Patents

Literature

1590 results about "Solid structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

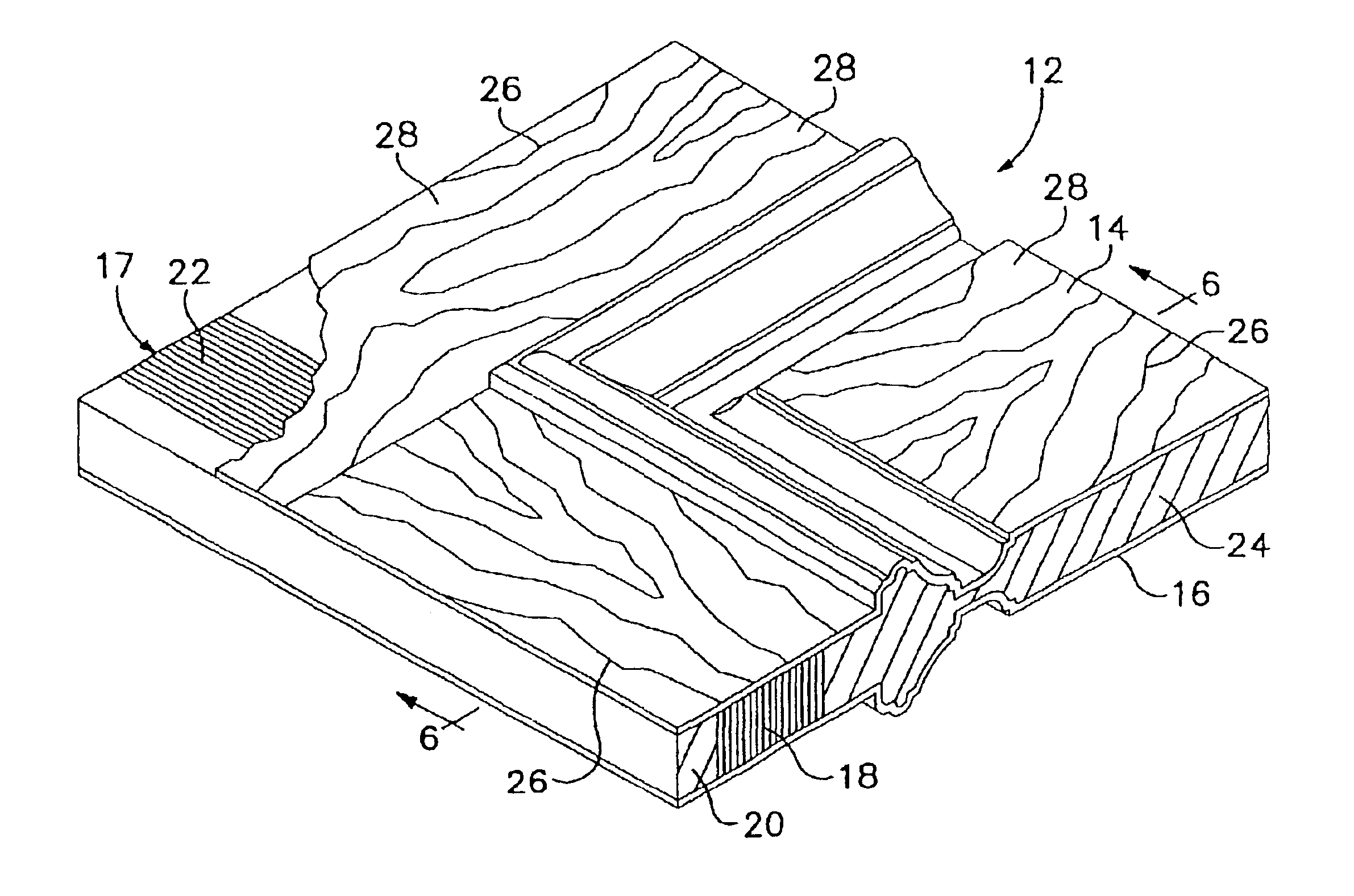

System and method for time reversal data communications on pipes using guided elastic waves

ActiveUS20130279561A1Efficient communicationClean signals for demodulationFrequency/rate-modulated pulse demodulationPosition-modulated pulse demodulationDiagnostic Radiology ModalityStructural health monitoring

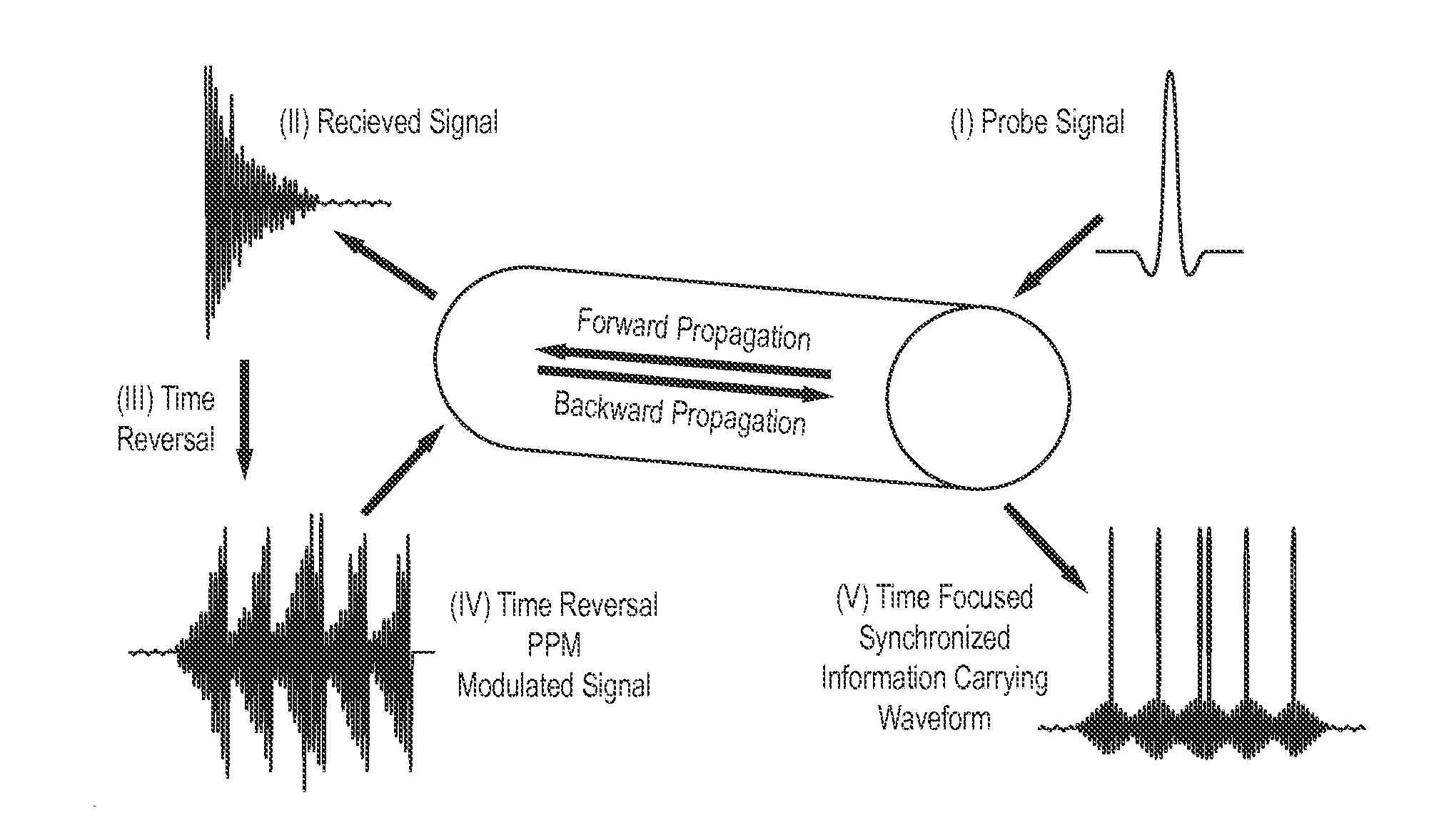

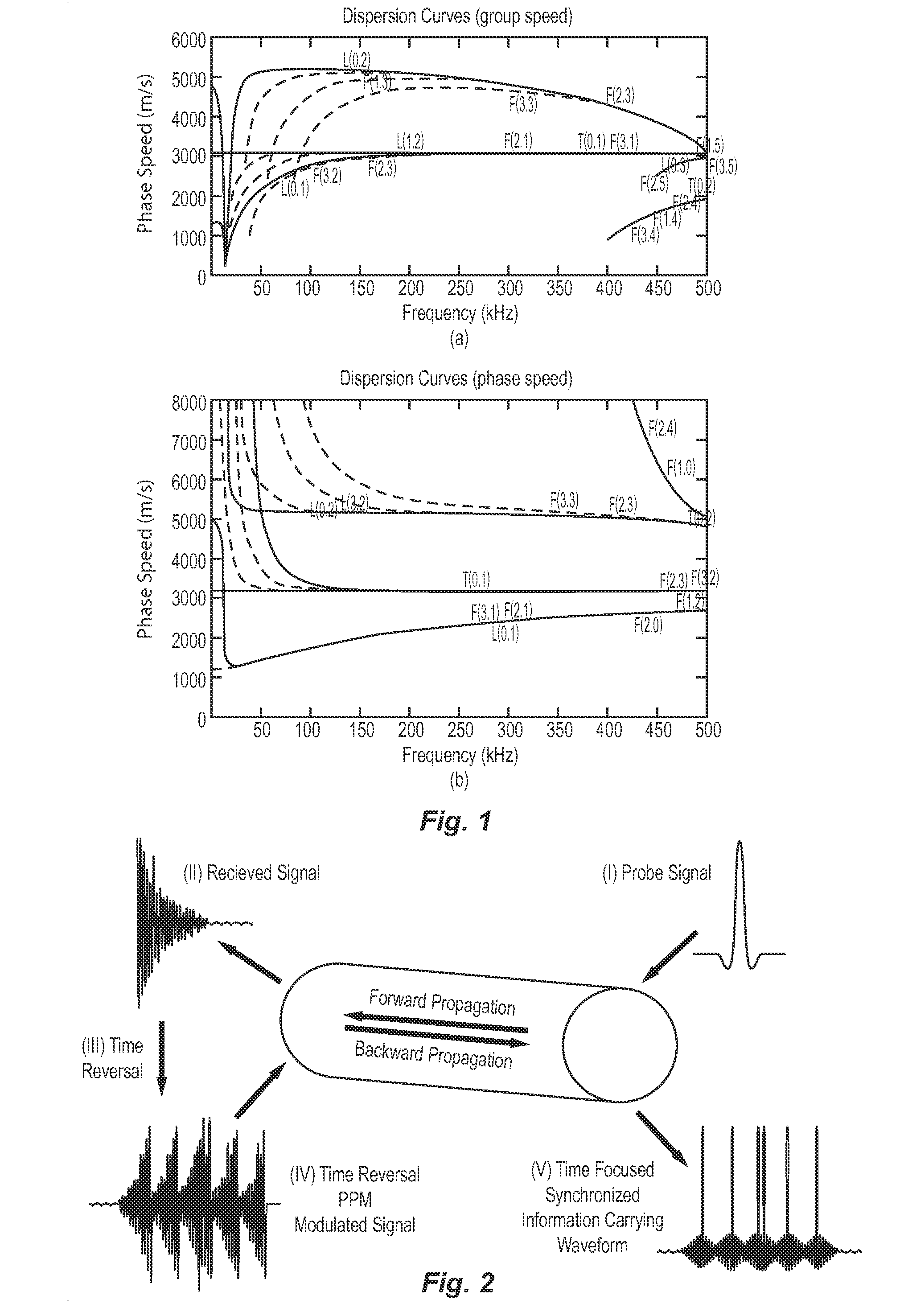

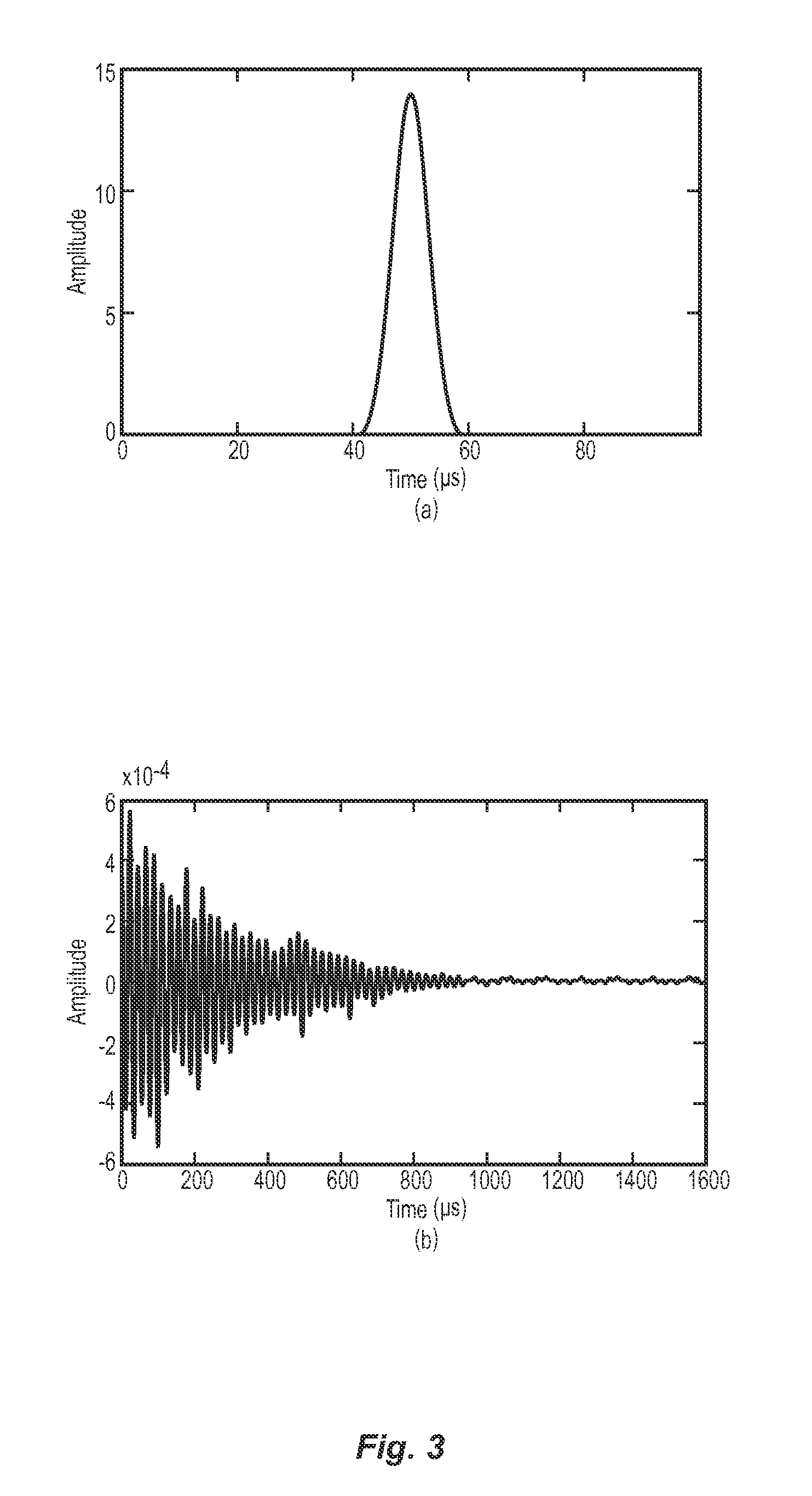

Embedded piezoelectric sensors in large civil structures for structural health monitoring applications require data communication capabilities to effectively transmit information regarding the structure's integrity between sensor nodes and to the central processing unit. Conventional communication modalities include electromagnetic waves or acoustical waves. While guided elastic waves can propagate over long distances on solid structures, their multi-modal and dispersive characteristics make it difficult to interpret the channel responses and to transfer useful information along pipes. Time reversal is an adaptive transmission method that can improve the spatiotemporal wave focusing. The present disclosure presents the basic principles of a time reversal based pulse position modulation (TR-PPM) method and demonstrates TR-PPM data communication by simulation. The present disclosure also experimentally demonstrates data communication with TR-PPM on pipes. Simulated and experimental results demonstrate that TR-PPM for data communications can be achieved successfully using guided elastic waves.

Owner:UNIV OF MARYLAND EASTERN SHORE +1

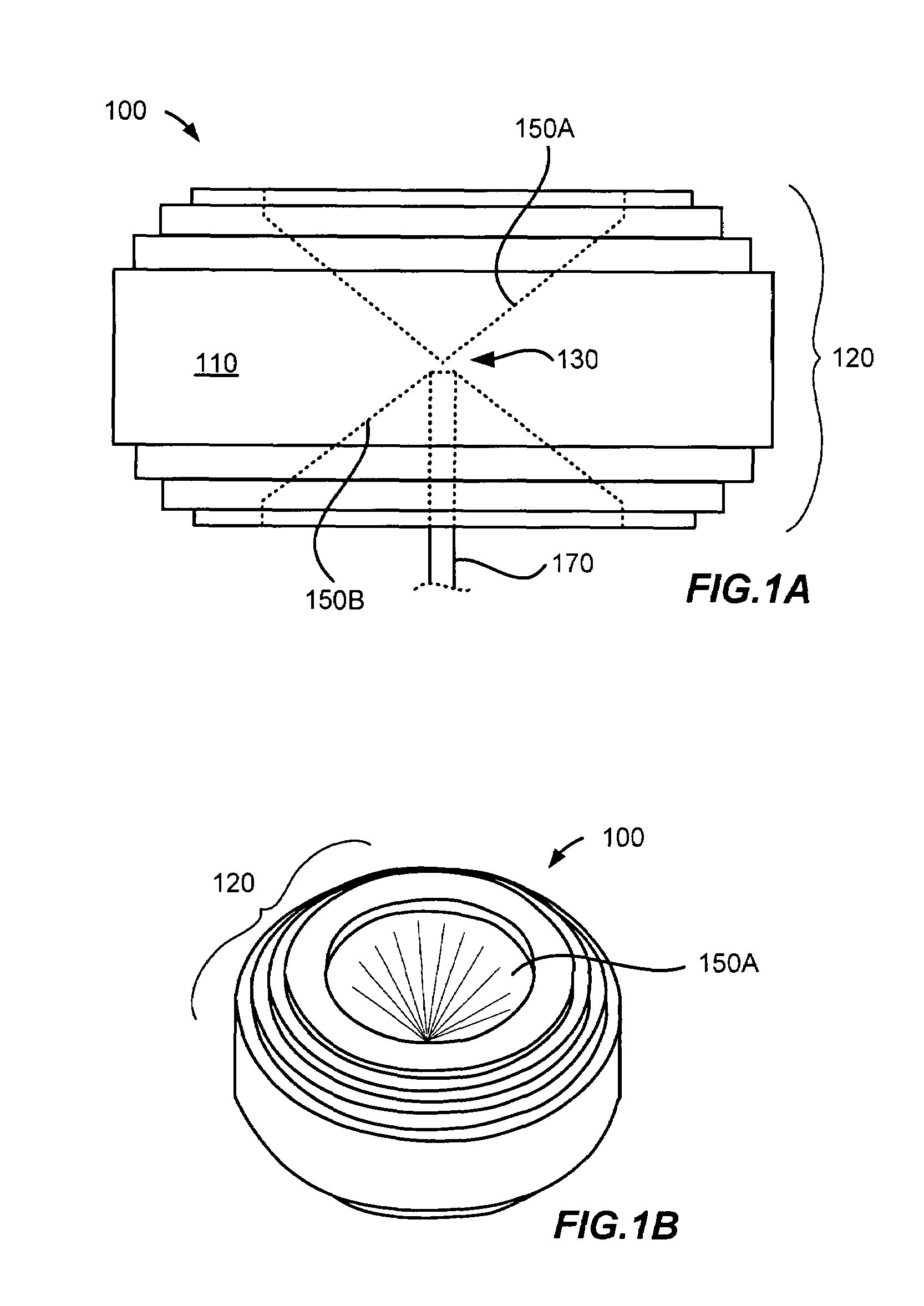

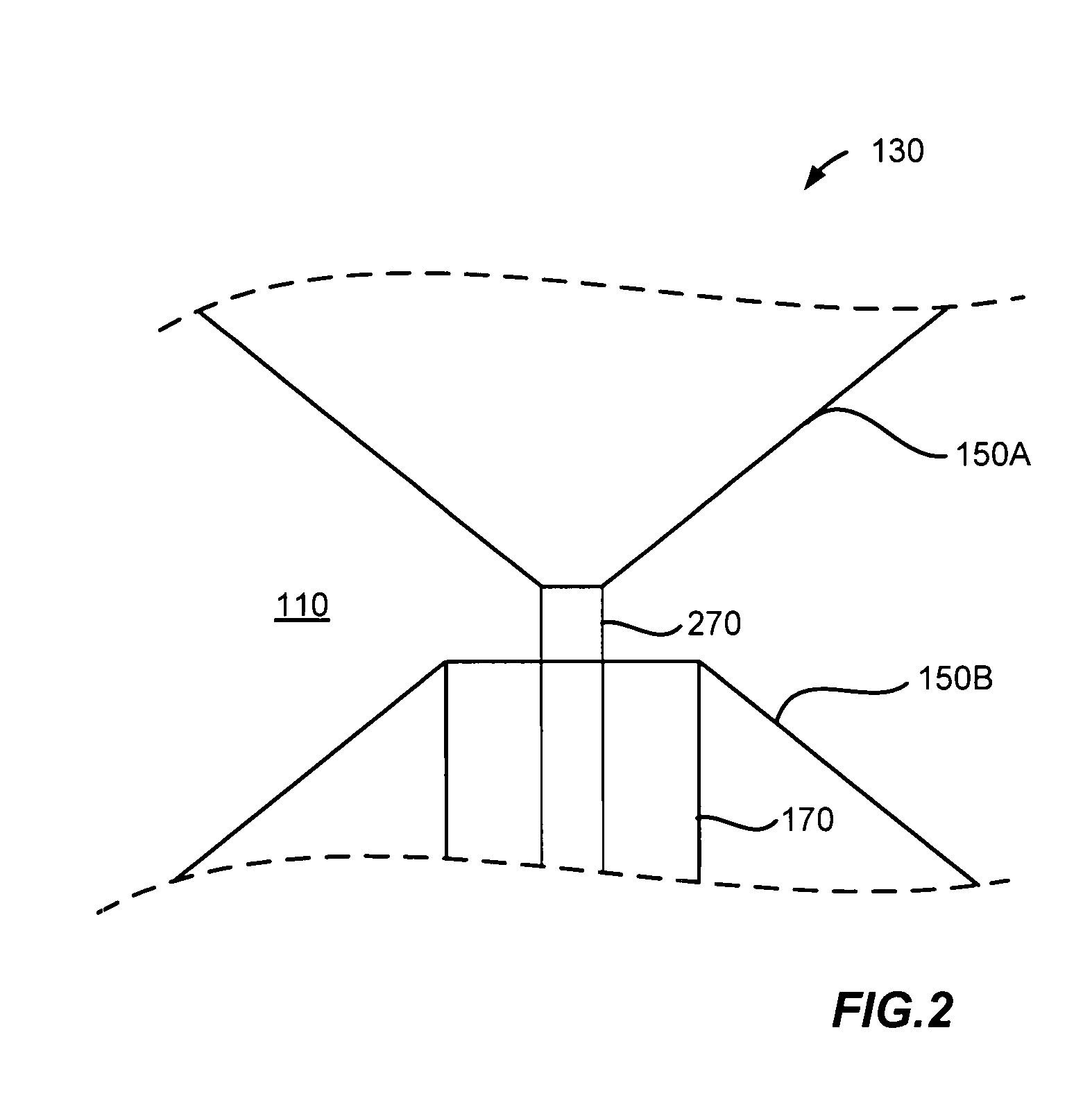

Bicone pattern shaping device

ActiveUS7525501B2Low costHigh gainAntenna feed intermediatesElectromagnetic radiationOmni directional

A broadband omni-directional bicone antenna. The antenna can comprise conductive surfaces of conical voids provided within a solid dielectric structure. The outside surface of the solid structure can support a radio frequency (RF) lens geometry operable for beam forming. The beam forming can modify the elevation pattern of the electromagnetic radiation from the bicone antenna. The solid dielectric structure may be machined or molded from a single piece of material. The conical voids provided within the solid structure can be metallized to provide conductive bicone radiators. The outer surface beam shaping lenses can be zoned or continuous and can provide elevation patterns with increased gain, cosecant squared falloff, or various other patterns. The beam shaping lens may be formed from any low-loss dielectric. Alternatively, the lens may be formed from a less dense material such as dielectric foam that can support radial conductive beam forming vanes.

Owner:EMS TECHNOLOGIES

Personal Care Composition in the Form of an Article

Personal care compositions, especially those personal care compositions in the form of an article that is a porous, dissolvable solid structure.

Owner:THE PROCTER & GAMBLE COMPANY

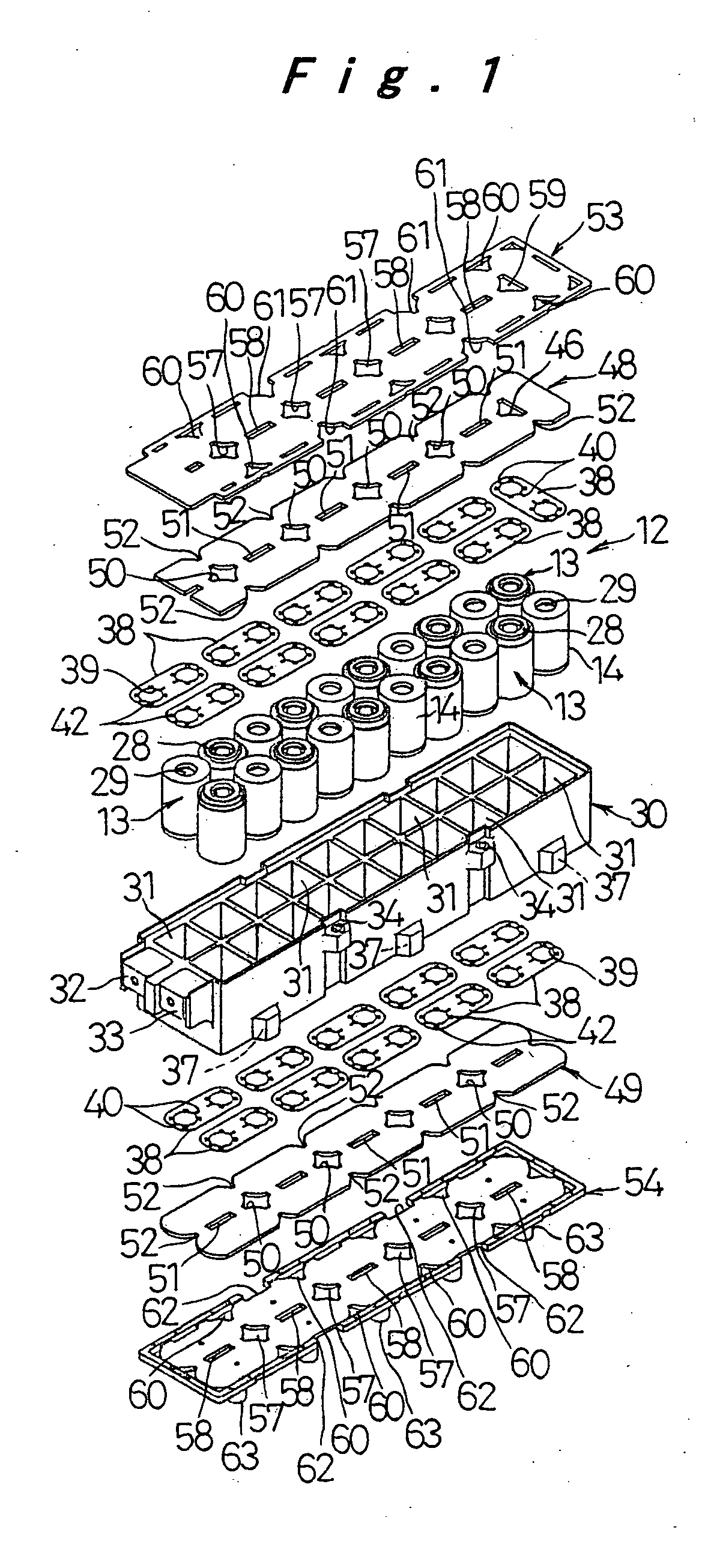

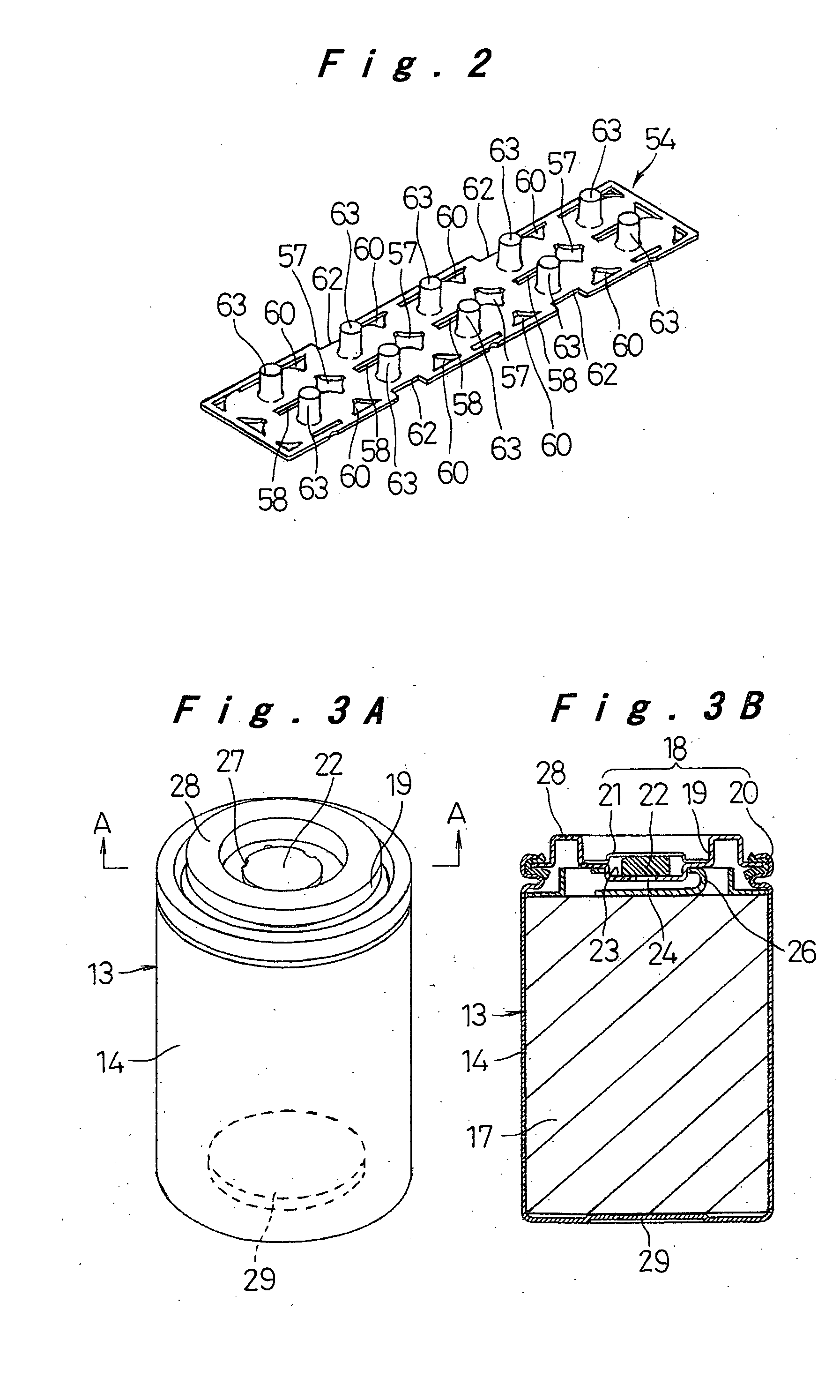

Battery connection structure, battery module, and battery pack

InactiveUS20050079408A1Increase productionReduce in quantityPrimary cell to battery groupingElectric propulsion mountingElectrical resistance and conductanceSolid structure

A connection plate in form of flat plate is welded to be connected to portion that are close to each other, i.e., a connection-electrode portion of one of two adjacent cells and a bottom of a cell case of the other cell, while being bridged between the connection-electrode portion and the bottom of the cell case, thereby forming an inexpensive connecting structure between cells, that reduces the electric resistance, by simple processes. A battery module having a solid structure impervious to vibration or shock is formed by accommodating cylindrical cells in cell-accommodating portions, each of which has a square shape seen from the front, of a holder case made of synthetic resin with their cell axes arranged in parallel, and by closing both sides of the holder case with cover members having radiation holes. Then, a battery pack is formed by attaching outer plates to a plurality of such battery modules that are arranged and integrating them.

