Patents

Literature

61results about How to "Stir vigorously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

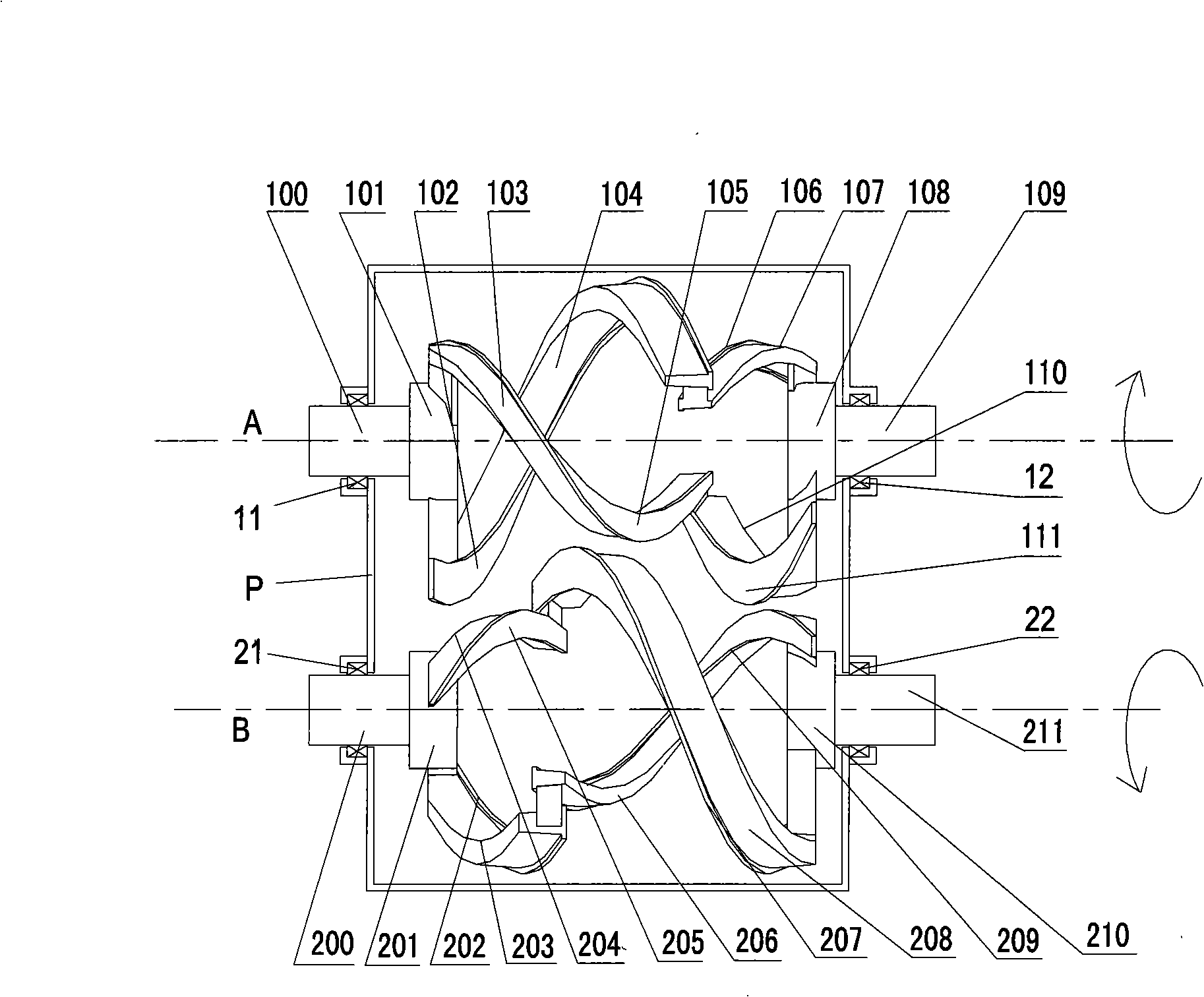

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

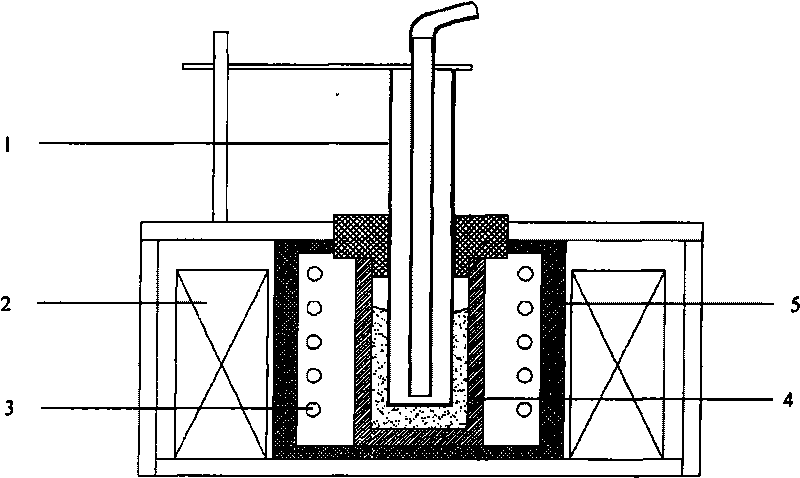

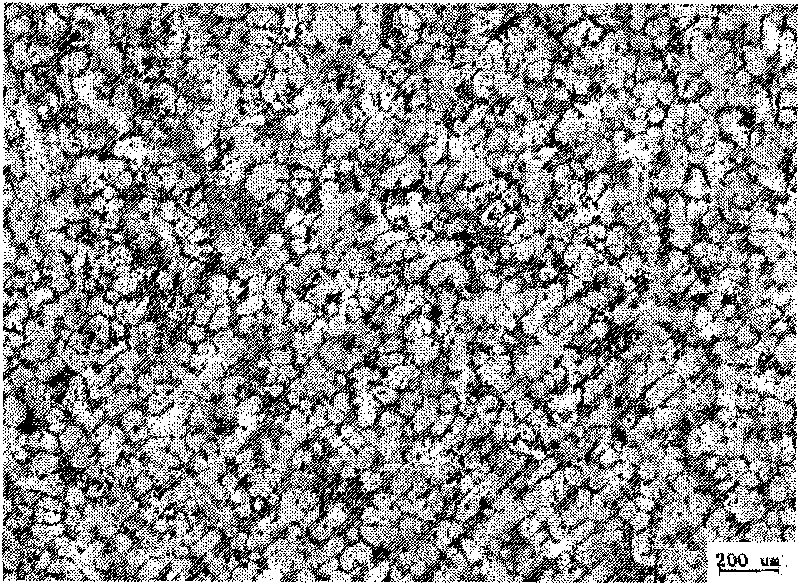

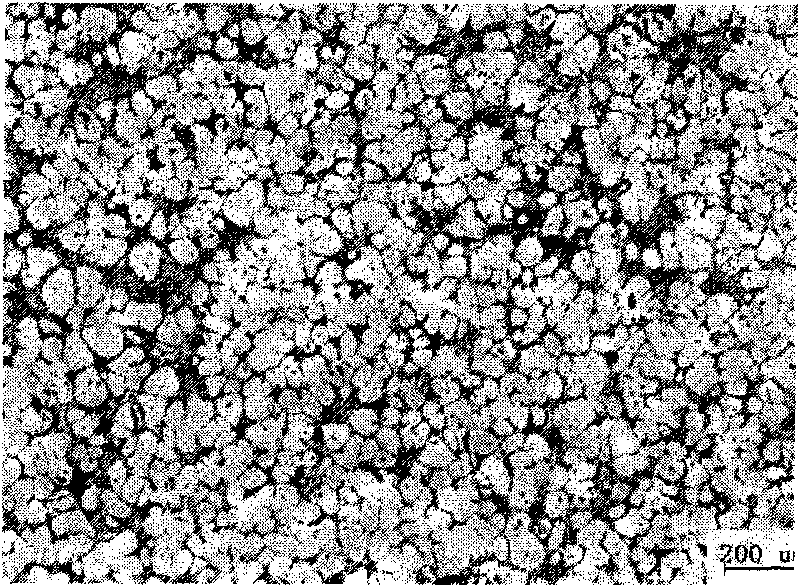

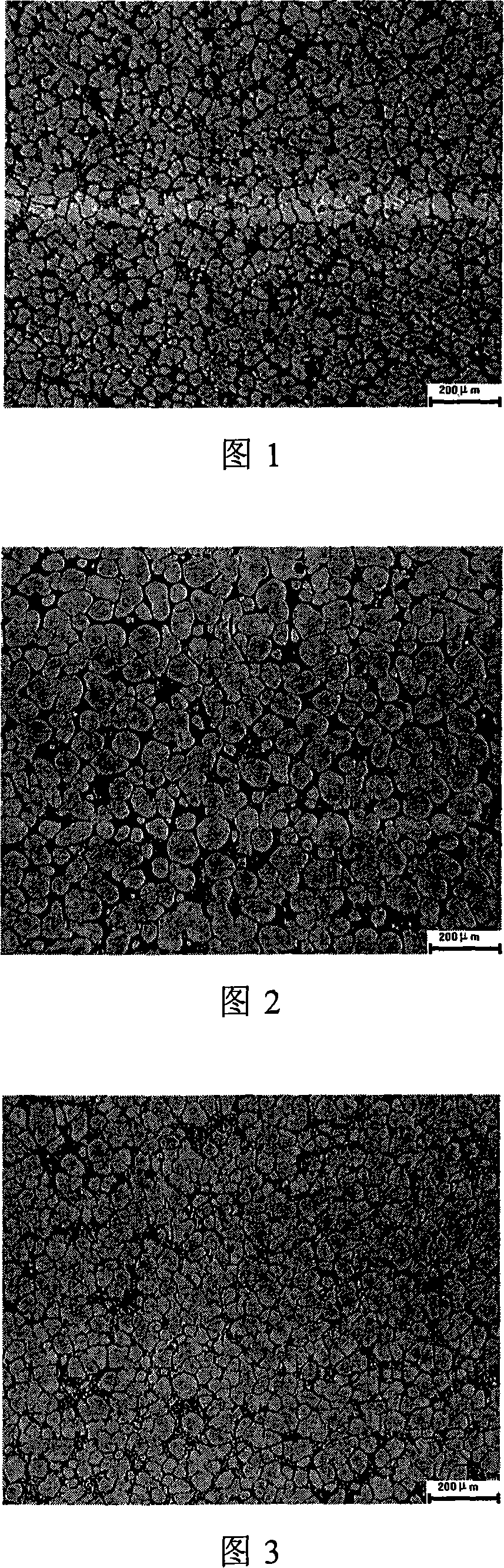

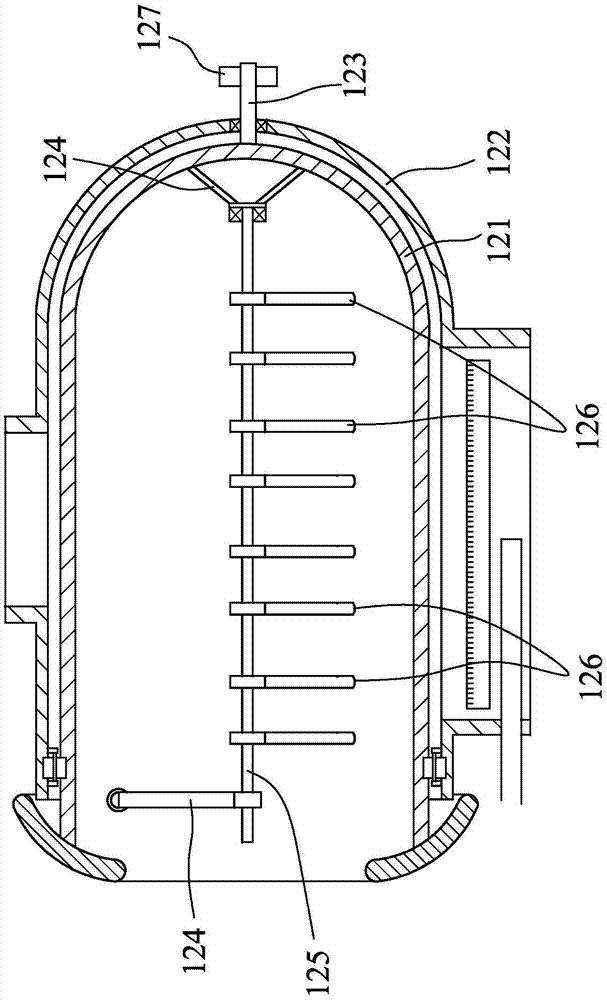

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

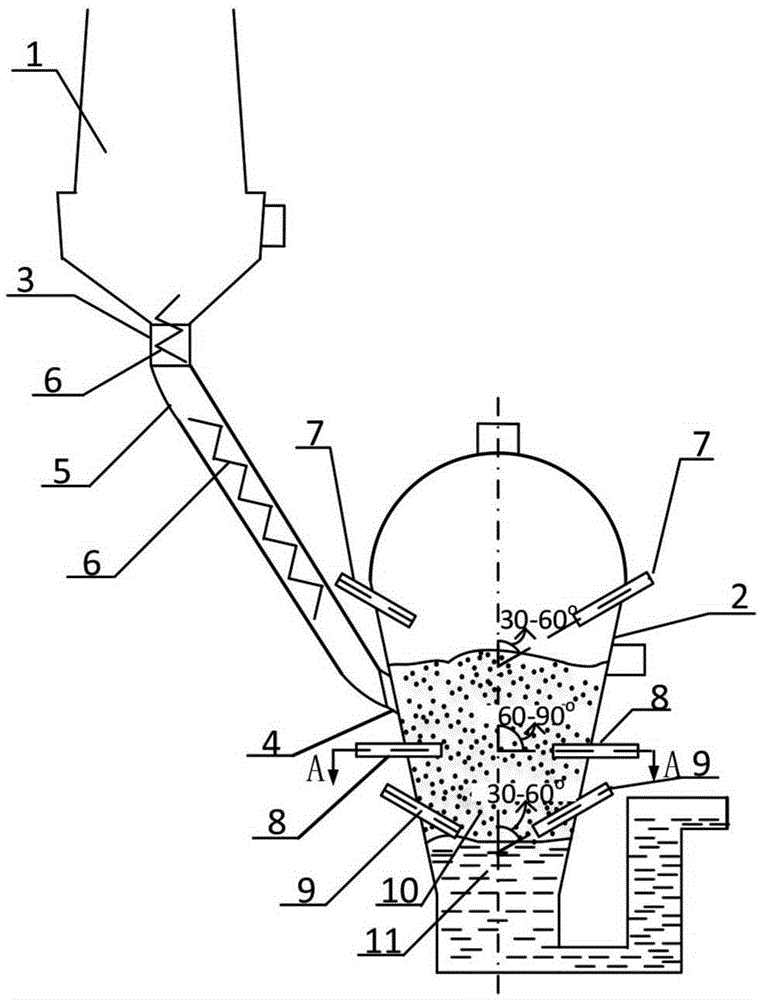

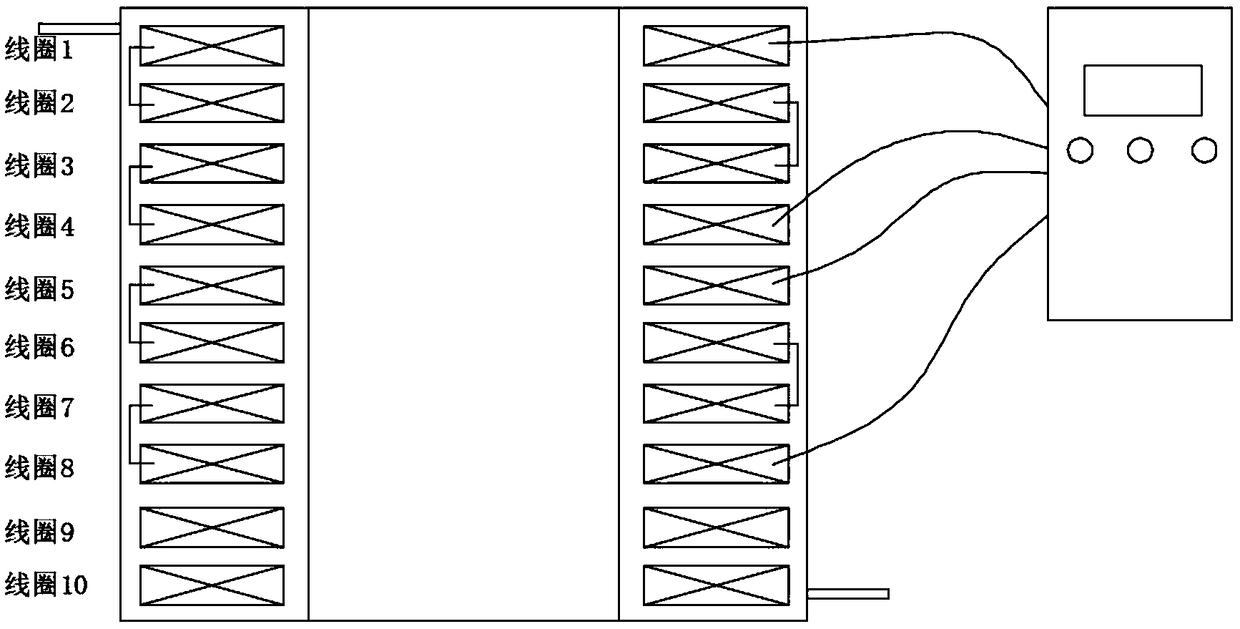

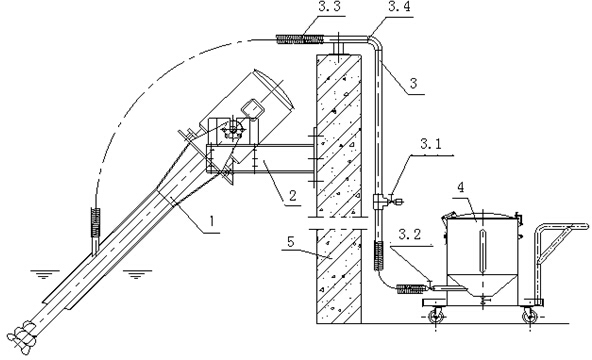

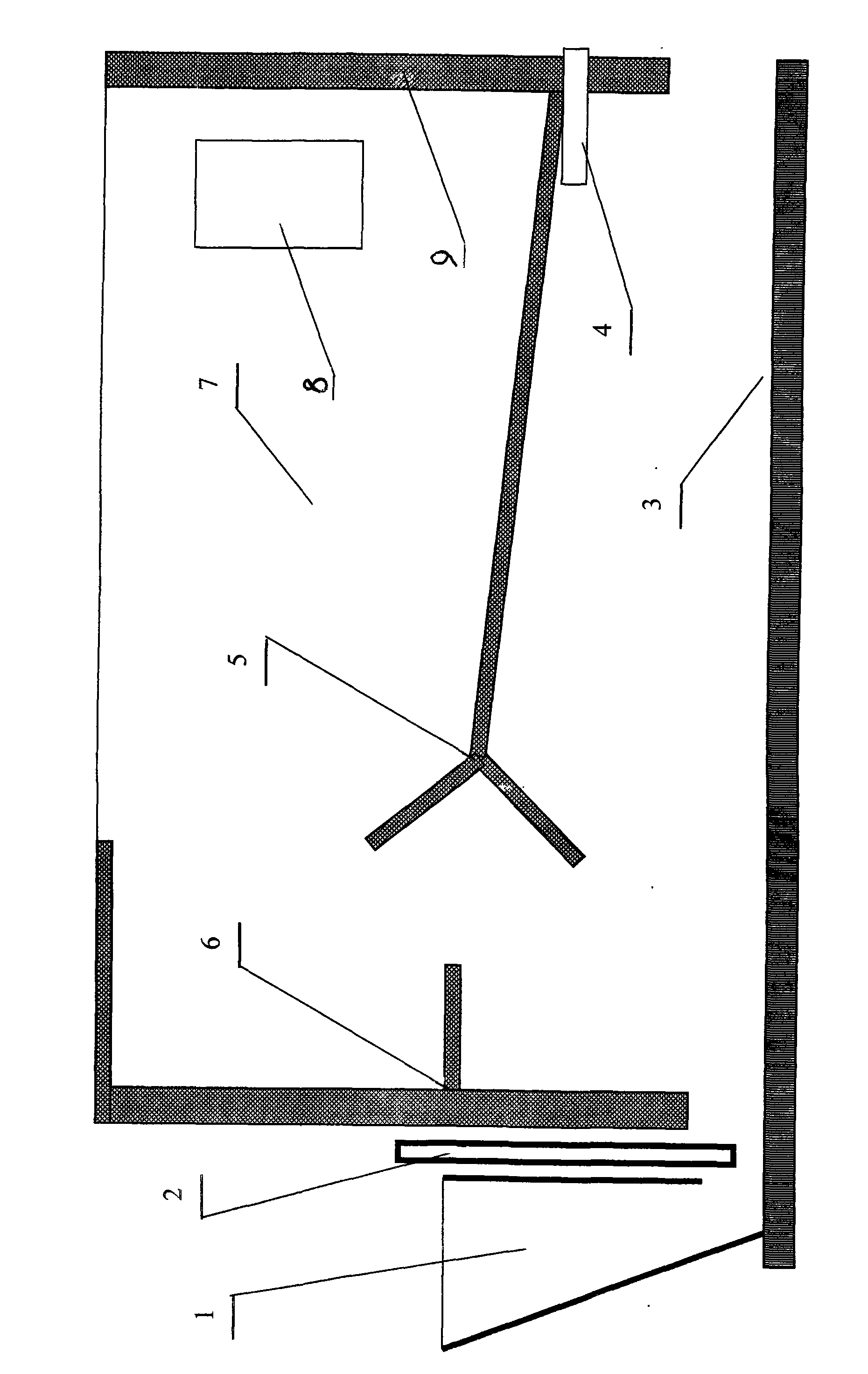

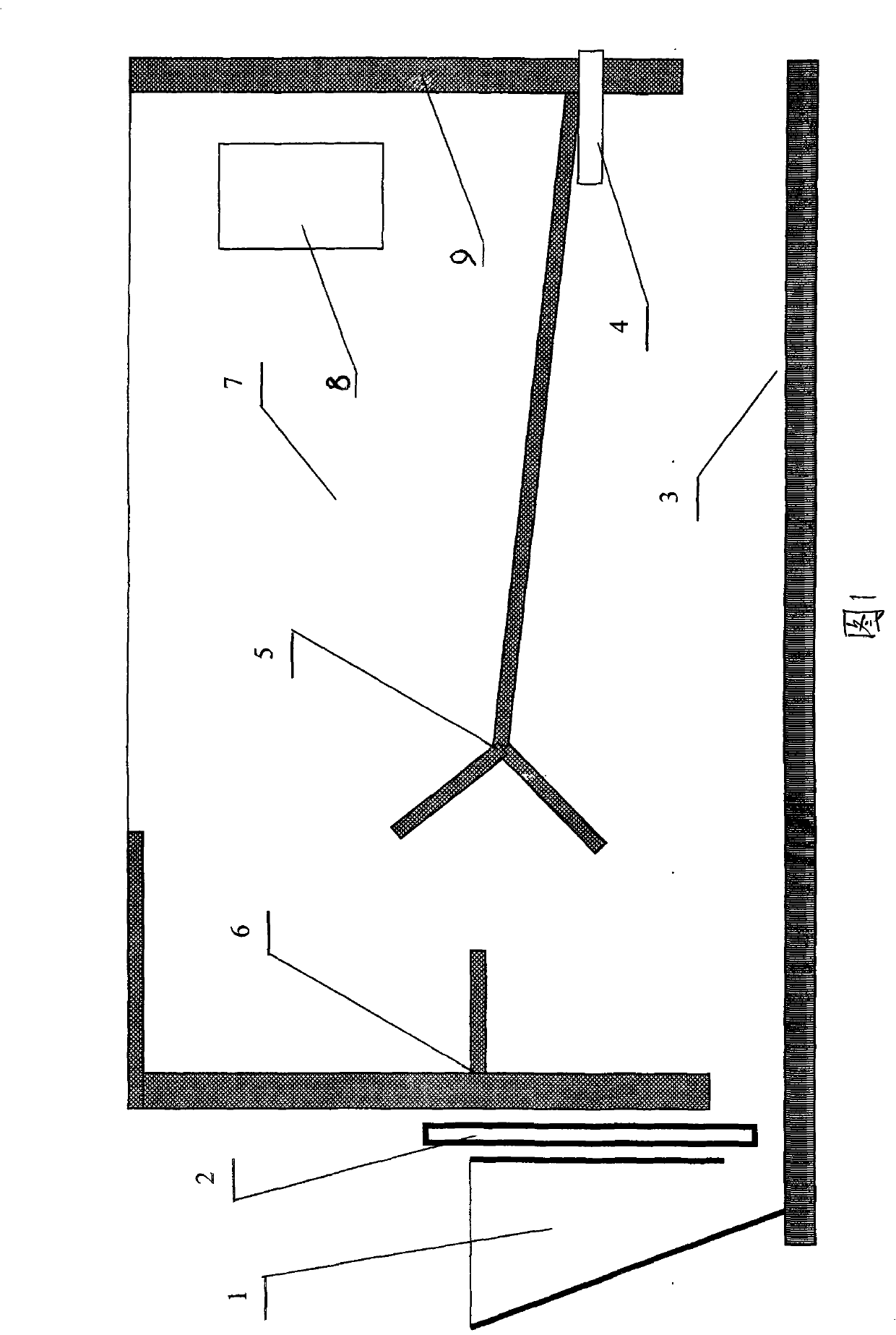

Method for preparing semi-solid metal slurry and rheologic molding

InactiveCN101130203AImprove liquidityEliminates the difficulty of pouringExtrusion control devicesVertical tubeCrucible

The invention discloses a preparing technique of semi-solid metal slurry and rheologic moulding equipment in the preparing technical domain of semi-solid metal slurry, which comprises the following steps: pouring the overheat metal liquid into straight-in composite tube path with an inclined tube and a vertical tube; moving the semi-solid metal slurry and preparing copper into the temperature controller after flowing the overheat metal liquid into the copper along the inner wall of the straight-in composite tube path; doing subsequent cooling or temperature field control for the semi-solid metal slurry; pouring the semi-solid metal slurry into pressing chamber with squeeze moulding machine or squeeze caster or forger to mould; opening or fetching the cast piece or squeeze cast or forge from mould. The invention simplifies the preparing technique, reduces energy consumption and shortens the technical flow path, which reduces the manufacturing cost of the semi-solid metal rheopectic casting die or rheopectic squeeze casting die or rheopectic forge.

Owner:UNIV OF SCI & TECH BEIJING

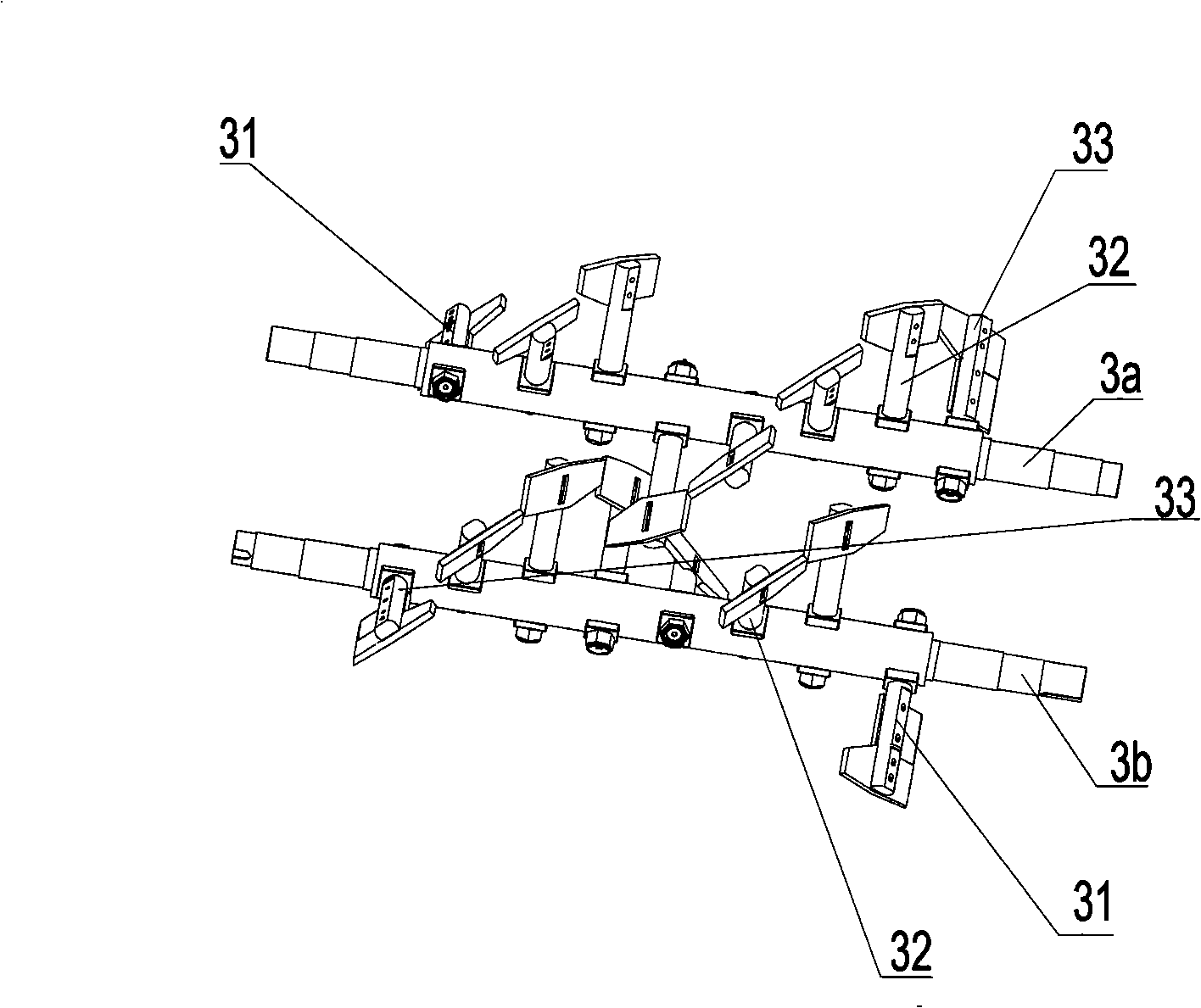

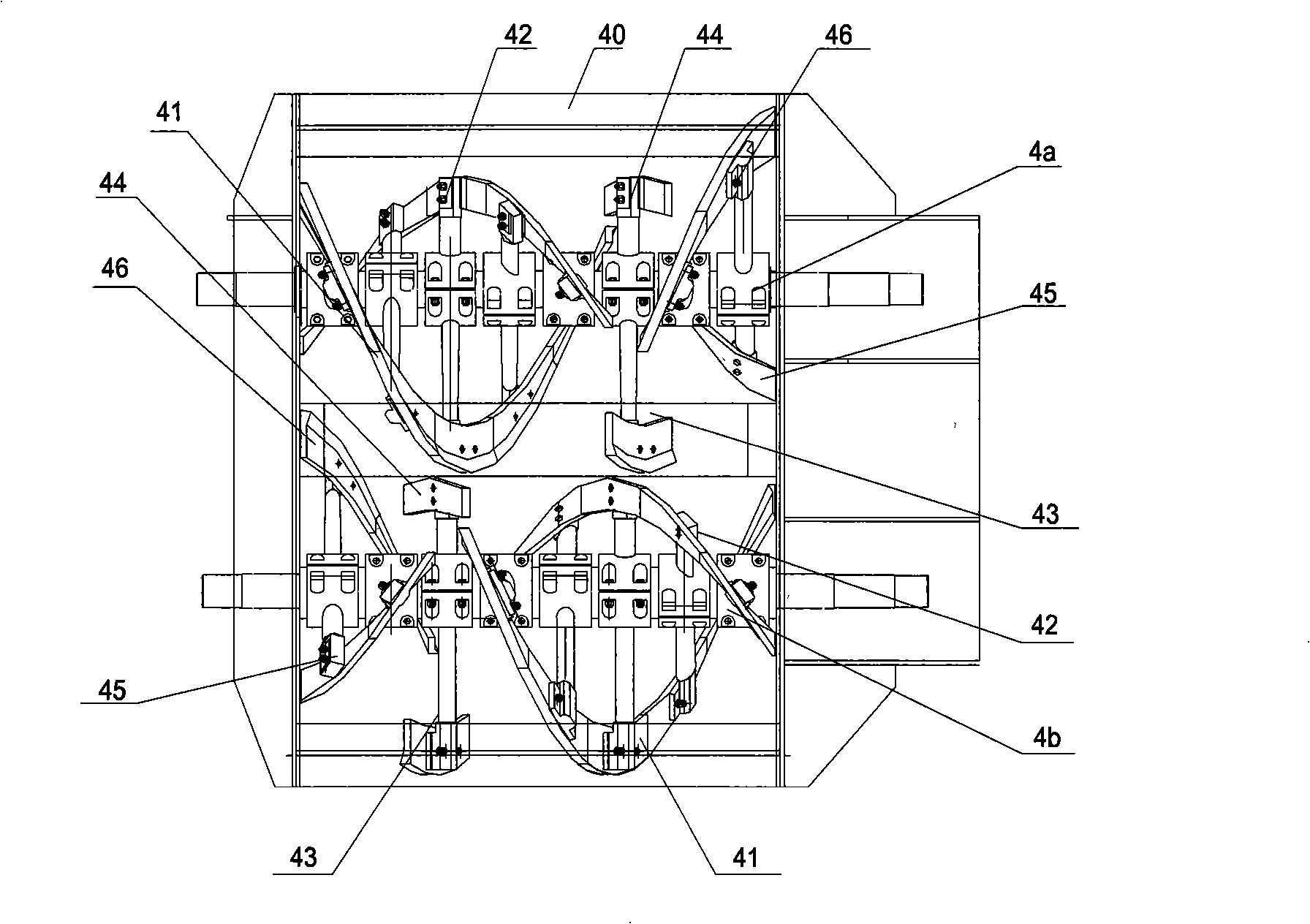

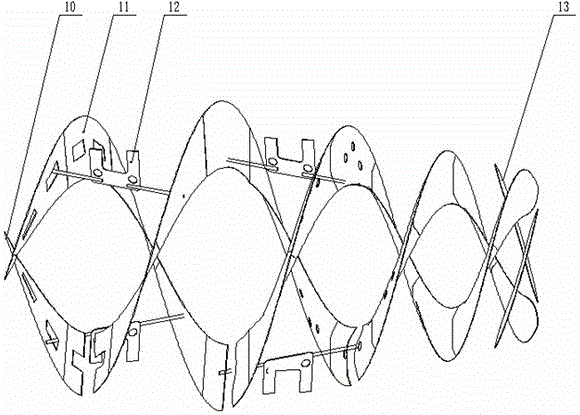

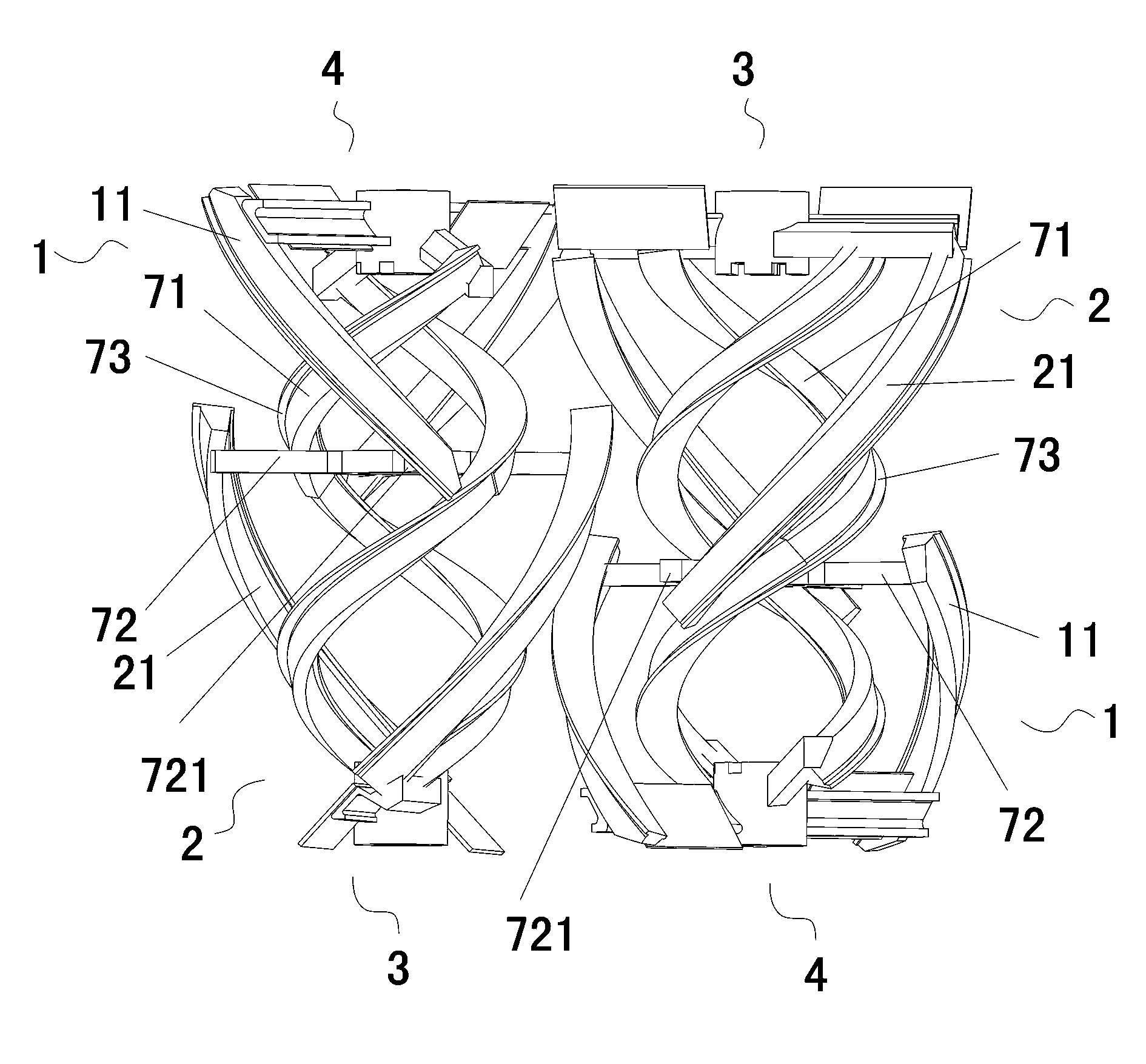

Double-helix shaft double-helical ribbon concrete batch plant

InactiveCN101347961ANot easy to hold the shaft and agglomerateSpeed up the flowCement mixing apparatusFistHorizontal axis

The invention relates to a double spiral axis double spiral ribbon concrete mixing plant, which relates to a mixer for clay or cement and other materials which turns around the horizontal or basically horizontal axis. The concrete mixing plant is provided with a machine body, a first agitation system and a second agitation system. The fist agitation system is provided with a left spindle head, a right spindle head and four spiral axes which are connected with the left and right spindle heads. The second agitation system is provided with the left spindle head, the right spindle and the four spiral axes which are connected with the left and right spindle heads. The direction of the spiral of an internal return unit shaft is opposite to that of the spiral of an internal feeding unit shaft; and the direction of the spiral of an external feeding unit shaft is opposite to that of the spiral of the external return unit shaft. The left and right spindle heads of the first agitation