Patents

Literature

119 results about "Full density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

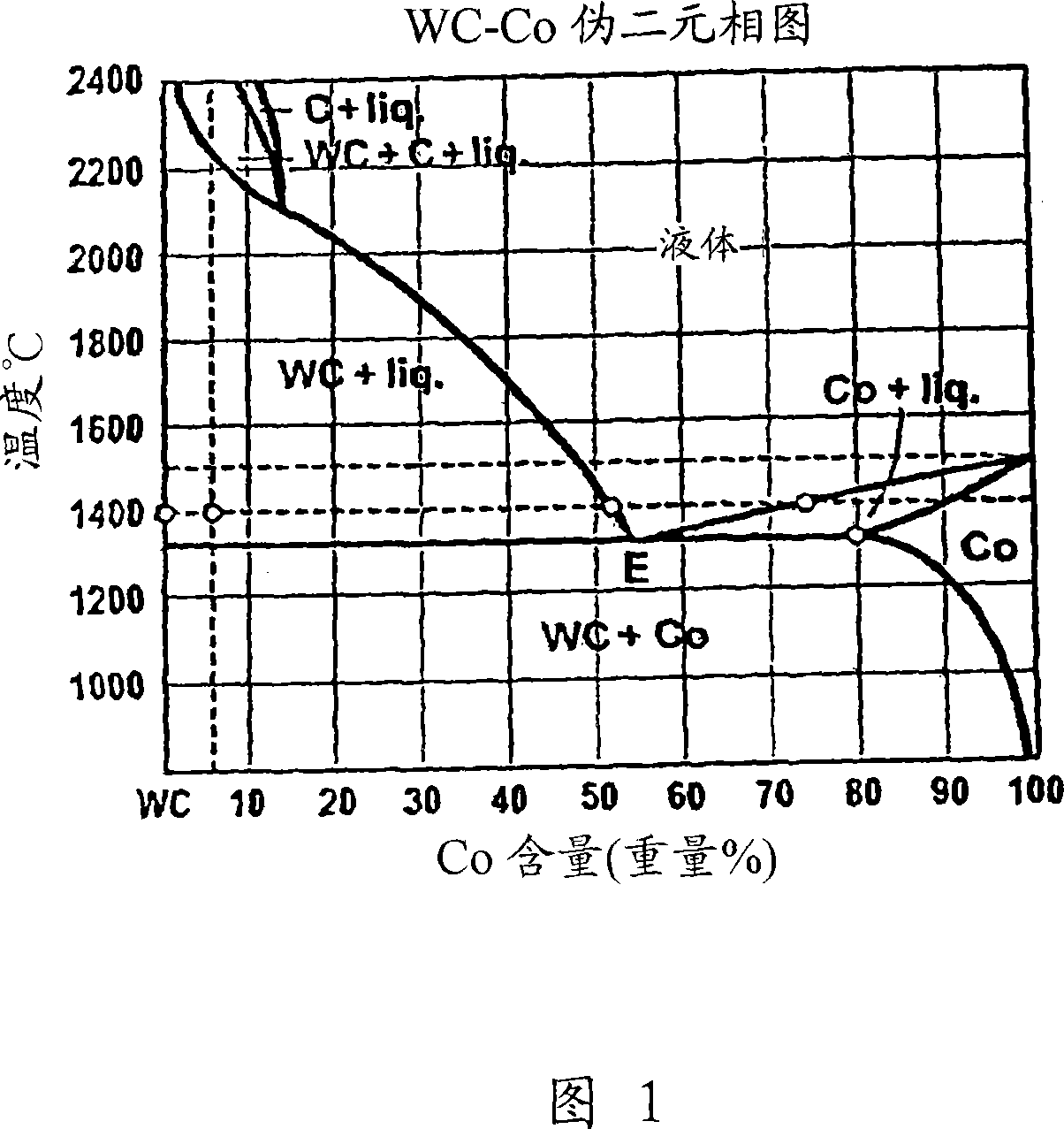

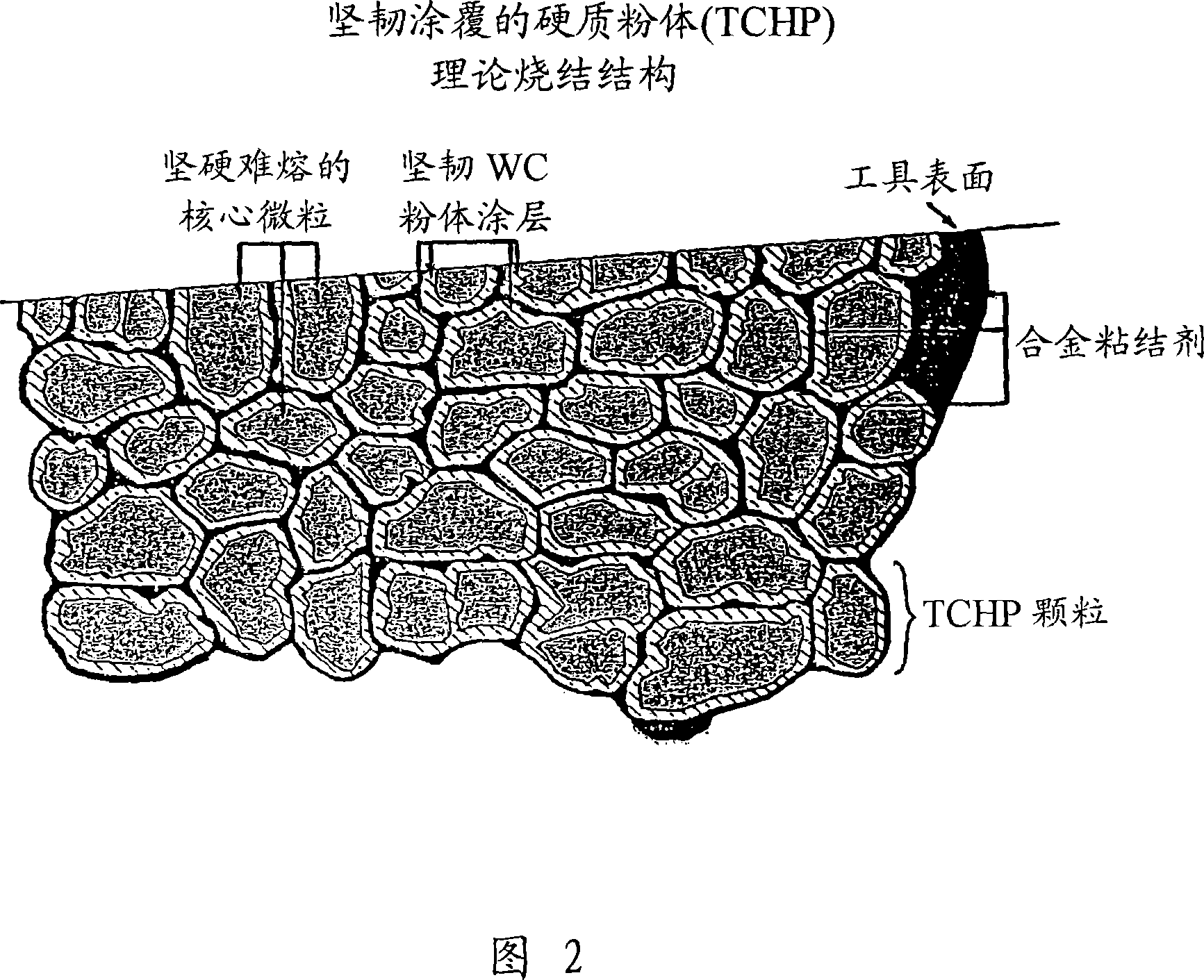

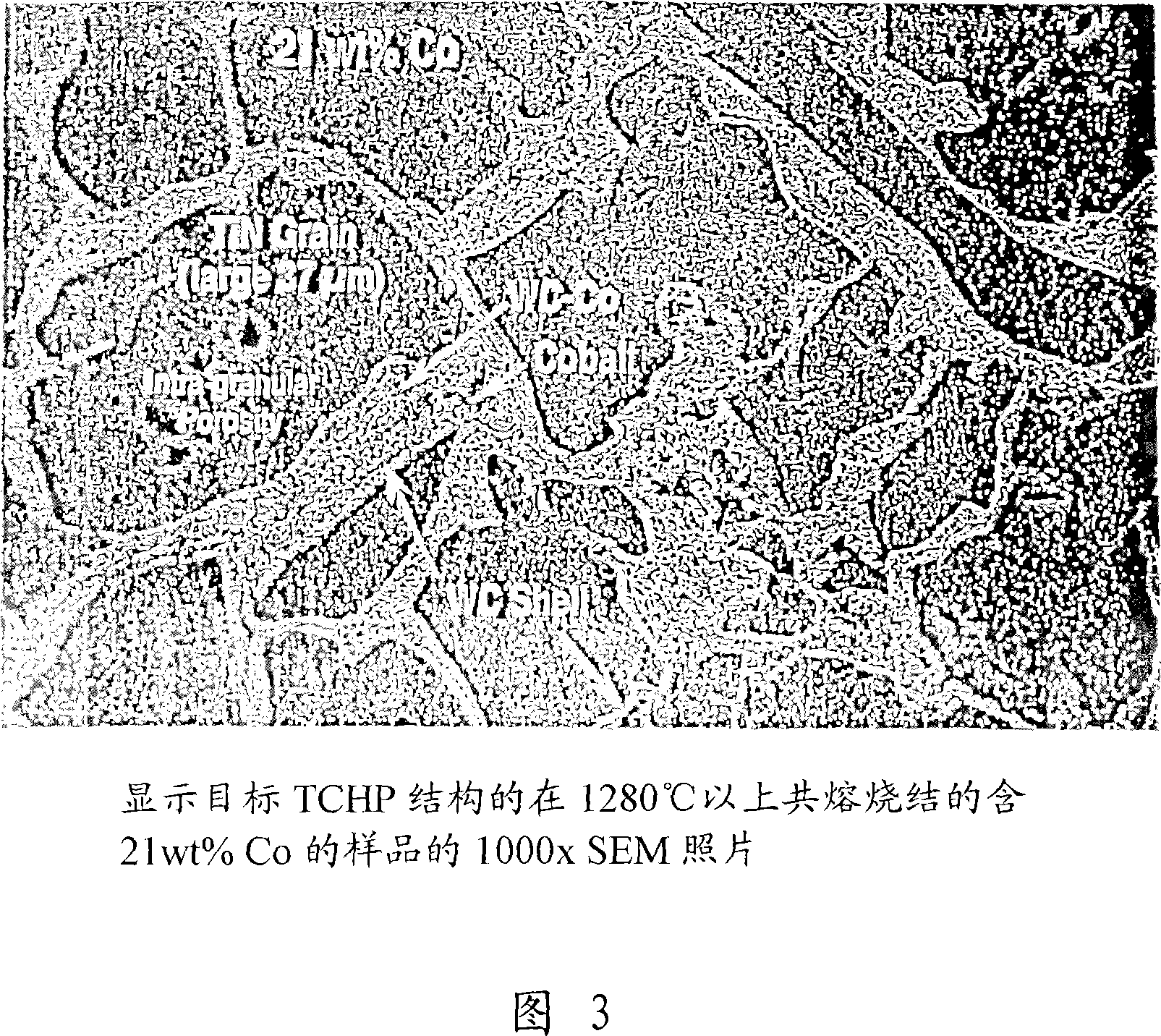

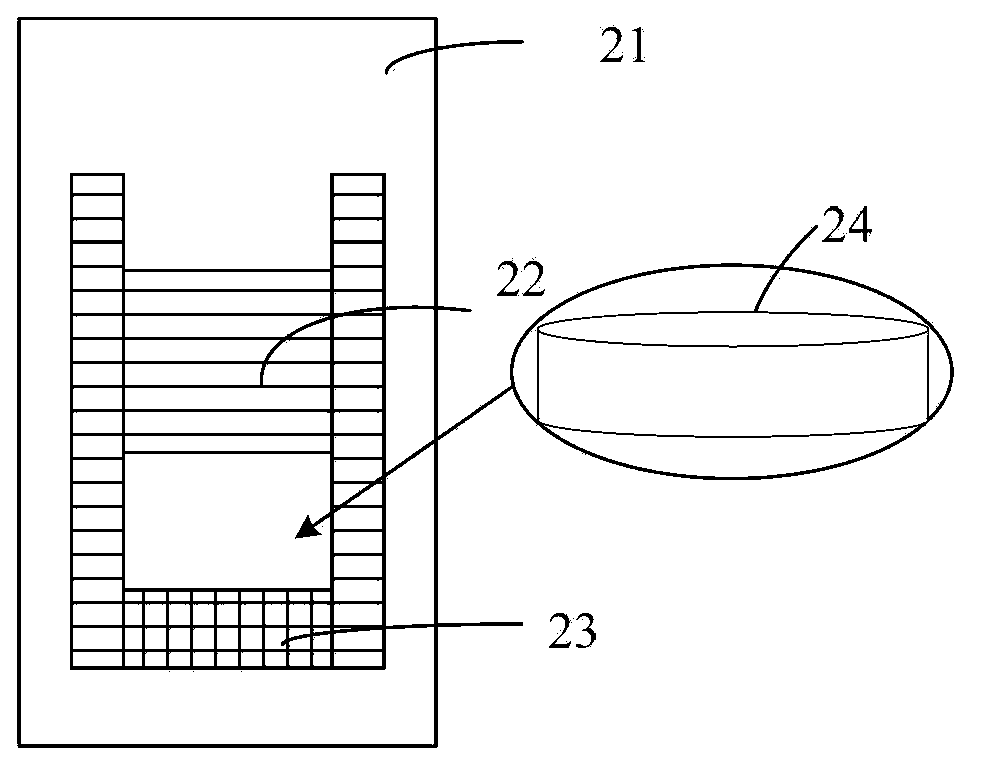

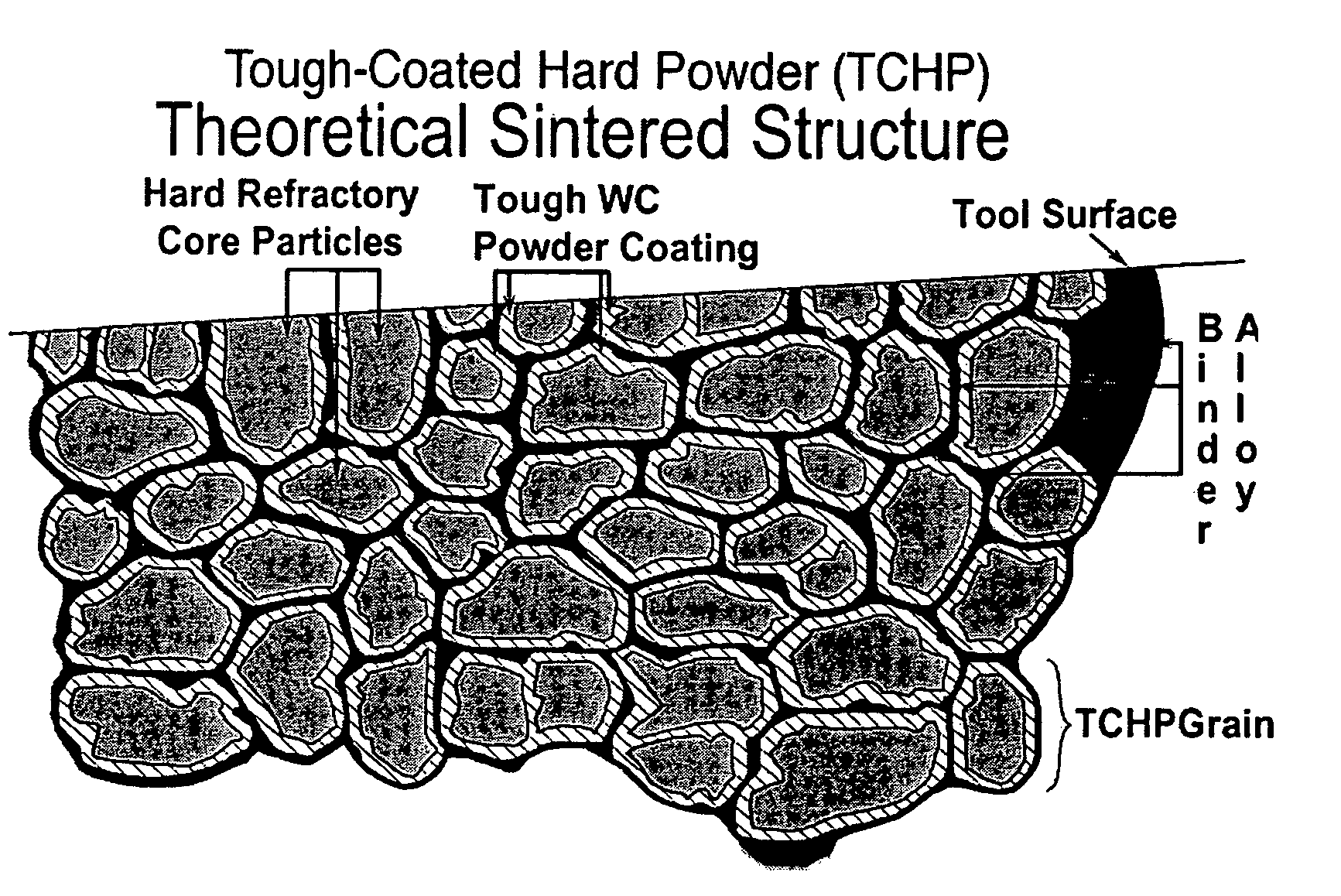

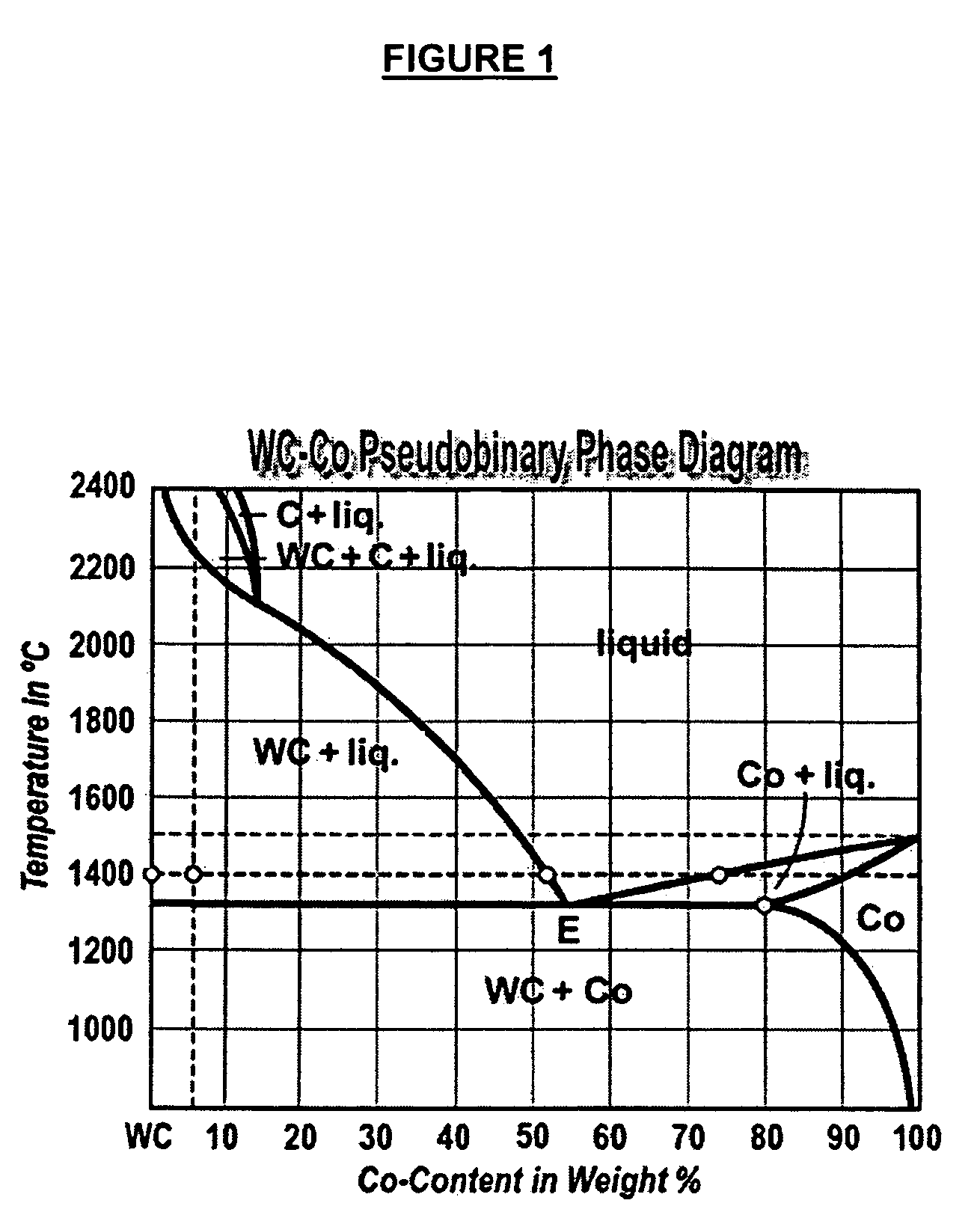

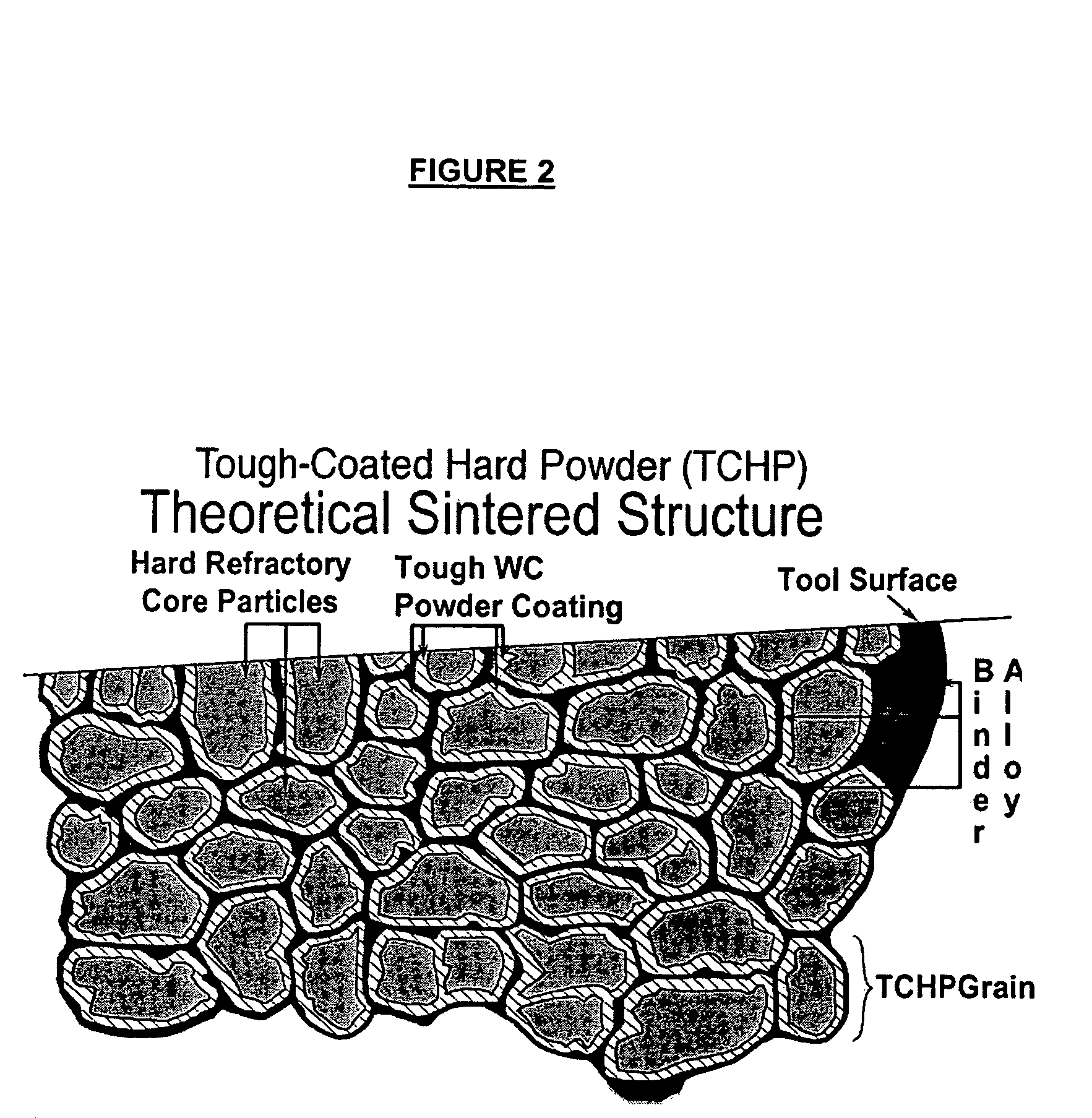

Method for consolidating tough coated hard powders

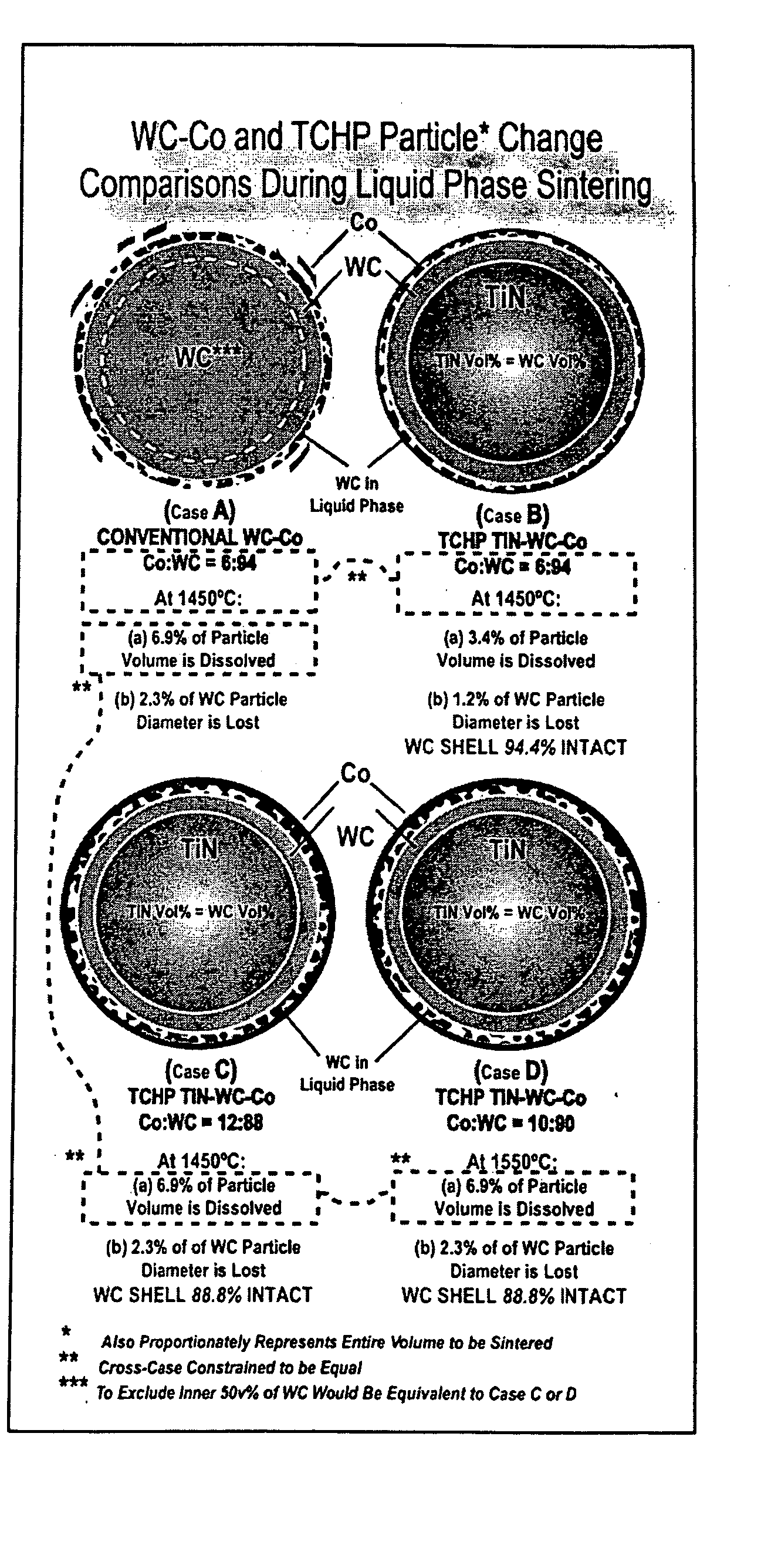

