Patents

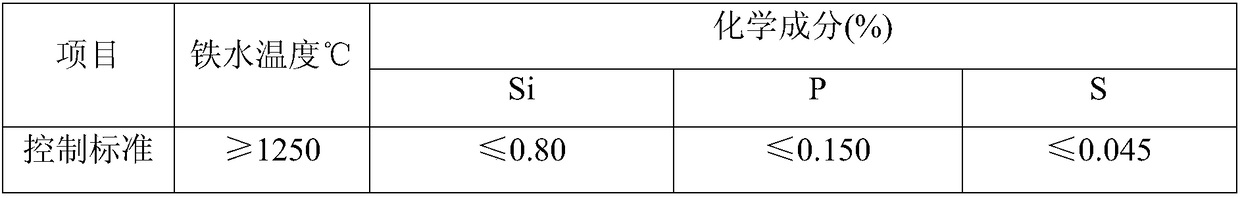

Literature

349results about How to "Reduce preparation energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

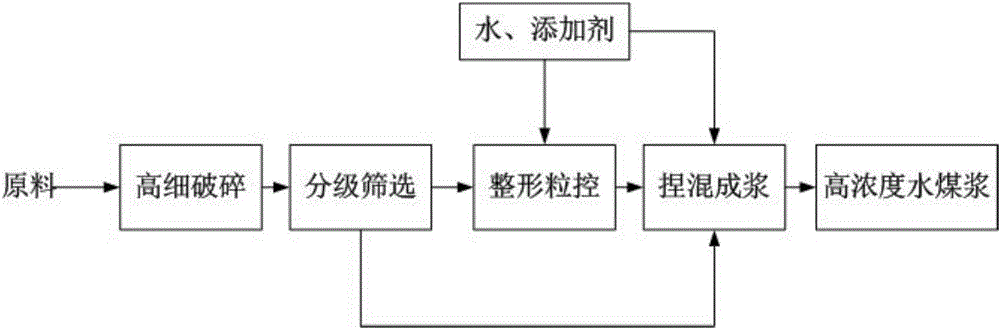

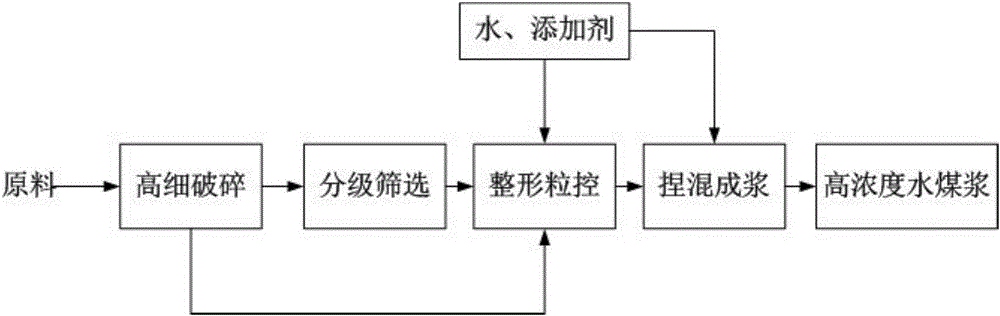

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

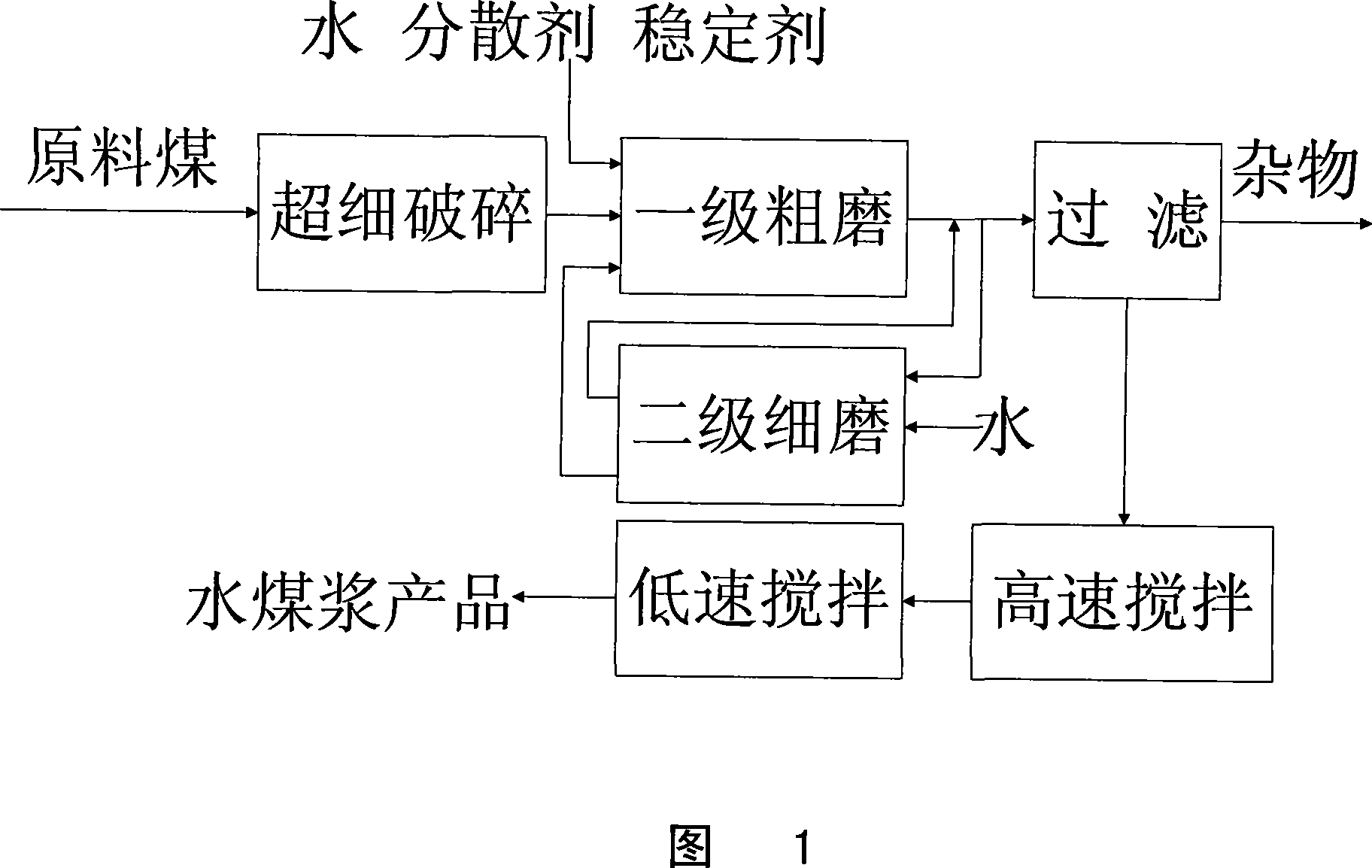

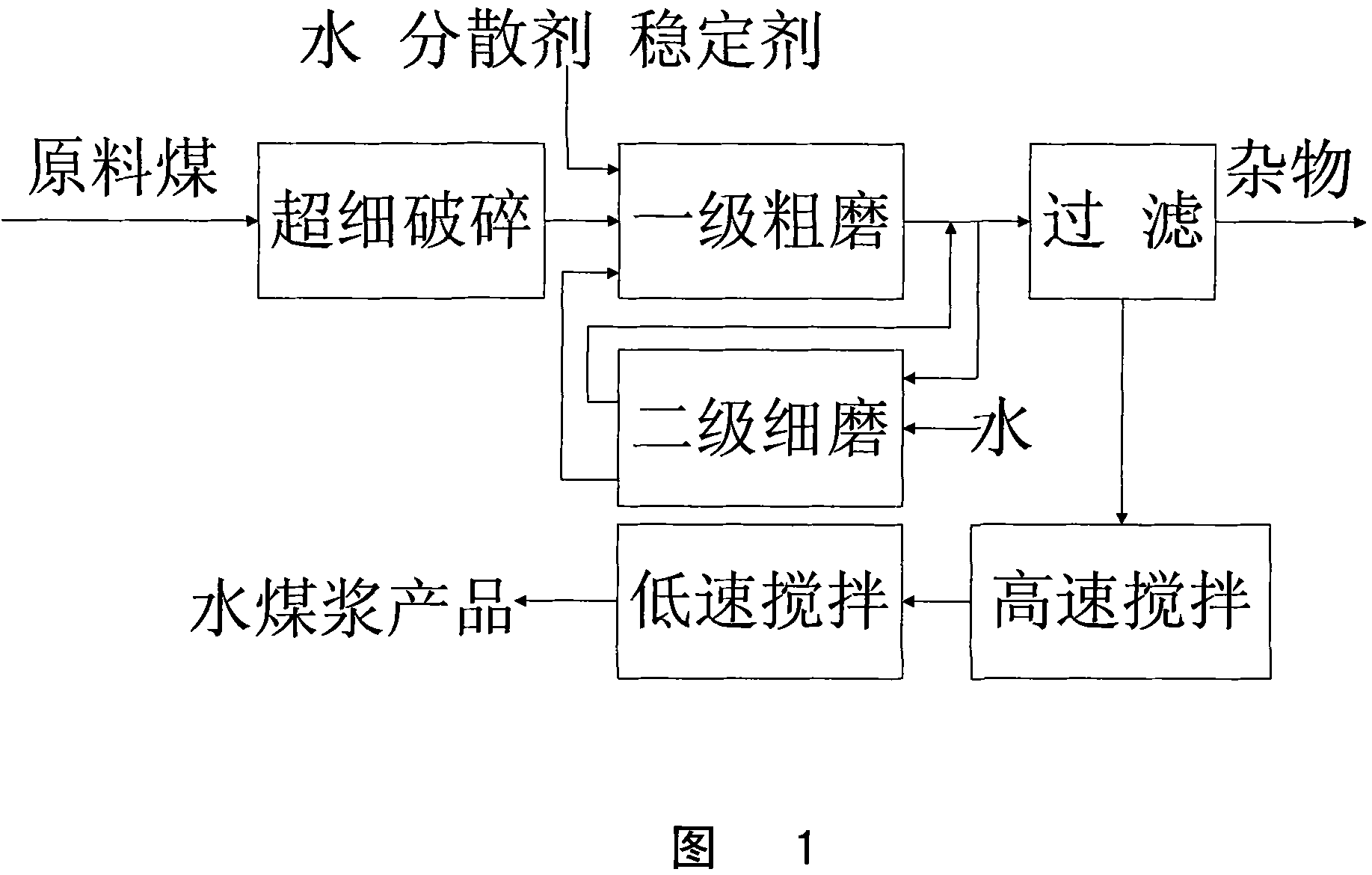

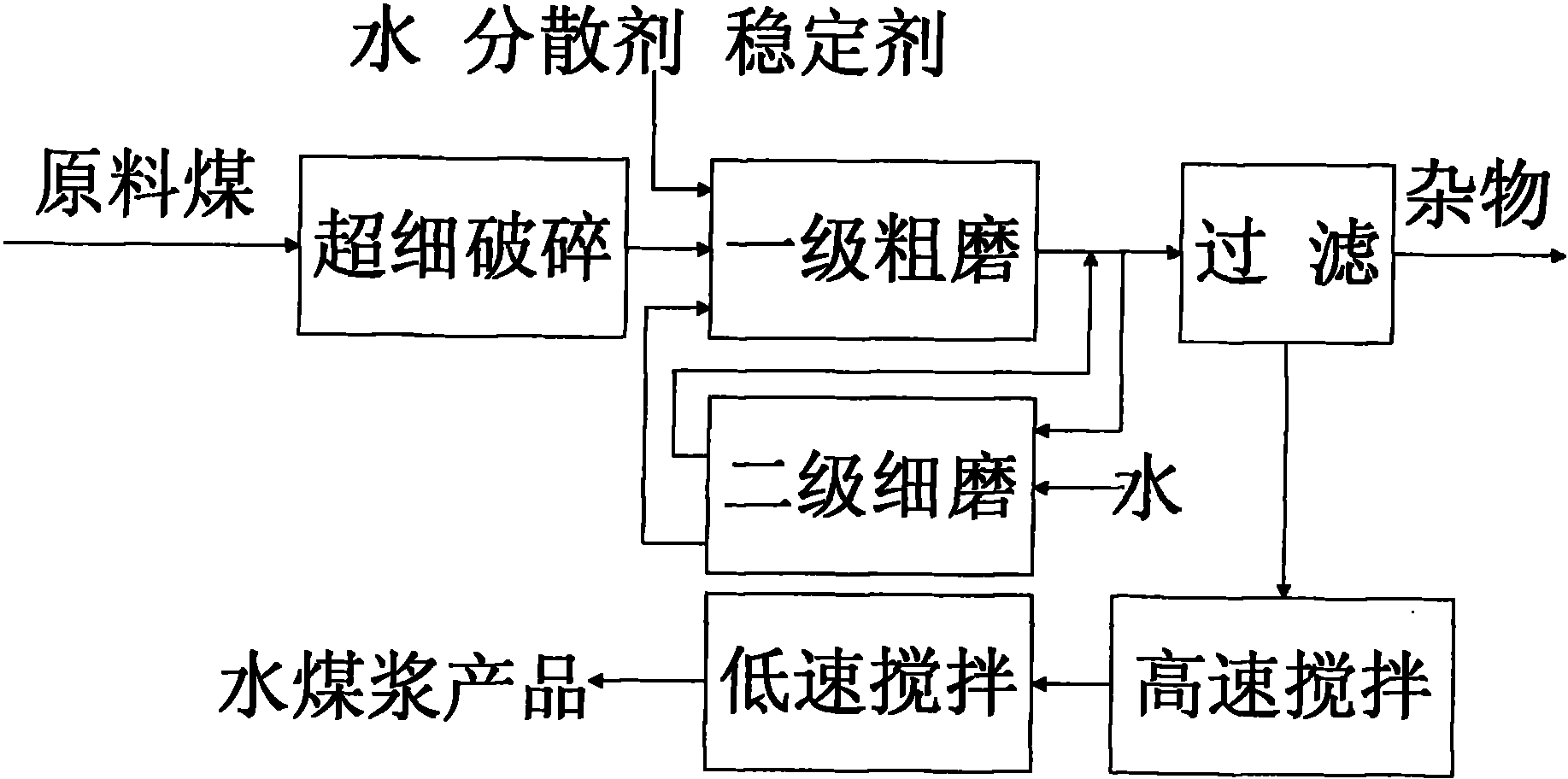

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

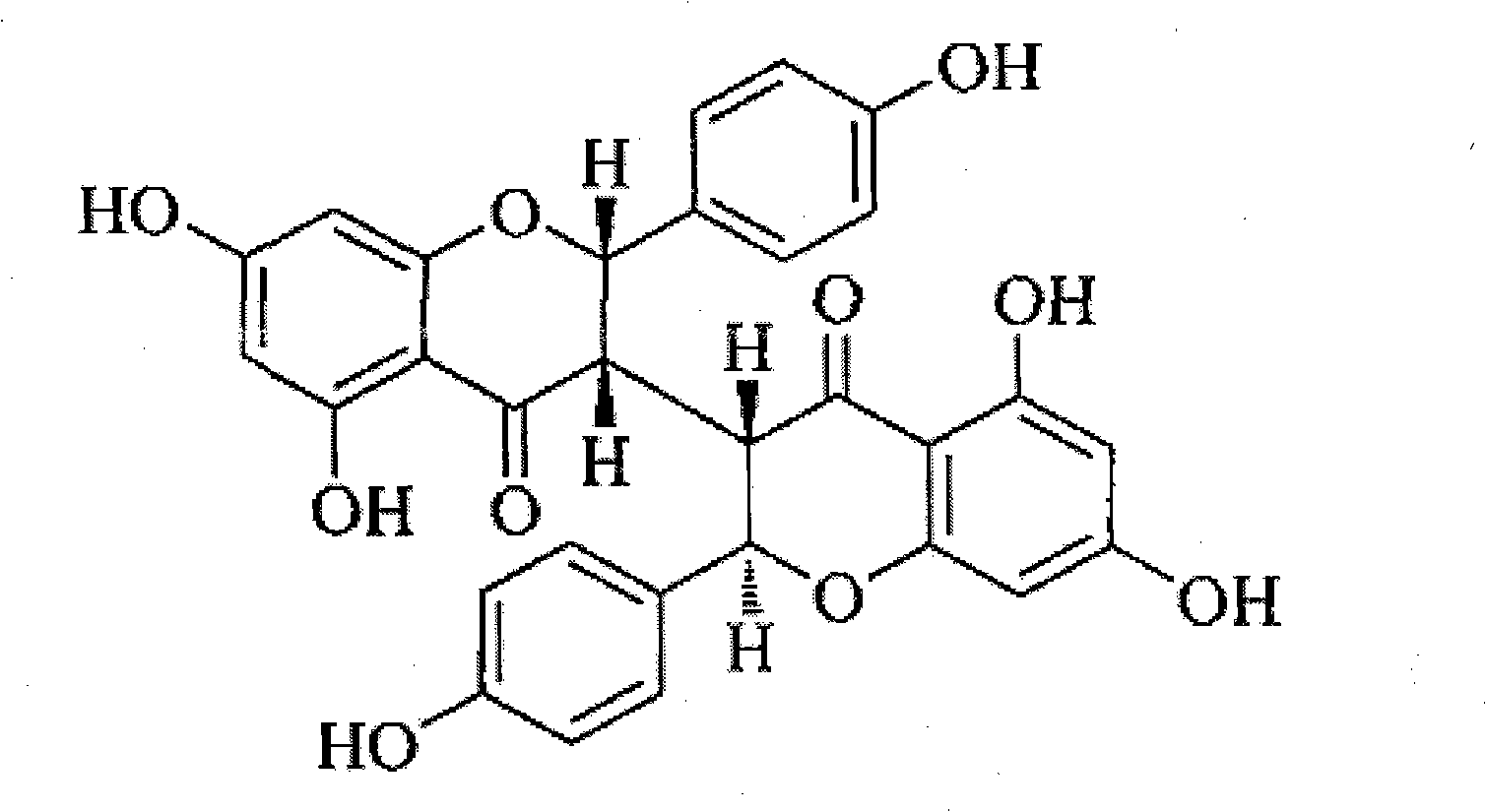

Method for extracting new chamaejasmine B from stellera chamaejasme. L

InactiveCN102060827ARelieve environmental pressureIncrease polarityOrganic chemistryReflux extractionMacroporous resin

The invention provides a method for extracting new chamaejasmine B from stellera chamaejasme. L, which comprises the process steps of: reflux-extraction after pulverization of stellera chamaejasme. L, alkali extraction and acid precipitation, separation with macroporous resins and crystallization. The method has the advantages of simple operation, low carbon, economy and high purity of product.

