Patents

Literature

224 results about "Dense material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

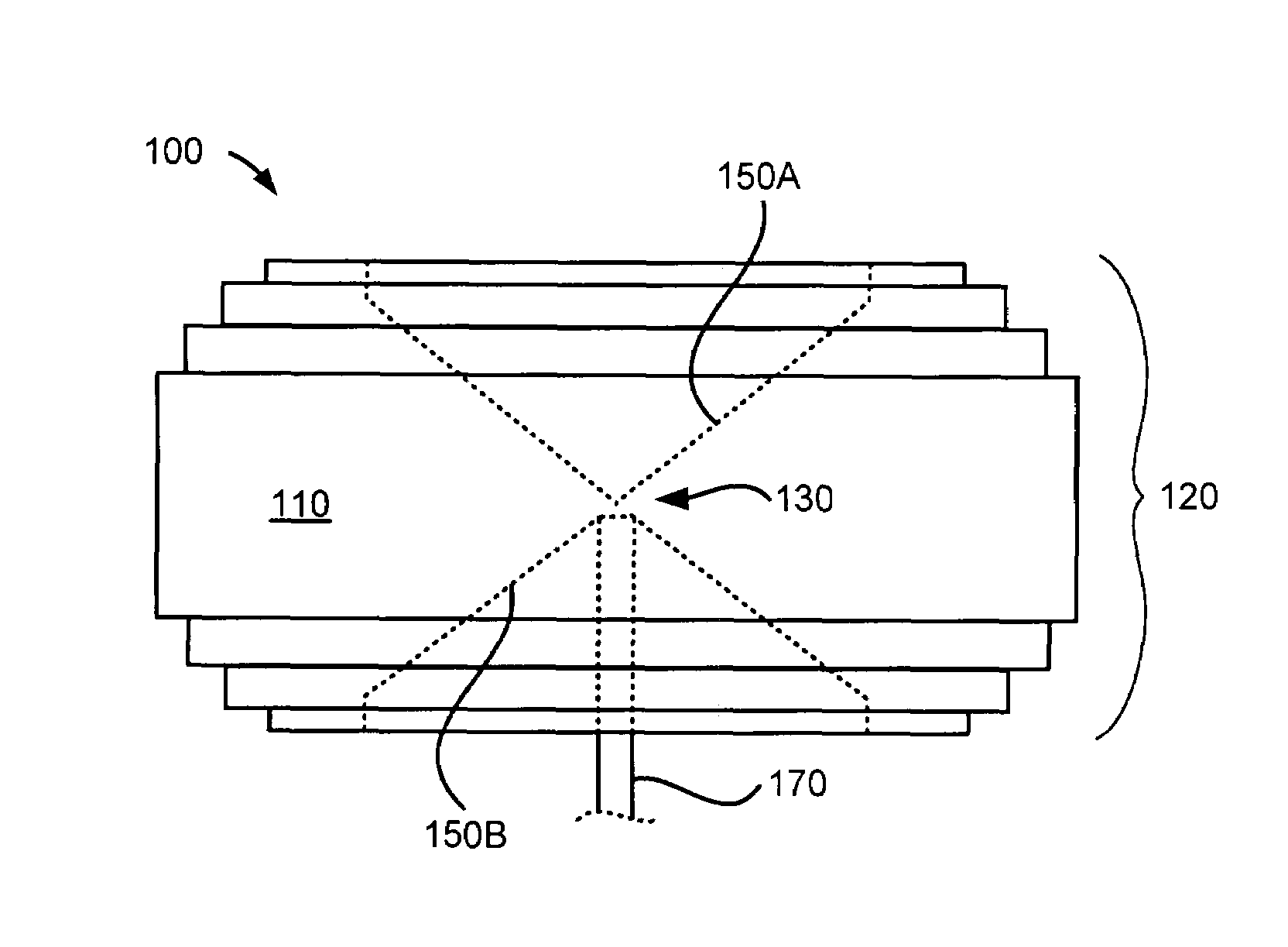

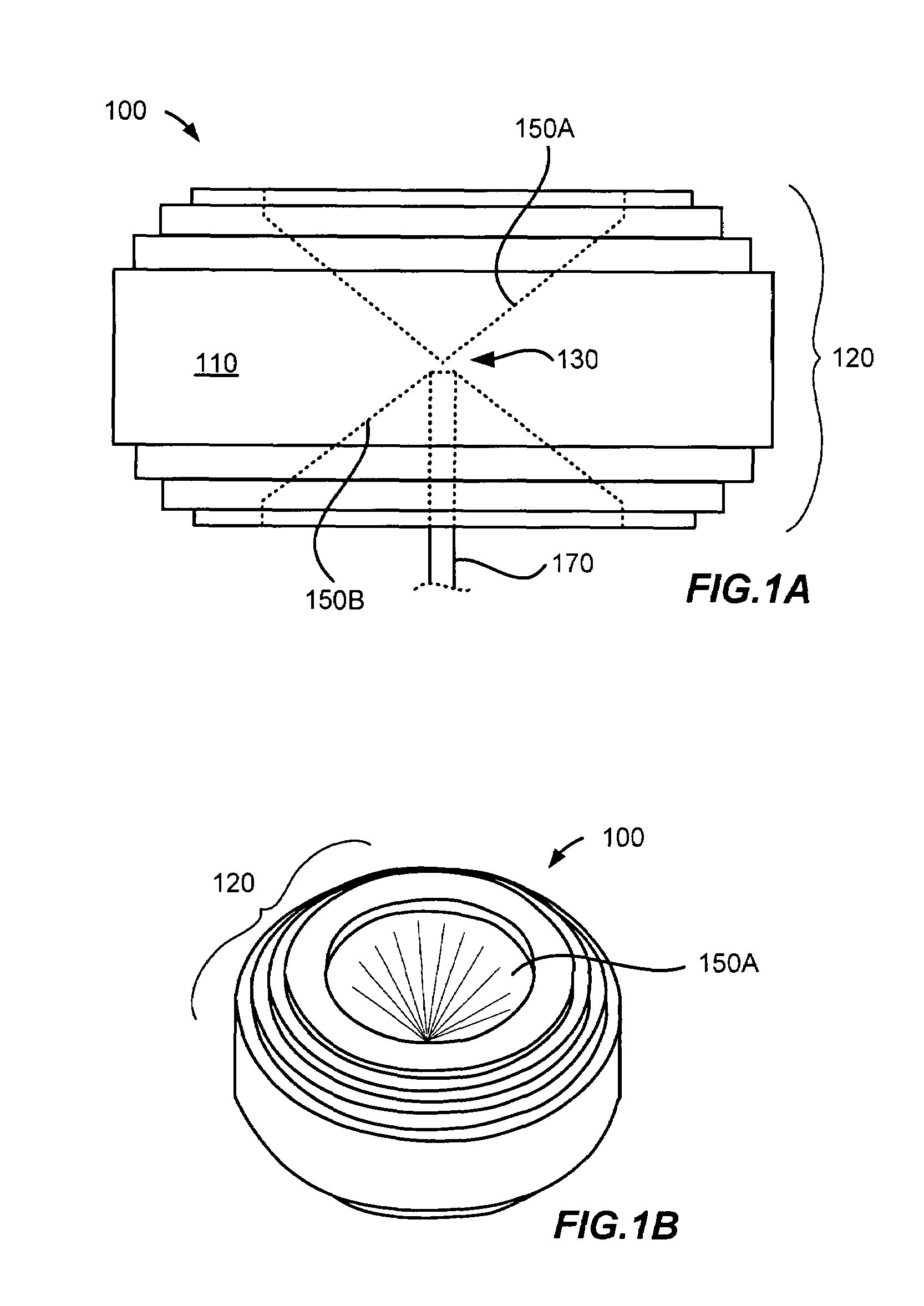

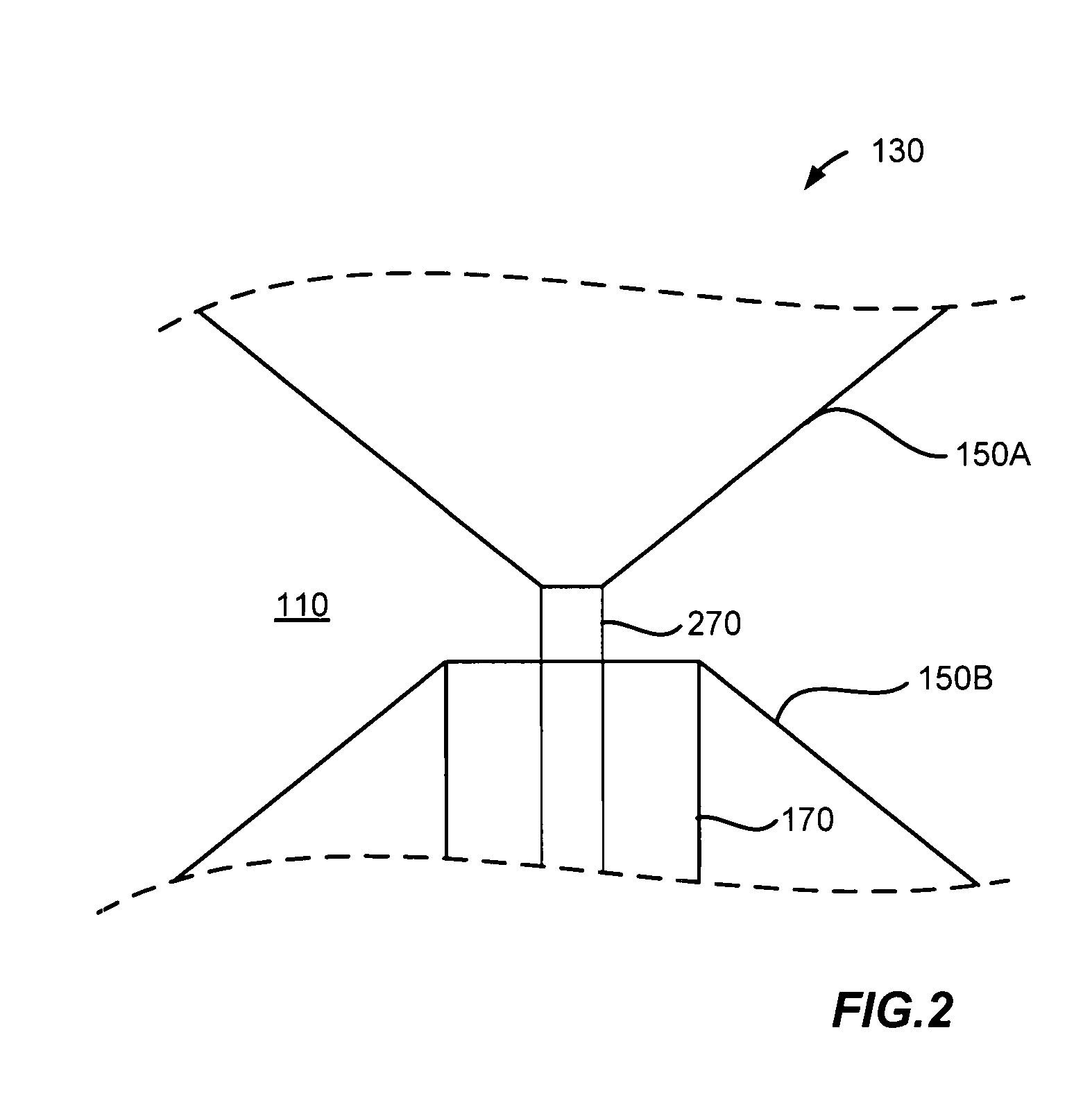

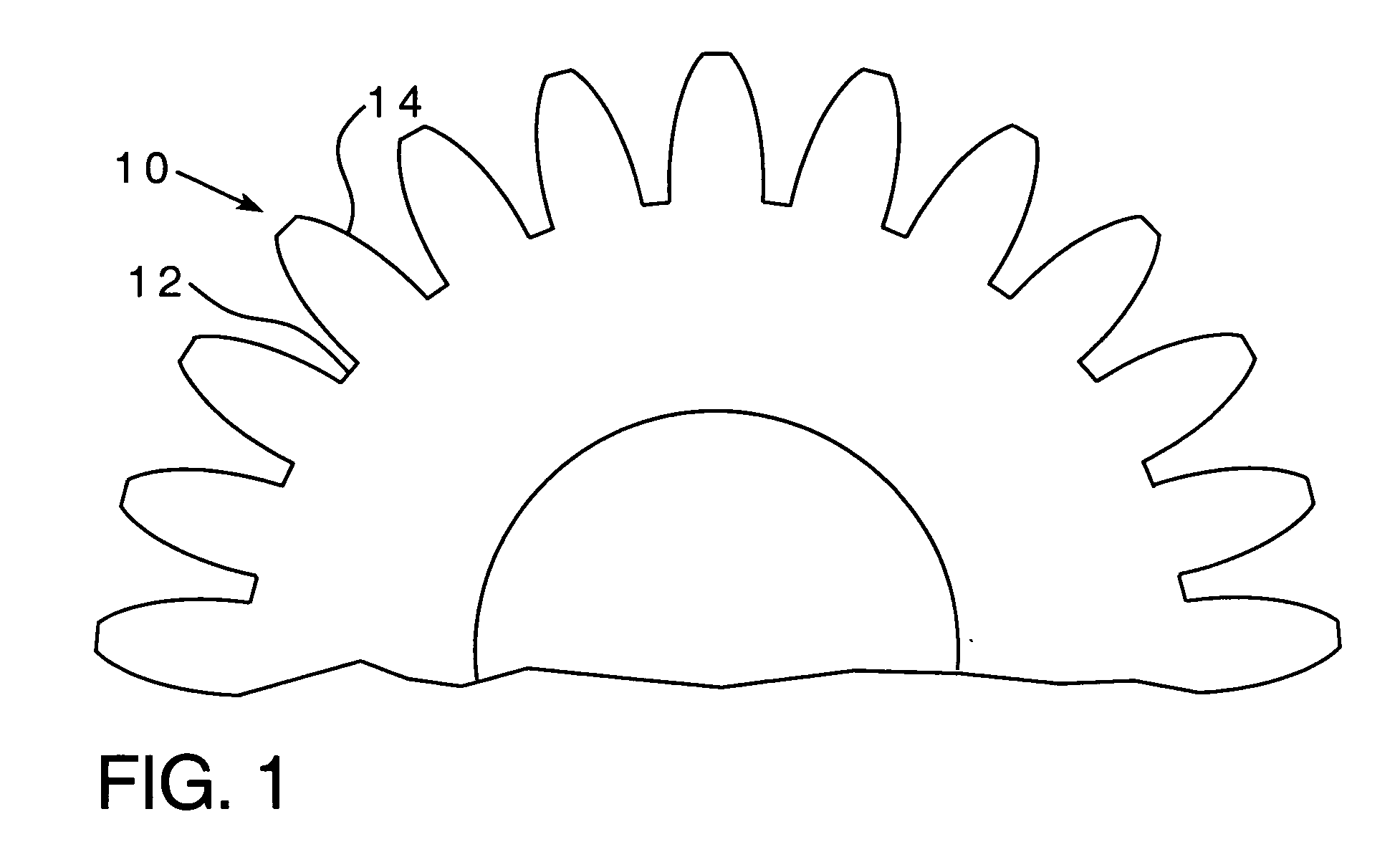

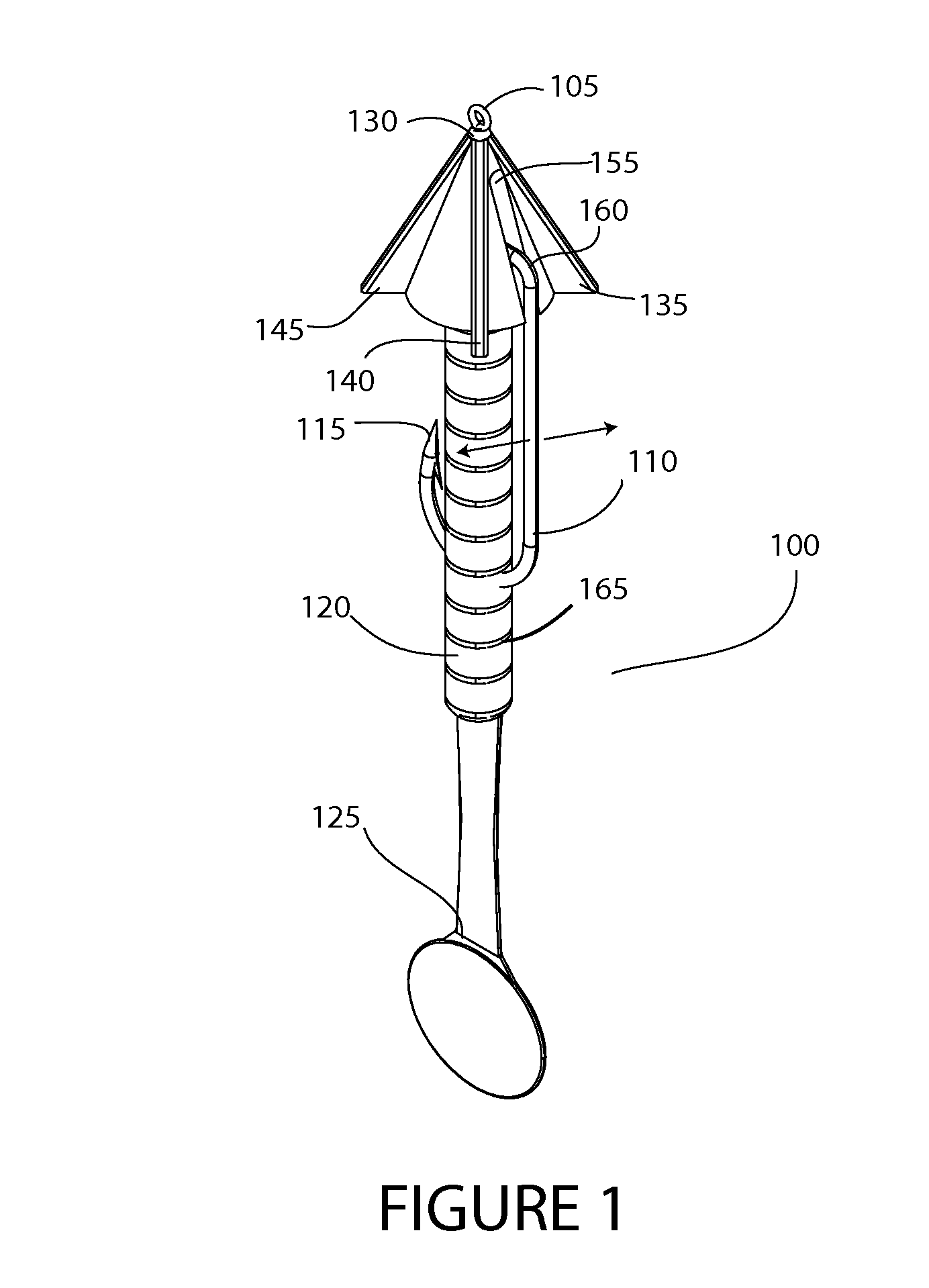

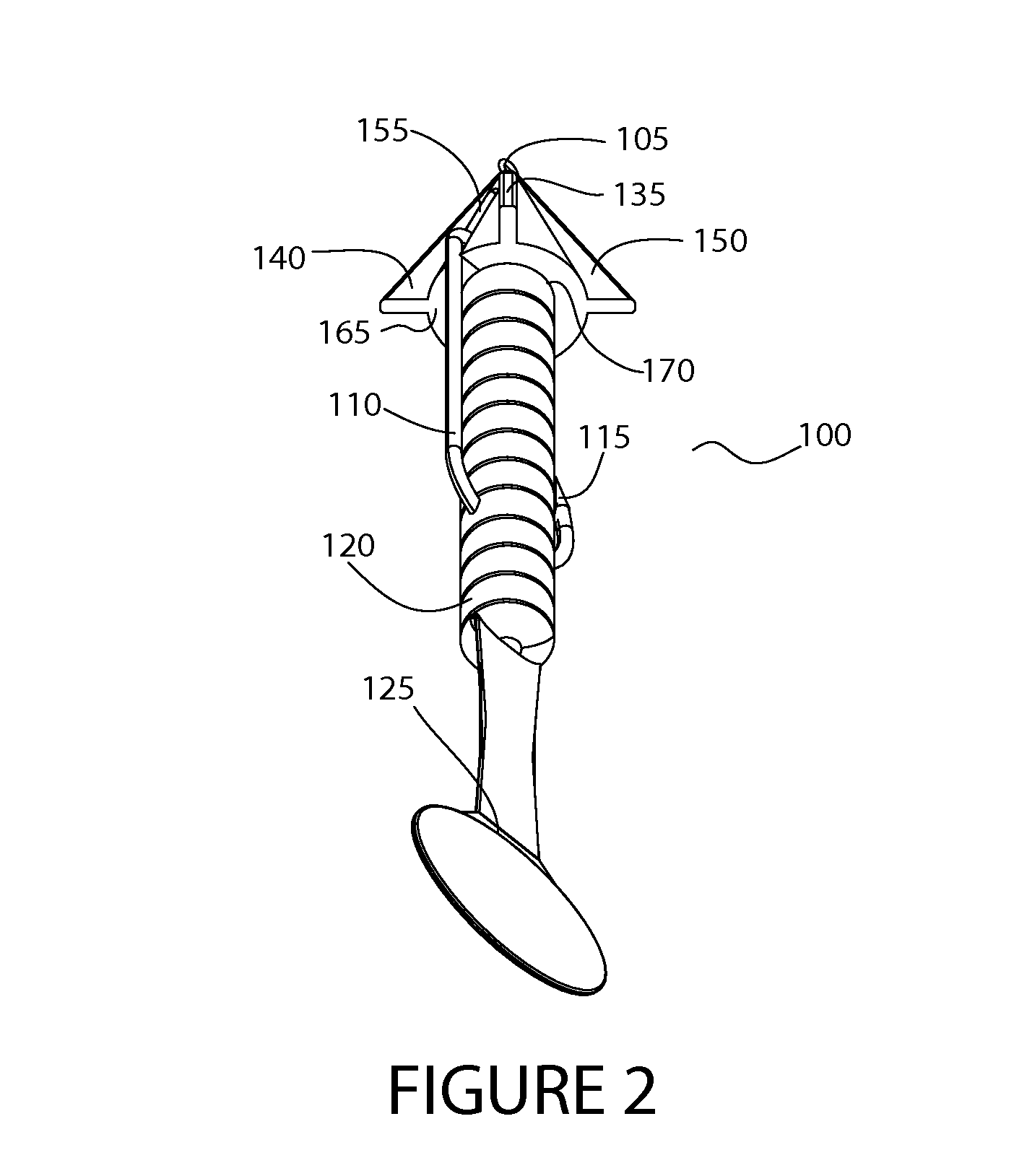

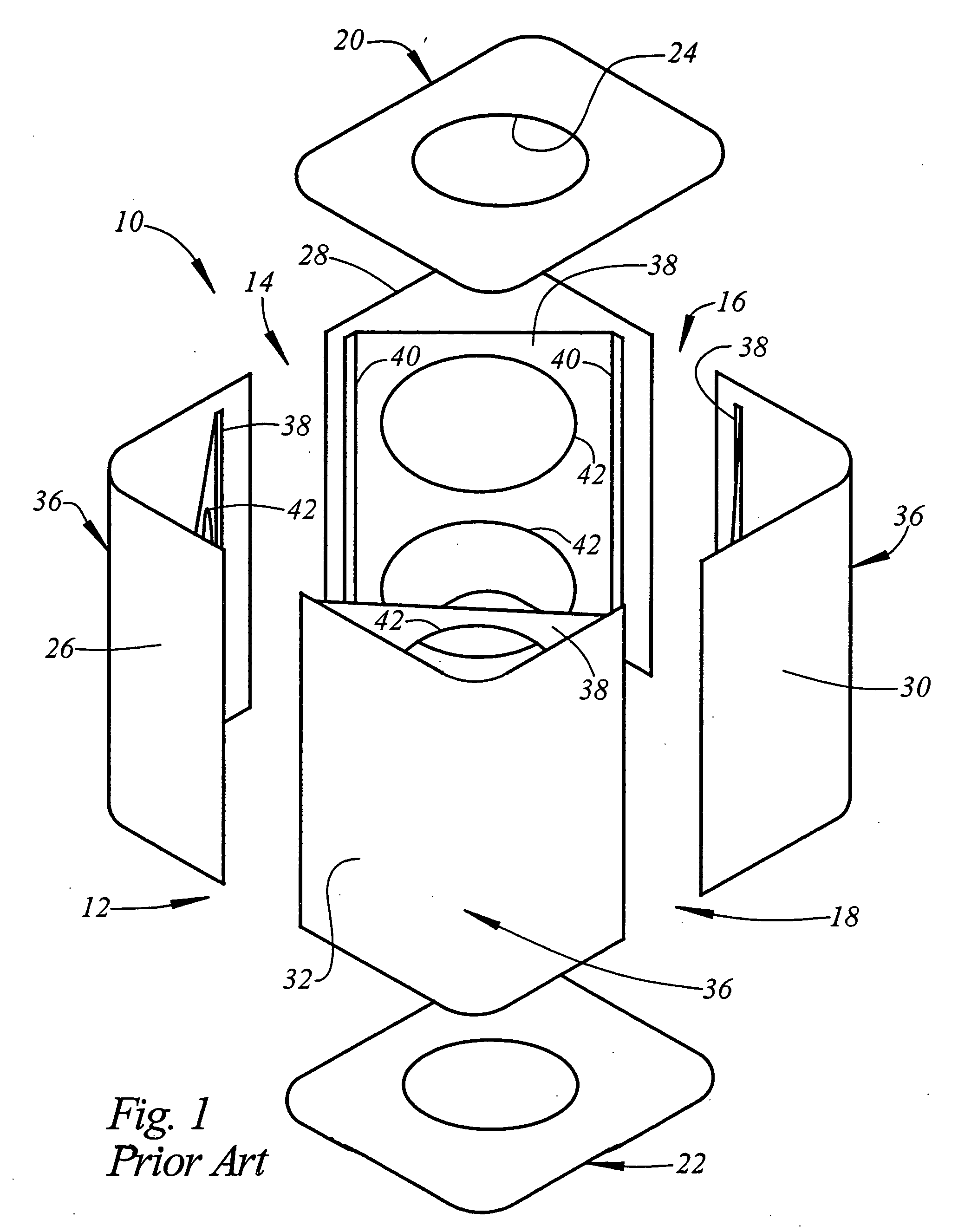

Bicone pattern shaping device

ActiveUS7525501B2Low costHigh gainAntenna feed intermediatesElectromagnetic radiationOmni directional

A broadband omni-directional bicone antenna. The antenna can comprise conductive surfaces of conical voids provided within a solid dielectric structure. The outside surface of the solid structure can support a radio frequency (RF) lens geometry operable for beam forming. The beam forming can modify the elevation pattern of the electromagnetic radiation from the bicone antenna. The solid dielectric structure may be machined or molded from a single piece of material. The conical voids provided within the solid structure can be metallized to provide conductive bicone radiators. The outer surface beam shaping lenses can be zoned or continuous and can provide elevation patterns with increased gain, cosecant squared falloff, or various other patterns. The beam shaping lens may be formed from any low-loss dielectric. Alternatively, the lens may be formed from a less dense material such as dielectric foam that can support radial conductive beam forming vanes.

Owner:EMS TECHNOLOGIES

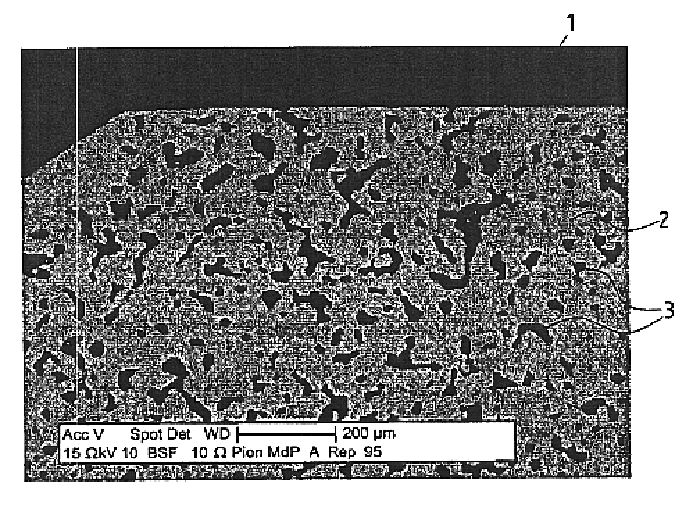

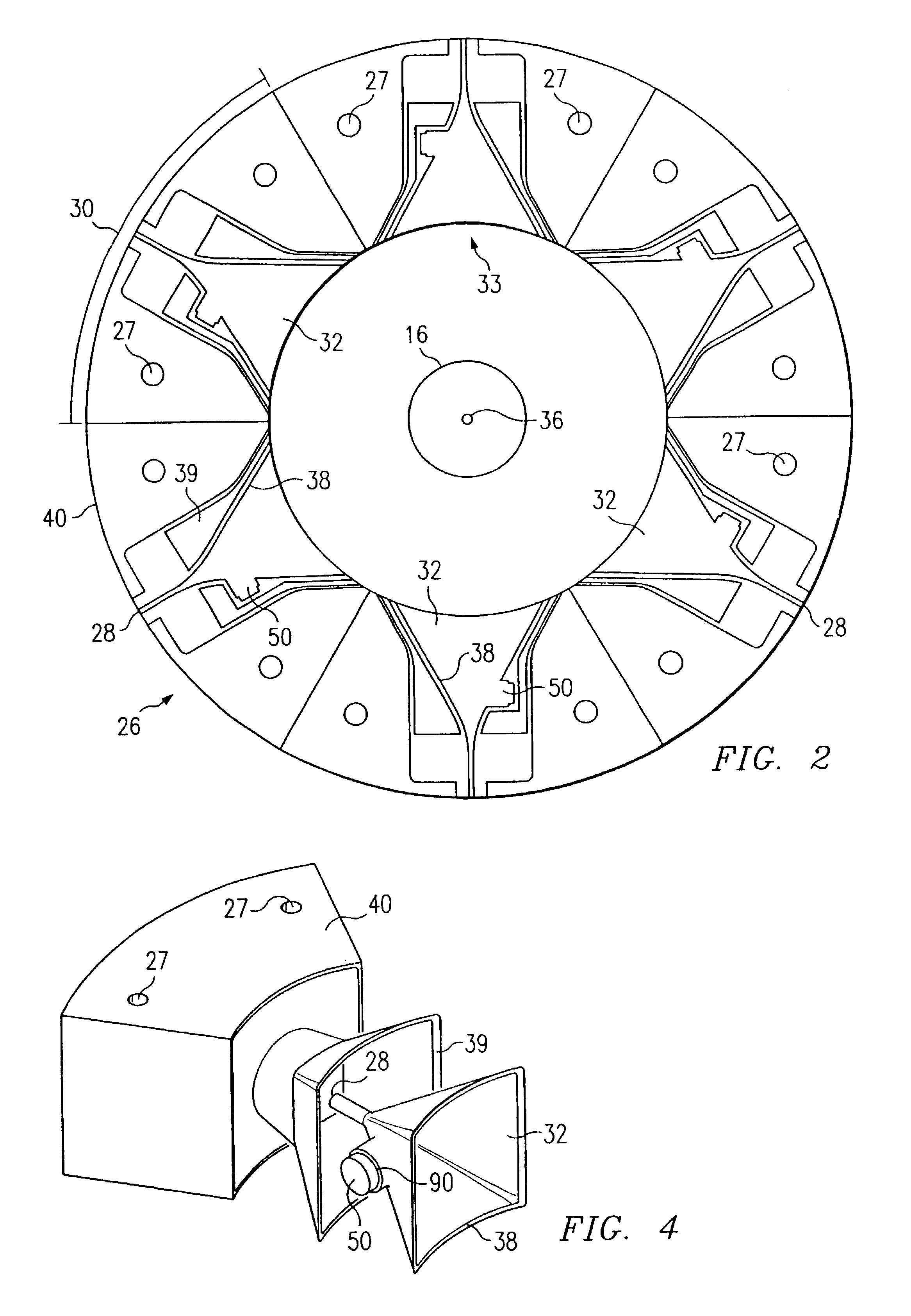

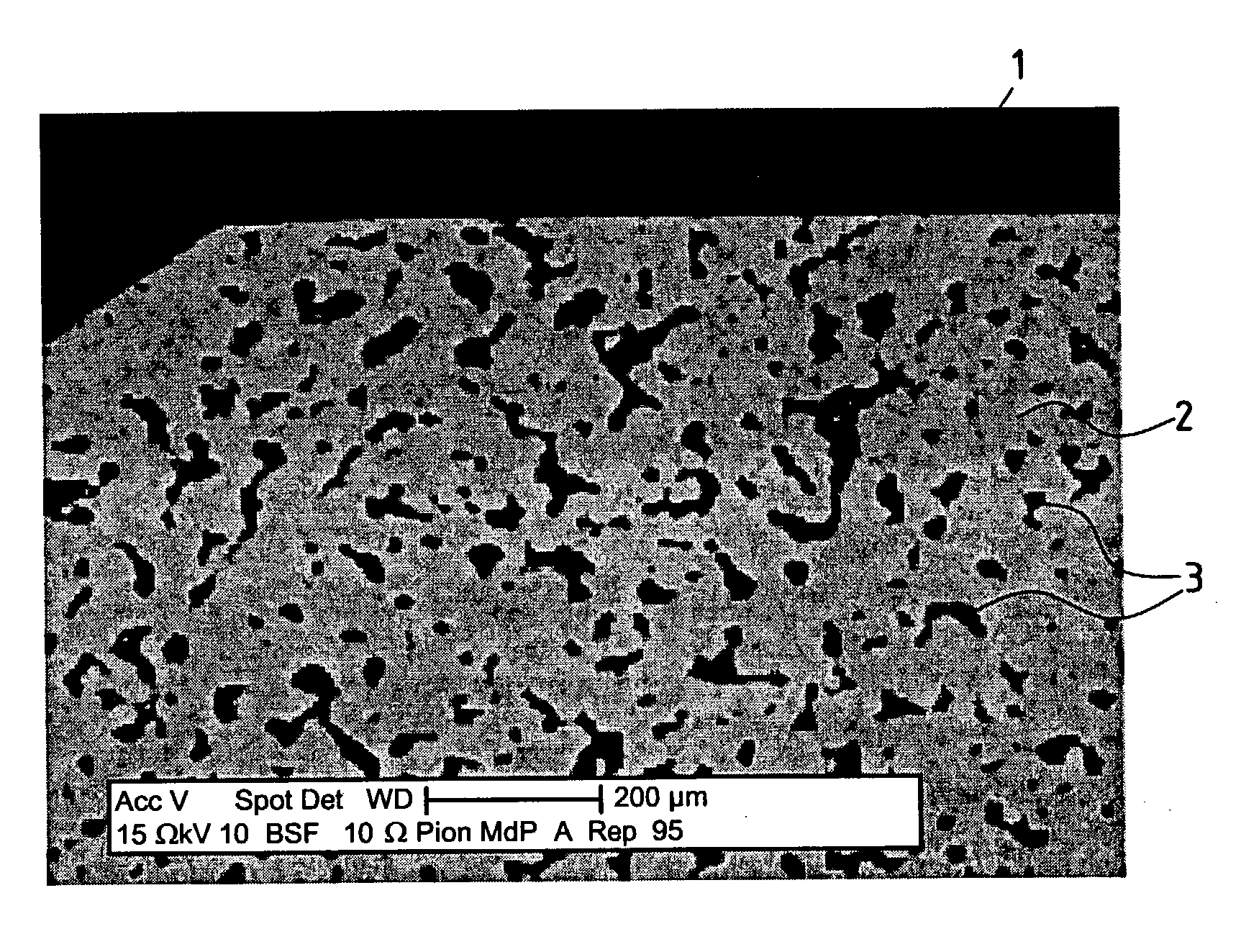

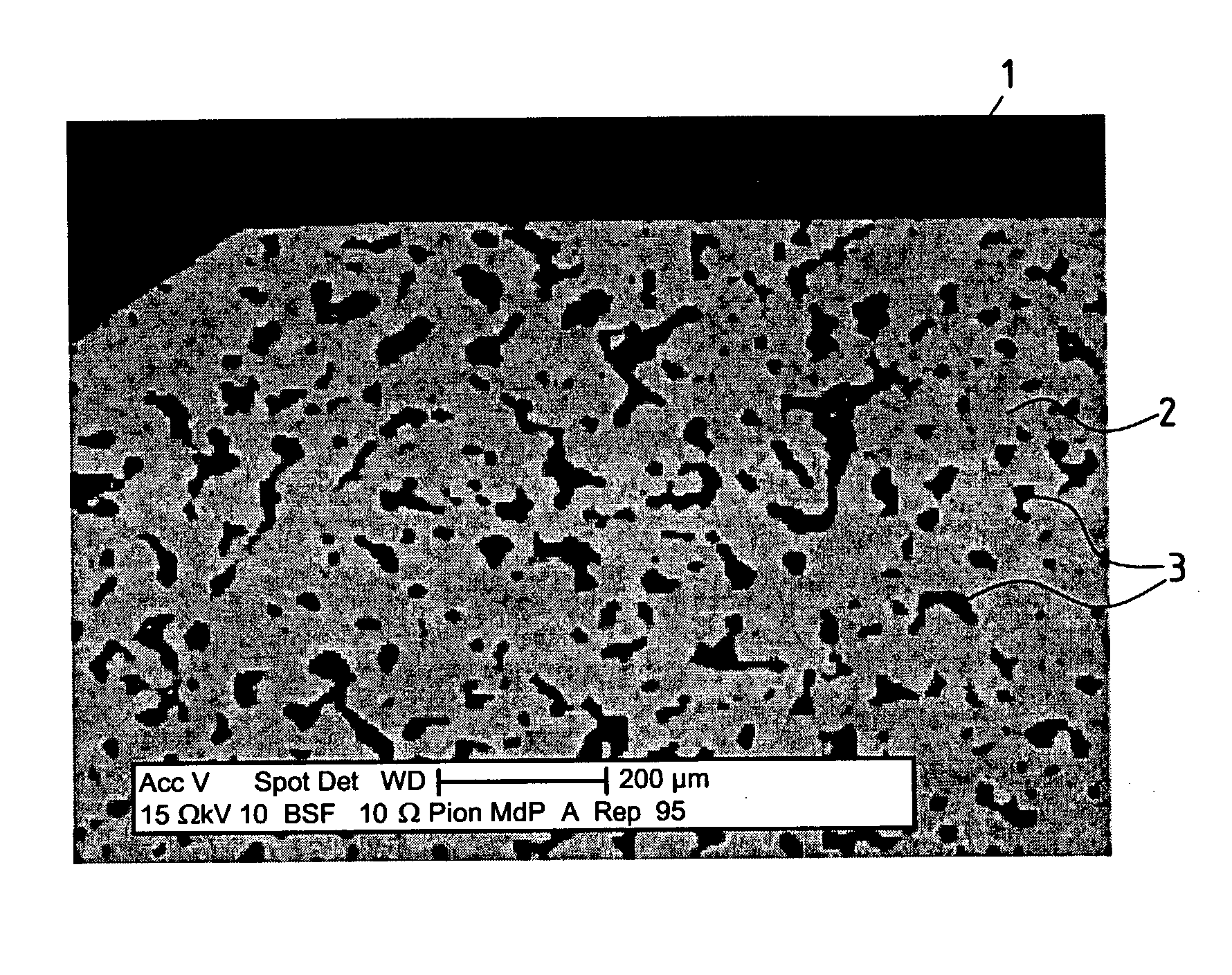

Powder metal materials and parts and methods of making the same

Embodiments of the present invention relate to methods of forming powder metals materials and parts. More specifically, certain embodiments of the present invention relate to methods of forming powder metals materials and parts by densifying at least a portion of a surface of the materials and / or parts after sintering and prior to densifying one or more core regions of the materials and / or parts. Other embodiment provide powder metal parts, such as gears and sprockets, having surface regions that are uniformly densified to full density to depth ranging from 0.001 inches to 0.040 inches, and core regions that can have at least 92 percent theoretical density and further can have essentially full density, or full density. Still other embodiments relate to brazed, welded, plated and gas-tight powder metal parts and components that can be made in accordance with the various non-limiting methods disclosed herein.

