Patents

Literature

34results about How to "Optimize investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

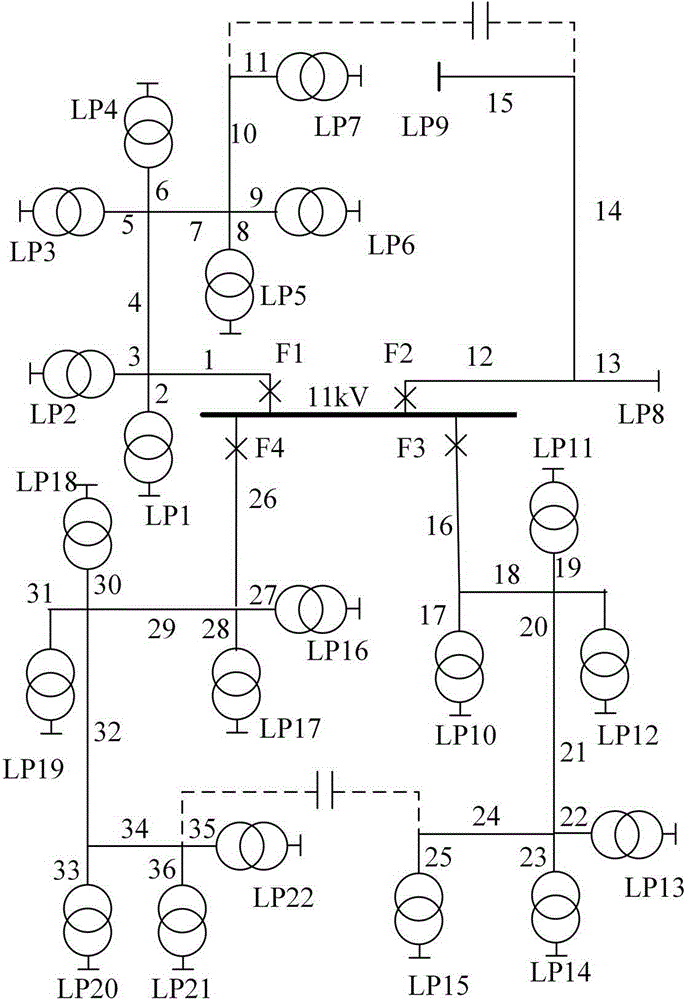

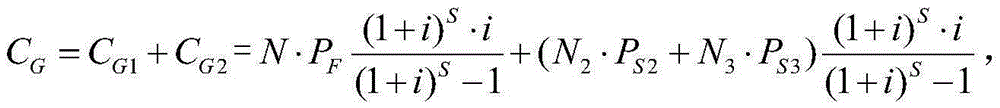

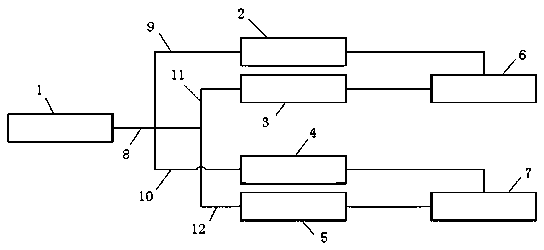

Configuration method of distribution automation terminal of intelligent power distribution network

InactiveCN105356610AExcellent investment costOptimize investmentCircuit arrangementsGenetic modelsEngineeringComputer terminal

The invention relates to a configuration method of a distribution automation terminal. The method includes: firstly, an optimization objective function is established, positions of to-be-installed switches are encoded, the optimization objective function is regarded as a fitness function, an initial population including a plurality of individuals is randomly generated, the fitness function of each individual is calculated, the fitness of the individual is obtained, and the individual with the lowest fitness in the initial population is finally found as the optimal individual; the next generation of population is obtained via selection, crossover, and mutation operation of the initial population, the fitness function of each individual is calculated, and the individual with the lowest fitness in the population is obtained as the optimal individual of the population; and if the mutual differences between the fitnesses of the optimal individuals of 10 continuous generations of populations are all less than a preset threshold, automation terminal configuration of the intelligent power distribution network is accomplished. According to the method, the economy and reliability of the configuration of switches and the distribution automation terminal of the intelligent power distribution network can be optimal.

Owner:JIANGSU ELECTRIC POWER CO +1

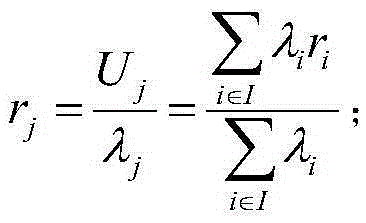

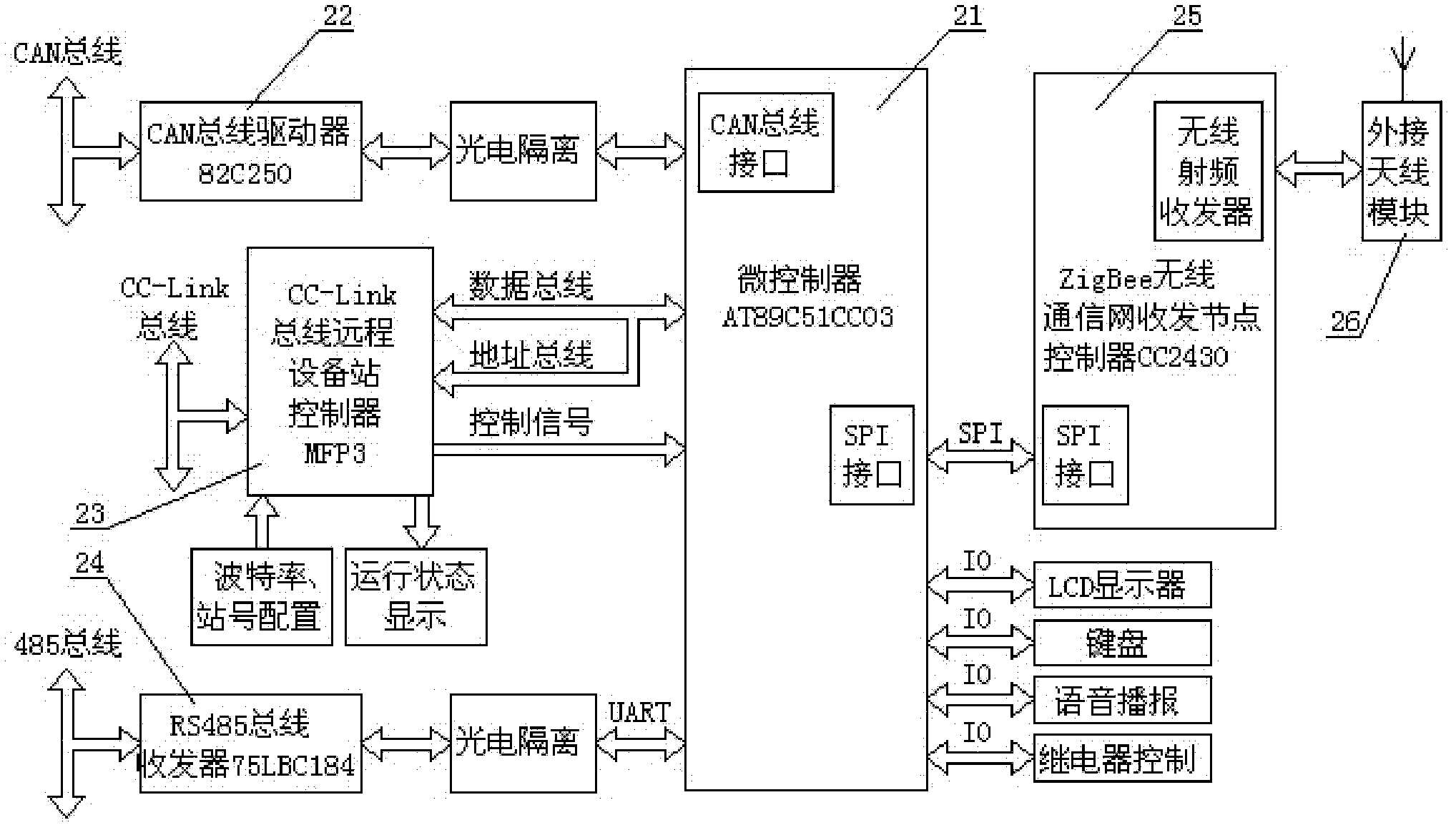

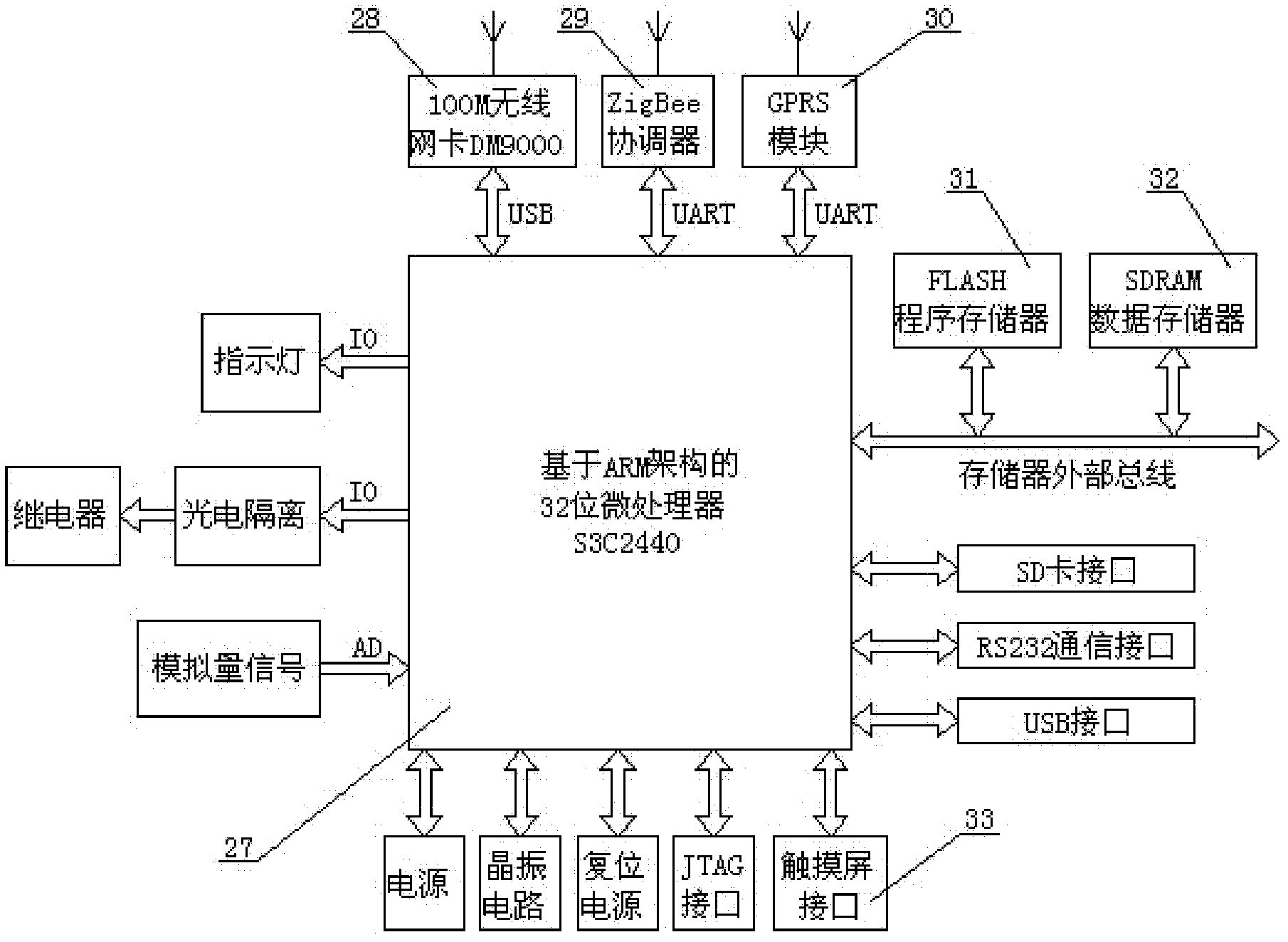

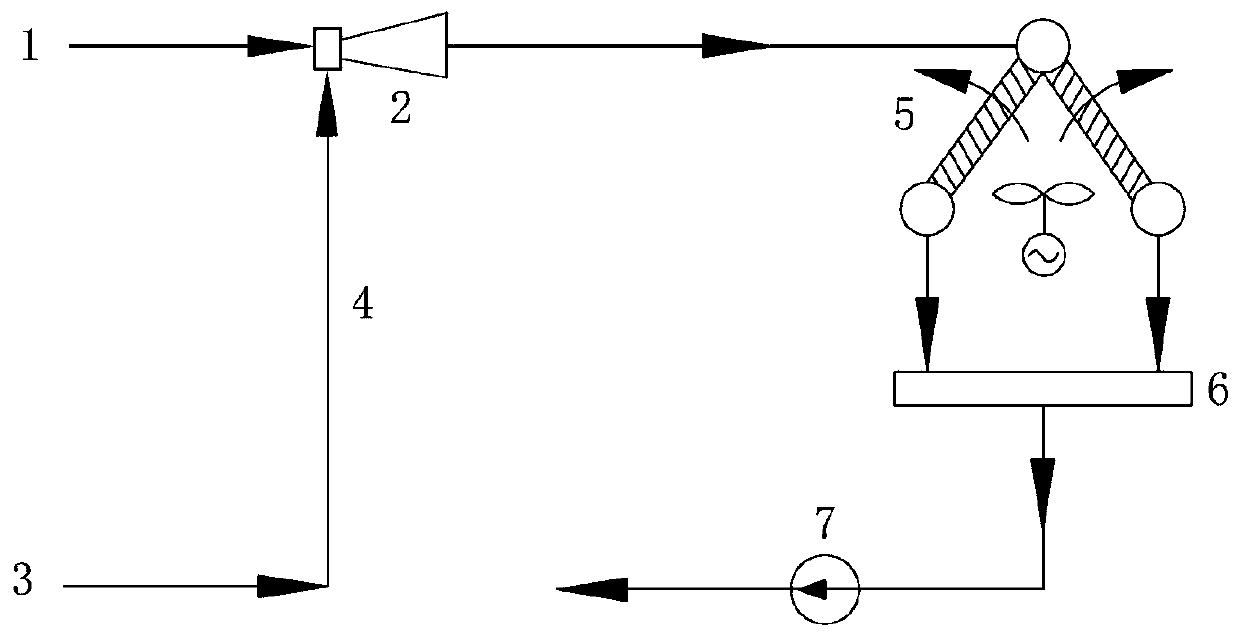

Heterogeneous network-based remote monitoring system for wind and light supplementary power station

InactiveCN102402213AImprove real-time performanceStrong real-timeTotal factory controlProgramme total factory controlExtensibilityOperational costs

The invention discloses a heterogeneous network-based remote monitoring system for a wind and light supplementary power station. The system comprises a field monitoring network unit, a heterogeneous network communication conversion interface unit, a wireless communication network unit, a wireless gateway unit and a remote access and control unit; and the five units are sequentially connected. The system consists of a wired monitoring network and a wireless monitoring network together, field real-time monitoring requirements of the wind and light supplementary power station and power supply equipment thereof can be met, and the monitoring data of each power station can be conveniently transceived, gathered and remotely transmitted; and the system has the advantages of high instantaneity, strong reliability, low construction and operational costs, wide monitoring range and strong expandability.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

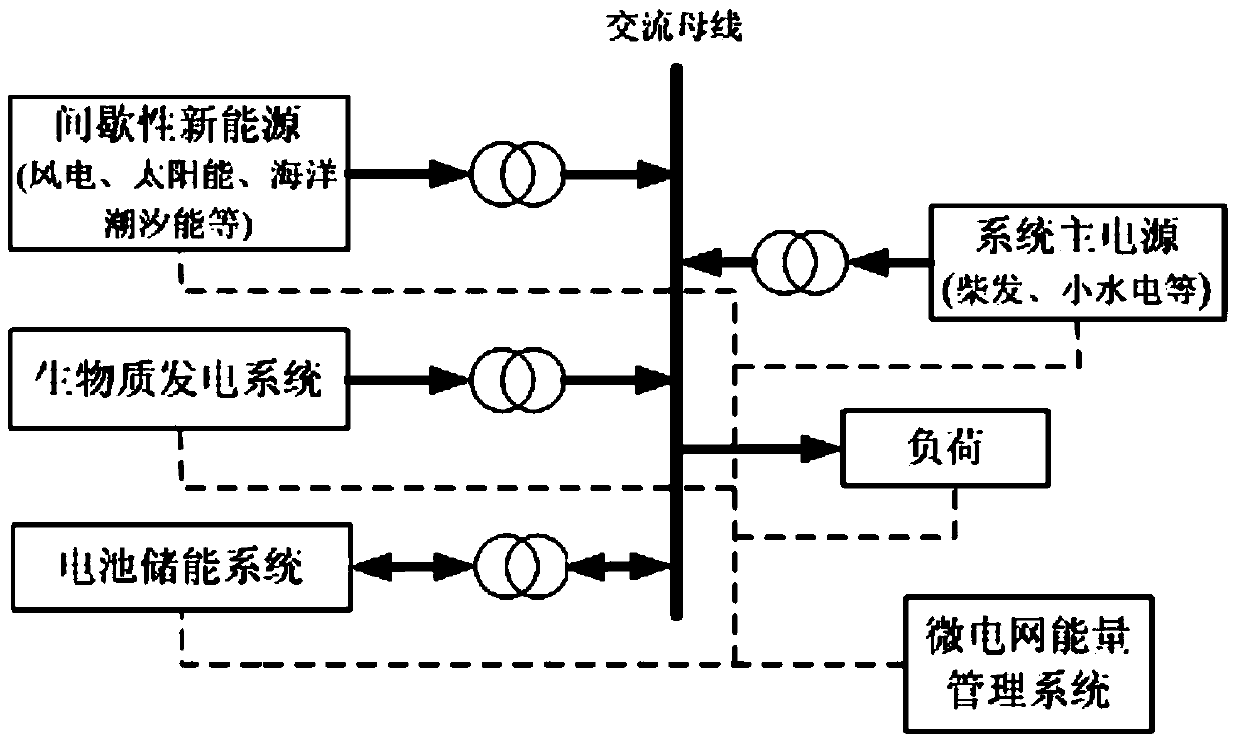

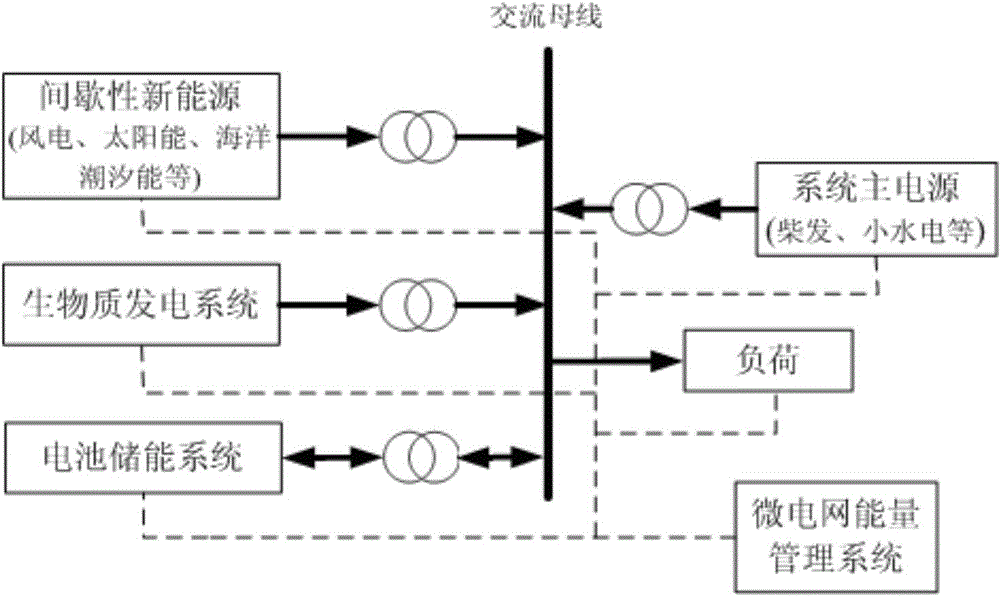

Method for controlling load following operation of micro-grid

ActiveCN103475020AReduce consumptionImprove permeabilityEnergy industrySingle network parallel feeding arrangementsNew energyFrequency modulation

The invention relates to a method for controlling load following operation of a micro-grid. The micro-grid comprises a main power supply, a biomass power generation system, an intermittent new energy source power generation system, an energy storage system and a micro-grid energy management system, wherein the main power supply undertakes payload fluctuation in an energy management scheduling period of a micro-grid system, the biomass power generation system undertakes the payload fluctuation when the duration of the micro-grid system is longer than the energy management scheduling period, and the energy storage system provides an emergency frequency modulation function when the system undergoes large disturbances. The method disclosed by the invention improves the permeability of renewable energy resources, reduces the consumption of diesel oil, and improves the economical efficiency of system power supply while realizing energy conservation and emission reduction.