Owner:苏州北商智业管理咨询有限公司

Method for increasing nitrogen content of vanadium-nitrogen alloy

ActiveCN101693975AAddressing Low Nitrogen ContentFix stability issuesNitrogen-metal/silicon/boron binary compoundsNitrogenAlloy

The invention discloses a method for increasing the nitrogen content of vanadium-nitrogen alloy, comprising the following steps of adding a nitridation accelerator into a mixture comprising vanadium oxide, a carburizing agent, catalyst and a bonding agent, making material blocks, and heating the material blocks for gasifying or decomposing the nitridation accelerator to generate gas and form crisscrossed micro holes or channels in the material blocks. The nitrogen content is greatly increased as nitrogen in the nitridation reaction enters the inside of the material blocks through the holes or channels to participate in the reaction to result in completion of the nitridation reaction. Compared with the prior art, the invention solves the problems of accelerating carburization and intensifying nitridation from the carburization and oxidation mechanisms of vanadium-nitrogen alloy through adding nitridation accelerators into materials, thereby greatly increasing the nitrogen content of the vanadium-nitrogen alloy and simultaneously reducing the general production cost and energy consumption of the vanadium-nitrogen alloy.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

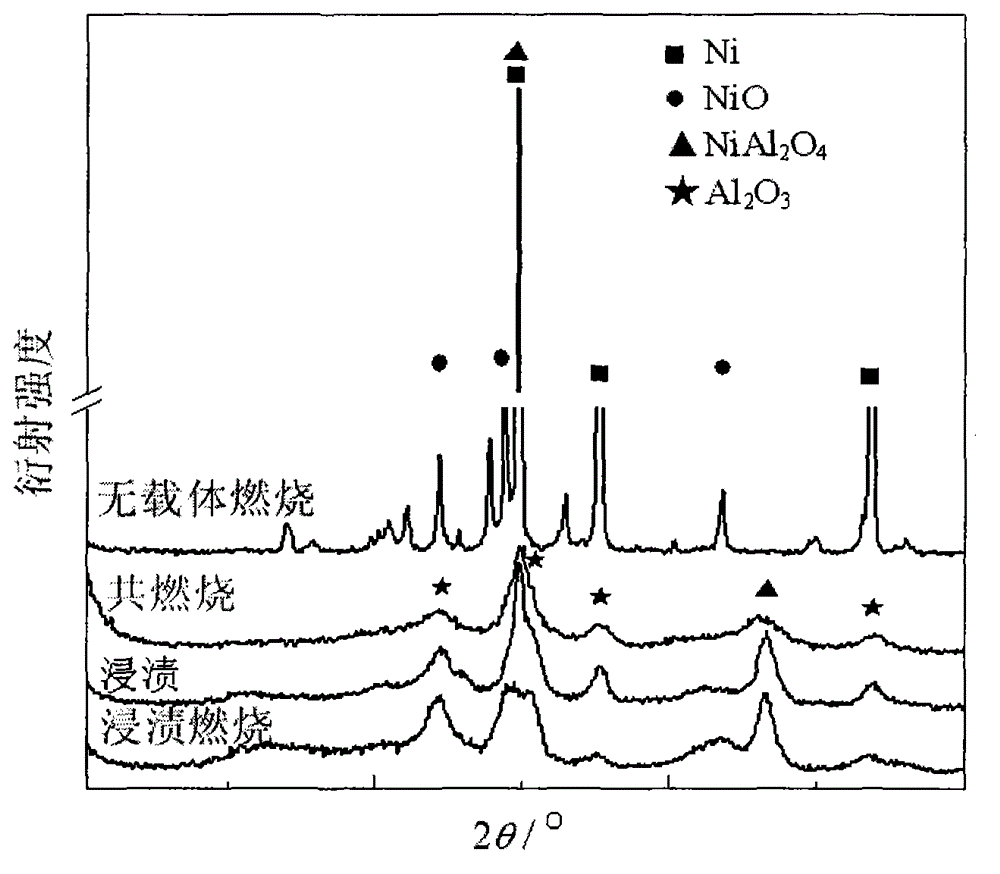

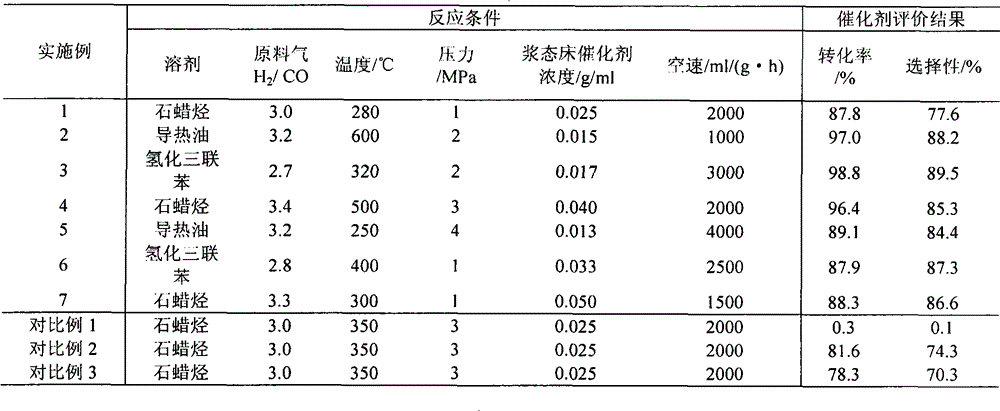

Loaded type nickel-based catalyst used for slurry bed methanation, and preparation method and application thereof

InactiveCN102872874AGood dispersionIncrease the number of active centersGaseous fuelsCatalyst activation/preparationWater bathsNitrate

The invention relates to a loaded type nickel-based catalyst used for slurry bed methanation, and a preparation method and an application thereof. The loaded type nickel-based catalyst is composed of, by weight, 10-40 wt% of NiO, 56-90 wt% of a carrier and 0-4 wt% of an auxiliary agent. The loaded type nickel-based catalyst is prepared by the steps of preparing a soluble salt solution of 0.5-1.3 g / mL nicdel nitrate and the auxiliary agent; adding a catalyst carrier and a soluble organic fuel to the salt solution in sequence; impregnating for 6-24 h while stirring; heating the solution for concentration in a water bath with a temperature of 60-90 DEG C after finishing the impregnation, or heating for igniting the solution at a temperature of 300-700 DEG C directly; collecting the combustion residue powder, grinding the powder and granulating, and reducing for 2-6 h with a reducing gas on a fixed bed at a temperature of 500-700 DEG C. The loaded type nickel-based catalyst has a slurry bed methanation process, and has the advantages of good and stable catalytic performance, and can be used for large-scale industrialization.

Owner:TAIYUAN UNIV OF TECH +1

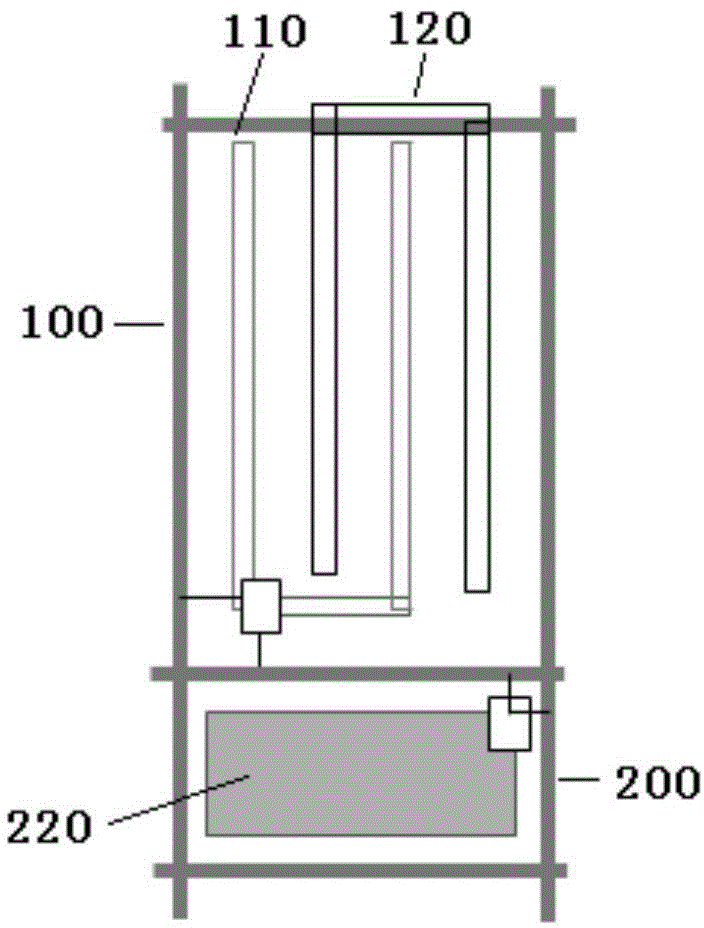

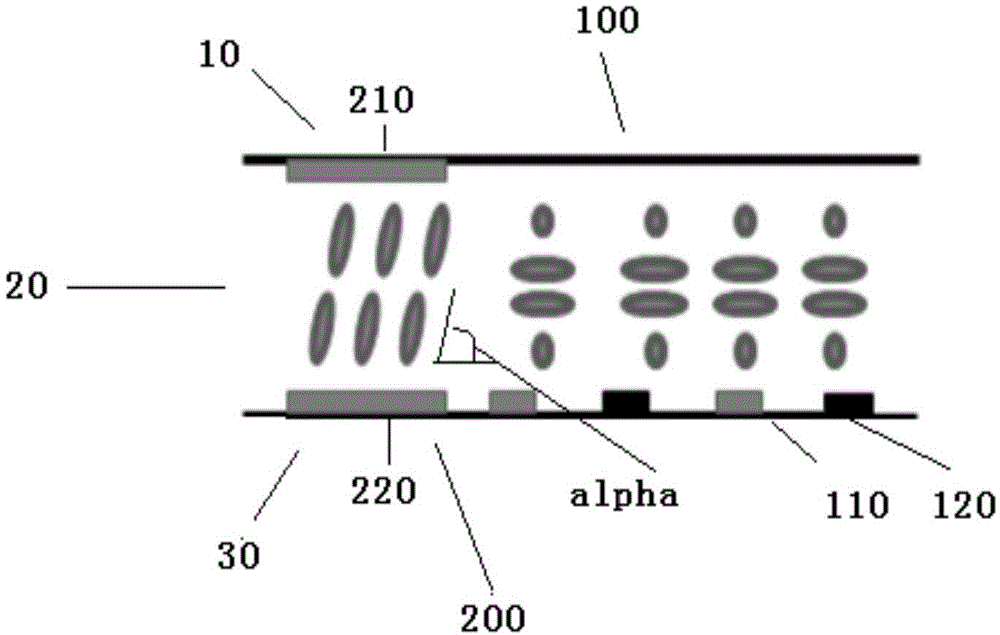

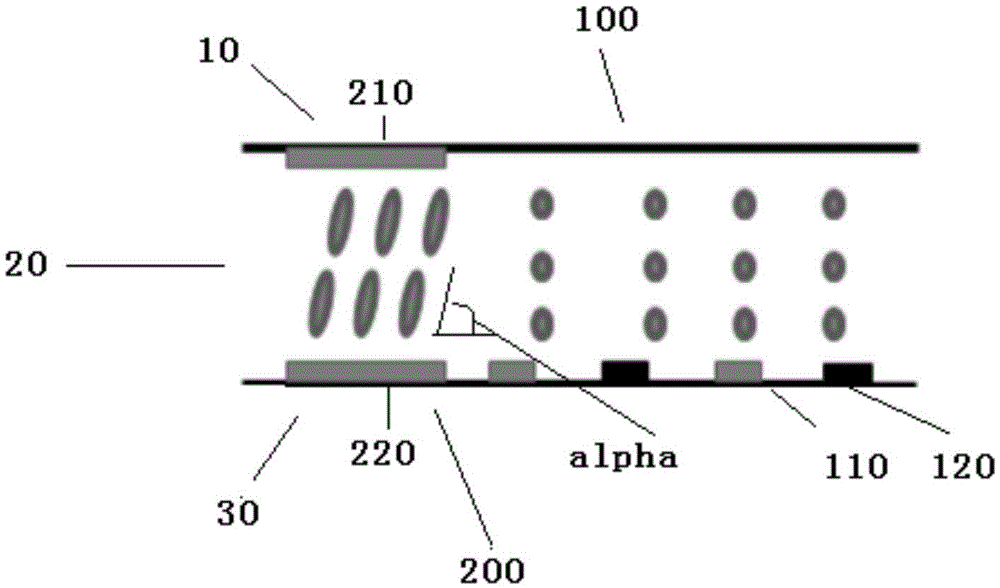

Liquid crystal display panel capable of switching viewing angle and drive method thereof

ActiveCN104460138AReduce thicknessEasy to operateStatic indicating devicesNon-linear opticsComputer scienceHomeotropic alignment

The invention discloses a liquid crystal display panel capable of switching the viewing angle and a drive method of the liquid crystal display panel. A pixel unit of a liquid crystal display panel display region comprises a primary pixel region and a secondary pixel region; the primary pixel region is homogeneous alignment and arranged in the primary pixel region, and a lower substrate is provided with pixel electrodes and public electrodes at intervals; the secondary pixel region is homeotropic alignment and arranged in the secondary pixel region, and an upper substrate and the lower substrate are correspondingly provided with an upper substrate electrode and a pixel electrode respectively. When no bias voltage is applied on the upper substrate electrode of the secondary pixel region, the liquid crystal molecules corresponding to the secondary pixel region do not defect, and the large viewing angle of the secondary pixel region leaks light, narrow viewing angle display is achieved; when the bias voltage is applied on the upper substrate electrode of the secondary pixel, the liquid crystal molecules corresponding to the secondary pixel region deflect to the plane-on state, the large viewing angle of the secondary pixel region does not leak the light any more, and wide-view-angle display is achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