system and the second agitation system are connected with a bearing bracket arranged on the machine body. The speed at which the spindle axes move relative to materials is larger;, so the materials are subject to smaller resistance when being mixed in the mixer, the cement is difficult to curdle around the axes, and the materials flow smoothly in the mixer, thus ensuring that the mixer has .lower energy consumption and higher mixing efficiency, reducing cleaning time and increasing the service efficiency of the mixer.

Owner:蔡达棋

Efficient anti-oxidative acne-removing handmade soap

InactiveCN107937176ADestructiveImprove antioxidant capacitySurface-active non-soap compounds and soap mixture detergentsDetergent compounding agentsBULK ACTIVE INGREDIENTSOAP

The invention relates to a high-efficiency anti-oxidation and anti-acne handmade soap, which is characterized in that: calculated according to the weight fraction, it includes the following components: 10-15 parts of Chinese medicine extract, 5-10 parts of Phyllostachys pubescens leaf extract, 1-10 parts of Pyracantha fruit extract 3 parts, 1-3 parts of indigo fruit extract, 1-2 parts of mangosteen husk extract, 1-2 parts of Italian Buglossia extract, 2-4 parts of lychee leaf extract, 2-4 parts of bayberry leaf extract, Perilla leaf extract 1‑2 parts, mugwort extract 1‑2 parts, nicotinamide 6‑10 parts, tea saponin 0.3‑1 part, seabuckthorn seed oil 70‑100 parts, natural soap base 250‑350 parts. The handmade soap raw material extract of the present invention is extracted by ultrasonic extraction. This process has high extraction efficiency, and the utilization rate of active ingredients in plant and fruit medicines is extremely high, because the biological transdermal accelerator is derived from plant extracts and has good biophase Capacitive, and will not cause damage to the skin, with safety.

Owner:宁波秋日小城智能科技有限公司

Smelting reduction iron-making device and method for avoiding re-oxidation of pre-reduction ores

The invention discloses a smelting reduction iron-making device and method for avoiding re-oxidation of pre-reduction ores, and belongs to the technical field of smelting reduction iron making. The smelting reduction iron-making device adopts an existing shaft furnace and an iron bath furnace as reduction reactors and also comprises a feed port which is used for conveying pre-reduction ores generated by the shaft furnace to the furnace body side surface of the iron bath furnace by adopting a pre-reduction furnace charge descending passage, the furnace charge is further pressed into a slag blanket of the iron bath furnace to avoid the pre-reduction ores from contacting with gas in a free space in the upper part of the iron bath furnace and generating re-oxidation, thereby ensuring that the secondary combustion rate of the gas in the free space is not limited. Three layers of spray guns are arranged on the furnace body of the iron bath furnace, and the secondary combustion rate and the temperature of the gas in the furnace can be adjusted by adjusting the oxygen blowing ratio and the coal injection ratio as well as the total oxygen blowing quantity and the total coal injection quantity of the three layers of the spray guns, thereby providing sufficient heat for a melting bath in the iron bath furnace.