Owner:KEYSTONE INVESTMENT CORP

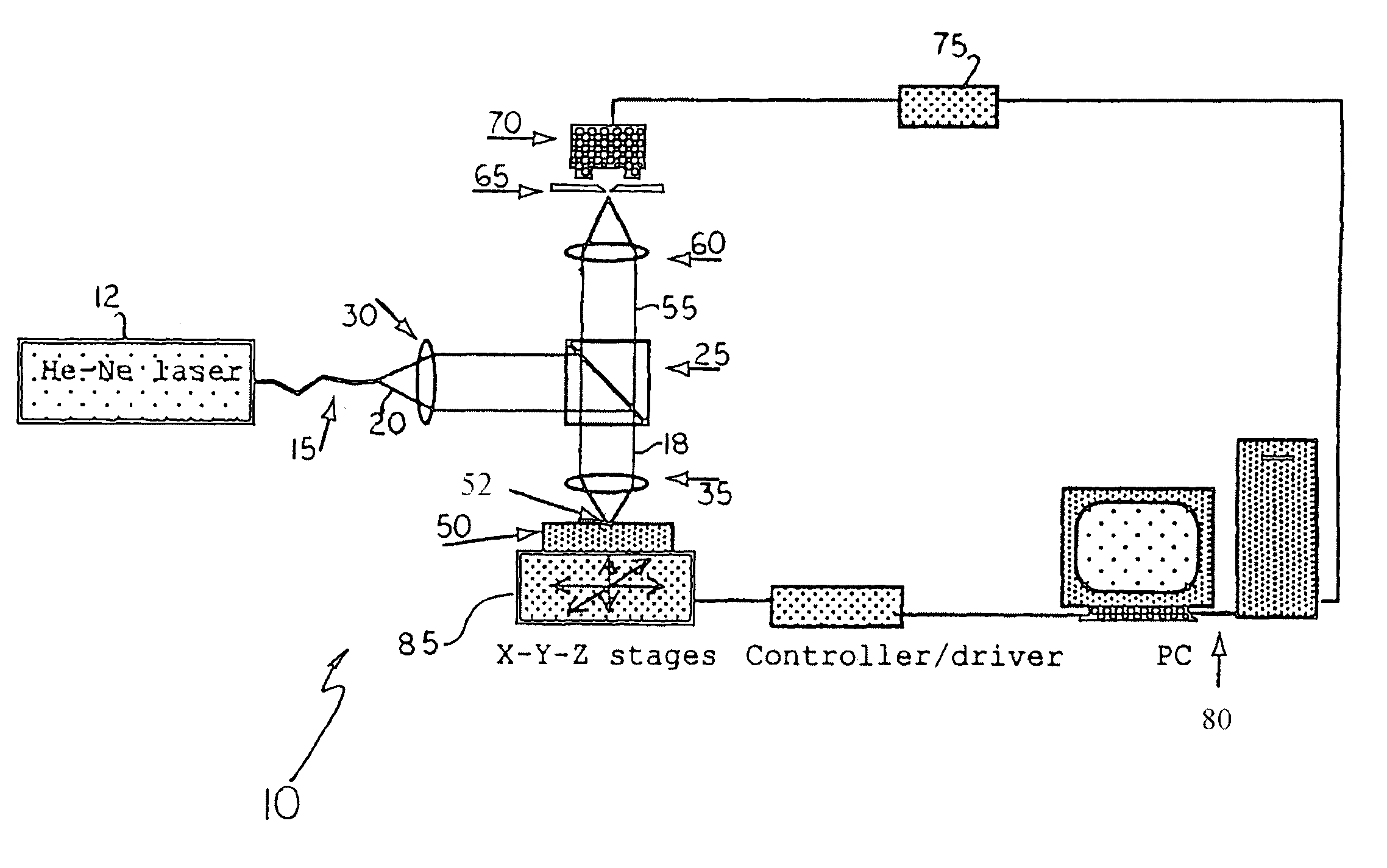

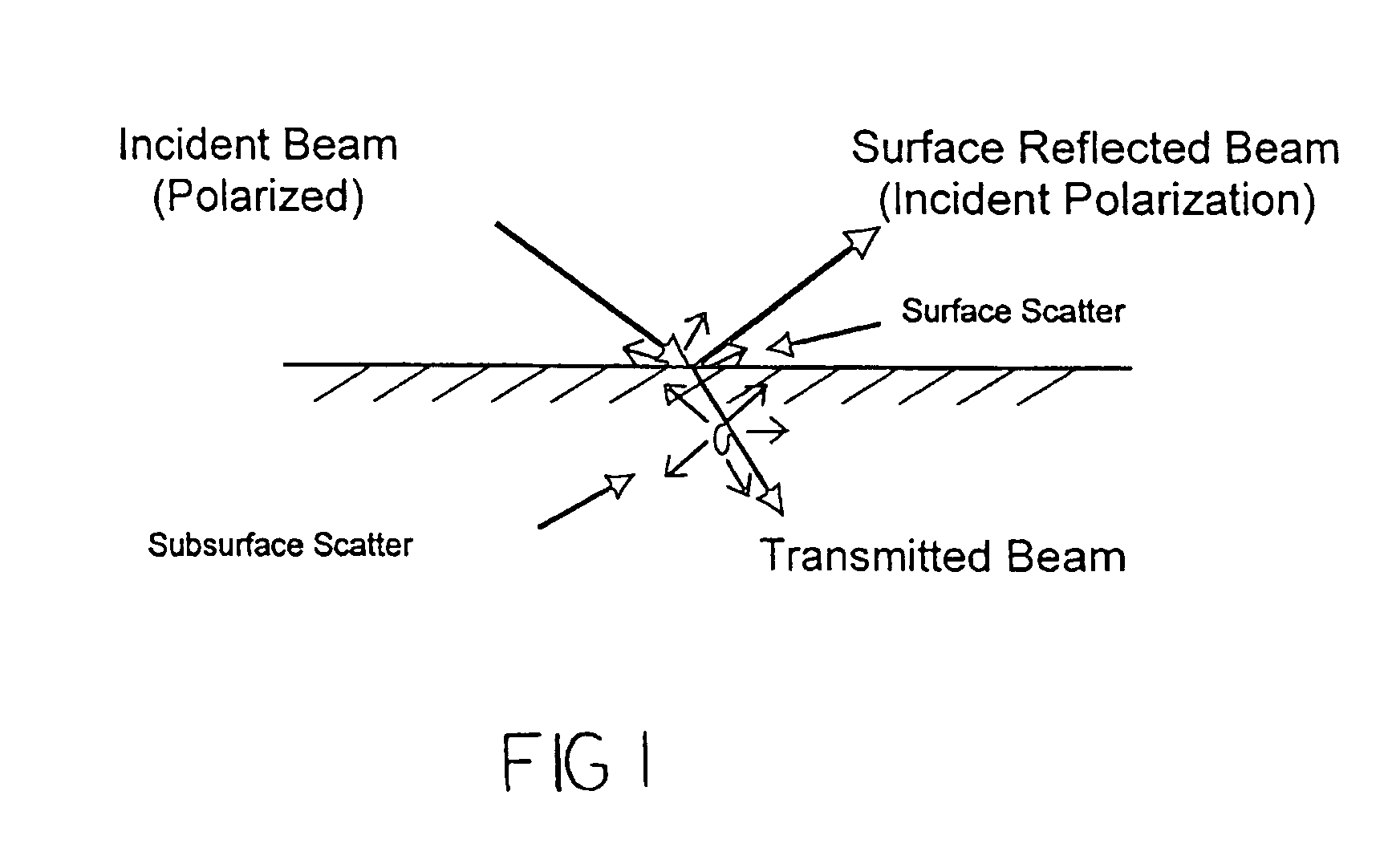

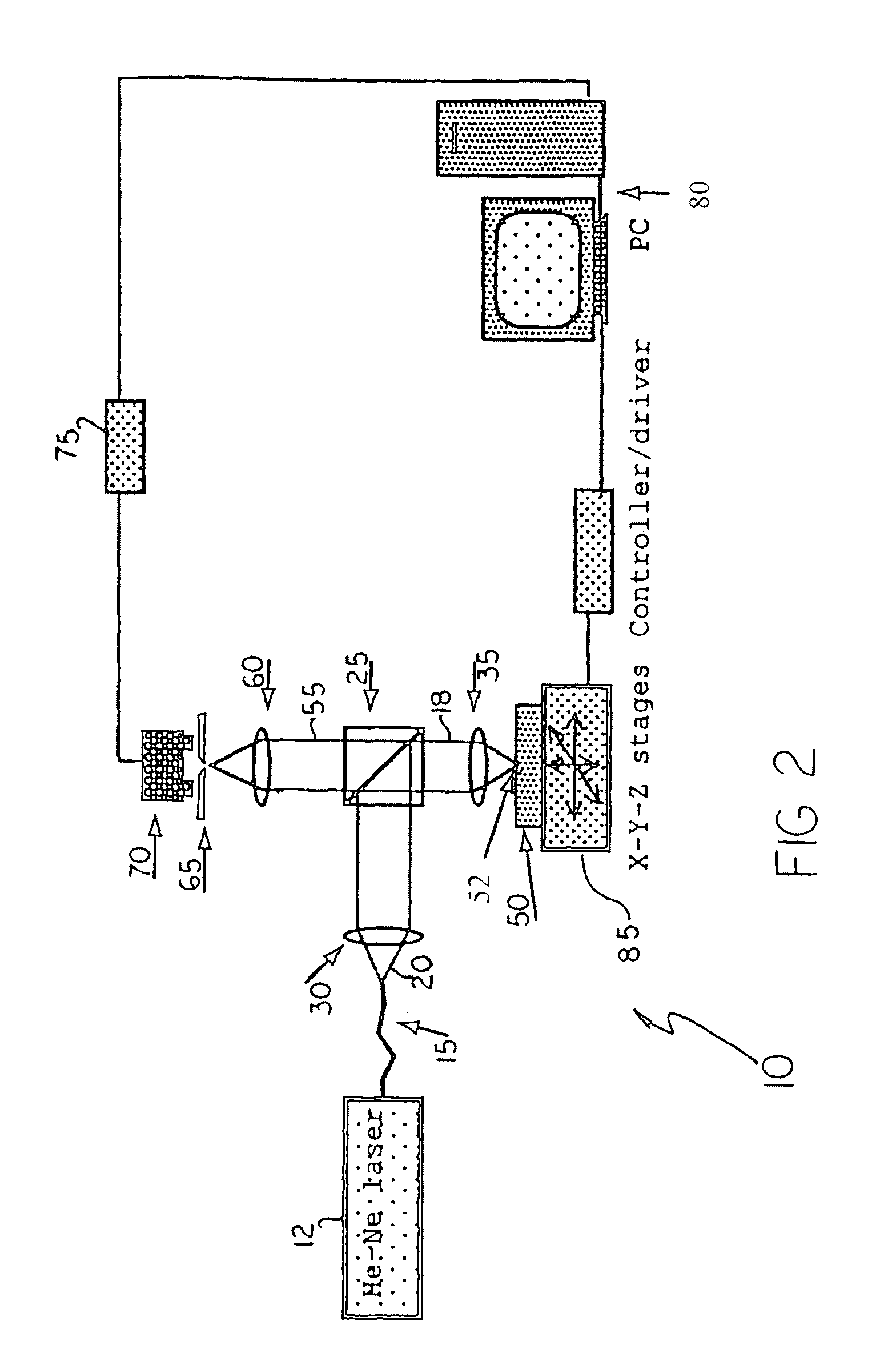

Device and nondestructive method to determine subsurface micro-structure in dense materials

InactiveUS7042556B1Optical rangefindersPolarisation-affecting propertiesNon destructiveMicro structure

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

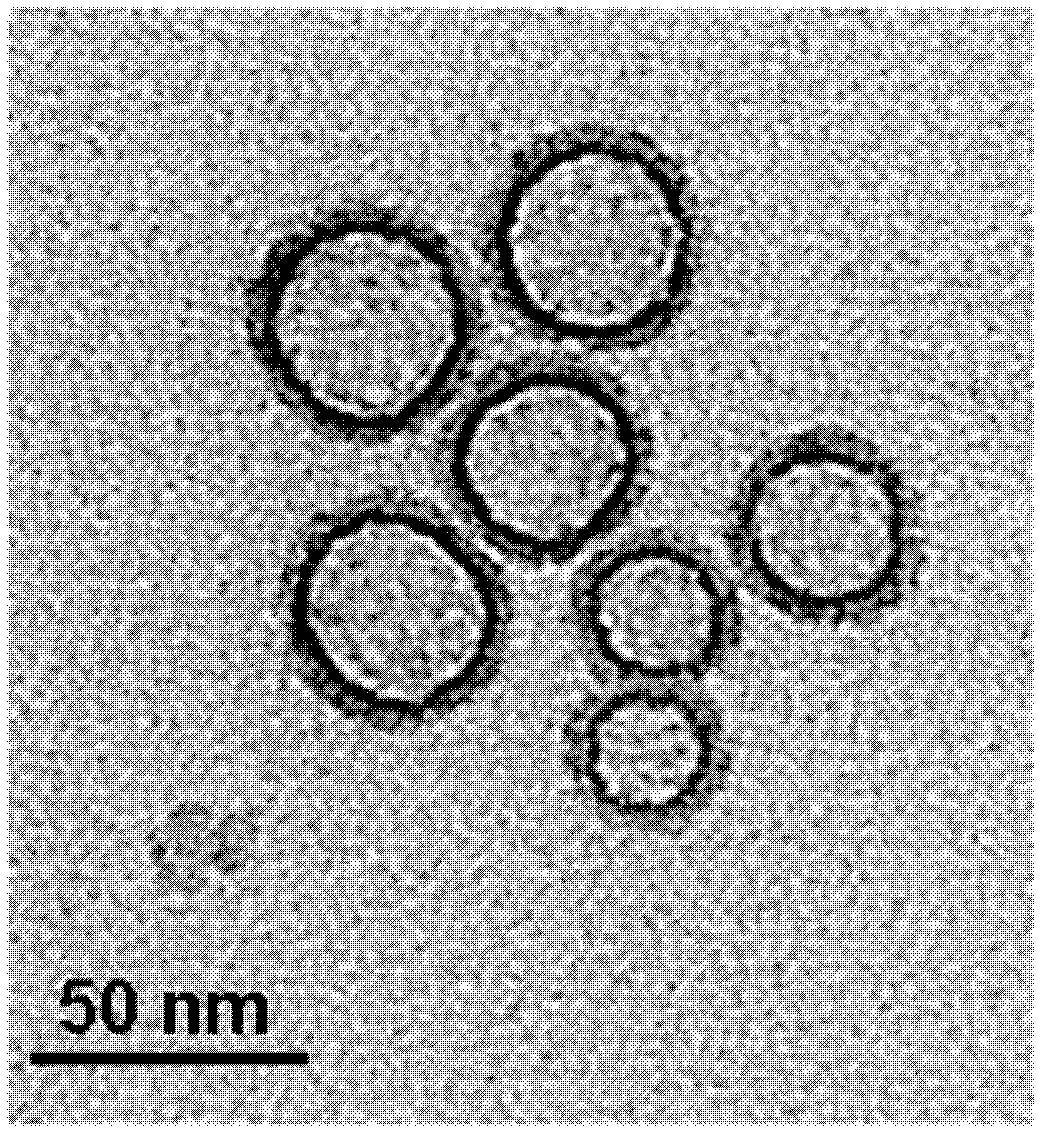

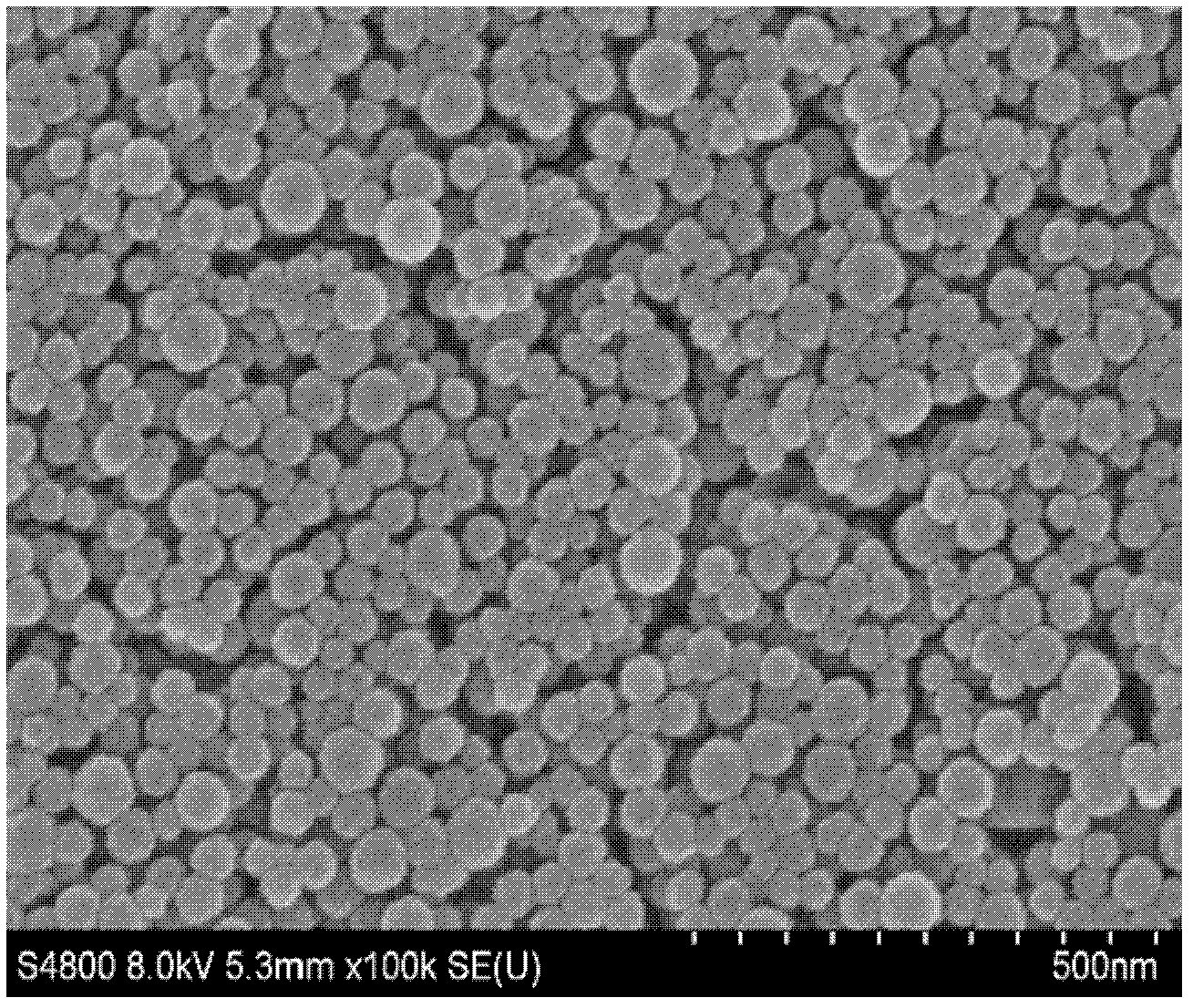

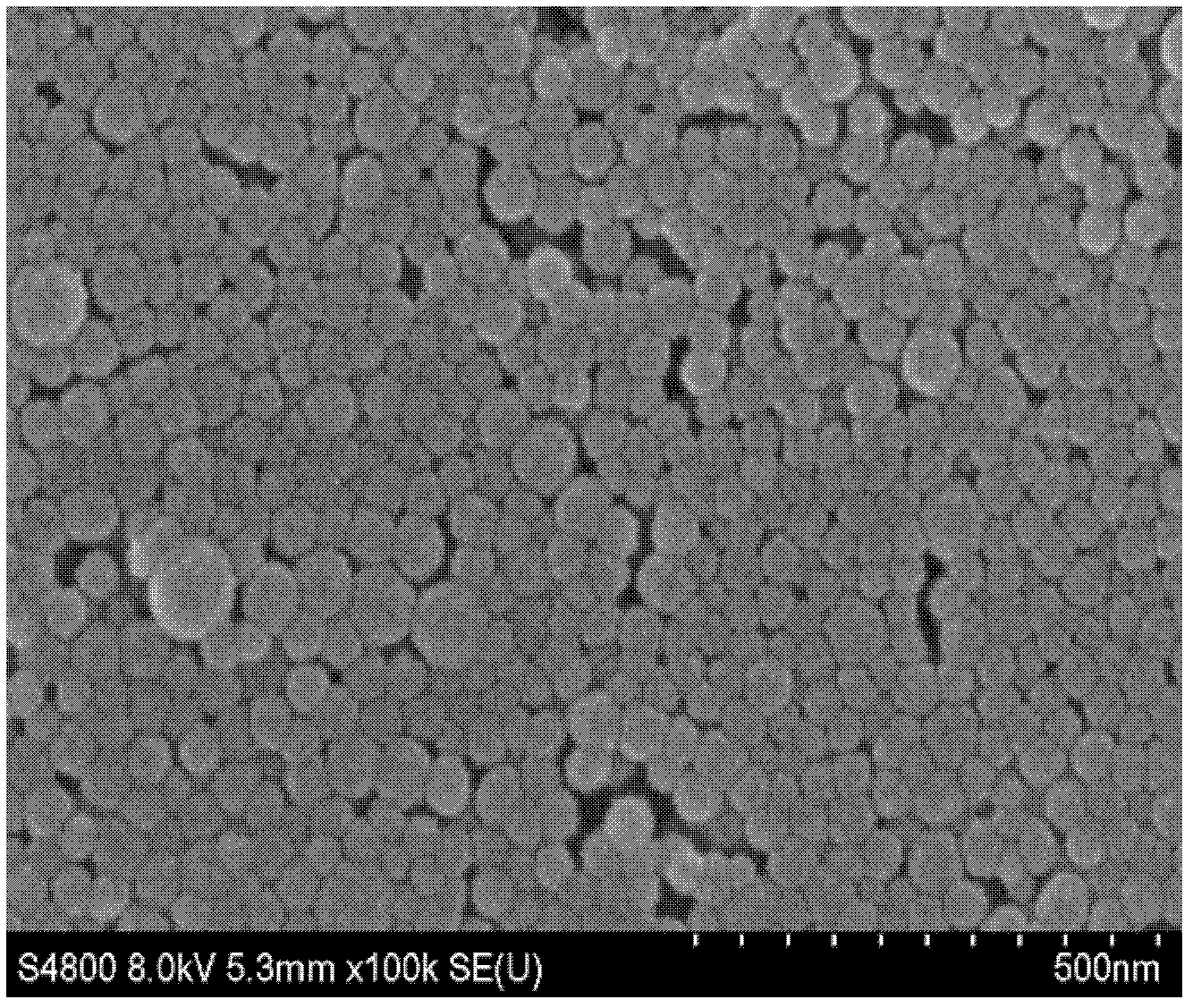

SiO2 antireflection thin film and preparation method thereof

The invention discloses a SiO2 antireflection thin film. The SiO2 antireflection thin film comprises a photovoltaic glass substrate, and a first SiO2 dense layer in the thickness of 10nm-30nm and a SiO2 nano hollow granular layer in the thickness of 50nm-300nm, which are sequentially coated on the photovoltaic glass substrate, as well as second SiO2 dense material filled in pores among SiO2 nano hollow granules in the SiO2 nano hollow granular layer; and the filling total amount of the second SiO2 dense material is equivalent to the amount of the SiO2 dense material in the first SiO2 dense layer in the thickness of 5nm-30nm. The thin film has excellent antireflection performance, resistance to wiping and durability. The invention further discloses a preparation method of the SiO2 antireflection thin film, and the preparation method comprises the following steps: preparing the first SiO2 dense layer on photovoltaic glass, further preparing the SiO2 nano hollow granular layer, filling the second SiO2 dense material and performing high-temperature treatment to obtain the SiO2 antireflection thin film. The method is simple to operate and suitable for industrial large-scale application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