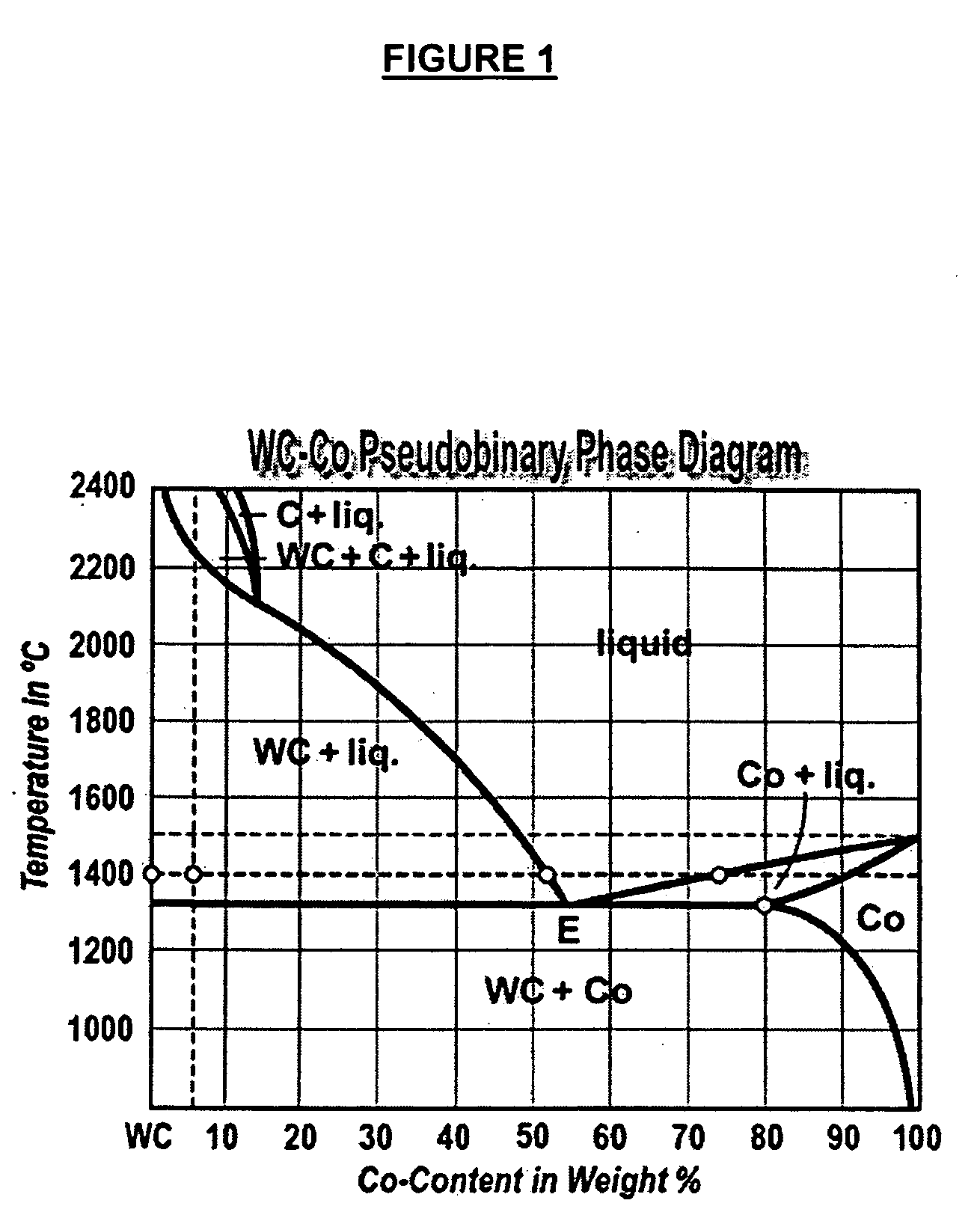

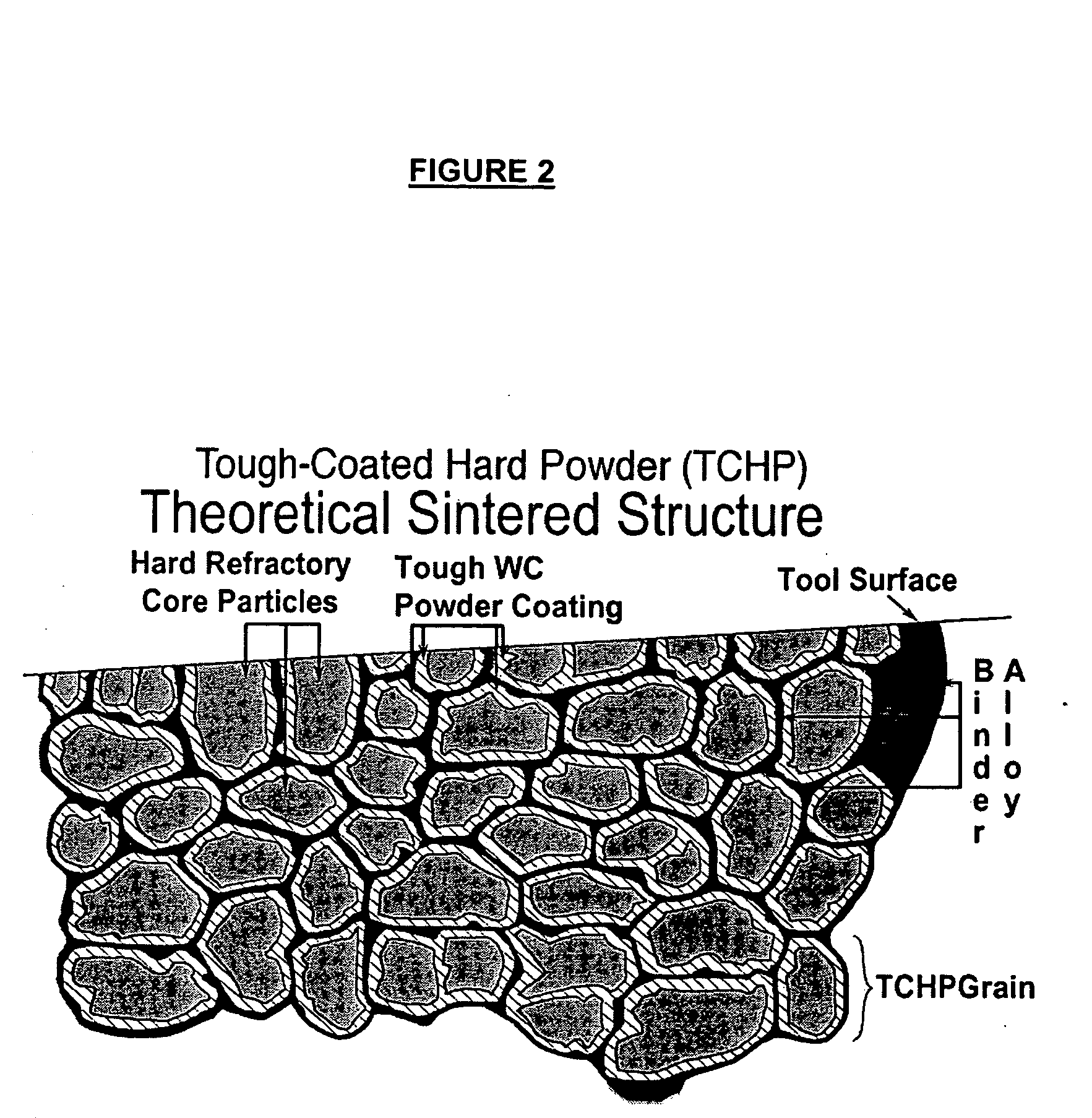

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:ETERNALOY HLDG GMBH

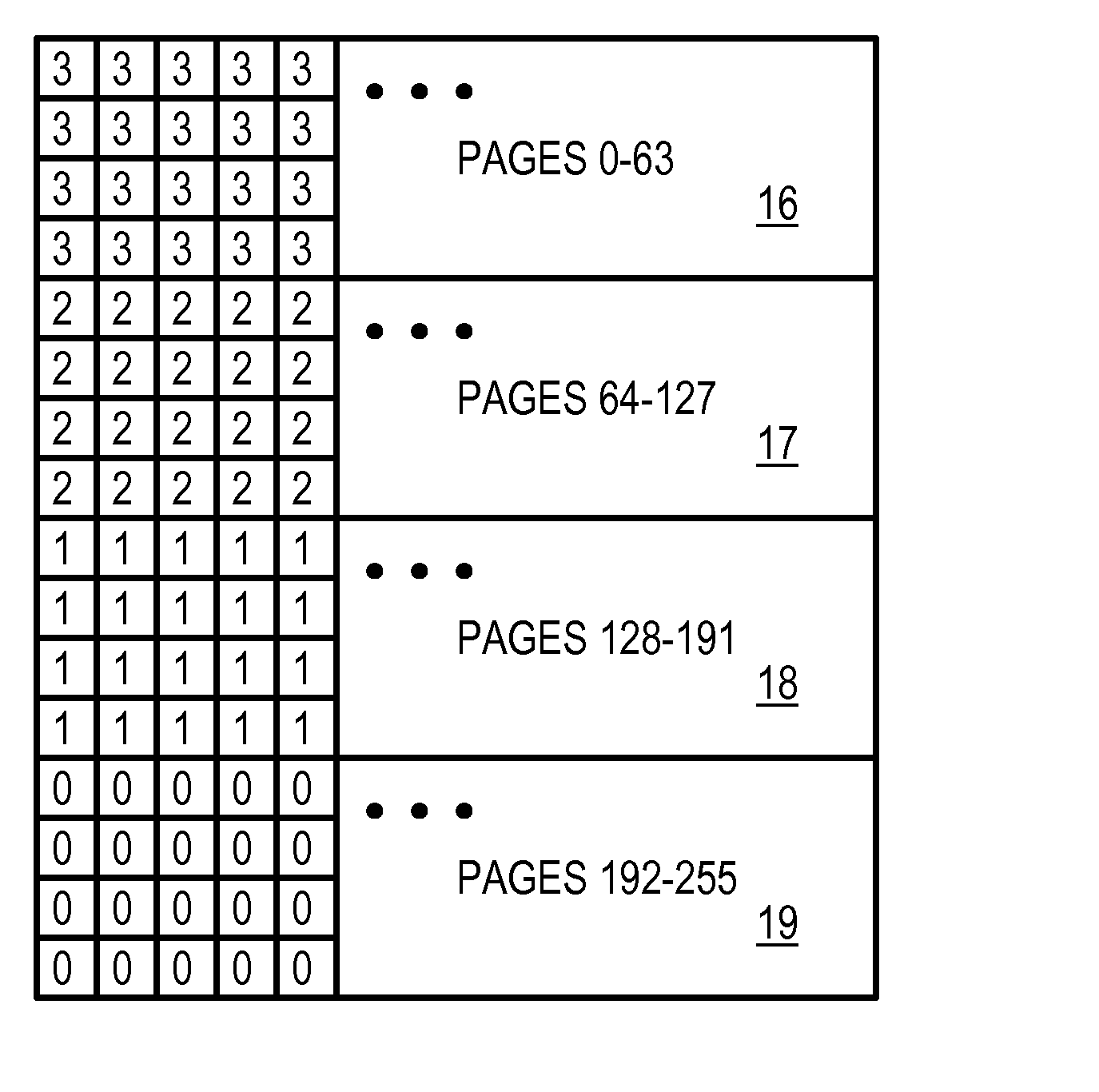

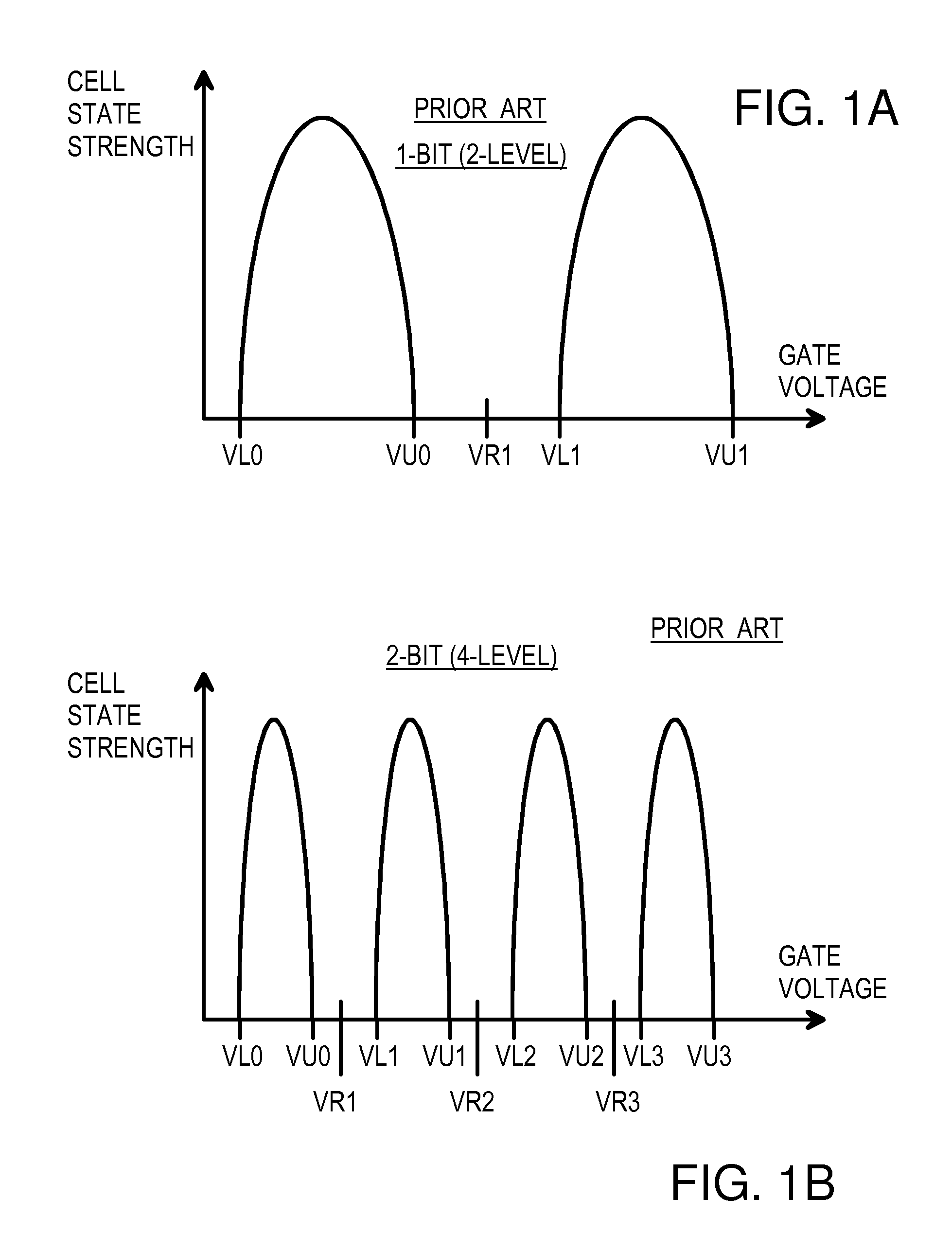

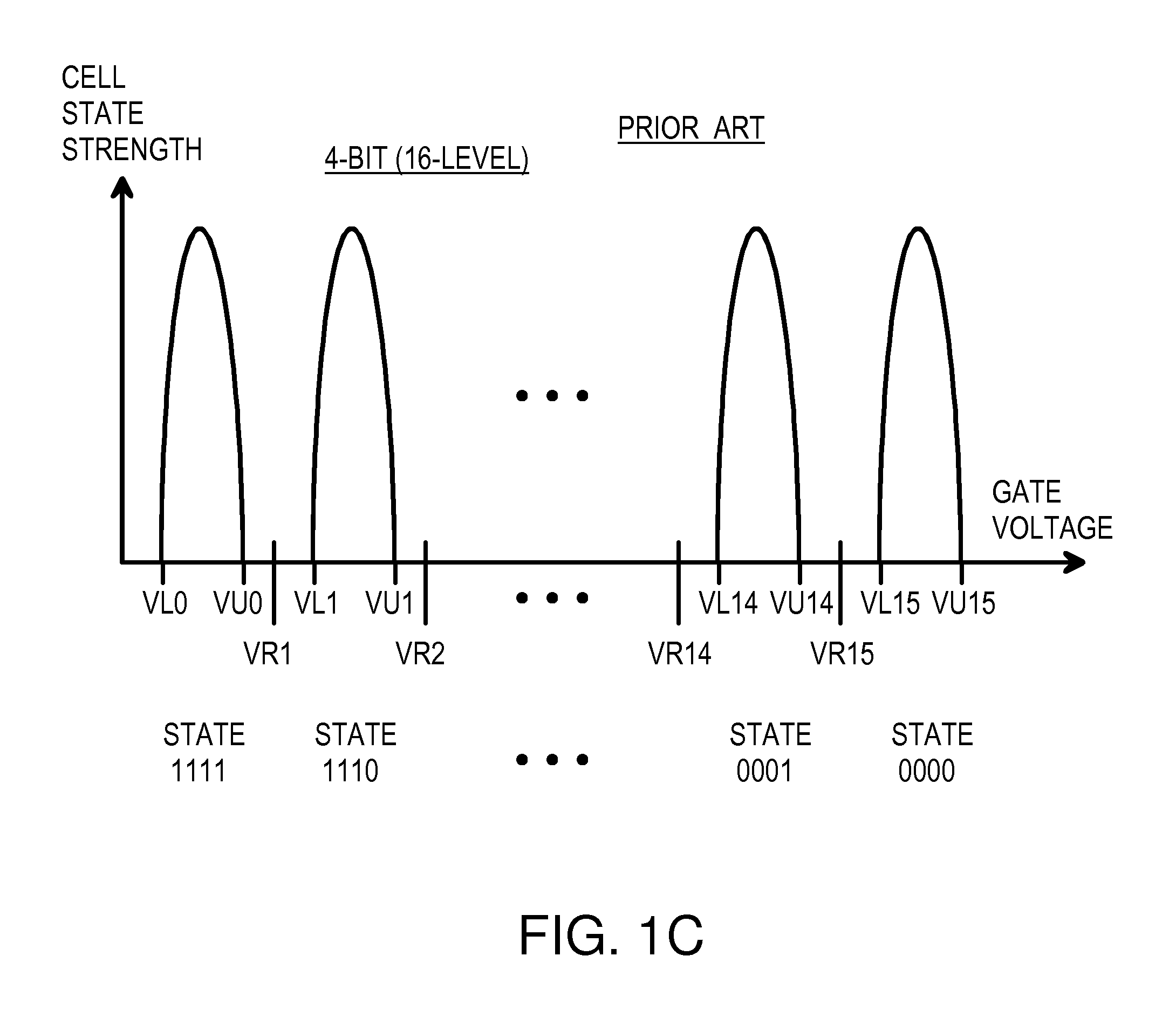

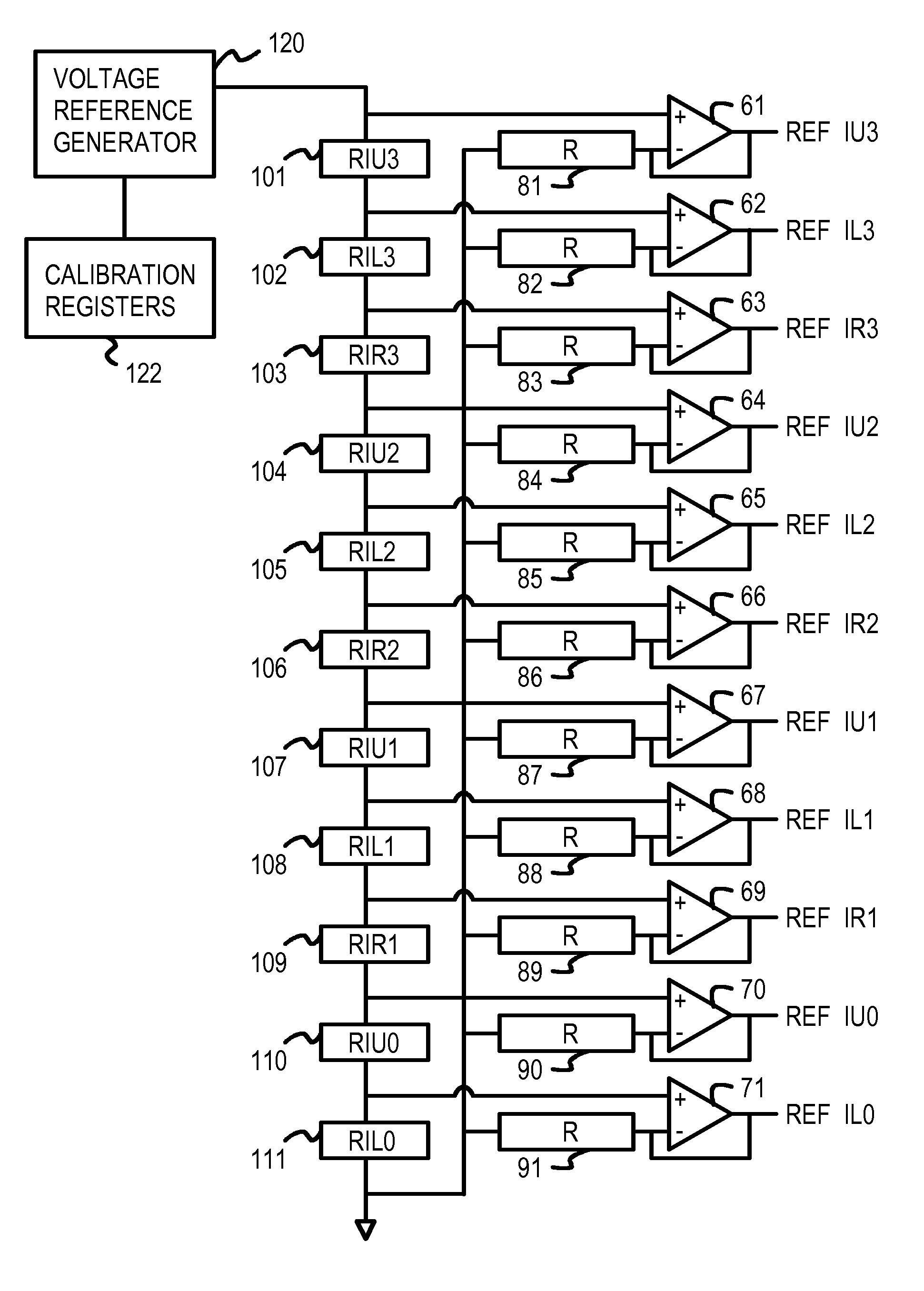

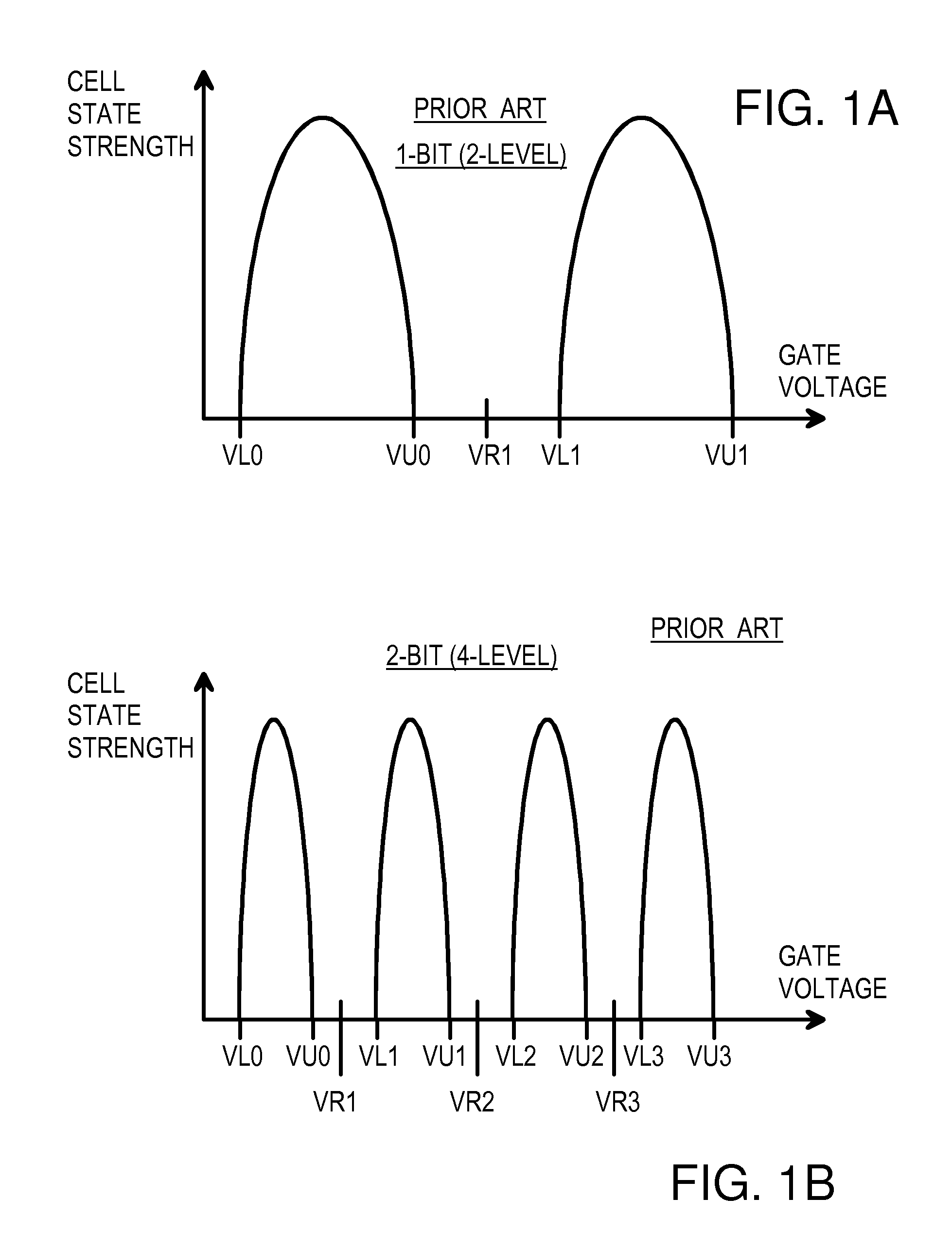

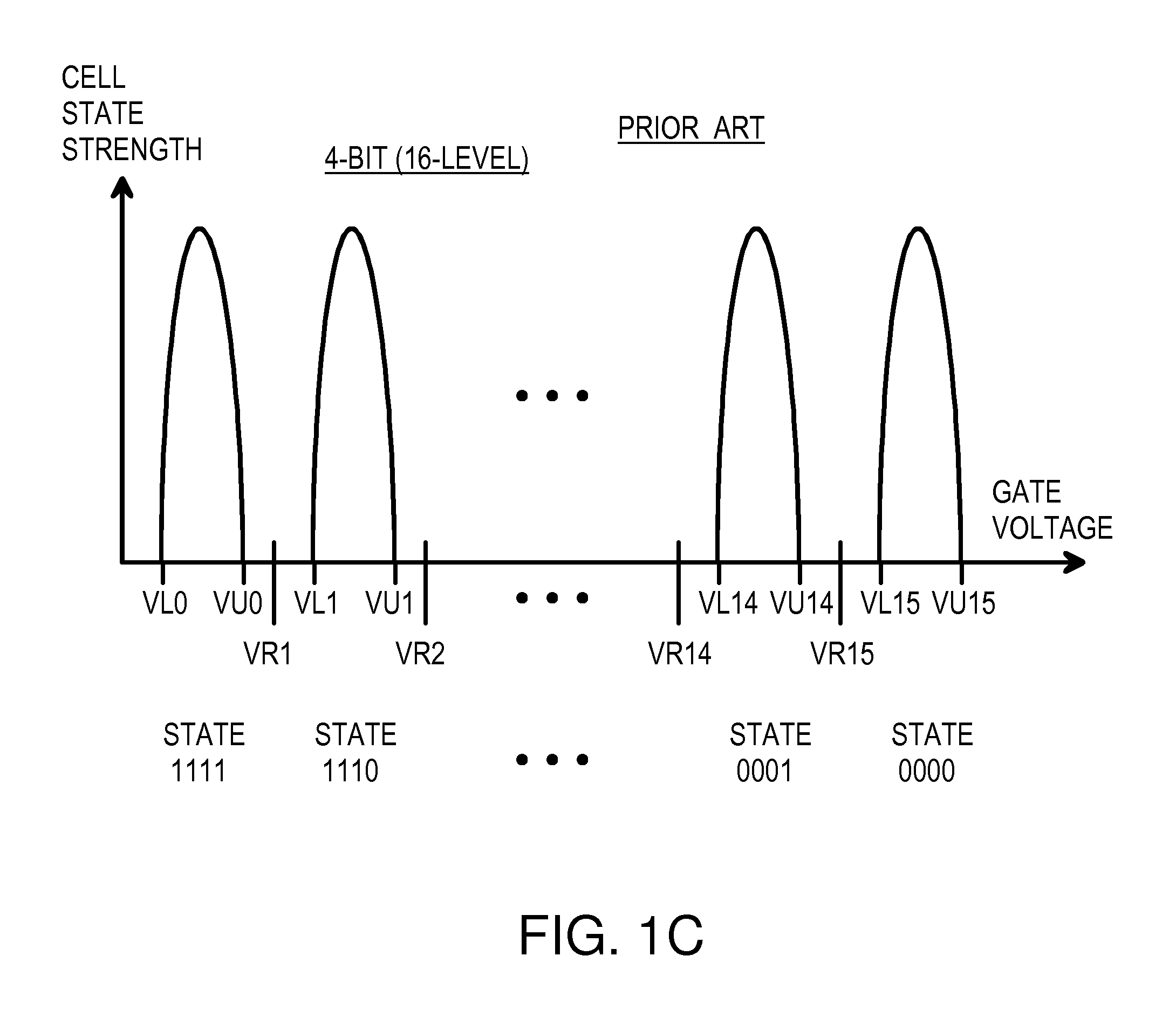

Cell-Downgrading and Reference-Voltage Adjustment for a Multi-Bit-Cell Flash Memory

