Method for preparing semi-solid metal slurry and rheologic molding

A semi-solid metal and slurry technology, used in metal extrusion control equipment, metal processing equipment, metal extrusion and other directions, can solve the problems of troublesome preparation process and complex overall equipment structure, so as to reduce preparation cost and reduce preparation Energy consumption, the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

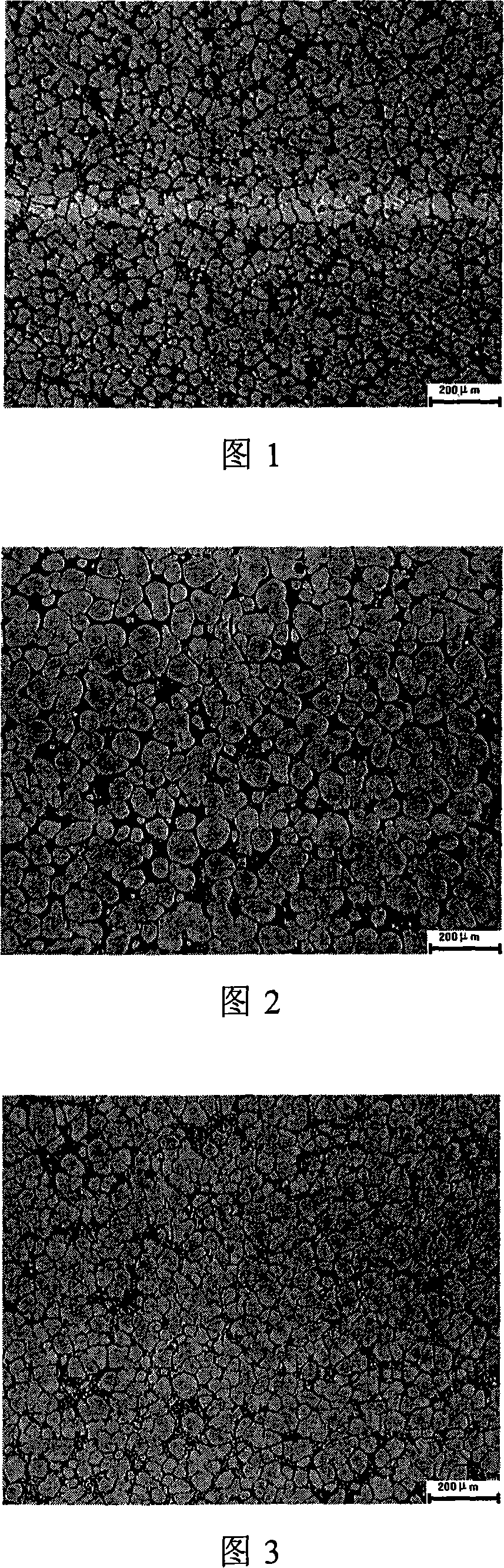

Embodiment 1

[0022] Embodiment 1, using a resistance melting furnace to produce a ZL101A aluminum alloy liquid with a degree of superheat of 15°C (that is, a pouring temperature of 630°C), the height of the inclined pipe section of the inclined straight composite pipe passage is 10mm, and the inner wall of the inclined pipe section is perpendicular to the ground plane. The included angle is 5 degrees; the height of the vertical section of the oblique straight composite pipe channel is 100 mm, the inner diameter of the oblique straight composite pipe channel is 15 mm, and the material of the oblique straight composite pipe channel is graphite. The ZL101A aluminum alloy liquid overheated at 15°C is directly poured into the channel of the inclined straight composite pipe, and flows into the cylindrical preparation crucible of austenitic stainless steel along the inner wall of the inclined straight composite pipe channel. When the ZL101A aluminum alloy When the liquid is partially solidified, t...

Embodiment 2

[0023] Embodiment 2, using a resistance melting furnace to produce a ZL101A aluminum alloy liquid with a degree of superheat of 15°C (that is, a pouring temperature of 630°C), the height of the inclined pipe section of the inclined straight composite pipe passage is 50mm, and the inner wall of the inclined pipe section is perpendicular to the ground plane. The included angle is 10 degrees; the height of the vertical pipe section of the oblique straight composite pipe channel is 50 mm, the inner diameter of the oblique straight composite pipe channel is 20 mm, and the material of the oblique straight composite pipe channel is graphite. The ZL101A aluminum alloy liquid overheated at 15°C is directly poured into the channel of the inclined straight composite pipe, and flows into the cylindrical preparation crucible of austenitic stainless steel along the inner wall of the inclined straight composite pipe channel. When the ZL101A aluminum alloy When the liquid is partially solidifi...

Embodiment 3

[0024] Embodiment 3, using a resistance melting furnace to produce a ZL101A aluminum alloy liquid with a degree of superheat of 85°C (that is, a pouring temperature of 700°C), the height of the inclined pipe section of the inclined straight composite pipe passage is 200mm, and the inner wall of the inclined pipe section is perpendicular to the ground plane. The included angle is 30 degrees; the height of the vertical pipe section of the oblique straight composite pipe passage is 200mm, the inner diameter of the oblique straight composite pipe passage is 30mm, and the material of the oblique straight composite pipe passage is graphite; in the process of pouring the ZL101A aluminum alloy liquid, The inclined and straight composite pipe channel is cooled by the cooling water jacket set outside. The ZL101A aluminum alloy liquid overheated at 85°C is directly poured into the inclined straight composite pipe channel, and flows into the cylindrical graphite preparation crucible along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com