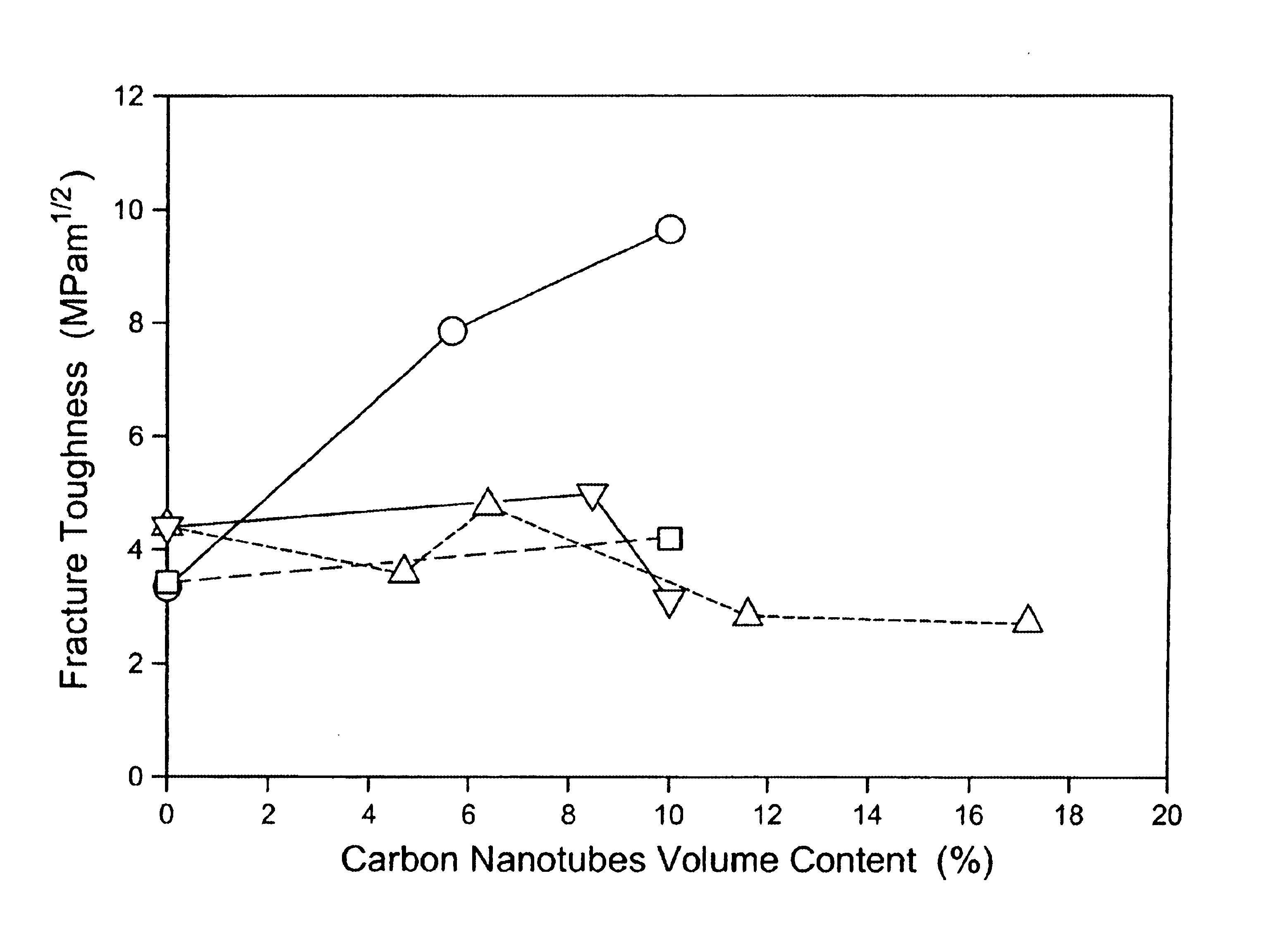

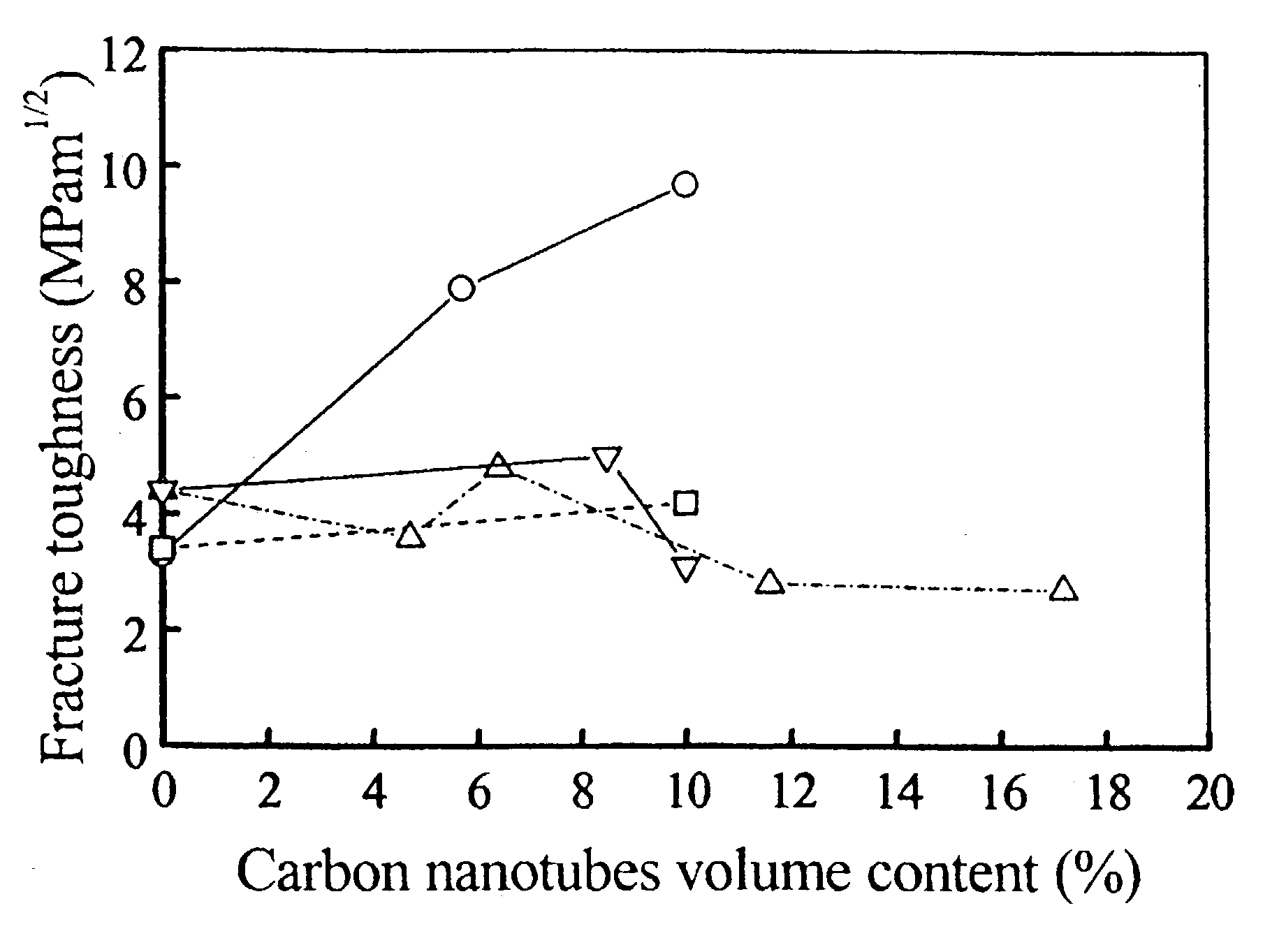

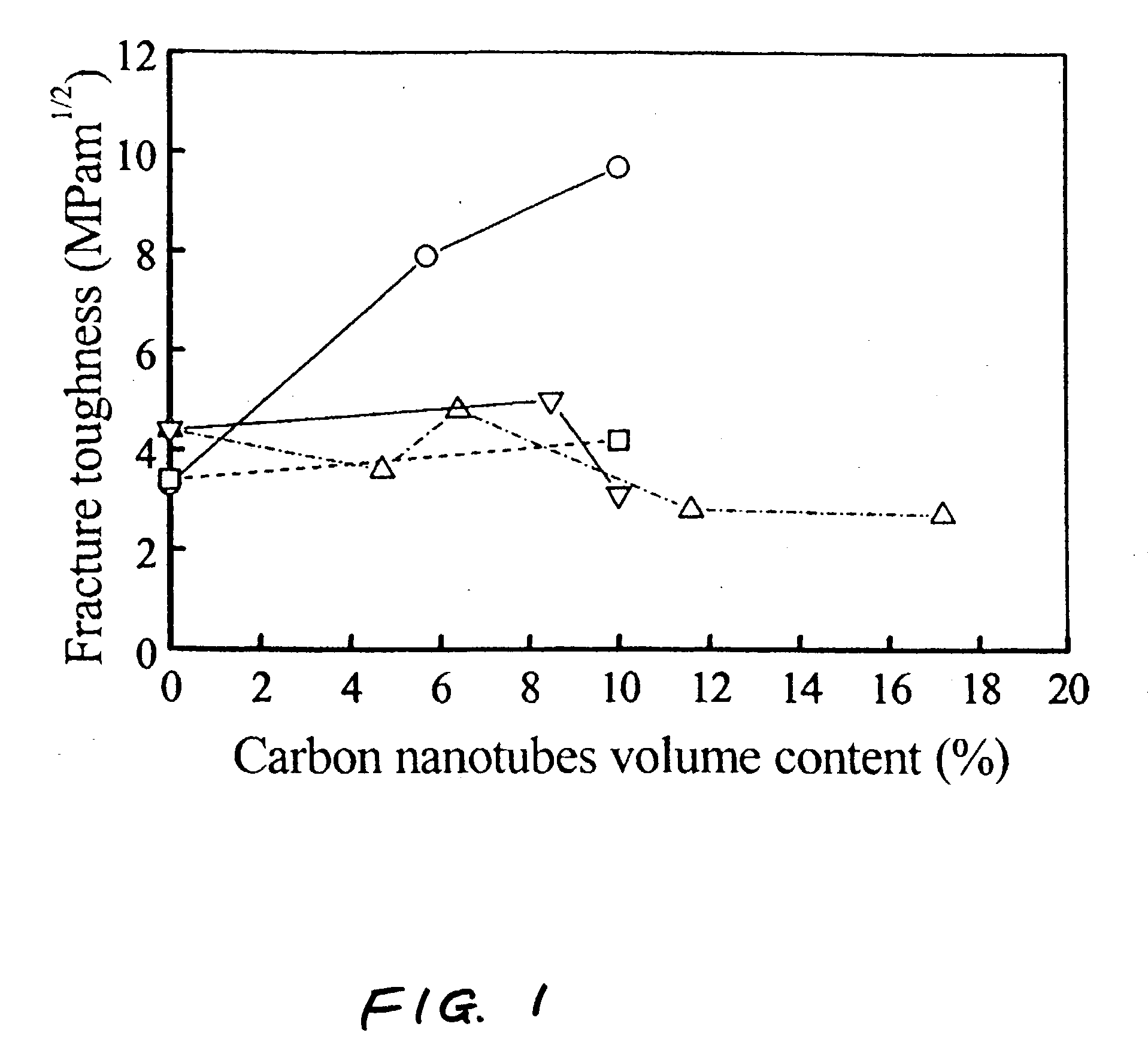

Nanocrystalline ceramic materials reinforced with single-wall carbon nanotubes

InactiveUS6858173B2Improve fracture toughnessImprove mechanical propertiesMaterial nanotechnologyTitanium dioxideHigh fractureCarbon nanotube

Composites of ceramic materials, notably alumina or metal oxides in general, with single-wall carbon nanotubes are consolidated by electric field-assisted sintering to achieve a fully dense material that has an unusually high fracture toughness compared to the ceramic alone, and also when compared to composites that contain multi-wall rather than single-wall carbon nanotubes, and when compared to composites that are sintered by methods that do not include exposure to an electric field.

Owner:RGT UNIV OF CALIFORNIA

Nanocrystalline ceramic materials reinforced with single-wall carbon nanotubes

Composites of ceramic materials, notably alumina or metal oxides in general, with single-wall carbon nanotubes are consolidated by electric field-assisted sintering to achieve a fully dense material that has an unusually high fracture toughness compared to the ceramic alone, and also when compared to composites that contain multi-wall rather than single-wall carbon nanotubes, and when compared to composites that are sintered by methods that do not include exposure to an electric field.

Owner:RGT UNIV OF CALIFORNIA

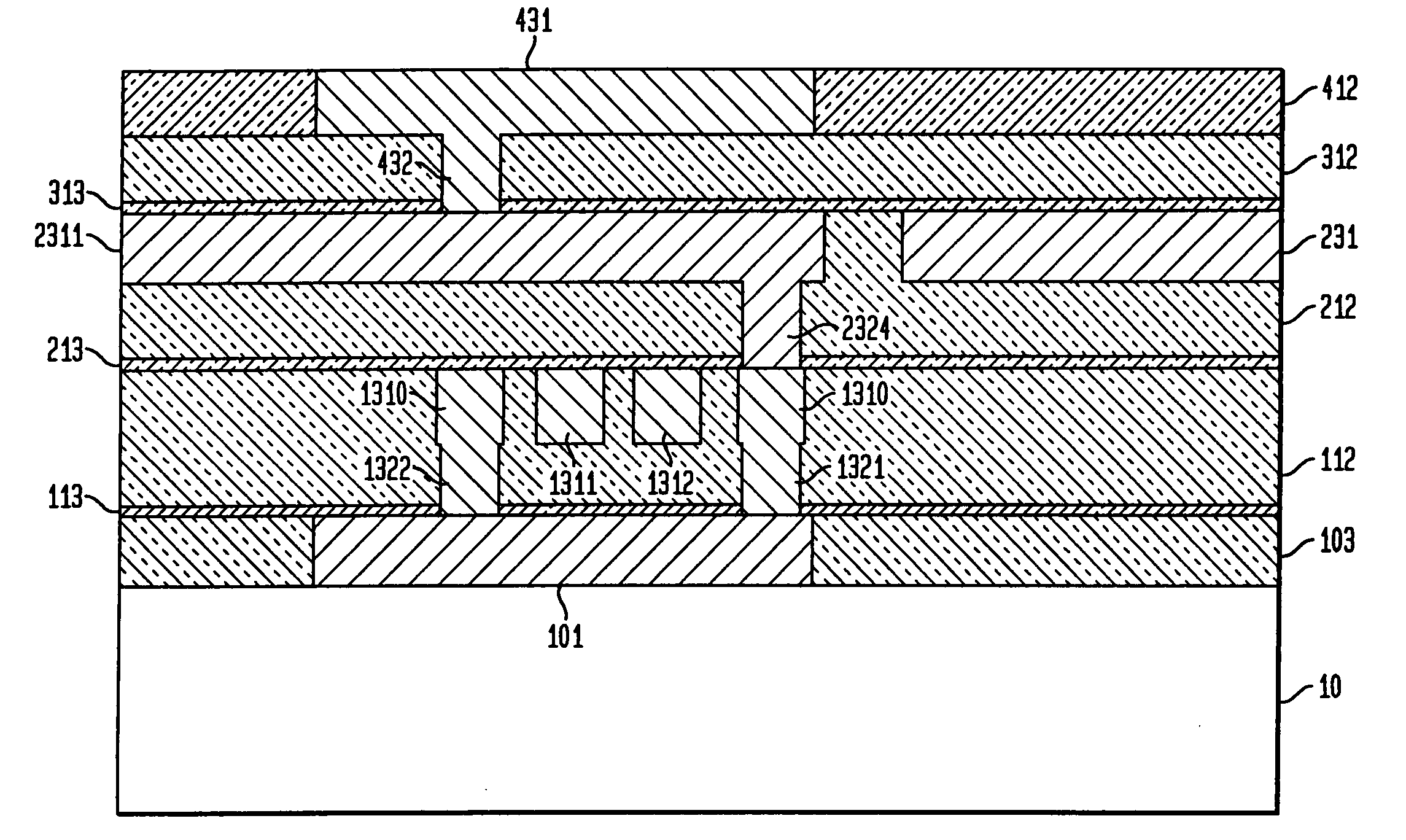

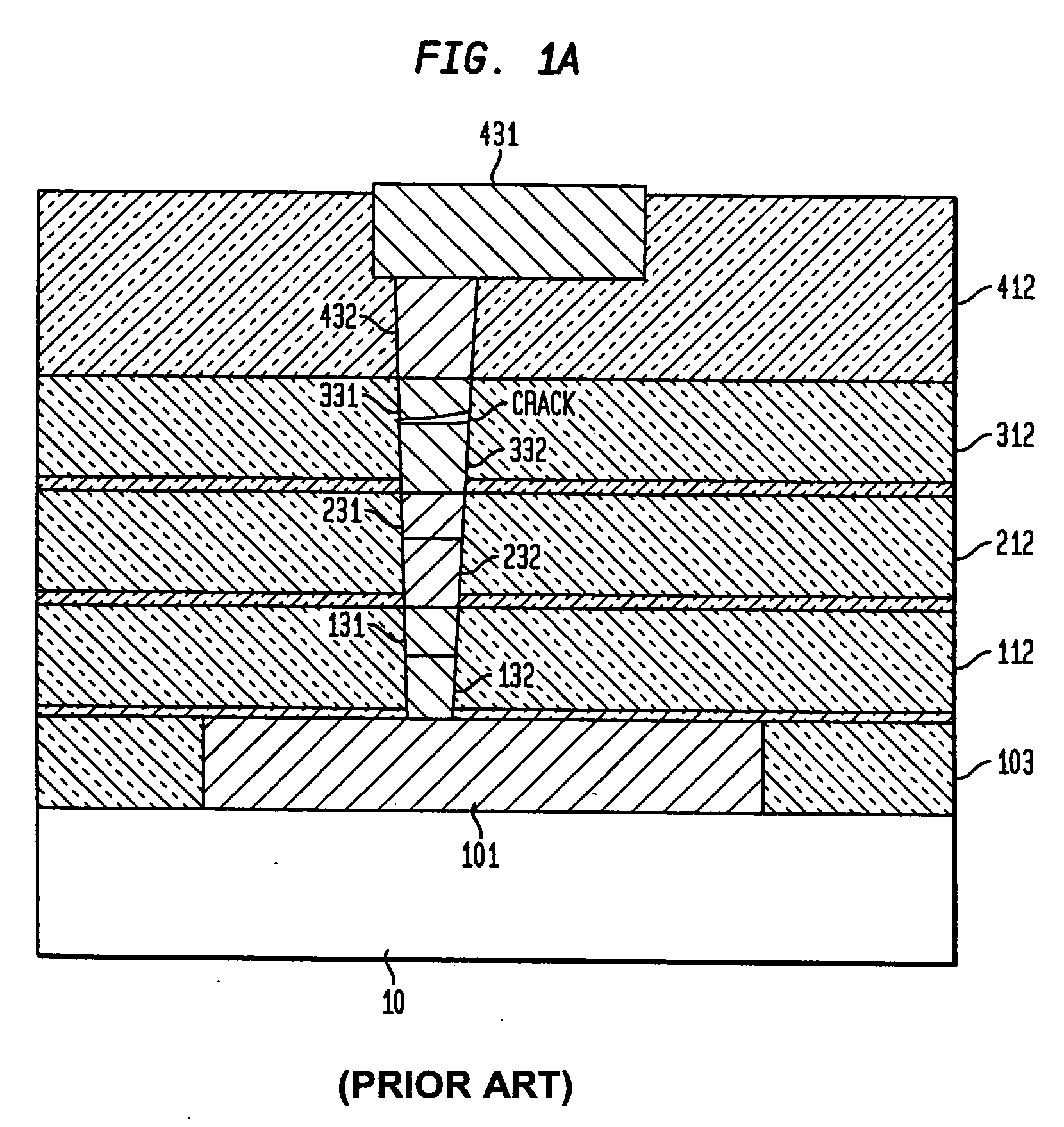

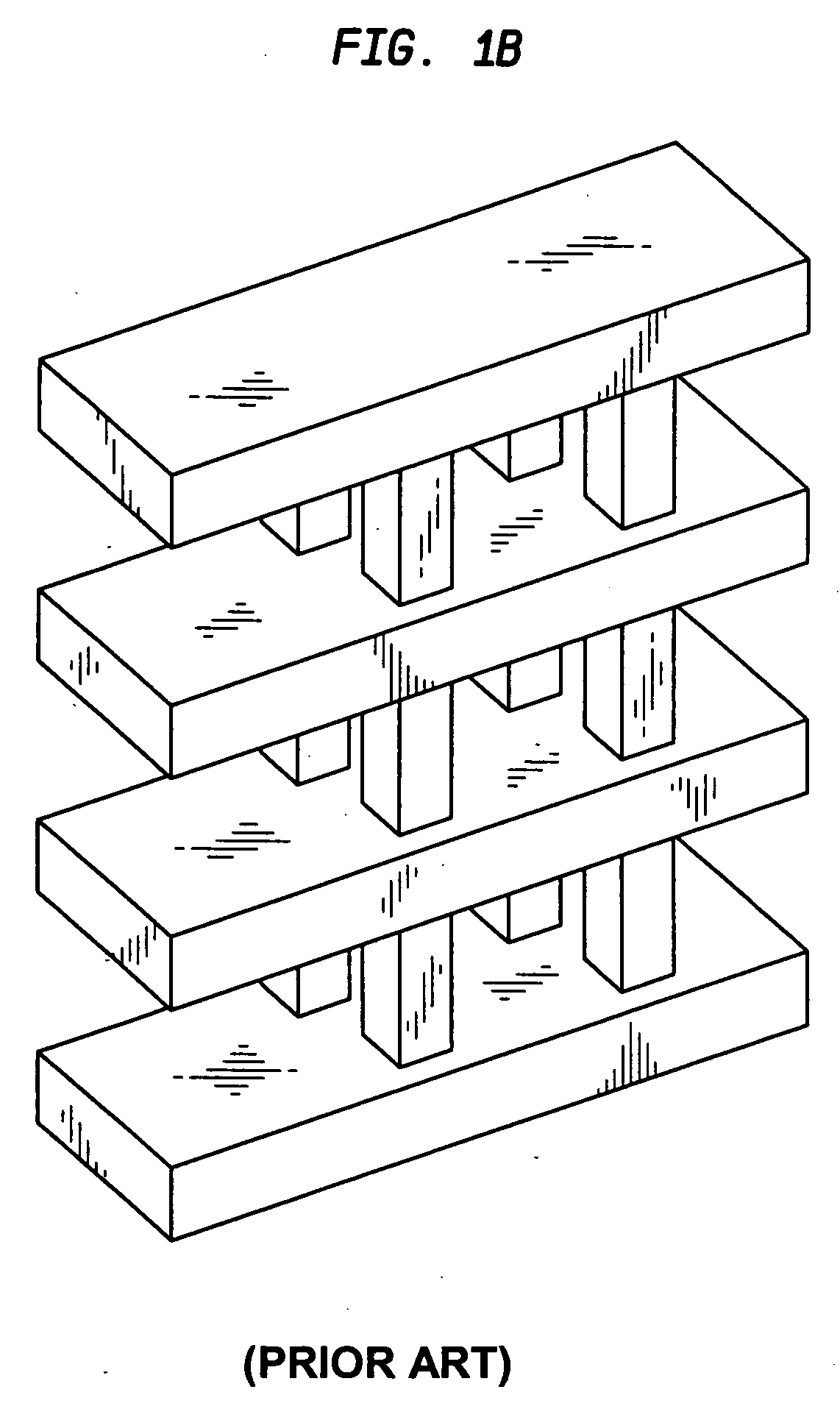

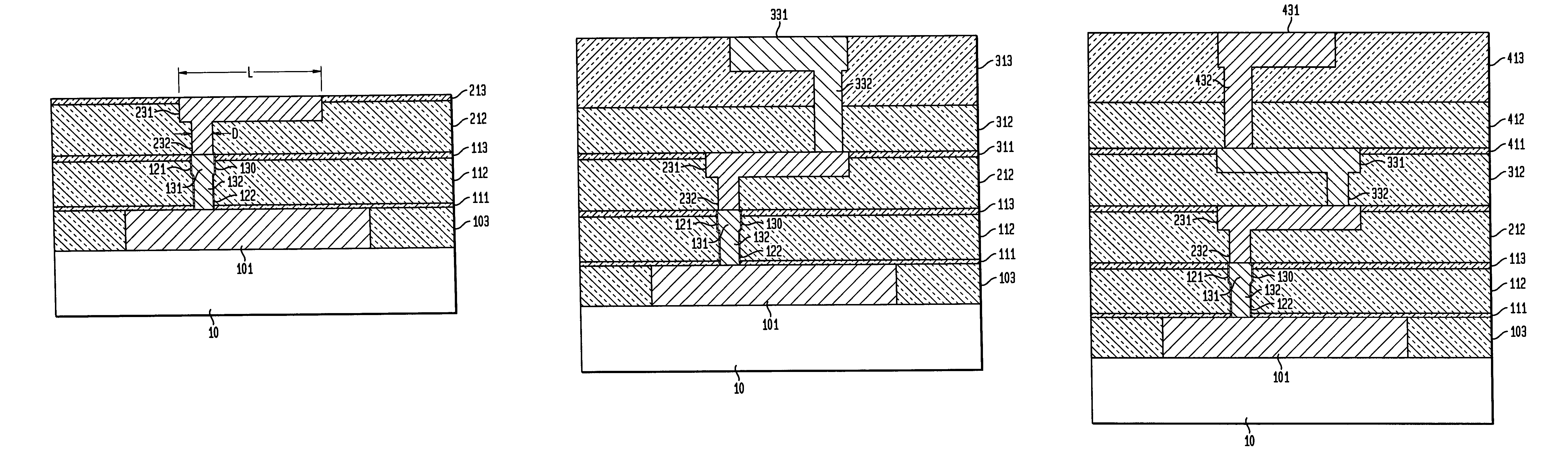

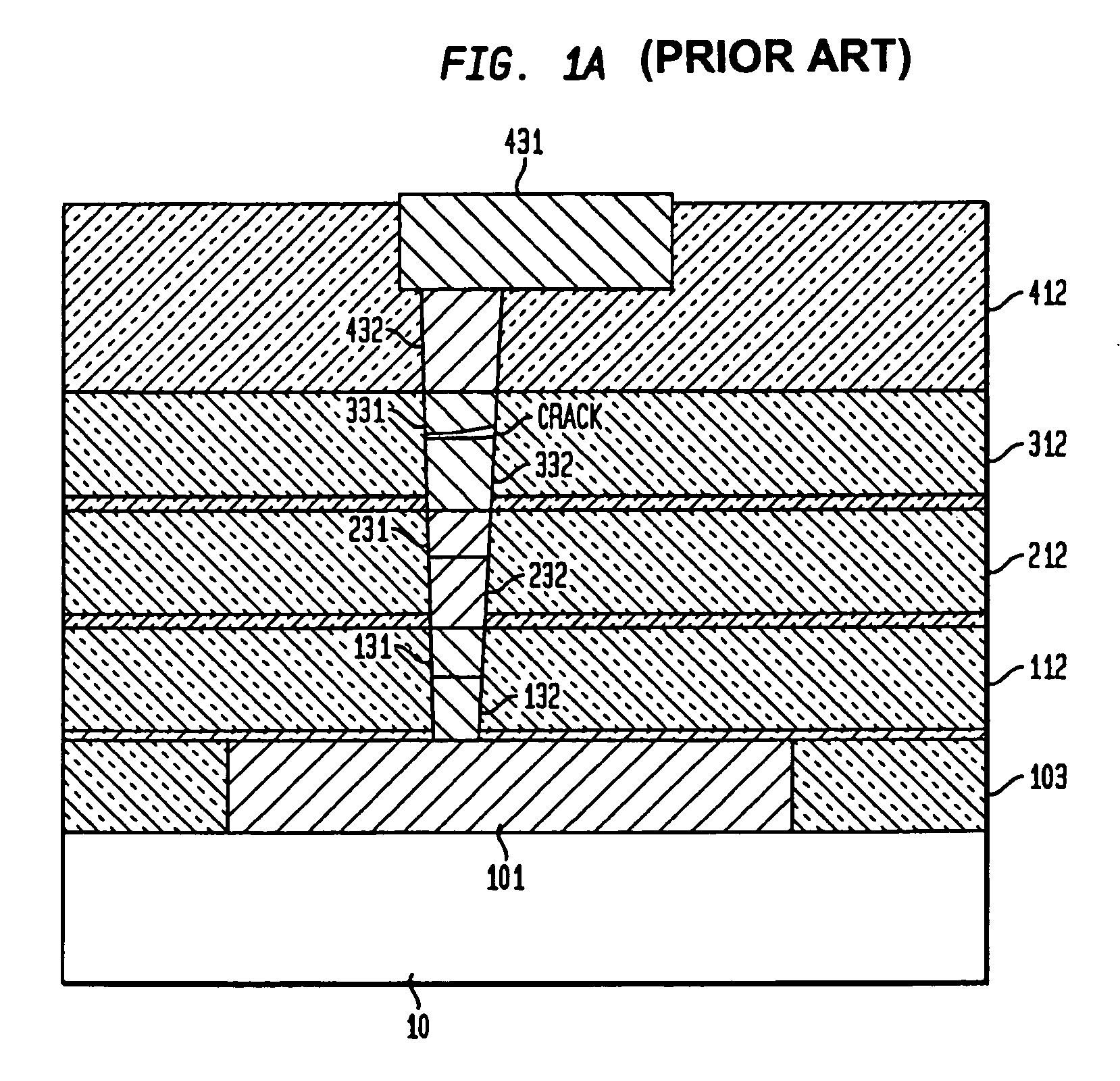

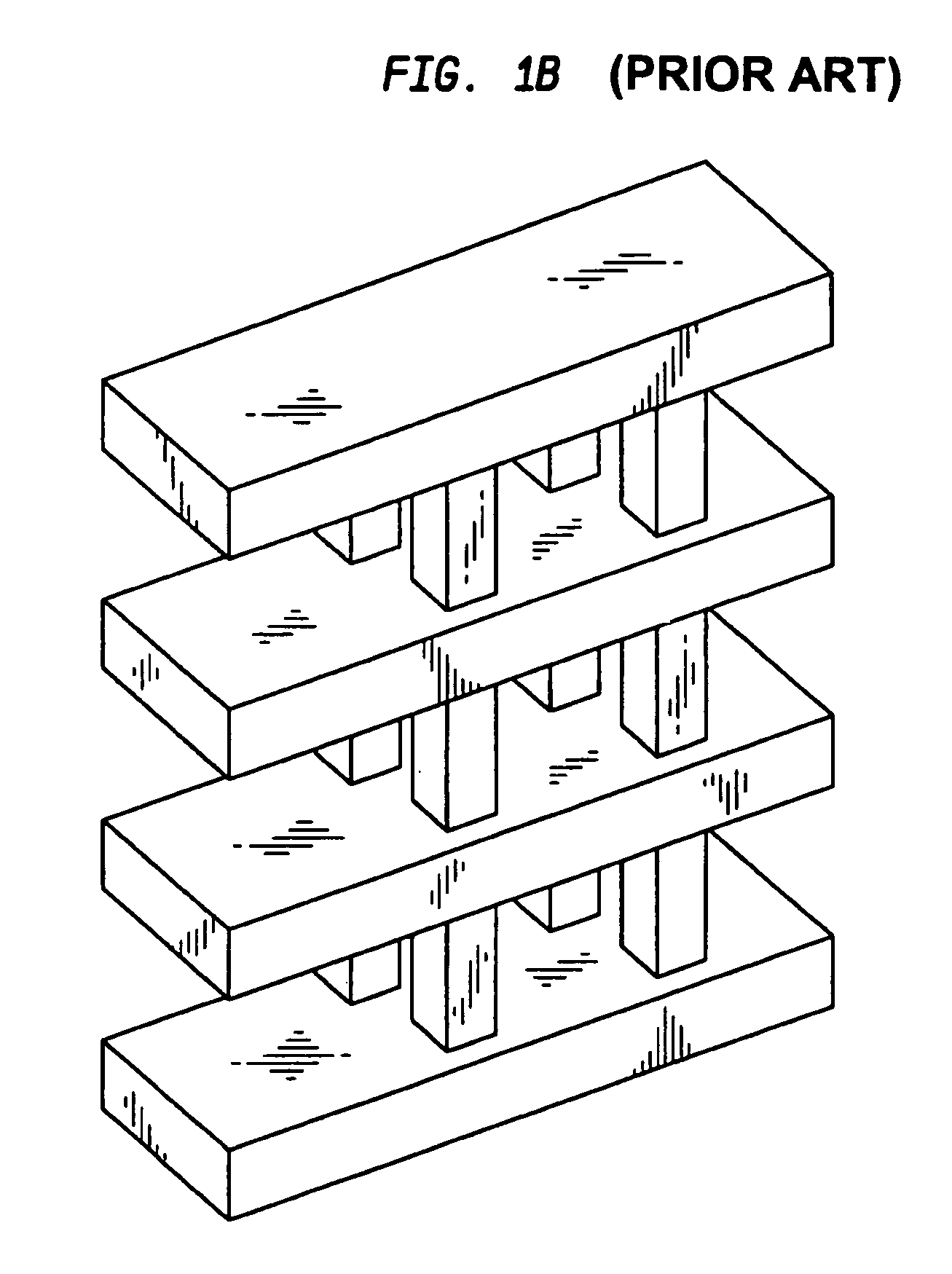

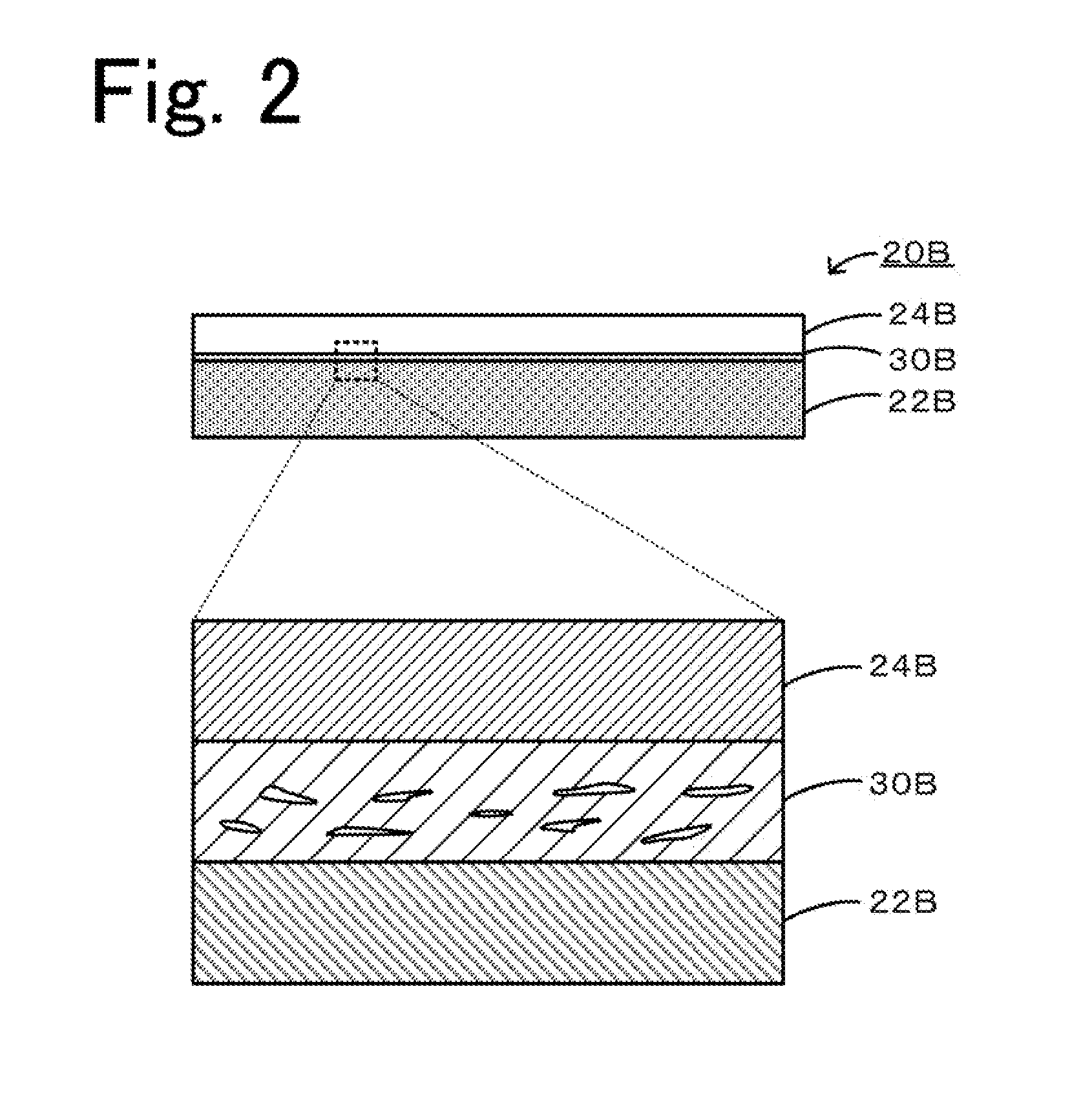

Stacked via-stud with improved reliability in copper metallurgy

InactiveUS20060014376A1Reduce intensityAllow flexibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMaterials science

A multilevel semiconductor integrated circuit (IC) structure including a first interconnect level including a layer of dielectric material over a semiconductor substrate, the layer of dielectric material comprising a dense material for passivating semiconductor devices and local interconnects underneath; multiple interconnect layers of dielectric material formed above the layer of dense dielectric material, each layer of dielectric material including at least a layer of low-k dielectric material; and, a set of stacked via-studs in the low-k dielectric material layers, each of said set of stacked via studs interconnecting one or more patterned conductive structures, a conductive structure including a cantilever formed in the low-k dielectric material. The dielectric layer of each of the multiple interconnection levels includes a soft low-k dielectric material, wherein the cantilever and set of stacked via-studs are integrated within the soft low-k dielectric material to increase resistance to thermal fatigue crack formation. In one embodiment, each of the set of stacked via-studs in the low-k dielectric material layers is provided with a cantilever, such that the cantilevers are interwoven by connecting a cantilever on one level to a bulk portion of the conductor line on adjacent levels of interconnection, thereby increasing flexibility of stacked via-studs between interconnection levels.

