Patents

Literature

194 results about "Refuse-derived fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refuse-derived fuel (RDF) is a fuel produced from various types of waste such as municipal solid waste (MSW), industrial waste or commercial waste.

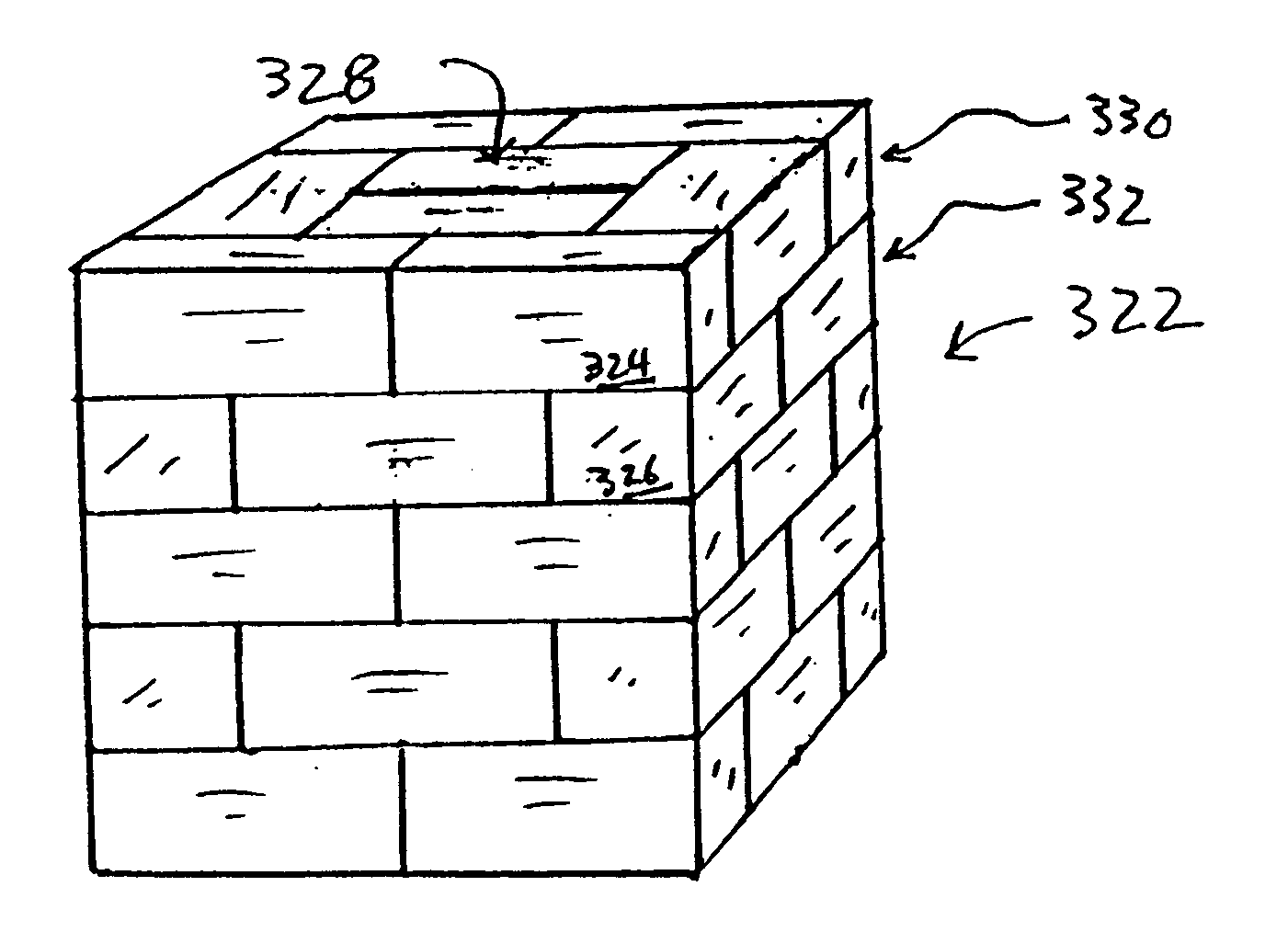

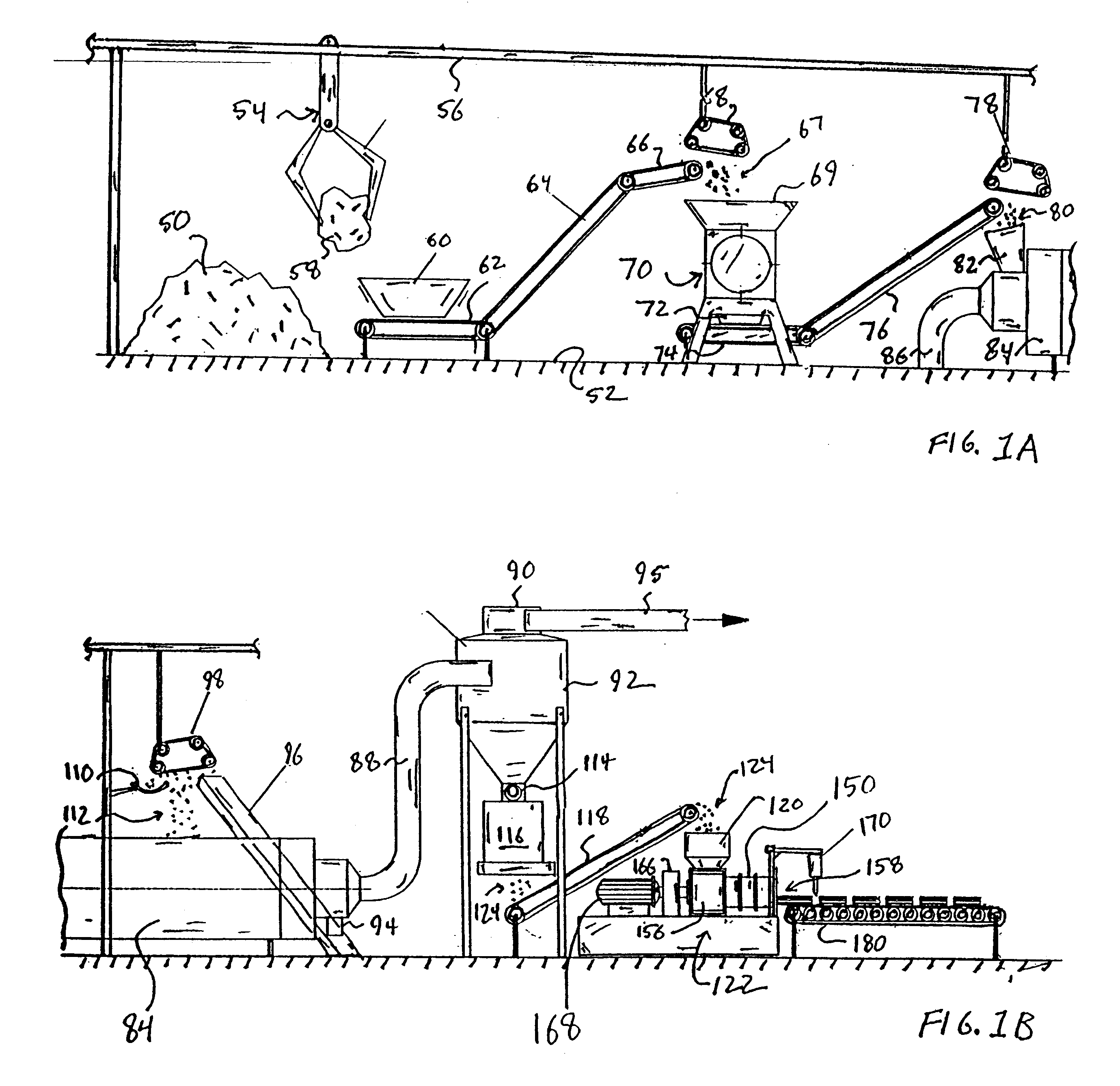

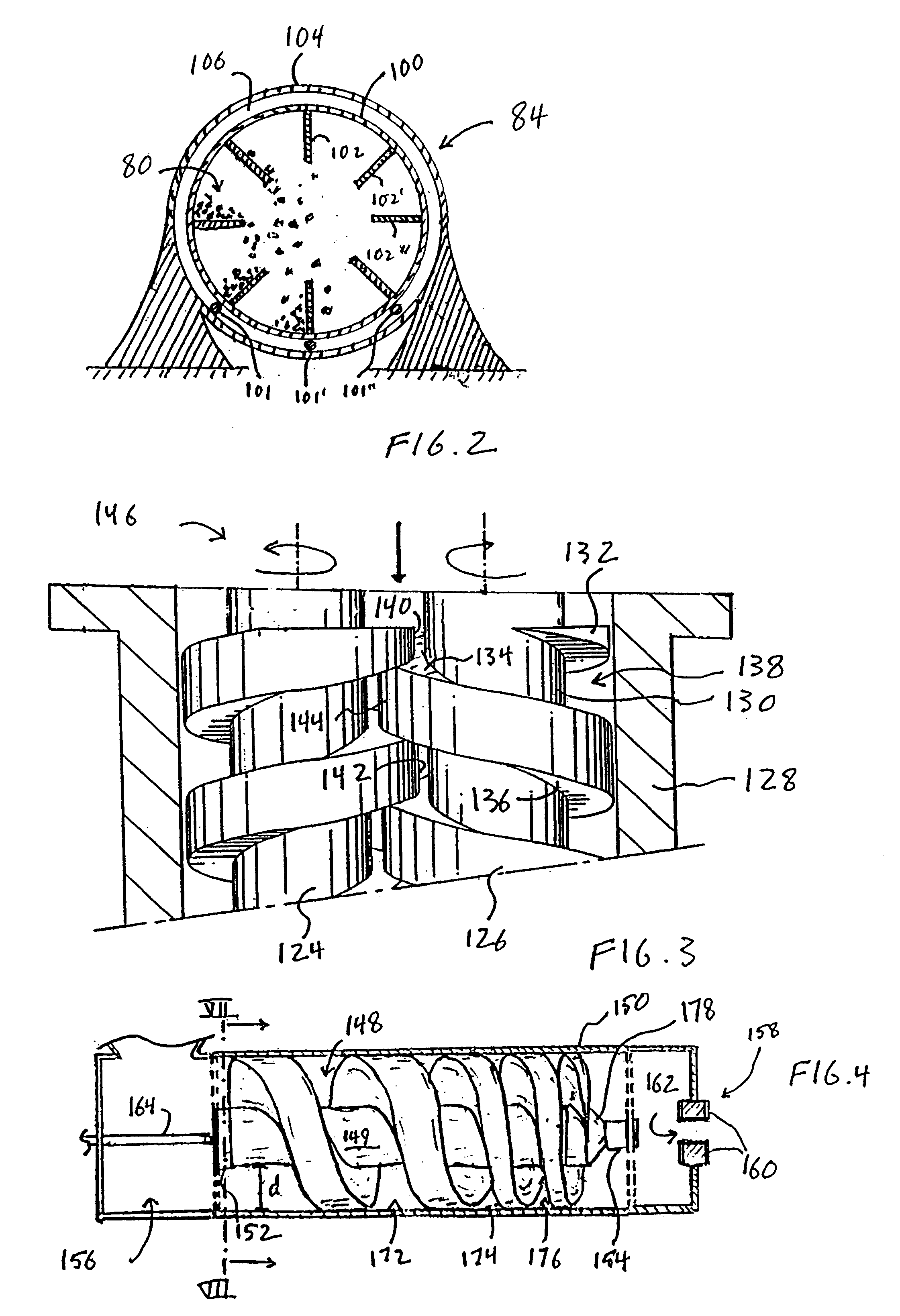

Municipal waste briquetting system and method of filling land

InactiveUS6692544B1Conveniently and economically transportedReduce the impactBiofuelsSolid fuelsRefuse-derived fuelMunicipal sewage

Mechanically and biologically stable briquettes and pellets are obtained from either municipal solid waste (MSW), Refuse Derived Fuel (RDF) or municipal sewage sludge and their combination for purposes of disposing said briquettes and pellets as fuel in waste-to-energy processes such as the one described herein or to form geometric aggregates with such briquettes for their disposal at landfill sites. The use of binding material is not required whereas fuel additives such as crushed coal and petroleum residues may be added to enhance fuel performance but are not needed to improve waste processing or product stability and mechanical properties.