A flash memory has multi-level cells (MLC) that can each store multiple bits per cell. Blocks of cells can be downgraded to fewer bits / cell when errors occur, or for storing critical data such as boot code. The bits from a single MLC are partitioned among multiple pages to improve error correctability using Error Correction Code (ECC). An upper reference voltage is generated by a voltage reference generator in response to calibration registers that can be programmed to alter the upper reference voltage. A series of decreasing references are generated from the upper reference voltage and are compared to a bit-line voltage. Compare results are translated by translation logic that generates read data and over- and under-programming signals. Downgraded cells use the same truth table but generate fewer read data bits. Noise margins are asymmetrically improved by using the same sub-states for reading downgraded and full-density MLC cells.

Owner:SUPER TALENT TECH CORP

Cell-downgrading and reference-voltage adjustment for a multi-bit-cell flash memory

A flash memory has multi-level cells (MLC) that can each store multiple bits per cell. Blocks of cells can be downgraded to fewer bits / cell when errors occur, or for storing critical data such as boot code. The bits from a single MLC are partitioned among multiple pages to improve error correctability using Error Correction Code (ECC). An upper reference voltage is generated by a voltage reference generator in response to calibration registers that can be programmed to alter the upper reference voltage. A series of decreasing references are generated from the upper reference voltage and are compared to a bit-line voltage. Compare results are translated by translation logic that generates read data and over- and under-programming signals. Downgraded cells use the same truth table but generate fewer read data bits. Noise margins are asymmetrically improved by using the same sub-states for reading downgraded and full-density MLC cells.