Owner:GLOBALFOUNDRIES INC

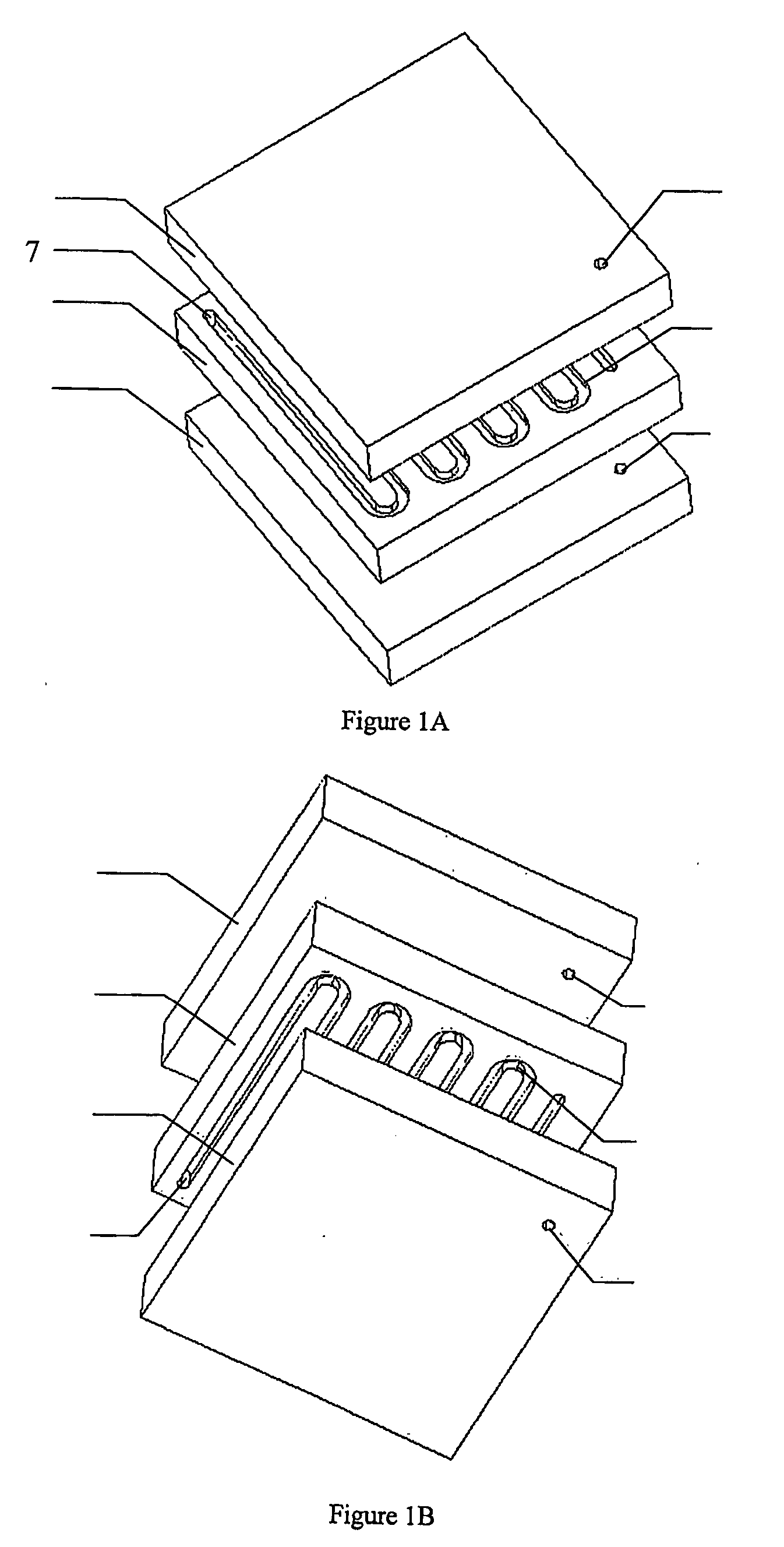

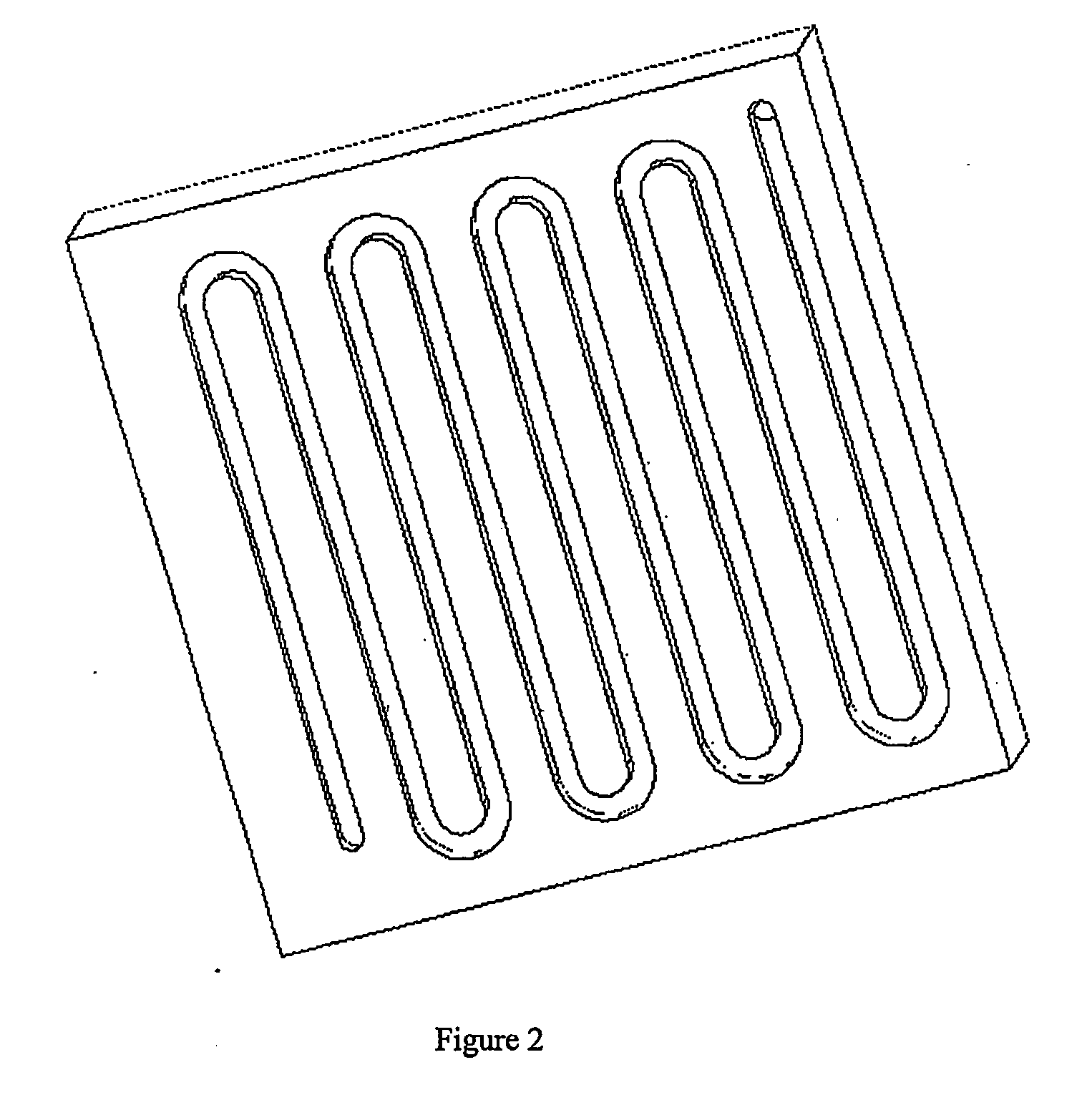

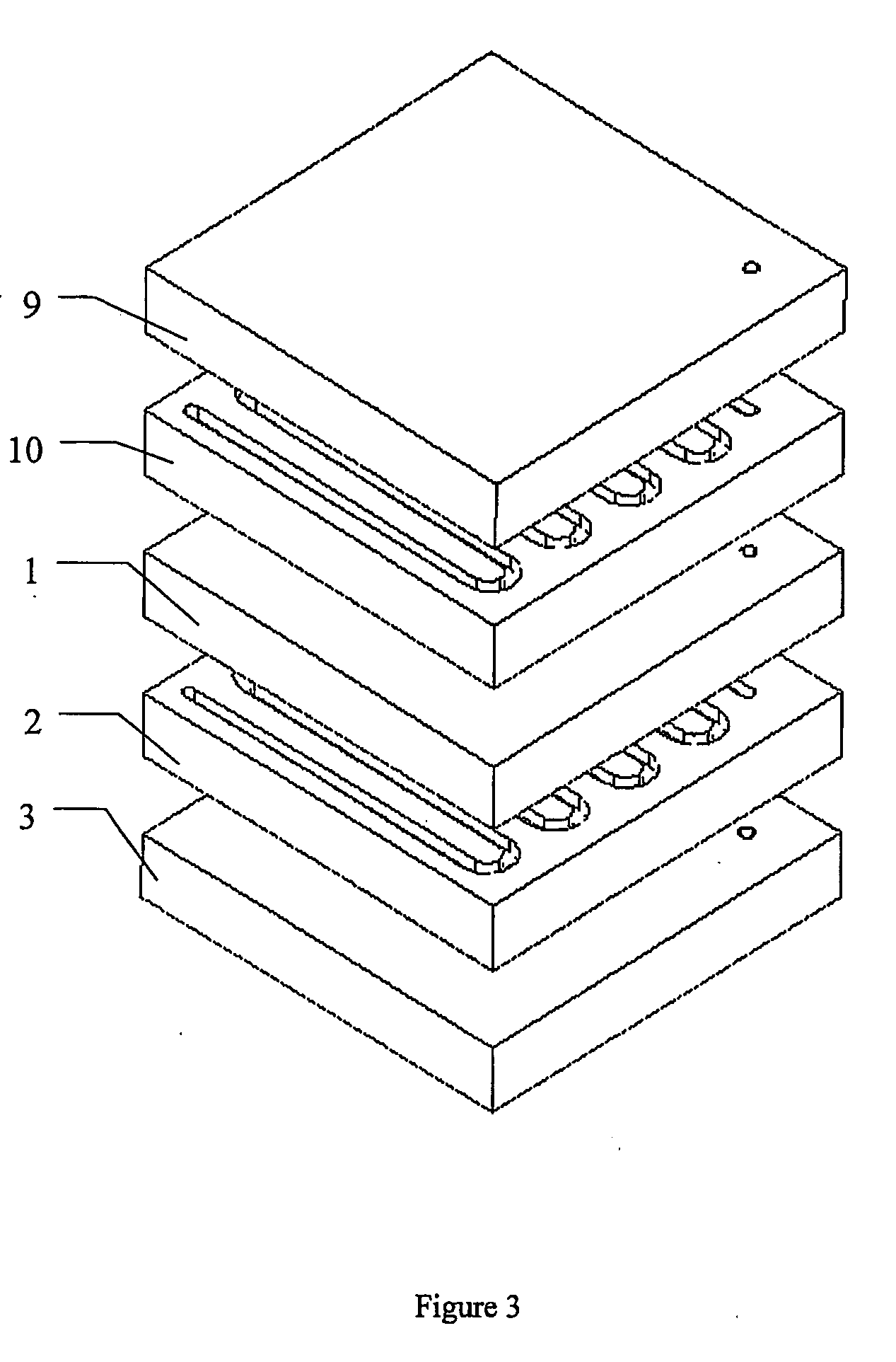

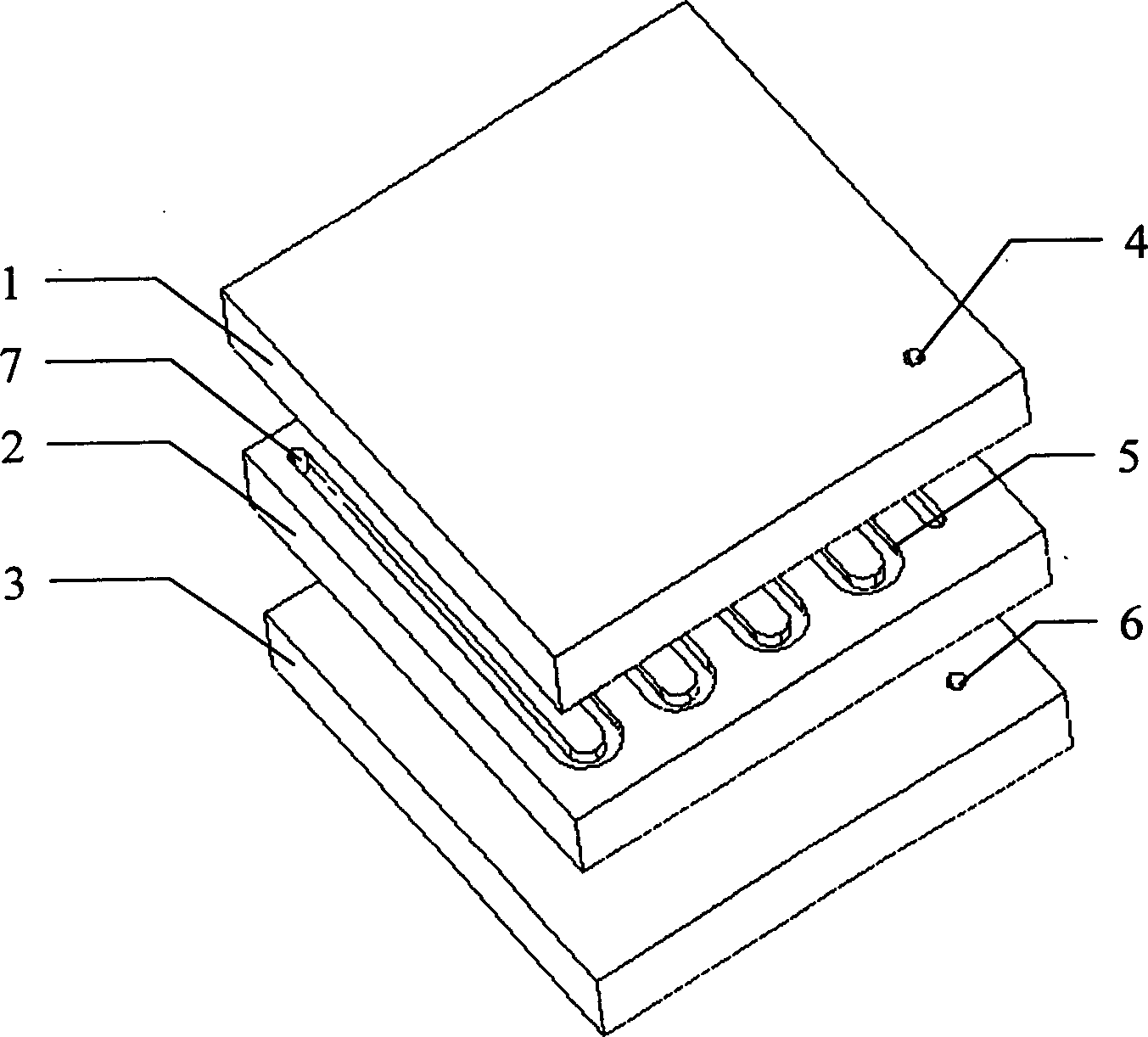

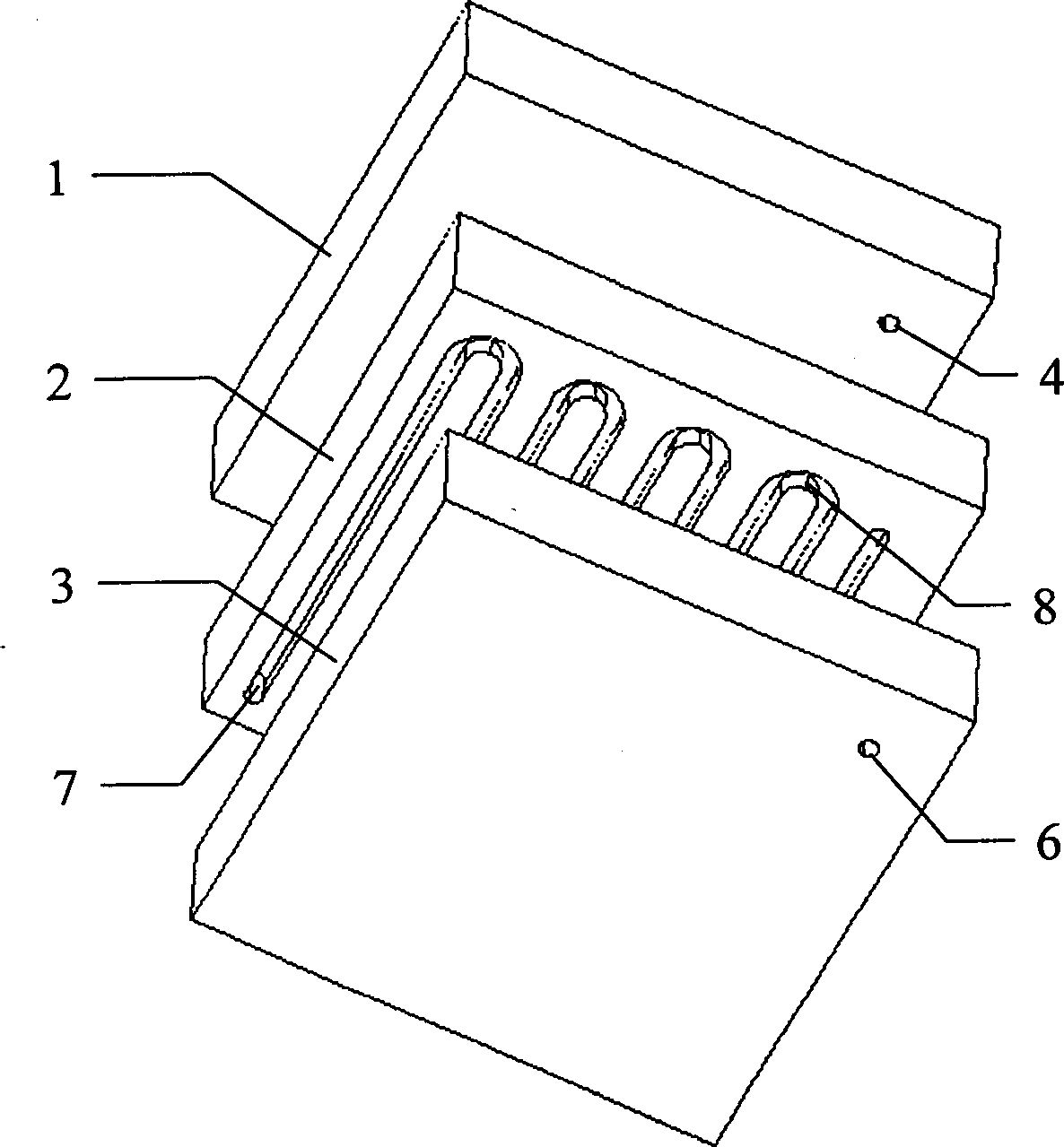

Microminiature gas chromatograph column

InactiveUS20060144237A1Compact structureEasy to numberComponent separationDispersed particle separationGas phaseMicrofabrication

This invention relates to the field of miniaturing gas chromatograph instruments using microfabrication technologies. In particular, the invention provides a gas chromatograph column, which column comprises at least two lid layers and a channel layer, wherein each of said layers comprises a compact material suitable for gas chromatograph, said channel layer comprises microfabricated channels on both sides, said microfabricated channels and a side of said lid layers form at least two capillaries, said at least two capillaries are connected to each other through a hole in said channel layer to form an integrated capillary, said integrated capillary is connected to outside atmosphere on both ends via holes on two outmost lid layers to serve as an inlet and an outlet.

Owner:CAPITALBIO CORP +1

Titanium carbonitride base metal ceramic machinery sealing material and preparation method thereof

InactiveCN101265543AImprove mechanical propertiesTaking into account high temperature resistanceTitanium carbonitrideHardness

The invention relates to an engineering material, particularly to a titanium carbonitride-base metal ceramic material for sealing pumps, valves and other machines. The titanium carbonitride-base metal ceramic material is prepared from Ti (C, N) powder, which has wide sources and low cost, as basic material, and binder, inhibitor and other additives as adjuvant materials. The preparation method comprises the steps of completely mixing the raw materials in ethanol or acetone solvent, drying, pressure moulding, placing the obtained blank into a reaction furnace, performing liquid sintering under vacuum or gaseous protection condition, and optimizing to obtain dense material with high hardness, and high bending strength and fracture toughness property. The inventive material has the advantages of resistance against high temperature, corrosion and abrasion, and low cost; and can be used for sealing pumps, valves and other machines. The preparation method has the advantages of simple process and applicability to industrial production; and has wide market application prospect.

Owner:SICHUAN UNIV

Stacked via-stud with improved reliability in copper metallurgy

InactiveUS6972209B2Facilitate redundant pathIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMaterials science

A multilevel semiconductor integrated circuit (IC) structure including a first interconnect level including a layer of dielectric material over a semiconductor substrate, the layer of dielectric material comprising a dense material for passivating semiconductor devices and local interconnects underneath; multiple interconnect layers of dielectric material formed above the layer of dense dielectric material, each layer of dielectric material including at least a layer of low-k dielectric material; and, a set of stacked via-studs in the low-k dielectric material layers, each of said set of stacked via studs interconnecting one or more patterned conductive structures, a conductive structure including a cantilever formed in the low-k dielectric material. The dielectric layer of each of the multiple interconnection levels includes a soft low-k dielectric material, wherein the cantilever and set of stacked via-studs are integrated within the soft low-k dielectric material to increase resistance to thermal fatigue crack formation. In one embodiment, each of the set of stacked via-studs in the low-k dielectric material layers is provided with a cantilever, such that the cantilevers are interwoven by connecting a cantilever on one level to a bulk portion of the conductor line on adjacent levels of interconnection, thereby increasing flexibility of stacked via-studs between interconnection levels.

Owner:GLOBALFOUNDRIES INC

Dry self-lubricating dense material; a mechanical part formed from said material; a method of manufacturing said material

InactiveUS6890368B2High strengthReduce coefficient of frictionTransportation and packagingMetal-working apparatusVolumetric Mass DensityUltimate tensile strength

The present invention provides:a material, which is dense, with a density of ≧90%, bulk dry self-lubricating, with a coefficient of friction of <0.3, constituted by a matrix that endows it with suitable strength, with a Rm of ≧400 MPa in a medium to high temperature range of 300° C.≦θ≦600° C.; said matrix including particles of solid lubricant in its volume;mechanical parts formed from said material;a method of manufacturing said material.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

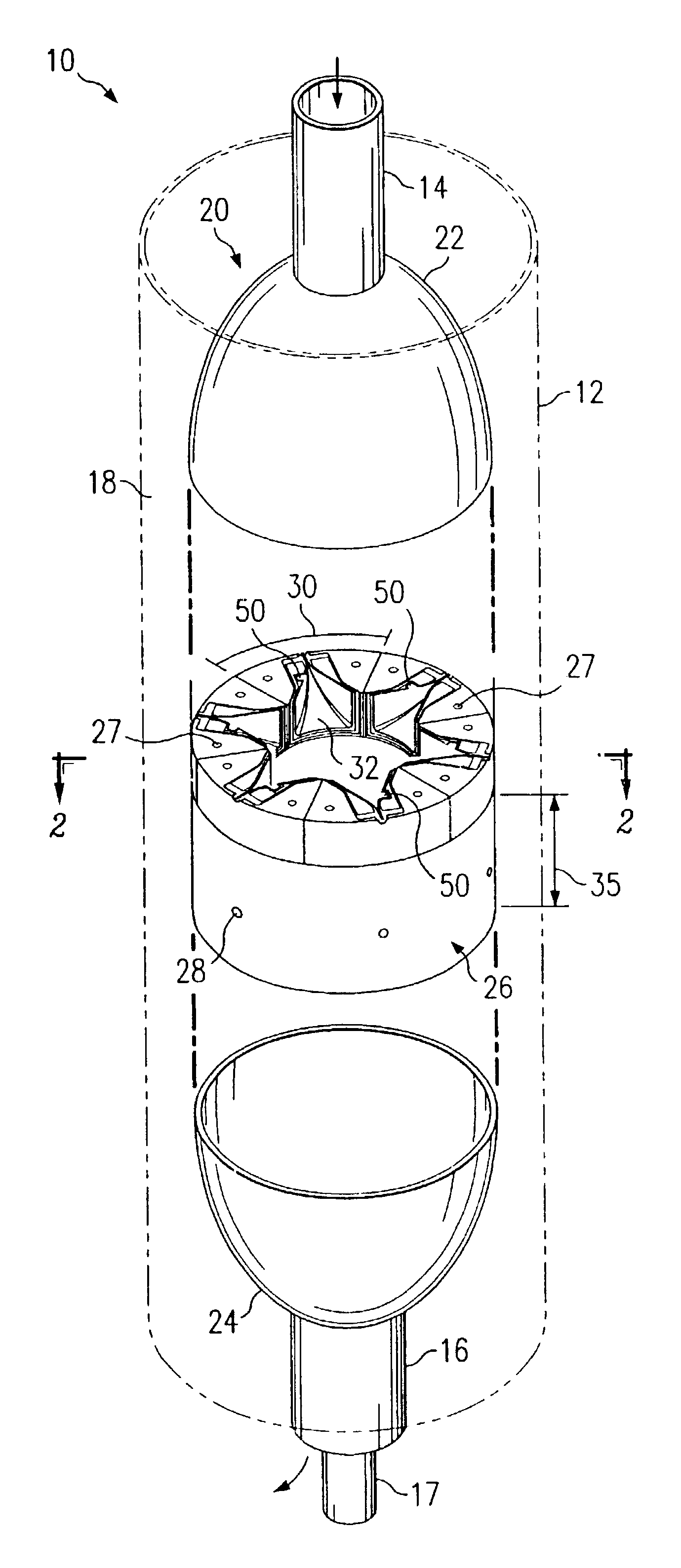

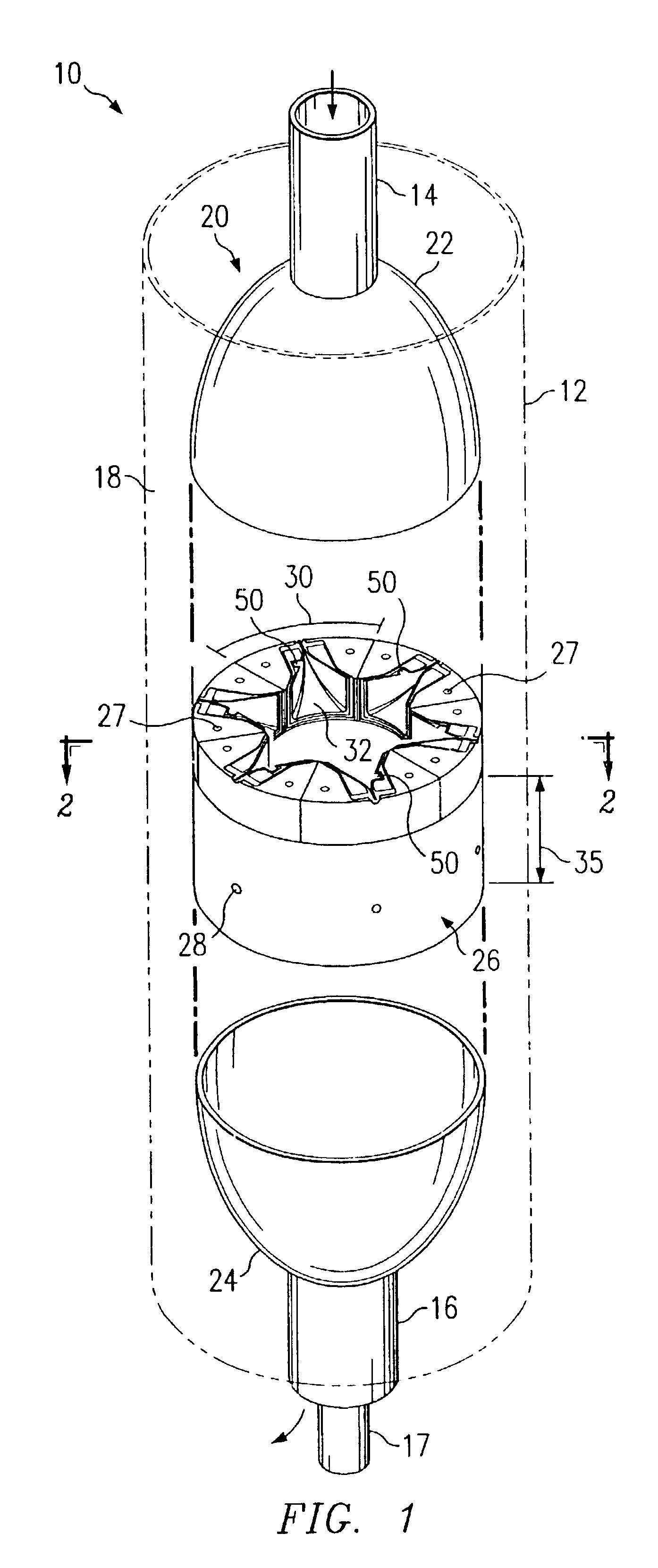

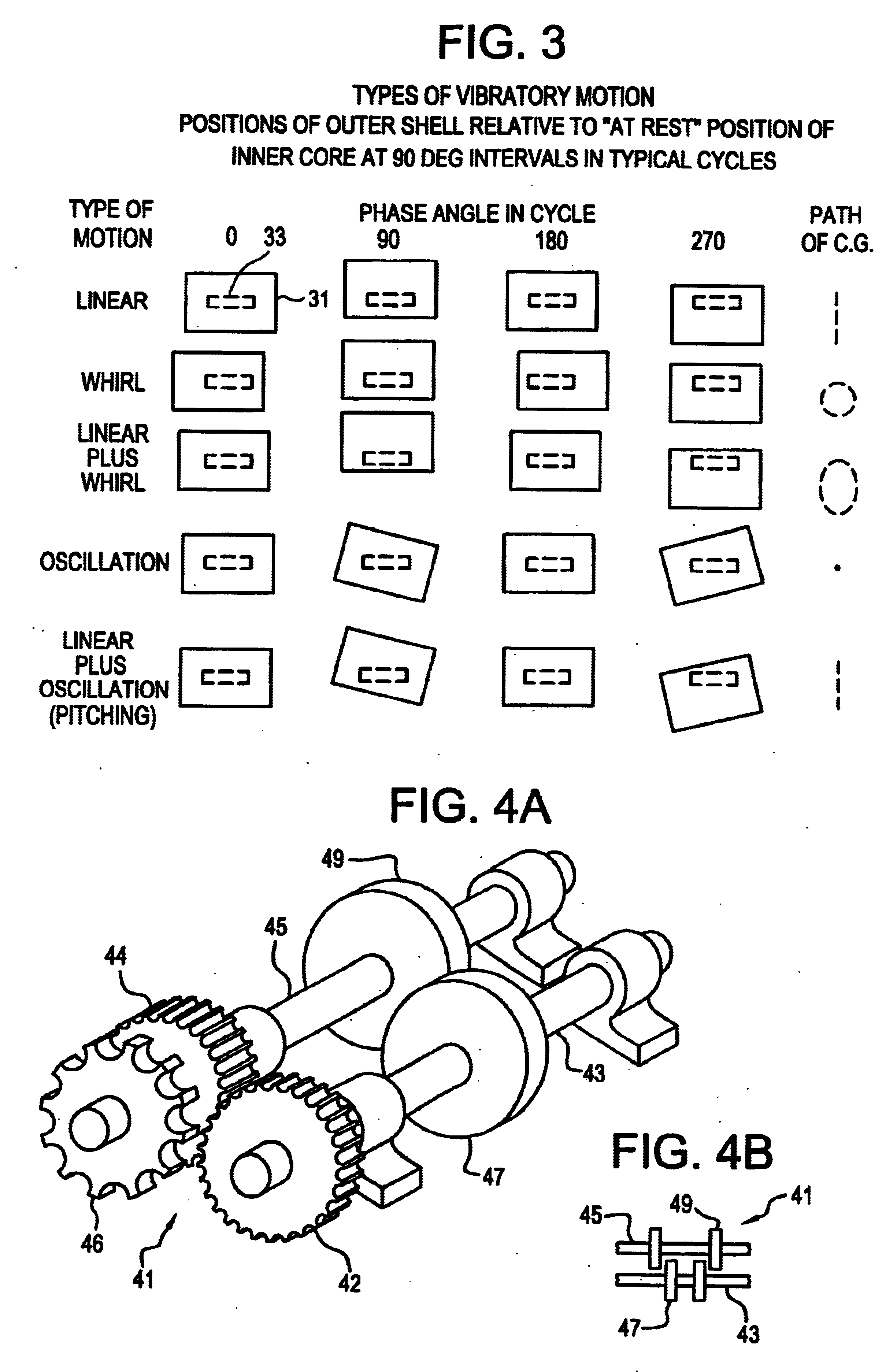

System for vibration in a centrifuge

InactiveUS6706180B2Reduce the effects of frictionReduce frictionWater/sewage treatment by centrifugal separationDispersed particle separationEngineeringVoid space

A system and method for vibration in a centrifuge is disclosed. A centrifuge for removing more dense material from a fluid medium includes a fluid separation wall placed within a non-rotating sleeve. The fluid separation wall rotates around the axis of rotation and includes an inner surface and an outer surface with at least one receptacle formed on the inner surface of the fluid separation wall. The receptacle aids in separation of more dense material from the fluid medium by forming a void space between the inner and outer surface. An excitation apparatus associated with the receptacle to create a vibration within the receptacle. A flow path may extend through the wall from the void area to the outer surface to transport more dense material to the containment zone.

