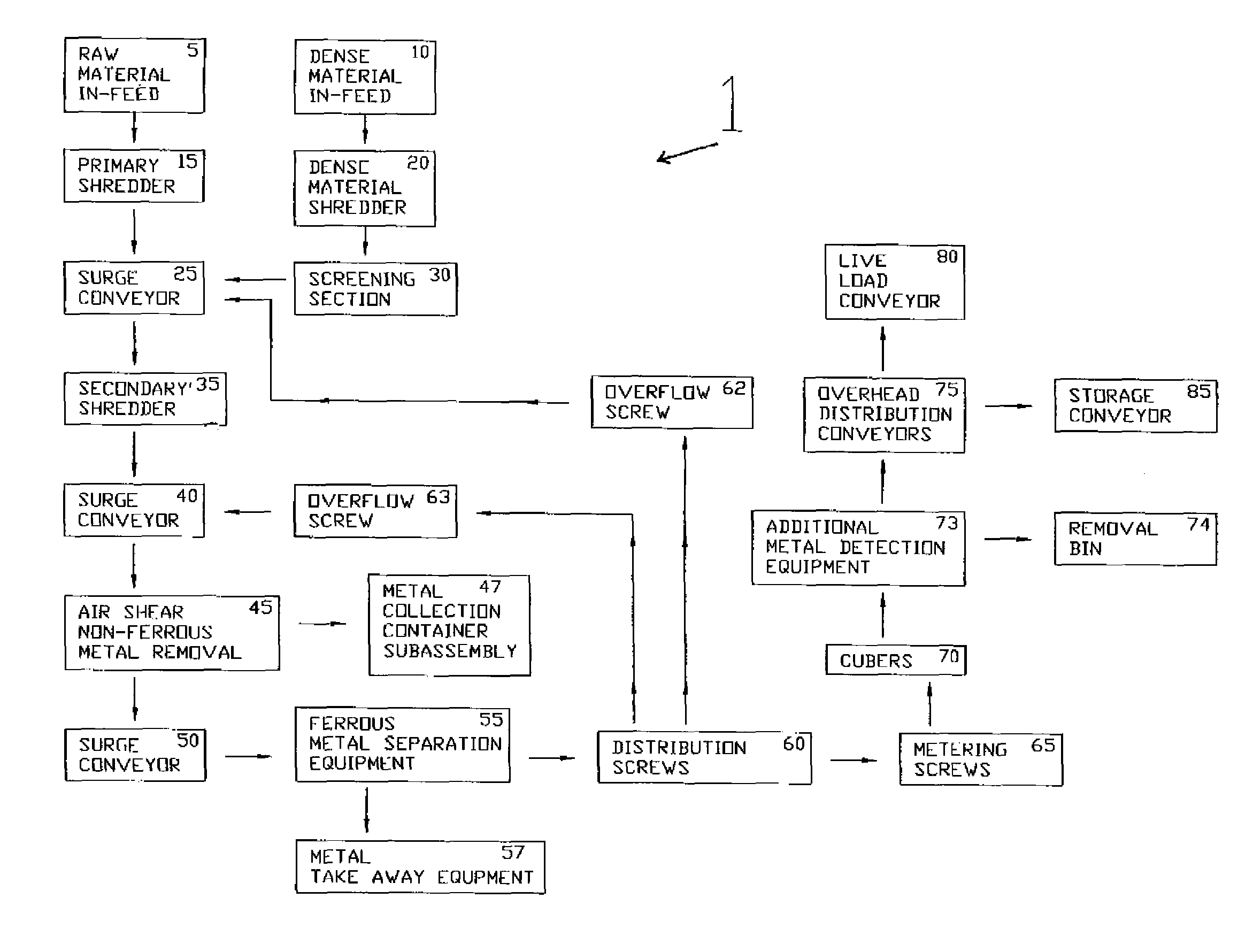

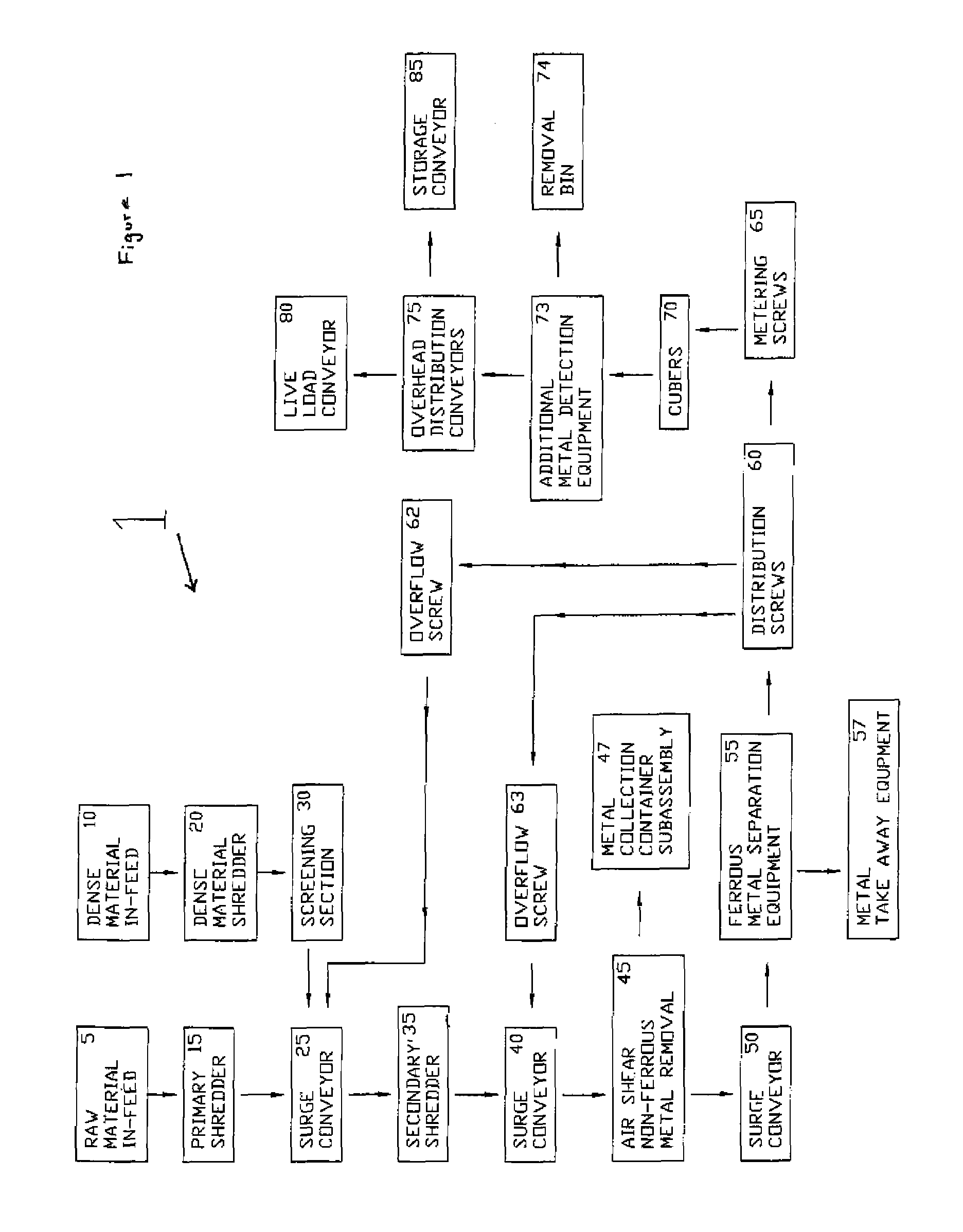

Municipal waste briquetting system and method of filling land

InactiveUS6692544B1Conveniently and economically transportedReduce the impactBiofuelsSolid fuelsRefuse-derived fuelMunicipal sewage

Mechanically and biologically stable briquettes and pellets are obtained from either municipal solid waste (MSW), Refuse Derived Fuel (RDF) or municipal sewage sludge and their combination for purposes of disposing said briquettes and pellets as fuel in waste-to-energy processes such as the one described herein or to form geometric aggregates with such briquettes for their disposal at landfill sites. The use of binding material is not required whereas fuel additives such as crushed coal and petroleum residues may be added to enhance fuel performance but are not needed to improve waste processing or product stability and mechanical properties.

Owner:ECOSYST PROJECTS

Absorbent core for disposable absorbent article

A method of making an absorbent core for use in an absorbent article. The method comprising the steps of:a. providing a first absorbent fibrous web material;b. providing a second absorbent fibrous web material;c. providing a pair of rolls forming a nip through which the first and second absorbent fibrous web materials can be processed, the pair of rolls being selected from the processes consisting of, ring rolling, SELF, micro-SELF, and rotary knife aperturing;d. deforming portions of the first absorbent fibrous web material by processing through the pair of rolls;e. deforming portions of the second absorbent fibrous web material by processing through the pair of rolls; andf. combining the first and second absorbent fibrous web materials to form the absorbent core.

Owner:THE PROCTER & GAMBLE COMPANY

Method of forming a shaped abrasive particle

A method for making abrasive grains, the method comprising mixing one or more solids with one or more liquids in a twin screw extruder to form a mixture, transferring the mixture to a high pressure piston extruder; and extruding the mixture from the high pressure piston extruder through a die to form an extrude. The method further includes segmenting the extrudate to form extruded shaped abrasive particles.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

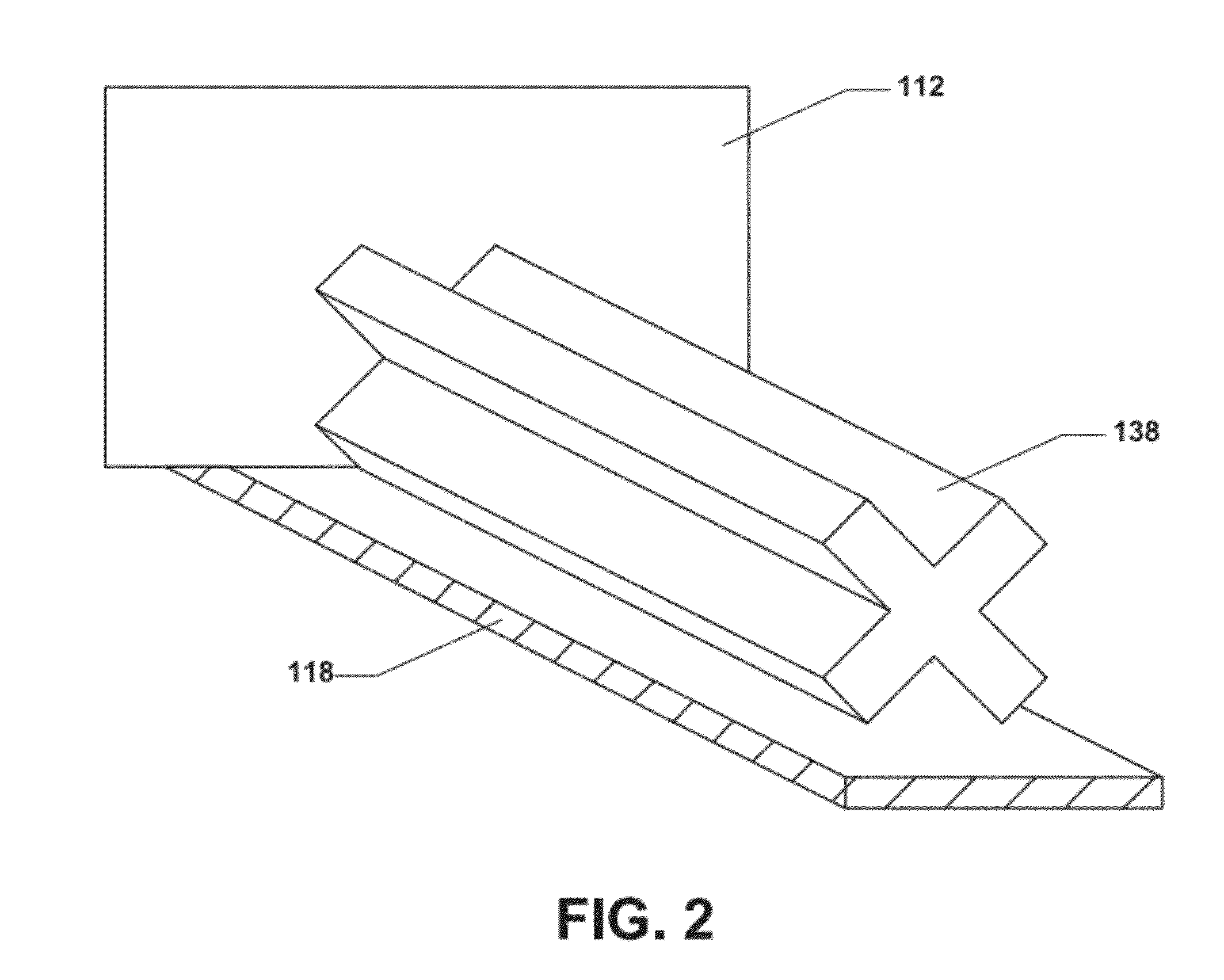

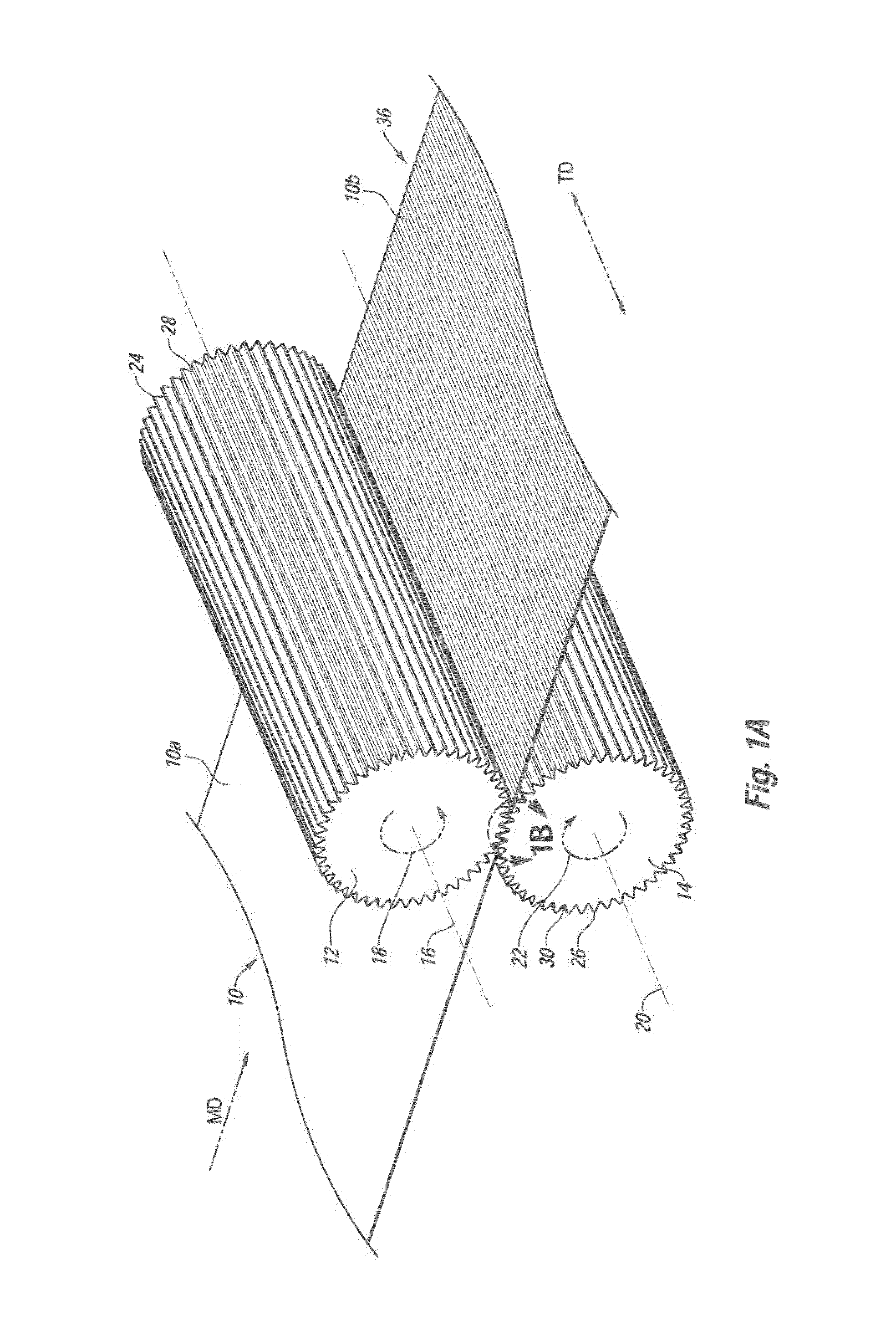

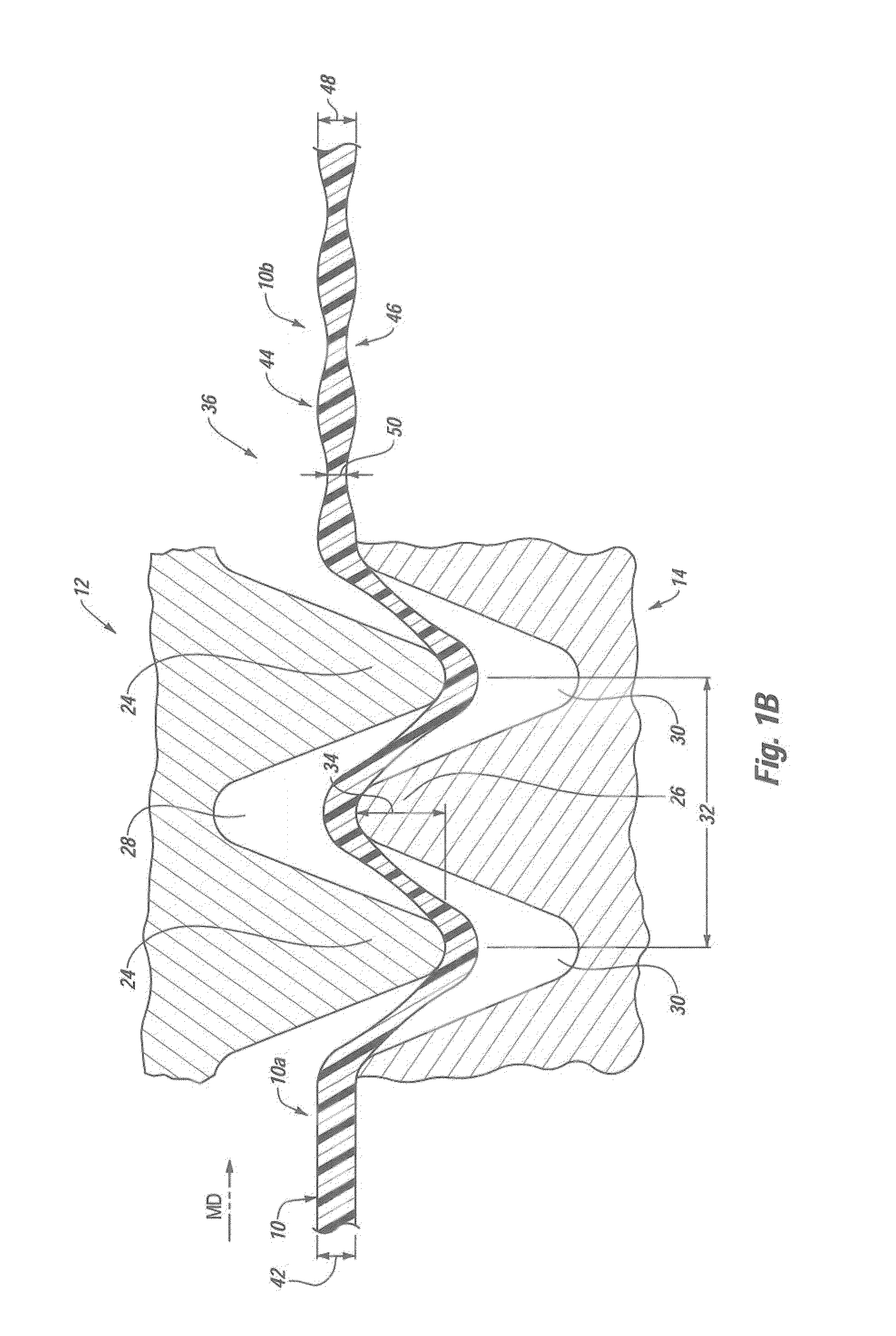

Incrementally-Stretched Adhesively-Laminated Films and Methods for Making The Same

ActiveUS20120039550A1Reduced gaugeReduce thicknessLamination ancillary operationsSynthetic resin layered productsUltimate tensile strengthStrength parameter

Incrementally-stretched adhesively-laminated films include two or more film layers adhesively bonded together. At least one of the two or more film layers is incrementally stretched. The incrementally-stretched adhesively-laminated films can have maintained or increased strength parameters despite a reduction in gauge. The incrementally-stretched adhesively-laminated films can be formed into bags for use as trash can liners or food storage. Methods of forming incrementally-stretched adhesively-laminated films include cold stretching one or more of the first and second film layers and adhesively bonding the film layers together.