Owner:GUODIAN UNITED POWER TECH

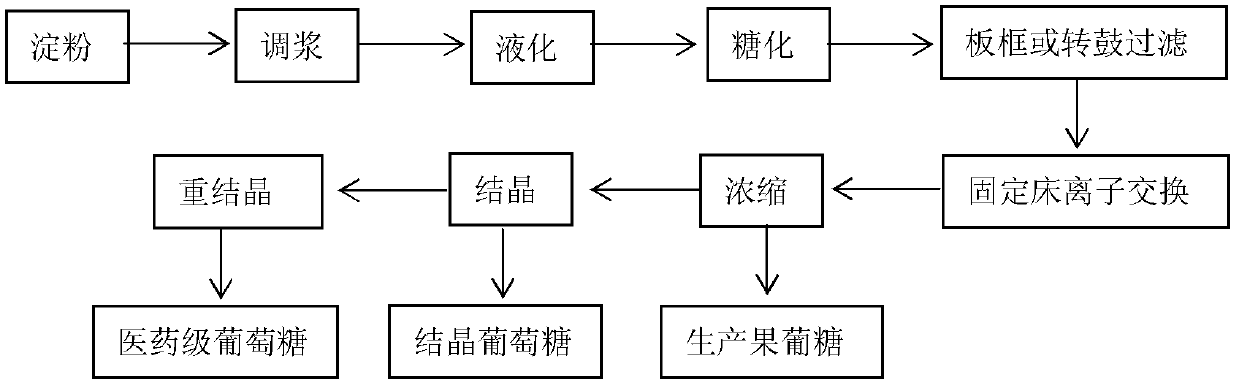

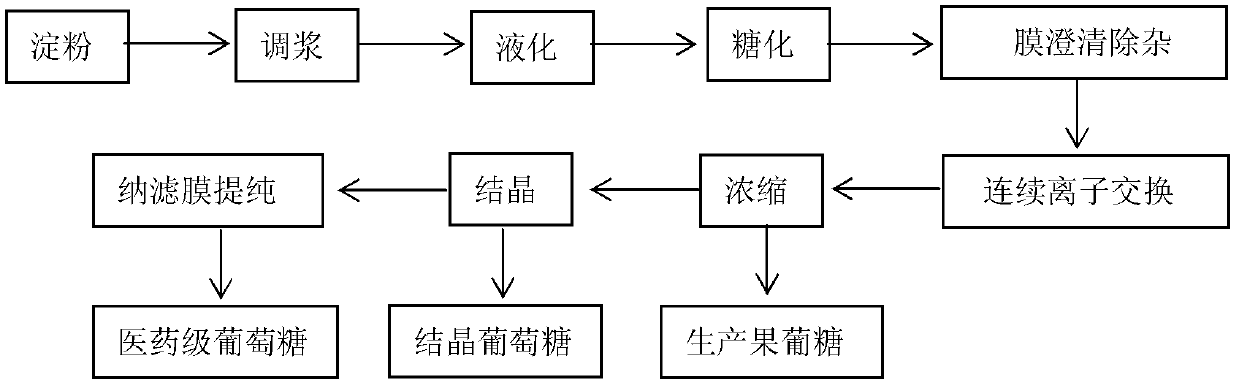

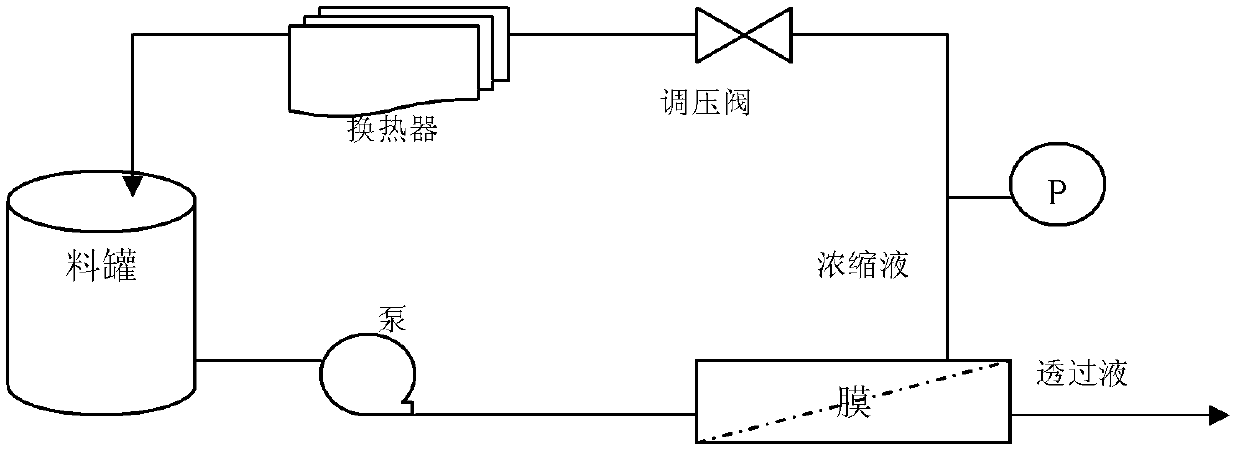

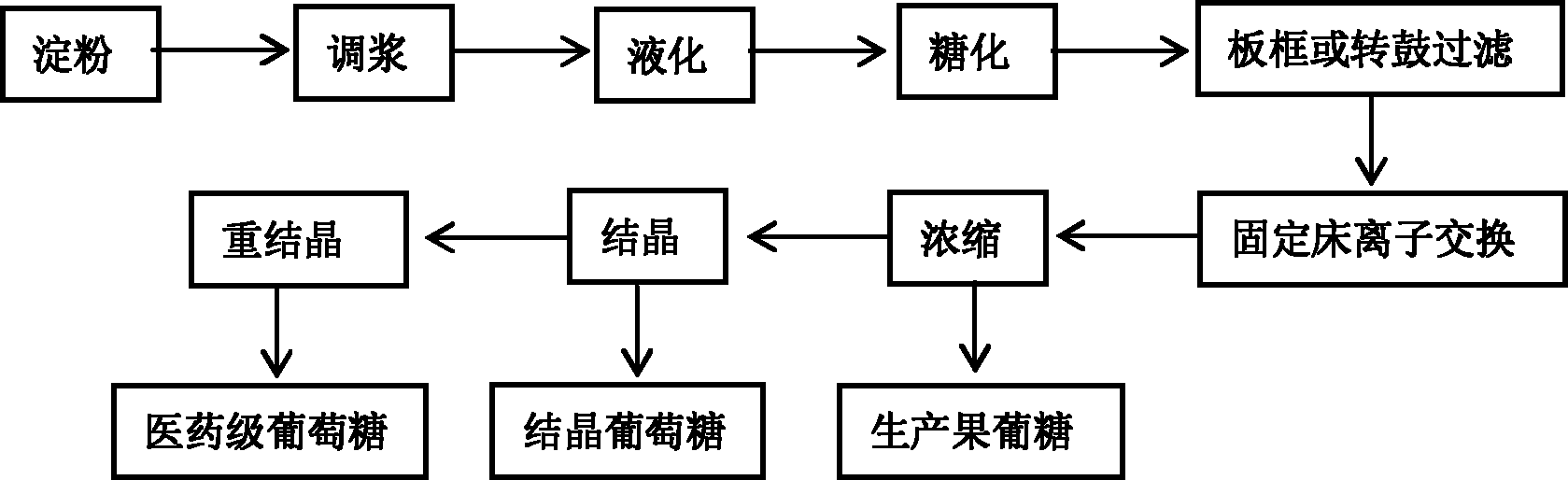

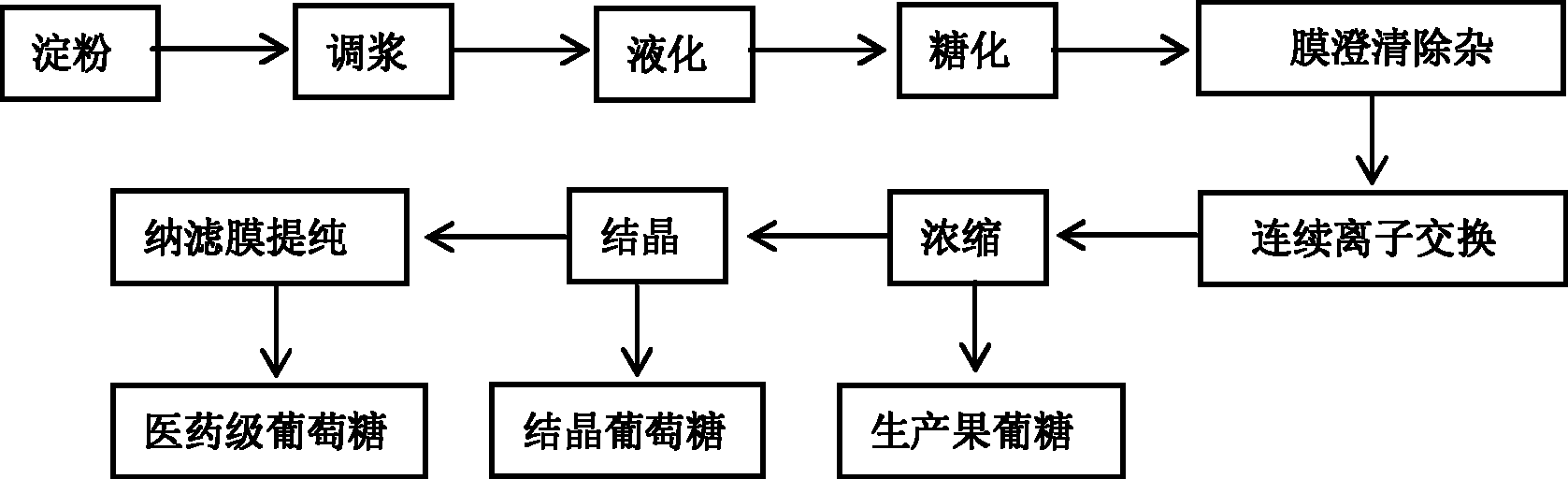

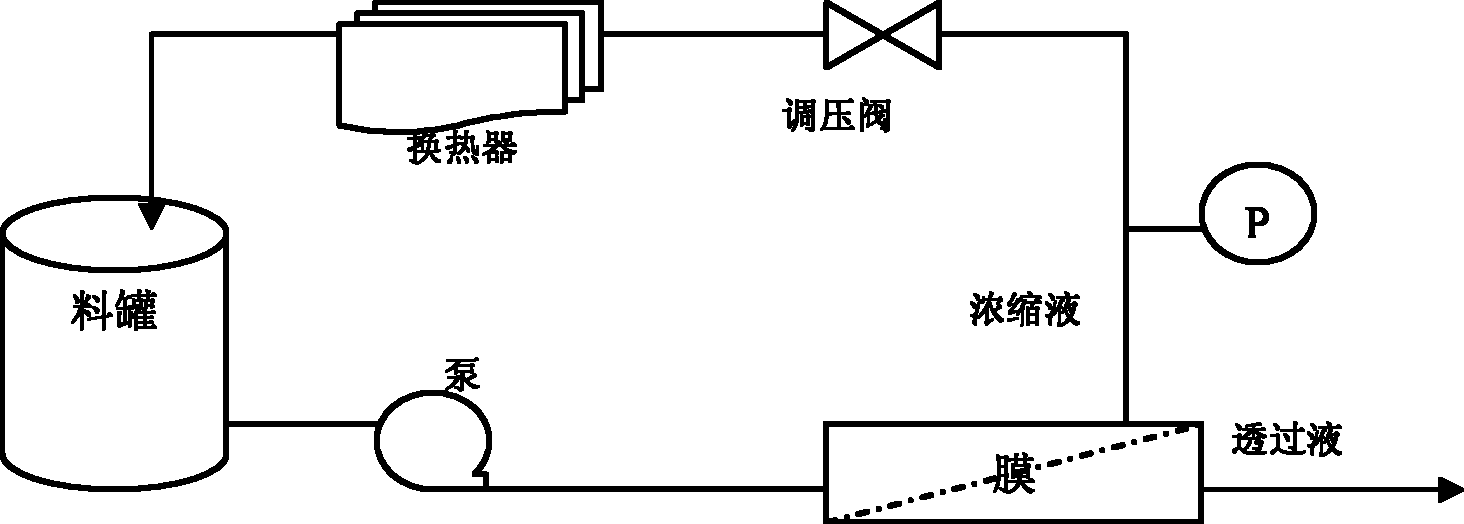

Manufacturing method of glucose

ActiveCN102586361AImprove economic efficiencyGood qualityIon-exchange column/bed processesUltrafiltrationIon exchangeIon

The invention discloses a manufacturing method of glucose, comprising the following steps of: (1) liquefying starch: by taking starch as the raw material, liquefying under the action of a liquefying enzyme after size mixing, and then, a glucose saccharified liquid under the action of a saccharifying enzyme; (2) filtering and decontaminating the saccharified liquid by a membrane filtering unit to obtain filtrate, wherein a filtering membrane has the aperture of 1-200nm or the molecular weight cut-off of 10-500kd; (3) carrying out continuous ion exchange on the filtrate by using a moving bed, removing salts to obtain a purified liquid; and (4) filtering the purified liquid by using a nanofiltering membrane to obtain pharmaceutical-grade glucose, wherein a concentrated solution is used for producing daily chemical alcohol or polysaccharose products. Continuous production is adopted in the manufacturing method, and therefore, the production efficiency is high.