Owner:PHASE

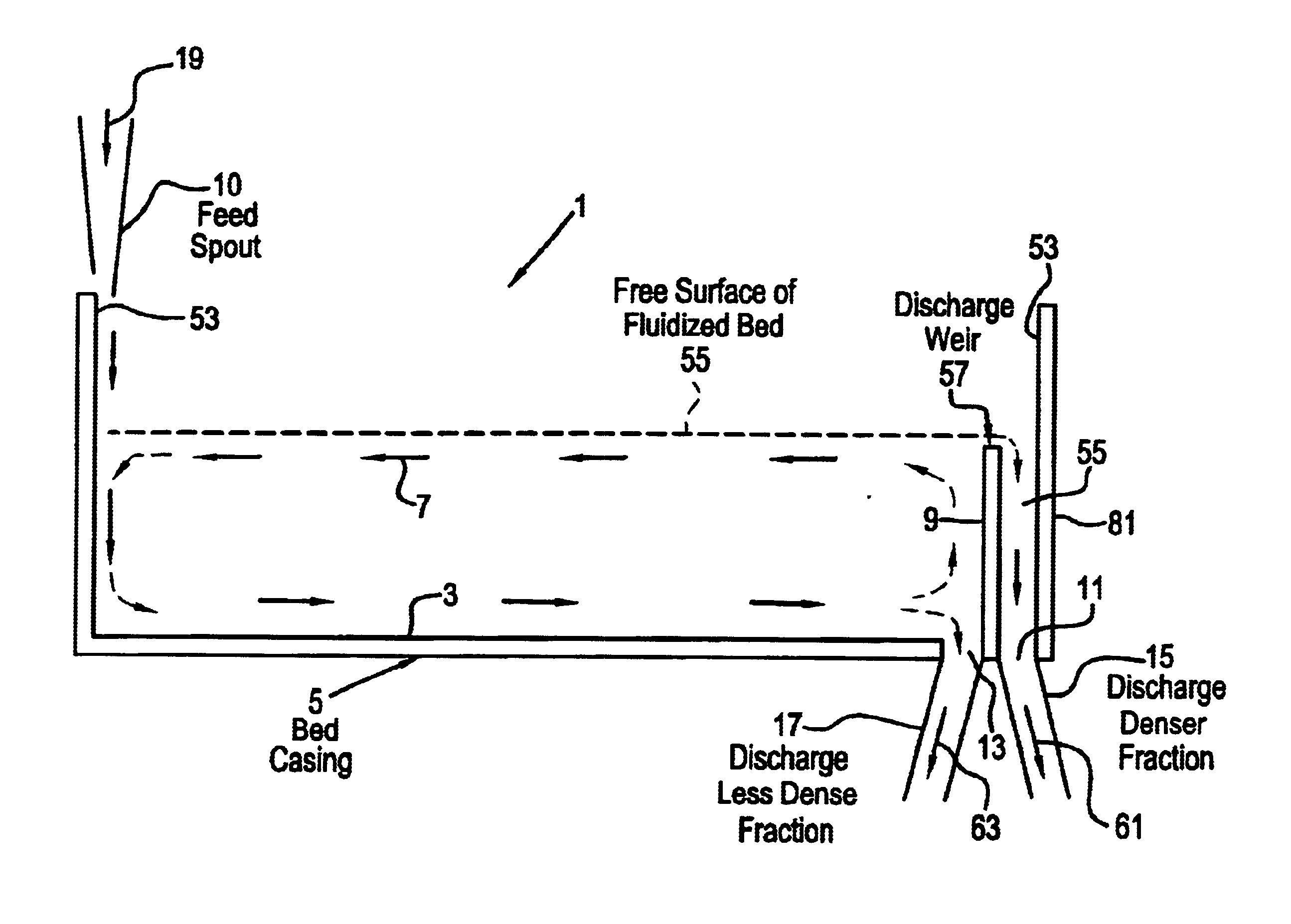

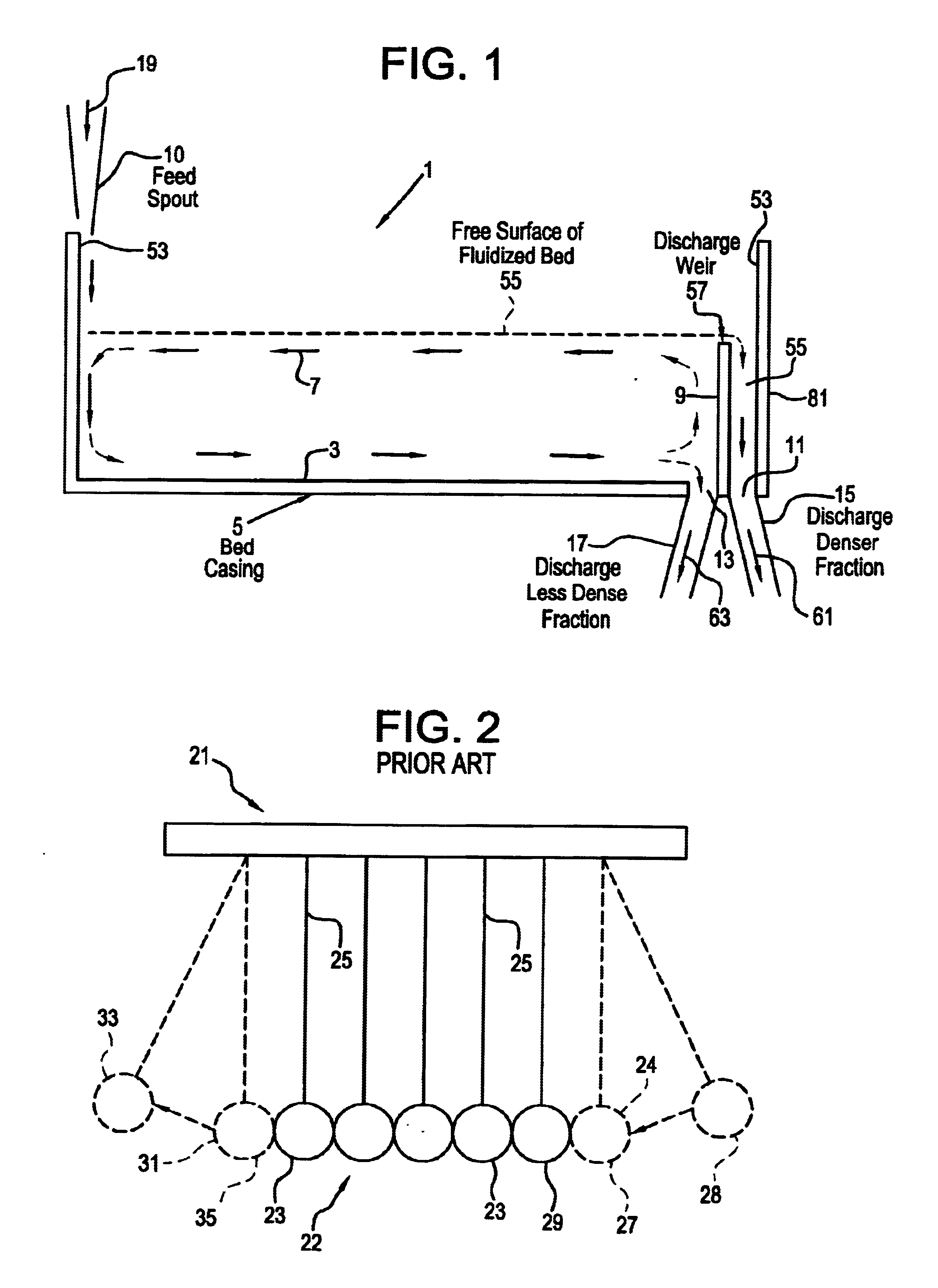

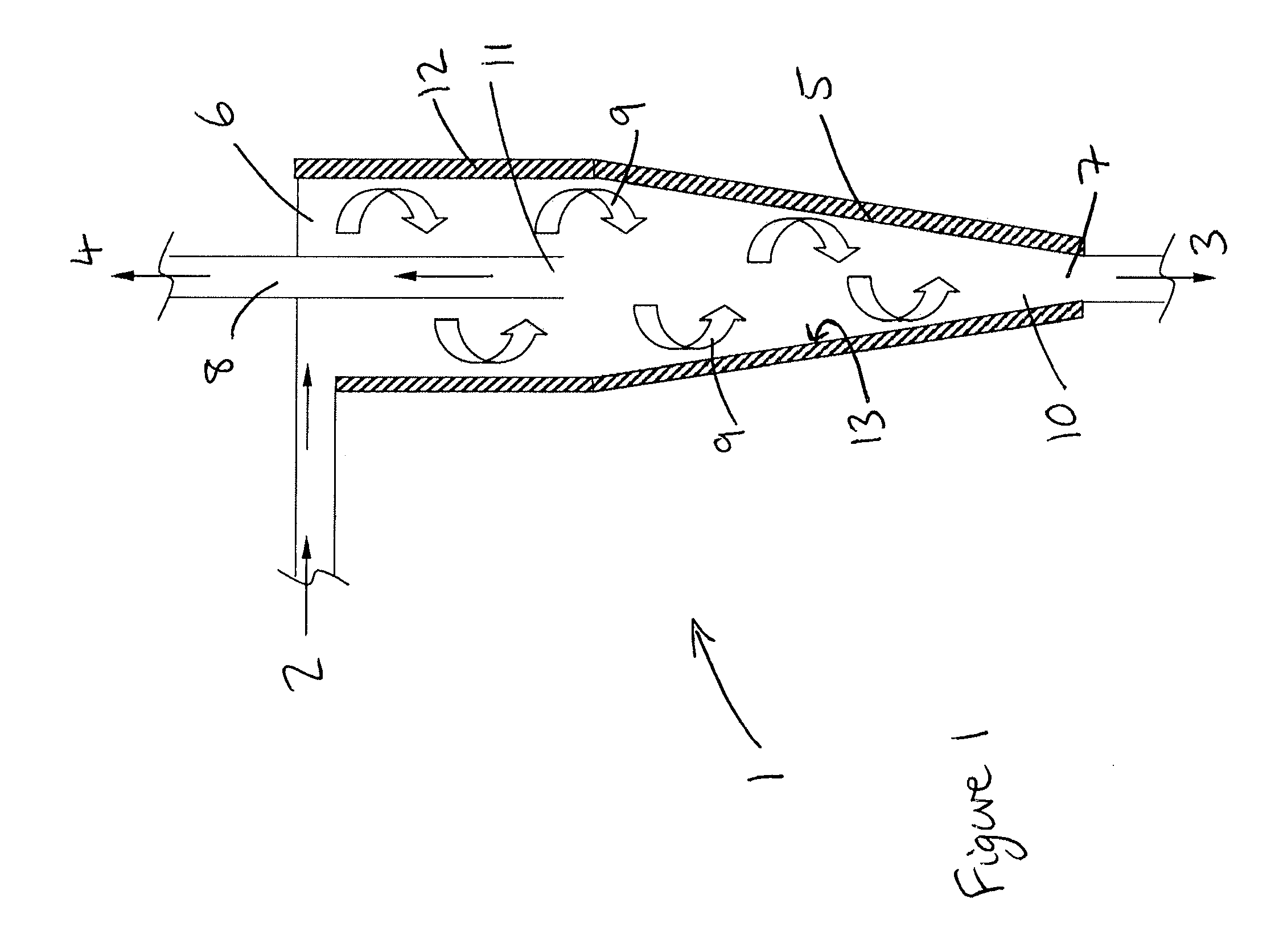

Application of complex-mode vibration-fluidized beds to the separation of granular materials of different density

InactiveUS6907996B1Reduce churnMinimizing decrepitationWet separationParticulatesVolumetric Mass Density

Opposite ends of a dry vibration-fluidized separator are moved with complex vibrations, including linear, whirl, linear plus whirl, oscillation, linear plus oscillation, pitch and roll. Near zero to large amplitudes up to about ±0.050 inches and low frequencies of about 30 Hz are used. Mixed particulate materials are fed into a first end and circulate across and along the separator in a shallow depth. More dense materials move linearly along a floor and are removed through an opening in a second end of the floor. The less dense materials flow over a weir at the second end of the separator.

Owner:MACLEAN MATTHEW J

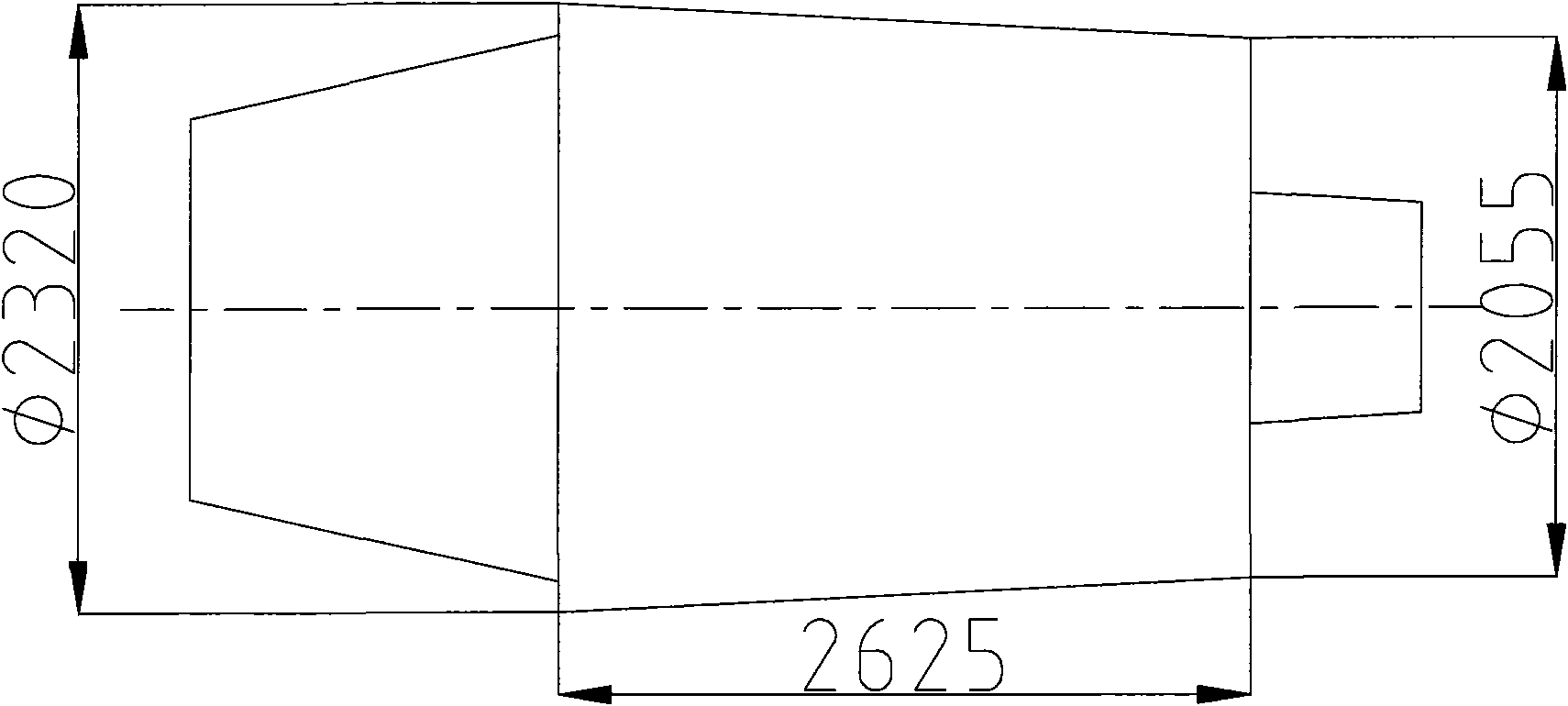

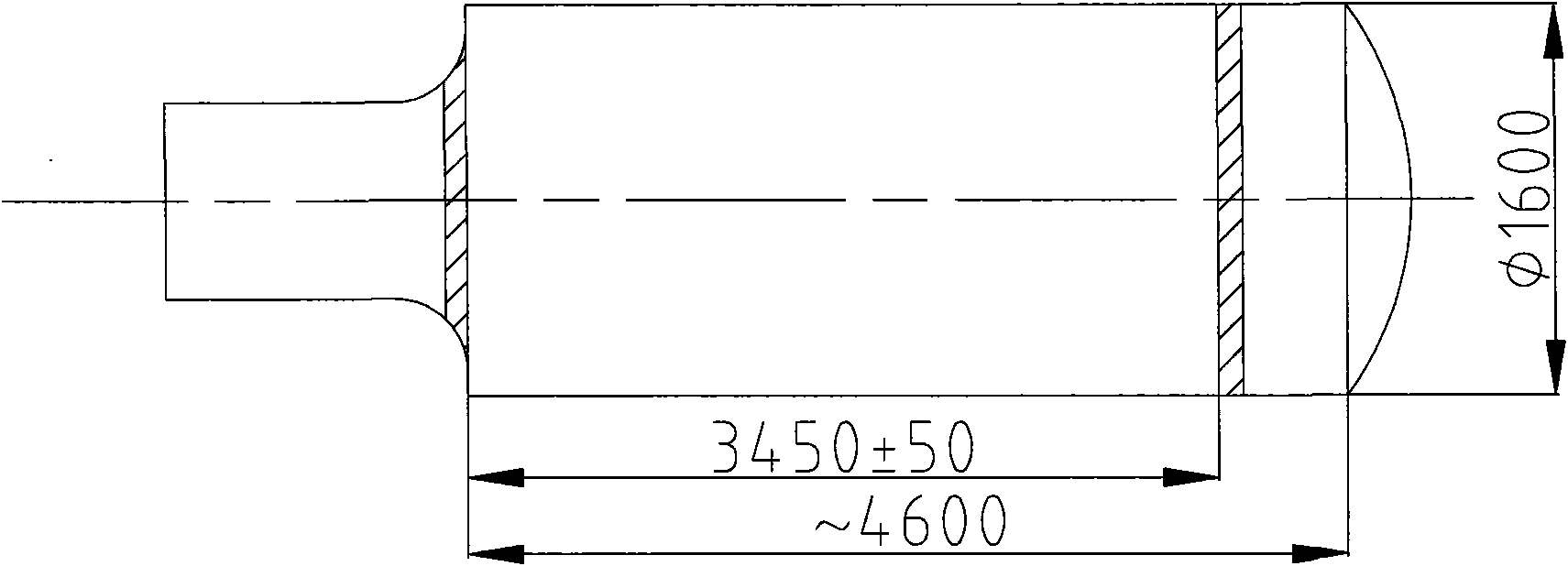

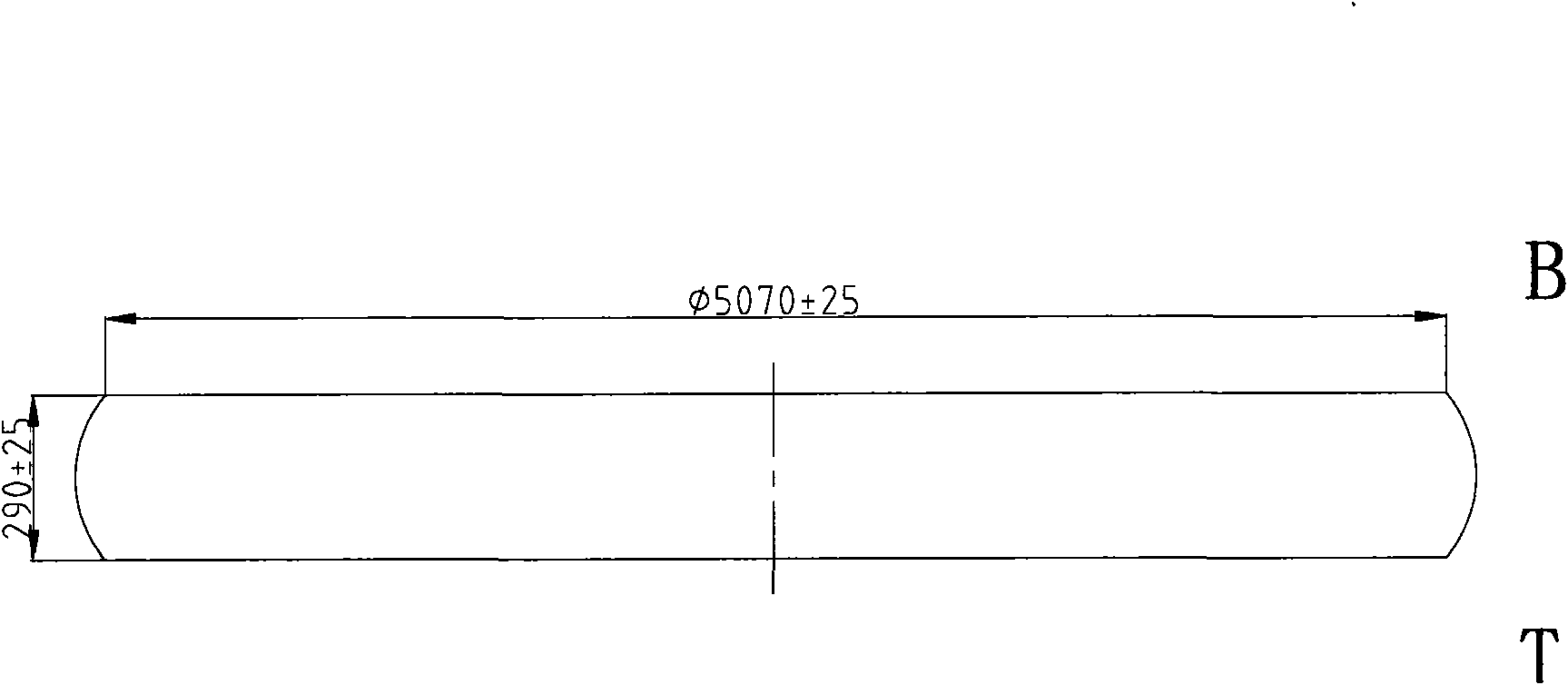

Forging method of lower sealing head forge piece of one-mega kilowatt nuclear-power reactor pressure vessel

ActiveCN101898224AReasonable distributionUniform compositionMetal-working apparatusReactor pressure vesselIngot

The invention discloses a forging method of a lower sealing head forge piece of a one-mega kilowatt nuclear-power reactor pressure vessel. In the method, a double-vacuum steel ingot made of 16MND5 with a weight of 103 tons is forged by using a hydraulic press of 12,000 tons, wherein the forging process sequentially comprises the following steps of: drawing: heating the double-vacuum steel ingot to 1,220+ / -10 DEG C, and changing a length of 2,625mm into 4,600mm; gas cutting blanking: removing a section of the bottom end of the forge piece to change the length of 4,600mm into 3,450mm, wherein the bottom of the double-vacuum steel ingot is guaranteed to be sufficiently cut off; upsetting: raising the temperature to 1,240+ / -10 DEG C and changing the length of 3,450mm into 290mm; rough machining: roughly machining the forge piece blank into a cake shape, wherein the diameter of the cake is 5,000mm, and the thickness is 220mm; and stamping and forming: heating the forge piece to 1,000+ / -10 DEG C and putting the forge piece on a special die for stamping and forming until the forging ratio reaches 1.2, and the forge piece forms a spherical crown shape. The invention can ensure that the forged lower sealing forge piece has the advantages of dense material, uniform component, reasonable metal streamline distribution and stable property.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

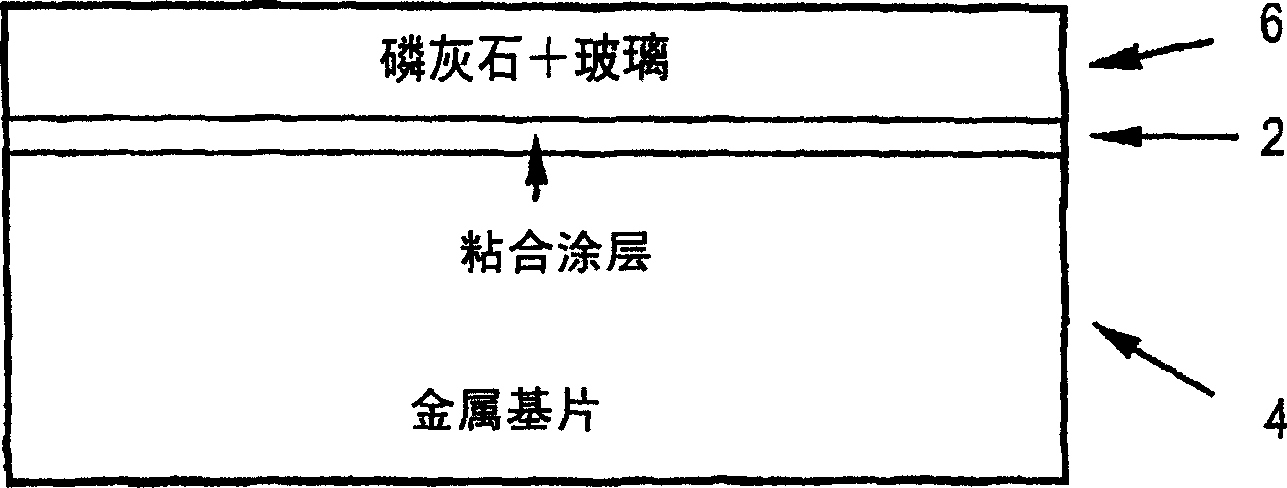

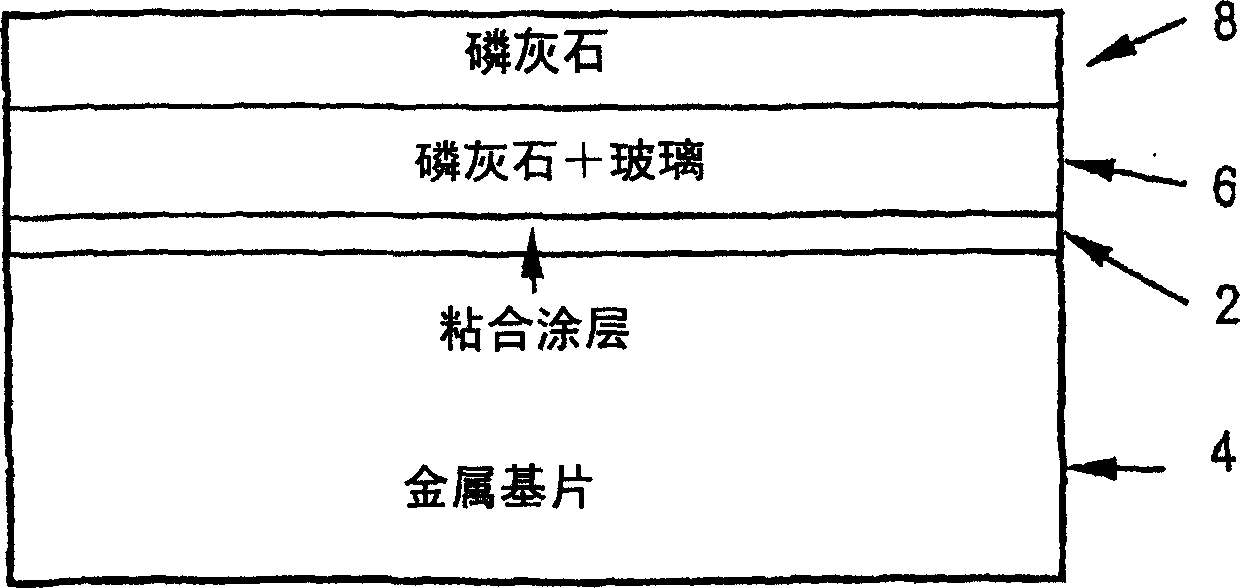

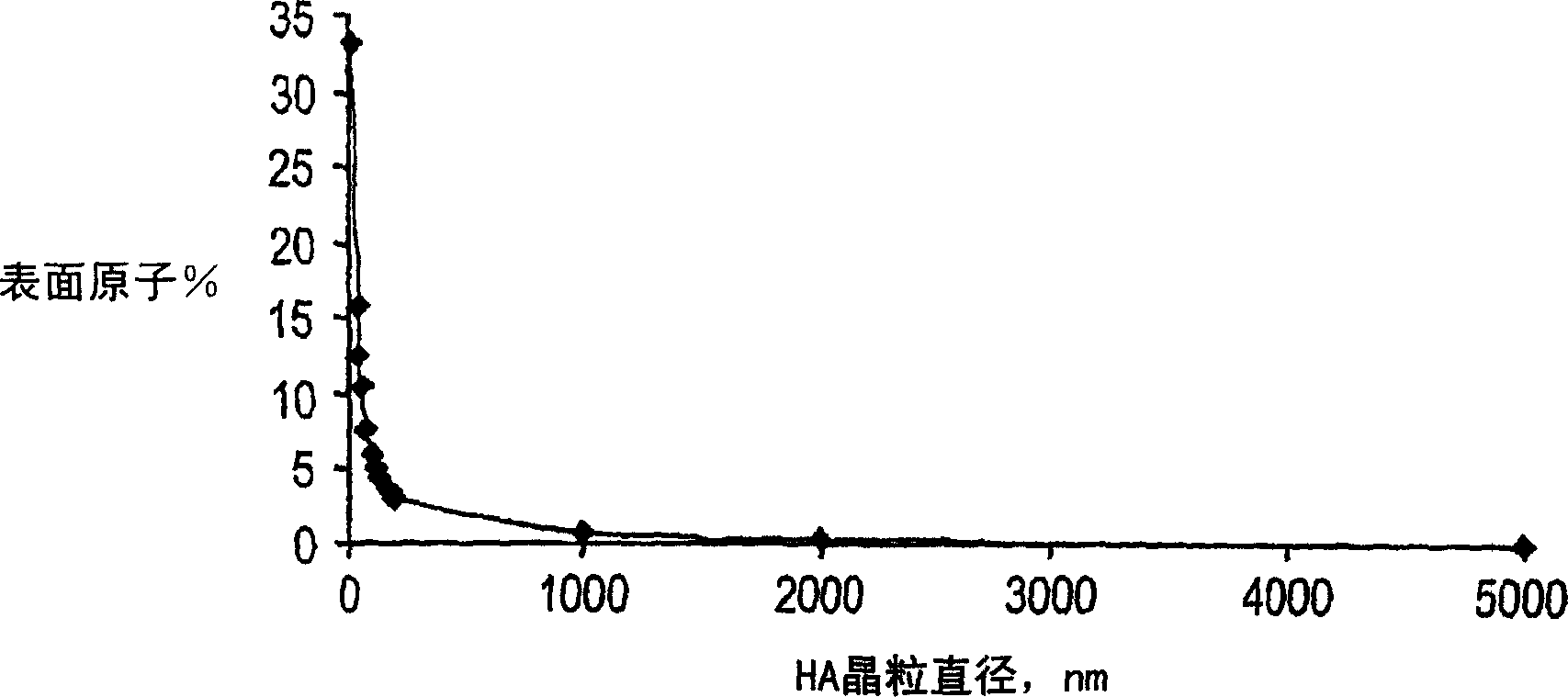

Coating, coated articles and methods of manufacture thereof

InactiveCN1589161AGood biological reactivityAvoid reactionCoatingsProsthesisThermal dilatationAdhesive

A multilayer coating especially suitable for coating implants, such as orthopedic and dental implants, especially metallic implants. The first layer includes a bond coat of a dense material that is insoluble and inert in body fluids. The second layer includes apatite and a binder. The first layer protects the metal implant from corrosion, dissolution of the apatite, and interfacial reactions with the apatite and the adhesive. The apatite in this second layer is a bioactive agent that osseobonds the tissue. Through this adhesive, the coefficient of thermal expansion between the coating and the metal substrate can be adjusted. The multi-layer coating has a high bonding strength to the implant and at the same time has excellent bioactivity to the surrounding body tissue.

Owner:美国英佛曼公司

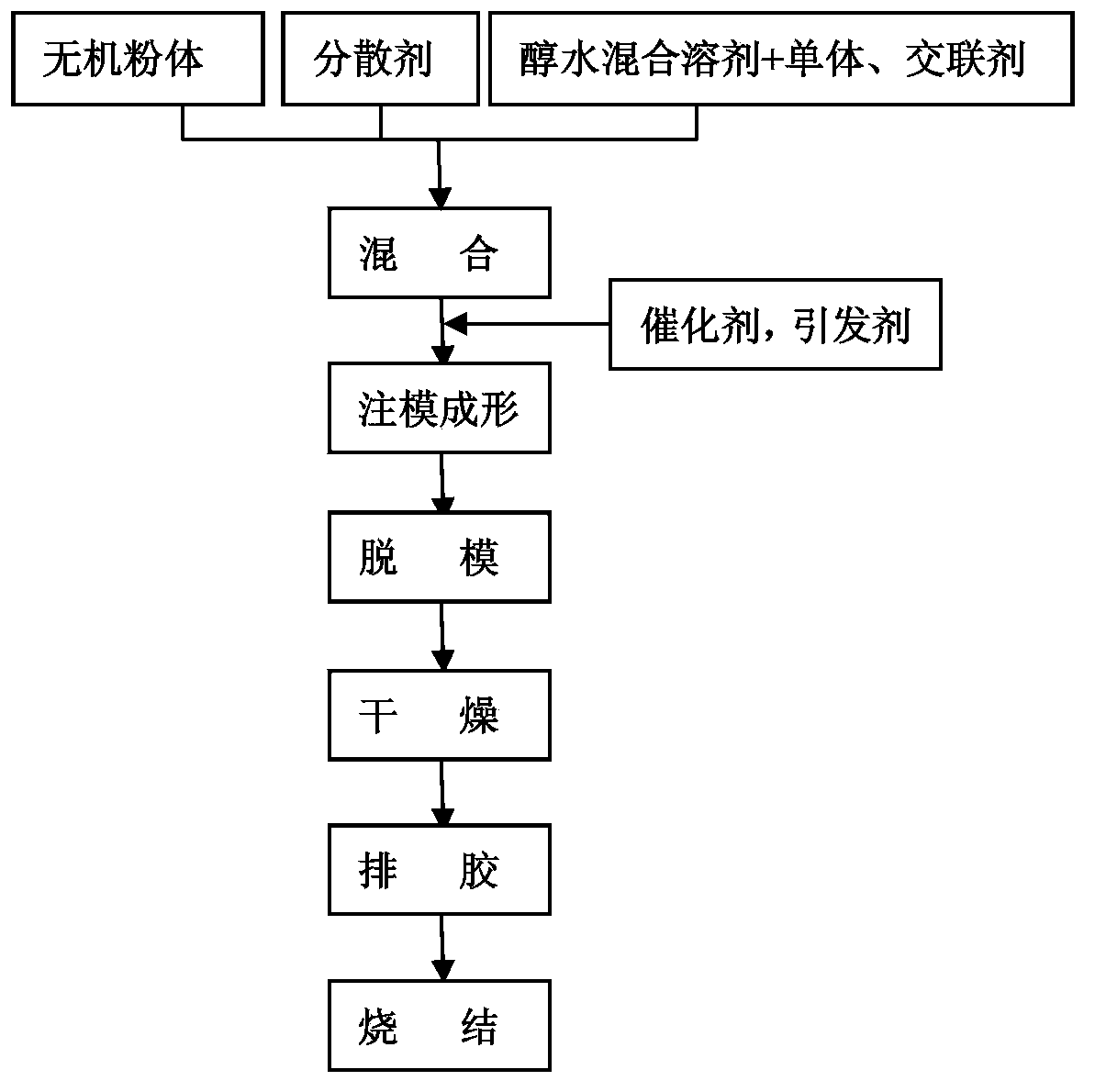

Formation technology for preparation of porous or compact material with gel-casting of alcohol-water basic material slurry

ActiveCN103406973ANot easy to shrink and deformGood dispersionCeramic shaping apparatusCross-linkAlcohol

The invention discloses a formation technology for preparation of porous or compact material with gel-casting of alcohol-water basic material slurry, which comprises the following steps: adding polymerized monomer and cross-linking agent to alcohol-water mixed solvent to premix to mixed solution, and dispersing ceramic powders or powder metallurgy powders in the obtained mixed solution through dispersing agent to prepare ceramic or powder metallurgy slurry; injecting the obtained ceramic or powder metallurgy slurry into a mould, and demoulding after solidification to obtain a wet body; conducting slowly heating up drying for the obtained wet body to obtain a dry body; and glue removing and sintering the dry body to obtain porous or compact ceramic or powder metallurgy material. According to the technology, the dry body with small shrinkage distortion and accurate size is obtained through the control for the alcohol-water ratio of the alcohol-water mixed solvent to prepare the wet body and then the combination of a special method to dry the wet body; the glue removing and the sintering can be conducted through a conventional method; the porous or compact ceramic or powder metallurgy material is prepared through the ceramic or powder metallurgy slurry cable of adapting to different solid content; the prepared porous or compact ceramic or powder metallurgy material has the advantages of uniform distribution, high bending-resistant and compressive strength, good repeatability, low cost, and the like, and facilitates the industrial production.