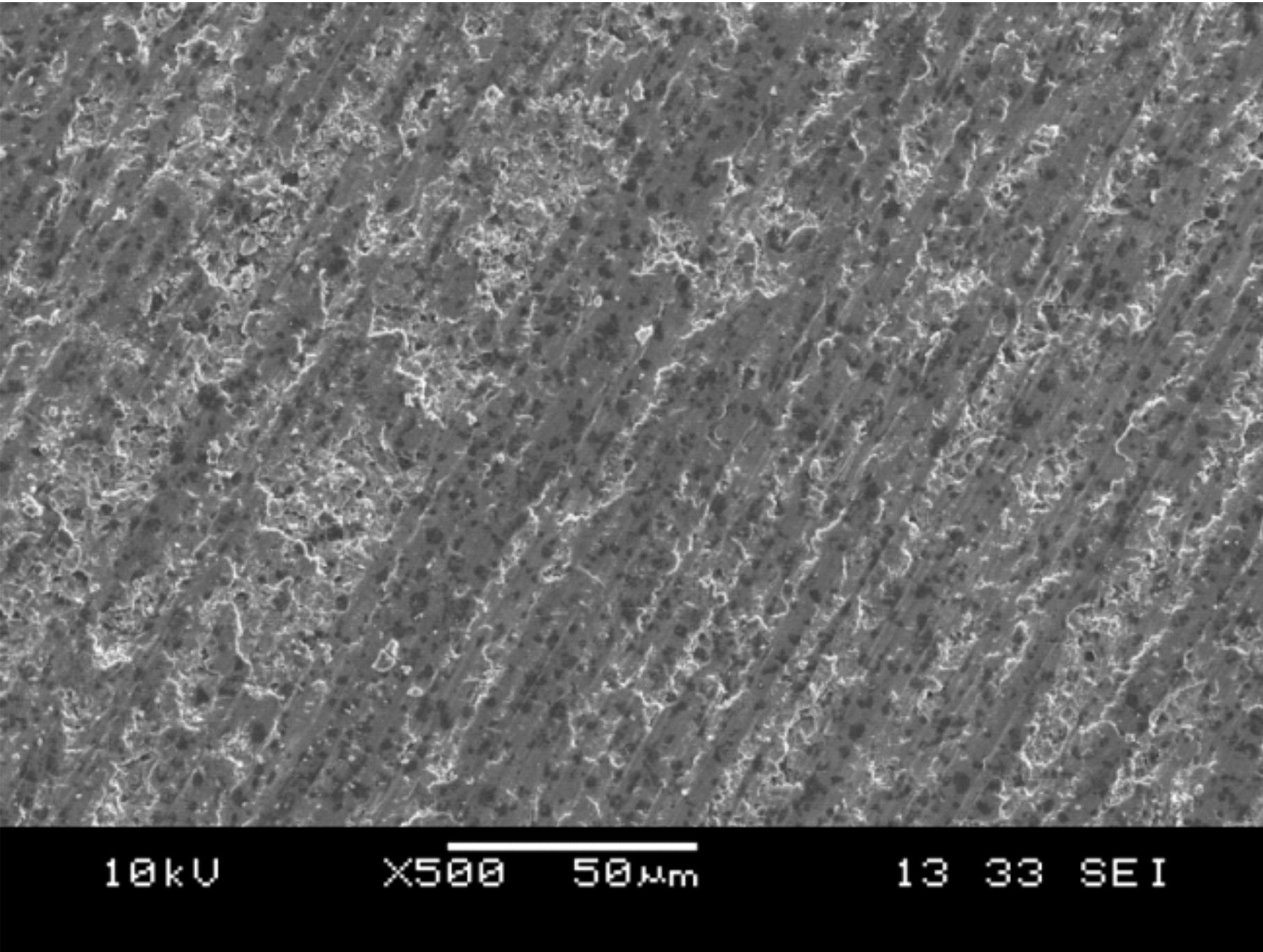

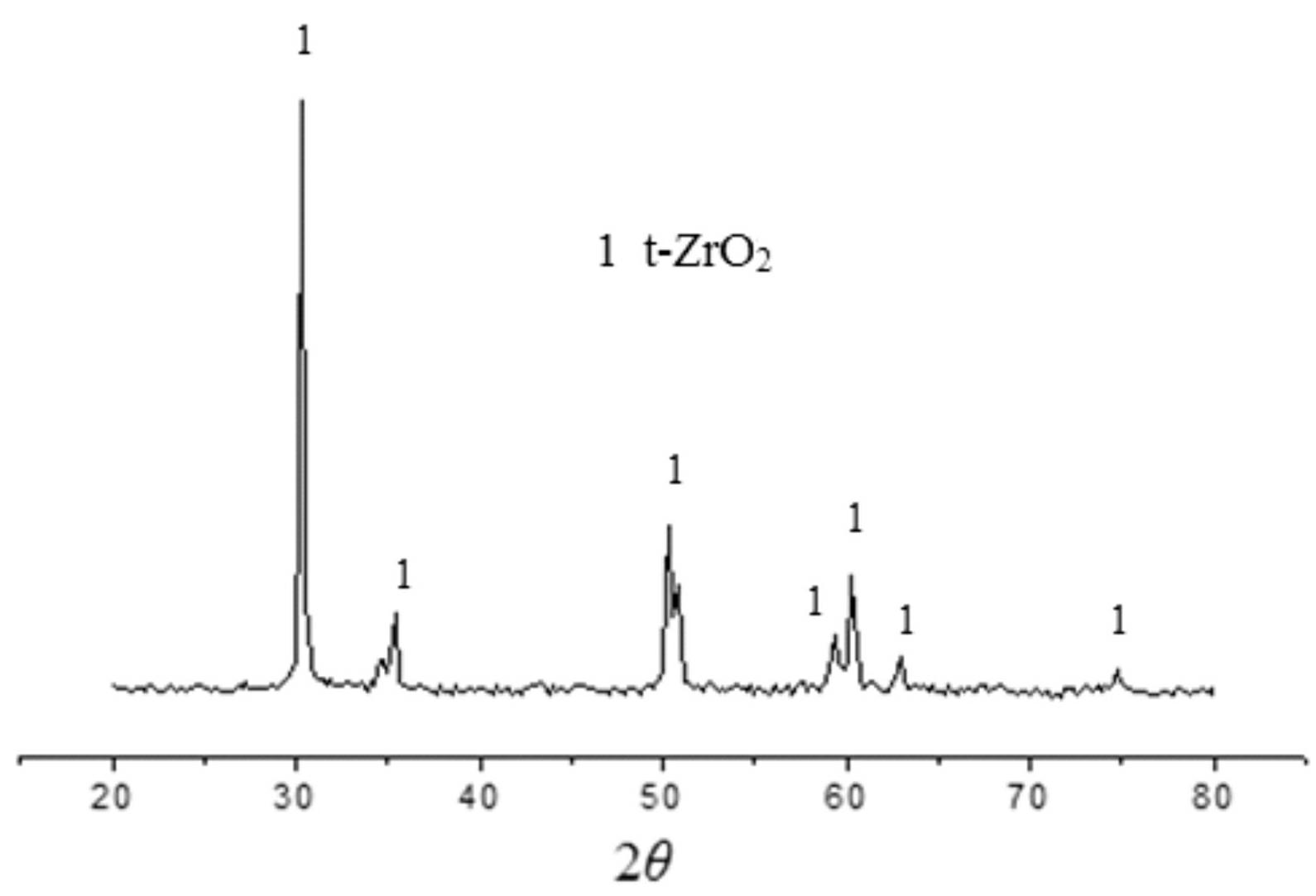

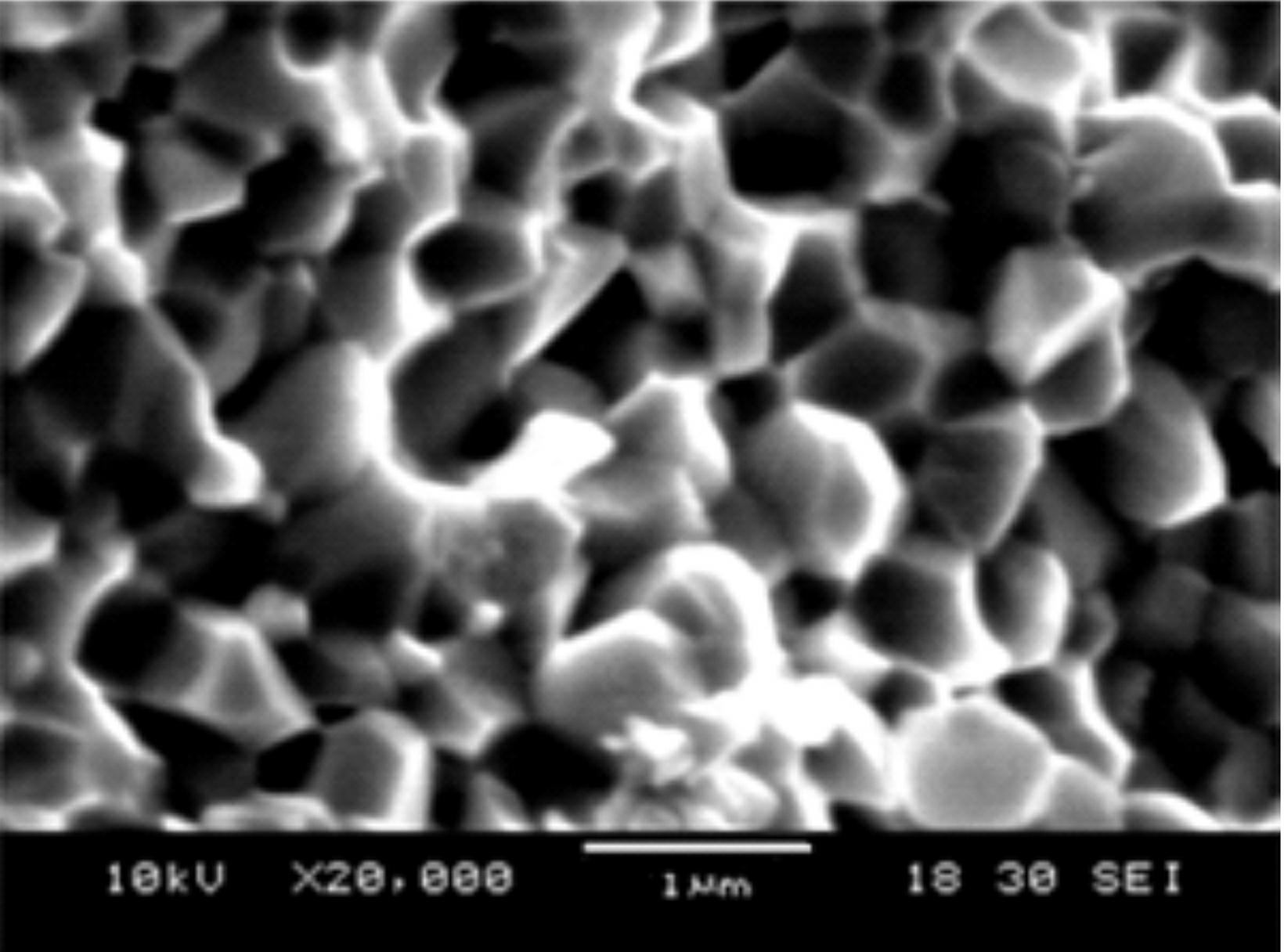

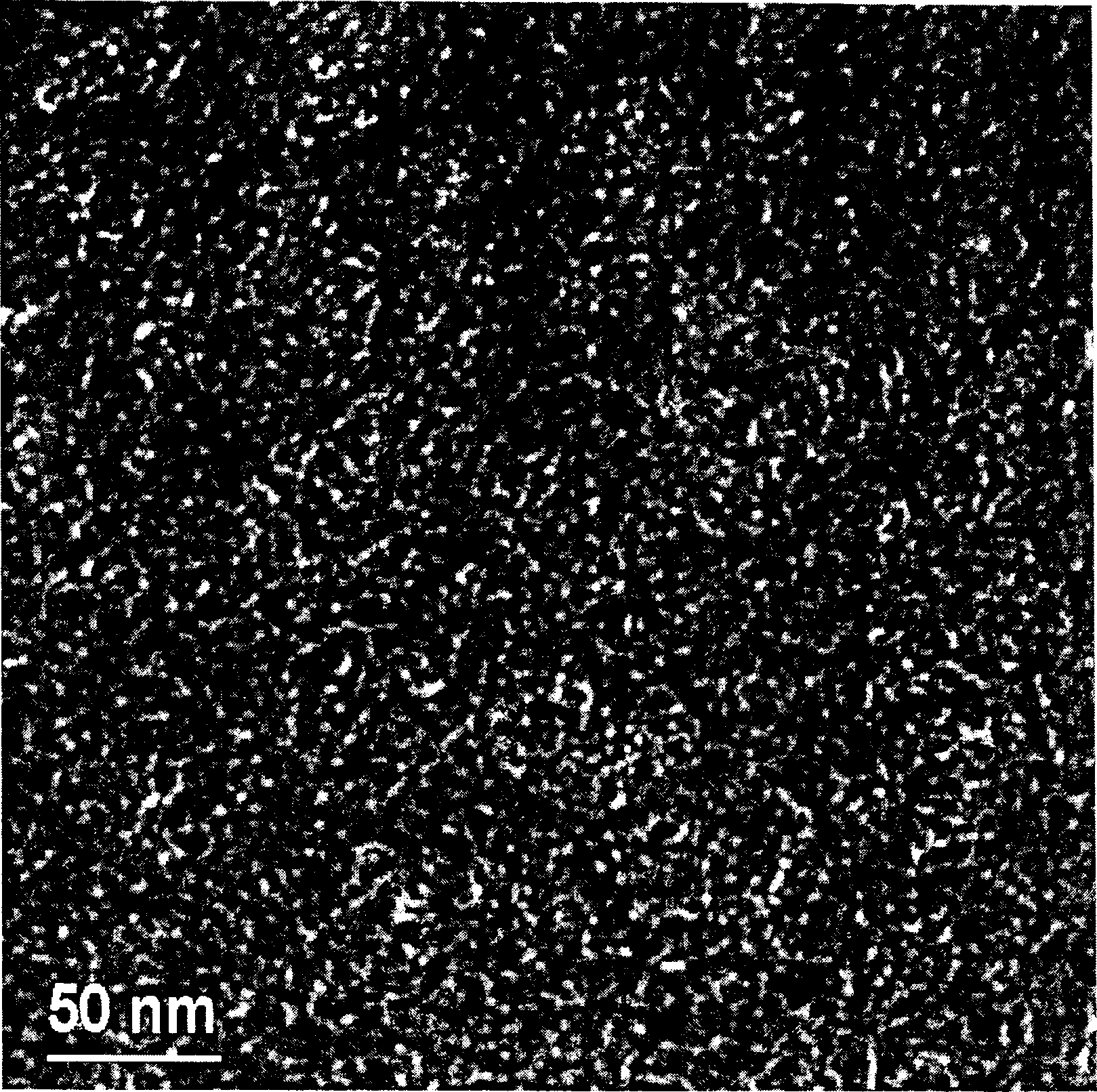

Zirconia ceramic cylinder liner material and preparation method thereof

InactiveCN102320830AWell mixedOvercome the disadvantage of uneven mixingComposite ceramicZirconia ceramic

The invention discloses a zirconia ceramic cylinder liner material and a preparation method thereof, and the material comprises the following components: 60-80 wt% of ZrO2, 20-30 wt% of Al2O3, 3.2-4.3 wt% of Y2O3, 3-4.2 wt% of TiO2, and 1.5-2.1 wt% of La2O3. The method prepares the ZrO2 ceramic cylinder liner material by using Al(NO3)3, ZrOCl2.8H2O, Y(NO3)3, TiCl4, LaCl3 as raw materials, using C6H12N4 as a precipitant, and by a coprecipitation method. Uniform mixing of each component at molecular level is effectively realized. The disadvantage of poor uniformity of the mixing of each component in the material due to routine ball milling mixing technology is overcome; the prepared zirconia ceramic powder has the characteristics of uniform dispersion, homogeneous particle size, and good fluidity; low-temperature sintering is realized; the ZrO2 composite ceramic material green body prepared by the method has bending strength of 980-1200 MPa, fracture toughness of 8.3-10 MPa.m1 / 2, vickers hardness of 2 GPa-14 GPa after calcination at 1330-1380 DEG C; the process is simple, and is applicable to large-scale production.