Owner:PANASONIC CORP

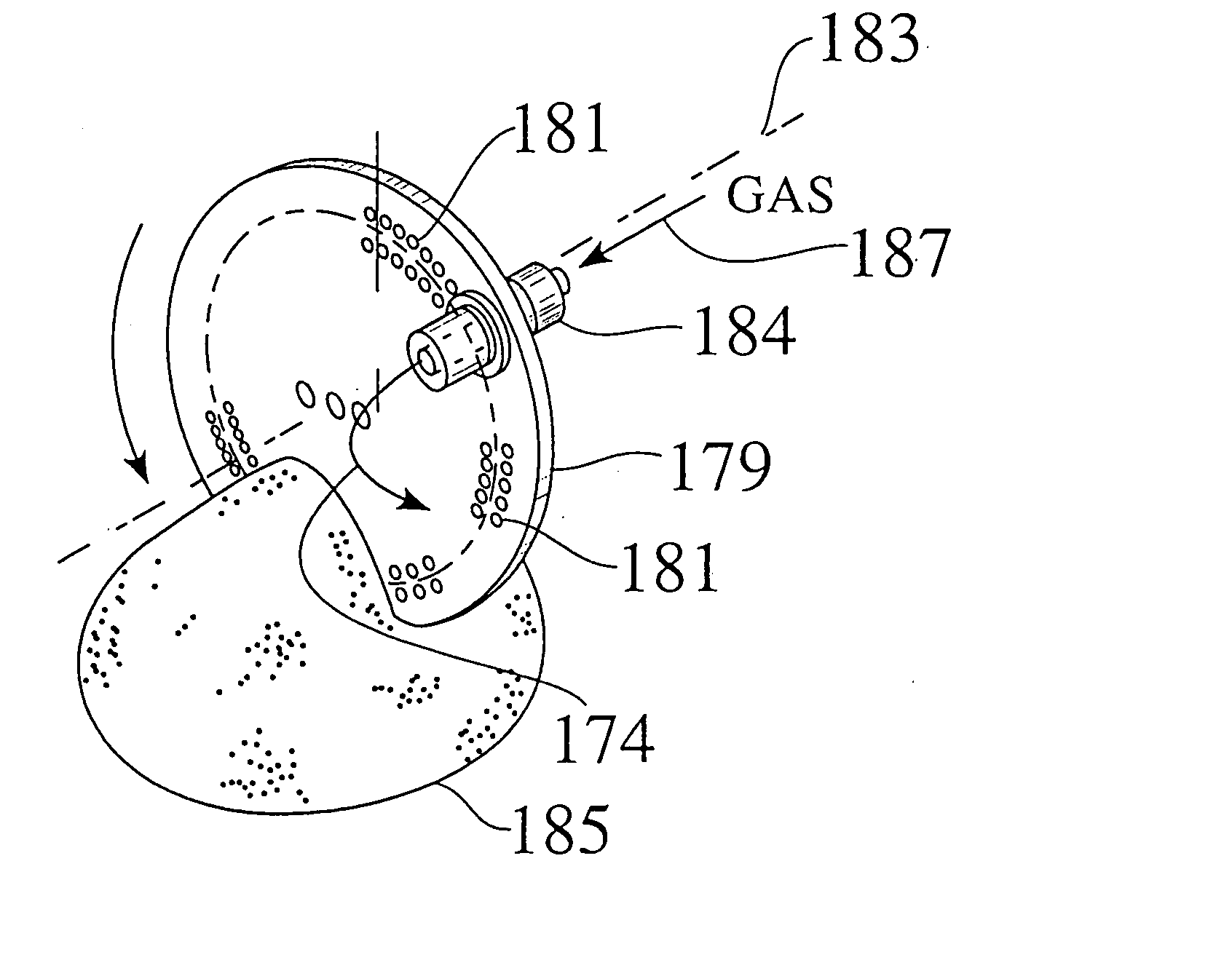

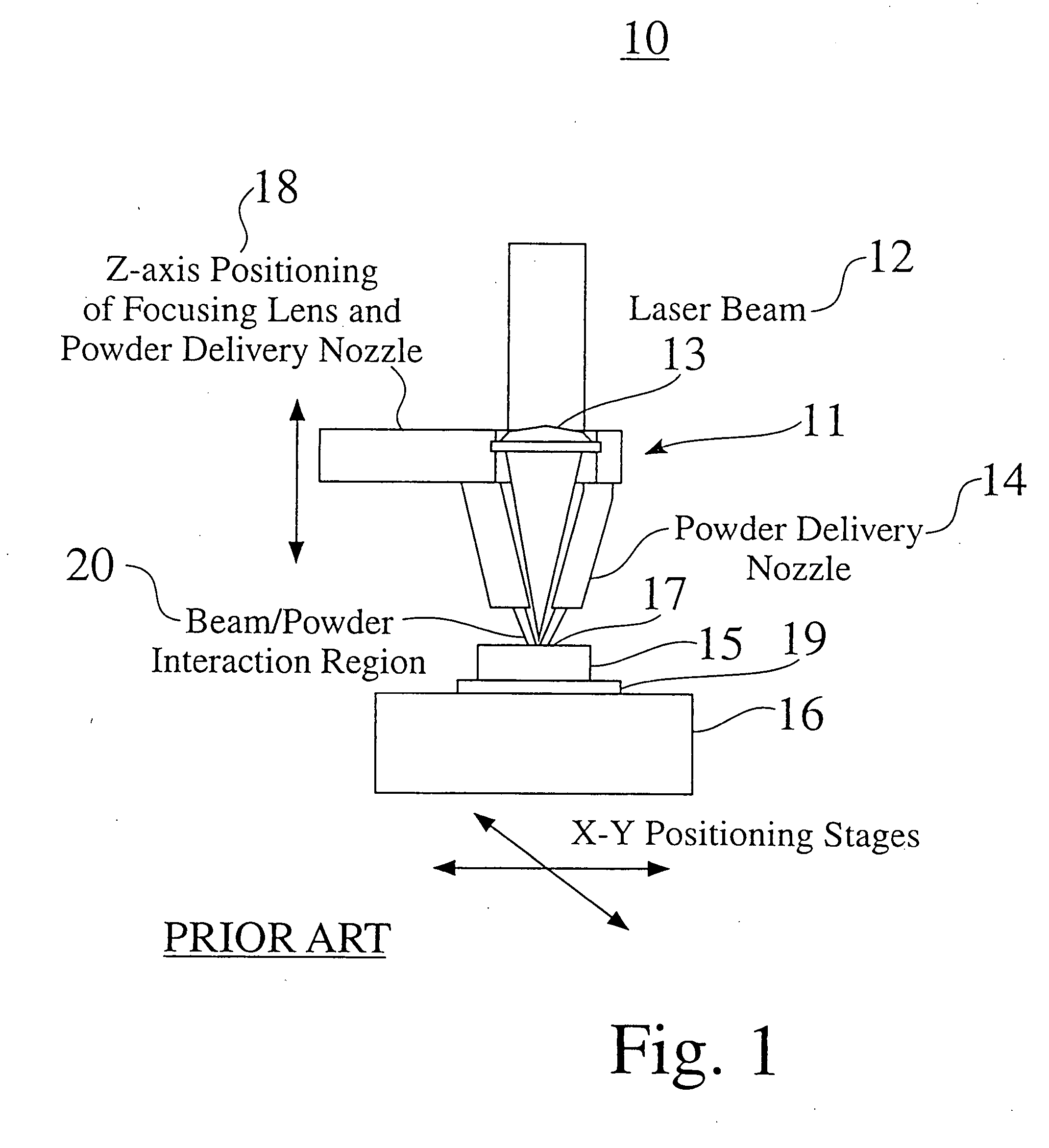

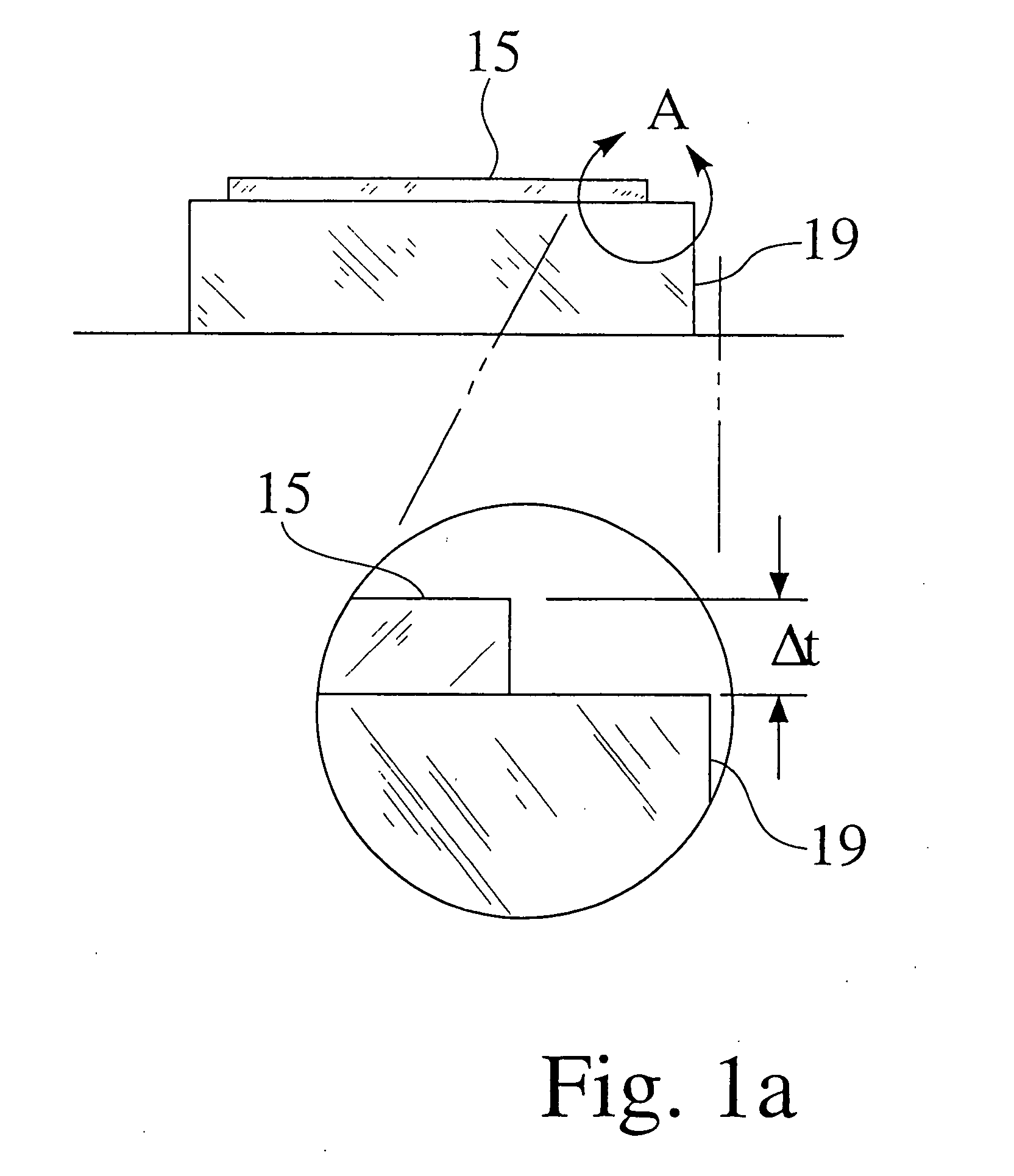

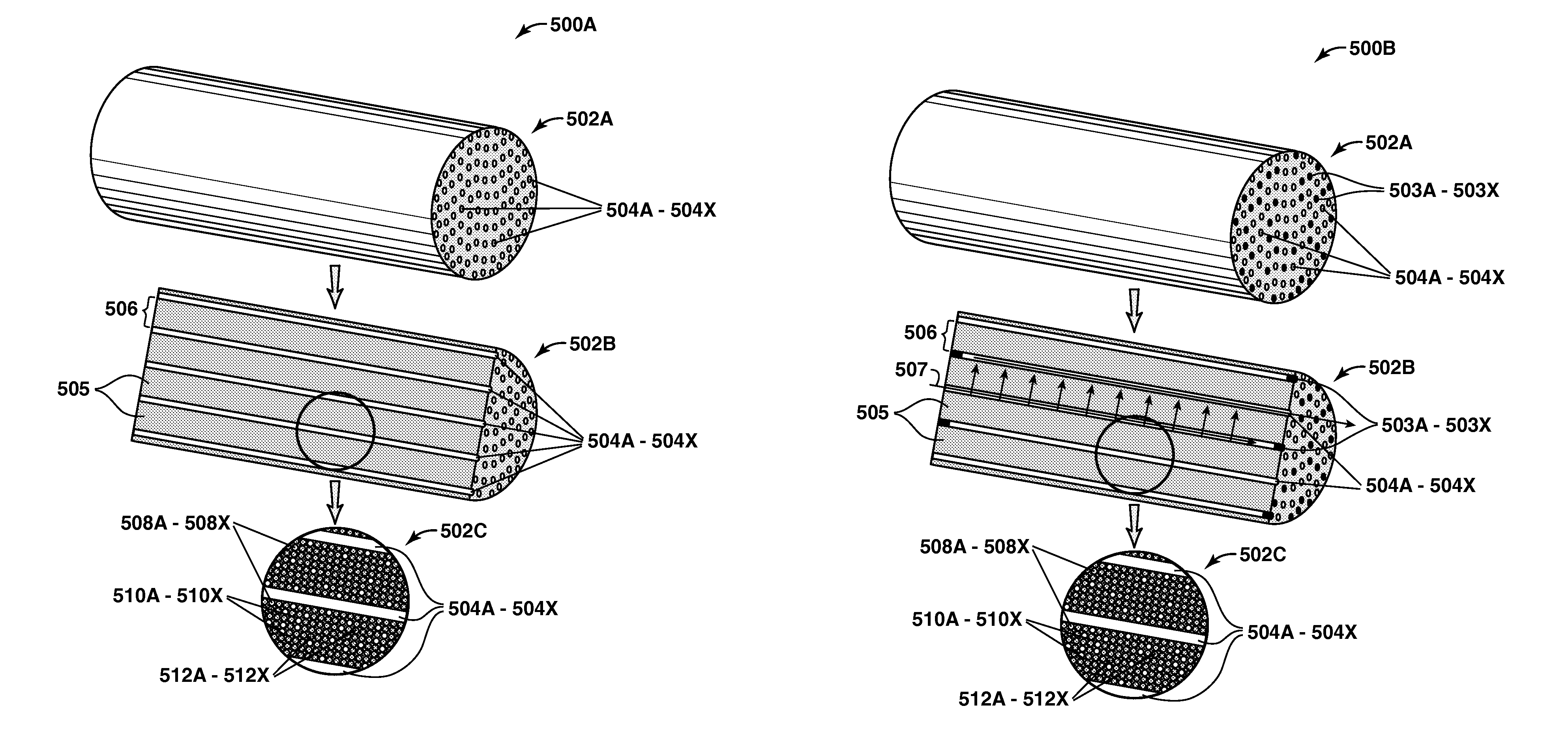

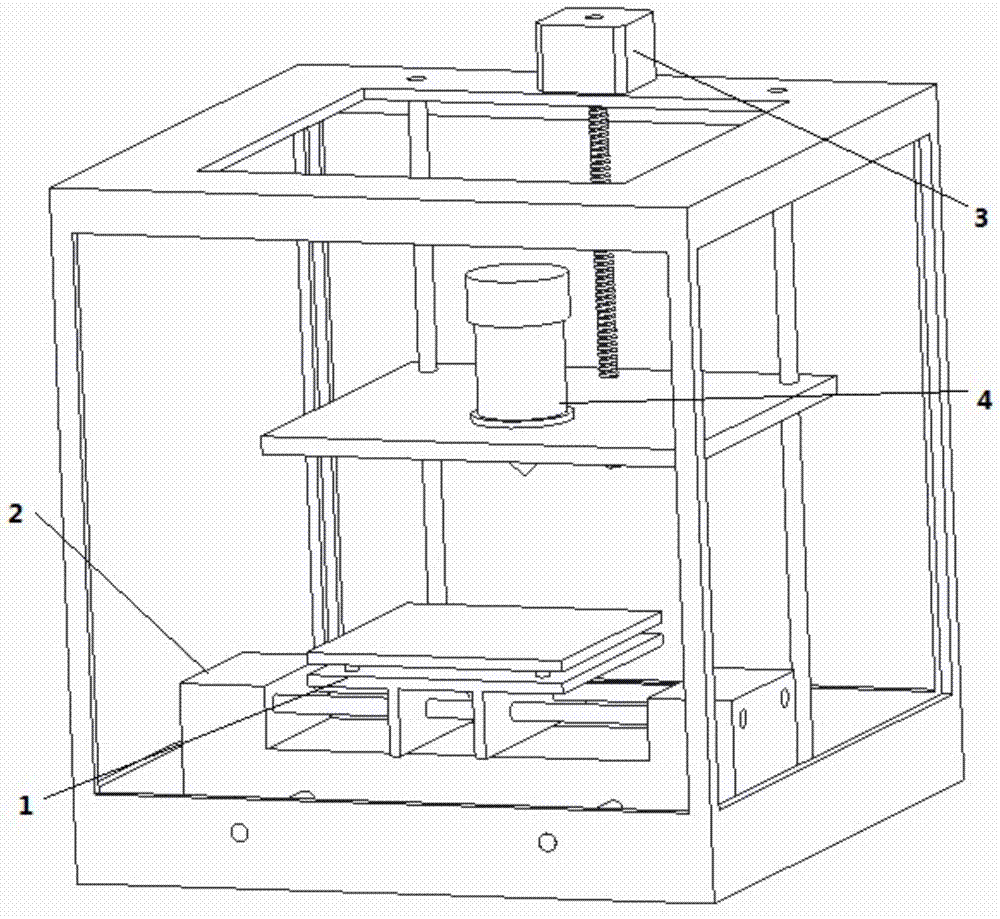

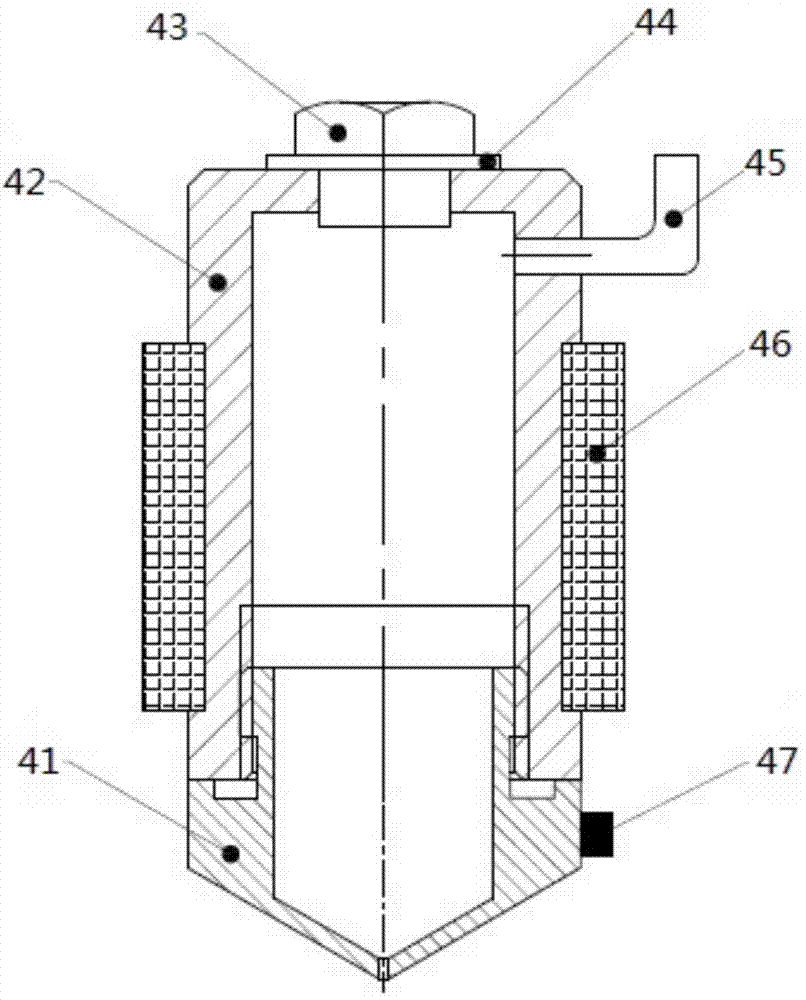

Powder feeder for material deposition systems

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

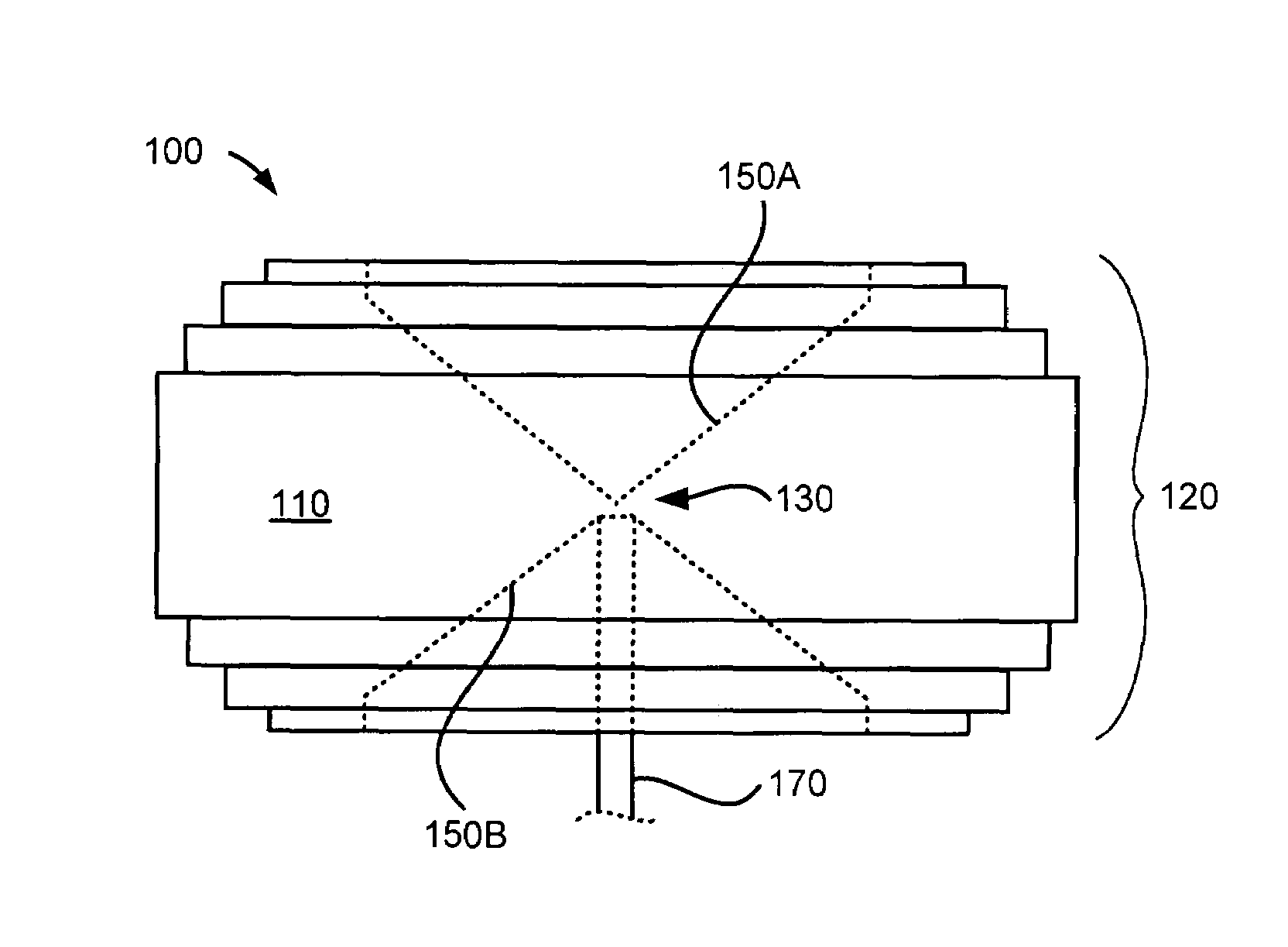

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

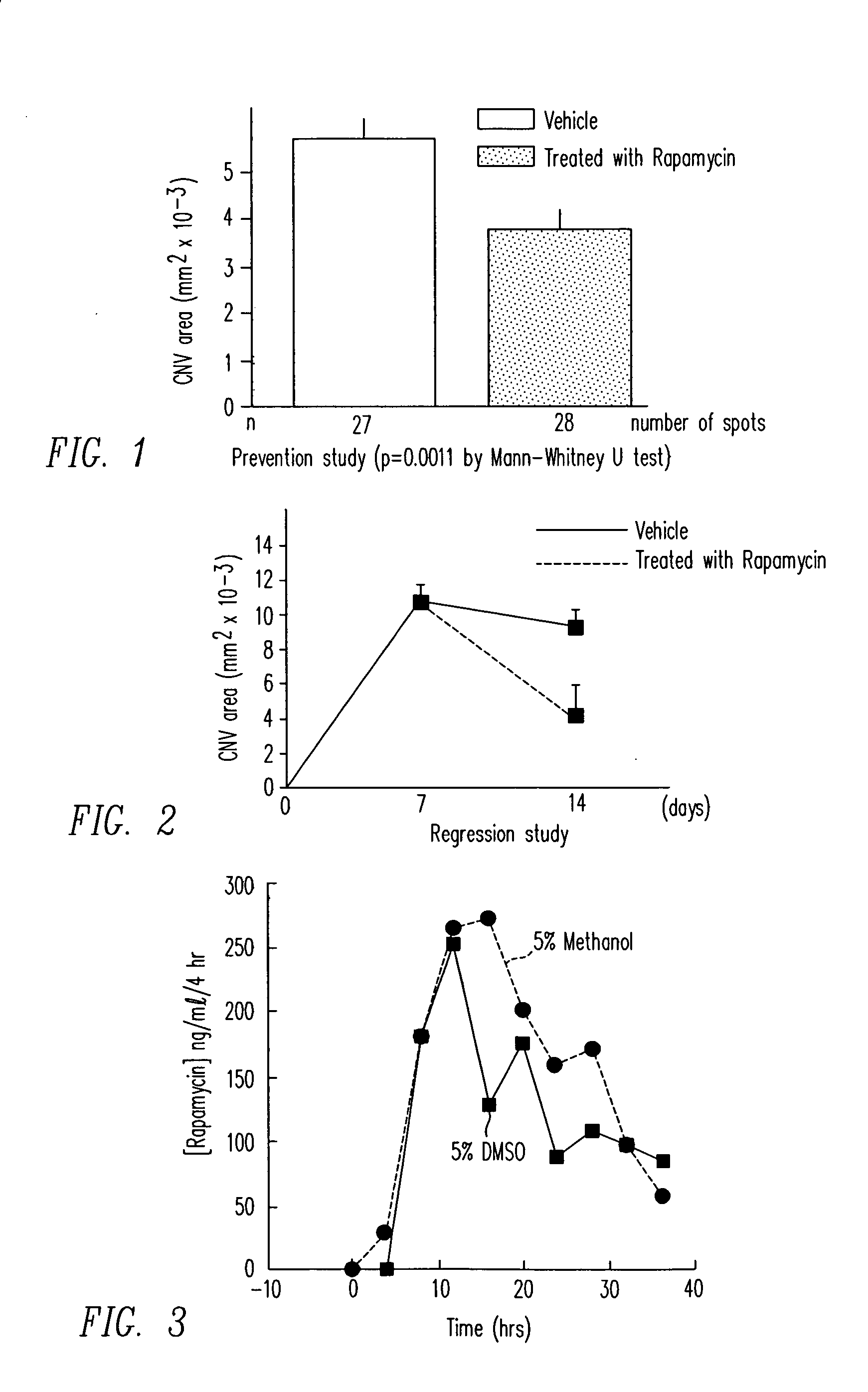

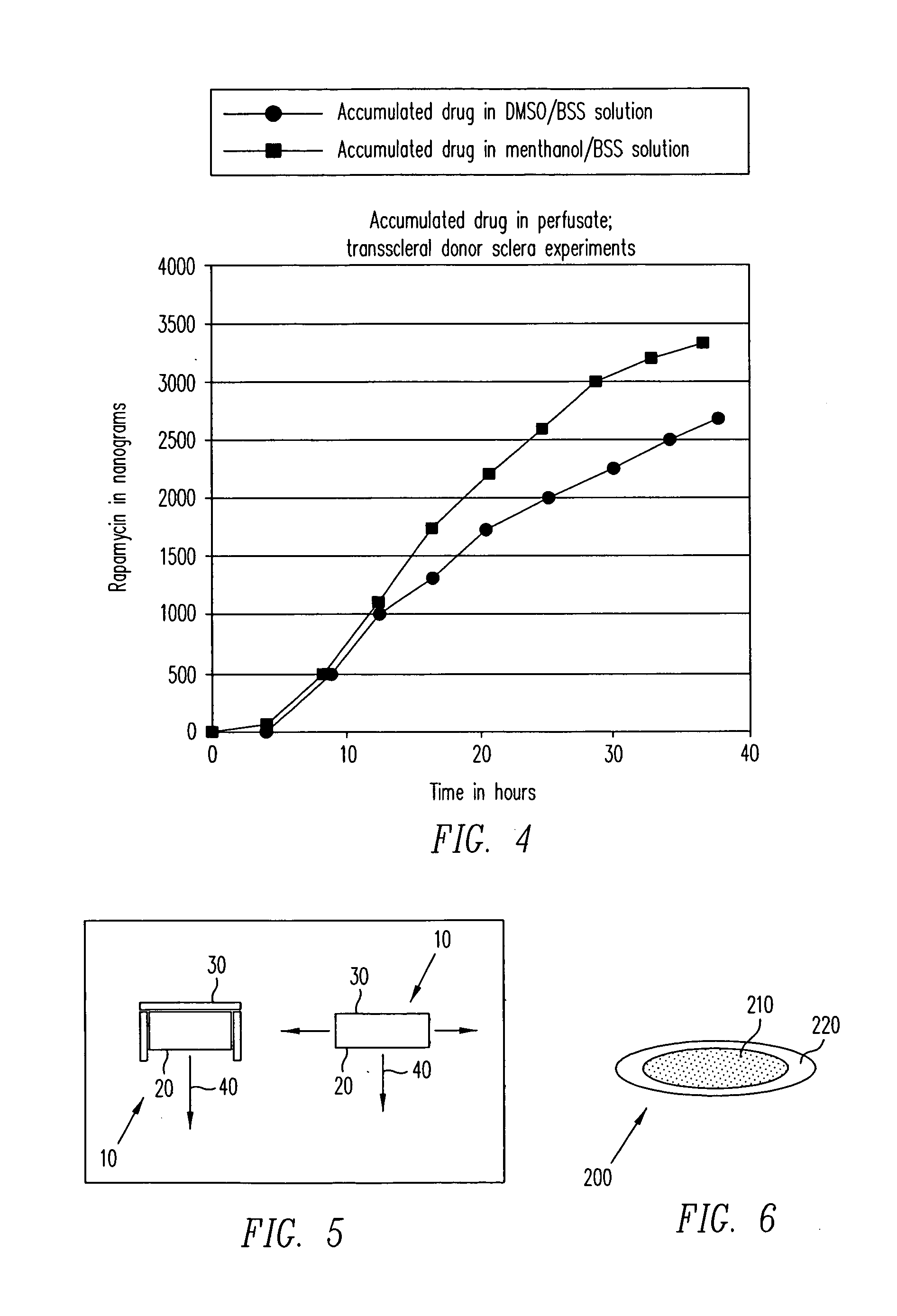

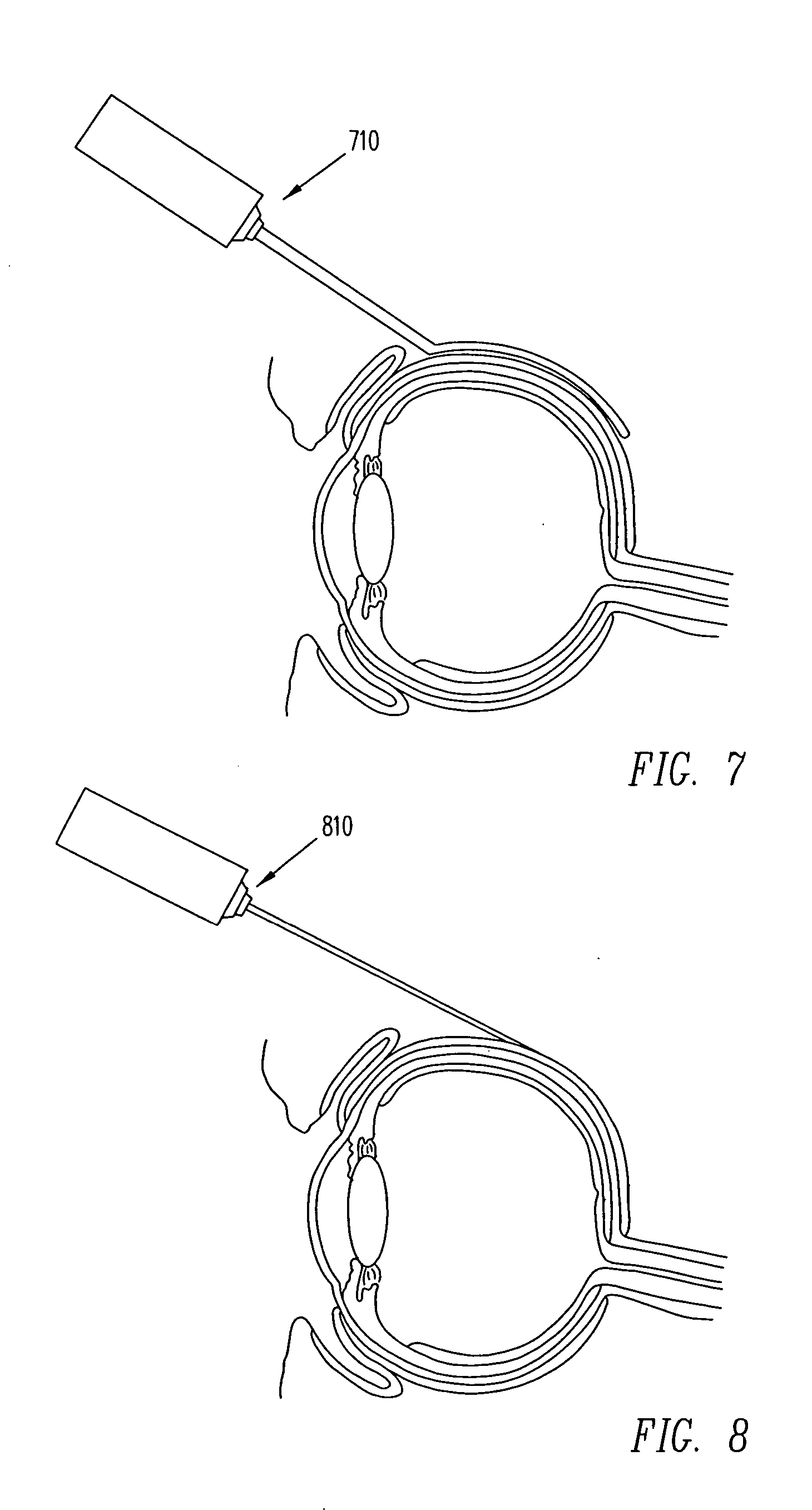

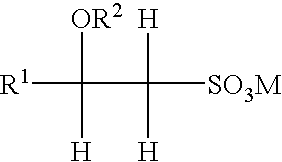

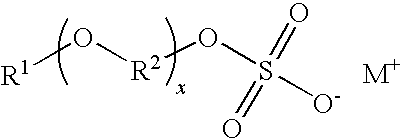

Transscleral delivery

Diseases associated with the tissues in the posterior segment of the eye can be effectively treated by administering therapeutic agents transsclerally to those tissues. Compositions, devices, and methods for delivering therapeutic agents so that they cross the sclera and reach these tissues include injecting solutions or suspensions adjacent to or within the sclera and implanting solid structures containing the therapeutic agent adjacent to or within the sclera. These methods may be used for administering rapamycin or related compounds to treat choroidal neovascularization associated with age-related macular degeneration.

Owner:SANTEN PHARMA CO LTD

Allograft bone composition having a gelatin binder

InactiveUS7045141B2Low tensile strengthIncrease delayImpression capsSurgical adhesivesCross-linkSolid structure

The invention is directed toward an osteoimplant for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing composition of demineralized allograft bone material mixed with an aqueous phosphate buffered gelatin which when lyophilized to remove water from the composition cross links the gelatin to form a solid structure.