Owner:ECOSYST PROJECTS

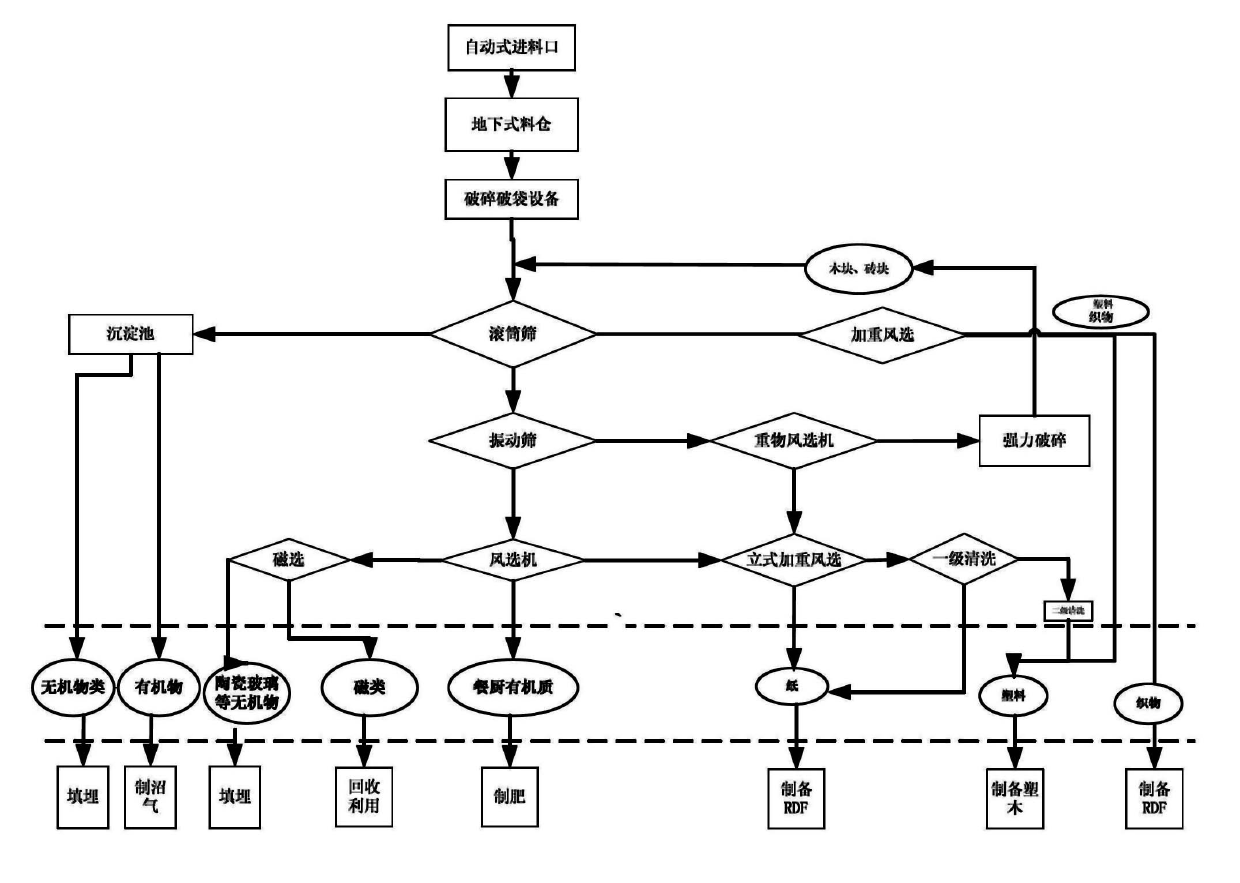

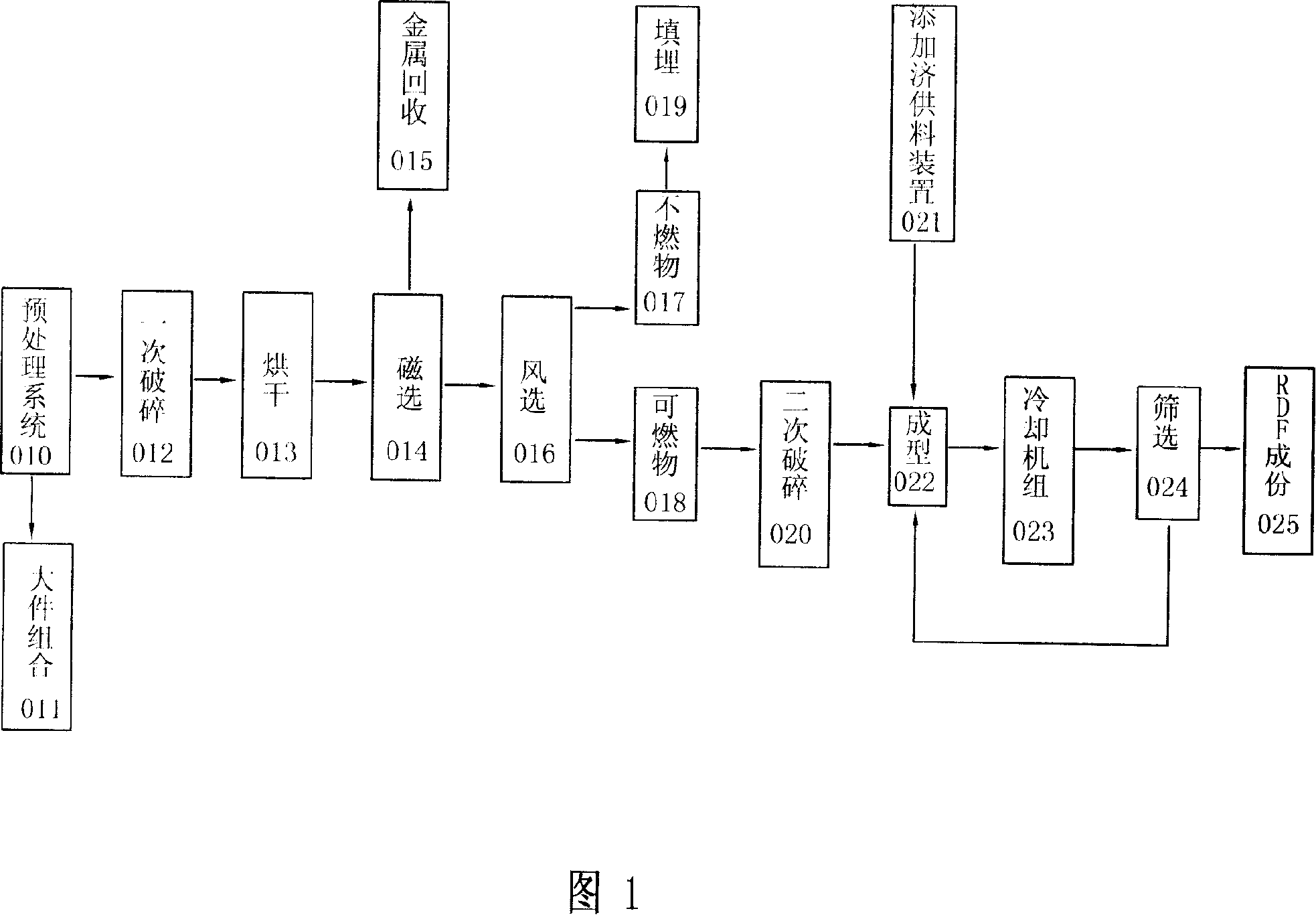

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

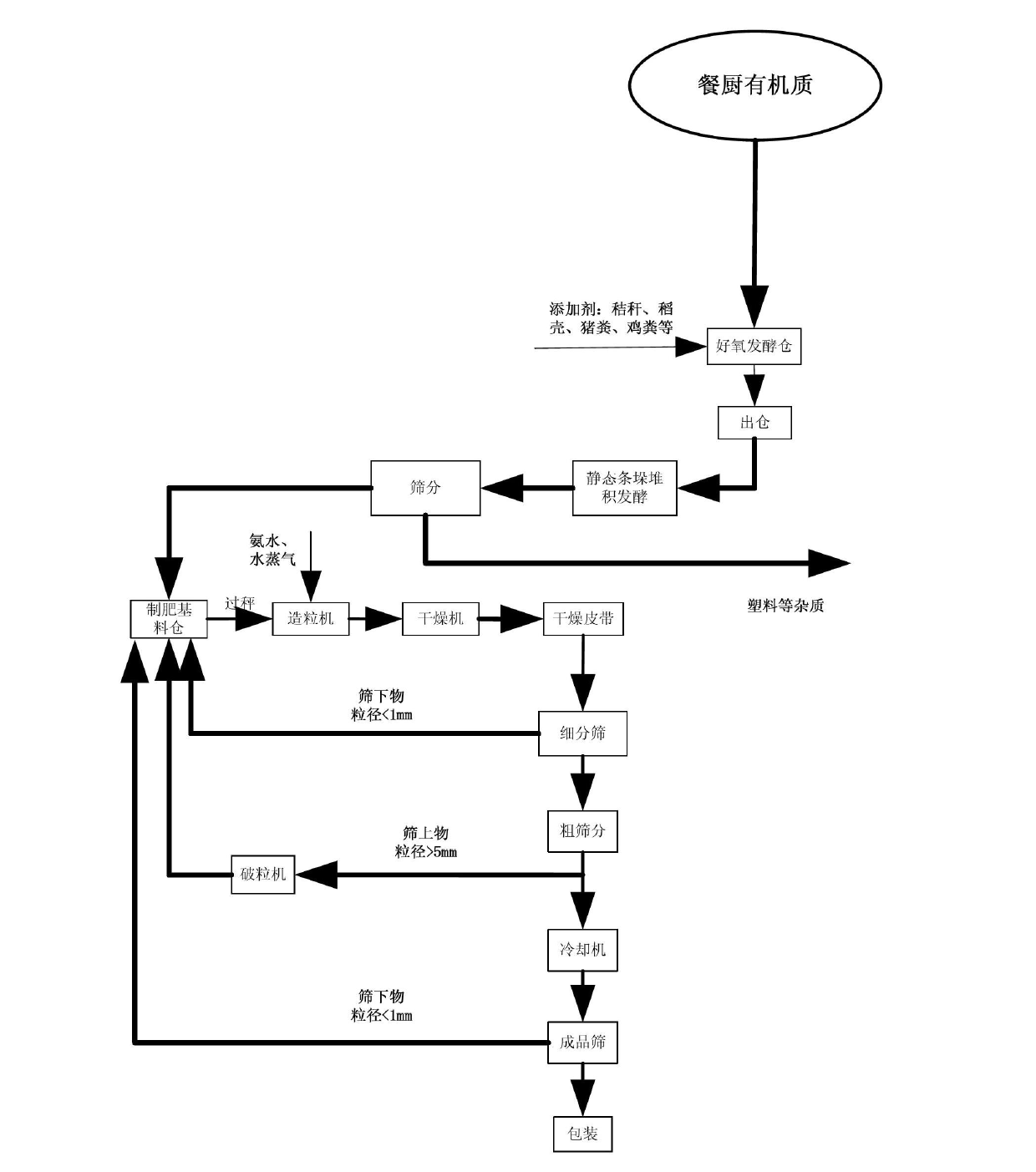

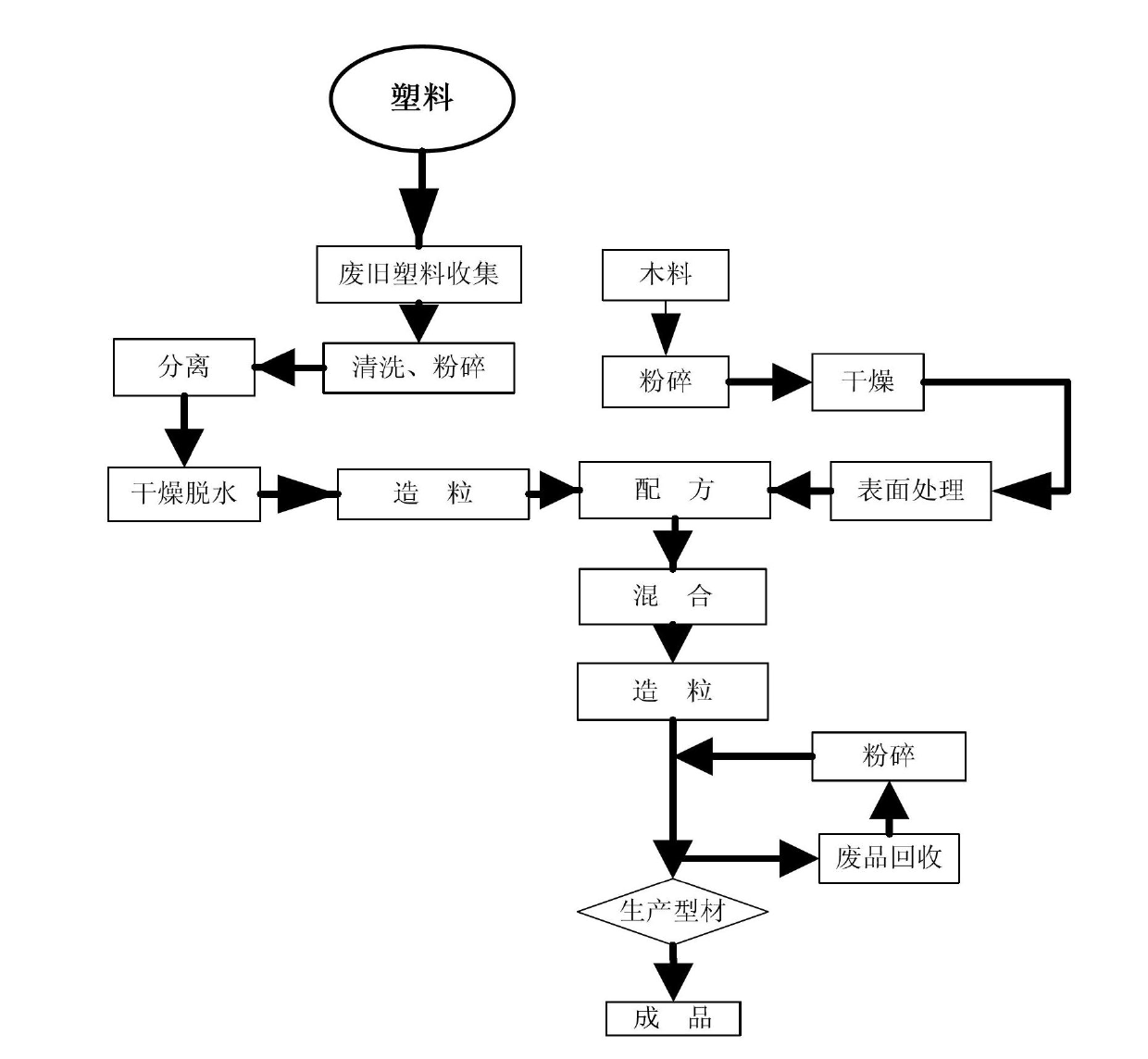

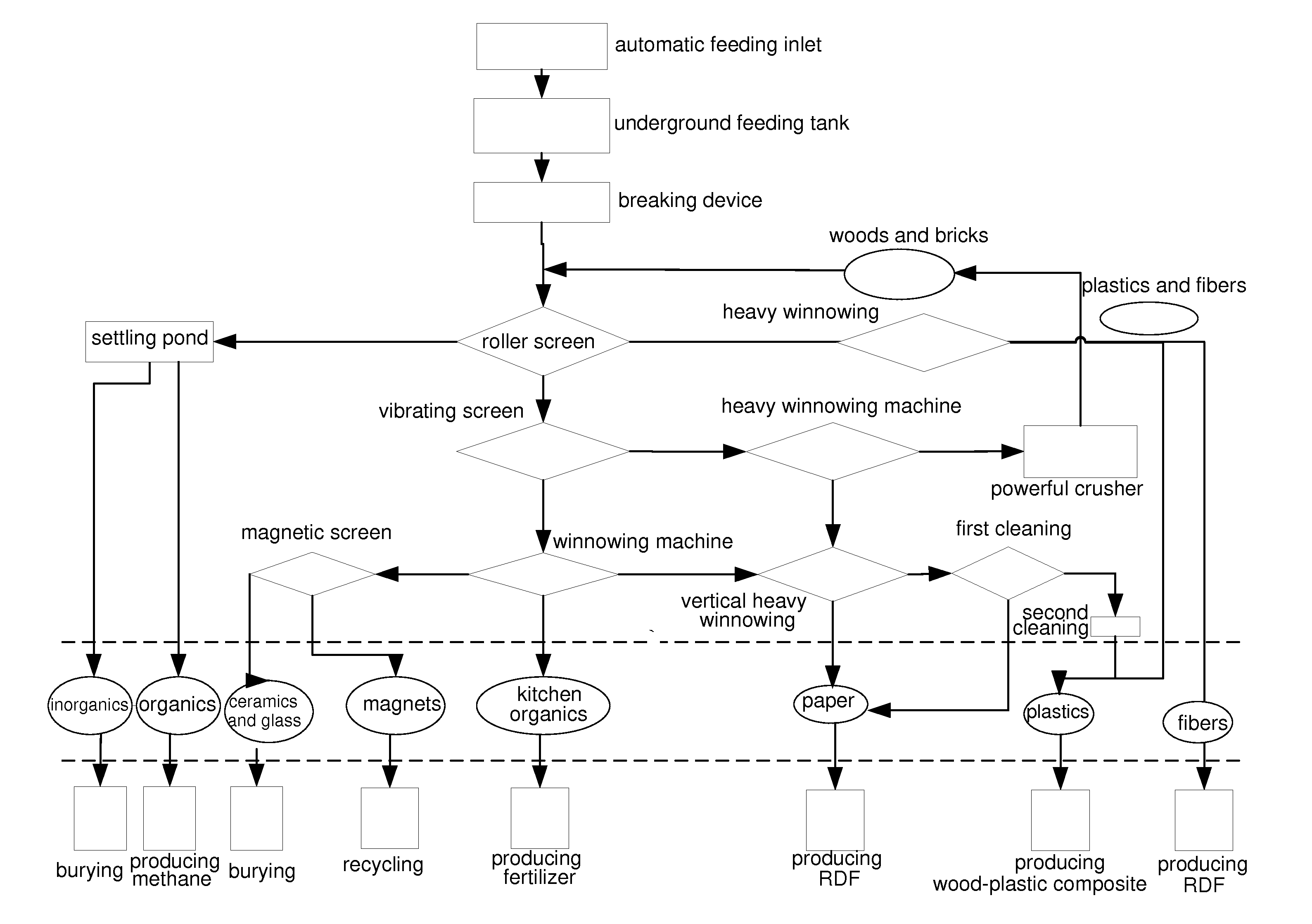

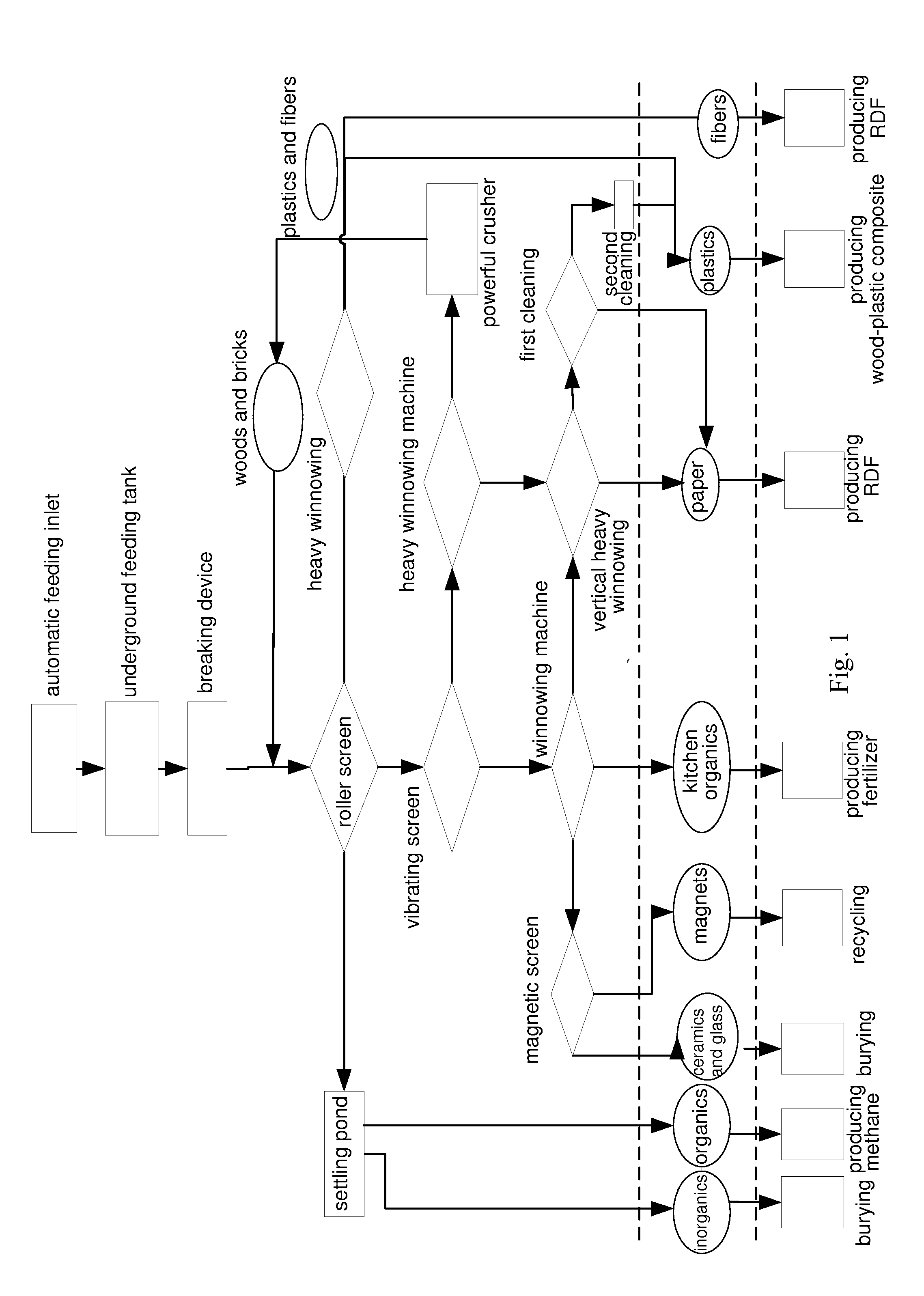

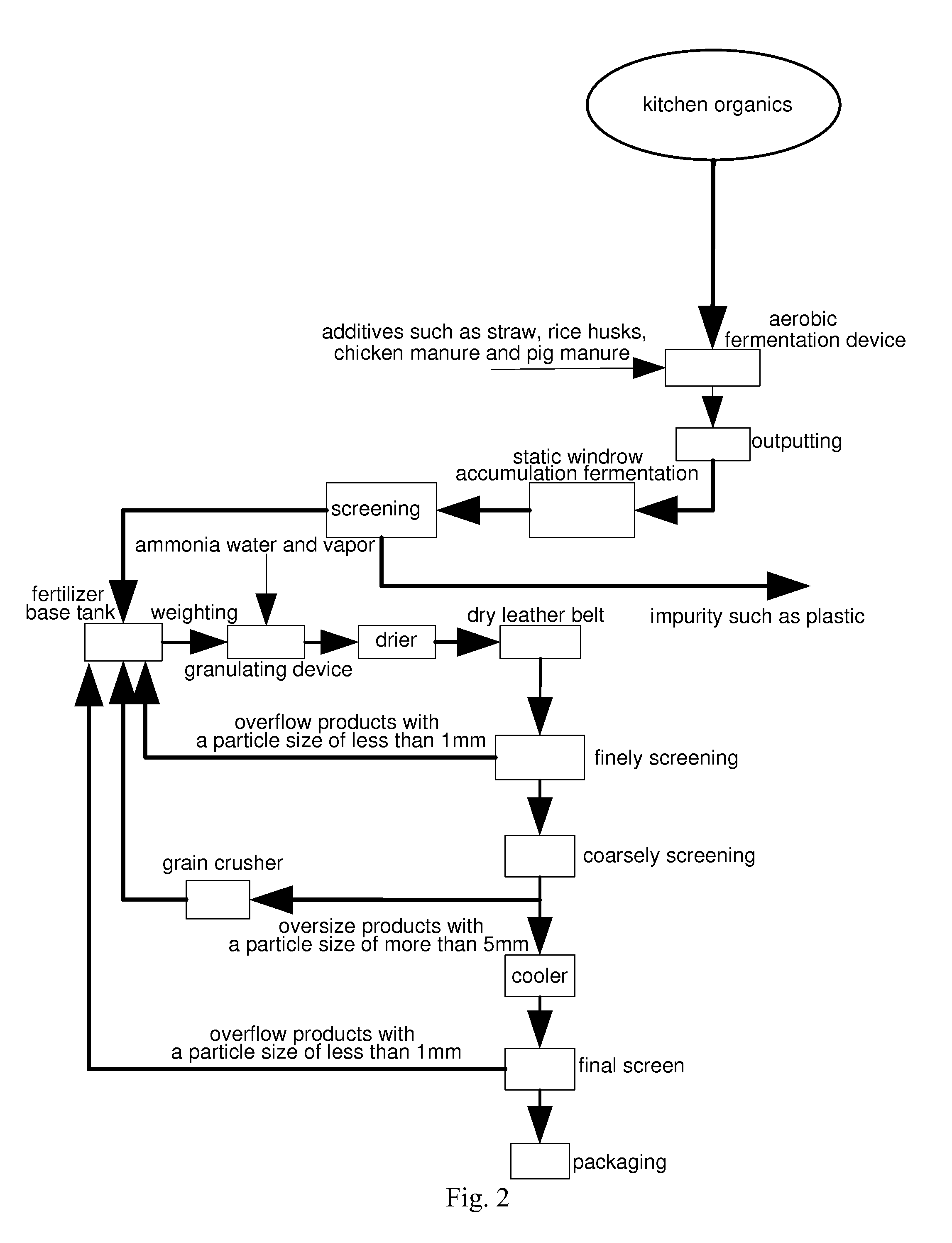

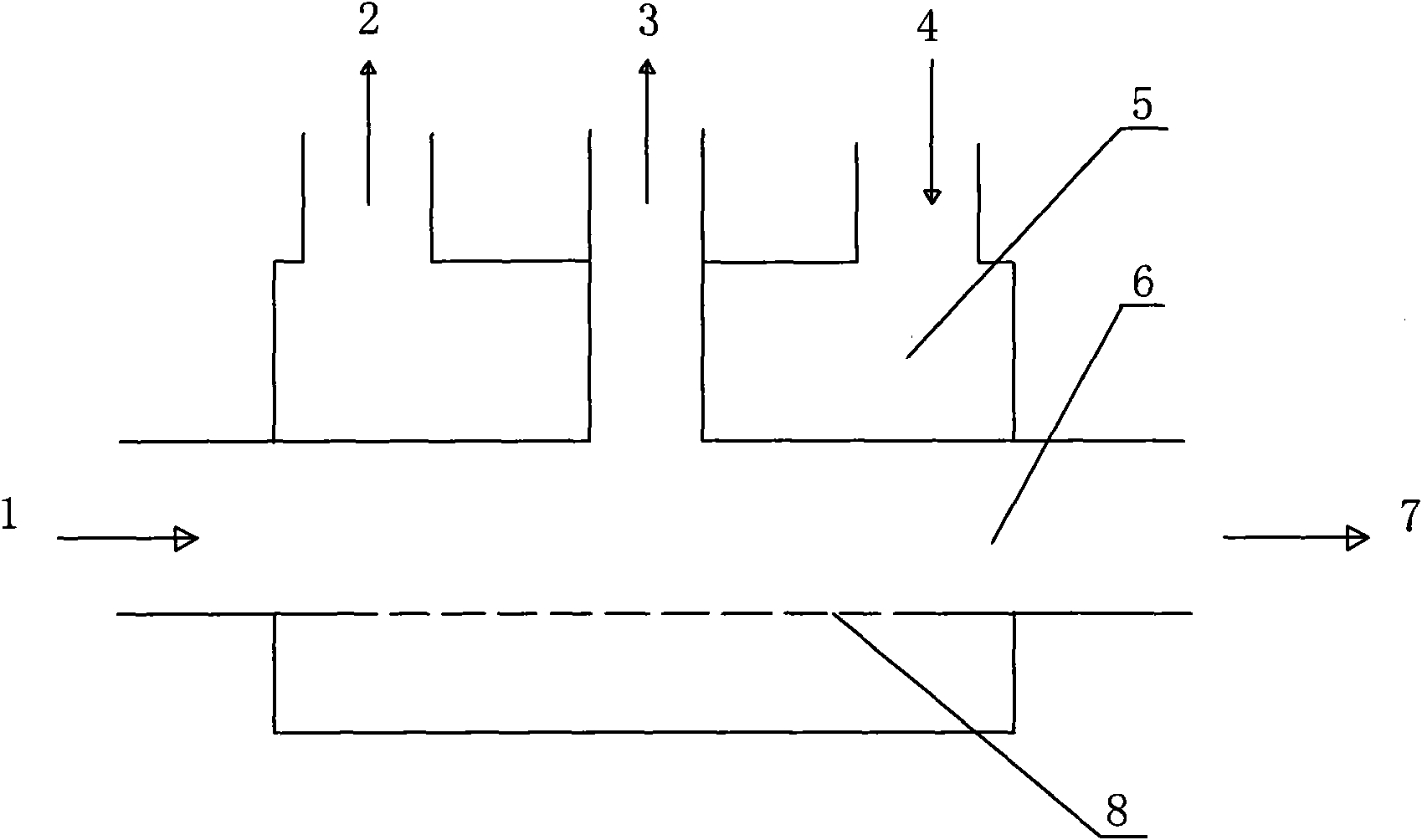

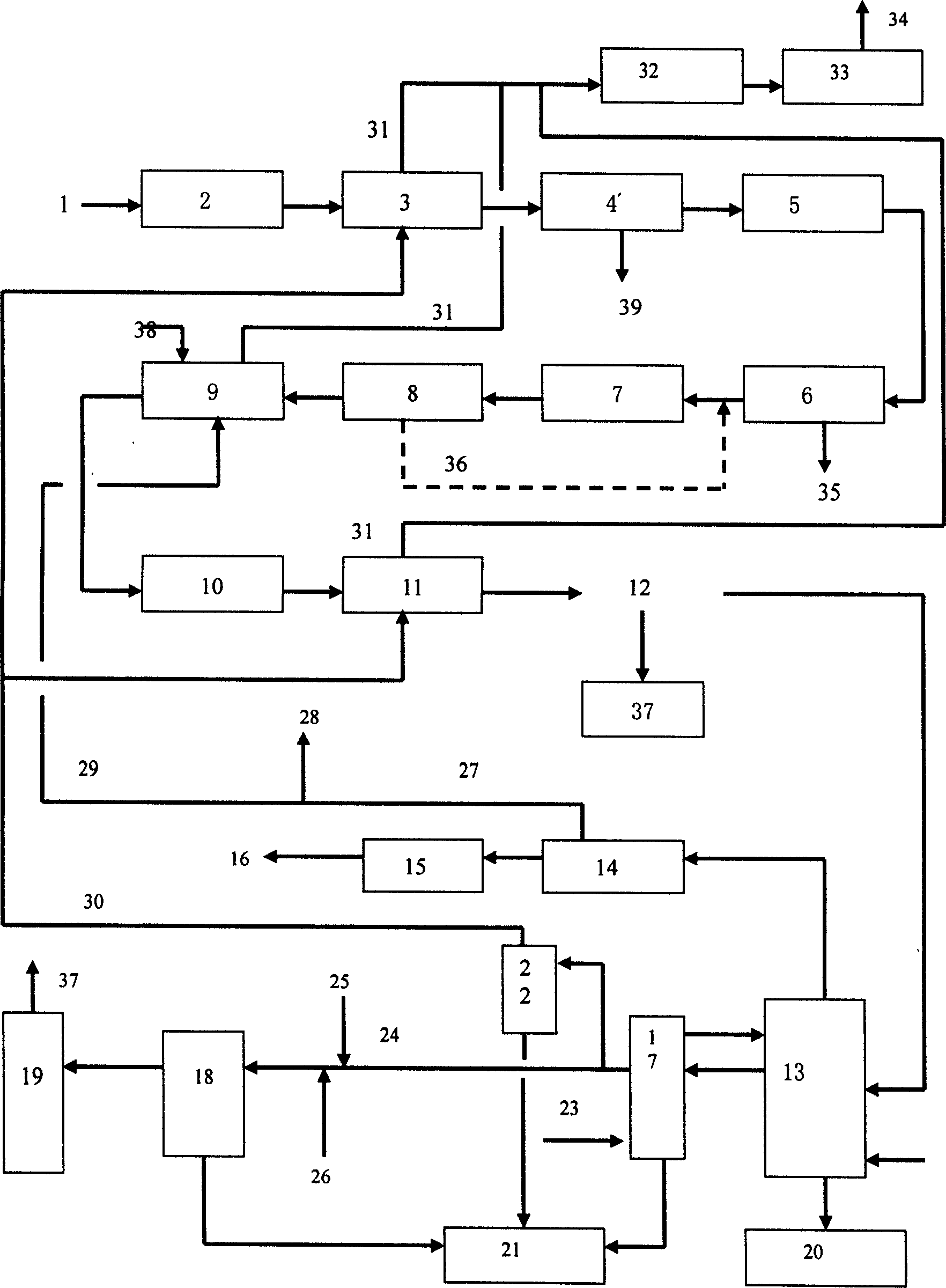

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

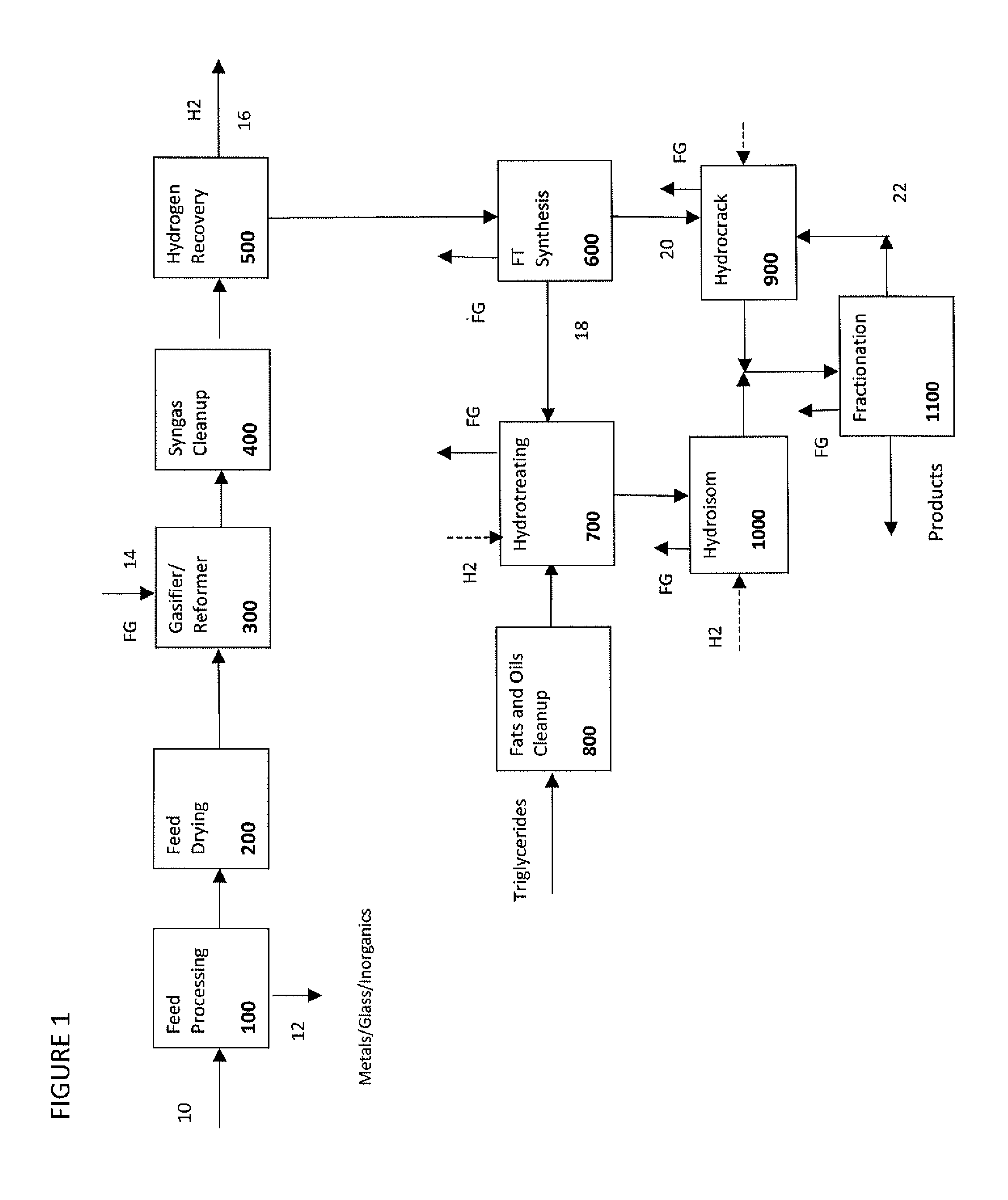

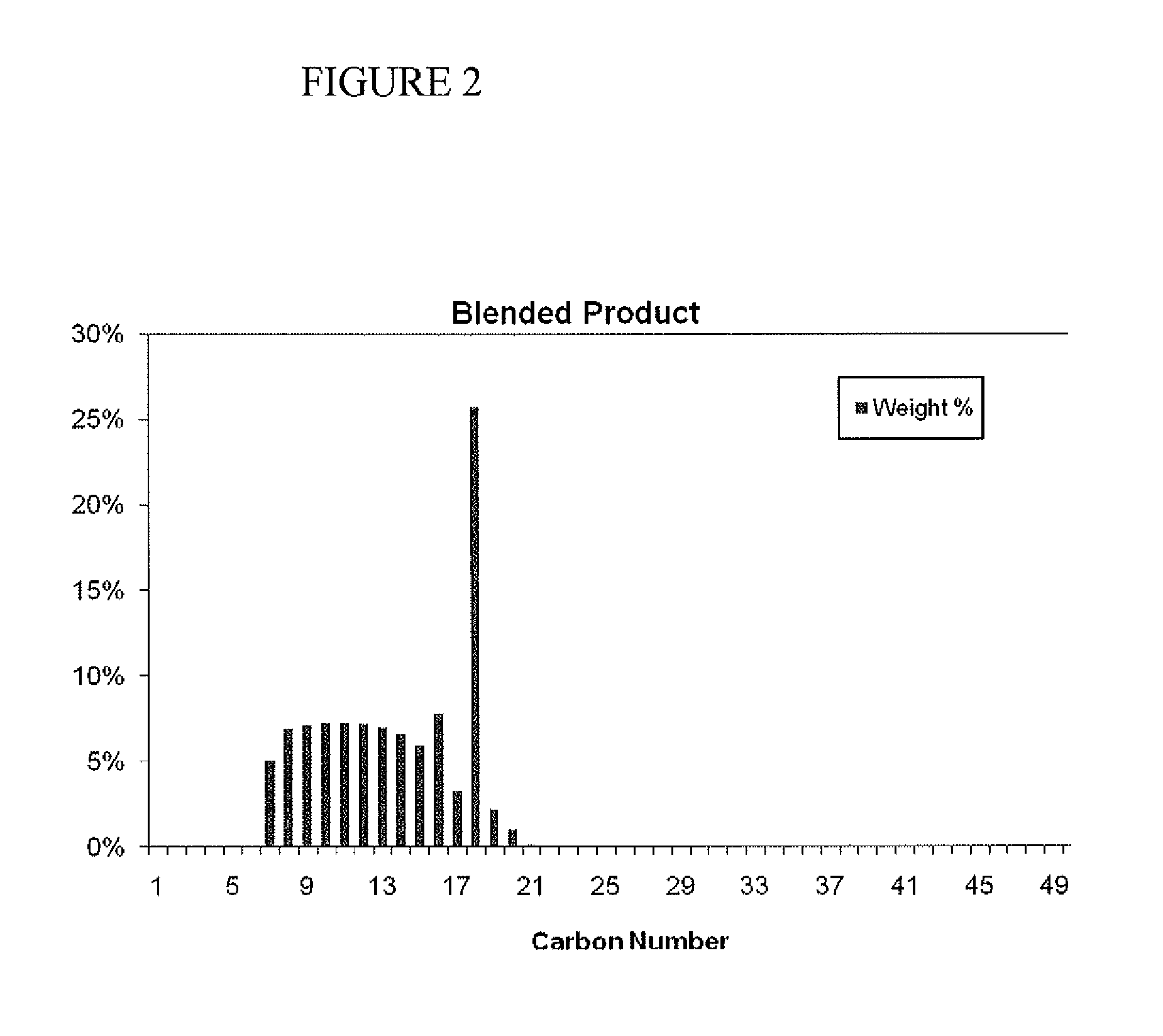

Production of distillate fuels from an integrated municipal solid waste/triglyceride conversion process

InactiveUS20110113676A1Refining to change hydrocarbon structural skeletonEnergy inputSyngasRefuse-derived fuel

A municipal solid waste material is converted to a refuse derived fuel then to syngas which is processed to produce a liquid feedstream via Fischer-Tropsch Synthesis. The Fischer-Tropsch liquid feedstream is combined with a triglyceride feedstream then hydroprocessed to produce a distillate fuel end product.