Owner:THE GLAD PROD CO

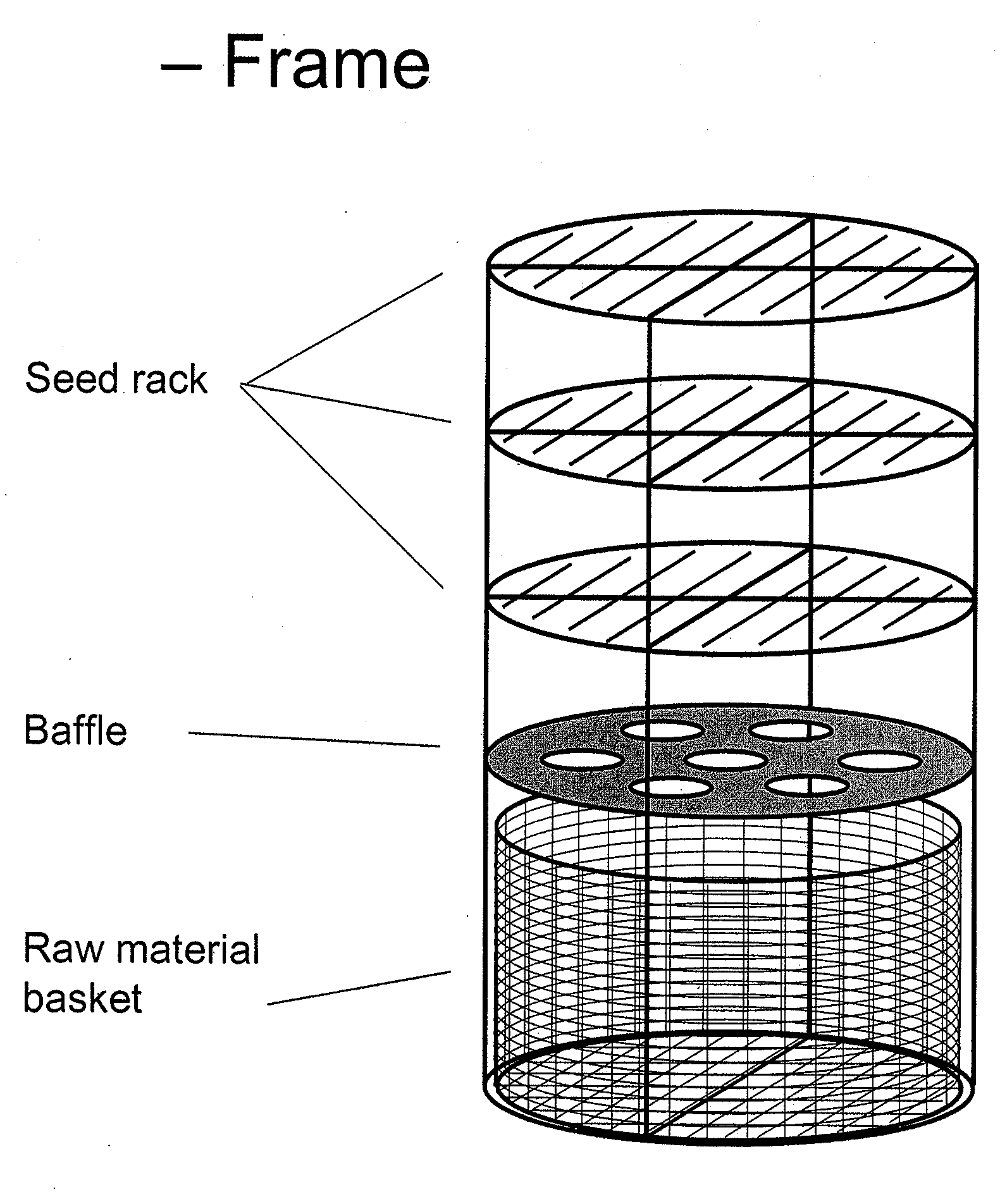

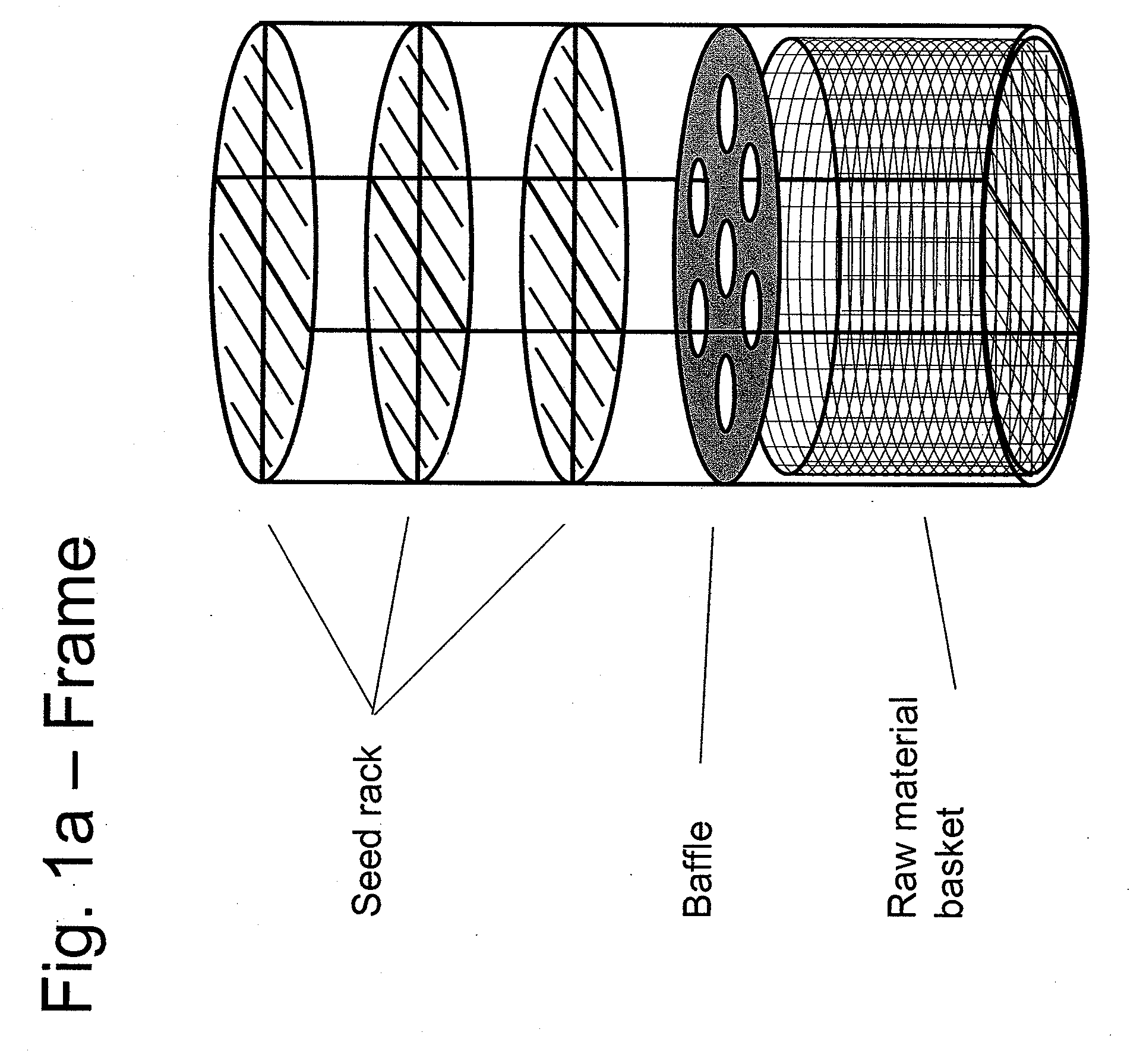

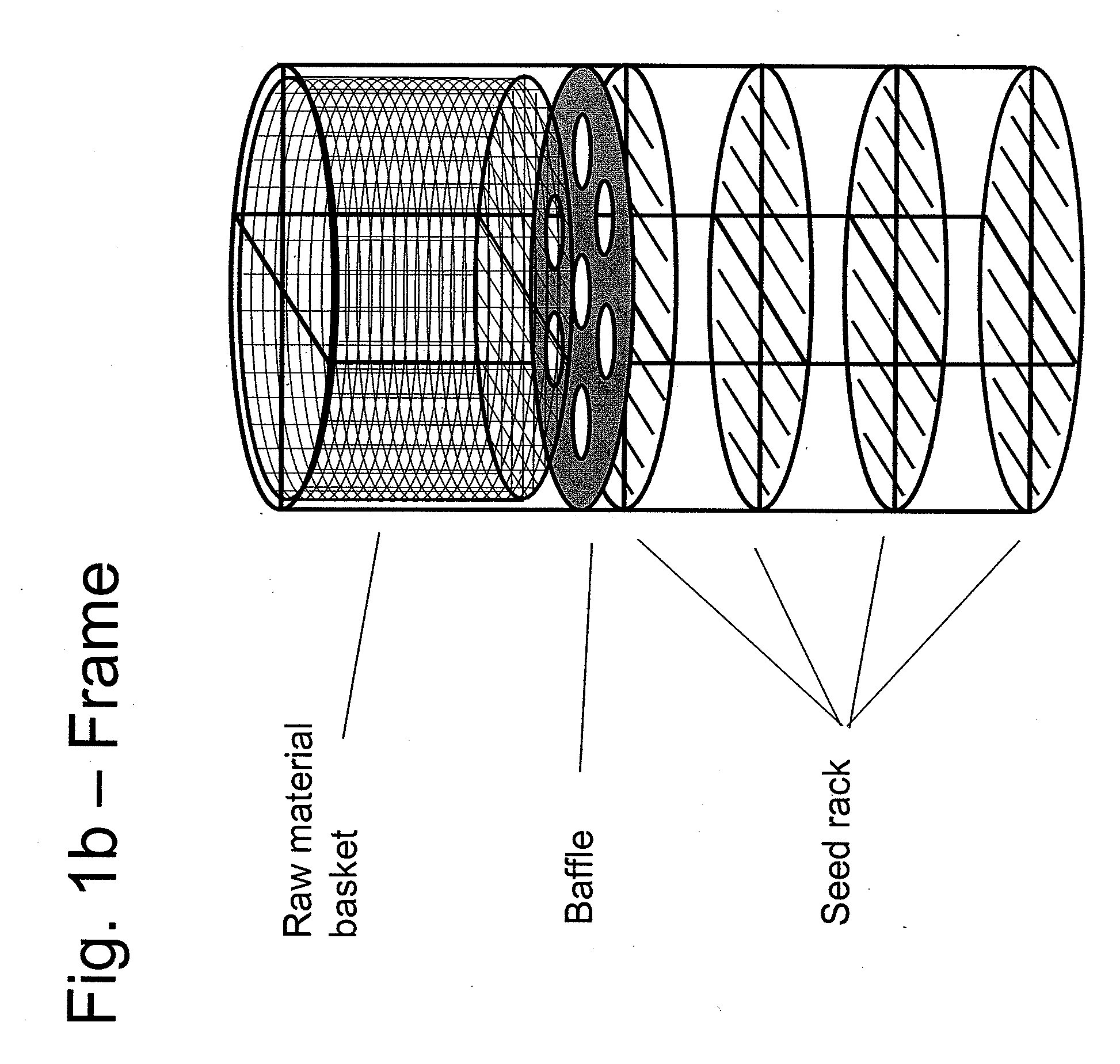

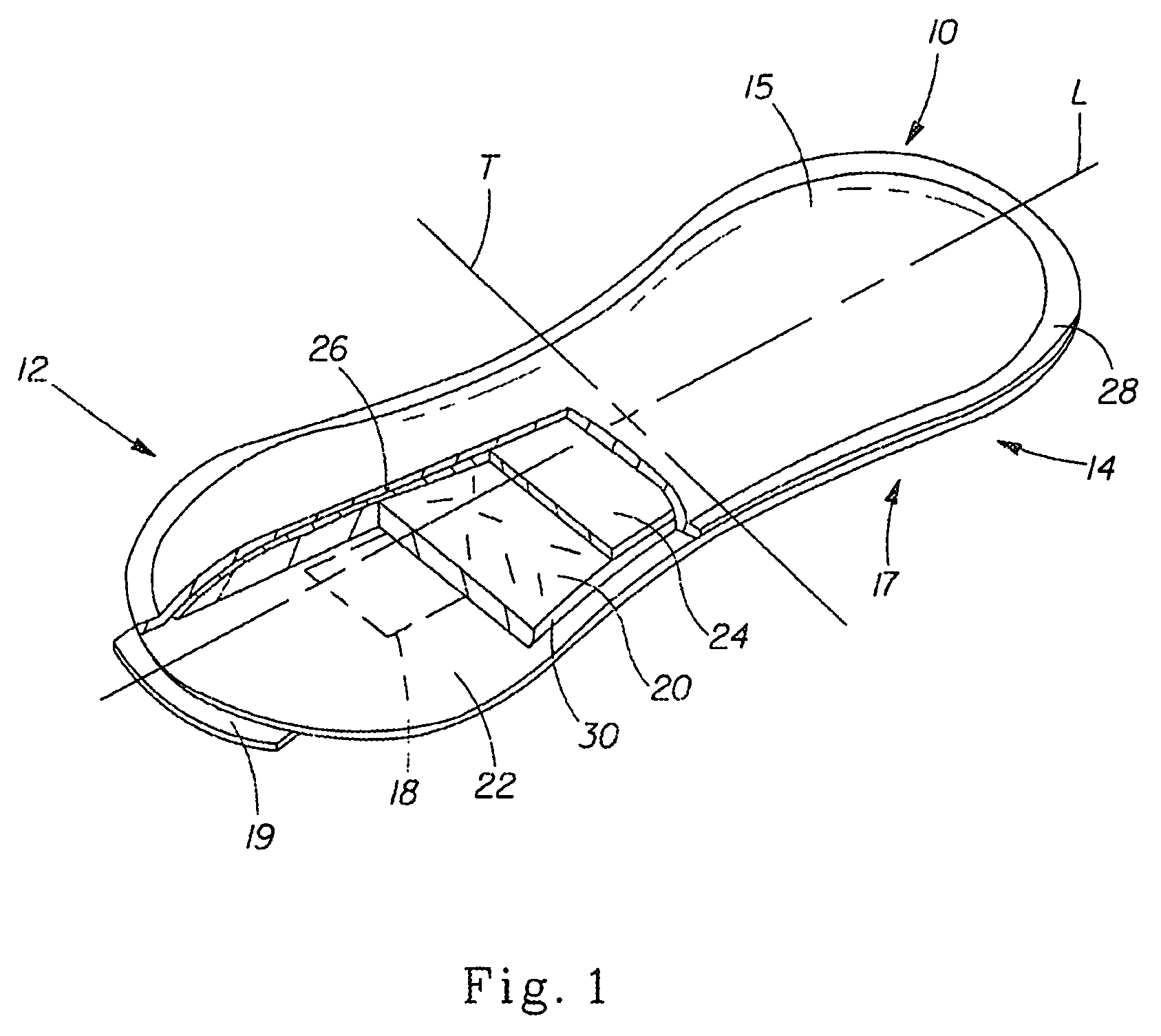

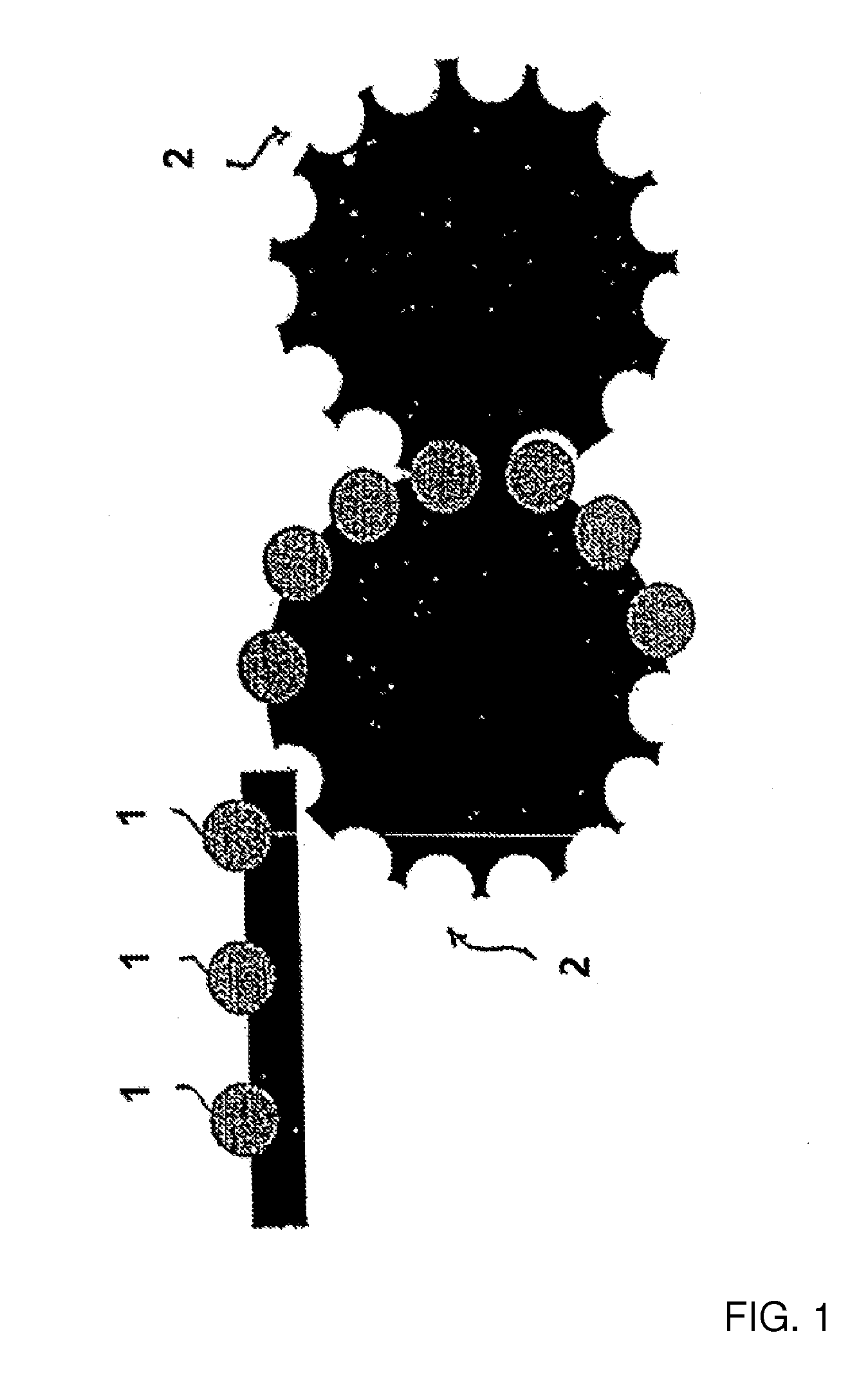

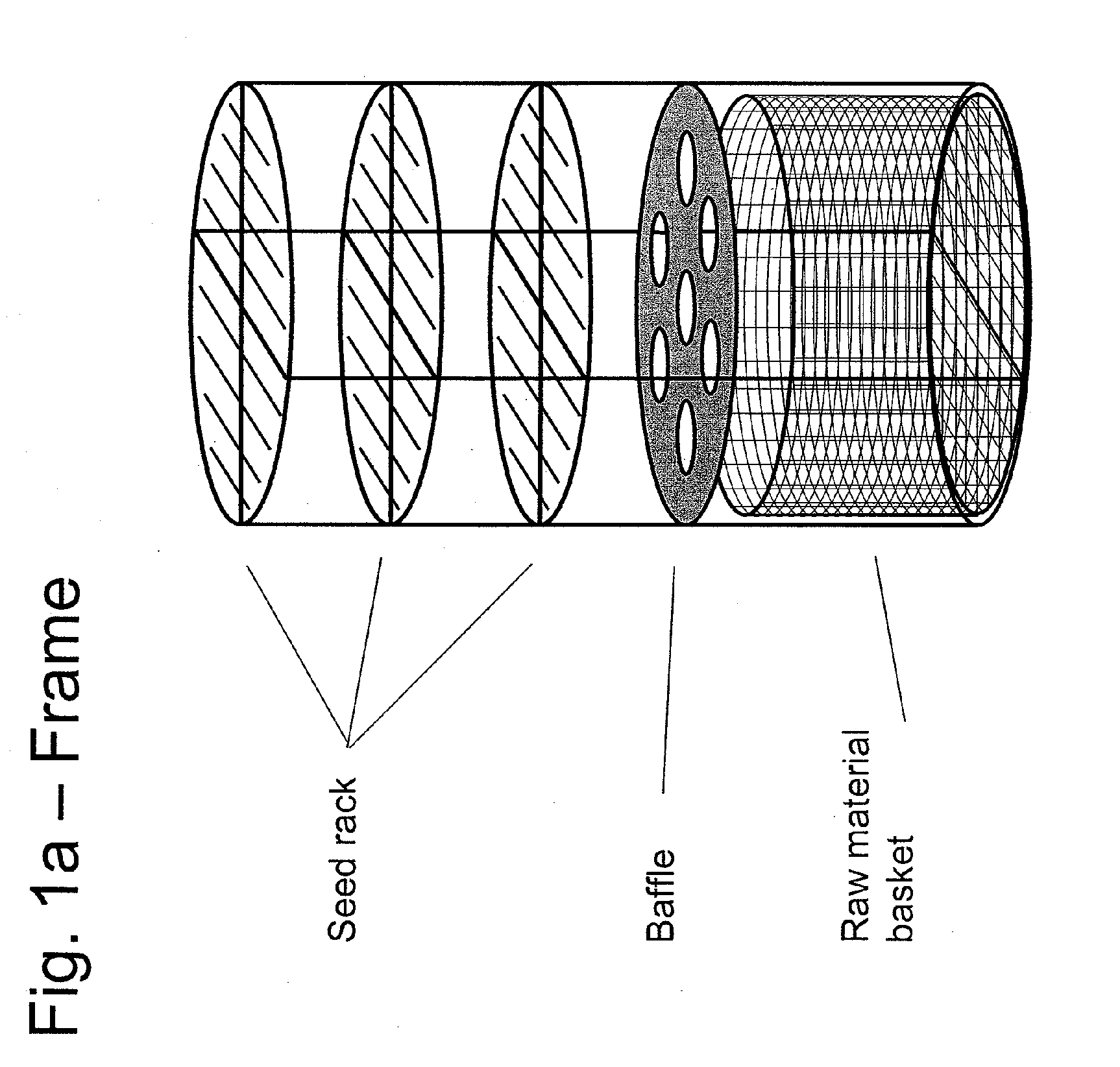

Basket process and apparatus for crystalline gallium-containing nitride

InactiveUS20100031873A1Avoid transportCost-effectivePolycrystalline material growthFrom normal temperature solutionsDopantCost effectiveness