Owner:SUPER TALENT TECH CORP

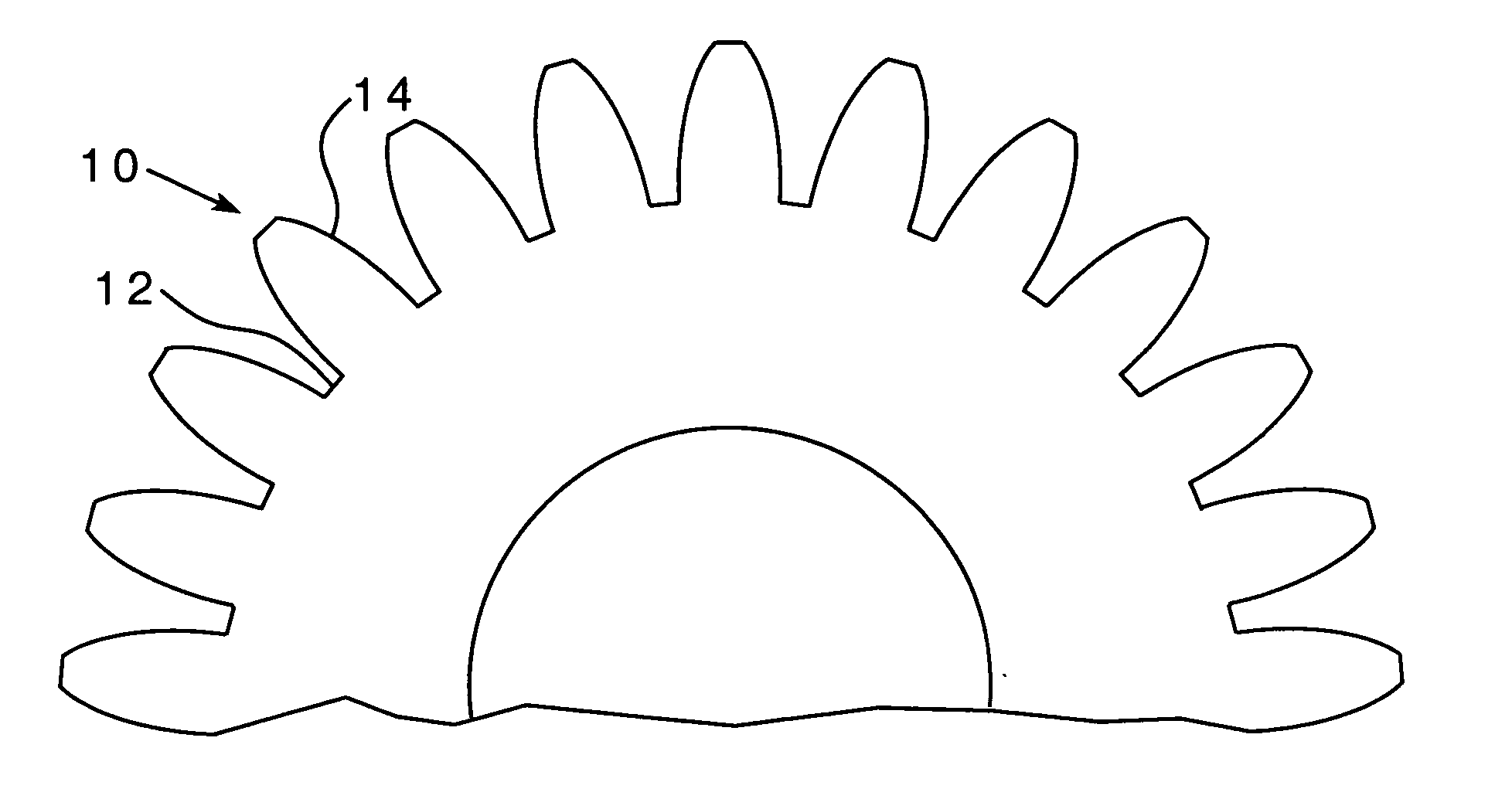

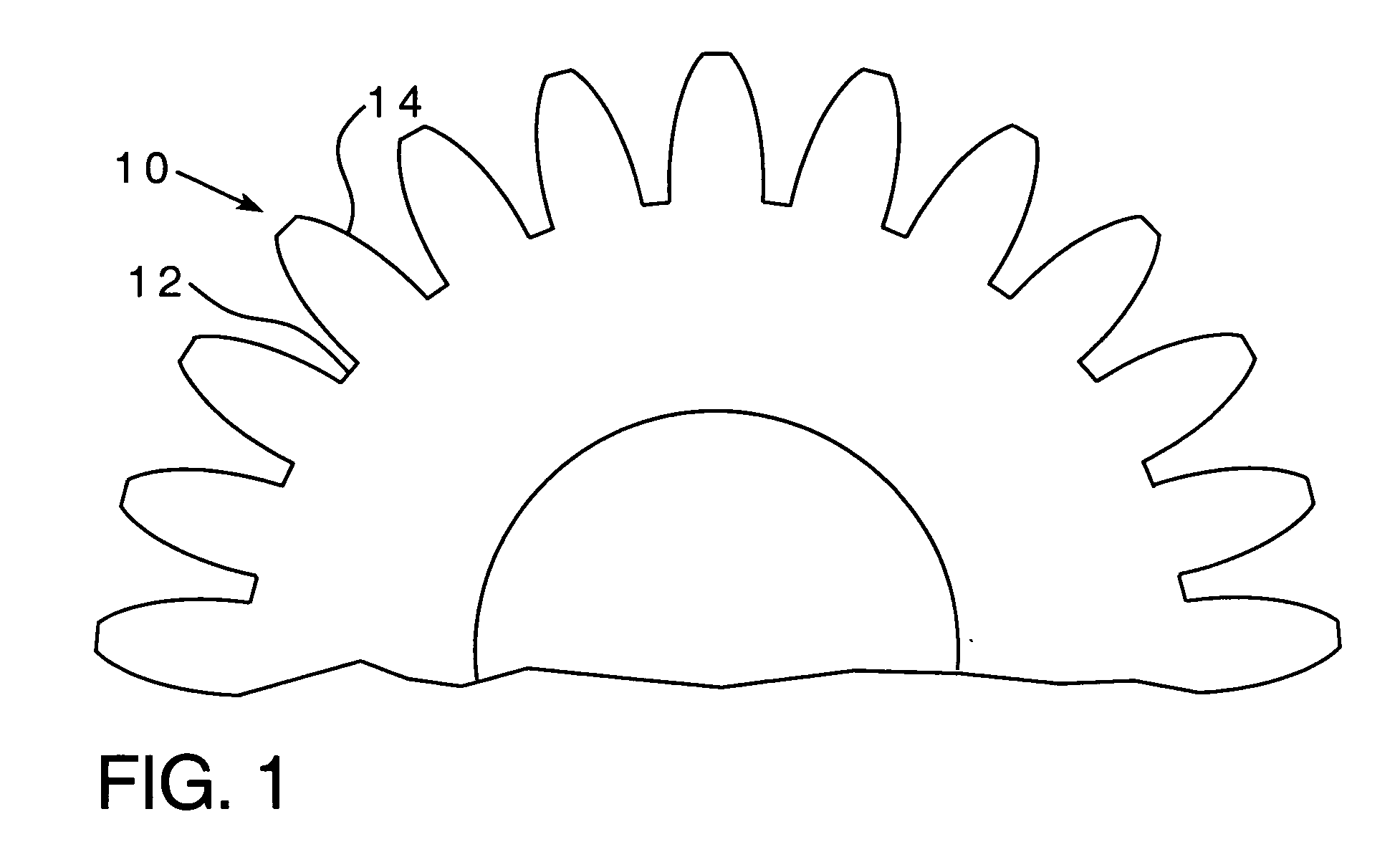

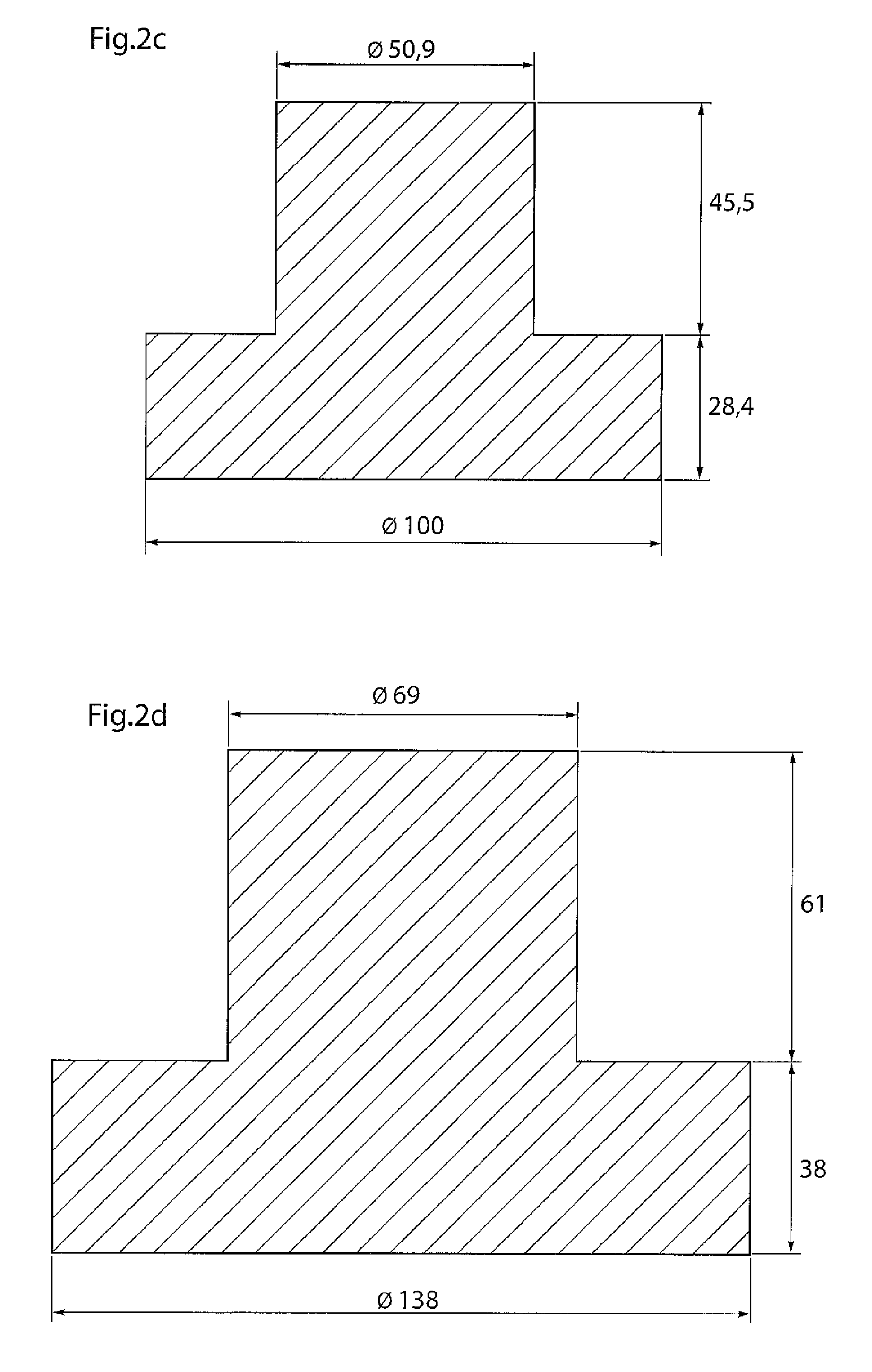

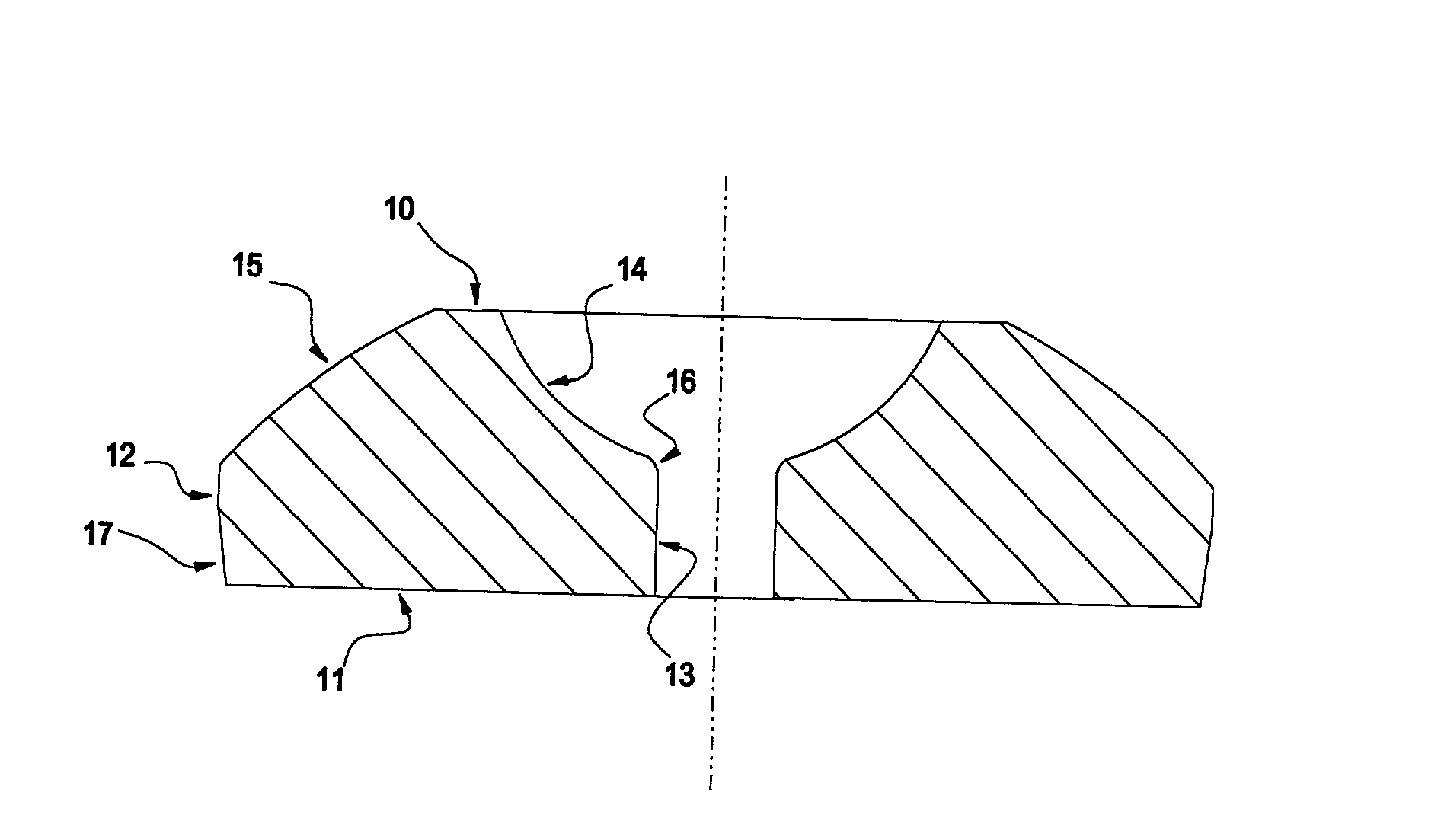

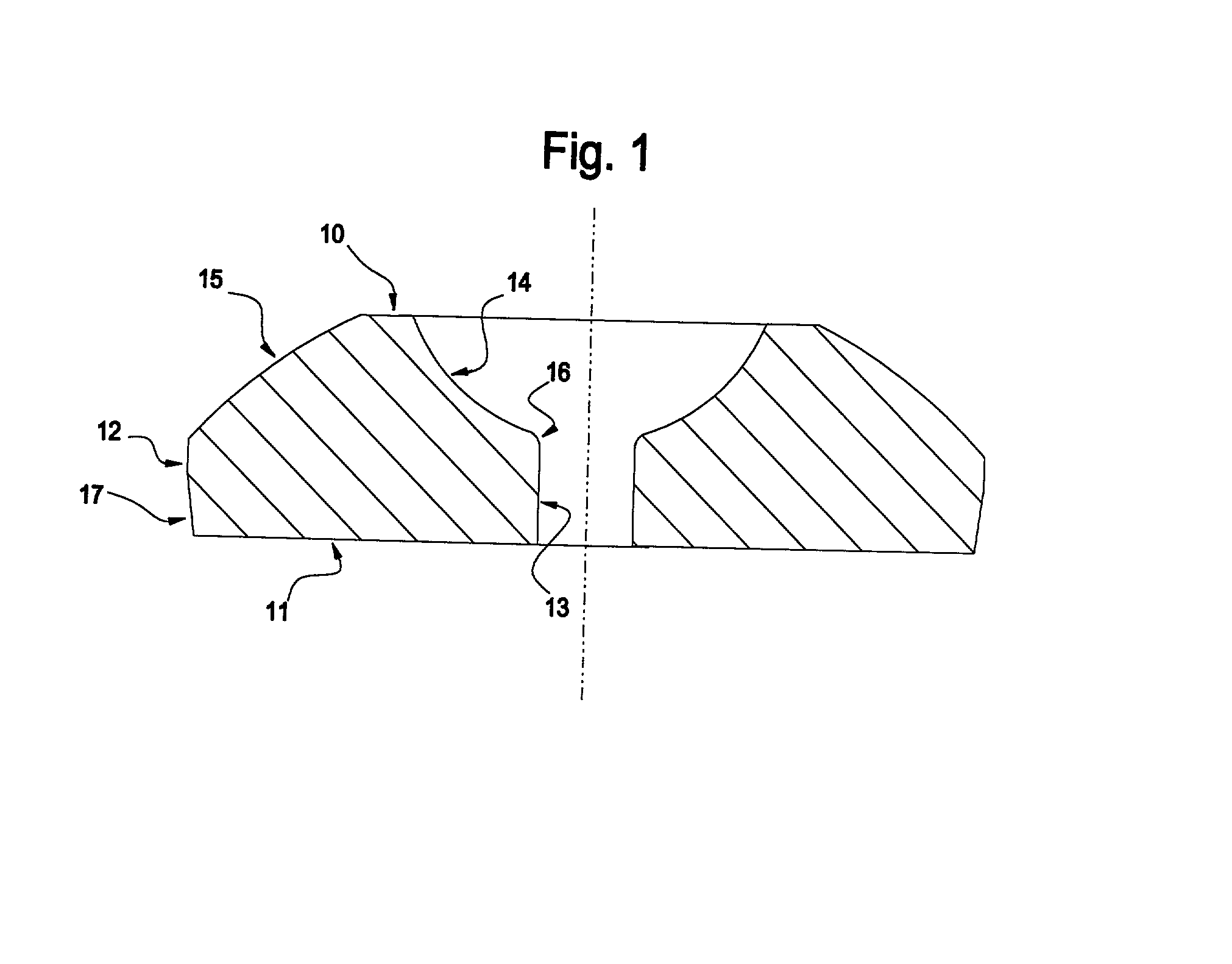

Powder metal materials and parts and methods of making the same

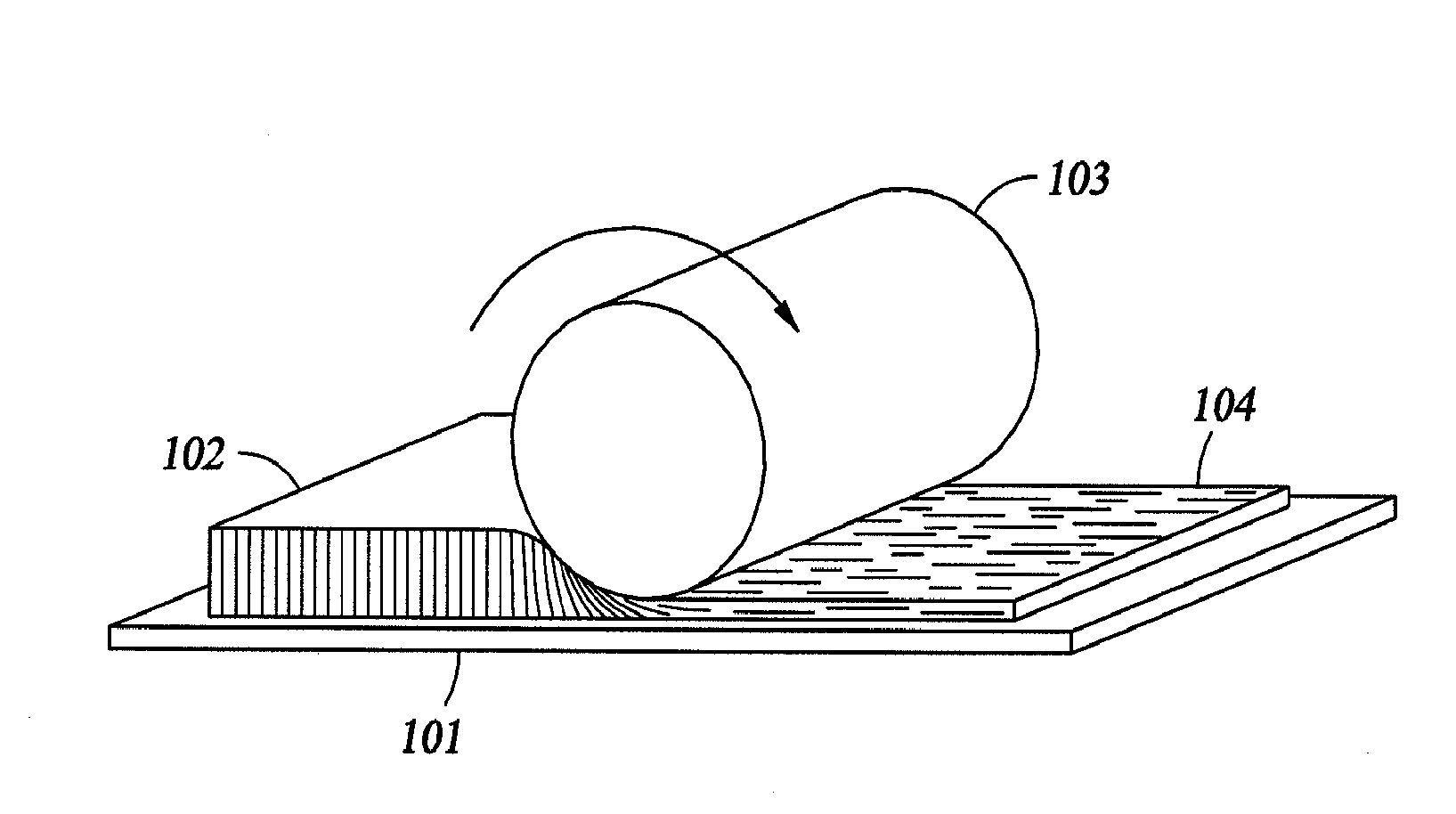

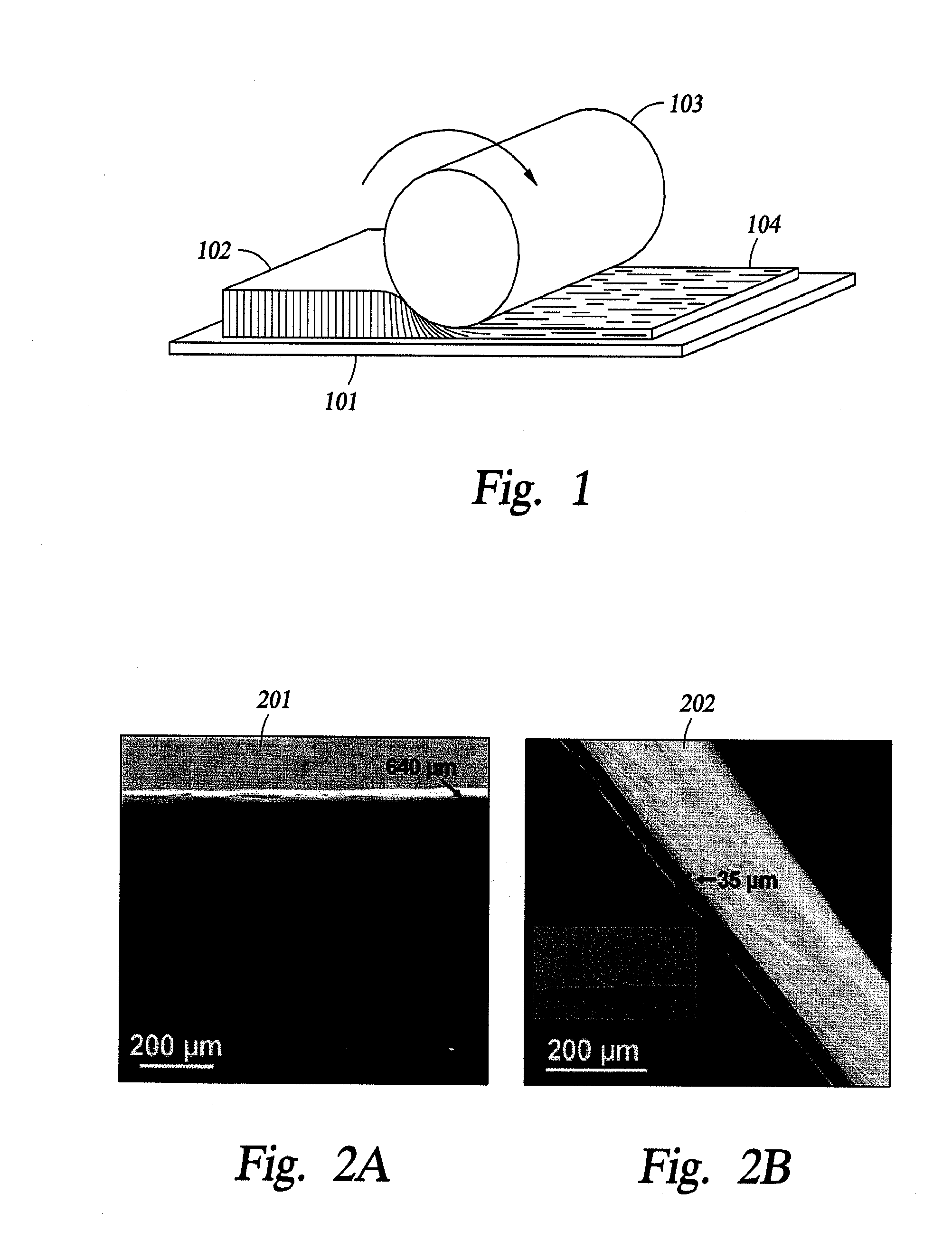

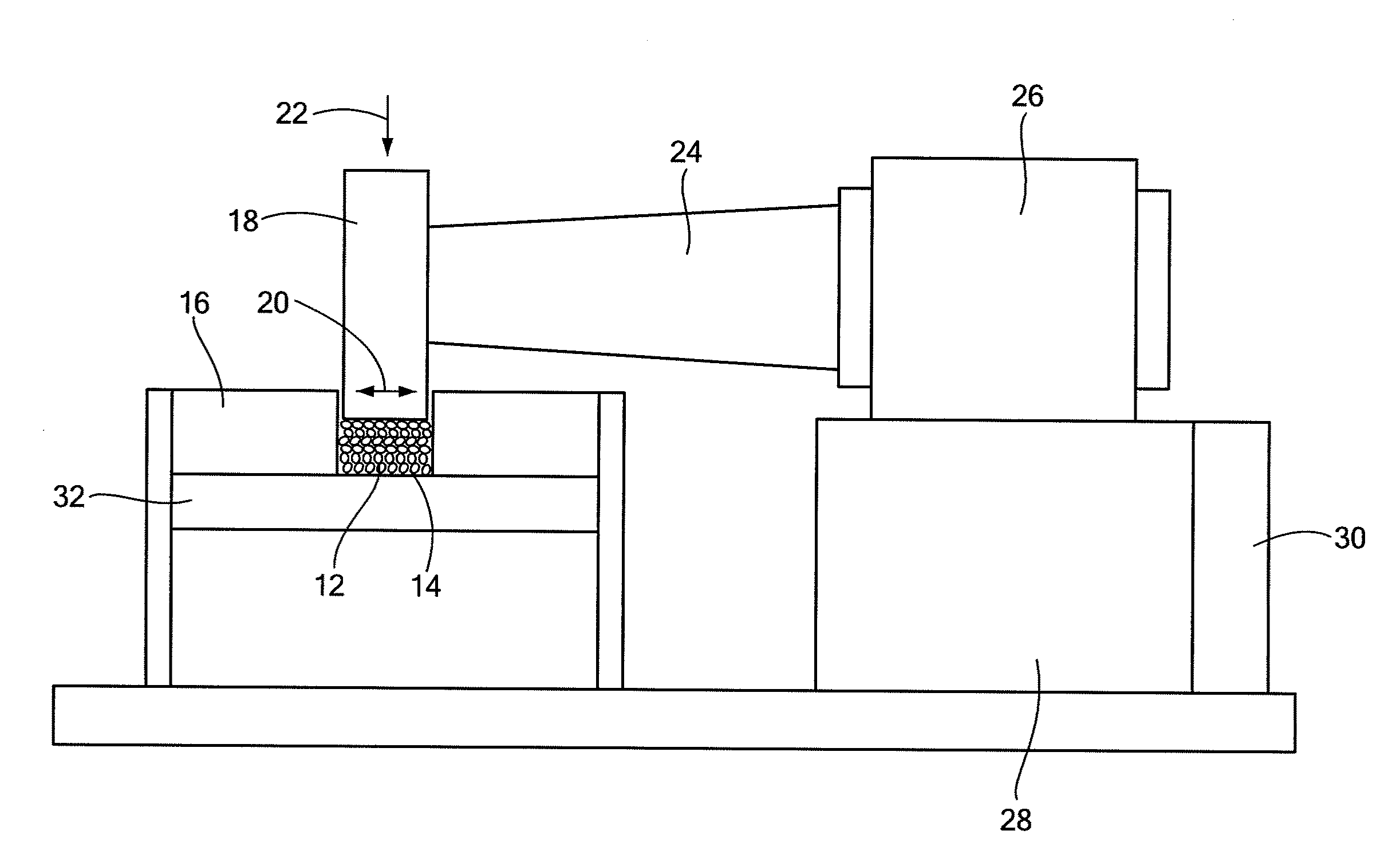

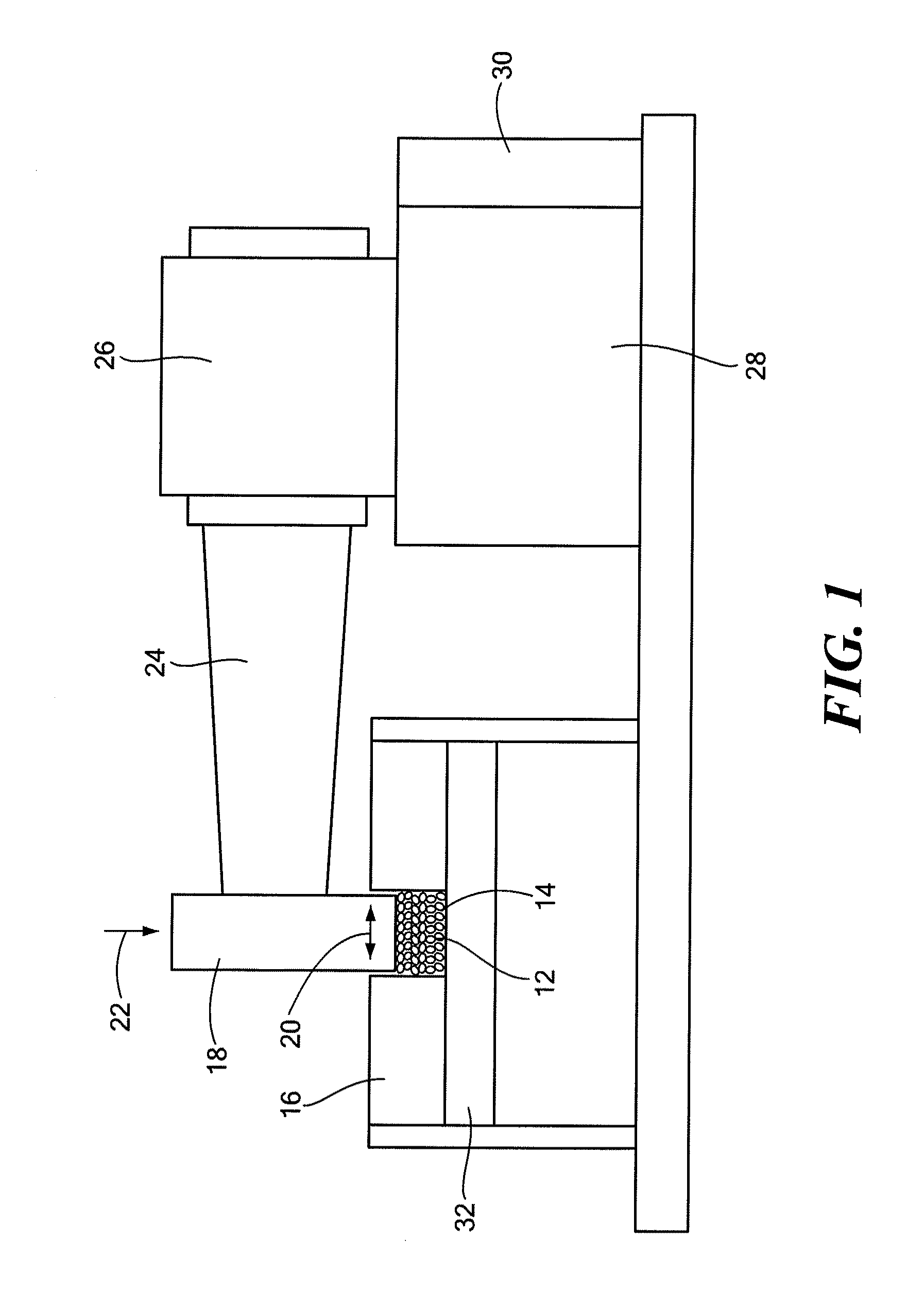

Embodiments of the present invention relate to methods of forming powder metals materials and parts. More specifically, certain embodiments of the present invention relate to methods of forming powder metals materials and parts by densifying at least a portion of a surface of the materials and / or parts after sintering and prior to densifying one or more core regions of the materials and / or parts. Other embodiment provide powder metal parts, such as gears and sprockets, having surface regions that are uniformly densified to full density to depth ranging from 0.001 inches to 0.040 inches, and core regions that can have at least 92 percent theoretical density and further can have essentially full density, or full density. Still other embodiments relate to brazed, welded, plated and gas-tight powder metal parts and components that can be made in accordance with the various non-limiting methods disclosed herein.

Owner:KEYSTONE INVESTMENT CORP

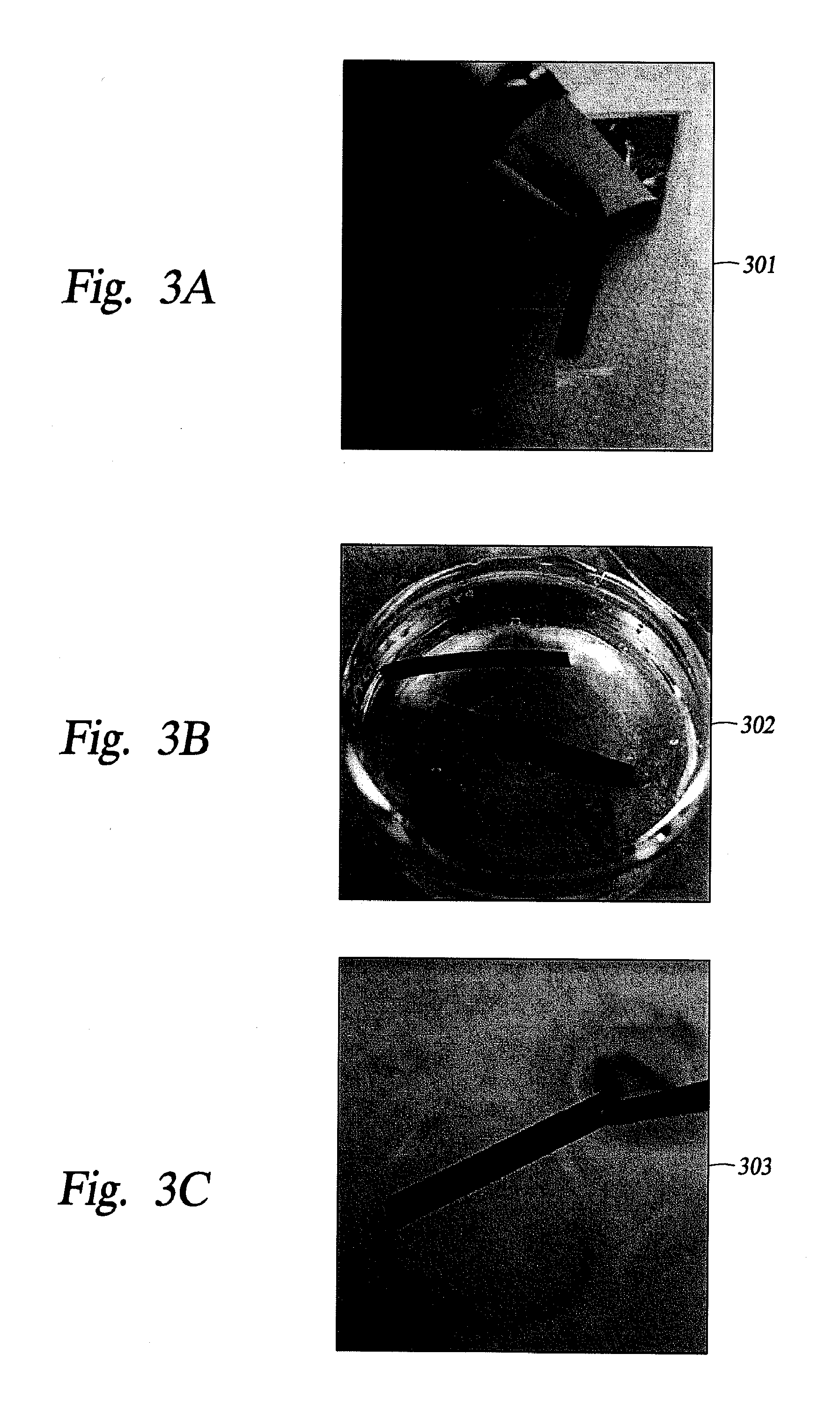

Method for Producing Aligned Near Full Density Pure Carbon Nanotube Sheets, Ribbons, and Films From Aligned Arrays of as Grown Carbon Nanotube Carpets/Forests and Direct Transfer to Metal and Polymer Surfaces

InactiveUS20110262772A1Material nanotechnologyDecorative surface effectsPolymeric surfaceCarbon nanotube

Methods for preparing carbon nanotube layers are disclosed herein. Carbon nanotube layers may be films, ribbons, and sheets. The methods comprise preparing an aligned carbon nanotube array and compressing the array with a roller to create a carbon nanotube layer. Another method disclosed herein comprises preparing a carbon nanotube layer from an aligned carbon nanotube array grown on a grouping of lines of metallic catalyst. A composite material comprising at least one carbon nanotube layer and prepared by the process comprising a) compressing an aligned single-wall carbon nanotube array with a roller, and b) transferring the carbon nanotube layer to a polymer is also disclosed.

Owner:RICE UNIV

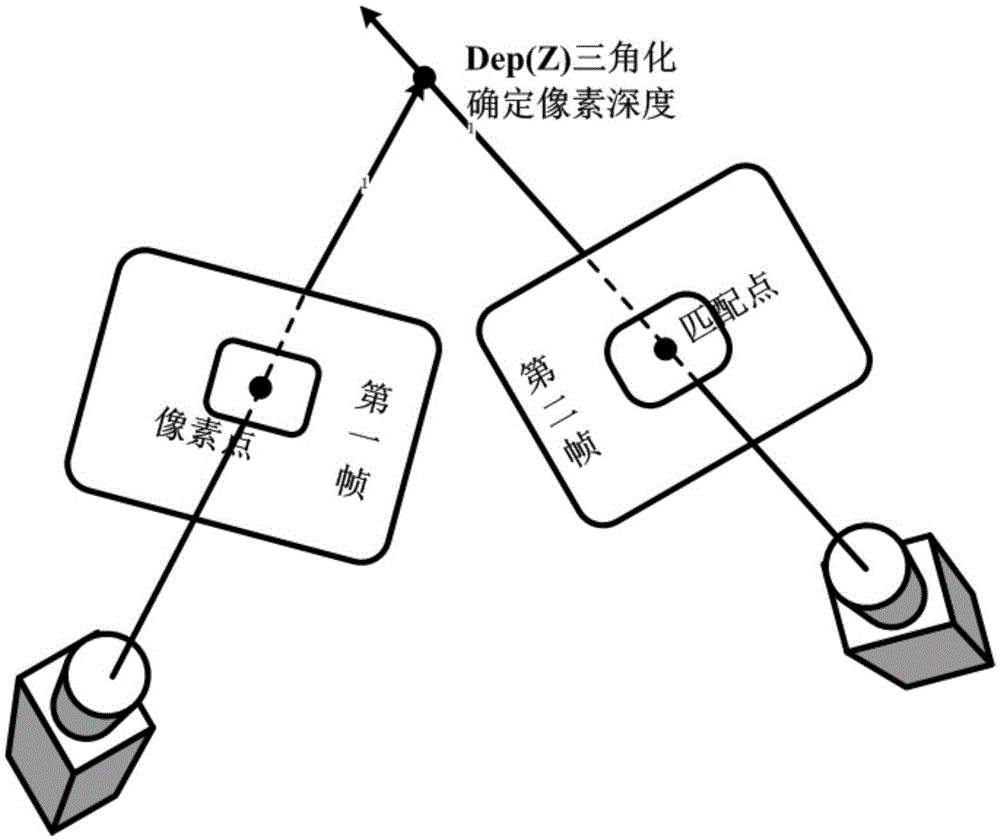

Unmanned aerial vehicle real-time map reconstruction method

ActiveCN105678754AImprove real-time performanceImage enhancementImage analysisEmergency rescueReconstruction method

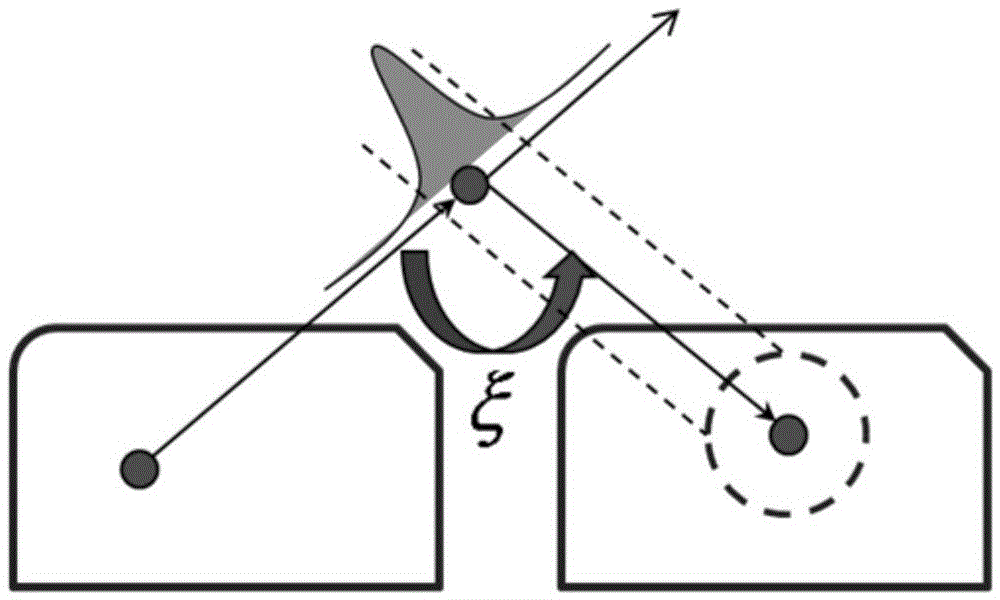

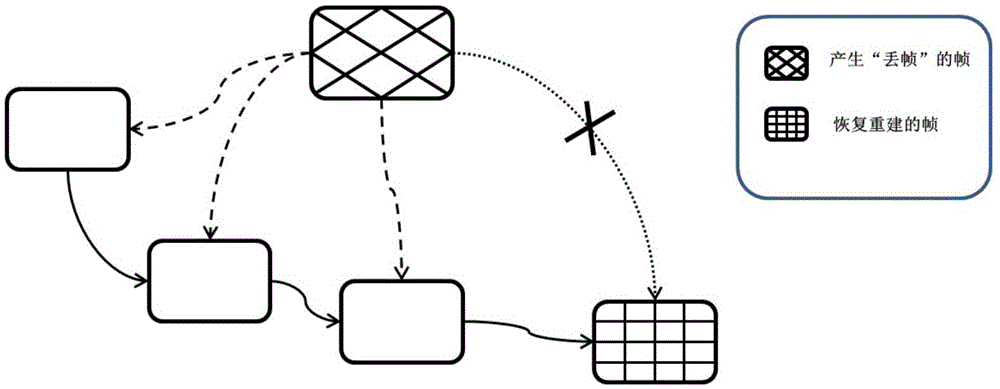

The present invention provides an unmanned aerial vehicle real-time map reconstruction method. By applying an unmanned aerial vehicle, the three-dimensional maps of the surrounding environment of the unmanned aerial vehicle are obtained, and the own positioning of the unmanned aerial vehicle is realized. According to the method, the unmanned aerial vehicle flies in the unknown airspace, and on the condition that the own position of the unmanned aerial vehicle is not clear, the own positioning of the unmanned aerial vehicle is obtained and the three-dimensional maps are constructed by detecting and comparing the environmental information, and extracting and matching the feature information of the environment. The unmanned aerial vehicle real-time map reconstruction method also comprises the geographic information fusion and an image mosaic technology. The unmanned aerial vehicle real-time map reconstruction method of the present invention can be applied to the fields, such as the battlefield demands, for example the unmanned aerial vehicle autonomous flight and attack, the disaster emergency rescue, such as fire hazard, earthquake, flood, etc., the unmanned aerial vehicle security administration and monitoring, etc. Compared with the conventional method, and according to the present invention, a position drifting amount, an angle drifting amount or an absolute error is above the average, and more environmental information is obtained. Moreover, compared with a full-density method, an experimental precision of the method still can reach a usage standard, and the method can be operated on a CPU directly and is good in real-time performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

Fully-dense discontinuously-reinforced titanium matrix composites and method for manufacturing the same

The invention is suitable for the manufacture of flat or shaped titanium matrix composite articles having improved mechanical properties such as lightweight plates and sheets for aircraft and automotive applications, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as for sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. A fully-dense discontinuously-reinforced titanium matrix composite (TMMC) material comprises (a) a matrix of titanium or titanium alloy as a major component, (b) ceramic and / or intermetallic hard particles dispersed in the matrix in the amount of ≦50 vol. %, and (c) complex carbide- and / or silicide particles at least partially soluble in the matrix at the sintering or forging temperatures such as Ti4Cr3C6, Ti3SiC2, Cr3C2, Ti3AlC2, Ti2AlC, Al4C3, Al4SiC4, Al4Si2C5, Al8SiC7, V2C, (Ti,V)C, VCr2C2, and V2Cr4C3 dispersed in the matrix in the amount of ≦20 vol. %. The method for manufacturing TMCC is comprised of the following steps: (a) preparing a basic powdered blend containing matrix alloy or titanium powders, dispersing ceramic and / or intermetallic powders, and powders of said complex carbide- and / or silicide particles, (b) preparing the Al—V master alloy containing ≦5 wt. % of iron, (c) preparing the Al—V—Fe master alloy fine powder having a particle size of ≦20 μm, (d) mixing the basic powdered blend with the master alloy powder to obtain a chemical composition of TMCC, (e) compacting the powder mixture at room temperature, (f) sintering at the temperature which provides at least partial dissolution of dispersed powders, (g) forging at 1500-2300° F., and (h) cooling. The resulting TMCC has density over 98% and closed discontinuous porosity after sintering that allows making hot deformation in air without encapsulating. The invention can be used to produce near-full density near-net shape parts from titanium matrix composite materials with acceptable mechanical properties without a hot deformation.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