Owner:NORTHEASTERN UNIV

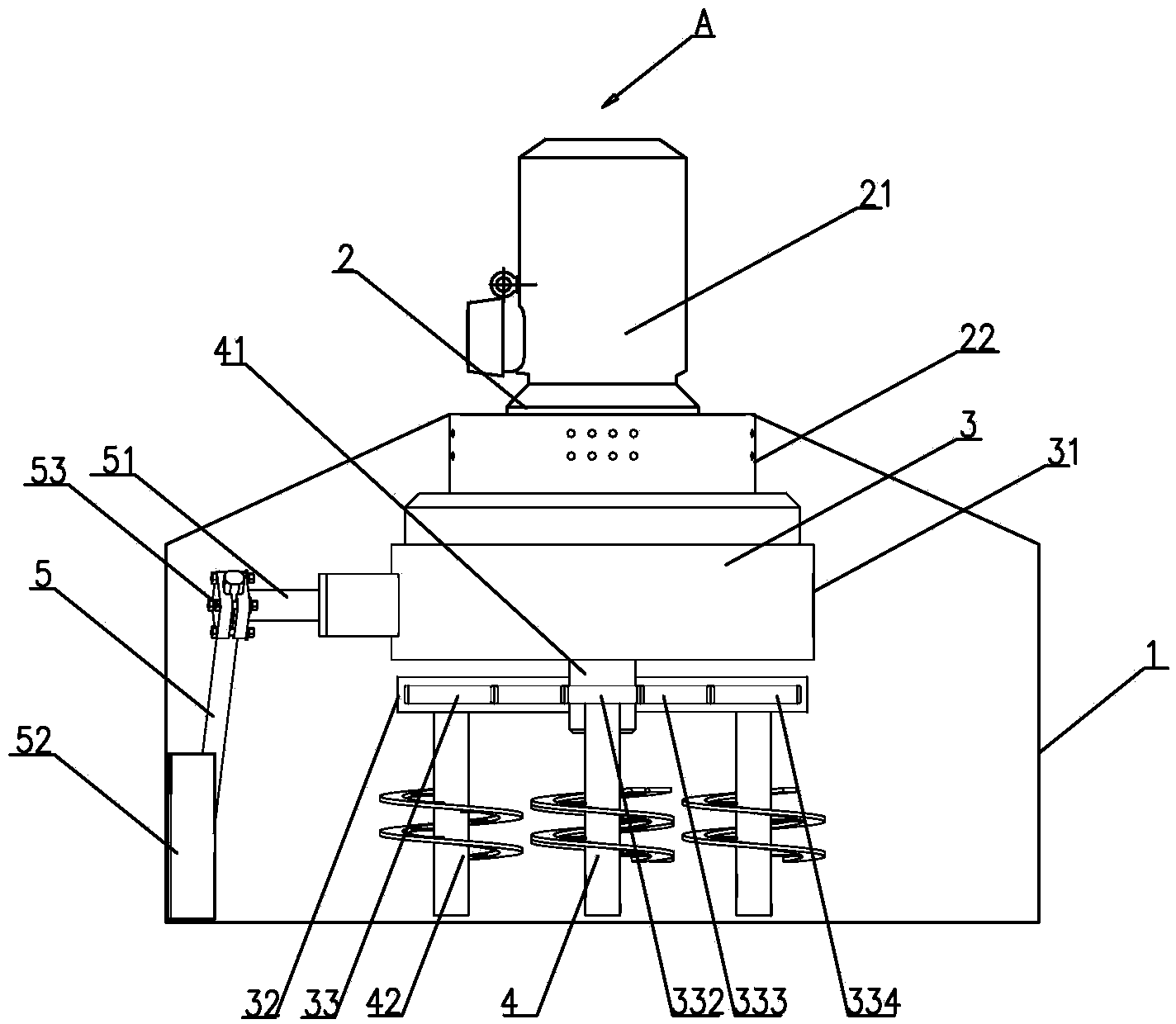

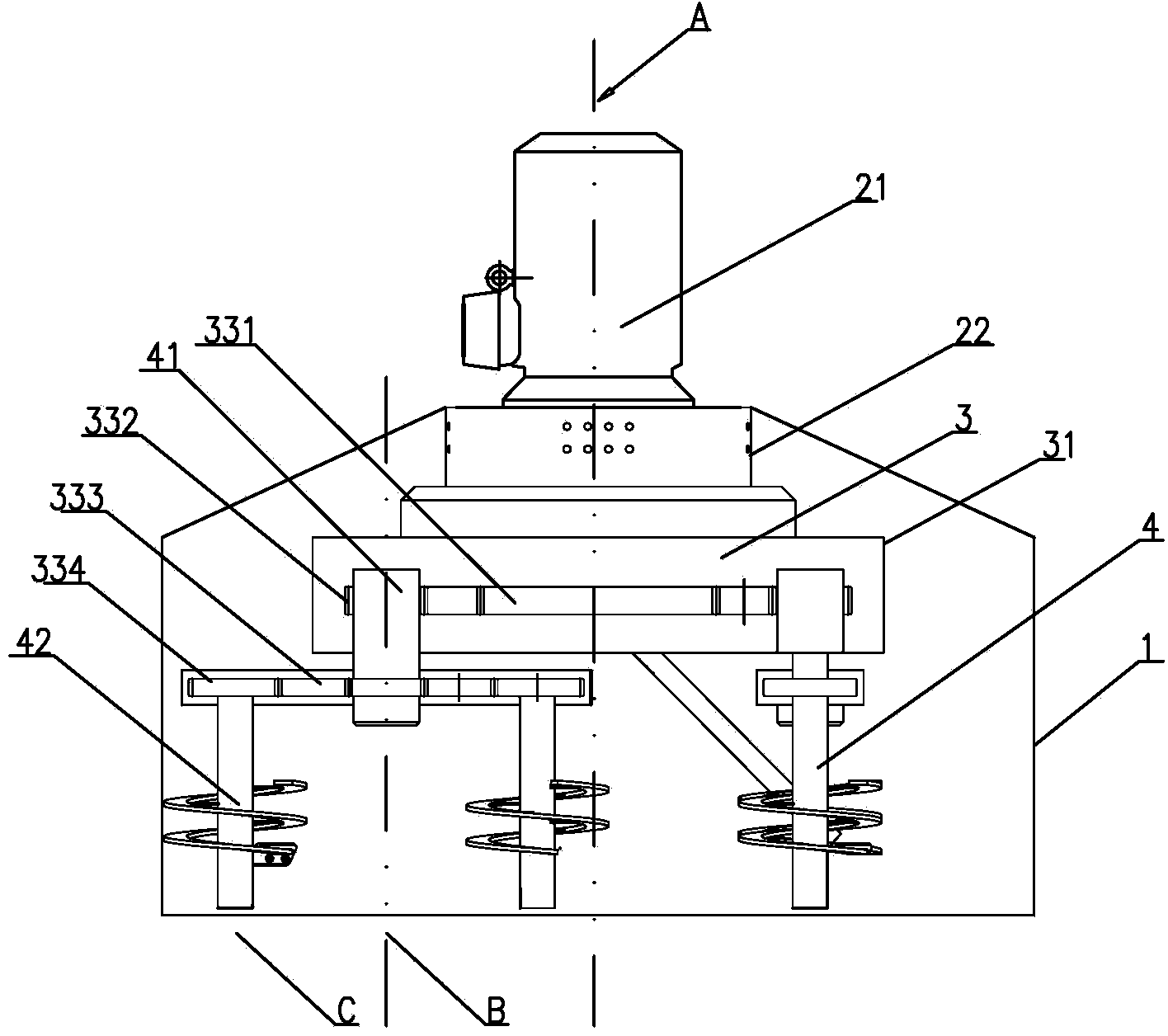

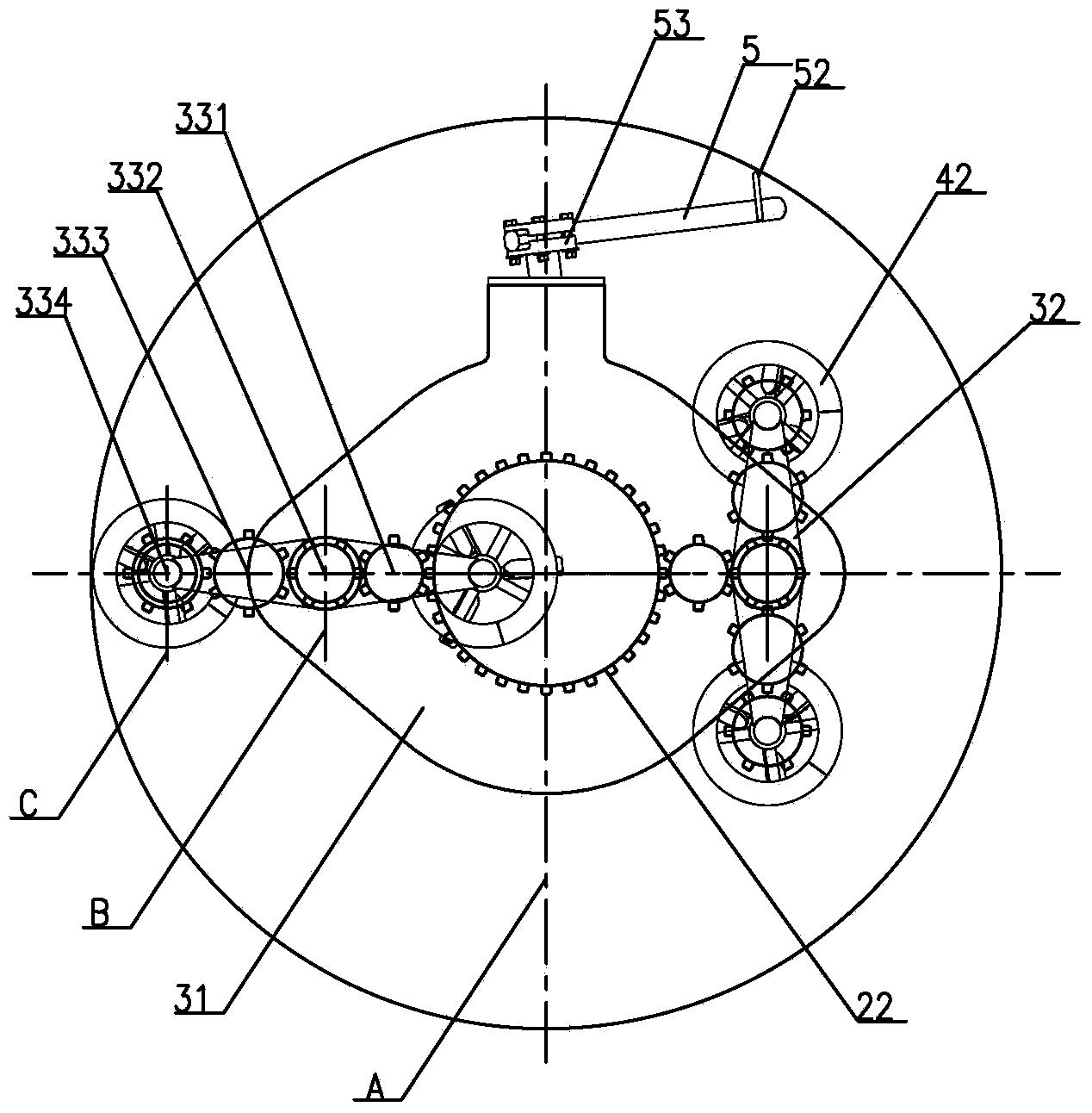

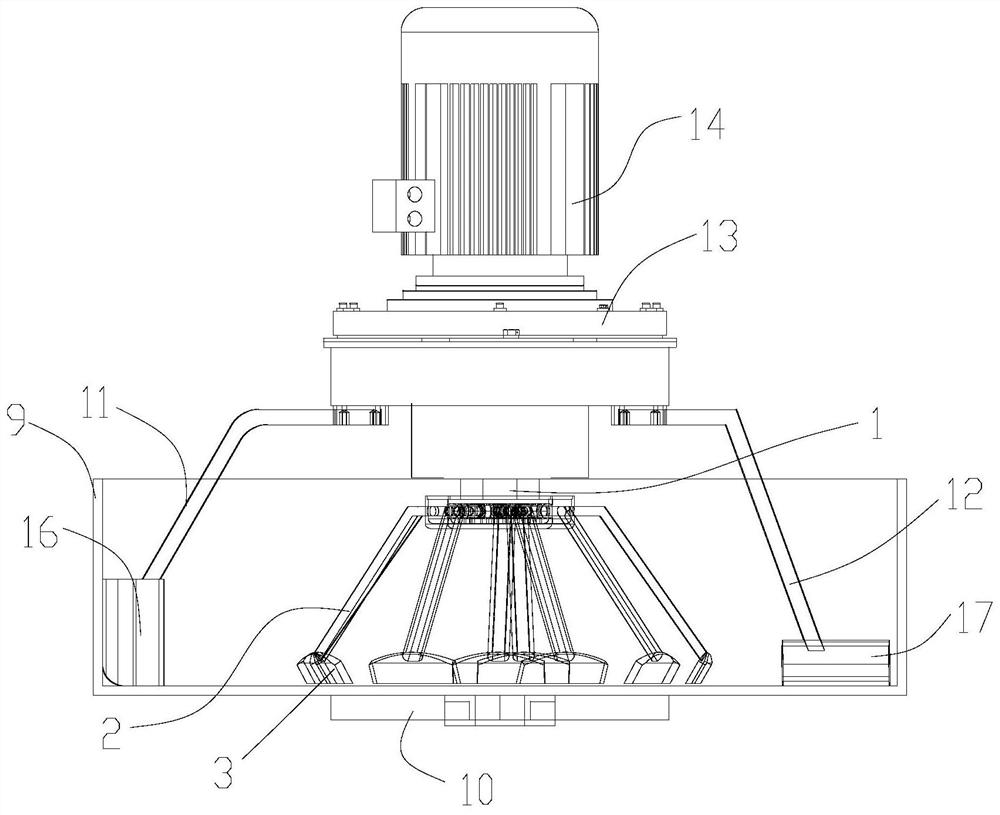

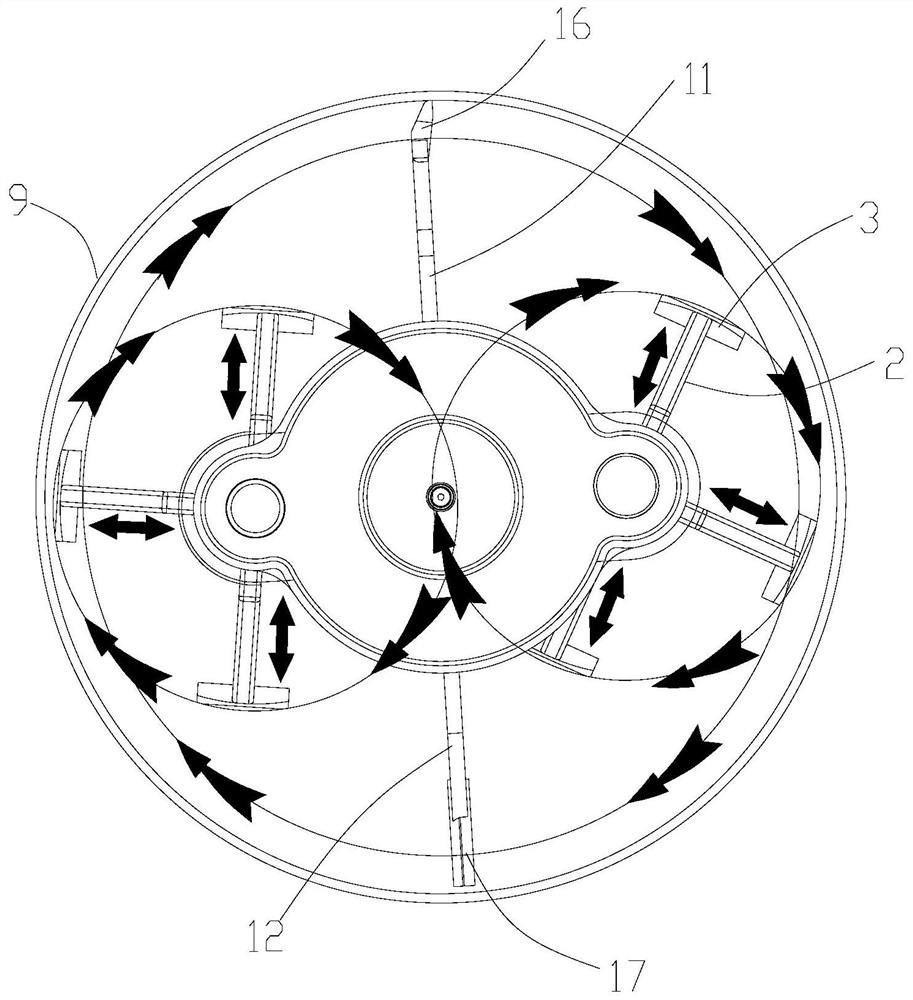

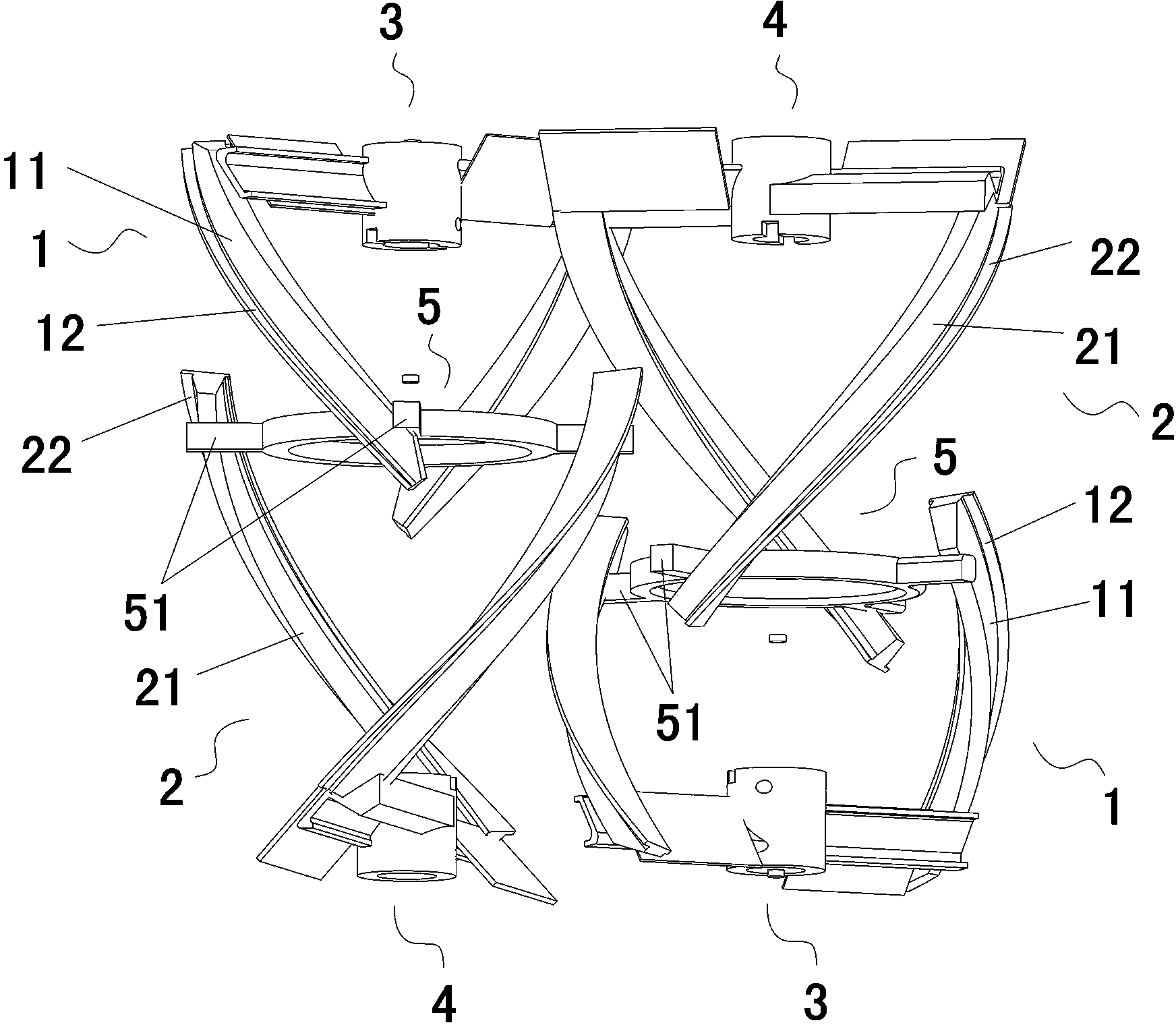

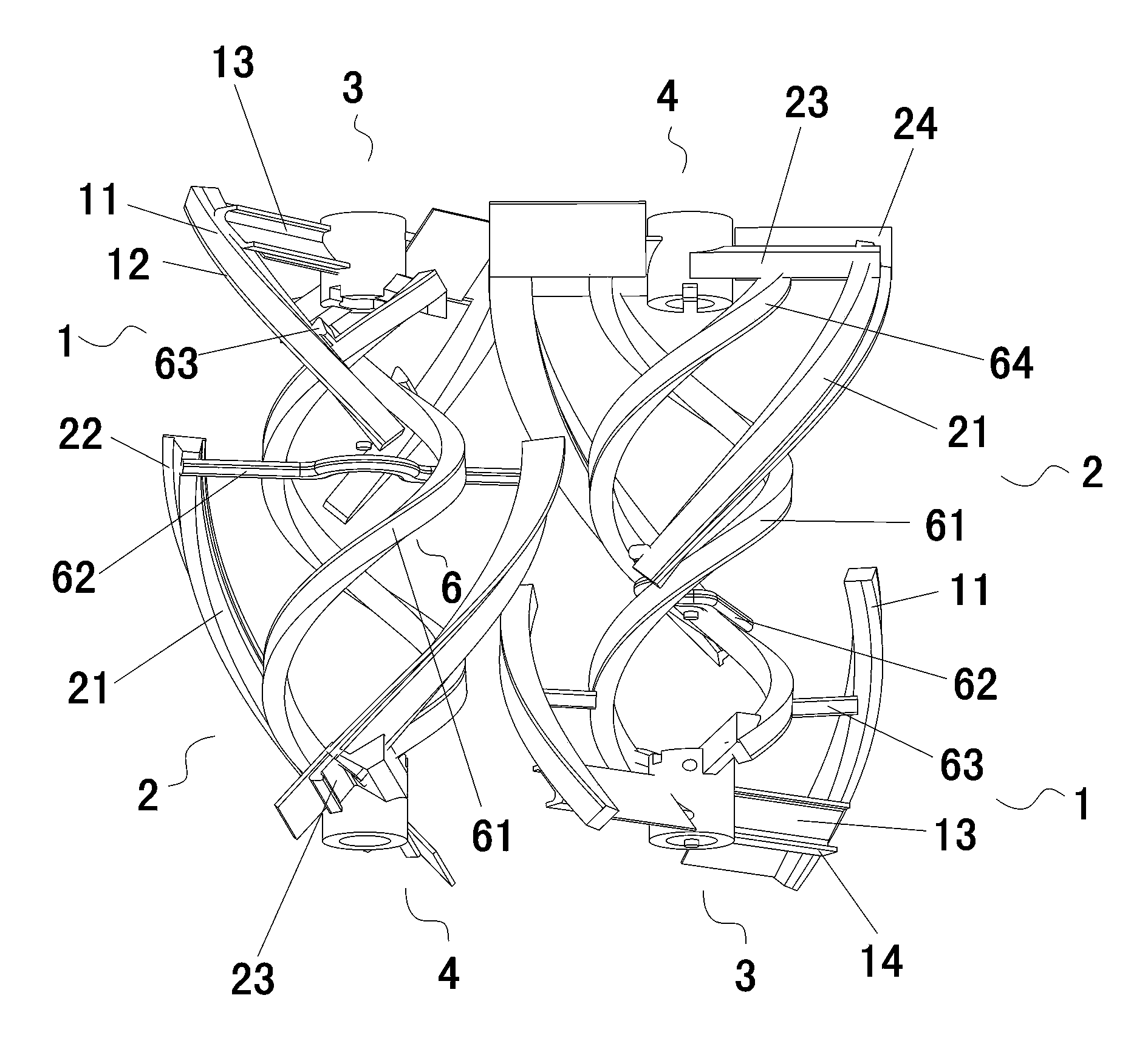

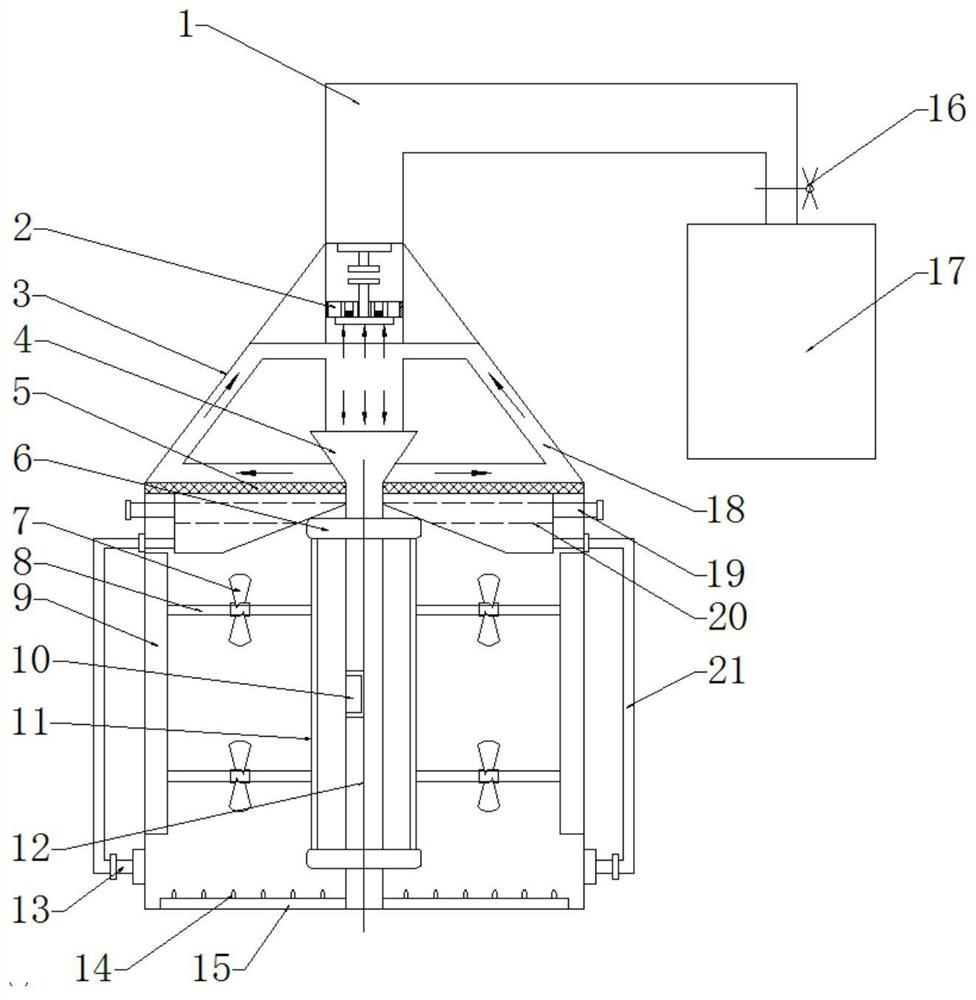

Multi-track vertical-shaft planetary mixer

ActiveCN103817797AFlexible speed adjustmentStir vigorouslyCement mixing apparatusGear wheelEnergy consumption

The invention relates to the technical field of concrete mixing, in particular to a multi-track vertical-shaft planetary mixer. The multi-track vertical-shaft planetary mixer comprises a barrel, a driving mechanism arranged on the barrel as well as a transmission mechanism and a mixing mechanism which are arranged in the barrel, wherein the driving mechanism drives the mixing mechanism through the transmission mechanism. The multi-track vertical-shaft planetary mixer is characterized in that the transmission mechanism comprises a primary revolution rotary disk, a secondary revolution rotary disk and a gear set; and the mixing mechanism comprises mixing shafts and mixing arms. According to the multi-track vertical-shaft planetary mixer, the transmission mechanism and the mixing mechanism adopt combination of two groups of autorotation and revolution forms, so that the rotating speeds of the mixing arms and the mixing shafts can be regulated flexibly, complicated motion track can be achieved in the barrel, a mixing dead angle is not formed in the barrel, materials are mixed violently, sufficiently and uniformly, further, the mixing time is shortened, energy consumption is reduced, and the mixing efficiency is increased.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