Owner:MUSCULOSKELETAL TRANSPLANT

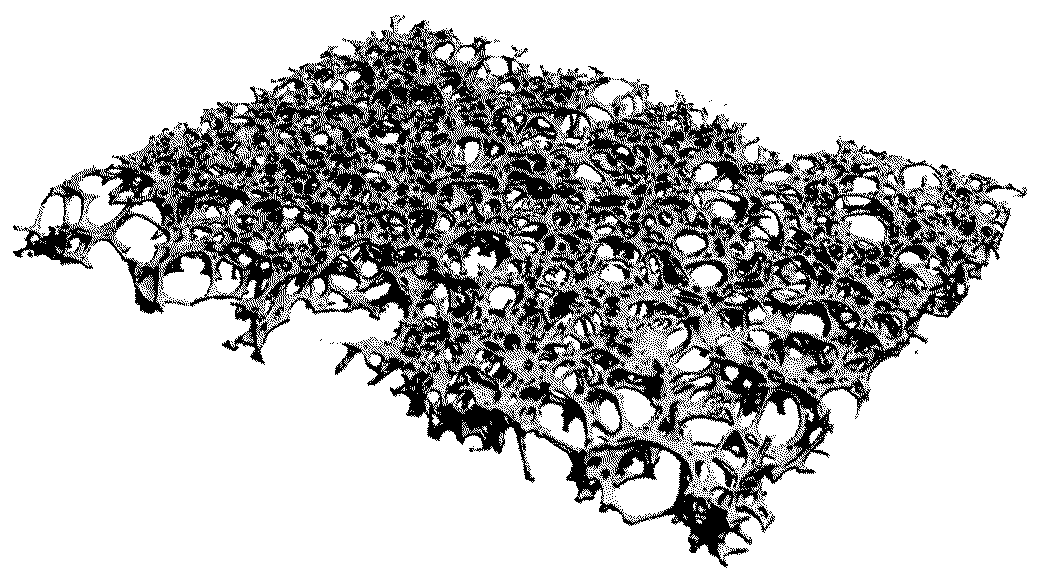

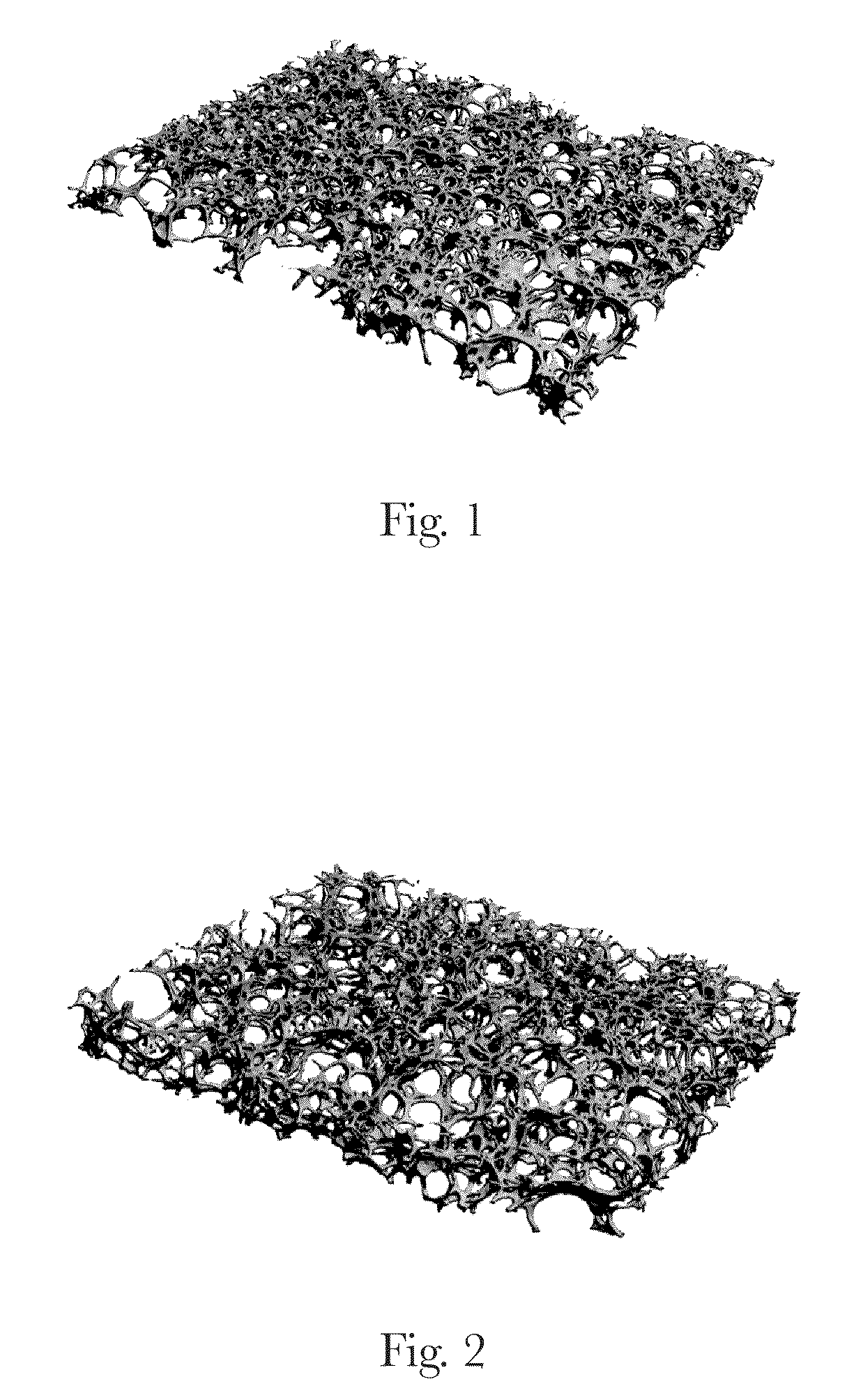

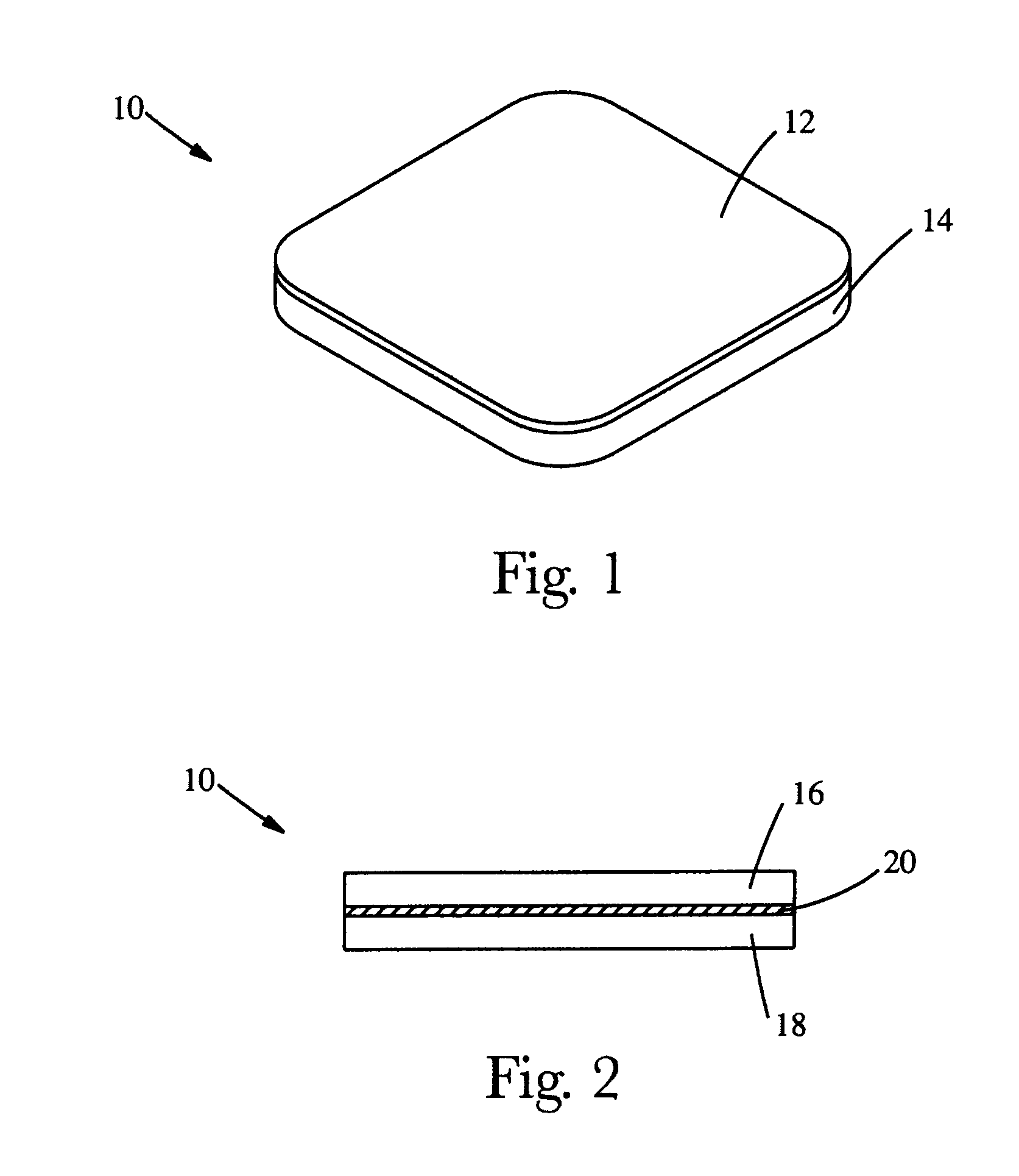

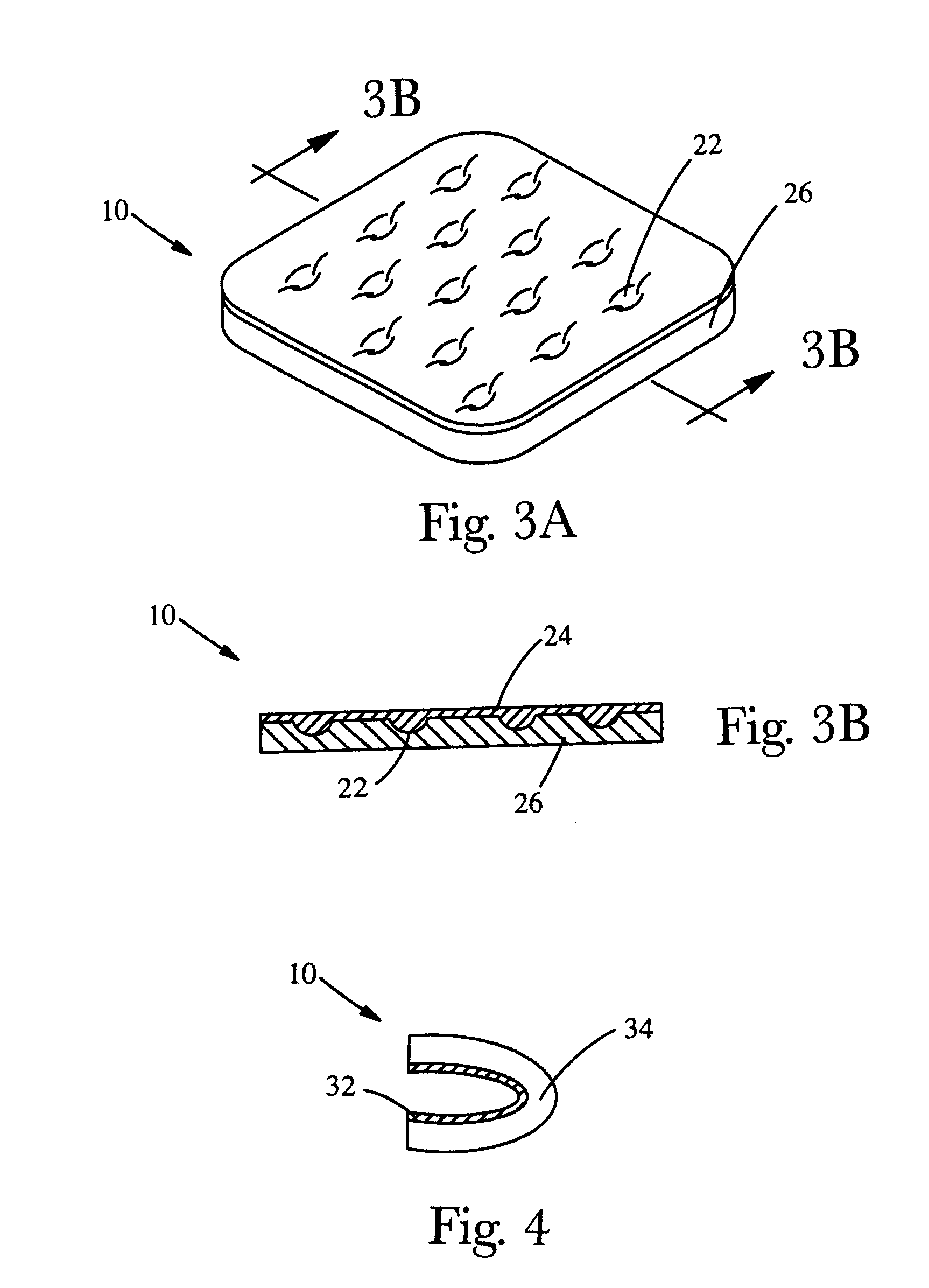

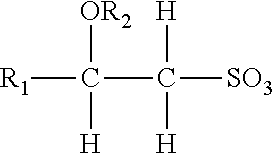

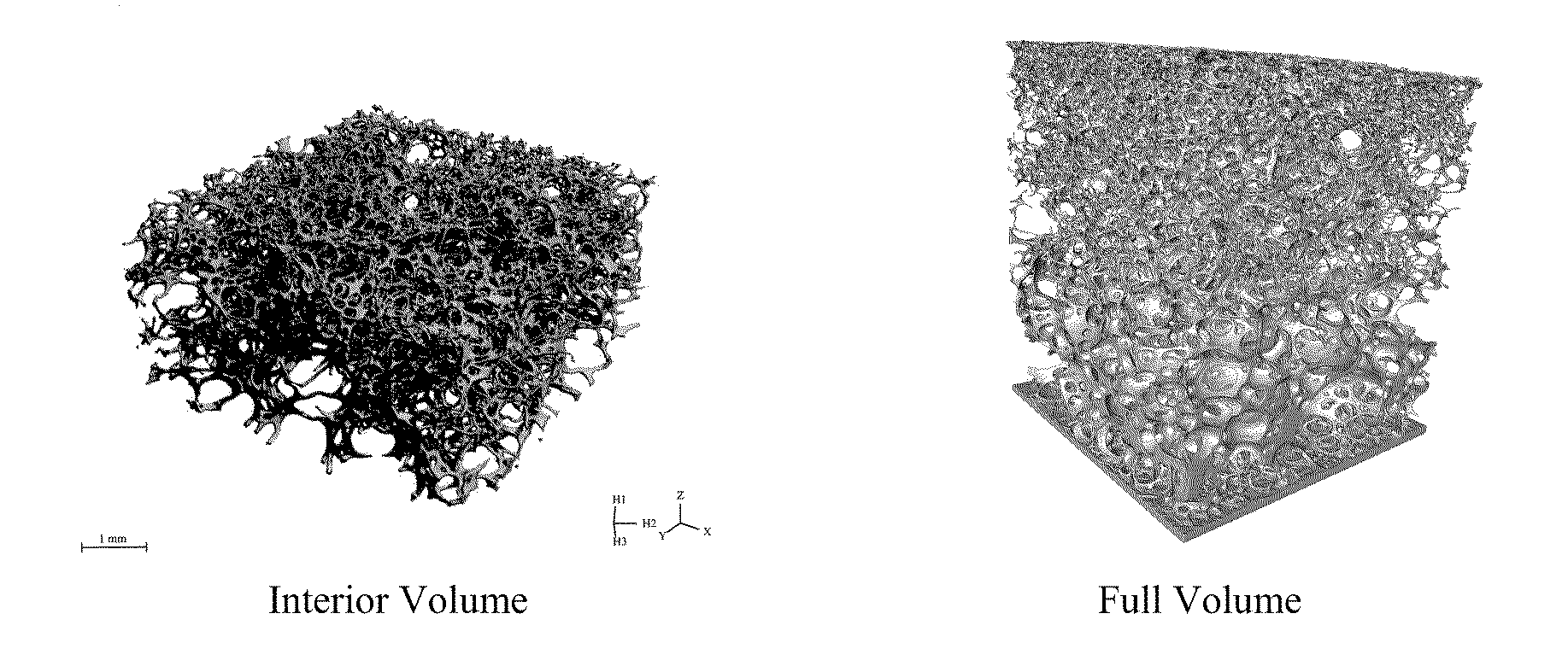

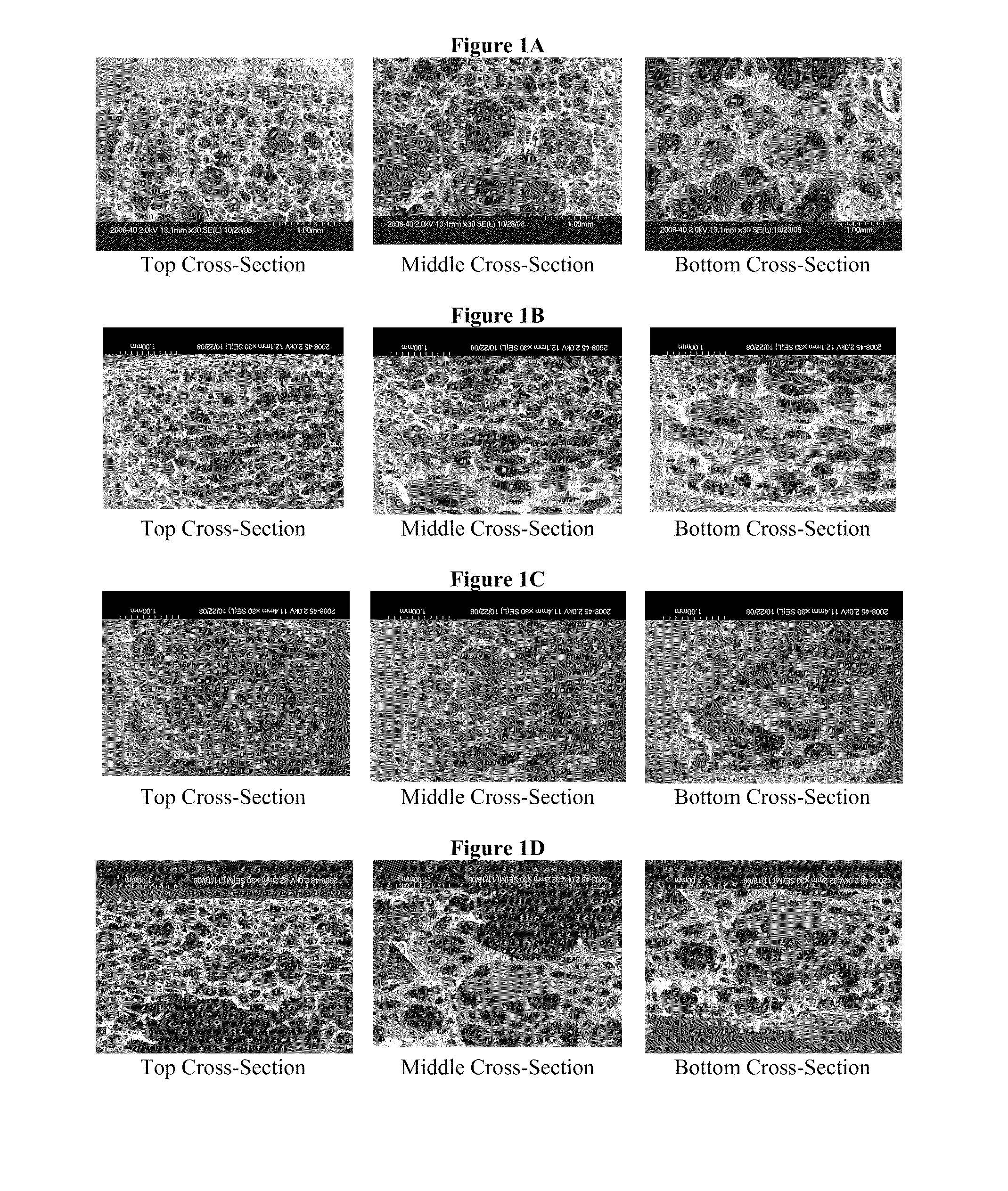

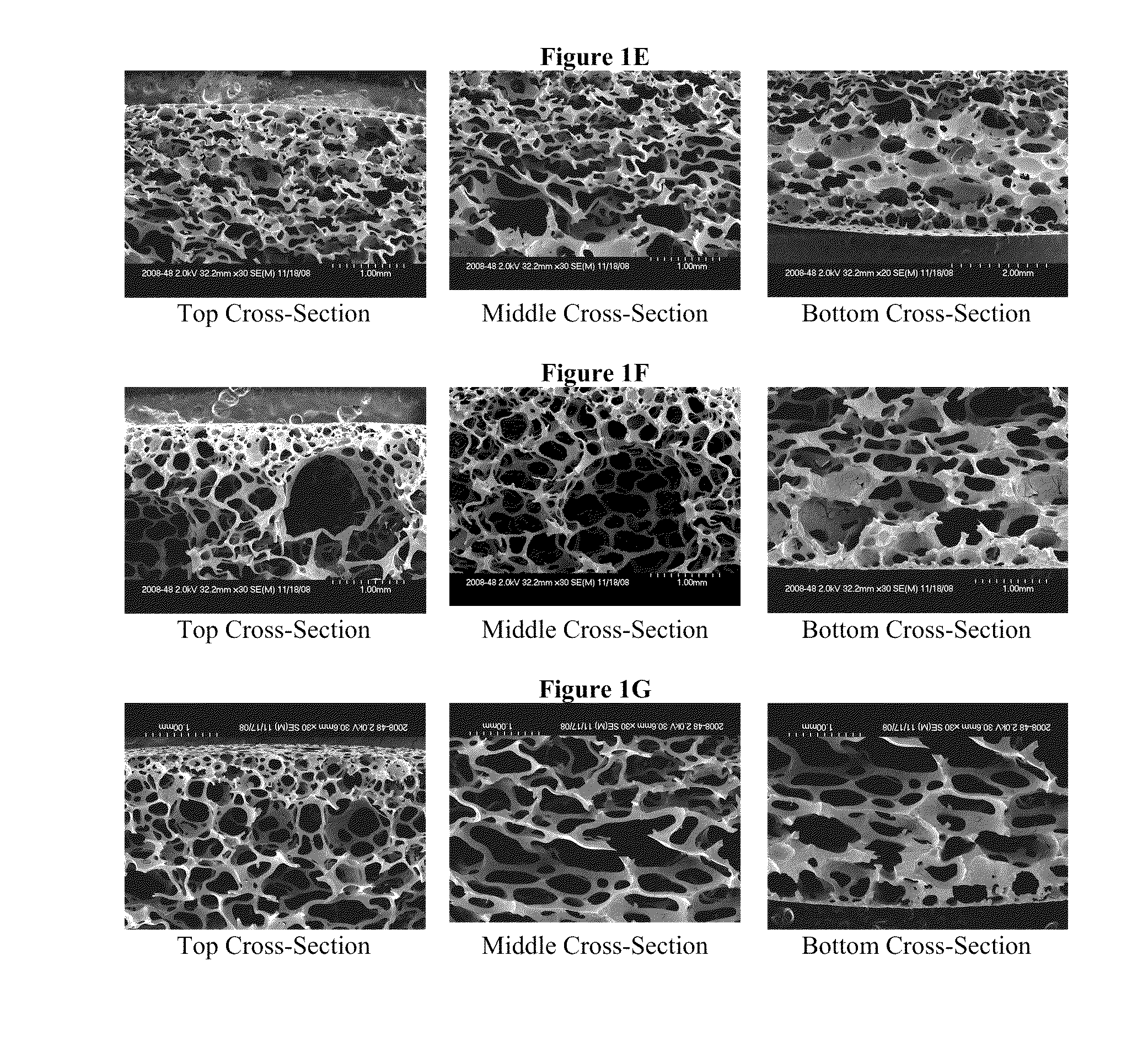

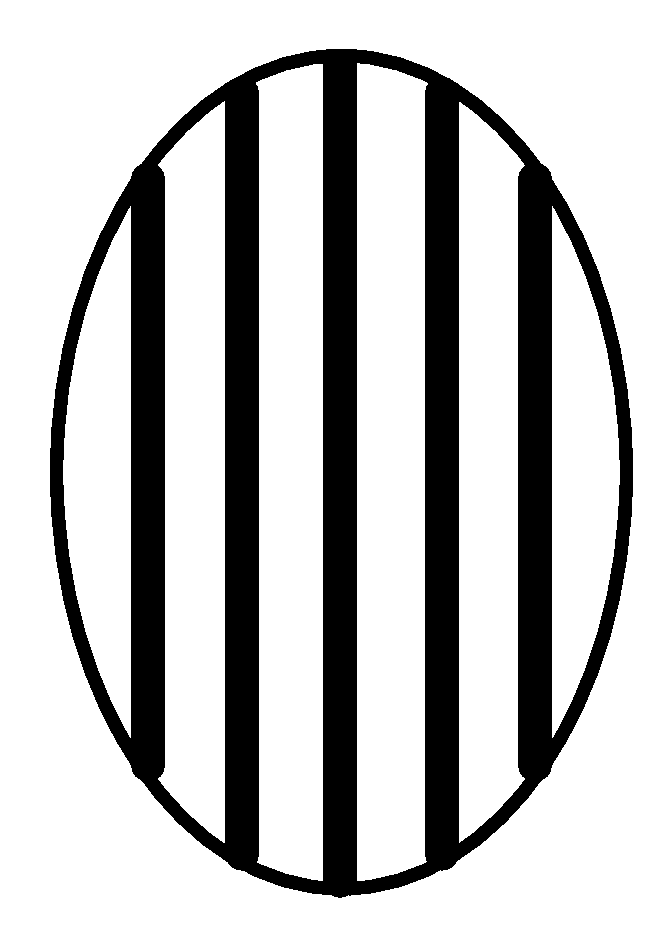

Personal care composition in the form of an article having a porous, dissolvable solid structure

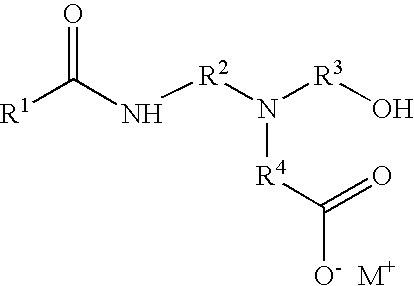

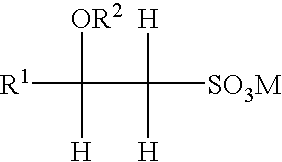

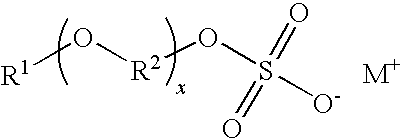

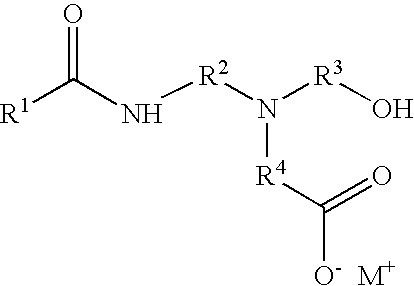

ActiveUS20100179083A1Cosmetic preparationsOrganic detergent compounding agentsPersonal careSolid structure

The present invention relates to a dissolvable article in the form of a porous dissolvable solid structure, comprising from about 23% to about 75% surfactant; wherein the surfactant has an average ethoxylate / alkyl ratio of from about 0.001 to about 0.45; from about 10% to about 50% water soluble polymer; and from about 1% to about 15% plasticizer; and wherein the article has a density of from about 0.05 g / cm3 to about 0.25 g / cm3.

Owner:THE PROCTER & GAMBLE COMPANY

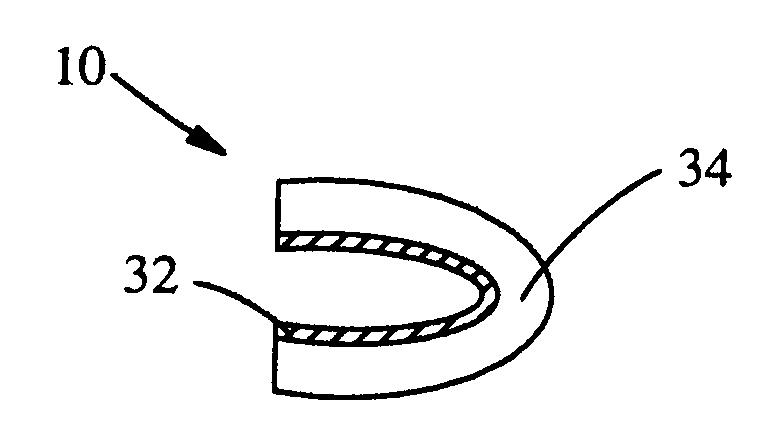

Oral Care Articles and Methods

An oral care article in the form of a flexible porous dissolvable solid structure, comprising: from about 1% to about 70% surfactant; from about 10% to about 70% water soluble polymer, from about 0% to about 25% plasticizer; and wherein said article comprises an oral care component and has a density of from about 0.03 g / cm3 to about 0.5 g / cm3.

Owner:THE PROCTER & GAMBLE COMPANY

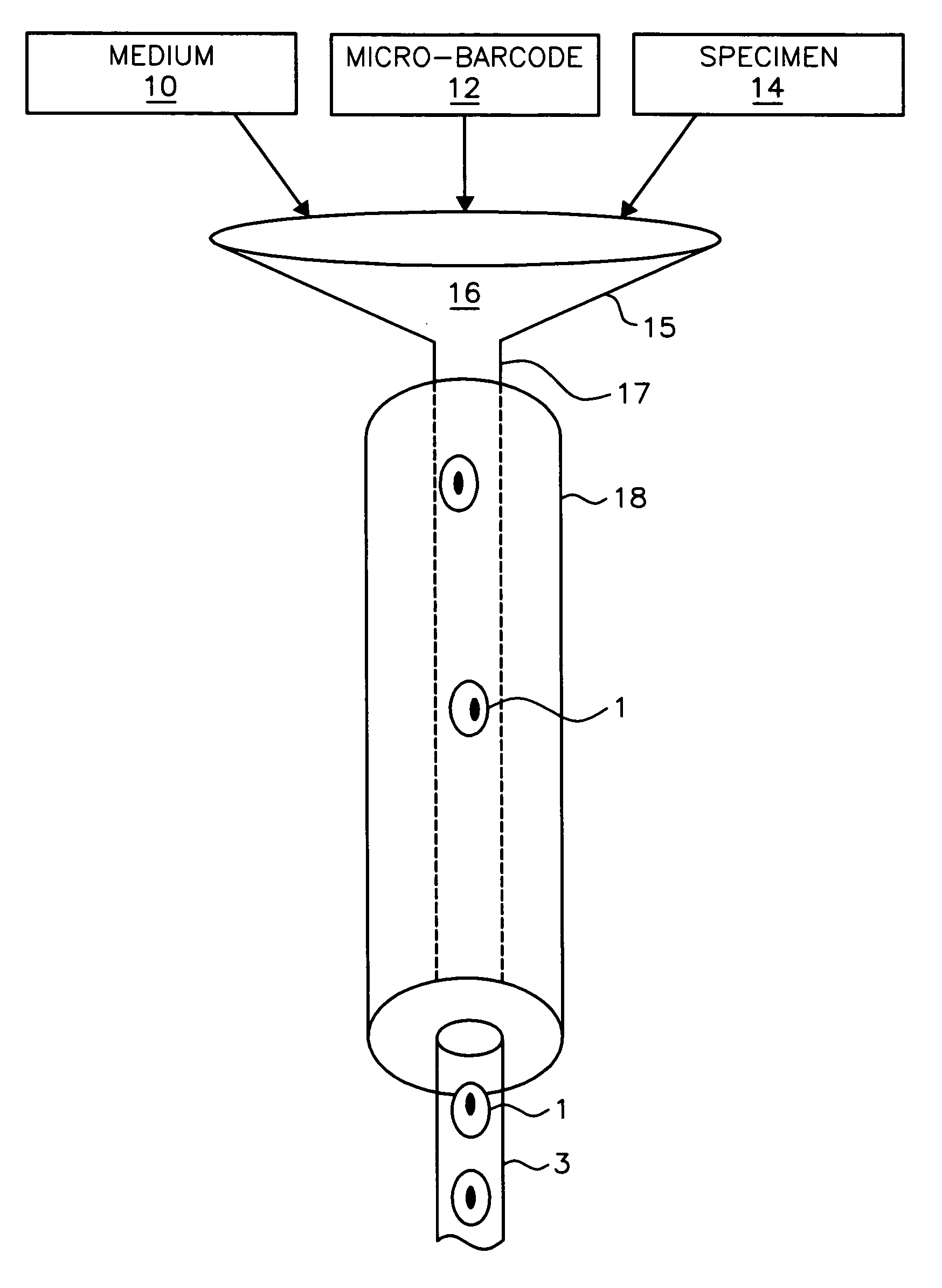

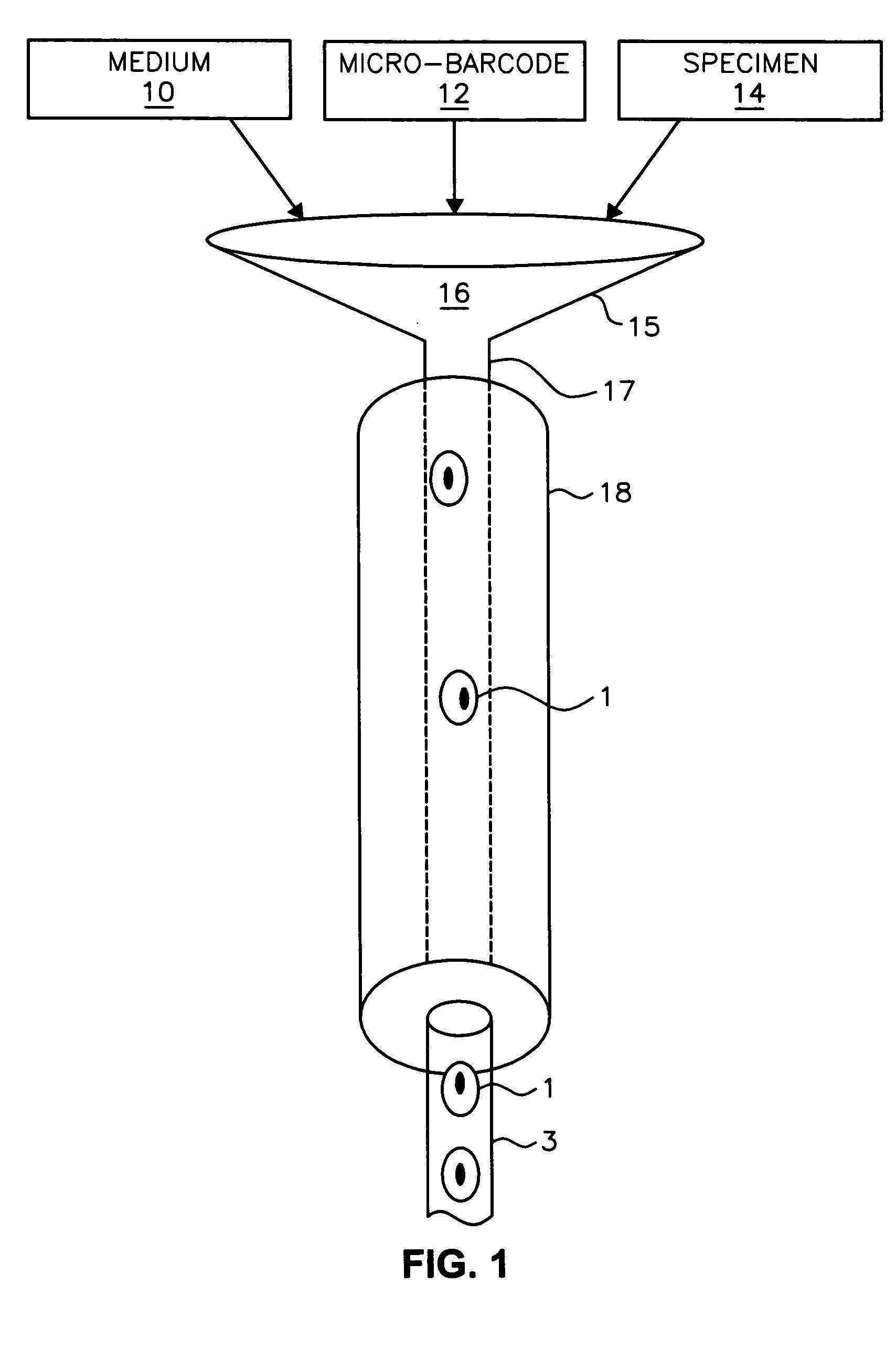

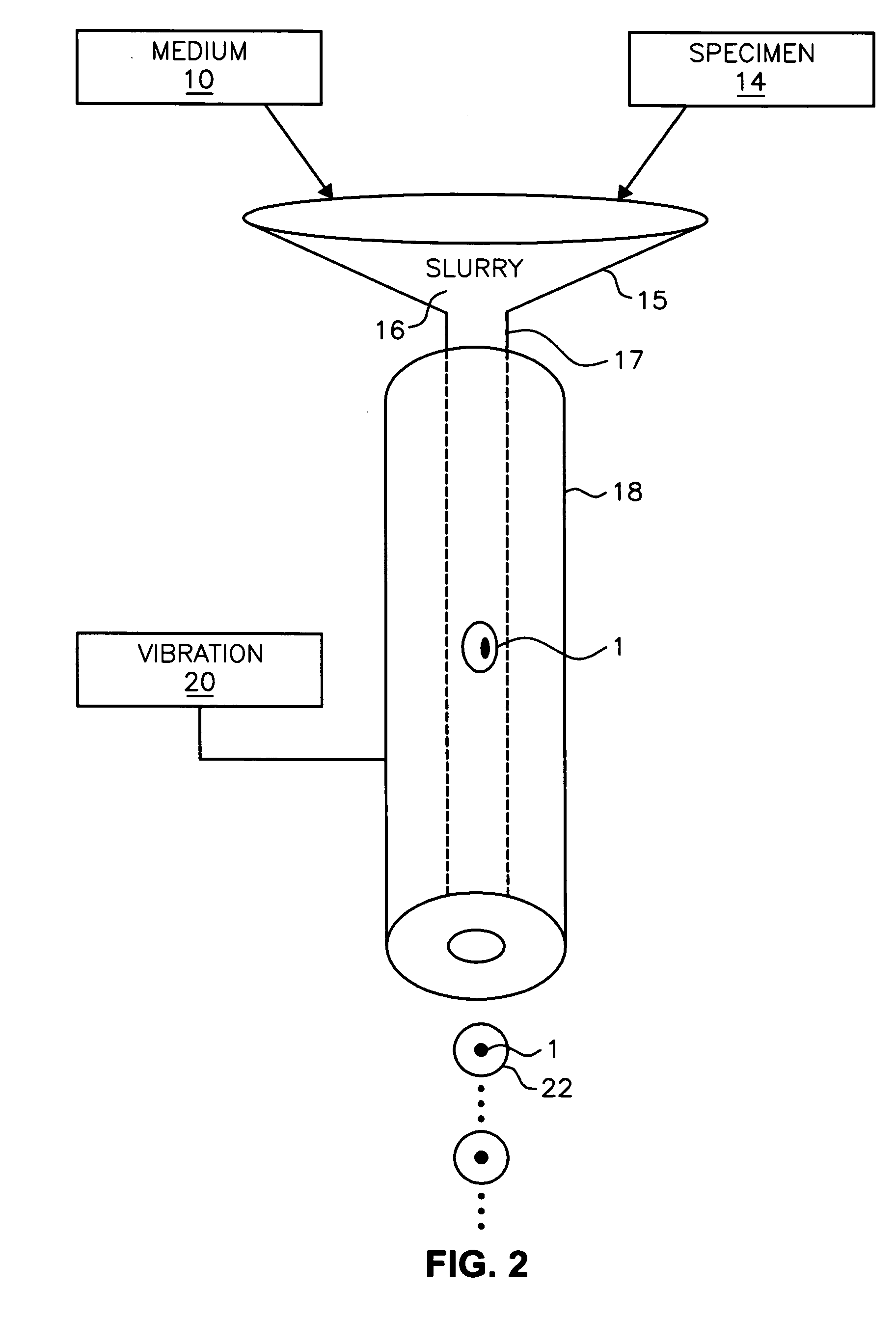

System and method for preparation of cells for 3D image acquisition

InactiveUS20050085708A1Reconstruction from projectionMaterial analysis using wave/particle radiationPolymer science3d image

The present invention provides a method for embedding particles in a solid structure including the steps of extruding a slurry of particles and a polymeric solution into a linear polymer medium having particles embedded into a polymer portion; and curing the polymer portion of the linear polymer medium.

Owner:UNIV OF WASHINGTON +1

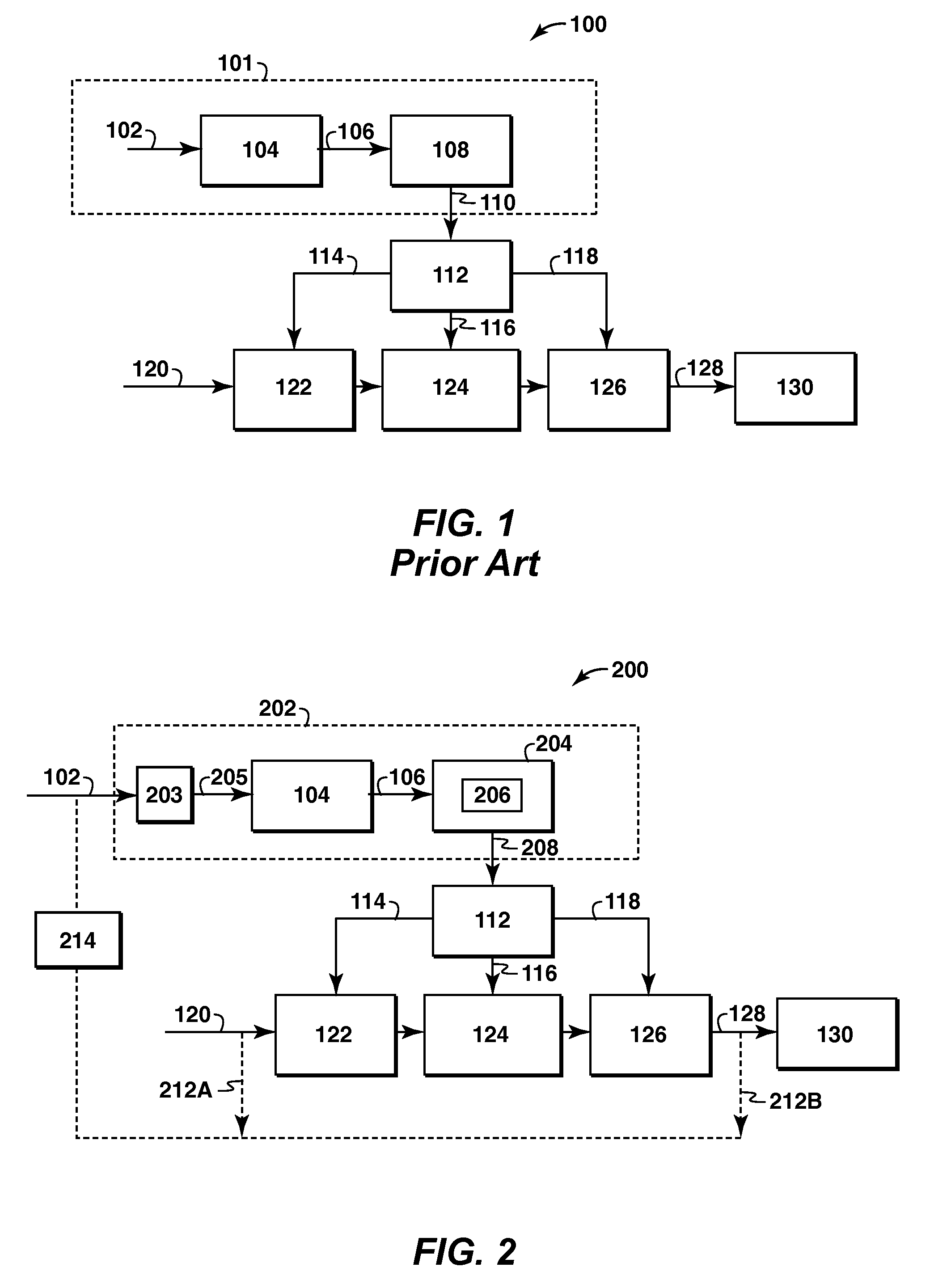

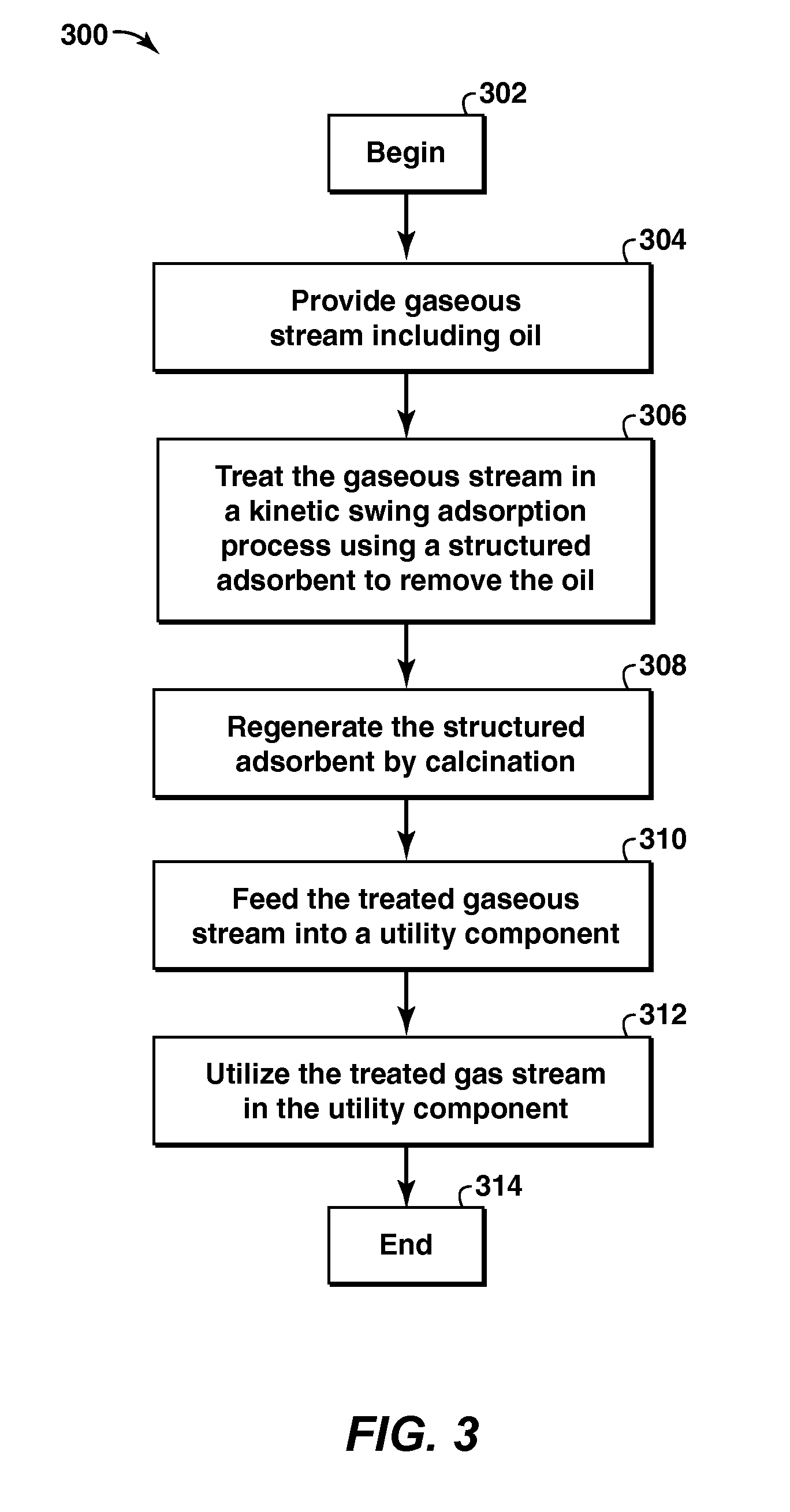