Owner:CENT SOUTH UNIV

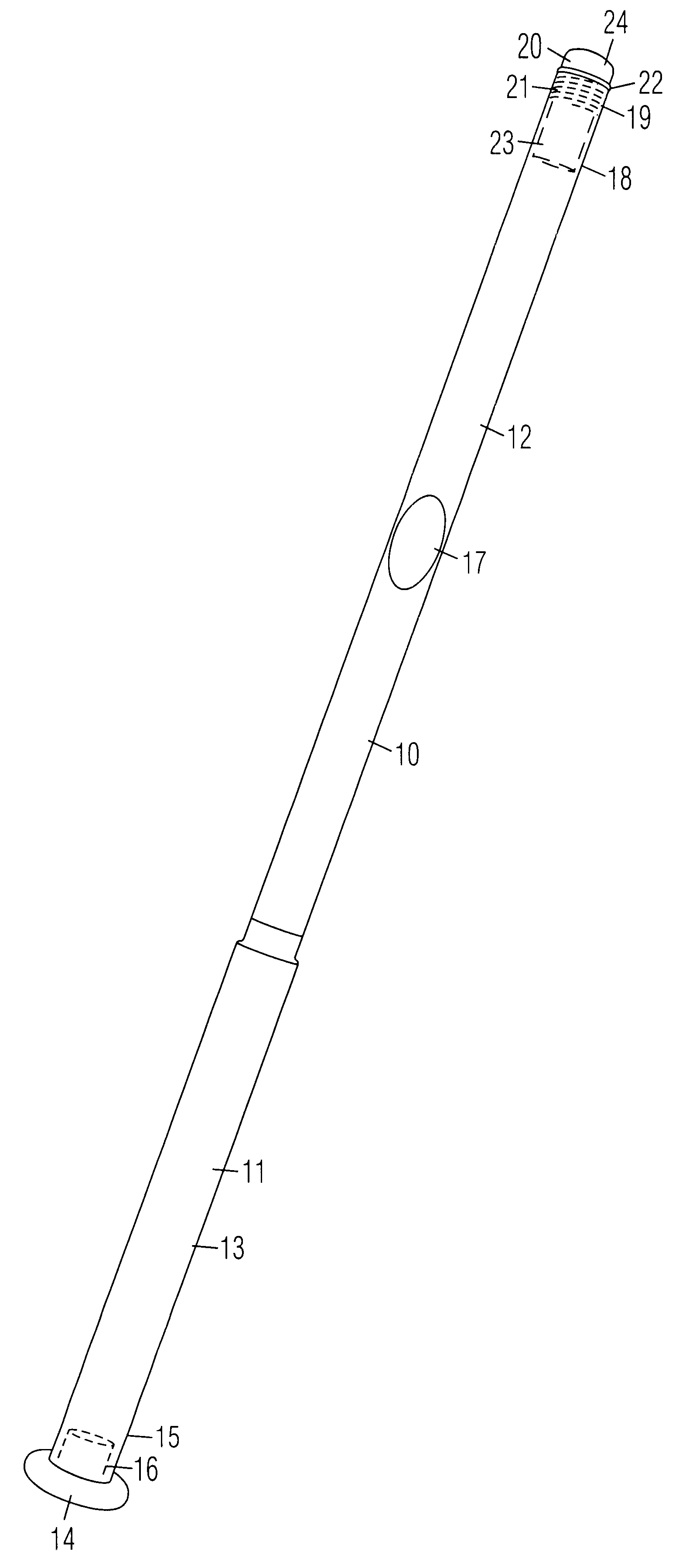

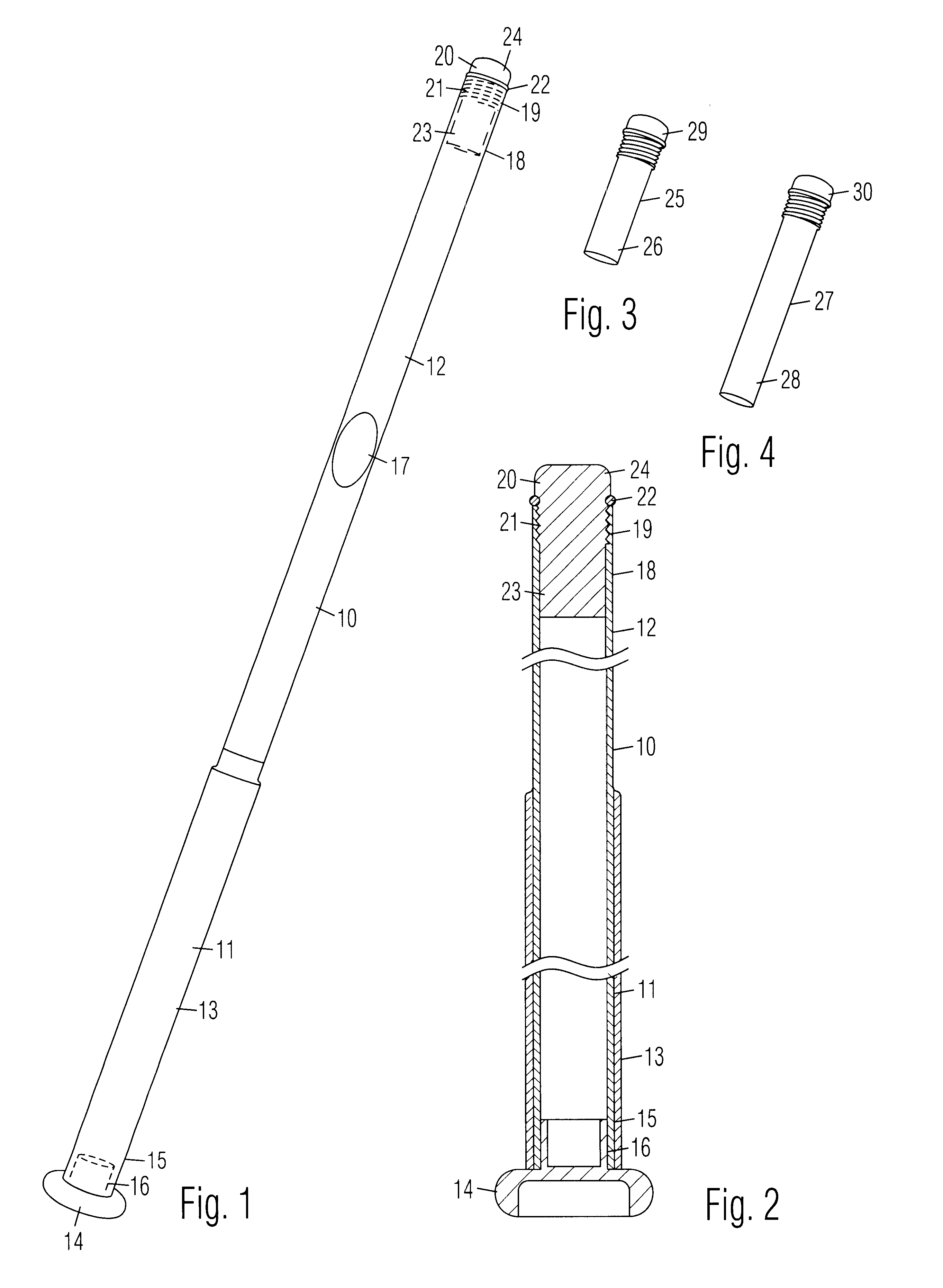

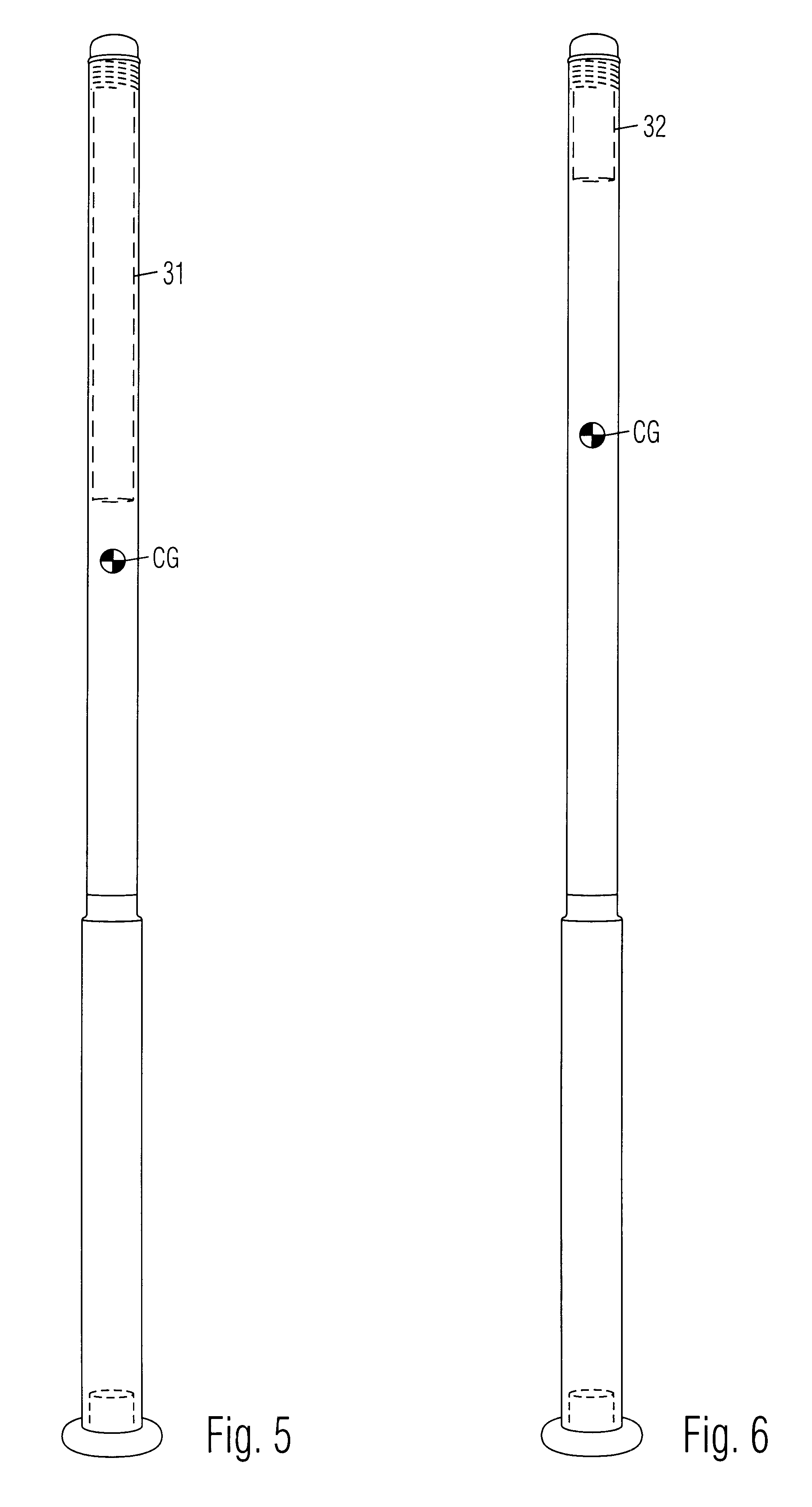

Baseball training bat

InactiveUS6918843B1High swing accuracySmall diameterBall sportsStringed racketsMicrochiropteraVolumetric Mass Density

The present baseball training bat is comprised of a hollow tube with a handle portion and a hitting portion. The hitting portion is substantially smaller in diameter than that on a conventional baseball bat for improving swing accuracy. The distal end of the tube has an internal thread. Interchangeable threaded weight plugs of different lengths and weights are provided. The weight of any selected conventional bat can be closely simulated by installing in the distal end of the tube a suitable plug to produce substantially the same total weight. The plugs are also provided in materials of different densities. A plug in a denser material is shorter than another plug of the same mass but in a less dense material. The balance of the bat is thus changeable without changing the total weight by substituting plugs of the same mass but of different densities and lengths.

Owner:FRANSSEN MICHEAL E

Joined body and method for producing the same

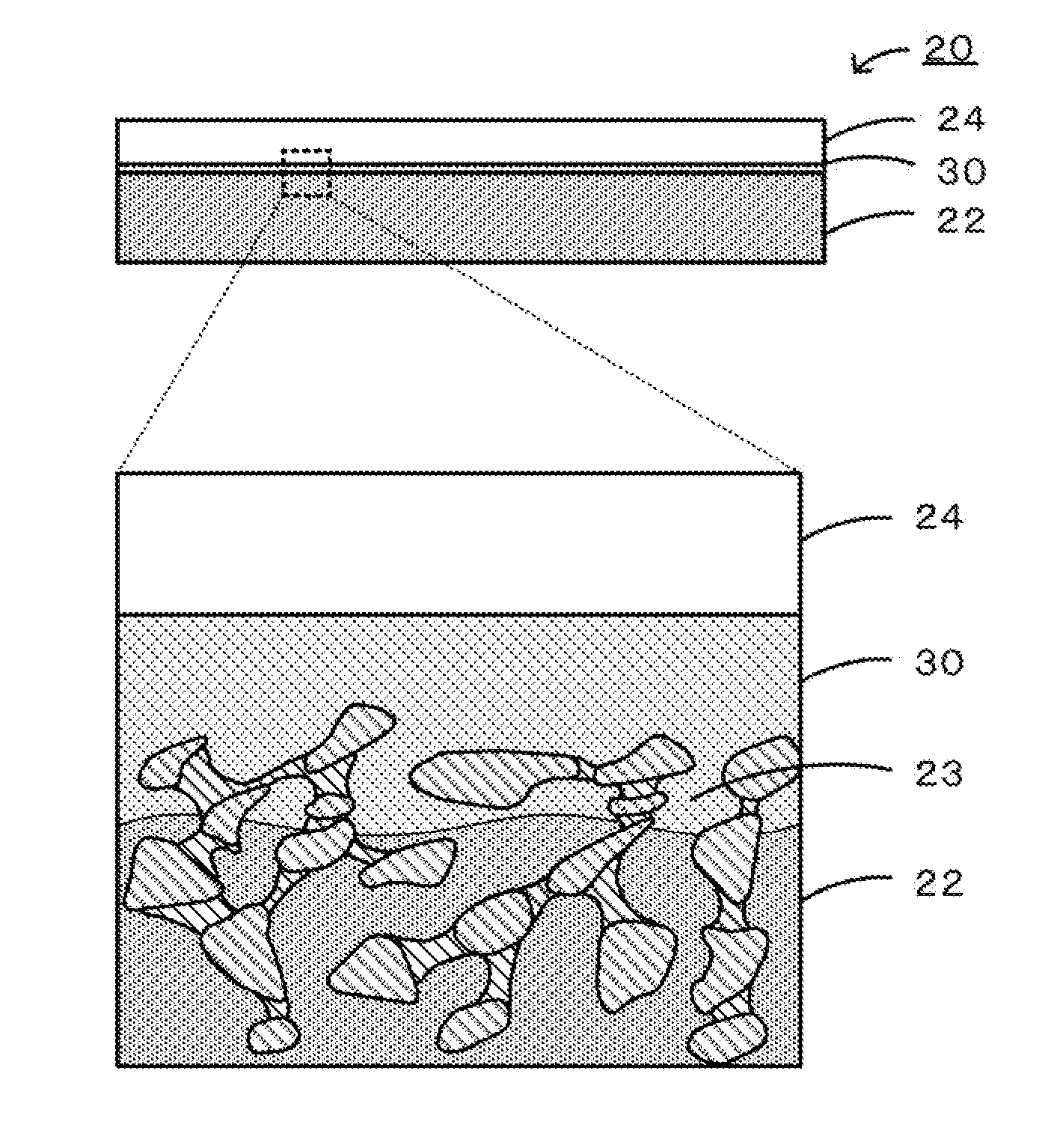

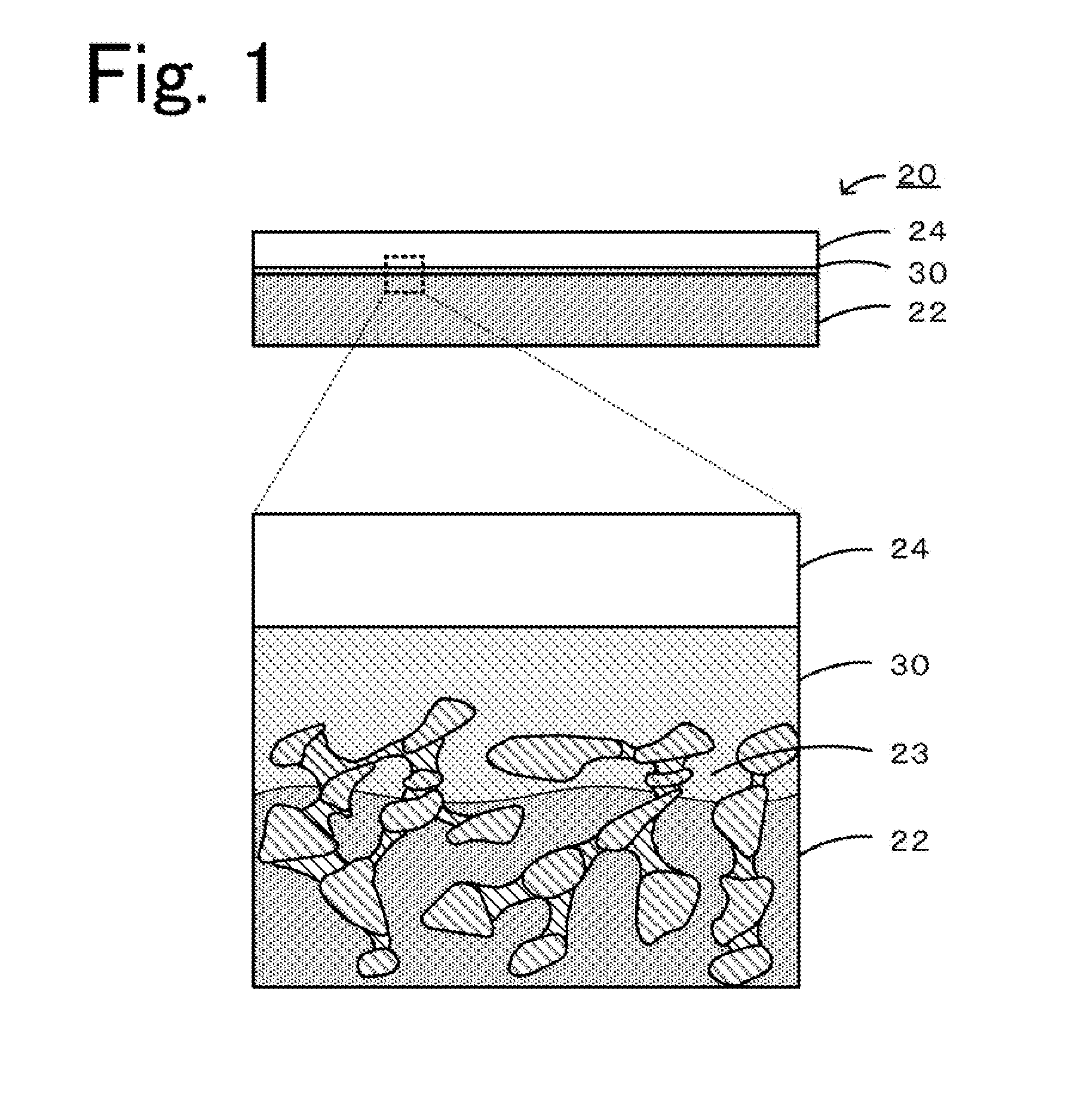

ActiveUS20160002110A1Easily react with memberLess reactiveRecord information storageLight beam reproducingOxide ceramicPorous ceramics

A joined body 20 according to the present invention includes a first member 22 made of a porous ceramic, a second member 24 made of a metal, and a joint 30 formed of an oxide ceramic of a transition metal, the joint 30 joining the first member 22 to the second member 24. Alternatively, a joined body may include a first member made of a dense material, a second member made of a dense material, and a joint formed of an oxide ceramic of a transition metal, the joint joining the first member to the second member.

Owner:NGK INSULATORS LTD

De-fluorination after via etch to preserve passivation

InactiveUS20060099785A1Improve functionalityEnhance layeringSemiconductor/solid-state device manufacturingEtchingIon current

Novel interconnect structures possessing a dense OSG material for 90 nm and beyond BEOL technologies in which a low power density oxygen-based de-fluorination plasma process is utilized to increase NBLoK selectivity are presented. These BEOL interconnect structures are capable of delivering enhanced reliability and performance due to the reduced risk of Cu exposure and hence electromigration and stress migration related failures. The oxygen based de-fluorination process is such that the plasma conditions employed {low power density (<0.3 Wcm−2); relatively high pressure (>100 mT); negligible ion current to wafer surface (applied source frequency only)} facilitate a physical expulsion of residual fluorine present on the chamber walls, wafer surface, and within the via structure; thus, minimizing the extent of NBLoK etching that can occur subsequent to removing polymeric byproducts of via etching.

Owner:GOOGLE LLC

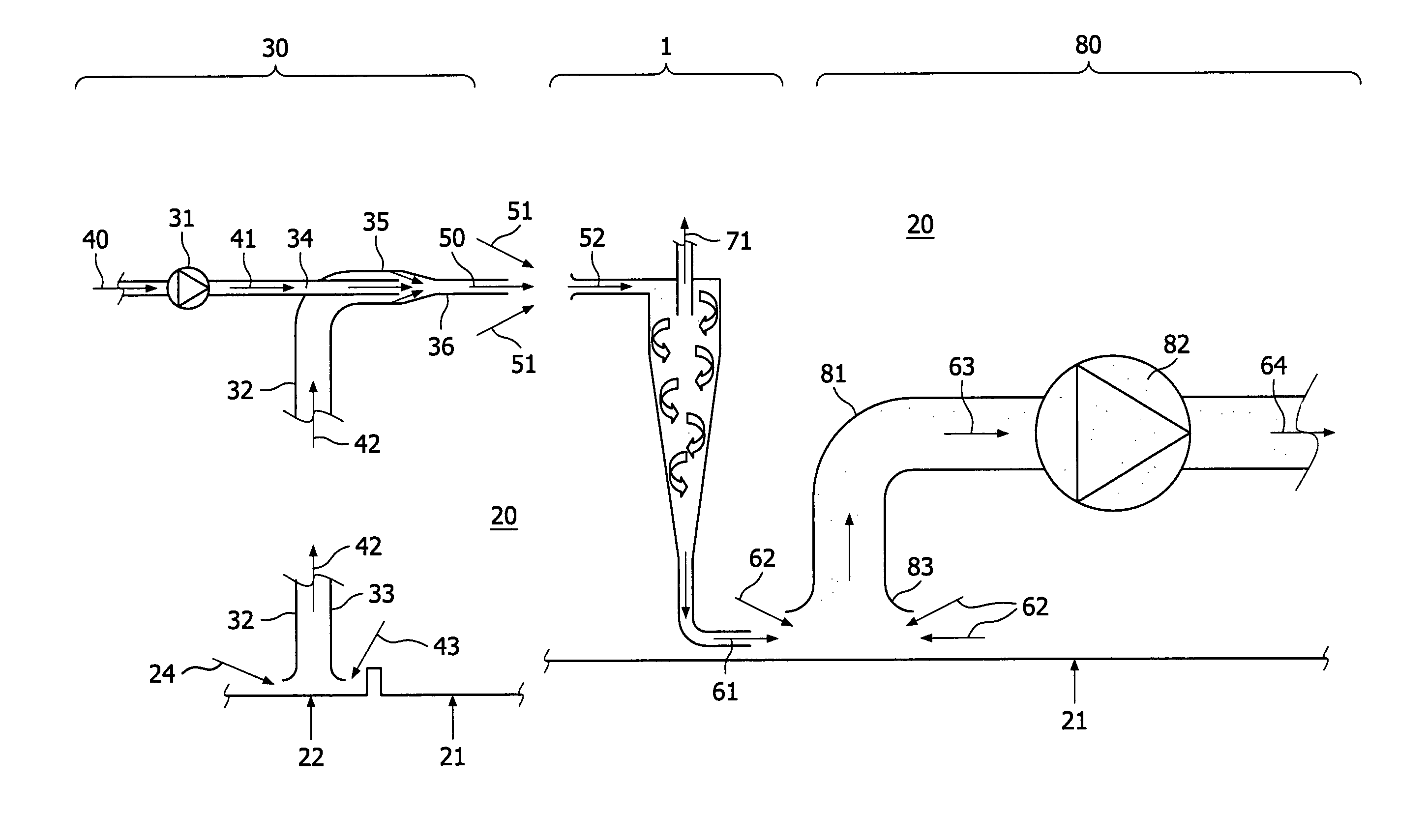

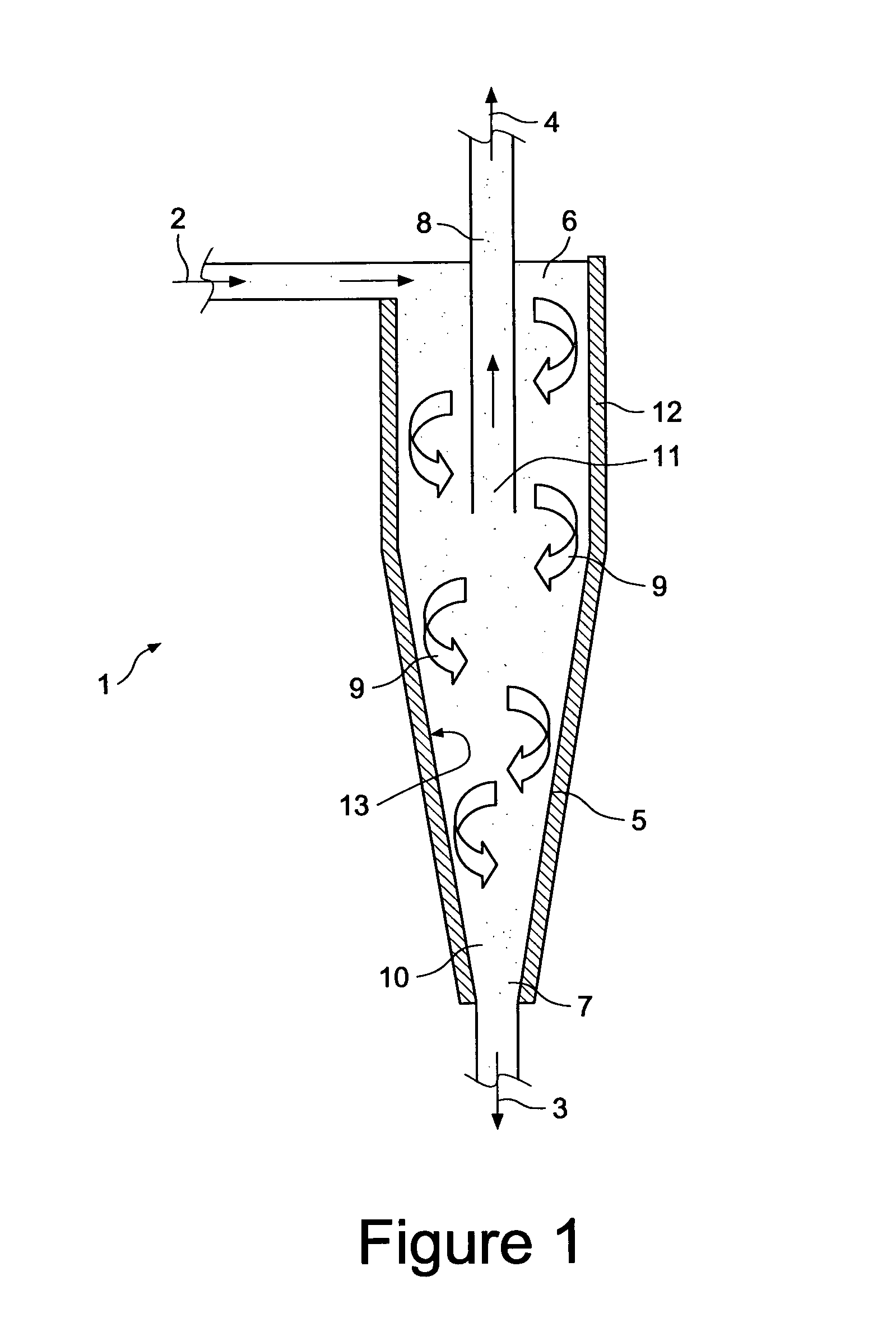

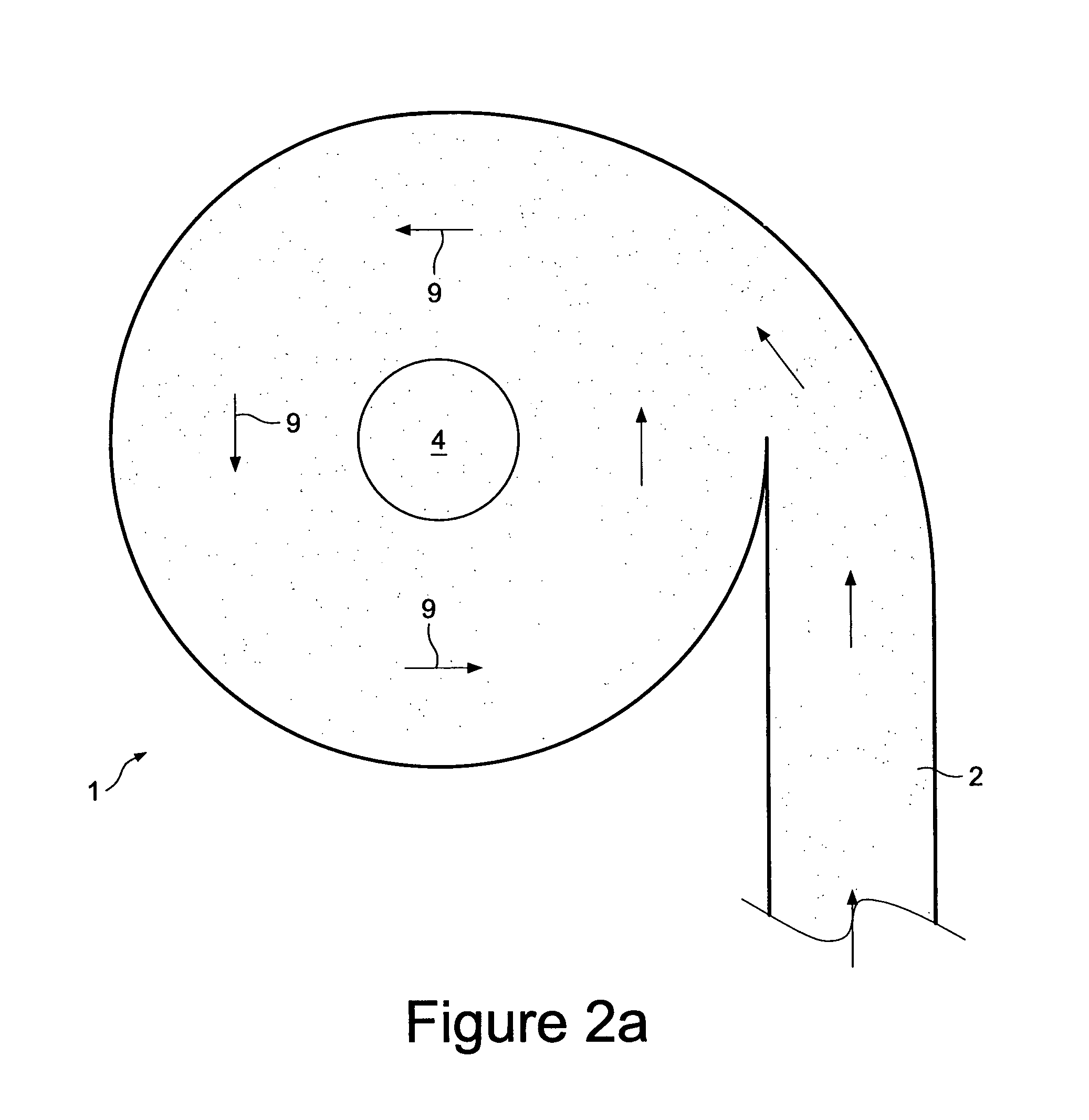

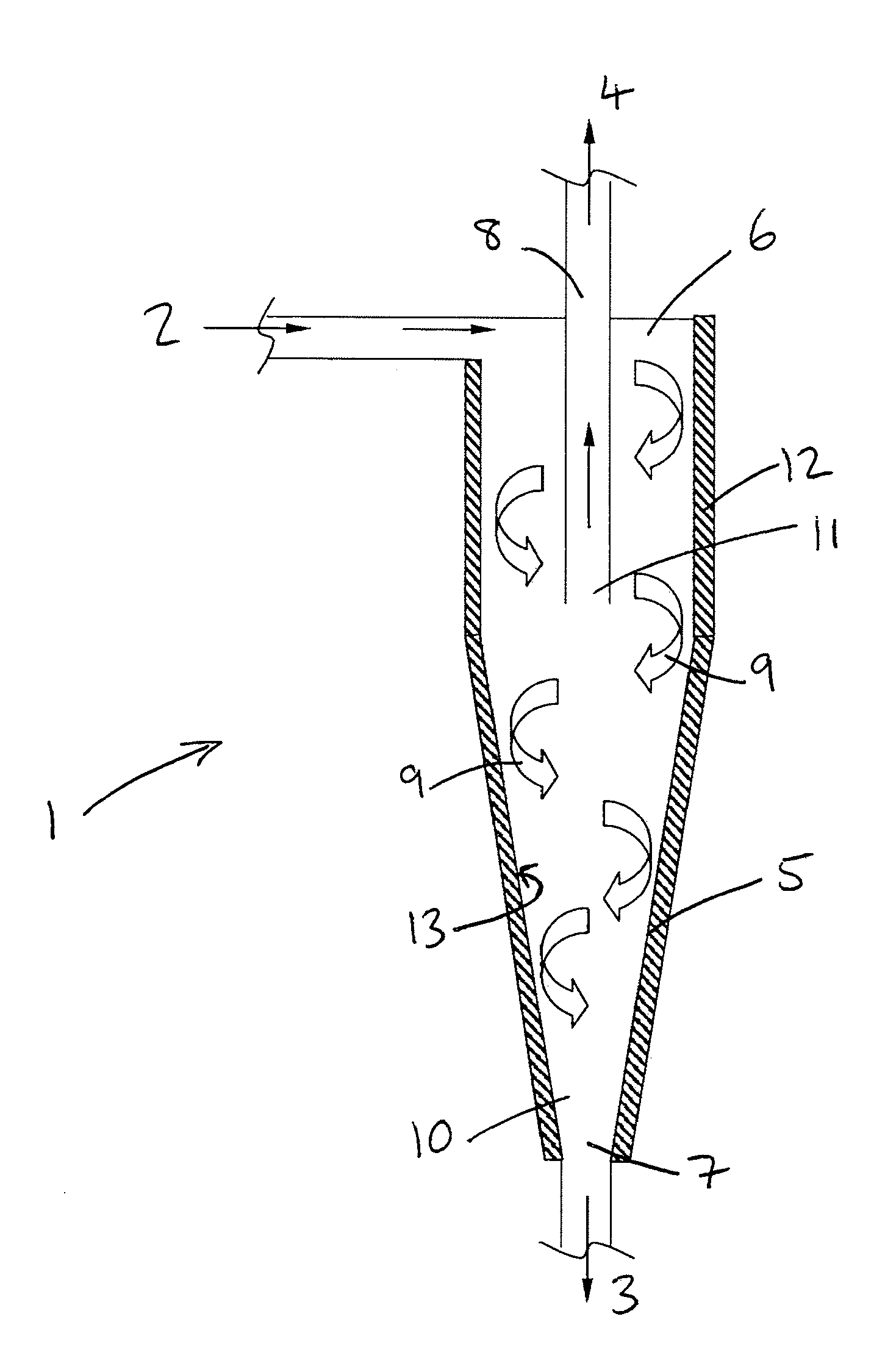

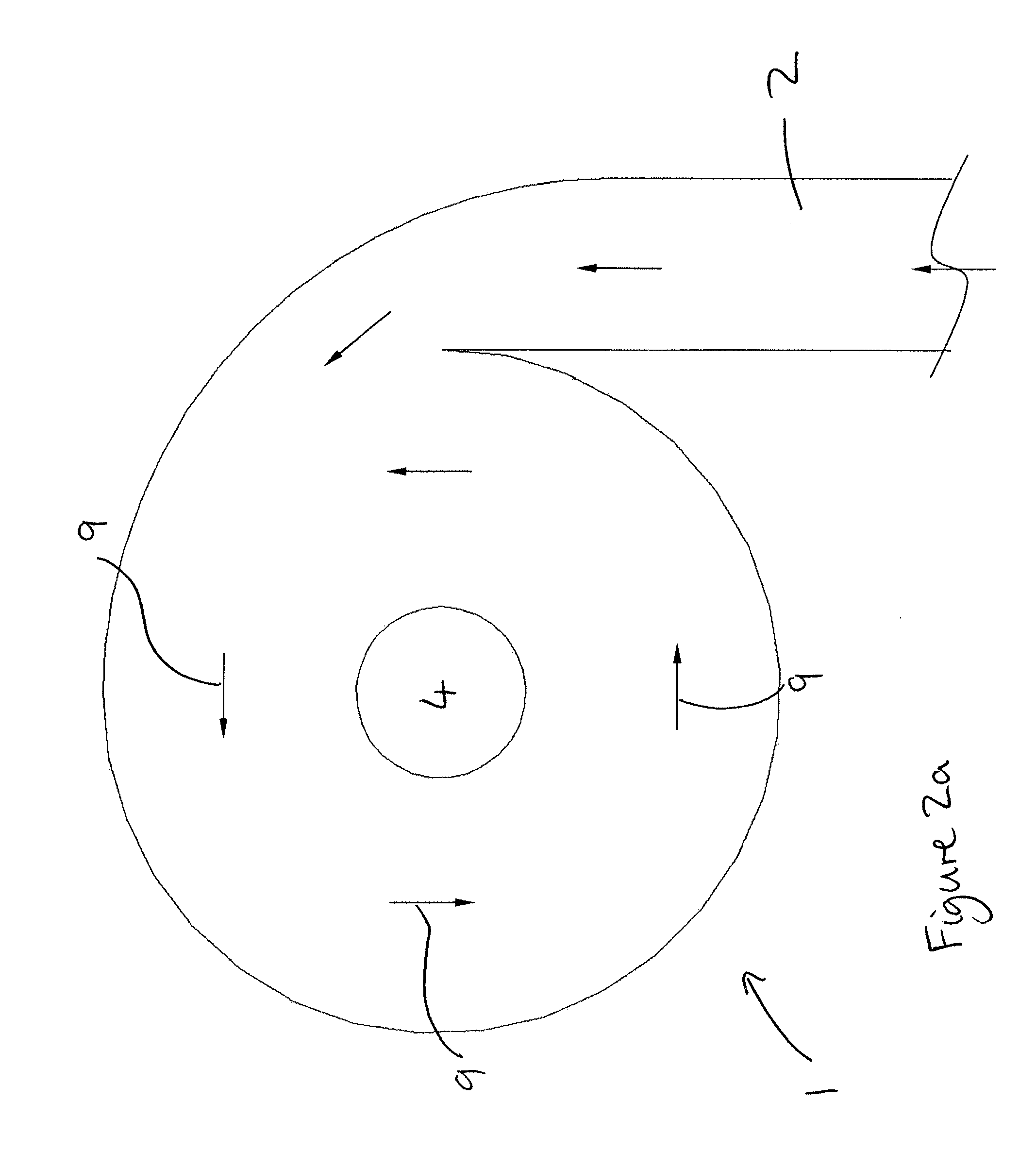

Cyclonic separator

ActiveUS8221633B2Prevent water condensationEasy to removeWater/sewage treatment by centrifugal separationReversed direction vortexFuel tankMotor fuel

A fuel system comprising a liquid fuel tank, an engine, and a cyclonic separator having an inlet fluidically connected to the fuel tank, a first outlet fluidically connected to an engine fuel feed system, and a second outlet. The cyclonic separator is adapted to discharge relatively denser material from the first outlet and relatively less dense material from the second outlet. The fuel system may be used to remove water or ice from the fuel tank by separating the liquid fuel in the tank into water rich fuel and purified fuel using the cyclonic separator. The water rich fuel is discharged to the engine where the water is burnt off with the fuel. The cyclonic separator may be retrofit in an existing fuel system. The fuel system may be in an aircraft.