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SORAA

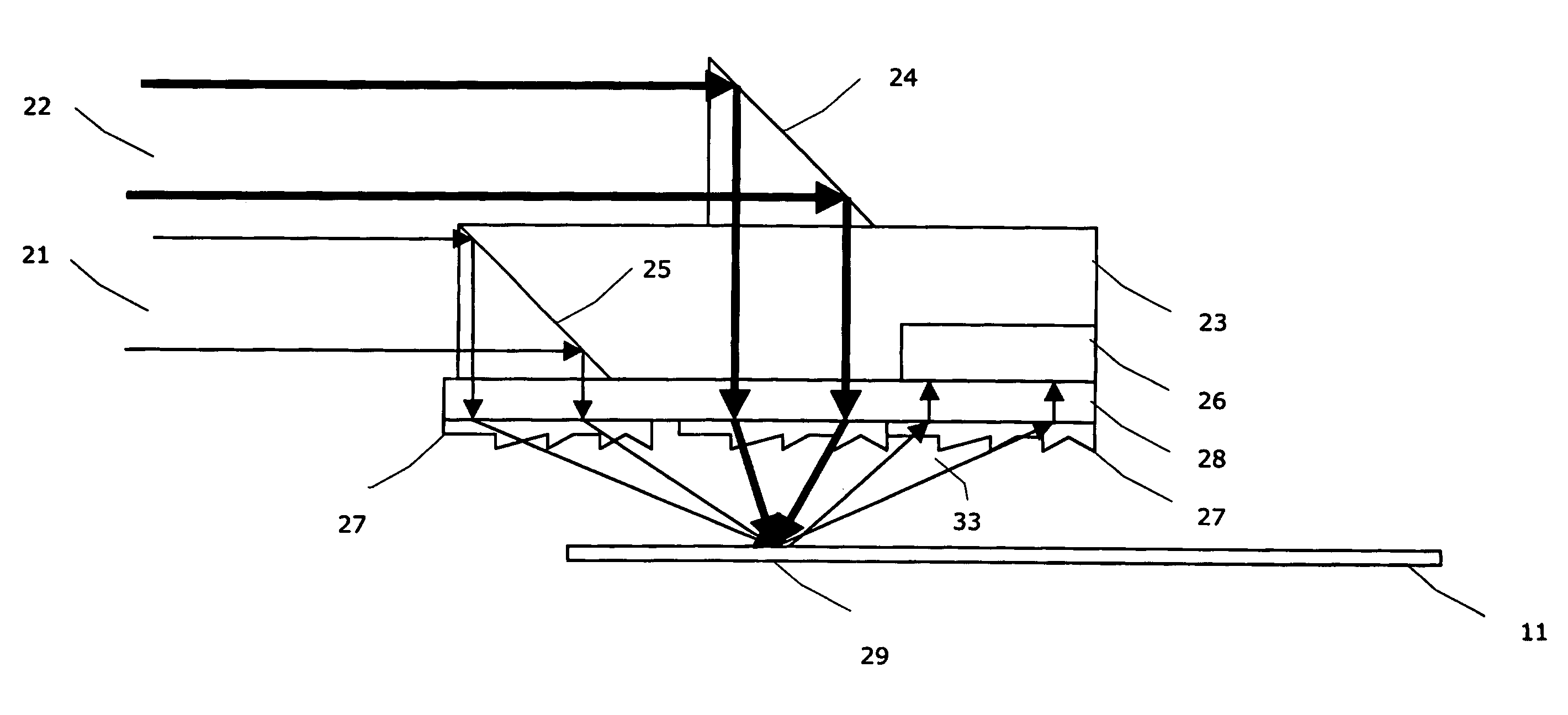

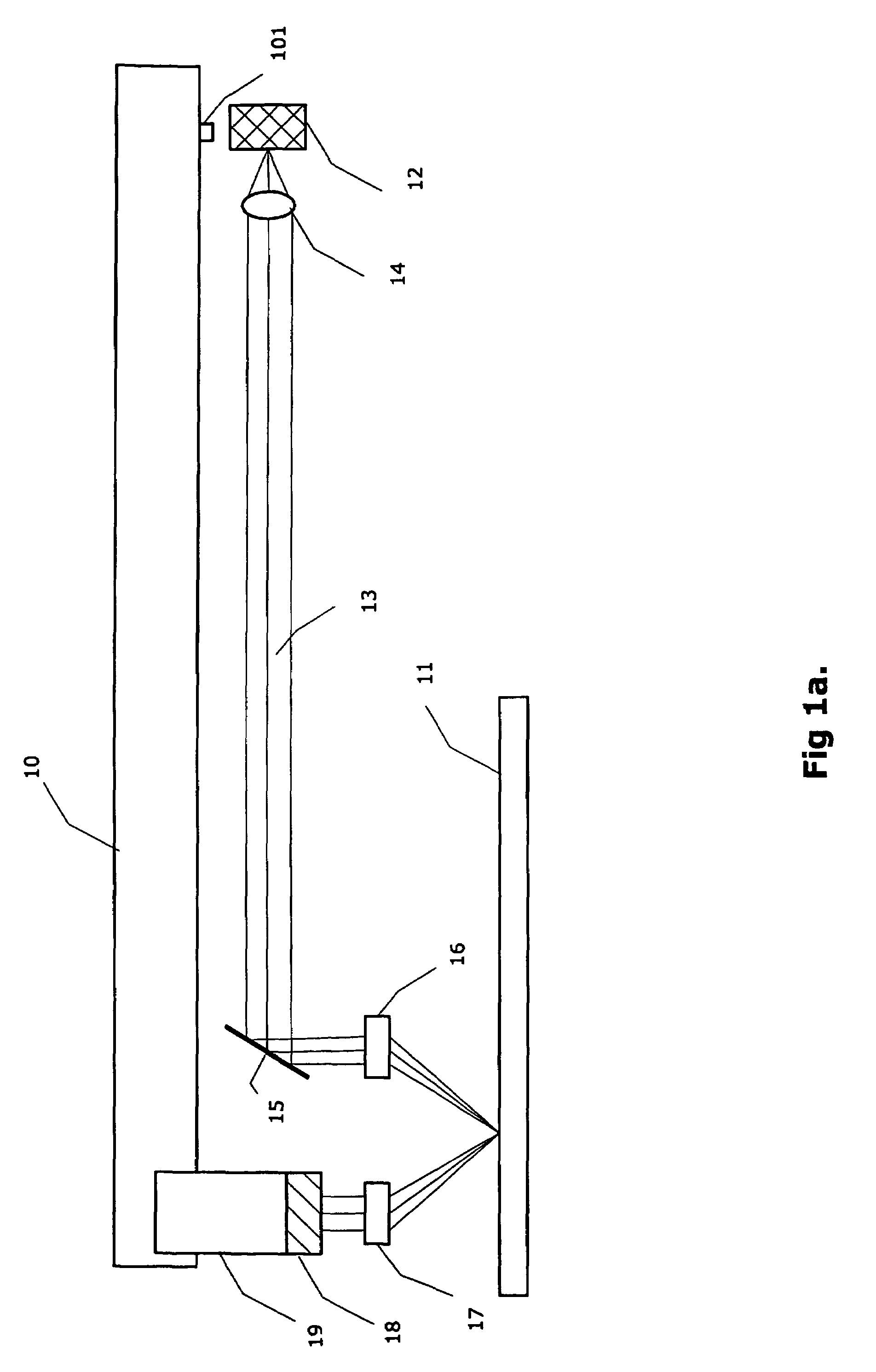

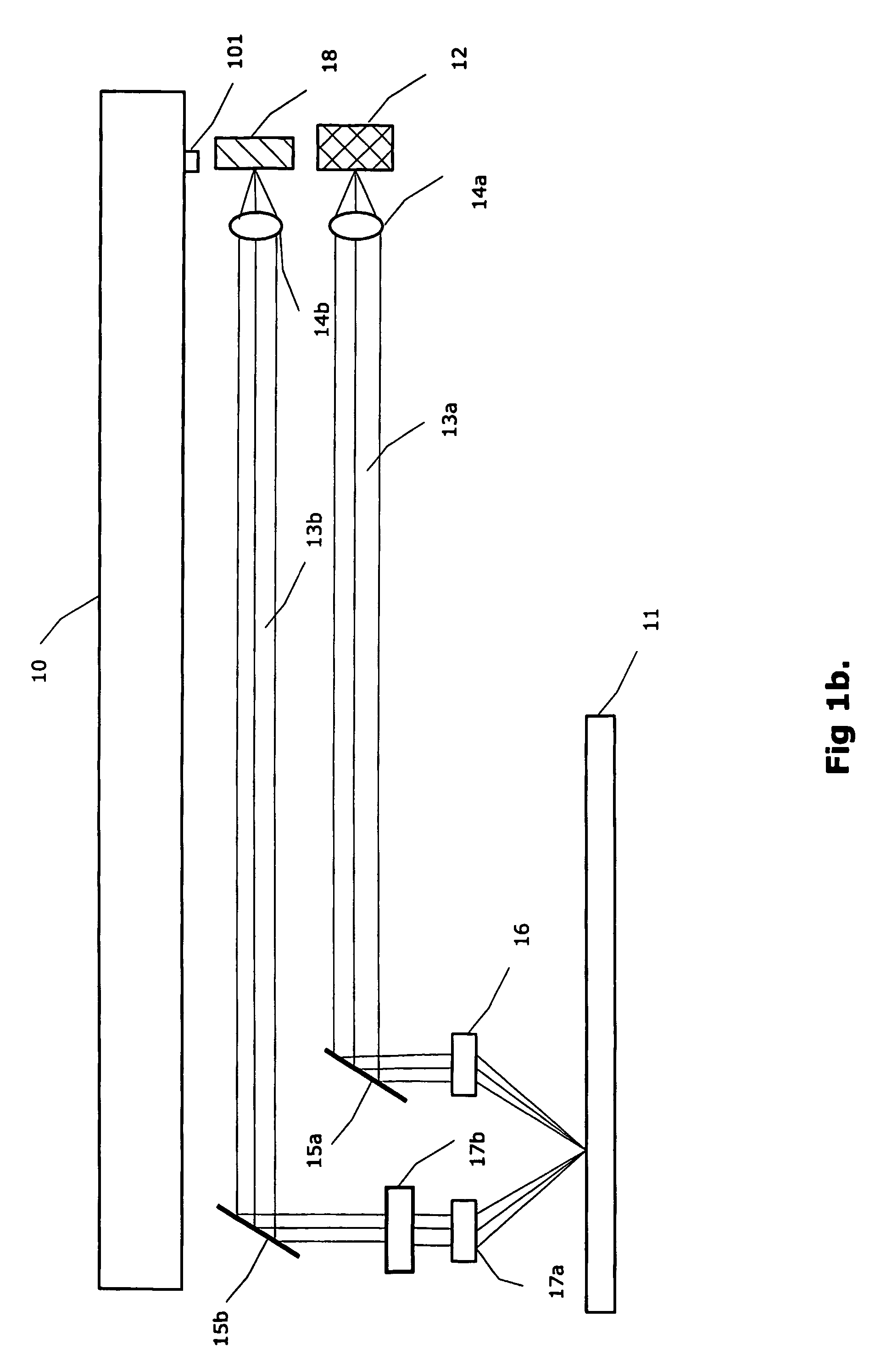

Read write device for optical memory and method therefore

InactiveUS7480215B2Small-size and low-weight optical storage systemGuaranteed uptimePharmaceutical product form changeRecord information storageLight beamOptical storage

A method and miniaturizable device is described to read / write information to an optical storage medium (11). A device comprises one or more light sources (12) bounded up with an access unit (10) which is arranged to be controllable to a position, in which light beams (21, 22) are transmitted transversal towards an optical storage medium, and reflected light beams (33) are analysed by a detector element (18, 26) which further informs the access unit whether to move or stand still to keep light beams in focus and on track. A device according to the invention is possible to implement in a small size and low weight due to reduced component count and thin access unit geometries. A communication device (80) according to the invention may be implemented to fulfil a crucial need for ultraminiature range of communication devices.

Owner:NOKIA CORP

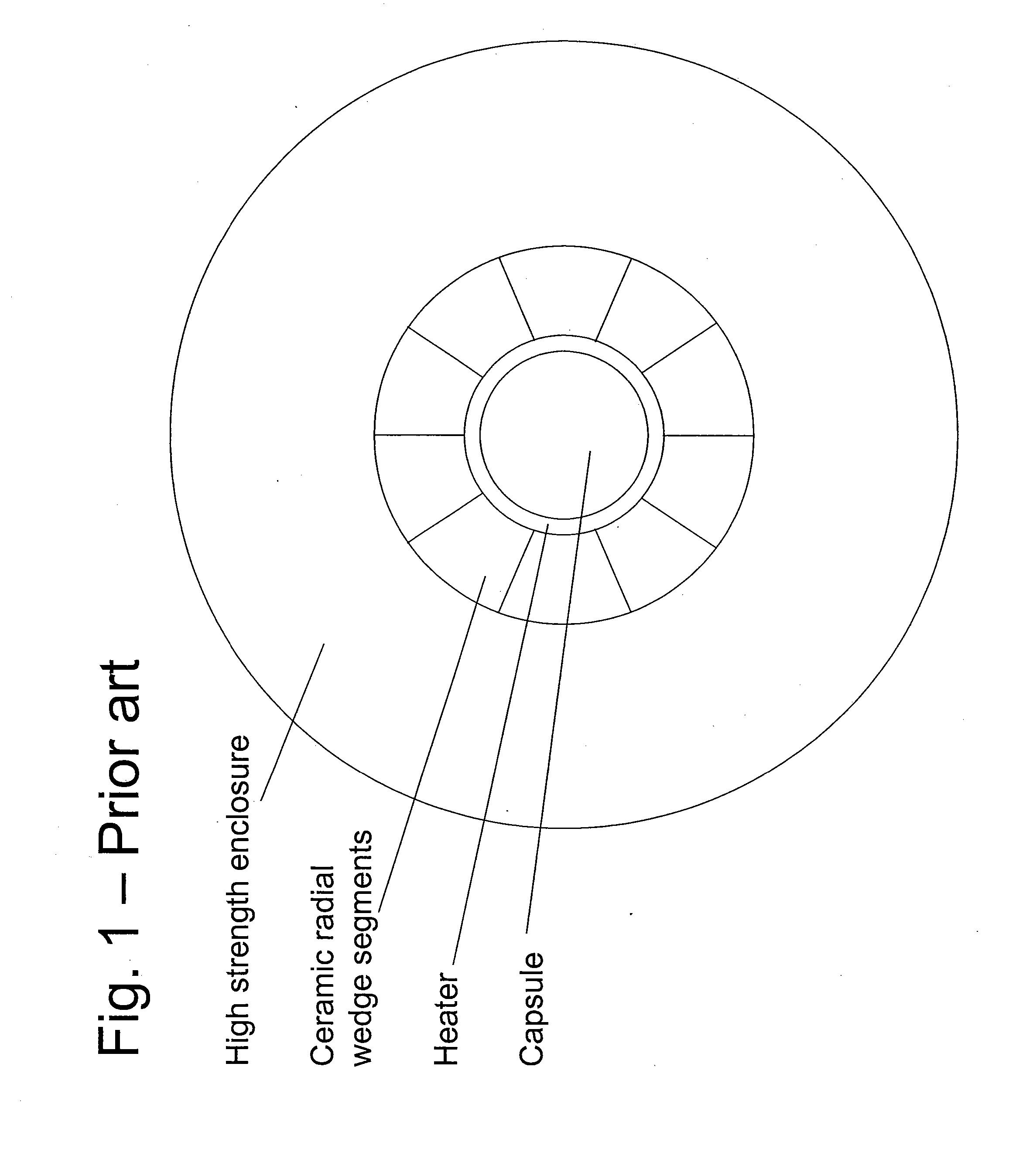

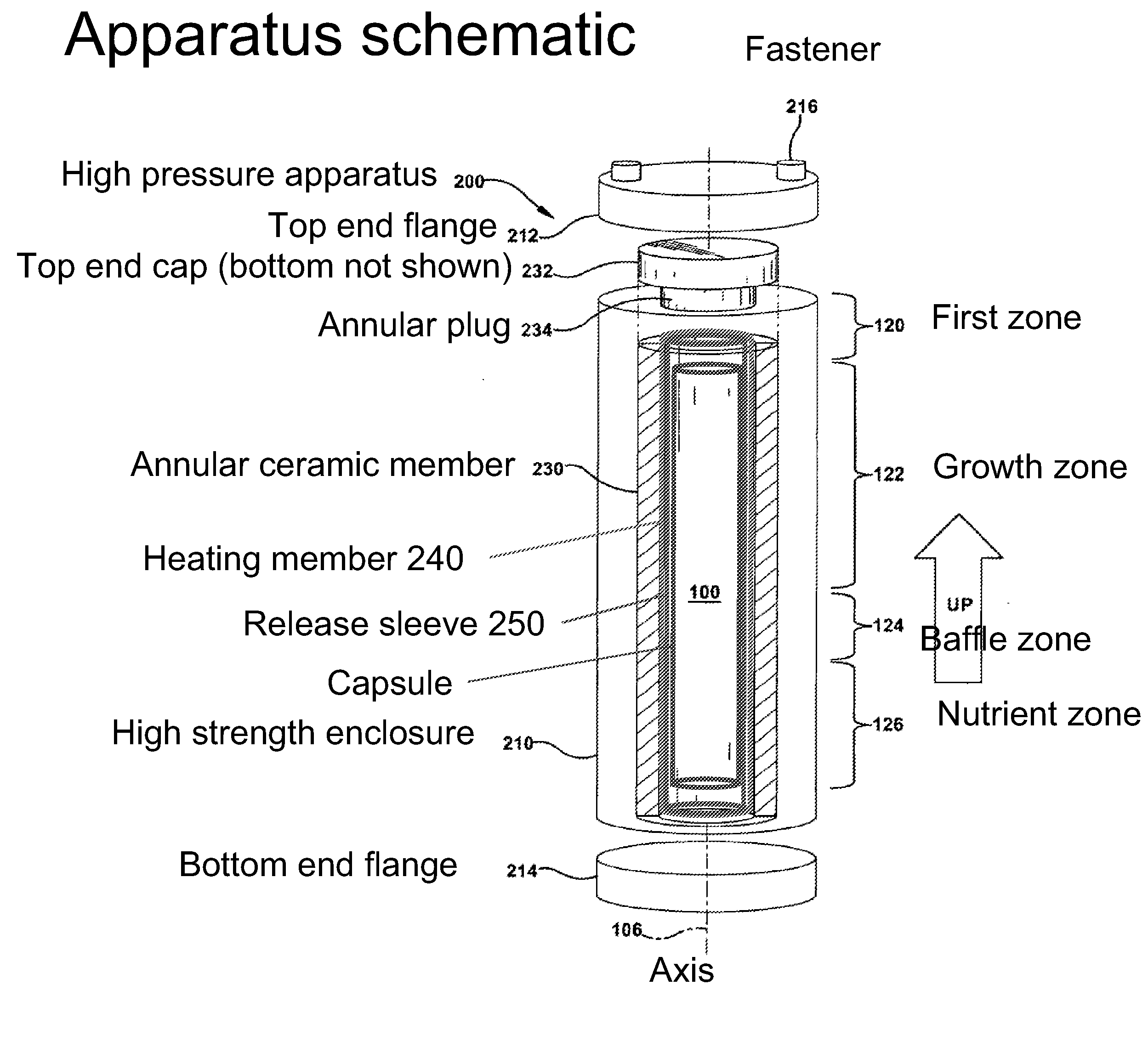

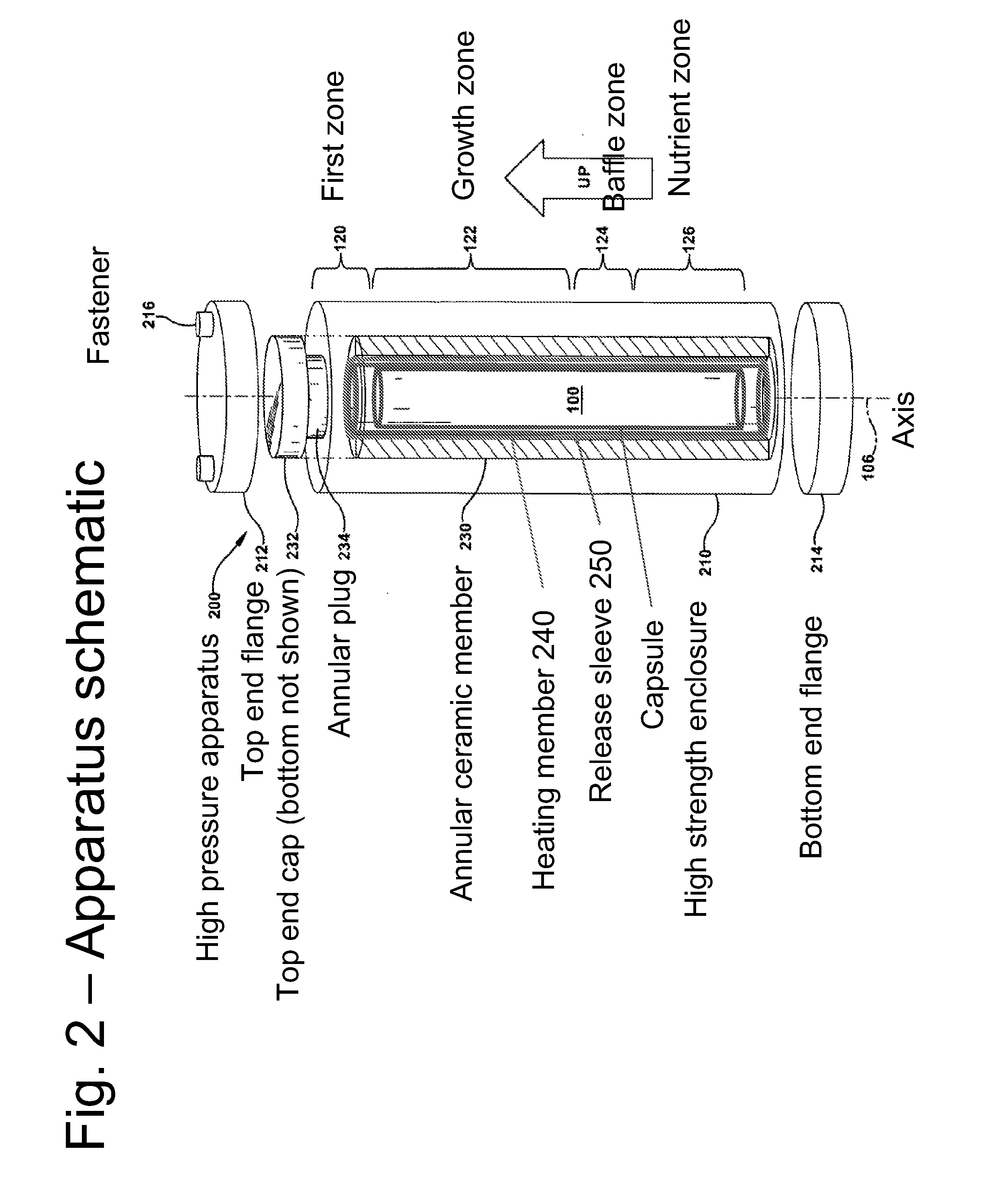

High pressure apparatus and method for nitride crystal growth

InactiveUS20100147210A1Simple and cost-effective to manufactureEasy to disassemblePolycrystalline material growthFrom normal temperature solutionsControl systemPower control system

An improved high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a release sleeve, a heater, at least one ceramic segment or ring but can be multiple segments or rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively. Following a run, the release sleeve may be at least partially dissolved or etched to facilitate removal of the capsule from the apparatus.