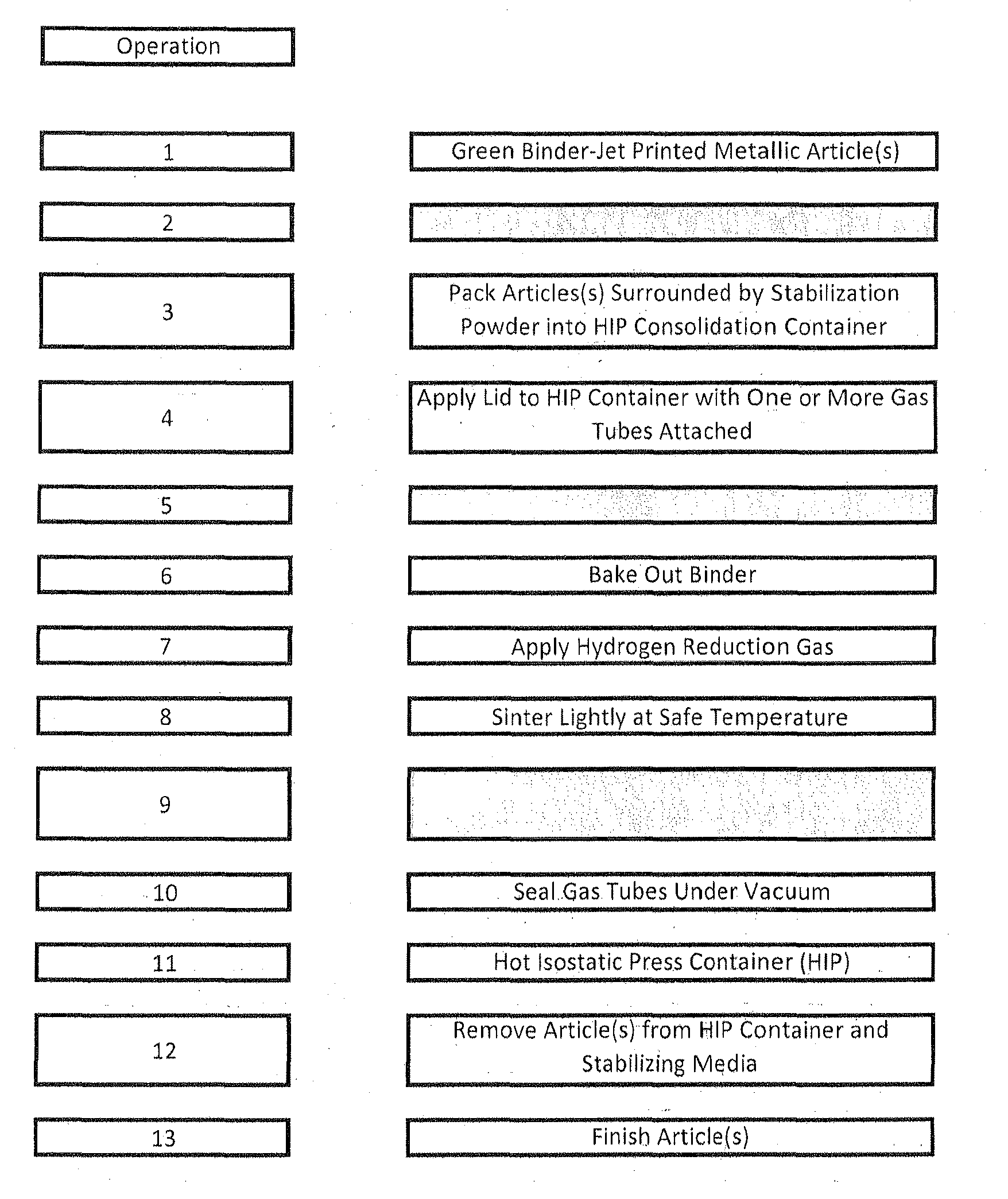

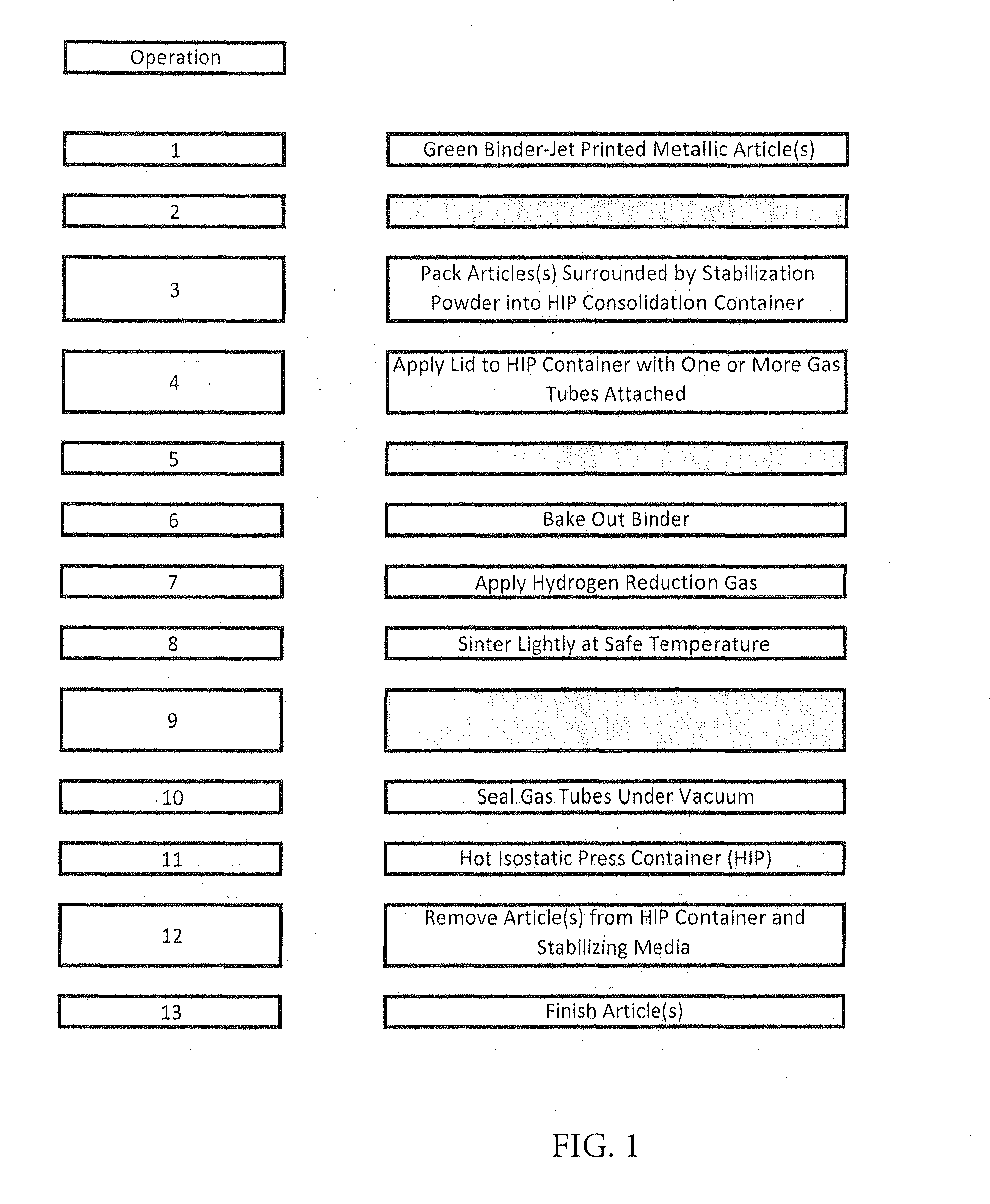

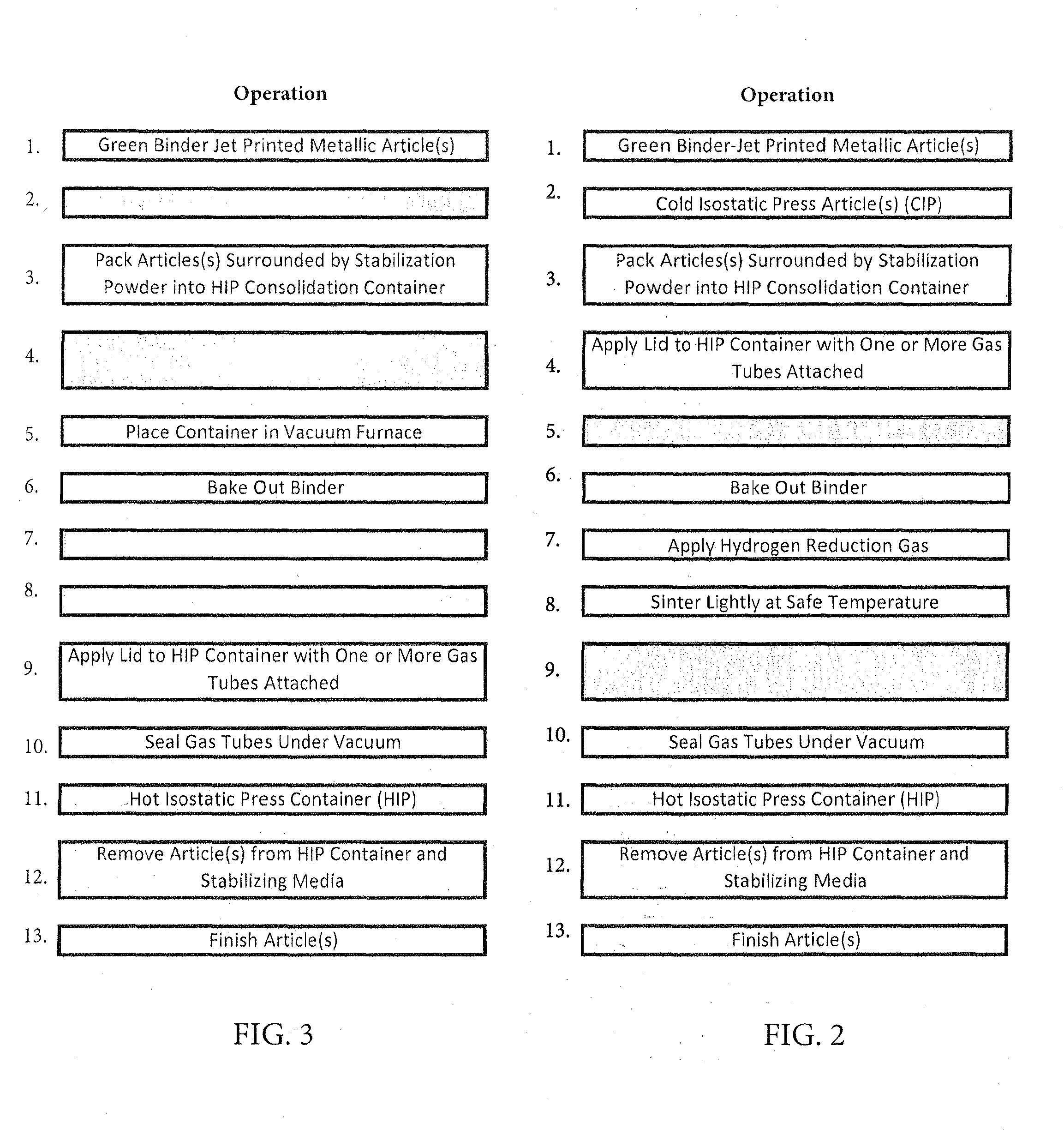

Method of achieving full density binder jet printed metallic articles

InactiveUS20160158843A1Assure shape retentionLow production costAdditive manufacturingIncreasing energy efficiencyPorosityDecomposition

A method of producing full density binder-jet printed metallic articles. A metallic 3-D printed article is produced using a binder-jet printing method and is positioned in a hot isostatic press (HIP) container surrounded by stabilization powder. A vacuum is introduced into the inside of the HIP container. A binder used to bond powder articles together in the printed article is removed by heating the HIP container to decompose the binder and removing decomposition products by applying a vacuum to the HIP container. The HIP container is sealed with a vacuum therein and compacted under heat and pressure to remove all porosity in the printed article. The printed article thereafter is removed from the HIP container and finished to a final form.

Owner:CARPENTER TECH CORP

Method for consolidating tough coated hard powders

InactiveCN1997475APrevent chemical interactionsTransportation and packagingMetal-working apparatusParticulatesHigh fracture

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:阿洛梅特公司

A preparation method of rare earth oxide dispersion strengthened fine grain tungsten materials

InactiveUS20170225234A1Uniform particle sizeFine granularityTransportation and packagingMetal-working apparatusRare-earth elementTungstate

This invention relates to a preparation method of rare earth oxide dispersion strengthened fee grain tungsten materials, the mass percent of the rare earth oxide is of 0.1-2%, and the rest ingredient is W. Weigh soluble rare earth salt and tungstate, dissolve into water to made into 50-100 g / L of rare earth salt solution and 150-300 g / L of tungstate solution, respectively. Firstly, add trace alkali in rare earth salt solution to control pH in 7-8, then add organic dispersant and stir to form evenly suspended R(OH)3 particle colloid (R refers to rare earth element). Secondly pour the tungstate solution into the R(OH)3colloid, add trace acid to control pH in 6-7, then add organic dispersant and stir to form tungstic acid micro particles, which wrap around the colloidal particles, forming coprecipitation coating particle colloid. Thirdly, the coprecipitation coating particle colloidal is spray-dried, forming tungsten and rare earth oxide compound precursor powder. Alter that, ultrafine or nanoscale tungsten powder with particle size of 50˜500 nm is obtained through a process of calcination subsequent with hydrogen thermal reduction. Finally, the tungsten powder is subjected to ordinary compression molding and then conventional high temperature sintering. The trace rare earth oxide dispersion strengthened high performance fine grain tungsten materials prepared by this invention, its density is close to full density (98.5% or higher), its grain size is uniform and very fine (average in 5˜10 microns), and the rare earth oxides particles evenly distribute in tungsten intracrystalline or grain, boundary with particle size of 100˜500 nm.

Owner:CENT SOUTH UNIV

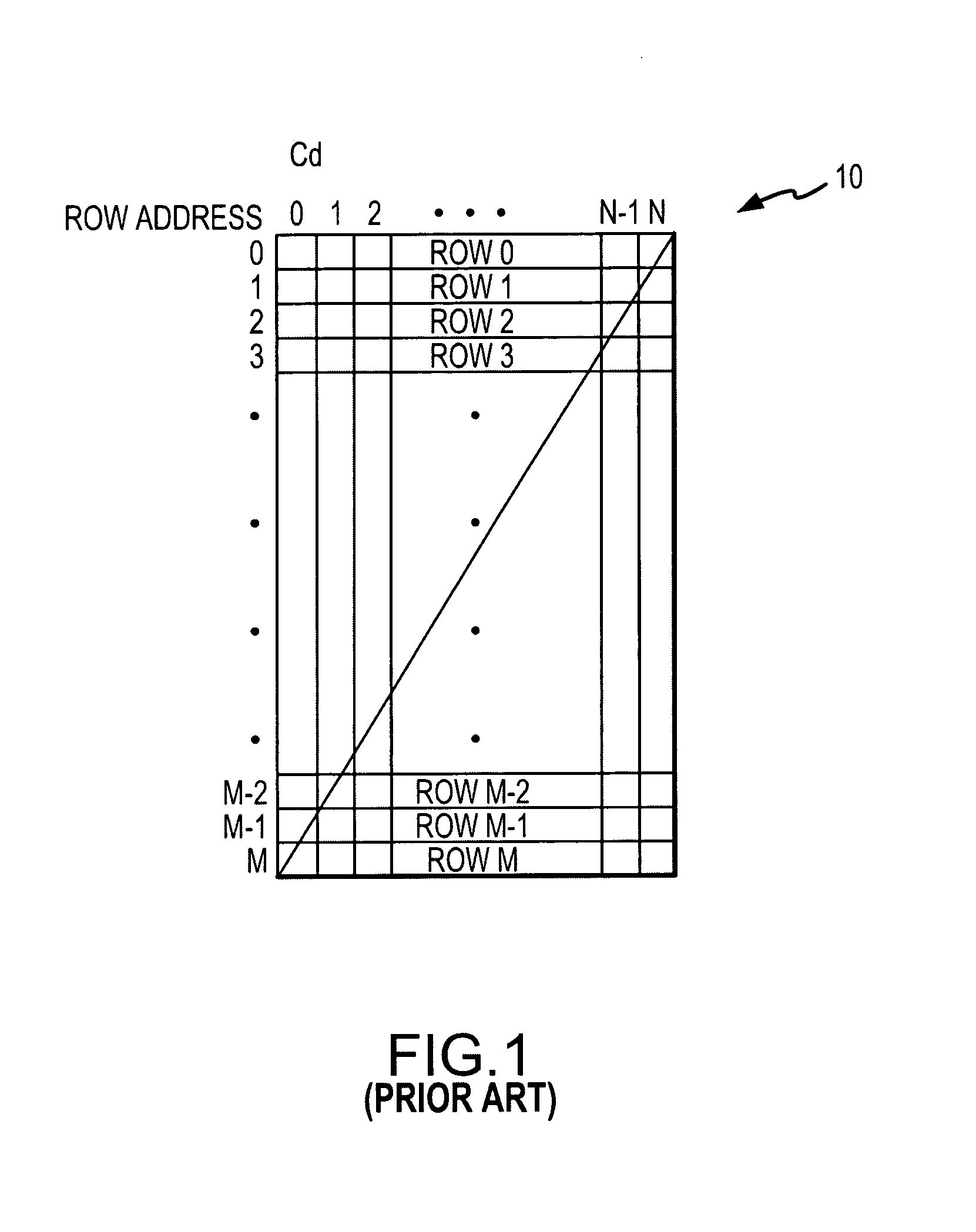

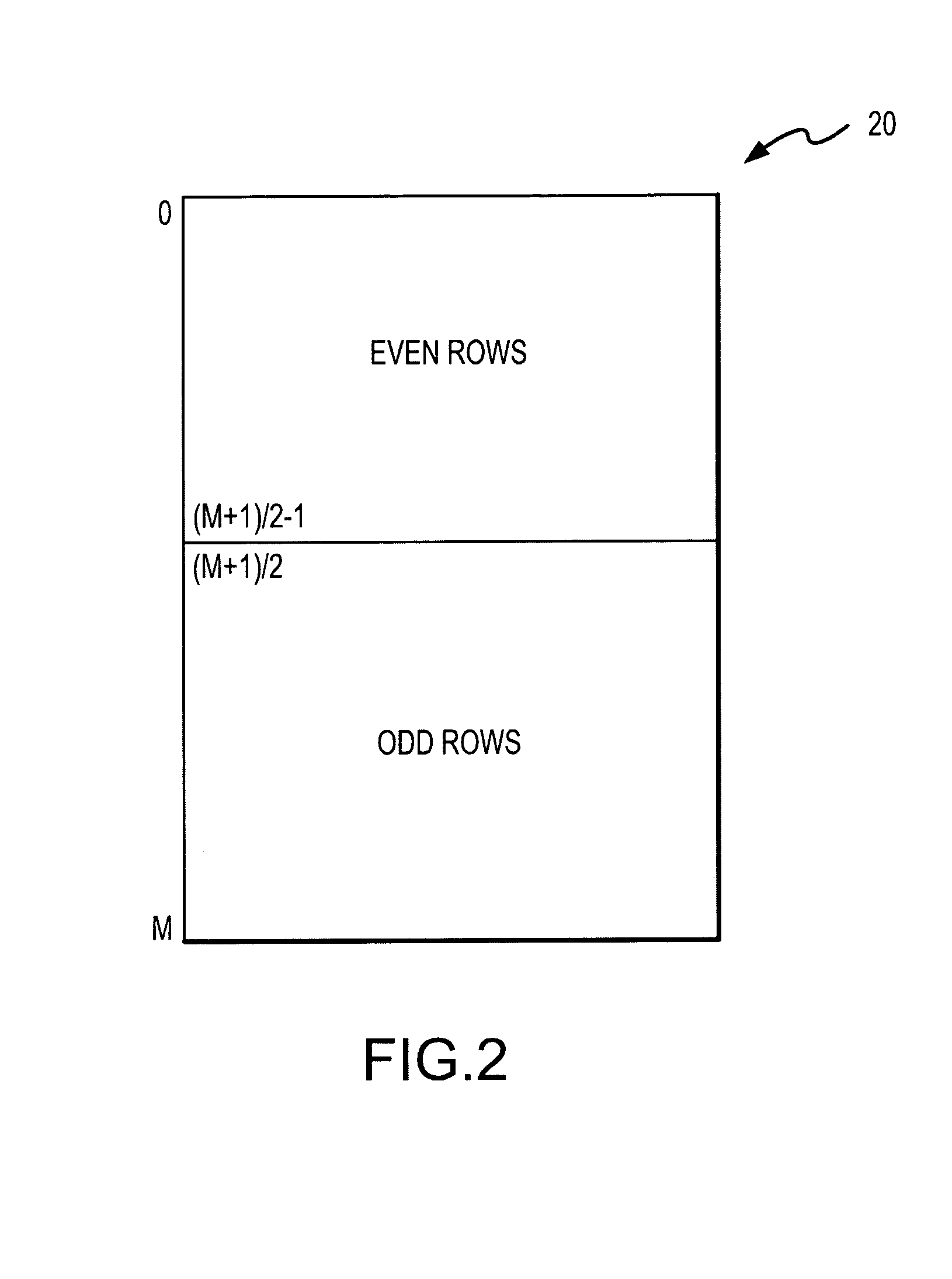

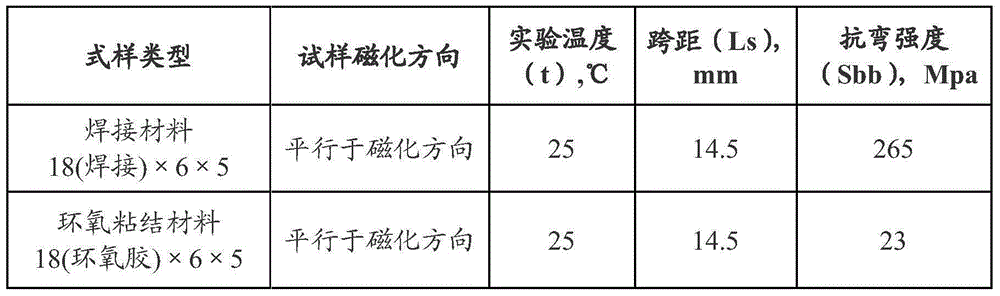

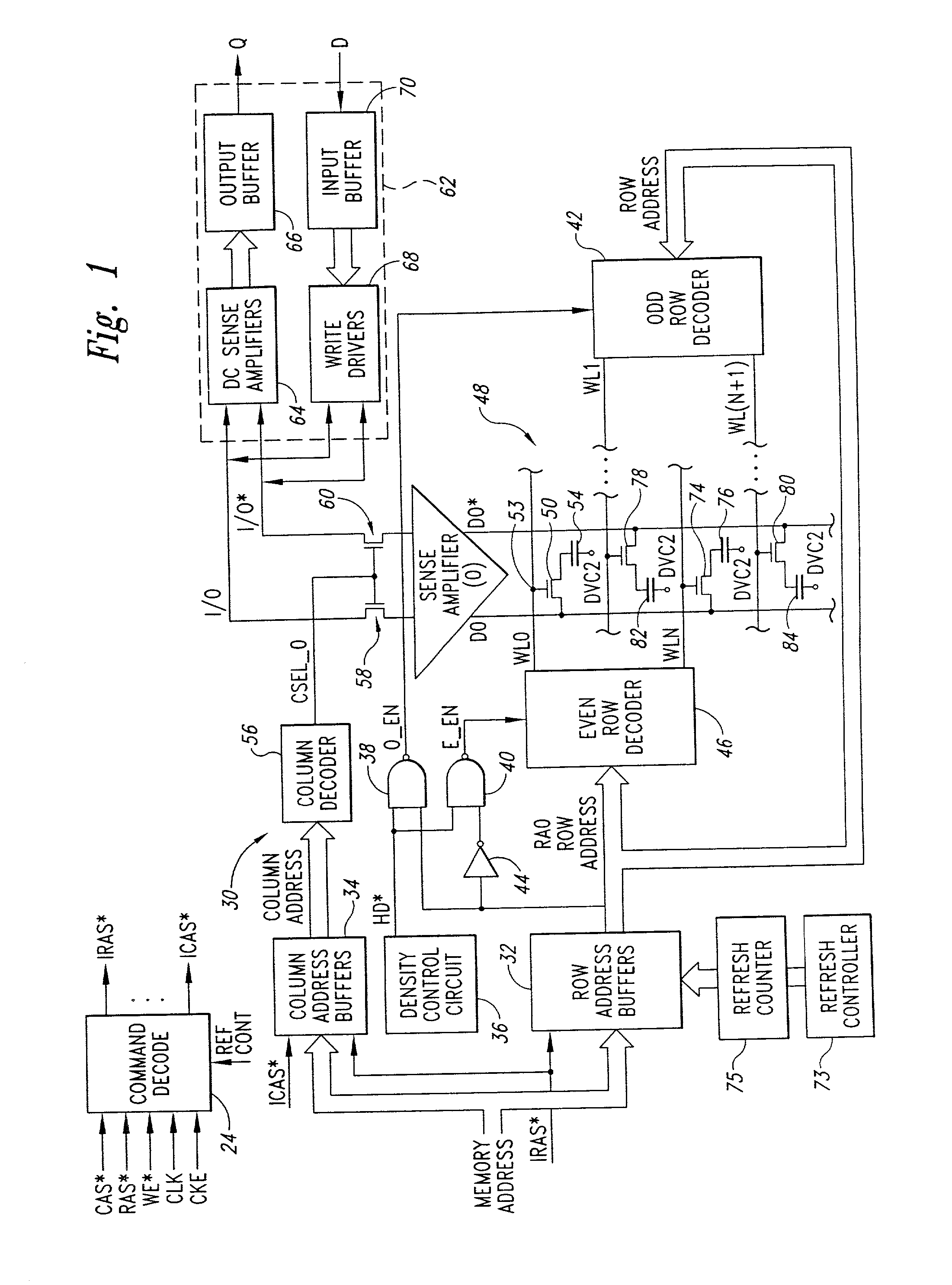

Method and system for low power refresh of dynamic random access memories

InactiveUS7072237B2Easy to switch quicklyLower refresh rateDigital storageStatic random-access memoryRandom access memory

A method and system for operating a DRAM device in either a high power, full density mode or a low power, half density mode. In the full density mode, each data bit is stored in a single memory cell, and, in the half density mode, each data bit is stored in two memory cells that are refreshed at the same time to permit a relatively slow refresh rate. When transitioning from the full density mode to the half density mode, data are copied from each row of memory cells storing data to an adjacent row of memory cells. The adjacent row of memory cells are made free to store data from an adjacent row by remapping the most significant bit of the row address to the least significant bit of the row address, and then remapping all of the remaining bits of the row address to the next highest order bit.