Owner:RATIONAL ENERGIES

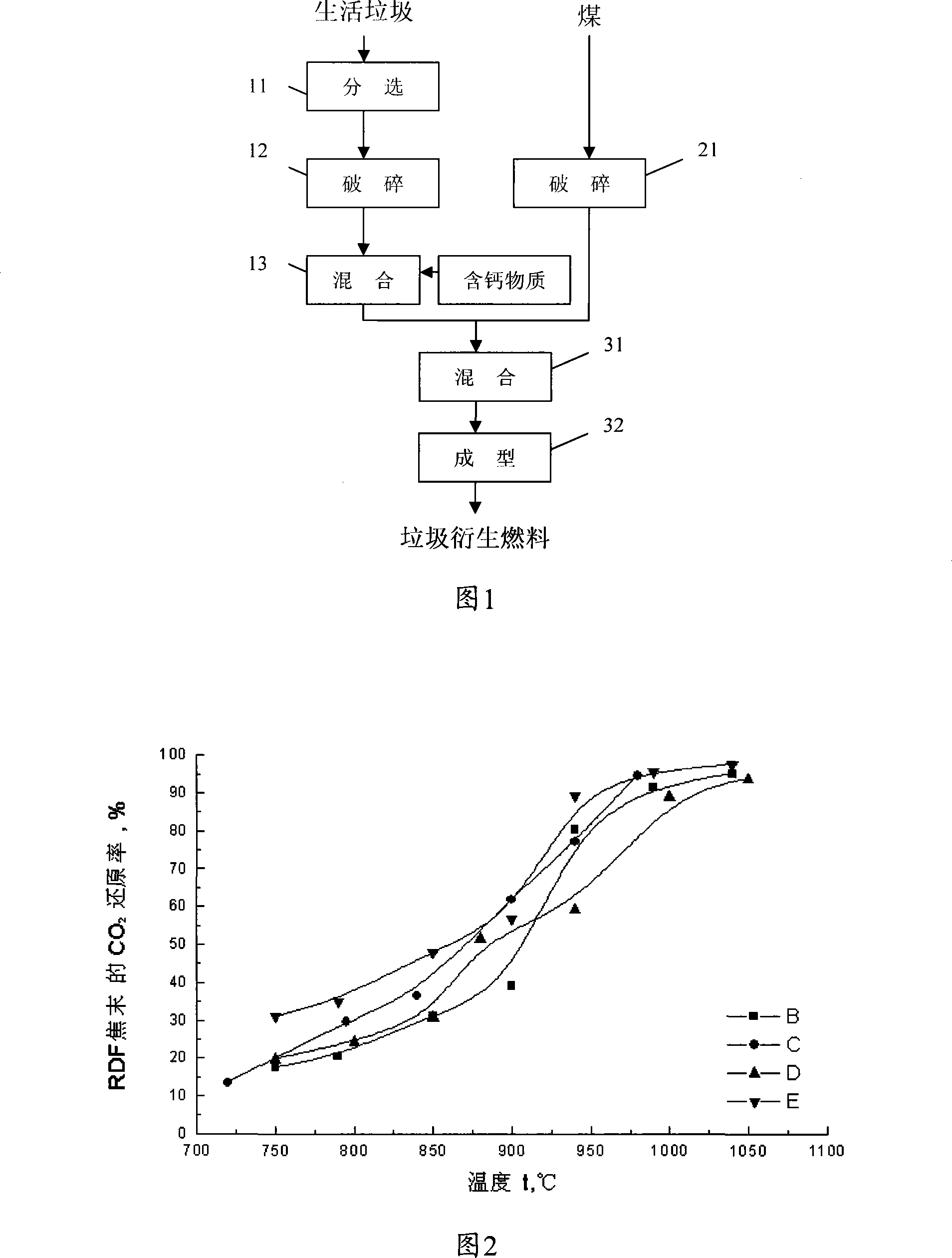

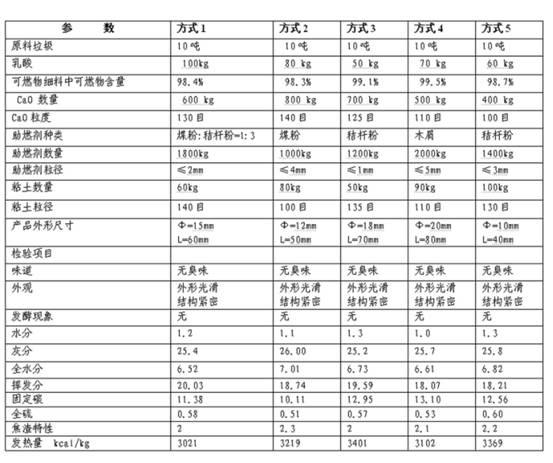

Garbage derived fuel and preparation method thereof

InactiveCN101215490AIncrease energy densityGuaranteed pyrolysisBiofuelsSolid fuelsRefuse-derived fuelCombustion

The invention discloses a refuse derived fuel and a process for preparation. The refuse derived fuel takes domestic refuse as main components and is added with the appropriate amount of coal and calcium materials. The process for preparation comprises following steps: sorting and crushing municipal domestic refuse, grinding the coal and pre-treating raw materials which contain calcium, then, proportioning according to certain proportion, adopting the high pressure molding technology without agglomerant, and preparing the refuse derived fuel with certain energy concentration, hot and cold intensity and technical properties. The refuse derived fuel can sufficiently utilize combustible constituents in the domestic refuse with simple manufacturing technique, low conversion cost, good combustion, pyrolysis and gasification performances and realize that the refuse is enabled to be resources and to be less and to be innocuous.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

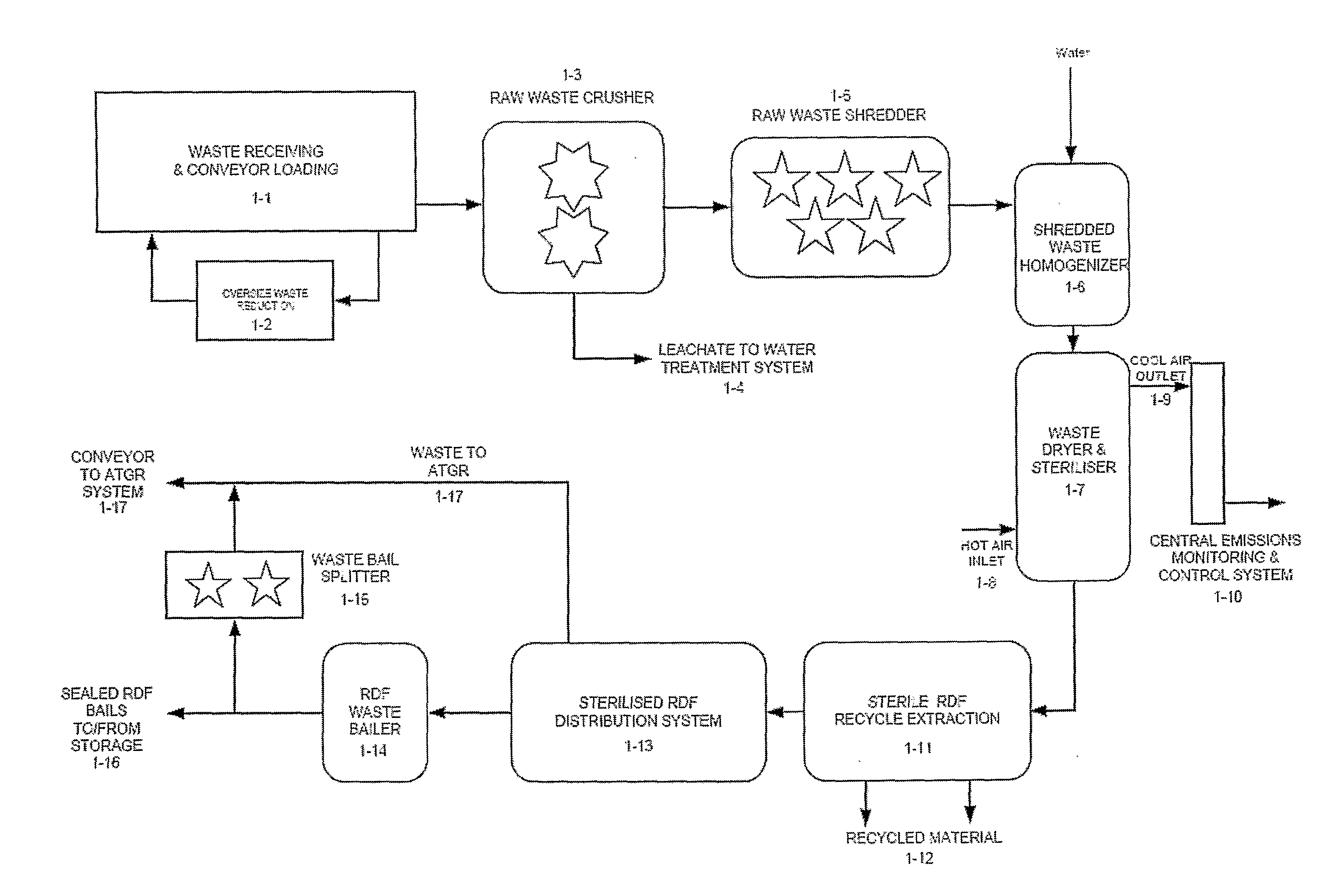

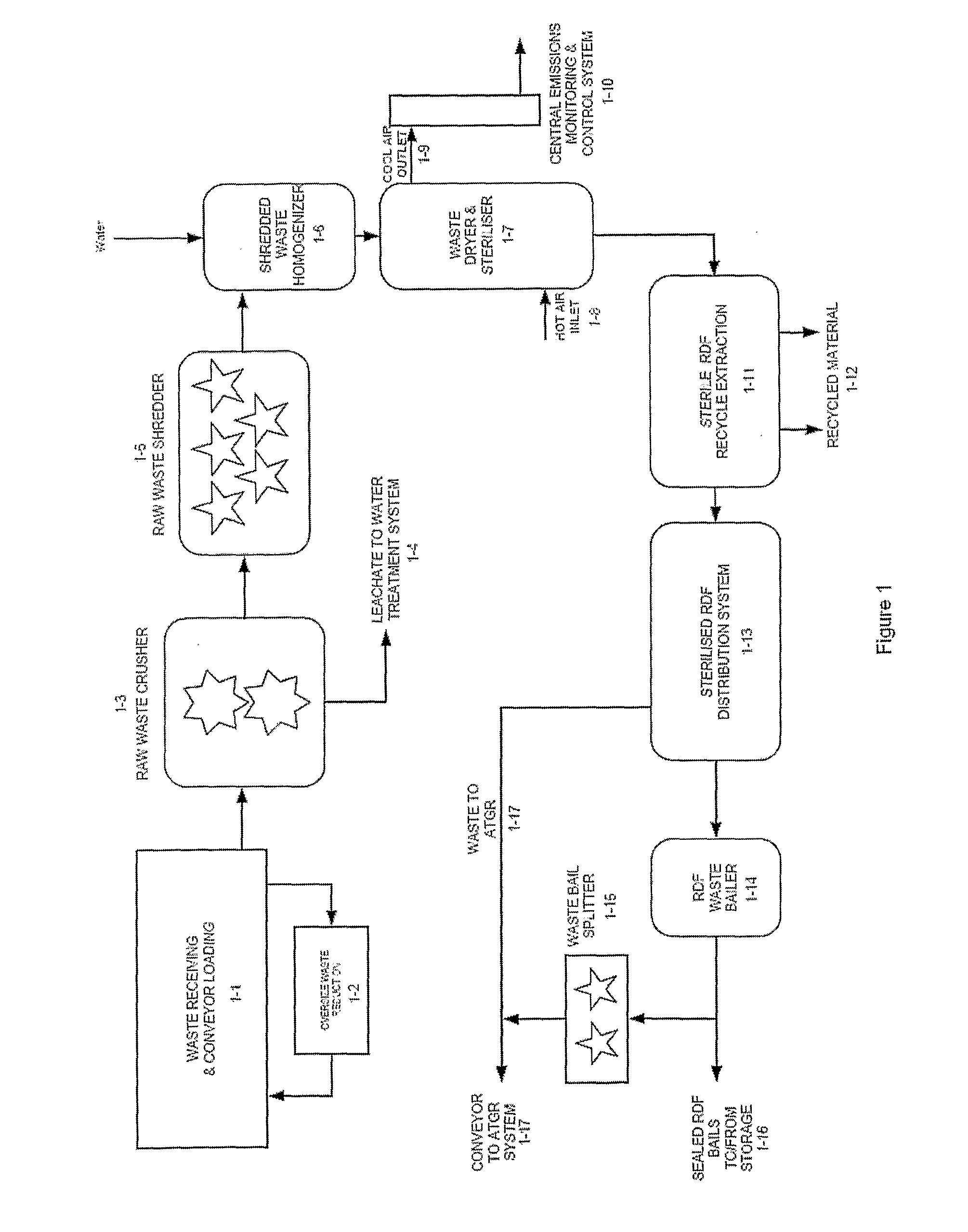

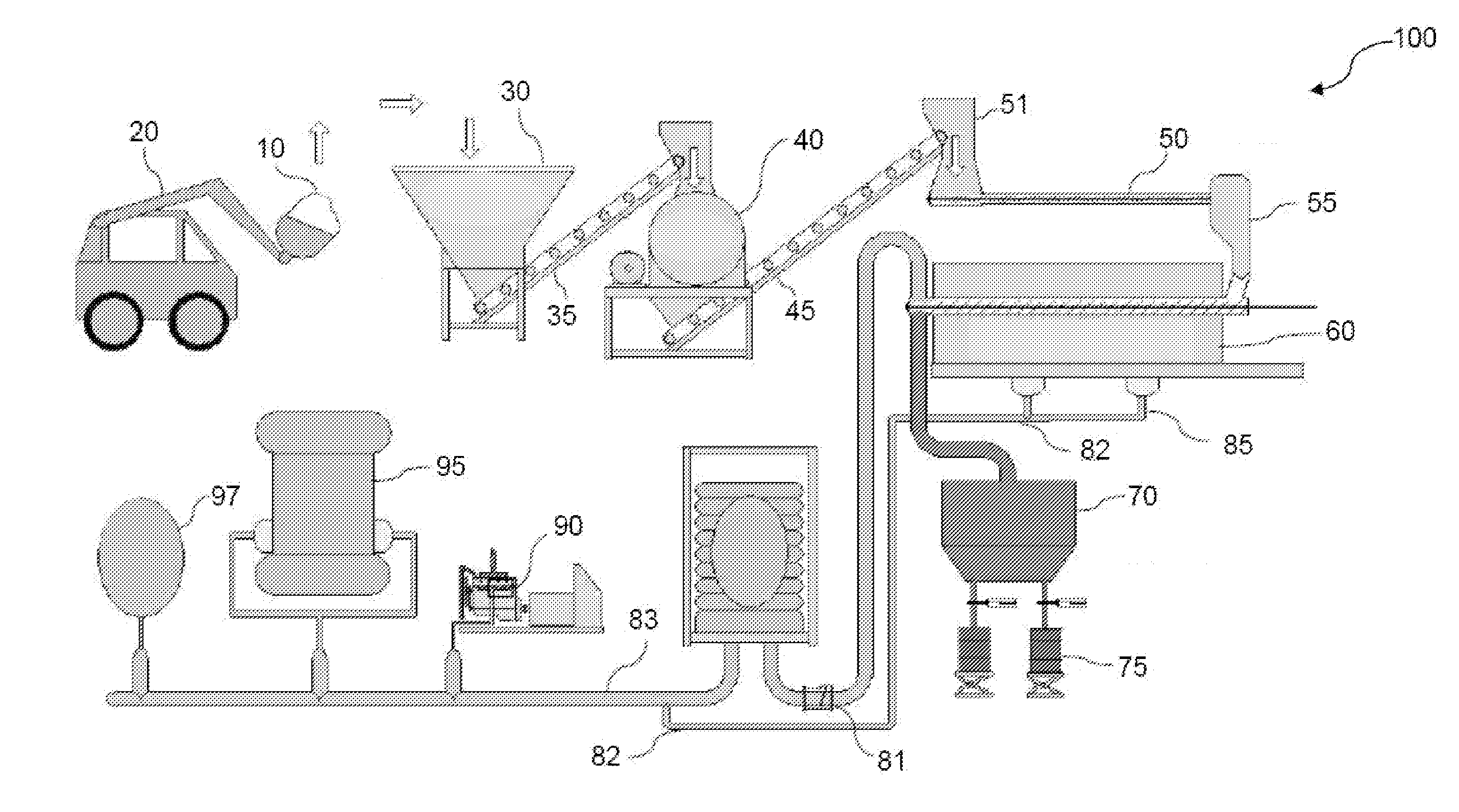

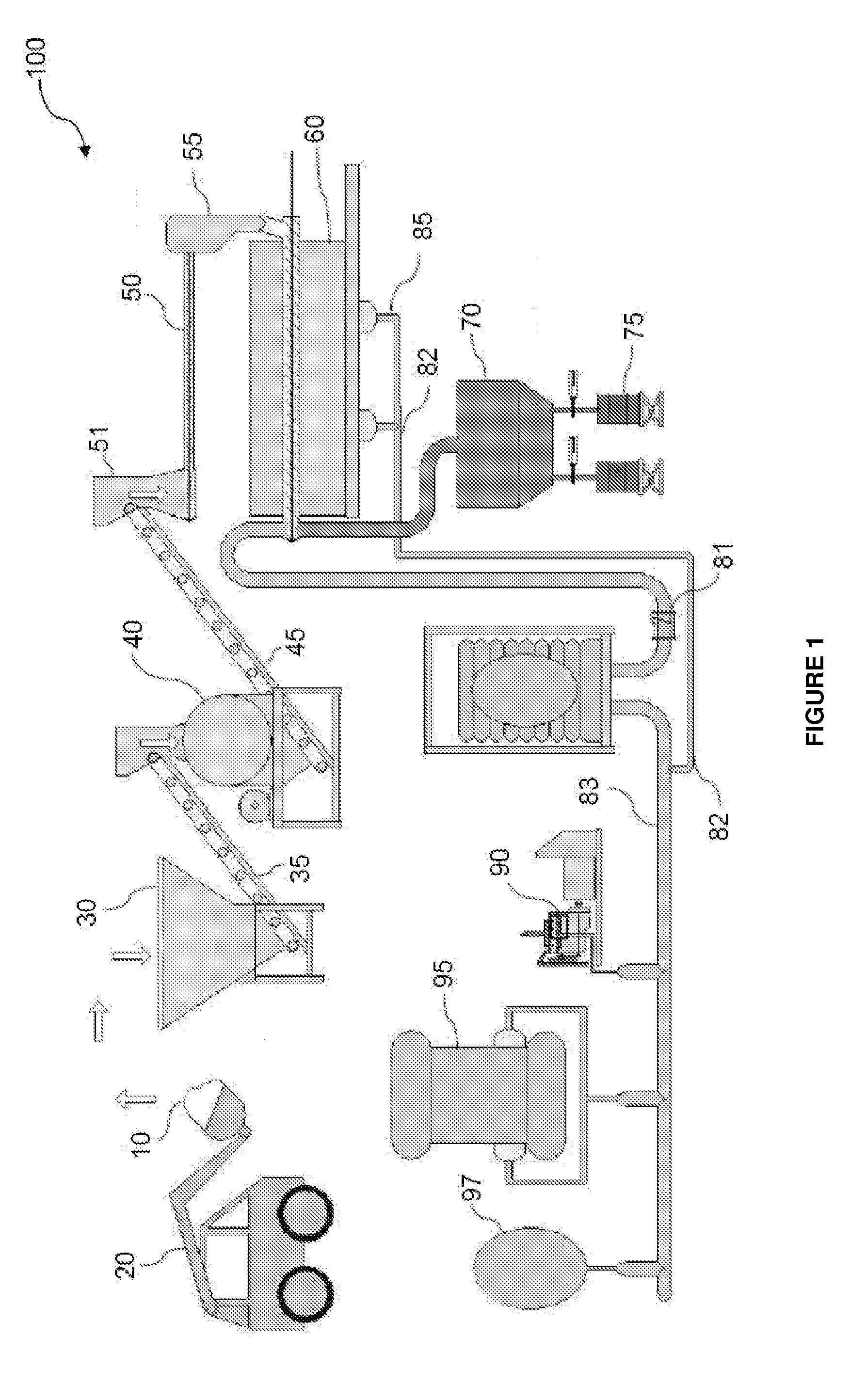

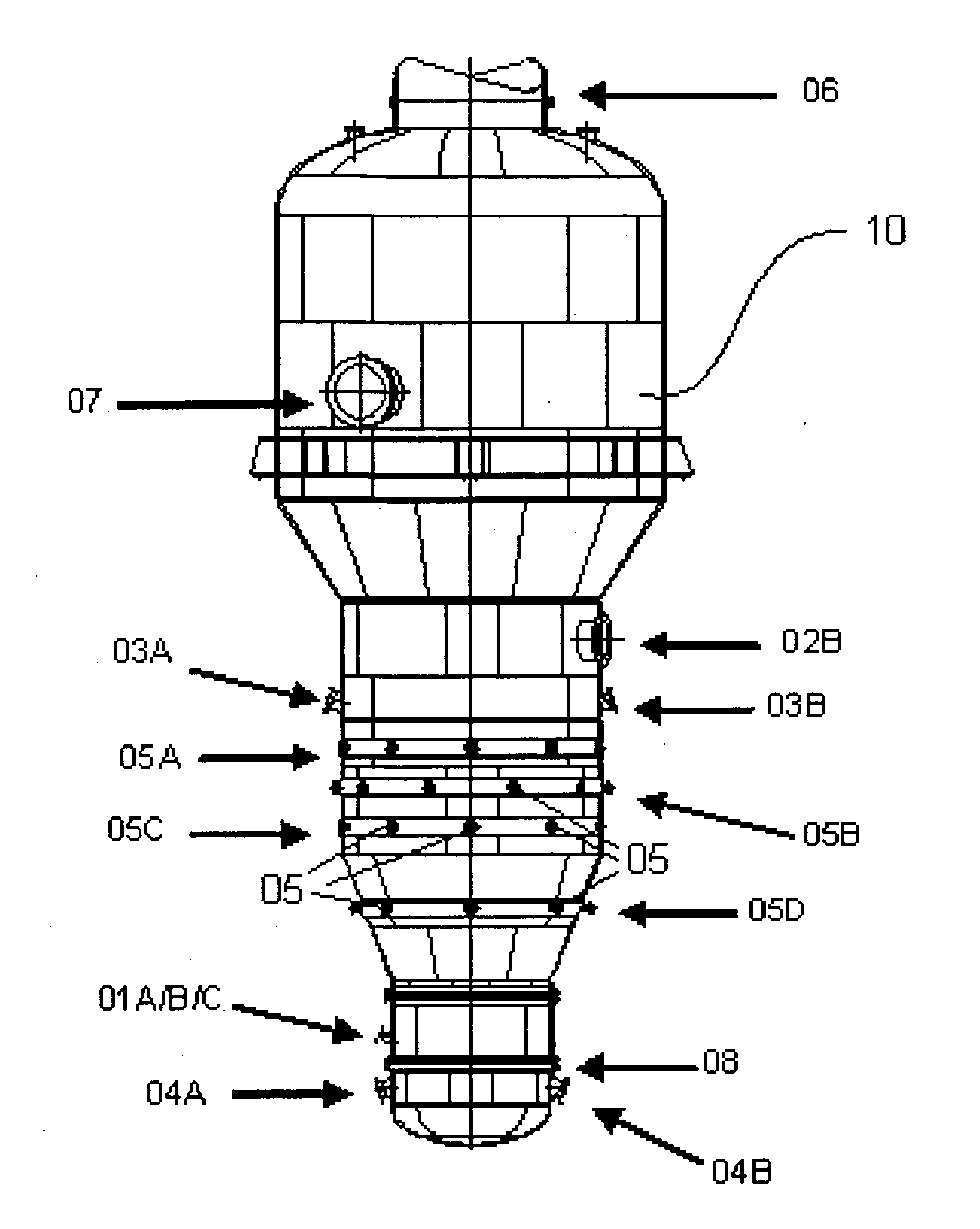

Method and system for producing energy from waste

A method and system for the conversion of waste into energy in a sealed system where combustion does not take place and the operating pressure prior to the inlet of the steam or power generating equipment is maintained below atmospheric pressure. Destruction of the RDF (refuse derived fuel) is accomplished by subjecting the RDF to a high temperature environment under controlled conditions in a purpose designed and built reactor. The high temperature environment, <5000° C., is achieved through the use of one or more non-transferred plasma torches for generation of plasma gas. The plasma gas exiting the torch and provides the thermal energy for the continual gasification of metallurgic coke configured as a carbon bed in the lower part of the reactor, which acts as a thermal catalyst and this provides the thermal energy for the gasification process.

Owner:GREEN ENERGY & TECH

Preparation method for preparing derived fuel by utilizing combustible materials in garbage

InactiveCN102041127AImprove sorting rateSuppress generationBiofuelsSolid fuelsRefuse-derived fuelAdhesive

The invention relates to a preparation method for preparing a derived fuel by utilizing combustible materials in garbage, comprising the following steps: (1) disinfecting; (2) carrying out rough selection on the garbage; (3) carrying out fine selection on the garbage; (4) adding CaO the weight of which accounts for 4%-8% of the total weight of the combustible materials into fine combustible materials, mixing and stirring uniformly; (5) adding a combustion improver and an adhesive, mixing and stirring uniformly; (6) draining and drying the fine combustion materials; (7) carrying out extrusion molding; (8) drying and cooling to obtain a finished product; and (9) detecting the heating value of the derived fuel. The preparation method has the beneficial effects that 1, the sorting index of the garbage is high, so that harmful substances in the derived fuel are effectively controlled; 2. the heat value of the derived fuel is high; 3, the CaO is added in the derived fuel of the garbage, effective disinfection is achieved and the generation of the harmful substances such as dioxin and the like in the combustion process is restrained; 4, the adhesive is added, so that the strength of a product is good, the product is not easy to break, and the structure shape is smooth; 5, the space formed by accumulation of the size of the shape of the finished product on a boiler grate is most beneficial to combustion; and 6, the resource utilization is maximized, the cost of production and manufacture is low, the production efficiency is high, the product quality is good, and the transportation and storage are convenient.