Owner:SANDA FILM SCI & TECH XIAMEN +1

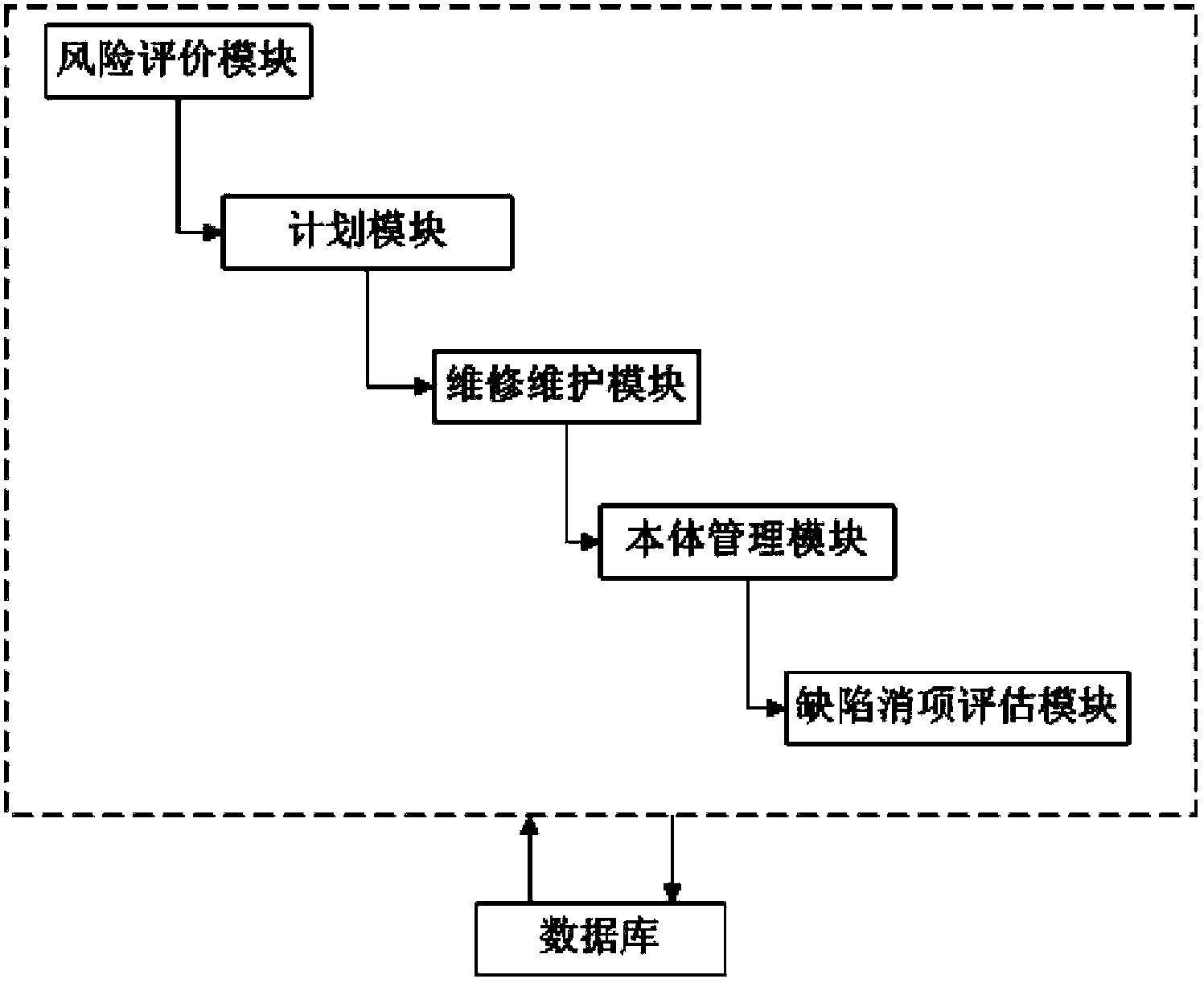

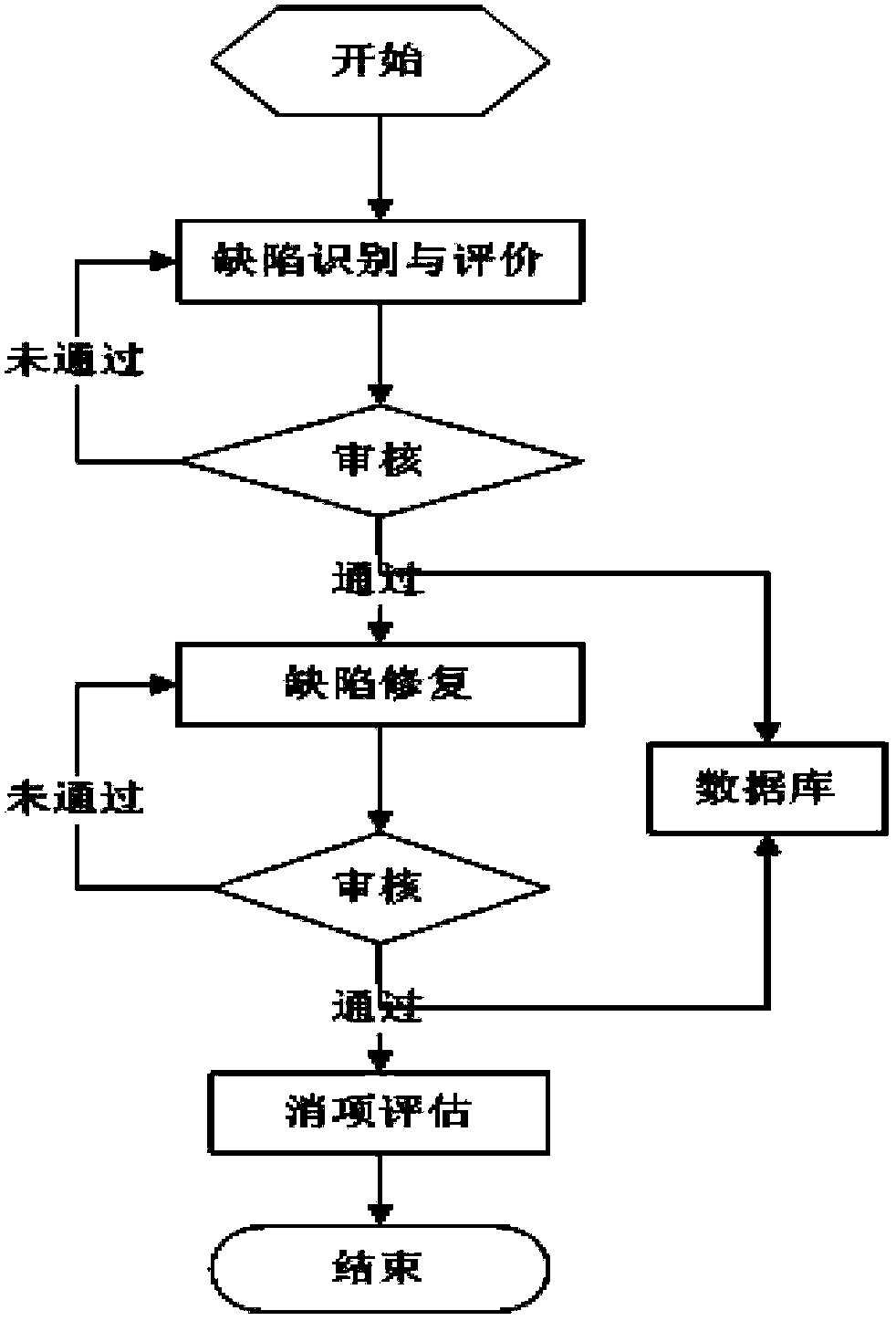

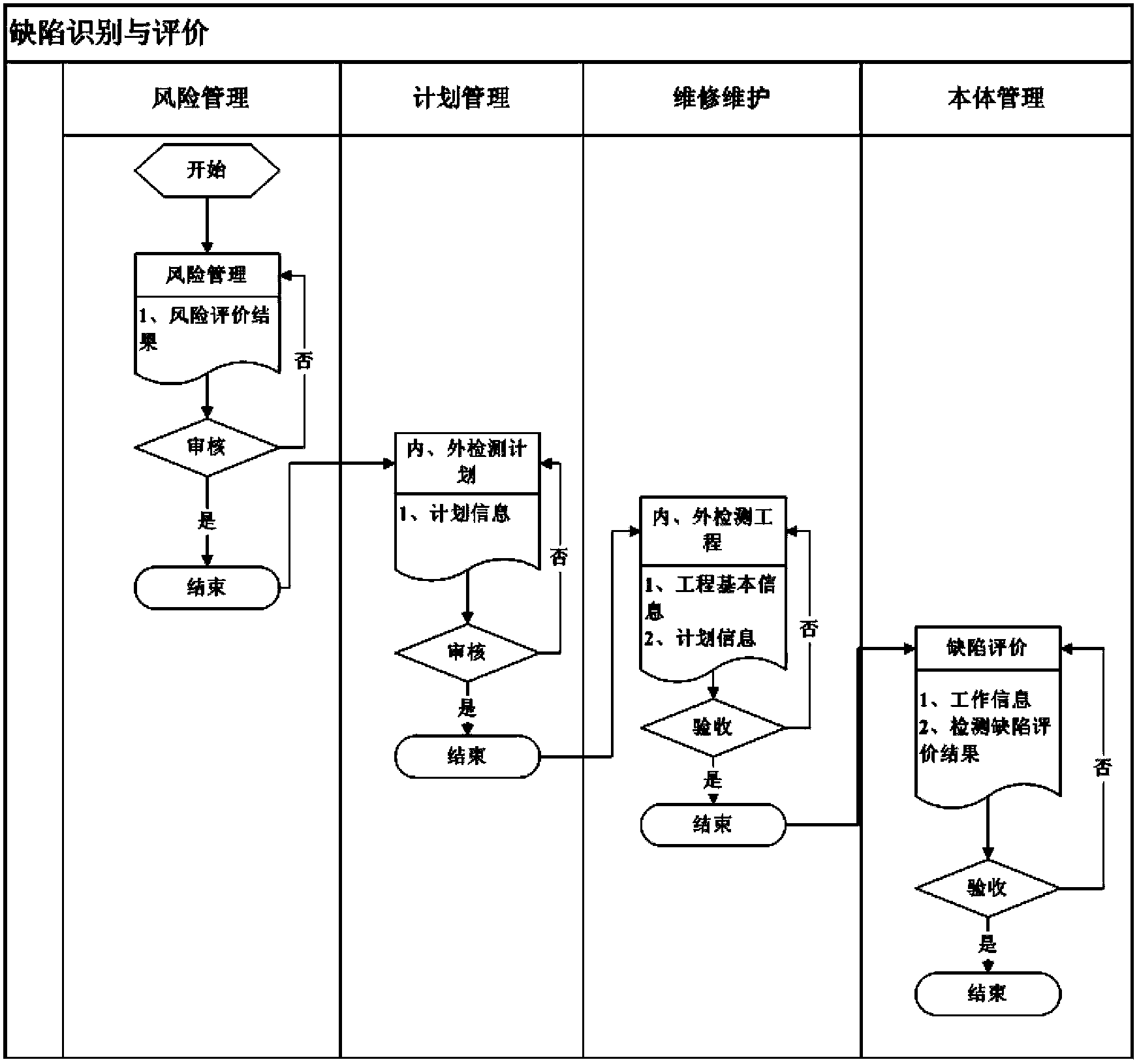

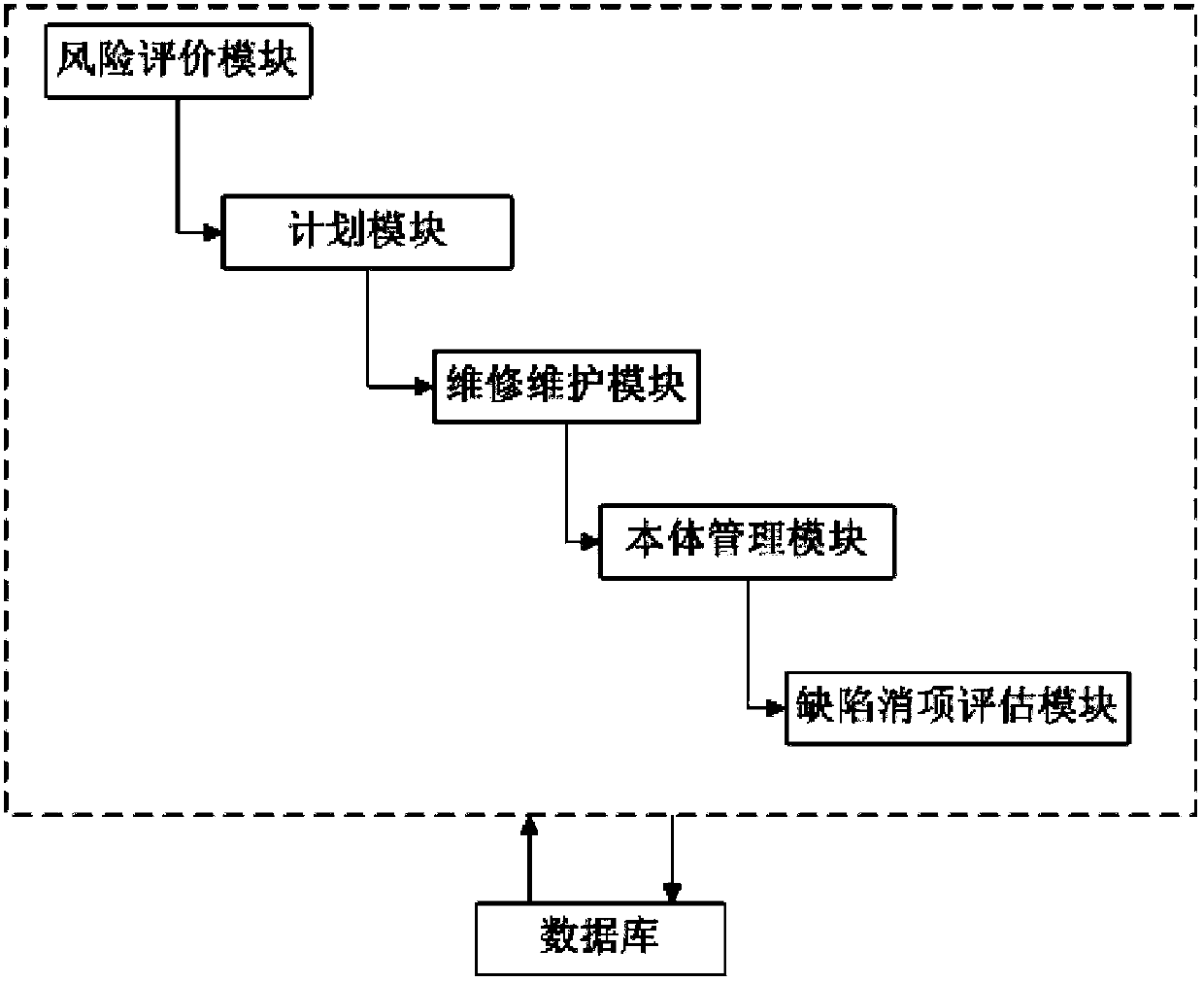

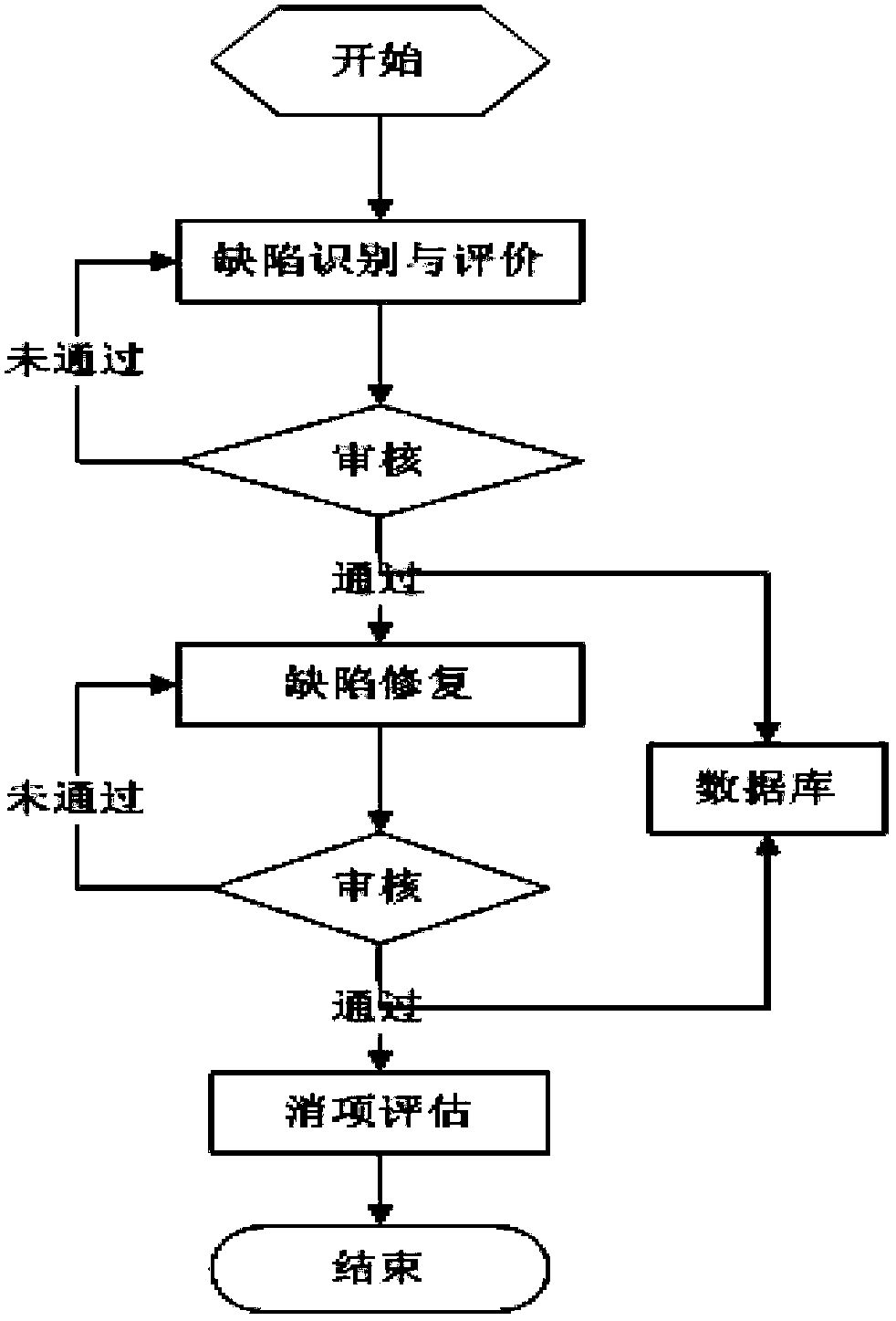

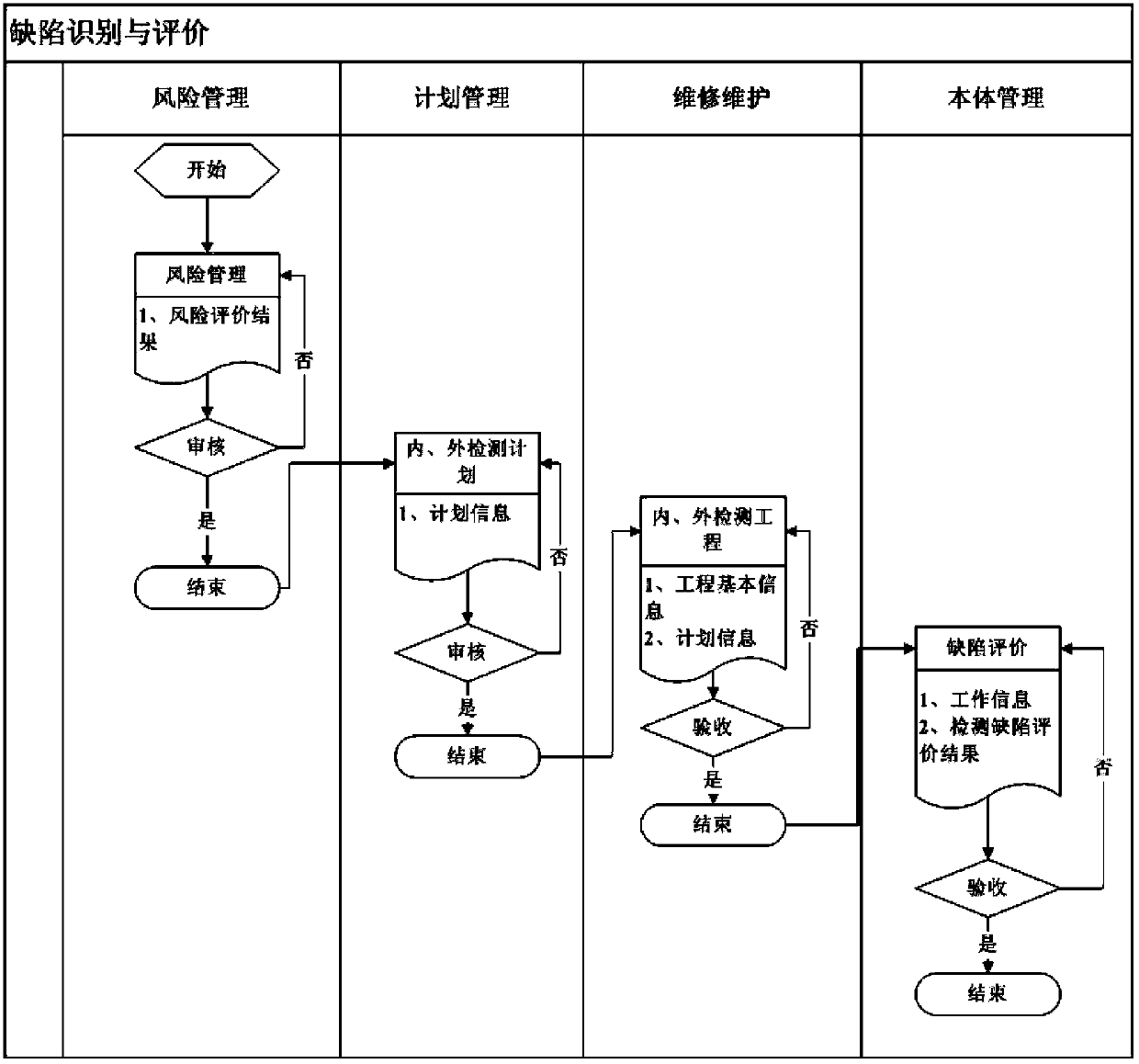

Method and system of closed loop assessment for pipe body defects of long-distance oil and gas pipeline

The invention discloses a method and system of closed loop assessment for pipe body defects of a long-distance oil and gas pipeline, and relates to the technical field of pipeline systems. The assessment method comprises the following steps: 1) beginning; 2) recognizing and assessing the pipe body defects; 3) examining and verifying; 4) if the examination and verification are not pass, returning to recognize and assess the pipe body defects, and if the examination and verification pass, moving to a database firstly and then conducting defect repairing; 5) examining and verifying; 6) if the examination and verification are not pass, returning to defect repairing, and if the examination and verification pass, moving to the database firstly and conducting item-removing assessment; 7) finishing. According to the invention, a closed loop monitoring of defect recognizing and assessing, defect repairing and defect item-removing assessment for a pipe body can be achieved, the operation process of the defect closed loop assessment is simplified, related service information is integrated, accurate and reliable data support is provided for service management and decision, and defect item removing effect is effectively assessed.

Owner:PIPECHINA SOUTH CHINA CO

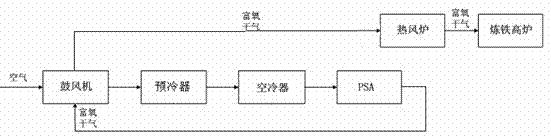

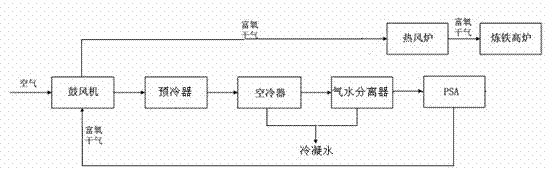

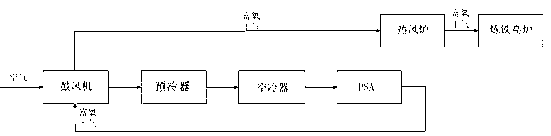

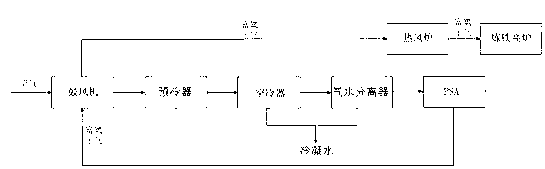

Oxygen-enriched dry gas supply process for blast furnace iron-making

InactiveCN102808056AReduce energy consumptionReduce preparation energy consumptionBlast furnace detailsHeating stovesThermodynamicsCombustion

The invention relates to the technical field of blast furnace iron-making processes, and provides an oxygen-enriched dry gas supply process adaptive to a smelting course of blast furnace iron-making. The oxygen-enriched dry gas supply process provided by the invention comprises the steps as follows: after air pressurized by a blast furnace blower is cooled by a precooler and an air cooler, water and partial nitrogen gas in the air are directly removed through pressure swing adsorption (PSA); and obtained oxygen-enriched dry gas returns to the precooler to be heated and then sent to a blast furnace by a hot blast stove to be used for supporting the combustion. According to the process, equipment in the prior smelting process of blast furnace iron-making is fully utilized, and the air pressurized via an outlet of the blast furnace blower is directly utilized to prepare the oxygen-enriched dry gas through PSA, so that the manner in the prior art that the oxygen-enriched dry gas can be prepared only by externally adding enriched oxygen is changed. The oxygen-enriched dry gas supply process has the characteristics of low equipment investment and low operational energy consumption.

Owner:李东林 +4

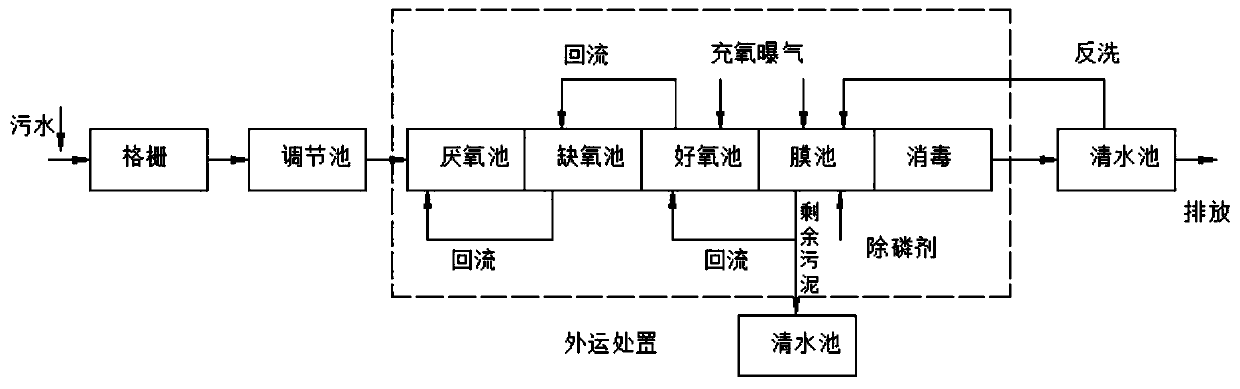

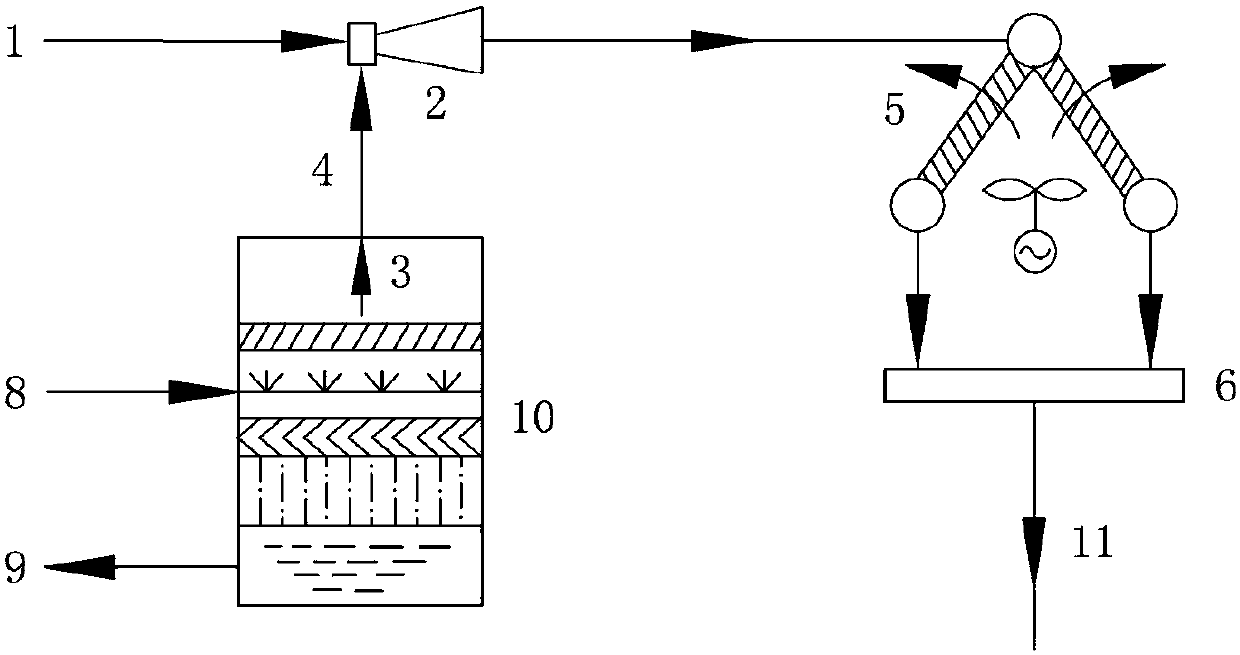

Enhanced type efficient nitrogen and phosphorus-removing sewage treatment system and treatment technology

PendingCN110040906AAvoid enteringLarge doseWater treatment parameter controlTreatment using aerobic processesWater treatment systemReaction rate

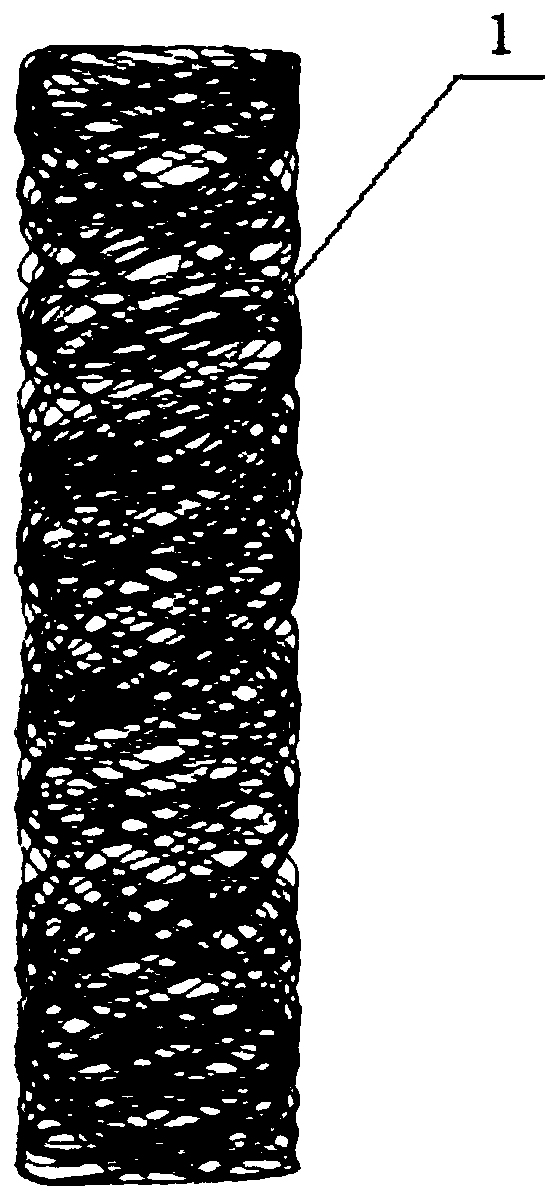

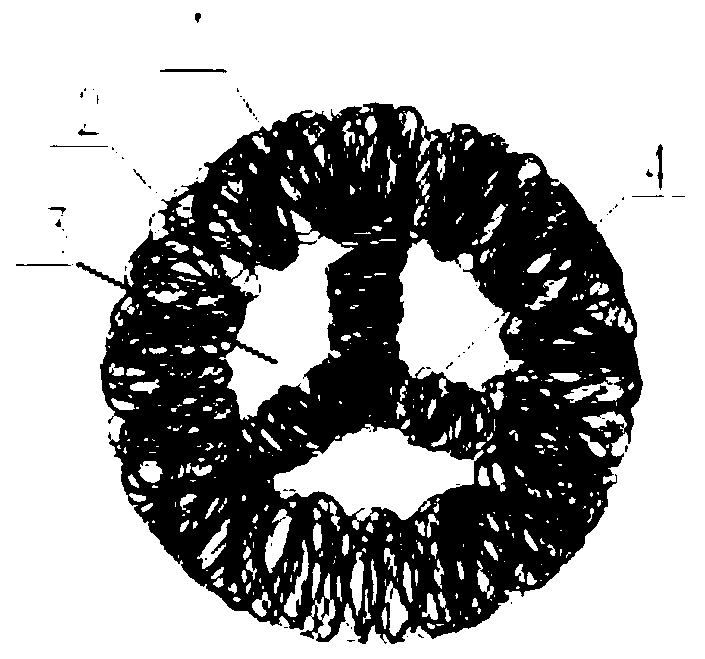

The invention relates to an enhanced type efficient nitrogen and phosphorus-removing sewage treatment system. A structure thereof comprises the following units: 1) a biochemical treatment unit, 2) a membrane treatment unit, 3) a backflow unit, 4) filling units and 5) a control unit, wherein the membrane treatment unit is connected with a water outlet end of the biochemical treatment unit; backflowsludge of the membrane treatment unit is connected with a water inlet end of an aerobiotic tank of the biochemical treatment unit, and the backflow rate is 300%-400%; the water outlet end of the aerobiotic tank flows back to the water inlet end of an anoxic tank through a backflow pipeline and a backflow device, the water outlet end of the aerobiotic tank and the water outlet end of an anaerobictank are jointly connected with the anoxic tank, and the backflow rate is 100%-200%; the water outlet end of the anoxic tank flows back to the water inlet end of the anaerobic tank through the backflow pipeline and the backflow device, the water outlet end of the anoxic tank and a pretreated water outlet end are jointly connected with the anaerobic tank, and the backflow rate is 100%-200%; the filling units are arranged in the anoxic tank and the aerobiotic tank. In the invention, a filler is added in a traditional A / A / O technical reactor, the backflow position and the backflow rate are adjusted, the carbon source is efficiently utilized, the nitrogen and phosphorus removal effect is enhanced, the reaction rate is effectively increased and the effluent index can be guaranteed.