Method and Apparatus For Removal Of Oil From Utility Gas Stream

The present application is directed to a method and system for preparing gaseous utility streams from gaseous process streams, particularly, removing oil contamination from such streams prior to use in a dry gas seal. The methods and systems may include at least one kinetic swing adsorption process including pressure swing adsorption, temperature swing adsorption, calcination, and inert purge processes to treat gaseous streams for use in dry gas seals of rotating equipment such as compressors, turbines and pumps and other utilities. The adsorbent materials used include a high surface area solid structured microporous and mesoporous materials.

Owner:EXXONMOBIL UPSTREAM RES CO

Laundry detergent compositions in the form of an article

InactiveUS20110028374A1Organic detergent compounding agentsNon-surface-active detergent compositionsWater dispersiblePlasticizer

A laundry additive article comprises surfactant, water-soluble and / or water-dispersible film-forming polymer, plasticizer, bleach, suds suppressor and Remaining Water. The article is in the form of a first flexible porous dissolvable solid structure having a dry density and having a Percent open cell content.

Owner:THE PROCTER & GAMBLE COMPANY

Personal care composition in the form of an article having a hydrophobic surface-resident coating

InactiveUS20100291165A1Conveniently and quickly dissolvedEfficient use ofCosmetic preparationsHair cosmeticsPersonal careMedicine

The present invention relates to personal care compositions, especially those personal care compositions in the form of an article that is a porous, dissolvable solid structure. The article has a hydrophobic surface-resident coating that can provide enhanced deposition efficiency of hydrophobic actives contained therein.

Owner:THE PROCTER & GAMBLE COMPANY

Non-Lathering Personal Care Composition in the Form of an Article

A non-lathering personal care article in the form of a porous dissolvable solid structure, comprising: from about 0% to about 10% ionic surfactant; from about 1% to about 60% of a non-surfactant cosmetic active; from about 15% to about 70% polymeric structurant, wherein the polymeric structurant has a weighted average molecular weight of from about 40,000 to about 500,000; and from about 1% to about 30% plasticizer. The article has a density of from about 0.03 g / cm3 to about 0.15 g / cm3.

