Oxygen-enriched dry gas supply process for blast furnace iron-making

A technology of oxygen-enriched dry gas and blast furnace ironmaking, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of high energy consumption in device system operation, large investment in power equipment, and large energy consumption in oxygen-enriched preparation, achieving Reduce preparation energy consumption, lower equipment investment, and optimize equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

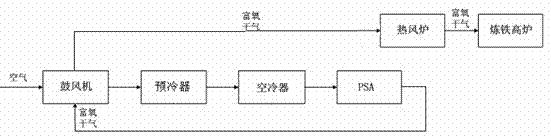

[0028] An oxygen-enriched dry gas supply process for blast furnace ironmaking, characterized in that: the process steps include: the air pressurized by a blast furnace blower is cooled by a precooler and an air cooler, and the moisture in it is directly removed by PSA And part of the nitrogen, the obtained oxygen-enriched dry gas returns to the pre-cooler to heat up, and then enters the hot blast stove and sends it to the blast furnace for combustion support.

[0029] The blast furnace blower is pressurized, and the gauge pressure of the outlet air of the blast furnace blower is 0.25MPa.

[0030] The PSA adopts a plurality of adsorption towers connected in parallel, and the adsorption towers are sequentially filled with dehydration adsorbents and oxygen-generating molecular sieves from bottom to top to absorb and remove trace amounts of water and nitrogen.

[0031] In the adsorption tower, the operation steps of each adsorption tower include adsorption, pressure equalization a...

Embodiment 2

[0036] Same reason, as embodiment 1.

[0037] An oxygen-enriched dry gas supply process for blast furnace ironmaking. The process steps include: the gauge pressure after being pressurized by the blast furnace blower is 0.35Mpa, after being cooled by the precooler and the air cooler, the air temperature before entering the PSA is 85 ℃, humidity 10g / m 3 , the water and part of the nitrogen are removed directly by PSA, and the dew point temperature of the oxygen-enriched dry gas is -10°C, the oxygen-enriched gas is 23%, and the humidity is 1.92 g / m 3 , the obtained oxygen-enriched dry gas is returned to the pre-cooler for heating, and then sent to the blast furnace for combustion after being heated by a hot blast stove.

Embodiment 3

[0039] The same reason, as mentioned above.

[0040] An oxygen-enriched dry gas supply process for blast furnace ironmaking. The process steps include: the air is pressurized by a blast furnace blower to obtain a gauge pressure of 0.45Mpa, and after being cooled by a precooler and an air cooler, the air temperature before entering the PSA is 75°C, humidity 8g / m 3 , the moisture and part of the nitrogen are directly removed by PSA, and the dew point temperature of the oxygen-enriched dry gas is -20°C, the oxygen-enriched gas is 22%, and the humidity is 0.76 g / m 3 , the obtained oxygen-enriched dry gas is returned to the pre-cooler for heating, and then sent to the blast furnace for combustion after being heated by a hot blast stove.

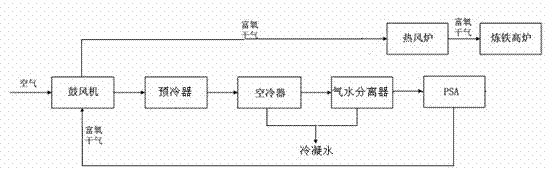

[0041] Among them, the air cooled by the pre-cooler and the air cooler passes through the gas-water separator, and then the moisture and part of the nitrogen are removed by PSA, and the obtained oxygen-enriched dry gas returns to the pre-cooler f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com