Owner:SHANTOU UNIV +1

Iron base catalyzer through Fischer-Tropsch synthesis and preparation method

InactiveCN1245255CReduce manufacturing costReduce preparation energy consumptionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMicrosphereSlurry

A Fe-base catalyst with high antiwear performance, activity and stability for the Fischer-Tropsch synthesis contains Fe, Zn, Cu, K and SiO2. It is prepared through proportionally mixing sodium carbonate solution as precipitant with the mixed solution of iron nitrate, zinc nitrate and copper acetate, depositing to obtain deposit slurry, adding the mixed solution of potassium silicate and silicon sol, spray drying and calcining.

Owner:中科合成油淮南催化剂有限公司

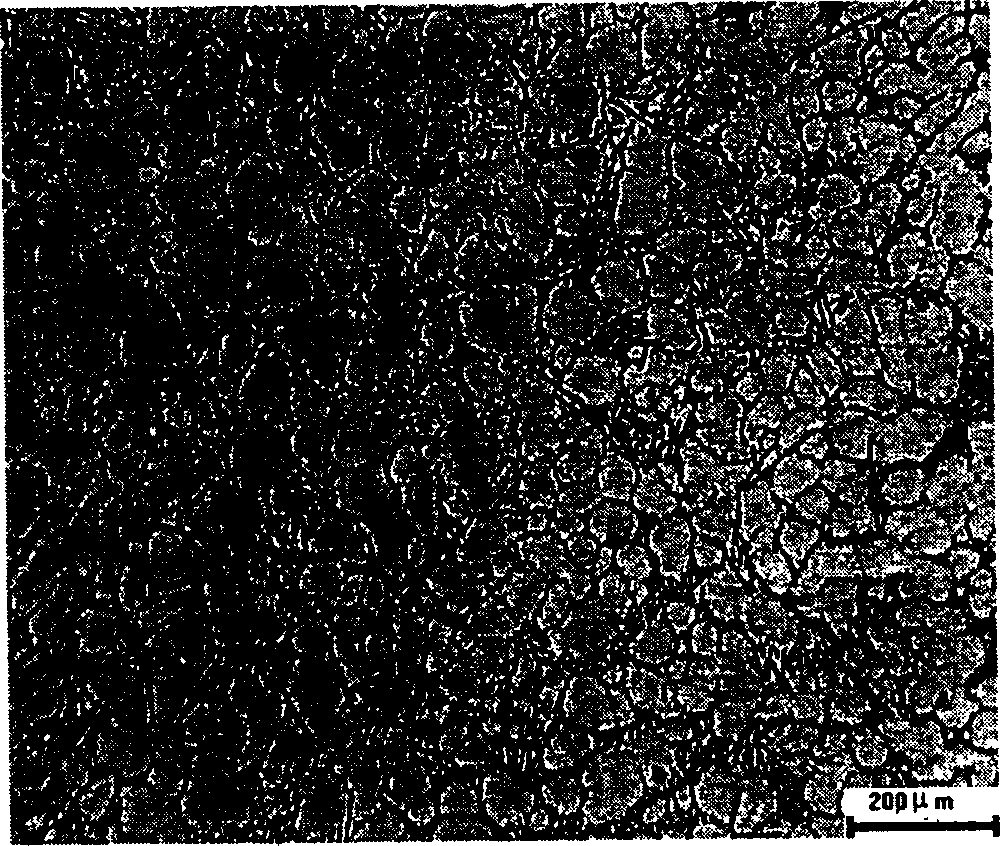

Method for preparing semi-solid metal slurry and rheologic molding

InactiveCN101130203AImprove liquidityEliminates the difficulty of pouringExtrusion control devicesVertical tubeCrucible

The invention discloses a preparing technique of semi-solid metal slurry and rheologic moulding equipment in the preparing technical domain of semi-solid metal slurry, which comprises the following steps: pouring the overheat metal liquid into straight-in composite tube path with an inclined tube and a vertical tube; moving the semi-solid metal slurry and preparing copper into the temperature controller after flowing the overheat metal liquid into the copper along the inner wall of the straight-in composite tube path; doing subsequent cooling or temperature field control for the semi-solid metal slurry; pouring the semi-solid metal slurry into pressing chamber with squeeze moulding machine or squeeze caster or forger to mould; opening or fetching the cast piece or squeeze cast or forge from mould. The invention simplifies the preparing technique, reduces energy consumption and shortens the technical flow path, which reduces the manufacturing cost of the semi-solid metal rheopectic casting die or rheopectic squeeze casting die or rheopectic forge.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing reactive nano calcium carbonate-native rubber composite material

The invention provides a preparation method for a reactive nanometer calcium carbonate-natural rubber composite material, which is characterized in that, the nanometer calcium carbonate or proper amount of coupler or anionic surfactant is added to deionized water to be stirred and ultrasonically dispersed, and then proper amount of emulsion epoxidized natural rubber is added to be continuously stirred and ultrasonically dispersed to prepare nanometer calcium carbonate aqueous dispersion; meanwhile, proper amount of non-ionic surfactant is used for stabilizing the proper amount of emulsion natural rubber; the nanometer calcium carbonate aqueous dispersion is uniformly mixed to the emulsion natural rubber under the condition of continuous stirring; the unsaturated carboxylic acid neutralizing solution with the pH value adjusted by potassium hydroxide and a triggered cross linker are dropped into the mixture under 60 DEG C of water bath condition to obtain the latex-stated nanometer calcium carbonate-natural rubber composite material. The vulcanizing film of the composite material can reach 25-30MPa of tensile strength, 800-950 percent of maximum elongation and 3.5-6.0MPa of 300 percent stretching stress.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Carbon film and LiFePO4 composite nm conductive material and its synthesis method

InactiveCN1442917AEfficient use ofSmall particle sizeCell electrodesConductive materialCooking & bakingCarbon film

A composite nano conductive material of carbon film and LiFePO4 is xC:yLiFePO4, where the value of x is 0.01-0.30 and the value of y is 0.70-0.99. It is prepared by first mixing polylol or sugar as conductive presoma material with raw material of lithium source, iron source and phosphorus source for synthesizing LiFePo4 in water uniformly and then followed with drying and baking.

Owner:FUDAN UNIV

A kind of preparation method of metal electrode of crystalline silicon solar cell

ActiveCN102299200AReduce manufacturing costImprove yieldFinal product manufactureSemiconductor devicesSilicon solar cellMetal electrodes

The invention discloses a method for preparing metal electrodes of a crystal silicon solar cell, which comprises the steps that: after the PN junction is prepared on a p-type crystal silicon substrate through diffusion, a silicon nitride antireflection layer is prepared on the surface of a n type emitting electrode, then, a thin Al layer with the thickness being 100nm to 1000nm is prepared on thesurface of a p-type conducting back through the vacuum sputtering technology, the vapor deposition technology or the screen printing technology, in addition, a thin Ag grid line layer with the thickness being 1mum to 5mum is prepared on the surface of the silicon nitride antireflection layer through the screen printing, next, an Al back field seed layer and an Ag grid line seed layer are formed through the traditional high-temperature sintering technology, finally, tin, copper or nickel is electroplated on the Ag grid line seed layer and the Al back field seed layer through the electroplatingprocess, and the metal electrodes are formed after the thickening. Compared with the prior art, the method combines the advantages of the screen printing process, the magnetron sputtering process, the vapor deposition process and the electroplating process, front metal grid line electrodes with high electrical conductivity and low light shielding rate can be obtained, and simultaneously, the consumption of expensive metal Ag can be effectively reduced, so important industrialized application prospects are realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Agglomerated rock pavior brick with pervious function and preparation thereof

InactiveCN101439953AReduce manufacturing costEnergy savingSolid waste managementFreeze thaw resistanceBuilding material

The invention belongs to the field of building materials, and in particular relates to an agglomerated rock paving brick with function of water permeability, which is characterized in that agglomerated rocks are used as a gelled material to give full play to the characteristics of no free Ca(OH)2 contained therein after hardening, strong freeze-thawing resistance, good durability and the like of the novel silicon-aluminum based gelled material. The production of the agglomerated rock paving water permeable brick is divided into an upper layer and a lower layer for material blending and forming. The brick can be formed manually or mechanically. The underlayer raw material comprises the following components by weight percentage: 75 to 78 percent of aggregate, 16.5 to 18.5 percent of agglomerated rock gelled material, 0.5 to 2.0 percent of water reducing agent, and 3.5 to 6.0 percent of water; and the upper layer raw material comprises: 71 to 75 percent of the aggregate, 20.8 to 22.1 percent of the agglomerated rock, 0.7 to 0.9 percent of the water reducing agent, and 3.5 to 6.0 percent of water. Compared with ceramic paving water permeable brick, the agglomerated rock paving brick can considerably reduce the cost of the paving water permeable bricks, and calcination is not needed at the same time for energy conservation and environmental protection. Compared with the prior cement-based paving water permeable brick, the agglomerated rock paving brick overcomes the defects of poor freeze-thawing resistance and short service life.

Owner:UNIV OF SCI & TECH BEIJING

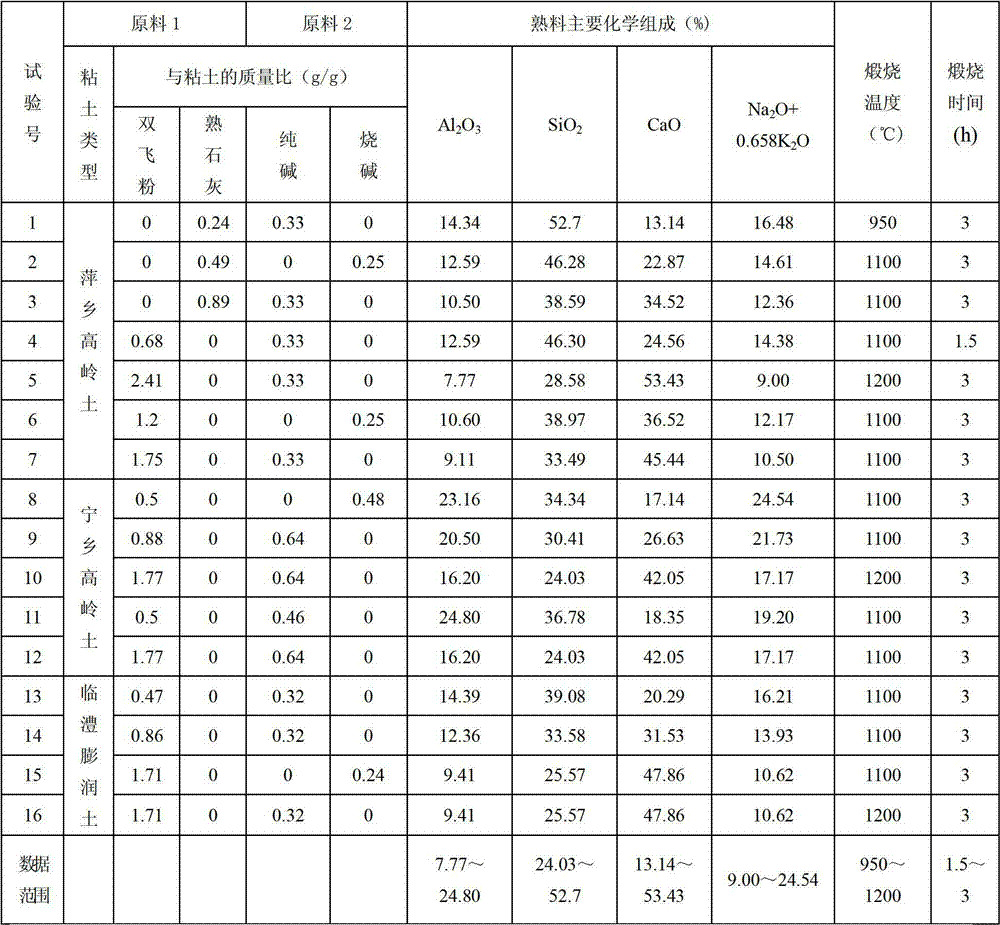

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996AExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

Polyaluminum ferrous chloride purifier and production method thereof

ActiveCN103420430AImprove product stabilityReduce miningIron halidesWater/sewage treatment by flocculation/precipitationAluminiumOxidizing agent

The invention provides a polyaluminum ferrous chloride purifier and a production method thereof. The production method using the following raw materials includes the steps of firstly, feeding technical hydrochloric acid and aluminum sludge into a sealed reaction vessel, and stirring at normal temperature and pressure; secondly, adding CaCl2 to the solution obtained by the first step, stirring at normal temperature and pressure until complete reaction, and filtering to remove sedimentation; thirdly, adding steel acid pickling waste liquor into the solution obtained after filtering of the second step, and well mixing by stirring; fourthly, adding oxidant to the solution obtained by the third step; fifthly, adding calcium aluminate powder to the solution obtained by the fourth step, allowing for reaction, and filtering and aging to obtain the polyaluminum ferrous chloride purifier. The production method has the advantages that CaCl2 is added to control contents of SO42- in the product so as to prevent SO42- from reacting with the subsequently added calcium aluminate powder, and product stability is increased.

Owner:江门市碧水源环保水处理有限公司

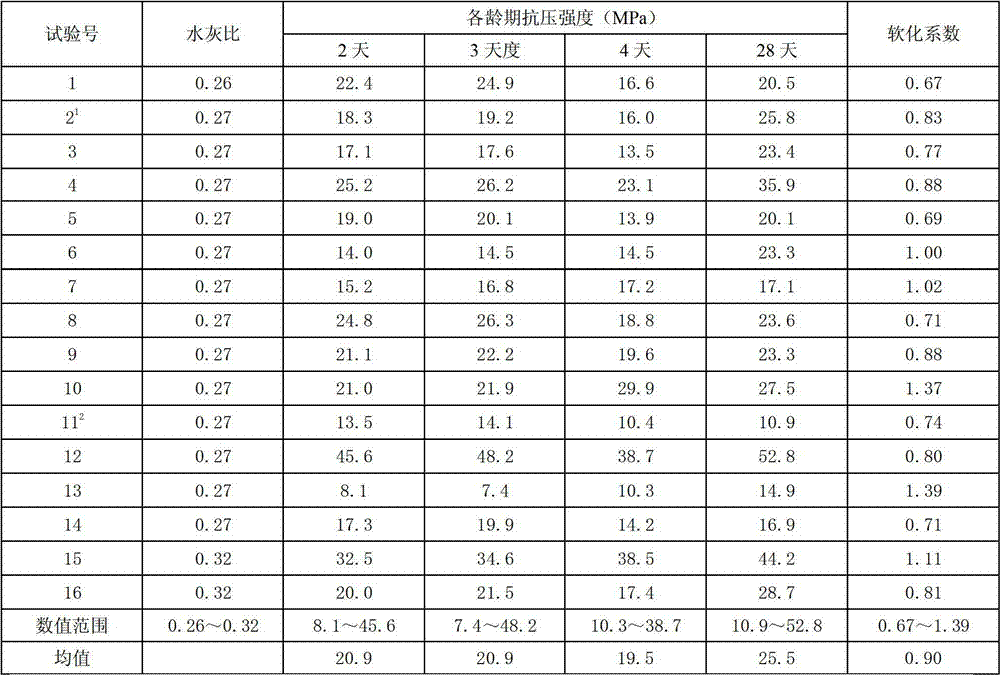

Red mud raw material-based non-steamed brick and production method thereof

InactiveCN104844141AImprove early strengthReduce preparation energy consumptionSolid waste managementBrickSlag

The invention relates to a red mud raw material-based non-steamed brick and a production method thereof, and belongs to a building material wall brick and a production method thereof. The brick is produced by adopting industrial waste residue red mud as a main raw material, granular blast furnace slag micro-powder, lime and gypsum as auxiliary materials and water glass as an alkaline exciting agent. The red mud raw material-based non-steamed brick concretely comprises, by mass, 70-80% of the red mud, 0-10% of desulfurized ash, 0-10% of slag, 5% of lime, 8-10% of desulfurized gypsum and 0-5% of water glass. The method comprises the following steps: drying the above ingredients, grinding, weighing the ingredients, mixing according to above proportions, molding, and carrying out standard maintenance and natural maintenance. The above molding process is simple, and is characterized by direct casting vibration molding without pressurization, and the above natural maintenance process is characterized by normal-temperature rapid reaction solidification, and has the advantages of no sintering, and no steam or steam press maintenance. The non-steamed brick has the advantages of high compressive strength, strong drying shrinkage resistance, and no efflorescence phenomenon after long-term storage. The method massively using the industrial waste slag has the advantages of resource and energy saving, low cost and small energy consumption.