Owner:THE PROCTER & GAMBLE COMPANY

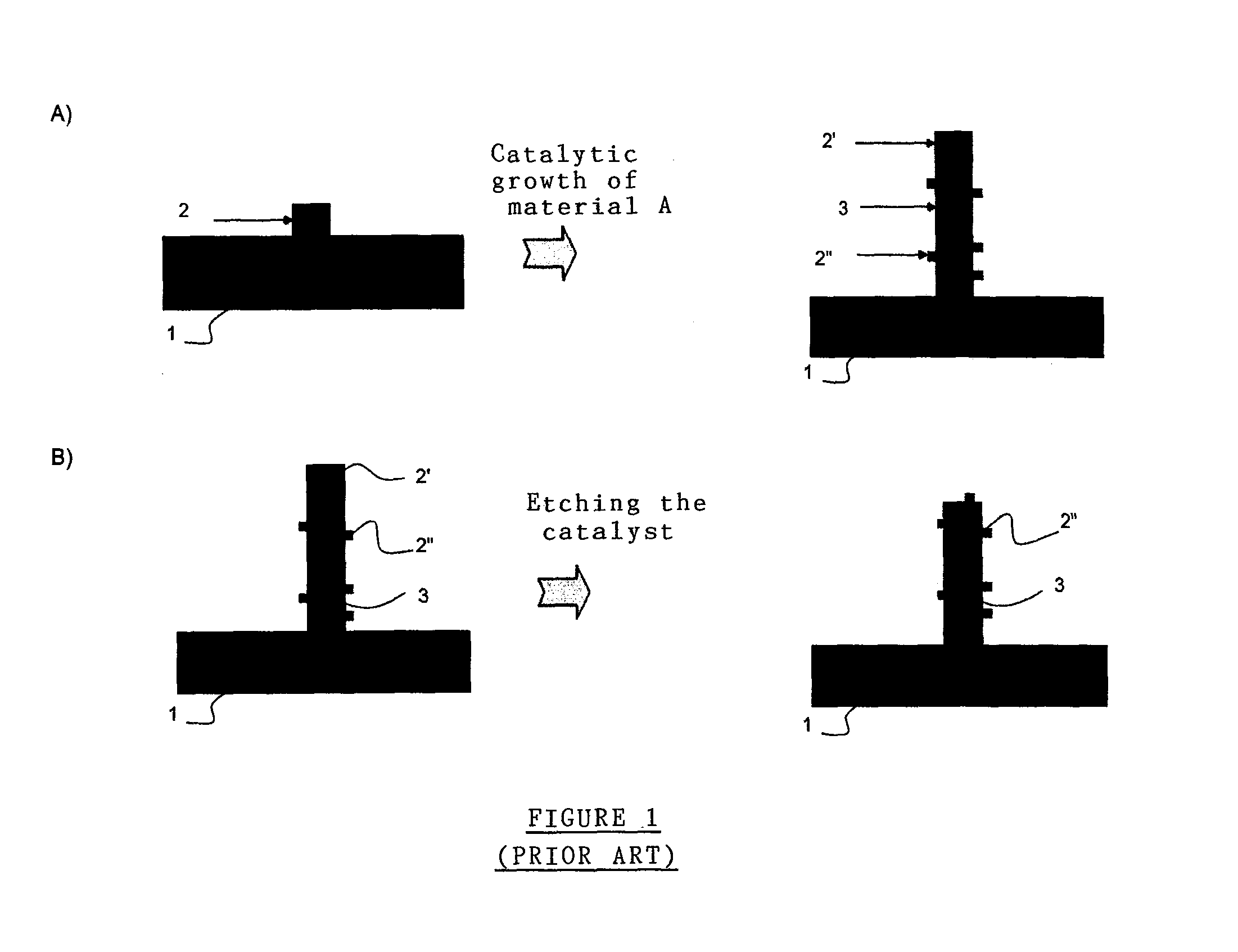

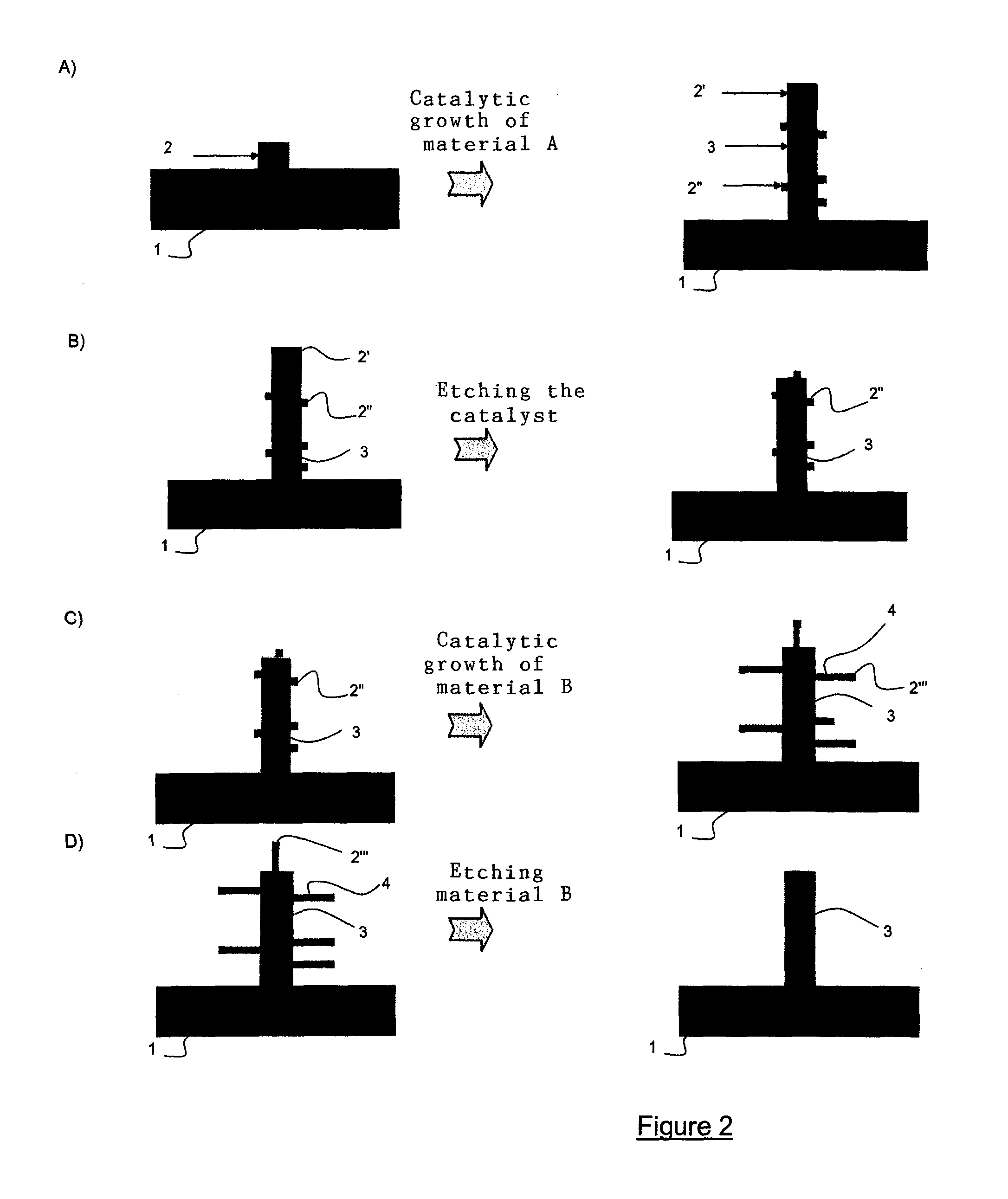

Method for eliminating the metal catalyst residues on the surface of wires produced by catalytic growth

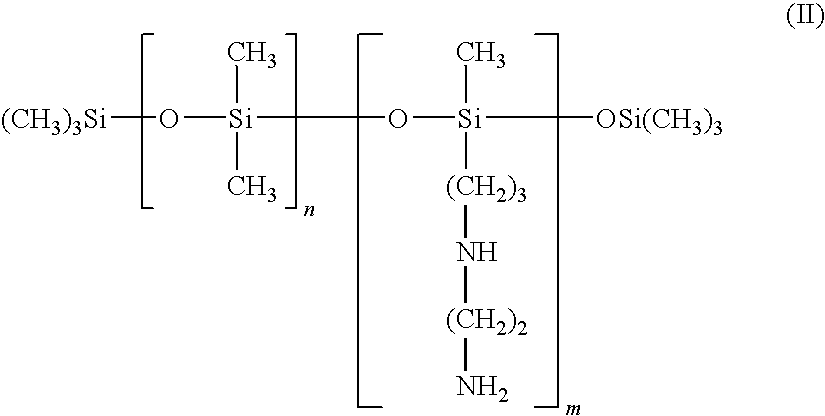

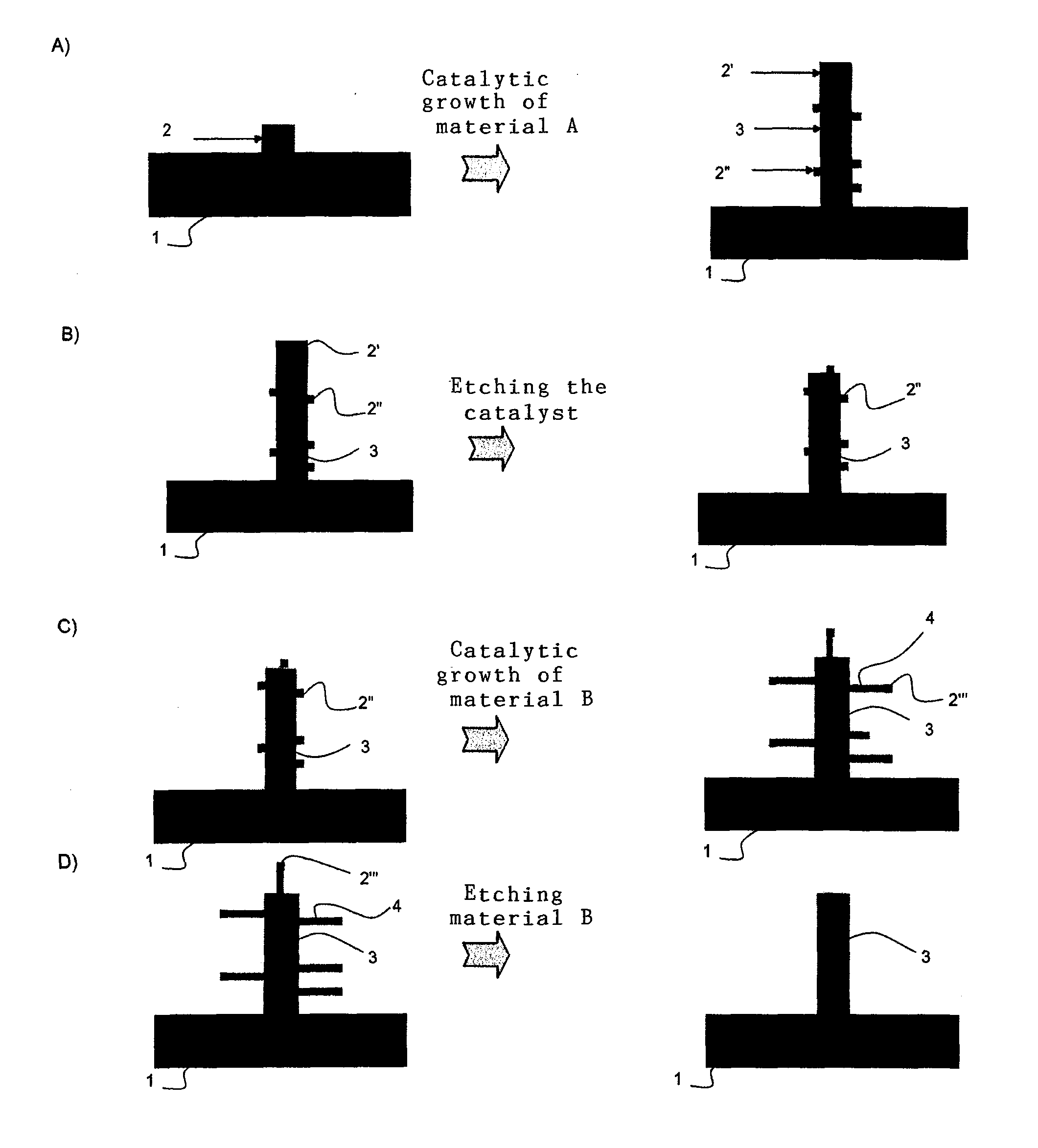

InactiveUS8669171B2Individual molecule manipulationSemiconductor/solid-state device manufacturingMetal catalystSolid structure

A method is provided for eliminating catalyst residues that are present on the surface of solid structures. The solid structures are made from a first material and are obtained by catalytic growth from a substrate. The method includes the following steps: catalytically growing, from the catalyst residues, solid structures made from a second material; and selectively eliminating the solid structures made from the second material, thereby eliminating the catalyst residues.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

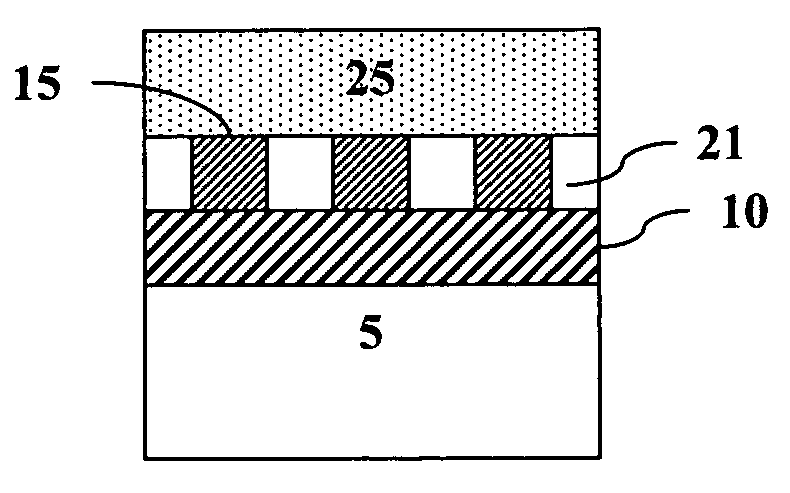

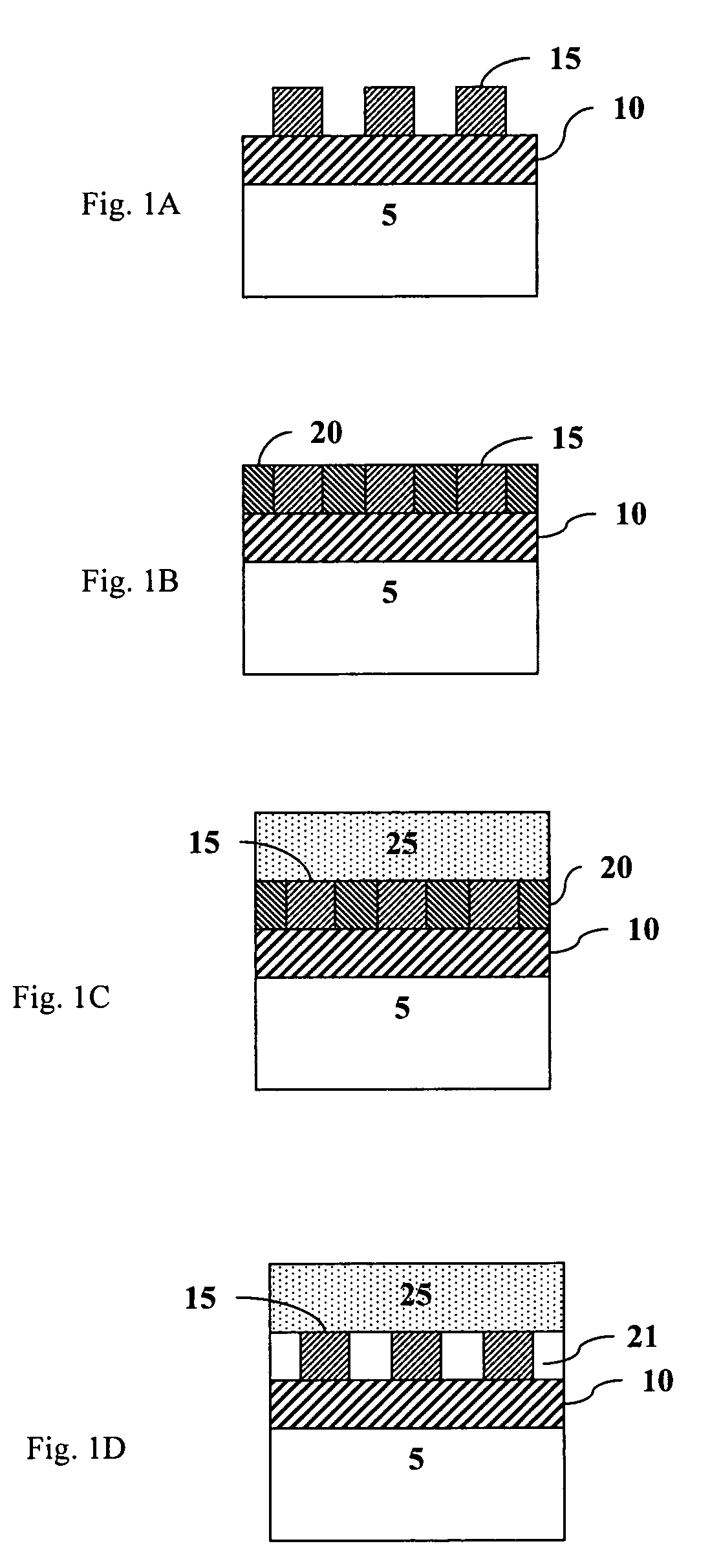

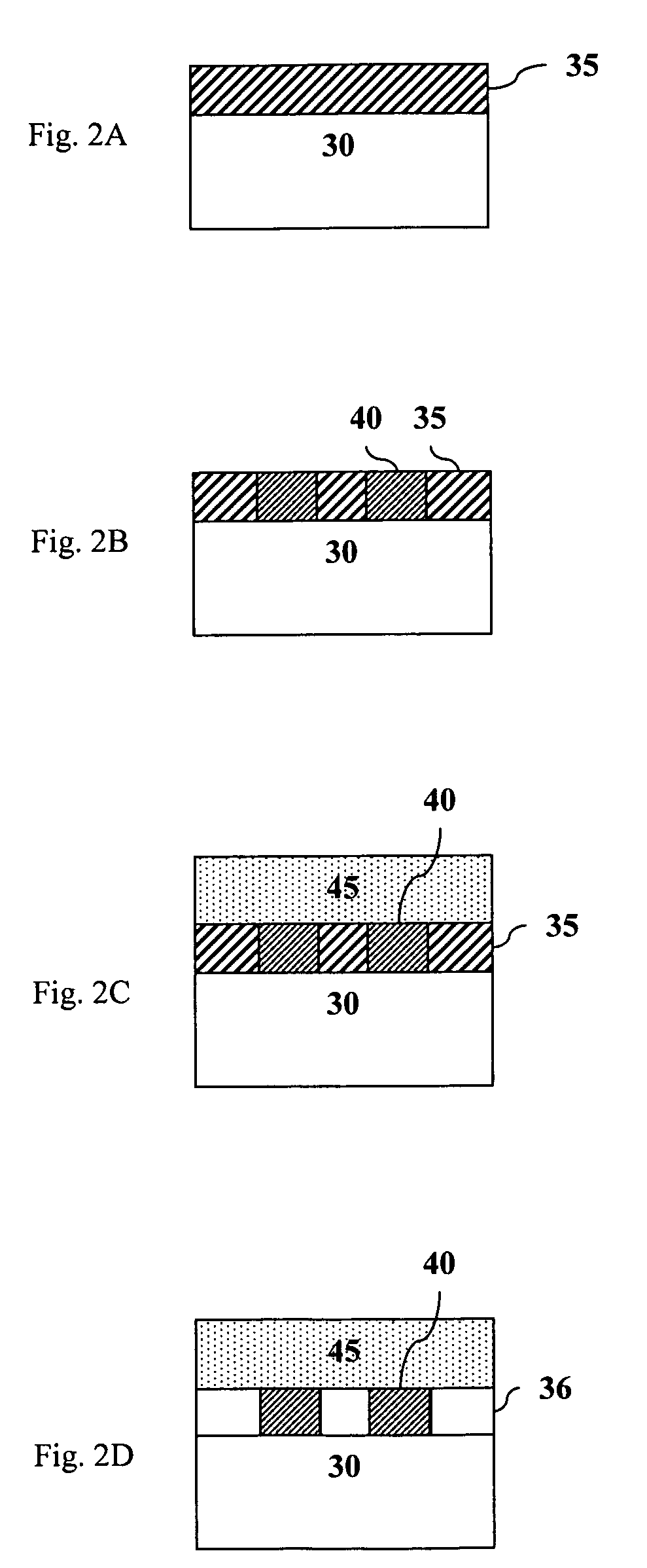

Air gap formation

ActiveUS7256127B2Reduce the amount requiredSemiconductor/solid-state device detailsSolid-state devicesSolid structureEngineering

A method of forming air gaps within a solid structure is provided. In this method, a sacrificial material is covered by an overlayer. The sacrificial material is then removed through the overlayer to leave an air gap. Such air gaps are particularly useful as insulation between metal lines in an electronic device such as an electrical interconnect structure. Structures containing air gaps are also provided.

Owner:SHIPLEY CO LLC

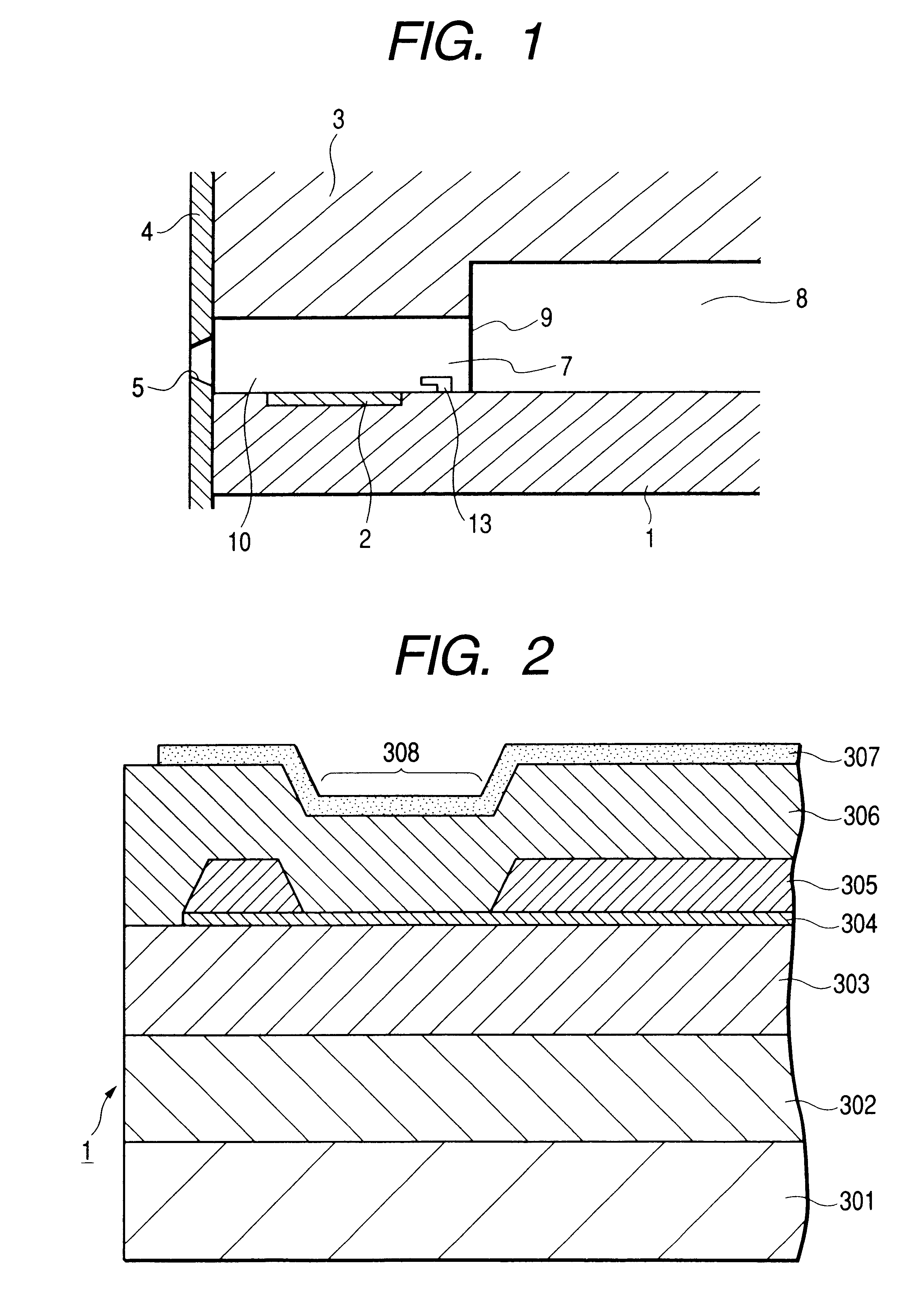

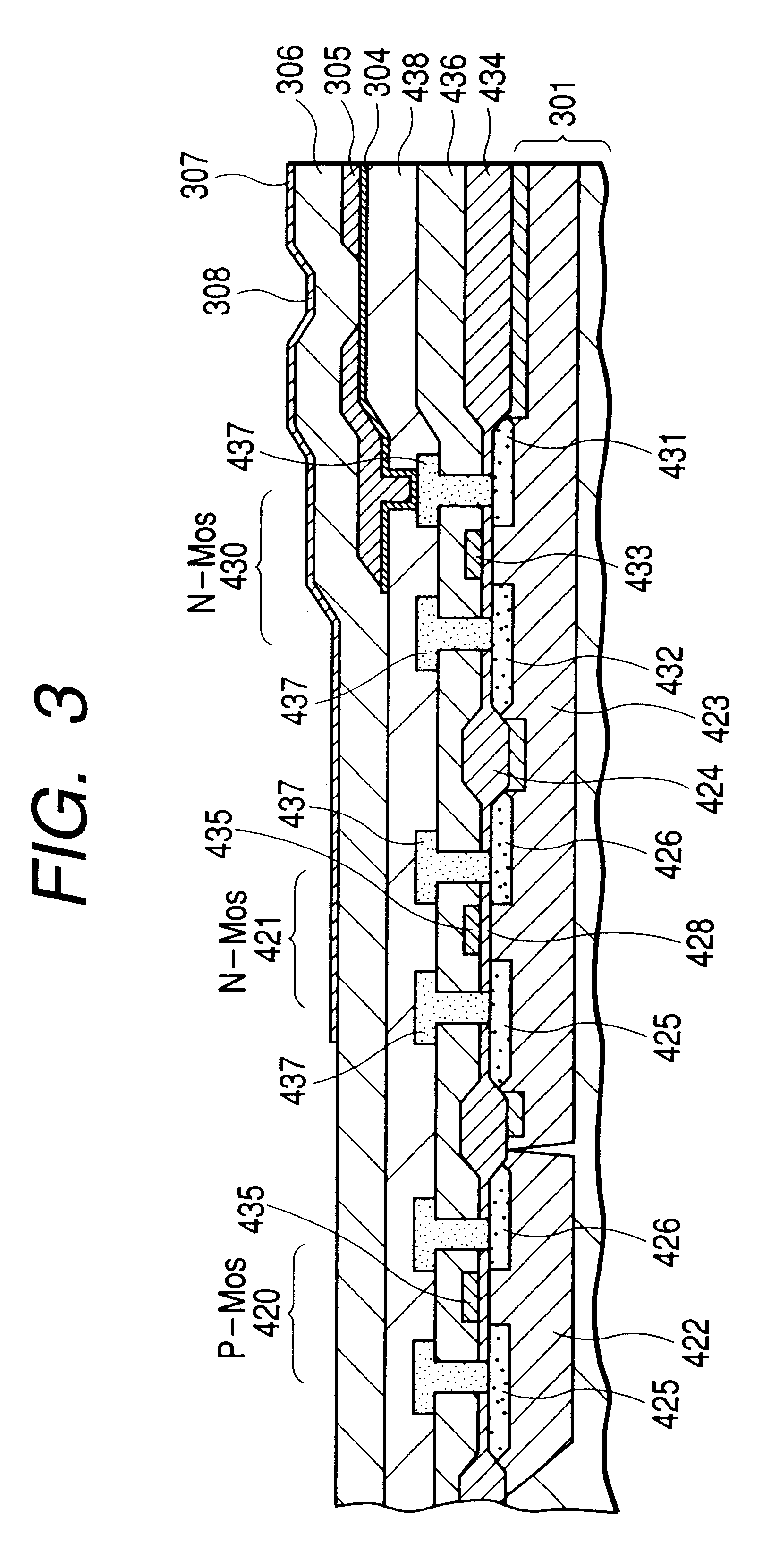

Liquid discharge head, liquid discharge apparatus and method for manufacturing liquid discharge head

The present invention provides a liquid discharge head comprising a plurality of discharge ports for discharging liquid, first and second substrates for defining a plurality of liquid flow paths communicated with the discharge ports, and a plurality of energy converting elements disposed in the liquid flow paths and adapted to convert electrical energy into discharge energy for liquids in the liquid flow paths, wherein sensors for detecting behavior of the liquid are provided in the respective liquid flow paths as solid structure portions protruded from walls of the liquid flow paths.