Owner:杨健

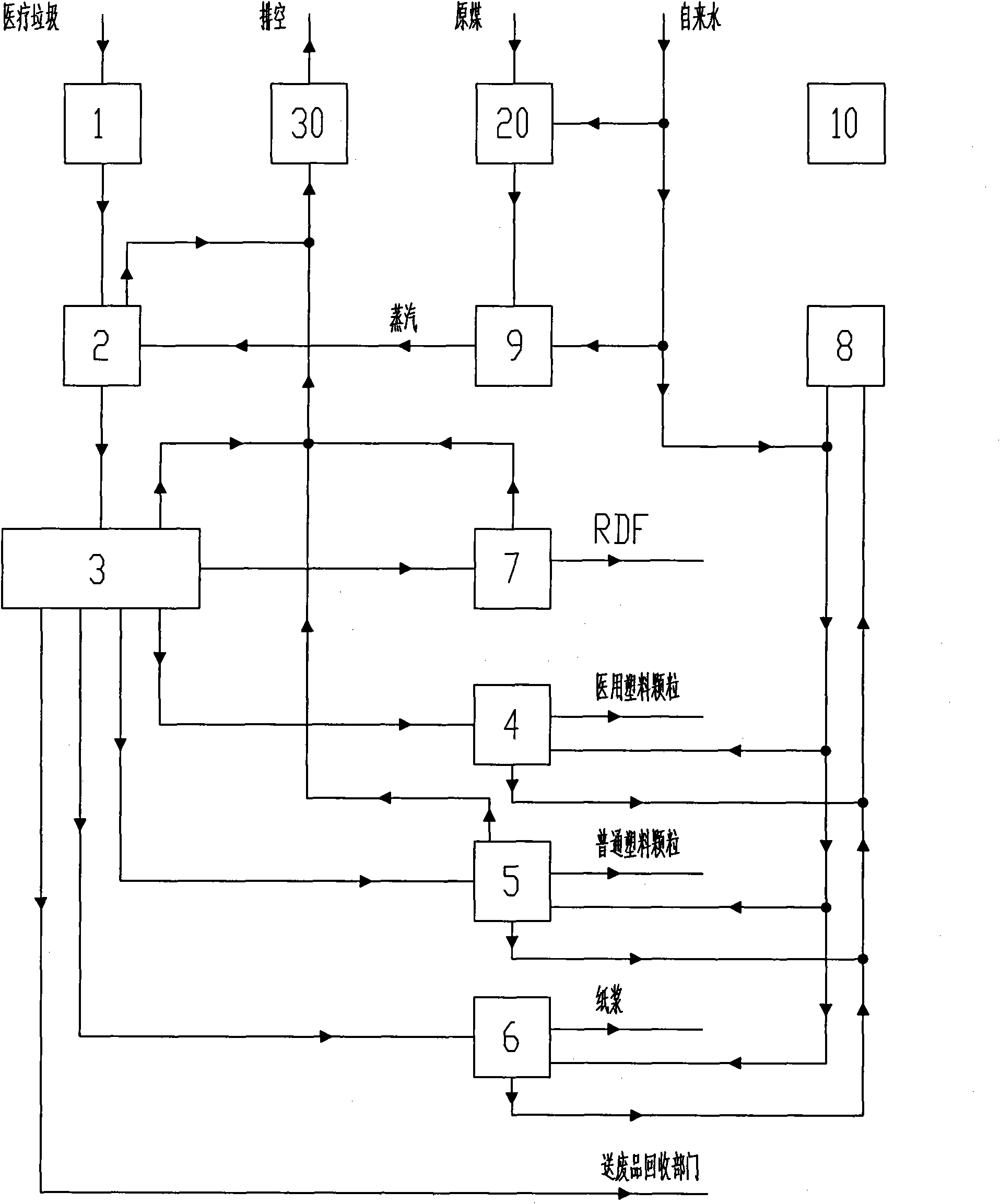

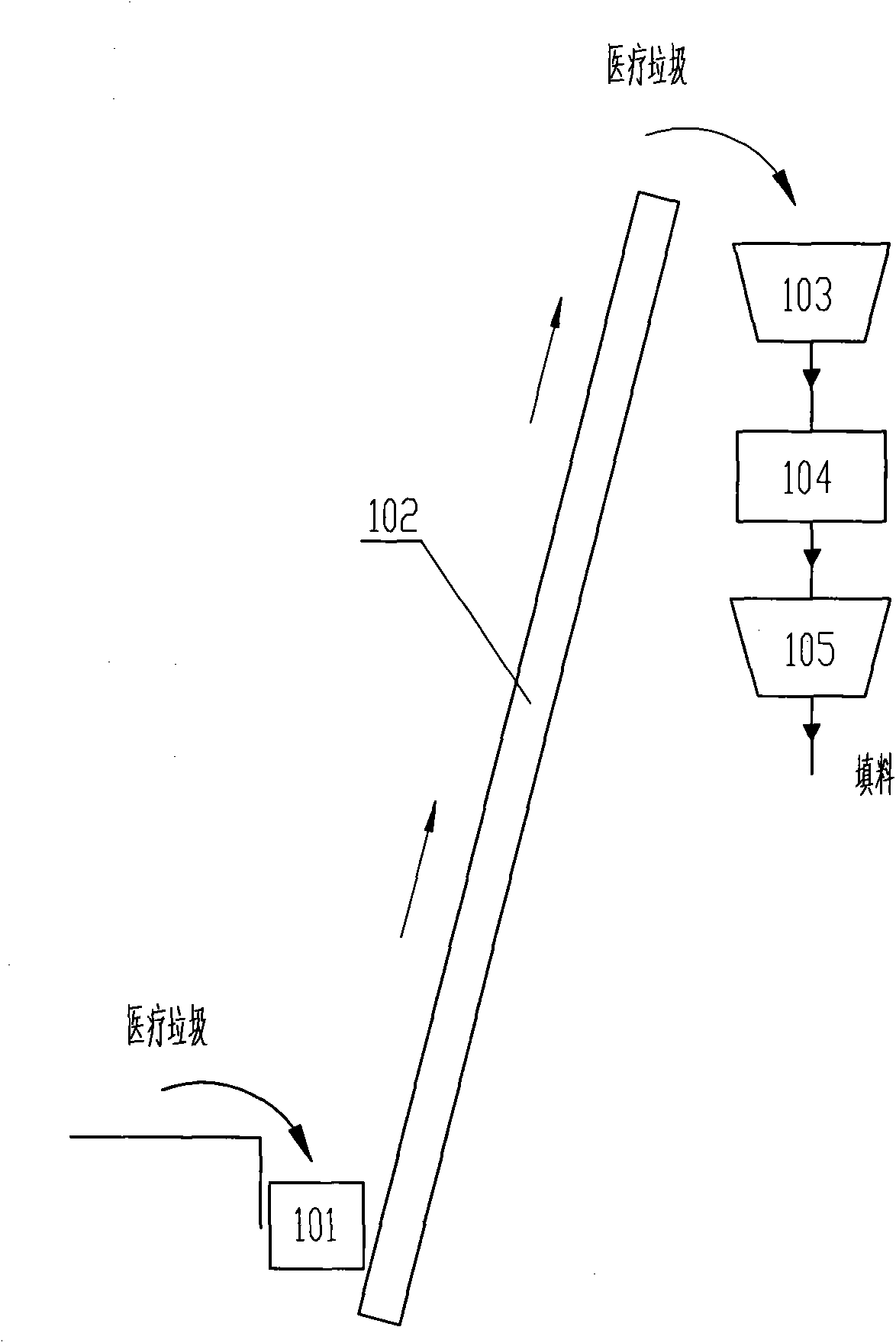

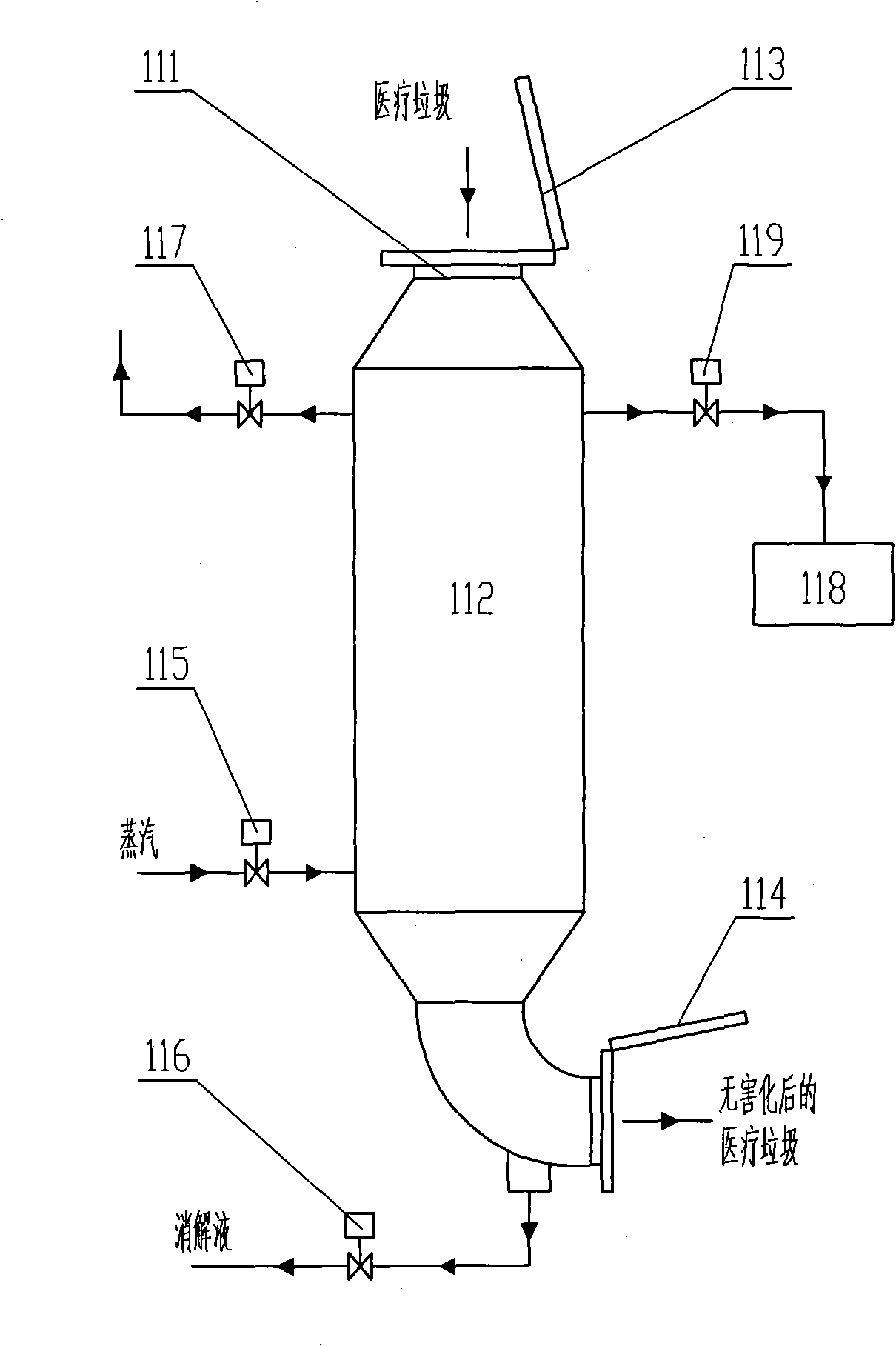

Medical rubbish harmless resource comprehensive utilization system

InactiveCN101972769AGood for harmonyPromote sustainable developmentSolid waste disposalMedical waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a medical rubbish harmless resource comprehensive utilization system. A comprehensive utilization method comprises the following steps of: sterilizing and disinfecting medical rubbish at high temperature and high pressure, sorting out disposable syringes, containers, trays and other medical hard plastics and disposable infusion tubes, infusion bags, blood bags, rubbish liquid bags and other medical soft plastics, collecting through splitting and classification, granulating, cleaning, drying and recycling; sorting out common waste plastics, recycling after cleaning, drying and granulating; sorting out paper plastic packaging materials, pulping, dewatering and recovering paper pulp; sorting out syringe needles, scalpels and other metal items and infusion bottles, smears and other glass items, and recycling at specialized rubbish recycling departments; and crushing, dewatering and drying the rest items, sending to produce RDF (Refuse Derived Fuel), and selling the RDF or using the RDF as a fuel of a steam boiler. Medical rubbish is completly recycled at high value. The medical rubbish resources do not emit pollutants during recycling and do not bring any harm to environment.

Owner:朱海生

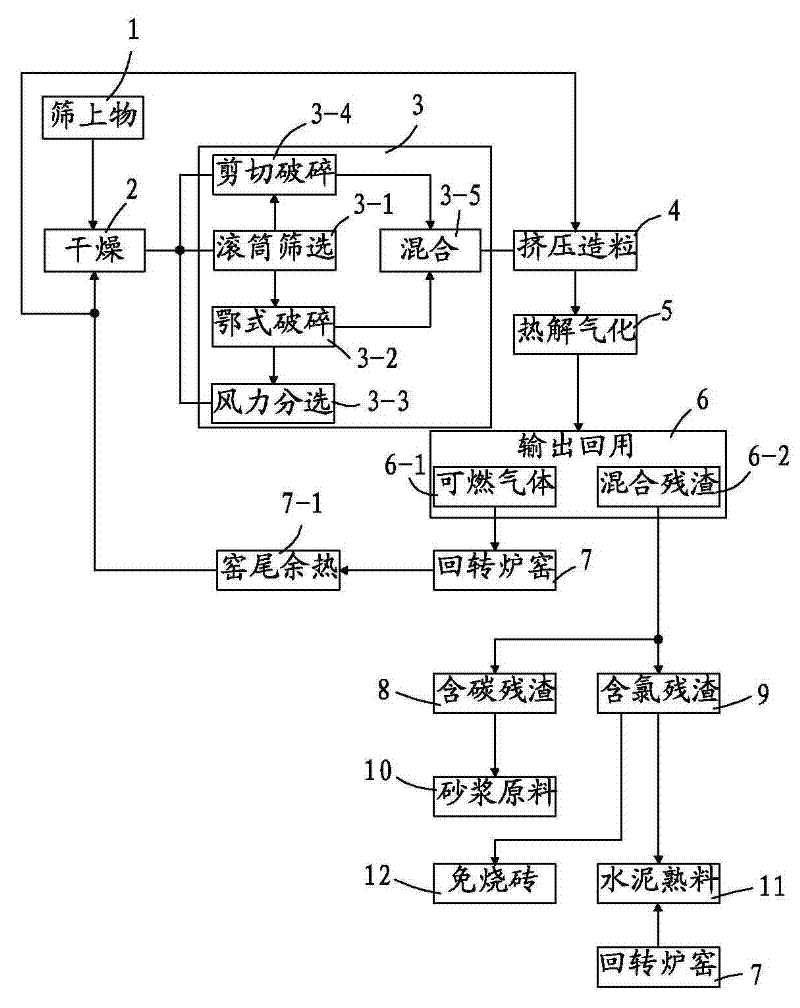

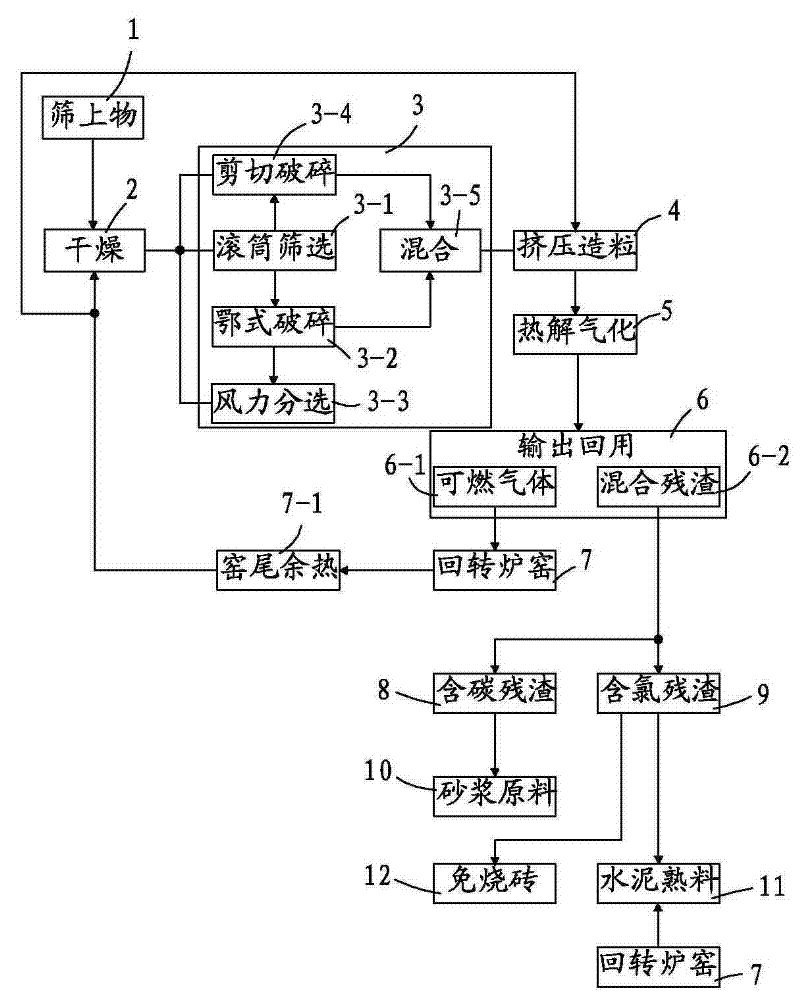

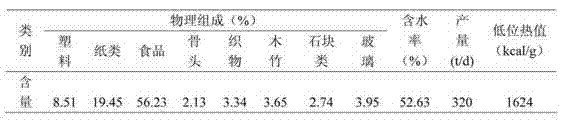

Method for performing pyrolysis uniting building-material utilization to rubbish oversize products

InactiveCN102500607AReduce moisture contentHigh calorific valueSolid waste disposalRefuse-derived fuelCement kiln

The invention discloses a method for performing pyrolysis uniting building-material utilization to rubbish oversize products. First rubbish undersize products with granularity smaller than 15mm are conveyed into a rubbish composting plant to perform composting or conveyed into a refuse landfill to serve as covering soil, and a treatment flow of the rubbish oversize products sequentially comprises drying, screening, crushing, winnowing, mixing, extrusion granulation, pyrolysis gasification and output recycling. Rubbish is processed into a refuse derived fuel (RDF) after waste heat drying at first, and not only are heat value and burning performance improved, but also secondary pollution of percolate, dioxin and the like is avoided. Combustible gas generated by a pyrolysis method enters into a cement kiln to be combusted, part of fuel required for cement clinker production can be replaced, and a stable high-temperature environment in the cement kiln can fully degrade dioxin generated by rubbish incineration. Ash residues serve as different building-material raw materials according to different heterogeneities, waste discharge is avoided, and no influence is caused on building-material production and product quality.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

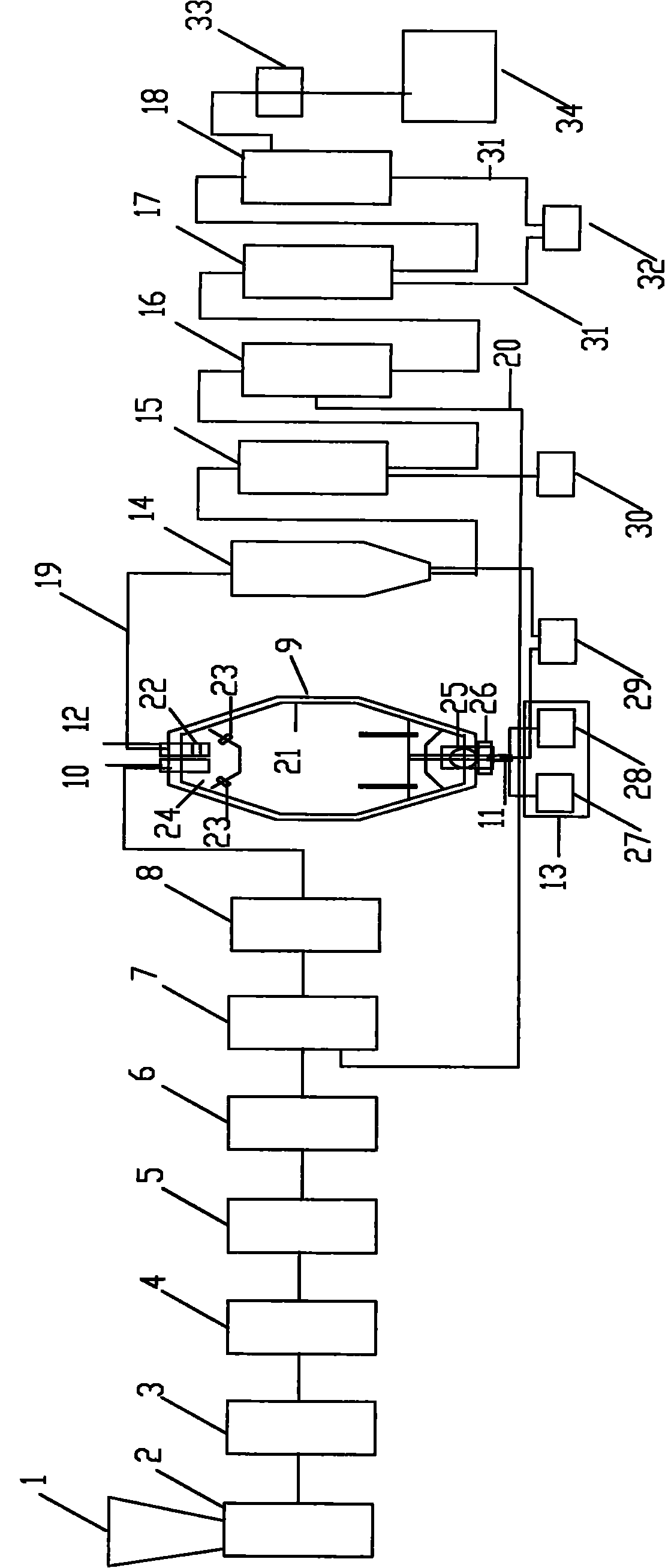

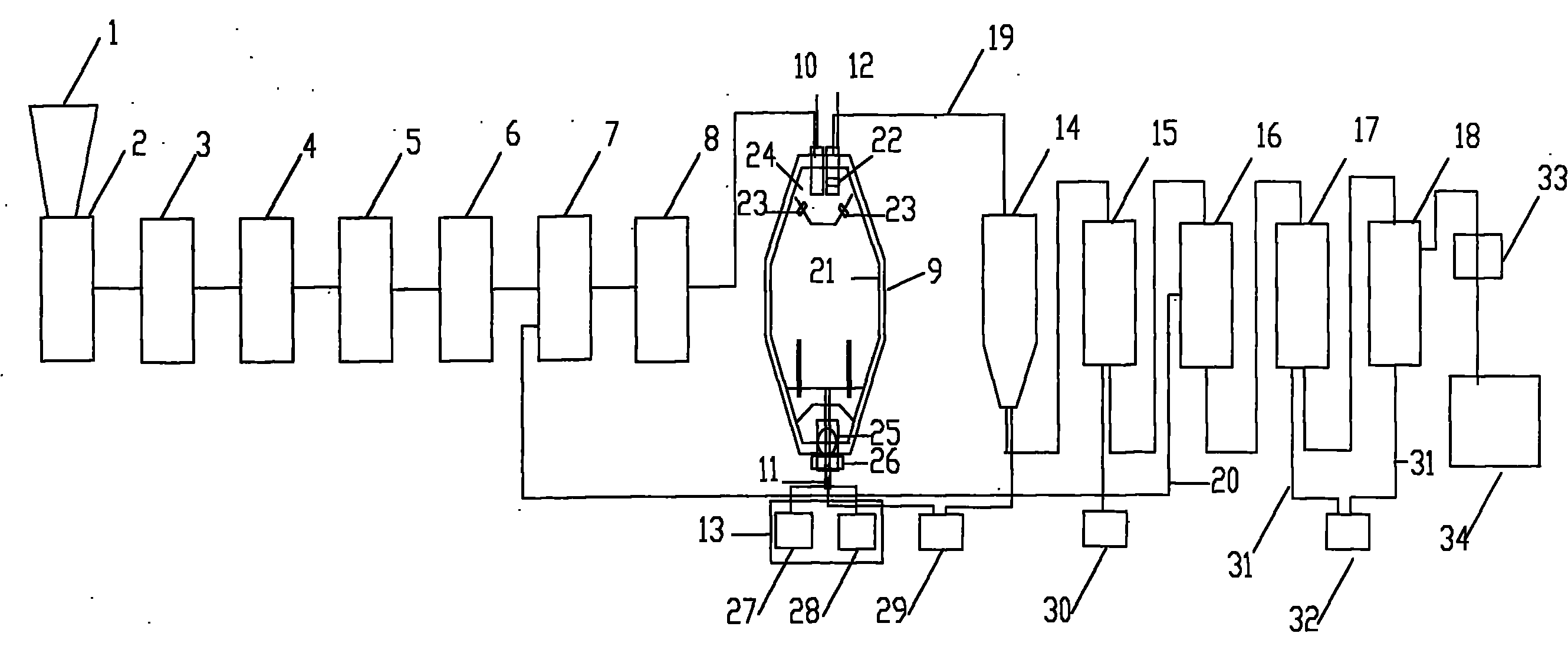

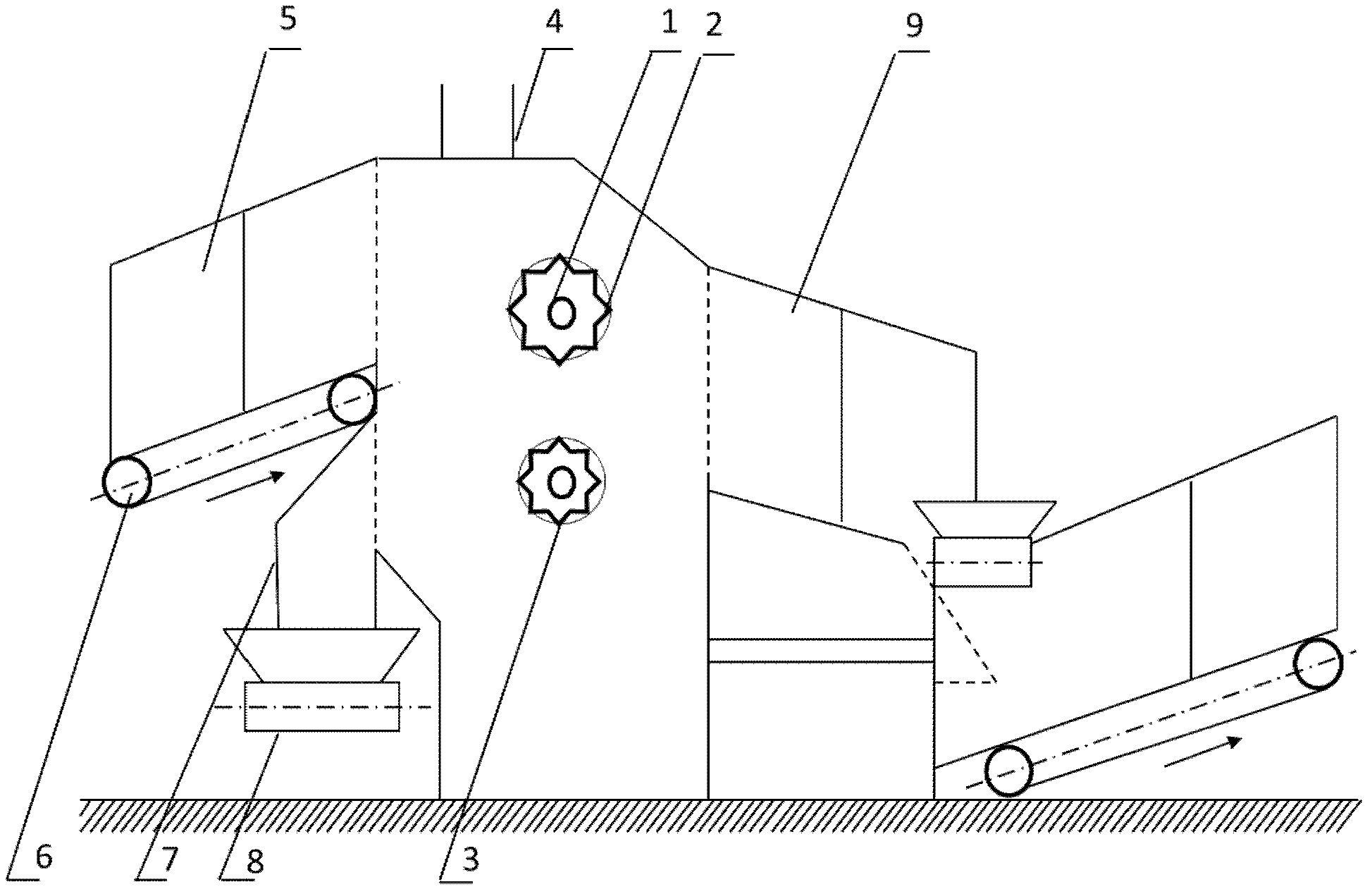

Gasification treatment device for household refuse

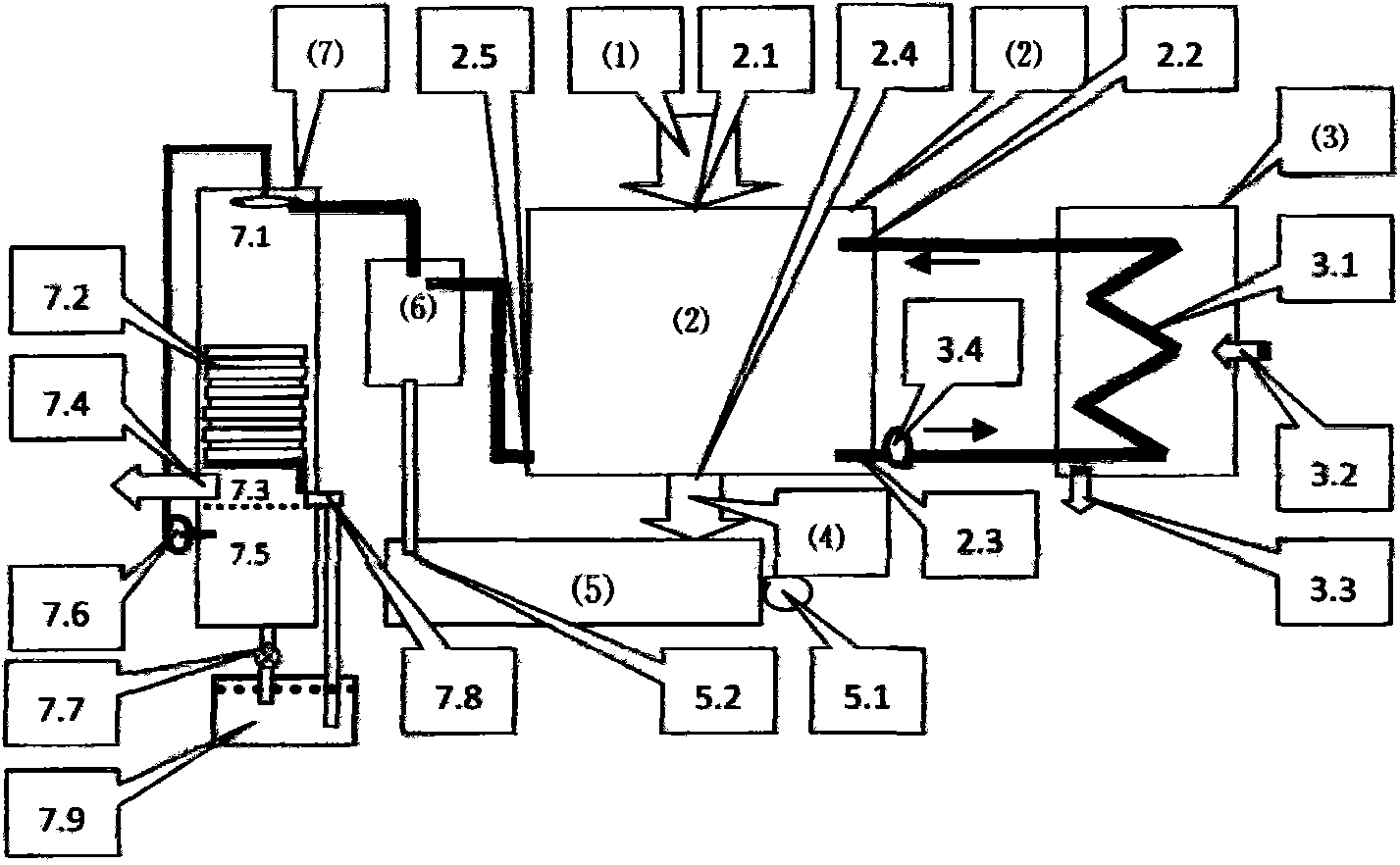

InactiveCN101817012ASolve intractableGood environmental benefitsSolid waste disposalCombustible gas purificationRefuse-derived fuelBrick