Owner:新权诚工程建设项目咨询管理有限公司

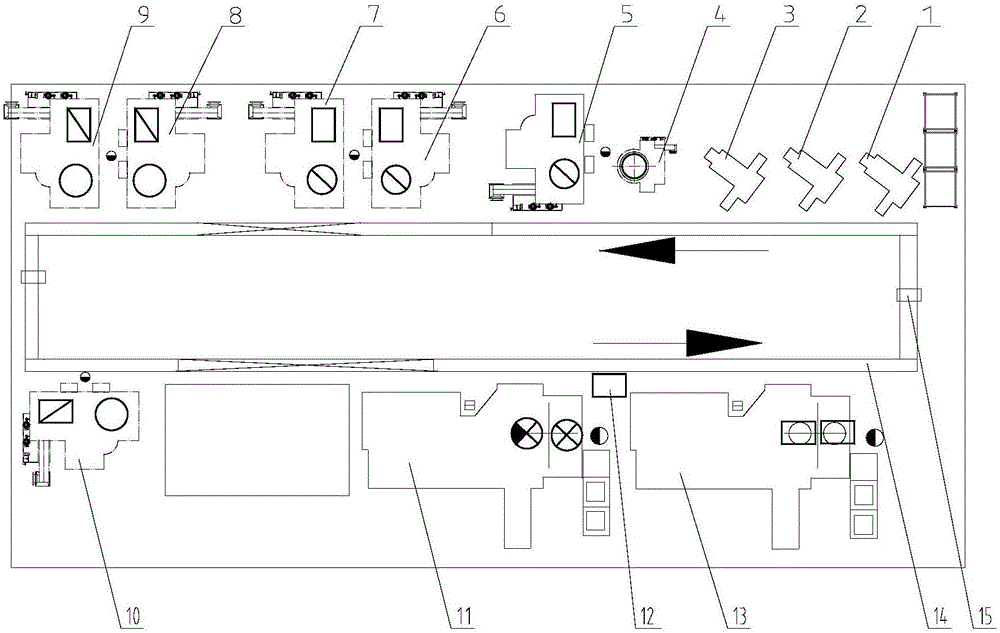

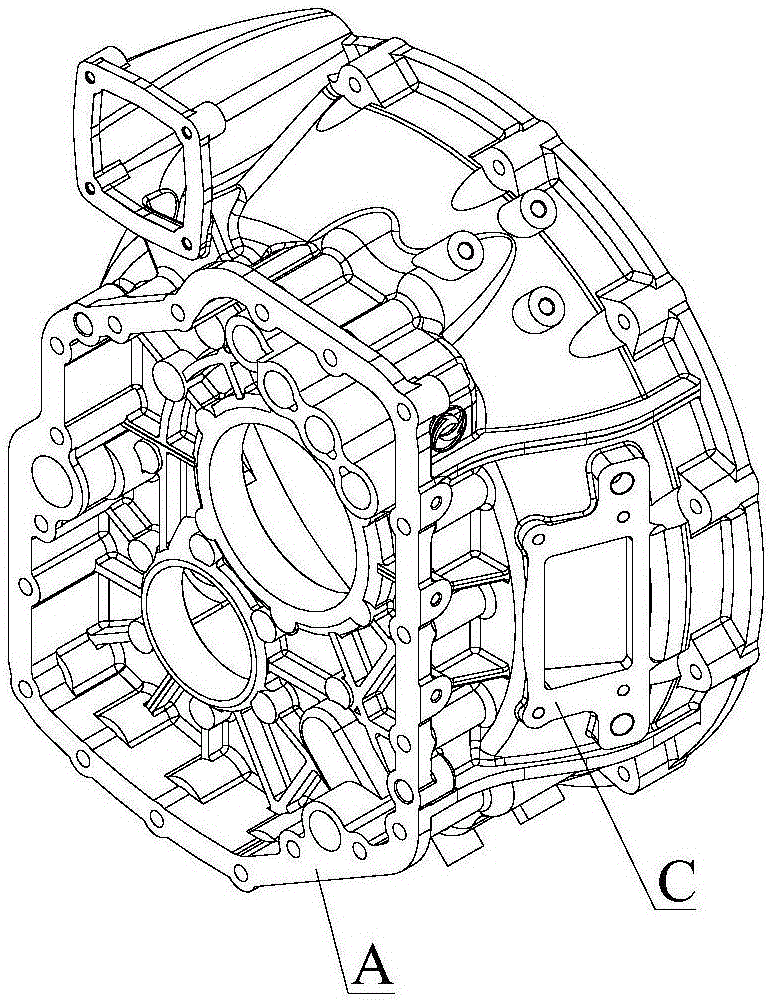

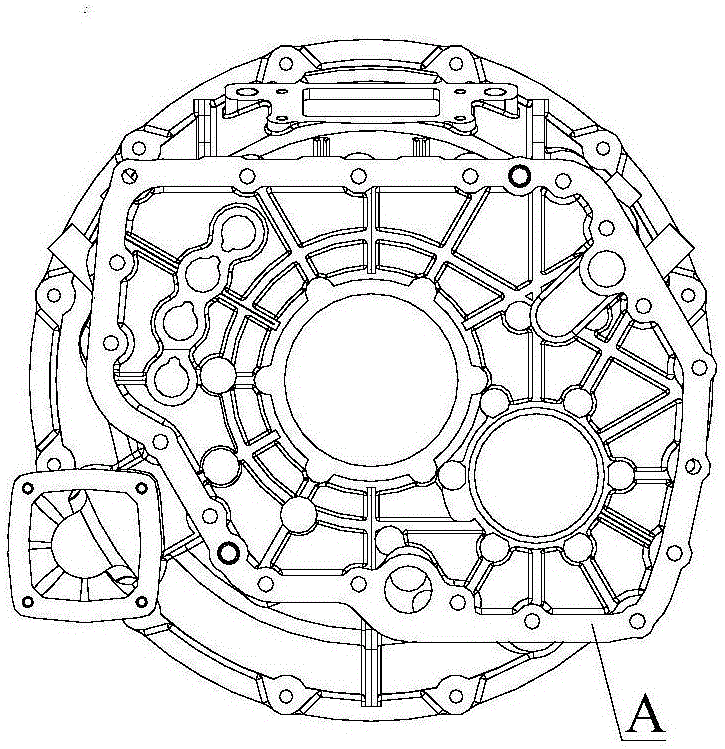

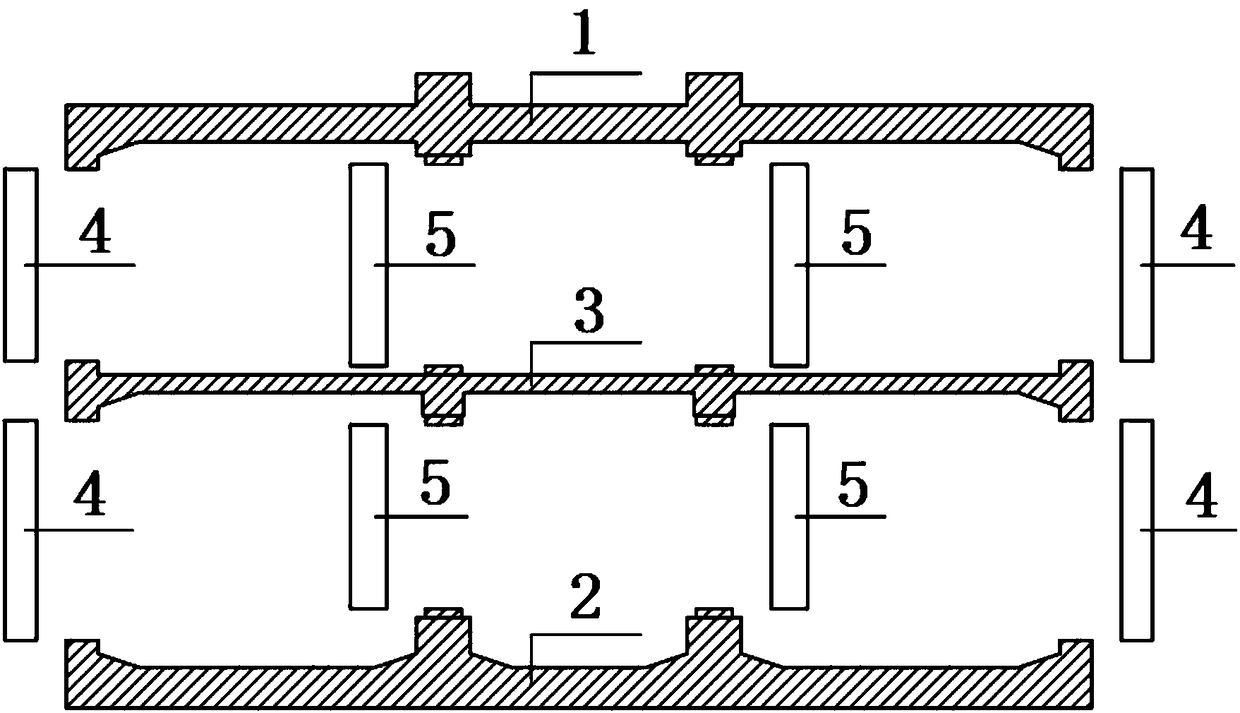

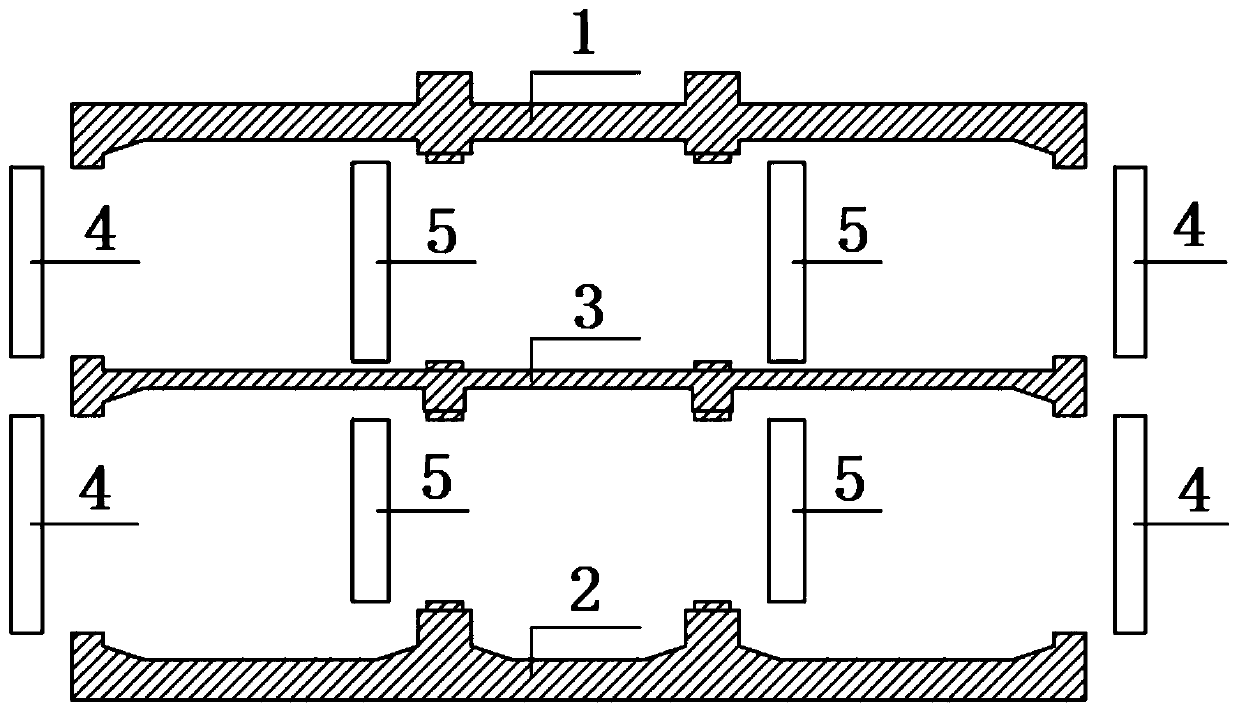

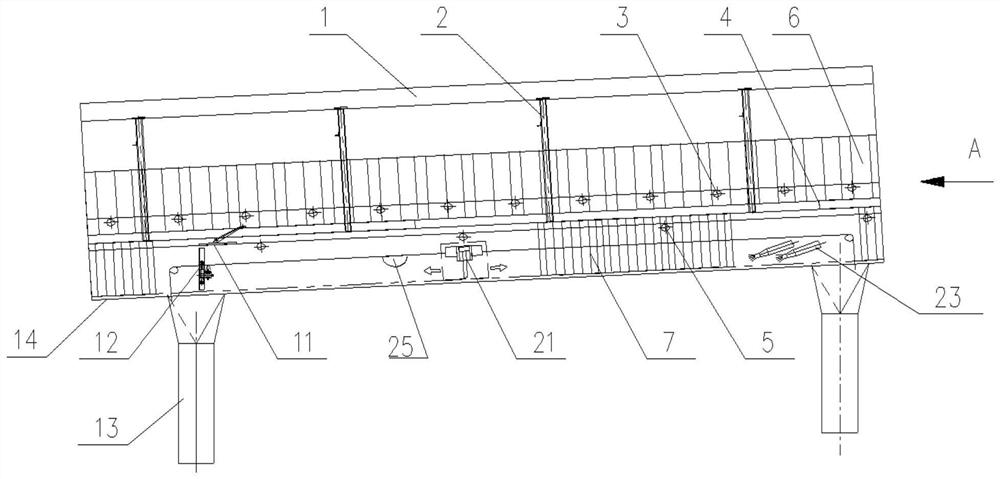

Transmission front shell and back shell mixed-flow production line and production method

ActiveCN106271672AEquipment investment optimizationLow costOther manufacturing equipments/toolsMetal working apparatusTime frameManufacturing engineering

The invention discloses a transmission front shell and back shell mixed-flow production line. An annular conveying roller way is arranged in the center of the production line; a reciprocating motion car for carrying transmission front shells and back shells to be machined is arranged on the conveying roller way; and the production line is provided with a set of vertical milling machines, a numerical control vertical lathe, two sets of vertical machining centers, a set of horizontal machining centers and a pneumatic marking machine in sequence in the conveying direction of the conveying roller way. The invention further provides a production method using the transmission front shell and back shell mixed-flow production line. The transmission front shell and back shell mixed-flow production line and the production method can realize mixed-flow production of the transmission front shells and back shells on the same one production line, can realize production of the front shells and the back shells as needed at different time frames and different classes, needs no replacements of tools and cutters for remodeling, is free of remodeling time, is more optimal in equipment investment, and is lower in cost.