Owner:SORAA

Modified release dosage forms

In one embodiment a dosage form comprises at least one active ingredient and a molded matrix which comprises 10-100% of a material having a melting point of less than about 100 degrees C. selected from the stamp consisting of thermoplastic polyalkylene oxides, low melting hydrophobic materials, thermoplastic polymers, thermoplastic starches and combinations thereof, and the matrix is capable of providing modified release of the active ingredient upon contacting of the dosage form with a liquid medium. The dosage form may additionally comprise uncoated particles which may contain at least one active ingredient. In another embodiment, a dosage form comprises at least one active ingredient, a plurality of particles and a molded matrix, wherein at least a portion of the particles are coated. The coated particles, the matrix or both may comprise at least one active ingredient, and the coated particles or the matrix or a combination thereof is capable of providing modified release of the active ingredient upon contacting of the dosage form with a liquid medium.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

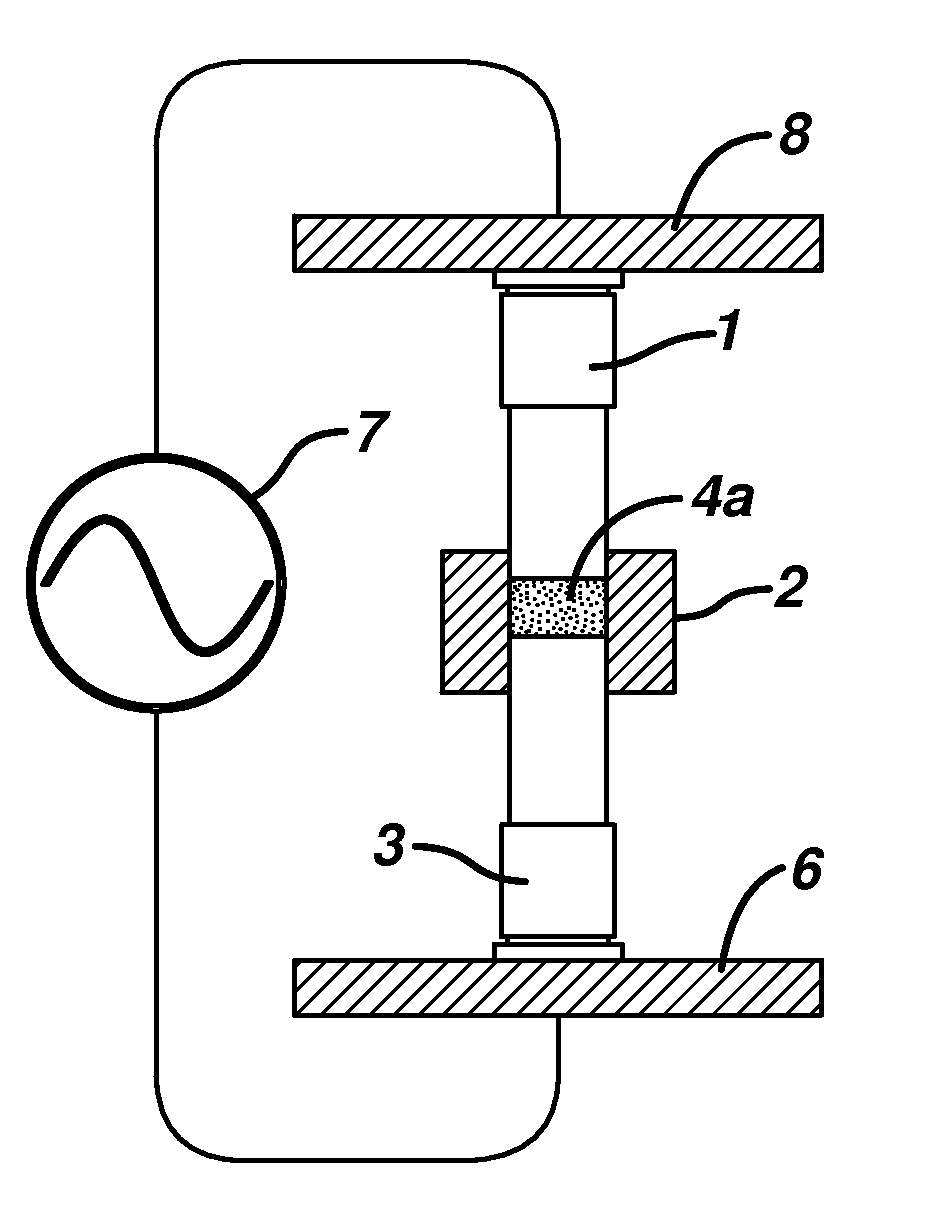

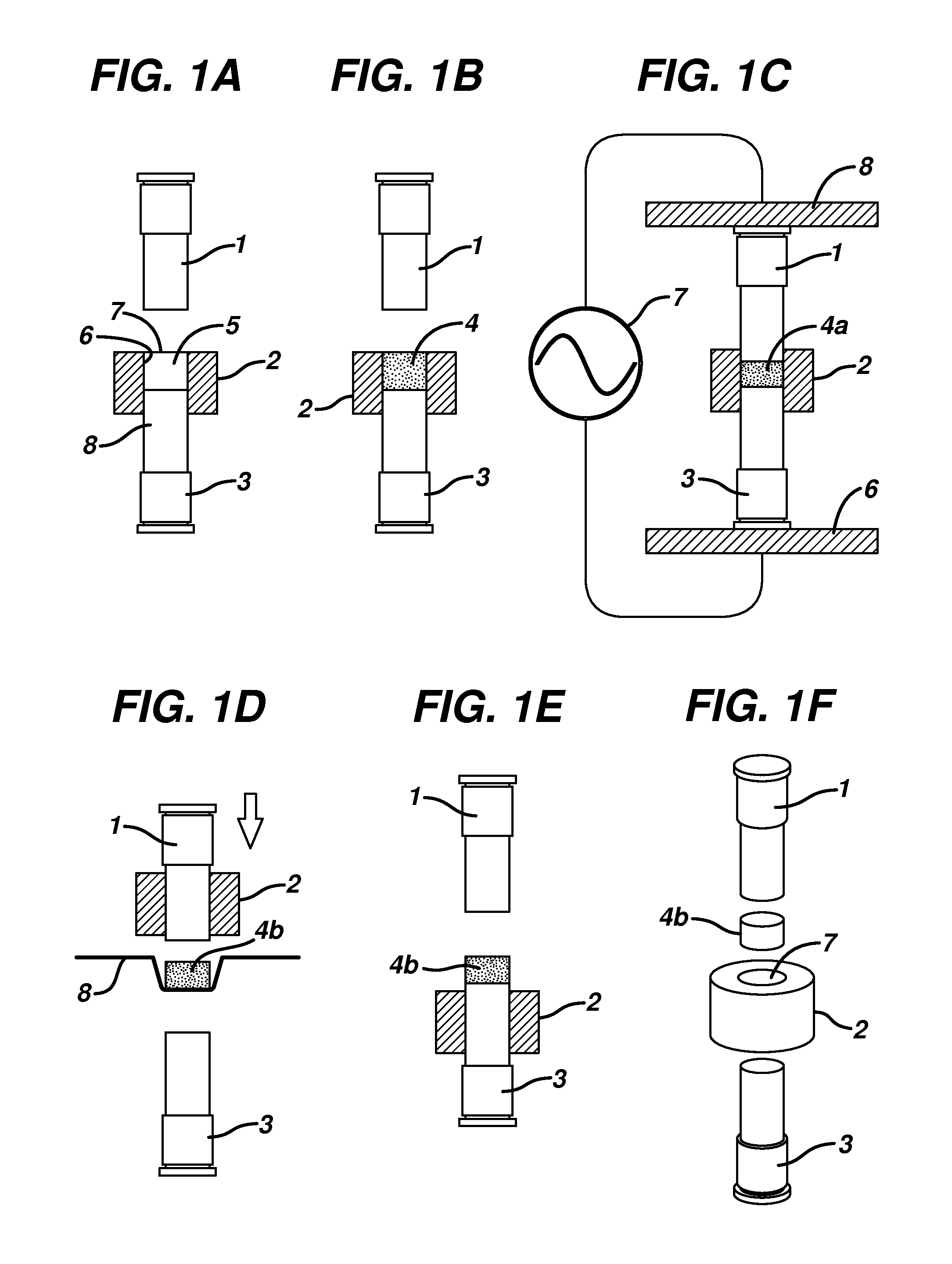

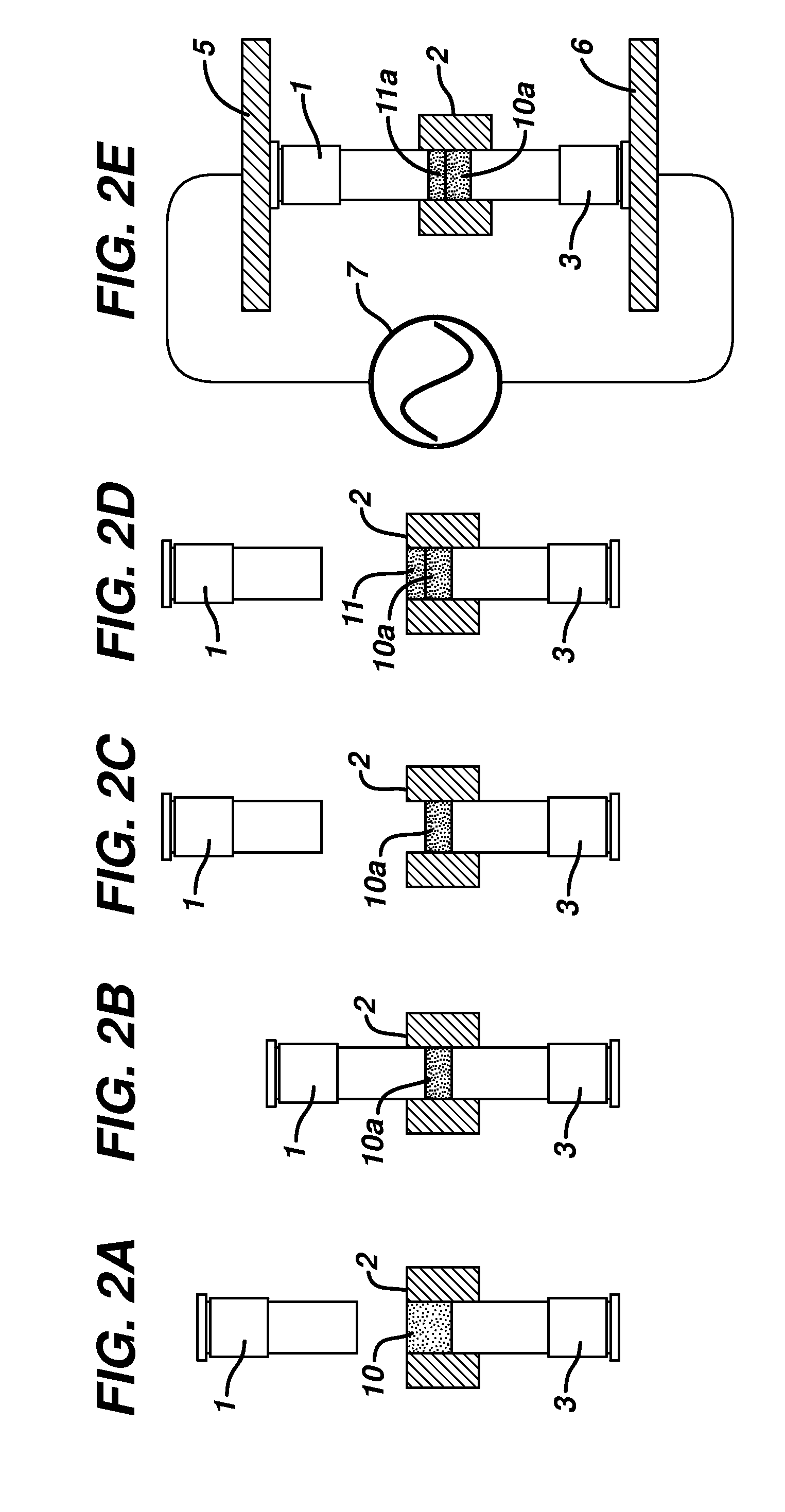

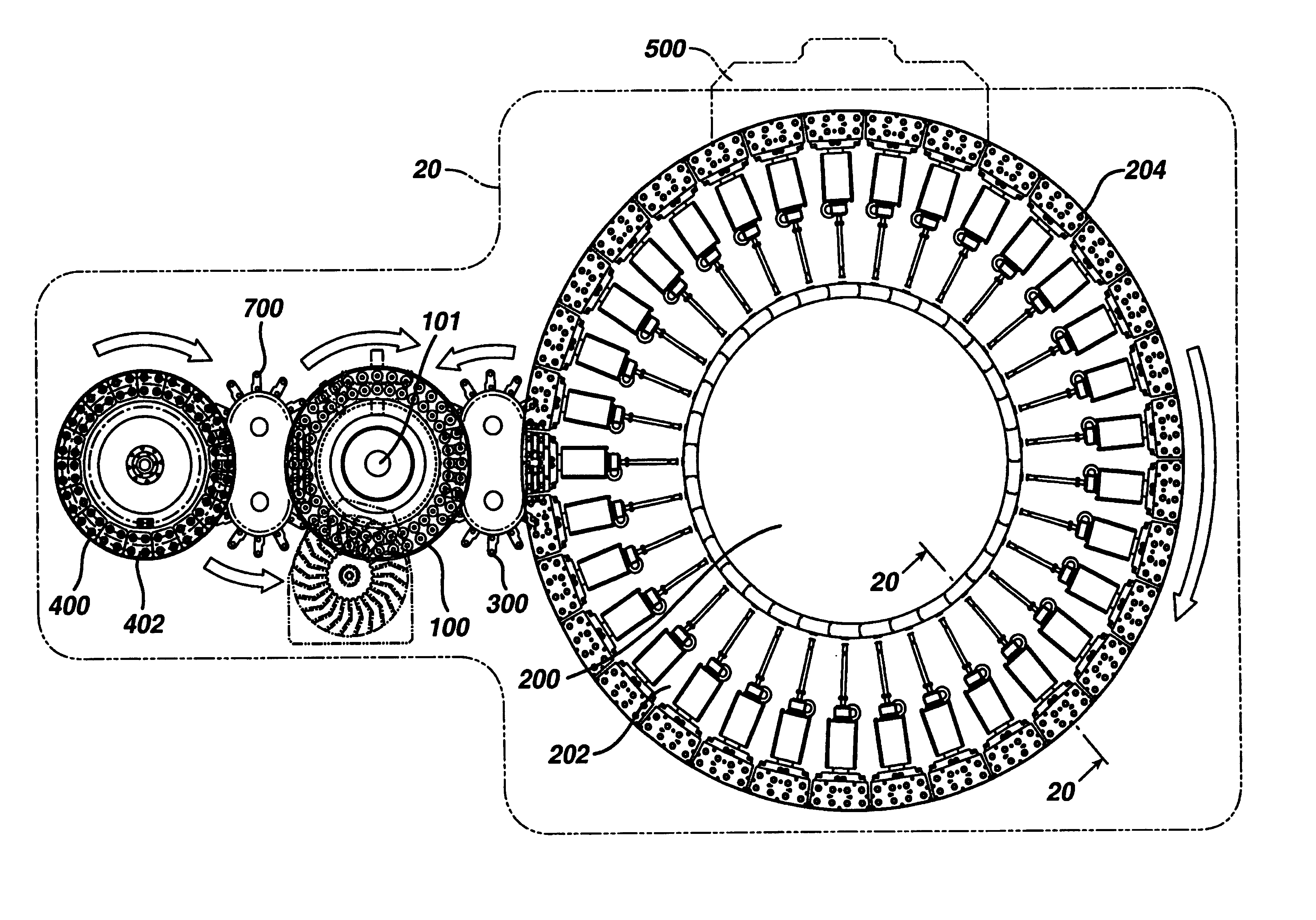

Machine for the manufacture of dosage forms utilizing radiofrequency energy

ActiveUS20110068511A1Organic active ingredientsNervous disorderSolid Dose FormBiomedical engineering

The present invention features the present invention features a machine for the production of a solid dosage form including: (a) a die platen having one or more forming cavities each having an inner wall, a first opening at the surface of one side of the die platen, and a second opening at the surface on the opposite side of the die platen; (b) one or more first forming tools each adapted to move into one of the forming cavities through the first opening of the forming cavity; (c) one or more second forming tools each adapted to move adjacent to one of the second openings or into one of the forming cavities through the second opening of the forming cavity; (d) at least one first RF electrode operably associated with the one or more first forming tools, the one or more second forming tools, or the inner wall of the one or more forming cavities; and (e) at least one second RF electrode operably associated with the one or more first forming tools.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