Owner:ROUND ROCK RES LLC

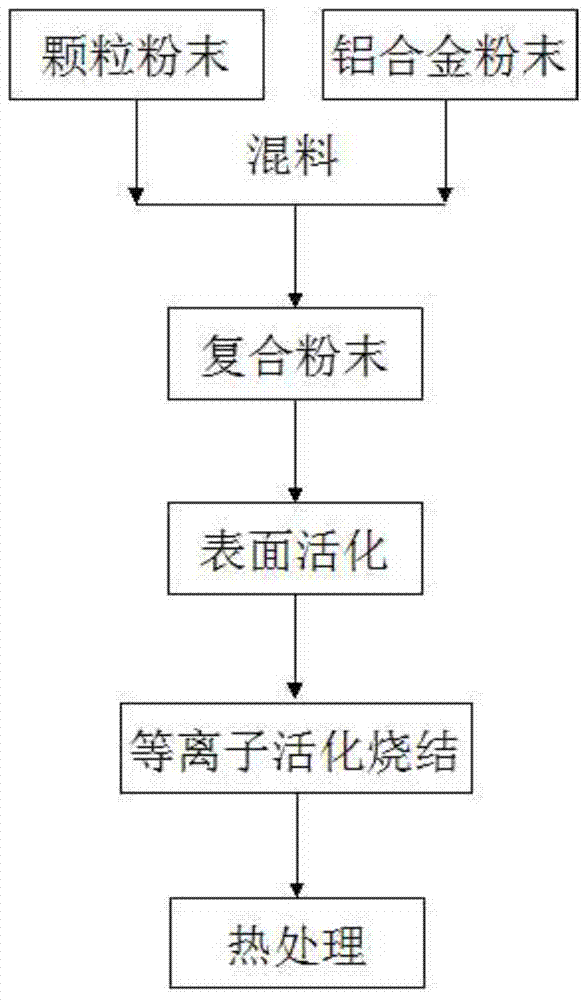

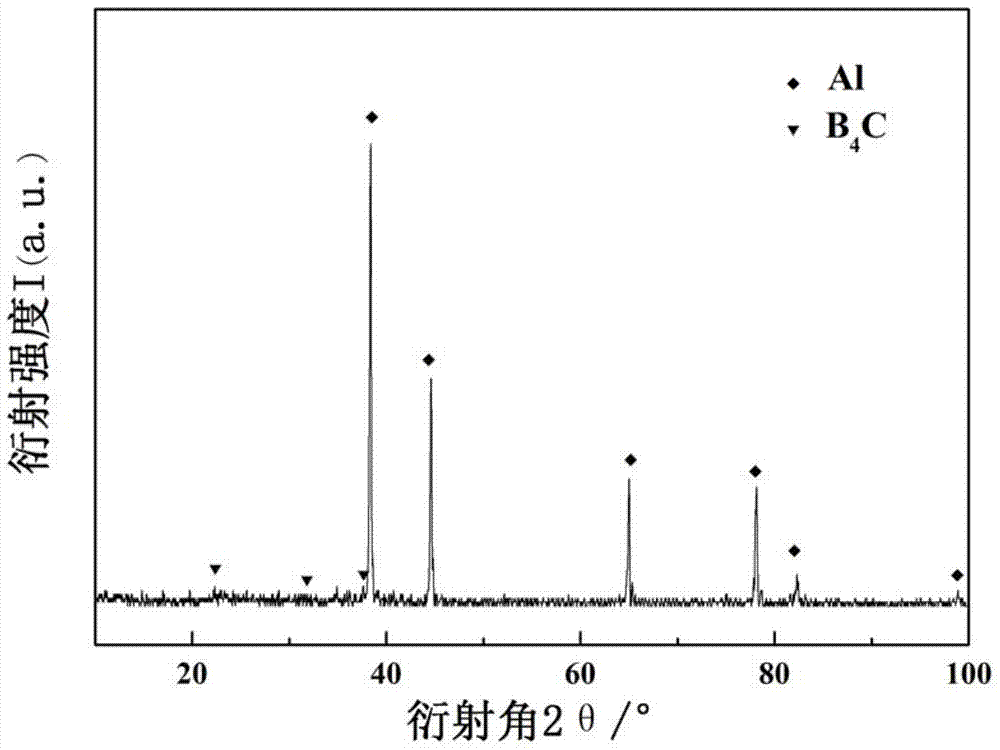

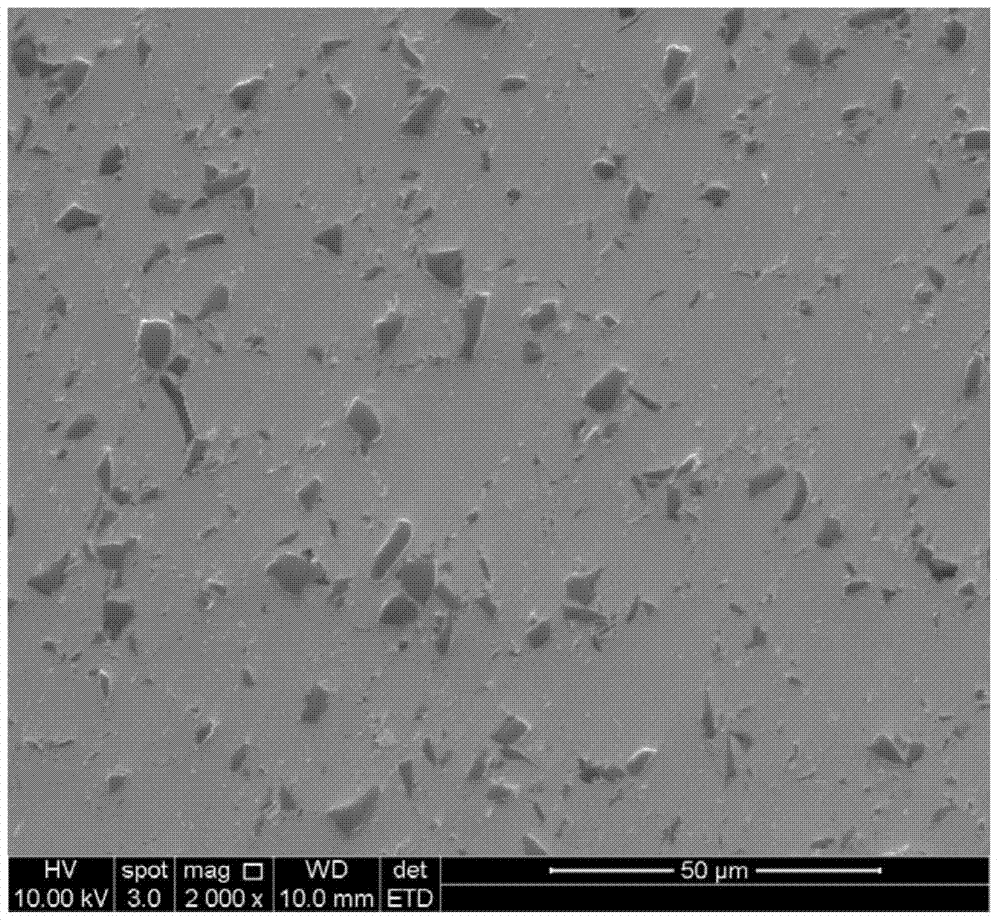

Preparation method of boron carbide particle enhanced aluminum-based composite material

The invention relates to the technical fields of aluminum-based composite materials and preparation thereof, in particular to a boron carbide particle enhanced aluminum-based composite material and a preparation method thereof. According to the composite material, aluminum alloy is used as a matrix; the mass percentage of boron carbide used as a wild phase is 2.5 to 30%; the boron carbide particles are distributed in the matrix uniformly. The specific preparation method comprises the following steps: mixing boron carbide powder and aluminum alloy powder; performing surface activation, plasma activated sintering and heat treatment to prepare a sintering test sample close to full density. The aluminum-based composite material prepared by the method has low sintering temperature, high density, small crystal particles and an excellent mechanical property, is simple to operate and high in controllability, and is a lightweight high-performance aluminum-based composite material.

Owner:WUHAN UNIV OF TECH

Brittle metal alloy sputtering targets and method of fabricating same

InactiveUS20090010792A1Easy to manufactureImproved brittle metal alloy and Ru—Ta alloy sputtering targetsCellsVacuum evaporation coatingMetal alloySemiconductor

A method of fabricating a sputtering target assembly comprises steps of mixing / blending selected amounts of powders of at least one noble or near-noble Group VIII metal at least one Group IVB, VB, or VIB refractory metal; forming the mixed / blended powder into a green compact having increased density; forming a full density compact from the green compact; cutting a target plate slice from the full density compact; diffusion bonding a backing plate to a surface of the target plate slice to form a target / backing plate assembly; and machining the target / backing plate assembly to a selected final dimension. The disclosed method is particularly useful for fabricating large diameter Ru—Ta alloy targets utilized in semiconductor metallization processing.

Owner:HERAEUS INC

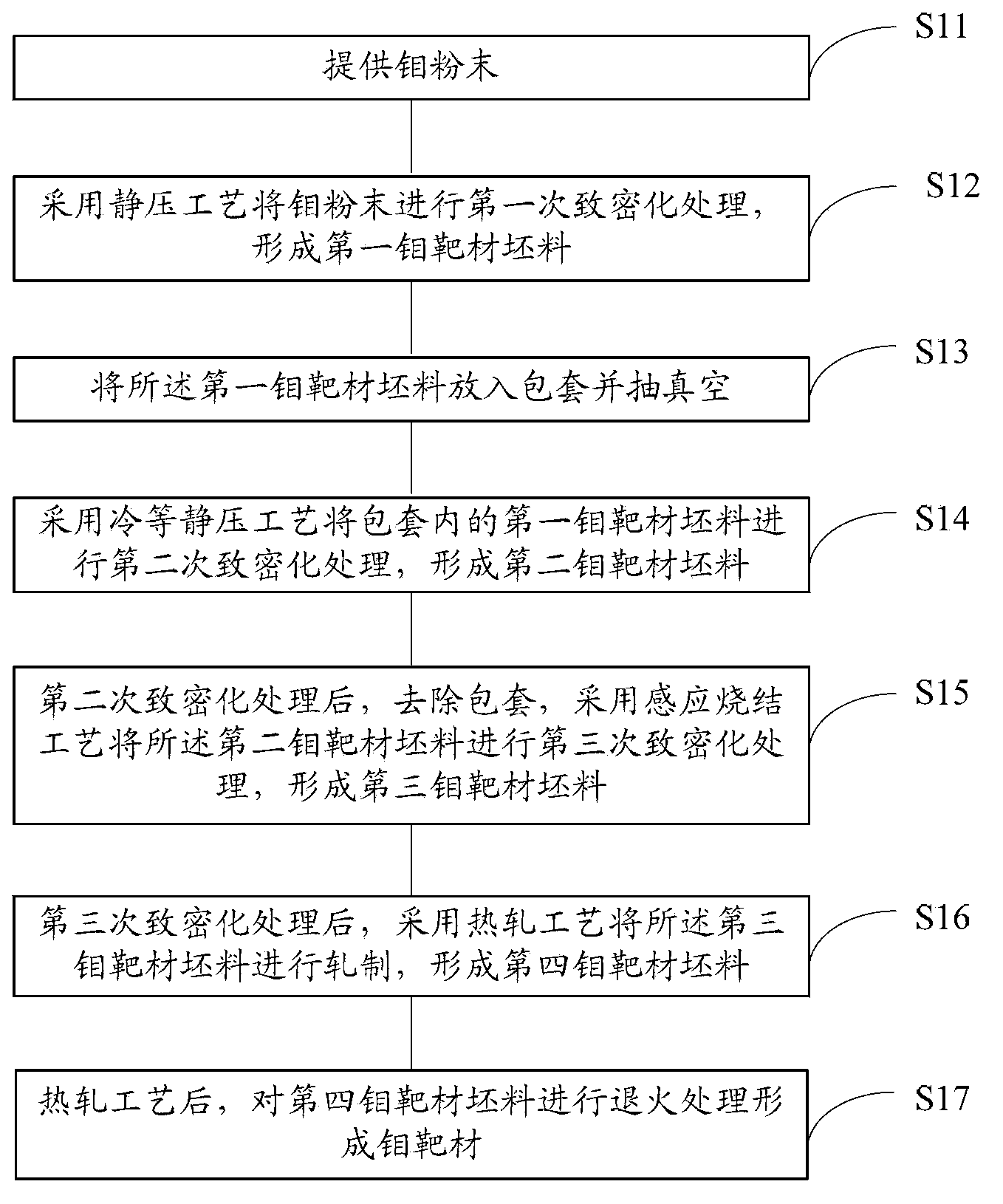

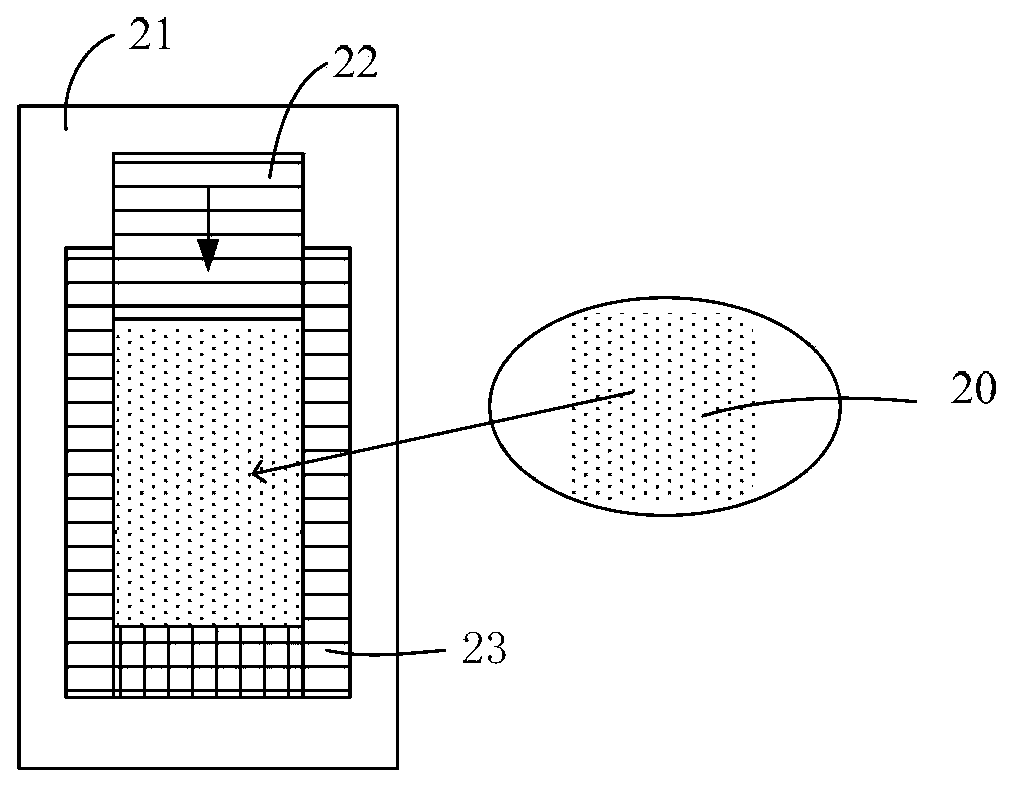

Manufacturing method of molybdenum targets

ActiveCN103567445AIncreased dislocation densityIncrease grain boundary areaVacuum evaporation coatingSputtering coatingMaterials scienceMolybdenum

Disclosed is a manufacturing method of a molybdenum target. The method comprises providing molybdenum powder; performing a first densification process on the molybdenum powder through isostatic pressing to obtain a first molybdenum target blank; putting the first molybdenum target blank into a sheath and vacuumizing the sheath; performing a second densification process on the first molybdenum target blank inside the sheath through cold isostatic pressing to form a second molybdenum target blank; after the second densification process, removing the sheath and performing a third densification process on the second molybdenum target blank through induction sintering to form a third molybdenum target blank; after the third densification process, rolling the third molybdenum target blank through hot rolling to form a fourth molybdenum target blank; after the hot rolling process, performing annealing on the fourth molybdenum target blank to obtain the molybdenum target. The manufacturing method of the molybdenum target can help produce full-density molybdenum targets, the uniformity of the internal organizational structure and the size, the purity and the surface dimension of grains of the molybdenum targets can well meet the ever-increasing requirements of the sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

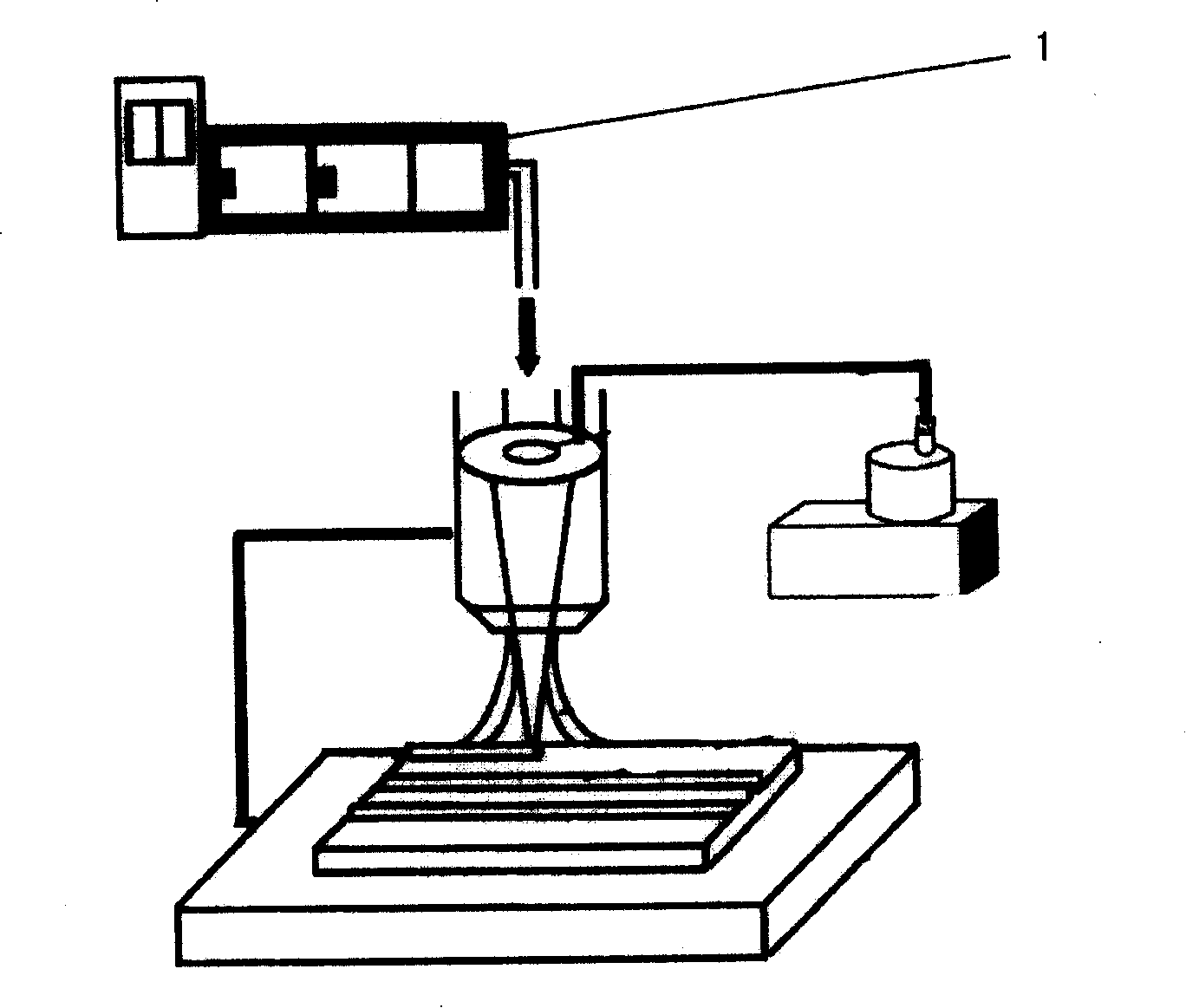

Method of preparing novel gradient functional material fine blanking die based on laser fusing-covering forming technique

InactiveCN101176950AImprove mechanical propertiesEliminate segregationMetallic material coating processesLaser beam welding apparatusMelting tankHigh energy laser beam

The invention relates to laser cladding molding technology; wherein, a common steel base is molded to high-performance material. The requirements for material performance are met during the manufacture process of fine blanking die. To prolong the service life of fine blanking die, the requirements for material are satisfied, which substitutes the costly metallurgical steel powders. Based on the laser cladding molding technology, the manufacture method of the new gradient functional material fine blanking die comprises the steps that: firstly, high-energy laser beam locally melt the metal surface of base to form a molten pool; secondly, metal materials are sent to the molten pool and forms a plurality of new metallic layers with low rate of dilution, combining with the base metal metallurgy. The invention has the advantages of enabling to achieve no-model rapid approximately-final molding of high-performance compact metal components, improving the prior rapid prototype technology to a new level of the directly molding of full-density high-intensity functional material component, and being an integration of rapid molding basic principle and laser process quintessence.

Owner:SHANGHAI MARITIME UNIVERSITY

Method for consolidating tough coated hard powders

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:ETERNALOY HLDG GMBH

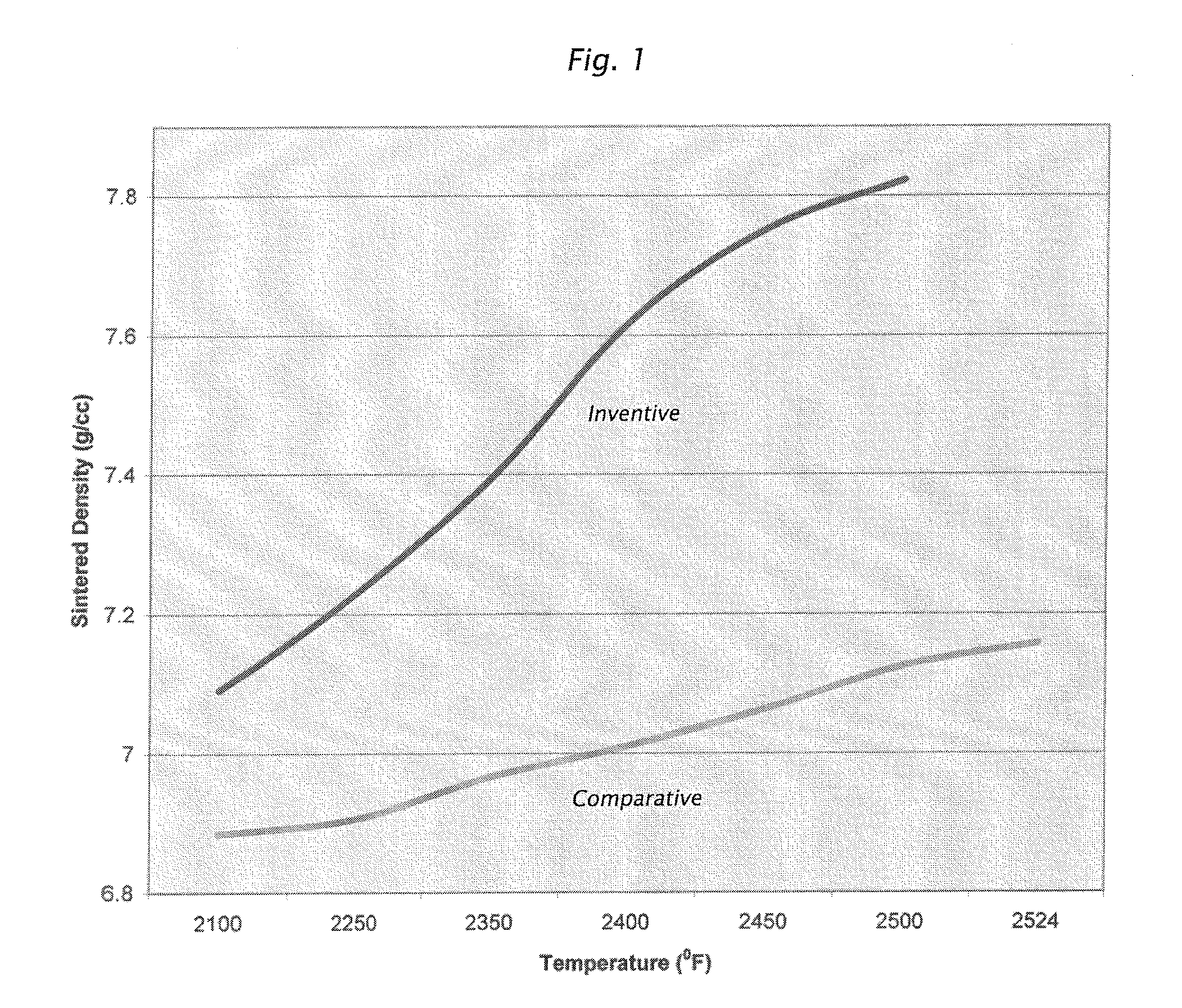

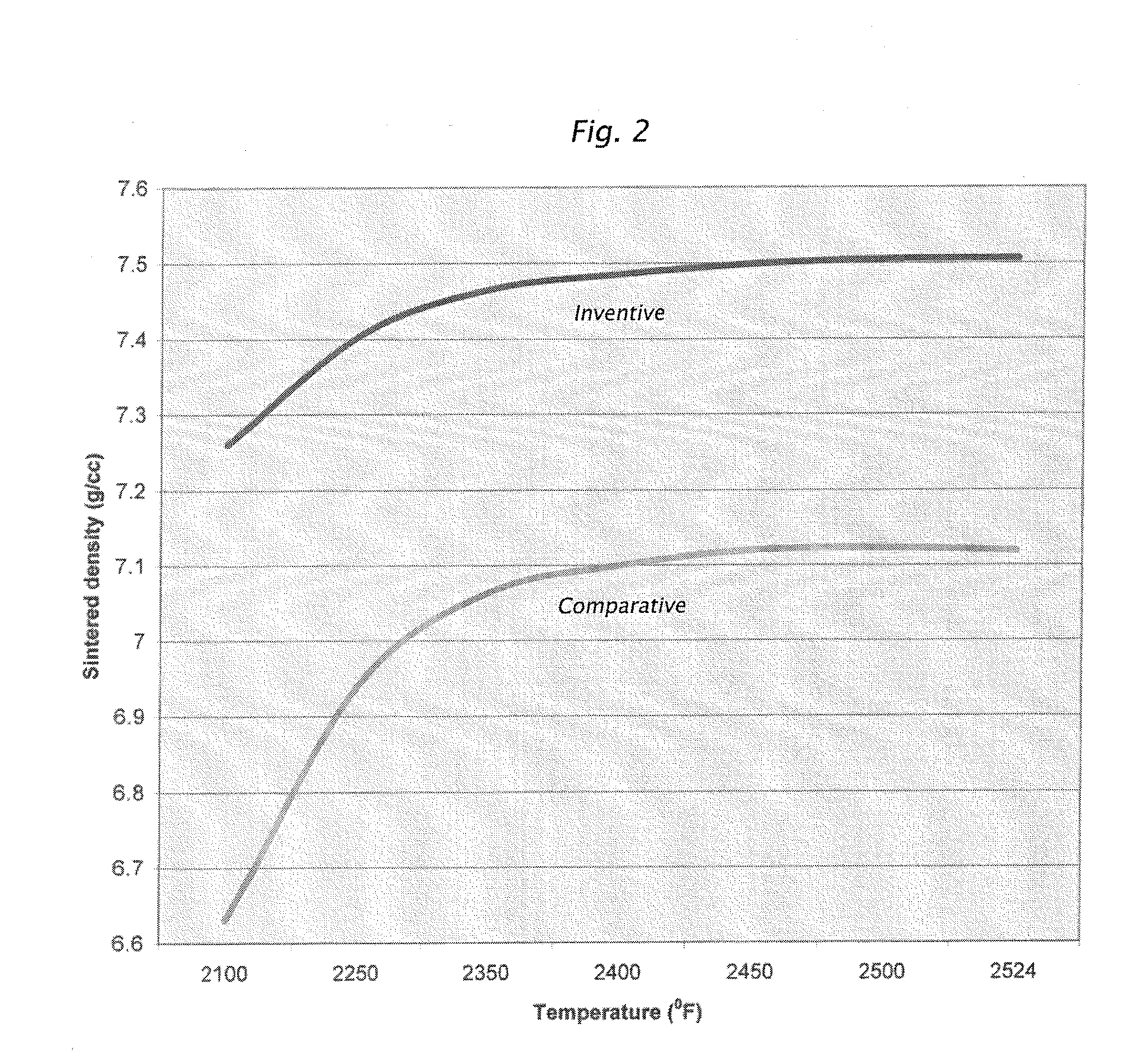

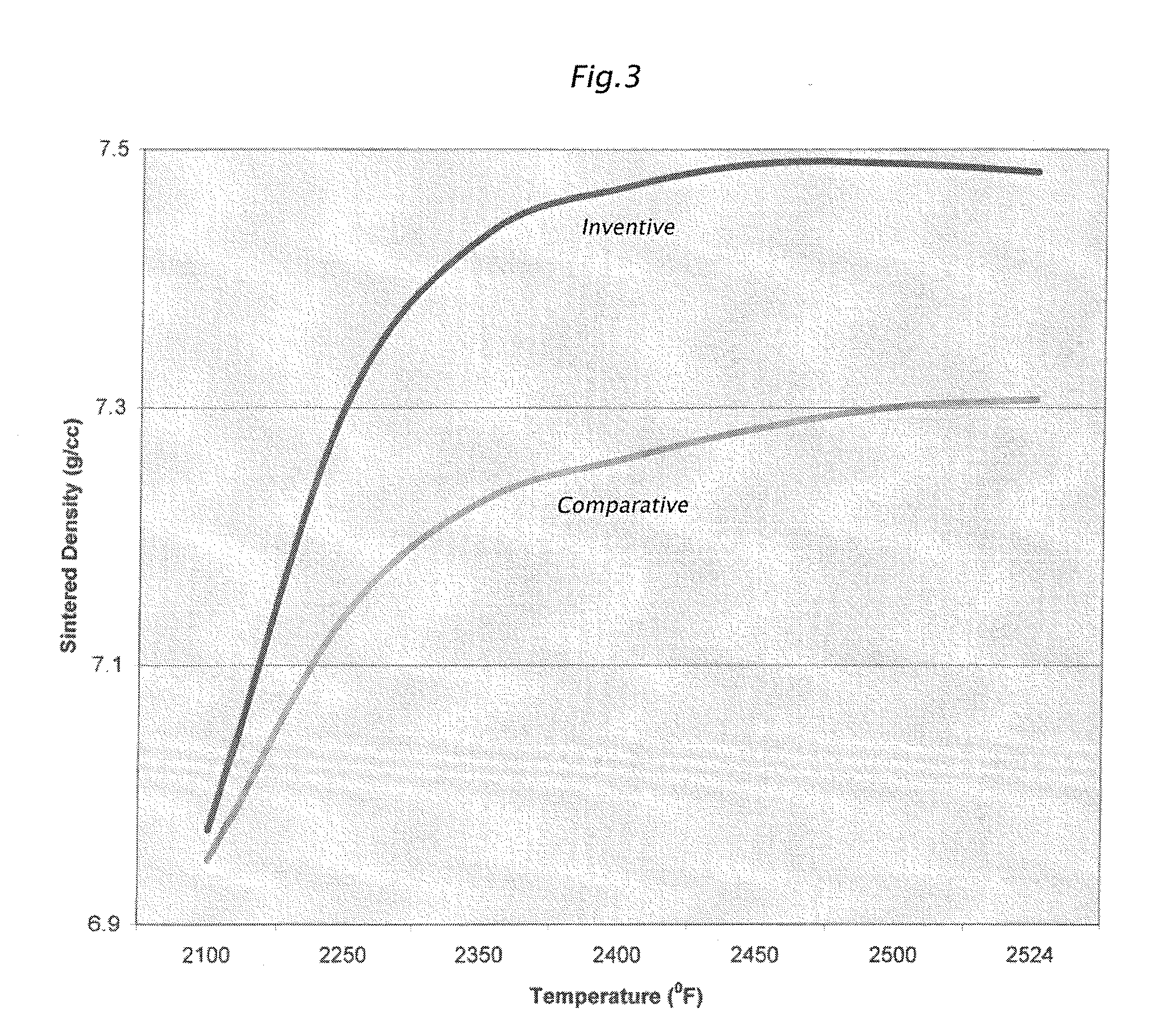

Powder Metallurgy Methods And Compositions

ActiveUS20090162236A1Faster rateImprove sintered densityTransportation and packagingMetal-working apparatusMetal powderPowder metallurgy

The present invention provides metal powder compositions for pressed powder metallurgy and methods of forming metal parts using the metal powder compositions. In each embodiment of the invention, the outer surface of primary metal particles in the metal powder composition is chemically cleaned to remove oxides in situ, which provides ideal conditions for achieving near full density metal parts when the metal powder compositions are sintered.