Owner:CANON KK

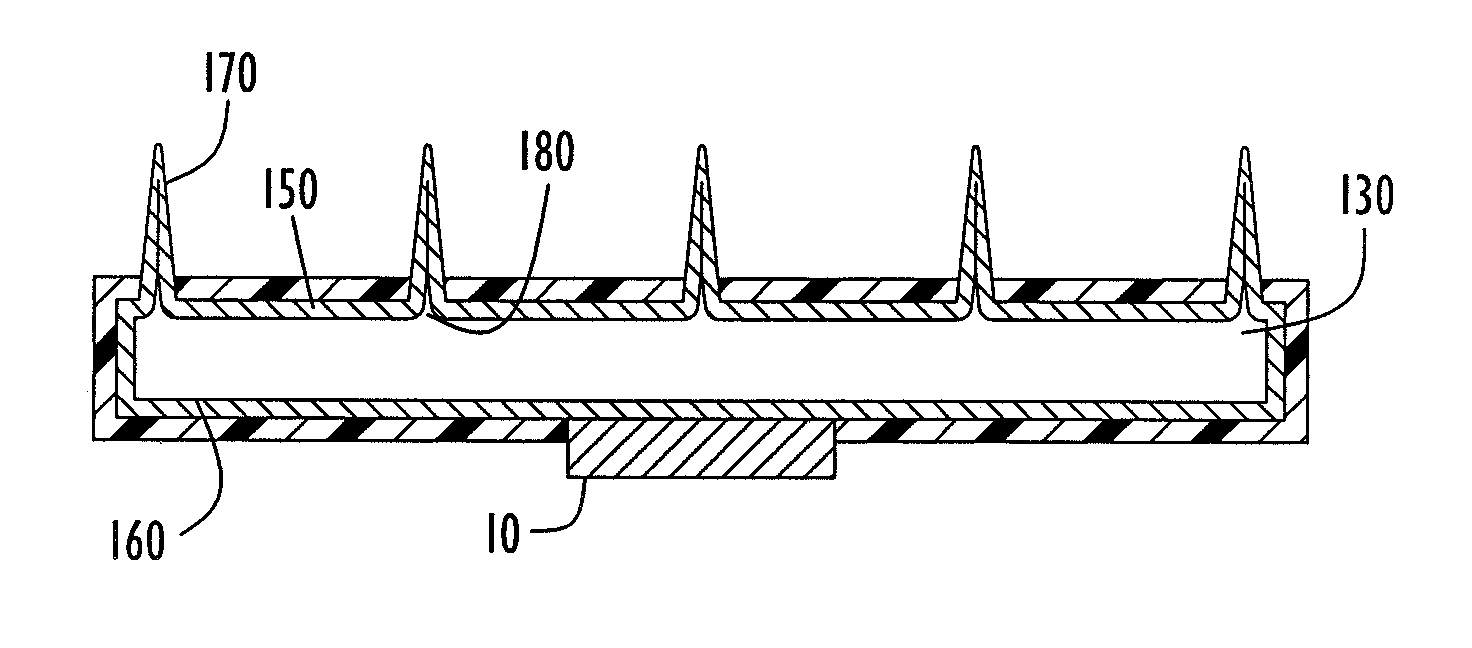

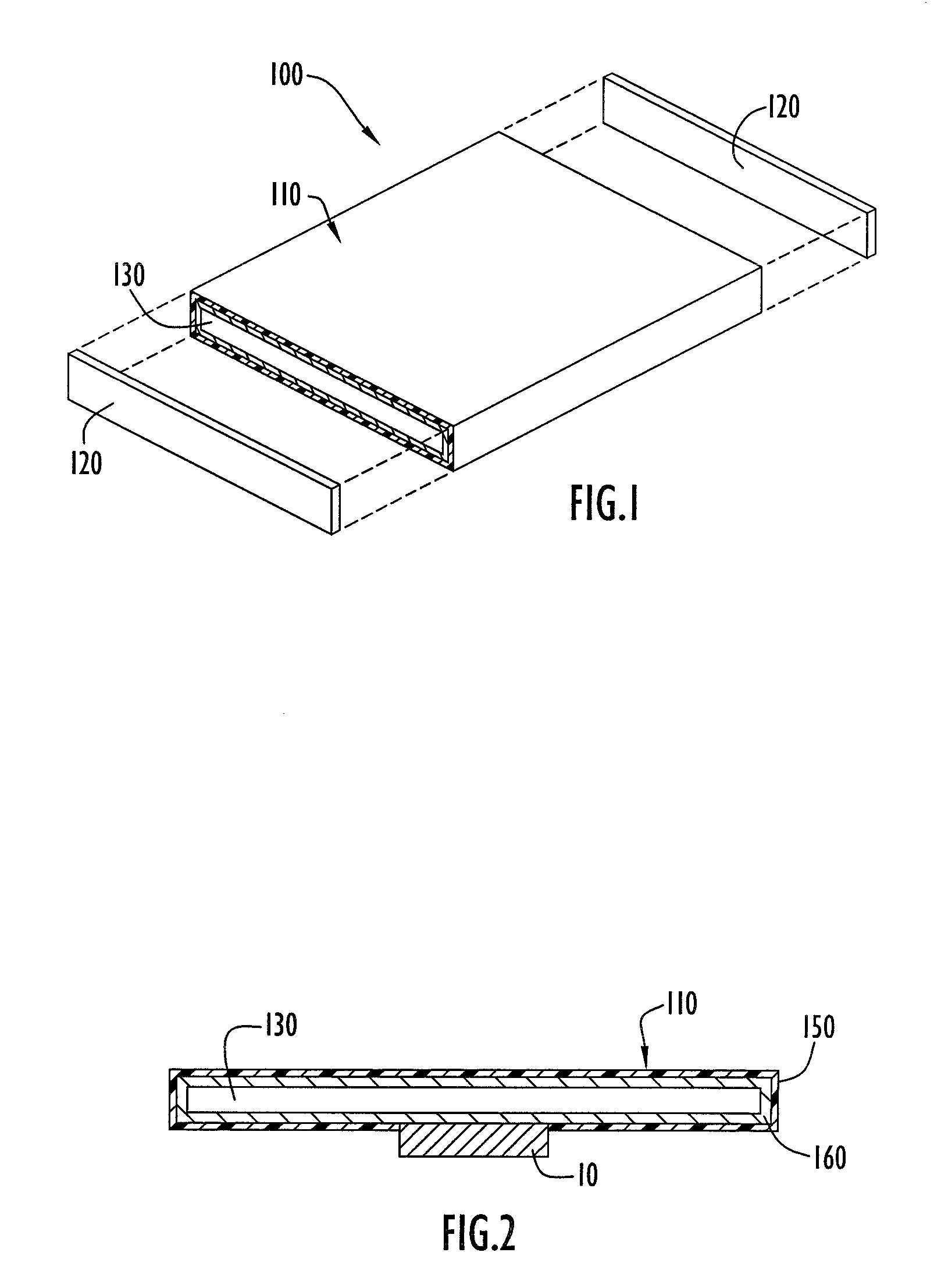

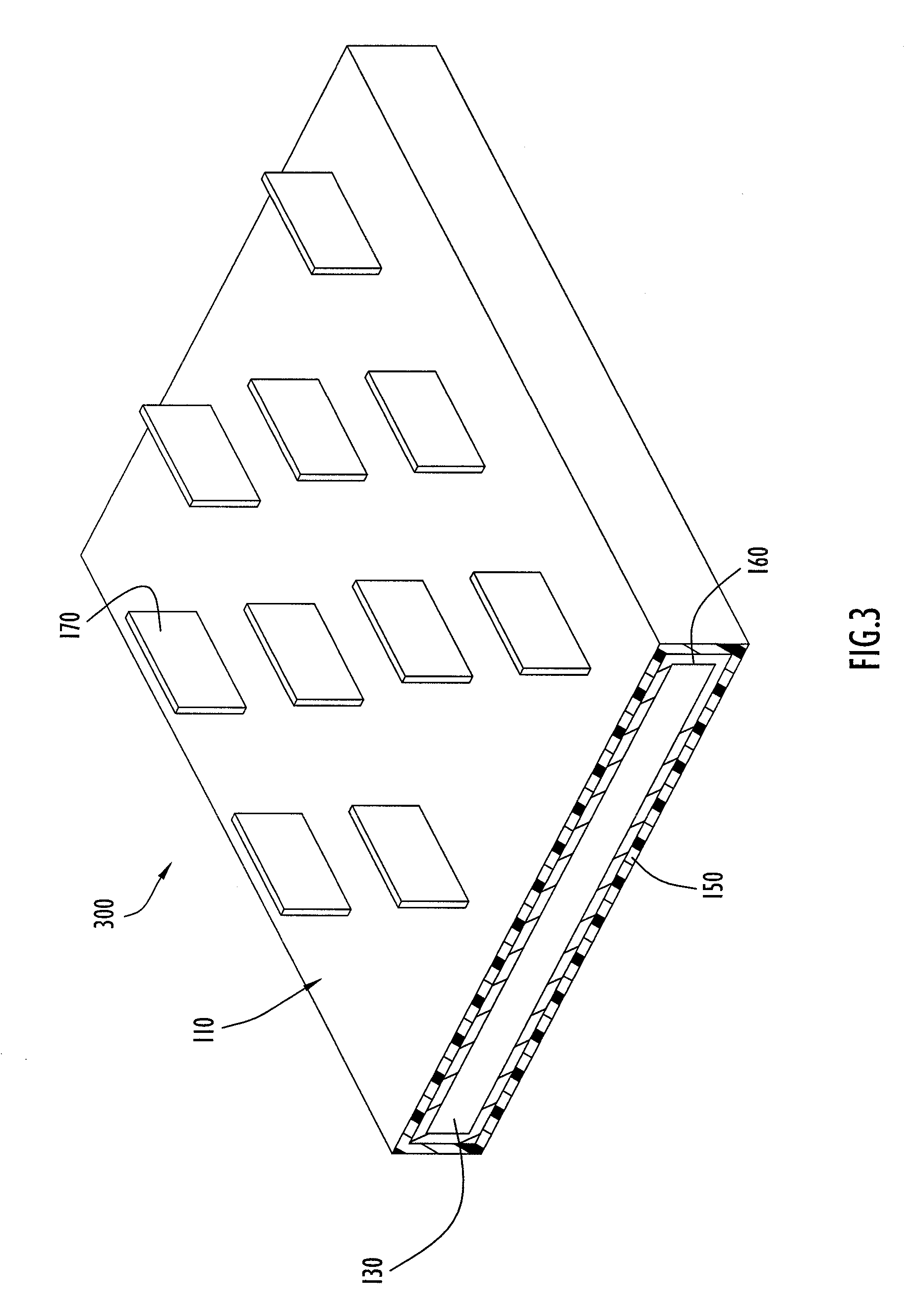

Heat Transfer Device

InactiveUS20070012429A1Semiconductor/solid-state device detailsSolid-state devicesSolid structureEngineering

A heat transfer device includes a vapor chamber that houses a phase change material such as water. The heat transfer device may be selectively formed from a combination of polymeric and non-polymeric materials. In one embodiment, the vapor chamber is formed from a polymer layer surrounding a sealing layer formed from non-polymeric material. The heat transfer device may further include one or more fin members operable to diffuse heat from the vapor chamber to the ambient / outside environment. The fins may be solid structures, or may each define a fin chamber in communication with the vapor chamber. In one embodiment, the fin members are formed from non-polymeric material.

Owner:CONVERGENCE TECH LTD

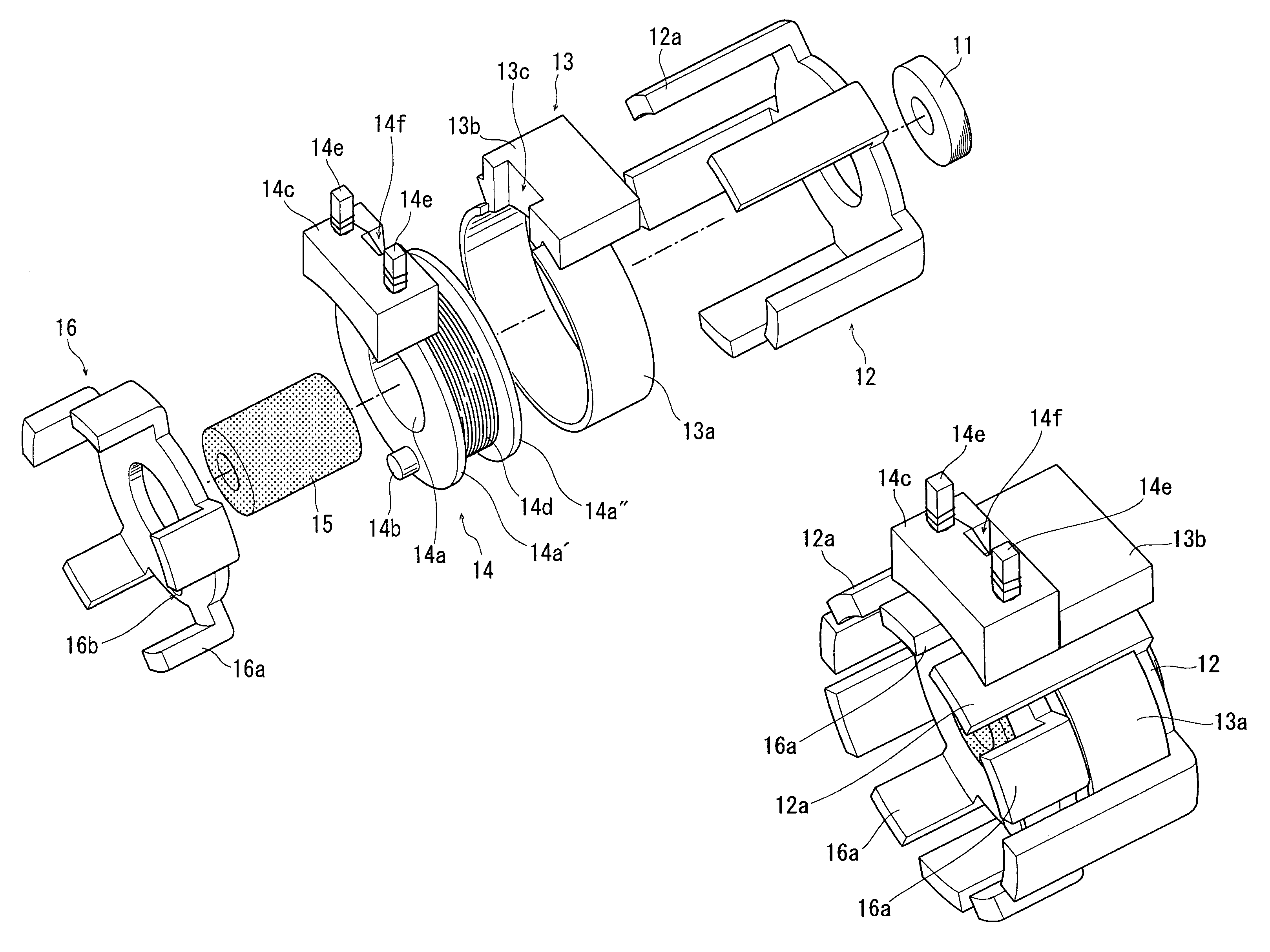

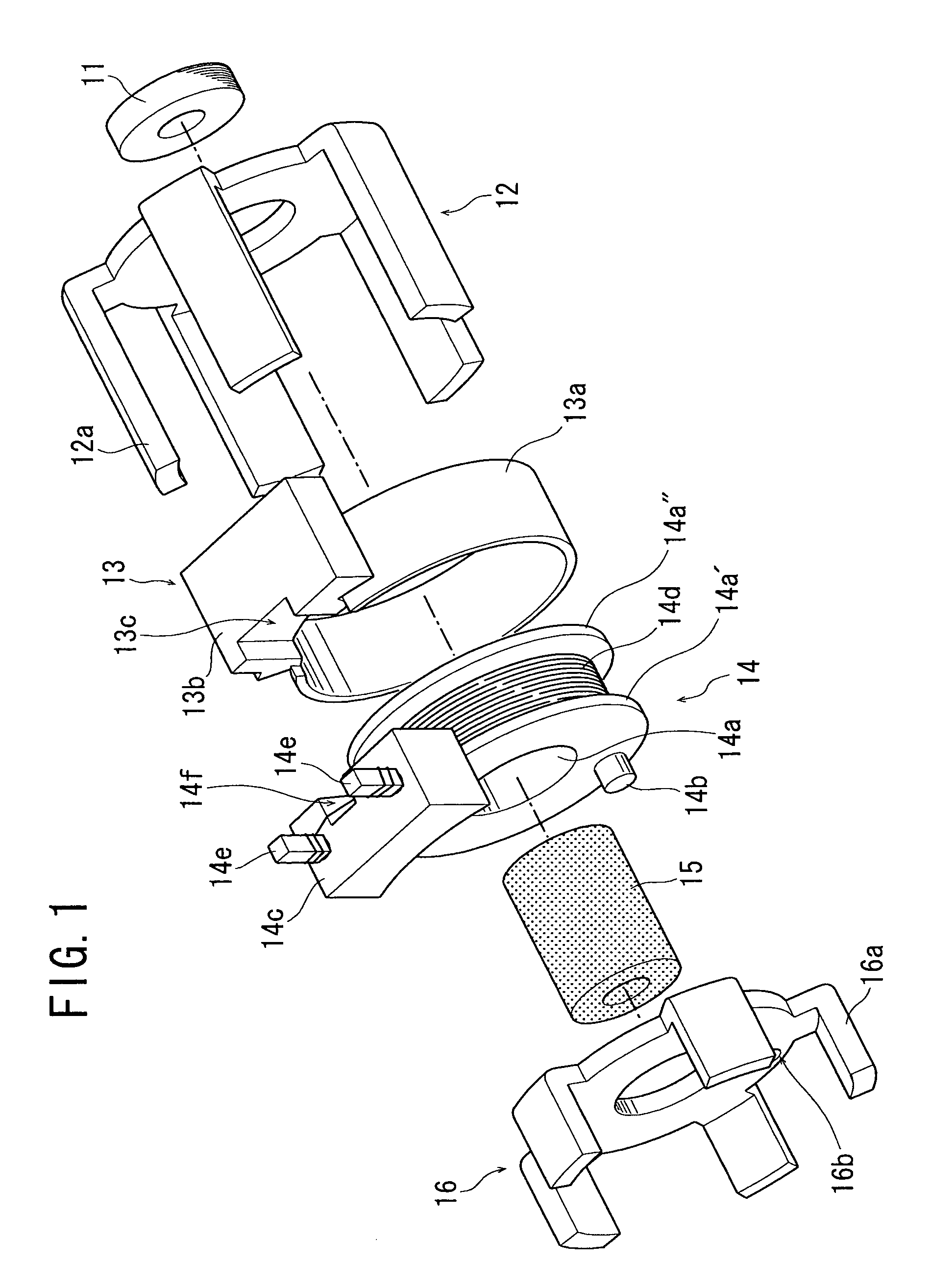

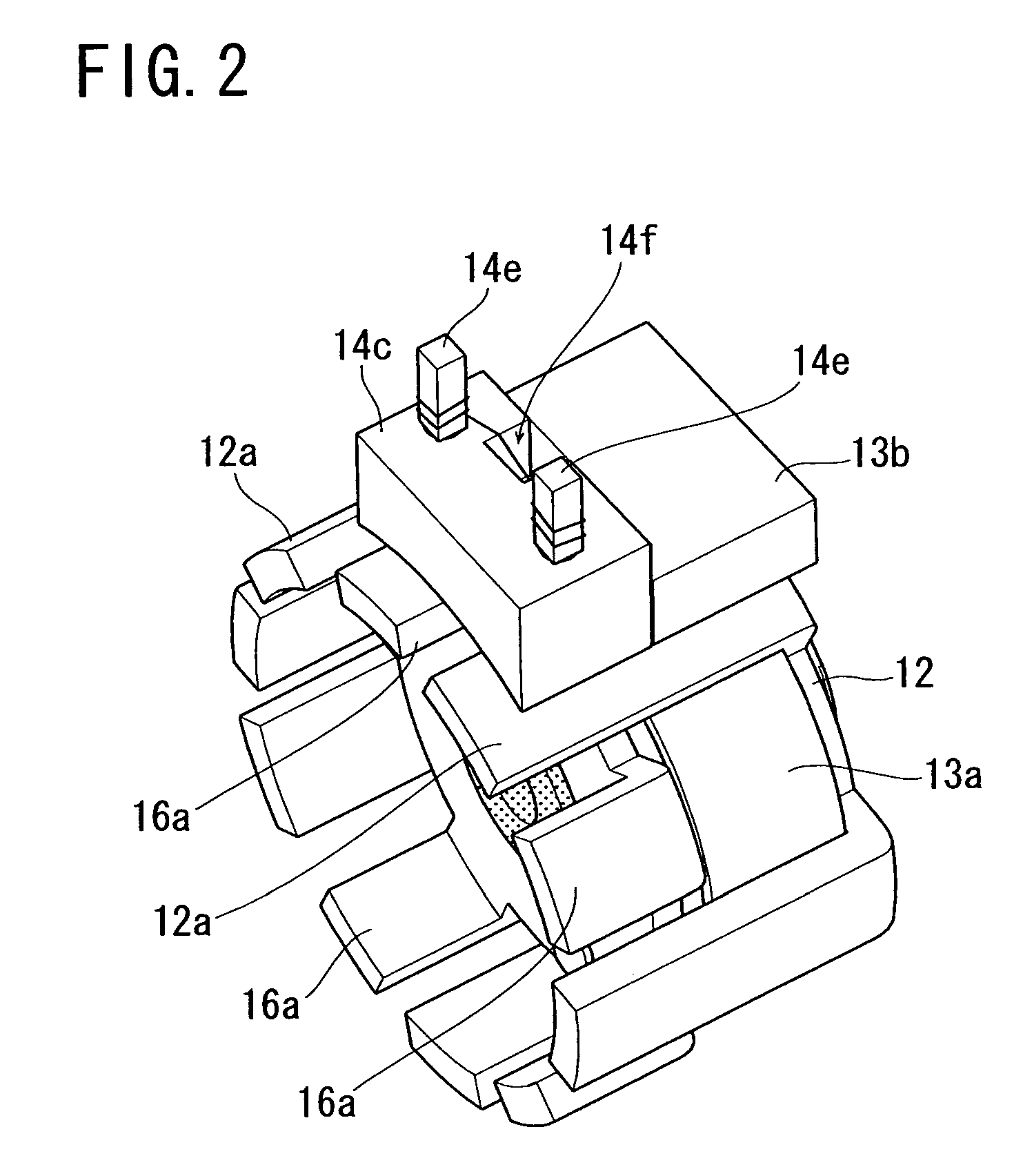

Claw-pole type stepping motor

InactiveUS7071593B2Reduce radial sizeMaintain mechanical strengthSynchronous generatorsWindingsBobbinSolid structure

A claw-pole type stepping motor comprises: a rotor assembly shaped substantially cylindrical, and having a center shaft; and a stator assembly composed of two cup-shaped stator units which are coupled to each other coaxially so as to axially sandwich the rotor assembly, and which each include a bobbin having a magnet wire wound therearound, and two pole tooth arrays magnetically connected to each other and shifted in phase from each other by an electrical angle of 180 degrees. In the motor, each stator unit further includes a cover ring which protects the magnet wire wound around the bobbin against resin injected when the stator unit is resin-molded for an integrated solid structure. The motor structured as described above can be successfully resin-molded so as to enable elimination of a motor case, thus achieving downsizing for the dimension of the eliminated motor case while maintaining a sufficient mechanical strength.

Owner:MINEBEA CO LTD

Personal care composition in the form of an article having a porous, dissolvable solid structure

ActiveUS20100286011A1Cosmetic preparationsOrganic detergent compounding agentsPersonal carePlasticizer

The present invention relates to a dissolvable article in the form of a porous dissolvable solid structure, comprising from about 10% to about 50% water soluble polymer; from about 1% to about 25% plasticizer; from about 23% to about 75% surfactant; wherein said surfactants comprise one or more surfactants from Group I, wherein Group I includes anionic surfactants, and one or more surfactants from Group II, wherein Group II includes a surfactant selected from the group consisting of amphoteric, zwitterionic and combinations thereof; wherein the ratio of Group I to Group II surfactants is from about 5:95 to about 30:70; and wherein said dissolvable article has a density of from about 0.05 g / cm3 to about 0.40 g / cm3.

Owner:THE PROCTER & GAMBLE COMPANY

Method of producing metal substructures for dental restorations

Methods are disclosed for forming a metal substructure that will subsequently be overcoated with ceramic layers to create a dental restoration. The methods involve the steps of providing a metal powder and applying the metal powder to a die and sintering the metal powder to form a solid structure that may be used as a coping. The application of the metal powder is done in a controlled fashion while minimizing the amount of necessary handwork. These application methods include: (a) alternatingly applying an adhesive and a metal powder to the selected portion of the die surface; and (b) forming the metal powder into a viscous slurry or slip and then dipping the die therein or spraying or pouring the slurry or slip onto the selected portion of the die surface.

Owner:THE EX ONE

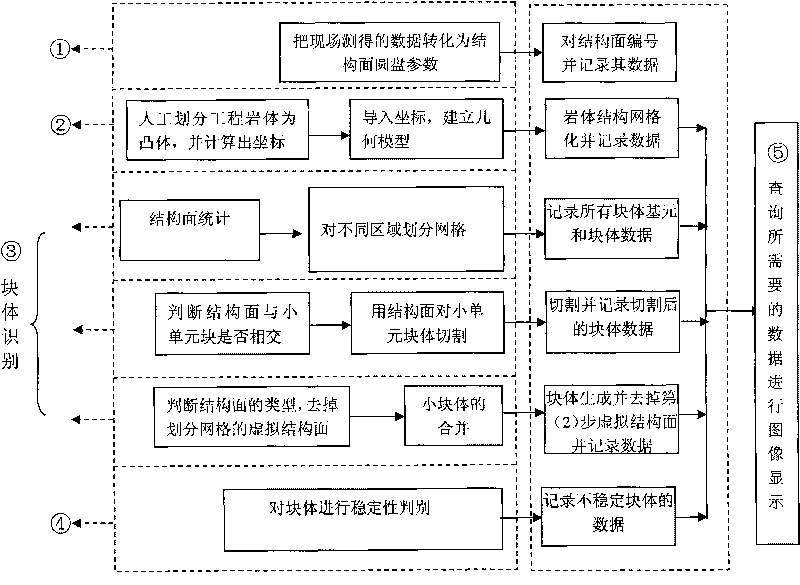

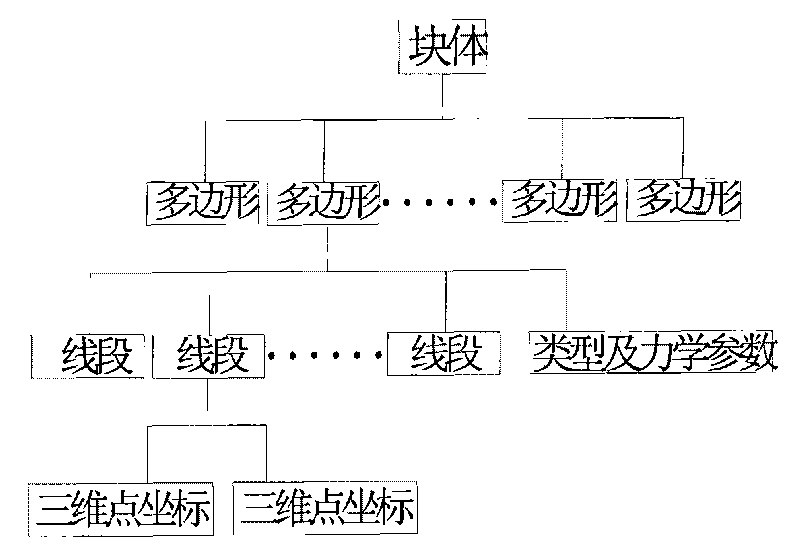

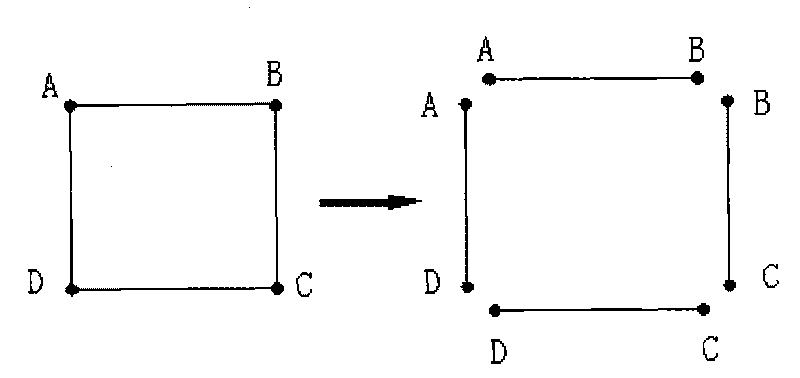

Three-dimensional space structure modeling and key block identifying method of engineering rock mass

The invention relates to a three-dimensional space structure modeling and key block identifying method of engineering rock mass, belonging to the fields of modeling and analysis of the entity structure of the rock mass engineering such as geotechnical engineering, mine exploitation, engineering construction, hydraulic engineering, underground structure and the like. The method of the invention comprises the following steps: (1) acquiring the structure original data of the engineering rock mass in the field; (2) processing and extracting the original data of the engineering rock mass; (3) constructing the model of the engineering rock mass; and (4) identifying blocks. The invention has the advantages as follows: the method realizes the purposes of quickly searching the structure of the engineering rock mass and identifying the key blocks, considers the requirement for quickly identifying a new structural surface in the engineering implementation process, and can be used for automatically searching the key blocks and counting the amount of movable blocks.