Owner:AIRBUS OPERATIONS LTD

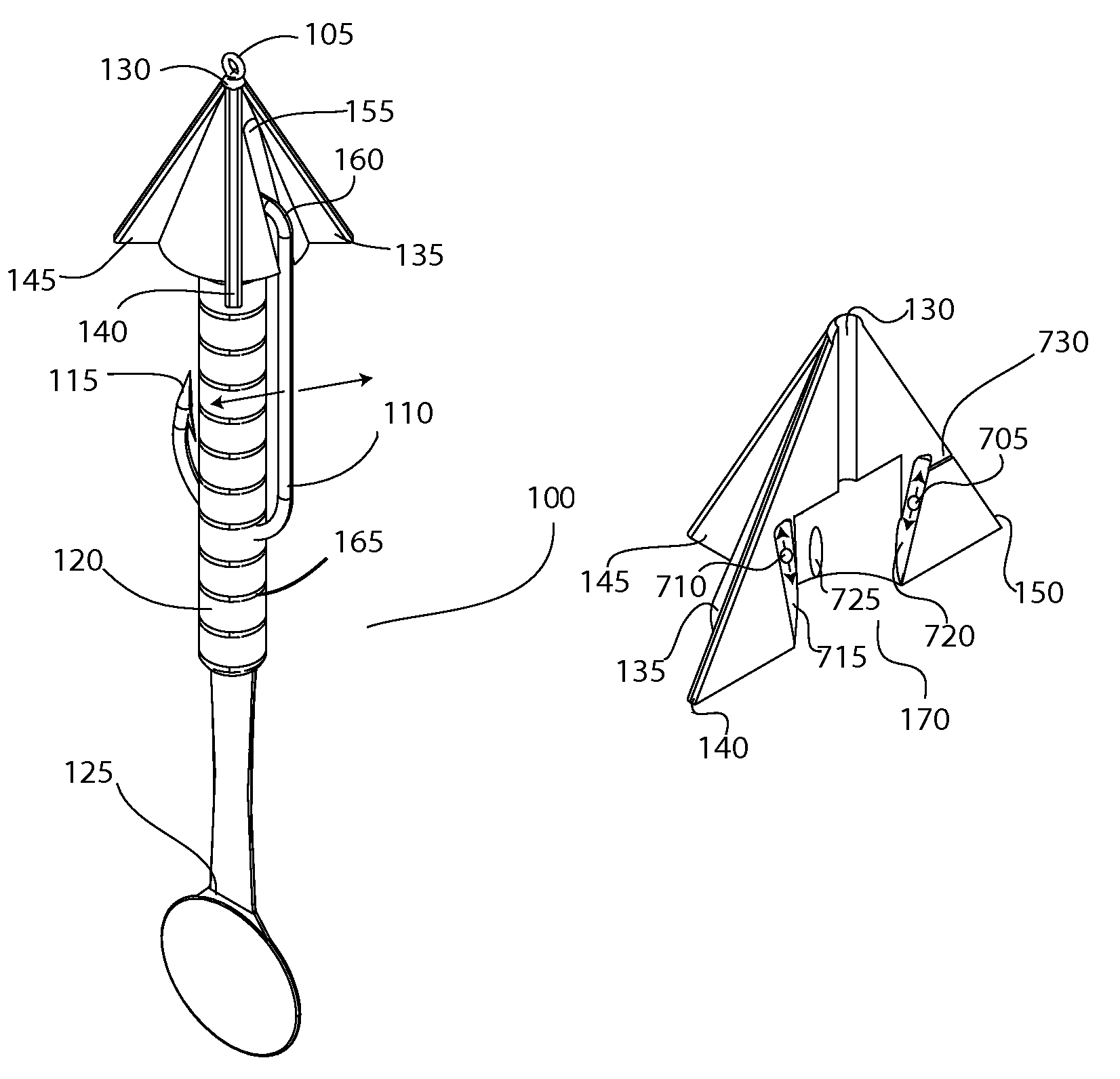

Fishing lure with weighted hydrodynamic head, mated plastic worm and pivoting hook

Owner:CORBITT VENTURES

Miniature gas chromatographic column, gas chromatographic system and method for analysizing composition in sample

InactiveCN1419123AIncrease the lengthSave spaceComponent separationGas liquid chromatographicPhysical chemistry

The invention refers to miniature gas-chromatograph field based on the micro-processing technique. It provides a gas-chromatograph column, including at least two cover layers and a gas-way layer, each layer material is compact, two sides of the gas-way layer both have micro-processed troughs, one side of the trough and the cover layer at least forms two capillaries, the capillaries are linked to form a complete one through the open hole in the gas-way layer, the complete capillary links to the exterior at two bottoms through the open holes of two most outer cover layers, one entrance and the other exit.

Owner:TSINGHUA UNIV +1

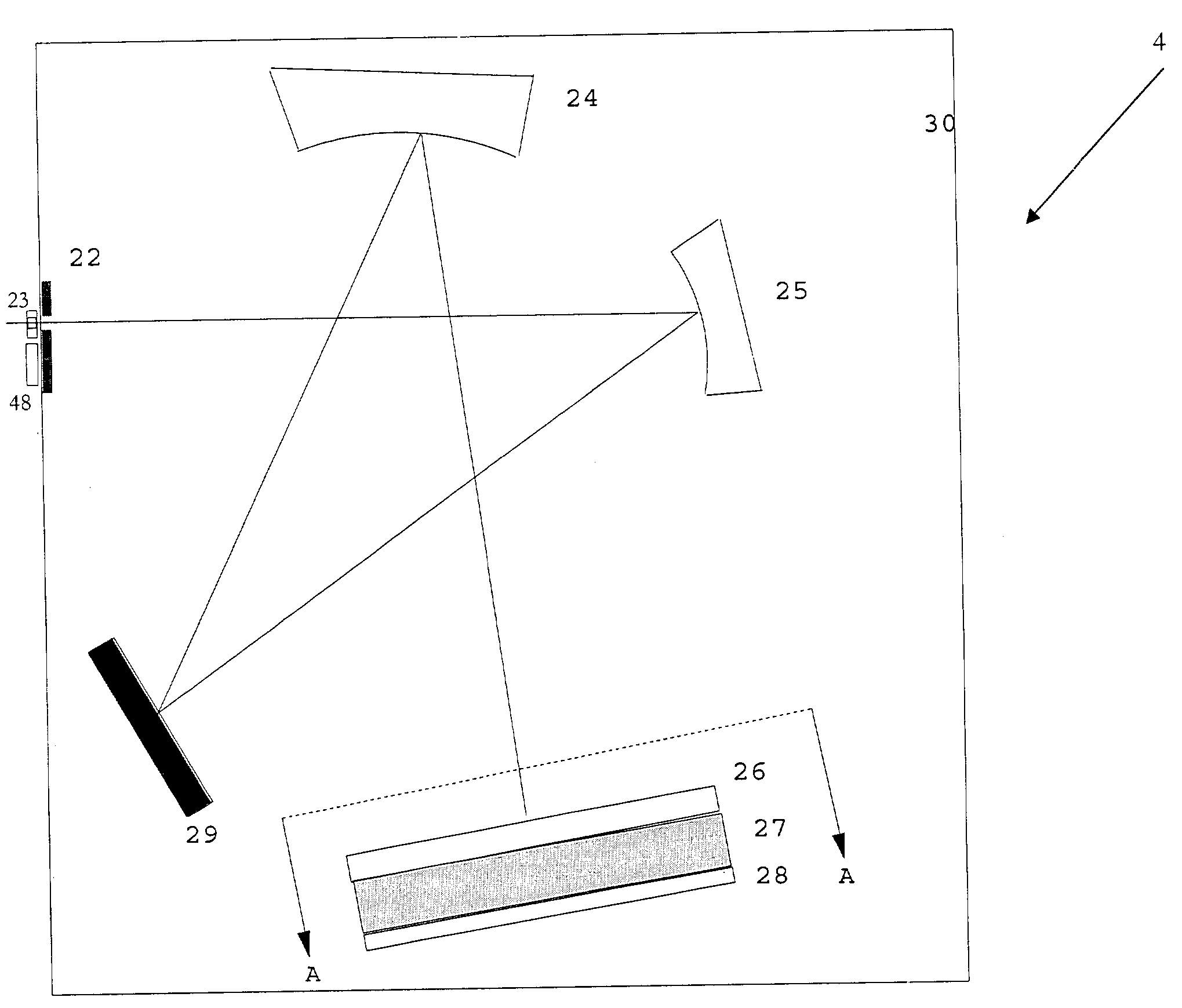

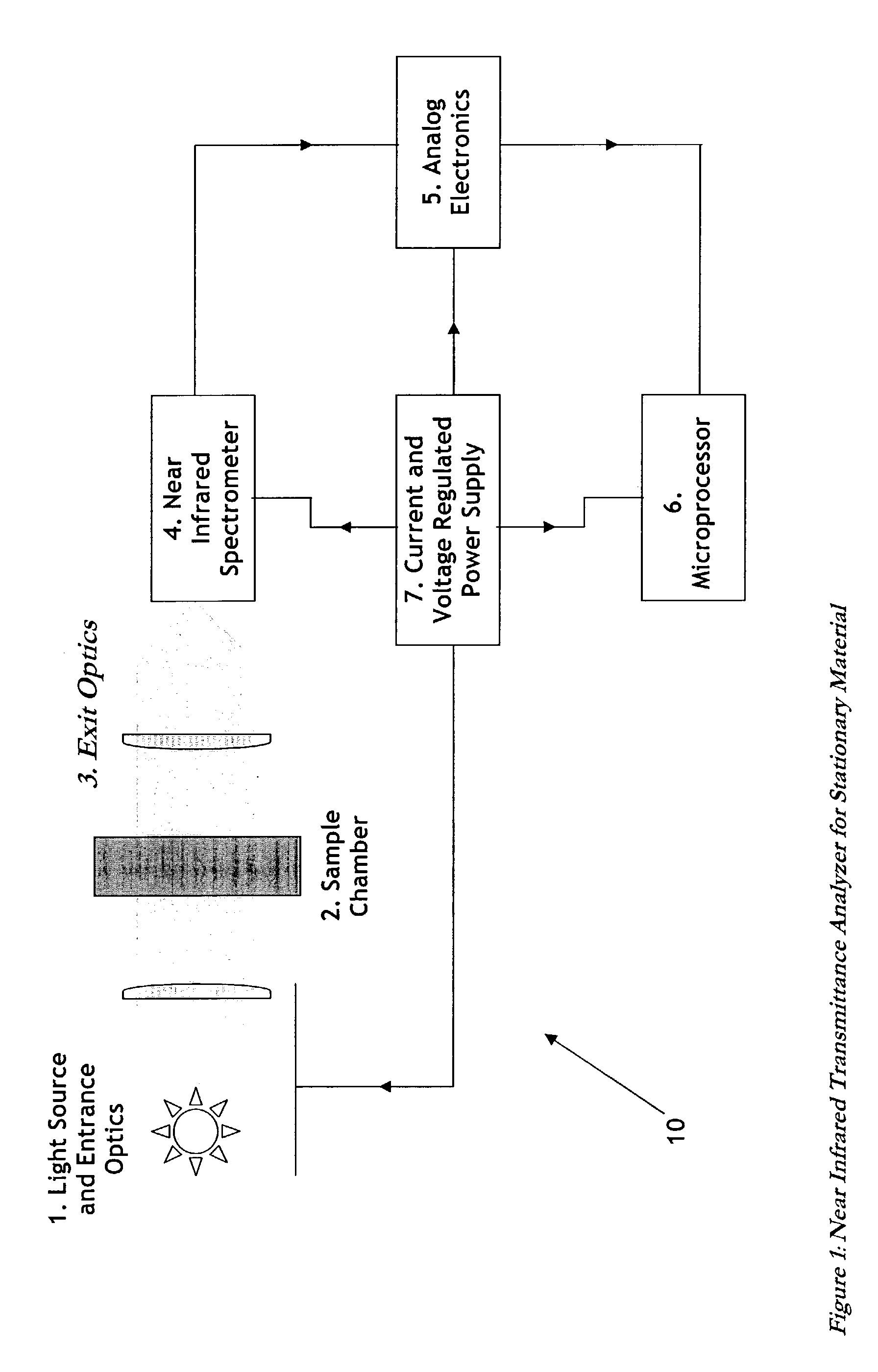

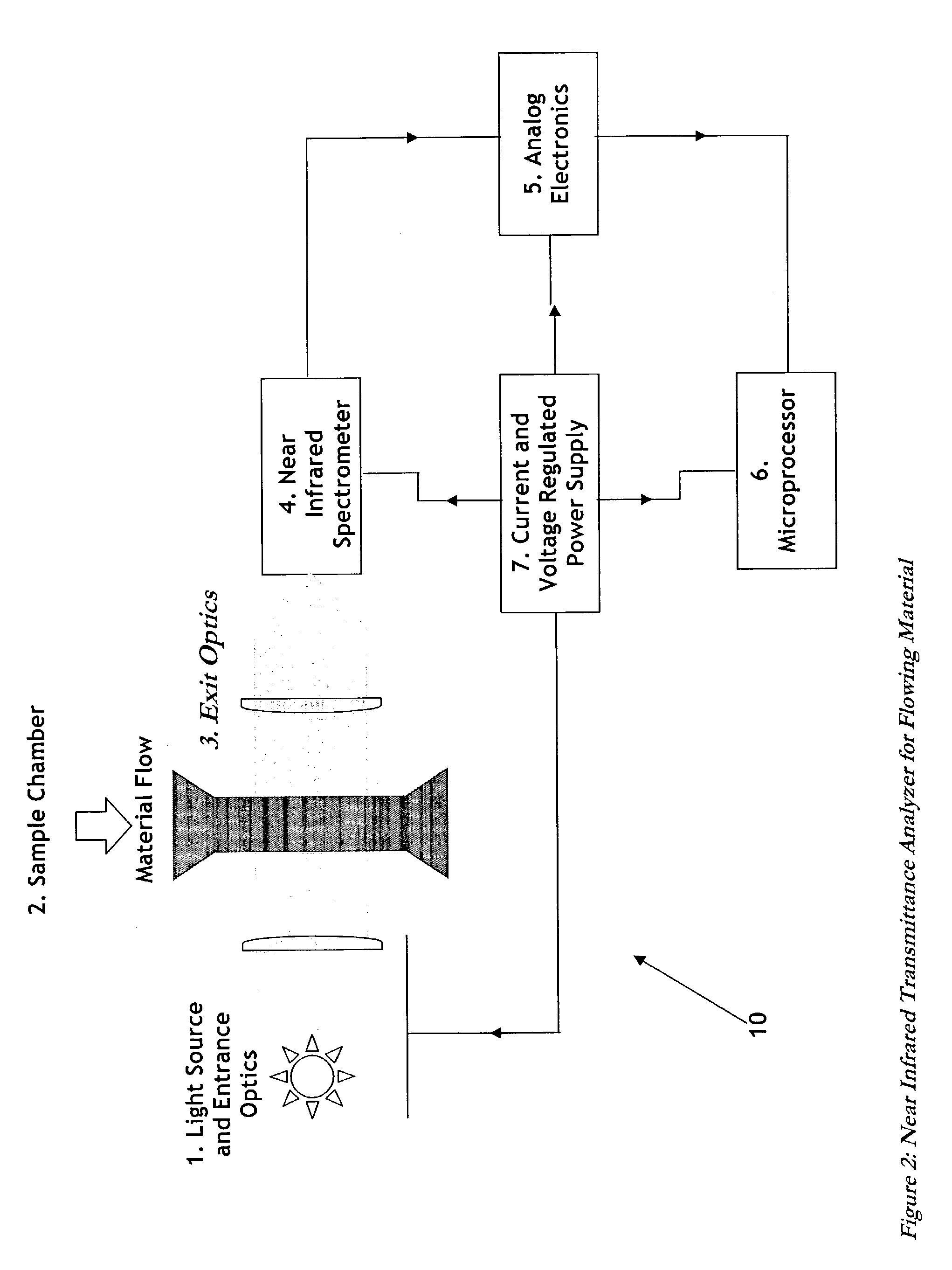

High speed analyzer using near infrared radiation transmitted through thick samples of optically dense materials

InactiveUS7087901B2Shorten the timeHigh sensitivityRadiation pyrometrySpectrum investigationMaterial under testLight spectrum

The present invention relates to an instrument for measuring in relatively short periods of time concentrations of constituents in optically dense materials using the spectra near infrared radiation transmitted through thick samples of the material while the material is either stationary or flowing. The invention uses a broadband incandescent intensity stabilized light source combined with collimating optics to transmit a parallel beam of light through the material under test. The light transmitted through the material is then collected by a focusing lens and imaged onto a rectangular entrance slit of a special purpose spectrometer. This spectrometer has no moving parts and employs a fixed diffraction grating to physically spread the image of the entrance slit into a continuous range of wavelengths. A portion of the diffracted slit images covering the selected portion of the near infrared range is focused onto an array of individual rectangular photodiodes. By using relatively large area photodiodes and a relatively small number of photodiodes, high sensitivity is achieved and low intensity radiation levels can be measured quickly. By using a relatively narrow spectral range, medium resolution can be achieved. The outputs of each photodiode, or the outputs of a selected number of the photodiodes, are fed into current to voltage converters: either resistive (instantaneous) or preferred capacitive (integrating). Thus the outputs of all photodiodes are measured in parallel, which reduces the time to acquire the spectra. The gain of these current to voltage converters is programmable so that both high intensity and low intensity near infrared radiation levels can be measured without reducing the intensity of the radiation incident on the material under test and thereby eliminating the need for moving parts in the spectrometer. After the spectra are acquired, they are operated on by models developed to predict the percentages of various constituents in the material. These models are pre-calibrated using spectra obtained from materials of known concentrations and developed using chemometric, neural net, and / or genetic algorithms.

Owner:LEADER TECH

Cyclonic separator

ActiveUS20120000864A1Prevent water condensationEasy to removeWater/sewage treatment by centrifugal separationReversed direction vortexFuel tankLiquid fuel

A fuel system comprising a liquid fuel tank, an engine, and a cyclonic separator having an inlet fluidically connected to the fuel tank, a first outlet fluidically connected to an engine fuel feed system, and a second outlet. The cyclonic separator is adapted to discharge relatively denser material from the first outlet and relatively less dense material from the second outlet. The fuel system may be used to remove water or ice from the fuel tank by separating the liquid fuel in the tank into water rich fuel and purified fuel using the cyclonic separator. The water rich fuel is discharged to the engine where the water is burnt off with the fuel. The cyclonic separator may be retrofit in an existing fuel system. The fuel system may be in an aircraft.

Owner:AIRBUS OPERATIONS LTD

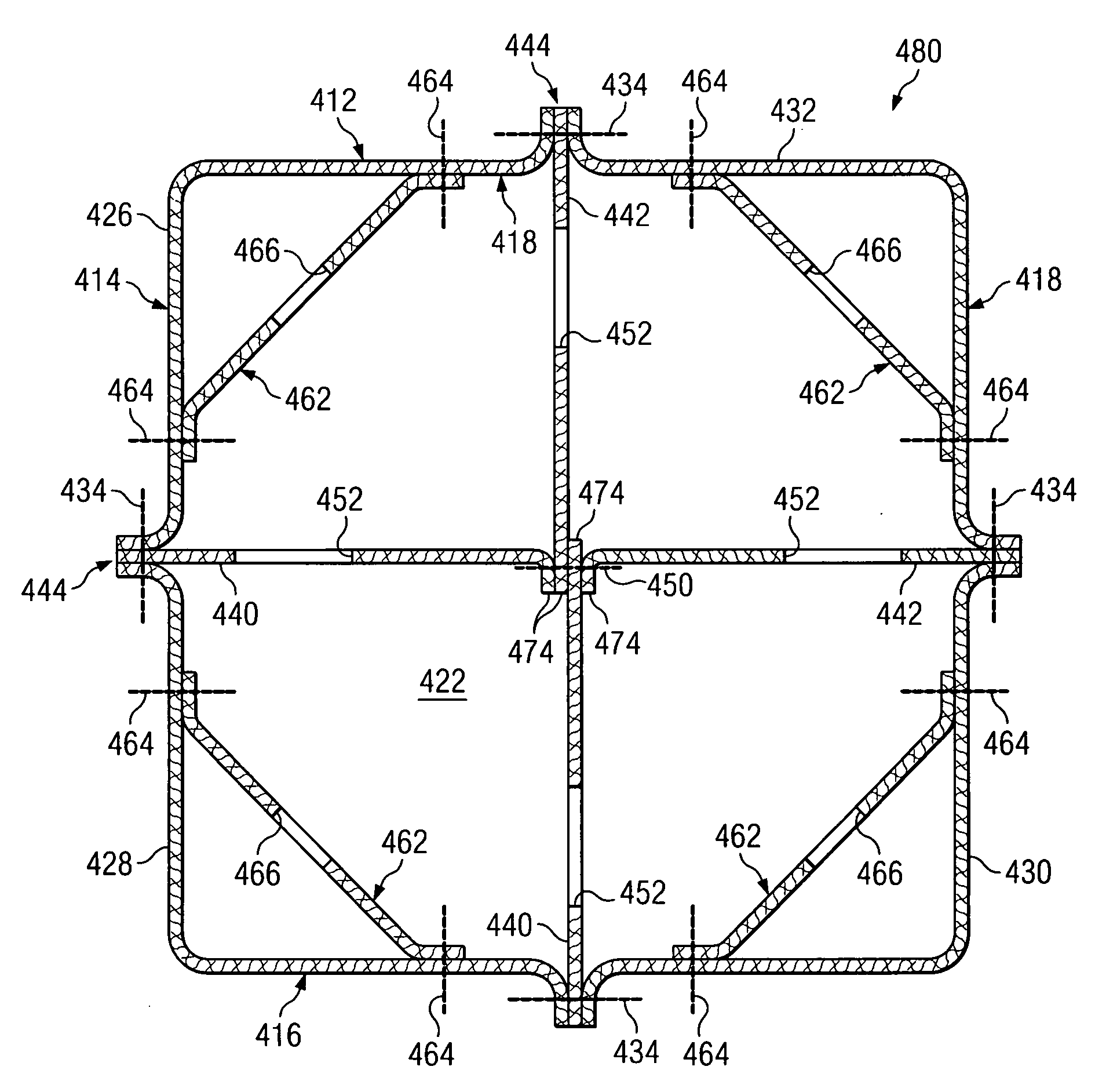

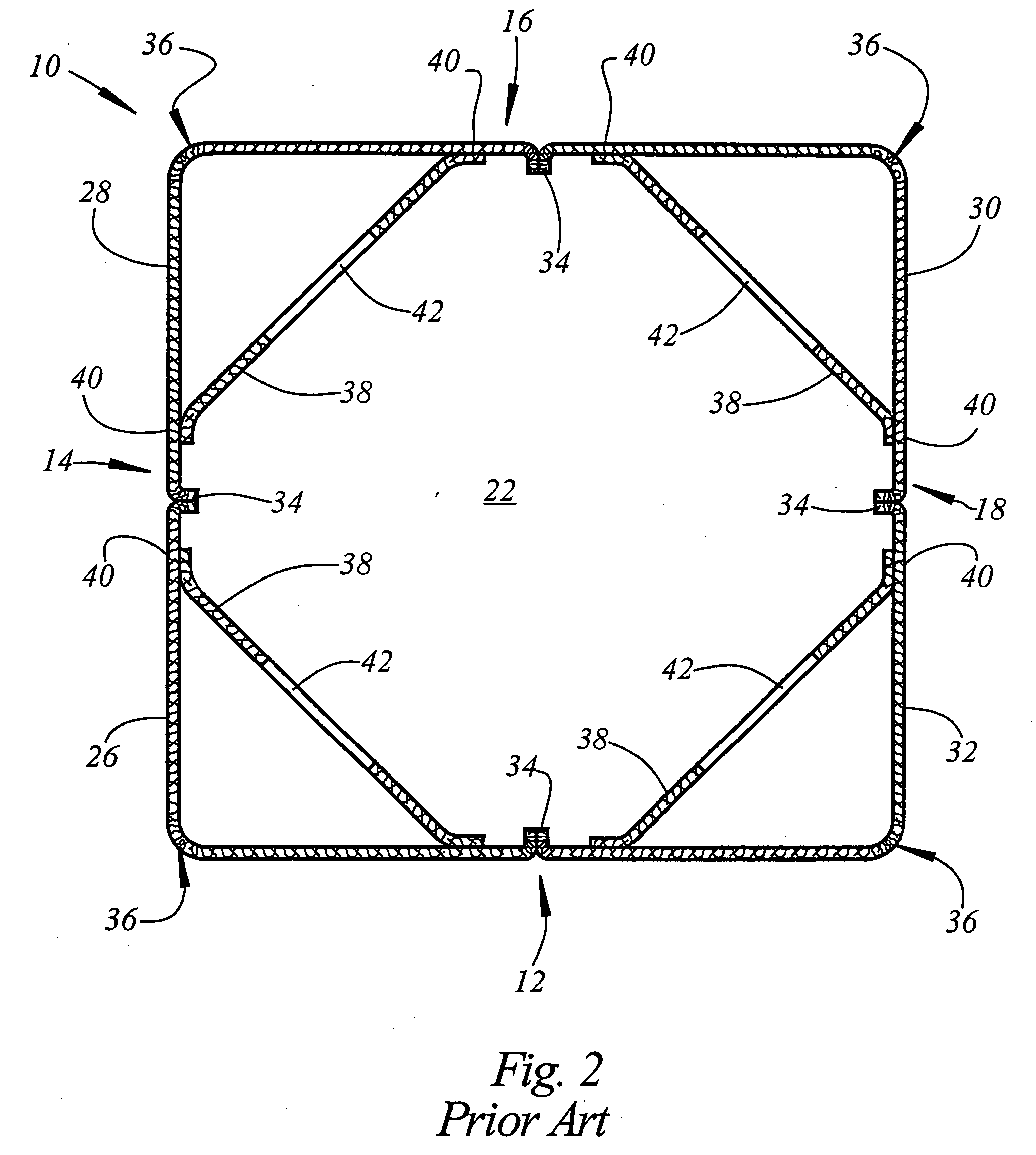

Bulk bag for dense materials

A bulk bag for dense materials includes side walls seamed together end-to-end to form a rectangular enclosure and at least a bottom wall secured to the lower ends of the side walls. Baffles are secured in the side wall seams and extend diagonally across the interior of the bulk bag to maintain the bulk bag in a rectangular cross-sectional configuration when filled with dense materials.

Owner:SUPER SACK MFG

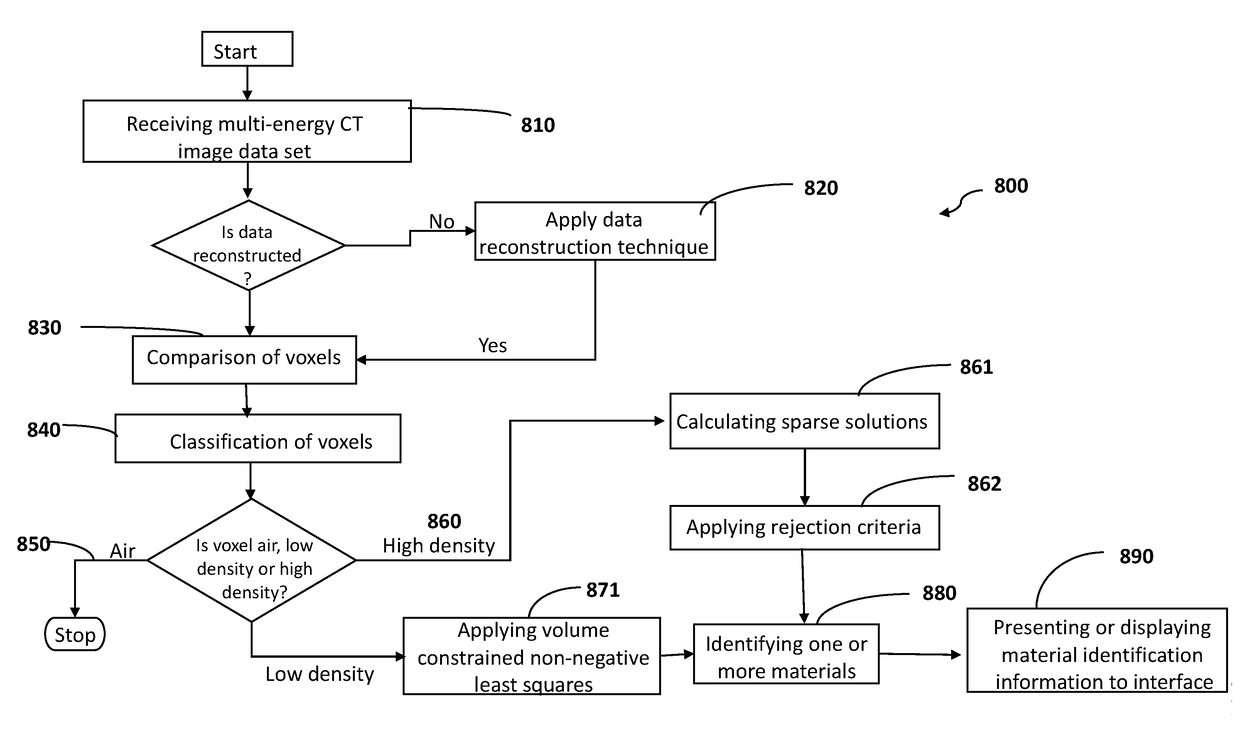

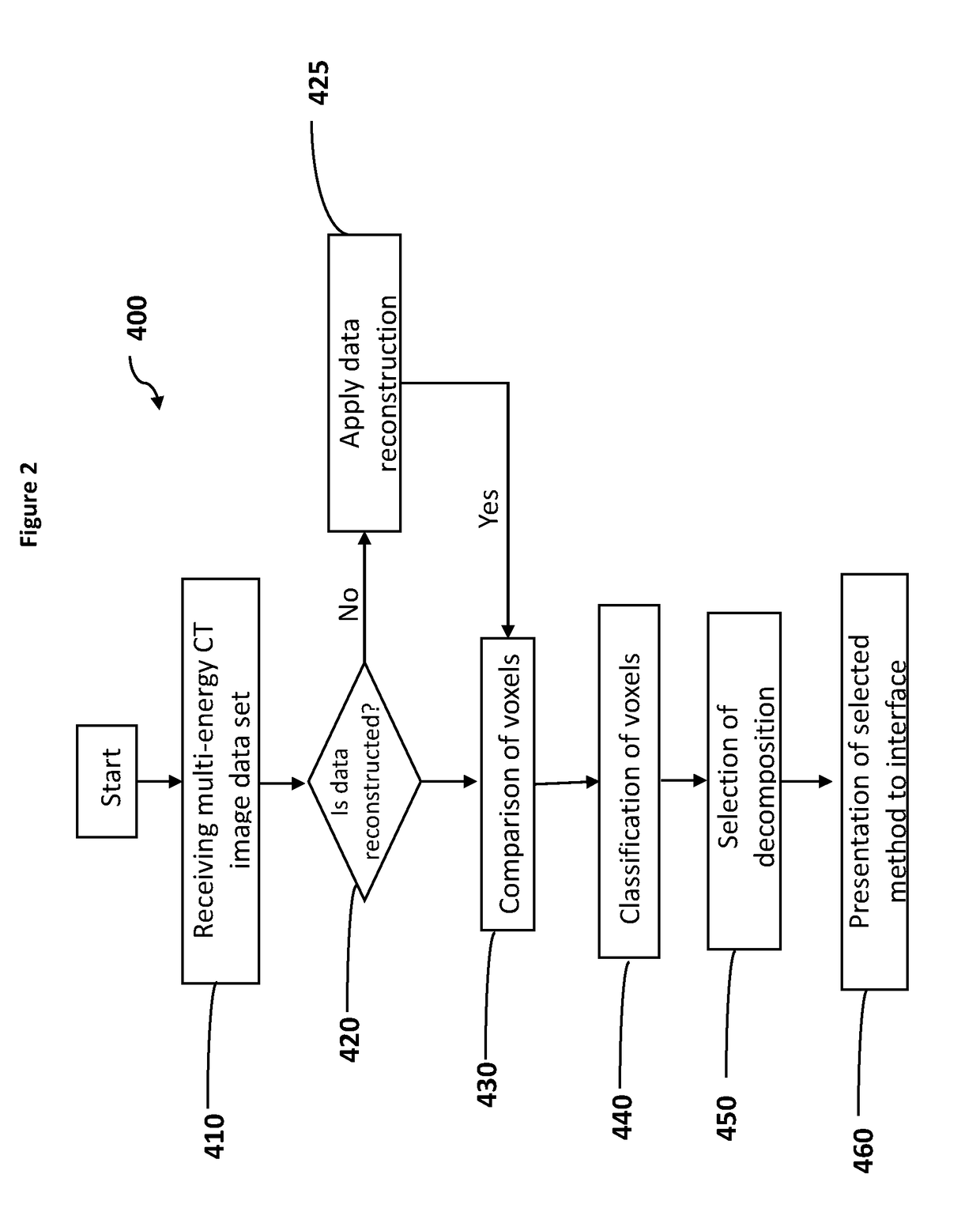

Improving material identification using multi-energy ct image data

ActiveUS20180114314A1Efficiently quantizedImage enhancementReconstruction from projectionMulti materialComputer science

Disclosed are methods for identification and quantification of a number of different materials within an object using one or more multi-energy CT imaging devices and the image data sets produced therefrom. Identification and quantification of different materials is achieved by using the following three properties: solve only for sparse solutions; separate the soft tissue problem from the dense material problem; and use a combinatorial approach to allow for simple application of different constraints to different combinations of materials. Also disclosed are one or more computer program products, computer systems or computer implemented methods for the identification of multiple materials within an object.