Owner:JOHNSON ELECTRIC NORTH AMERICA

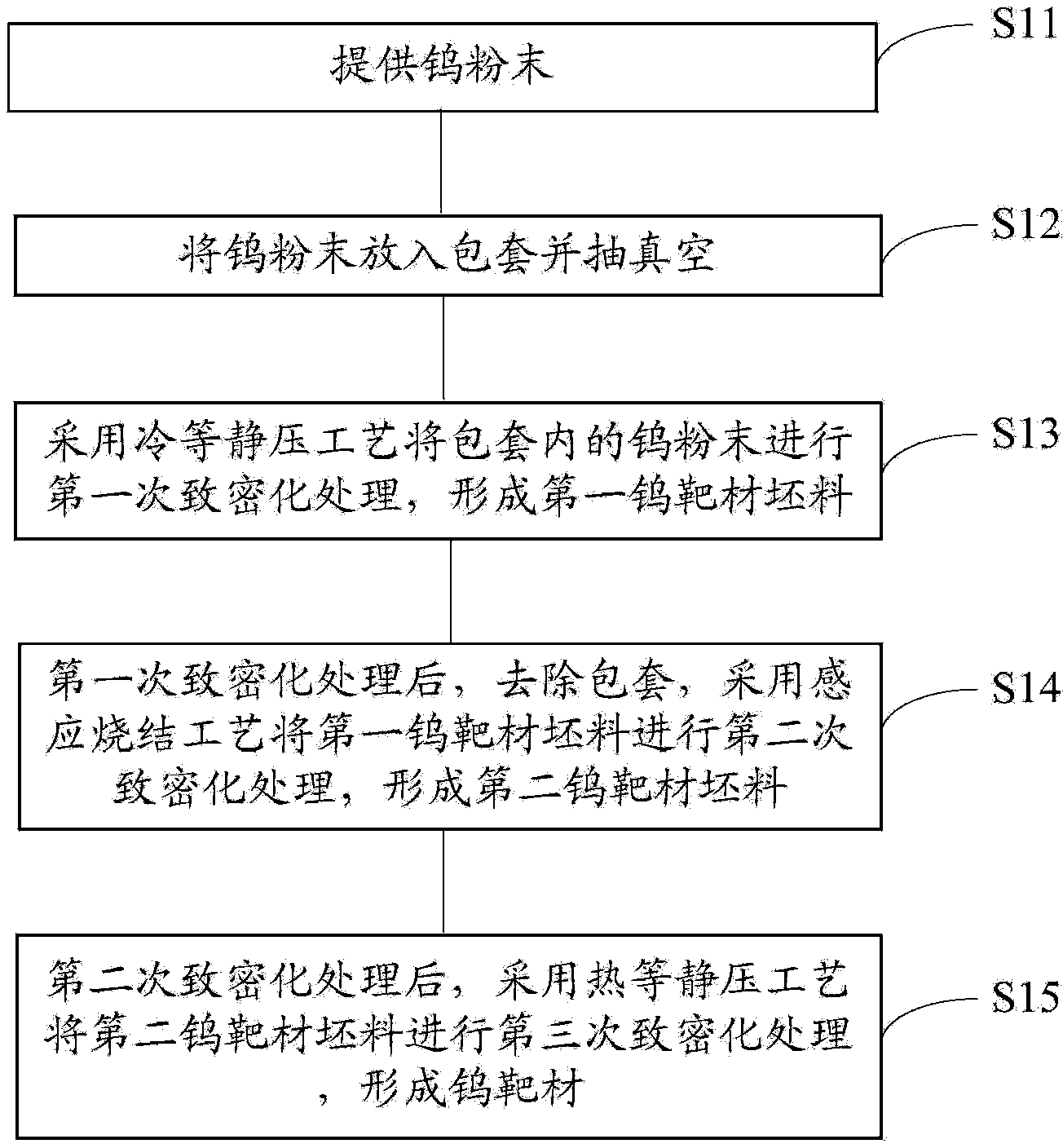

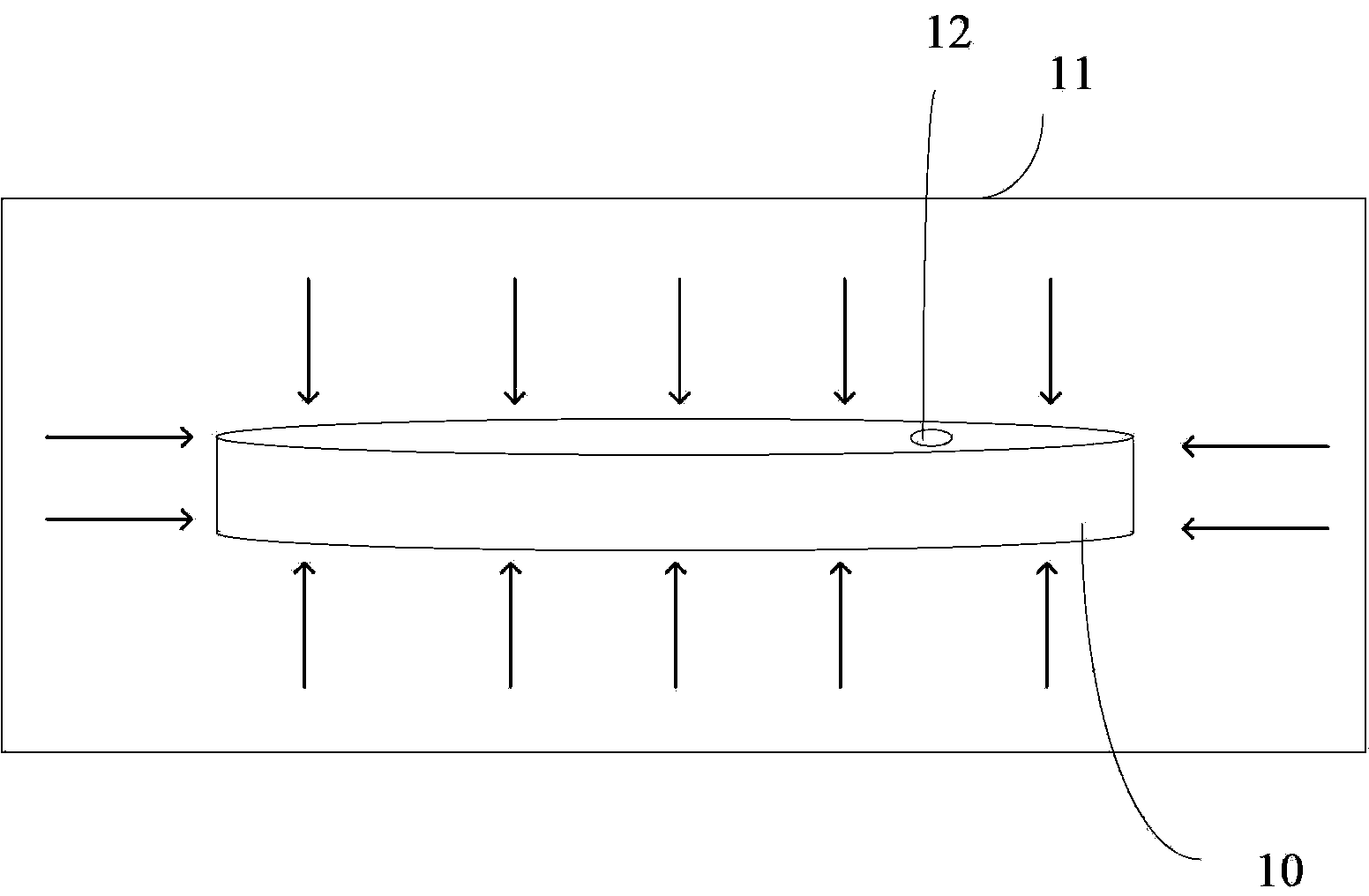

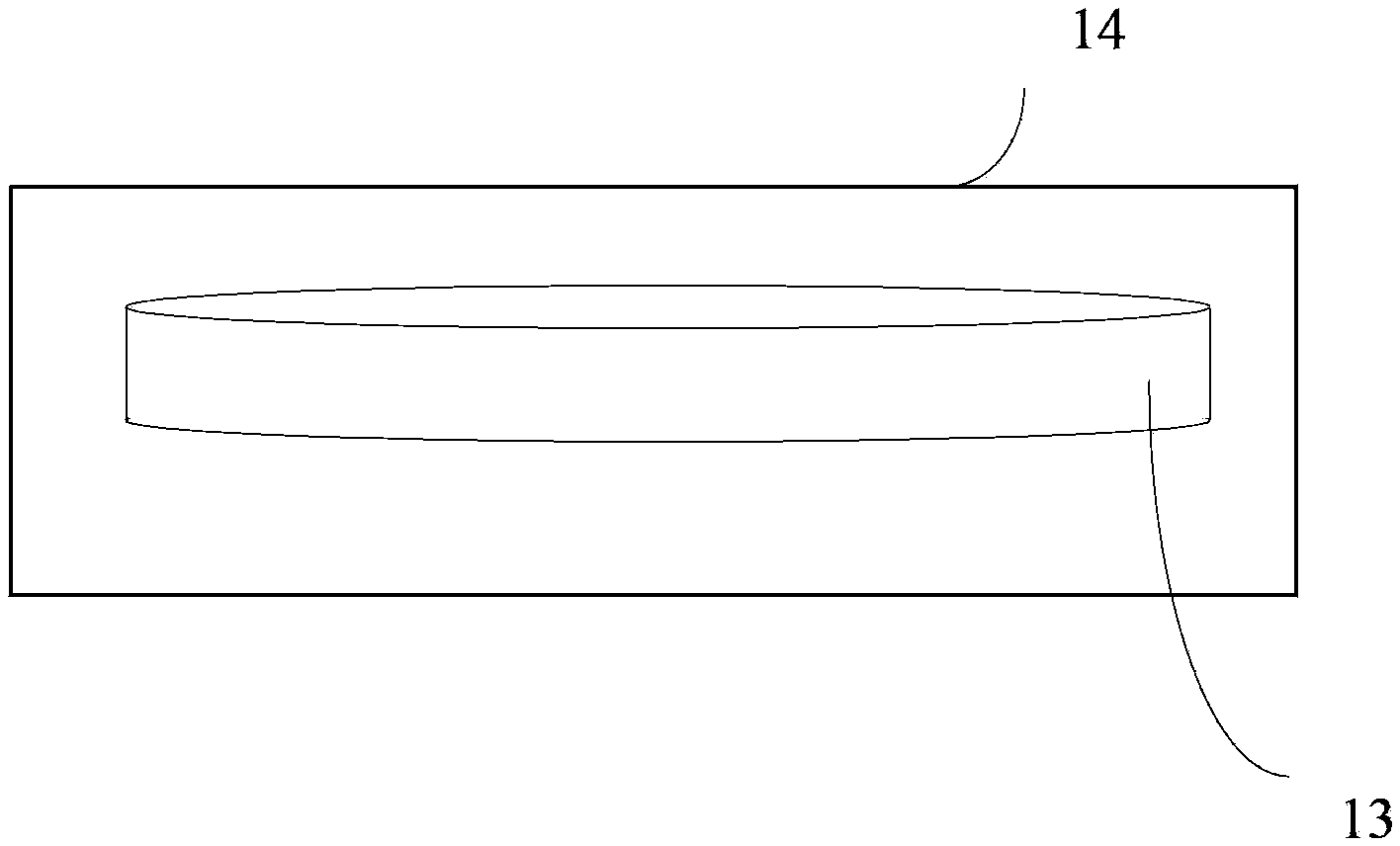

Tungsten target manufacturing method

ActiveCN103567444APrevent oxidationAvoid mutual contaminationVacuum evaporation coatingSputtering coatingVacuum pumpingVolumetric Mass Density

A tungsten target manufacturing method comprises the steps of providing tungsten powder; placing the tungsten powder in a package sleeve and performing vacuum pumping; adopting a cold isostatic pressing to enable the tungsten powder in the package sleeve to undergo primary densifying processing, and forming primary tungsten target blank; after the primary densifying processing, removing the package sleeve, adopting an induction sintering process to enable the primary tungsten target blank to undergo secondary densifying processing, and forming secondary tungsten target blank; after the secondary densifying processing, adopting a hot isostatic pressing process to enable the secondary tungsten target blank to undergo third-time densifying processing, and forming a tungsten target. The tungsten target with the full density of over 99.4% can be manufactured through the tungsten target manufacturing method; and the uniformity of the internal organizational structure and the grain size of the tungsten target meet a sputtering process with the requirement higher and higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for producing TiAl alloy plates through beta-gamma TiAl pre-alloy powder

A method for producing TiAl alloy plates through beta-gamma TiAl pre-alloy powder relates to a method for producing TiAl alloy plates. The purpose is to solve problems of the TiAl alloy plates produced by the existing method of macroscopic segregation, dendritic segregation and chemical composition unevenness, poor performance and production difficulty. The method includes: raw material preparing, hot isostatic pressing, sheath packing, high temperature pack rolling and pack removing. The method produces TiAl alloy plates by adopting hot isostatic pressing and follow-up high temperature pack rolling, a large number of disordered body-centered cubic beta phases are introduced in beta-gamma TiAl pre-alloy powder at the processing temperature, thus the hot workability of TiAl alloy can be improved and later TiAl alloy roll forming can be facilitated, and full-density large-size TiAl alloy plates can be produced easily. The method is applicable to producing of TiAl alloy plates.

Owner:HARBIN INST OF TECH

Tungsten alloy material containing yttria and preparation method thereof

The invention provides a tungsten alloy material containing yttria and a preparation method thereof by optimizing and selecting of a tungsten alloy composition formulation and a sintering process. The method concretely includes the steps of matching raw material powder according to the following mass percentage: 92.50- 93 .50 of W, 4.50-5.50 of Ni, 1.00-2.00 of Fe and 0.05-0.60 of Y2O3; then uniformly mixing the powder by a roller type flour mixing machine; and then performing charge plasma rapid sintering to the powder with the sintering pressure of 30-50MPa, sintering with the heating rate of 50-300 DEG C / min, sintering at the temperature of 1170-1300 DEG C, sintering and holding for 2-10 minutes and sintering with the vacuum of not more than 4Pa, thereby obtaining a high-proportion tungsten alloy block material which has the characteristics of nearly full-density, high hardness, good bending strength resistance under room temperature, excellent high-temperature mechanical performance, and the like and has good price-performance advantage and broad application prospect.

Owner:SOUTH CHINA UNIV OF TECH

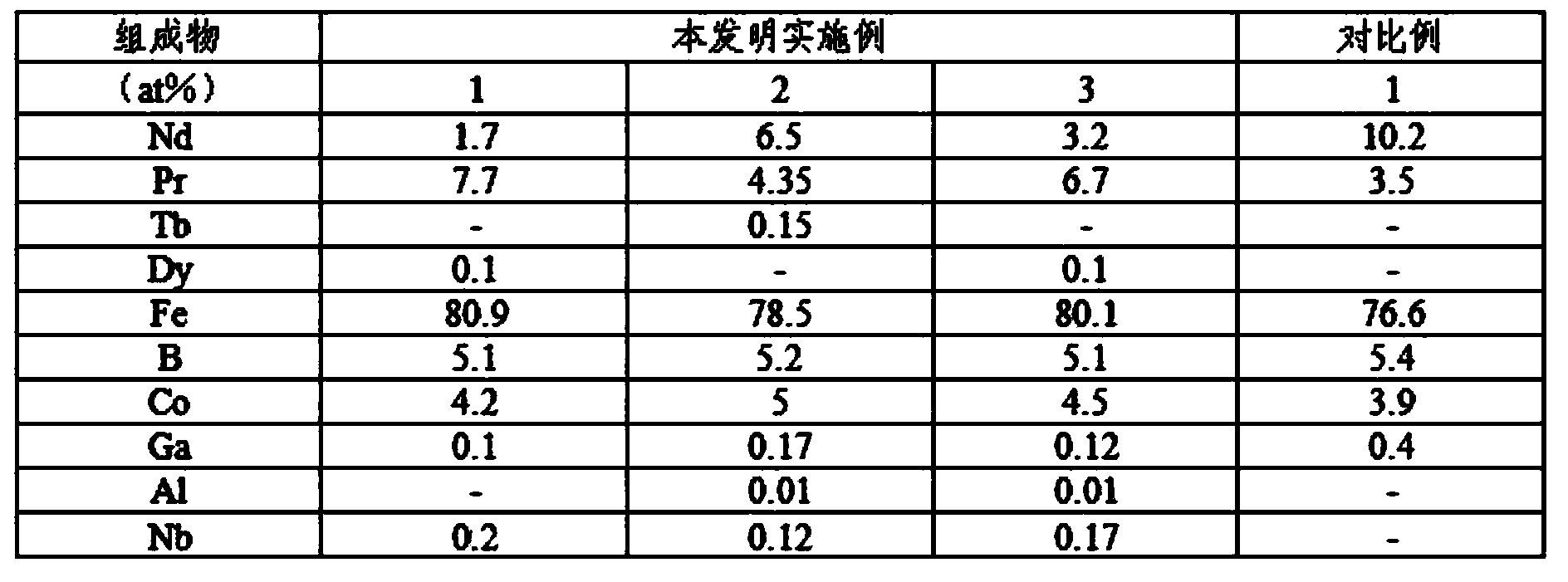

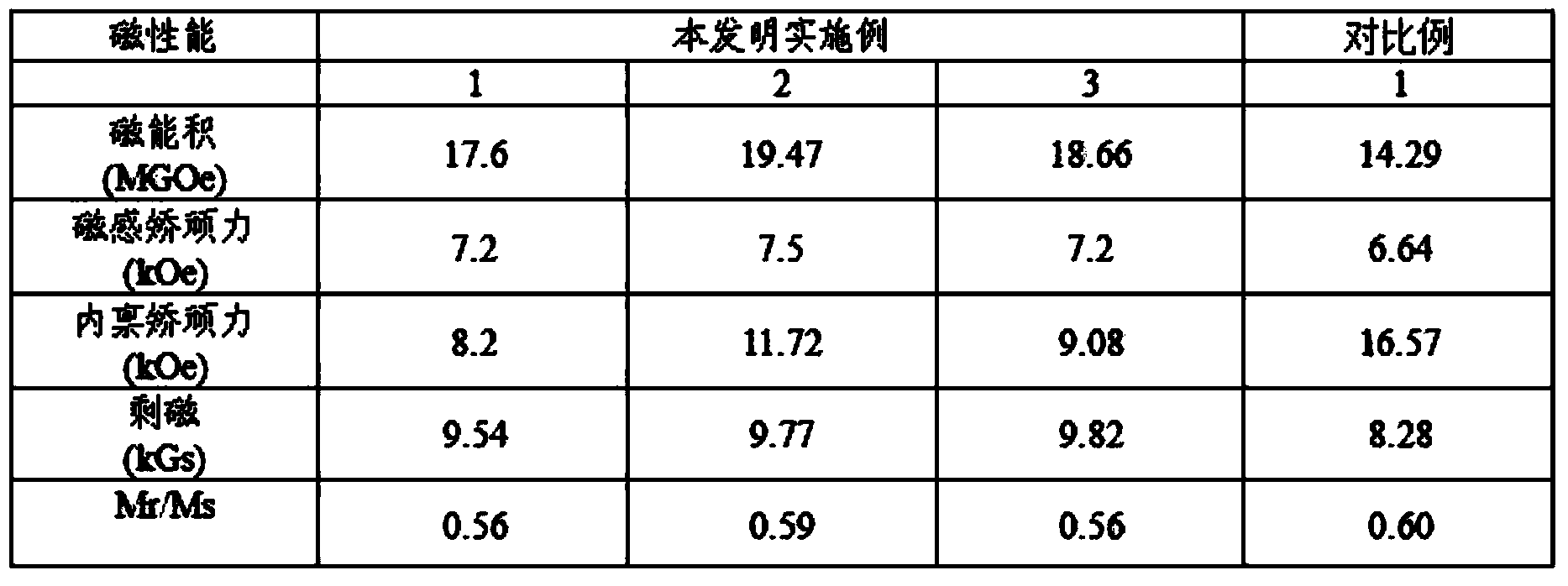

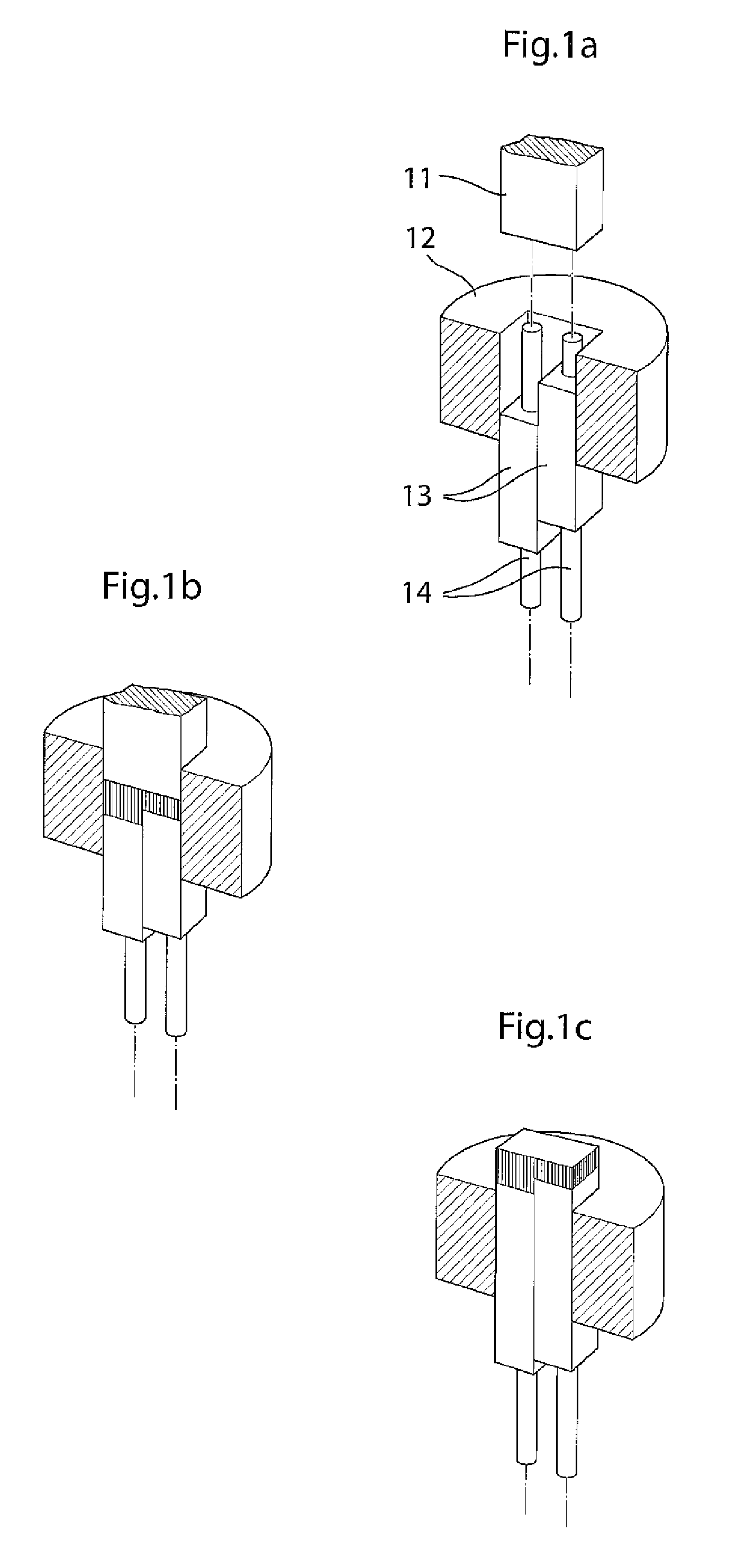

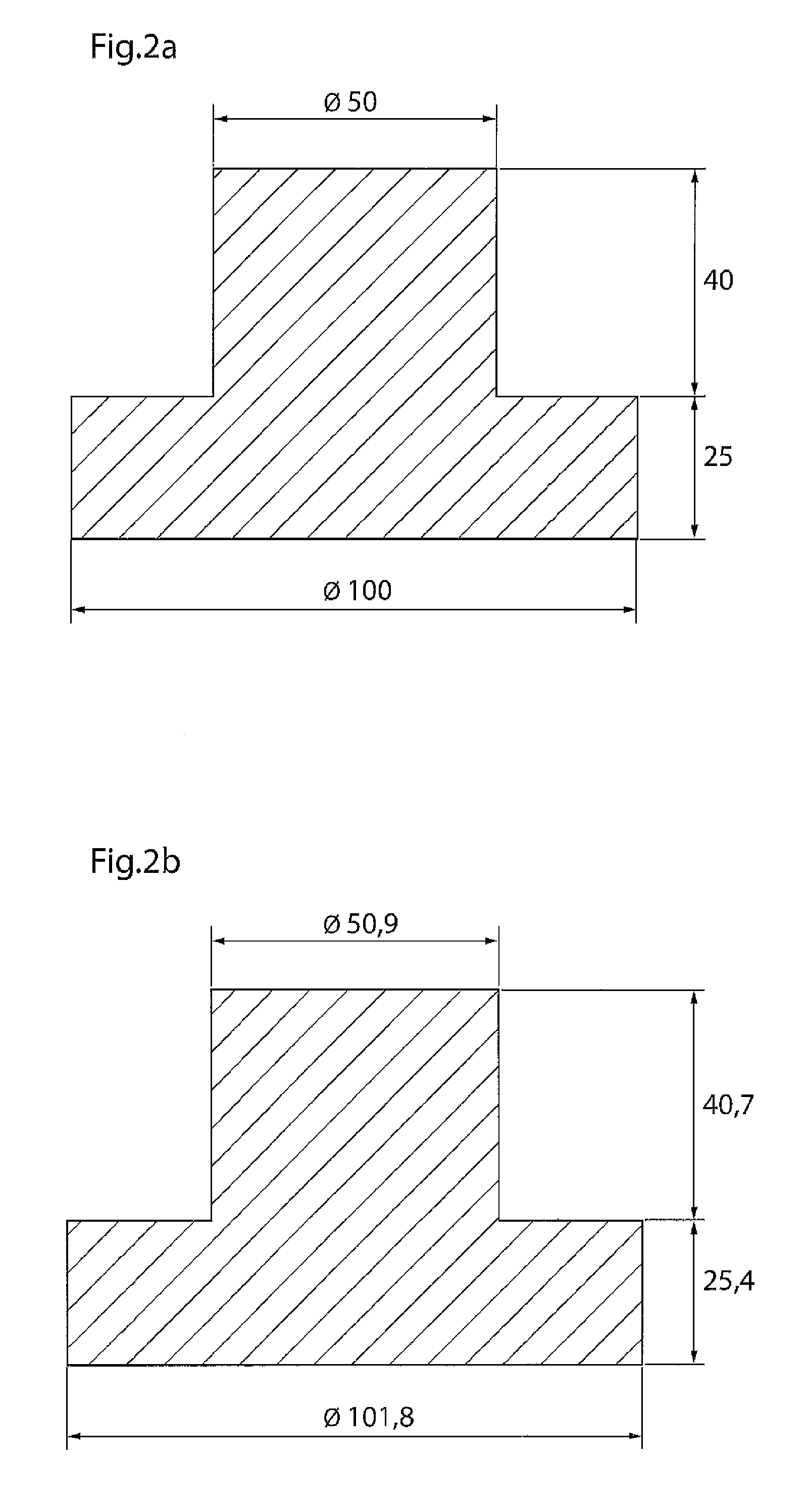

Nano biphase isotropic composite permanent magnet and preparation method thereof

ActiveCN103730227AGood overall magnetic propertiesPrevent oxidationPermanent magnetsInductances/transformers/magnets manufactureRare earthAlloy

The invention discloses a rare earth permanent magnet and a preparation method thereof. According to a nano biphase isotropic composite permanent magnet provided by the invention, a general formula of nano biphase rapid quenching alloy powder components based on an atom ratio is RxFe100-x-y-xByMz, wherein x ranges from 6.0 to 11.7, y ranges from 5.0 to 6.0, z ranges from 4.0 to 10.0, R is selected from one or more of Pr, Nd, Tb and Dy, and M is selected from one or more of Co, Ga, Al and Nb. The nano biphase isotropic composite permanent magnet prepared by adopting a vacuum hot pressing method has the characteristics of full density of isotropy, and can be magnetized into a multipole ring with poles of any even number according to the application requirement.