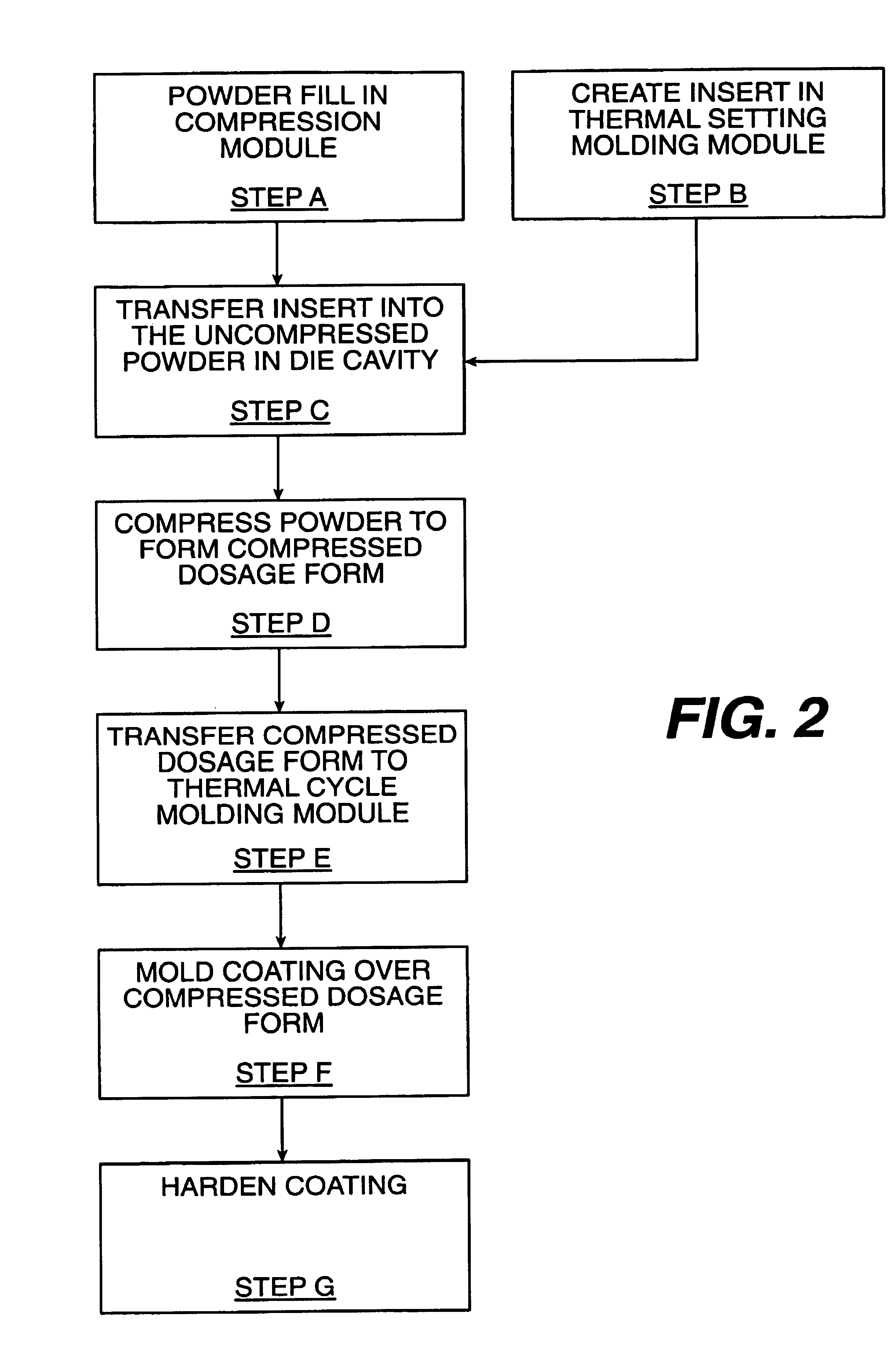

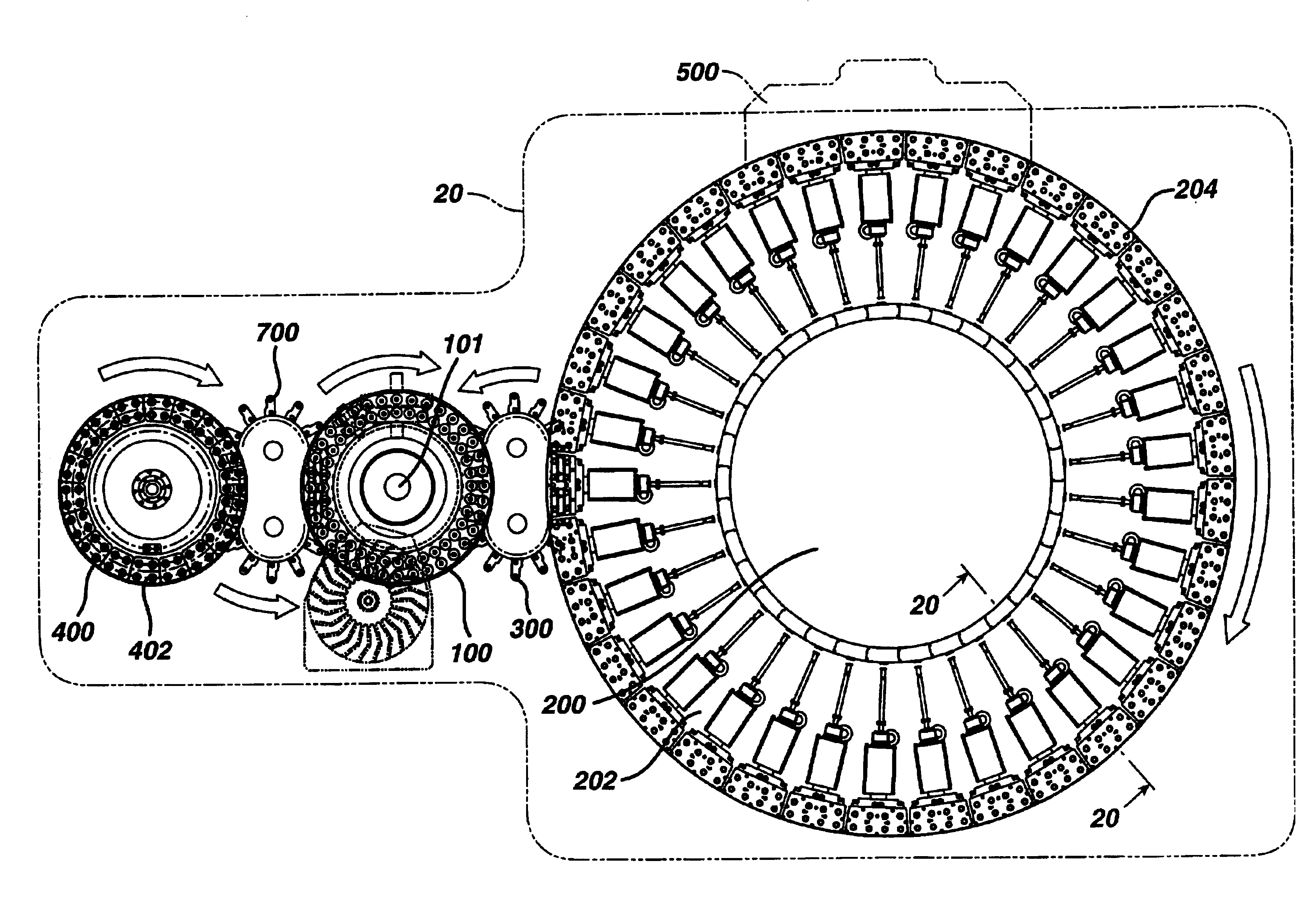

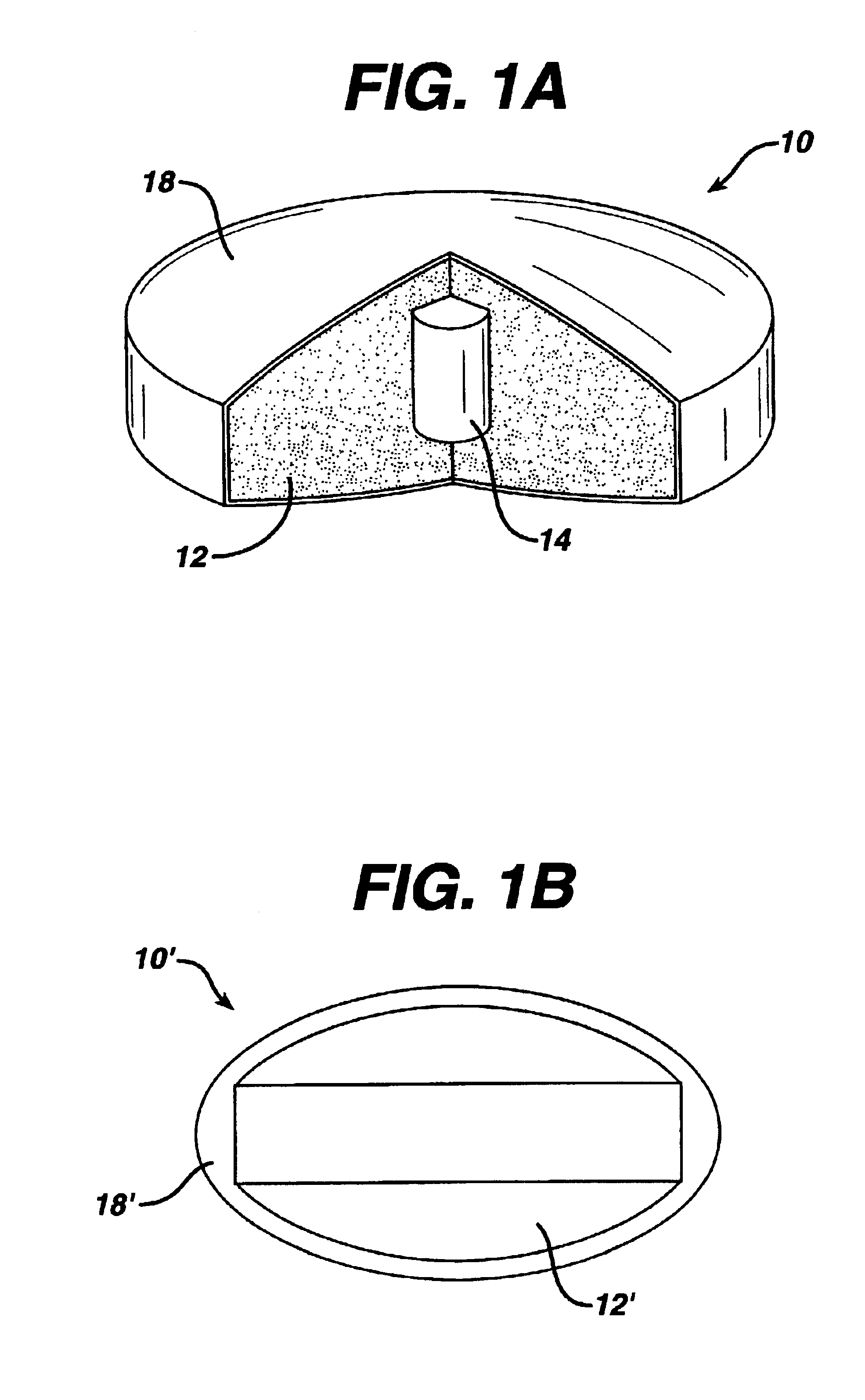

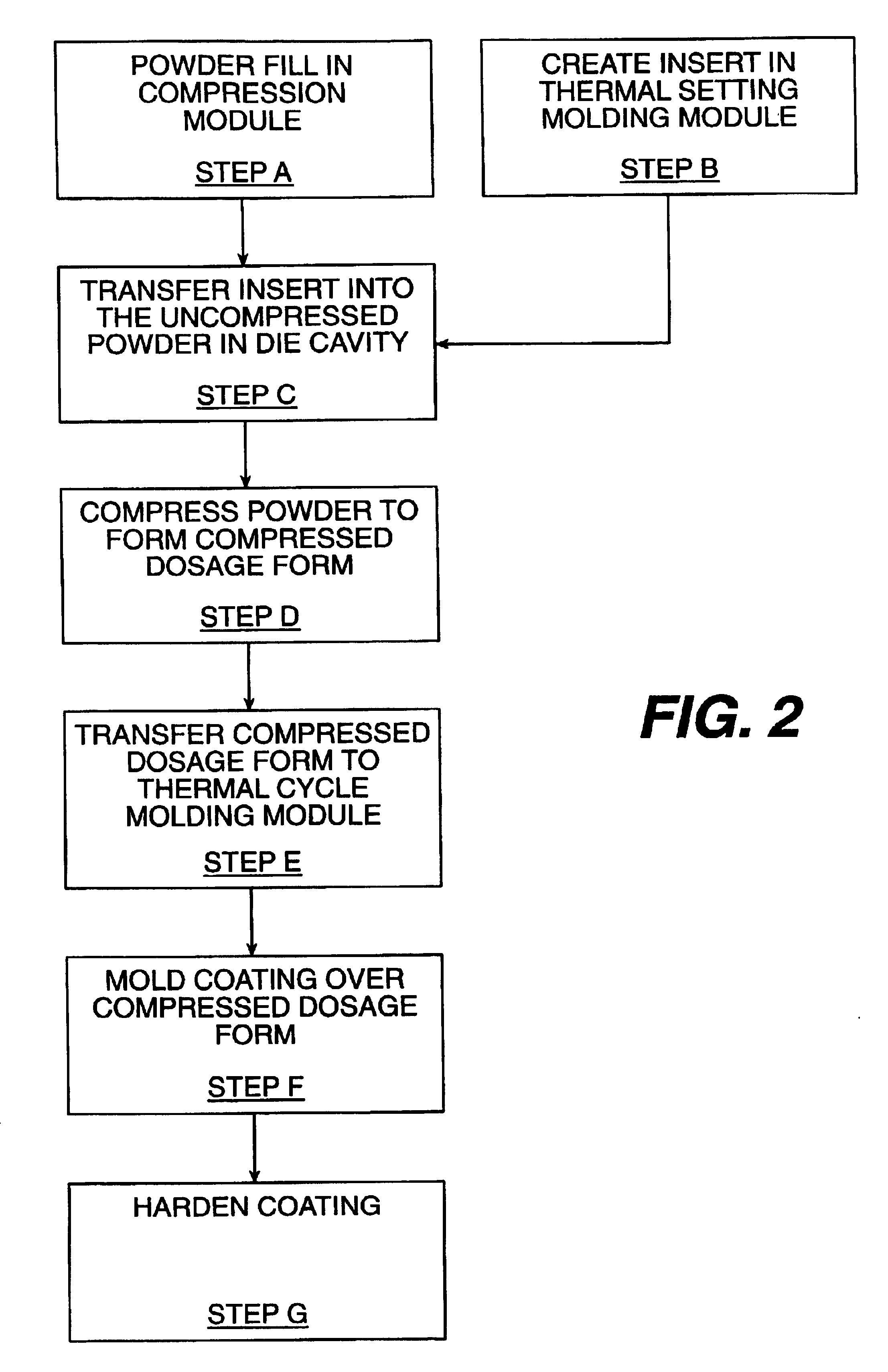

Systems, methods and apparatuses for manufacturing dosage forms

Systems, methods and apparatuses for manufacturing dosage forms, and to dosage forms made using such systems, methods and apparatuses are provided. Novel compression, thermal cycle molding, and thermal setting molding modules are disclosed. One or more of such modules may be linked, preferably via novel transfer device, into an overall system for making dosage forms.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

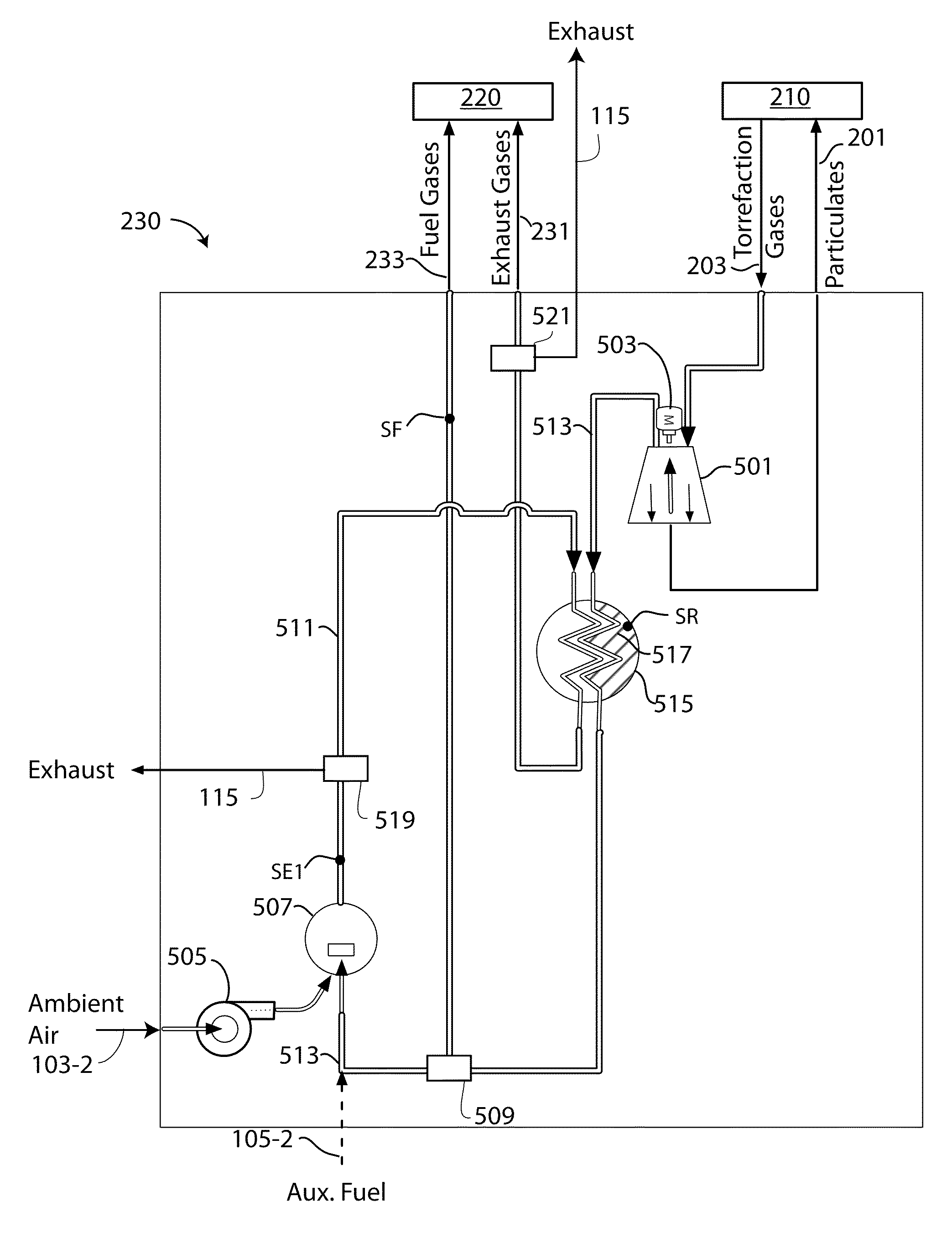

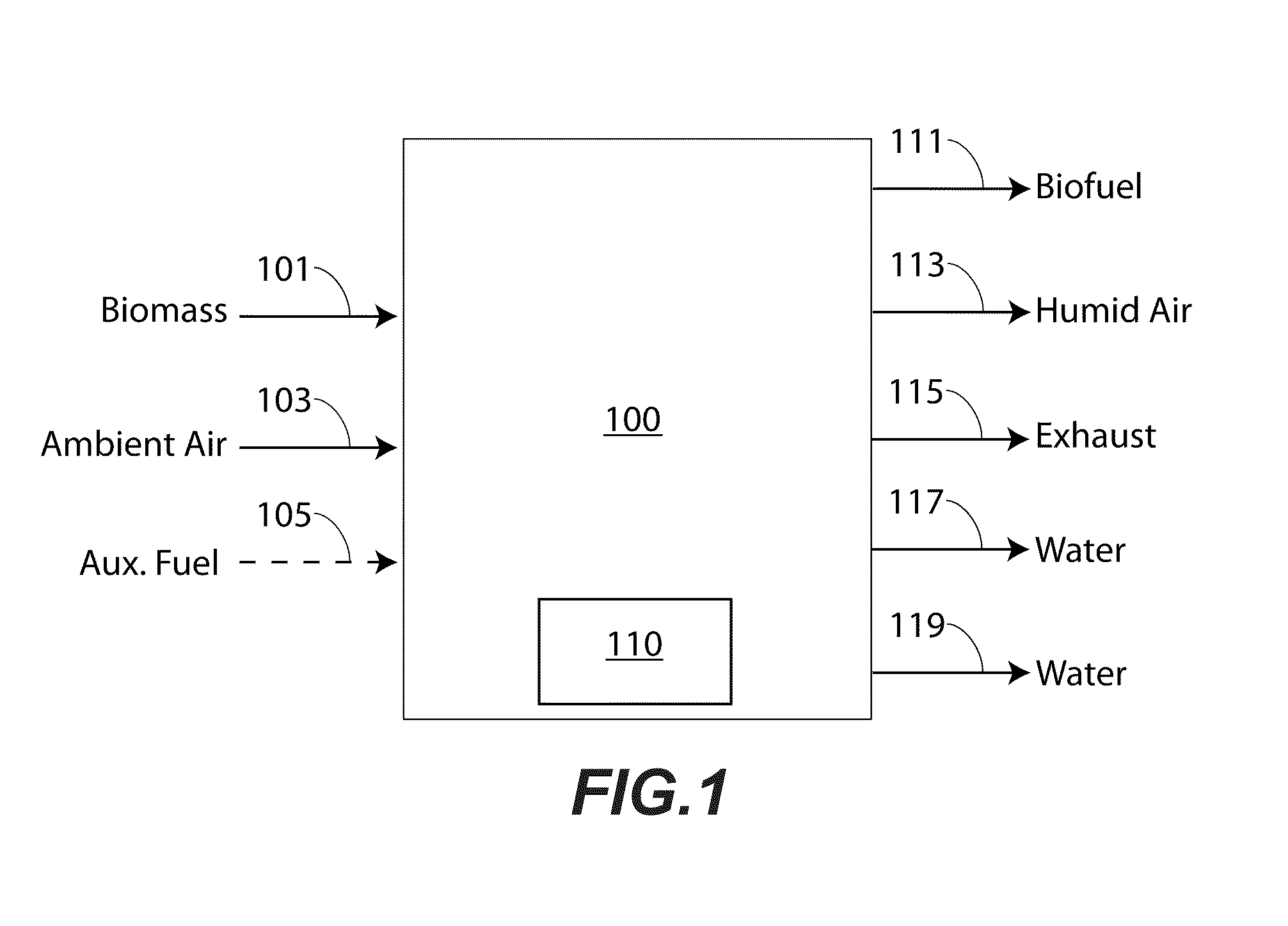

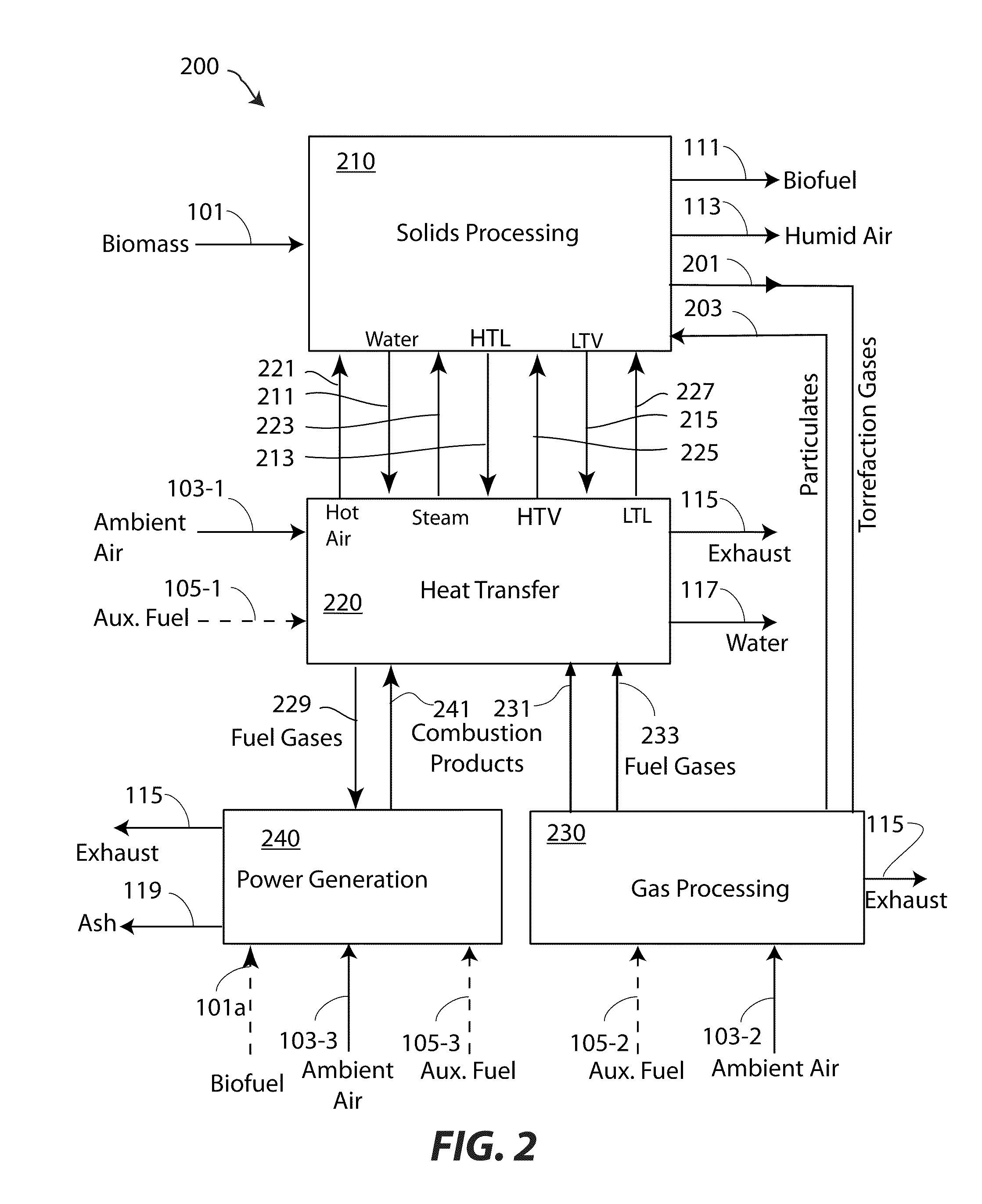

Device and method for conversion of biomass to biofuel

Embodiments presented herein describe an apparatus and method to convert carbonaceous materials, particularly biomass and those biomass resources which are remotely located, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a continuous process which can be completely powered by the energy contained in the biomass. The heat, mechanical power and electrical power are provided from the energy in the biomass, through the methods described. In this way, the apparatus is free to operate in remote locations, where no power or auxiliary fuel sources are available.