Owner:CHINA UNIV OF MINING & TECH

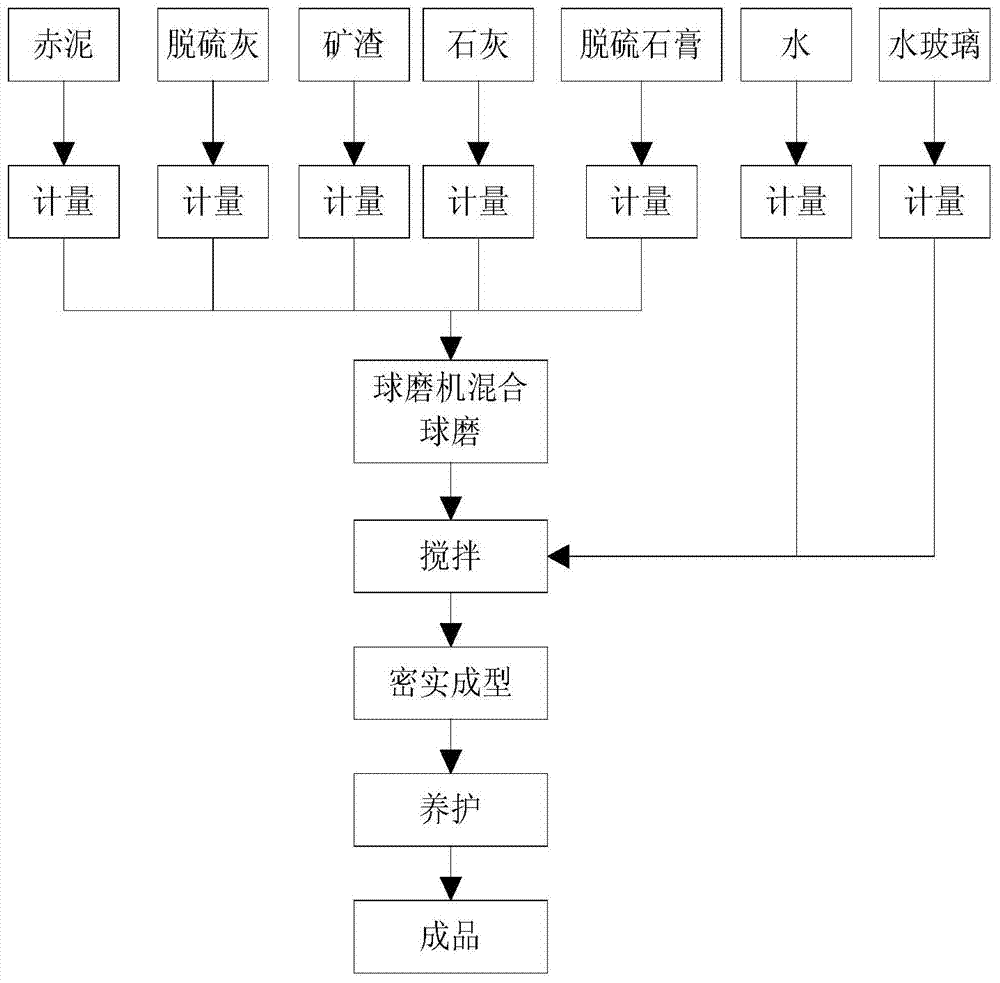

Method for utilizing sulfur-containing refining waste residue for refining slag

InactiveCN101717843AGive full play to the maximum utility valueImprove cleanlinessProcess efficiency improvementCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSlag

The invention relates to a method for recycling sulfur-containing refining waste residue generated in the process of liquid steel refining for refining slag, which is characterized by taking cooling pulverization pretreatment fine powders, roasting the sieving fine powders in the weak oxidizing atmosphere that an oxygen partial pressure is between 0.08 and 0.15atm at a temperature of more than or equal to 1100 DEG C to convert a harmful component CaS to an effective component CaO so as to remove sulfur impurities, and decomposing calcium hydroxide. In the method, the recycling of the sulfur-containing refining waste residue is directly used for reusing the refining slag with high utilization value, and the maximum utility value of the abandoned sulfur-containing refining slag is fully exerted. Compared with the conventional technology application, the invention can increase the value added for each ton of the abandoned sulfur-containing refining slag by more than 800 RMB. Moreover, the sulfur in the sulfur-containing refining waste residue is removed by a simple oxidizing and roasting process to guarantee the cleanliness of the recyling product, the liquid steel resulfurization can not be caused in the recycling process of carrying out the liquid steel desulfuration, the cumulative effect of the sulfur can not be generated in the metallurgy process, and a novel way of recycling the sulfur-containing refining slag is developed.

Owner:NORTHEASTERN UNIV +1

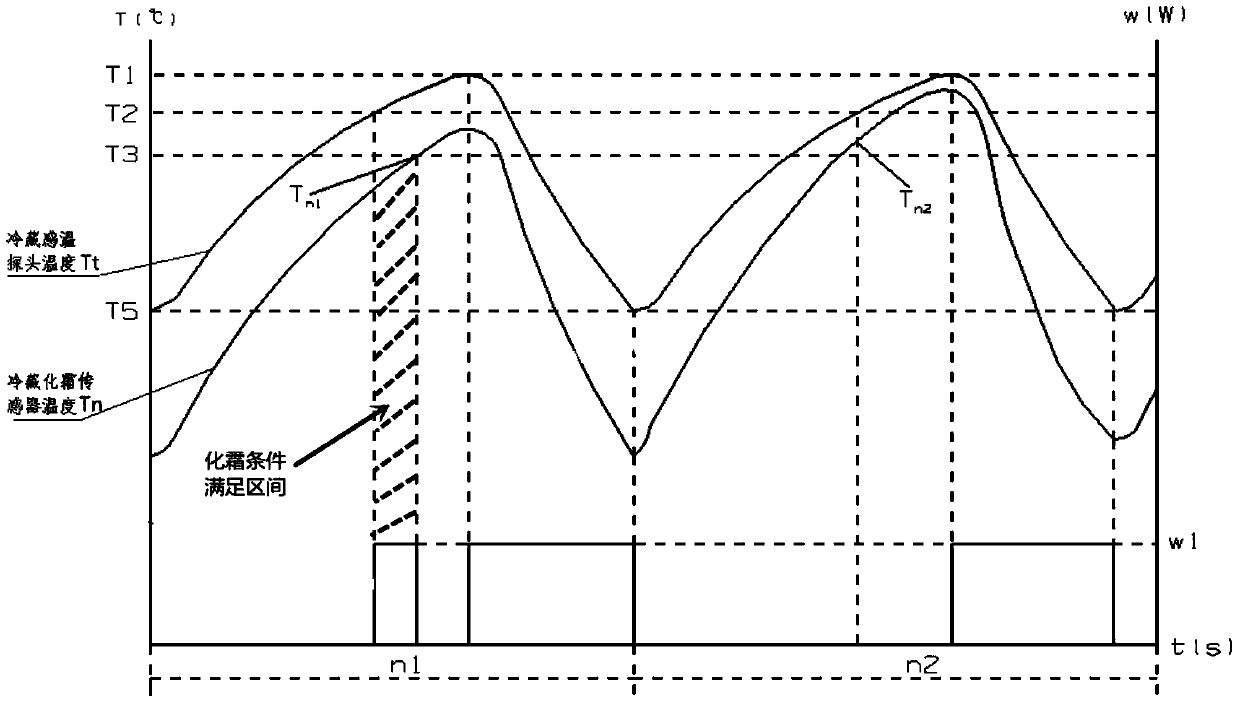

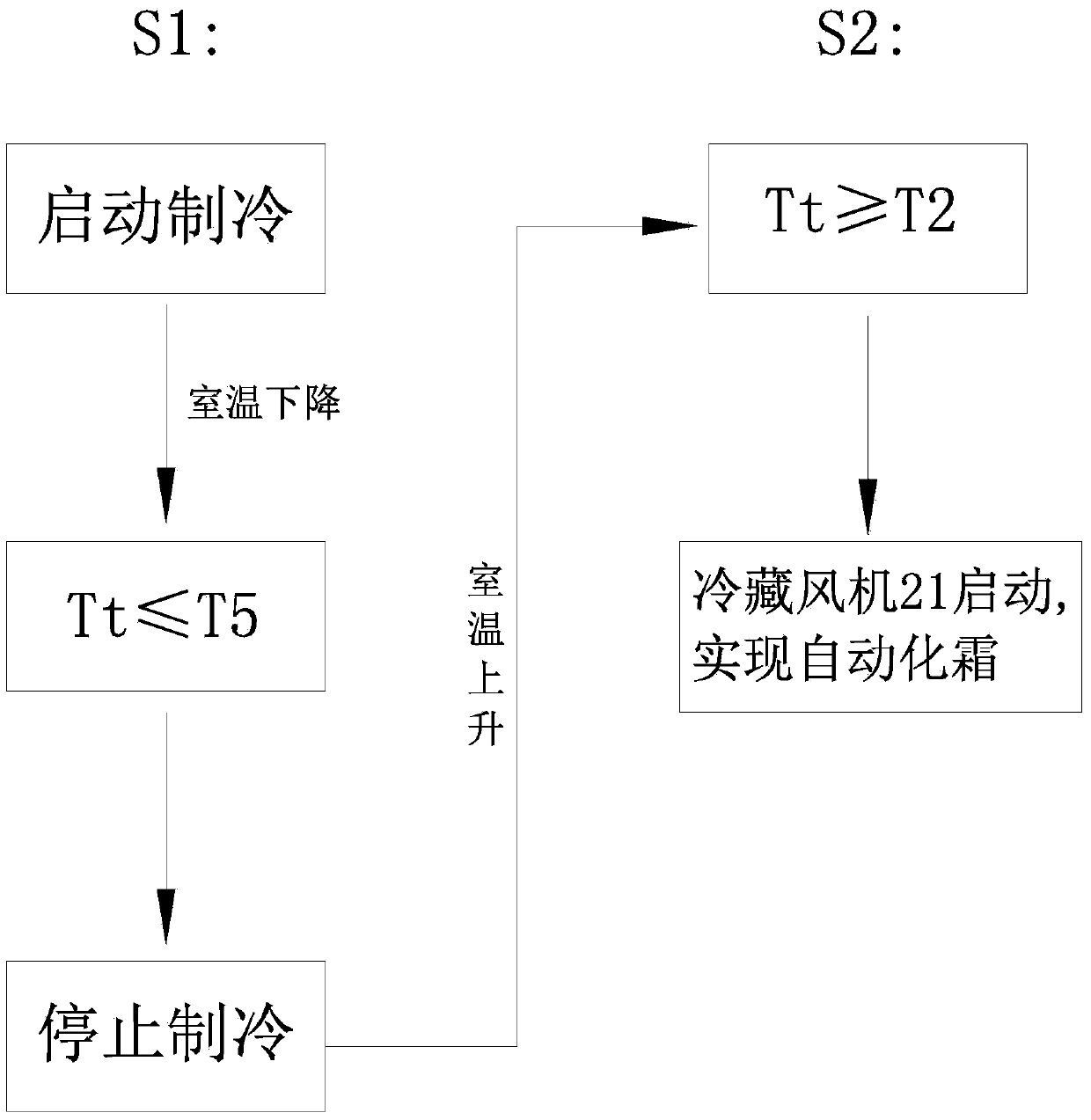

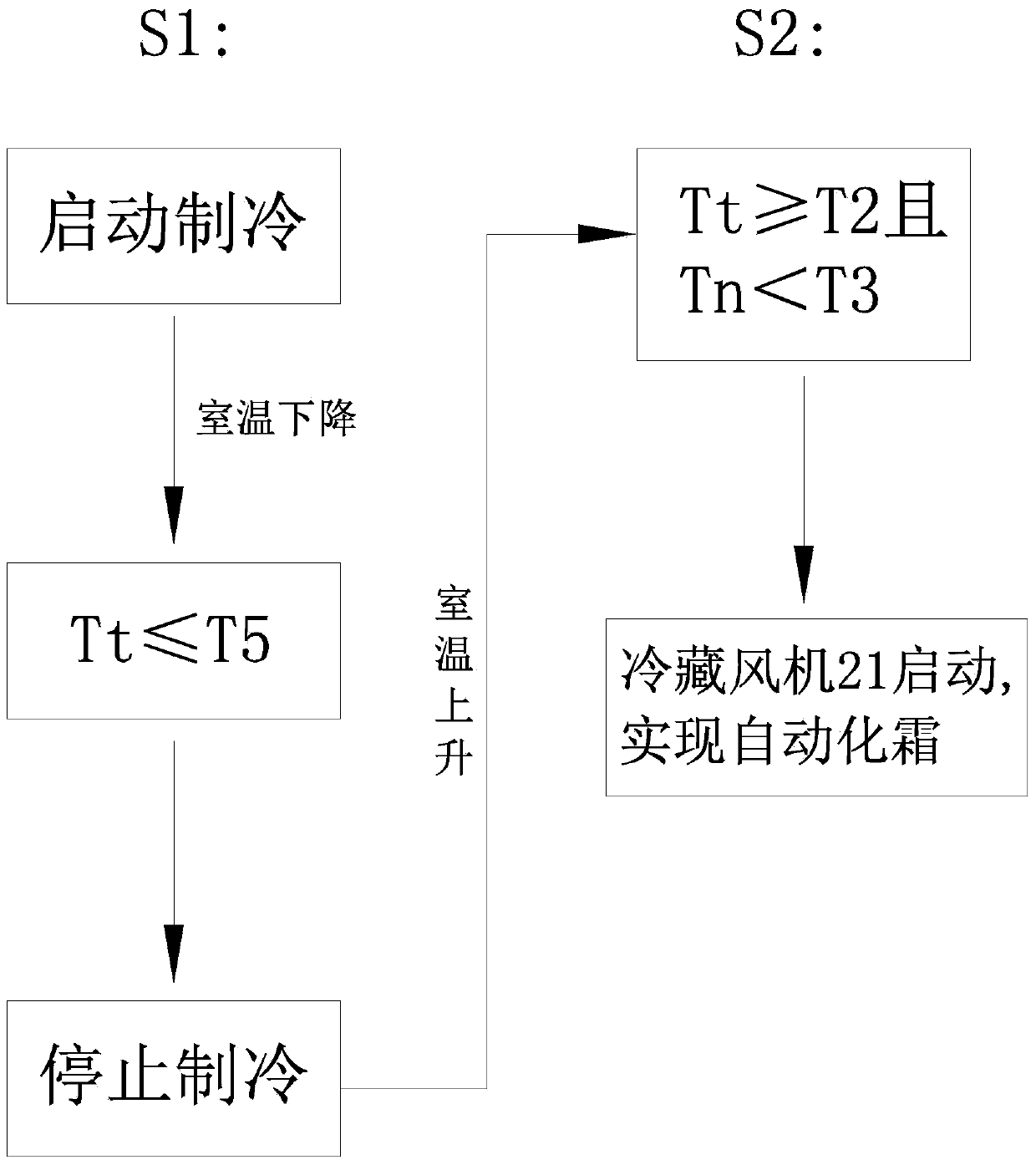

Refrigerator evaporator defrosting method

InactiveCN104329872AReduce manufacturing costs and energy consumptionReduce manufacturing costLighting and heating apparatusDefrostingPhysicsCool storage

The invention relates to the technical field of refrigeration, in particular to a refrigerator evaporator defrosting method. The refrigerator evaporator defrosting method comprises the following steps that S1, in a power-on state of a refrigeration system, when the temperature of a cold storage chamber is lowered to the preset halting temperature, the refrigeration system stops, and in addition, a cold storage fan is closed; S2, in a halting state of the refrigeration system, when the temperature of the cold storage chamber rises to the preset defrosting temperature of the cold storage chamber, the cold storage fan starts, and air circulation between the cold storage chamber and an evaporator is formed for carrying out defrosting on the evaporator. The refrigerator evaporator defrosting method has the advantages that in the halting state of the refrigeration system, the rising degree of the temperature of the cold storage chamber is judged, the cold storage fan is automatically started, the air circulation between the cold storage chamber and the evaporator is formed, and warm air flow of the cold storage chamber can be utilized for carrying out defrosting on the evaporator, so the evaporator can realize automatic defrosting, the additional increase of defrosting components is not needed, and the manufacturing cost and the energy consumption are effectively reduced.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