Owner:CHENGDU GALAXY MAGNETAB

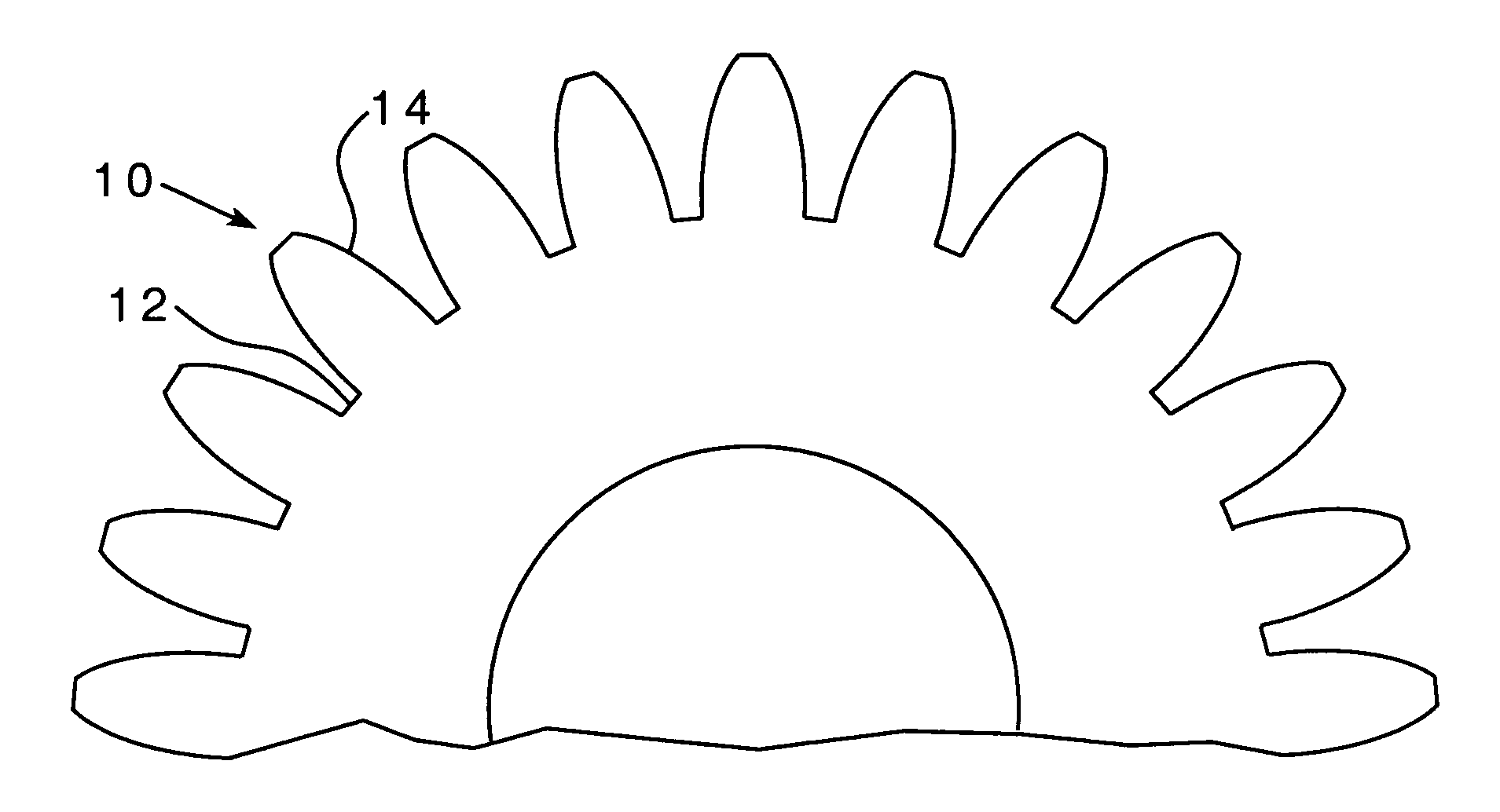

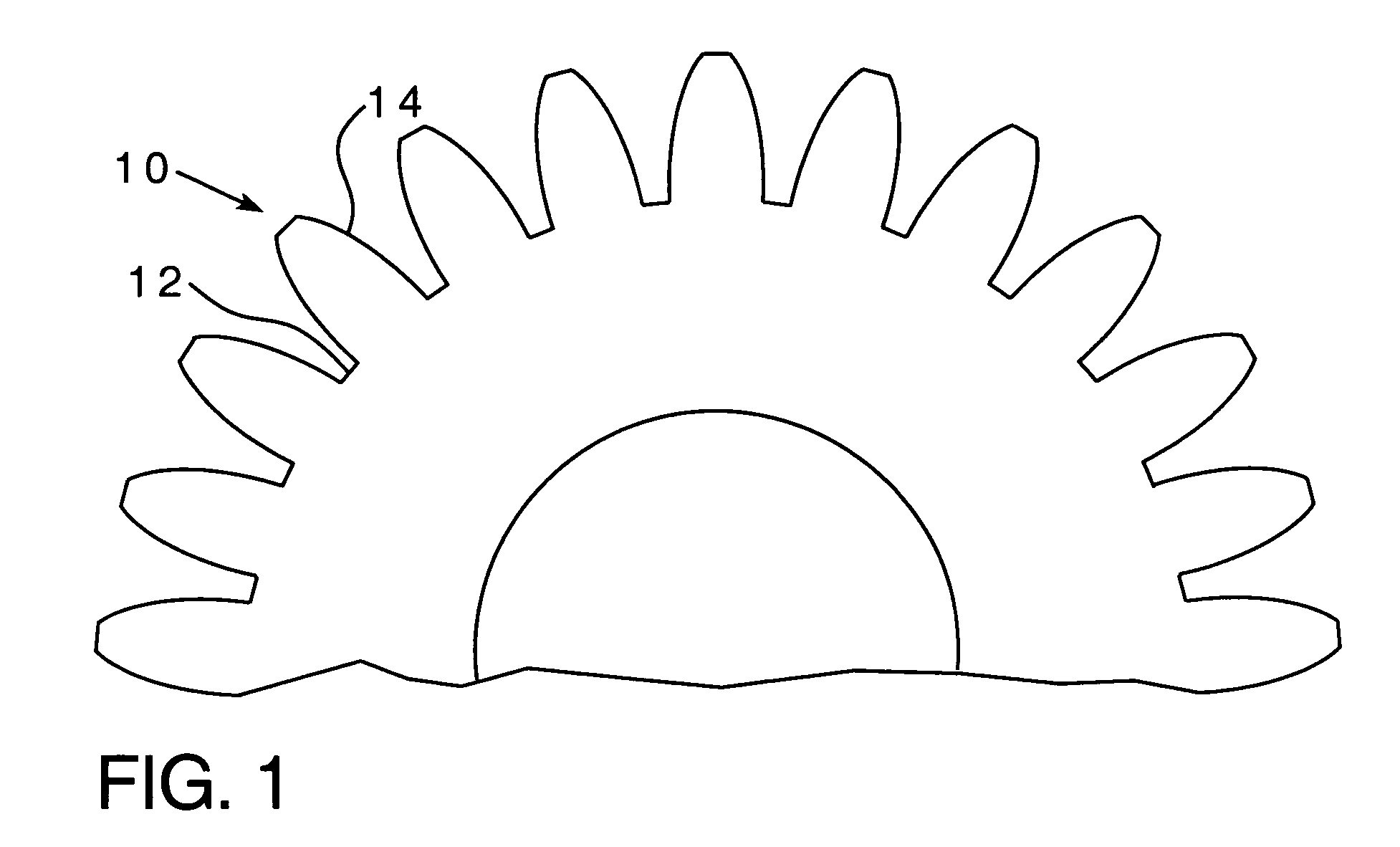

Multilevel parts from agglomerated spherical metal powder

ActiveUS9101982B2Improve toleranceImprove mechanical propertiesLayered productsThin material handlingMetal powderHigh velocity

Owner:METAL ADDITIVE TECH

Method for making micromolds

InactiveUS20020037233A1Without energy wastageWithout materialTransportation and packagingSemiconductor/solid-state device detailsParticulatesMicrometer

A method is disclosed to form micromolds and micromold components from mixtures of micrometer or nanometer-sized particulates dispersed in an organic binder. Following extraction of the organic binder the green micromolds or micromold components are sintered to full density, upon which they shrink by accurately predetermined amounts. The method allows to achieve complex-shaped micrometer and nanometer-sized precision parts such as MEMS devices and MEMS packages.

Owner:OURTFG CORP

Powder metal materials and parts and methods of making the same

Embodiments of the present invention relate to methods of forming powder metals materials and parts. More specifically, certain embodiments of the present invention relate to methods of forming powder metals materials and parts by densifying at least a portion of a surface of the materials and / or parts after sintering and prior to densifying one or more core regions of the materials and / or parts. Other embodiment provide powder metal parts, such as gears and sprockets, having surface regions that are uniformly densified to full density to depth ranging from 0.001 inches to 0.040 inches, and core regions that can have at least 92 percent theoretical density and further can have essentially full density, or full density. Still other embodiments relate to brazed, welded, plated and gas-tight powder metal parts and components that can be made in accordance with the various non-limiting methods disclosed herein.

Owner:KEYSTONE INVESTMENT CORP

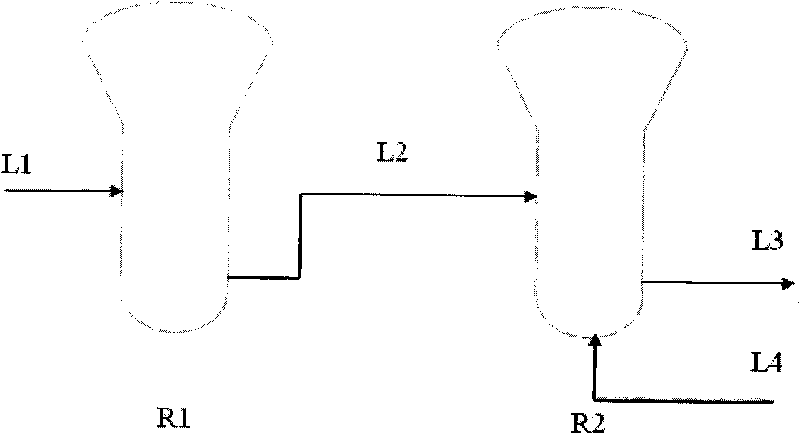

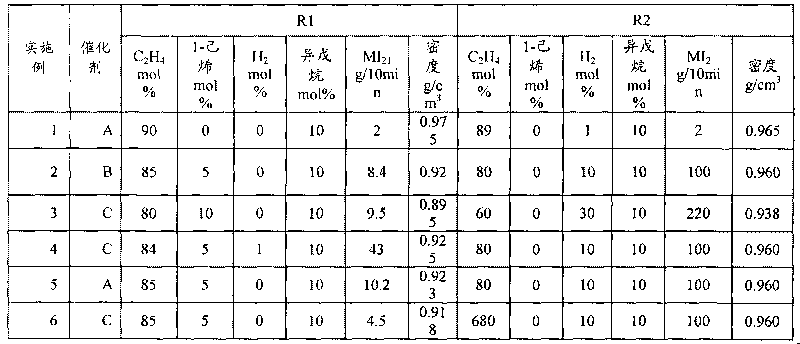

Double series reactor process for preparing polyethylene

InactiveCN101735348AResolve interactionSolve various problems caused byLow-density polyethylenePolymer science

The invention discloses a double series reactor process for preparing polyethylene, which comprises the following steps: ethylene and alpha-alkene comonomer react in a first reactor under the effect of a composite catalyst, the material in the first reactor after reaction is directly transferred to a second reactor, and ethylene and hydrogen react in the second reactor. The composite catalyst comprises: (1) a Ziegler Natta catalyst loaded on a carrier; (2) a polymer layer covered on the Ziegler Natta catalyst loaded on the carrier; and (3) a metallocene catalyst loaded in or loaded on the polymer layer. High molecular weight low-density polyethylene is produced in the first reactor, and low-molecular weight high-density resin is produced in the second reactor. No degasser is additionally arranged in the series polymerization process. The obtained polyethylene blend product has a melt flow ratio of about 40-500 and full density polyethylene of 0.900-0.975g / cm3.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polycrystalline watch jewels and method of fabrication thereof

InactiveUS20020135108A1Economic and simple and energyEconomic and simple and and materialMaterial nanotechnologyTransportation and packagingMetallurgyNet shape

A method to produce polycrystalline sapphire or ruby watch jewels is disclosed. Green watch jewels are formed from a mixture of fine ceramic powders with a thermoplastic binder. Following extraction of the binder the parts are sintered to net shape and full density. The method obviates the inefficient and labor intensive technique of monocrystalline watch jewel manufacturing. The purity of the raw materials and processing conditions result in sintered polycrystalline rubies or sapphires with homogeneous microstructures, small grain size and hardness similar to that of their synthetic monocrystalline counterparts.

Owner:BILLIET ROMAIN L +1

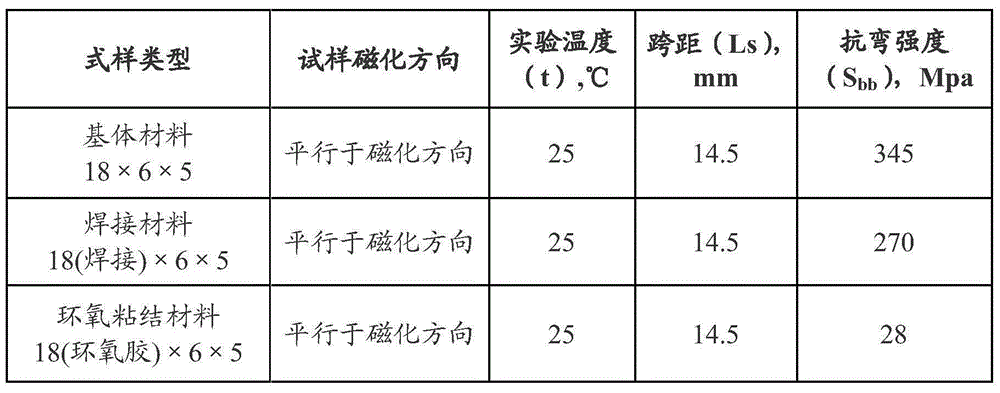

Welding method for sintered NdFeB permanent magnets

InactiveCN105057827ADoes not affect magnetismImprove flexural strengthWelding/cutting media/materialsWelding/soldering/cutting articlesEpoxyMachine parts

The invention belongs to the technical field of rare-earth permanent magnet brazing, and particularly relates to a welding method for sintered NdFeB permanent magnets. The method is implemented in the manufacturing process of the sintered NdFeB permanent magnets and includes the following steps that 1, full-density blanks obtained after NdFeB sintering are machined to obtain a needed shape, and brazing filler is clamped between the welding end faces of two NdFeB blank machined parts needing to be welded and then is compressed; 2, the NdFeB blank machined parts with the brazing filler clamped are placed in a tempering furnace, and welding is completed while tempering treatment is performed. The method solves the problem that the NdFeB permanent magnets can not be welded, and can completely meet various welding requirements for performance, dimensions and shapes of the NdFeB permanent magnets. The welding process is also a process of improving the microstructure and coercivity of the NdFeB permanent magnets, subsequent magnetic performance of the magnets is not influenced, and production process cost increase caused by welding is avoided. The brazing bending strength of the magnets welded through the method is 8 times higher than that of magnets bonded through epoxy resin.

Owner:CENT IRON & STEEL RES INST

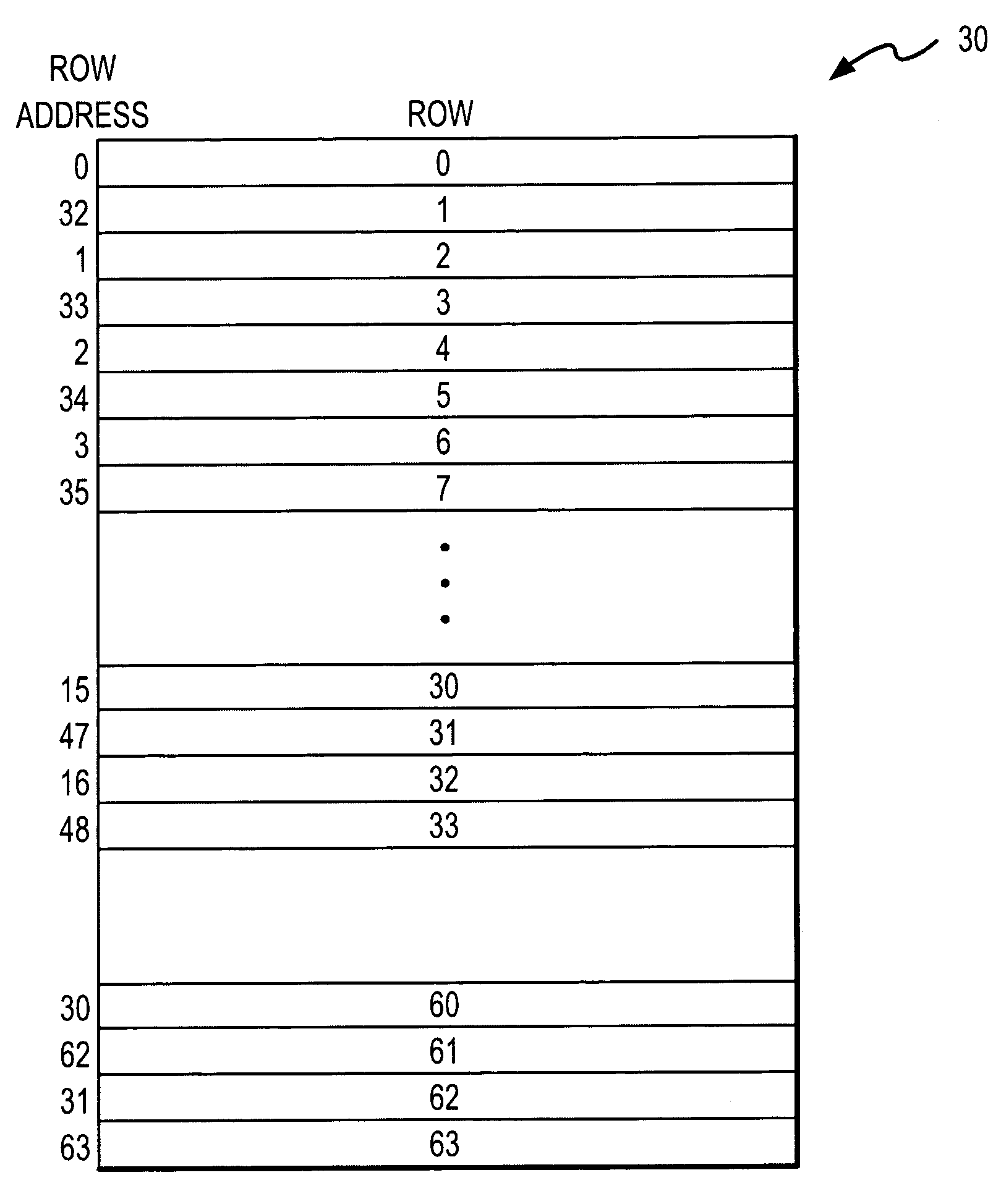

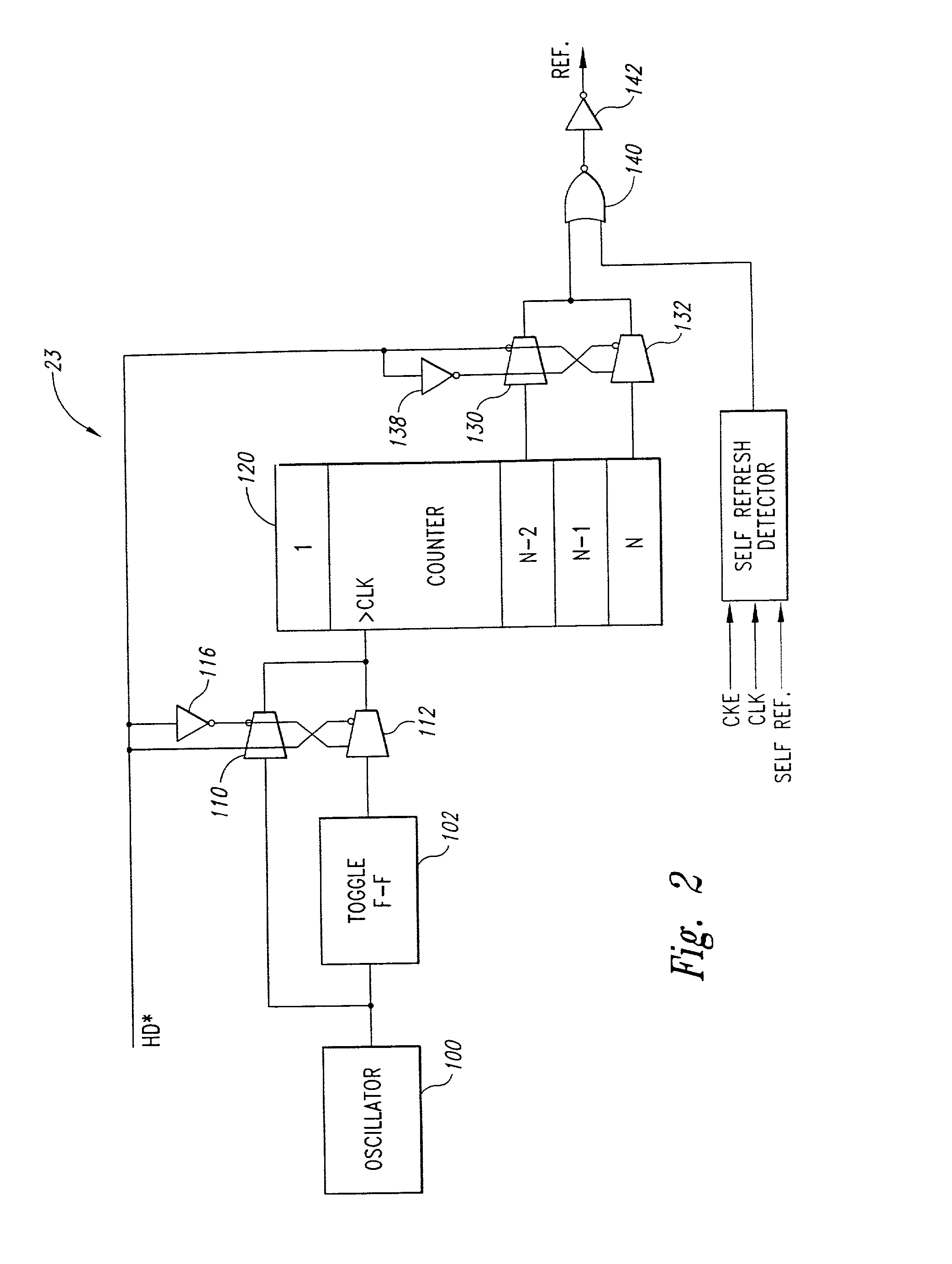

Refresh controller and address remapping circuit and method for dual mode full/reduced density DRAMs

InactiveUS20020126558A1Reduced density modeExcessively consuming powerDigital storageDual modeComputer science

A dual mode, full density / half density SDRAM includes a refresh controller specifically adapted to refresh memory cells of the SDRAM in the half density mode at a rate that is significantly slower than the rate at which the memory cells are refreshed in the full density mode. In the full density mode, the refresh controller increments a counter at a rate that is half the rate the counter is incremented in the full density mode. A refresh trigger pulse, which initiates the refresh of the memory cells, is generated when the counter has incremented to one of a first counter stage in the full density mode and a counter stage two stages beyond the first counter stage in the half density mode. Circuitry is also provided for ignoring some auto-refresh commands applied to the SDRAM in the half density mode so that the memory cells are also refreshed less frequently in the auto-refresh mode. The SDRAM also includes circuitry for remapping one of the row address bits for use as a column address bit in the half density mode so that the SDRAM can interface with system adapted for conventional dual mode SDRAMs.

Owner:ROUND ROCK RES LLC

Vibratory powder consolidation

InactiveUS20100003158A1Low costMinimum structural degradationMechanical vibrations separationShaping pressStructural degradationMetallurgy

A vibratory powder consolidation process is provided in which a powder material is subjected to vibratory energy while under static compressive loading. The process provides rapid, full-density powder consolidation with minimum or no structural degradation.

Owner:NORTHEASTERN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com