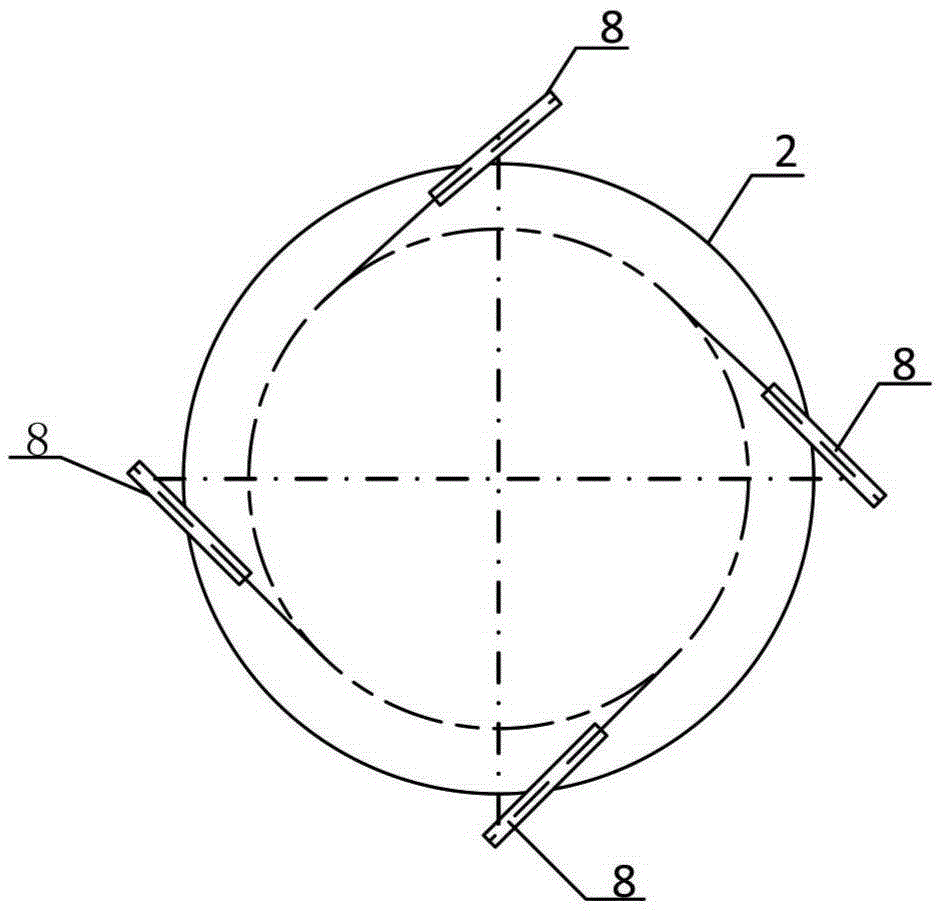

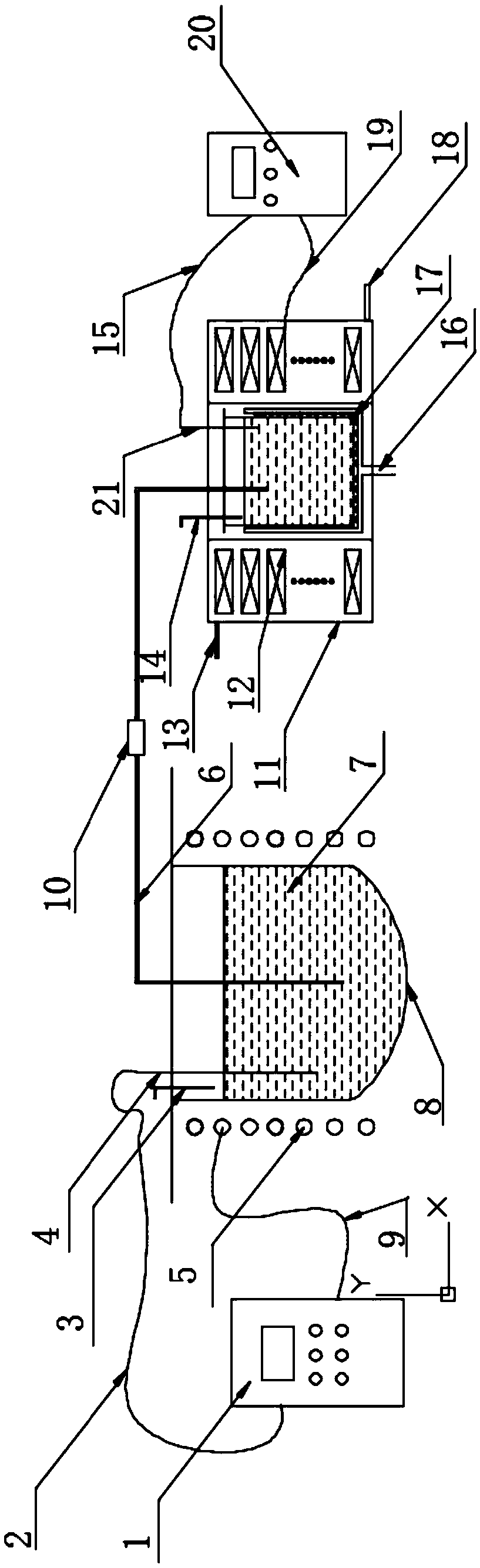

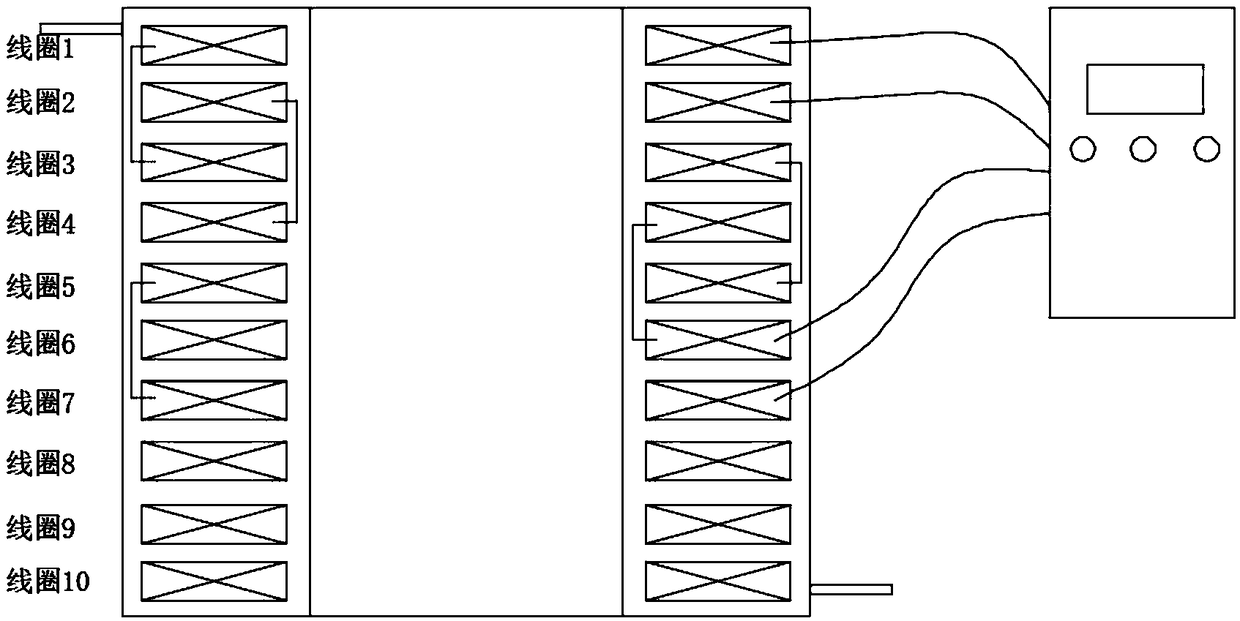

Treatment method of magnesium alloy melt

The invention belongs to the technical field of metal materials and metallurgy and in particular relates to a treatment method of a magnesium alloy melt. The treatment method comprises the following steps: putting a prepared magnesium alloy material into a melting furnace and melting; then carrying out refining; after the refining is finished, carrying out standing on the melt; before the melt istreated, setting pulse current, pulse frequency and pulse forms of an electromagnetic generation system containing an electromagnetic coil group, and phase difference parameters of current accessed into different coils; putting a mold system into the electromagnetic generation system with a cooling function; then transferring the melt subjected to the standing into the mold system with a cooling control device and treating the alloy melt by adopting the electromagnetic coil group; after melt treatment is finished, firstly closing the electromagnetic generation system; after condensing and cooling the melt through the cooling control device, closing the cooling control device of the mold system and taking out a casting ingot. The method is simple, easy to control and easy to control and hasno pollution, high treatment efficiency and a good treatment effect; the method can be used for treating in a whole process and is easily applied to industrial production.