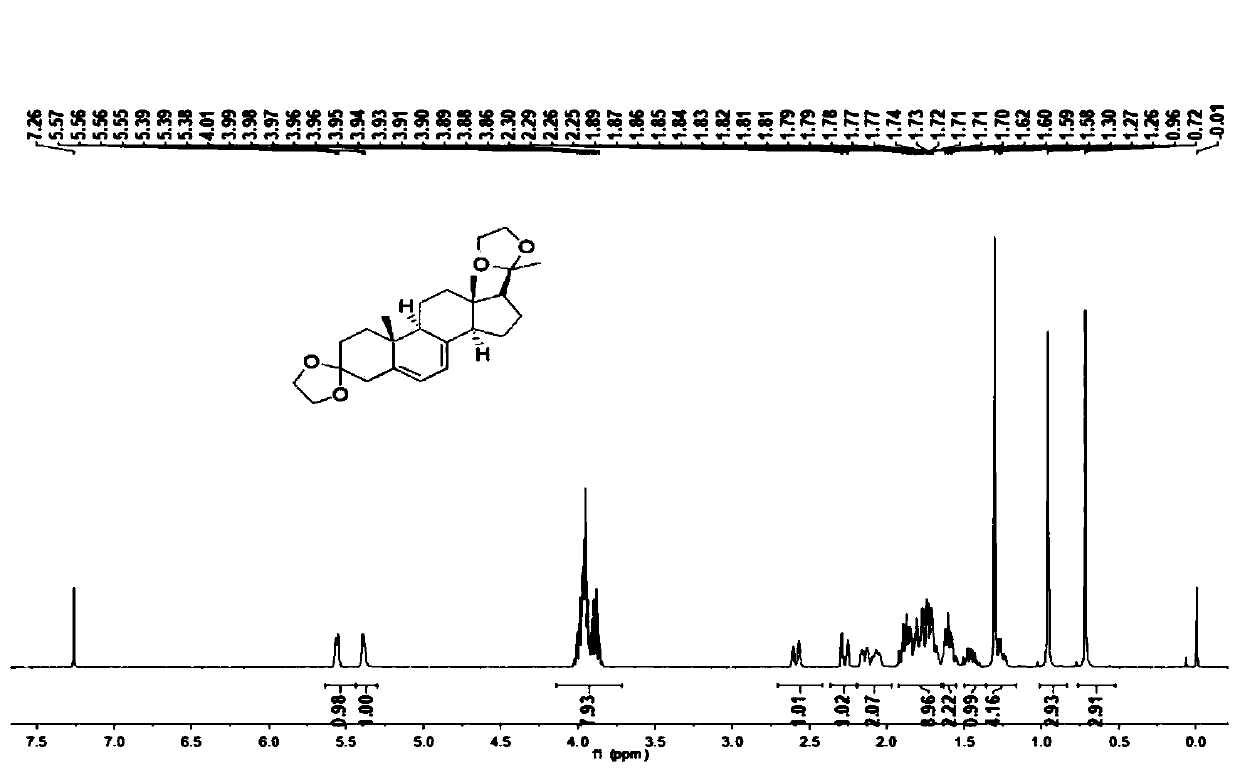

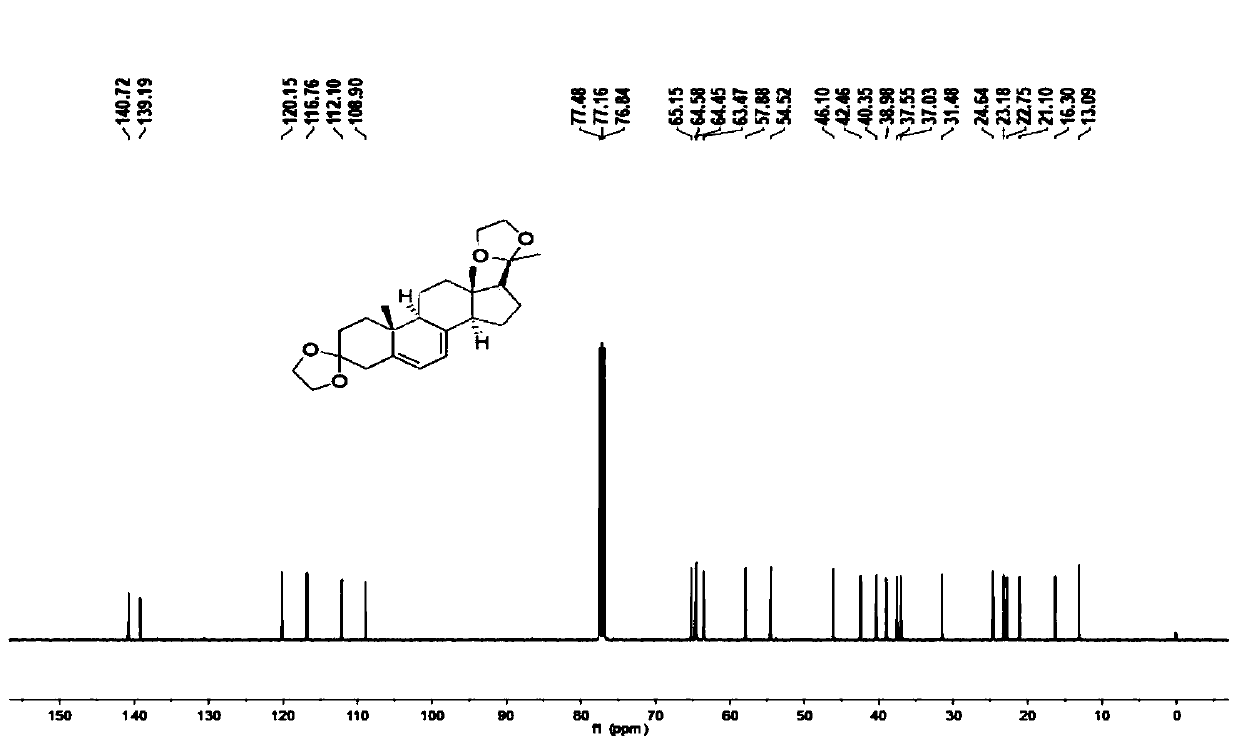

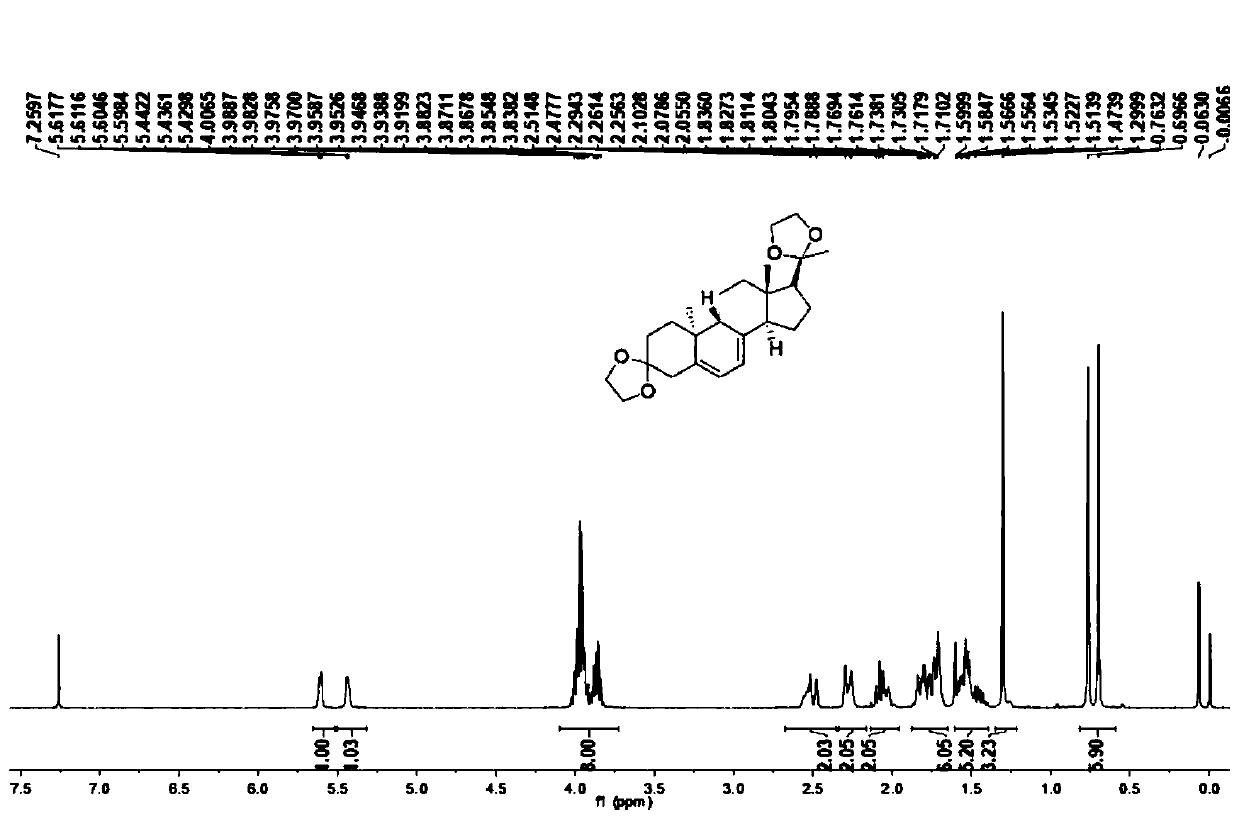

Production process capable of industrially synthesizing dydrogesterone

The invention discloses a production process capable of industrially synthesizing dydrogesterone. Easily available progesterone is used as a raw material, and dydrogesterone is prepared through the steps of carbonyl protection, bromination, debromination, photochemical ring-opening reaction, photochemical ring-closing reaction, deprotection and double bond isomerization. The production process hasthe advantages of easily available initial raw materials, and easiness in implementation of each step and higher yield; the production process is simple and convenient to operate, is green and environment-friendly, and can be easily amplified to industrial production.

Owner:GUANGXI NORMAL UNIV

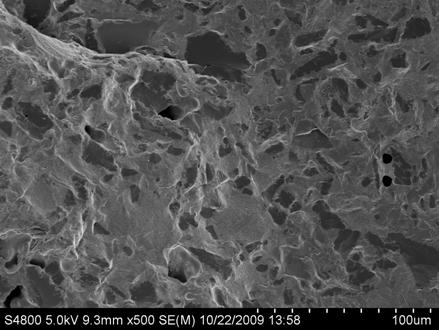

B4C/SiC whisker/SiC multiphase ceramic matrix composite and preparation method thereof

InactiveCN102219536AHigh bonding strengthImprove overall performanceCeramic matrix compositeWhiskers

The invention which belongs to the technical field of ceramic matrix composites concretely relates to a ceramic matrix composite containing multiple ceramic phases of SiC whiskers, SiC particles and B4C particles and a preparation method of a product thereof. The B4C / SiC whisker / SiC multiphase ceramic matrix composite is prepared through carrying out a Si or Si alloy infiltration reaction on a prefabricated member, and the prefabricated member is prepared through carrying out compression molding on raw materials containing at least one of SiC and carbon, SiC whiskers and B4C powder. The B4C / SiC whisker / SiC multiphase ceramic matrix composite containing the multiple ceramic phases of the SiC whiskers, the SiC particles and the B4C particles prepared in the invention allows integrated performances of the composites to be improved. In the invention, the spontaneous infiltration reaction method is employed, each advantage of the spontaneous infiltration reaction method is inherited, and the compact multiphase ceramic matrix composite and the product thereof are obtained by carrying out infiltration and reaction sintering on the porous prefabricated member which is composed of B4C and rice hull silicon carbide whiskerizing products containing abundant SiC with Si or the Si alloy.

Owner:ZHEJIANG UNIV

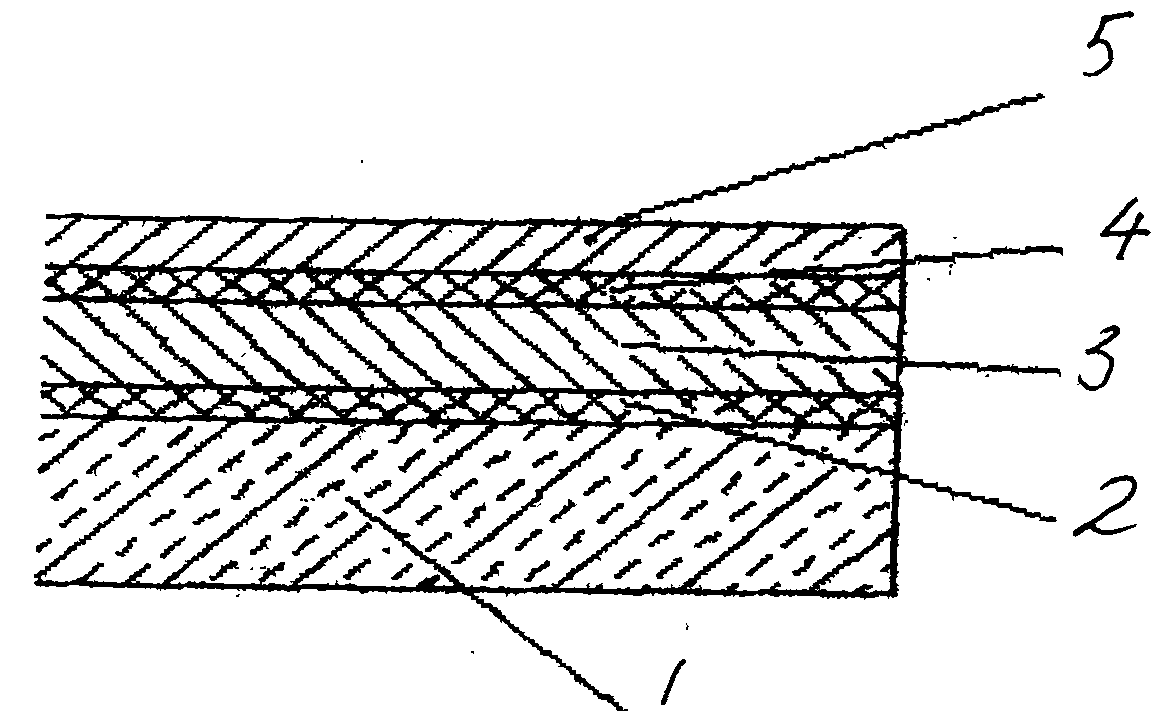

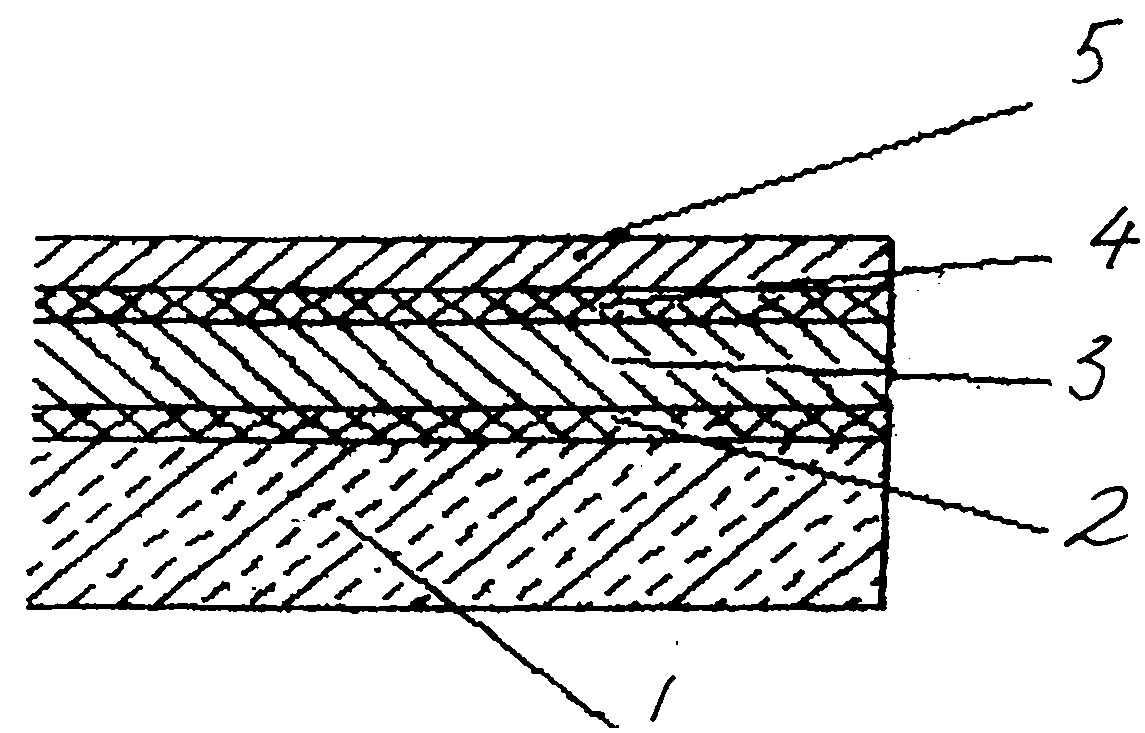

Weather-resistant silver mirror and preparation method thereof

ActiveCN101776778AImprove reliabilityExtended service lifeMirrorsIntermediate frequencyReflective layer

The invention discloses a weather-resistant silver mirror which is particularly suitable for trough solar thermal power generation and a preparation method thereof. The silver mirror orderly consists of a transparent substrate, a first Al2O3 adhesive layer, an Ag reflective layer, a second Al2O3 adhesive protective layer and a SiOx protective layer. The preparation method thereof comprises the step of orderly and respectively plating the first Al2O3 adhesive layer, the Ag reflective layer, the second Al2O3 adhesive protective layer and the SiOx protective layer by adopting a multi-target intermediate frequency response vertical magnetic control sputter to prepare the weather-resistant silver mirror of the invention. The finished product of the weather-resistant silver mirror of the invention has the characteristics of high reflectivity, reliable work, long service life and the like. The preparation method of the invention has the characteristics of advance, reasonability, low cost, low energy consumption, good quality of the finished product and the like.