Owner:MARS BIOIMAGING LTD

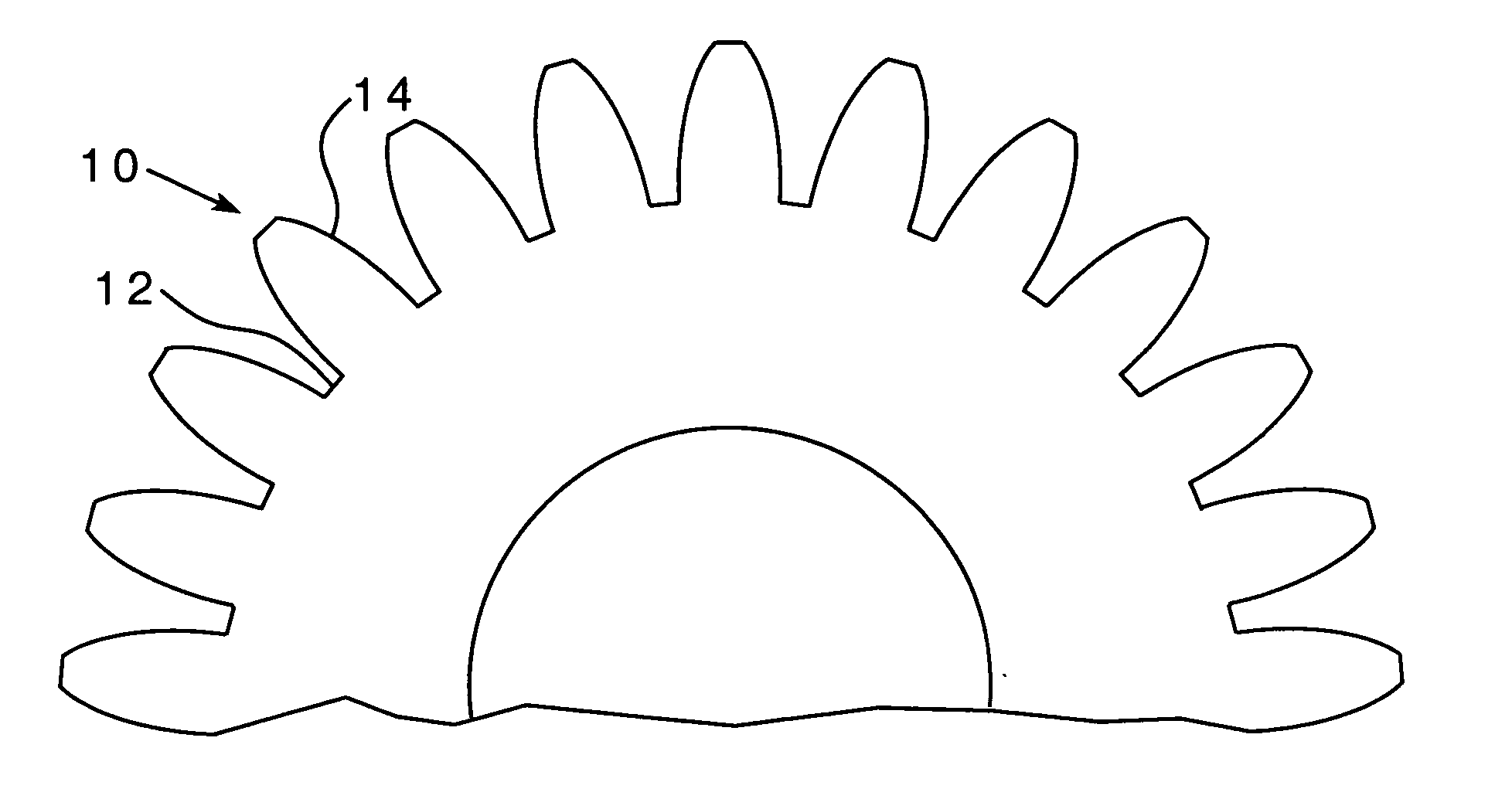

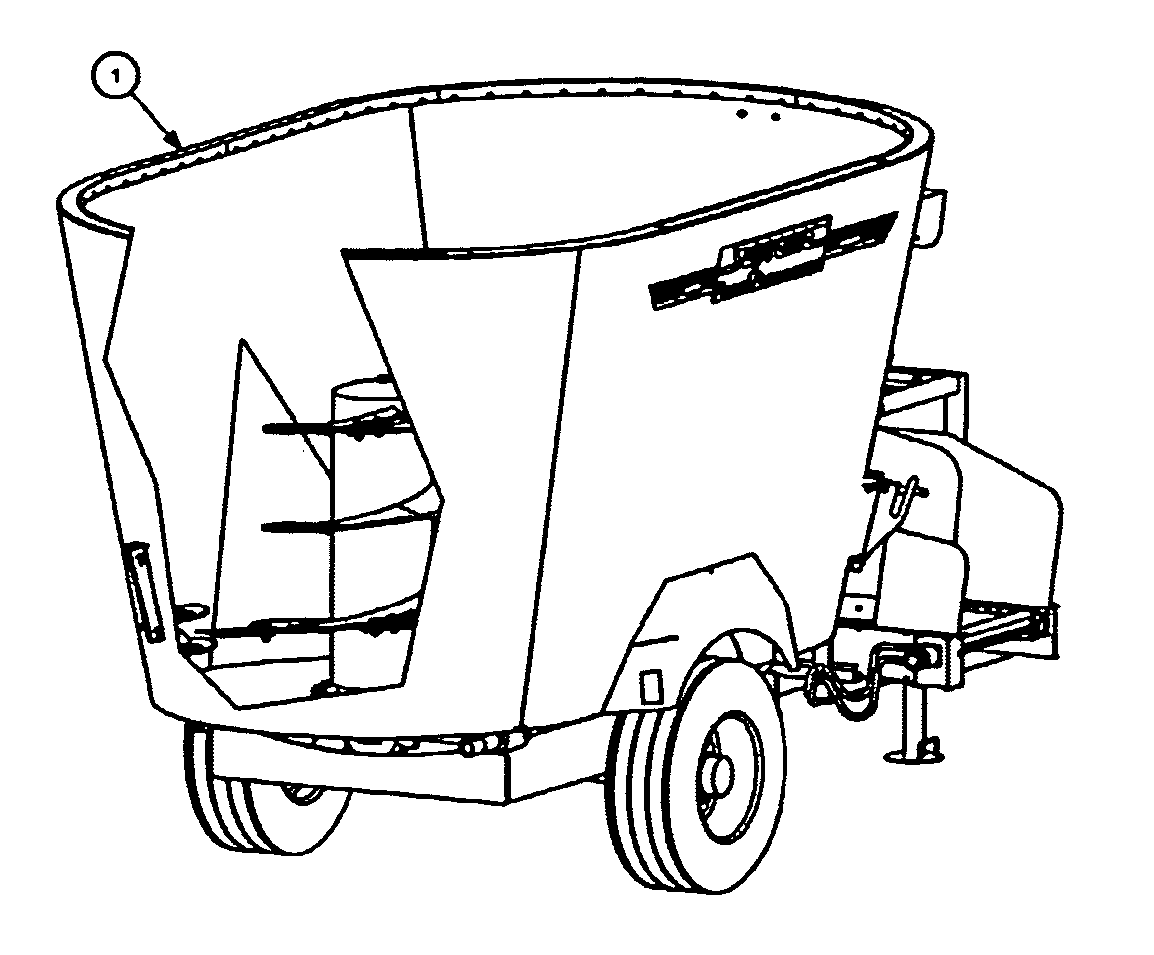

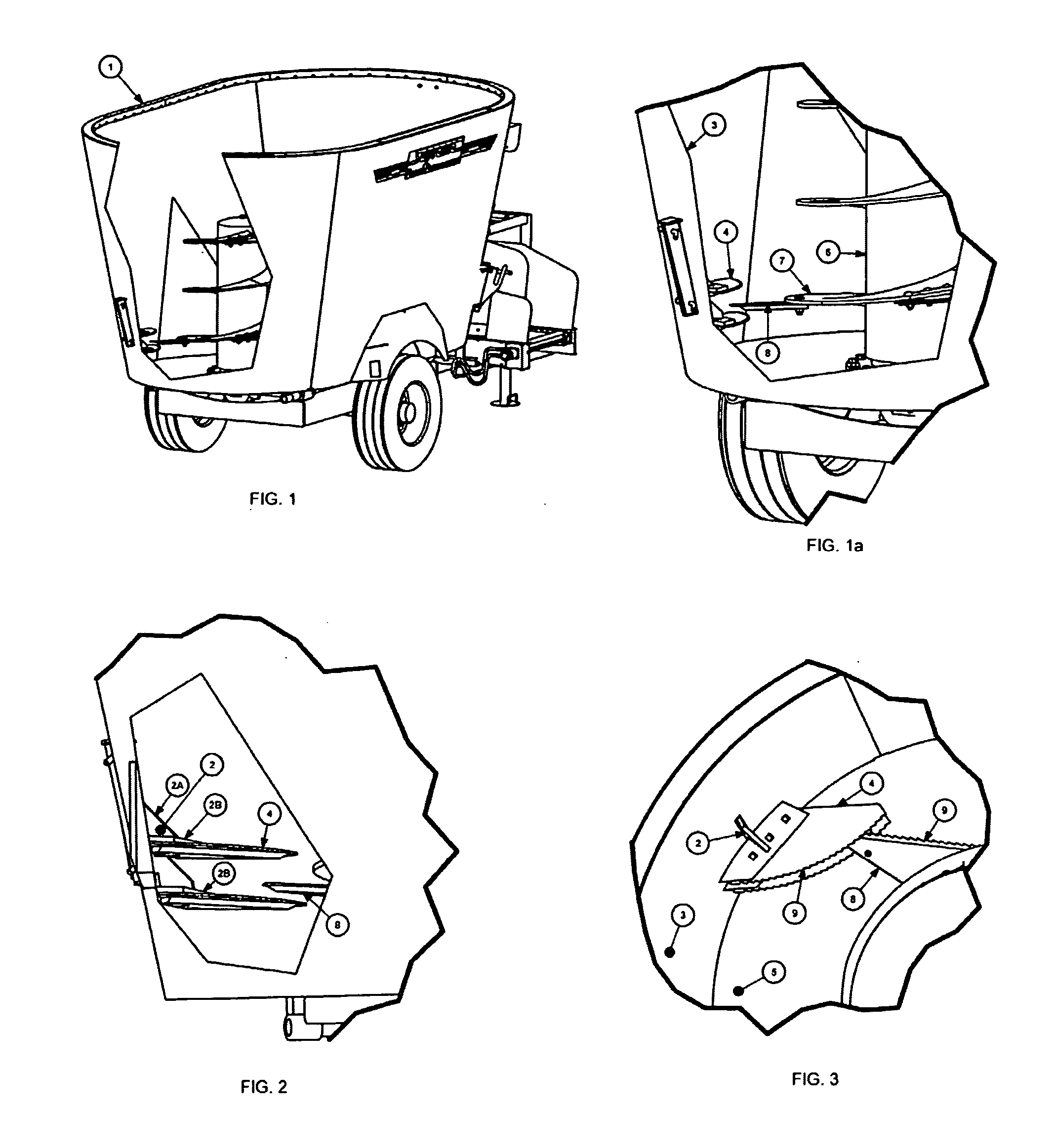

Vertical mixer with interference knives

InactiveUS20060108464A1Aggressive cutting actionEfficient cuttingGrain huskingGrain polishingEngineeringDense material

There is a new and useful invention for the cutting, processing and mixing of material. The invention is comprised of a vertical mixer containing stationary knives interacting with rotating knives. The stationary knives mounted on the tub wall interact with the rotating knives mounted on the radial edge of the rotating auger. This interaction facilitates cutting of large, coarse and dense materials otherwise not readily processed by vertical mixers.

Owner:RUS GUSTAAF MAARTER

Dry self-lubricating dense material; a mechanical part formed from said material; a method of manufacturing said material

InactiveUS20030231975A1Minimize avoid formationAffect material propertyTransportation and packagingMetal-working apparatusVolumetric Mass DensityUltimate tensile strength

The present invention provides: a material, which is dense, with a density of >=90%, bulk dry self-lubricating, with a coefficient of friction of <0.3, constituted by a matrix that endows it with suitable strength, with a Rm of >=400 MPa in a medium to high temperature range of 300° C.<=theta<=600° C.; said matrix including particles of solid lubricant in its volume; mechanical parts formed from said material; a method of manufacturing said material.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

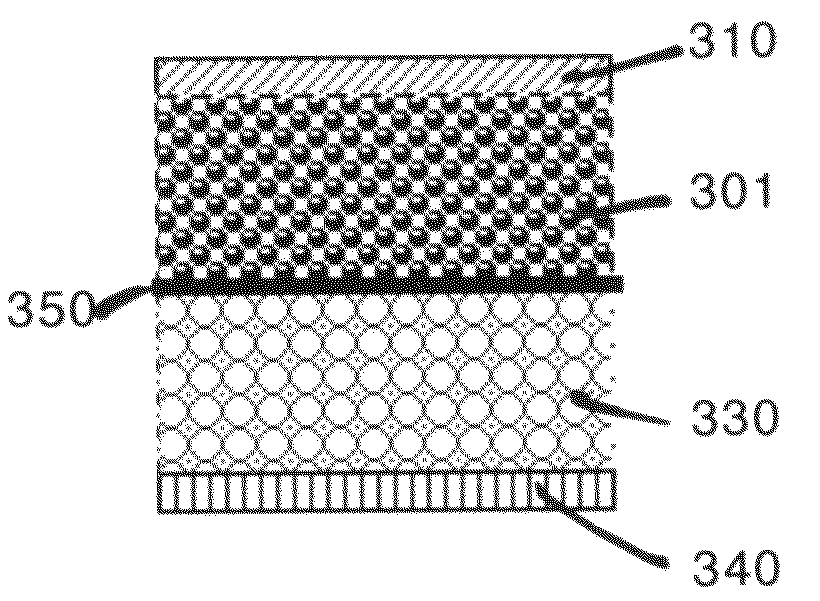

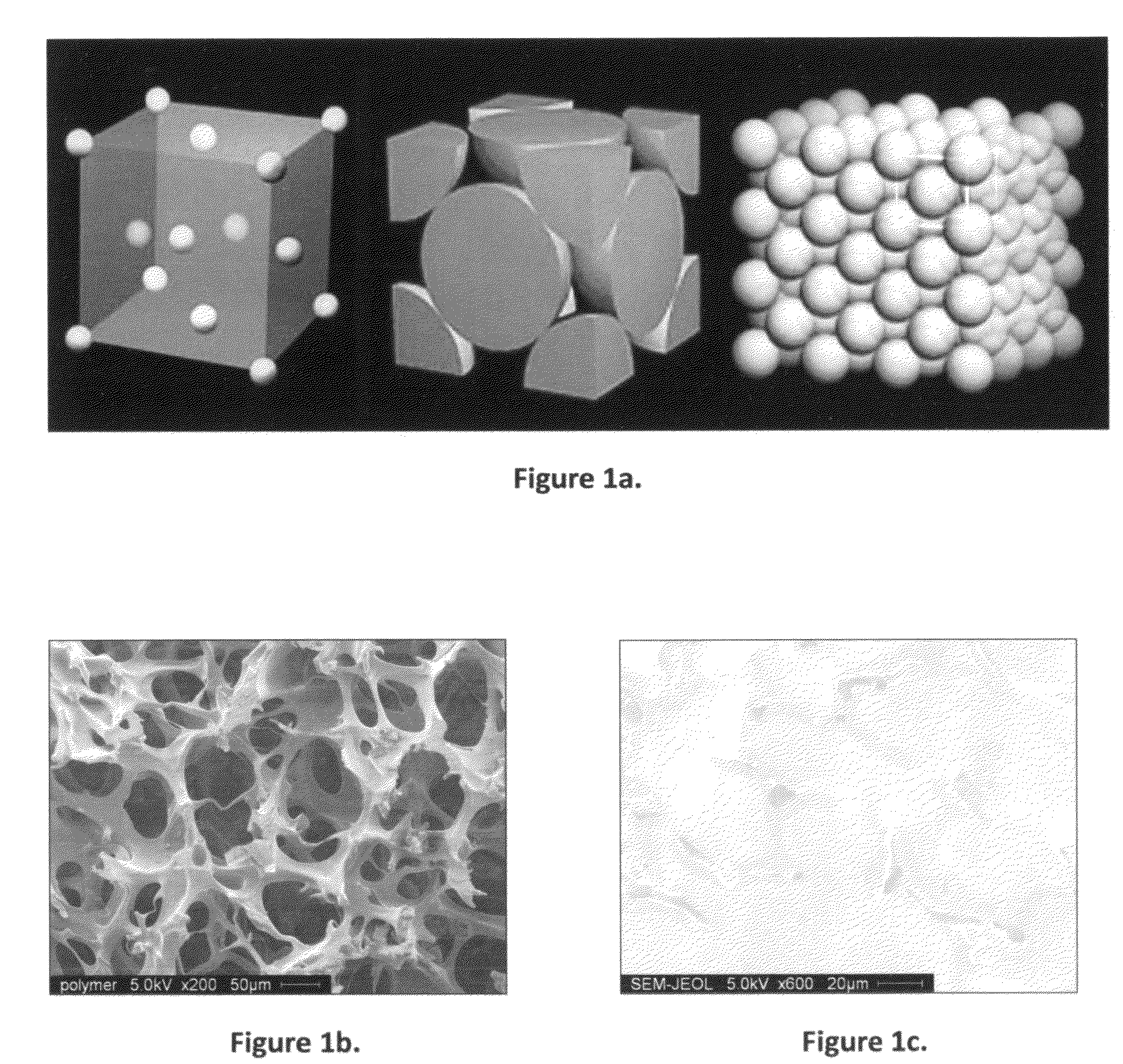

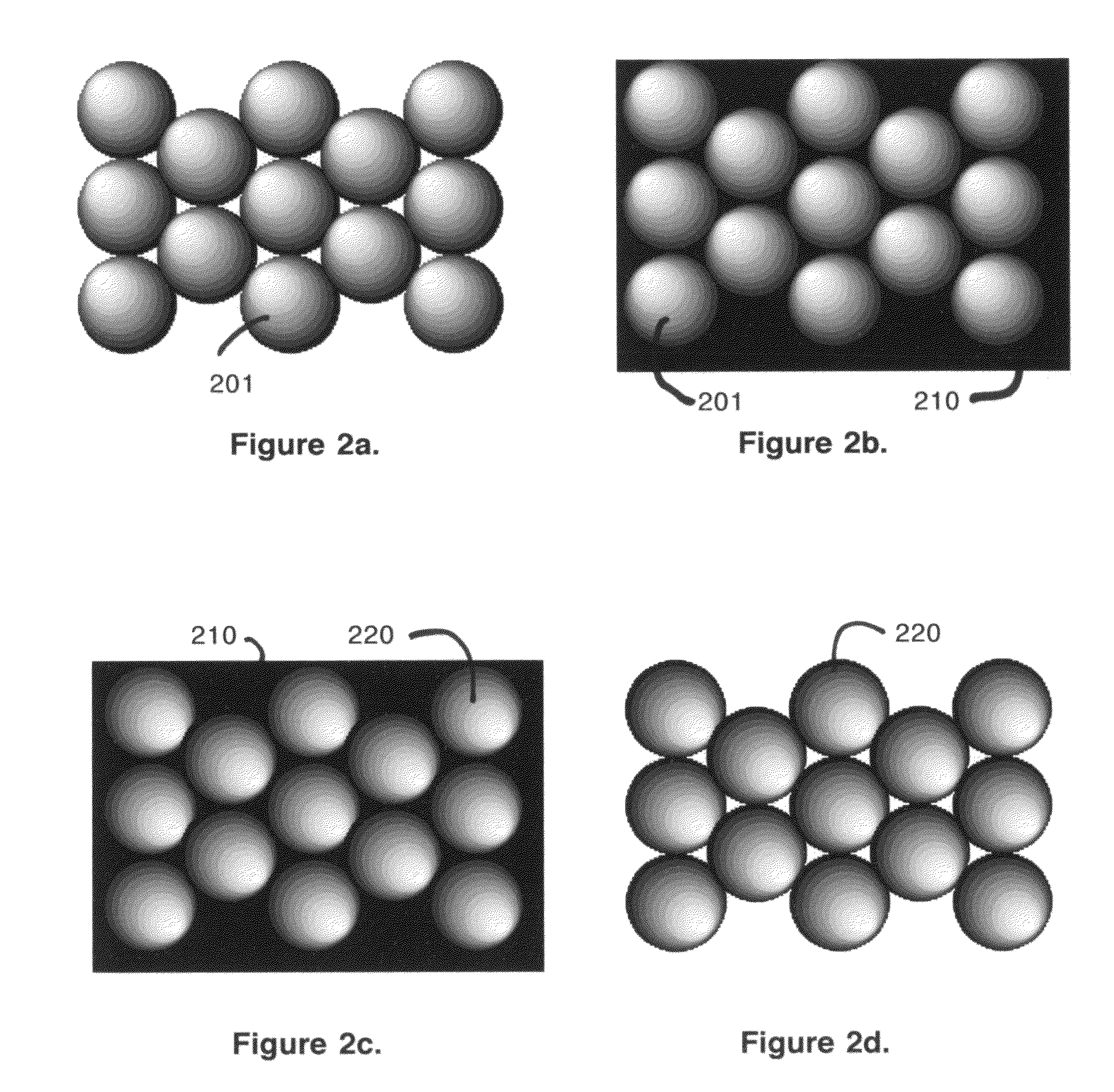

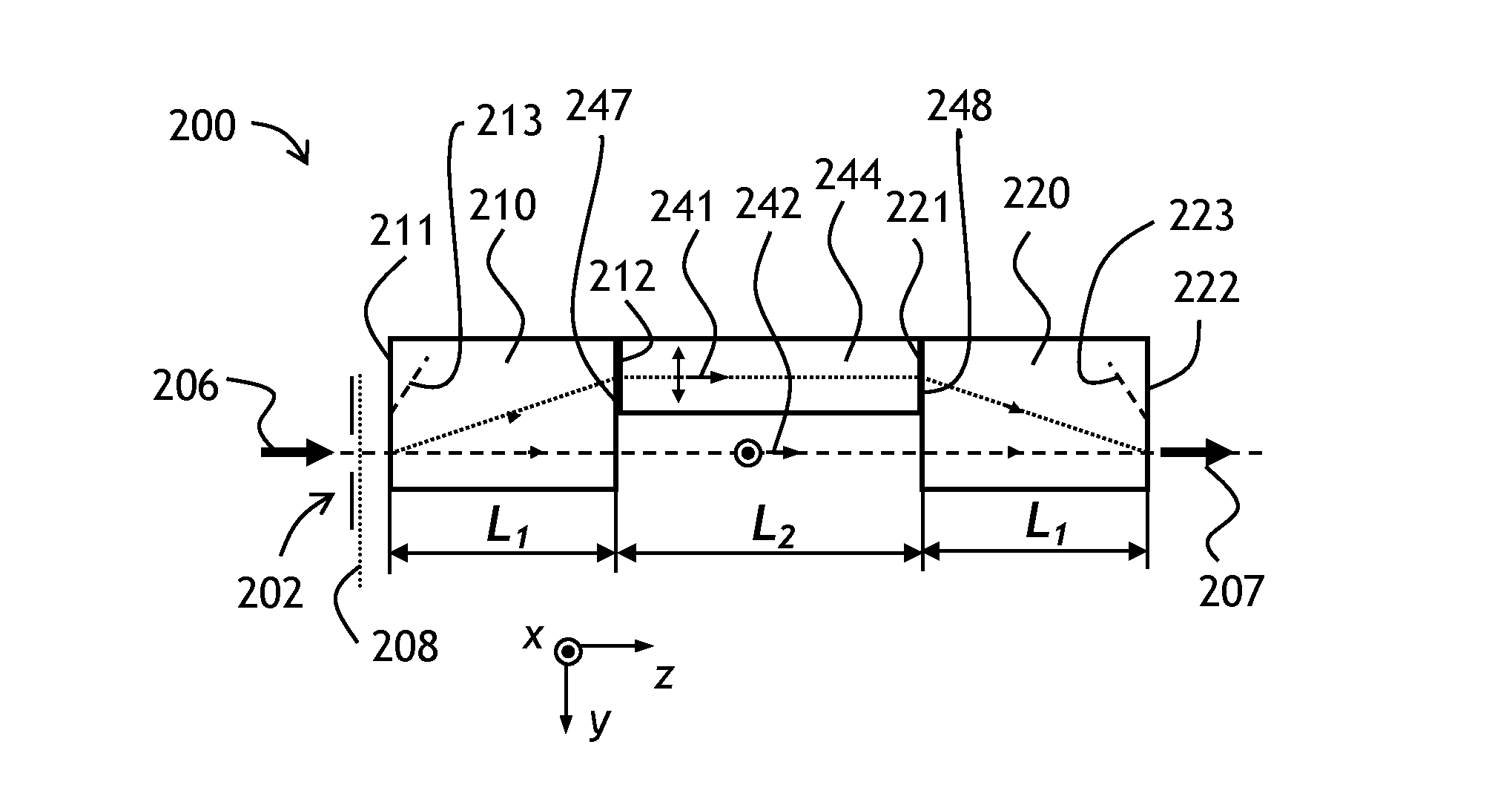

Methods for synthesizing bulk, composite and hybrid structures from polymeric ceramic precursors as well as other polymeric substances and compounds

This invention relates to polymer derived ceramics (PDC's) and more particularly, to methods and product made by using polymeric derived ceramic precursors to synthesize dense, crack-free bulk ceramics in a technique using sacrificial molds, coating processes, replication processes, assembly processes and finishing processes; where gas release paths are created and maintained during these processes to release gases generated during pyrolysis of the ceramic precursor. It is a primary objective of the present invention to provide a well defined method to create PDC voxels which are interconnected as a bulk (high density) material. Such a material is effectively a lattice with face centered cubic or hexagonal close pack geometry. A second objective of the present invention is to provide a method for bulk, high density material to be combined with fully dense material in a hybrid material. A third objective of the present invention is to provide a method for different types of bulk and fully dense materials, and other items (optionally), to be combined in to a composite material.

Owner:FEI WEIFENG +2

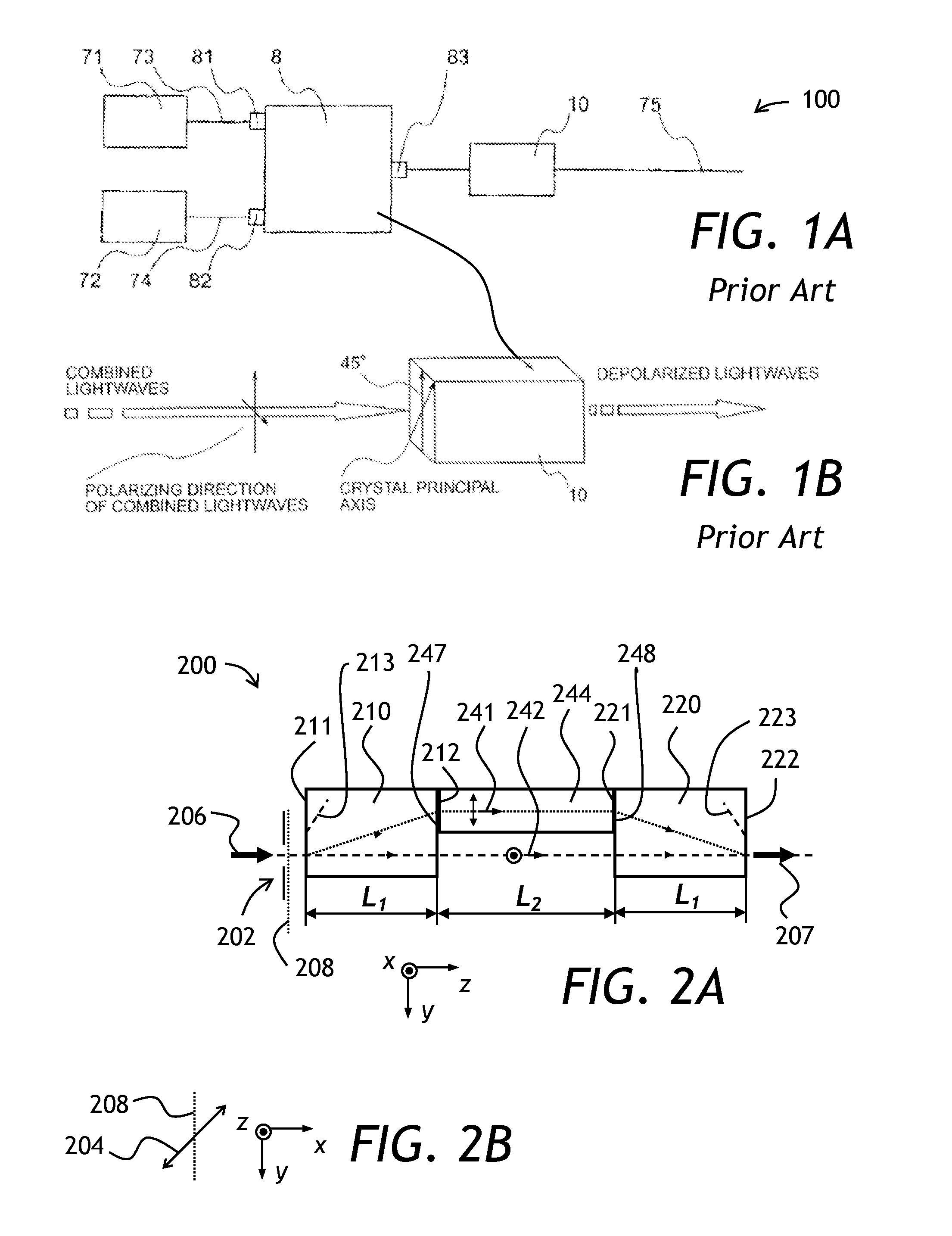

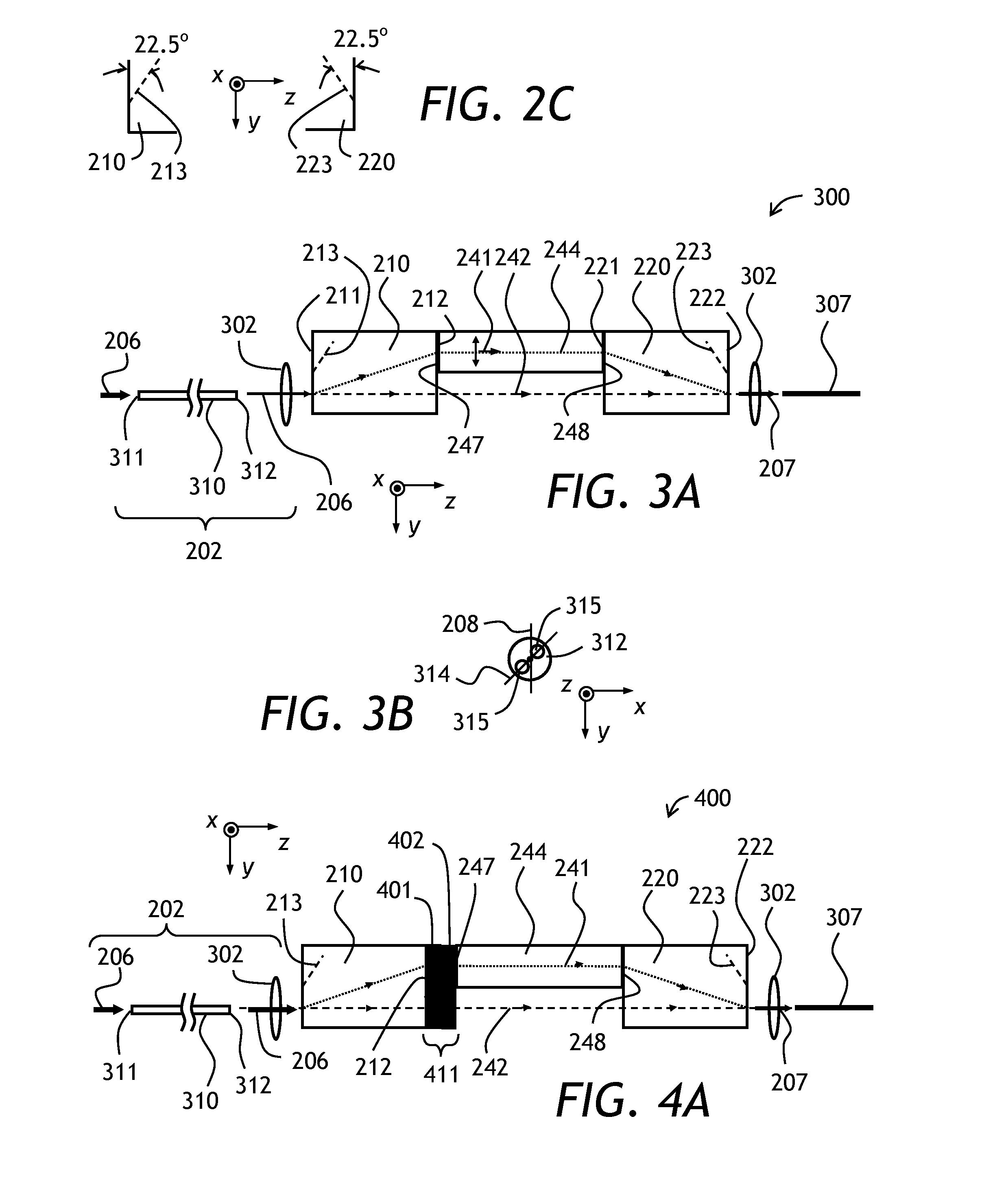

Optical depolarizer

ActiveUS20130250416A1Large optical path differenceCompact polarizationPolarising elementsOptical light guidesDual coreLight beam

A polarized light beam having a coherence length L can be depolarized by splitting the beam into orthogonally polarized sub-beams and delaying one of the sub-beams relative to the other by a length larger than L. This spatial delay is created by splitting the beam in a walk-off crystal and disposing in the optical path of one of the sub-beams a slab of an optically dense material, while allowing the other sub-beam to propagate outside and near the slab. The sub-beams remain parallel to each other, allowing another walk-off crystal to be used to recombine the sub-beams. A dual-core fiber ferrule and a microlens array can be used to combine fiber-coupled output beams of two laser diodes in a single compact walk-off crystal.

Owner:LUMENTUM OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com