Owner:NORTHEASTERN UNIV

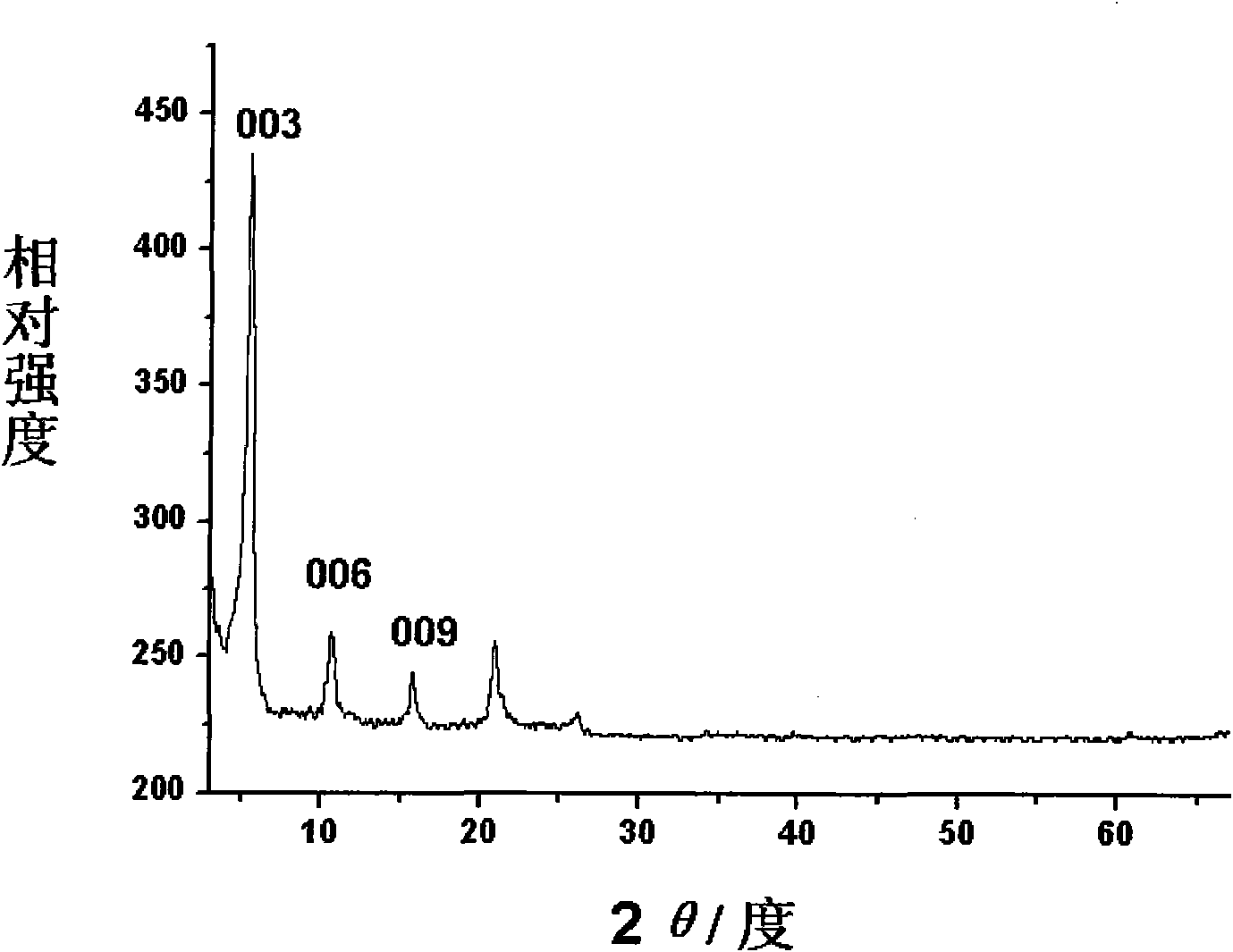

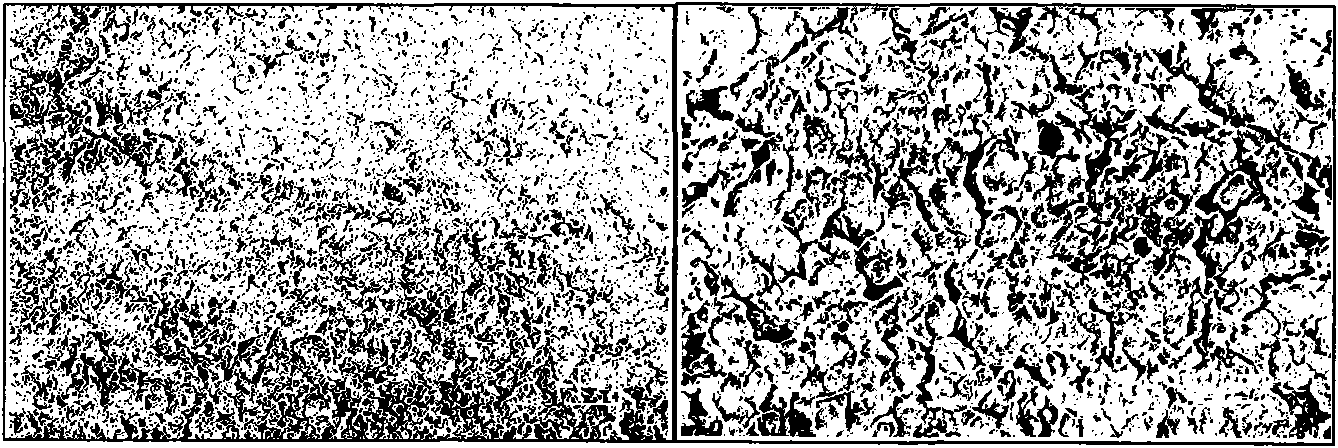

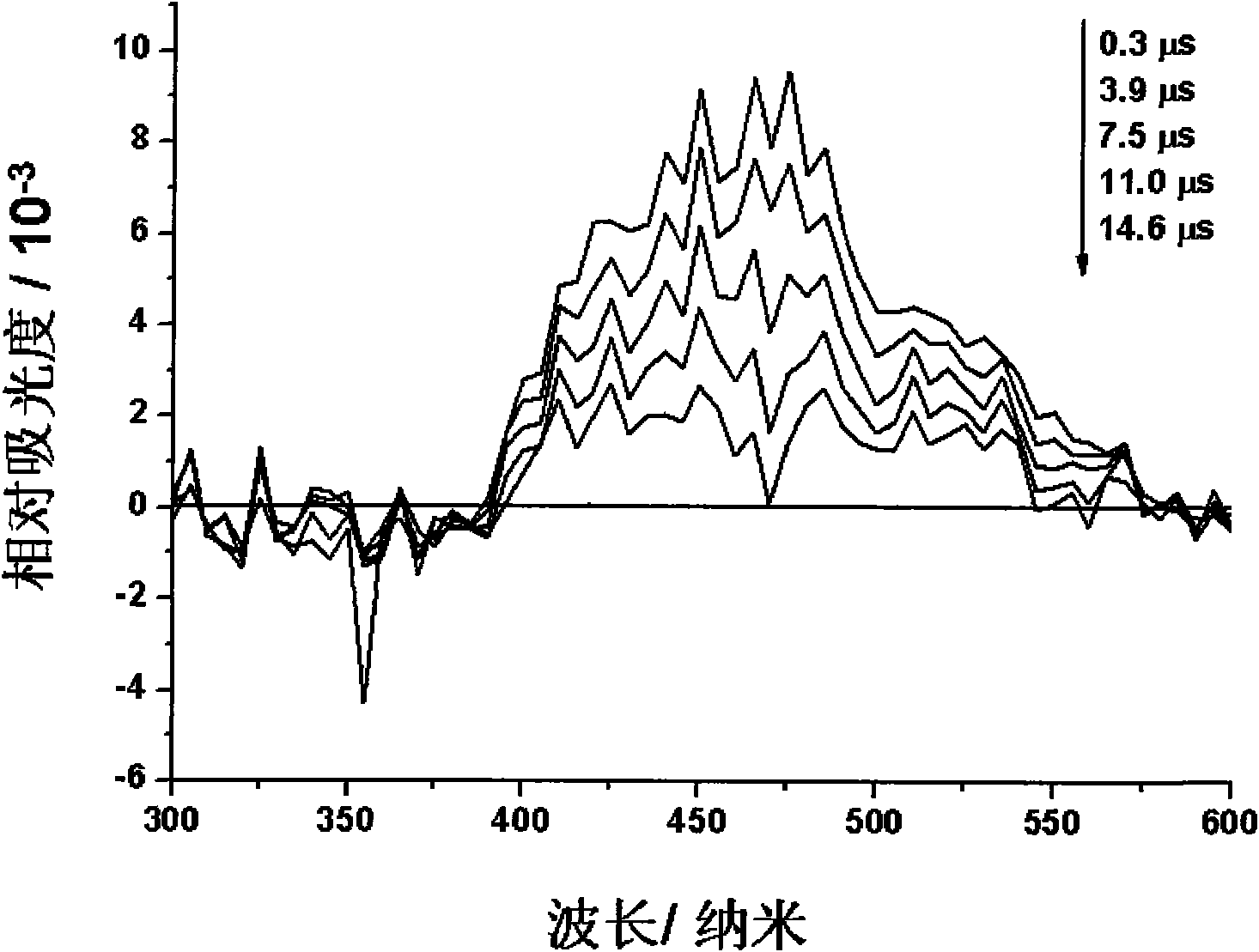

Photosensitive composite film and preparation method thereof

InactiveCN101775277AStir vigorouslyWide application backgroundTenebresent compositionsComposite filmSolvent evaporation

The invention discloses a photosensitive composite film and a preparation method thereof, which belong to the technical field of the preparation of the optical function composite material. The technical scheme of the invention is that firstly a hydrotalcite precursor is prepared, then an ion exchange method is adopted to prepare a hydrotalcite composite material co-intercalated with a Schiff-base dye and a surface active agent, and a solvent evaporation method is utilized to assemble the hydrotalcite composite material into a photosensitive film material. The composite film material utilizes the interaction between the subject and the object. The synergistic effect of interlayer water and the surface active agent makes the composite film material have photosensitive property of ultrafast response. The photosensitive composite film has wide application background. Compared with the traditional photochromic materials, the photosensitive composite film has the advantages of simple and easy preparation, friendly environment, high stability for the optothermal and long storage time. The method has simple process and good product performance, and is suitable for the industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Tobacco essential oil prepared by use of tobacco wastes, and application and preparation method thereof

The invention discloses a tobacco essential oil prepared by use of tobacco wastes. The tobacco essential oil is prepared by performing extraction on one or more from tobacco roots, tobacco stems and tobacco branches in the tobacco wastes. The invention further brings forward an application of the tobacco essential oil prepared by use of the tobacco wastes. A tobacco essential oil solution is prepared by adding the tobacco essential oil into propylene glycol, and the tobacco essential oil solution is used as a component of an e-cigarette liquid. The invention also brings forward a preparation method of the tobacco essential oil prepared by use of the tobacco wastes. The method comprises the following steps: crushing the tobacco wastes into 50-100 meshes, and placing the crushed tobacco wastes and the propylene glycol into a mixing tank for mixing. The wastes are changed into valuable things, the tobacco essential oil is applied into an e-cigarette liquid, the fragrance of the e-cigarette liquid is rich, the tobacco flavor is pure, the liquid fluidity is good, the flue-cured tobacco flavor of an e-cigarette can be enhanced, the e-cigarette tastes like a real cigarette, the mouth feeling is good, the fragrance is sufficient, the tobacco essential oil is a ideal additive of the e-cigarette oil liquid, and the tobacco essential oil is suitable for promotion.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

Sponge city ceramic permeable bricks prepared by convection planetary mixing and preparation method

ActiveCN107324836ASolve the problem of unstable water permeabilitySolve uneven production process problemsSingle unit pavingsPaving gutters/kerbsMaterials preparationBrick

The invention discloses sponge city ceramic permeable bricks prepared by convection planetary mixing and a preparation method. The sponge city ceramic permeable bricks are prepared from the following components in parts by weight through firing: 100 parts of waste ceramsite, 5 to 8 parts of river sand, 5 to 8 parts of flint clay, 5 to 6 parts of a pore-forming agent, 5 to 8 parts of a binding agent, 2 to 5 parts of a fluxing agent, 6 to 9 parts of kaolin, 1 to 3 parts of glaze and 2 to 5 parts of water. The preparation of the sponge city ceramic permeable bricks comprises a crushing step, a material preparation step, a mixing step, a raw blank preparation step and a firing step. According to the sponge city ceramic permeable bricks disclosed by the invention, the raw materials are stirred through a specific convection planetary ceramic permeable brick raw material stirring device, so that the problem of a common conventional method in the prior art that agglomeration is easy to occur and the permeable rate of the permeable bricks is unstable is solved and the production technology problem of current ceramic permeable bricks that aggregates and auxiliary materials are not uniformly mixed is solved; the stability of the quality of the ceramic permeable bricks is also greatly improved, so that the sponge city ceramic permeable bricks have a wide market prospect.

Owner:佛山生态海绵城市科技发展有限公司

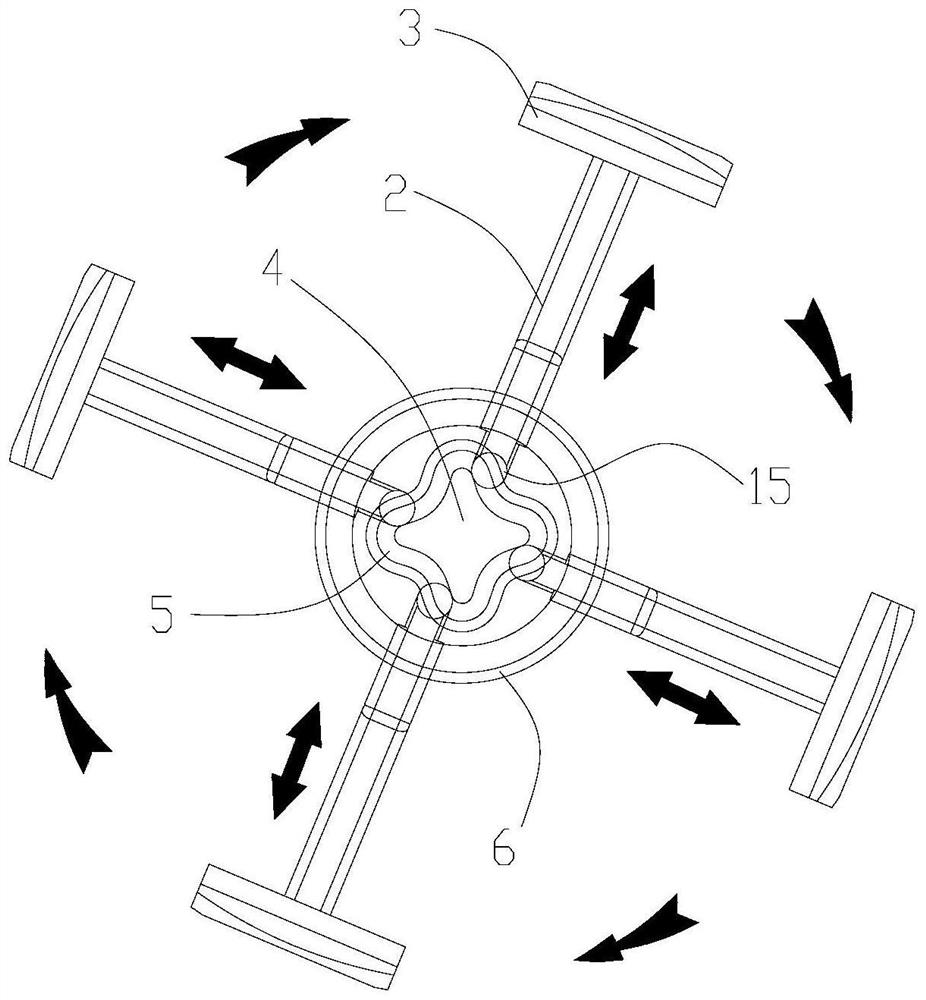

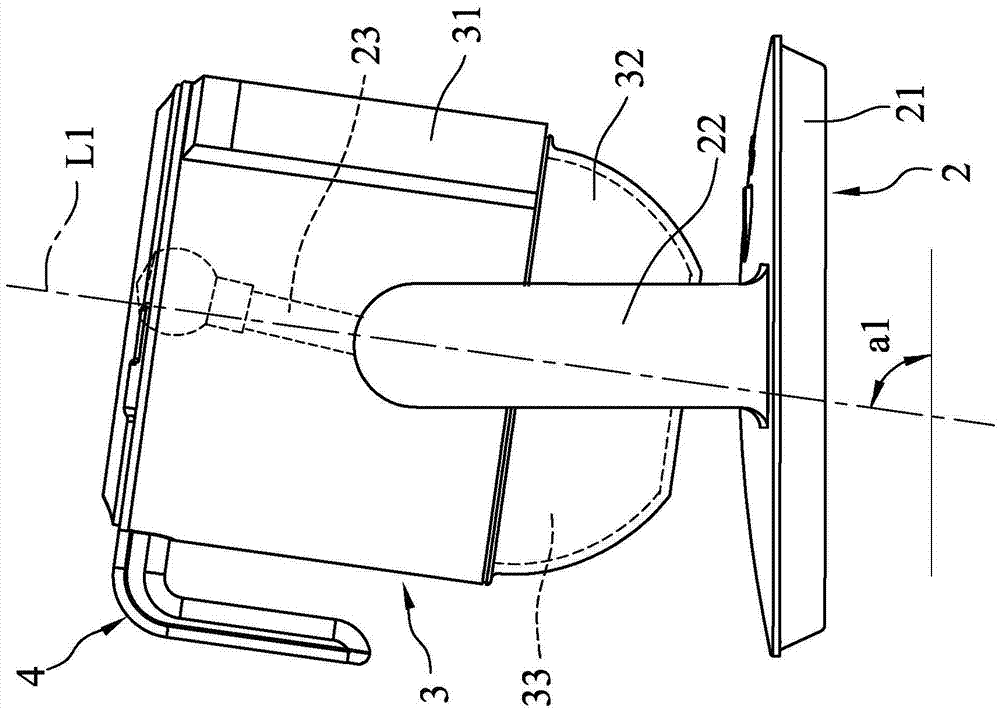

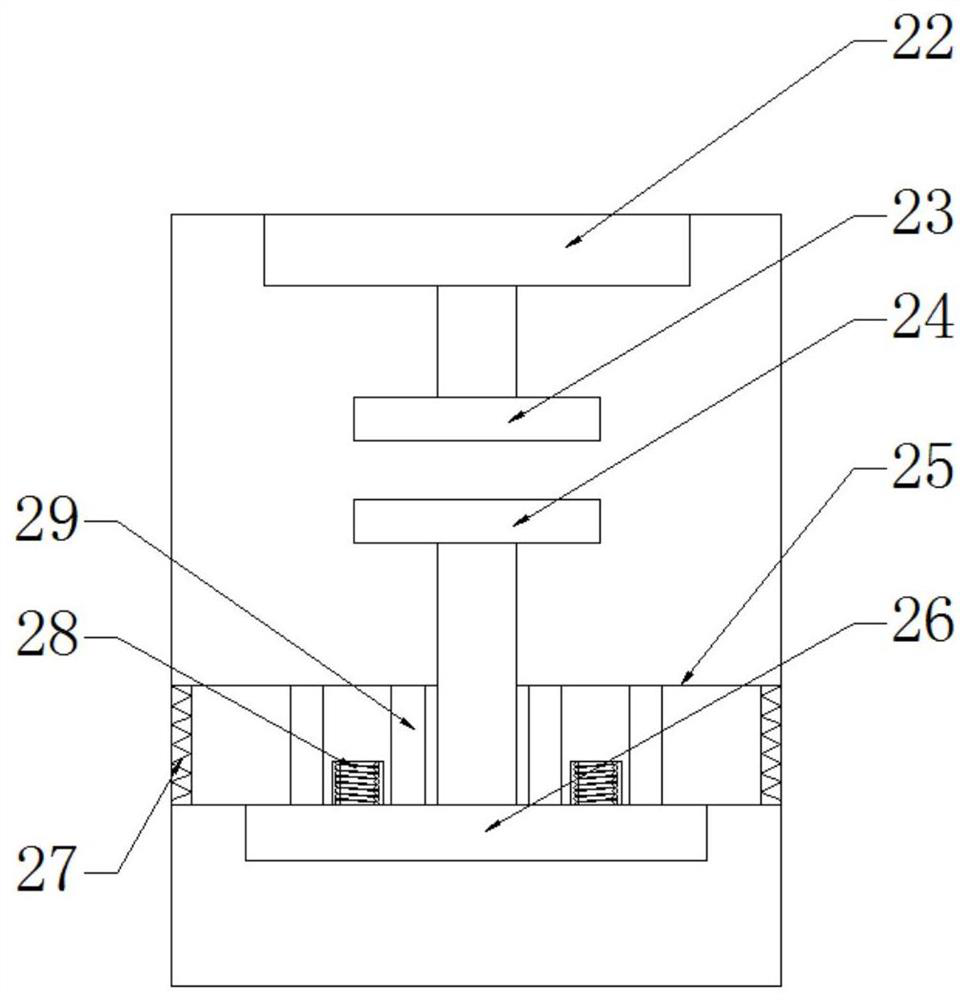

Planetary mixer

InactiveCN111905605AExtend the trajectoryComplicated trajectoryRotary stirring mixersTransportation and packagingReciprocating motionEngineering

The invention relates to the field of stirrers, and discloses a planetary stirrer, which comprises a stirring assembly capable of revolving around the revolving axis of the planetary stirrer, and thestirring assembly comprises a stirring shaft (1), a rotation stirring arm (2) capable of rotating around the stirring shaft (1) and extending out of the stirring shaft (1) in the radial direction, anda stirring part (3) connected to the rotation stirring arm (2); wherein the autorotation stirring arm (2) can do radial reciprocating motion while autorotating around the stirring shaft (1). According to the technical scheme, radial reciprocating motion is added on the basis of autorotation motion of the autorotation stirring wall, so that the motion trail of the stirring part is longer and morecomplex, materials can be stirred more sufficiently and violently, the stirring efficiency is improved, the stirring time is shortened, and the stirring effect is improved.

Owner:湖南中联重科混凝土机械站类设备有限公司 +1

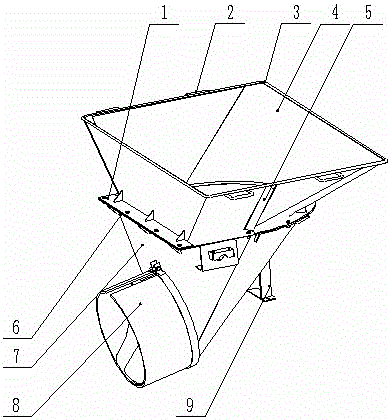

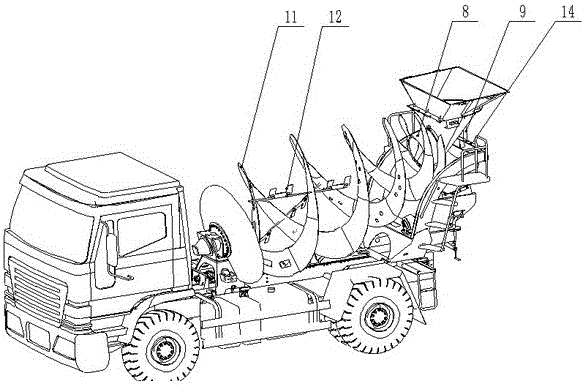

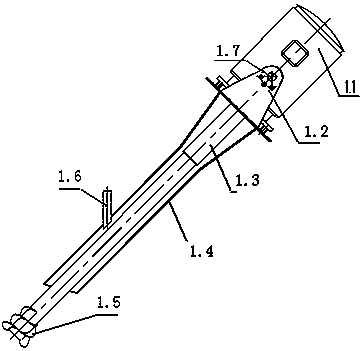

Mixing transporter applied to dry concrete

ActiveCN106541501AImprove liquidityStir vigorouslyMixing operation control apparatusCement mixing apparatusSpiral bladeEngineering

A mixing transporter applied to dry concrete comprises a feeding hopper and a mixing cylinder. A material guide tongue extending into the mixing cylinder is arranged at an outlet of the lower portion of the feeding hopper. Two main spiral blades are arranged in the mixing cylinder. Multiple mixing plate assemblies are mounted between the two main spiral blades. Each main spiral blade is composed of a compensation blade, a logarithm blade and an auxiliary blade. The compensation blades are connected with a front cone of the mixing cylinder. The auxiliary blades are connected with a rear cone of the mixing cylinder in the direction of a discharging opening. In use, various dried concrete materials are conveyed into the feeding hopper through a loader or a belt conveyor, the powder slides into the mixing cylinder, the dry powder advances and turns over along the spiral blades under the effect of the spiral blade effect, and overturning and mixing of the powder are intensified through the mixing plate assemblies at the same time; and after mixing is performed for a period of time, water is added according to the proportion, and mixing is performed in the transportation process till the required labeled concrete is formed. The mixing transporter solves the problem of the working condition that pre-mixed concrete cannot be produced, the usage range of the mixing transporter is broadened, and application of the mixing transporter is expanded.