Owner:NORTHEASTERN UNIV

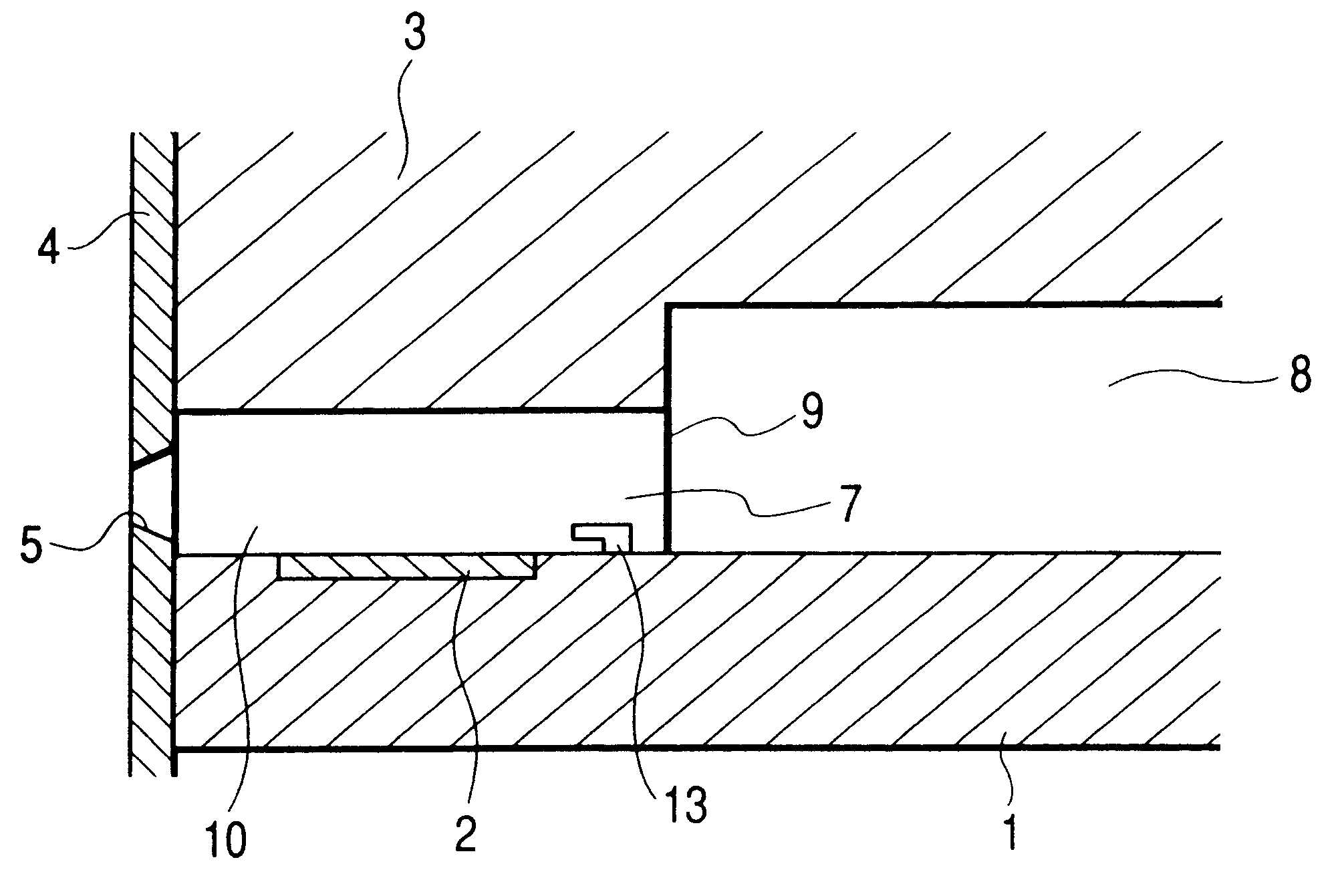

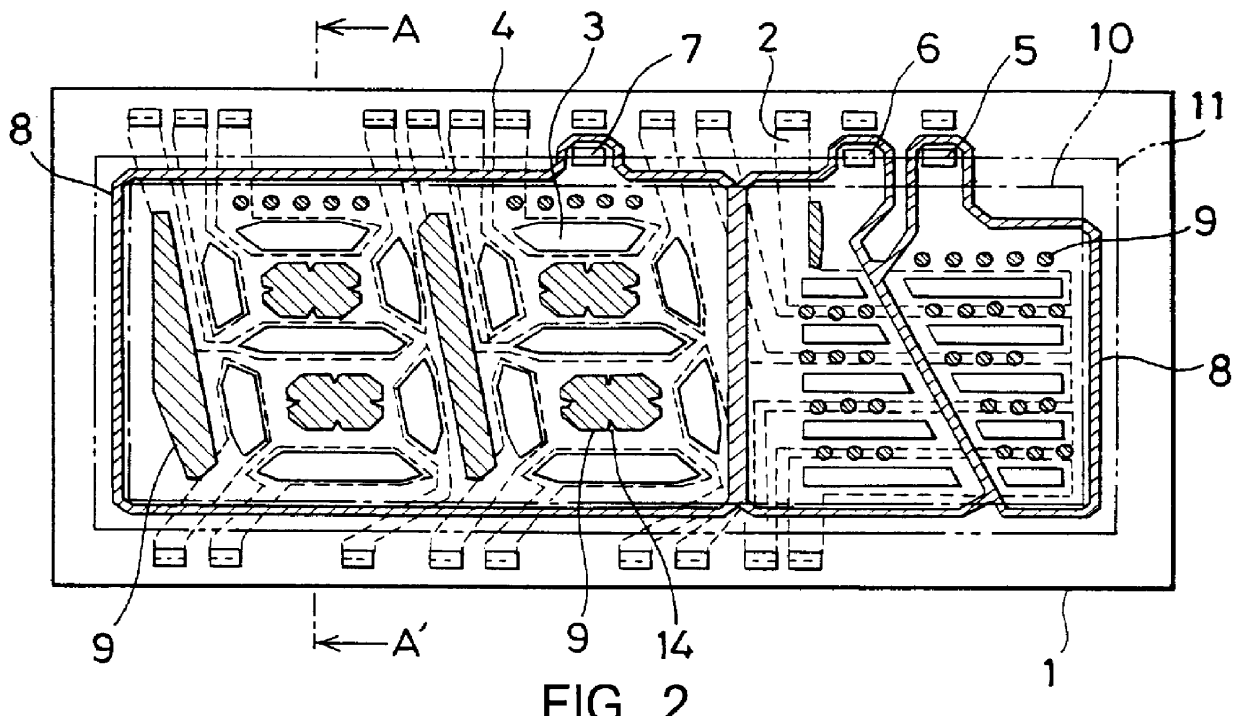

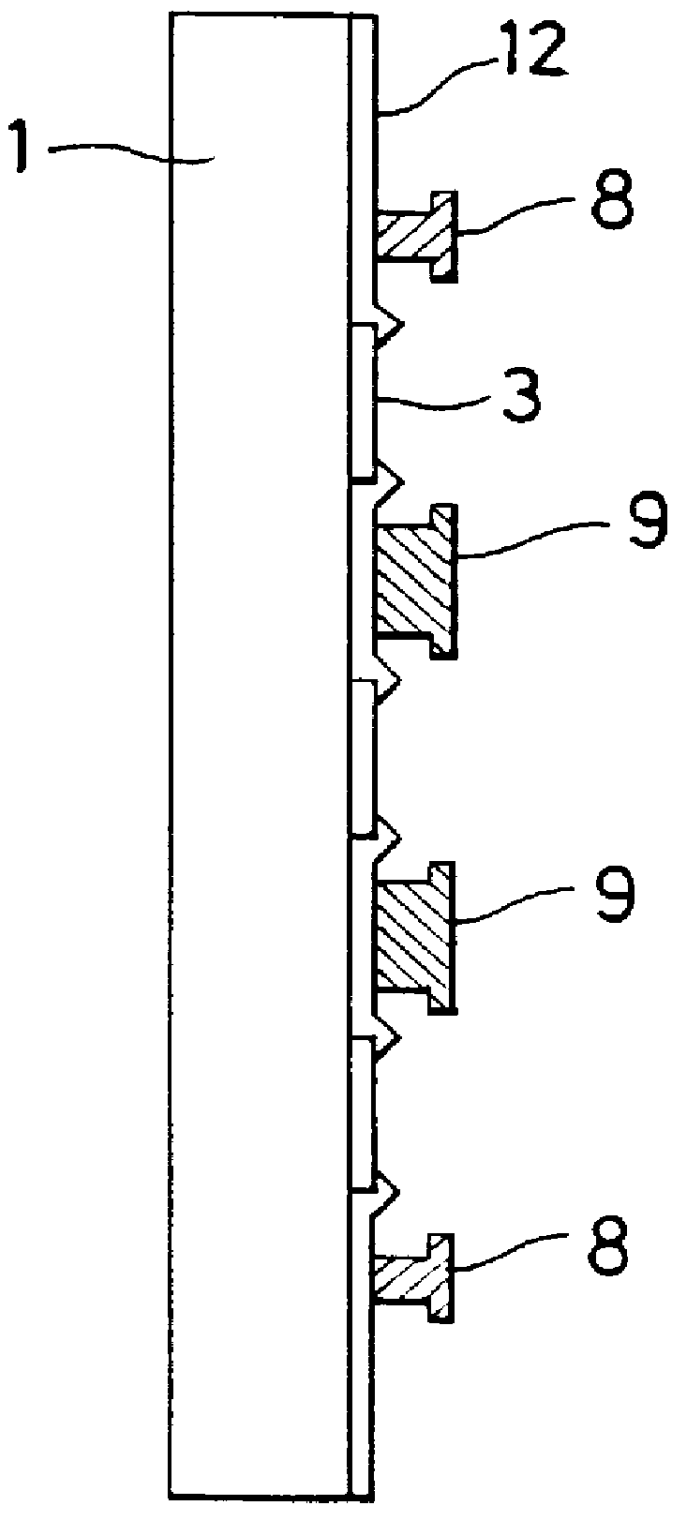

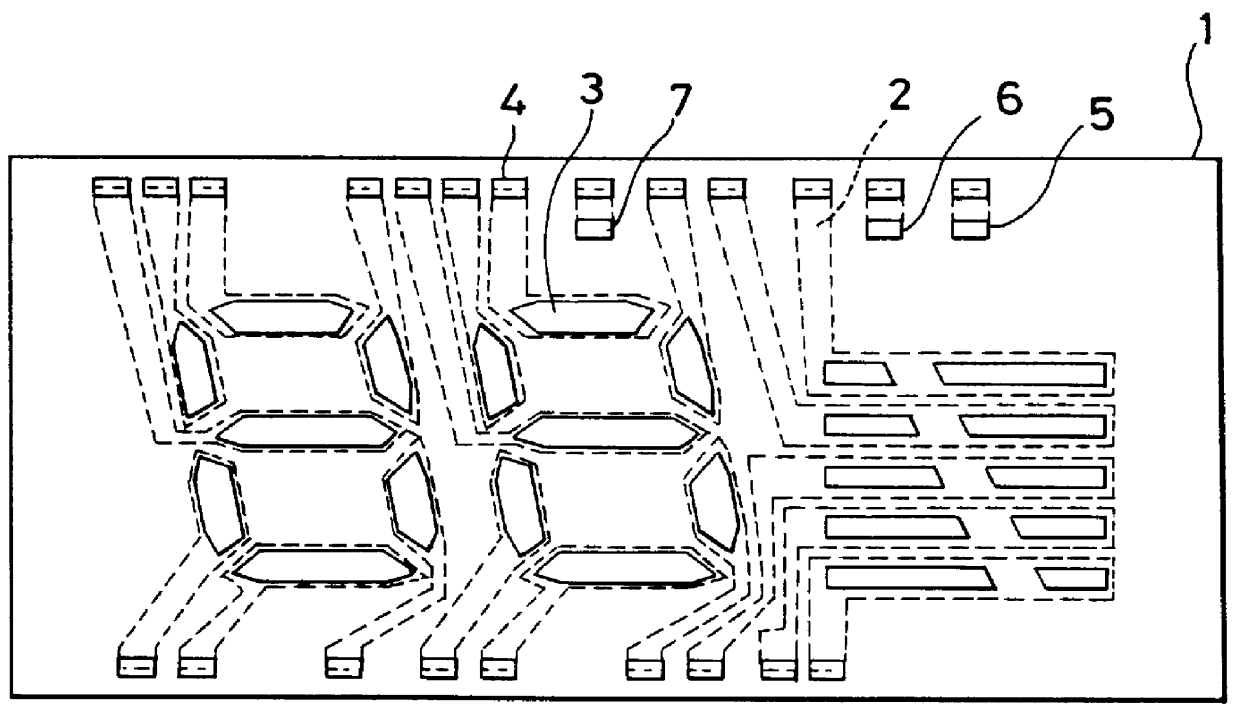

Organic electroluminescent display with filter layer

InactiveUS6114805AIncadescent screens/filtersDischarge tube luminescnet screensElectron injectionSolid structure

An organic electroluminescent display includes a substrate (1), and, in order from the substrate, a hole injection electrode, at least one organic layer, an electron injecting electrode, and a sealing plate, and wherein the substrate further includes thereon an element-isolating structure (7,8) for isolating planar structures of the organic layer and the electron injection electrode from each other during film formation, the element isolating structure being a solid structure containing a base part formed on the substrate side and an overhang part larger in width than the base part, and provided on a portion where the organic layer is isolated from the electron injecting electrode as well as other portions, so that the element isolating structure can function as a spacer for the sealing plate, and at least one type of filter layer (14a-14c) is interleaved between the element-isolating structure serving as the spacer and the substrate.

Owner:FUTABA CORPORATION

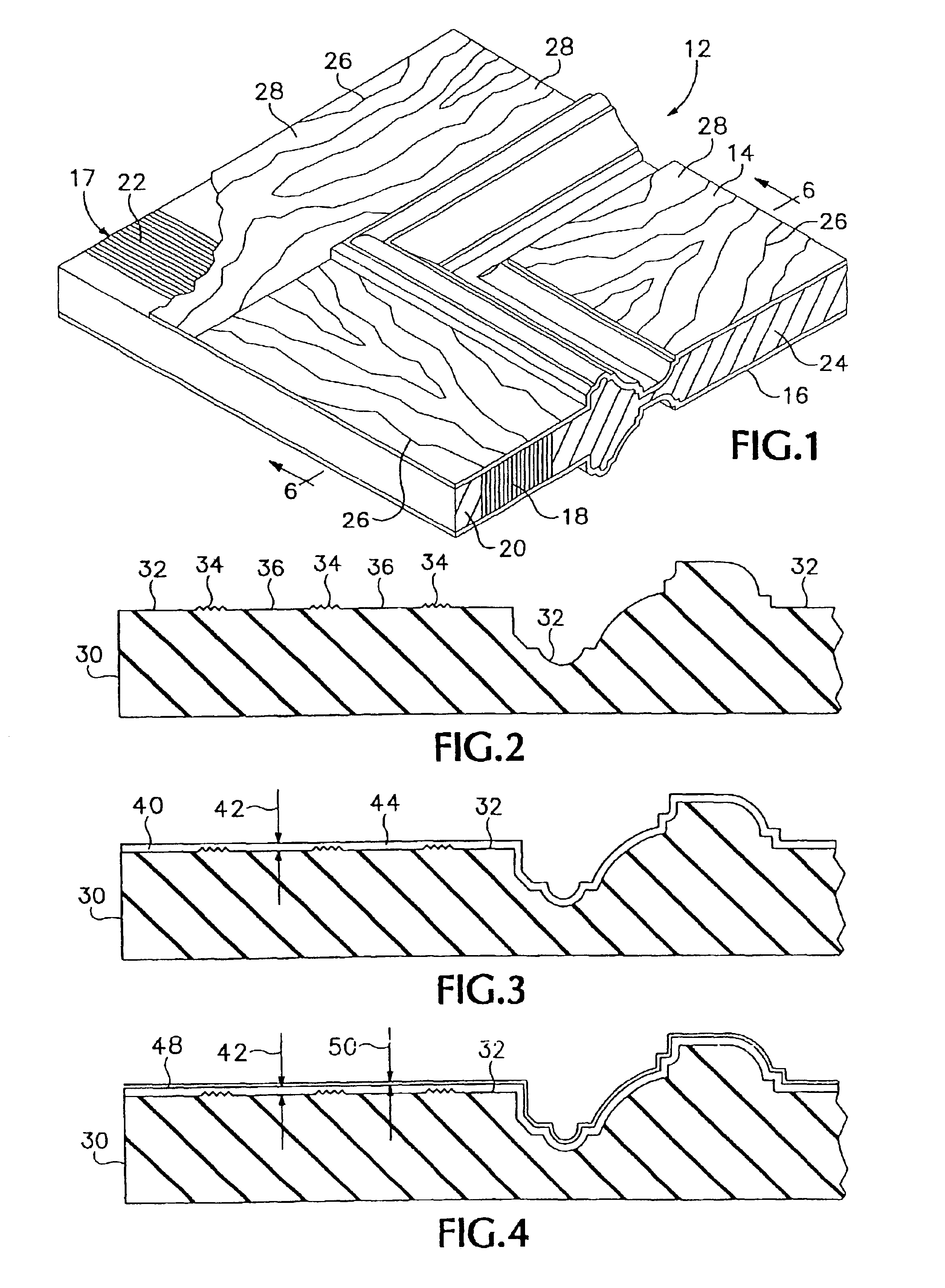

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

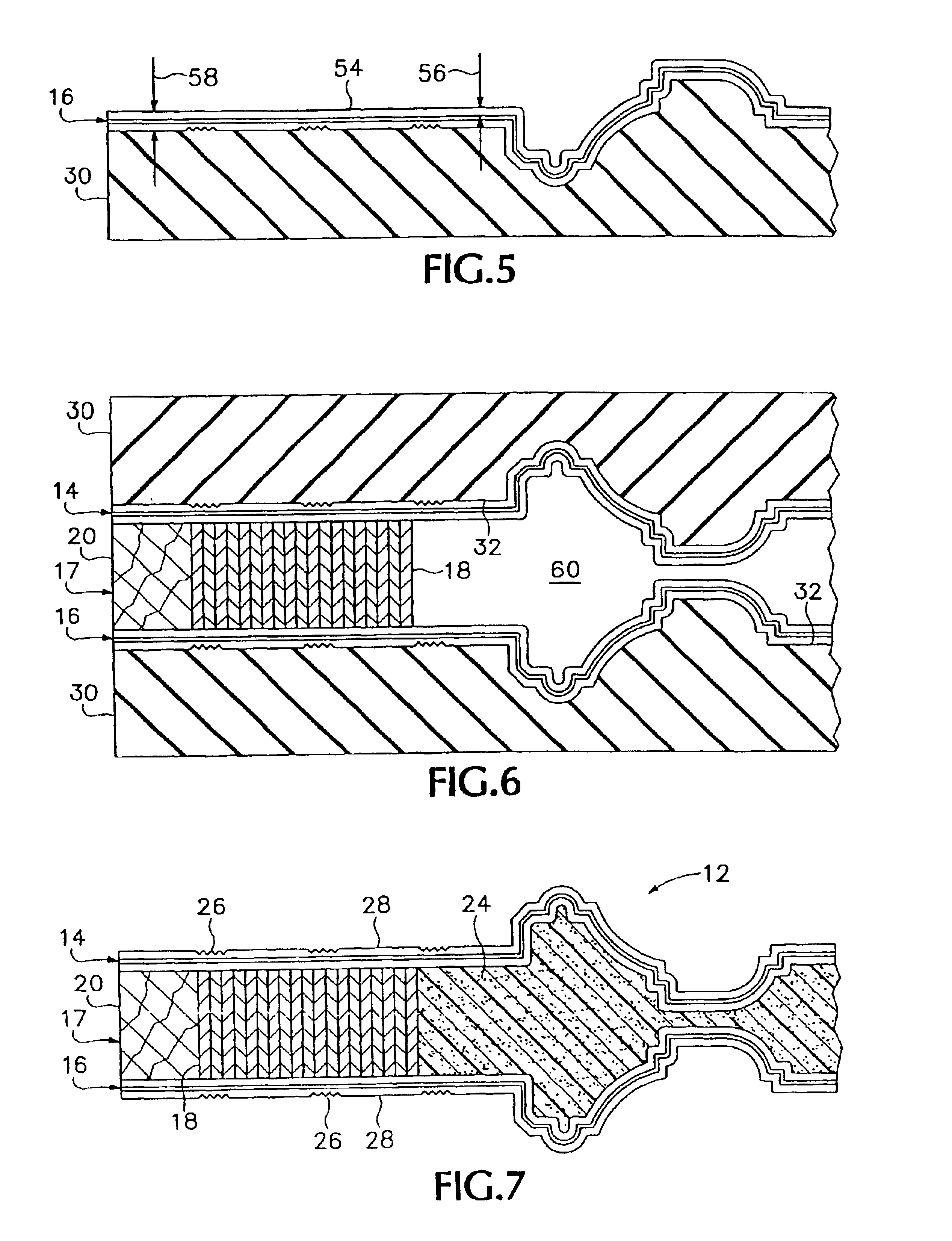

3D-printing-based machining method of three-dimensional micro-fluidic chip and printing device

ActiveCN103895226AReduce processing costsEasy and fast processingLaboratory glasswaresLiquid stateMicrofluidics

The invention discloses a 3D-printing-based machining method of a three-dimensional micro-fluidic chip. The machining method comprises the following steps: (1) drawing a three-dimensional micro-runner figure; (2) layering three-dimensional runners in the three-dimensional micro-runner figure, and carrying out layer-by-layer slicing on the three-dimensional runners along the bottom surface direction parallel to a chip; (3) pouring a liquid-state chip material on a micro-runner solid structure at a previous layer, sequentially printing the micro-runner solid structure and pouring the chip material on each layer according to layering and slicing sequences of the runners, and sequentially finishing the shape printing of the runners, so as to obtain a three-dimensional runner solid structure; (4) dissolving the three-dimensional runner solid structure, so as to obtain the three-dimensional micro-fluidic chip. The invention further discloses a printing device for implementing the method. The 3D-printing-based machining method has the advantages that a machining process is simple, convenient and rapid, the production efficiency is high, the industrial mass production is easily realized, the obtained three-dimensional micro-fluidic chip does not need to be subjected to post-processing processes such as bonding, a packaging process is simplified, a three-dimensional micro-runner with a complex structure can be manufactured, and the shape and precision of the runner are controllable.

Owner:ZHEJIANG UNIV

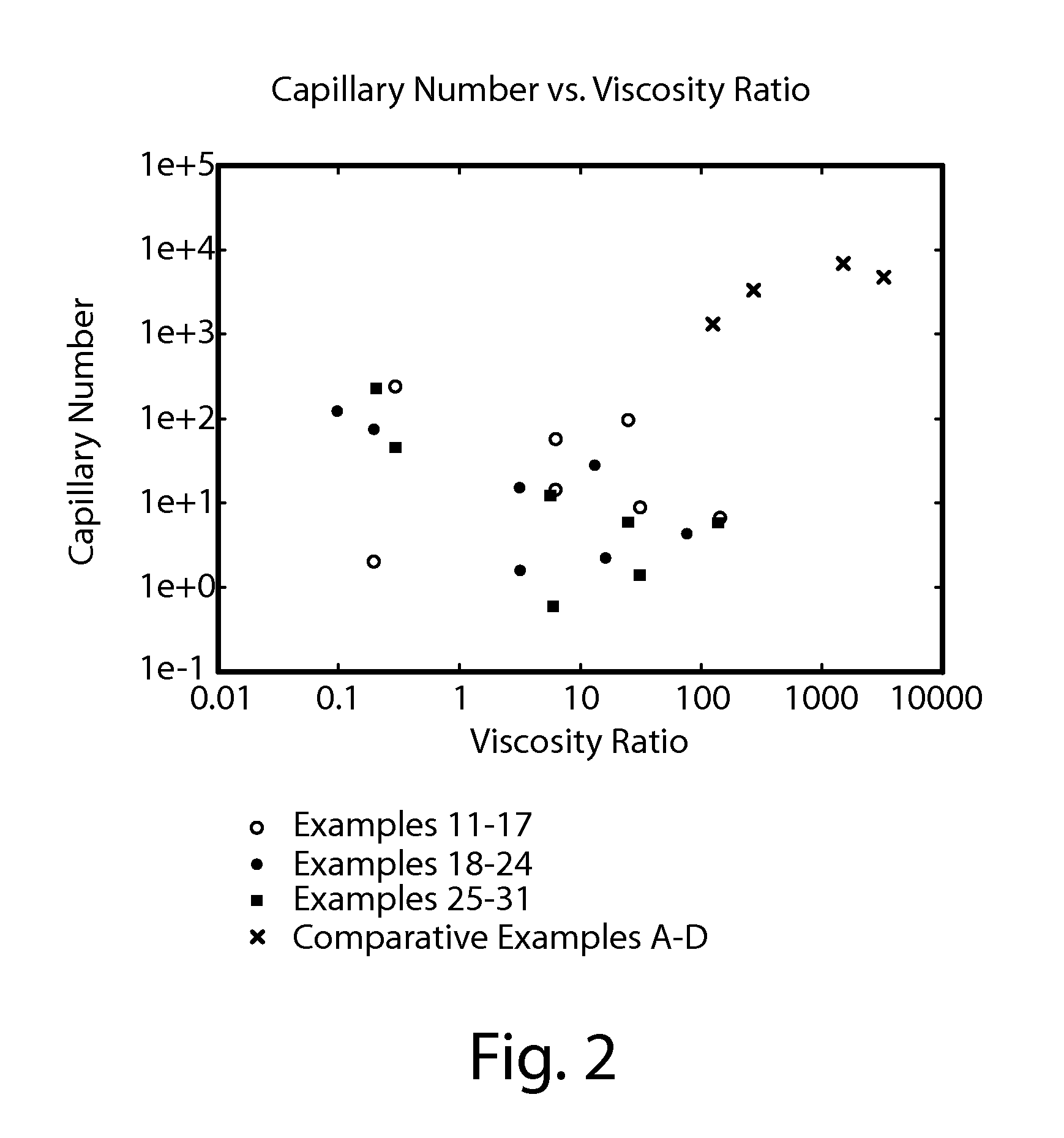

Methods of Forming an Aqueous Treatment Liquor

ActiveUS20150313807A1Enhanced consumer benefitImprove efficiencyCosmetic preparationsHair removalSolid structureAqueous solution

A method of forming an aqueous treatment liquor comprising a benefit agent, the method comprising the steps of: (a) providing a consumer product comprising: (i) a porous dissolvable solid structure, and (ii) a hydrophobic coating comprising a benefit agent, the hydrophobic coating applied to the porous dissolvable solid structure; (b) providing an aqueous solution; and (c) dissolving the consumer product in the aqueous solution to form an aqueous treatment liquor comprising a hydrophobic portion and an aqueous portion. The method provides a Capillary Number of less than about 1000.

Owner:THE PROCTER & GAMBLE COMPANY

Personal care composition in the form of an article having a porous, dissolvable solid structure

The present invention relates to a dissolvable article in the form of a porous dissolvable solid structure, comprising from about 23% to about 75% surfactant; wherein the surfactant has an average ethoxylate / alkyl ratio of from about 0.001 to about 0.45; from about 10% to about 50% water soluble polymer; and from about 1% to about 15% plasticizer; and wherein the article has a density of from about 0.05 g / cm3 to about 0.25 g / cm3.