The invention discloses a gasification treatment device for household refuse. Combustible materials in the household refuseare treated and processed into refuse derived fuel RDF, and the RDF is subjected to pyrolysis gasification of a fixed bed gasifier and purification into clean gas. The device comprises an RDF processing system, a gasification system and a gas purification system, wherein the RDF processing system comprises a discharge hopper, a plate feeder, a refuse breaker, a rotary screen, a magneticseparator, a dehydrator, a rotary dryer and a refuse press; the gasification system comprises a normal-pressure fixed bed gasifier, a feeding hole, a slag hole, a gas hole and a blower device; and the gas purification system comprises a cyclone dust collector, an electrical tar precipitator, a heat exchanger, a washer and an adsorption tower. The RDF is subjected to pyrolysis gasification of the fixed bed gasifier to form combustible gas, the combustible gas is purified by the gas purification system, and finally the gas is delivered to a gas holder through a Roots blower; the slag after the gasification is delivered to a brick making device for producing building materials; and wastewater generated by gas purification enters a wastewater tank for further treatment.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

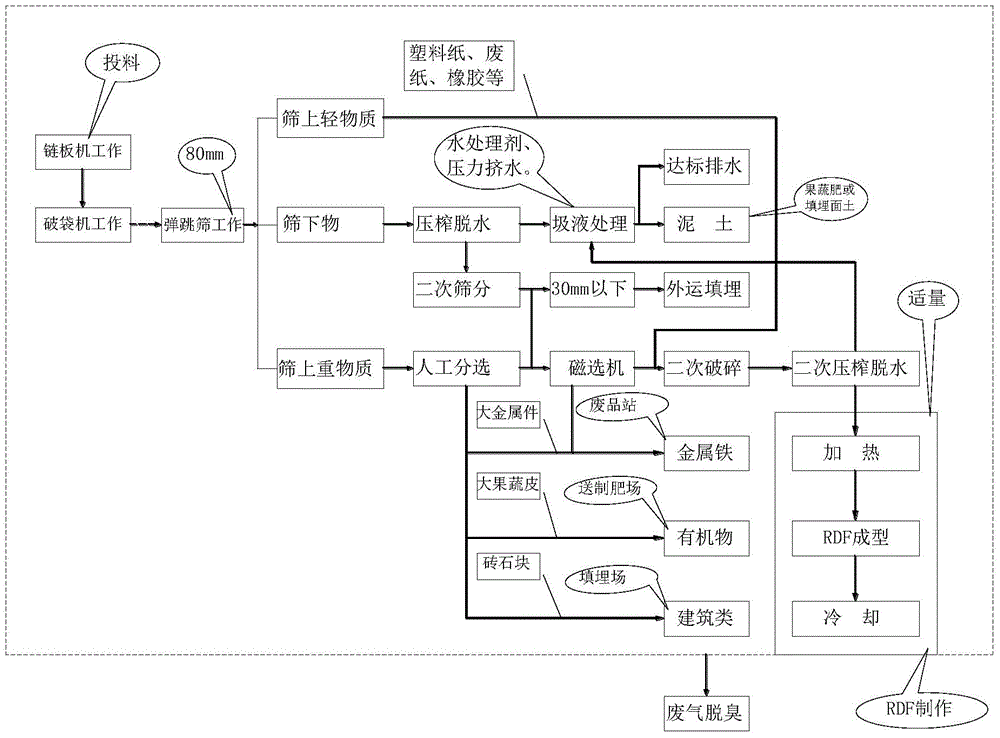

Human household garbage disposition and recycling method

ActiveCN103934251AOptimize investmentOptimized footprintSolid waste disposalRefuse-derived fuelMagnetic separator

The invention provides a human household garbage disposition and recycling method. The human household garbage disposition and recycling method comprises following steps: 1) human household garbage is sieved using a bouncing sieve so as to divide the human household garbage into an oversize light material, an oversize heavy material, and an undersize material; 2) the oversize light material is subjected to secondary crushing and secondary squeezing and dewatering, an obtained product is subjected to refuse derived fuel (RDF) treatment; the oversize heavy material is subjected to sorting firstly, an obtained residue is subjected to sorting using a magnet separator, and an obtained material is subjected to RDF treatment; the undersize material is subjected to squeezing and dewatering, an obtained solid material is subjected to secondary sorting using a secondary separating sieve, an obtained secondary oversize product is subjected to sieving using the magnet separator, an obtained nonmetallic substance is subjected to secondary crushing and secondary squeezing and dewatering, and an obtained processed product is subjected to RDF treatment. According to the human household garbage disposition and recycling method, fermentation chamber ponds and fermentation equipment are not needed; the human household garbage disposition and recycling method is friendly to the environment, is very suitable for city building, and is relatively in cost, so that the human household garbage disposition and recycling method is especially suitable for small and medium garbage disposal plants in medium and small towns.

Owner:上海程胜环保科技有限公司

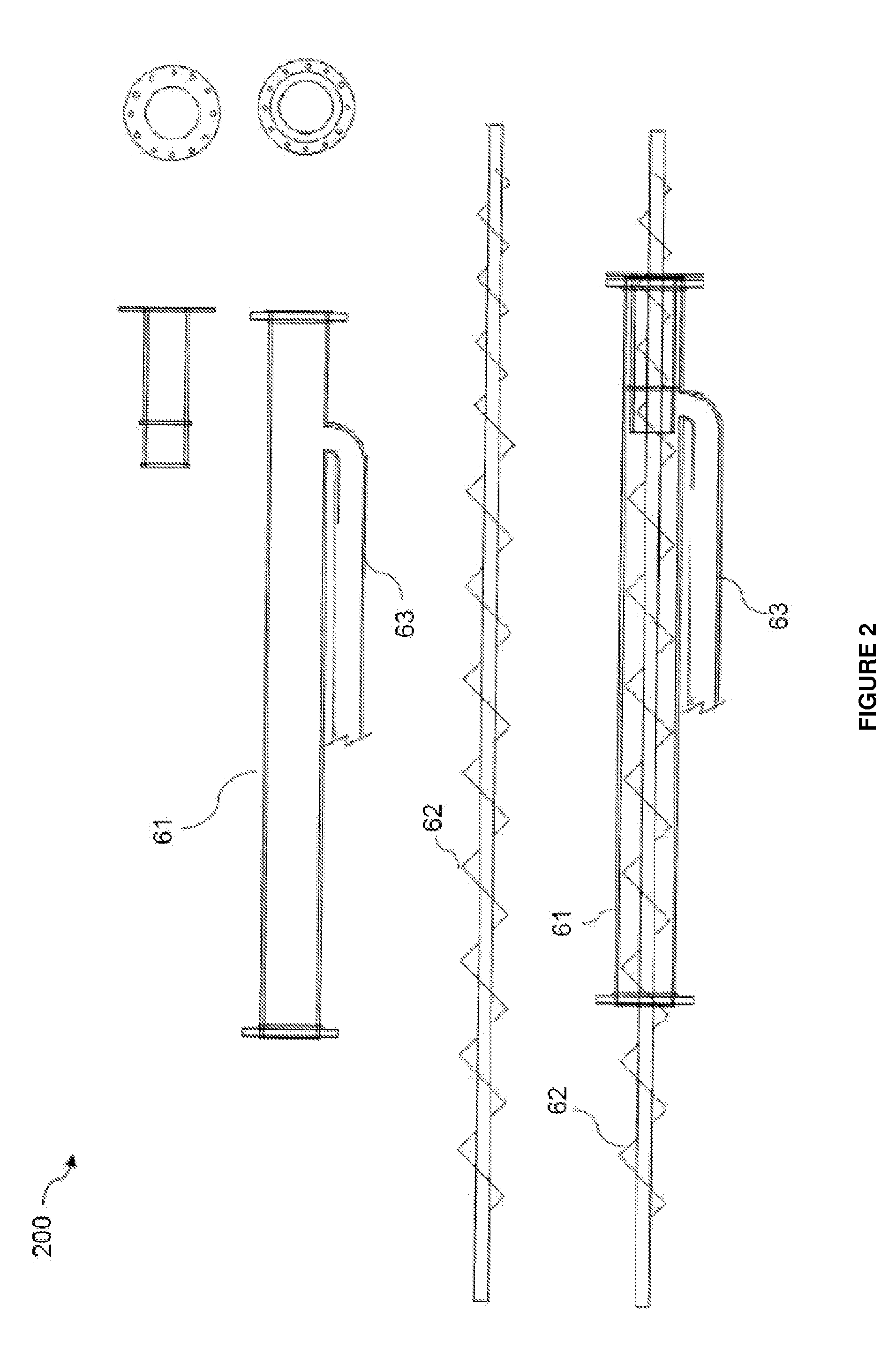

Process and device for devolatizing feedstock

ActiveUS20140069798A1Combustible gas coke oven heatingSolid waste disposalRefuse-derived fuelHydrogen

Provided herein is a method, device and installation for devolatizing a solid feedstock, comprising carbon-based waste selected from the group consisting of hazardous material, biomass, animal manure, tires, municipal solid waste and refuse derived fuel. The method comprises treating the solid feedstock to a produce a particle size laying between about 1 cm3 and about 100 cm3. The solid feedstock is passed into a jacketed system. The solid feedstock is contacted with a heated gas, comprising hydrogen, inside the jacketed system at a temperature of about 500° C. to about 1000° C. for a time of about 60 seconds to about 120 seconds, whereby the solid feedstock is converted into a gas stream and a solid stream.

Owner:D4 ENERGY GRP INC

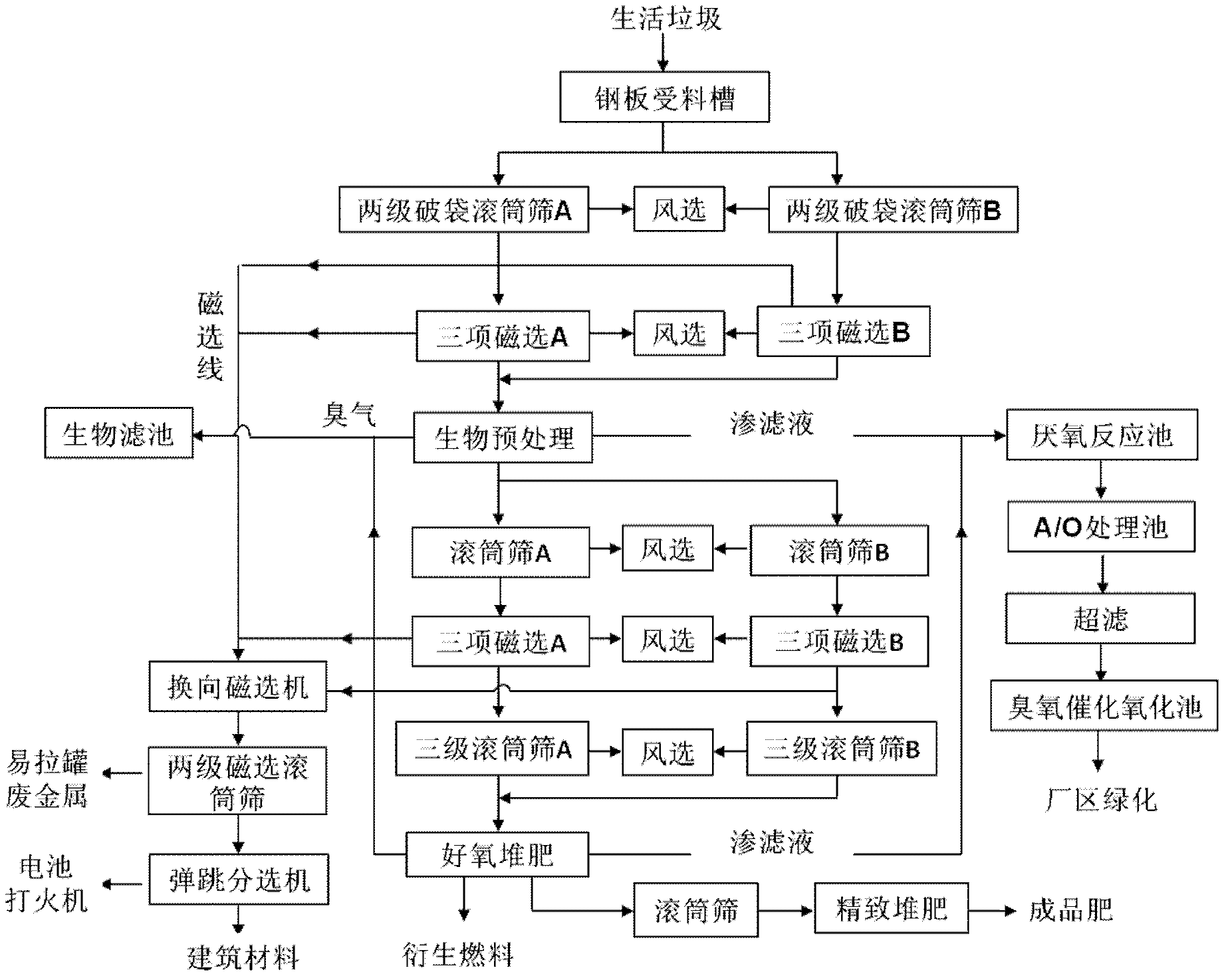

Method for comprehensive treatment of household refuses and secondary pollution control

ActiveCN103008326ACompact layoutReasonable configurationBio-organic fraction processingWaste processingRefuse-derived fuelUnit device

The invention provides a method for comprehensive treatment of household refuses and secondary pollution control. The method comprises the following procedures of: 1) coarse separation of the household refuses; 2) pretreatment of the household refuses; 3) fine separation of the household refuses; 4) aerobic composting of the household refuses; 5) biological organic fertilizer preparation; 6) fabrication of refuse derived fuels; and 7) secondary pollution control. The method employs parallel dual-separation lines which are compact in arrangement; each functional unit device is rational in configuration, easy to operate and mechanically control; the sorting efficiency and the energy source recovery effect are obviously improved; and minimization, harmless treatment, recycling and energy conversion of the household refuses can be realized.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

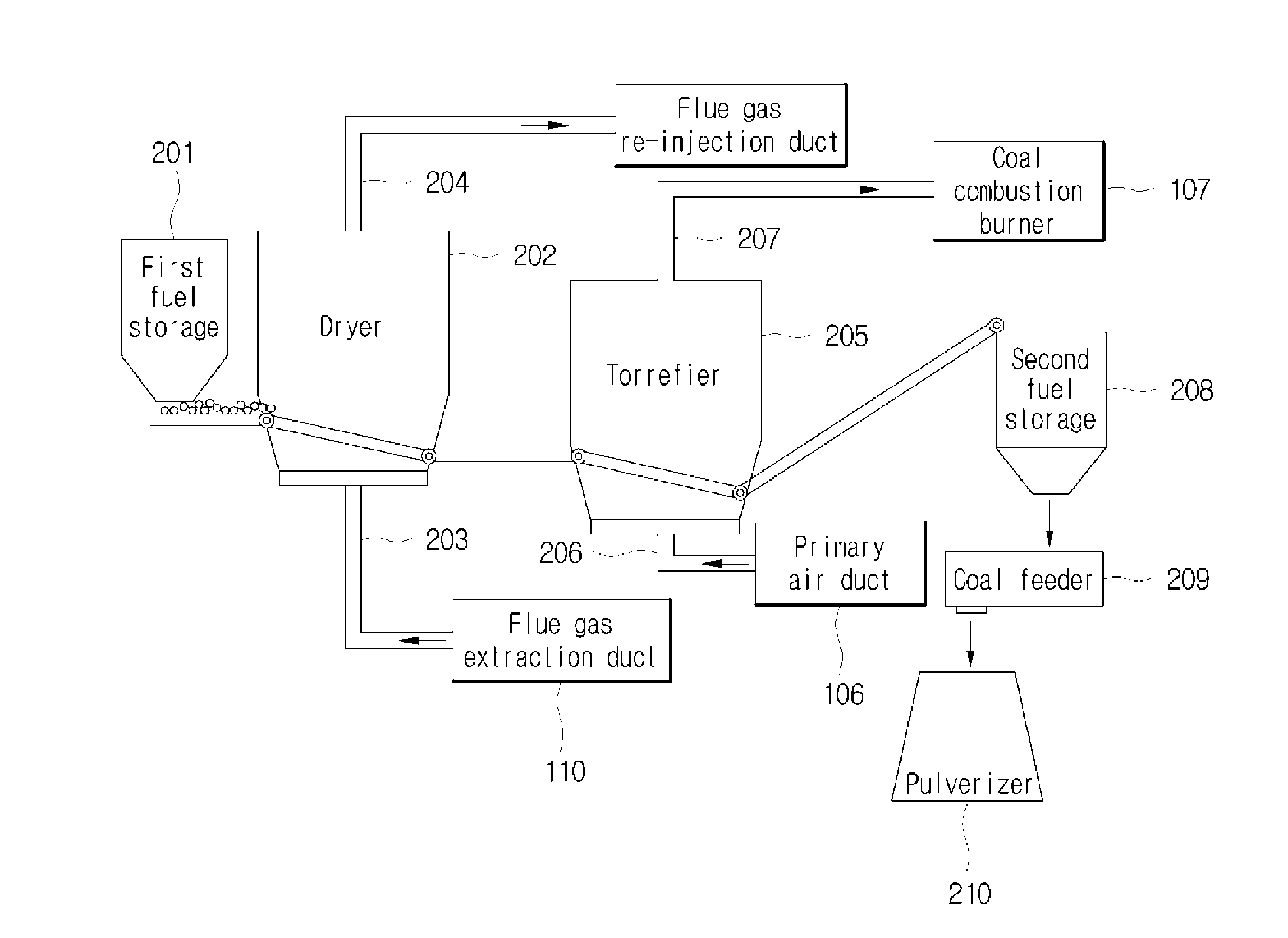

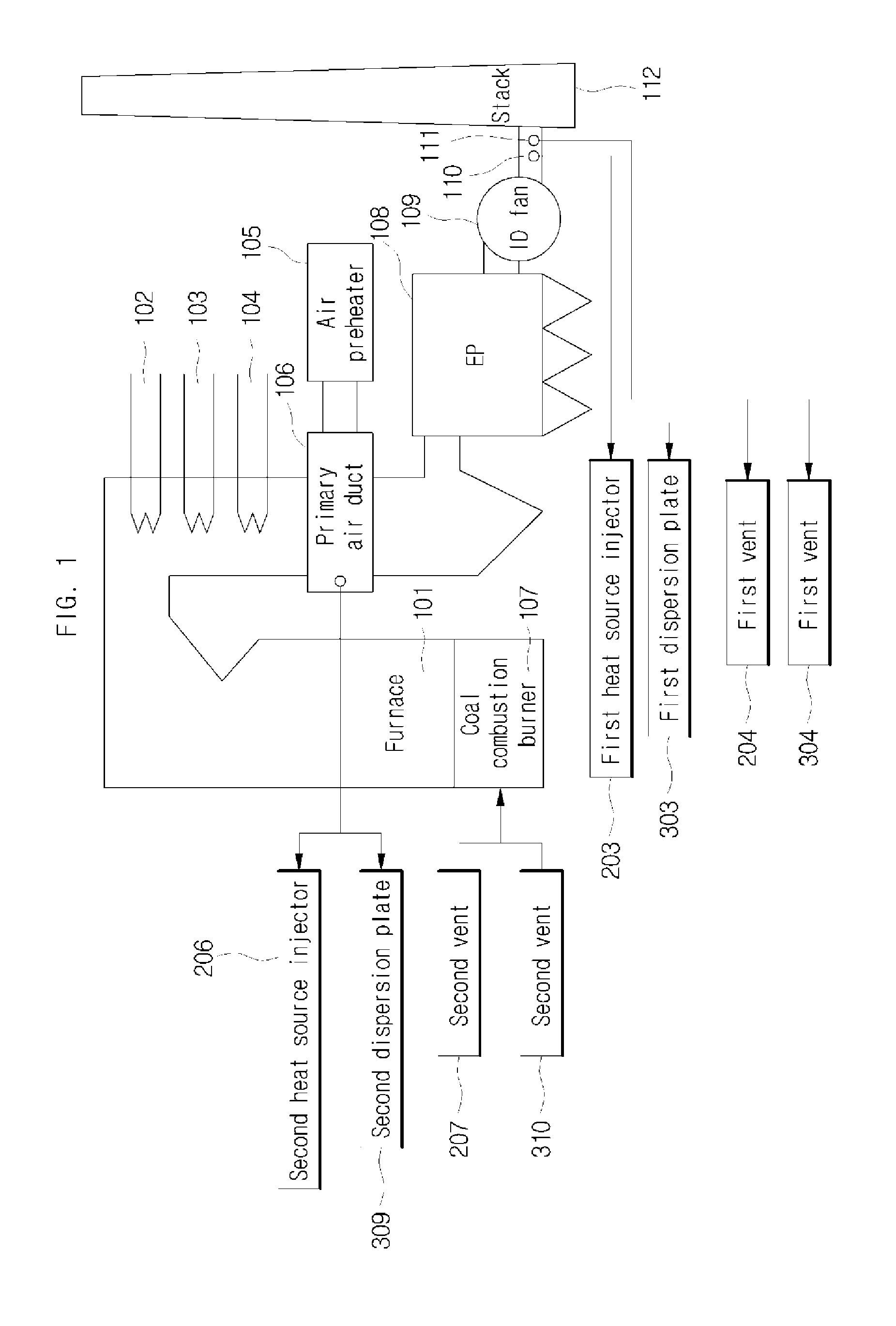

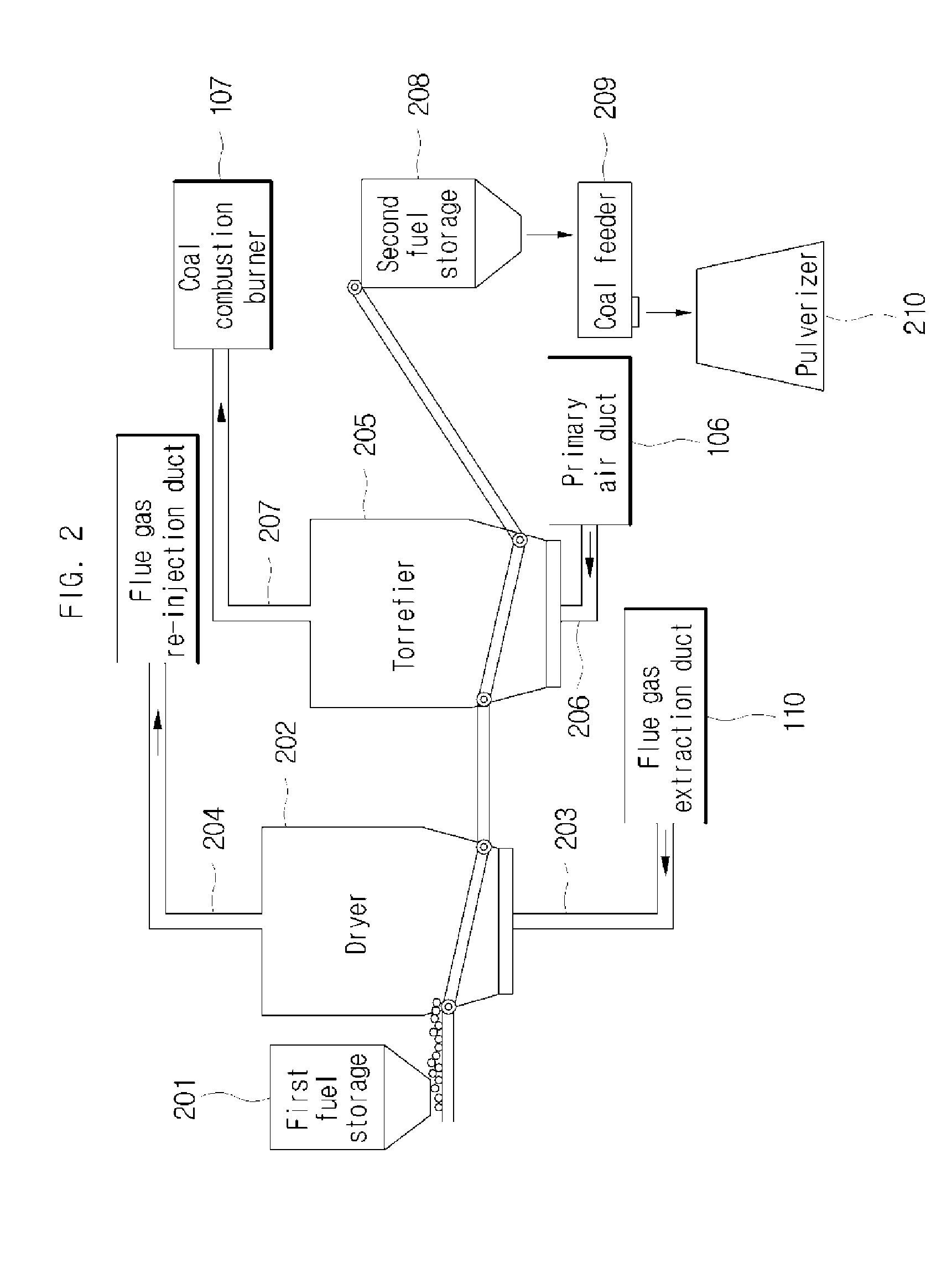

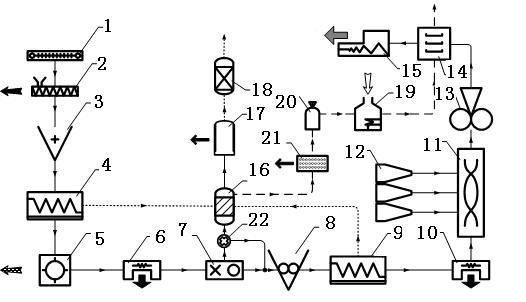

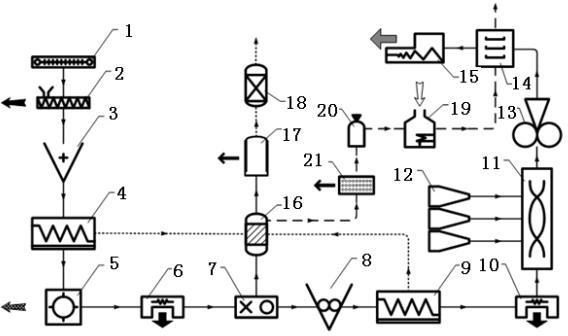

Fuel preprocess system for coal combustion boiler

A fuel preprocess system for a coal combustion boiler is disclosed. The fuel preprocess system for a coal combustion boiler that dries biomass or refuse-derived fuel in accordance with the present invention can include: a dryer configured to dry the biomass or refuse-derived fuel by use of flue gas generated after combustion in the boiler; and a torrefier configured to devolatilize a fibrous component contained in the dried fuel from the fuel dried in the dryer by use of primary air that is heat-exchanged after the combustion in the boiler.