Owner:HUBEI JIANGSHAN SPECIAL PURPOSE VEHICLE

Antibacterial, anti-inflammation, acne-removal and repairing facial mask

InactiveCN107951813AEffective reliefWon't hurtCosmetic preparationsToilet preparationsMethacrylateBiocompatibility Testing

The invention relates to an antibacterial, anti-inflammation, acne-removal and repairing facial mask. The facial mask comprises, by weight, 0.3-0.8 part of a detoxifying component, 0.5-1 part of a blood stasis removing and pain alleviating component, 3-5 parts of an anti-inflammation and antiseptic component, 2-4 parts of a skin whitening and repairing component, 1-3 parts of an antibacterial component, 10-25 parts of a moisturizing agent, 0.1-0.3 part of glyceryl polymethacrylate, 0.1-0.2 part of carbomer, 0.1-0.2 part of xanthan gum, 0.1-0.4 part of sodium polyacrylate and 60-88 parts of deionized water. By scientific selection of the components, various pertinent components are combined together to efficiently give play to antibacterial, anti-inflammation, acne-removal and repairing efficacies of the whole facial mask. Since a biological transdermal promoting agent is derived from animal and plant extracts, high biological compatibility is achieved, skin injuries are avoided, and safety is achieved.

Owner:宁波秋日小城智能科技有限公司

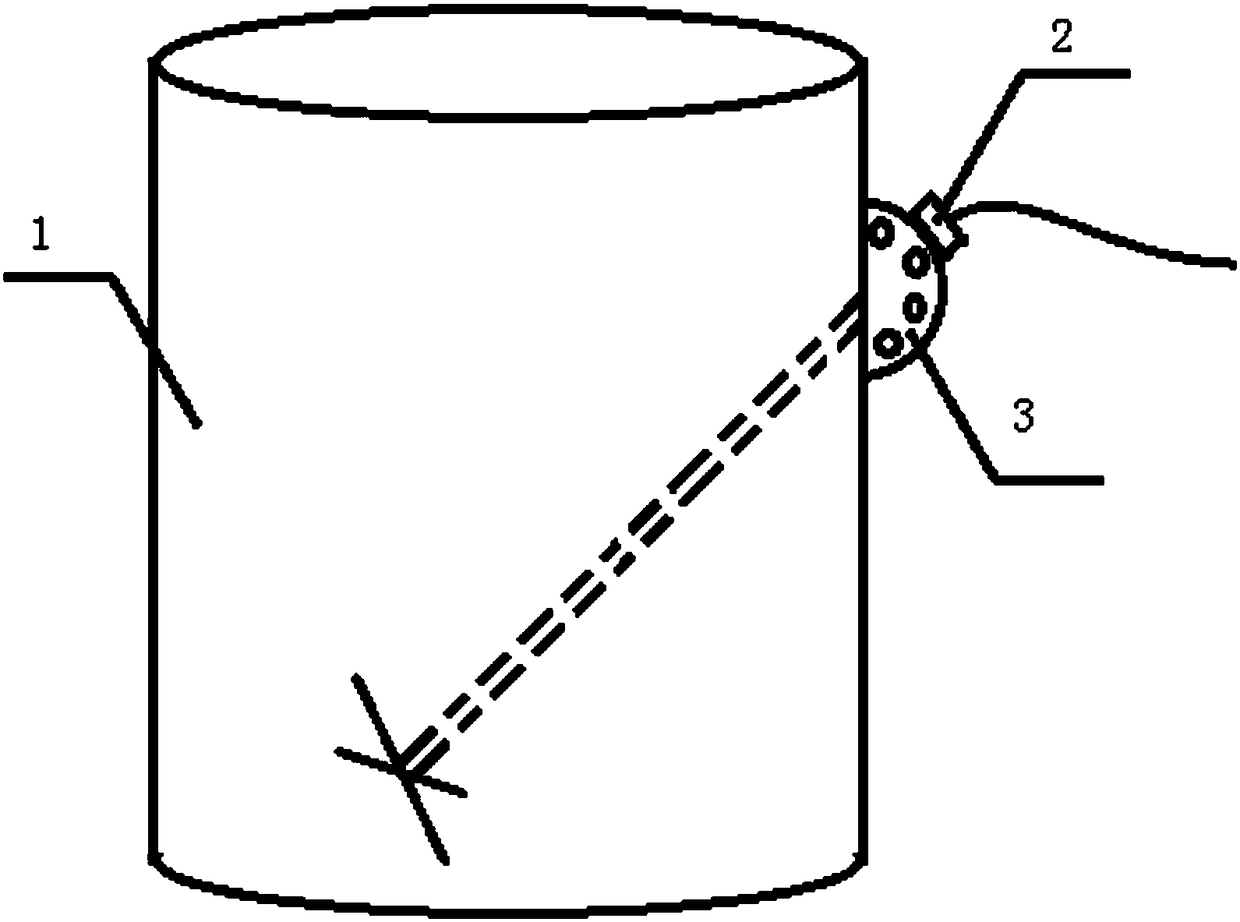

Chemical phosphorus removal medicament adding device for sewage treatment

ActiveCN104045136AImprove suction capacityImprove phosphorus removal efficiencyWater/sewage treatment by flocculation/precipitationChemical storageImpeller

The invention relates to a chemical phosphorus removal medicament adding device for sewage treatment. The device comprises a chemicals adding host machine, a chemicals storage tank and a chemicals conveying pipe connecting the chemicals adding host machine and the chemicals storage tank, wherein the chemicals adding host machine comprises a motor, a main shaft hood and a main shaft which is connected to the motor and placed in the main shaft hood; a spiral impeller is arranged at the lower end of the main shaft, the motor output end is connected with a host machine installation base and is fixed on a pool wall through a frame, the lower end of the main shaft hood is open and the upper end of the main shaft hood is fixedly connected with the host machine installation base in an airtight manner, so that the inner cavity of the main shaft hood becomes a chamber with the upper end closed and the lower end open; a chemicals suction opening is arranged at the lower half section of the main shaft hood; both ends of the medicament conveying pipe are respectively connected with a chemicals outlet of the chemicals storage tank and the lower semi-section of the main shaft hood on the main shaft hood, and chemicals are correctly added through adjustment by virtue of a vacuum degree control valve and a dosage control valve. Different from conventional chemical phosphorus removal methods, the device has the advantages that the chemicals are directly added and the liquid chemicals exported by a plant is added, so that the system for preparing and conveying the liquid chemicals is omitted. The device is simple, convenient and reliable and has a high practical value.

Owner:中节能国祯环保科技股份有限公司

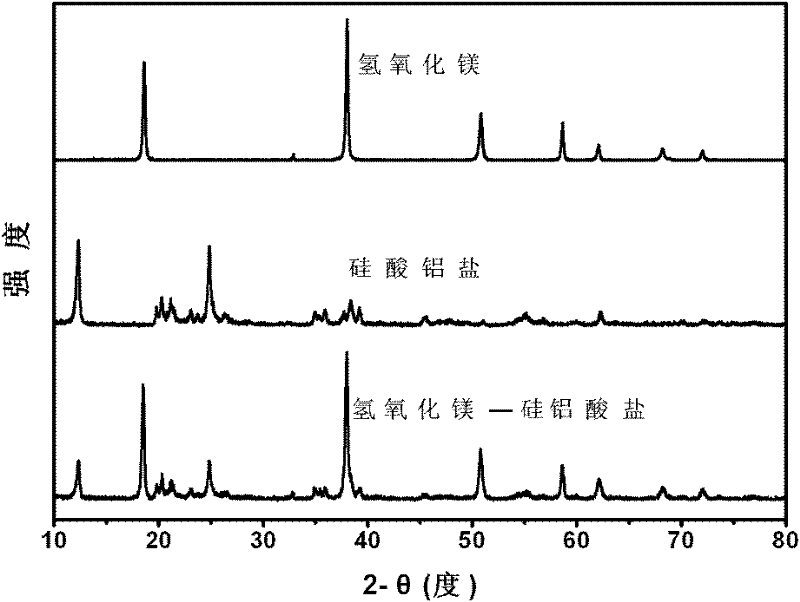

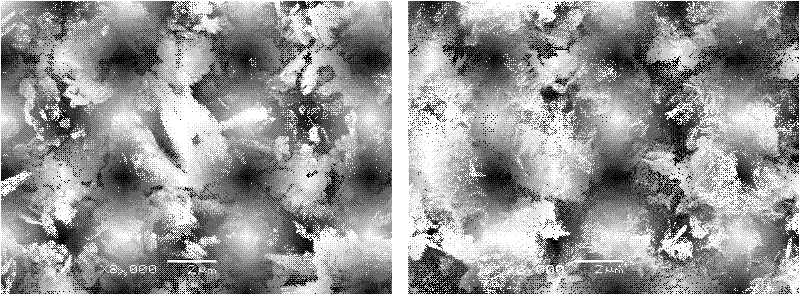

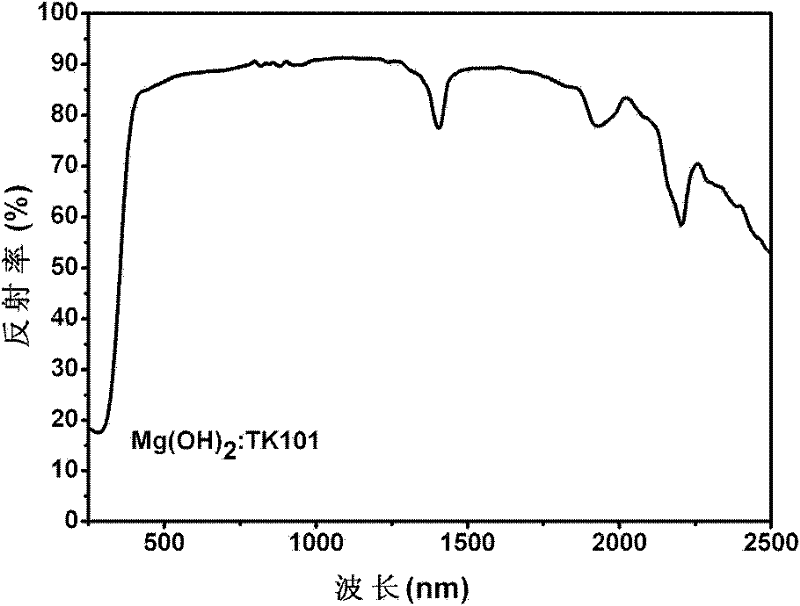

Flame-retarding thermal-insulation composite nano material and preparation method and use thereof

InactiveCN102303960AStir vigorouslyIncrease reflectionCovering/liningsHeat proofingAluminum silicateThermal radiation

The invention discloses a flame-retarding thermal-insulation inorganic composite nano material and a preparation method and use thereof. The flame-retarding thermal-insulation inorganic composite nano material is prepared by depositing magnesium hydroxide on aluminiumsilicate serving as a substrate. Compared with the prior art, the invention has the advantages that: the flame-retarding thermal-insulation inorganic composite material taking aluminiumsilicate as a substrate is prepared for the first time, the heat ray reflection rate of the flame-retarding thermal-insulation inorganic compositematerial is over 90 percent, so the composite material can effectively prevent heat radiation of the sun and other kinds of heat radiation; the composite material also can absorb ultraviolet rays andhas a function of resisting damage by ultraviolet rays and an excellent flame-retarding effect, and therefore is a multifunctional environment-friendly composite material; and flame-retarding and thermal-insulation coating is prepared for the first time, the heat ray reflection rate of the coating is over 90 percent, the difference between the thermal-insulation temperature of the coating and a blank substrate is more than 10 DEG C, and the coating has good flame-retarding performance. The flame-retarding thermal-insulation inorganic composite nano material product disclosed by the invention has the advantages of safety, no toxicity, stable chemical properties, easy long-term storage, stable heat-reflection, thermal-insulation and flame-retarding performance and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

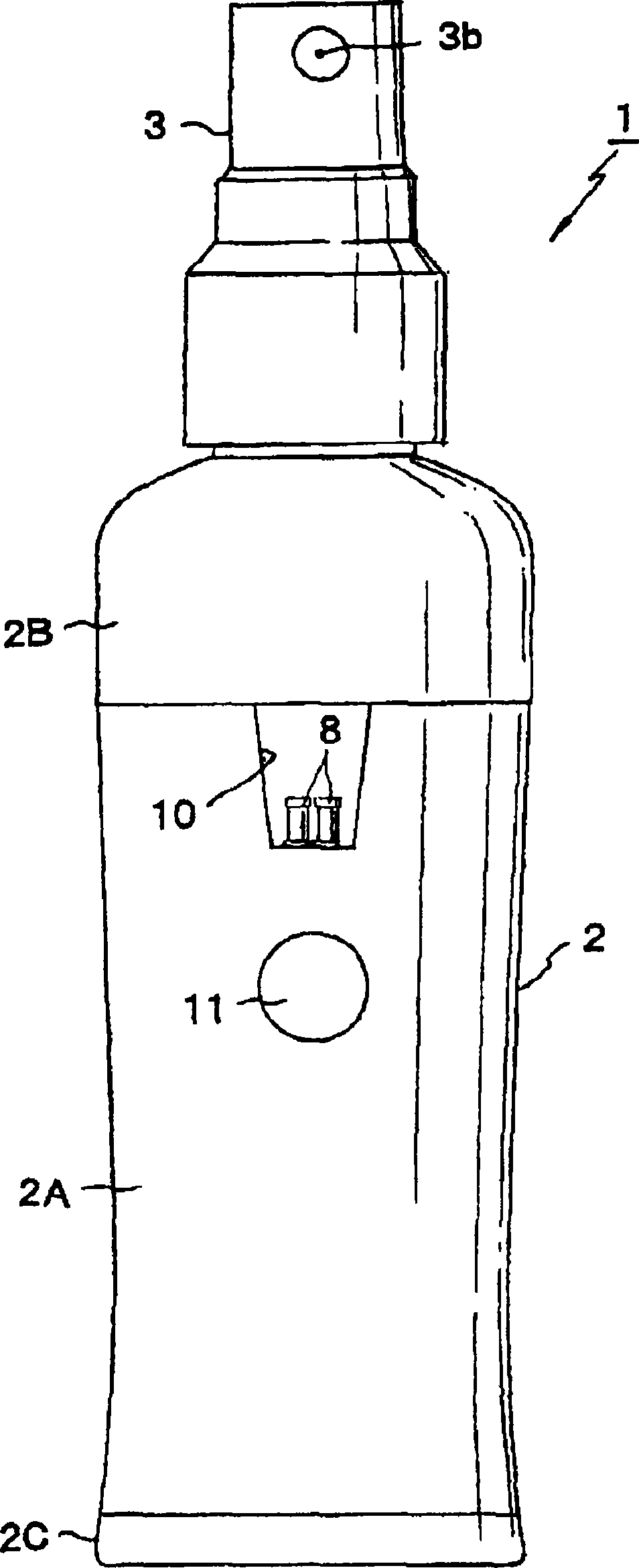

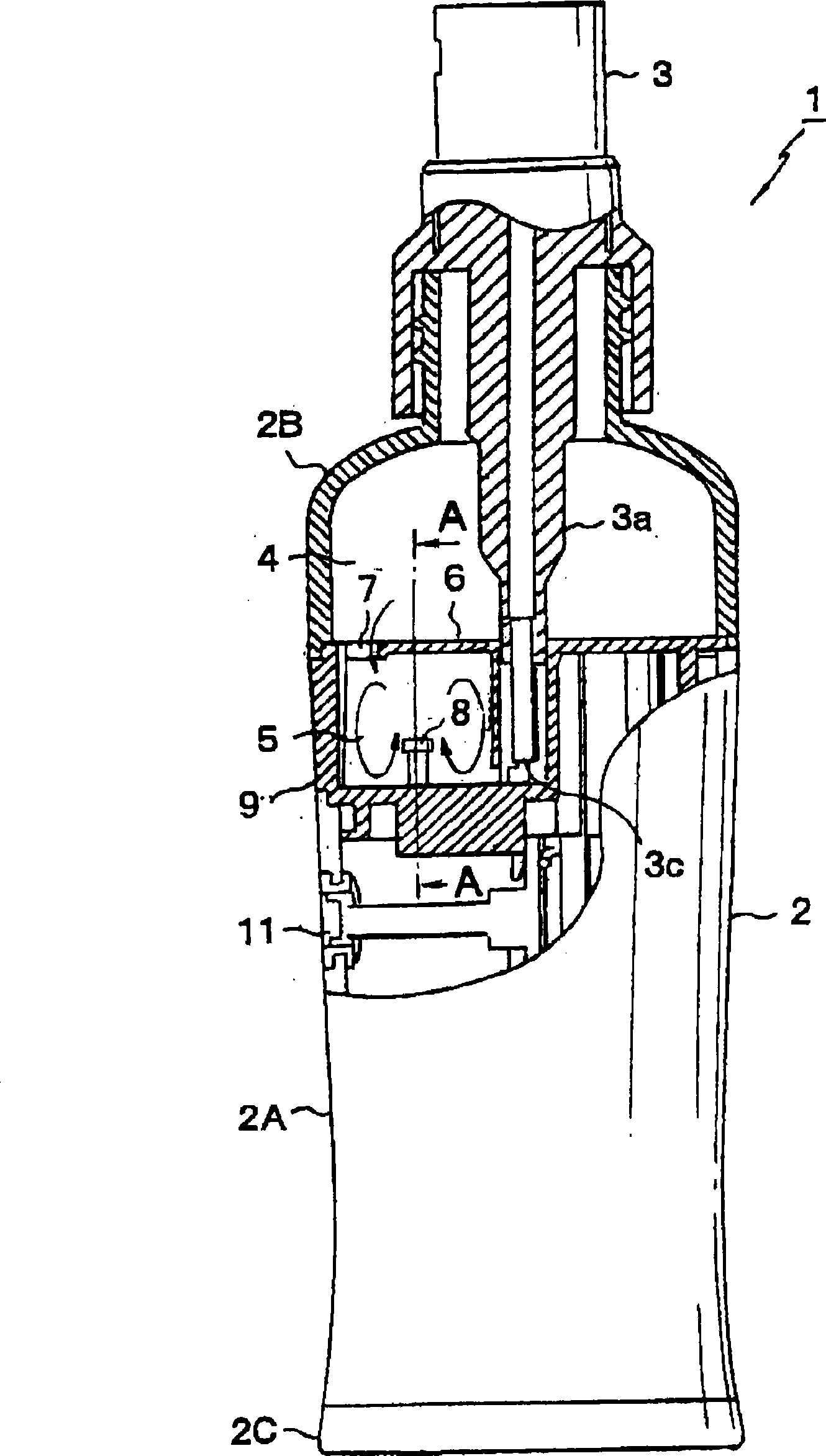

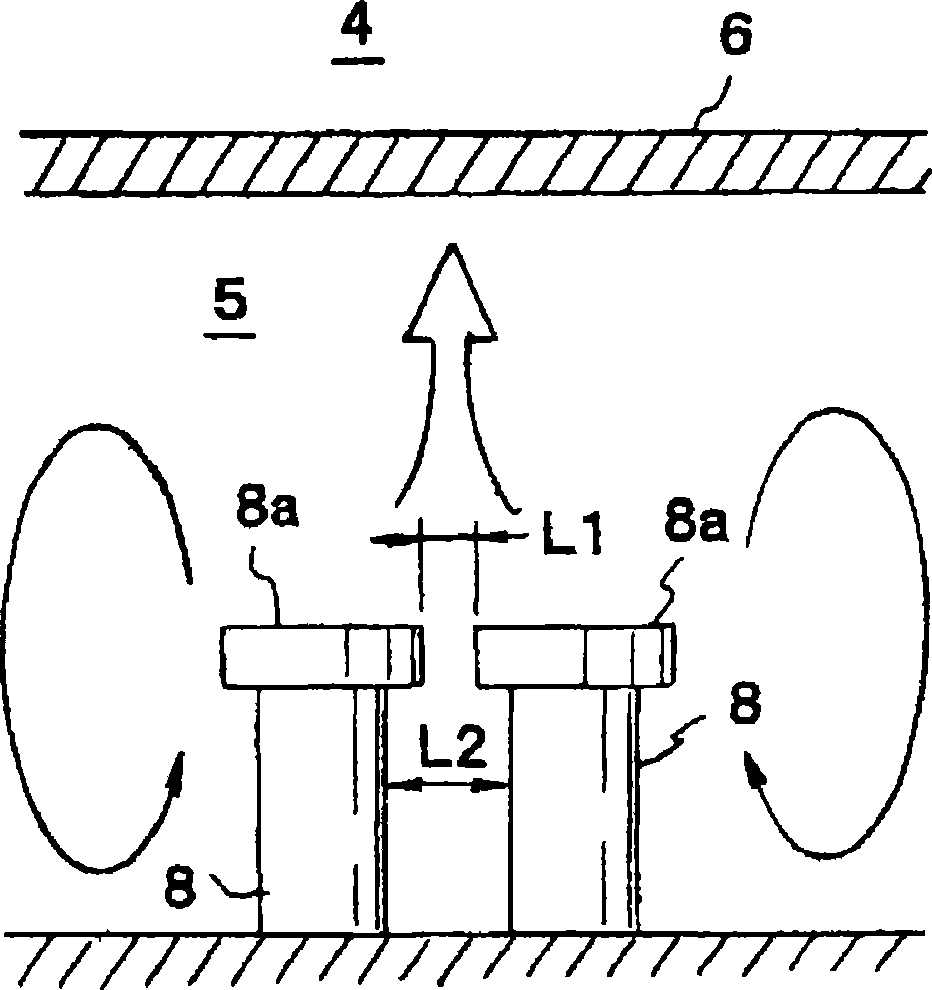

Electrolyzed water generating and spraying device

InactiveCN101468831AConfirm the status of electrolysisAvoid smallDispensing apparatusWater/sewage treatment by electrochemical methodsElectrolysed waterWaste management

Owner:MIKUNI CORP

Preparation method of high-efficiency antioxidant acne-removing handmade soap

InactiveCN107805559ADestructiveImprove antioxidant capacitySurface-active non-soap compounds and soap mixture detergentsSkin careWater bathsPyracantha fortuneana fruit extract

The invention relates to a preparation method of a high-efficiency antioxidant acne-removing handmade soap. The preparation method is characterized by comprising the following steps of: (1) heating seabuckthorn seed oil in a water bath to 62 DEG C, and carrying out uniform-speed stirring to obtain A; (2) adding deionized water, nicotinamide, tea saponin and a natural soap base into A, and uniformly stirring the materials to obtain a mixture B; (3) uniformly mixing a traditional Chinese medicine extract, a phyllostachys pubescens leaf extract, a pyracantha fortuneana fruit extract, a lonicera caerulea extract, a mangosteen skin extract, an Italian anchusa italica extract, a litchi leaf extract, a myrica rubra leaf extract, a perilla leaf extract and a mugwort extract in parts by weight, adding the mixture into the mixture B, carrying out stirring for 28min to fully mix the mixture, pouring the mixture into a grinding tool, and curing the mixture for 28h at a constant temperature of 44 DEG C to obtain a semi-finished product; and (4) demoulding the semi-finished product, putting the semi-finished product in a cool and dry place for 12 days, and trimming and packaging the semi-finished product to obtain a finished product of the handmade soap.