Owner:东风汽车底盘系统有限公司

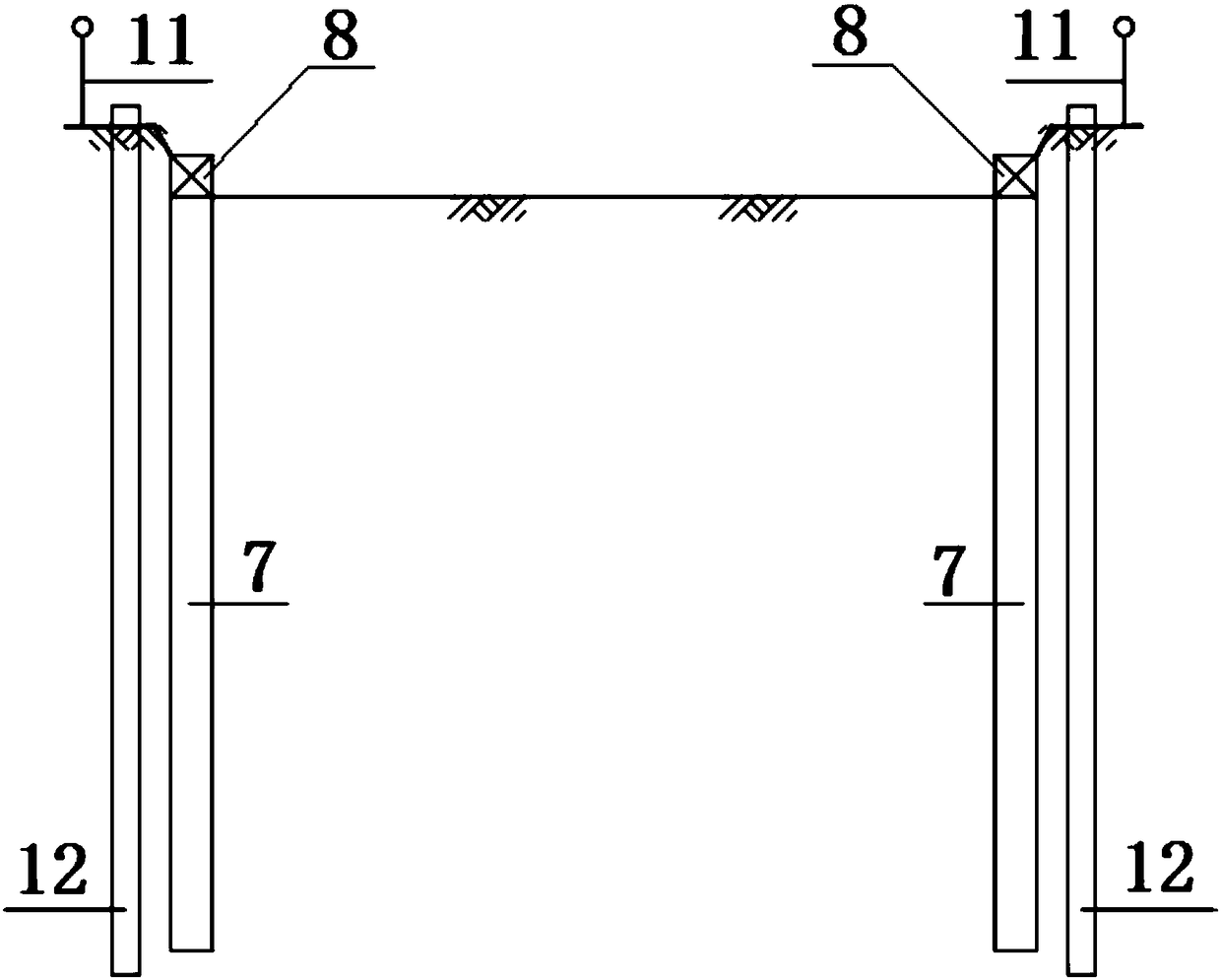

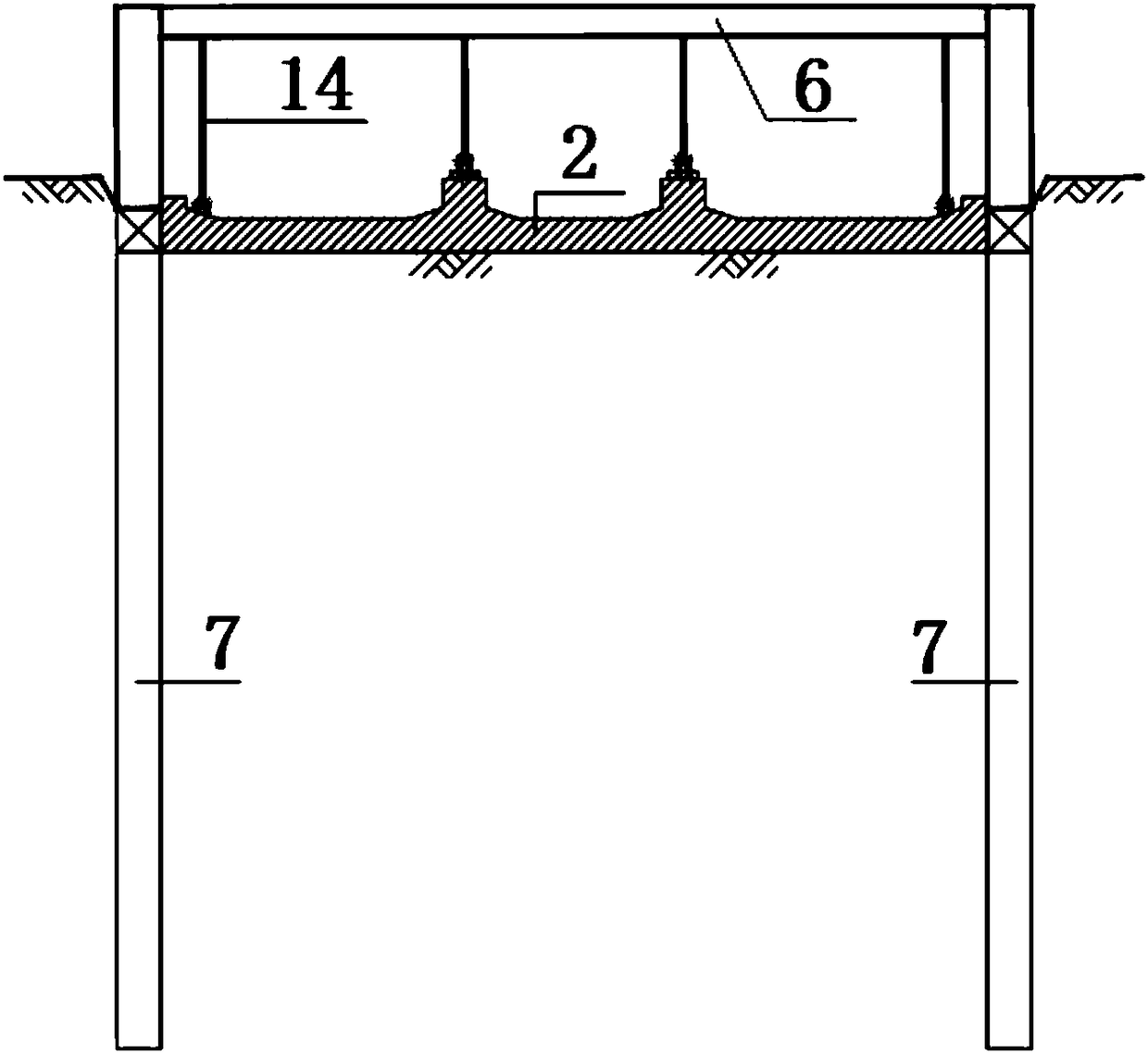

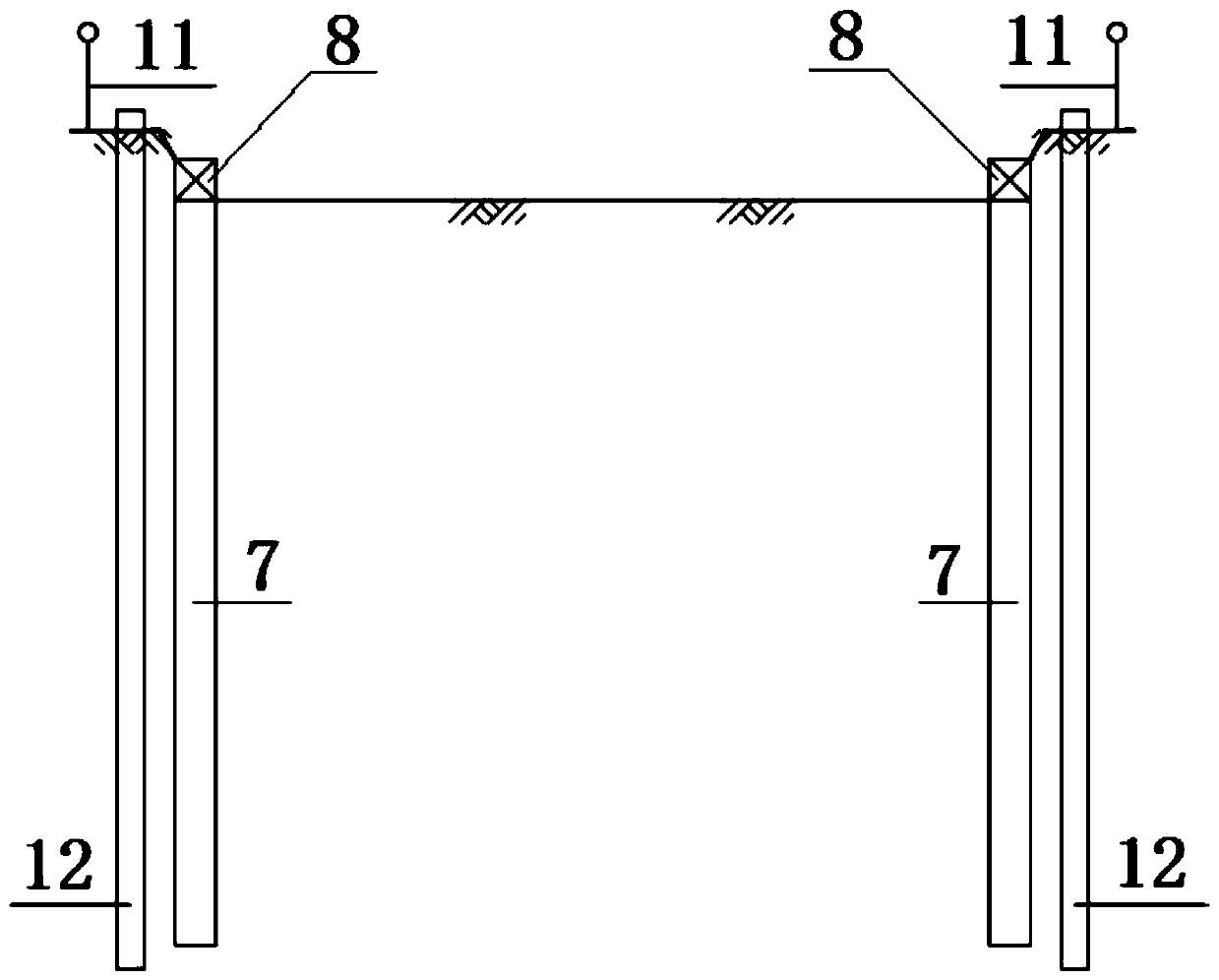

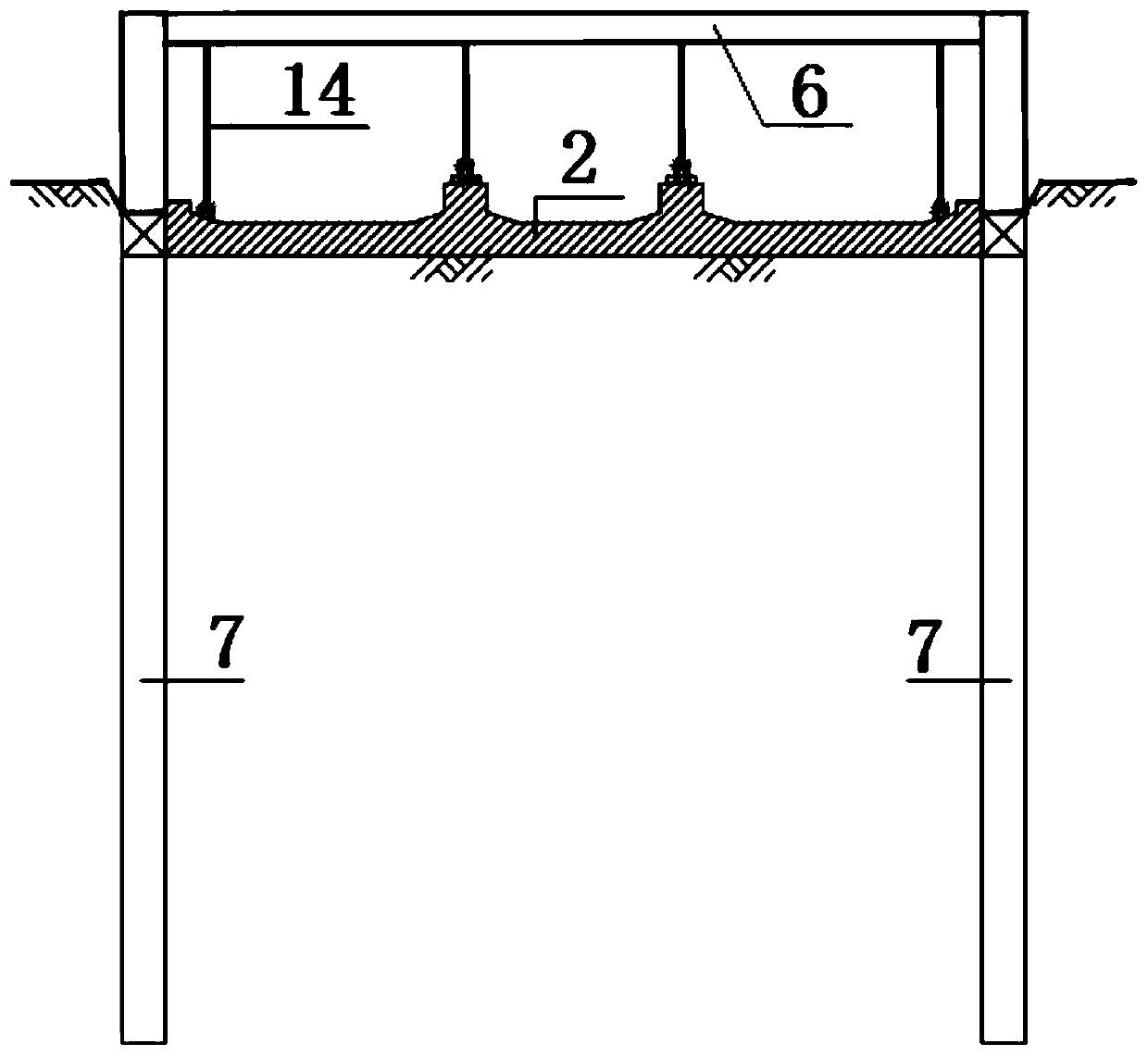

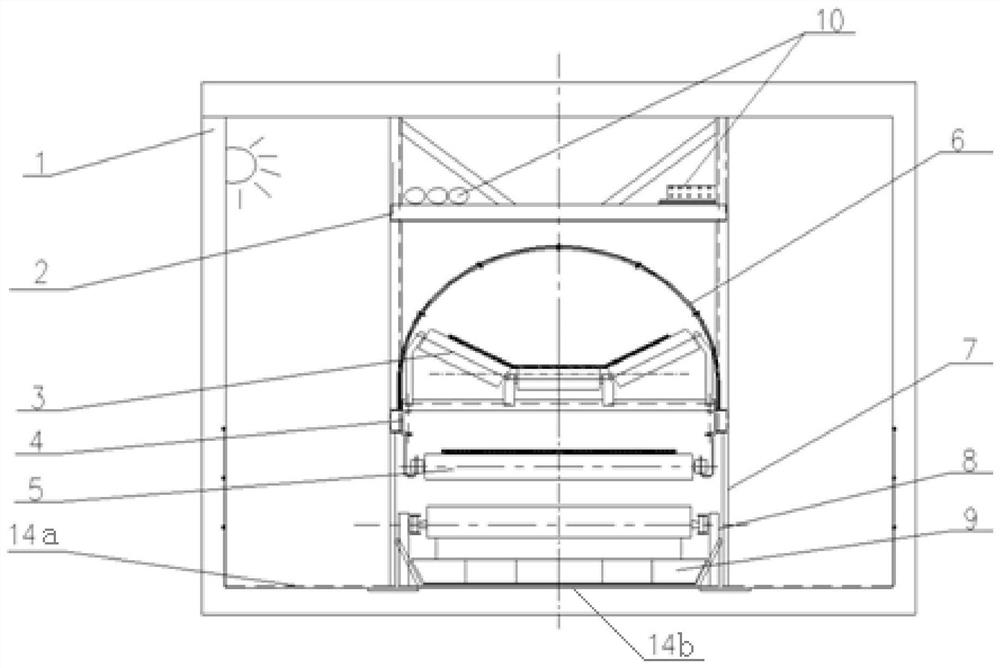

Engineering prefabricated main structure and supporting structure integration method based on open cut method

ActiveCN108571010ALess investmentOptimize investmentArtificial islandsUnderwater structuresArchitectural engineeringStructure support

The invention discloses an engineering prefabricated main structure and supporting structure integration method based on an open cut method. The method comprises the following steps: required prefabricated plates are prefabricated; a foundation pit enclosure structure with hoisting system guide rails embedded is implemented; top beams are cast at the top end of the enclosure structure, and a hoisting system is erected on the top beams; foundation pit earth is excavated, and prefabricated slabs of a bottom plate, prefabricated slabs of intermediate plates and prefabricated slabs of a top plateare positioned sequentially to force required positions of a foundation pit in a grouped manner by the hoisting system according to vertical cutting depth and longitudinal cutting length in real timeuntil the plates reach designed elevation; the grouped prefabricated slabs of the bottom plate, prefabricated slabs of the intermediate plates and prefabricated slabs of the top plate are spliced in regular sequence respectively until splicing for each plate is finished; slide wall components and columnar components are mounted in a grouped manner between adjacent prefabricated slabs, related facilities are dismounted, and earthing backfill is performed. Overall support stiffness of the foundation pit is improved by the layered prefabricated slabs, deformation of the foundation pit is limitedto the greatest extent, anchor ropes and supports are reduced, and force transformation is reduced.

Owner:贾永刚

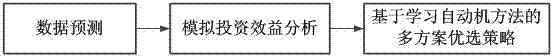

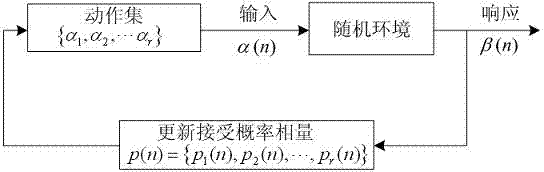

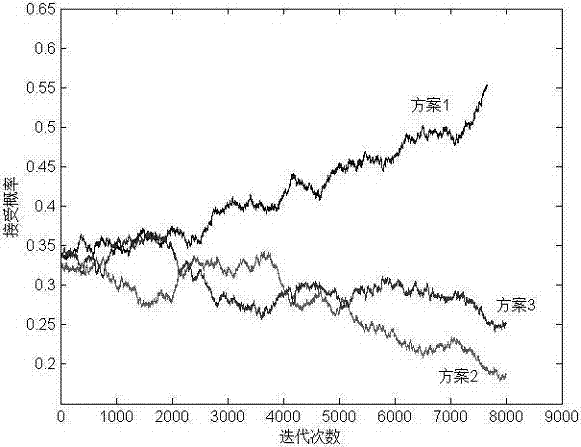

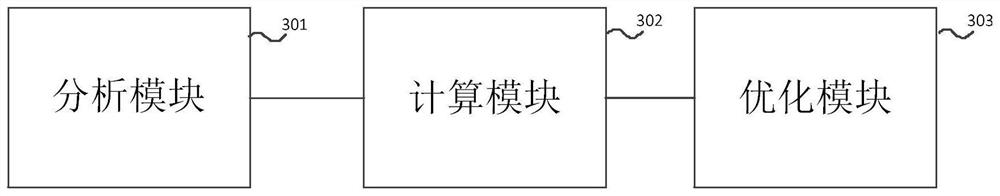

Power grid investment optimization method based on simulation investment benefit analysis and learning automatons

InactiveCN103886393AOptimize investmentInvestment objectiveForecastingSystems intergating technologiesLearning automataElectric power system

The invention relates to the technical field of electric power system planning, in particular to a power grid investment optimization method based on simulation investment benefit analysis and learning automatons. The method comprises the following steps that first, a grey prediction model is used for conducting data prediction on power grid development data; second, related indexes in an investment benefit index system are calculated according to prediction schemes of various obtained investment data through data prediction for the coming year, and then the simulation investment benefit analysis is carried out to obtain simulation investment comprehensive score results; third, the score results obtained through different schemes are optimized based on a multi-scheme optimization strategy of a learning automaton method, and finally the optimal investment scheme is obtained. The power grid investment optimization method based on the simulation investment benefit analysis and the learning automatons is beneficial to optimizing power grid investment and good in using effect.

Owner:STATE GRID CORP OF CHINA +3

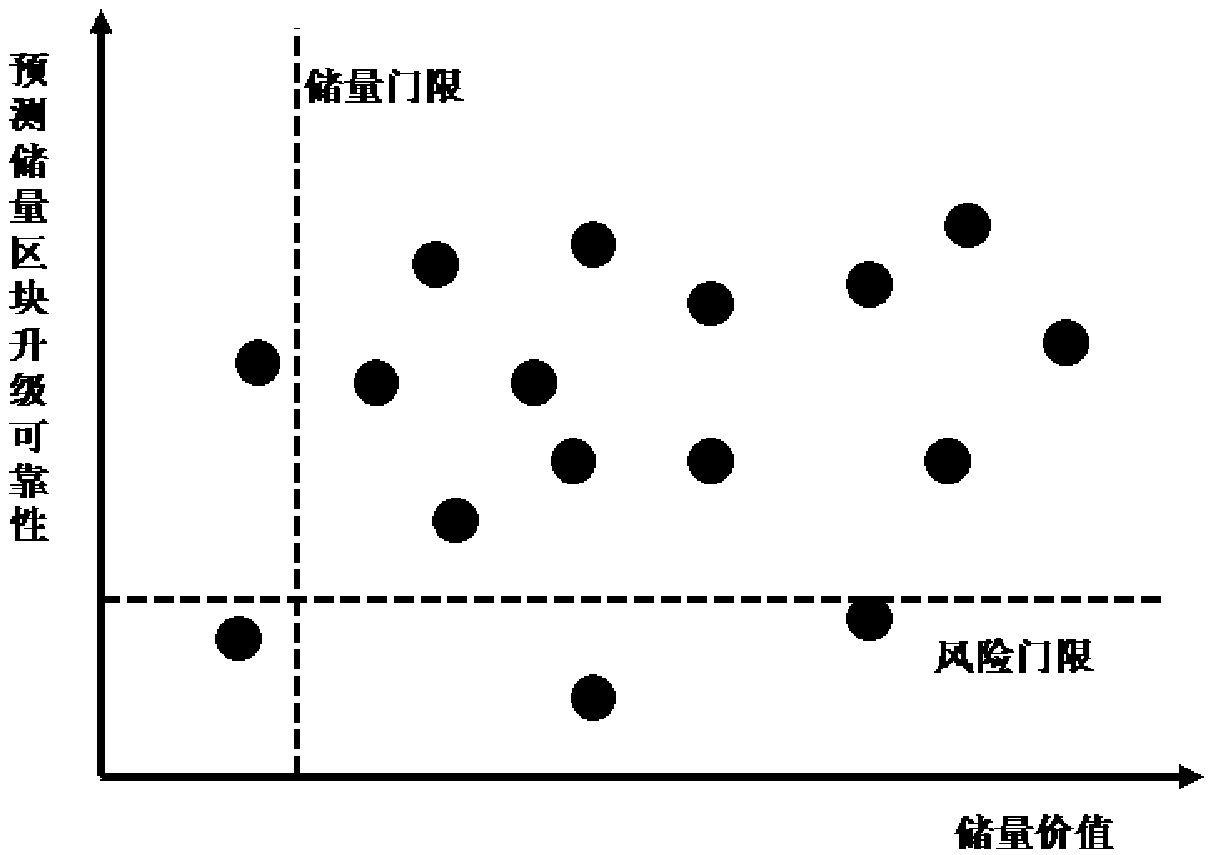

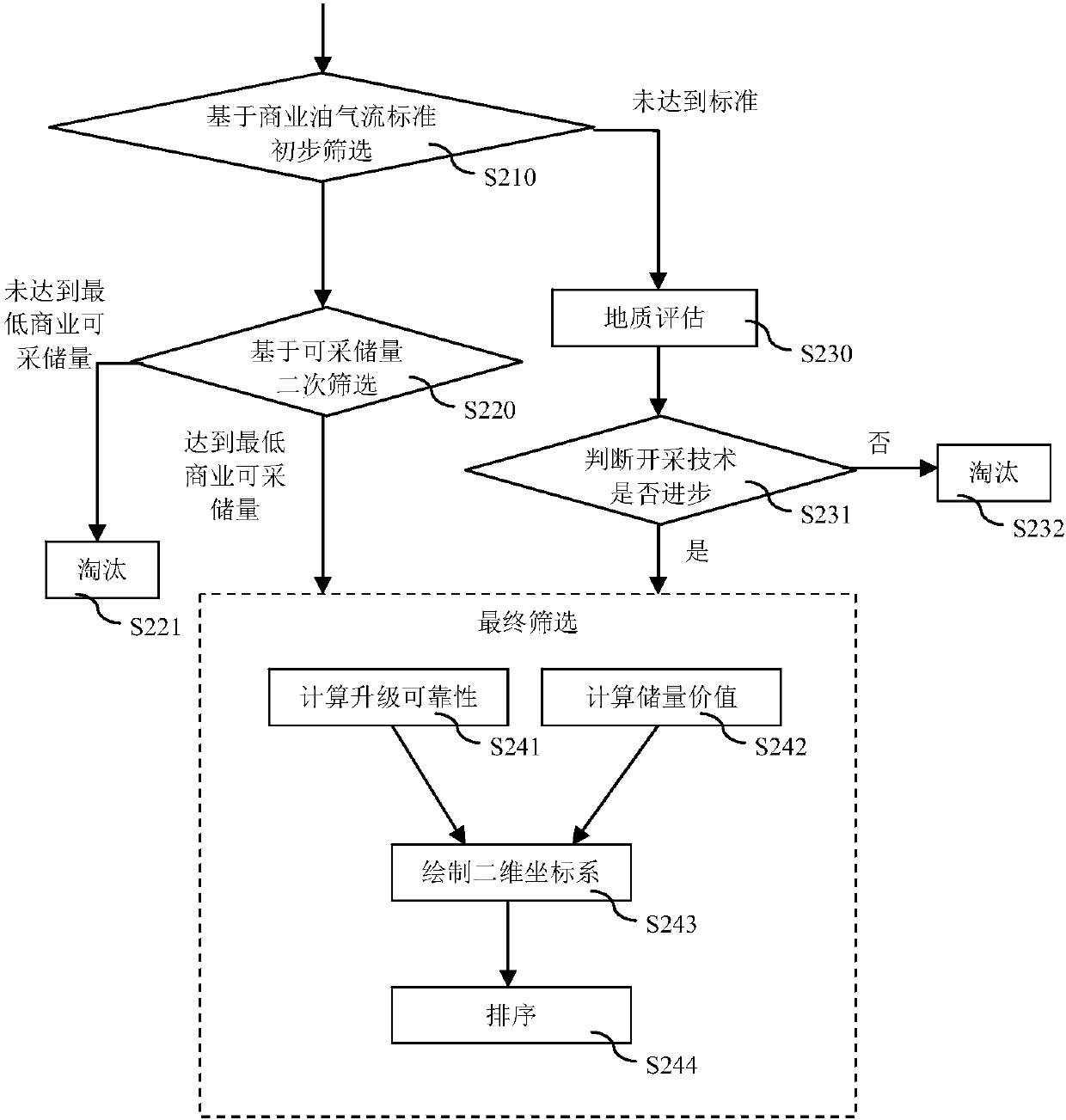

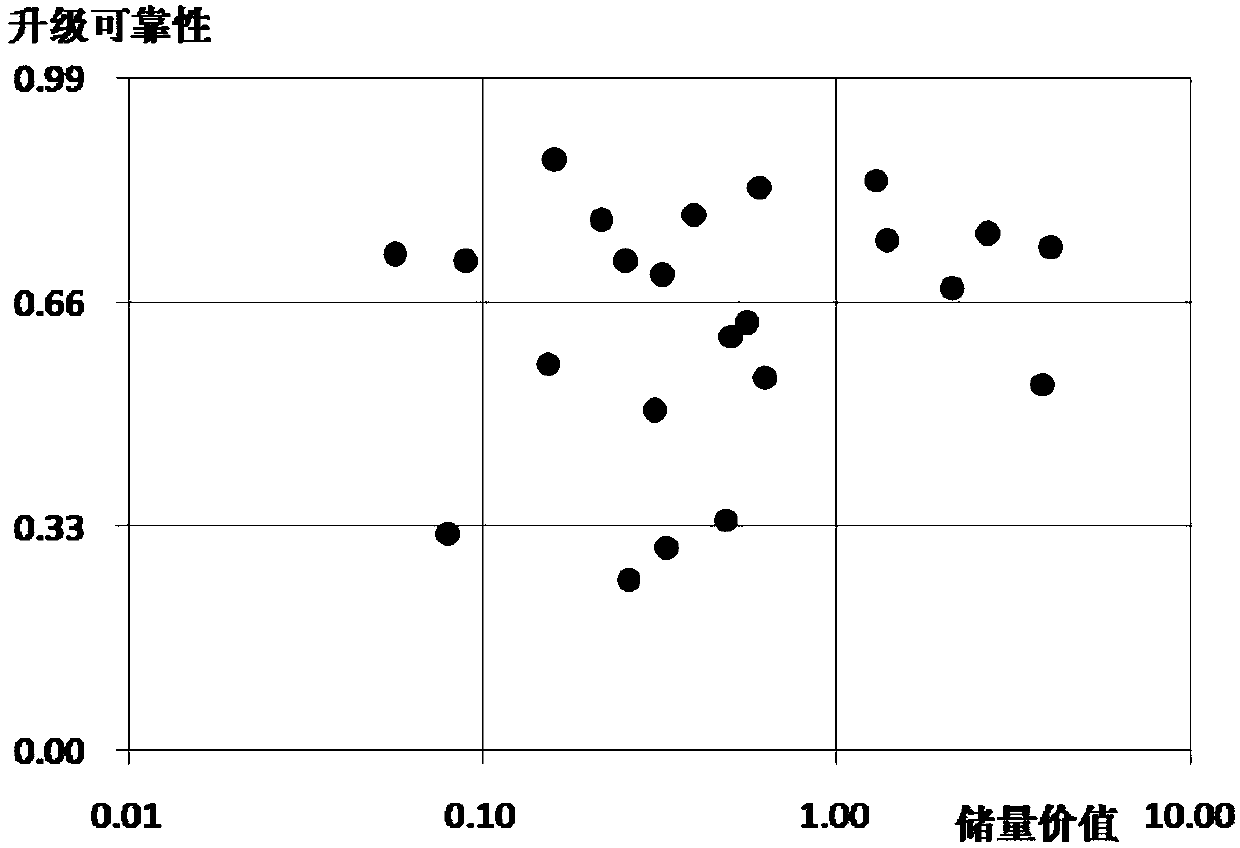

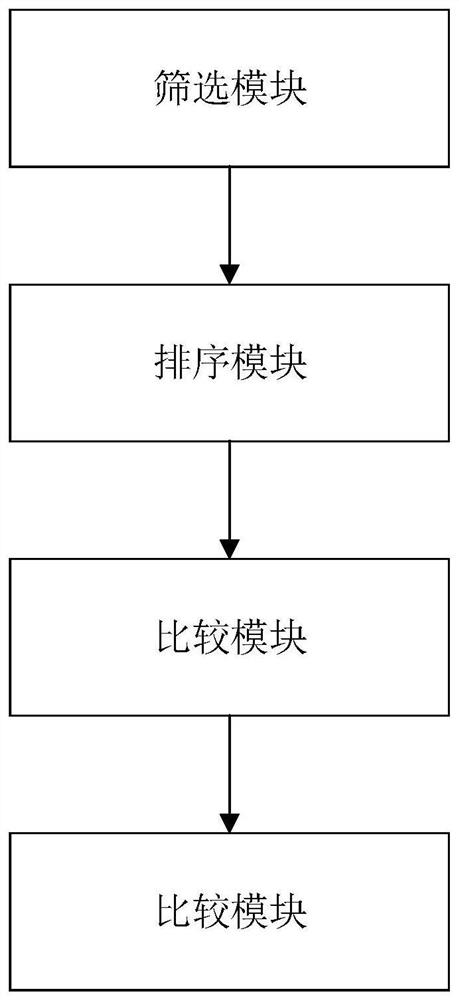

Screening method for predicted reserve blocks

InactiveCN107784376AReduce distractionsImprove reliabilityForecastingScreening methodComputer science

The invention discloses a screening method for predicted reserve blocks. The method comprises steps: the upgrading reliability of to-be-screened predicted reserve blocks and the reserve values are subjected to quantitative calculation; according to limitations of screening results, screening thresholds for the upgrading reliability and the reserve values are calculated and acquired; and the quantitative calculation results of the upgrading reliability and the reserve values are integrated, and according to the screening thresholds, the to-be-screened predicted reserve blocks are screened. According to the method, predicted reserve blocks in different areas and different fields can be simply and quickly screened on a unified platform; and compared with the prior art, the method greatly reduces interference of human factors during the screening process, the screening result reliability is greatly improved, and a powerful basis is provided for exploration focus and order determination, investment optimization and plan making for an oil company.

Owner:CHINA PETROLEUM & CHEM CORP +1

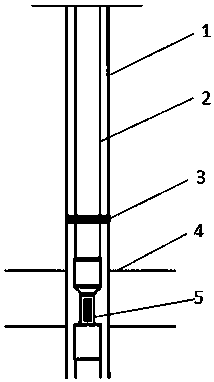

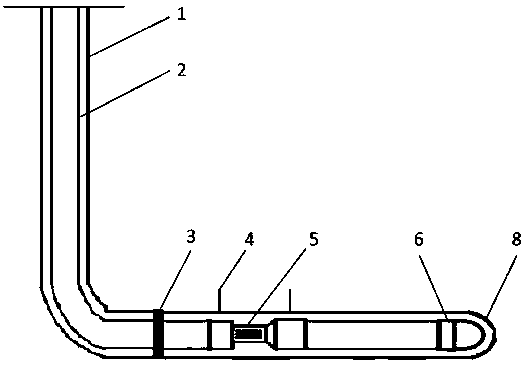

Sidetrack well optional drilling-grinding-free well completion device and method

PendingCN111101858AGreat advantageShorten the construction periodDirectional drillingSealing/packingWell drillingHorizontal wells

The invention provides a sidetrack well optional drilling-grinding-free well completion device and method. The sidetrack well optional drilling-grinding-free well completion device comprises positioning centralizers and removable drilling-grinding-free windowing devices; the positioning centralizers are located in a shaft, the exact position of a sidetrack well section is positioned, and the shaftand a sleeve are centralized; the removable drilling-grinding-free windowing devices are located in the position, at a oil reservoir part needing windowing and sidetrack drilling, of the sleeve, whena windowing sidetrack well section needing to be branched is drilled, the removable drilling-grinding-free windowing devices are remotely controlled to be started, a sleeve section needing to be subjected to sidetrack drilling and windowing is directly opened, and the position, at the windowing part, of the sleeve does not need to be drilled and ground. According to the sidetrack well optional drilling-grinding-free well completion device and method, the sidetrack well drilling cost is greatly reduced, the well drilling efficiency is improved, the actual well drilling cycle of a sidetrack well and a sidetrack horizontal well is shortened, the investment efficiency and return rate are improved, the labor intensity of operators is relieved, the operation time is shortened, and the operationcost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of glucose

ActiveCN102586361BQuality improvementImprove quality indicatorsIon-exchange column/bed processesUltrafiltrationAlcoholIon exchange

The invention discloses a manufacturing method of glucose, comprising the following steps of: (1) liquefying starch: by taking starch as the raw material, liquefying under the action of a liquefying enzyme after size mixing, and then, a glucose saccharified liquid under the action of a saccharifying enzyme; (2) filtering and decontaminating the saccharified liquid by a membrane filtering unit to obtain filtrate, wherein a filtering membrane has the aperture of 1-200nm or the molecular weight cut-off of 10-500kd; (3) carrying out continuous ion exchange on the filtrate by using a moving bed, removing salts to obtain a purified liquid; and (4) filtering the purified liquid by using a nanofiltering membrane to obtain pharmaceutical-grade glucose, wherein a concentrated solution is used for producing daily chemical alcohol or polysaccharose products. Continuous production is adopted in the manufacturing method, and therefore, the production efficiency is high.