Owner:常州龙腾光热科技股份有限公司

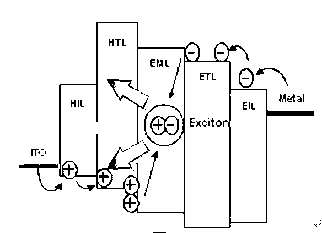

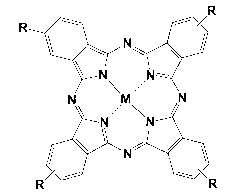

Hole injection material for organic light-emitting device, as well as preparation method and application thereof

InactiveCN103319490AImprove organic solubilityIncrease migration rateOrganic chemistrySolid-state devicesAlkaneElectron hole

The invention relates to a hole injection material for an organic light-emitting device. During a material synthesis process, a straight-chain paraffin group is introduced in the alpha-site of the traditional phthalocyanine ring structure, and different metal substituted ions are used at the centre of the phthalocyanine ring. The hole injection material disclosed by the invention is obtained by performing alkyl substitution on the alpha-site of metal phthalocyanine, simple and convenient to synthesize and purify, and easy to industrially produce in a large scale. Moreover, the pi-conjugated system accumulation of material molecules after film-forming is enhanced, and the carrier migration rate of the material is increased by modifying the interaction force among alkyl groups; a part of isomers can be formed during a synthesis process of alpha-tetra-alkyl substituted phthalocyanine, so that the defect of too high film roughness caused by excessive crystallization during the traditional phthalocyanine molecule film-forming process can be prevented.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

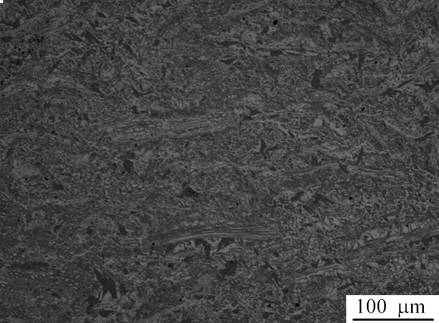

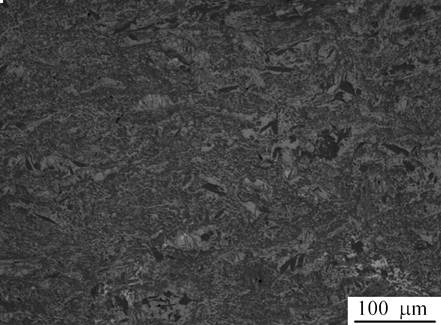

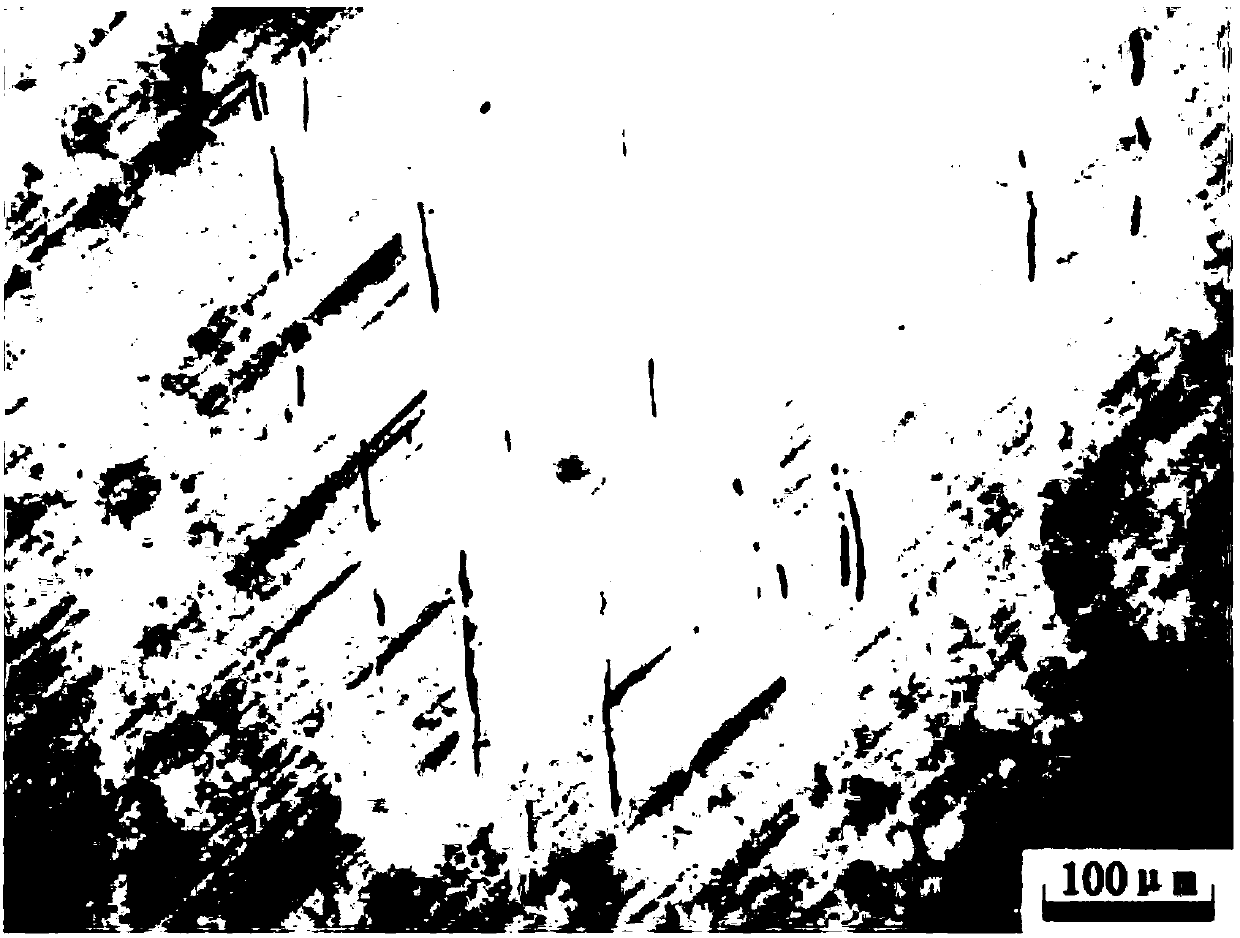

Non-quenched and tempered steel and method for manufacturing automobile semi-axle using non-quenched and tempered steel

InactiveCN109554618AImprove mechanical propertiesReduce preparation energy consumptionQuenchingImpurity

The invention discloses non-quenched and tempered steel and a method for manufacturing an automobile semi-axle by using the non-quenched and tempered steel. The non-quenched and tempered steel is prepared from the components in percentage by mass: 0.43-0.47% of C, 0.50-0.80% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.035% of S, 0.15-0.30% of Cr, 0.10-0.15%of V, 0.01-0.05% of Al, less than or equal to 0.045% of Nb, 0.015-0.035% of Ti, 0.01-0.02% of N, less than or equal to 0.25% of Ni, less than or equal to 0.10% of Mo, less than or equal to 0.03% of Sn, less than or equal to 0.20% of Cu and the balance of Fe and impurities. According to the non-quenched and tempered steel and the method for manufacturing the automobile semi-axle by using the non-quenched and tempered steel, the high-performance micro-alloyed non-quenched and tempered steel is adopted to replace 42CrMoH quenched and tempered steel for the implementation of a semi-axle controlled-forging and controlled cooling manufacturing process, and the quenching and tempering heat treatment process is eliminated, so that energy consumption of the automobile semi-axle manufacturing can besaved by 40-50%, the cost can be reduced by 10-20%, meanwhile, deformation and cracking caused by quenching during quenching and tempering can be reduced, the straightening process is simplified, andthe technical level reaches the domestic leading position.

Owner:SHAANXI AUTOMOBILE GROUP +1

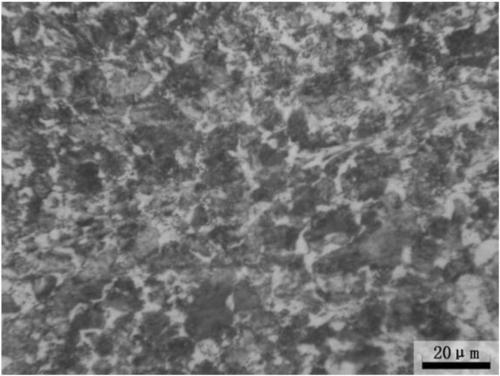

High-concentration coal water slurry and method for efficient classified grain control preparation of high-concentration coal water slurry

ActiveCN106244268AIncrease concentrationReasonable particle size distributionLiquid carbonaceous fuelsHigh concentrationCoal water

The invention provides high-concentration coal water slurry and a method for efficient classified grain control preparation of the high-concentration coal water slurry. Components of the high-concentration coal water slurry comprise coarse-grained coal powder, fine-grained coal slurry or fine-grained coal powder, an additive or water, and the concentration of the coal water slurry is 50 to 75 weight percent, wherein the mass ratio of the dry basis content of the coarse-grained coal powder, the dry basis content of the fine-grained coal slurry or the fine-grained coal powder and the additive is (0-90):(10-100):(0.1-1.0). The high-concentration coal water slurry is reasonable in grain size distribution and high in coal slurry concentration, flowability, stability and atomization performance. By the preparation method, the accumulation efficiency of the coal slurry can be improved, grain size distribution of the coal slurry can be optimized, and compared with a conventional single-rod / ball mill water coal slurry preparation process, the method has the advantage that the concentration can be increased by 4-6 percent or above; the flow is simple, extremely high in operability and extremely low in energy consumption, and long-term safe and continuous production requirements can be met; the prepared coal slurry can meet requirements on gasifying water coal slurry and combustion coal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

Preparation method for semisolid metal and alloy pulp or blank

The invention provides a semi-solid metal and alloy slurry or blank production method. Temperature of over-heat metal and alloy liquid which produce low superheat degree is precontrolled above 5-100 DEG C of its actual liquid line. The said over-heat metal and alloy liquid are directly poured into a crucible i.e. a receiving container. The method is characterized in that: Firstly, at 200-1500mm height, the said over-heat metal and alloy liquid are directly poured into a crucible i.e. a receiving container, after pouring, the crucible and spherical primary crystal semi-solid metal and alloy slurry in the crucible are transferred into structure controller, then spherical primary crystal semi-solid metal and alloy slurry is cooled or uniformly heated, which make spherical primary crystal round and optimizing, and semi-solid metal and alloy slurry temperature field uniform. The advantages of the invention lie in simplified production process, low energy consumption, reducing cost of casting or forging.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing and rheologic molding semisolid alloy pulp

InactiveCN101003863AReduce difficultyReduce manufacturing costMetal-working apparatusTemperature controlCrucible

This invention discloses a method for preparing and rheological-molding semi-solid alloy slurry. The method comprises: pouring overheated molten alloy into a crucible through a vertical snake-shaped channel, transferring the crucible with semi-solid alloy slurry into a temperature controller, post-cooling or controlling the temperature field of the semi-solid alloy slurry, pouring the semi-solid alloy slurry into the chamber of an extrusion-casting machine or a press-casting machine, or into the mold of a forging machine, pressing for molding, curing, demolding, and talking out the cast. The method has such advantages as simplified process, lowered energy consumption, shortened process flow, and lowered cost.