Owner:宁波秋日小城智能科技有限公司

Cooking device

InactiveCN107198456AStir vigorouslyImprove the mixing effectRoasting apparatusCooking insertsEngineering

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Efficient concrete stirrer

ActiveCN103395123ASpeed up the flowStir vigorouslyCement mixing apparatusEngineeringMechanical engineering

A disclosed efficient concrete stirrer comprises more than one stirring assembly, and the installing directions and the rotating directions of the adjacent stirring assemblies are opposite. One end of an outer spiral feeding shaft and one end of a spiral returning shaft in each stirring assembly are respectively connected with the active end and the passive end of a motor, and the other ends are connected with each other via a connection piece. The connection piece is an annular piece, the ends of the outer spiral feeding shafts and the ends of the spiral returning shafts are uniformly distributed on and connected with the annular piece; or an inner spiral feeding shaft is additionally disposed for connection of the active end and the passive end of the motor; or on the basis of additional arrangement of the inner spiral feeding shaft, the annular piece is dismantled into a first connection piece and a second connection piece, wherein the first connection piece is connected with the inner spiral feeding shaft and the outer spiral feeding shaft, and the second connection piece is connected with the inner spiral feeding shaft and the spiral returning shaft. The stirrer of the invention helps to solve the problem in the prior art that operation vibration is large because of large eccentricity, and has stable operation, increased material flow speed, severer stirring, fuller and more uniform mixing, and higher stirring efficiency.

Owner:陈建凡

Preparation method of longan extract

InactiveCN107982159AAcne Removal Sustained and EffectiveSustained high-efficiency anti-inflammatory and antibacterialCosmetic preparationsToilet preparationsPectinaseCellulase

The invention relates to a preparation method of longan extract. The preparation method adopts a pectase and cellulase simultaneous enzymolysis extraction method. The preparation method comprises thefollowing steps: drying fresh longan with hot air of 80 DEG C, removing peels and kernels, obtaining dried longan pulp, adding deionized water, soaking for 12h, wherein a material-to-water ratio is 1:3, and mashing by using a high-speed tissue mashing machine; adding deionized water into a mashed matter, wherein a material-to-water ratio is 1:12, simultaneously enzymolysing by adopting pectase andcellulase, wherein by calculating according to a weight percentage, the consumption of pectase is 0.6 percent, the consumption of cellulase is 0.05 percent, adjusting a pH value to be 3.1, the enzymolysis temperature is 52 DEG C, the enzymolysis time is 160 min, after the enzymolysis is ended, deactivating the enzyme for 30min at 90 DEG C, filtering for 200 meshes, collecting filtrate, concentrating the filtrate into half-flowing pulp, dissolving the pulp into the deionized water according to a volume ratio of 1:10, stirring, uniformly shaking, thus obtaining the longan extract.

Owner:宁波秋日小城智能科技有限公司

A double circulation anaerobic reactor

ActiveCN108455726BImprove work efficiencyEfficient responseTreatment with anaerobic digestion processesElectric machineryProcess engineering

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

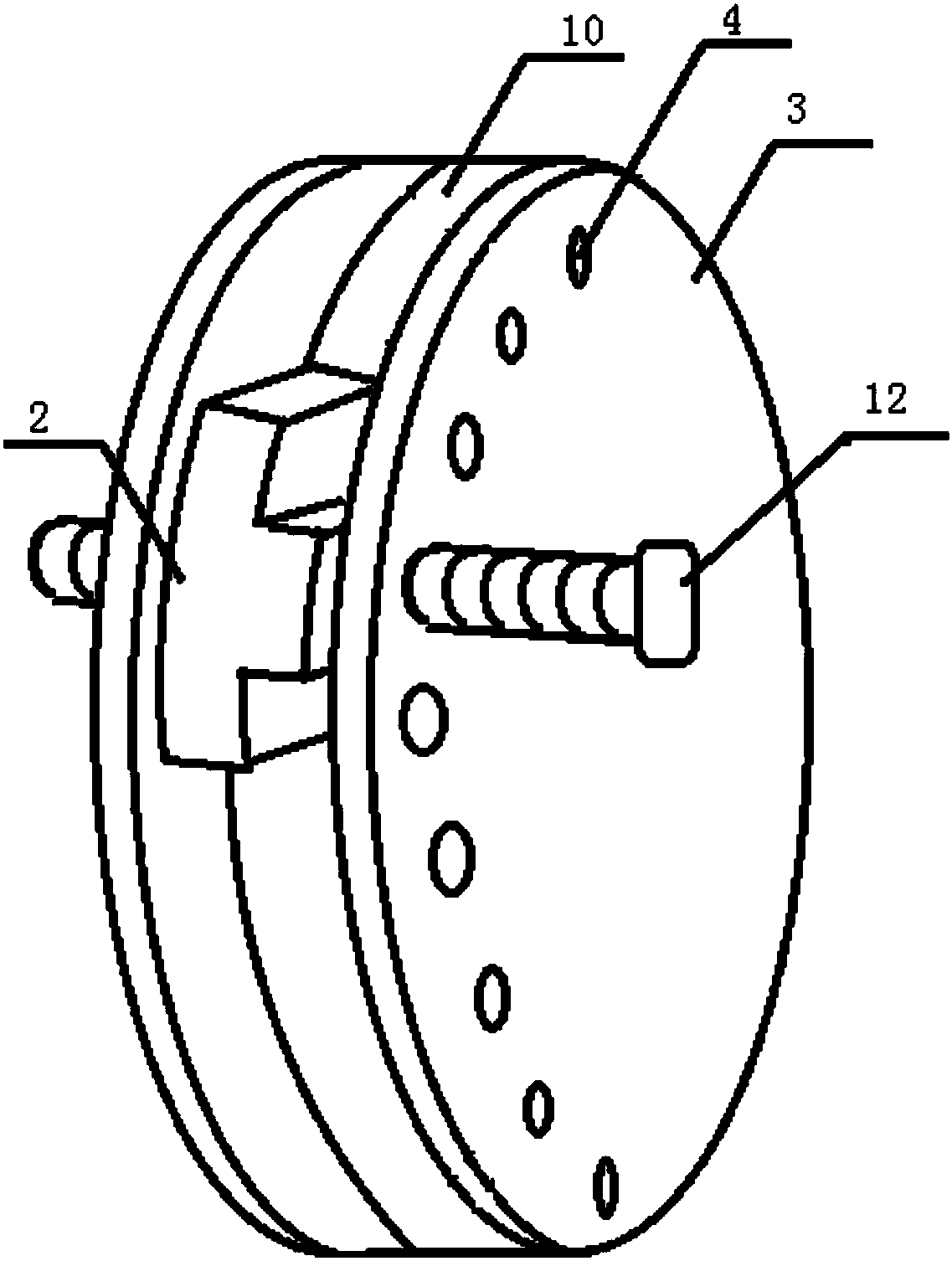

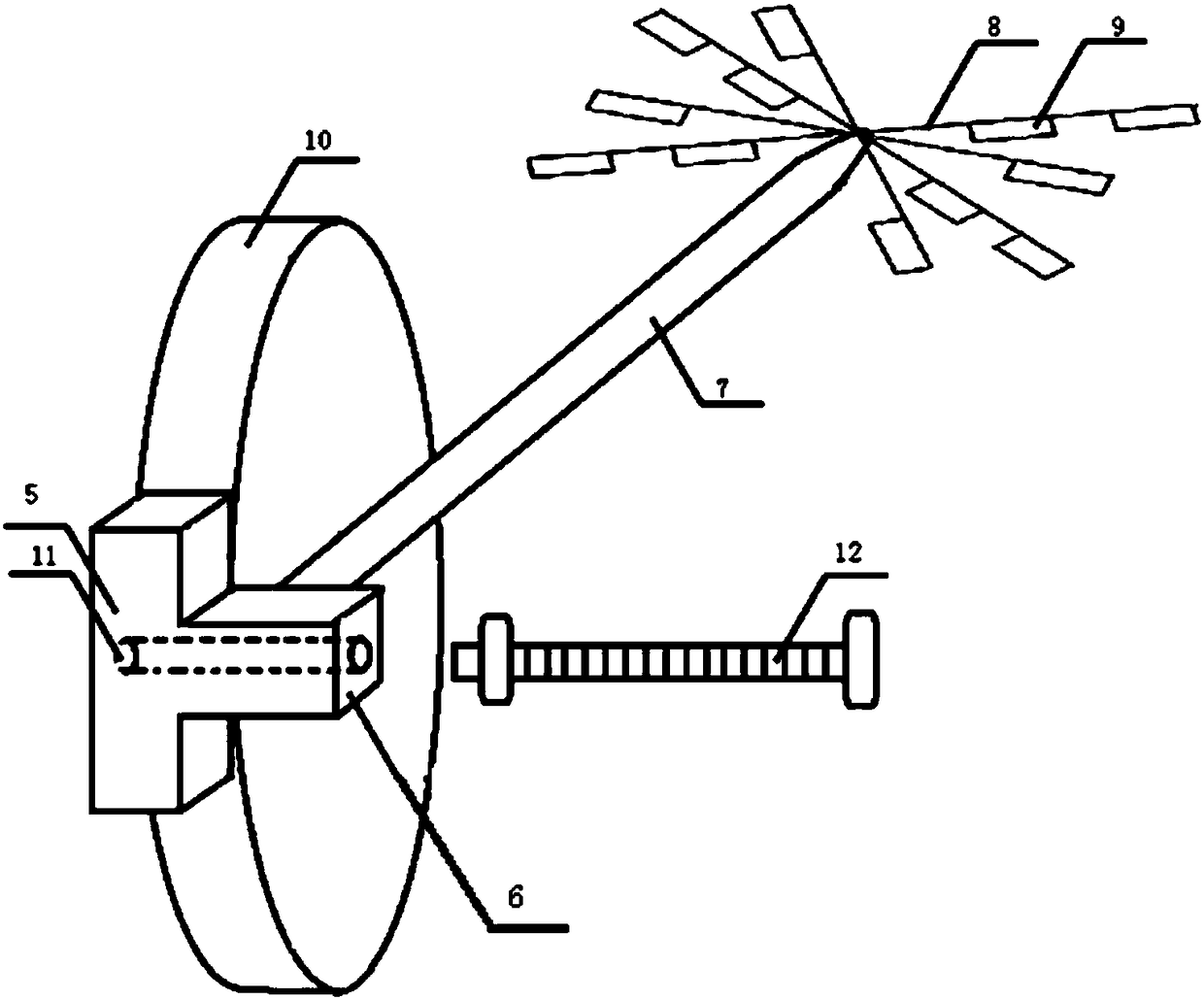

Adjustable-angle stirring device for photocatalyst mixing and working method of stirring device

InactiveCN108159920AStir fully and evenlyStir wellRotary stirring mixersTransportation and packagingEngineeringUltimate tensile strength

The invention relates to the technical field of photocatalysts, in particular to an adjustable-angle stirring device for photocatalyst mixing and a working method of the stirring device. The device comprises a sealing part and a stirring part which are integrally formed, wherein the sealing part is integrally connected with a sealing disk, the stirring part is detachably connected with staggered paddles, and the stirring device is obliquely inserted into the interior of the kettle body of a material mixing kettle from top to bottom from a support base on the outer side wall of the material mixing kettle; gaps among the support base can be completely sealed through the sealing disk, a plurality of fixing holes are formed in the support base, and the stirring device is positioned by a screwthrough a through hole and the fixing holes in the support base in a pin mode. The stirring device has the advantages that the fixing holes in the support base can be selected according to different inclination angles so as to change stirring depth, stirring strength and stirring in the material mixing kettle and form a vortex state, so that a good stirring effect is achieved; the gaps among the support base can be completely sealed through the sealing disk, so that it is ensured that the entire material mixing kettle is in a sealed state; diffraction can be formed among the long staggered paddles and short staggered paddles during stirring, and therefore the direction of liquid flow is disordered, so that a better stirring effect is achieved.