Owner:KOREA ELECTRIC POWER CORP

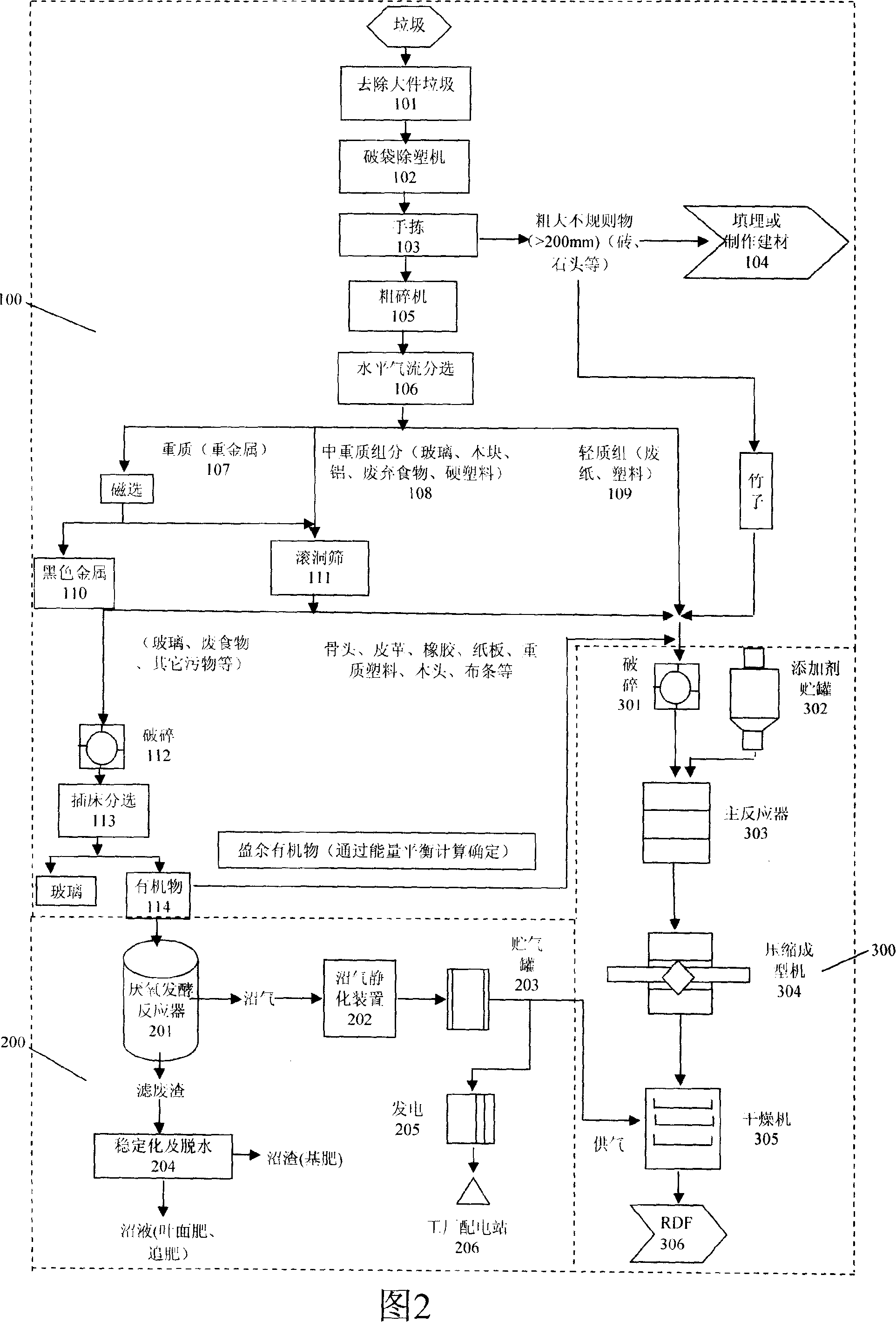

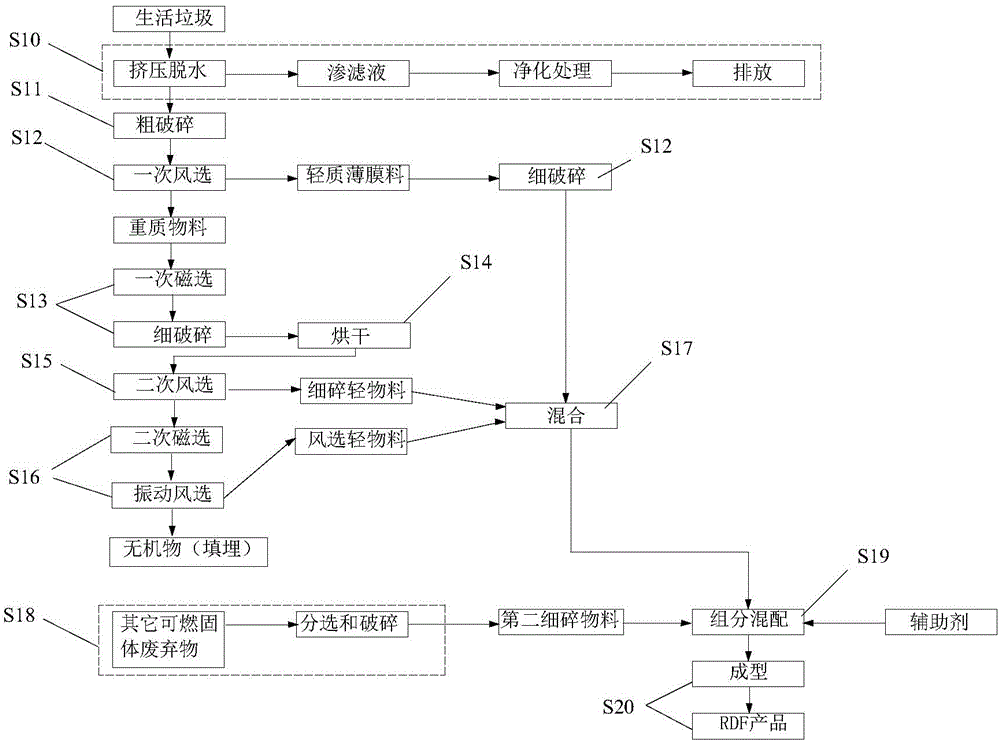

Energy supply method for production of garbage derived fuel and energy equilibrium deploying method

InactiveCN101153230AReduce manufacturing costHigh calorific valueSolid waste disposalGaseous fuelsRefuse-derived fuelEnergy balanced

An energy supplying method and an energy balancing-allocating method for producing refuse derived fuel are provided, wherein, the energy supplying method for producing refuse derived fuel comprises: firstly, crude refuse is separated according to different components; secondly, according to separation results, the refuse is fed into corresponding systems for treatment respectively; finally, the energy generated by a refuse fermenting system is supplied to a refuse derived fuel manufacturing system for use. The energy balancing-allocating method is that: according to the surplus conditions of a refuse derived fuel factory in energy use, partial organic refuse originally used for the fermenting system is also used as the raw materials in the production of refuse derived fuel, so as to realize the supply of the fermenting system and the energy balance needed in the production process of refuse derived fuel. The present invention has the advantages that: RDF production cost is reduced; RDF heat value is improved; the amount of biodegradable component used for fermentation can be flexibly adjusted according to the concrete conditions of energy balance.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA

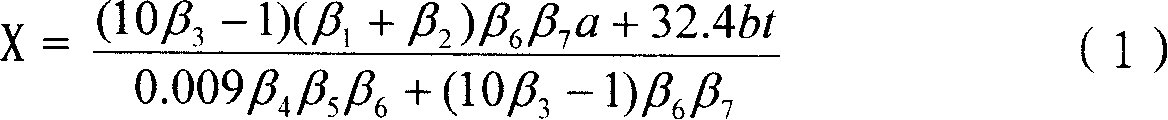

Recycling method of combustible solid waste

ActiveCN104084414AUniform compositionImprove performanceSolid waste disposalBiofuelsRefuse-derived fuelMixed materials

The invention discloses a recycling method of combustible solid waste. The recycling method comprises the steps of preprocessing household garbage to obtain a first fine crushing material, preprocessing other combustible solid waste to obtain a second fine crushing material, mixing the first fine crushing material and the second fine crushing material with an auxiliary agent in a certain ratio to obtain a mixed material, and shaping the mixed material on a forming machine to produce a garbage deriving fuel in a preset shape. The recycling method of the combustible solid waste provided by the invention solves the problems that the cost is high, the investment of incineration equipment is large and the environmental pollution is serious when household garbage and other combustible solid waste are processed.

Owner:HUNAN VARY TECH

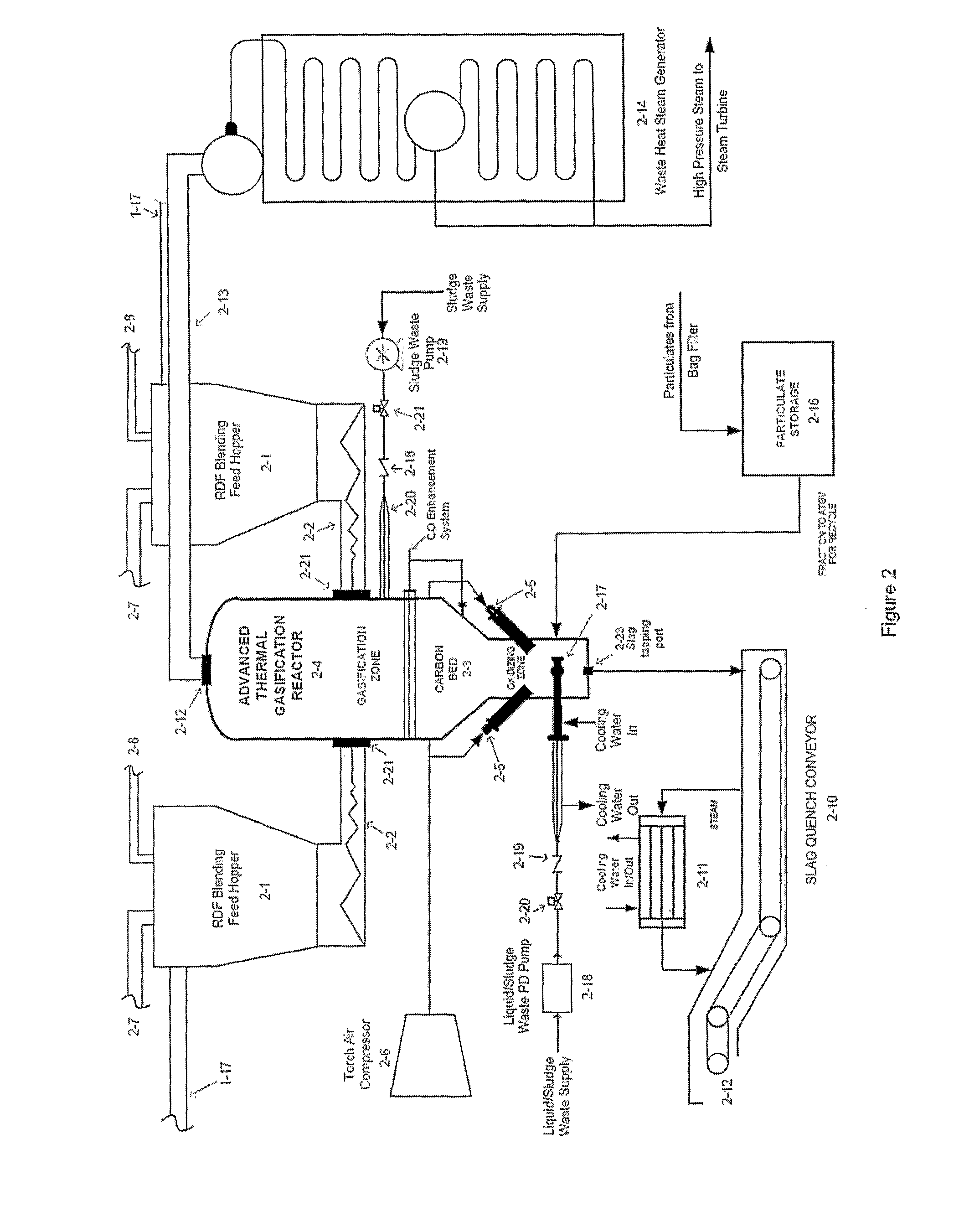

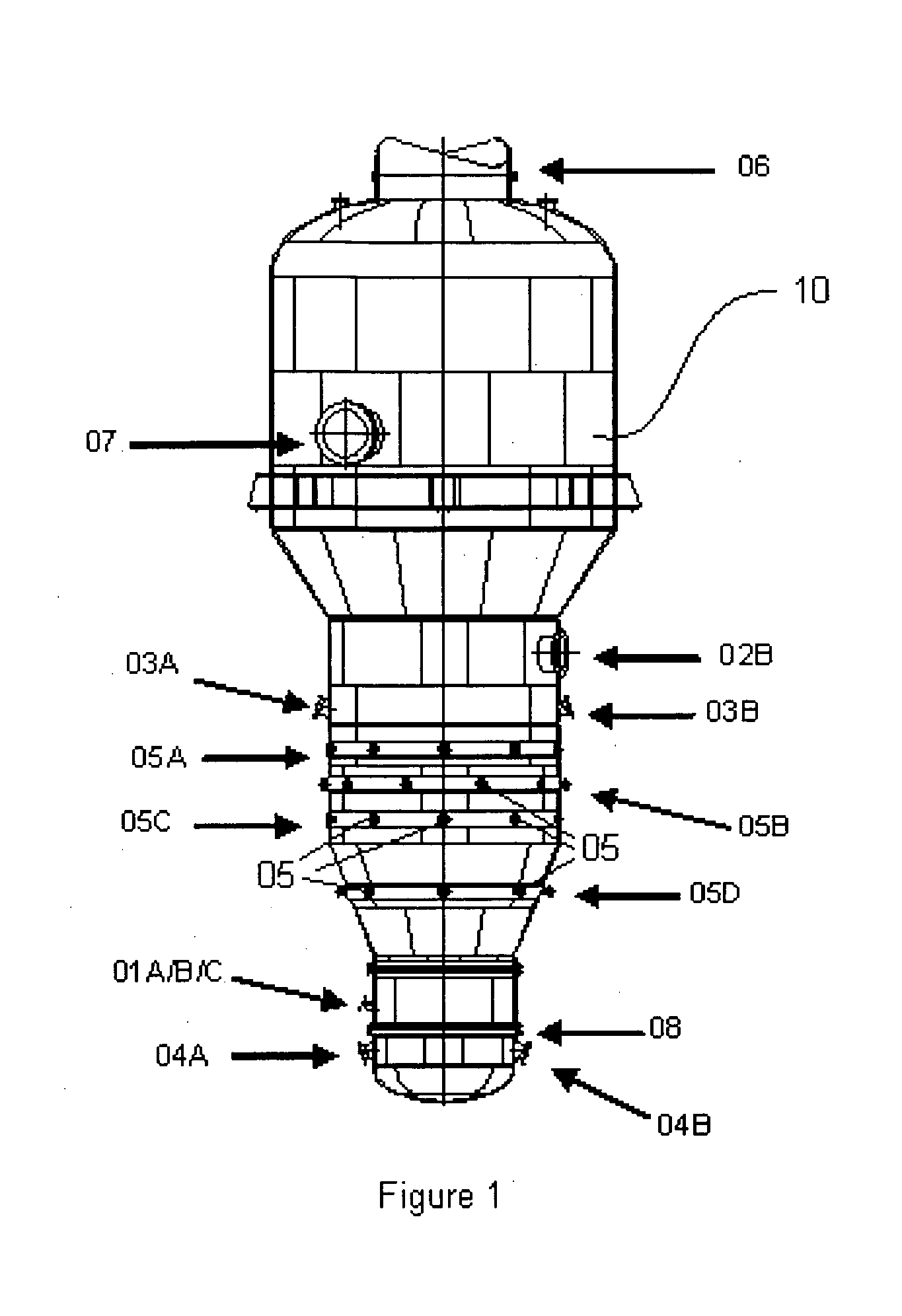

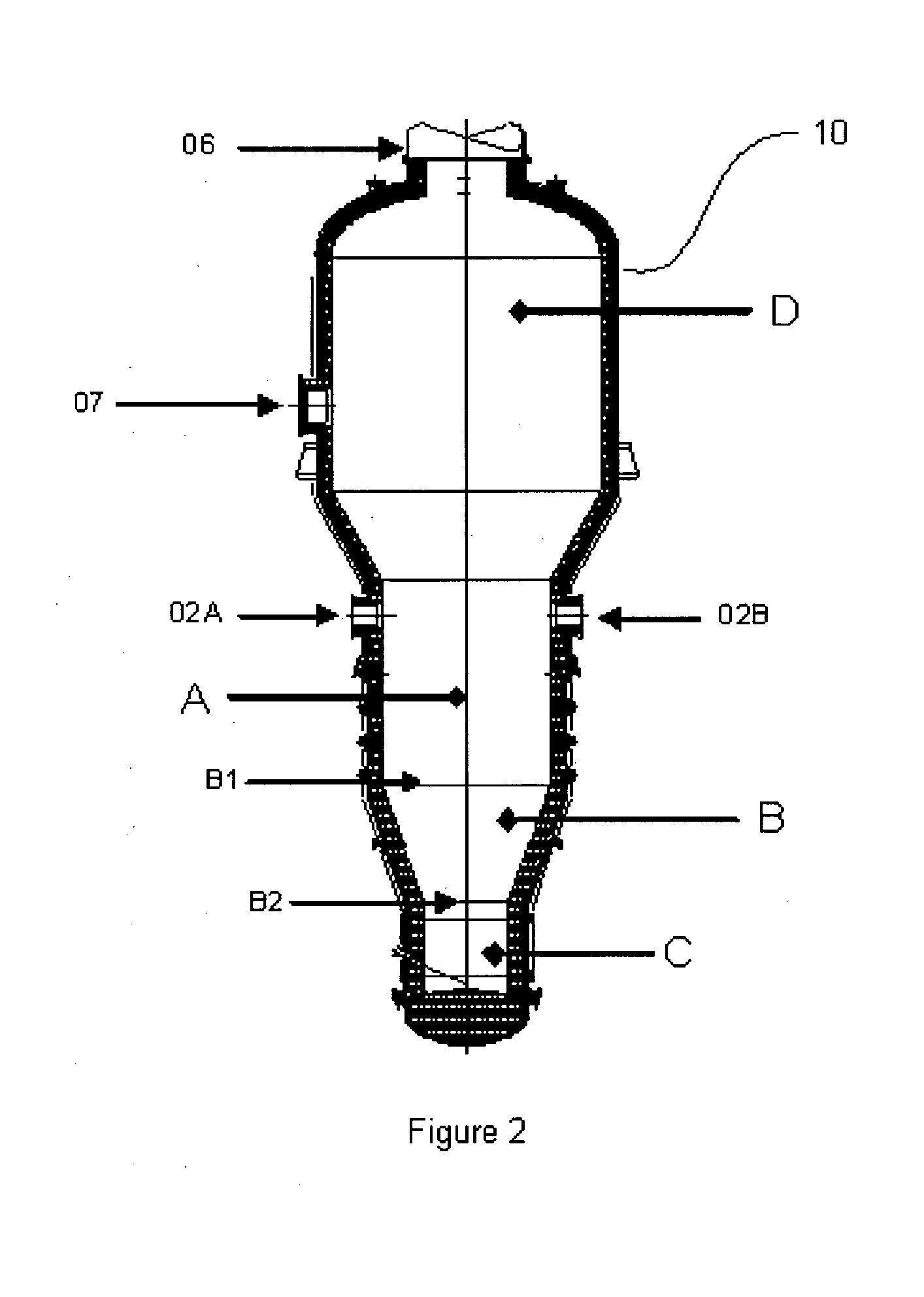

Thermal gasification reactor for producing heat energy from waste

ActiveUS20120121477A1Ameliorate aforementioned disadvantageDestroy wasteSolid waste disposalBiofuelsSyngasElectricity

A thermal reactor for producing usable heat energy by destroying waste including a vessel wherein organic waste upon entering said vessel gasifies as it falls onto a carbon bed and is transformed into a synthesis gas with high heat and kinetic energy that can be harnessed to produce electricity. Inorganic waste upon entering melts as it falls onto the carbon bed and exits via slag ports to form an inert slag. Because there is no oxygen present in the gasification zone, the waste is not combusted and neither furan or dioxin are formed. The waste includes either prepared refuse derived fuel (RDF) or unprepared raw waste or a combination thereof.

Owner:GREEN ENERGY & TECH

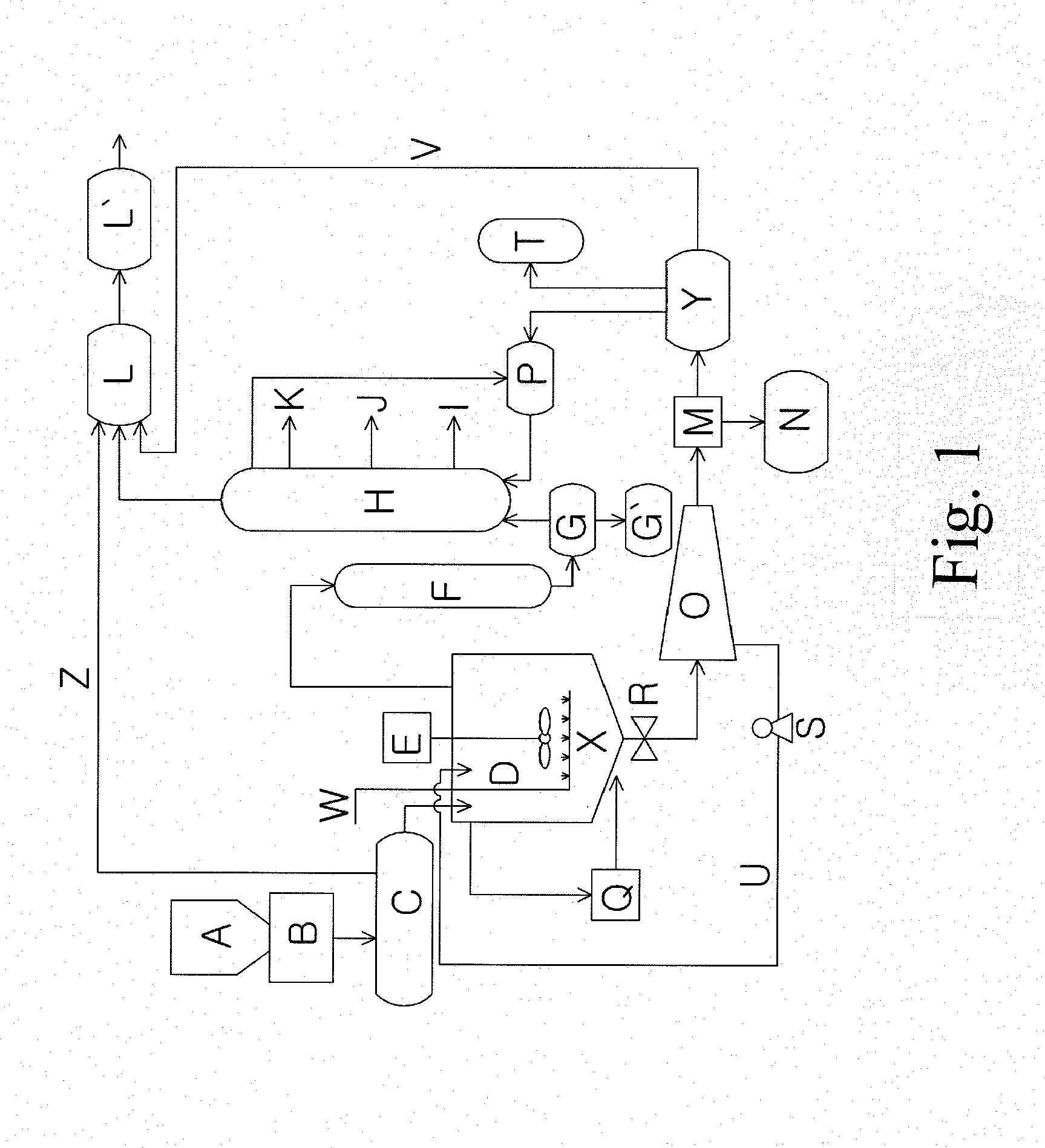

System for producing oil from waste material and catalyst thereof

InactiveUS20130136665A1Quality improvementImprove oil qualityMolecular sieve catalystsSolid waste disposalRefuse-derived fuelCellulose

A system for producing oil from waste material includes a catalytic decomposition reactor providing a stirrer for stirring at least one kind of raw material; the raw material being selected from a group consisting of lingo cellulosic hydrocarbon, biomass like marine plants, waste plastic, waste, waste oil, RDF (Refuse derived fuel) and RPF (Refuse plastic fuel), and a catalyst for decomposing the selected raw materials; the catalytic decomposition reactor serving for decomposing the raw materials and producing vapor and gaseous oil and sludge; a condenser for condensing the gaseous oil generated from the catalytic decomposition reactor; a storing container for storing oil condensed from the condenser; and a distillation tower oil from the storing container by heat from a steam boiler and collecting heavy oil, diesel oil and gasoline through a heavy oil output port, a diesel output port and a gasoline output port in boiling points.