Owner:SANDA FILM SCI & TECH XIAMEN +1

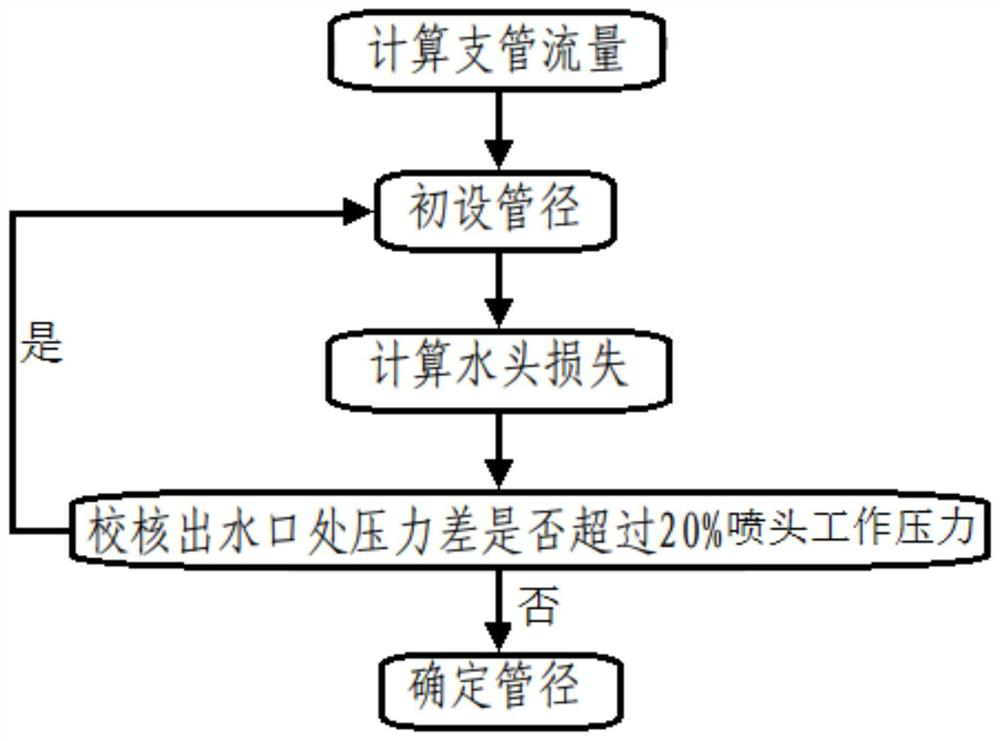

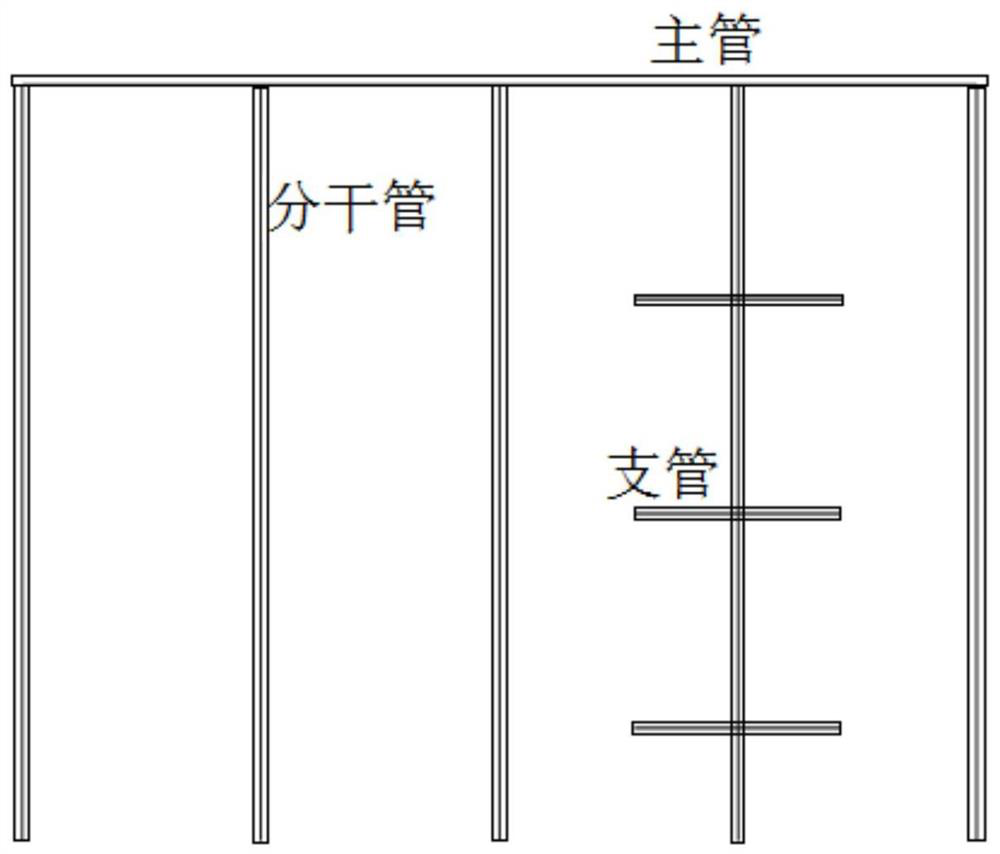

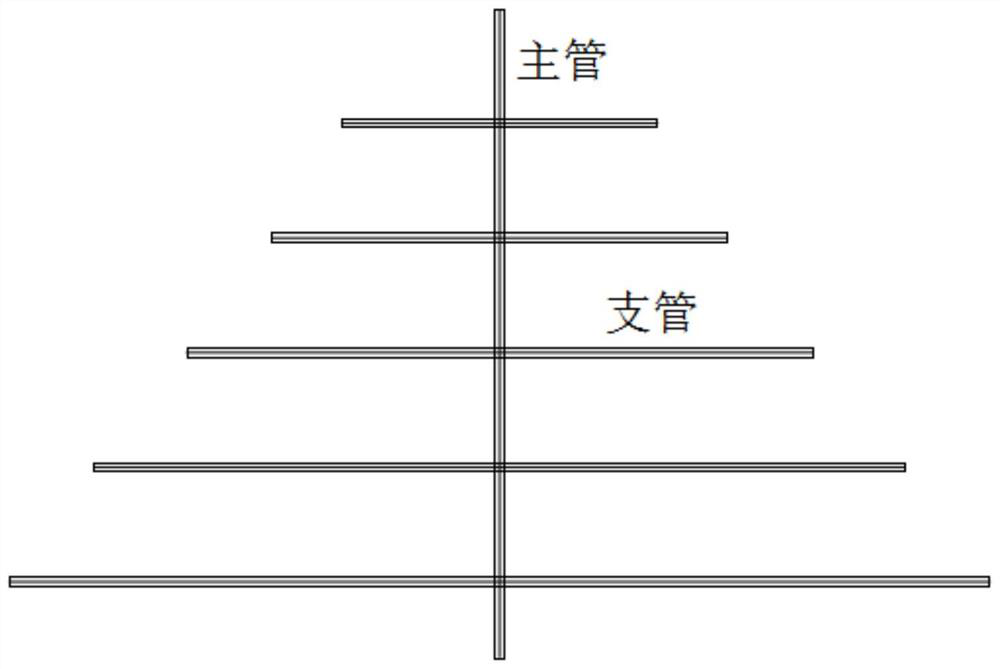

Pipe net of sloping field spray-irrigation system project and pipeline design improving method

ActiveCN111642364AReduce pipe network investmentImprove pipe network utilization efficiencyClimate change adaptationWatering devicesAgricultural engineeringSoil science

The invention provides a pipe net of a sloping field spray-irrigation system project and a pipeline design improving method. The invention analyzes the pressure characteristics of the sloping field spray-irrigation pipe net aiming at the remarkable terrain characteristics of high terrain and low water source of a sloping field irrigation region and provides a distribution method of a pipeline of the sloping field spray-irrigation system project and a design method of the sloping field spray-irrigation system project. A machine-pressing spray-irrigation tree-shaped pipe net optimizing model isestablished, investment of the pipe network and minimum operation management cost are taken as targets, the length of a standard pipe size and the pump head are taken as decision variables, and integer coding is adopted. Based on an empirical design, a distribution manner of the pipe net is known, the pipe net model is optimized and calculated by virtue of an evolutionary algorithm, and pipe diameters of partial pipe sections are optimized, so that the investment of the pipe network is saved, the utilization efficiency of the pipe net is improved, and the spray-irrigation quality of the sloping field spray-irrigation system project is improved.

Owner:王程

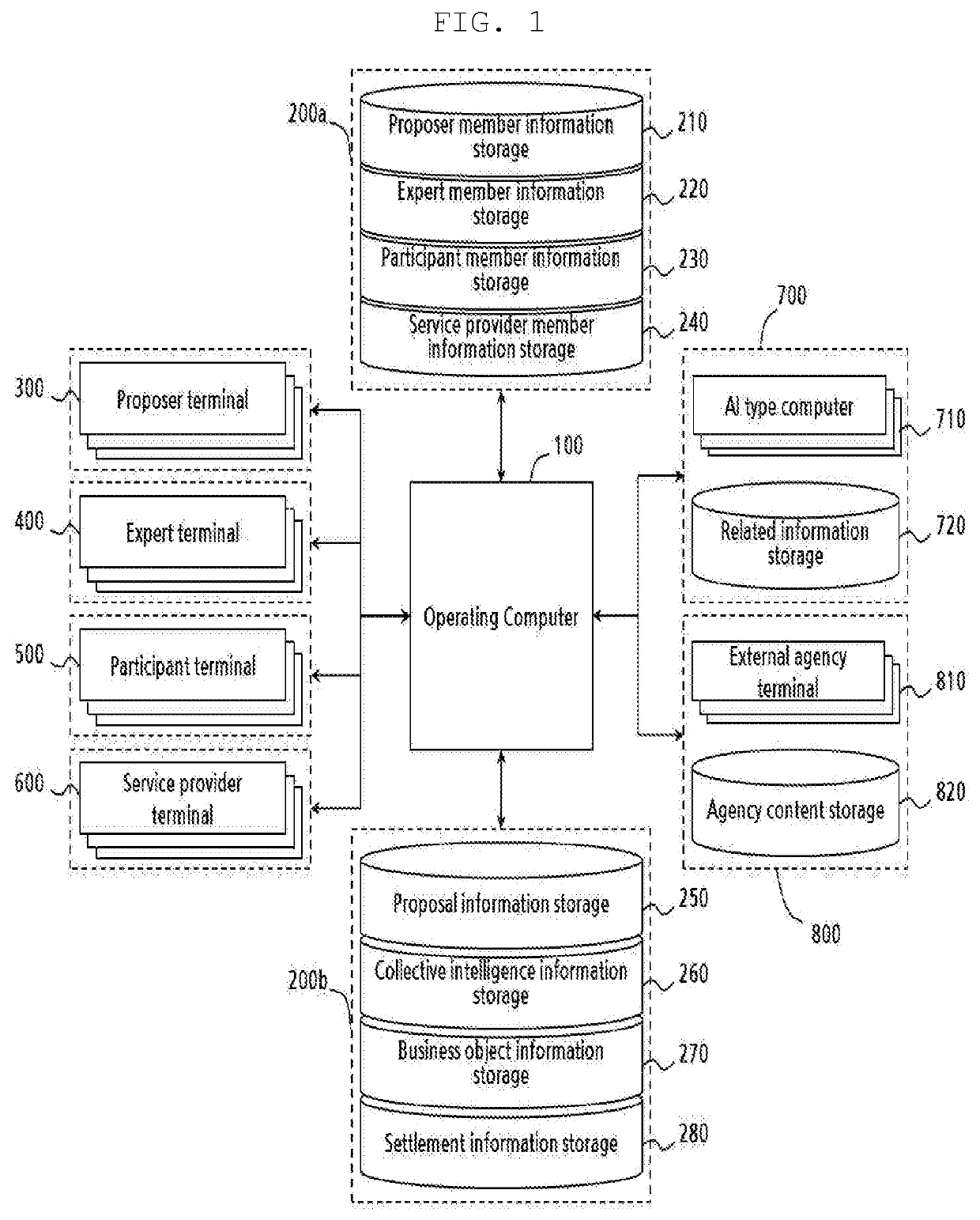

Business execution system and method therefor

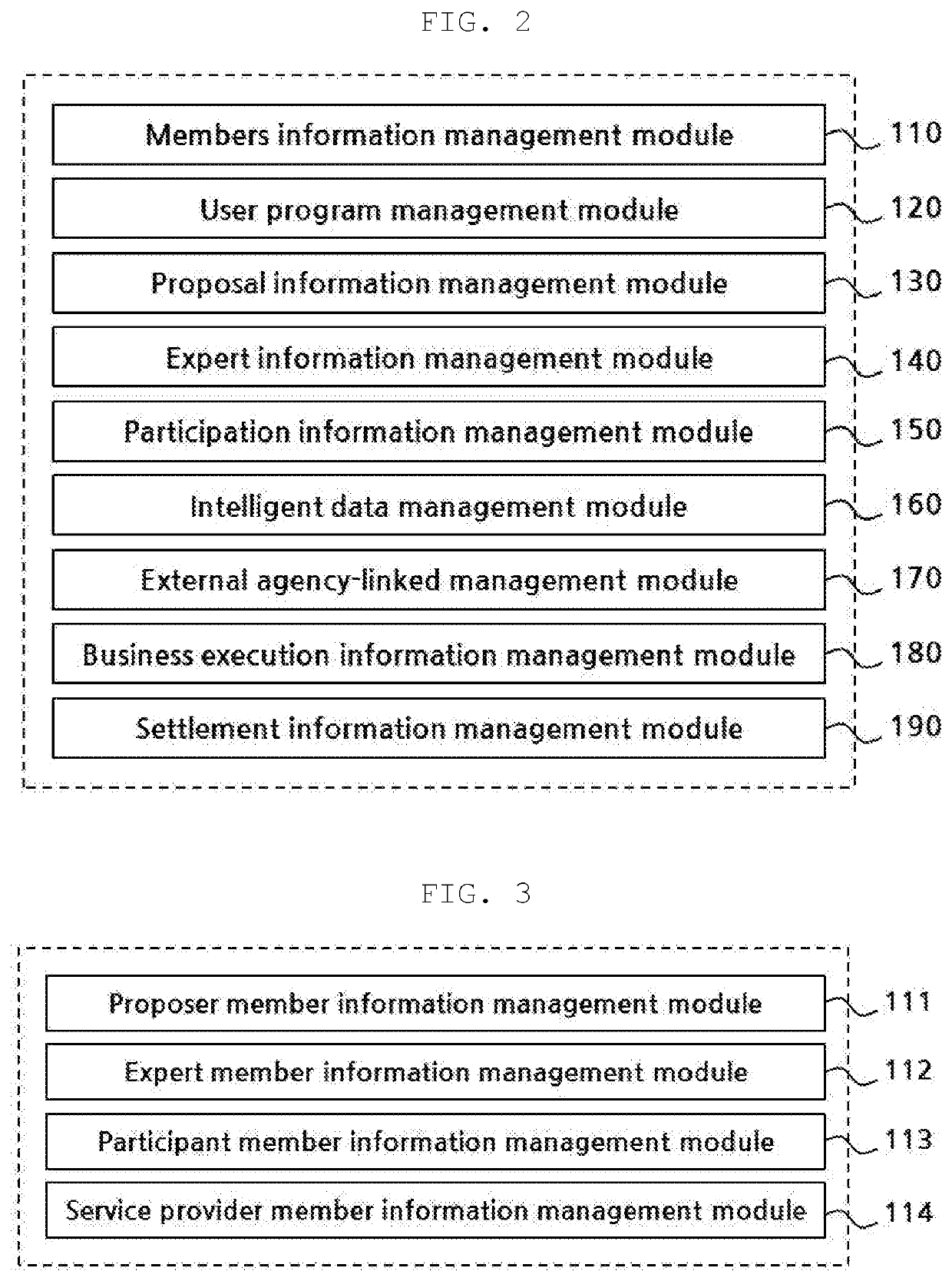

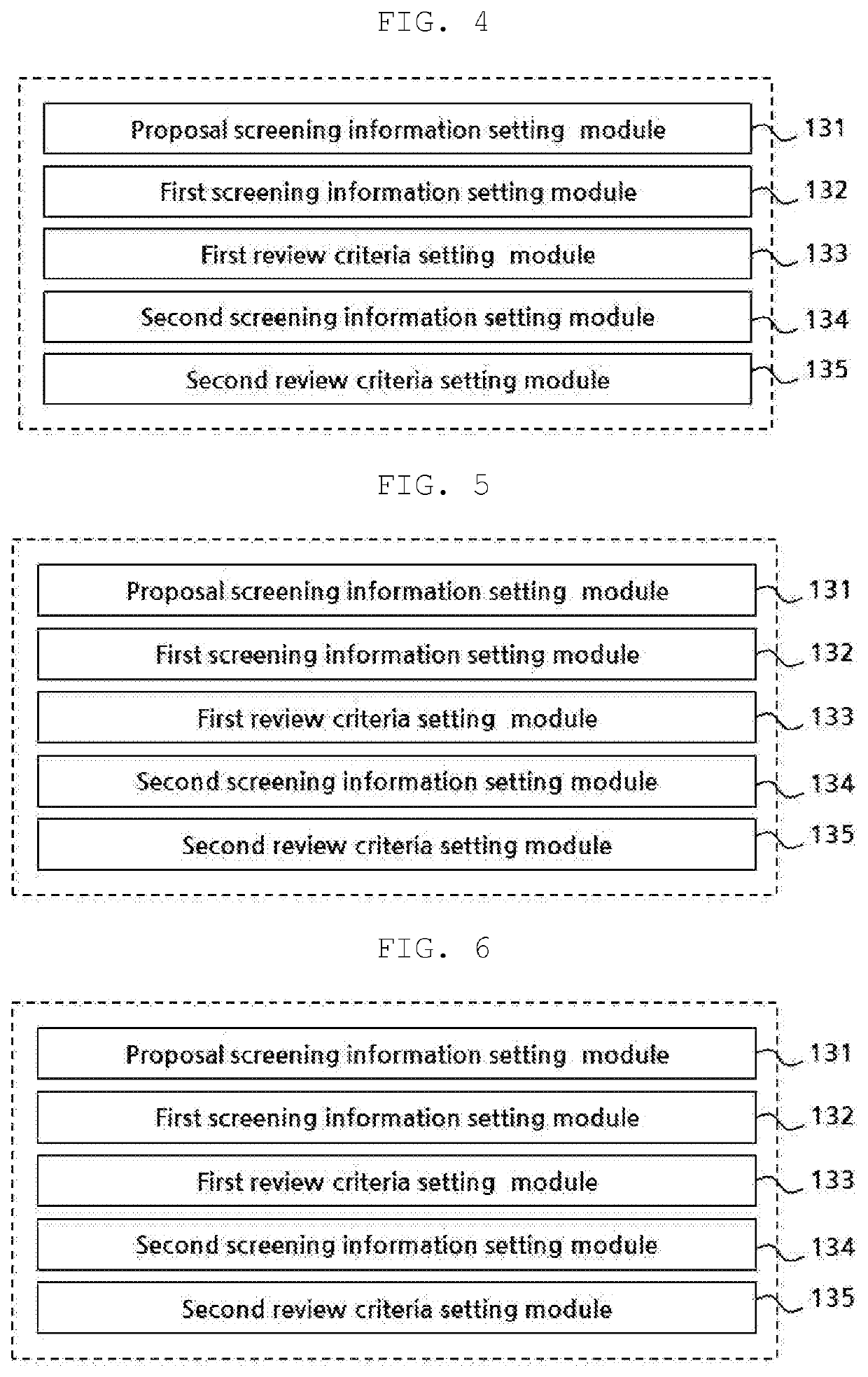

InactiveUS20210004908A1Optimize investmentVerify feasibilityFinanceOffice automationExpert opinionSoftware engineering

A business execution system and a method thereof. The business execution system includes: an operating computer; and a user program that is communicatively connected to the operating computer and is output or executed on at least one user terminal for engaging in business execution, wherein the operating computer provides at least one necessary viewing opinion per business item generated on the basis of expert opinion data through a collective intelligence convergence system, converges at least one participant's opinion on the required reading opinion to verify business items and business execution, and prevents abuse from experts by expert check.