Owner:PROCTER & GAMBLE CO

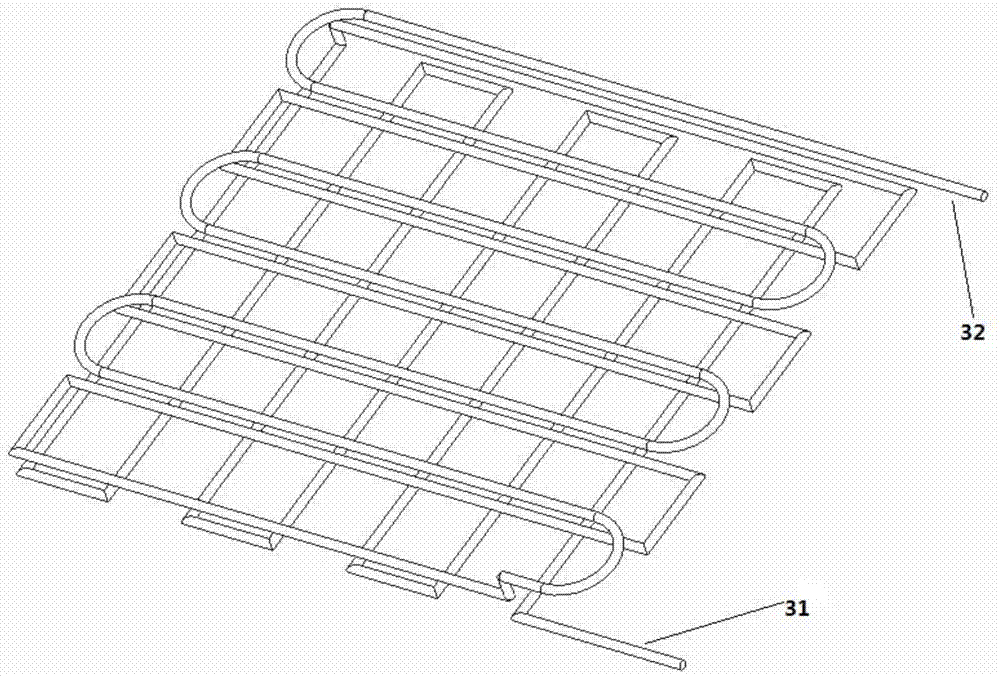

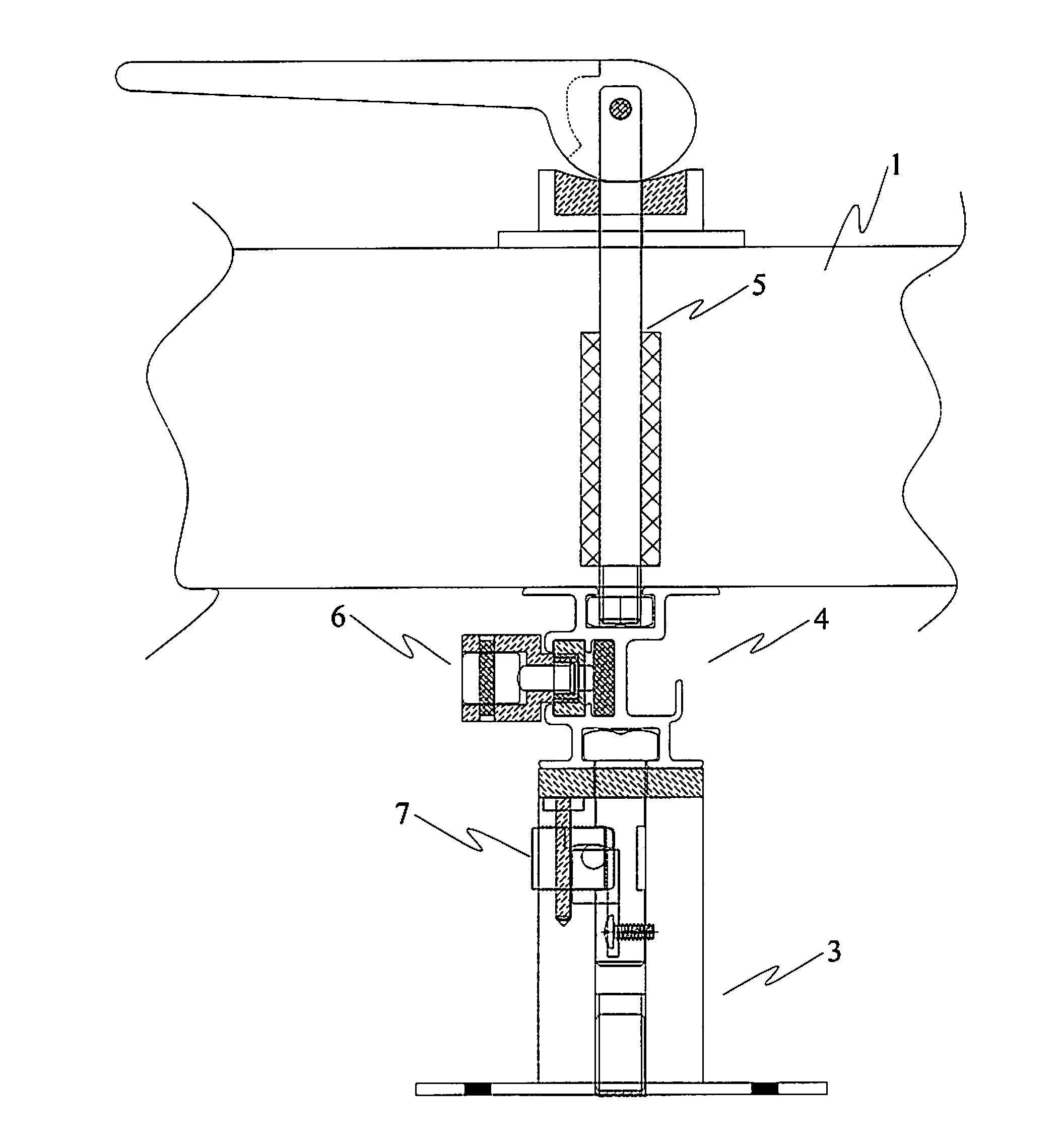

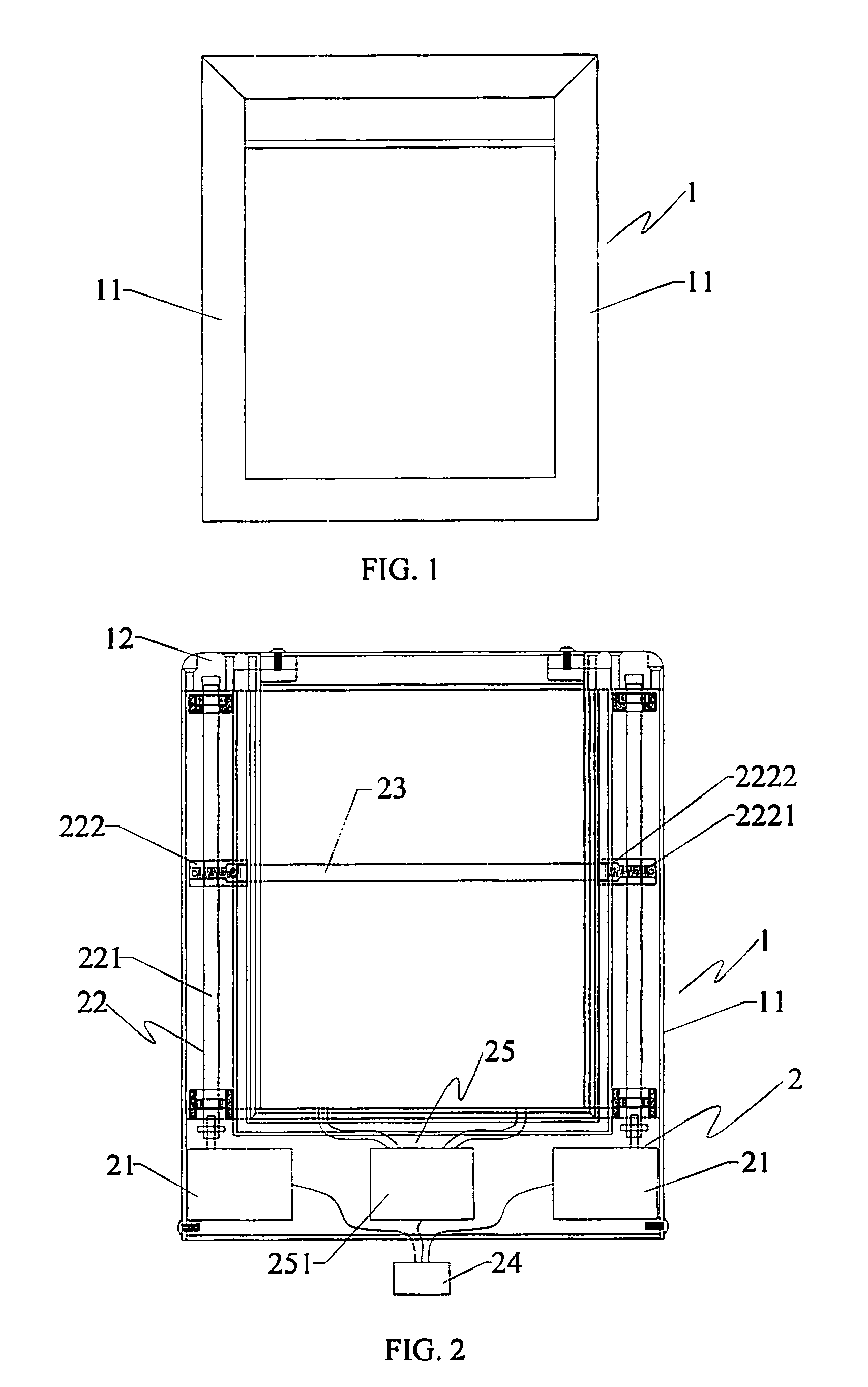

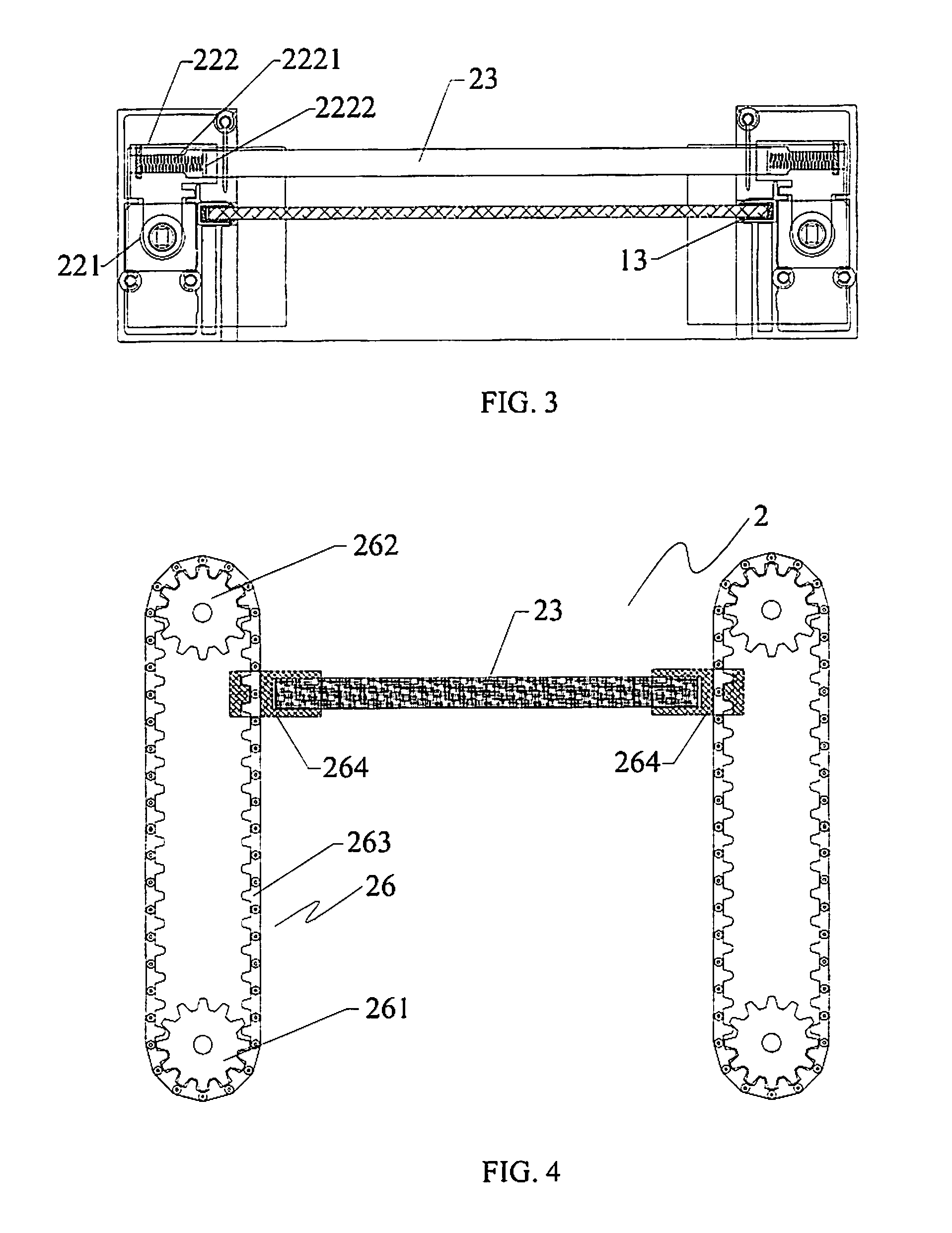

Solar energy panel frame and installation system device thereof

InactiveUS20110000525A1Low costEfficient processPhotovoltaic supportsSolar heating energyRemote controlSolid structure

The present invention disclosed a solar energy panel frame and installation system device there of. Said solar energy panel frame includes a frame body which is consist of a plurality of profile brackets abutting joint to each other. Wherein an automatic cleaning device is set on said frame body. And said automatic cleaning device comprises a motor located in the profile bracket symmetrically, a transmission mechanism connected to the output shaft of the motor, a cleaning brush moved in upper and lower direction by said transmission mechanism which it connected to, and a remote control integrated circuit system. Said installation system device of the solar energy panel frame includes a pedestal, a rail bracket which is fixedly connected to the pedestal by a bracket fixing part, and a frame fixing part which is used to lock up the solar energy panel. Wherein said rail bracket is consist of a plurality of profiles having a grooved rail which is on the match usage with above component parts, and said bracket fixing part and said frame fixing part are both eccentric rotary locking solid structure.

Owner:WU WENXIANG +1

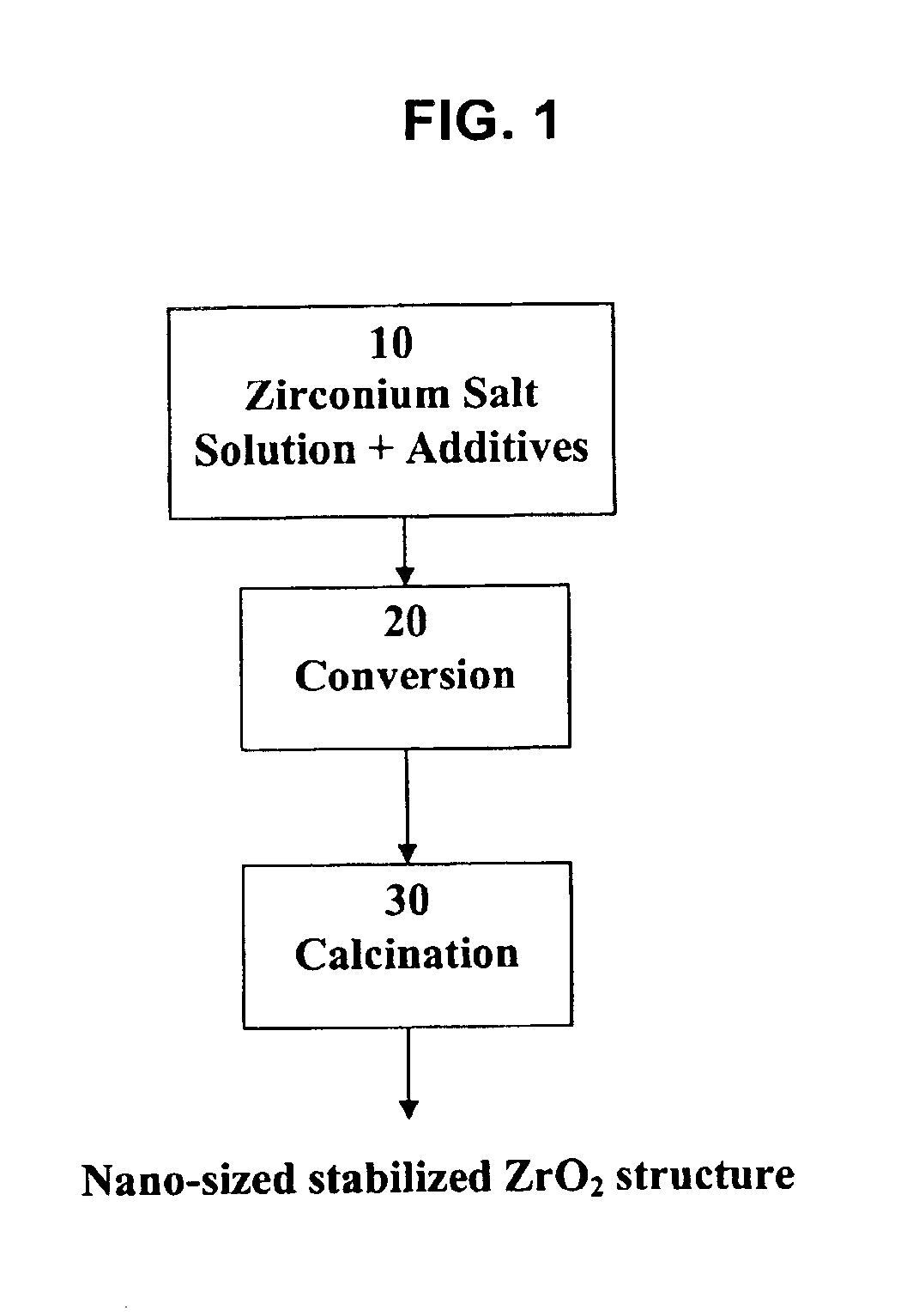

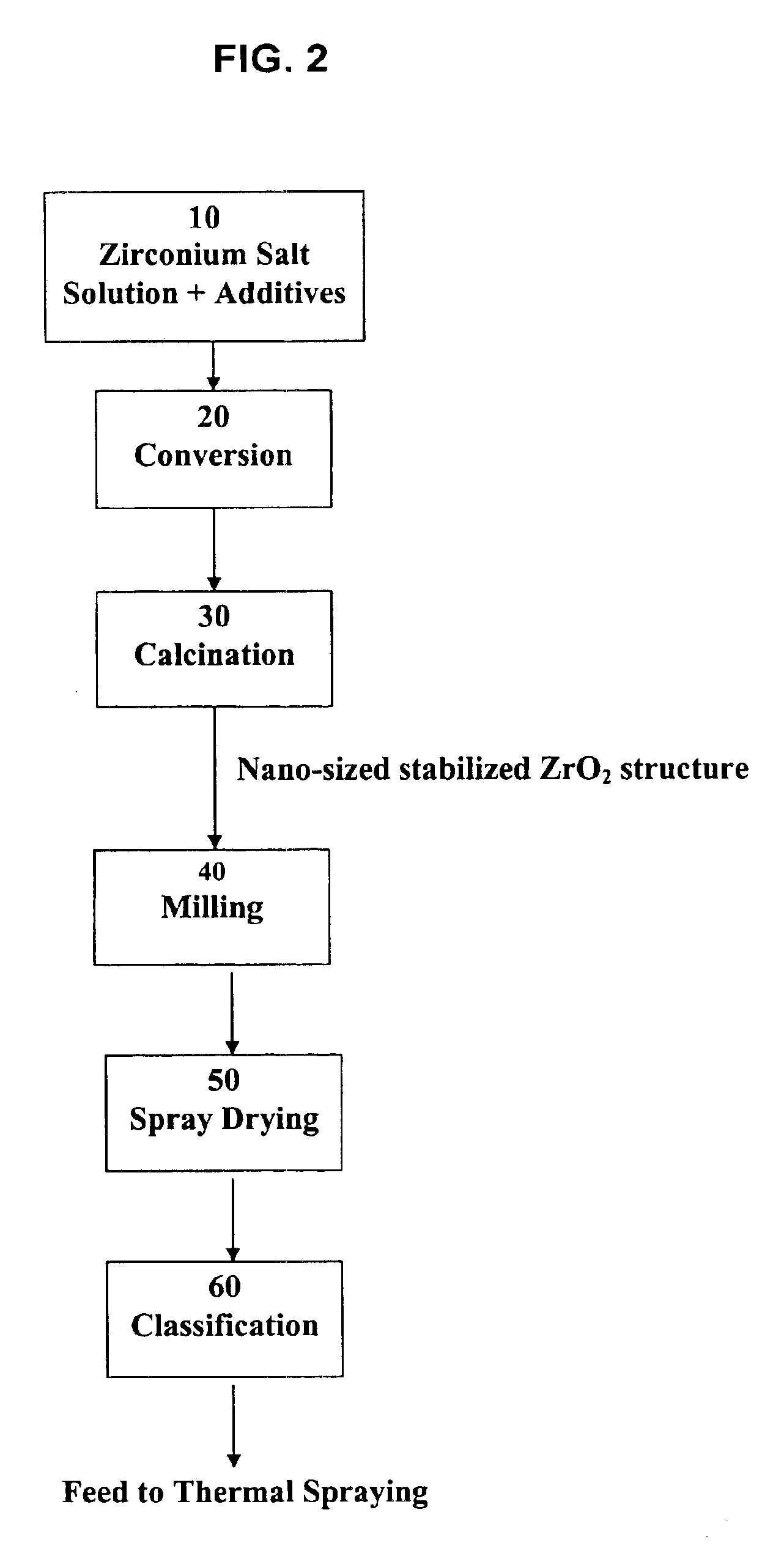

Process for making nano-sized stabilized zirconia

A process to produce stabilized zirconia from a solution of zirconium salt and a stabilizing agent. The zirconium salt may include zirconium oxysulfate, zirconium oxychloride, zirconium oxynitrate, zirconium nitrate, and other water-soluble zirconium salts. The stabilizing agent may include calcium, magnesium, yttrium salts of oxides and rare earth oxides. The process is conducted by evaporation of the solution above the boiling point of the solution but below the temperature where there is significant crystal growth. The evaporation step is followed by calcination to produce the desired nano-sized structure. Further processing by sintering may be applied to produce solid structures or by milling and classification to produce material for thermal spray coating.

Owner:ALTAIR NANOMATERIALS INC

Multi-layer structure and method for forming a thermal interface with low contact resistance between a microelectronic component package and heat sink

InactiveUS6761928B2Semiconductor/solid-state device detailsSynthetic resin layered productsSolid structurePhase change

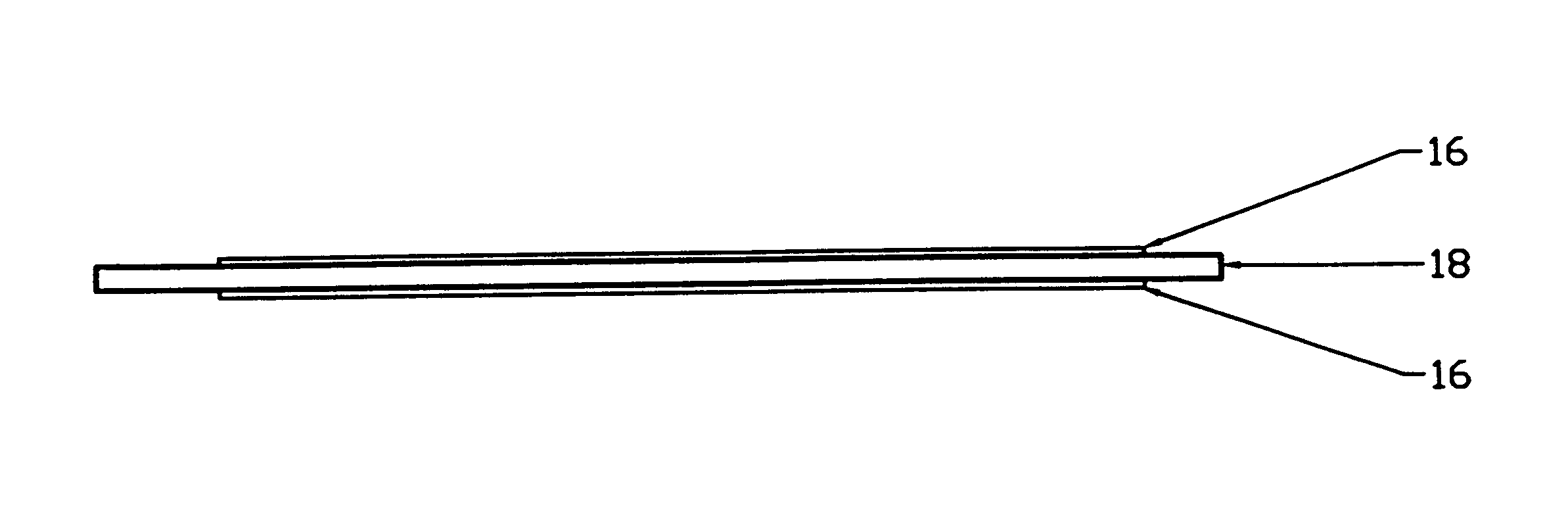

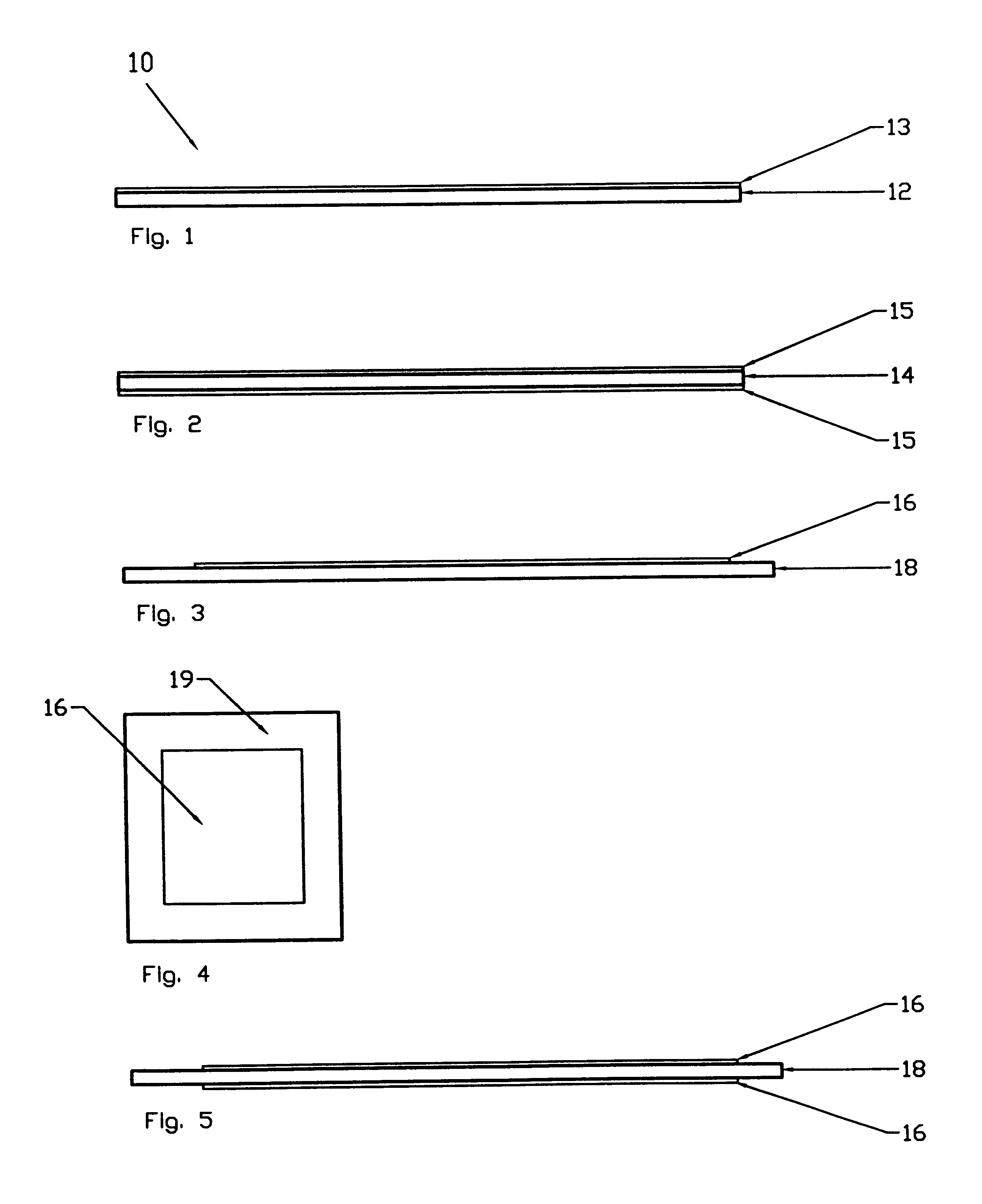

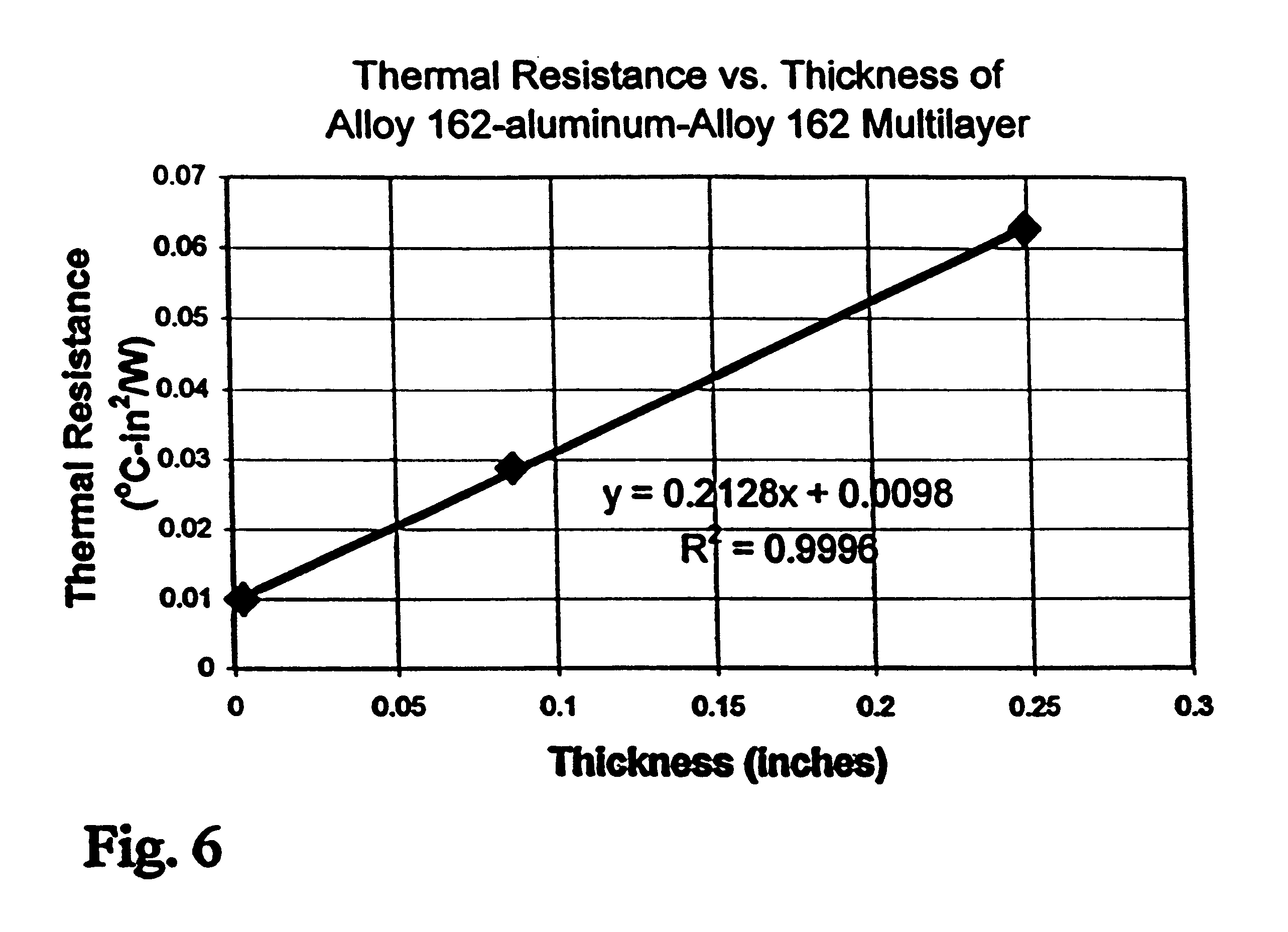

A multi-layer solid structure and method for forming a thermal interface between a microelectronic component package and a heat sink so that the structure has a total thermal resistance of no greater than about 0.03° C.-in<2> / W at a pressure of less than 100 psi. The structure comprises at least two metallic layers each of high thermal conductivity with one of the two layers having phase change properties for establishing low thermal resistance at the interface junction between the microelectronic component package and the heat sink.

Owner:THERMAGON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com