Owner:RENEWABLE FUEL TECH

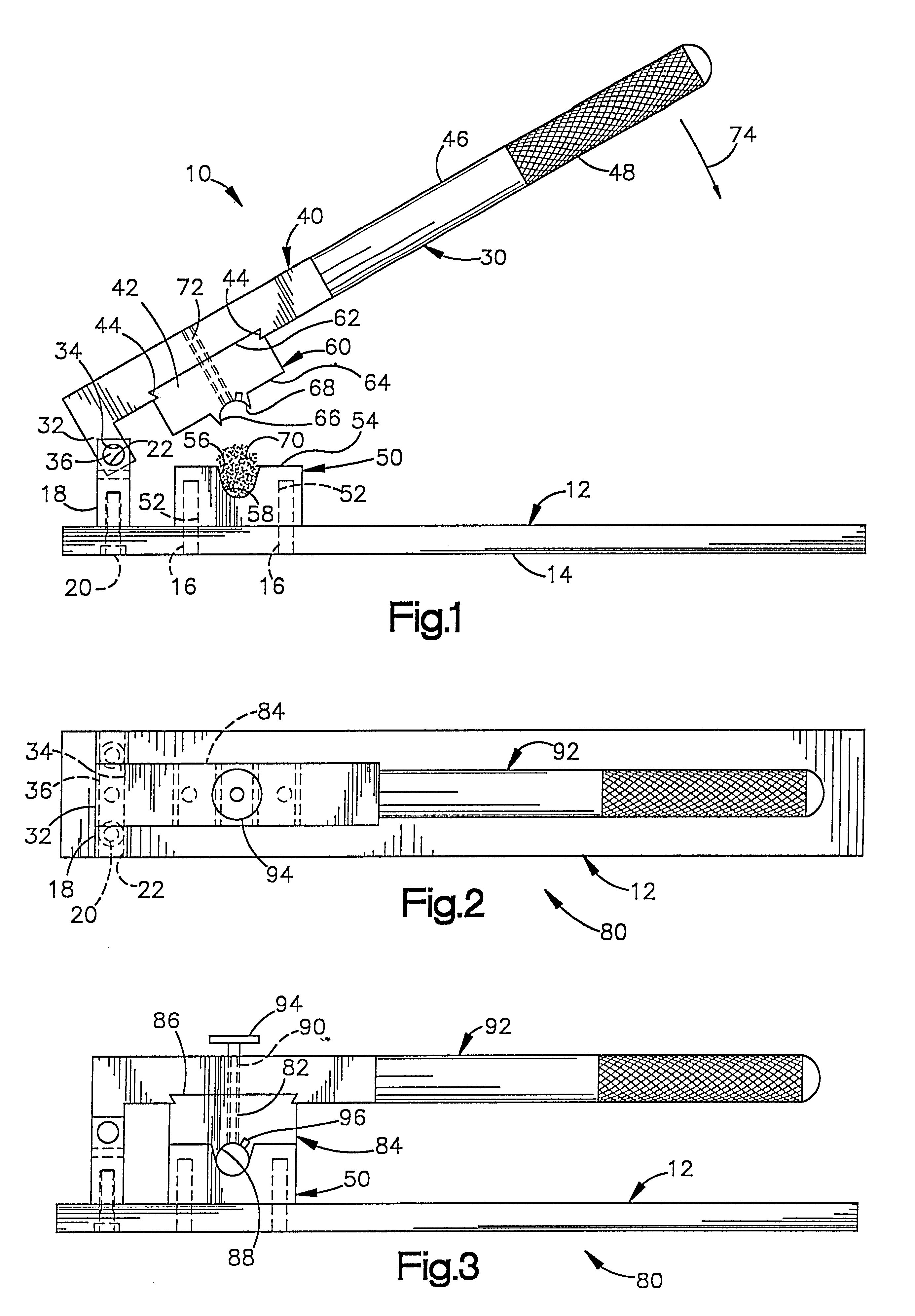

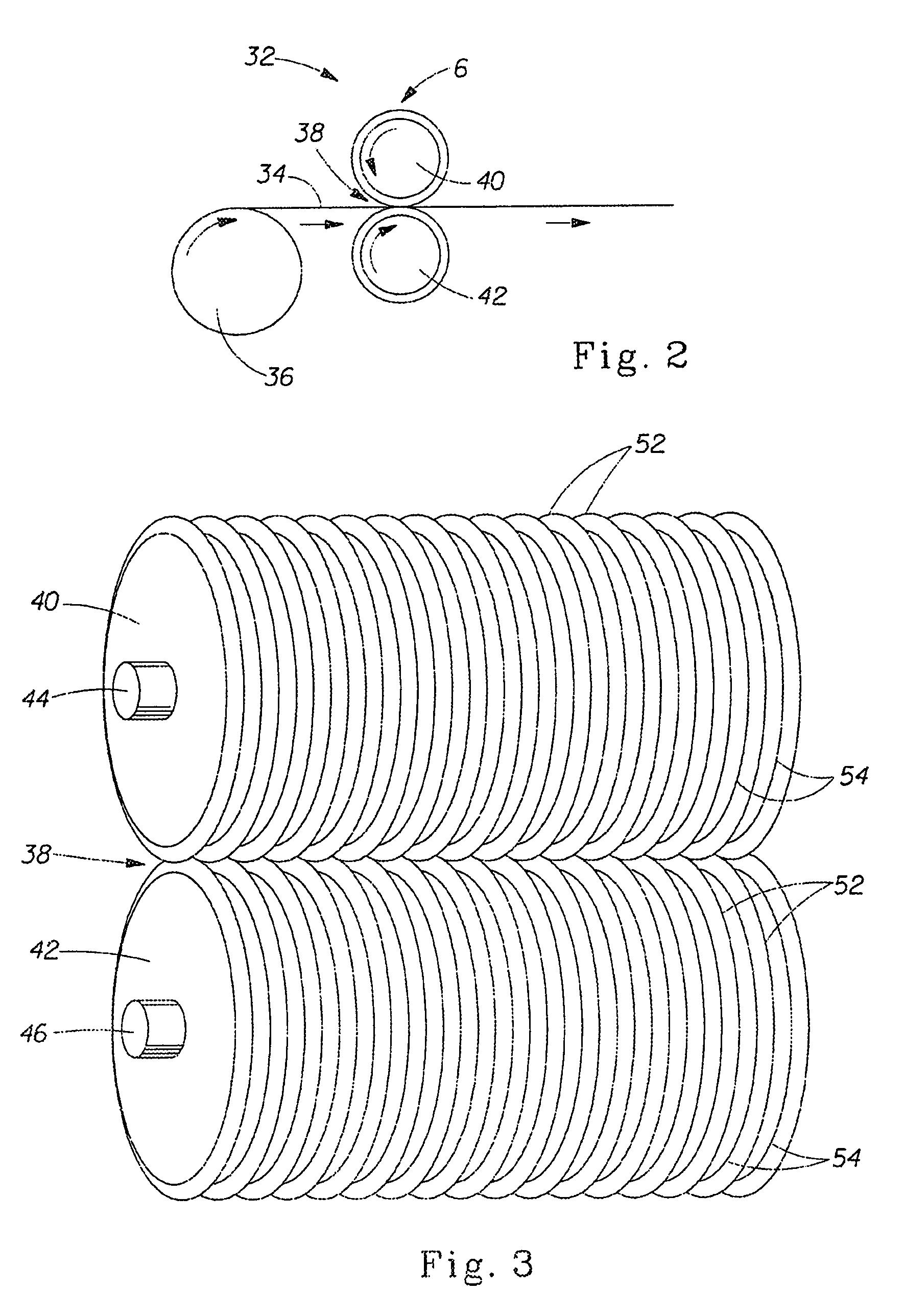

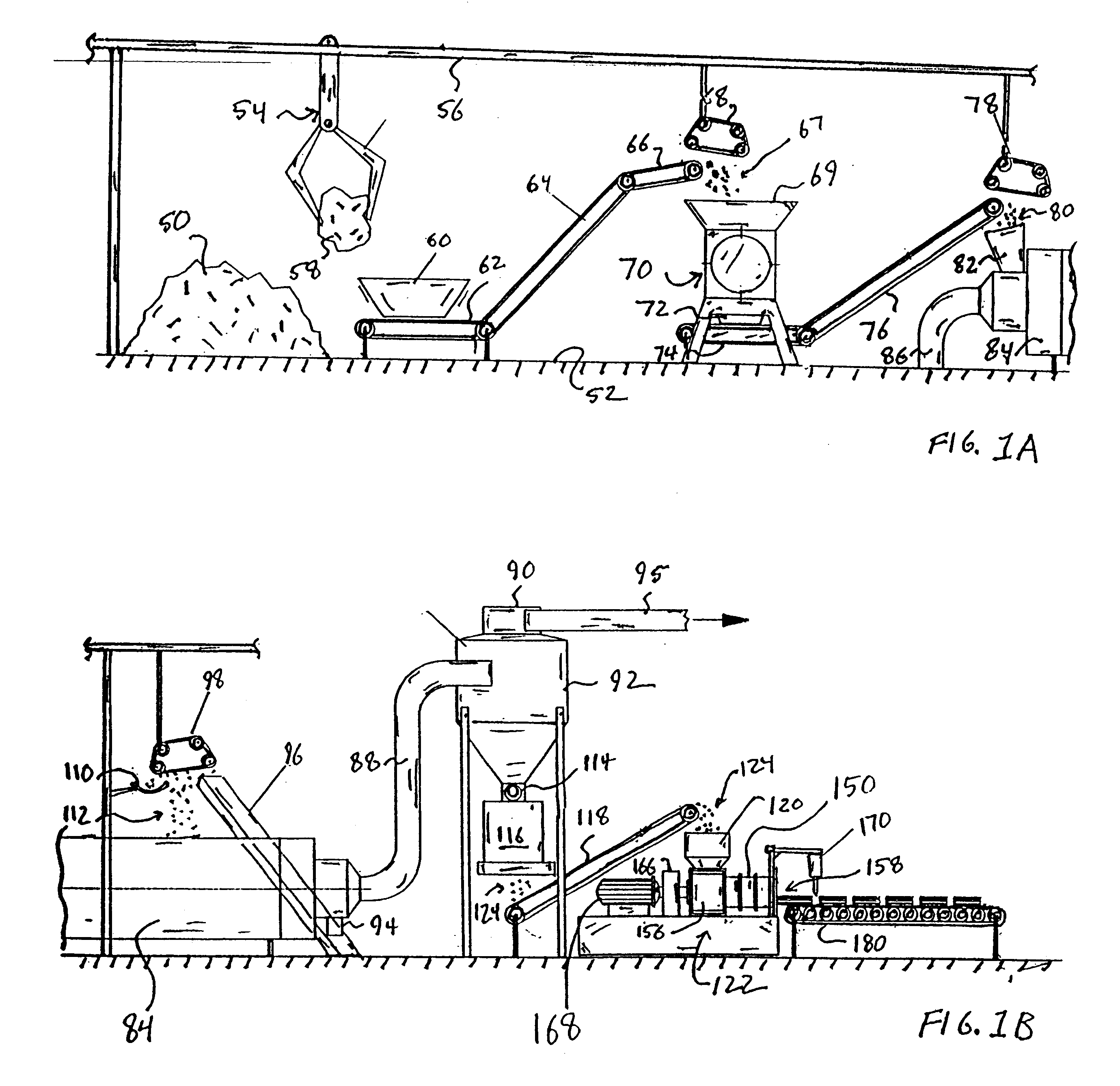

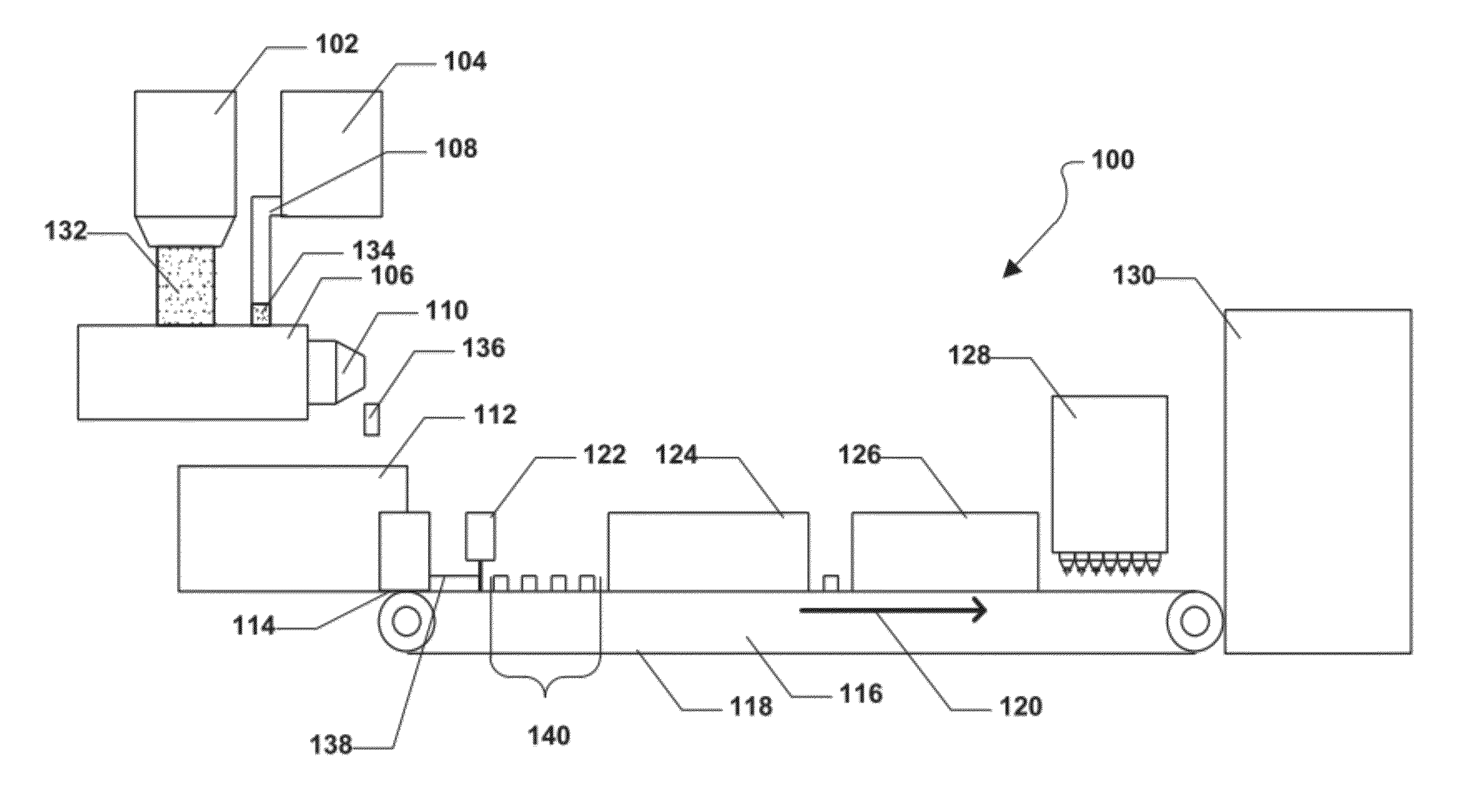

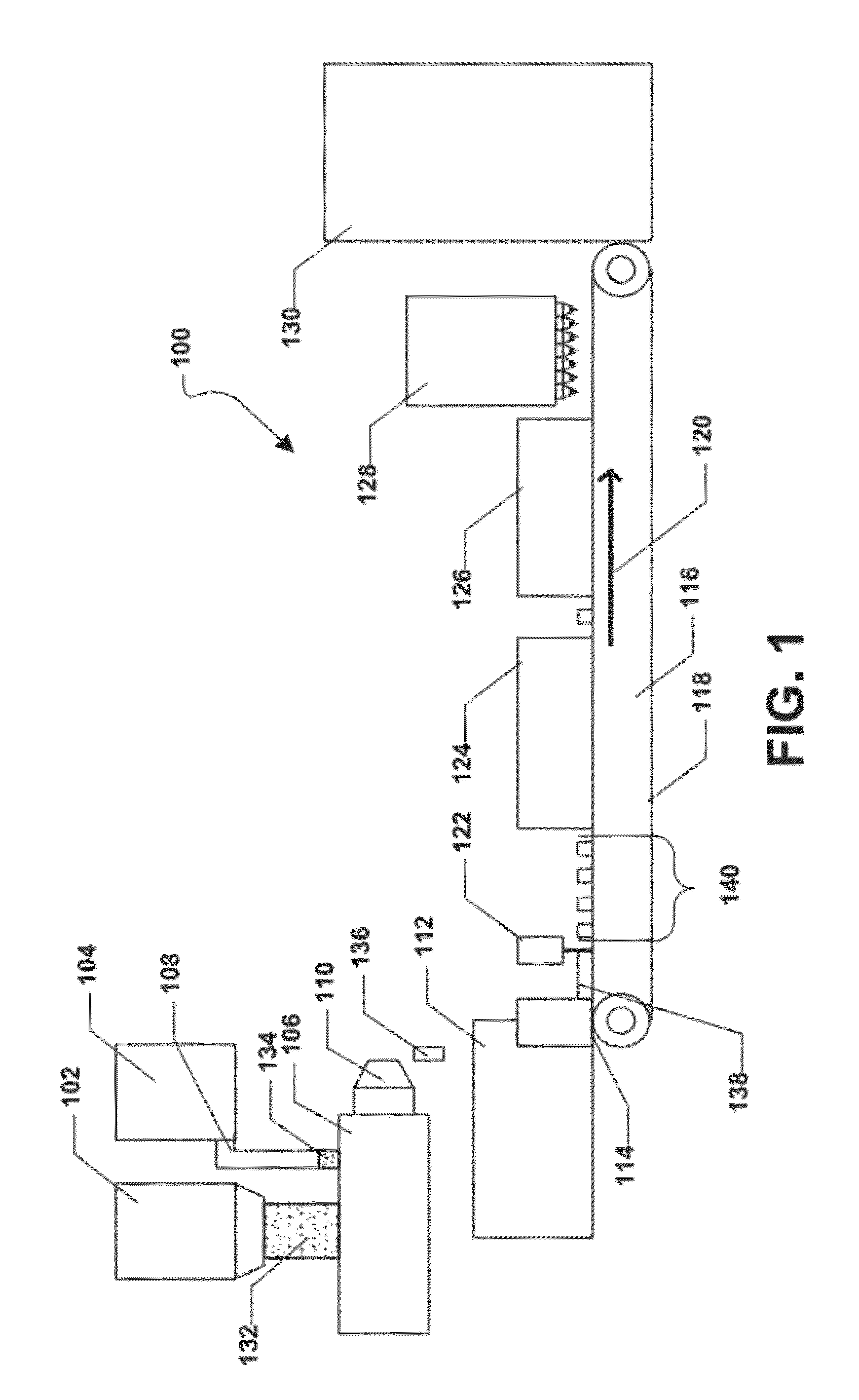

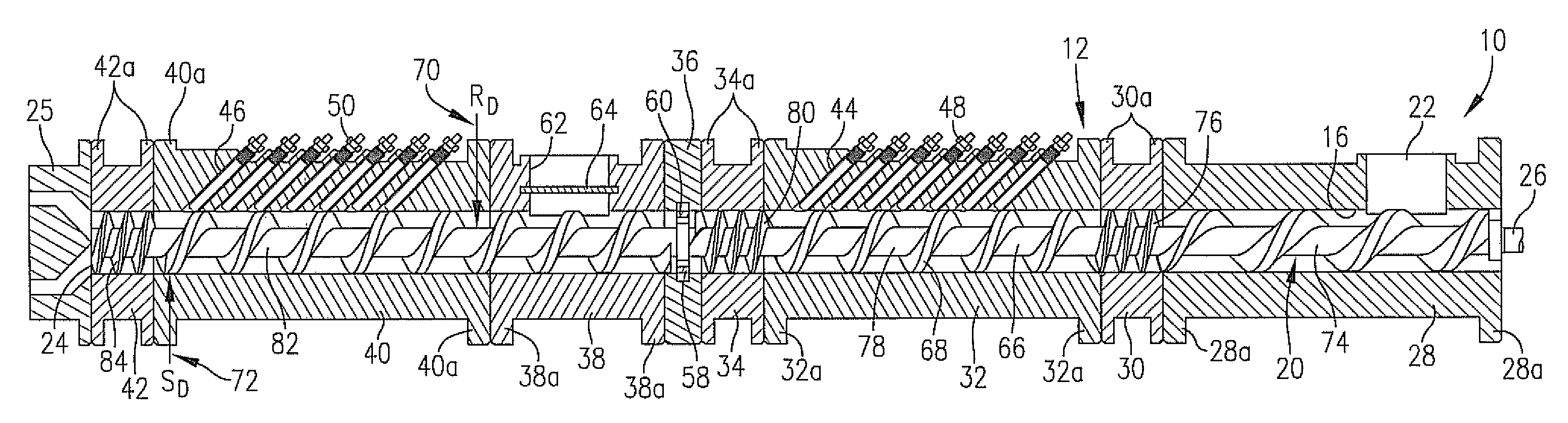

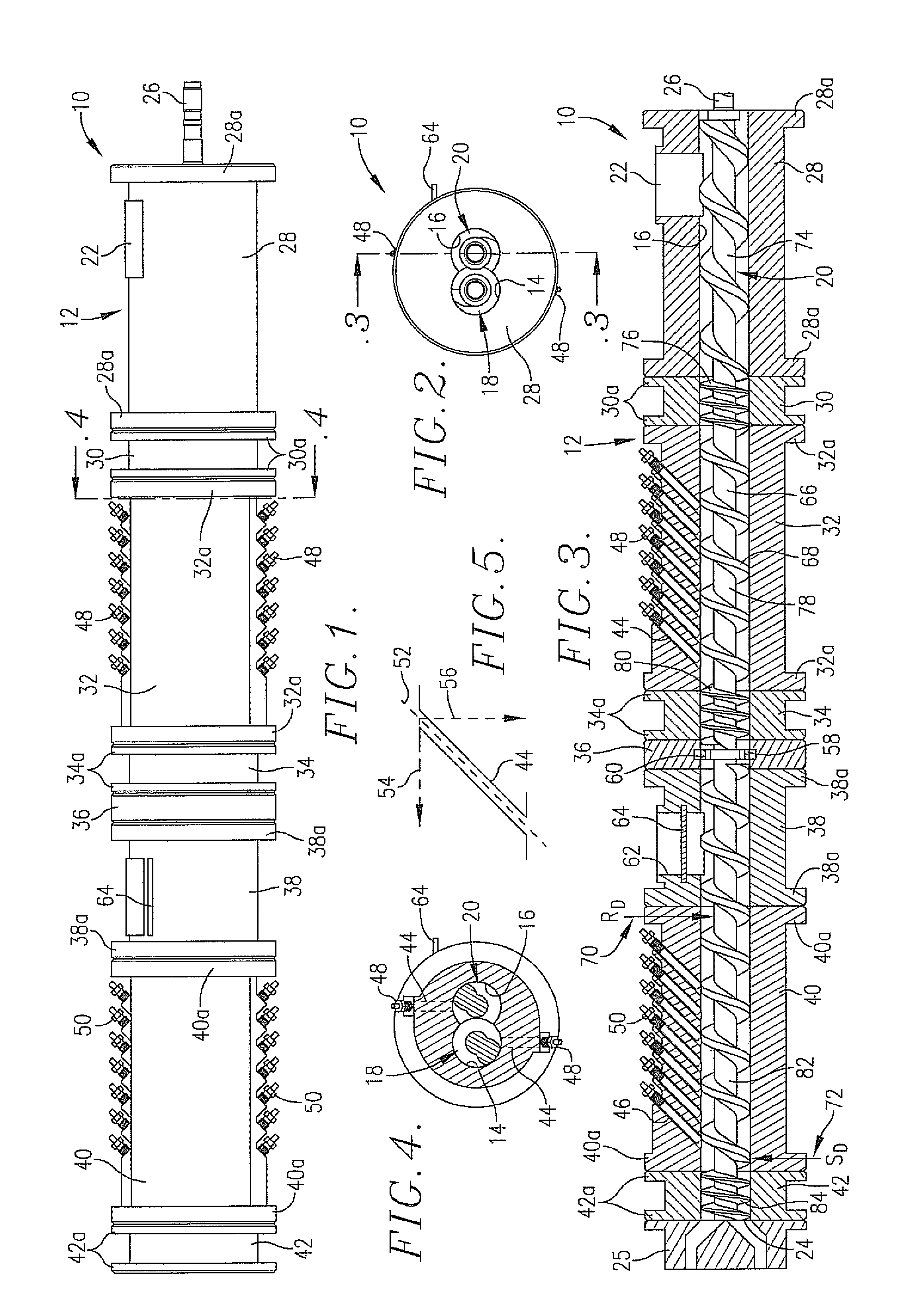

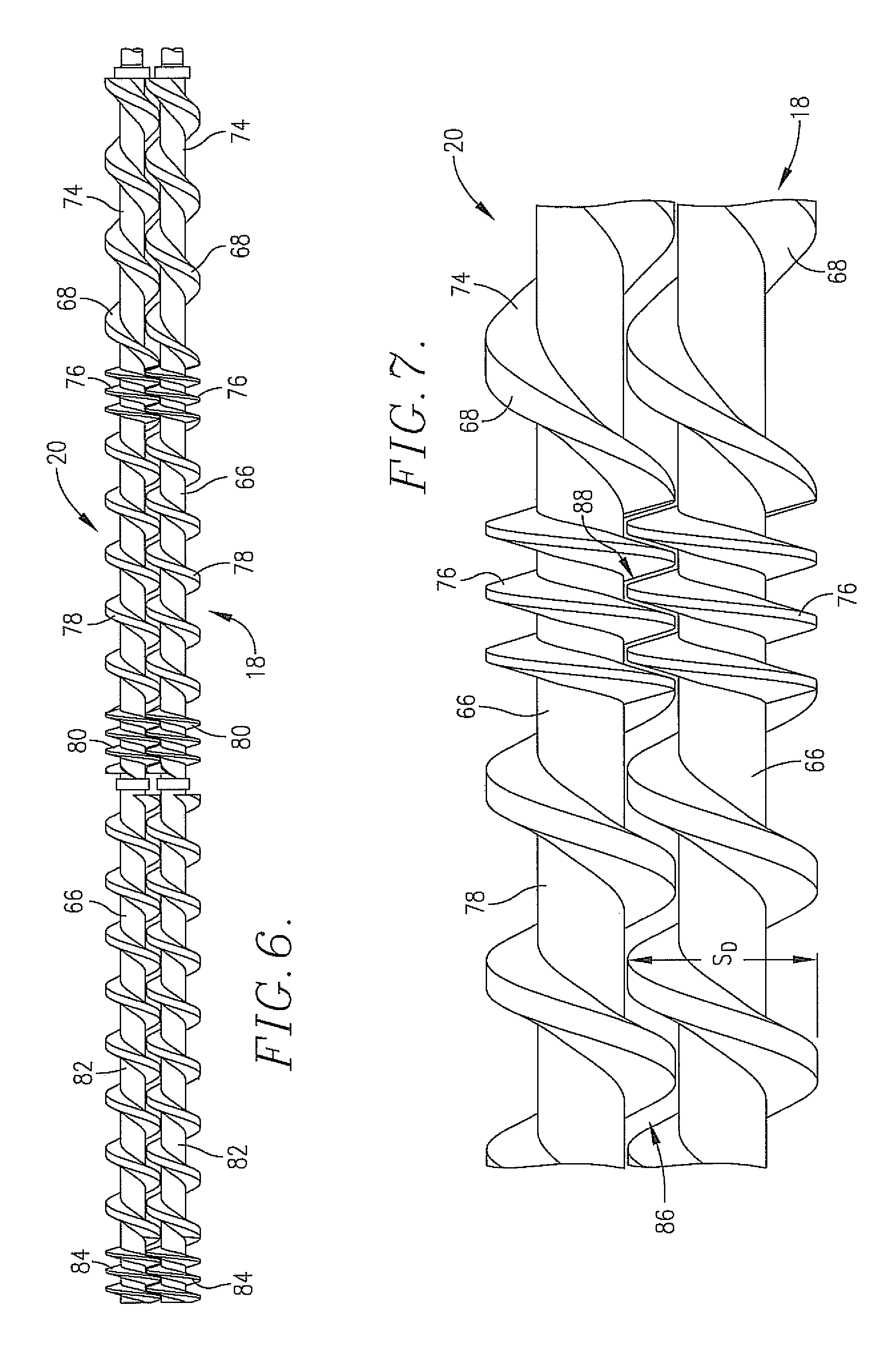

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

ActiveUS7521076B1The implementation process is simpleLow costMilk preservationFeeding-stuffEngineeringPreconditioner

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MFG LLC

High pressure apparatus and method for nitride crystal growth

ActiveUS8097081B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

Owner:SLT TECH

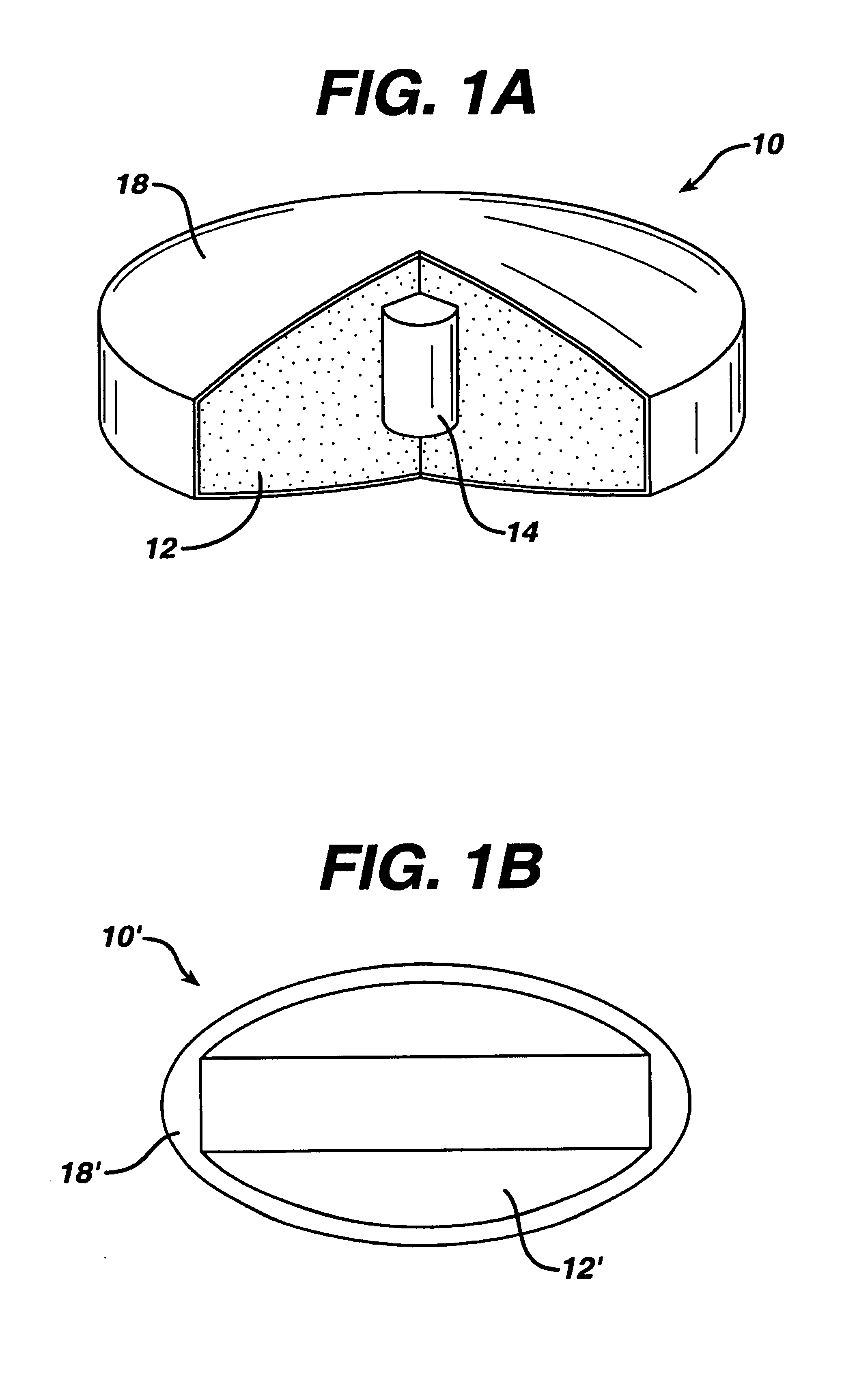

Powder compaction and enrobing

InactiveUS20050147710A1RobustQuicker release characteristicLayered productsConfectioneryMetallurgyMethyl cellulose

An apparatus and method is disclosed for forming a compacted powder slug coated with a film. The powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of a material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH

Method of Producing a Composite Multi-Layered Printed Absorbent Article

Owner:THE PROCTER & GAMBLE COMPANY

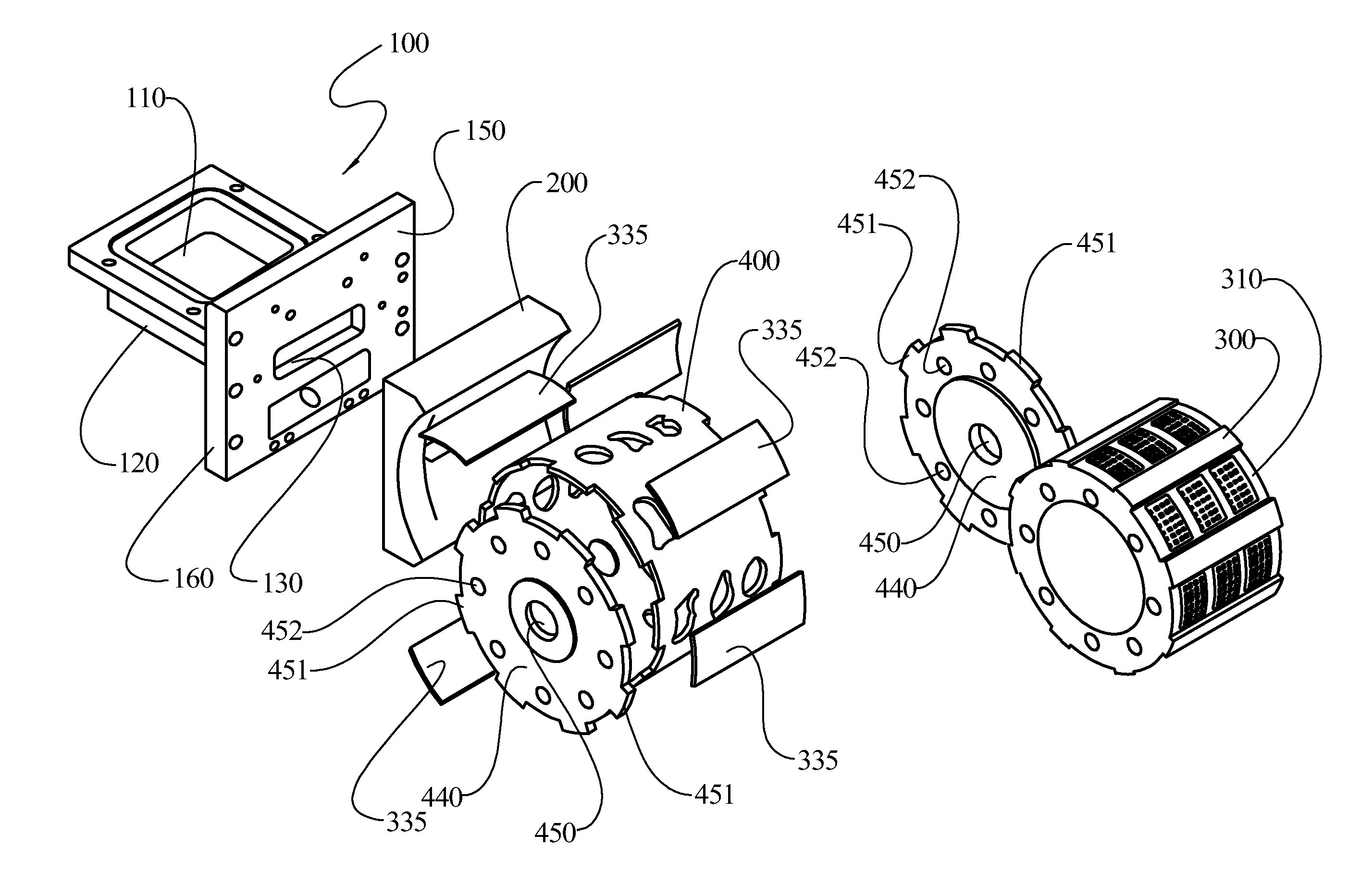

Method and apparatus for manufacturing a cutting insert

A method for manufacturing a cutting insert green body having undercuts includes providing a die cavity formed in closed top and bottom dies; closing a bottom of the die cavity by a bottom punch accommodated in a punch tunnel formed in the bottom die; filling the die cavity with a pre-determined amount of sinterable powder; moving a top punch towards the die cavity through a punch tunnel formed in the top