Owner:UNIV OF SCI & TECH BEIJING

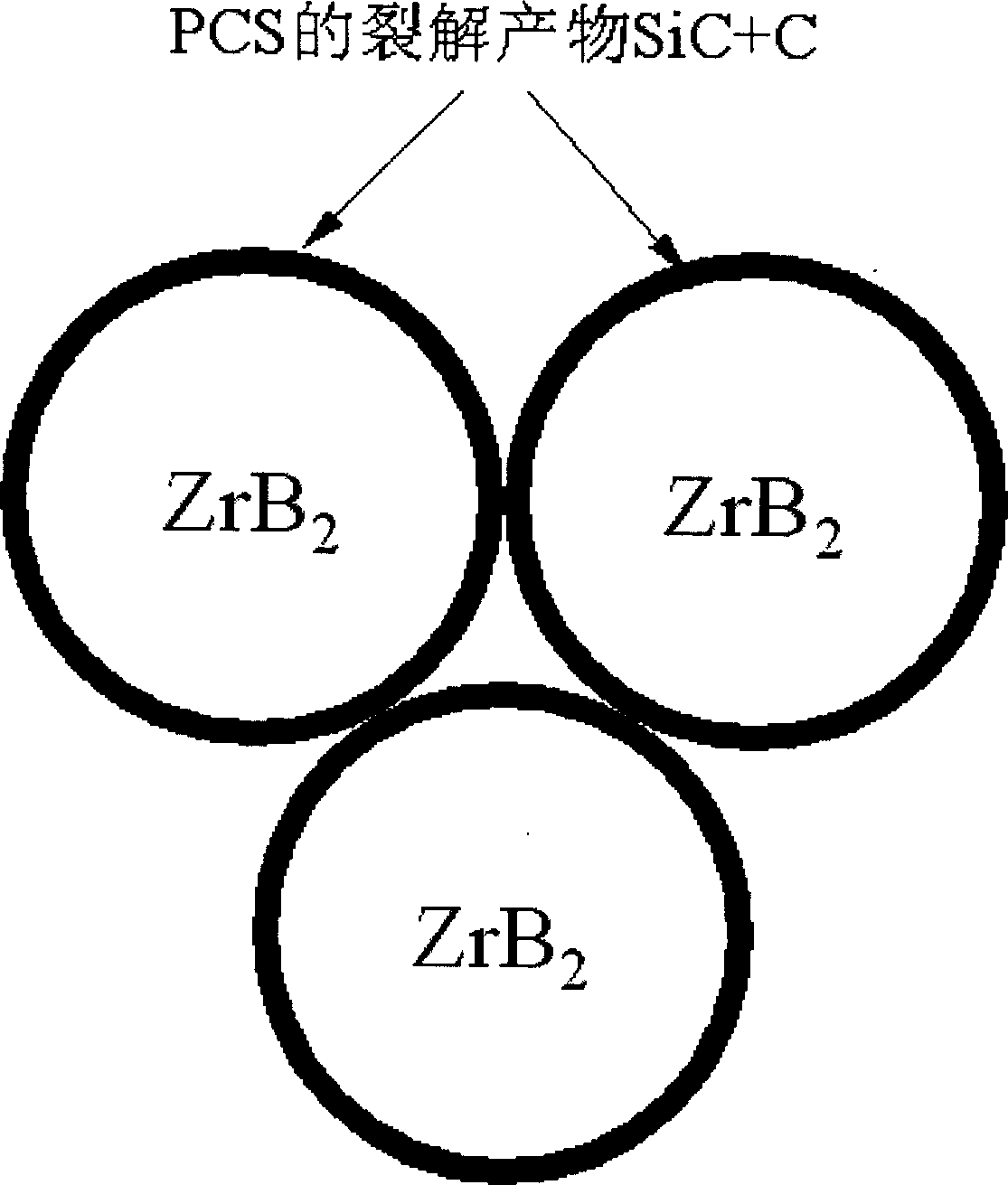

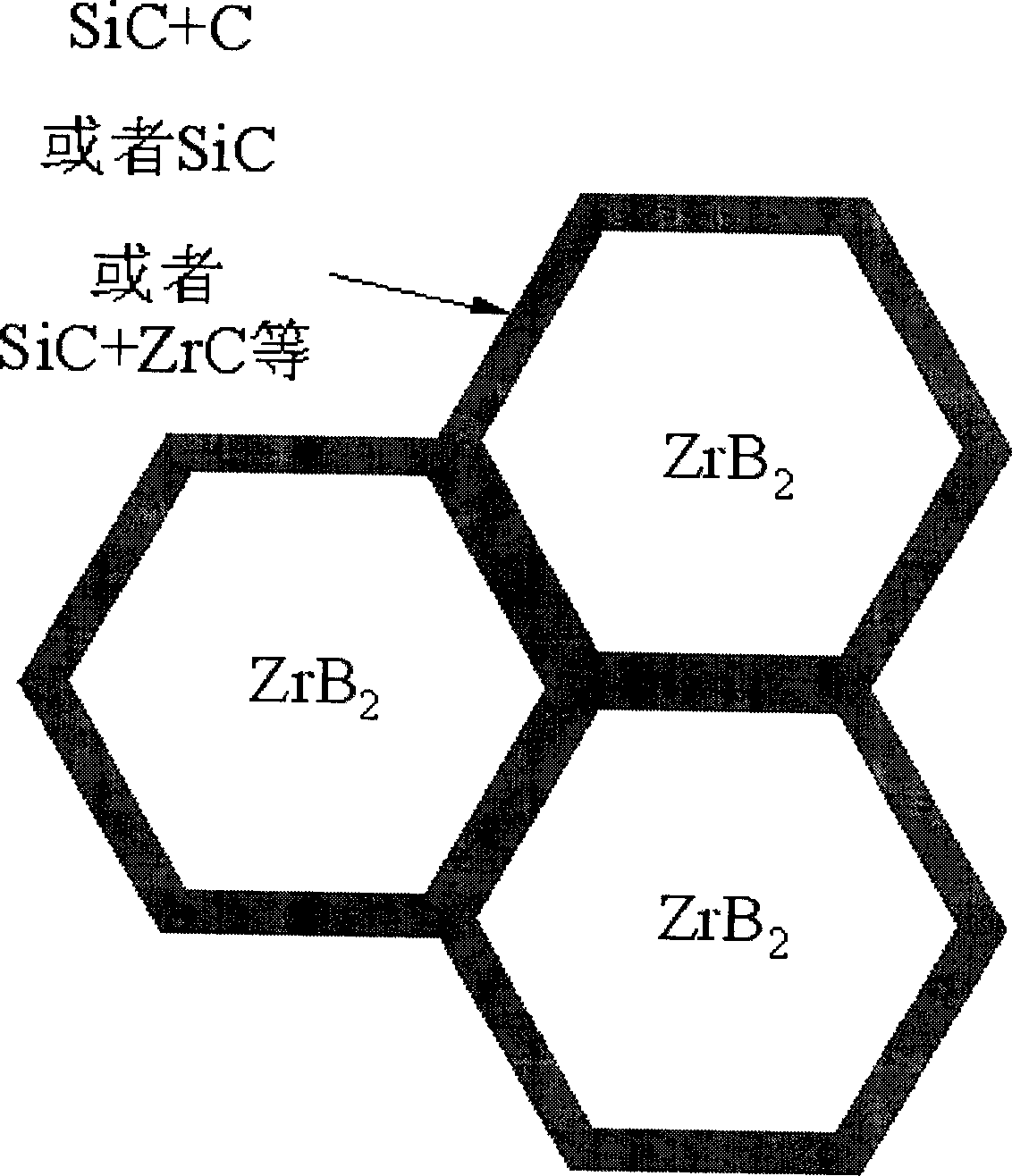

Boride-silicon carbide multiple phase ceramic and its preparation method

The invention provides a preparation method for the boride-silicon carbide multiple-phase ceramic by thermal pressing at 1700~1900Deg with 1-12wt% zirconium boride, titanium boride and hafnium boride by the activity of silicon carbide from polysilane cracking. Wherein, the active carbon is packed and combines with the bride. This invention needs not other auxiliary-fire agent to ensure material performance at high temperature, and improves the composite material properties.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

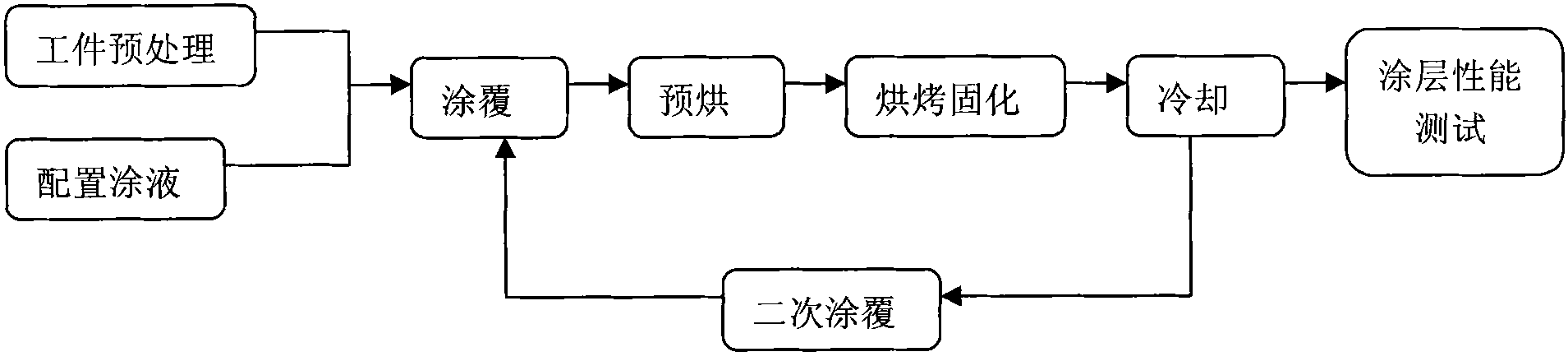

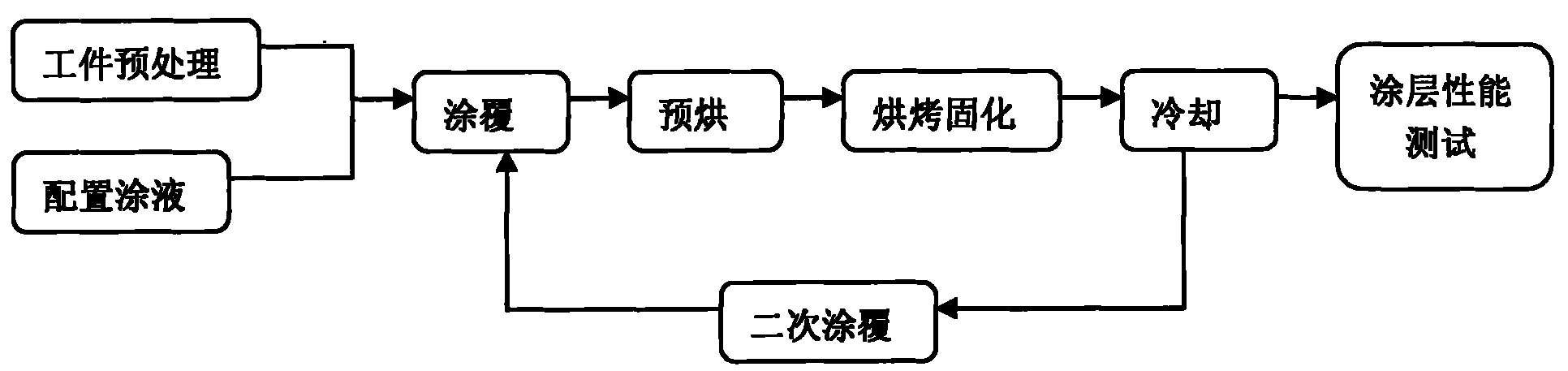

Coating-processing process for marine-climate resisting engineering-part surface coating

ActiveCN102463212AReduce preparation energy consumptionSexual stabilityPretreated surfacesSpecial surfacesOrganic solventSilicon alloy

The invention relates to a coating-processing process for marine-climate resisting engineering-part surface coatings, which comprises the followings steps of: preprocessing a workpiece; configuring a coating solution, wherein the coating solution comprises aluminum-zinc-silicon alloy powder, an organic solvent, a nano-oxide particle enhancer, deionized water, a binder, a corrosion inhibitor, a dispersant and a thickener; coating; preliminarily drying; roasting and curing; cooling; and coating for the second time after cooling the roasted workpiece to the room temperature.

Owner:JIANGSU LINLONG NEW MATERIALS

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765BImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

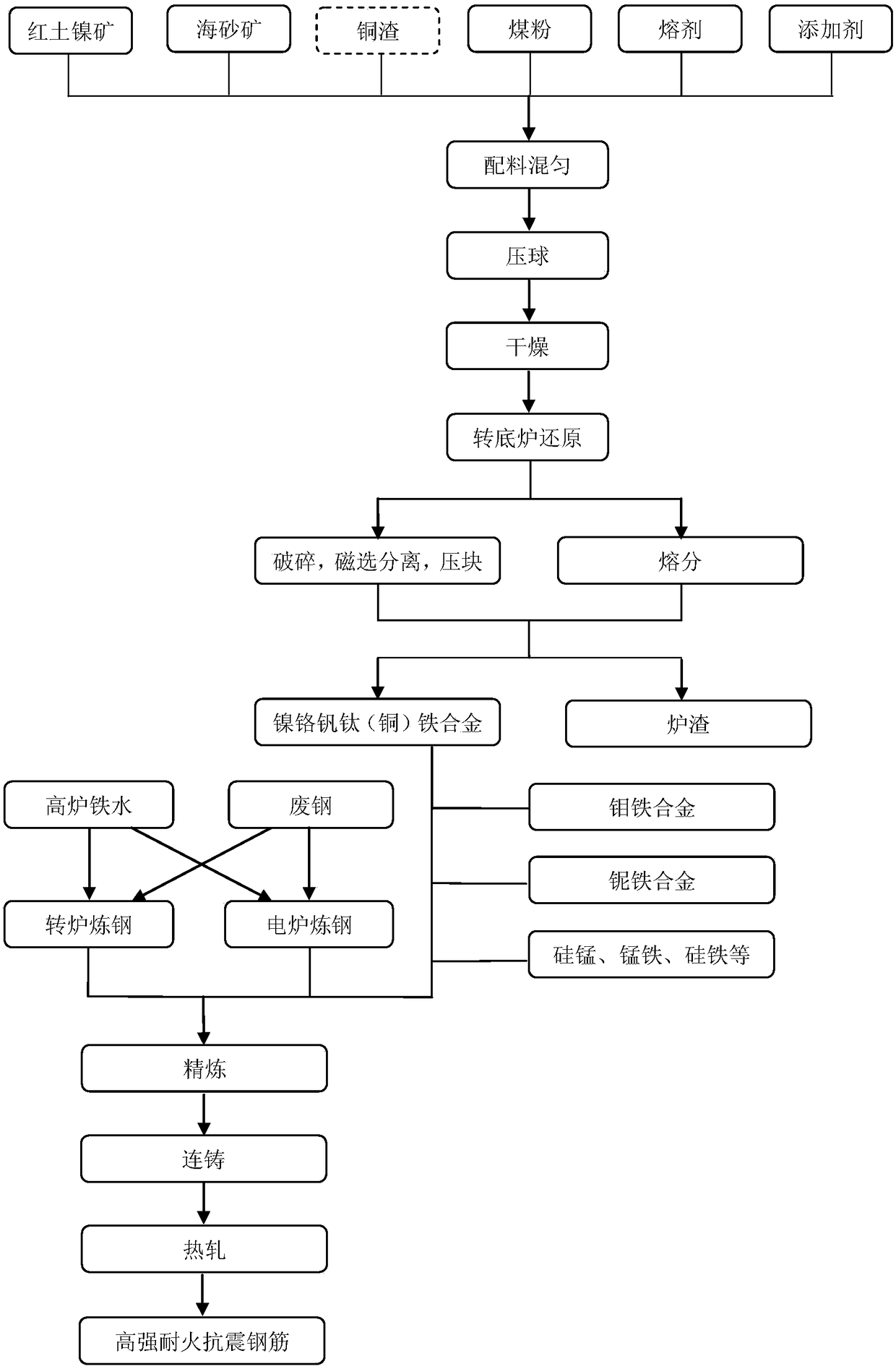

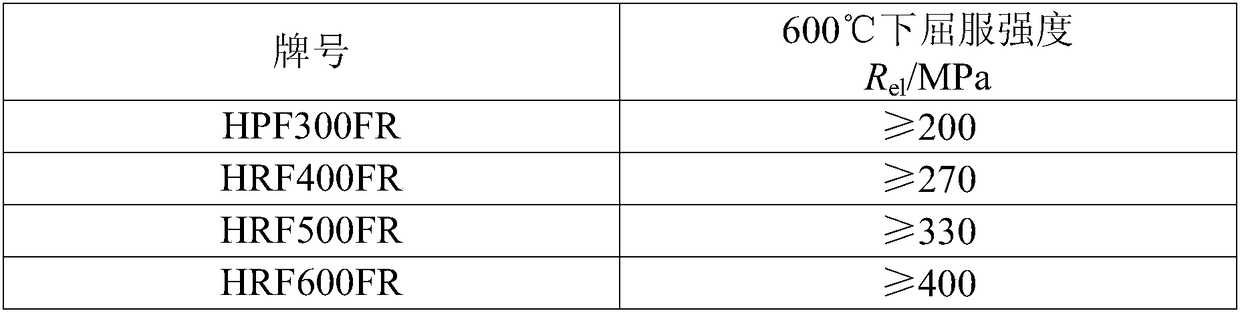

High-strength refractory anti-seismic steel bar and low-cost preparation cost thereof

The invention relates to a low-cost preparation method of a high-strength refractory anti-seismic steel bar, and further discloses the high-strength refractory anti-seismic steel bar. The low-cost preparation method comprises the steps that 1, laterite nickel ore, marine placer and pulverized coal are dried, crushed, levigated and screened to obtain mixed particles; 2, a fusing agent of slaked lime and an additive of syrup are added into the mixed particles to obtain a to-be-reacted material; 3, the to-be-reacted material is subjected to ball pressing treatment to obtain a pellet; 4, the pellet is subjected to direct reduction-magnetic separation or smelting separation treatment to obtain an alloy; and 5, the alloy and ferromolybdenum or ferrocolumbium are added into molten steel, and LF refining, continuous casting and rolling are conducted to obtain the high-strength refractory anti-seismic steel bar. According to the low-cost preparation method of the high-strength refractory anti-seismic steel bar and the high-strength refractory anti-seismic steel bar, compared with separate use of the laterite nickel ore or the marine placer or copper slag, the reduction cost is greatly reduced, and an obtained nickel chromium vanadium titanium copper iron alloy can be directly used for low-cost production of the high-strength refractory steel bar; and the laterite nickel ore, the marineplacer and the copper slag are reasonably utilized, and energy saving and emission reducing are facilitated.

Owner:钢研晟华科技股份有限公司

Preparation method and application of eggshell type molybdenum carbide catalyst

ActiveCN103657633AImprove performanceAchieve eggshell distributionHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsEggshellAlkyne

The invention discloses a fast reaction film formation method to prepare an eggshell type molybdenum carbide catalyst and belongs to the technical field of industrial catalysis. The method comprises the following steps: a carrier with a molybdenum oxide perssad adsorbed on the surface is added into a melamine solution, a film composed of a molybdenum carbide precursor is rapidly generated on the surface of the carrier through the fast reaction of melamine and the molybdenum oxide perssad, and the eggshell type molybdenum carbide catalyst is formed via pyrolysis of the film. According to the invention, the technology is simple, the thickness of the shell layer can be controlled, the energy consumption during the process is low, and the utilization rate and the stability of the active components in the prepared eggshell type molybdenum carbide catalyst are high and excellent. The eggshell type molybdenum carbide catalyst has excellent industrial application prospect and can be used for alkene-alkyne selective hydrogenation reaction and other reactions represented by phenylacetylene selective hydrogenation.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com