Owner:鞍山奇典光触媒高科技有限公司

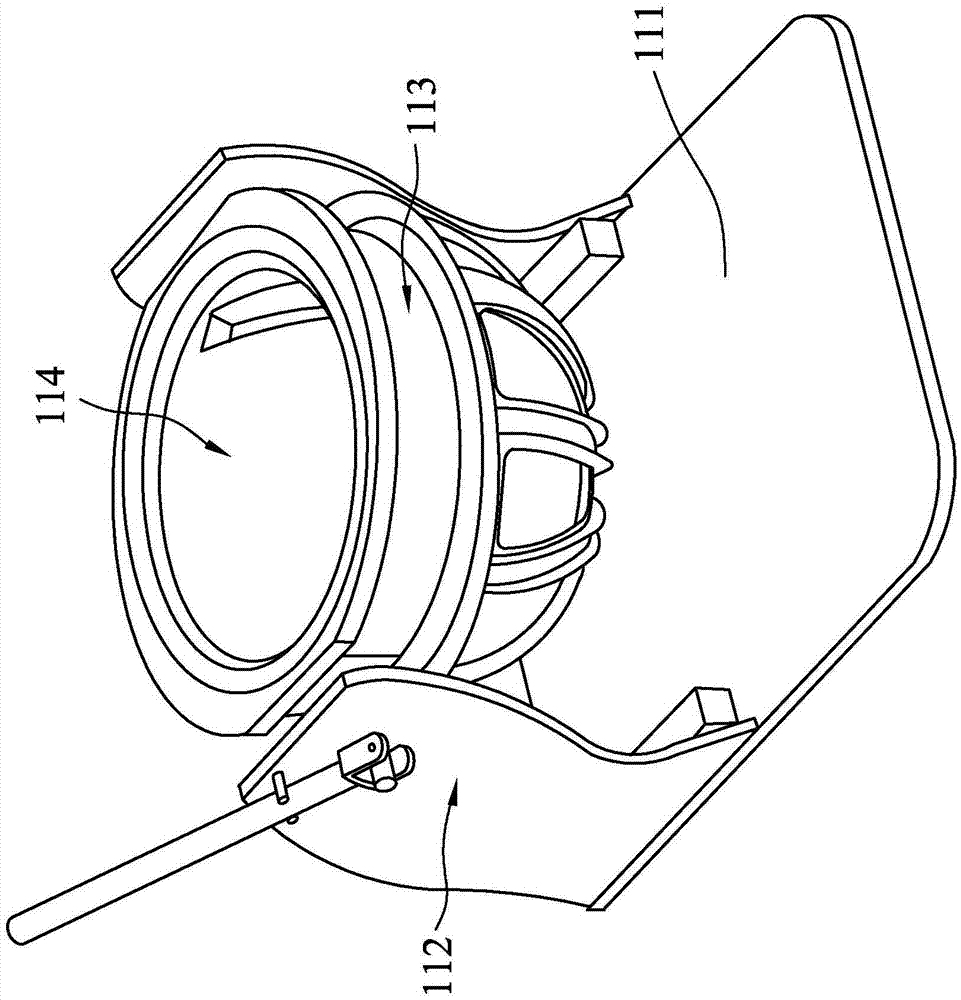

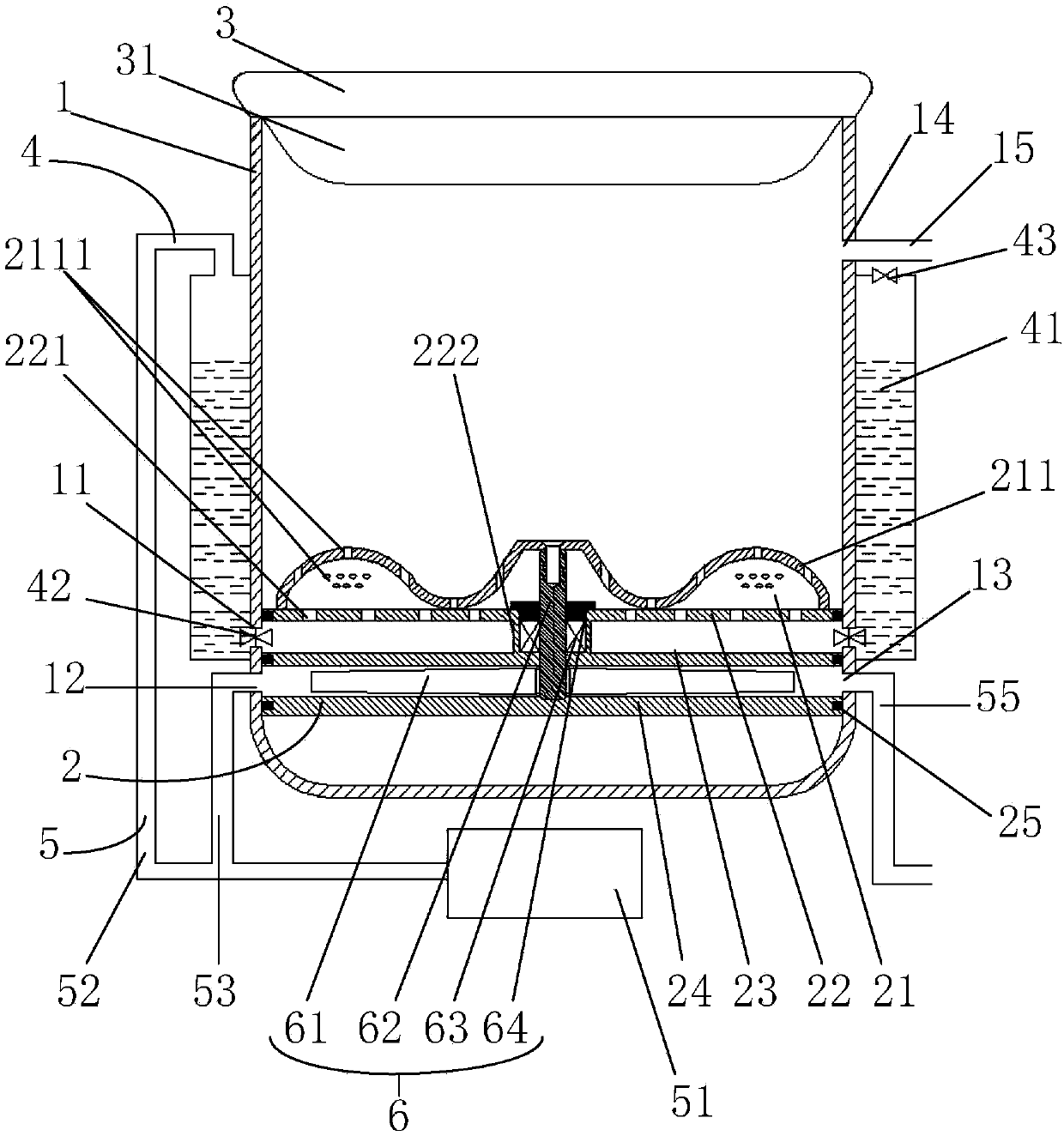

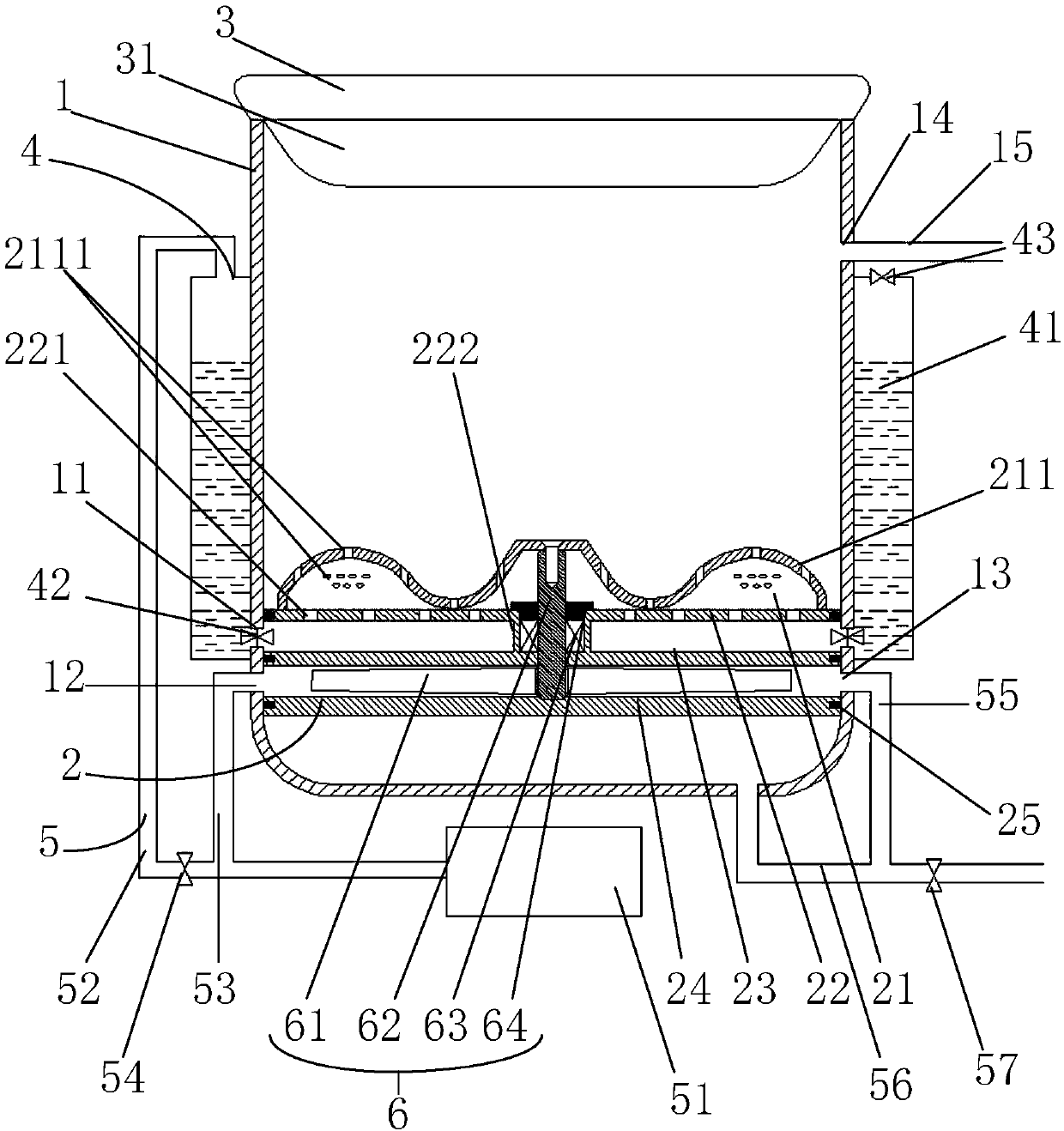

Washing equipment

ActiveCN110318204AImprove washing effectStir vigorouslyOther washing machinesWashing machine with receptaclesProcess engineeringLiquid storage

The invention belongs to the technical field of clothes treating equipment, and particularly relates to washing equipment. The washing equipment comprises a washing barrel, a wave wheel rotationally arranged in the washing barrel, a liquid storage assembly communicated with the washing barrel and a gas conveying assembly which is in sealing connection with the liquid storage assembly; the gas conveying assembly can make liquid in the liquid storage assembly through the method of conveying gas into the liquid storage assembly pressed into the washing barrel. In this way, the washing equipment can make the liquid enter the washing barrel simply by making the closed liquid storage assembly and the gas conveying assembly in sealing connection, and the sealing requirement of the washing equipment is lowered. In addition, the washing equipment further comprises a rotating assembly connected with the wave wheel, the gas conveying assembly can drive the rotating assembly to rotate through gasconveying so as to make the wave wheel rotate, that is to say, the gas conveying assembly can not only make the liquid pressed into the washing barrel, but also drive the wave wheel to rotate, thus the force of the wave wheel stirring clothes is guaranteed, and the washing efficiency of the clothes is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Composition with efficacy of removing acne

ActiveCN107875059AAntibacterial and anti-inflammatoryAcne Removal Sustained and EffectiveCosmetic preparationsToilet preparationsBiocompatibility TestingApple extract

The invention relates to composition with efficacy of removing acne. The composition is characterized by being prepared from components in parts by weight as follows: 10-15 parts of a traditional Chinese medicine extract, 3-5 parts of a ficus pumila syconium extract, 3-5 parts of a fructus momordicae extract, 4-6 parts of a lonicera edulis extract, 2-4 parts of a Guangxi sweet tea fruit extract, 6-8 parts of a mango extract, 6-8 parts of a longan extract, 10-12 parts of an apple extract, 0.5 parts of nano graphene, 0.01 parts of fibroblast growth factors, 1-2 parts of dextran, 0.05-0.1 parts of polyglutamic acid, 2-4 parts of mannitol and 65-85 parts of deionized water. Active ingredients in nano graphene, fibroblast growth factors and wholly pure natural fruit extracts are combined for the first time, and the non-irritant composition with no preservatives and lasting and efficient anti-inflammatory, bacteriostasis, acne removal and pockmark prevention functions is prepared. A biological transdermal enhancer is derived from whole fruit extracts, so that the composition has good biocompatibility, cannot injure skin and is safe.

Owner:浙江塑青春美容科技有限公司

Method for extracting dihydromyricetin from ampelopsis grossedentata

The invention discloses a method for extracting dihydromyricetin from ampelopsis grossedentata. The method comprises the following steps: (1) performing pretreatment; (2) performing enzymolysis; (3) extracting; (4) concentrating; (5) primary crystallization; (6) recrystallization; (7) purification; and (8) vacuum drying. According to the method disclosed by the invention, the yield and purity of the dihydromyricetin can be improved.

Owner:CHANGSHA SHENGKAI BIOLOGICAL TECH

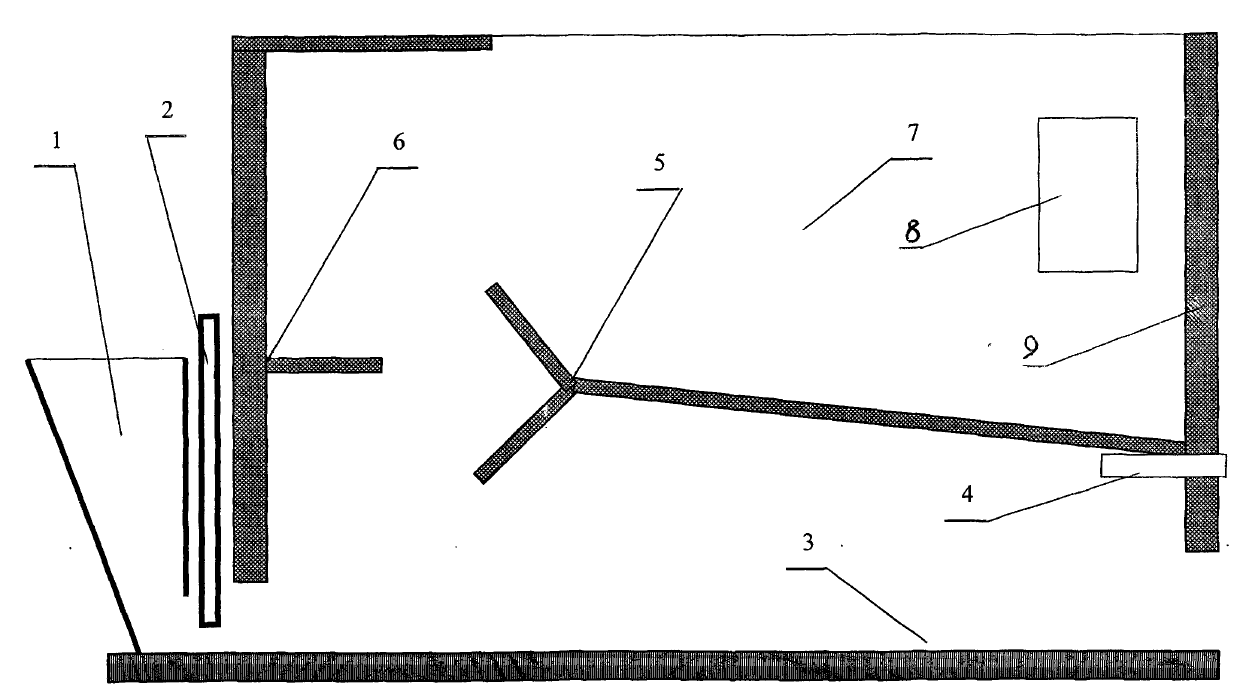

Dewatered sludge endless grate incinerator

InactiveCN101539297APrevent flying outReduced flow areaIncinerator apparatusCombustionCooling chamber

A dewatered sludge endless grate incinerator belongs to the technical field of hazardous waste incineration equipment. The invention aims at providing a dewatered sludge endless grate incinerator with a small amount of flying ash and high furnace exit fume temperature. The technical key points are as follows: a furnace above an endless grate (3) is internally provided with a front arch (6) with F-shaped longitudinal section and a rear arch (5) with horizontally Y-shaped longitudinal section and the two arches are mutually matched; an upper branch on the horizontal segment of the F-shaped front arch closely clings to the furnace top and a lower branch on the horizontal segment is positioned between an upper branch and a lower branch of the horizontally Y-shaped rear arch; the space between the outlet of the rear arch and the front arch forms a main combustion area; a nozzle of an air channel (4) of a secondary air system is arranged at the rear part of the rear arch by attaching to the wall; and a radiation cooling chamber (7) is arranged between the furnace outlet and an outlet smokestack (8) . The incinerator realizes the two basic conditions for complete decontamination by incinerating harmful solid waste under high temperature: extremely small amount of flying ash and extremely high furnace exit smoke temperature, has simple structure, easy operation and is an ideal facility for incinerating harmful wastes.

Owner:陈宝林

Composition with anti-acne effect

ActiveCN107875059BAcne Removal Sustained and EffectiveSustained high-efficiency anti-inflammatory and antibacterialCosmetic preparationsToilet preparationsBiotechnologyApple extract

The invention relates to composition with efficacy of removing acne. The composition is characterized by being prepared from components in parts by weight as follows: 10-15 parts of a traditional Chinese medicine extract, 3-5 parts of a ficus pumila syconium extract, 3-5 parts of a fructus momordicae extract, 4-6 parts of a lonicera edulis extract, 2-4 parts of a Guangxi sweet tea fruit extract, 6-8 parts of a mango extract, 6-8 parts of a longan extract, 10-12 parts of an apple extract, 0.5 parts of nano graphene, 0.01 parts of fibroblast growth factors, 1-2 parts of dextran, 0.05-0.1 parts of polyglutamic acid, 2-4 parts of mannitol and 65-85 parts of deionized water. Active ingredients in nano graphene, fibroblast growth factors and wholly pure natural fruit extracts are combined for the first time, and the non-irritant composition with no preservatives and lasting and efficient anti-inflammatory, bacteriostasis, acne removal and pockmark prevention functions is prepared. A biological transdermal enhancer is derived from whole fruit extracts, so that the composition has good biocompatibility, cannot injure skin and is safe.

Owner:浙江塑青春美容科技有限公司

Dewatered sludge endless grate incinerator

InactiveCN101539297BPrevent flying outReduced flow areaIncinerator apparatusCombustionCooling chamber

A dewatered sludge endless grate incinerator belongs to the technical field of hazardous waste incineration equipment. The invention aims at providing a dewatered sludge endless grate incinerator with a small amount of flying ash and high furnace exit fume temperature. The technical key points are as follows: a furnace above an endless grate (3) is internally provided with a front arch (6) with F-shaped longitudinal section and a rear arch (5) with horizontally Y-shaped longitudinal section and the two arches are mutually matched; an upper branch on the horizontal segment of the F-shaped front arch closely clings to the furnace top and a lower branch on the horizontal segment is positioned between an upper branch and a lower branch of the horizontally Y-shaped rear arch; the space betweenthe outlet of the rear arch and the front arch forms a main combustion area; a nozzle of an air channel (4) of a secondary air system is arranged at the rear part of the rear arch by attaching to thewall; and a radiation cooling chamber (7) is arranged between the furnace outlet and an outlet smokestack (8) . The incinerator realizes the two basic conditions for complete decontamination by incinerating harmful solid waste under high temperature: extremely small amount of flying ash and extremely high furnace exit smoke temperature, has simple structure, easy operation and is an ideal facility for incinerating harmful wastes.

Owner:陈宝林

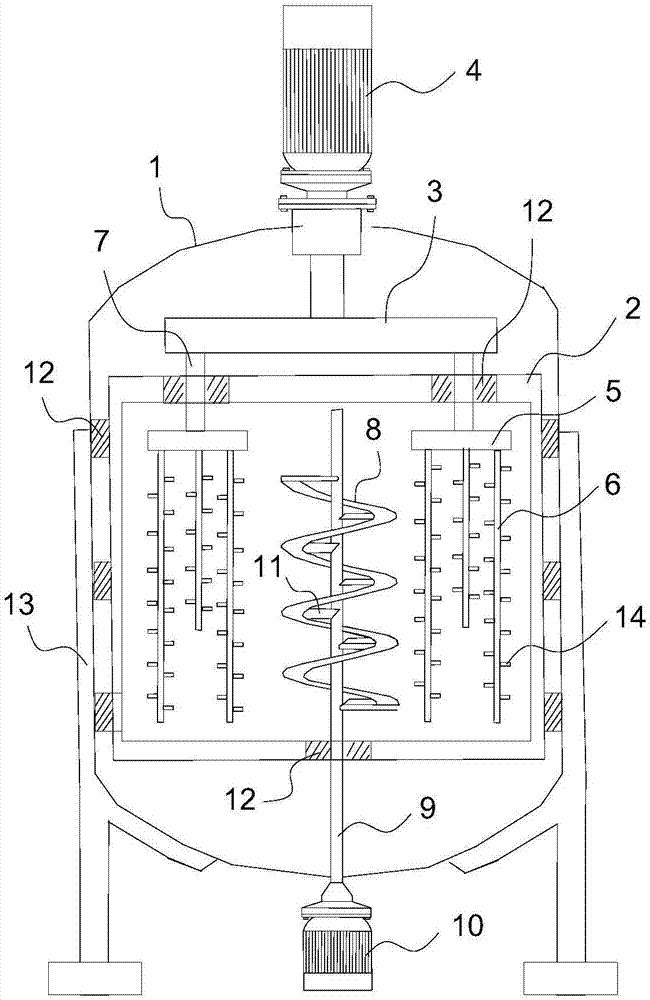

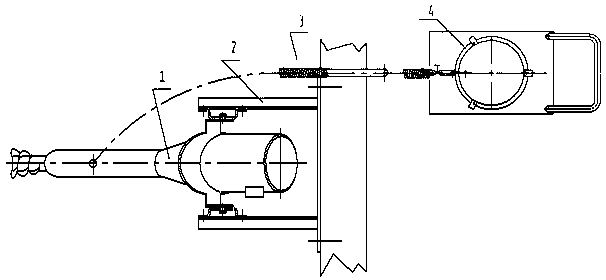

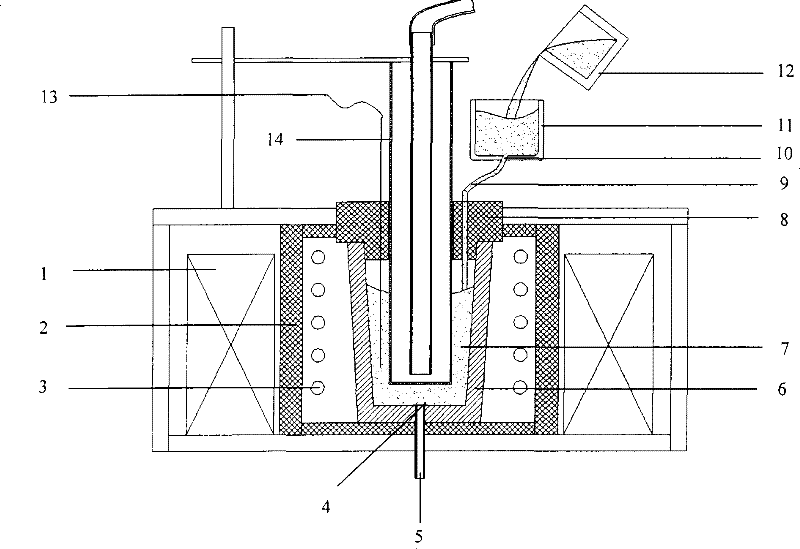

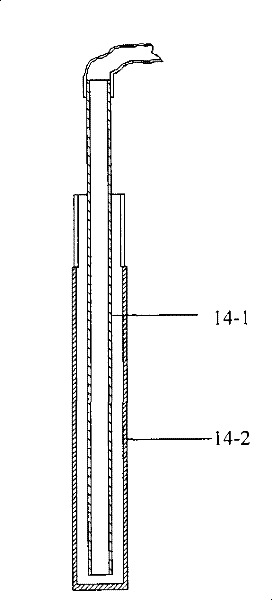

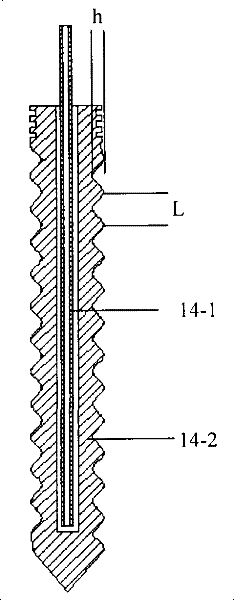

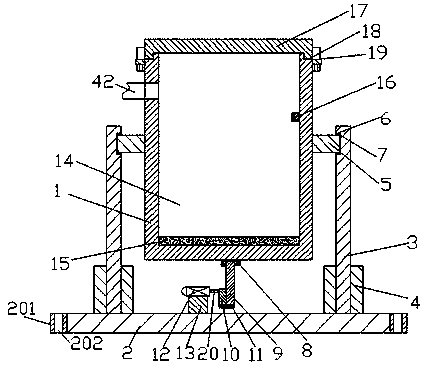

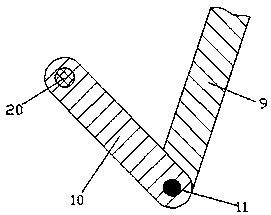

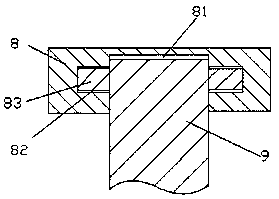

Device for preparing semi-solid alloy rheological slurry or blank

The invention discloses a device for preparing semi-solid metal and alloy slurry, which mainly comprises an electromagnetic stirrer, an insulating layer, an external cooling controller, a valve, a draft tube, a preparation crucible, an insulating crucible cover, a standing crucible, a melting crucible and a thermocouple. The middle part of the preparation crucible is provided with an internal cooling controller, and the outer wall of the internal cooling controller forms a clearance with the inner wall of the preparation crucible. The device can be connected with a press-casting machine, an extruder, a continuous casting machine and a forging machine, wherein the press-casting machine consists of a press-casting fixed die, a press-casting movable die, an injection chamber and a punch head; the extruder consists of a right extrusion die profile, a left extrusion die profile, an extrusion cylinder and an extrusion rod; the continuous casting machine consists of a tundish, a crystallizer, a cooling water nozzle and a traction mechanism; and the forging machine consists of a forging die cavity and a forging die. The device has the advantages that the device has simple and compact structure, low investment cost and strong practicability; the temperature field and tissue of the prepared slurry are distributed evenly; the semi-solid alloy slurry is pure, does not bubble and has good self cleanness; and the device can produce large-specification semi-solid slurry or blank, and is quite suitable for the preparation and formation of the semi-solid slurry or the blank.

Owner:有研金属复材技术有限公司

An improved urban sewage treatment reclaimed water production device

ActiveCN108383184BStir vigorouslyStirring rapidlyWater/sewage treatment by heatingWater/sewage treatment apparatusReclaimed waterWater production

The invention discloses an improved urban sewage treatment regeneration water production device, which comprises a base, an oscillator and a collector, wherein support posts are mutually and symmetrically arranged at the left and right side of the upper end surface of the base; connecting rods are mutually symmetrically arranged in the middle part of the left and right ends of the oscillator; oneend, far away from the oscillator, of the connecting rod is respectively connected with the top of the support posts at the left end and the right end; a sealed accommodating cavity is formed betweenthe oscillator and a sealed cover arranged at the upper end of the oscillator; a heater is fixedly connected onto the lower end wall of the sealed accommodating cavity; a sensor is arranged on the right end wall of the sealed accommodating cavity; locking devices are symmetrically arranged at the left and right ends of the sealed cover.

Owner:斯邦泽生态环境科技(厦门)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com