die; compacting the powder by urging the top and bottom punches towards each other, thereby forming the green body; and moving the top die and punch away from the bottom die and punch, thereby enabling removal of the formed green body. An apparatus for manufacturing a cutting insert green body having undercuts includes top and bottom dies which abut each other and top and bottom punches which slide in their respective dies.

Owner:ISCAR LTD

Densification system

A densification system for shredding and densifying specification raw materials for use as an alternative fuel source. The densified specification raw materials formed by the inventive system are readily transportable to a fuel processing site where they may be used to generate energy.

Owner:MLMC II HLDG LLC

Method and apparatus for rotary molding

ActiveUS20120058213A1Shorten speedEliminates and minimizes disadvantageMouldsMeat processingShell moldingEngineering

A rotary molding system for molding food products, mold cavities formed when a mold shell rotates mold shapes disposed along the mold shell into a fill position between a fill plate and a wear plate. Molded food products are removed from mold cavities using knock-out cups, the use of air pressure, or the use of a vacuum source disposed below the mold cavity, without the need to slow the rotation of the mold shell. Knock-out cups may be used with a heating system to reduce accumulation of unwanted materials on the knock-out cups. The rotary molding system can also be used to form products with contoured surfaces. A smart tagging system can be used to ensure that compatible sets of mold shells and knock out cups are being used. A vacuum region may be disposed upstream of the fill position to remove air within the mold cavity prior to filling.