Owner:OIL CITY

Chlorine fixing agent suitable for waste derived fuel, and preparation method and application thereof

The invention aims to provide a chlorine fixing agent suitable for reducing chloride emission in combustion gas of tail gas waste derived fuel. The chlorine fixing agent comprises the following components of acetylene sludge, fly ash and exciting agent in percentage of (60-80): (15-30): (3-10) by weight. With the adoption of the chlorine fixing agent, the purpose of treatment of wastes with processes of wastes against one another is realized; the waste is extruded into waste gas waste derived fuel at normal temperature under normal pressure, and the energy consumption is low; the volatilization rate of S-element and Cl-element are reduced greatly, so the chlorine fixing agent is beneficial for the waste combustion treatment; and the inflaming property of the waste is reduced. The waste derived fuel prepared by the preparation method has high compressive strength, and is suitable for the subsequent use of the waste derived fuel in combustion furnace and gasification furnace.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

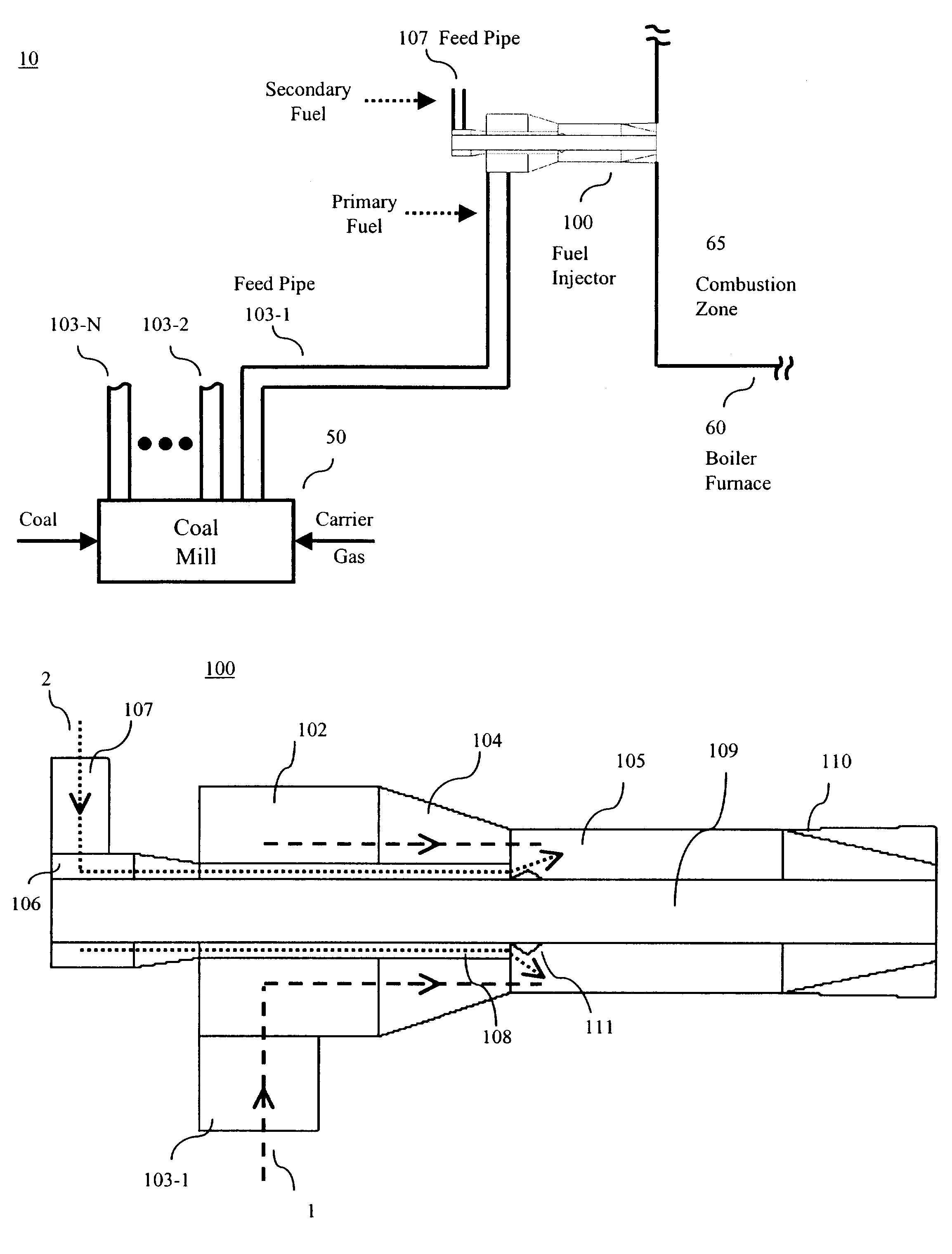

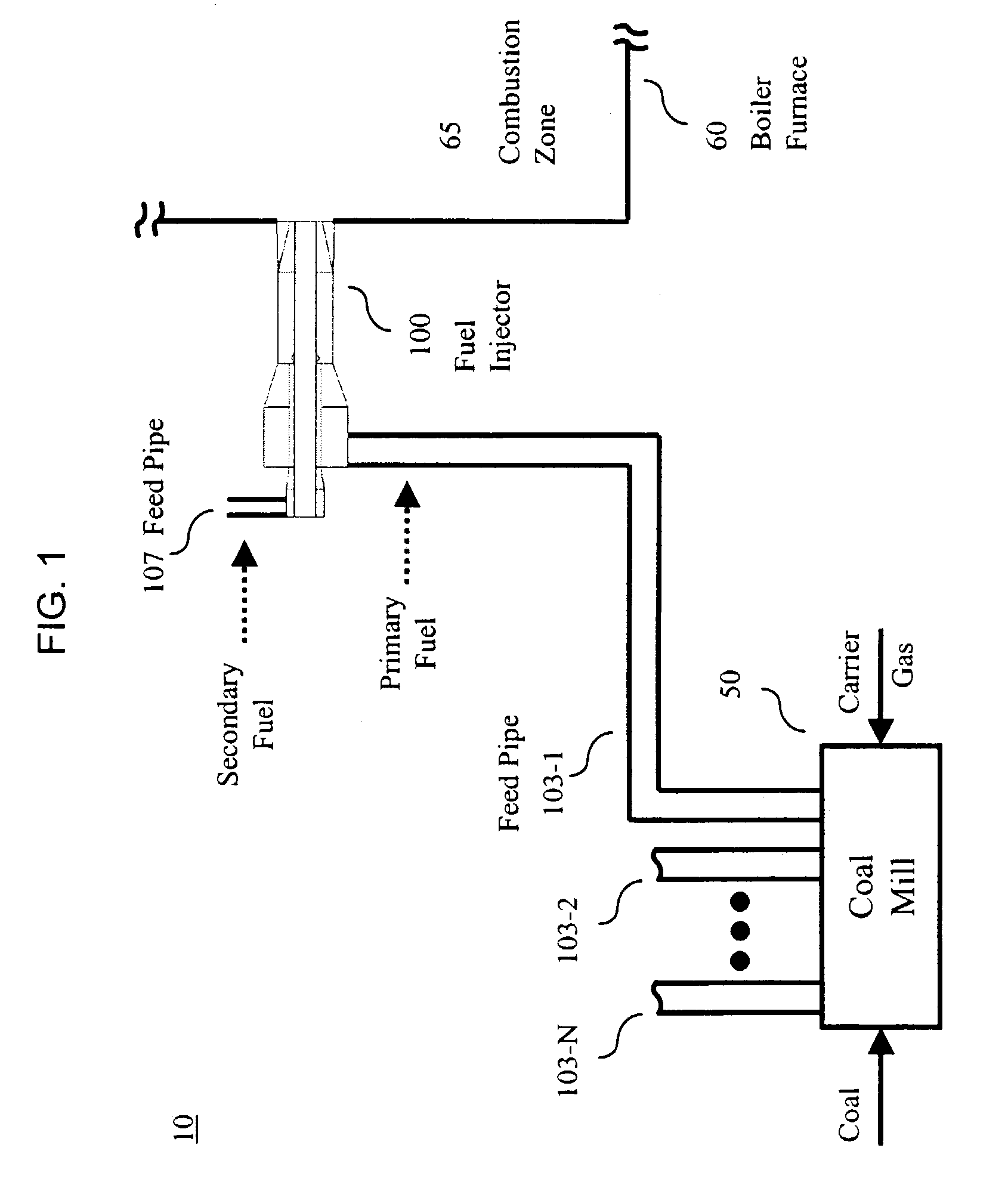

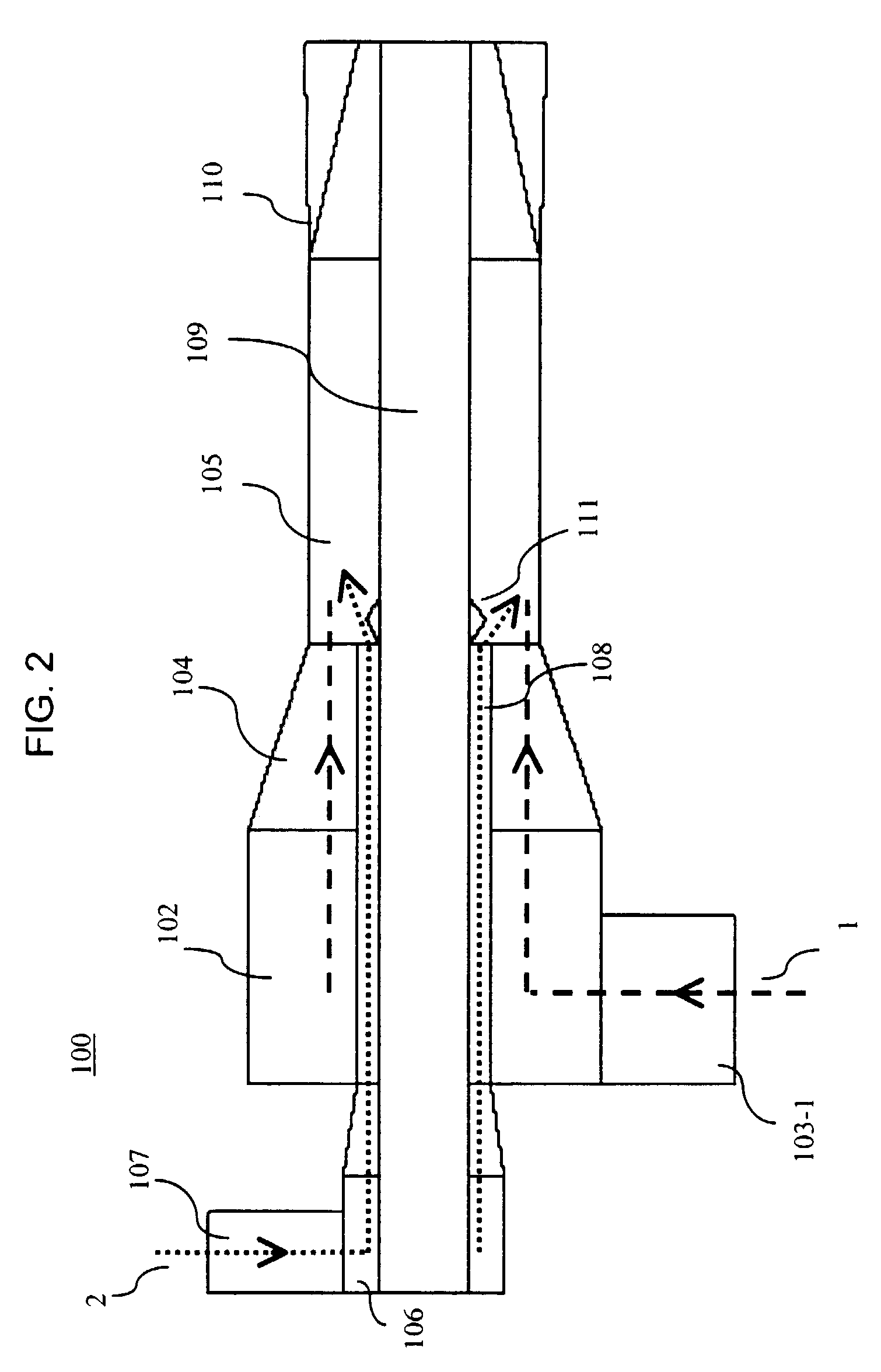

Burner system and method for mixing a plurality of solid fuels

InactiveUS6986311B2Well mixedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelRefuse-derived fuelCombustor

A burner assembly cofires a primary solid fuel and a secondary solid fuel in a combustion zone of a boiler. The burner assembly includes a fuel injector that mixes the primary solid fuel and the secondary solid fuel prior to injection into the combustion zone of the boiler. The primary solid fuel may be pulverized coal, pulverized petroleum coke, or the like, while the secondary solid fuel may be a biomass fuel or refuse-derived fuel.

Owner:FOSTER WHEELER NORTH AMERICA CORP

Municipal solid wastes processing method and device thereof

InactiveCN101612629ANo emissionsHarmless productionSolid waste disposalOrganic fertiliser preparationRefuse-derived fuelBrick

The invention discloses a processing method of municipal solid wastes and a device thereof, the method comprises the following steps: presorting native incoming wastes by a waste screen, presorting large-piece masonry and too large organic matter to obtain presorted wastes; smashing the presorted large-piece masonry into brick making raw material, mixing the smashed too large organic matter and the presorted wastes, feeding the mixture into a drum screen to screen, with the undersized waste used for composting or is disinfected at high temperature into brick making raw material, feeding the dried oversized material into a garbage winnowing device, winnowing heavy material, humified organic matter, non-recyclable combustible material and light plastic. Metal is recovered from the heavy material and the heavy material is disinfected at high temperature after being picked out of the battery, smashed into brick making raw material; the humified organic matter is used for composting and is burned directly in an incinerator; non-recyclable combustible material is smashed to prepare refuse derived fuel; light plastic is used for preparing regeneration particles. The invention has the advantages of small investment, small floor area, low operation cost, no secondary pollution and thorough reduction.

Owner:SHANXI RUNHE ENVIRONMENTAL ENG GROUP

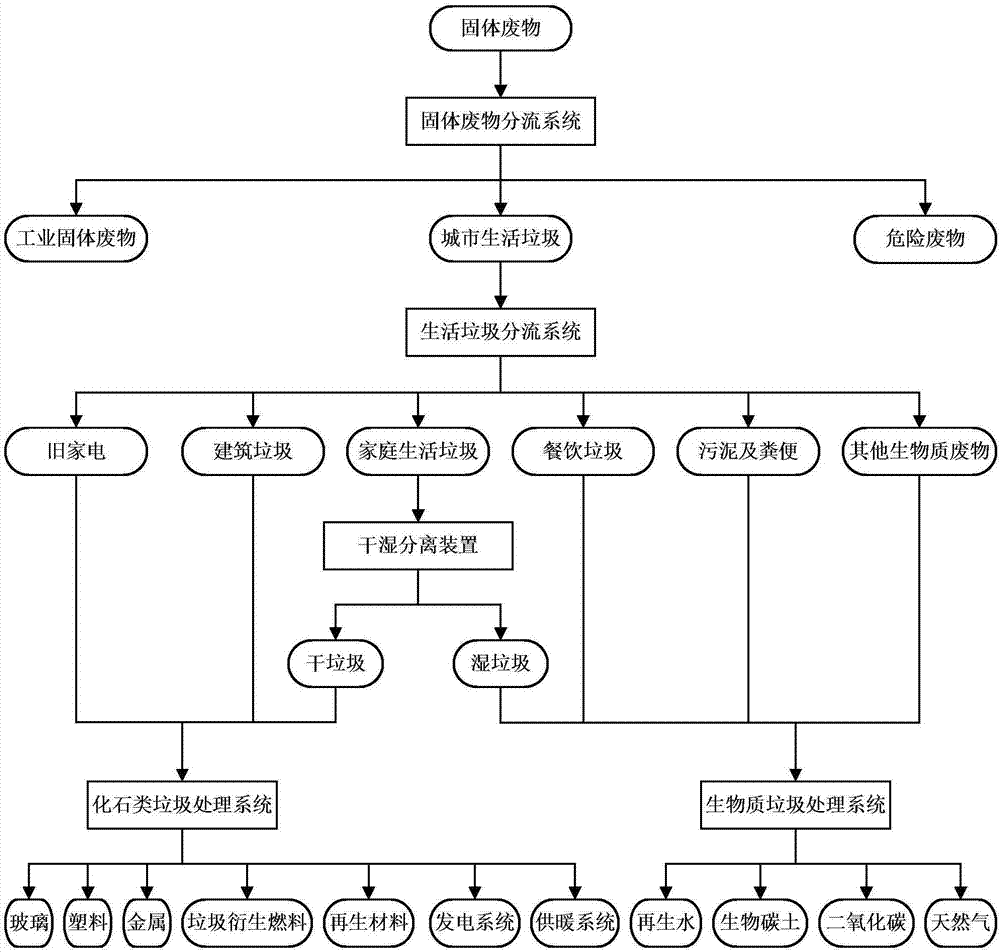

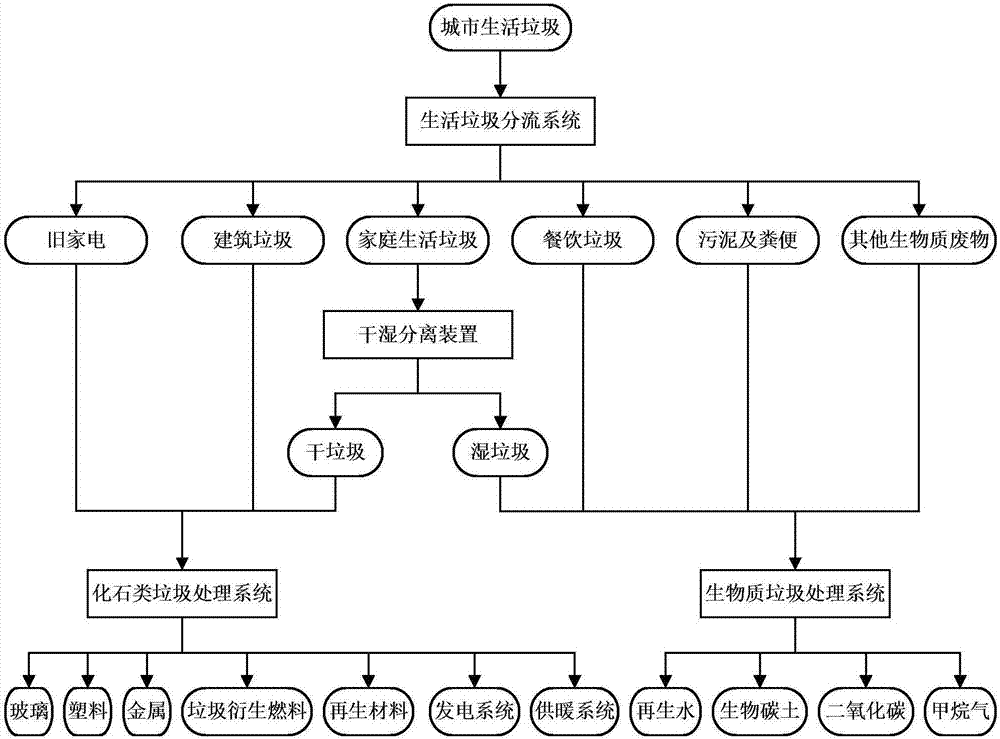

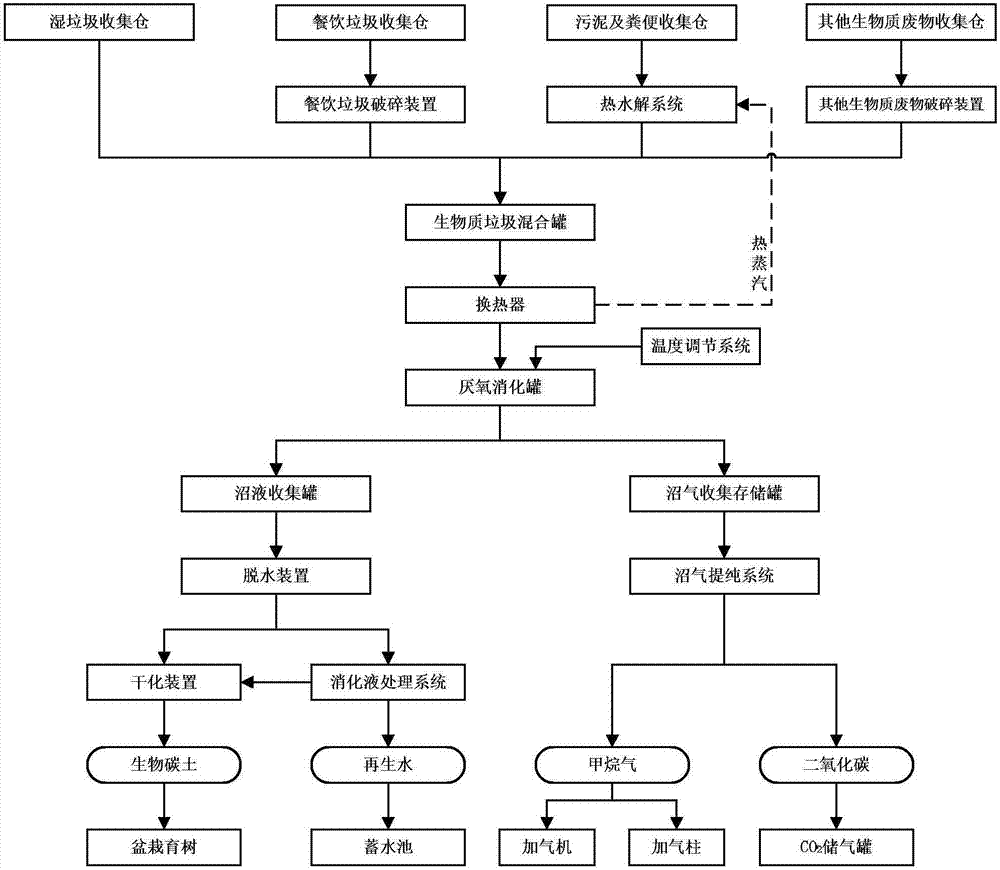

Urban venous industrial park and construction method as well as solid waste processing system and method

ActiveCN107008733AAchieve recyclingHealthy natural cycleConstruction waste recoveryWaste processingRefuse-derived fuelSludge

The invention relates to an urban venous industrial park. Municipal solid waste is divided into old home appliances, construction waste, household waste, food waste, sludge, faeces and other biomass waste by a household waste separating system; the household waste is divided into dry waste and wet waste by a dry and wet separation device; the old home appliances, the construction waste and the dry waste are treated by a fossil waste processing system so as to form glass, plastic, metal, refuse derived fuel and recycled materials, and additionally, the fossil waste processing system is respectively connected with a generating system and a heating system; and the wet waste, the food waste, the sludge, the faeces and the other biomass waste are treated by a biomass waste processing system so as to form recycled water, biological carbon soil, methane gas and carbon dioxide. According to the urban venous industrial park, a resource-product-renewable resource closed-loop mode is realized, and the waste is changed into valuables and is recycled.