Owner:YOON SEONG MIN

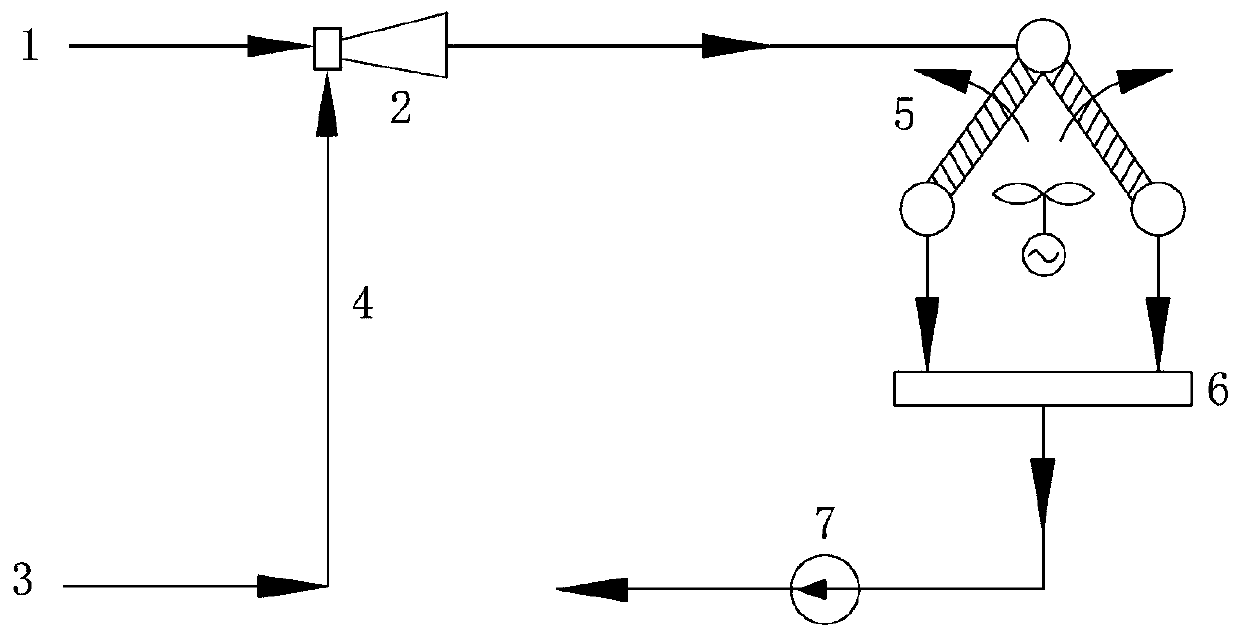

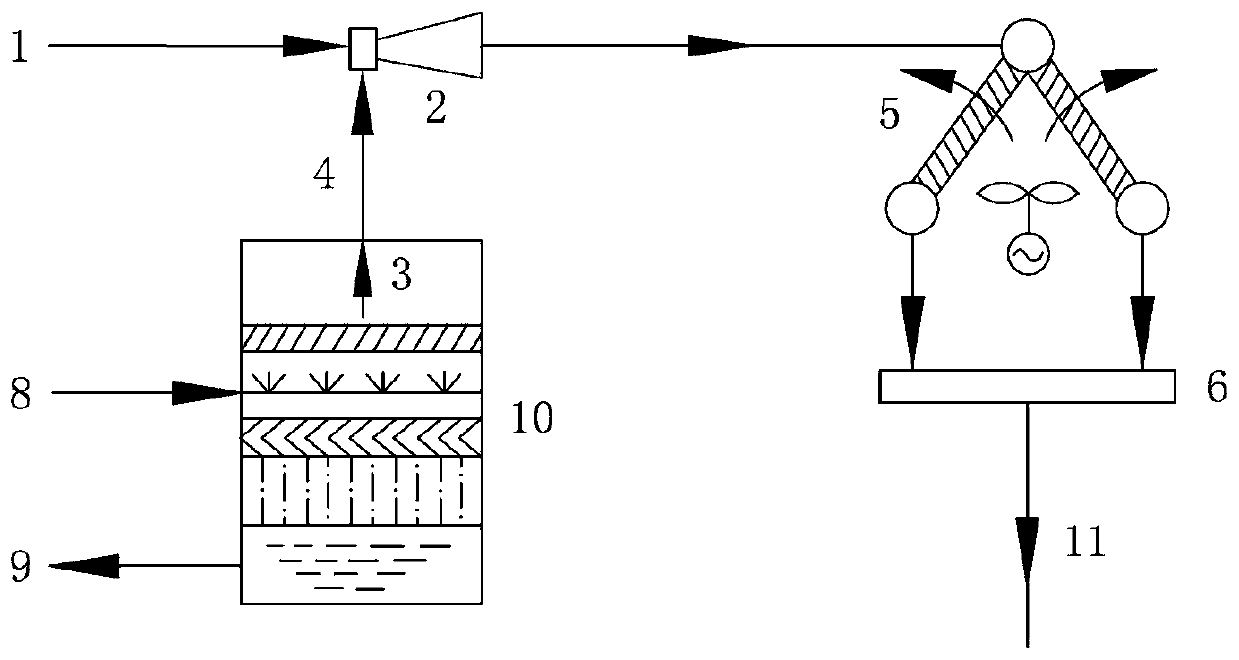

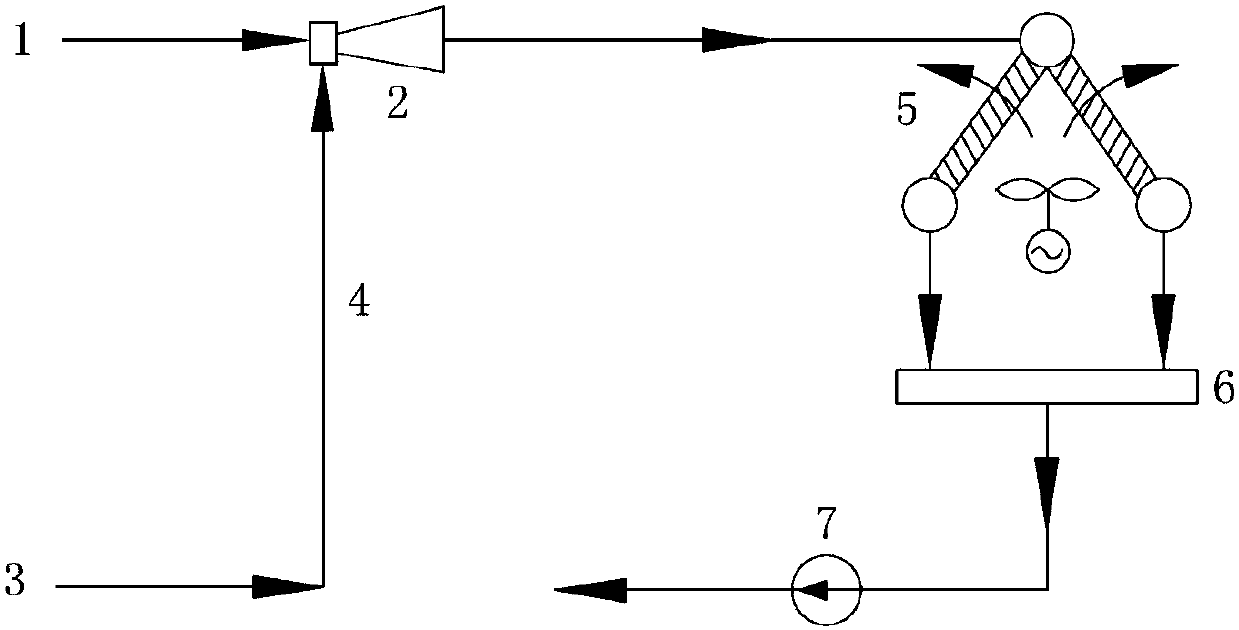

A method and system for improving the heat exchange capacity of a direct air cooling system

ActiveCN107860242BImprove heat transfer effectIncrease temperature differenceSteam/vapor condensersWorking fluidTemperature difference

The invention discloses a method and system for improving the heat exchange capacity of a direct air cooling system. High-temperature adjusting steam is introduced to be used as work fluid of a spraypump and sprayed out by a spray nozzle, and vacuum is formed in a mixing chamber of the spray pump; steam to be condensed is sucked into the mixing chamber of the spray pump through a steam conveyingpipeline, the temperature of the high-temperature adjusting steam is higher than that of the steam to be condensed, the high-temperature adjusting steam and the steam to be condensed are mixed to formmixed steam, the mixed steam enters a finned tube radiator through a diffusion chamber and the steam conveying pipeline, the mixed steam and cooling air conduct surface type heat exchange, and then the mixed steam is condensed into condensate; the temperature of the mixed steam is higher than that of the steam to be condensed, by the adoption of the method, the temperature difference between thesteam in finned tubes of the direct air cooling system and external cooling air is increased, and the heat exchange capacity of the direct air cooling system is improved.

Owner:温高

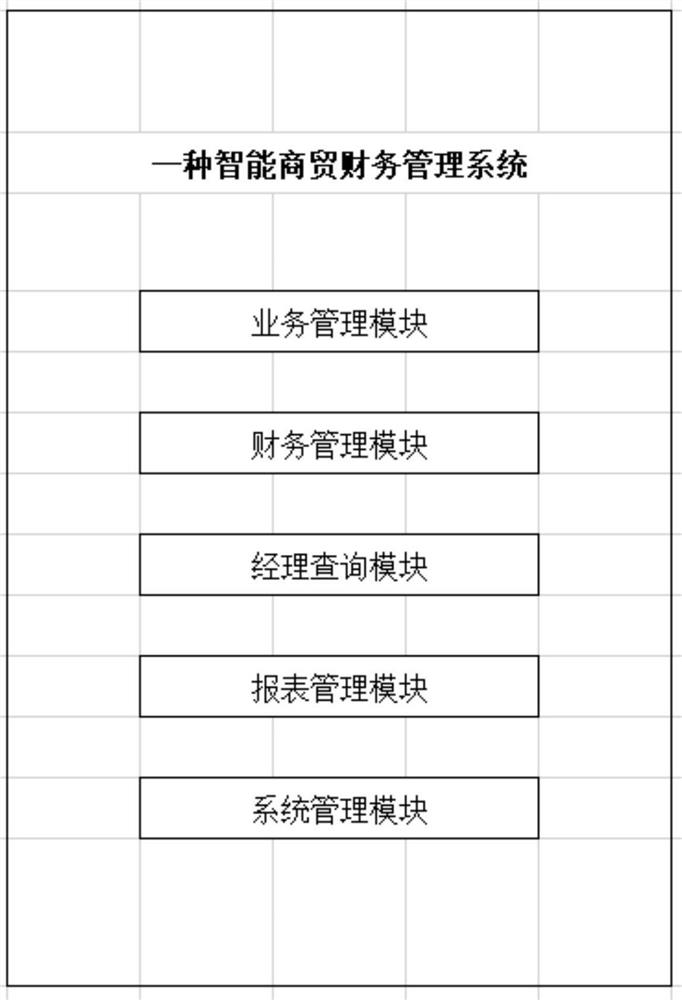

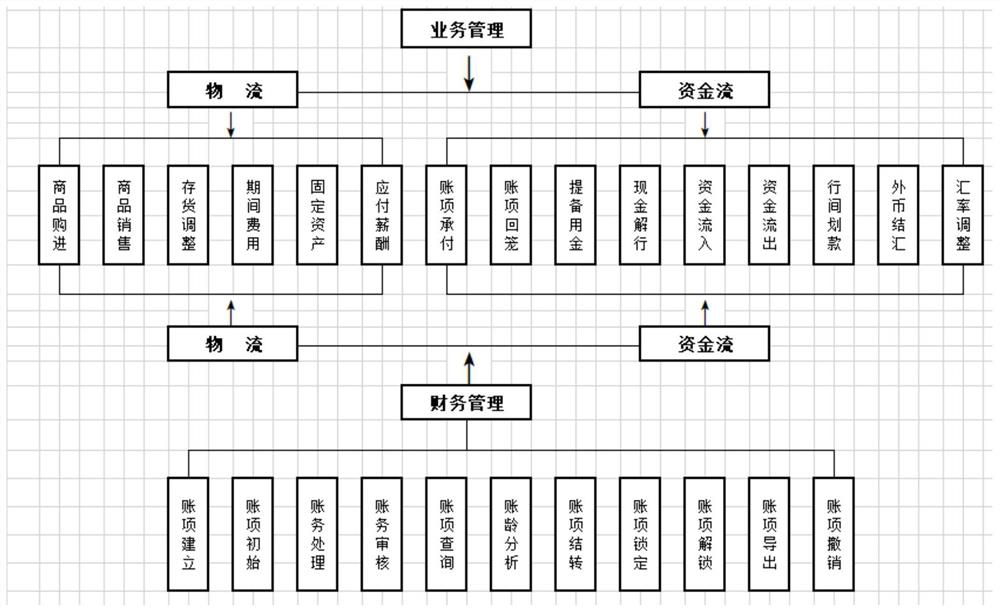

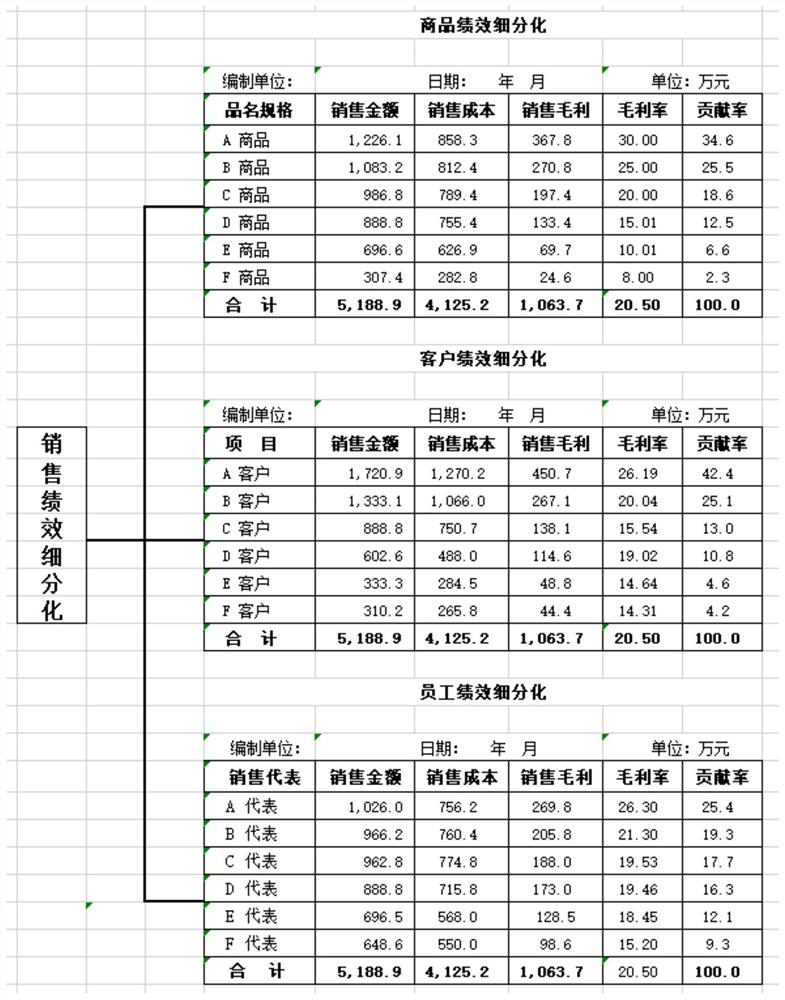

Intelligent commerce and trade financial management system

PendingCN113344685AAchieve sharingSolve the whole process of intelligent collectionDatabase management systemsFinanceManagement toolBusiness enterprise

The invention provides an intelligent commerce and trade financial management system, and relates to the field of modern office automation. An intelligent commerce and trade financial management system comprises five big modules: a business management module, a financial management module, a manager query module, a report management module and a system management module. The system is characterized in that integrated financial management is constructed; intelligent generation of accounting information is realized; and a management mode of finance and tax management integration, sales performance subdivision and enterprise risk assessment normalization is realized. The intelligent commerce and trade financial management system is researched and developed according to the characteristics of the commerce and trade industry and industry accounting management requirements, the system achieves the original intention of design through many years of tests and practices, and the system is an ideal management tool with innovative significance in the commerce and trade industry.

Owner:上海自能信息科技有限公司

Rich oxygen supply system of dry rotary kiln cement production

InactiveCN105509087ATake advantage ofOxygen enrichmentIndirect carbon-dioxide mitigationAir/fuel supply for combustionDecompositionProcess engineering

The invention provides a rich oxygen supply system of dry rotary kiln cement production. The system comprises a VPSA oxygen production unit, coal air fans, multi-air-way coal powder burners and clean air fans; the VPSA oxygen production unit is connected with a main pipe; the main pipe is provided with a branch pipe 1 and a branch pipe 2 respectively connected with coal air fan sucking ports of a rotary kiln and a decomposition furnace; coal air fans of the rotary kiln and the decomposition furnace are respectively connected with respective multi-air-way coal powder burners; the main pipe is provided with a branch pipe 3 and a branch pipe 4 respectively connected with clean air fan sucking ports of the rotary kiln and the decomposition furnace; and the clean air fans of the rotary kiln and the decomposition furnace are respectively connected with respective multi-air-way coal powder burners. The rich oxygen supply system satisfies rich oxygen combustion assisting demands in burning of dry rotary kiln cement clinkers without changing any traditional cement production equipment, and has the characteristics of low equipment investment, low operation energy consumption and obvious energy saving benefit.

Owner:德阳瑞泰科技有限公司

Method and system for improving heat exchange capacity of direct air cooling system

ActiveCN107860242AImprove heat transfer effectAvoid damageSteam/vapor condensersWorking fluidTemperature difference

The invention discloses a method and system for improving the heat exchange capacity of a direct air cooling system. High-temperature adjusting steam is introduced to be used as work fluid of a spraypump and sprayed out by a spray nozzle, and vacuum is formed in a mixing chamber of the spray pump; steam to be condensed is sucked into the mixing chamber of the spray pump through a steam conveyingpipeline, the temperature of the high-temperature adjusting steam is higher than that of the steam to be condensed, the high-temperature adjusting steam and the steam to be condensed are mixed to formmixed steam, the mixed steam enters a finned tube radiator through a diffusion chamber and the steam conveying pipeline, the mixed steam and cooling air conduct surface type heat exchange, and then the mixed steam is condensed into condensate; the temperature of the mixed steam is higher than that of the steam to be condensed, by the adoption of the method, the temperature difference between thesteam in finned tubes of the direct air cooling system and external cooling air is increased, and the heat exchange capacity of the direct air cooling system is improved.

Owner:温高

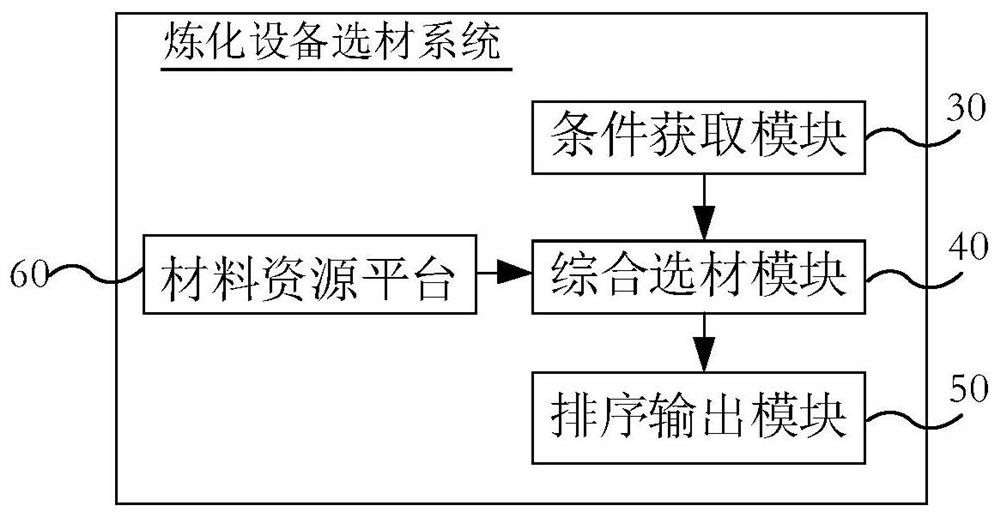

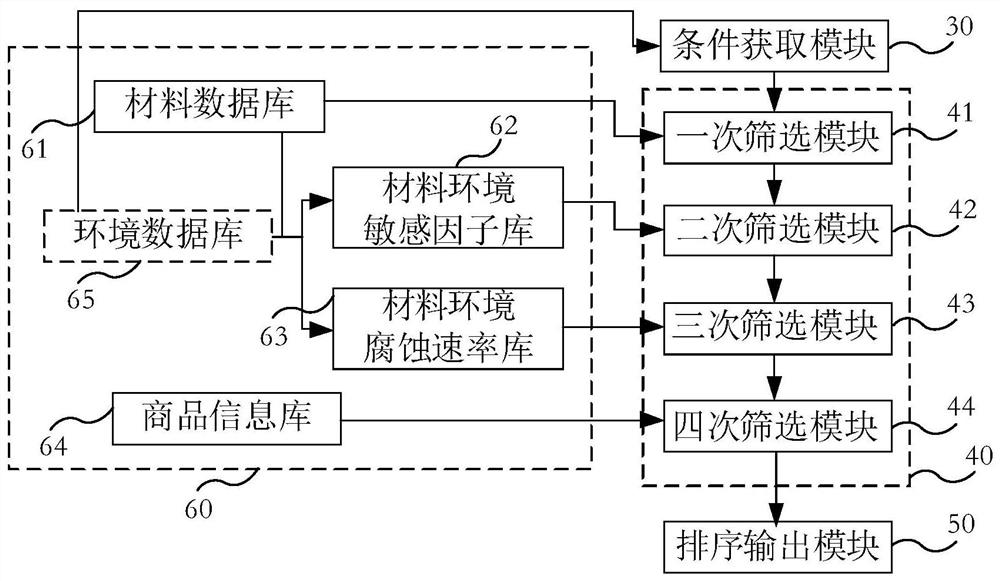

Material selection system and method for refining equipment and electronic equipment

PendingCN114121182AEasy to useImprove material selection efficiencyCheminformatics data warehousingChemical processes analysis/designProcess engineeringMaterial resources

The invention provides a refining equipment material selection system and method and electronic equipment, and belongs to the field of data processing technology.The refining equipment material selection system comprises a material resource platform, a comprehensive material selection module, a condition obtaining module and a sorting output module, and the material resource platform stores material use information of various materials; according to damage factor information, corrosion rate information and commodity information in various environments, a condition acquisition module acquires basic performance, service environment, grade threshold and corrosion information of required material selection, and a comprehensive material selection module selects material information meeting the basic performance based on a material resource platform. In the service environment, the damage factor information meets the grade threshold value, the corrosion rate information meets the corrosion information, and the multiple pre-selected materials have commodity information, the sorting output module comprehensively sorts the multiple pre-selected materials to obtain and output a material selection result table, material selection is automatically completed, and the material selection efficiency is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

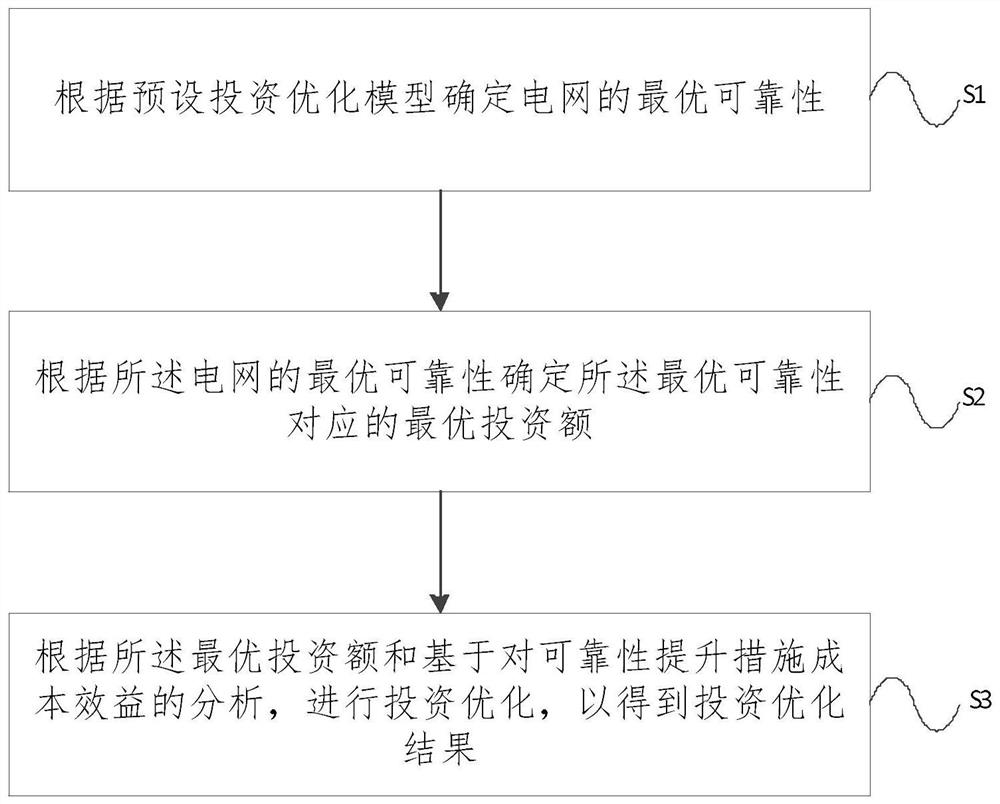

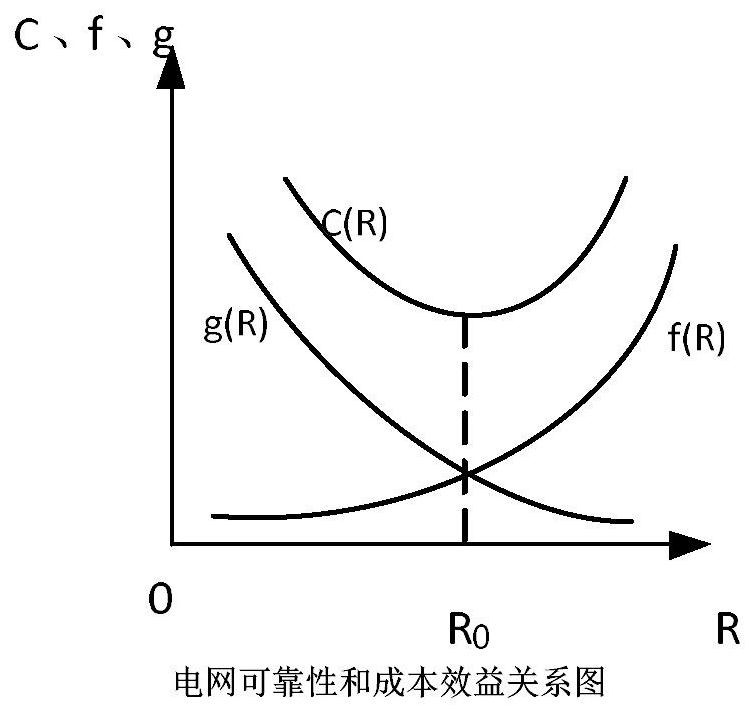

Reliability investment optimization method and device considering interruptible load participation in power grid

ActiveCN110829442BOptimize investmentPower network operation systems integrationAc network voltage adjustmentPower gridLoad following power plant

The embodiment of the invention provides a reliability investment optimization method and device considering interruptible load participation in a power grid. The method comprises the following steps:the optimal reliability of the power grid is determined according to a preset investment optimization model, a target function of the preset investment optimization model is the sum of a first function and a second function, the first function is an investment cost function used for improving the reliability of the power grid, and the second function is a function used for representing the interruptible load cost variation; an optimal investment amount corresponding to the optimal reliability is determined according to the optimal reliability of the power grid; and investment optimization isperformed according to the optimal investment amount and based on the analysis of the cost effectiveness of the reliability improvement measures so as to obtain an investment optimization result. According to the embodiment of the invention, the optimal reliability of the power grid is determined through the preset investment optimization model, the balance point of the cost and the benefit duringreliability improvement is found based on the analysis of the cost and the benefit of the reliability improvement measures, and the power grid investment is effectively optimized.