Owner:PROVISUR TECHNOLOGIES INC

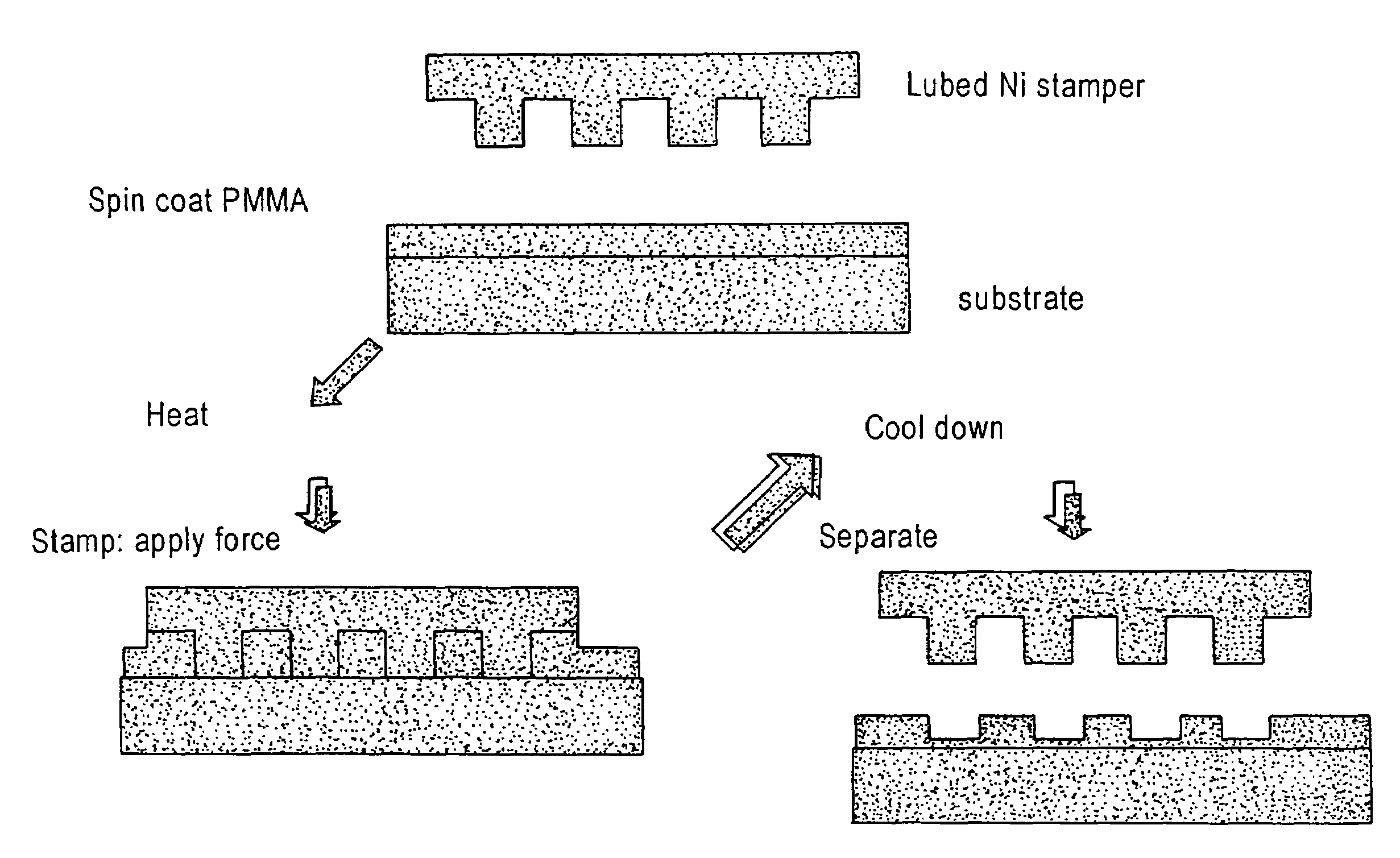

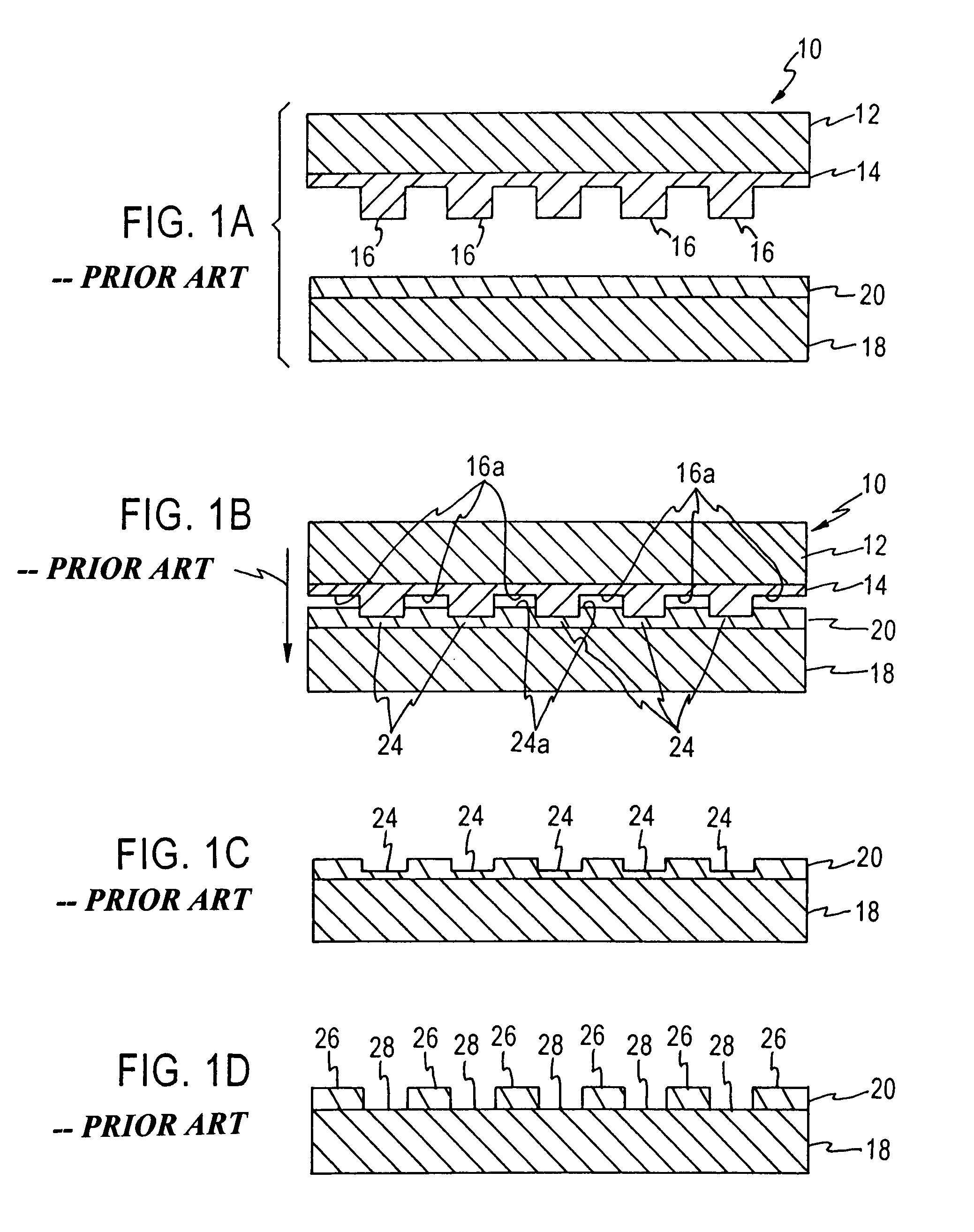

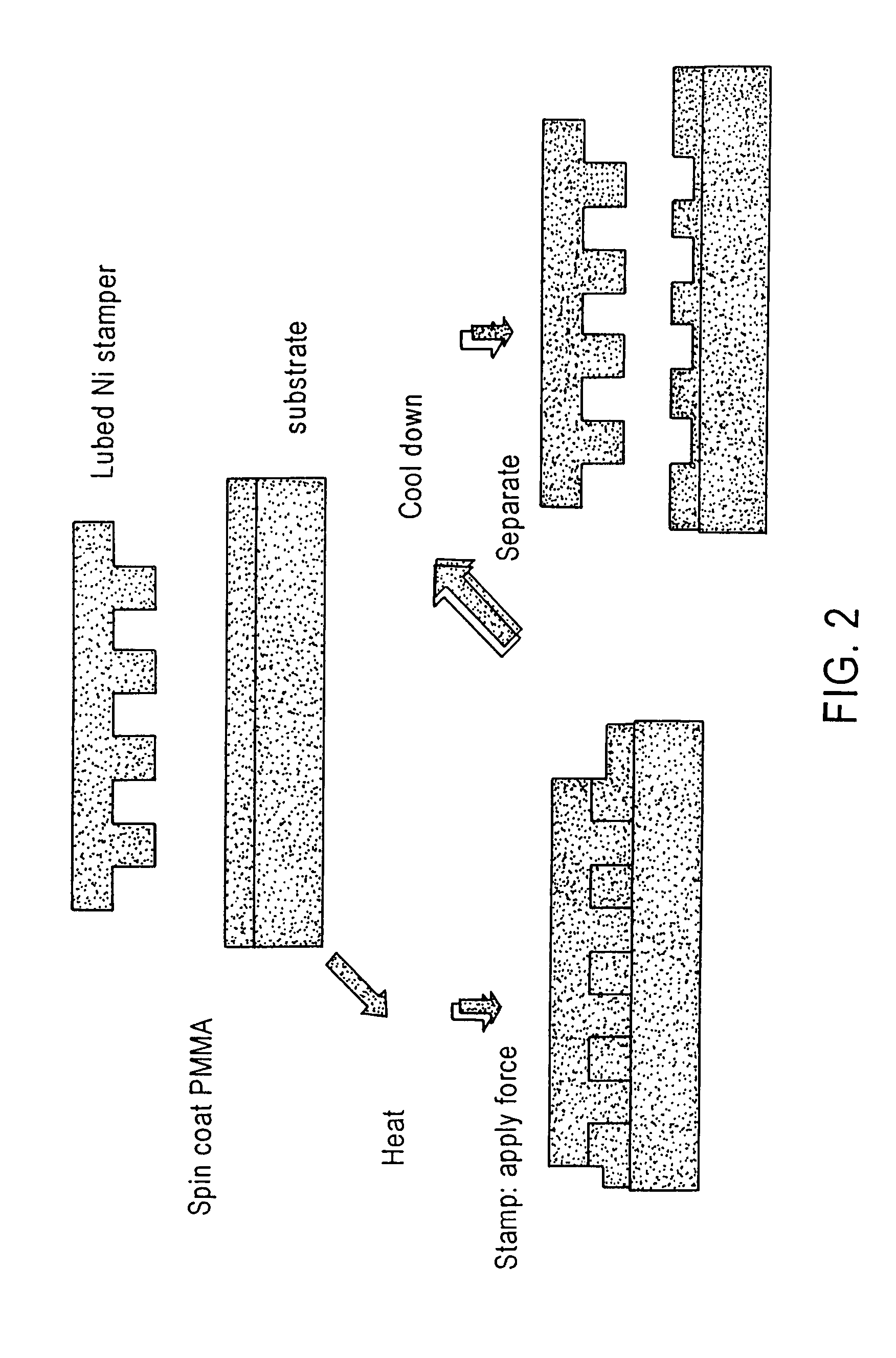

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

Composite dosage forms

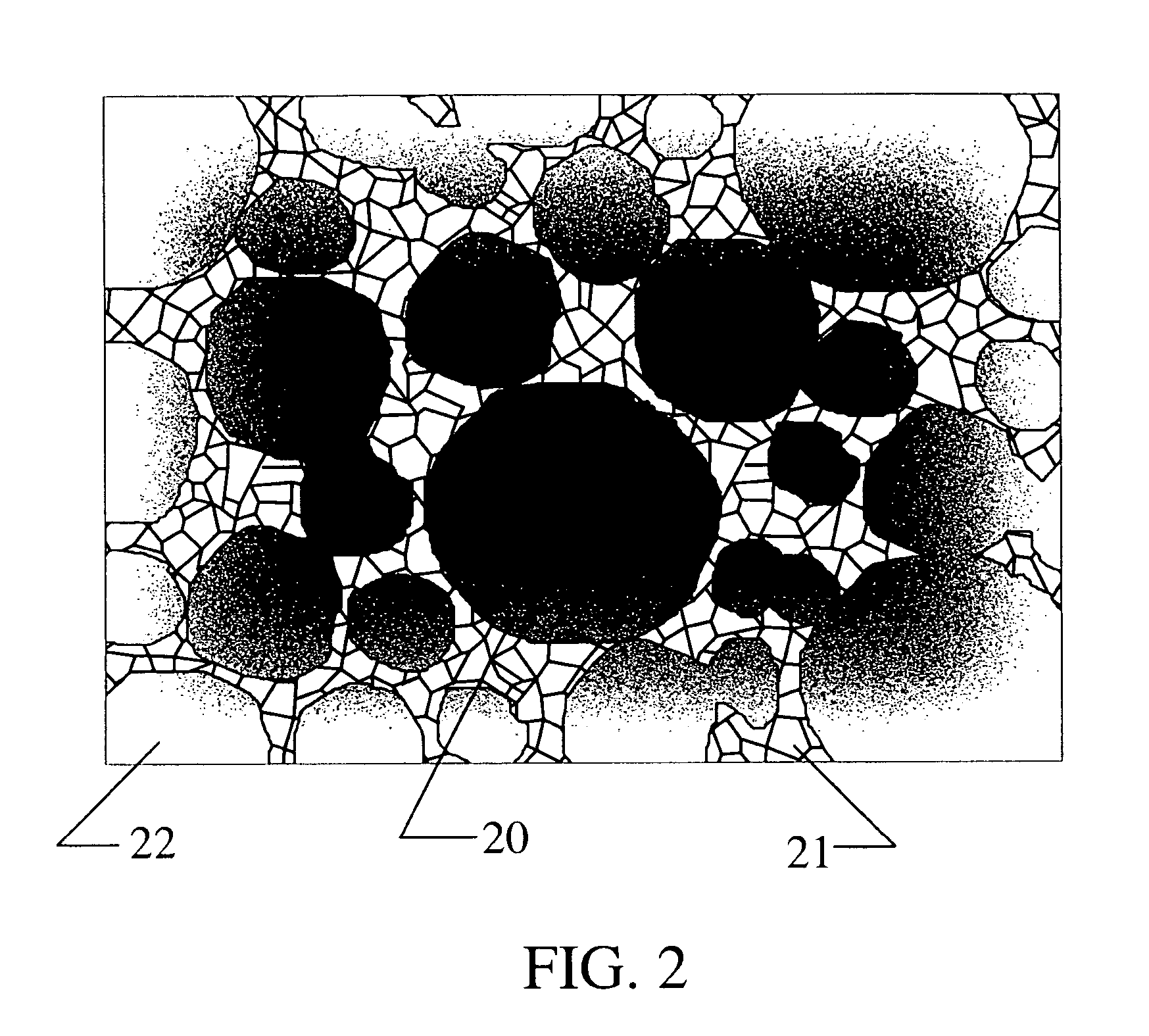

InactiveUS20050019407A1Large sectionPowder deliveryConfectioneryBULK ACTIVE INGREDIENTActive ingredient

Owner:MCNEIL PPC INC

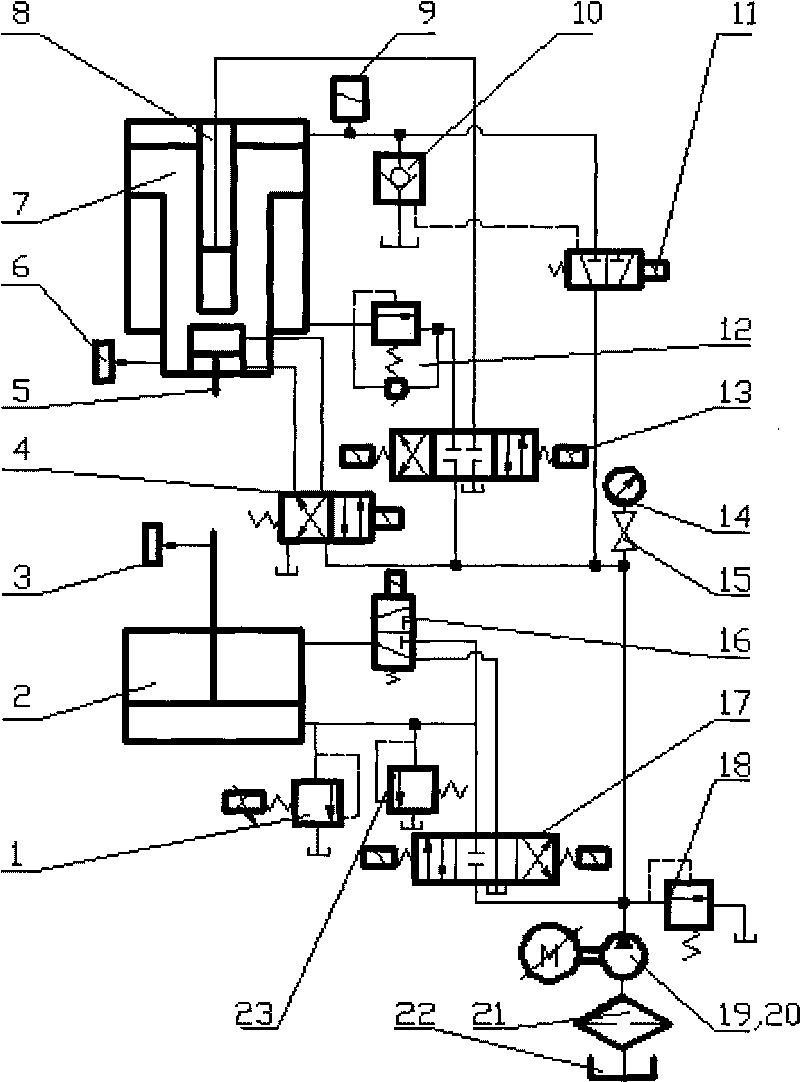

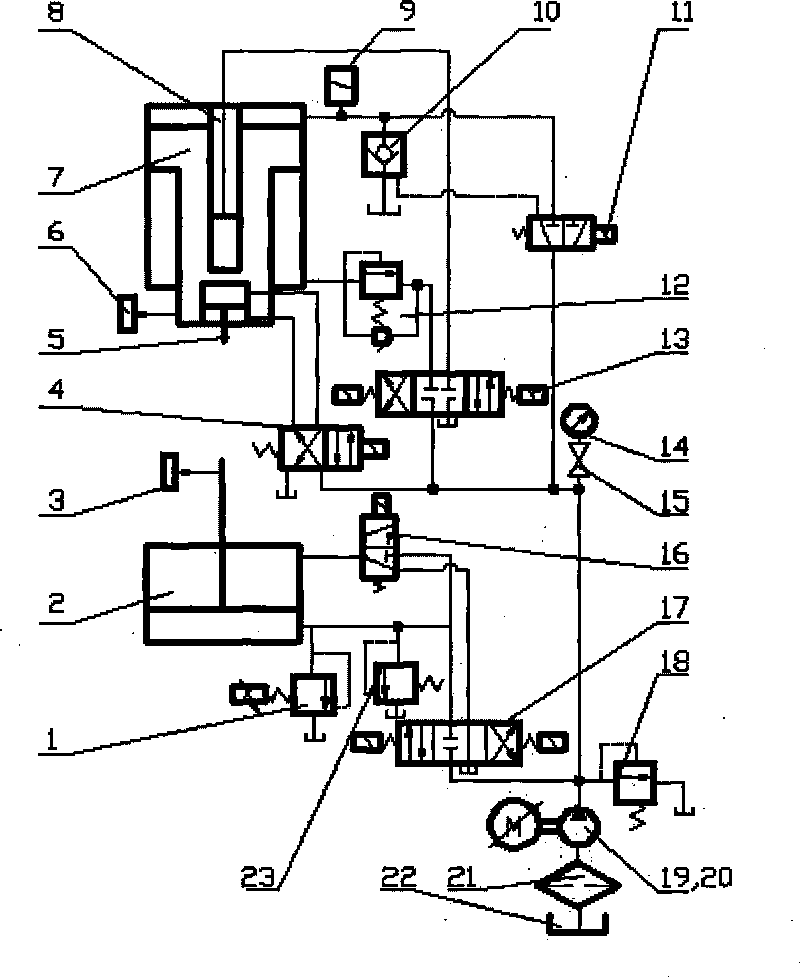

High performance and energy-saving double-acting hydrostatic press driven by servo motor

InactiveCN101712207AImprove performanceOvercome a series of disadvantagesExtrusion control devicesForging press detailsClosed loopHydrostatic pressure

The invention relates to a high performance and energy-saving double-acting hydrostatic press driven by a servo motor. The invention retains the rapid liquid-filling and direction control circuits in the common hydrostatic press, but uses a controllable hydraulic source composed of an AC servo motor and a quantitative oil pump to replace an uncontrollable hydraulic source driven by a common induction motor and combine with various sensors, and realizes the energy-saving pressure, position and speed control of the system under the control and regulation of the electrical motor; displacement sensors are added in a main cylinder and an auxiliary cylinder, a pressure sensor is added in the oil inlet line of the main cylinder, thus realizing the closed-loop control of position, speed and pressure; and a proportional relief valve is added at the oil outlet of the auxiliary cylinder, thus realizing variable blank holder force floating blank-holding of the auxiliary cylinder, wherein the electrical motor is the high-power AC servo motor, the electrical motor is connected with a controller, and the flow control and the volume velocity-governing and pressure-regulating of the main oil line can be realized by controlling the speed of the electrical motor. The invention completely uses the advantages of the high-power AC servo motor such as high efficiency, controllable performance, adjustable performance and good reliability to realize the optimization of process parameters, improve the hydrostatic press performance and reduce the energy consumption.

Owner:GUANGDONG UNIV OF TECH

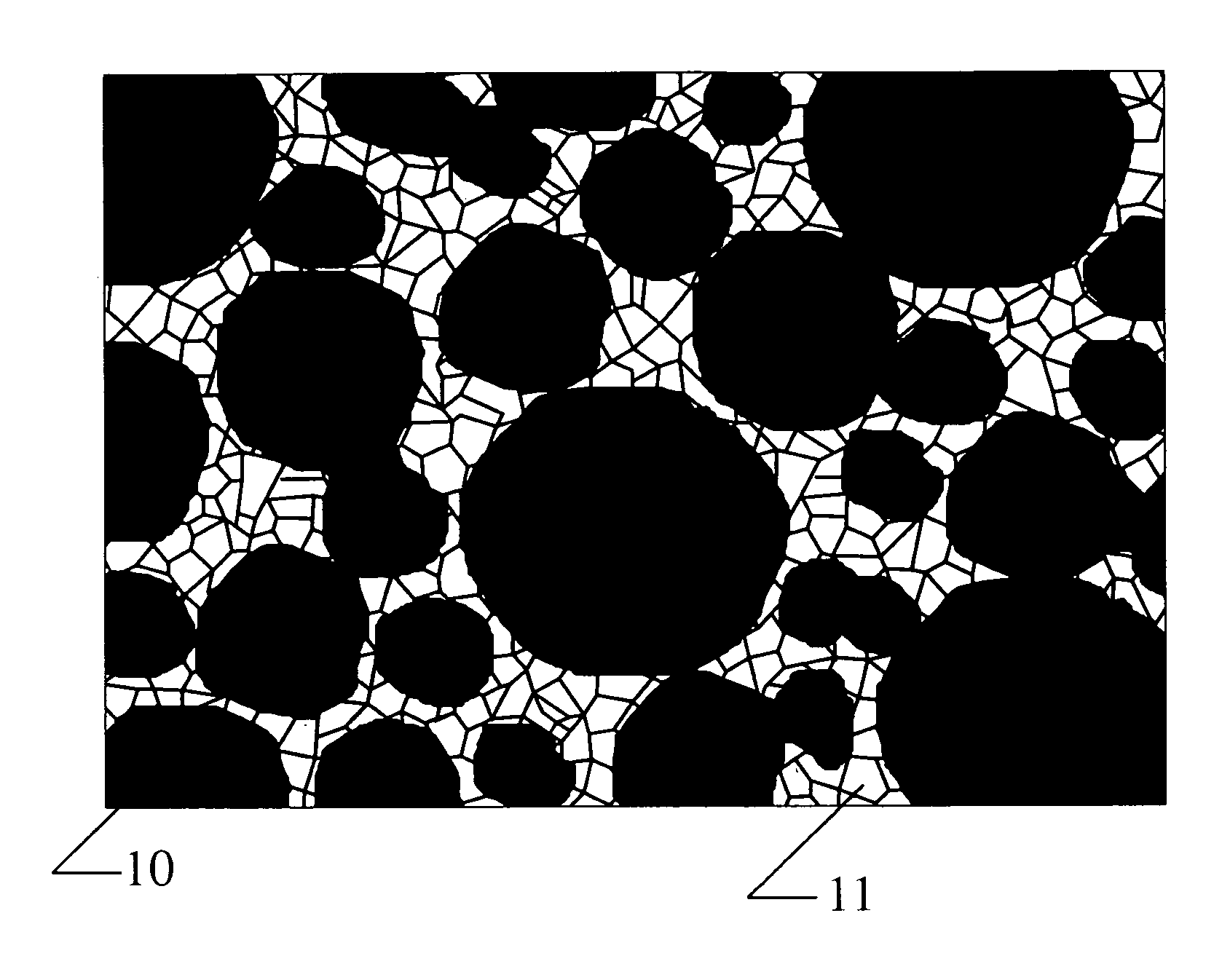

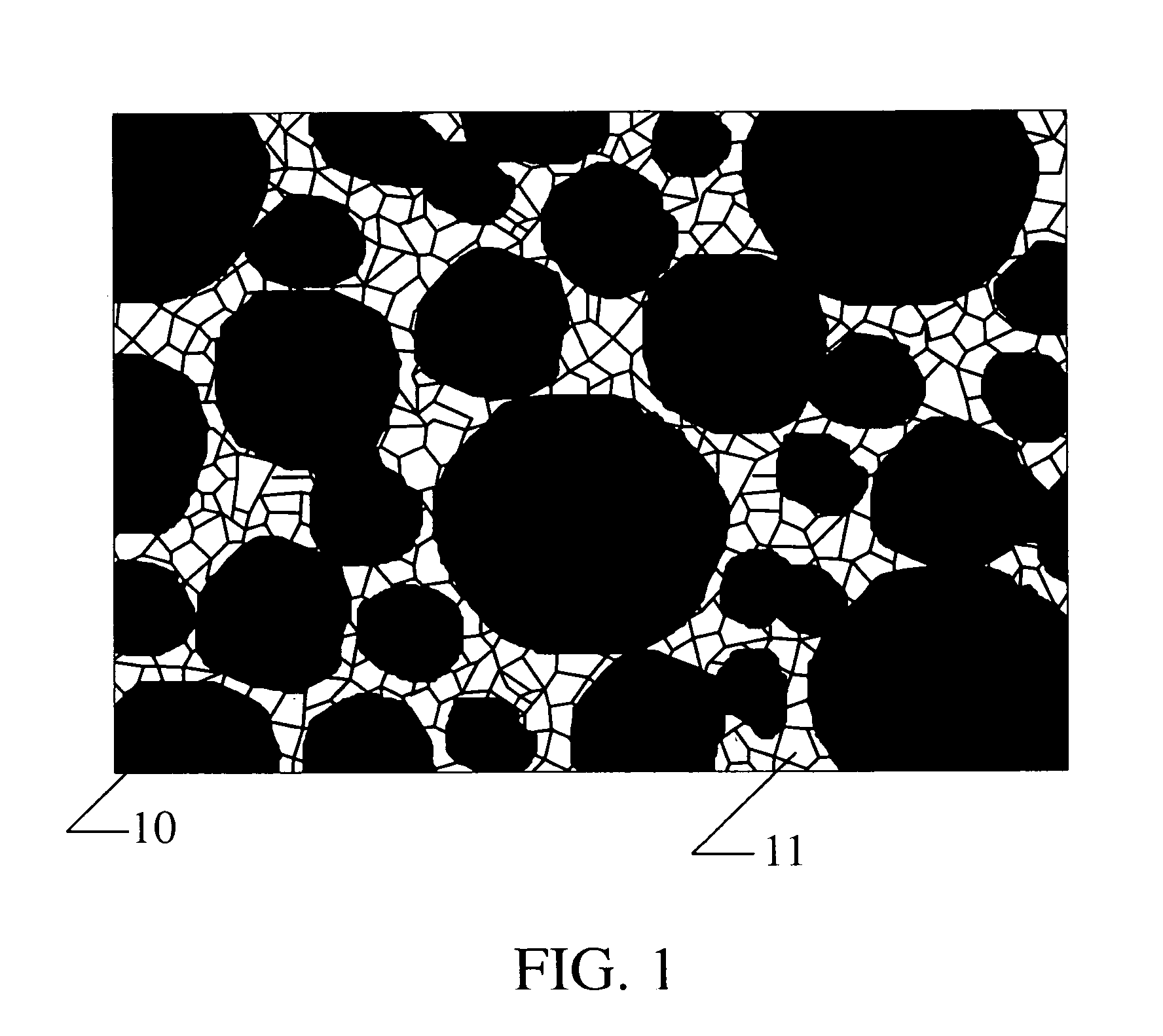

Porous metal articles having a predetermined pore character

A porous metal article having a predetermined pore structure. The porosity is provided by the use of an extractable particulate in a powder forming route to create a desired porosity. Extraction of the pore forming particulate prior to sintering of the powder minimizes contamination of the sintered article and allows for the processing of material sensitive to contamination such as titanium. Added functionality can be gained by co-forming the porous material with non-porous material to create an article with layers of differing characteristics. The article is suitable for use as an implant body is porous enough to facilitate tissue in-growth and bony fusion.

Owner:PRAXIS POWDER TECH

Apparatus for manufacturing dosage forms

InactiveUS6837696B2Organic active ingredientsTurning machine accessoriesComputer moduleBiomedical engineering

Systems, methods and apparatuses for manufacturing dosage forms, and to dosage forms made using such systems, methods and apparatuses are provided. Novel compression, thermal cycle molding, and thermal setting molding modules are disclosed. One or more of such modules may be linked, preferably via novel transfer device, into an overall system for making dosage forms.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com