Owner:北京汇园生态科技有限公司

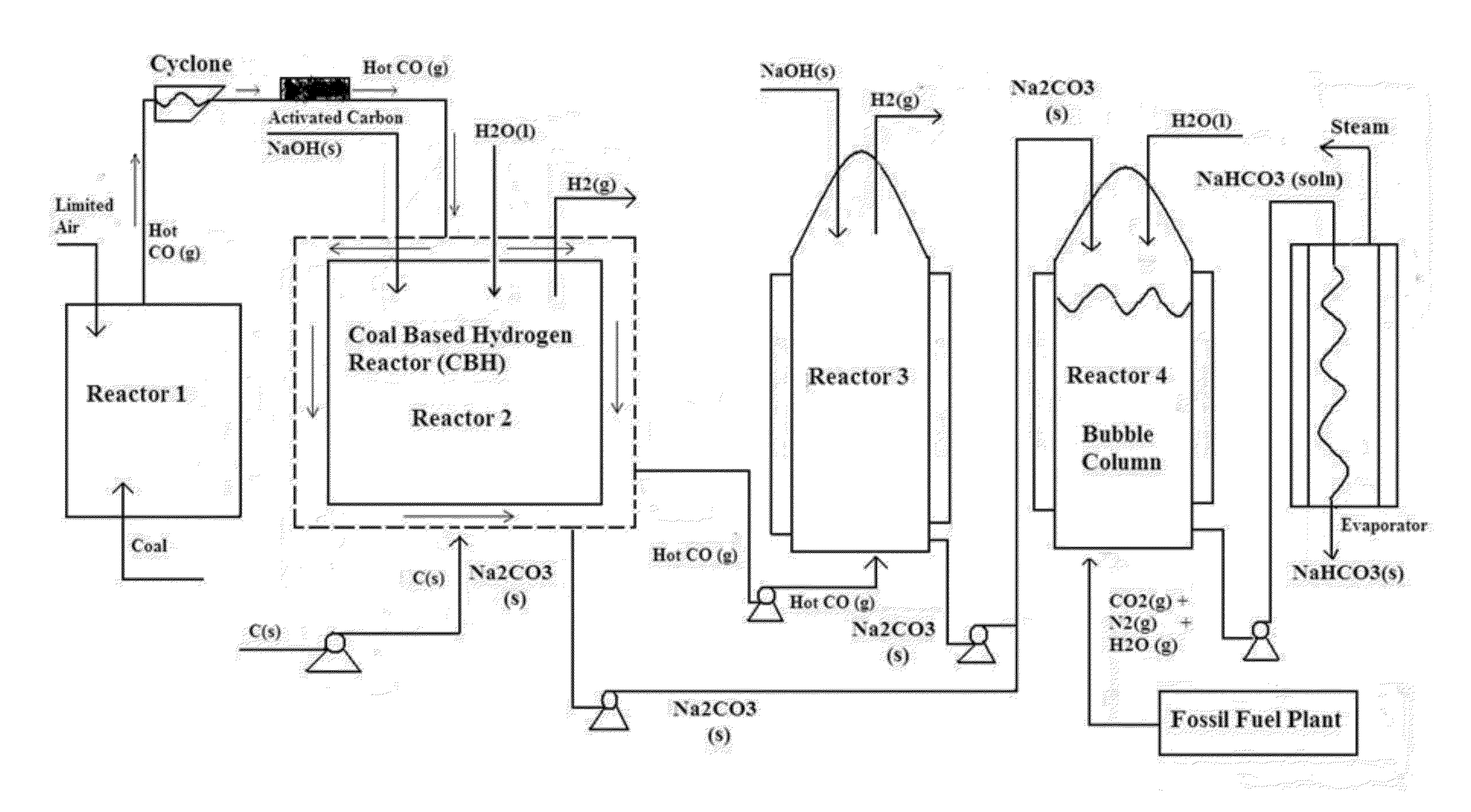

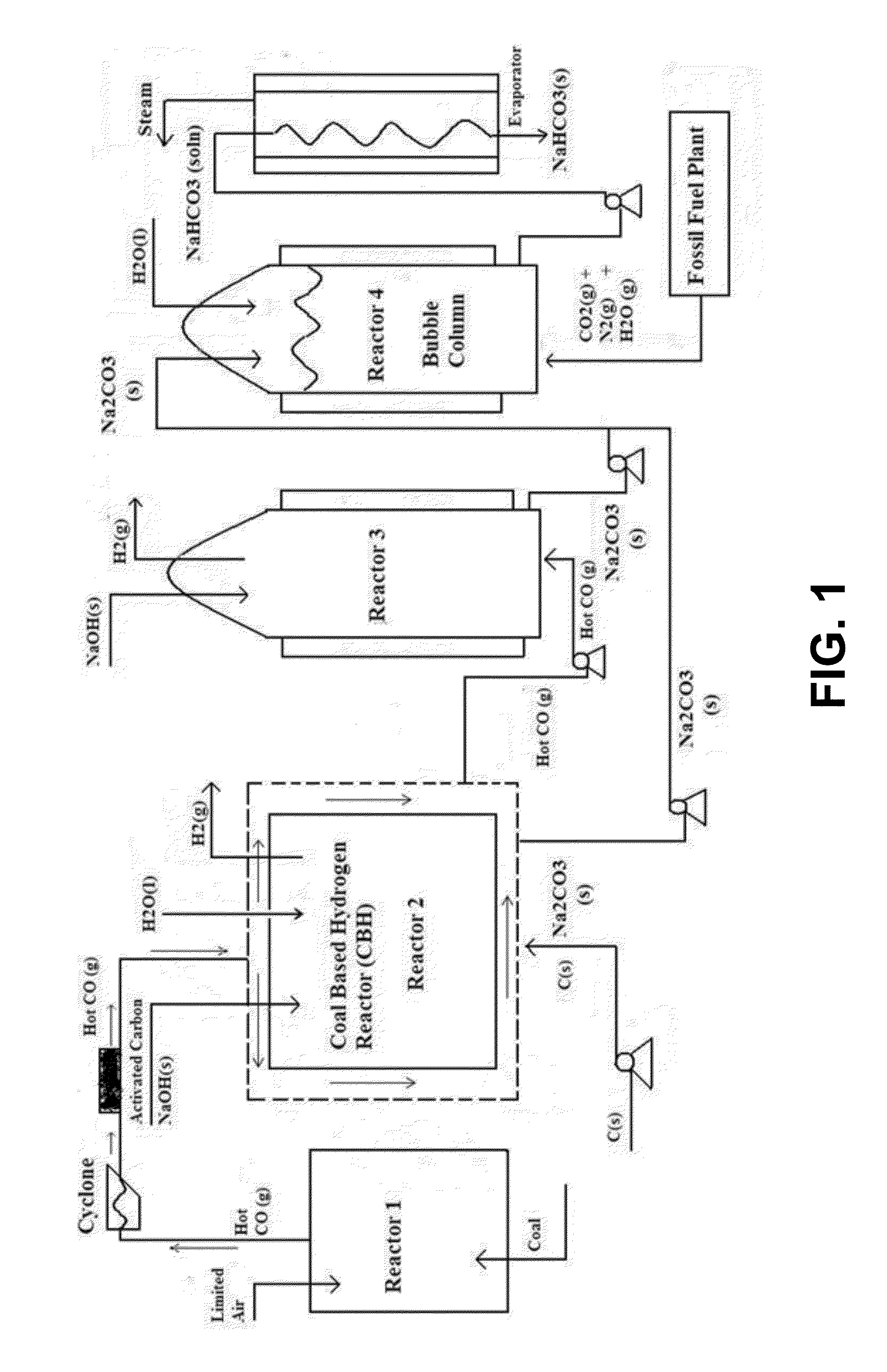

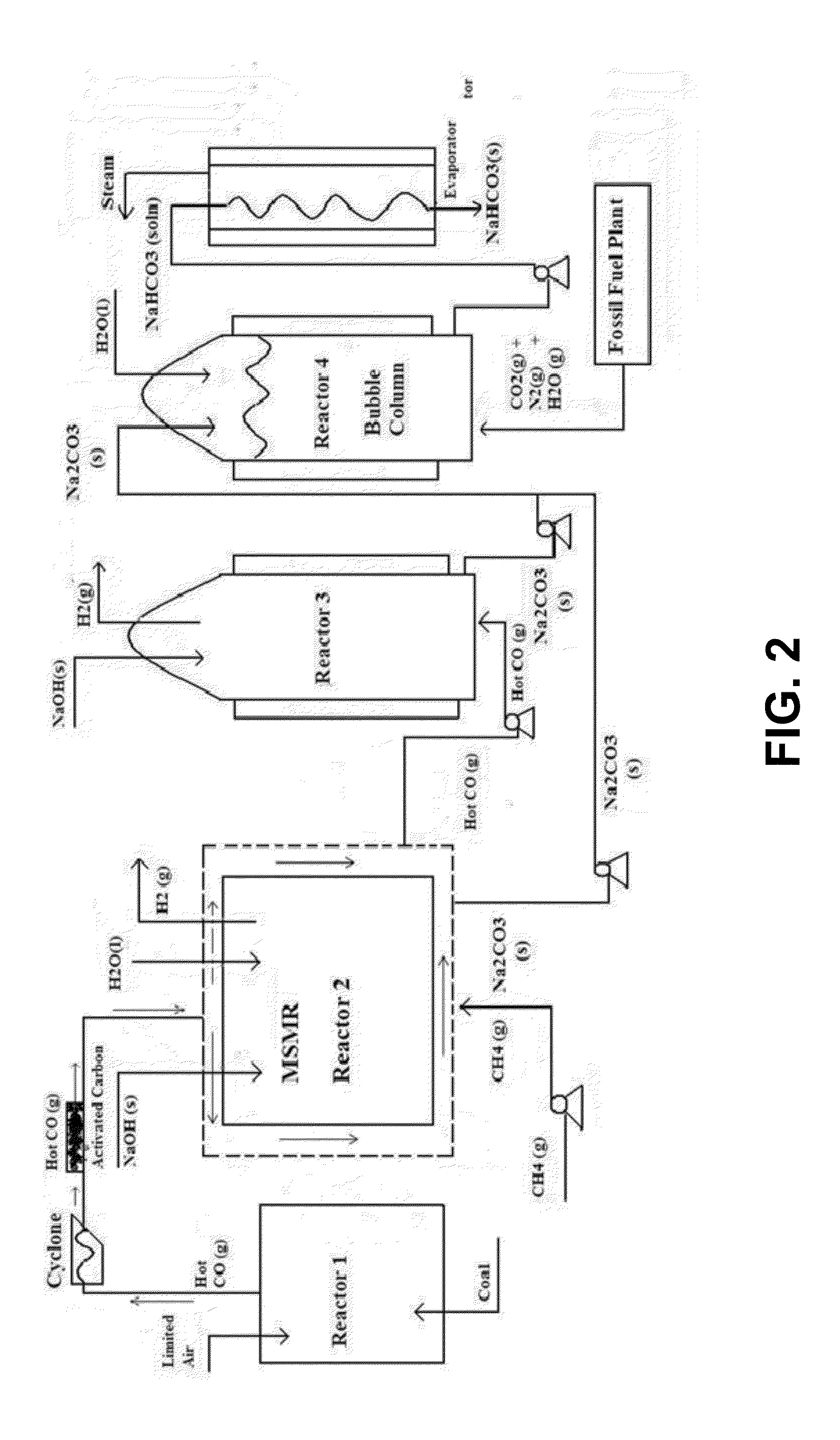

Carbon Sequestration in Municipal Solid Waste to Energy Plants

InactiveUS20130019785A1Limited applicationReduce carbon emissionsDirect carbon-dioxide mitigationHydrogen/synthetic gas productionRefuse-derived fuelExhaust fumes

This invention describes a process for a complete sequestration of carbon (CO2) from Municipal Solid Waste (MSW) to energy plants which produce Refuse Derived Fuel and the associated exhaust gases. The described process results in production of energy from the waste and disposal of the MSW with zero carbon emission.

Owner:SAXENA SURENDRA

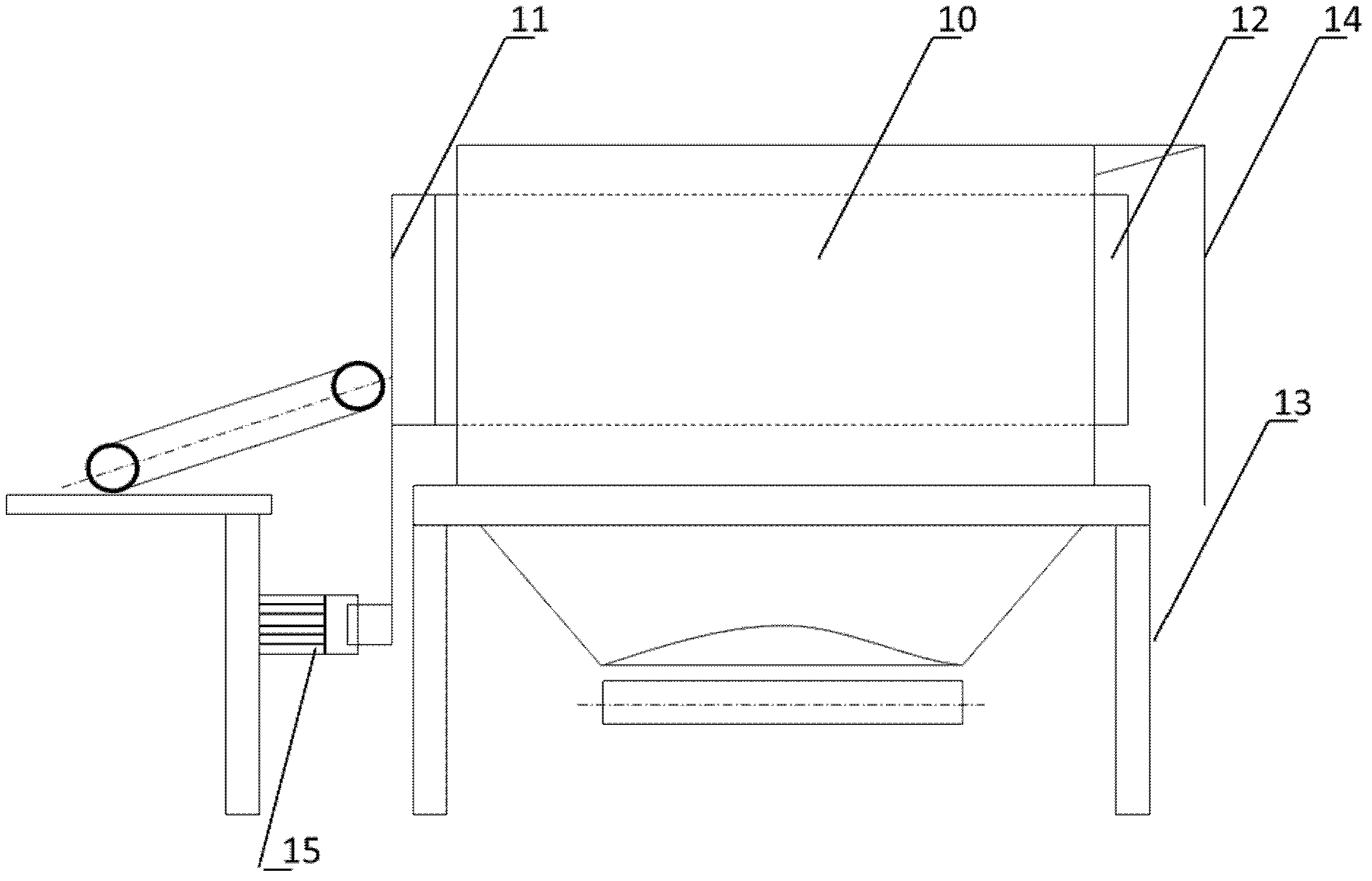

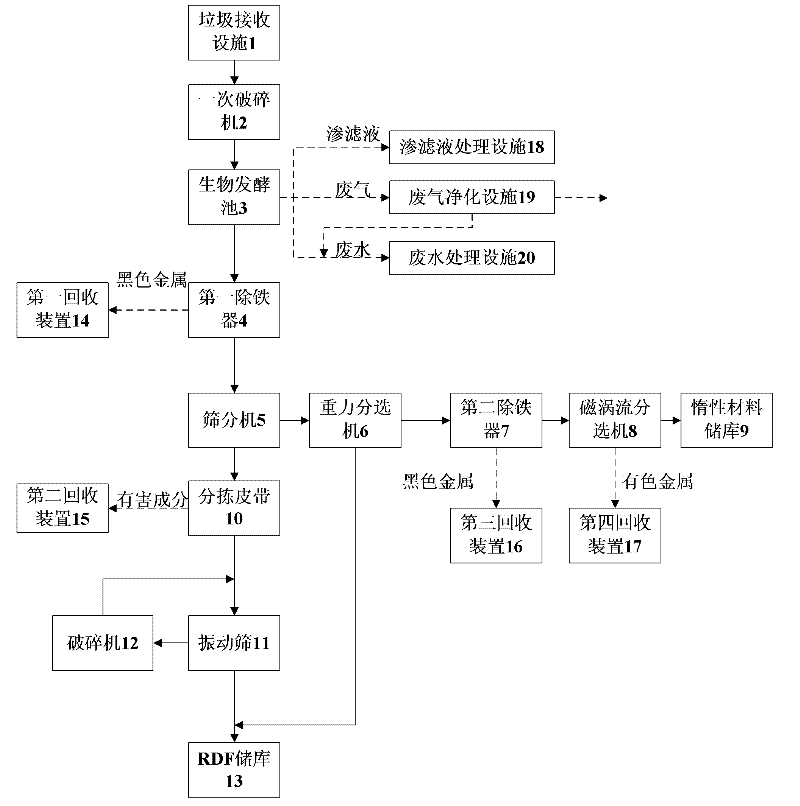

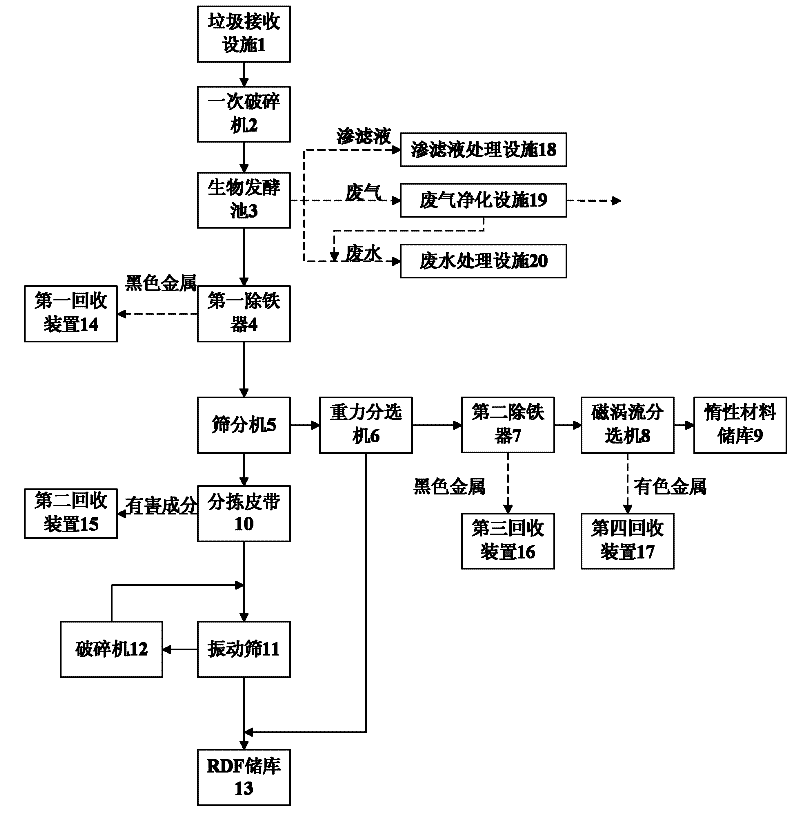

System for extracting rubbish derived fuel (RDF) from municipal rubbish

The invention relates to a system for extracting rubbish derived fuel (RDF) from municipal rubbish. The system is characterized by comprising a rubbish receiving device, a first crushing machine, a biological fermentation pond, a first iron remover, a sieving machine, a gravity separator, a second iron remover, a vortex separator, an inert material storage bank, a sorting belt, a vibrating sieve,a second crushing machine and an RDF storage bank, wherein a conveying device is arranged between the rubbish receiving device and an input port of the first crushing machine; a conveying device is arranged between the output port of the first crushing machine and the biological fermentation pond; the oversize product output port of the sieving machine is positioned above the input end of the sorting belt; the output end of the sorting belt is communicated with the input port of the vibrating sieve; and a conveying device is arranged between the undersize product output port of the vibrating sieve and the RDF storage bank. The system can extract the RDF from the municipal rubbish and is applicable to extracting the RDF from mixed and collected original rubbish.

Owner:华新环境工程有限公司

A municipal household waste treating method and a device thereof

A municipal household waste treating method and a device thereof are disclosed. Raw waste conveyed to a plant is subjected to pre-sorting through a screen for waste to sort out large bricks and stones and large and long organic matters, thus obtaining presorted waste. The sorted large bricks and stones are smashed and adopted as raw materials for manufacturing bricks. The large and long organic matters are smashed, then mixed with the presorted waste, conveyed to a rotary screen, and screened. Screen underflow materials are used for compost or adopted as raw materials for manufacturing bricks after the screen underflow materials are disinfected at high temperatures. Oversize products are dried, fed into a waste air classification apparatus, and subjected to air classification to obtain heavy materials, humified organic matters, unrecyclable combustible materials and light plastic. Metals are recovered from the heavy materials, batteries are sorted out from the heavy materials, and then the heavy materials are disinfected at high temperatures and smashed as raw materials for manufacturing bricks. The humified organic matters are used for compost or are directly incinerated in an incinerator. The unrecyclable combustible materials are smashed and are used for preparing waste-derivative fuels. The light plastic is used for preparing plastic reclaimed particles. The method and the device are advantaged by low investment, saved occupied space, a low running cost, no secondary pollution, thorough reduction, and the like.

Owner:哈尔滨万向迎欣科技开发有限公司

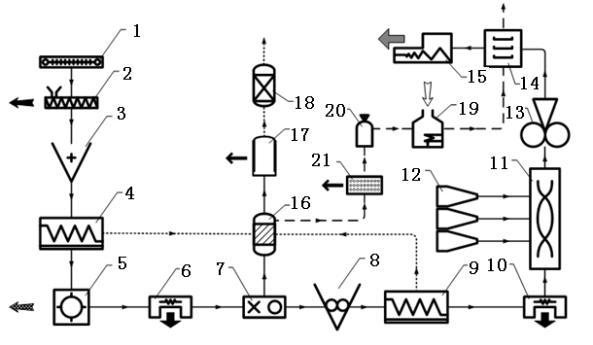

Integral process and equipment of garbage fuel synthesis and burning generation

InactiveCN1912354AImprove energy utilizationImprove power generation efficiencySteam generation heating methodsBiofuelsRefuse-derived fuelProcess engineering

An integral process of synthesizing garbage fuel and incinerating it to generate power includes preparing garbage made fuel by process of grinding, drying, magnetic selecting, modifying, mixing and pressing; sending prepared garbage made fuel into boiler to burn it for generating power; using boiler tail fume and steam of steam turbine in preparing course of garbage fuel to provide heat source being used in drying unit and modifying unit in preparing course of garbage fuel.

Owner:HANGZHOU WEIHUA ENVIRONMENT ENG TECH

Method of harmless and recycle treatment of garbage

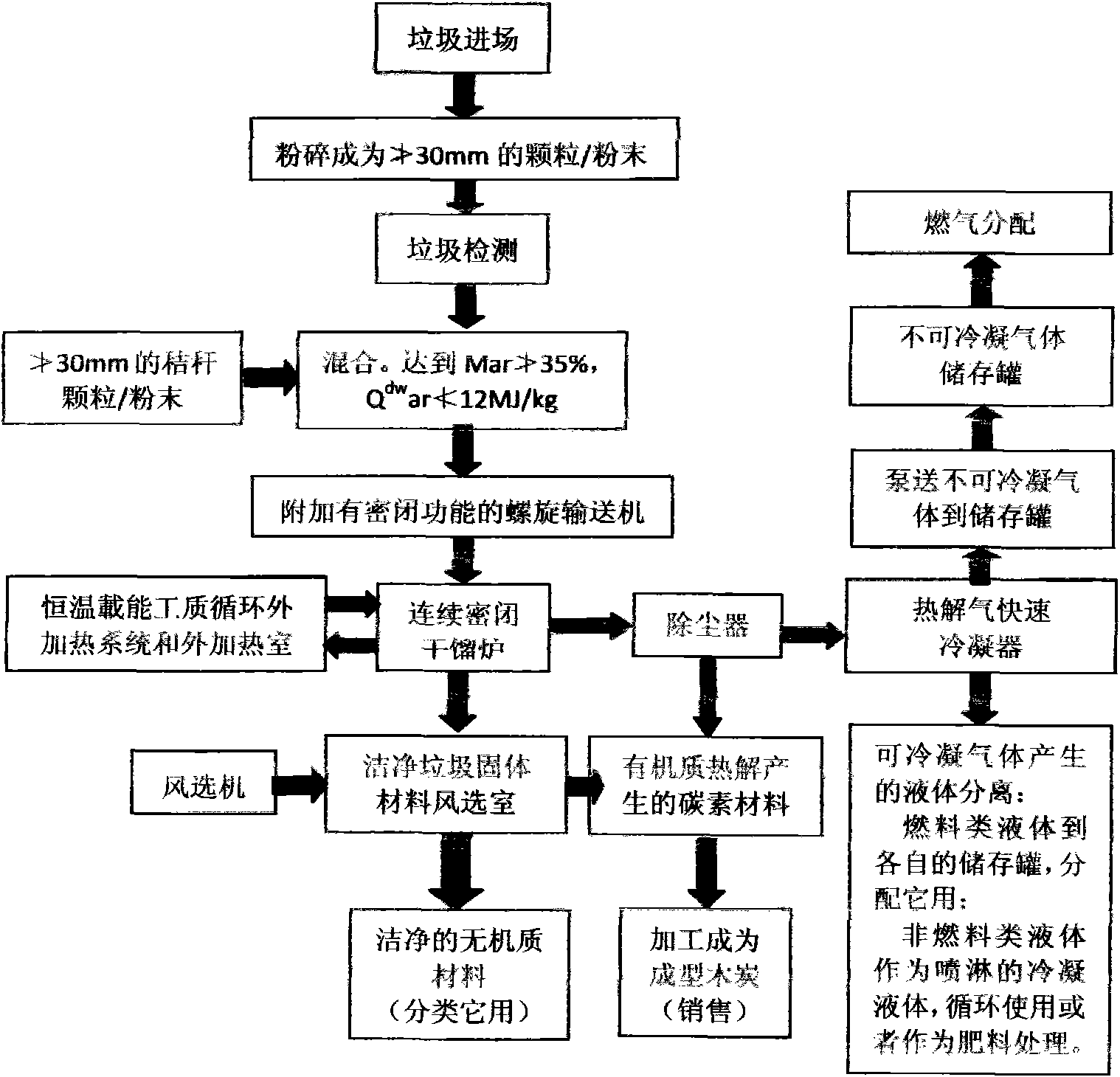

InactiveCN102247966ASolid waste disposalSpecial form destructive distillationRefuse-derived fuelClassification methods

Garbage generated in our country has a large amount of household meal residuals, so garbage has obvious characteristics of a high moisture as received (Mar is not less than 50%) and a low lower heating value (Q<dw>ar is not more than 5MJ / kg). A method of increasing biomass energy is employed by the invention. First, garbage is conversed to garbage derivative fuel, and a method of complete isolation from air and external heating is adopted to realize drying, deodorizing, disinfecting and carbonization and pyrolysis of garbage material under a 300-6000 DEG C constant temperature working condition; at last, a rapid condensation method is conducted to rapidly separate condensable gas components and incondensable gas components in gas generated from pyrolysis; and solid materials are separated through an air classification method and answer the purpose intended. According to the garbage treatment method of the invention, no extra processing on the received garbage is needed; and no dioxins or even little secondary pollution is generated; so that various substances in the garbage can be recycled by 100%.

Owner:许绍良

Municipal refuse treatment device and method

InactiveCN102615092AReduce heat loadReduce consumptionWaste processingSolid waste disposalRefuse-derived fuelChemical oxygen demand

The invention discloses a municipal refuse treatment device and a municipal refuse treatment method. A primary selection machine, a coarse crusher, a primary dehydrator, a winnowing machine, a primary metal sorting machine, a screening machine, a fine crusher, a secondary dehydrator, a secondary metal sorting machine, a mixer, a refuse derived fuel (RDF) molding machine and a drying machine are sequentially connected in series between a feeder and an RDF racking machine, wherein the screening machine is connected with an anaerobic generator; a stable dehydrator is connected in series between the anaerobic generator and a biochemical treater; the bottoms of the primary dehydrator and the second dehydrator are provided with water outlets, and the water outlets are connected with a water inlet of the anaerobic generator through a pipeline; and a methane purifier, a gas storage tank and a methane boiler are sequentially connected in series between the anaerobic generator and hot air of the drying machine. Due to a two-stage dehydration mode, a thermal load of the drying machine is effectively reduced before refuse enters the drying machine, and the consumption of external energy is effectively reduced; and moreover, in the process of anaerobic reaction, the chemical oxygen demand (COD) of the effluent is reduced, and the pressure of a subsequent biochemical reactor is reduced.

Owner:苏州天荣能源环境科技有限公司

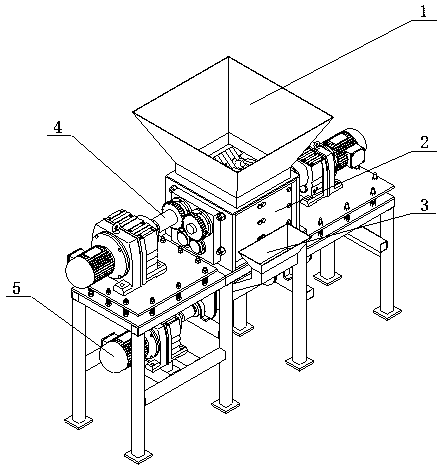

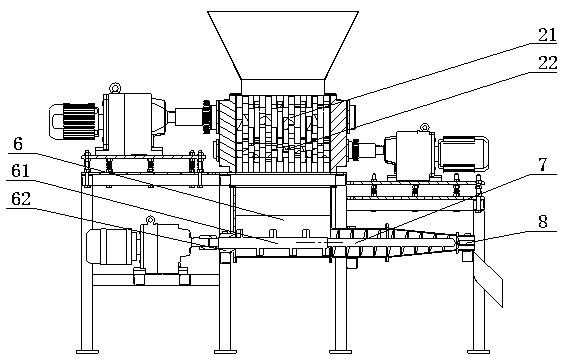

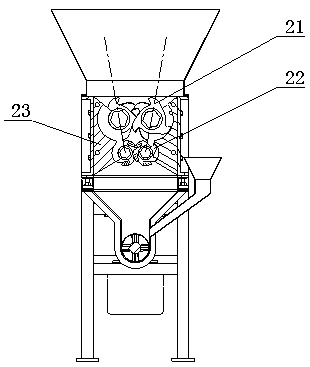

RDF production equipment and RDF preparation method

InactiveCN109022095AEvenly dispersedIncrease the calorific value of combustionTransportation and packagingBiofuelsRefuse-derived fuelCombustion

The invention discloses RDF (refuse derived fuel) production equipment. The equipment includes a crushing box internally equipped with a crushing mechanism, the top of the crushing box is equipped with a feed inlet, the bottom of the crushing box is equipped with a crushing discharge port, and a mixing box communicated with the crushing discharge port is disposed under the bottom of the crushing box. The box wall of the mixing box is equipped with an additive feed inlet, the mixing box is internally equipped with a stirring shaft, one end of the stirring shaft extends out of the box wall of the mixing box and is in power connection with a stirring motor, and the other end of the stirring shaft is connected to a screw conveying extrusion moulding machine. The screw conveying extrusion moulding machine includes a shell communicated with the mixing box and a screw conveying shaft coaxially connected to the stirring shaft. The equipment also includes a heating device for heating the mixingbox or the shell of the screw conveying extrusion moulding machine. The invention also provides an RDF preparation method using the RDF preparation equipment. The equipment and method provided by theinvention can increase the combustion heat of refuse derived fuel, have no need for an adhesive, are beneficial to environmental protection and are convenient for storage and transportation.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com