Owner:JIANGSU ELECTRIC POWER CO +1

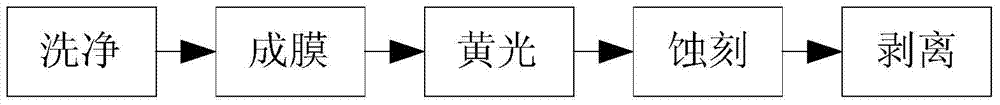

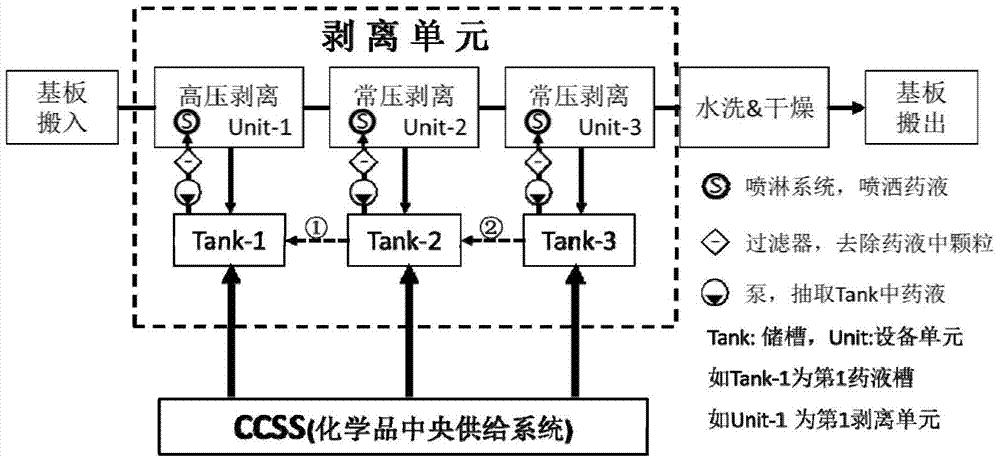

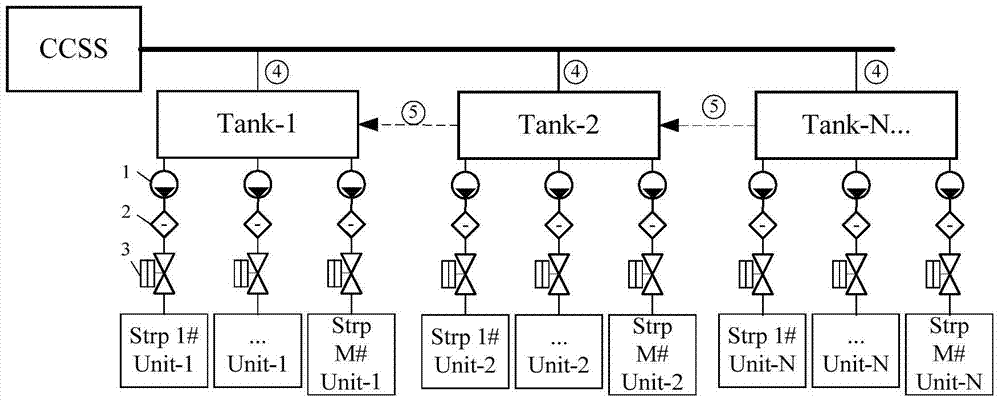

A stripping liquid supply system

ActiveCN105118770BReduce usageEasy to manageSemiconductor/solid-state device manufacturingPhotosensitive material processingHardware structureBiochemical engineering

The invention discloses a stripping liquid supply system. The system comprises a plurality of drug tanks used for containing stripping liquid and a plurality of stripping equipment units used for receiving the stripping liquid supplied by the drug tanks and performing stripping processing of stripped materials, the grouping of the plurality of stripping equipment units is performed based on a predetermined principle, and the stripping equipment units in the same group after grouping are connected to the same drug tank. According to the system, the usage quantity of the drug tanks can be reduced, the equipment hardware structure can be simplified, the equipment investment is reduced, unified management of drug liquid is facilitated, the uniformity of product operation caused by the drug liquid is improved, and photoresistance residue due to impurities in the stripping liquid can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A closed-loop evaluation method and system for pipe body defects of long-distance oil and gas pipelines

The invention relates to a closed-loop evaluation method and system for pipe body defects of long-distance oil and gas pipelines, and relates to the technical field of pipeline systems. The evaluation methods include: 1) start; 2) identification and evaluation of pipe defects; 3) review; 4) if it fails, it will return to the identification and evaluation of pipe defects; Review; 6) If it fails, it will be transferred back to the defect repair; if it is passed, it will be transferred to the database first, and the item elimination evaluation will be performed; 7) End. The invention can realize the closed-loop monitoring of pipe body defect identification and evaluation, defect repair to defect elimination item evaluation, simplify the operation process of defect closed-loop evaluation, integrate related business information, provide accurate and reliable data support for business management and decision-making, and effectively evaluate defect elimination item effect.

Owner:PIPECHINA SOUTH CHINA CO

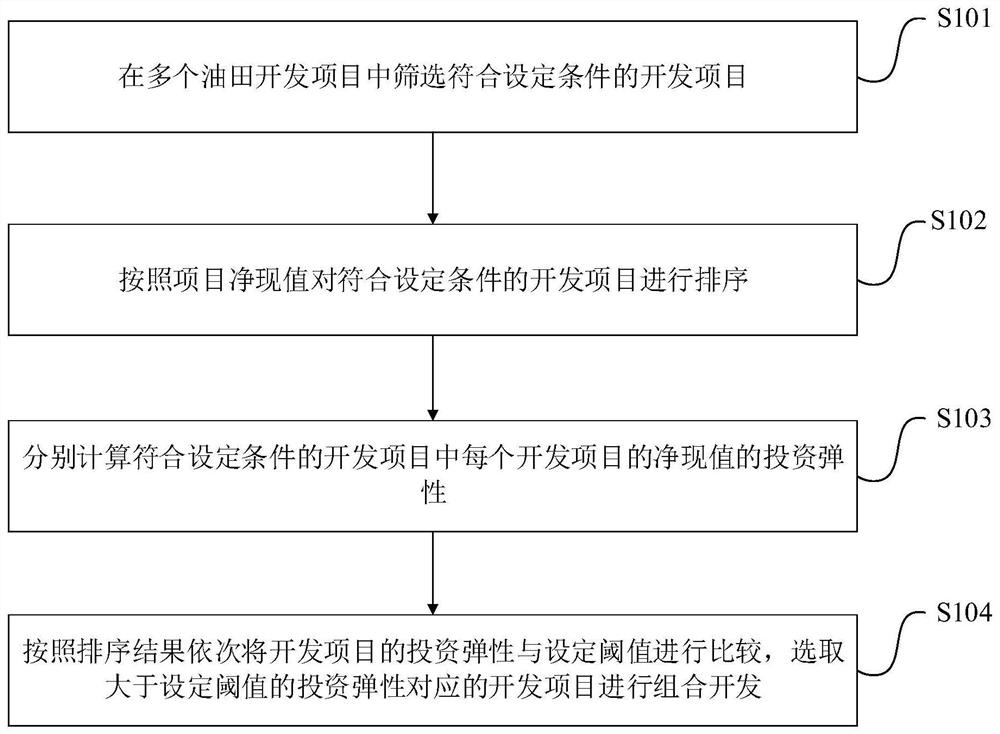

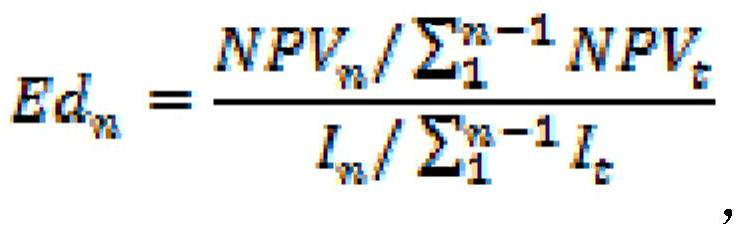

Oilfield development project investment portfolio optimization method and device and electronic equipment

PendingCN114862331AOptimize investmentGuaranteed NPVOffice automationResourcesOil fieldIndustrial engineering

The embodiment of the invention discloses an optimization method and device for an oilfield development project portfolio and electronic equipment. The optimization method for the oilfield development project investment portfolio comprises the following steps: screening development projects meeting set conditions from a plurality of oilfield development projects; sorting the development projects meeting the set conditions according to the project net present values; respectively calculating the investment elasticity of the net present value of each development project in the development projects meeting the set conditions; sequentially comparing the investment elasticity of the development projects with a set threshold value according to a sorting result, and selecting the development projects corresponding to the investment elasticity greater than the set threshold value for combined development. The purpose of giving consideration to the overall benefits and resource utilization rates of the single project and the project combination is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for controlling load following operation of micro-grid

ActiveCN103475020BReduce consumptionImprove permeabilityEnergy industrySingle network parallel feeding arrangementsNew energyFrequency modulation

The invention relates to a method for controlling load following operation of a micro-grid. The micro-grid comprises a main power supply, a biomass power generation system, an intermittent new energy source power generation system, an energy storage system and a micro-grid energy management system, wherein the main power supply undertakes payload fluctuation in an energy management scheduling period of a micro-grid system, the biomass power generation system undertakes the payload fluctuation when the duration of the micro-grid system is longer than the energy management scheduling period, and the energy storage system provides an emergency frequency modulation function when the system undergoes large disturbances. The method disclosed by the invention improves the permeability of renewable energy resources, reduces the consumption of diesel oil, and improves the economical efficiency of system power supply while realizing energy conservation and emission reduction.

Owner:GUODIAN UNITED POWER TECH

Production method of horizontal centrifugal rotary continuous casting metal billet and hollow continuous casting billet

InactiveCN113290214AReduce investment in infrastructure equipmentImprove working environmentContinuous productionManufacturing engineering

The invention discloses a production method of a horizontal centrifugal rotary continuous casting metal billet and a hollow continuous casting billet. A crystallizer adapter is adopted to replace a horizontal continuous casting separation ring and is tightly connected with a crystallizer, and a horizontal continuous casting technology is adopted to be matched with a subsequent rotary throwing machine; the whole casting billet is compact in structure without defects and low in component segregation in the crystallization process through the centrifugal force generated by rotation of the casting billet, so that a continuous casting metal billet with the quality higher than that of an arc-shaped continuous casting machine is produced, and continuous production of the hollow annular casting billet is finally realized through structural change of the crystallizer adapter on the basis of realizing solid continuous casting; and water-free cooling is adopted, low-temperature gas is adopted for replacing original water spraying cooling, heat energy replacement and recovery are carried out, the annular hollow casting billet thoroughly eliminates the punching procedure of seamless pipe production, the production cost is greatly reduced, an arc-shaped section is omitted, straightening cracks of the casting billet are thoroughly eradicated, and the pulling speed and the production efficiency are greatly improved.

Owner:侯雷

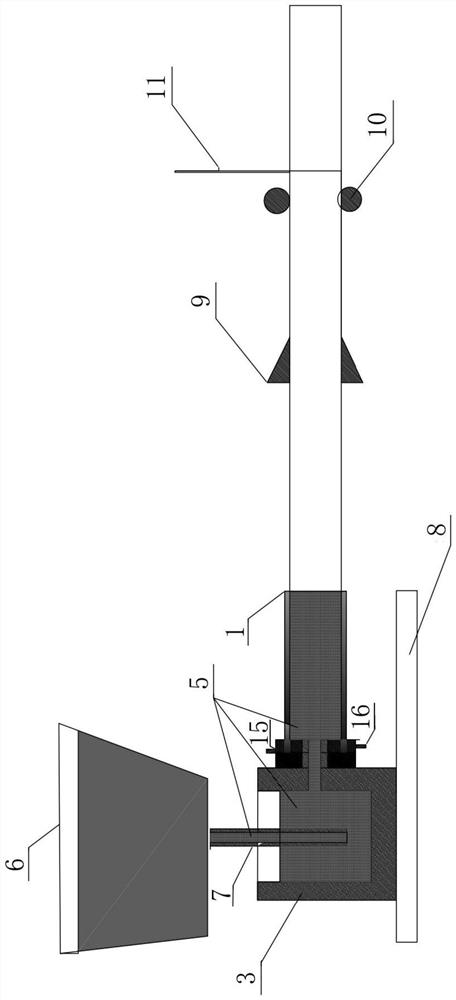

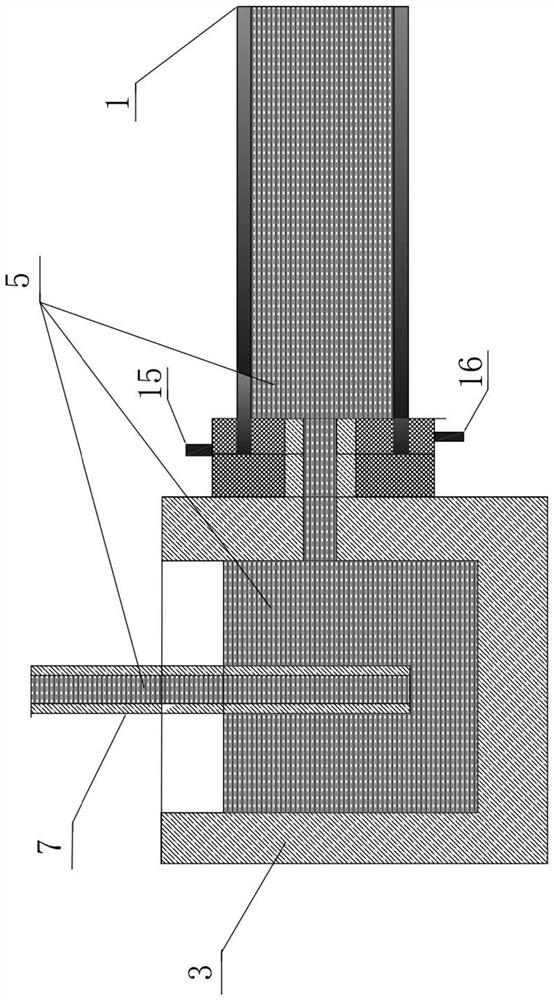

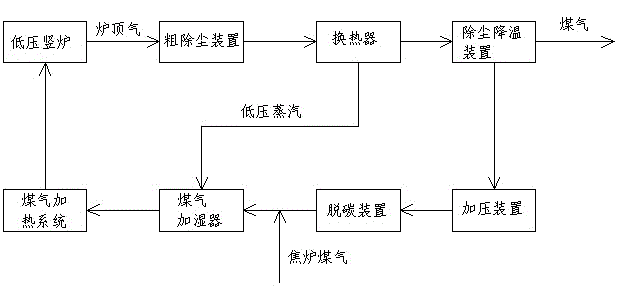

Direct reduction process for producing sponge iron by using coke oven gas

ActiveCN102268504BImprove responseReduce consumption costsProcess efficiency improvementShaft furnaceThermal energyCoke oven

The invention discloses a direct reduction process for producing sponge iron by using coke oven gas. The process comprises the following steps: a, introducing the purified and pressurized coke oven gas into a gas humidifier for humidification; b, introducing the humidified coke oven gas into a gas heating system for heating; and c, introducing the heated coke oven gas into a low-pressure shaft furnace for reducing the iron ore and generating the furnace top gas of the shaft furnace. According to the process, by utilizing the catalytic action of the fresh sponge iron reduced in the low-pressure shaft furnace and utilizing carburization reaction of sponge iron and CH4, CH4 in the coke oven gas is transformed and modified so as to generate CO and H2, thereby avoiding the investment of an external reforming furnace and the consumption cost of a Ni-based noble metal catalyst and the like; by using the low-pressure shaft furnace, the problems of high pressure equipment, high pressure seal and the like of a high pressure shaft furnace can be avoided, and simultaneously, the limitation of H2 / CO can be relaxed, so that the investment, operation and flexibility of the process are greatly improved; and in the process, the heat energy of the furnace top gas of the shaft furnace can be fully recycled, and operation cost is low.

Owner:CISDI ENG CO LTD

A method for the integration of prefabricated main structure and support structure in open-cut engineering

ActiveCN108571010BLess investmentOptimize investmentArtificial islandsUnderwater structuresArchitectural engineeringEngineering

The invention discloses an engineering prefabricated main structure and supporting structure integration method based on an open cut method. The method comprises the following steps: required prefabricated plates are prefabricated; a foundation pit enclosure structure with hoisting system guide rails embedded is implemented; top beams are cast at the top end of the enclosure structure, and a hoisting system is erected on the top beams; foundation pit earth is excavated, and prefabricated slabs of a bottom plate, prefabricated slabs of intermediate plates and prefabricated slabs of a top plateare positioned sequentially to force required positions of a foundation pit in a grouped manner by the hoisting system according to vertical cutting depth and longitudinal cutting length in real timeuntil the plates reach designed elevation; the grouped prefabricated slabs of the bottom plate, prefabricated slabs of the intermediate plates and prefabricated slabs of the top plate are spliced in regular sequence respectively until splicing for each plate is finished; slide wall components and columnar components are mounted in a grouped manner between adjacent prefabricated slabs, related facilities are dismounted, and earthing backfill is performed. Overall support stiffness of the foundation pit is improved by the layered prefabricated slabs, deformation of the foundation pit is limitedto the greatest extent, anchor ropes and supports are reduced, and force transformation is reduced.

Owner:贾永刚

Oxygen-rich dry gas supply device for blast furnace iron-making

InactiveCN102808053AReduce energy consumptionReduce preparation energy consumptionBlast furnace componentsBlast furnace detailsSmelting processProcess engineering

The invention relates to the technical field of blast furnace iron-making process, and provides an oxygen-rich dry gas supply device adapting to a blast furnace iron-making smelting process. The oxygen-rich dry gas supply device is characterized in that a blast furnace blower is connected with a precooler; the precooler is connected with an air cooler; the air cooler is connected with a PSA (Pressure Swing Adsorption) oxygen making unit; the PSA oxygen making unit is connected with the precooler; and the precooler is connected with a hot air furnace. According to the device, equipment used in the conventional blast furnace iron-making process is fully utilized, and air supercharged at the outlet of the blast furnace blower is subjected to pressure varying adsorption for directly preparing oxygen-rich dry gas, so that a way for preparing the oxygen-rich dry gas by externally adding rich oxygen in the prior art is changed; and the device has the advantages of small equipment investment and low running energy consumption.

Owner:李东林 +4

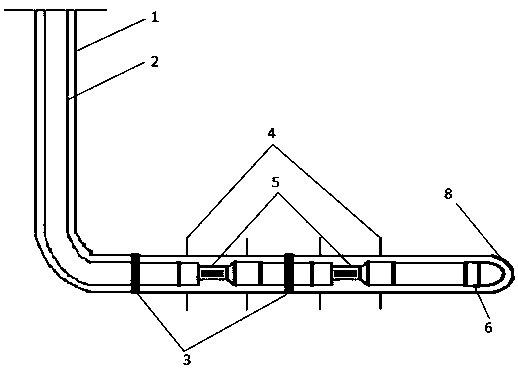

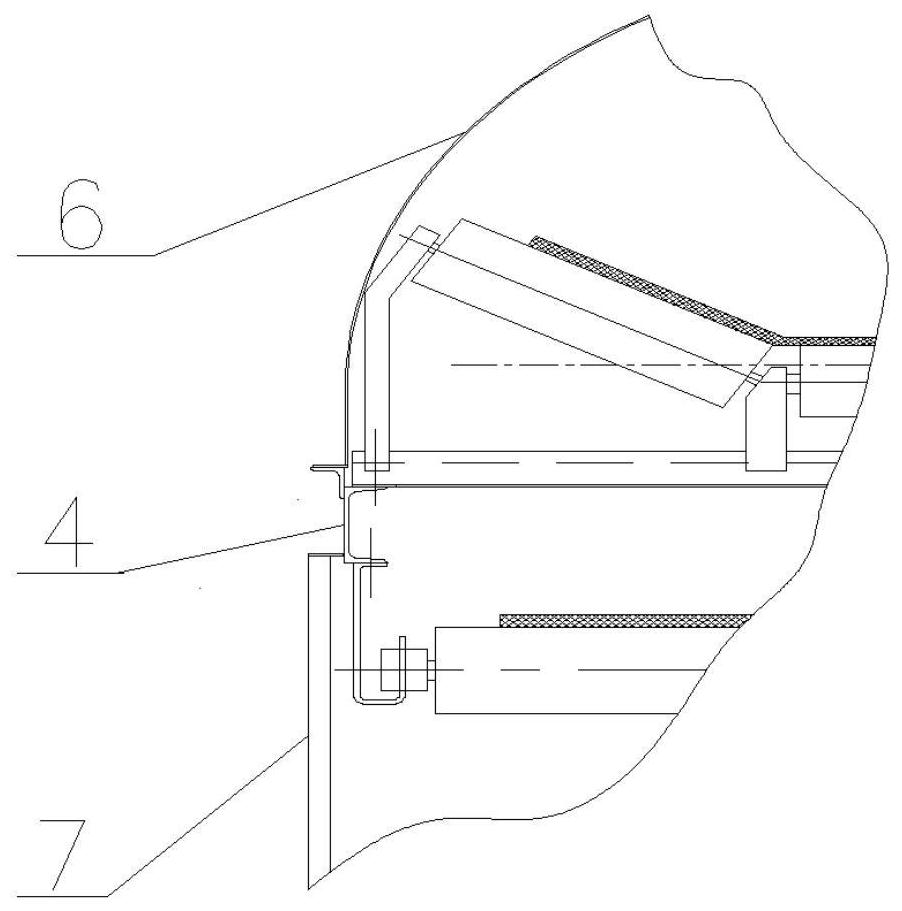

Improved method for closed vestibule of belt conveyor

PendingCN113697387AHandy dustImprove the environmentConveyorsCleaningClassical mechanicsWorking environment

The invention relates to a method for improving a closed vestibule of a belt conveyor, and belongs to the technical field of bulk material conveying. The method comprises the steps that a conveyor is hung on the top of a vestibule main frame through a rack; an upper belt face sealing cover covers the upper portion of an upper carrier roller combination of the conveyor, meanwhile, lower belt face sealing plates are arranged on the two sides of a lower carrier roller combination of the conveyor, a carrier roller mounting frame in the conveyor serves as an mounting foundation of the upper belt face sealing cover and the lower belt face sealing plates, and thus the upper belt surface sealing cover and the lower belt surface sealing plates are matched to form a closed cover so as to separate a maintenance channel outside; and a scattered material collecting support plate and an automatic material scraping and cleaning device are correspondingly arranged below a return belt surface of the conveyor, and the width of the scattered material collecting support plate needs to completely cover the width of the belt face of the conveyor. According to the method, the working conditions of big dust and poor working environment in a personnel maintenance channel in a conventional closed vestibule are improved, and the problems that the working space below the return belt face is limited and cleaning is inconvenient are solved.

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com